Patents

Literature

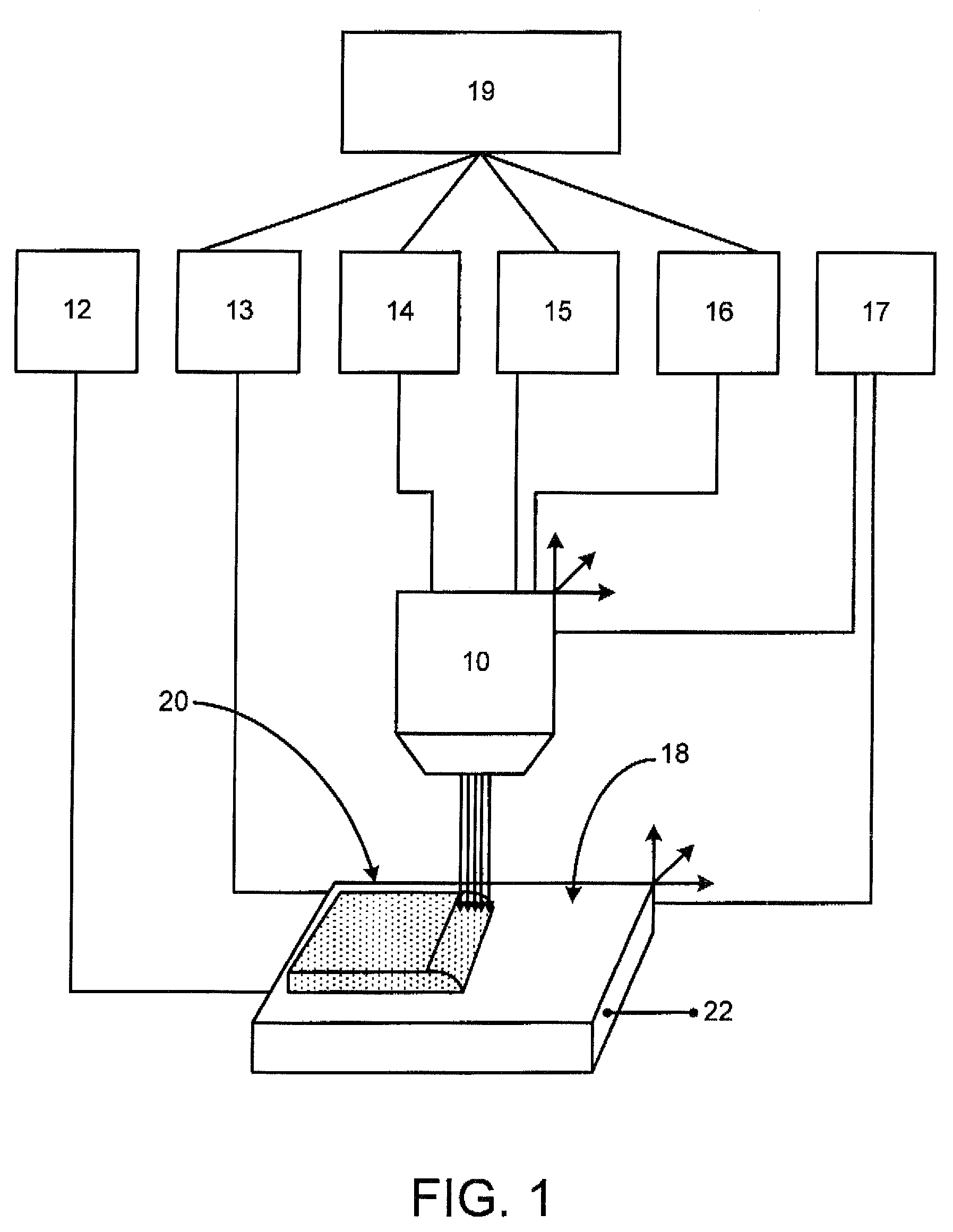

438results about "Additive manufacturing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

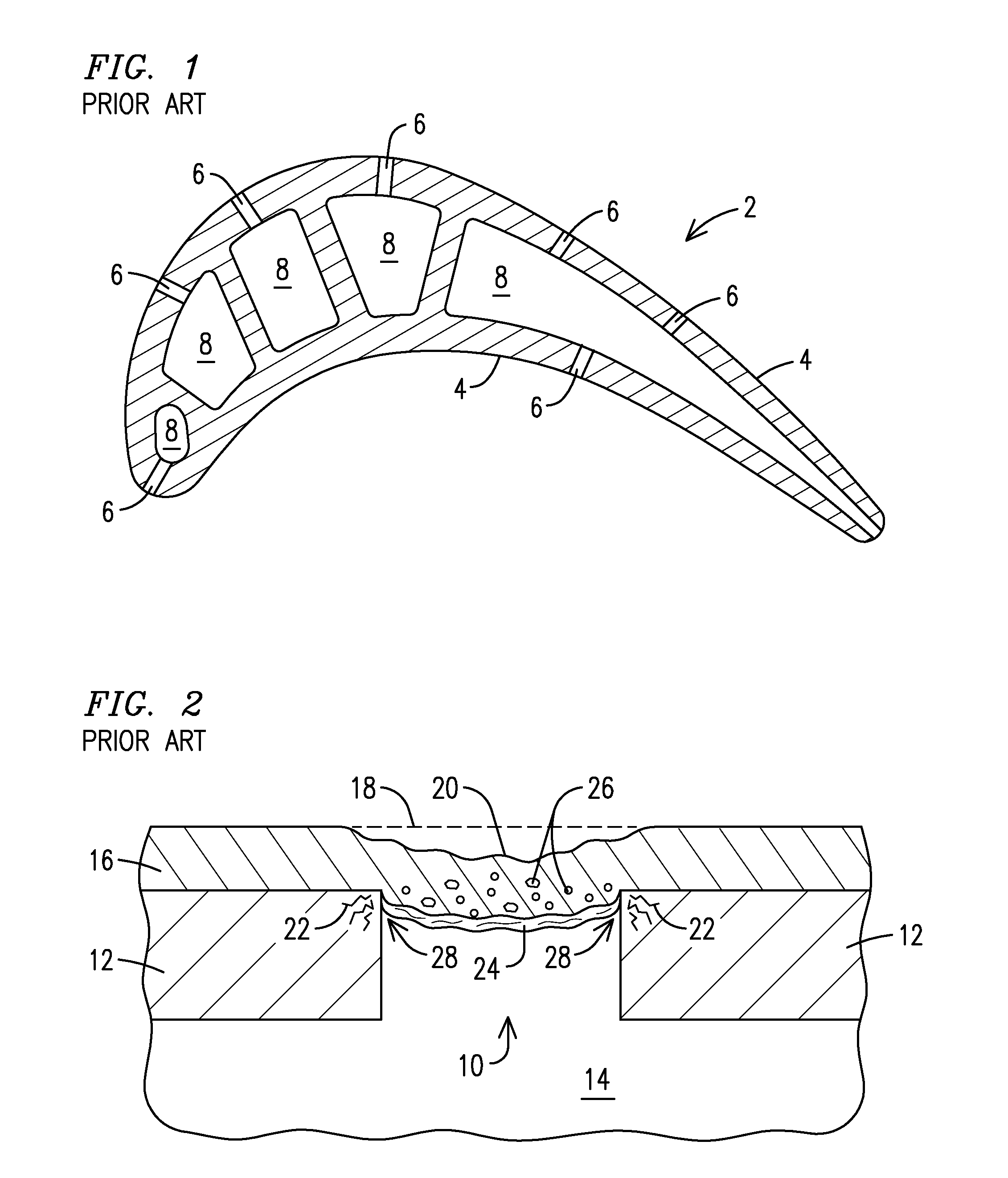

Implants based on engineered composite materials having enhanced imaging and wear resistance

This invention relates to a metal composite orthopedic device. The device can comprise a metallic substrate cladded or joined to one or more metallic layer(s). The substrate and metallic layer(s) can be selected of different metals and metal alloys to provide desired wear performance, imaging characteristics and optionally to serve as a reservoir for therapeutic agents.

Owner:WARSAW ORTHOPEDIC INC

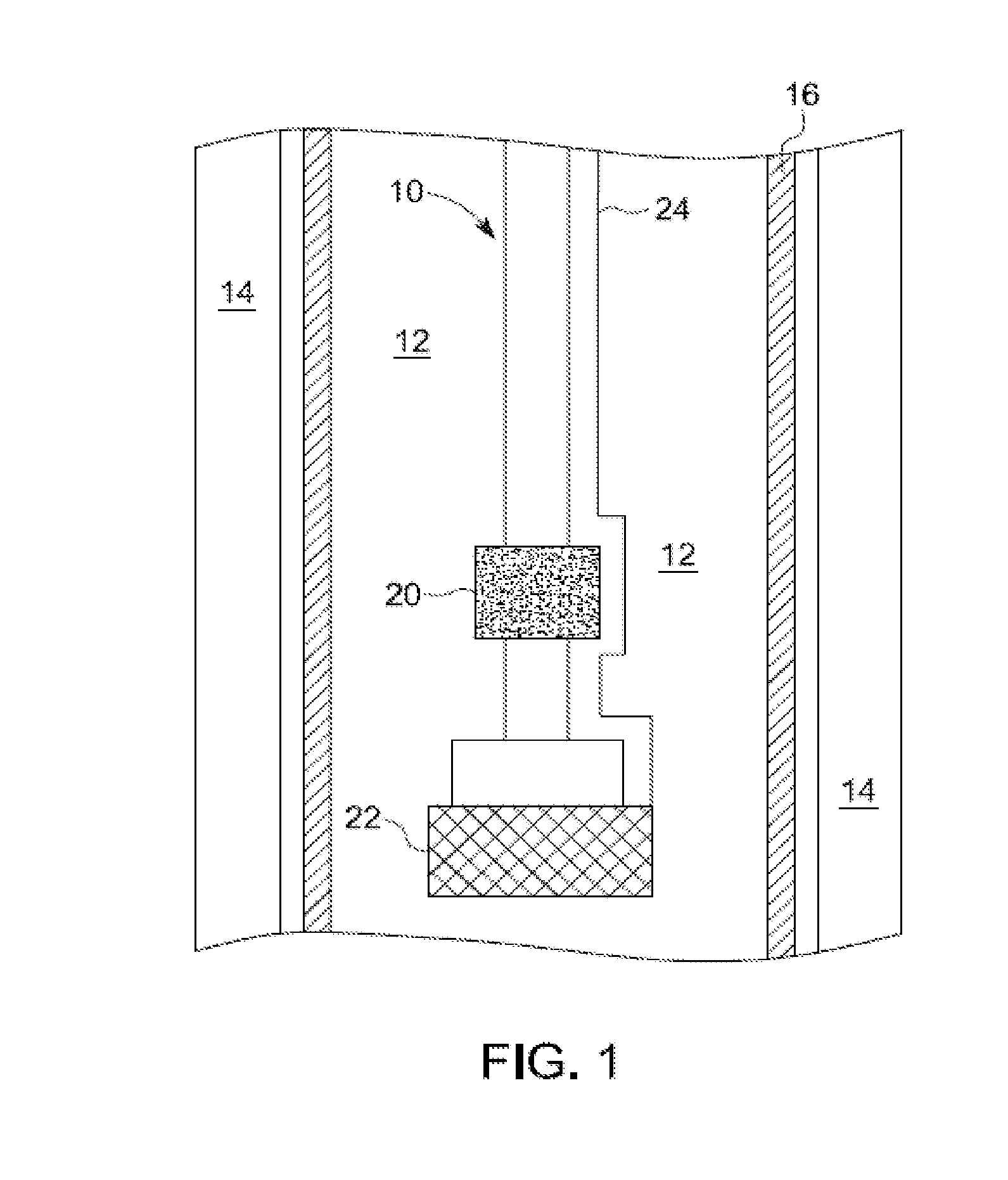

Methods of manufacturing medical devices for controlled drug release

The present invention is a medical device for controlling the release of an active agent. The medical device has a supporting structure having a porous body disposed therein. At least one elution rate controlling matrix containing an effective amount of at least one active agent is disposed within the pores of the porous body in a manner that protects the matrix from mechanical damage. The medical device may therefore be used for controlled drug release applications. Additionally, the present invention discloses a method for using the medical device for the treatment and prevention of diseases in mammals. This invention further relates to a method for using the medical device for treating and preventing vascular diseases.

Owner:ABBOTT LAB INC

3-D Printing of near net shape products

InactiveUS20100279007A1Easy to handleHigh porosityAdditive manufacturingCeramic shaping apparatusPorosityCeramic metal

The disclosed method relates to manufacture of a near net-shaped products such as ceramic containing products such as ceramic-metal composites. The method entails forming a mixture of a build material and a binder and depositing that mixture onto a surface to produce a layer of the mixture. An activator fluid then is applied to at least one selected region of the layer to bond the binder to the build material to yield a shaped pattern. These steps may be repeated to produce a porous whitebody that is heat treated to yield a porous greenbody preform having a porosity of about 30% to about 70%. The greenbody then is impregnated with a molten material such as molten metal. Where the build material is SiC, the molten metal employed is Si to generate a SiC—Si composite.

Owner:STORM DEV LLC +1

Porous sintered metal-containing materials

InactiveUS20060211802A1Adversely affecting the physical and/or chemical stabilityInhibit aggregationAdditive manufacturingTransportation and packagingSolvent freeMetallic materials

A process for manufacturing a porous metal-containing material is provided. For example, a composition is provided comprising particles dispersed in at least one solvent, the particles comprising at least one polymer material and at least one metal-based compound. The solvent can be substantially removed from the composition, and the polymer material can be substantially decomposed, thereby converting the solvent-free particles into a porous metal-containing material. In addition, metal-containing materials produced in accordance with the above process and their use in implantable medical devices can be provided.

