Patents

Literature

436results about How to "Improve drilling quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

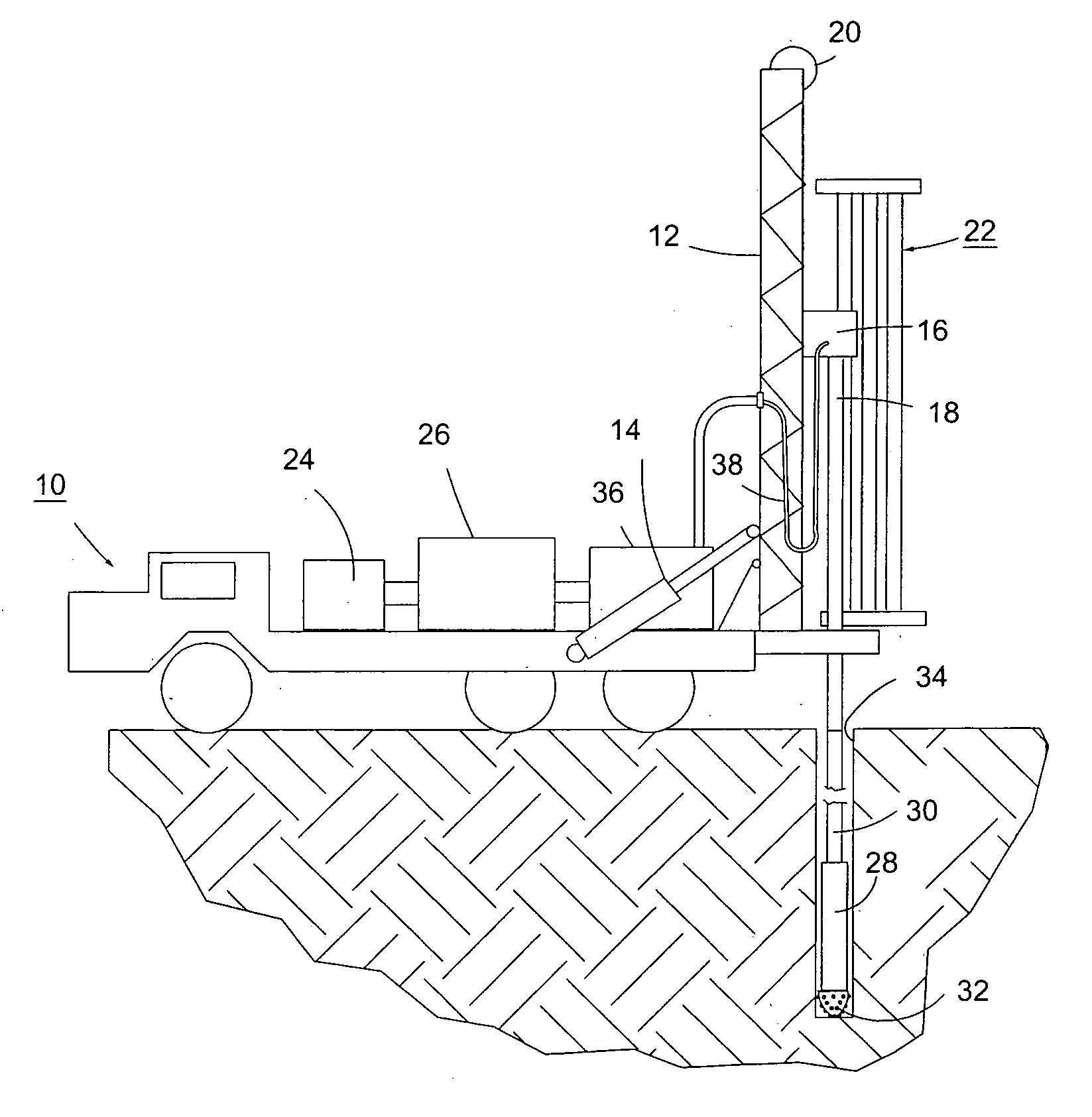

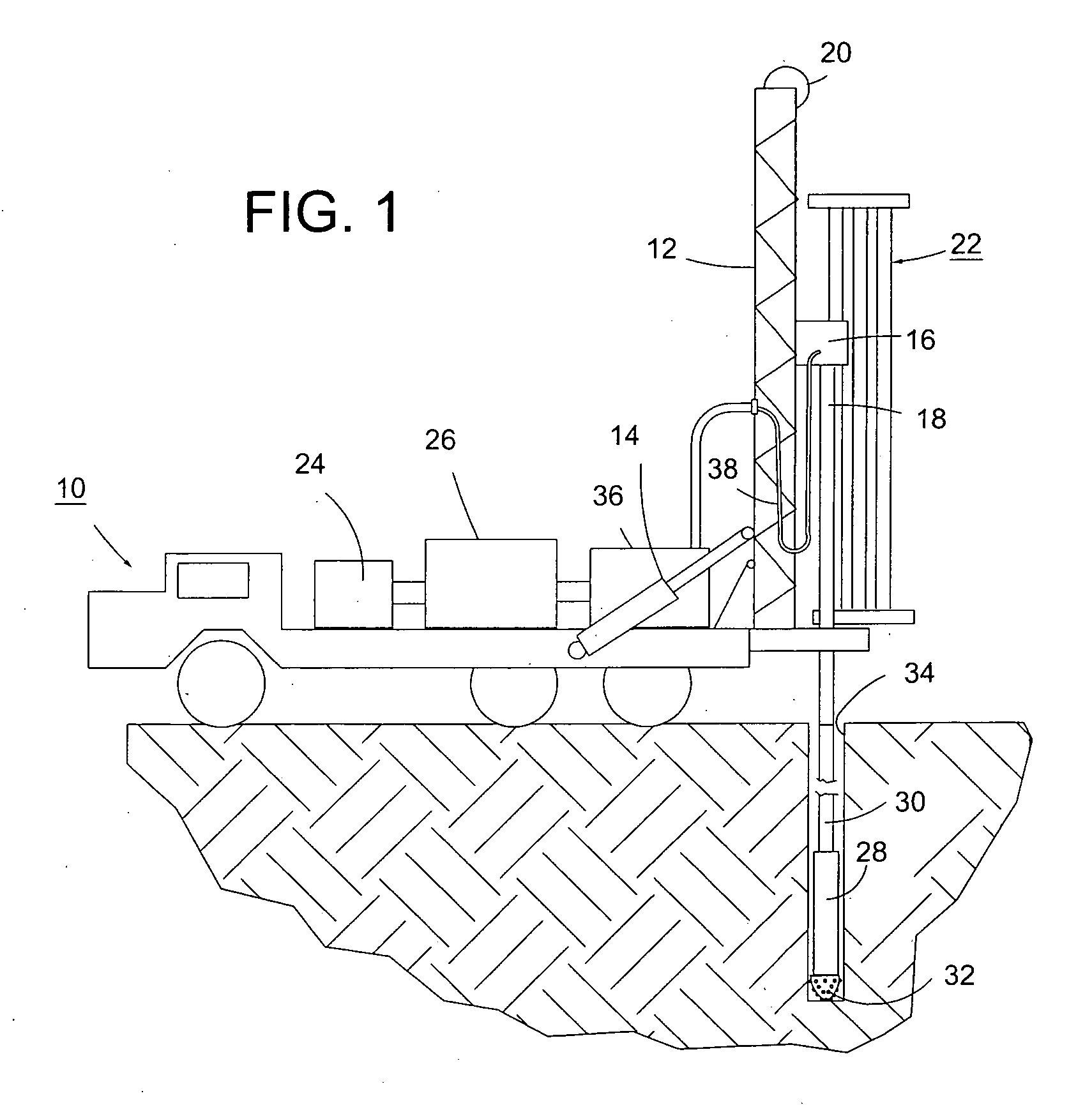

Earth drilling rig having electronically controlled air compressor

InactiveUS20070246262A1Reduce generationImprove drilling qualityDrilling rodsConstructionsCritical levelElectronic controller

In an earth drilling rig in which an air compressor and one or more hydraulic pumps are driven by the same engine, the intake throttle of the compressor is controlled by an electronic controller having a proportional integral derivative control. The controller minimizes unloading of the compressor, allowing the engine to operate more efficiently, the hydraulic system to provide more consistent power to drilling functions and the volume and pressure of compressed air to be optimized for the drilling conditions encountered. The electronic controller also operates a blowdown valve at the discharge side of an air receiver, and effects various overrides of the control system, for example when air discharge temperature approaches a critical level, or when an overpressure condition is detected.

Owner:SCHRAMM INC

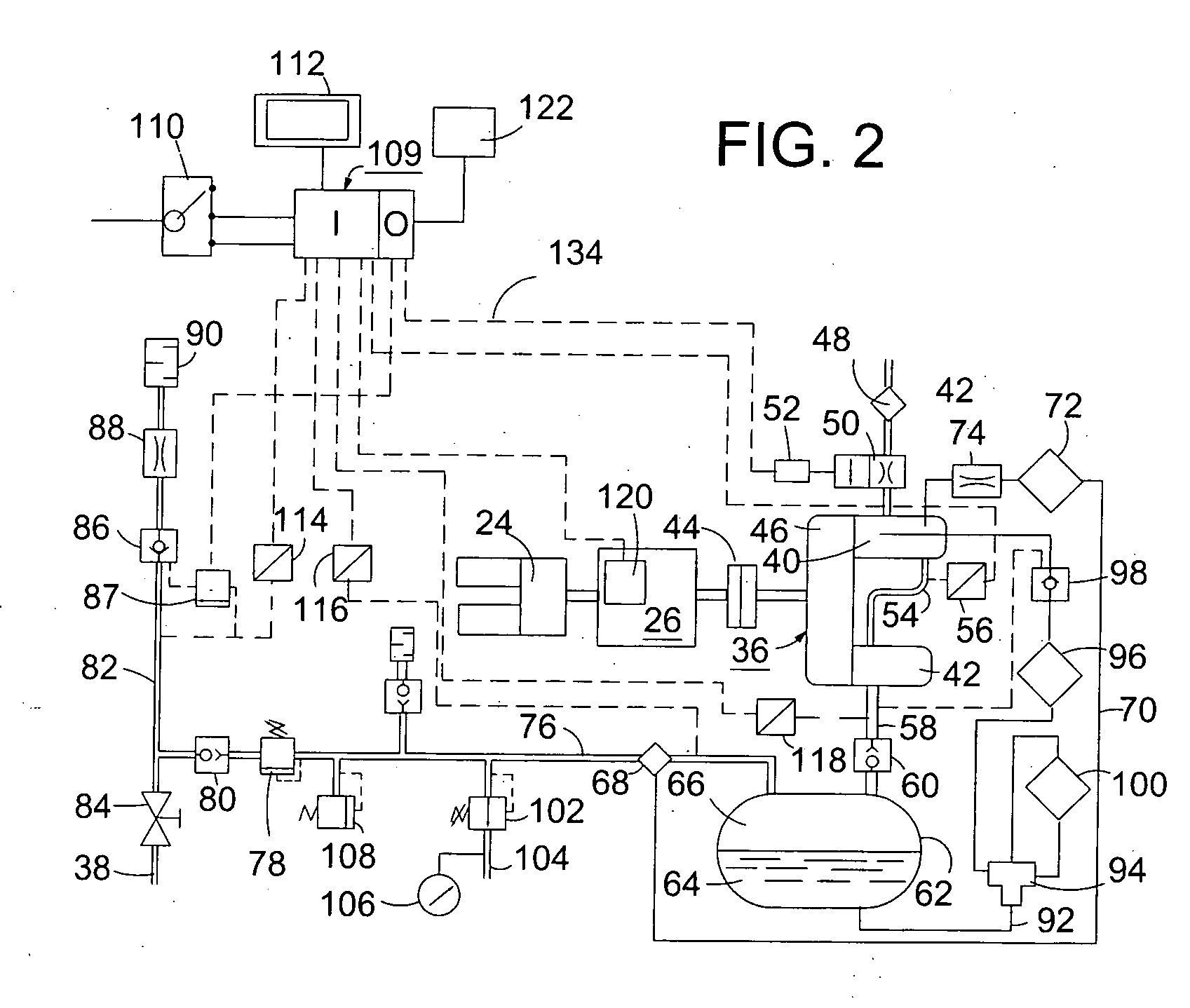

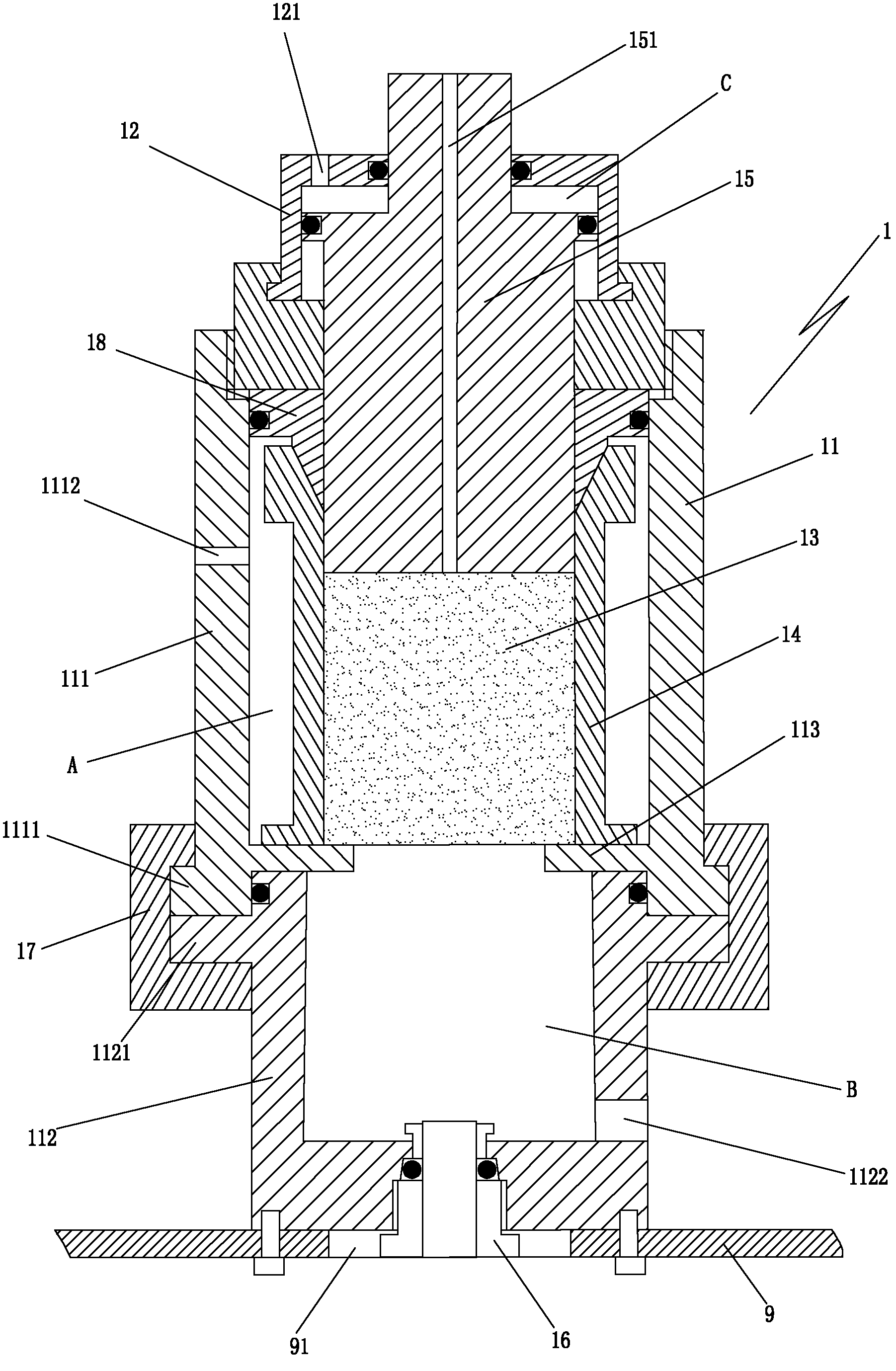

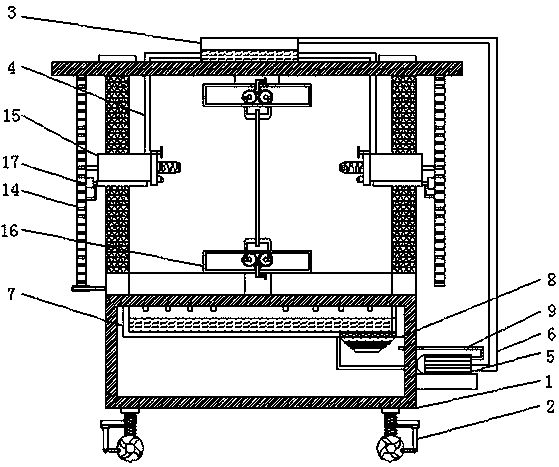

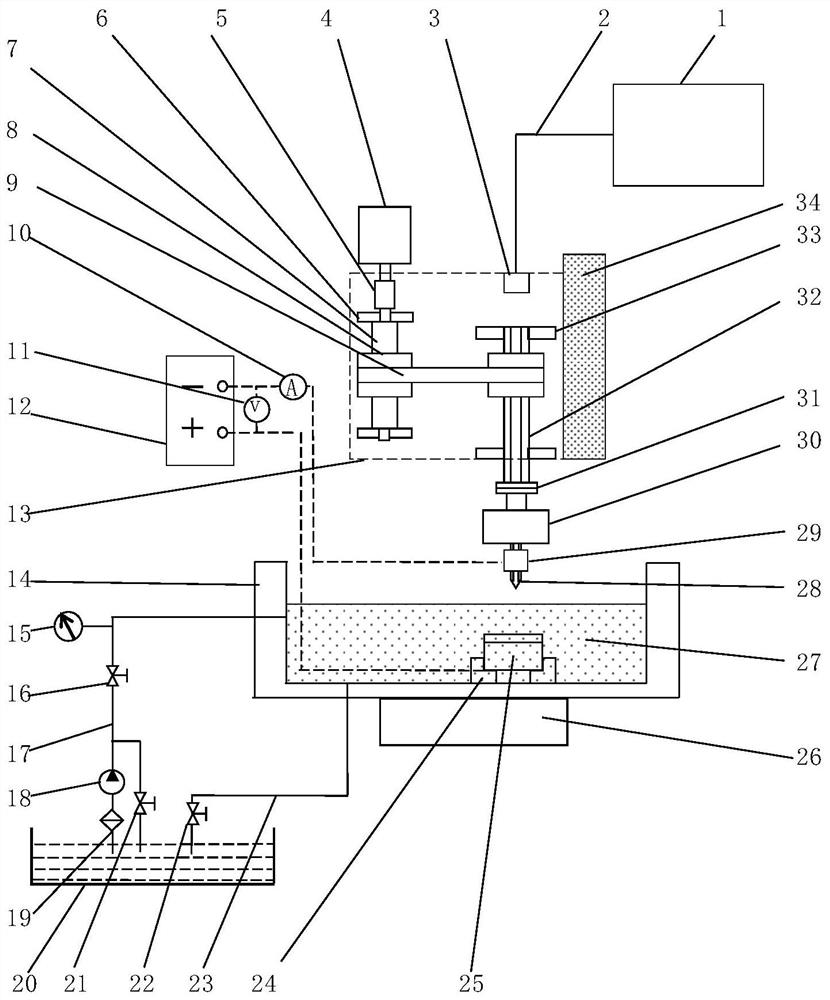

Drilling simulation experiment device

InactiveCN102288742AIncrease drilling speedImprove drilling qualityEarth material testingRock coreWell drilling

The invention relates to a well drilling simulation test device. The well drilling simulation test device comprises a rock core clamping mechanism, a drilling mechanism, a pressing mechanism and a pressing control pipeline, wherein the rock core clamping mechanism and the drilling mechanism are concentrically arranged above and below a test frame; constant pressure liquid which is applied to the upper end of the rock core by a constant pressure pump of the pressing mechanism and constant pressure liquid or high pressure gas which is pressed on the rock core by a constant pressure pump of the drilling mechanism or a high pressure gas source are converged in a simulated cavity at the bottom of the well, and are controlled to flow out by the pressing control pipeline consisting of a filter, a back pressure device and a flowmeter; the back pressure device is connected with the high pressure gas source of the drilling mechanism and controls the pressure of the simulated cavity at the bottom of the well by controlling the gas supply pressure of the high pressure gas source; the pressing mechanism, a pressure sensor of the back pressure device and the flowmeter transmit signals to a computer; and change of related parameters is controlled by the computer program, so that various drilling schemes are simulated and tested, and indoor test data is provided for increasing drilling speed,improving drilling quality and reducing drilling cost.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

