Capillary tube blanking pier protrusion forming machine

A technology for capillary tubes and forming machines, applied in other manufacturing equipment/tools, heat exchange equipment, manufacturing tools, etc., to achieve the effects of high equipment automation, high safety performance, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

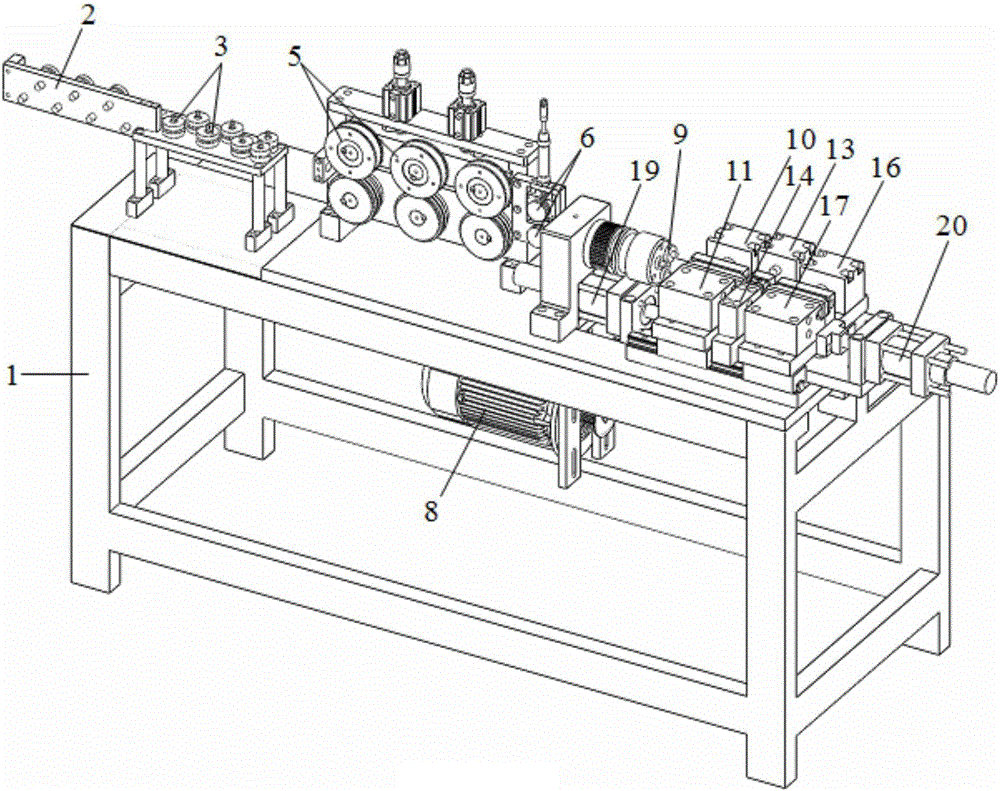

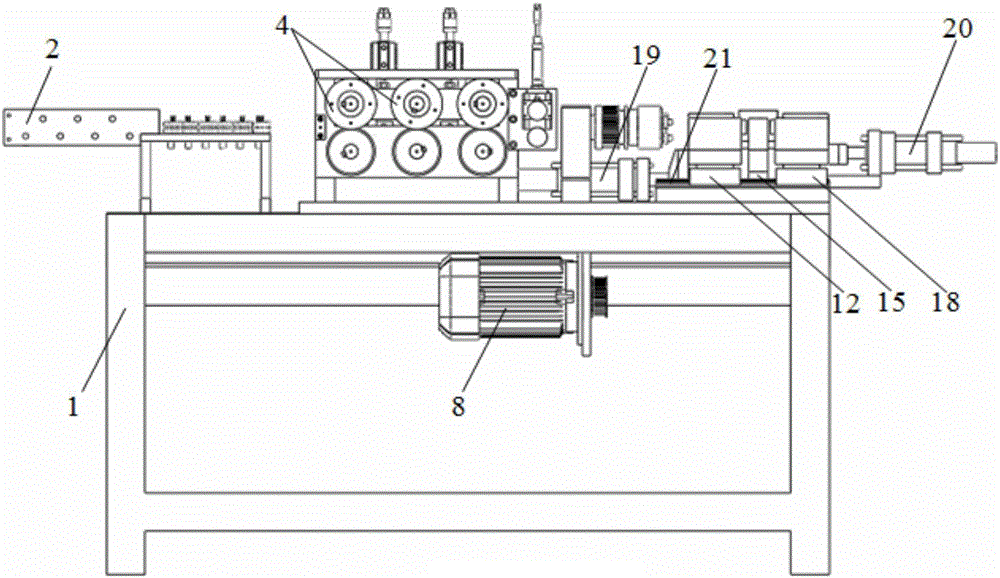

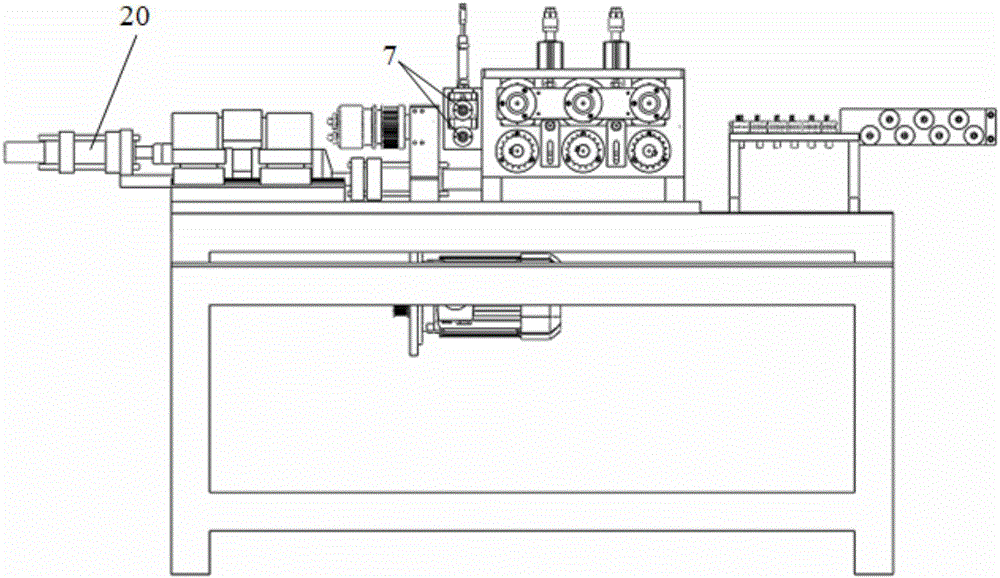

[0015] See attached Figure 1-7 As shown, the capillary tube blanking pier convex molding machine includes a frame 1 and a straightening mechanism, a feeding mechanism, a guide counting mechanism, a chipless cutting mechanism, a pier convex forming mechanism, and a control system provided on the frame 1. The straightening mechanism is composed of a straightening wheel 2 mounted on a straightening plate 3; the feeding mechanism is formed by a stepping motor 4 that is symmetrical up and down driving a transfer wheel 5 connected to it and engaged with each other; the guide counting The mechanism is composed of a guide wheel 6 that matches up and down, and the guide wheel 6 is connected to the encoder 7; the chipless cutting mechanism is composed of a motor 8 driving a cutter head 9 through a timing belt wheel; The mechanism includes a first hydraulic cylinder 10, a first clamping mold 11, a first slider 12, a second hydraulic cylinder 13, a second clamping mold 14, a second fixing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com