Patents

Literature

284 results about "Machining fluid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Function of cutting fluid in Machining: The cutting fluid cool the tool and workpiece. When the heat produced during the machining operation is carried out by the fluid. The cutting fluid lubrication of cutting tool and reduce the coefficient of friction in between work and tool.

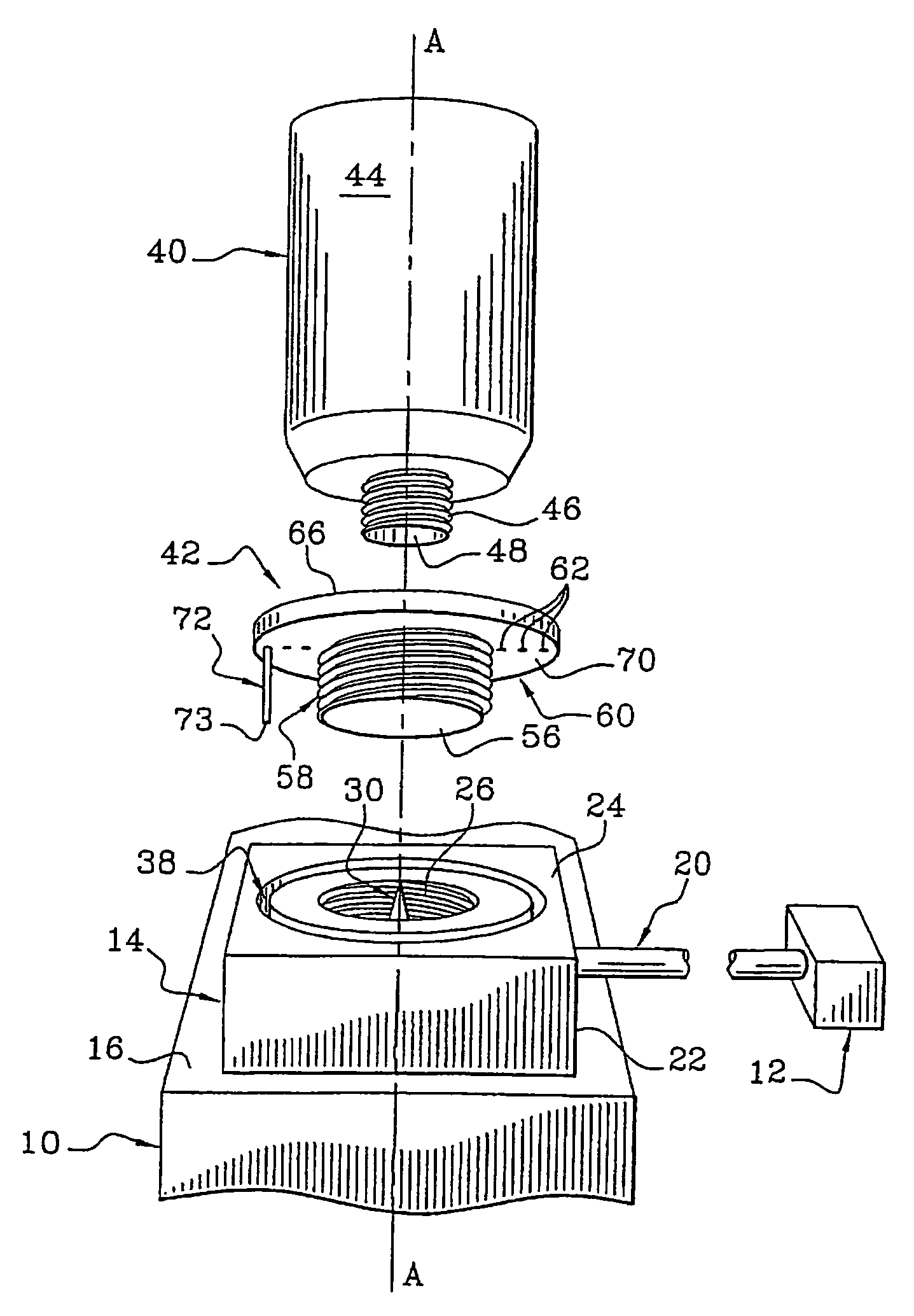

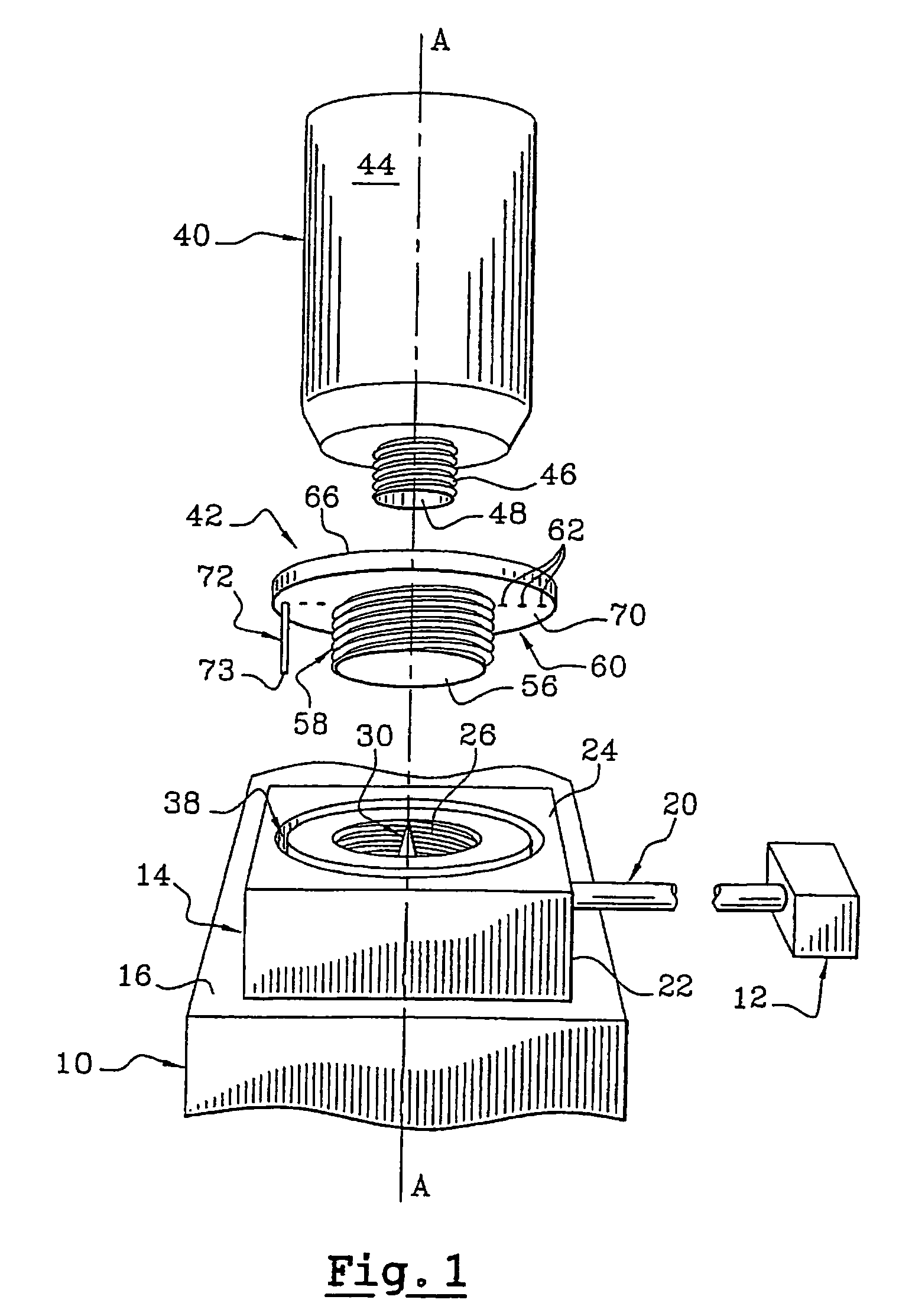

Machine fluid supply assembly comprising keying means

The invention relates to a fluid supply assembly for a device, particularly a printing machine. The assembly includes a lower base and is of the type in which the fluid is conditioned in an upper container which is intended to be connected to a fill opening in the base by a coupling. In order to mount the coupling on the base, the coupling is moved linearly along a vertical assembly axis and then pivoted around the assembly axis. The coupling has at least one keying pin which is received in a complementary groove in one face of the base when the coupling is being moved linearly. The invention also relates to a printing machine containing one such assembly.

Owner:GEMPLU

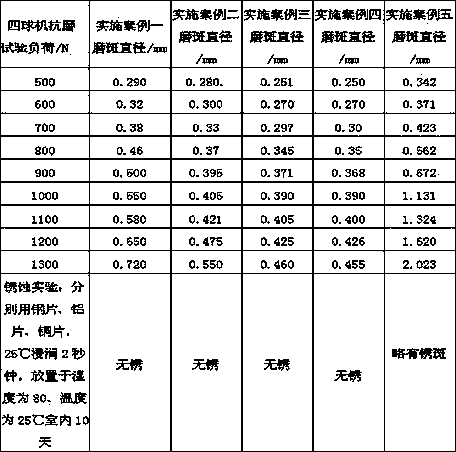

Preparation of metal working fluid special for aluminum alloy

InactiveCN101696367AExcellent lubricity and protection against aluminumExcellent corrosion protectionLubricant compositionCorrosionSemi synthetic

The invention relates to a semi-synthetic metal working fluid special for aluminum and aluminum alloys, which has an excellent lubricating property and protective properties for aluminum and various aluminum alloys. The excellent lubricating property of the metal working fluid is manifested by simultaneously satisfying various processing modes of the aluminum alloys, such as turning, milling, drilling, tapping and the like. The excellent protective properties for the aluminum and the aluminum alloys are manifested by processing various aluminum alloys, generating no corrosion to the aluminum alloys and ensuring the requirements on the luminance brightness of the aluminum alloys. Besides, the metal working fluid also has excellent anti-rust properties and anti-foaming properties, and is added with a biological inhibitor which can effectively inhibit the growth and the reproduction of bacteria, prolong the service life of the metal working fluid and reduce the cost.

Owner:益田润石(北京)化工有限公司

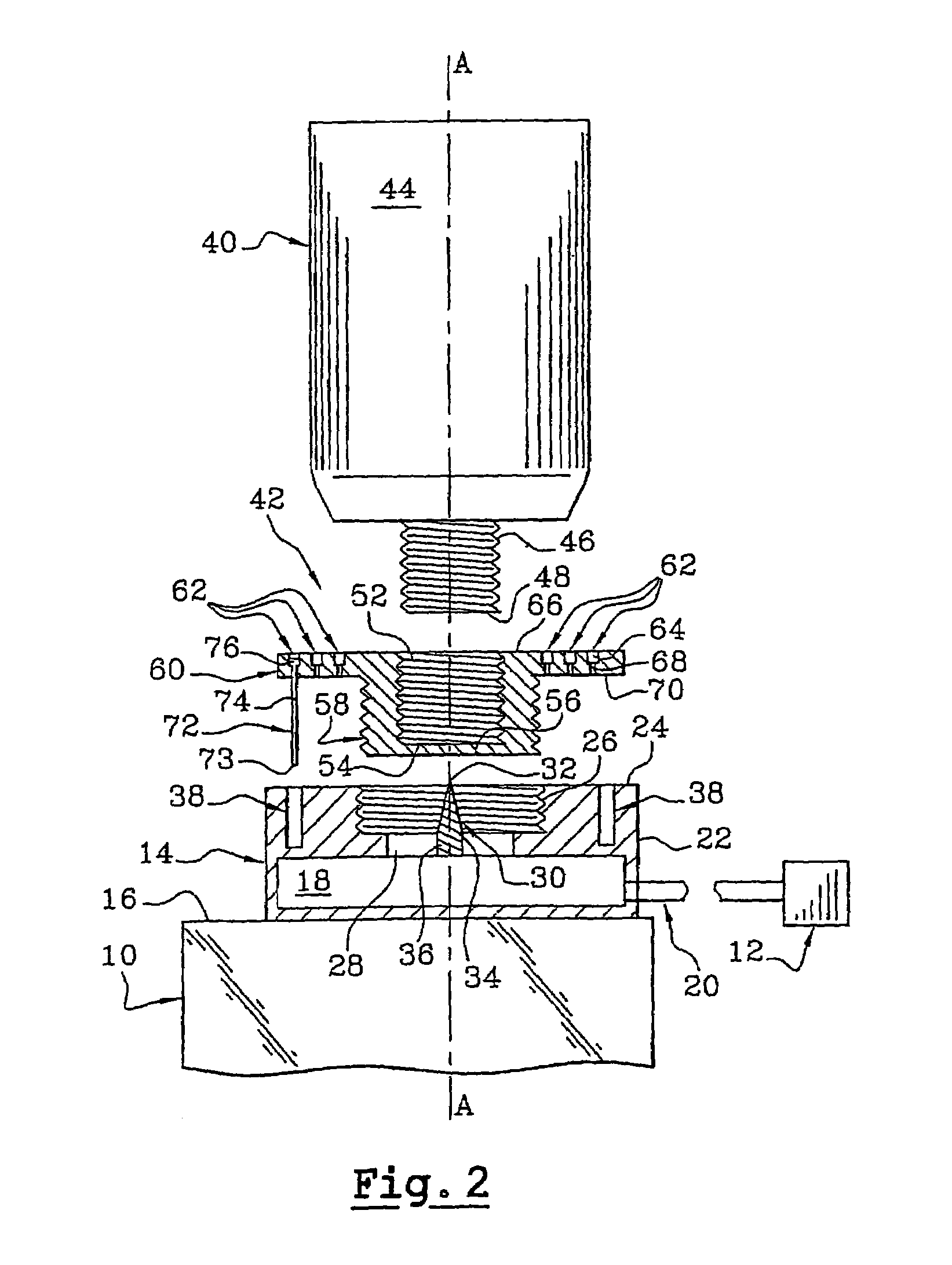

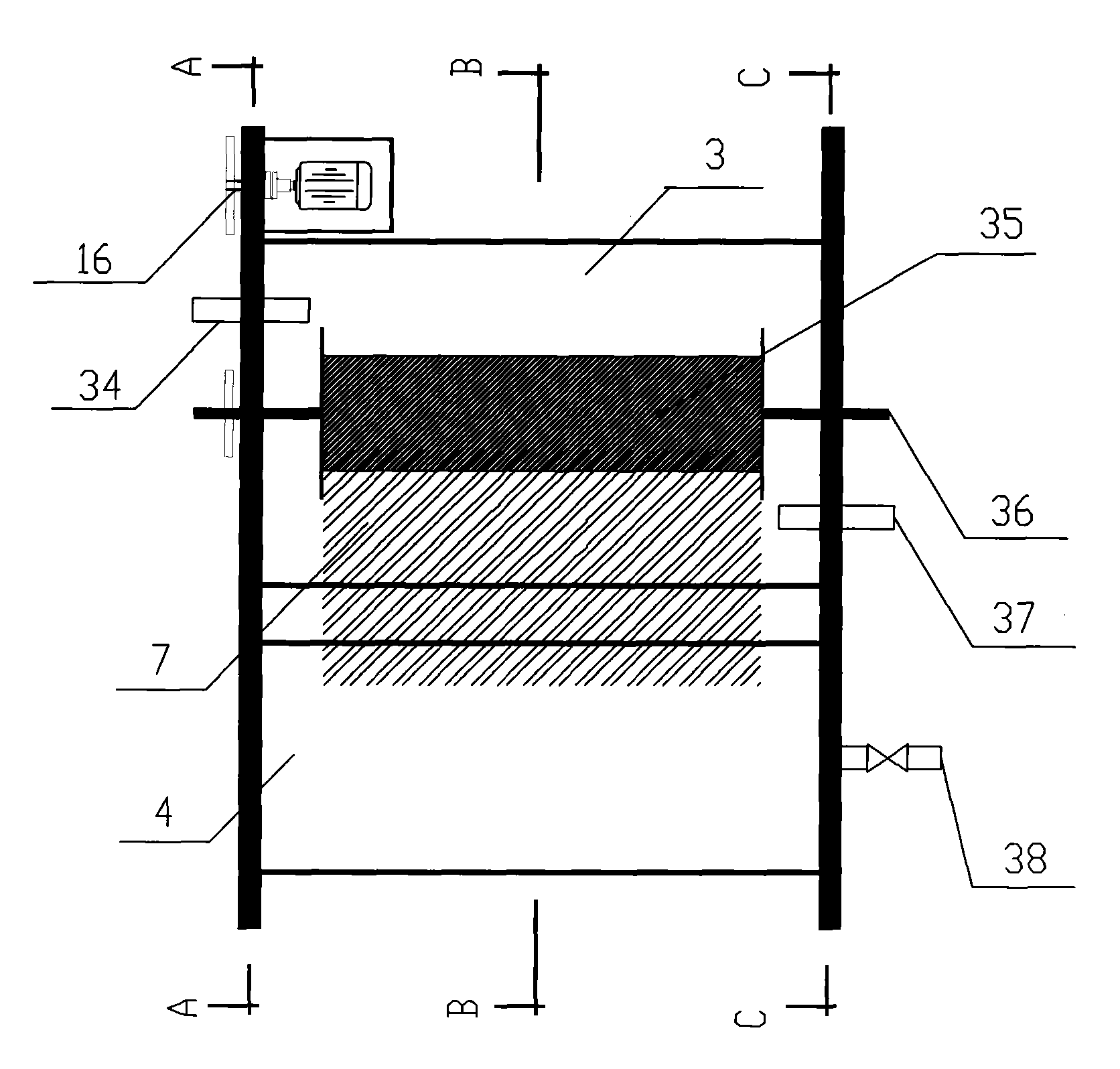

On-line purification equipment for metal machining fluid and purification method thereof

InactiveCN101575153AAchieve purification effectRealize the use effectWater/sewage treatment by magnetic/electric fieldsWaste water treatment from metallurgical processLiquid wastePurification methods

The invention discloses on-line purification equipment for a metal machining fluid and a purification method thereof. The equipment comprises a purification fluid tank, a stock solution tank, a magnetic separation pool, a magnetic slag tank, a drum type multi-stage magnetic separation device, a gas-liquid mixing pump, an ozone generator, an ozone copolymerization air-float sterilization separation device and a Y-shaped water outlet pipe, wherein the drum type multi-stage magnetic separation device adopts a drum-shaped structure, the inner wall of the drum is embedded with a plurality of same permanent magnets at certain intervals along the same axial direction; and the inside of the ozone copolymerization air-float sterilization separation device is orderly provided with a grid, a baffle plate and an ozone contact generator from bottom to top, and the upper part of the ozone contact generator is a separation zone. The method comprises the main steps of magnetic separation, gas dissolution, sterilization and water and slag discharge. The method has the advantages of realizing the on-line circular purification and use of the machining fluid, prolonging the service life of the machining fluid, greatly reducing the amount of waste fluid generated and achieving the aims of water conservation, emission reduction and clean production.

Owner:DALIAN JIAOTONG UNIVERSITY

Machining fluid and method of machining

InactiveUS6316394B1Resists oil contaminationImprove the immunityWork treatment devicesAdditivesWater dispersiblePhosphate

A synthetic aqueous machining fluid admixture, that is free of sulfur containing and chlorine containing lubricants, and usable in heavy duty machining (e.g. stamping, punching and drawing) operations comprises a) water, b) a water soluble or dispersible fatty acid or water soluble or dispersible fatty acid salt, c) a water soluble or dispersible ethylene oxide propylene oxide copolymer having at least one terminal hydroxyl group or water soluble or dispersible derivative of an ethylene oxide propylene oxide copolymer and d) a water soluble or dispersible organic phosphate ester. Methods for heavy duty machining comprise the steps of applying a force to a workpiece by a tool contacting the workpiece and applying the synthetic aqueous fluid admixture to the interface between the tool and workpiece. The fluid exhibits safety and environmental advantages in use compared to prior art fluids comprising vanishing oils while providing equal or superior lubricity.

