Patents

Literature

32350 results about "Drill hole" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method and apparatus for fastening together structural components

Owner:HAYTAYAN HARRY M

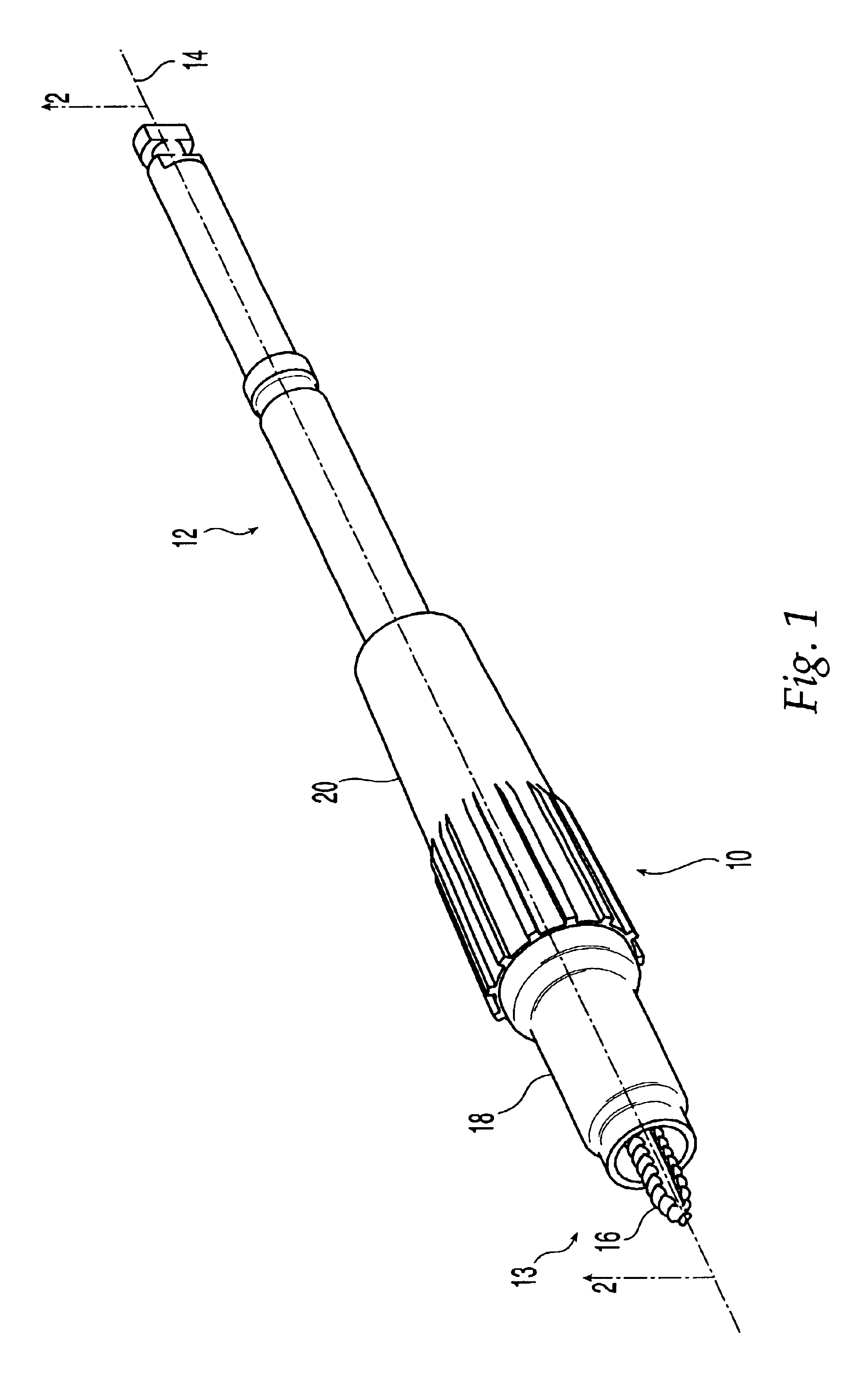

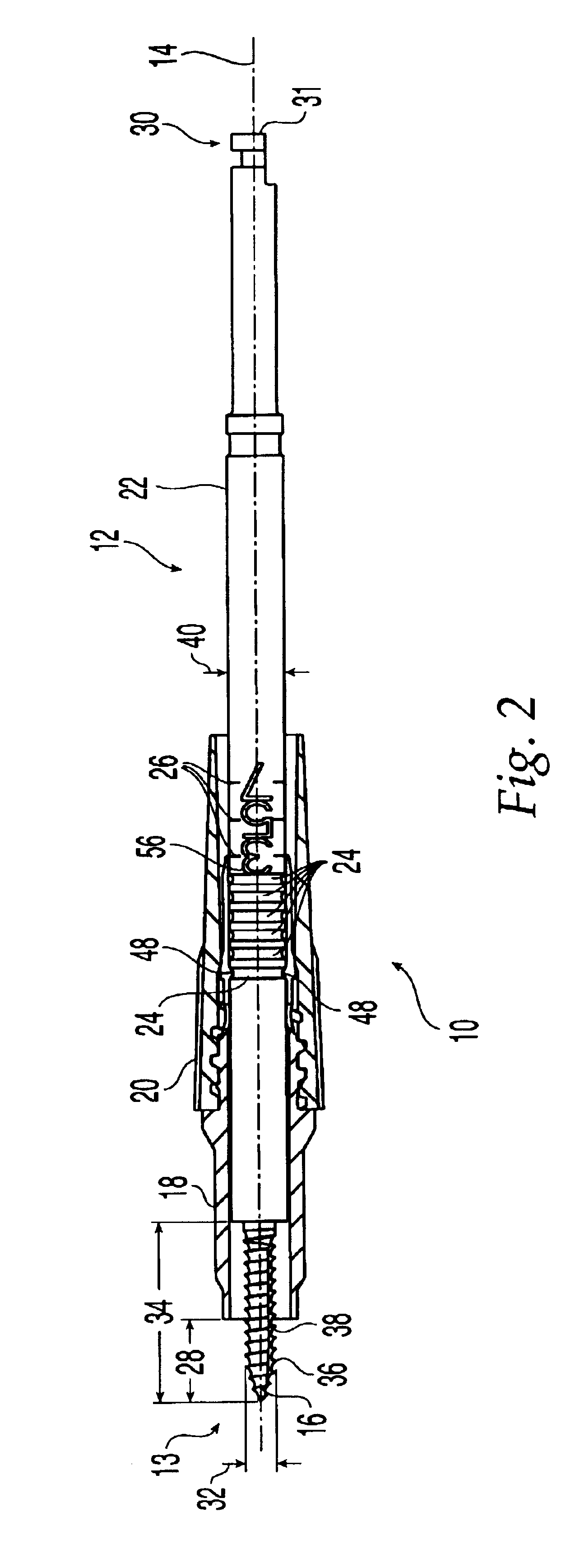

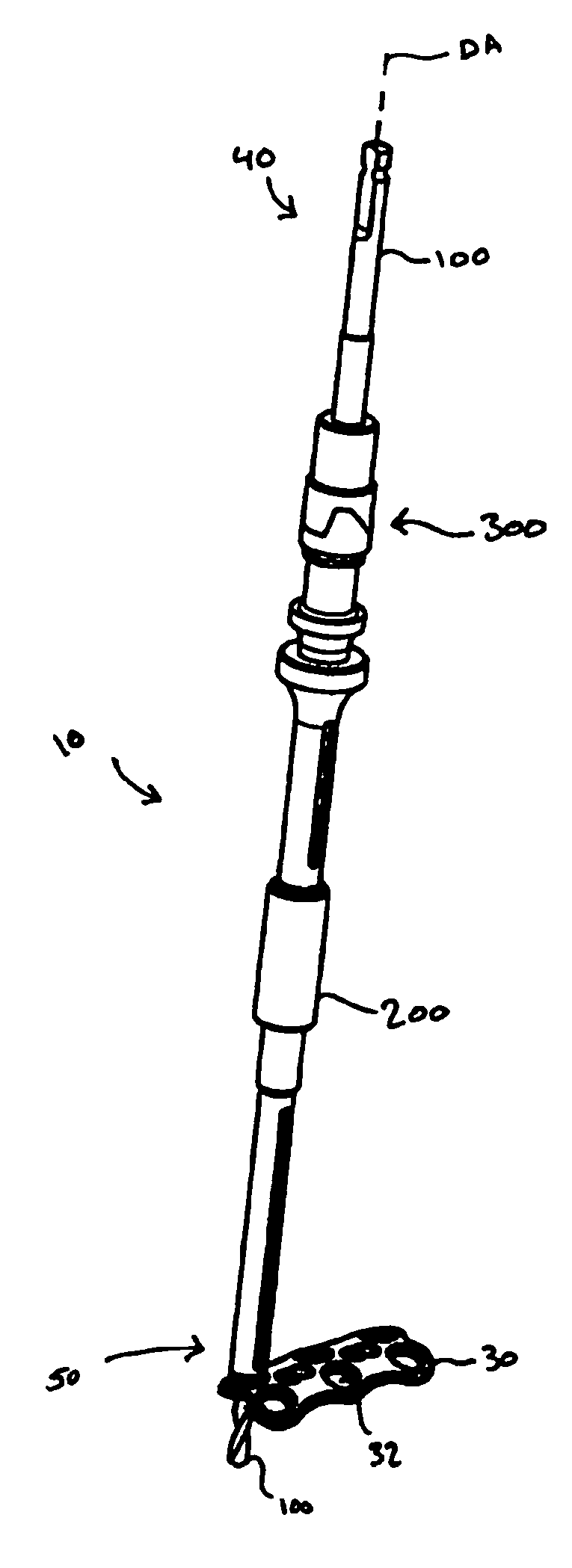

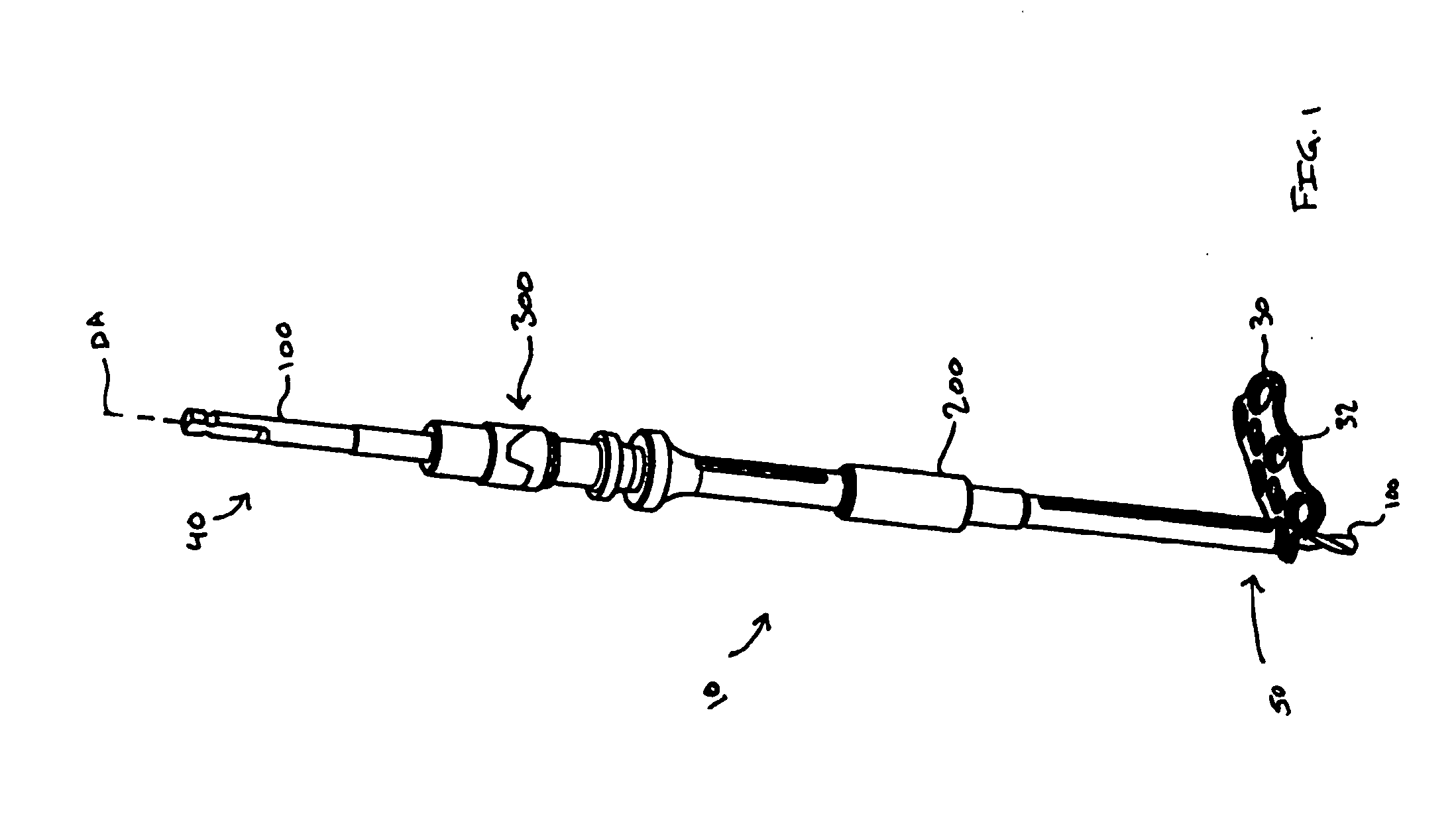

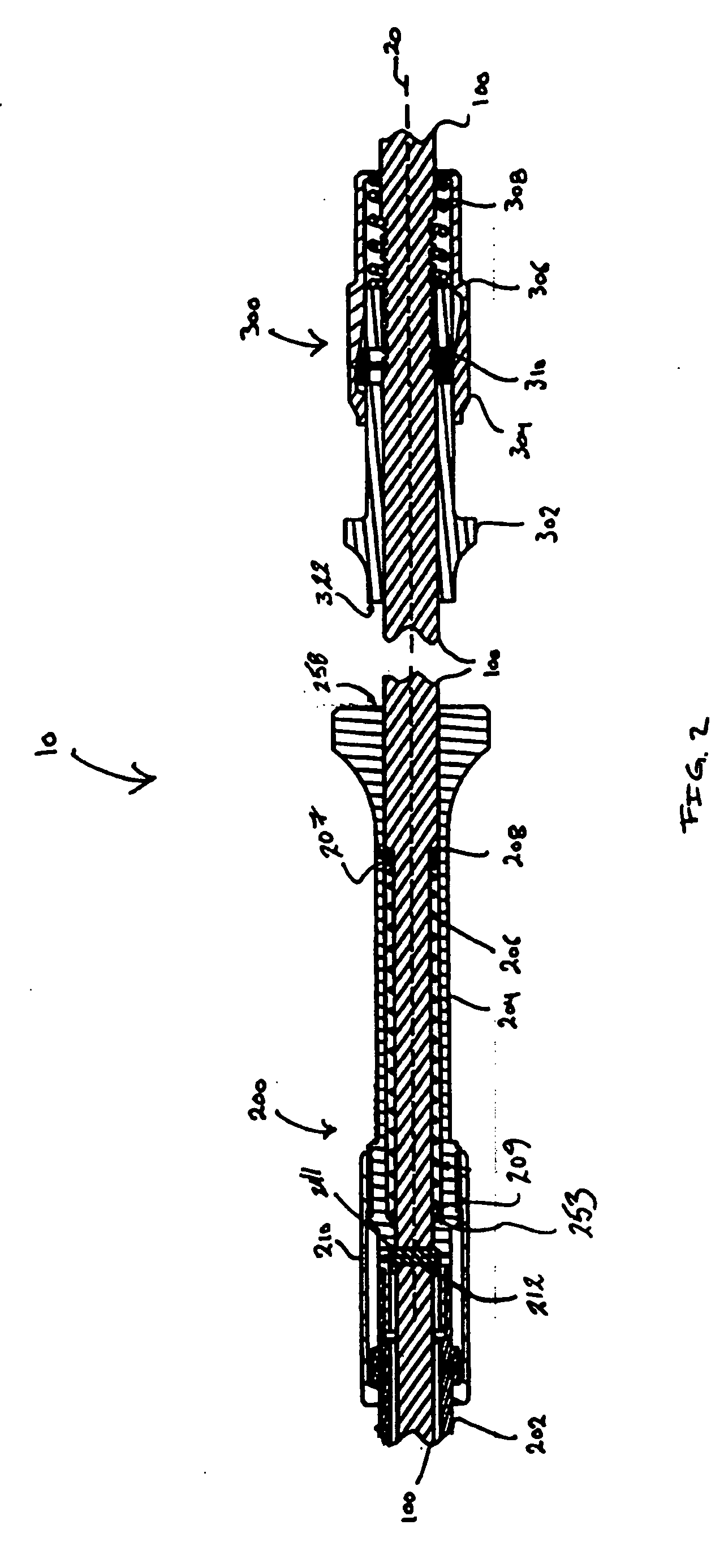

Adjustable length tap and method for drilling and tapping a bore in bone

InactiveUS6951562B2Impeding translational movementDiagnosticsSurgeryEffective lengthOrthopedic Procedures

The present invention is directed to an adjustable self drilling tap assembly and method for drilling and tapping bores in bone for use in orthopedic procedures to treat bone. The adjustable length tap assembly includes a shaft having cutting threads for drilling holes in bone, a stop collar configured and dimensioned to be translatable along the longitudinal axis of the shaft, and a locking collar comprising a member configured and dimensioned to be received over at least a portion of the stop collar. The locking collar preferably is configured and dimensioned to engage with the stop collar to adjustably set the effective length for the cutting threads and to prevent movement of the stop collar along the longitudinal axis of the shaft.

Owner:SYNTHES USA

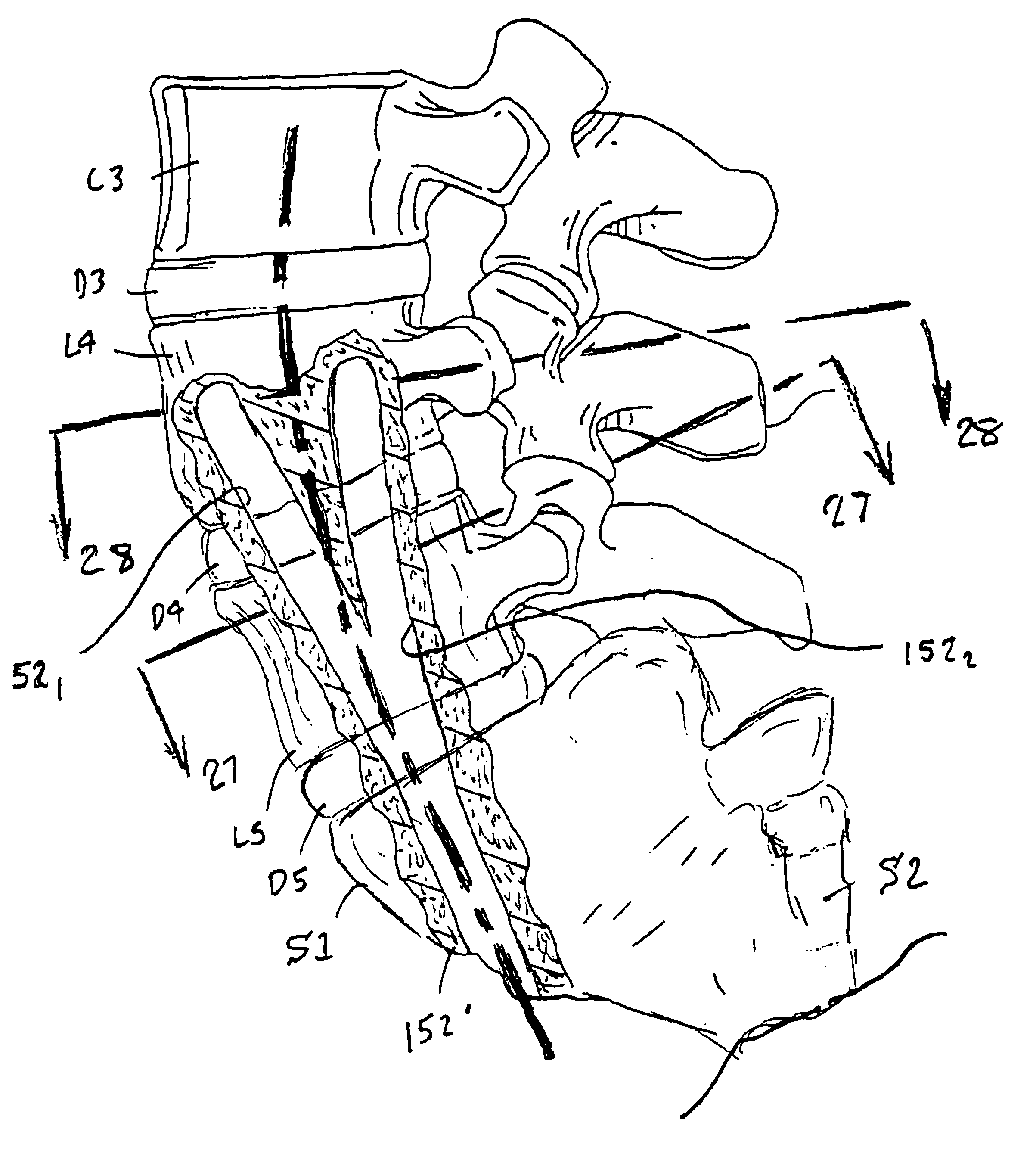

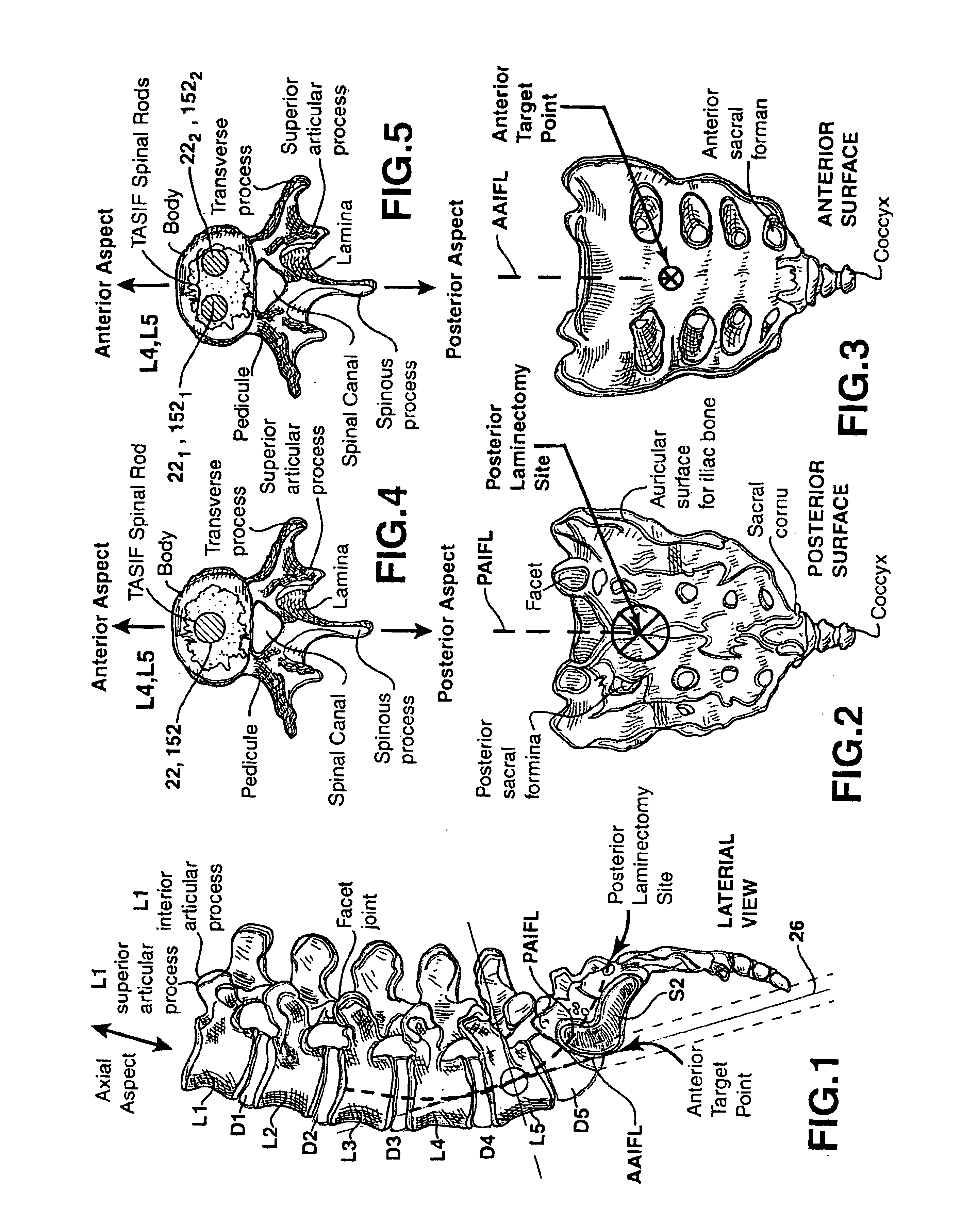

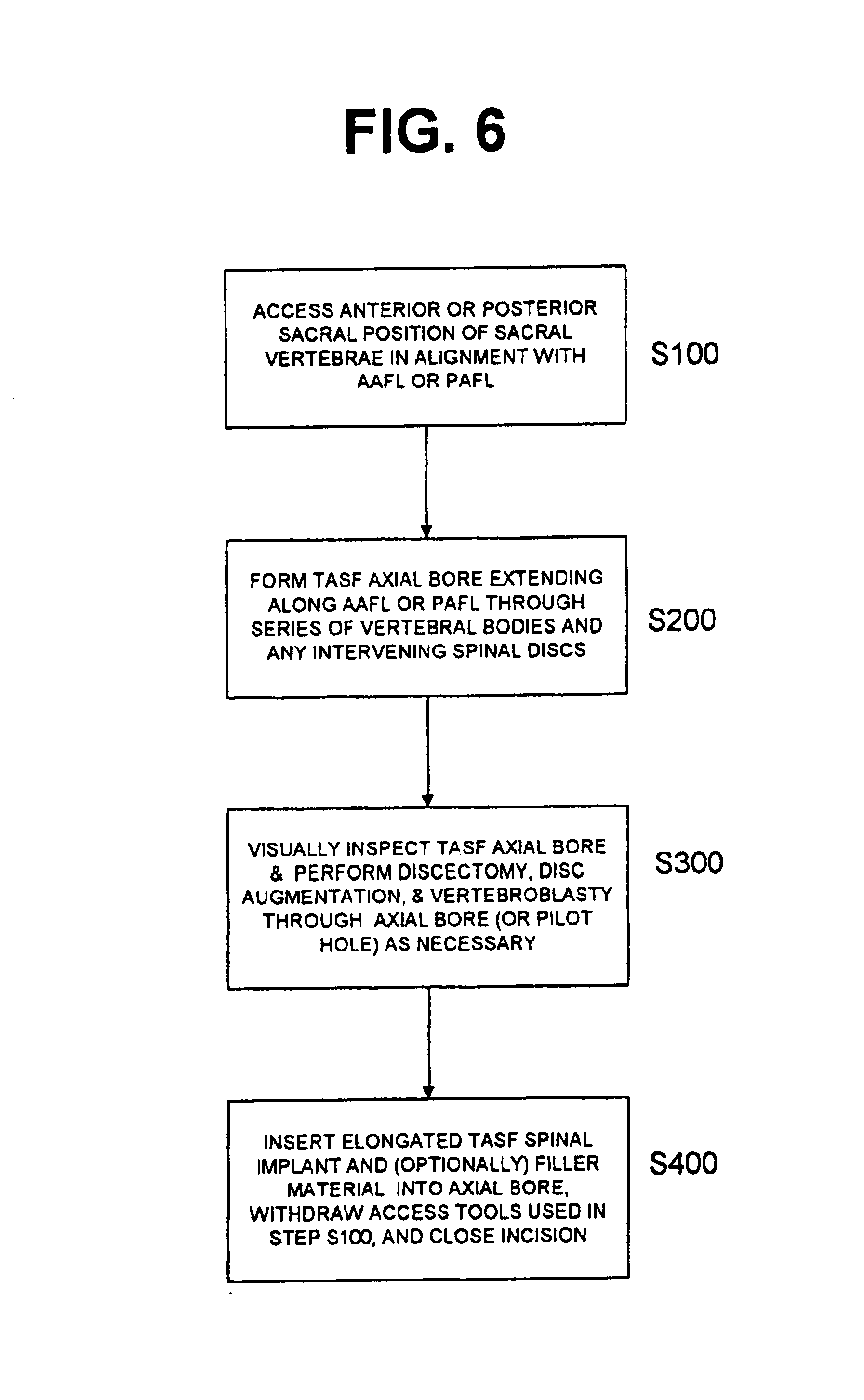

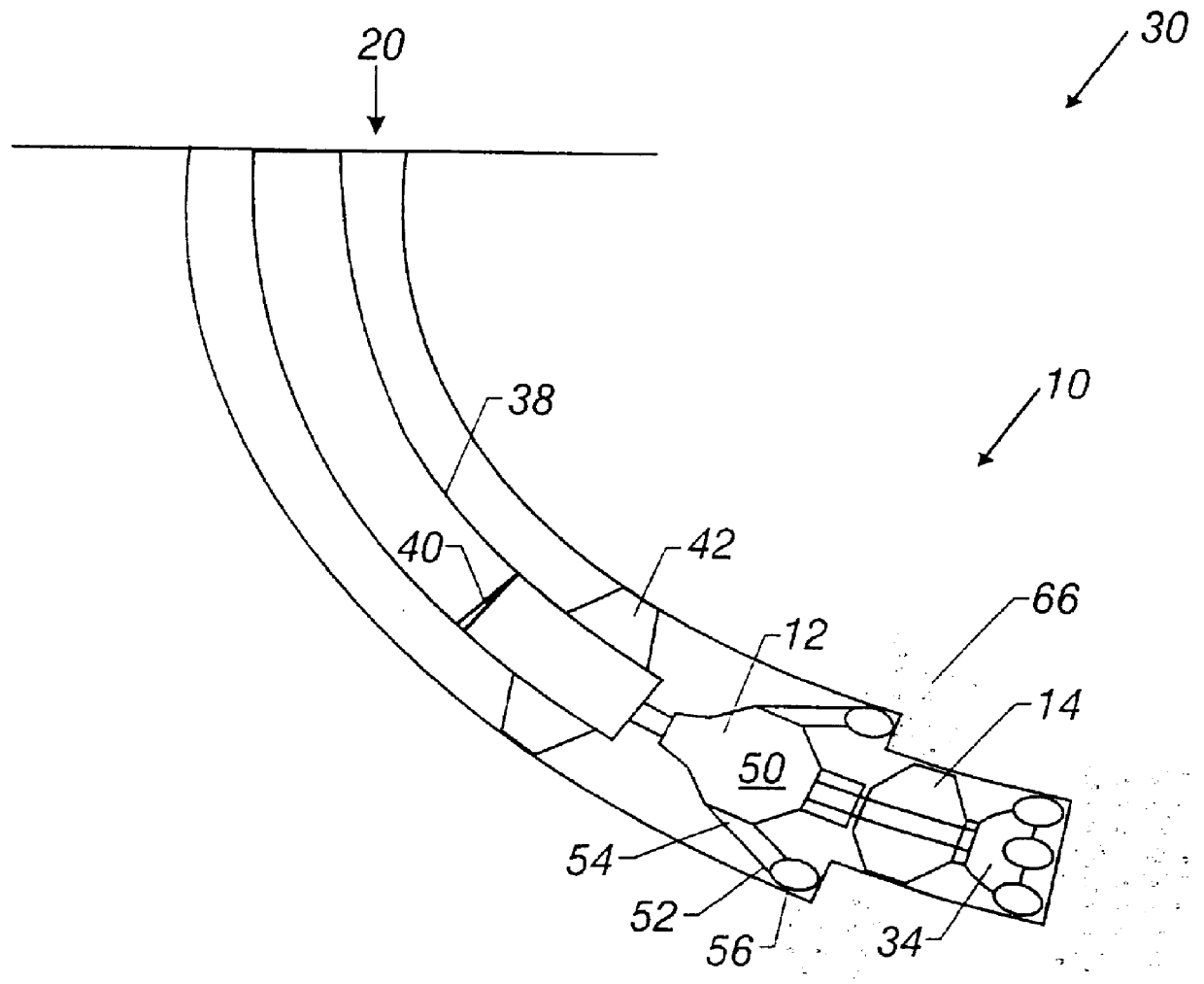

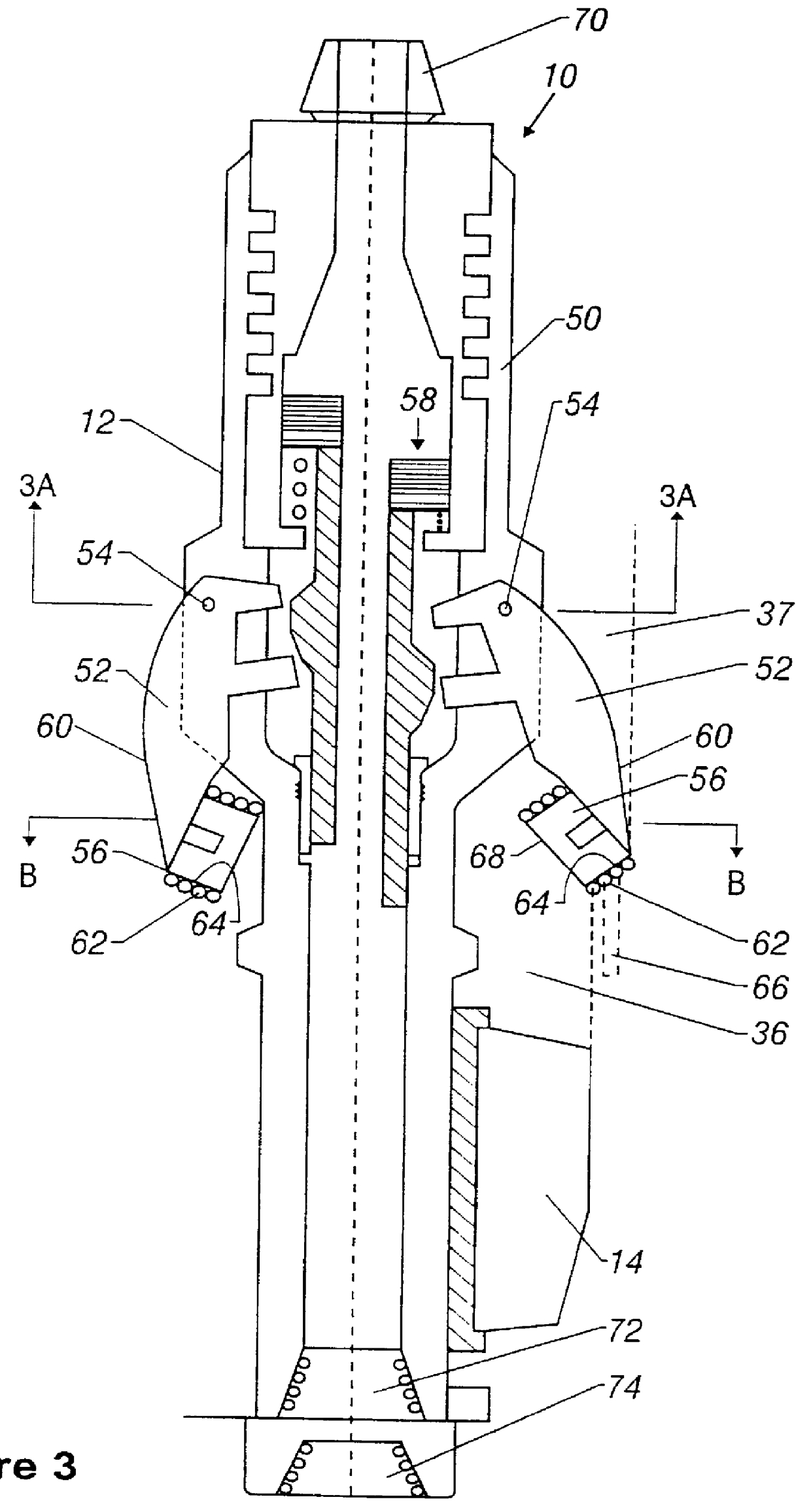

Methods and apparatus for forming curved axial bores through spinal vertebrae

One or more curved axial bore is formed commencing from an anterior or posterior sacral target point and cephalad through vertebral bodies in general alignment with a visualized, trans-sacral axial instrumentation / fusion (TASIF) line in a minimally invasive, low trauma, manner. An anterior axial instrumentation / fusion line (AAIFL) or a posterior axial instrumentation / fusion line (PAIFL) that extends from the anterior or posterior target point, respectively, in the cephalad direction following the spinal curvature through one or more vertebral body is visualized by radiographic or fluoroscopic equipment. Generally curved anterior or posterior TASIF axial bores are formed in axial or parallel or diverging alignment with the visualized AAIFL or PAIFL, respectively. The anterior and posterior TASIF axial bore forming tools can be manipulated from proximal portions thereof to adjust the curvature of the anterior or posterior TASIF axial bores as they are formed in the cephalad direction. The boring angle of the distally disposed boring member or drill bit can be adjusted such that selected sections of the generally curved anterior or posterior TASIF axial bores can be made straight or relatively straight, and other sections thereof can be made curved to optimally traverse vertebral bodies and intervening disc, if present.