Owner:CINVENTION AG

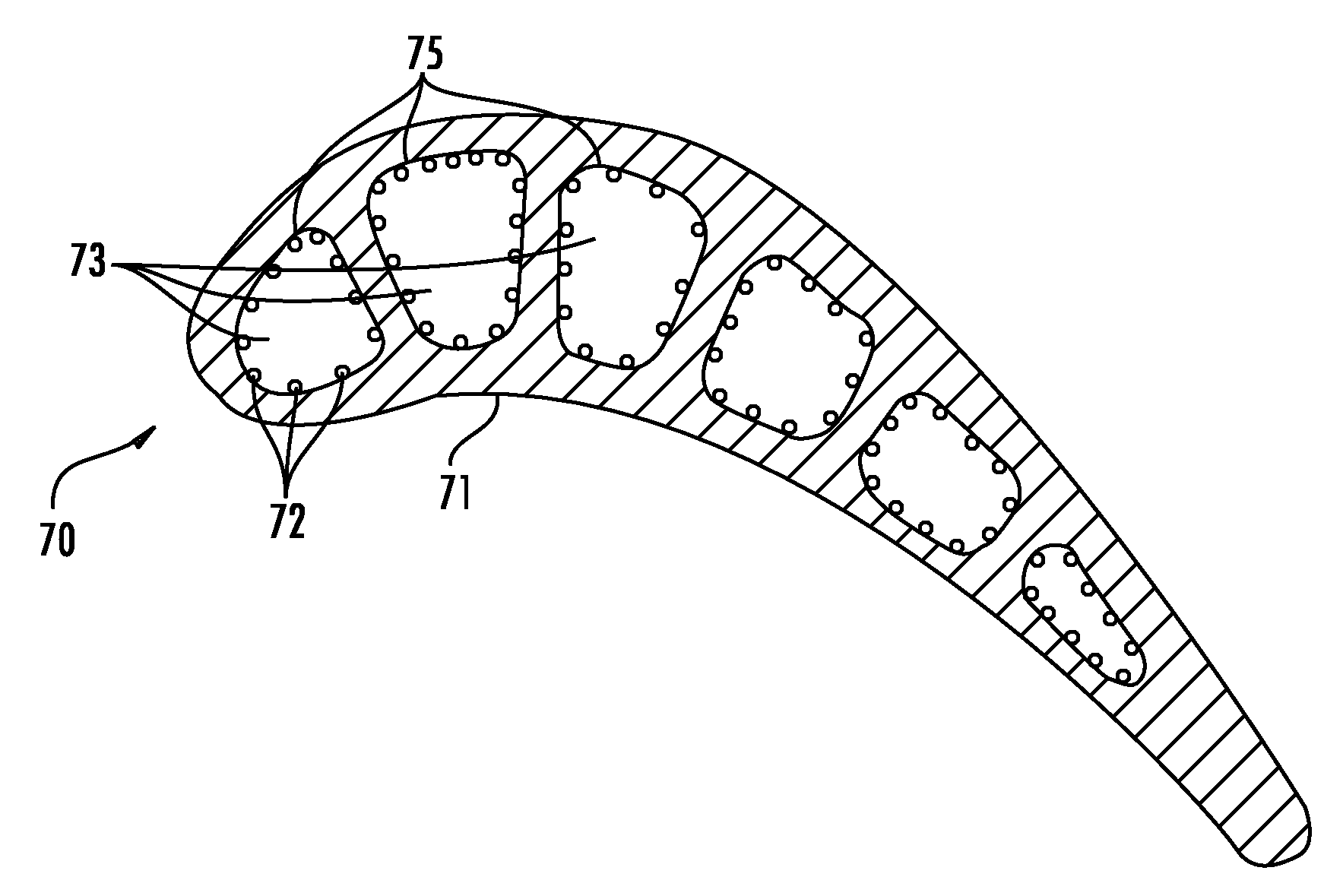

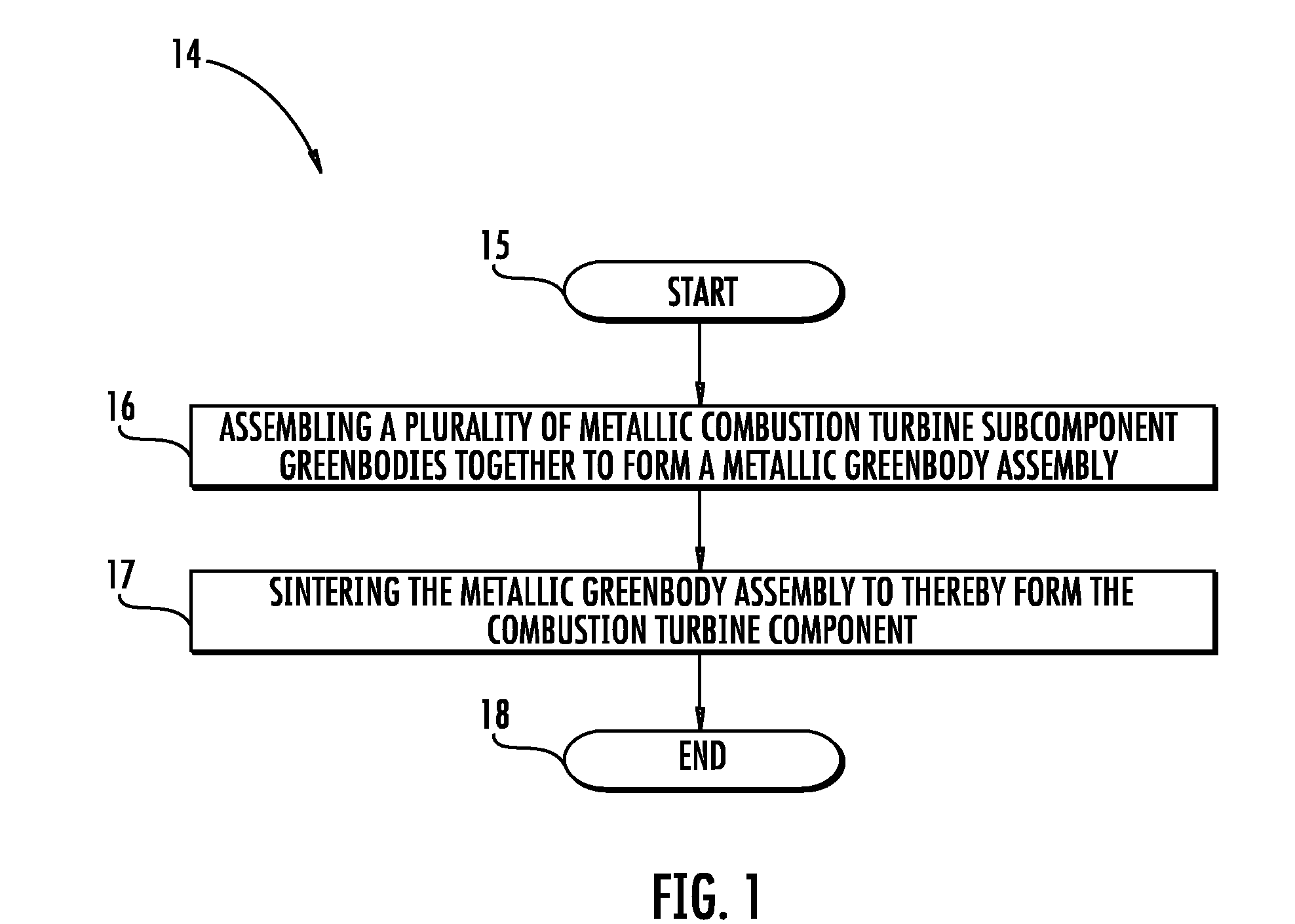

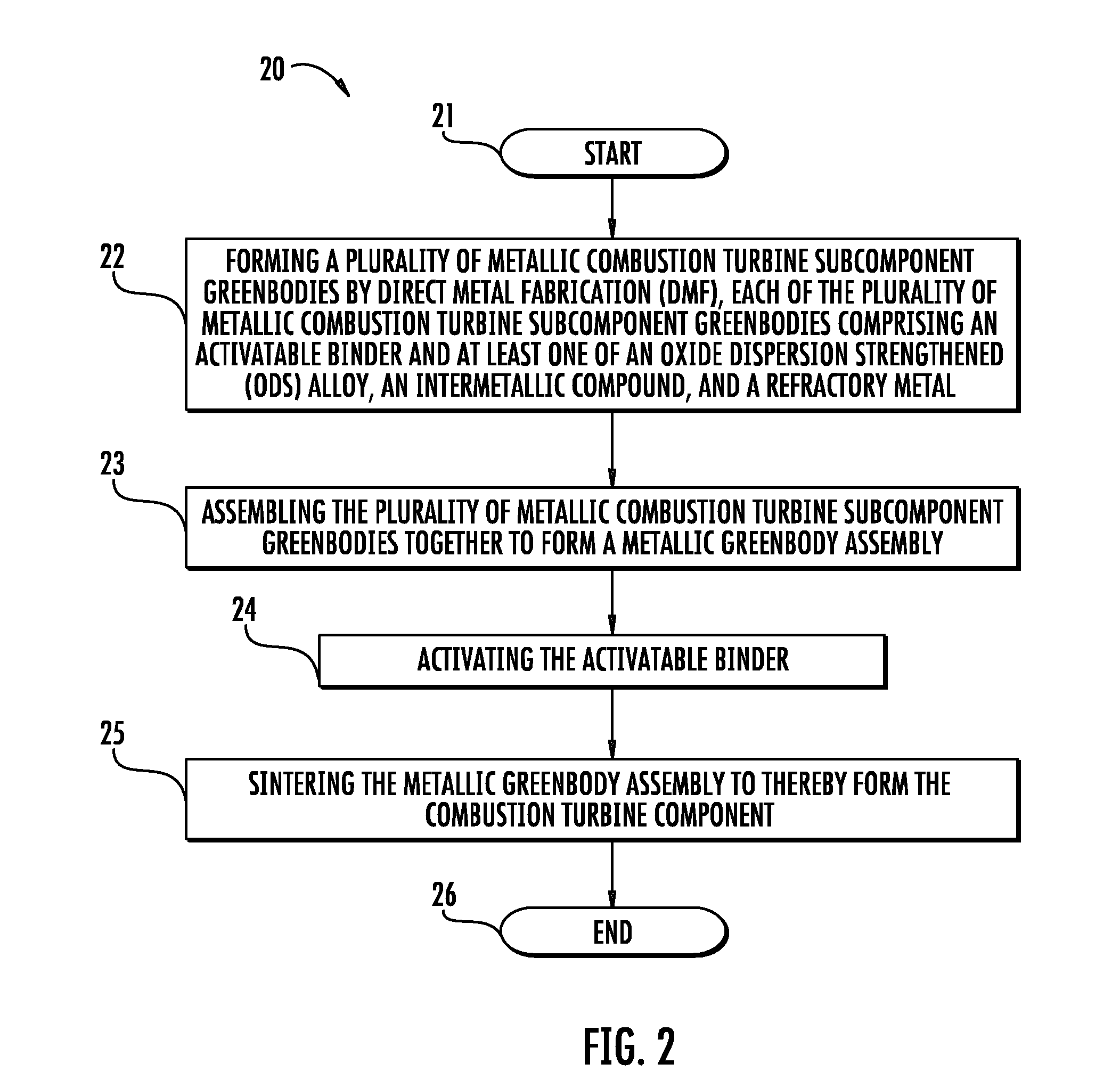

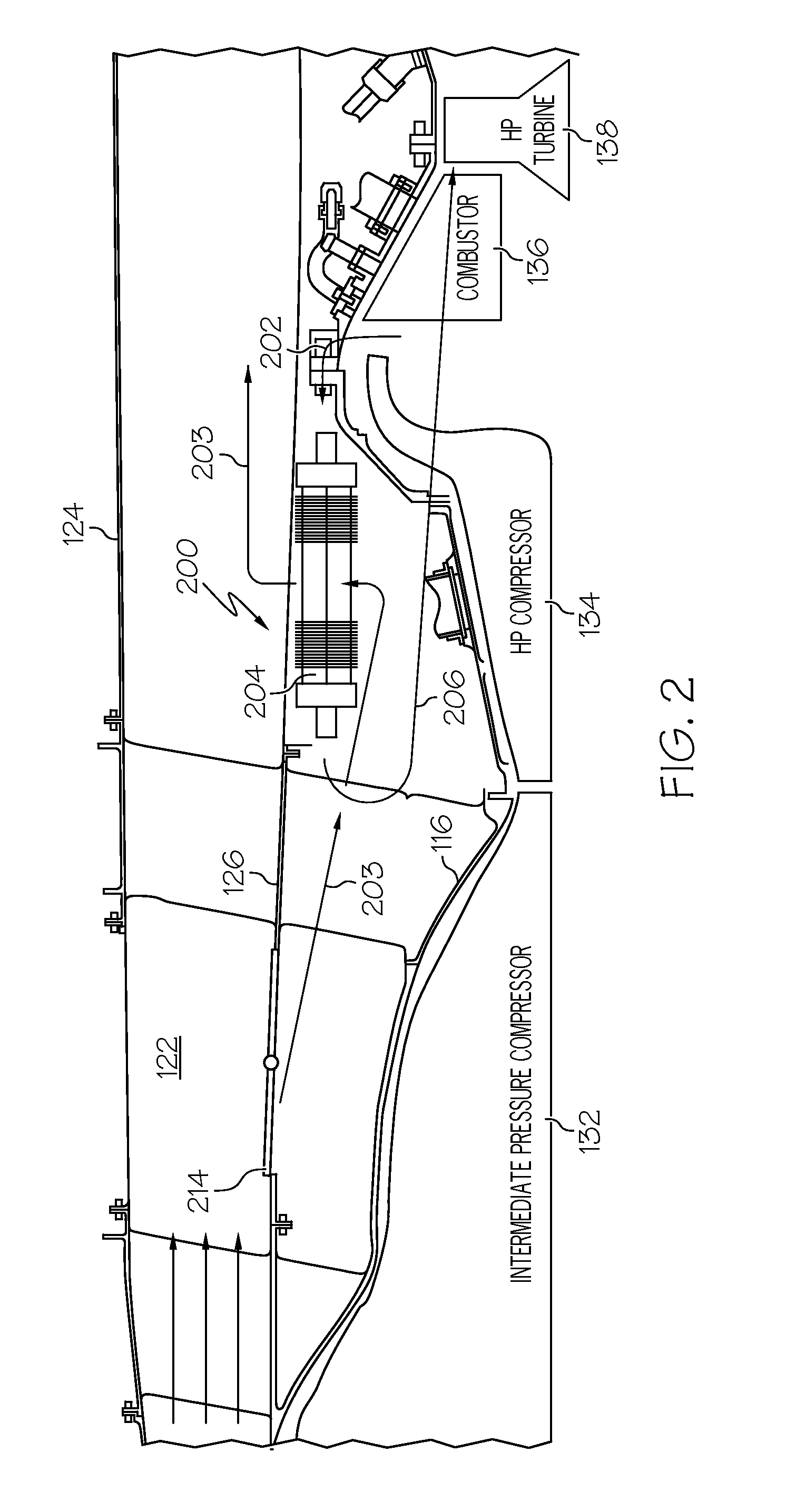

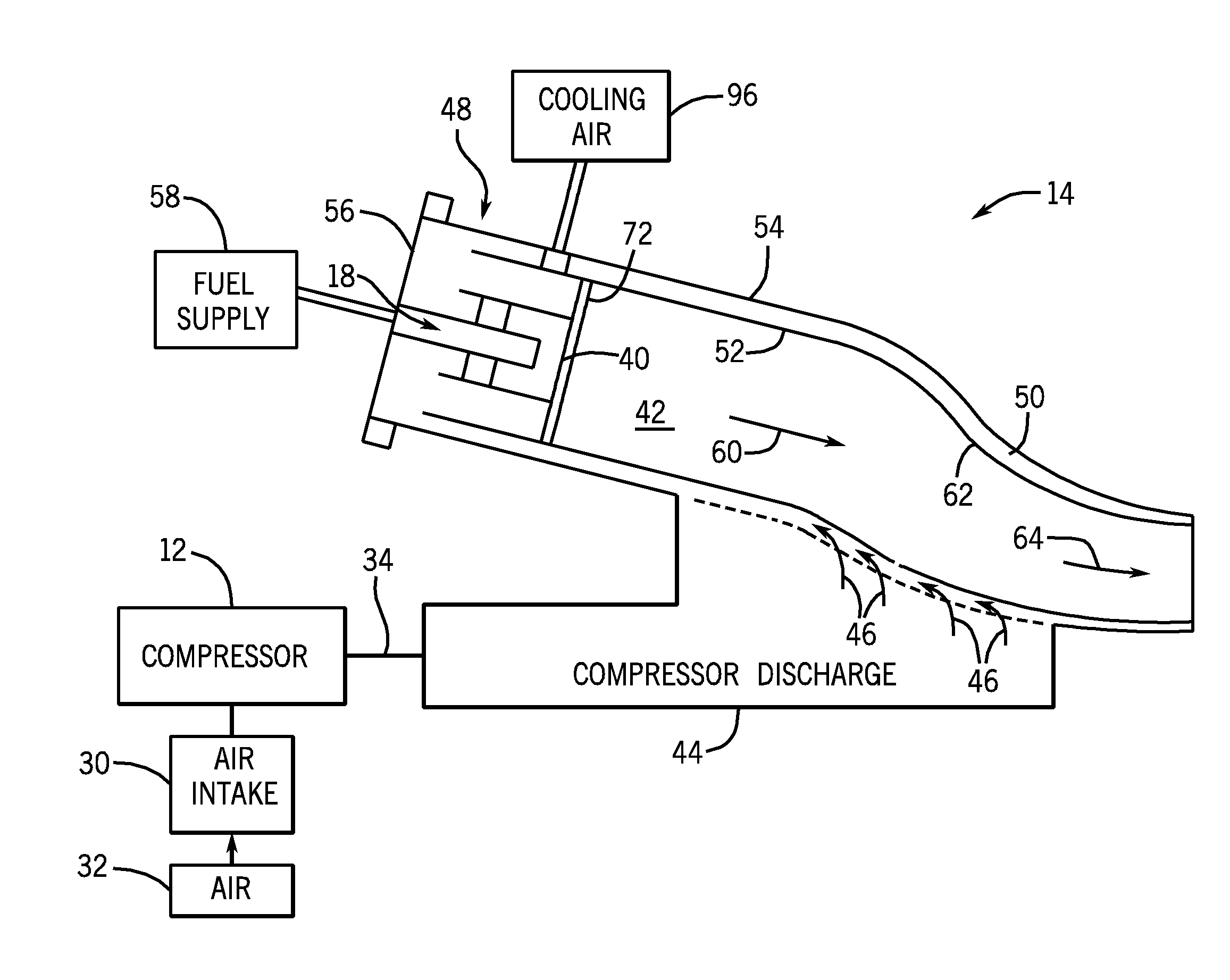

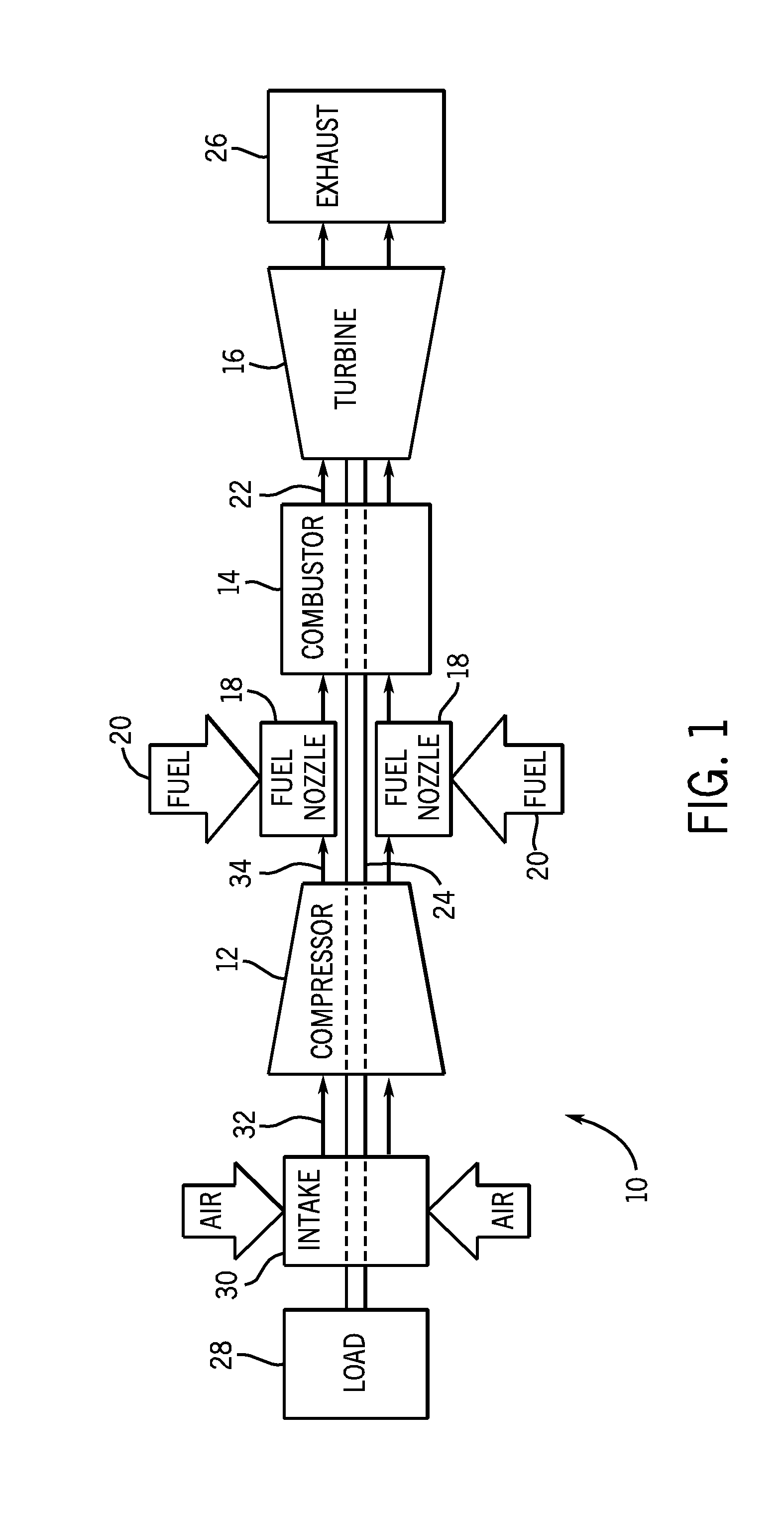

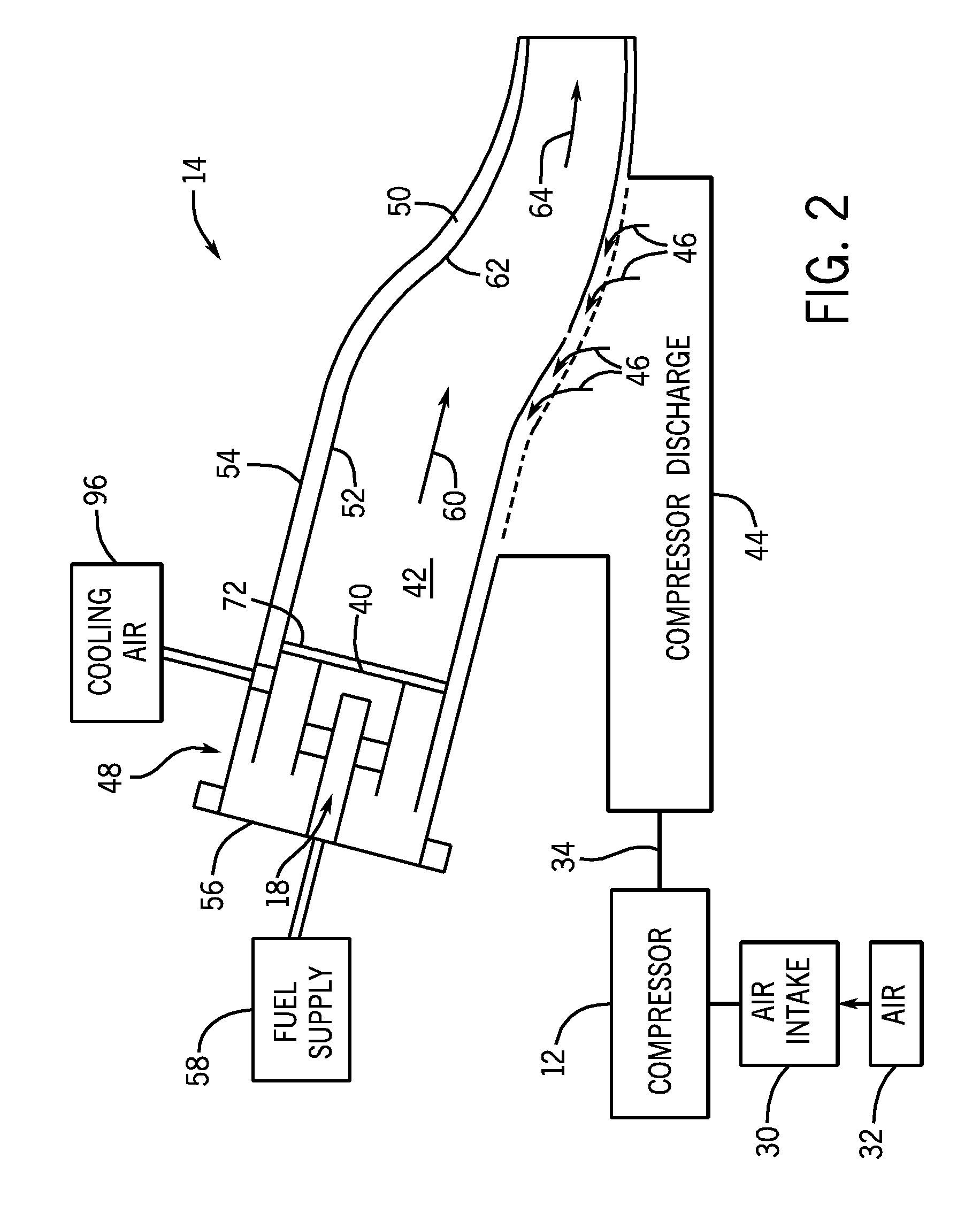

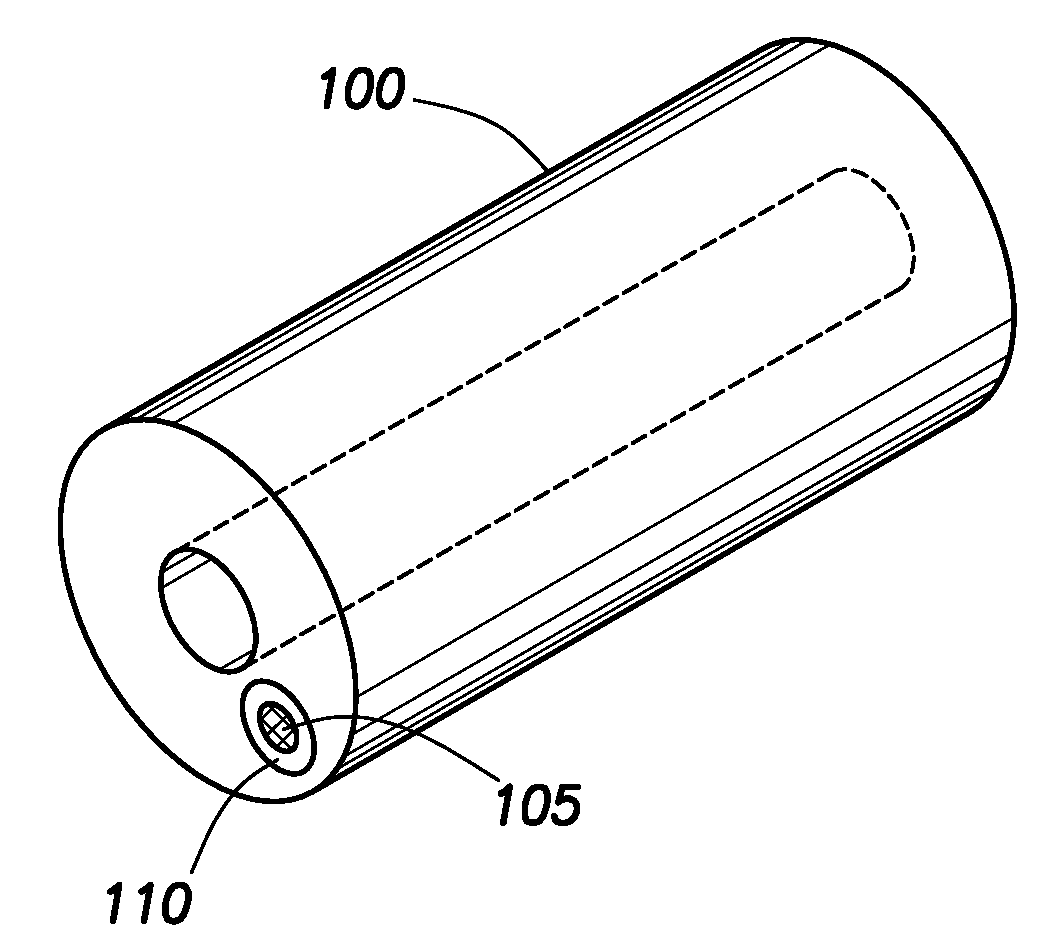

Method of Making a Combustion Turbine Component from Metallic Combustion Turbine Subcomponent Greenbodies

InactiveUS20090183850A1Improve cooling effectHigh temperature resistanceTurbinesAdditive manufacturingCombustionMetal fabrication

A method of making a combustion turbine component includes assembling a plurality of metallic combustion turbine subcomponent greenbodies together to form a metallic greenbody assembly and sintering the metallic greenbody assembly to thereby form the combustion turbine component. Each of the plurality of metallic combustion turbine subcomponent greenbodies may be formed by direct metal fabrication (DMF). In addition, each of plurality of metallic combustion turbine subcomponent greenbodies may include an activatable binder and the activatable binder may be activated prior to sintering.

Owner:MIKRO SYSYTEMS INC +1

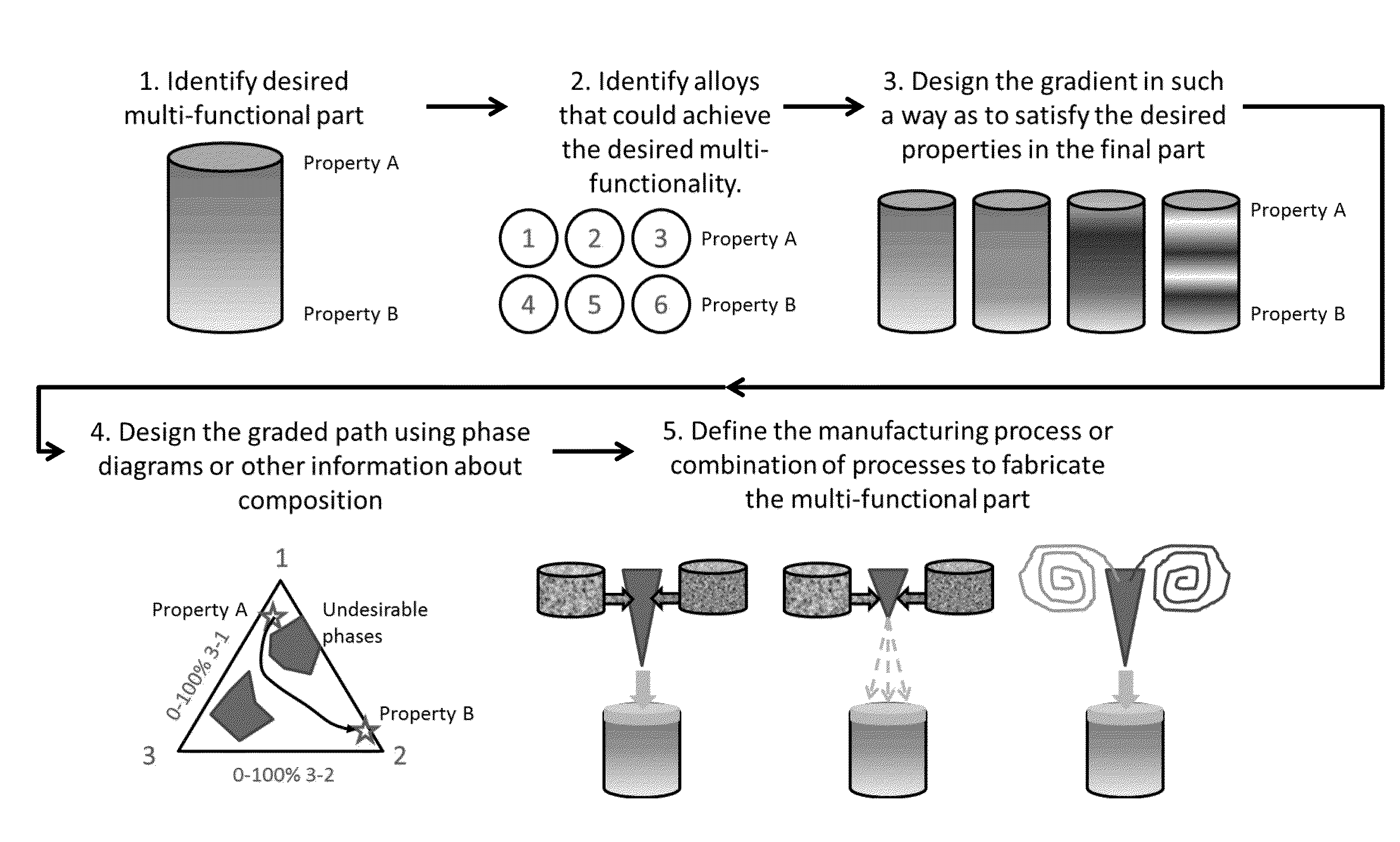

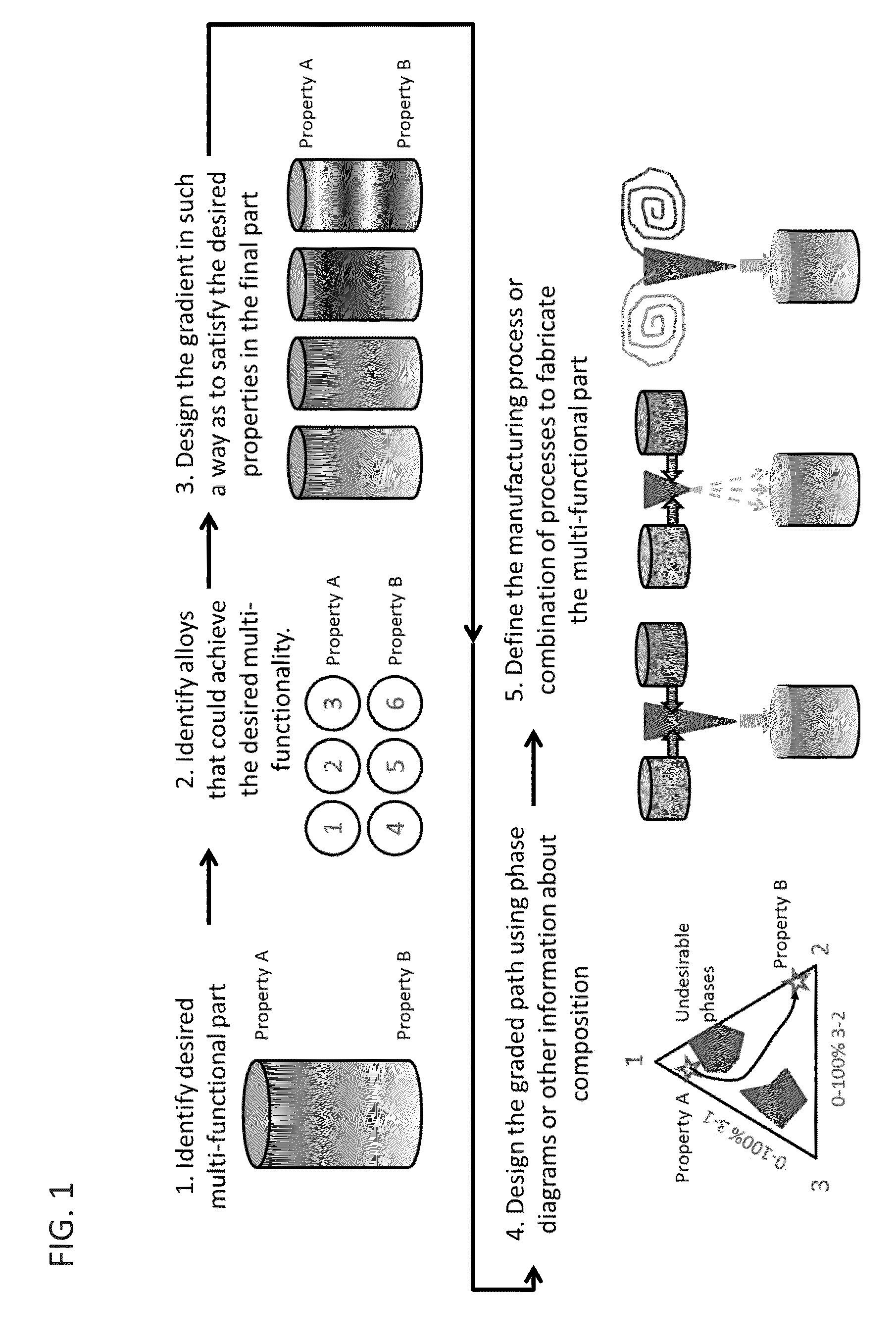

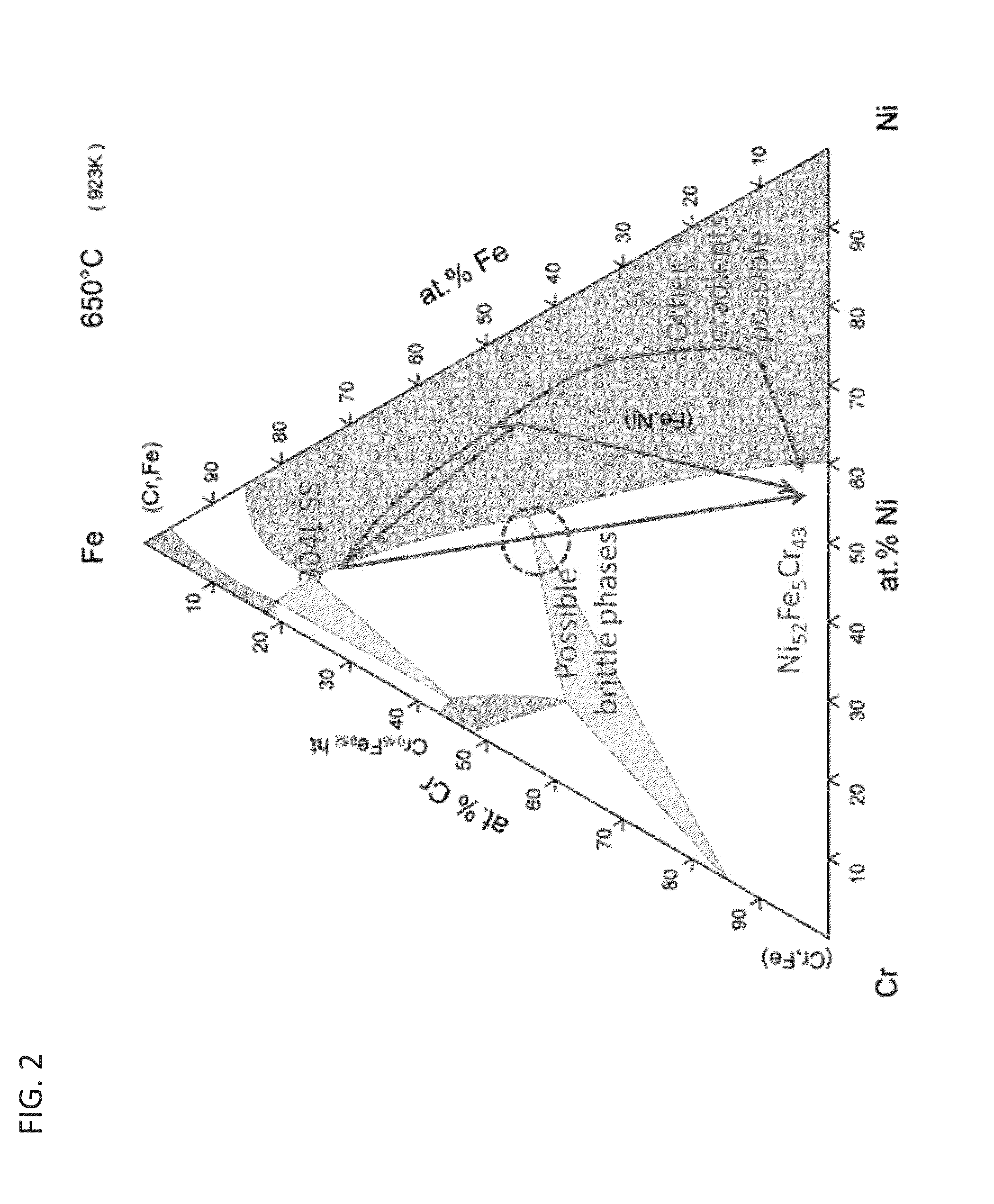

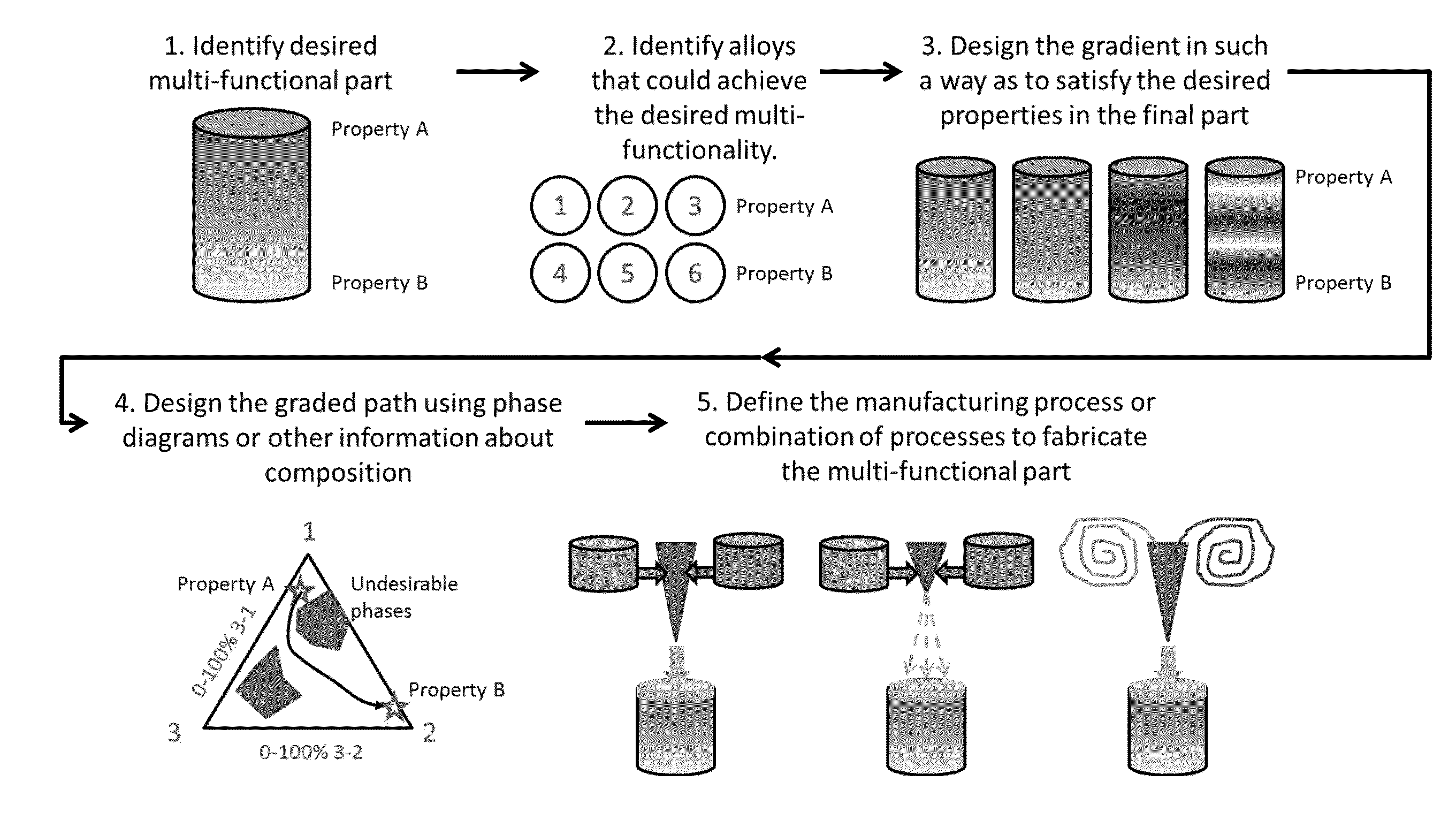

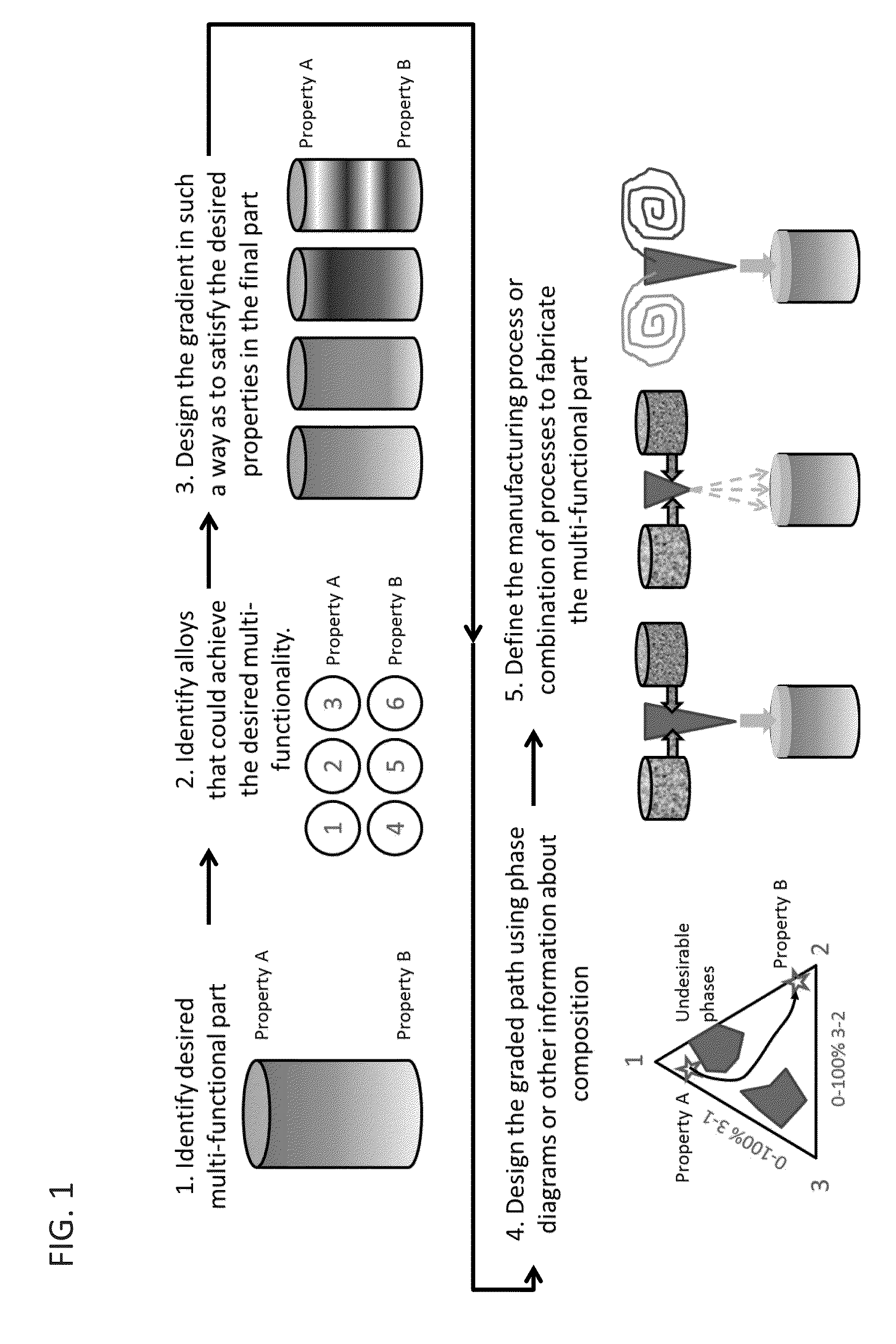

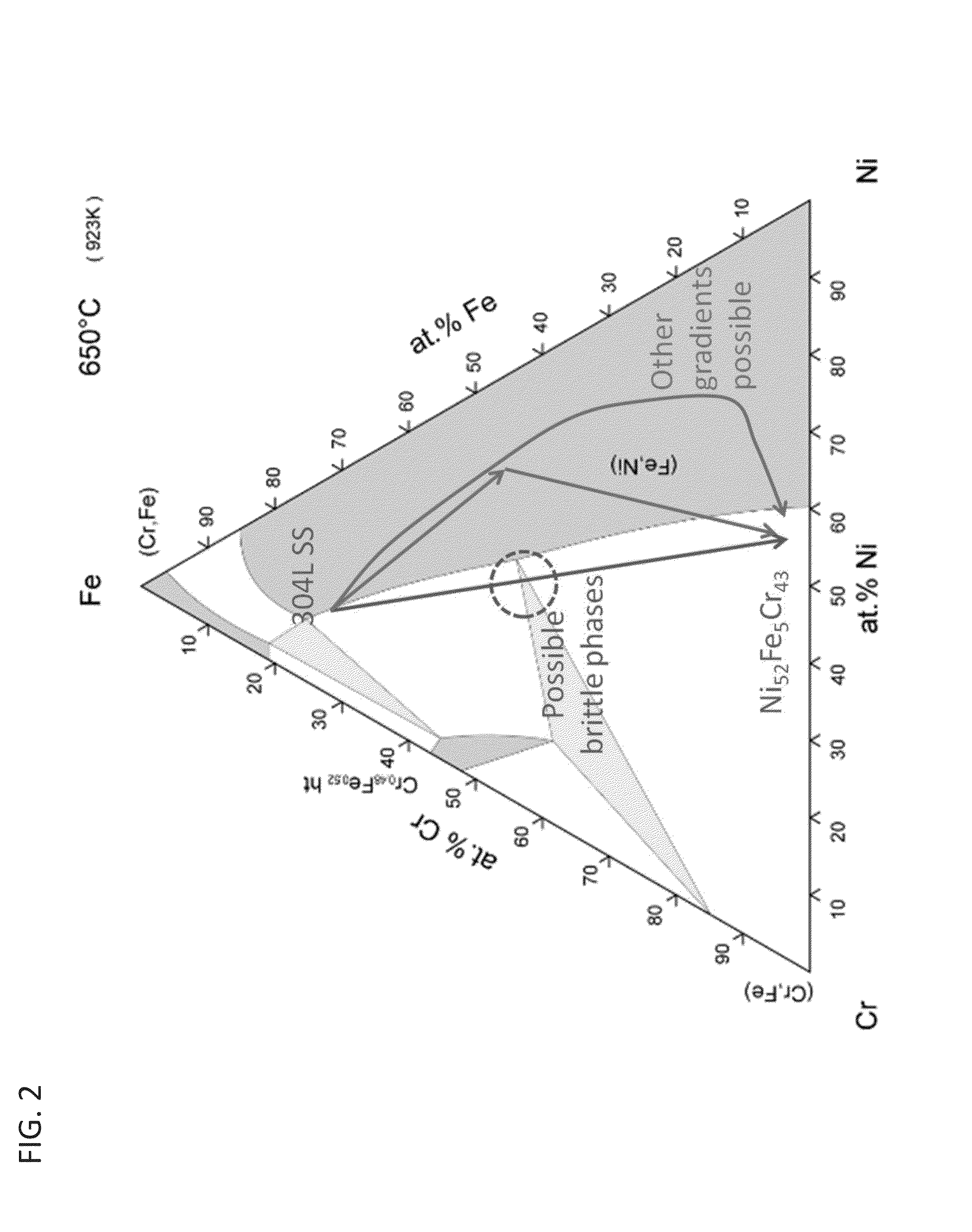

Methods for fabricating gradient alloy articles with multi-functional properties

Systems and methods for fabricating multi-functional articles comprised of additively formed gradient materials are provided. The fabrication of multi-functional articles using the additive deposition of gradient alloys represents a paradigm shift from the traditional way that metal alloys and metal / metal alloy parts are fabricated. Since a gradient alloy that transitions from one metal to a different metal cannot be fabricated through any conventional metallurgy techniques, the technique presents many applications. Moreover, the embodiments described identify a broad range of properties and applications.

Owner:CALIFORNIA INST OF TECH

Methods for fabricating gradient alloy articles with multi-functional properties

ActiveUS20150044084A1High speedSufficient cooling rateAdditive manufacturingMolten spray coatingMetal alloyGradient material

Systems and methods for fabricating multi-functional articles comprised of additively formed gradient materials are provided. The fabrication of multi-functional articles using the additive deposition of gradient alloys represents a paradigm shift from the traditional way that metal alloys and metal / metal alloy parts are fabricated. Since a gradient alloy that transitions from one metal to a different metal cannot be fabricated through any conventional metallurgy techniques, the technique presents many applications. Moreover, the embodiments described identify a broad range of properties and applications.