Owner:MILACRON IND PROD

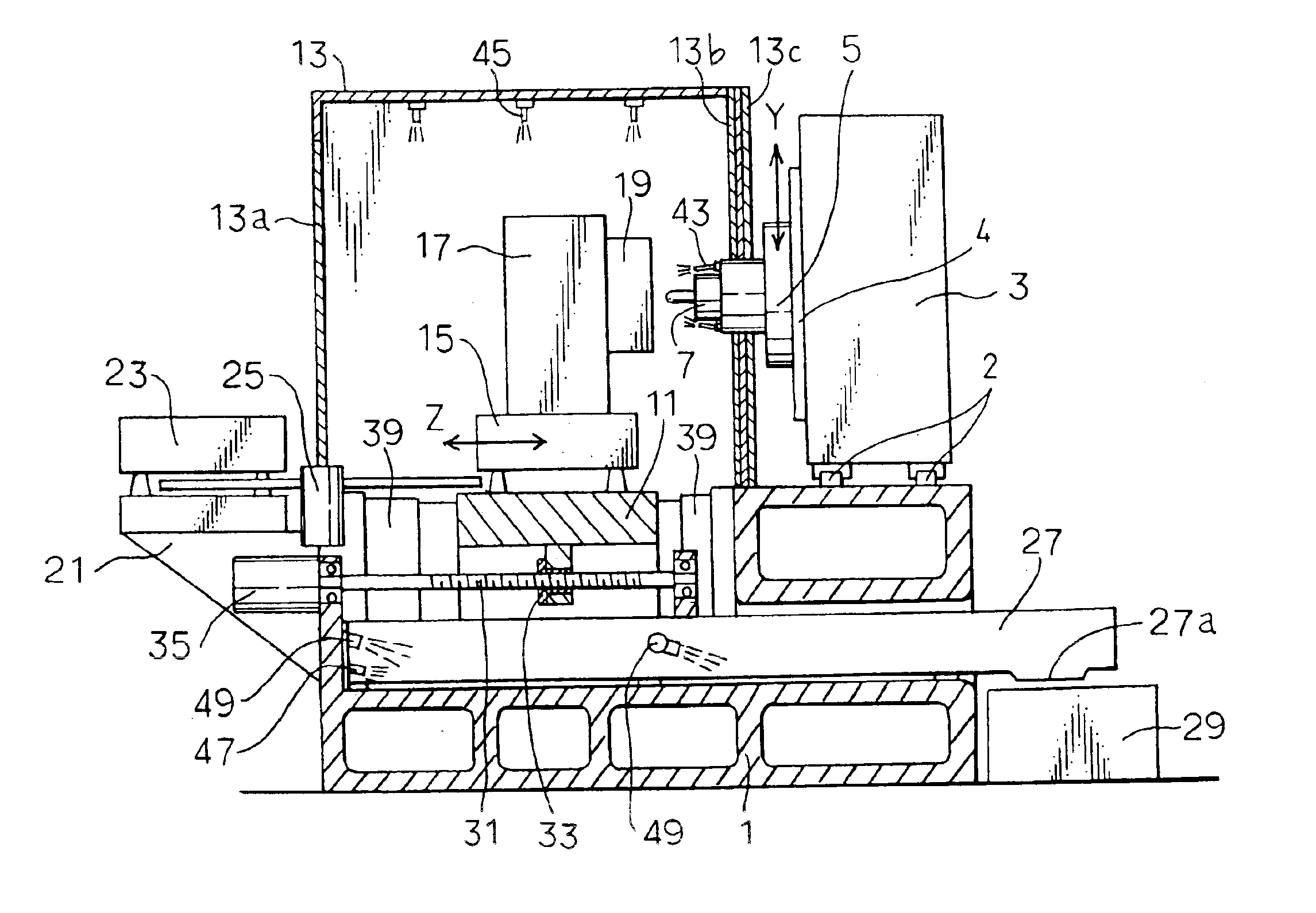

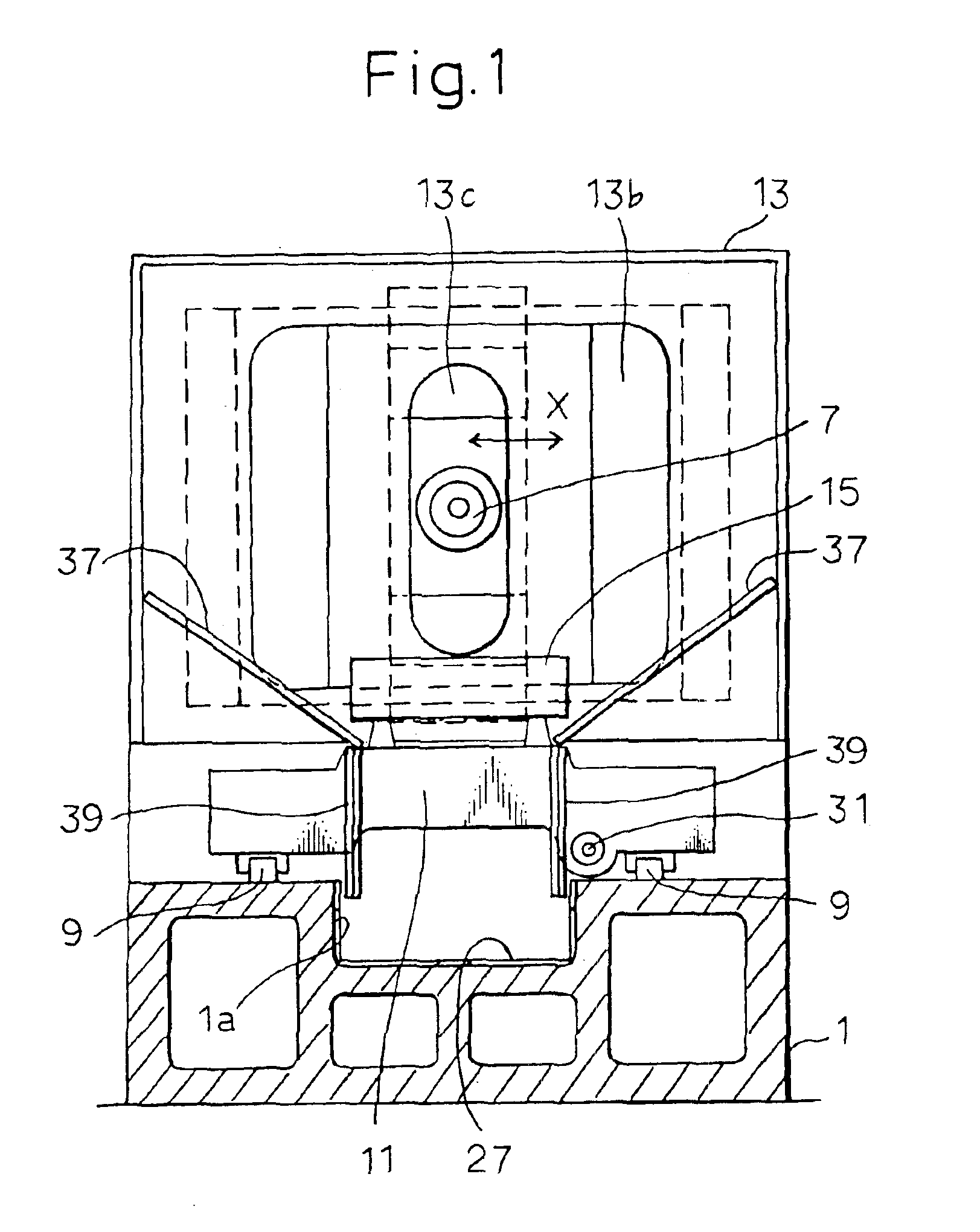

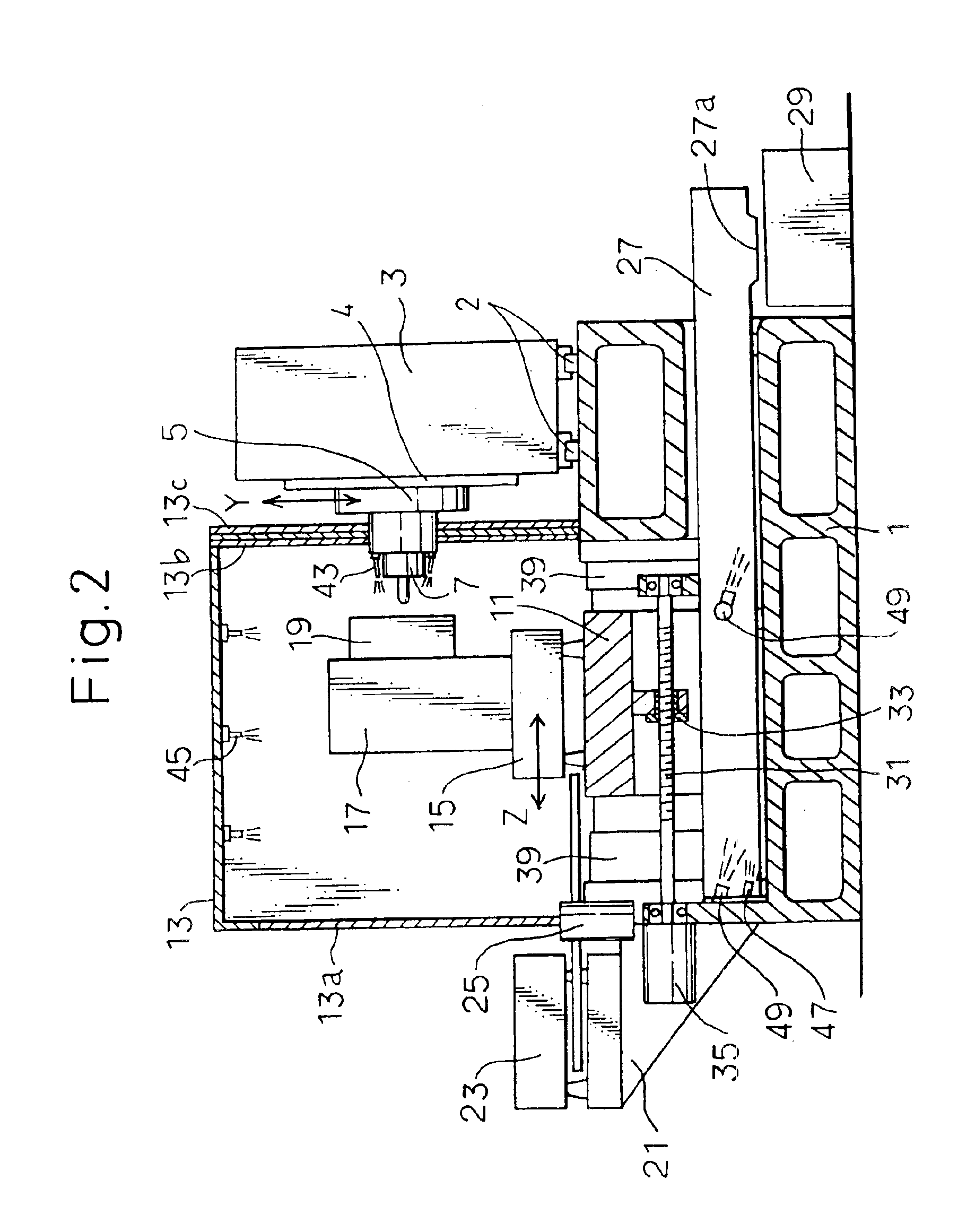

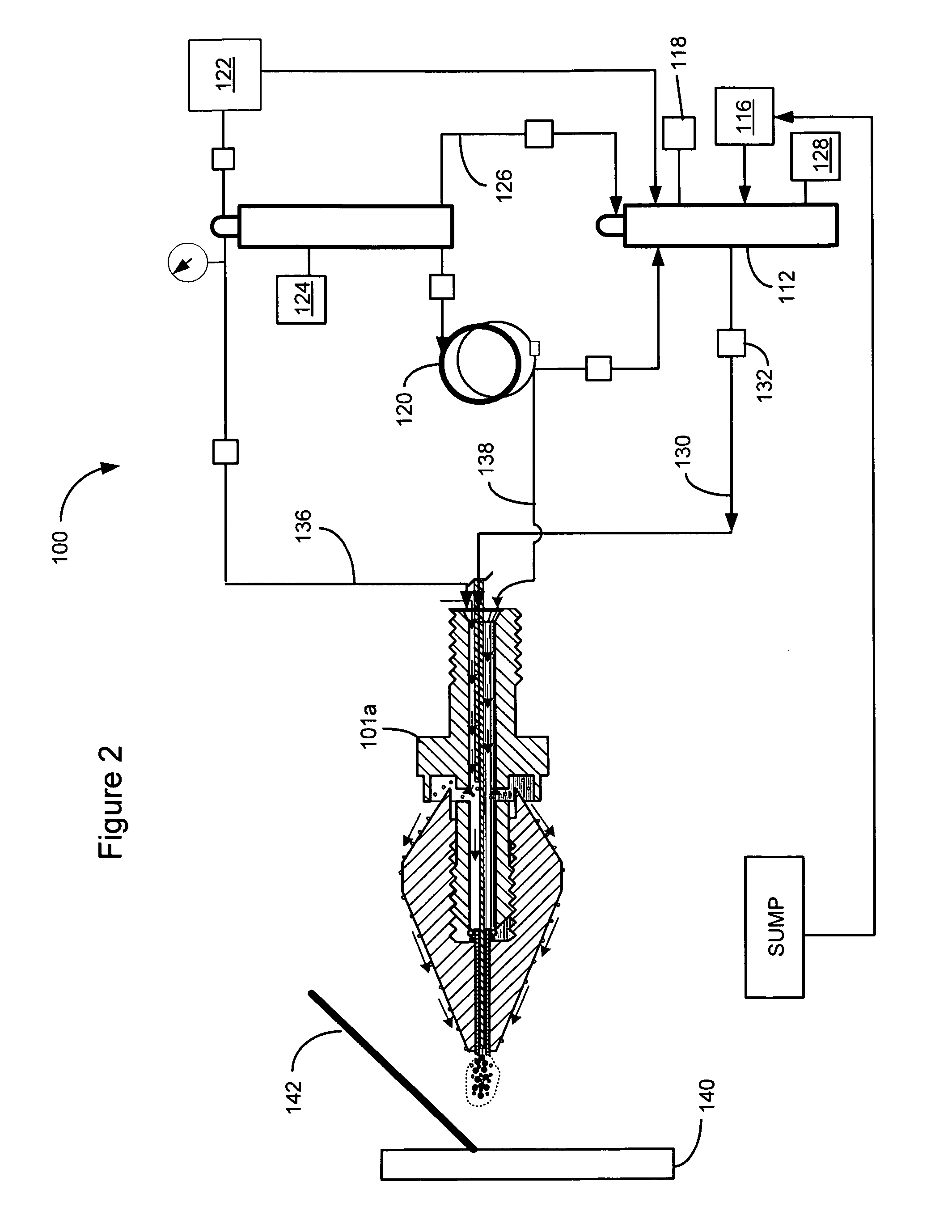

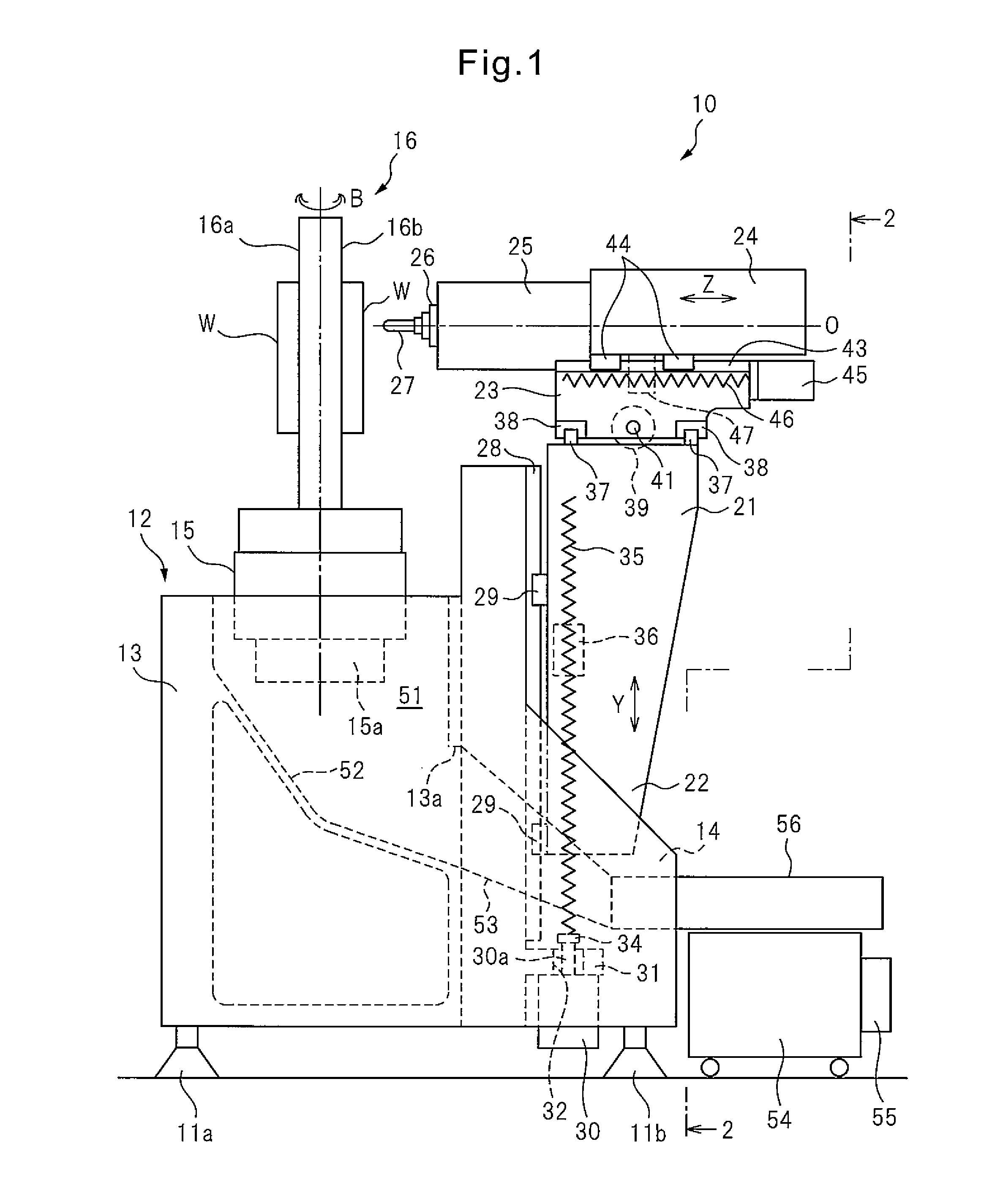

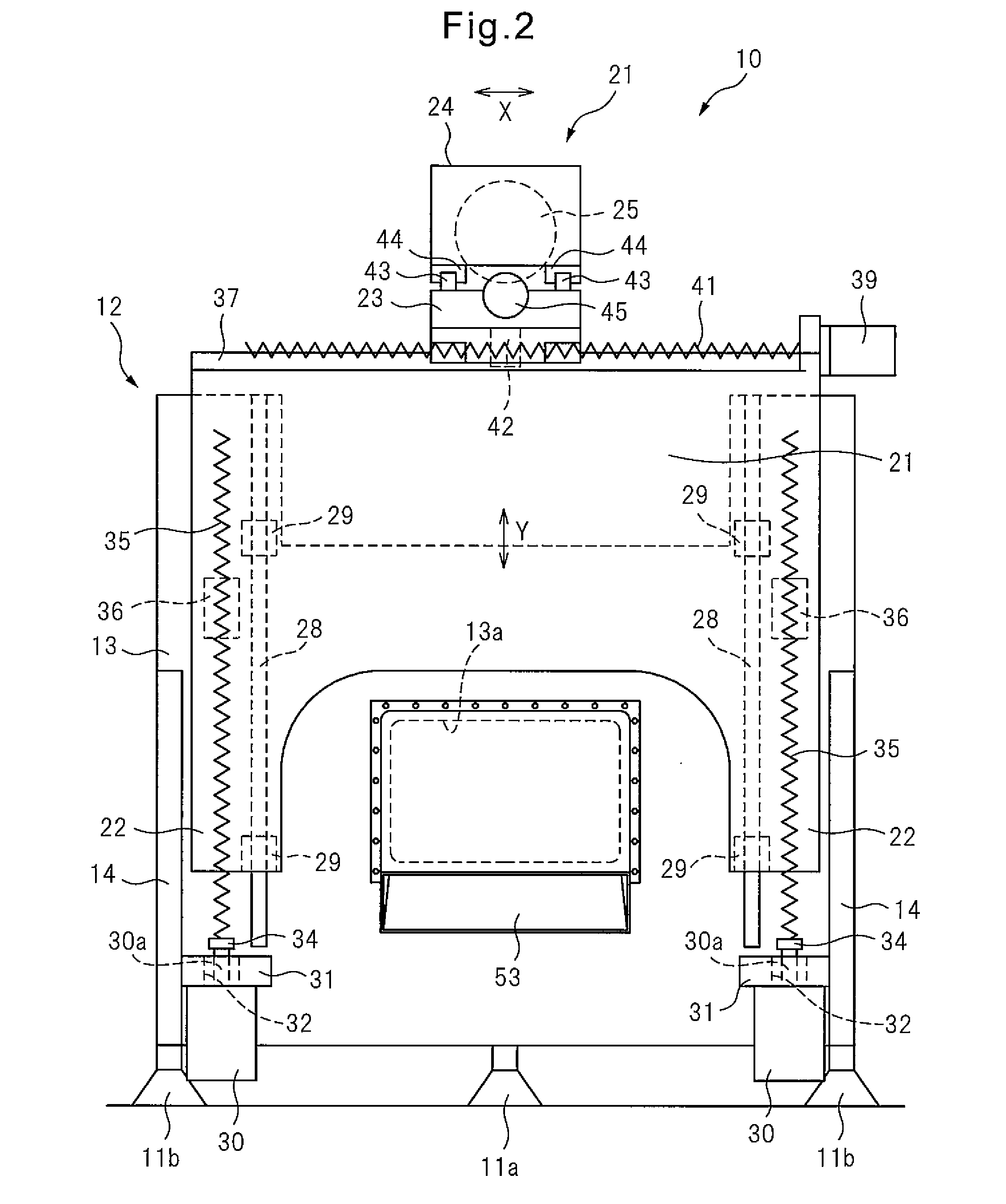

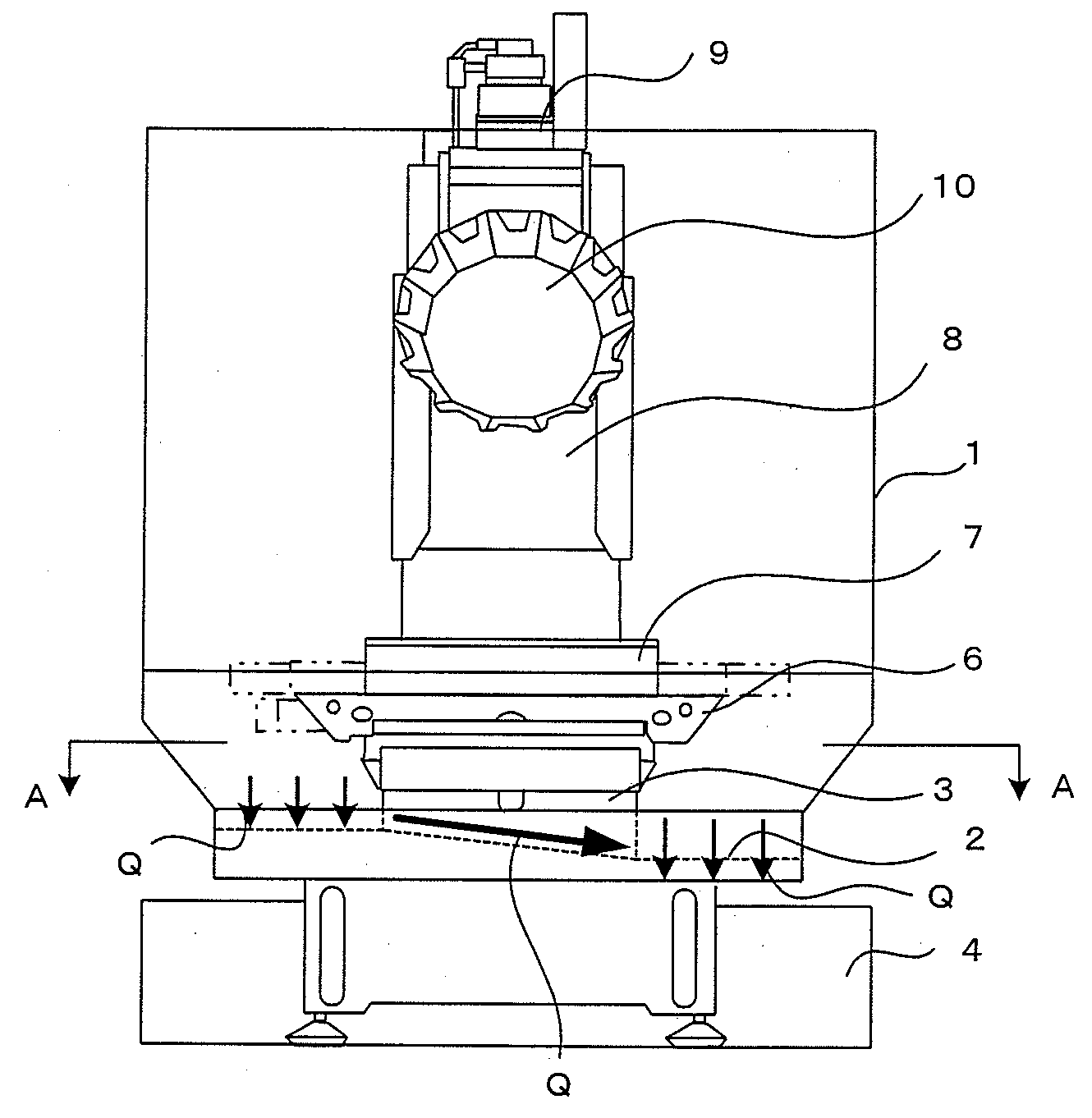

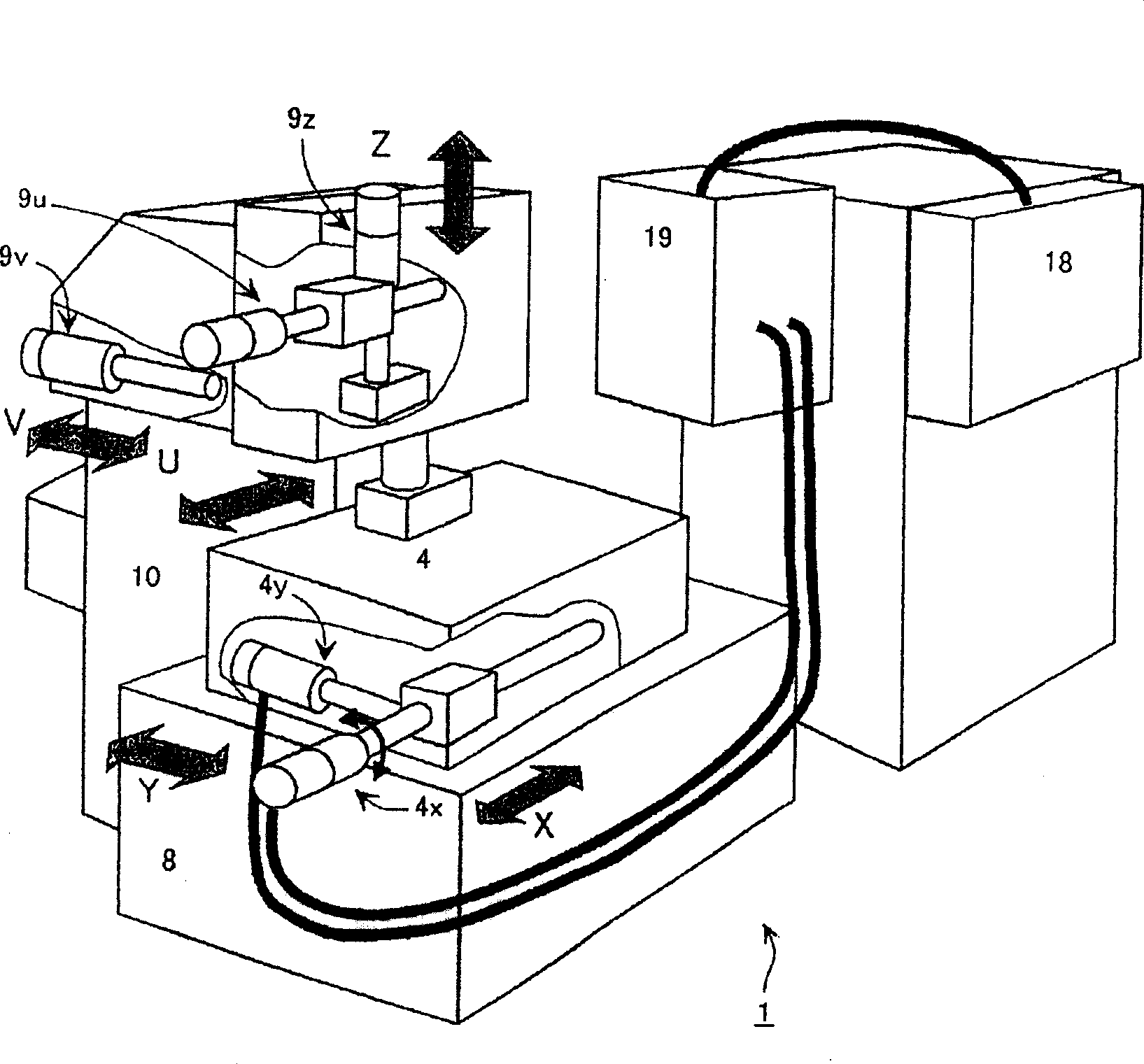

Machine tool

InactiveUS6884009B2Simple configurationEnsures the collection and ejection of the chipsLarge fixed membersMilling equipment detailsEngineeringRelative motion

The invention relates to a machine tool which processes a workpiece through the relative motions between a tool and the workpiece in X-, Y- and Z-axes three directions. The object of the invention is to ensure the collection and ejection of the chips with a simple configuration. The invention comprises a trough 27 provided in the central part of a bed 1 to extend in back-and-forth direction, a pair of guides 9 disposed at left-and-right sides of the trough 27, a Z-axis feed screw 31 disposed adjacent one of the guides 9, and slant covers 37 and Z-axis telescopic covers 39 for covering the pair of guides 9 and the Z-axis feed screw 31. Chip conveyer nozzles 47 and 49 are provided within the trough 27 for directing the machining fluid to eject the chips from the machine.

Owner:MAKINO MILLING MASCH CO LTD

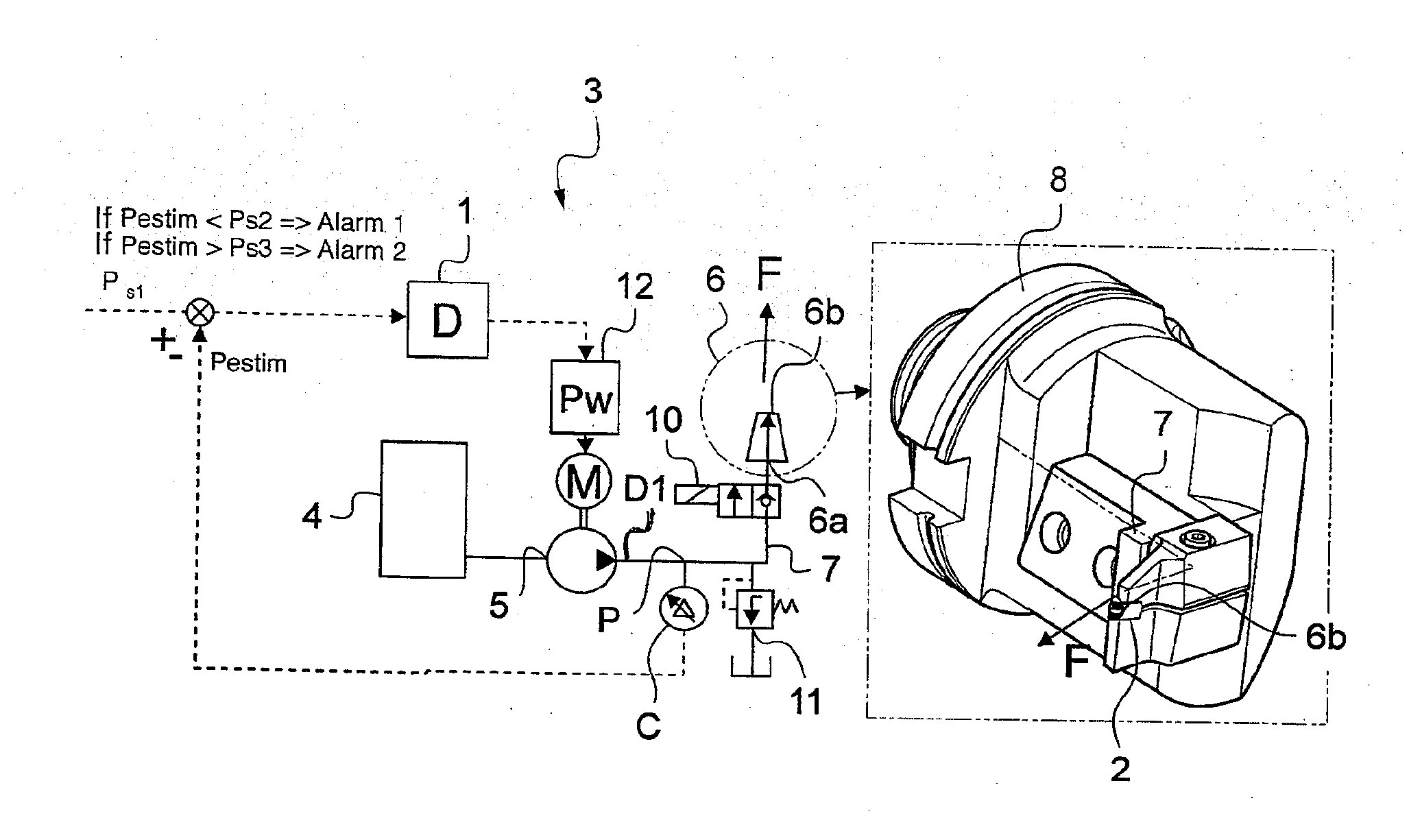

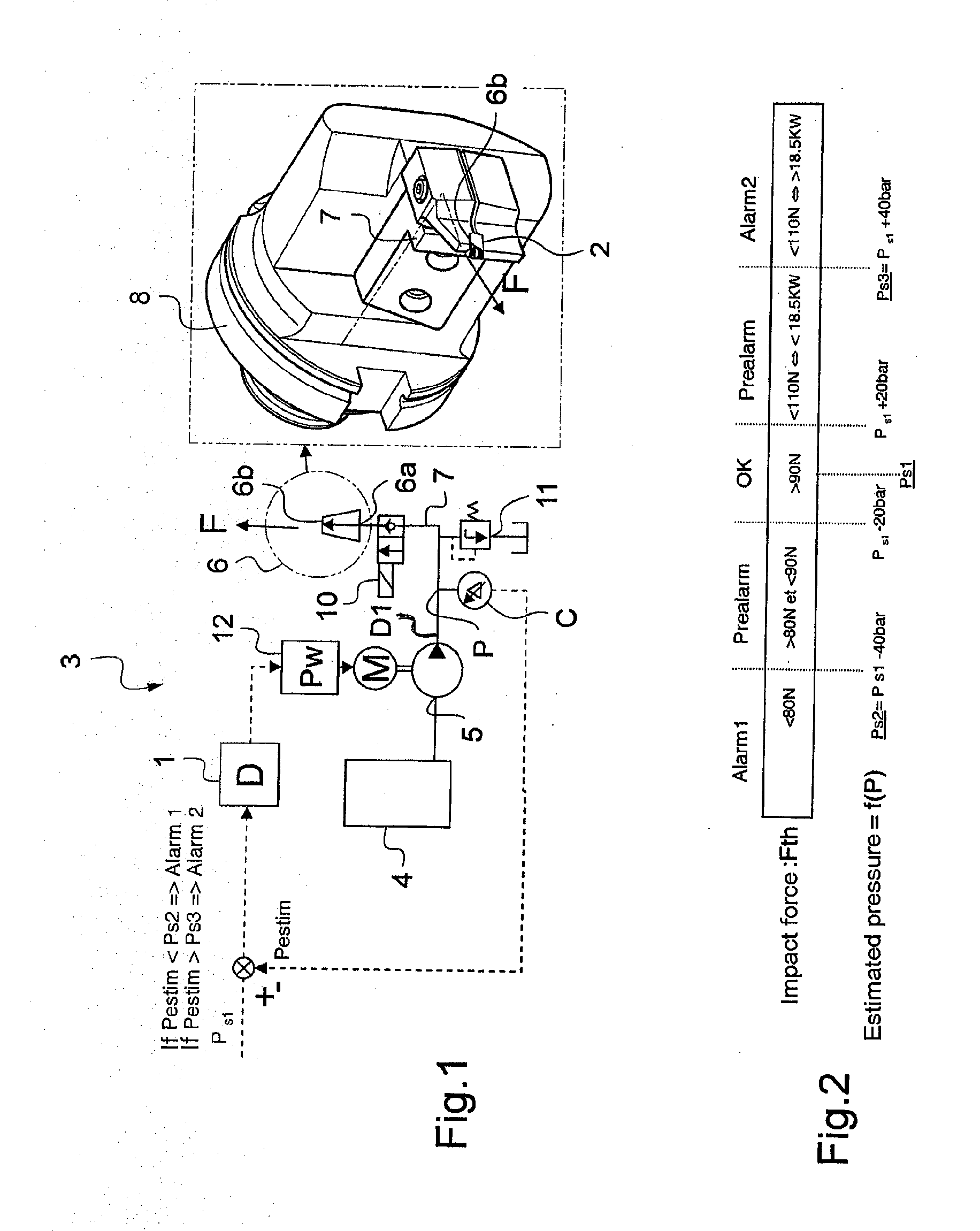

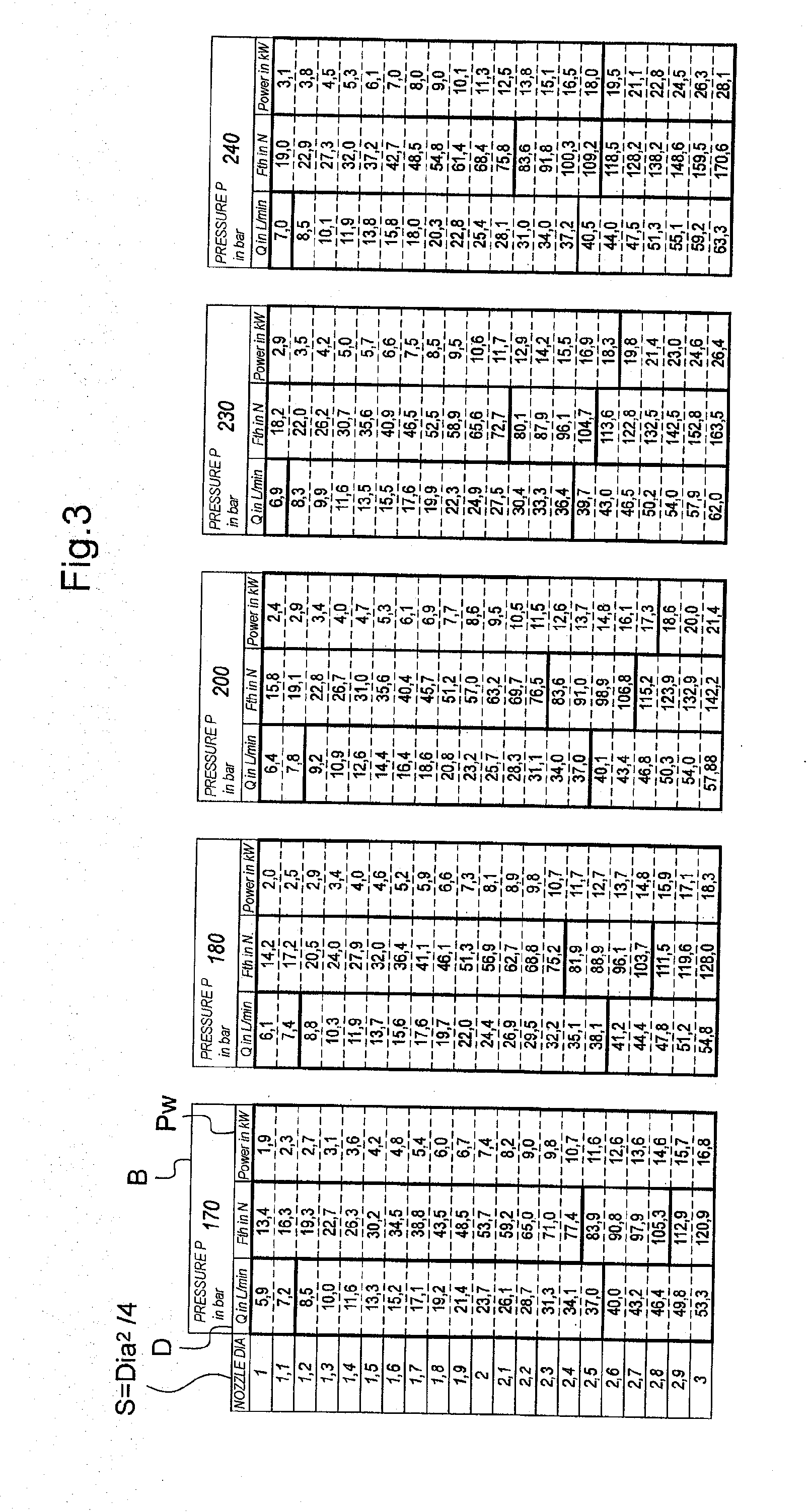

Method of controlling a cooling device for a machine tool

ActiveUS20120245742A1Improve cutting conditionsReduce downtimeMeasurement/indication equipmentsRatio controlEngineeringPressure threshold

A method of controlling a cooling device for cooling a cutting tool in a machine tool. The method comprising the steps of:controlling the motor to drive the pump in such a manner that the pump feeds the nozzle with machining fluid at a constant flow rate D1 that is equal to a first flow rate setpoint;measuring a parameter P representative of a fluid outlet pressure from the nozzle; andcomparing an estimated outlet pressure Pestim as estimated from the parameter P with a first predetermined pressure threshold Ps1, and controlling the motor so as to increase the fluid flow rate D1 as delivered by the pump if the estimated output pressure drops below the first pressure threshold Ps1.