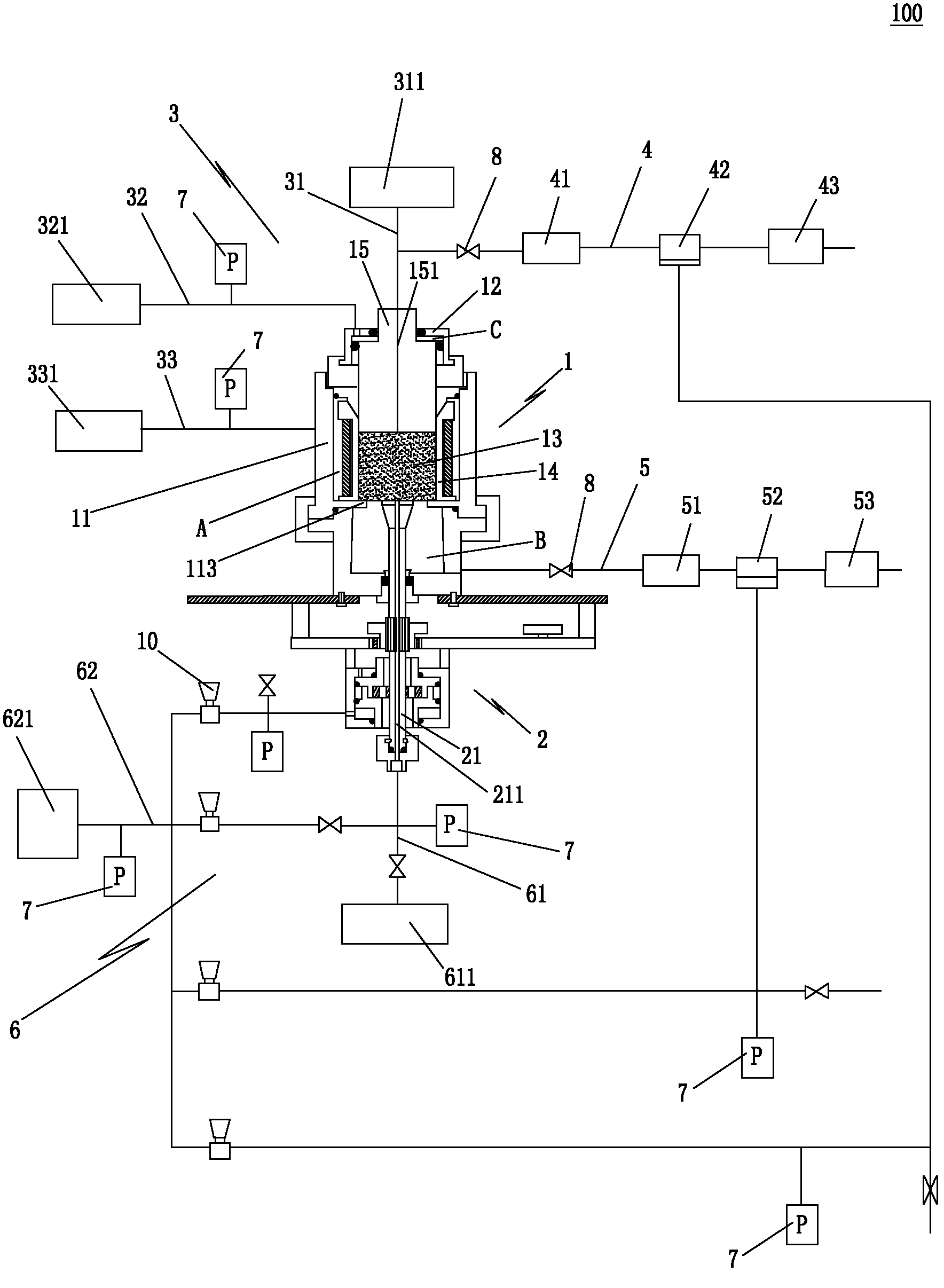

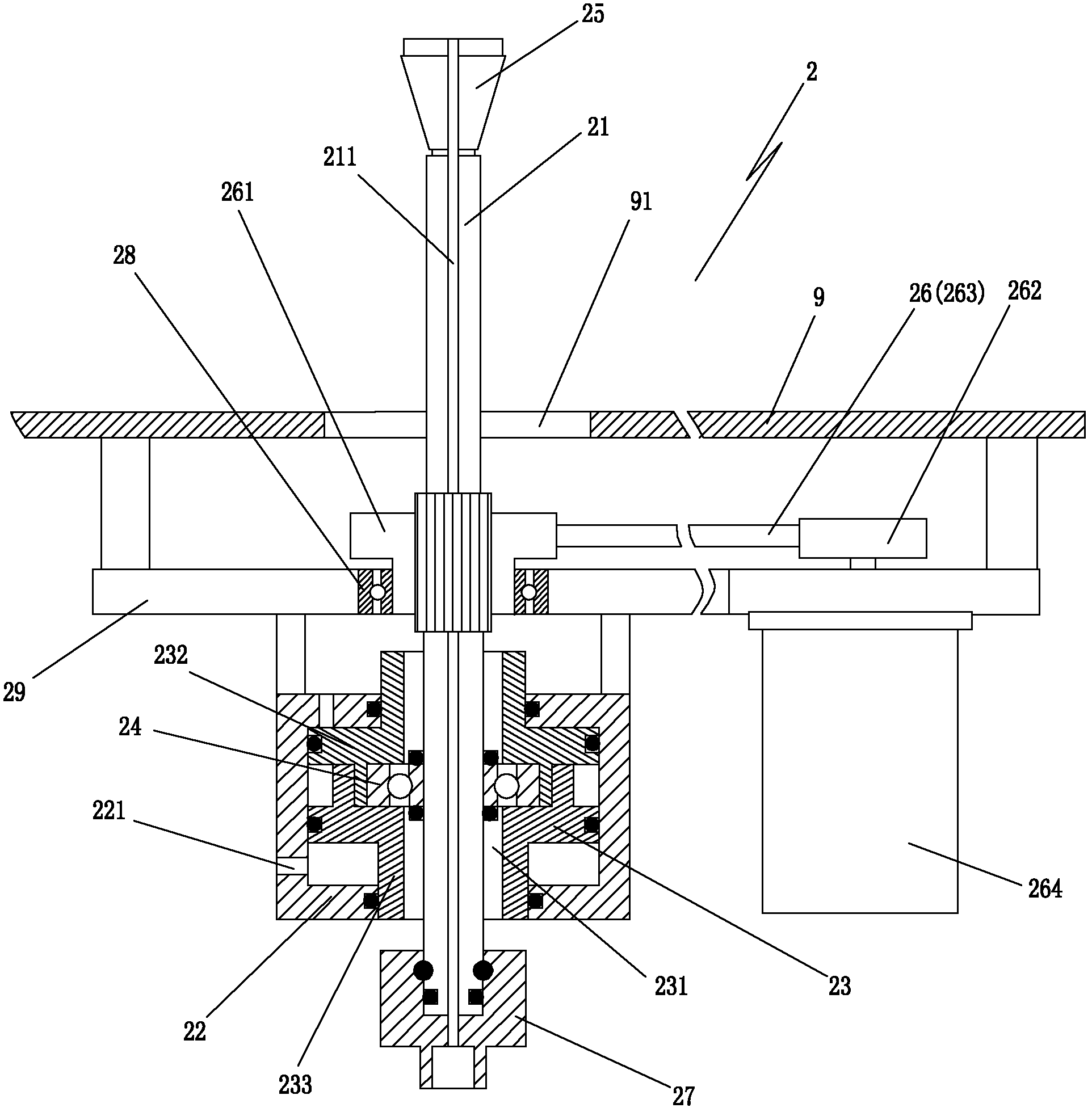

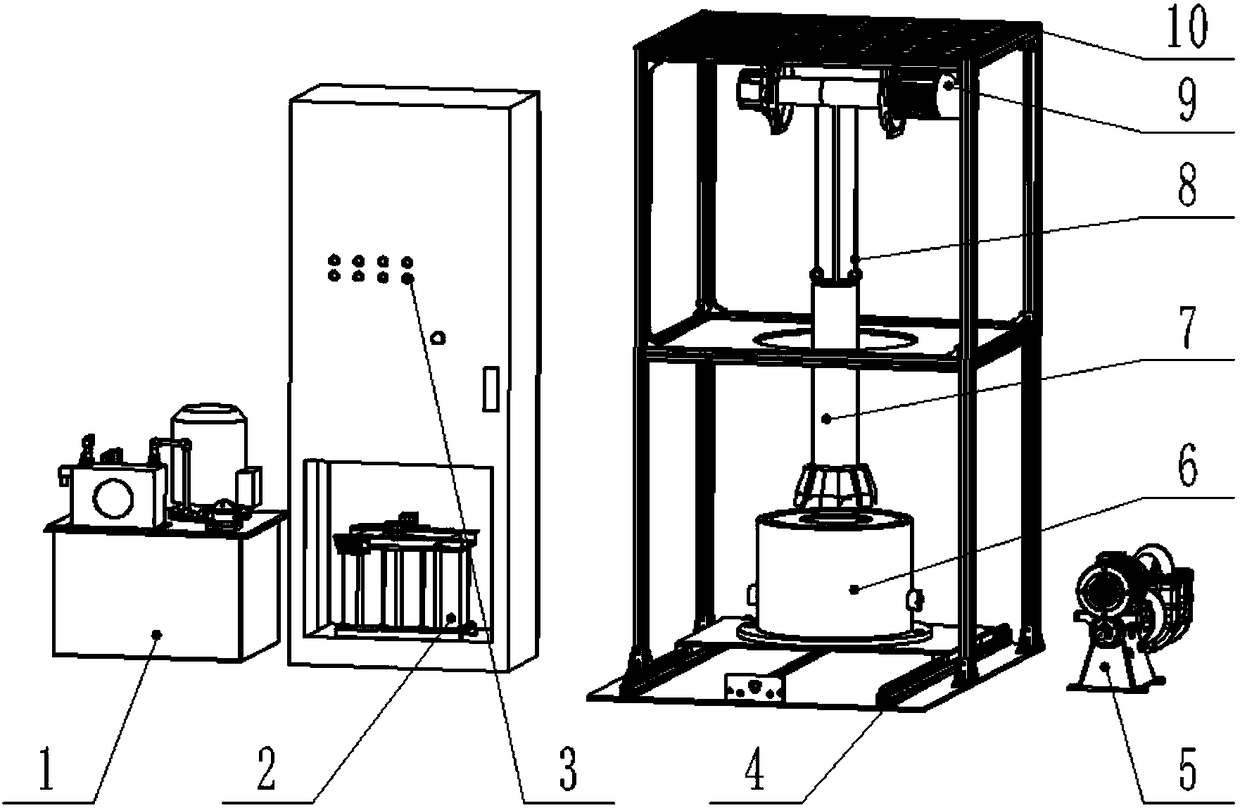

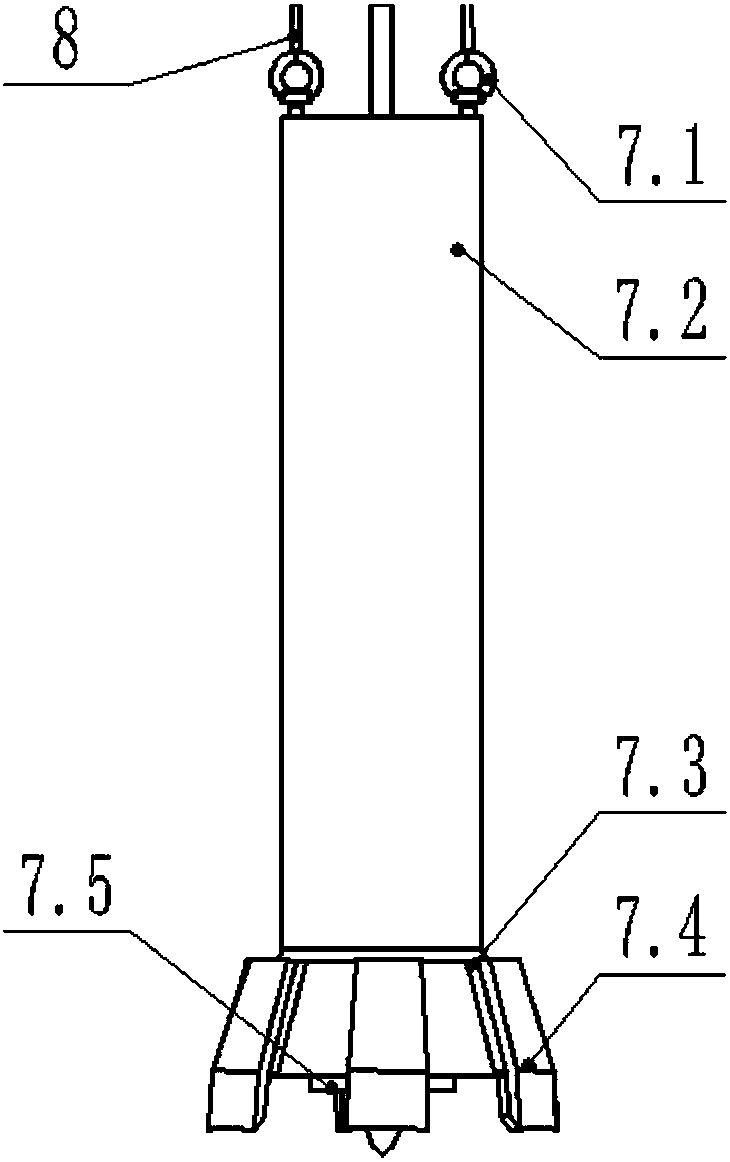

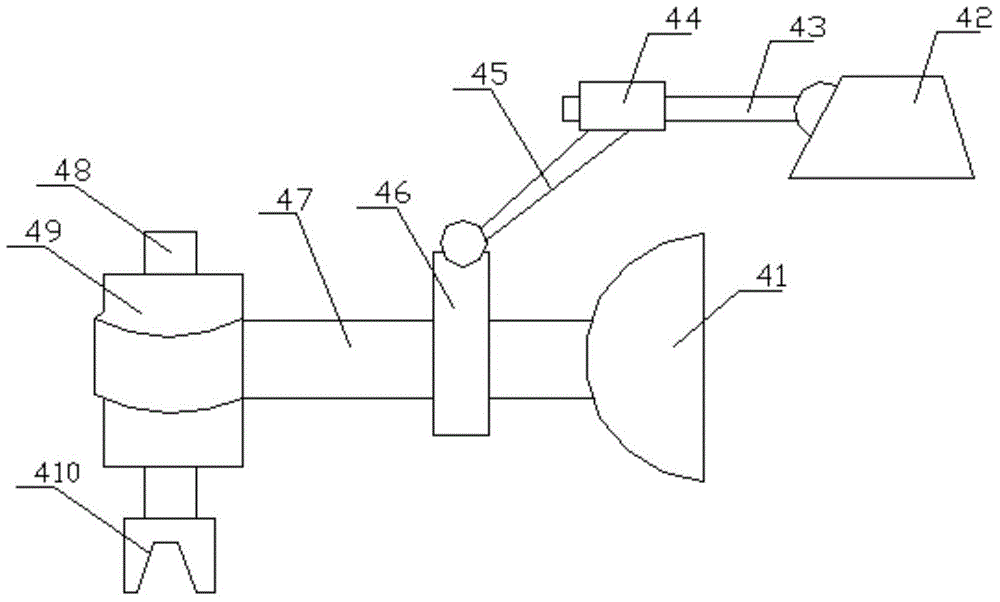

Electric pulse rock-breaking dill bit and experimental facility thereof

ActiveCN108222838AImprove energy efficiencyImprove drilling qualityMachine part testingDrill bitsLow voltageElectrical impulse

The invention discloses an electric pulse rock-breaking dill bit and an experimental facility thereof. The electric pulse rock-breaking experimental facility comprises a confining pressure pumping station, a pulsed power supply, a PLC control device, a confining pressure cylinder horizontal-moving device, a water inlet and outlet pump, a confining pressure cylinder assembly, a high-pressure electric pulse rock-breaking drill bit body, and the like. The high-voltage pulsed power supply is used for transmitting high-voltage pulse electricity from a high voltage electrode to a low voltage electrode through a cable, the high-voltage pulse electricity meeting certain conditions breaks through rocks firstly to generate a discharge channel, a plasma channel expands when heated, when the pressureexceeds the stress intensity of the rocks, and the rocks are broken and the high-voltage pulse discharge drilling is realized. The high-pressure electric pulse rock-breaking experimental facility cansimulate the high voltage environment of deep drilling in the earth, electric pulse drilling experiments carried out on high temperature and high pressure deep wells and ultra-deep wells are more close to actual drilling environments, experimental studies on the geometrical shape, distribution, spacing and electrode materials of electrodes of high-voltage electric pulse rock-breaking drill bit inthe deep wells and the ultra-deep wells can be realized, and the high-voltage pulse discharge drilling has broad development prospects.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN) +1

