Patents

Literature

97results about How to "Optimization properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

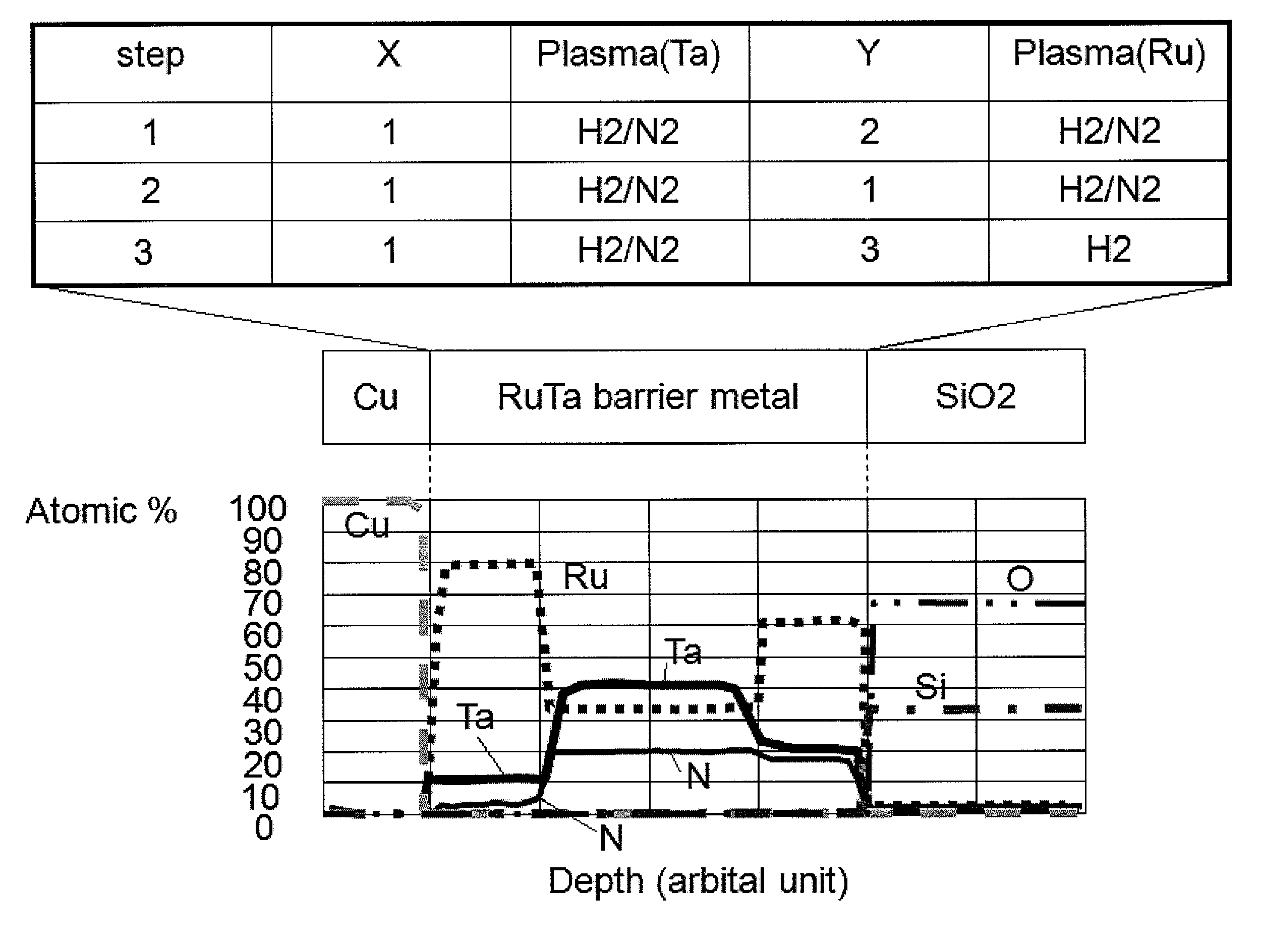

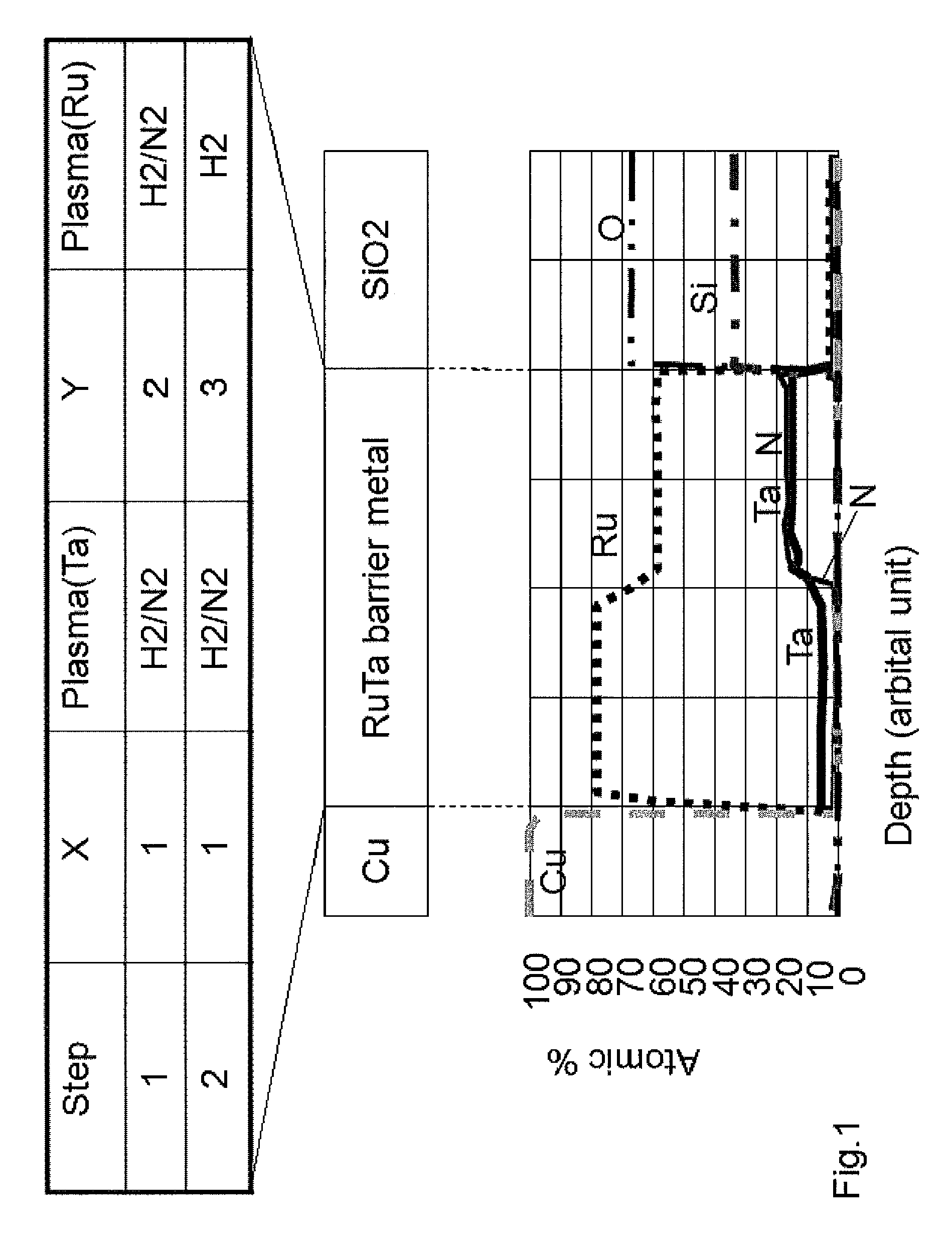

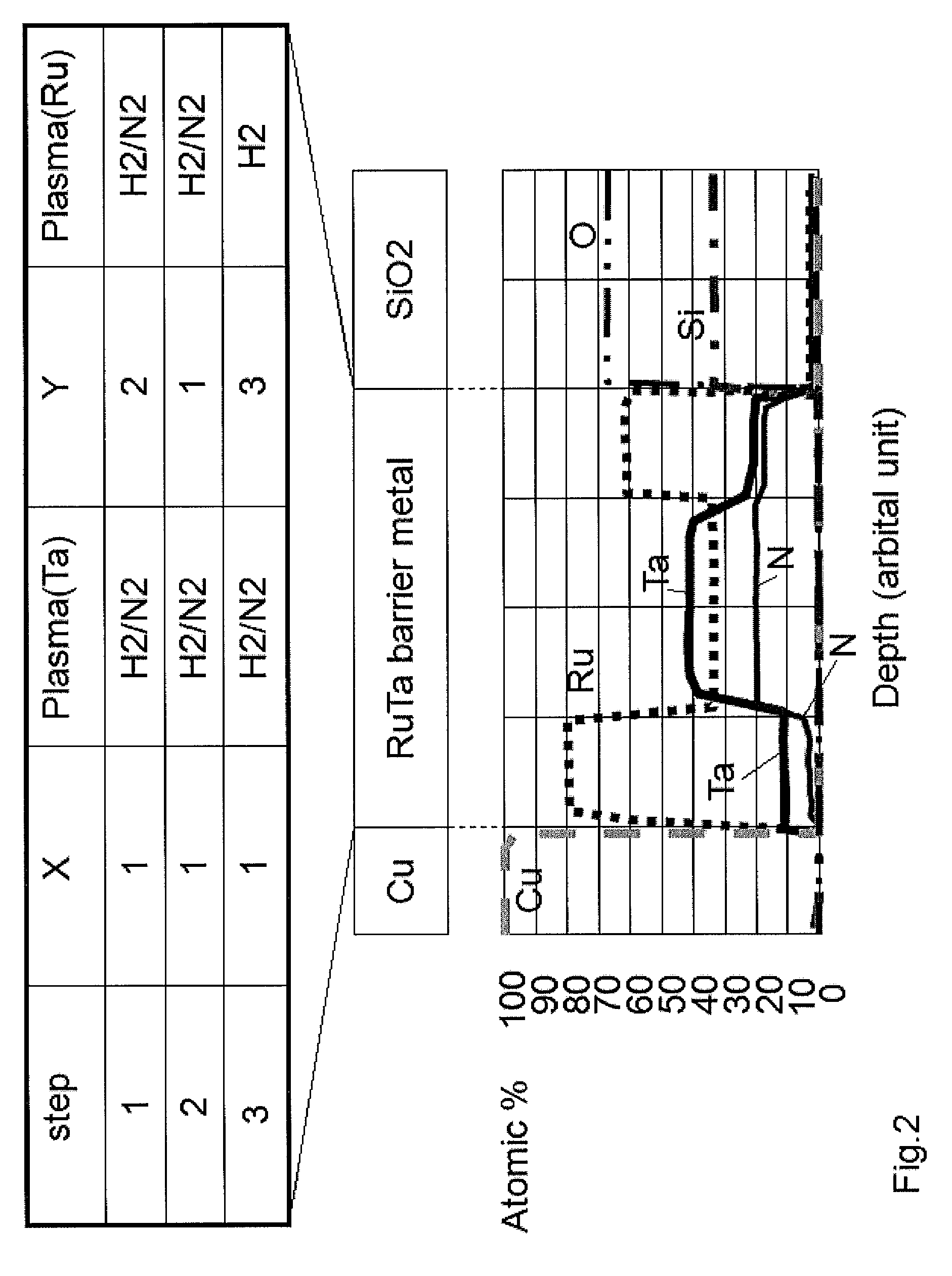

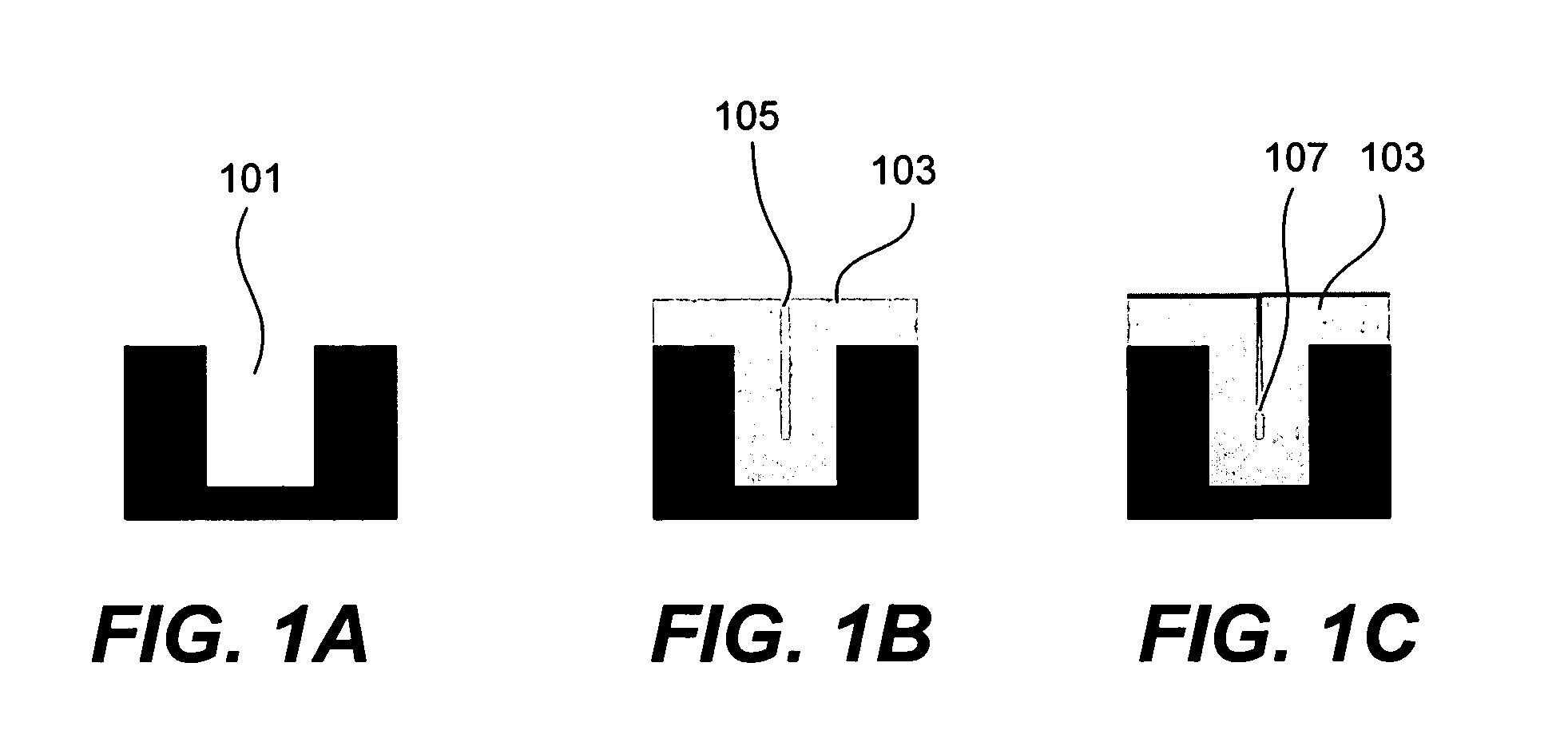

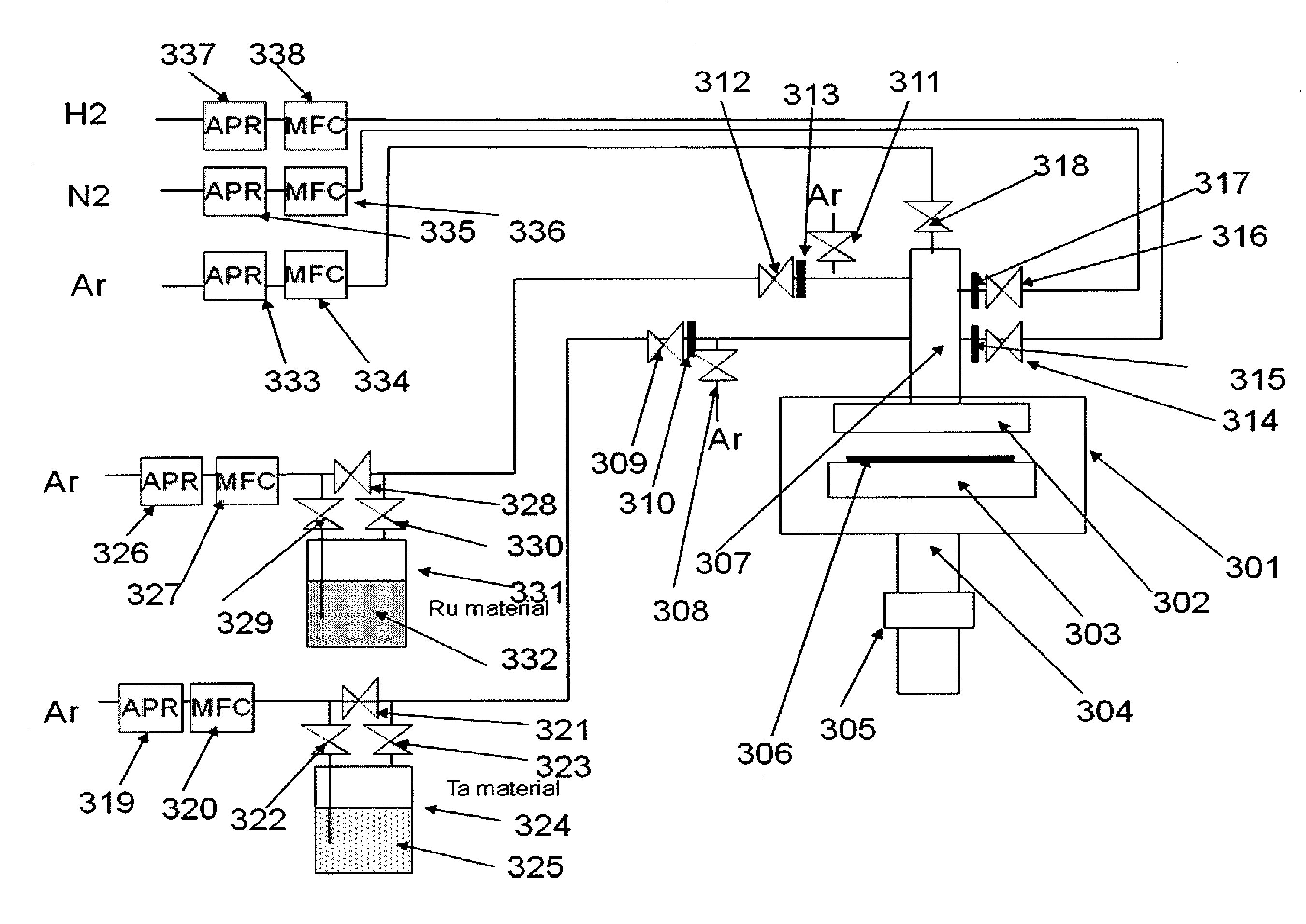

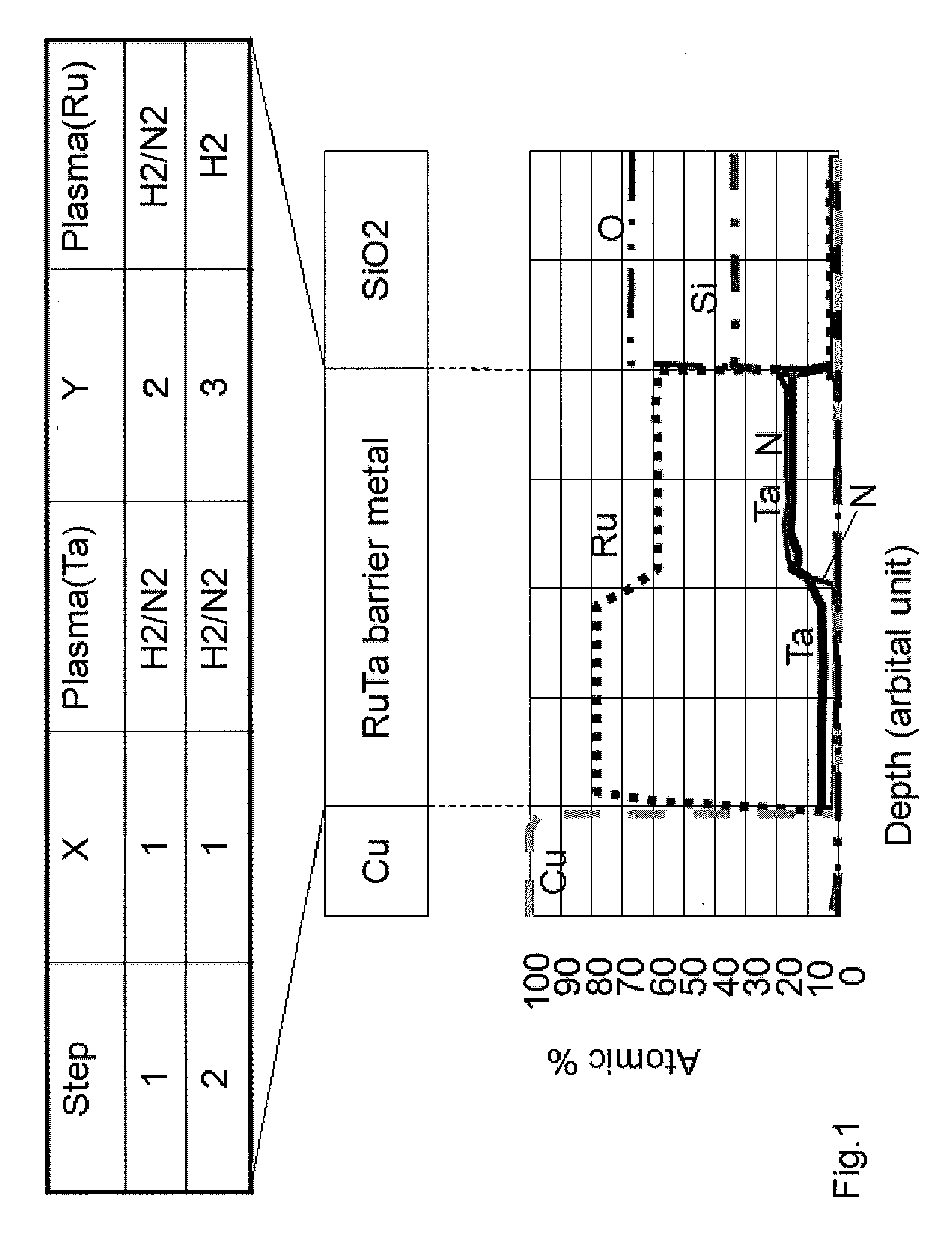

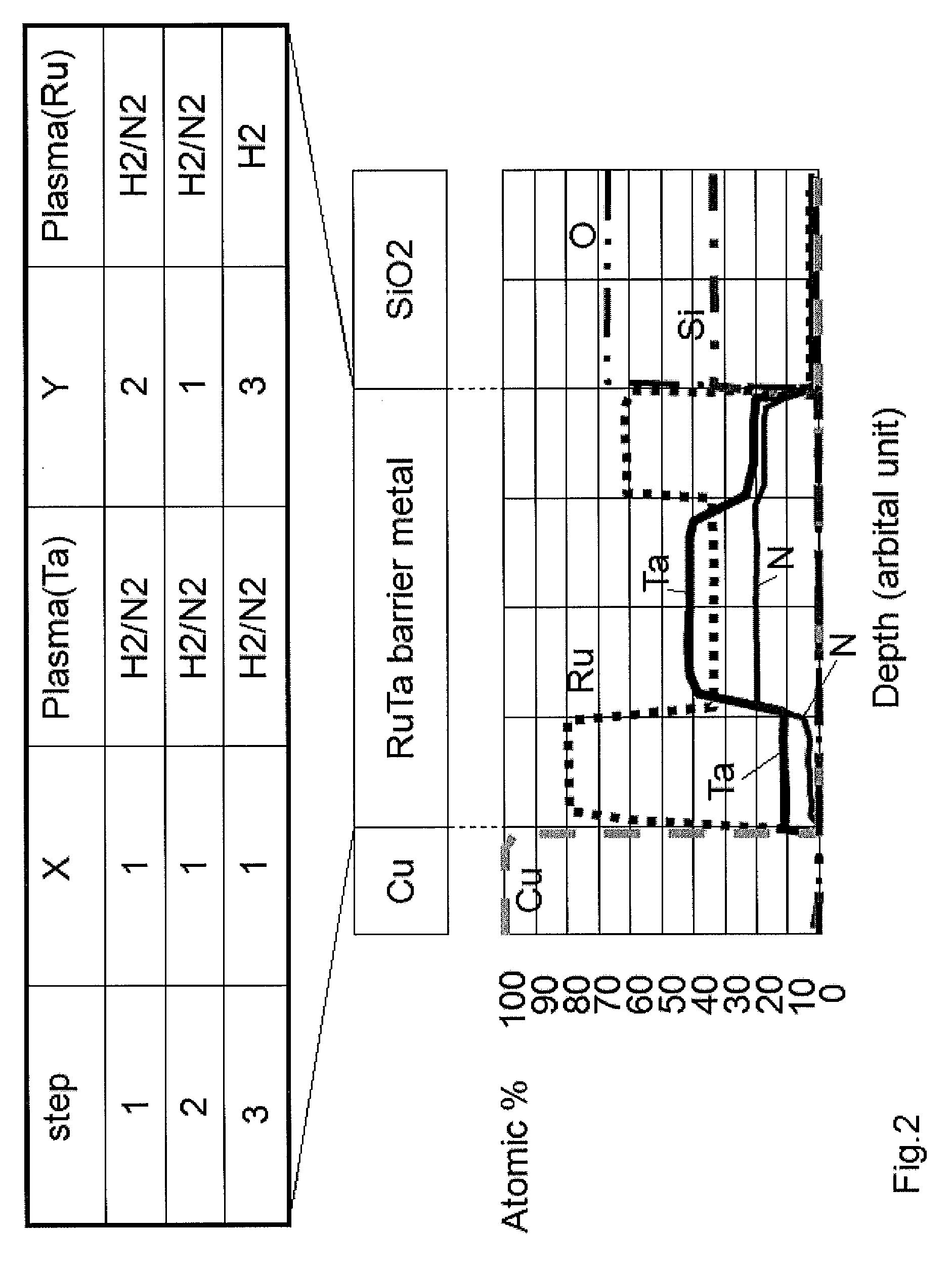

Atomic composition controlled ruthenium alloy film formed by plasma-enhanced atomic layer deposition

ActiveUS8084104B2Reduce resistanceLow densitySemiconductor/solid-state device detailsSynthetic resin layered productsRutheniumAlloy

A metal film composed of multiple atomic layers continuously formed by atomic layer deposition of Ru and Ta or Ti includes at least a top section and a bottom section, wherein an atomic composition of Ru, Ta or Ti, and N varies in a thickness direction of the metal film. The atomic composition of Ru, Ta or Ti, and N in the top section is represented as Ru(x1)Ta / Ti(y1)N(z1) wherein an atomic ratio of Ru(x1) / (Ta / Ti(y1)) is no less than 15, and z1 is 0.05 or less. The atomic composition of Ru, Ta or Ti, and N in the bottom section is represented as Ru(x2)Ta / Ti(y2)N(z2) wherein an atomic ratio of Ru(x2) / (Ta / Ti(y2)) is more than zero but less than 15, and z2 is 0.10 or greater.

Owner:ASM JAPAN

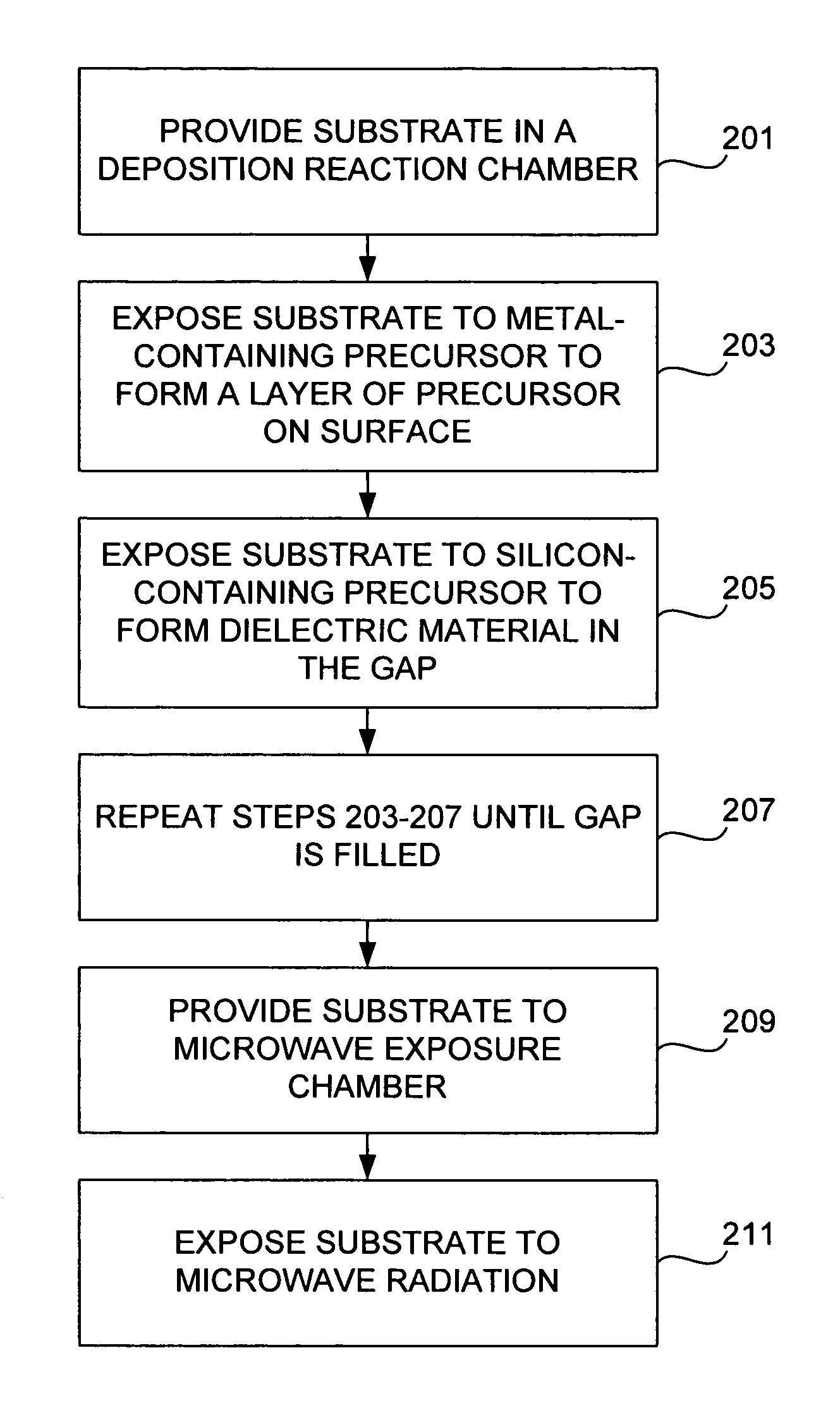

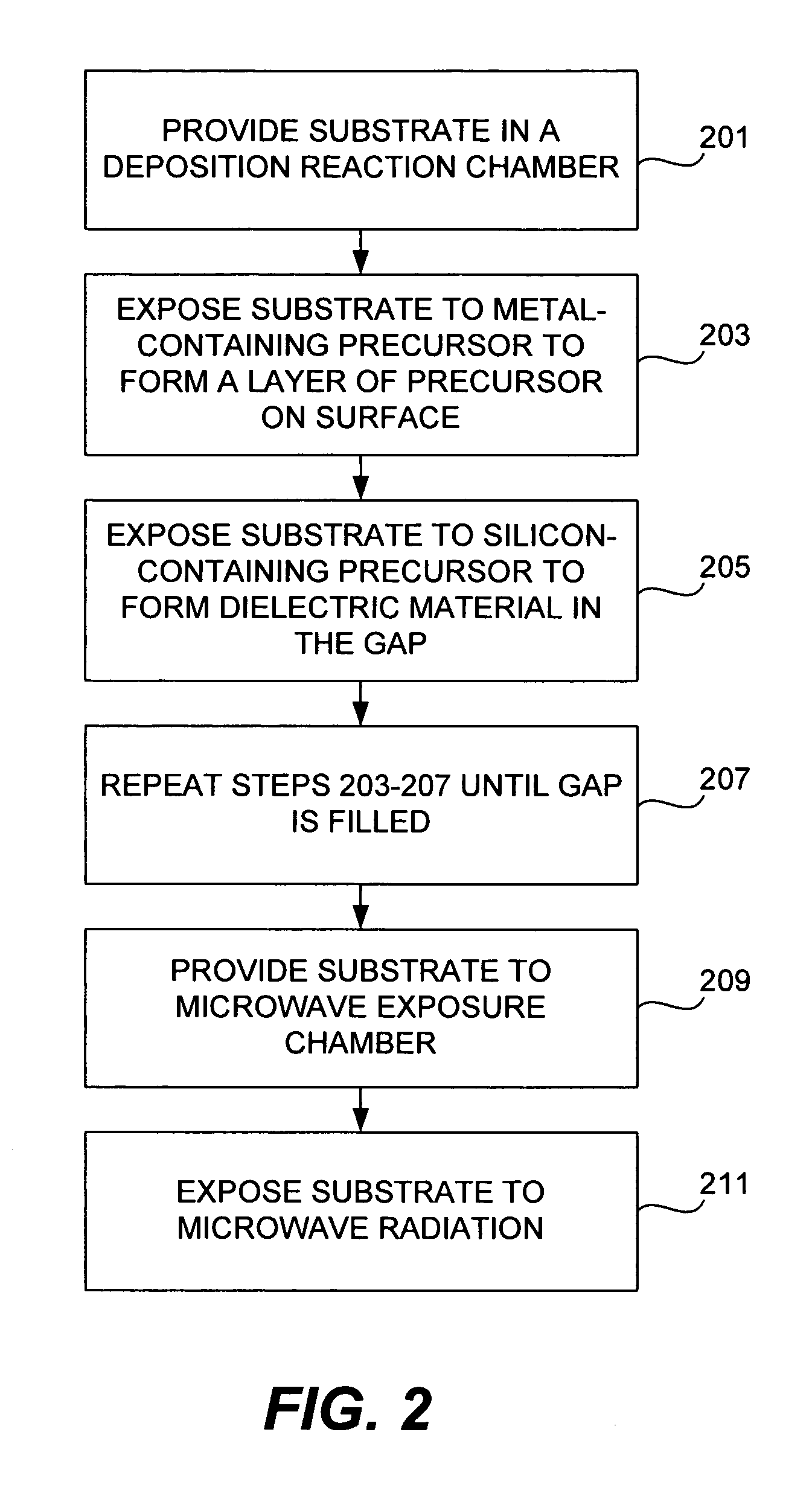

Hydroxyl bond removal and film densification method for oxide films using microwave post treatment

ActiveUS7589028B1High densityImprove film propertiesRadiation applicationsSemiconductor/solid-state device manufacturingDielectricMicrowave

Methods of forming dielectric films with increased density and improved film properties are provided. The methods involve exposing dielectric films to microwave radiation. According to various embodiments, the methods may be used to remove hydroxyl bonds, increase film density, reduce or eliminate seams and voids, and optimize film properties such as dielectric constant, refractive index and stress for particular applications. In certain embodiments, the methods are used to form conformal films deposited by a technique such as PDL. The methods may be used in applications requiring low thermal budgets.

