Method of achieving full density binder jet printed metallic articles

a technology of binder jet and metallic articles, applied in the field of binderjet printing, can solve the problems of significant impact on cost, alloys such as titanium or superalloys experience undesirable microstructural changes, and unsatisfactory microstructures, so as to reduce product cost, reduce cost, and ensure the shape retention of printed articles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

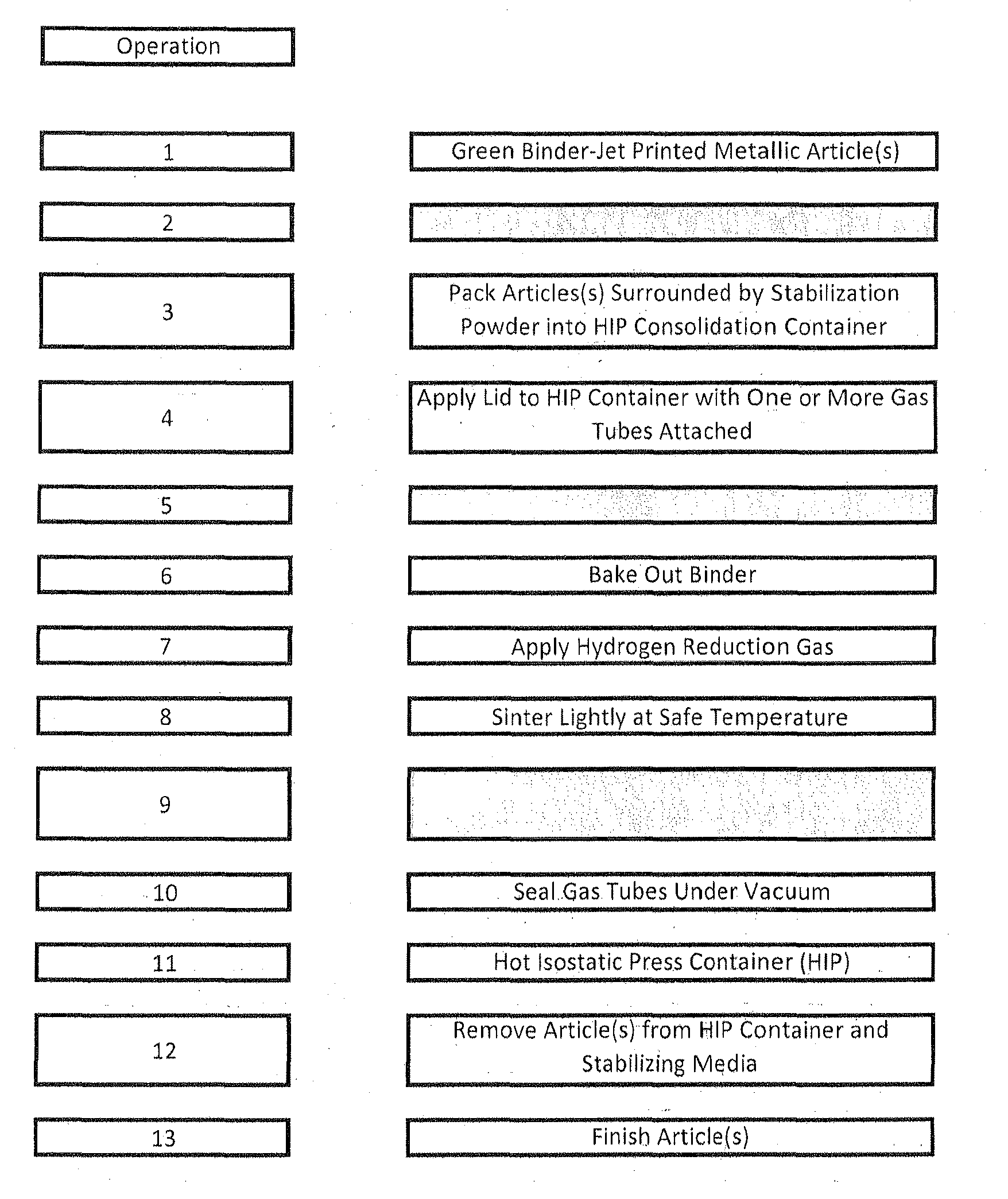

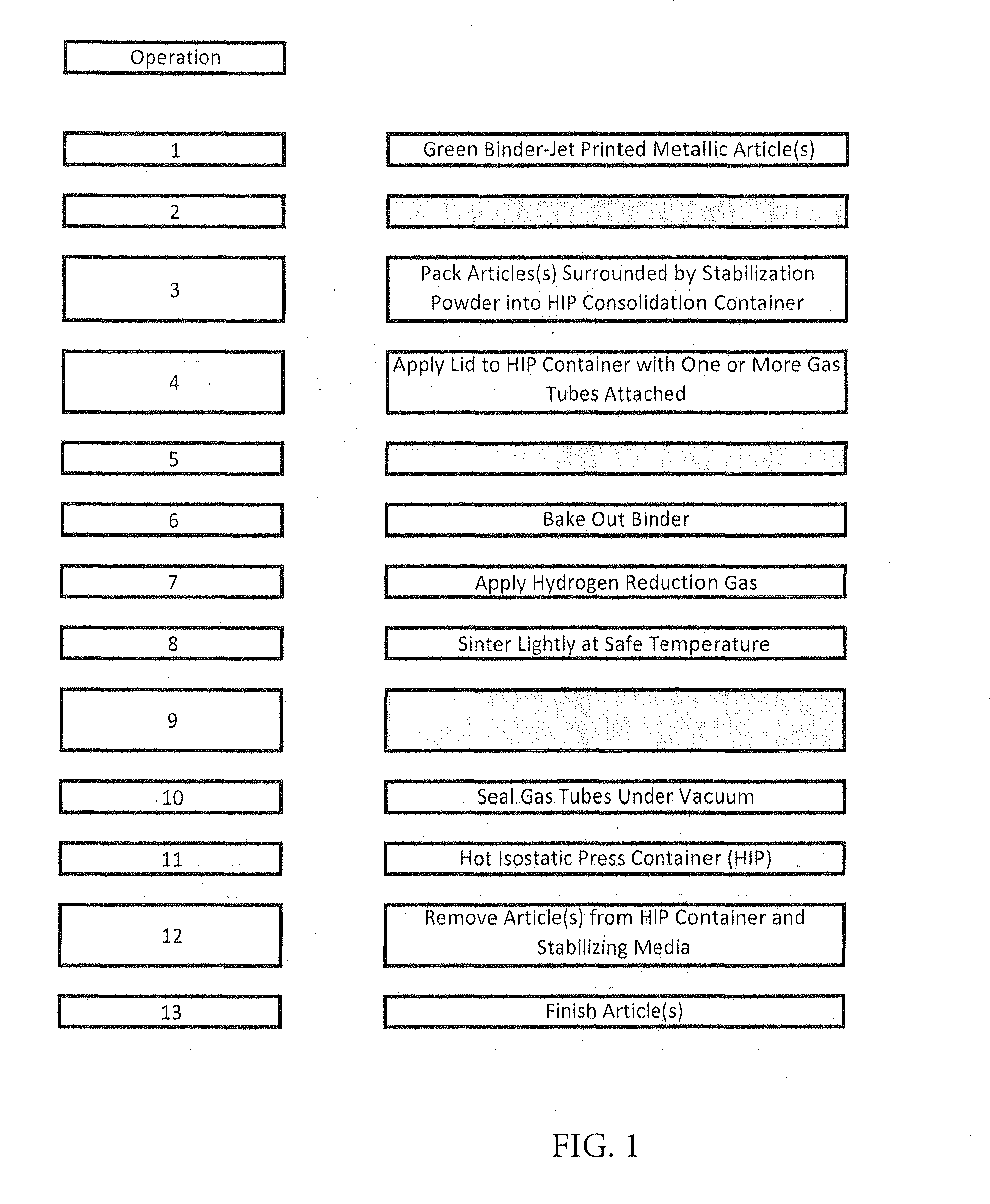

