Patents

Literature

16765results about "Heat exchange apparatus" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

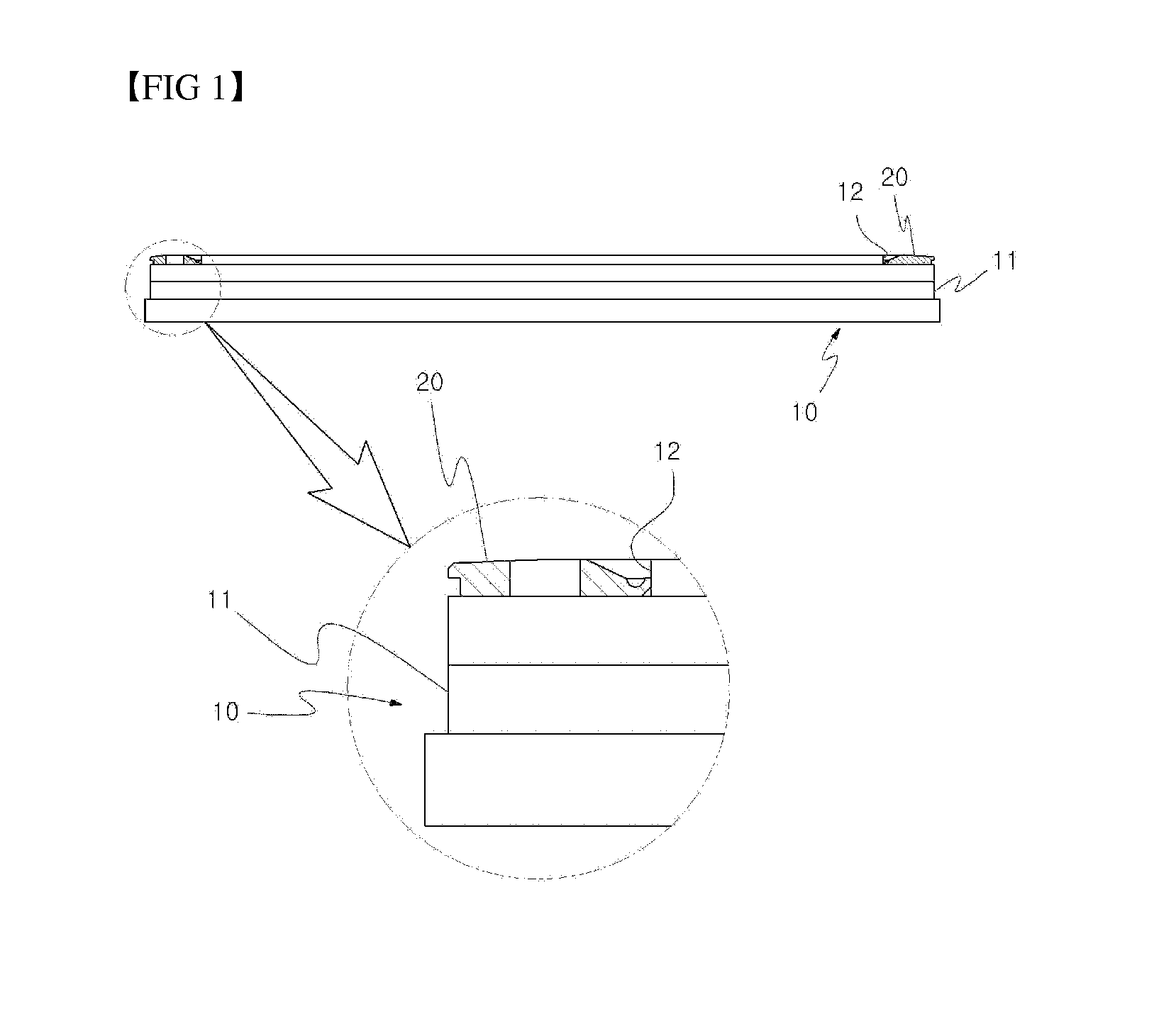

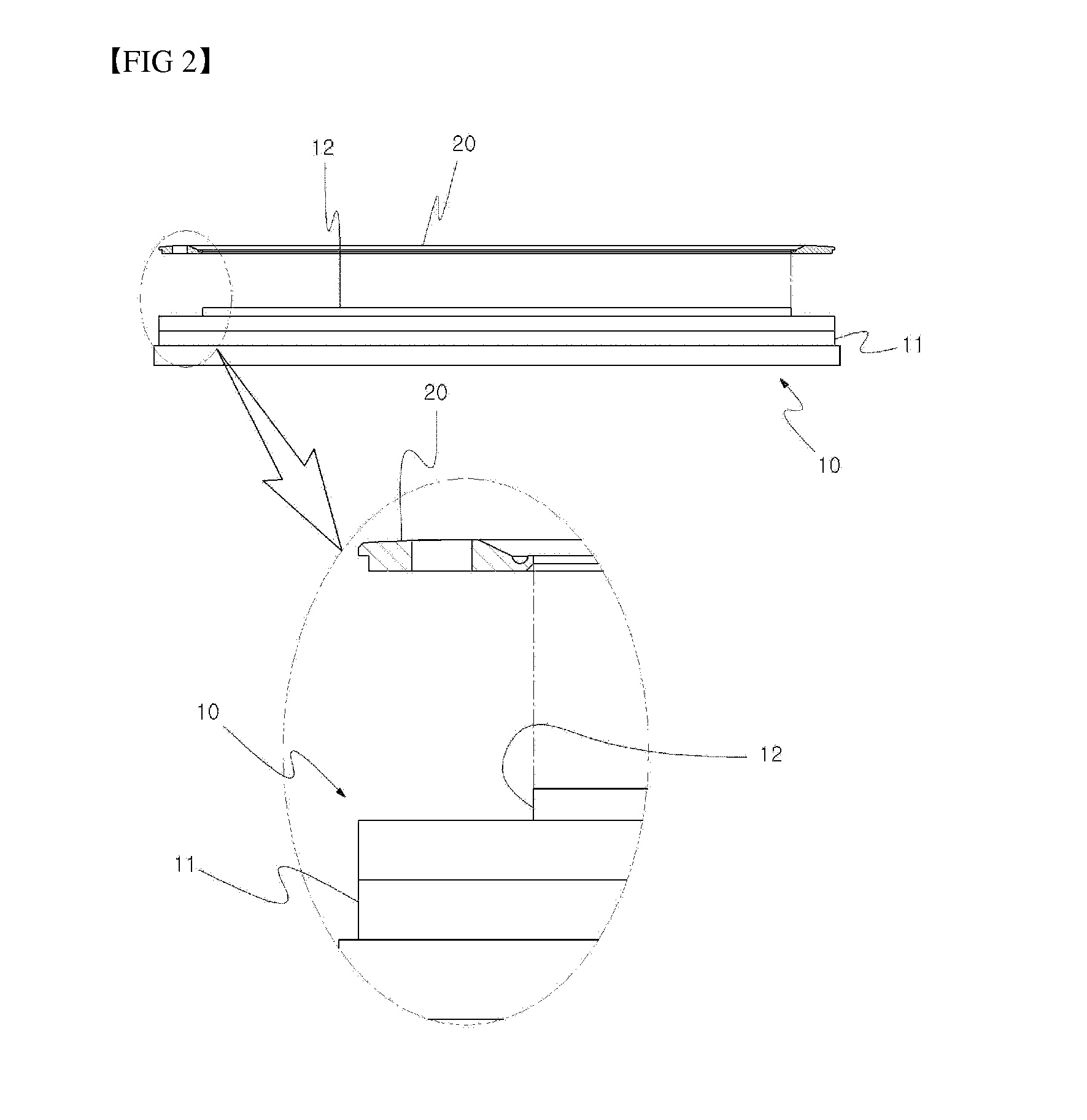

Electronic device

ActiveUS9313915B2Improve cooling efficiencyPump componentsDigital data processing detailsHeat conductingElectron device

An electronic device includes an upper cover, a lower cover combined with the upper cover, and a heat conducting pillar. An accommodating space is formed by the upper cover and the lower cover. The heat conducting pillar is disposed in the accommodating space and physically connected with the upper cover and the lower cover to balance the temperature of the upper cover and the lower cover.

