Patents

Literature

31results about How to "Extended bit life" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

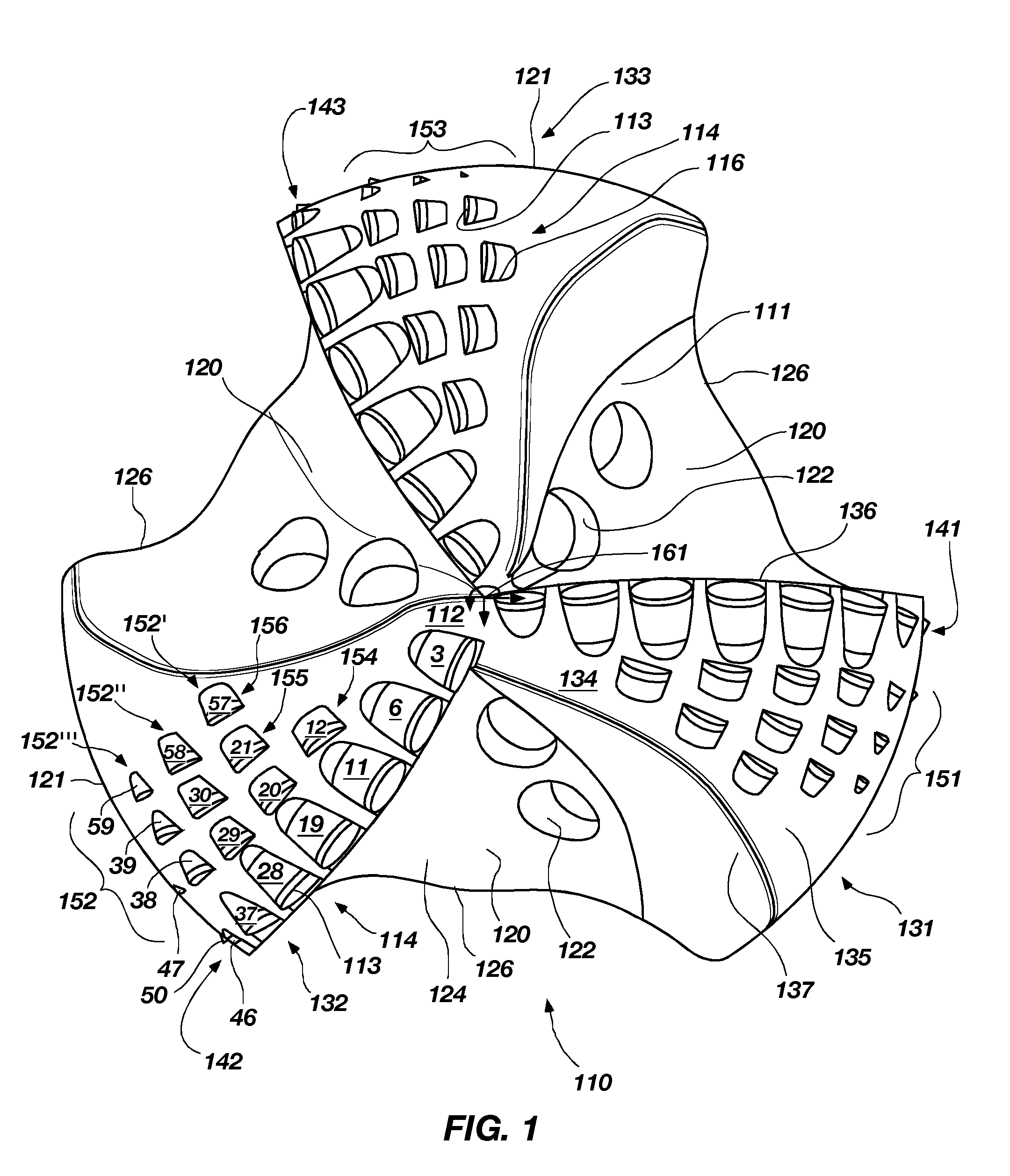

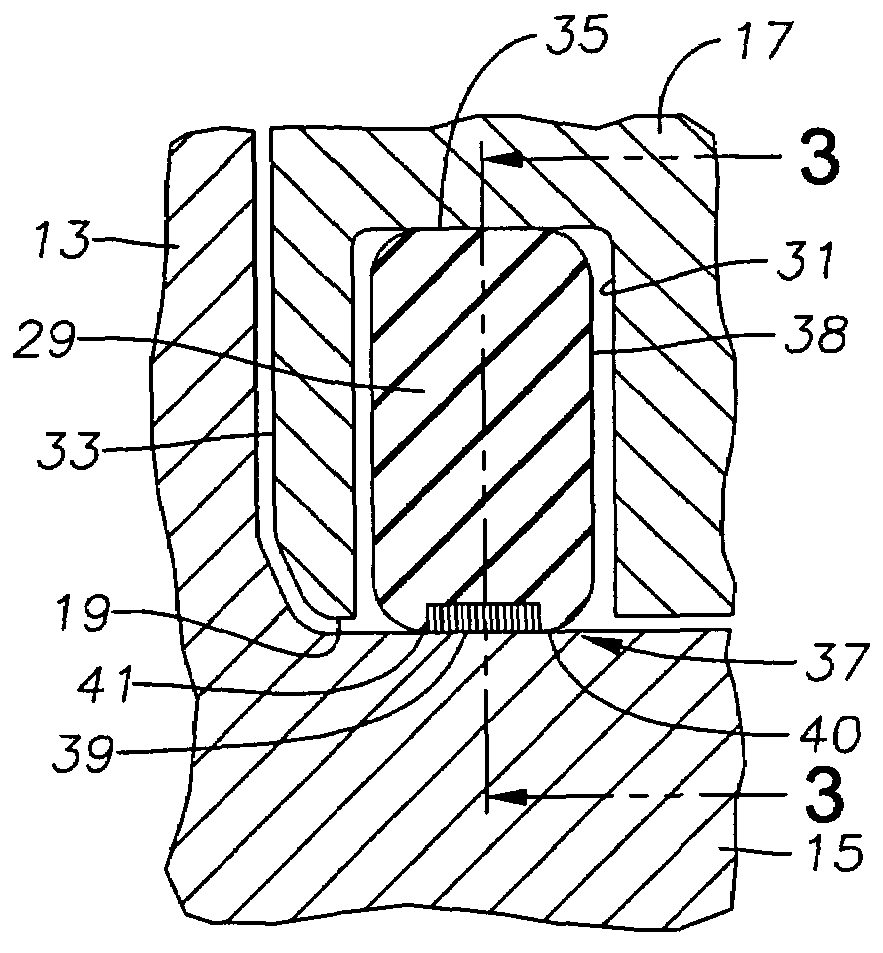

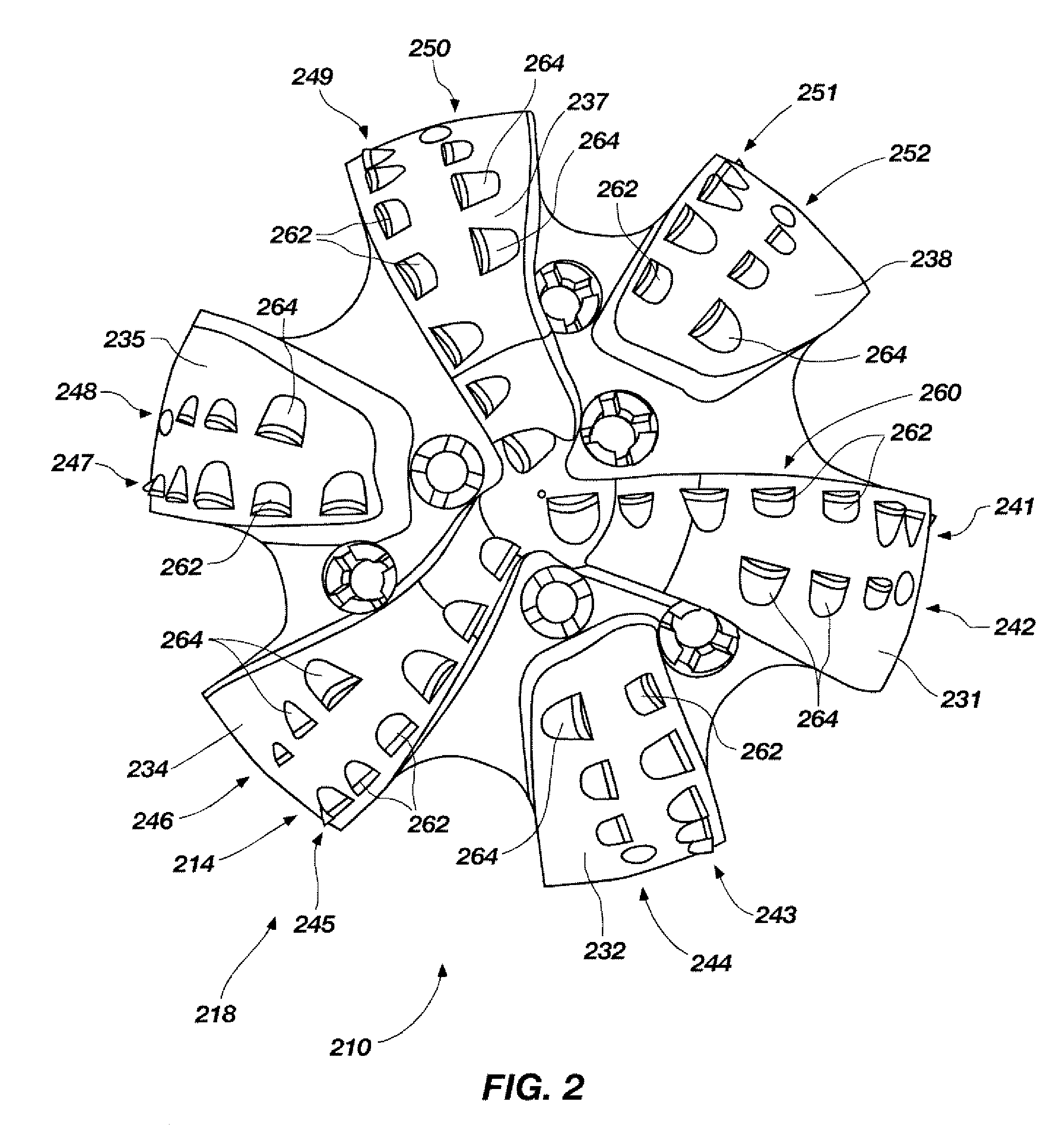

Drill bit arcuate-shaped inserts with cutting edges and method of manufacture

InactiveUS7331410B2Extended bit lifeImprove abilitiesDrill bitsMetal-working drilling toolsStress relievingEngineering