Owner:MIS IP HLDG LLC

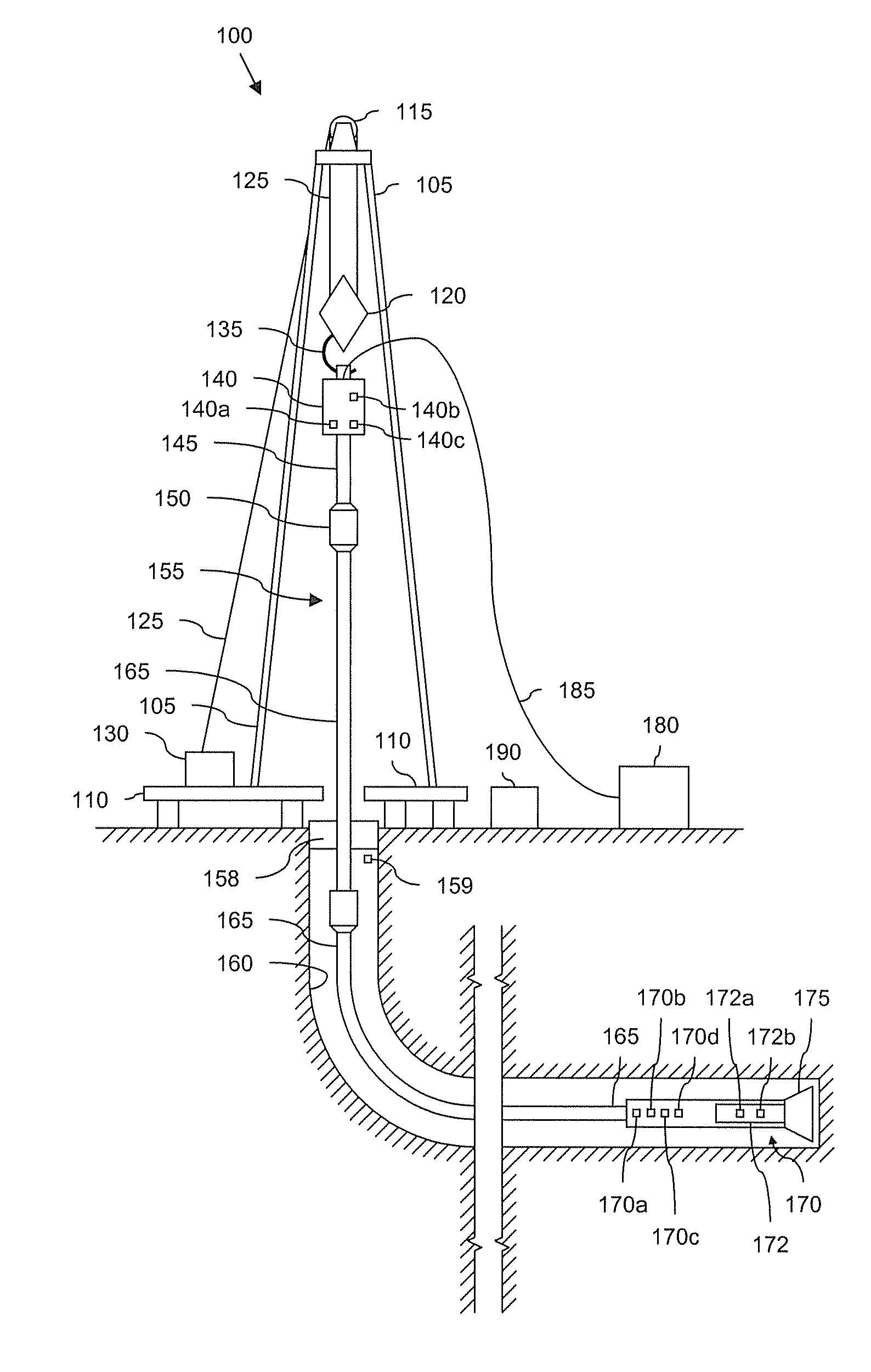

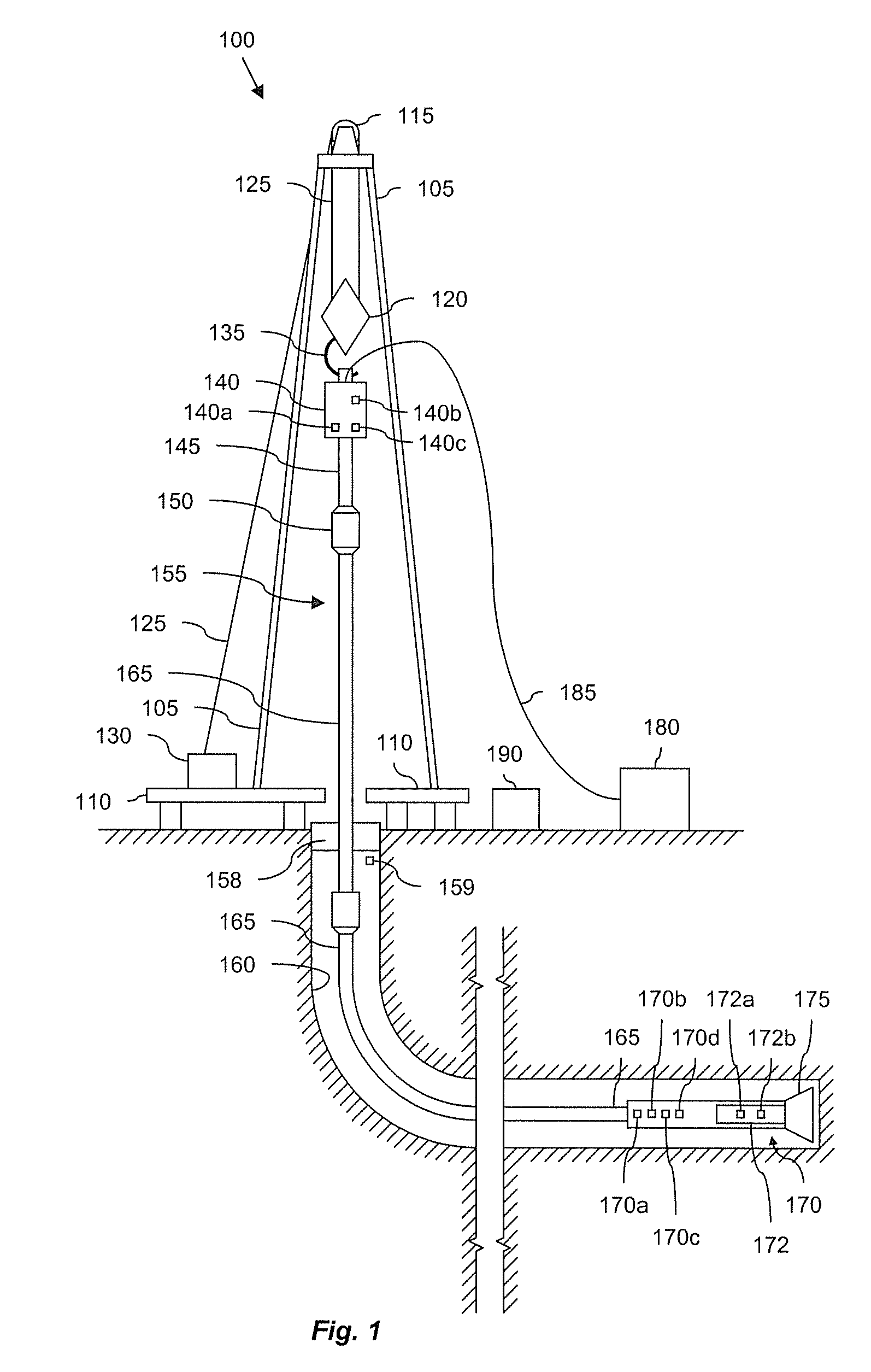

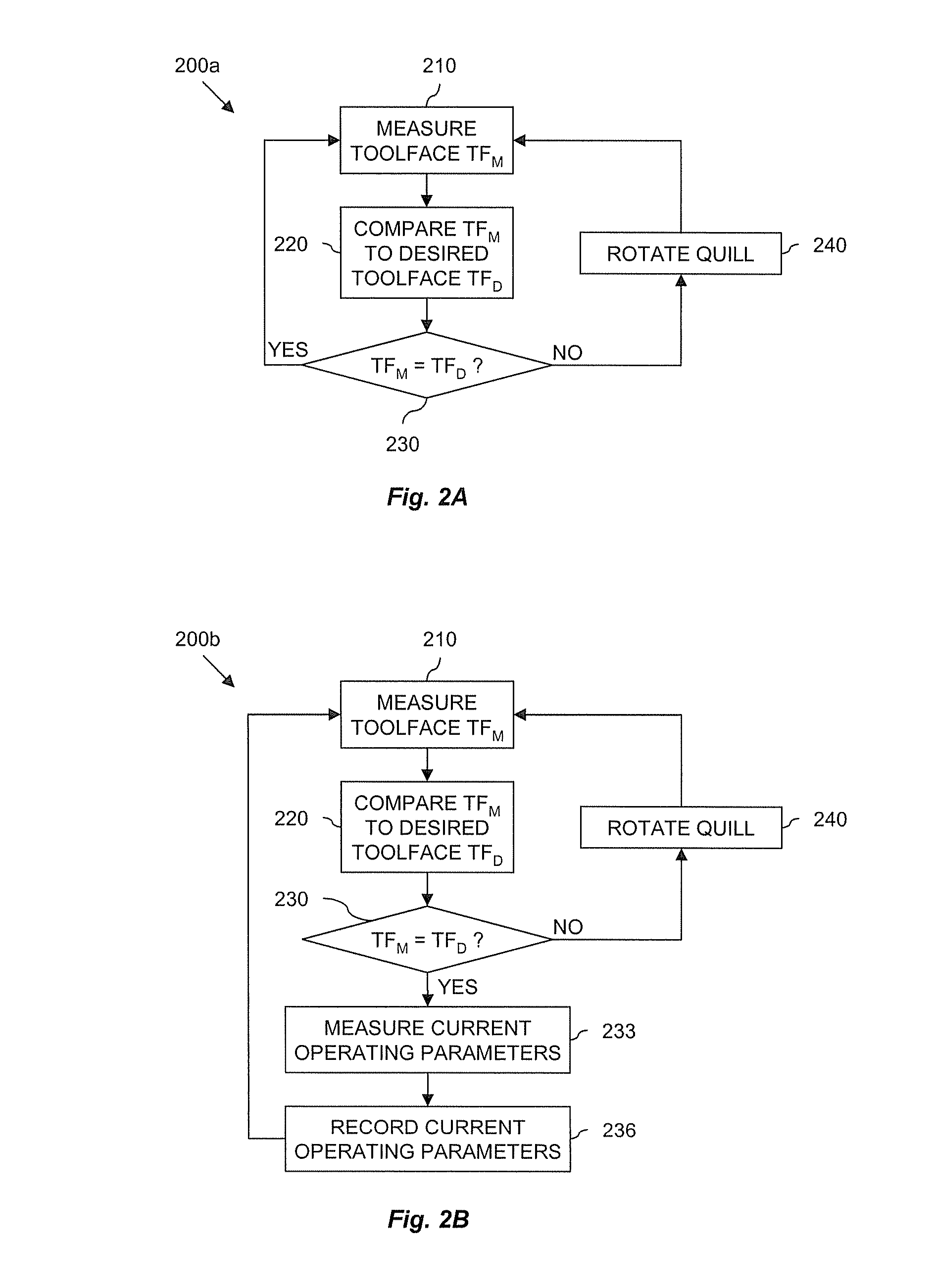

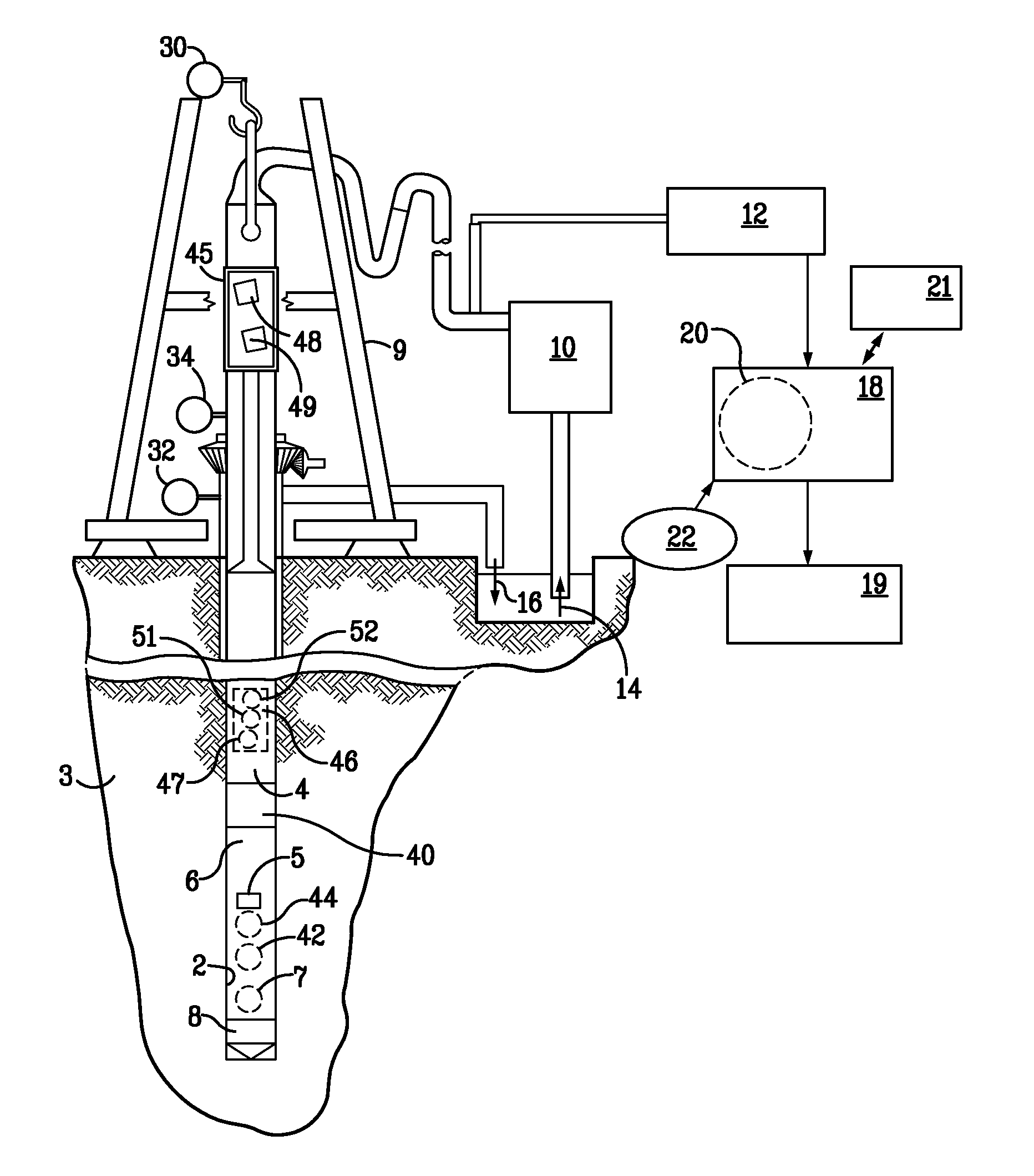

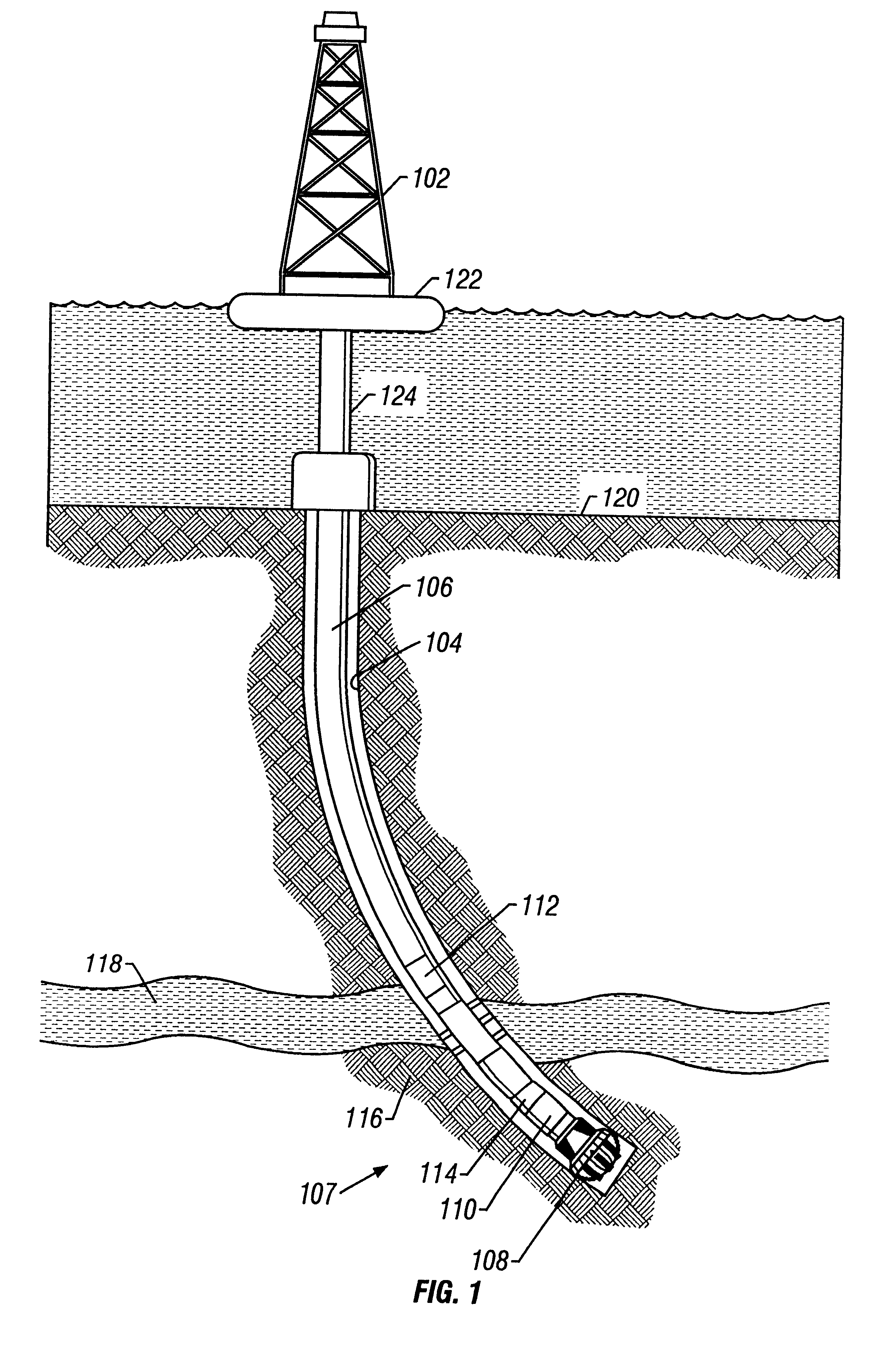

Automated directional drilling apparatus and methods

Methods and systems for drilling to a target location include a control system that receives an input comprising a planned drilling path to a target location and determines a projected location of a bottom hole assembly of a drilling system. The projected location of the bottom hole assembly is compared to the planned drilling path to determine a deviation amount. A modified drilling path is created to the target location as selected based on the amount of deviation from the planned drilling path, and drilling rig control signals that steer the bottom hole assembly of the drilling system to the target location along the modified drilling path are generated.