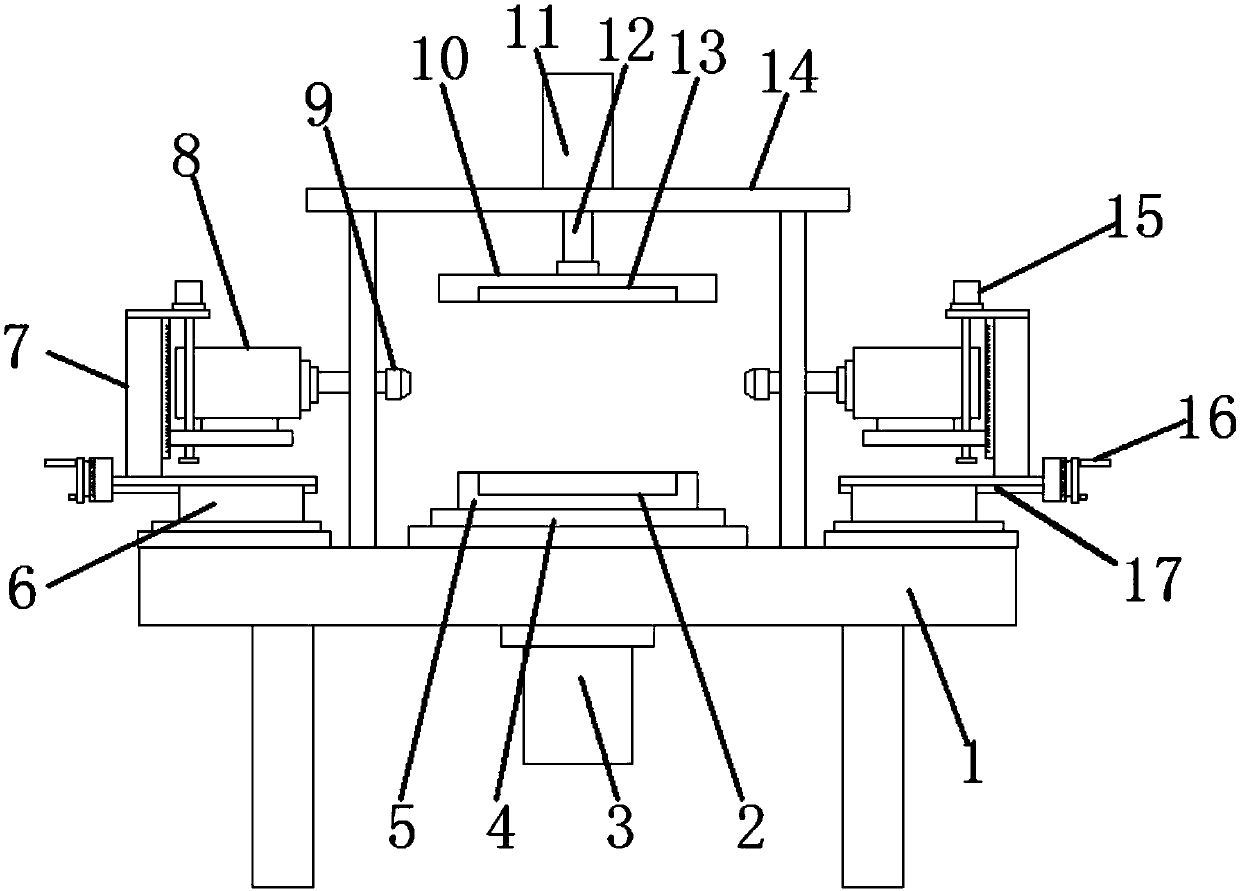

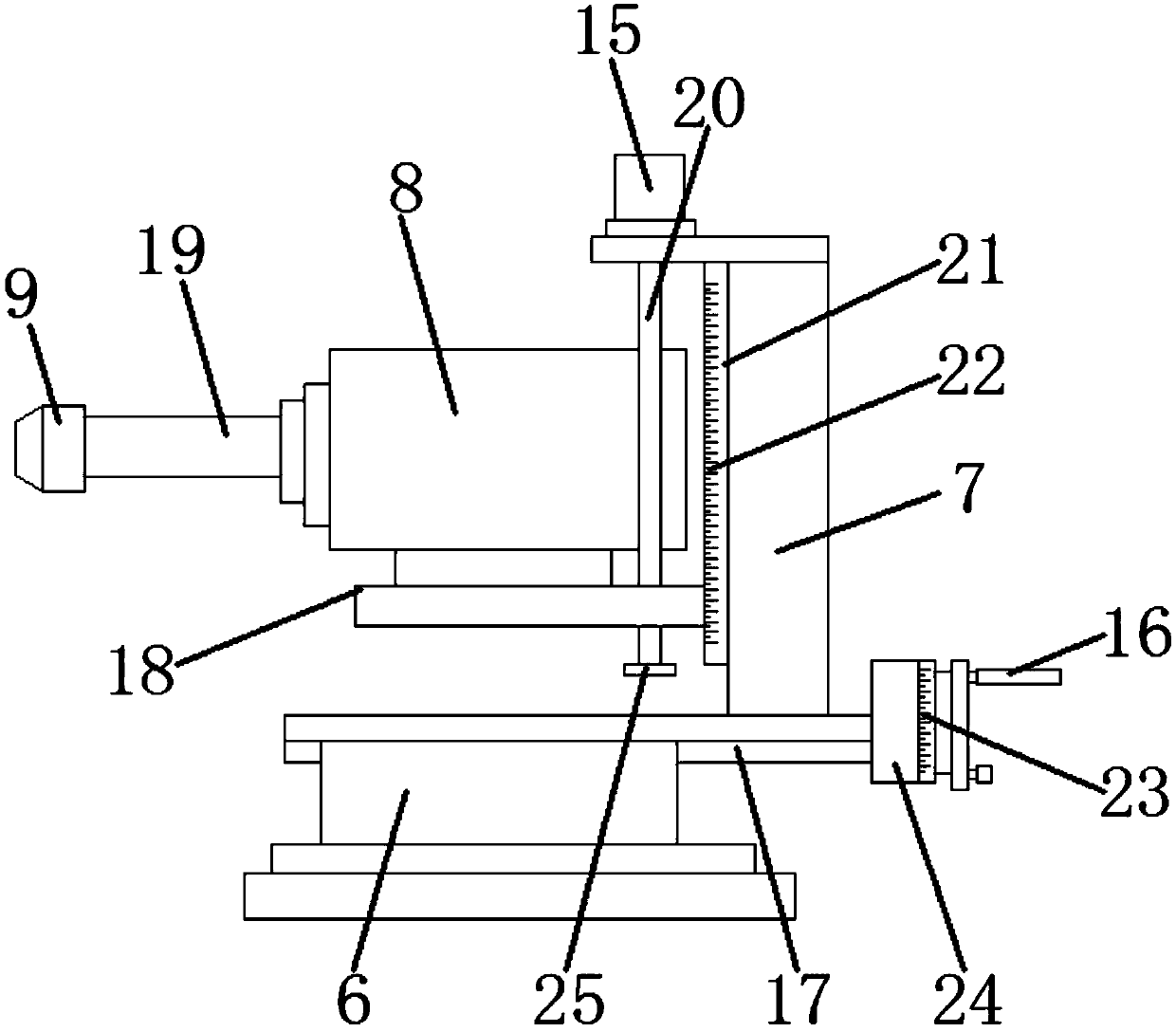

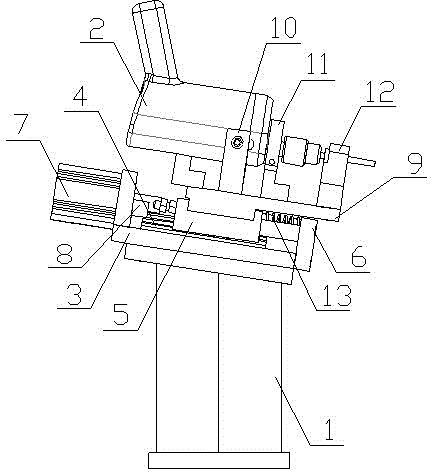

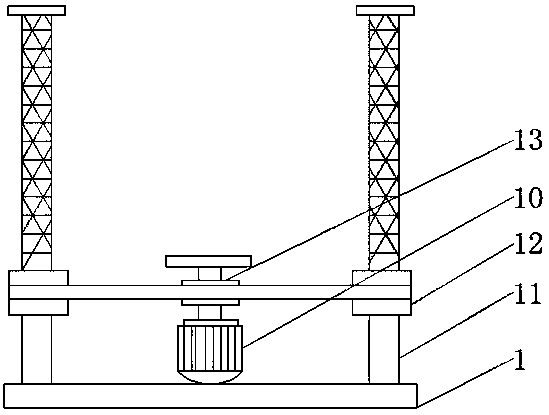

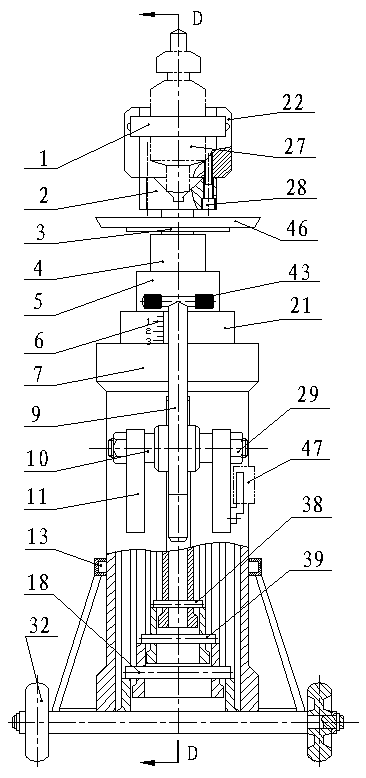

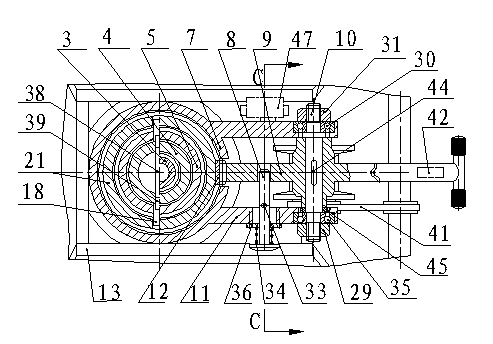

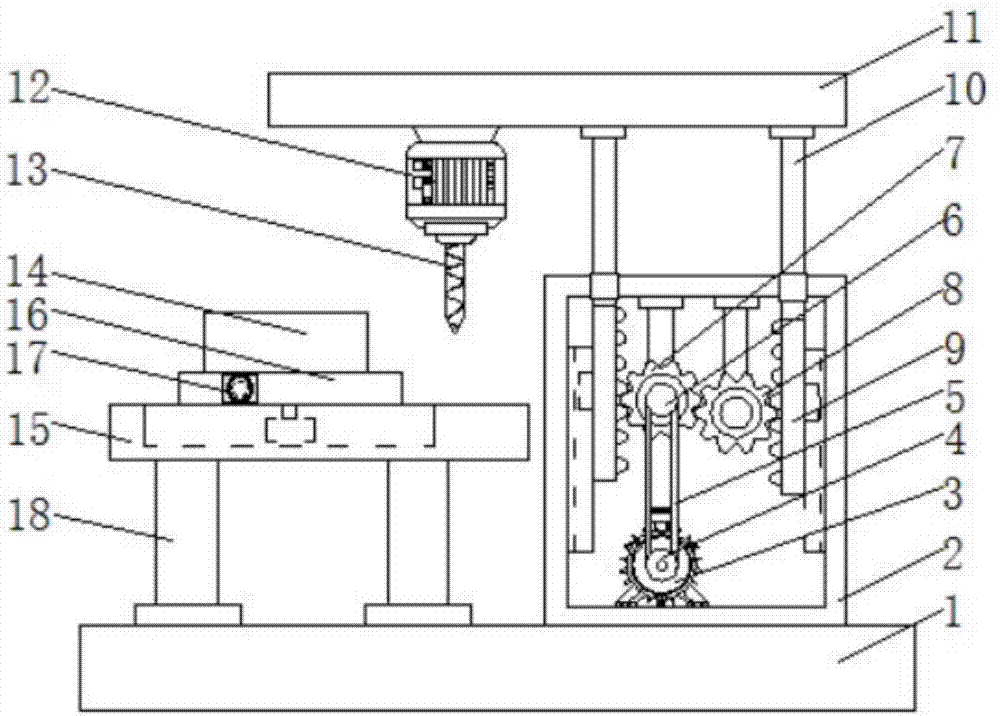

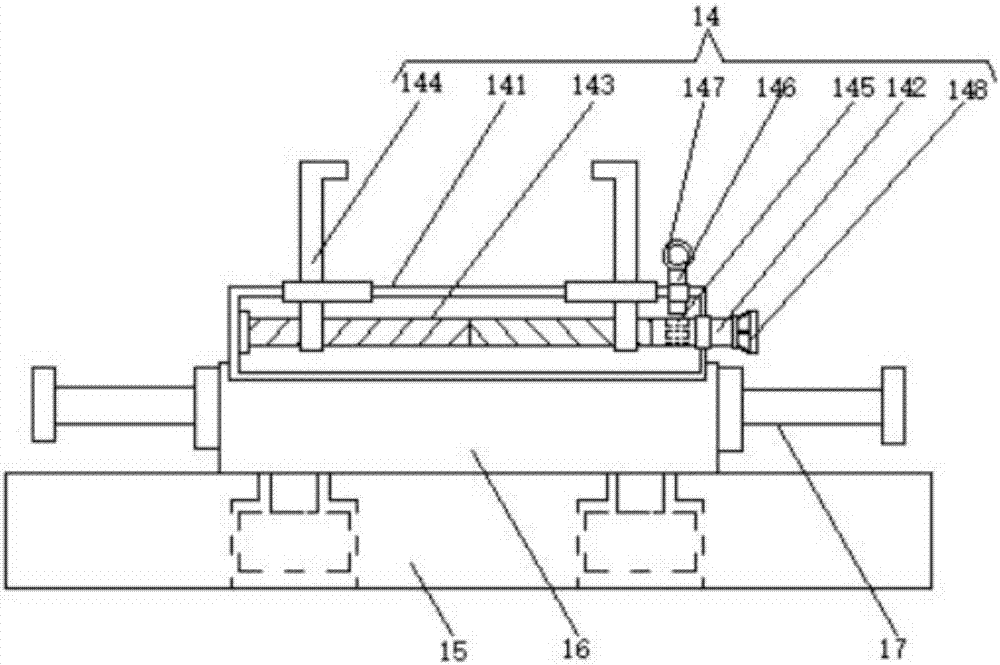

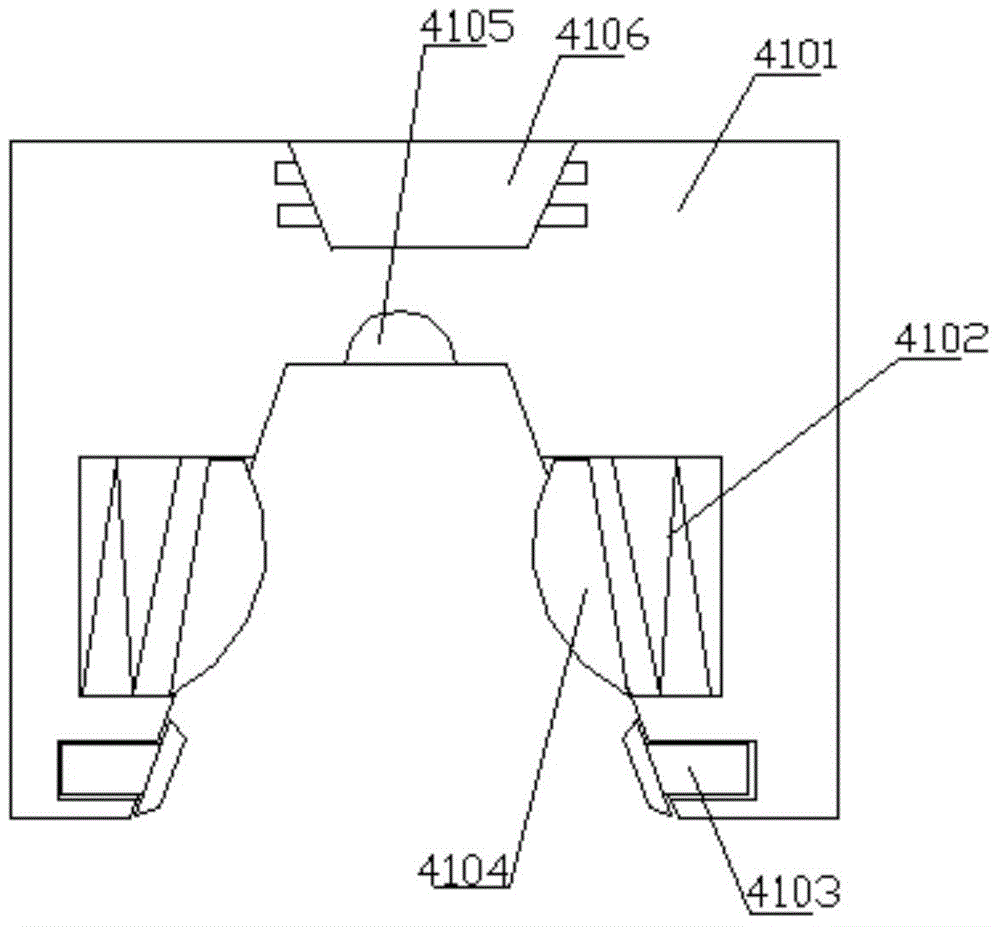

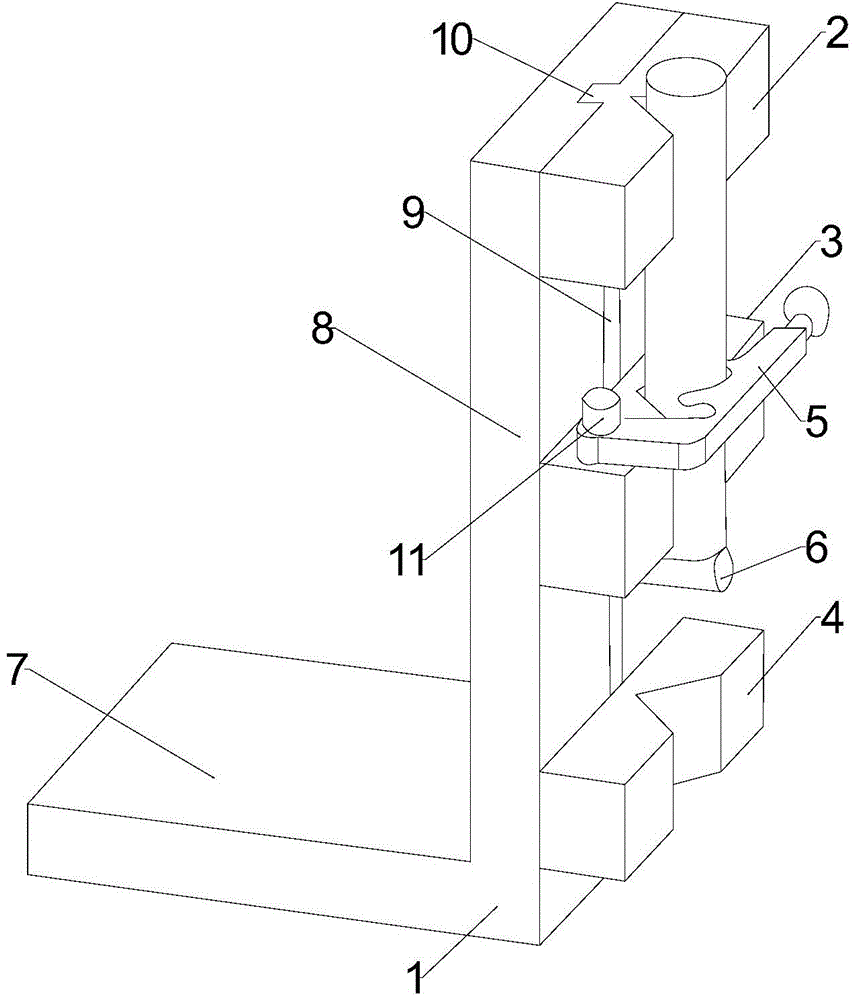

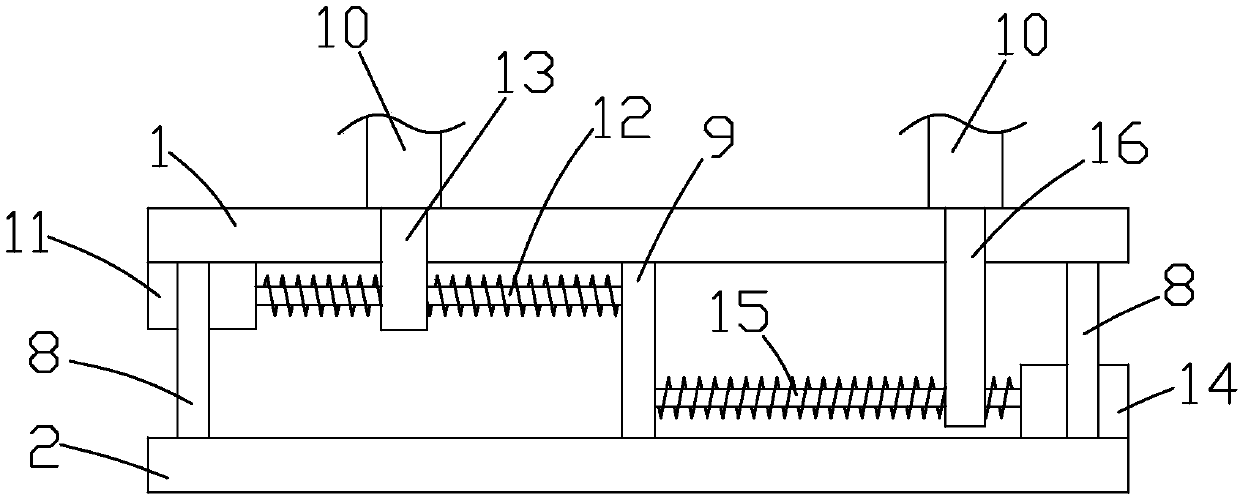

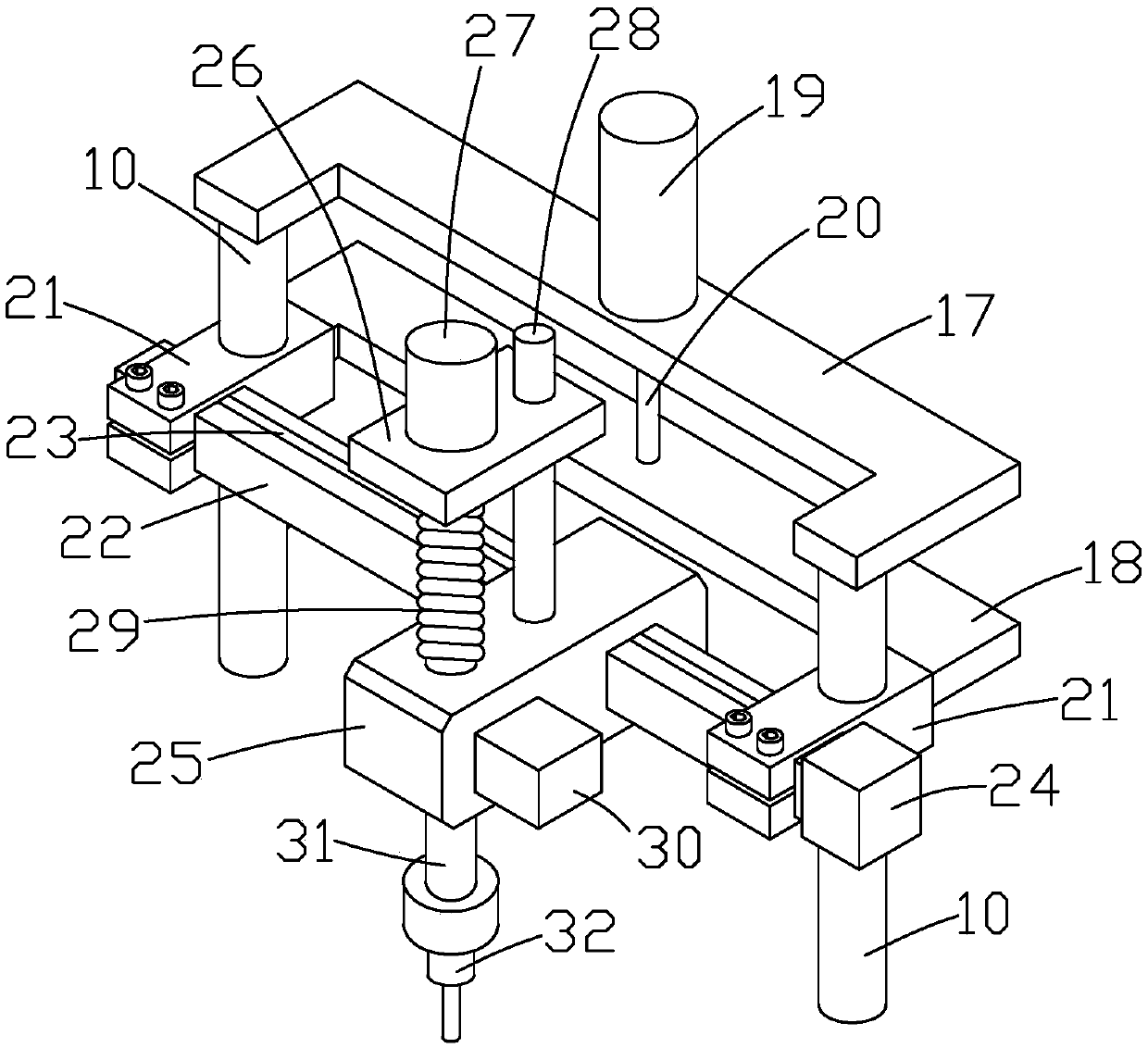

Rotating and clamping type drilling machine for workpieces

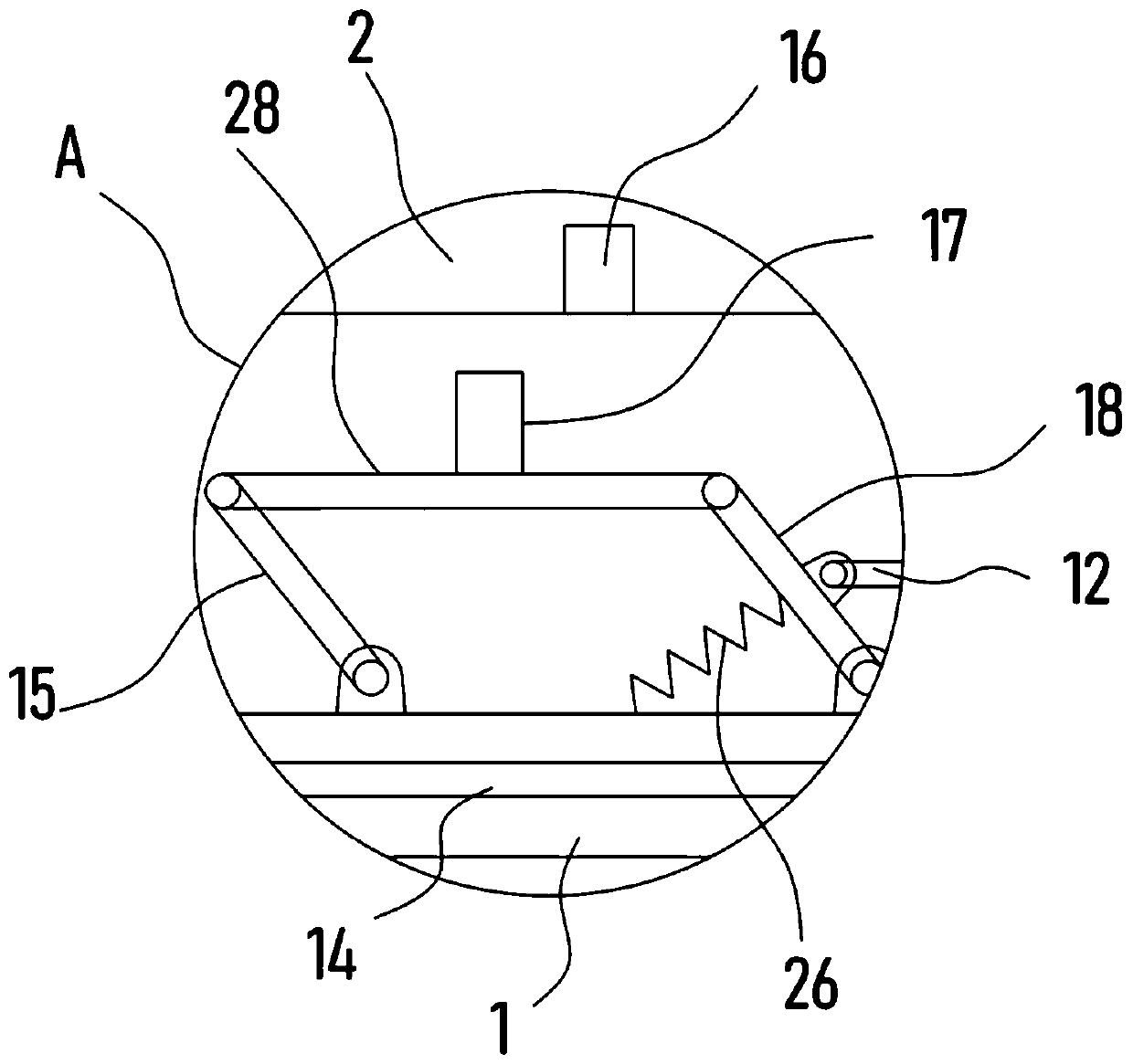

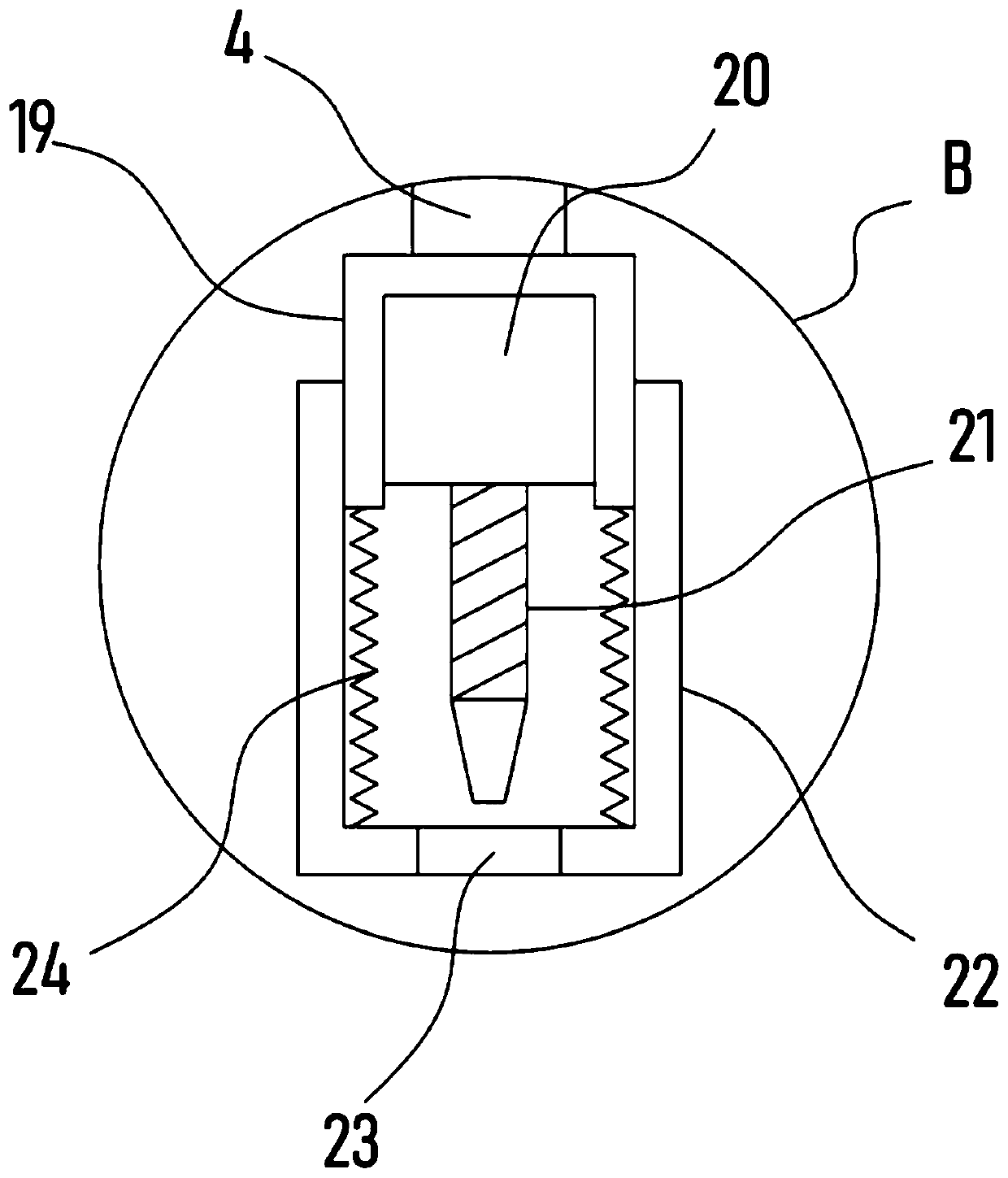

InactiveCN107649702AEasy to processEasy grippingPositioning apparatusMetal working apparatusHydraulic cylinderEngineering

The invention discloses a rotating and clamping type drilling machine for workpieces. The rotating and clamping type drilling machine comprises a worktable, a rotary plate, a clamping plate, transverse sliding rails and lifting plates. The upper end of the worktable is connected with a gantry. A hydraulic cylinder is mounted in the middle of the top end of the gantry. The hydraulic cylinder is connected with a piston rod. The bottom end of the piston rod is connected with the clamping plate. An upper clamping groove is formed in the bottom of the clamping plate. The rotary plate is arranged below the clamping plate. A transverse adjusting block is connected to one end of each transverse sliding rail. A lifting stand column is mounted on the upper side of each transverse adjusting block. Alifting sliding rail is arranged on the side face of each lifting stand column. The lifting plates are slidably arranged in the lifting sliding rails. A lifting screw penetrates through each lifting plate. A drilling motor is mounted on each lifting plate. The drilling motors are connected with drilling bits through drilling rods. By the adoption of the rotating and clamping type drilling machinefor the workpieces, workpiece clamping and direction switching are achieved conveniently, machining of the workpieces is facilitated, and no multi-time clamping fixing and changing of the direction isneeded; and in cooperation with horizontal movement of transverse adjusting blocks and vertical movement of the lifting plates, the drilling work of the drilling bits is facilitated, and the drillingefficiency and quality are improved.

Owner:NANCHANG INST OF TECH

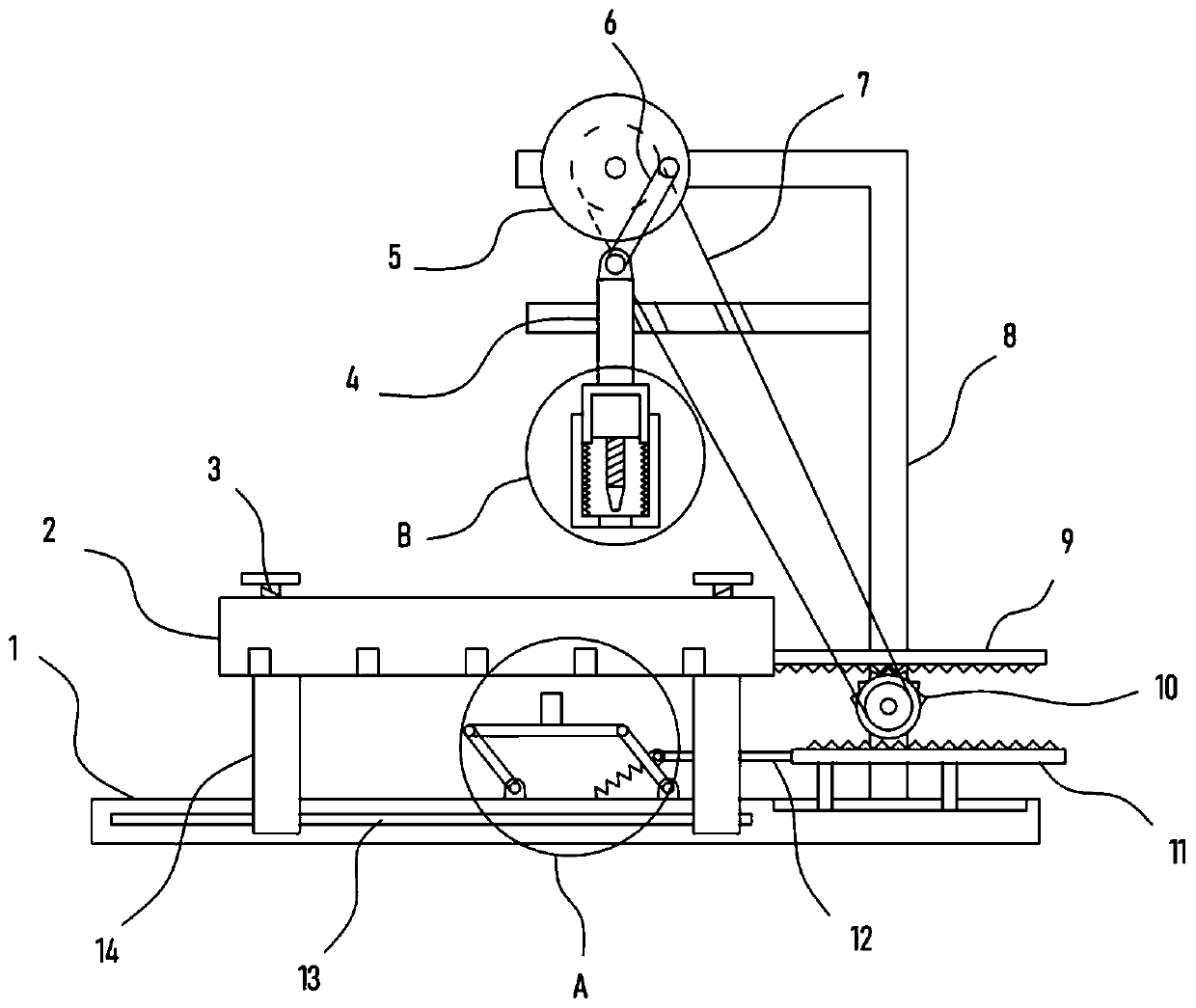

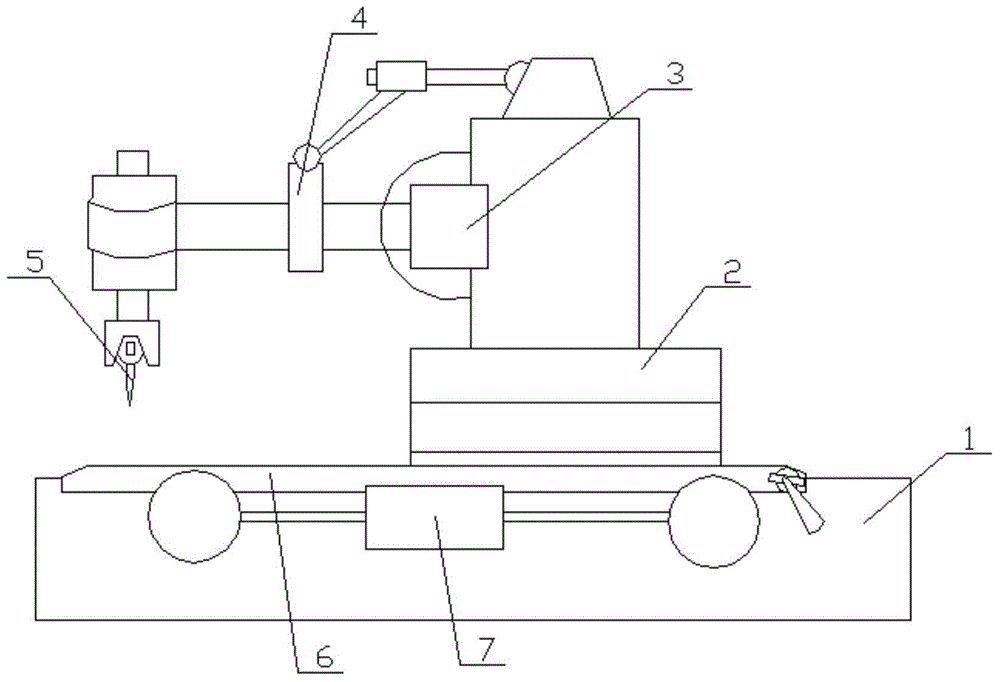

Automatic equidistance punching device for metal strip plate

ActiveCN110125456APlay a fixed effectImprove drilling qualityFeeding apparatusDriving apparatusMetal stripsPunching

The invention discloses an automatic equidistance punching device for a metal strip plate, and relates to the technical field of metal plate punching. The automatic equidistance punching device comprises a bottom plate, wherein a bracket is fixedly arranged on the bottom plate; a fixed frame is mounted on the bracket in a sliding mode; a locking mechanism for metal plate clamping is arranged on the fixed frame; a rack I fixed with the fixed frame is in engaged connection at the upper side of an incomplete gear; a swing mechanism which is fixed with the fixed frame intermittently is arranged onthe bottom plate; and the swing mechanism comprises a rack II which is positioned at the lower side of the incomplete gear and is in engaged adaption to the incomplete gear. Each time the fixed frameof the automatic equidistance punching device drives the metal plate to leftwards move by certain distance, a drill bit moves downwards by certain distance to accomplish single-time drilling of the metal plate; in a step type leftward moving process of the metal plate, equidistance automatic drilling operation of the metal plate is accomplished, so that degree of automation is high; and meanwhile, the swing mechanism can be arranged to realize fixing effect during metal plate drilling, so that drilling quality of the metal plate is greatly improved.

Owner:FUYU PRECISION COMPONENTKUNSHANCO LTD

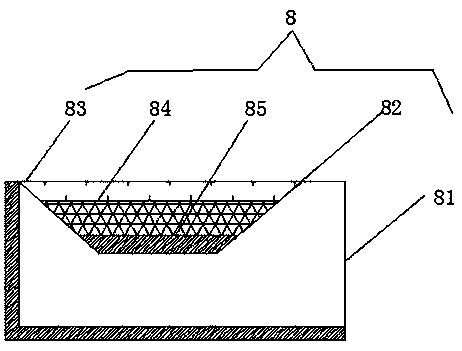

Full-automatic plate material drilling machine

A full-automatic plate material drilling machine comprises a machine frame, the machine frame is provided with a positioning frame for fixing a plate material and a drilling machine for drilling the plate material, the positioning frame is provided with a positioning groove for making the plate material placed longitudinally and positioned, the bottom of the positioning groove is provided with discharge ports, each discharge port is provided with a supporting limit block, and each supporting limit block is arranged on a first gas cylinder; the top of the positioning groove is connected with a feeding device, the feeding device comprises a placing frame, the placing frame is provided with a groove body for making the plate material transversely placed, the groove body is vertically arranged, the bottom of the groove body is provided with a supporting seat, the side edge of the bottom of the groove body is provided with a plate material outlet, and the supporting seat is provided with a second gas cylinder for pushing the plate material out of the plate material outlet; a guide channel is arranged between the plate material outlet and the top of the positioning groove.

Owner:恒达传动禹城有限公司

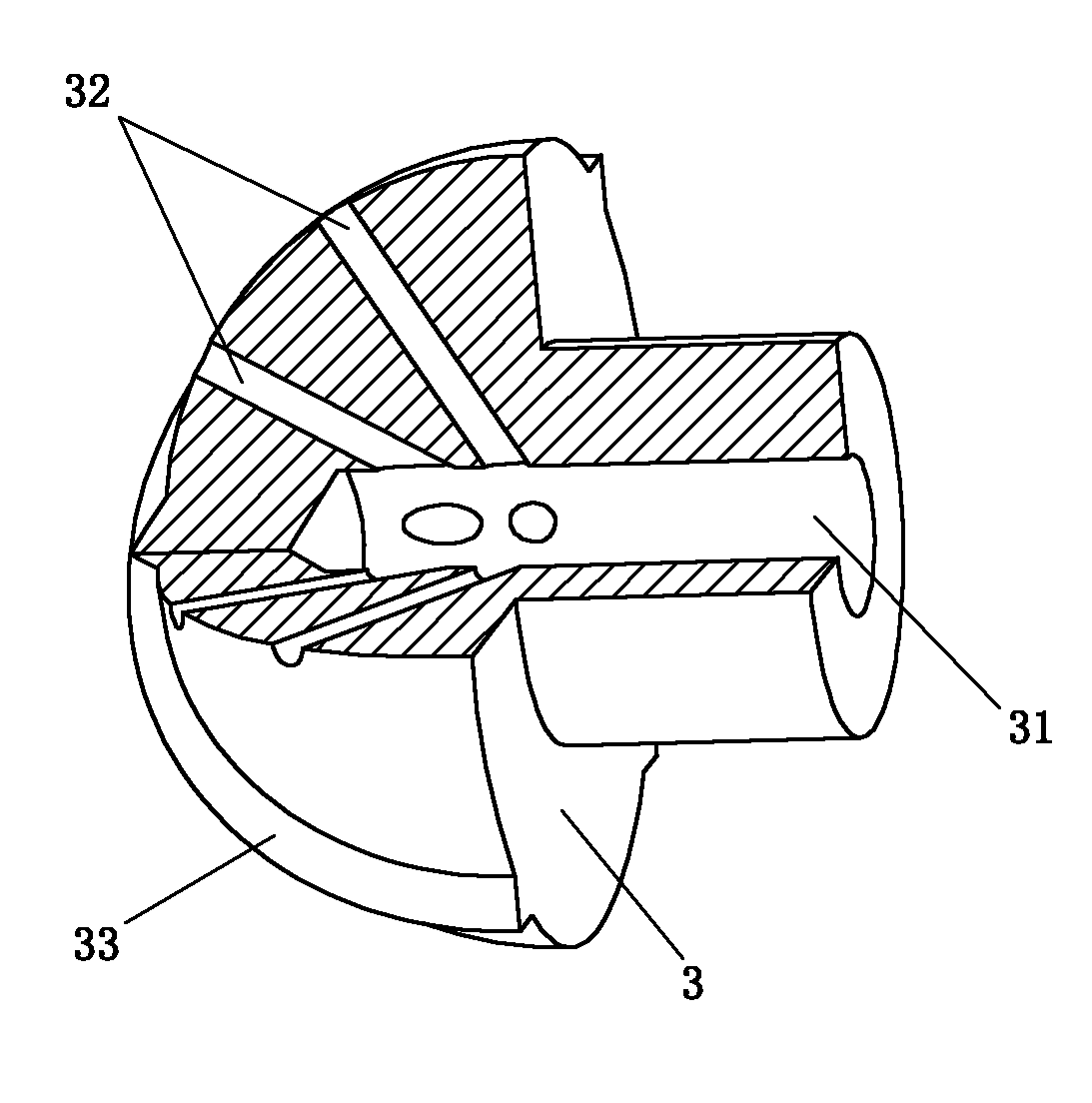

Self-rotating jet drilling device

ActiveCN102031931AAchieve stress reliefIncrease gas well productivityDrill bitsLiquid/gas jet drillingSprayerEngineering

The invention relates to a self-rotating jet drilling device, which comprises a cylindrical shell, wherein the back end of the shell is provided with a tubular connecting part; a rotating part is rotatably arranged in the shell; the outer diameter of the rotating part is corresponding to the inner diameter of the shell; the front end of the rotating part is provided with a cylindrical extending section along the axial direction; the extending section extends out of the front end of the shell and is fixedly connected to a sprayer along the axial direction; the periphery of the rotating part is provided with a plurality of helical grooves; an axial through hole is arranged on the rotating part; blind holes are arranged in the sprayer from back to forth; the blind holes are communicated with the through hole; and the surface of the front end of the sprayer is provided with a plurality of jet holes connected to the blind holes and is also fixed with a cutter. The device can increase the drilling efficiency and the aperture quality, can form a jet hole unloading strip having a certain of diameter and depth on a coal layer by the double action of the cut drilling and jetting, can efficiently increase the gas well capacity on the coal layer and can increase the gas recovery ratio of the coal layer.