Owner:ASUSTEK COMPUTER INC

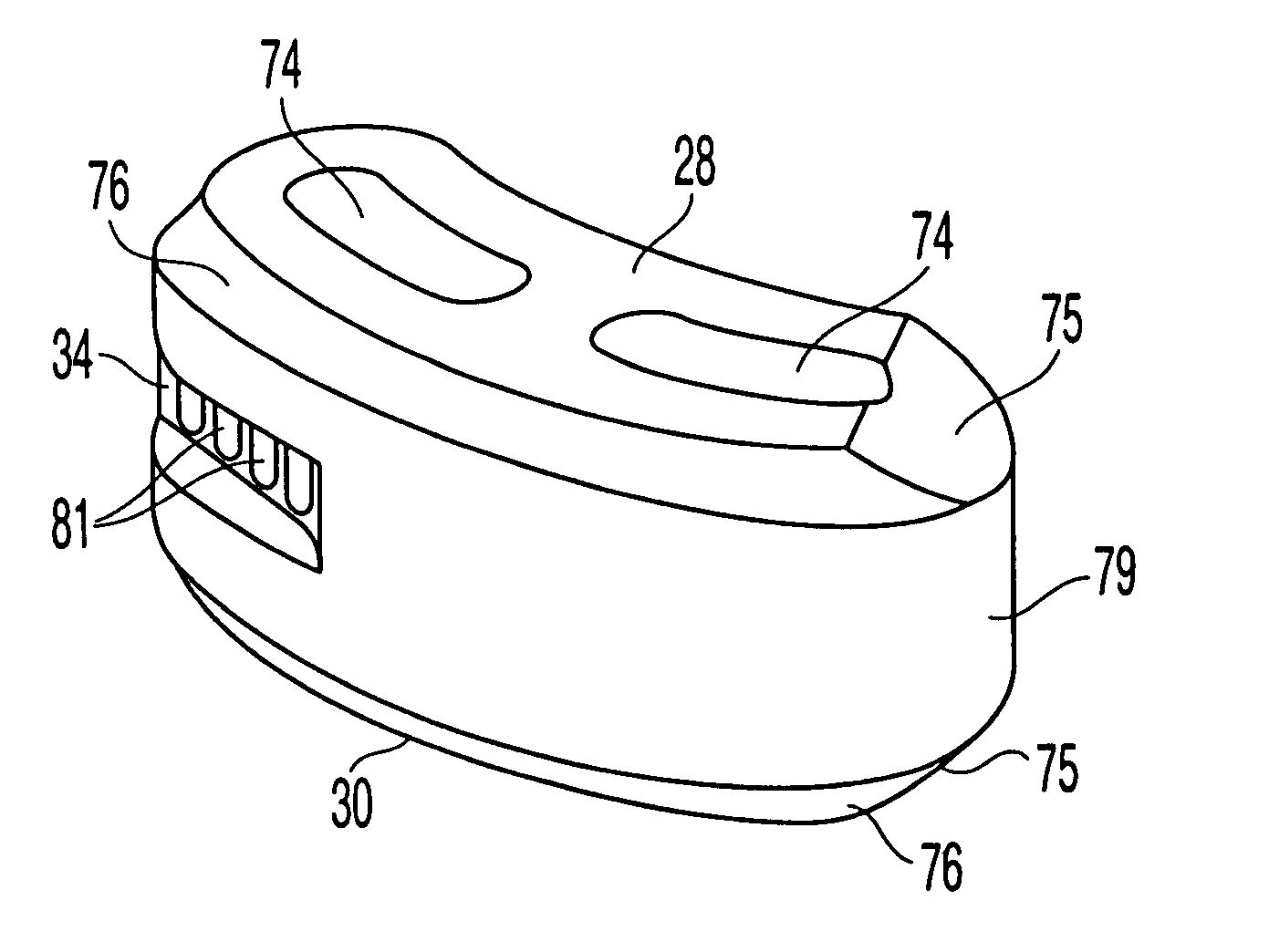

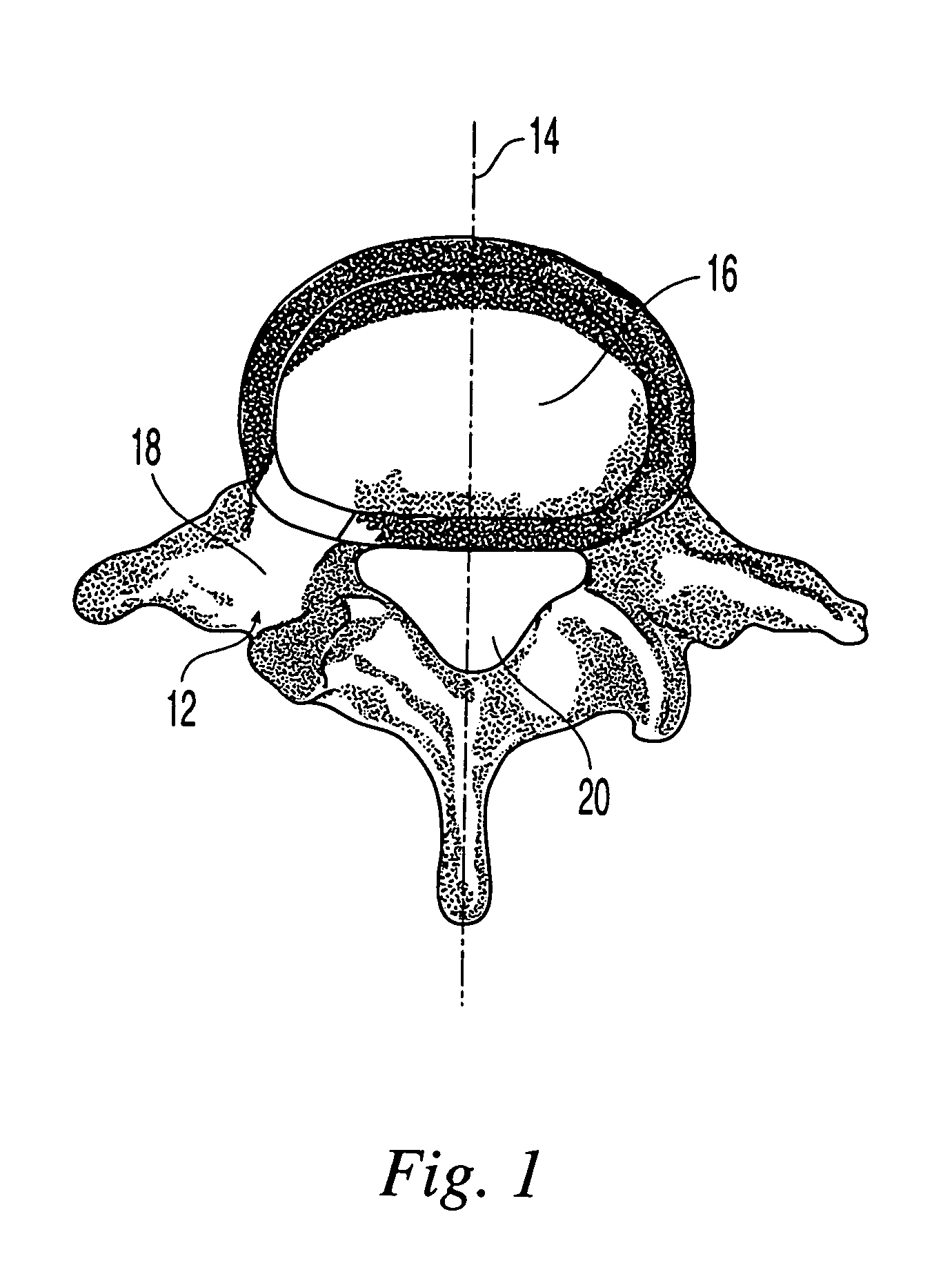

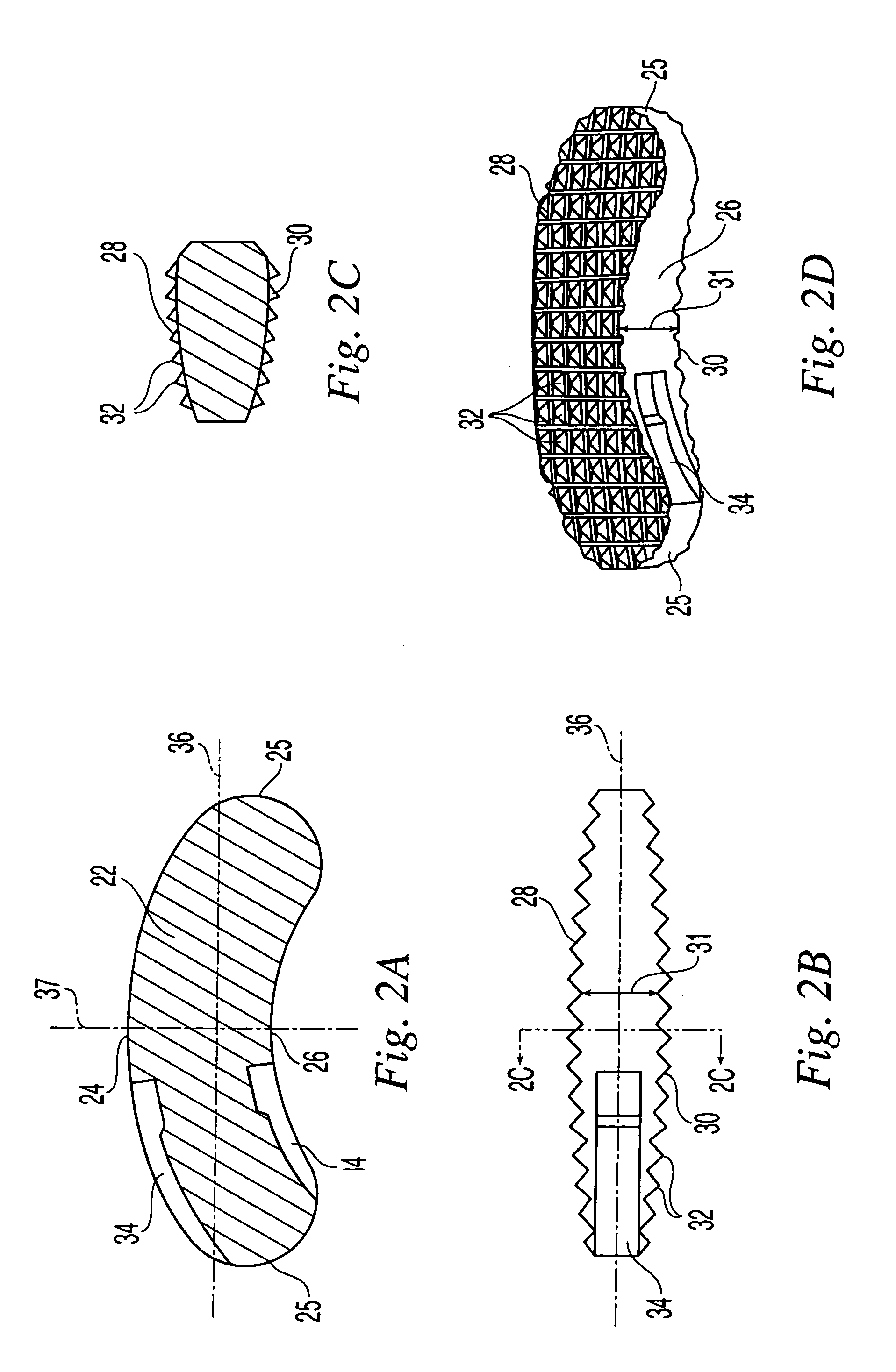

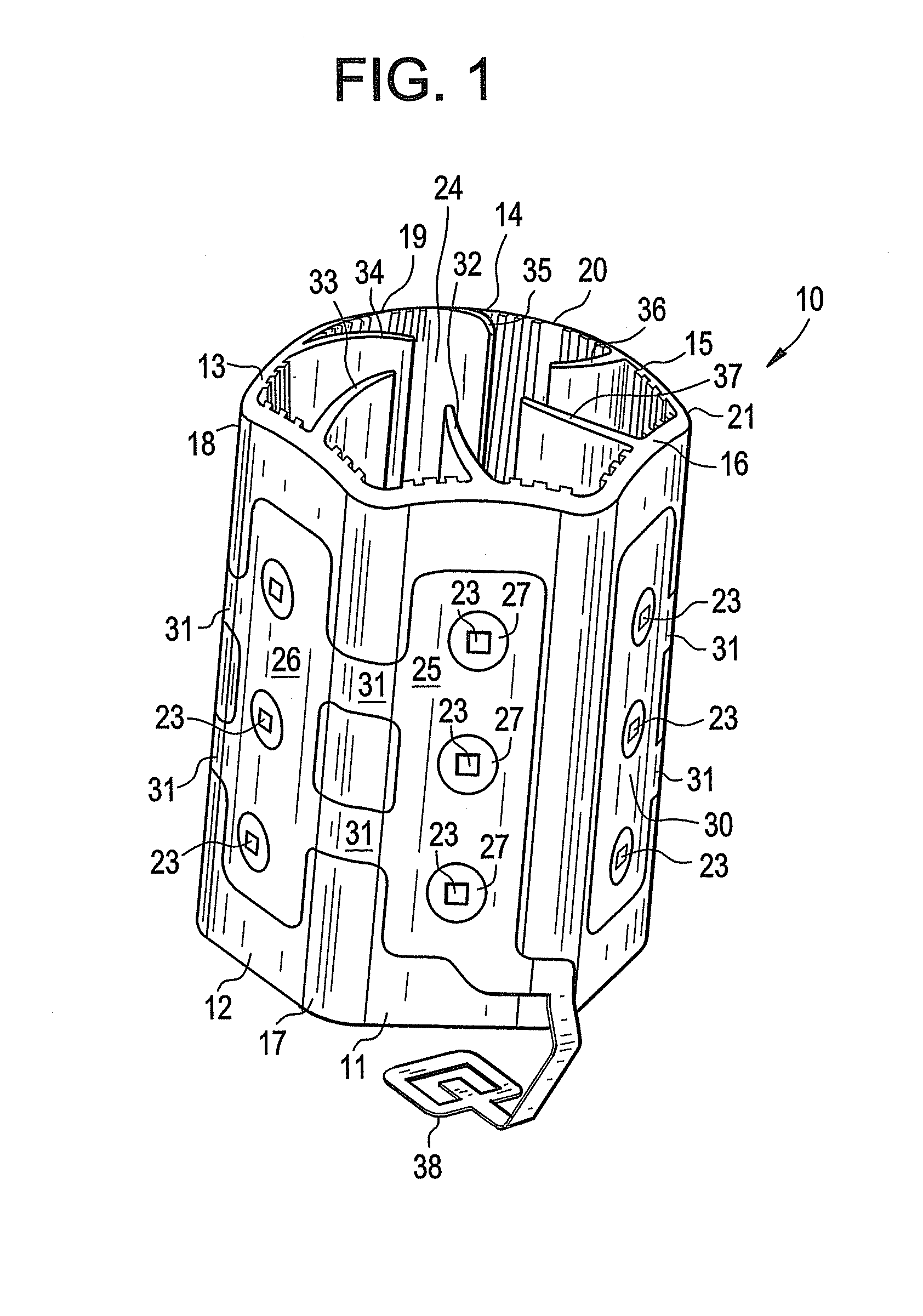

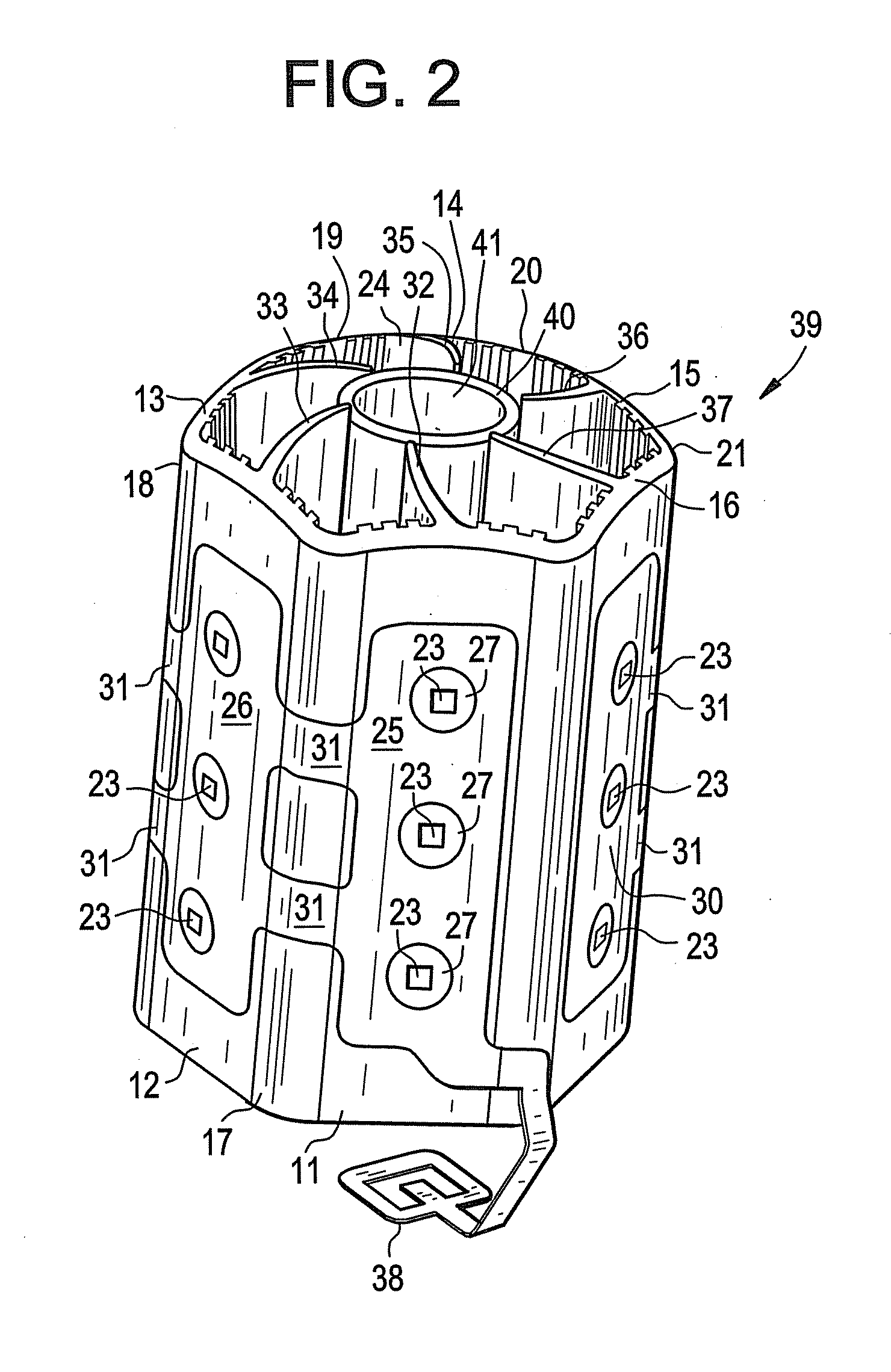

Intervertebral implant for transforaminal posterior lumbar interbody fusion procedure

InactiveUS6974480B2Easy to insertPrevent slippingBone implantSurgeryTransforaminal approachSpinal column

An intervertebral implant for fusing vertebrae is disclosed. The implant has a body with curved, substantially parallel posterior and anterior faces separated by two narrow implant ends, superior and inferior faces having a plurality of undulating surfaces for contacting upper and lower vertebral endplates, and at least one depression in the anterior or posterior face for engagement by an insertion tool, at least two vertical through-channels extending through the implant from the superior face to the inferior face, a chamfer on the superior and inferior surfaces at one of the narrow implant ends, and a beveled edge along a perimeter of the superior and inferior faces. The arcuate implant configuration and the chamfers on the superior and inferior faces at the narrow end facilitate insertion of the implant from a transforaminal approach into a symmetric position about the midline of the spine so that a single implant provides balanced support to the spinal column. The implant may include radiopaque markers extending through the thickness of the implant to indicate the location and size of the implant. The implant may be formed of a plurality of interconnecting bodies assembled to form a single unit. An implantation kit and method are also disclosed.