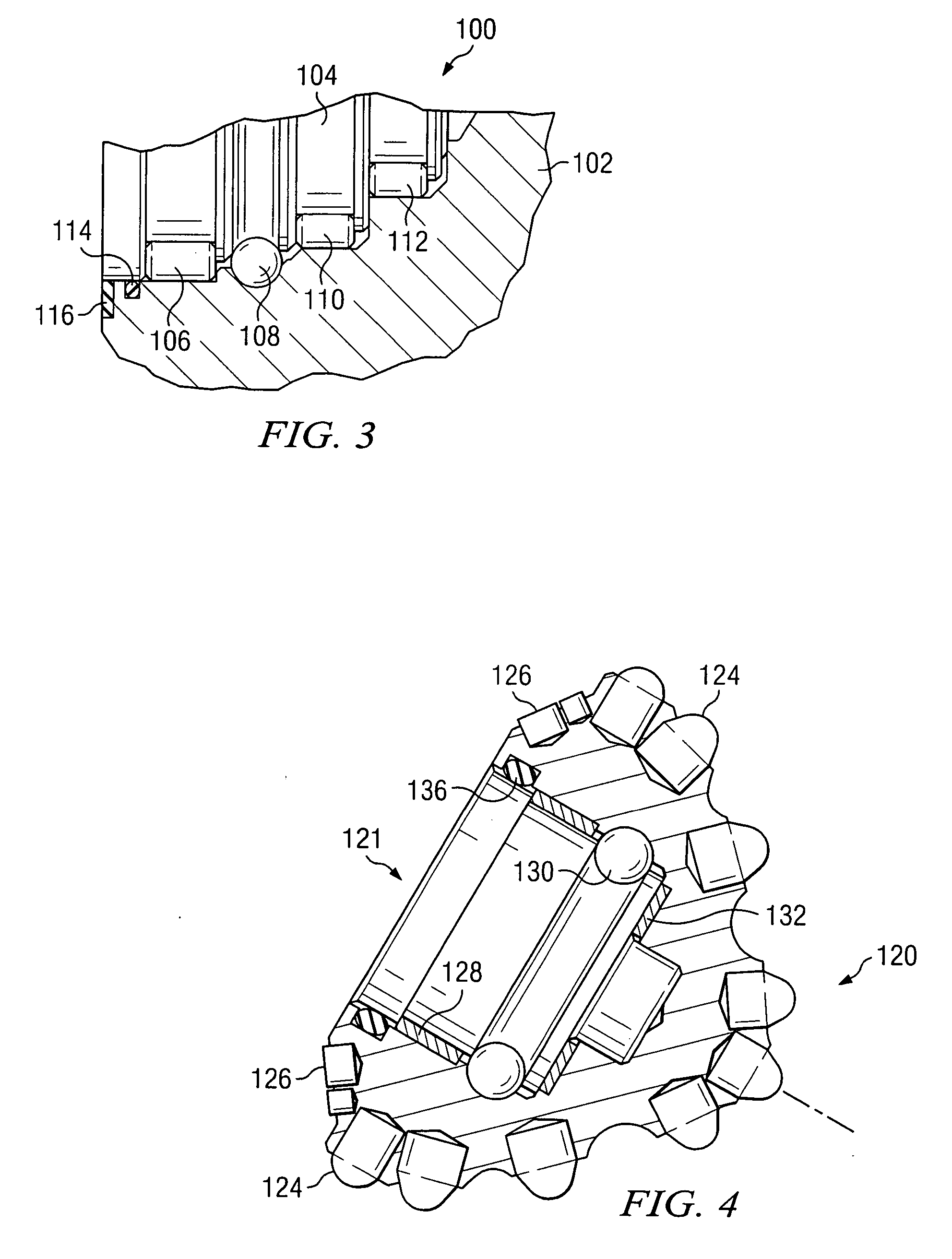

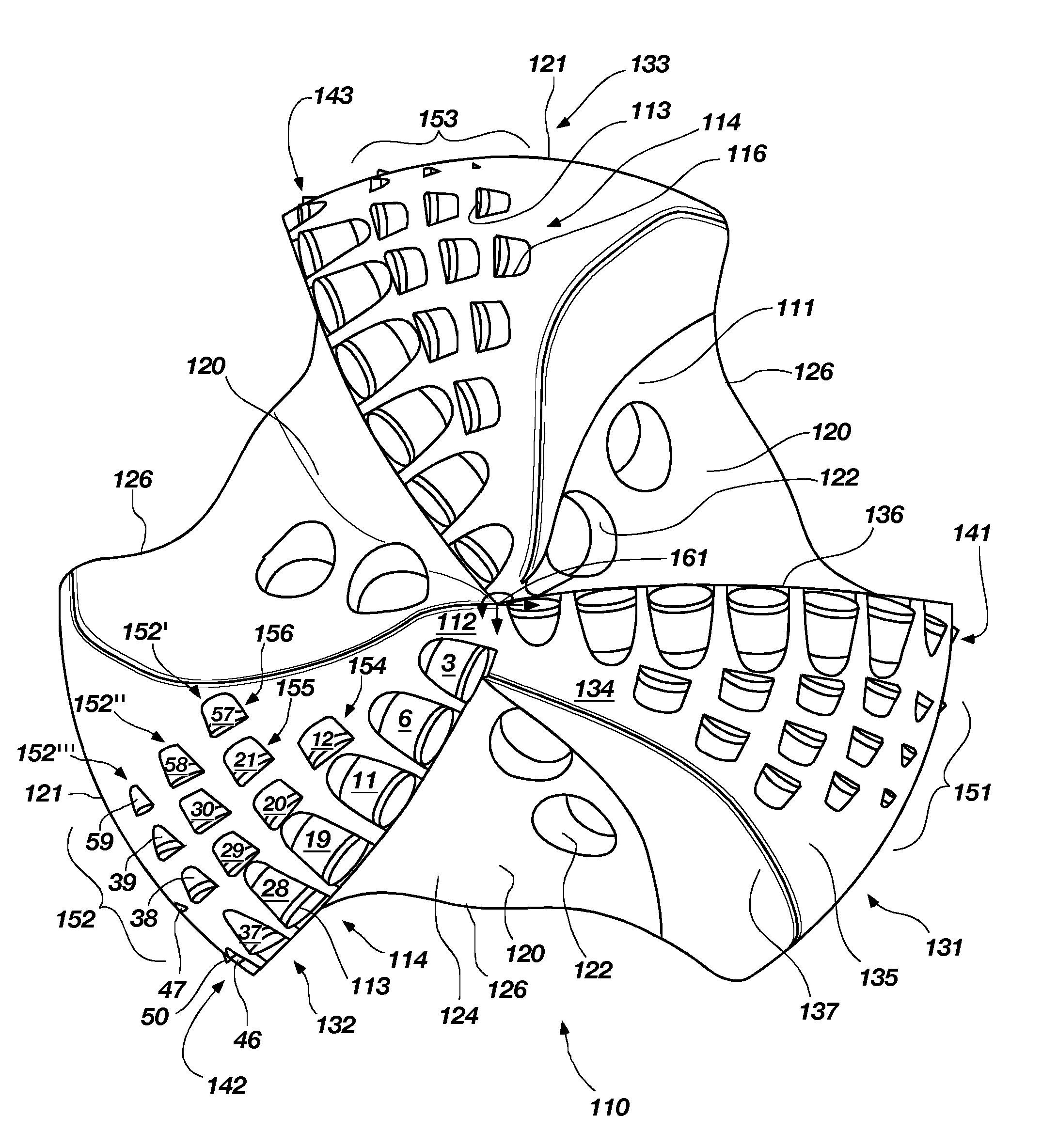

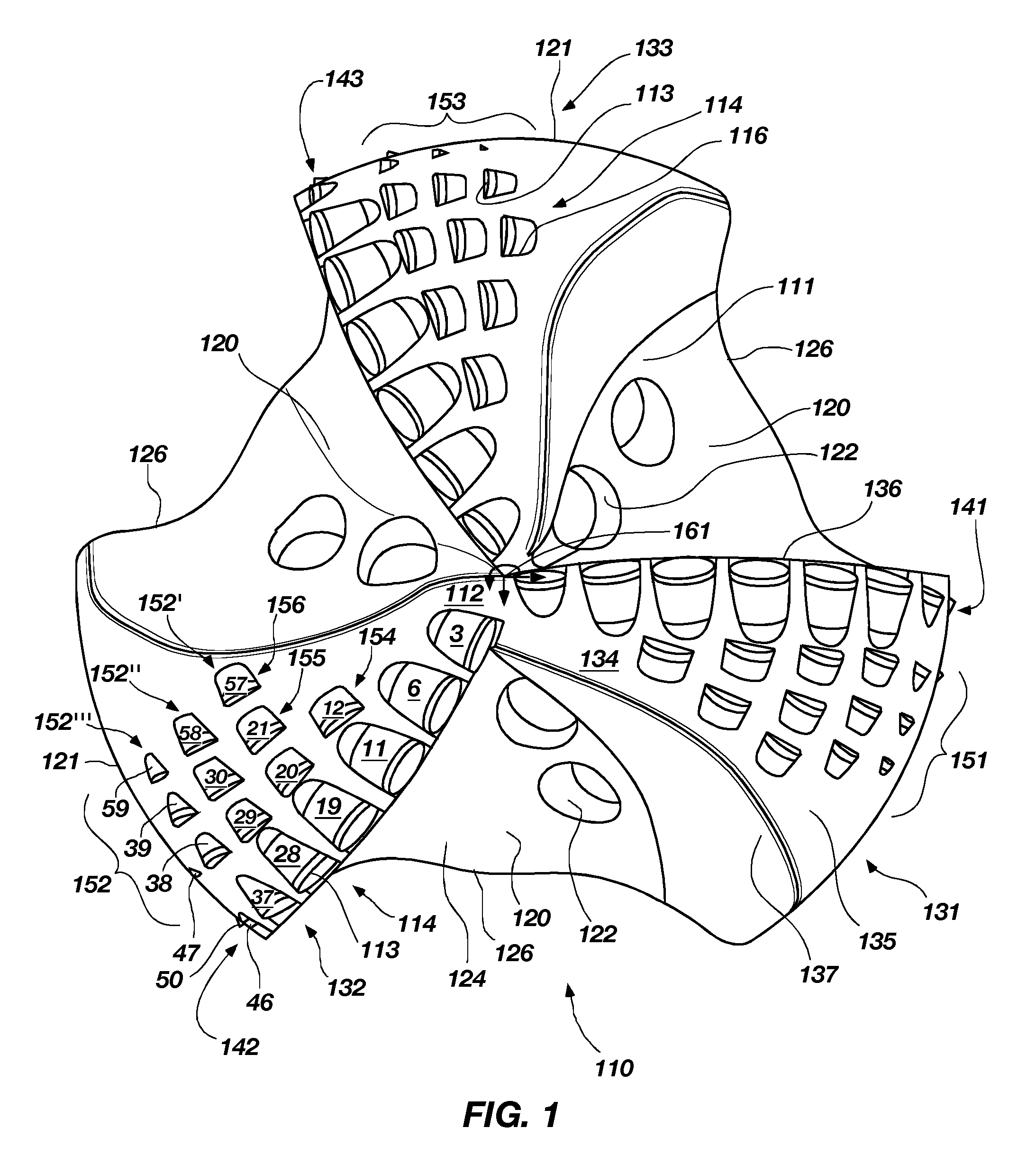

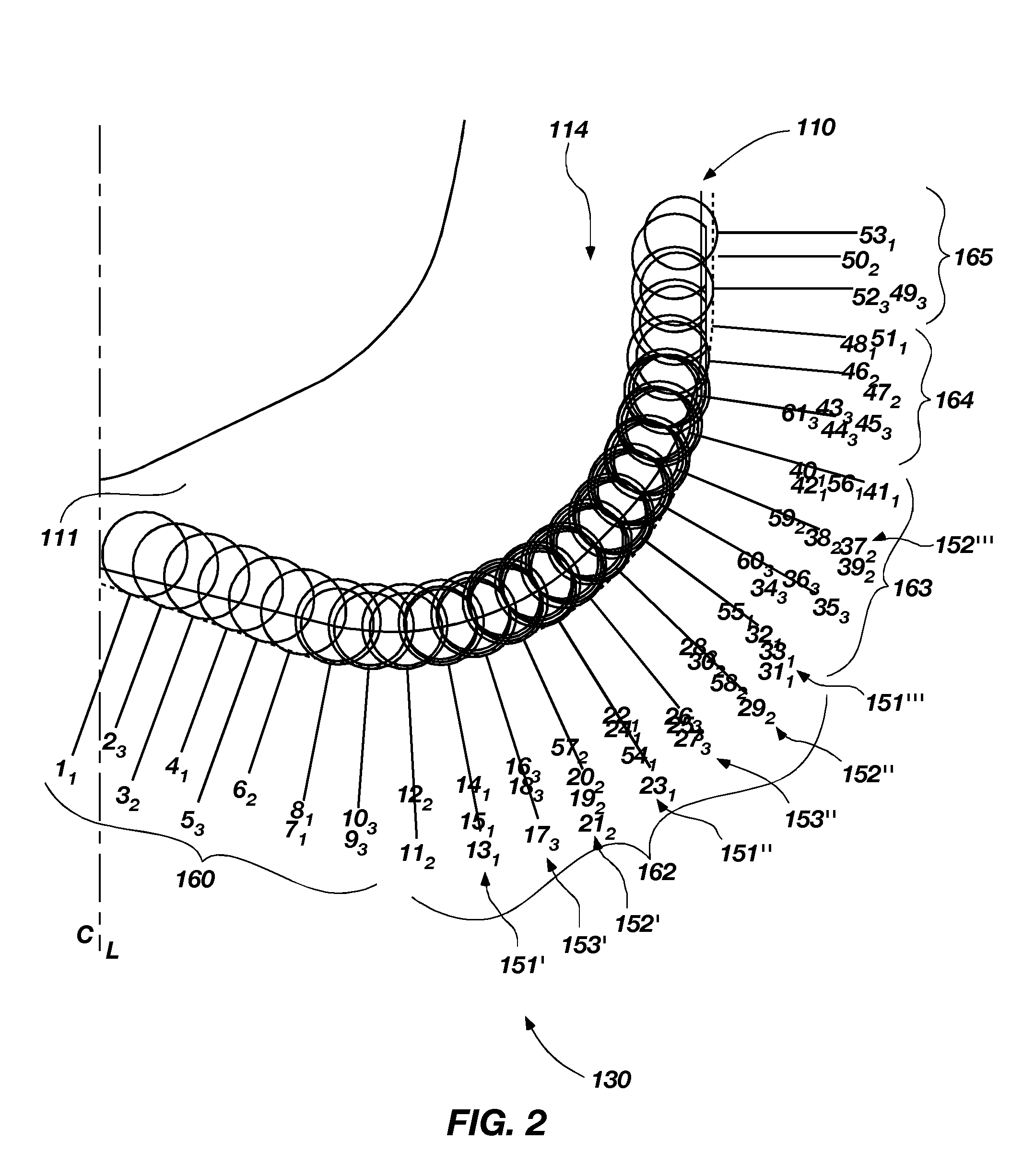

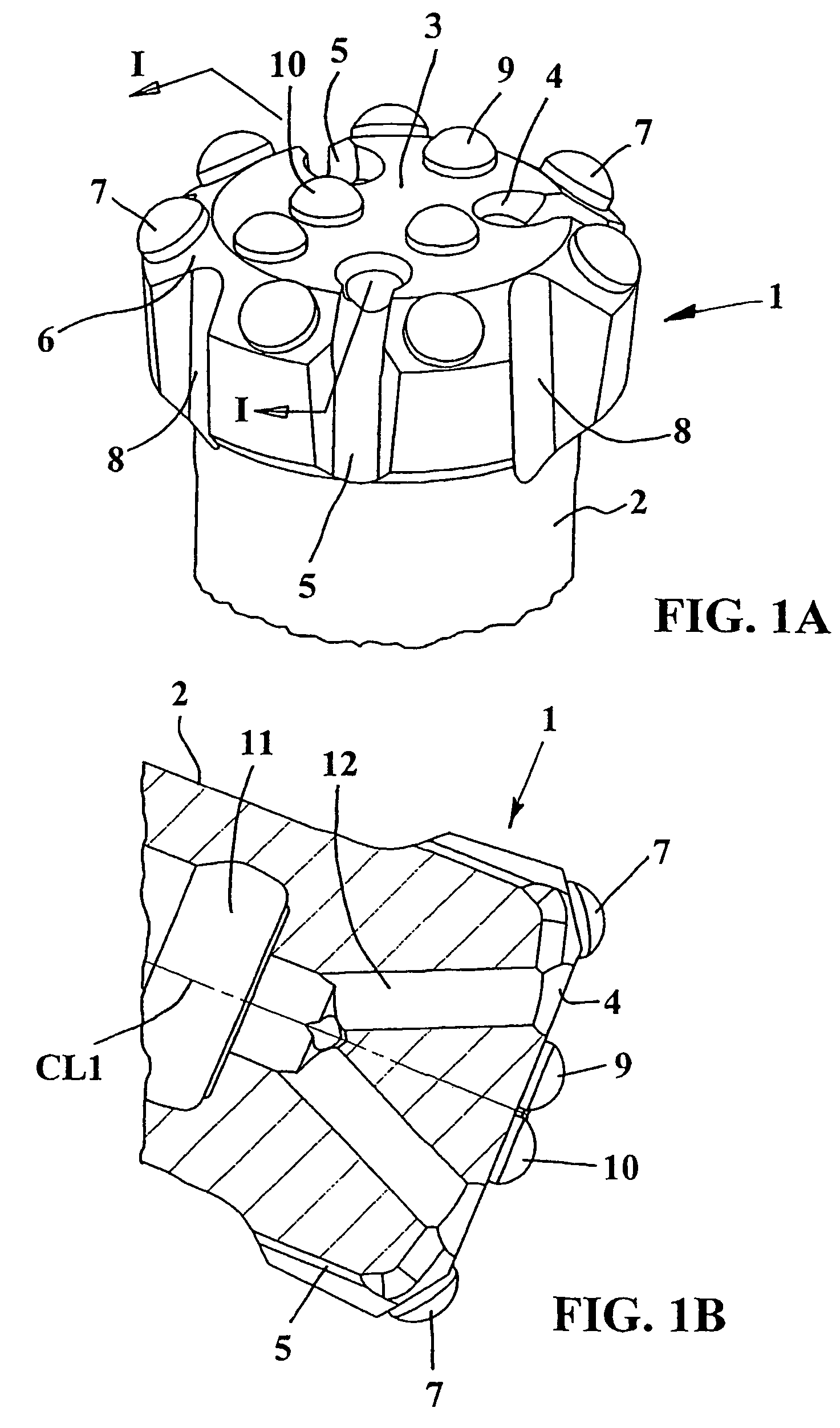

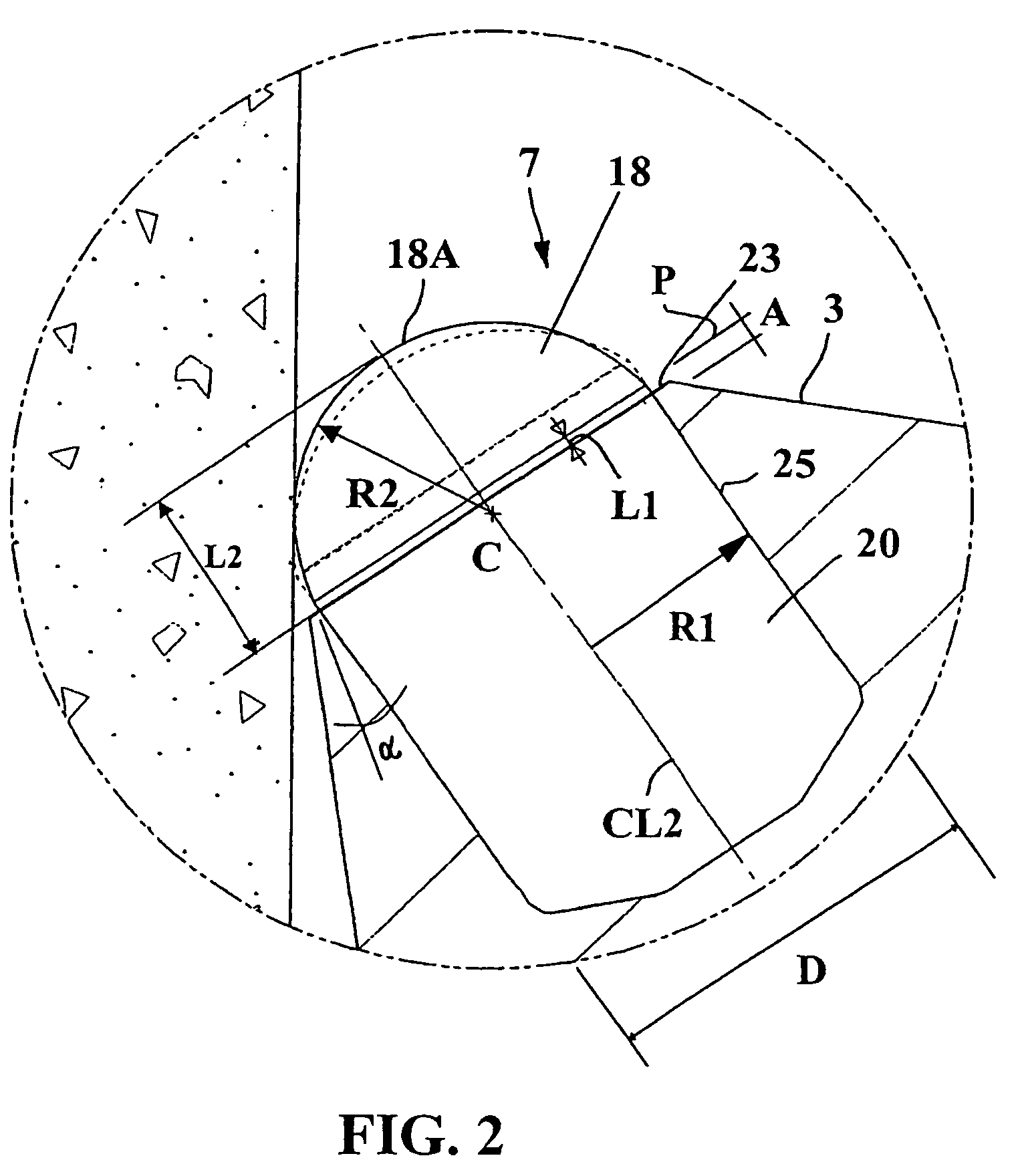

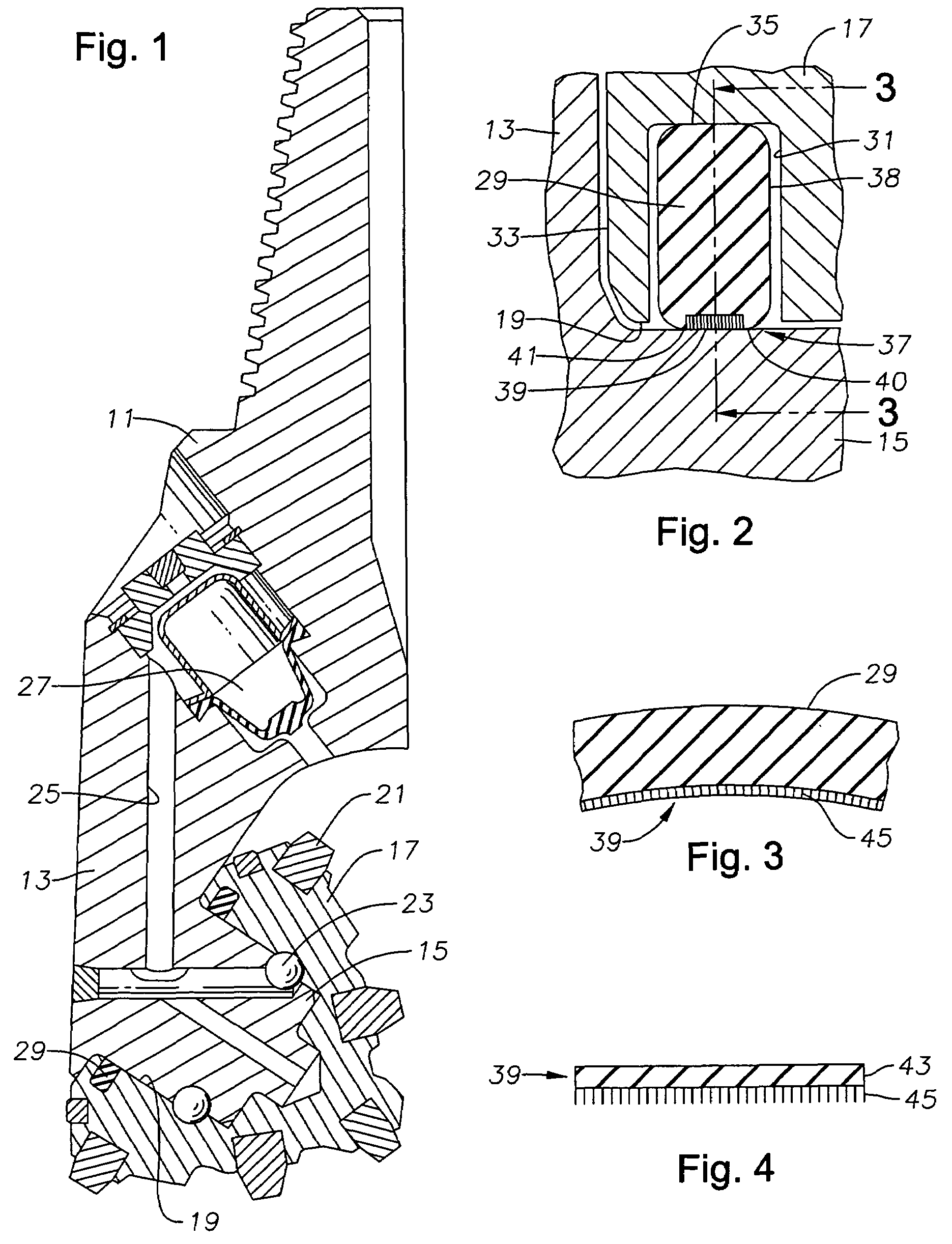

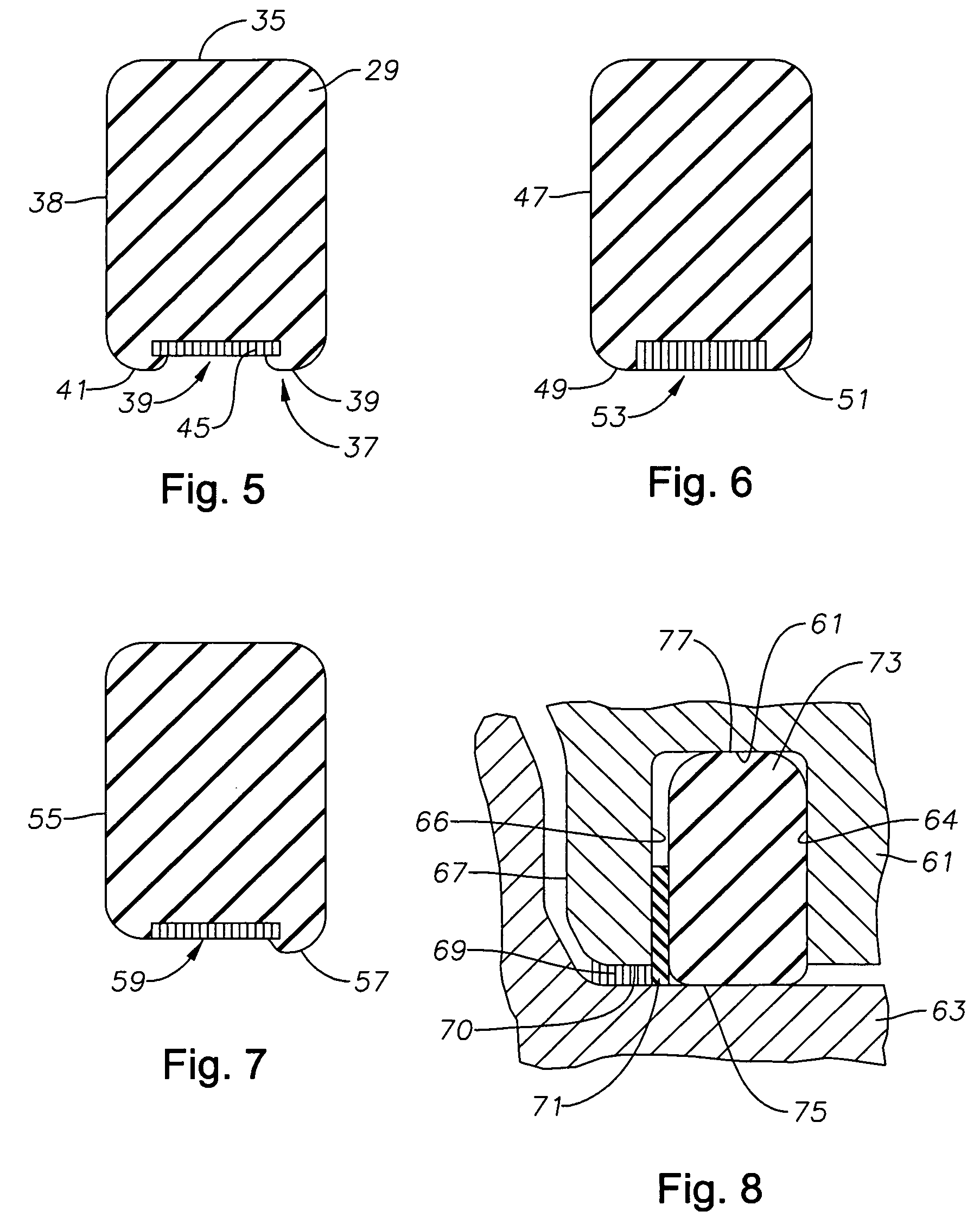

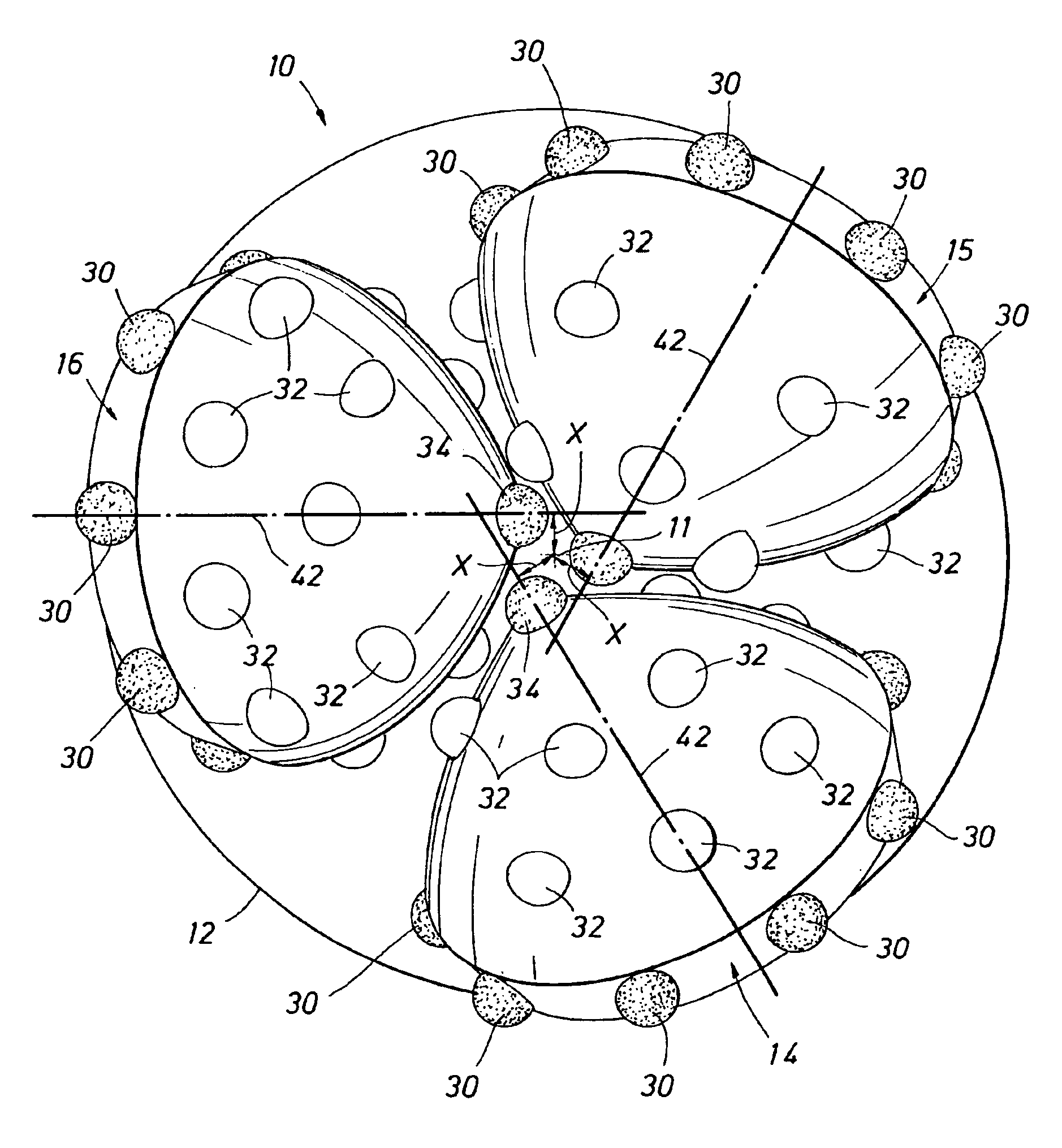

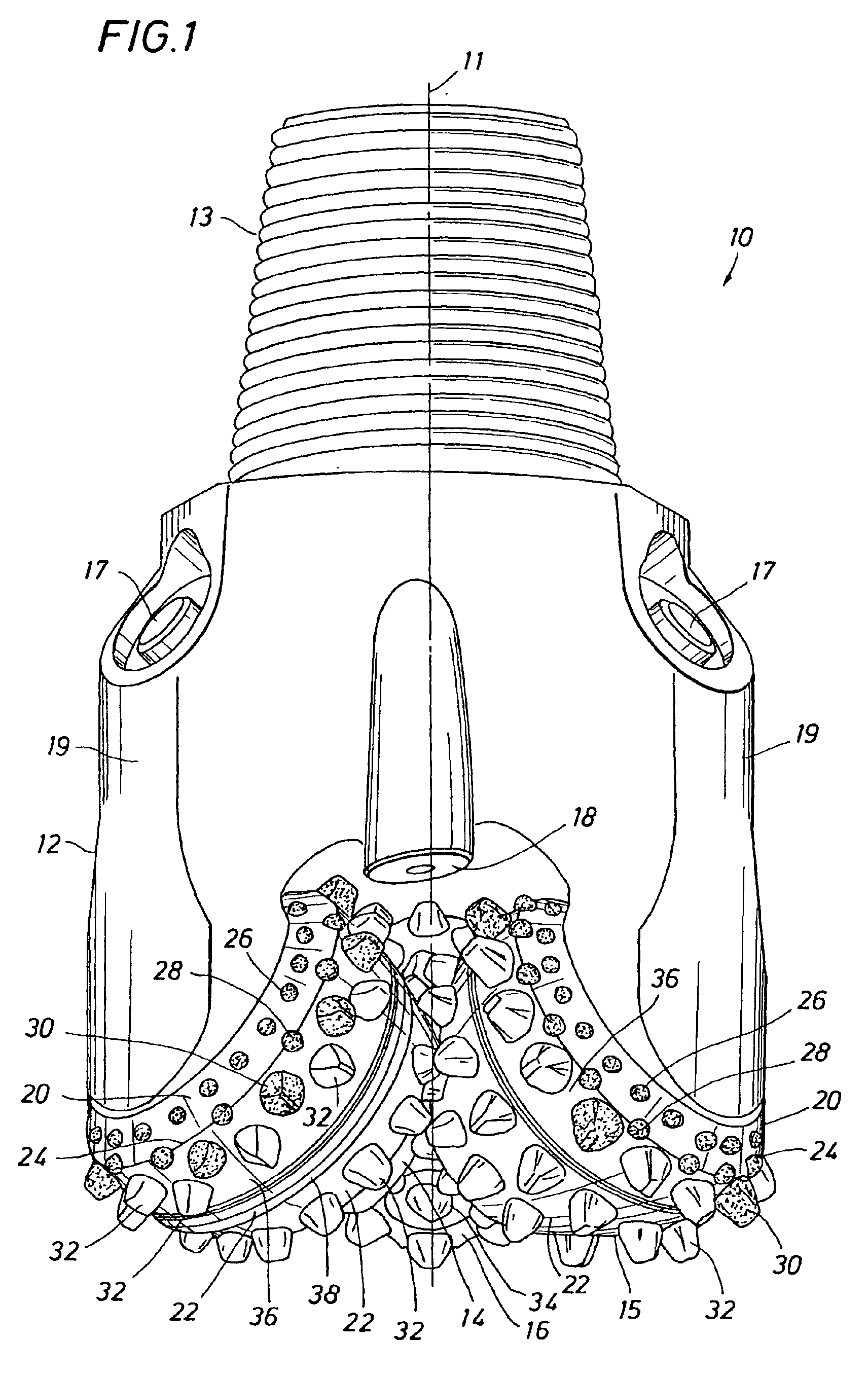

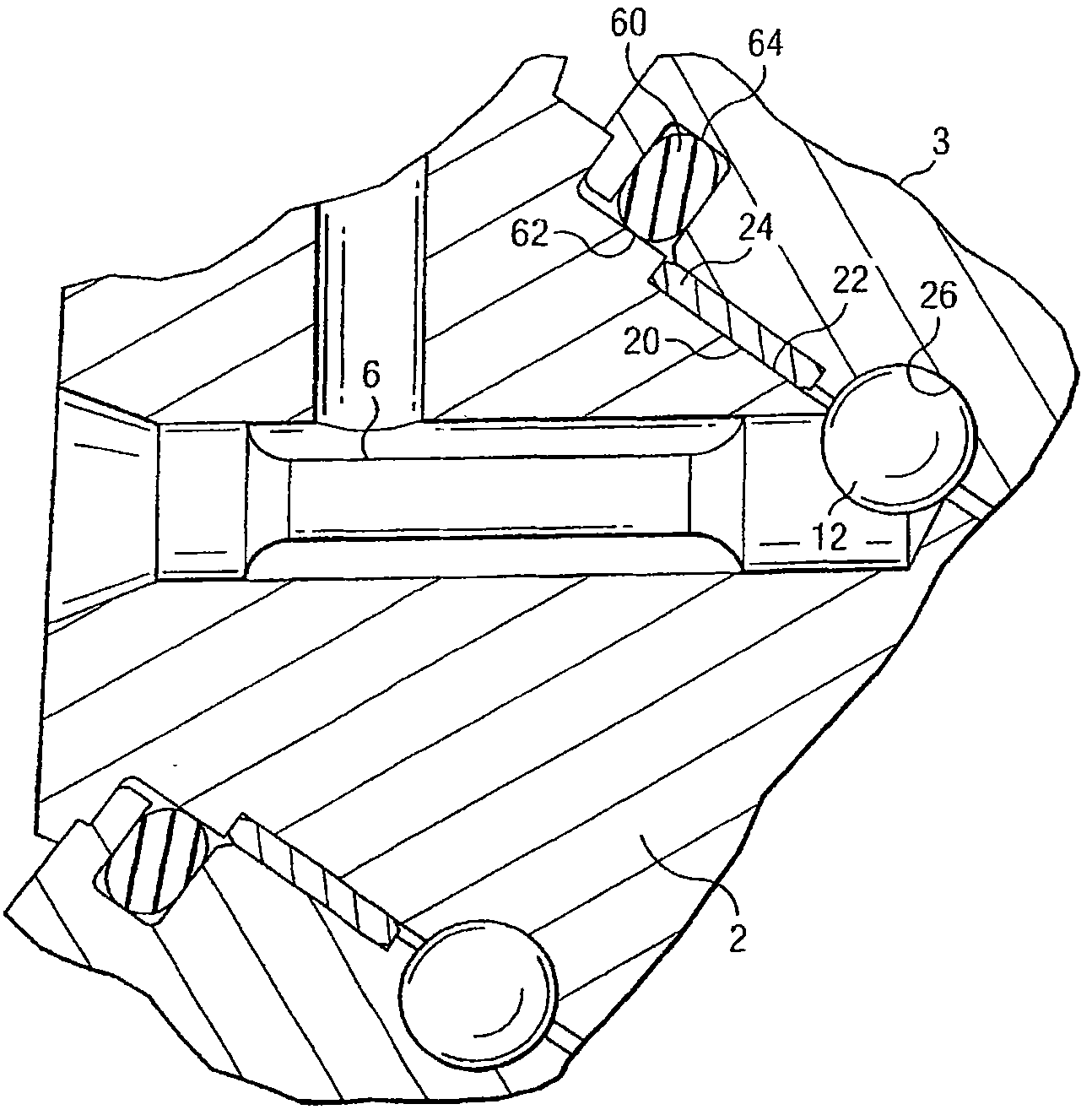

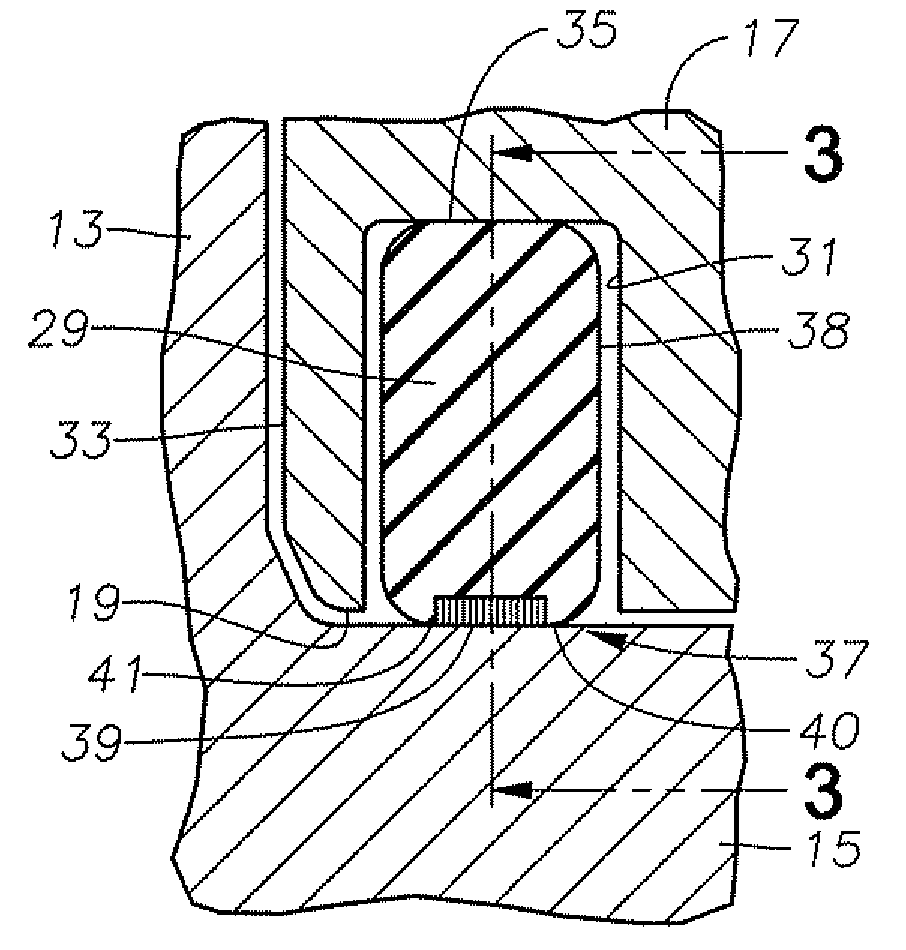

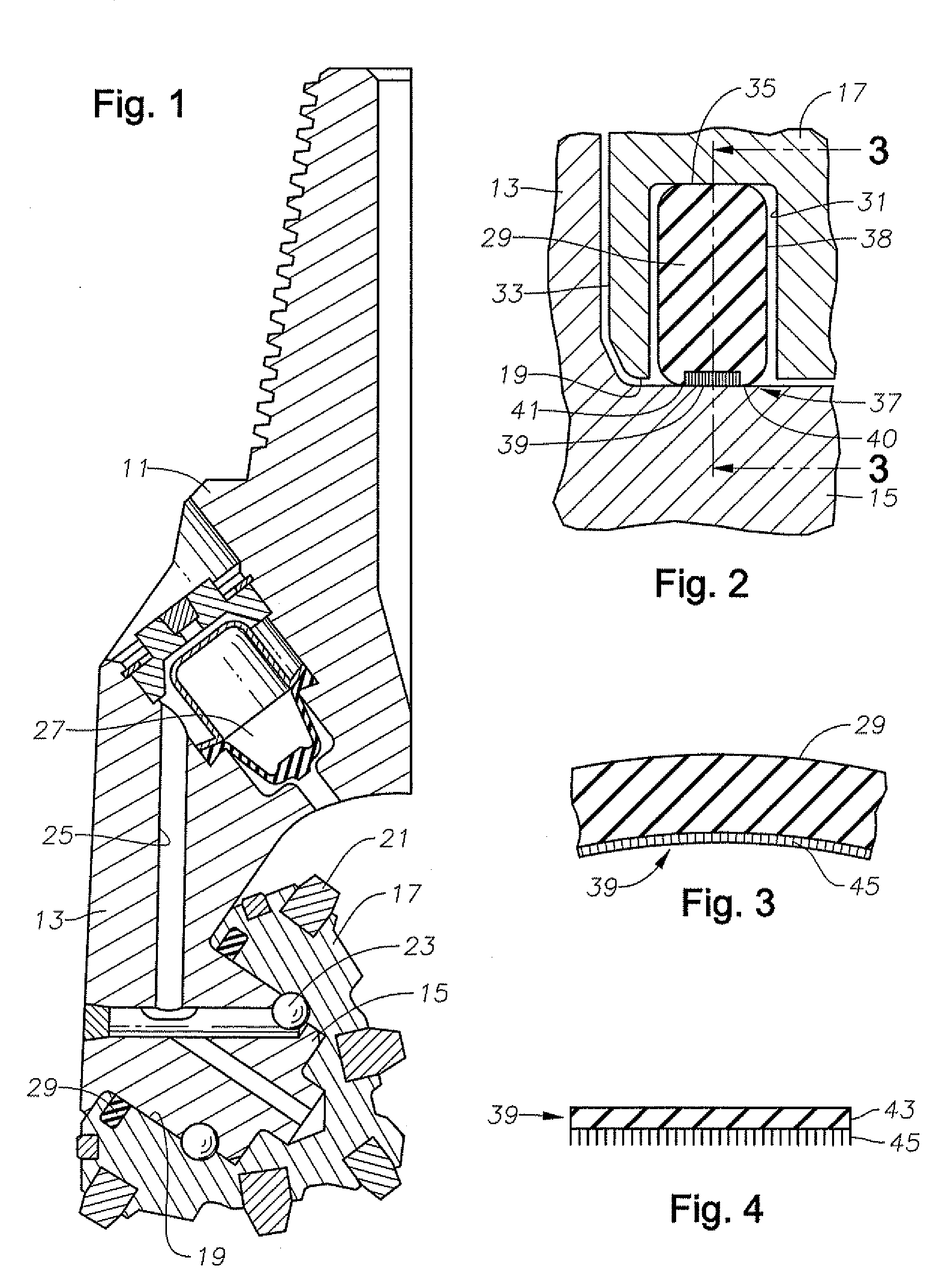

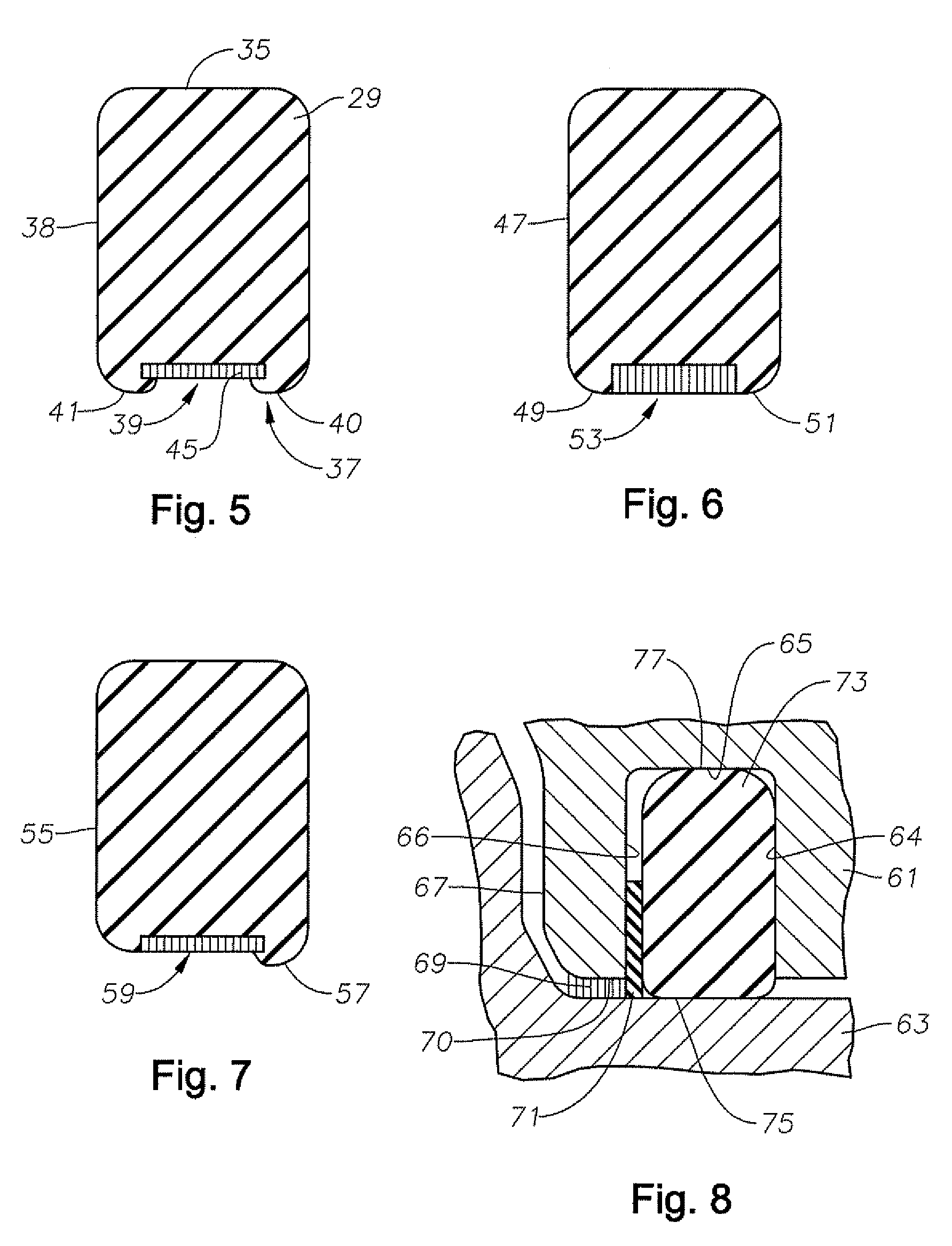

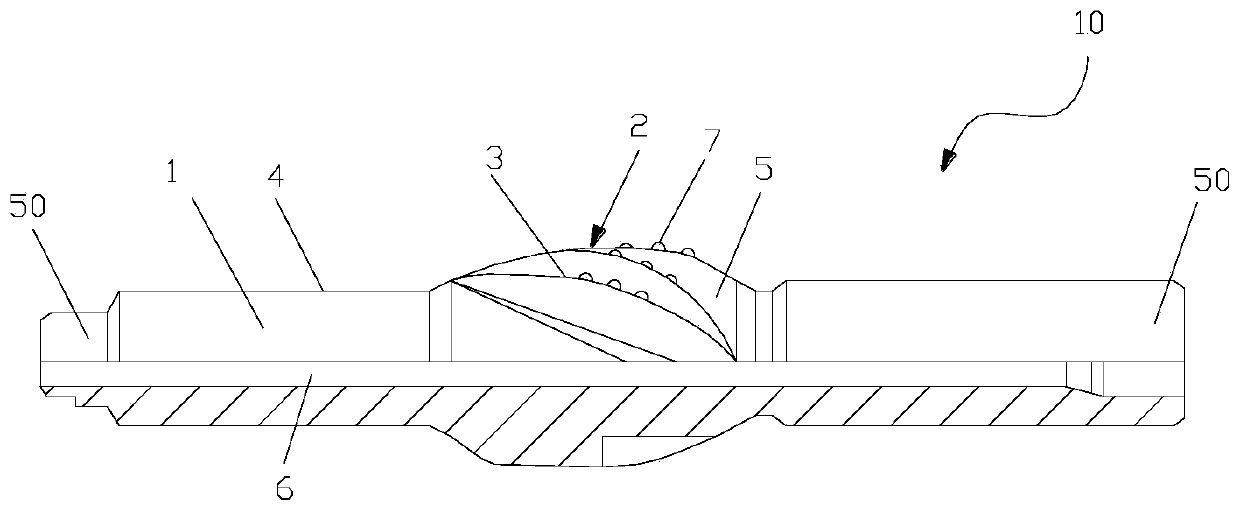

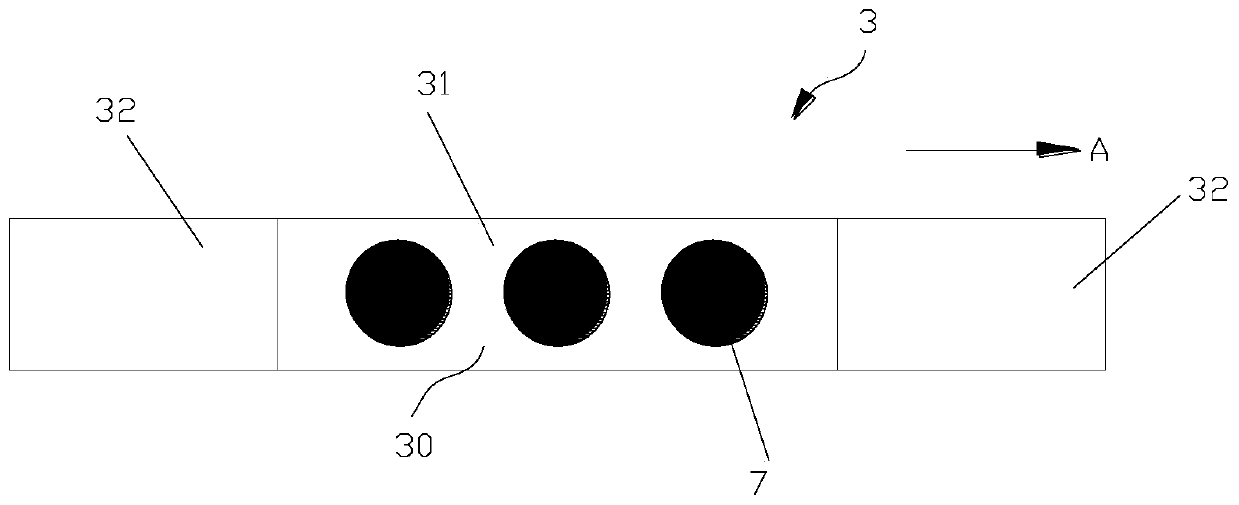

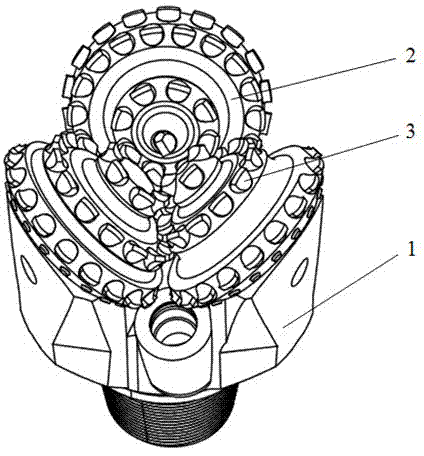

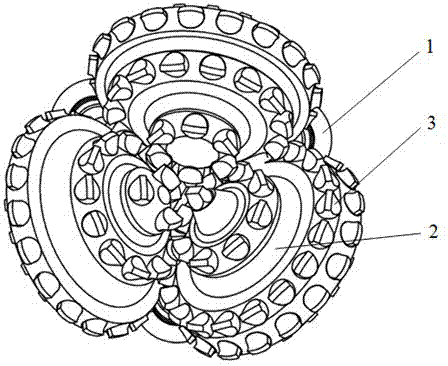

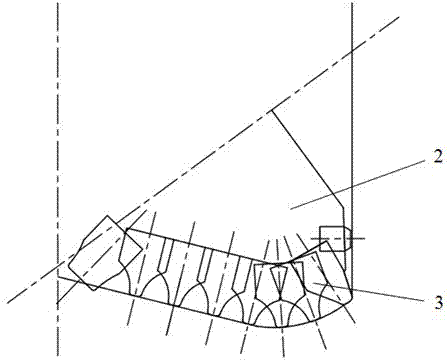

Disclosed are a variety of arcuate-shaped inserts for drill bits, and in particular, for placement in rolling cone cutters of drill bits. The arcuate inserts include 360° or ring-shaped inserts, as well as inserts of smaller arcuate length. The arcuate inserts are suitable for use in all surfaces of the rolling cone cutter, and in other locations in drill bits, and may have specialized cutting surfaces and material enhancements to enhance their cutting duty performance. Certain arcuate inserts may include stress relieving discontinuities such that, upon assembly into the cone or during drilling, the arcuate inserts may fragment in a controlled and predicted manner into shorter arcuate lengths.