Owner:NOVELLUS SYSTEMS

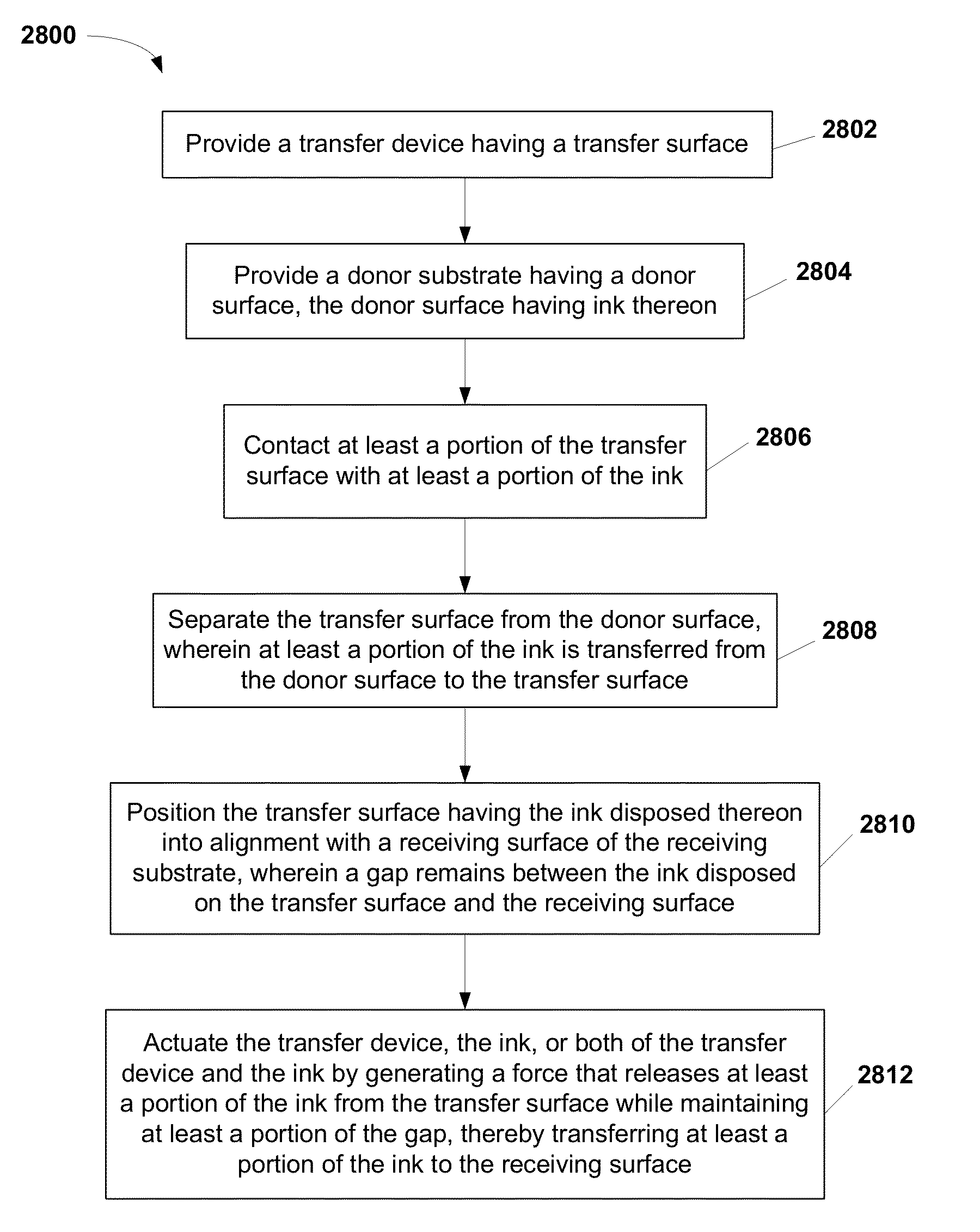

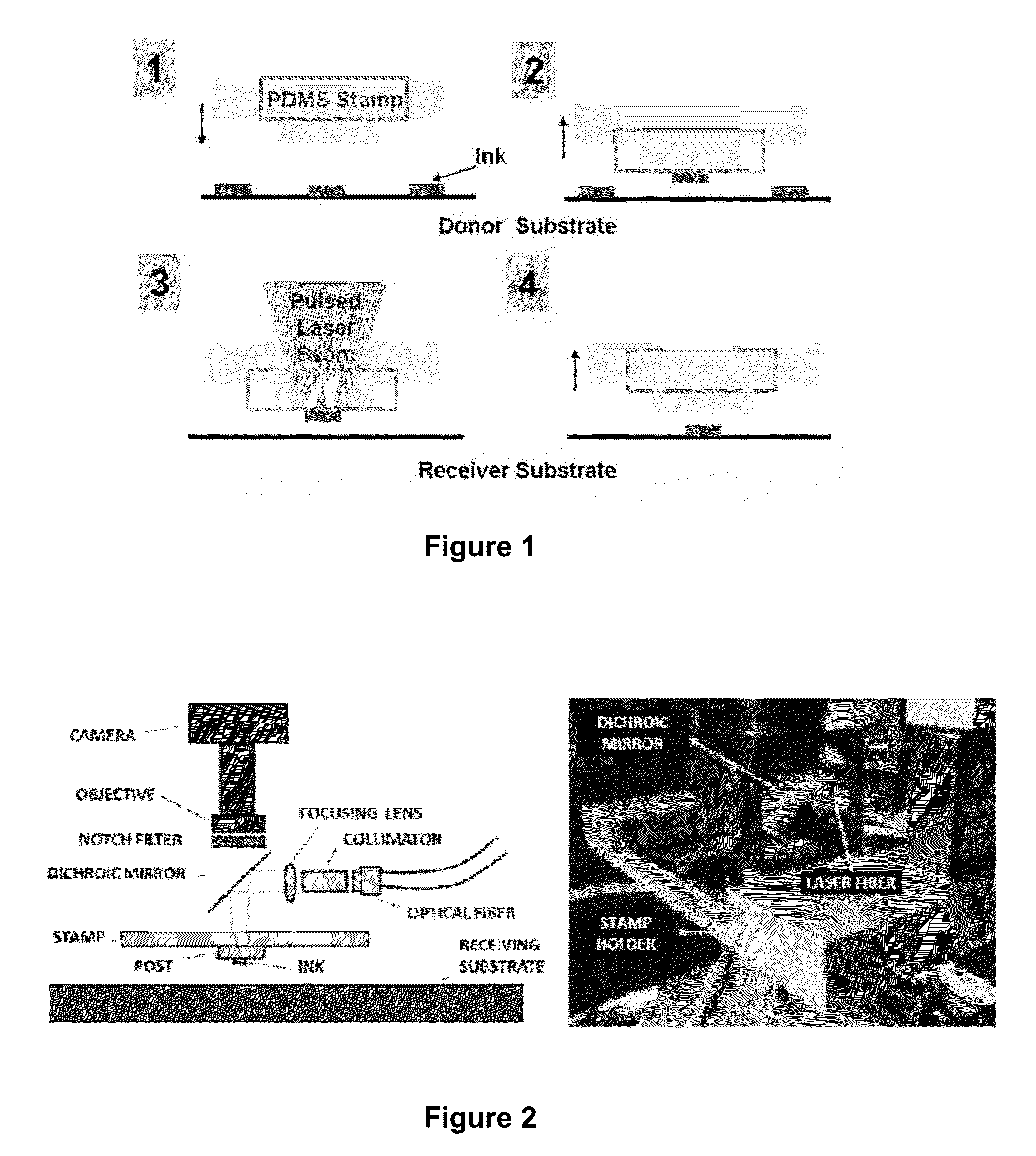

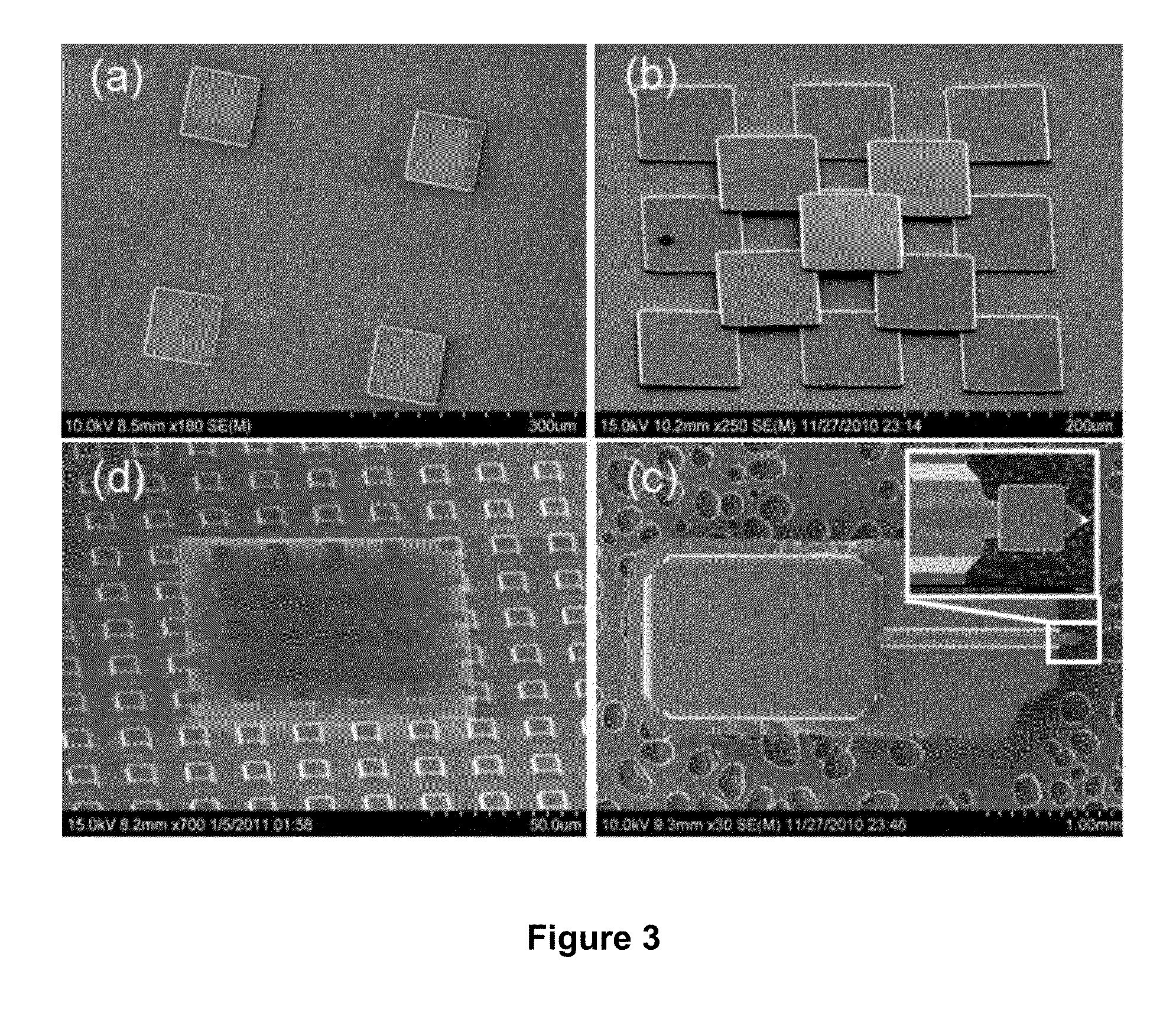

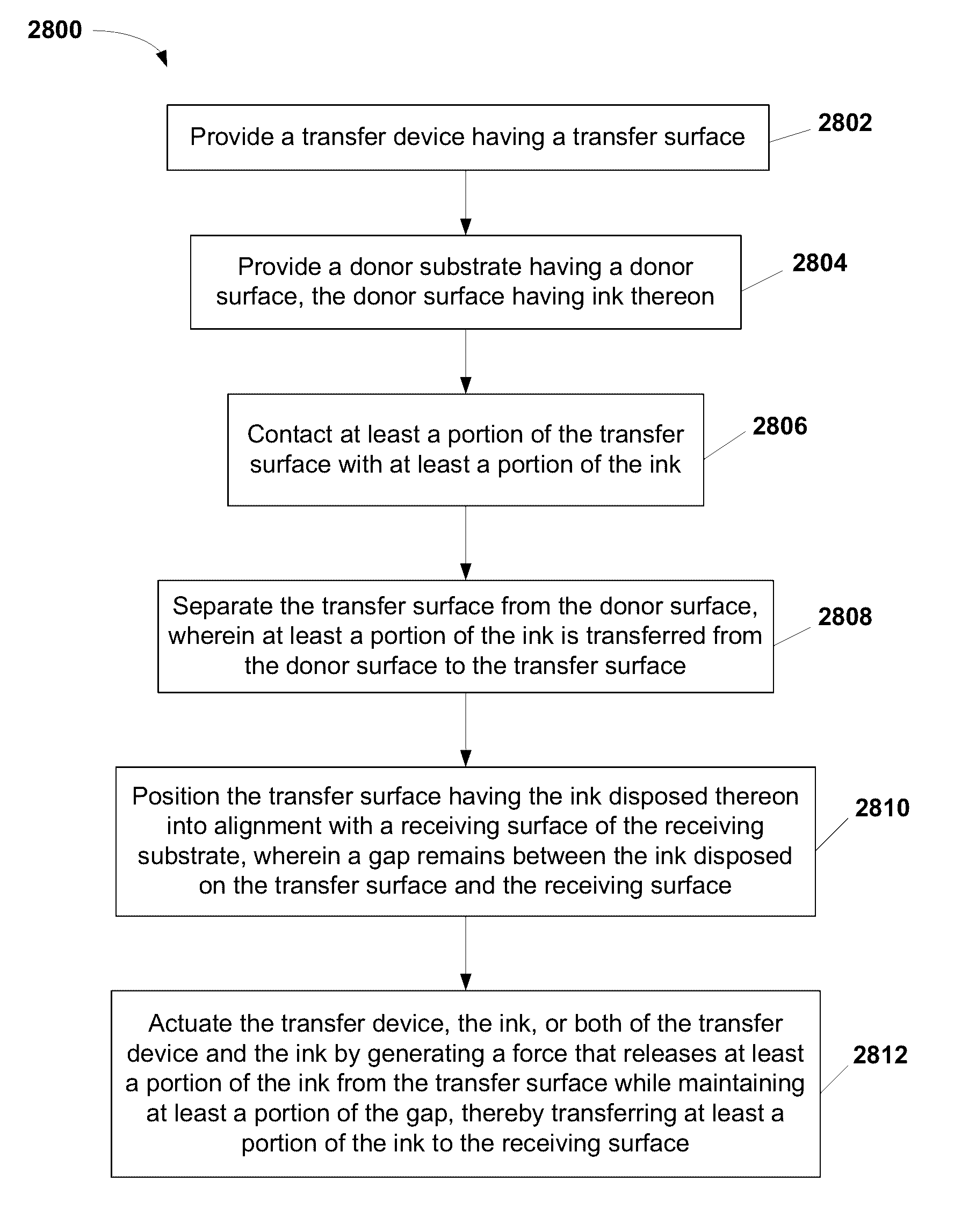

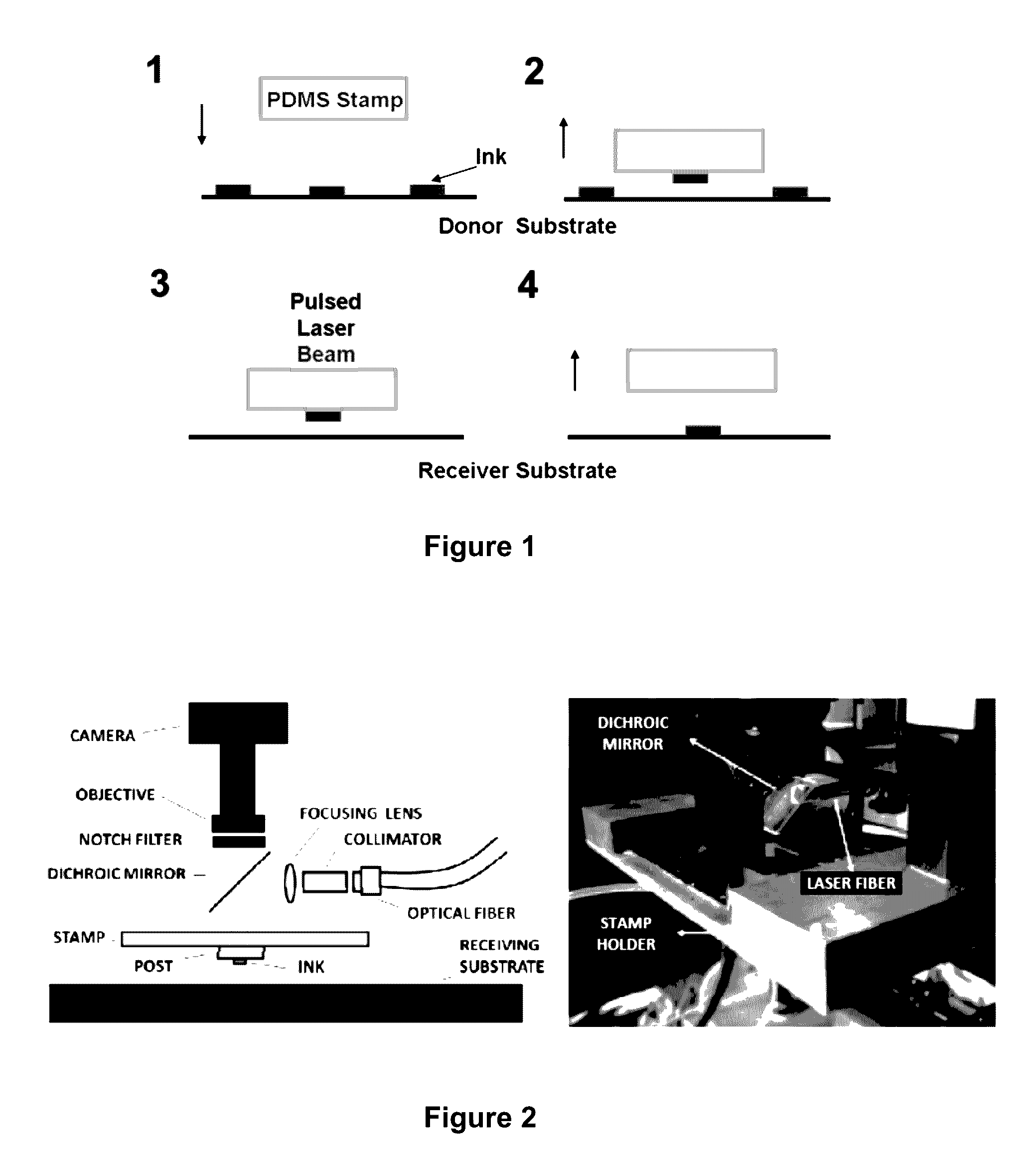

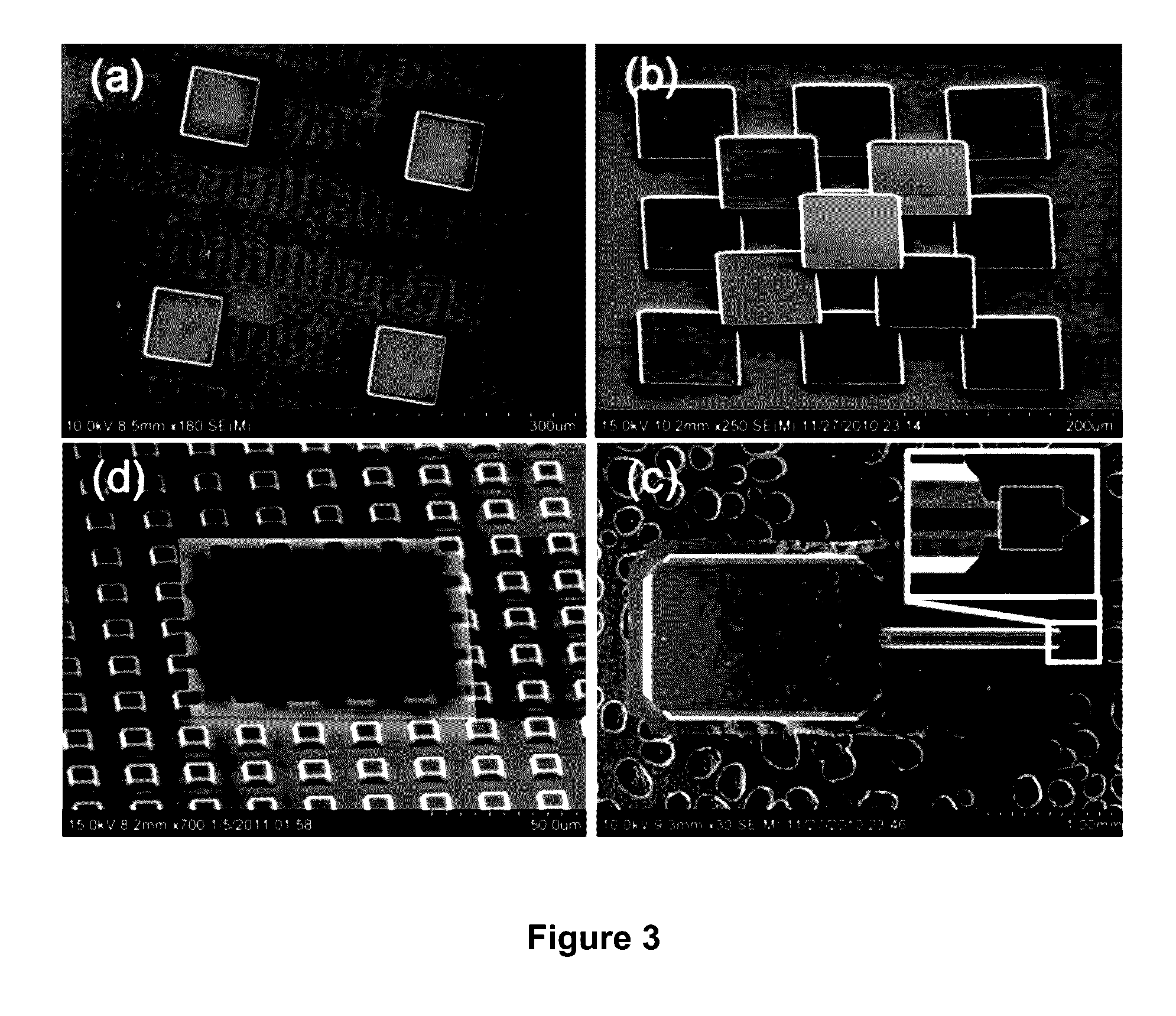

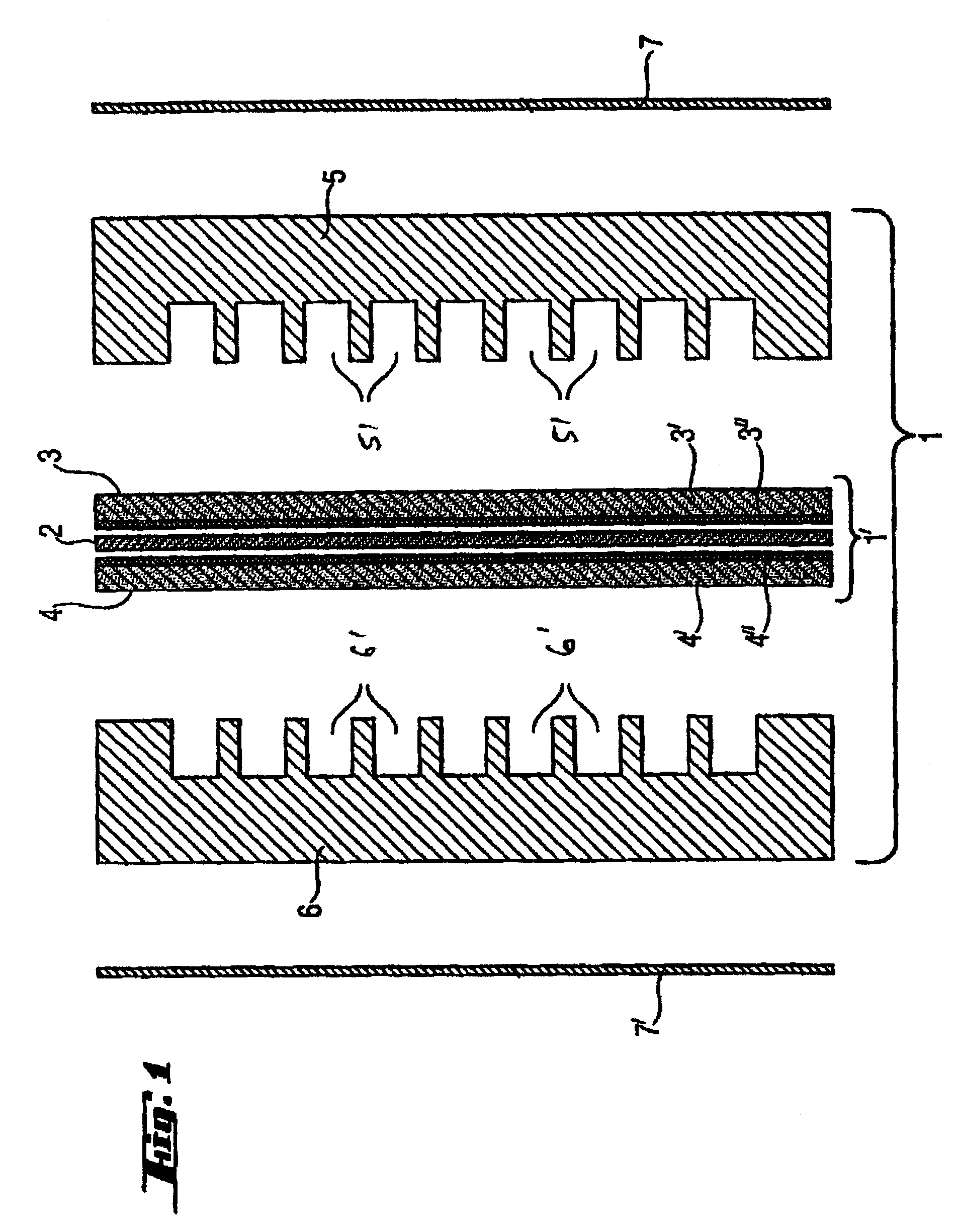

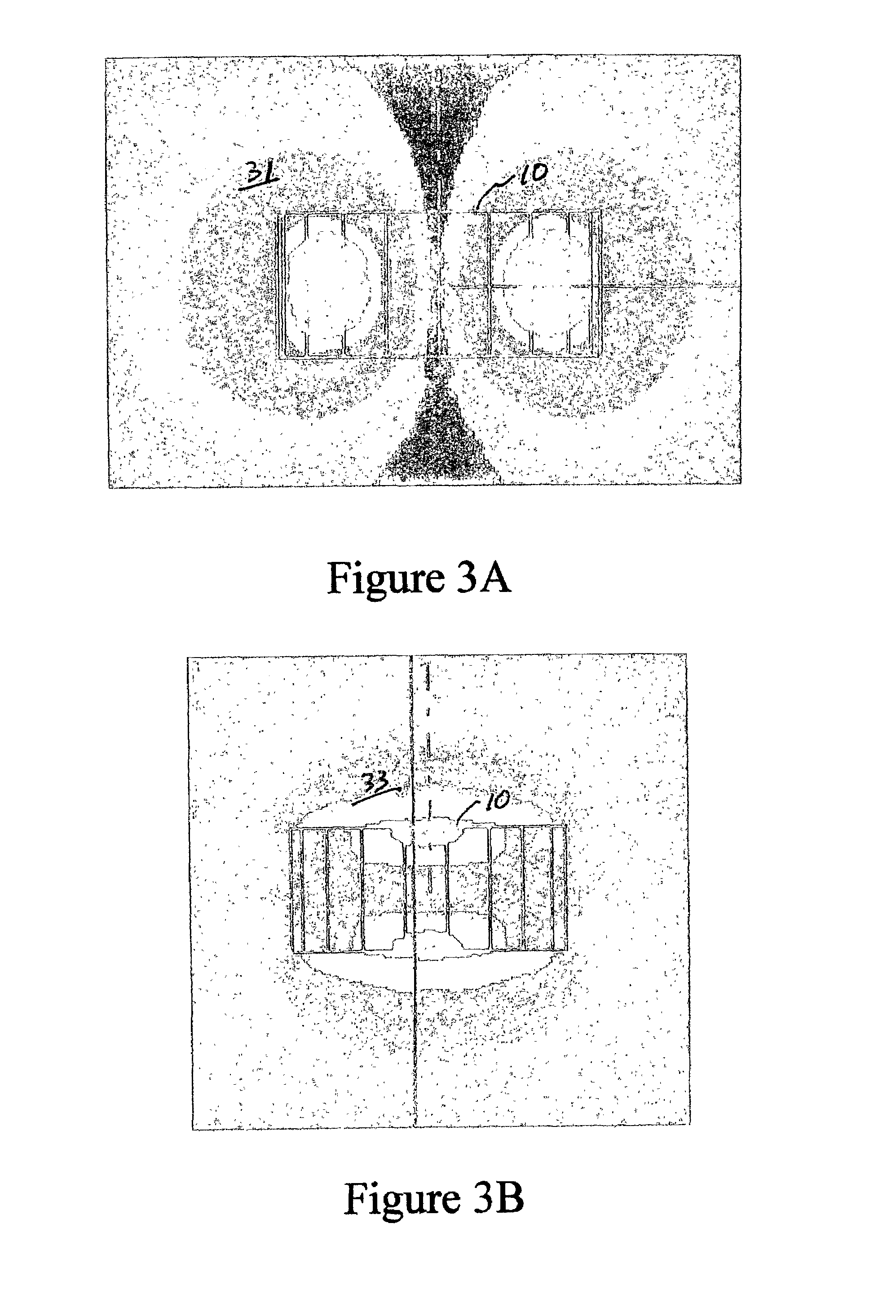

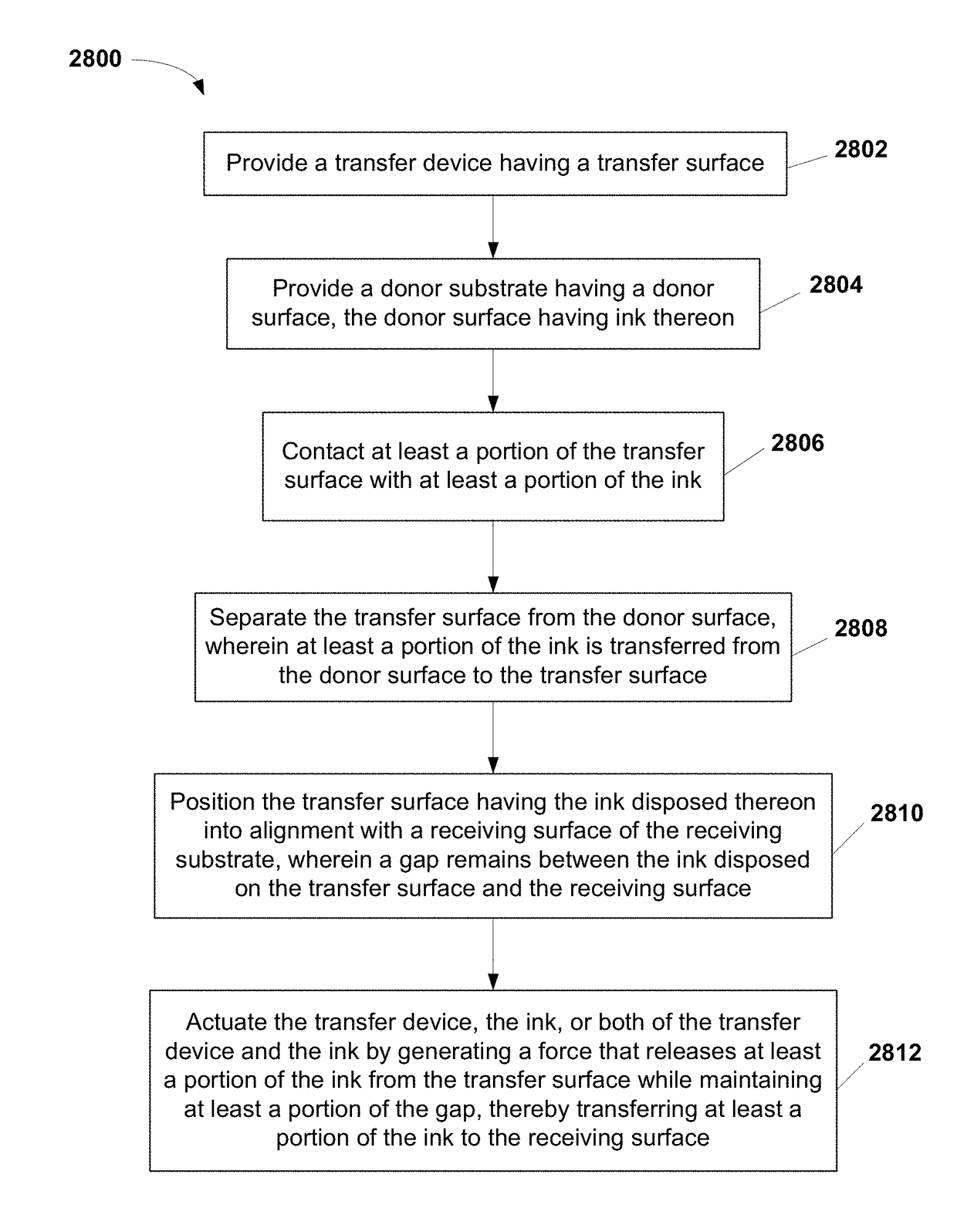

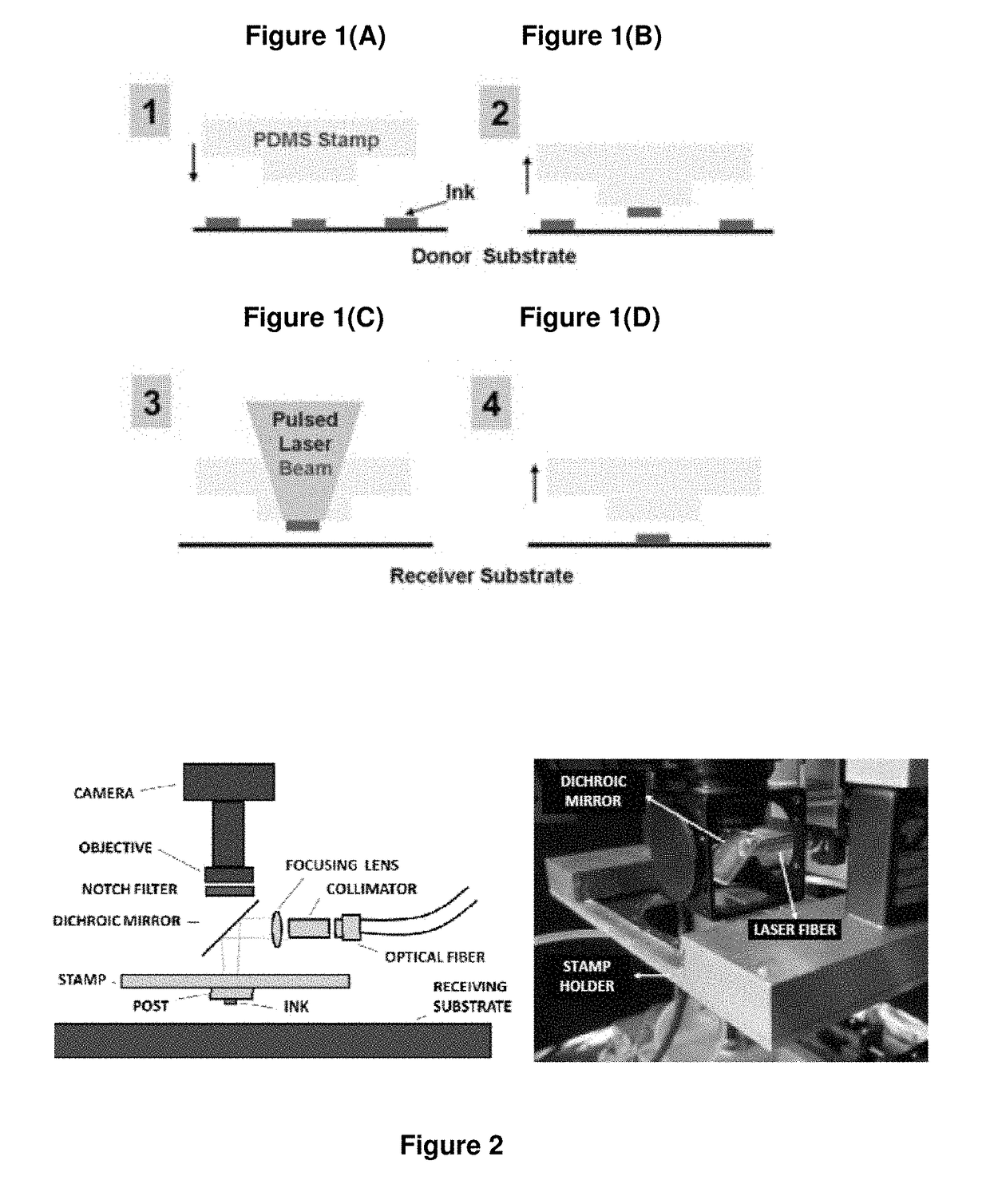

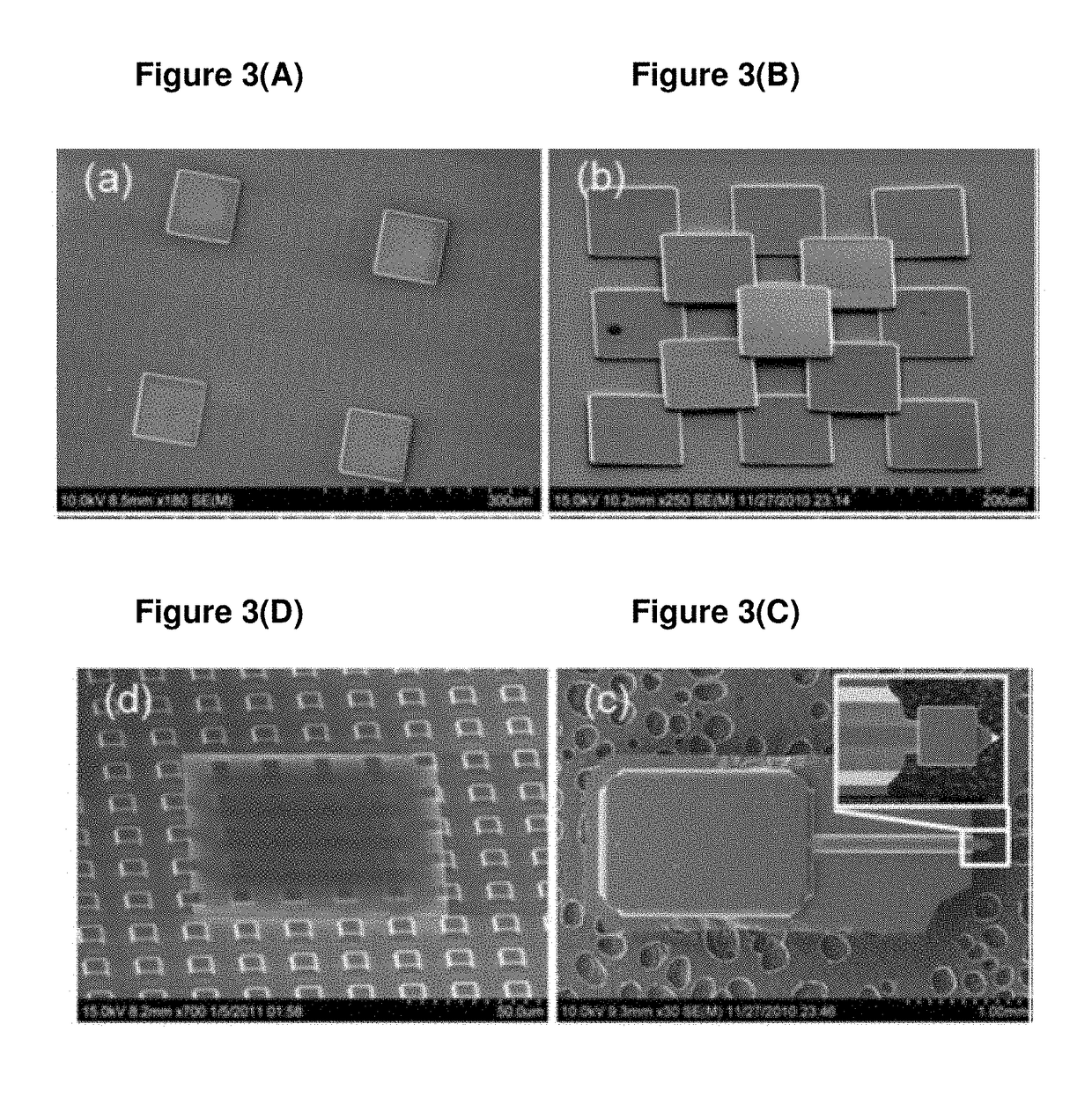

Non-contact transfer printing

ActiveUS20130036928A1Avoid damageNot to damageTransfer printingDuplicating/marking methodsNano-deviceLight-emitting diode

A transfer printing process that exploits the mismatch in mechanical or thermo-mechanical response at the interface of a printable micro- or nano-device and a transfer stamp to drive the release of the device from the stamp and its non-contact transfer to a receiving substrate are provided. The resulting facile, pick-and-place process is demonstrated with the assembling of 3-D microdevices and the printing of GAN light-emitting diodes onto silicon and glass substrates. High speed photography is used to provide experimental evidence of thermo-mechanically driven release.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

Non-contact transfer printing

ActiveUS9555644B2Avoid damageNot to damageTransfer printingDuplicating/marking methodsNano-deviceLight-emitting diode

A transfer printing process that exploits the mismatch in mechanical or thermo-mechanical response at the interface of a printable micro- or nano-device and a transfer stamp to drive the release of the device from the stamp and its non-contact transfer to a receiving substrate are provided. The resulting facile, pick-and-place process is demonstrated with the assembling of 3-D microdevices and the printing of GAN light-emitting diodes onto silicon and glass substrates. High speed photography is used to provide experimental evidence of thermo-mechanically driven release.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