Owner:SAFRAN LANDING SYSTEMS

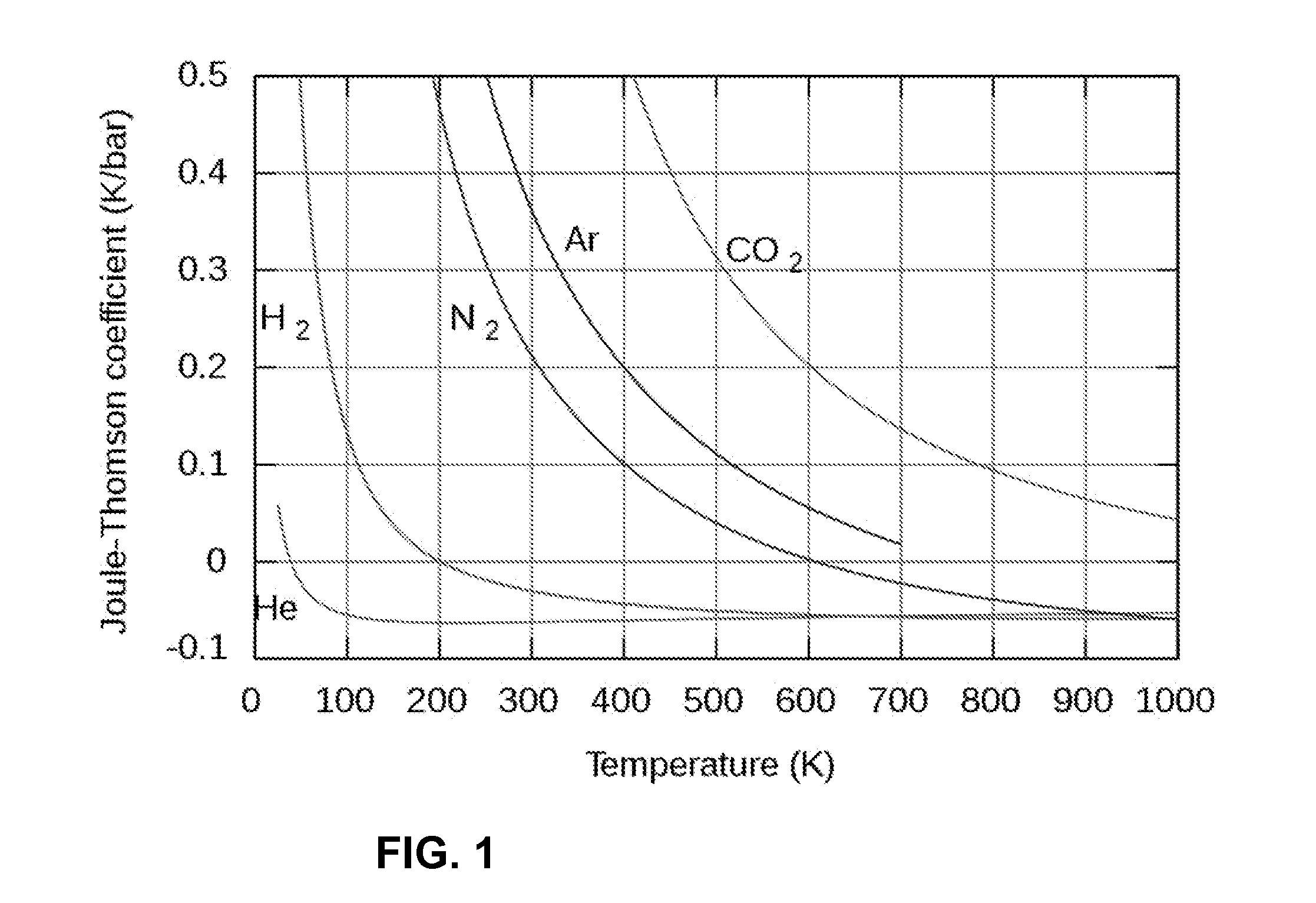

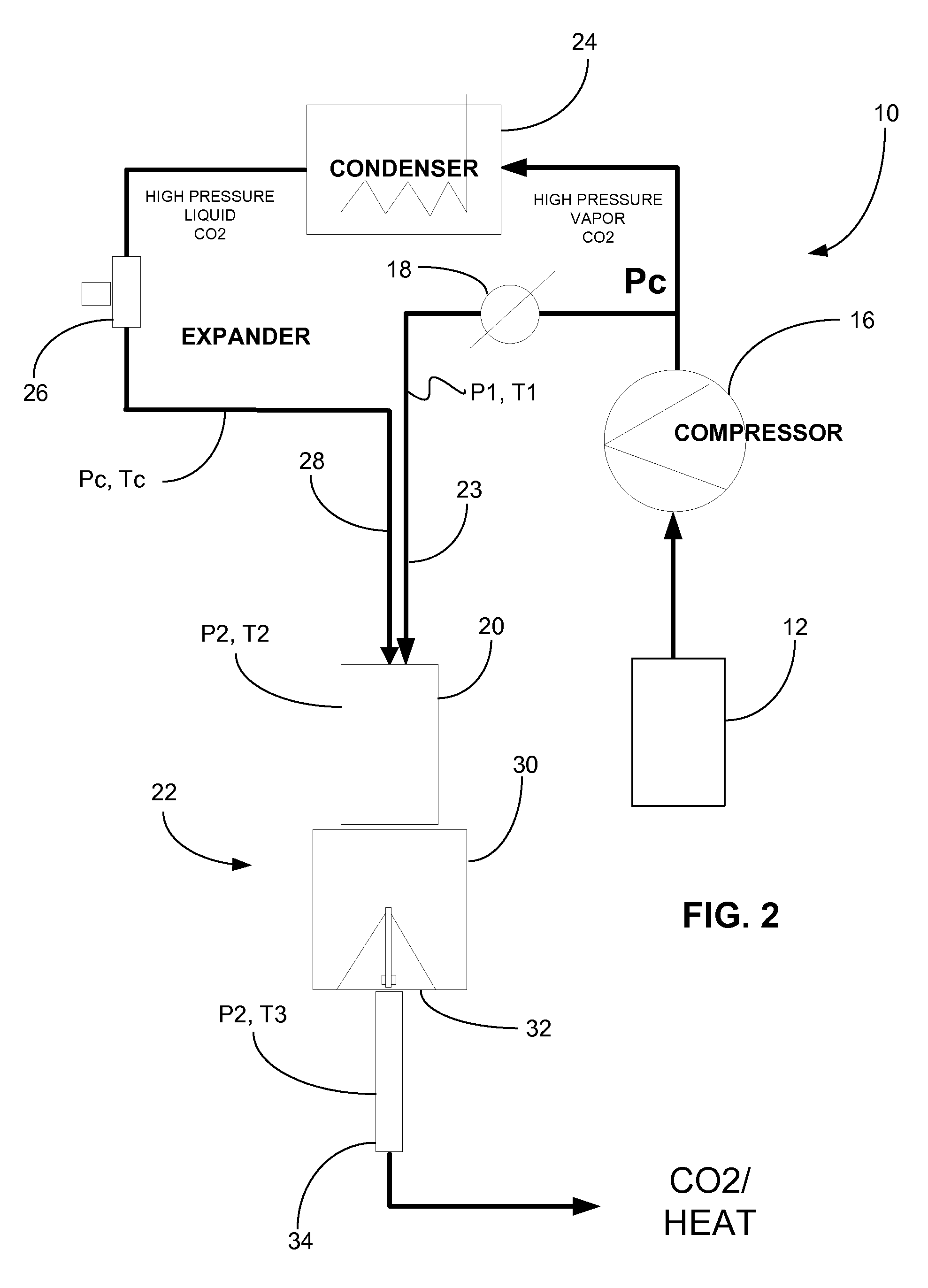

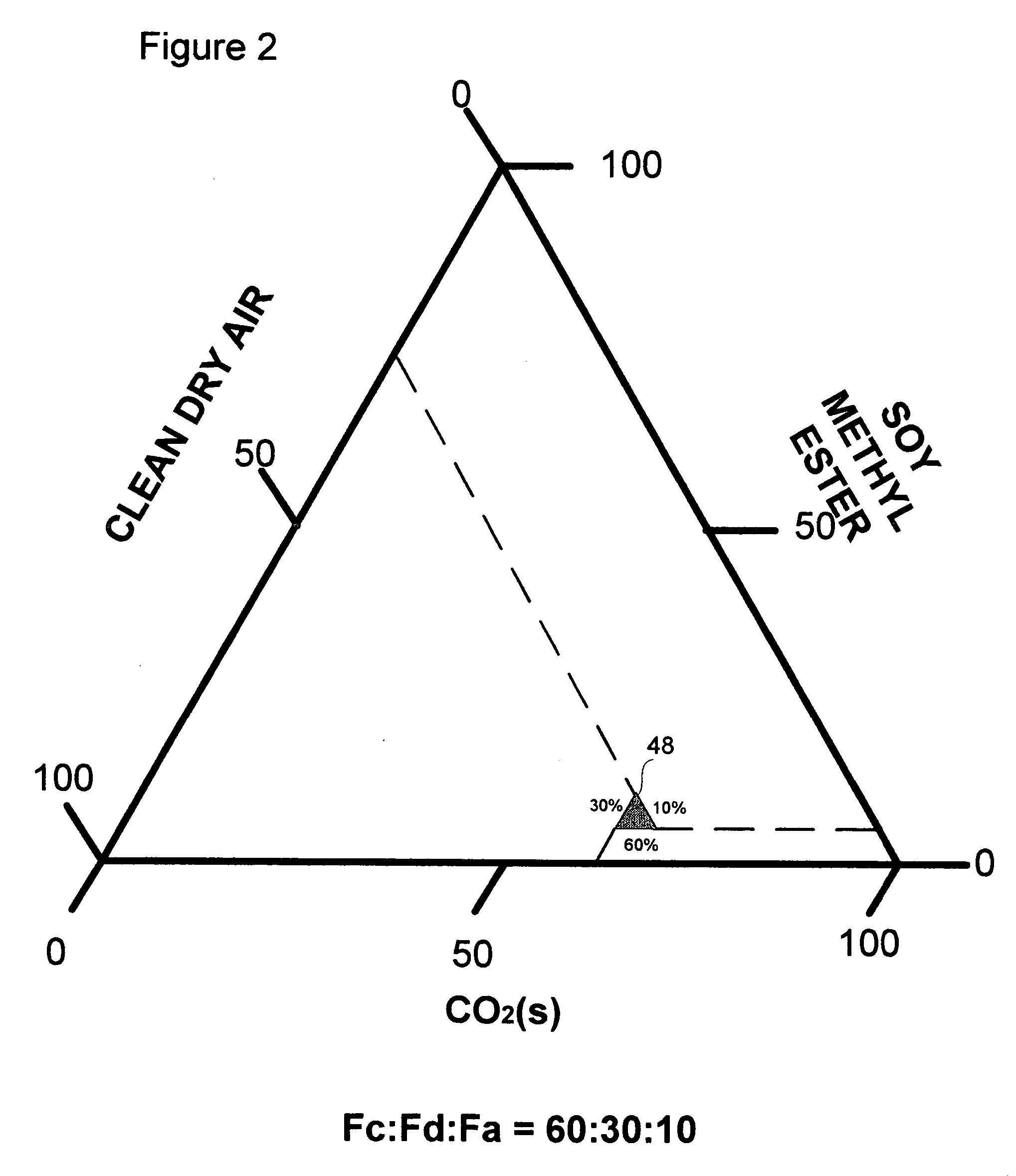

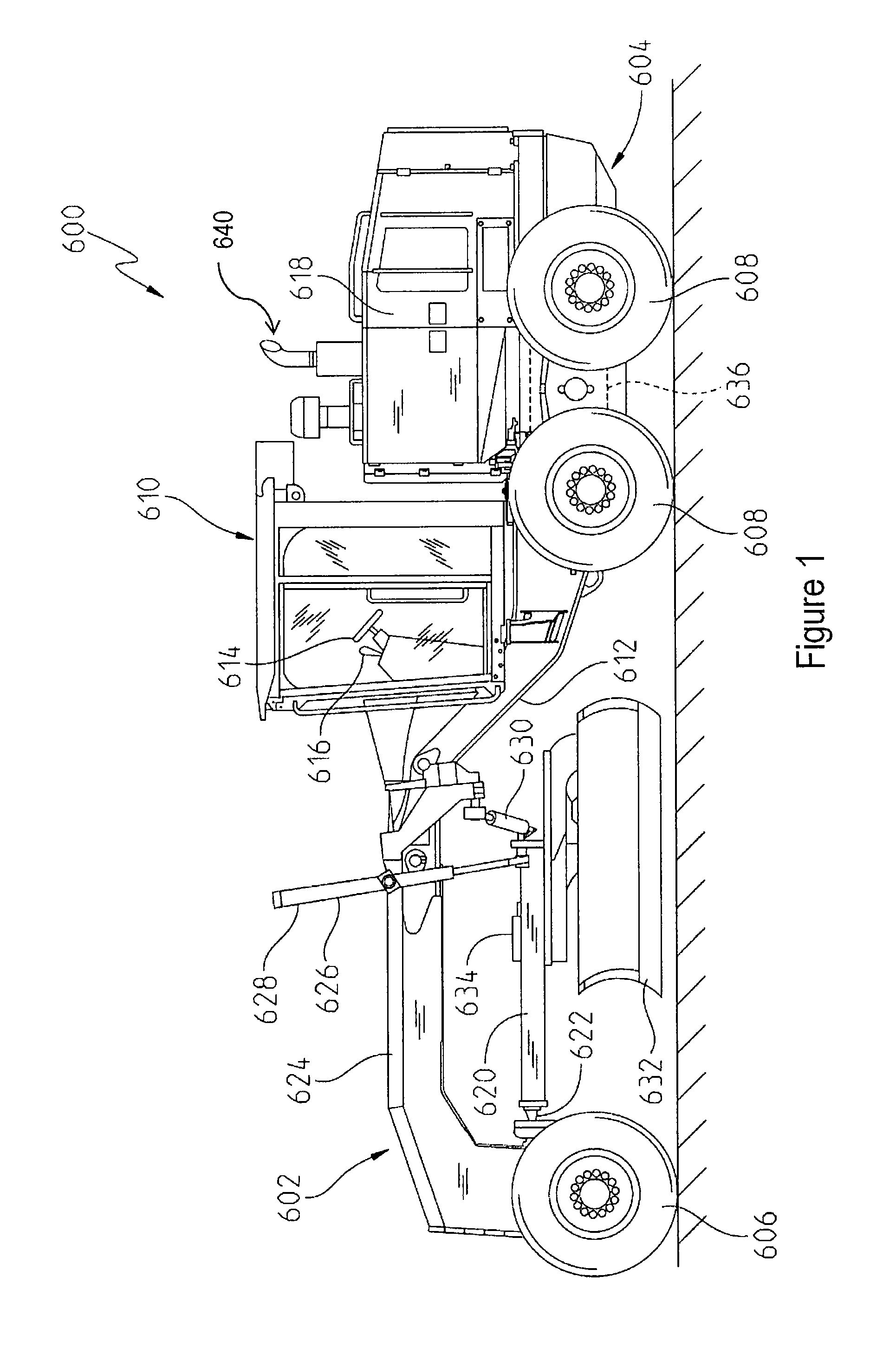

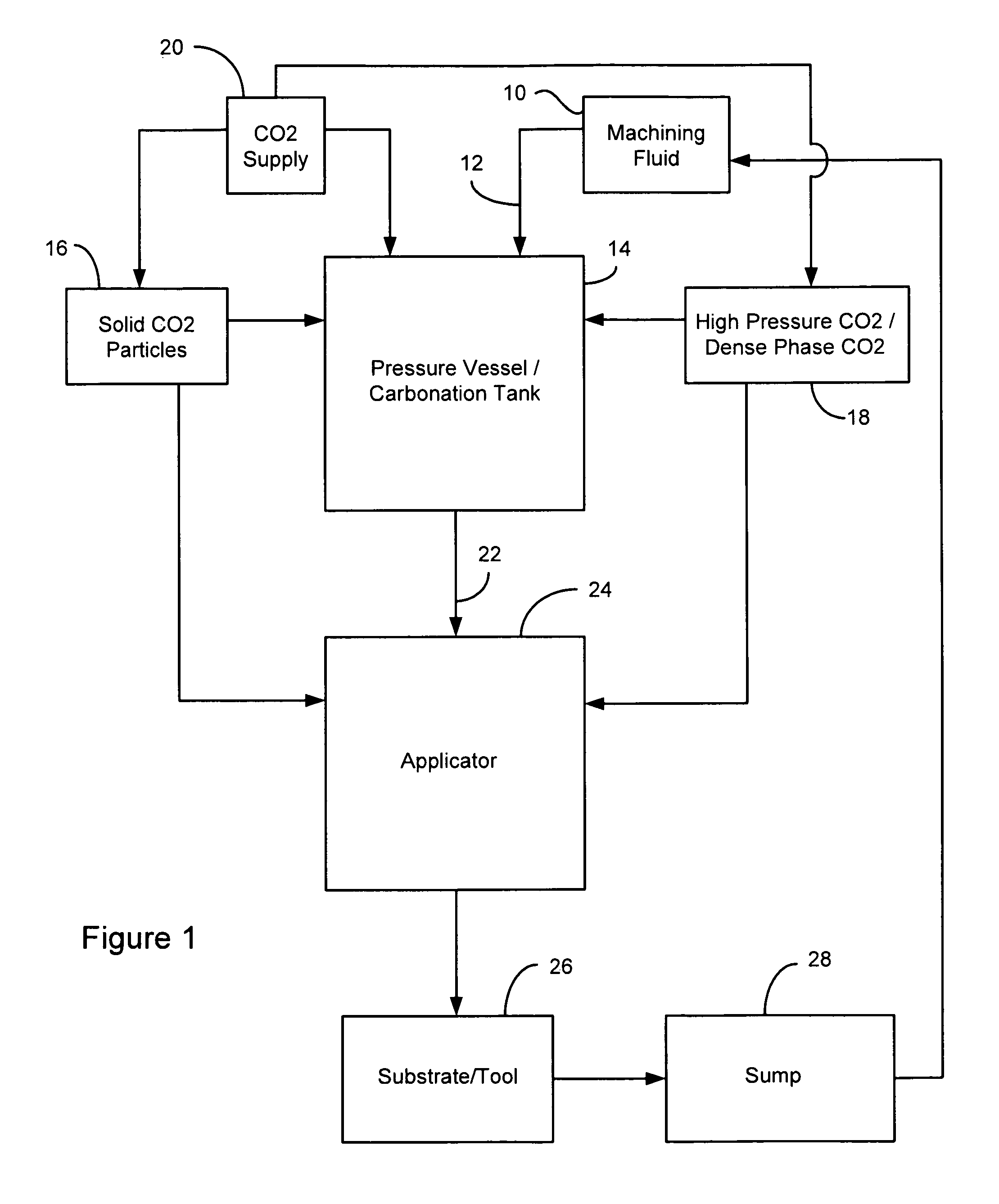

Method and apparatus for thermal control within a machining process

Method and apparatus for mixing within a rotary union of a computer numerical control machine a constant pressure gas with a relatively higher-pressure, lower-temperature dense fluid to produce a dense isobaric fluid deliverable through a rotating tool without gelling or solidifying therein. The constant pressure gas may include carbon dioxide, nitrogen, air or mixtures thereof. The dense fluid preferably includes liquid carbon dioxide at or above its triple point. The liquid carbon dioxide and isobaric gas are independently fed to the rotary union. When mixed, a pressurized flowing carbon dioxide machining fluid composition is formed exhibiting a temperature between about 20° F. and 70° F. at pressures between 75 psi and 1,000 psi.

Owner:COOL CLEAN TECH

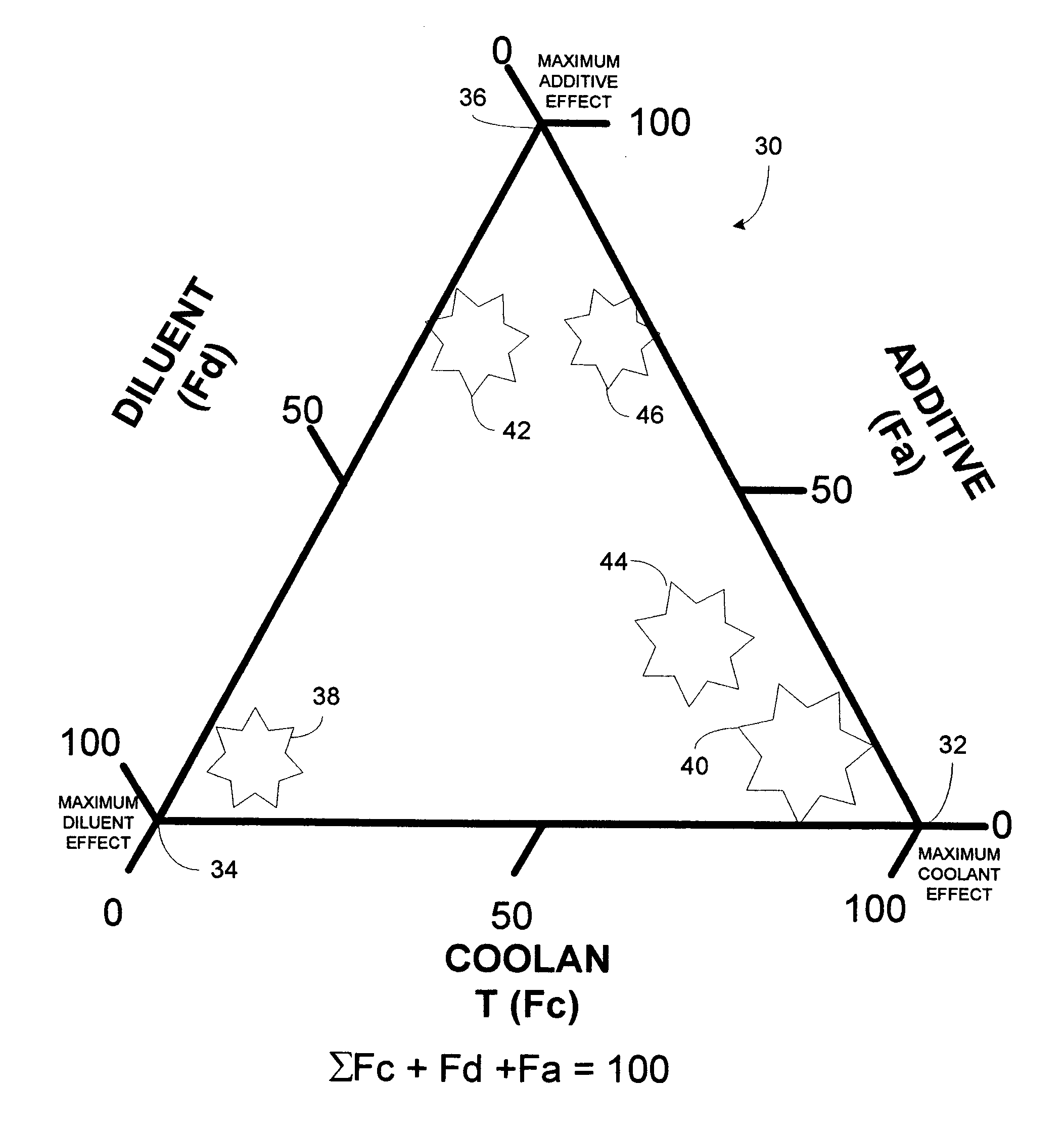

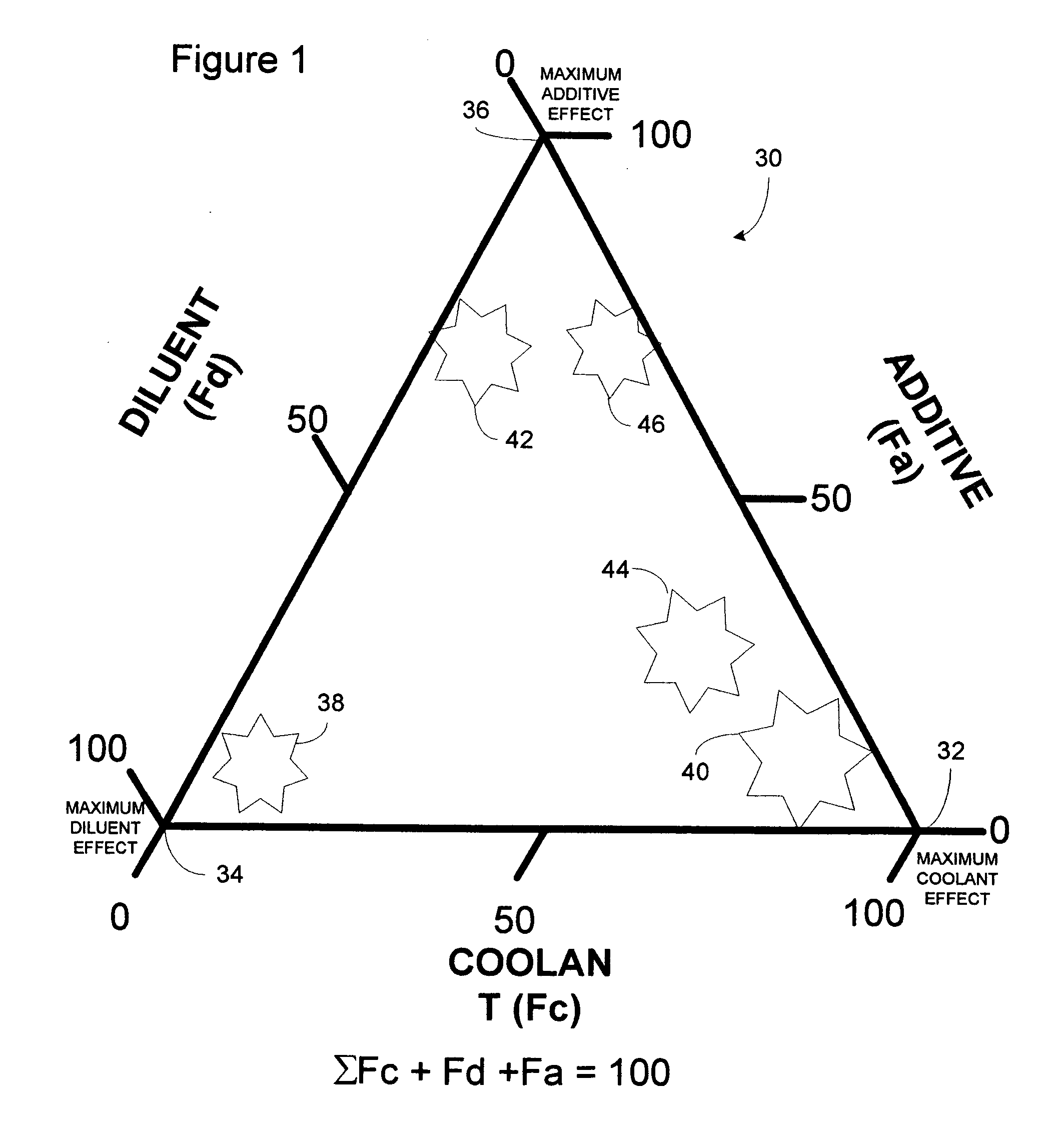

Cryogenic fluid composition

InactiveUS20070114488A1Heat-exchange elementsMaintainance and safety accessoriesGas phaseHigh pressure

A cryogenic fluid composition, and method of forming same, having hyperbaric, lubricating and cooling properties includes selectivity combining a solid phase carbon dioxide, an inert diluent gas and additives in various proportions. The cryogenic machining fluid can be derived by combining a solid carbon dioxide coolant, which may contain or entrain one or more machining lubricant additives, and a diluent phase which is an inert and relatively non-condensing gas phase in various concentrations. The cryogenic fluid composition can be used in cleaning, machining or manufacturing processes to cool, lubricate or ablate a substrate. The cryogenic fluid composition can also be used in conjunction with laser treatment or machining processes without adversely affecting lasing qualities of the laser.