Owner:CALIFORNIA INST OF TECH

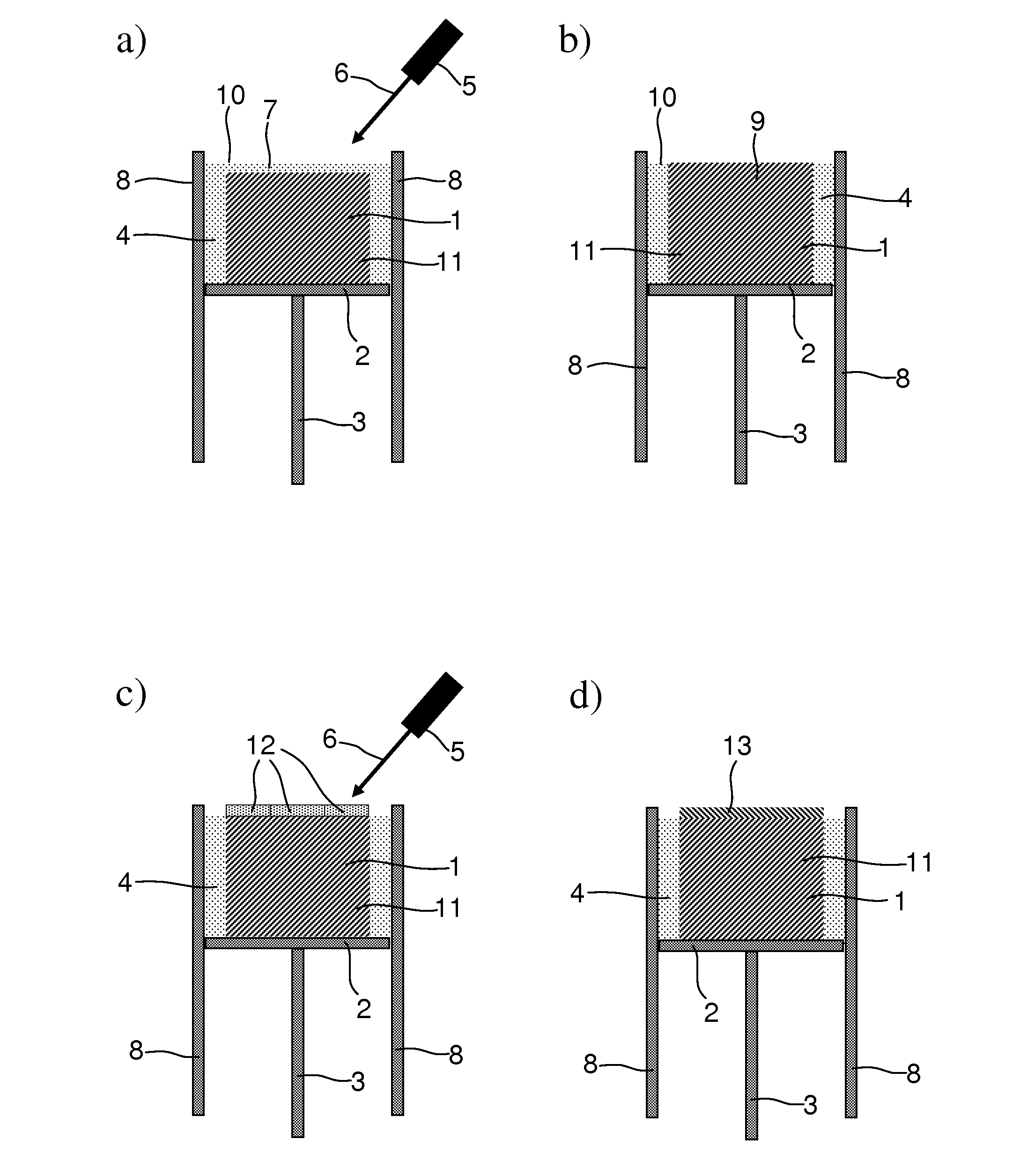

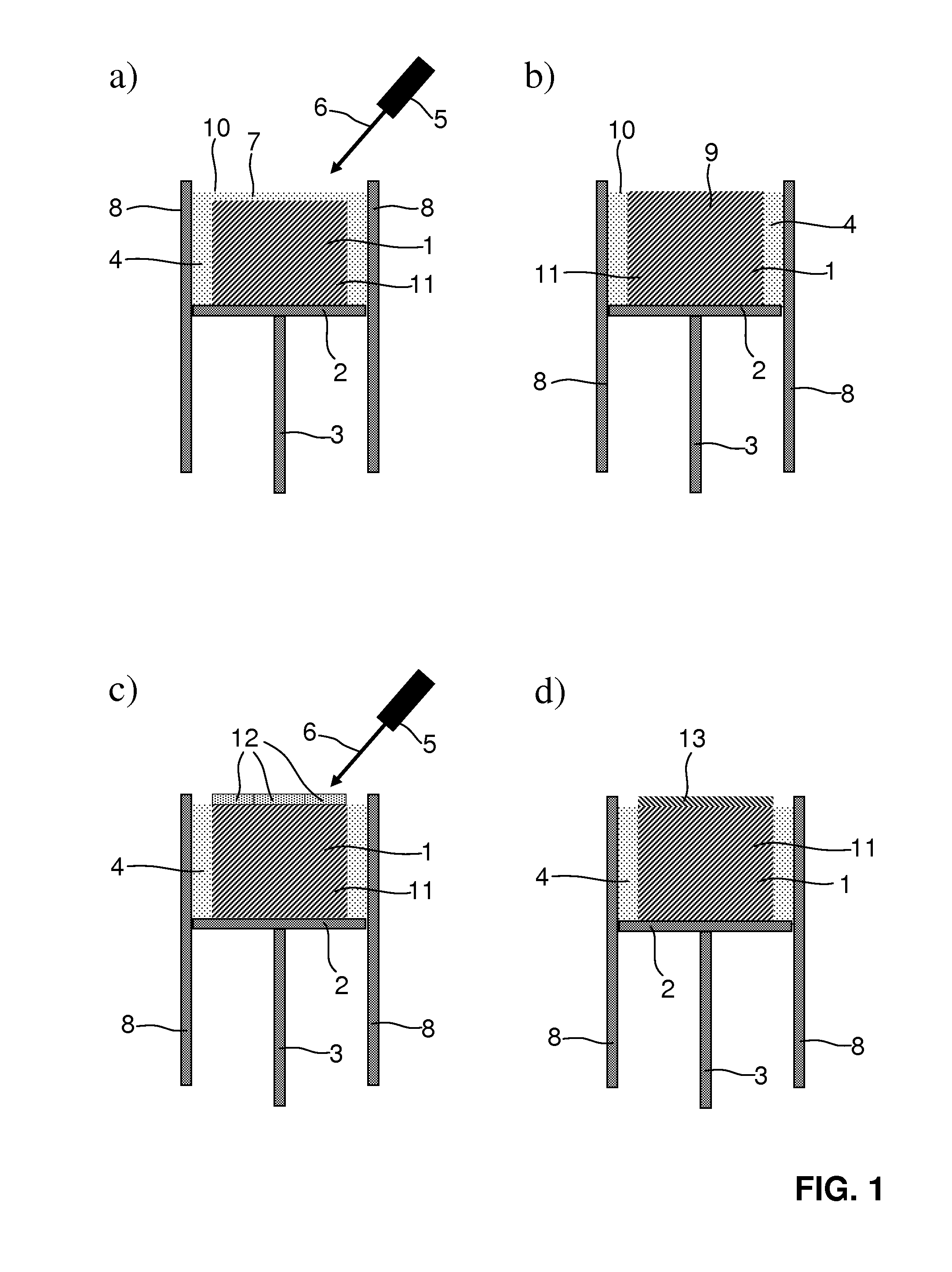

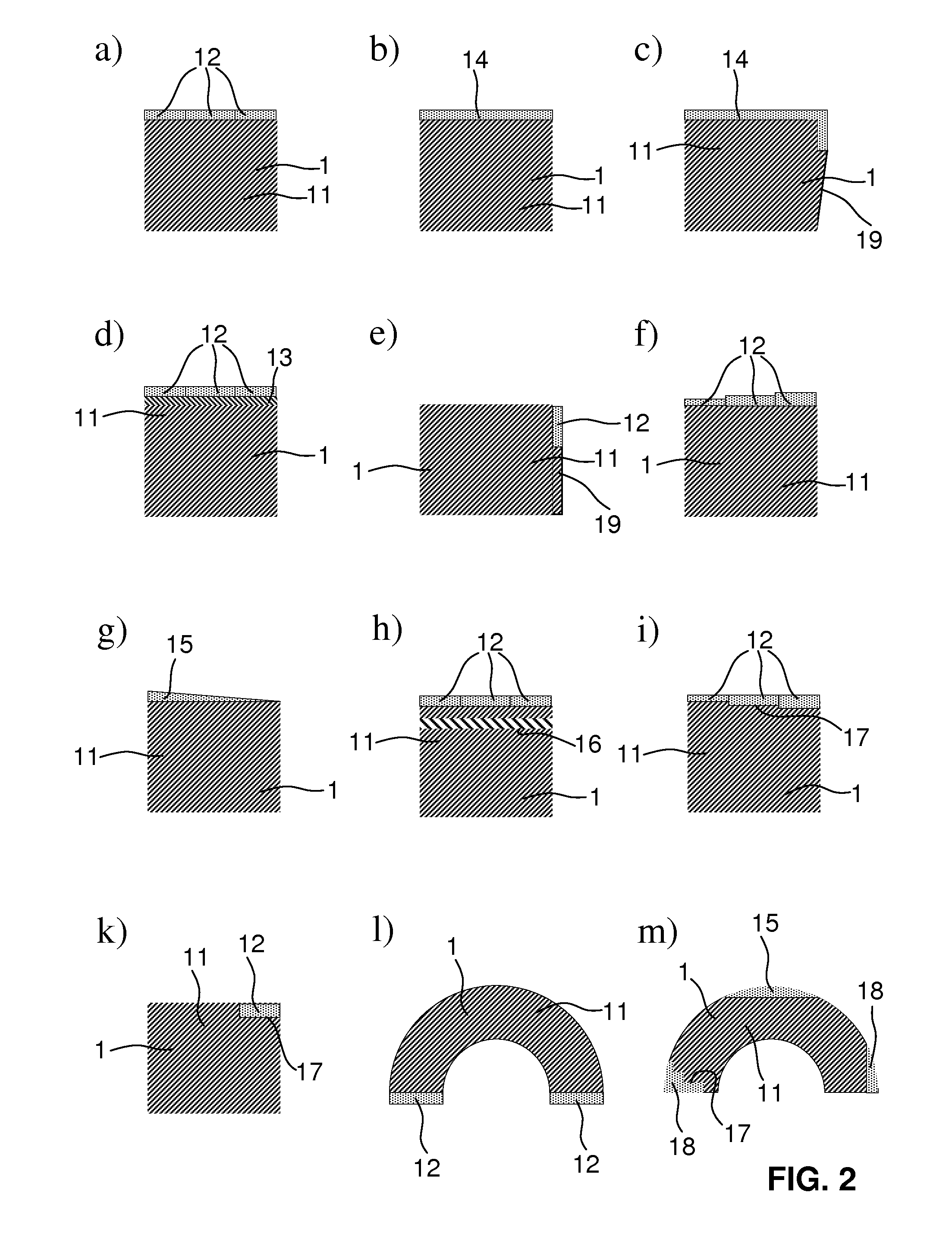

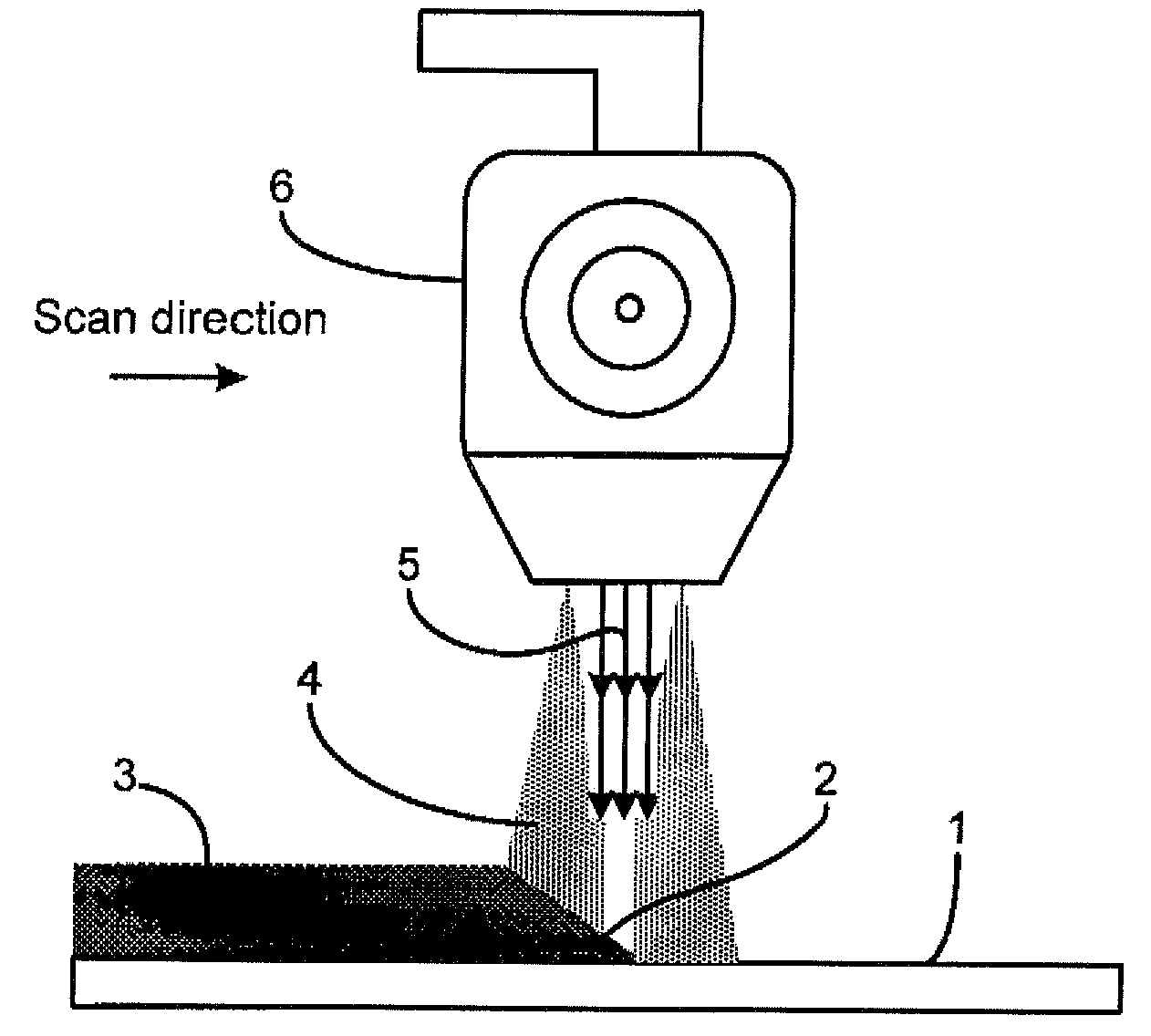

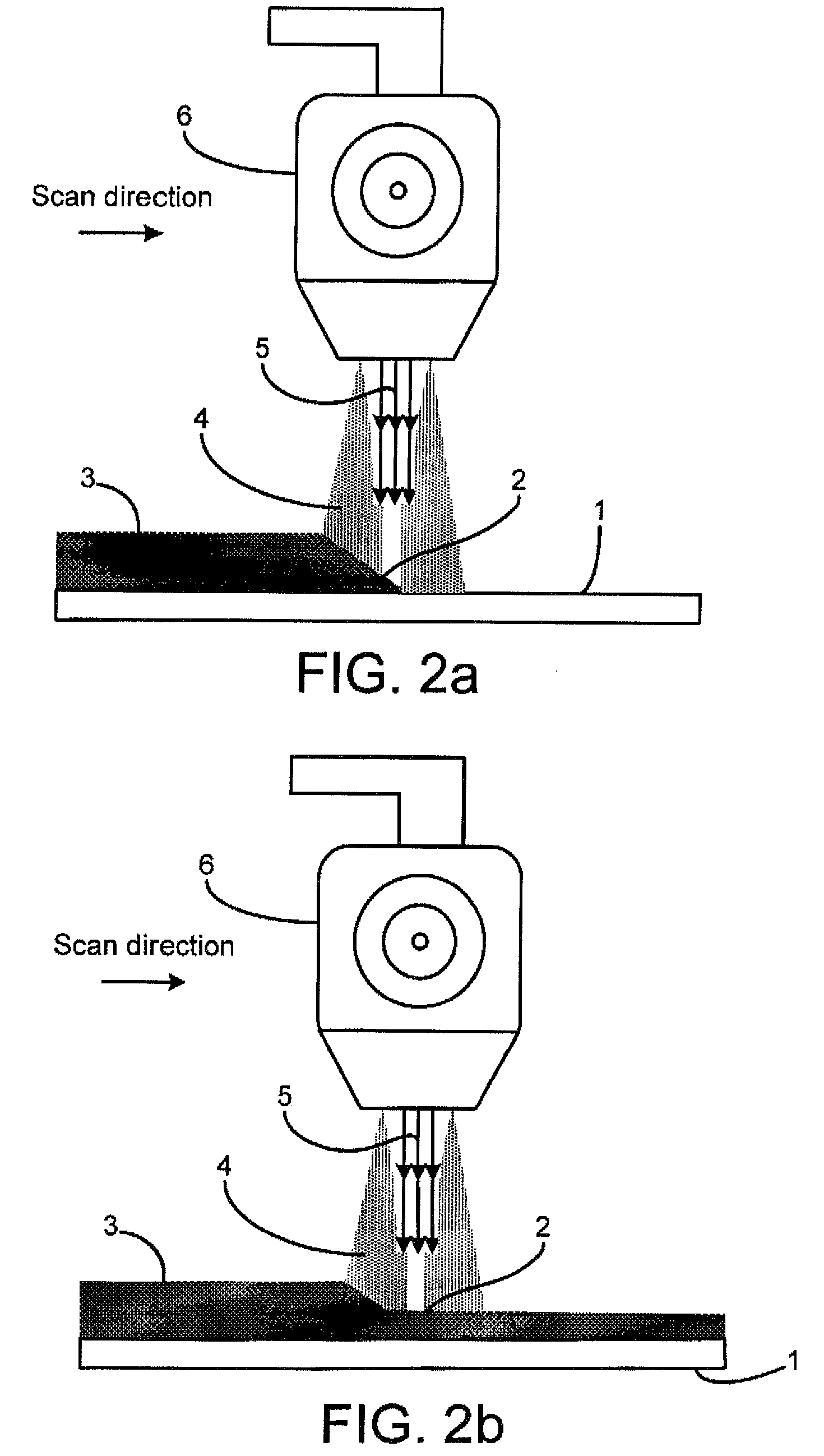

Method of applying multiple materials with selective laser melting on a 3D article

InactiveUS20110106290A1Increase weld ability/brazeabilityEasy to optimizeTurbinesAdditive manufacturingMulti materialSelective laser melting

In a method for manufacturing an article (1), particularly a prototype of a product or component, a tool prototype or spare part, by using selected laser melting, for the application onto the article (1) of a layer (13) or portion of a second metallic material, which is different from the material of the first metallic powder (4), a tape (12), sheet (14), foil or three-dimensional pre-form (18) of a second material is applied to the article (1) and is heated by a focused laser or electron beam (6) to a specified temperature such that the tape (12), sheet (14), foil or pre-form, respectively, are made molten by the electron laser beam (6), wherein the focused beam (6) is applied to a given area corresponding to a selected cross-sectional area of the model of the article (1) under formation of a new layer or part made of second material integral with the article (1).

Owner:ANSALDO ENERGIA IP UK LTD

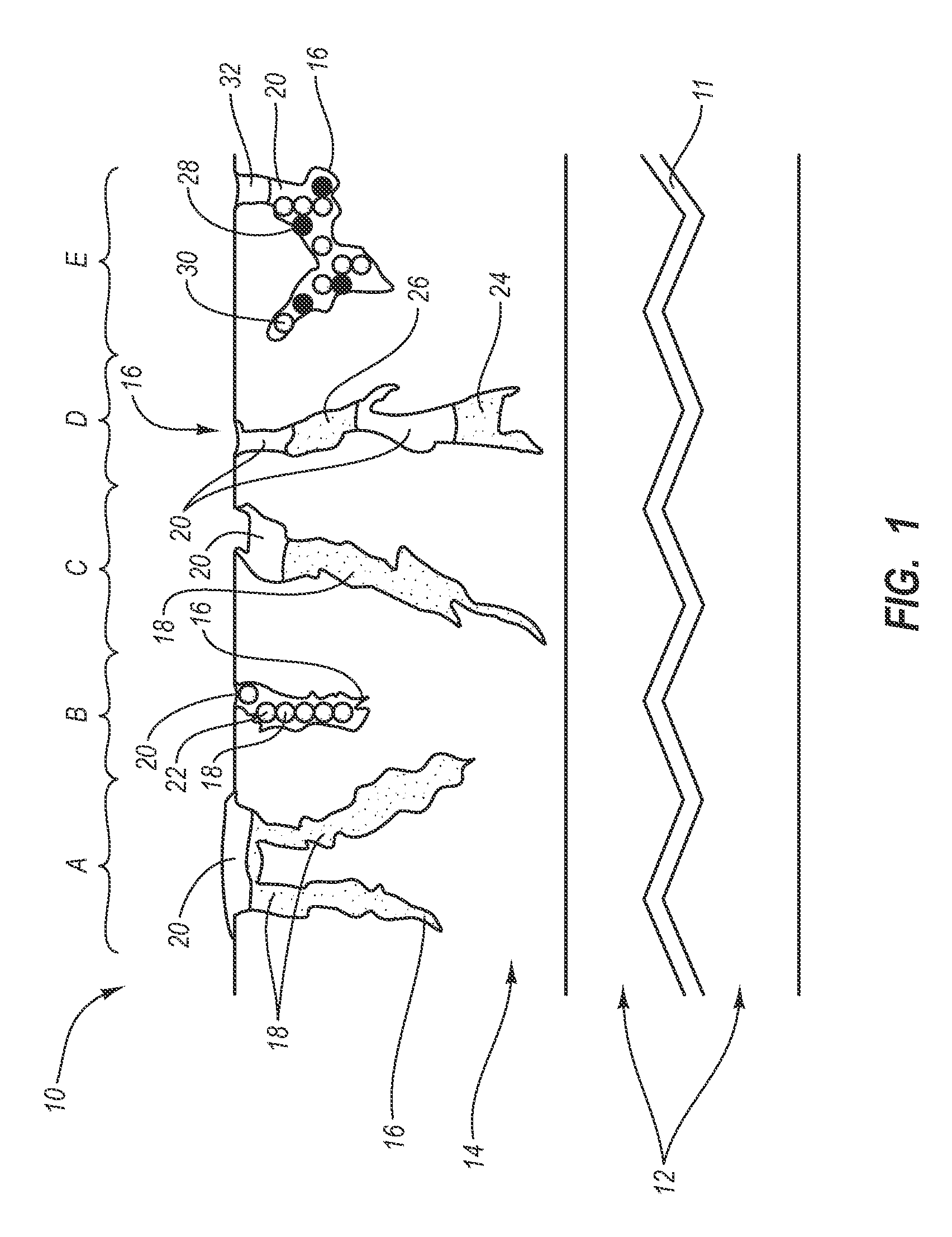

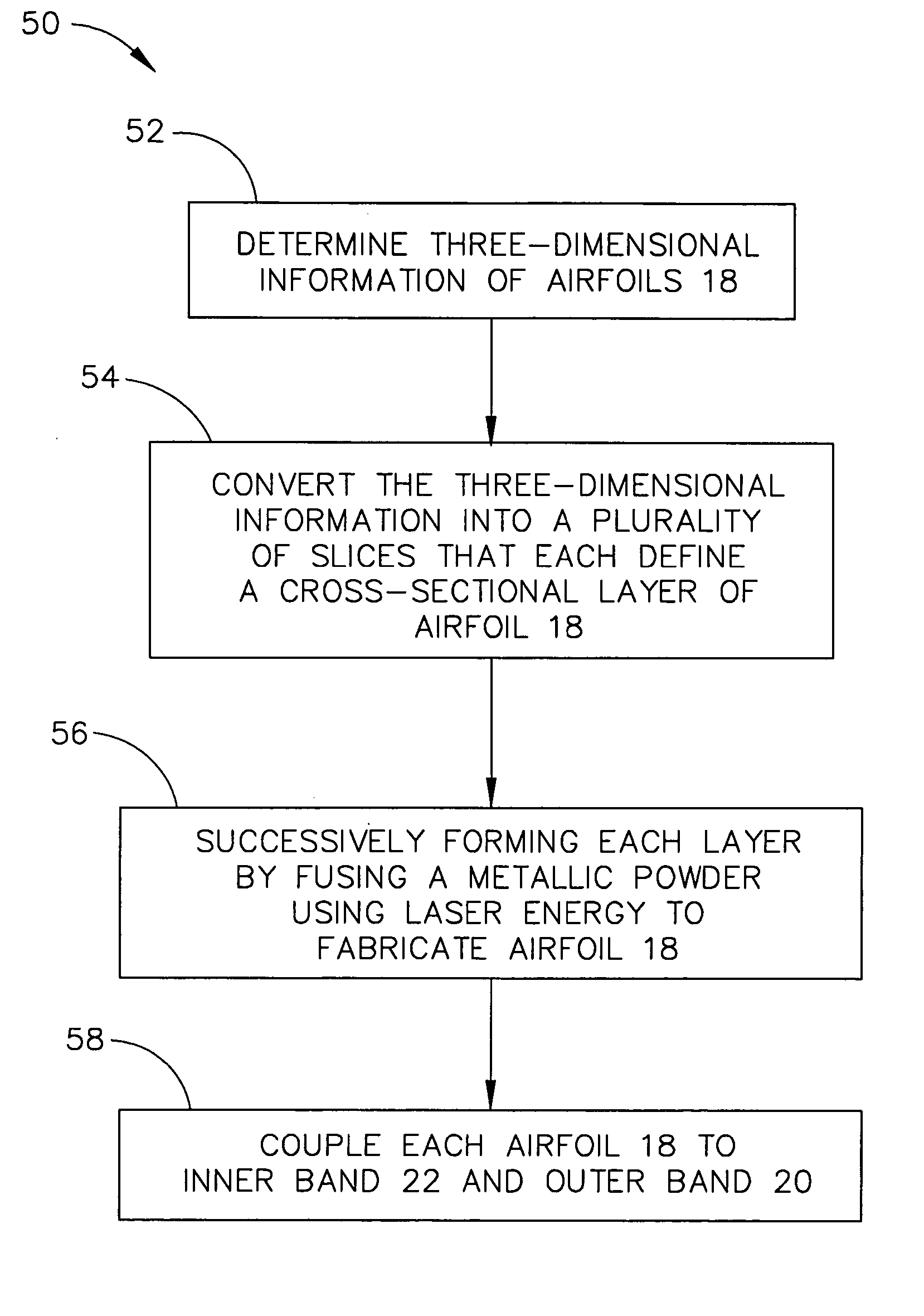

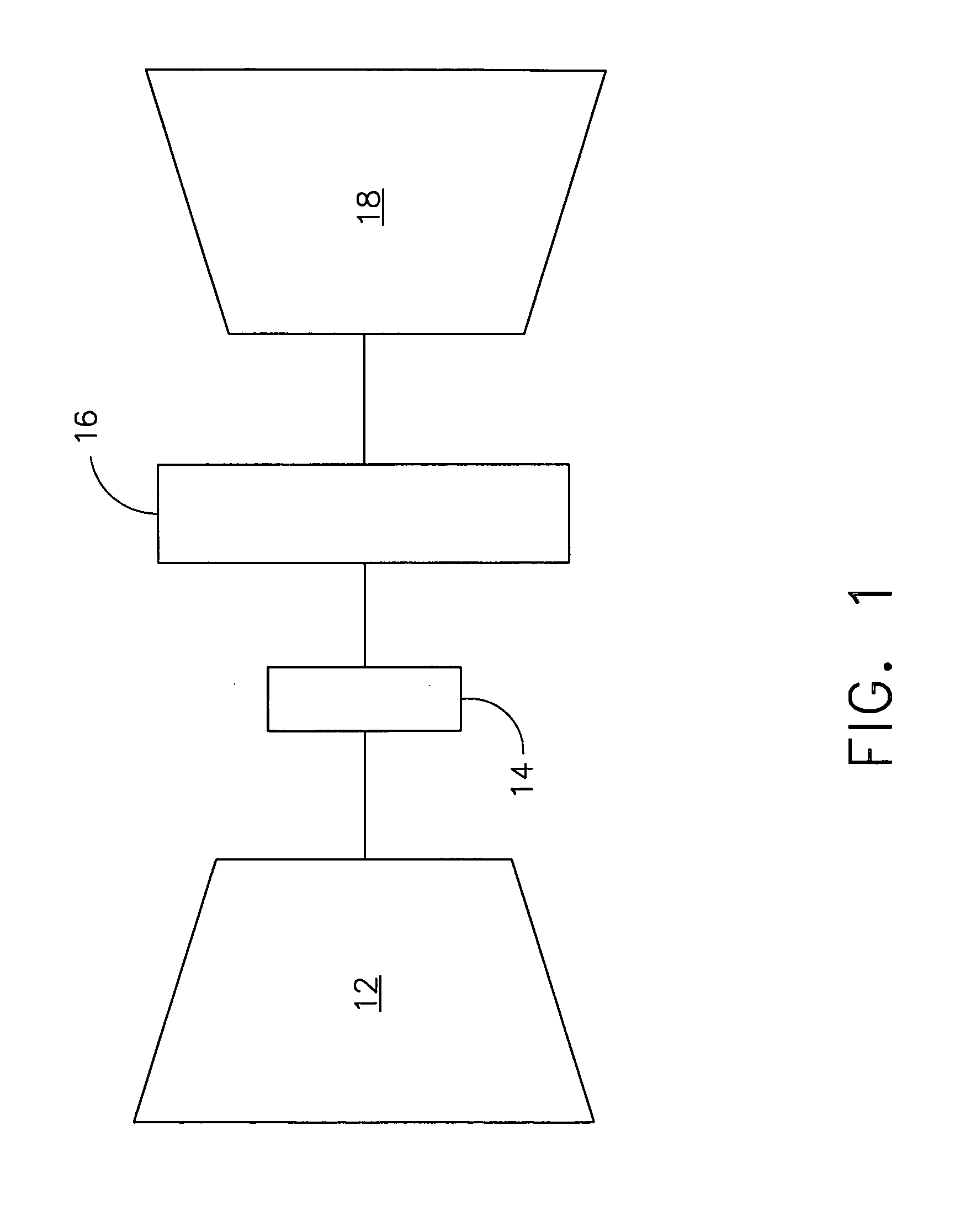

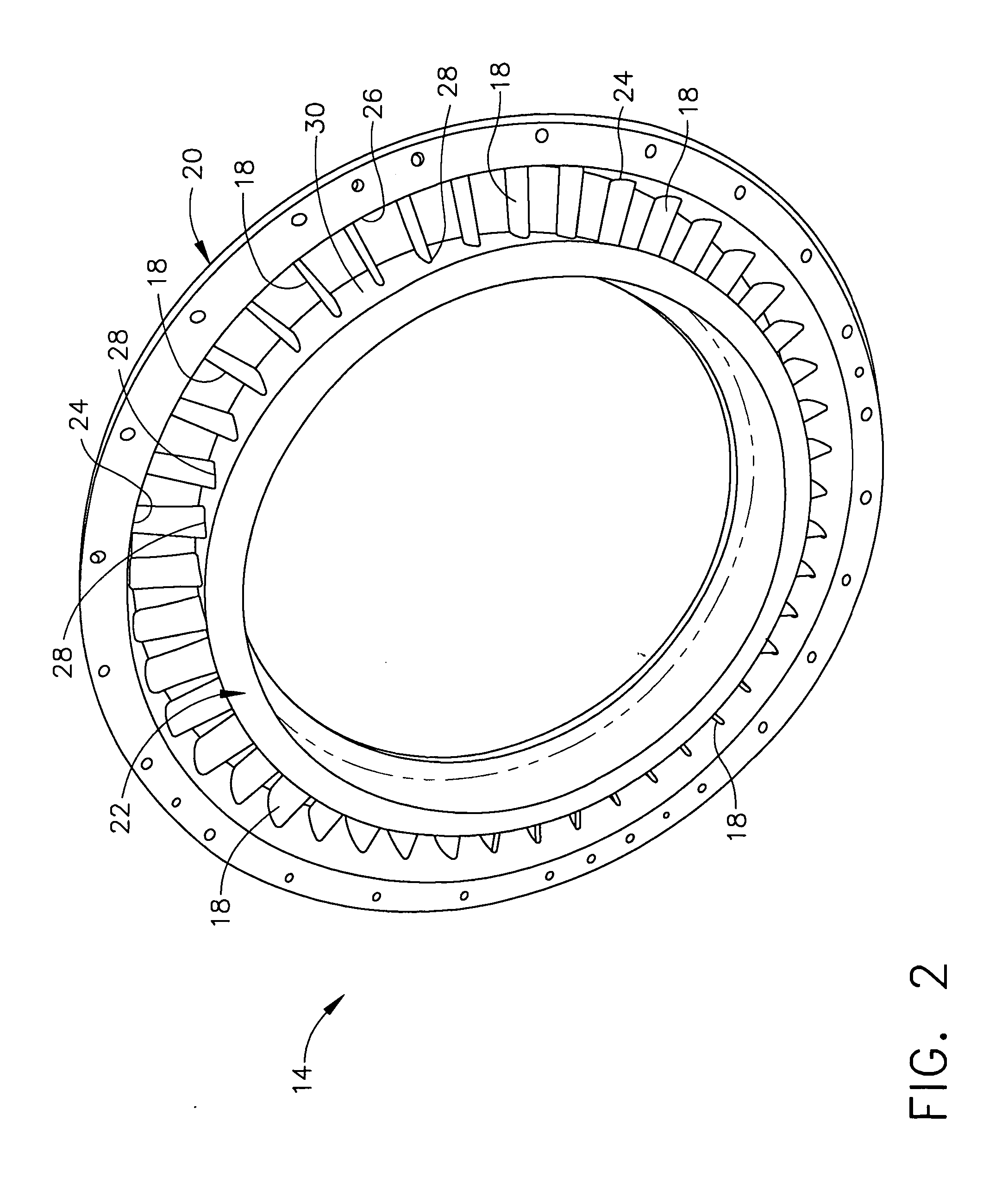

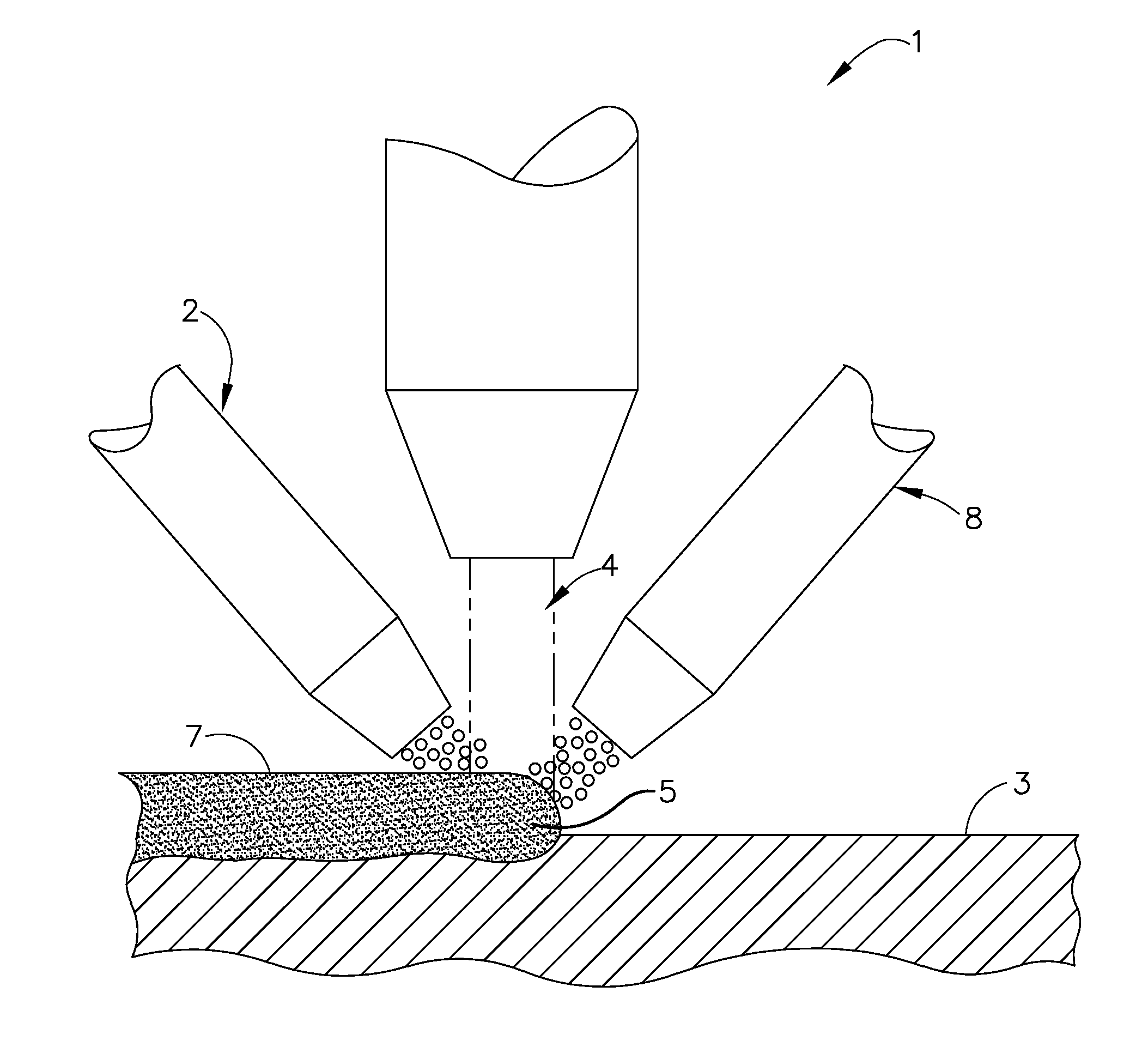

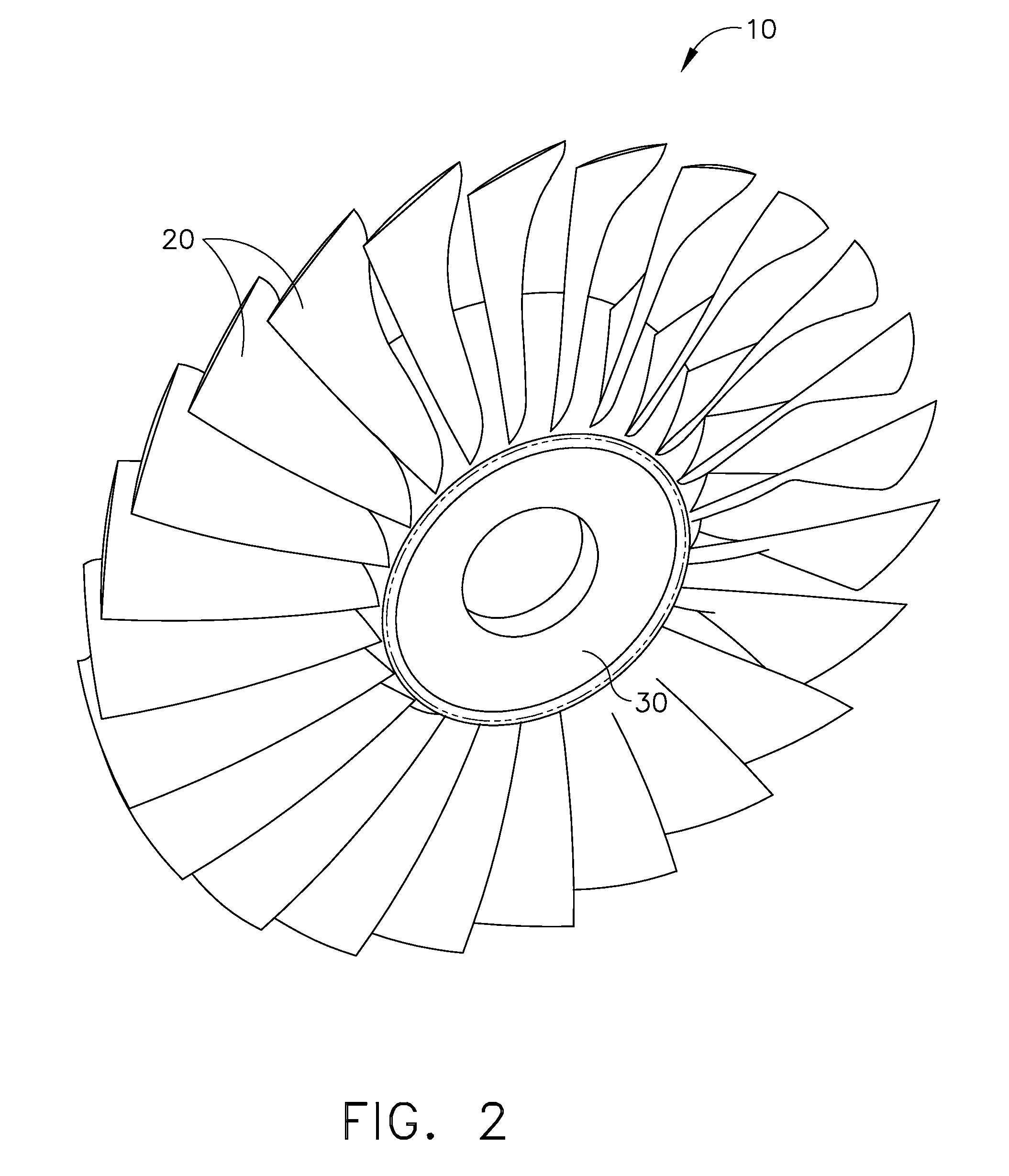

Methods for fabricating components

A method for fabricating an assembly having an airfoil extending radially outwardly from a member includes determining three-dimensional information of the airfoil, converting the three-dimensional information into a plurality of slices that each define a cross-sectional layer of the airfoil, successively forming each layer of the airfoil by fusing a metallic powder using laser energy, and coupling the airfoil to the member such that the airfoil extends radially outward from the member.