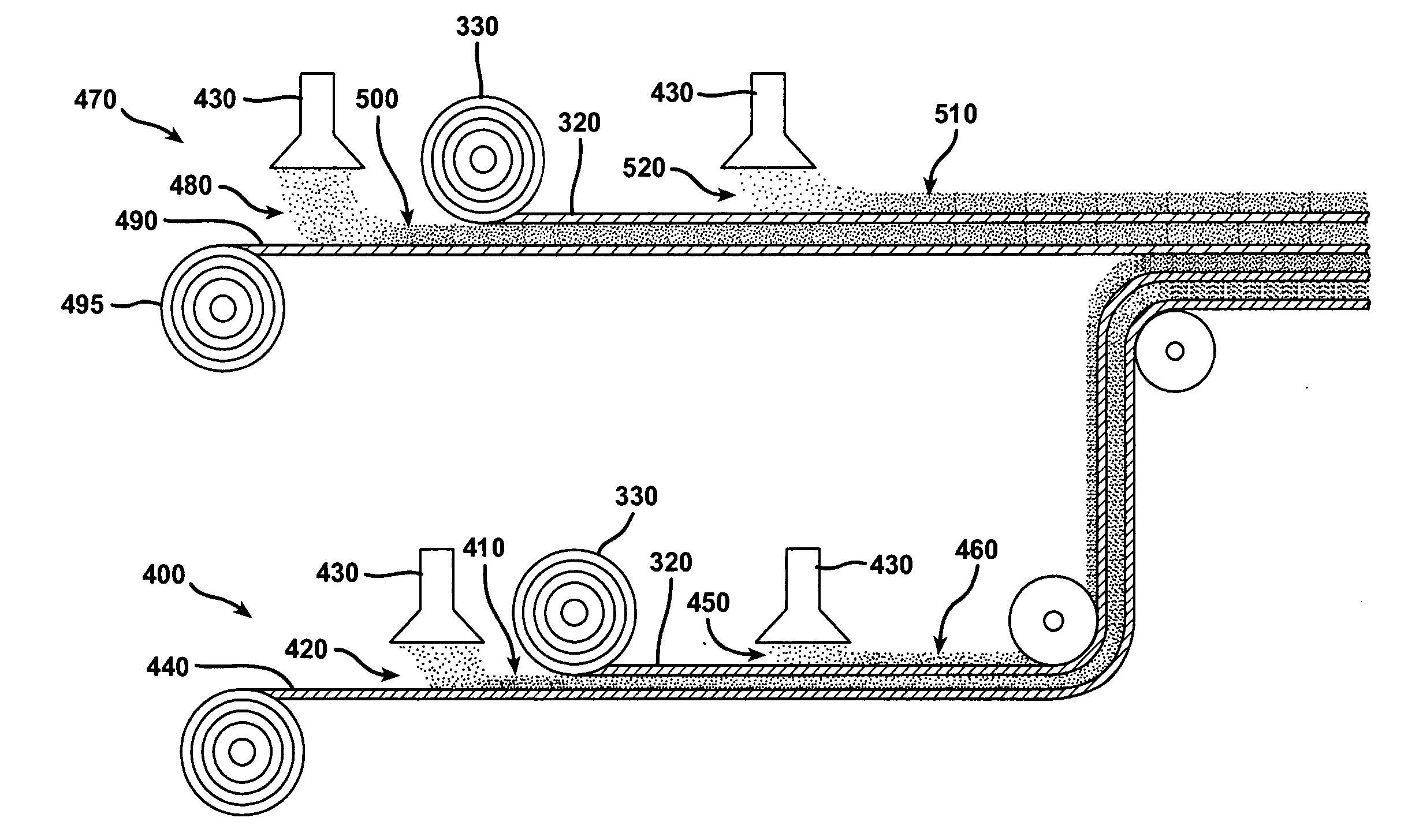

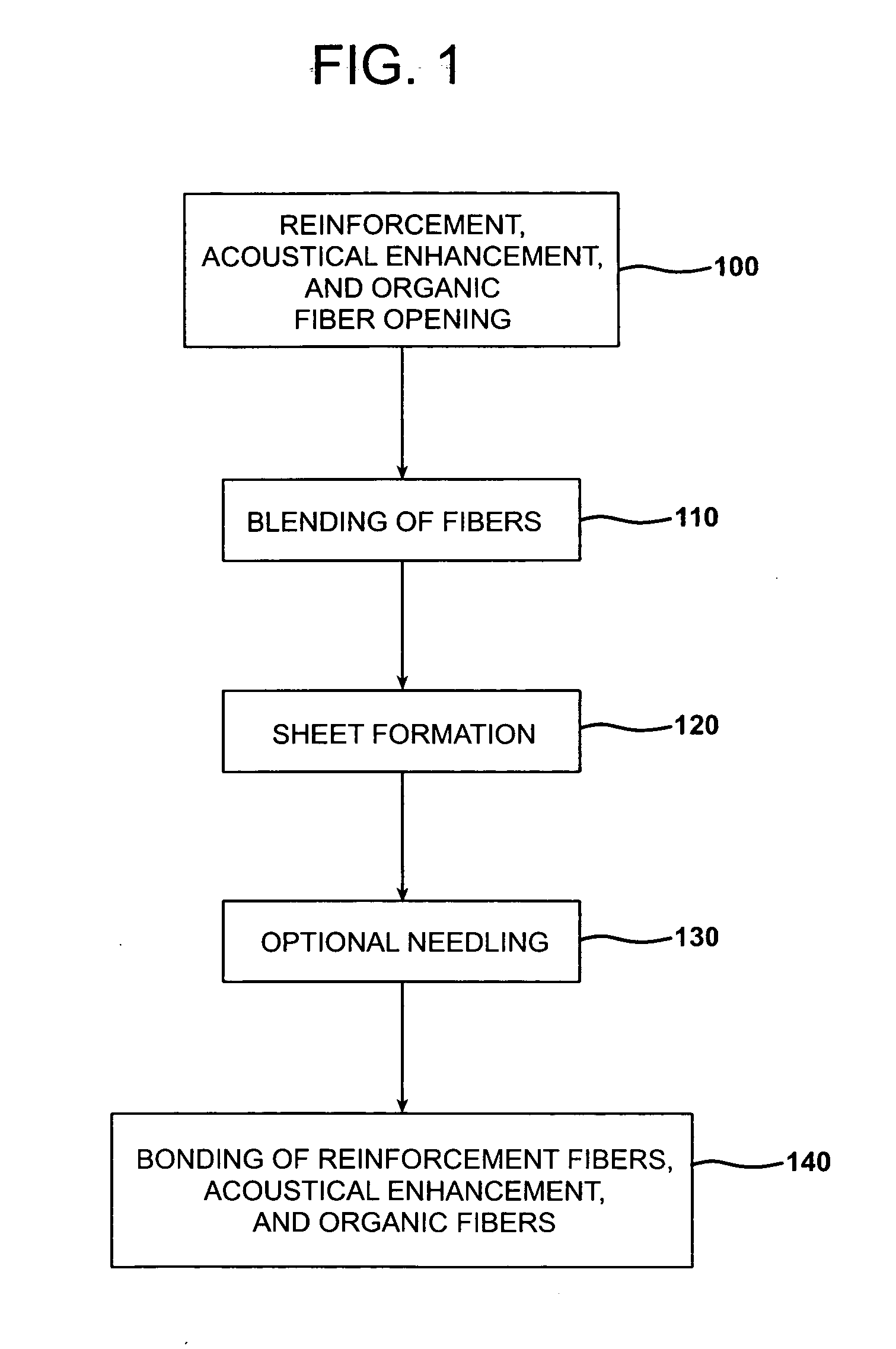

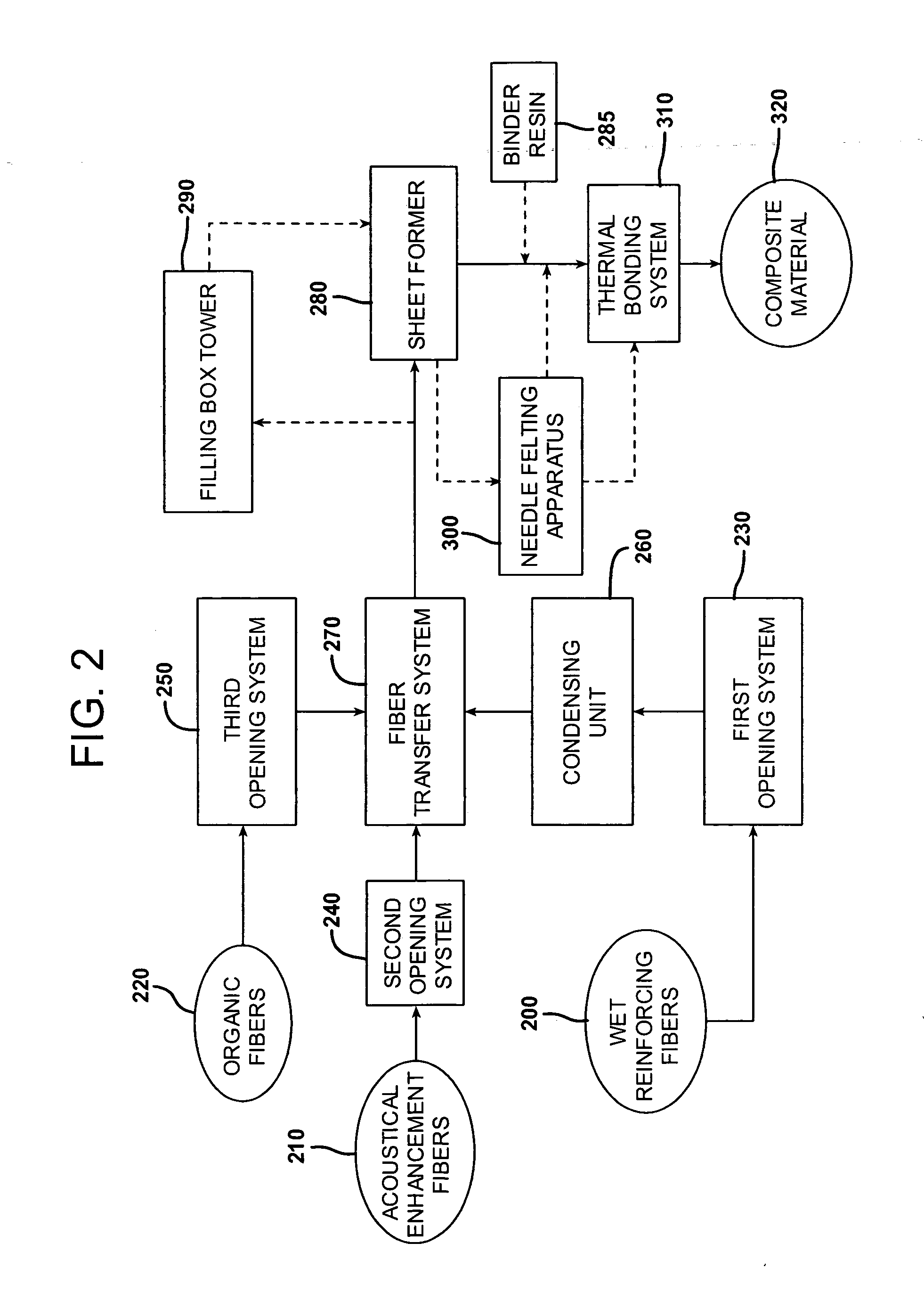

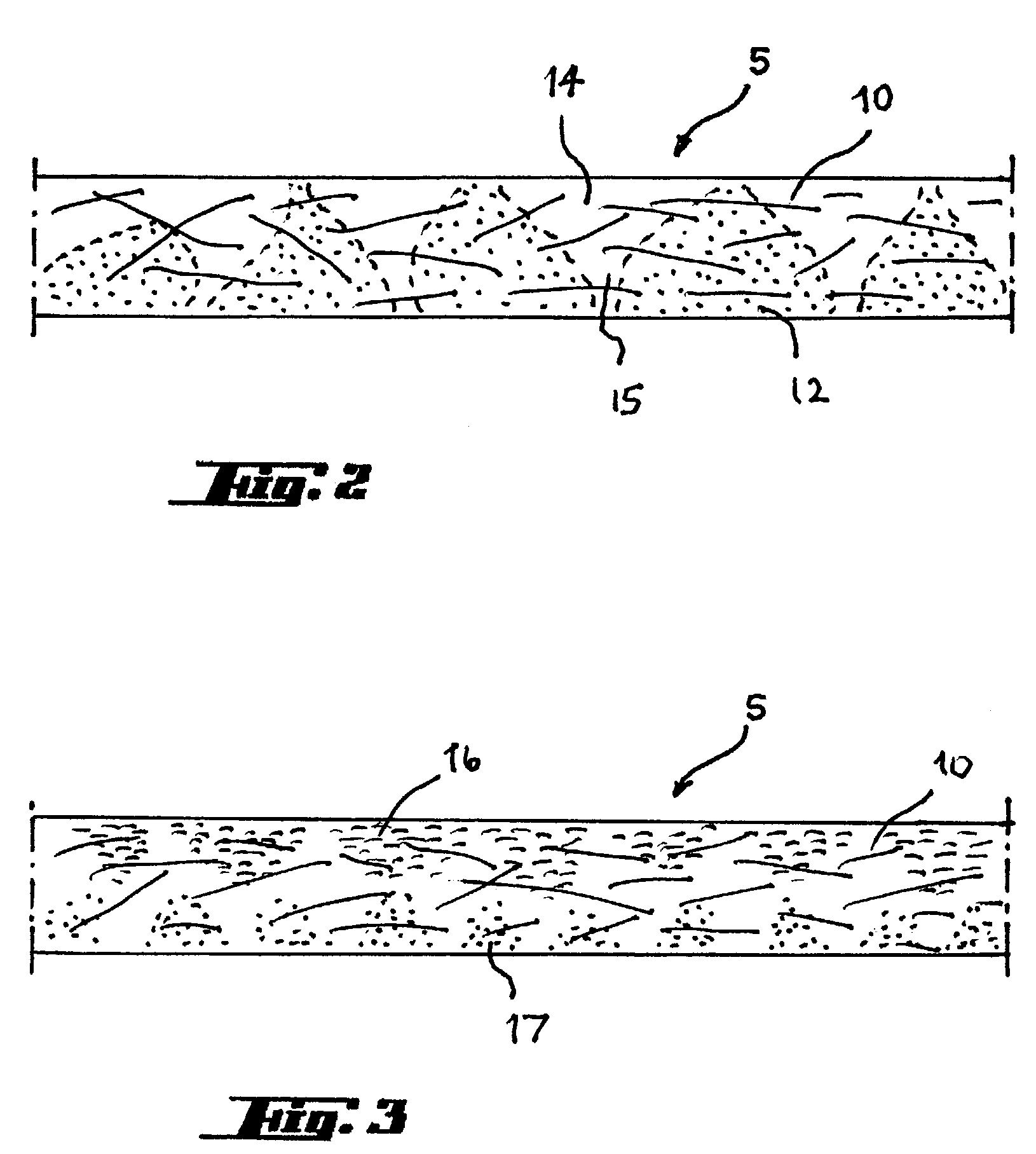

Thermoplastic composites with improved sound absorbing capabilities

InactiveUS20060137799A1Alter its performanceOptimization propertiesWood working apparatusBaby linensGlass fiberPolyethylene terephthalate

A composite material formed of reinforcement fibers, acoustical enhancing fibers such as polyethylene terephthalate (PET) fibers or modified polyethylene terephthalate fibers, and one or more organic fibers is provided. The acoustical enhancing fiber may be any fiber that provides increased or enhanced acoustical absorbance, particularly at low frequencies. The composite material may be formed by partially opening wet reinforcing fibers, acoustical enhancing fibers, and organic fibers, mixing the reinforcing, acoustical enhancement, and organic fibers, forming the fibers into a sheet, and bonding the fibers in the sheet. Preferably the reinforcing fibers are wet use chopped strand glass fibers. The composite material may be formed of a single layer of reinforcement, acoustical enhancement fibers, and organic fibers. Alternatively, the composite material may be a multi-layered composite in which the acoustical enhancement fibers are located in an acoustical layer laminated to a thermal layer formed of the organic fibers and reinforcement fibers.

Owner:OWENS CORNING INTELLECTUAL CAPITAL LLC

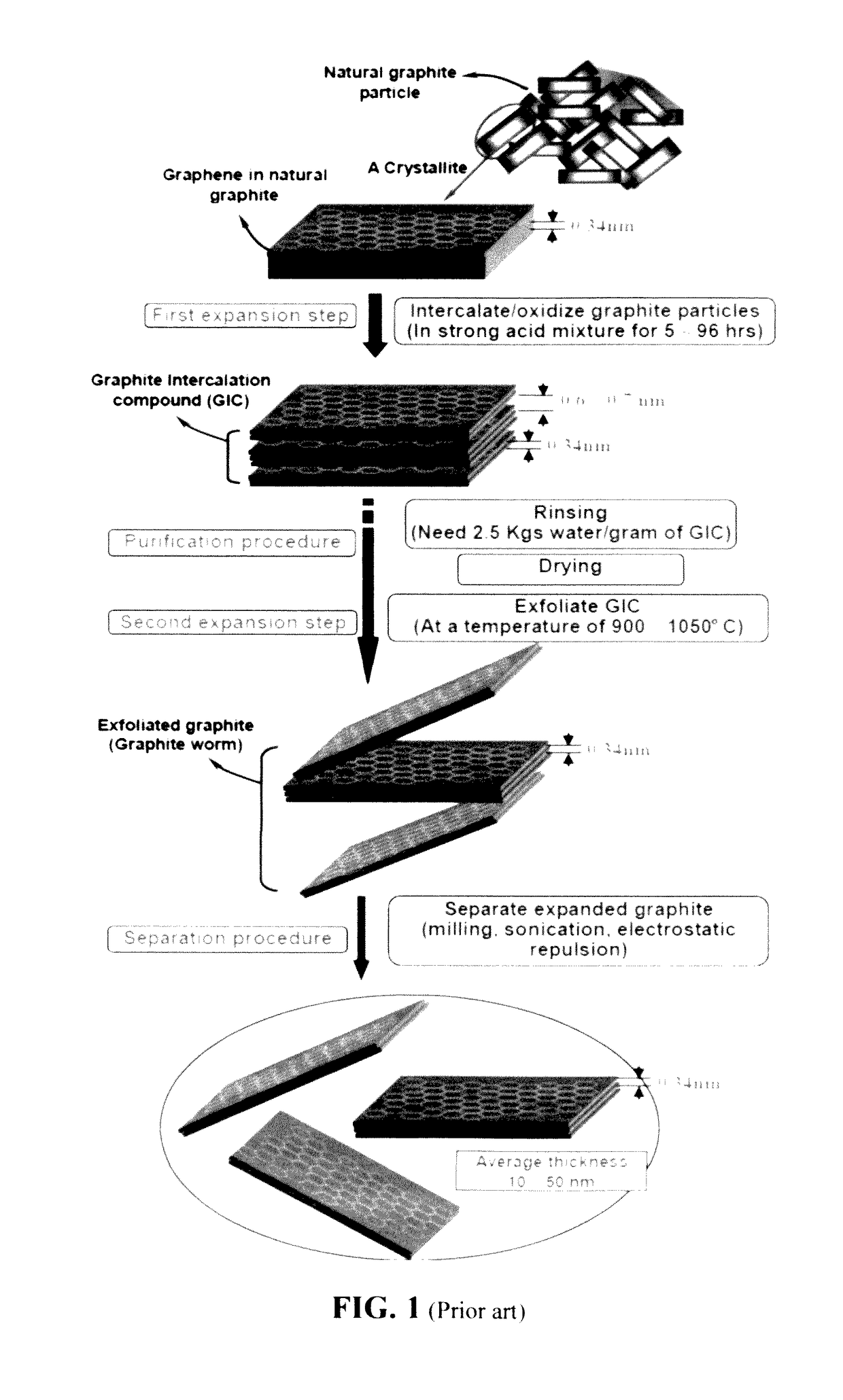

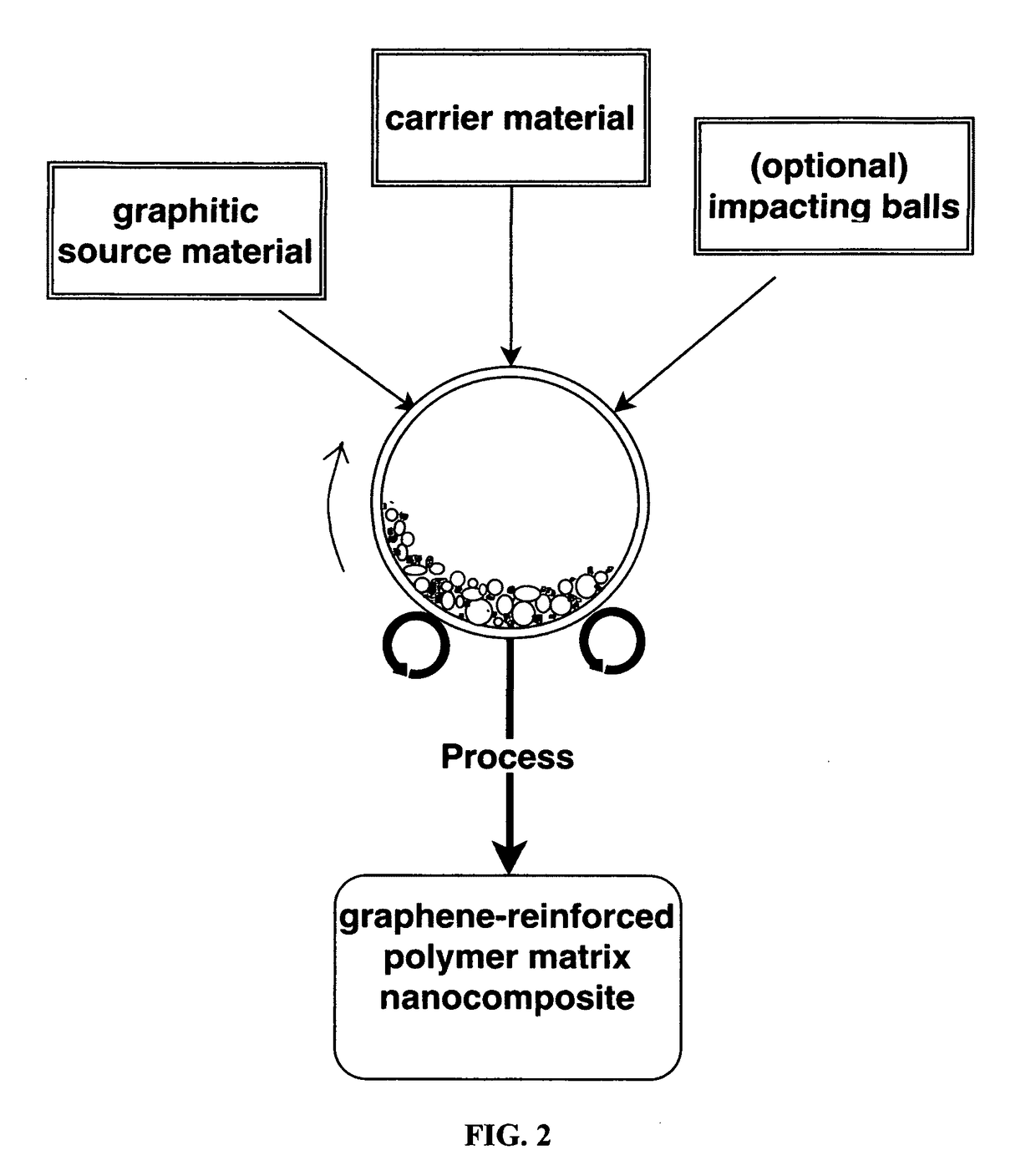

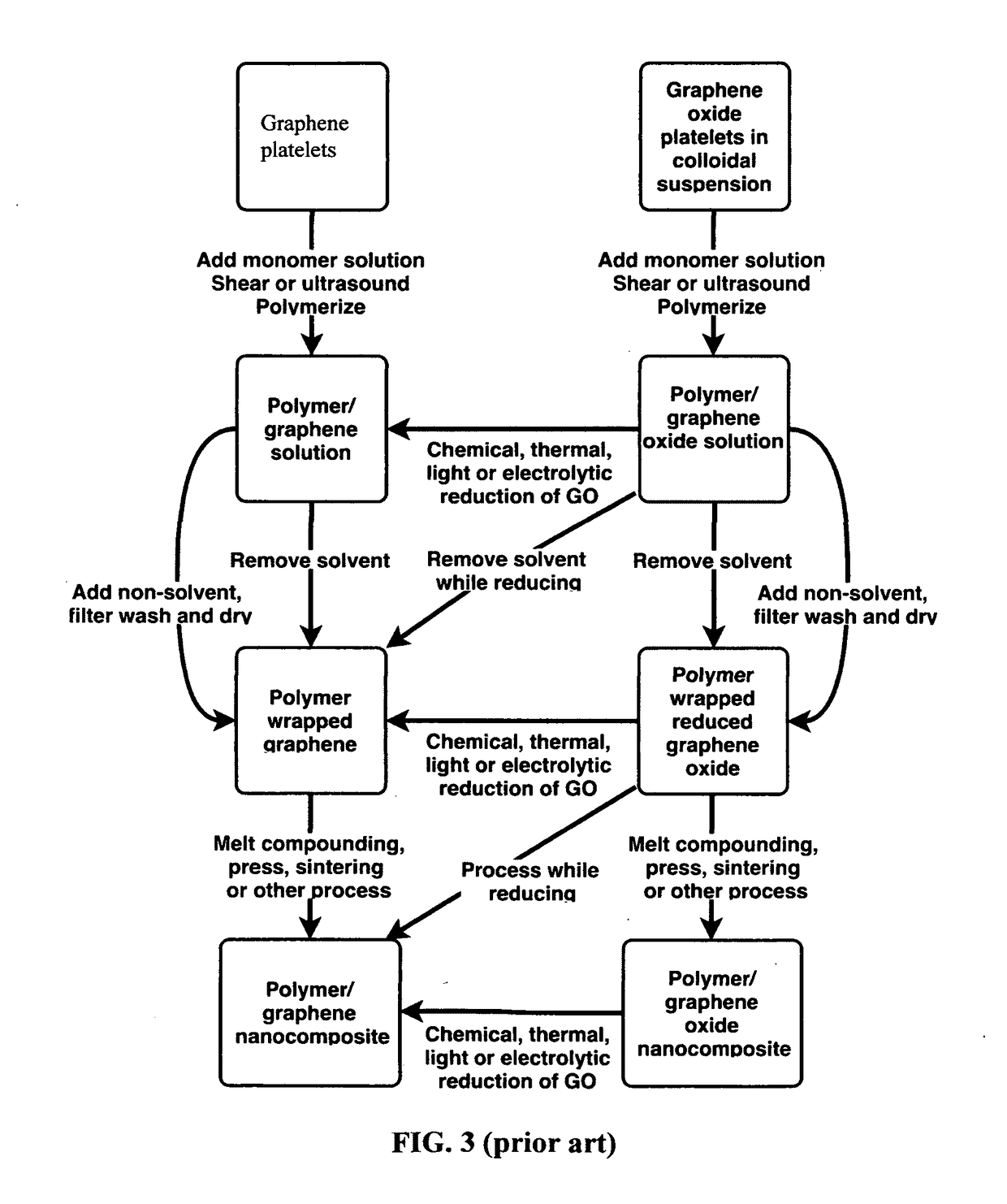

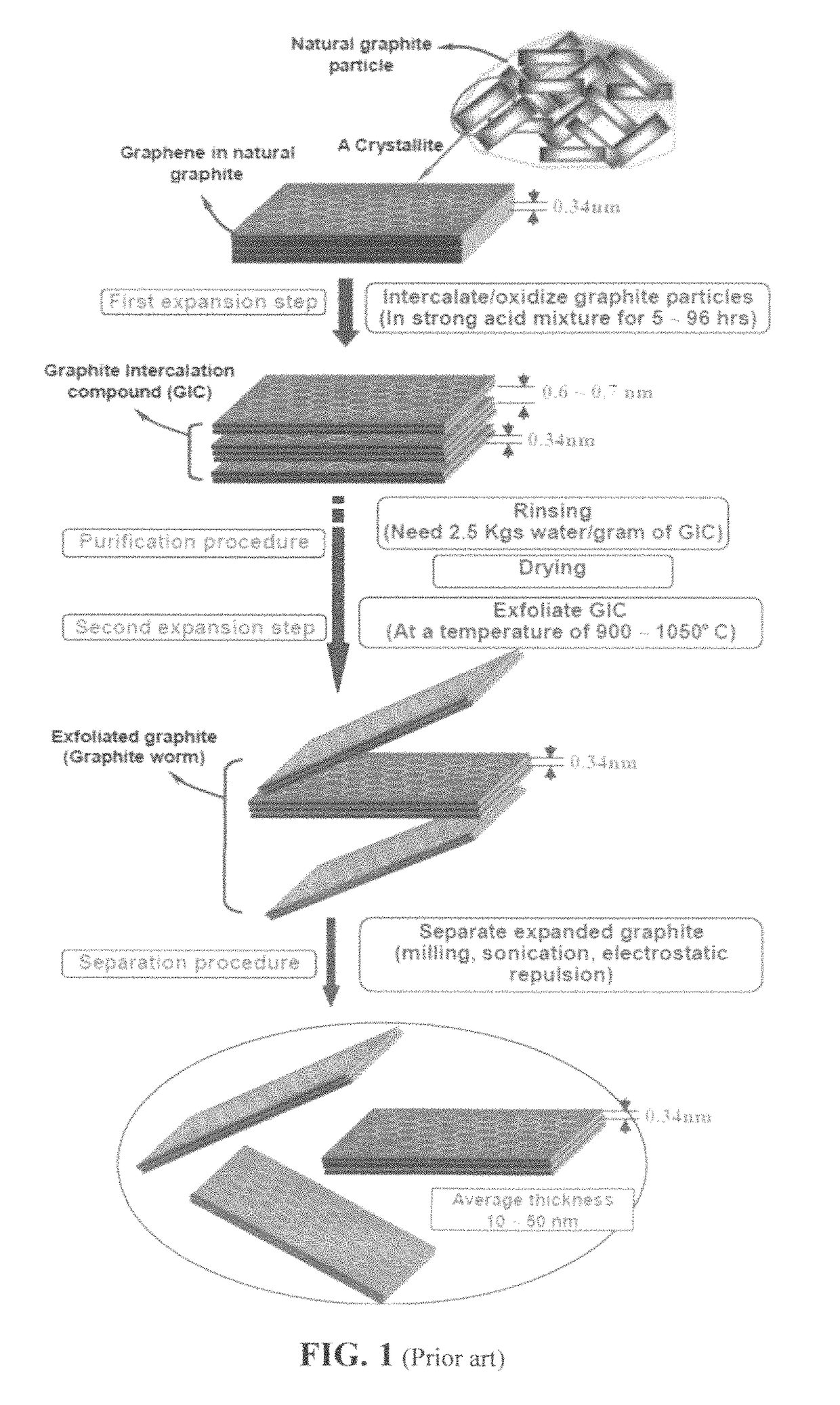

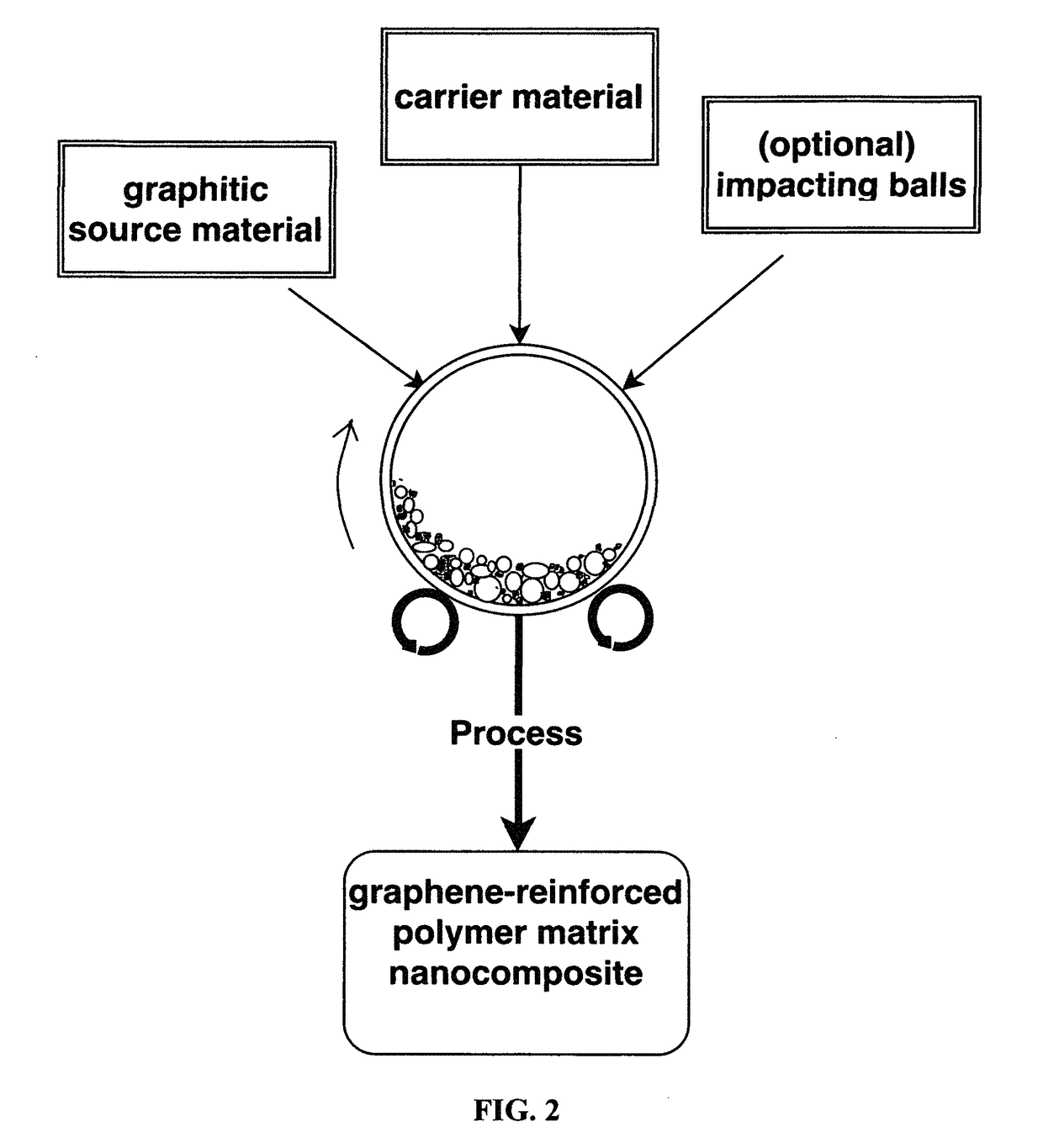

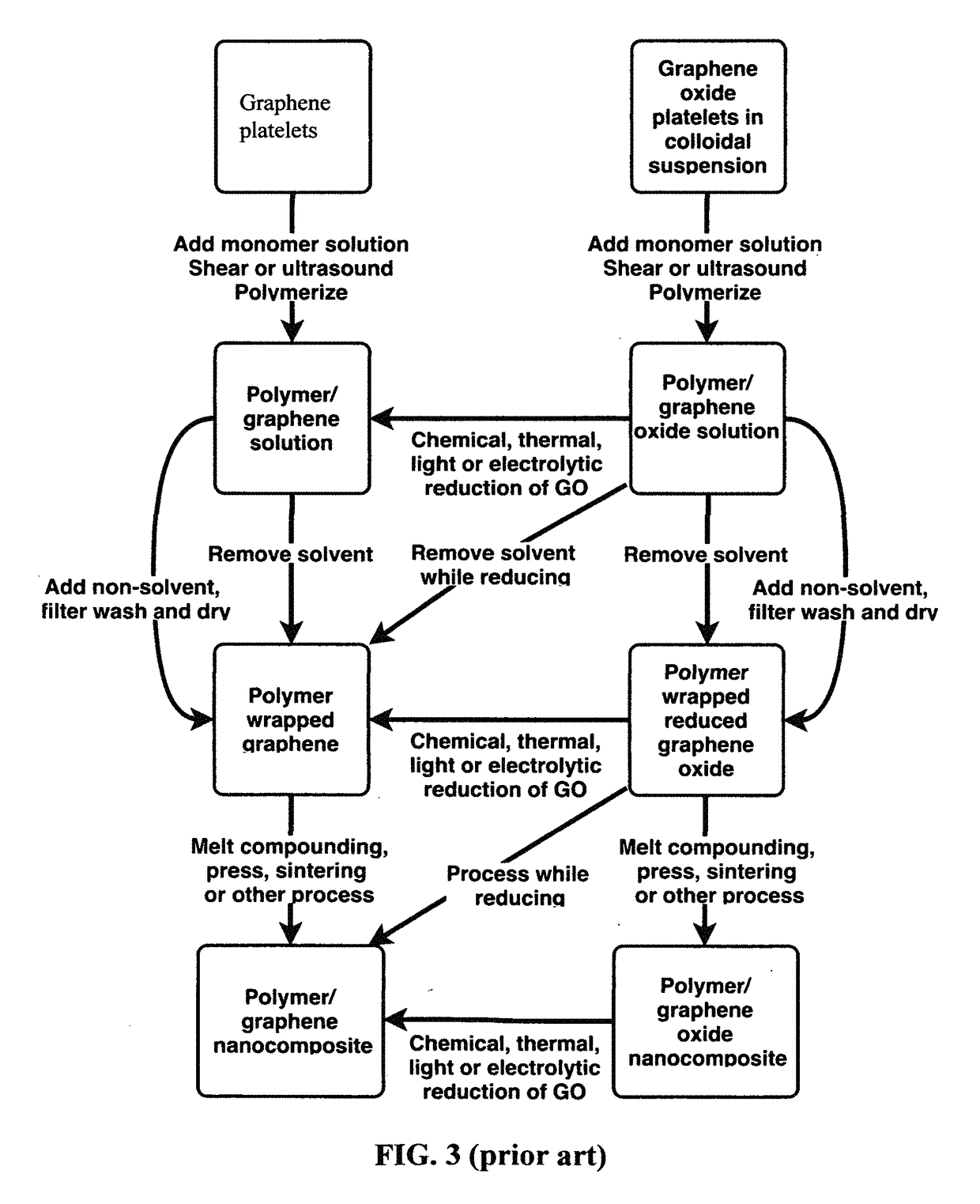

Chemical-free production of graphene-reinforced polymer matrix composites

ActiveUS20170166722A1Optimization propertiesOptimize throughputAdditive manufacturing apparatusLiquid surface applicatorsPolymer scienceGraphite

Provided is a simple, fast, scalable, and environmentally benign method of producing a graphene-reinforced polymer matrix composite directly from a graphitic material, the method comprising: (a) mixing multiple particles of a graphitic material and multiple particles of a solid polymer carrier material to form a mixture in an impacting chamber of an energy impacting apparatus; (b) operating the energy impacting apparatus with a frequency and an intensity for a length of time sufficient for peeling off graphene sheets from the graphitic material and transferring the graphene sheets to surfaces of solid polymer carrier material particles to produce graphene-coated or graphene-embedded polymer particles inside the impacting chamber; and (c) forming graphene-coated or graphene-embedded polymer particles into the graphene-reinforced polymer matrix composite. Also provided is a mass of the graphene-coated or graphene-embedded polymer particles produced by this method.