Owner:山西尚道能源开发有限公司

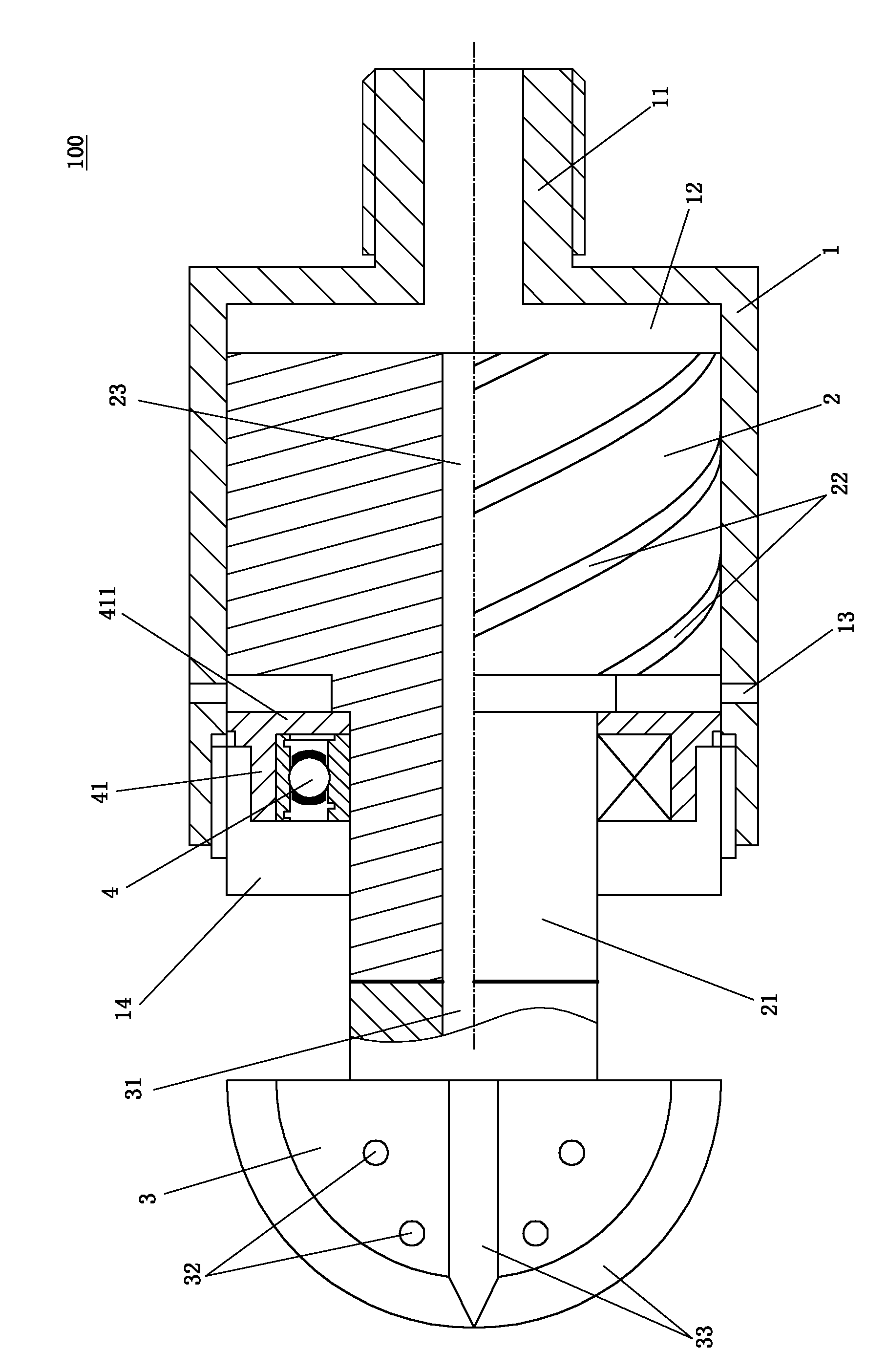

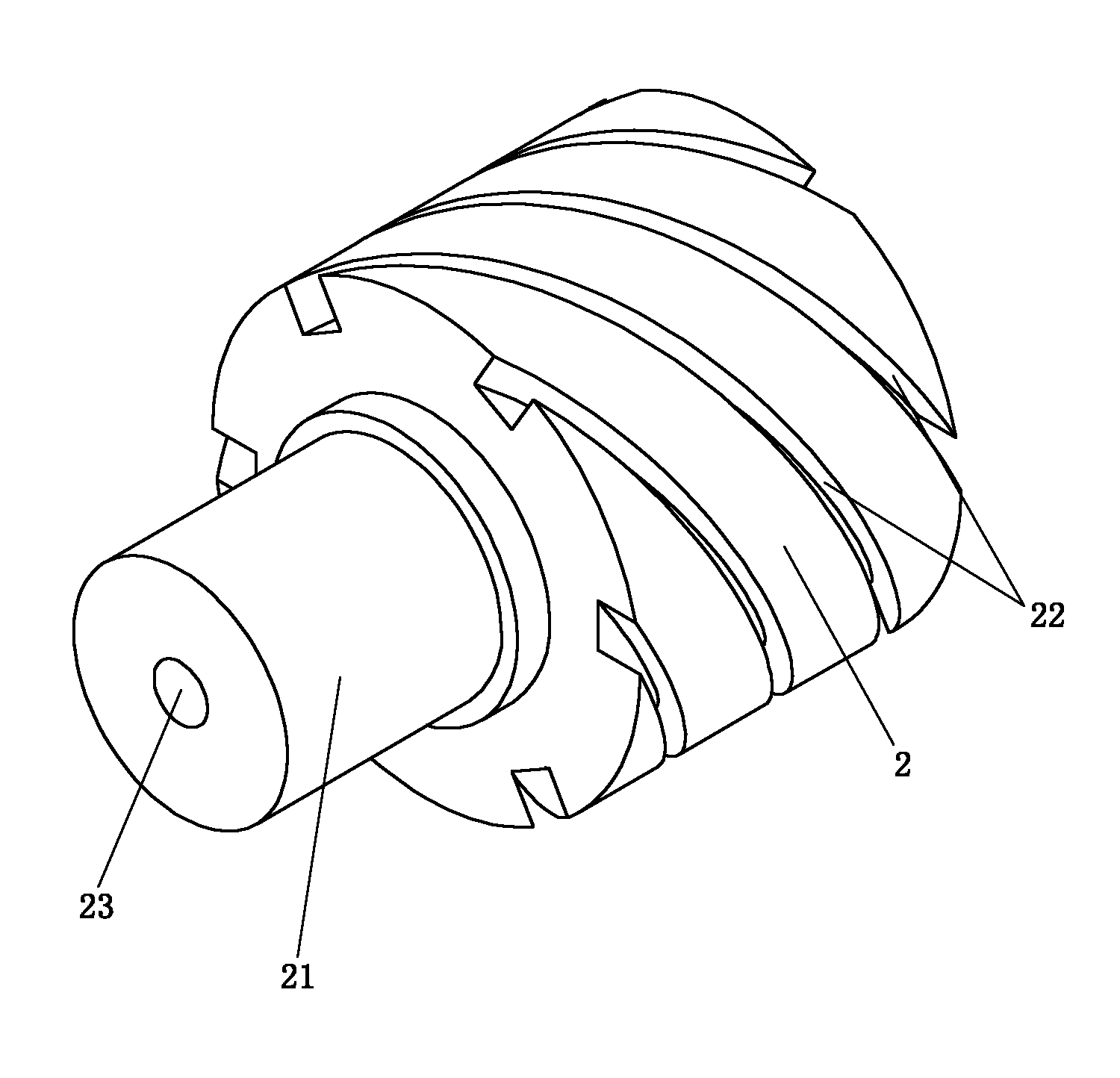

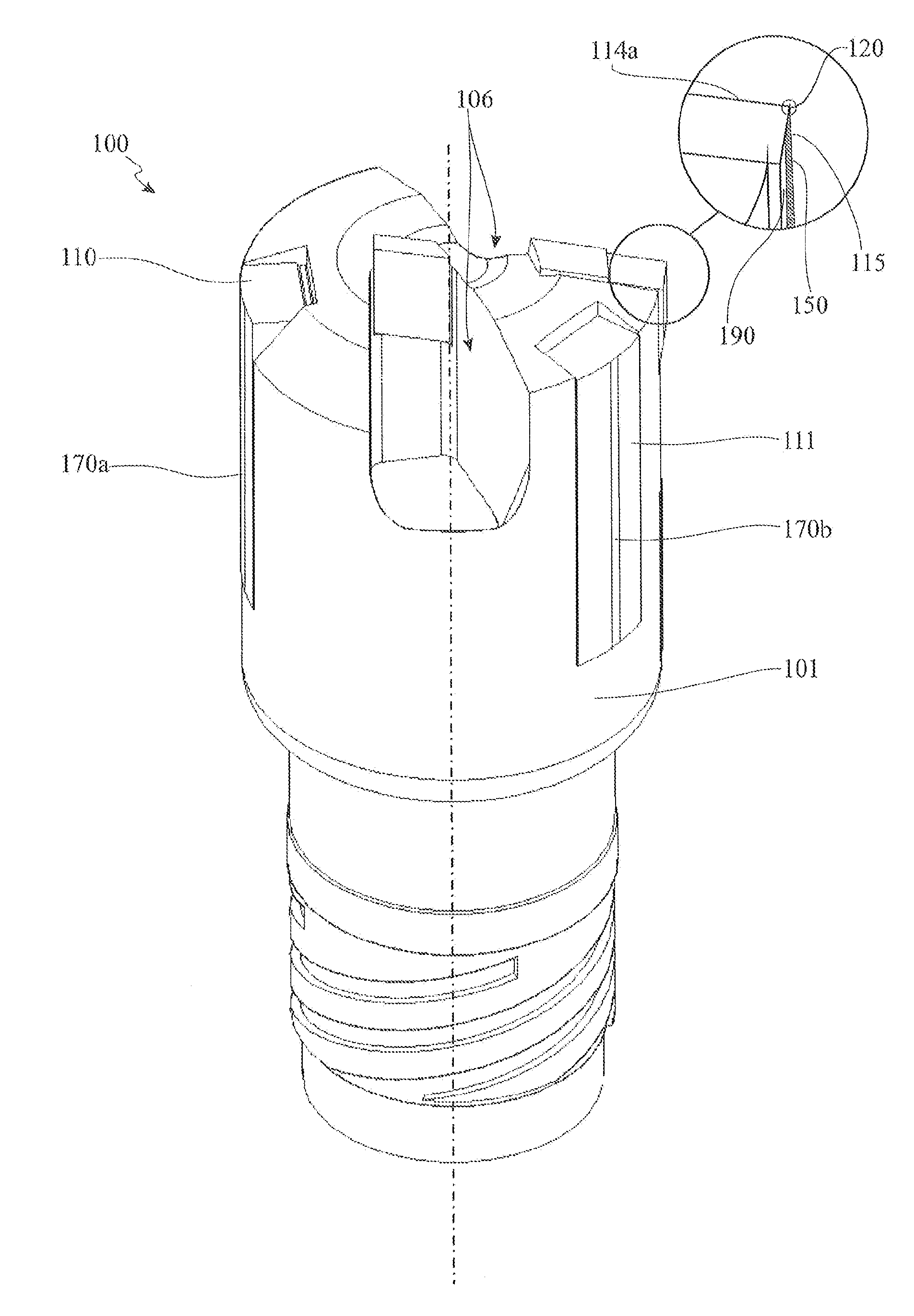

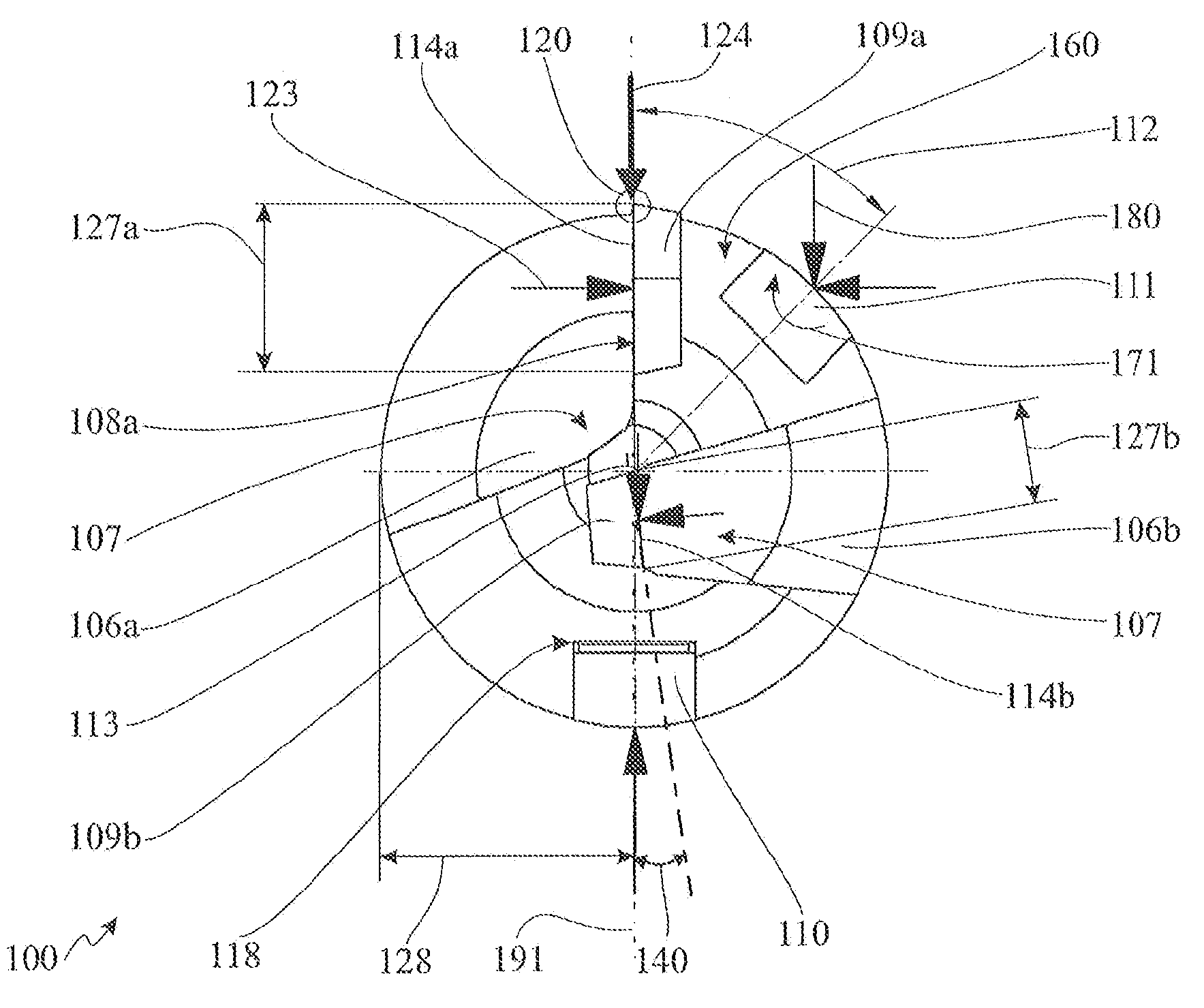

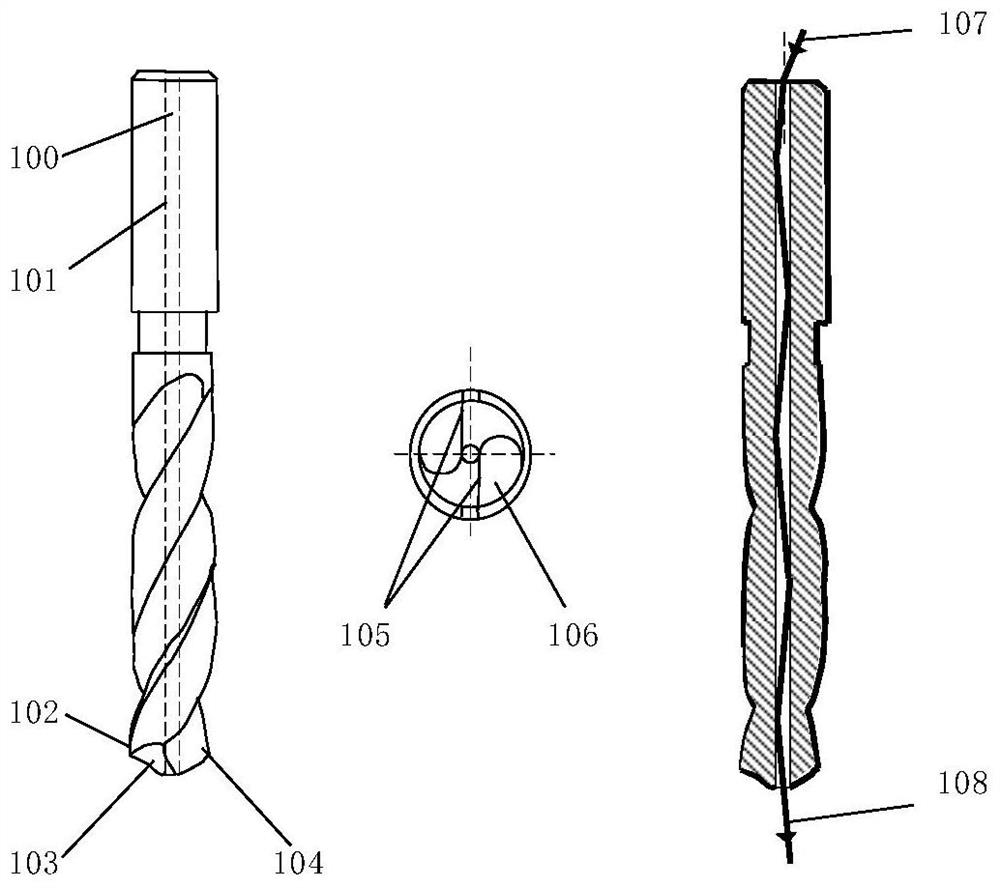

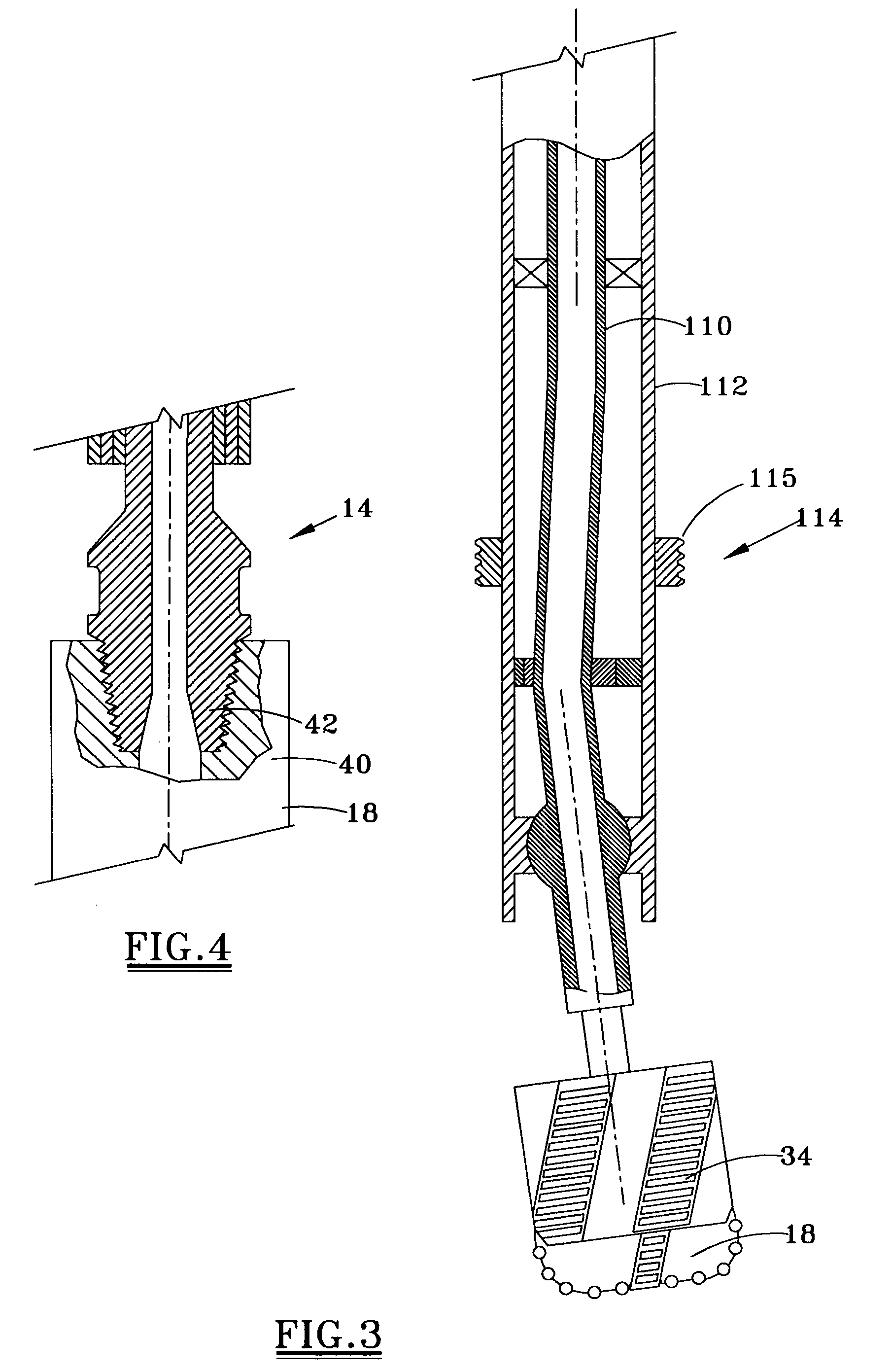

Drill head for a deep hole drilling tool for BTA deep hole drilling, and deep hole drilling tool

InactiveCN102985203AExtend your lifeVibration trend lowTransportation and packagingMetal working apparatusEngineeringDeep hole

A drill head (100) for a BTA / STS or ejector deep hole drilling tool, comprising a drill head body (101) that can be rotated about an axis of rotation (113), having a drilling side (160) and a hollow channel (107) with a chip collecting opening (106) on the drilling side (160), a cutting blade (109) located thereon, which has a main cutting blade edge (114) and a secondary cutting blade edge (115), wherein the secondary cutting blade is arranged on a radial outer side of the cutting blade and the main cutting blade edge (114) and the secondary cutting blade edge (115) form a cutting blade corner (120) and define a face (108), which is arranged adjacent to the chip collecting opening (106), and bearing pads (110, 111), wherein a first bearing pad (111) is arranged in the circumferential half of the drill head body (101) that is averted away from the face (108); and a second bearing pad (110) is arranged diametrically opposite the cutting blade corner (120). At the same time, it is provided that the first bearing pad (111) is arranged offset from the cutting blade corner (120) by a bearing pad angle (112), measured in the circumferential direction of the drill head (100). According to the invention, the bearing pad angle (112) is less than 70 degrees.

Owner:TBT TIEFBOHRTECHN

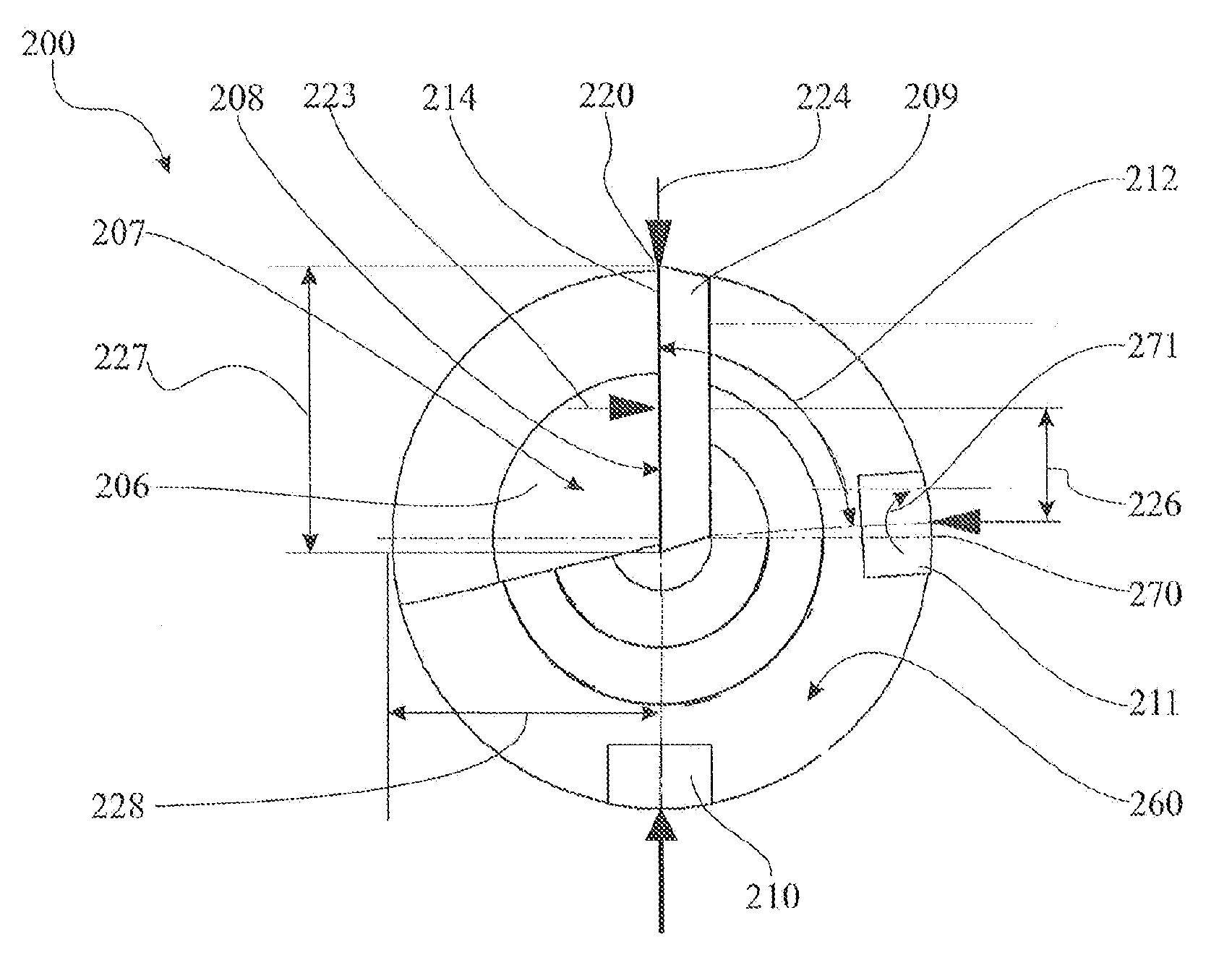

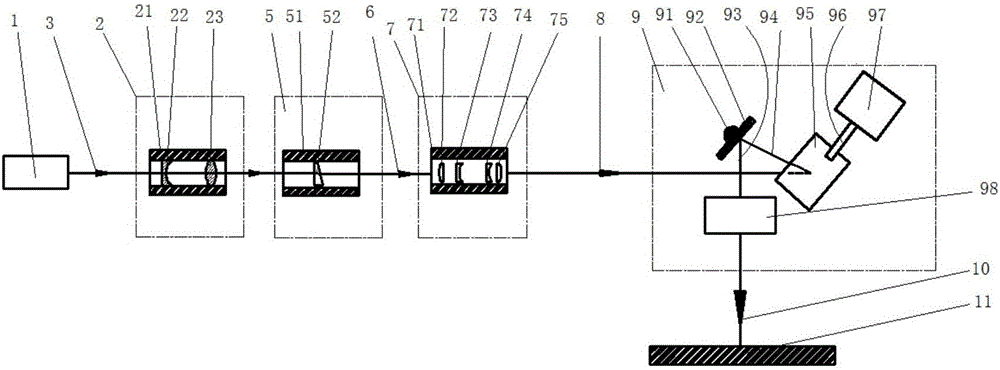

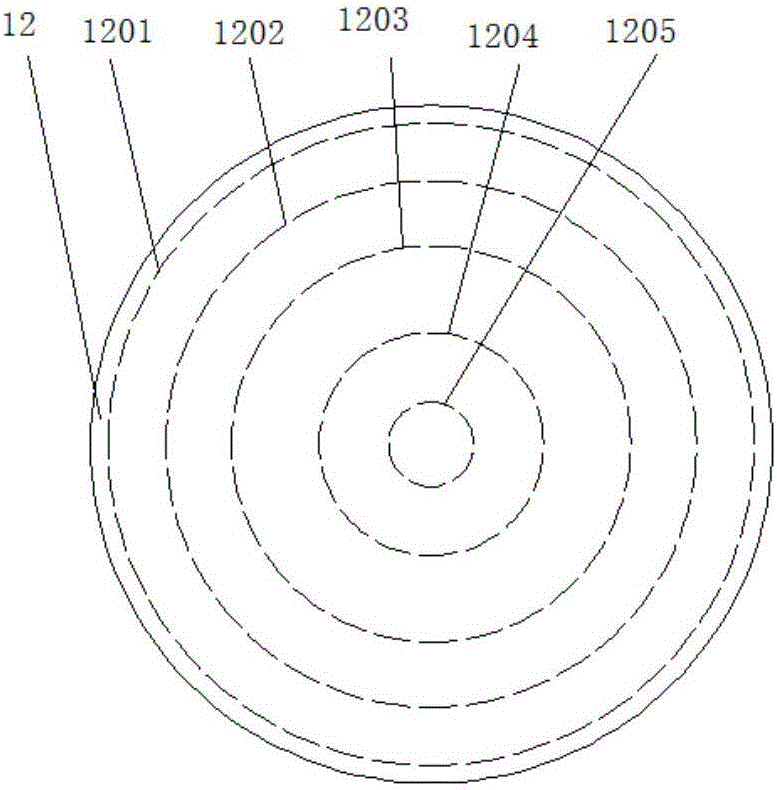

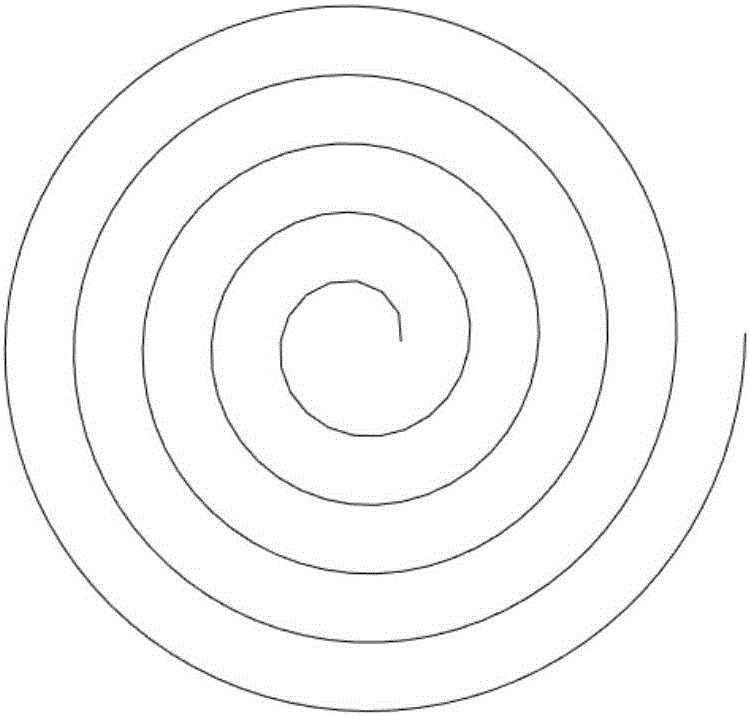

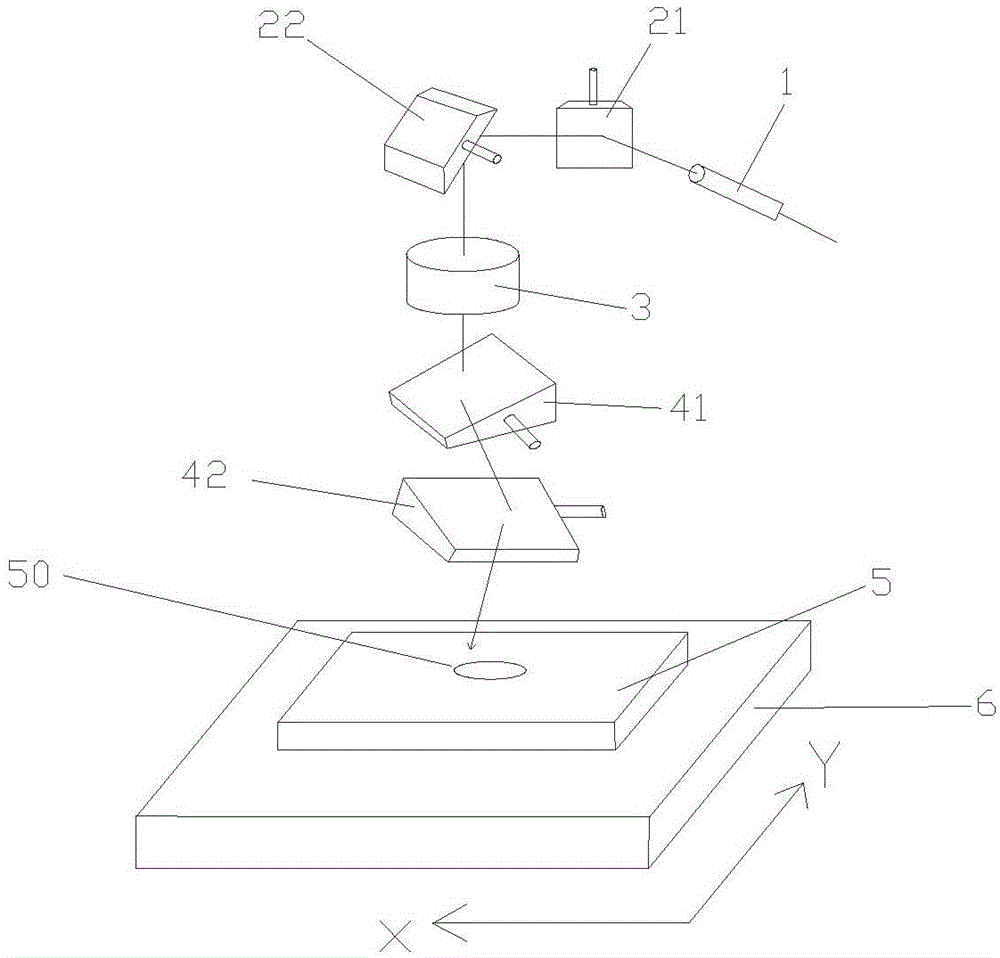

Large-size high-speed micropore drilling system

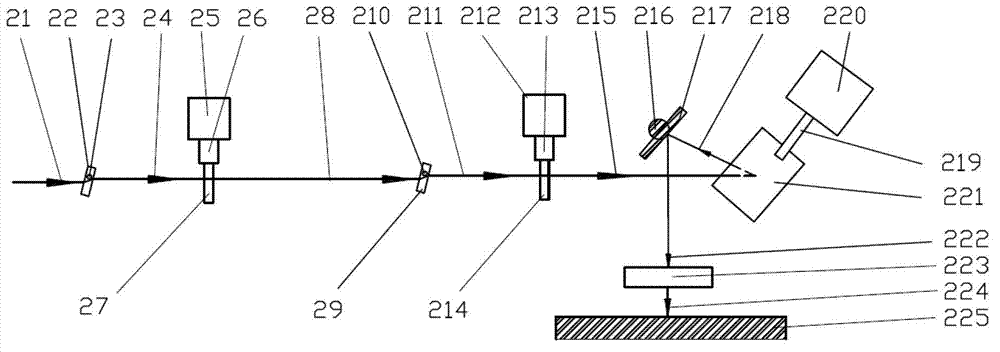

ActiveCN103203552AQuick switchImprove drilling efficiencyLaser beam welding apparatusFine structureLight beam

The invention relates to a large-size high-speed micropore drilling system which comprises a light beam space modulation module and a galvanometer scanning flat field focusing module. Particularly, the light beam space modulation module, particularly a plurality of transparent flat optical elements are combined with the galvanometer scanning flat field focusing module, the light beam space modulation module is used for modulating the space trace of a laser light beam, the galvanometer scanning flat field focusing module is used for focusing laser and rapidly switching laser spots at different machining positions, and the two modules are in division and cooperation. By the aid of the scheme, large-size micropore drilling can be realized, laser drilling efficiency and drilling quality are greatly improved, the large-size high-speed micropore drilling system is quite suitable for drilling straight holes, laser light beam filling and scanning shapes and sizes can be dynamically controlled, micropore drilling pore diameters can be dynamically changed, and fine structures can be flexibly machined.