Owner:GENERAL ELECTRIC CO

Laser net shape manufacturing and repair using a medial axis toolpath deposition method

InactiveUS20080182017A1Eliminate and reduce numberAdditive manufacturingTurbinesMedial axisNet shape

A method is disclosed for laser net shape manufacturing a part or repairing an area of a part comprising providing a CAD model of the part to be manufactured or repaired, digitally slicing the CAD model into a plurality of deposition layers, determining a medial axis for each of the deposition layers of the part or repair area; and depositing a bead of a material in a pattern centered upon the medial axis of each of the deposition layers so as to build-up the material by each of the deposition layer until the part is manufactured or repaired.

Owner:GENERAL ELECTRIC CO

Methods of using medical devices for controlled drug release

InactiveUS20080057103A1Treating and preventing diseaseStentsOrganic active ingredientsDiseaseVascular disease

The present invention is a medical device for controlling the release of an active agent. The medical device has a supporting structure having a porous body disposed therein. At least one elution rate controlling matrix containing an effective amount of at least one active agent is disposed within the pores of the porous body in a manner that protects the matrix from mechanical damage. The medical device may therefore be used for controlled drug release applications. Additionally, the present invention discloses a method for using the medical device for the treatment and prevention of diseases in mammals. This invention further relates to a method for using the medical device for treating and preventing vascular diseases.

Owner:ABBOTT LAB INC

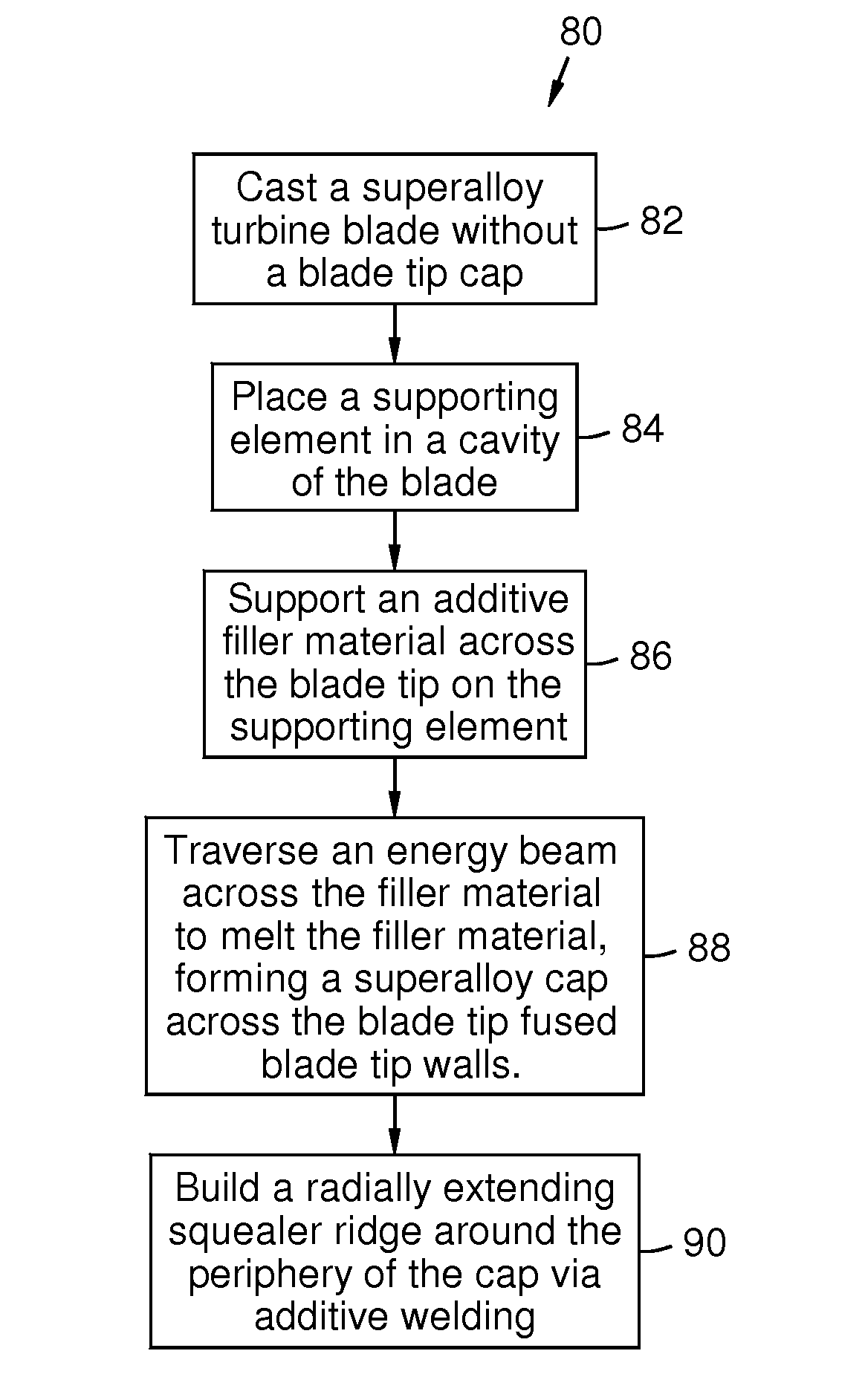

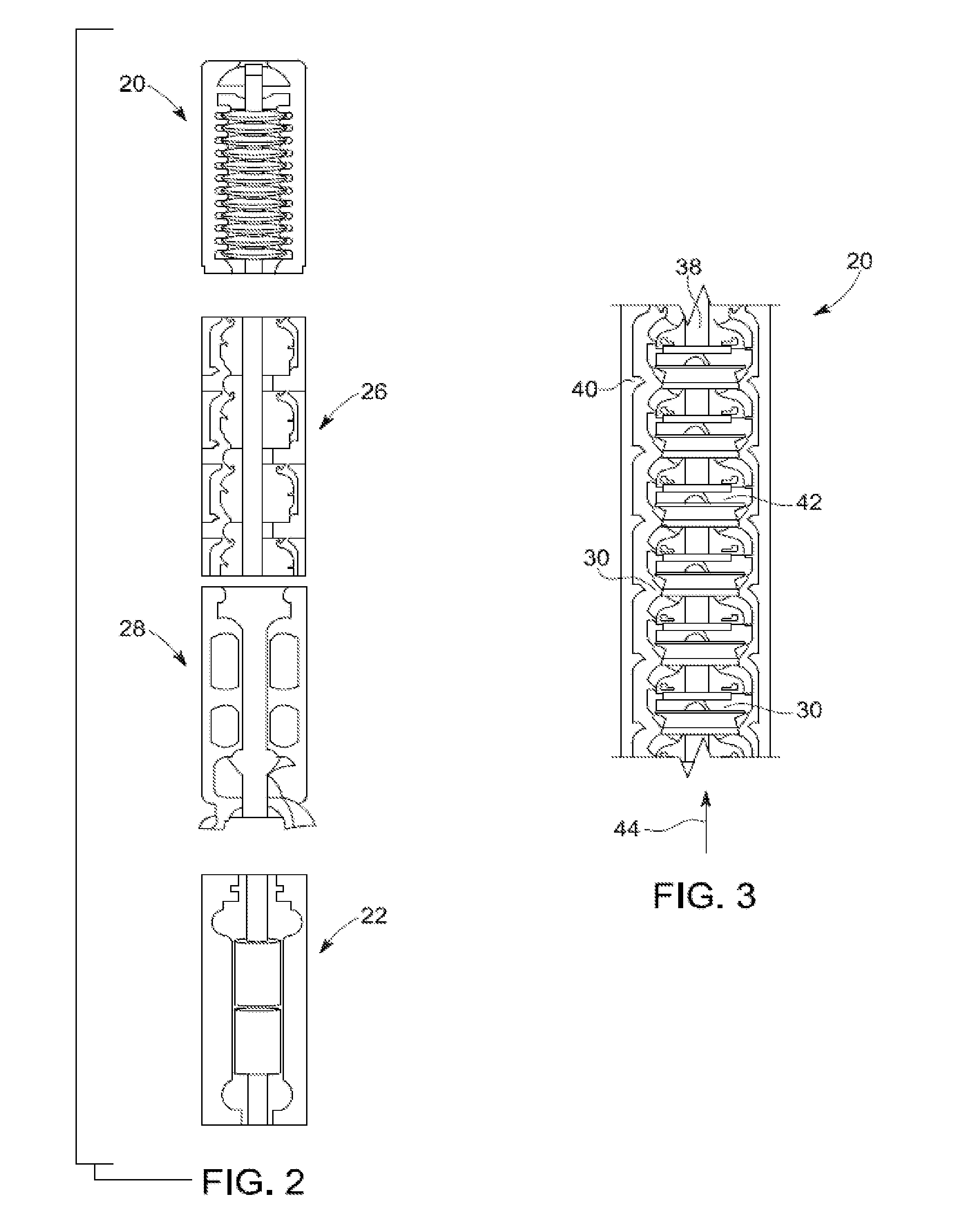

Building and repair of hollow components

A method of building or repair of a hollow superalloy component (20, 61) by forming an opening (38, 62) in a wall (28) of the component; filling a cavity (22B, 64) behind the opening with a fugitive support material (34, 52, 54, 68) to support a filler powder (36) across the opening; traversing an energy beam (42) across the filler powder to form a deposit (44) that spans and closes the opening; in which the deposit is fused to the edges (32, 62) of the opening. The filler powder includes at least metal, and may further include flux. The support material may include filler powder, a solid (54), a foam (52) insert, a flux powder (34) and / or other ceramic powder (68). Supporting powder may have a mesh size smaller than that of the filler powder.

Owner:SIEMENS ENERGY INC

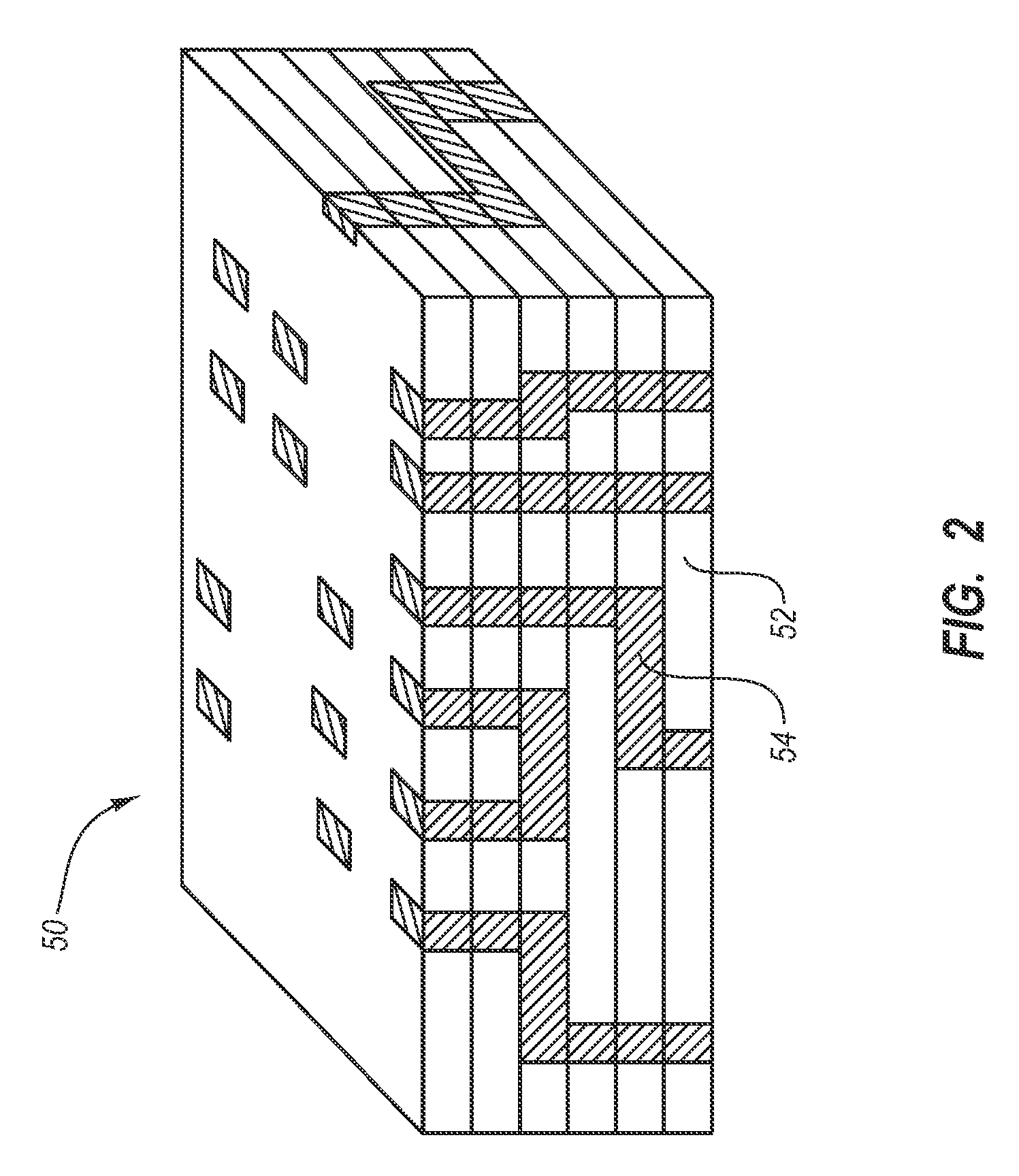

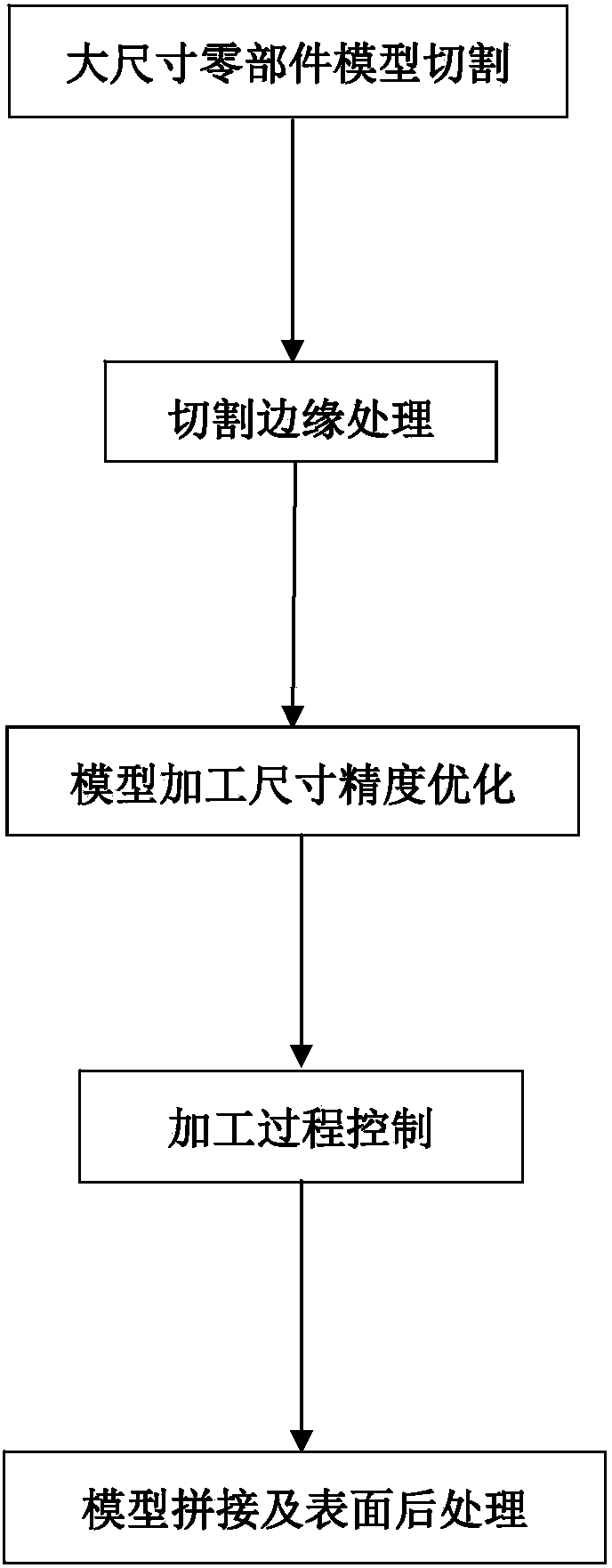

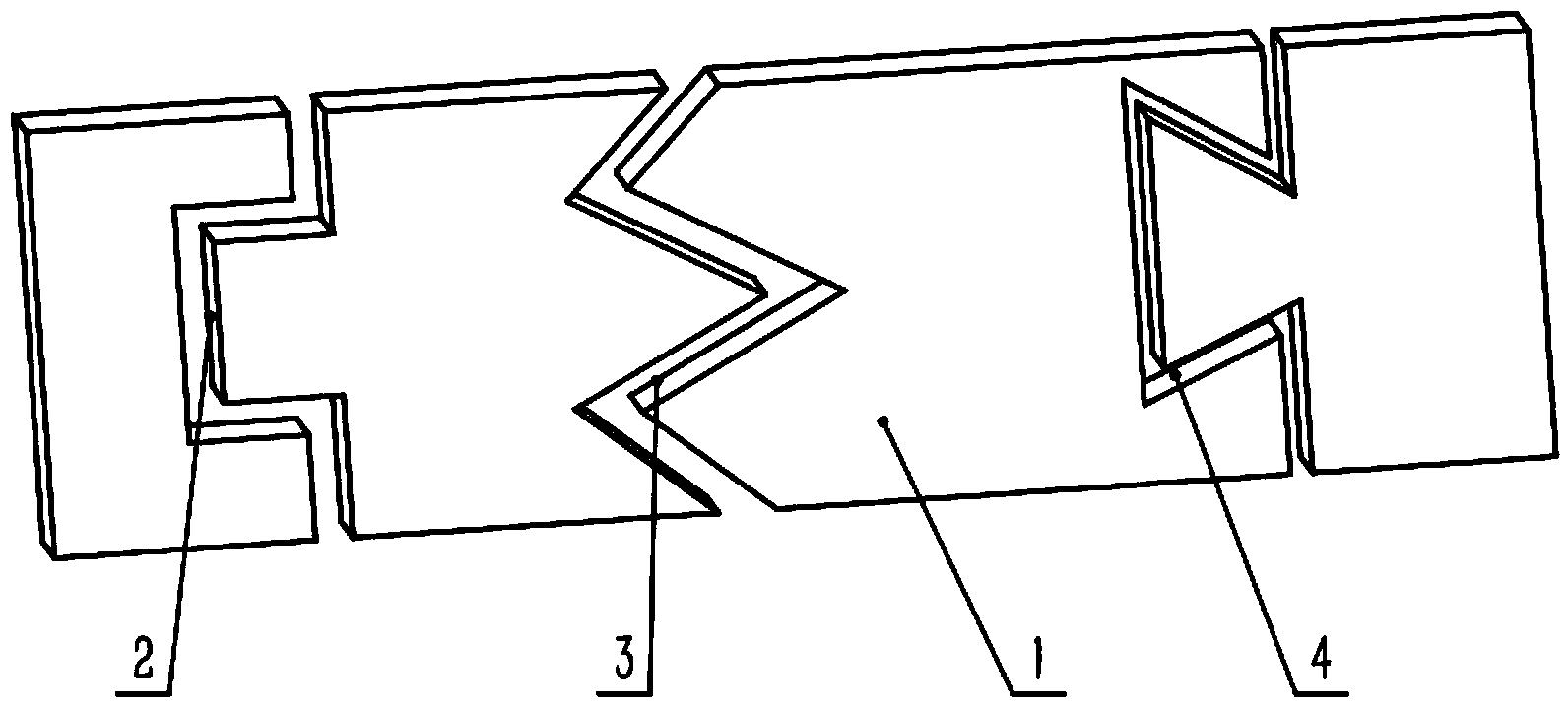

3D printing manufacturing method for large-size part

ActiveCN104226988AGuaranteed performanceGuaranteed dimensional accuracyAdditive manufacturingEffective solutionLarge size

The invention discloses a 3D printing manufacturing method for a large-size part, which comprises the following steps: a) cutting a model of a to-be-manufactured large-size part into a plurality of sub-part models in a preset size scope; b) manufacturing and finishing the processing and forming of all sub-parts by adding materials on the basis of the sub-part models; c) jointing and fixing all the sub-parts, thereby forming the large-size part. According to the invention, the 3D printing device in insufficient effective processing size can be used for manufacturing the large-size part, the property and the whole size precision of the large-size part after being cut and spliced can be ensured, and a quick and efficient solution is supplied to the manufacturing of the sample or end product of the large-size parts in various fields.

Owner:SHENZHEN SUNSHINE LASER & ELECTRONICS TECH CO LTD

Medical devices for controlled drug release

The present invention is a medical device for controlling the release of an active agent. The medical device has a supporting structure having a porous body disposed therein. At least one elution rate controlling matrix containing an effective amount of at least one active agent is disposed within the pores of the porous body in a manner that protects the matrix from mechanical damage. The medical device may therefore be used for controlled drug release applications. Additionally, the present invention discloses a method for using the medical device for the treatment and prevention of diseases in mammals. This invention further relates to a method for using the medical device for treating and preventing vascular diseases.

Owner:ABBOTT LAB INC

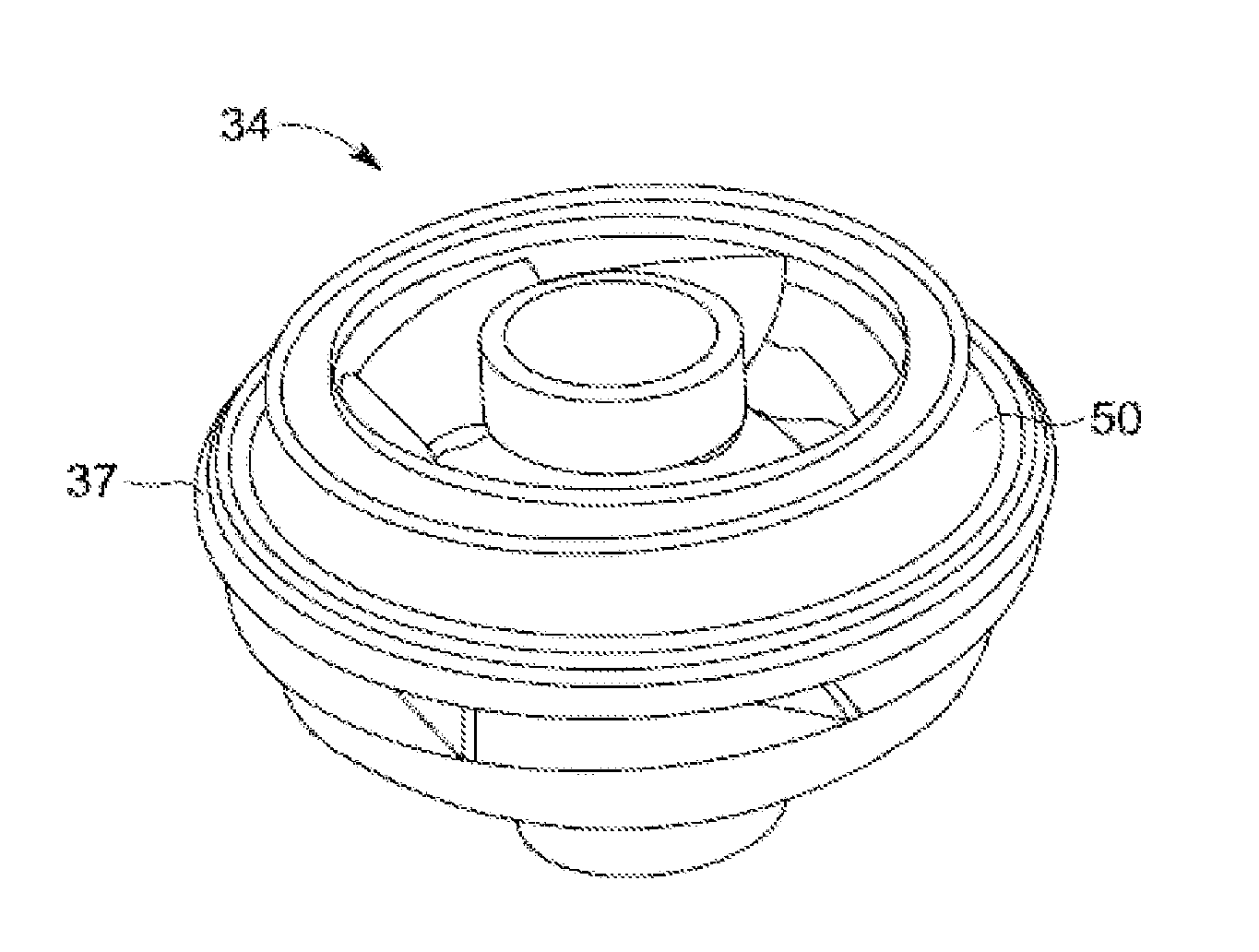

Electrical submersible pump and pump system including additively manufactured structures and method of manufacture

An electric submersible pump and pump system including additively manufactures structures and method of manufacture are disclosed. The pump system including the electric submersible pump and an electric motor configured to operate the electric submersible pump. The electric submersible pump including a housing, at least one impeller and at least one diffuser disposed within the housing in cooperative engagement. The housing, the at least one impeller, and the at least one diffuser defining an internal volume configured to receive a fluid. At least one of the at least one impeller and the at least one diffuser configured as a monolithic additively manufactured structure comprised of a metal matrix composite. Also provided is an electric submersible pump including an impeller and a diffuser, wherein at least one of the impeller and the diffuser is configured as a monolithic additively manufactured structure comprised of a tungsten carbide (WC) dispersed in a metal matrix.

Owner:GENERAL ELECTRIC CO

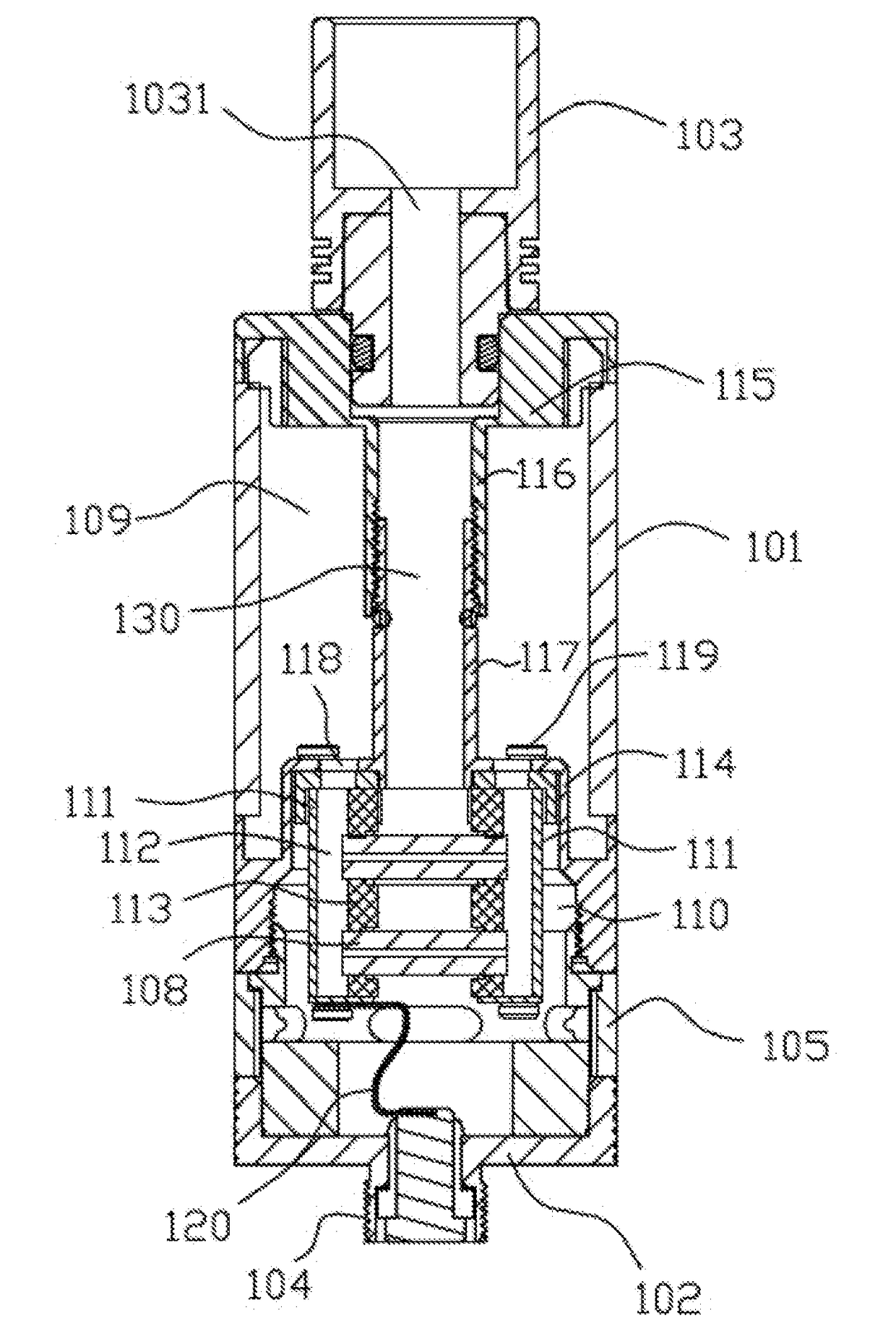

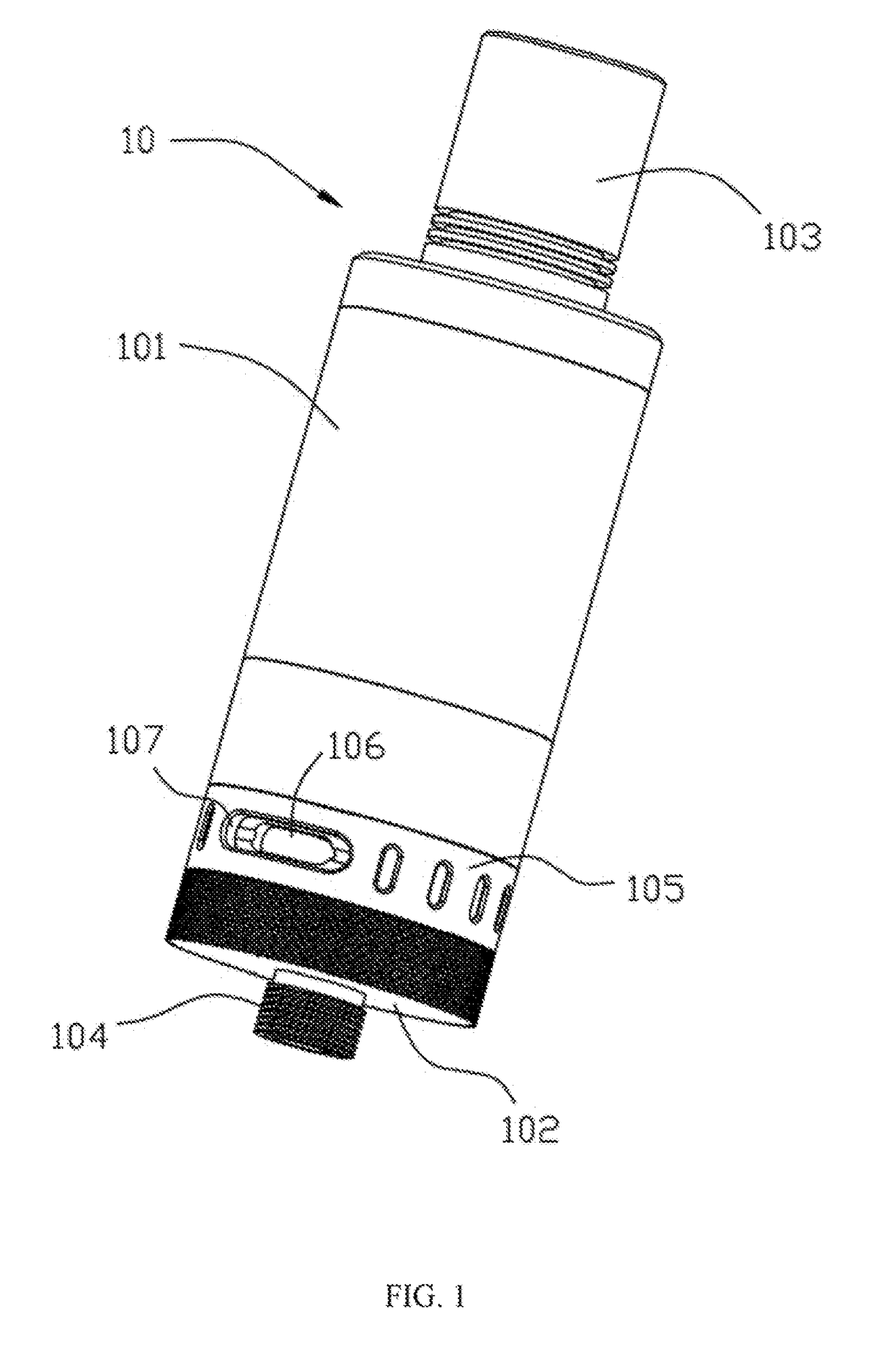

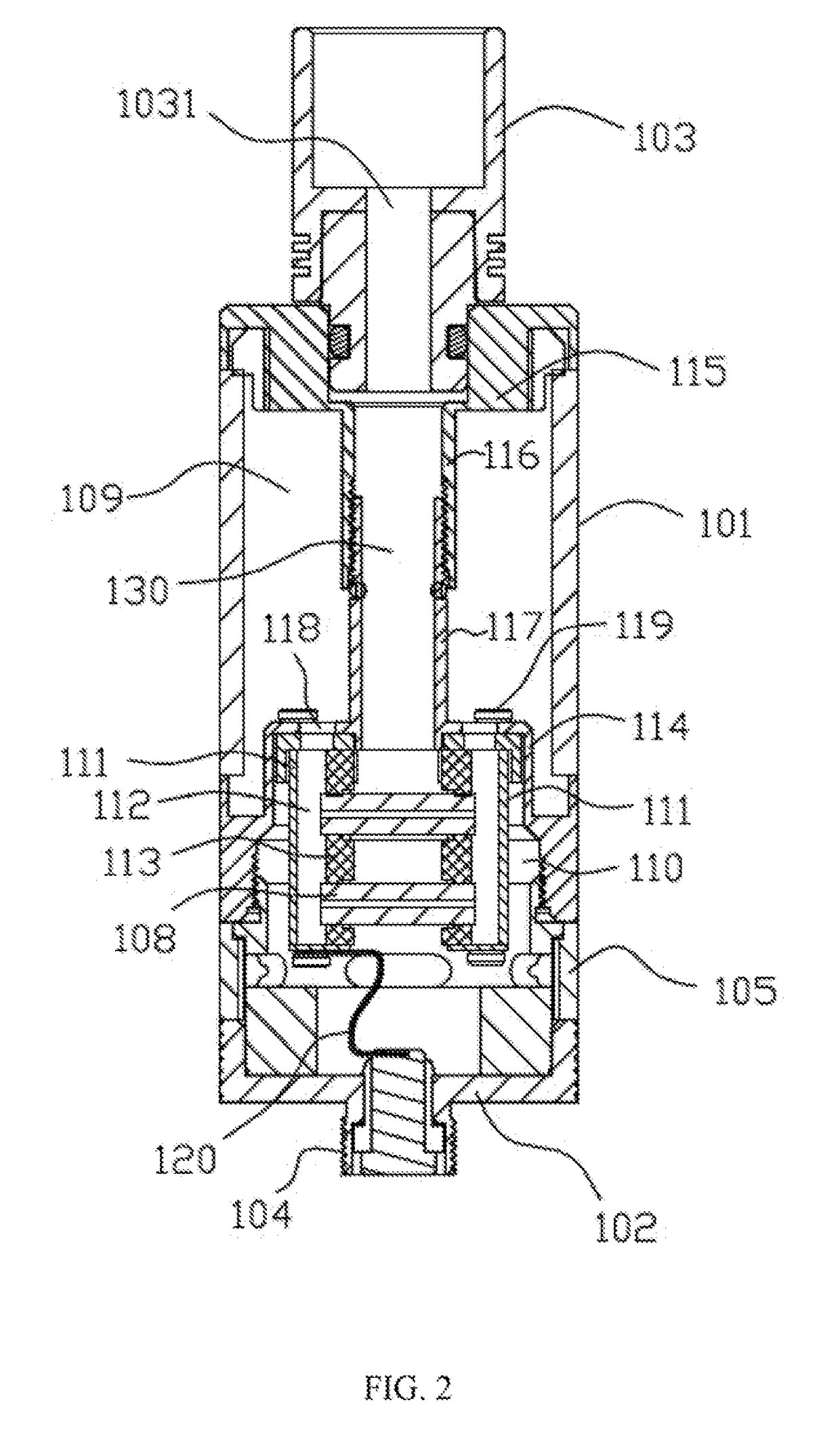

Atomizer and electronic smoking device having same

ActiveUS20170105453A1Unsatisfactory user experienceUnevenness of gapAdditive manufacturingOhmic-resistance waterproof/air-tight sealsElectricityEngineering

An exemplary atomizer includes a housing, a conductive part at an end of the housing, a mouthpiece with an air outlet, a liquid chamber, and at least one heating element. The liquid chamber is in the housing and configured for storing tobacco liquid. The at least one heating element is electrically connected to the conductive part. The heating element includes a liquid carrier and a heating part integrally formed with the liquid carrier. The liquid carrier has a micro porous structure. The liquid carrier is in contact with the tobacco liquid. The liquid carrier is configured for absorbing the tobacco liquid, and the heating part is configured for heating the tobacco liquid to form aerosol.