Owner:SMITH INT INC

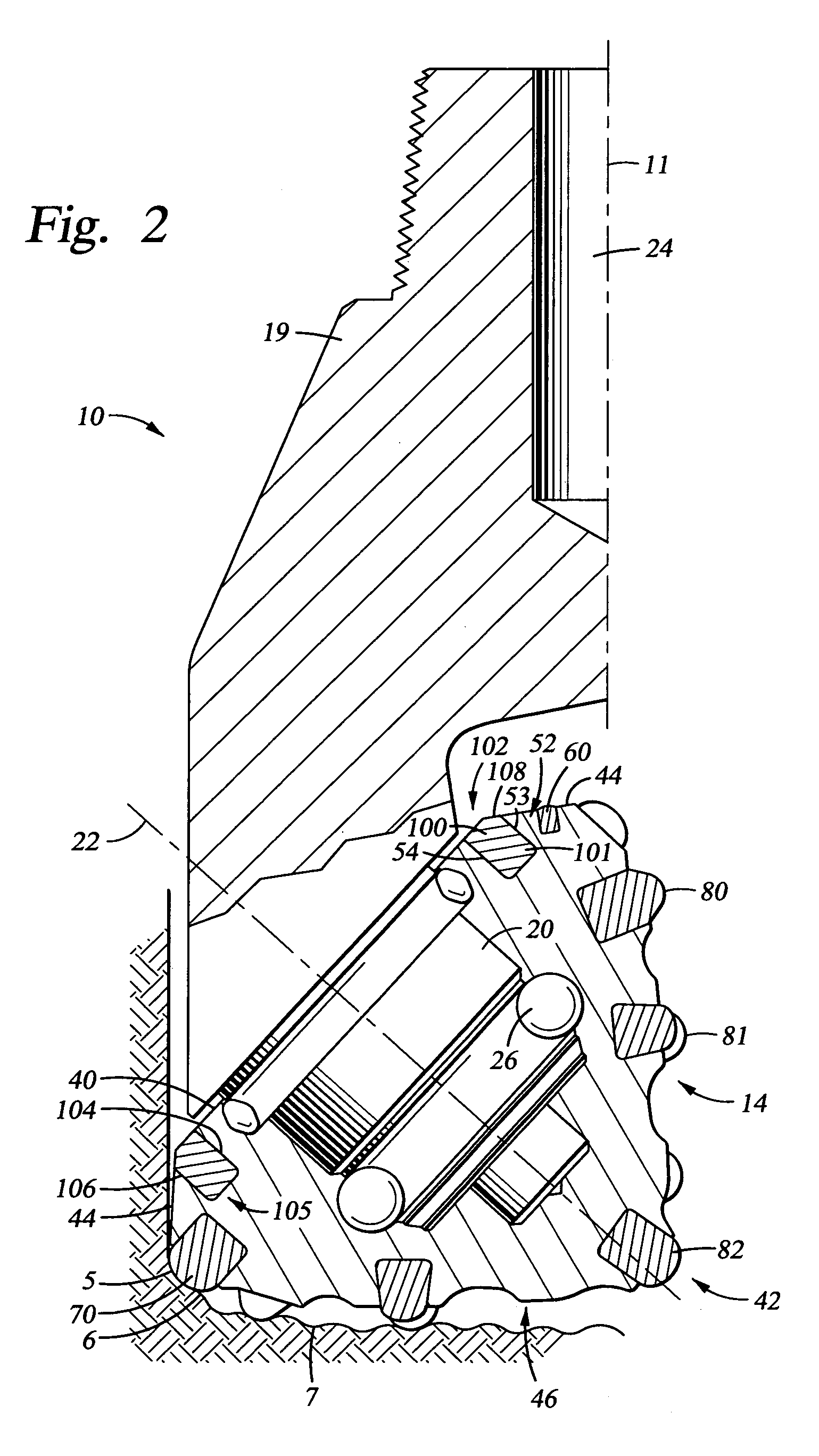

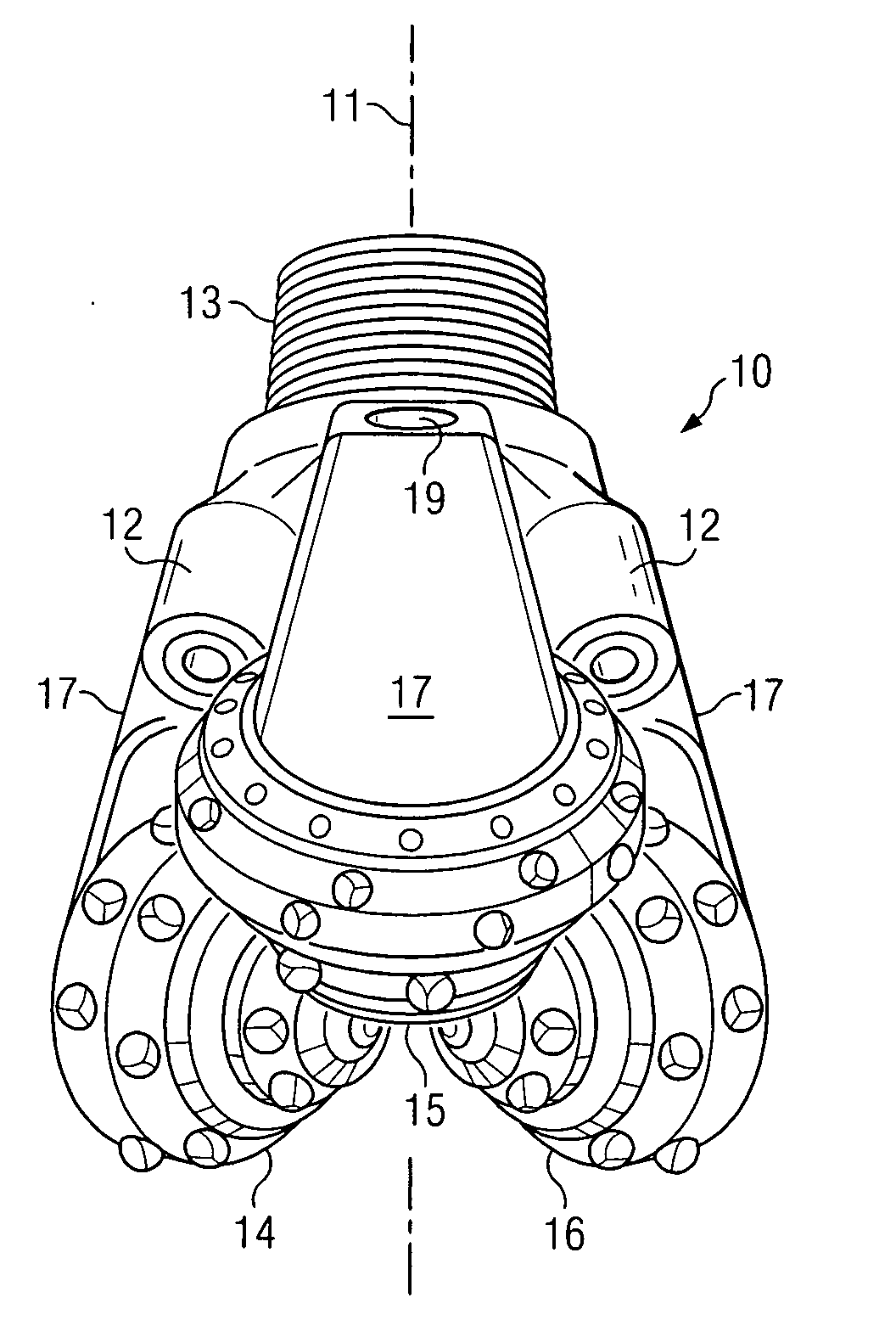

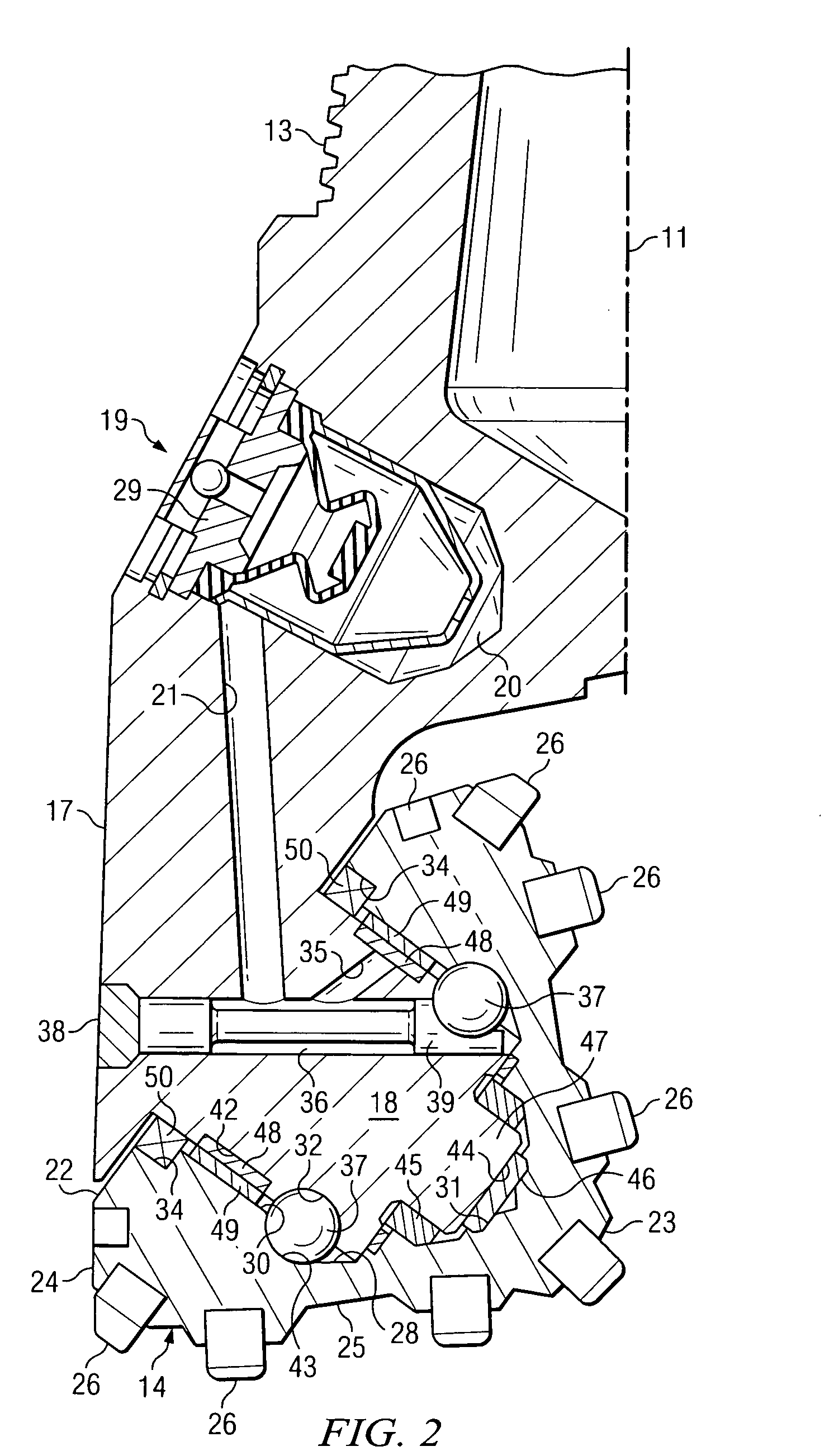

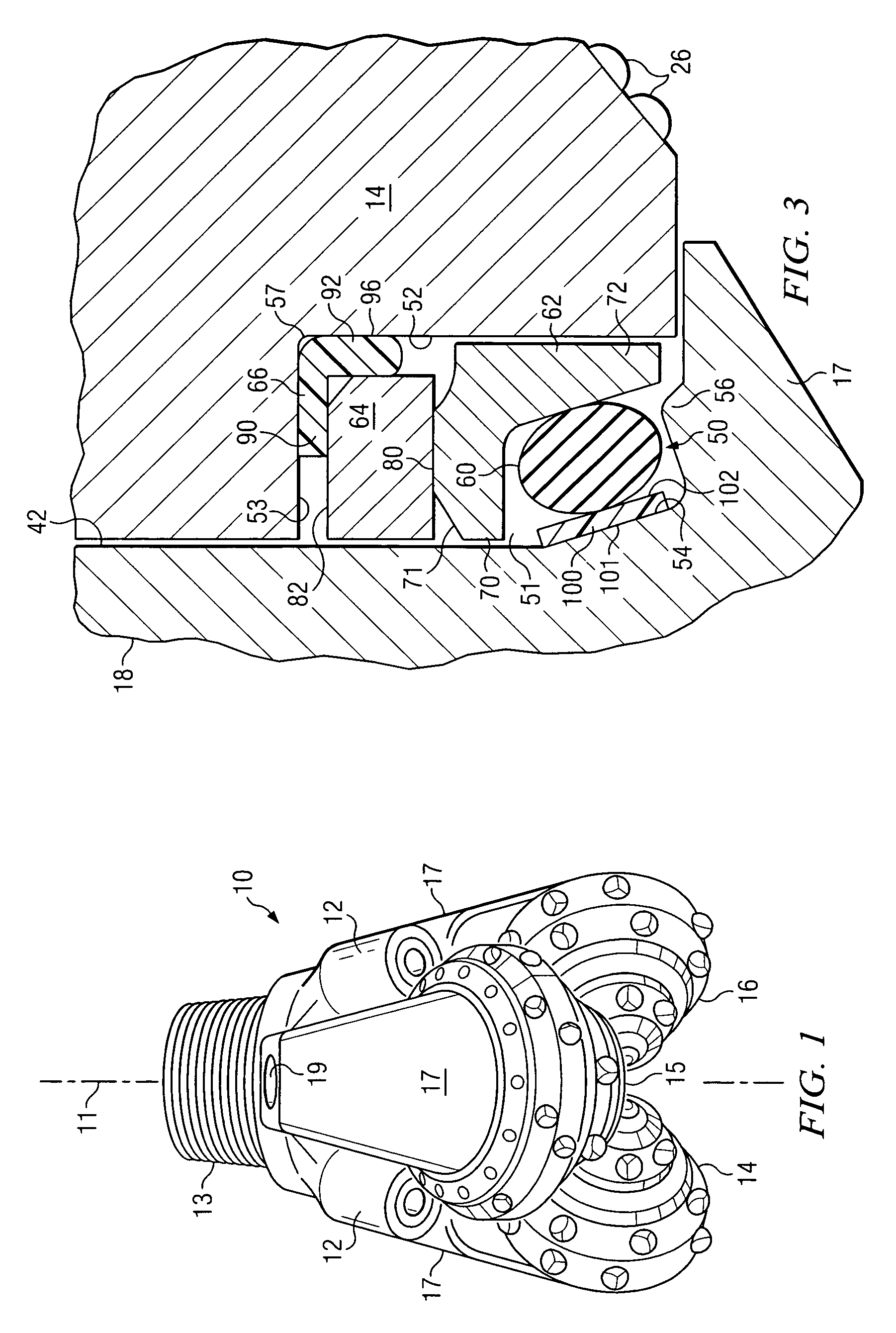

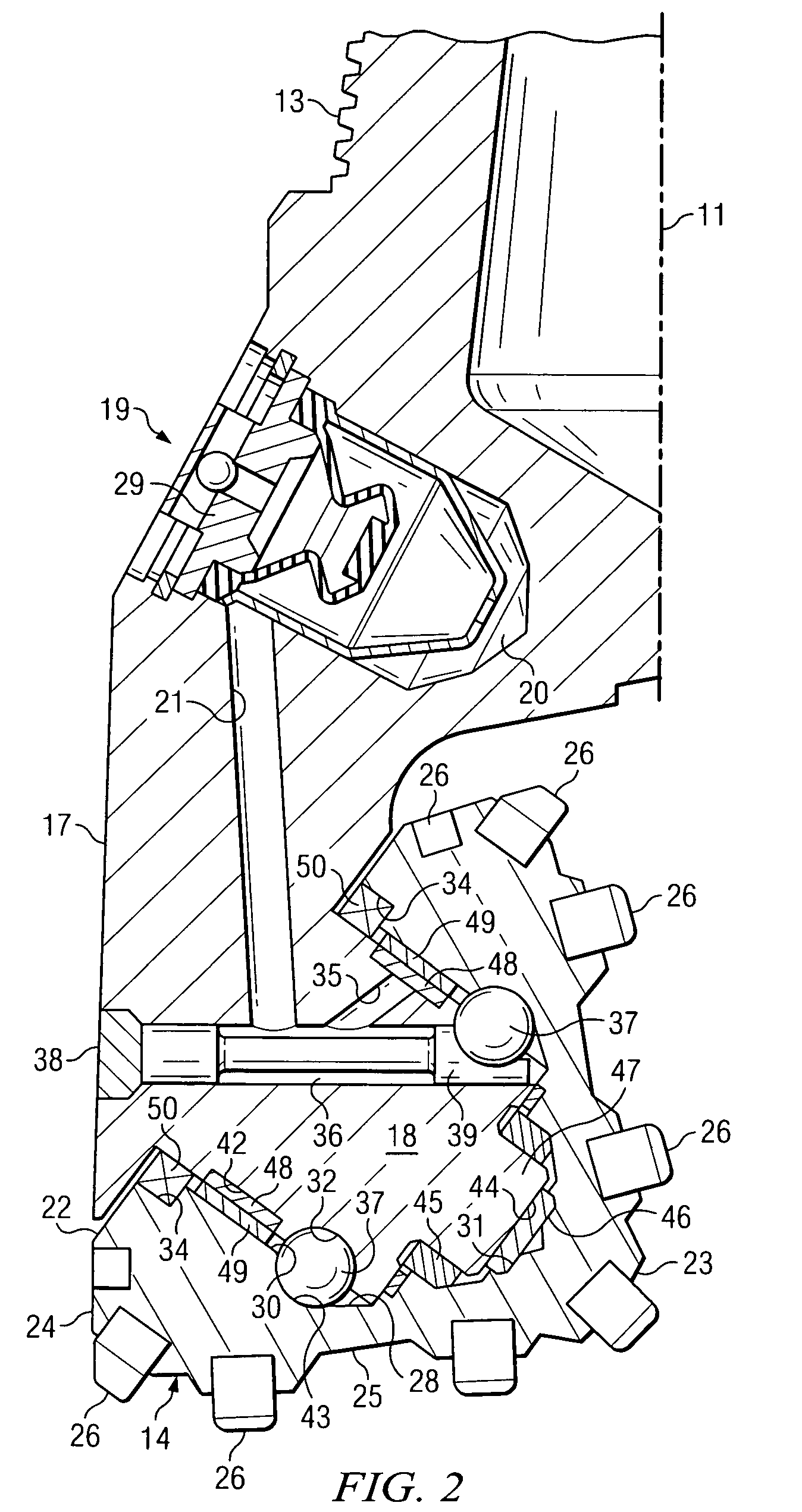

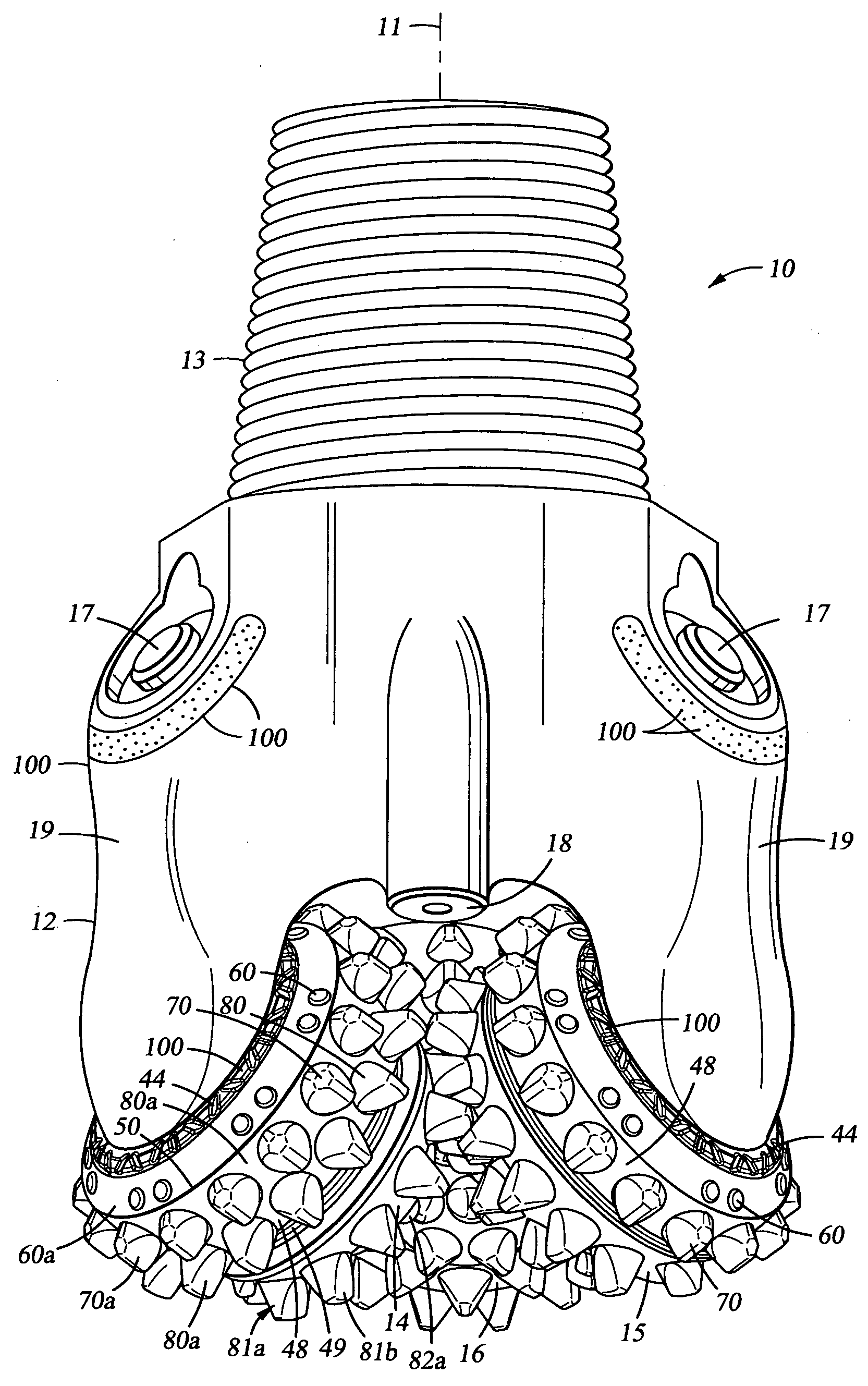

Earth boring apparatus and method offering improved gage trimmer protection

InactiveUS6883623B2Less wear resistantWear down quicklyDrill bitsDrilling rodsLeading edgeEngineering

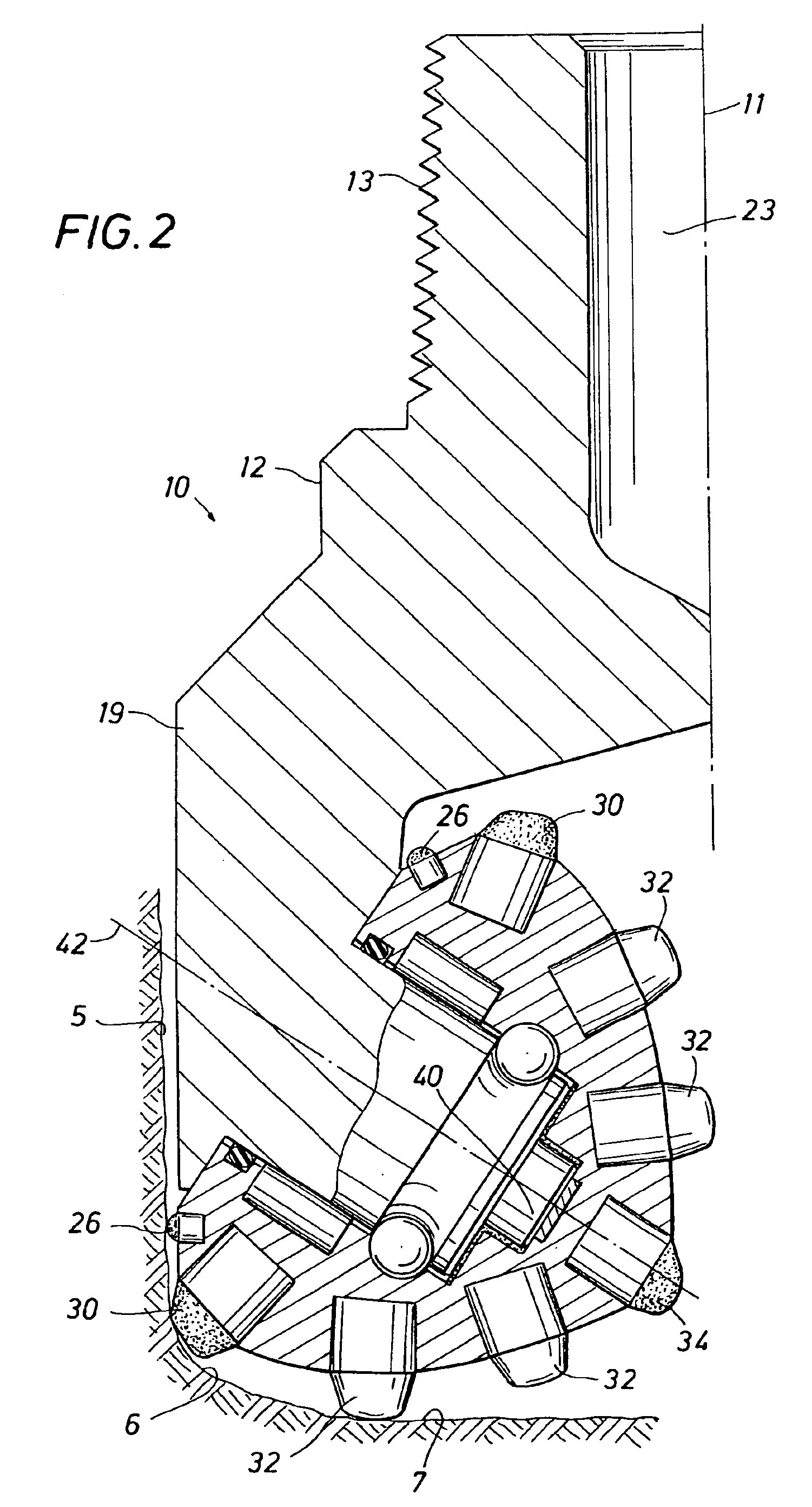

A rotary drill bit for drilling subterranean formations configured with at least one protective structure proximate to the rotationally leading and trailing edges of a gage trimmer, wherein the at least one protective structure is positioned at substantially the same exposure as its associated gage trimmer. Particularly, the apparatus of the present invention may provide protection for gage trimmers during drilling, tripping, and / or rotation within a casing; i.e., when changing a drilling fluid. Protective structures may be configured and located according to anticipated drilling conditions including helix angles. In addition, a protective structure may be proximate to more than one gage trimmer while having a substantially equal exposure to each associated gage trimmer. Methods of use and a method of rotary bit design are also disclosed.