Owner:COOL CLEAN TECH

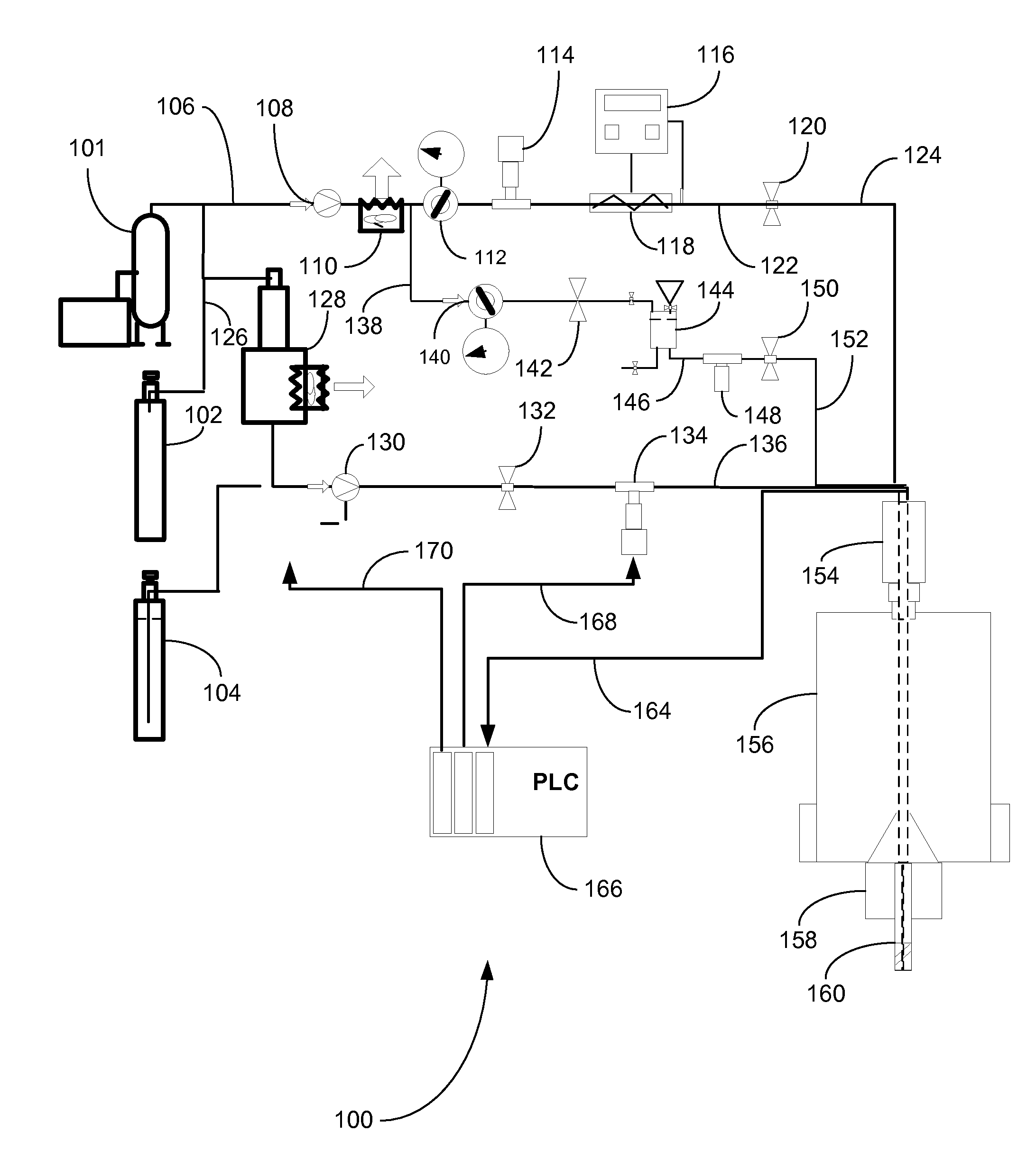

Methods and systems for performing, monitoring and analyzing multiple machine fluid processes

InactiveCN1836095AImprove performanceExtended service lifeLubricant transferMachines/enginesFluid systemBiomedical engineering

In one embodiment, a method is provided for performing a fluid process within a machine having a fluid system including at least two reservoirs of different types of fluids. The method includes the steps of identifying a first reservoir for use in performing a fluid process; (a) adjusting a configuration of a valve system operatively coupled to the fluid system to permit a fluid evacuation process to be performed for the reservoir, (b) subsequently performing the fluid evacuation process for the reservoir, (c) subsequently adjusting the configuration of the valve system to permit a fluid refill process to be performed for the reservoir, (d) subsequently performing the fluid refill process for the reservoir; and, subsequently identifying an additional reservoir and performing at least one of the steps (a), (b), (c) and (d) for the additional reservoir, wherein the first reservoir includes a fluid of a type which is different from a type of a fluid of the additional reservoir. Various system and computer-readable media embodiments are also provided.

Owner:RPM IND LLC

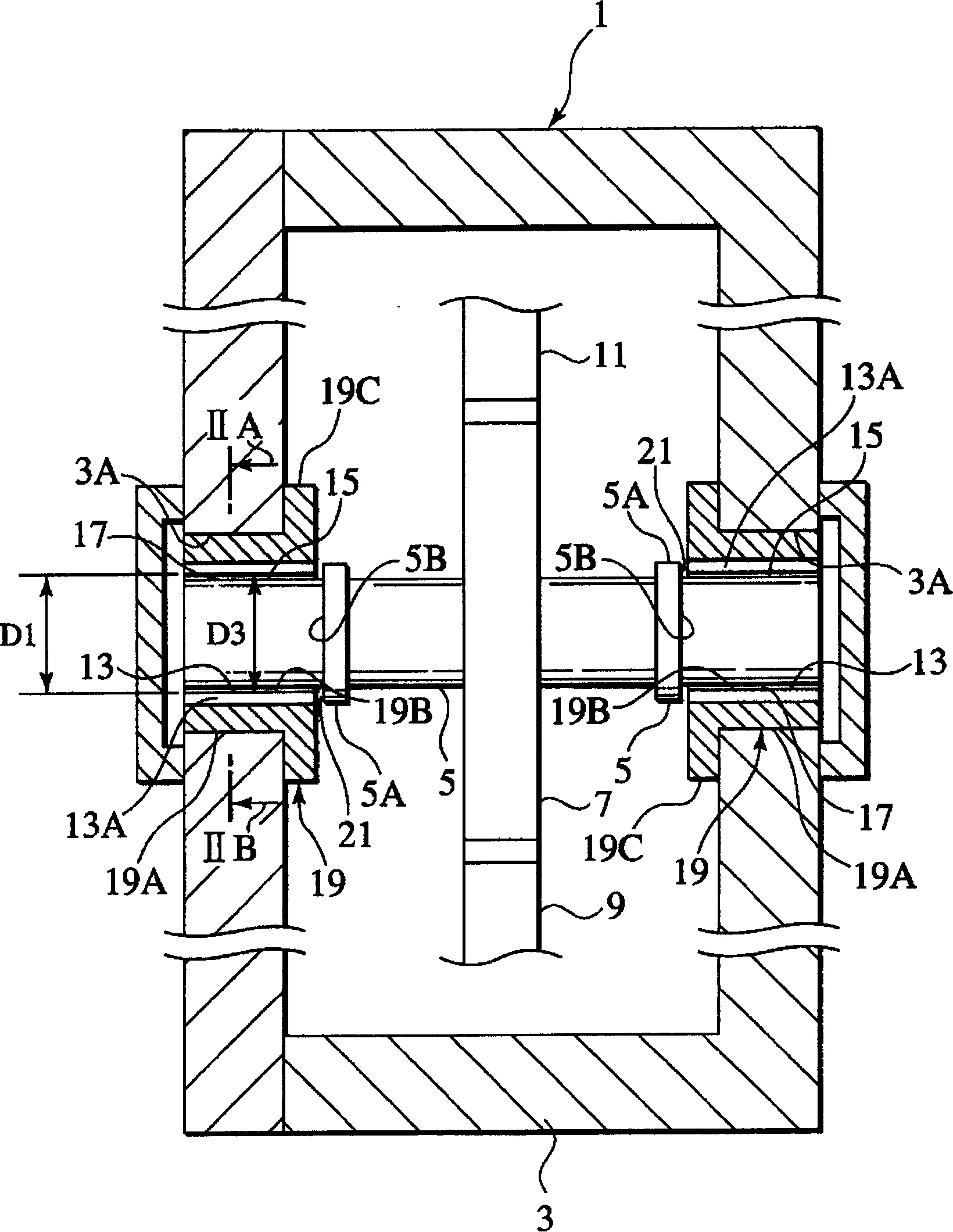

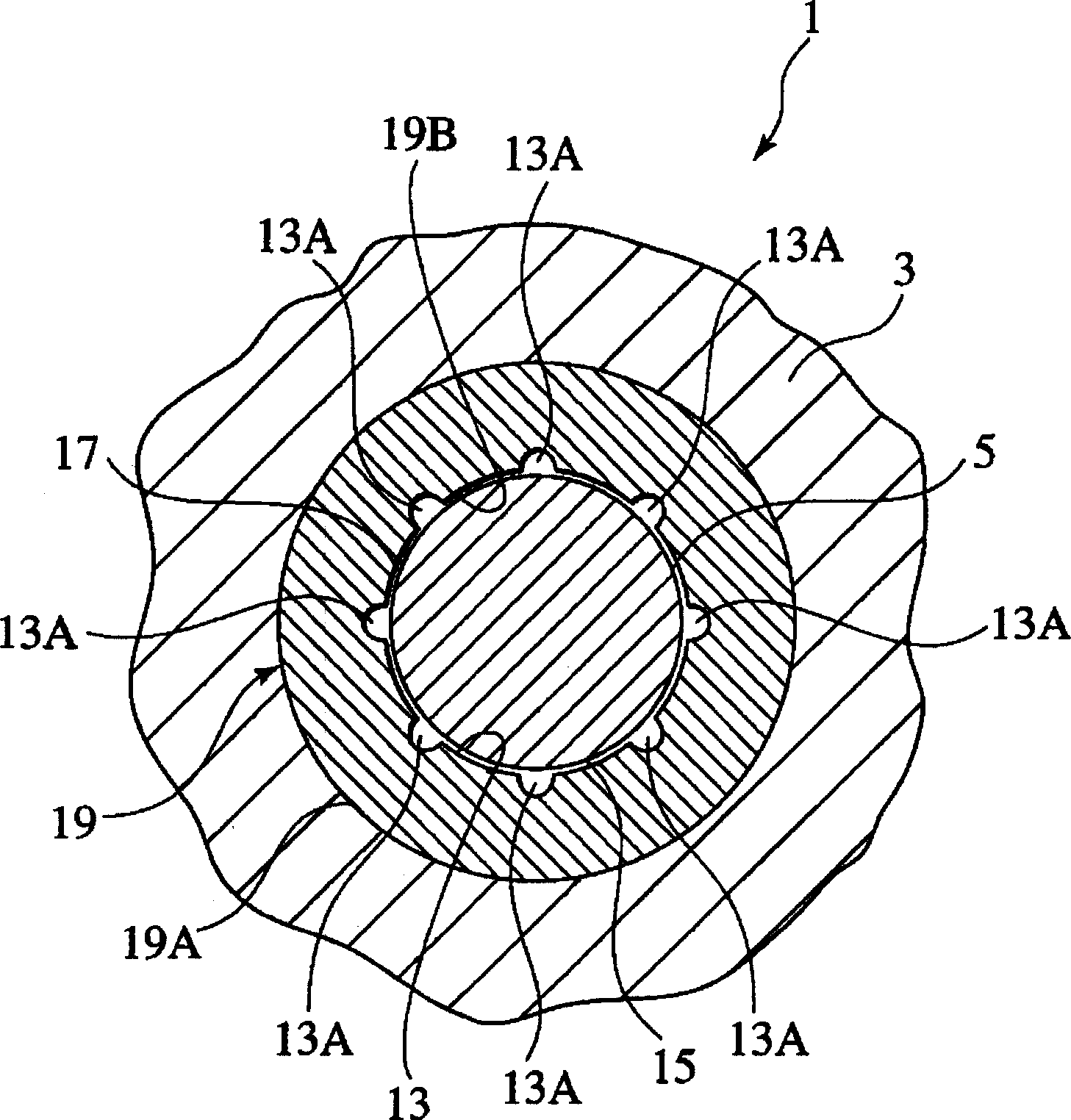

Rotating member, housing, bearing, gearbox, rotating machine, shaft structure, and surface treatment method

In a rotation member (5) rotatably engaged with a housing (3), a pulsing electric discharge is generated in a processing liquid or in a gas, between an electrode and the rotation member (5). The electrode is a chemical compound from metallic powder or metal, or a molded body formed by molding ceramic powder, or a molded body obtained by heating the molded body. Energy of the electric discharges causes coating to be formed on an engagement portion (15) engaging the housing (3), the coating formed from the material of the elctrode or a substance to which the electrode material combined by the energy of the electric discharges.

Owner:IHI CORP +1

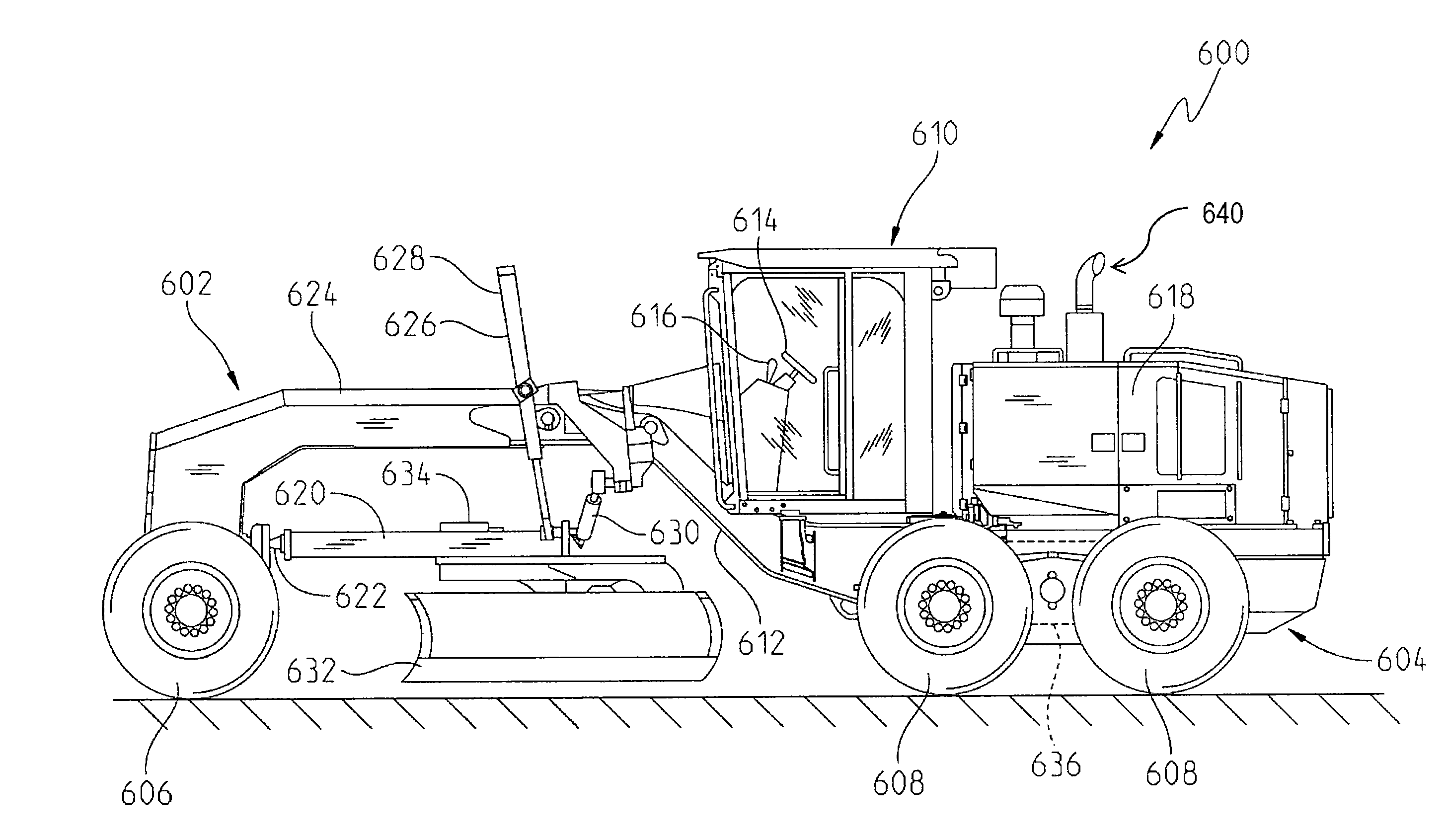

Controlled engine shutdown method and engine shutdown prediction for exhaust system durability

A controlled engine shutdown method is disclosed that includes monitoring exhaust system temperature, monitoring operator shutdown commands, and delaying engine shutdown based on exhaust system temperature. The method can include inhibiting any process that affects exhaust temperatures, for example DPF regeneration. The method can use a shutdown timer, allow operator override of the shutdown delay, and display a delay notification message. The method can also include predicting when an engine shutdown is expected, and delaying or aborting any process that would affect exhaust temperatures when an engine shutdown is predicted. Predicting can include monitoring various machine states, determining an average activity interval for the machine, determining a geographic shutdown area, determining a shutdown time of day and / or monitoring a machine fluid level.

Owner:DEERE & CO

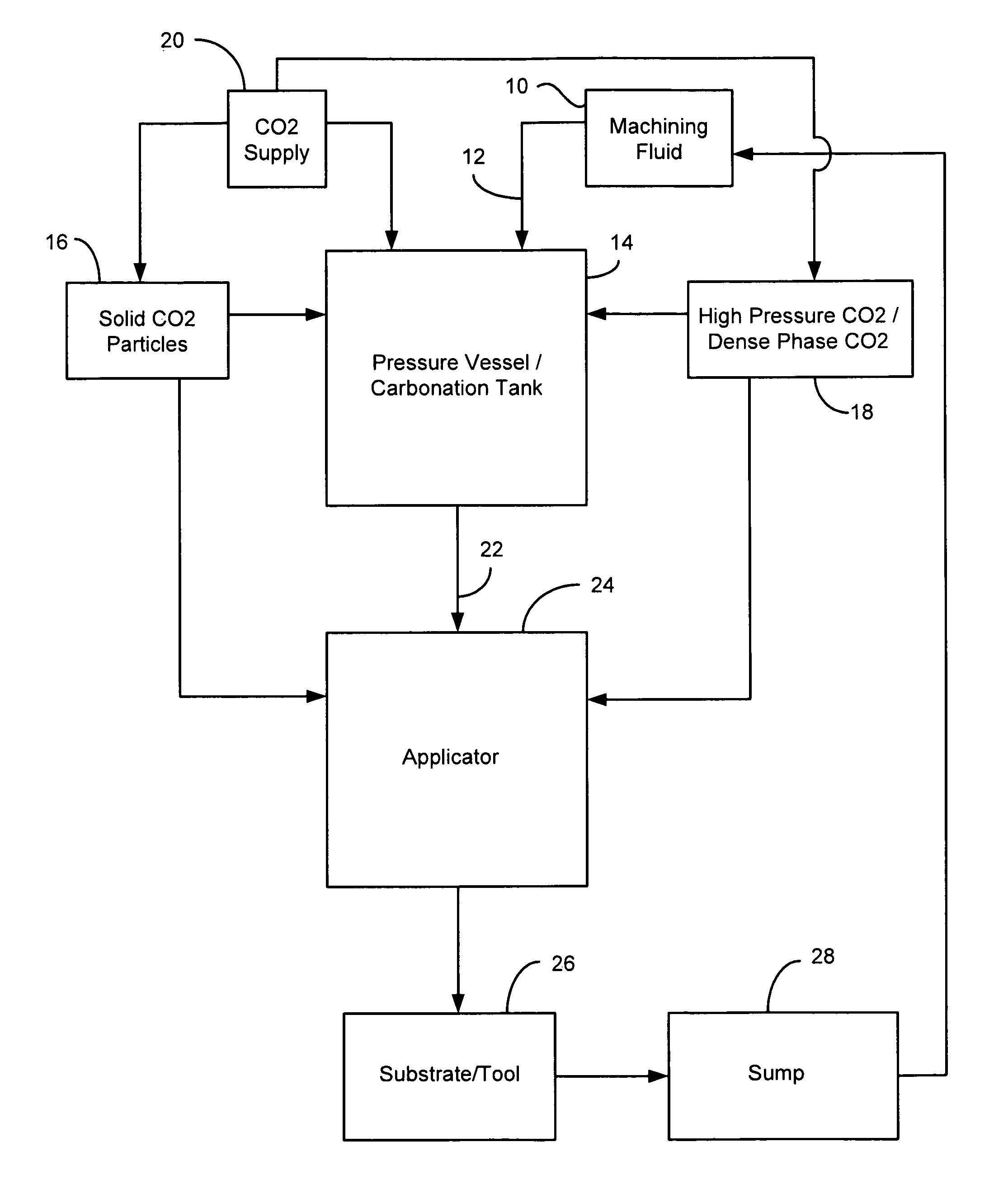

Method of forming and using carbonated machining fluid

ActiveUS8048830B1Optimization propertiesBeneficial change in flow and penetration and heat transfer qualityAdditivesMaintainance and safety accessoriesEngineeringMachining process

A method of forming and delivering a carbonated machining fluid to be used in a machining process, the machining process including a tool contacting a substrate, comprises supplying a pressure vessel with a non-carbonated machining fluid and non-supercritical carbon dioxide. The machining fluid and carbon dioxide are allowed to admix such that at least a portion of the carbon dioxide dissolves into the machining fluid to form the carbonated machining fluid. The carbonated machining fluid is then delivered under pressure from the vessel to an applicator and applied to the tool or the substrate to impart cooling and lubricating effects.

Owner:COOL CLEAN TECH

Water-soluble magnesium alloy machining fluid

The invention discloses a water-soluble magnesium alloy machining fluid.The water-soluble magnesium alloy machining fluid is prepared from, by weight, 40-50% of base oil or oiliness agent, 5-15% of an anionic surfactant, 0.5-3% of a nonionic surfactant, 3-6% of a black metal sustained-release agent, 5-10% of a coupling agent, 0.5-2% of a copper alloy corrosion inhibitor, 2-8% of a magnesium / aluminum alloy corrosion inhibitor, 1-3% of a bactericide, 0.2-1% of an antifoaming agent and 3-12% of pure water.The water-soluble magnesium alloy machining fluid is high in universality, suitable for various metals, particularly applicable to machining of magnesium alloy and magnesium-aluminum alloy parts, excellent in corrosion resistance effect on magnesium alloy, long in efficacy lasting time and effective in prevention of oxidative discoloration of sensitive magnesium alloy and magnesium-aluminum alloy and inhibition of hydrogen generation and magnesium ion dissolution.In addition, the water-soluble magnesium alloy machining fluid has excellent lubricating performance and anti-rusting performance, remarkable hard water resistance and the like, long in service life, free of toxic and harmful substances such as nitrites and phenols and beneficial to environment and health.

Owner:DONGGUAN NASHENG LUBRICATING OIL TECH CO LTD

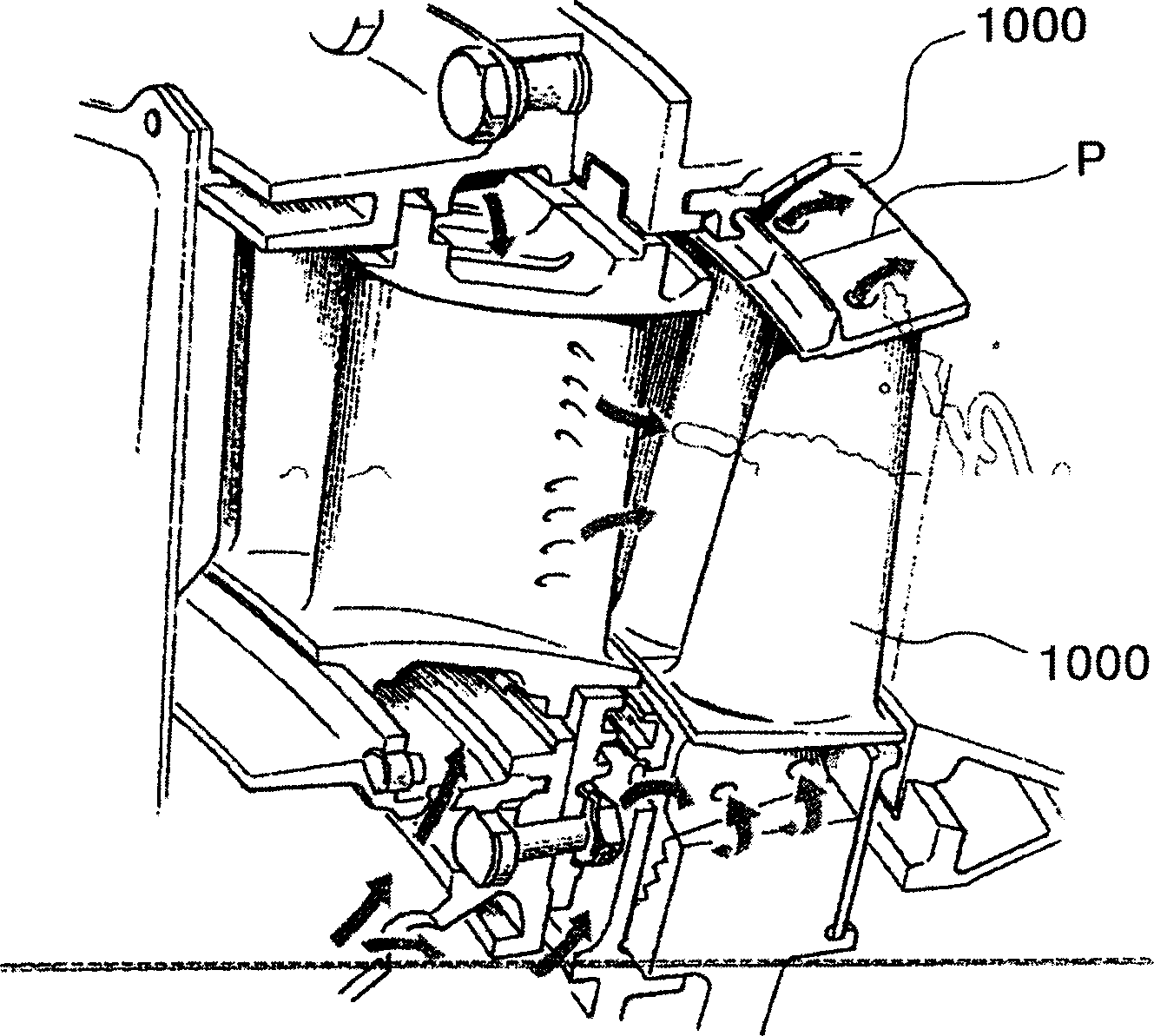

Machine tool

ActiveUS20150367472A1Ensure safety efficiencyProduction and the safety are ensuredAutomatic/semiautomatic turning machinesAuxillary equipmentMachine toolMachining fluid

A work-machine splash guard for enclosing a space for machining a workpiece, and preventing the spraying of chips and machining fluid, is equipped with: a front-surface door for opening and closing in the horizontal direction via an arc-shaped movement, and positioned on the front-surface side of the work machine; a side-surface door for opening and closing by performing an arc-shaped movement that is concentric with the front-surface door, and overlapping with the front-surface door; and door-locking switches for selectively allowing the opening / closing of the front-surface door and the side-surface door according to an opening / closing pattern.

Owner:MAKINO MILLING MASCH CO LTD

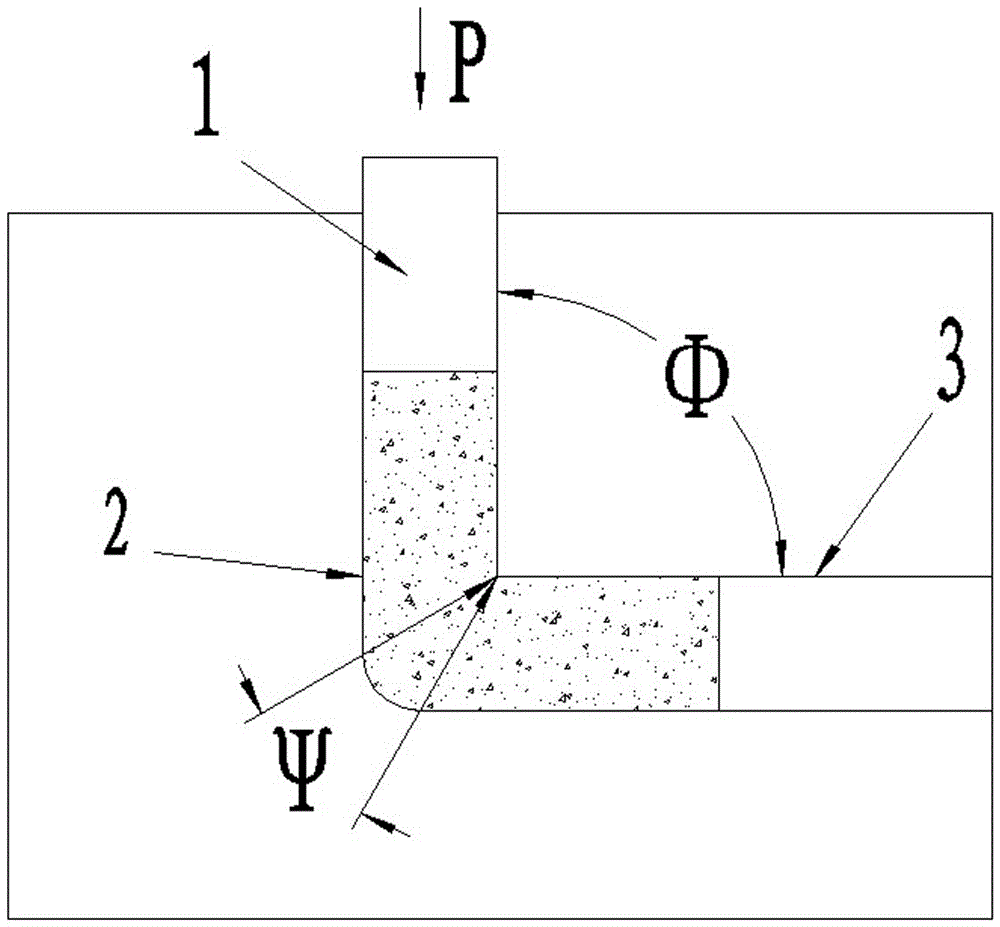

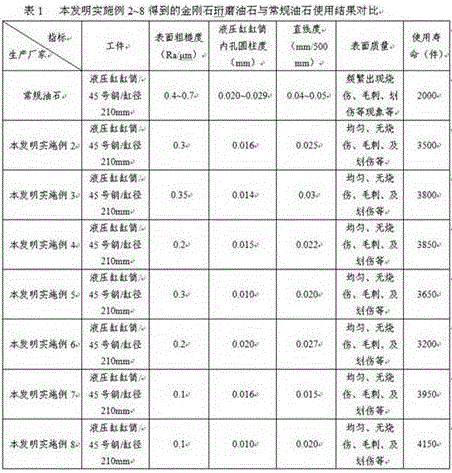

Diamond honing oilstone and preparation method thereof

ActiveCN106217273AImprove cooling effectImprove plasticityAbrasion apparatusGrinding devicesHydraulic cylinderGranularity

The invention provides a diamond honing oilstone and a preparation method thereof. The diamond honing oilstone is prepared from, by weight percent, 5%-10% of diamond micro-powder with the granularity ranging from 400 meshes to 1000 meshes and 90%-95% of a metal bond. The metal bond is composed of 45%-55% of copper-tin pre-alloyed powder, 12%-20% of silver powder, 30%-33% of magnesium powder and 2%-5% of talcum powder with the granularity ranging from 200 meshes to 800 meshes. The specific preparation method includes the steps that an oilstone blank is prepared through the procedures such as material mixing, mold forming, sintering and equal channel angular extrusion; and finally, machining is conducted on the oilstone blank, and a finished product with the qualified size precision is obtained. The oilstone manufactured through the method solves the problems that at present, a hydraulic cylinder barrel honing oilstone machining hydraulic cylinder barrel is low in cylindricity and poor in straightness accuracy, the surface roughness does not reach the standard, and burns, burrs and hydraulic cylinder barrel inner hole surface scratches exist, meanwhile, hardness of the oilstone is improved, the shape retention is improved, and the service life is prolonged.