Owner:SHENZHEN FIRST UNION TECH CO LTD

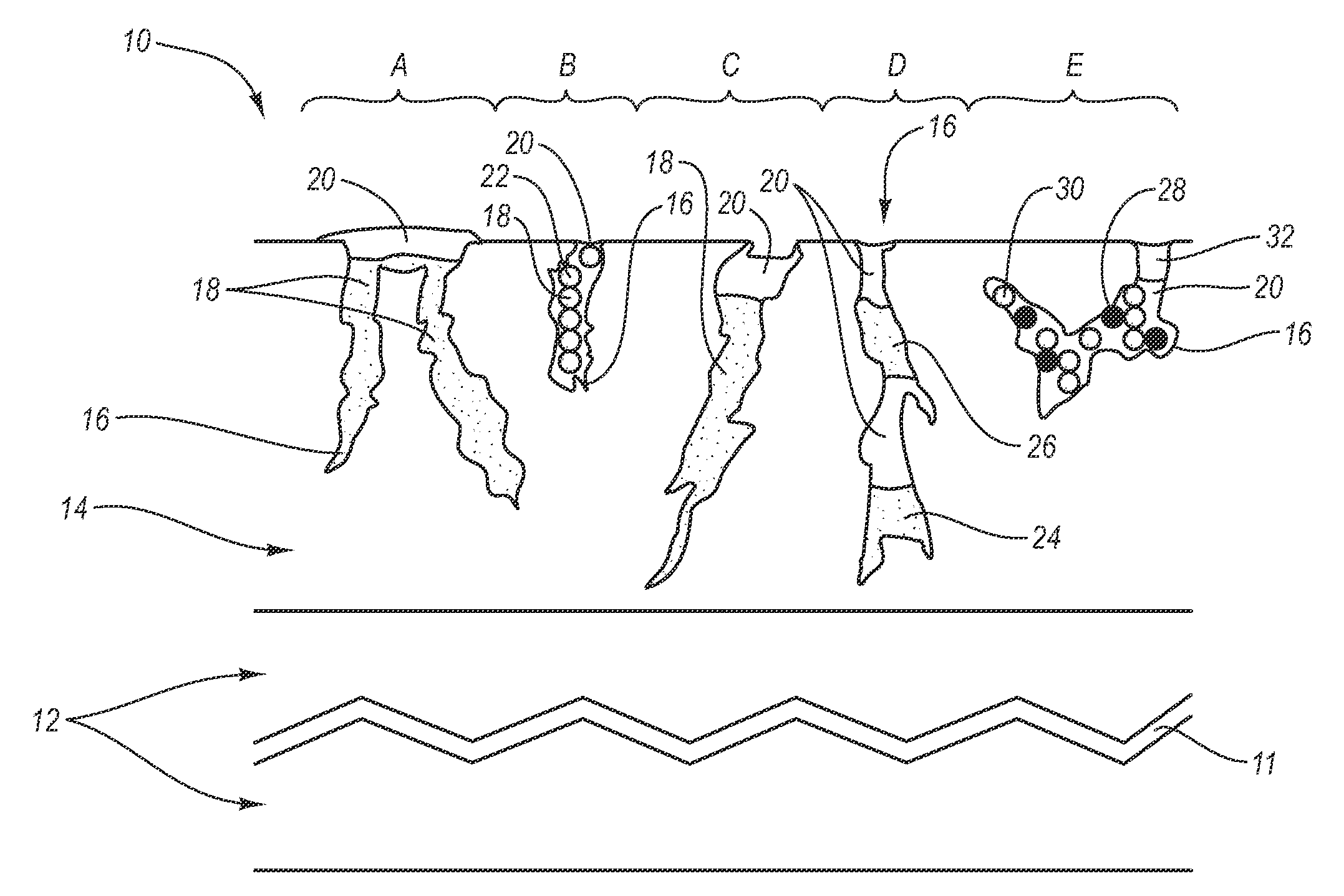

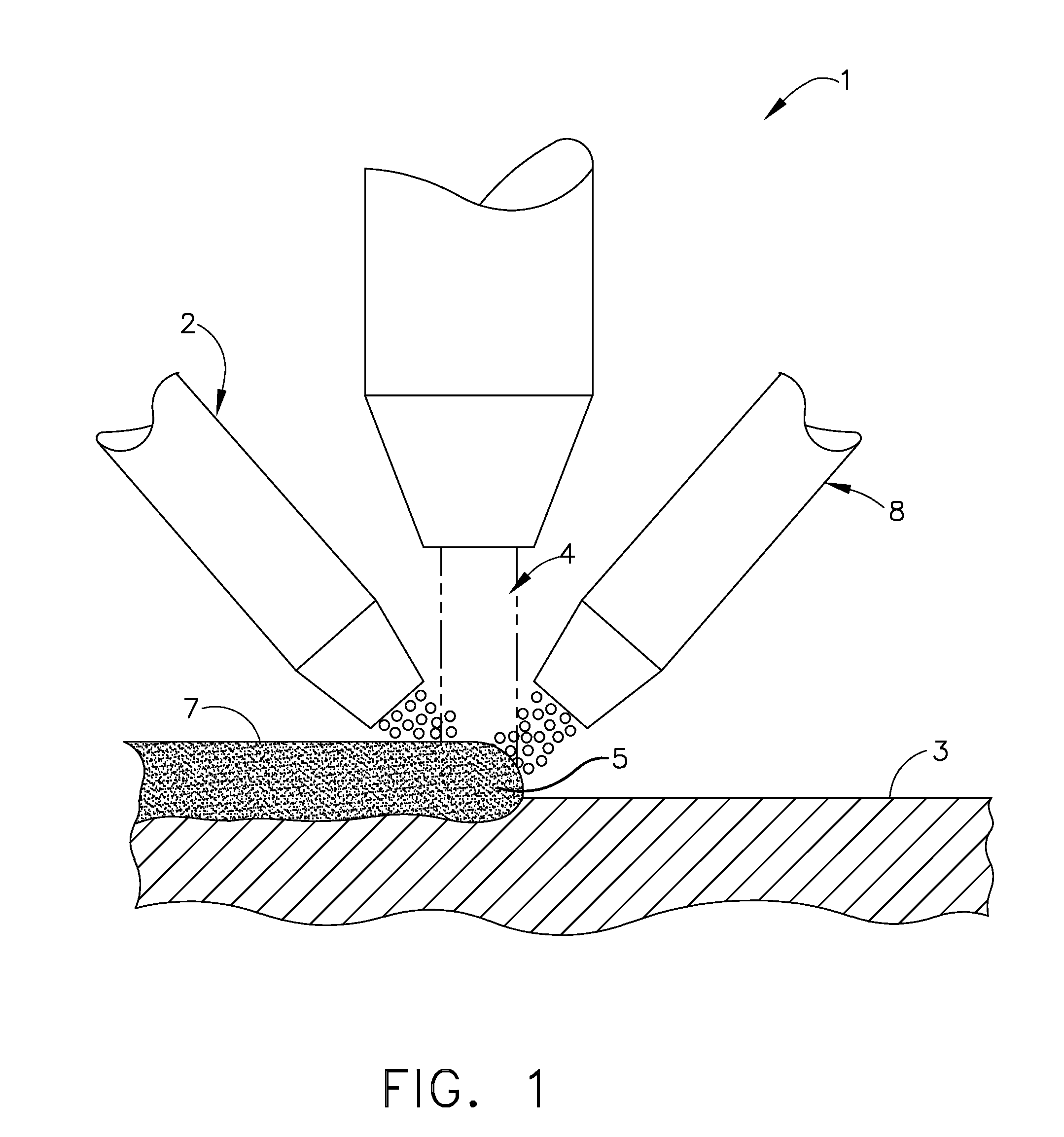

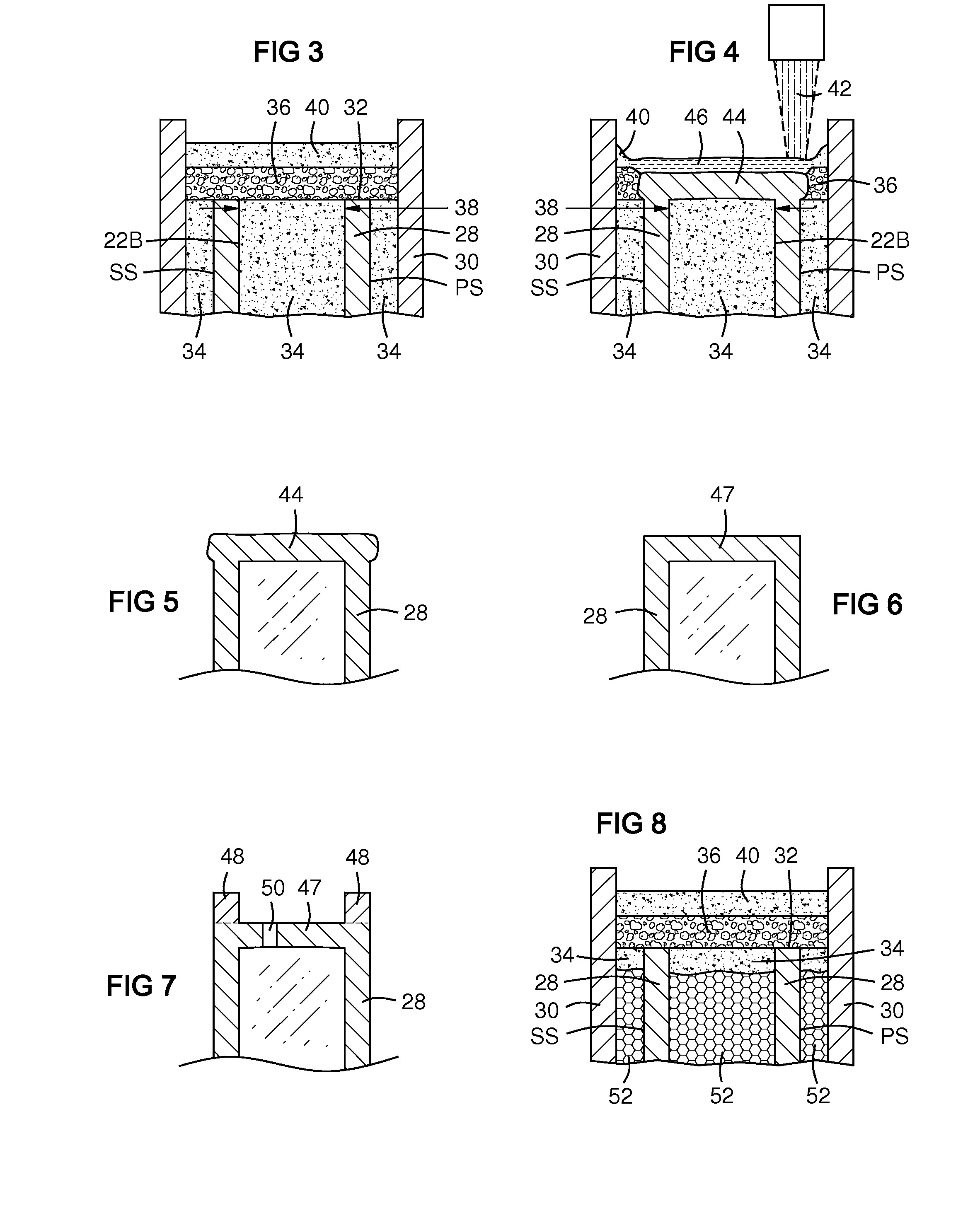

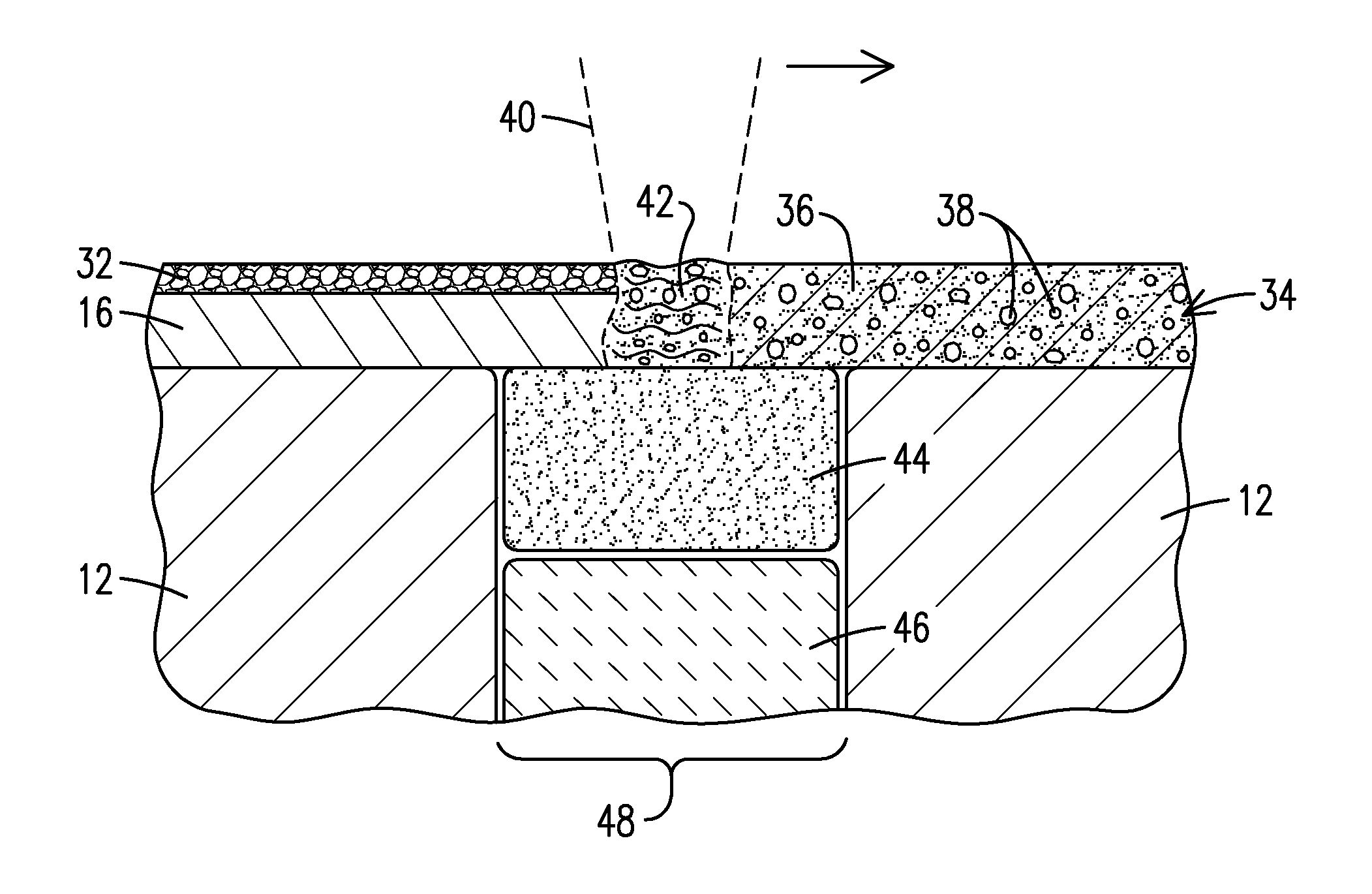

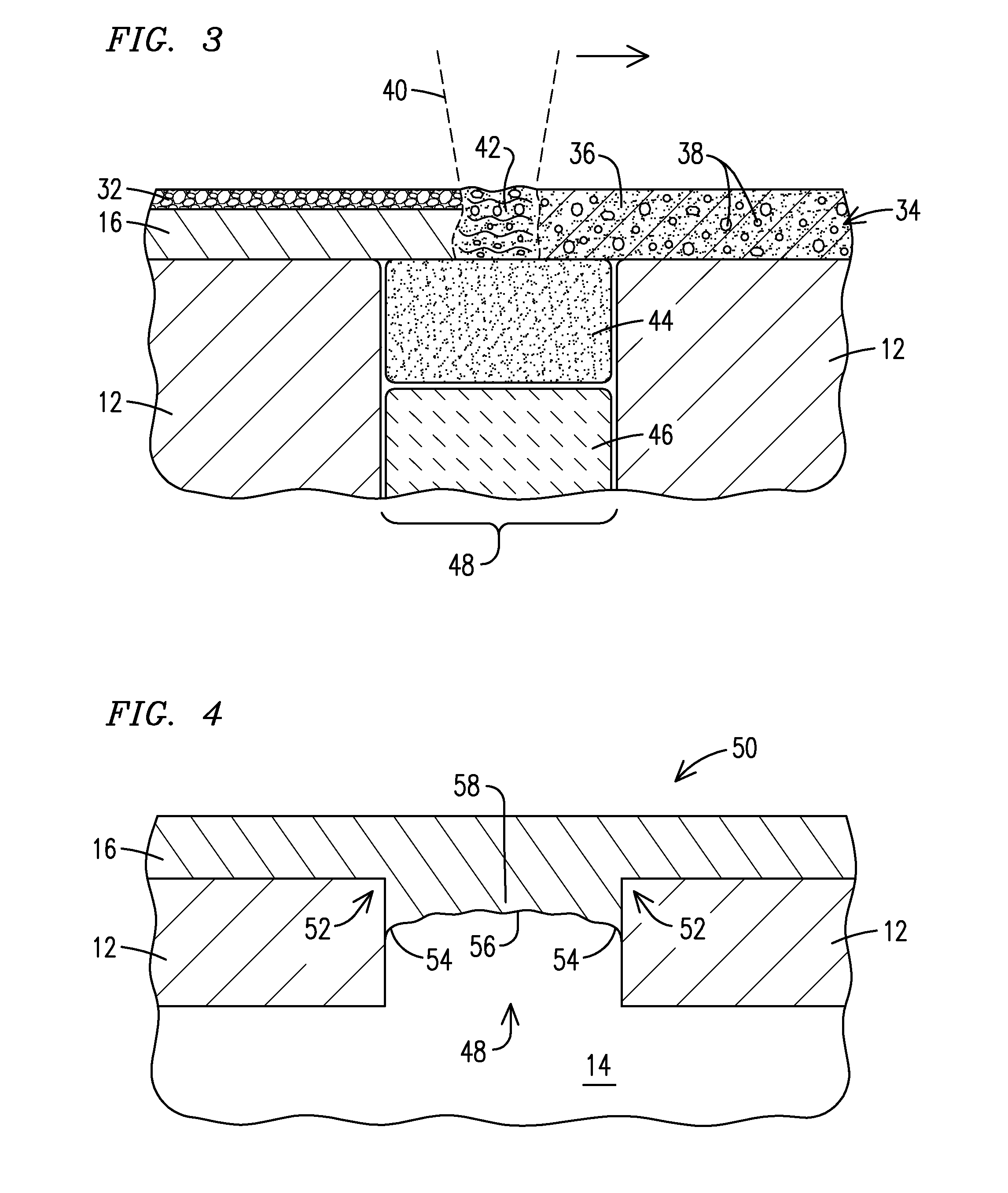

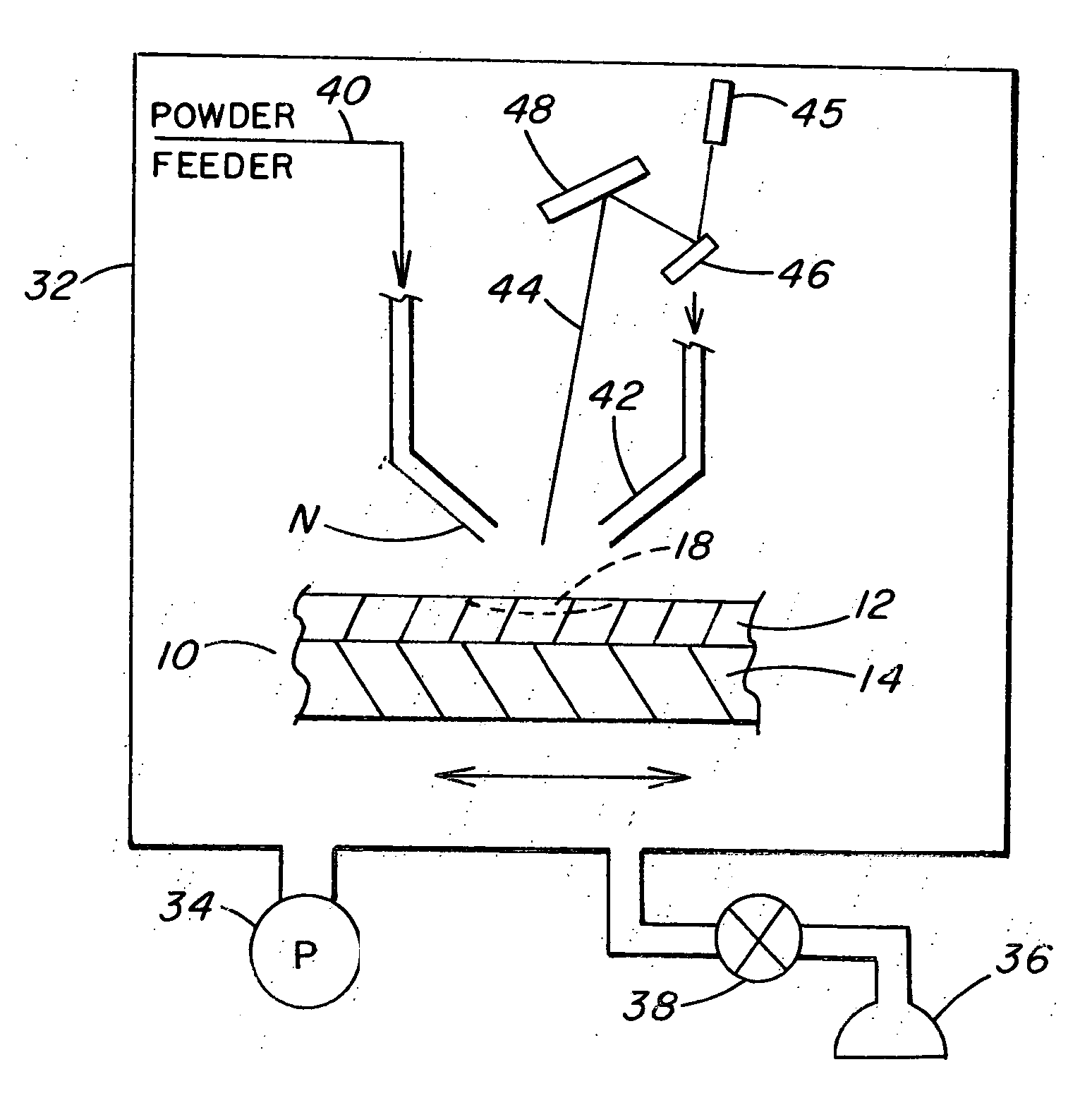

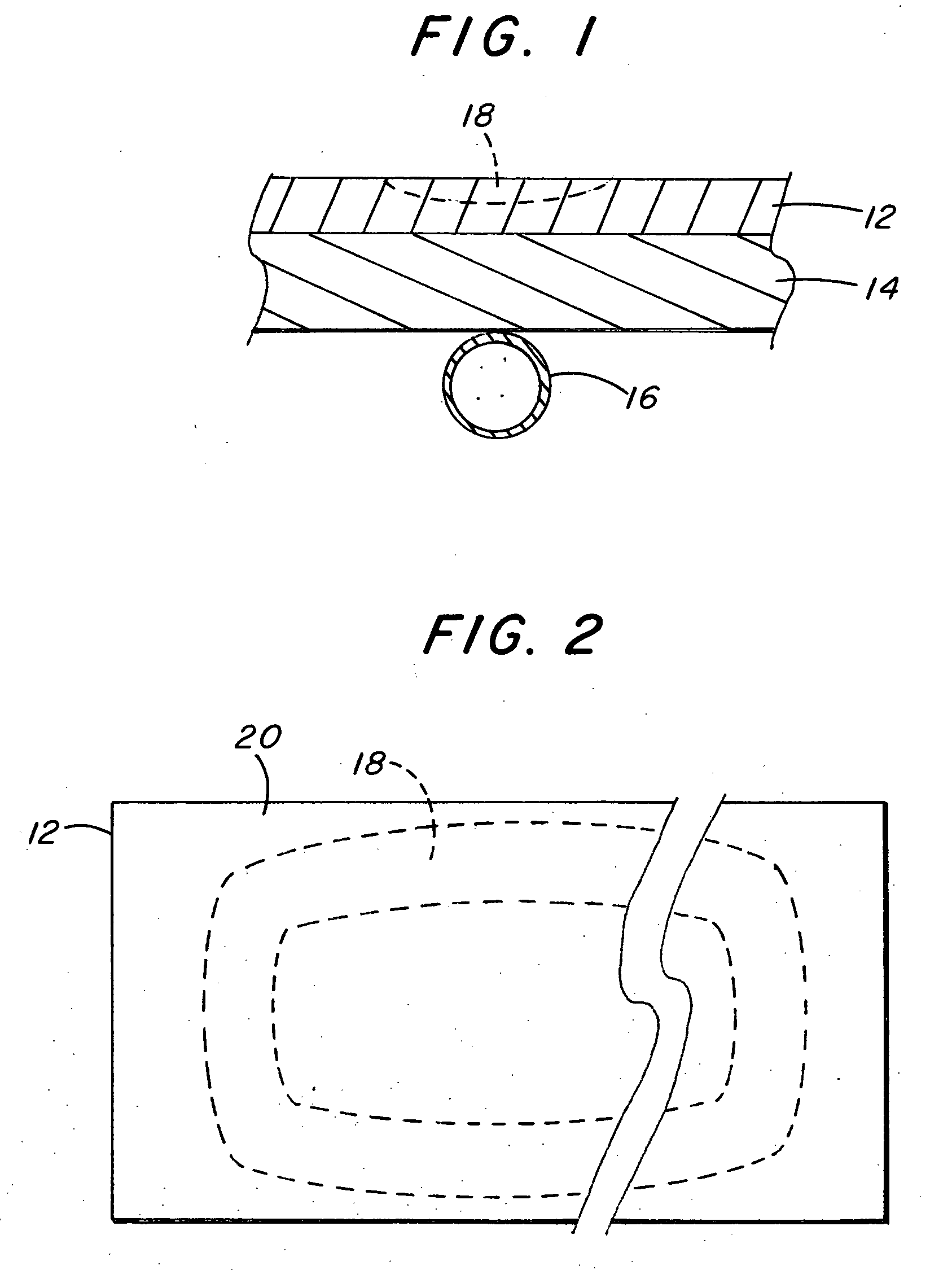

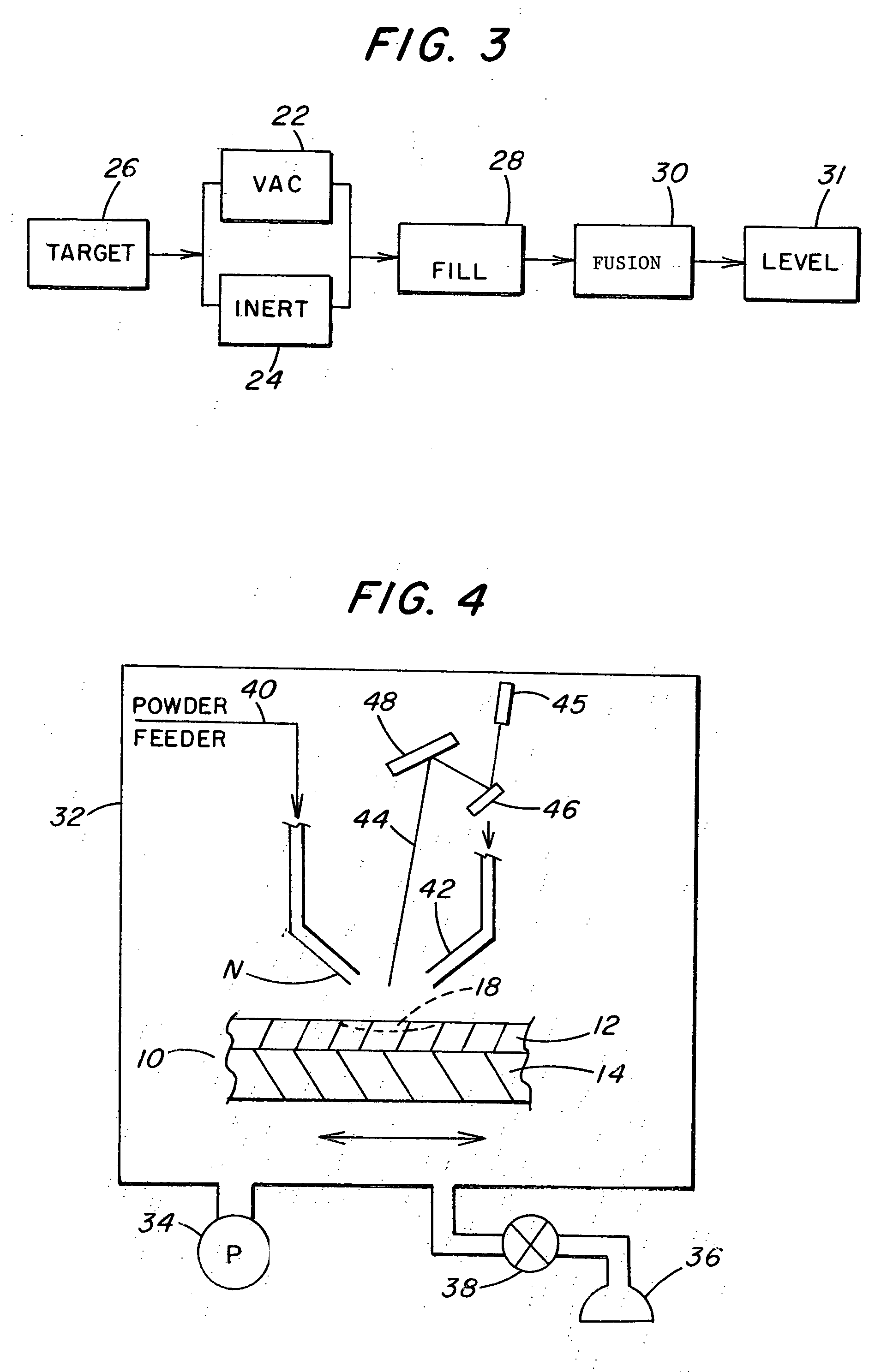

Methods and preforms to mask holes and support open-substrate cavities during laser cladding

This invention relates to methods in which a protective material (44) is introduced into a metallic component, or is used to block a hole (48) in the metallic component, a filler material (34) is pre-placed or directed to an external surface of the metallic component, the filler material is heated with at least one energy beam (40) to melt or sinter a metal powder (36) contained in the filler material to form a cladding layer (16), and the protective material is removed from the metallic component, such that the protective material contains, or generates upon being heated, a protective substance. The present invention also relates to preforms (72) containing an upper section (74) containing a powdered metal (36) and a flux (38), and a lower section (76) containing a protective material (78), such that the protective material contains, or generates upon being heated, a protective substance.