Owner:张立国

Inner and outer layer copper thickness-differentiated thick copper circuit board and preparation method thereof

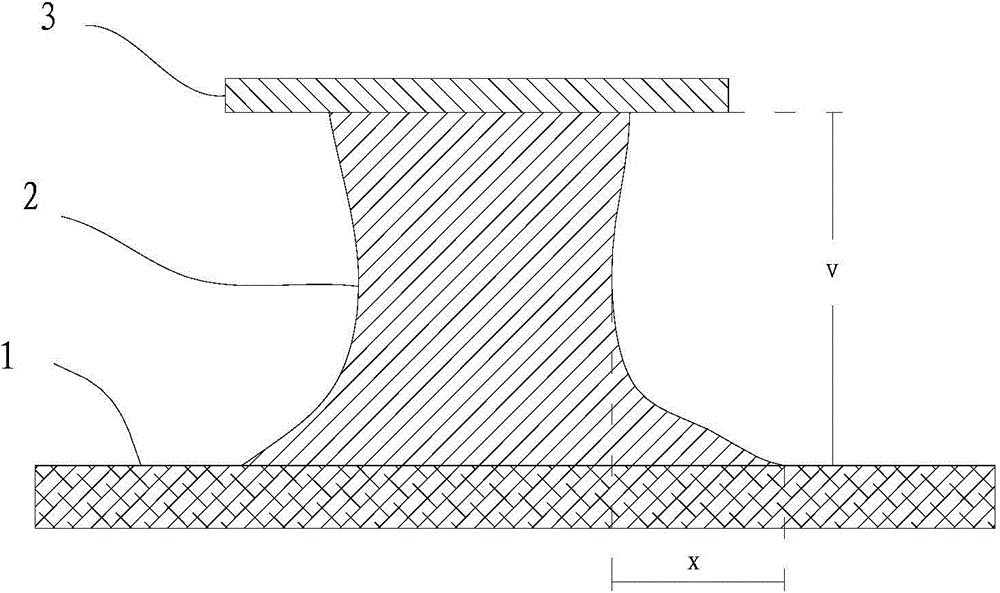

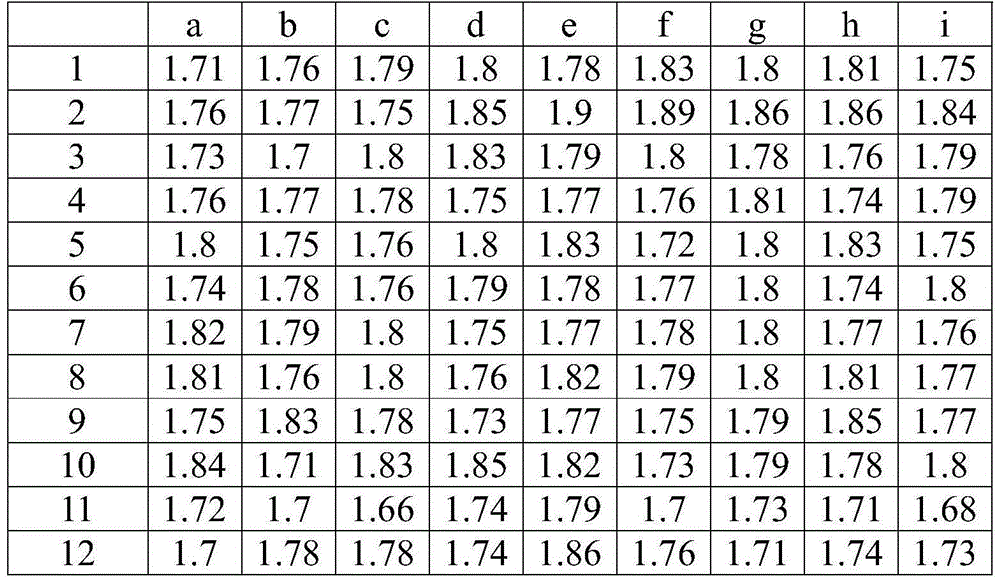

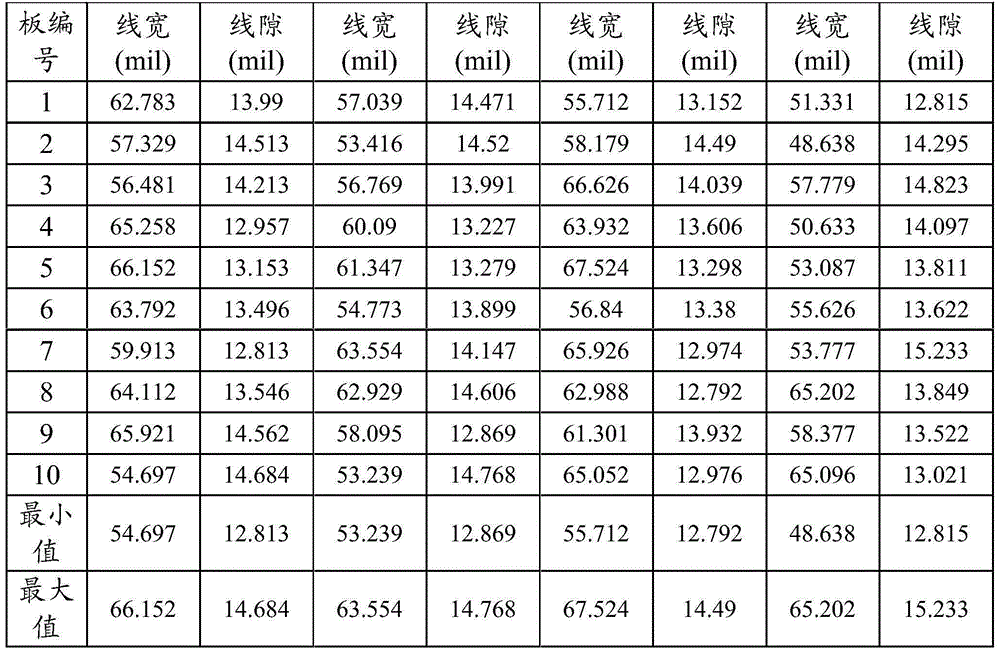

ActiveCN104486914AEvenly filledUniform pressure distributionConductive material chemical/electrolytical removalMultilayer circuit manufactureProcess engineeringMechanical engineering

The invention discloses an inner and outer layer copper thickness-differentiated thick copper circuit board and a preparation method thereof and belongs to the PCB technical field. The method includes the steps of board pressing process, drilling process and etching process. According to the board pressing process, a prepreg of which the resin content is equal to or larger than 65% is selected; hot pressing process and cold pressing process are sequentially adopted to perform board pressing; the parameter conditions of the hot pressing process are as follows: pressure ranges from 250 to 450 PSI, temperature ranges from 175 to 220 DEG C, vacuum degree ranges from 0 to 68 cm Hg, and time ranges from 90 to 150 min; and the parameter conditions of the cold pressing process are as follows: pressure ranges from 50 to 450 PSI, temperature ranges from 165 to 220 DEG C, and time ranges from 130 to 230 min. According to the preparation method, a laminated structure and a board lamination mode are adopted, and temperature rising and pressurization control are utilized in cooperation, and therefore, the filling of flowing resin can be uniform, and pressure distribution is uniform when board pressing is performed, and an excellent filling effect can be realized, and air bubble generation can be avoided, and press fit can be excellently realized.

Owner:KALEX MULTI LAYER CIRCUIT BOARD (ZHONGSHAN) CO LTD

Guide rail machining device

ActiveCN104924080AImprove rigidityHigh strengthOther manufacturing equipments/toolsSynchronous motorMotor drive

A guide rail machining device comprises a working table. A drilling tool main shaft driven by a DC synchronous motor is arranged on the working table, arranged on a transverse guide rail and connected with a lead screw and nut mechanism driven by a motor. A supporting table for supporting a workpiece and a pressing cylinder for fixing the workpiece are installed on the working table. A pull rod for pulling the workpiece is arranged at the front end of the working table. By means of the structure, the guide rail is moved through the pull rod and fixed through the pressing cylinder, the drilling tool main shaft is only moved transversely without being moved longitudinally, and therefore the hopping of the drilling tool main shaft is reduced, and the machining quality of the guide rail is improved. The lead screw and nut mechanism driven by the motor mainly comprises a motor, a lead screw and a nut pair, wherein the motor drives the lead screw to rotate and drives the nut pair to move as well.