Owner:NABORS DRILLING TECH USA INC

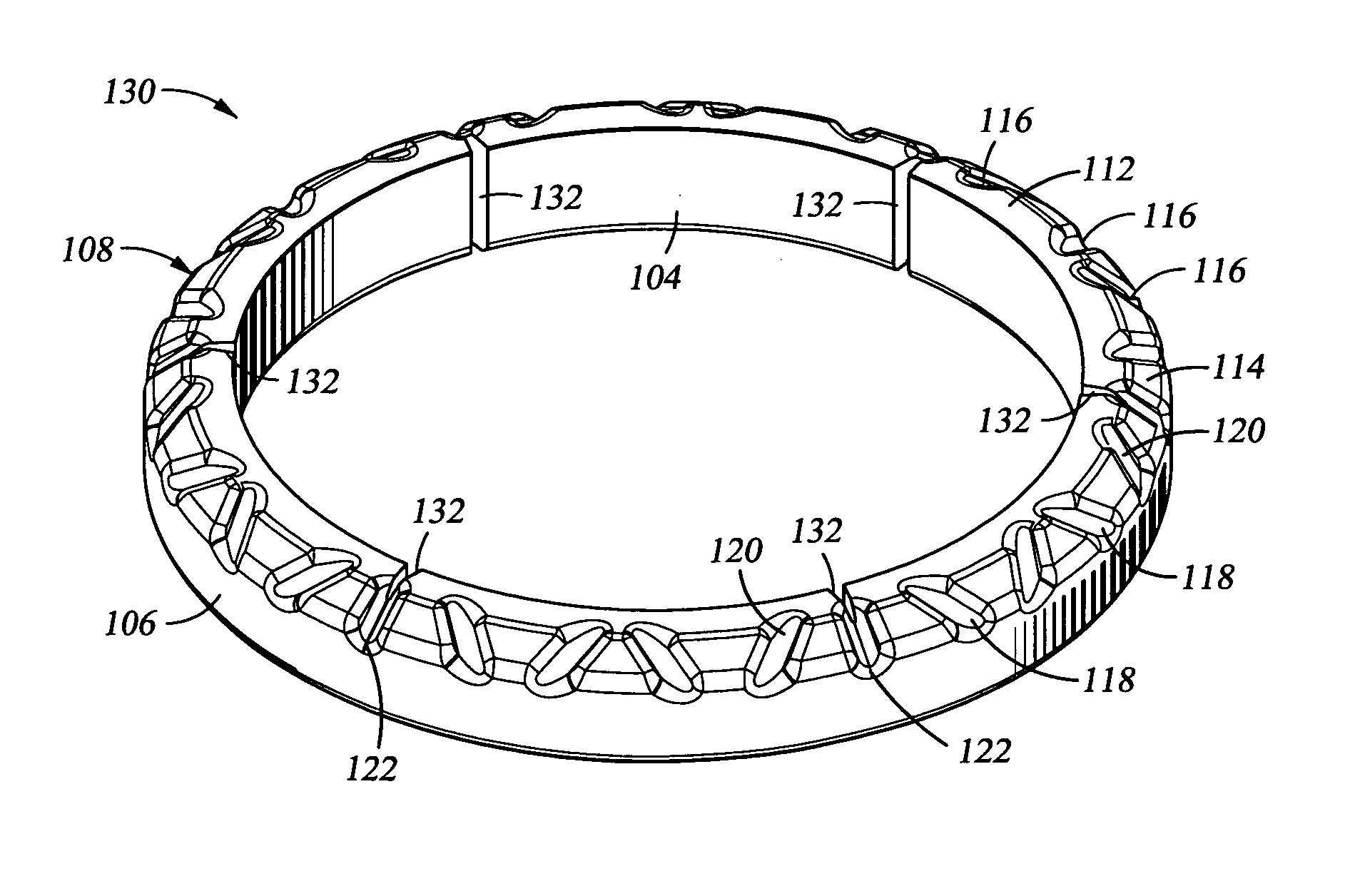

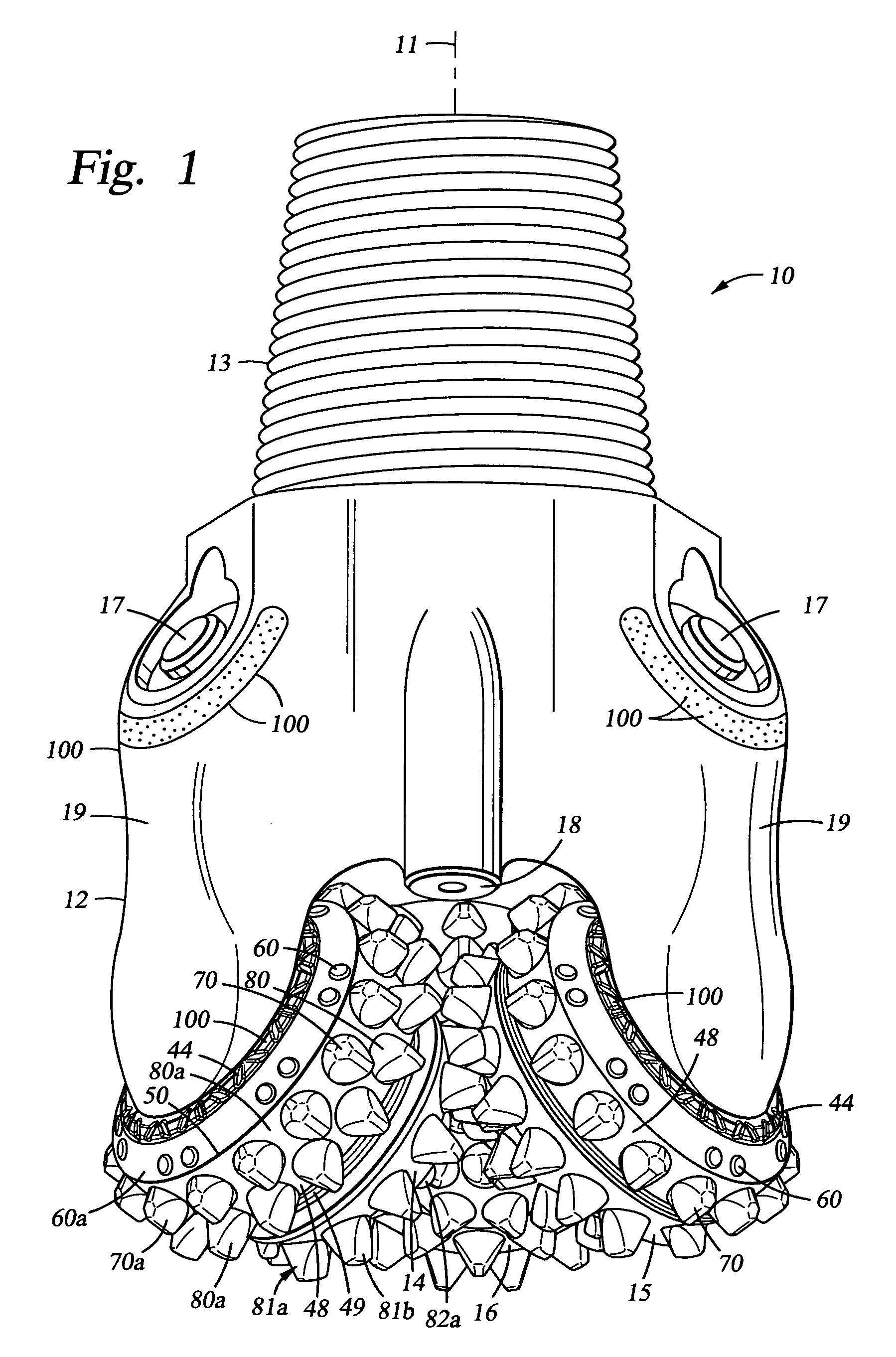

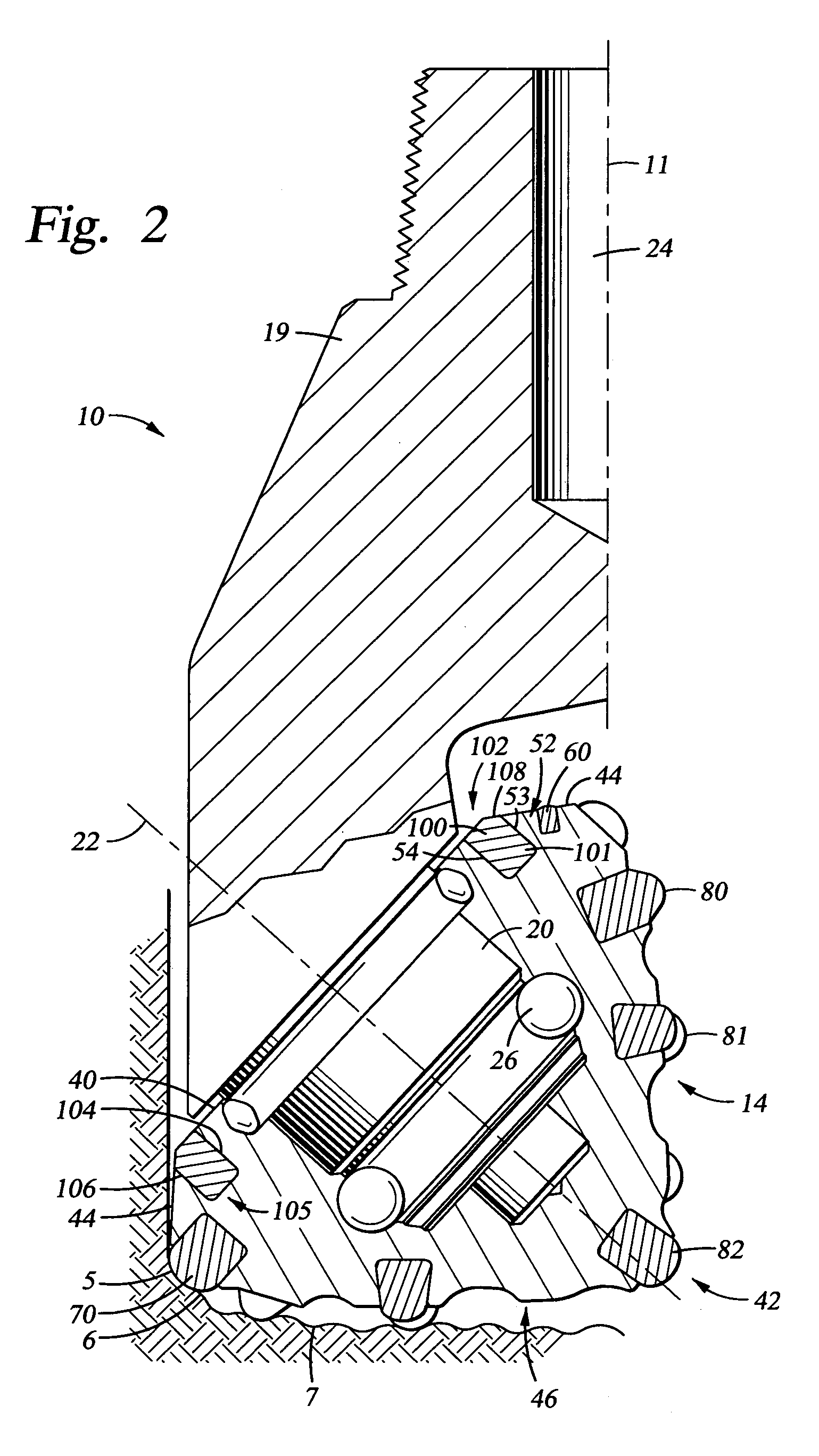

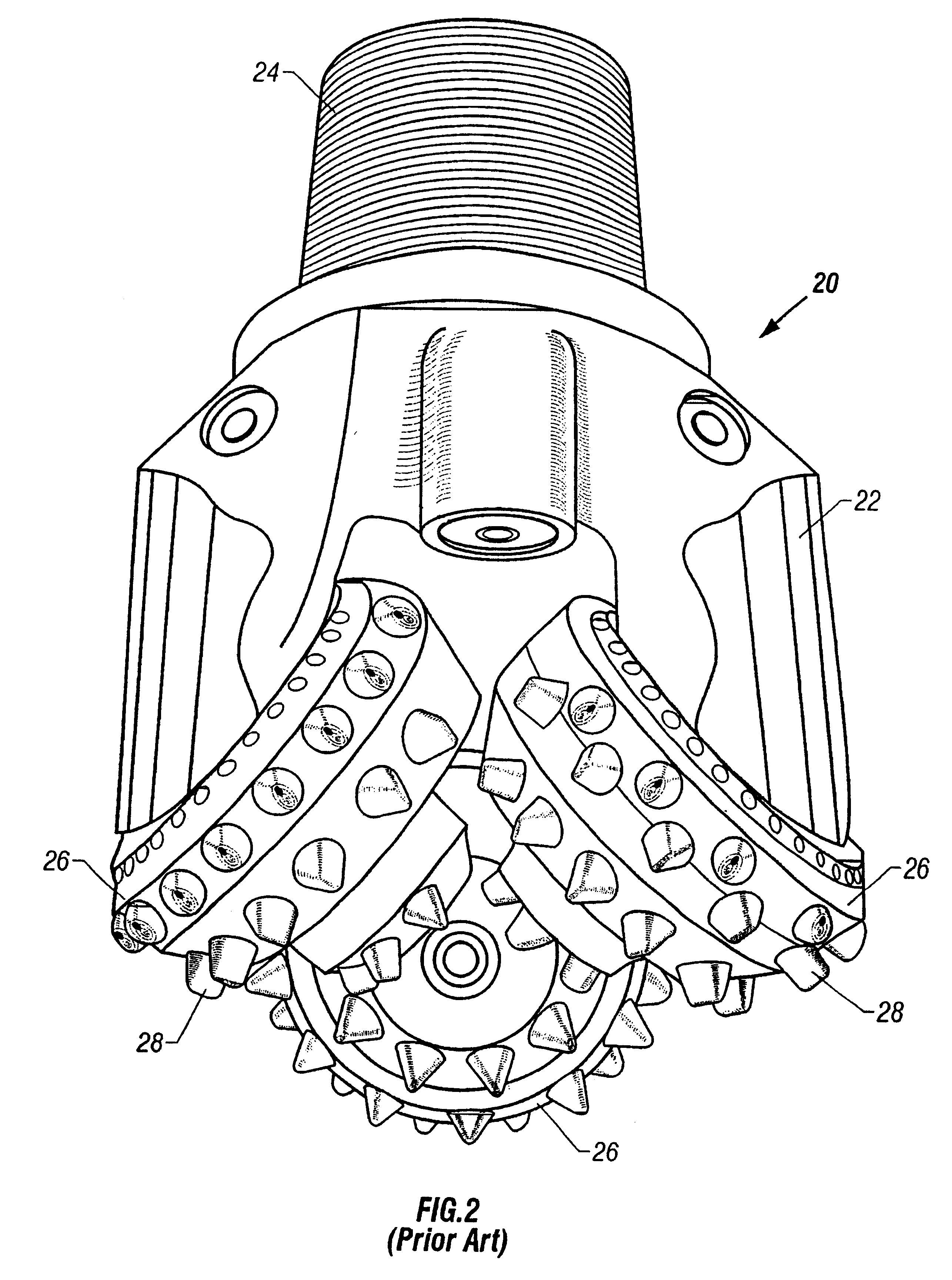

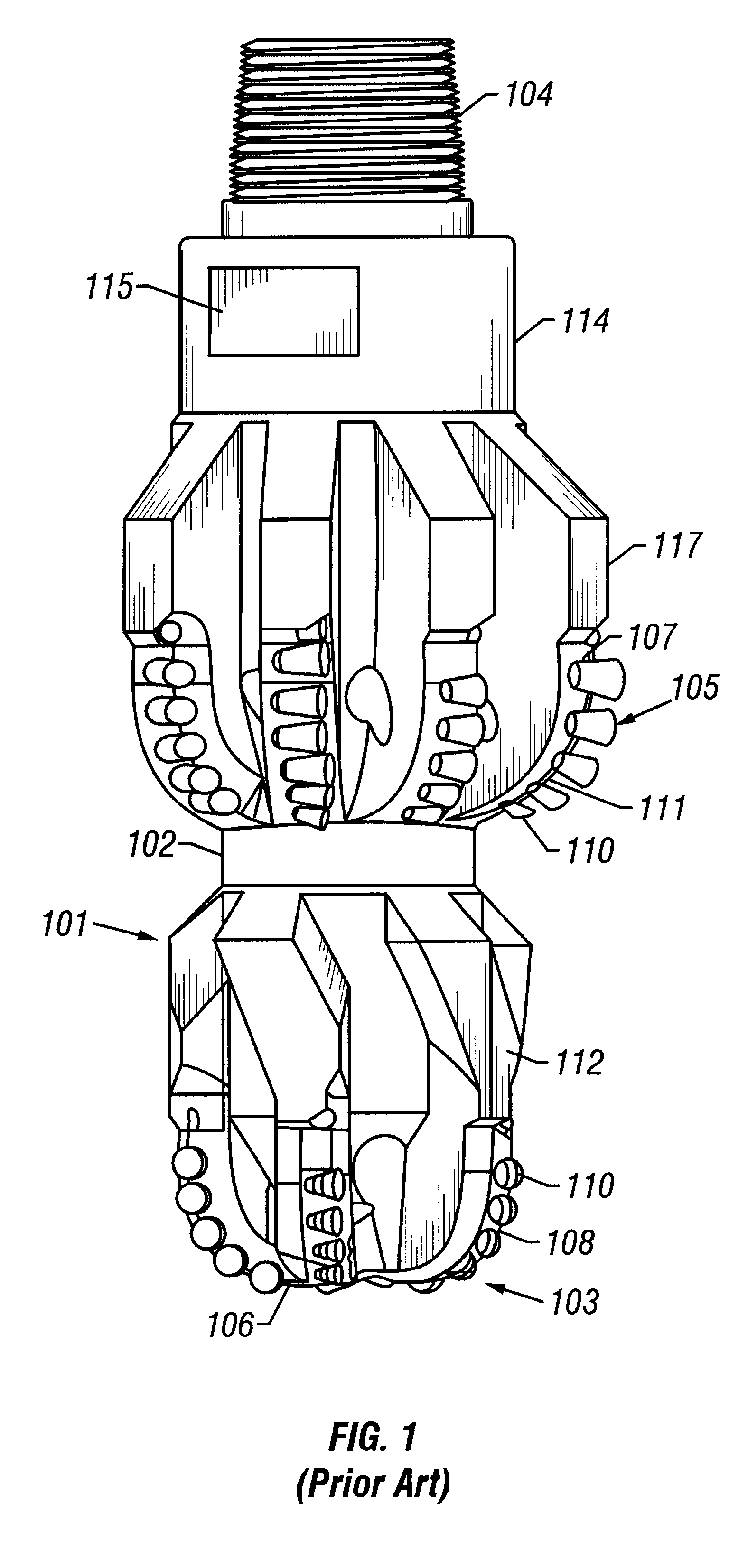

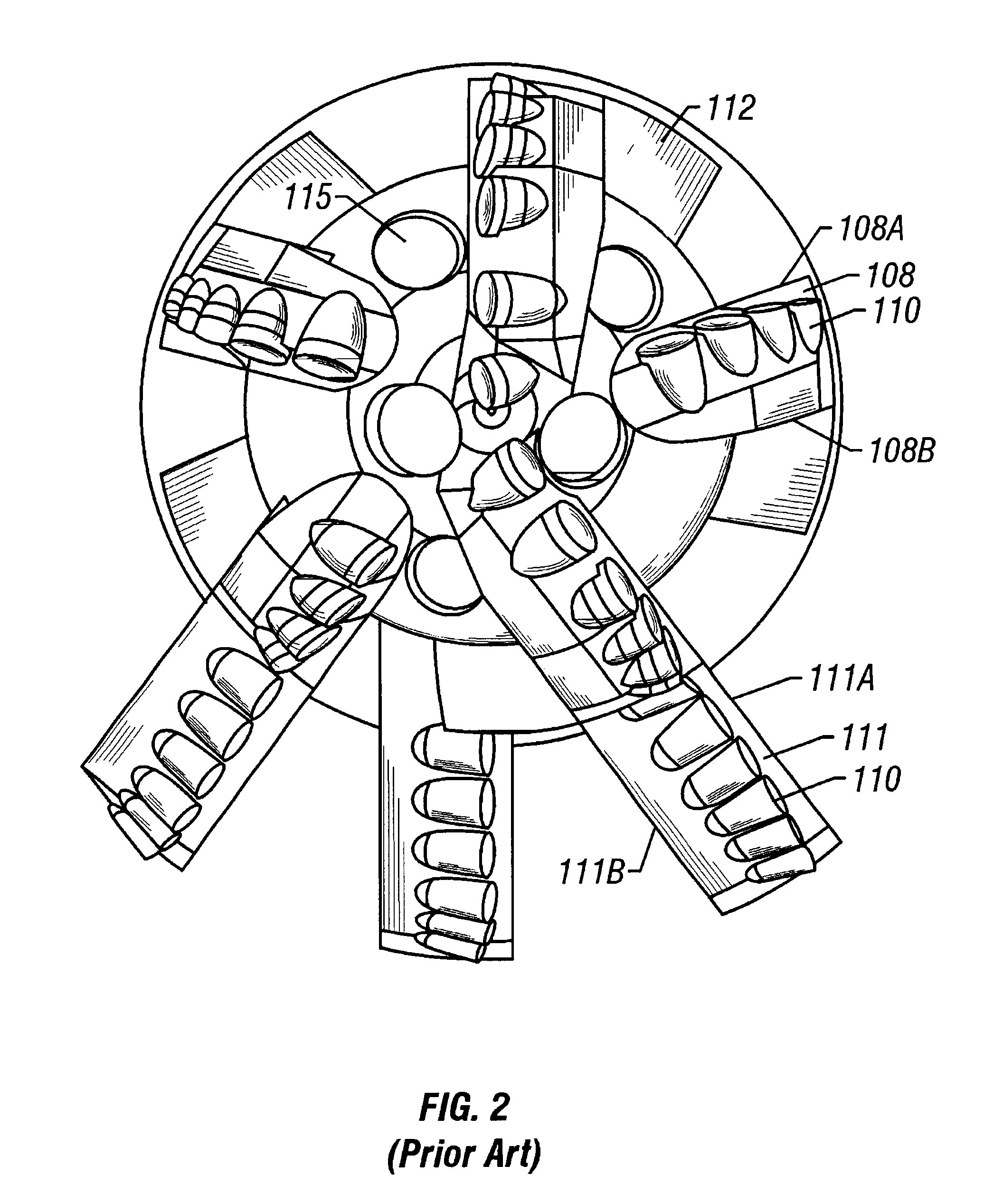

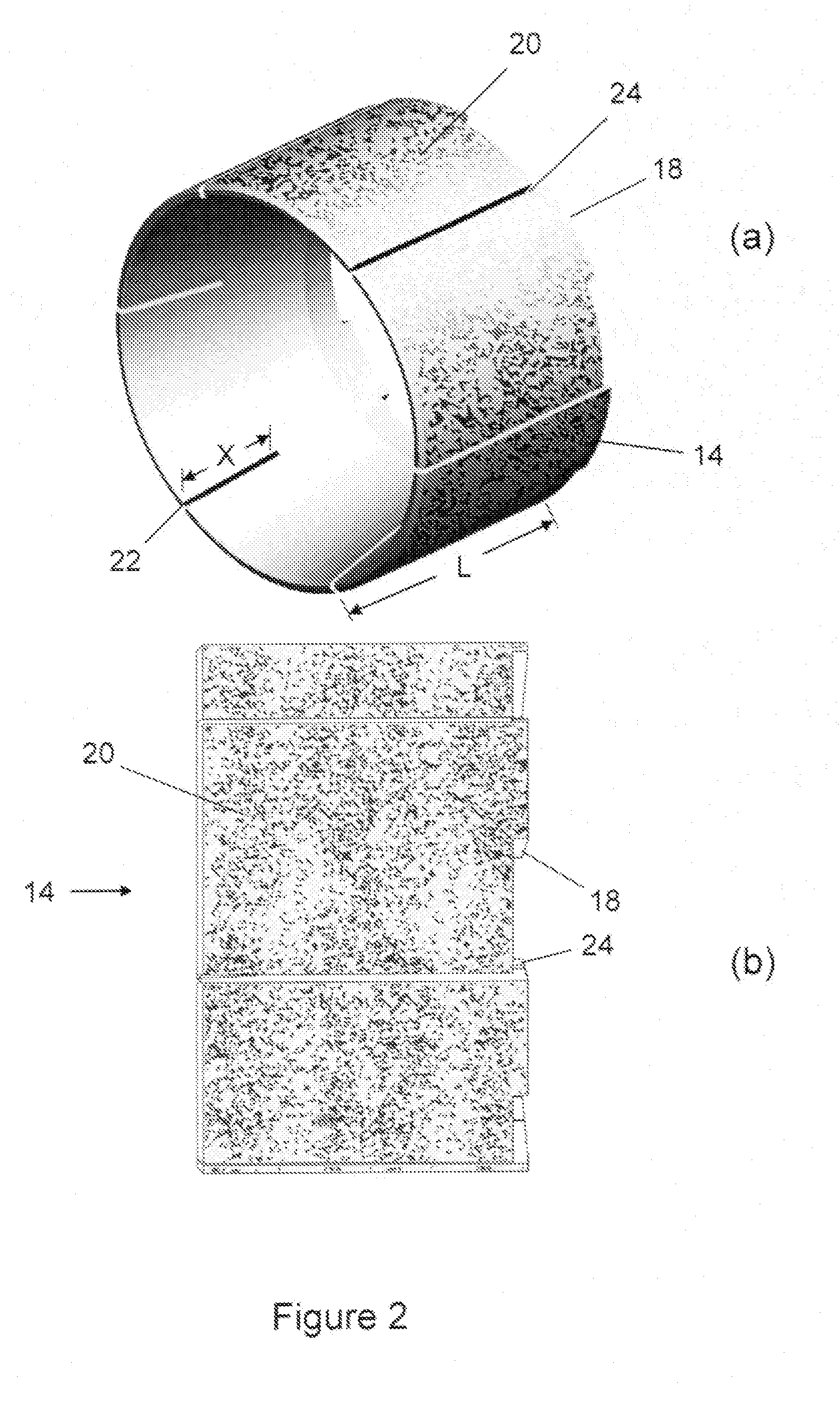

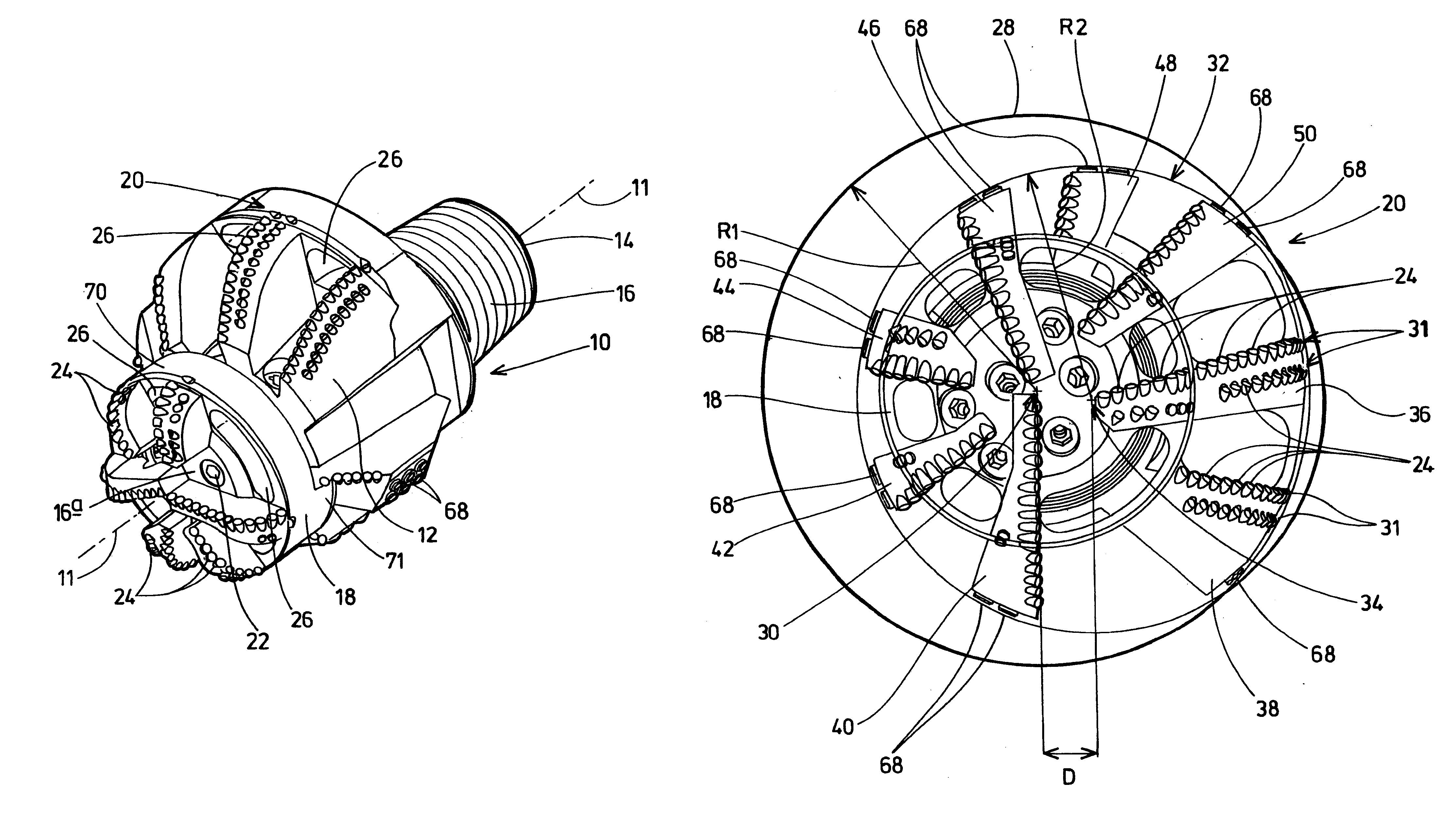

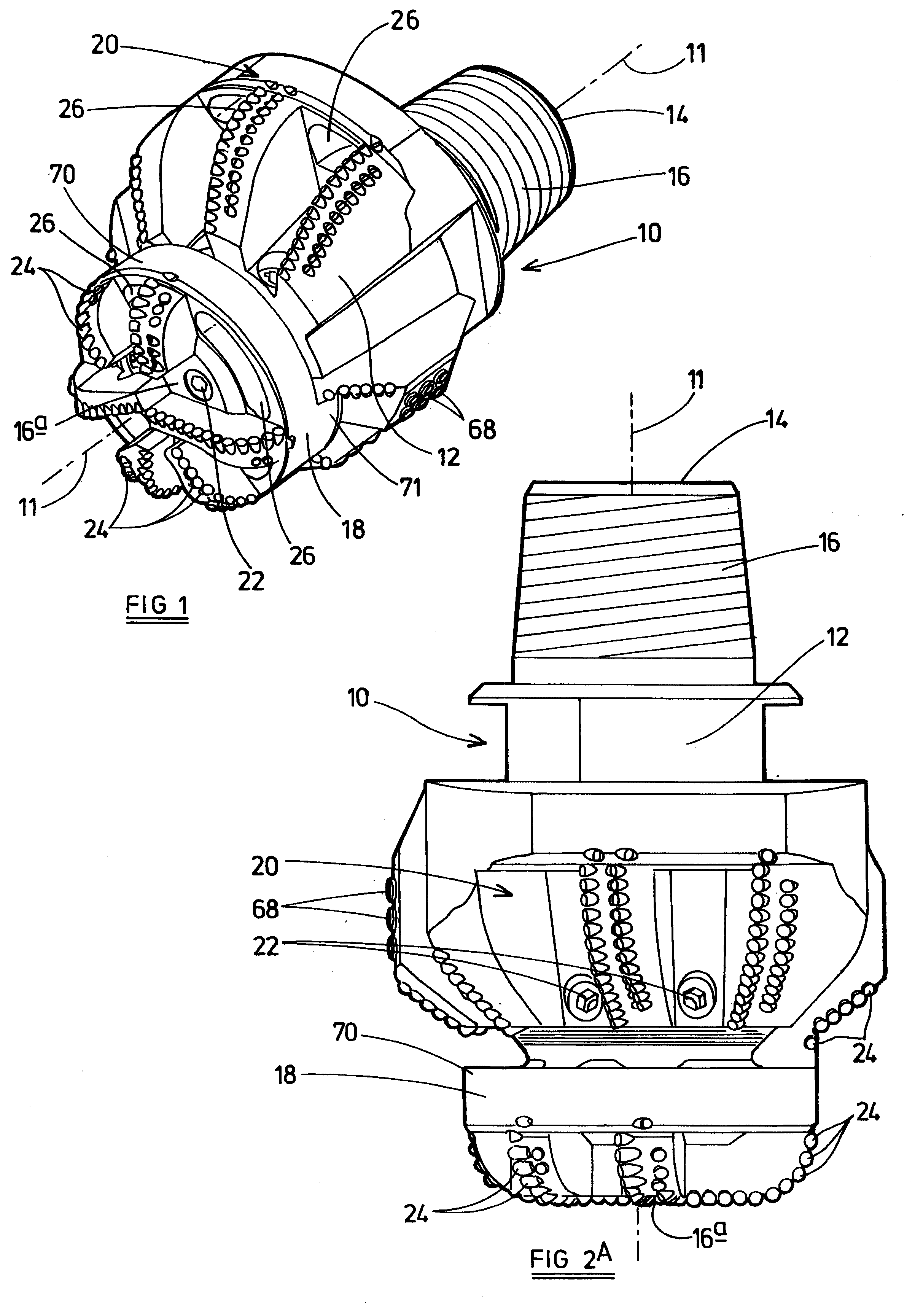

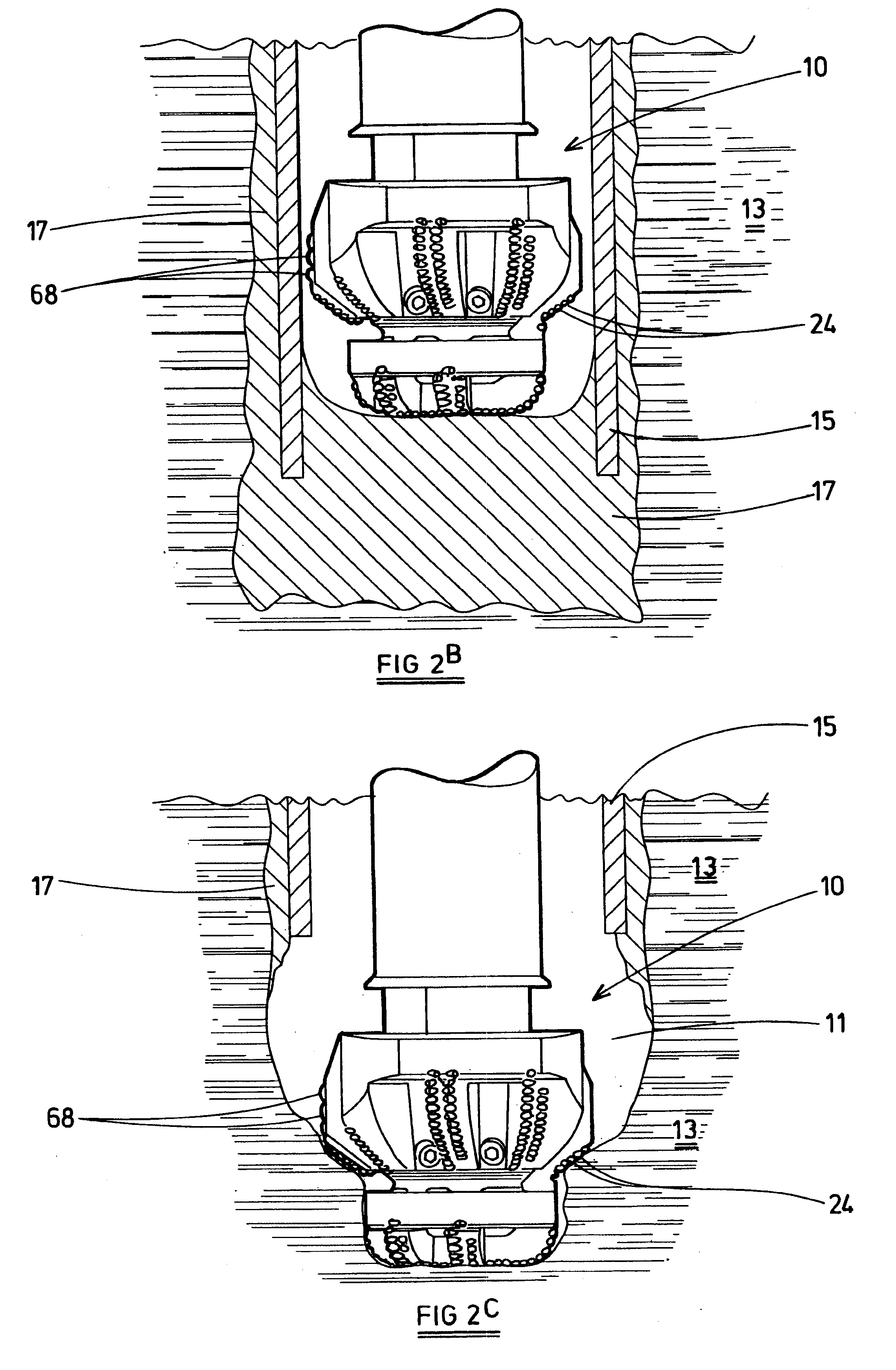

Drill bit arcuate-shaped inserts with cutting edges and method of manufacture

InactiveUS7331410B2Extended bit lifeImprove abilitiesDrill bitsMetal-working drilling toolsStress relievingEngineering

Disclosed are a variety of arcuate-shaped inserts for drill bits, and in particular, for placement in rolling cone cutters of drill bits. The arcuate inserts include 360° or ring-shaped inserts, as well as inserts of smaller arcuate length. The arcuate inserts are suitable for use in all surfaces of the rolling cone cutter, and in other locations in drill bits, and may have specialized cutting surfaces and material enhancements to enhance their cutting duty performance. Certain arcuate inserts may include stress relieving discontinuities such that, upon assembly into the cone or during drilling, the arcuate inserts may fragment in a controlled and predicted manner into shorter arcuate lengths.

Owner:SMITH INT INC

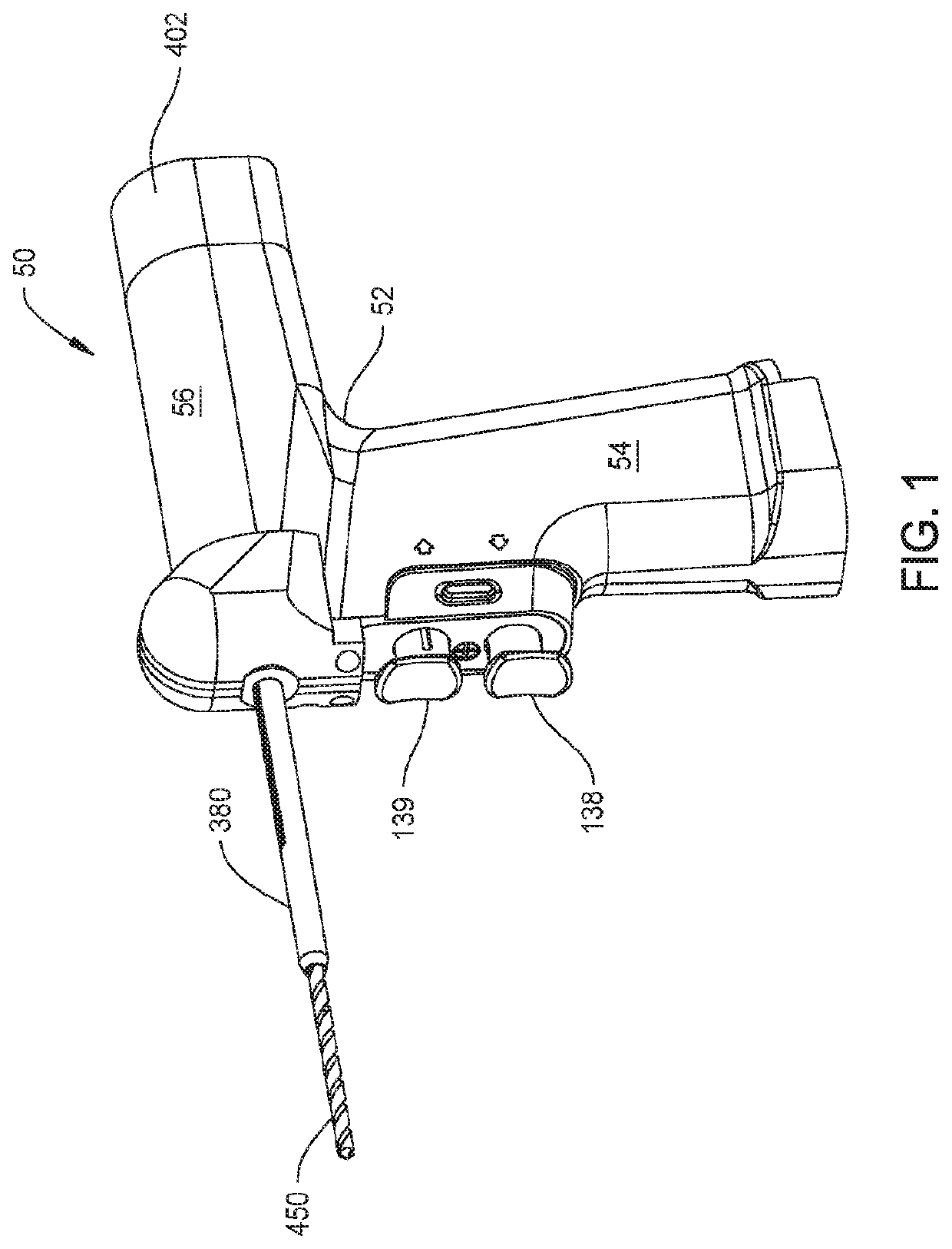

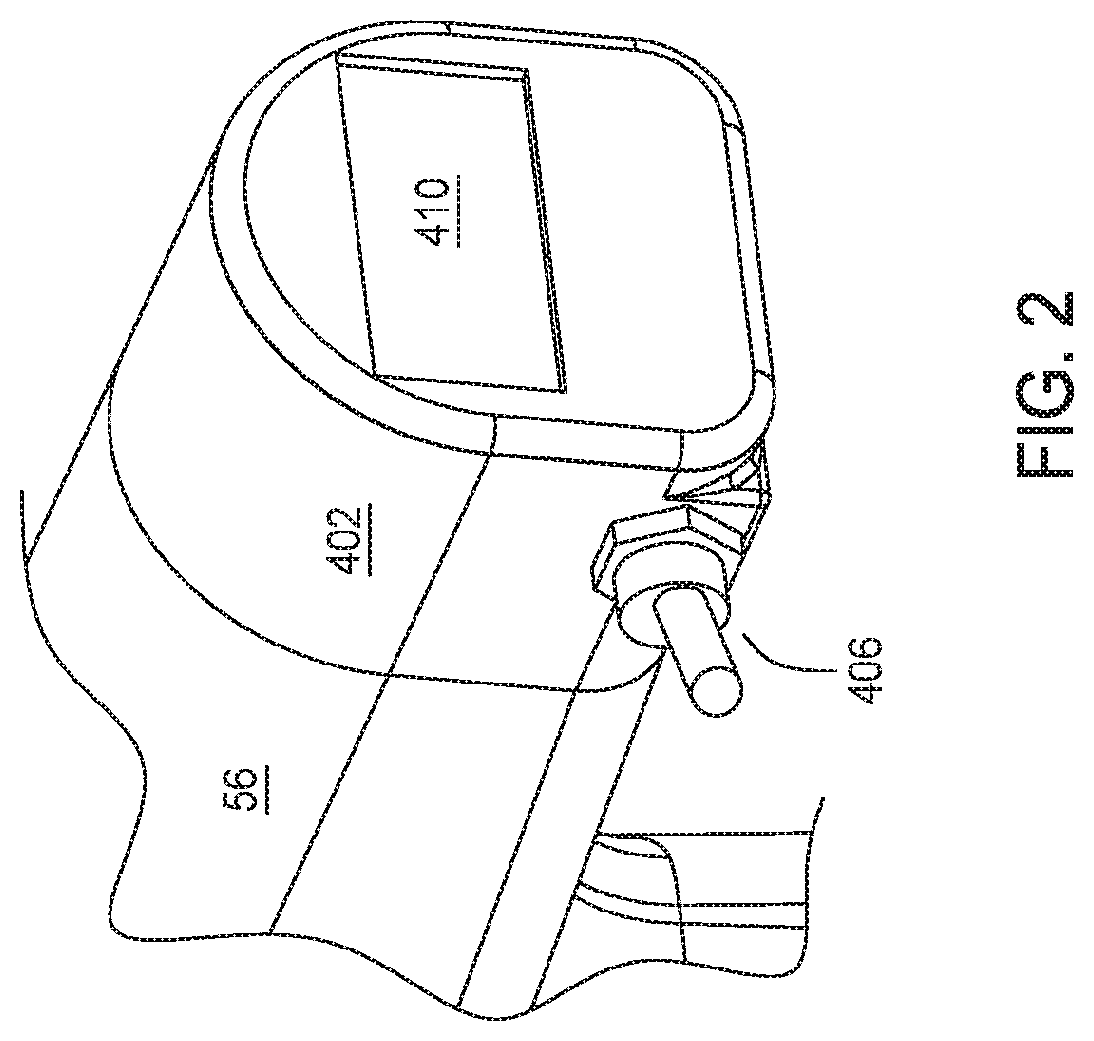

Powered surgical drill with integral depth gauge that includes a probe that slides over the drill bit

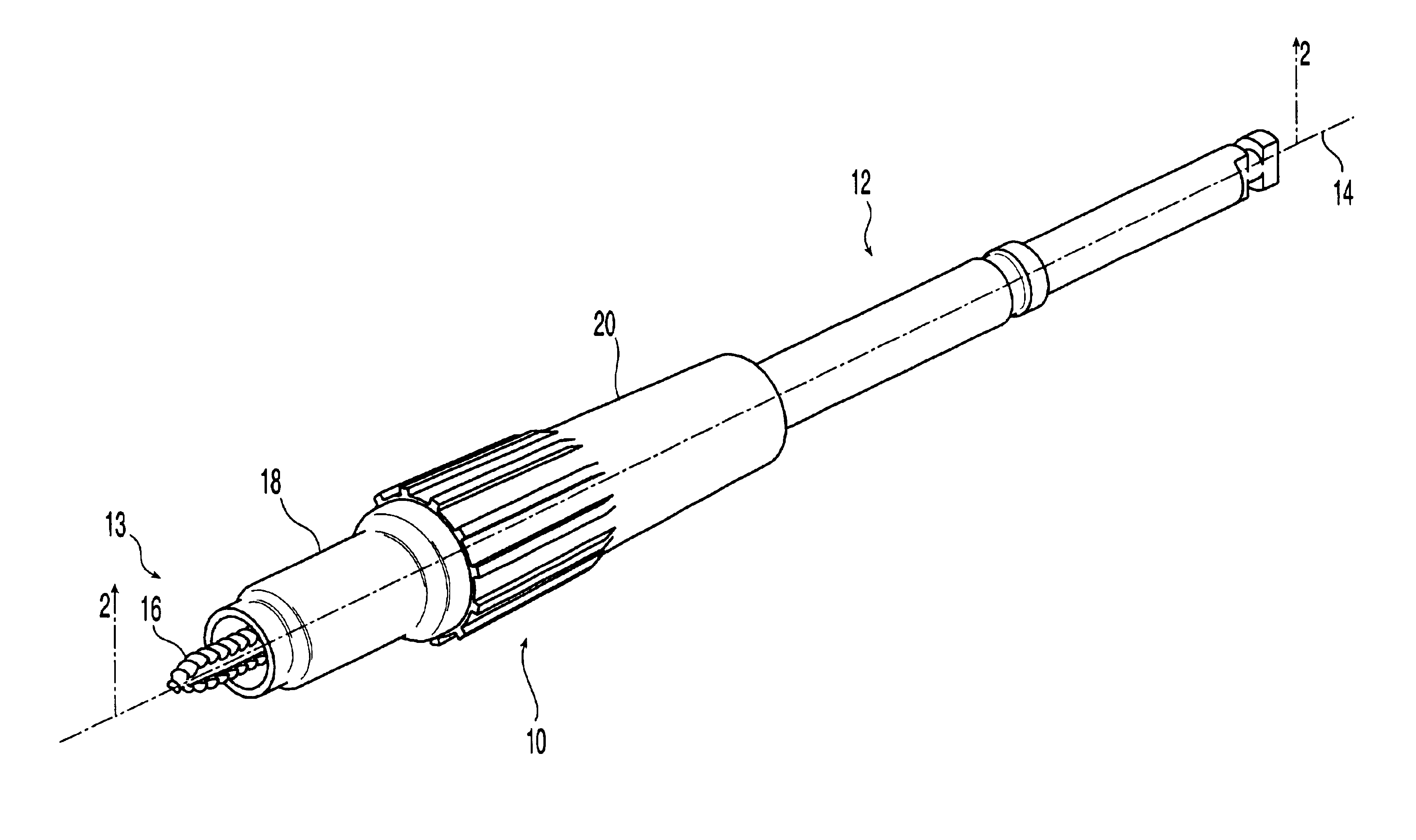

A drill for driving a drill bit into a solid object such as bone. The drill includes a rotor with a bore that transmits rotational movement to the drill bit. The drill bit extends through the rotor bore. A probe extends forward from the drill to measure bore depth. The probe is moveably mounted to the drill so as to extend into the rotor bore. As the drill and drill bit advance forward the probe remains static. As a result of the advancement of the drill the rotor extends over the proximal end of the probe.

Owner:STRYKER CORP

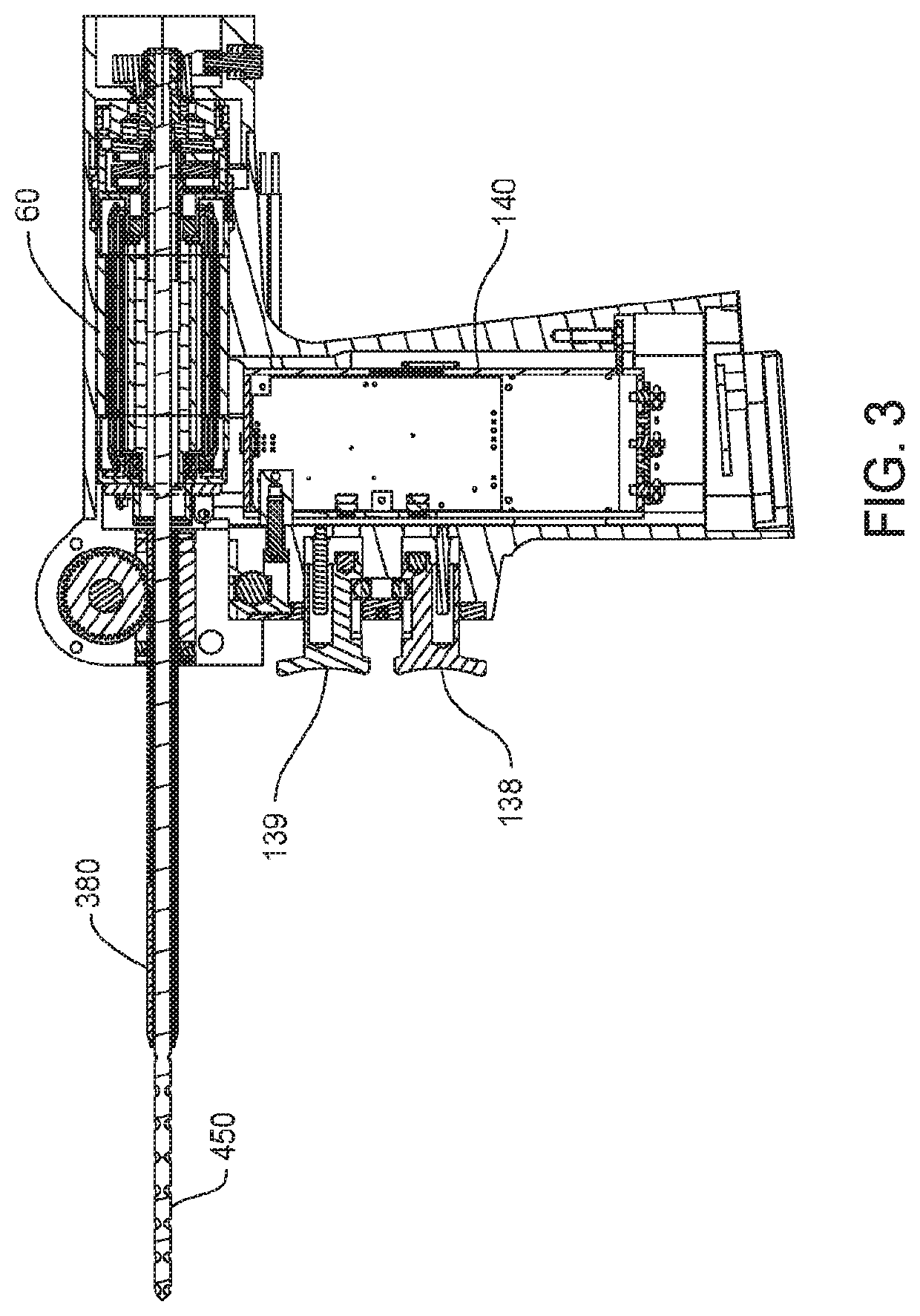

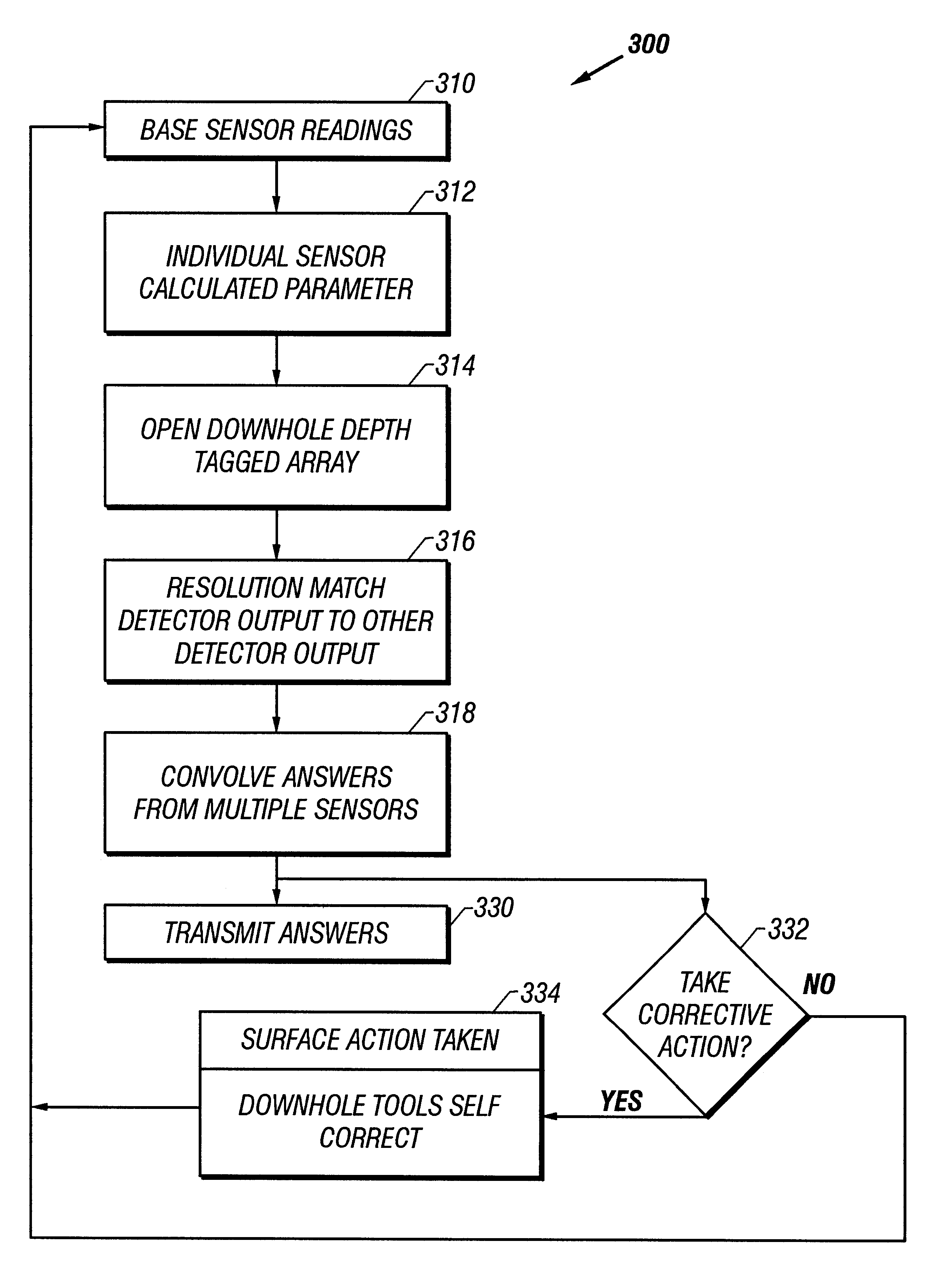

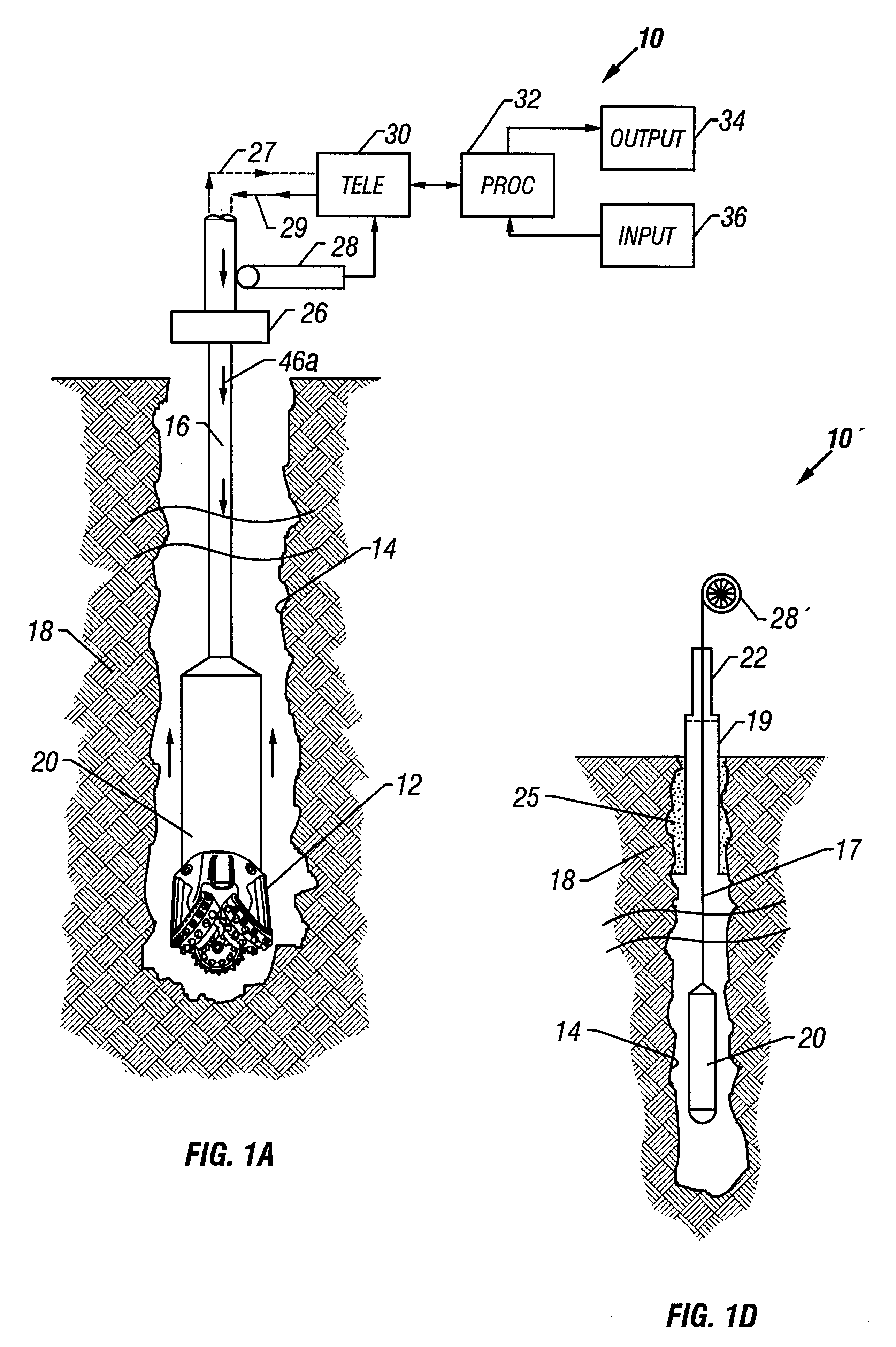

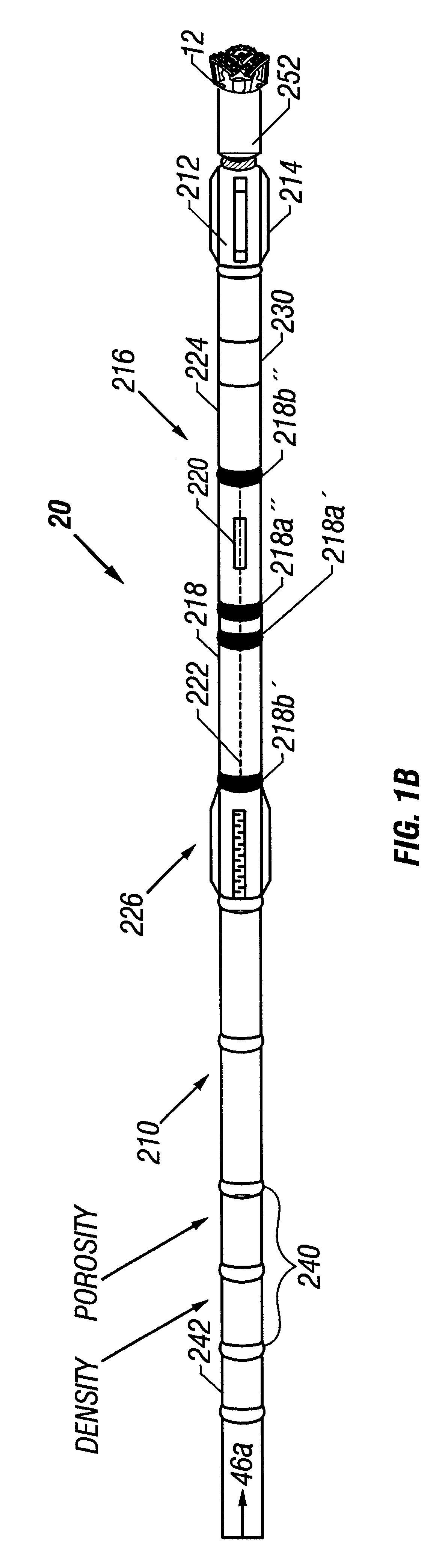

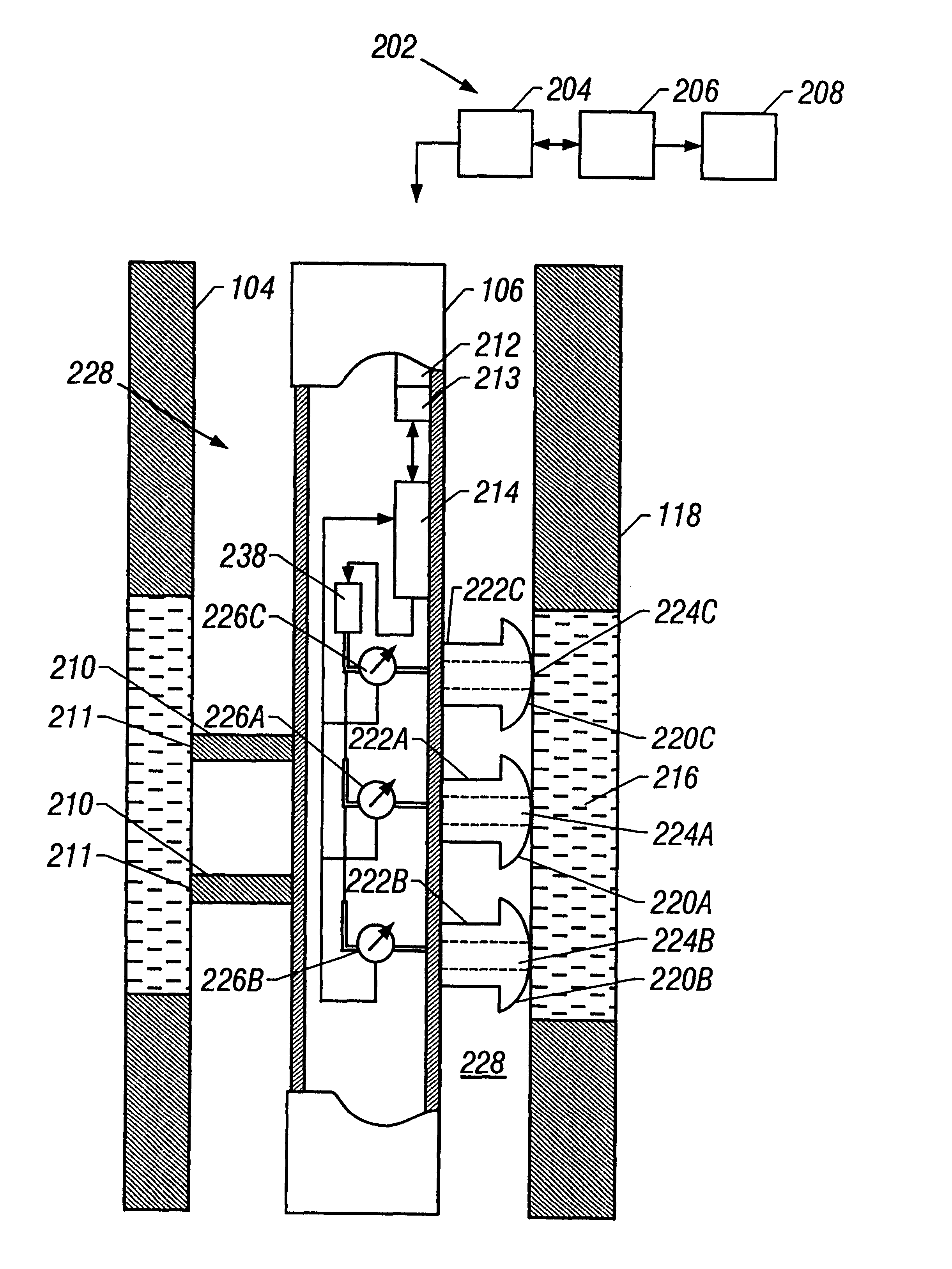

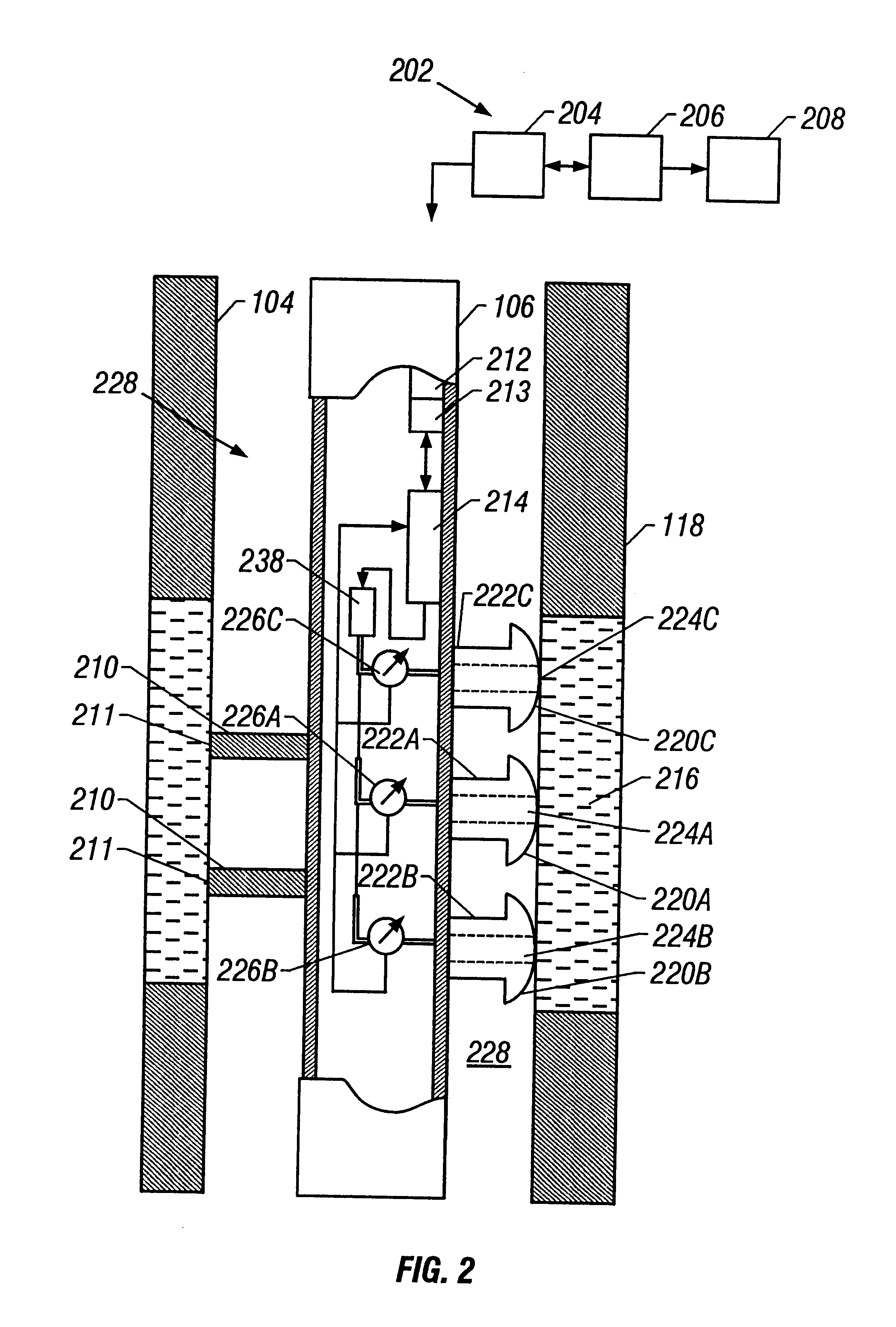

Drilling system with downhole apparatus for determining parameters of interest and for adjusting drilling direction in response thereto

The present invention provides a measurement-while-drilling (MWD) system having a downhole computer and multiple downhole sensors. Relatively large amounts of basic or "raw" data are measured by downhole sensors, and these data are processed within a downhole computer to be reduced to parameters of interest, which may be utilized to control the drilling operation by downhole devices, stored downhole, telemetered to the surface, or both. The measurements may be correlated downhole with stored reference data thereby providing additional information pertaining to the drilling operation. Downhole depth correlation between downhole measured parameters may be made by utilizing surface determined or downhole determined borehole depth.