Owner:BAKER HUGHES INC

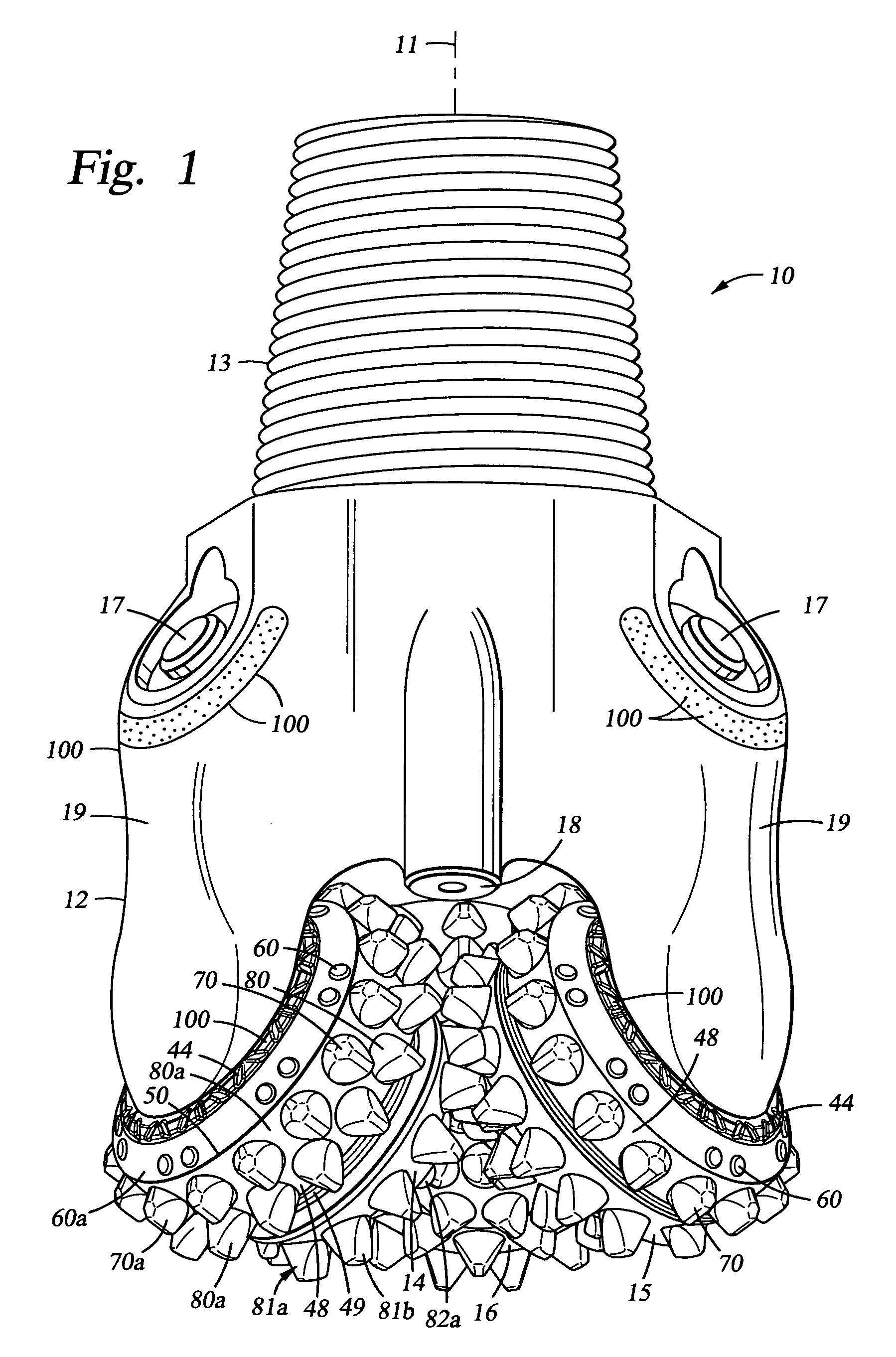

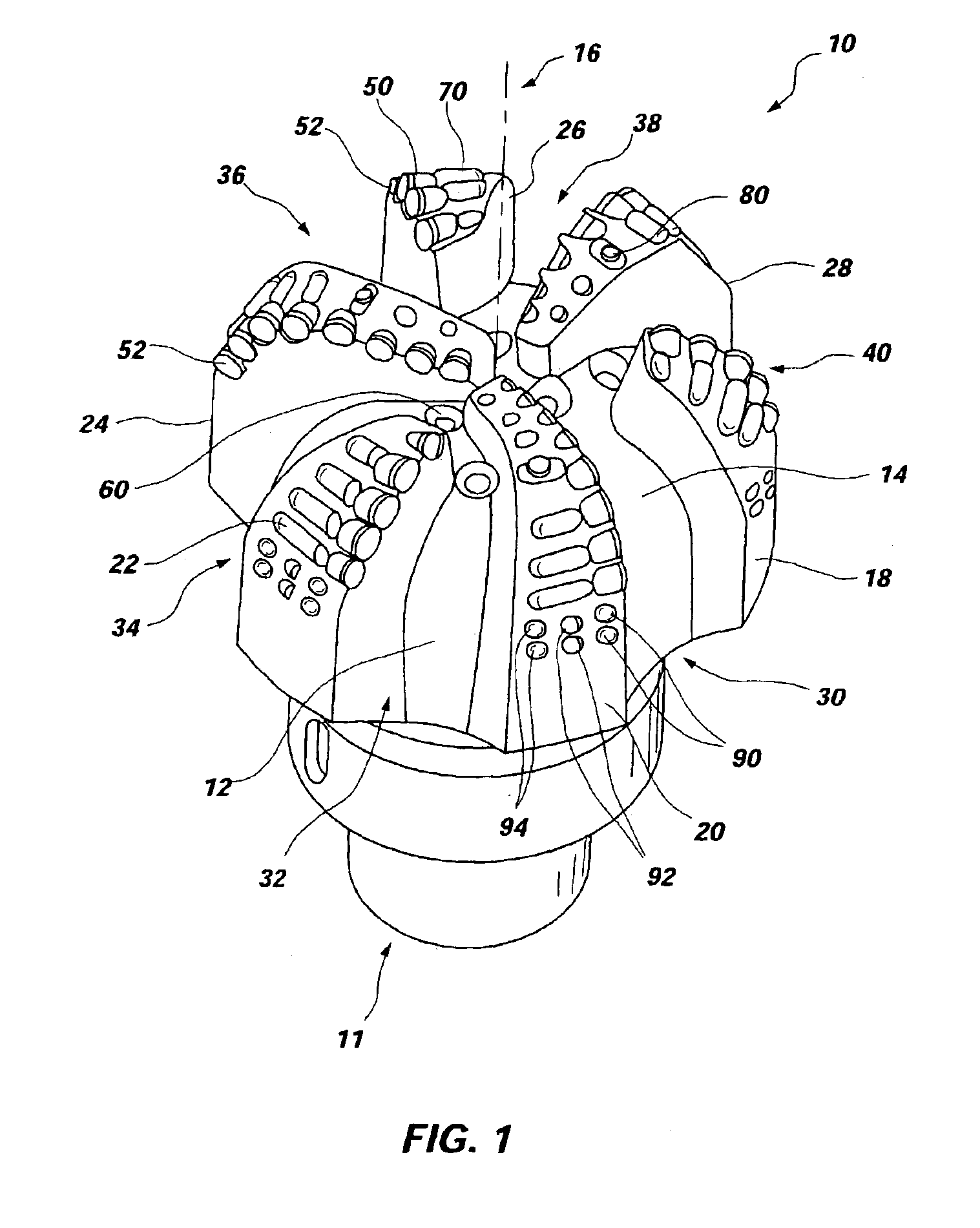

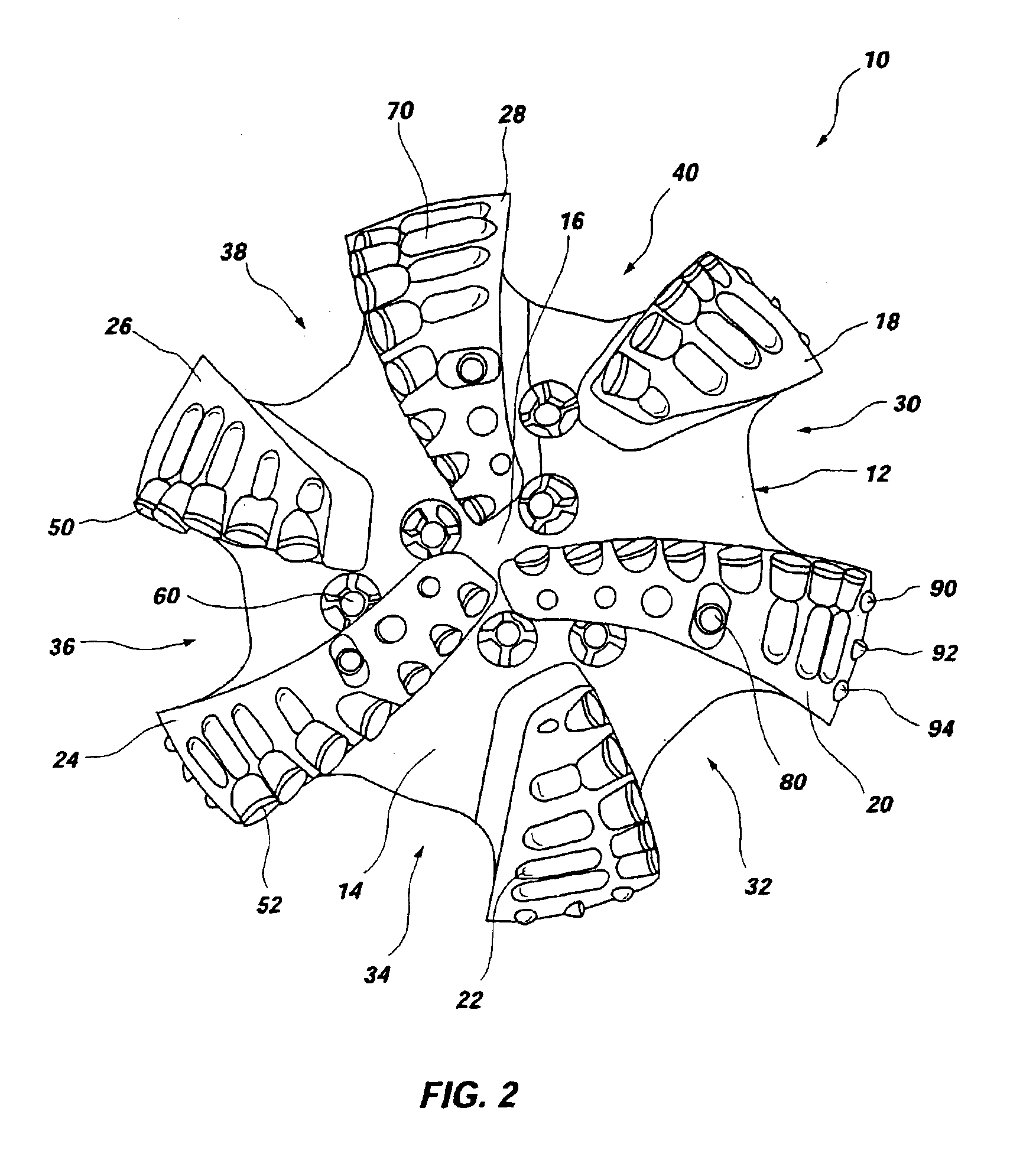

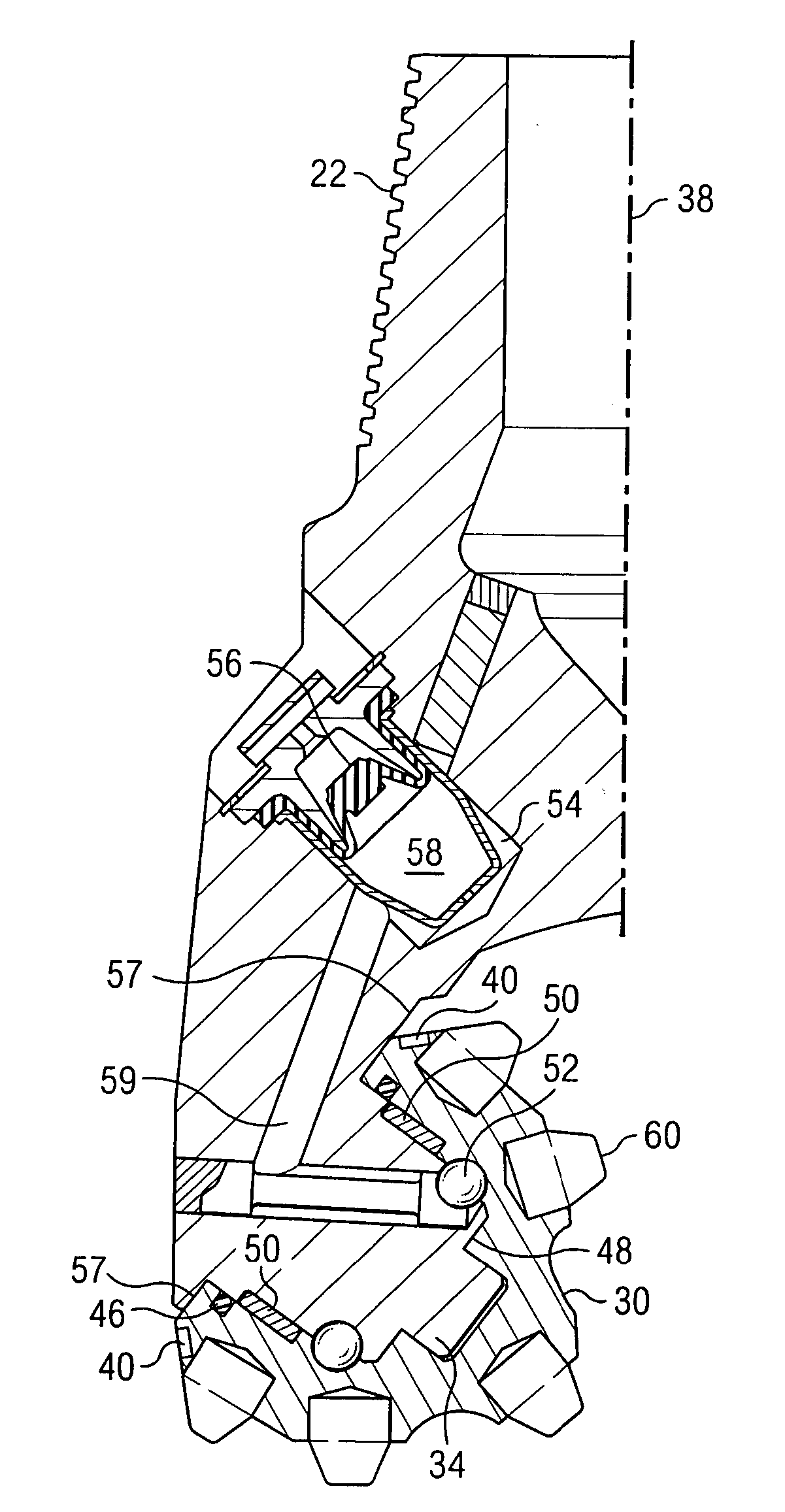

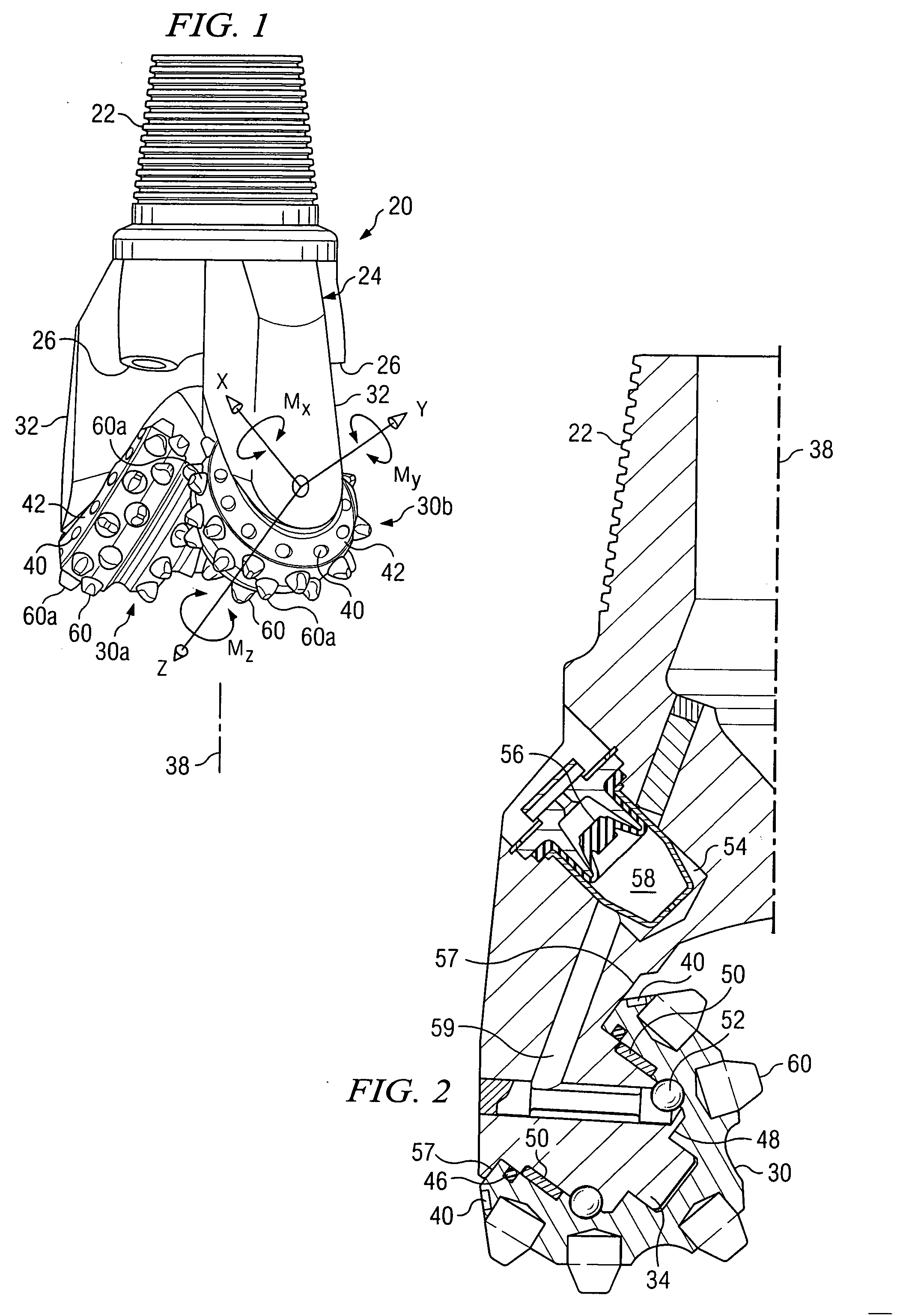

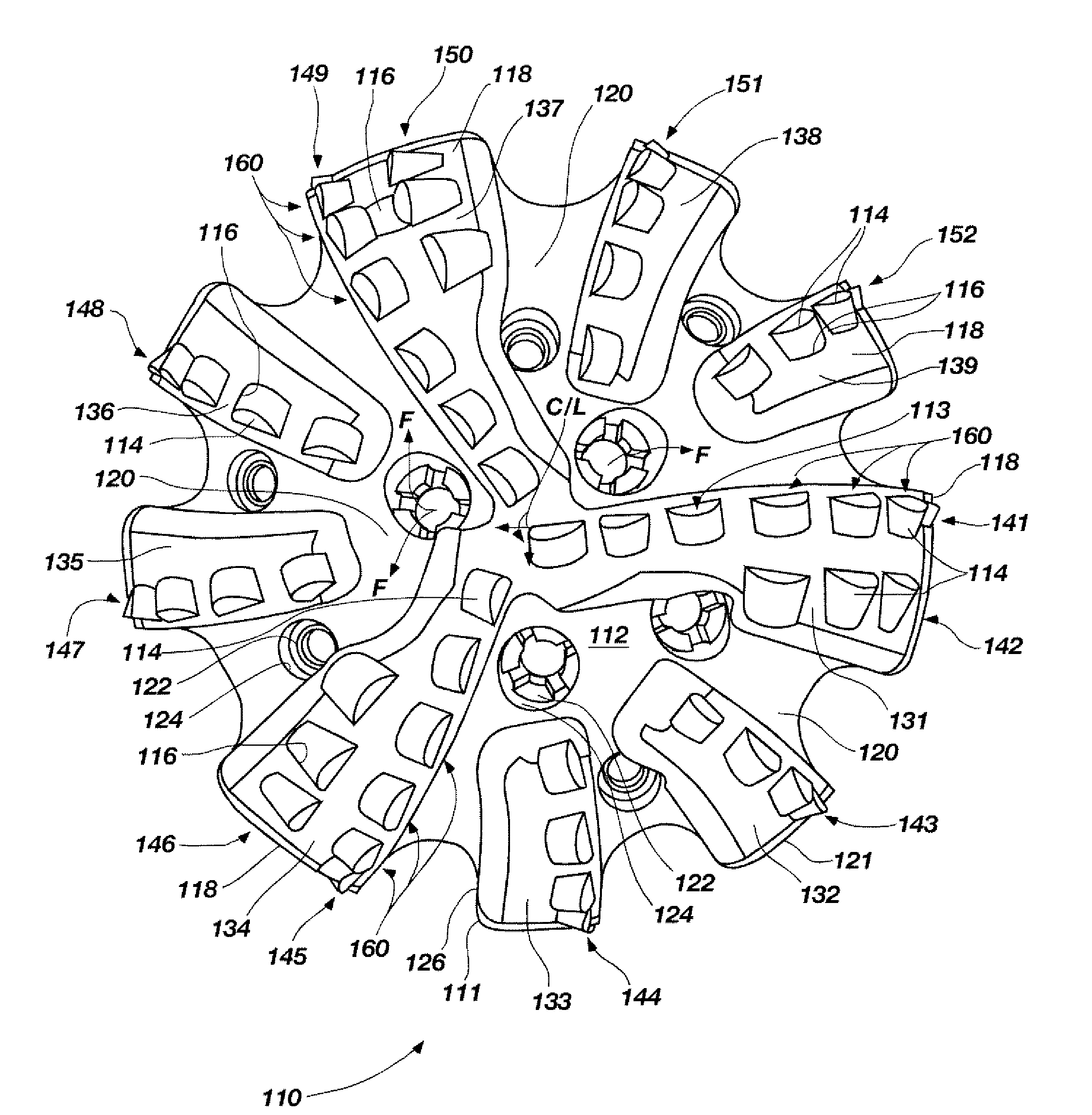

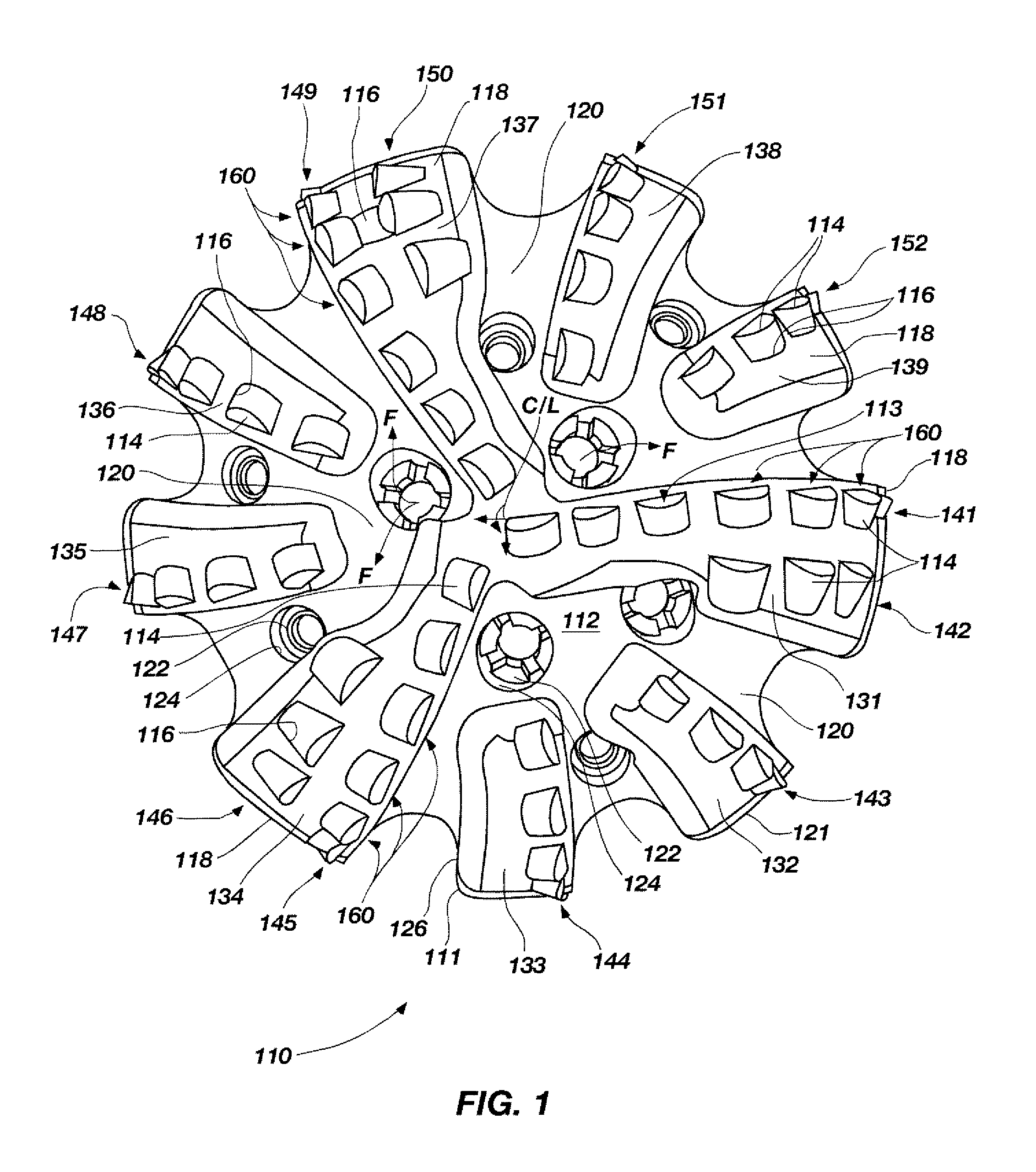

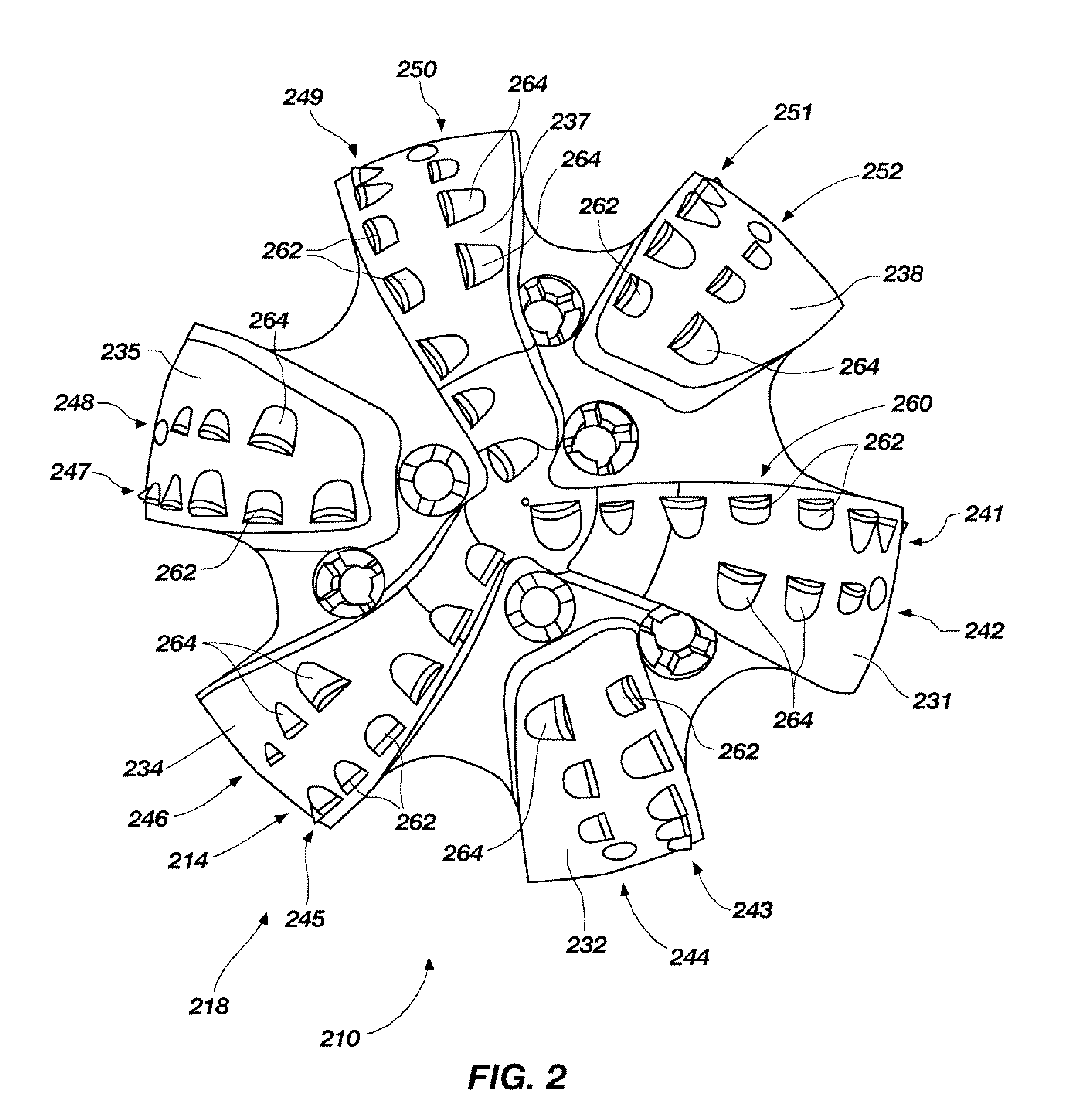

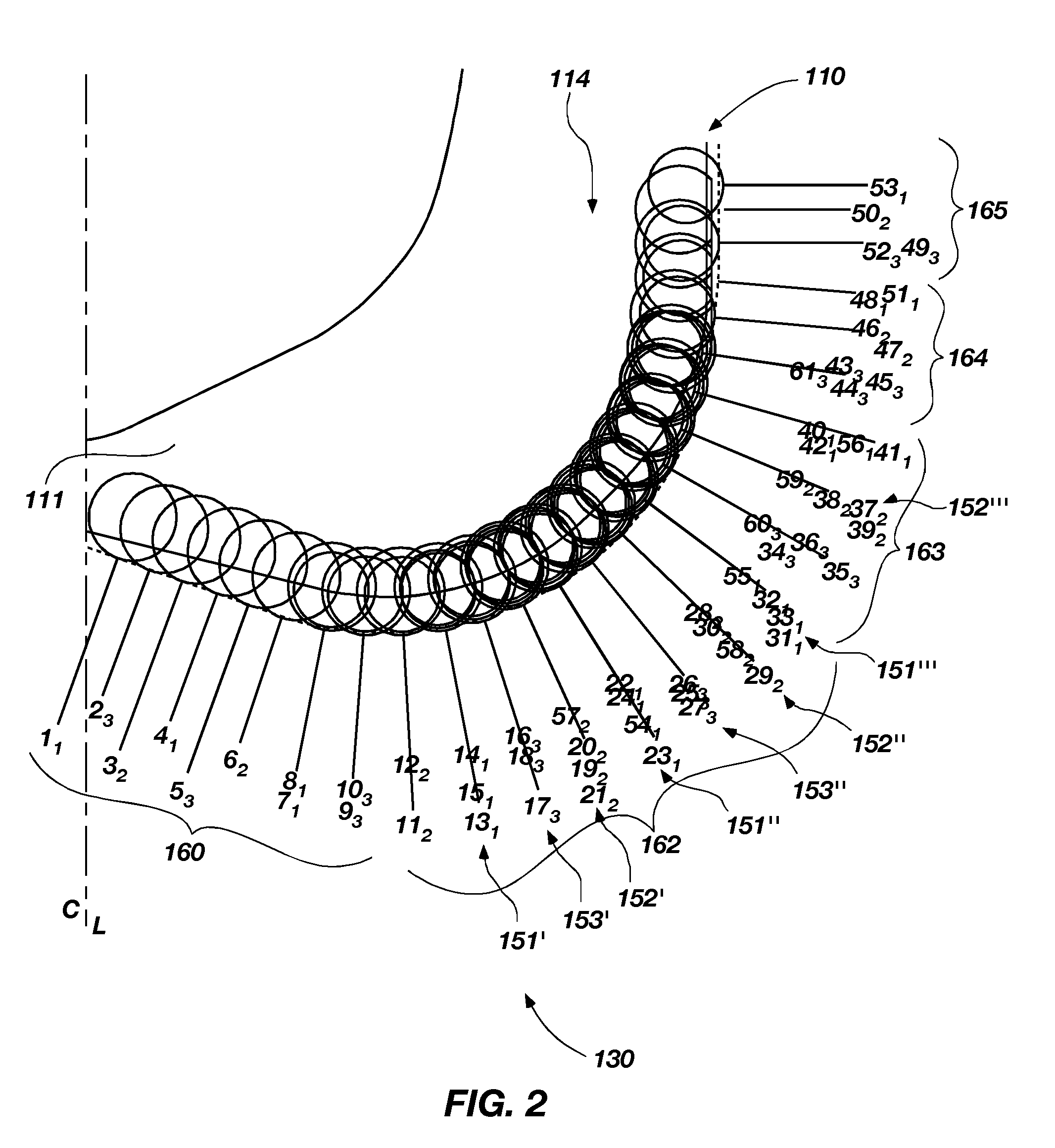

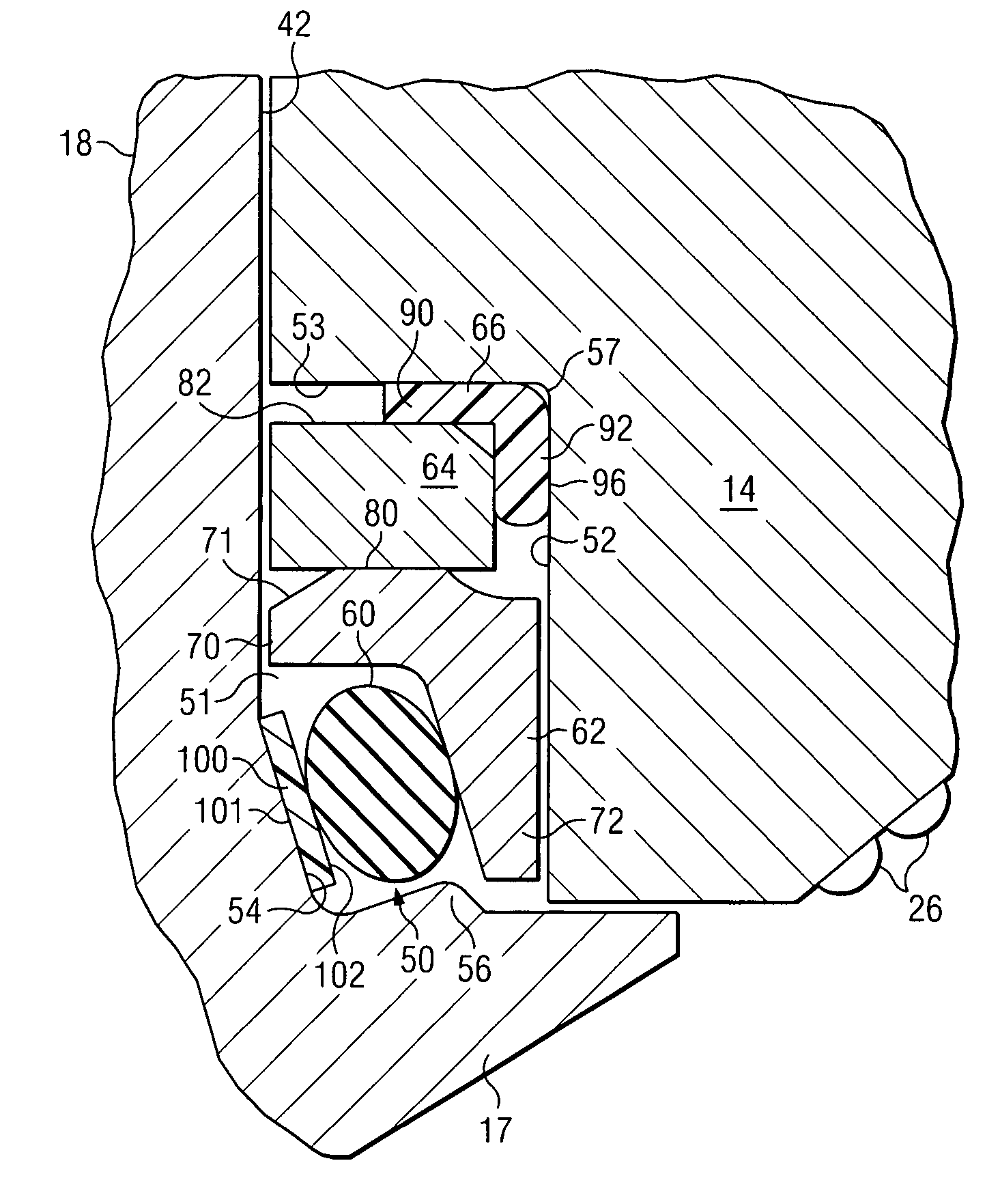

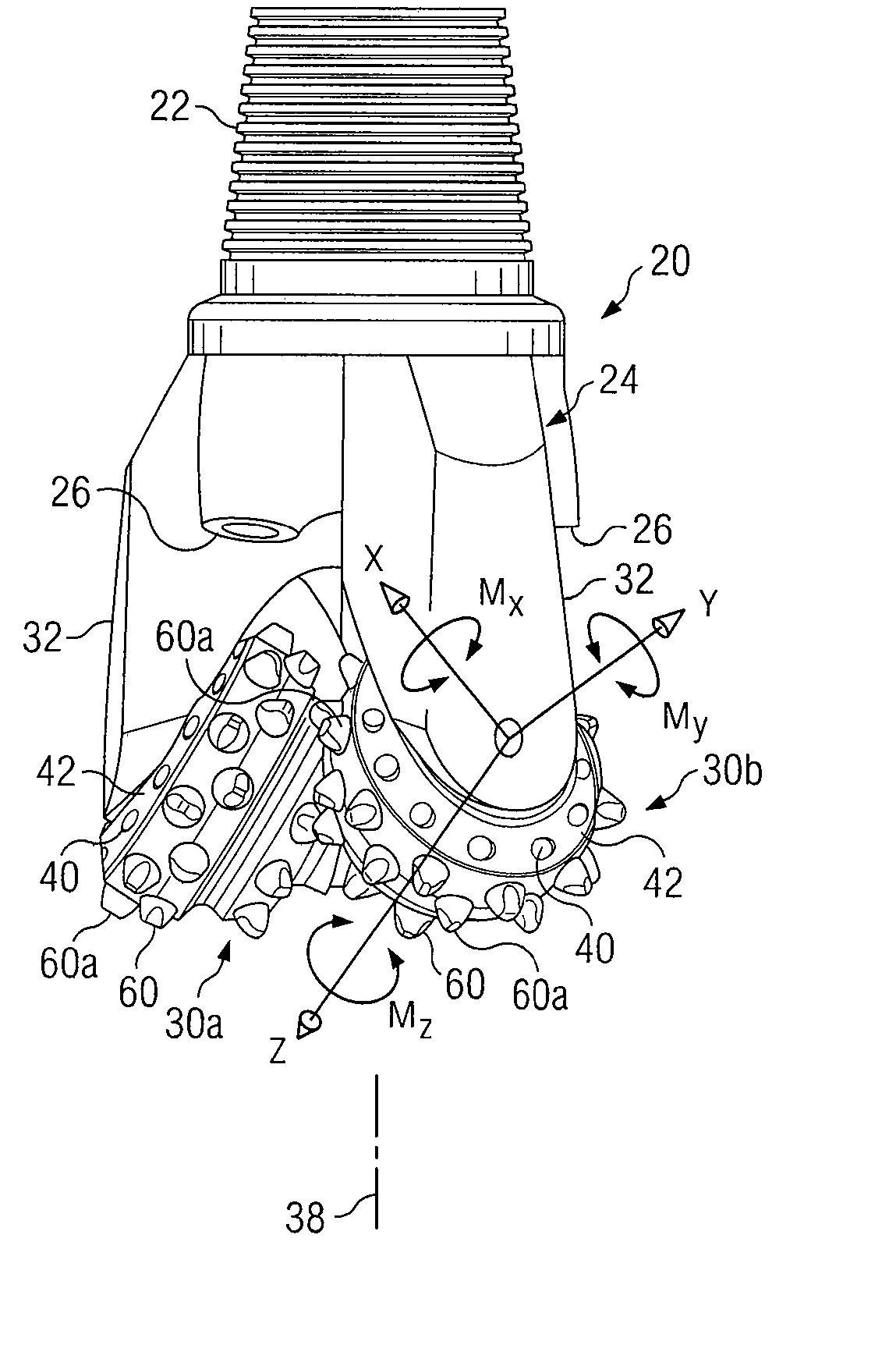

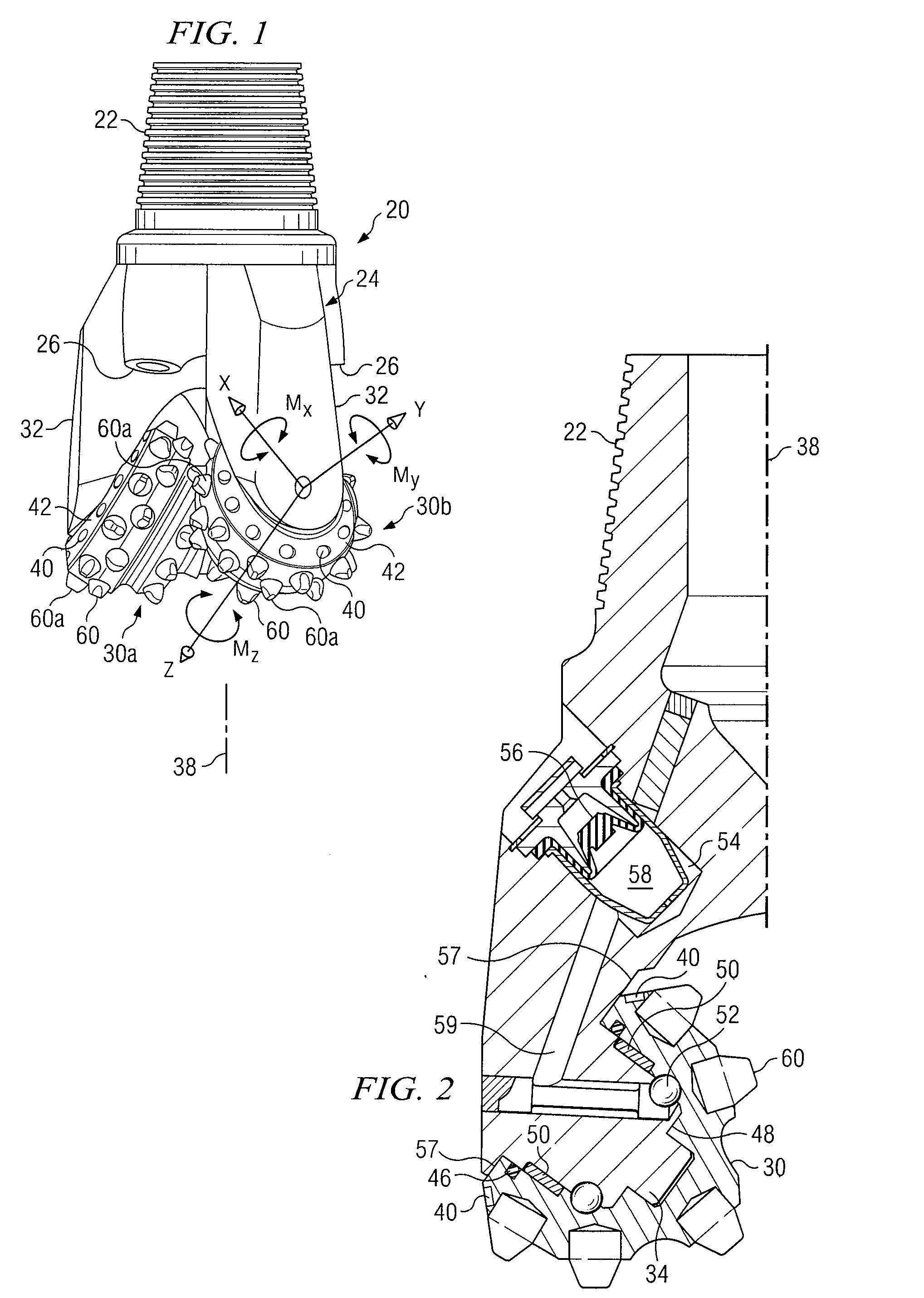

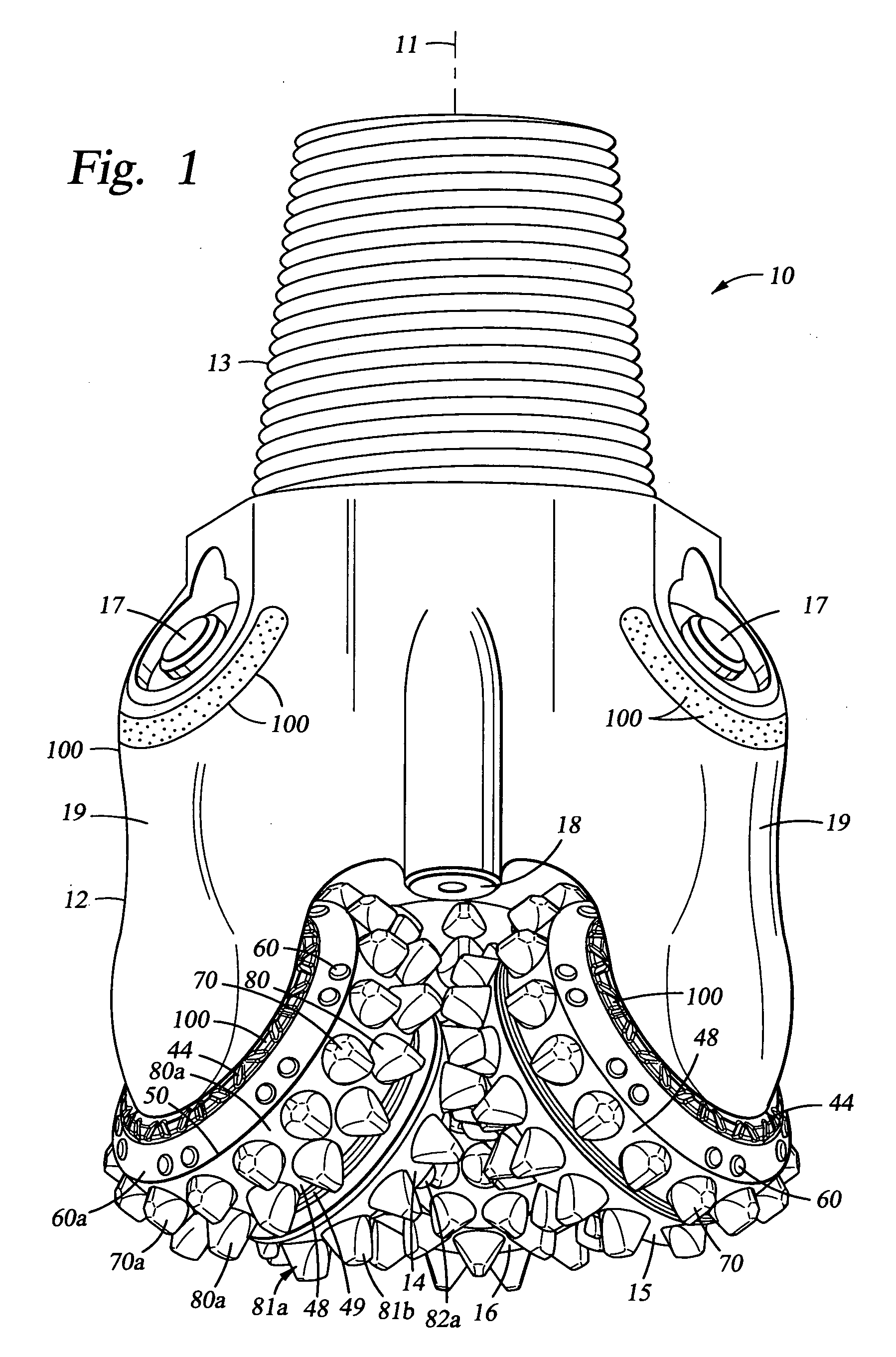

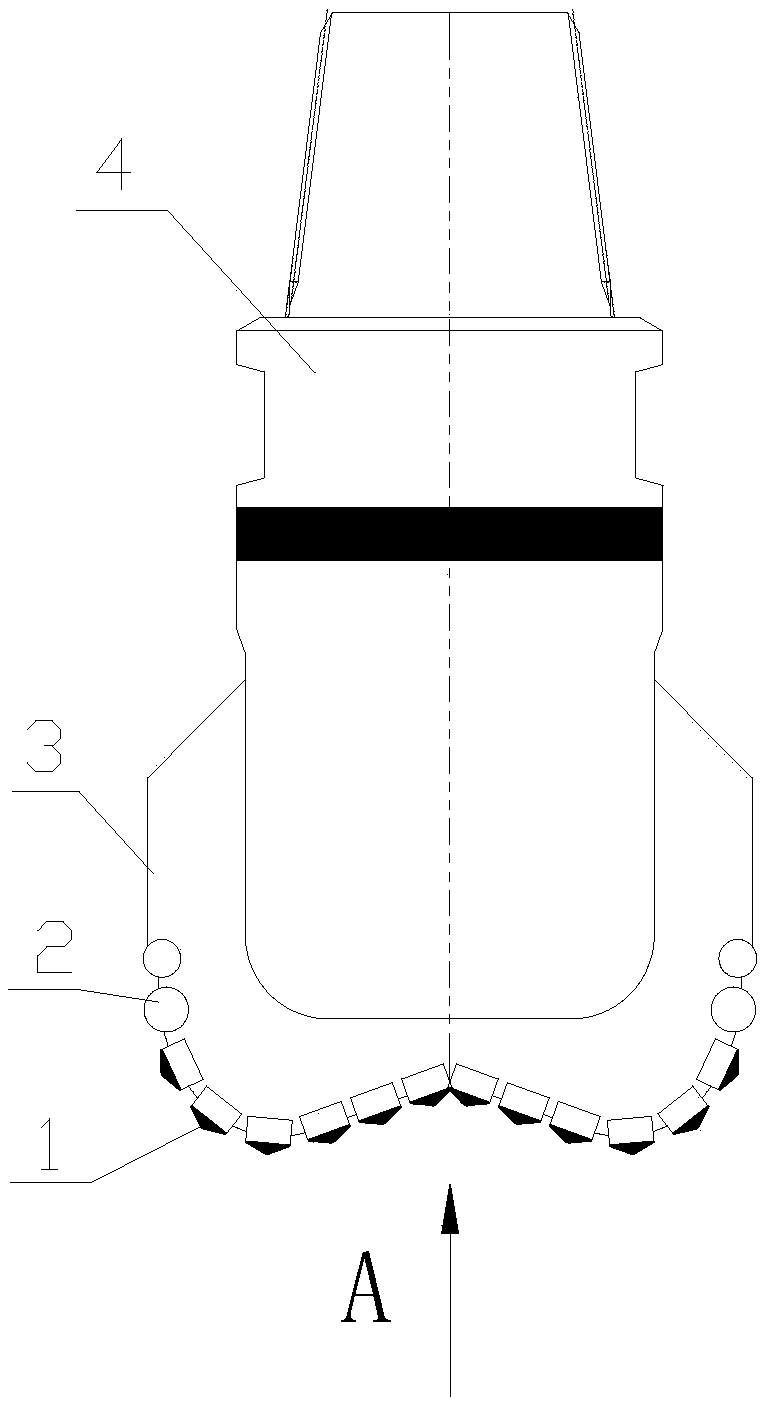

Roller cone drill bits with optimized bearing structures

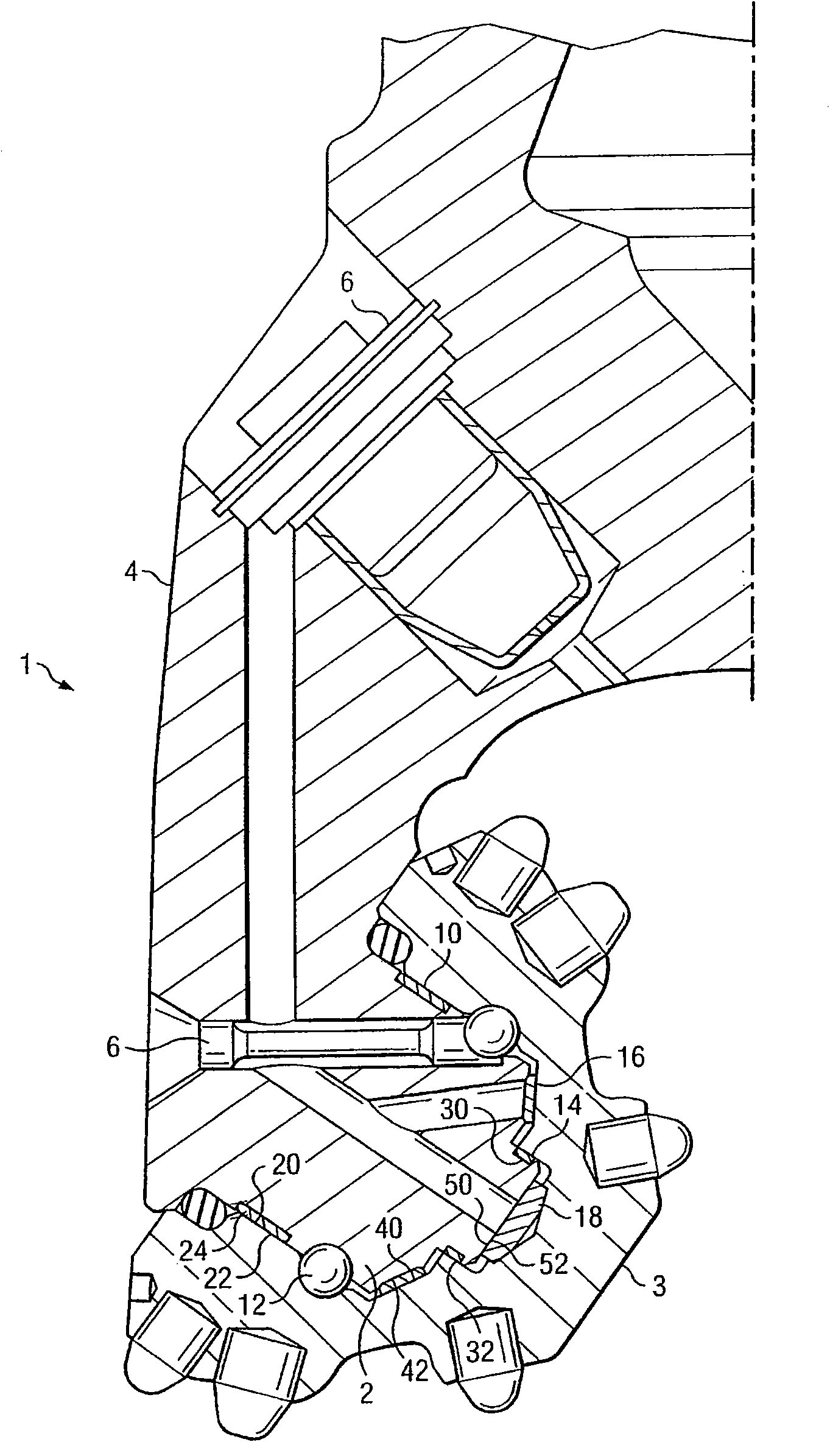

ActiveUS20060032674A1Reduce bearing loadDisplacement minimizationSurveyDrill bitsEngineeringDrill bit