Owner:LISHUI UNIV

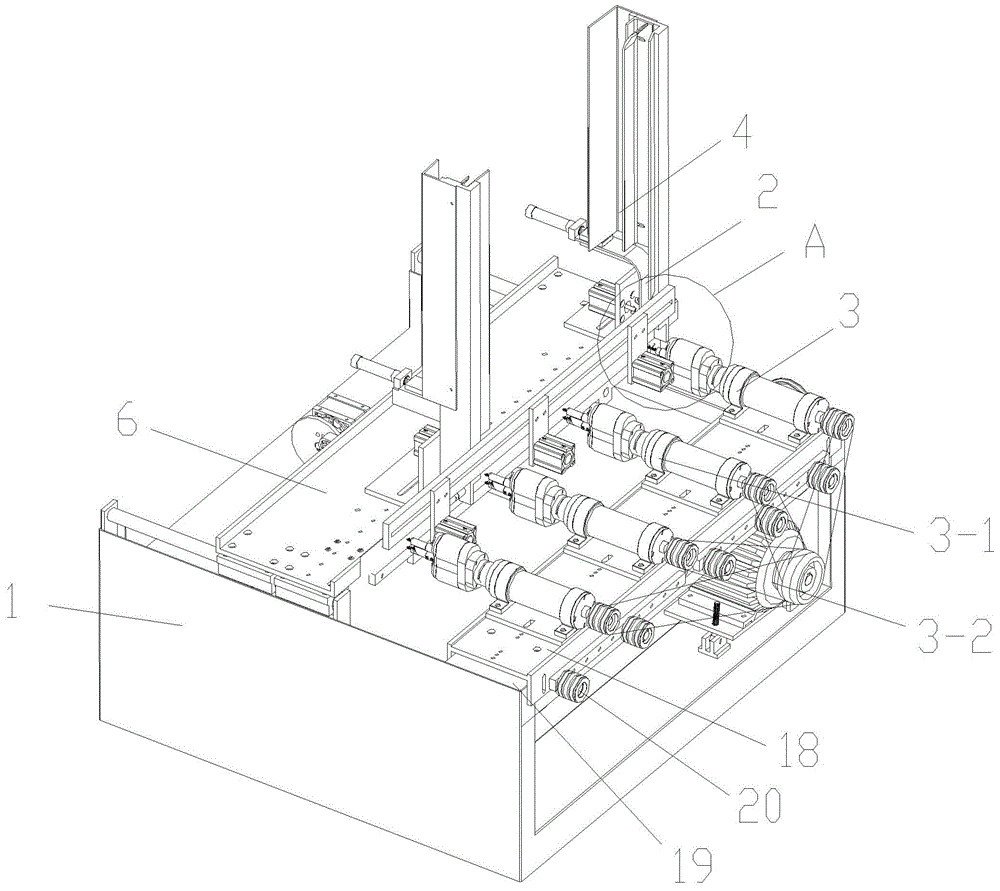

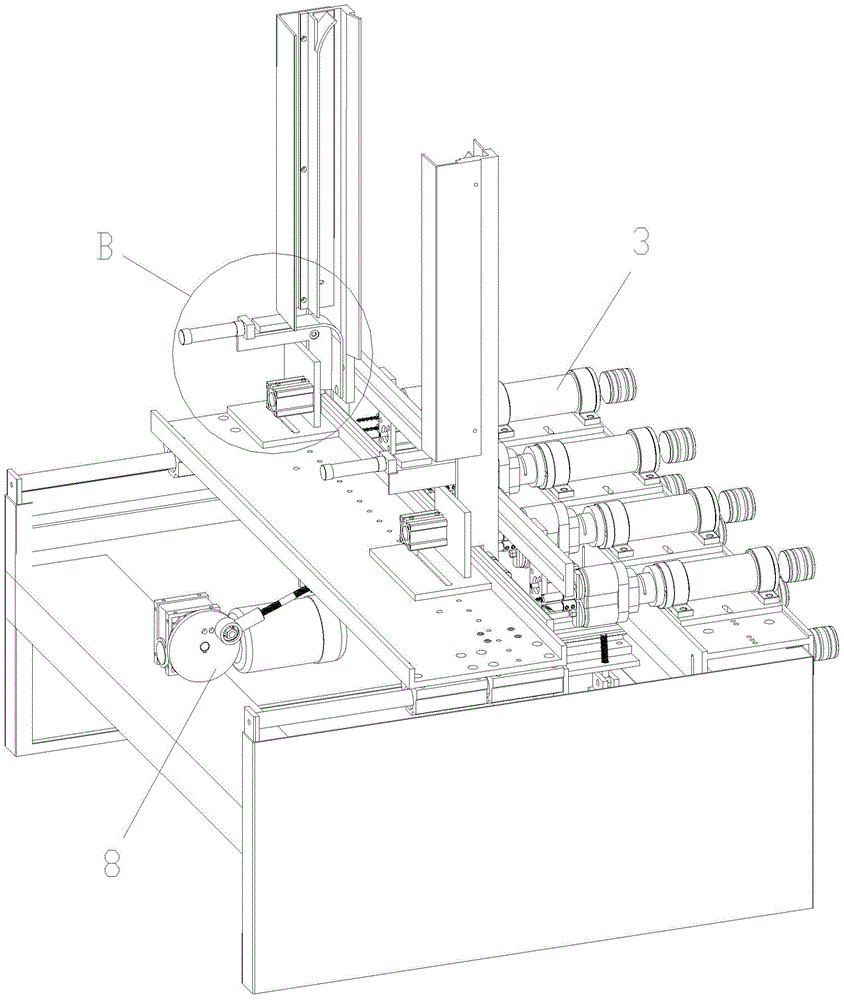

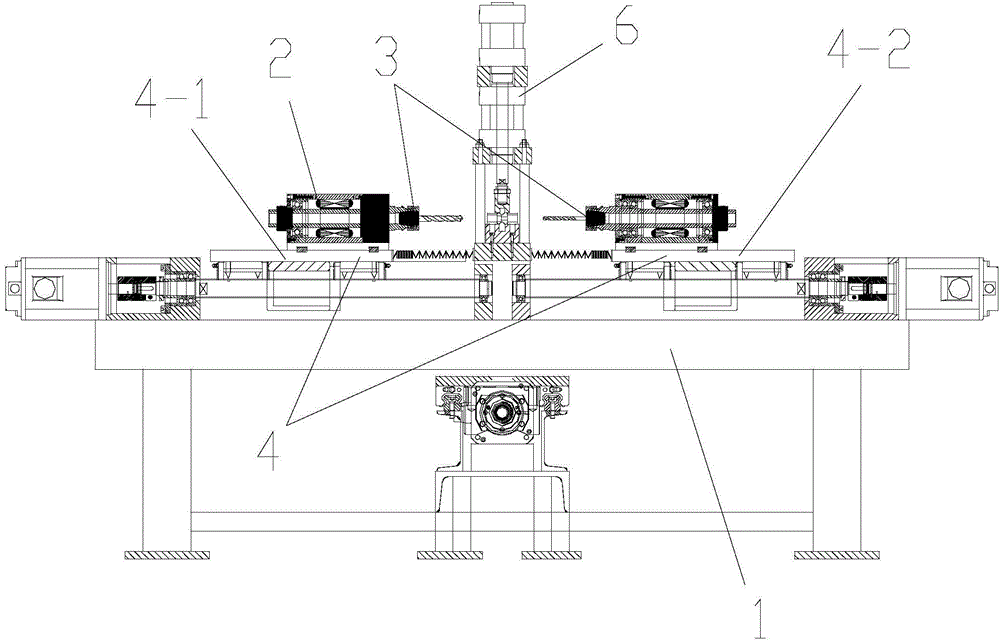

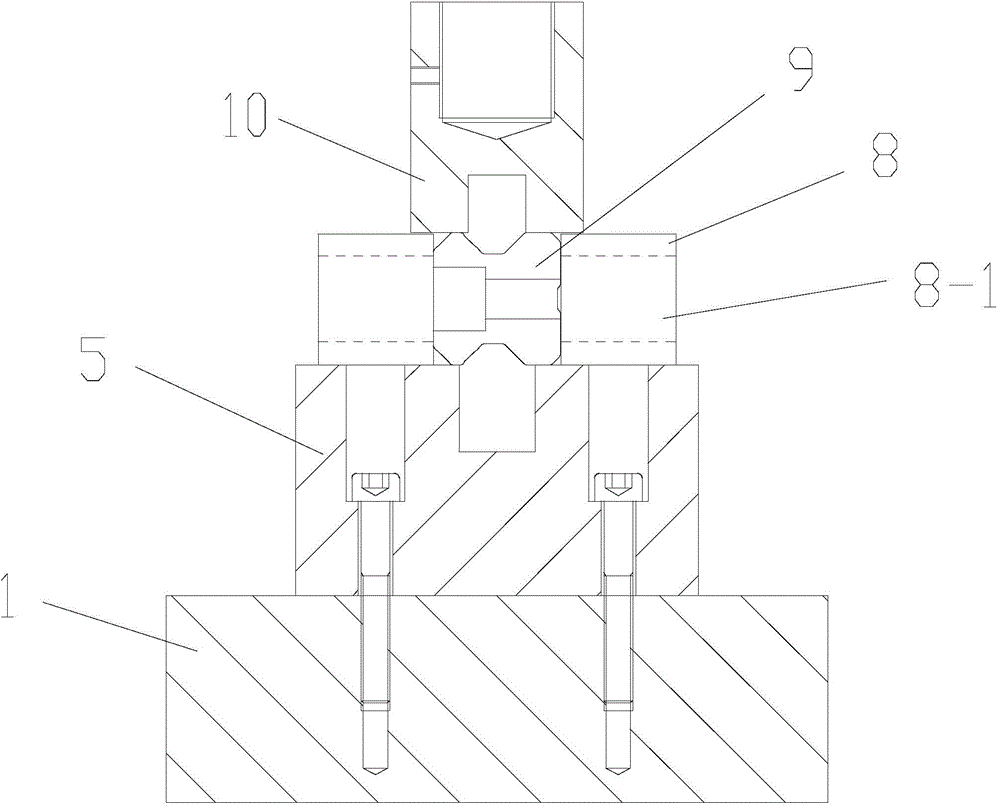

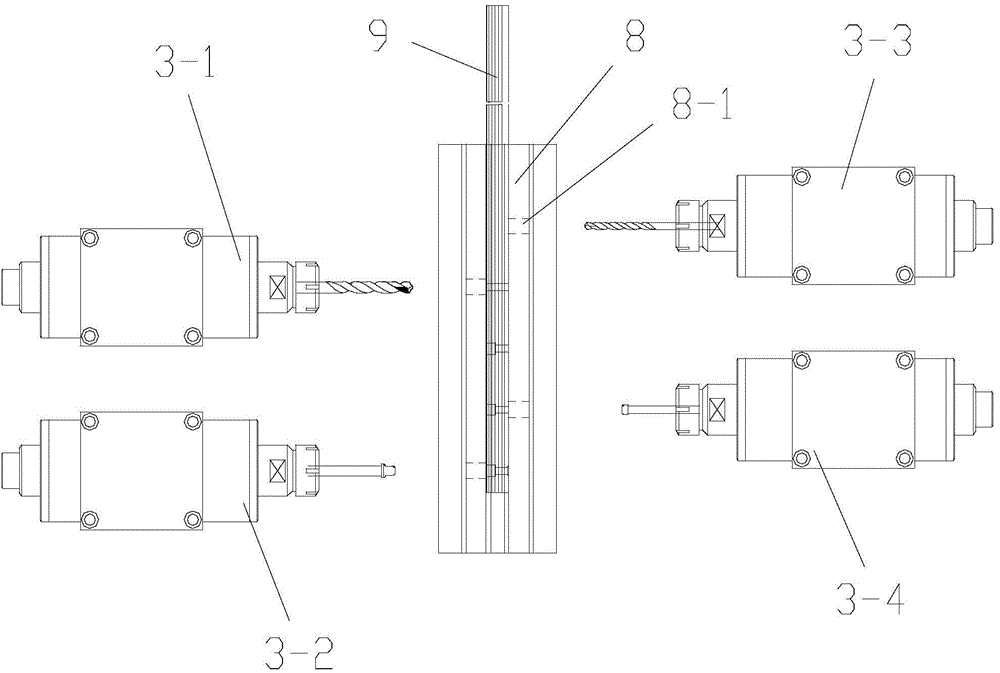

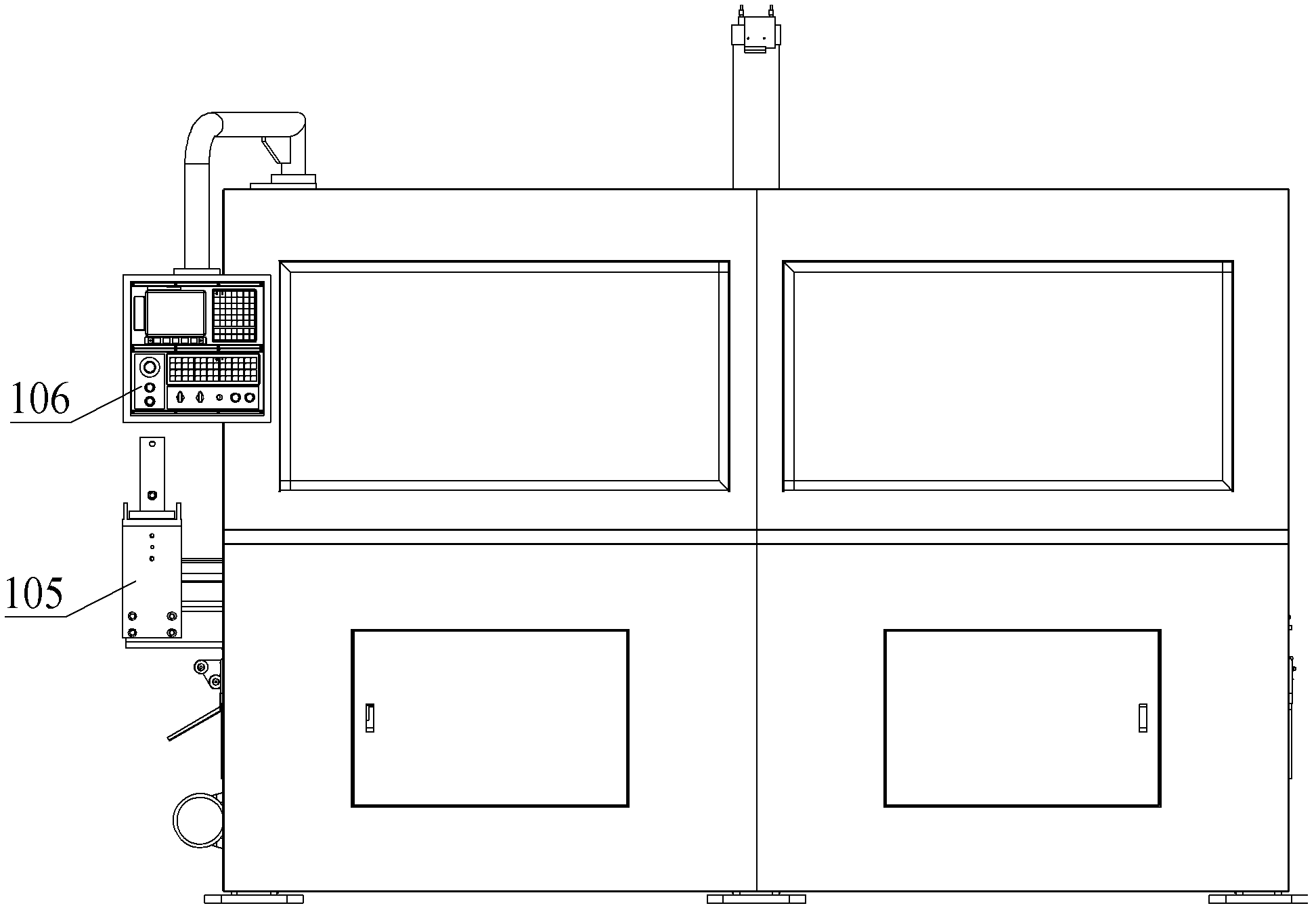

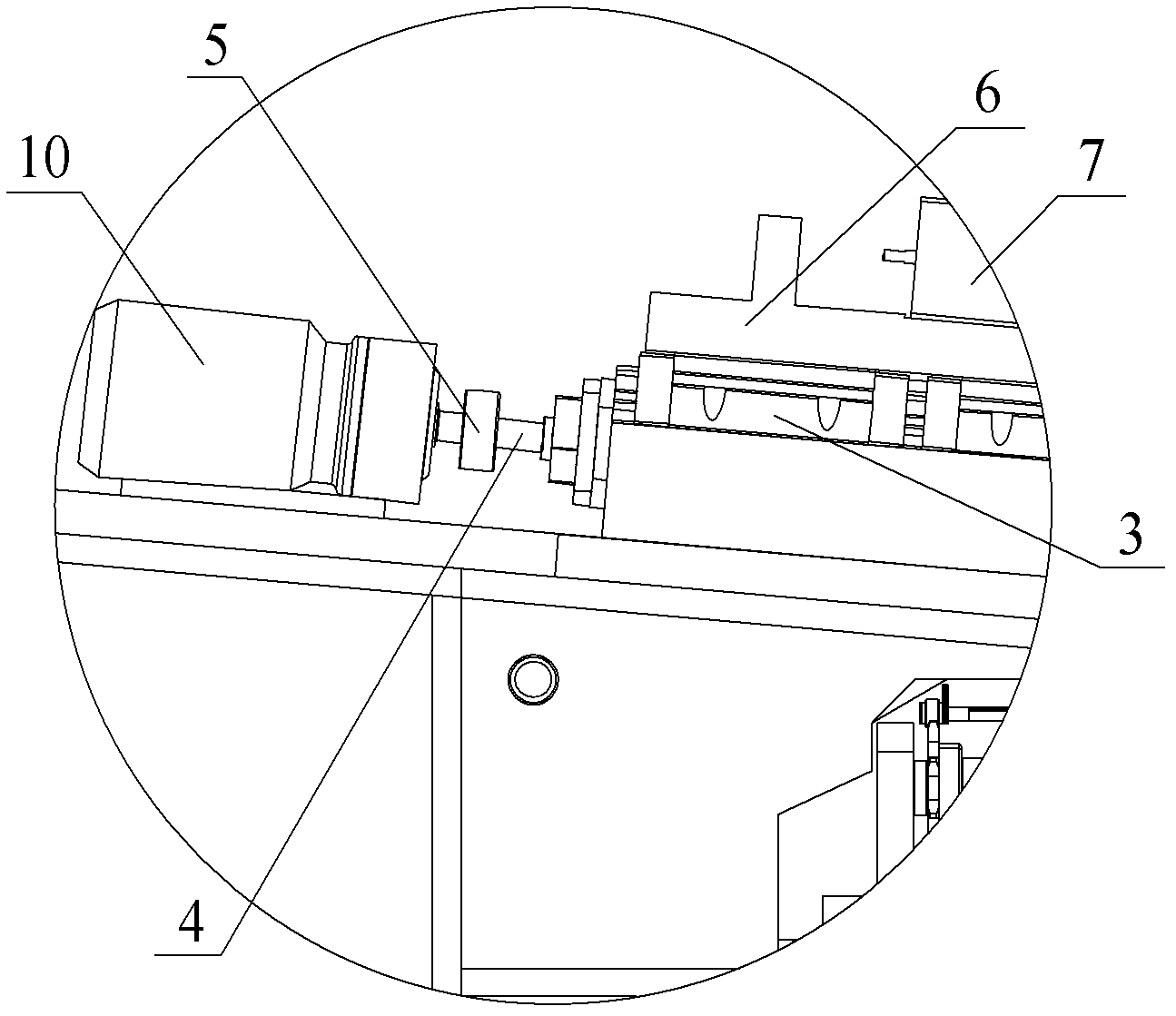

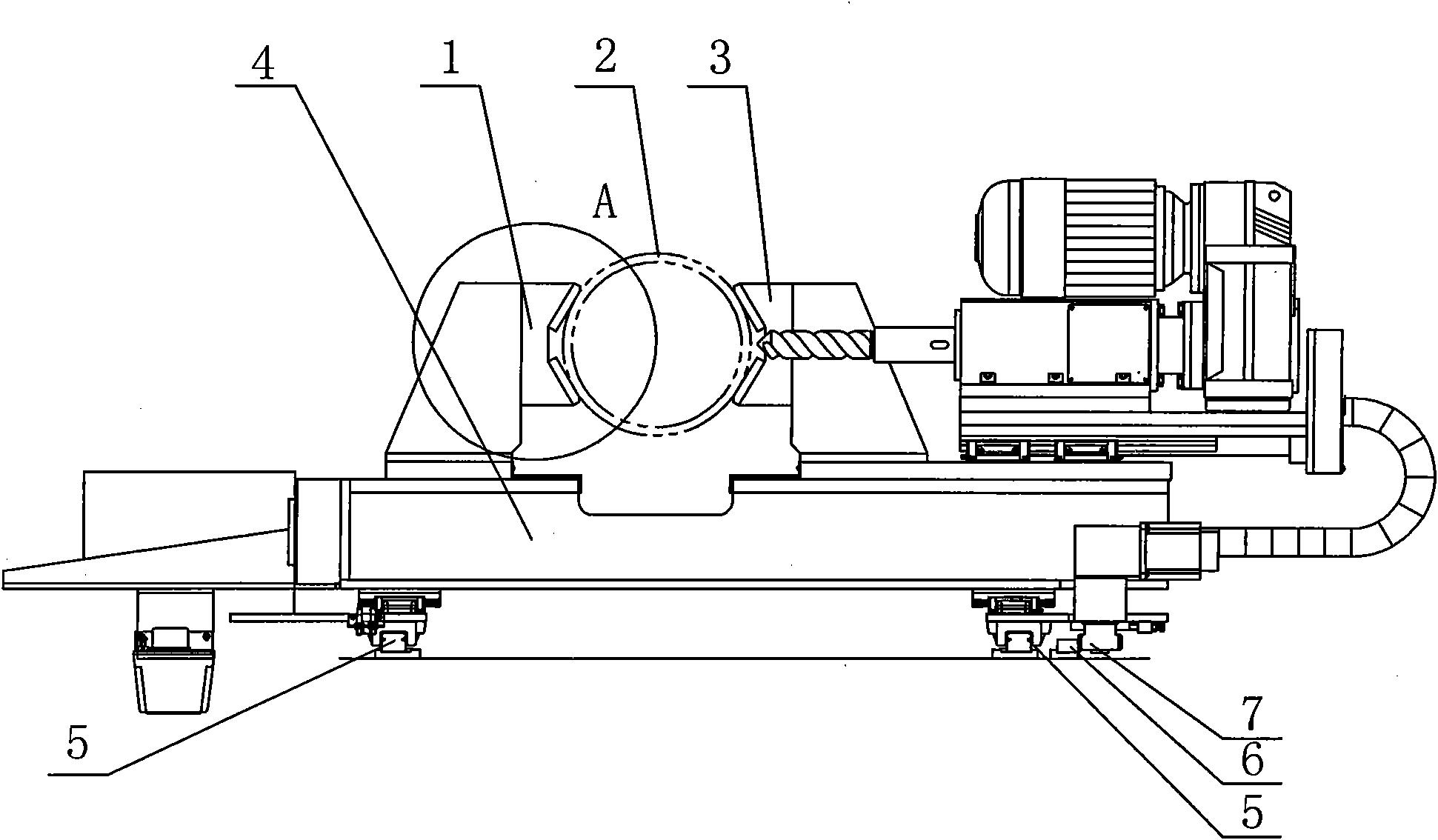

Multistation numerical control drilling center of high-precision super-long work piece

ActiveCN102218555AHigh degree of equipment automationImprove drilling quality and efficiencyPositioning apparatusBoring/drilling componentsAluminum compositesSteel belt

The invention discloses a multistation numerical control drilling center of a high-precision super-long work piece. The drilling center provided by the invention comprises a host, a feeding system, a blanking system, a pneumatic and vacuum system, a drill adjusting, drill breaking and bald drilling detection and identification system and a CNC (Computer Numerical Control) and operation system, wherein a guide rail bracket is fixed on a main body rack; a linear guide rail is fixed on the guide rail bracket; a linear guide rail slide block is spliced and sheathed on the linear guide rail; a motor bracket is fixed by virtue of bolts or welded on the linear guide rail slide block; a variable frequency motor is fixed on the motor bracket by virtue of bolts; a ball screw and a drilling servo motor are fixed on the guide rail bracket and are connected by virtue of a coupler; a host hydraulic pressing mechanism comprises a hydraulic cylinder, a hydraulic pressing tool and a connecting rod; the hydraulic cylinder is fixed on the main body rack by virtue of bolts; and one end of the connecting rod is hinged with the hydraulic cylinder, and the other end of the connecting rod is hinged with the hydraulic pressing tool. By utilizing the multistation numerical control drilling center, the machining quality and the production efficiency of stainless steel belt holes can be improved, and the integral quality of a steel-aluminum composite conductor rail is guaranteed.

Owner:CHINA CREC RAILWAY ELECTRIFICATION BUREAU GRP +1

Automatic drilling frame for instrument panel beam drilling device

InactiveCN104439387AMove quicklyEasy to moveDrilling/boring measurement devicesWork benchesPiston rodDrill

The invention discloses an automatic drilling frame for an instrument panel beam drilling device. The automatic drilling frame comprises a supporting frame and an electric drill. A supporting plate is arranged on the supporting frame. A sliding rail is arranged on the supporting plate. A sliding block is arranged on the sliding rail in a sliding fit mode. The two ends of the supporting plate are each provided with a baffle. An electric drill mounting plate is arranged on the sliding block. The electric drill is in rotating connection with the electric drill mounting plate through a mounting support. An electric drill positioning frame is arranged on the electric drill mounting plate. An air cylinder is arranged on one baffle. A piston rod of the air cylinder is connected with the sliding block after penetrating through the baffle. According to the automatic drilling frame, drilling can be rapidly completed, the drilling stability is good, and therefore the drilling efficiency and quality are improved.

Owner:CHONGQING HUAQING AUTOMOBILE PARTS

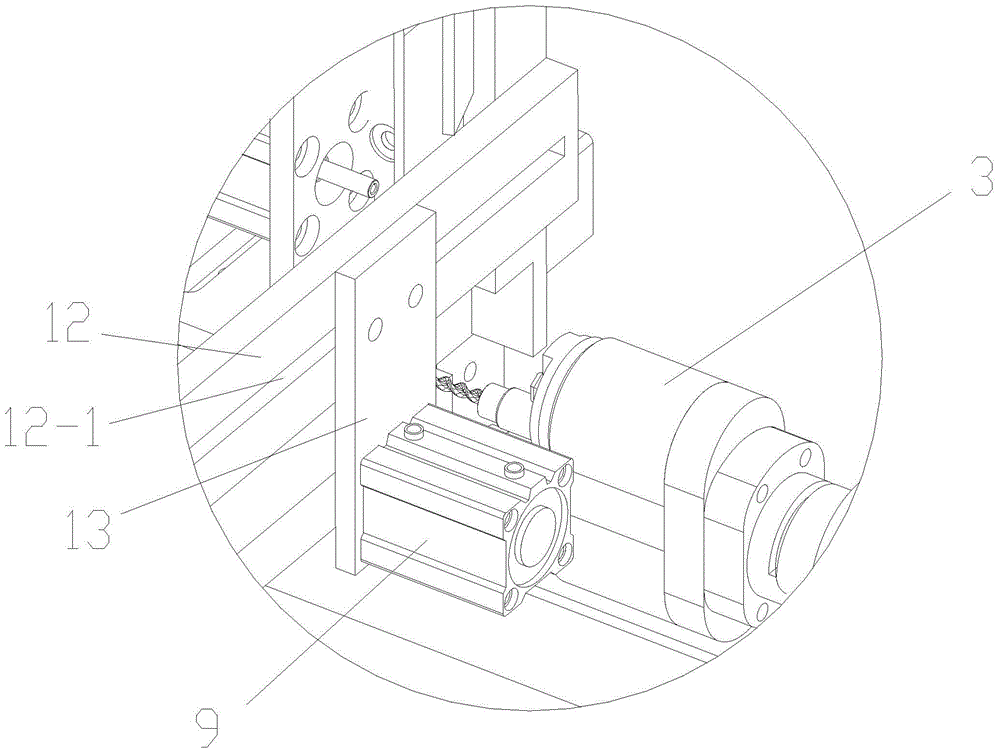

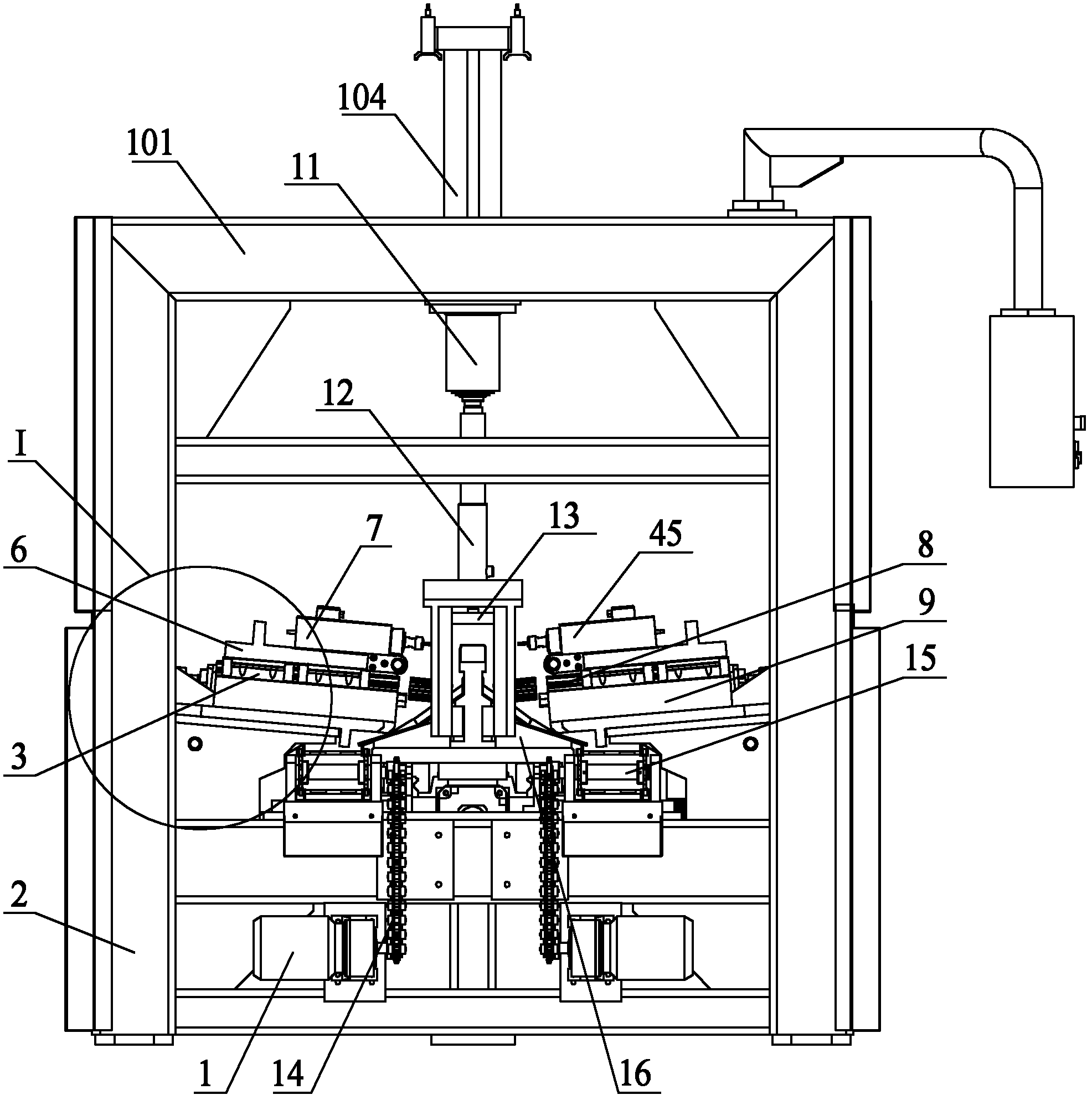

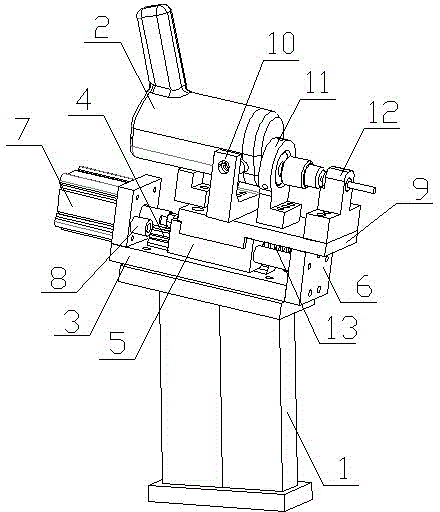

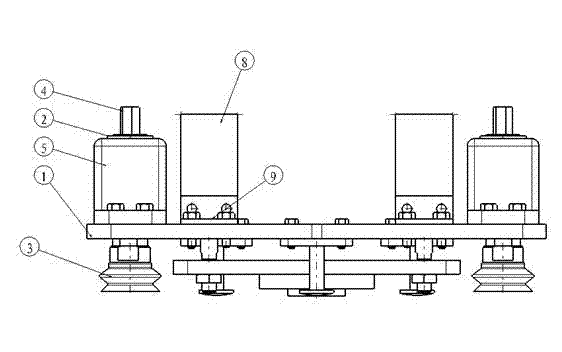

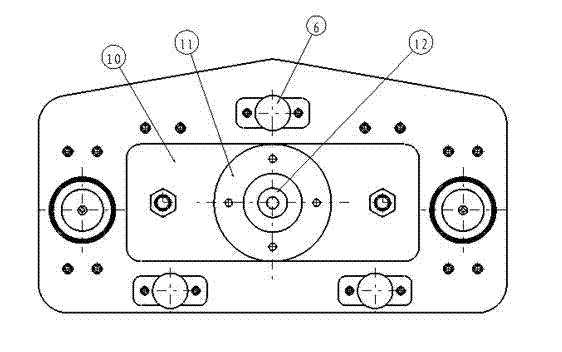

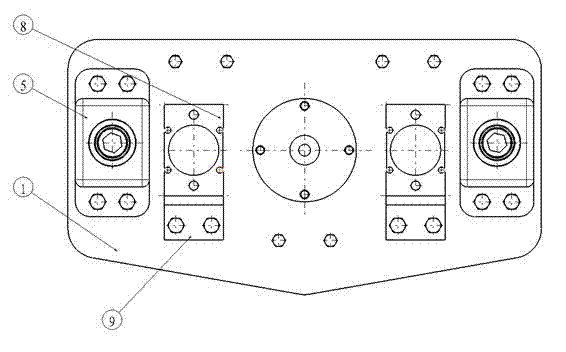

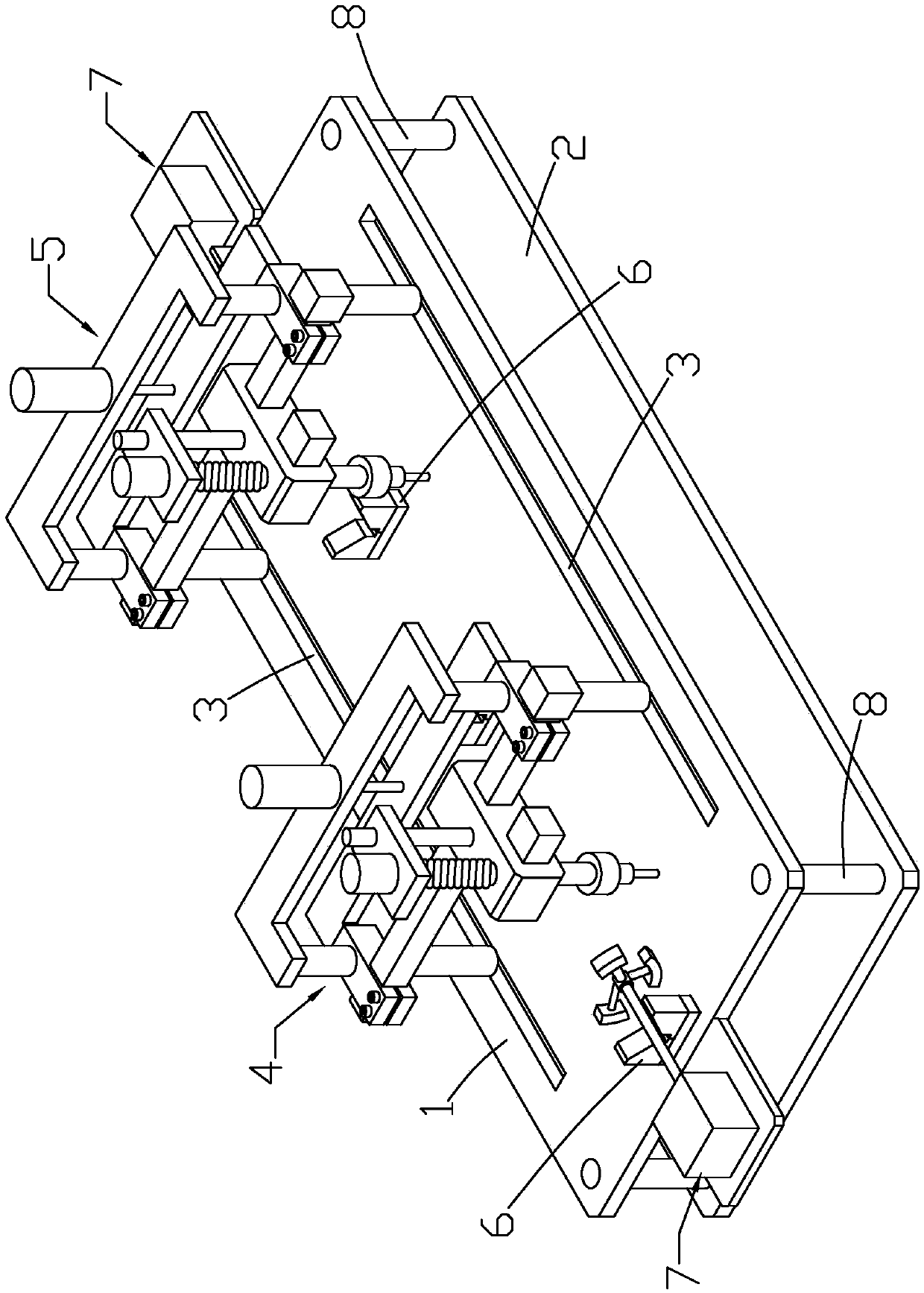

Device and method capable of reducing interlayer burrs during making holes for aircraft assembly

InactiveCN102513580AImplement the insert functionReasonable structureDrilling/boring measurement devicesPortable drilling machinesEngineeringAirplane

The invention discloses a device and method capable of reducing interlayer burrs during making holes for aircraft assembly. The device is characterized by comprising a main frame plate (1), at least two vacuum chucks (3), at least three locating shafts (6) and at least two driving cylinders (8), wherein the vacuum chucks (3) are evenly and fixedly arranged on the main frame plate (1); the drivingcylinders (8) are arranged on the main frame plate (1) through a cylinder installation assisting plate (9), output shafts of the driving cylinders (8) are connected with a pressure foot frame (10), and a pressure foot (11) is arranged on the pressure foot frame (10); a drilling and riveting sleeve (12) is arranged in a central hole of the pressure foot (11), and the tool center of the drilling and riveting sleeve (12) is coincided with the center of the pressure foot (11). The device is simple in structure, covneient to manufacture and capable of greatly reducing interlayer burrs so that technological requirements are met.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

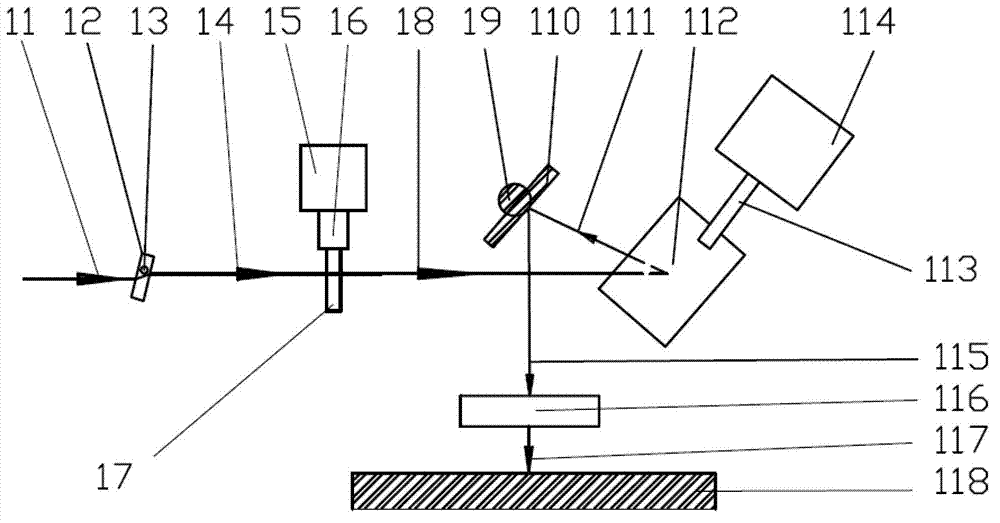

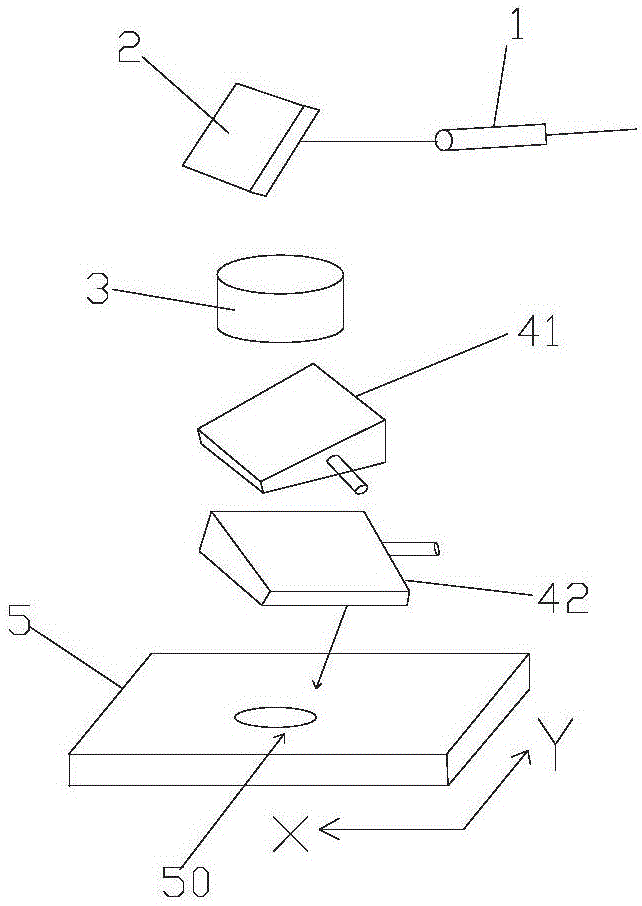

Laser drilling and drilled-hole filling system and method

ActiveCN106312335AImprove processing efficiencyFlexible to change aperture sizeLaser beam welding apparatusLaser processingLight beam

The invention discloses a laser drilling and drilled-hole filling system and method. The laser drilling and drilled-hole filling system comprises a laser light source module, an incident beam rotary movement module, a beam rotation angle compression ratio adjustable module and a laser focusing and focus switching module. As the beam rotation angle compression ratio adjustable module is introduced, during high-speed rotation of laser, the beam rotation angle compression ratio of the beam rotation angle compression ratio adjustable module is adjusted to realize focus rotary movement track diameter adjustment of a focused beam, and the focus rotary movement track diameter is in adjustable perfect combination with the aperture of a drilled hole; a beam expansion ratio compensation module is introduced, so that when the beam rotation angle compression ratio adjustable module performs rotation angle compression on an incident rotary beam, the entry light spot diameter of the incident rotary beam is changed correspondingly, the stability of the focus light spot diameter of the focused beam is guaranteed, and the stability and the processing effect of the laser processing technology are facilitated.

Owner:张立国

Drilling machine for machining bridge-cutoff aluminum alloy doors and windows

PendingCN109590507AStop exactly toAccurately pinpointMeasurement/indication equipmentsLarge fixed membersWater resourcesAlloy

The invention provides a drilling machine for machining bridge-cutoff aluminum alloy doors and windows, and relates to the technical field of machining. The drilling machine for machining the bridge-cutoff aluminum alloy doors and windows comprises a machine body, wherein a moving device is fixedly arranged at the bottom of the machine body, the moving device comprises spring columns, and transverse plates are fixedly arranged on the outer surface of the spring columns, sliding grooves are arranged in the lower surfaces of the transverse plates, and clamping rods are connected to the inner wall of the sliding grooves in a sliding mode, wheels are movably installed at the bottoms of the spring columns, and a water tank is fixedly arranged at the top of the machine body, the left side of thewater tank is communicated with a first water pipe, and the right side of the machine body is fixedly provided with a water pump. According to the drilling machine for the bridge-cutoff aluminum alloy doors and windows, water is used for eliminating and collecting dust, and the drill bits are subjected to heat dissipation by water, the health of an operator is protected, and the service life of the drill bits is prolonged, meanwhile, the water resources are recycled by the aid of a filtering device, and the environment-friendly theme of the current society is attached.

Owner:杭州佧斯家居设计有限公司

Swing clamp for pipe numerical control drilling machine

InactiveCN101954601AStable clampingSafe and stable drilling operationPositioning apparatusMetal-working holdersNumerical controlEngineering

The invention relates to a swing clamp for a pipe numerical control drilling machine. A V-shaped gap is arranged on one side of the clamp; and a pivot hole is arranged at the middle of the other side of the clamp and is pivoted with a clamping block base through a circular shaft. By adopting a clamp structure which can swing around the pivot, the invention can self-adaptively adjust various bent or deformed pipes and can firmly clamp the processed pipes for being convenient to safely and stably drill, thereby fully improving the drilling quality.