Owner:SIEMENS ENERGY INC

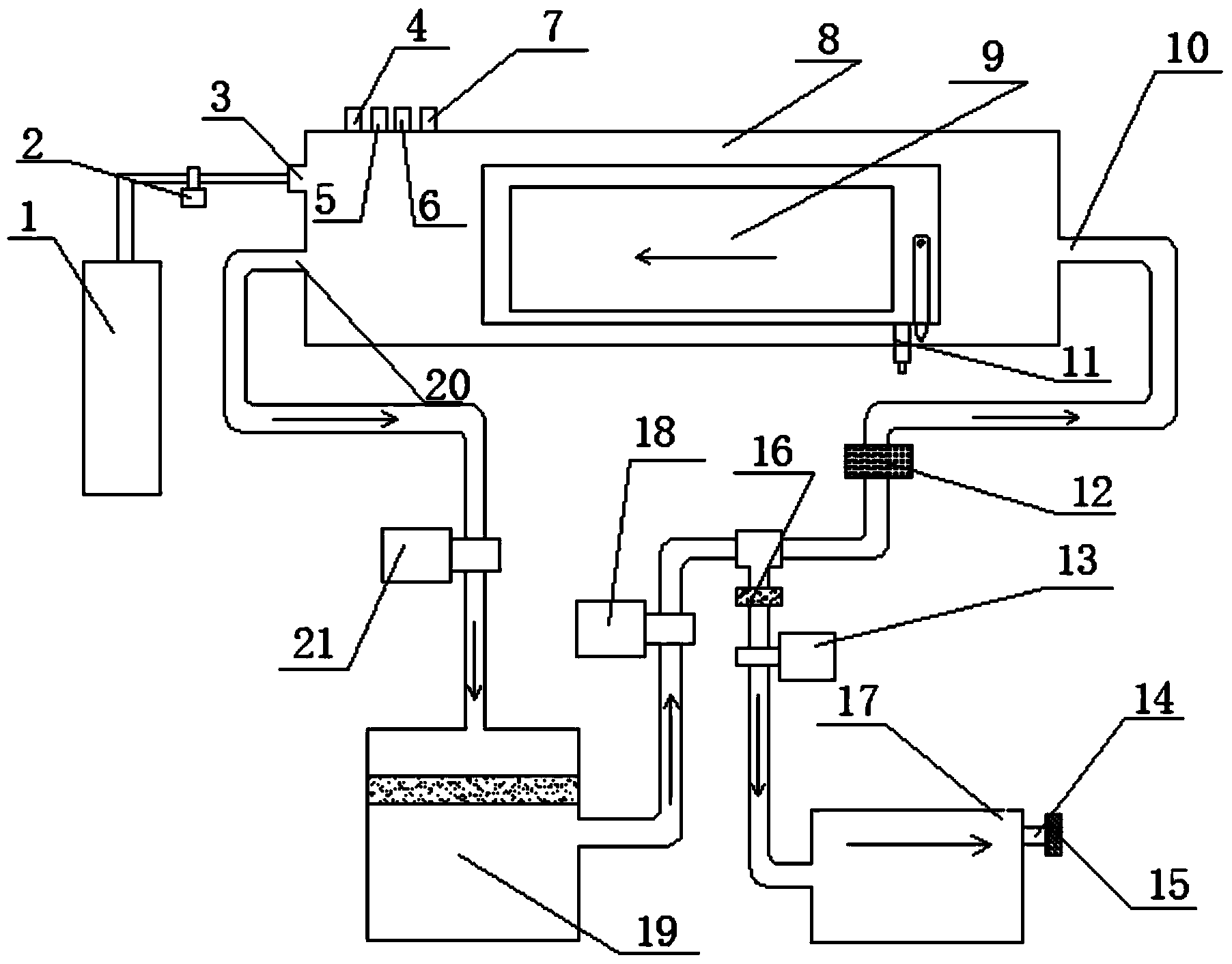

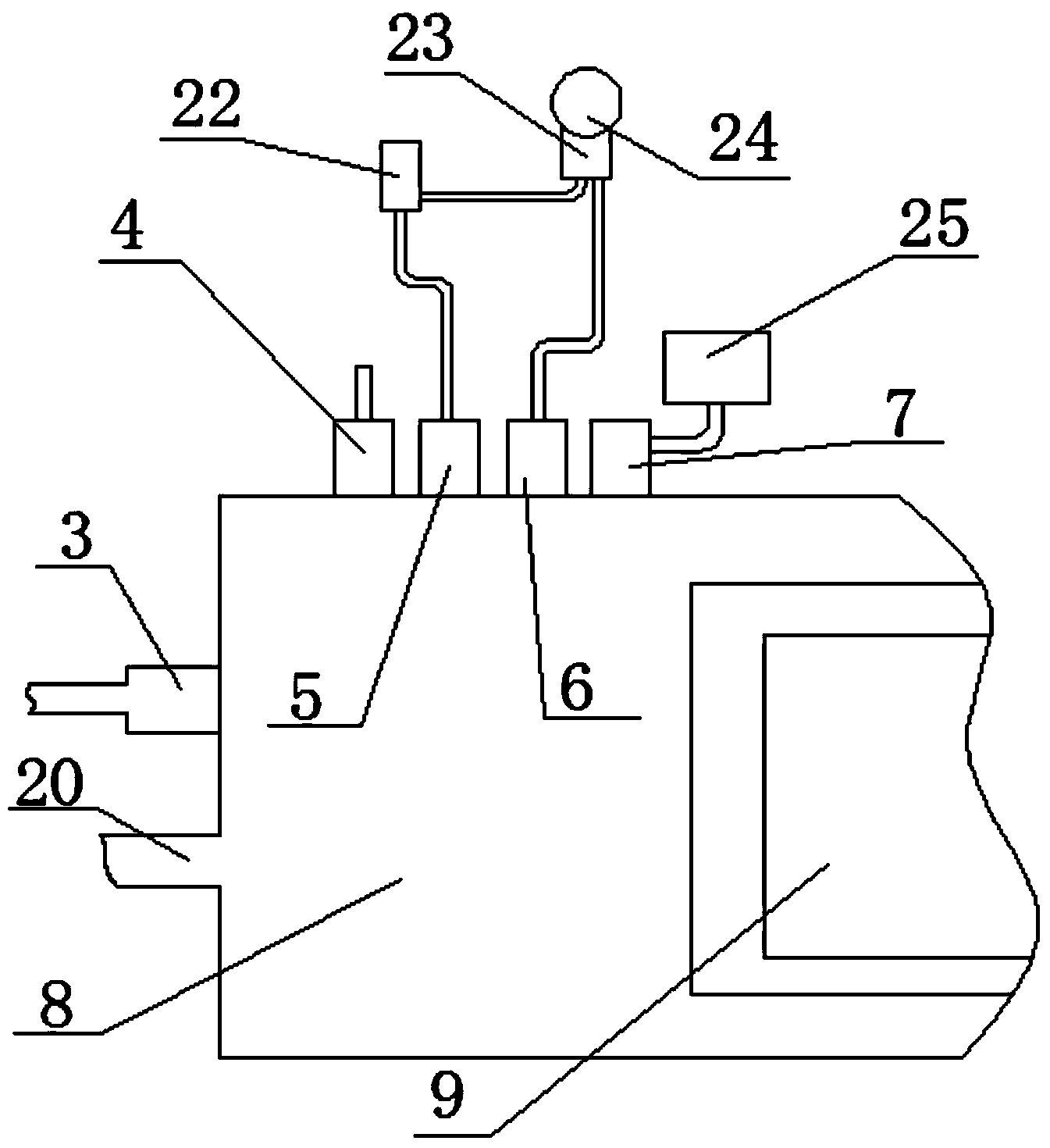

Method and equipment of sealed chamber atmosphere deoxygenization and circulating purification for metal 3D printer

ActiveCN104353832ALow oxygenReduce usageAdditive manufacturingIncreasing energy efficiencyMolecular sieveSolenoid valve

The invention discloses a method and equipment of sealed chamber atmosphere deoxygenization and circulating purification for a metal 3D printer. A gas inlet and a gas outlet are respectively formed in two ends of a forming chamber; the gas inlet and the gas outlet are mutually connected through a gas circulating pipeline; a first pneumatic butterfly valve, a dust purifier, a second pneumatic butterfly valve and a water removal drier are arranged on the gas circulating pipeline; a branch pipeline is arranged on the gas circulating pipeline between the second pneumatic butterfly valve and the water removal drier; the tail end of the branch pipeline is connected with a vacuum pump; a molecular sieve and a vacuum pipeline solenoid valve are arranged on the branch pipeline; the forming chamber is connected with an inert gas source. According to the method, firstly the oxygen content in the forming chamber is reduced to a required range before machining, and gas circulating purification is started during machining, so that gas purity degree in the forming chamber is kept; pressure detection and oxygen content detection are introduced, so that the oxygen content and pressure are within a reasonable range at all time during machining. The method and the equipment improve the forming efficiency and quality of the 3D printer, and guarantee the safety and the reliability of the machining process.

Owner:SOUTH CHINA UNIV OF TECH

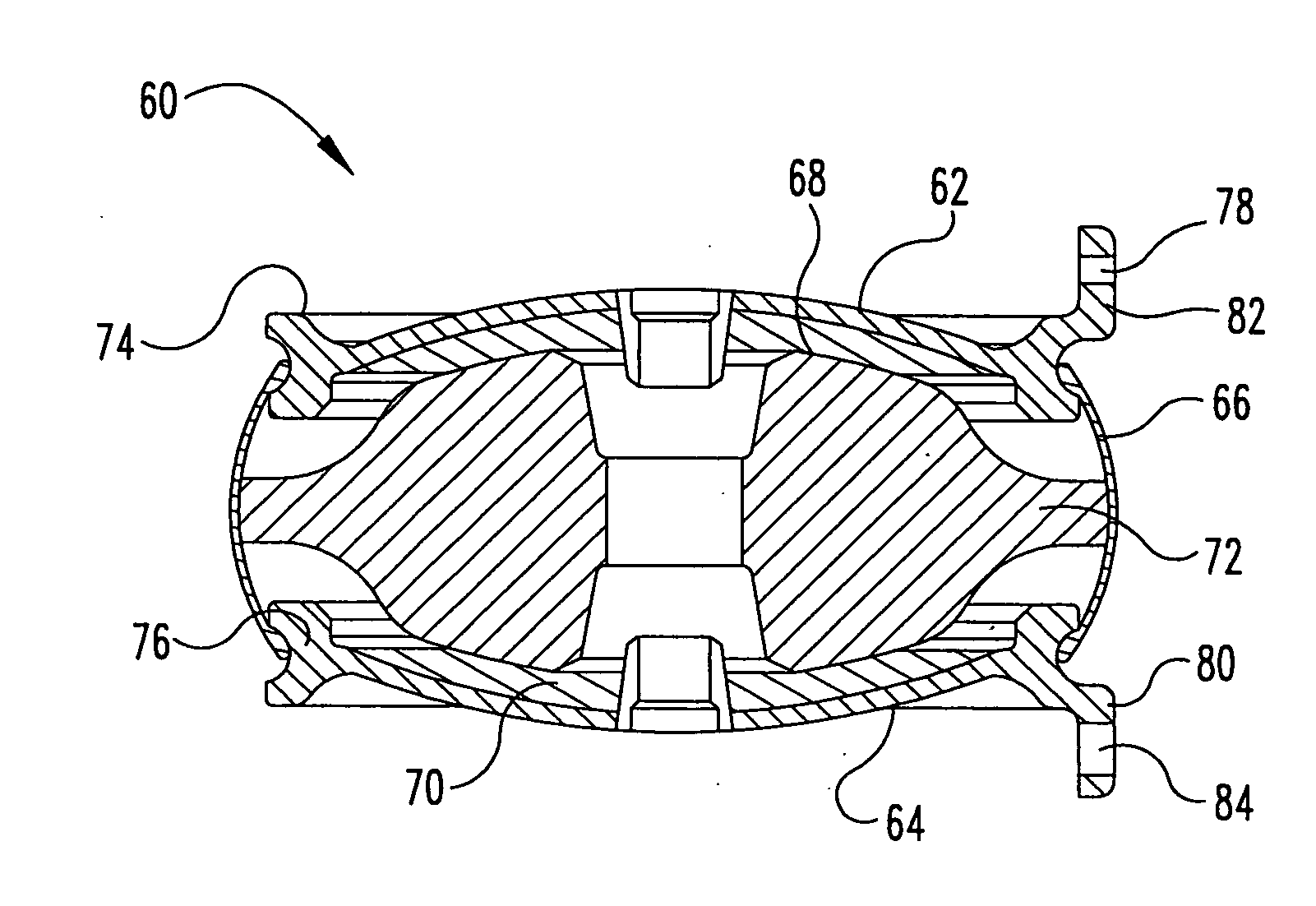

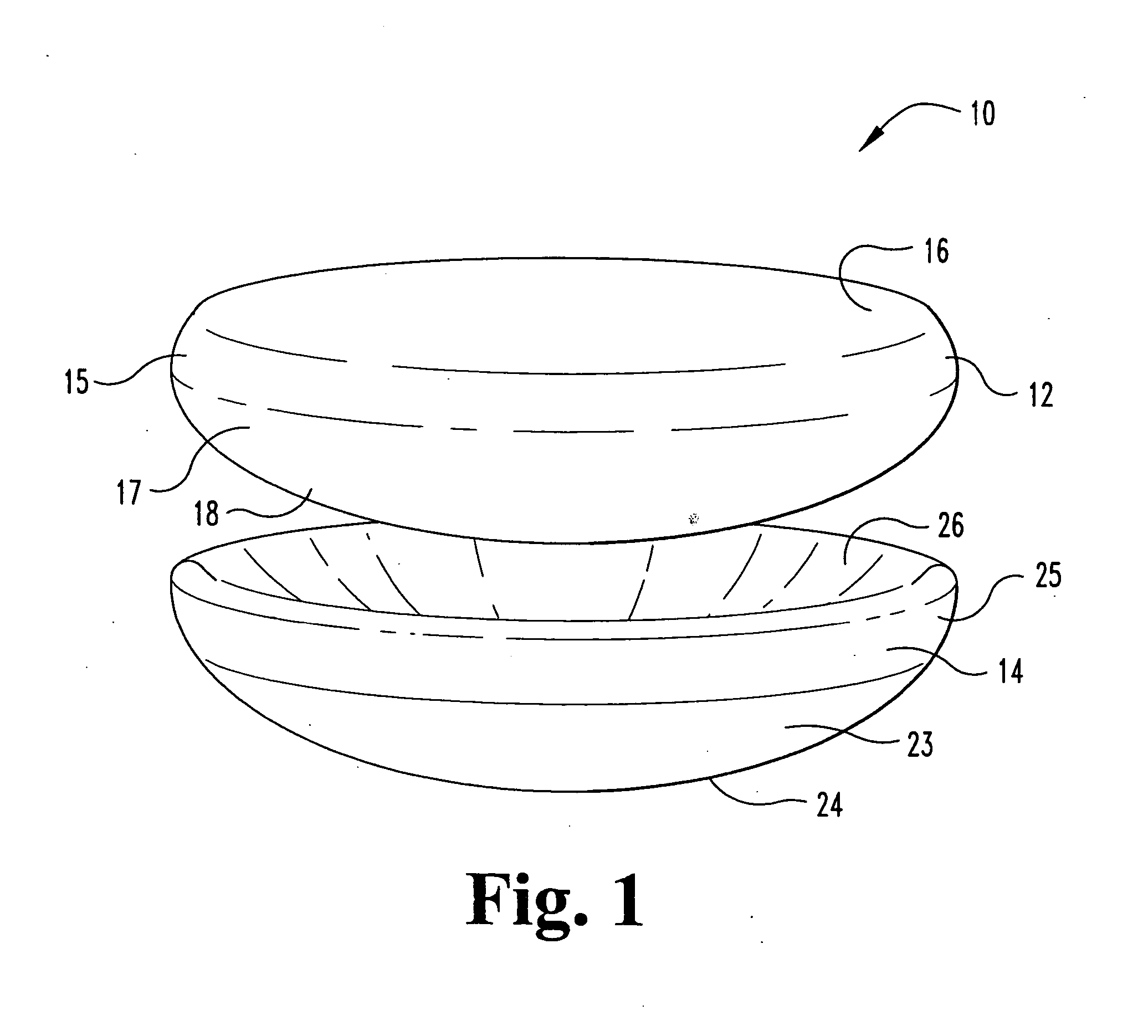

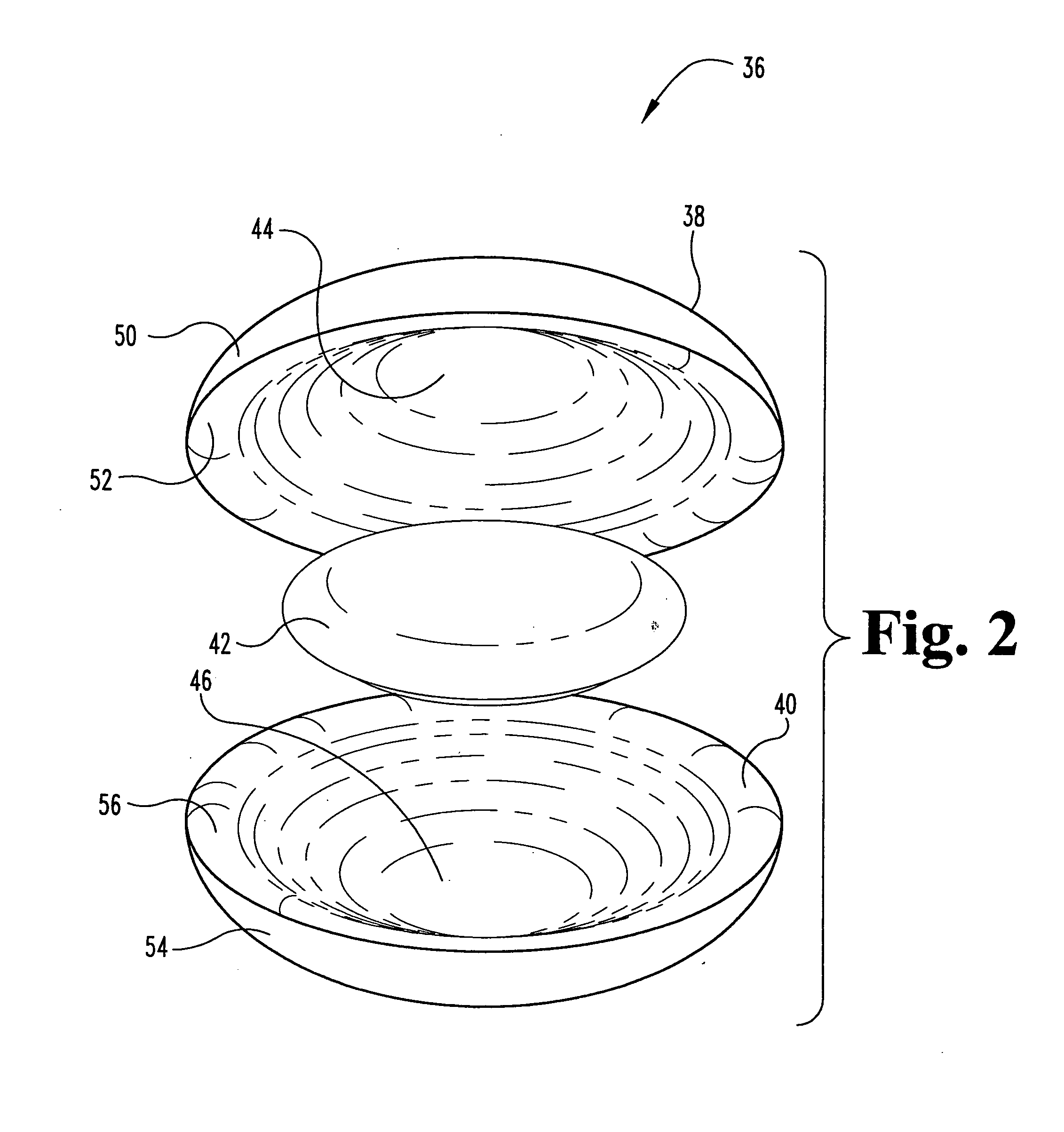

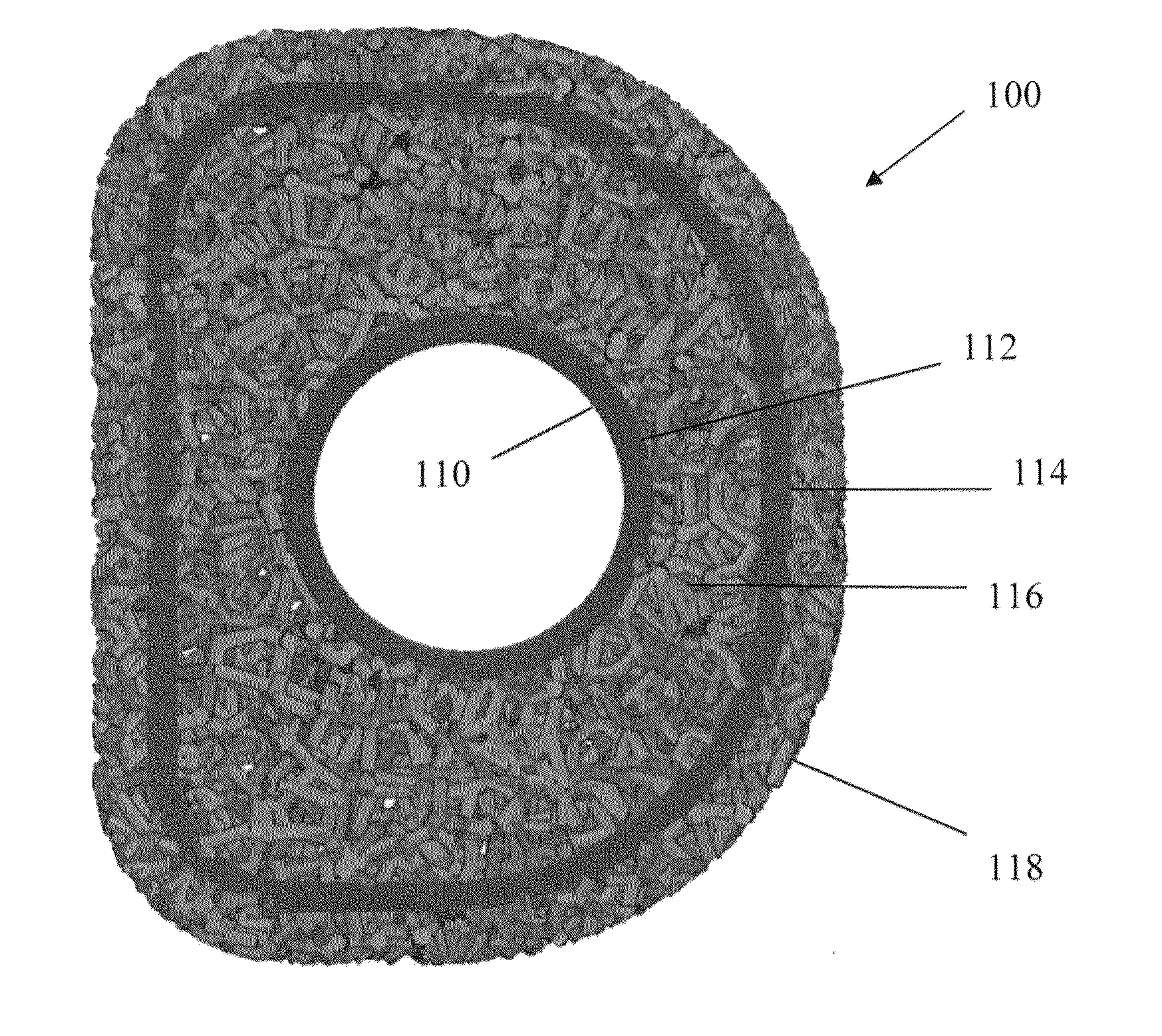

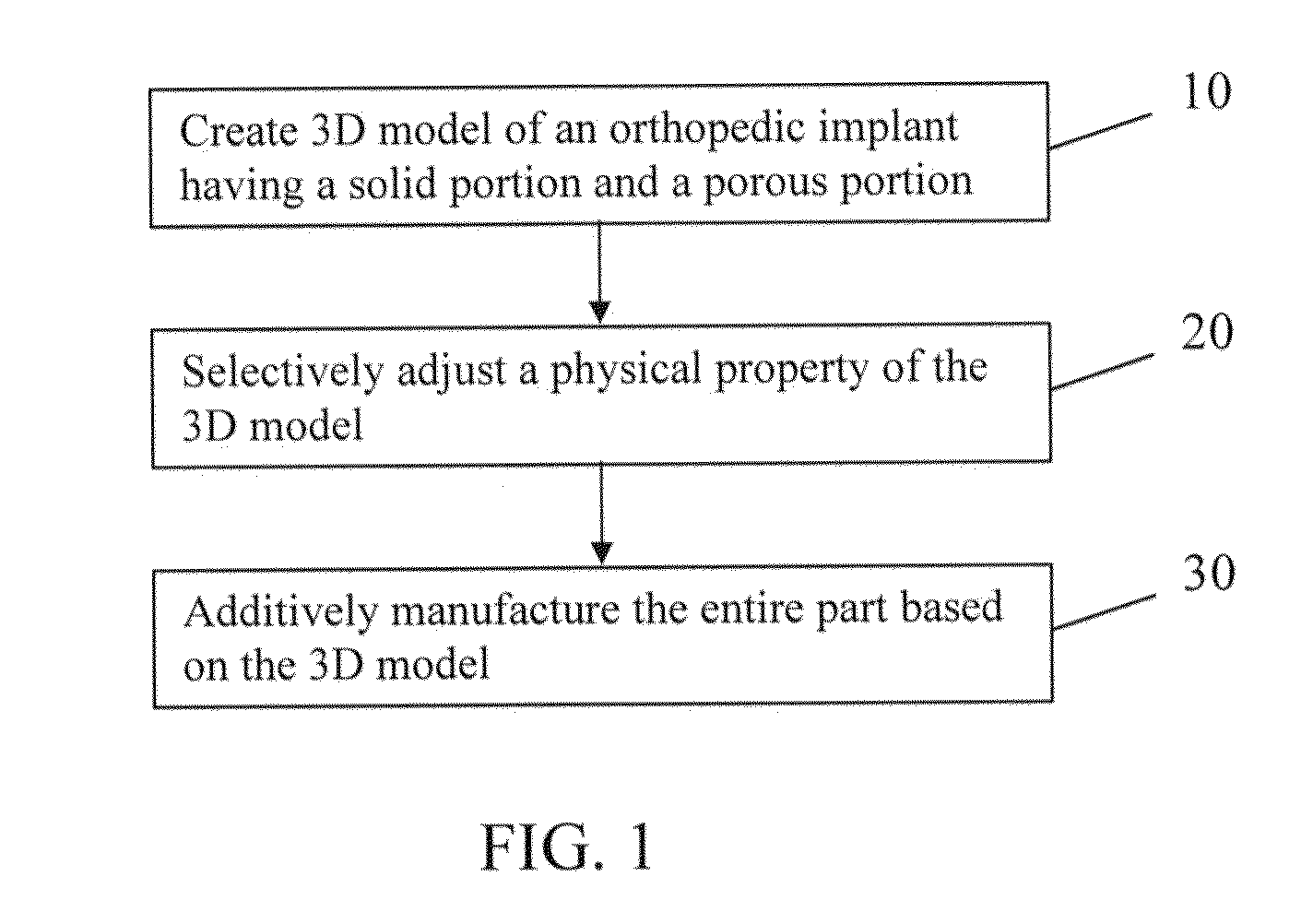

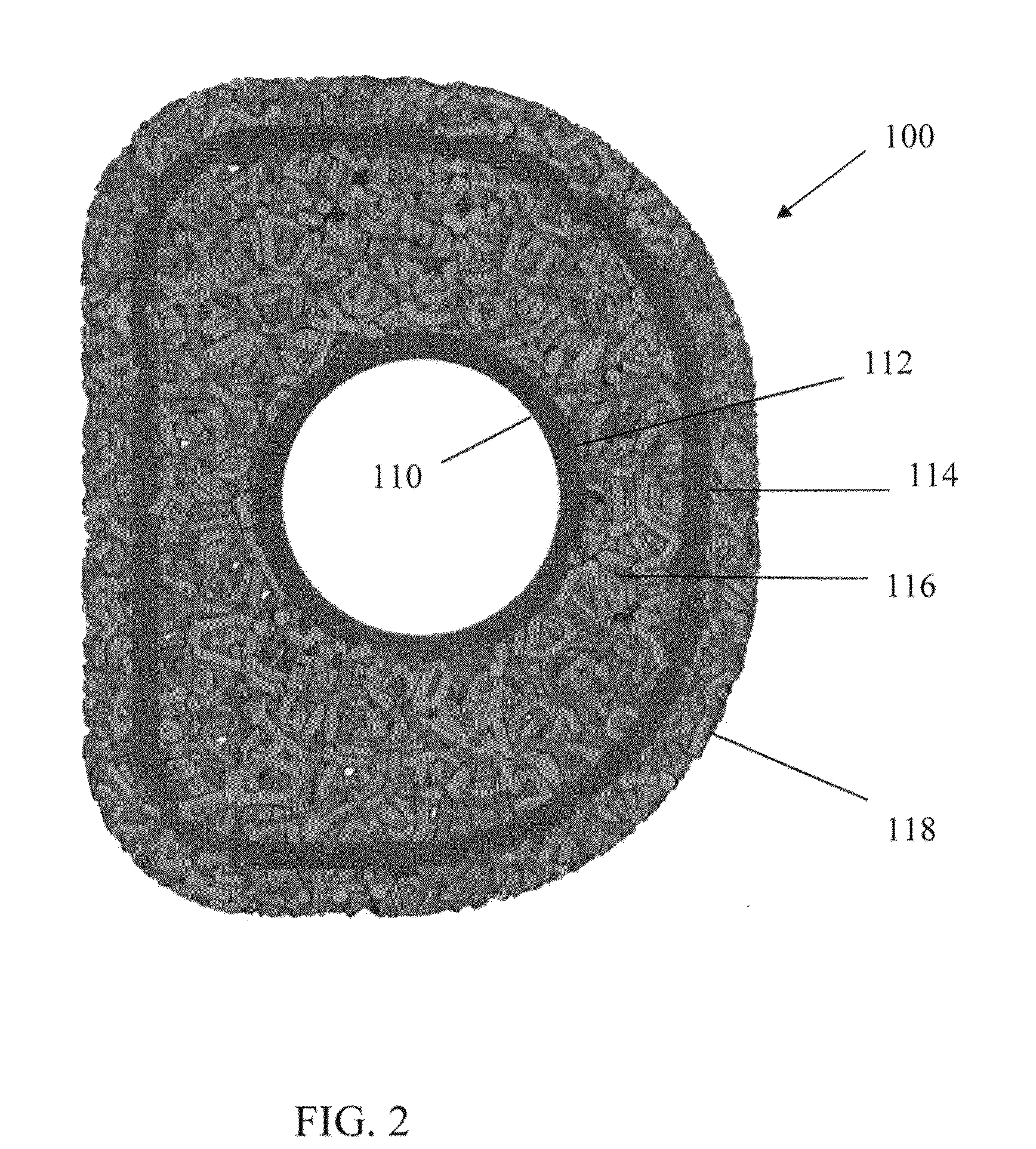

Orthopedic implants and methods of manufacturing orthopedic implants

ActiveUS20150045903A1Optimization propertiesSimple structureAdditive manufacturingAnkle jointsPorosityPlastic surgery

A method of manufacturing an orthopedic implant is provided. The method includes creating a 3D model of an orthopedic implant having a solid portion and a porous portion and selectively adjusting a physical property of at least one of porosity of the porous portion, lattice thickness of the porous portion, beam profile of the porous portion, and topography of the 3D model. The entire implant is then additively manufactured based on the 3D model.

Owner:KAPSTONE MEDICAL LLC

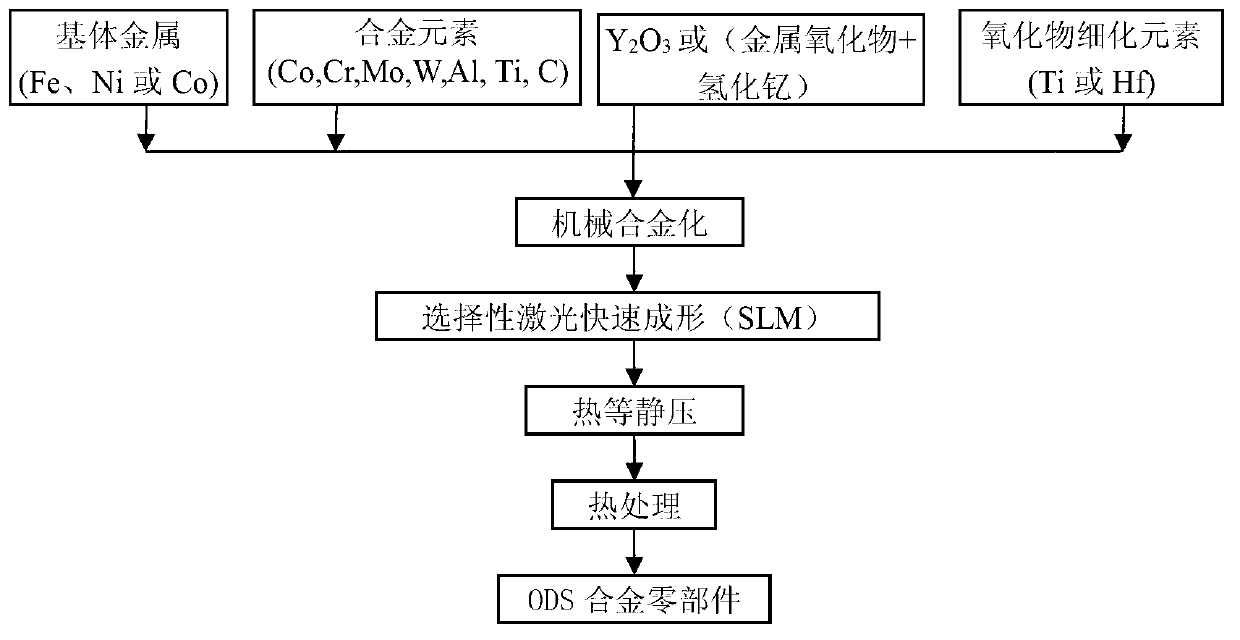

Method for preparing oxide dispersion strengthened alloy by rapid forming

InactiveCN103008657AHigh densitySmall particle sizeAdditive manufacturingIncreasing energy efficiencyOxide dispersion-strengthened alloySoftware design

The invention belongs to the technical field of high-temperature alloy near net shape forming and discloses a method for preparing oxide dispersion strengthened alloy by rapid forming. The method includes: using the mechanical alloying process to obtain oxide dispersion strengthened alloy powder, using CAD (computer-aided design) software to design a three-dimensional solid model of an ODS (oxide dispersion strengthened) alloy part, subjecting the three-dimensional model to layering and slicing to disperse the three-dimensional model into a series of two-dimensional layers, smelting the ODS alloy powder layer by layer according to slicing information to obtain a laser rapidly formed blank in a needed shape, eliminating residue pores in the laser rapidly formed blank by means of hot isostatic pressing, and optimizing structure property by means of subsequent annealing or solid solution and aging heat treatment to obtain an ODS alloy part in a complex shape. Wrap packaging or fixture moulds are not needed, the complexity of shapes of parts is unlimited, and alloy components and structures are easy to control. The prepared ODS alloy is small in oxide dispersed phase, and products are high in compactness and excellent in comprehensive mechanical property.