Owner:BAKER HUGHES INC

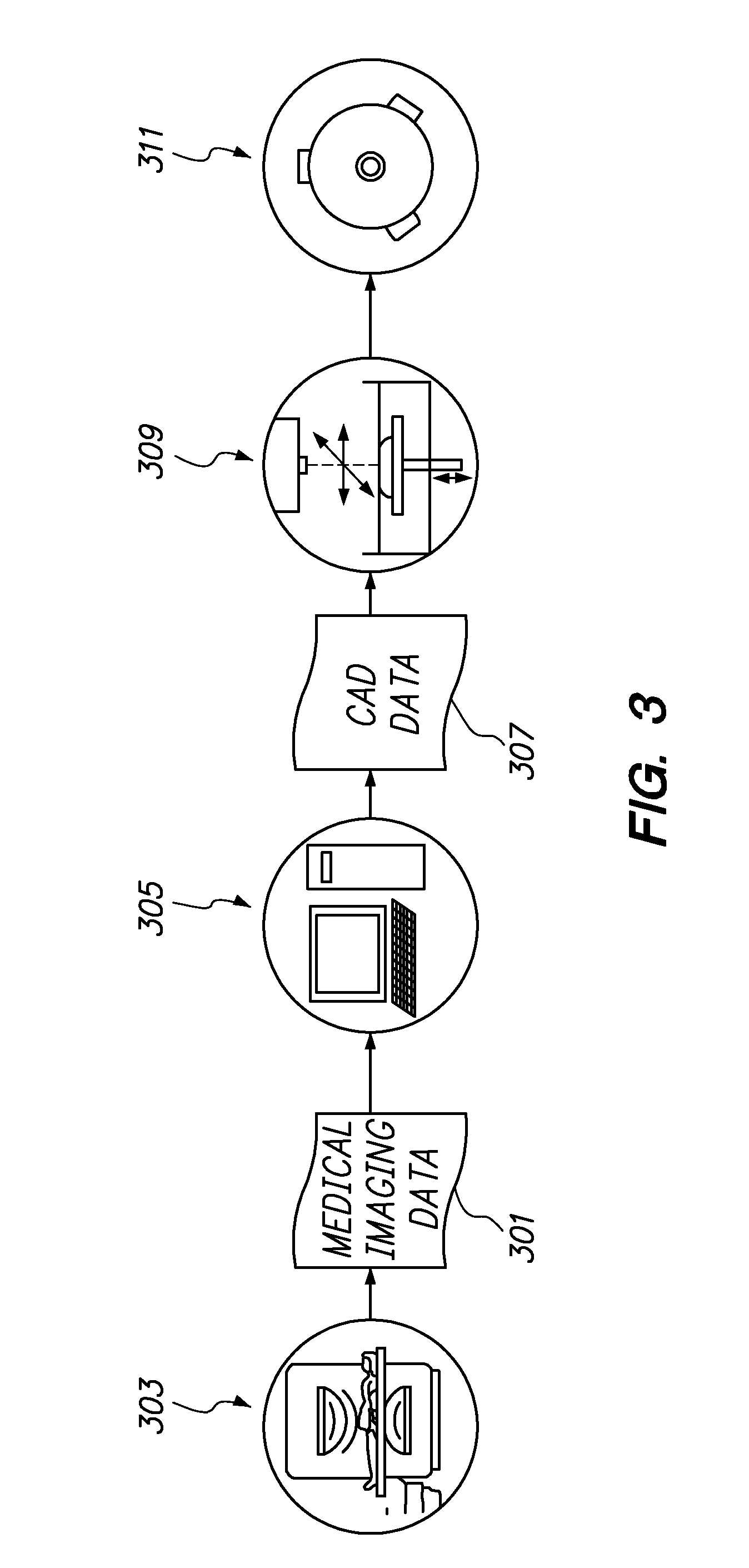

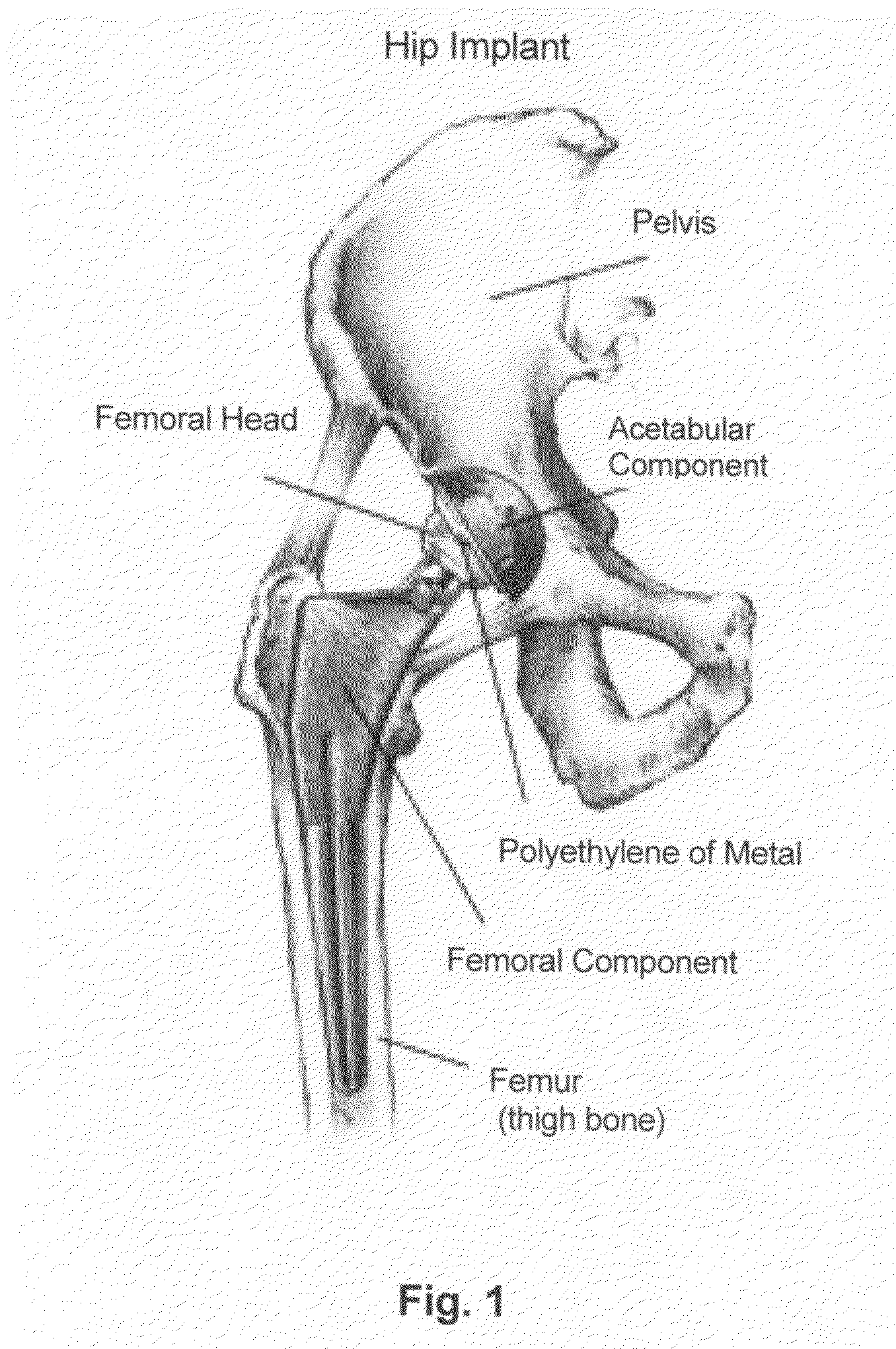

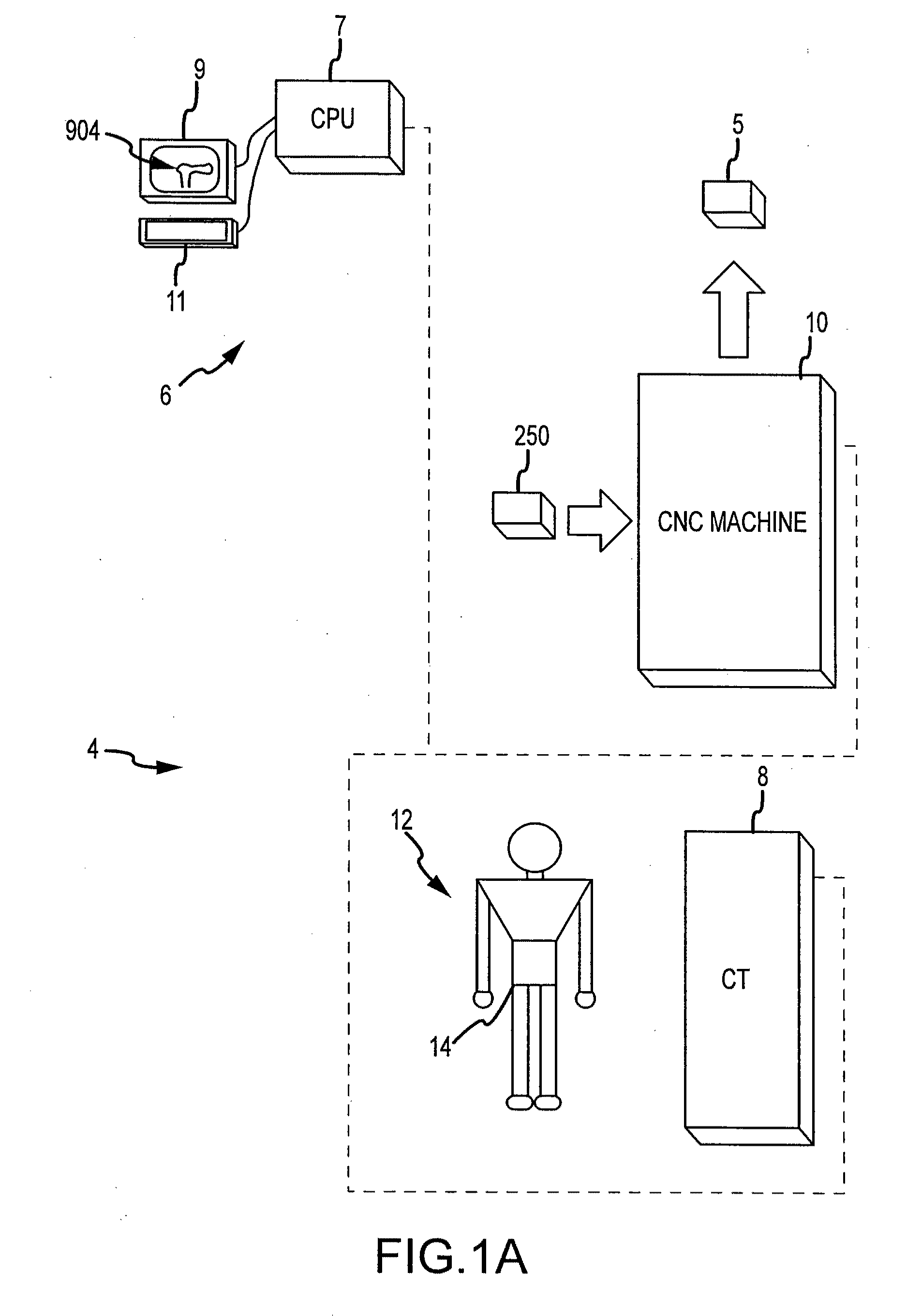

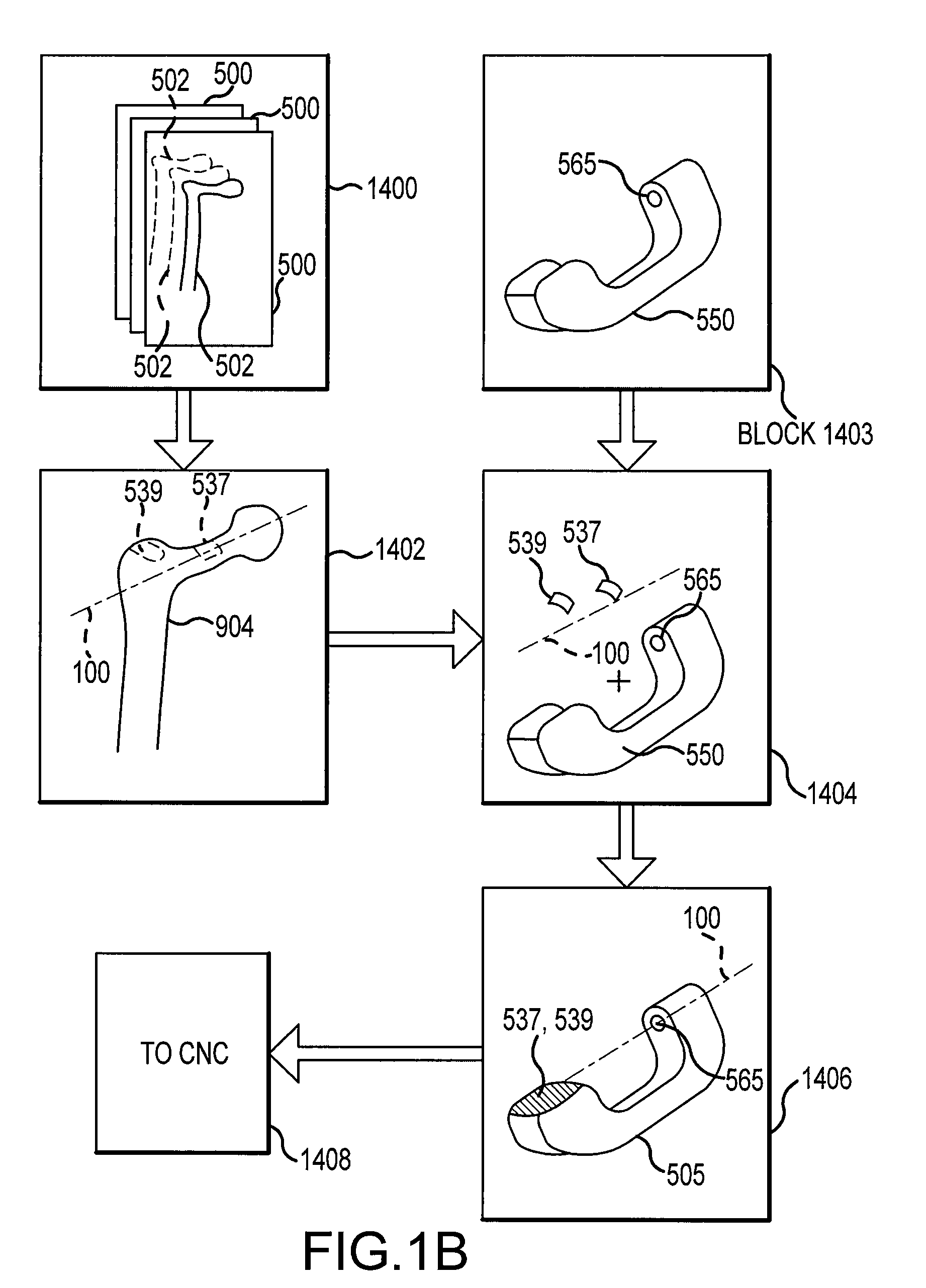

Device and method for achieving accurate positioning of acetabular cup during total hip replacement

InactiveUS20100274253A1DiagnosticsComputer-aided planning/modellingMedical imaging dataHip resurfacing

A method and device are provided in order to achieve optimal or desired orientation of an acetabular cup for total hip replacement or hip resurfacing. The method and device utilize preoperative medical imaging such as CT or MRI scans, 3D computer modeling and a patient-specific alignment jig created from medical imaging data such as CT or MRI data and computer 3D modeling. The device allows accurate placement of a drill hole to establish an acetabular axis, and placement of an acetabular cup perpendicular to the axis.

Owner:URE KEITH J

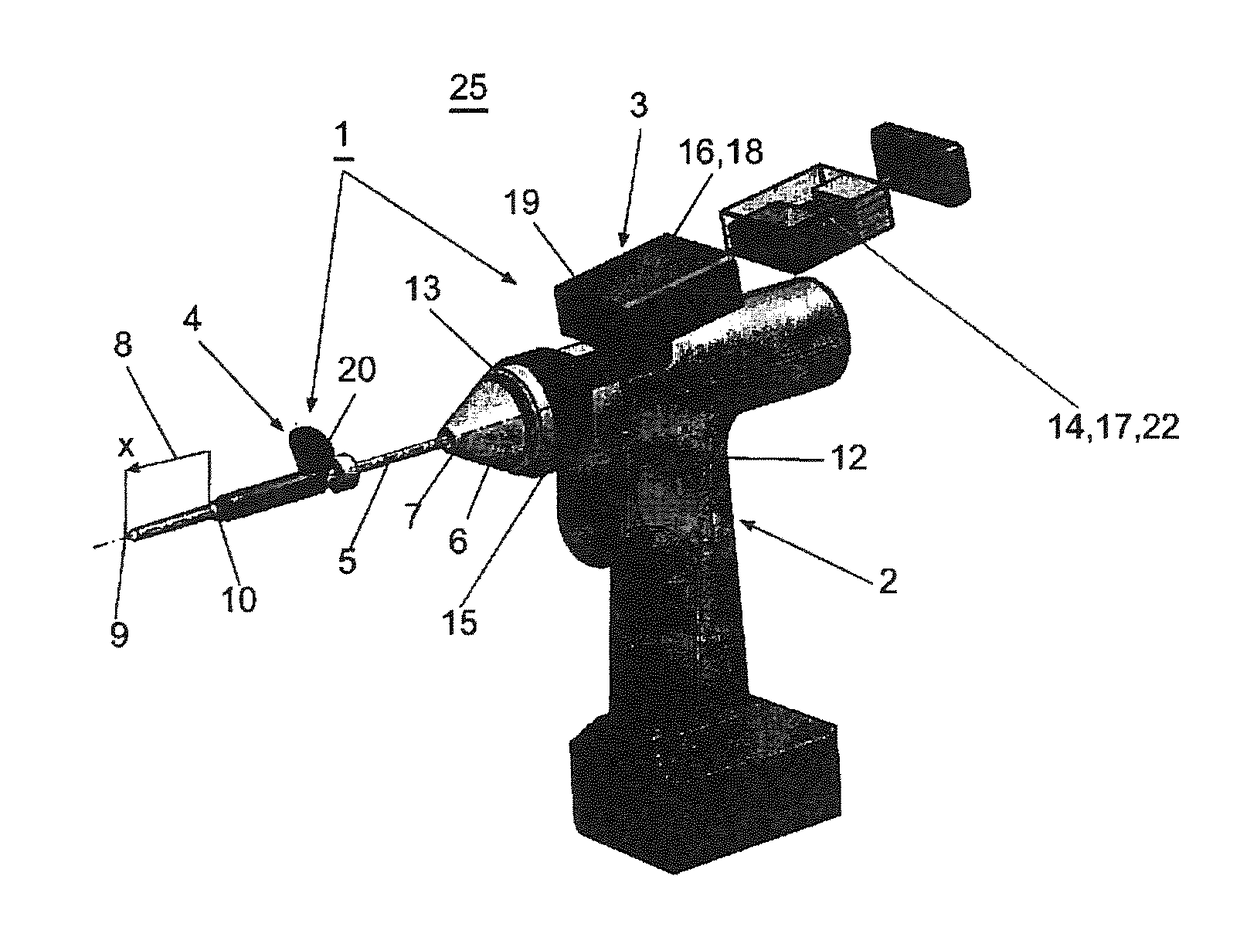

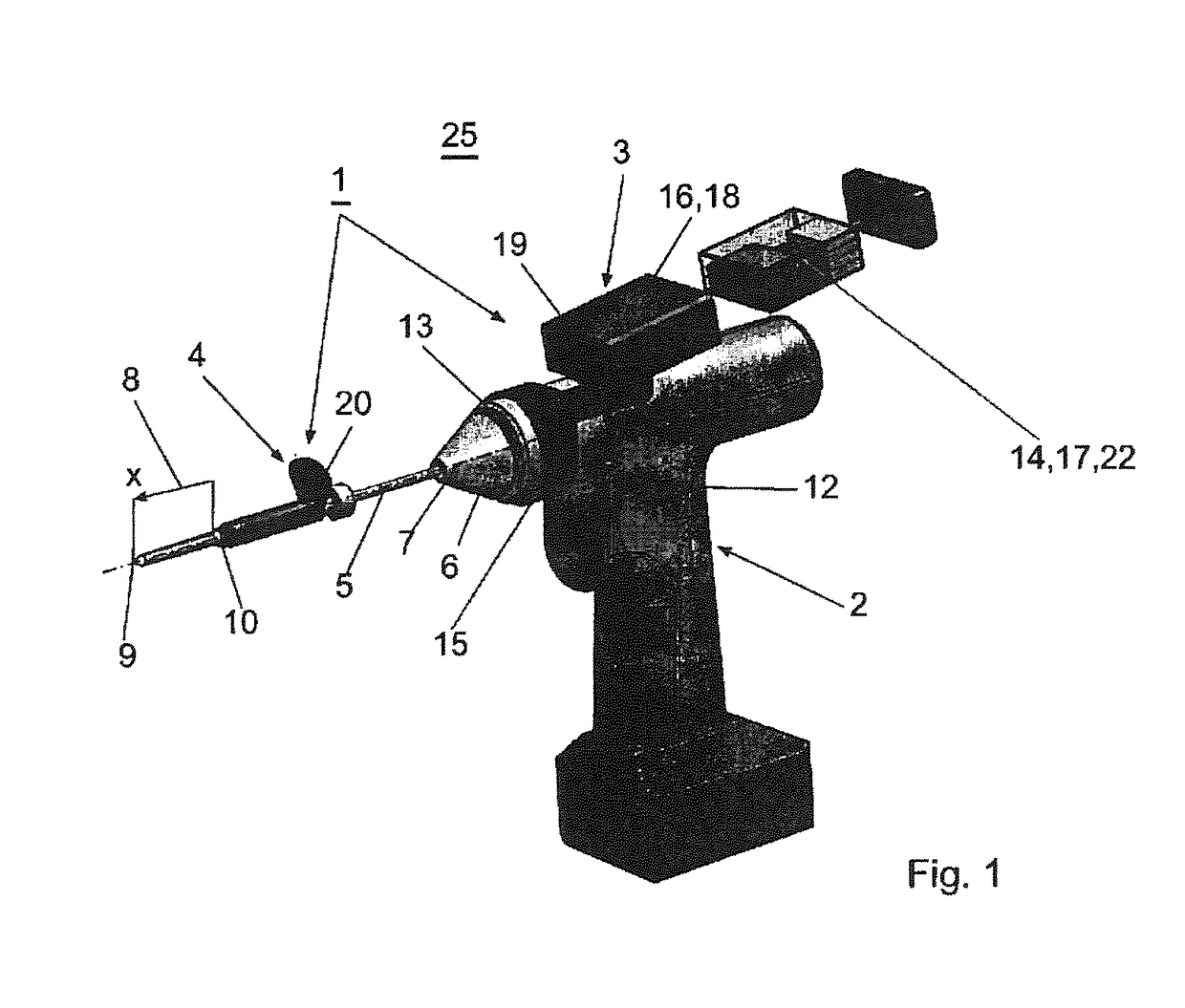

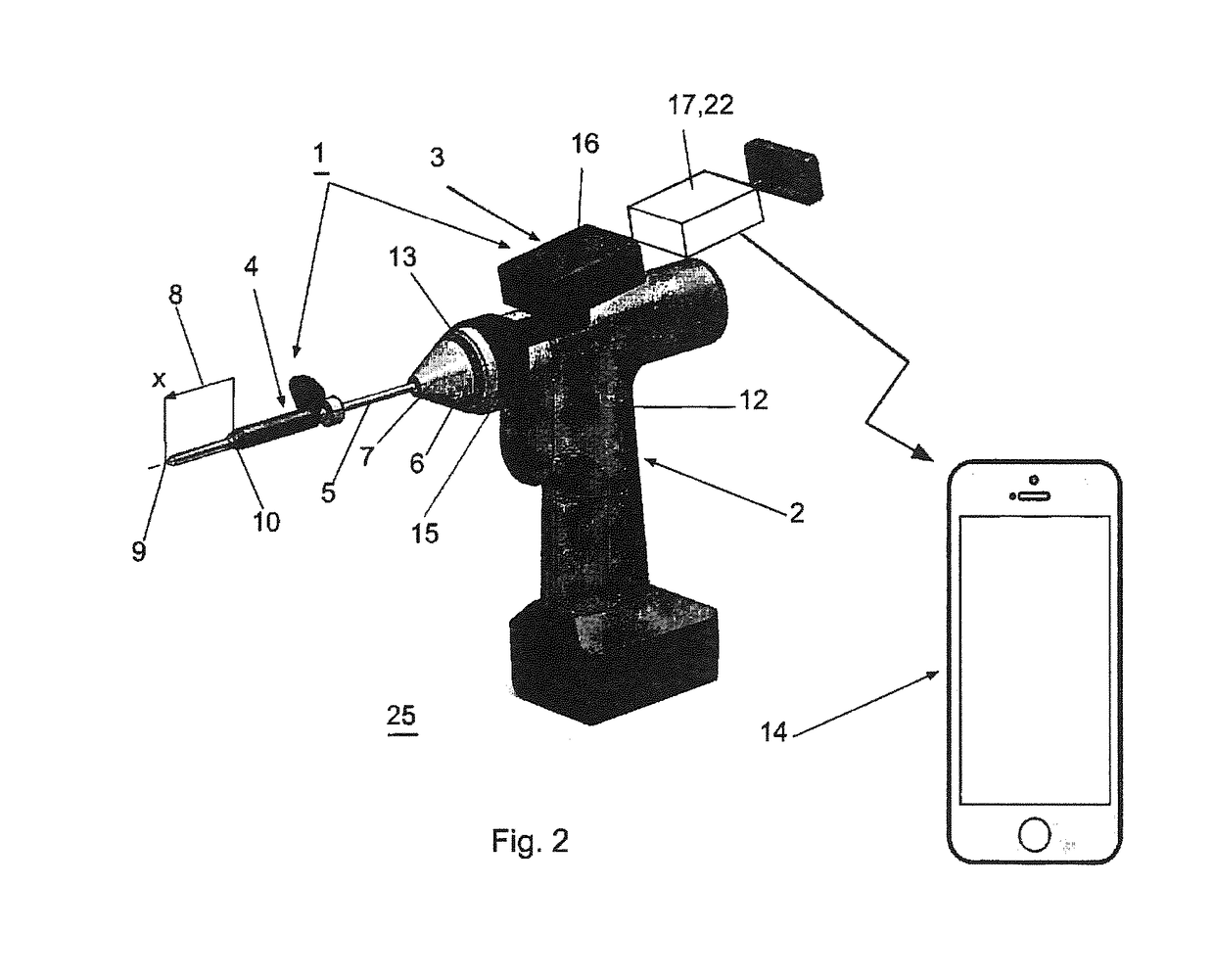

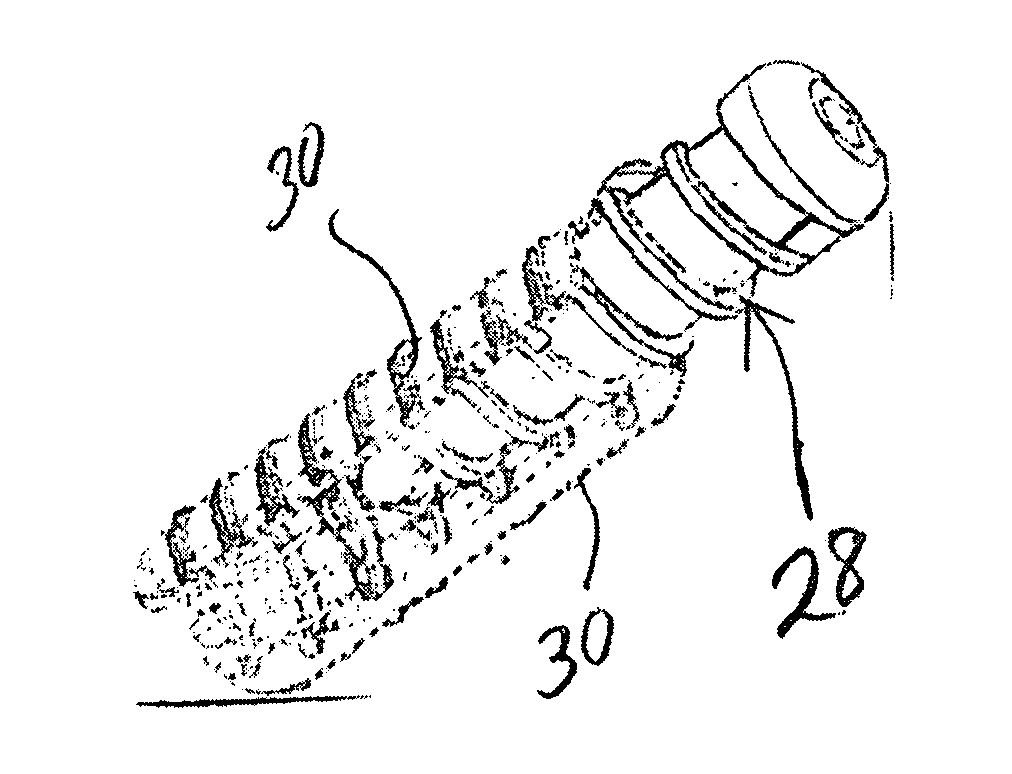

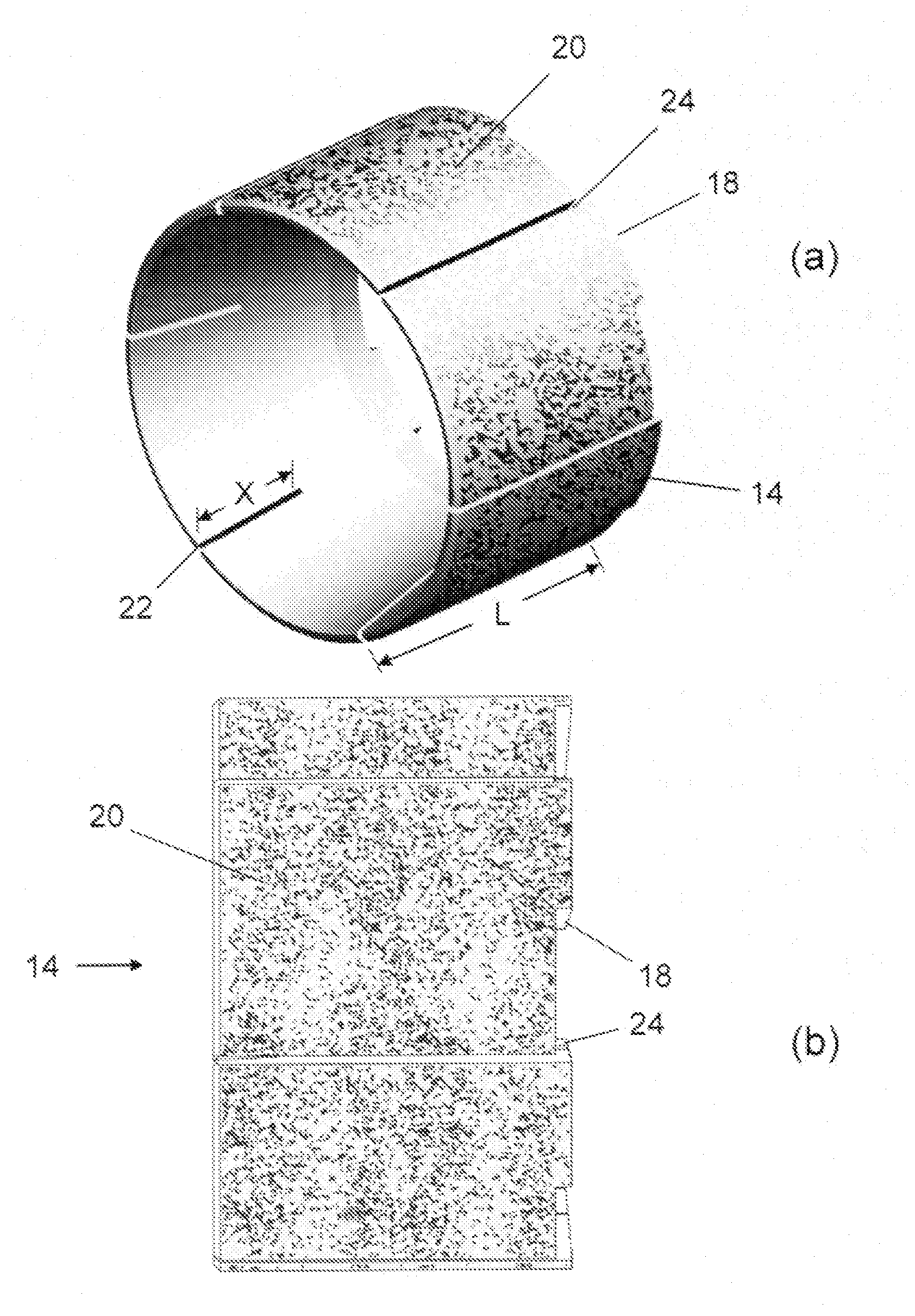

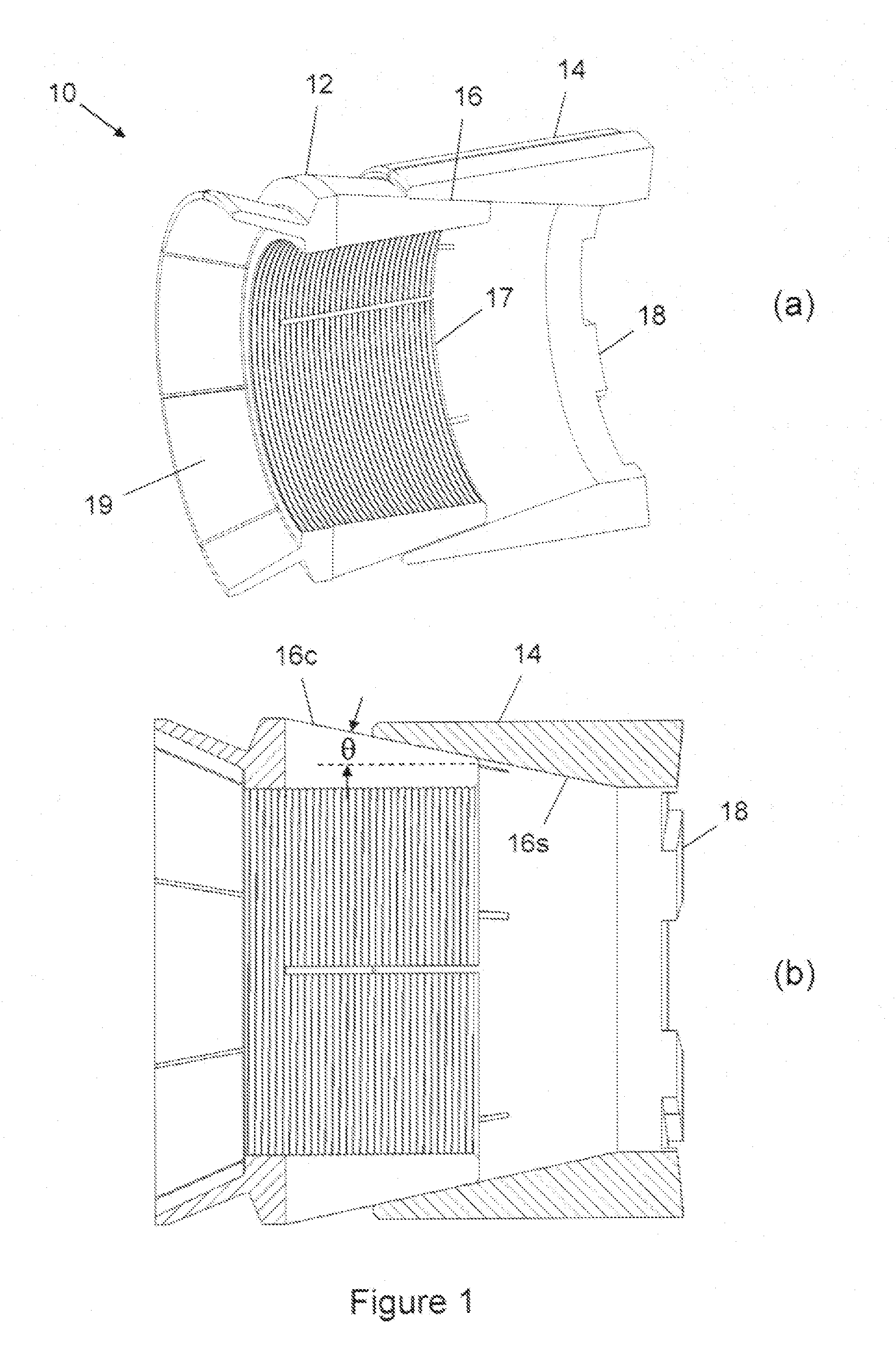

Surgical power drill including a measuring unit suitable for bone screw length determination

A device (25) for drilling holes in bone and configured to determine bone screw length, the device (25) including a surgical power drill (2) comprising: a) a housing (12) and; b) a measuring device (1) releasably attached or fixed to the housing (12), wherein the measuring device (1) is configured to measure the distance (x) covered by the housing (12) in the direction of the longitudinal axis (7) and relative to a surface of an implant (26) or a bone during a drilling process, wherein the measuring device (1) comprises a processing unit (14) to record the distance (x) covered with respect to time; the processing unit (14) comprises one or more differentiators to determine at least the first and second derivatives of the distance (x) covered with respect to time; and the processing unit (14) further comprises a peak detector to analyze one or more peaks occurring in the graph of the highest derivative with respect to time, and wherein the measuring device (1) comprises a laser device or an ultrasound position sensor for displacement assessment.