Owner:WUXI HUALIAN PRECISION MACHINERY

Combined machining method for blade air film holes and device thereof

ActiveCN112171184AReduce drilling difficultyImprove drilling efficiencyMetal working apparatusElectrolytic agentHeat-affected zone

The invention discloses a combined machining method for blade air film holes and a device thereof, and relates to the field of non-traditional machining. The combined machining method comprises the steps that the air film holes with the needed size are rapidly drilled in a thermal barrier coating high-temperature alloy matrix through laser heating auxiliary drilling; secondly, a drill bit rotatingat a high speed serves as a cathode, blades serve as an anode, the drill bit moves up and down, online electrolysis aftertreatment is conducted on part of the air film holes of the metal matrix, andthe defects of residual stress, a heat affected zone and the like in the drilling process are eliminated; and meanwhile, tiny abrasive particles are suspended in the electrolyte, tiny impact scratching is conducted on the hole wall under the driving of the drill bit rotating at a high speed, the similar grinding and polishing effect is achieved, and the quality of the whole inner wall of the air film holes including the thermal barrier coating is further improved. The method is simple and easy to implement, laser transmission is not affected by the surrounding environment, the environmental adaptability is high, repeated tool setting is not needed, and the defects that the thermal barrier coating cannot be machined through a conventional electric machining method, the single crystal alloylaser machining efficiency is low, and thermal damage is likely to be generated are overcome.

Owner:JIANGSU UNIV

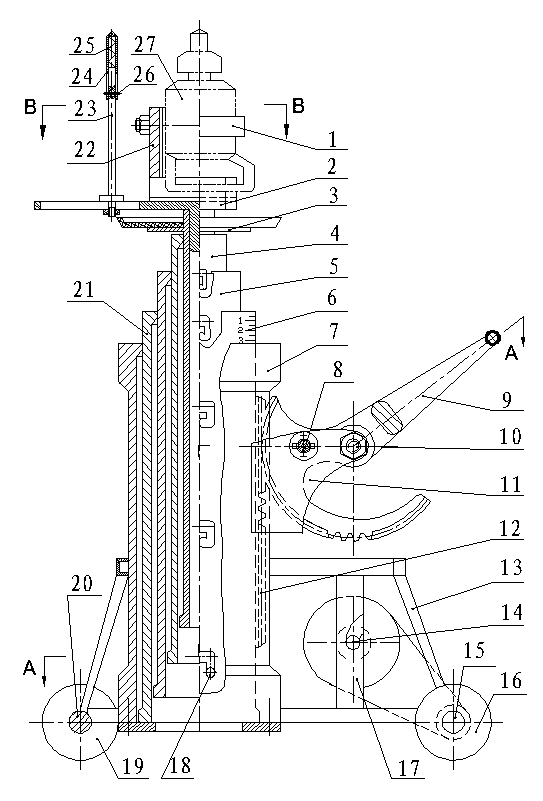

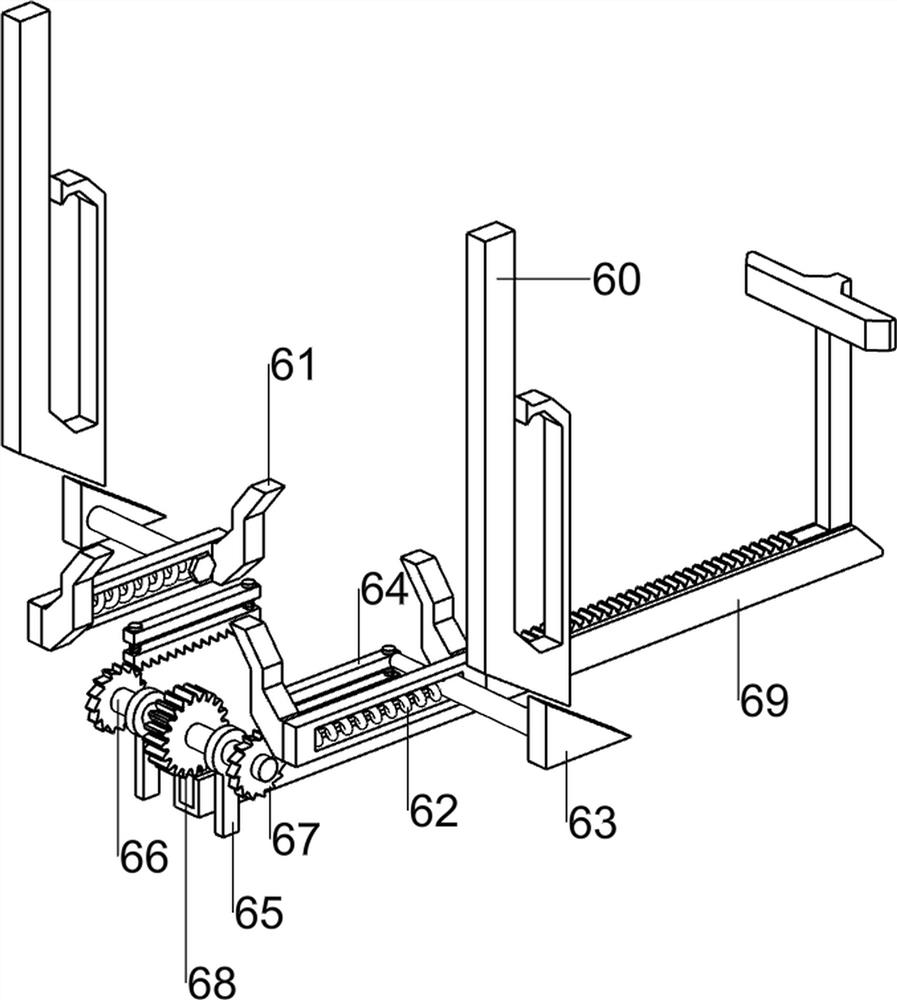

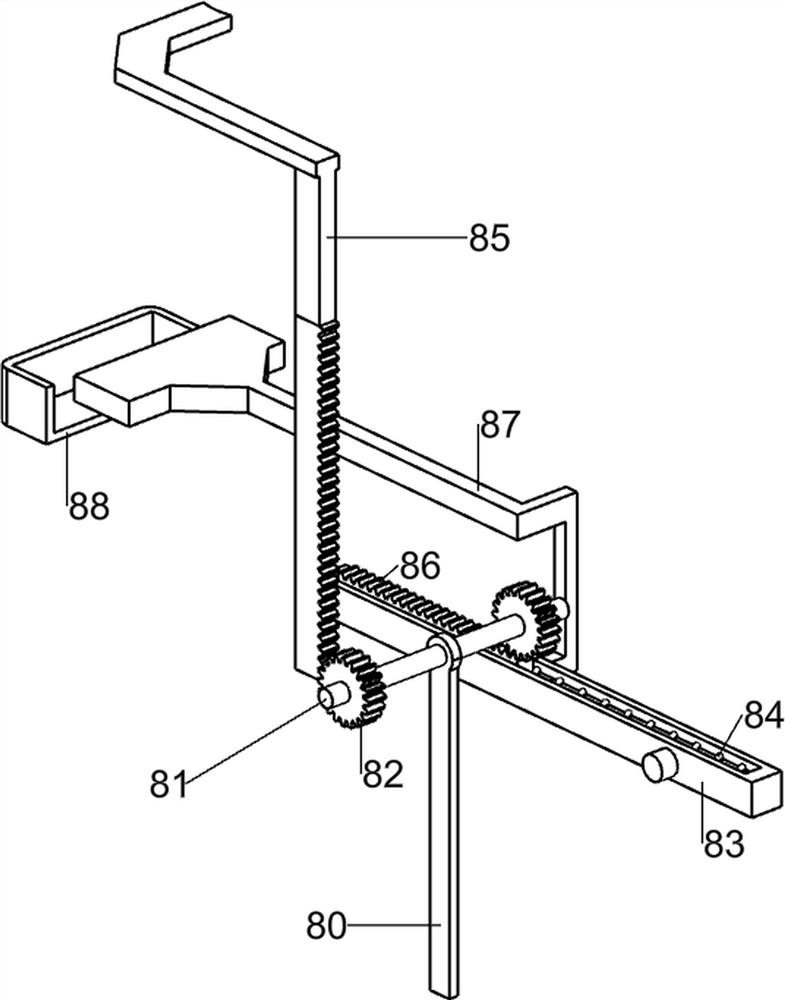

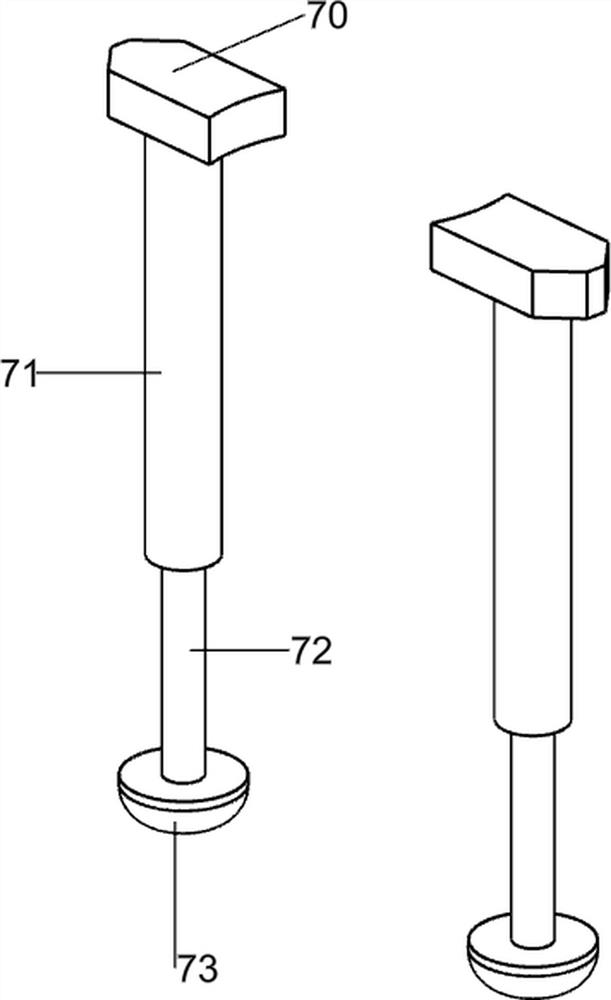

Hand-held electric hammer uphole drilling device

ActiveCN102990789AAvoiding the dangers of flying aroundAvoid difficultyStone-like material working toolsVehicle frameGear wheel

The invention discloses a hand-held electric hammer uphole drilling device. The hand-held electric hammer uphole drilling device comprises a carriage body, a telescopic link, a connector and a drilling self-feeder, wherein the carriage body is provided with the telescopic link, the top of the telescopic link is provided with the connector, and the drilling self-feeder is arranged on the telescopic link, so that the drilling device is integrally formed. The hand-held electric hammer uphole drilling device disclosed by the invention takes the carriage as a storage carrier, can be used for forming the telescopic link through multi-sectional steel tubes, adopting the gear transmission as a drilling motion feeding mechanism, displaying the drilling azimuth and the equal-unequal hole pitch value by dint of a universal cursor positioning instrument, a stopwatch and a positioning rod, makes up the blank that an operator cannot carry out uphole drilling operation without a hand-held electric hammer driller through an automatic power line collecting-releasing function, has the advantages of high positioning accuracy, high speed, large drilling adaptation height range, flexible movement and visible and controllable drilling depth and can outstandingly reduce the labor intensity, improve the work efficiency, enhance the drilling quality and effectively solve the problem of predicament of people working under a dust scattering area.

Owner:HUAIAN OF JIANGSU ELECTRIC POWER COMPANY POWER SUPPLY +1

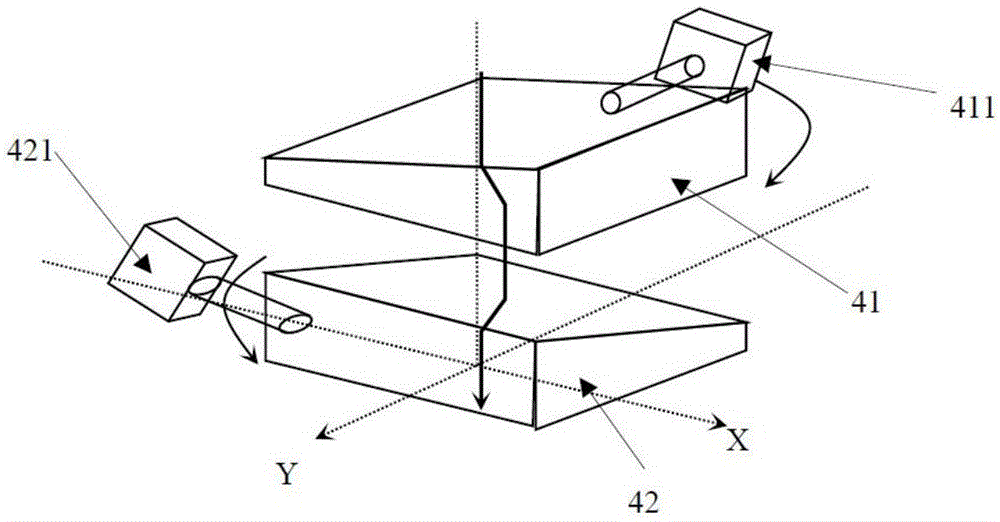

High-quality conicity-controllable drilling machining device and method

ActiveCN105033470AEasy to adjustImprove applicabilityLaser beam welding apparatusLight beamOptoelectronics

A high-quality conicity-controllable drilling machining device is characterized by comprising a light beam rotating module, a focusing lens, a first wedge-shaped optical glass substrate, a second wedge-shaped optical glass substrate and a rotating device in the laser radiating direction in sequence, wherein the rotating device is connected to the first wedge-shaped optical glass substrate and the second wedge-shaped optical glass substrate; laser sequentially passes through the light beam rotating module, the focusing lens, the first wedge-shaped optical glass substrate and the second wedge-shaped optical glass substrate focusing and dynamic scanning are carried out on a laser beam, and the laser acts on a workpiece to be machined; and the first wedge-shaped optical glass substrate and the second wedge-shaped optical glass substrate are controlled by the rotating device to rotate so as to change a laser irradiating route. According to the machining device, the module is simple in structure and can be machined and integrated with a common laser, manufacturing is easy, cost is low, and the light path adjustment is easier. The zero-taper and inverted-cone drill hole high-quality machining can be rapidly achieved.

Owner:INNO LASER TECH CORP LTD

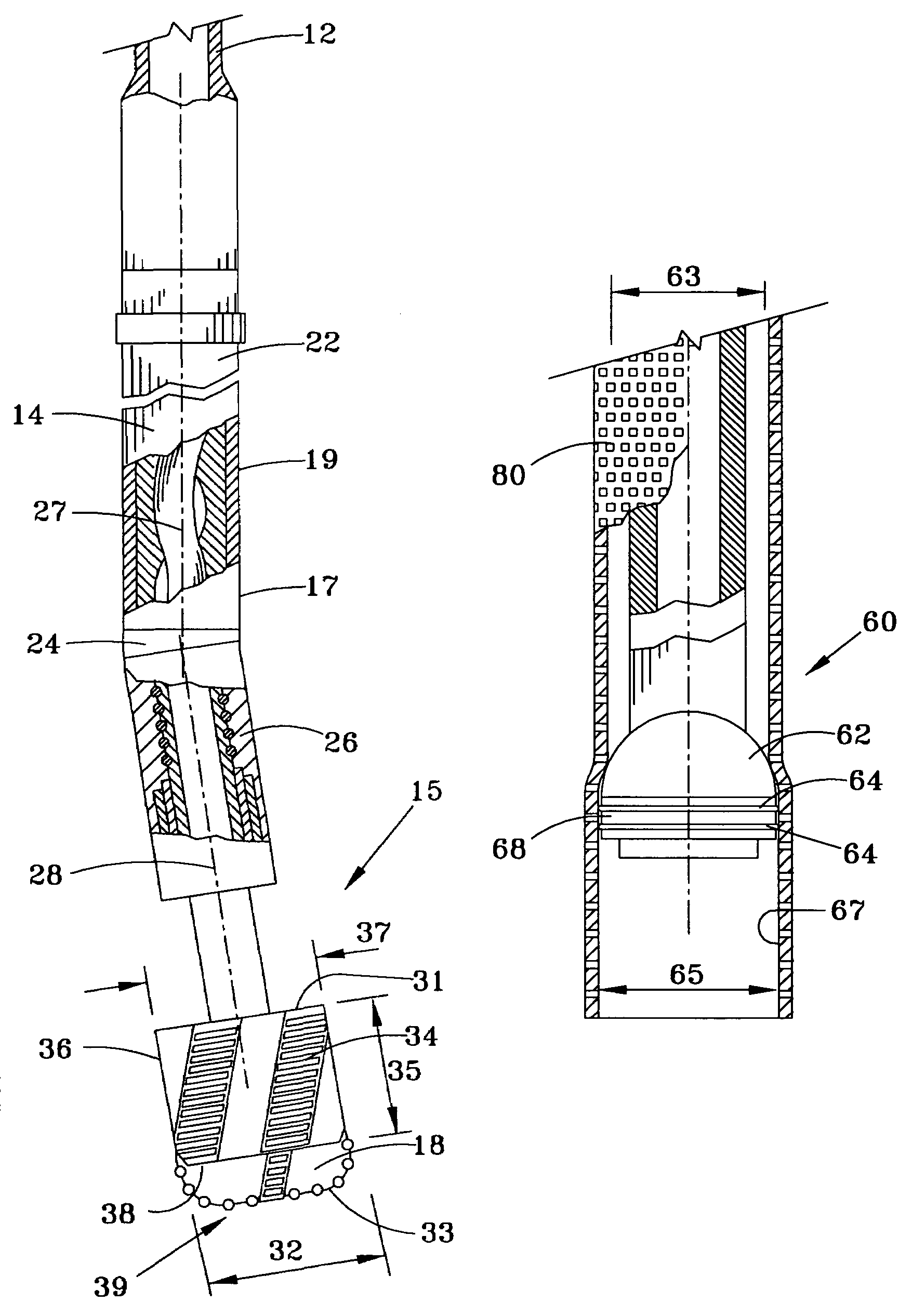

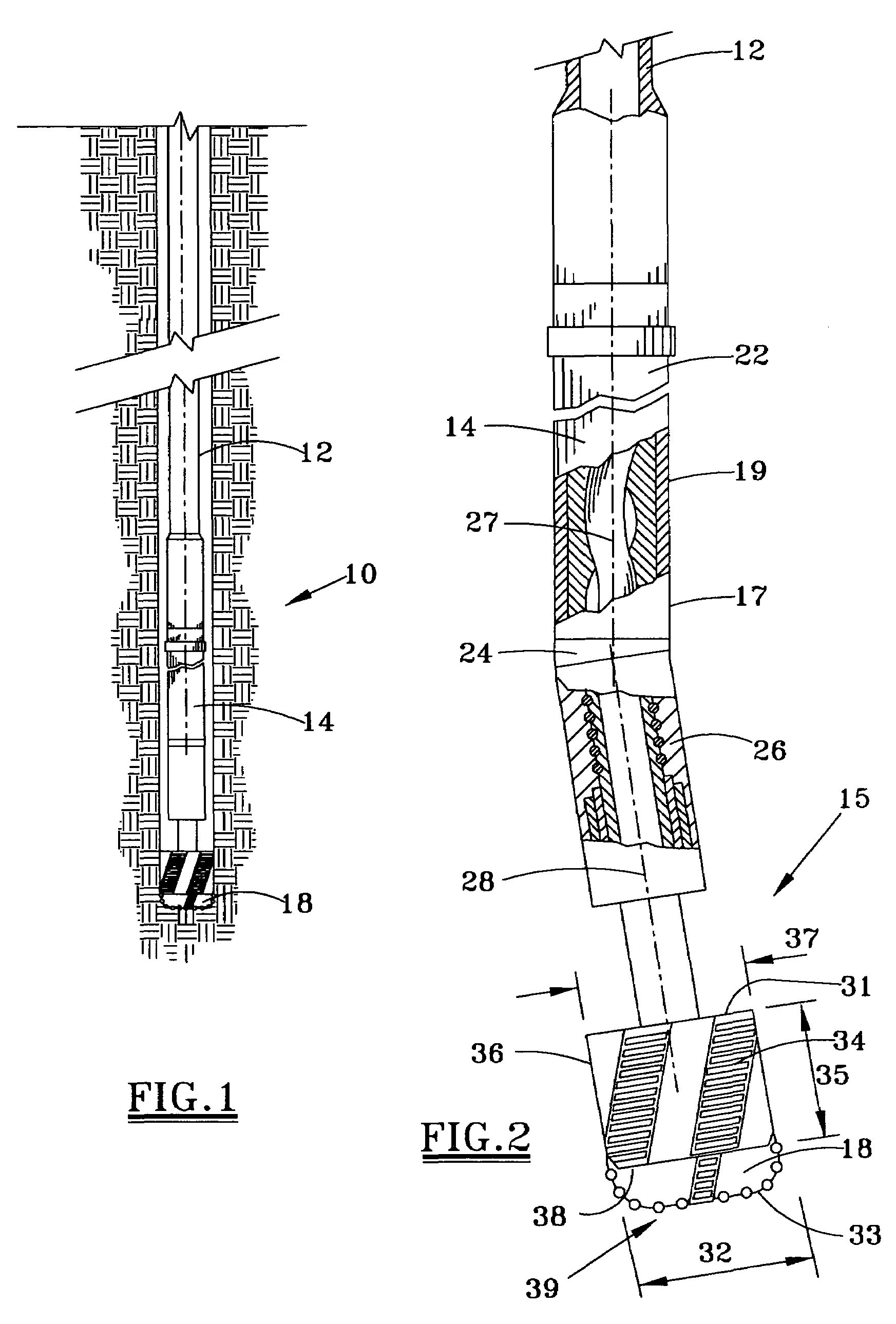

Expanded downhole screen systems and method

ActiveUS7066271B2Improve drilling qualityReduced borehole spiralingDrilling rodsFluid removalWellboreDrill bit

An improved system and method is disclosed for expanding a fluid permeable tubular downhole in an open hole completion. A high quality borehole is first drilled using a bottomhole assembly having a long gauge bit and a short bit-to-bend ratio. A fluid-permeable tubular is then inserted into an open-hole portion of the wellbore and preferably expanded in place. The expandable tubular may include an external filtering medium. Hydrocarbons may pass from the formation through the expanded fluid permeable tubular and into the borehole, to be recovered.

Owner:HALLIBURTON ENERGY SERVICES INC

Plate drilling device for computer production

InactiveCN107199358AEasy feedingImprove drilling qualityFeeding apparatusLarge fixed membersGear wheelEngineering

The invention discloses a plate drilling device for computer production, and relates to the technical field related to computers. The plate drilling device comprises a base; one side of the top of the base is fixedly connected with a housing; the bottom of the inner wall of the housing is fixedly connected with a first motor; an output shaft of the first motor is fixedly connected with a first belt pulley; the surface of the first belt pulley is in transmission connection with a second belt pulley through a belt; one side of the second belt pulley is fixedly connected with a first gear; and the first gear is mutually engaged with a second gear fixedly arranged at the top of the inner wall of the housing. According to the plate drilling device for the computer production, the first motor works to drive a top plate to move and thus the height of the second motor is adjusted, so that the feeding is facilitated; the second motor works to drive a drill bit to rotate to drill a plate, so that different-depth drilling is realized; the position of the plate is adjusted by pushing a handle, and different positions of the plate are drilled; and the plate drilling device is simple and convenient in operation, high in drilling quality and good in using effect.

Owner:合肥北顾信息科技有限公司

Drilling machine

ActiveCN105033314AEasy to adjustEasy to operateFeeding apparatusDriving apparatusEngineeringMechanical equipment

The invention relates to the technical field of mechanical equipment, in particular to a drilling machine. The drilling machine comprises a substrate, and further comprises a main rack, a second motor, a transmission component, a drilling component, a conveying component and a first motor, wherein the main rack is arranged at the upper end of the substrate; the second motor is arranged on the upper portion of the main rack; the transmission component is arranged on the upper portion of the main rack and connected to the second motor in a screwed mode; the drilling component is arranged at the end, away from the second motor, of the transmission component in a screwed mode. The drilling machine is convenient to operate and adjust, drilling efficiency is high, and drilling quality is good.

Owner:ZHEJIANG TONGTAI BEARING

Equidistant drilling machine for high-end equipment

ActiveCN112809052ADrilling automaticSave human effortPositioning apparatusMetal working apparatusProcess engineeringDrill hole

The invention relates to a drilling machine, in particular to an equidistant drilling machine for high-end equipment. The technical problem is to provide the equidistant drilling machine which can achieve automatic measurement and save time and labor and is used for the high-end equipment. According to the technical scheme, the equidistant drilling machine for the high-end equipment comprises a base, a support, a containing mechanism and a drilling mechanism, and the support is arranged on the base. The containing mechanism is arranged on the support. The drilling mechanism is arranged on one side of the base. Through cooperation of the containing mechanism, the drilling mechanism and a lifting mechanism, materials can be automatically drilled, and therefore manpower is saved.