Owner:DEPUY SYNTHES PROD INC +1

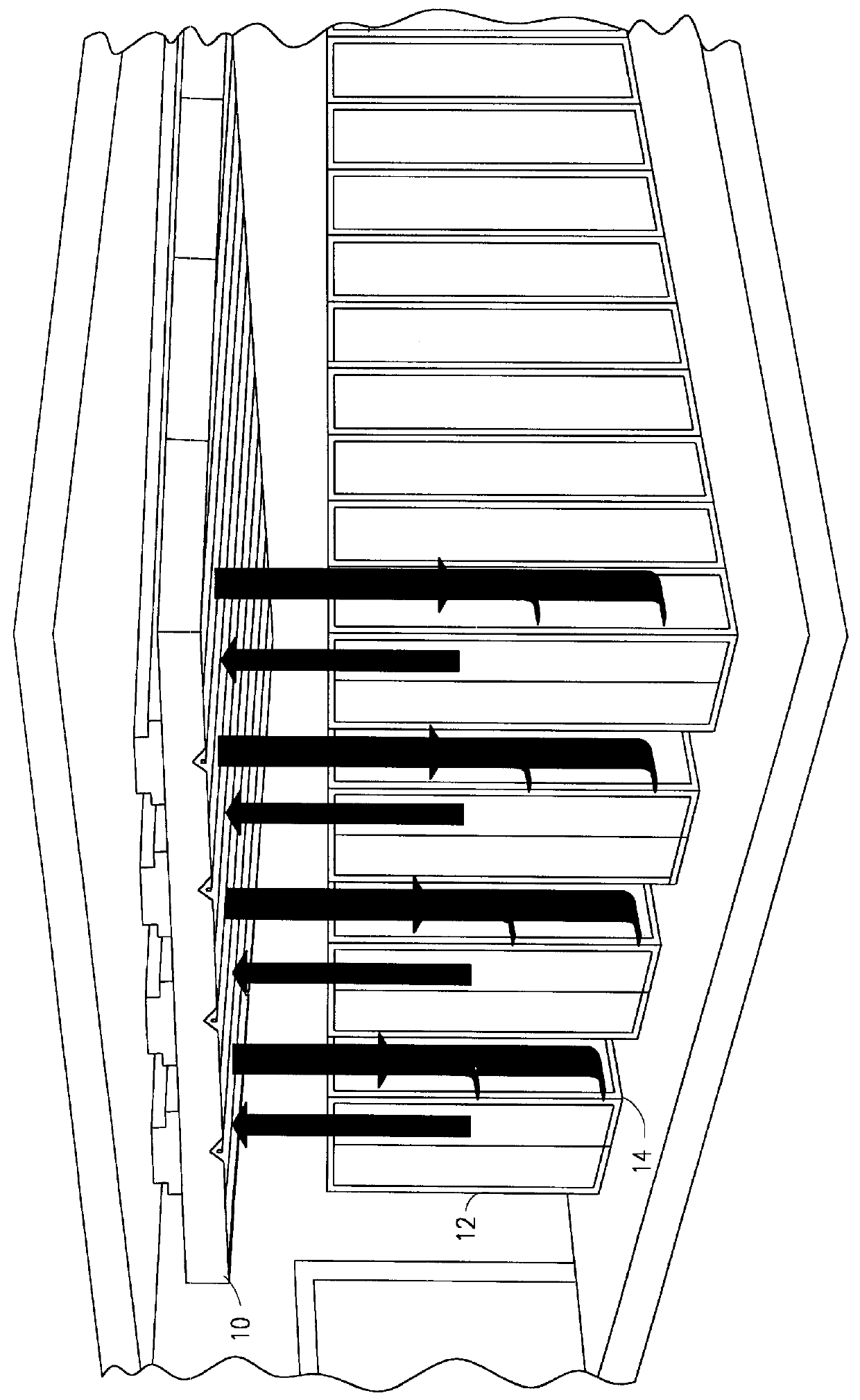

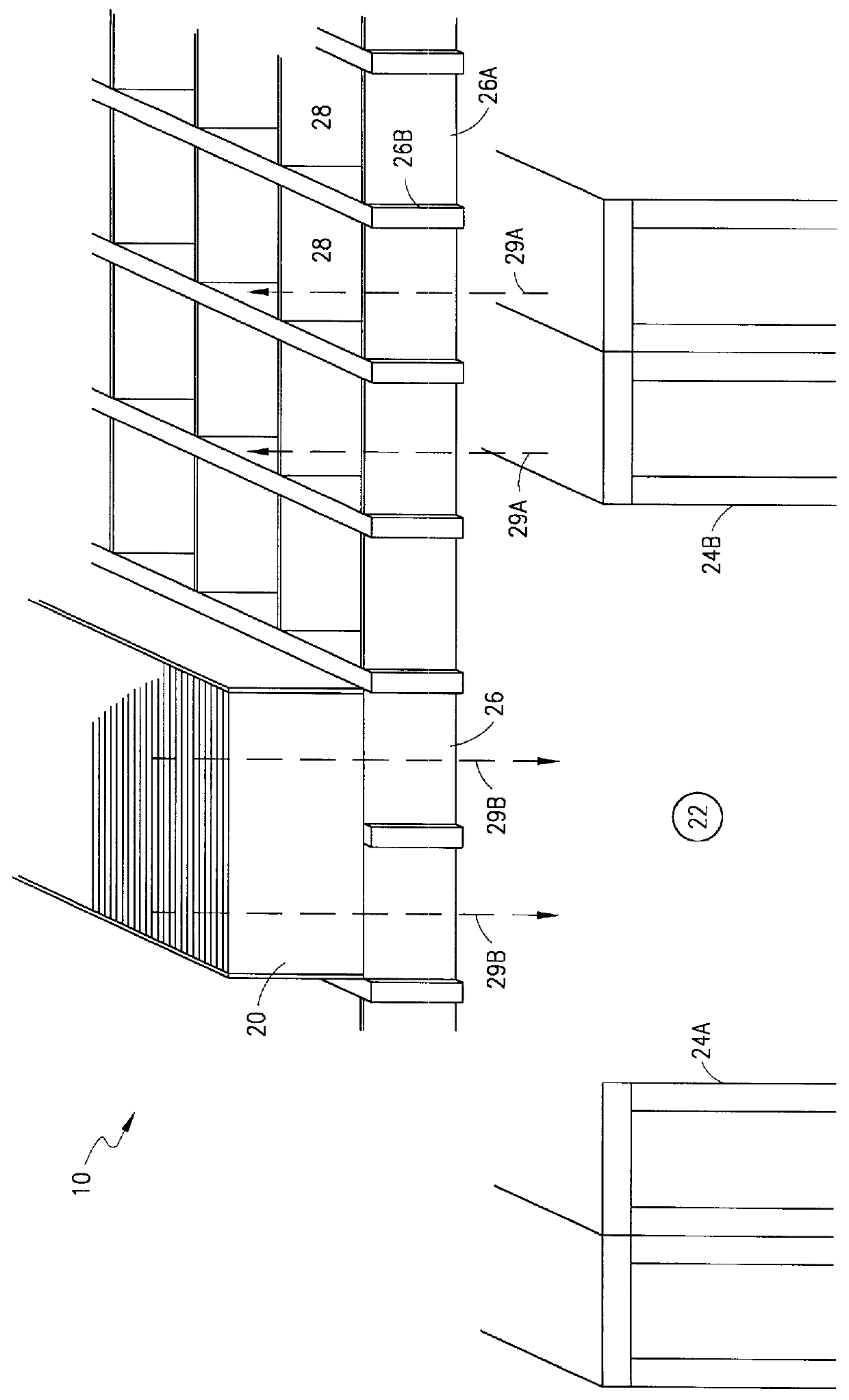

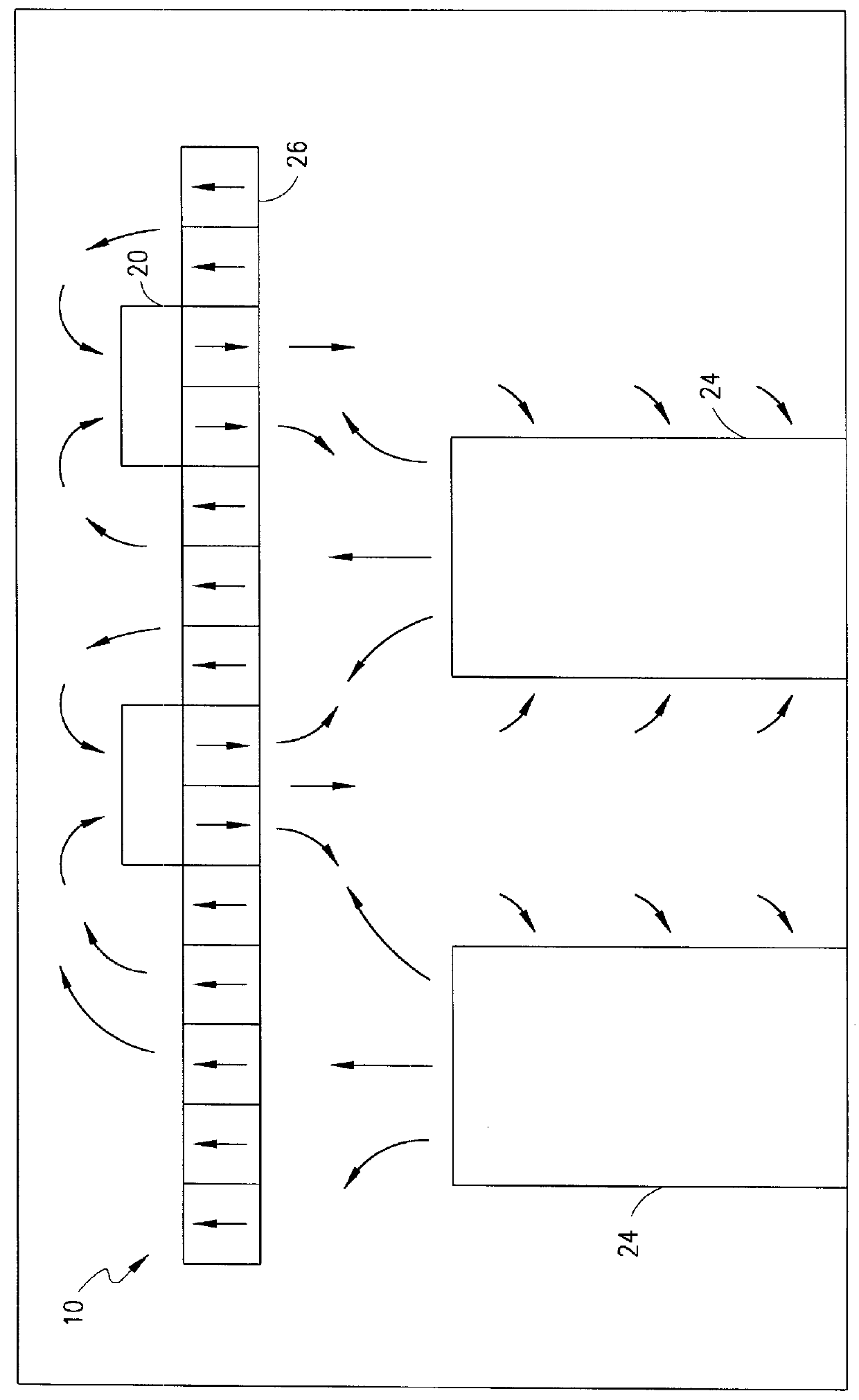

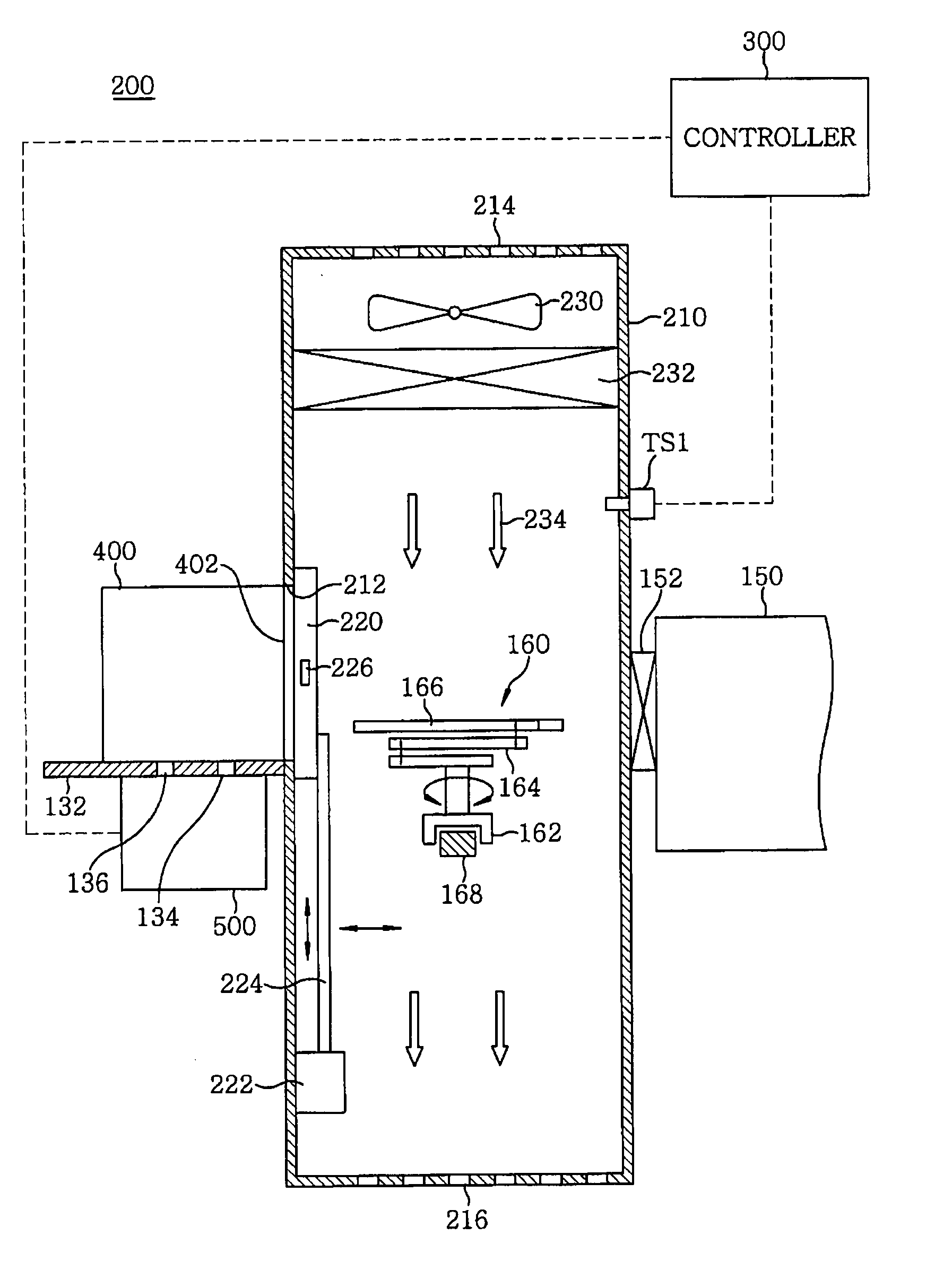

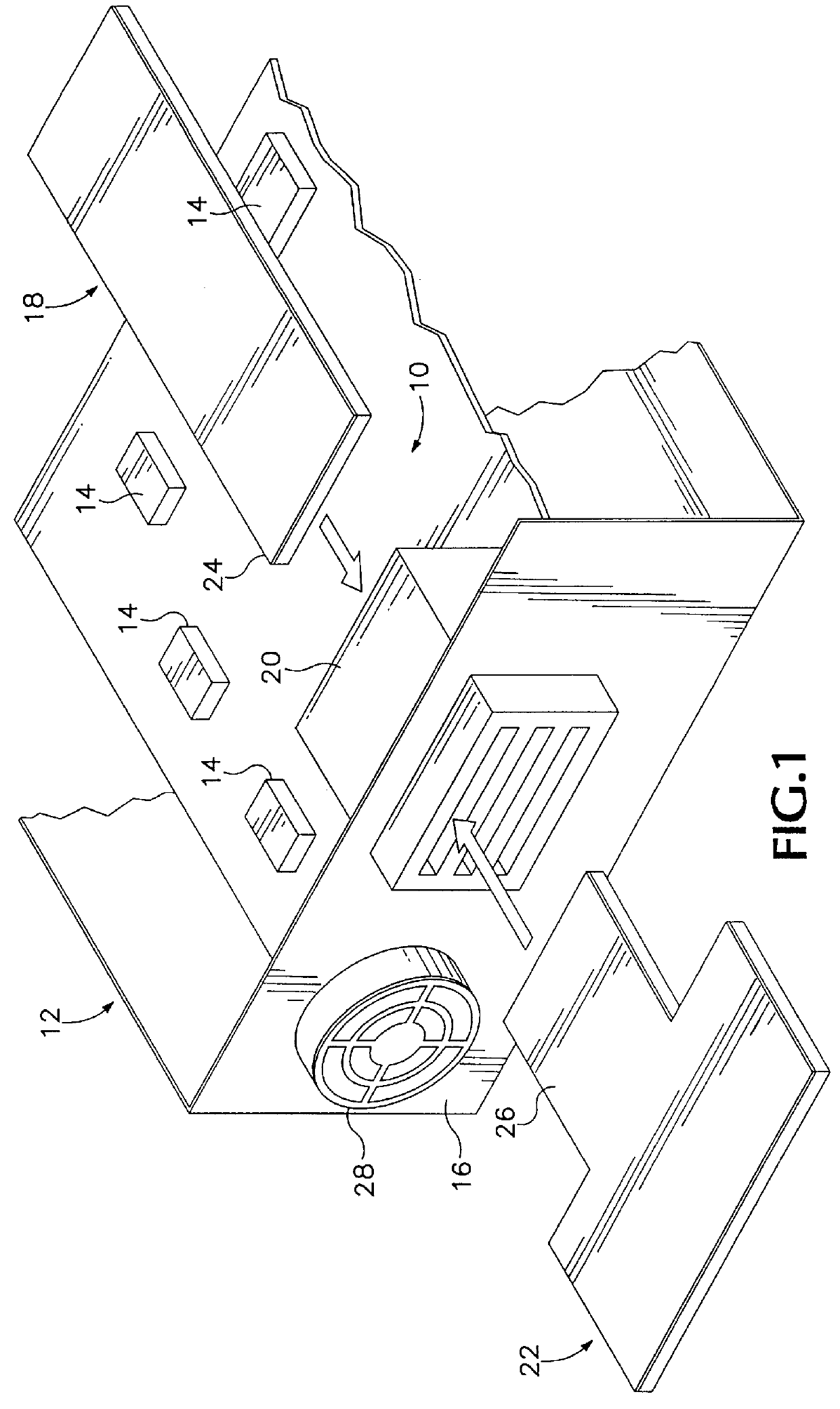

System and method for separating air flows in a cooling system

InactiveUS6034873AGreat and great efficiencyImprove efficiencyHeat exchange apparatusCooling/ventilation/heating modificationsMulti materialEngineering

A cooling system and method employing separation chutes and baffles is disclosed. The separation chutes separate the cooled air descending from a heat exchanger positioned above heat-generating equipment in an equipment room from heated air ascending from the heat-generating equipment. Separation of the airflows reduces turbulence and increases cooling efficiencies. The separation chutes are made of a variety of materials, both rigid and flexible, for a variety of applications.