Owner:SYNTHES GMBH

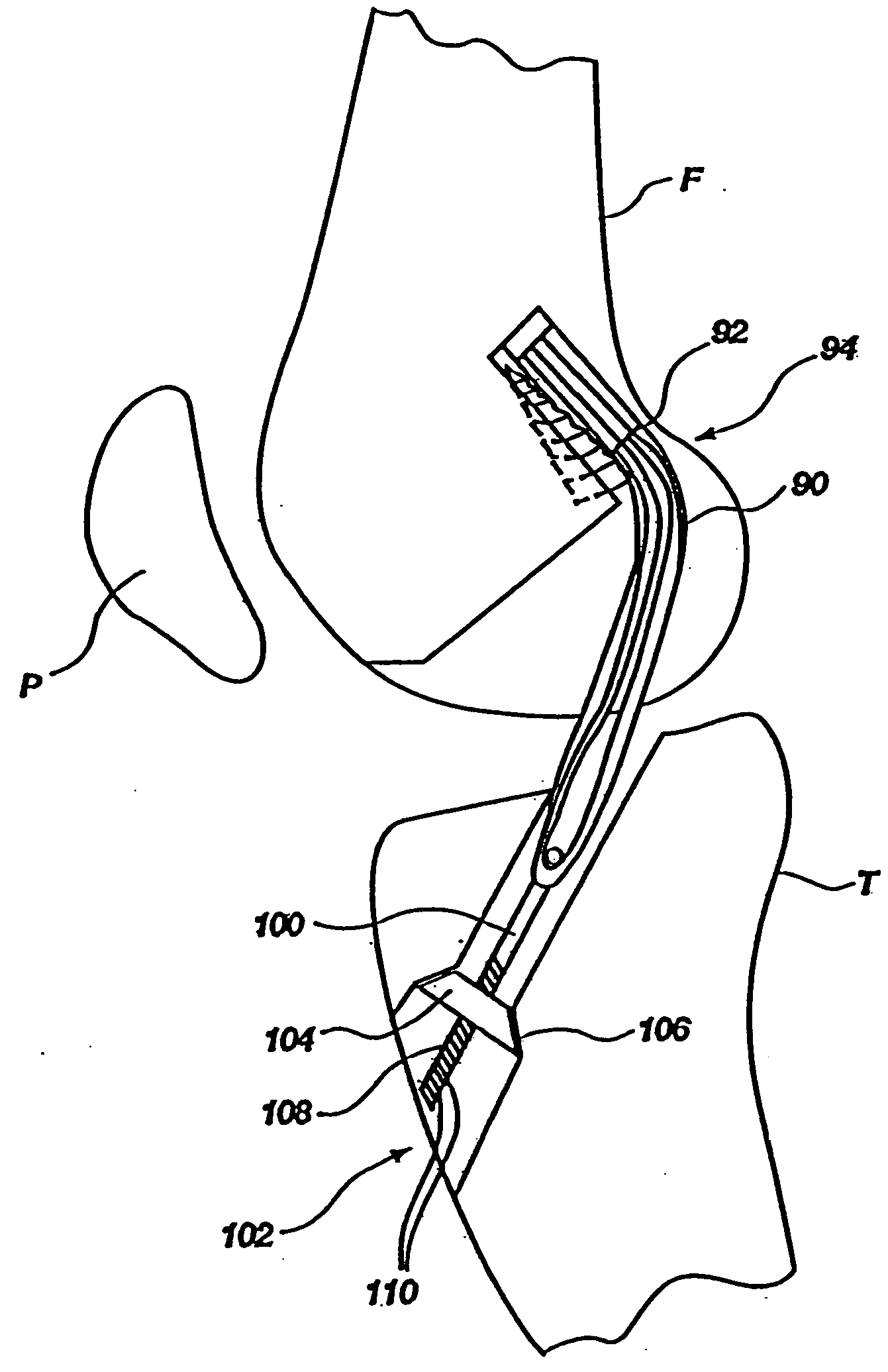

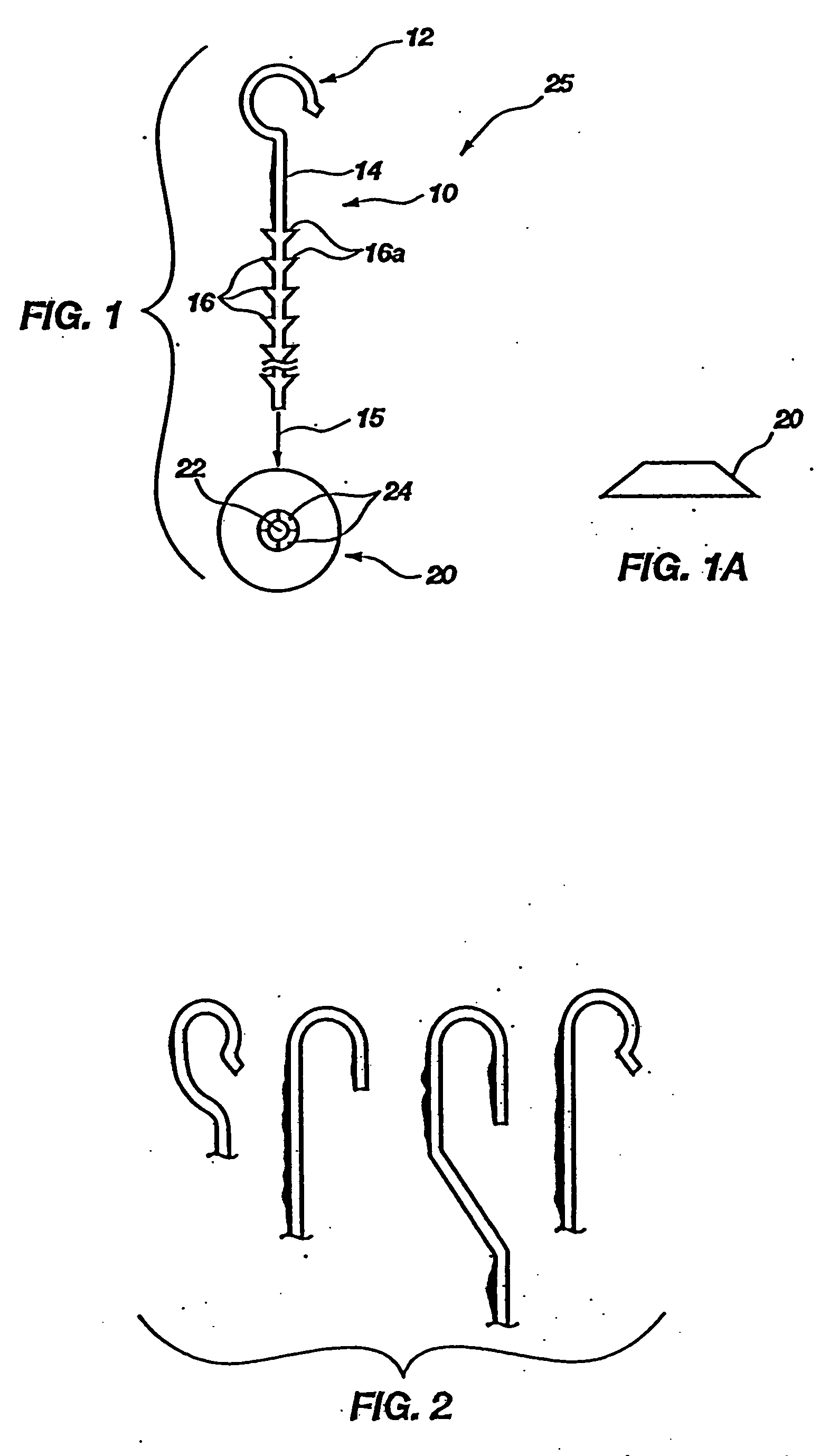

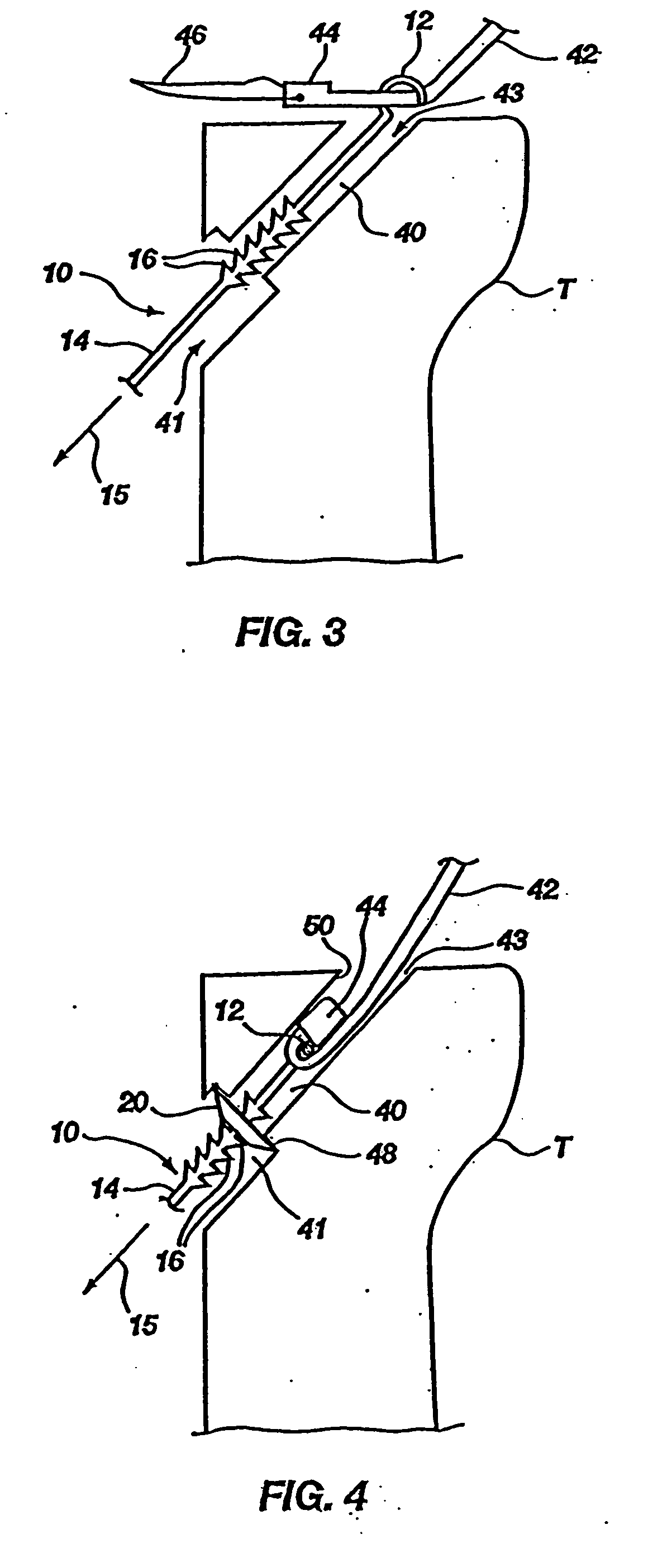

Endosteal tibial ligament fixation with adjustable tensioning

A system for endosteal tibial ligament fixation with adjustable tensioning is disclosed. A grasping hook located on a shaft is used to draw a ligament graft into a contoured drill hole formed in a bone. A series of slanted ridges on the shaft can pass in only one direction through a securing push nut residing in the contoured drill hole, resulting in an interference fit that secures the attachment system, while allowing the tension of the ligament graft to be adjusted.

Owner:CLARK RON +1

Devices, systems and methods for material fixation

A material fixation system is particularly adapted to improve the tendon-to-bone fixation of hamstring autografts, as well as other soft tissue ACL reconstruction techniques. The system is easy to use, requires no additional accessories, uses only a single drill hole, and can be implanted by one person. Additionally, it replicates the native ACL by compressing the tendons against the aperture of the tibial tunnel, which leads to a shorter graft and increased graft stiffness. It is adapted to accommodate single or double tendon bundle autografts or allografts. It also provides pull out strength measured to be greater than 1000 N.

Owner:CAYENNE MEDICAL INC

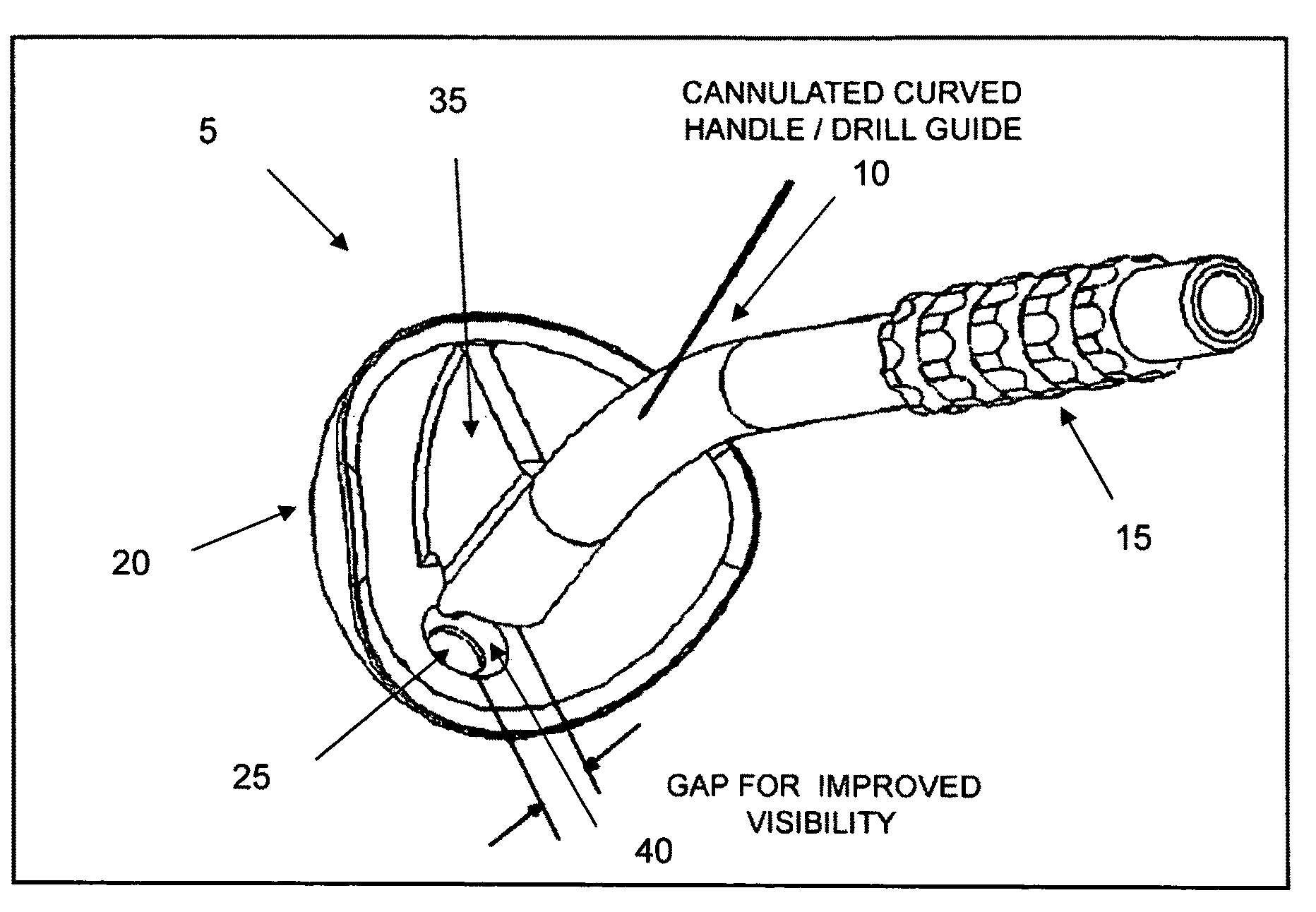

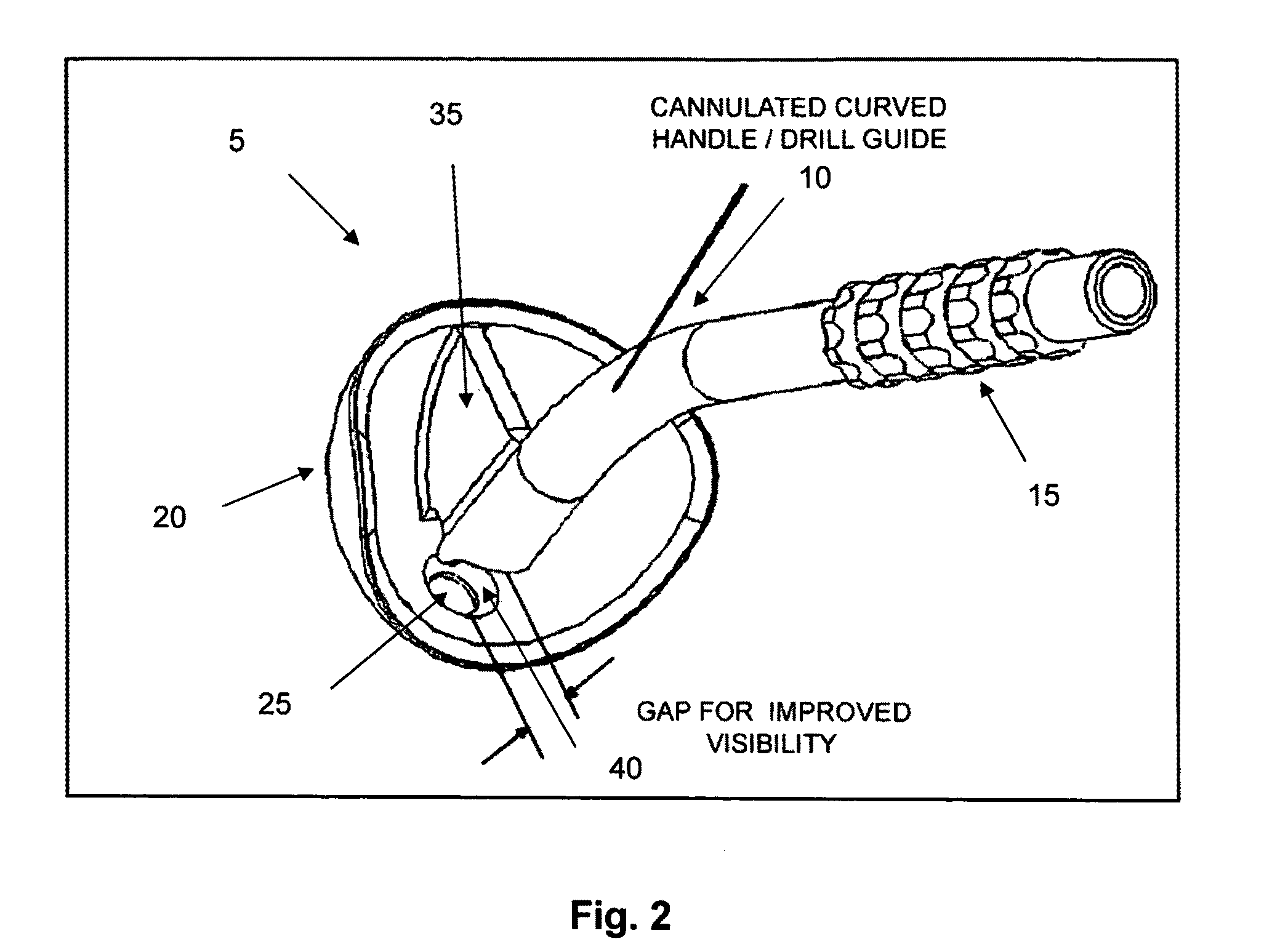

Drill system for acetabular cup implants

InactiveUS20090012526A1Joint implantsNon-surgical orthopedic devicesDrill guideBiomedical engineering

A drill guide system comprising:a hemispherical cup having an opening therein;a body having a distal end, a proximal end and a lumen extending between the distal end and the proximal end; anda connector for connecting the body to the hemispherical cup so that the lumen at the distal end of the body is aligned with the opening in the hemispherical cup.

Owner:FLETCHER HENRY H

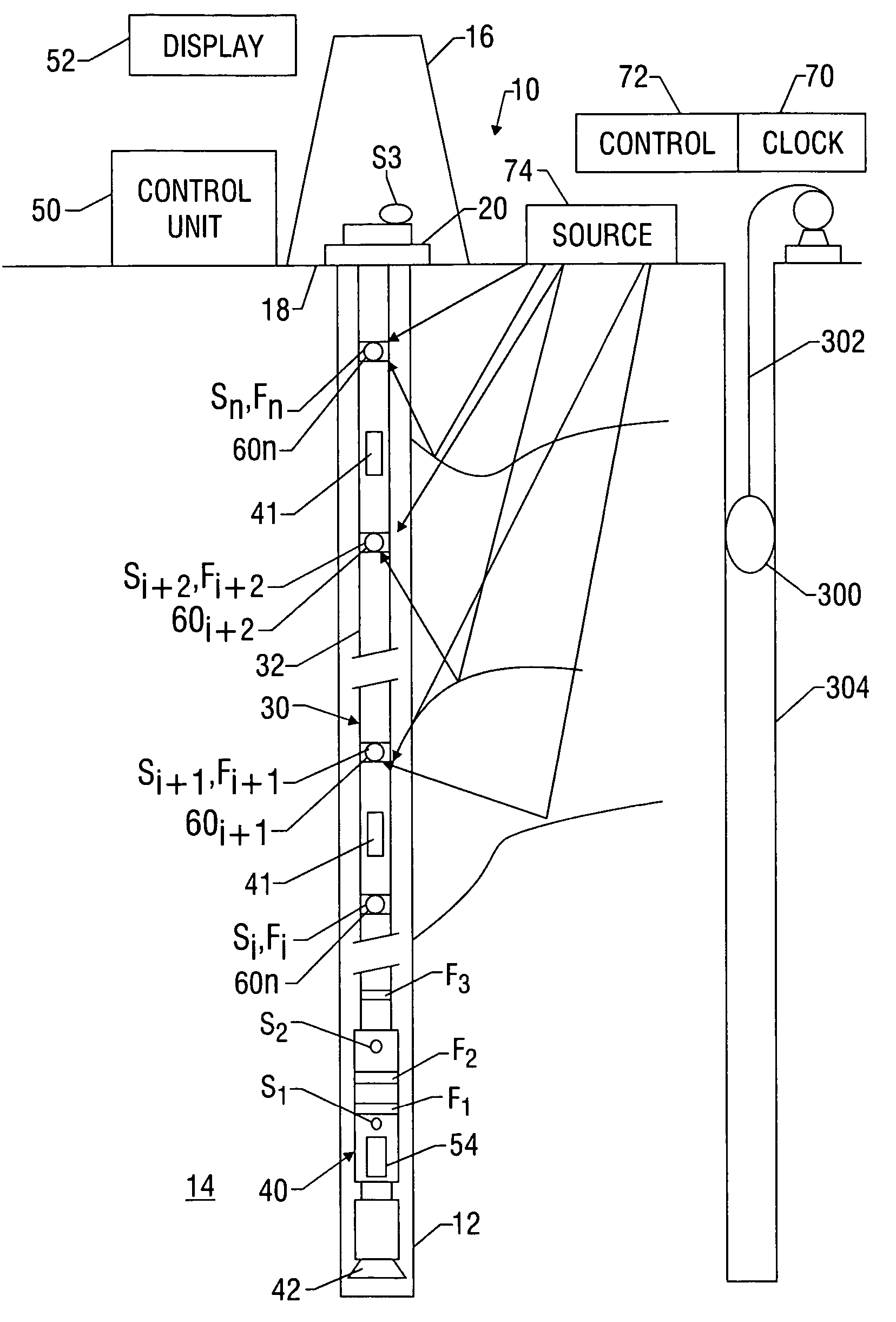

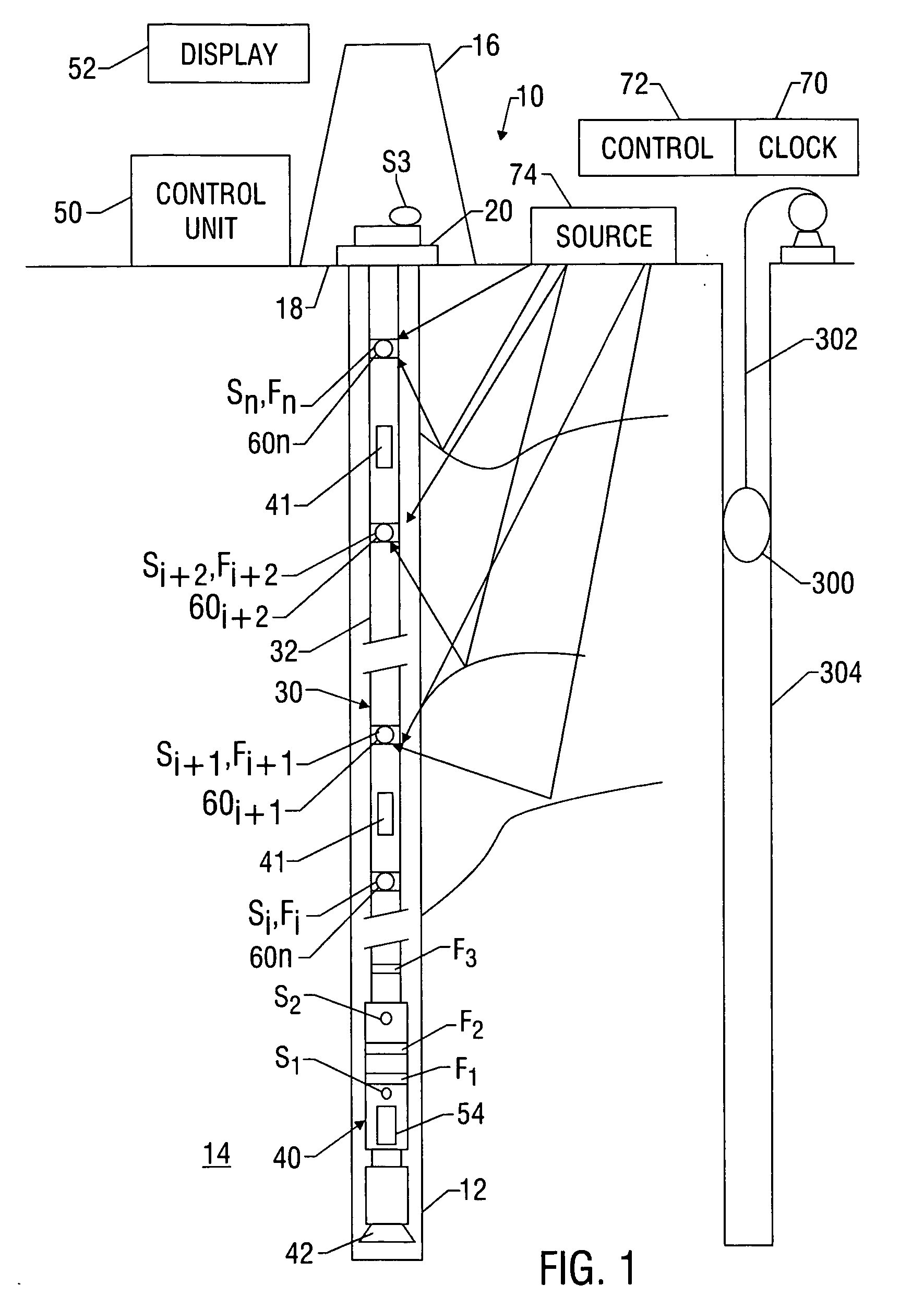

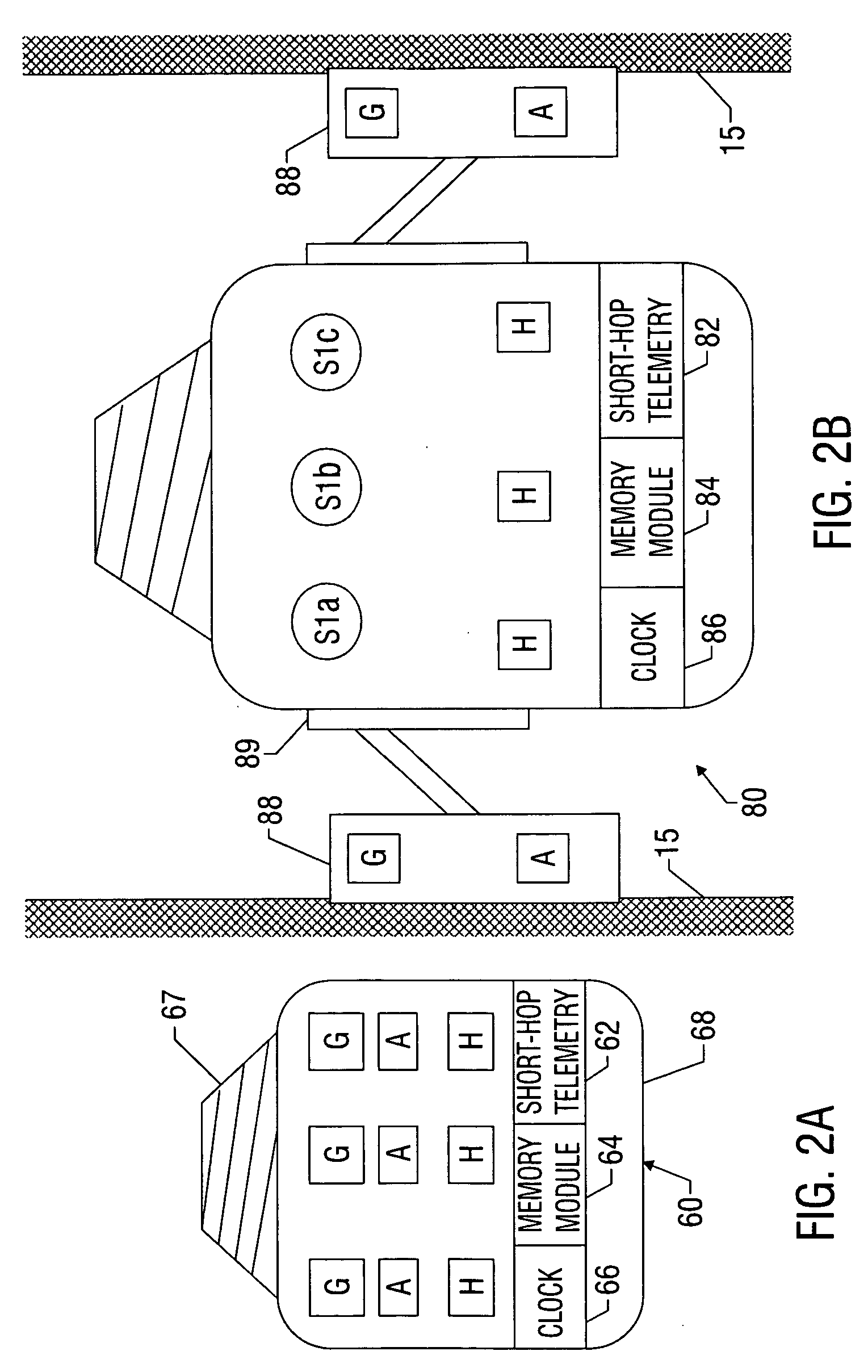

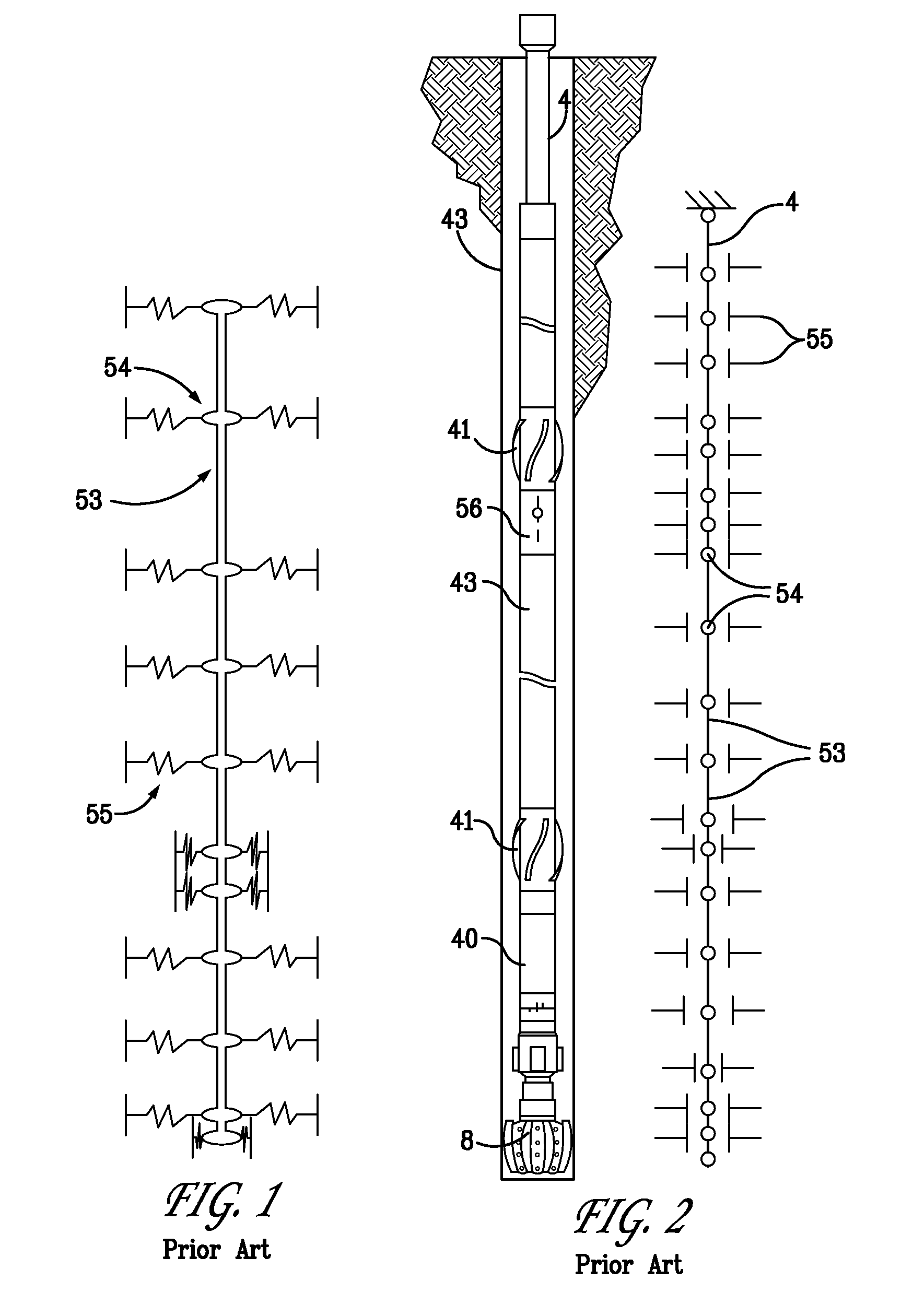

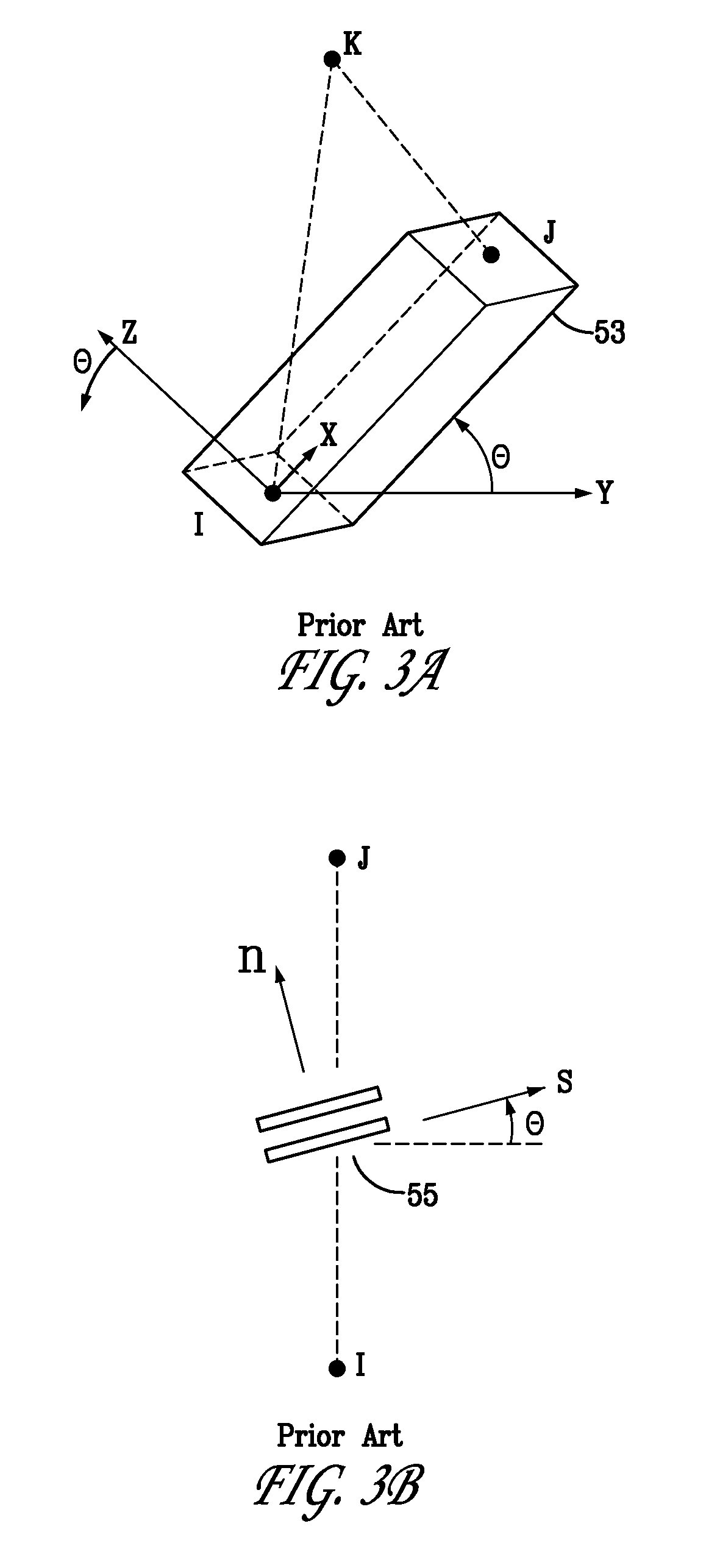

Drilling wellbores with optimal physical drill string conditions

ActiveUS20050279532A1Improve efficiencyEnhance reliabilitySurveySeismic signal processingSubmarineGraphical user interface

A drilling system includes a control unit and a bottomhole assembly (BHA) coupled to a drill string. The control unit uses measurements from sensors distributed throughout the drill string and BHA to determine the physical condition of the drill string and BHA and to determine whether drilling can be optimized. The drill string sensors are housed in receiver subs and optionally can be positioned on extensible members. The receiver sub also can include a short-hop telemetry module, a processor module, and a clock module. In one embodiment, the receiver subs include seismic sensors for enabling vertical seismic profiling. During operation, the processor visually presents to the operator via one or more graphical user interfaces a dynamically updated pictorial image representing the drilling system. The image is annotated with an appropriate visual signal to indicate a determined physical condition at a given location or component. The processor can also display recommended adjustments to drilling parameters for increasing drilling rates, improving tool life, and more precise steering.

Owner:BAKER HUGHES INC

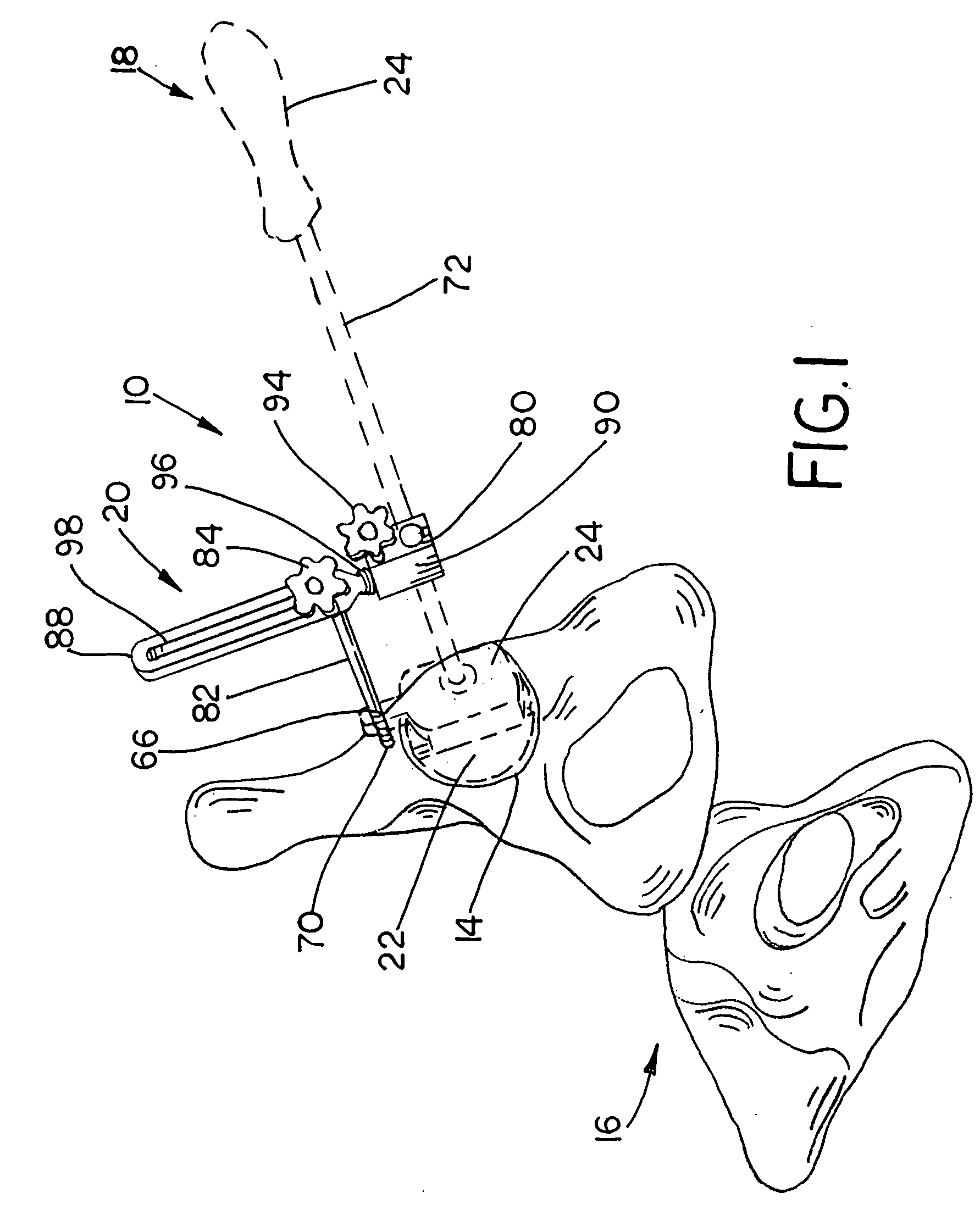

Acetabular instrument alignment guide

InactiveUS20060161167A1Eliminate needSave surgical timeDiagnosticsJoint implantsEngineeringPlastic surgery

An acetabular instrument alignment guide for aligning at least one orthopaedic instrument relative to an acetabulum in a pelvis. The acetabular instrument alignment guide includes an interchangeable head configured for positioning within the acetabulum where the interchangeable head has a primary axis. A drill guide is releasably connected to the interchangeable head. The drill guide includes a drill bore offset from the primary axis, and the drill bore is configured for aligning a drill relative to the pelvis. The acetabular instrument alignment guide further includes at least one reference pin and an instrument guide connected to the at least one reference pin, the instrument guide being both rotatable and translatable relative to the at least one reference pin. The reference pin is configured for placement in at least one hole in the pelvis produced by the drill.