Owner:GLOBAL GRAPHENE GRP INC

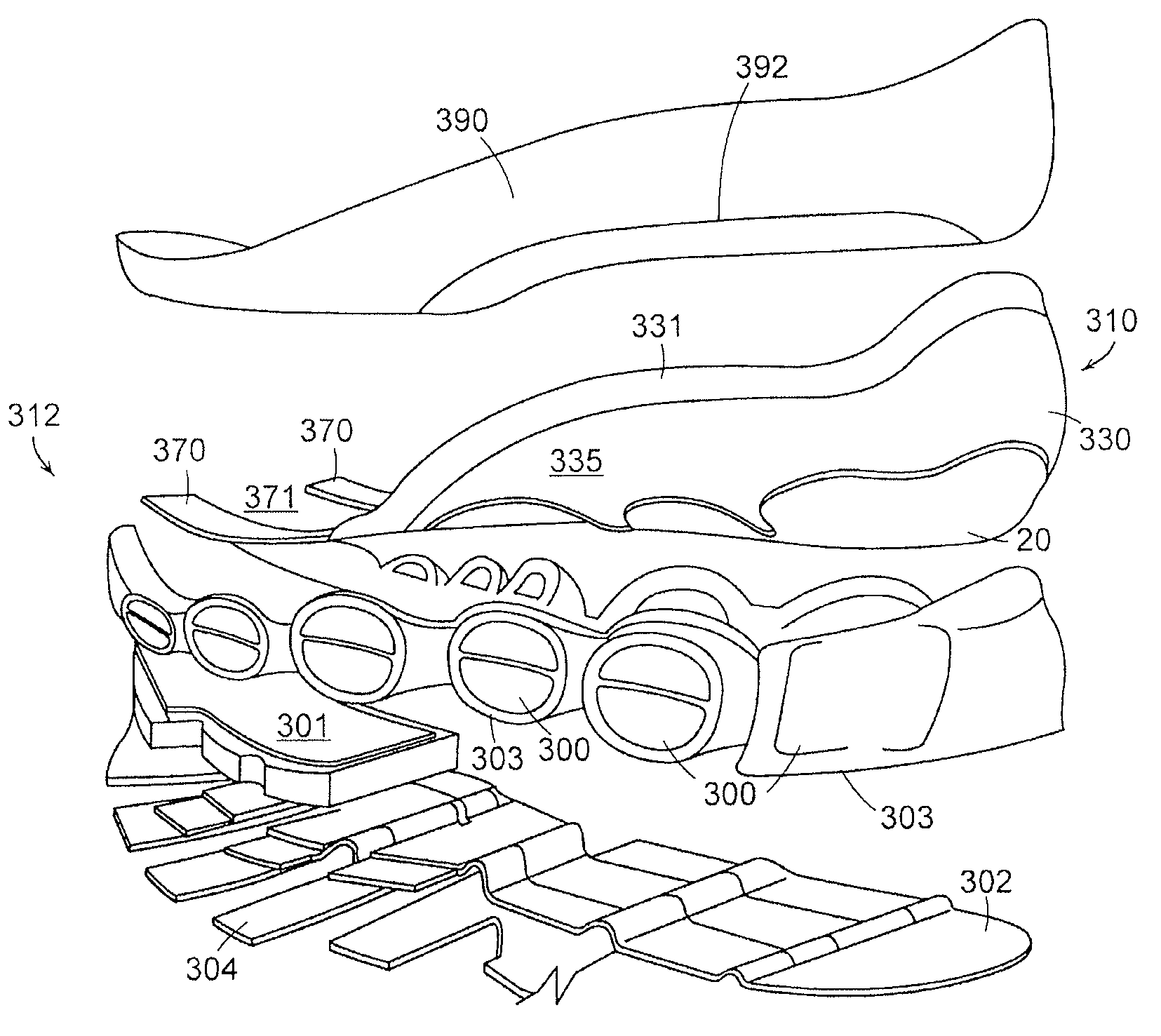

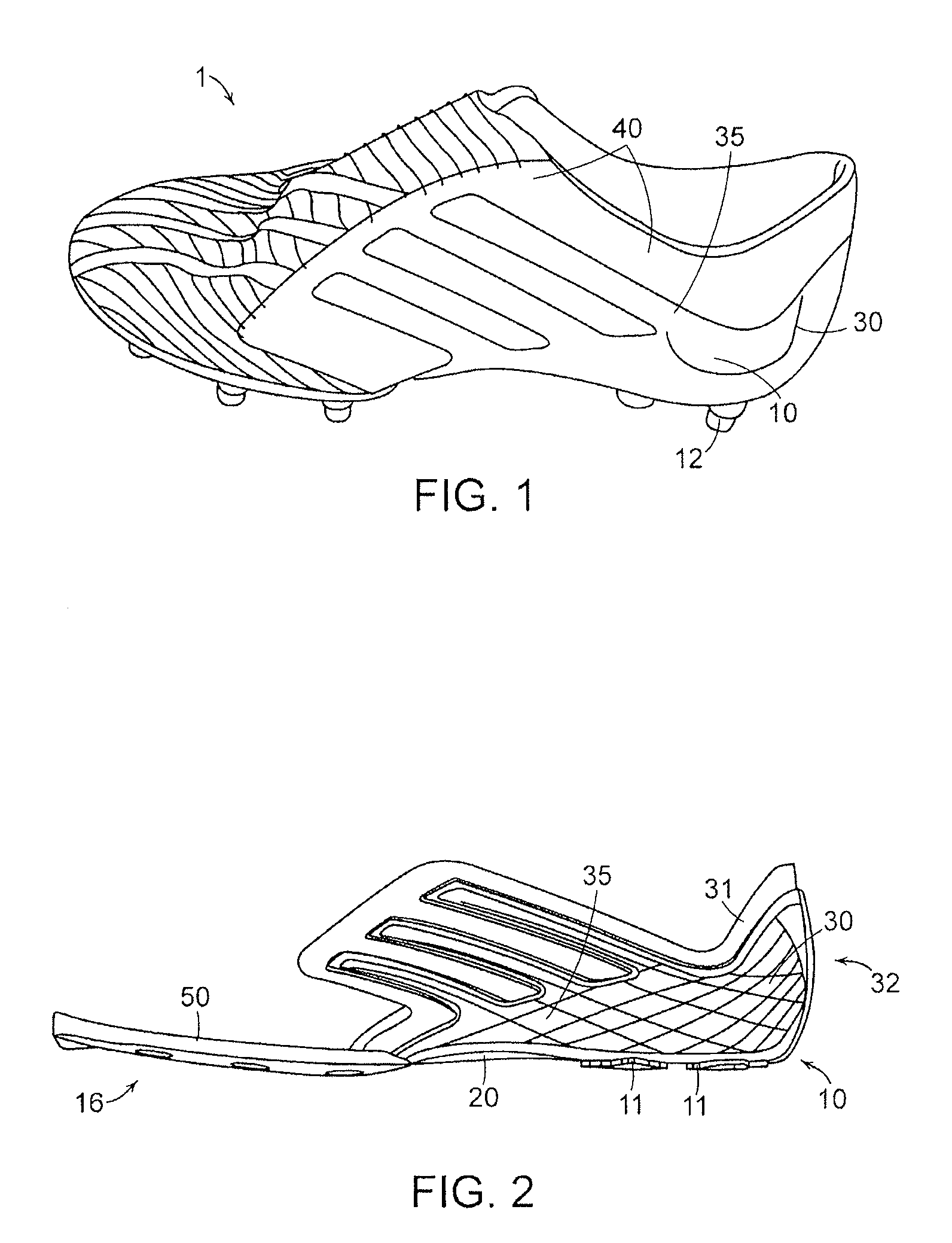

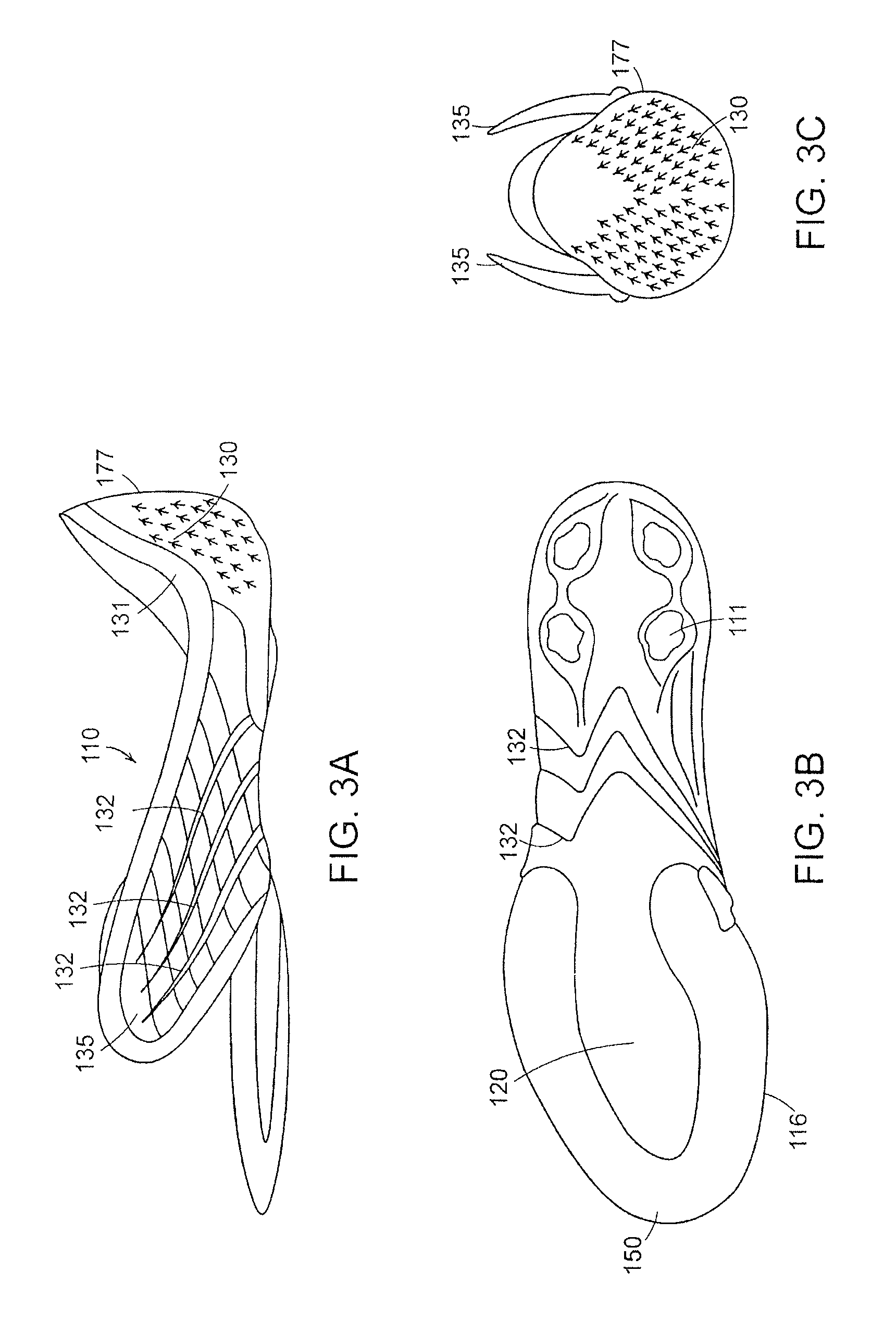

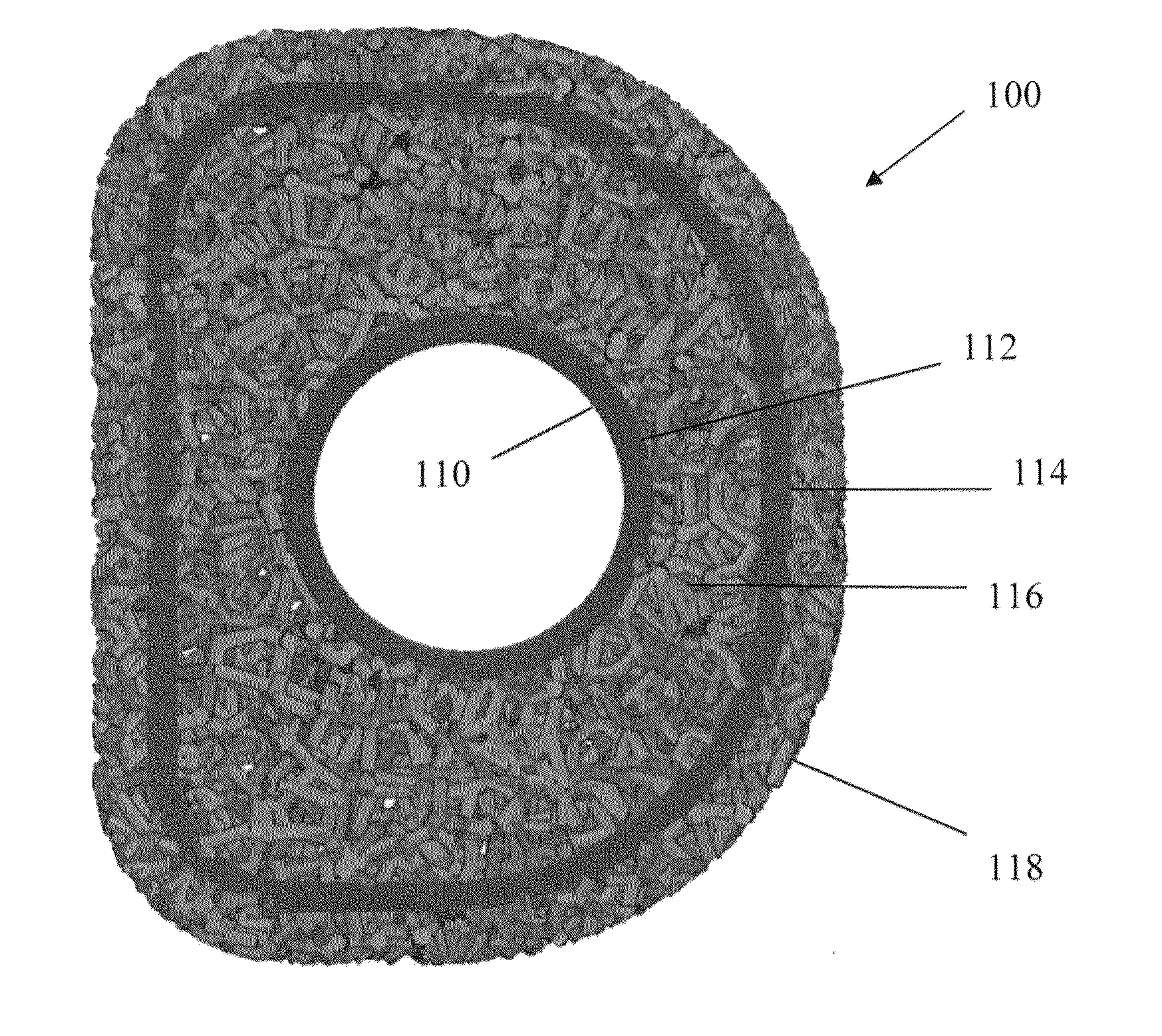

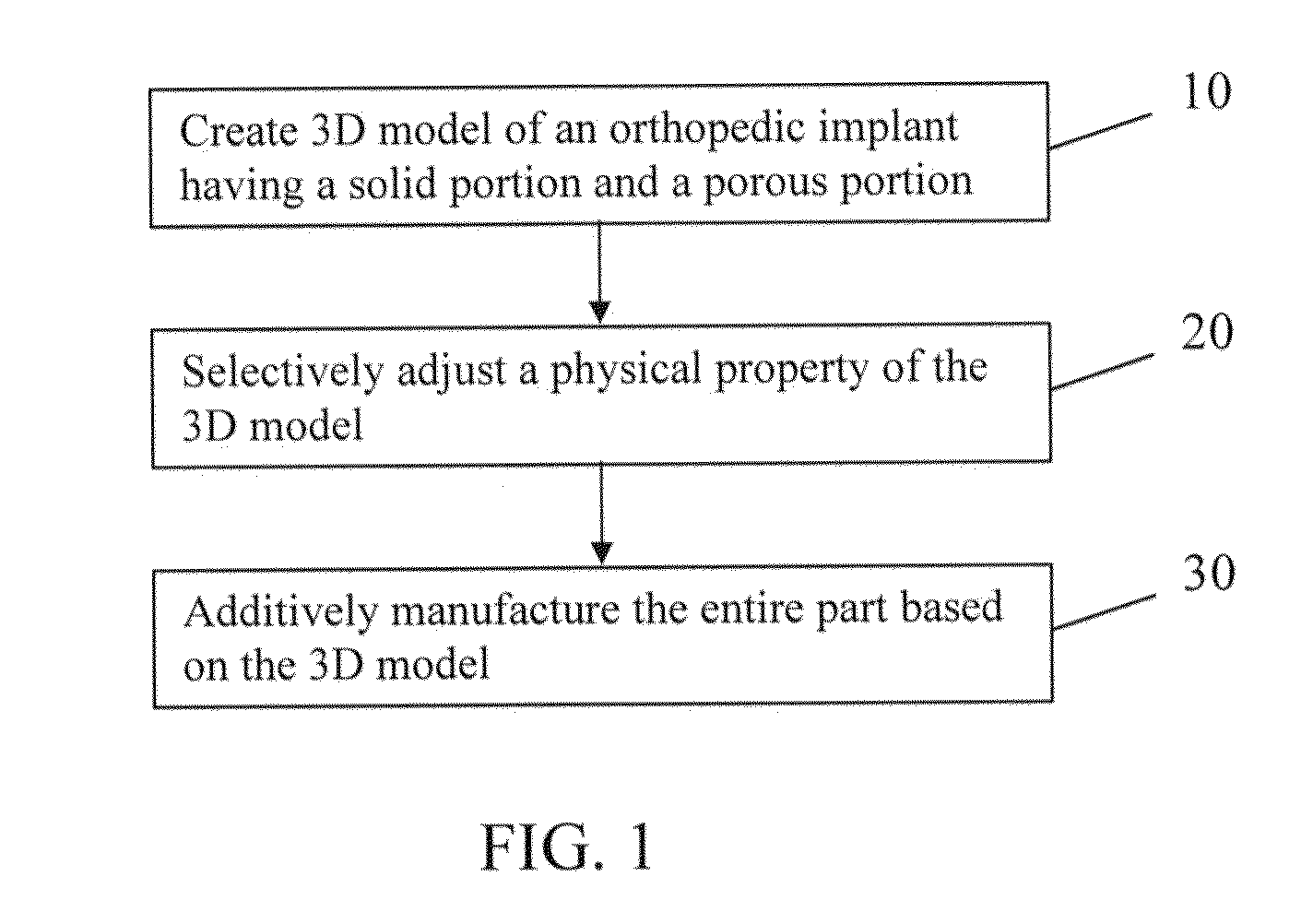

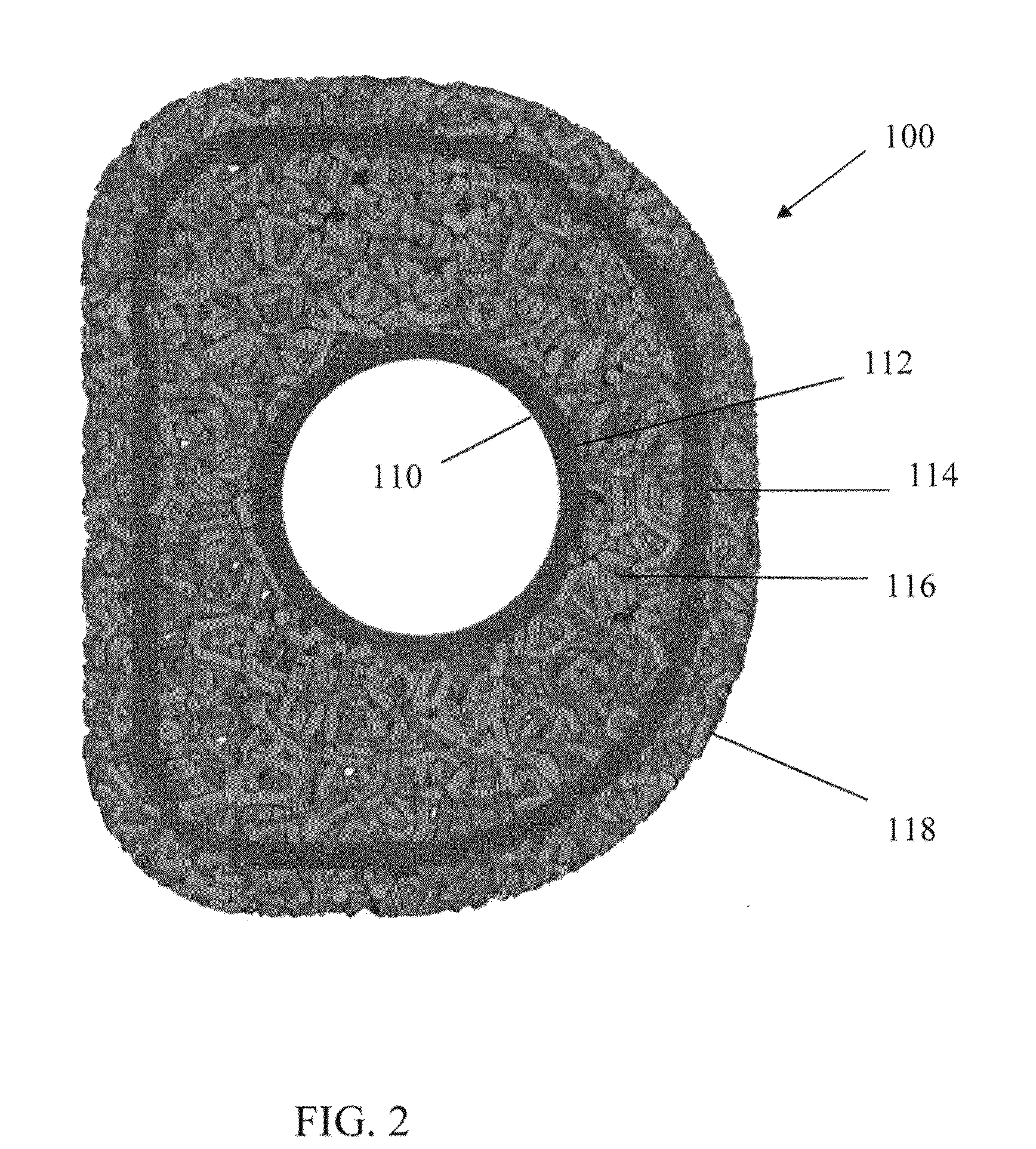

Orthopedic implants and methods of manufacturing orthopedic implants

ActiveUS20150045903A1Optimization propertiesSimple structureAdditive manufacturingAnkle jointsPorosityPlastic surgery

A method of manufacturing an orthopedic implant is provided. The method includes creating a 3D model of an orthopedic implant having a solid portion and a porous portion and selectively adjusting a physical property of at least one of porosity of the porous portion, lattice thickness of the porous portion, beam profile of the porous portion, and topography of the 3D model. The entire implant is then additively manufactured based on the 3D model.

Owner:KAPSTONE MEDICAL LLC

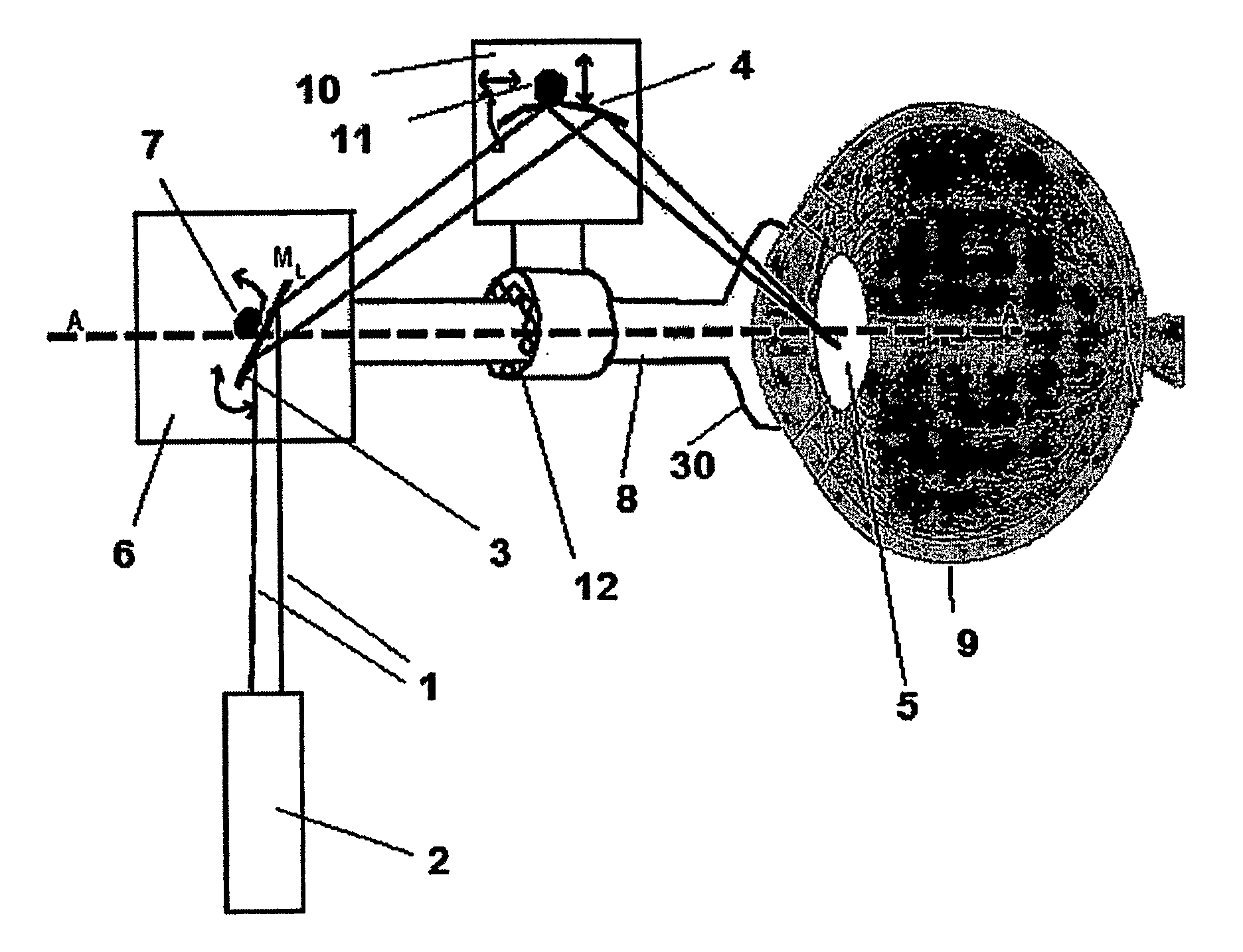

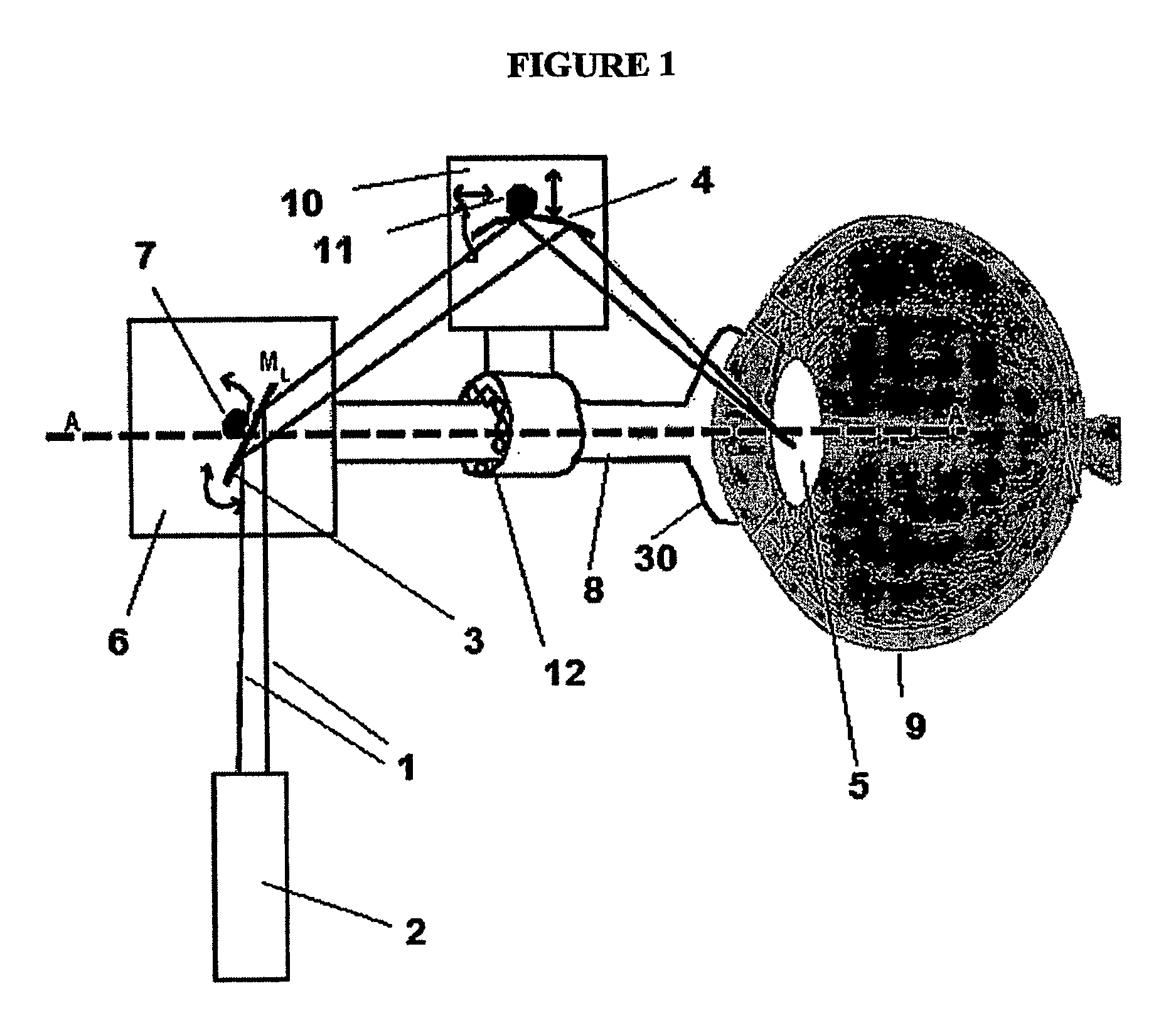

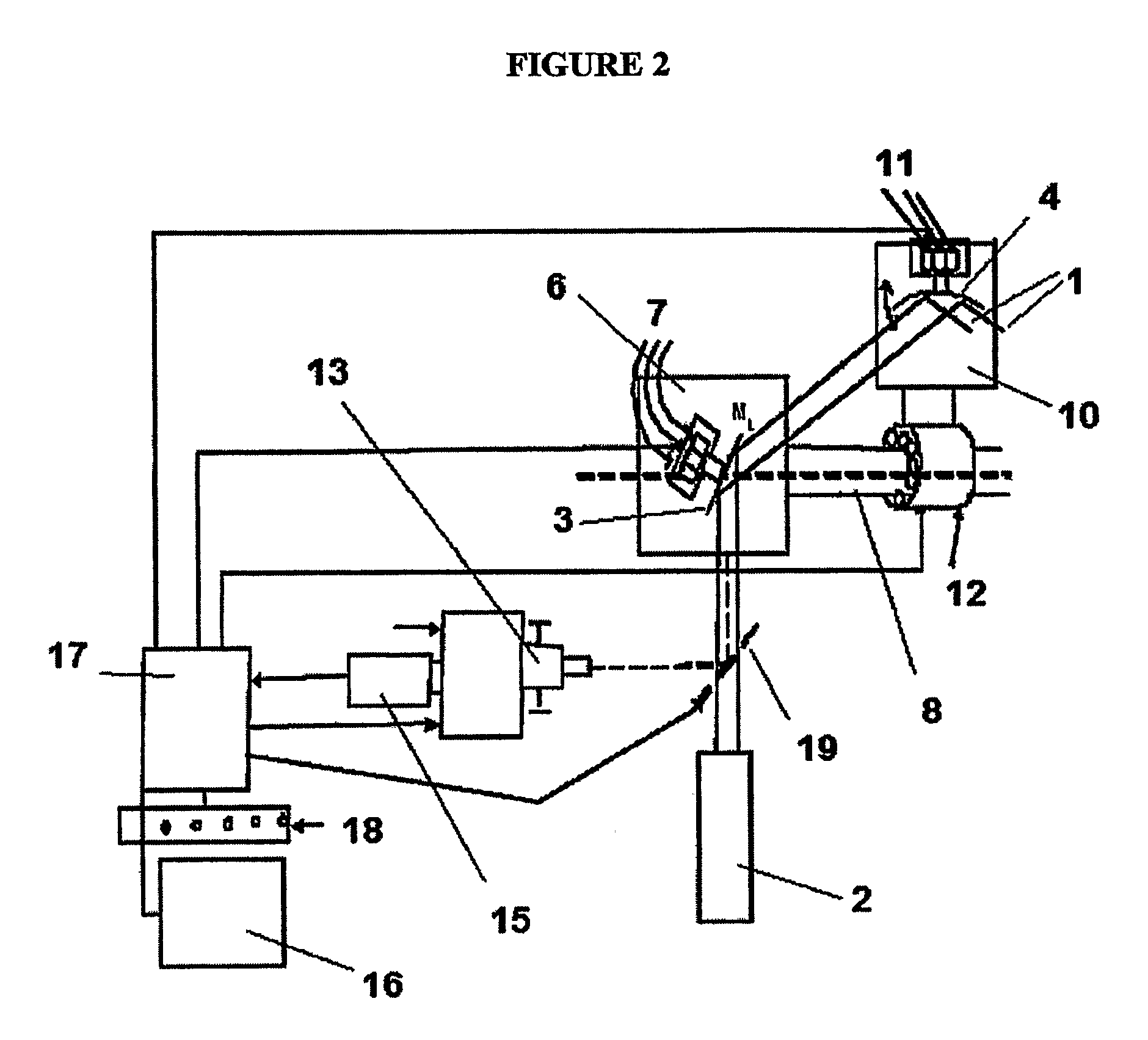

Devices, Methods and Compositions for Presbyopia Correction Using Ultrashort Pulse Laser

ActiveUS20100076417A1Improve elasticityImprove visionLaser surgerySurgical instrument detailsUltrashort pulse laserPresbyopia

The invention relates to devices, compositions and methods used to improve vision and / or to treat an eye lens disease or condition. In some embodiments, the invention relates to altering or removing eye lens material for the treatment of presbyopia. In additional embodiments, the invention relates to placing compositions in a lens of an eye to improve elasticity of the lens both therapeutically by improving elasticity and / or improving refractive properties and / or prophylactically by preventing renewed stiffening and / or renewed deterioration of the lens refractive properties. In further embodiments, the invention relates to devices and methods of obtaining and analyzing data for use in altering the lens to optimize its elasticity and / or refractive properties.

Owner:FEMTO VISION LTD +1

Carbon fiber electrode substrate for electrochemical cells

ActiveUS7144476B2High carbon contentImprove conductivityNon-fibrous pulp additionNatural cellulose pulp/paperFiberCarbon fibers

This invention relates to electrode substrates for electrochemical cells, particularly low-temperature fuel cells, and processes for their production. Low-cost carbon fiber paper structures are used as precursor for preparation of an all-carbon product that has a high electric conductivity and porosity and can be processed in a continuous reel-to-reel mode. These paper materials are further impregnated and processed to adjust the final product properties. This all-carbon electrode substrate is not brittle thereby avoiding the main disadvantage of the prior art.