Owner:UNIV OF SCI & TECH BEIJING

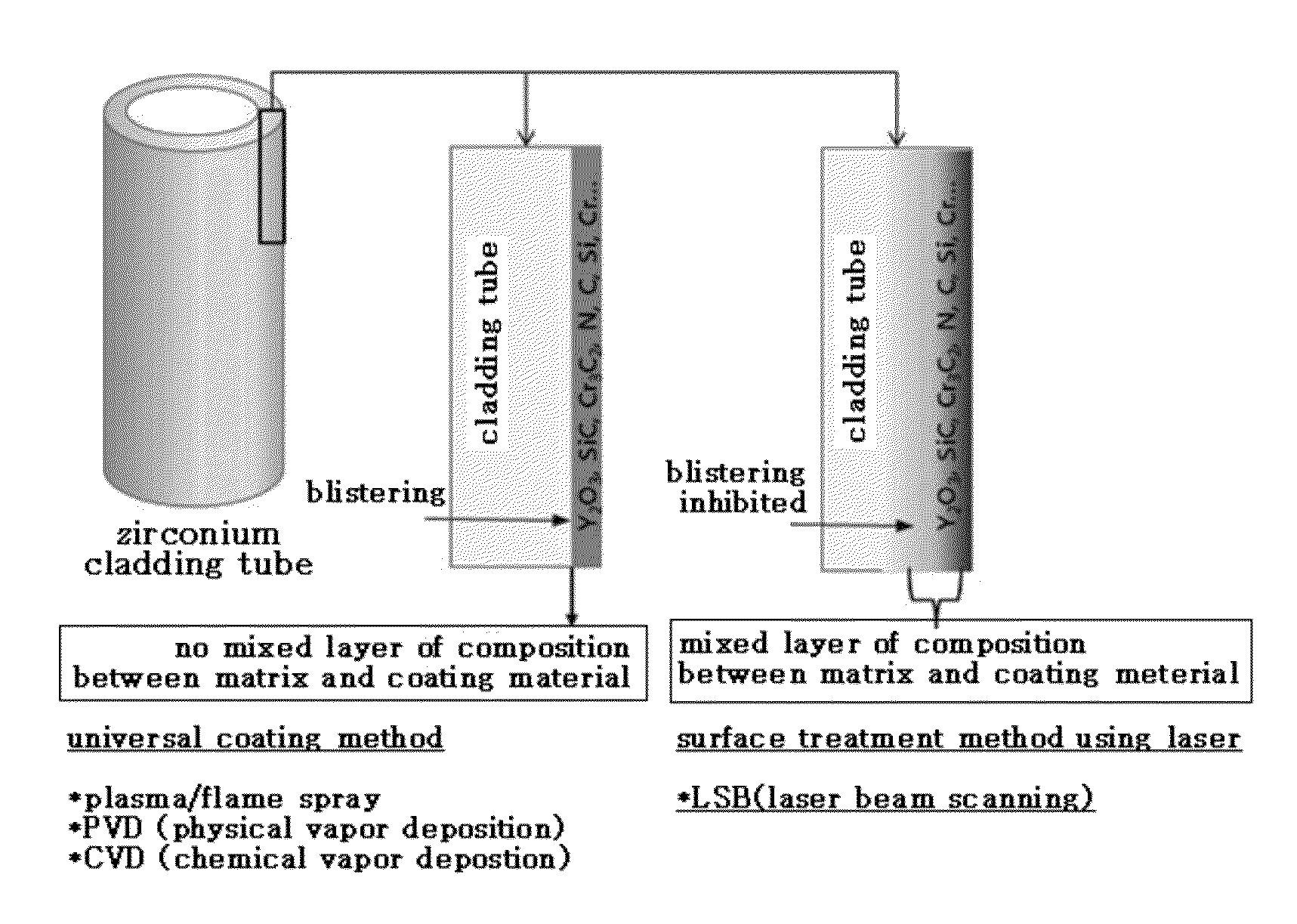

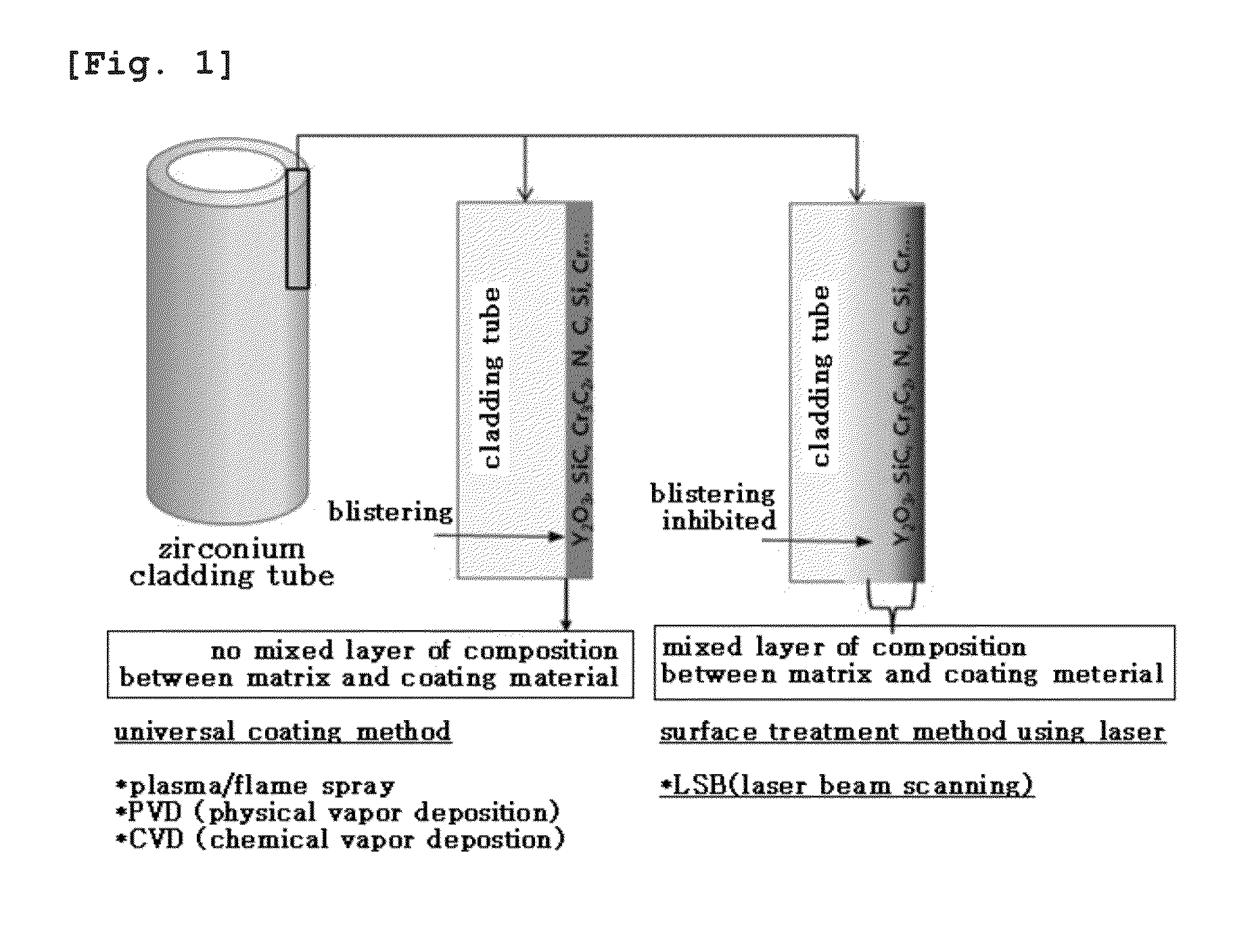

Zirconium alloy with coating layer containing mixed layer formed on surface, and preparation method thereof

InactiveUS20130344348A1High-temperature anticorrosiveAvoid physical damageAdditive manufacturingPretreated surfacesOxidation resistantZirconium alloy

A zirconium alloy with a coating layer formed on a surface comprising a mixed layer, the mixed layer comprises one or more very high temperature oxidation resistant material and zirconium alloy parent material selected from the group consisting of Y2O3, SiO2, ZrO2, Cr2O3, Al2O3, Cr3C2, SiC, ZrC, ZrN, Si and Cr, and in a vertical direction on a boundary between the mixed layer and the zirconium alloy parent material is formed a gradient of compositions between the very high temperature oxidation resistance material and the zirconium alloy parent material.

Owner:KOREA ATOMIC ENERGY RES INST +1

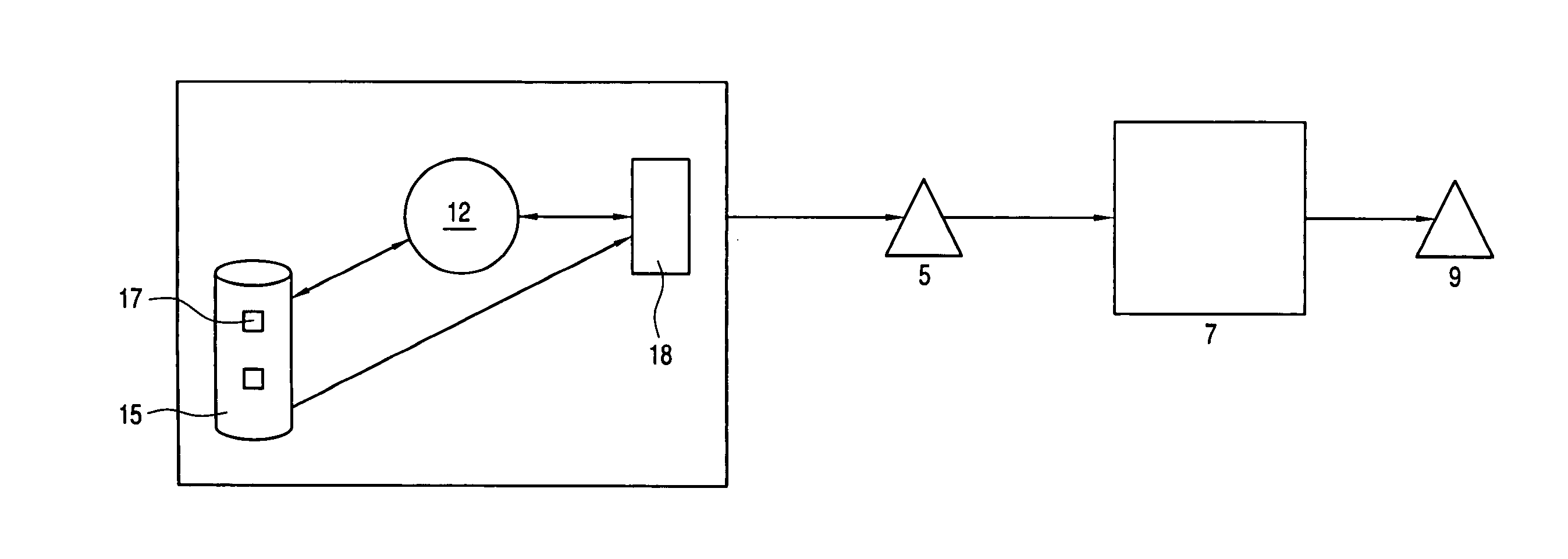

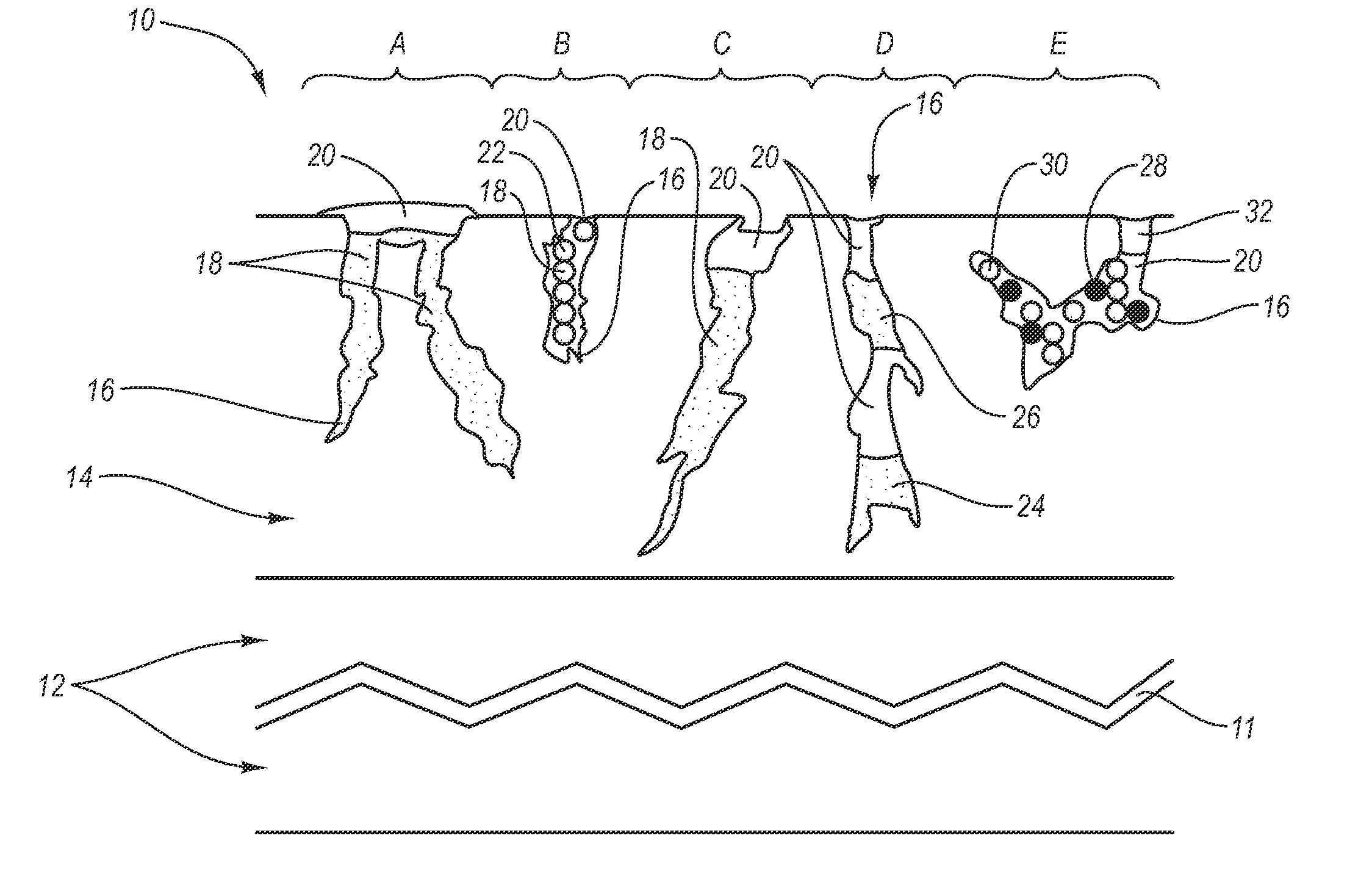

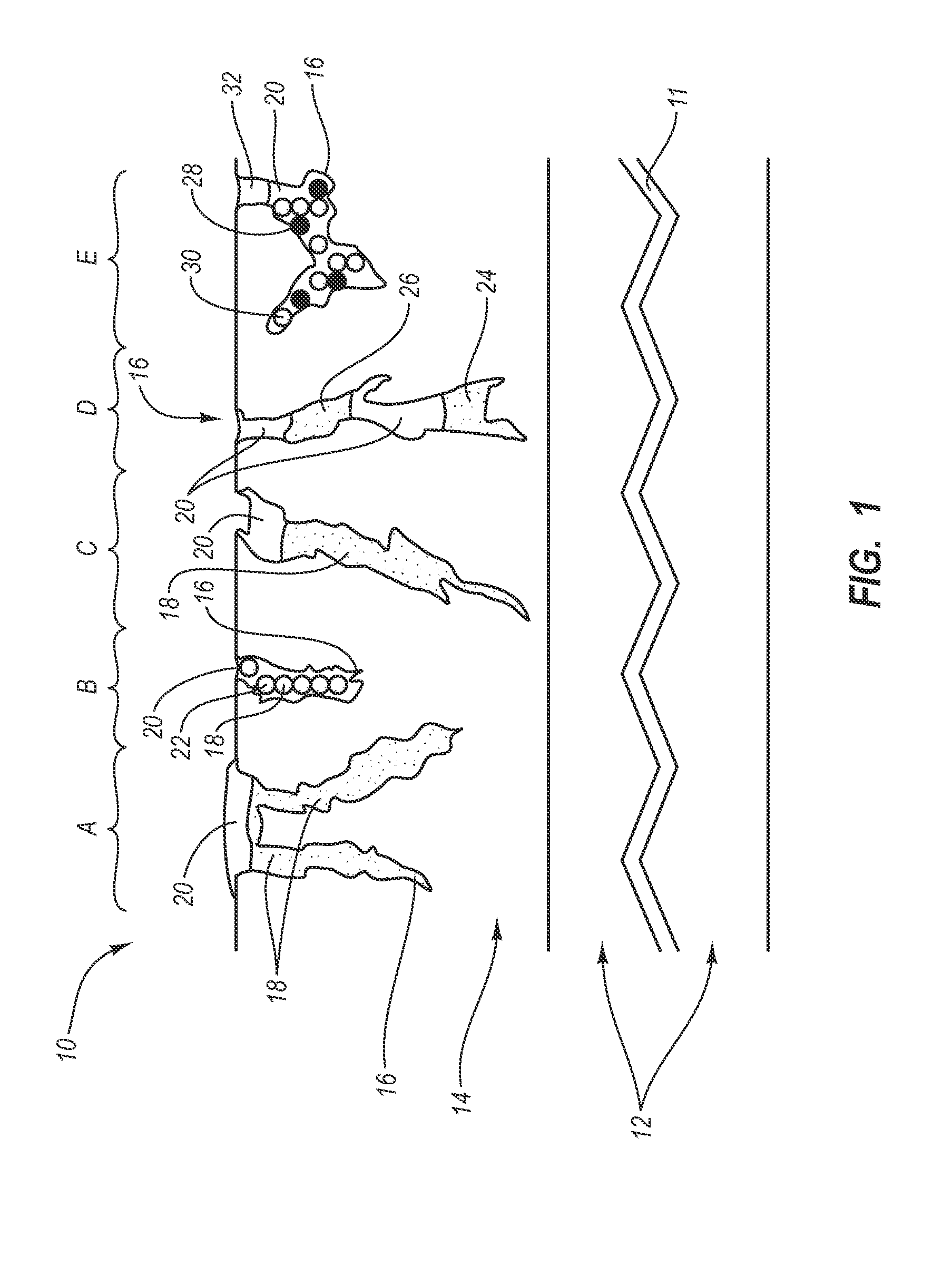

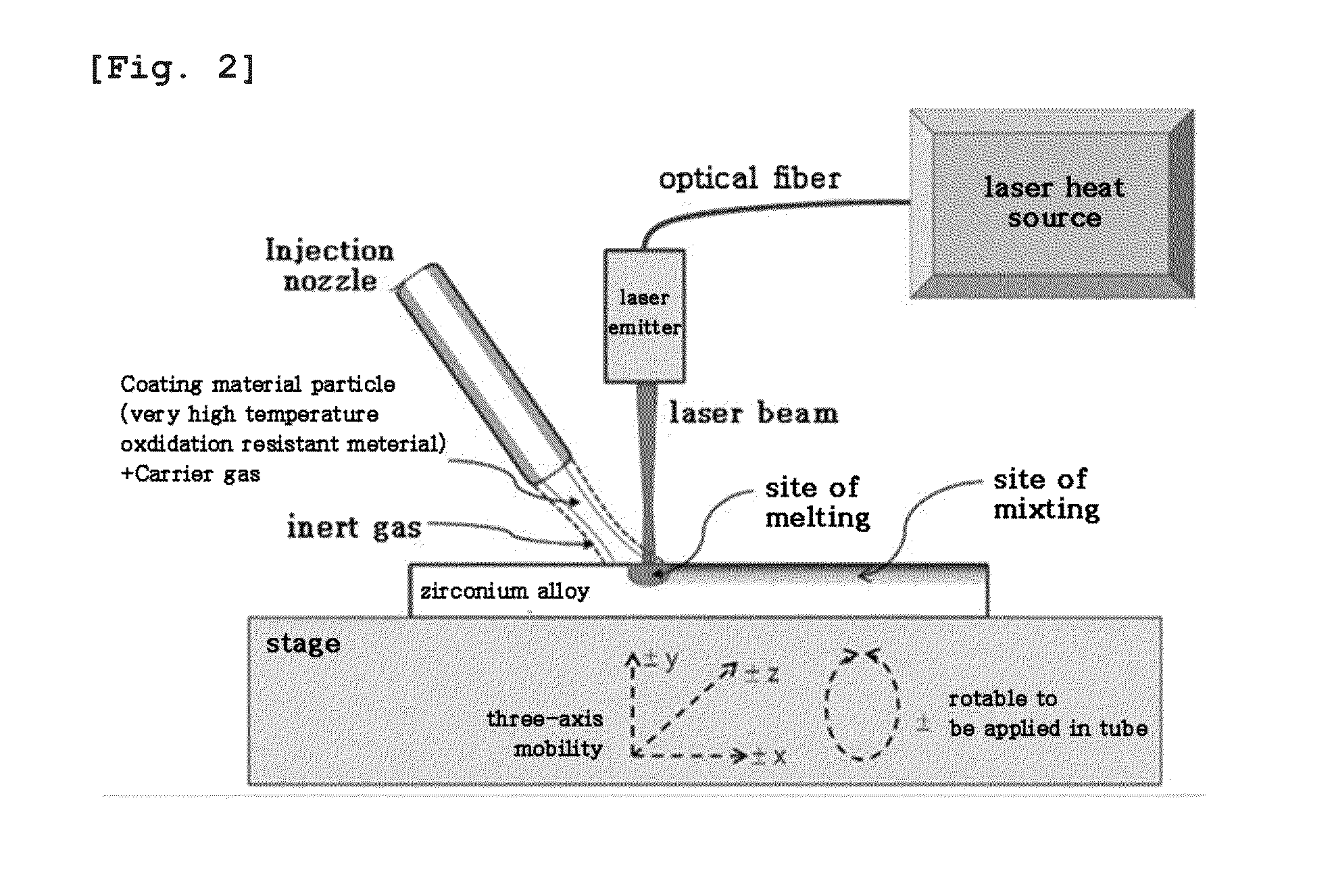

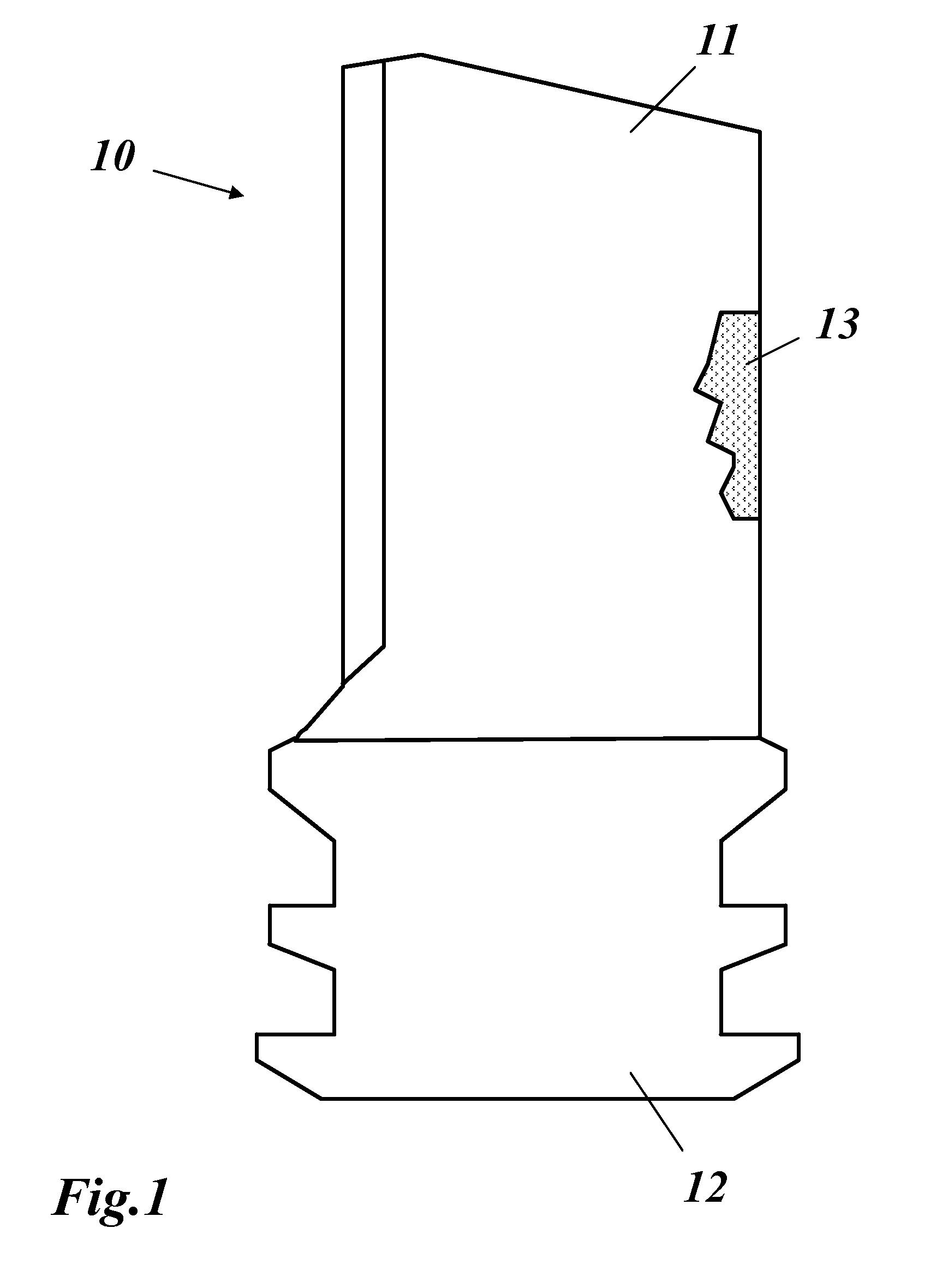

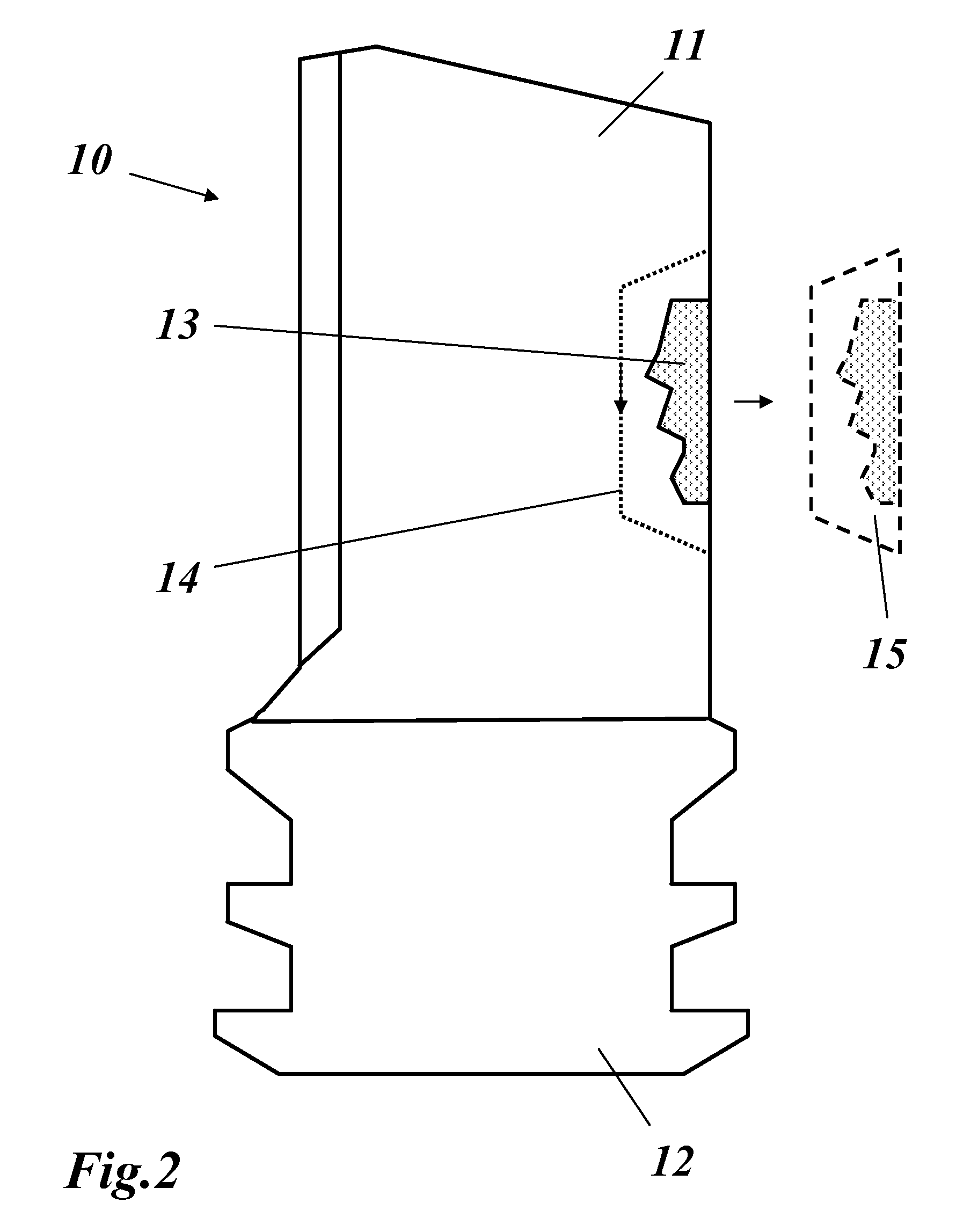

Method for repairing a gas turbine component

InactiveUS20110099810A1Low costQuality improvementTurbinesAdditive manufacturingProduction rateSplit lines

A method for repairing an ex-service gas turbine component (10) includes the steps of: removing a damaged section (13) from the gas turbine component (10), manufacturing a 3-D article, which fits in the gas turbine component (10) to replace the removed damaged section (13), and joining the gas turbine component (10) and the 3-D article inserted therein. Reduced cost, improved flexibility and productivity, and simplified handling are achieved by removing the damaged section (13) in the form of a cut-out section along a split line (14) as one single cut-out piece (15), measuring the cut-out piece (15) to obtain the actual non-parametric geometry data set of the cut-out piece (15), and manufacturing the 3-D article based on the geometry data set of the cut-out piece (15).

Owner:ALSTOM TECH LTD

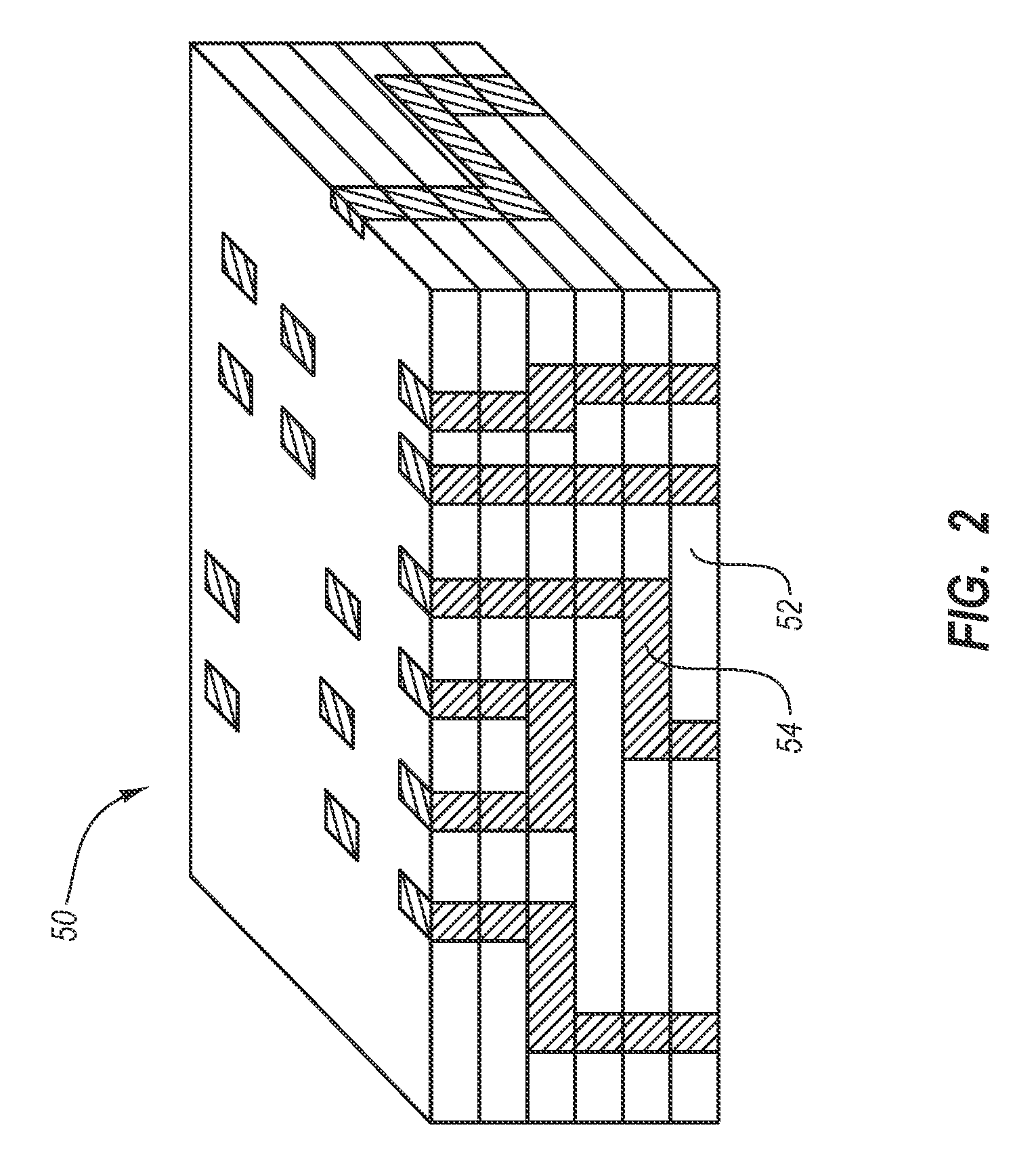

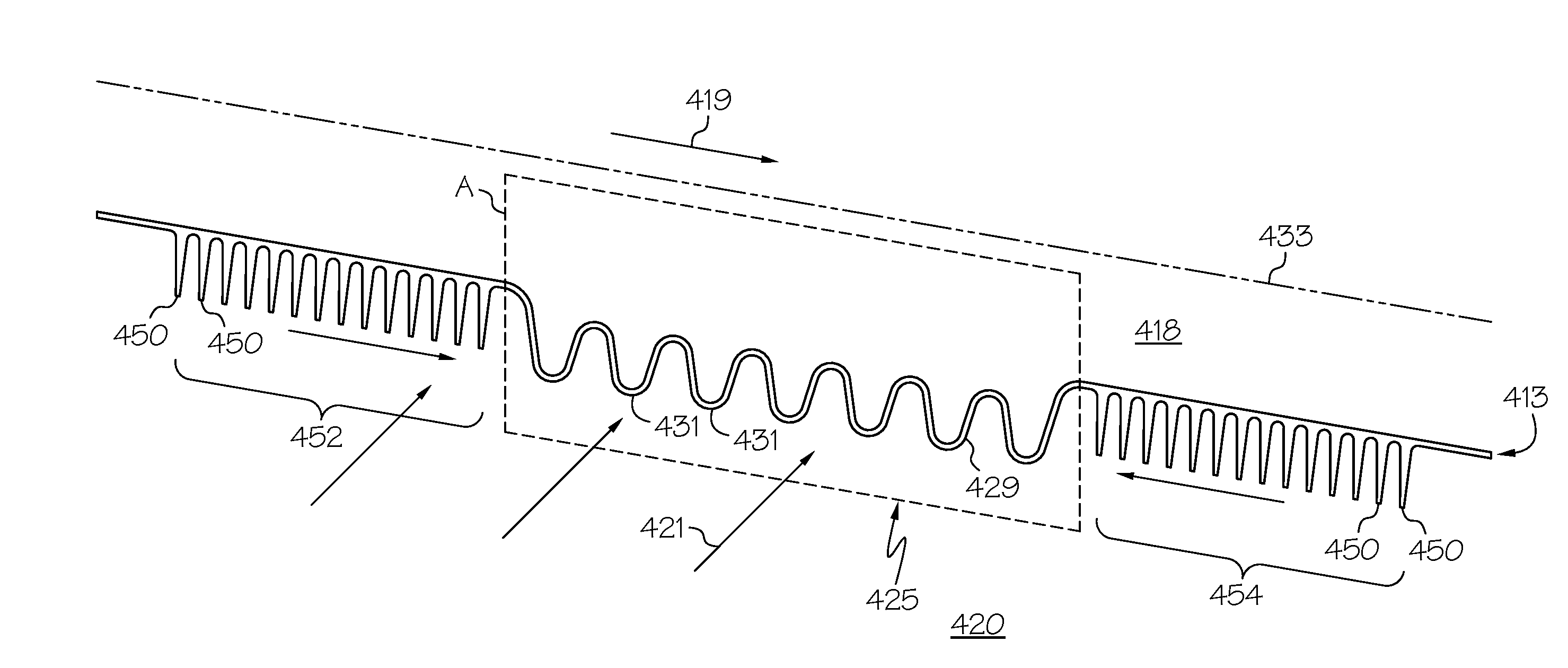

Unitary heat exchangers having integrally-formed compliant heat exchanger tubes and heat exchange systems including the same

ActiveUS20140360698A1Low costLow variabilityAdditive manufacturingSafety devices for heat exchange apparatusPlate heat exchangerEngineering

Unitary heat exchangers having integrally-formed compliant heat exchanger tubes and heat exchange systems including the same are provided. The unitary heat exchanger comprises an inlet plenum and an outlet plenum and a plurality of integrally-formed compliant heat exchanger tubes. The plurality of integrally-formed compliant heat exchanger tubes extend between and are integral with the inlet and outlet plenums to define a heat exchanger first flow passage. Each integrally-formed compliant heat exchanger tube comprises a tubular member and a plurality of integral heat transfer fins extend radially outwardly from at least one portion of the tubular member. The tubular member has a proximal tube end and a distal tube end and comprises a tubular wall having an outer wall surface and an inner wall surface.

