Multistation numerical control drilling center of high-precision super-long work piece

A high-precision, multi-station technology, applied in the field of machine tools, can solve the problems of low automation and machining accuracy, achieve stable equipment, improve drilling quality and efficiency, and improve equipment automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

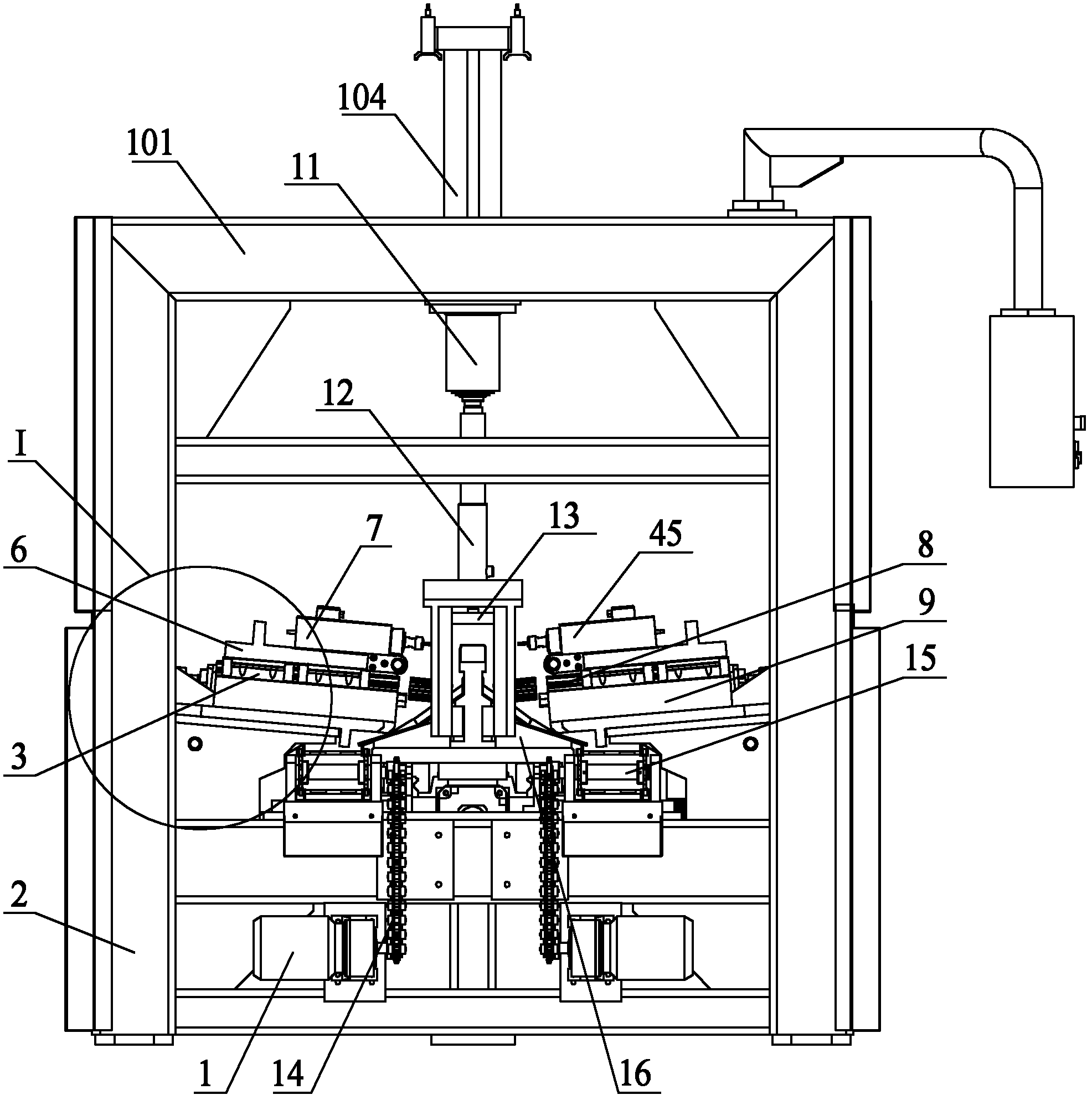

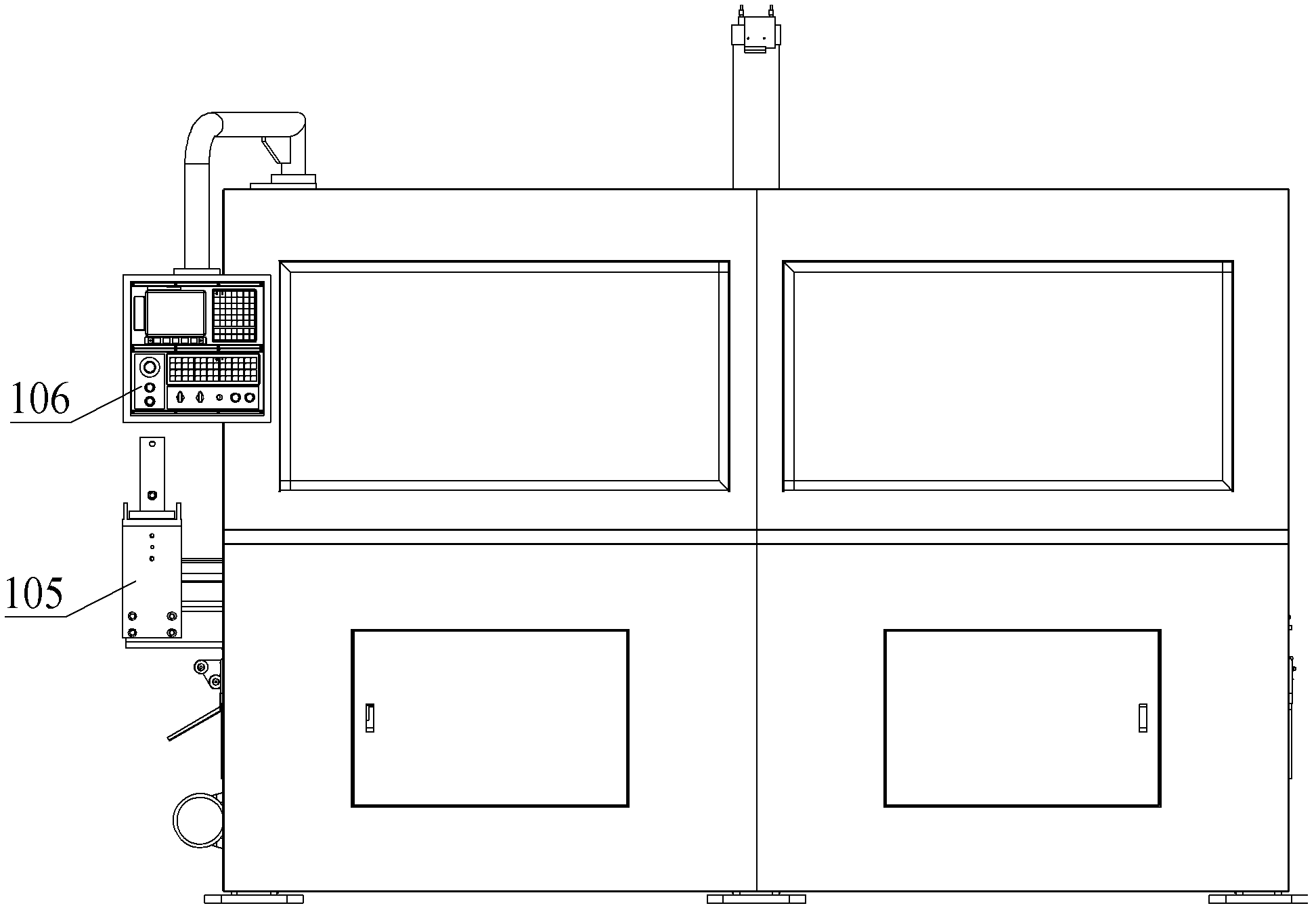

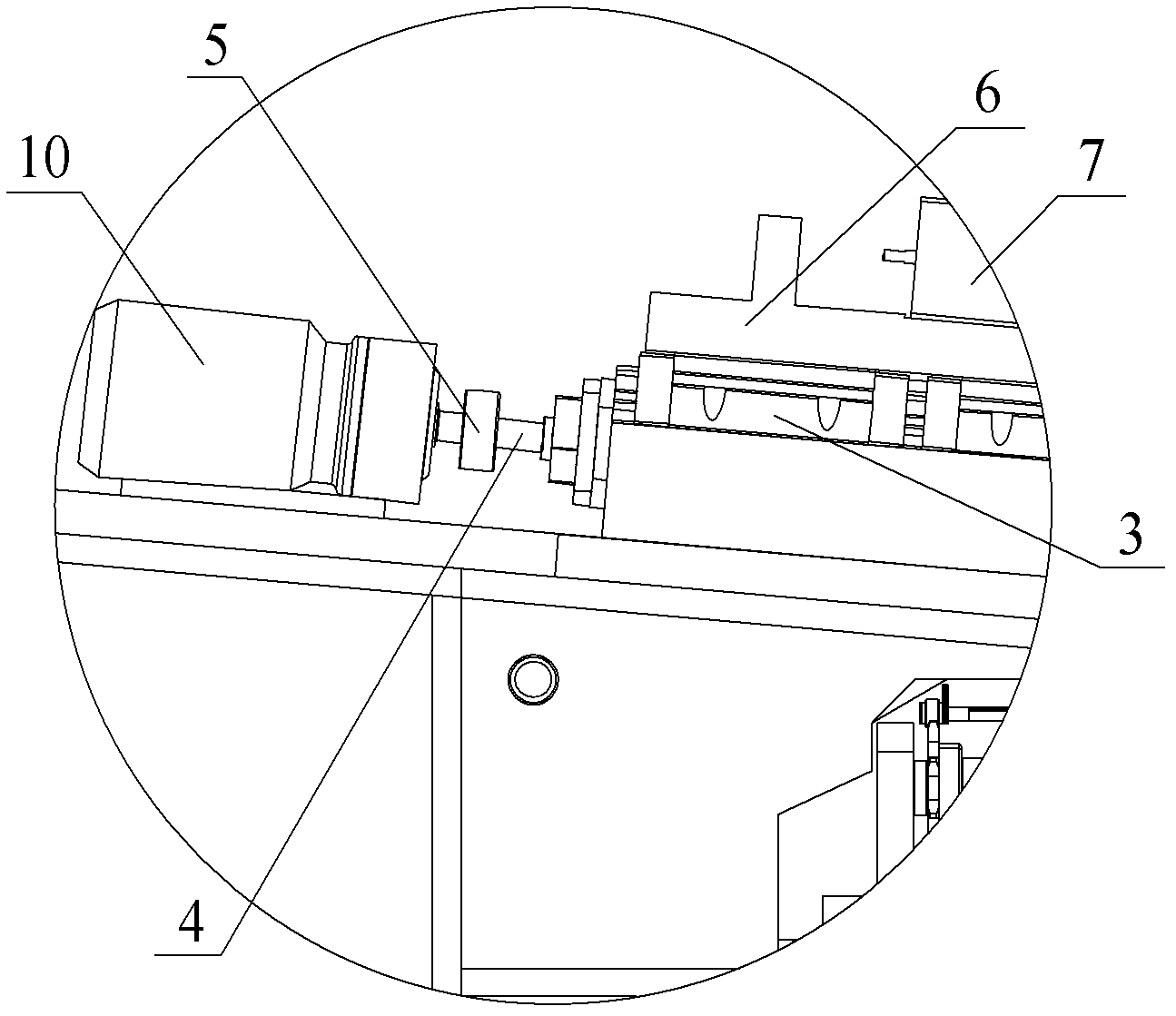

[0029] Example: see Figure 1 to Figure 10 As shown, the multi-station CNC drilling center for high-precision and ultra-long workpieces includes a main machine 101, a feeding system 102, a blanking system 103, a pneumatic and vacuum system 105, and a CNC numerical control and operating system 106; the feeding system 102 is placed on the main machine The front end of 101, the blanking system 103 is placed at the rear end of the main machine 101; the pneumatic and vacuum system 105 is fixed on the main machine 101, the CNC numerical control and the operating system 106 are fixed on the main frame 2, and the main frame 2 is fixed with a guide rail bracket 9. The linear guide rail 8 is fixed on the guide rail bracket 9, the linear guide rail slider 3 is inserted and sleeved on the linear guide rail 8, the motor bracket 6 is bolted or welded on the linear guide rail slider 3, and the variable frequency motor 7 is bolted on the motor bracket 6 , the ball screw 4 and the drilling ser...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com