Owner:SYMMETERY MEDICAL

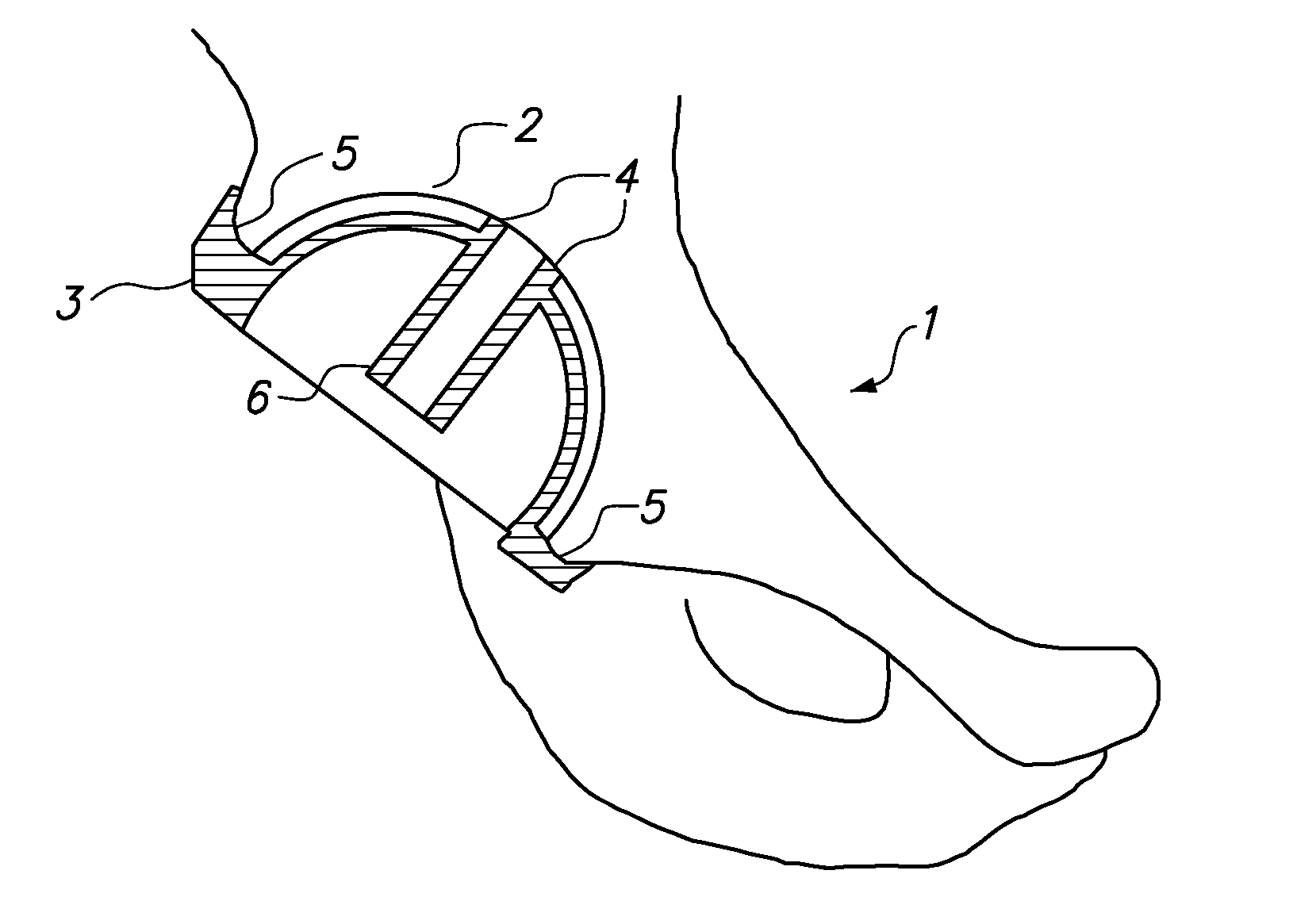

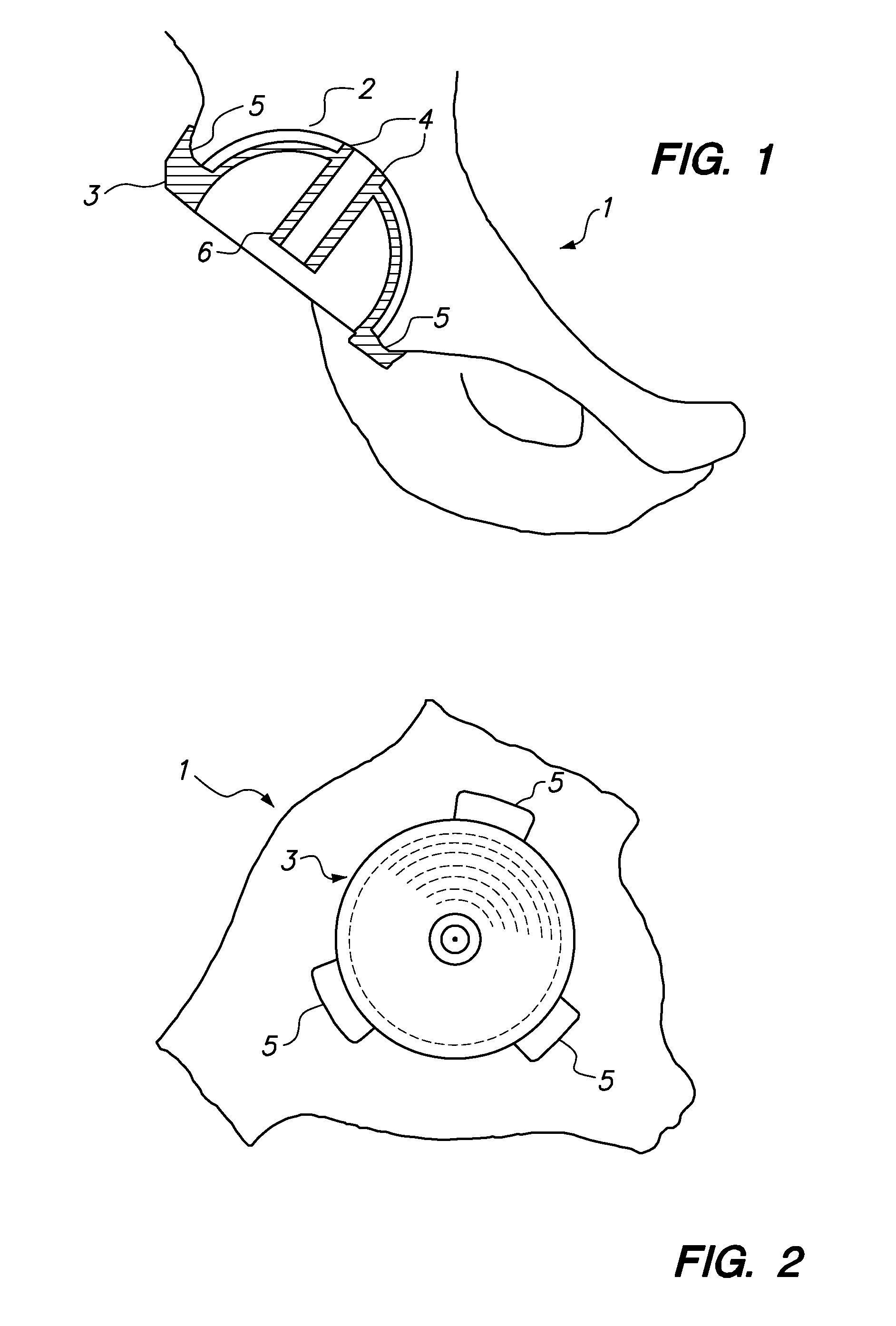

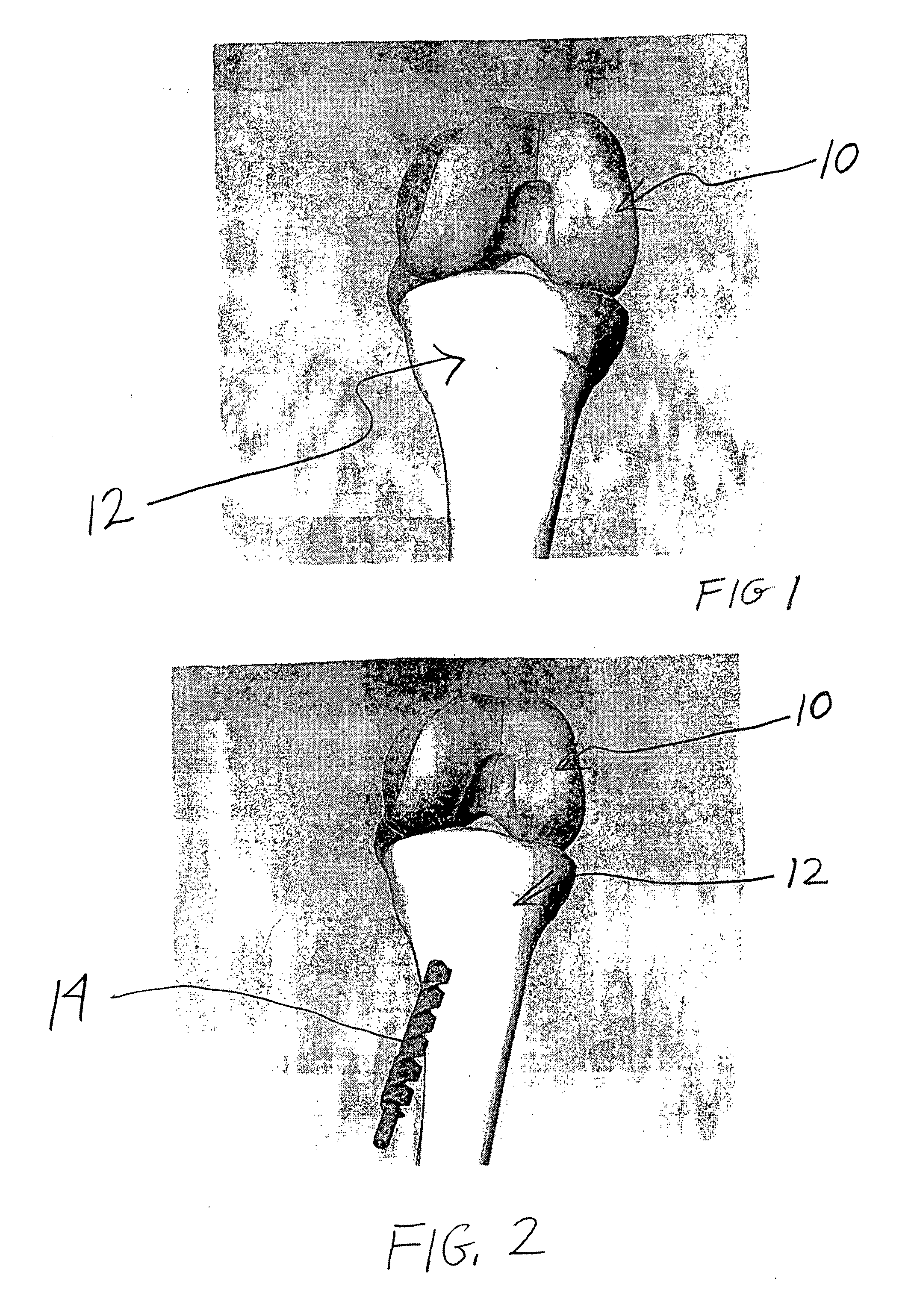

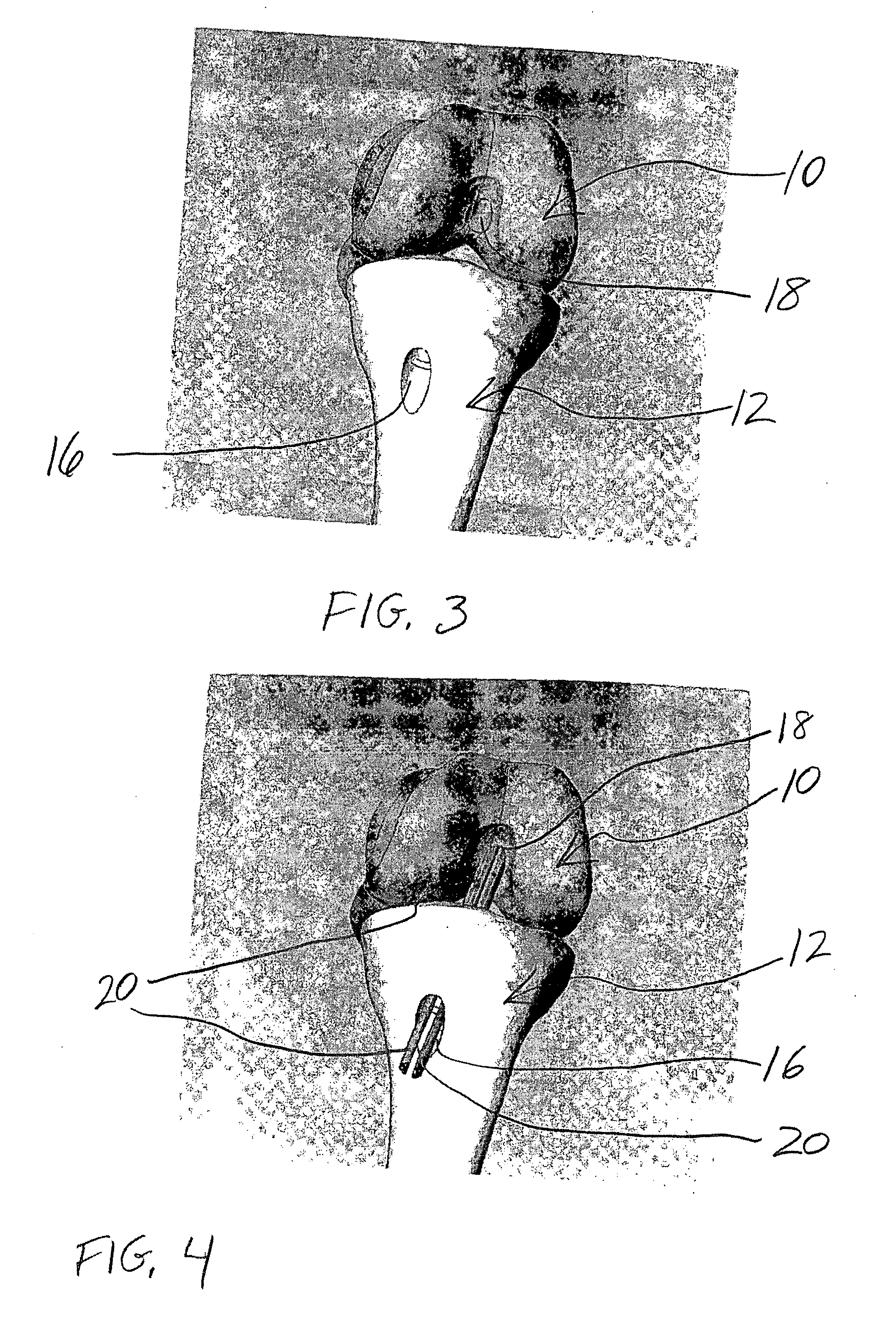

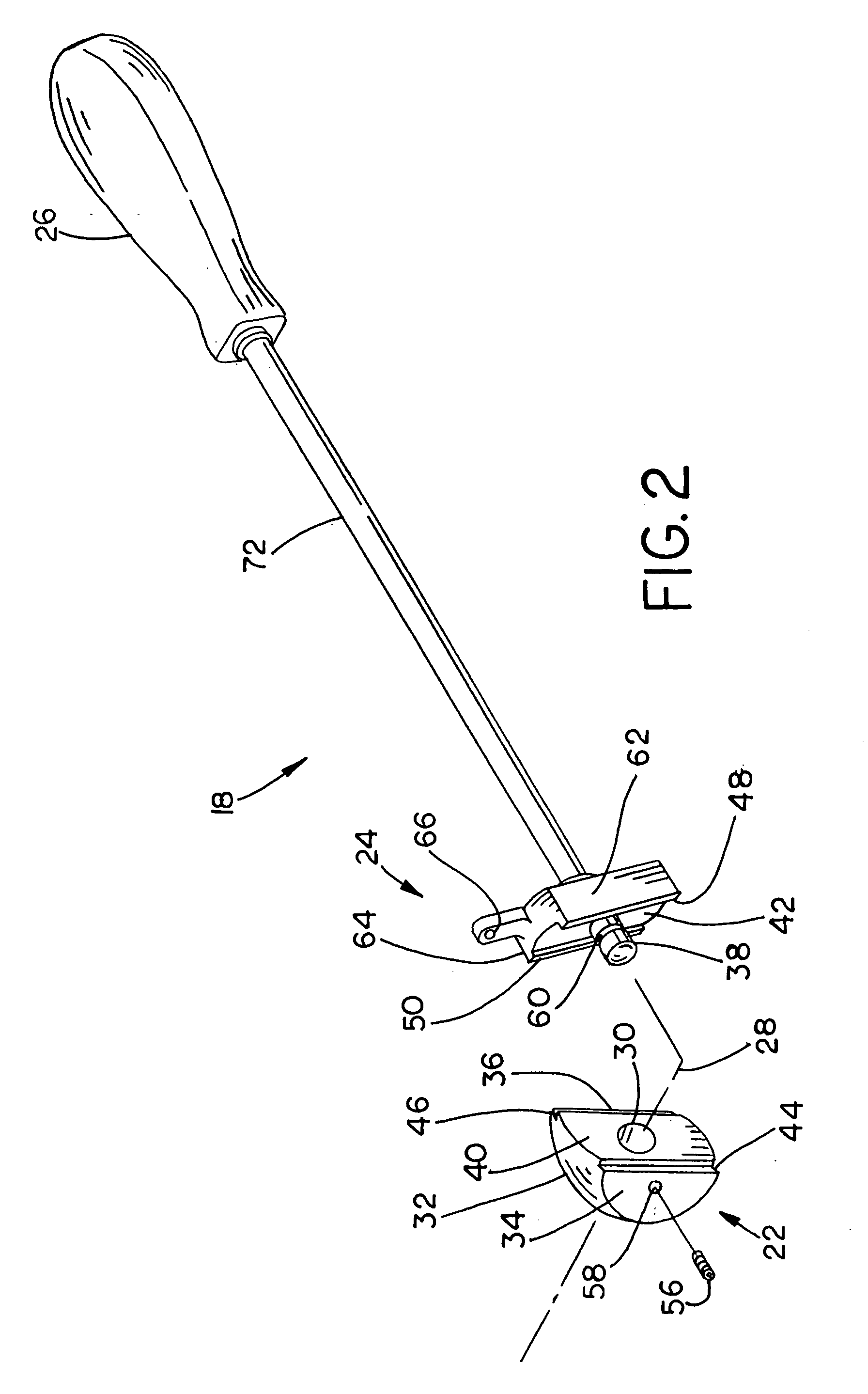

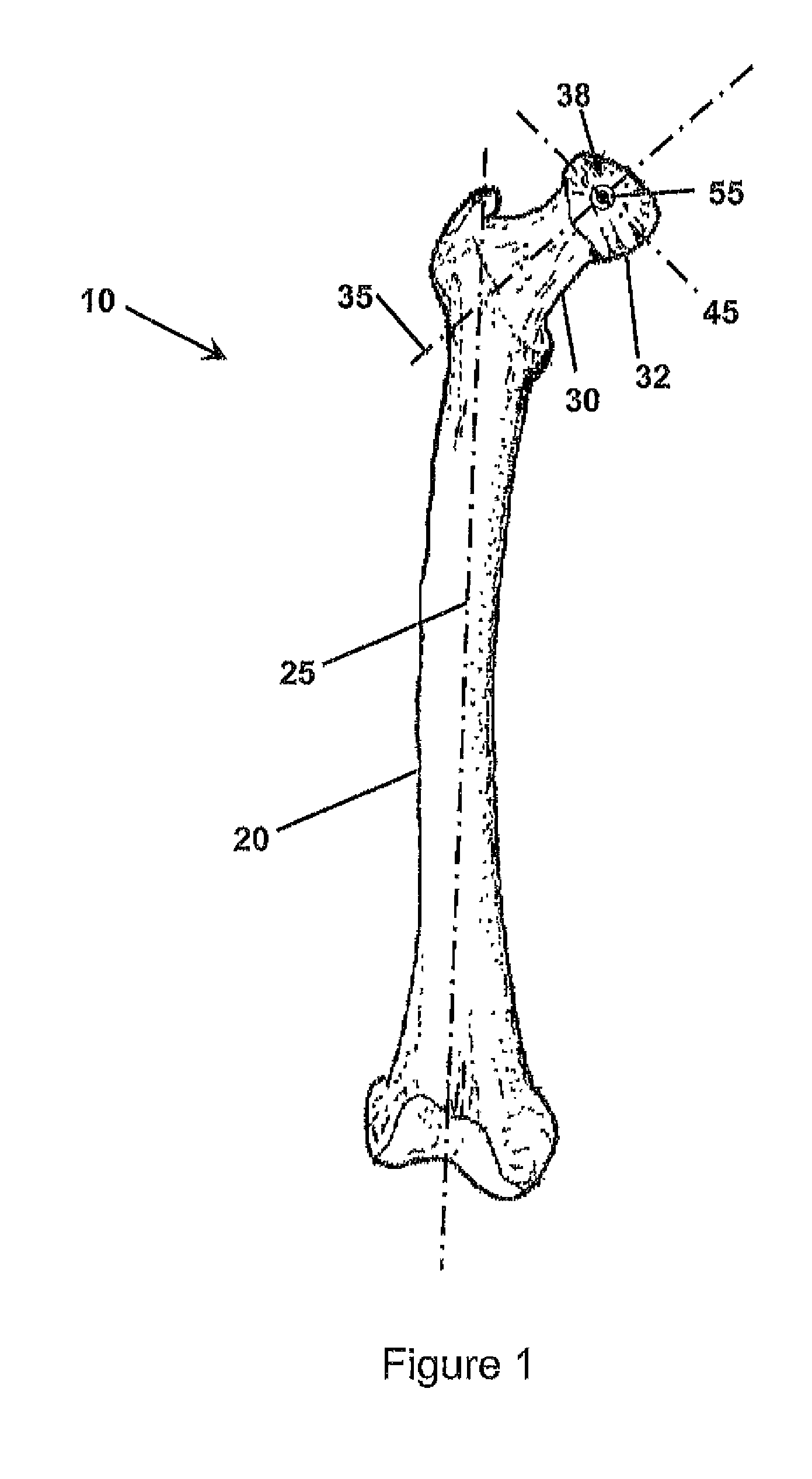

Hip resurfacing surgical guide tool

ActiveUS20090222015A1Increase in sizeProgramme controlAdditive manufacturing apparatusArticular surfacesRight femoral head

Disclosed herein is a tool for guiding a drill hole along a central axis of a femur head and neck for preparation of a femur head that is the subject of a hip resurfacing surgery. In one embodiment, the tool includes a mating region and a guide hole. The mating region is configured to matingly receive a predetermined surface of the femur. The mating region and guide hole are positionally correlated or referenced with each other such that when the mating region matingly receives the predetermined surface of the femur, the guide hole will be generally coaxial with a central axis extending through the femur head and the femur neck.

Owner:HOWMEDICA OSTEONICS CORP

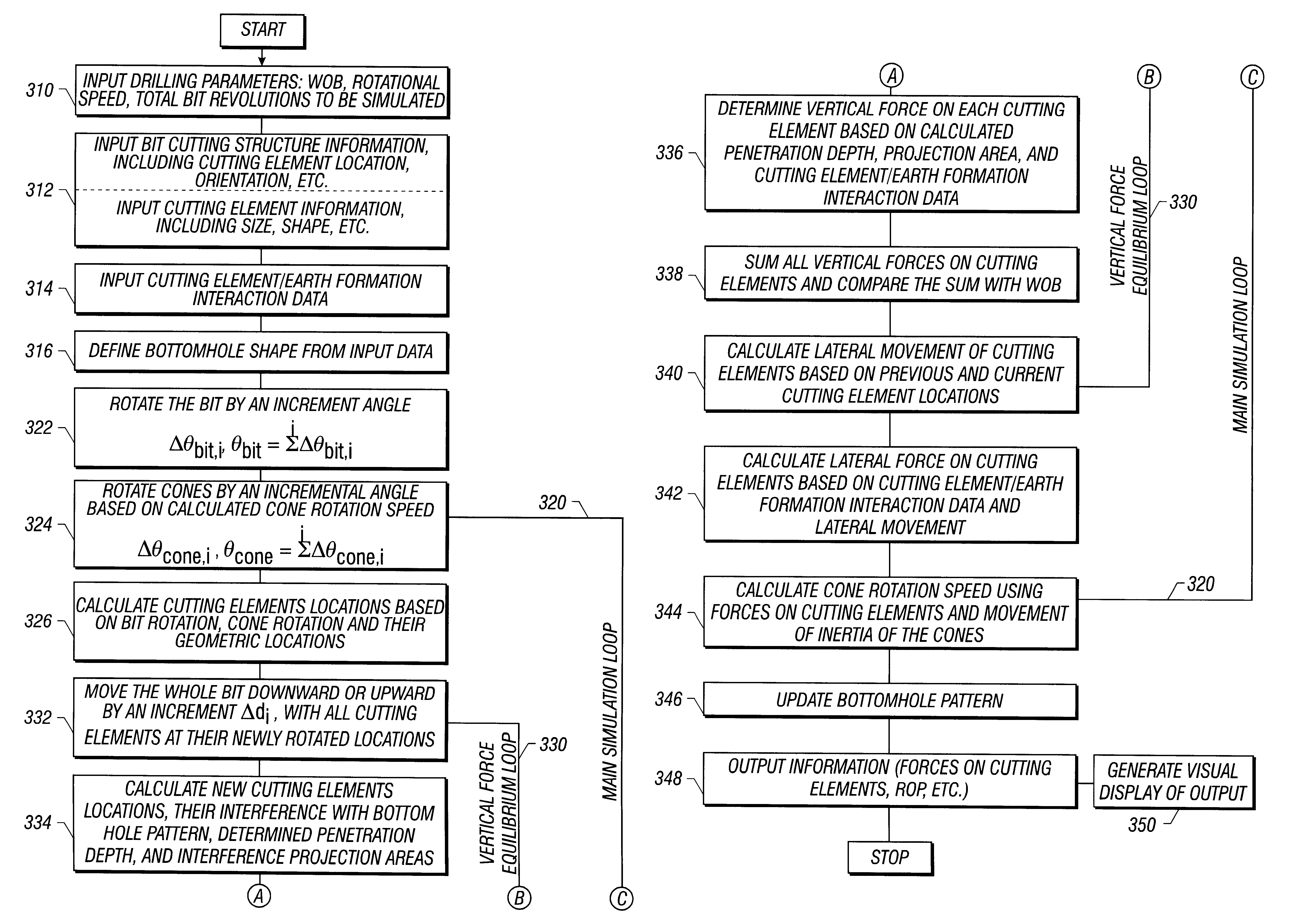

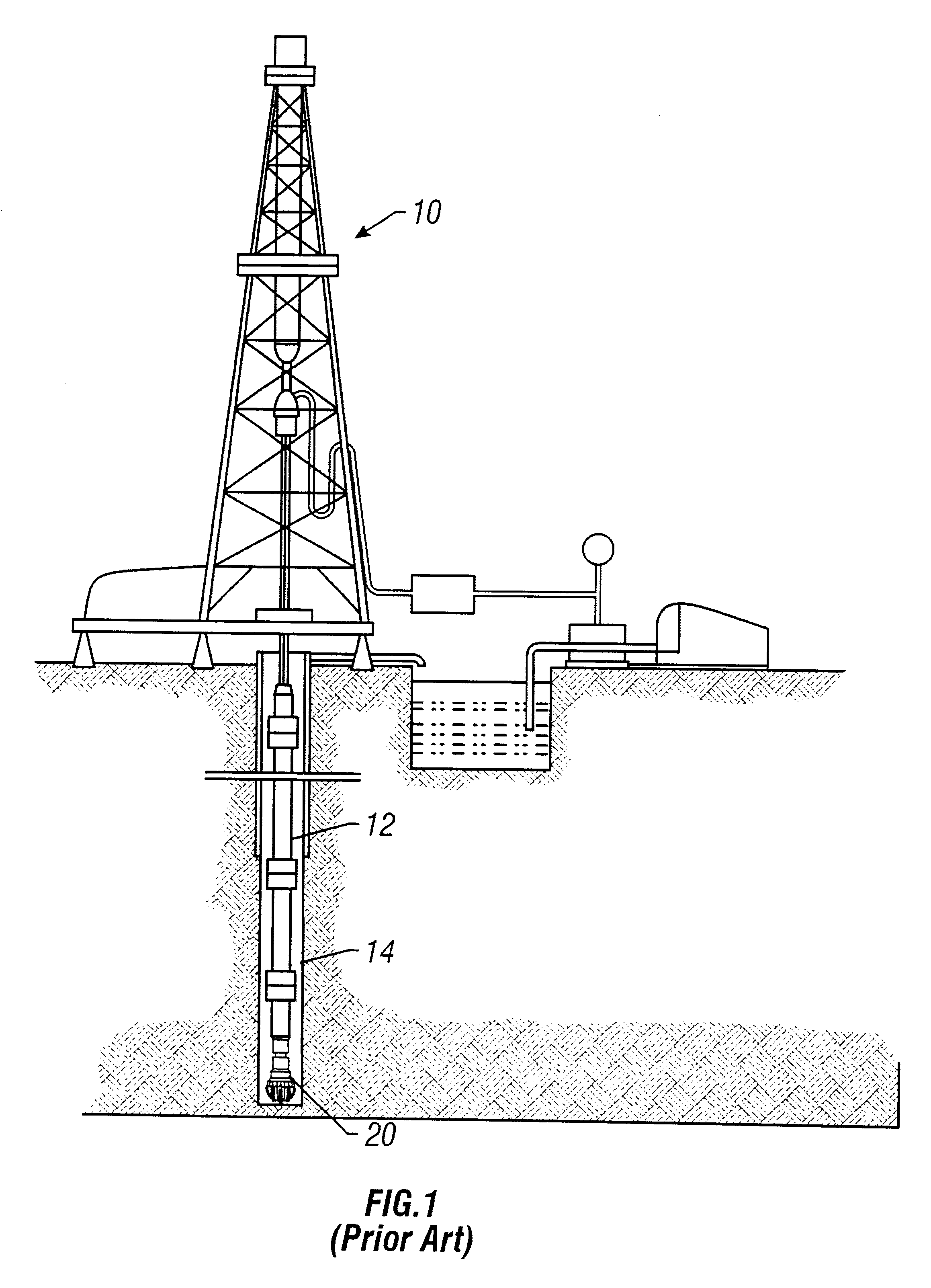

Method for simulating drilling of roller cone bits and its application to roller cone bit design and performance

InactiveUS6516293B1Electric/magnetic detection for well-loggingDrill bitsEngineeringVisual perception

A method for simulating the drilling performance of a roller cone bit drilling an earth formation may be used to generate a visual representation of drilling, to design roller cone drill bits, and to optimize the drilling performance of a roller cone bit. The method for generating a visual representation of a roller cone bit drilling earth formations includes selecting bit design parameters, selecting drilling parameters, and selecting an earth formation to be drilled. The method further includes calculating, from the bit design parameters, drilling parameters and earth formation, parameters of a crater formed when one of a plurality of cutting elements contacts the earth formation. The method further includes calculating a bottomhole geometry, wherein the crater is removed from a bottomhole surface. The method also includes incrementally rotating the bit and repeating the calculating of crater parameters and bottomhole geometry based on calculated roller cone rotation speed and geometrical location with respect to rotation of said roller cone drill bit about its axis. The method also includes converting the crater and bottomhole geometry parameters into a visual representation.

Owner:SMITH INT INC

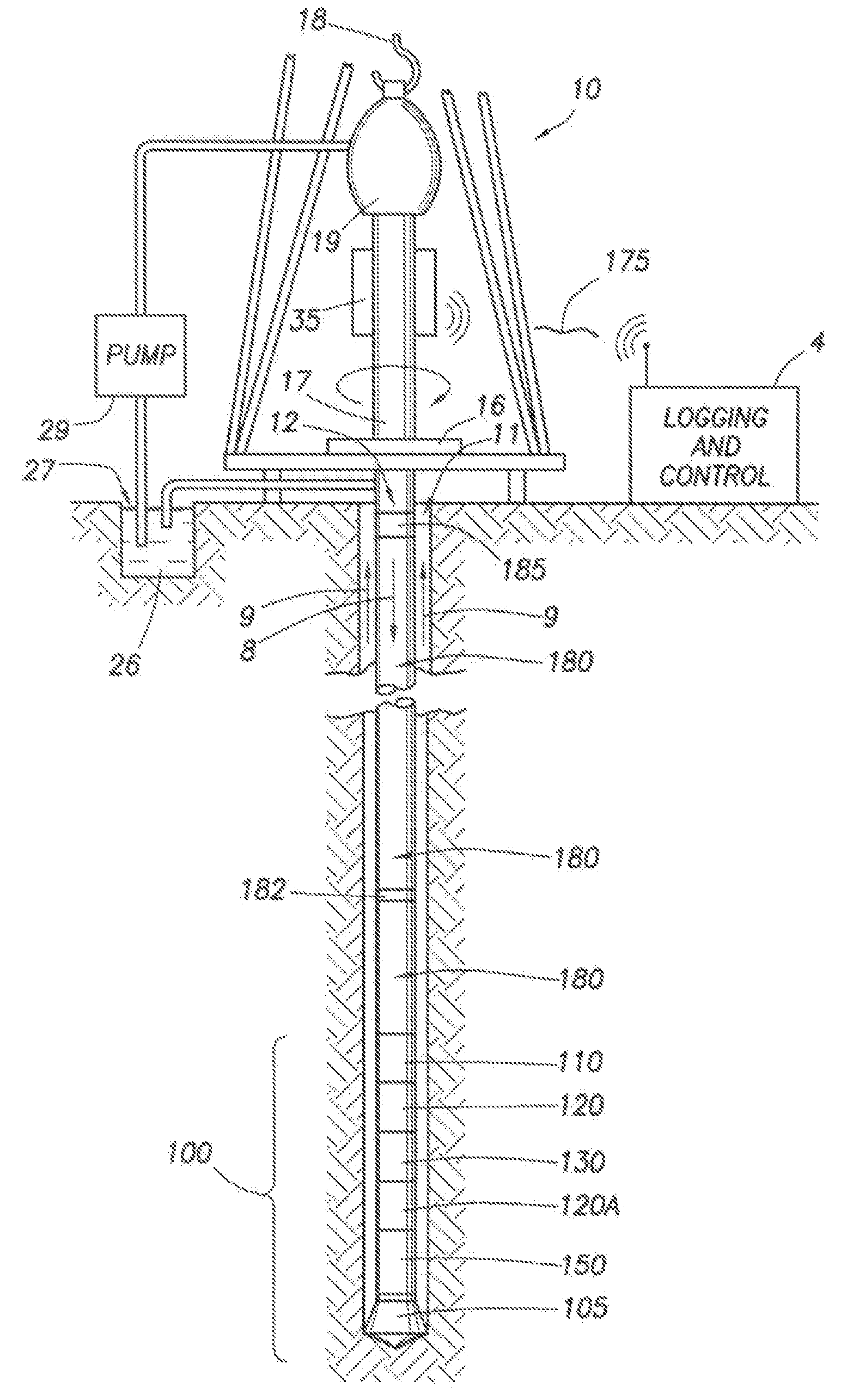

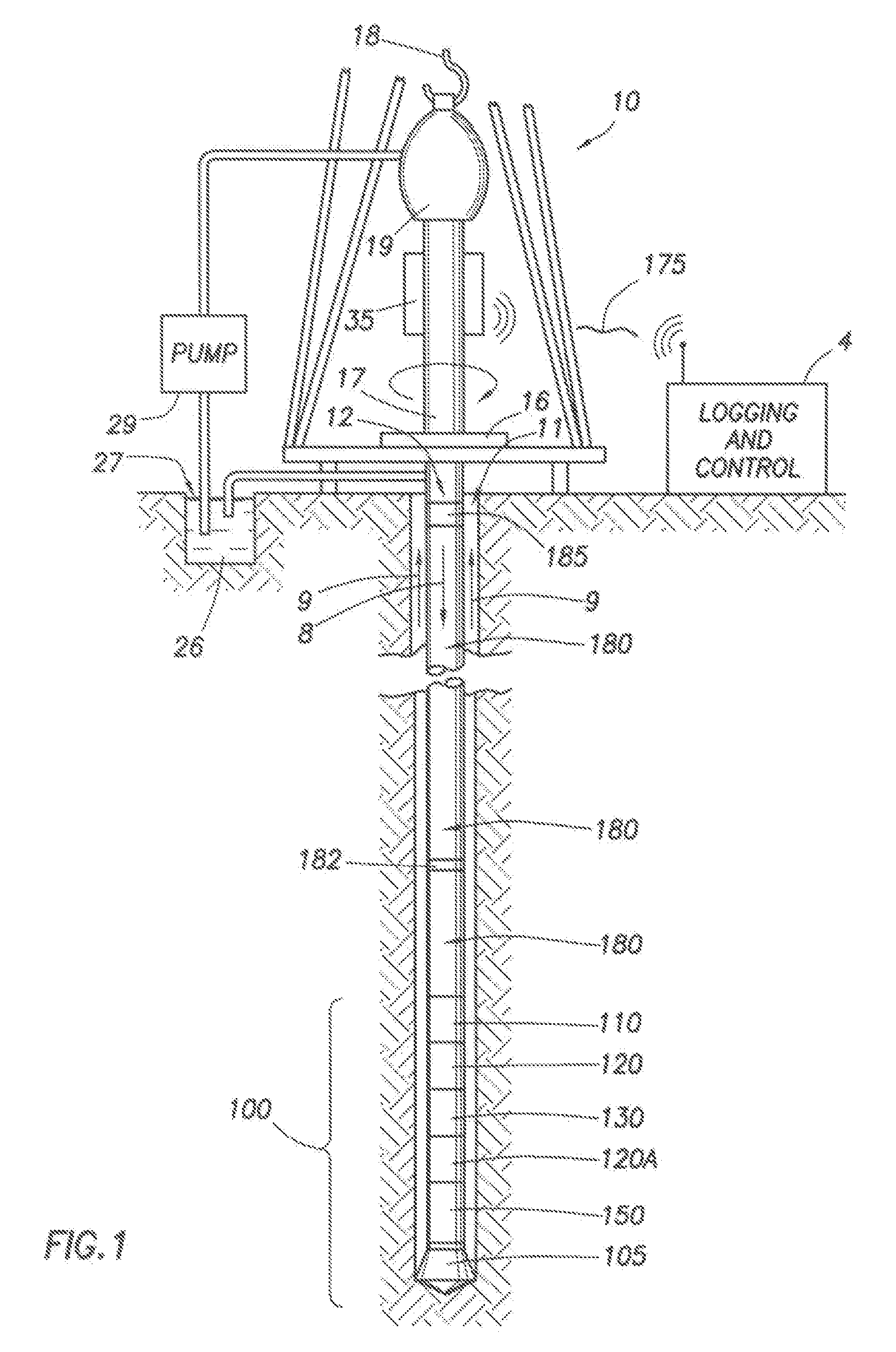

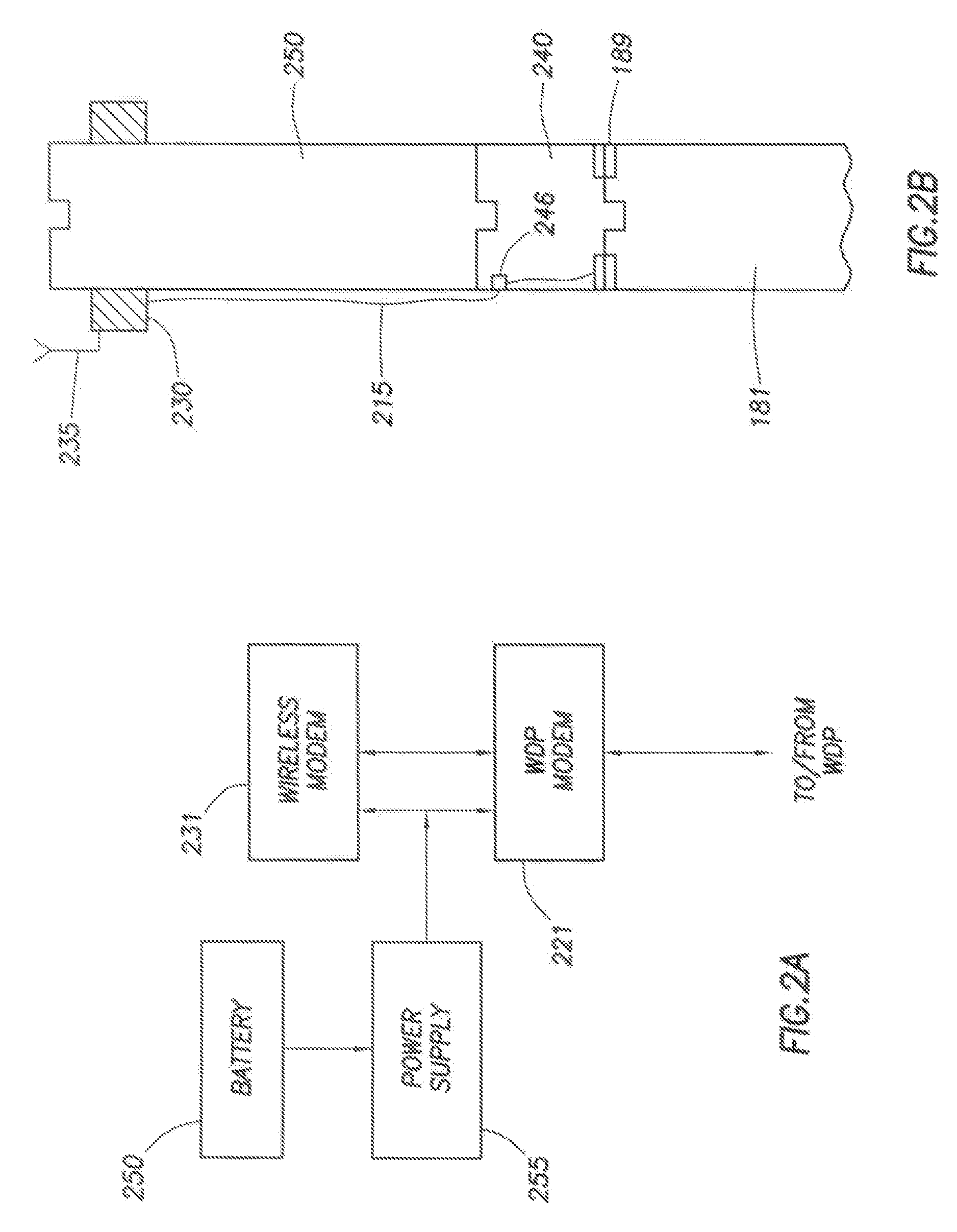

System and Method for Monitoring and Controlling Underground Drilling

ActiveUS20110186353A1Reduce the differenceVibration measurement in solidsMachine part testingFinite element techniqueResonance

A system and method for monitoring underground drilling in which vibration is monitored by creating a model of the drill string using finite element techniques or finite difference techniques and (i) predicting vibration by inputting real time values of operating parameters into the model, and then adjusting the model to agree with measured vibration data, (ii) predicting the weight on bit and drill string and mud motor speeds at which resonance will occur, as well as when stick-slip will occur, so that the operator can avoid operating regimes that will result in high vibration, (iii) determining vibration and torque levels along the length of the drill string based on the measured vibration and torque at one or more locations, (iv) determining the remaining life of critical components of the drill string based on the history of the vibration to which the components have been subjected, and (v) determining the optimum drilling parameters that will avoid excessive vibration of the drill string.

Owner:APS TECH

Integrated directional under-reamer and stabilizer

The present invention is an apparatus for use in drilling operations. It uses an under-reamer having a plurality of elongated arms with cutting elements at the ends of the arms for enlarging a previously drilled borehole drilled by a drill bit. One or more stabilizers in close proximity to the under-reamer provide stability to the under-reamer and the drill bit. The stabilizer could be rotating or non-rotating; and could be positioned between the under-reamer and the drill bit, or above the under reamer or above a directional device on the drillstring. The cutting arms are selectively operable to perform the enlargement. The stabilizer may be provided with members that closely fit the size of the borehole.