Owner:ZHENGZHOU RES INST FOR ABRASIVES & GRINDING CO LTD

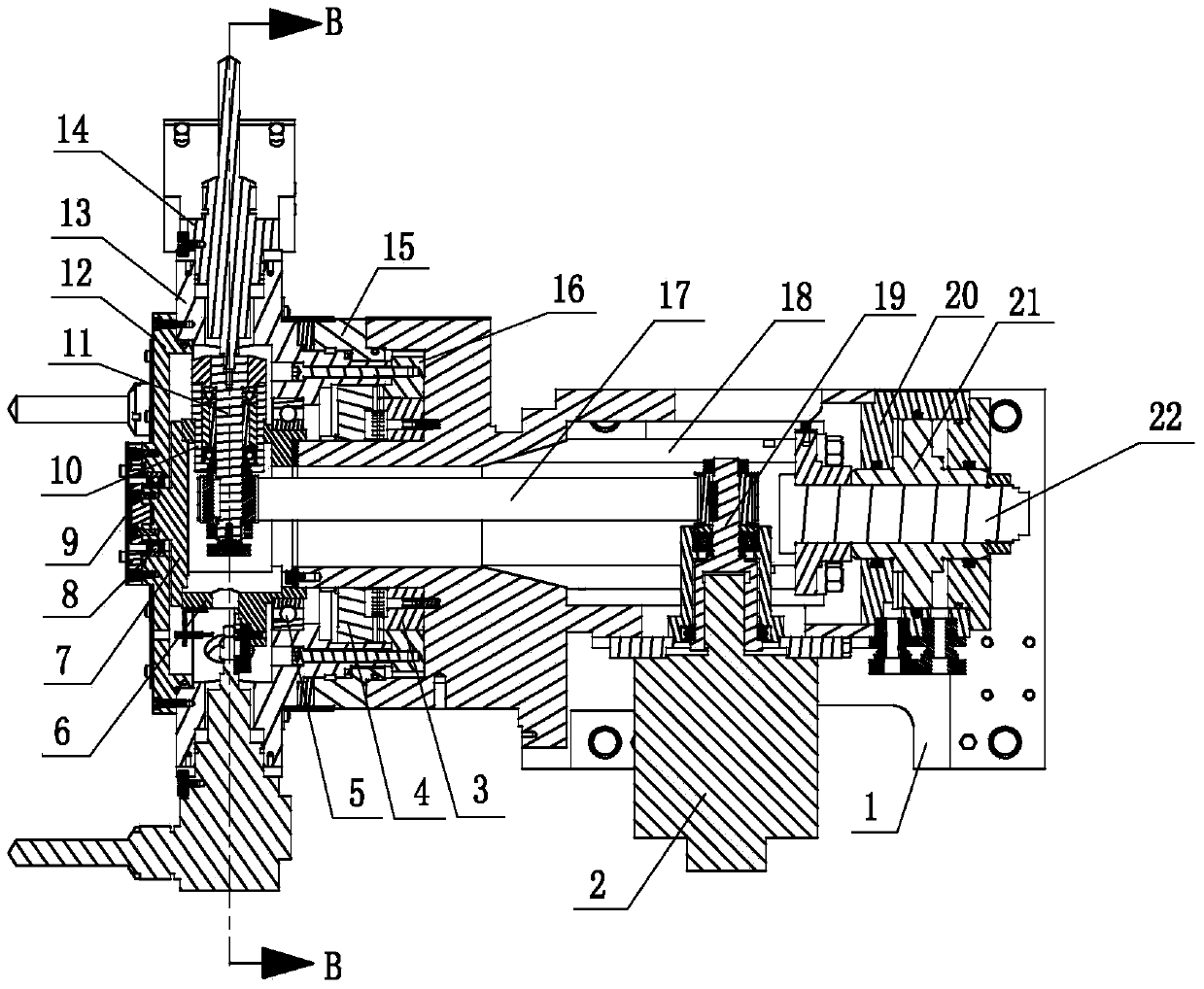

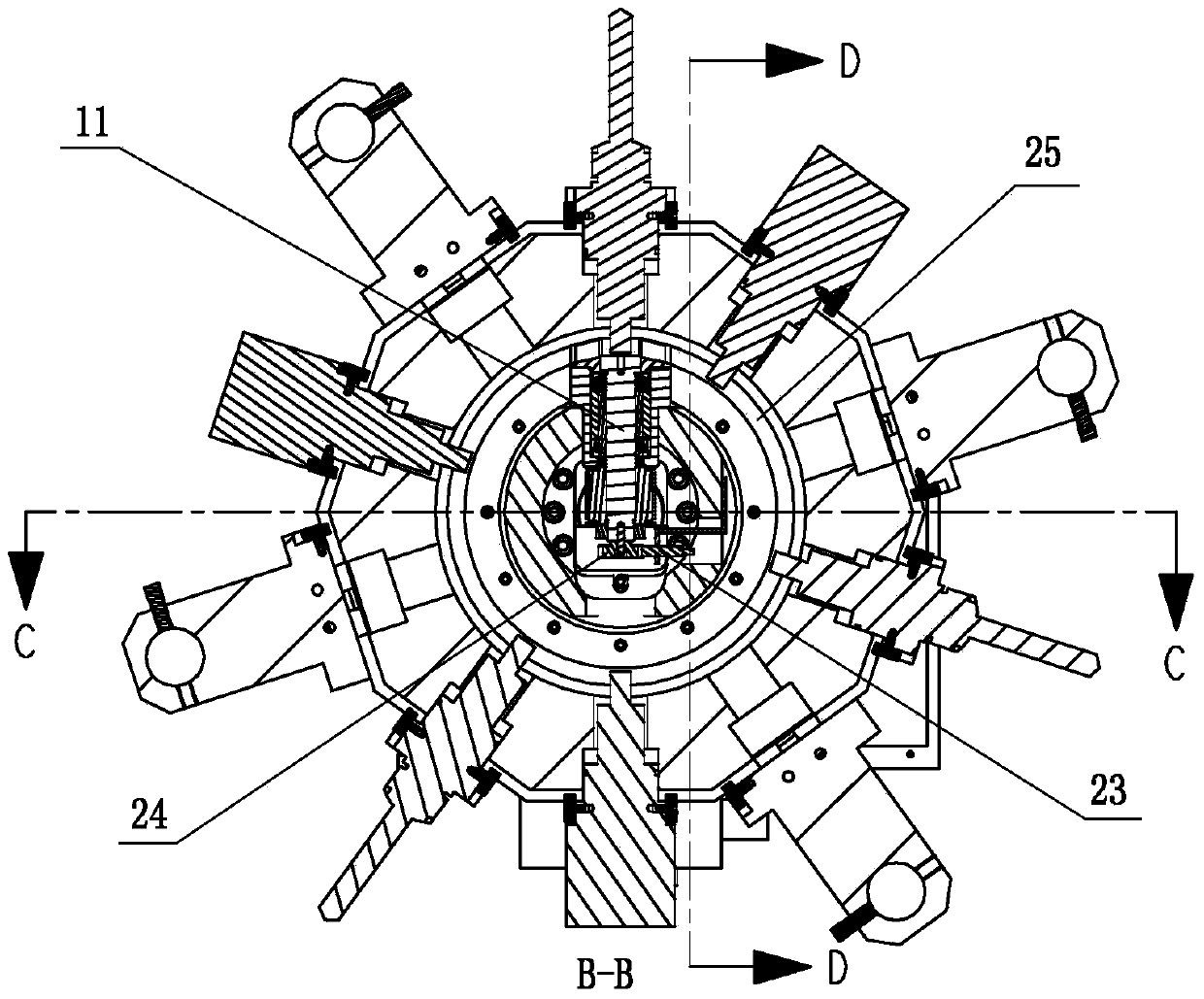

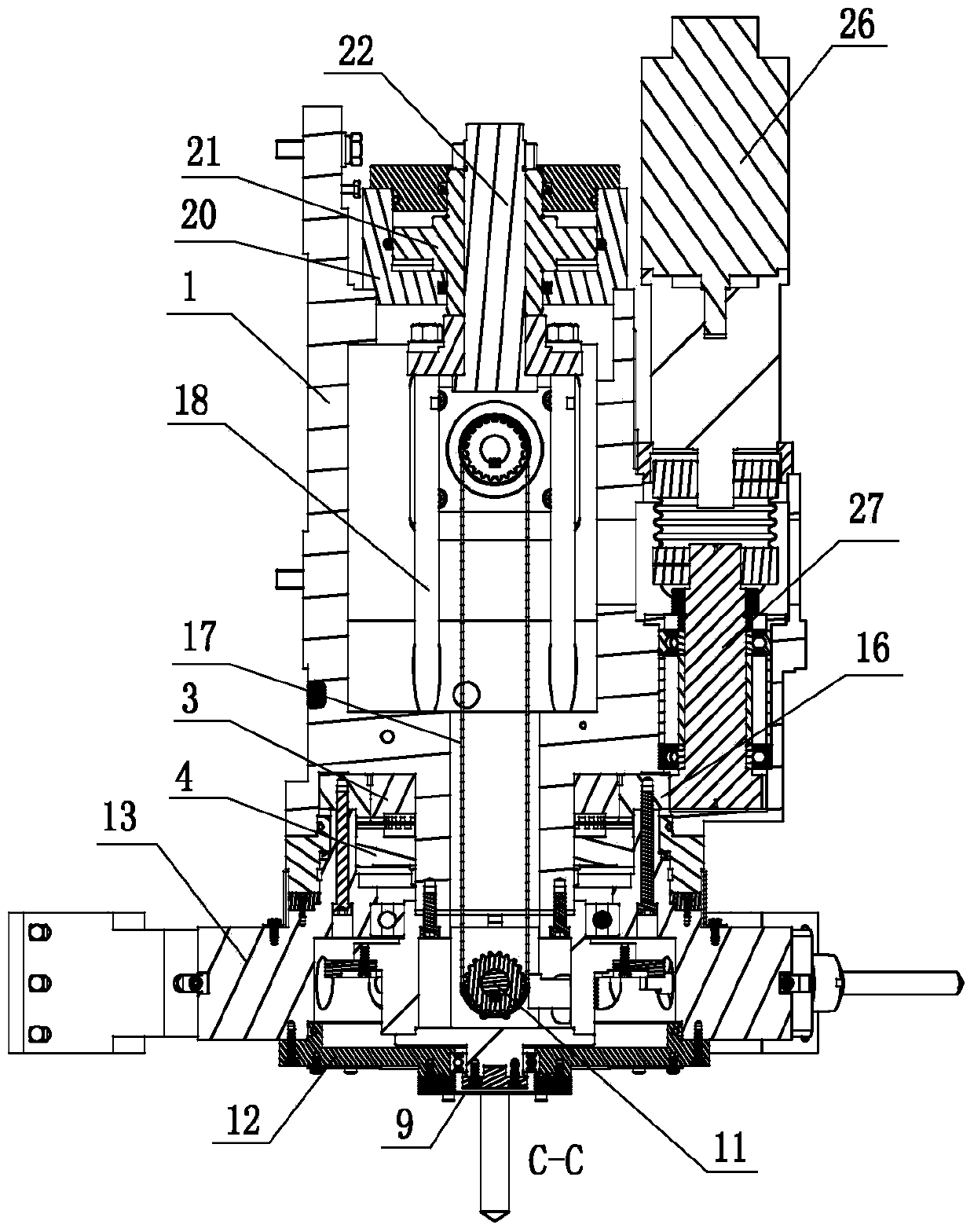

Combined machining hydraulic locking power tool table

ActiveCN104190973AAdapt to functional requirementsVersatileTool holdersPositioning apparatusDrive shaftControl engineering

The invention discloses a combined machining hydraulic locking power tool table, and belongs to machine tool parts. A plurality of power tool bases are arranged on a tool disc at intervals in the circumferential direction, the tool disc is fixedly connected with a transposition tooth disc and is supported through a bearing, and a gear shaft is meshed with a gear on the outer peripheral face of the transposition tooth disc for transmitting power of a tool changing drive motor. A lock oil cylinder piston is connected with a locking tooth disc through a connection piece to drive a tooth groove in the rear end face of the locking tooth disc to be correspondingly meshed with a tooth groove in the front end face of the transposition tooth disc and a tooth groove in the front end face of a fixing tooth disc fixed to a tool table base so as to achieve locking. A power drive motor transmits the rotating power to the power tool base through a drive shaft and a driven shaft which are connected in a transmission mode, the driven shaft and the power tool base are matched through a clamping groove and a clamping tenon, a driven shaft angle sensing mechanism feeds back signals to control the rotating angle of the driven shaft, the driven shaft is arranged in a radial driven shaft hole in a flange base through a bearing in a supported mode, and the tool table base is provided with a front transmission cavity and a rear transmission cavity which are used for passing of a transmission mechanism. The combined machining hydraulic locking power tool table is simple in structure and solves the problem that a traditional power tool table is complex in structure.

Owner:ZHEJIANG RIFA PRECISION MACHINERY

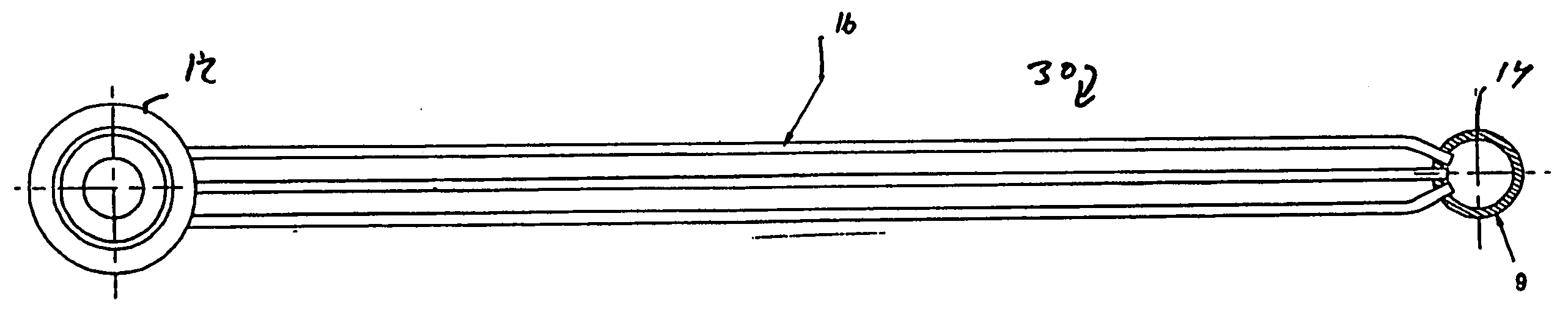

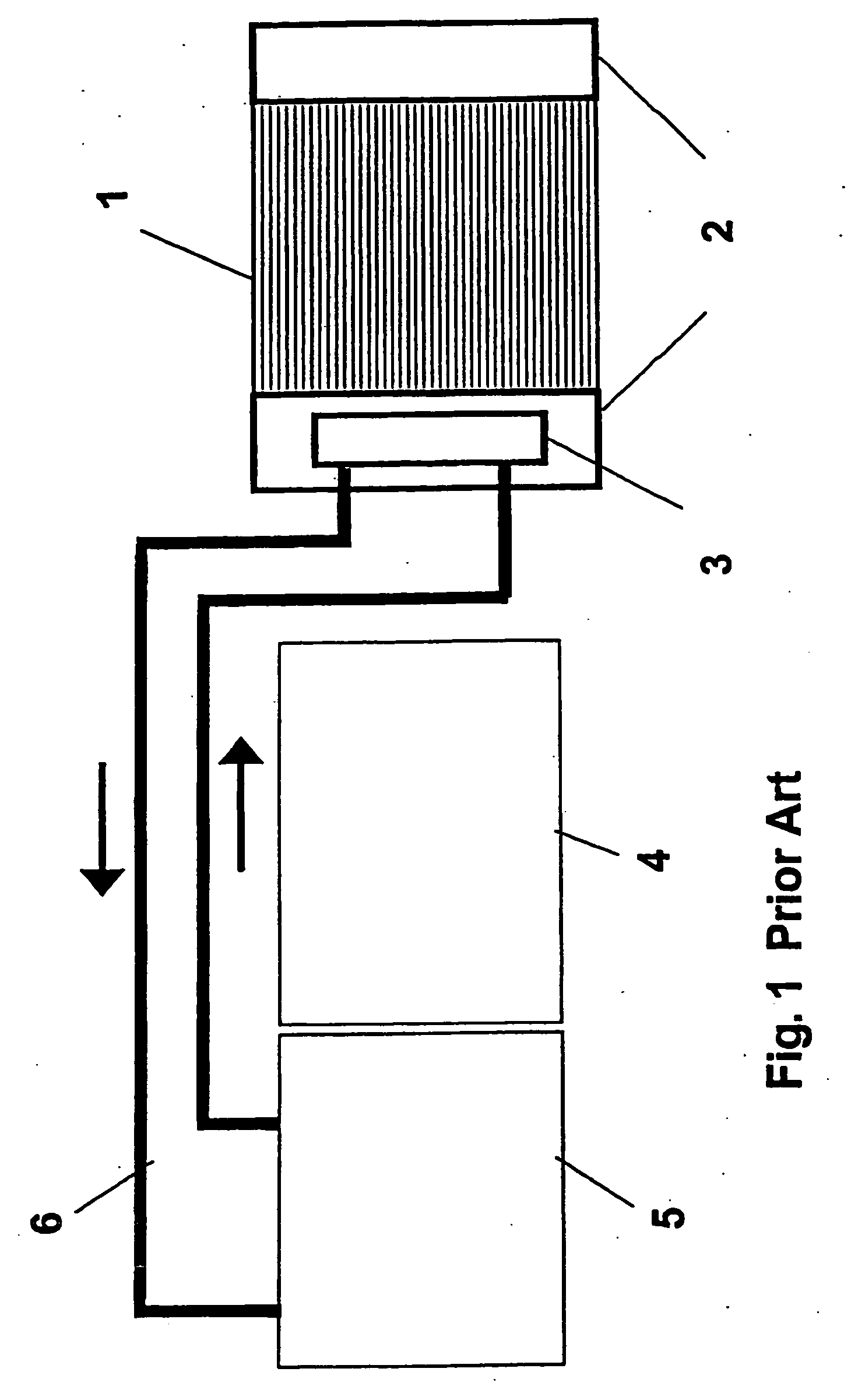

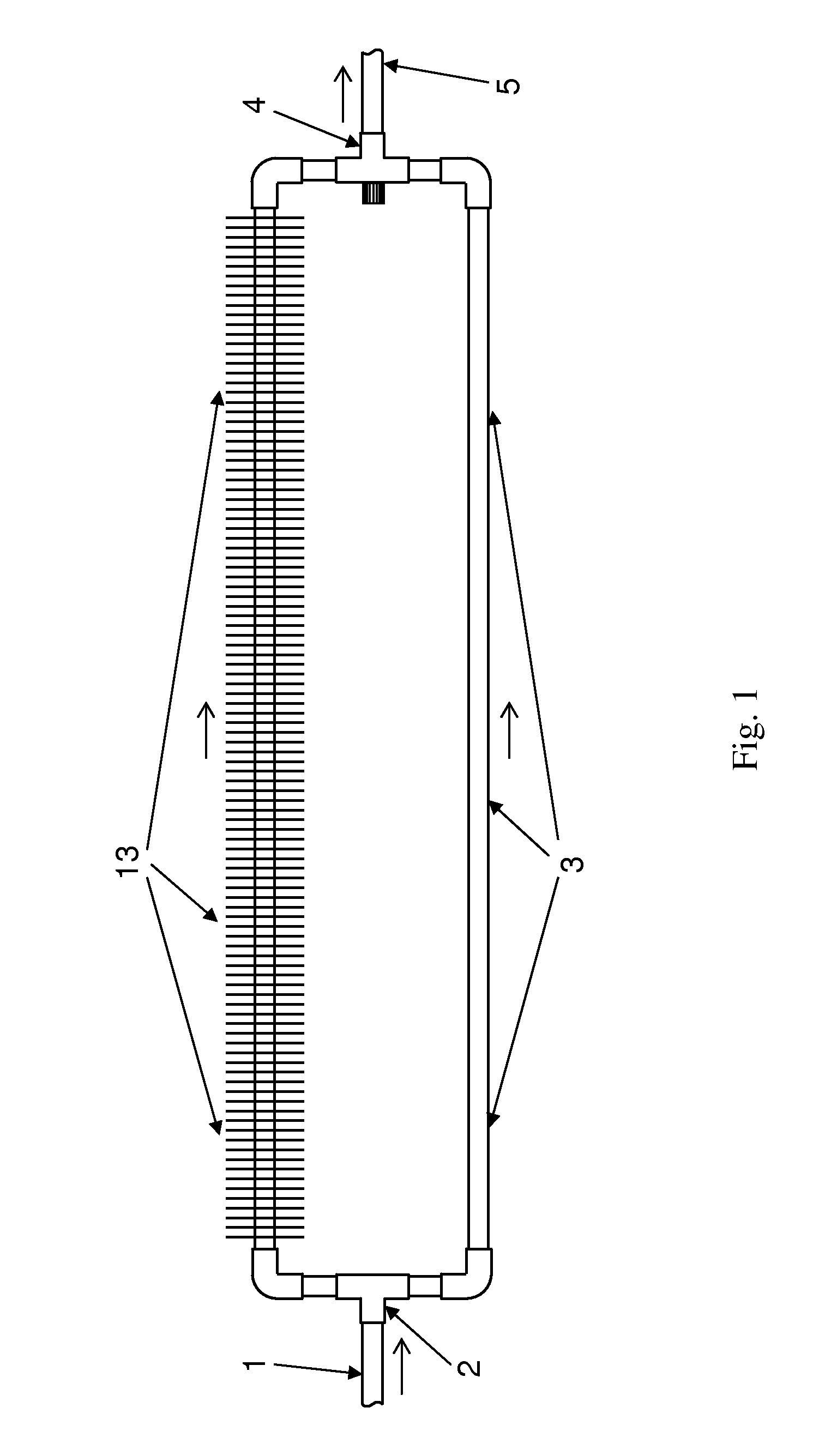

Heat exchanger and associated method

InactiveUS20050217833A1Stationary conduit assembliesHeat exchanger casingsPlate heat exchangerEngineering

A heat exchanger for cooling a machine fluid of a vehicle, and associated method. The heat exchanger can include a fluid inlet tank, a fluid outlet tank, and a plurality of heat transfer tubes connecting the inlet tank to the outlet tank. Each tube can include first and second substantially flat sidewalls, a plurality of internal webs extending between the first and second sidewalls, and a plurality of first dimples formed on the first sidewall, each first dimple formed over one of the webs.