Owner:SGL CARBON SE

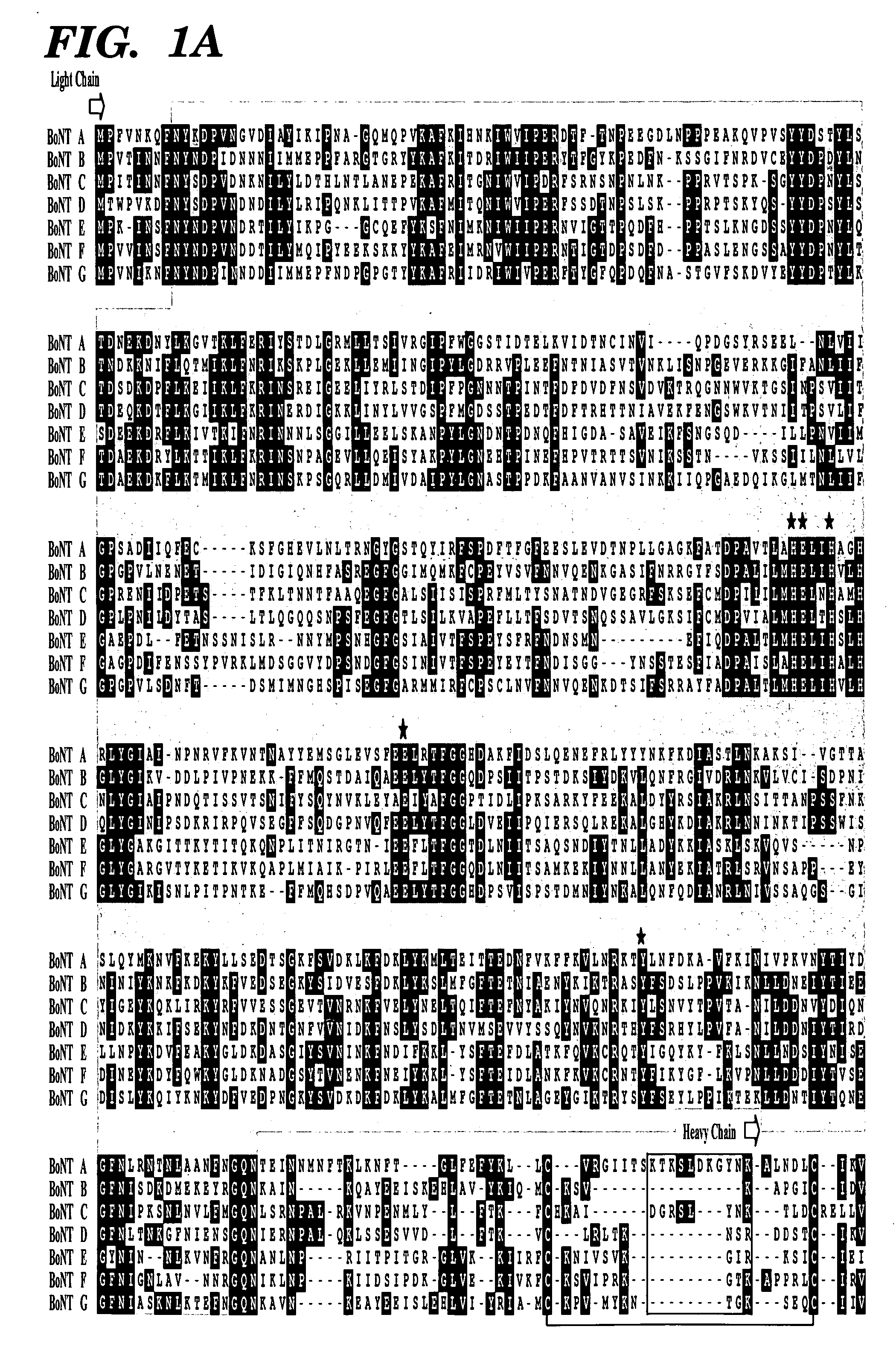

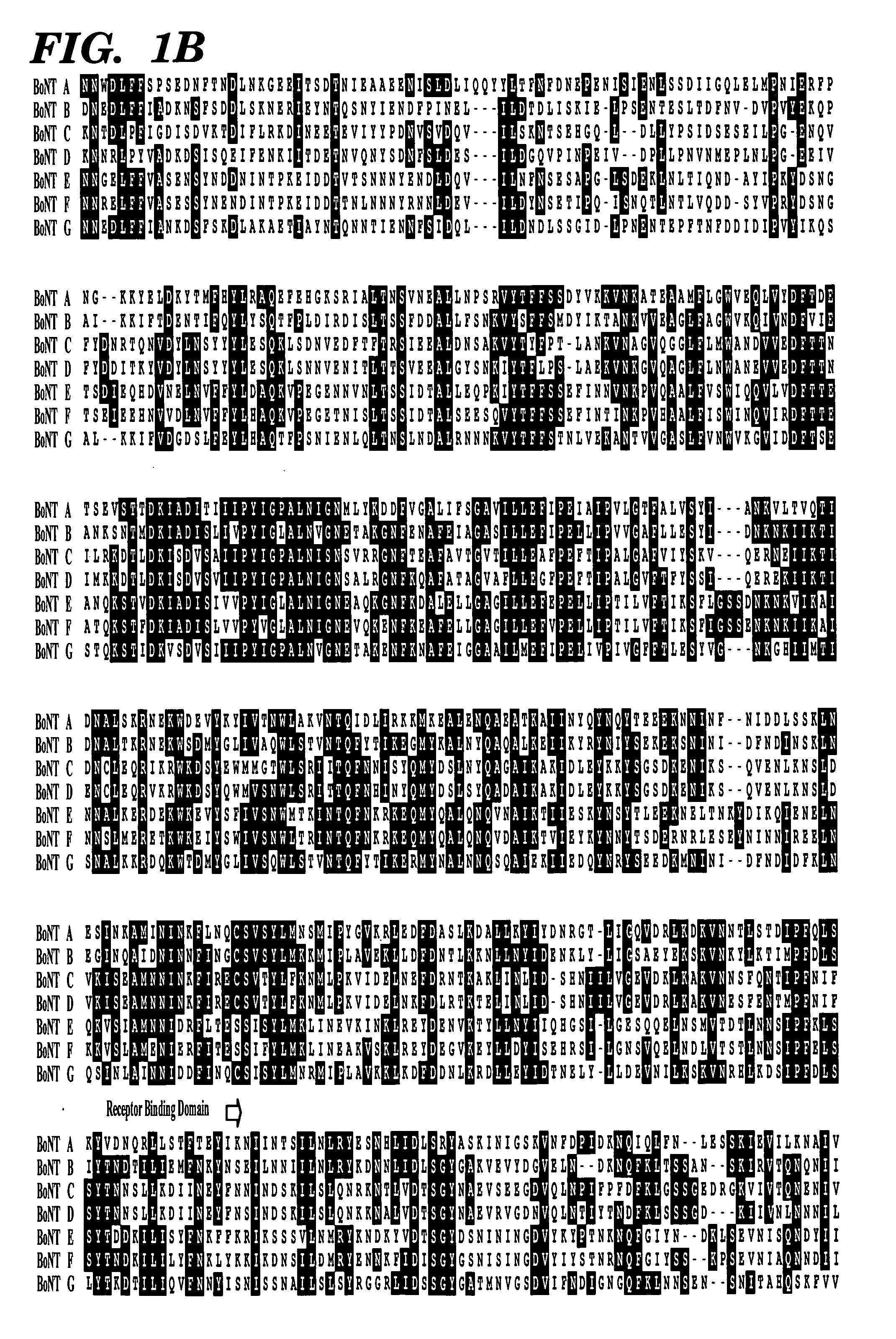

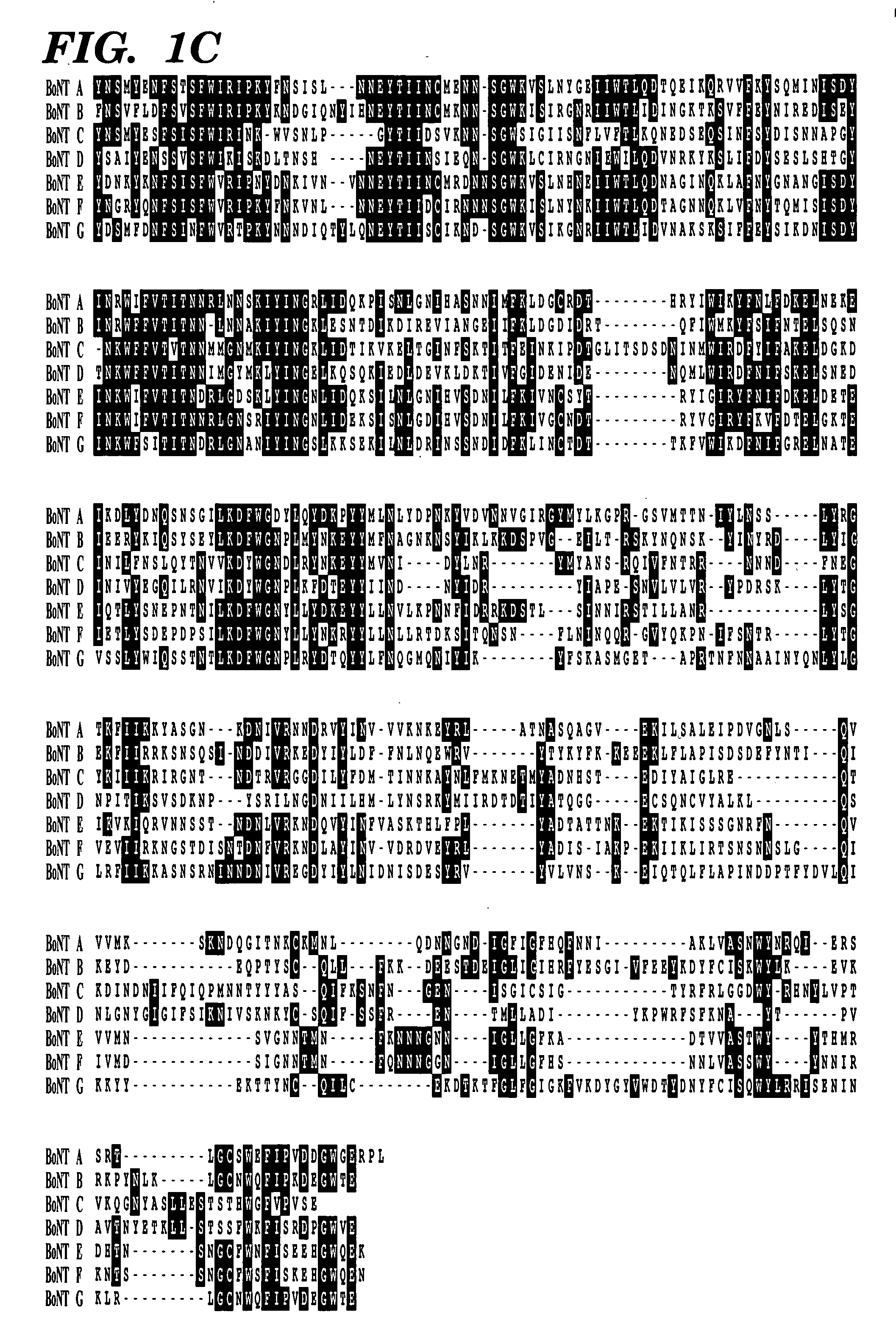

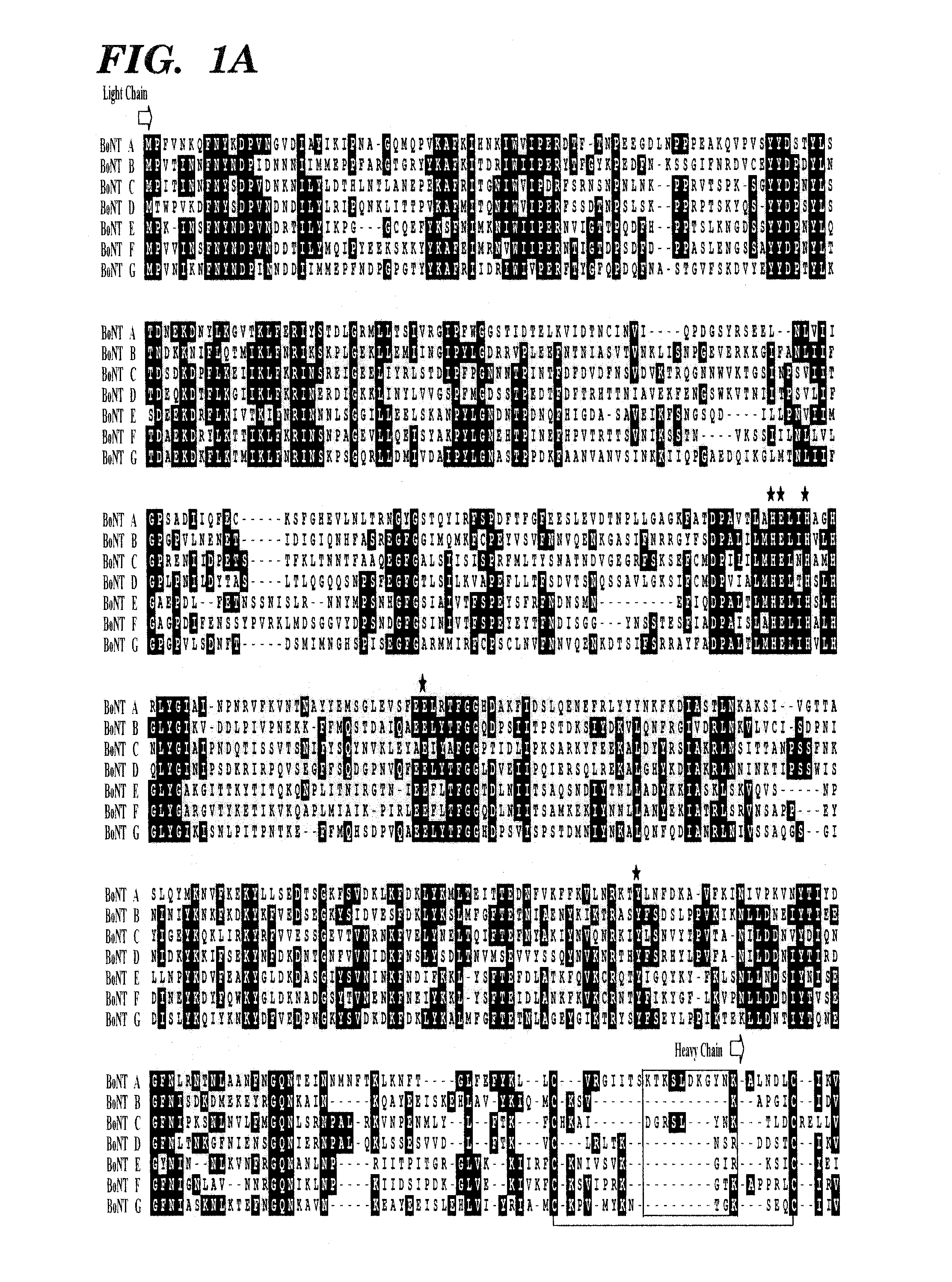

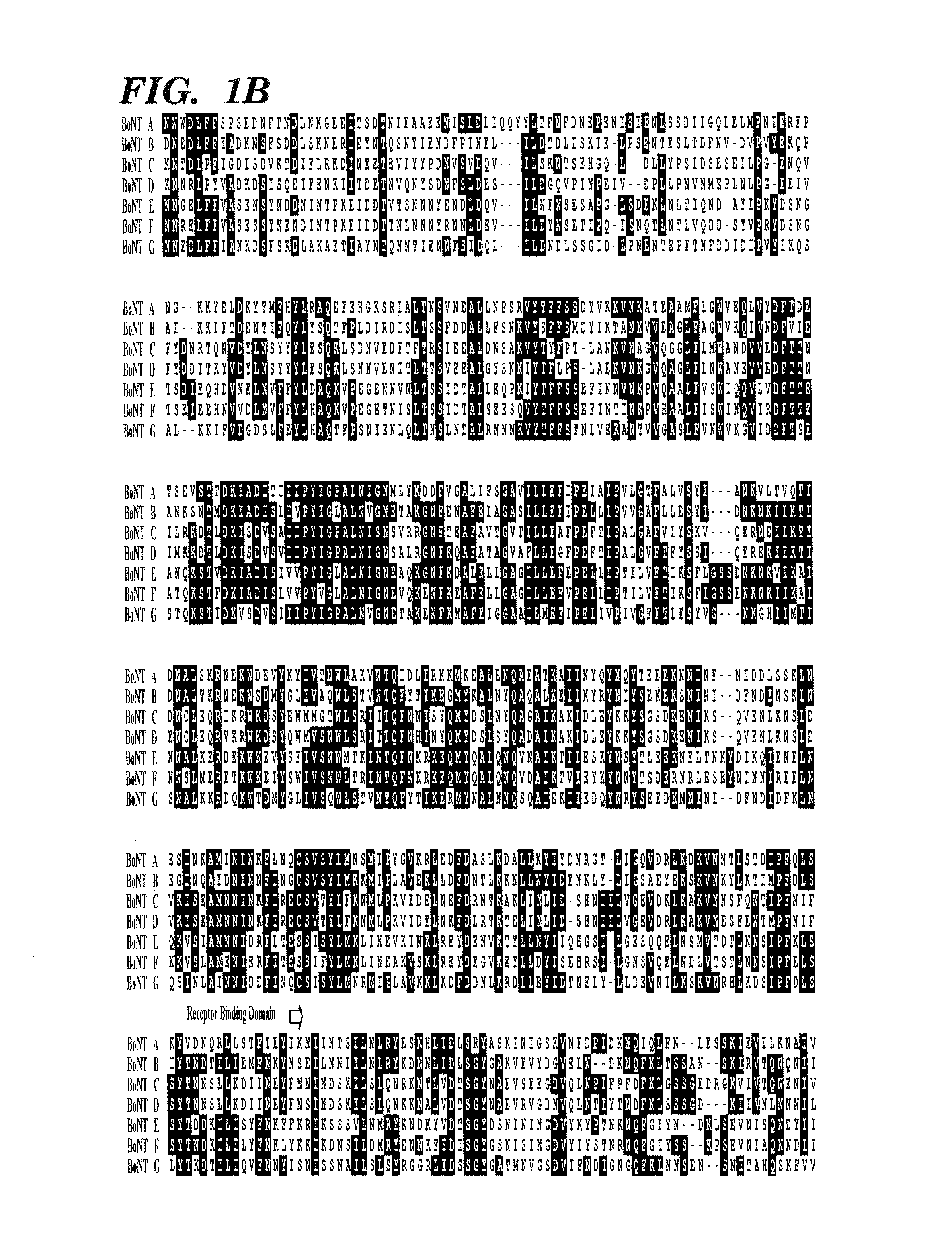

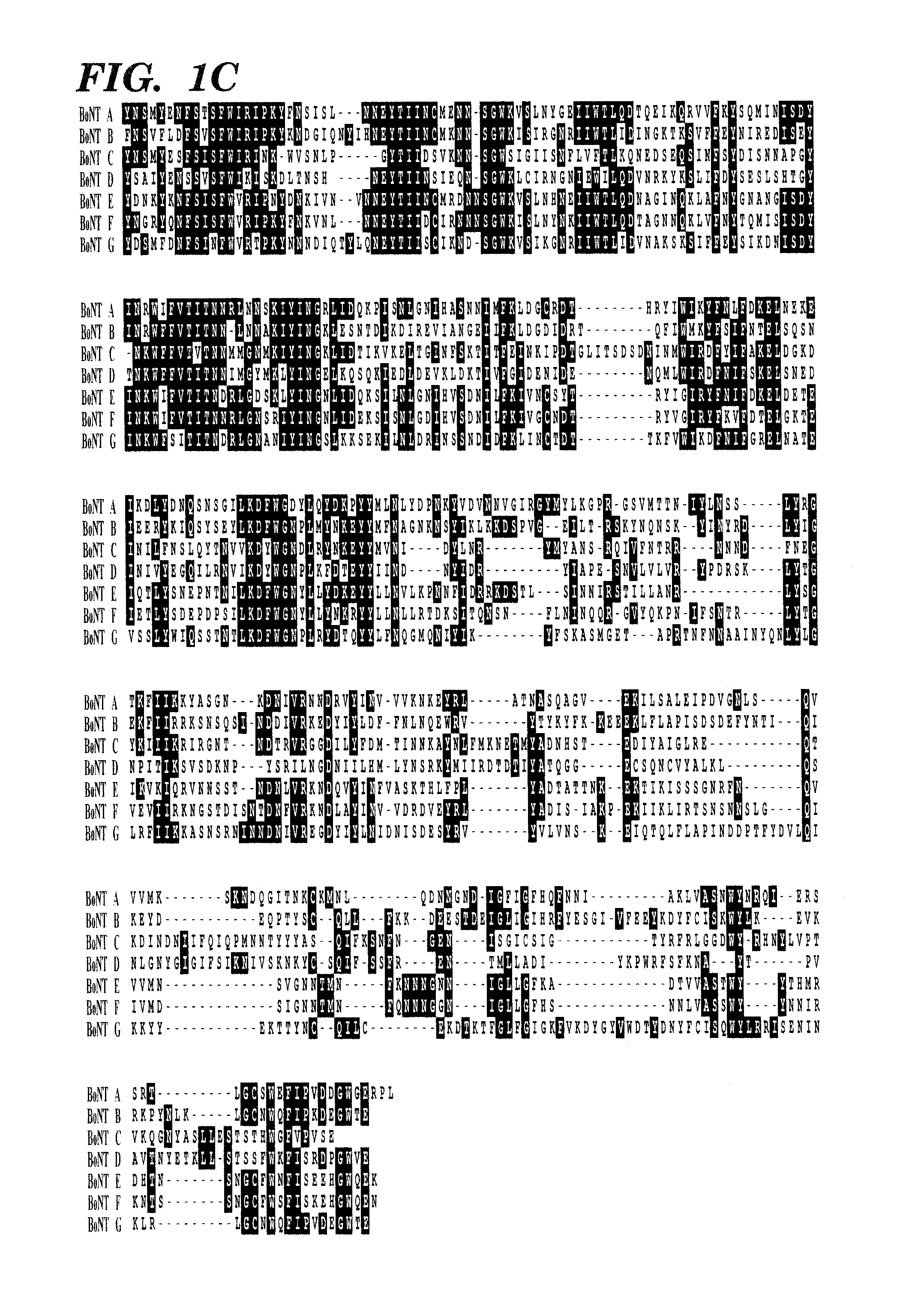

Genetically engineered clostridial genes, proteins encoded by the engineered genes, and uses thereof

InactiveUS20060204524A1Optimized biological propertyOptimized therapeutic propertyAntibacterial agentsSenses disorderHeavy chainAntidote

The present invention relates to an isolated Clostridial neurotoxin propeptide having a light chain region, a heavy chain region, where the light and heavy chain regions are linked by a disulfide bond, and an intermediate region connecting the light and heavy chain regions. An isolated nucleic acid molecule encoding a Clostridial neurotoxin propeptide is also disclosed. Also disclosed is an isolated, physiologically active Clostridial neurotoxin produced by cleaving a Clostridial neurotoxin propeptide, a vaccine or antidote thereof, and methods of immunizing against or treating for toxic effects of Clostridial neurotoxins. Methods of expressing recombinant physiologically active Clostridial neurotoxins are also disclosed. Also disclosed is a chimeric protein having a heavy chain region of a Clostridial neurotoxin and a protein with therapeutic functionality. A treatment method is also disclosed.

Owner:NEW YORK UNIV

Atomic composition controlled ruthenium alloy film formed by plasma-enhanced atomic layer deposition

ActiveUS20100055433A1Increase flow rate ratioLow densitySemiconductor/solid-state device detailsSynthetic resin layered productsAtomic compositionAtomic ratio

A metal film composed of multiple atomic layers continuously formed by atomic layer deposition of Ru and Ta or Ti includes at least a top section and a bottom section, wherein an atomic composition of Ru, Ta or Ti, and N varies in a thickness direction of the metal film. The atomic composition of Ru, Ta or Ti, and N in the top section is represented as Ru(x1)Ta / Ti(y1)N(z1) wherein an atomic ratio of Ru(x1) / (Ta / Ti(y1)) is no less than 15, and z1 is 0.05 or less. The atomic composition of Ru, Ta or Ti, and N in the bottom section is represented as Ru(x2)Ta / Ti(y2)N(z2) wherein an atomic ratio of Ru(x2) / (Ta / Ti(y2)) is more than zero but less than 15, and z2 is 0.10 or greater.

Owner:ASM JAPAN

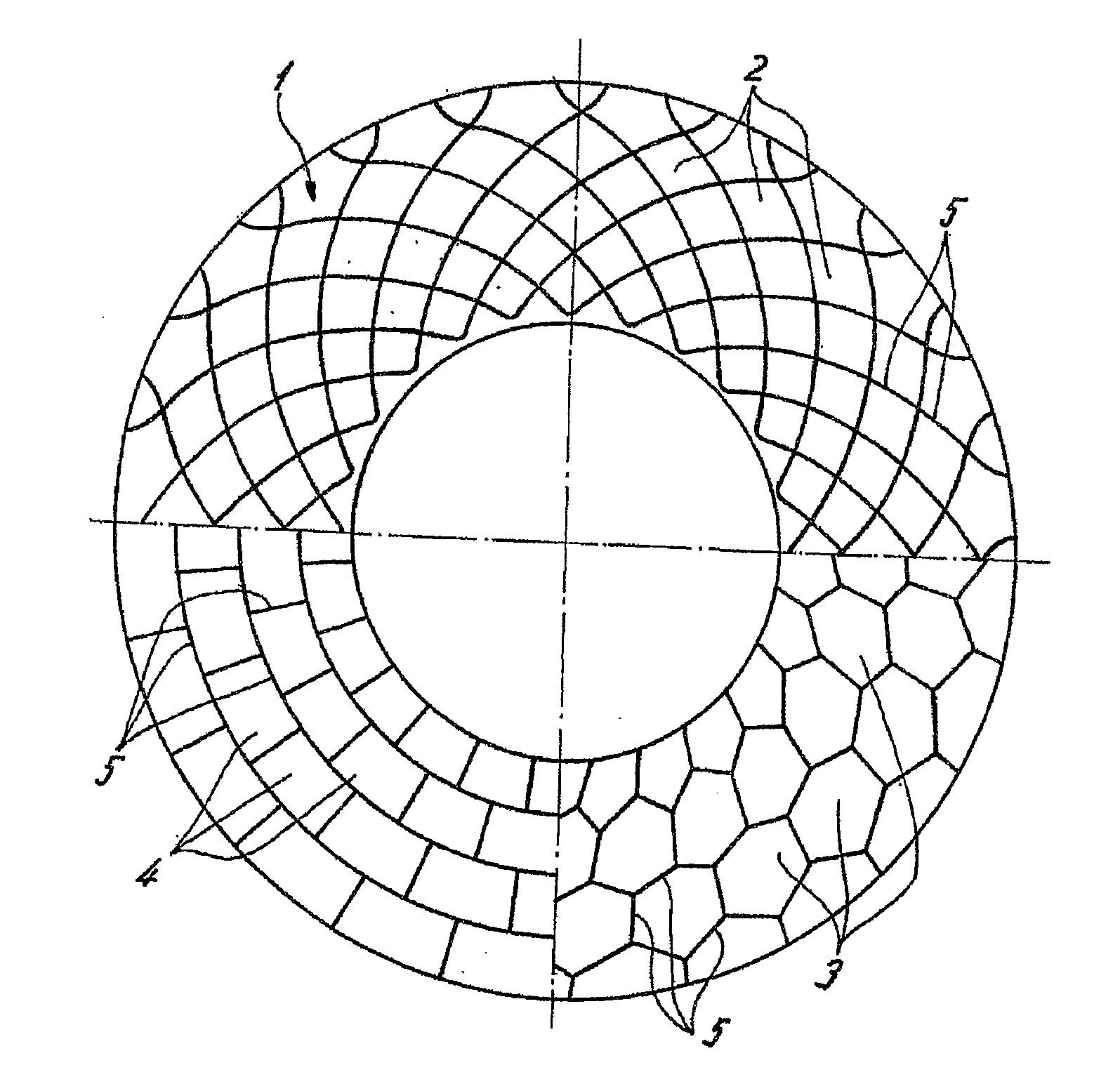

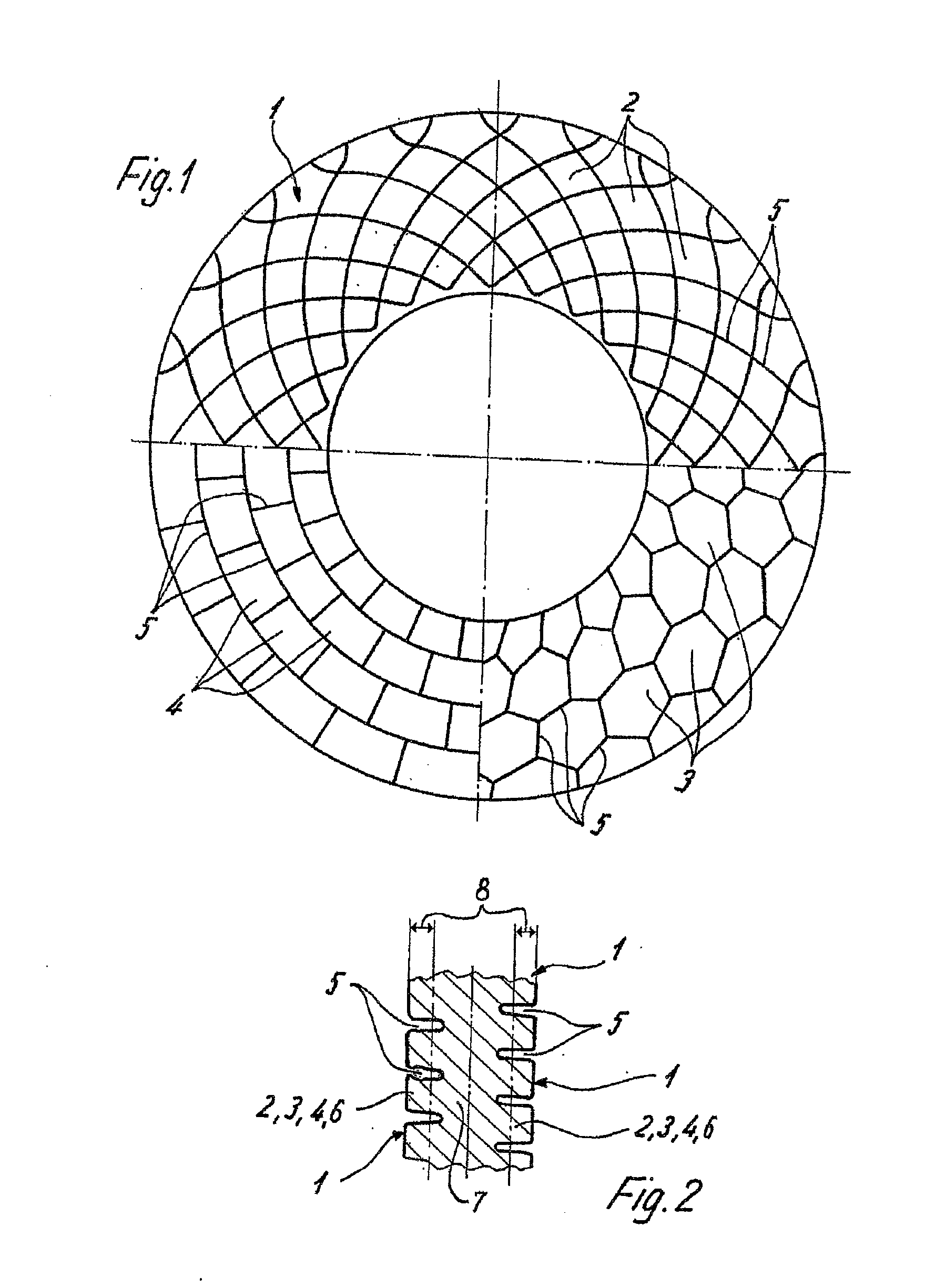

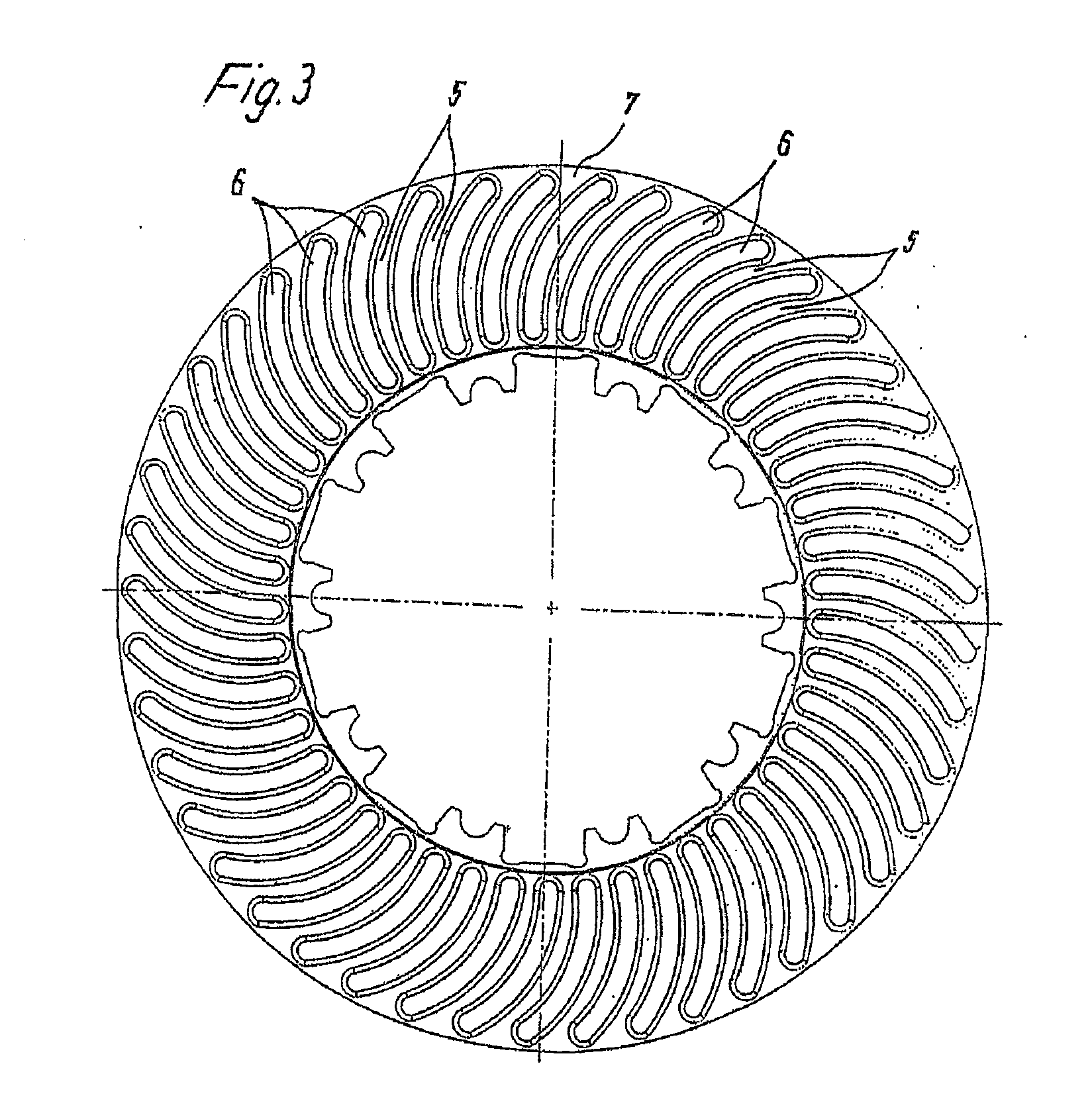

Brake Disk, In Particlular for a Vehicle

InactiveUS20080041675A1Reduce widthEasy to wearBraking discsFriction liningEngineeringExpansion joint

A brake disc for a vehicle has at least one annular friction surface provided on at least one outer face of the disc to which a brake pad can be applied for braking purposes. The friction surface has a large number of subsegments, at least some of which are physically separated from one another by expansion joints. The brake disc is configured in such a way that the depth of the expansion joints is greater than the permissible rate of wear of the friction surface.