Owner:VERTIV CORP

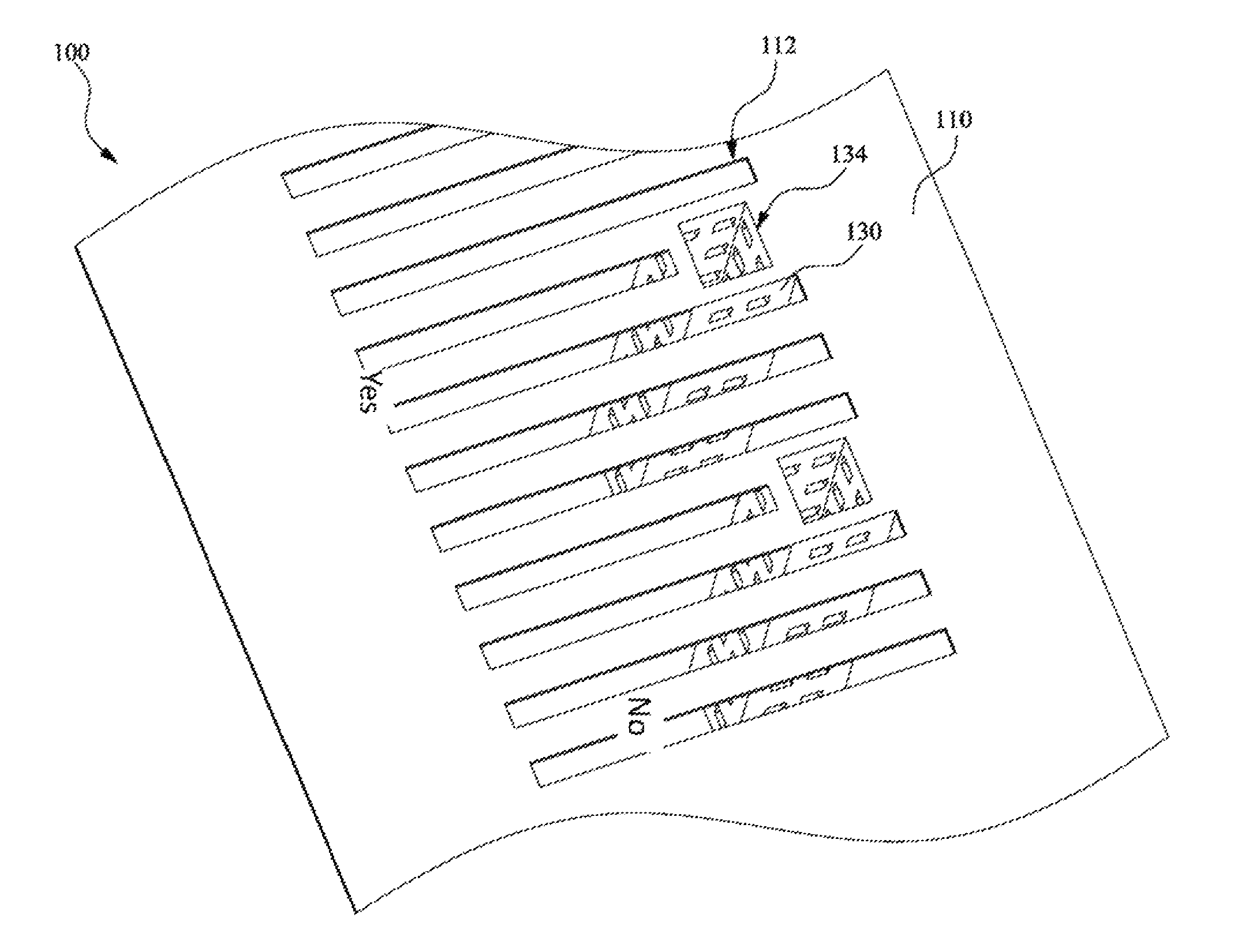

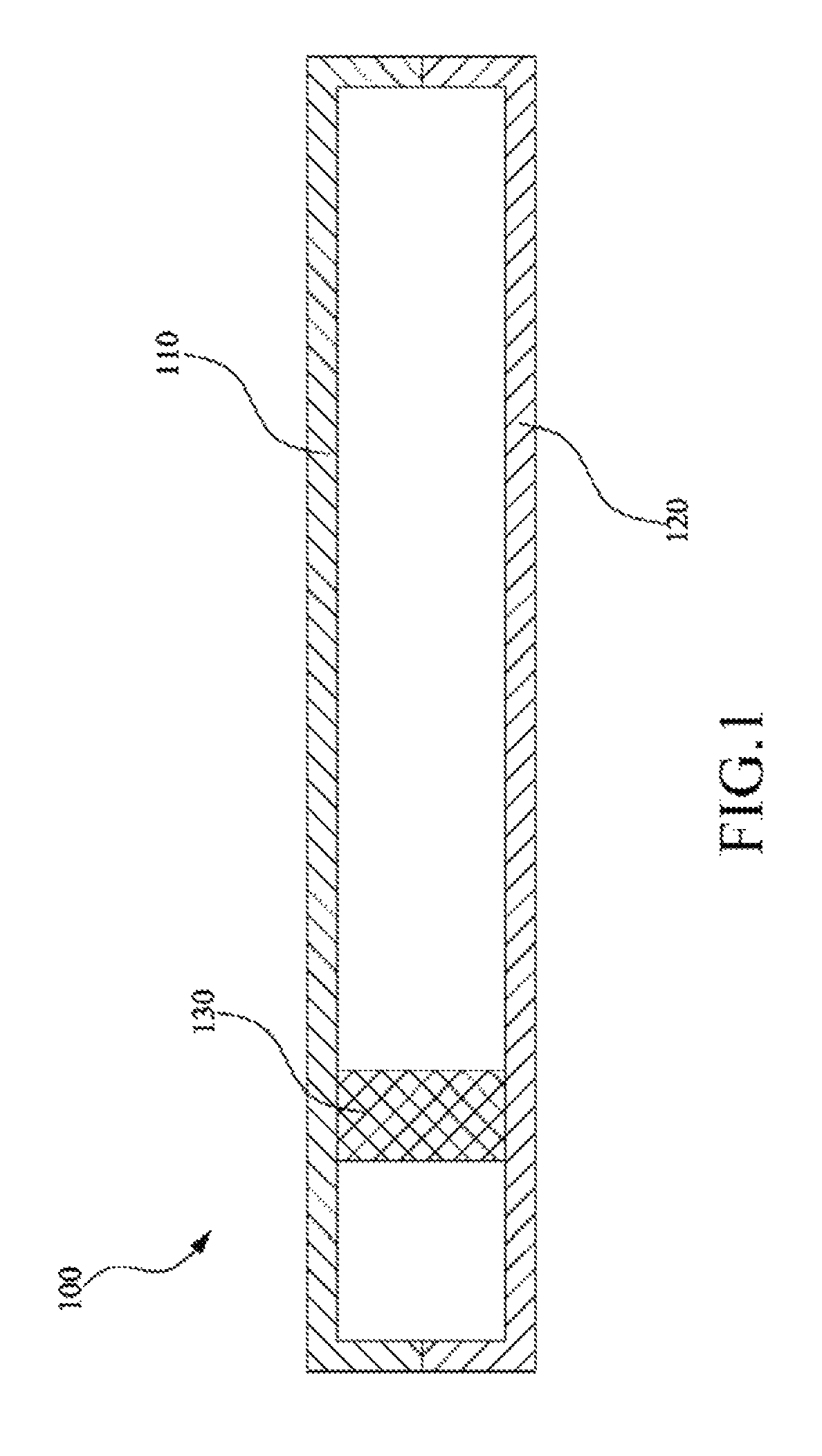

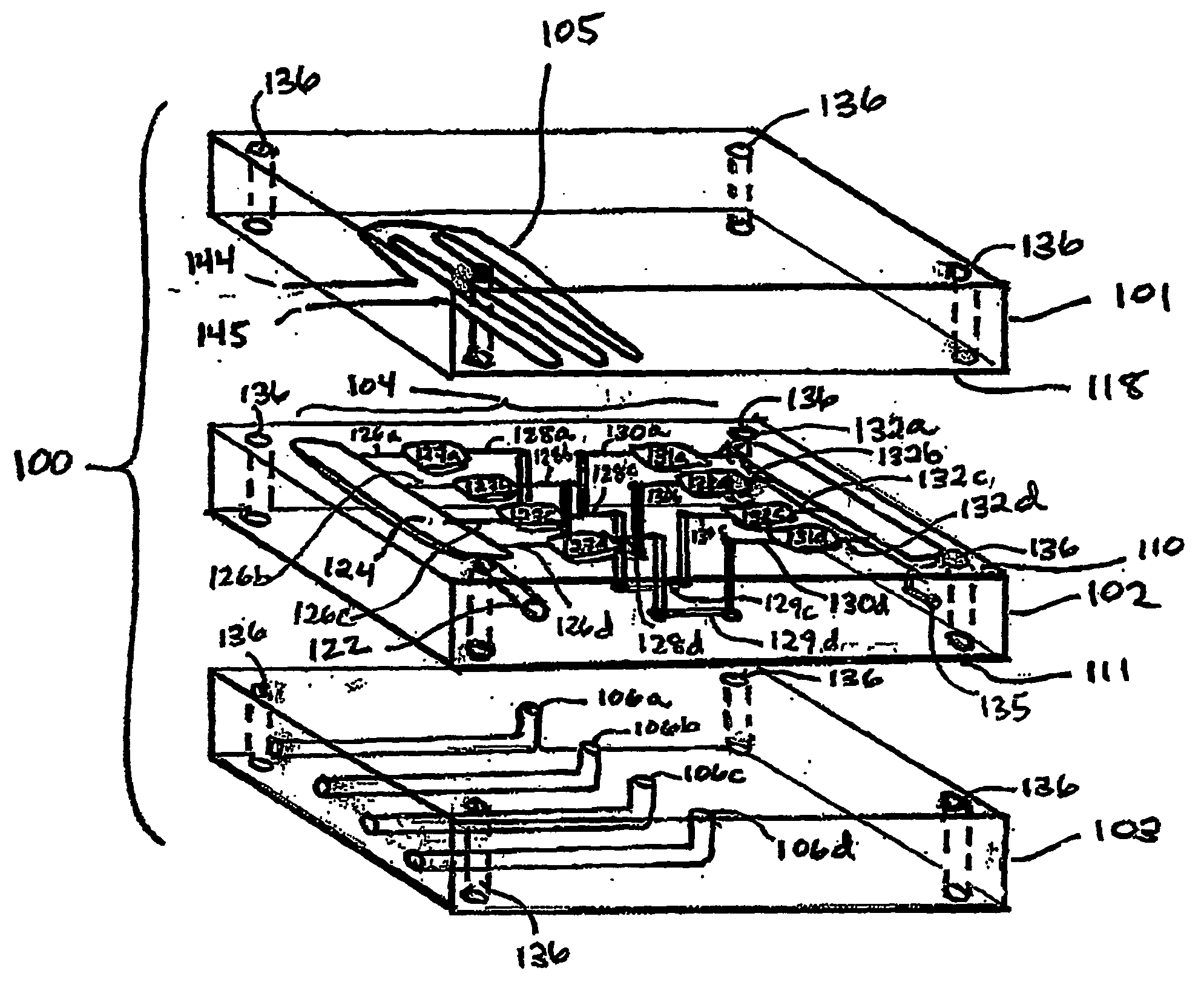

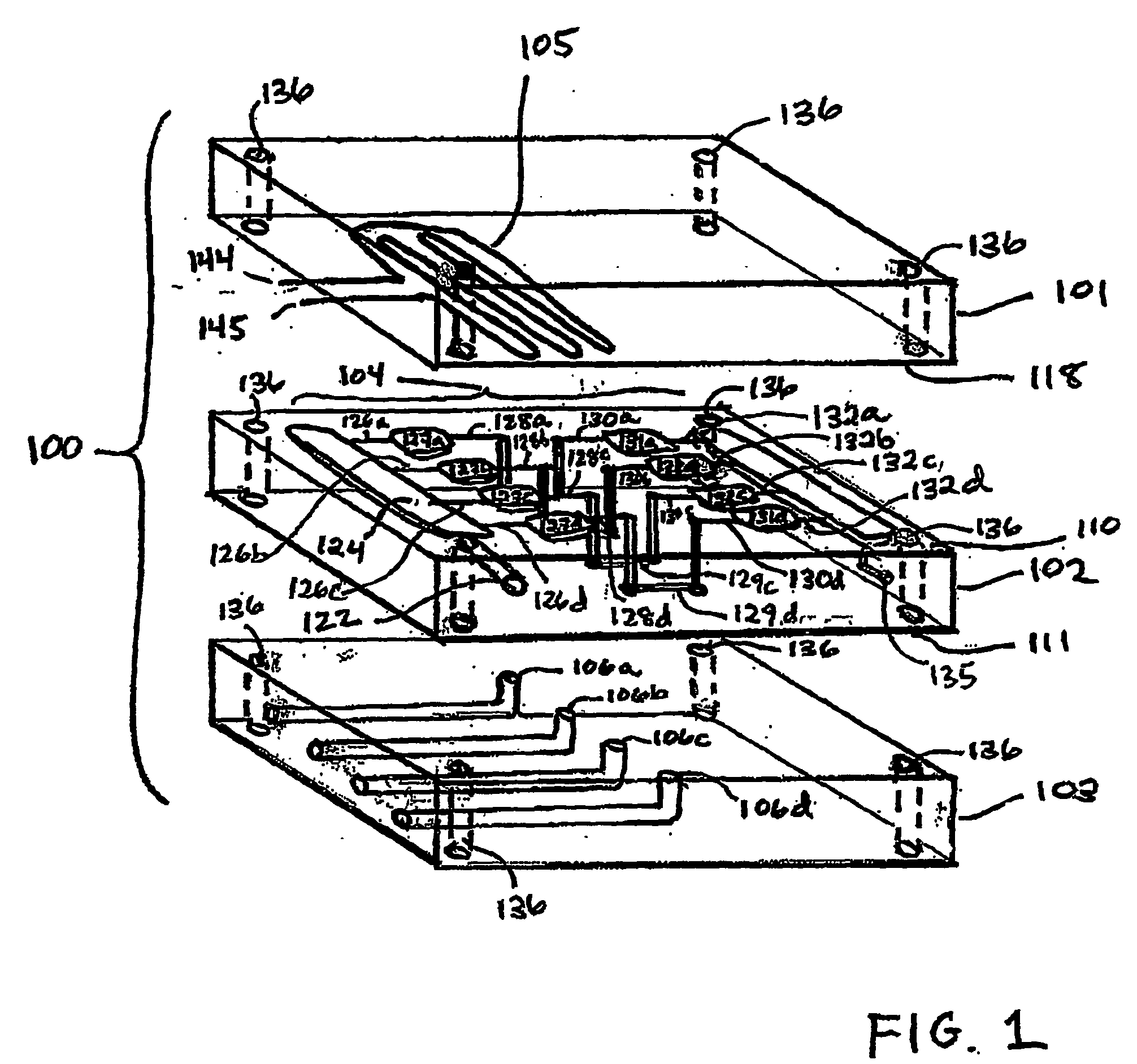

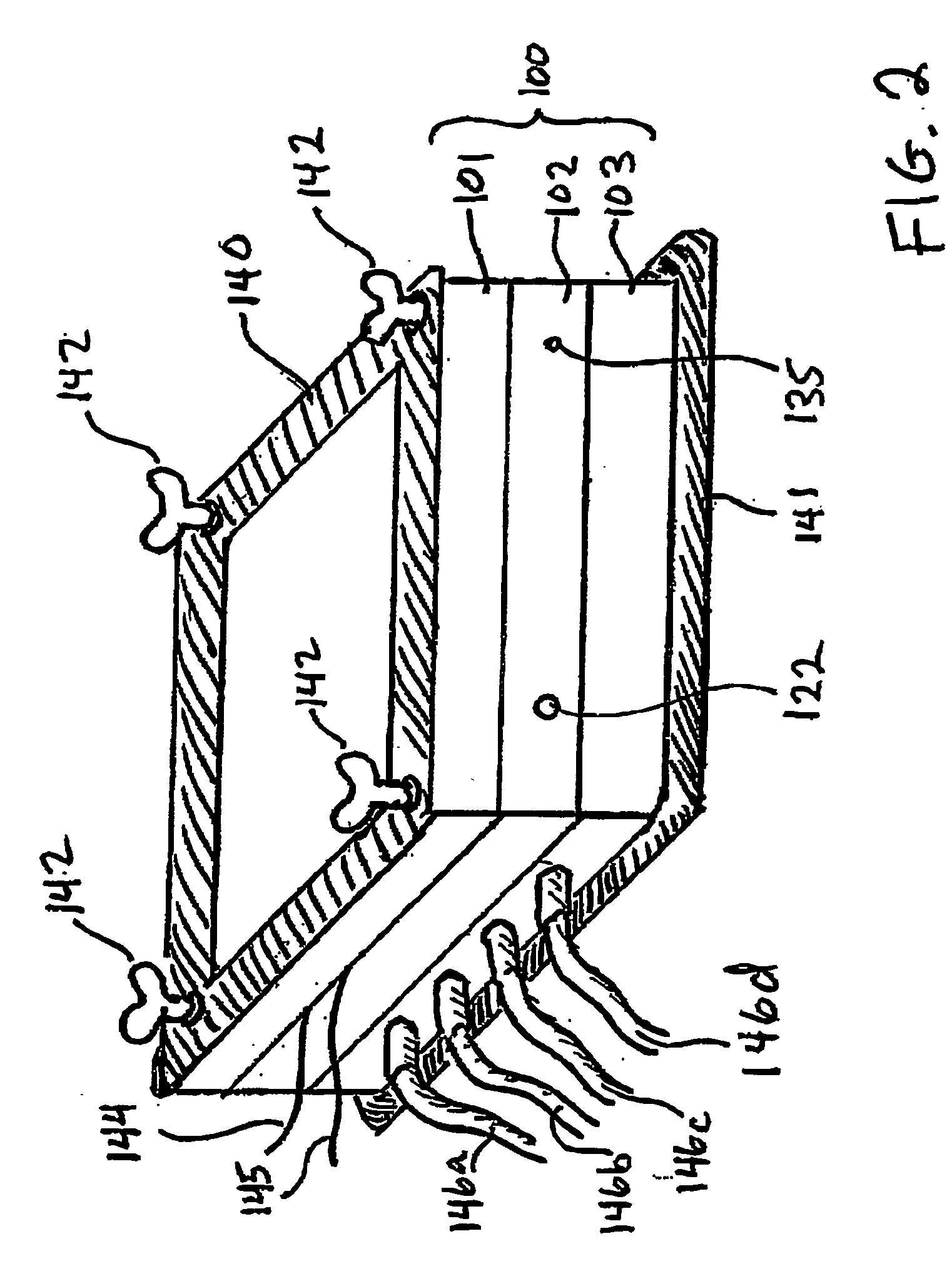

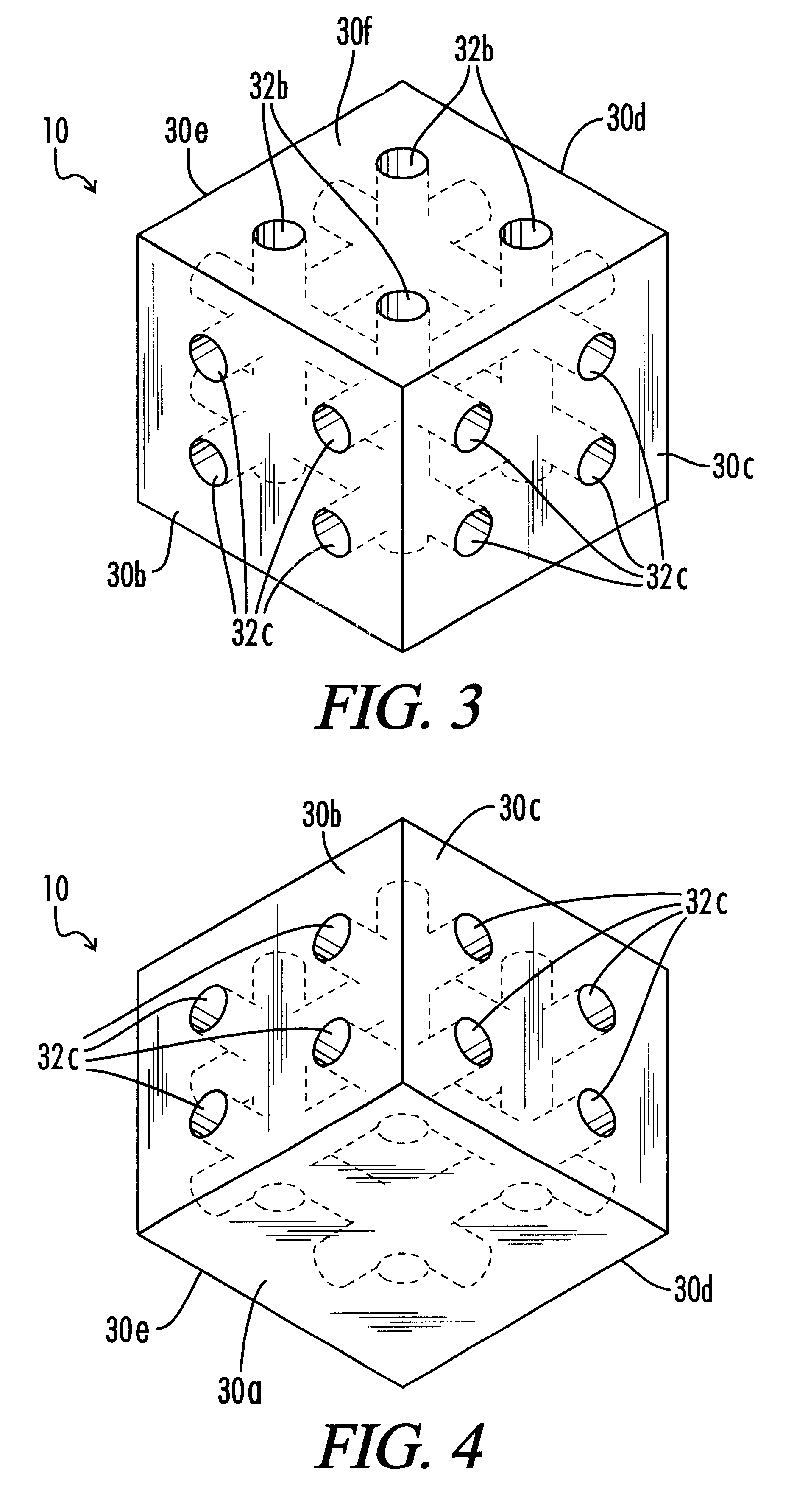

Three-dimensional microfluidics incorporating passive fluid control structures

InactiveUS20040109793A1Simple and effective and versatile controlShaking/oscillating/vibrating mixersHeating or cooling apparatusFluid controlMicrofluidics

A three-dimensional microfluidic device (100) formed from a plurality of substantially planar layers (101, 102, 103) sealed together is disclosed