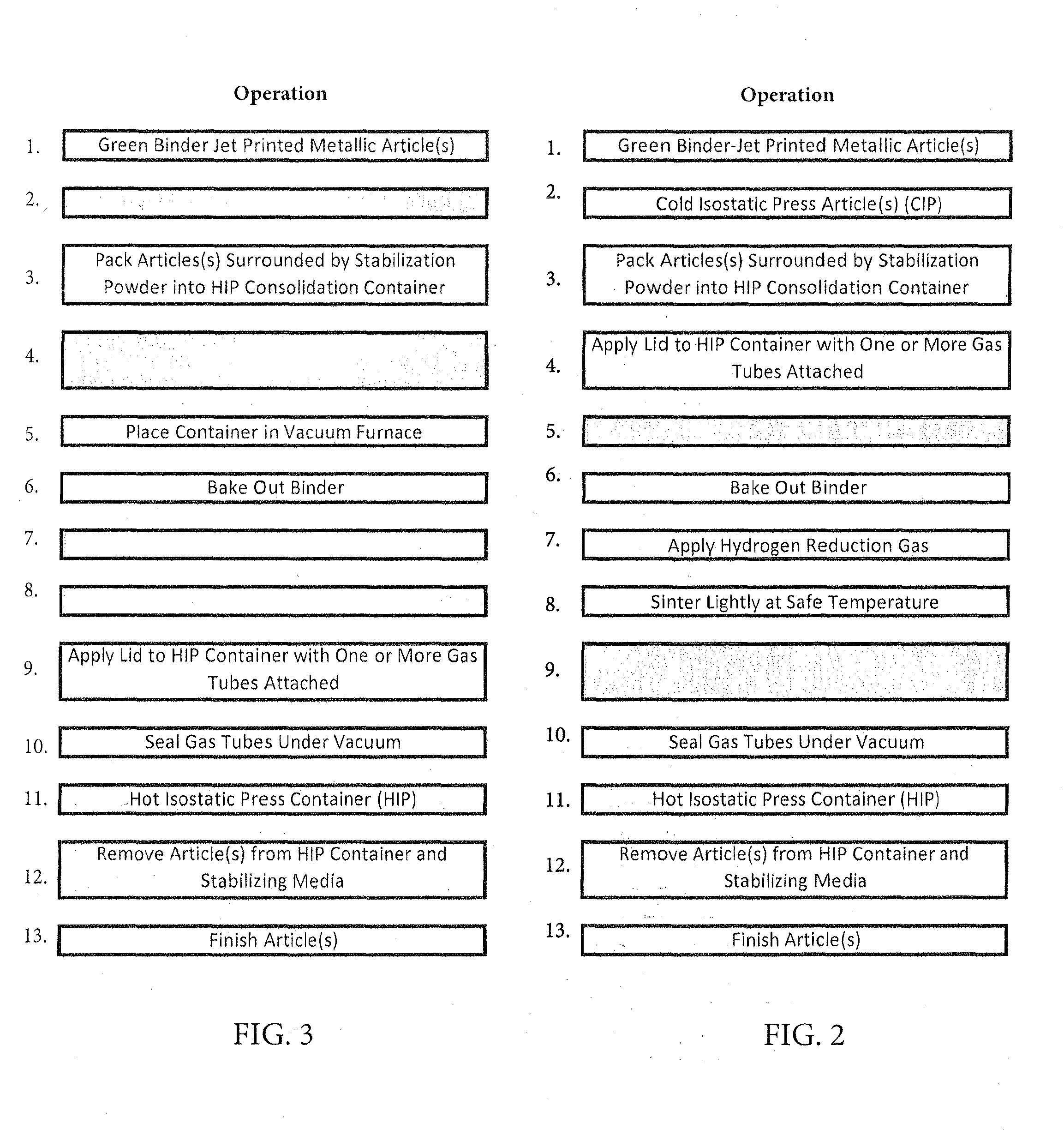

[0017]Referring to FIG. 1, the description of the method steps is as follows:

Operation 1

[0018]The first operation is to produce a metallic 3-D printed article using a binder-jet printing method. The result is a near net shaped article with a solid metal fraction between 40 and 80 percent held together with a removable polymeric binder. Printing machines of this type are primarily produced by ExOne and Voxeljet.

Operation 3

[0019]This operation establishes a hot isostatic press (HIP) container with the green as-printed article(s) and surrounding stabilizing powder fill.

[0020]Container—The container can be cylindrical, rectangular, or other convenient shape, sized and shaped to hold one or more articles. The container material is selected so that it is elastic at HIP conditions, tough enough to withstand HIP compaction and exhibits minimal reaction with the stabilizing fill powder at HIP conditions. Examples of HIP container materials include mild steel, stainless steel, and titanium.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Force | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com