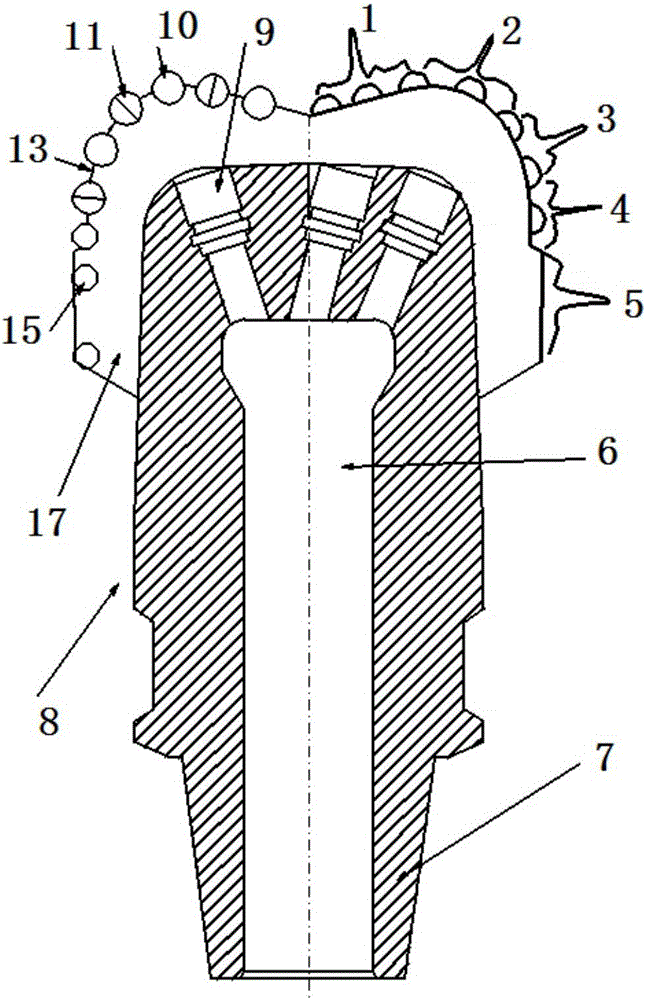

A roller cone drill bit may include optimally designed bearing structures and cutting structures. The roller cone drill bit may include three cone assemblies rotatably mounted on respective spindles via respective bearing structures. Each cone assembly may have a respective cutting structure with a minimal moment center located along each respective axis of rotation. Each respective bearing structure has a center point located proximate each respective minimal moment center.

Owner:HALLIBURTON ENERGY SERVICES INC

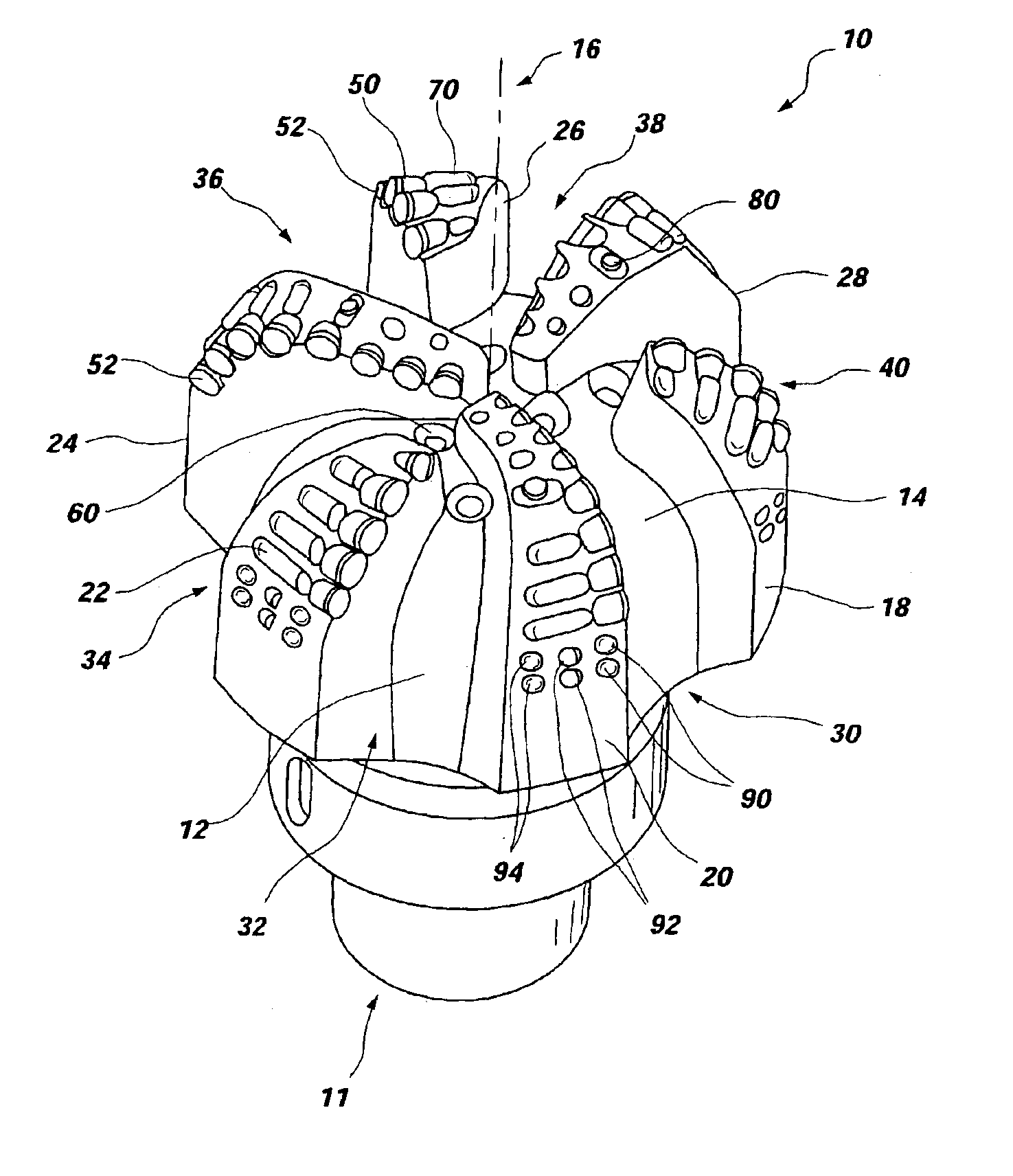

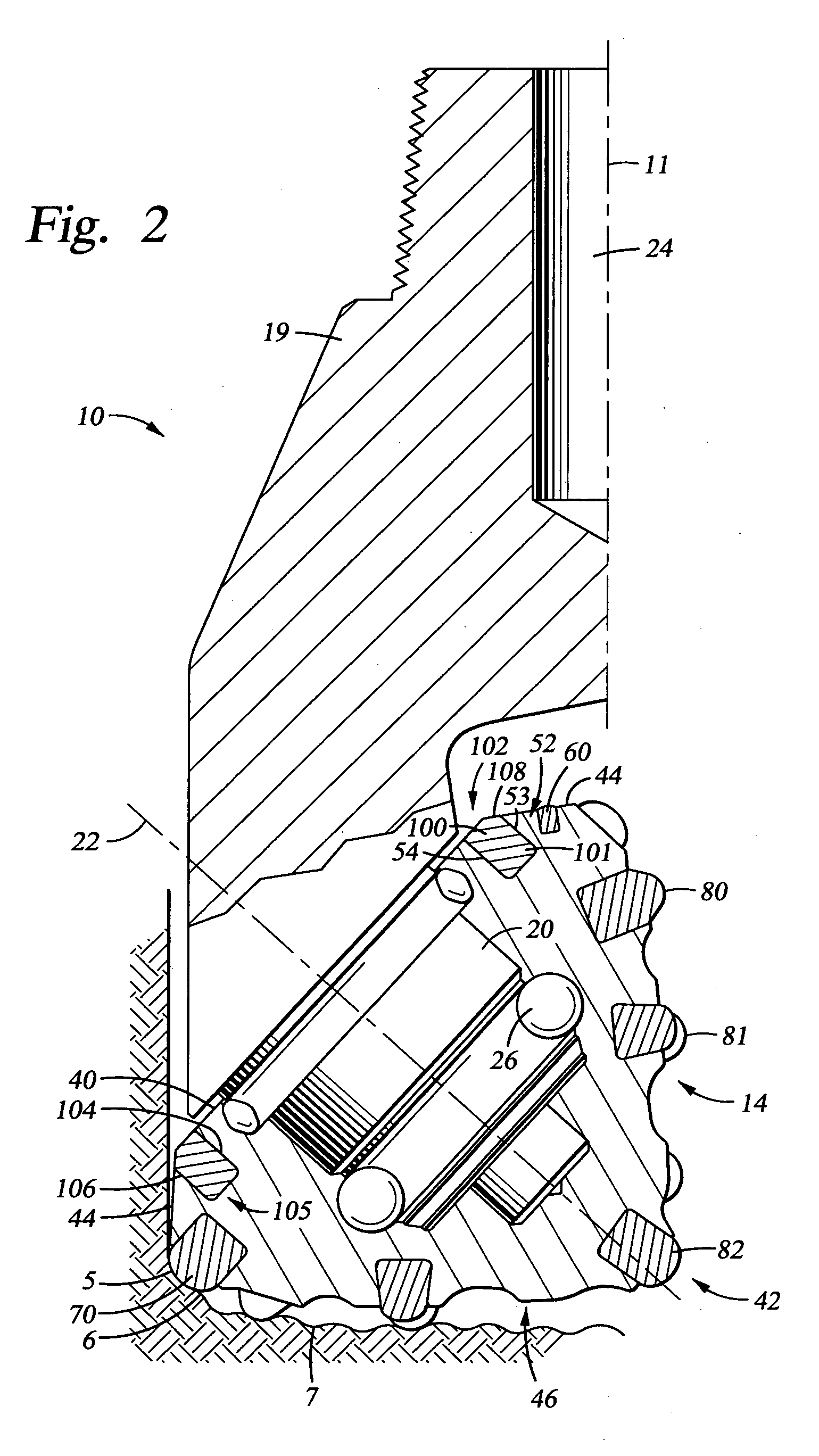

Rotary drag bits having a pilot cutter configuraton and method to pre-fracture subterranean formations therewith

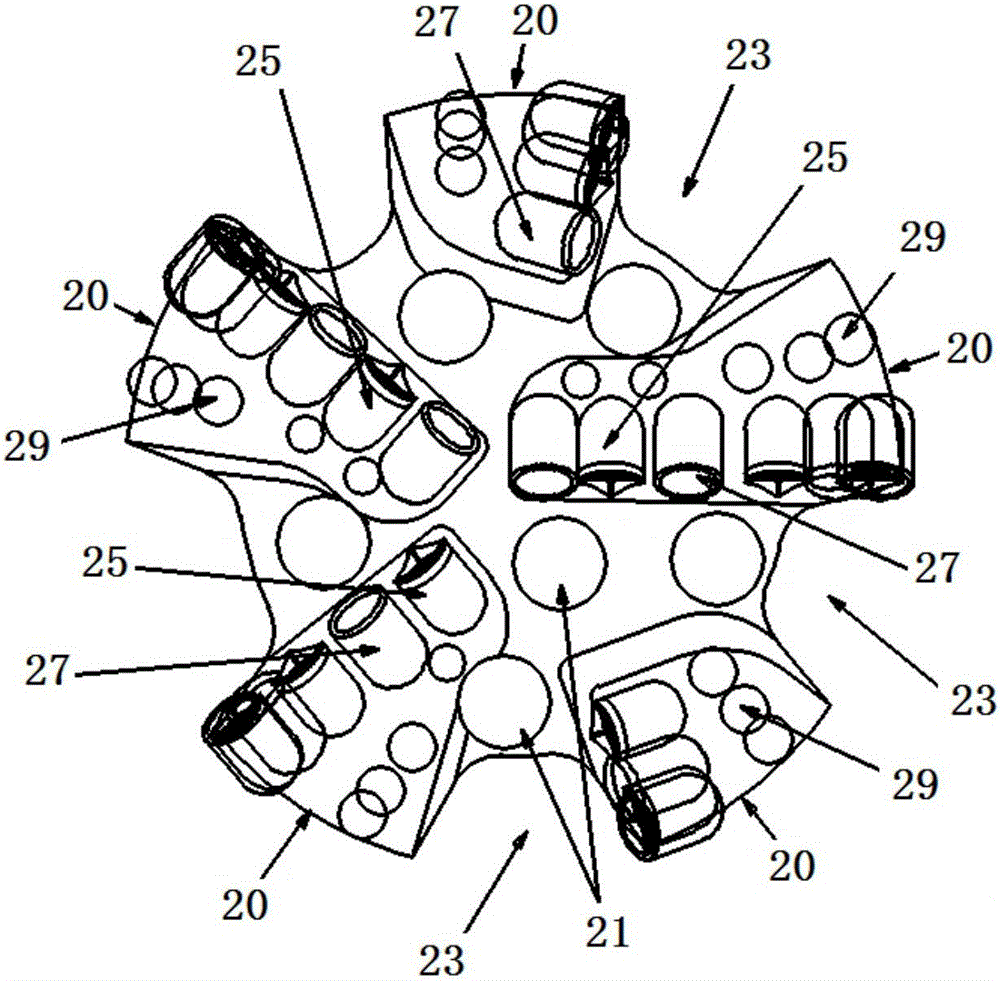

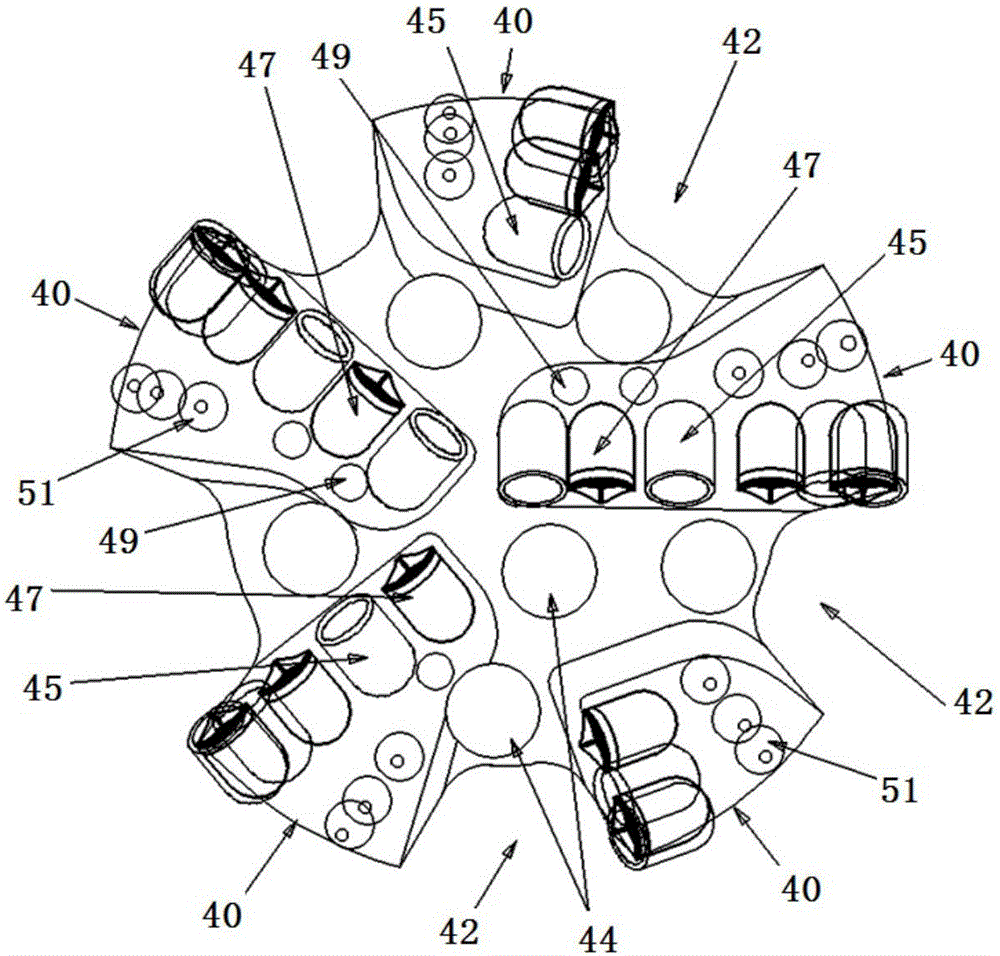

A rotary drag bit exhibiting enhanced cutting efficiency and extended life is provided. The rotary drag bit comprises a bit body having a face surface, and a plurality of cutters coupled to the face surface of the bit body. The plurality of cutters comprises at least one pilot cutter and a rotationally trailing larger, primary cutter at substantially the same radius and, optionally of slightly less exposure. The pilot cutter is sized and positioned to pre-fracture the formation and perform an initial cut, while the primary cutter removes weakened, remaining formation material along the same rotational path. A method to pre-fracture subterranean formations using a rotary drag bit having a pilot cutter configuration is also provided.

Owner:BAKER HUGHES INC

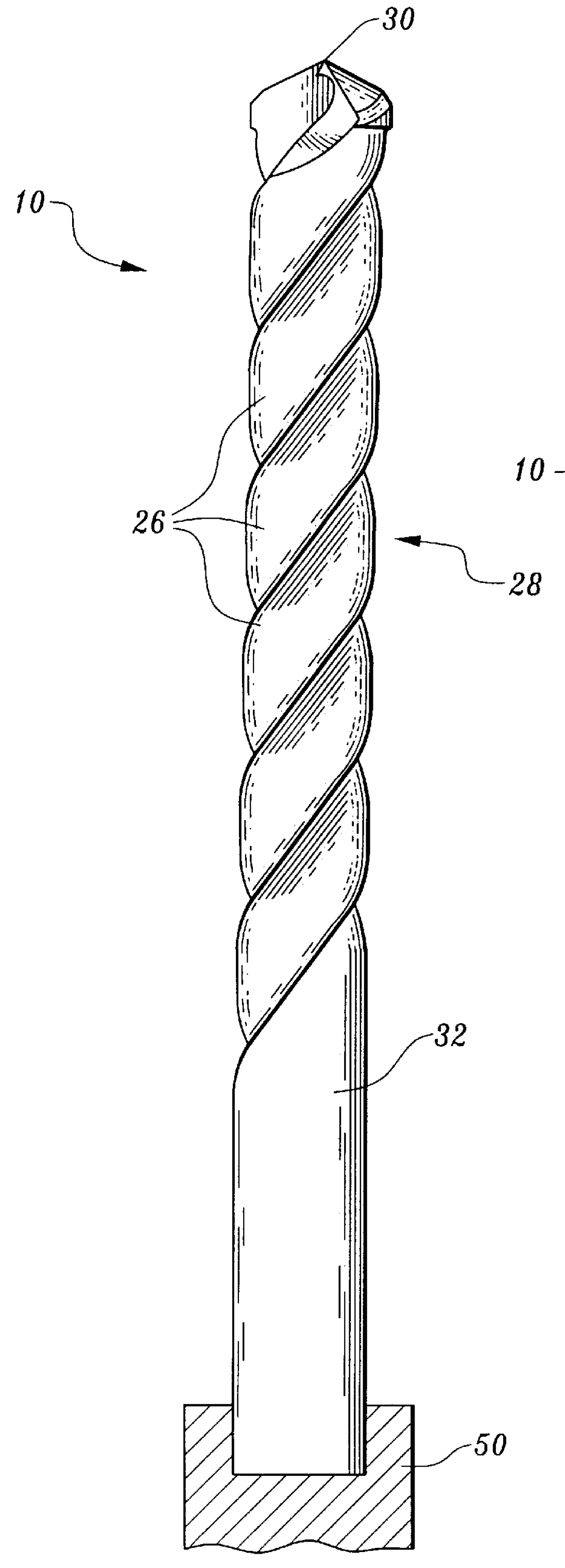

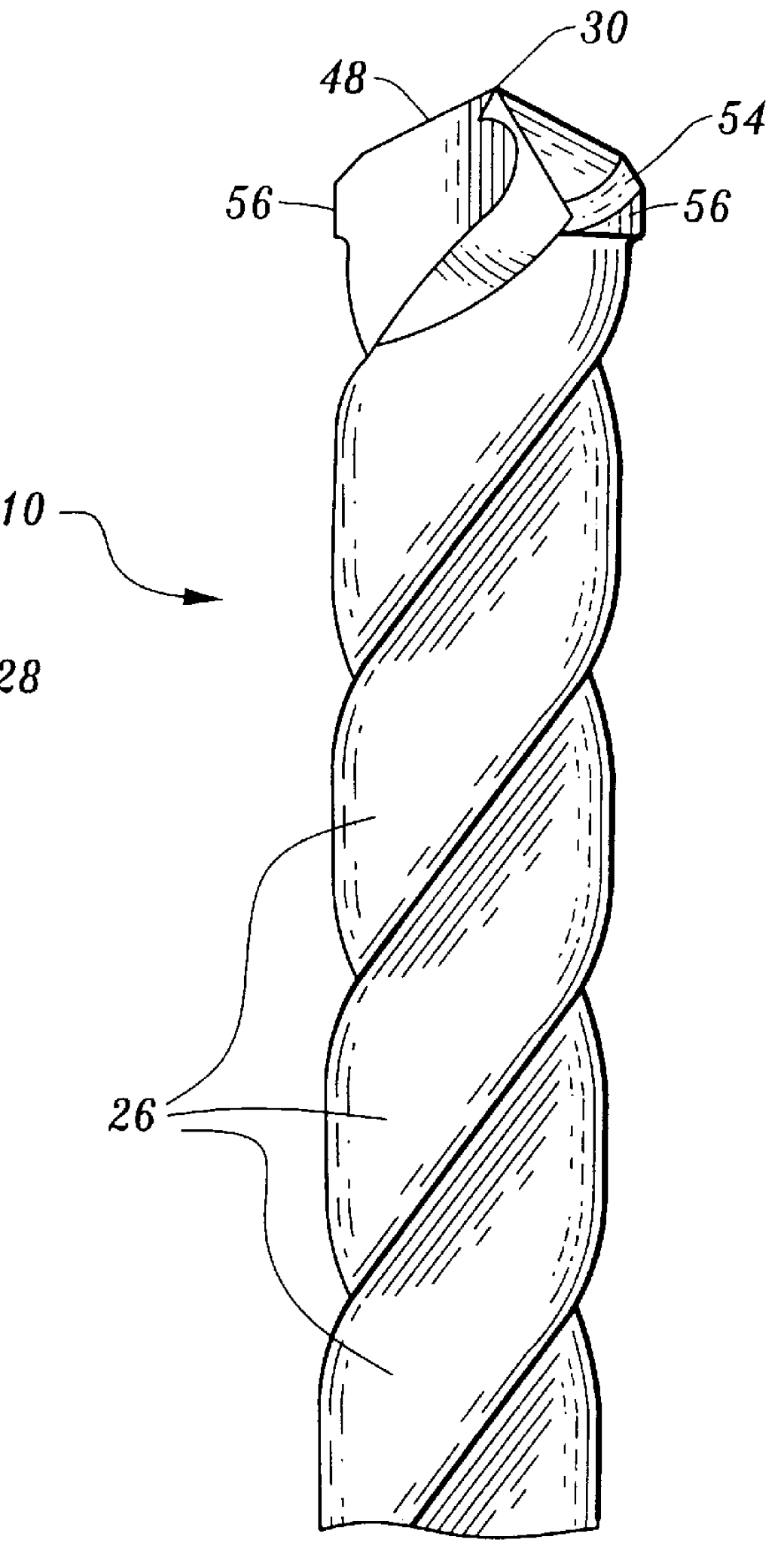

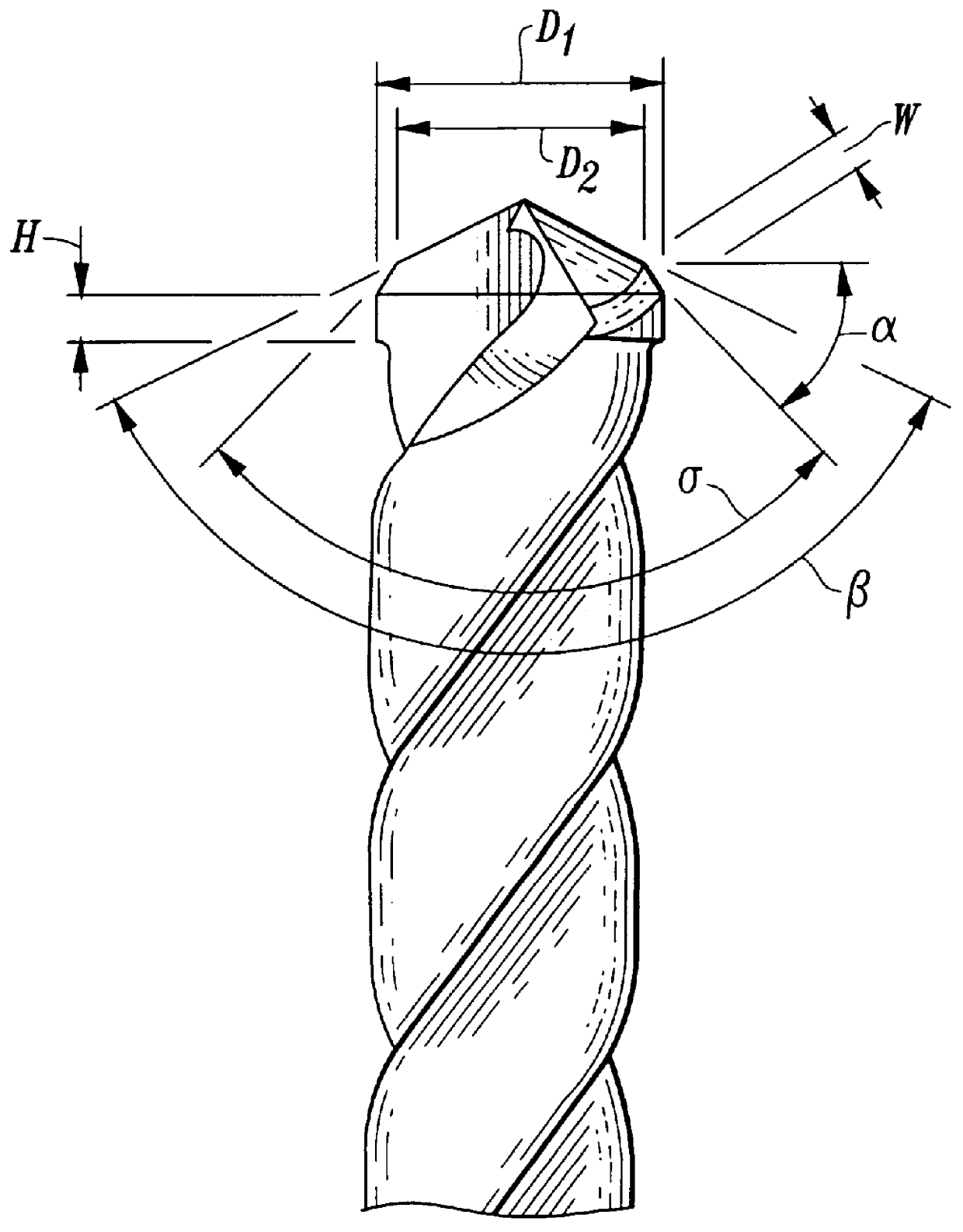

Precision drill bit

InactiveUS6126367AReduce frictionExtended bit lifeWood turning toolsTransportation and packagingHand heldDrill bit

Owner:LOCK N STITCH INC

Rotary drag bit

A rotary drag bit includes a primary cutter row comprising at least one primary cutter and a multiple backup cutter group. The multiple backup cutter group comprises a first and second trailing cutter row, each comprising at least one cutter positioned to follow the at least one primary cutter. The rotary drag bit life is extended by the multiple backup cutter groups making the bit more durable and extending the life of the cutters. Further, the cutters of the multiple backup cutter group are configured to selectively engage a subterranean formation material being drilled, providing improved bit life and reduced stress upon the cutters. Other embodiments of rotary drag bits are provided.