Owner:BIOMICRO SYST

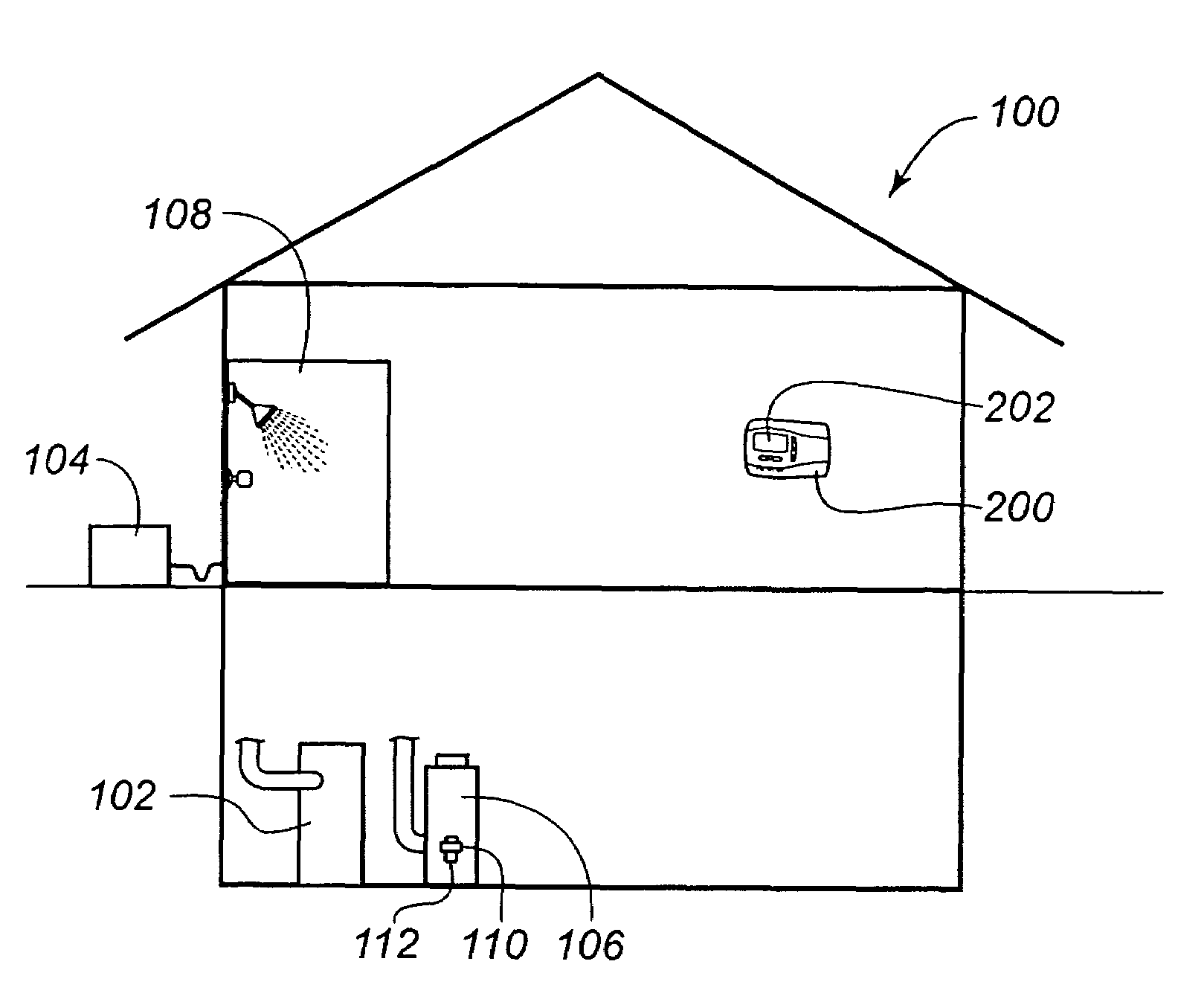

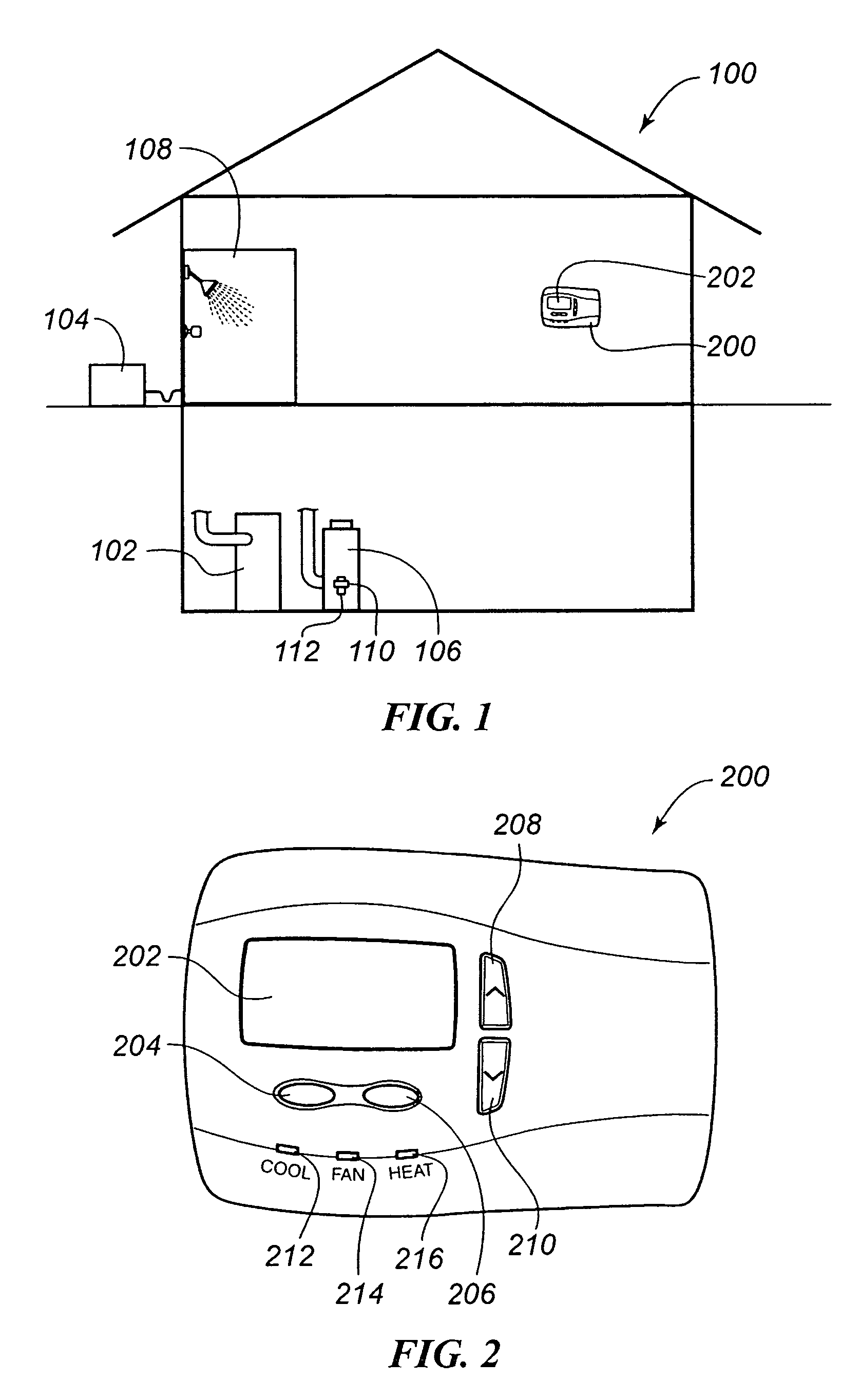

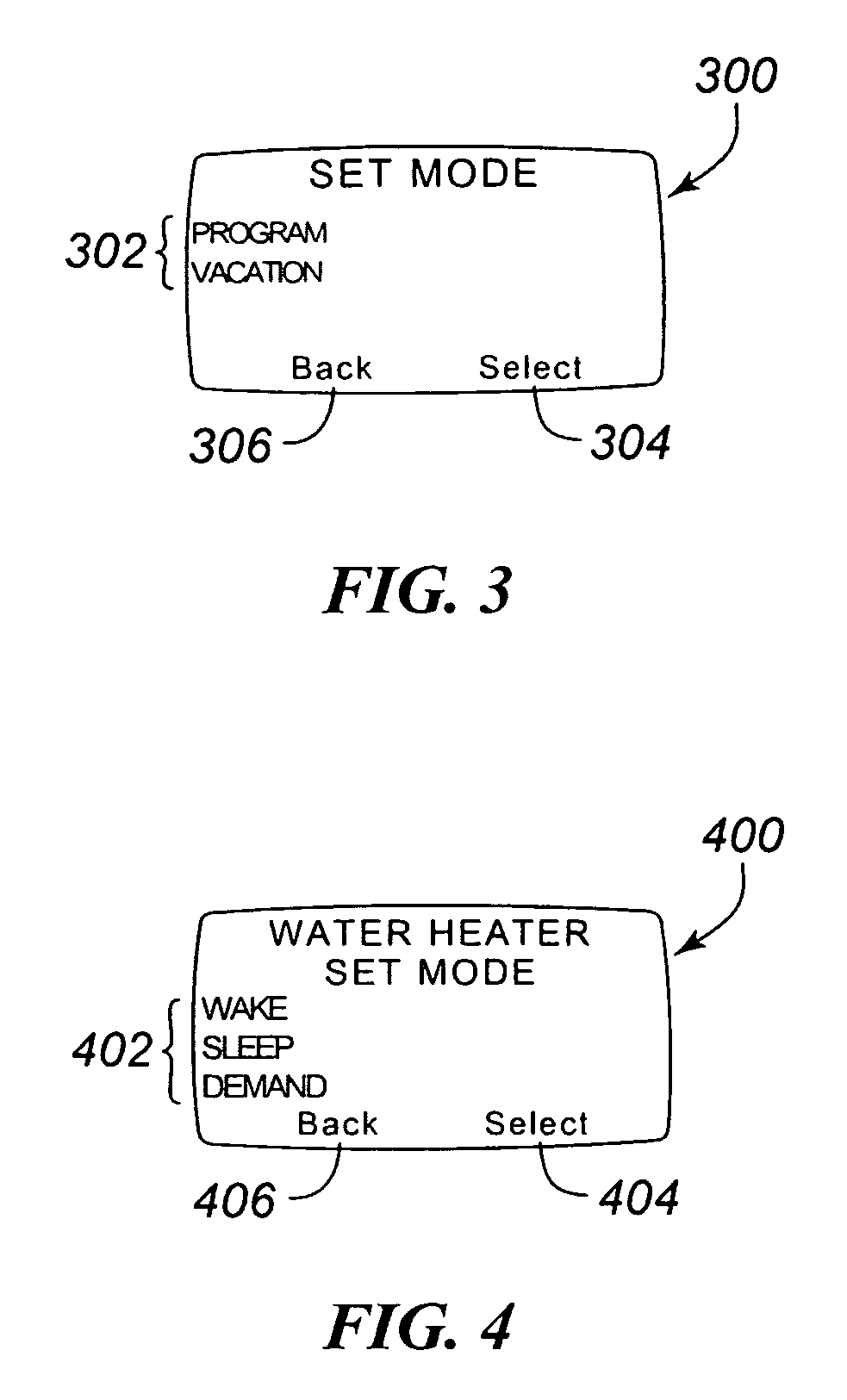

System and method for controlling appliances and thermostat for use therewith

InactiveUS7469550B2Save energySaving of operationTemperature control without auxillary powerMechanical apparatusThermostatEngineering

An energy saving control for appliances via an intelligent thermostat is provided. This intelligent thermostat provides programmatic control over the HVAC system, and provides coordinated control over the appliances. This control over the appliances is accomplished via a communications network between the intelligent thermostat and the appliances. The appliances include occupancy sensors and transmit usage and occupancy information to the intelligent thermostat. The intelligent thermostat processes this information to determine the occupancy of the dwelling. The thermostat controls the HVAC system and the appliances according to the determined occupancy of the dwelling.

Owner:ROBERTSHAW CONTROLS CO

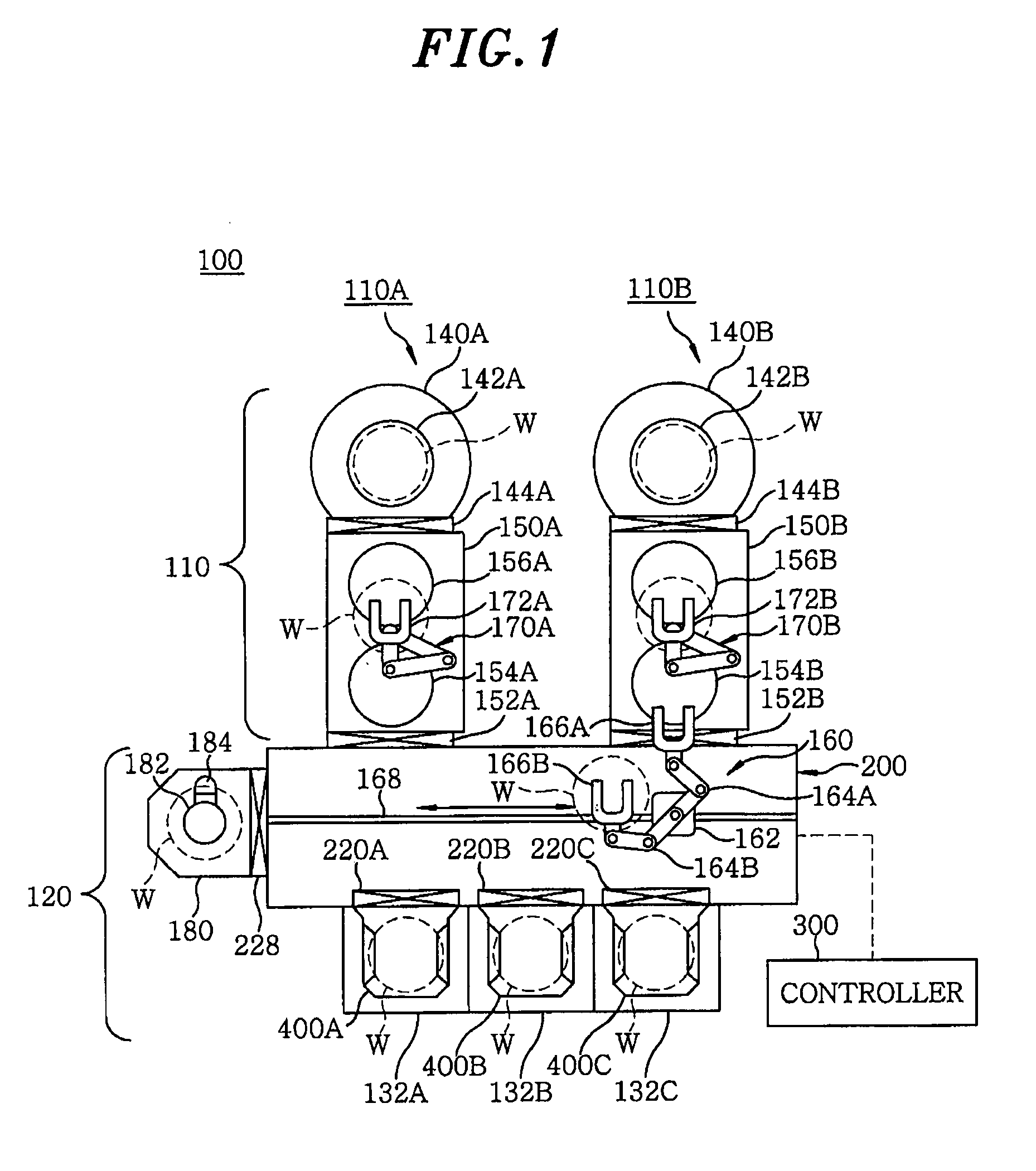

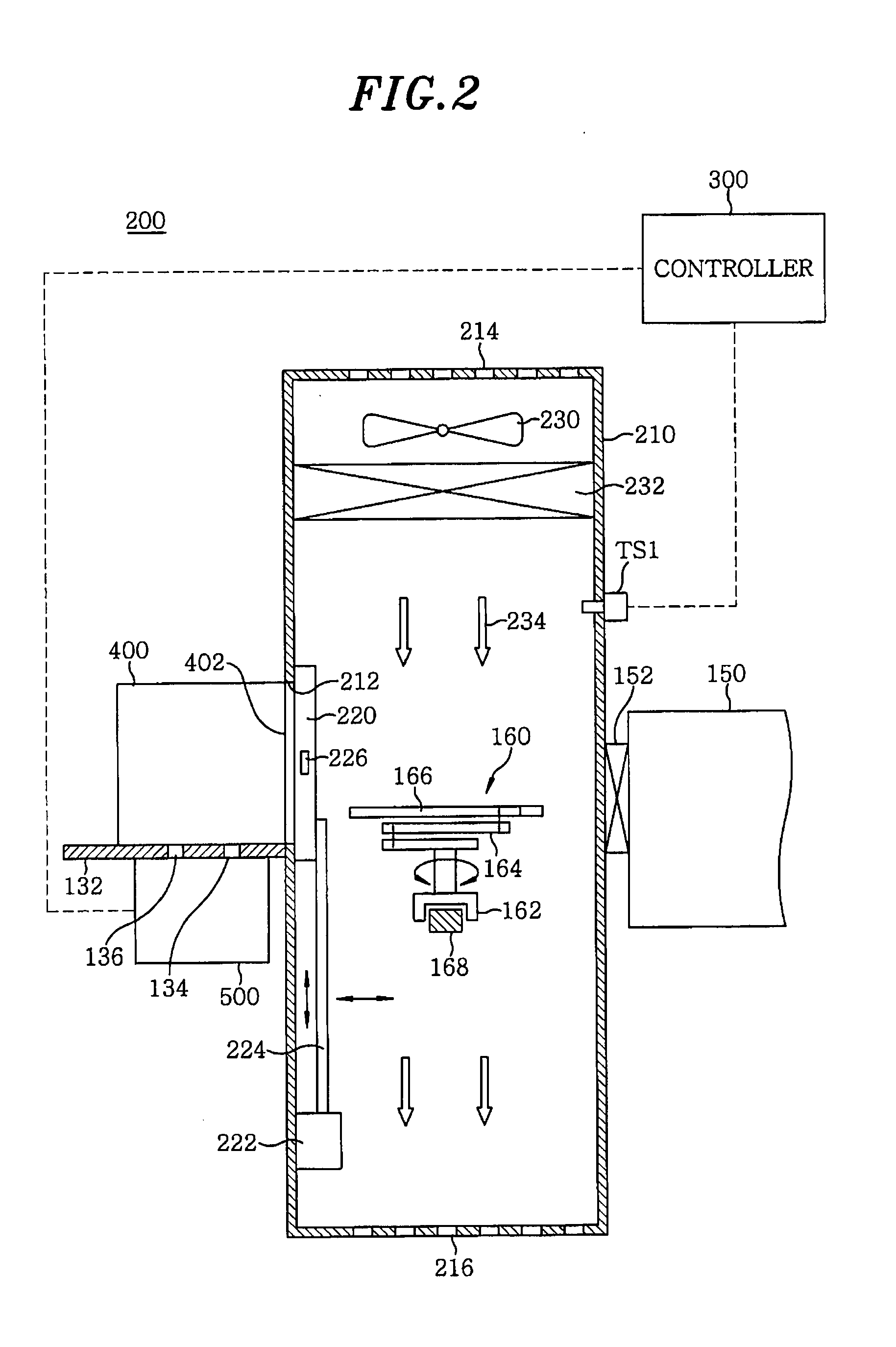

Substrate processing apparatus and particle adhesion preventing method

ActiveUS20100111648A1Avoid stickingSecure performanceElectric discharge tubesTemperatue controlTemperature controlParticle adhesion

Owner:TOKYO ELECTRON LTD

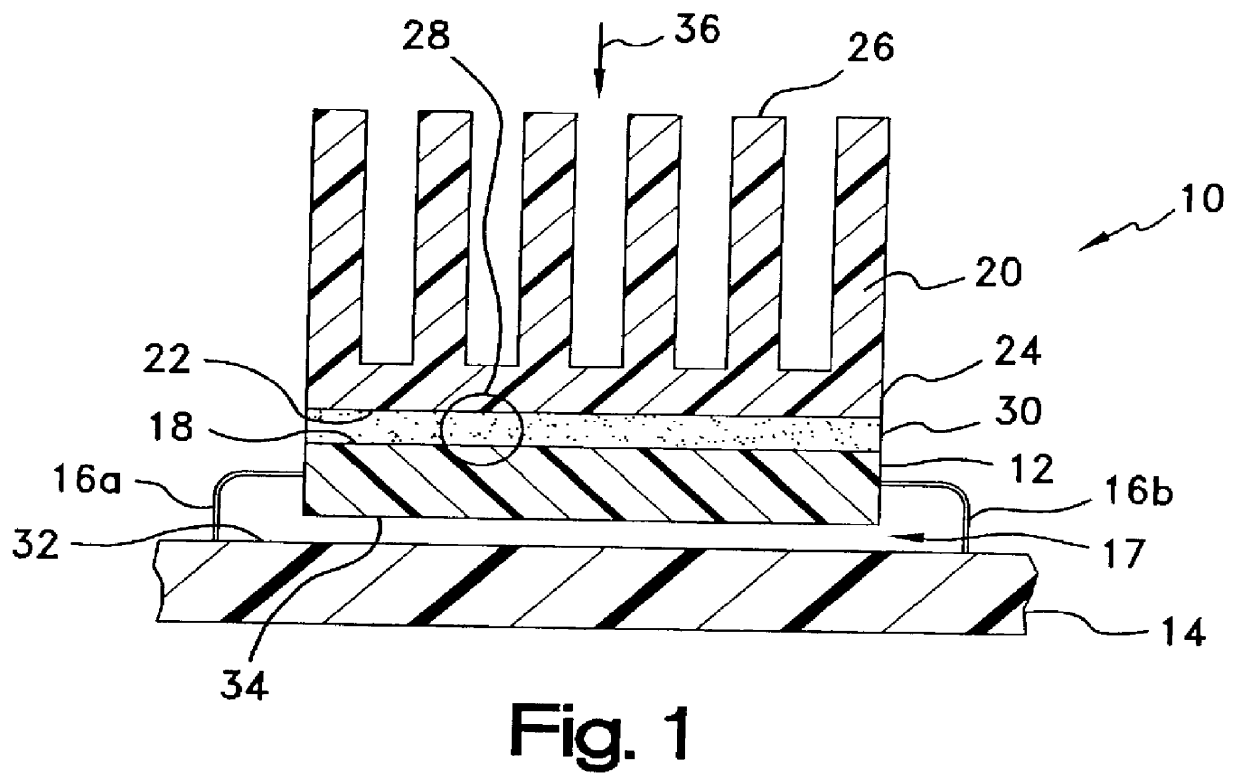

Conformal thermal interface material for electronic components

InactiveUS6054198AOptimize allocationReadily apparentSemiconductor/solid-state device detailsSolid-state devicesRoom temperatureConductive materials

A thermally-conductive interface for conductively cooling a heat-generating electronic component having an associated thermal dissipation member such as a heat sink. The interface is formed as a self-supporting layer of a thermally-conductive material which is form-stable at normal room temperature in a first phase and substantially conformable in a second phase to the interface surfaces of the electronic component and thermal dissipation member. The material has a transition temperature from the first phase to the second phase which is within the operating temperature range of the electronic component.