Owner:EDC AUTOMOTIVE

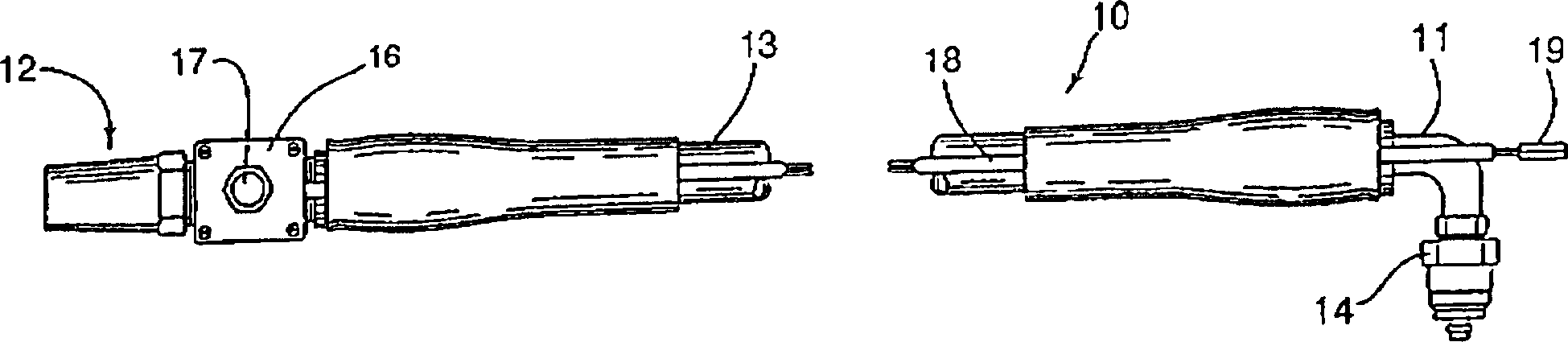

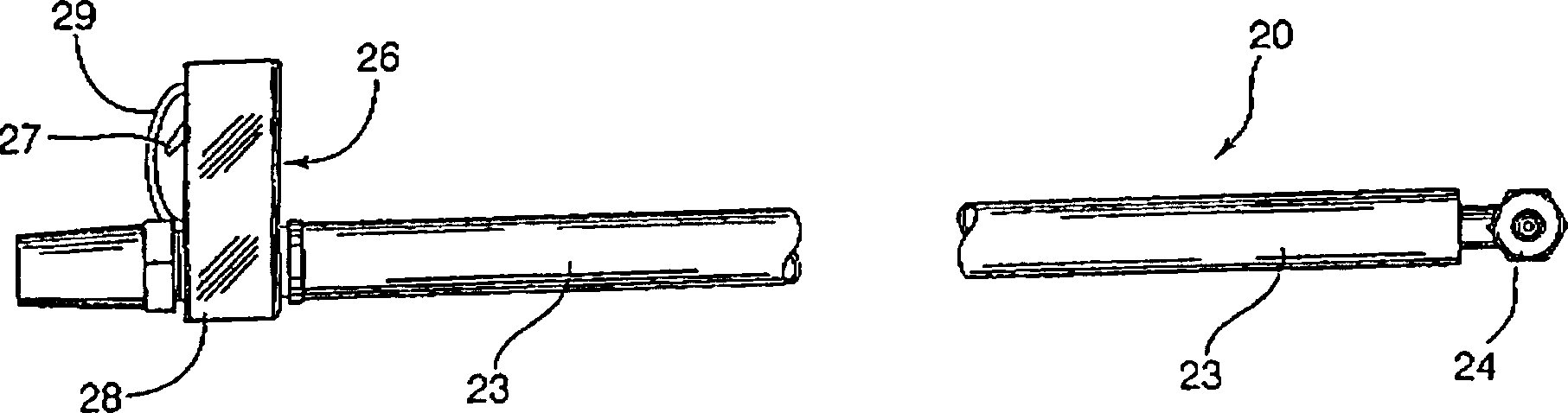

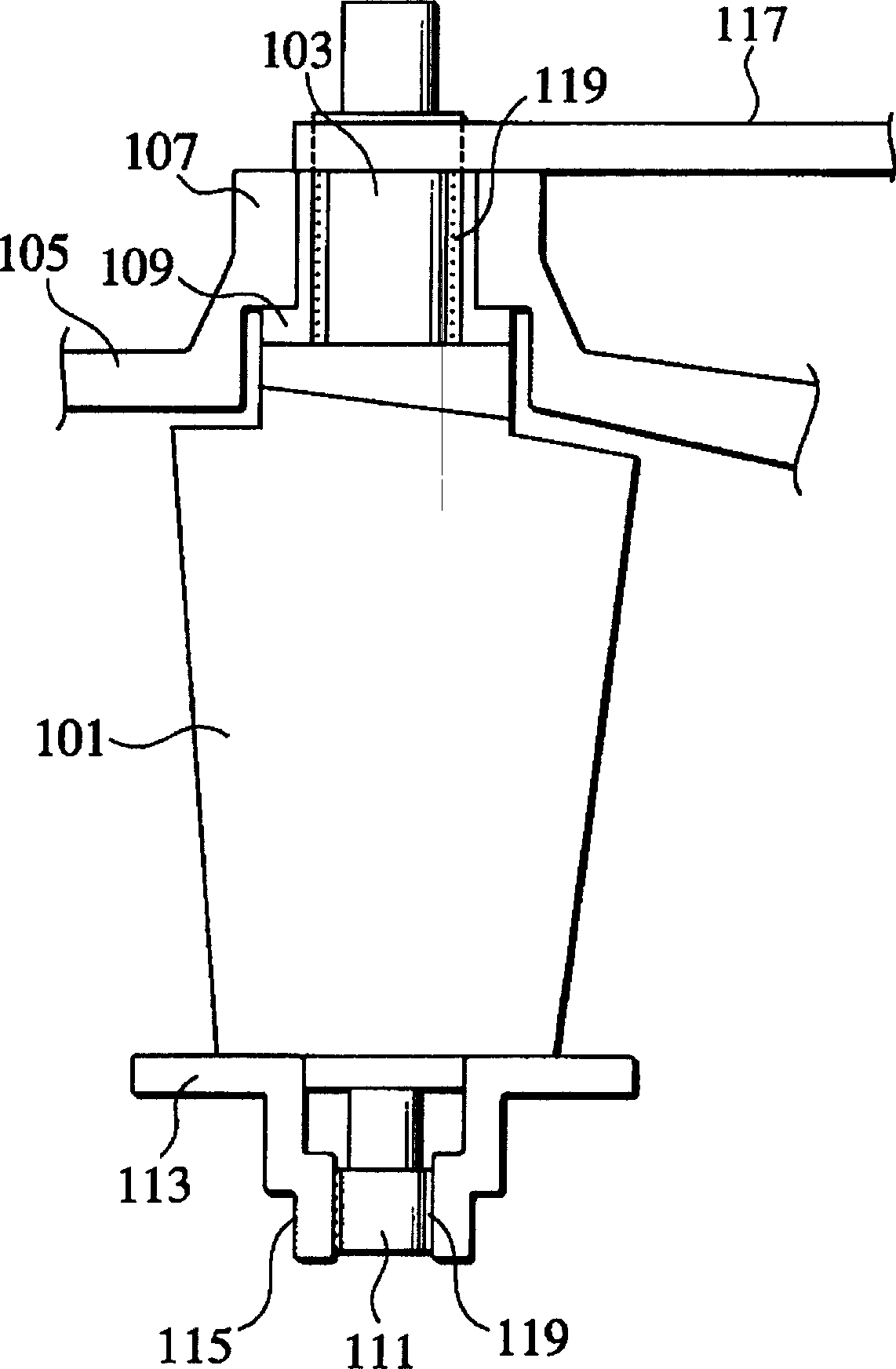

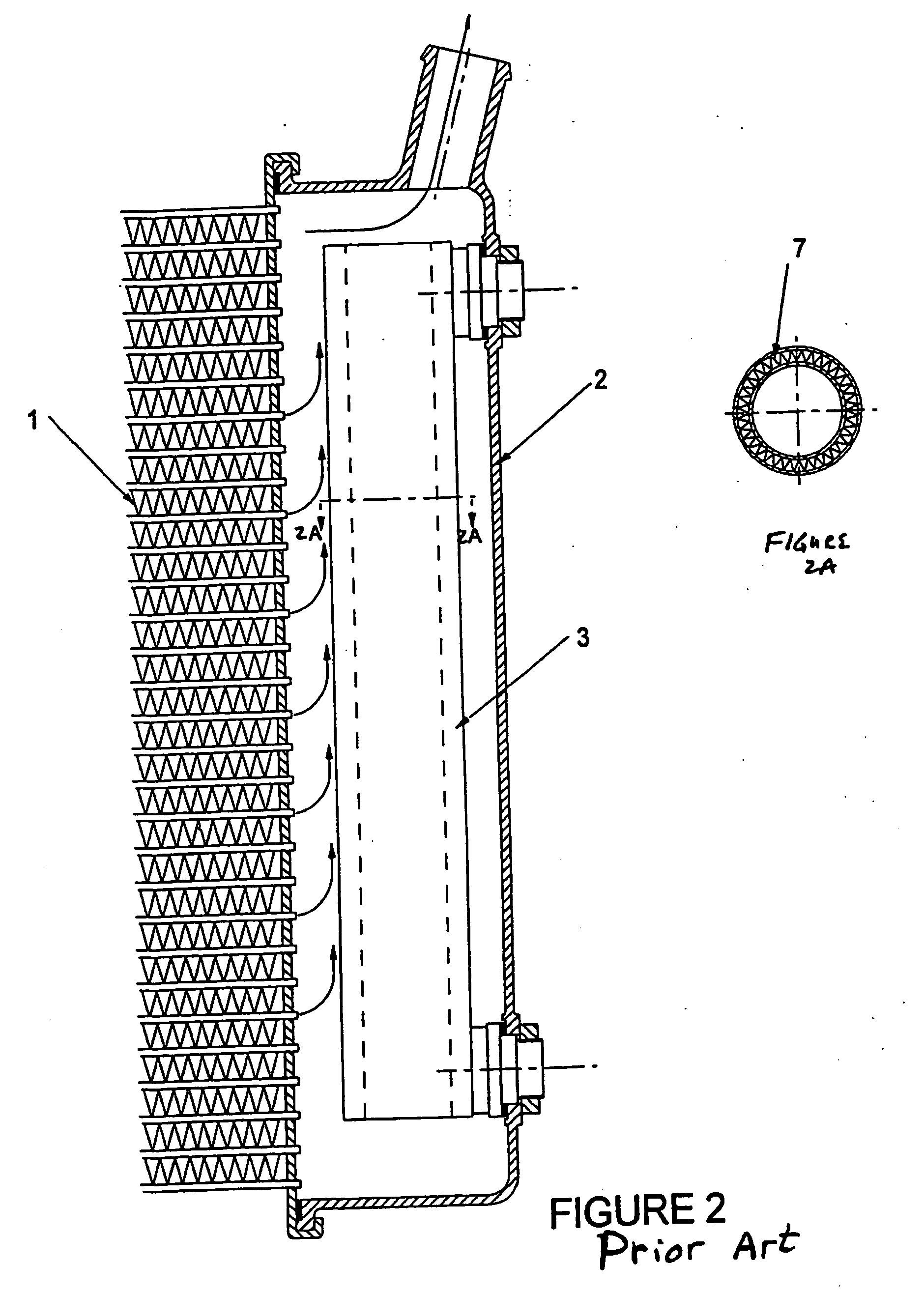

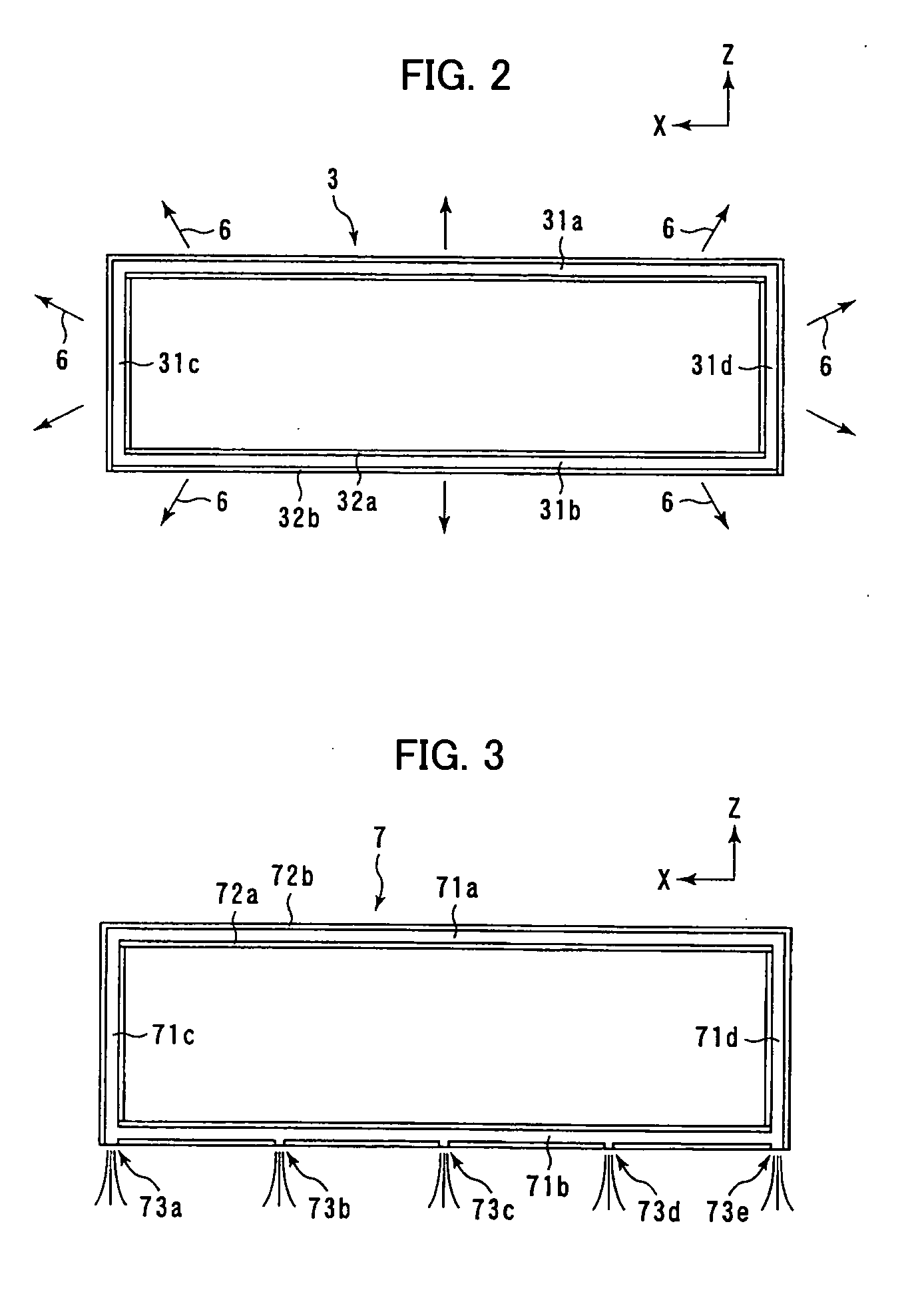

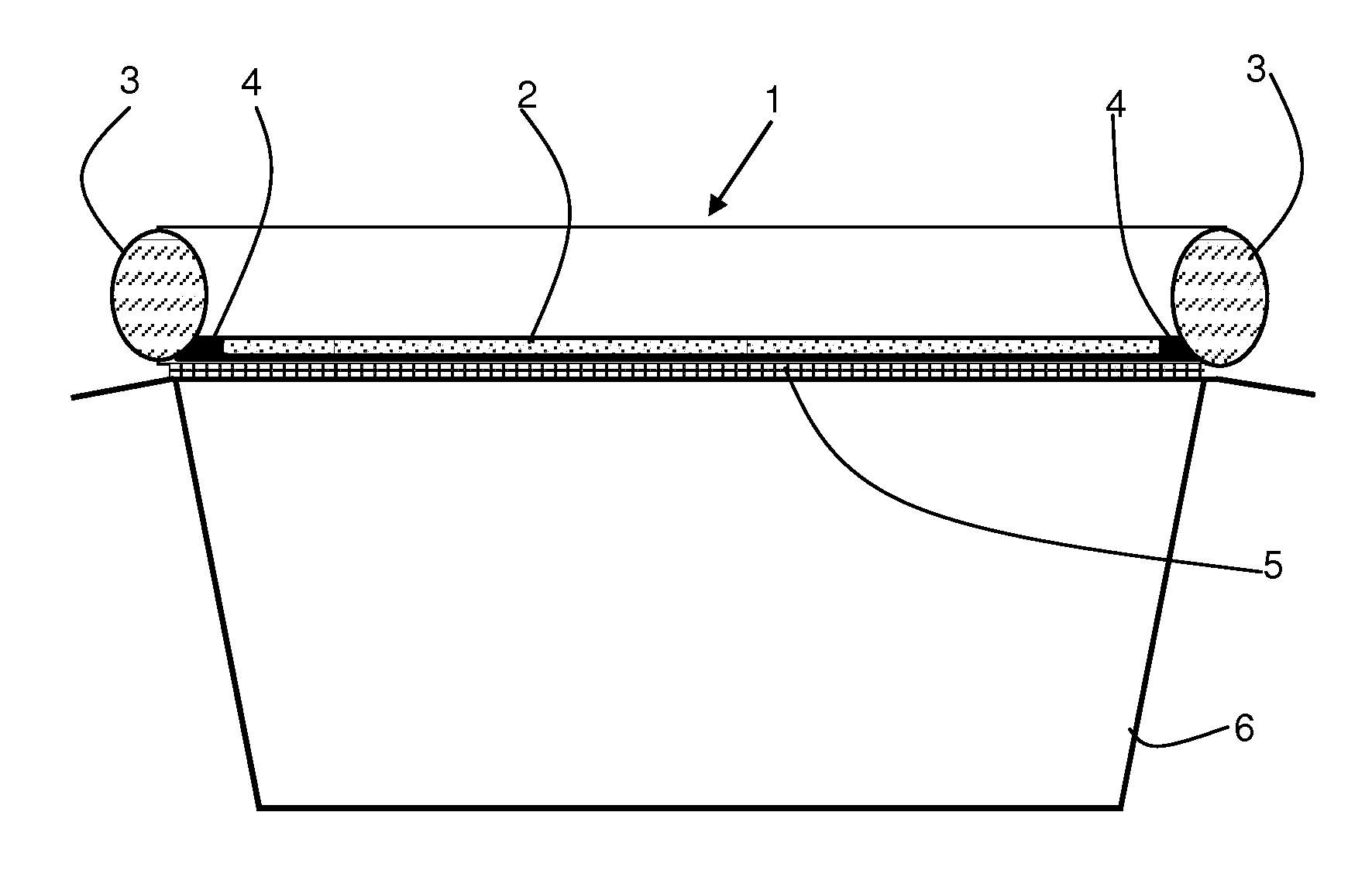

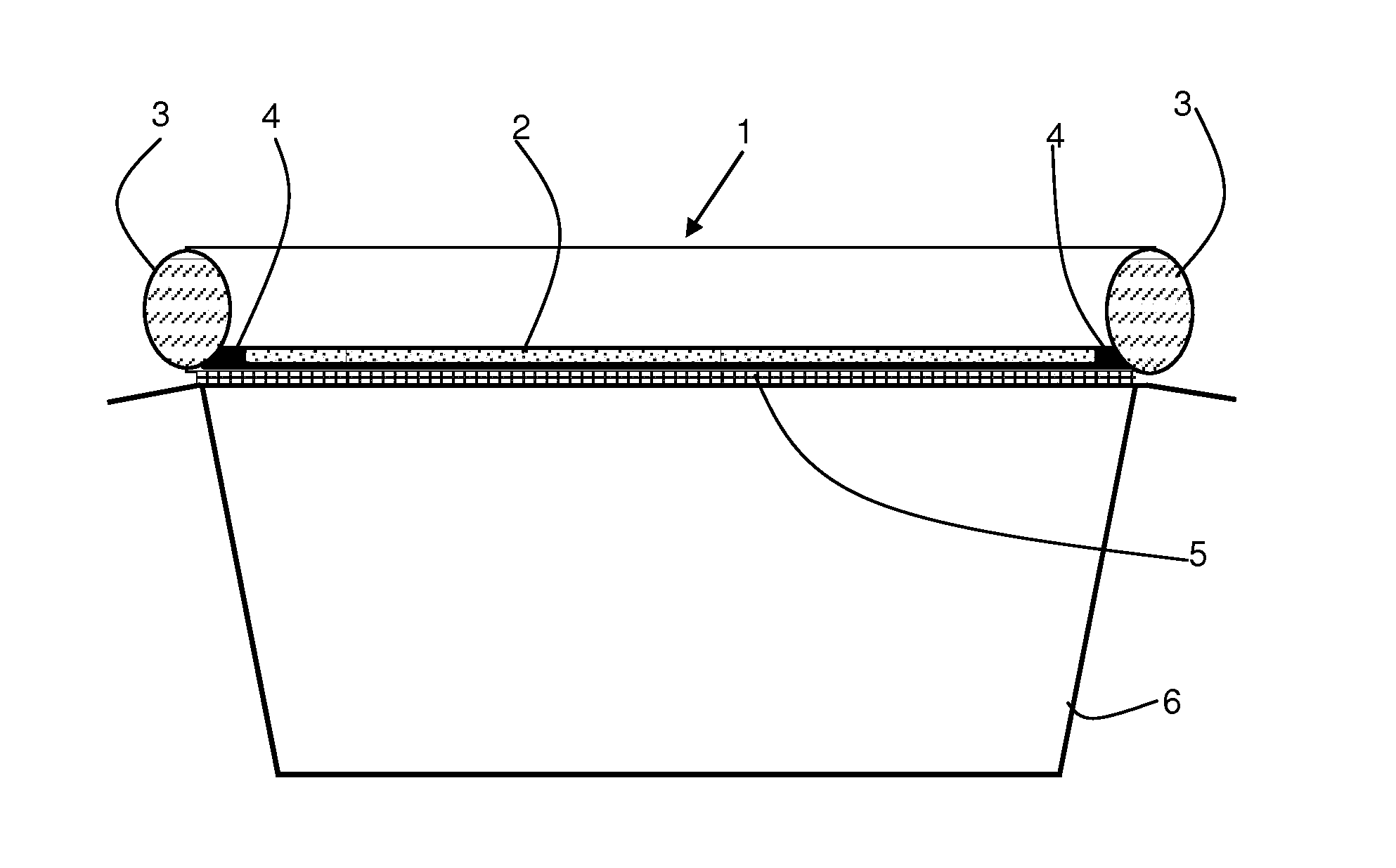

Seal structure for a wire-cut electric discharge machine

ActiveUS20060237915A1Facilitate countermeasuresImprove reliabilityEngine sealsPiston ringsEngineeringMechanical engineering

A seal structure that channels drainage of machining fluid from the periphery of an opening for a lower arm of a wire-cut electric discharge machine. A seal structure that restricts flowage to the outside of machining fluid through the opening (slot) in a side of a machining tank has a first seal means and a second seal means (a seal plate) affixed to the first seal means so as to cover the opening. An unevenly shaped part including ridges and grooves extending in the long direction of the first seal means is formed on the first seal means, and passages are provided that communicate with the groove and the outside to channel the machining fluid drainage path. The first seal means may be composed of a plurality of members. The passages are provided by notches or through-holes formed in a ridge, or by through-holes extending from the groove to the exterior of the first seal means without passing through the ridges. Suction means that sucks up machining fluid draining from the passages may be provided.