Owner:KNORR-BREMSE SYST FUER NUTZFAHRZEUGE GMBH

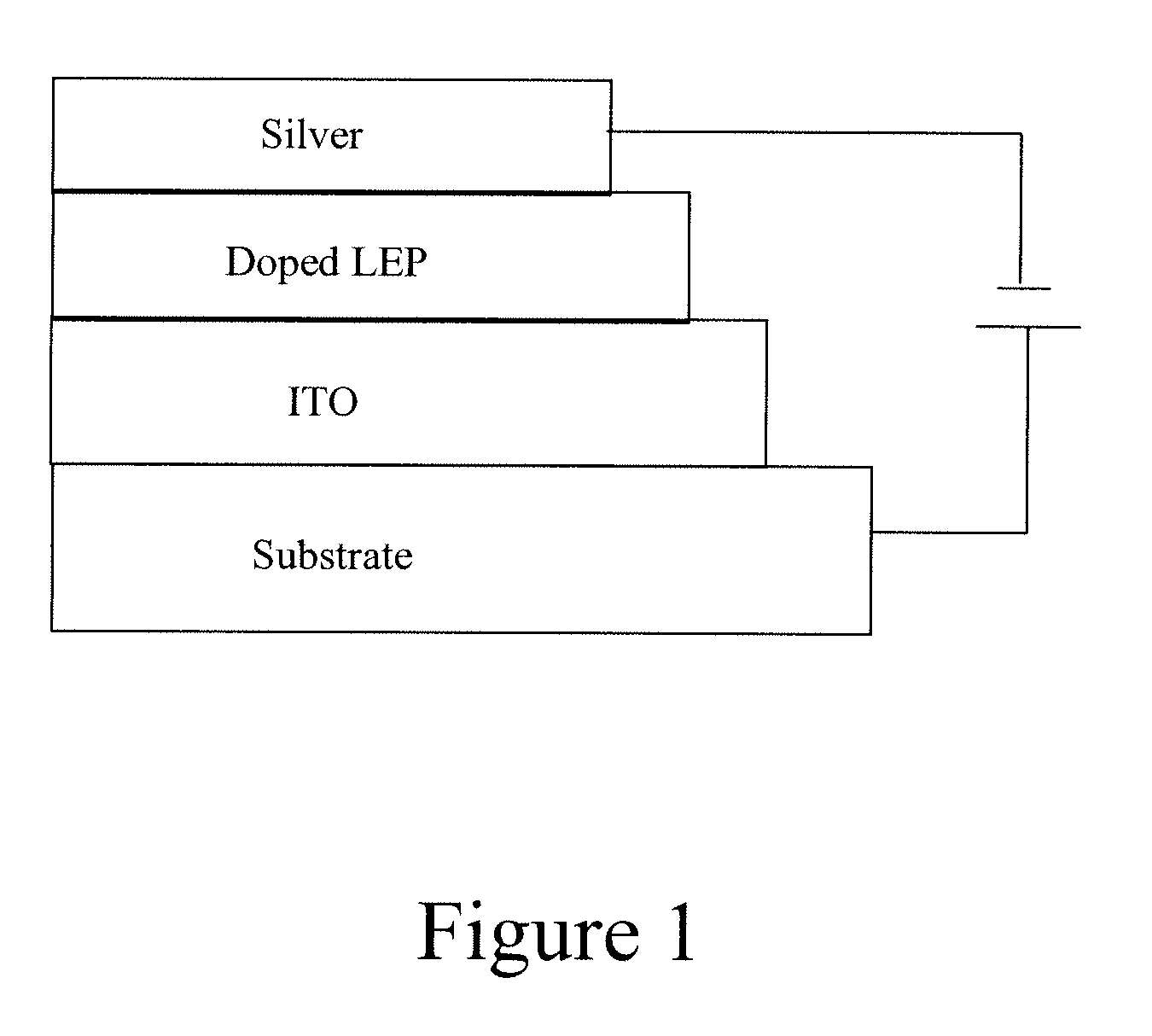

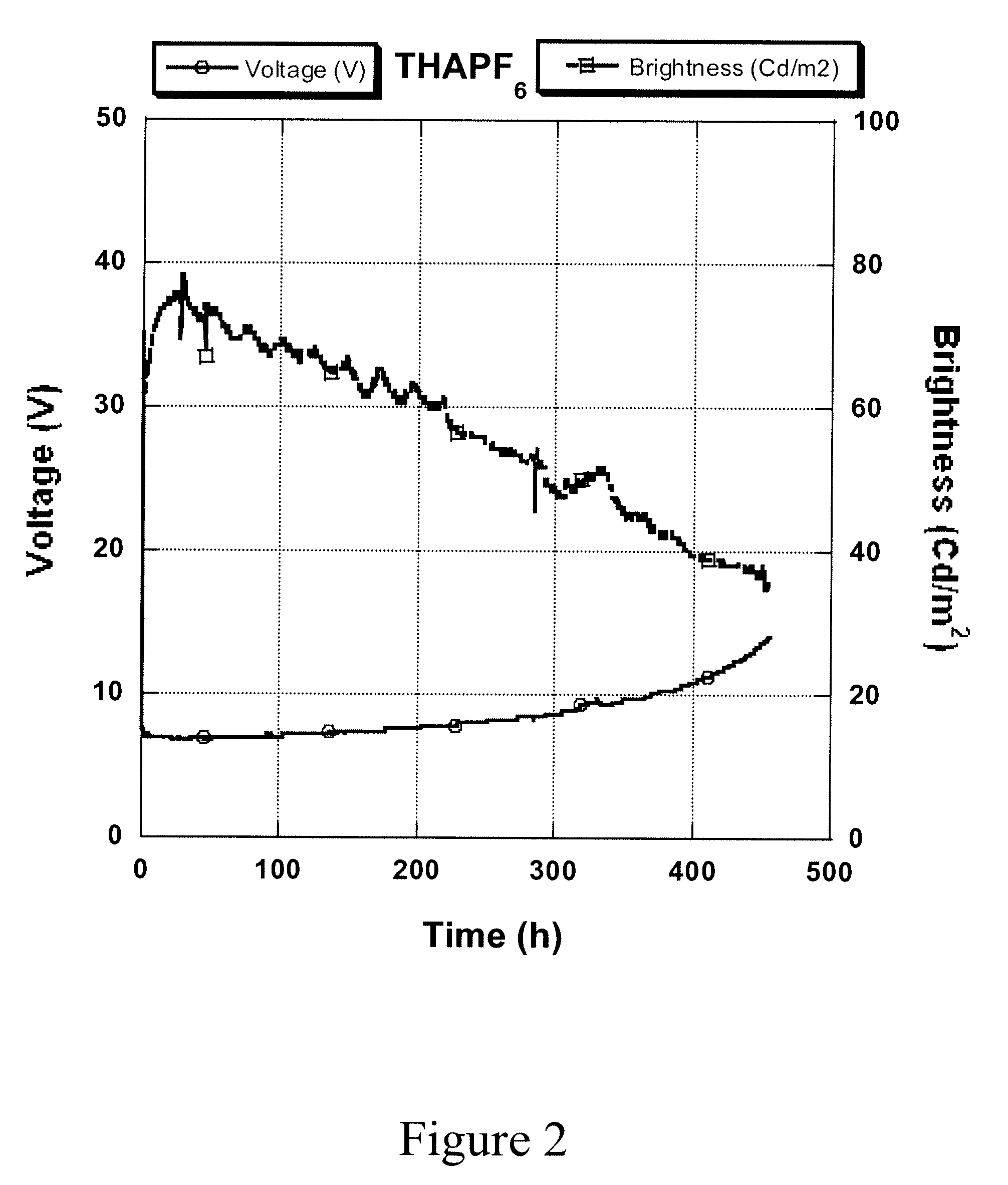

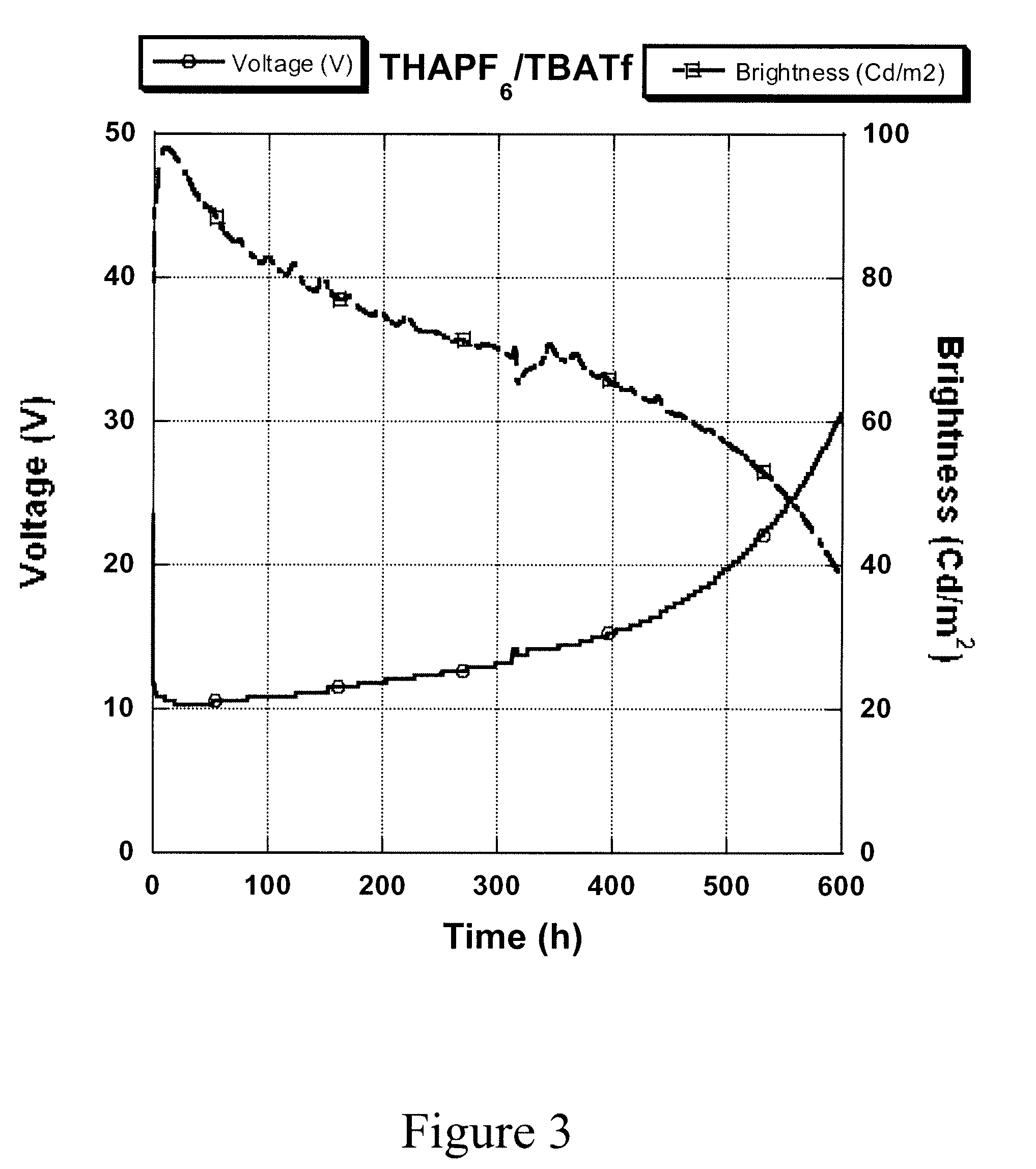

Ionic salt combinations in polymer electroluminescent inks

InactiveUS20110057151A1Fast switching speedEffective balanceSolid-state devicesInksLuminescent polymersCompatibilization

Luminescent ink formulations containing multiple salts selected for good ionic mobility, thermal stability, compatibility with light emitting polymers, good solubility in ink solvents, and electrochemical stability improve the performance of electroluminescent ink. As one salt may not contain all the required properties, a combination of salts is chosen based on the physical and chemical properties of different salts. When multiple salts are incorporated into a light emitting polymer layer, devices show improved lifetime and overall device performance.

Owner:SUMITOMO CHEM CO LTD

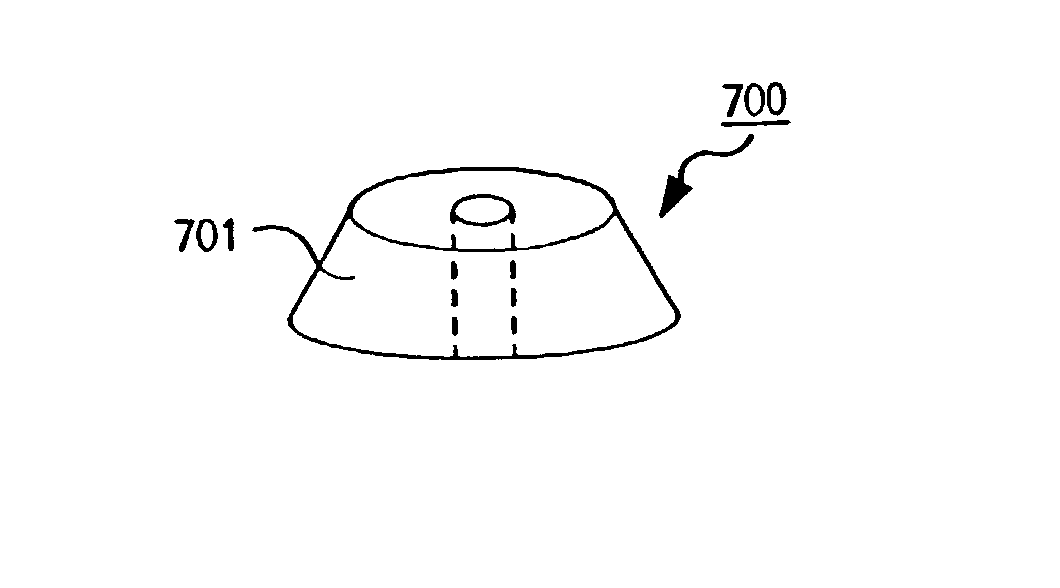

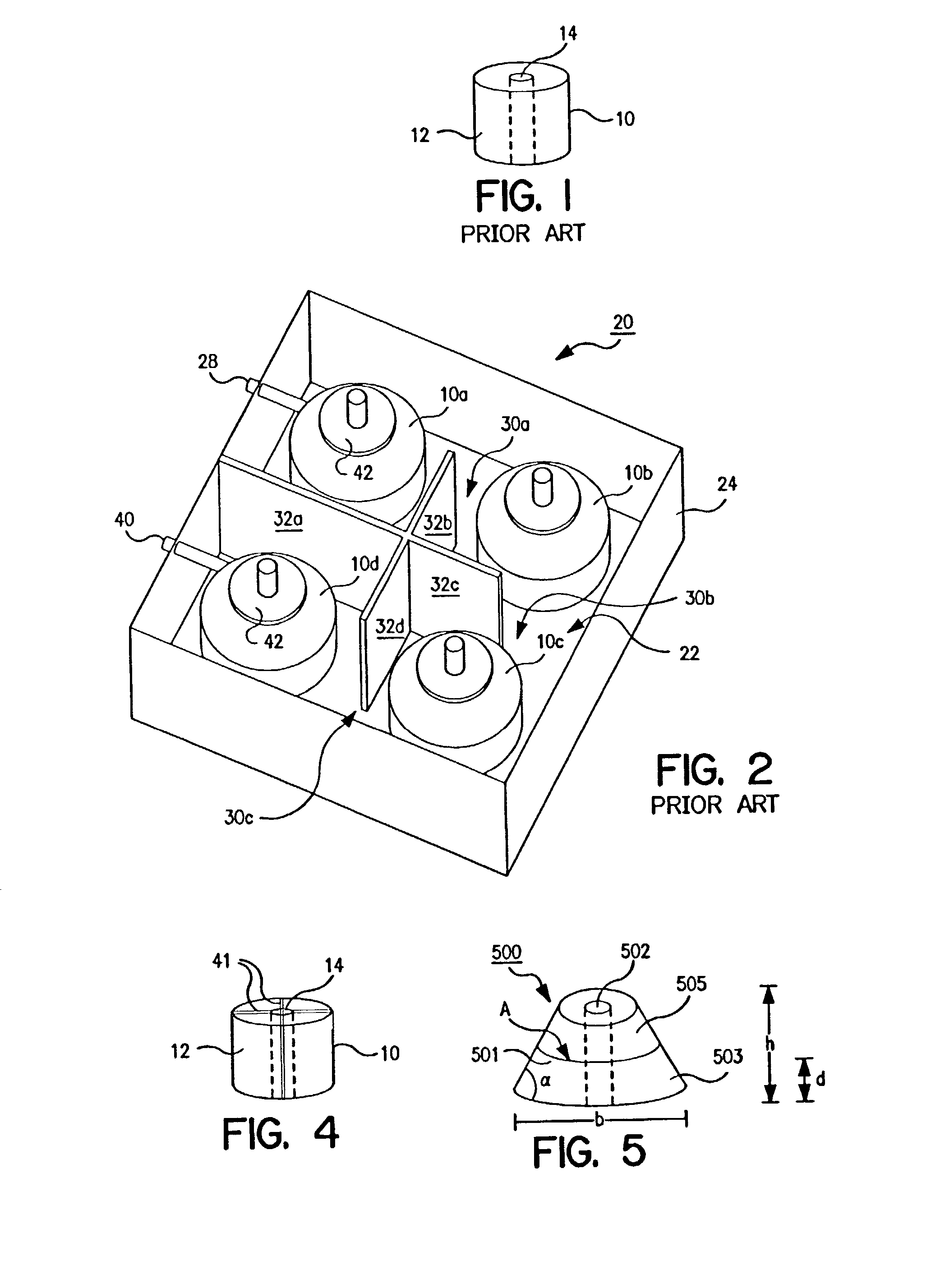

Dielectric resonators and circuits made therefrom

InactiveUS7310031B2High quality factor per unit volumeCompact designResonatorsDielectric resonator antennaCoupling

A dielectric resonator having variable cross-section, preferably varying monotonically, and, most preferably, the resonator being in the shape of a truncated cone. Such shapes displace the H11 mode from the TE mode in the longitudinal direction of the cone. Truncating the cone to eliminate the portion of the cone where the H11 mode exists, virtually eliminates the H11 mode. A circuit comprising a plurality of these resonators may be arranged in an enclosure with each resonator longitudinally inverted relative to adjacent resonator(s) to provide a compact design with enhanced coupling and adjustability. A spiral coupling loop provides high magnetic flux in a small physical volume for coupling energy into or out of the circuit. Alternately, the resonator can coupled to a microstrip by placing the resonator upside-down near the microstrip, whereby the TE mode is immediately above the microstrip, providing enhanced coupling there between.

Owner:COBHAM DEFENSE ELECTRONICS SYST CORP

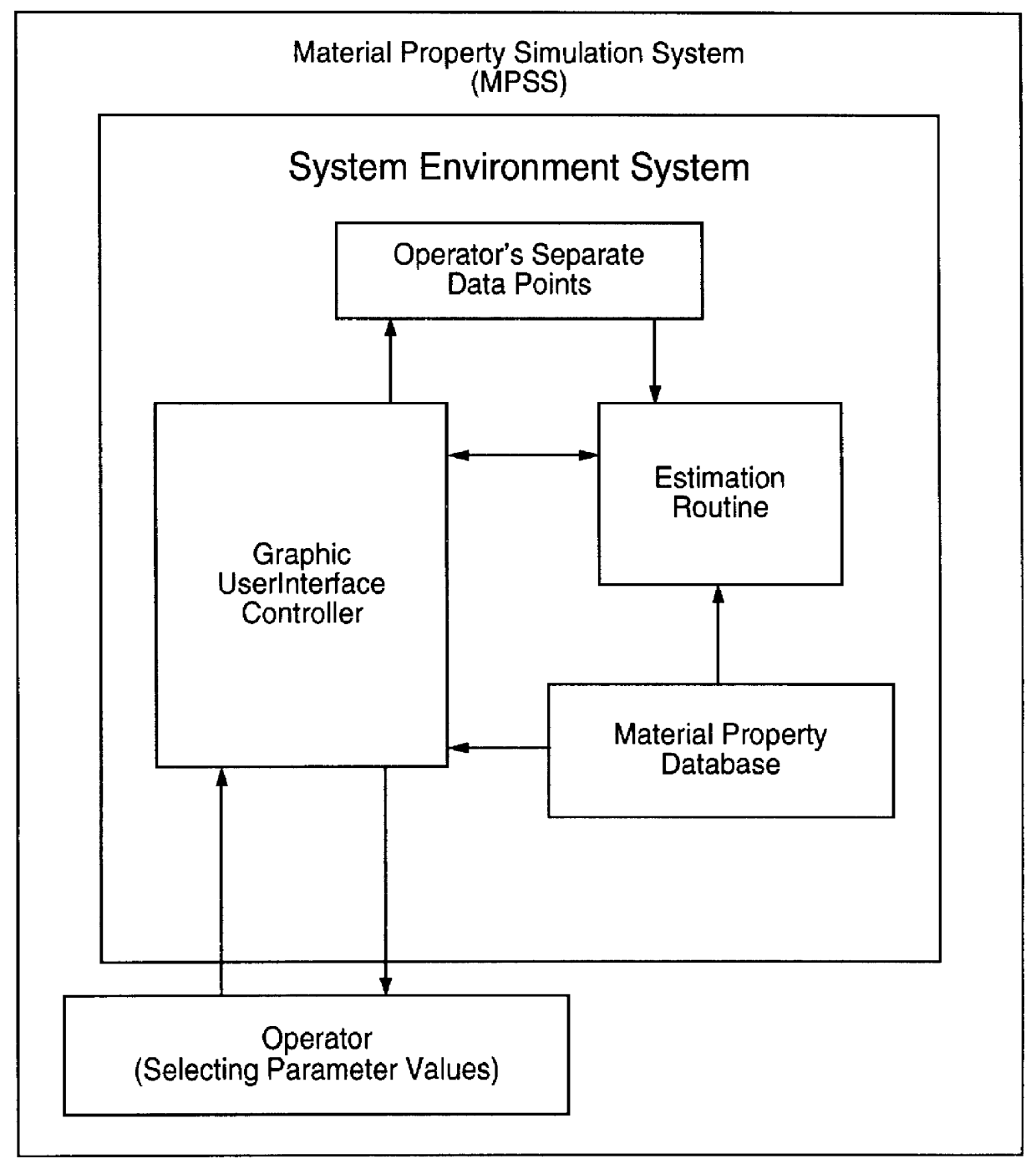

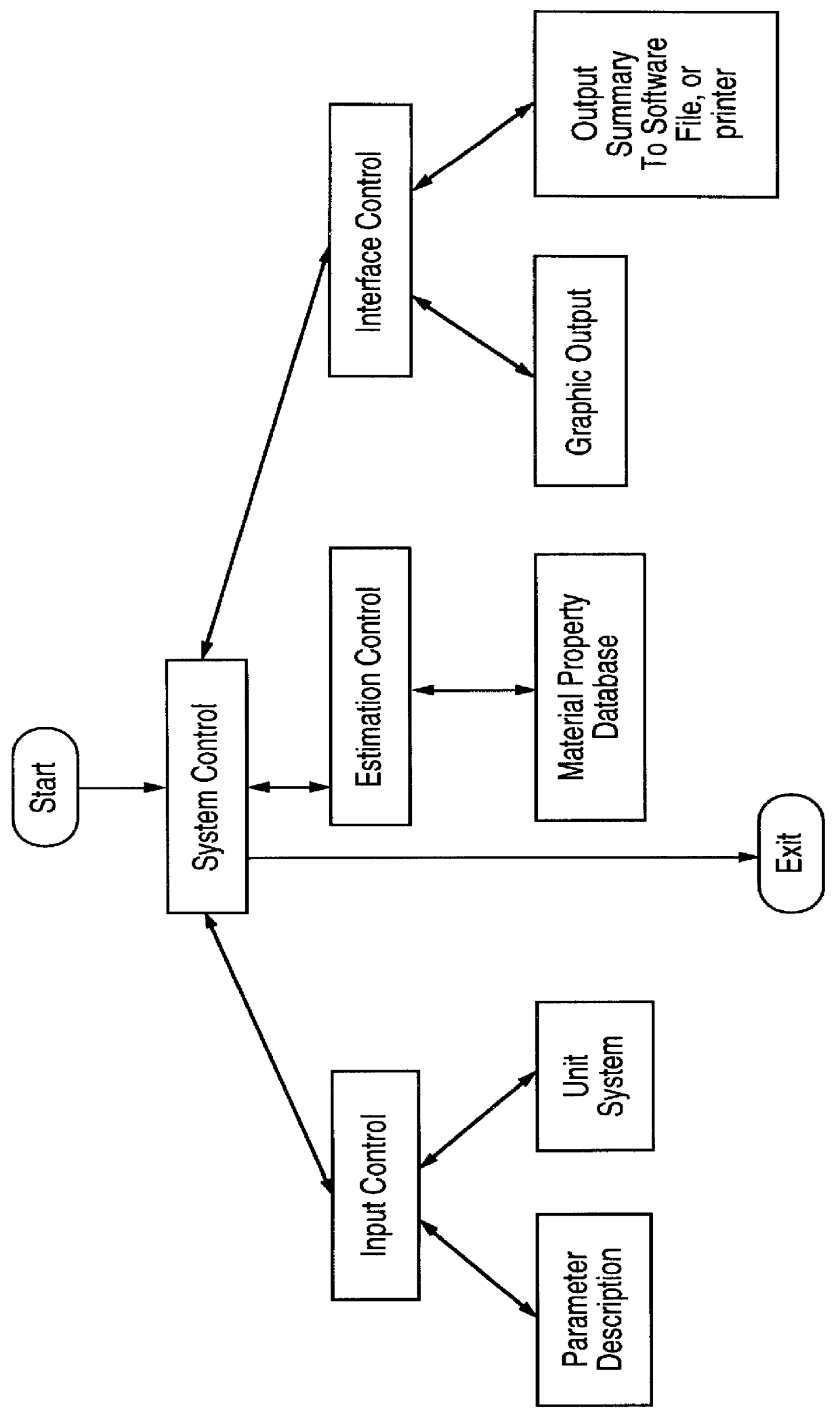

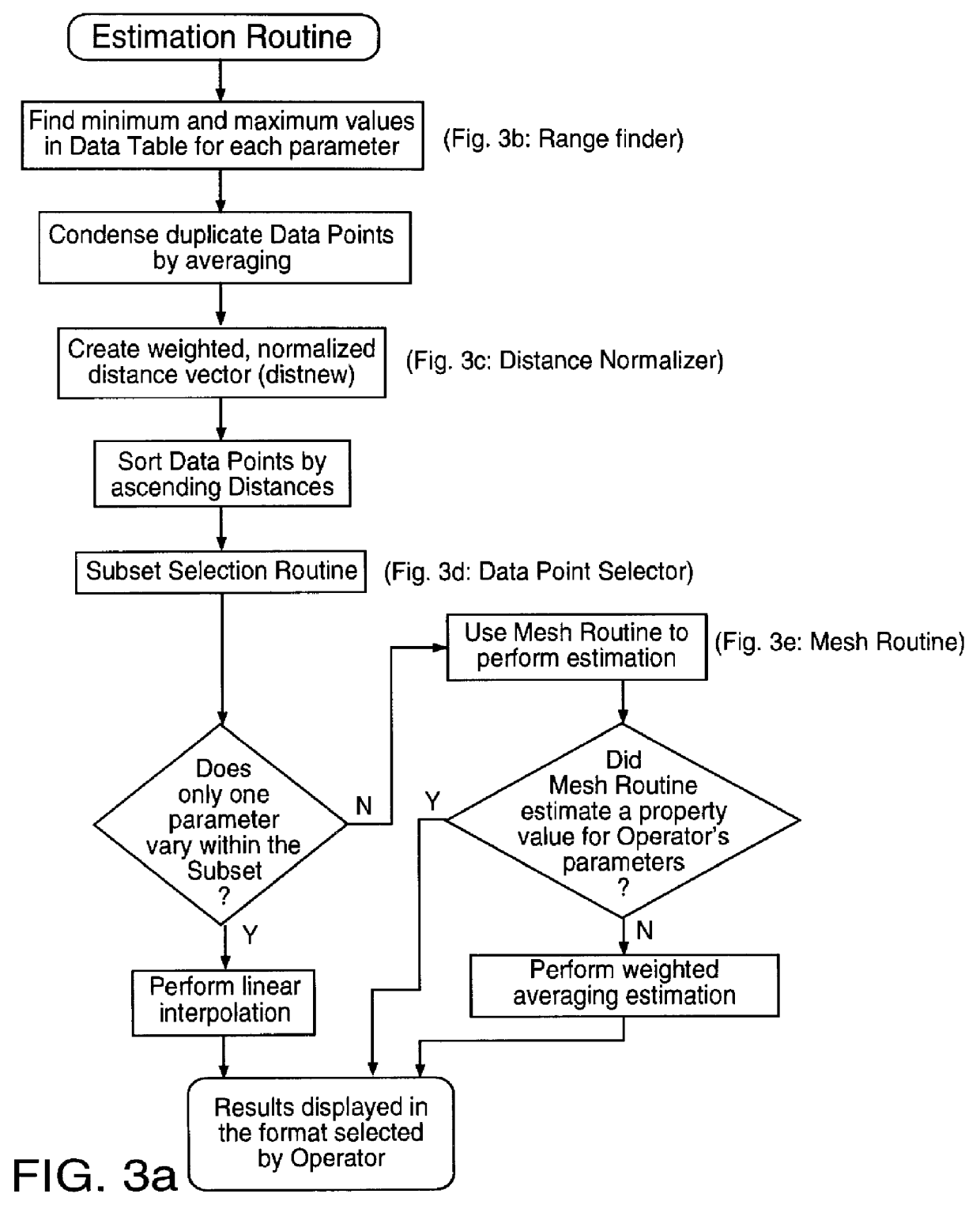

Knowledge based system and method for determining material properties from fabrication and operating parameters

InactiveUS6157900AEasy to optimizeReduce expensesSemiconductor/solid-state device testing/measurementComputation using non-denominational number representationComputer-aidedComputer aid

A knowledge based, computer-aided system and method is disclosed for simulating any set of linear or nonlinear simultaneous parametric dependencies. The preferred embodiment creates a model and provides an estimate of the material properties of materials comprising thin films disposed on semiconductor materials. However the system and method are suitable for creating a model and providing an estimate of the physical properties of materials undergoing other material fabrication processes that are dependent on several parameters. The method is suitable for implementation on exisitng general purpose computers. The method involves the general steps of entering parameter values for the material being subjected to the fabrication process, interrelating the user provided parameter values with a database of stored parameter values, calculating numerical solutions for the interrelated parameter and property values according to an Estimation Routine, and providing an output of numerical and graphical data relating to the desired physical properties. The system is capable of being implemented to include a dual hierarchical feedback and feed-foreward loop where a control system uses the Estimation Routine to determine what additional data acquisition is required. Such a feedback loop could also be employed in conjunction with this method to yield an optimized value for the material properties in question.

Owner:INTELLISENSE +1

Genetically engineered clostridial genes, proteins encoded by the engineered genes, and uses thereof

ActiveUS20100196421A1Optimization propertiesOptimized therapeuticAntibacterial agentsSenses disorderEngineered geneticGenetically engineered

The present invention relates to an isolated Clostridial neurotoxin propeptide having a light chain region, a heavy chain region, where the light and heavy chain regions are linked by a disulfide bond, and an intermediate region connecting the light and heavy chain regions. An isolated nucleic acid molecule encoding a Clostridial neurotoxin propeptide is also disclosed. Also disclosed is an isolated, physiologically active Clostridial neurotoxin produced by cleaving a Clostridial neurotoxin propeptide, a vaccine or antidote thereof, and methods of immunizing against or treating for toxic effects of Clostridial neurotoxins. Methods of expressing recombinant physiologically active Clostridial neurotoxins are also disclosed. Also disclosed is a chimeric protein having a heavy chain region of a Clostridial neurotoxin and a protein with therapeutic functionality. A treatment method is also disclosed.

Owner:NEW YORK UNIV

Non-Contact Transfer Printing

ActiveUS20170210117A1Avoid damageNot to damageTransfer printingDuplicating/marking methodsNano-deviceHigh-speed photography

A transfer printing process that exploits the mismatch in mechanical or thermo-mechanical response at the interface of a printable micro- or nano-device and a transfer stamp to drive the release of the device from the stamp and its non-contact transfer to a receiving substrate are provided. The resulting facile, pick-and-place process is demonstrated with the assembling of 3-D microdevices and the printing of GAN light-emitting diodes onto silicon and glass substrates. High speed photography is used to provide experimental evidence of thermo-mechanically driven release.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

Method of forming rubber-metal composites

InactiveUS6805768B2Improve adhesionSimple and economical to operateLiquid surface applicatorsAdhesive processes with surface pretreatmentEpoxyPolymer science

A film of a polymer or polymer precursor such as an epoxy resin is autodeposited on an active metal surface and then used to form an adhesive bond directly between the metal surface and the surface of a rubber substrate. Excellent adhesion of the metal to the rubber is obtained without the need to either phosphate the metal surface or use a primer or adhesive other than the autodeposited coating.

Owner:HENKEL KGAA

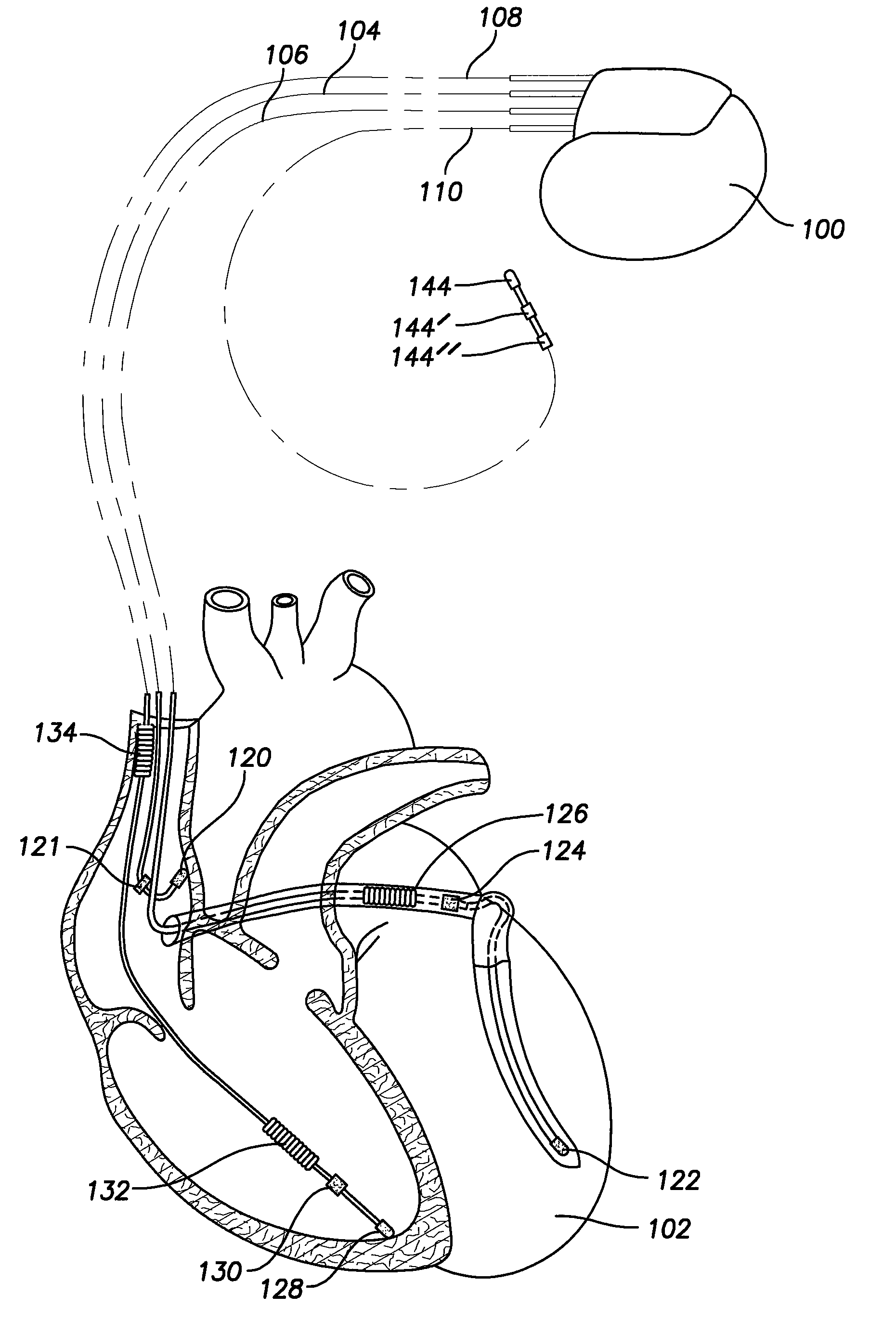

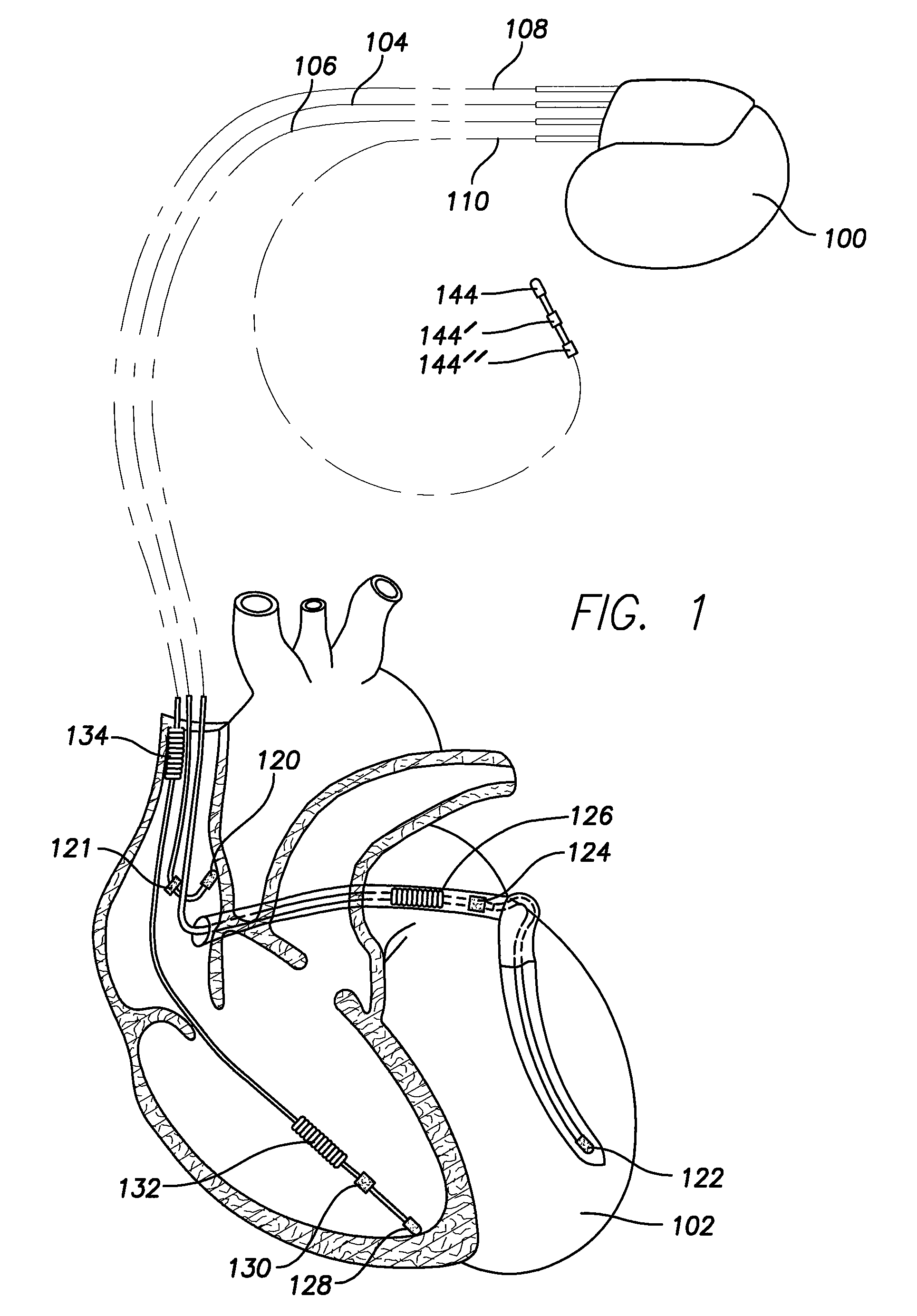

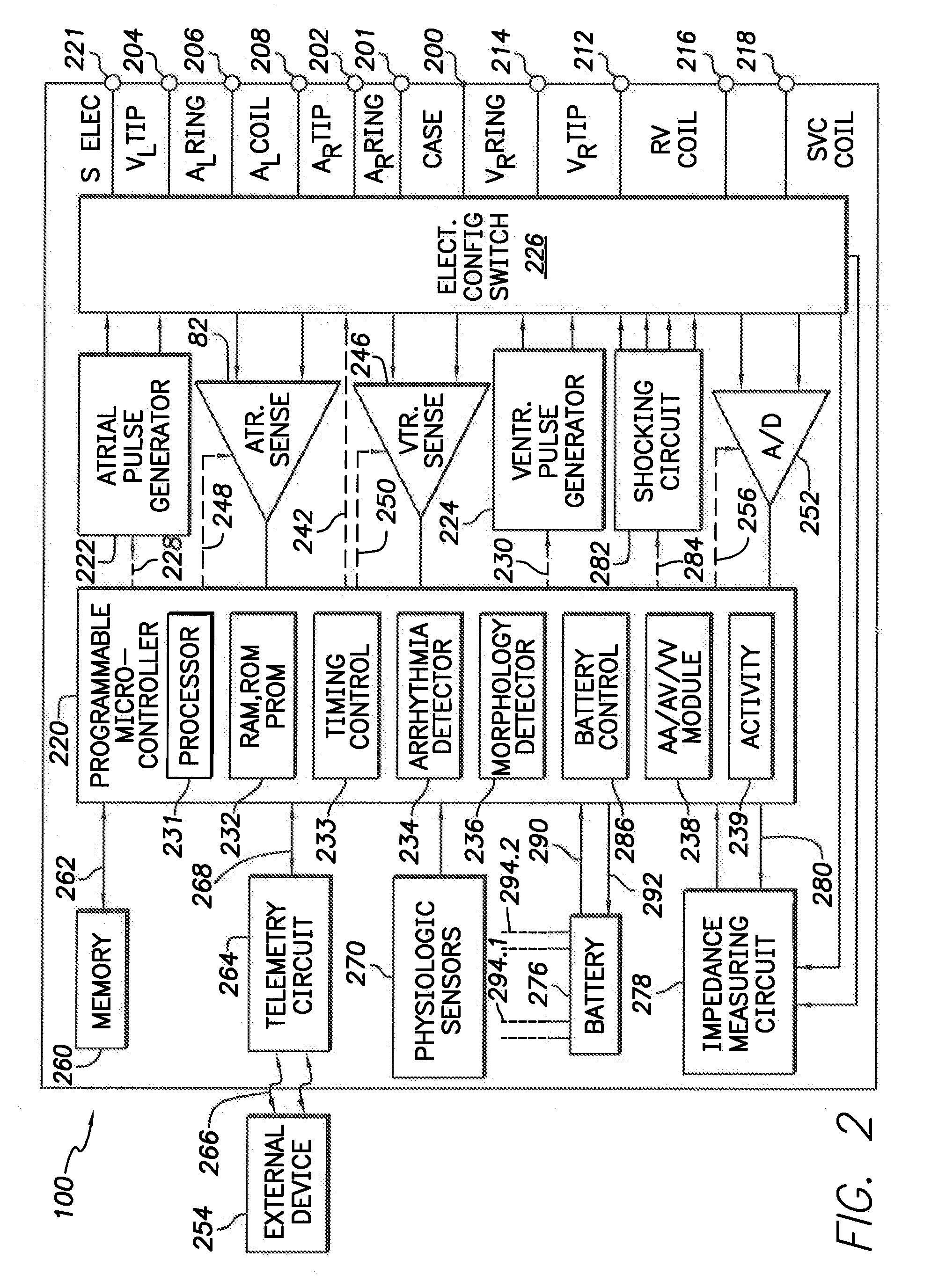

Small caliber implantable biometric leads and cables for same

ActiveUS20100204767A1Optimal mechanical and electrical performanceReduce the overall diameterInternal electrodesInsulated cablesAlloySmall caliber

Implantable medical leads have reduced diameter while providing for optimized mechanical and electrical properties, by reducing the diameters of the conducting cables used within the leads for sensing and delivery of therapeutic electrical stimulation. In an embodiment, conducting filaments within a cable have oval cross-sectional areas. Suitably orienting the oval filaments increases the contact surface between adjacent filaments, broadly distributing the pressure between filaments and reducing fretting fatigue, while the oval cross-sectional area also increases conductivity. In an embodiment, non-conducting coatings around filaments within a cable, or around groups of filaments organized into cable-layers, reduce fretting fatigue. In an embodiment, the cross-sectional area of filaments decreases as the filaments are positioned at increasing radial distances from the center of the cable. In an embodiment, the relative composition of various filament metals and / or alloys is varied in filaments at different radial distances from the center of the cable.