Owner:PARKER INTANGIBLES LLC

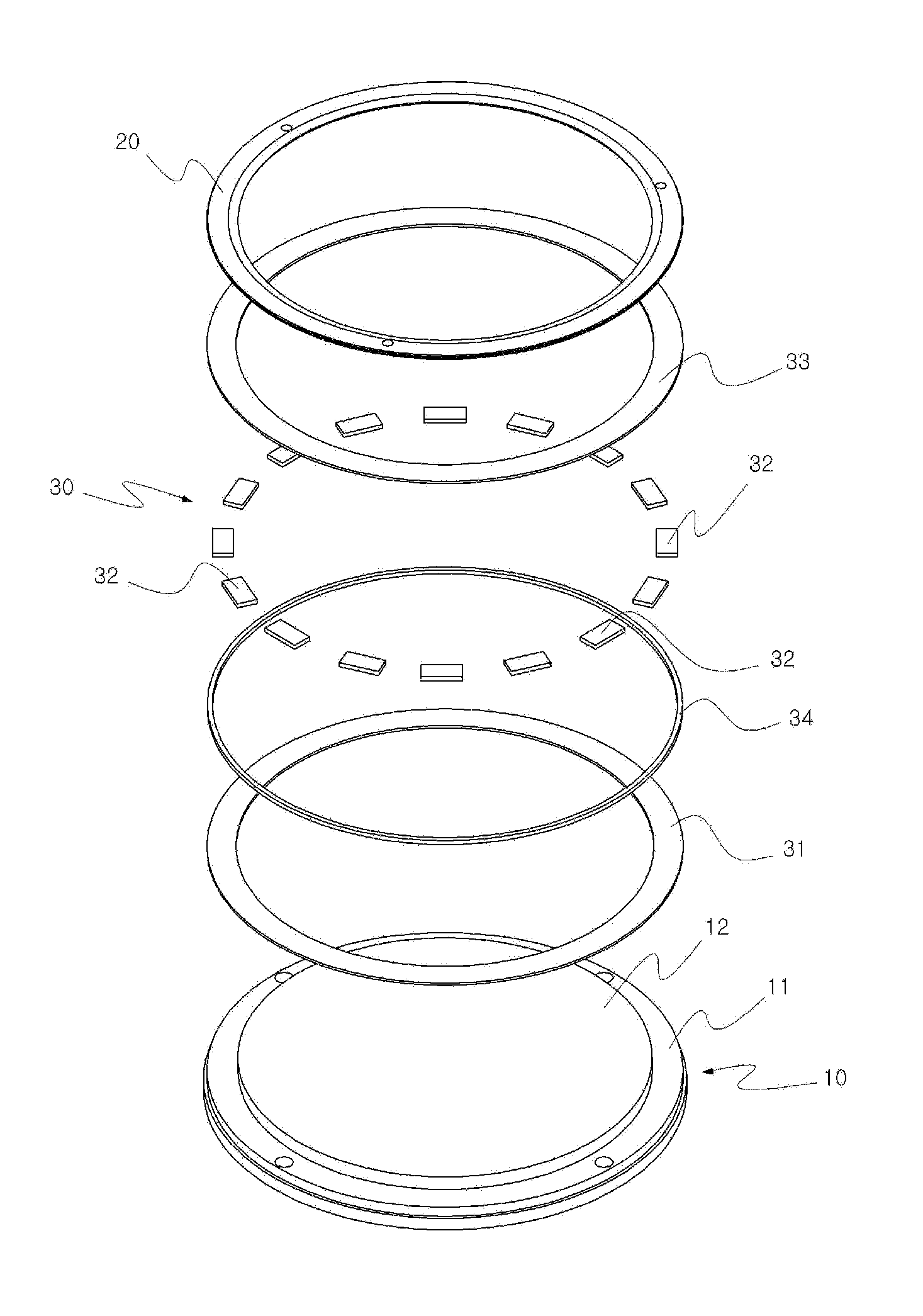

Edge ring cooling module for semi-conductor manufacture chuck

InactiveUS20140262193A1Yield ratio can be improvedLow failure rateSemiconductor/solid-state device manufacturingHeat exchange apparatusElectronics coolingYield ratio

An edge ring cooling module for semiconductor manufacturing chuck is provided which effectively cools the edge ring equipped in electrostatic chuck. The edge ring cooling module forcibly exhausts the heat of an edge ring (20) using an electronic cooling device (32) to top of a large-diameter portion (11) to effectively cool the edge ring (20) so that the temperature of the edge ring (20) is similar to that of top of a small-diameter portion (12) of a chuck body (10) to eventually improve the yield ratio while reducing the failure ratio.