Owner:BAKER HUGHES INC

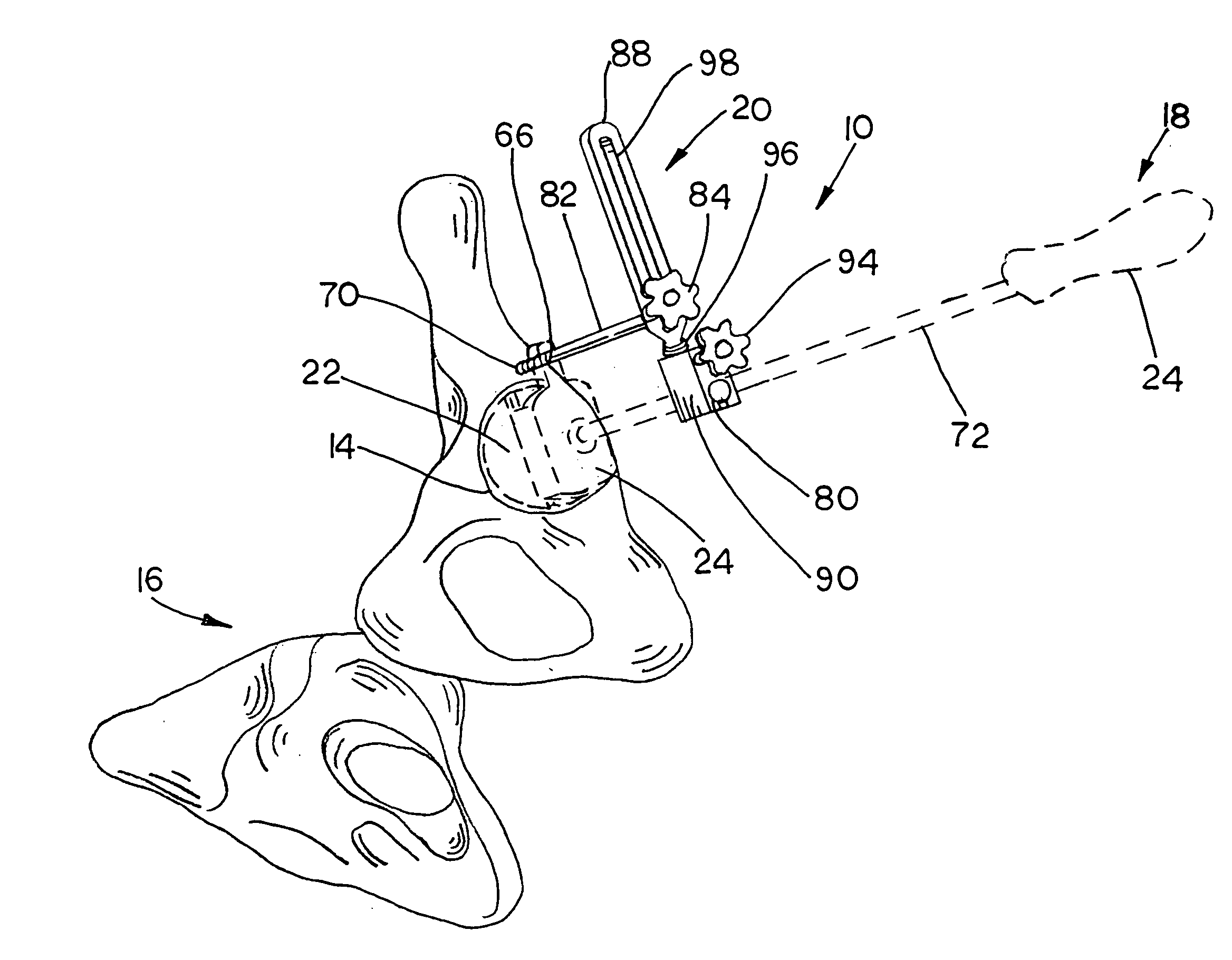

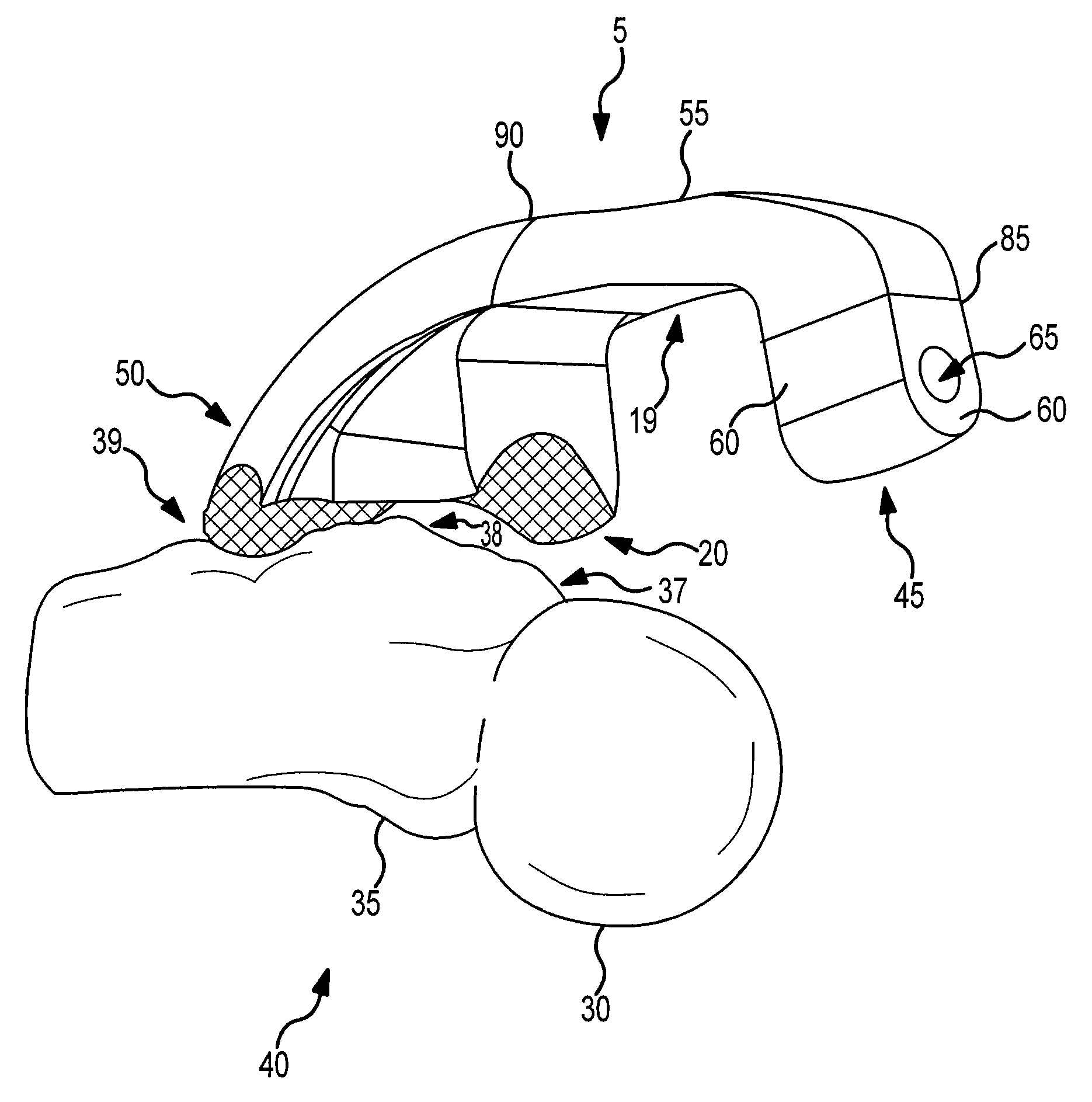

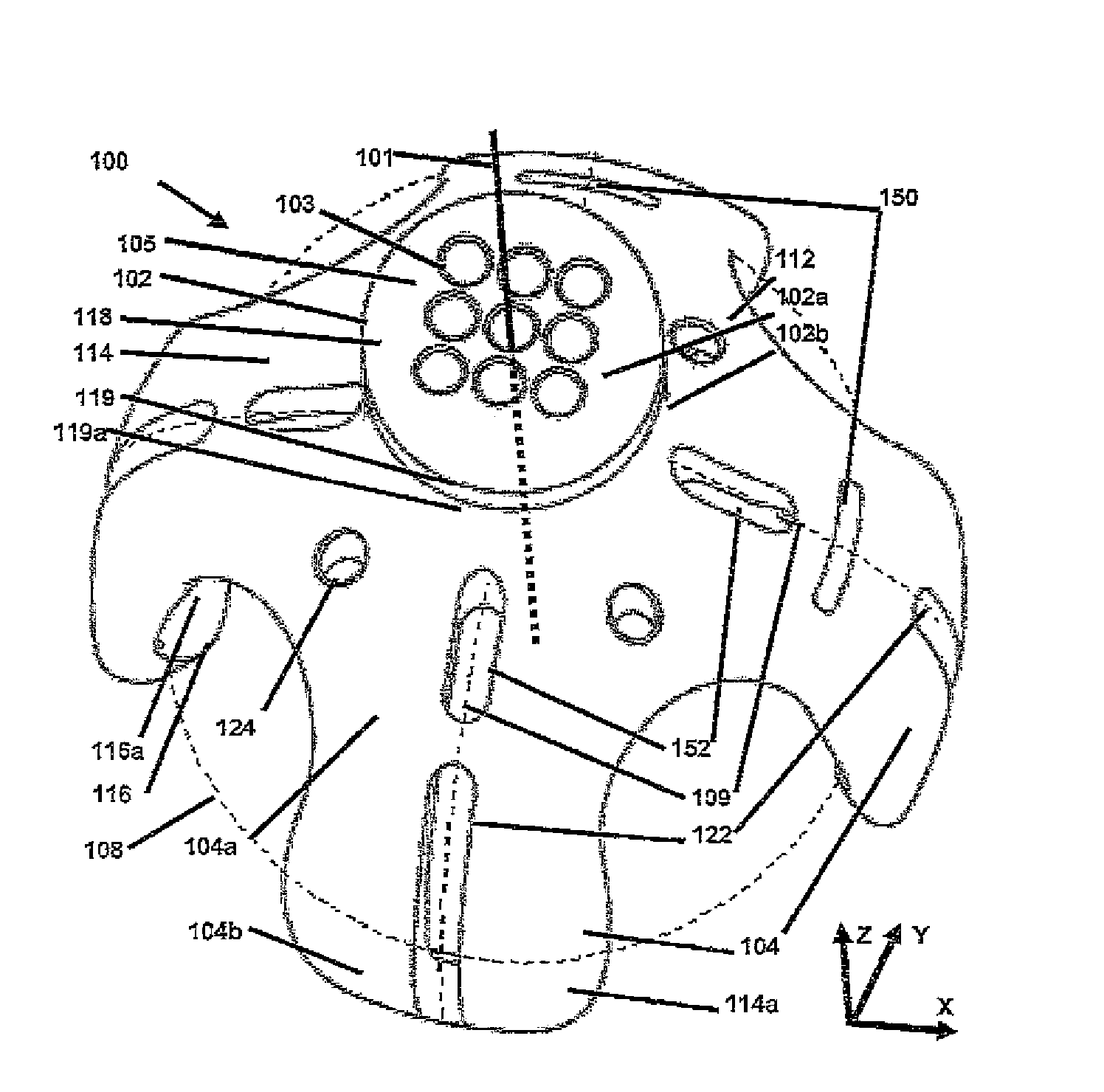

Apparatus and Method for Aligning a Guide Pin for Joint Re-Surfacing

A drill guide for aligning a guide pin. In an embodiment, the drill guide comprises a base having a concave inner surface, an outer surface, and a central axis perpendicular to the inner surface. In addition, the drill guide comprises a drilling template extending axially from the outer surface of the base along the central axis. The drilling template includes a plurality of through-bores. Further, the drill guide comprises a first curved member extending along a central longitudinal axis from a fixed end integral with the base to a free end distal the base, and a second curved member extending along a central longitudinal axis from a fixed end integral with the base to a free end distal the base. The first curved member and the second curved member are angularly spaced about 180° apart relative to the central axis and include an elongate locking slot.

Owner:KREUZER STEFAN

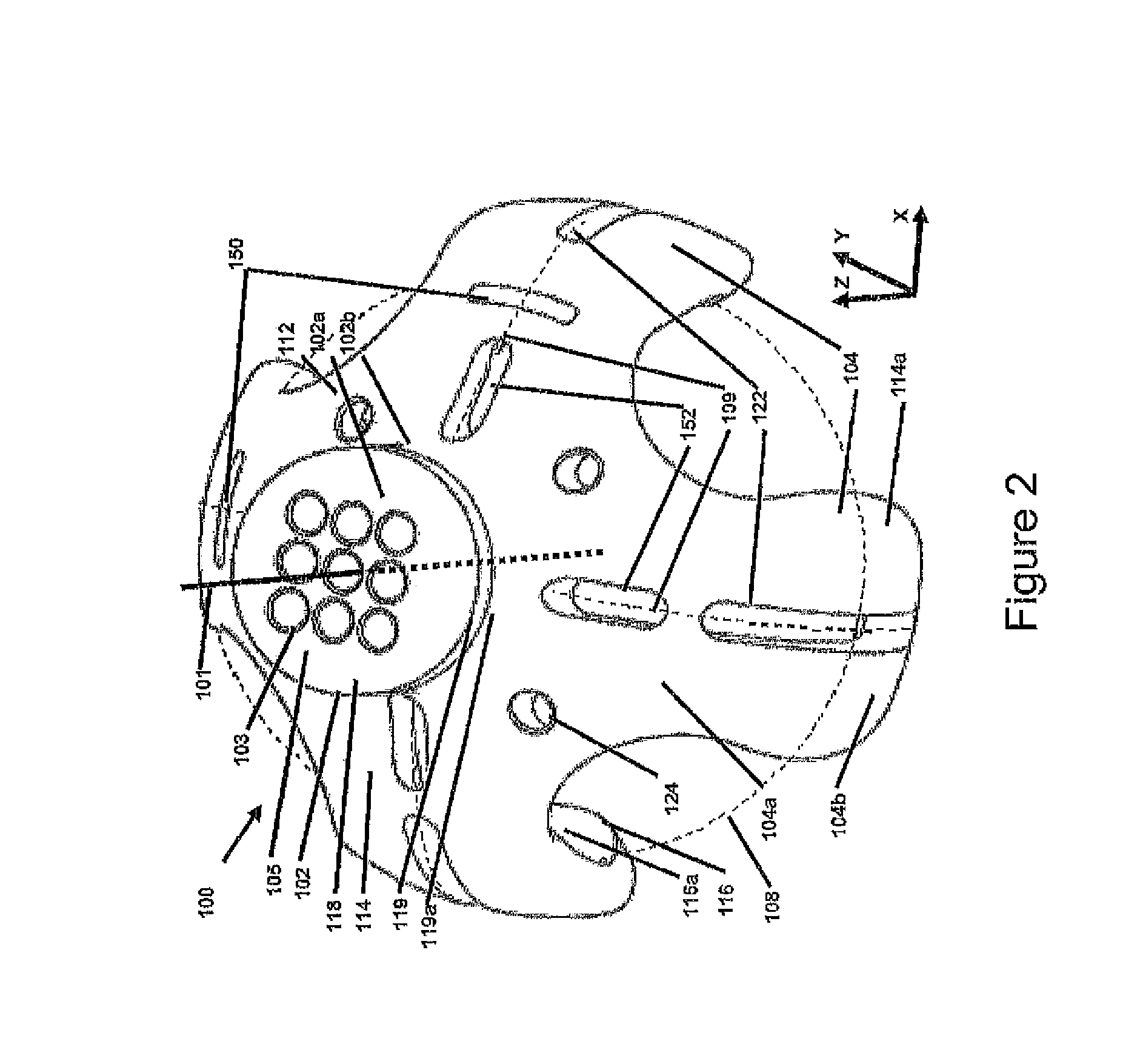

Bi-centered drill bit having improved drilling stability mud hydraulics and resistance to cutter damage

A bi-center drill bit includes pilot and reaming blades affixed to a body at azimuthally spaced locations. The blades have PDC cutters attached at selected positions. In one aspect, the pilot blades form a section having length along the bit axis less than about 80 percent of a diameter of the section. In another aspect, selected pilot blades and corresponding reaming blades are formed into single spiral structures. In another aspect, shapes and positions of the blades and inserts are selected so that lateral forces exerted by the reaming and the pilot sections are balanced as a single structure. Lateral forces are preferably balanced to within 10 percent of the total axial force on the bit. In another aspect, the center of mass of the bit is located less than about 2.5 percent of the diameter of the bit from the axis of rotation. In another aspect, jets are disposed in the reaming section oriented so that their axes are within about 30 degrees of normal to the axis of the bit. In another aspect, the reaming blades are shaped to conform to the radially least extensive, from the longitudinal axis, of a pass-through circle or a drill circle, so the cutters on the reaming blades drill at the drill diameter, without contact to the cutters on the reaming blades when the bit passes through an opening having about the pass-through diameter.

Owner:SMITH INT INC

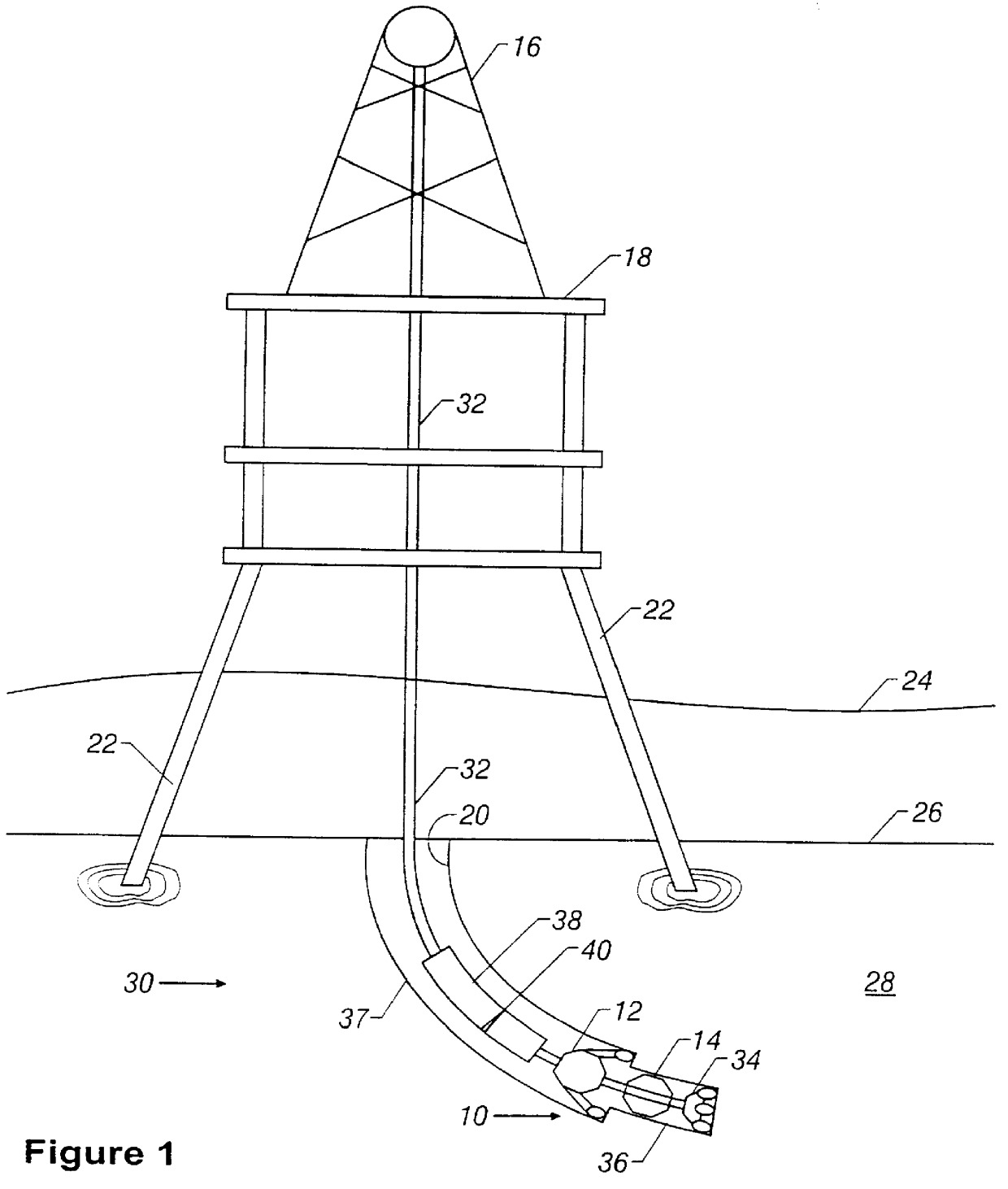

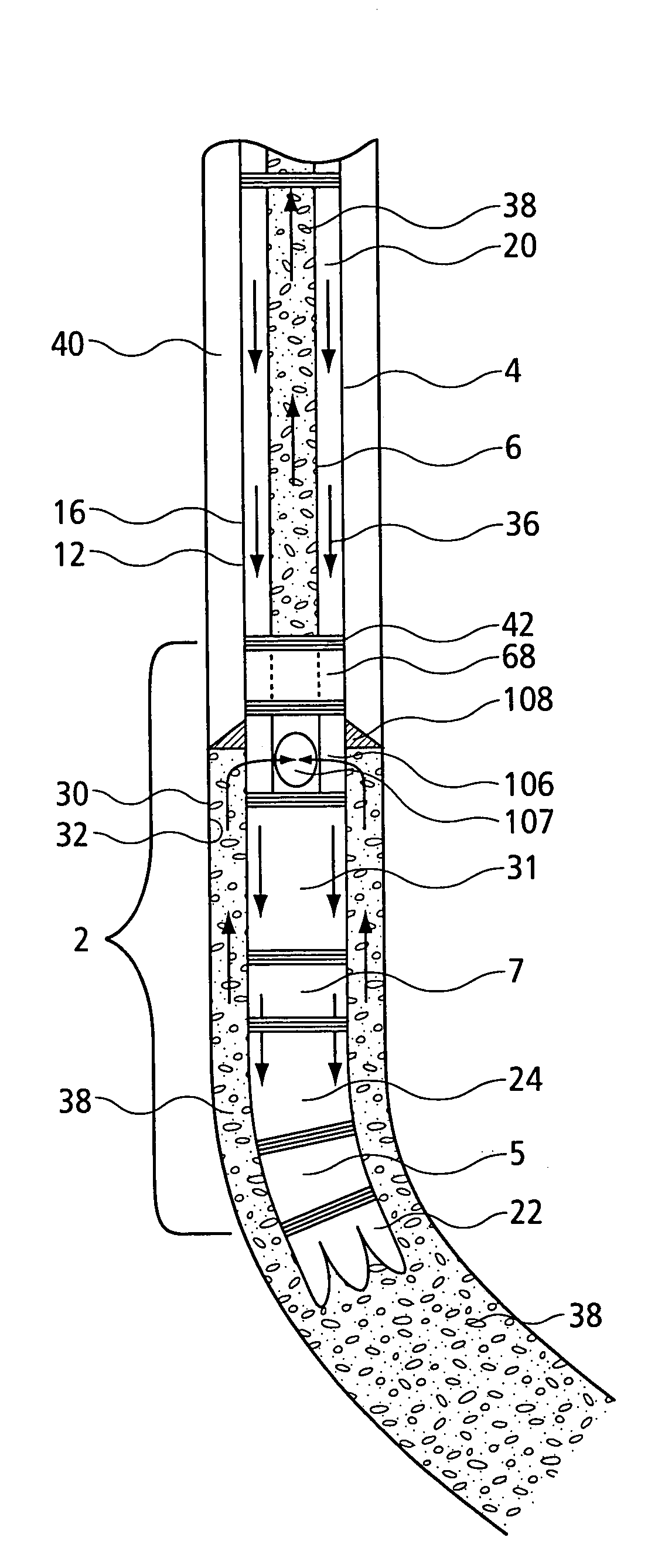

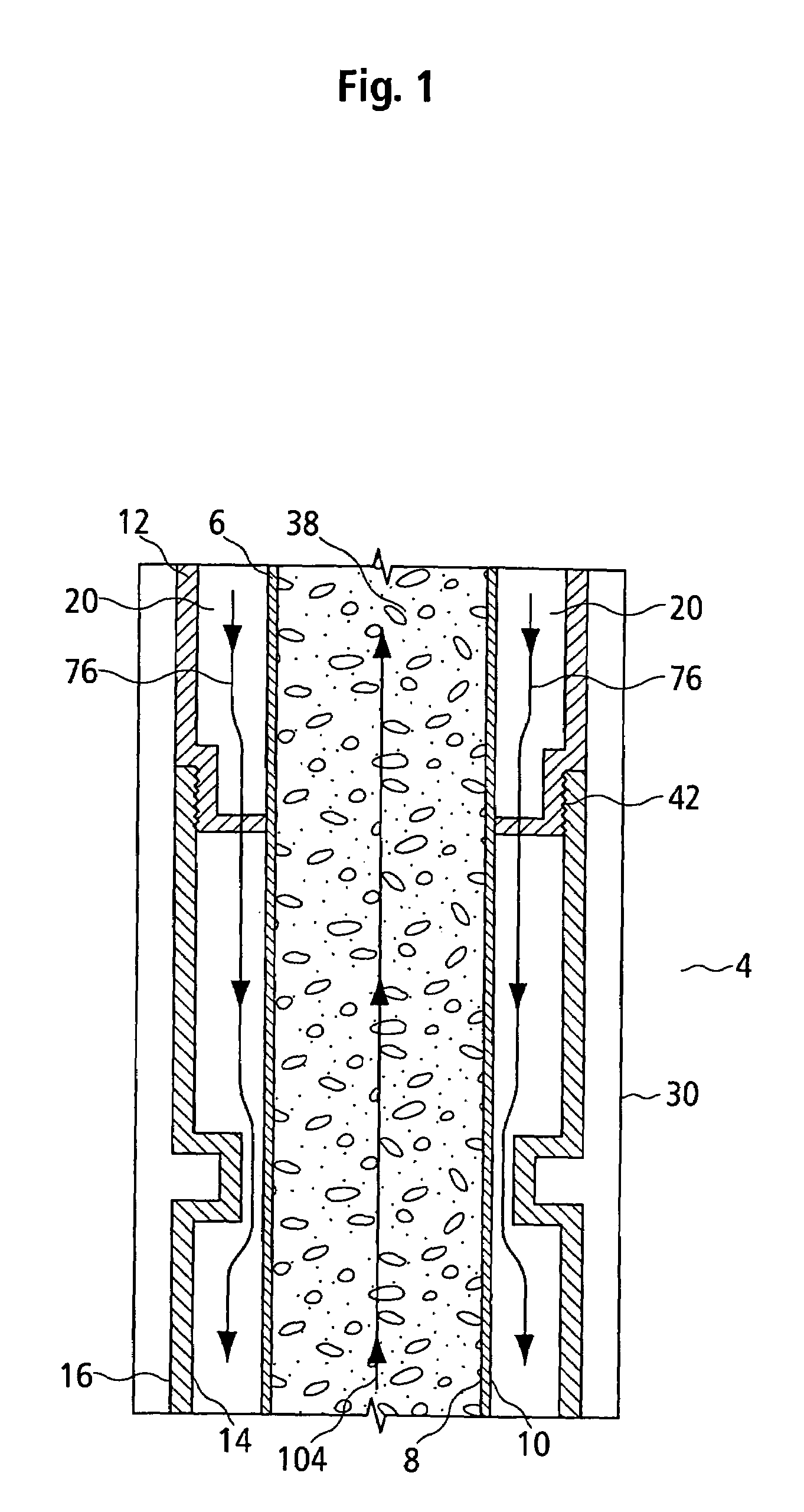

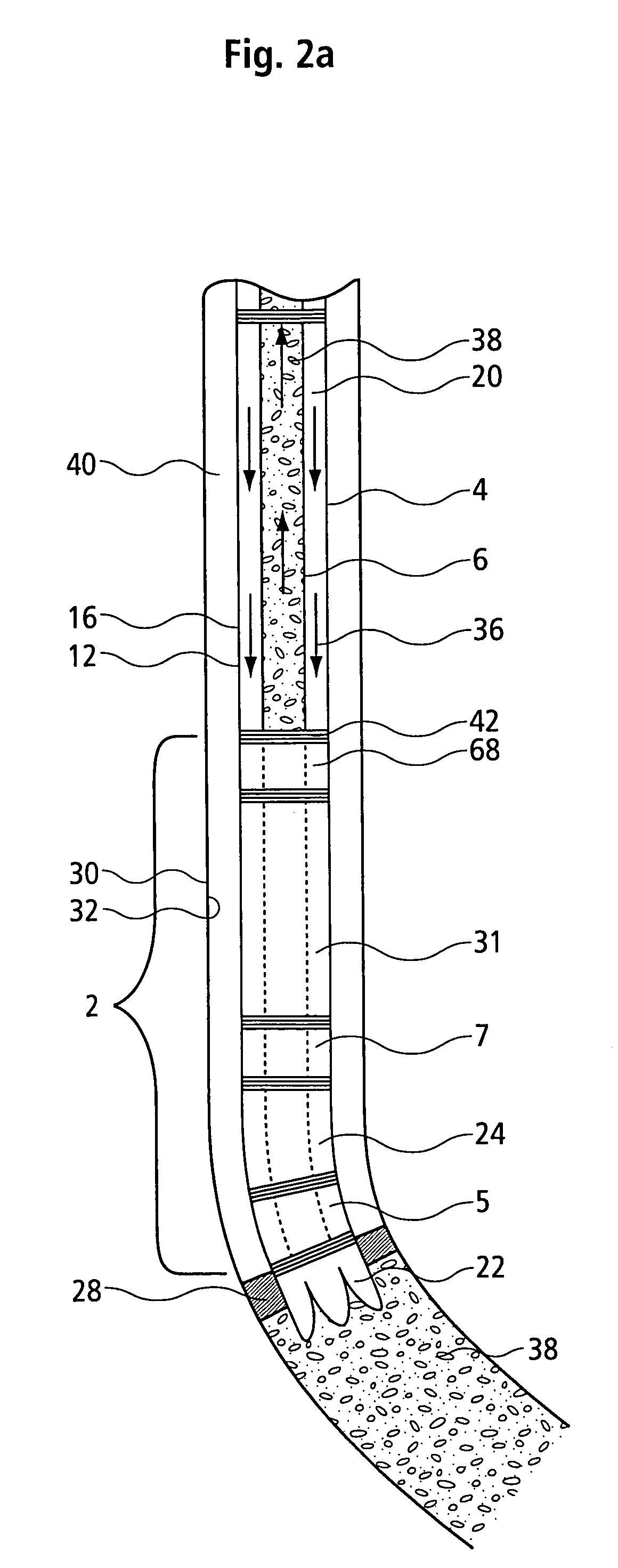

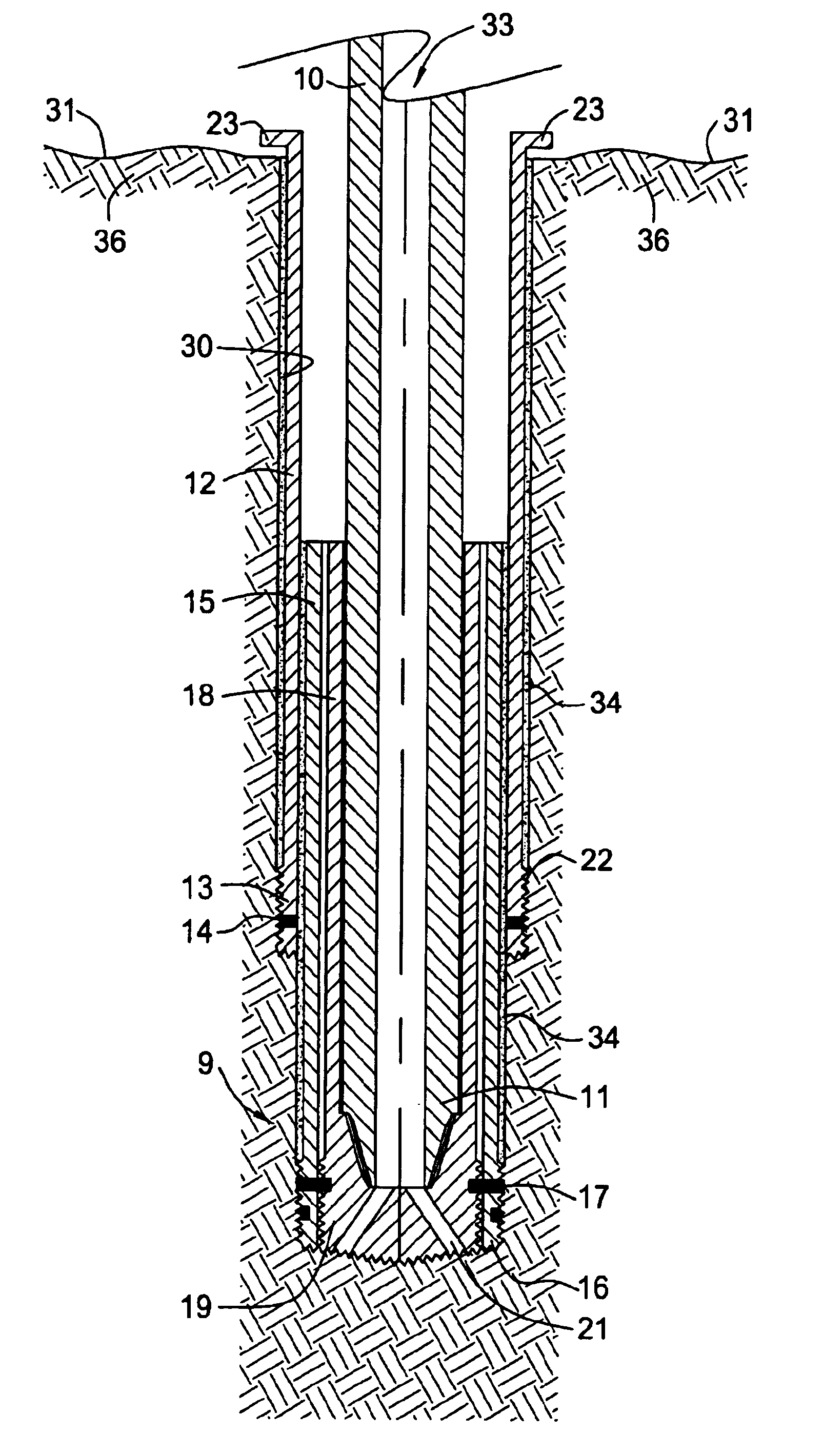

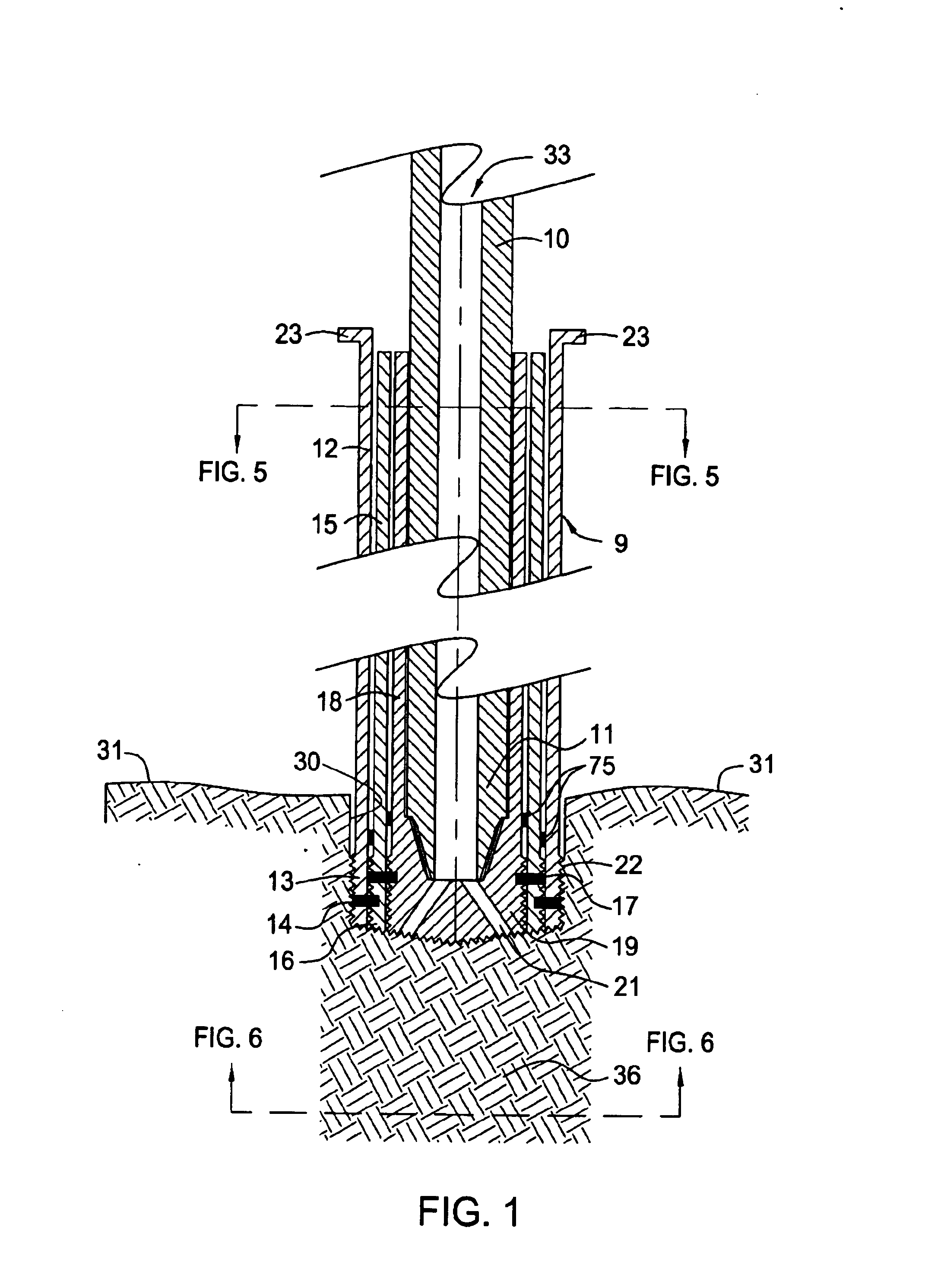

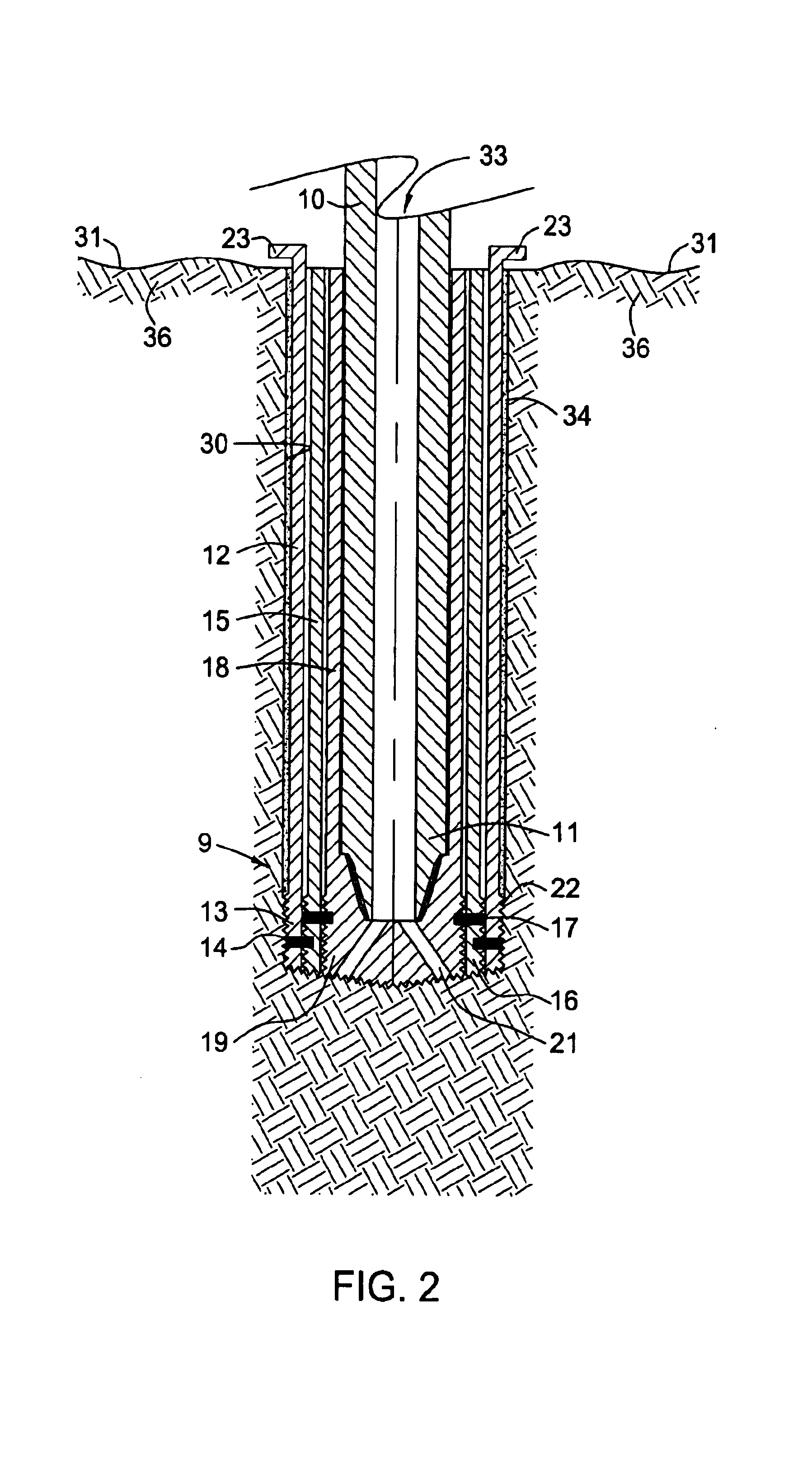

Reverse circulation directional and horizontal drilling using concentric drill string

InactiveUS7204327B2Avoid damageSafe and economical mannerDrilling rodsDirectional drillingWell drillingDirectional drilling

Method and apparatus for drilling a directional or horizontal wellbore in a hydrocarbon formation using concentric drill string having an inner pipe and an outer pipe defining an annulus there between. A bottomhole assembly comprising a directional drilling means such as an air hammer or a rotary drill bit and driving system is provide at the lower end of the concentric drill string and drilling medium is delivered through the annulus or inner pipe for operating the directional drilling means to form a borehole. Exhaust drilling medium, drilling cutting and hydrocarbon are removed from the wellbore by extracting the exhaust drilling medium, drilling cutting and hydrocarbon through the other of the annulus or inner pipe.