Owner:FANUC LTD

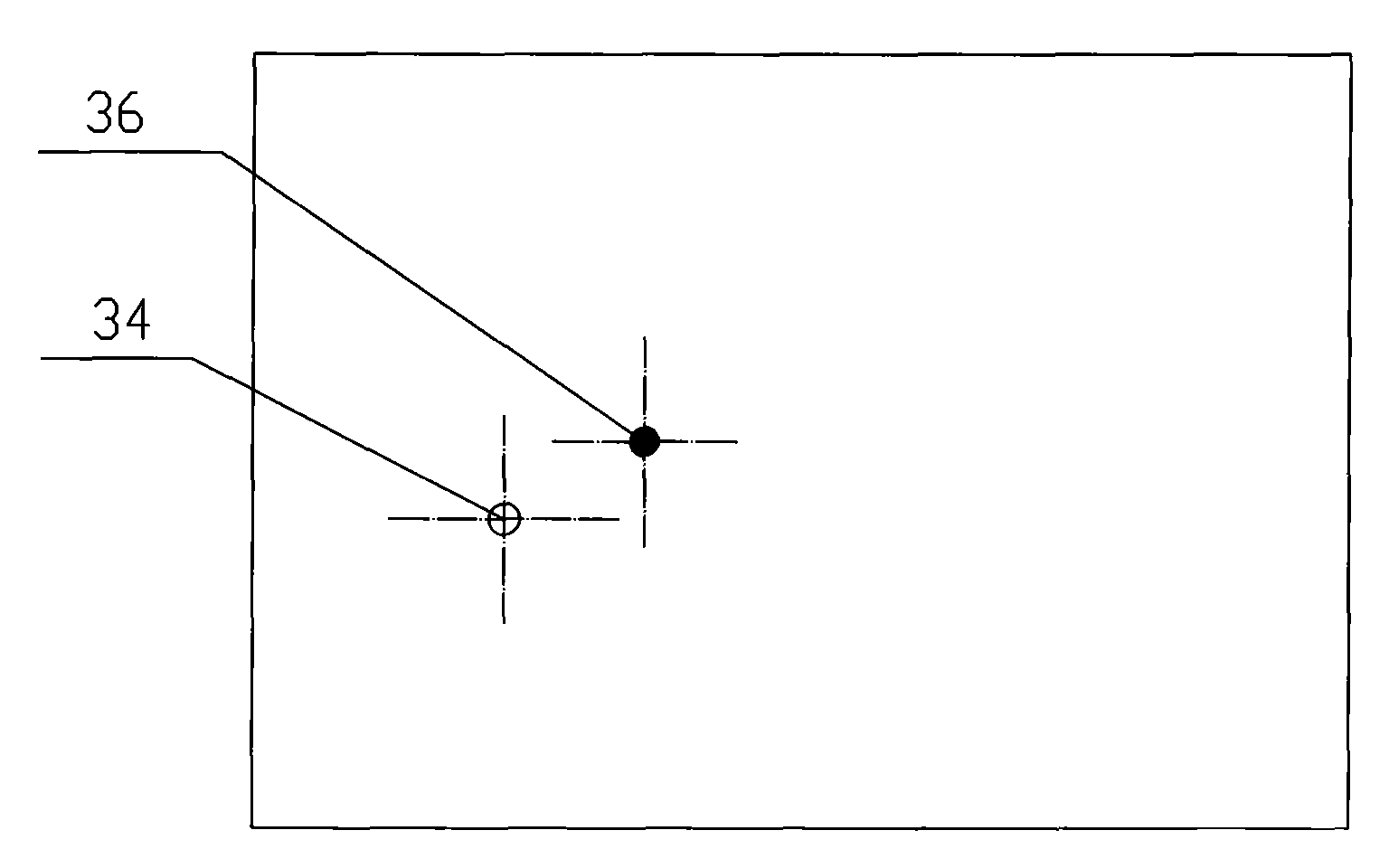

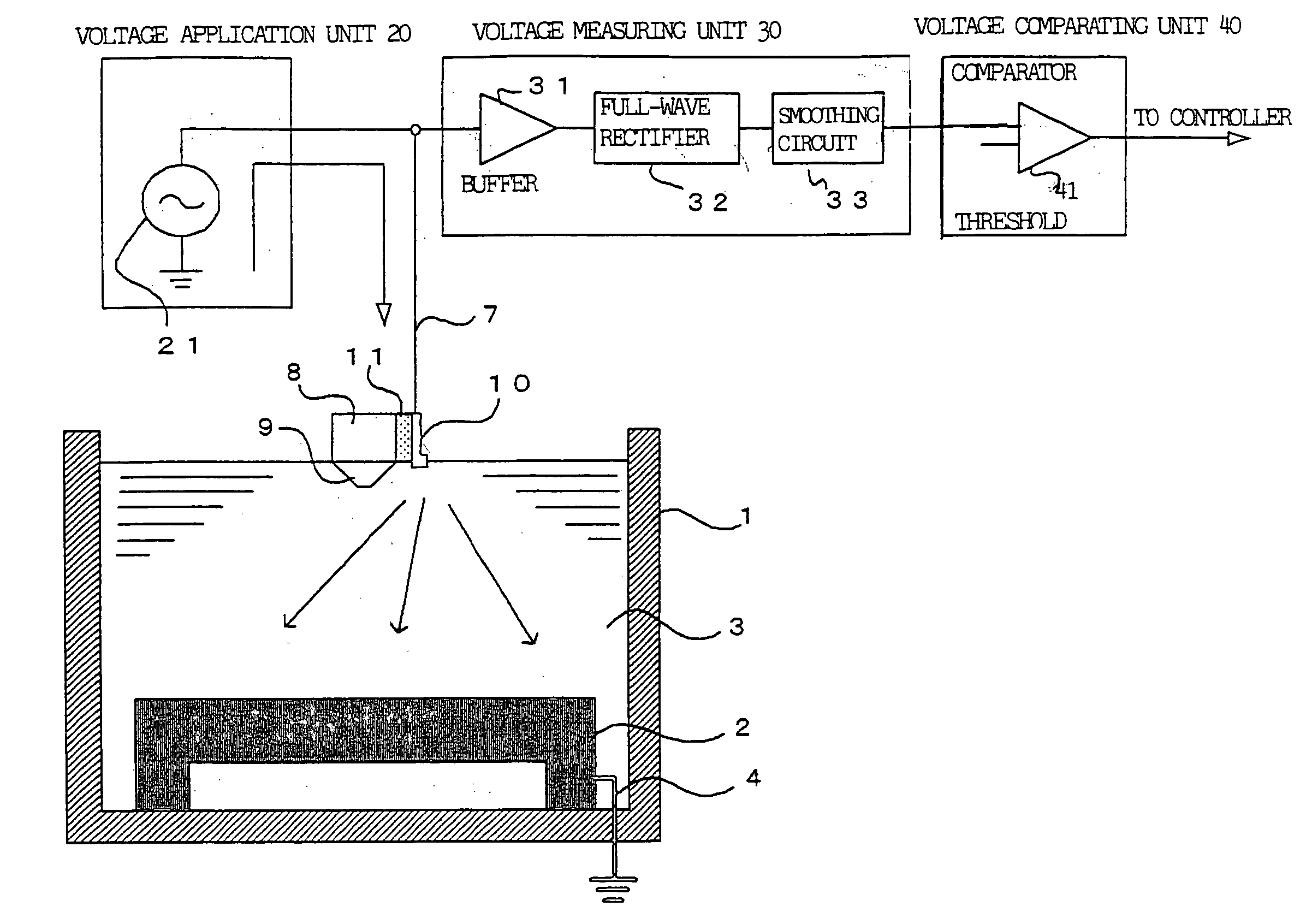

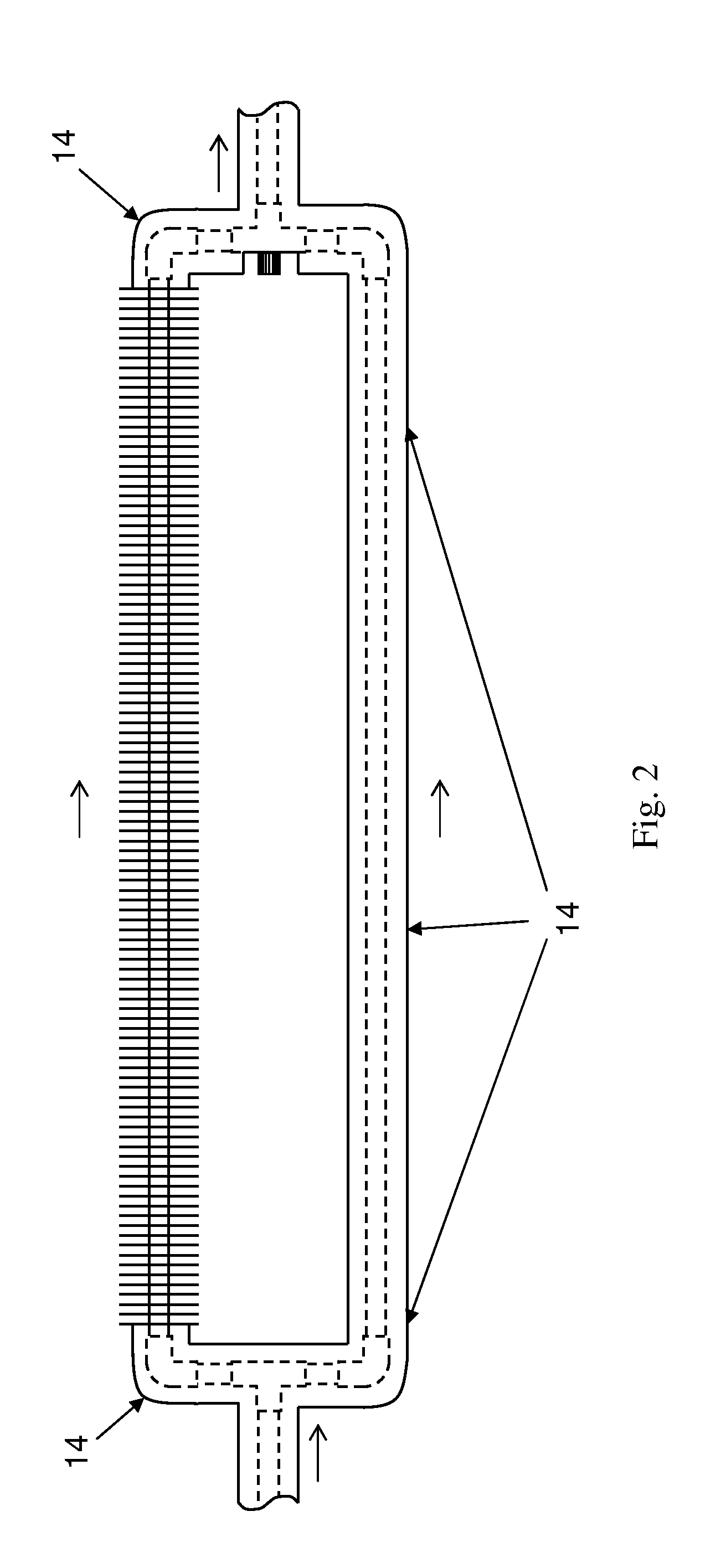

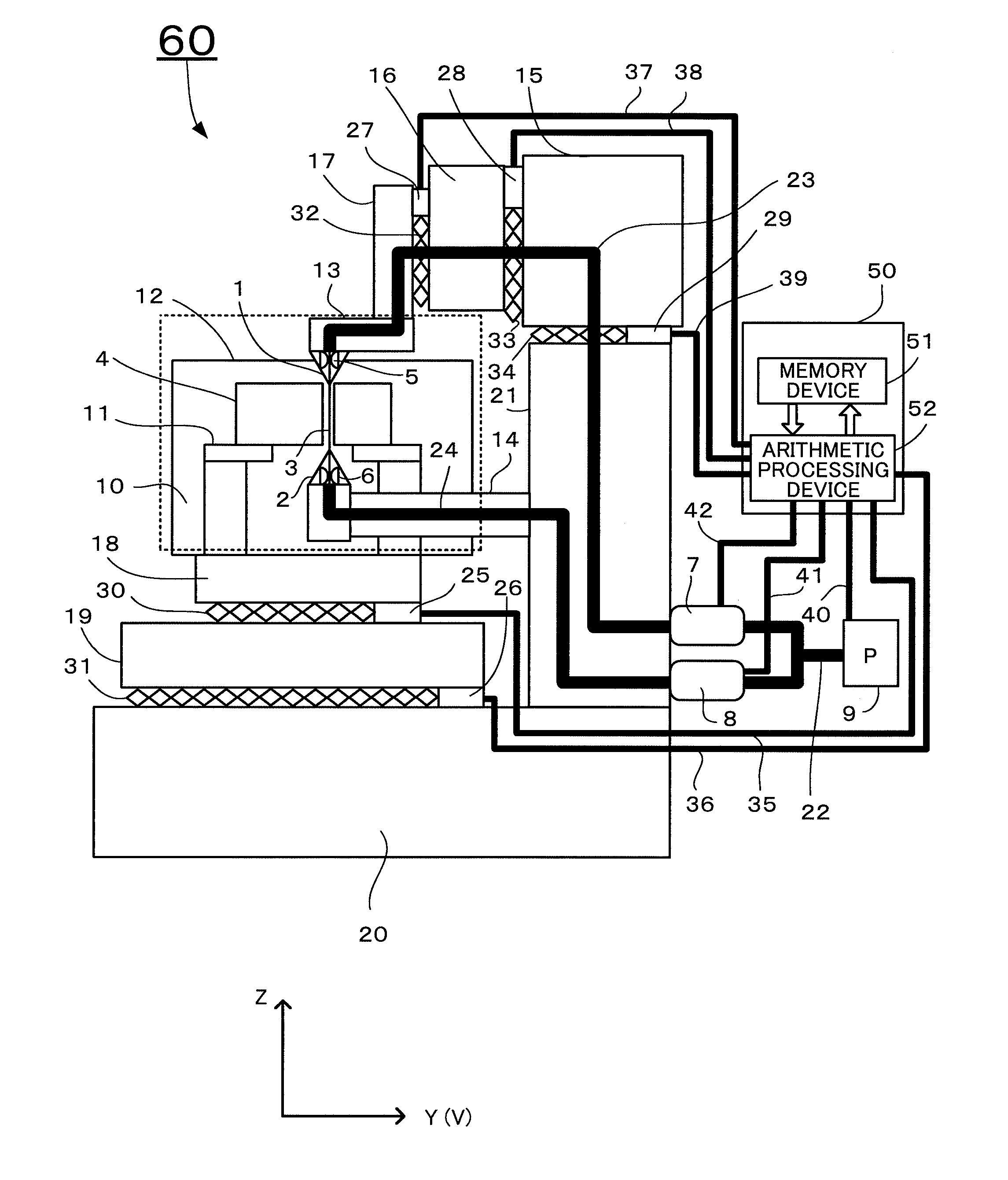

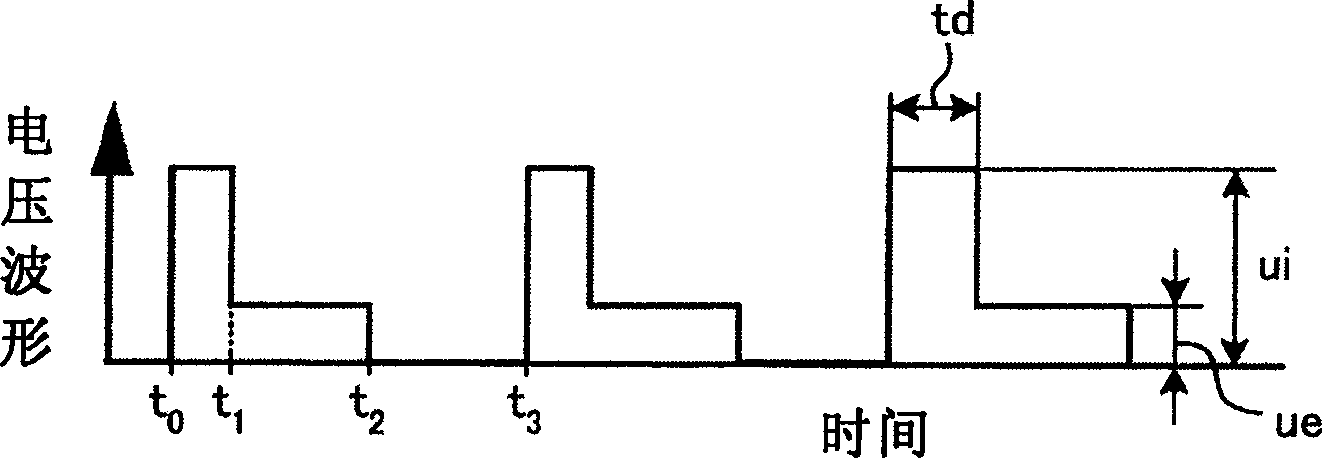

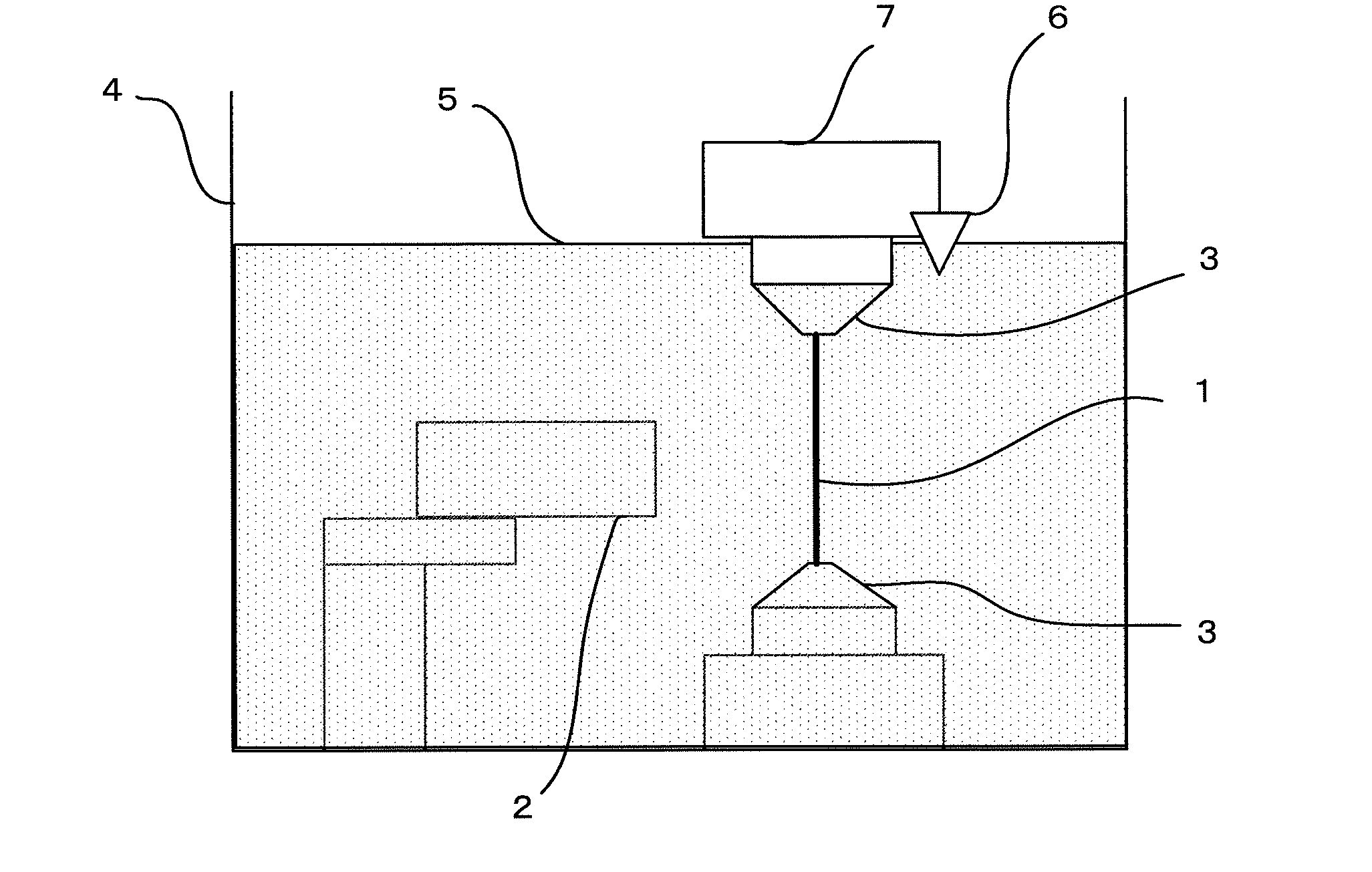

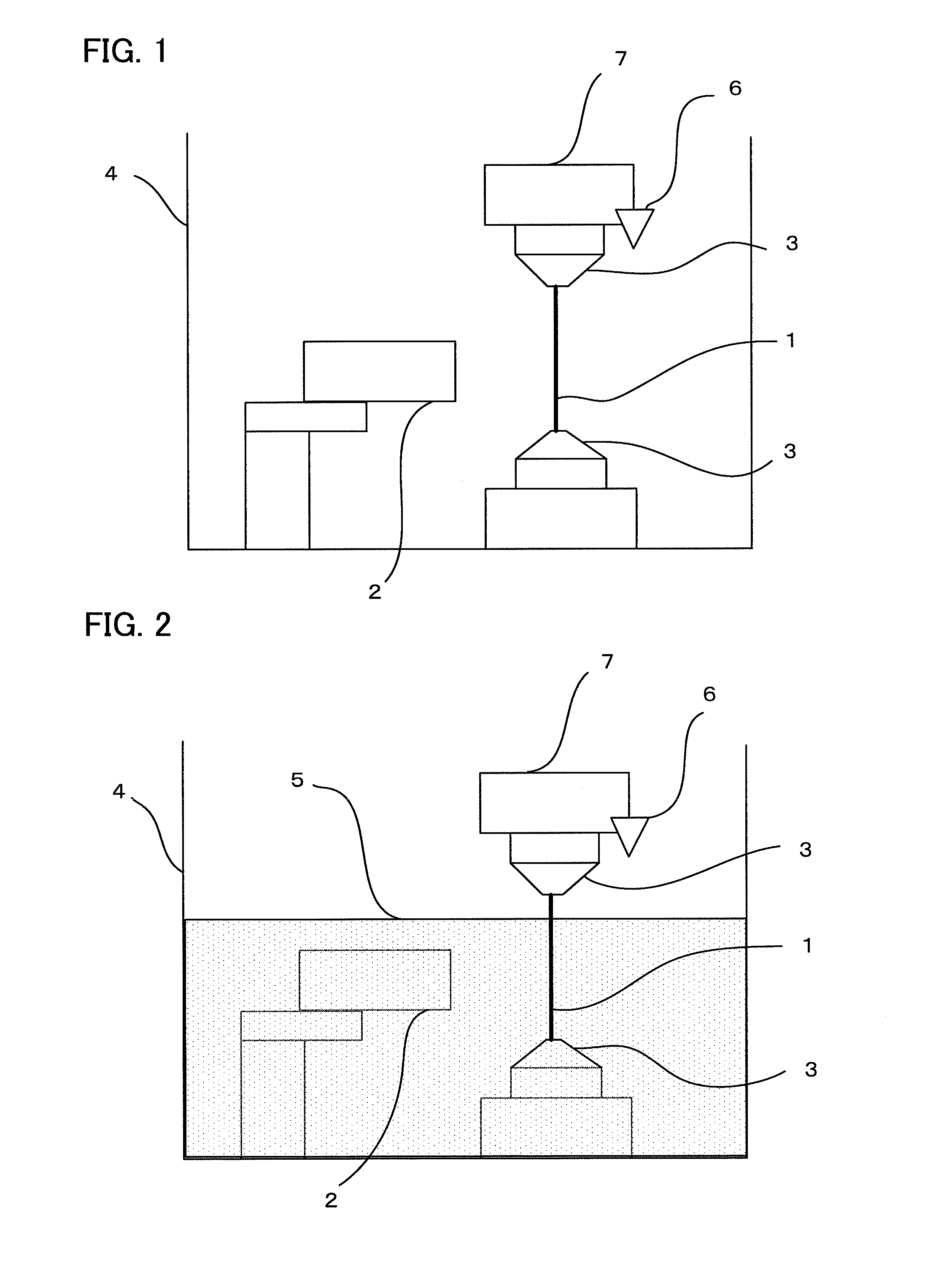

Machining fluid level detection device for wire cut electrical discharge machines

A table for placing a workpiece is grounded. An electrode for detecting machining fluid level is attached to an upper guide that guides the wire electrode, with the electrode insulated from the upper guide. A voltage is applied to the electrode, and the voltage between the electrode and the grounded table is detected and compared with a threshold value to determine whether the machining fluid level has reached a predetermined height.

Owner:FANUC LTD

Temperature limiter for fluidic systems

InactiveUS20150168020A1Simple and inexpensiveControl circuitry was requiredTemperature control without auxillary powerSolar heating energyThermal energyEngineering

The present invention limits fluid temperature at a point in a fluidic system to below a predetermined temperature by cooling the fluid when needed and without requiring a separate cold fluid source. The present invention “clips” the temperature of the fluid at a point in the system to within a temperature range and prevents overcooling the fluid. When the fluid temperature is below the temperature range, the temperature of the fluid is unchanged as it passes through the apparatus of the present invention. The present invention may operate without external power, can function in any orientation, and works for unpressurized and pressurized systems. The present invention has application in the areas of solar thermal energy systems, fluid tanks, engine oil and coolant systems, transmission fluid systems, hydraulic systems, machining fluid systems, and cutting fluid systems, among others.

Owner:PO BOX 32598

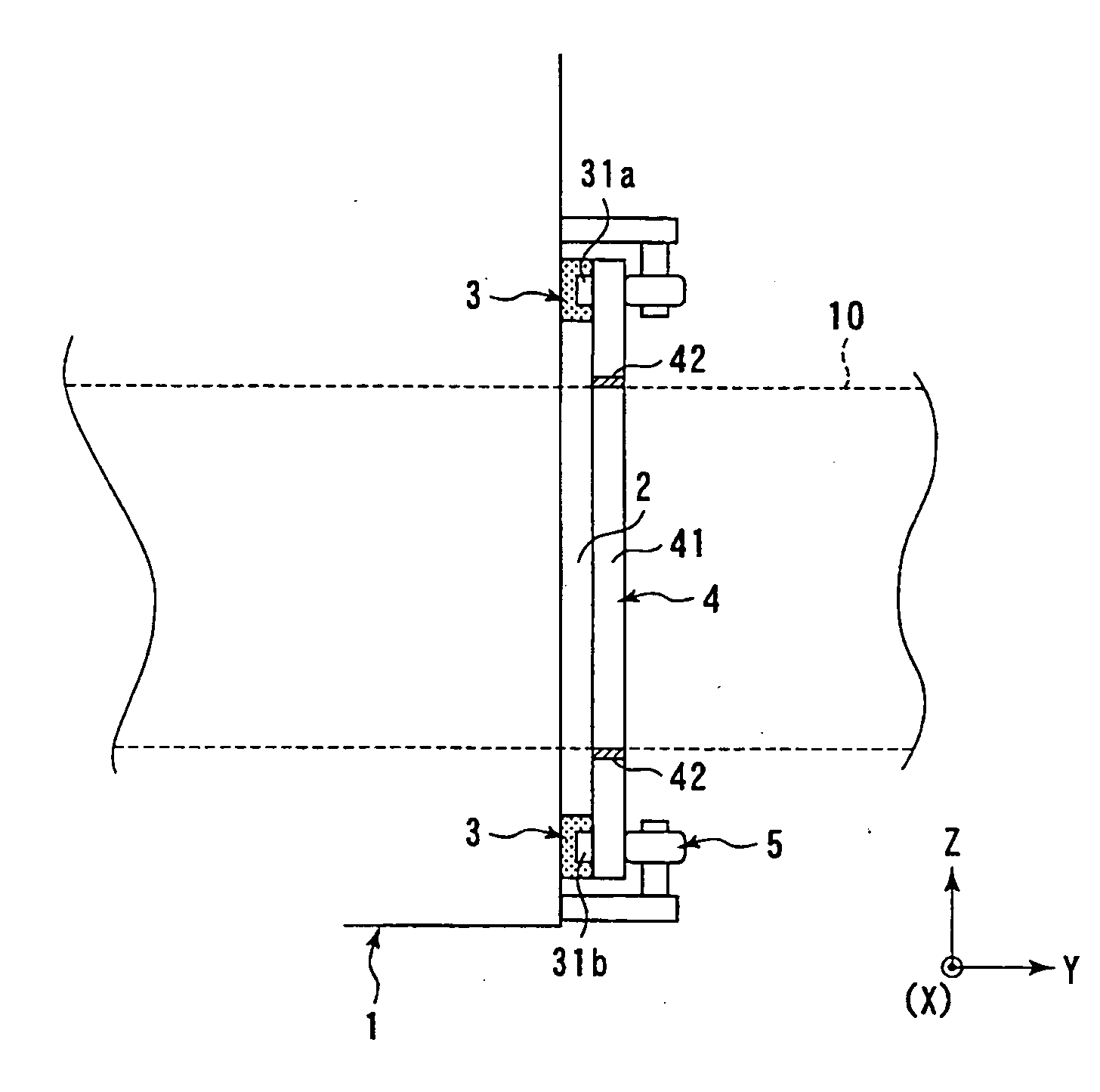

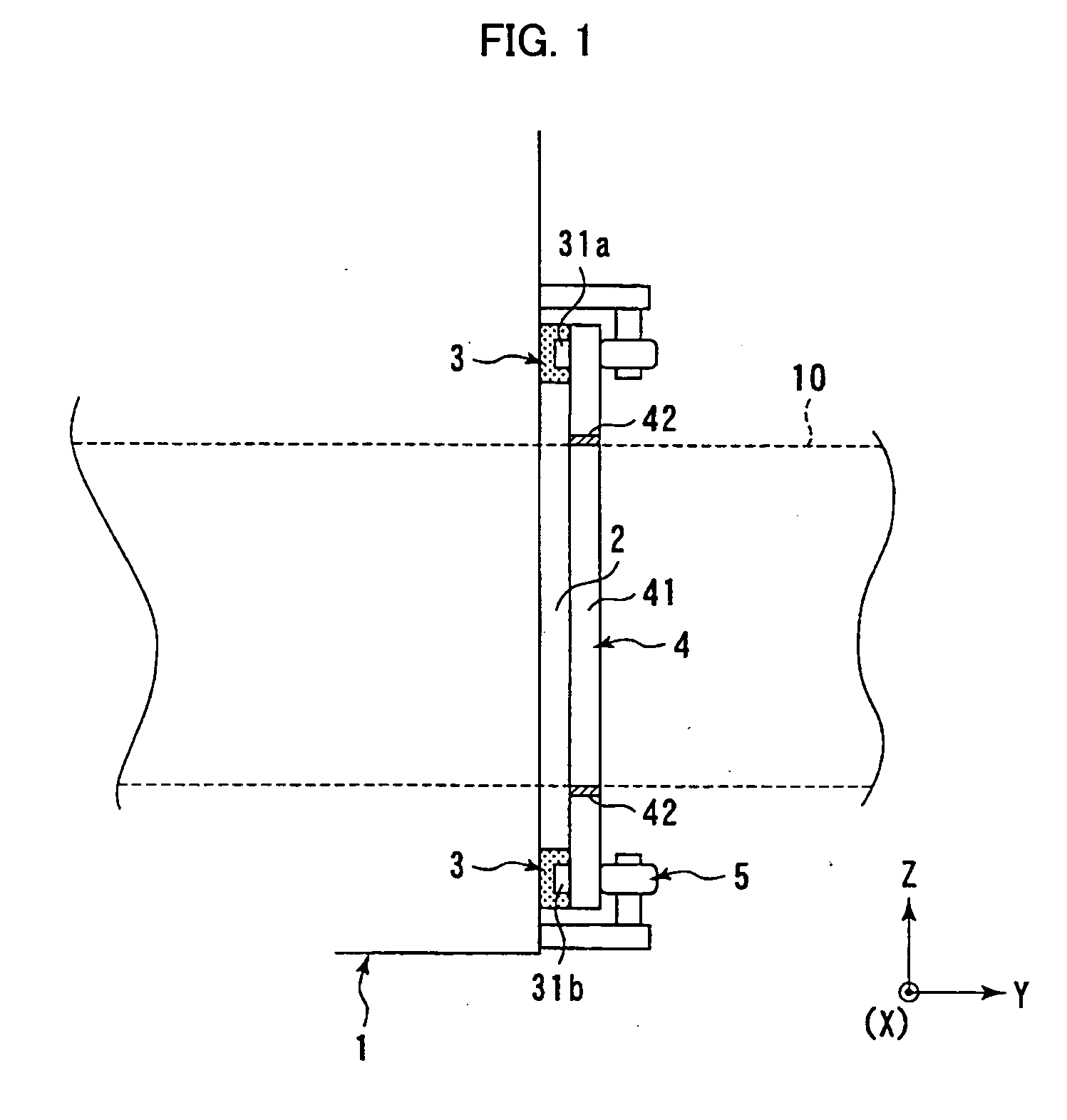

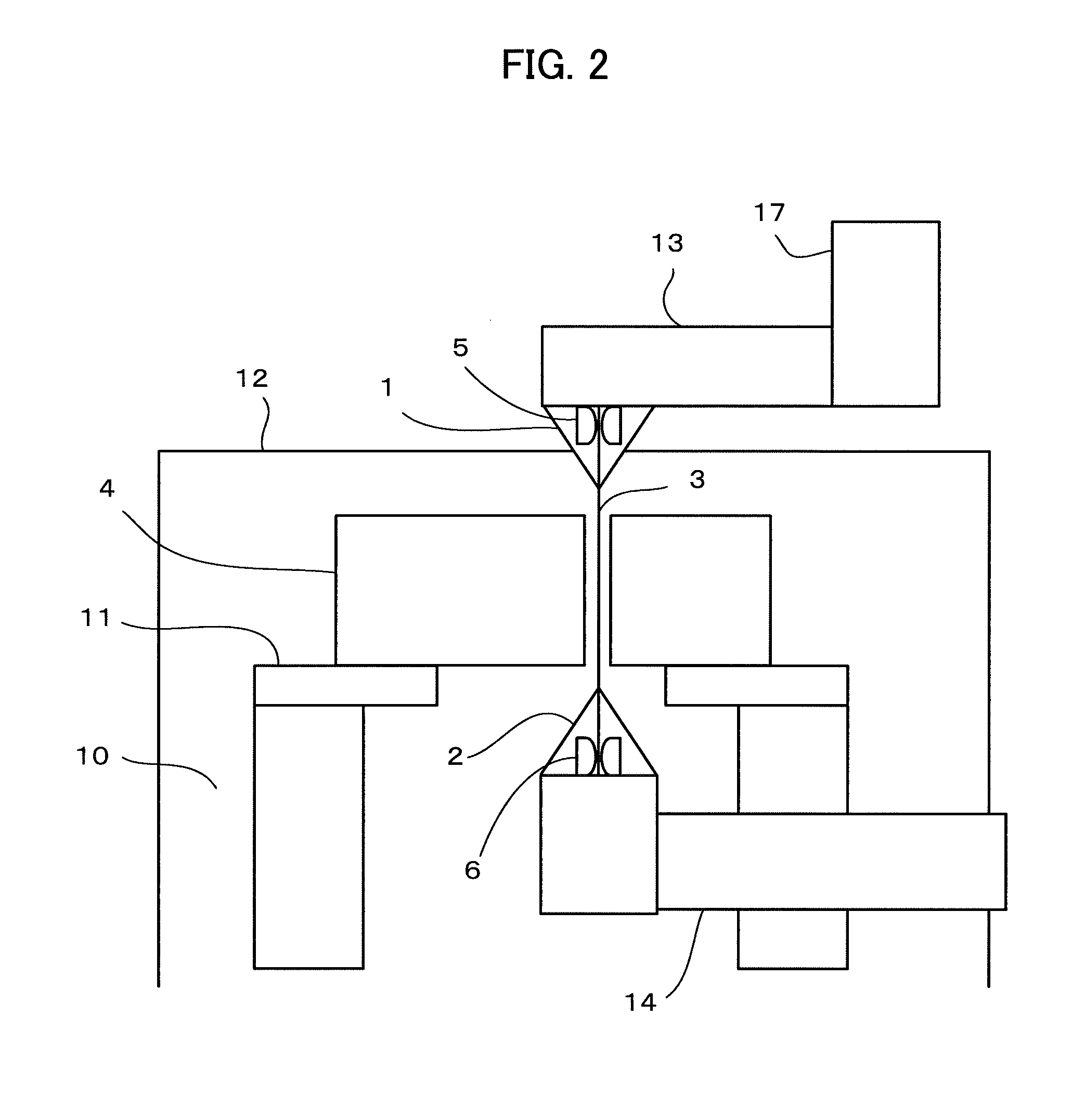

Wire electric discharge machine having function of compensating position of wire electrode

InactiveUS20140197138A1Programme controlElectrical-based machining electrodesEngineeringMachining fluid

While machining is carried out according to a machining program by an electric discharge machine, the pressures of a machining fluid supplied from upper and lower nozzles are detected and displacement amounts of upper and lower wire guides are obtained from the detected pressures. Further, positional compensation values of the upper and lower wire guides are calculated on the basis of the obtained displacement amounts, and command values of the machining program are compensated on the basis of the calculated positional compensation values.

Owner:FANUC LTD

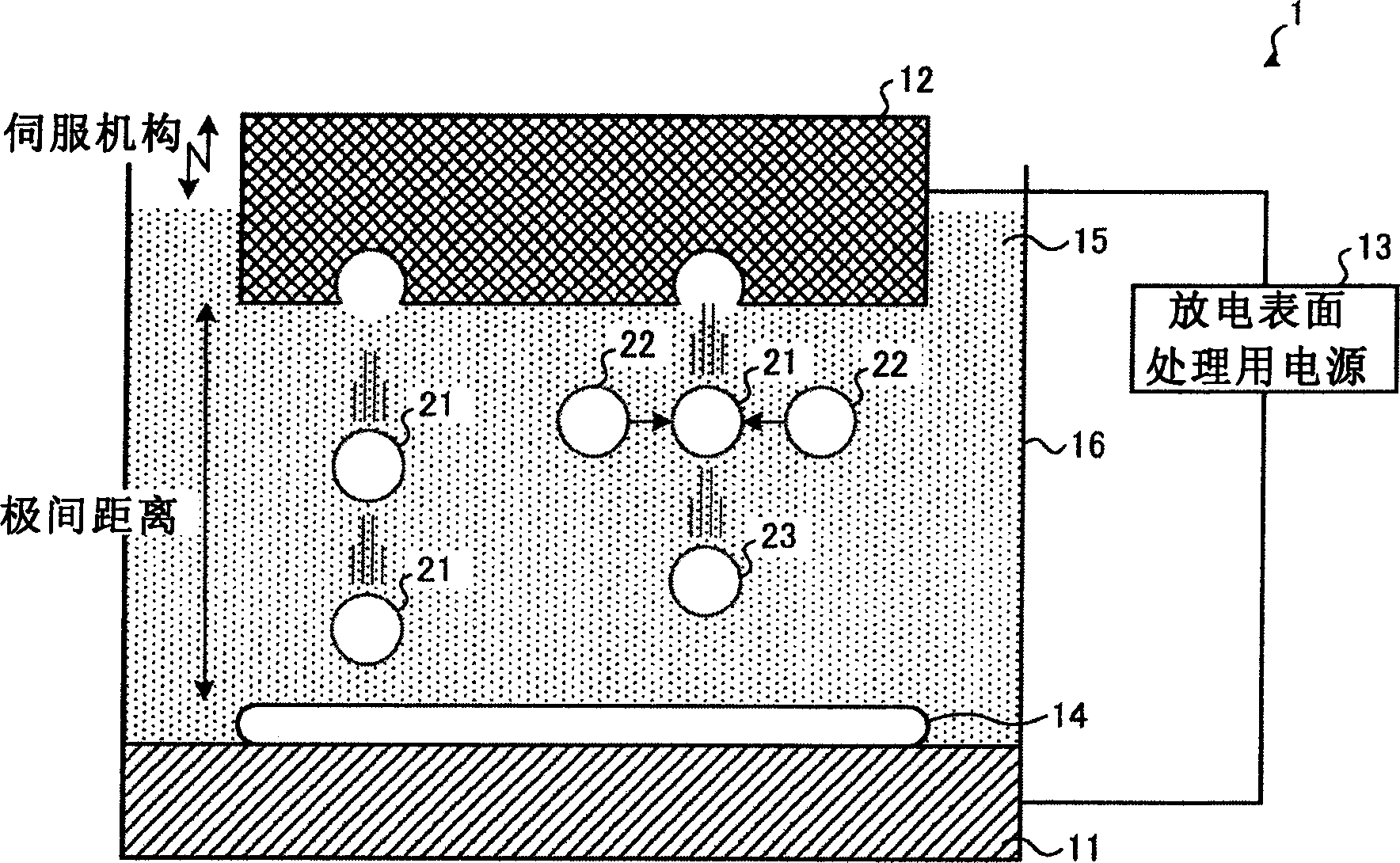

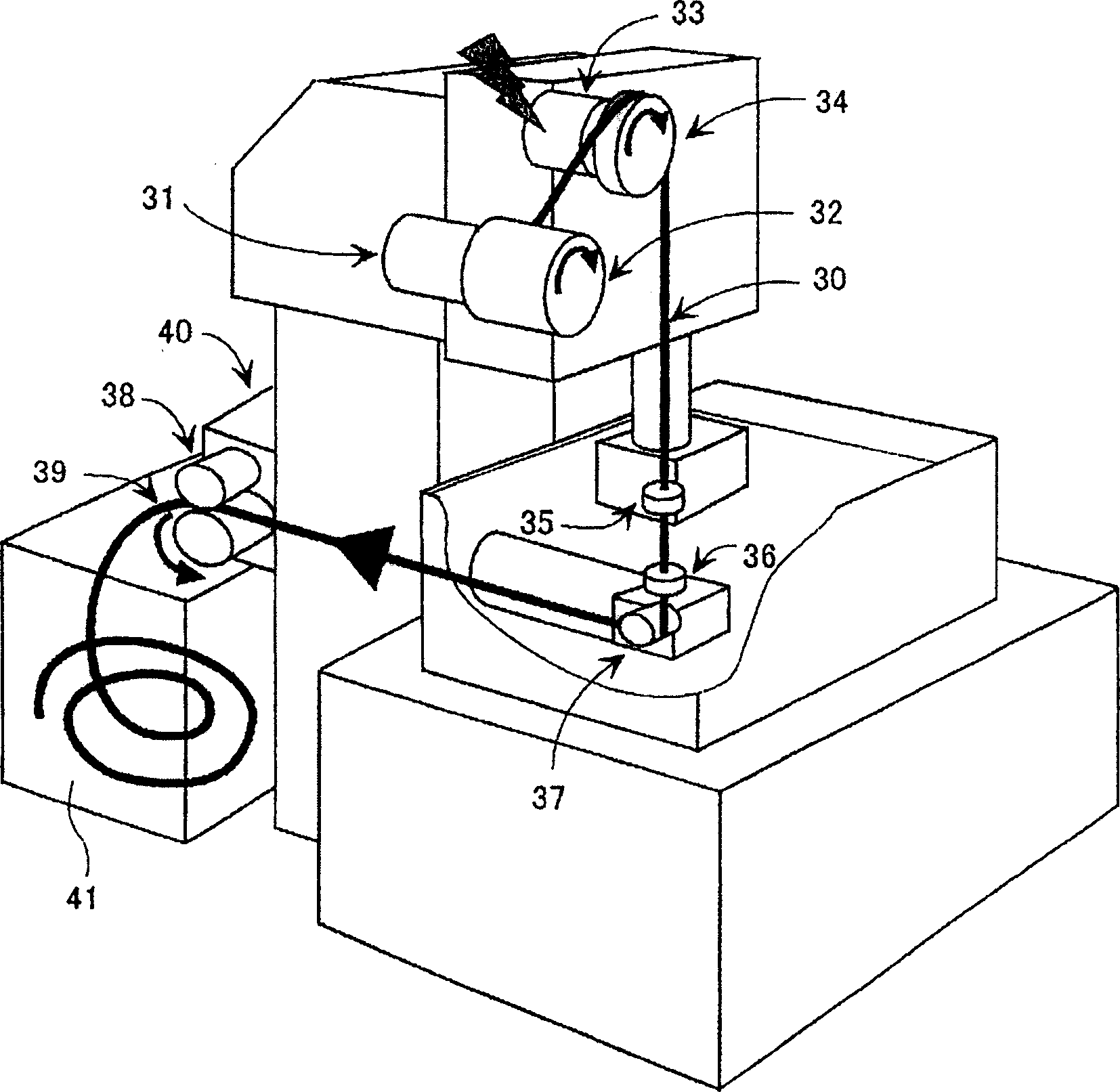

Discharge surface treatment electrode, process for producing discharge surface treatment electrode, discharge surface treatment apparatus and discharge surface treatment method

An electrode (12) is used for discharge surface treatment for causing, with a green compact obtained by compression-molding powder containing metal or a metallic compound as an electrode (12), electric discharge between the electrode (12) and a work piece (11) in a machining fluid (15) or in an air and forming, using discharge energy of the electric discharge, a film 14 consisting of an electrode (12) material or a substance generated by reaction of the electrode (12) material due to the discharge energy on a surface of the work piece. The powder has an average value of particle diameters not more than 3 micrometers.

Owner:MITSUBISHI ELECTRIC CORP +1

Aluminum metal machining fluid lubricating concentrate

A concentrate particularly suitable for aluminum machining containing: alkenylsuccinic acid derivative, sodium hydroxide salt; ether carboxylate; alkyl benzene sodium sulfate; fatty alcohol polyglycol ether; tall oil fatty acid having about 18 carbon atoms; trimethyl propylene; butylcarbitol; (44%) potassium hydroxide; and blended with about 50% by weight of a mineral oil and added to water to form a working composition.