Owner:TECHEST

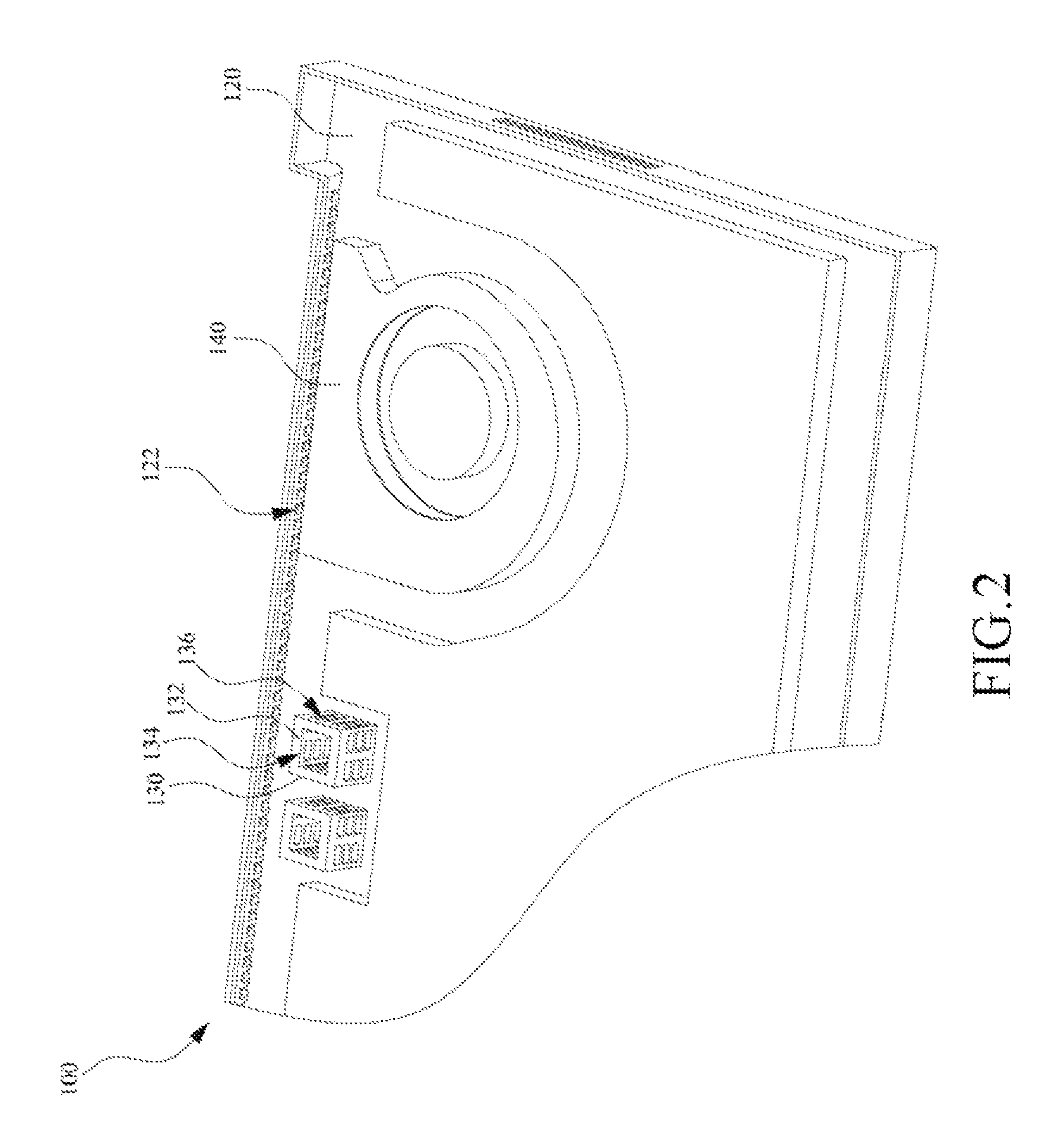

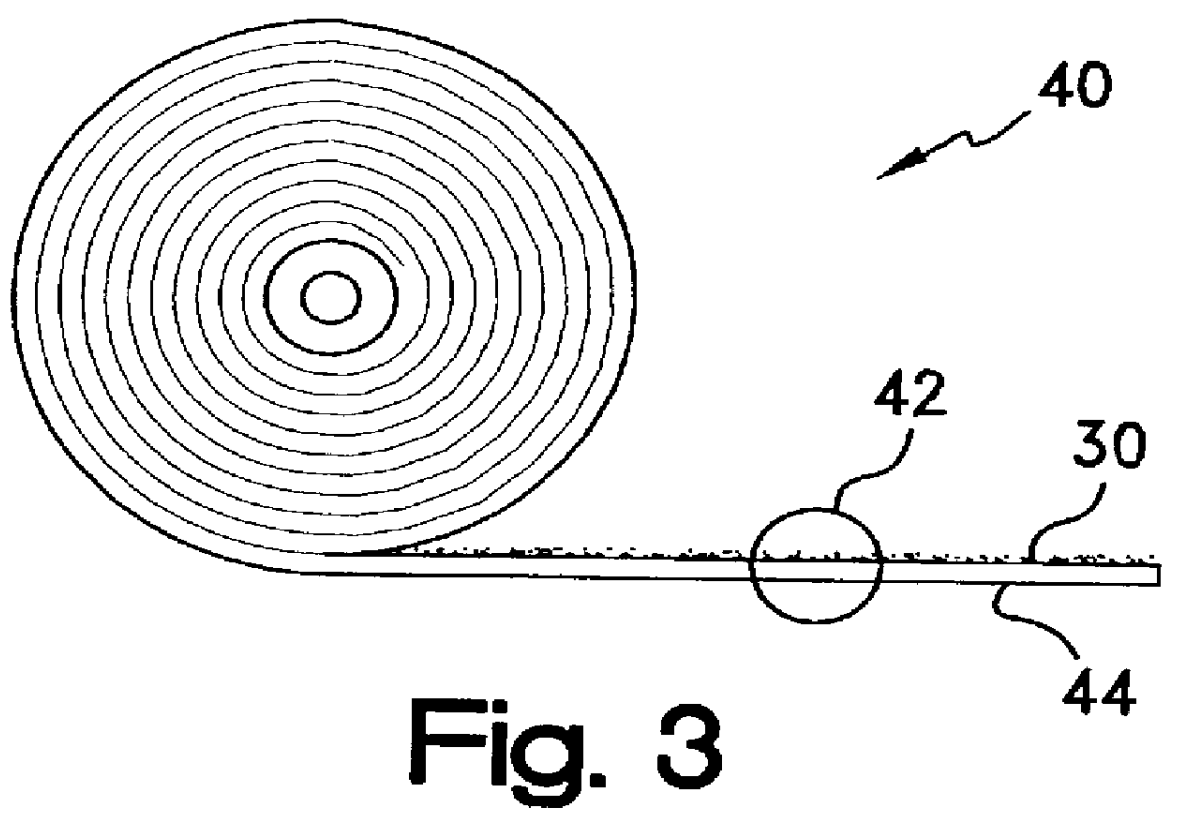

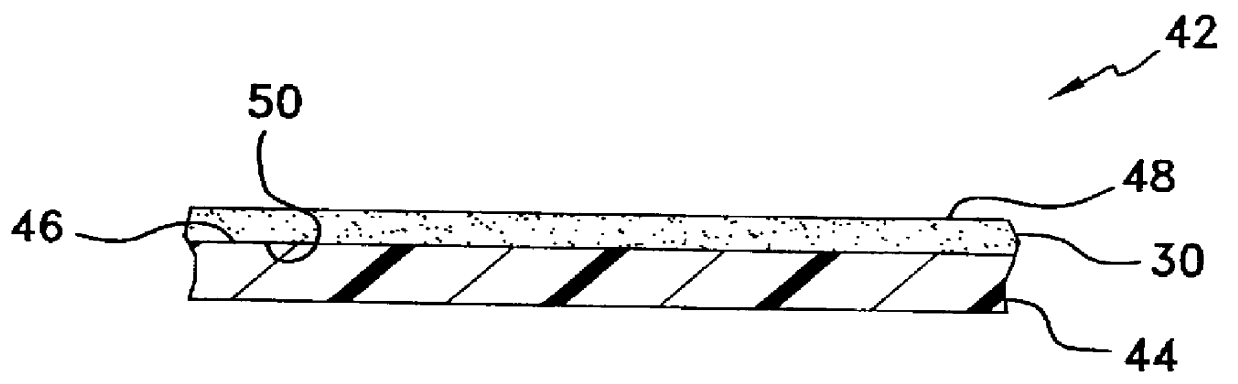

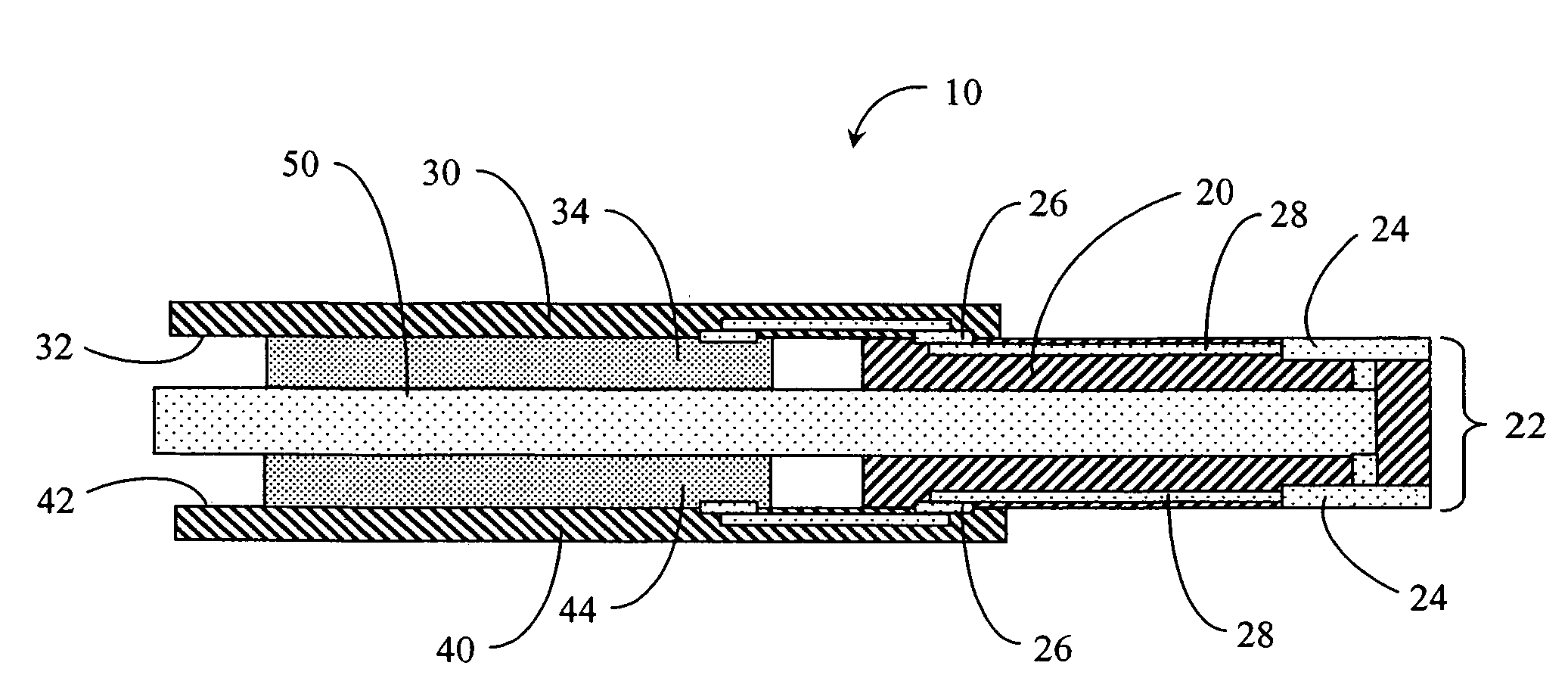

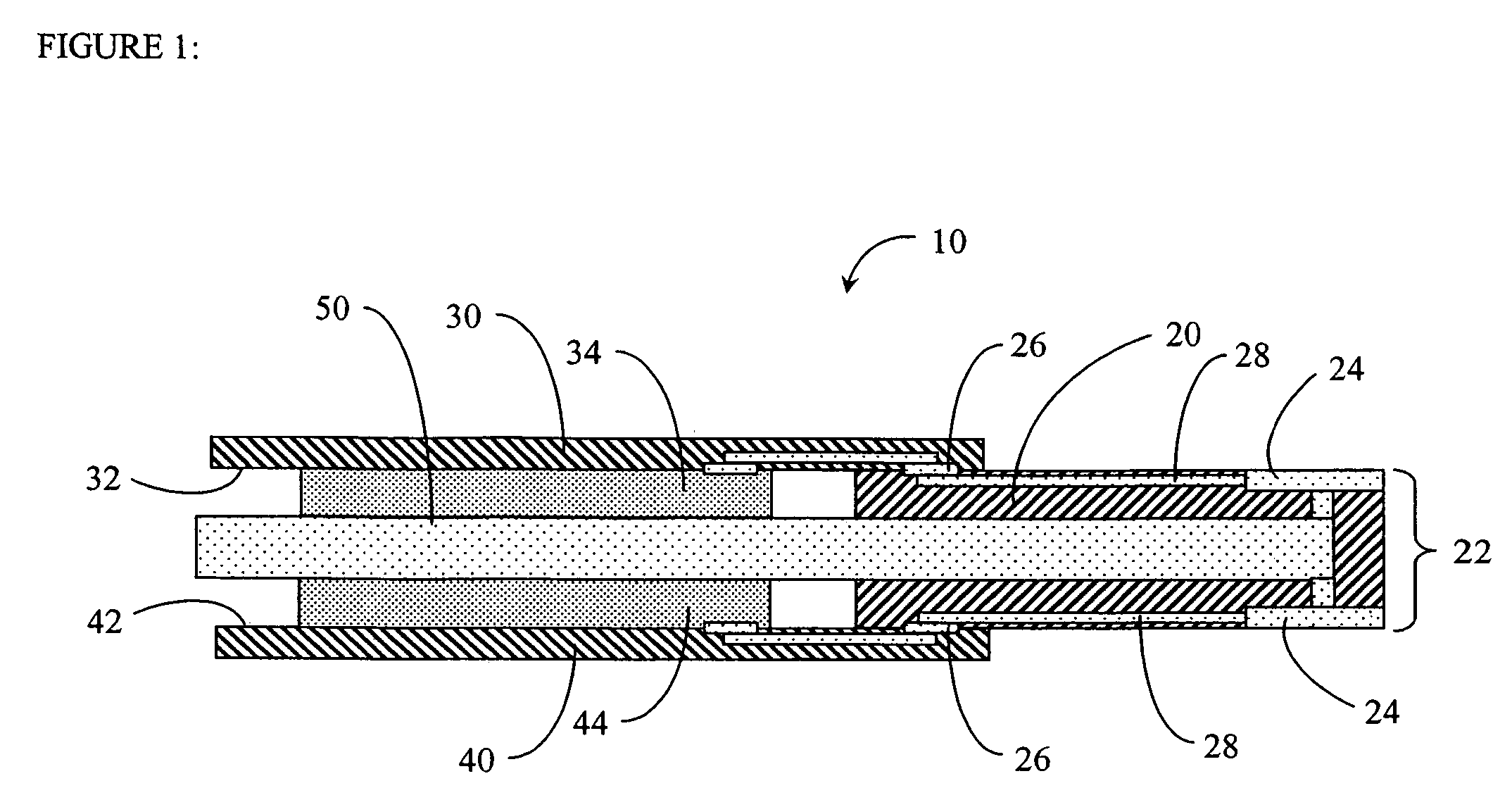

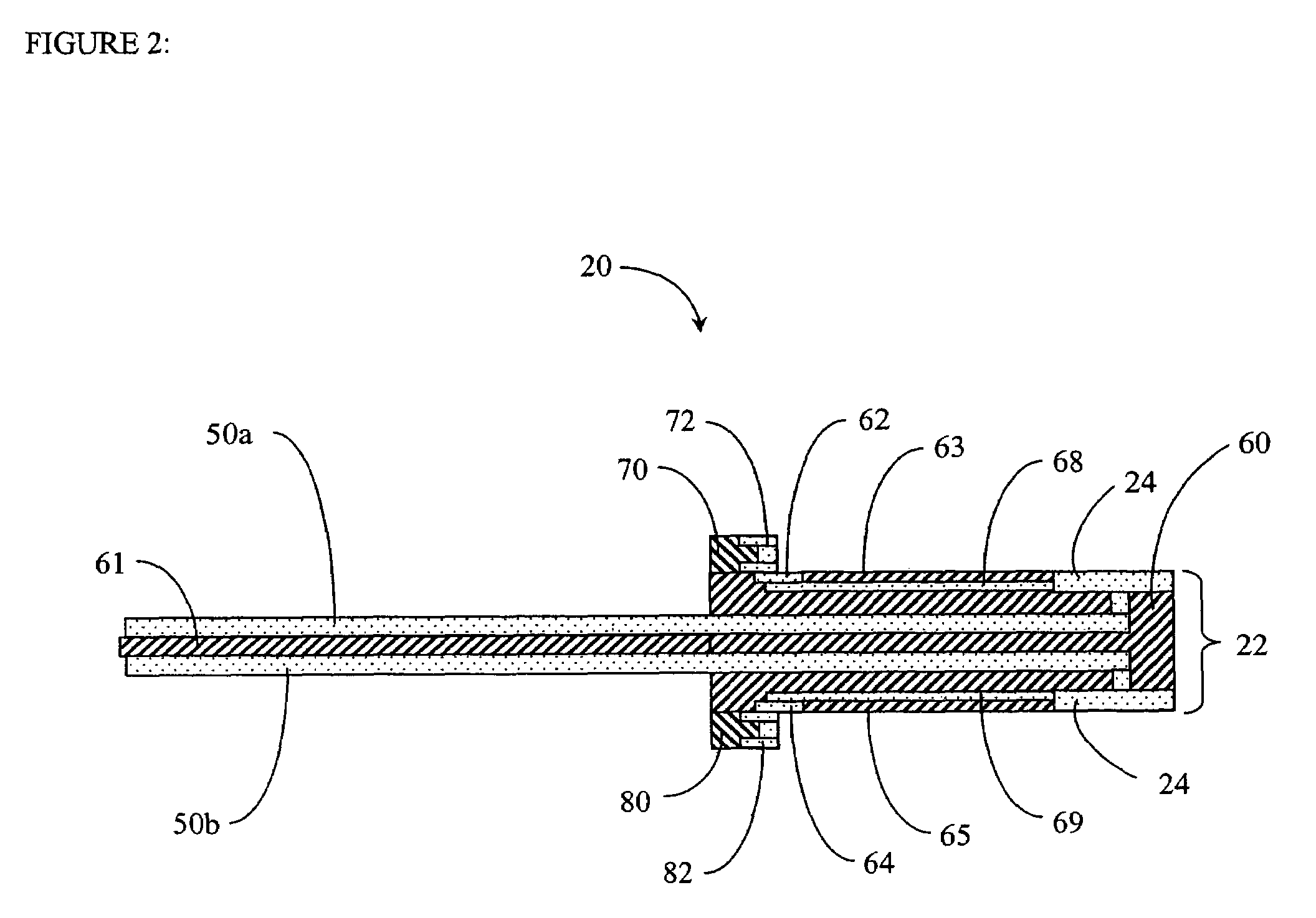

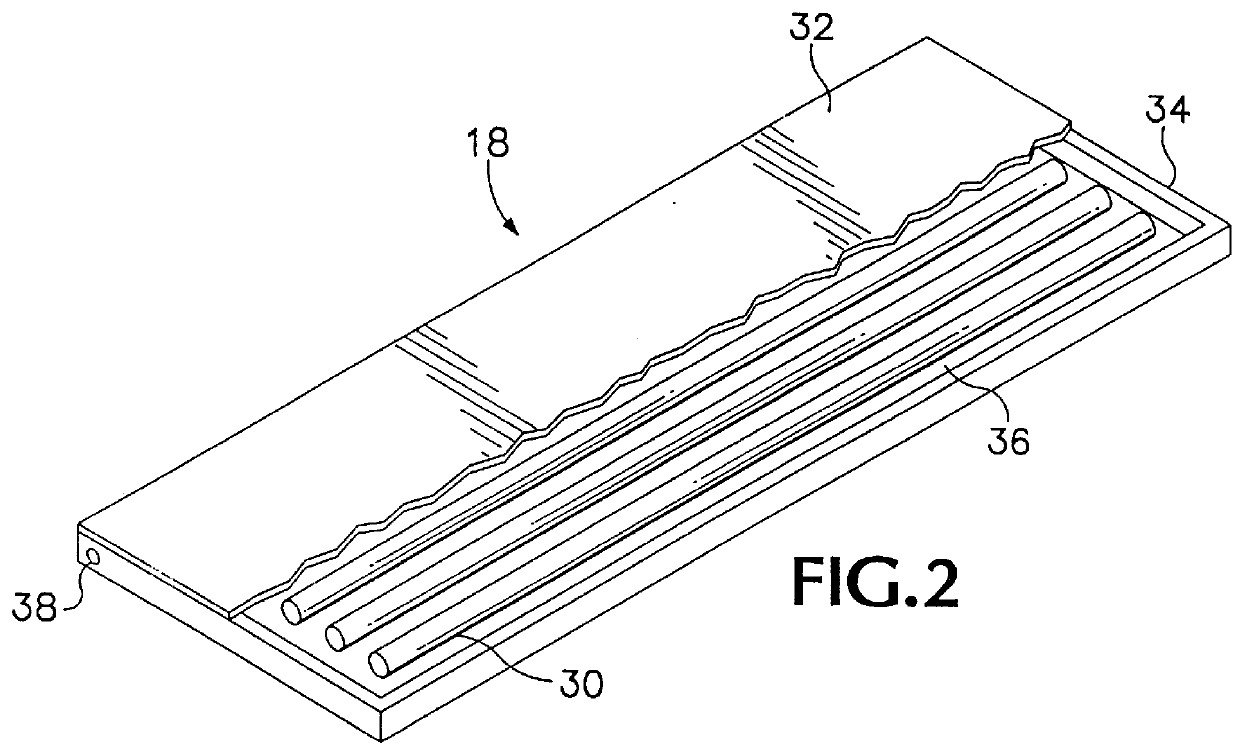

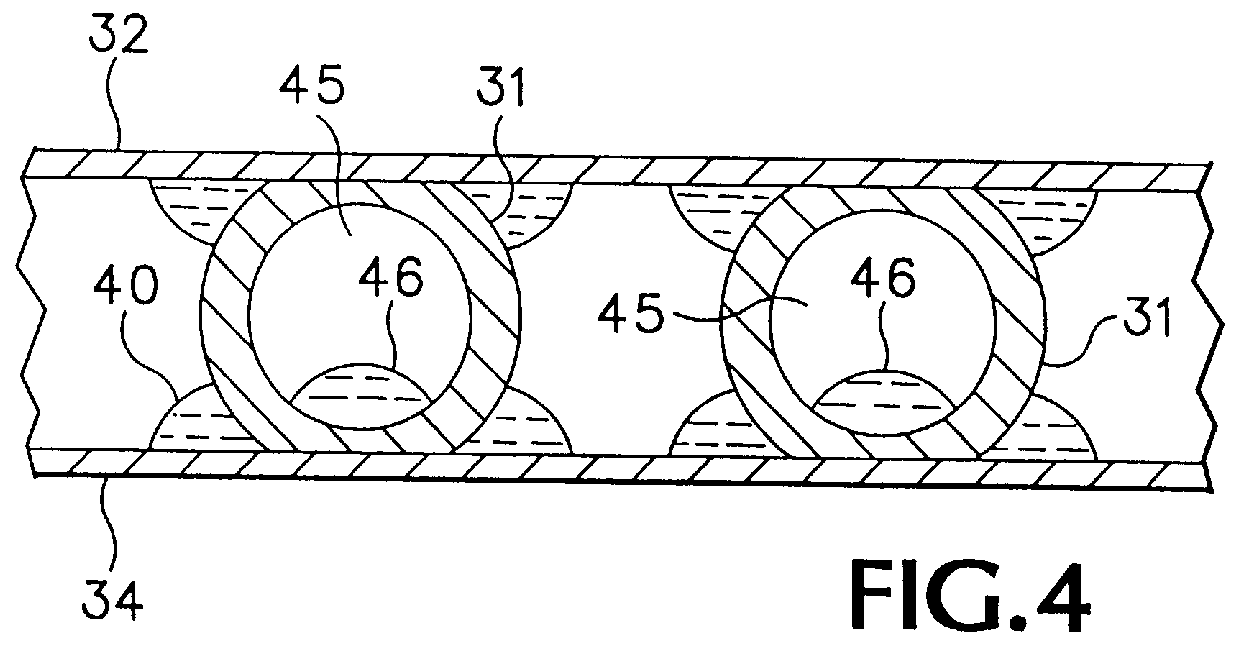

Integrated cooling system

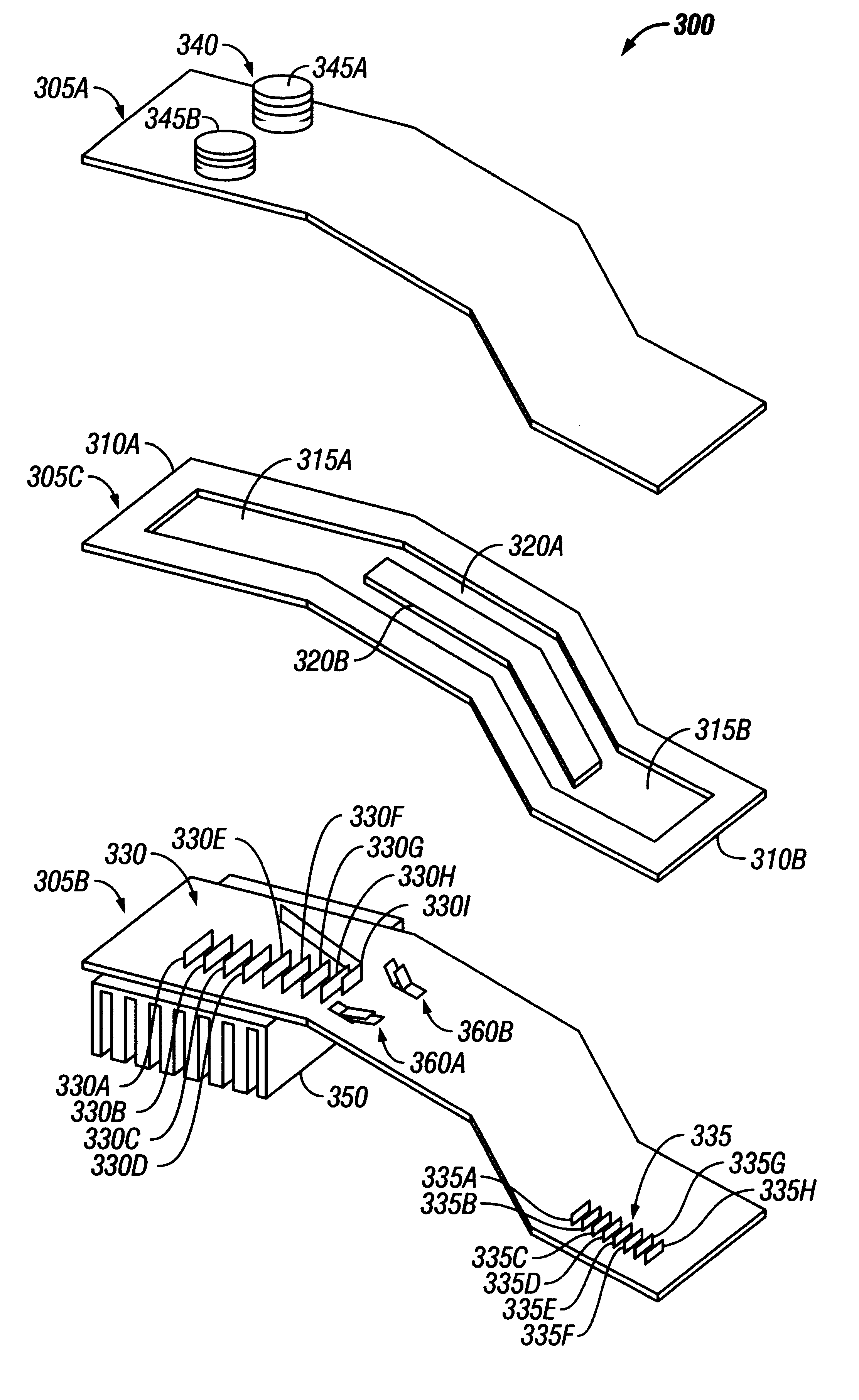

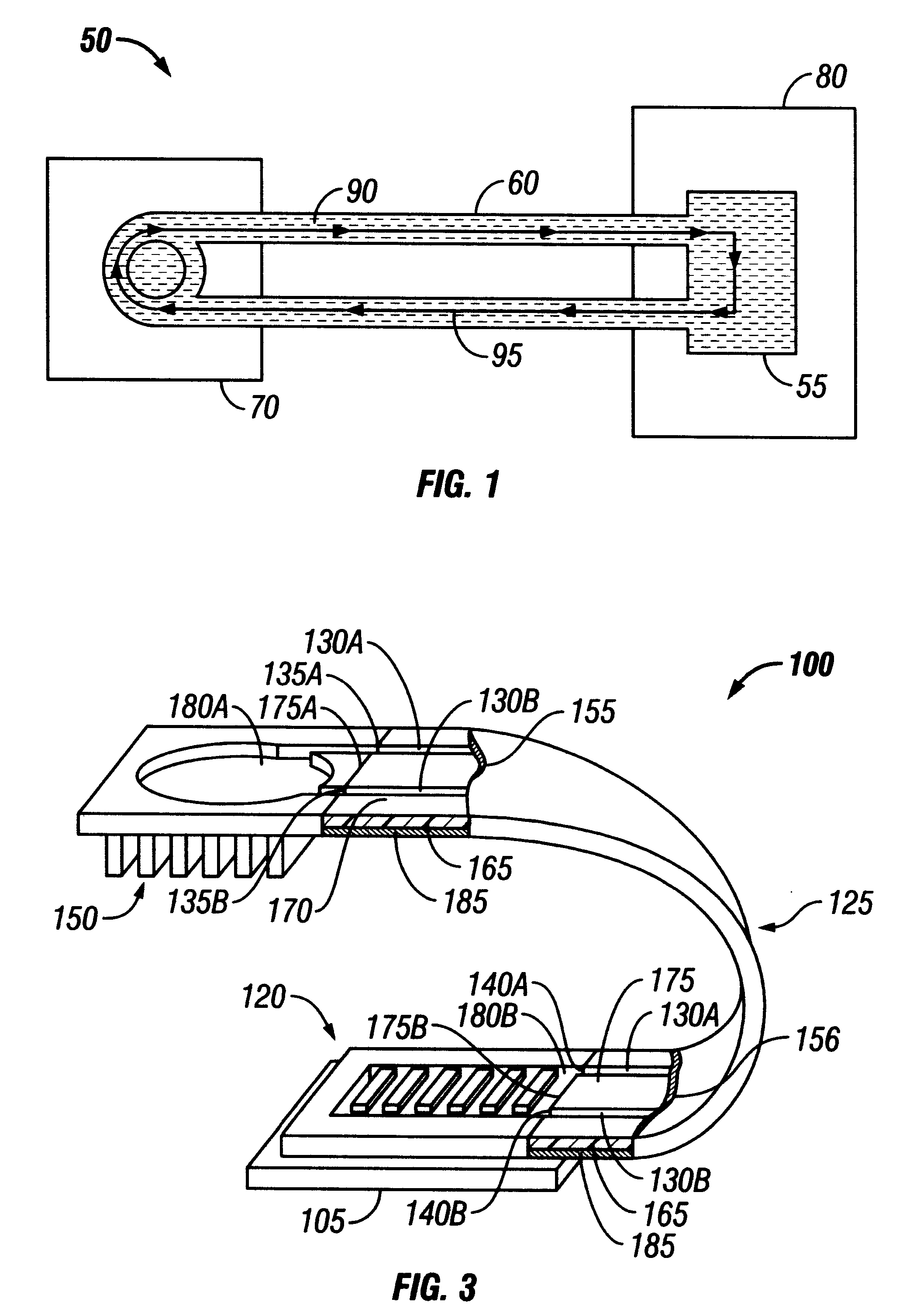

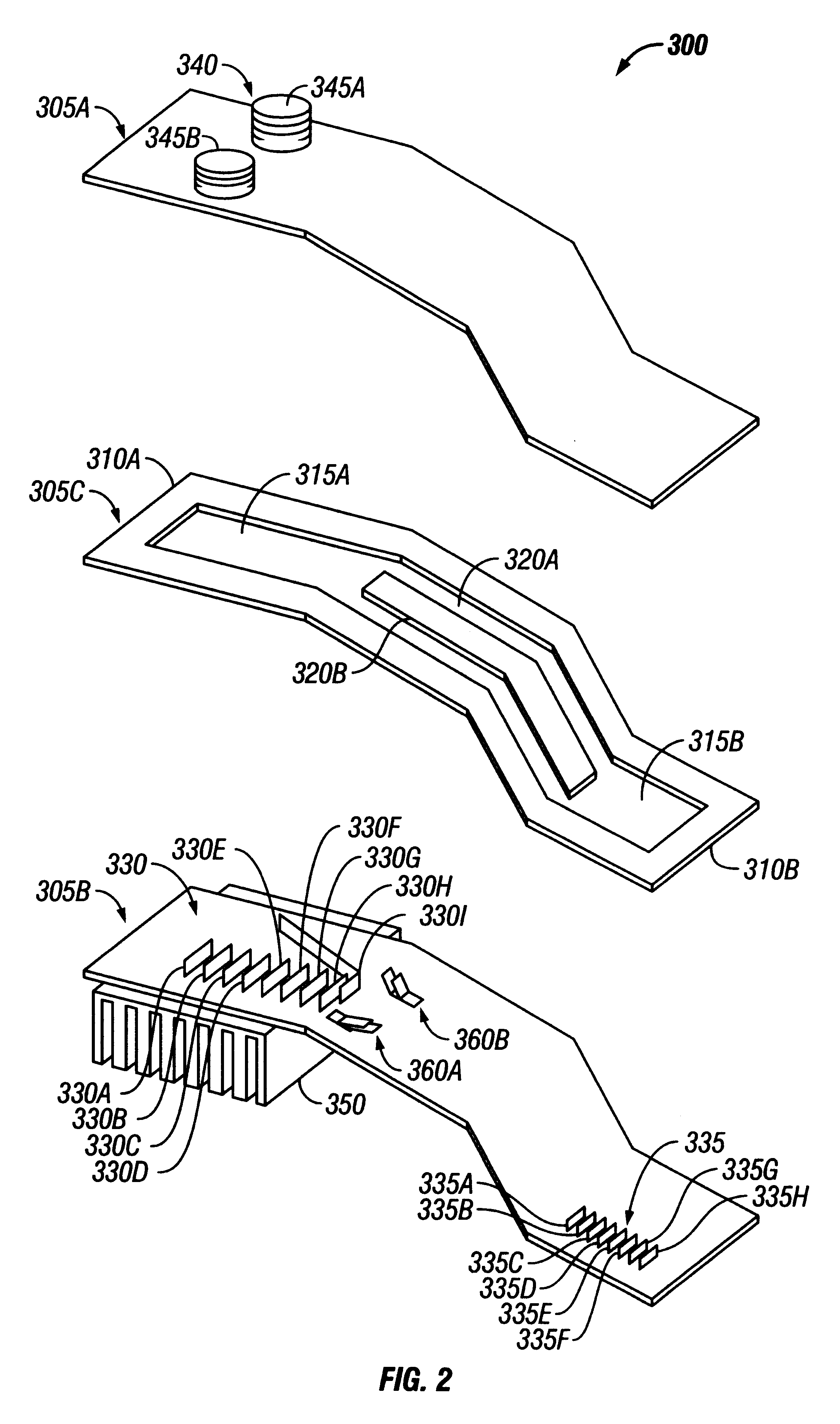

InactiveUS6529377B1Cost effectiveQuality improvementOrganic active ingredientsDigital data processing detailsClosed loopEngineering

Systems and methods are described for integrated cooling system. A method includes: circulating a liquid inside a flexible multi-layer tape; and transporting heat between a heat source that is coupled to the flexible multi-layer tape and a heat sink that is coupled to the flexible multi-layer tape. A method includes installing a flexible multi-layer tape in an electrical system, wherein the flexible multi-layer tape includes a top layer; an intermediate, layer coupled to the top layer; and a bottom layer coupled to the intermediate layer, the intermediate layer defining a closed loop circuit