Owner:BAKER HUGHES INC

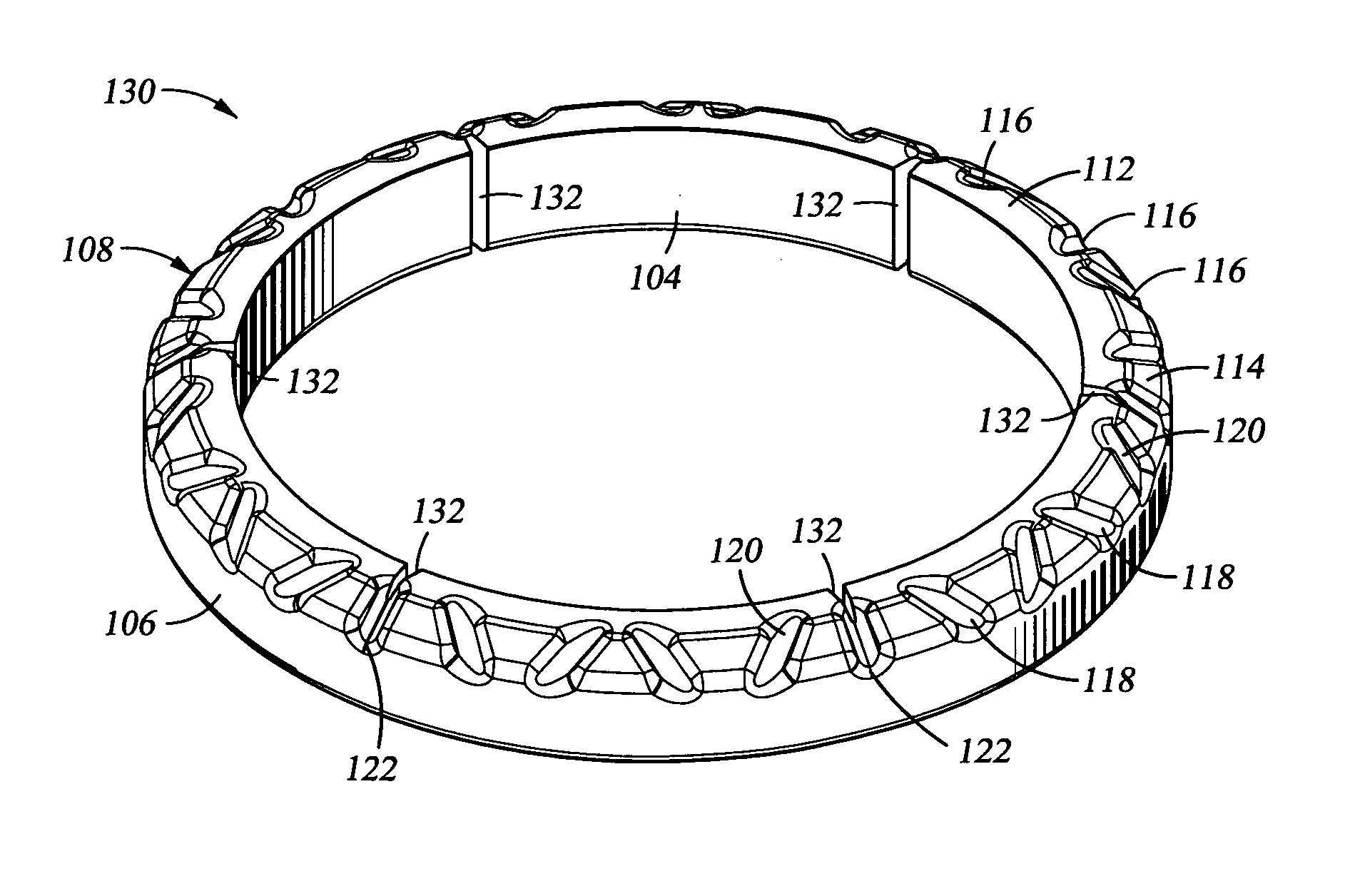

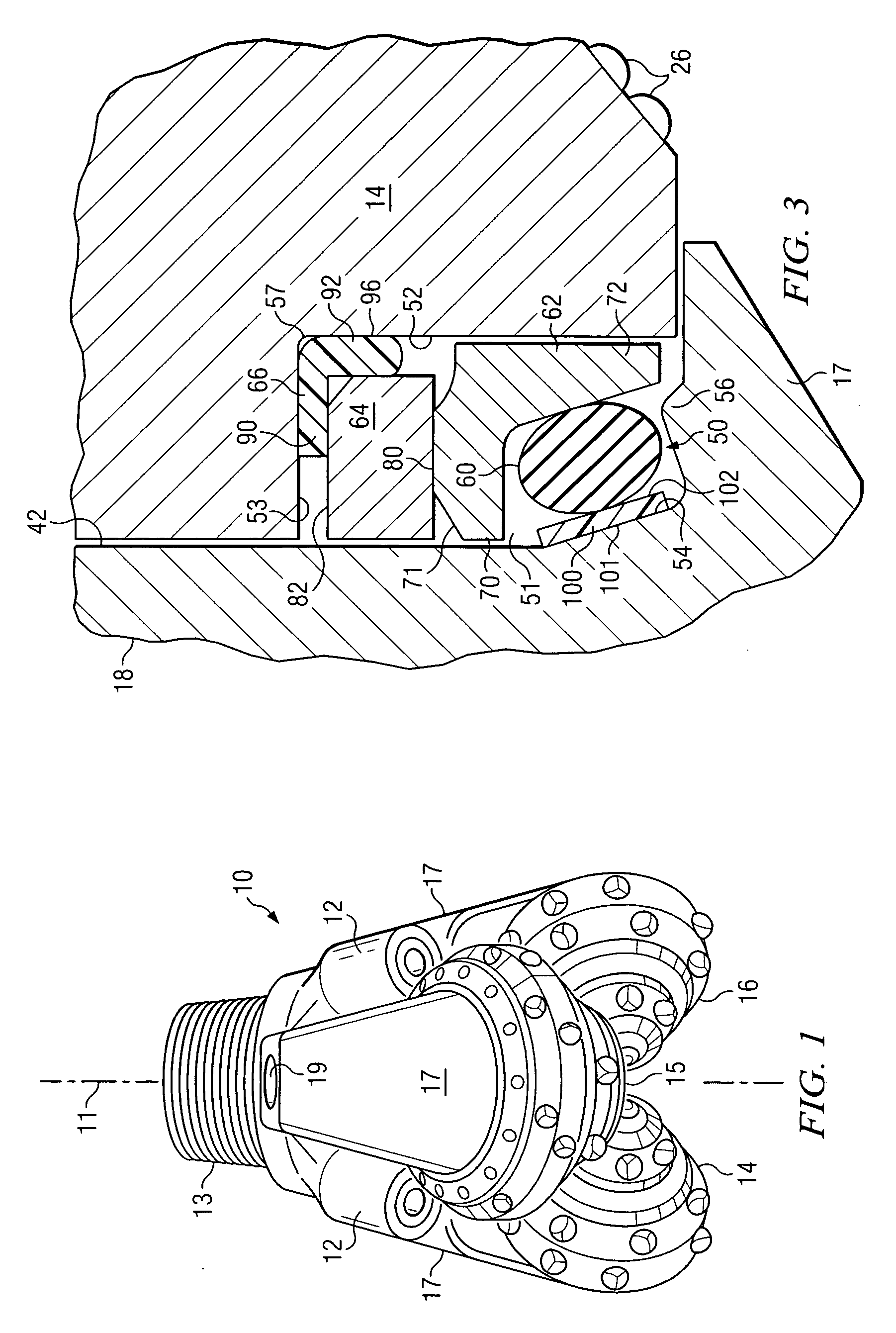

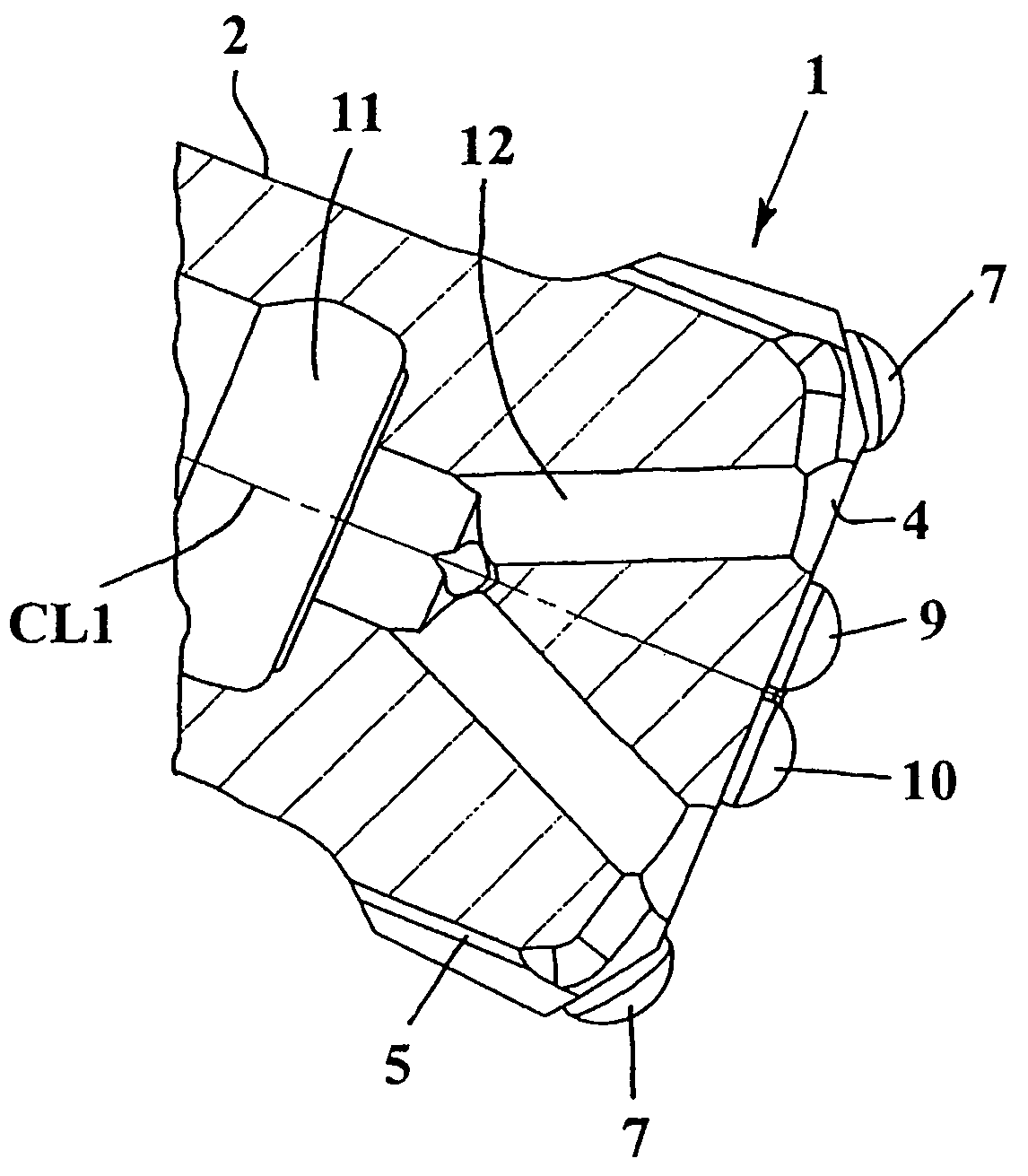

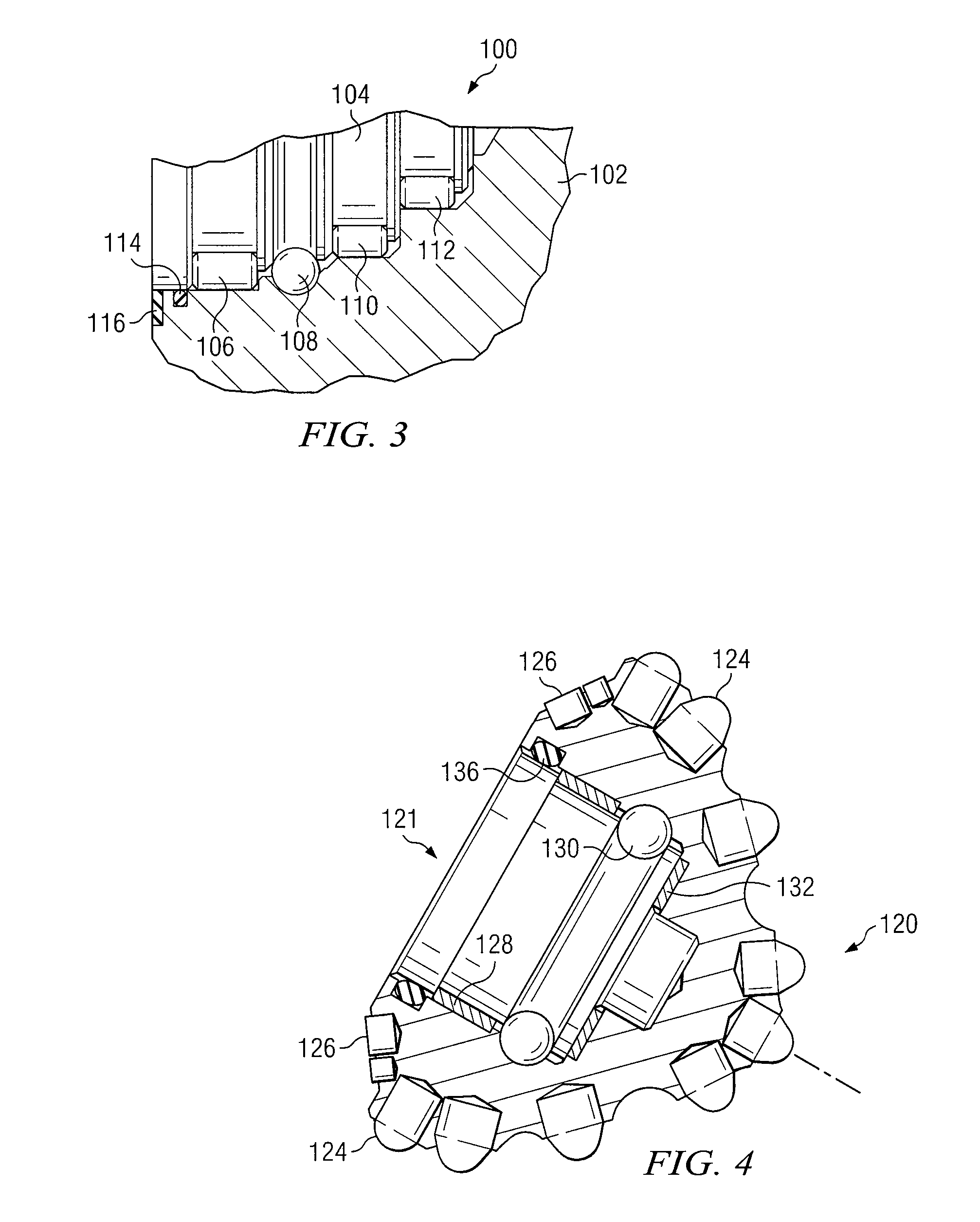

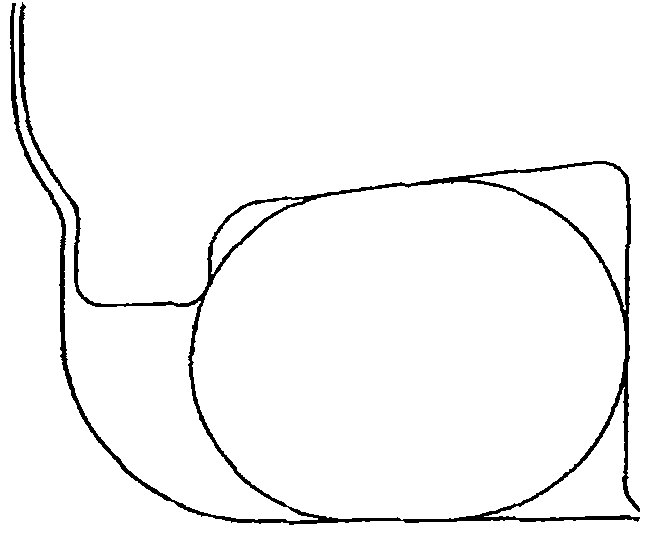

Multi-part energizer for mechanical seal assembly

An energizer for a mechanical seal assembly for use in a drill bit is disclosed. The energizer is a composite of at least two resilient materials, one having a durometer hardness that is greater than the other. The material contacting a journal provides relatively high frictional forces so as to prevent the energizer from rotating in relation to adjacent components. The relatively softer resilient material provides the energizing force necessary to maintain a good dynamic seal between the metal seal rings. The energizer components may be separate components that engage one another upon assembly, or may be bonded together to form a ring prior to assembly into the drill bit.

Owner:SMITH INT INC

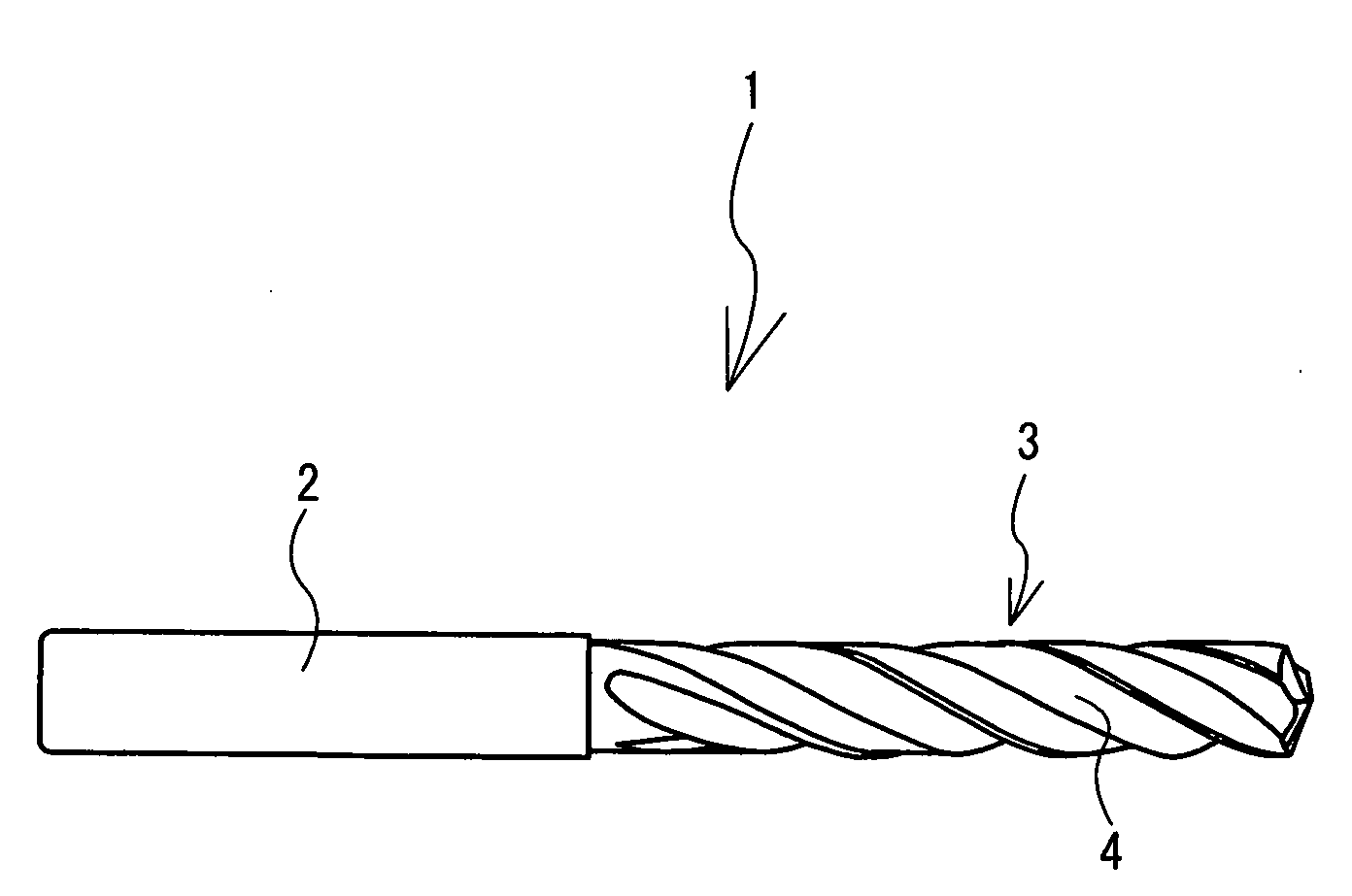

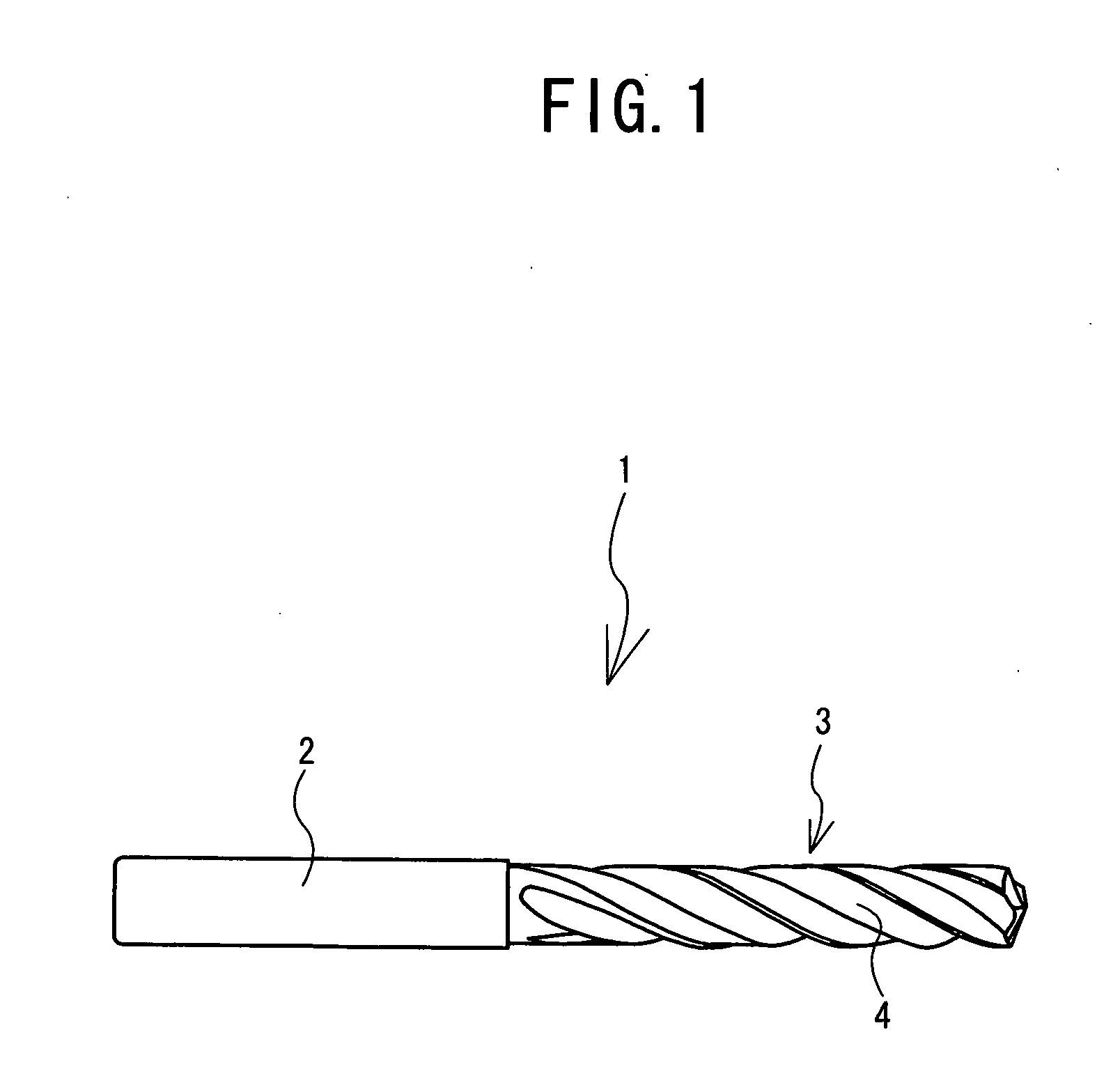

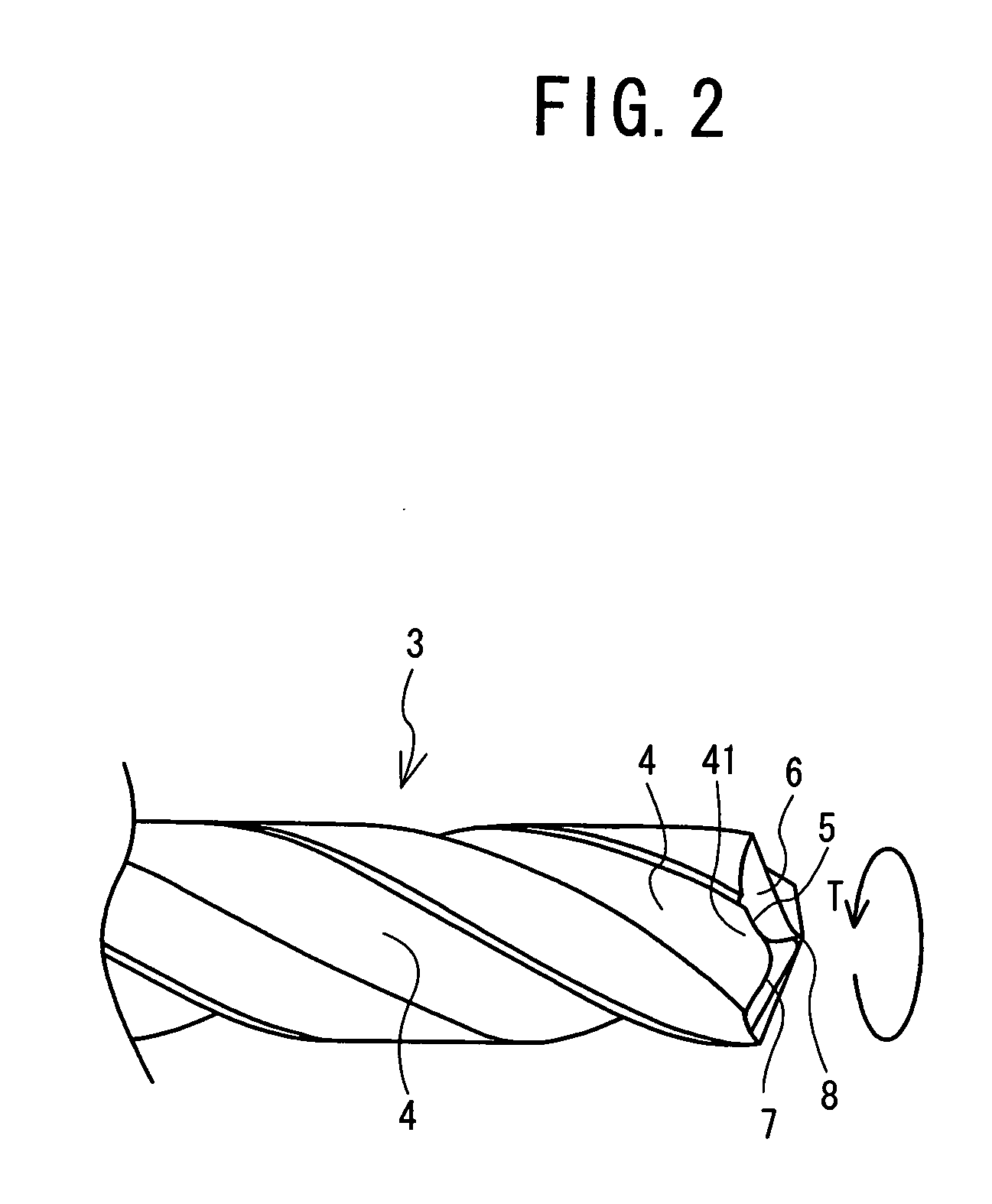

Drill

InactiveUS20100054884A1Inhibit wearEasy to disassembleWood turning toolsTransportation and packagingFluteEngineering

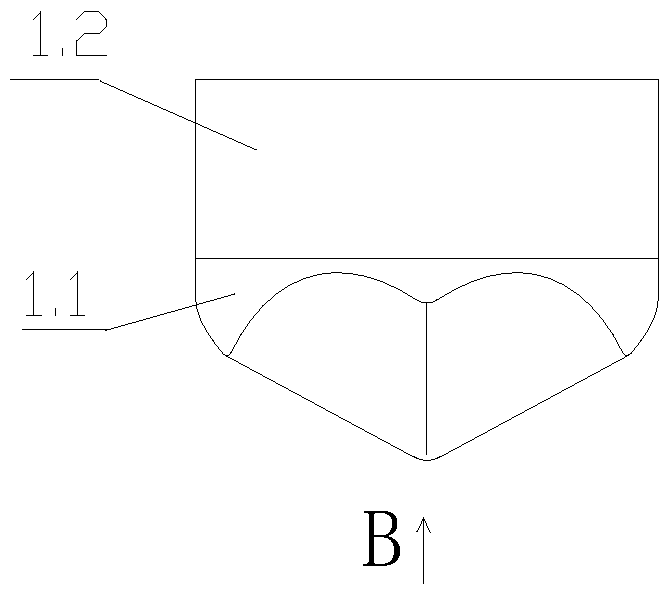

A drill in which a flute is formed from a point to a base end side of a body of the drill, on a side face to be rotated about an axis, a cutting edge is formed between a wall surface of the flute which faces a drill rotational direction side and a flank at the point of the body, and a thinned portion is provided to a web portion of the point. The cutting edge is formed in a convex arc shape with a curvature radius 0.25 to 1 times a drill diameter; a radial rake angle at an outer peripheral portion of the cutting edge is −60 to −15 degrees; a corner portion, closer to the center of the point, of the thinned portion is formed in an arc shape with a curvature radius of at least 0.1 mm and not greater than 0.05 times the drill diameter; and the drill includes three flutes and three cutting edges.

Owner:OSG +1

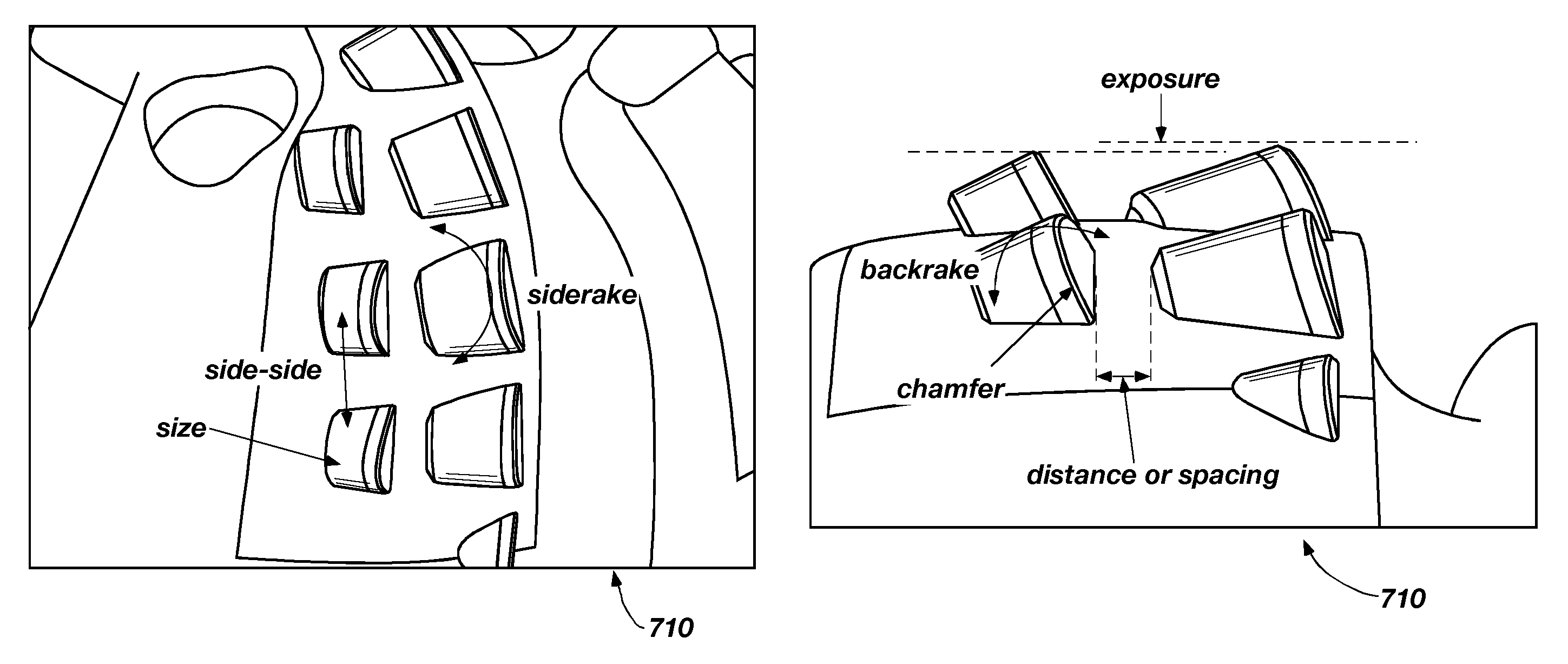

Rotary drag bit and methods therefor

A rotary drag bit includes a primary cutter row comprising at least one primary cutter, and at least two additional cutters configured relative to one another. In one embodiment, the cutters are backup cutters of a backup cutter group located in respective first and second trailing cutter rows, oriented relative to one another, and positioned to substantially follow the at least one primary cutter. The rotary drag bit life is extended by the backup cutter group, making the bit more durable and extending the life of the cutters. In other of the embodiments, the cutters are configured to selectively engage a subterranean formation material being drilled, providing improved bit life and reduced stress upon the cutters. Still other embodiments of rotary drag bits include backup cutter configurations having different backrake angles and siderake angles, including methods therefor.