Owner:PACESETTER INC

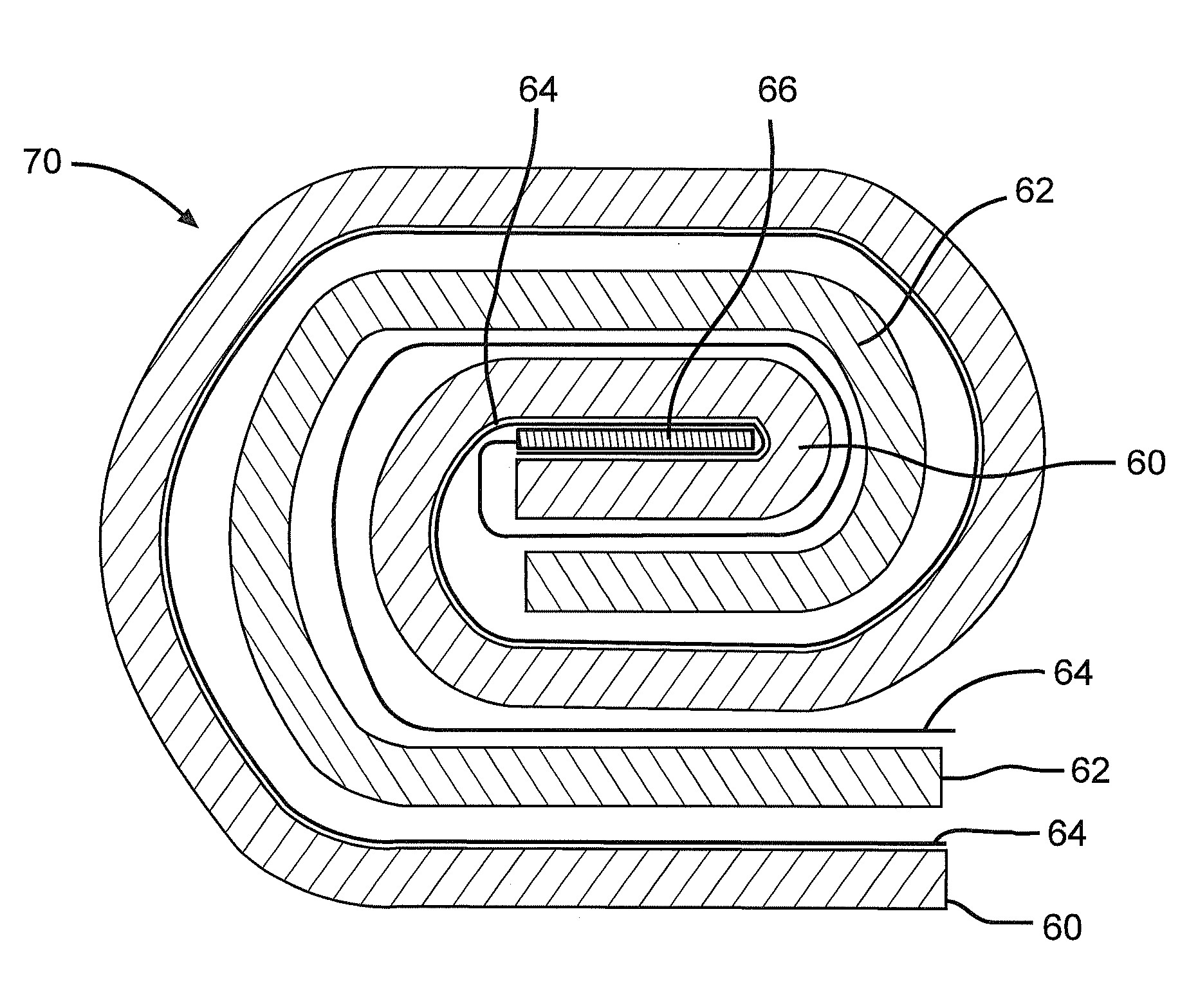

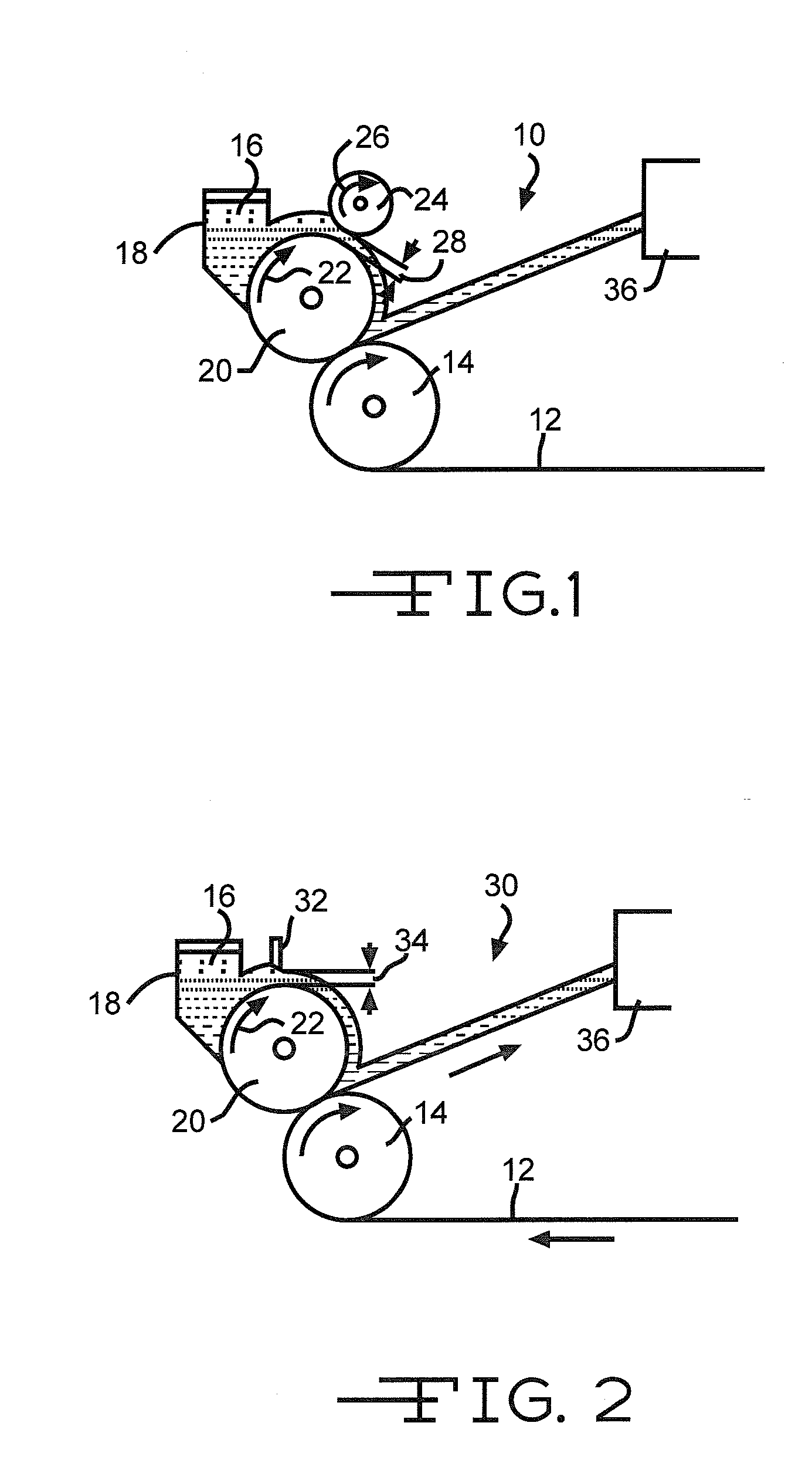

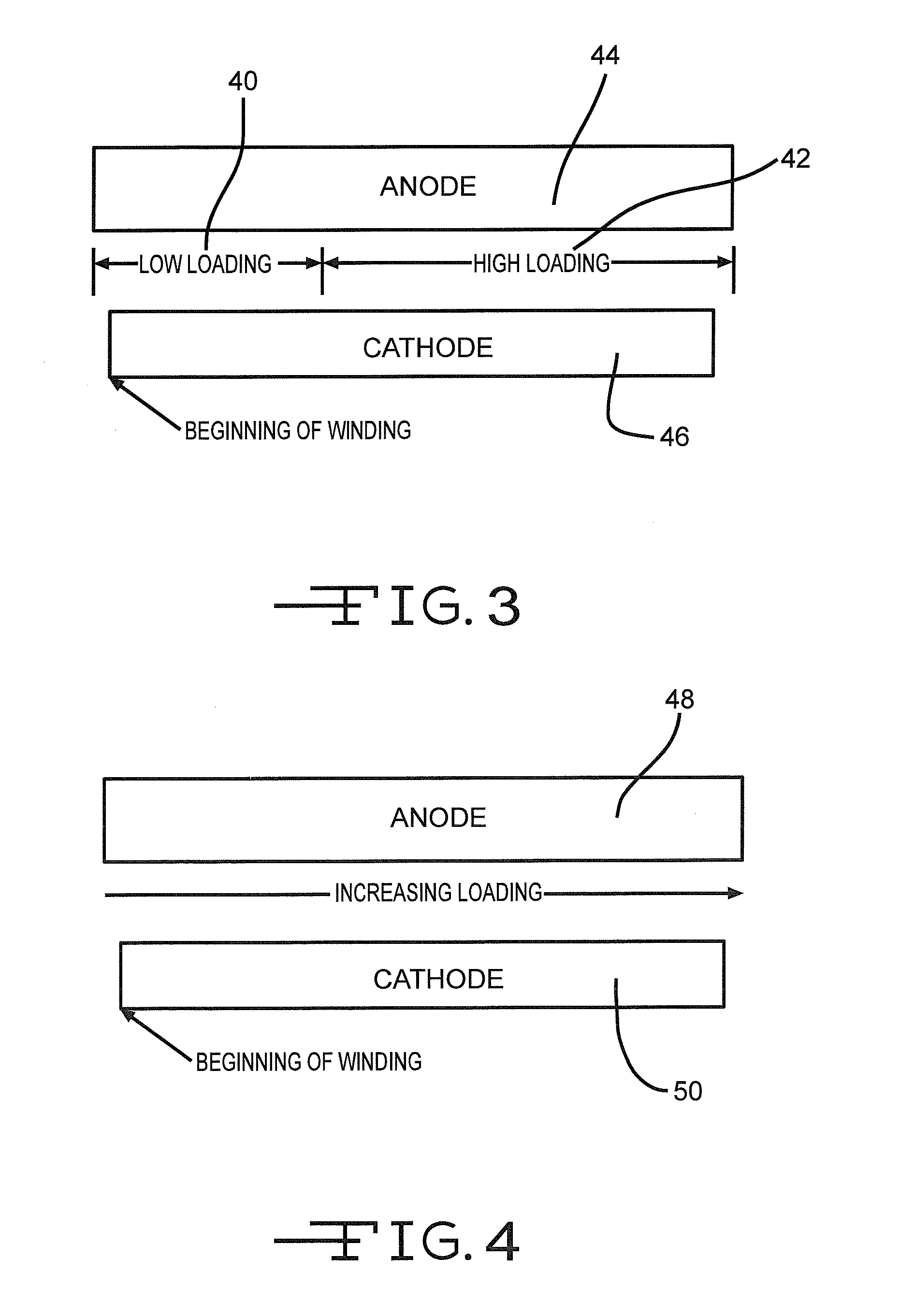

Method of making electrodes with distributed material loading used in electrochemical cells

InactiveUS20120308861A1Optimization propertiesIncrease energy densityElectrode manufacturing processesElectrode carriers/collectorsHigh energyRechargeable cell

A method of making electrodes with distributed material loadings used in rechargeable electrochemical cells and batteries is described. This method controls electrode material loading (mass per unit area) along the electrode's length while maintaining uniform compaction throughout the electrode. Such prepared electrode maintain sufficient mechanical flexibility for winding and are compact and robust to have high energy density and long cycle life in rechargeable cells and batteries.

Owner:WILSON GREATBATCH LTD

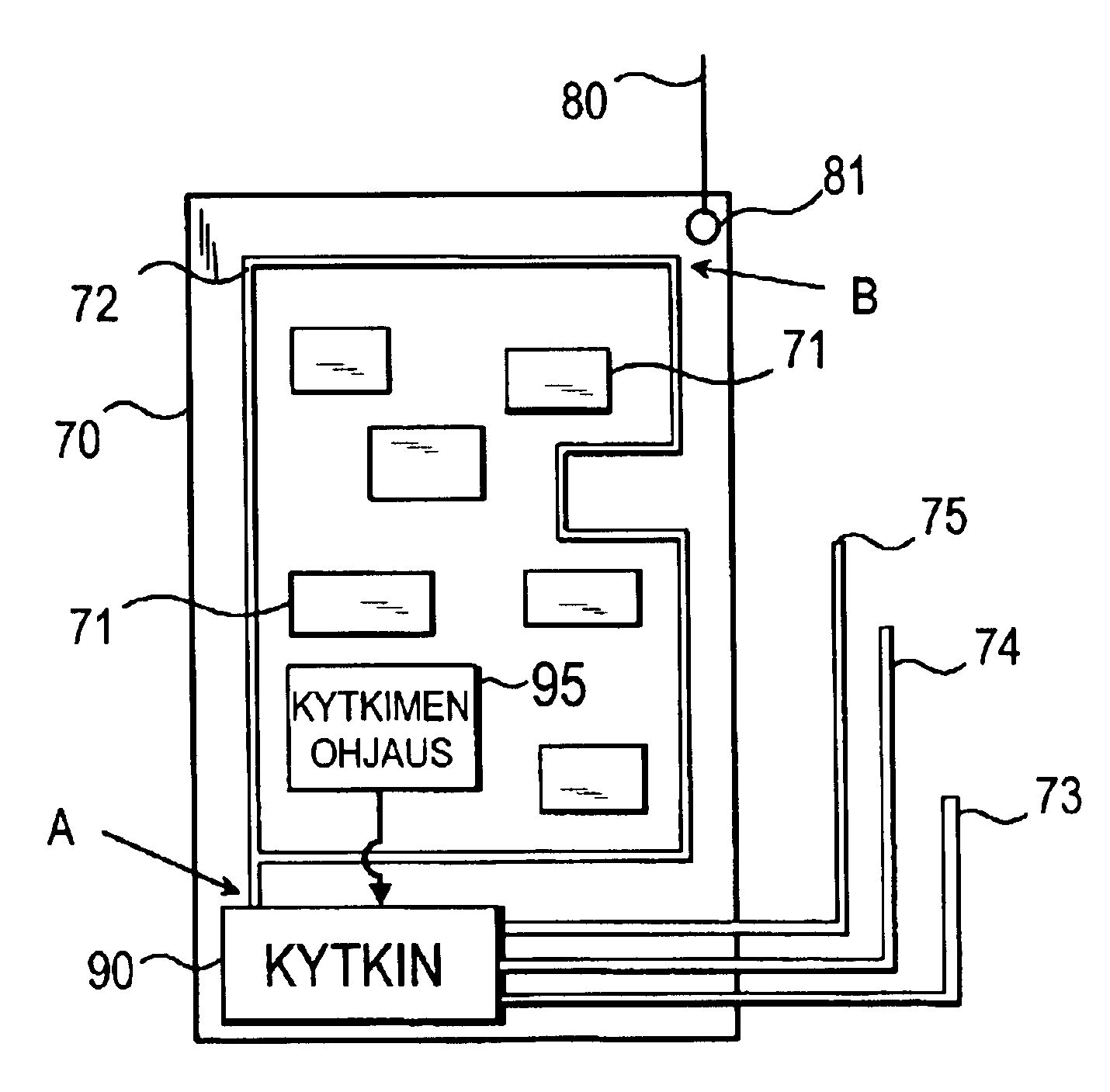

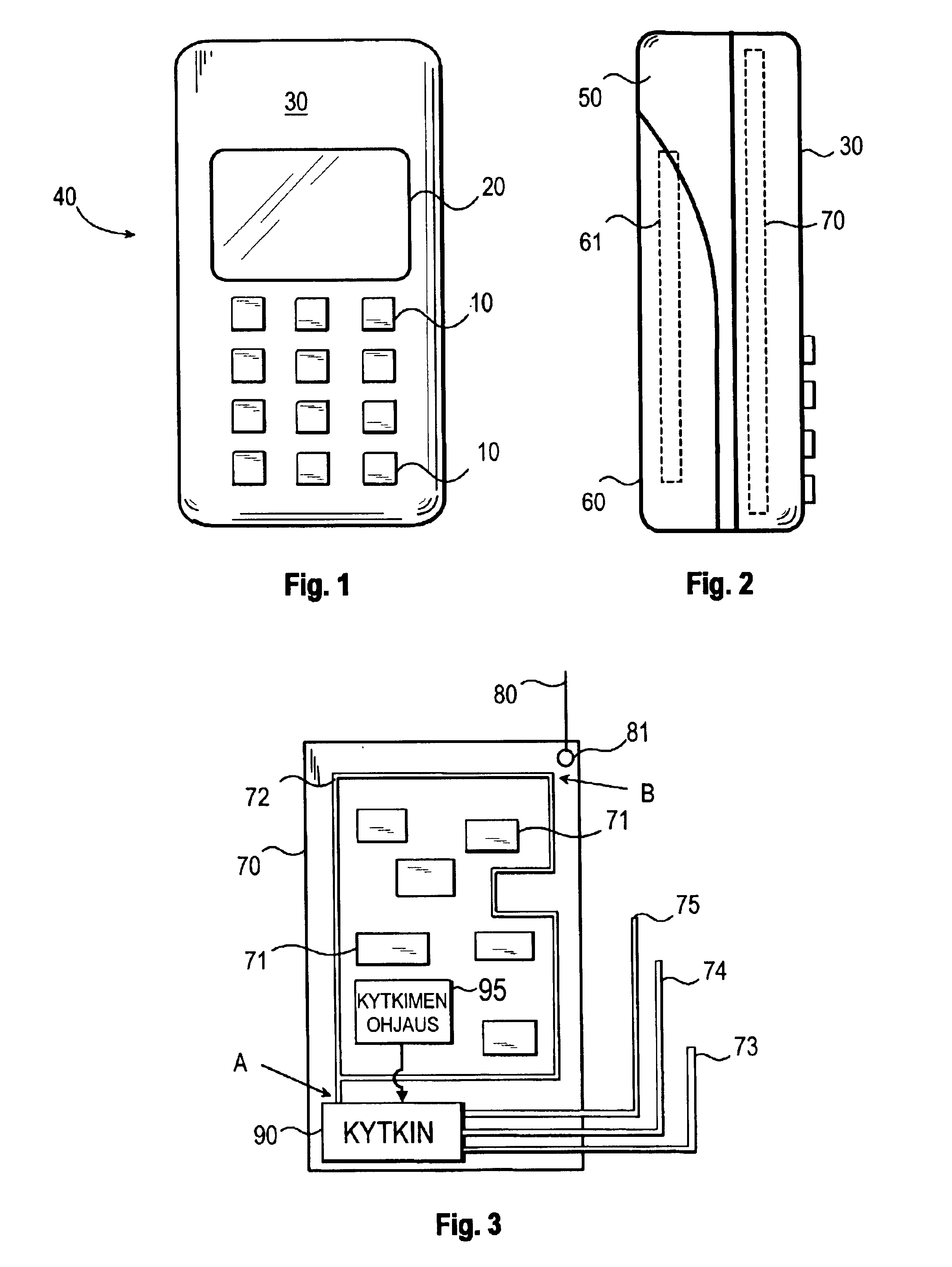

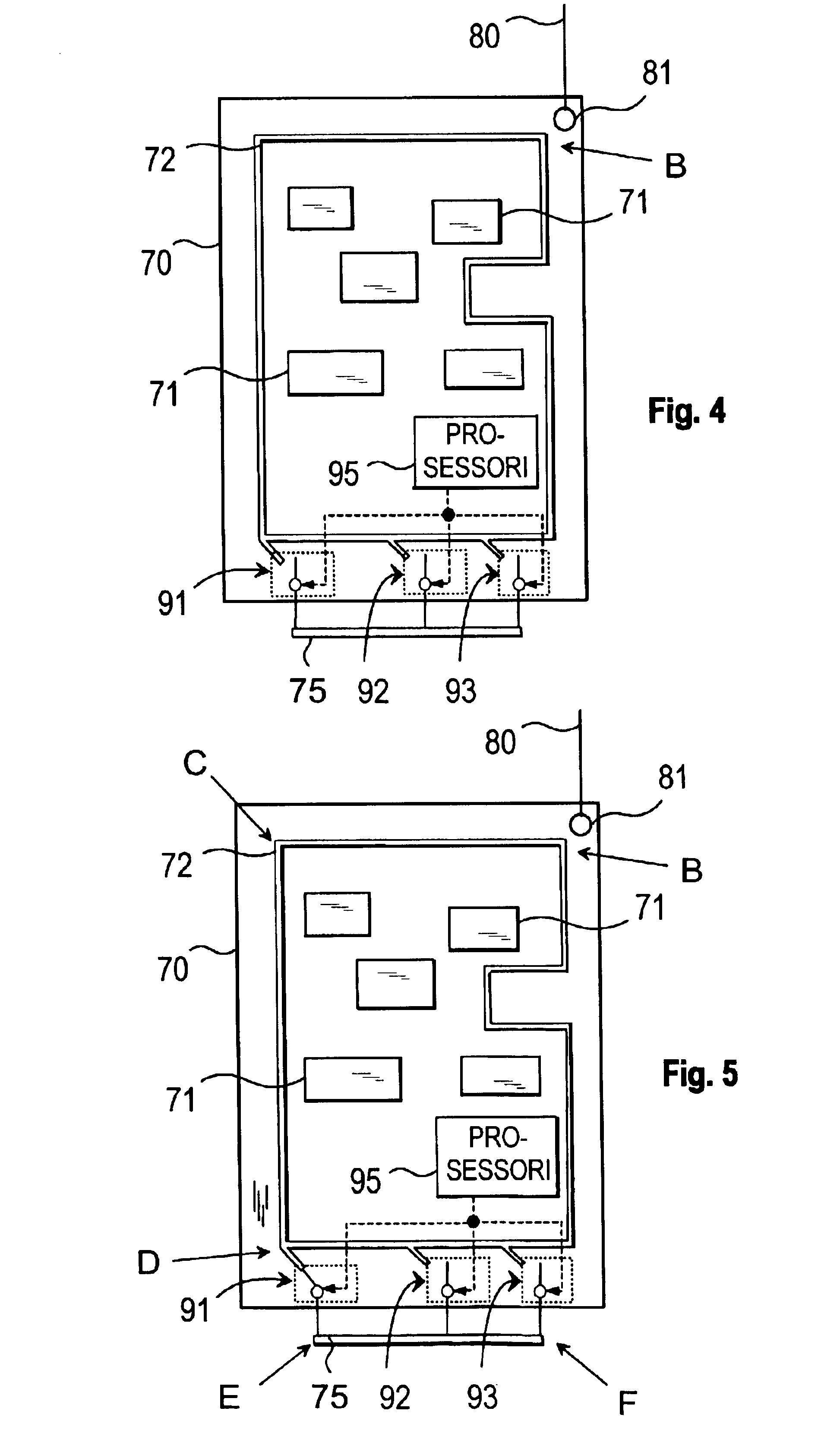

Ground arrangement for a device using wireless data transfer

InactiveUS6987486B2Minimize SAR valueOptimization propertiesAntenna supports/mountingsAntenna earthingsEngineeringElectric properties

Owner:FLEXTRONICS SALES & MARKETING A P

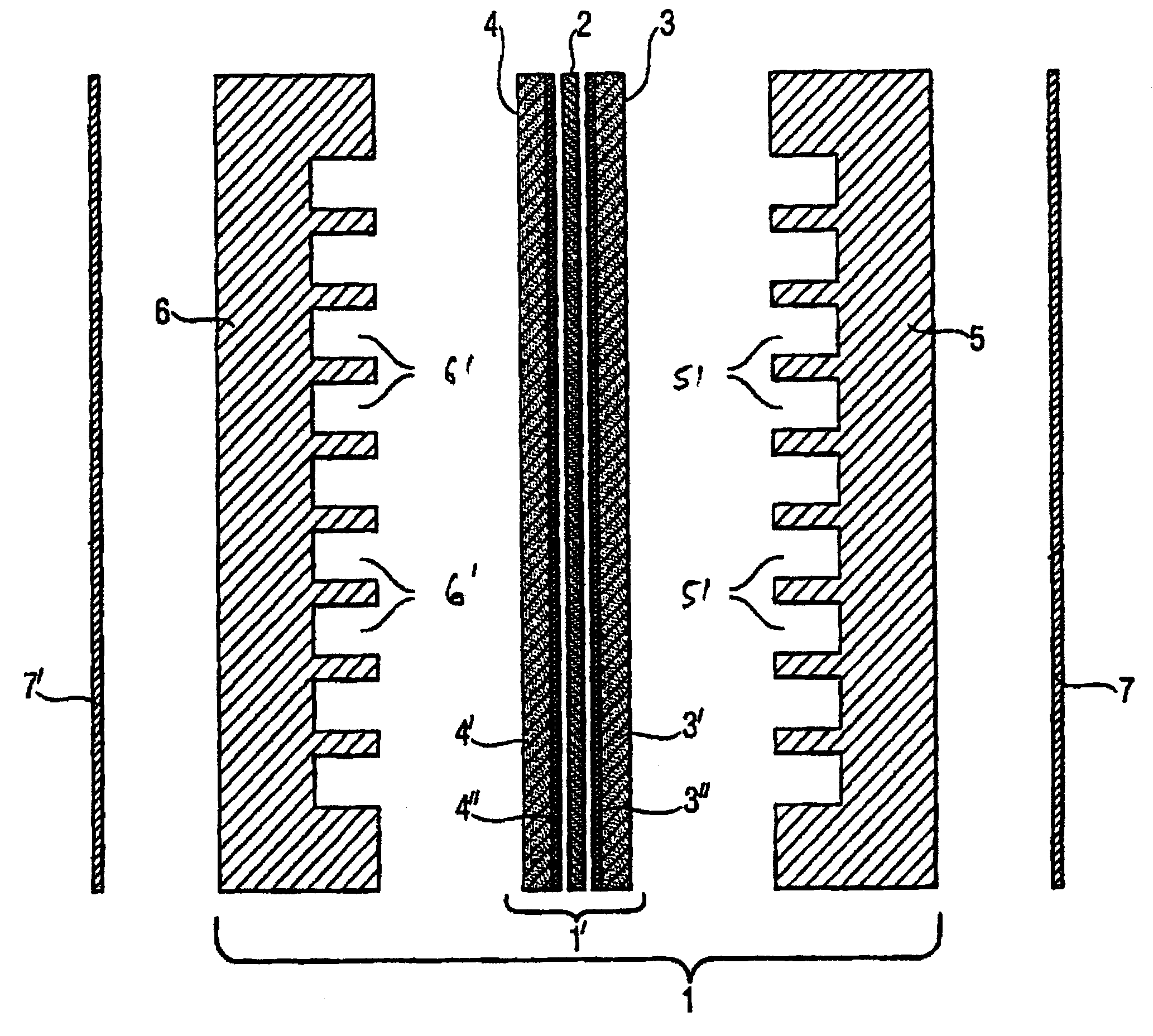

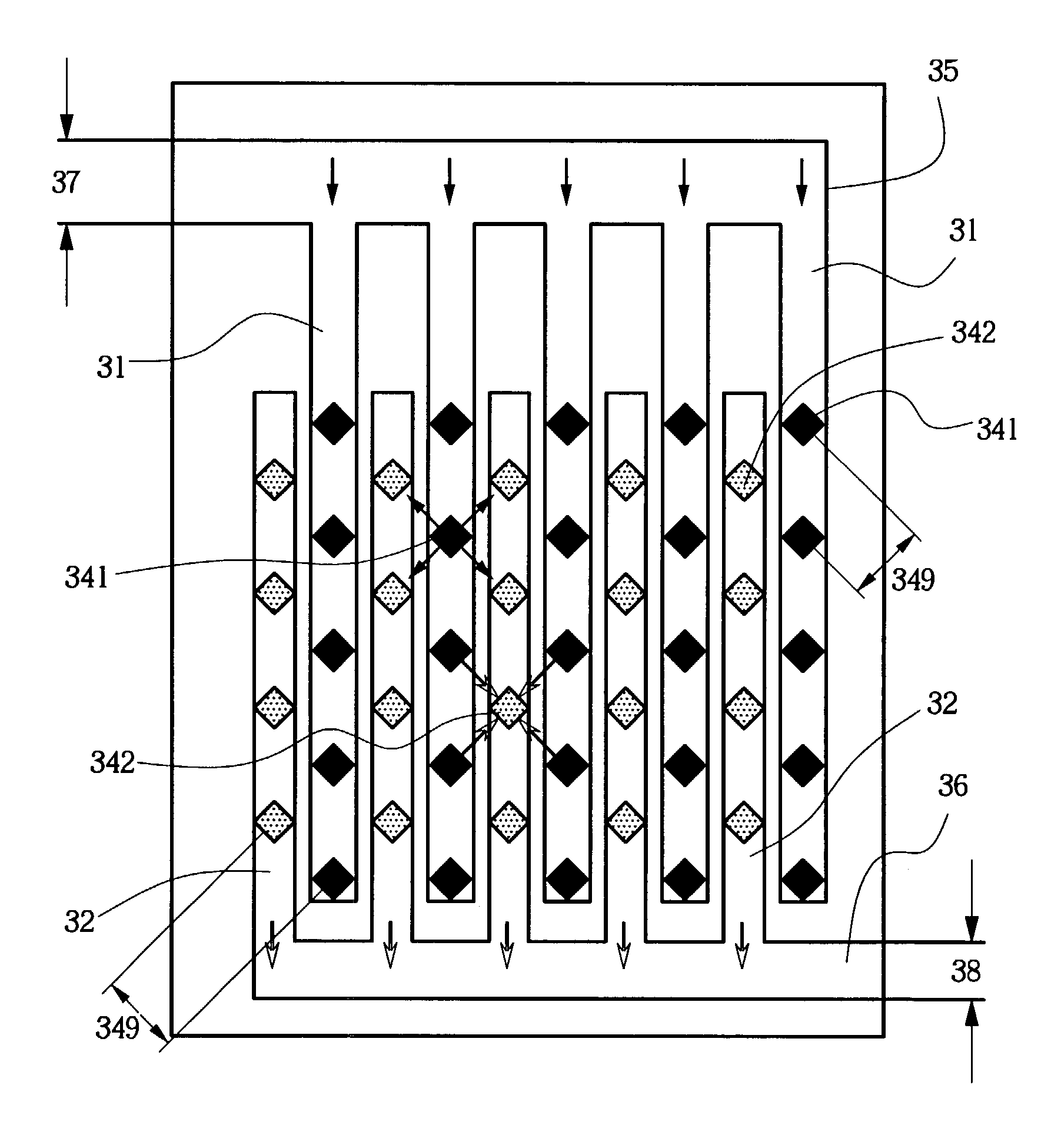

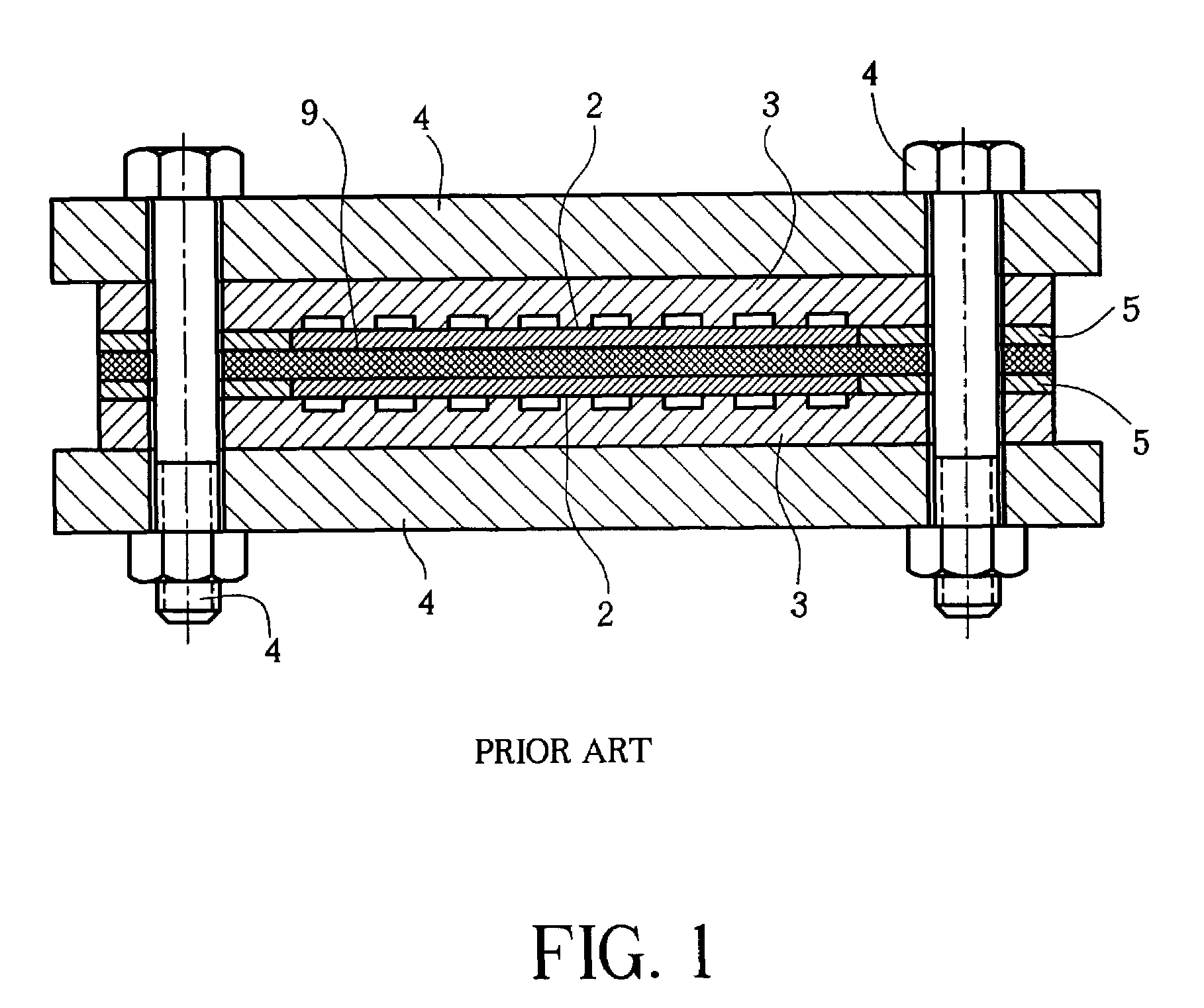

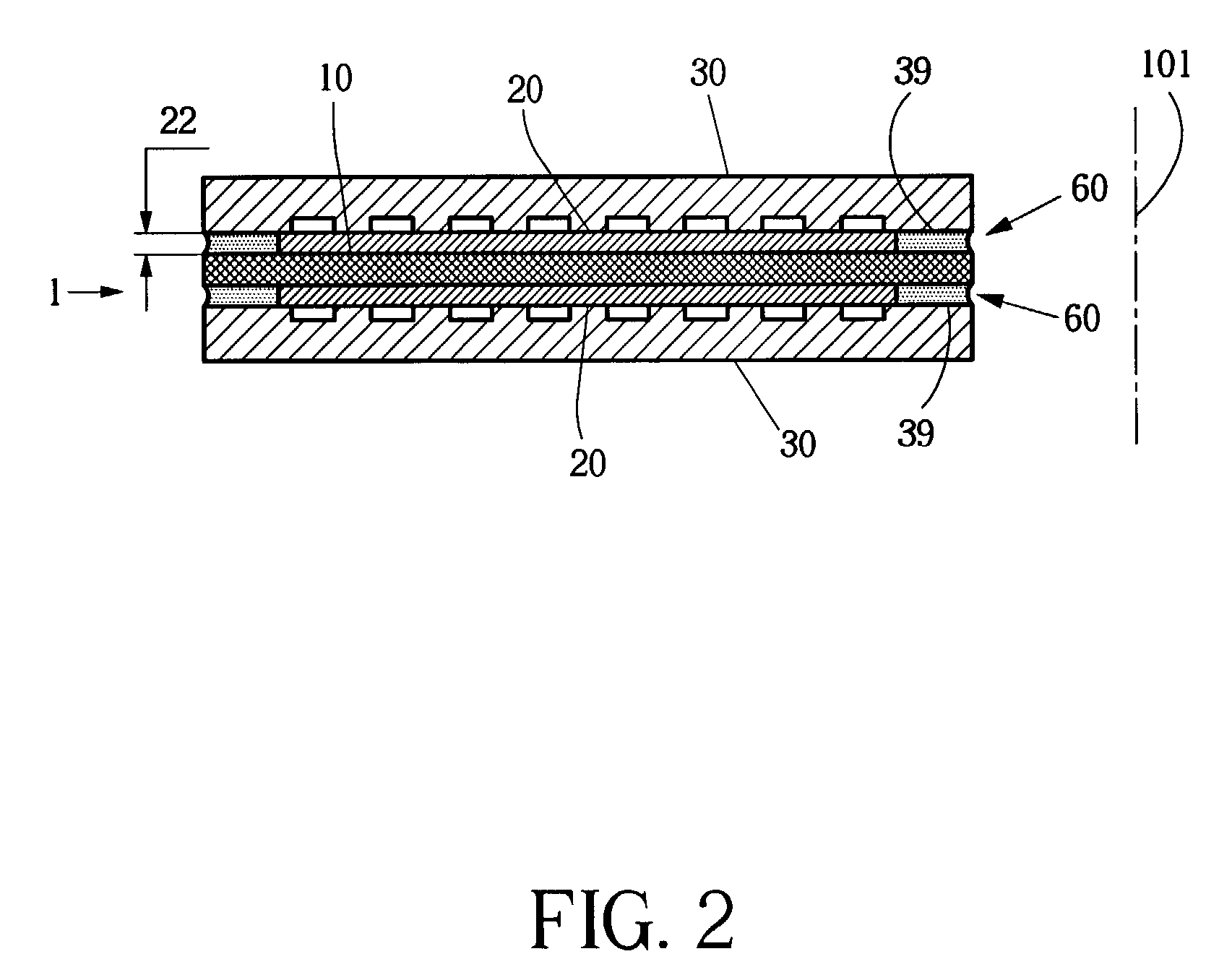

Fuel cell

InactiveUS7341800B2Bonded firmlyIncreased durabilityFuel cells groupingCell electrodesIn planeFlow resistivity

A simple, inexpensive and highly efficient fuel cell has boundary structures made of a photo-sensitive material in combination with selective patterning. Printed circuit board (PCB) fabrication techniques combine boundary structures with two and three dimensional electrical flow path. Photo-sensitive material and PCB fabrication techniques are alternately or combined utilized for making micro-channel structures or micro stitch structures for substantially reducing dead zones of the diffusion layer while keeping fluid flow resistance to a minimum. The fuel cell assembly is free of mechanical clamping elements. Adhesives that may be conductively contaminated and / or fiber-reinforced provide mechanical and eventual electrical connections, and sealing within the assembly. Mechanically supporting backing layers are pre-fabricated with a natural bend defined in combination with the backing layers' elasticity to eliminate massive support plates and assist the adhesive bonding. Proton insulation between adjacent and electrically linked in-plane cell elements is provided by structural insulation within the central membrane.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV +1

Chemical-free production of graphene-reinforced polymer matrix composites

ActiveUS9926427B2Optimization propertiesOptimize throughputAdditive manufacturing apparatusLiquid surface applicatorsPolymer scienceEnergy impact

Provided is a simple, fast, scalable, and environmentally benign method of producing a graphene-reinforced polymer matrix composite directly from a graphitic material, the method comprising: (a) mixing multiple particles of a graphitic material and multiple particles of a solid polymer carrier material to form a mixture in an impacting chamber of an energy impacting apparatus; (b) operating the energy impacting apparatus with a frequency and an intensity for a length of time sufficient for peeling off graphene sheets from the graphitic material and transferring the graphene sheets to surfaces of solid polymer carrier material particles to produce graphene-coated or graphene-embedded polymer particles inside the impacting chamber; and (c) forming graphene-coated or graphene-embedded polymer particles into the graphene-reinforced polymer matrix composite. Also provided is a mass of the graphene-coated or graphene-embedded polymer particles produced by this method.