Owner:PRESSSOL

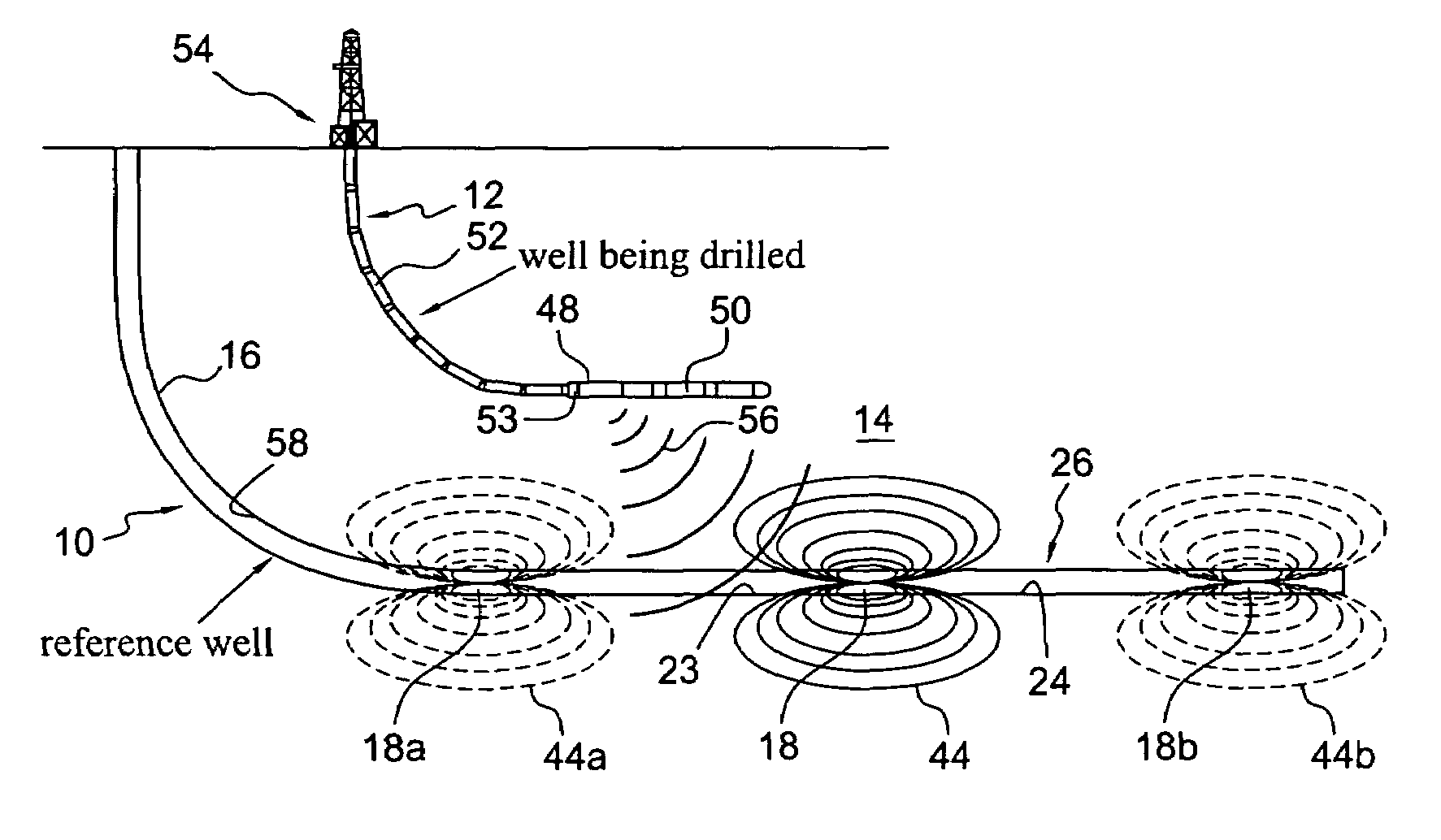

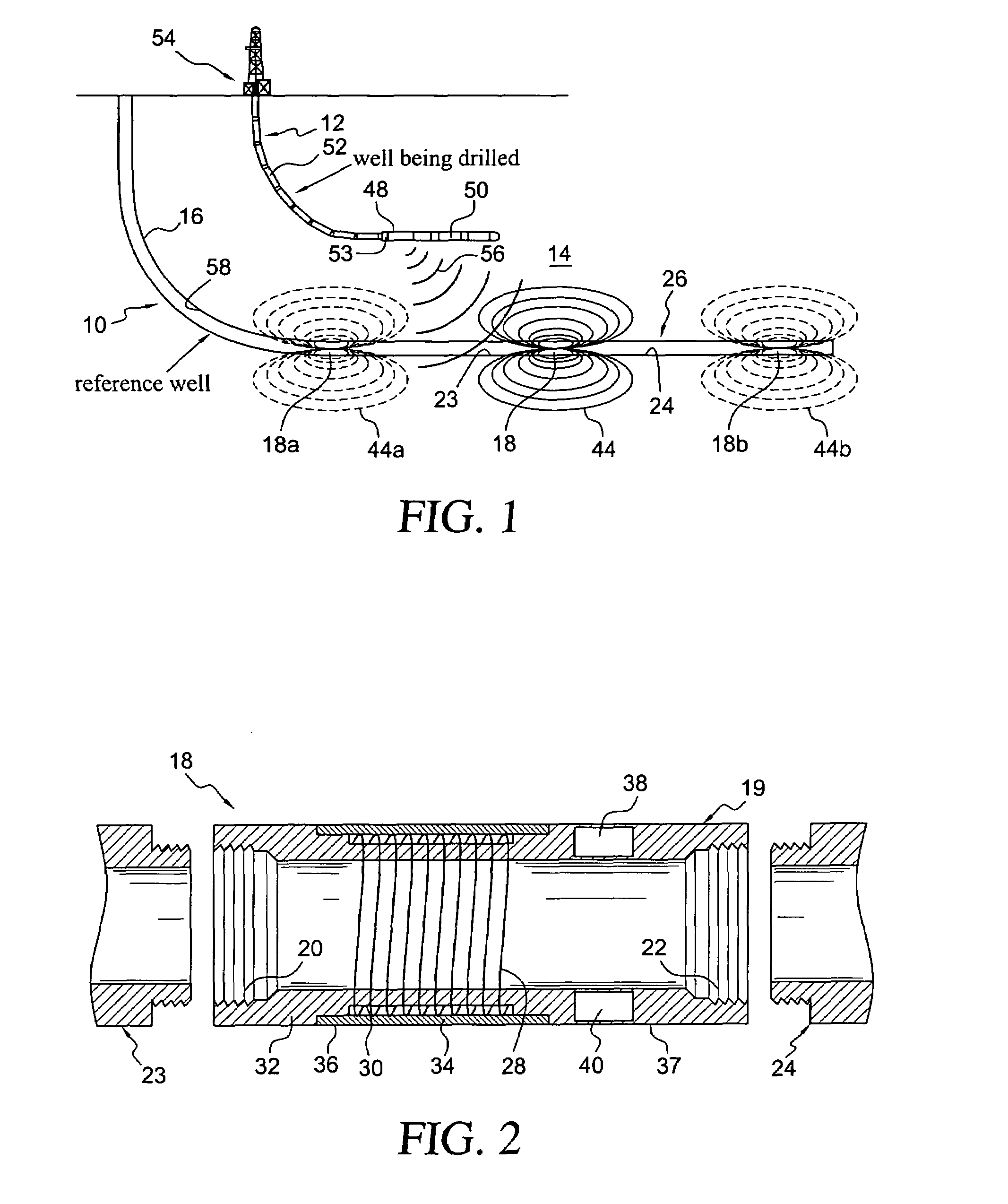

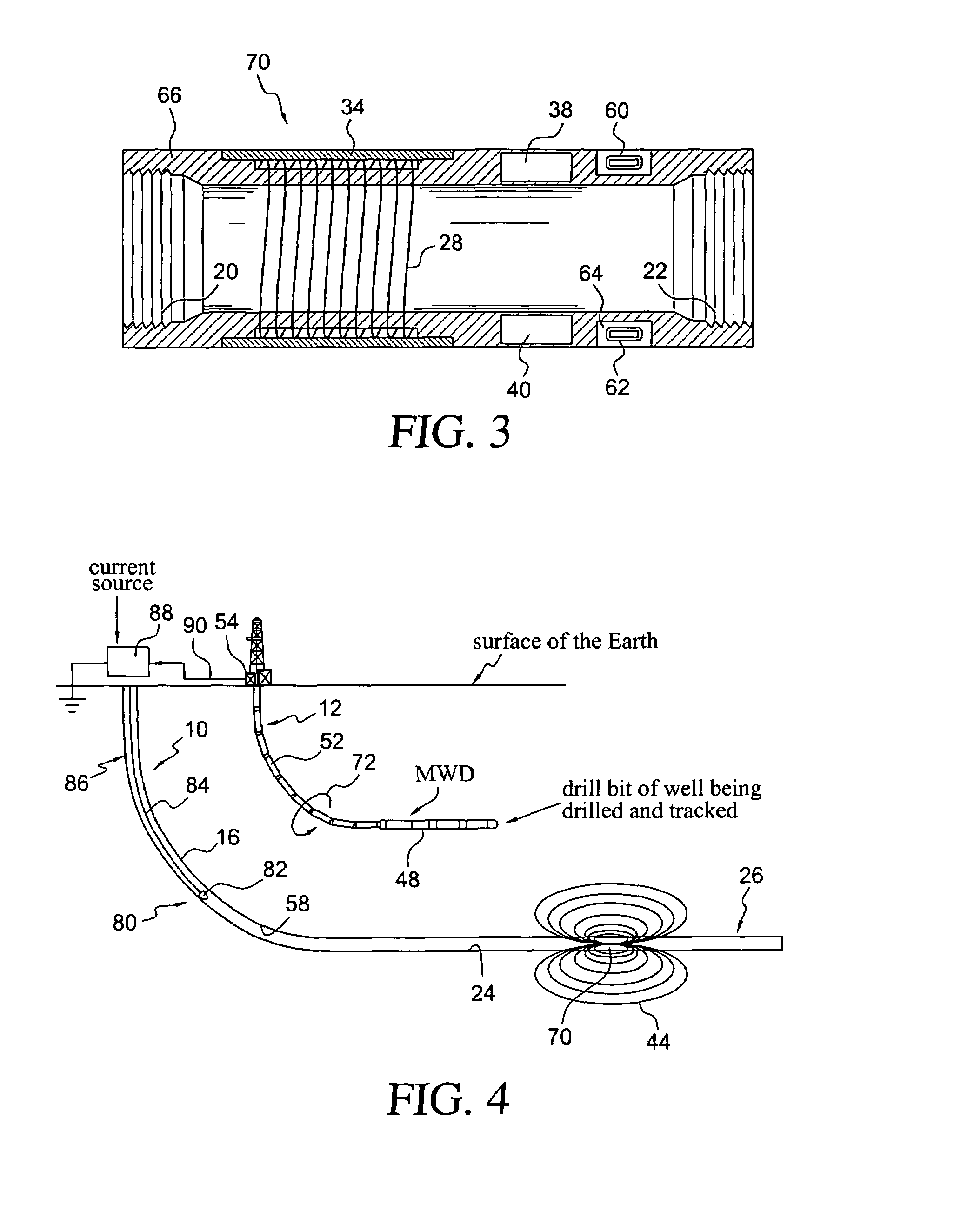

Electromagnetically determining the relative location of a drill bit using a solenoid source installed on a steel casing

Electrically powered electromagnetic field source beacons installed in a reference well in combination with a down-hole measurement while drilling (MWD) electronic survey instrument near the drill bit in the borehole being drilled permit distance and direction measurements for drilling guidance. Each magnetic field source beacon consists of a coil of wire wound on a steel coupling between two lengths of steel tubing in the reference well, and powered by an electronic package. Control circuitry in the electronic package continuously “listens” for, and recognizes, a “start” signal that is initiated by the driller. After a “start” signal has been received, the beacon is energized for a short time interval during which an electromagnetic field is generated, which is measured by the MWD apparatus. The generated magnetic field may be an AC field, or switching circuitry can periodically reverse the direction of a generated DC electromagnetic field, and the measured vector components of the electromagnetic field are used to determine the relative location coordinates of the drilling bit and the beacon using well-known mathematical methods. The magnetic field source and powering electronic packages may be integral parts of the reference well casing or may be part of a temporary work string installed therein. Generally, numerous beacons will be installed along the length of the reference well, particularly in the important oil field application of drilling steam assisted gravity drainage (SAGD) well pairs.

Owner:HALLIBURTON ENERGY SERVICES INC

Non-Damaging Slips and Drillable Bridge Plug

ActiveUS20100276159A1Easily drillablePrevent from rotateFluid removalSealing/packingSmooth surfaceDuctile materials

A non-damaging slip assembly includes slips having grit on a smooth surface, the slips preferably made from a ductile material, such that the slips do not cause damage to the wall of a tubular when the slips are set. The slips fail under tensile force during setting. The cone used to expand the slips may have slits that narrow during setting of the slips. The slip assembly may be used to anchor a variety or devices inside a tubular. A drillable, non-damaging bridge plug using the non-damaging slip assembly has a threaded mandrel holding the cone by threads inside the cone. When the slips are set, the slits in the cone narrow such that threads in the cone do not allow rotation of the slips as they are drilled. The bridge plug can be drilled by a PDC bit without damaging the tubular.

Owner:INNOVEX DOWNHOLE SOLUTIONS INC

Formation testing while drilling apparatus with axially and spirally mounted ports

Owner:BAKER HUGHES INC

Drilling with concentric strings of casing

InactiveUS6857487B2Cost for assemblyReduce equipment costsEarth drilling toolsDrilling rodsWell drillingEngineering

The present invention provides a method and apparatus for setting concentric casing strings within a wellbore in one run-in of a casing working string. In one aspect of the invention, the apparatus comprises a drilling system comprising concentric casing strings, with each casing string having a drill bit piece disposed at the lower end thereof. The drill bit pieces of adjacent casing strings are releasably connected to one another. In another aspect of the invention, a method is provided for setting concentric casing strings within a wellbore with the drilling system. In another aspect of the invention, the releasably connected drill bit pieces comprise a drill bit assembly.

Owner:WEATHERFORD TECH HLDG LLC

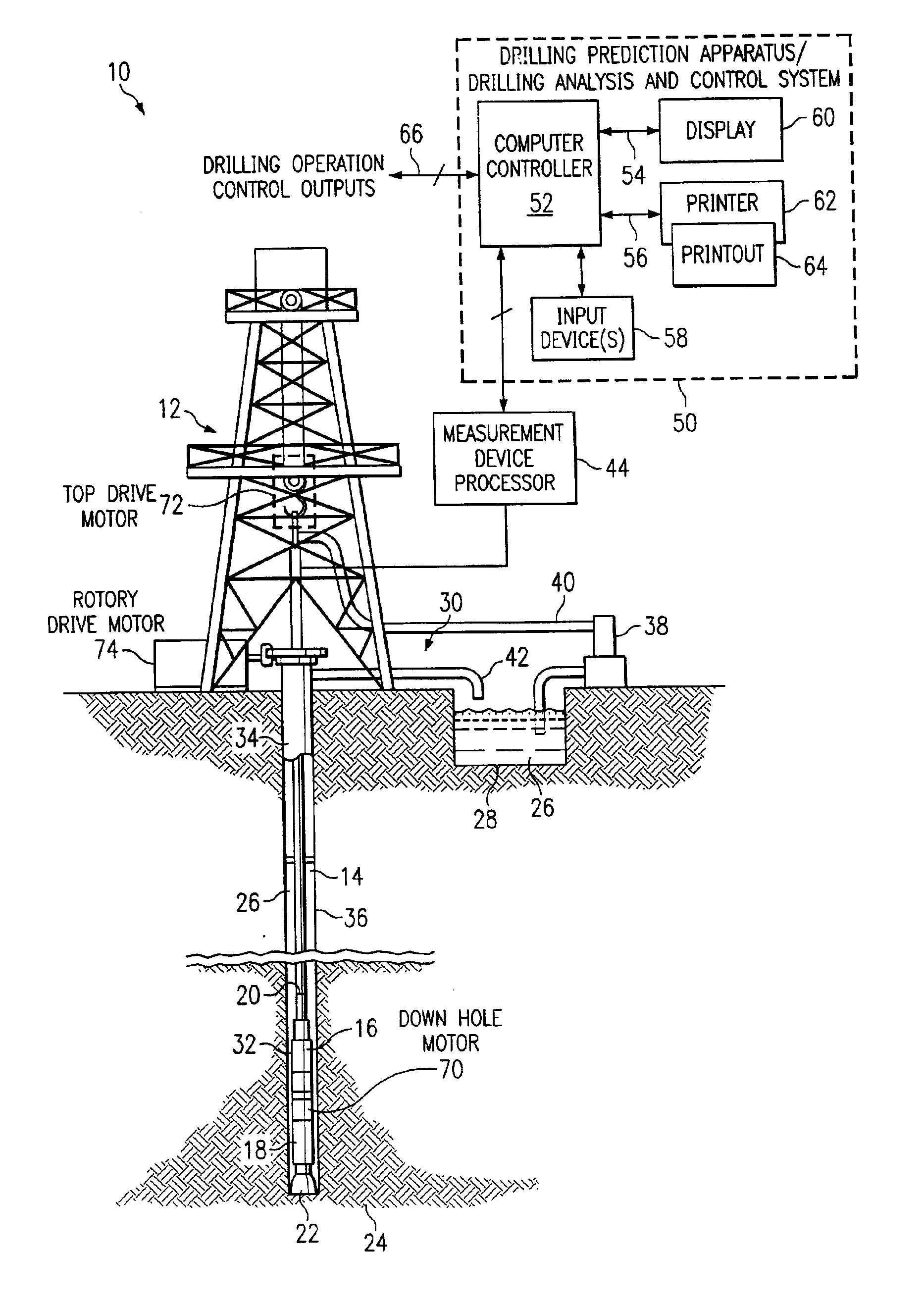

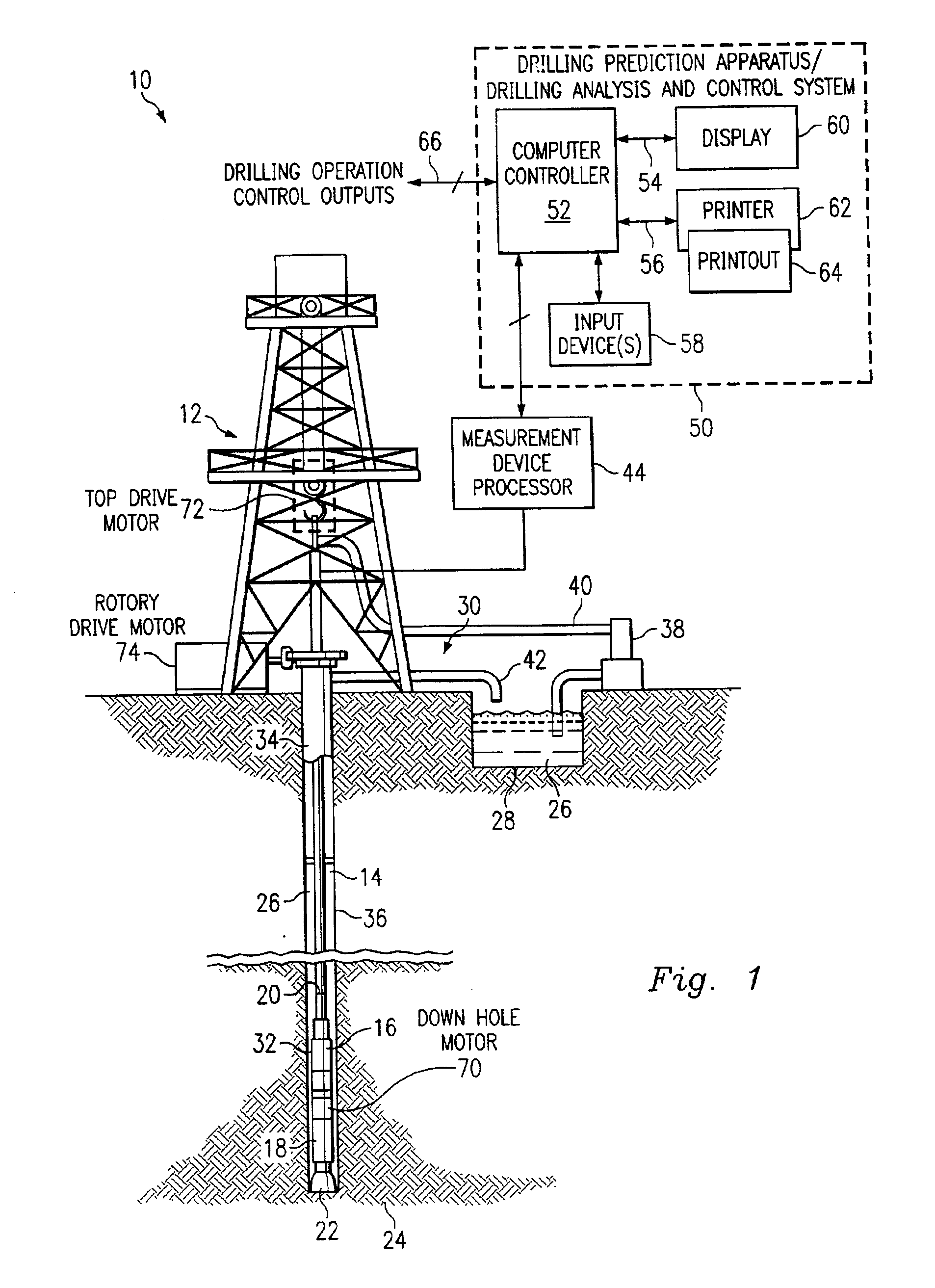

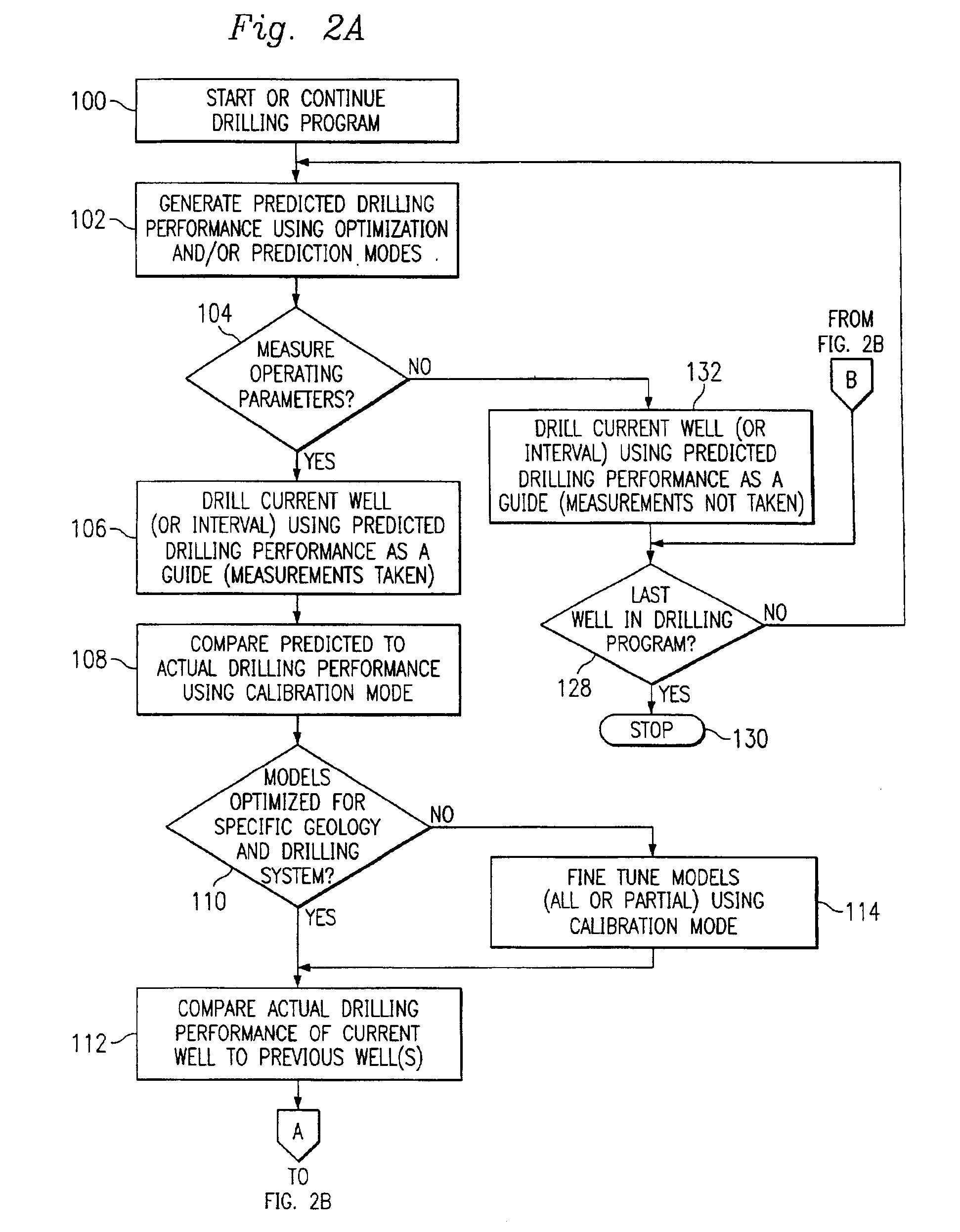

Method and system for predicting performance of a drilling system of a given formation

InactiveUS7032689B2Electric/magnetic detection for well-loggingEarth drilling toolsComputer printingDisplay device

A method and apparatus for predicting the performance of a drilling system for the drilling of a well bore in a given formation includes generating a geology characteristic of the formation per unit depth according to a prescribed geology model, obtaining specifications of proposed drilling equipment for use in the drilling of the well bore, and predicting a drilling mechanics in response to the specifications as a function of the geology characteristic per unit depth according to a prescribed drilling mechanics model. Responsive to a predicted-drilling mechanics, a controller controls a parameter in the drilling of the well bore. The geology characteristic includes at least rock strength. The specifications include at least a bit specification of a recommended drill bit. Lastly, the predicted drilling mechanics include at least one of bit wear, mechanical efficiency, power, and operating parameters. A display is provided for generating a display of the geology characteristic and predicted drilling mechanics per unit depth, including either a display monitor or a printer.

Owner:HALLIBURTON ENERGY SERVICES INC

Method of releasing stuck pipe or tools and spotting fluids therefor

Aphron-containing spotting fluids and their use in releasing pipe or tools stuck in the filter cake on the sides of a borehole are disclosed. The spotting fluids comprise a liquid, either aqueous, oleaginous, or mixtures thereof, a viscosifier which imparts a low shear rate viscosity to the fluids of at least 10,000 centipoise, an aphron-generating surfactant, and aphrons. The spotting fluids are used in a conventional method of releasing pipes or tools stuck in the filter cake on the sides of a borehole during conventional drilling or well servicing operations.

Owner:ENVENTIVES LLC

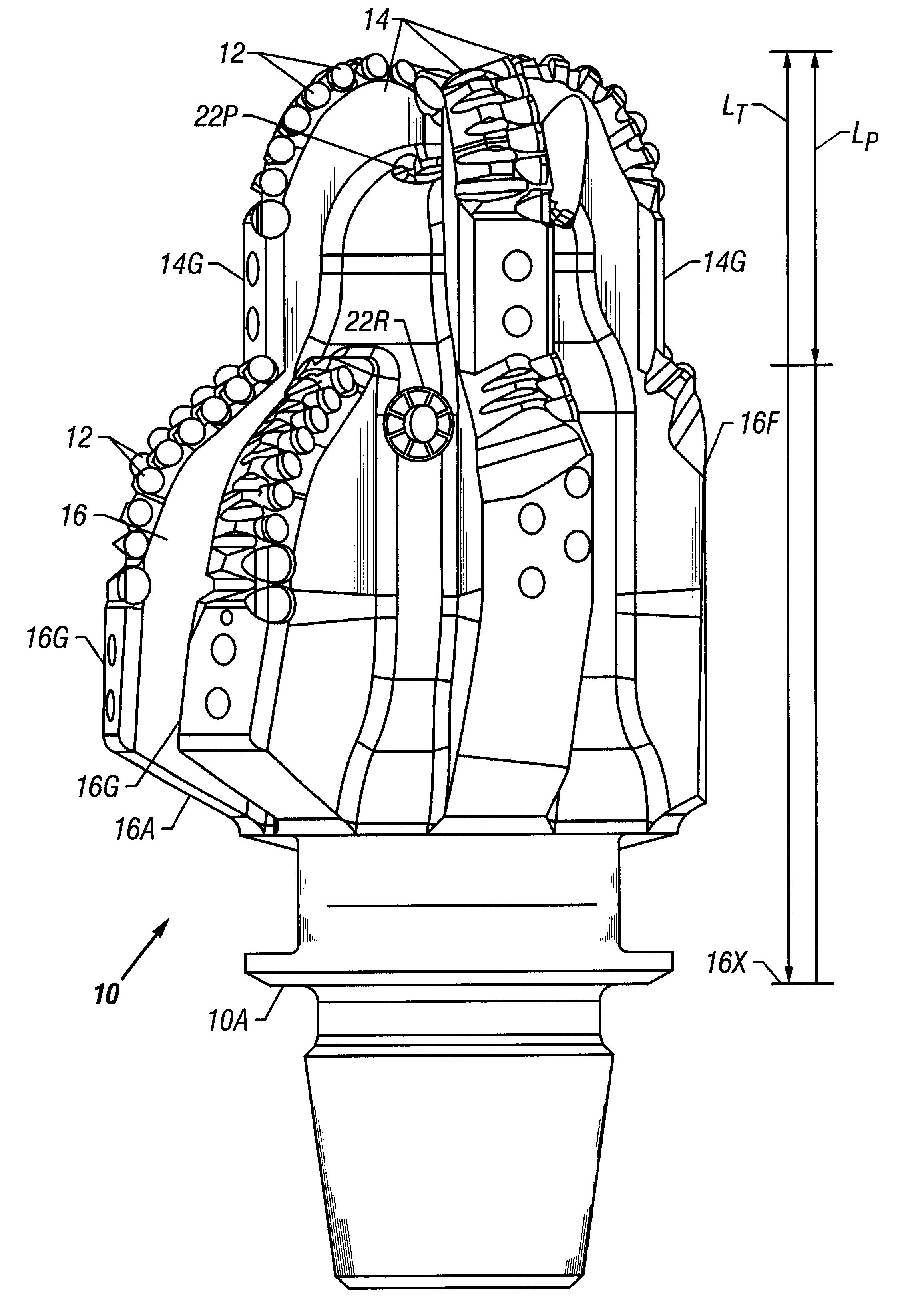

Drillout bi-center bit

The present invention is a bi-center drill bit designed to drill out the cement and other material in the casing and then proceed to drill out the full gauge drilling diameter borehole with a diameter greater than the inside of the casing. The bi-center drill bit is configured with non-drilling bearing elements that contact with the casing when the bit is drilling the cement without allowing the gauge cutting elements of the bi-center drill bit to contact the casing. The bi-center drill bit also has a cutting element configuration which prevents reverse scraping of the cutting elements when drilling both the cement and the formation.

Owner:CAMCO INT

Bidirectional drill string telemetry for measuring and drilling control

The disclosure has application for use in conjunction with an operation of drilling an earth borehole using: a drilling rig, a drill string having its generally upper end mechanically coupleable with and suspendable from the drilling rig, and a bottom hole assembly adjacent the lower end the drill string, the bottom hole assembly including a drill bit at its lower end. A method is set forth for obtaining information about at least one parameter sensed at the bottom hole assembly, including the following steps: providing at least one measuring device in the bottom hole assembly, the at least one measuring device producing measurement data representative of a measured condition at the bottom hole assembly; providing an uphole processor system at the earth's surface; providing a drill string telemetry system coupled with the at least one measuring device and coupled with the uphole processor system; and transmitting the data from the measuring device to the uphole processor system via the drill string telemetry system.

Owner:SCHLUMBERGER TECH CORP

Adjustable depth drill bit

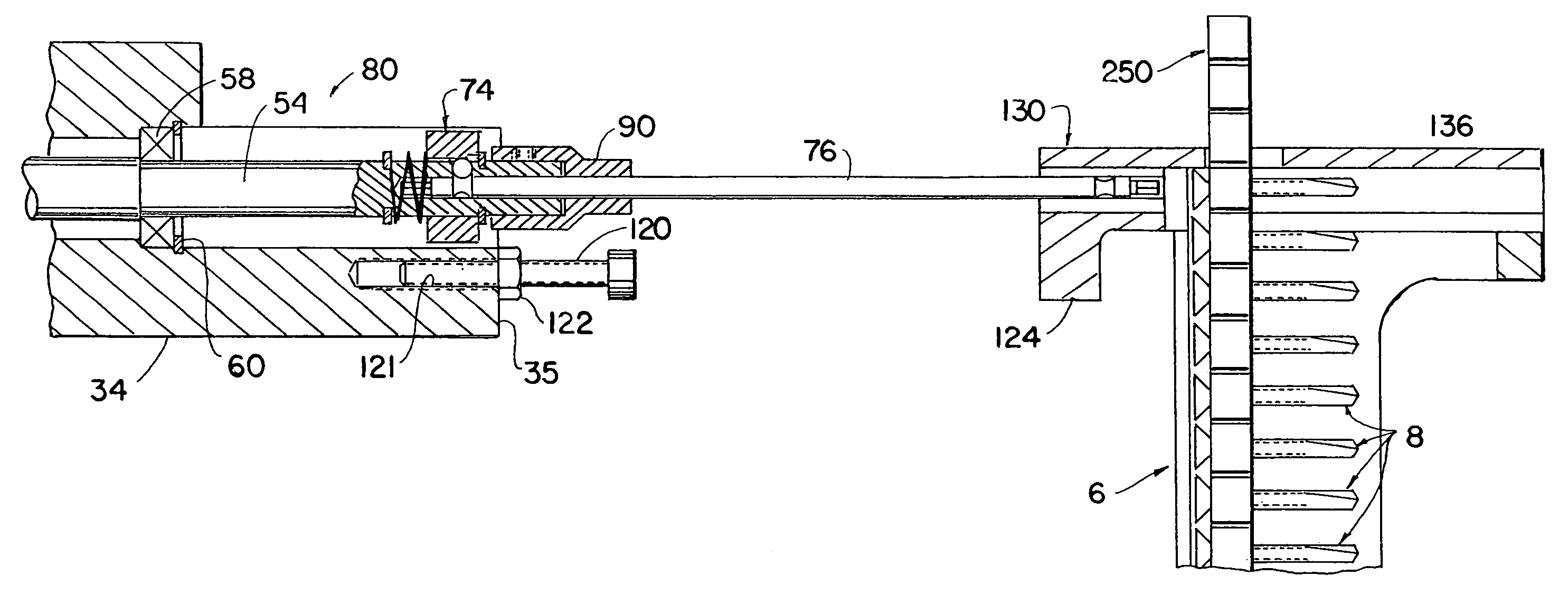

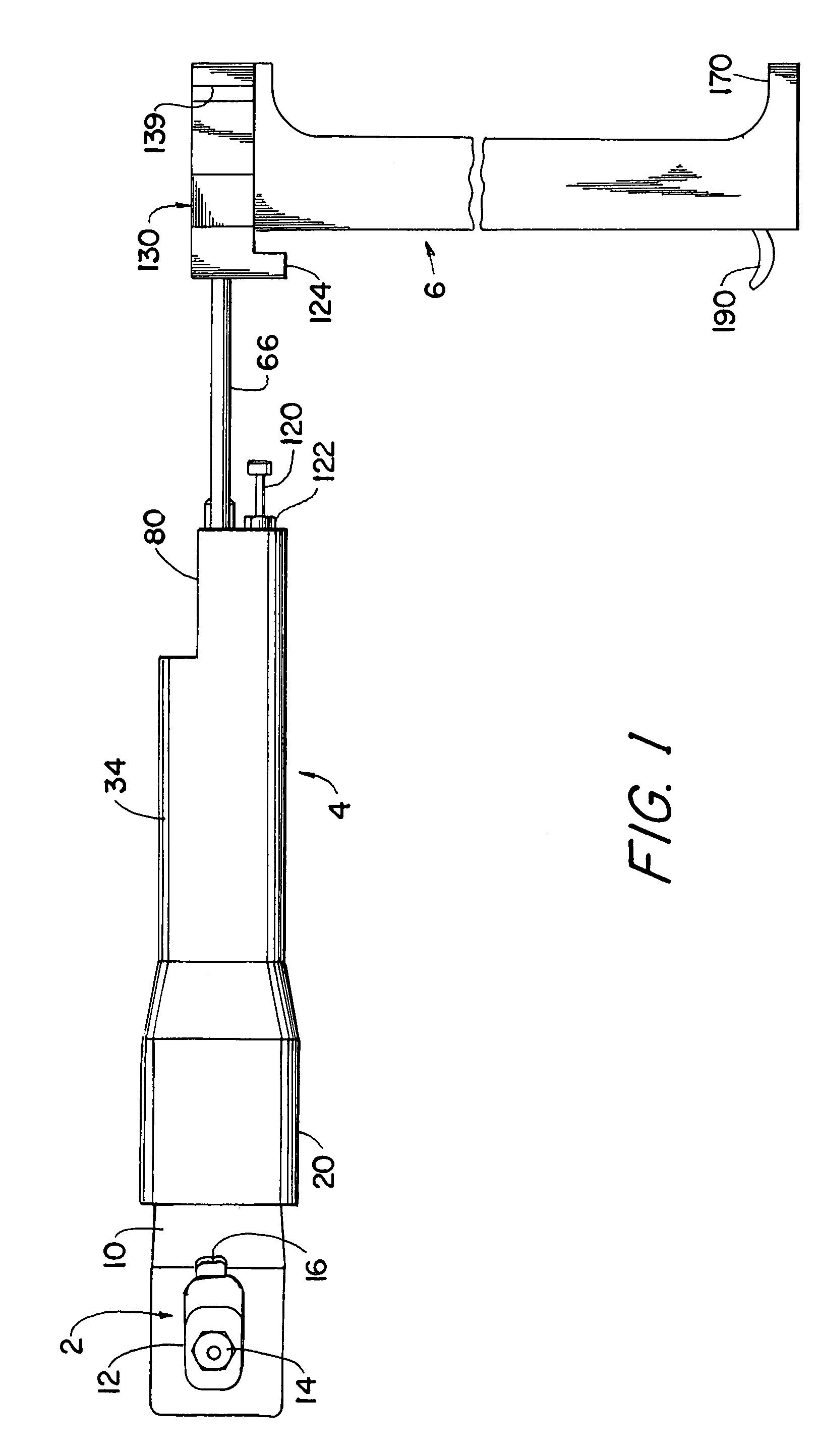

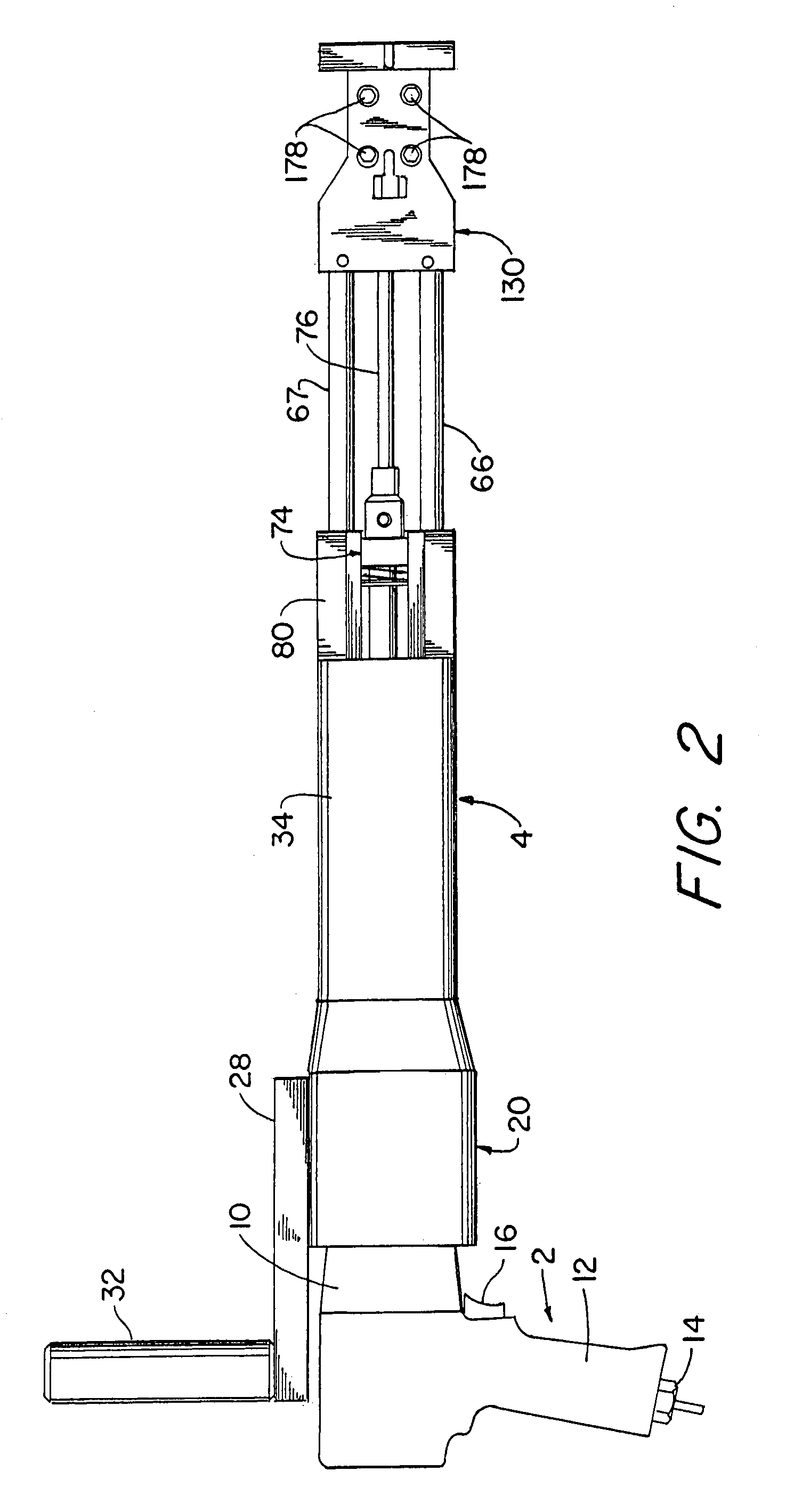

ActiveUS20050222571A1Easy to cleanImprove the bactericidal effectDiagnosticsProsthesisBiomedical engineeringDrill guide

A drill guide with integral drill bit is provided for drilling a hole into bone. The drill guide may have a housing for engaging a screw hole of a bone plate to fix the trajectory of the drill guide and drill with respect to the bone plate. An adjustable stop assembly is also provided and is axially slidable along the drill bit. The adjustable stop has a drill bit engaging mechanism to selectively lock the adjustable stop to the drill bit at a desired location to limit the depth that the drill may penetrate into the bone.

Owner:SYNTHES USA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com