Owner:BAKER HUGHES INC

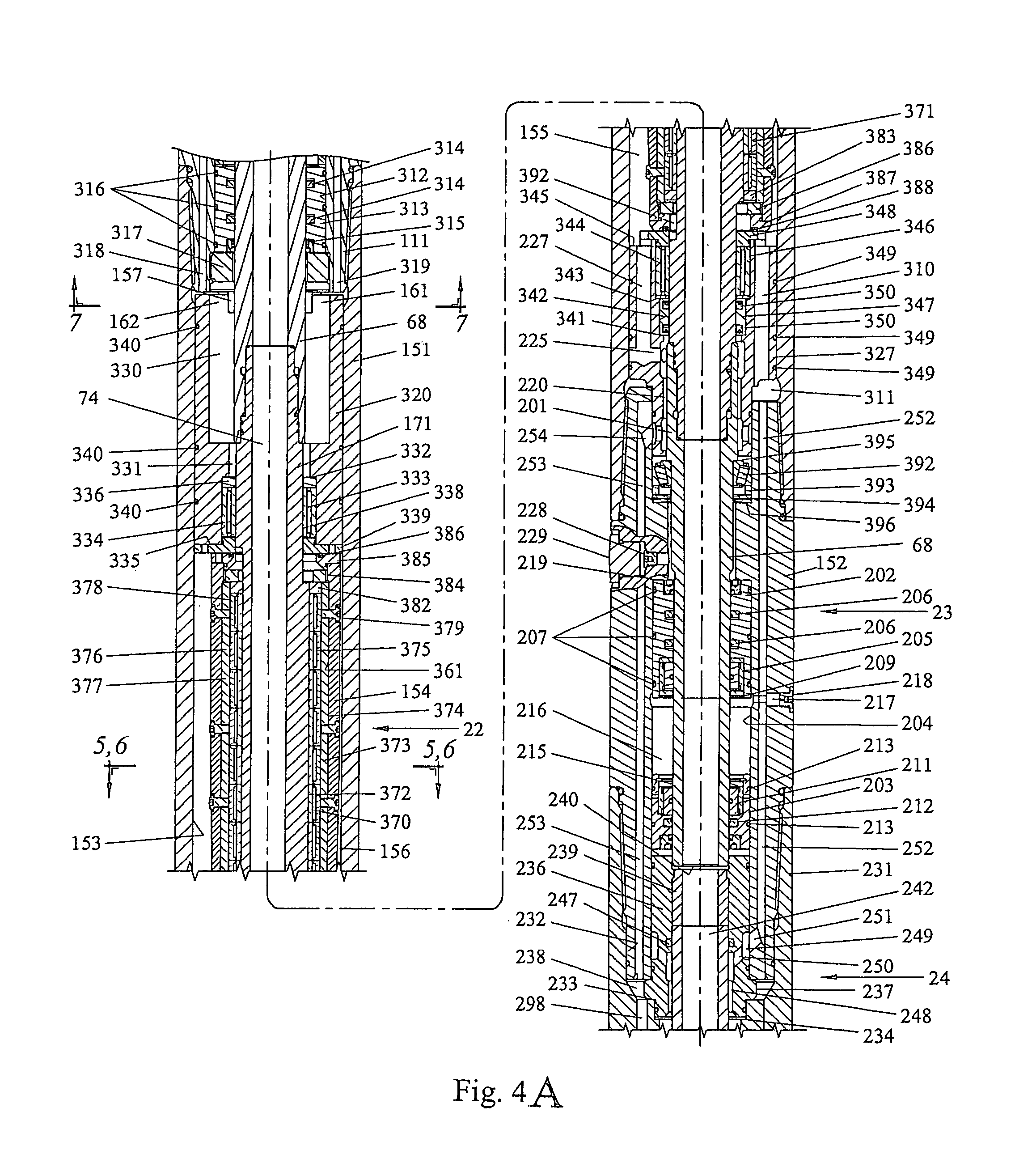

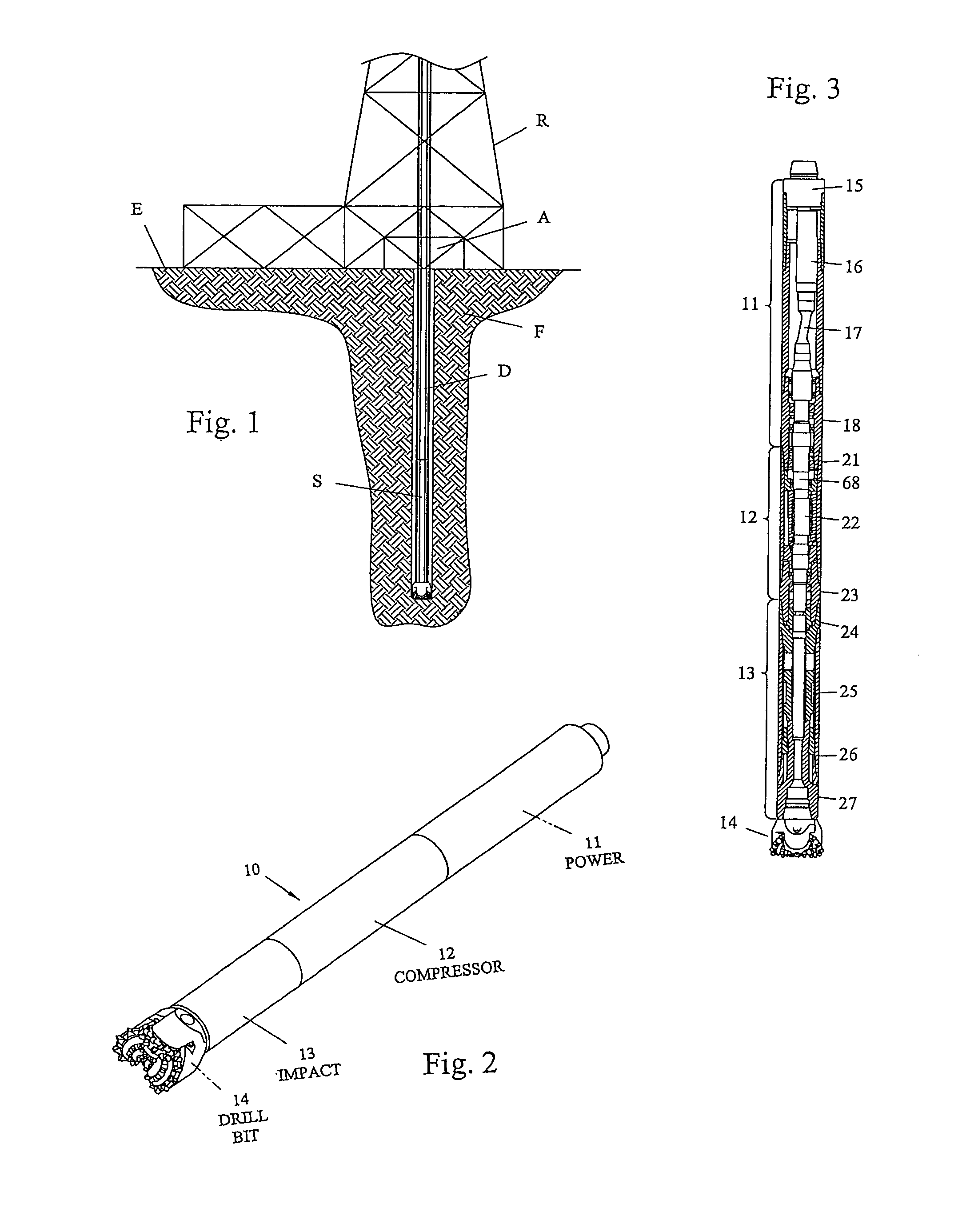

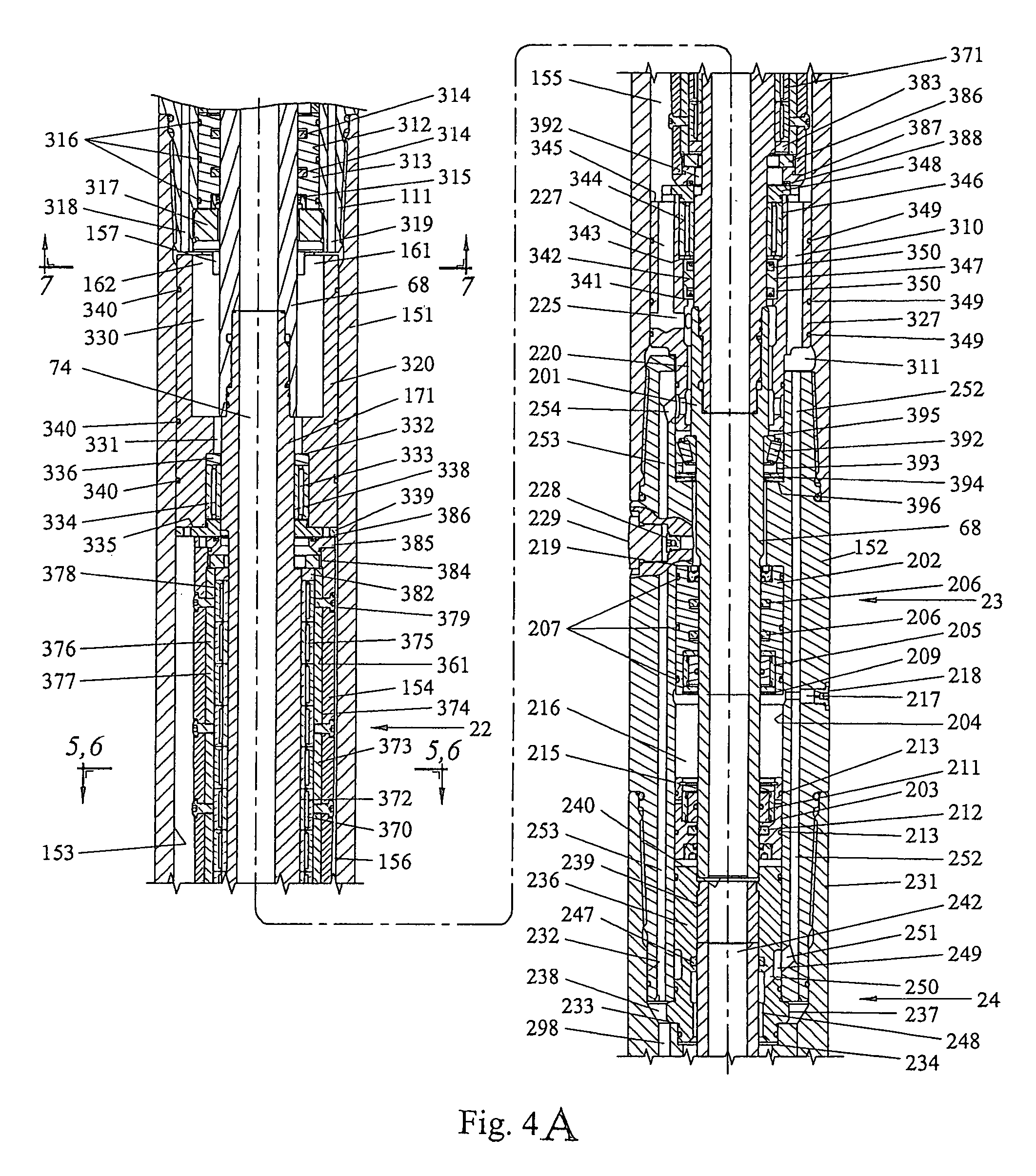

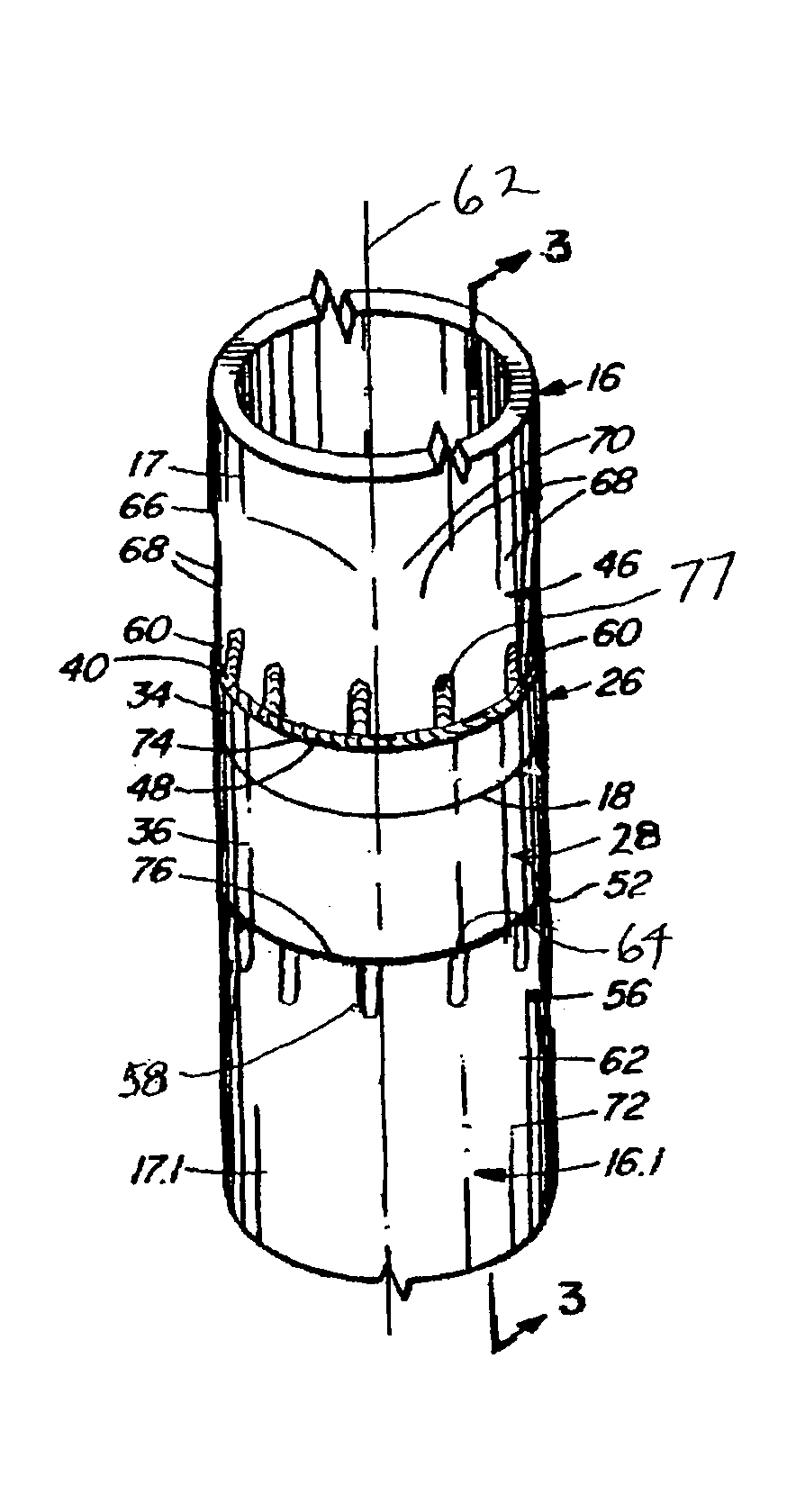

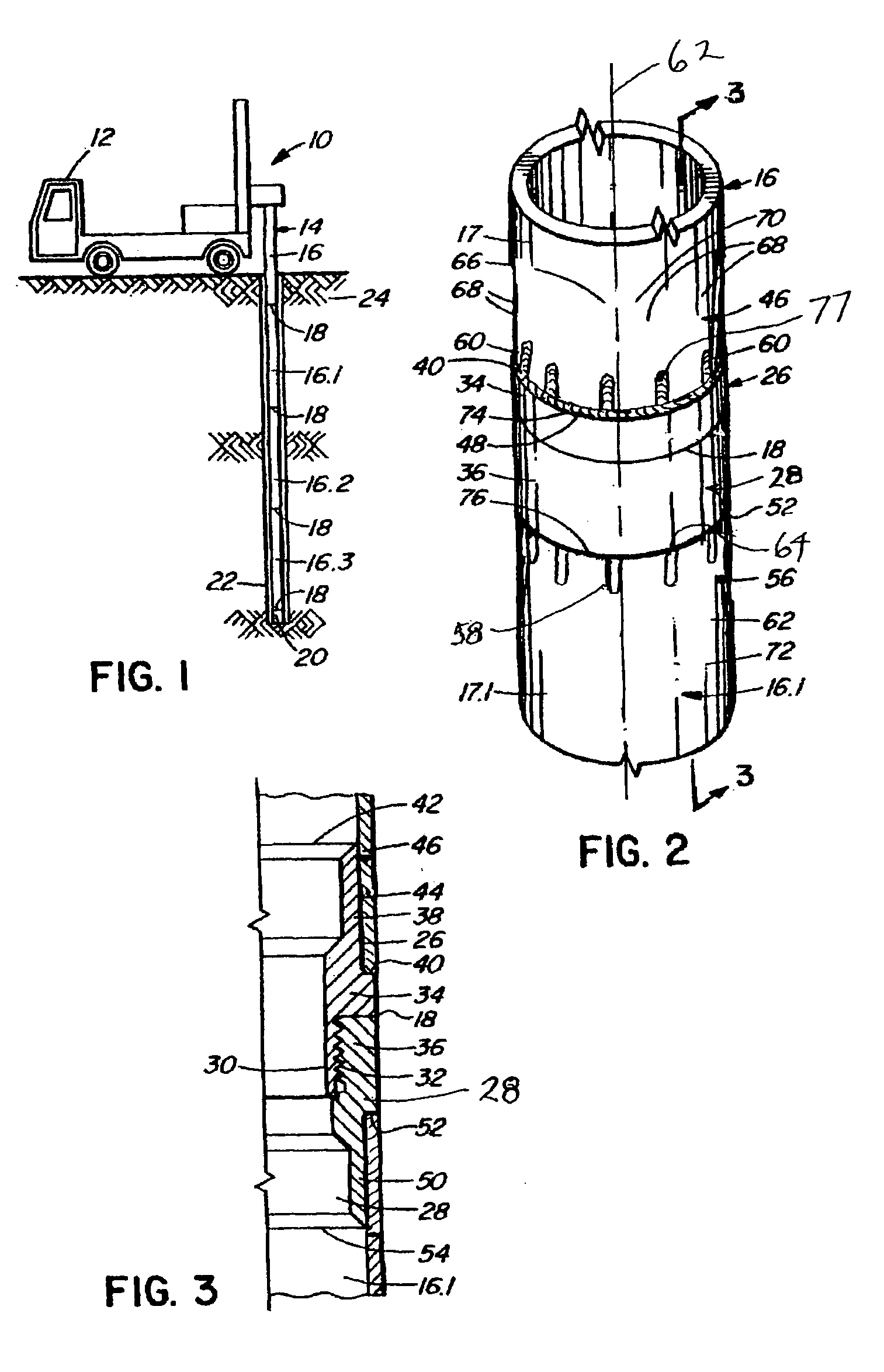

Drilling systems

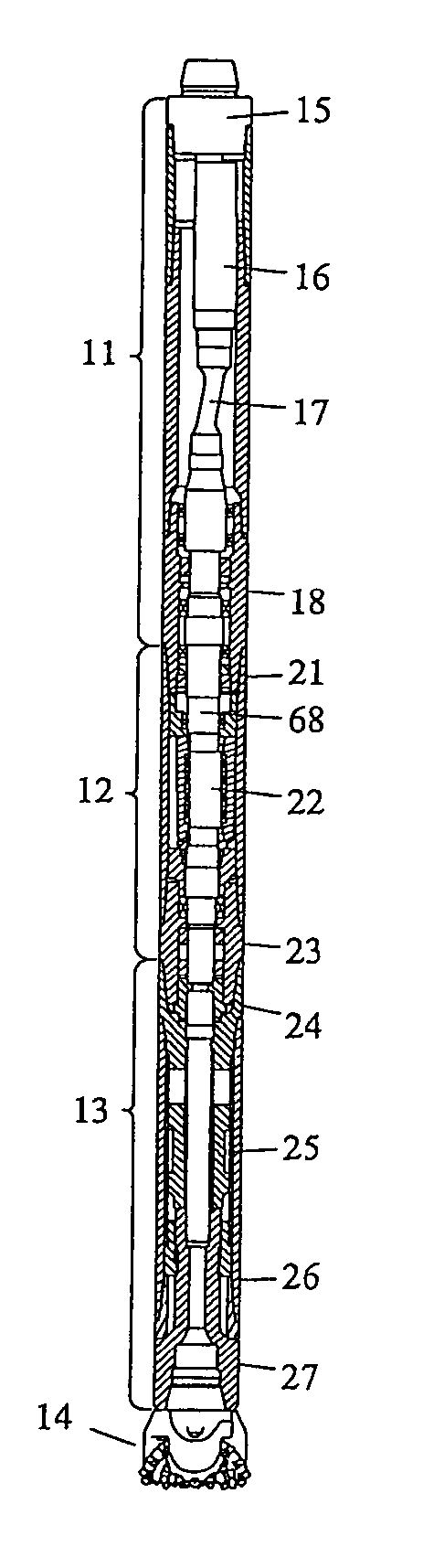

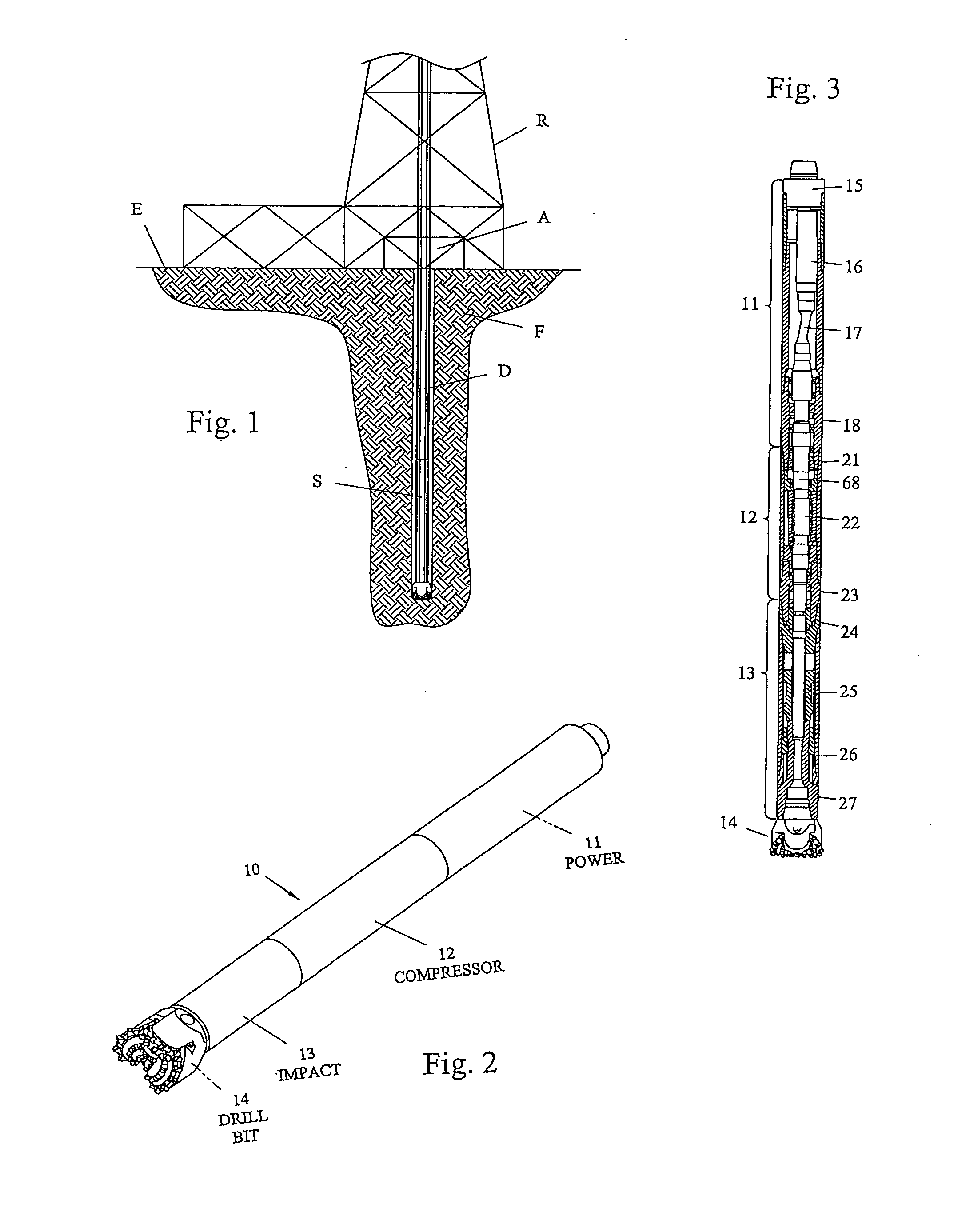

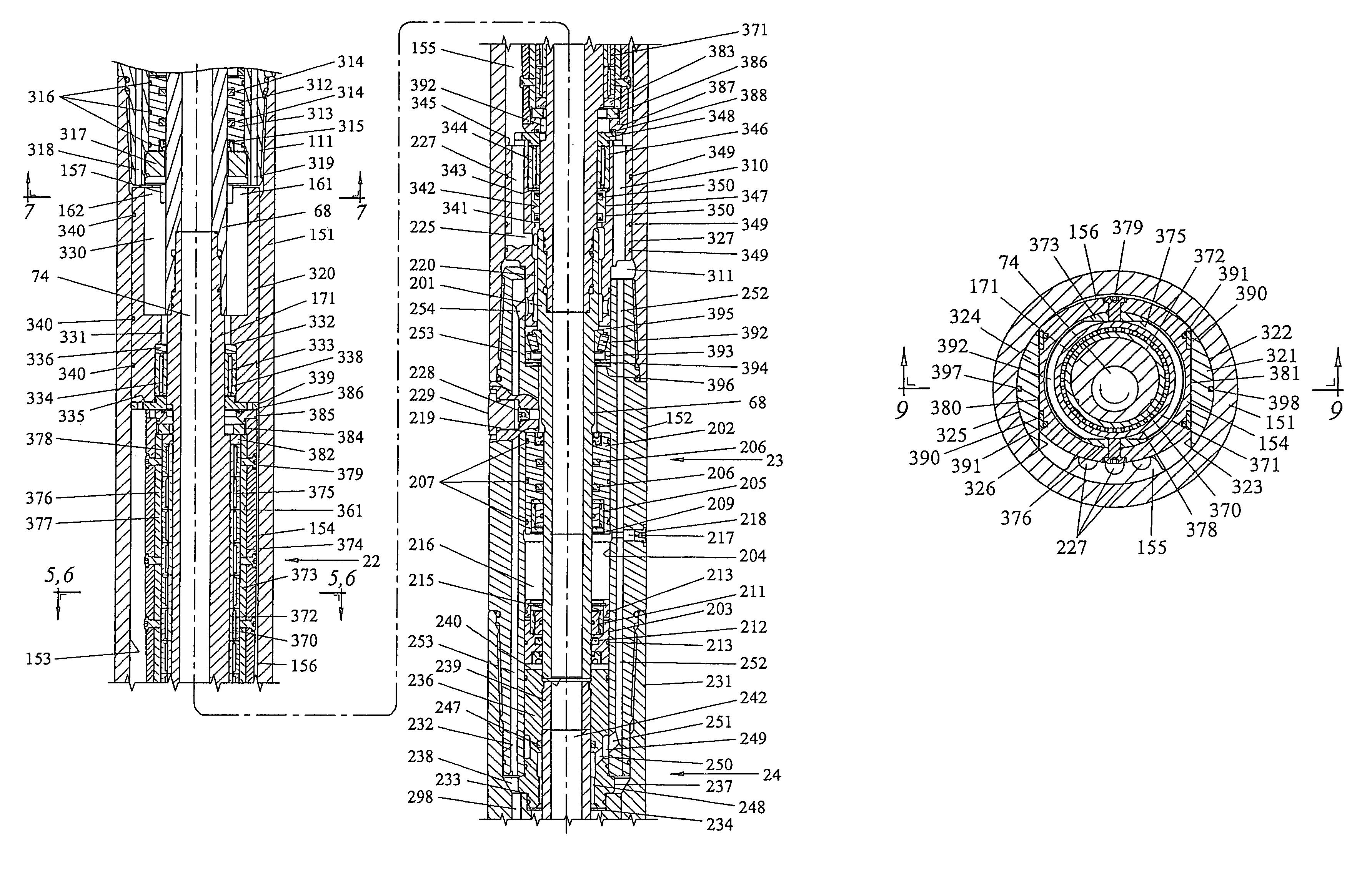

ActiveUS20050126822A1Extended bit lifeReduce inertial loadDrill bitsReciprocating drilling machinesDrilling systemEngineering

The present invention discloses, in certain asp cts, systems and methods for producing cyclical impacts and, in certain aspects for moving a drilling apparatus for drilling a borehole in a formation, the system in certain embodiments including a housing with a longitudinal axis and a movable member movably disposed therein and movable within the housing transversely to the longitudinal axis of the housing and positioned within the housing with a first space on a first side thereof and a second space on a second side thereof, the movable member substantially fluidly isolating the two spaces and movable to compress gas in one of the first space and the second space while decompressing gas in the other space so that a charge of compressed gas exits from the housing to move an impact member; e.g. for impacting a pile to be driven into the earth or for impacting a drill apparatus for drilling a wellbore, the movable member movable continuously to provide a series of impacts.

Owner:CCT TECH

Multi-part energizer for mechanical seal assembly

An energizer for a mechanical seal assembly for use in a drill bit is disclosed. The energizer is a composite of at least two resilient materials, one having a durometer hardness that is greater than the other. The material contacting a journal provides relatively high frictional forces so as to prevent the energizer from rotating in relation to adjacent components. The relatively softer resilient material provides the energizing force necessary to maintain a good dynamic seal between the metal seal rings. The energizer components may be separate components that engage one another upon assembly, or may be bonded together to form a ring prior to assembly into the drill bit.

Owner:SMITH INT INC

Roller cone drill bits with optimized bearing structures

ActiveUS20080087471A1Improve performanceReduce bearing loadDrill bitsBorehole/well accessoriesEngineeringDrill bit

A roller cone drill bit may include optimally designed bearing structures and cutting structures. The roller cone drill bit may include three cone assemblies rotatably mounted on respective spindles via respective bearing structures. Each cone assembly may have a respective cutting structure with a minimal moment center located along each respective axis of rotation. Each respective bearing structure has a center point located proximate each respective minimal moment center.

Owner:HALLIBURTON ENERGY SERVICES INC

Protector for rock bit seals

Owner:BAKER HUGHES INC

Rotary drag bits having a pilot cutter configuraton and method to pre-fracture subterranean formations therewith

Owner:BAKER HUGHES INC

Arcuate-shaped inserts for drill bit

InactiveUS20050077092A1Improve abilitiesExtended bit lifeDrill bitsMetal-working drilling toolsStress relievingMilling cutter

Disclosed are a variety of arcuate-shaped inserts for drill bits, and in particular, for placement in rolling cone cutters of drill bits. The arcuate inserts include 360° or ring-shaped inserts, as well as inserts of smaller arcuate length. The arcuate inserts are suitable for use in all surfaces of the rolling cone cutter, and in other locations in drill bits, and may have specialized cutting surfaces and material enhancements to enhance their cutting duty performance. Certain arcuate inserts may include stress relieving discontinuities such that, upon assembly into the cone or during drilling, the arcuate inserts may fragment in a controlled and predicted manner into shorter arcuate lengths.

Owner:SMITH INT INC

Diamond drill bit composition used for sapphire bar drawing-out and preparing method of diamond drill bit composition

ActiveCN106756648AGood edgeExtended bit lifeTurbinesOther manufacturing equipments/toolsMaterials processingCobalt

The invention belongs to the field of hard and brittle material machining and provides a diamond drill bit composition used for sapphire bar drawing-out. The composition includes diamond and carcass powder. The carcass powder includes, by weight, 20-30 parts of superfine cobalt powder, 5-15 parts of nickel carbonyl powder, 0-20 parts of copper-tin pre-alloyed powder, 10-20 parts of superfine iron powder, 1-10 parts of phosphorus-copper powder, 5-15 parts of tungsten-copper pre-alloyed powder and 1-5 parts of beta-silicon carbide whiskers. The invention further provides a preparing method of the diamond drill bit composition used for sapphire bar drawing-out. A diamond drill bit used for sapphire bar drawing-out and prepared through the diamond drill bit composition used for sapphire bar drawing-out has the beneficial effects that both toughness and embrittlement are good, the diamond exposure is good, the drawing-out efficiency is high, the service life of the drill bit is long, and the drawing-out yield is high.

Owner:BEIJING GANG YAN DIAMOND PROD CO +1

High offset bits with super-abrasive cutters

A roller bit is provided having super-abrasive inserts on cutting portions to assure that the bit will maintain cutting efficiency. In the described exemplary bits, the axes of the roller cones are also offset by a significant or “high offset” amount from the central longitudinal axis of the bit, thereby providing for increased shearing and grinding action by the bit. The use of high offset in combination with super-abrasive inserts provides for optimal bit cutting designs which provide increases in ROP while preserving the bit's ability to hold gage and remain durable to achieve acceptable footage. Minimum high offsets and preferred high offsets are described for various bit sizes, designs and nomenclatures, including milled tooth bits and insert-type bits designed for use in soft-through-medium formation hardnesses as well as formations with greater hardnesses.

Owner:SMITH INT INC

Texturing of the seal surface for a roller cone rock bit

Surface texturing is employed to modify the topography of one or more surfaces (radial or cylindrical) of the sealing system for a roller cone rock bit. The surface texturing results in a dimpled surface which retains additional lubricant helpful in reducing friction in the boundary and mixed lubrication regimes. Shot peening is disclosed as one method for texturing the desired surface.

Owner:山特维克矿山机械工程工具股份有限公司

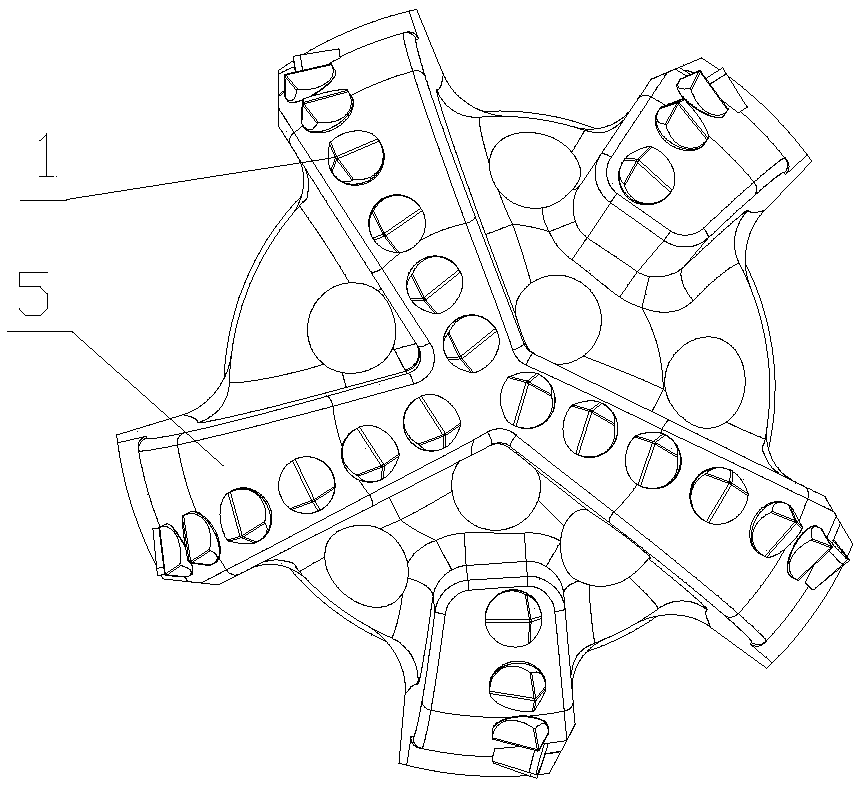

Special tooth PDC drill bit

PendingCN109630025AStrong anti-abrasion performanceExtended bit lifeConstructionsDrill bitImpact resistance

The invention provides a special tooth PDC drill bit, belongs to rotary drilling drill bits for petroleum and geology, and particularly relates to a drill bit of a special tooth special structure. Thespecial tooth PDC drill bit comprises a drill bit body and a connector. The drill bit body is composed of multiple knife wings and a gage. PDC special teeth are further brazed on the knife wings, diamond layers are arranged on base bodies of the PDC special teeth, and the diamond layers are vertical to respective normal directions. The diamond layers are provided with front bulging ridges, rear bulging ridges and sharp corners. The special tooth PDC drill bit has the advantages that the diamond layers of the PDC special teeth are vertical to the respective normal directions, all the diamond layers can participate in cutting, the drill bit has higher grinding resistance, and the service life of the drill bit is prolonged. The force bearing mode of the diamond layers is changed, the axial impact resistance of the drill bit can be improved in multiples, and the possibility that the drill bit is damaged by bit bouncing and percussion drilling is reduced.