Owner:青岛春泉液压设备有限公司

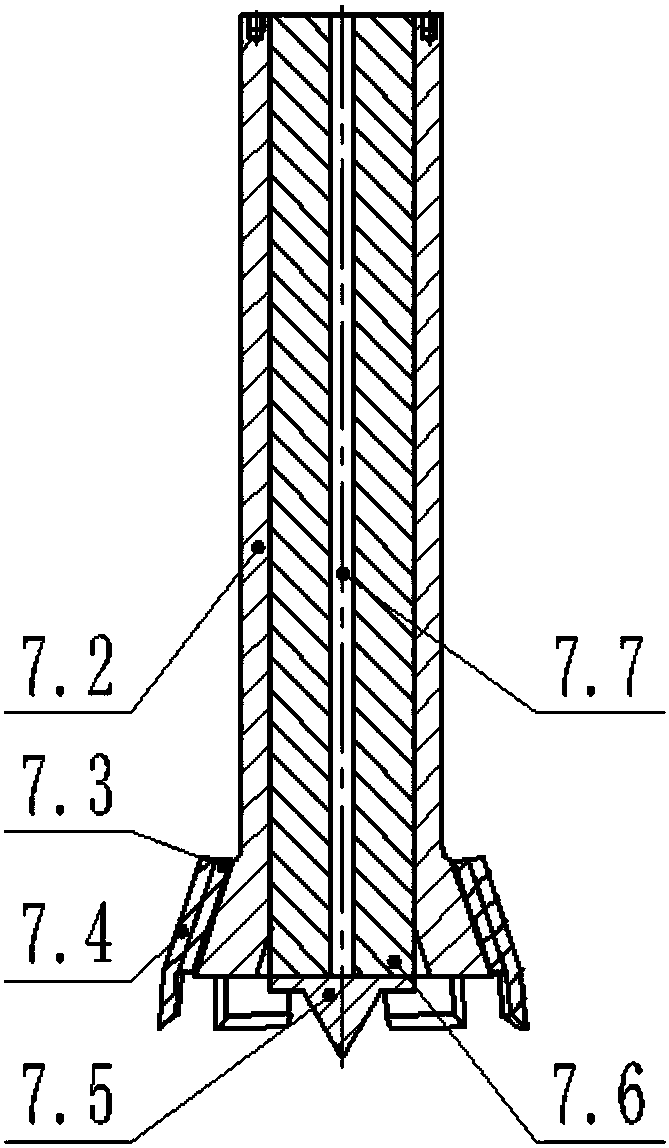

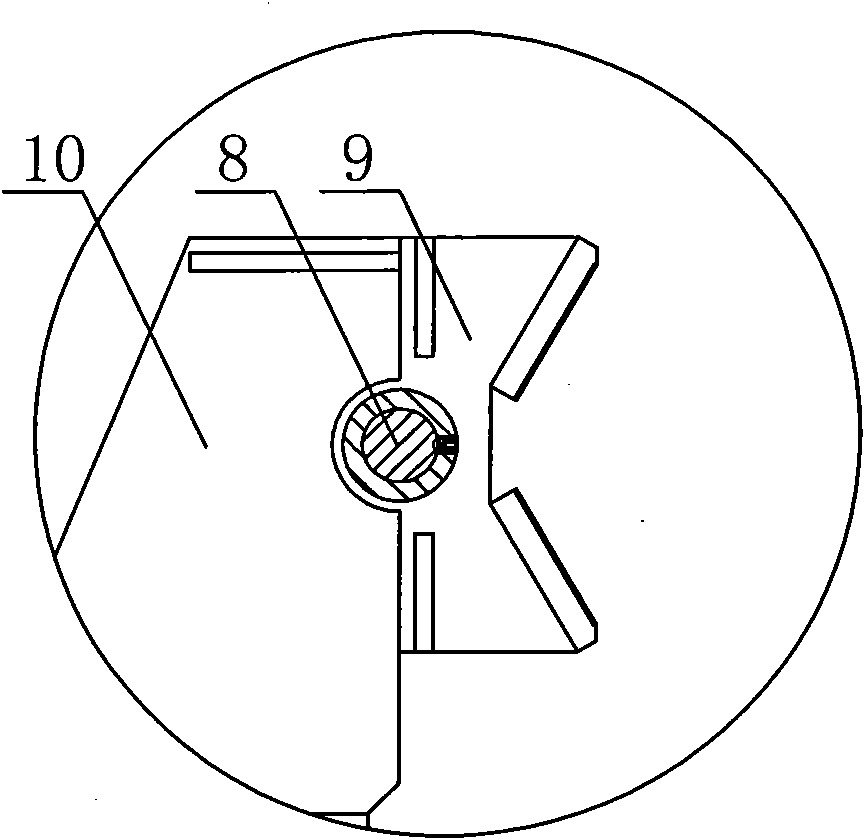

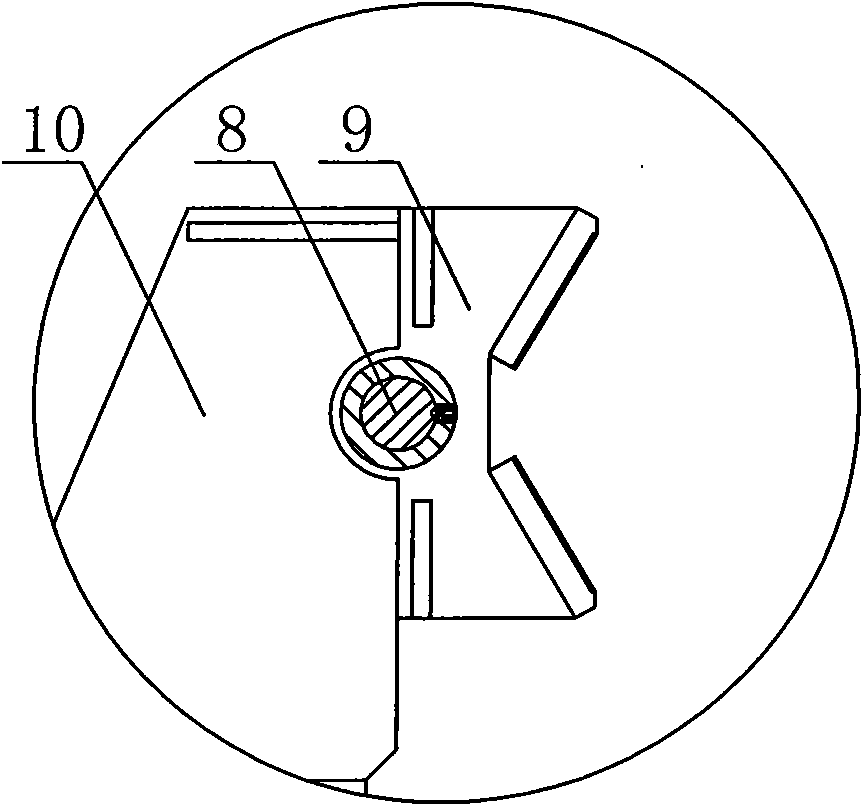

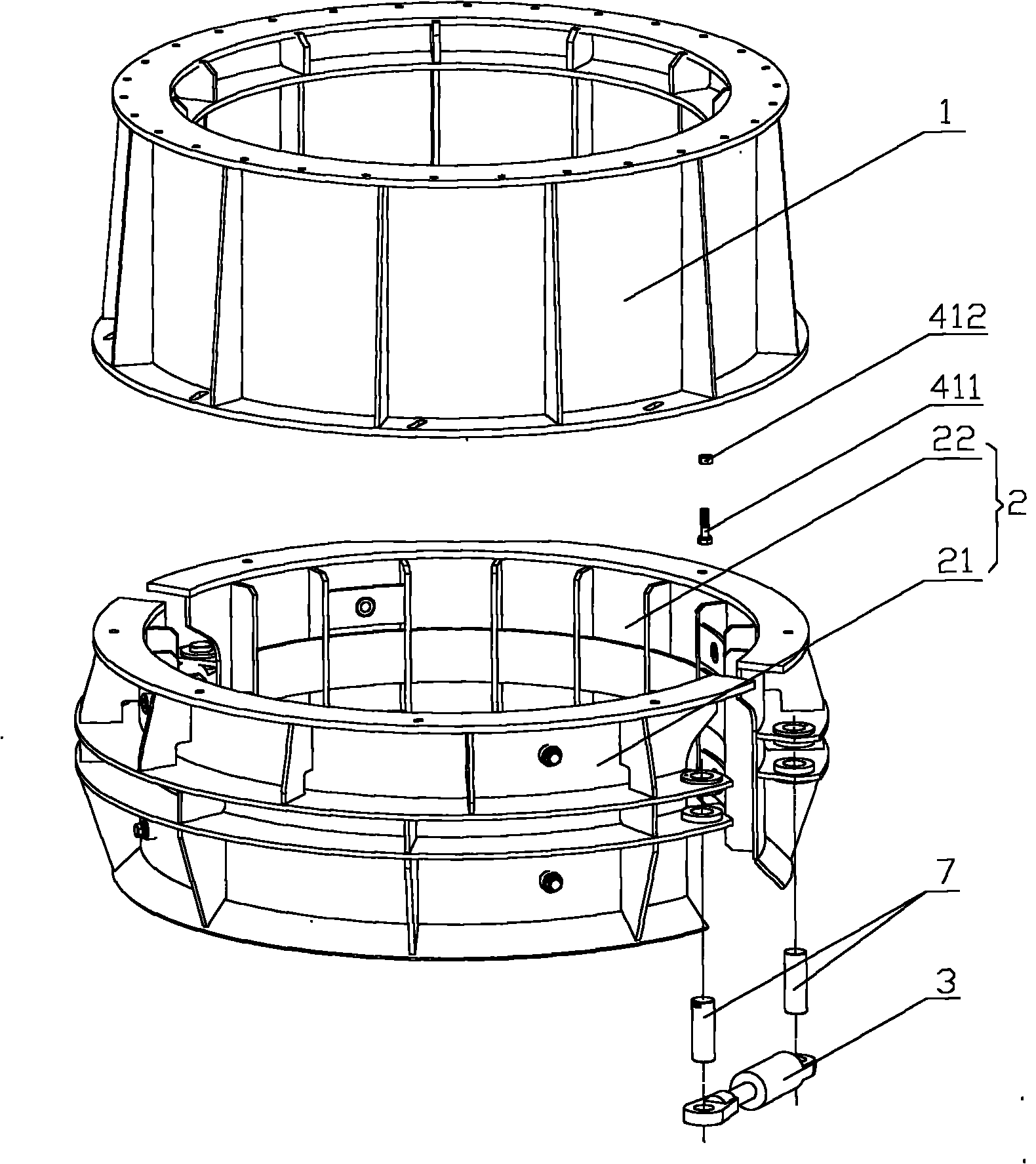

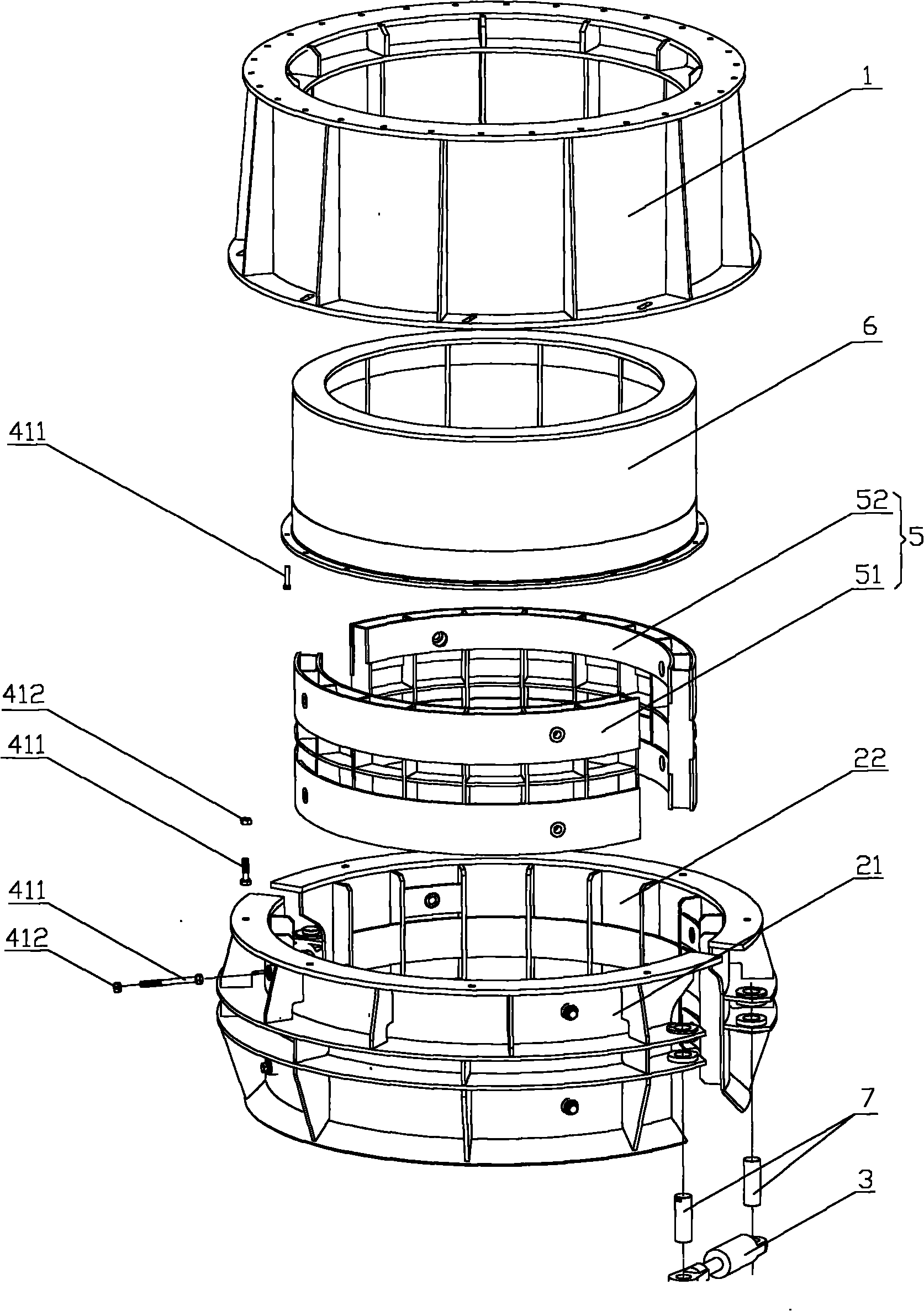

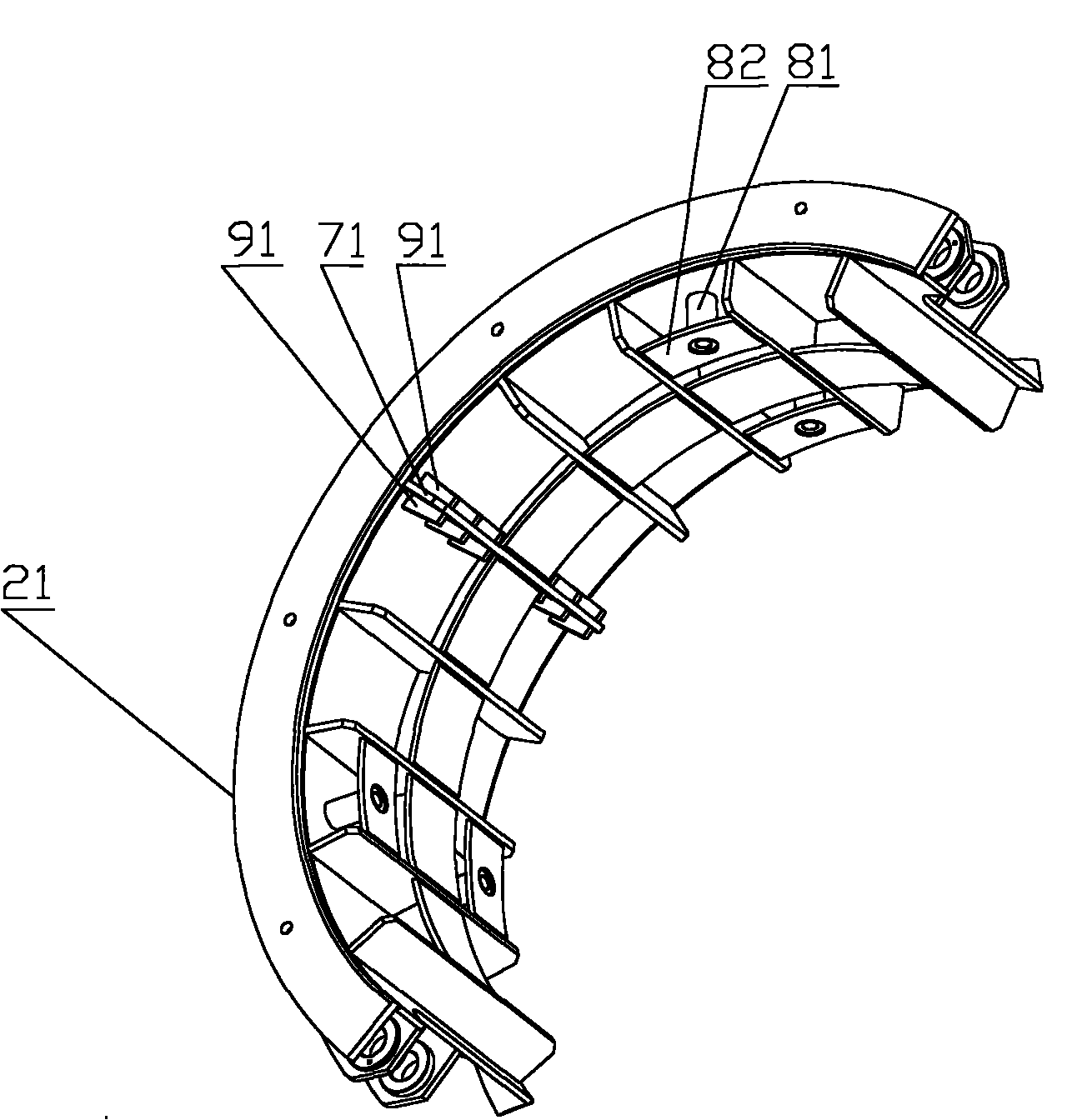

Reverse circulation drill and gripper for same

InactiveCN102116136AReduce movementImprove drilling qualityDrilling rodsDerricks/mastsEngineeringDrill hole

The invention provides a gripper for a reverse circulation drill, comprising a gripping component (2) and a sleeve base (1), wherein the gripping component (2) is sheathed on a sleeve in a dismountable manner, the sleeve base (1) is coaxially installed on the gripping component (2), and a reverse circulation drill body is installed on the sleeve base (1). The reverse circulation drill body is fixed on the sleeve through the gripping component (2), and the sleeve is reliably fixed on the ground so that during the operation of the drill, the drill body can be reliably fixed on the ground and can be prevented from being moved under the action of reacting force; and when inclined holes are drilled, the drill can also be prevented from being overturned, thereby effectively improving the drilling quality of the drill, improving the safety performance and prolonging the service life of the drill. The invention also provides the reverse circulation drill comprising the gripper.

Owner:BEIJING SANY HEAVY MASCH CO LTD

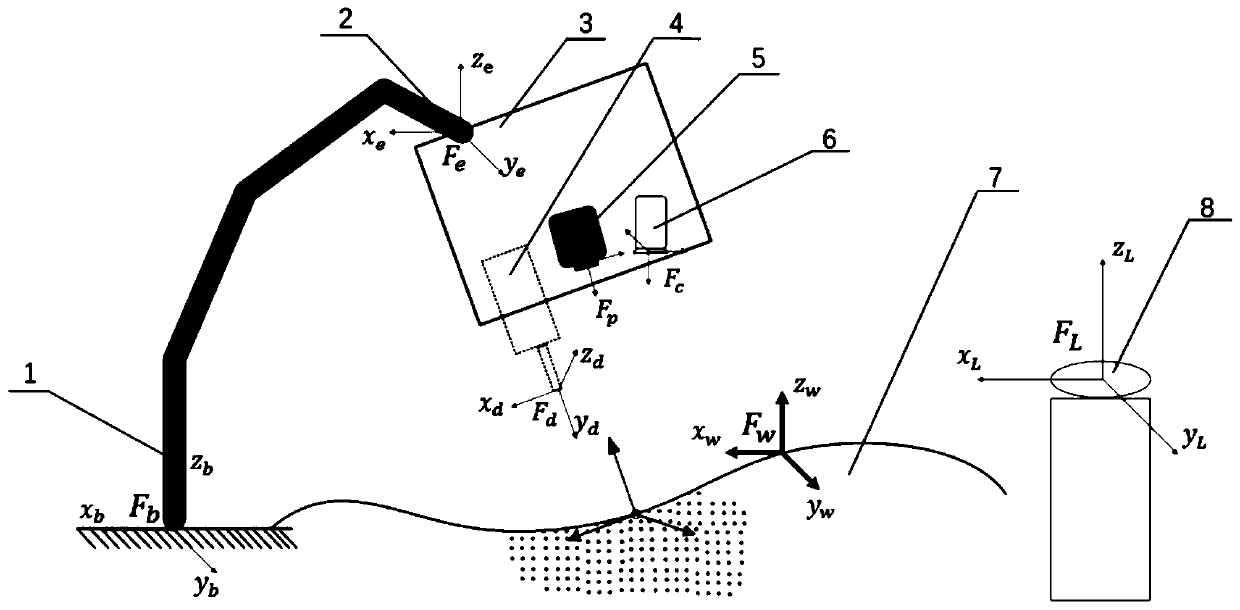

Drill bit position and posture optimizing method for robot drilling

ActiveCN110125455AImprove pose accuracyHigh measurement accuracyManipulatorBoring/drilling componentsSimulationDrilling system

The invention provides a drill bit position and posture optimizing method for robot drilling and belongs to the field of drill bit position and posture optimization and adjustment in robot drilling operation. The method comprises the following steps: firstly, building a robot drilling system based on a fringe projection method and visual servo control, performing system parameter calibration and performing off-line planning of robot drilling operation to obtain a series of route points; secondly, at each route point, calculating a phase diagram of the drill bit under the expected position andposture of the route point, and designing visual feature and deducing an interaction matrix and a visual servo control law; finally, optimizing the drill bit position and posture of each route point subjected to off-line planning by the visual servo control law until the visual servo convergence of each route point is completed to improve the perpendicularity of the axis of the drill bit and the section of a to-be-drilled point, so that the drilling quality and the surface flatness are improved. By the drill bit position and posture optimizing method for robot drilling, the advantages of highmeasuring precision of a fringe projection outline measuring method and high visual servo control precision are combined, and the position and posture of the drill bit in the actual robot drilling operation can be optimized effectively.

Owner:TSINGHUA UNIV +1

Rapid centre hole drilling tooling

InactiveCN104400497AEasy to get on and off the workpieceFast loading and unloading of workpiecesPositioning apparatusMetal-working holdersTransverse planeEngineering

Owner:常州正康硬质合金有限公司

Surface hole drilling device for non-excavation construction pipelines

ActiveCN109570557AImprove drilling efficiencyIncrease flexibilityLarge fixed membersPositioning apparatusArchitectural engineeringPipe support

The invention discloses a surface hole drilling device for non-excavation construction pipelines. The device comprises a base board, a bottom board, a first hole drilling machine, a second hole drilling machine and pipeline rotary mechanisms; the bottom board is located below the base board; the base board is fixedly connected with the bottom board through a supporting rod; two guide grooves are formed in the top face of the base board in parallel; the first hole drilling mechanism and the second hole drilling mechanism are movably connected to the guide groove; a drive mechanism is arranged between the base board and the bottom board and is connected with the first hole drilling mechanism and the second hole drilling mechanism; pipeline supporting mechanisms are arranged on the center straight line of the top face of the base board at equal intervals; and the two pipeline rotary mechanisms are symmetrically arranged on two sides of the base board. The surface hole drilling device fornon-excavation construction pipelines is simple in structure and high in practicability, not only can achieve single-hole or dual-hole machining for construction pipelines and improve the hole drilling efficiency, but also can clamp and position construction pipelines, rotates construction pipelines at the constant speed according to hole drilling needs at the same time, and greatly improves the hole drilling precision and quality.

Owner:嵊州市越通非开挖建设有限公司

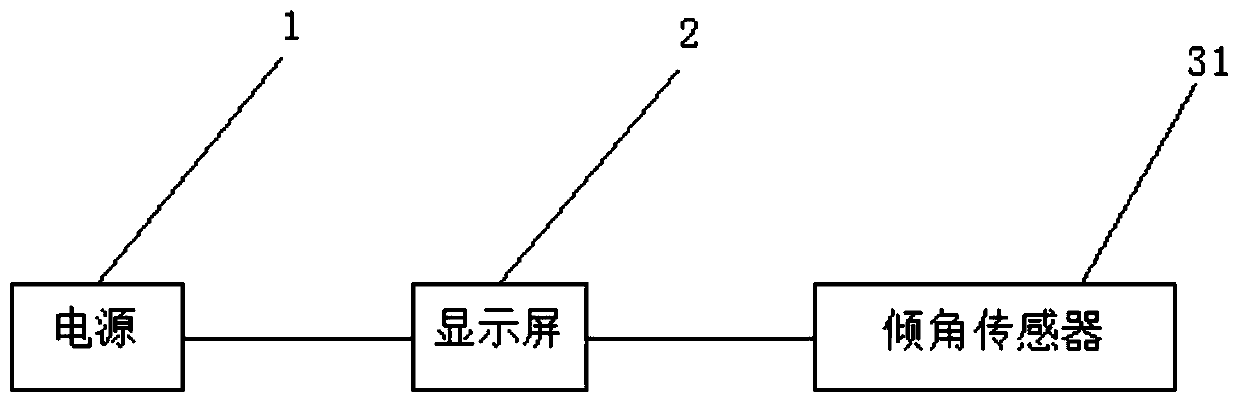

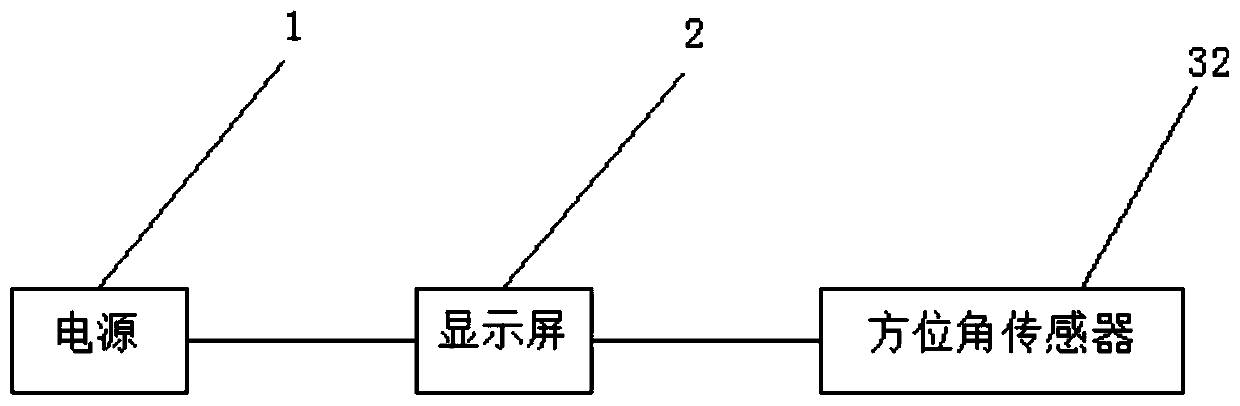

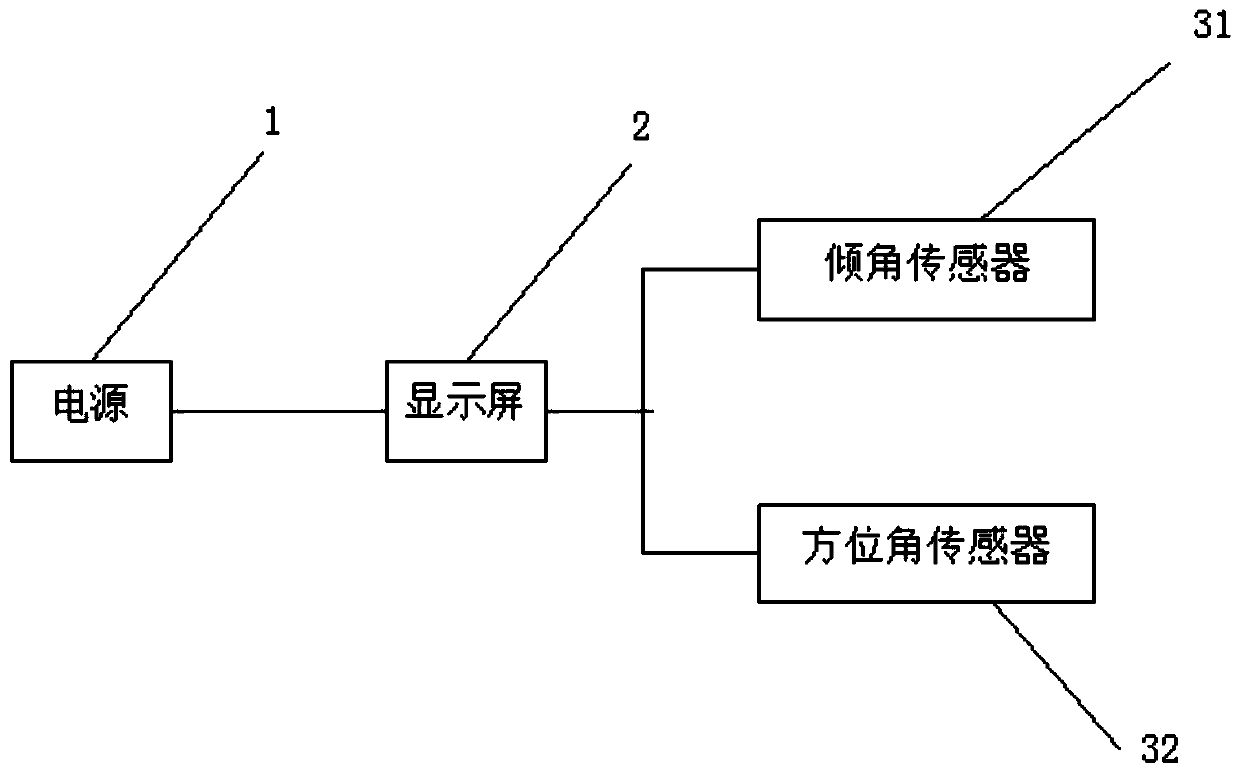

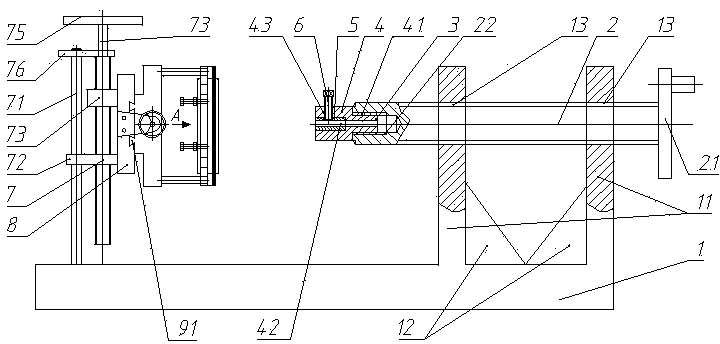

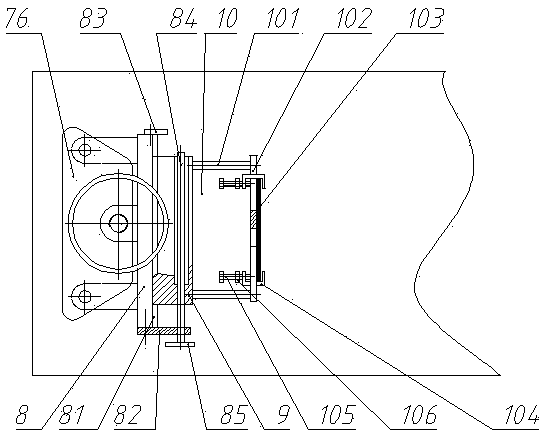

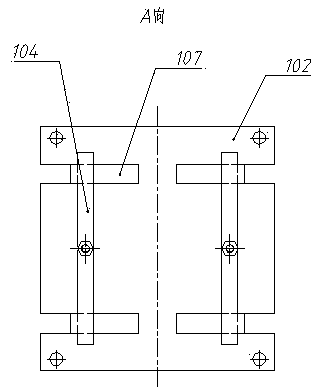

Online accurate measurement and control device for drilling rig angle and method of online accurate measurement and control device

PendingCN109707366AAccurately measure and adjustQuickly measure and adjustSurveyAutomatic control for drillingPressure sensorPetroleum engineering

The invention relates to an online accurate measurement and control device for the drilling rig angle and a method of the online accurate measurement and control device. The online accurate measurement and control device comprises a display screen, a drilling rig body, and parameter measuring sensor devices; the parameter measuring sensor devices are installed on operating mechanisms of the drilling rig body; the parameter measuring sensor devices and the display screen are connected through cables; and the parameter measuring sensor devices comprise any one or more combinations of the following: a tilt angle sensor, an azimuth sensor, a rolling pitching angle sensor, a temperature sensor, a pressure sensor, a rotating speed sensor, and a displacement sensor. The online accurate measurement and control device for the drilling rig angle and the method of the online accurate measurement and control device have the advantages that fast perforating can be achieved, measuring can be achieved quickly and accurately, the angle is adjusted, the safety is good, the drilling efficiency is high, and the labor cost is saved.

Owner:CHONGQING PINGSHAN MINING ELECTROMECHANICAL EQUIP

Manual drilling machine for drilling holes in thin plate

InactiveCN103978245AConvenient and flexible processingImprove drilling qualityPositioning apparatusMetal-working holdersEngineeringMechanical engineering

The invention discloses a manual drilling machine for drilling holes in a thin plate. The manual drilling machine comprises a base, drilling screw rods, a drill bit clamping device, an adjusting device and a fixing device. Two parallel supporting plates are fixedly arranged at one end of the base, and two parallel guiding columns are fixedly arranged at the other end of the base. The supporting plates are provided with threaded holes I, the drilling screw rods penetrate through the threaded holes I in the two supporting plates to form a threaded pair, a hand wheel I is arranged at one end of each drilling screw rod, a threaded hole II is formed in the other end of each drilling screw rod, and the drilling screw rods are connected with the drill bit clamping device. The manual drilling machine is simple in structure, convenient to operate, safe and reliable, and capable of effectively solving the technical problem that an existing device can not be used for economically drilling holes in a single thin plate type part.

Owner:赵夫超

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com