Owner:GLOBAL GRAPHENE GRP INC

Tissue-adhesive porous haemostatic product

ActiveUS20180221531A1Improve propertiesWithout adversely affectingPeptide/protein ingredientsPharmaceutical delivery mechanismPorous substrateSolvent

A process of preparing an adhesive haemostatic product is provided. The process comprises: (a) coating a porous solid substrate with a coating liquid that comprises an electrophilically activated polyoxazoline (EL-POX) and a solvent to produce a coated substrate; and (b) removing the solvent from the coated substrate. The EL-POX comprises at least 2 reactive electrophilic groups. The process enables the application of an EL-POX coating that leaves the pore structure of the substrate largely intact so that the ability of the porous substrate to absorb body fluids, such as blood, remains essentially unaffected. The EL-POX coated haemostatic product obtained by the present process has excellent adhesive properties due to the presence of electrophilic reactive groups that are capable of reacting with e.g. amine groups that are naturally present in tissue, under the formation of covalent bonds.

Owner:GATT TECH

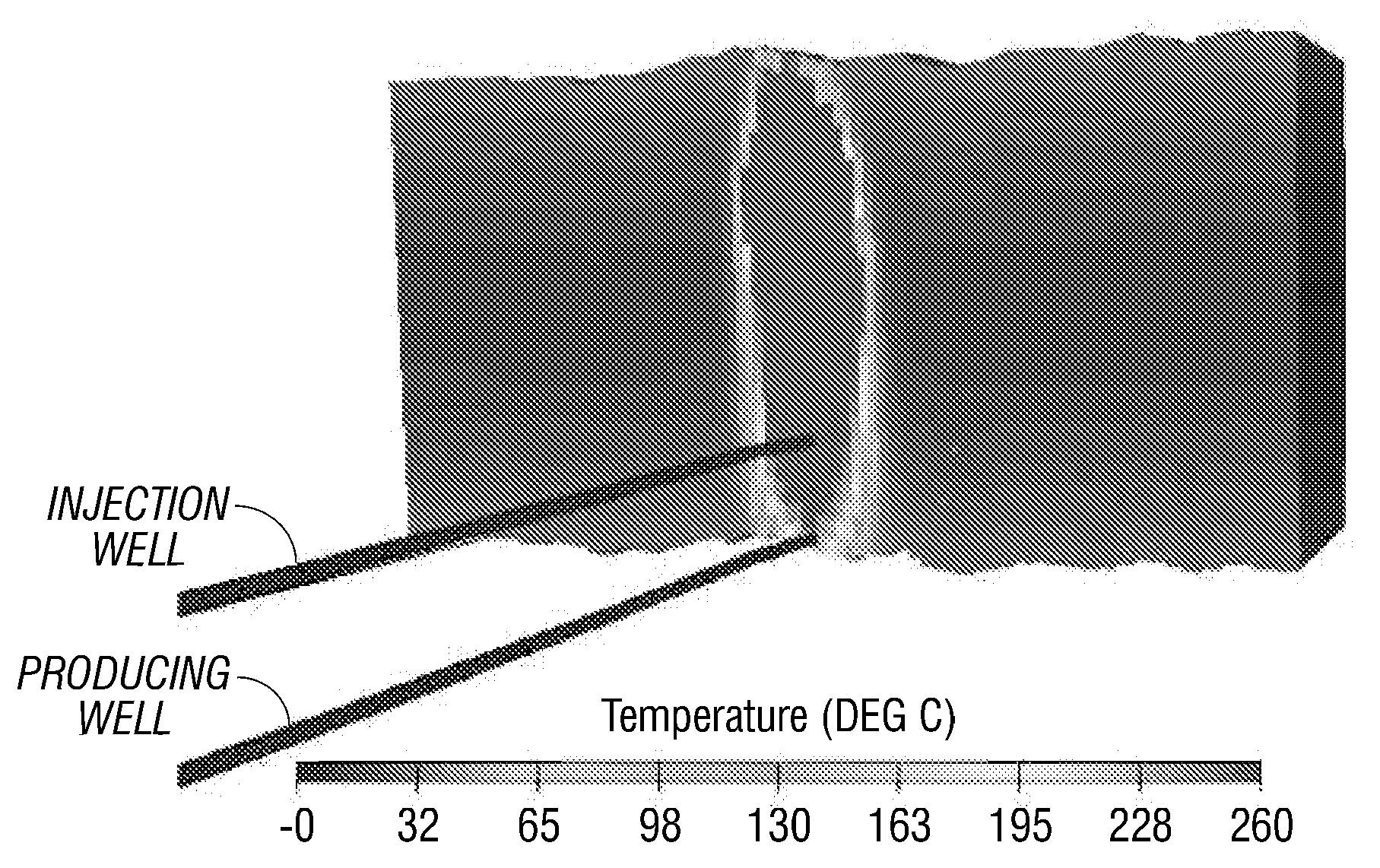

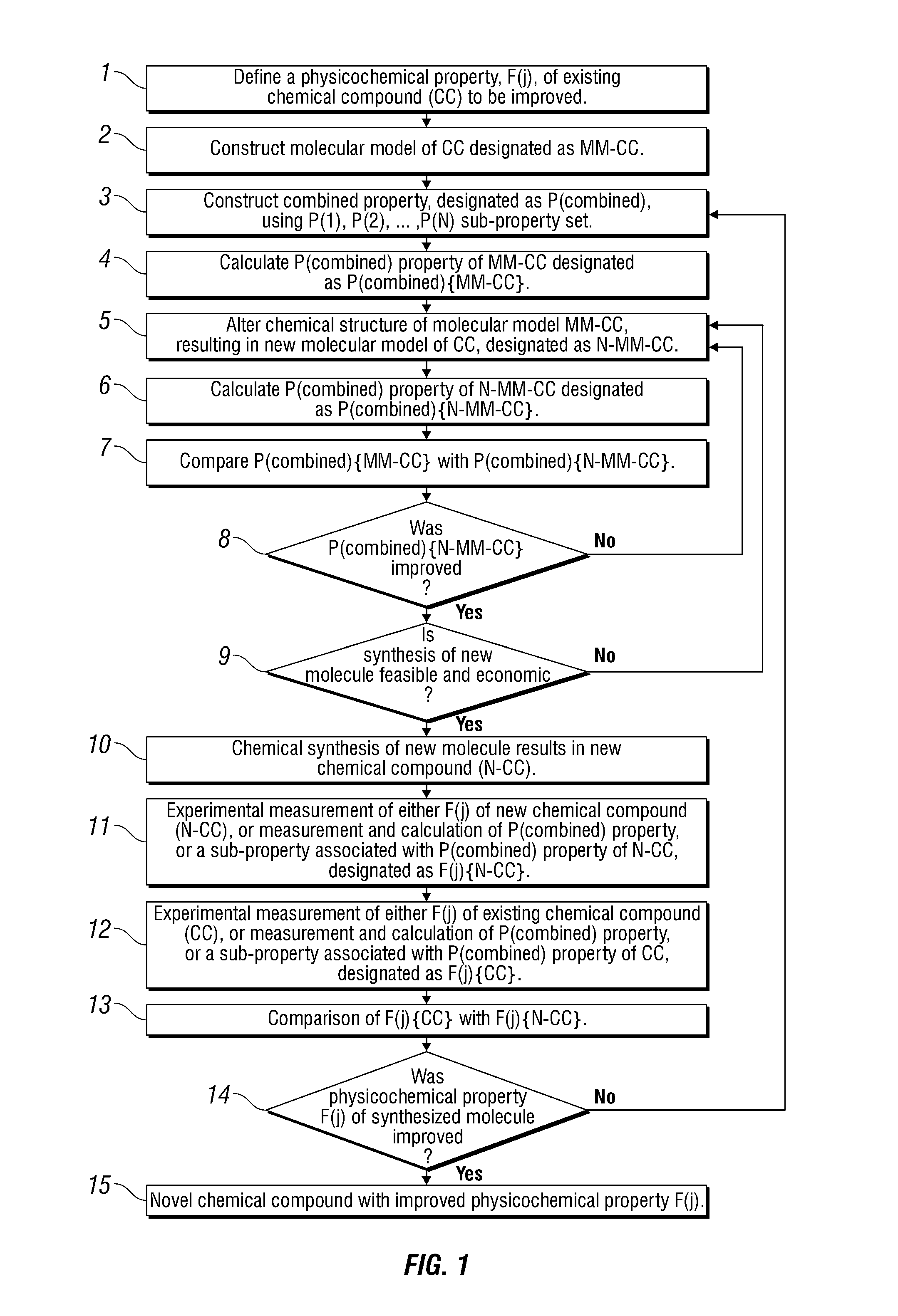

Methods for identifying compounds useful for producing heavy oils from underground reservoirs

InactiveUS20090114387A1Improve developmentImprove efficiencySurveyMaterial analysisCompound (substance)Fuel oil

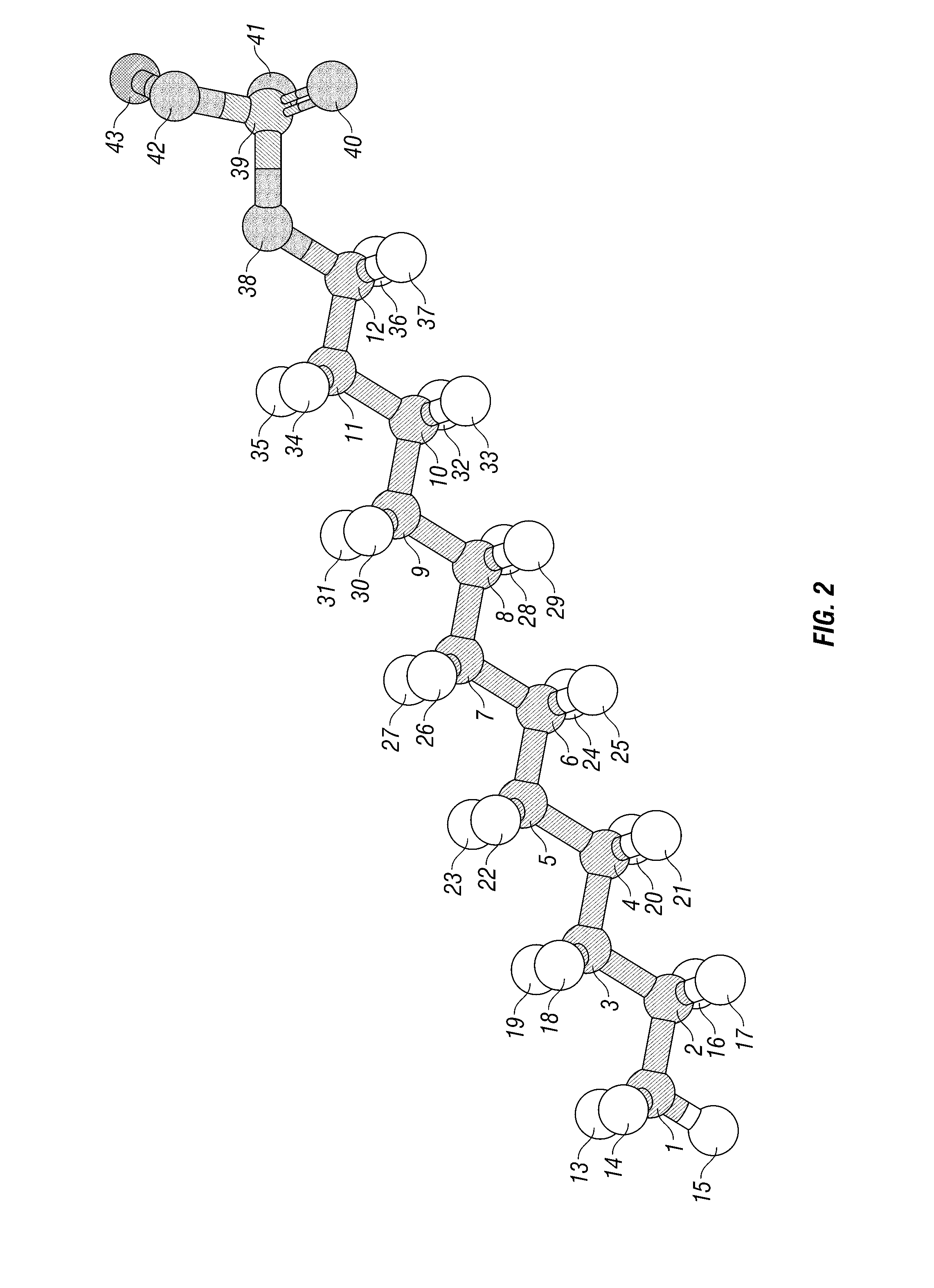

Described herein are methods for identifying compounds useful for producing heavy oil from an underground reservoir. The methods facilitate the development of chemicals with improved physicochemical features. The methods generally involve first identifying a physicochemical property of a compound that needs to be improved in order to increase the efficiency of heavy oil removal from underground reservoirs. Next, the physicochemical property is calculated by molecular modeling using semi-empirical or ab-initio calculations. By modifying the molecular model of the compound, the targeted physicochemical property can be optimized. After a suitable compound has been identified, the compound can be synthesized and evaluated.

Owner:SCHLUMBERGER TECH CORP

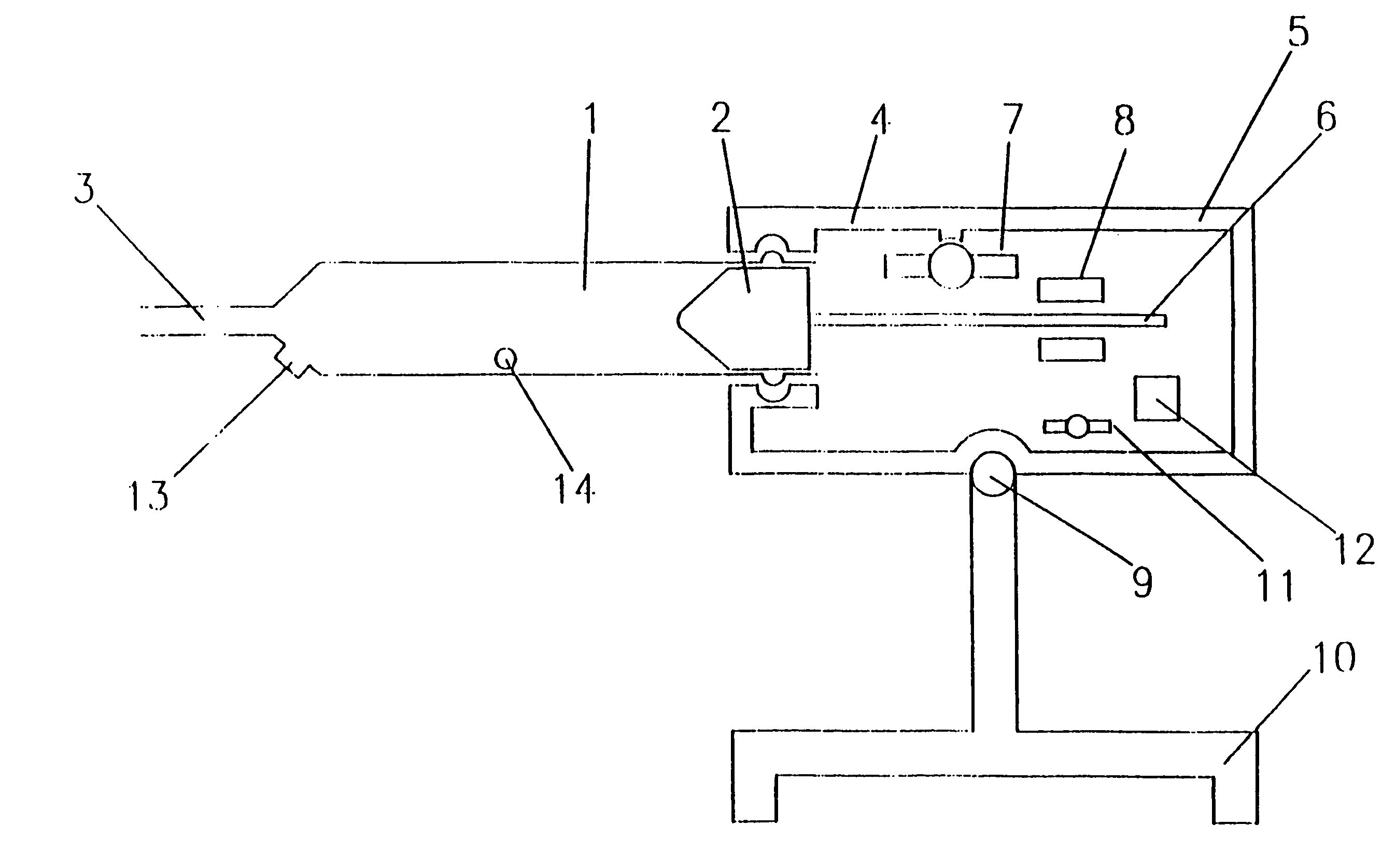

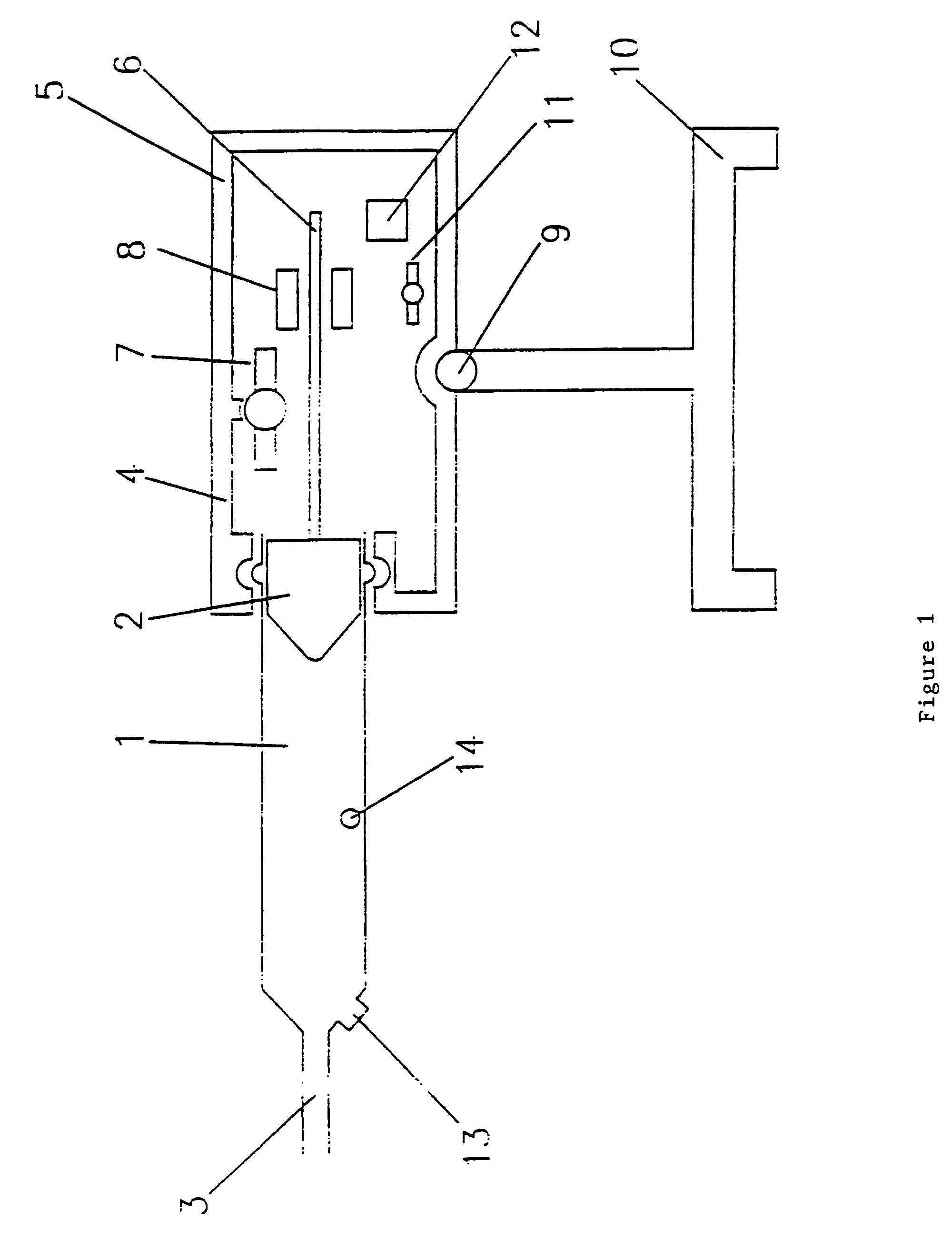

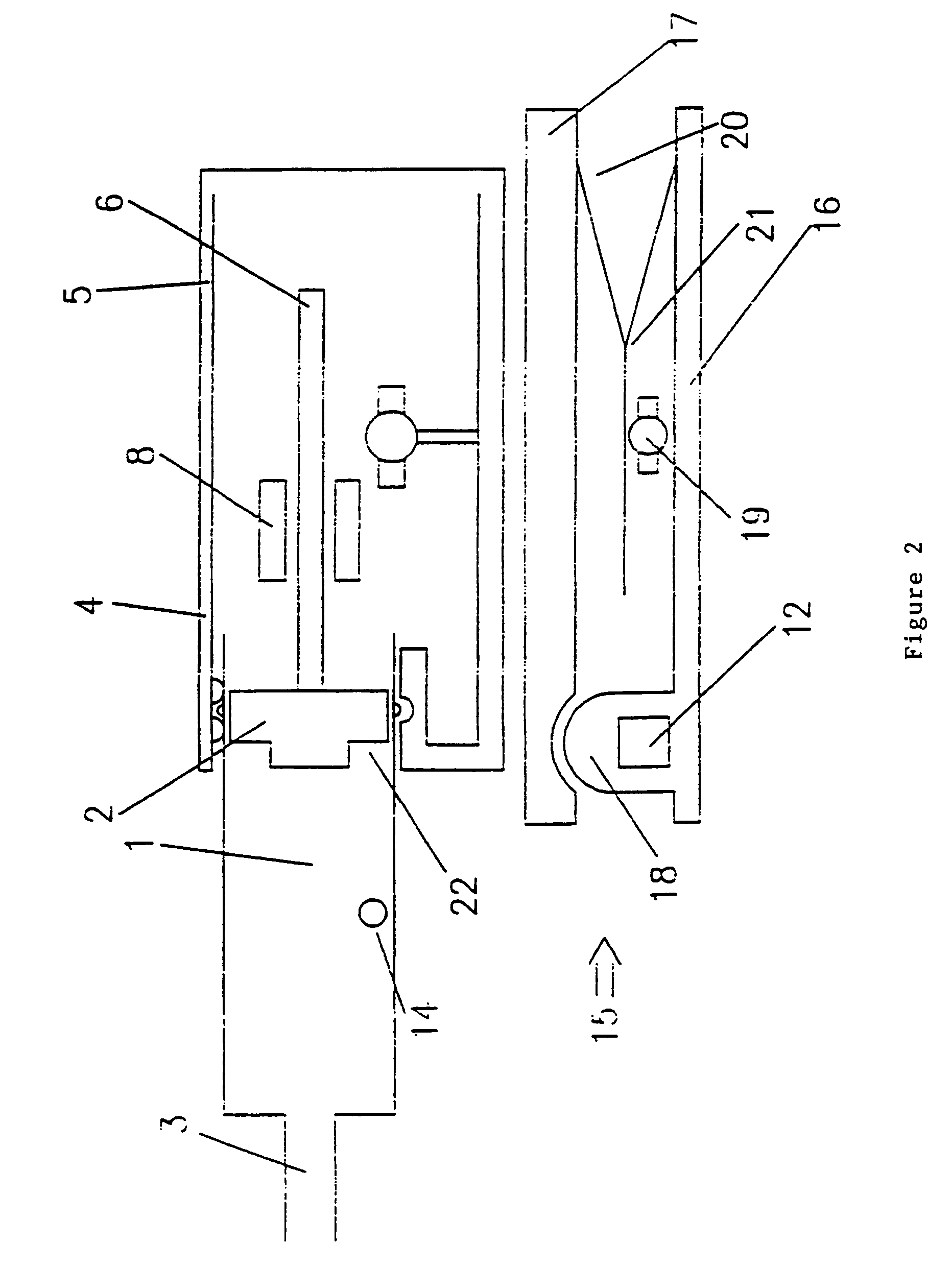

Syringes and injectors incorporating mechanical fluid agitation devices

InactiveUS6966894B1Property damageImprove attributesShaking/oscillating/vibrating mixersTransportation and packagingUltrasound contrast mediaBiomedical engineering

A syringe for use with an injector includes a body comprising a distal discharge end, a plunger movably disposed within the body, and an agitation element disposed within the body between the plunger and the distal discharge end. A movement mechanism is operably associated with the injector to move the syringe in such a way that the at least one agitation element agitates a fluid contained in the syringe. Preferably, the syringe contains an ultrasound contrast agent that is agitated by the agitation element. An injector system and a method for agitating the contents of a syringe are also provided.

Owner:SCHERING AG

Multi-layer high moisture barrier polylactic acid film

ActiveUS20130143057A1Excellent gas barrier performanceImprove barrier propertiesLiquid surface applicatorsPig casting plantsEmulsionMoisture barrier

Owner:TORAY PLASTICS (AMERICA) INC

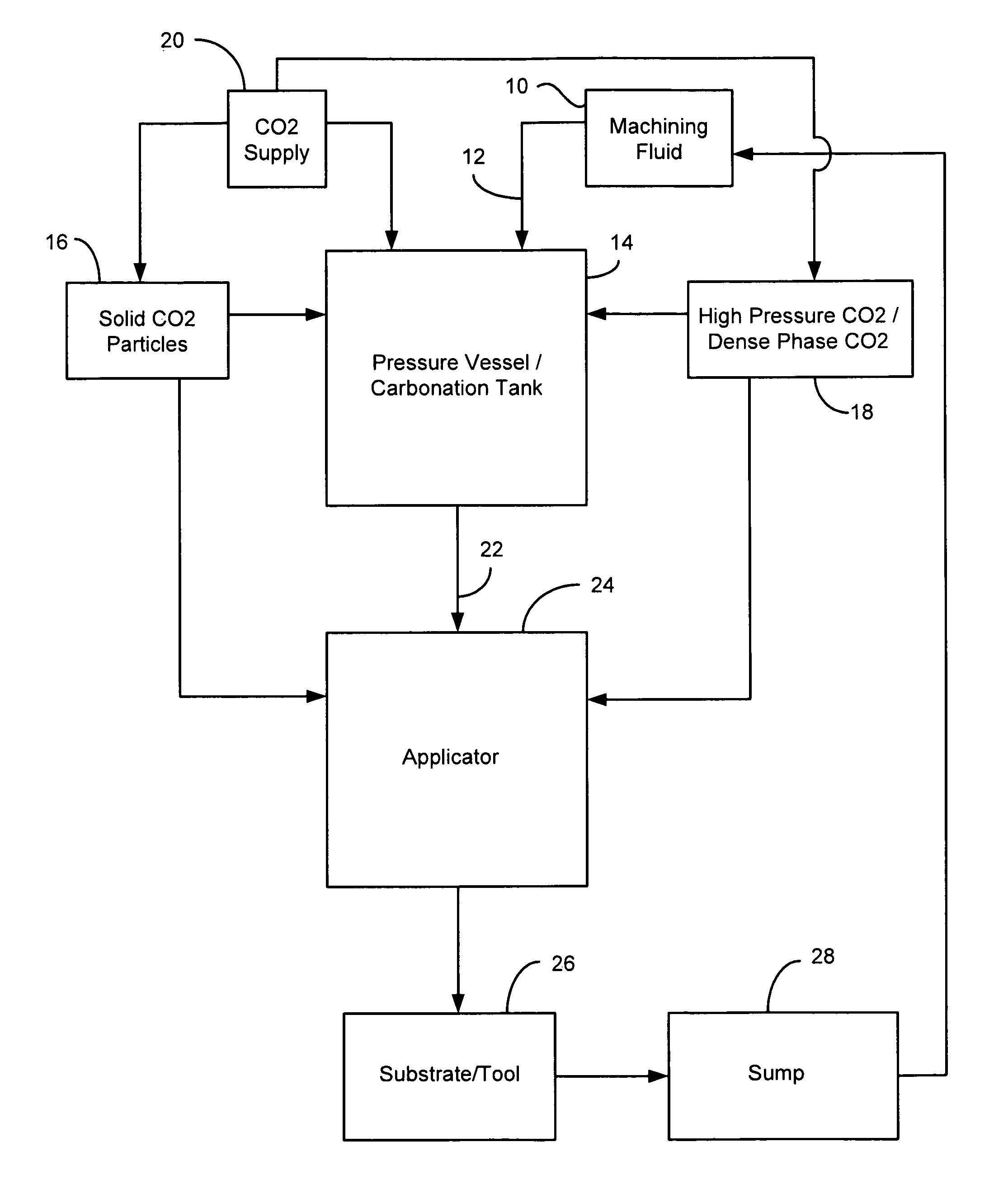

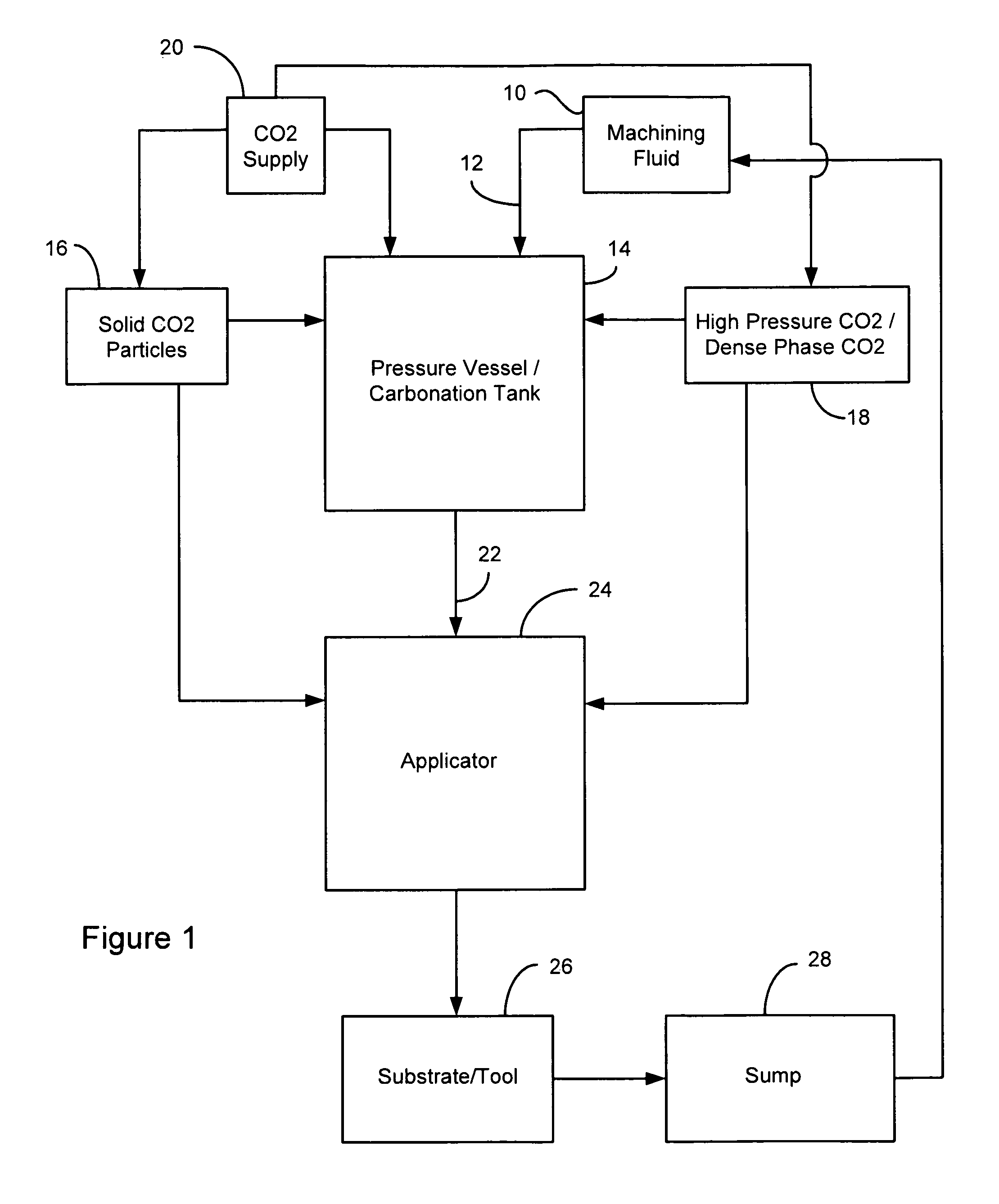

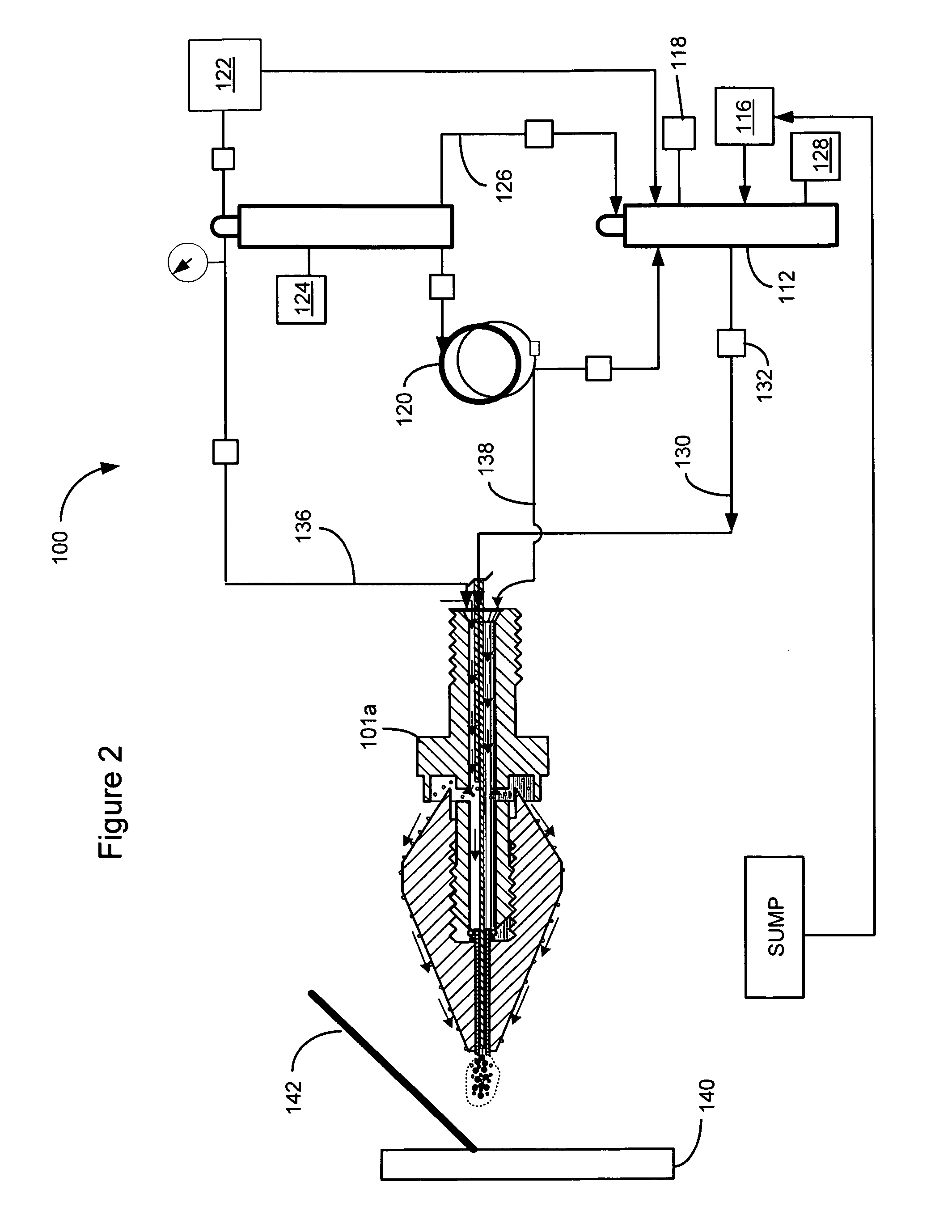

Method of forming and using carbonated machining fluid

ActiveUS8048830B1Optimization propertiesBeneficial change in flow and penetration and heat transfer qualityAdditivesMaintainance and safety accessoriesEngineeringMachining process

A method of forming and delivering a carbonated machining fluid to be used in a machining process, the machining process including a tool contacting a substrate, comprises supplying a pressure vessel with a non-carbonated machining fluid and non-supercritical carbon dioxide. The machining fluid and carbon dioxide are allowed to admix such that at least a portion of the carbon dioxide dissolves into the machining fluid to form the carbonated machining fluid. The carbonated machining fluid is then delivered under pressure from the vessel to an applicator and applied to the tool or the substrate to impart cooling and lubricating effects.

Owner:COOL CLEAN TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com