Owner:四川川石金刚石钻头有限公司

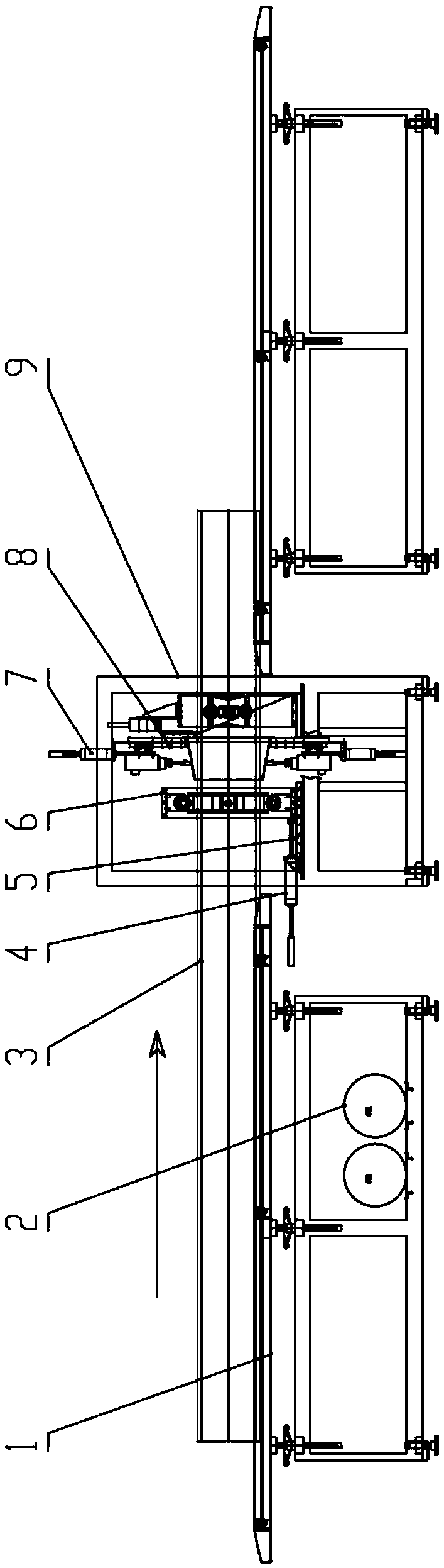

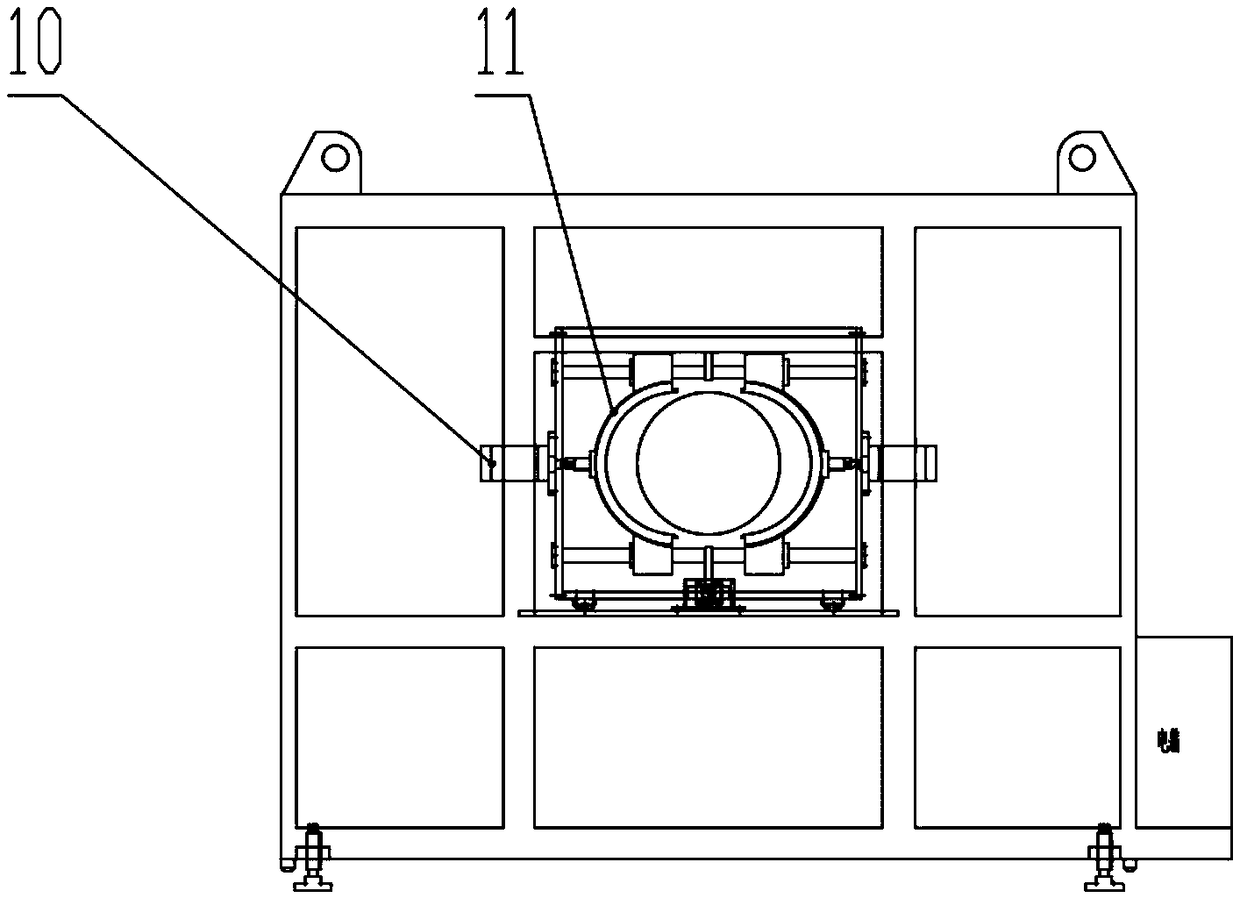

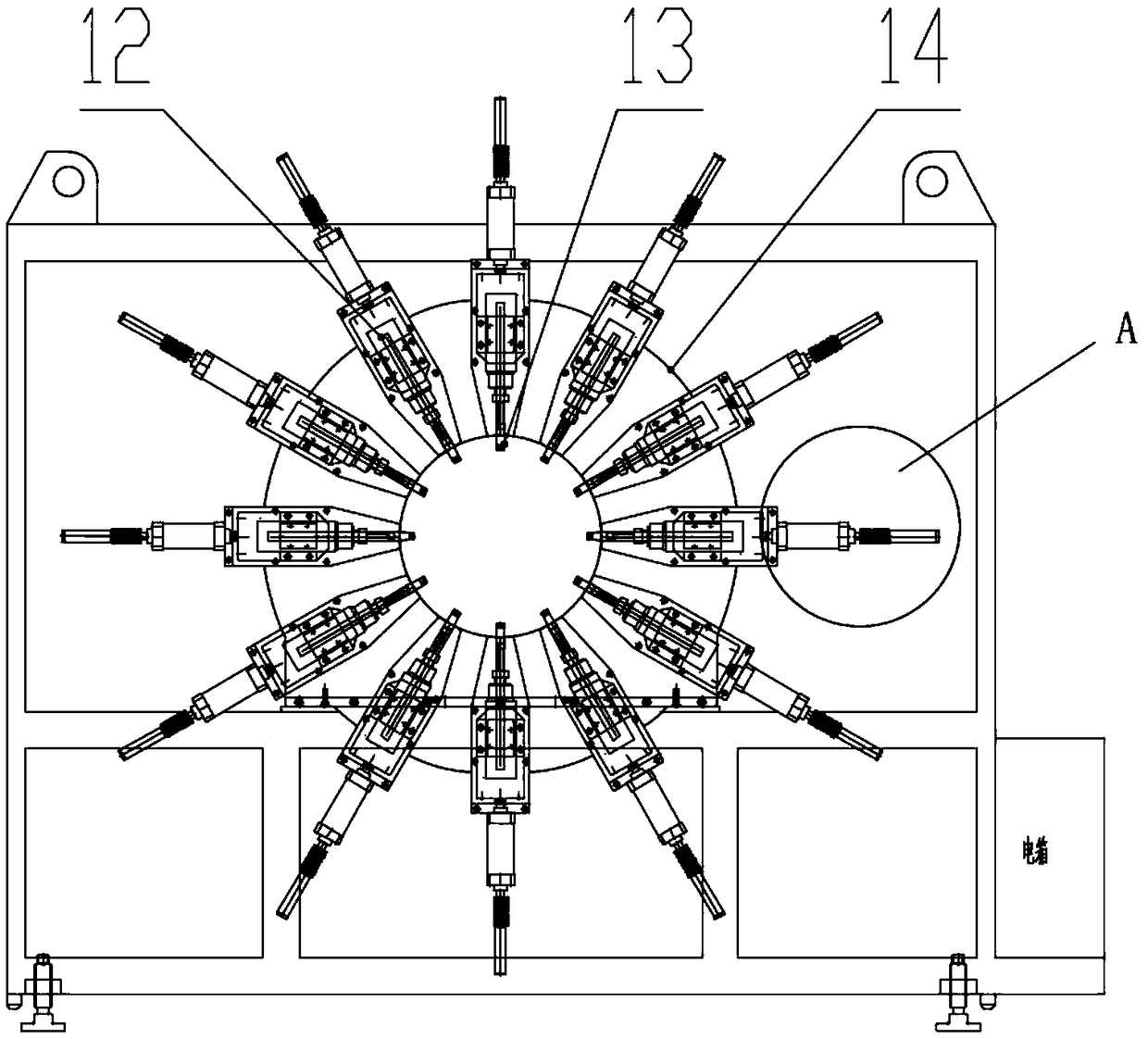

Plastic pipe punching machine

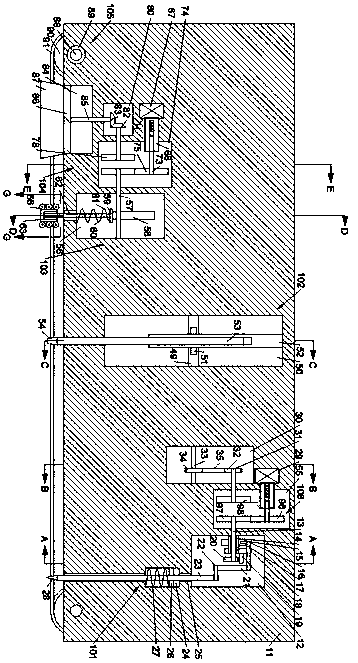

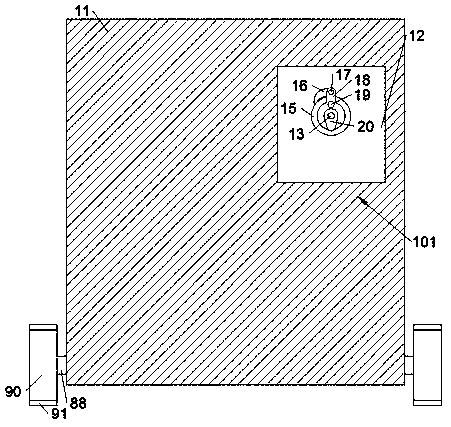

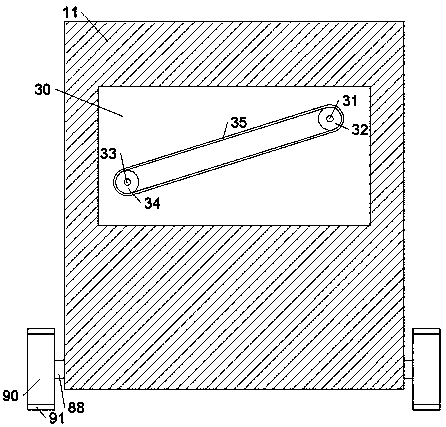

The invention relates to a plastic pipe punching machine. The plastic pipe punching machine comprises a punching device and a machine body located on the two sides of the punching device, wherein a to-be-punched plastic pipe is placed on the machine body, the machine body mainly plays a role of supporting, a plurality of rollers are arranged on the machine body, the plastic pipe is arranged on therollers, so that the plastic pipe can move on the machine body conveniently. The punching device comprises a punching machine frame and a clamping mechanism, a punching mechanism and a pressing mechanism which are arranged on the punching machine frame in sequence, wherein the clamping mechanism is mainly used for clamping the plastic pipe, the punching mechanism is used for punching the plasticpipe, and the pressing mechanism is used for setting the plastic pipe right and clamping the other end of the plastic pipe during punching. The punching machine has the advantages that the automationis realized, the consistency of the axial hole spacing is ensured, the uniformity of each circumference section hole and the hole angle is achieved, the quality of each plastic pipe is guaranteed, andthe hidden danger caused by inconsistent manual punching is eliminated.

Owner:江苏煜宇塑料机械科技有限公司

Protector for rock bit seals

Owner:BAKER HUGHES INC

Drilling systems

ActiveUS7040417B2Extended bit lifeReduce inertial loadDrill bitsConstructionsWell drillingEngineering

The present invention discloses, in certain aspects, systems and methods for producing cyclical impacts and, in certain aspects for moving a drilling apparatus for drilling a borehole in a formation, the system in certain embodiments including a housing with a longitudinal axis and a movable member movably disposed therein and movable within the housing transversely to the longitudinal axis of the housing and positioned within the housing with a first space on a first side thereof and a second space on a second side thereof, the movable member substantially fluidly isolating the two spaces and movable to compress gas in one of the first space and the second space while decompressing gas in the other space so that a charge of compressed gas exits from the housing to move an impact member; e.g. for impacting a pile to be driven into the earth or for impacting a drill apparatus for drilling a wellbore, the movable member movable continuously to provide a series of impacts.

Owner:CCT TECH

Lock body steel easy to drill and fast in chip removal and preparation method thereof

The invention discloses lock body steel easy to drill and fast in chip removal and a preparation method thereof, and belongs to the technical field of locks. The steel comprises the following chemical components in percentage by mass of 0.01-0.03% of C, 0-0.04% of Si, 1.6%-2.0% of Mn, 0.010%-0.030% of P, 0.40%-0.55% of S, 0.15%-0.22% of Bi, 0.005%-0.01% of Se, 0.003%-0.006% of T[O], 0.004%-0.006% of B and the balance of Fe and inevitable impurities. According to the steel, a certain amount of Bi and Se are compositely added, and the content of Mn and S in the steel is optimized, so that the sizes and forms of Mn (S, Se), ferrite and pearlite of the lock body steel are effectively controlled, the hardness of the steel is further reduced, the chip removal and breaking capabilities in the drilling process of the steel are improved, and the service life of a drill bit is prolonged; and in the preparation process, through forging, hot rolling, staged cooling and shot blasting processes, a lock body steel product with a matrix ferritic structure, a small amount of pearlite structures and excellent drilling performance is finally obtained, and the product is low in hardness, easy to drill, fast in chip removal, fast in heat dissipation and small in abrasion to a high-speed drill bit and can be widely used for manufacturing padlocks and calabash lock bodies.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

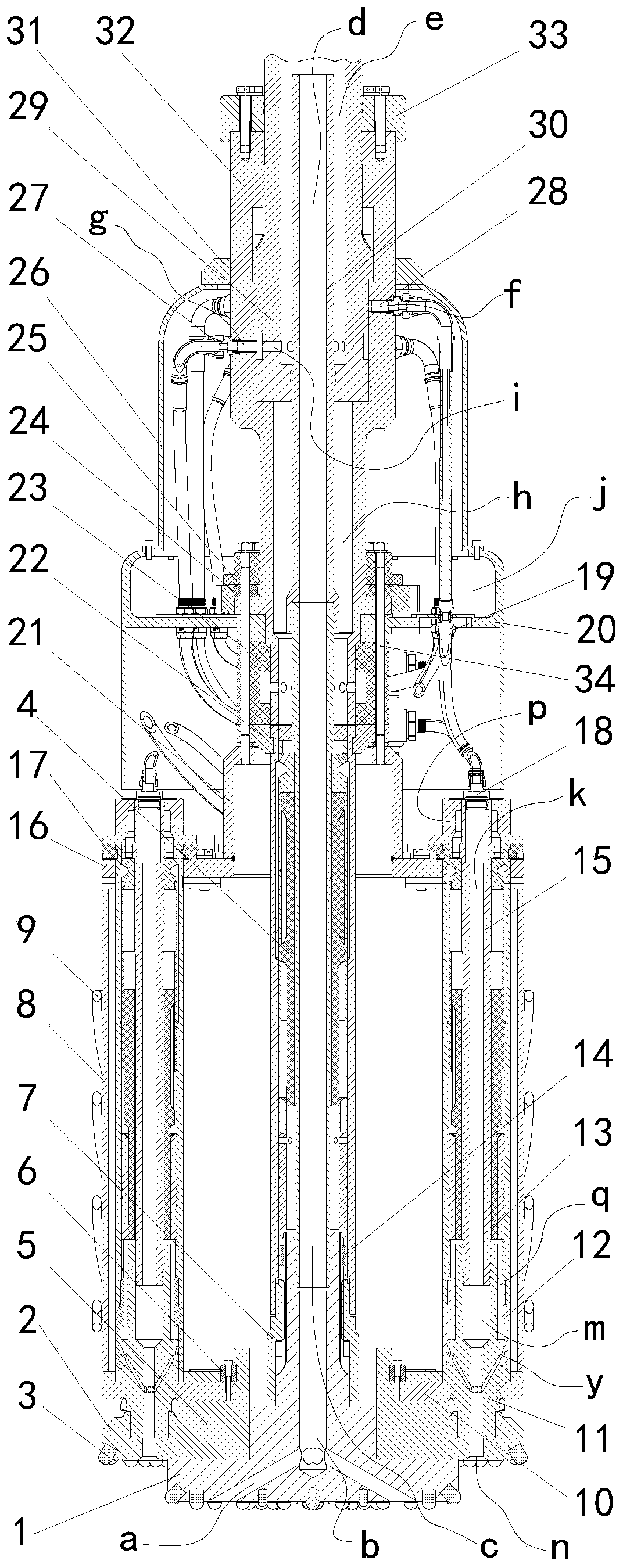

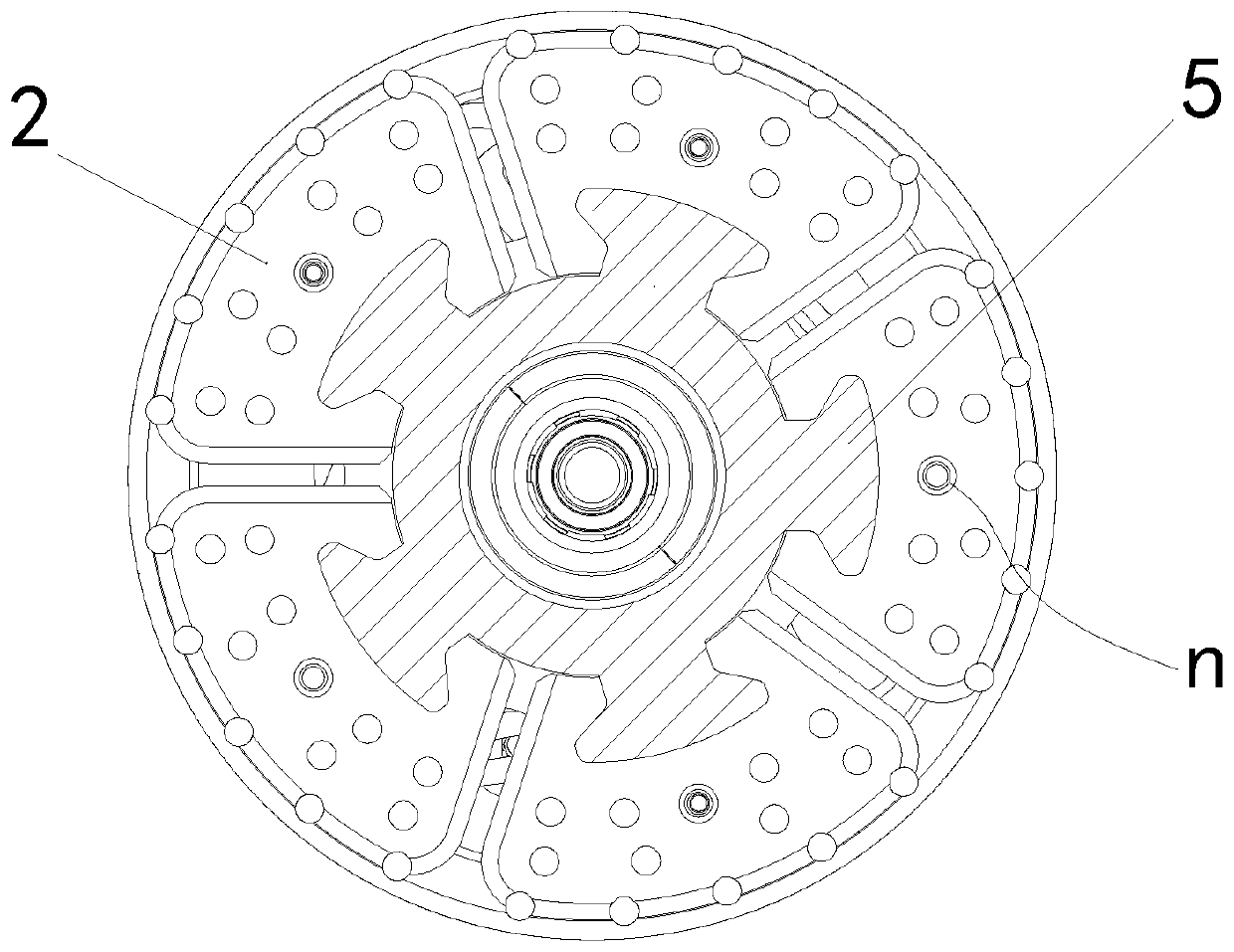

Large-diameter combined type air reverse circulation down-the-hole hammer

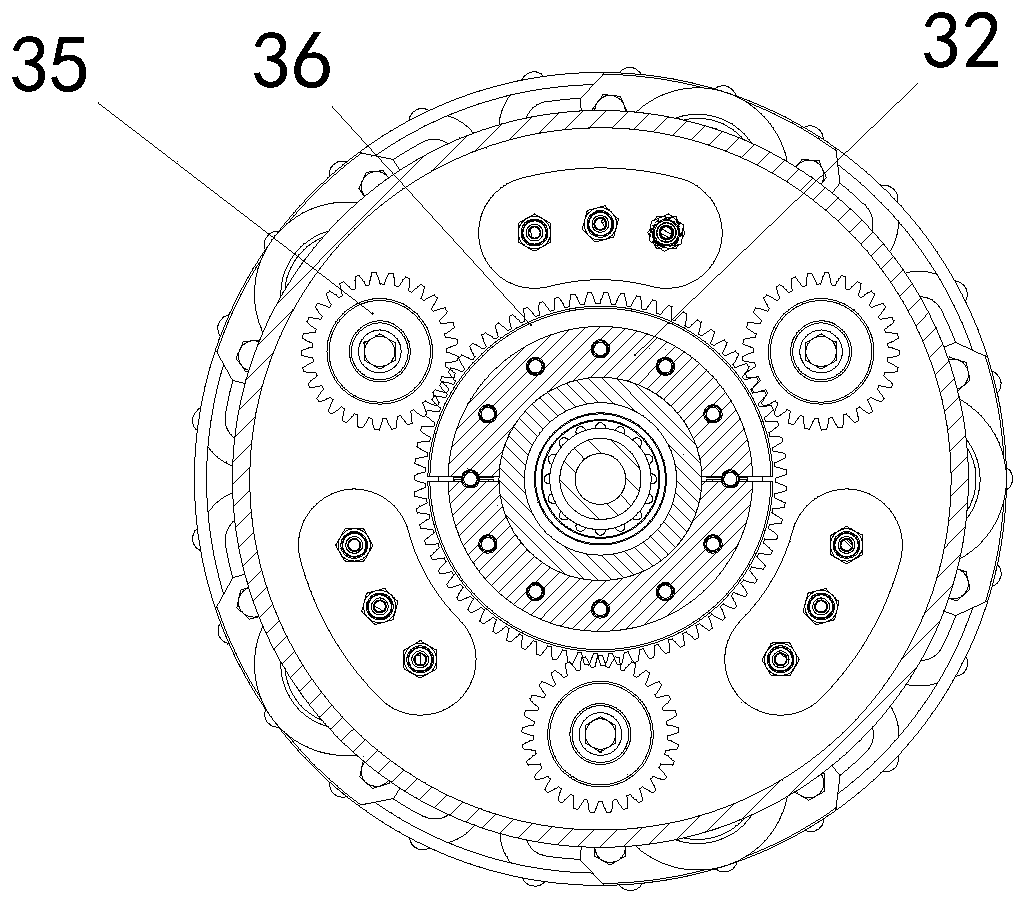

PendingCN111594039AImprove drilling efficiencyImprove drilling qualityDrill bitsConstructionsGear wheelEngineering

The invention provides a large-diameter combined type air reverse circulation down-the-hole hammer. The large-diameter combined type air reverse circulation down-the-hole hammer comprises an air distribution joint assembly, a planetary gear shunt, a center hammer, side hammers, a bell-shaped shield, a connecting cover and a protective cylinder, wherein the air distribution joint assembly transmitstorque through a floating spline; the function switching of rotary-percussion drilling and strong blowing for removing slag after lifting a drill is realized by changing the position of a floating upper shaft; high-pressure gas is evenly distributed to each side hammer and the center hammer through the planetary gear shunt; the side hammers are evenly arranged around the center hammer; the bottomlip surface of a drill bit of the center hammer is ahead of the bottom lip surfaces of the drill bits of the side hammers; the bottom lip surface of the drill bit of the center hammer and the bottomlip surfaces of the drill bits of the side hammers are combined to form a complete circular cross section; the drill bit of each side hammer is installed by adopting a T-shaped slot structure, and canfloat in an axial direction; and the central drill bit is arranged by adopting a clip key type spline shaft. The down-the-hole hammer comprises an integral type outer protective cylinder; and the upper air distribution section comprises the bell-shaped shield. The down-the-hole hammer has stable gas distribution, compact structure and high rock crushing efficiency, is convenient to maintain and can realize multiple drilling techniques.

Owner:JILIN UNIV

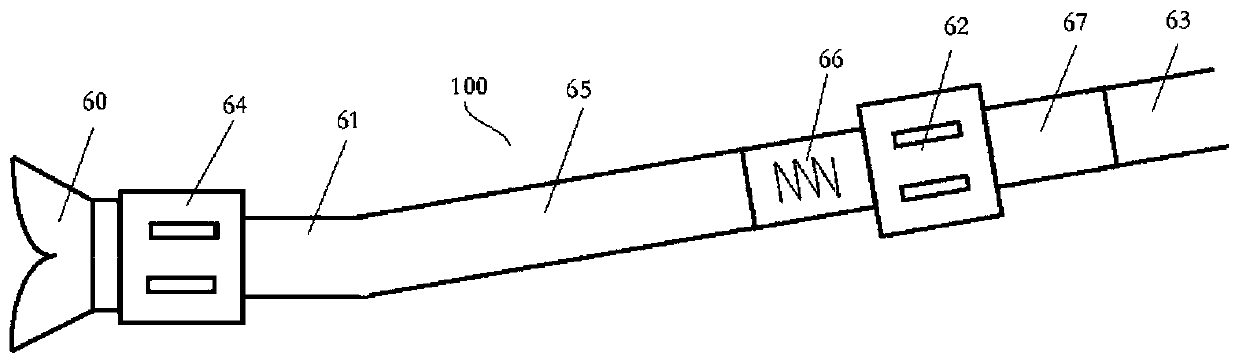

a drilling tool assembly

ActiveCN107965277BImprove job stabilityExtended bit lifeDrilling rodsDrilling casingsMining engineeringPetroleum engineering

The invention provides a drilling tool assembly. The drilling tool assembly comprises a drill bit, a power drilling tool which is disposed above the drill bit and capable of providing a deviation reduction force, a first stabilizer disposed above the power drilling tool, and a drill collar disposed above the first stabilizer. The drilling tool assembly has the advantages of high anti-deviation ability and stable operation of the drill bit.

Owner:CHINA PETROLEUM & CHEM CORP +1

Drilling machine capable of drilling after positioning

The invention discloses a drilling machine capable of drilling after positioning. The drilling machine capable of drilling after positioning comprises a drilling machine body; a punching device is arranged on the right side inside the drilling machine body; a drilling device is arranged on the left side of a chain wheel cavity; an earth fetching device is arranged on the left side of the drillingdevice; a cleaning device is arranged on the left side of the earth fetching device; the cleaning device and the earth fetching device are connected via power; and a driving device is arranged on thelower side of the drilling machine body. According to the drilling machine capable of drilling after positioning, via the mode that a prepared hole is positioned before drilling, the prepared hole isautomatically dug at an accurate position without manual operation, and a rotating drill bit is used for drilling. Therefore, wear of a drill bit caused by soil on the ground in the drilling process is reduced, the service life of the drill bit is prolonged, the processes of prepared hole digging and drilling can be completed by one machine, manual carrying of other equipment is not required, thecost is lowered, and labor force is released.

Owner:浙江杭博电动工具有限公司

Insert cone bit

ActiveCN103114811AImprove rock breaking efficiencyExtended service lifeDrill bitsFoundation engineeringPetroleum

The invention discloses an insert cone bit, belongs to the technical field of drilling equipment for petroleum and natural gas, mine engineering, building foundation engineering construction, geology, hydrology and the like, and particular discloses a cone bit. The insert cone bit comprises a bit body and at least one cone, transversely inserted teeth are inserted and fixed on each cone, and a value range of a tooth crest deflection angle alpha of each transversely inserted tooth satisfies that 70 degrees < / =alpha< / =90 degrees. By the provided novel structure, the teeth in the structure are acted on shaft bottom rock in a rolling grinding and splitting manner, the insert cone bit has unique advantages particularly for drilling of hard and brittle formations and hard abrasive formations, high rock-breaking efficiency of the bit is guaranteed while service lives of the bit teeth and bearings are prolonged, and further service life of the bit is prolonged.

Owner:SOUTHWEST PETROLEUM UNIV

Welded joints for rotary-vibratory drills having reduced stress

InactiveUS7290623B2Extended bit lifeProspect of losing expensive drills down a drill hole is significantly reducedDrilling rodsTransportation and packagingScrew threadDrill pipe

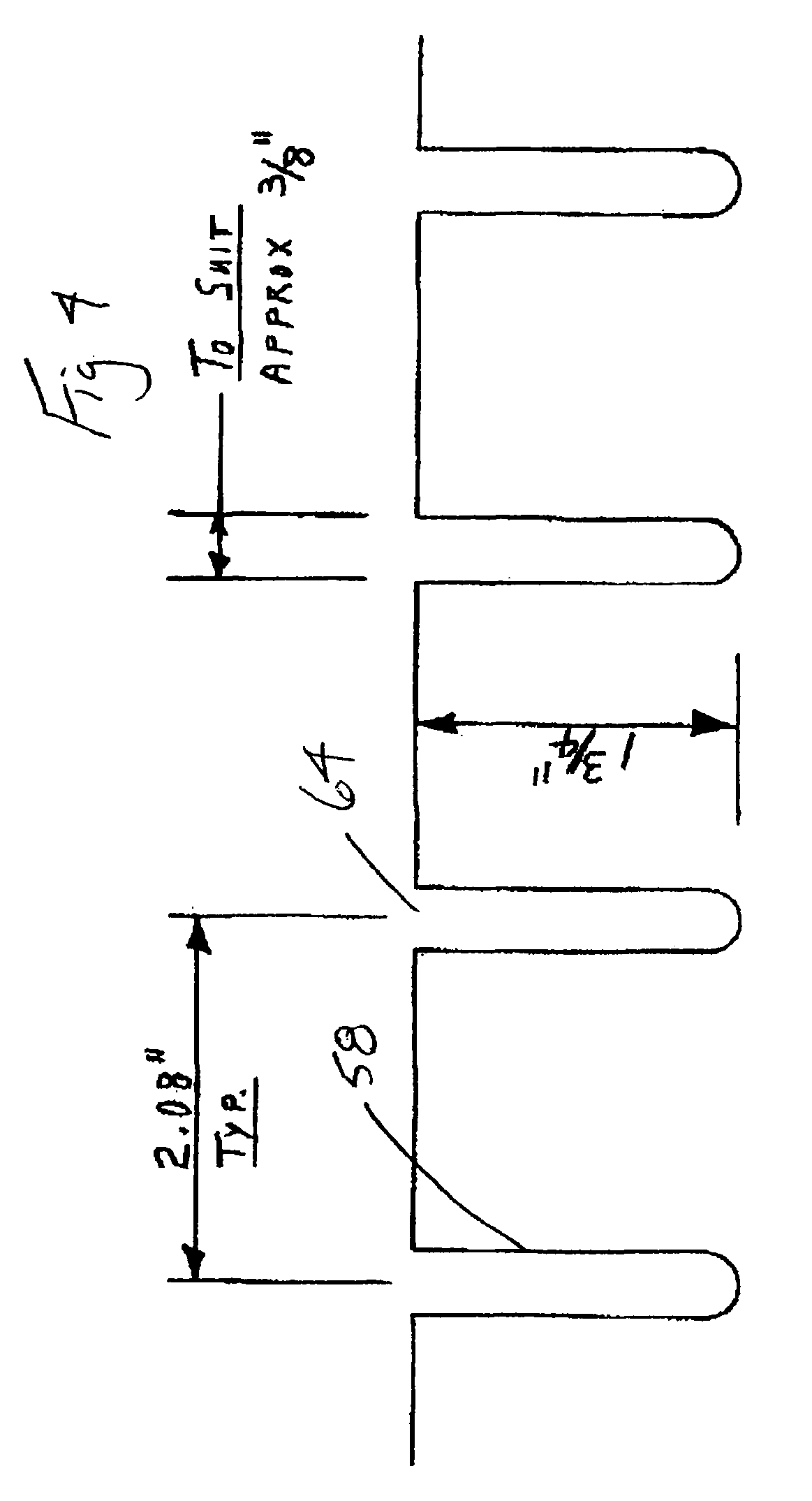

A drill string for a rotary-vibratory drill comprises a plurality of drill pipes. Each of the drill pipes has a longitudinal axis and at least one end. A female connector member and a male connector member are between the ends of adjacent said drill pipes, the female connector member having a first portion mating with a first of the adjacent drill pipes and a second portion extending away from the first of the drill pipes. The male connector member has a first portion mating with a second of the adjacent drill pipes and a second portion extending away from the second of the drill pipes, the second portion of the female connector threadedly engaging the second portion of the male connector. One of said each drill pipe and the connectors has a plurality of spaced-apart slots adjacent to the end of the drill pipe and communicating outwardly at the end. The slots are parallel to the longitudinal axis. Each of the connectors is connected to one of the adjacent drill pipes by welding extending about an adjacent said end of the one drill pipe and along the slots.

Owner:ROUSSY RAYMOND JOSEPH

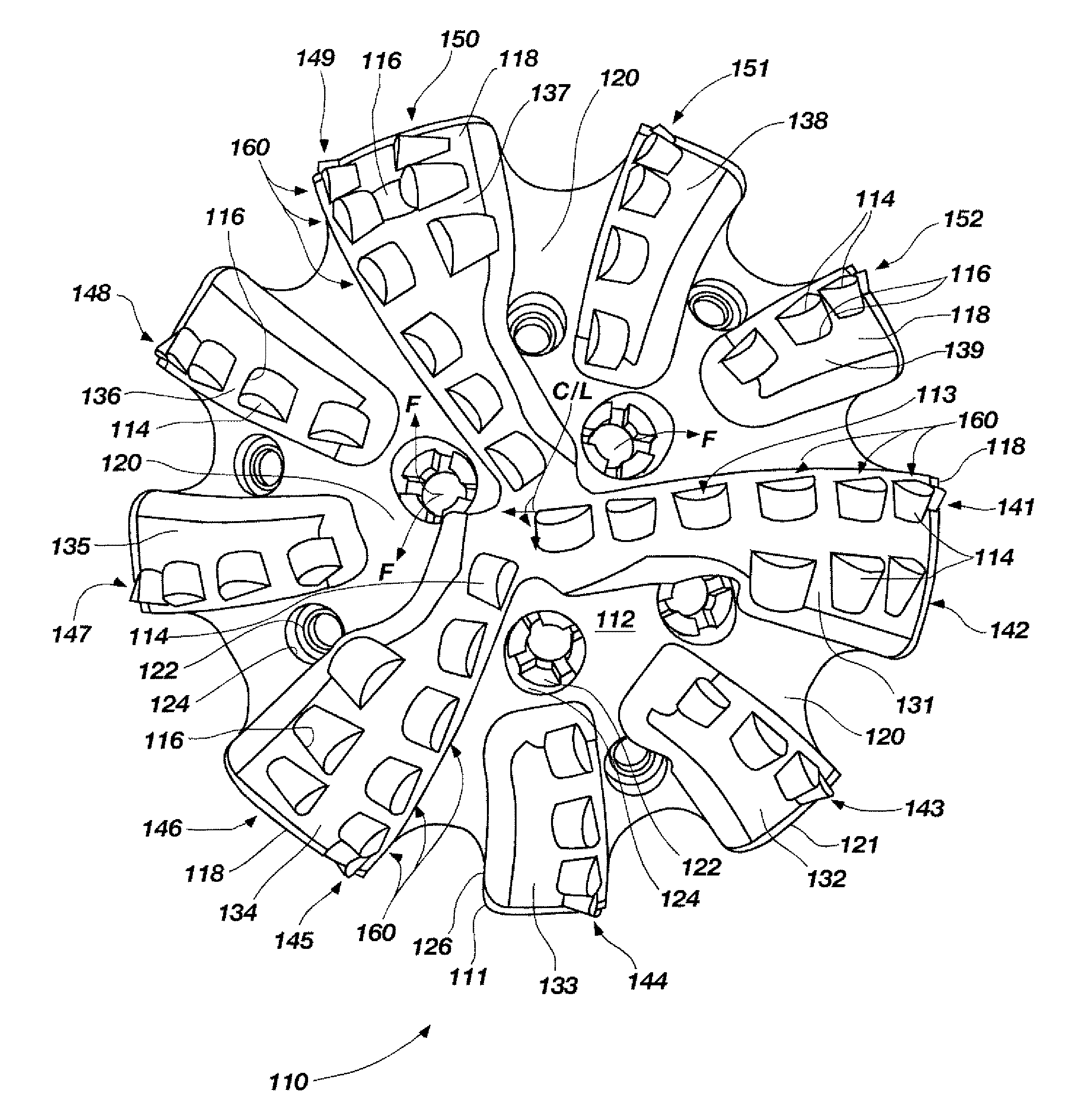

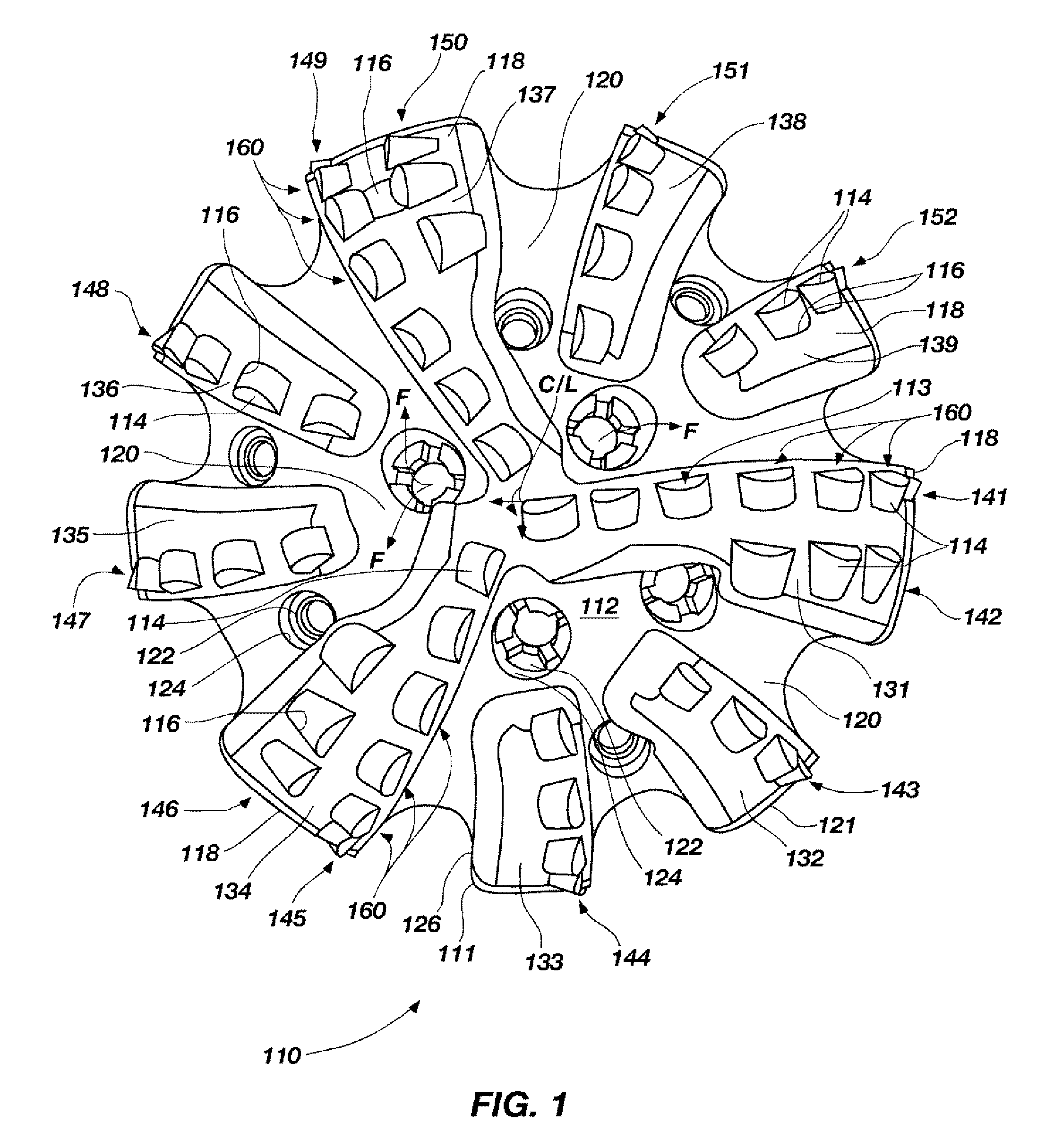

Novel PDC drill bit with combination teeth

InactiveCN106545299AReduce torque rippleImprove impact resistanceDrill bitsConstructionsWell drillingPetroleum engineering

The invention discloses a novel PDC drill bit with combination teeth. The drill bit comprises a drill bit body, a plurality of scrapers are distributed on the drill bit body, the structure outlines of cutting teeth of the scrapers comprise inner cones, nose parts, outer cones, circular beads and gauge protection blocks, and various cutting teeth are arranged on the multiple scrapers; with the rotation direction in the cutting process of the scrapers as the front, front-row teeth on at least one of the scrapers on the drill bit body comprise two kinds of shearing teeth, and rear-row teeth on the scraper at least comprise one kind of the shearing teeth or one kind of limiting teeth; and the shearing teeth comprise disc-shaped shearing teeth and rib-shaped shearing teeth, and the limiting teeth comprise spherical cylindrical teeth and conical cylindrical teeth. According to the drill bit, by designing a structure of the cutting teeth of the drill bit with the combination of the various cutting teeth and cutting depth control over the drill bit, the torque fluctuation of the drill bit can be reduced, the ability of the drill bit to resist grinding and shocking can be improved, the service life of the cutting teeth of the drill bit can be prolonged, the cutting ability and the adaptability of the drill bit can be improved, the mechanical drilling speed of the drill bit can be increased, the stability of the drill bit can be improved, and the well drilling cost can be lowered for users.

Owner:CHENGDU BEST DIAMOND BIT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com