Owner:RAYFIELD STEVEN E

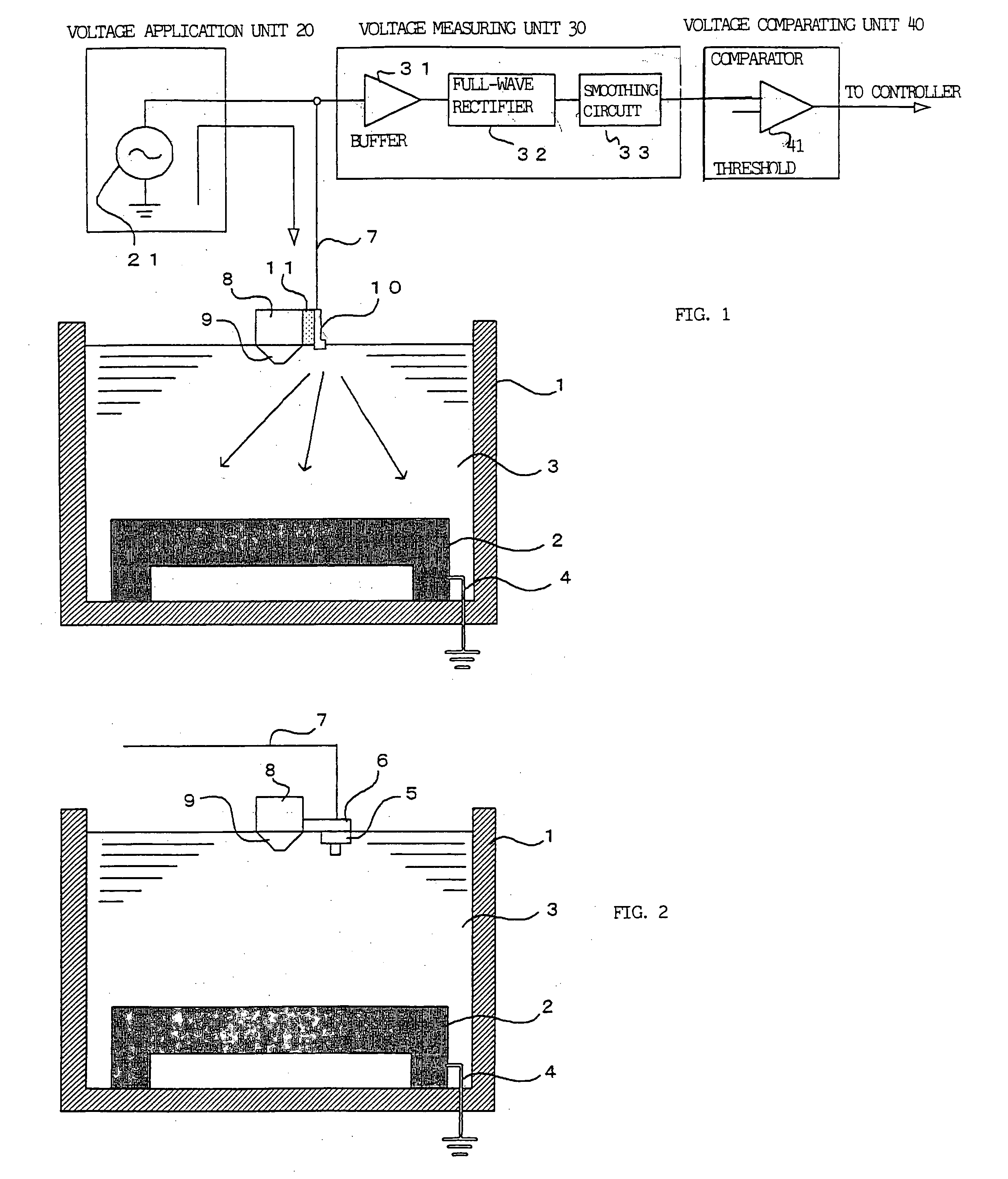

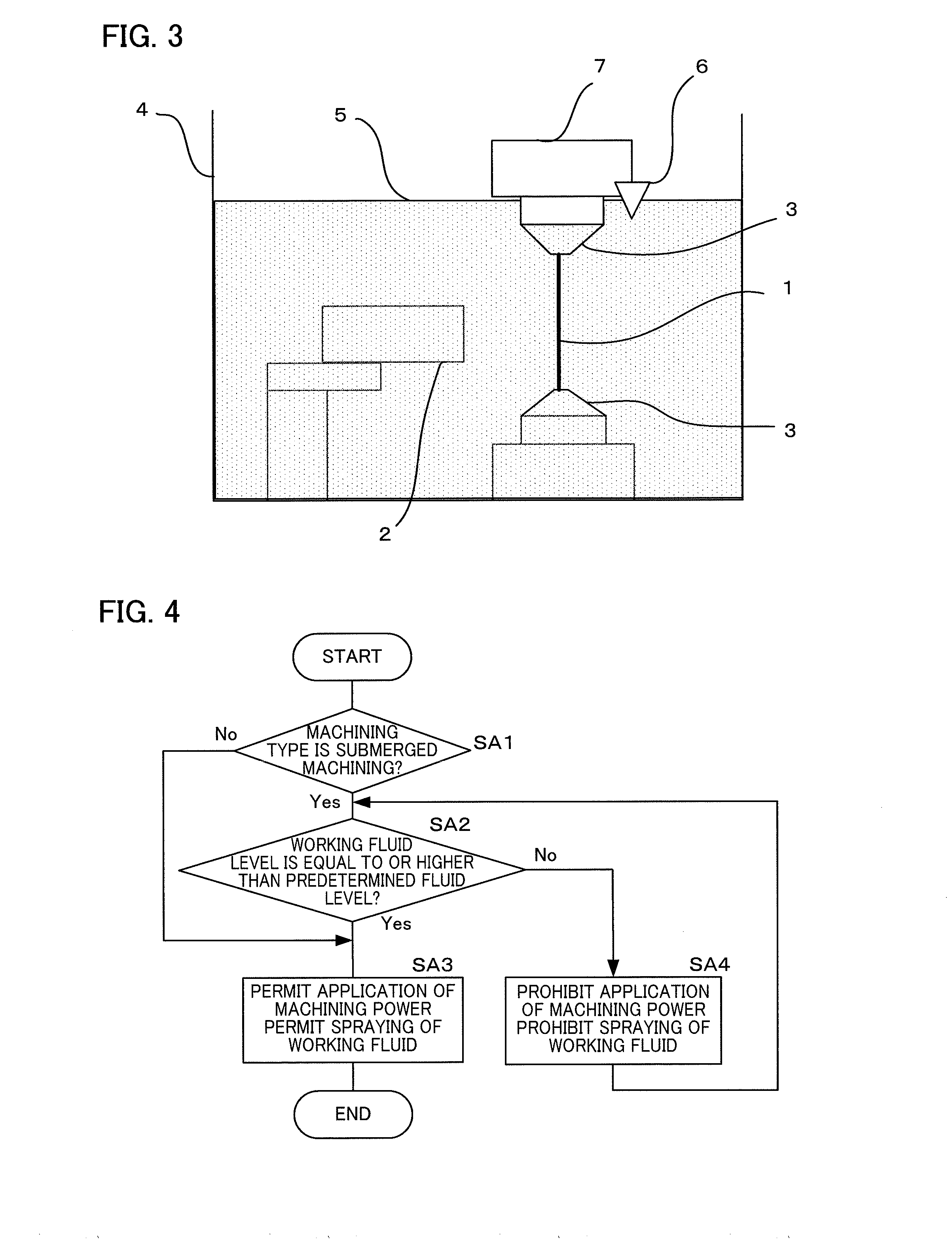

Wire electric discharge machine having function for discriminating state in work tank

The wire electric discharge machine determines whether machining is submerged machining or flushing machining. If the machining is the submerged machining, when a fluid level of working fluid is lower than a predetermined height, the wire electric discharge machine prohibits a machining power from being applied. Thus, it is possible to prohibit the machining power from applied in a state in which the working fluid is insufficient and the submerged machining cannot be appropriately performed, thereby preventing an electric shock due to contact with a wire electrode and machining parts of a workpiece and preventing the working fluid from scattering to the air, and improving safety.

Owner:FANUC LTD

High-performance galvanized copper alloy wire rod and preparation method thereof

InactiveCN105349840AImprove corrosion resistanceStable tensile strengthHot-dipping/immersion processesZinc alloysCobalt

The invention discloses a high-performance galvanized copper alloy wire rod and a preparation method thereof. The high-performance galvanized copper alloy wire rod comprises a core material and a clad layer. The core material is prepared from the following raw materials of, by weight, 2.3-4.4 parts of germanium, 1.3-2.4 parts of tin, 5-8 parts of lead, 3-6 parts of nickel, 1-4 parts of tungsten, 1.3-5.1 parts of silver, 2.1-5.2 parts of chrome, 2-4 parts of aluminum, 30-50 parts of copper, 2-6 parts of cobalt, 4-11 parts of molybdenum, 1.2-4.4 parts of neodymium, 3.3-3.5 parts of cerium, 2-4 parts of carbon and 10-12 parts of thermal conductive fillers. According to the high-performance galvanized copper alloy wire rod and the preparation method thereof, the corrosion resistance of a wire in machining fluid is increased, the cutting performance of the wire is improved significantly, and the obtained wire has the stable tensile strength; the wire rod is provided with a certain copper-zinc alloy layer, so that the gasification temperature is increased, and more heat is conducive to being taken away; the operability is high; the preparation steps are few; the production equipment is simple, therefore, products meeting the requirements are prepared easily, and the large-scale production and the automatic production are achieved easily.

Owner:WUHU CHUJIANG ALLOY COPPER

Environmental-friendly water-based cutting fluid

InactiveCN103361164AImprove general performanceImprove corrosion resistanceLubricant compositionLiquid wasteHazardous substance

The invention relates to the technical field of cutting fluids for metals, especially to an environmental-friendly water-based cutting fluid. The environmental-friendly water-based cutting fluid comprises a water-based basic solution, a cleaning agent, an oiliness agent, an antirust agent, a dimeric acid rare earth compound, a copper alloy corrosion inhibitor, an anticorrosive agent, a defoaming agent, an aluminum alloy corrosion inhibitor and a stabilizing agent of the aluminum alloy corrosion inhibitor. The cutting fluid provided by the invention has good versatility, is applicable to a plurality of metals and processing of aluminum alloy parts, exerts an excellent corrosion resistance effect on a copper alloy and an aluminum alloy and can effectively prevent the color of a sensitive aluminum alloy from changing; the cutting fluid has an excellent lubricating property, thereby ensuring processing precision and the service life of a cutter; the cutting fluid has an excellent antirust property, thereby preventing a workpiece and expensive machine tool equipment from rusting; the cutting fluid has protruding anticorrosion capability and hard water resistance; and the cutting fluid can be cyclically used for a long time, does not contain poisonous and harmful substances like nitrous acid, is beneficial for the environment and health, has good liquid waste disposal performance and can be treated as common industrial waste water.

Owner:LUNAN RES INST OF COAL CHEM

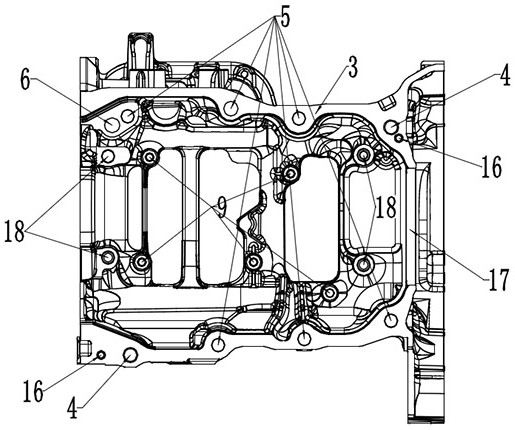

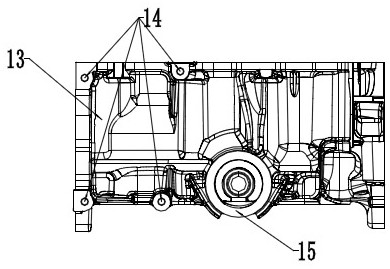

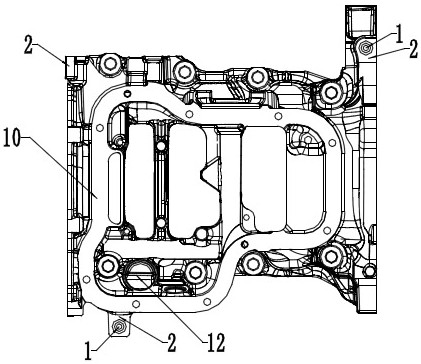

Machining method for lower cylinder body single body of three-cylinder engine

ActiveCN112122886AHigh precision requirementsImprove stabilityCasingsMachines/enginesEngineeringCylinder block

The invention relates to a machining method for a lower cylinder body single body of a three-cylinder engine. The machining method comprises the steps that a lower cylinder body to be machined is clamped on a clamp; a cylinder body connecting face is pre-milled; a second-order positioning hole is finely drilled; bolt running holes and oil duct holes in the periphery are finely drilled; a lower oilpan mounting face is milled, and threaded holes are drilled; a liquid level sensor mounting hole and a liquid level oil filter mounting hole are finely machined; a filter mounting face and threaded holes are finely machined; a third-order positioning hole is finely drilled; the cylinder body connecting face is finely milled; a fourth-order positioning hole is finely drilled; an oil seal mountinghole is finely milled; a balance shaft mounting face is finely milled, and threaded holes are drilled; a chain cover mounting face and a gearbox mounting face are pre-milled, and drilling threaded holes are drilled; oil duct hole sealing grooves and end faces are milled; oil duct holes and threaded holes are drilled in the end faces of the oil duct holes; and the chain cover mounting face, a starter mounting face and the gearbox mounting face are finely milled. The machining method is used for machining the lower cylinder body of the novel three-cylinder engine, the high-precision requirementand high stability of products are achieved through a more optimized process, and stable mass production and high machining precision of the products are guaranteed.

Owner:GUANGDONG HONGTUNANTONGDIE CASTING +1

Machine tool

InactiveUS20080267723A1Low costSimple structureTurning machine accessoriesPlaning/slotting machinesEngineeringMachine tool

A machine tool capable of removing chips from the machine with a simple structure. A continuous groove is formed at the lowest position of a splash guard surrounding a bed so as to extend from a rear end of the machine along one side portion, a front portion and the other side portion of the bed. Machining fluid brought into the groove from a coolant tank flows along the groove and is recovered into the coolant tank. A bottom of the groove has a continuous slope such that an inlet side where the machining fluid is brought in through the discharge port is highest (or the groove is shallowest) and a discharge side for the coolant tank is lowest (or the groove is deepest). The chips dropped in the groove are discharged together with the machining fluid into the coolant tank where the chips and the machining fluid are separated.

Owner:FANUC LTD

Oil collecting device

InactiveUS20120241460A1Light weightEasy to deployOther chemical processesSynthetic resin layered productsMachining fluidWaste management

A mat for use in a portable collector for machine fluids, the mat having a self supporting perimeter wall upstanding from a base layer, the base layer comprising a layer of an oil permeable hydrophobic material and the wall comprising a layer of water permeable oleophilic material, whereby oily fluid falling on the mat passes through the base layer and water falling on the mat escapes through the wall.

Owner:MANVERS ENG

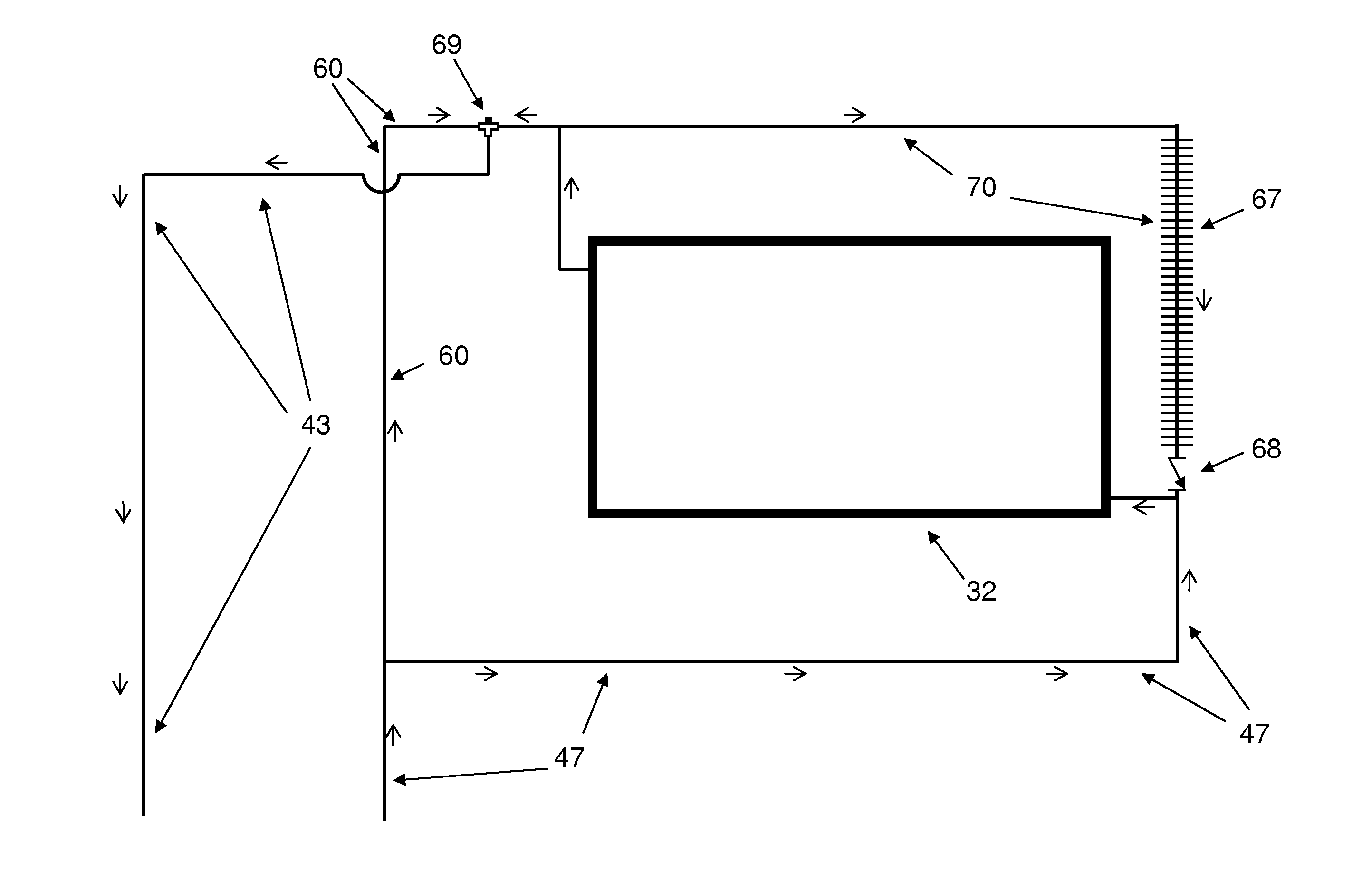

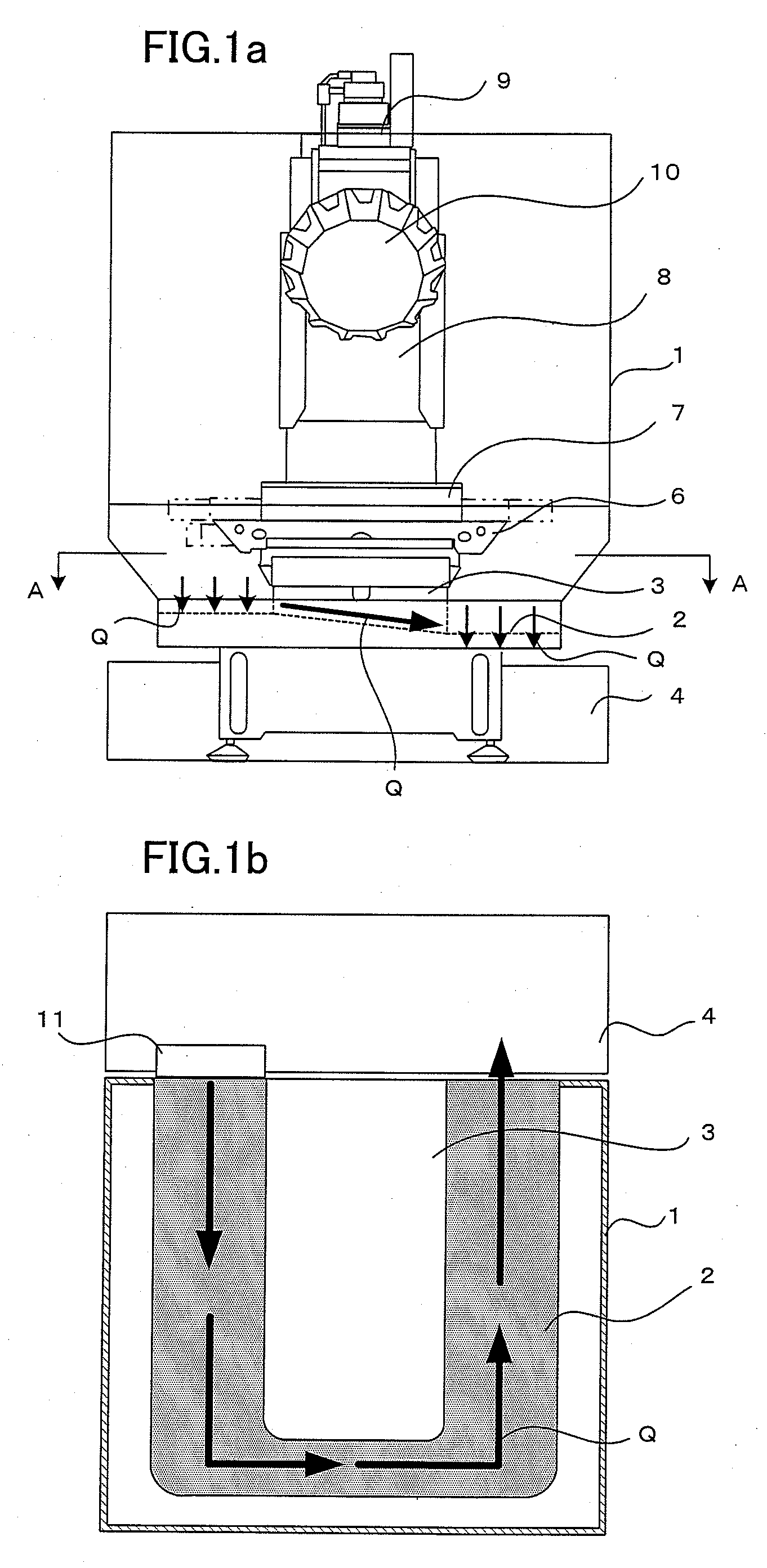

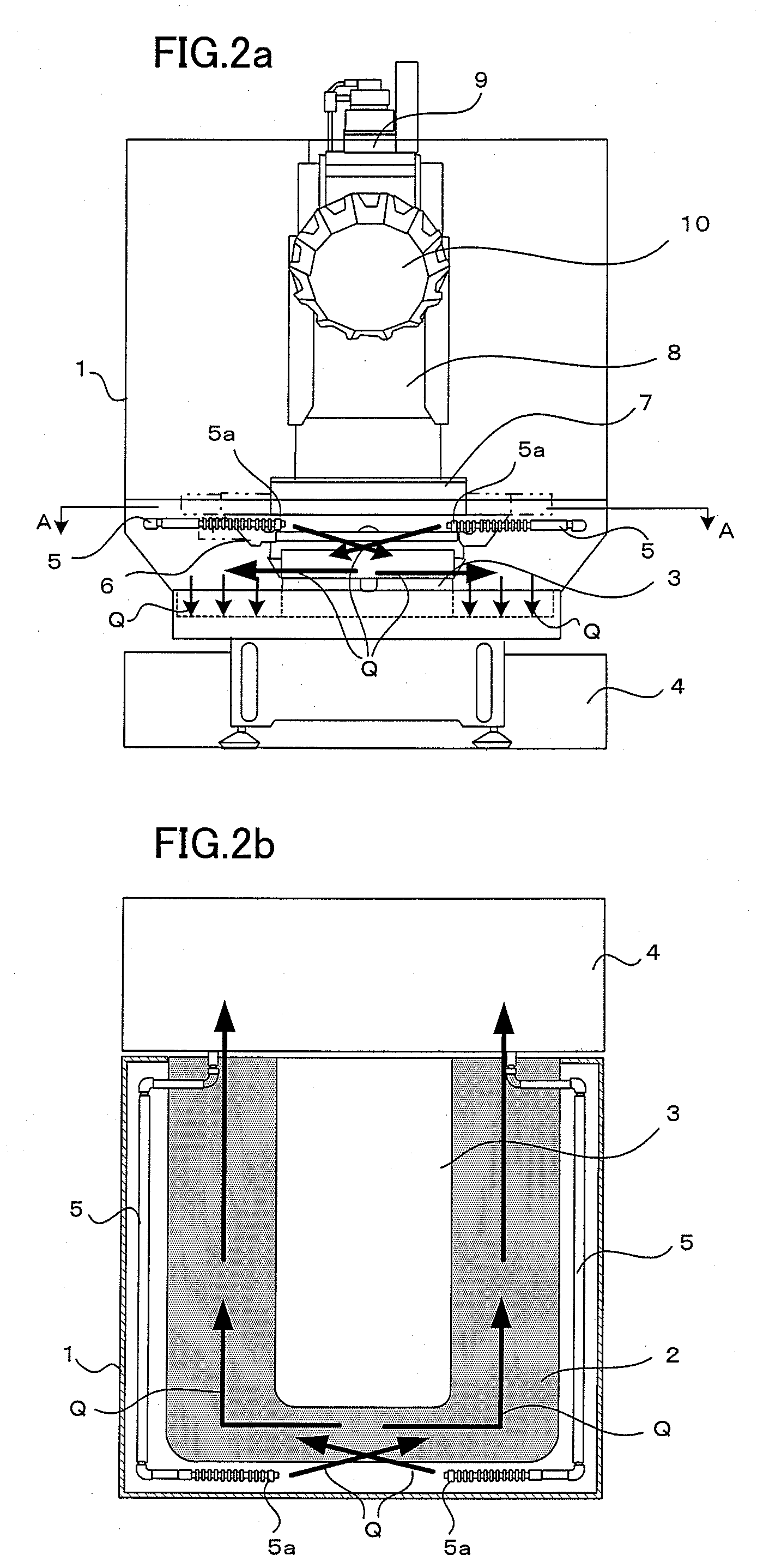

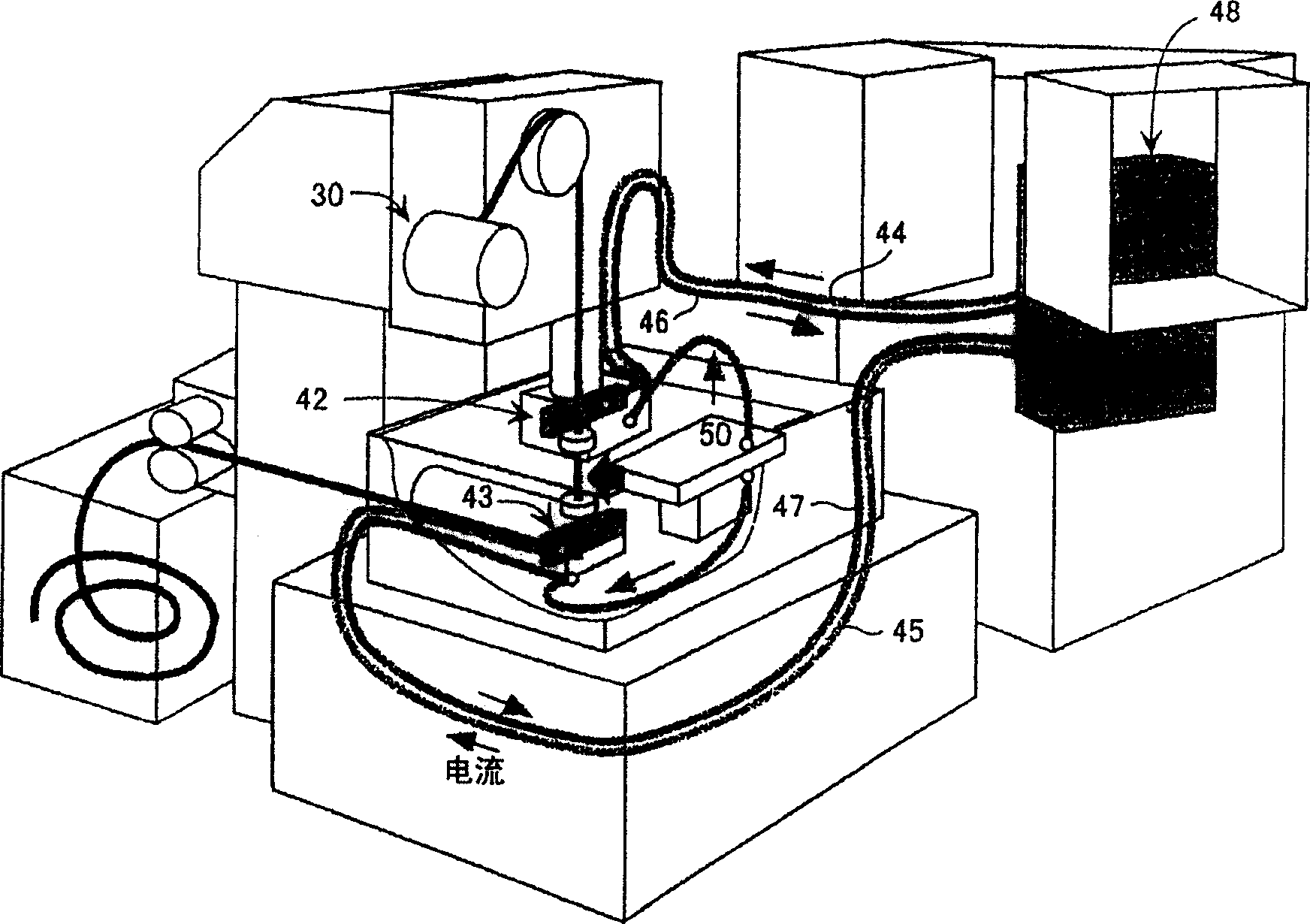

Electric discharge machine and machining fluid cooling device

InactiveCN1701886ATemperature controlImprove machining accuracyElectrical-based machining electrodesTemperature controlLine tubing

An electric discharge machine controls temperature fluctuations of machining fluid discharged by a discharge pump so as to improve machining accuracy, and a machining fluid cooling device keeps the temperature of the discharged machining fluid constant regardless of the operating state of the discharge pump. The electric discharge machine pumps machining fluid in a temperature controlled clean fluid tank with a discharge pump and discharges the machining fluid to a machining area through piping, and has a machining fluid cooling device for cooling machining fluid discharged from the discharge pump. The machining fluid cooling device passes a portion of the piping through the clean fluid tank and exchanges heat between the machining fluid inside the piping and the clean fluid in the clean fluid tank, thus dispersing the heat added from the discharge pump to the clean fluid side and lowering the temperature of the machining fluid inside the piping.

Owner:FANUC LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com