Owner:HONEYWELL INT INC

Method for producing 3D print fastening piece of three-layer structure from inside to outside

InactiveCN103611934AImprove performancePrecise positioningAdditive manufacturingElectrographic process apparatusGraphicsLatent image

A method for producing a 3D print fastening piece of a three-layer structure from inside to outside comprises the specific steps that computer modeling and layer-by-layer cutting are carried out; graphs are converted to light beams carrying graph information, a photosensitive drum is charged to obtain electric potential, and an electrostatic latent image is formed through light beam scanning; the electrostatic latent image passes through a magnetic brush and attracts powder to from an internal component, the surface of the internal component is processed, the steps are executed repeatedly to print the intermediate layer and the outer layer, and the surfaces of the intermediate layer and the outer layer are processed. The 3D print fastening piece made through the method has the advantages of being high in manufacturing precision, long in service life, and good in performance.

Owner:NINGBO JINPENG HIGH STRENGTH FASTENER

Rejuvenation of refractory metal products

InactiveUS20060032735A1Increase speedImprove microstructureCellsAdditive manufacturingMaterials scienceMetal

Refractory metal products, such as tantalum, can be rejuvenated after metal consumption in selected zones by filling the zones with powder and simultaneously applying focused radiant energy to the powder.

Owner:MATERION NEWTON INC

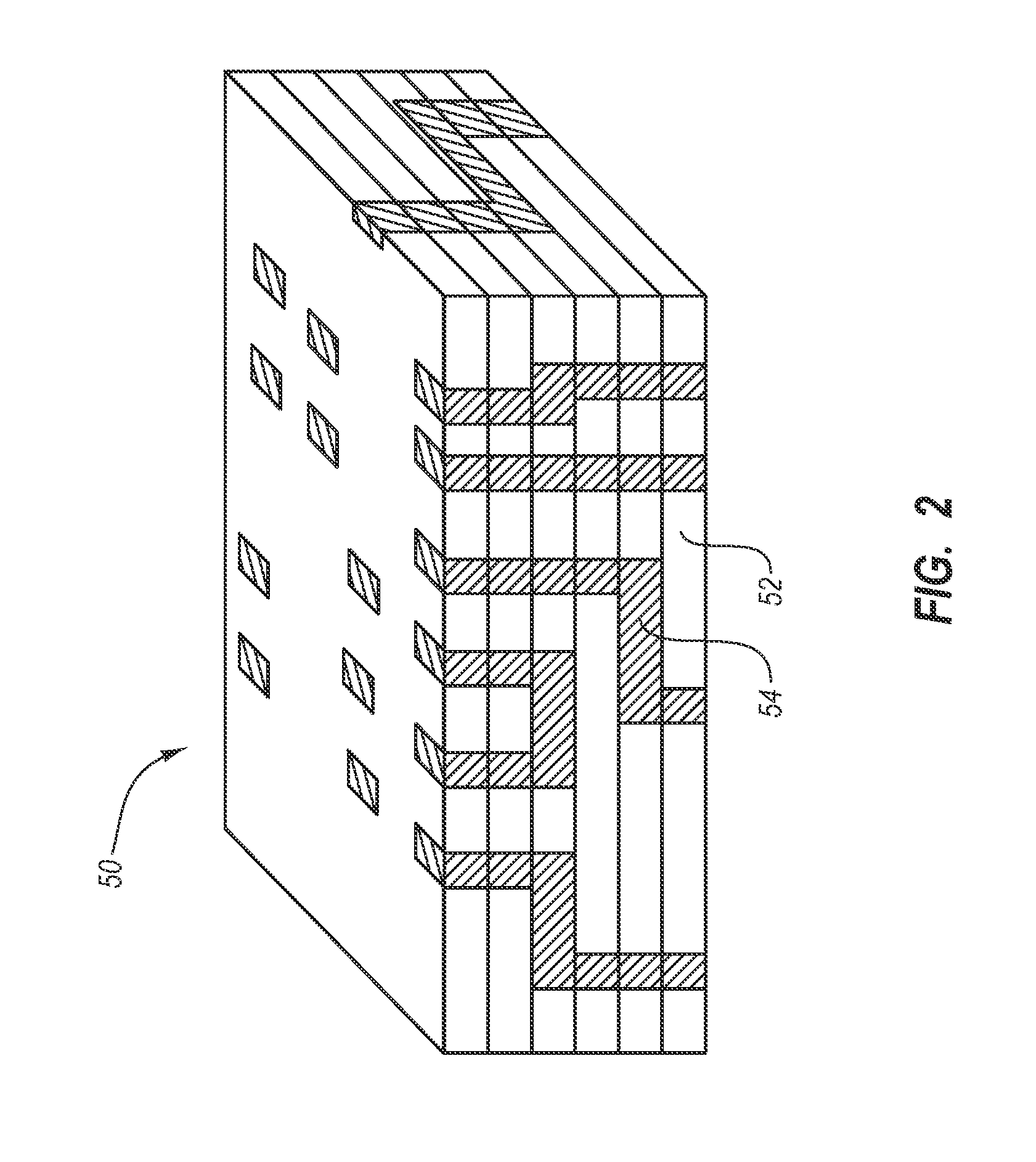

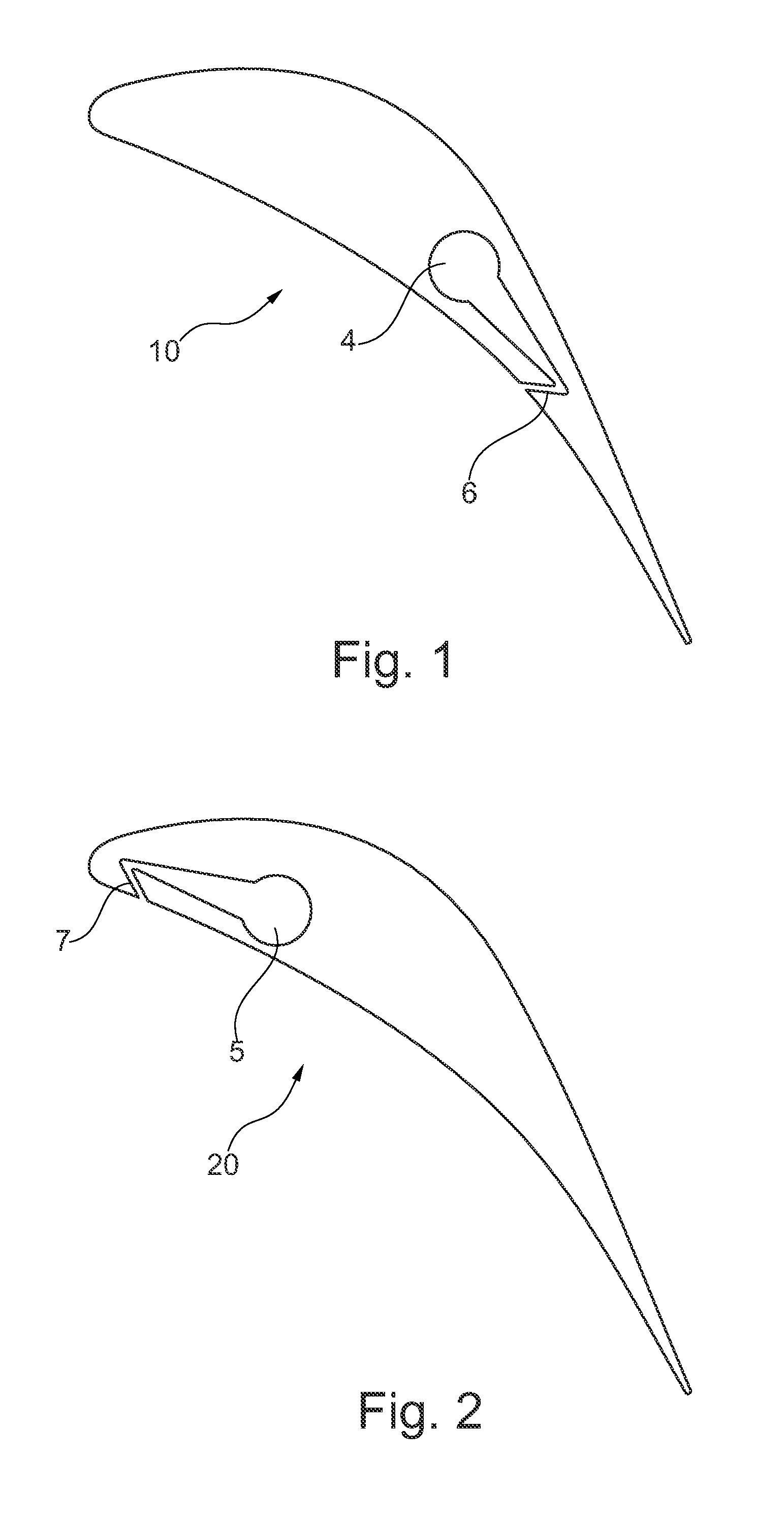

Effusion plate using additive manufacturing methods

Additive manufacturing techniques may be utilized to construct effusion plates. Such additive manufacturing techniques may include defining a configuration for an effusion plate having one or more internal cooling channels. The manufacturing techniques may further include depositing a powder into a chamber, applying an energy source to the deposited powder, and consolidating the powder into a cross-sectional shape corresponding to the defined configuration. Such methods may be implemented to construct an effusion plate having one or more channels with a curved cross-sectional geometry.

Owner:GENERAL ELECTRIC CO

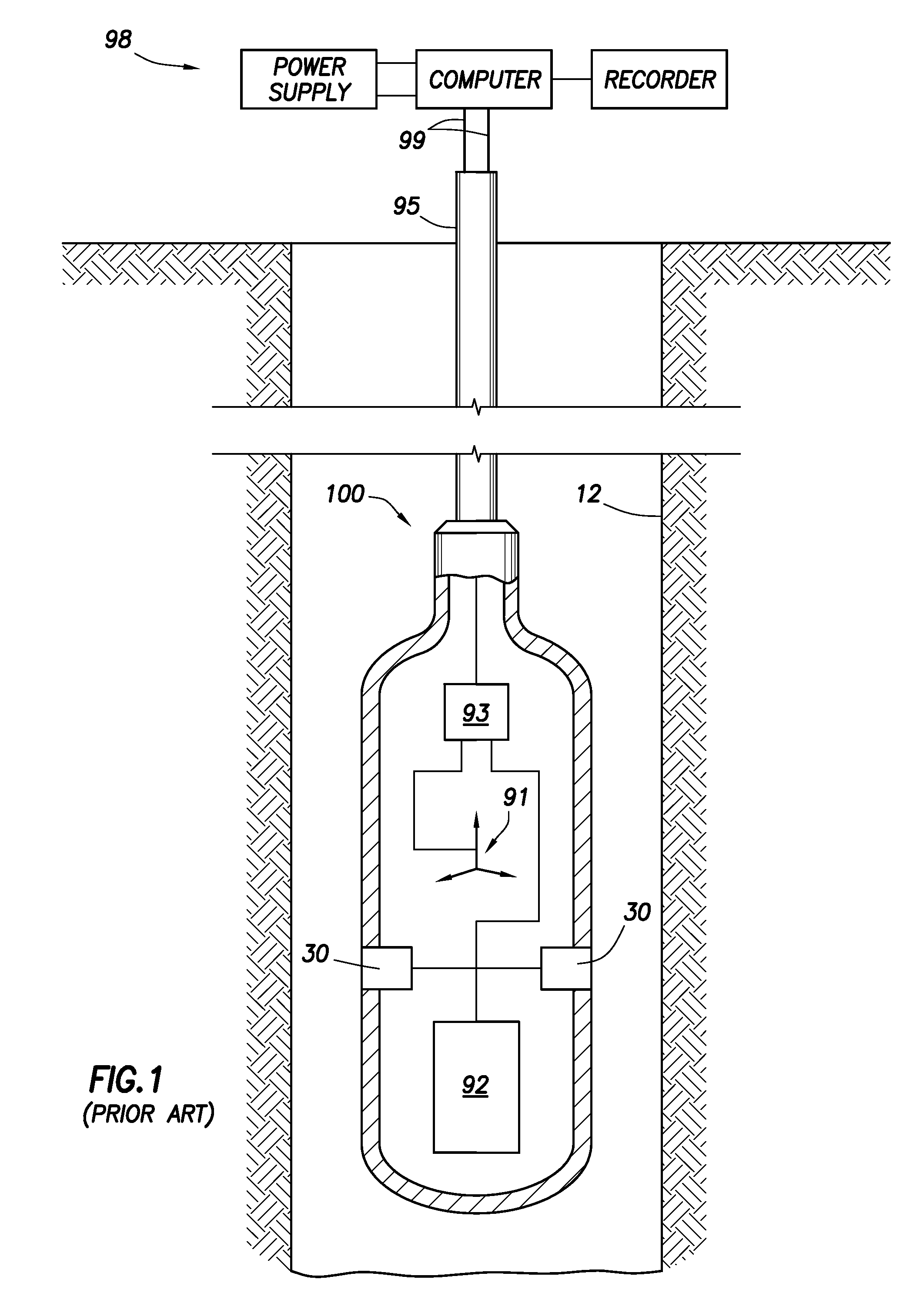

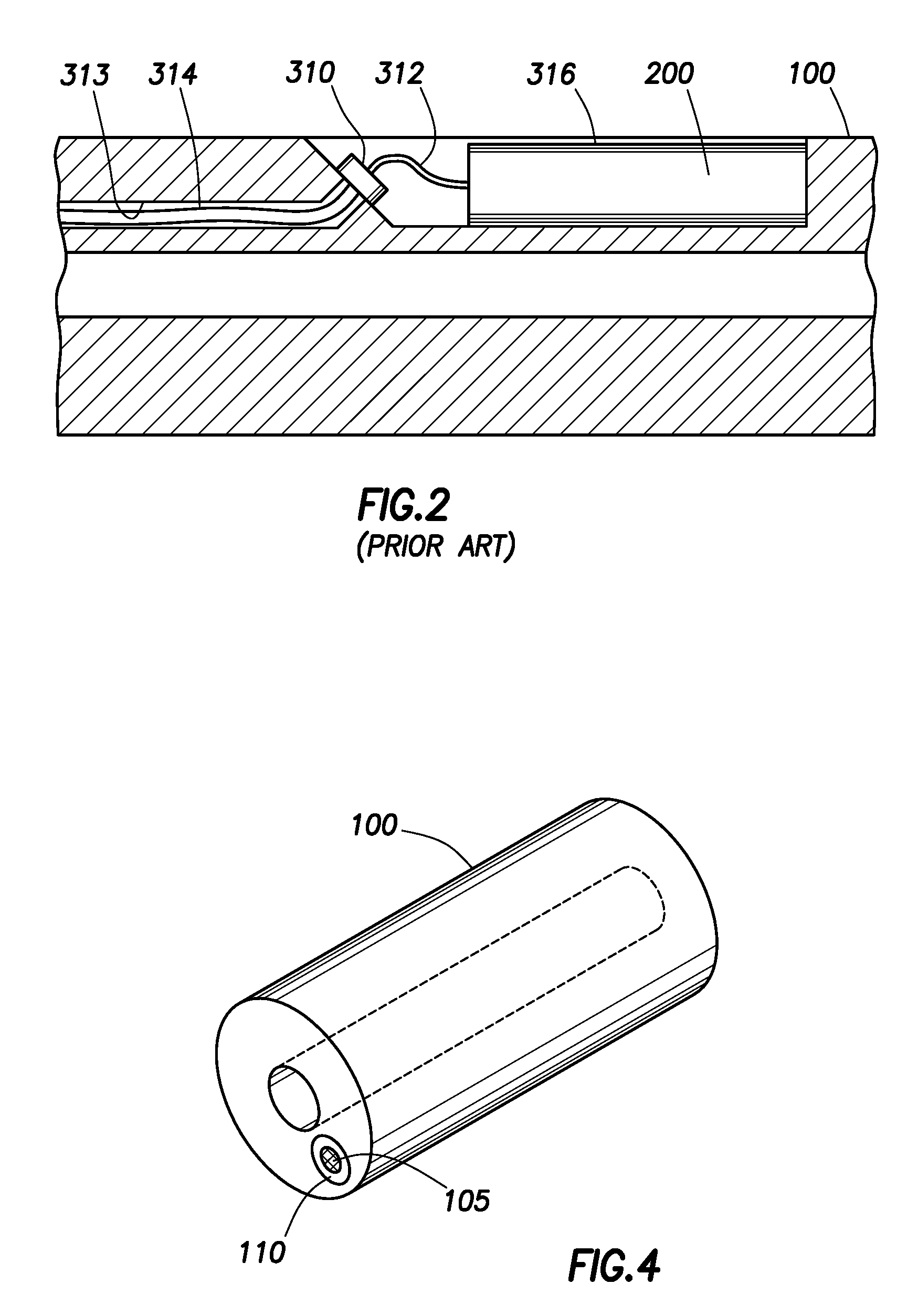

Metal Powder Layered Apparatus for Downhole Use

A method for manufacturing a downhole tool includes obtaining a three-dimensional model of the downhole tool; converting the three-dimensional model of the downhole tool into a model having a plurality of two-dimensional layers; and building the downhole tool, layer-by-layer, by melting a metal powder or an alloy powder using an electron beam based on the model having a plurality of two-dimensional layers. A downhole tool manufactured by a process includes obtaining a three-dimensional model of the downhole tool; converting the three-dimensional model of the downhole tool into a model having a plurality of two-dimensional layers; and building the downhole tool, layer-by-layer, by melting a metal powder or an alloy powder using an electron beam based on the model having a plurality of two-dimensional layers.

Owner:SCHLUMBERGER TECH CORP

Method and apparatus for manufacturing porous articles

InactiveUS20090047439A1High melting pointOvercome disadvantagesAdditive manufacturingLiquid surface applicatorsPorosityMetallurgy

A method for producing porous materials which comprises directing a plasma stream containing particles of a base material in liquid or solid / liquid form onto a substrate under controlled conditions in which the particles spot weld to the substrate or to one another without full fusion, and establishing relative movement between the plasma stream and the substrate whereby the material is deposited as a porous structure of desired porosity and shape.

Owner:MATERIALS & ELECTROCHEM RES

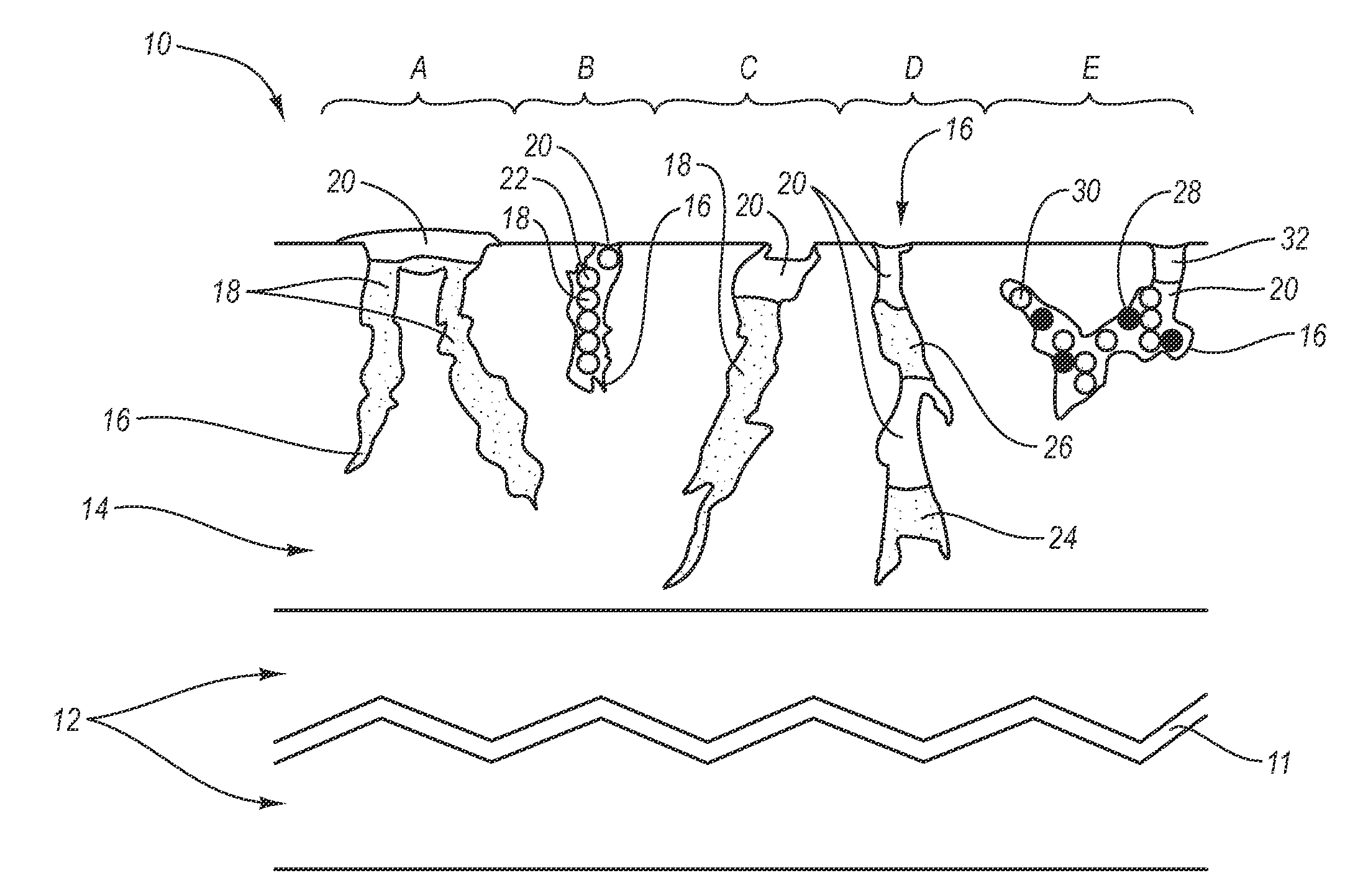

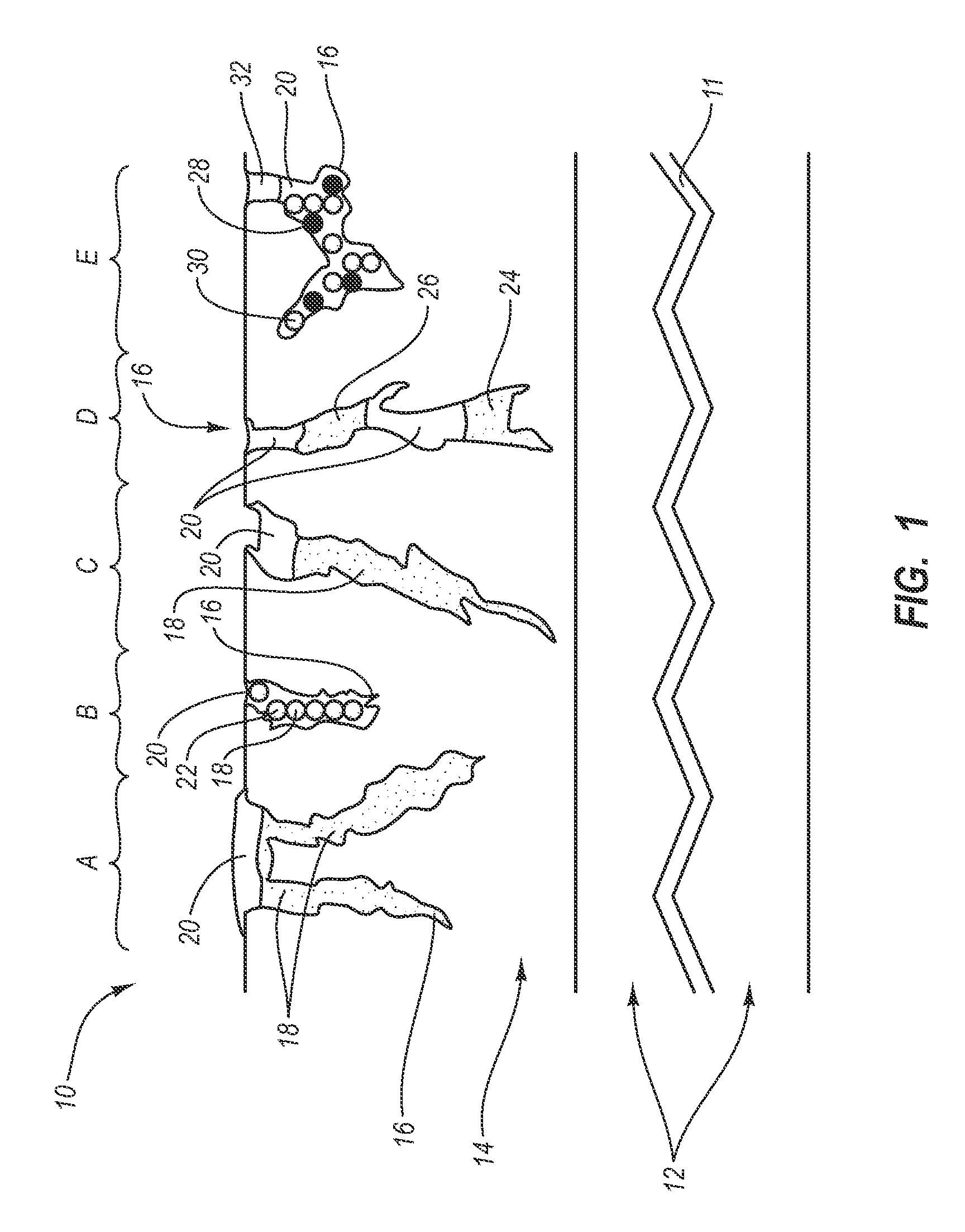

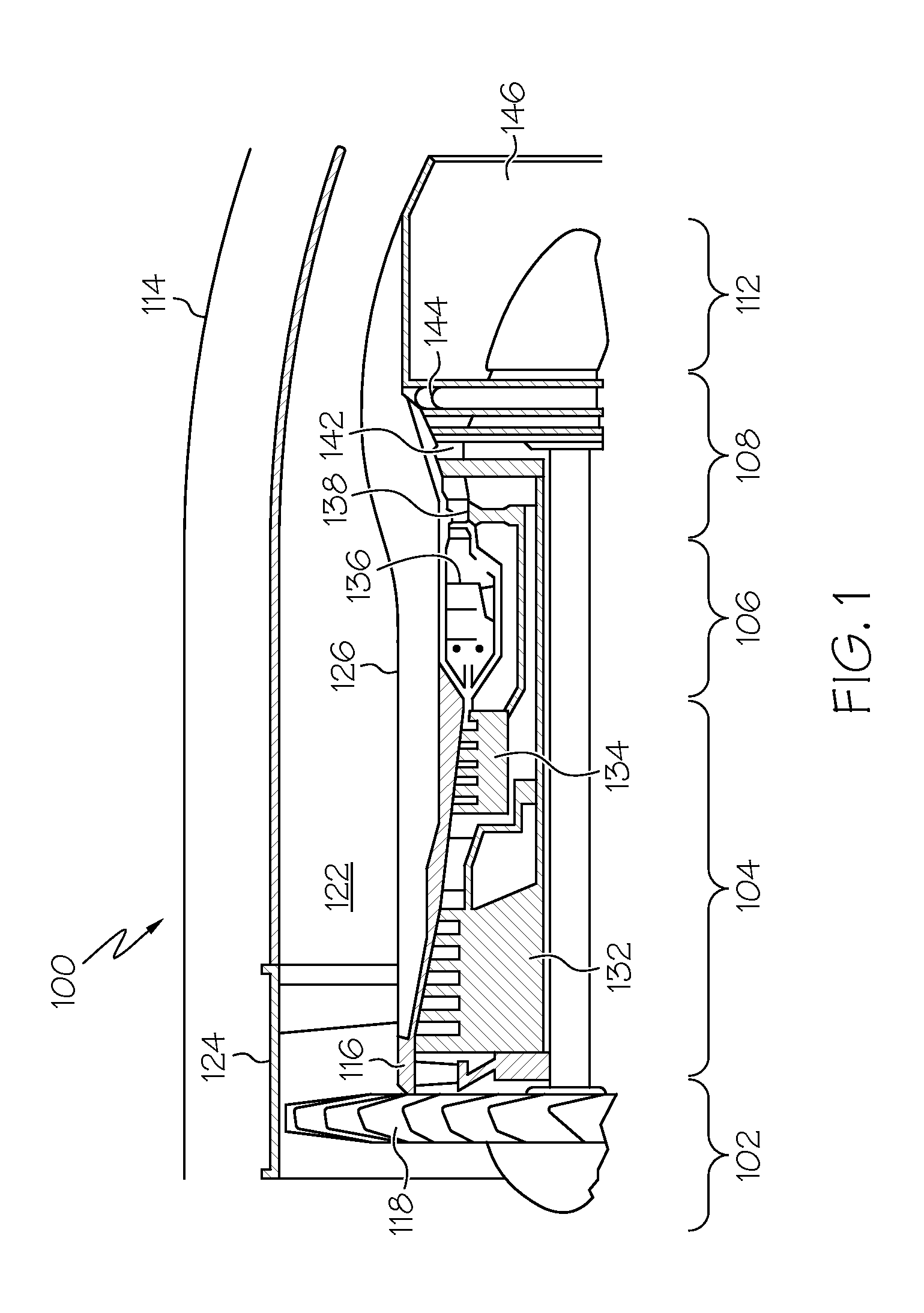

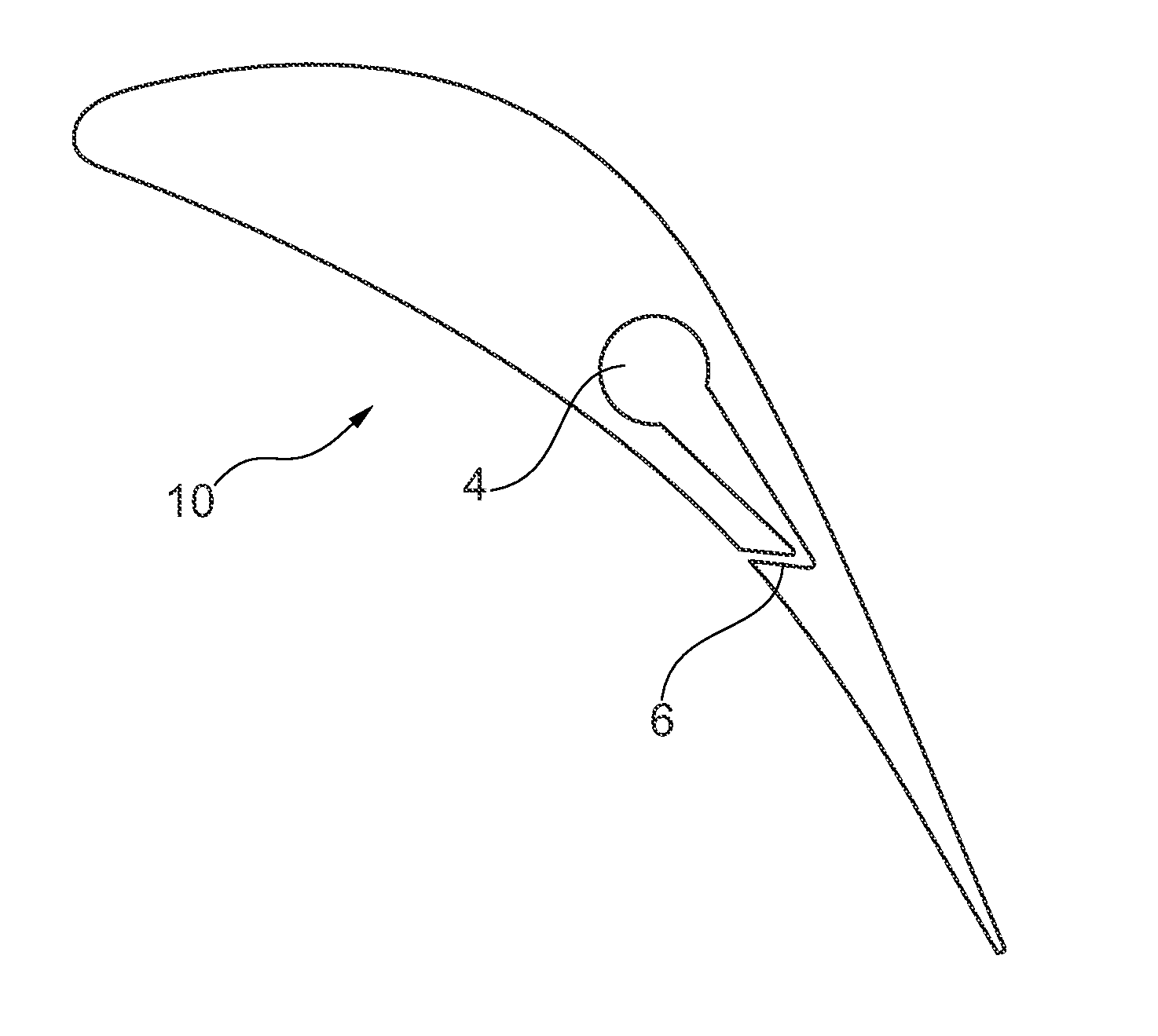

Methods of manufacturing turbomachines blades with shaped channels by additive manufacturing, turbomachine blades and turbomachines

InactiveUS20140205454A1Improve accuracyLow production costTurbinesAdditive manufacturingAdditive layer manufacturingBiomedical engineering

A hollow blade for a turbomachine comprises an airfoil portion; the airfoil portion extends longitudinally for a length; the airfoil portion is defined laterally by an external surface; the airfoil portion has at least one internal cavity extending along said length and defined laterally by an internal surface; the airfoil portion has a set of channels extending from the external surface to the internal surface; the openings of said channels on said external surface are aligned along a curved line that reflects an isobar on said external surface.

Owner:BAKER HUGHES INC +1

Metal base ceramic phase reinforced alloy tool steel powder for 3D printing, preparation method and application thereof

ActiveCN105714209AHigh hardnessImprove wear resistanceAdditive manufacturingTransportation and packagingAlloyWear resistance

The invention discloses metal base ceramic phase reinforced alloy tool steel powder for 3D printing. The alloy tool steel powder is characterized by comprising the following elements in percentage by mass: 0.2-5% of C, 0.2-1% of Si, 0.1-1% of Mn, 0.3-1% of Ni, 3-25% of Cr, 0.2-15% of Mo, 0.2-14.5% of V, 0.3-15% of W, 1-18% of Co, 0.2-1% of Nb, 0.2-8% of metal base ceramic phase metal elements, and the balance of iron. The invention designs a ceramic phase reinforced alloy tool steel powder material; and the component design of the material embodies better hardness, wear resistance and high-temperature performance of the material.

Owner:HUAZHONG UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com