for a circulating fluid. An apparatus includes a flexible multi-layer tape, including: a top layer; an intermediate layer coupled to the top layer; and a bottom layer coupled to the intermediate layer, wherein the intermediate layer defines a closed loop circuit for a circulating fluid.

Owner:STOVOKOR TECH

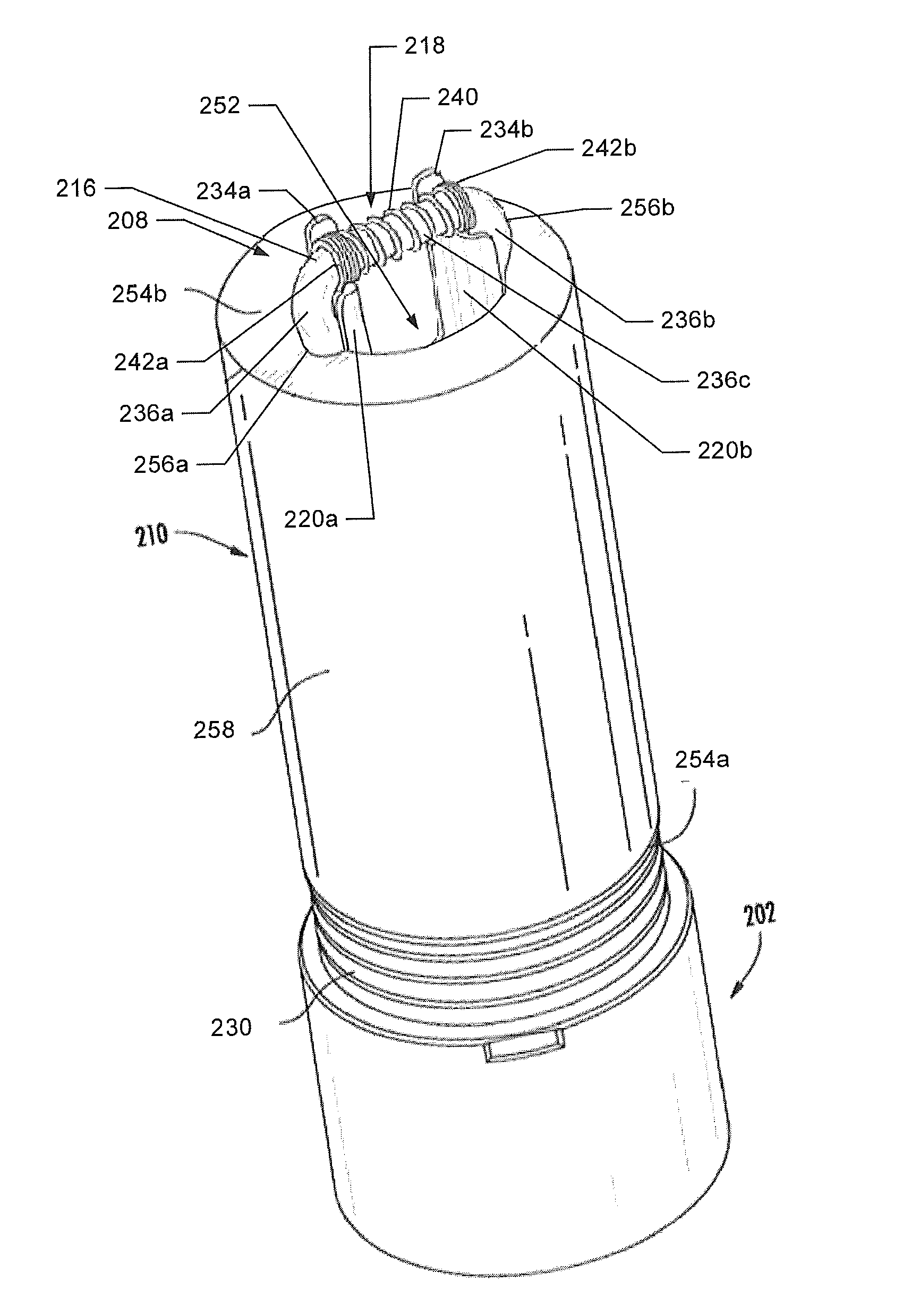

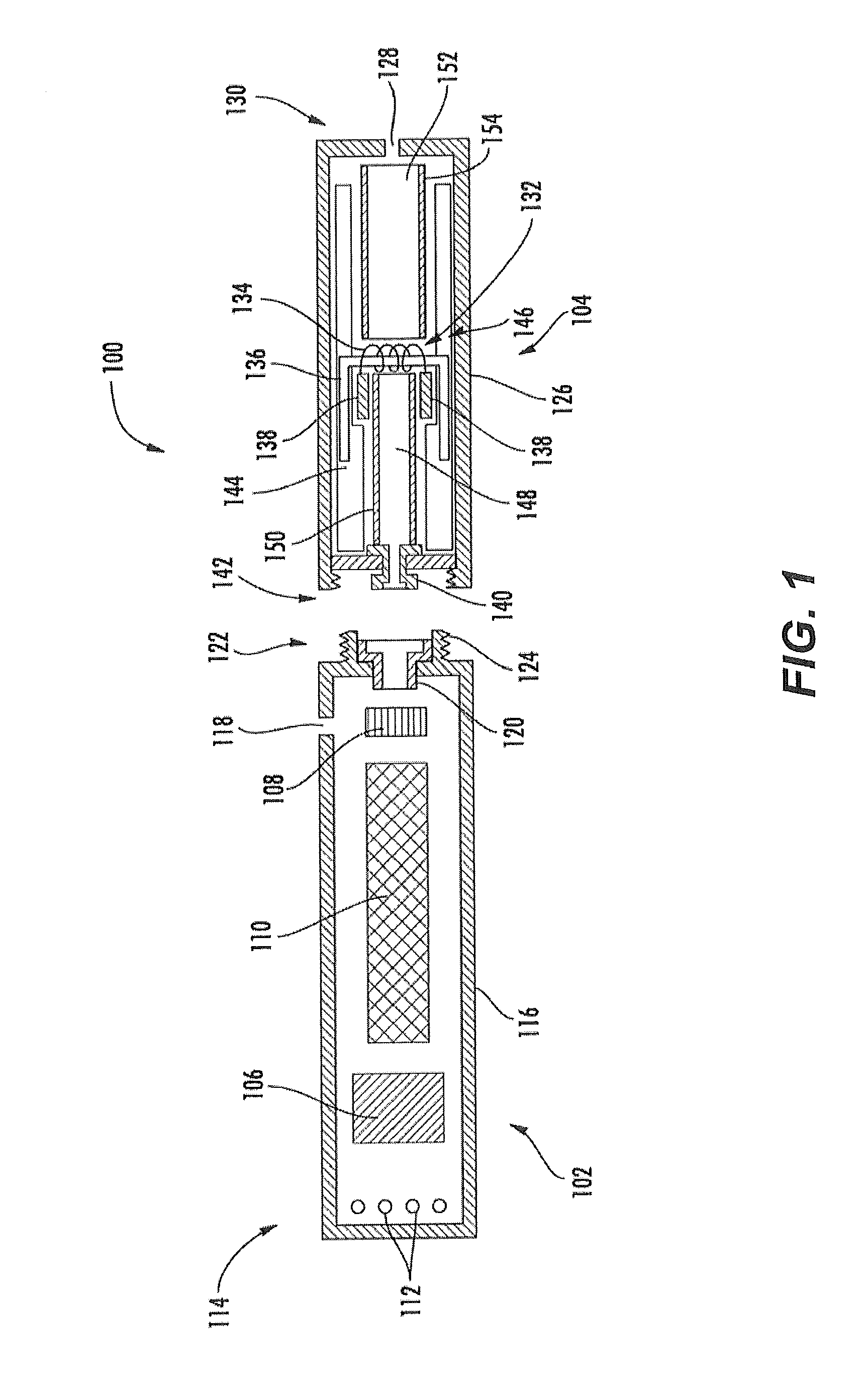

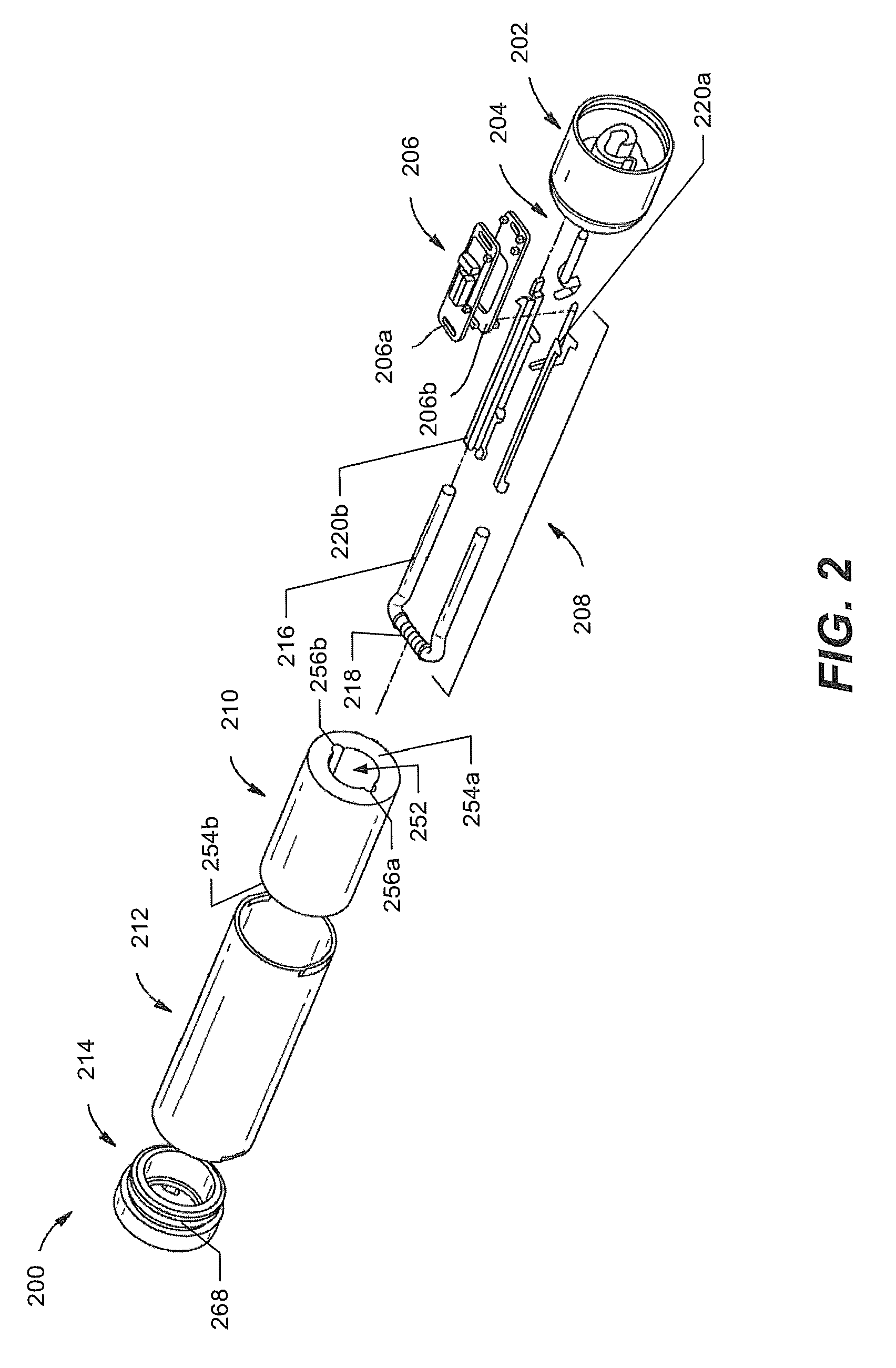

Atomizer for an aerosol delivery device and related input, aerosol production assembly, cartridge, and method

The present disclosure relates to atomizers for an aerosol delivery device such as a smoking article. The atomizer may include a liquid transport element and a wire extending along at least a portion of a longitudinal length thereof. The wire may define contact portions configured to engage heater terminals and a heating portion configured to produce heat. The heating portion may include a variable coil spacing. In other atomizers, the wire may extend at least partially through the liquid transport element proximate the contact portions. Related inputs, cartridges, aerosol production assemblies, and methods of forming atomizers are also provided.

Owner:RAI STRATEGIC HLDG INC

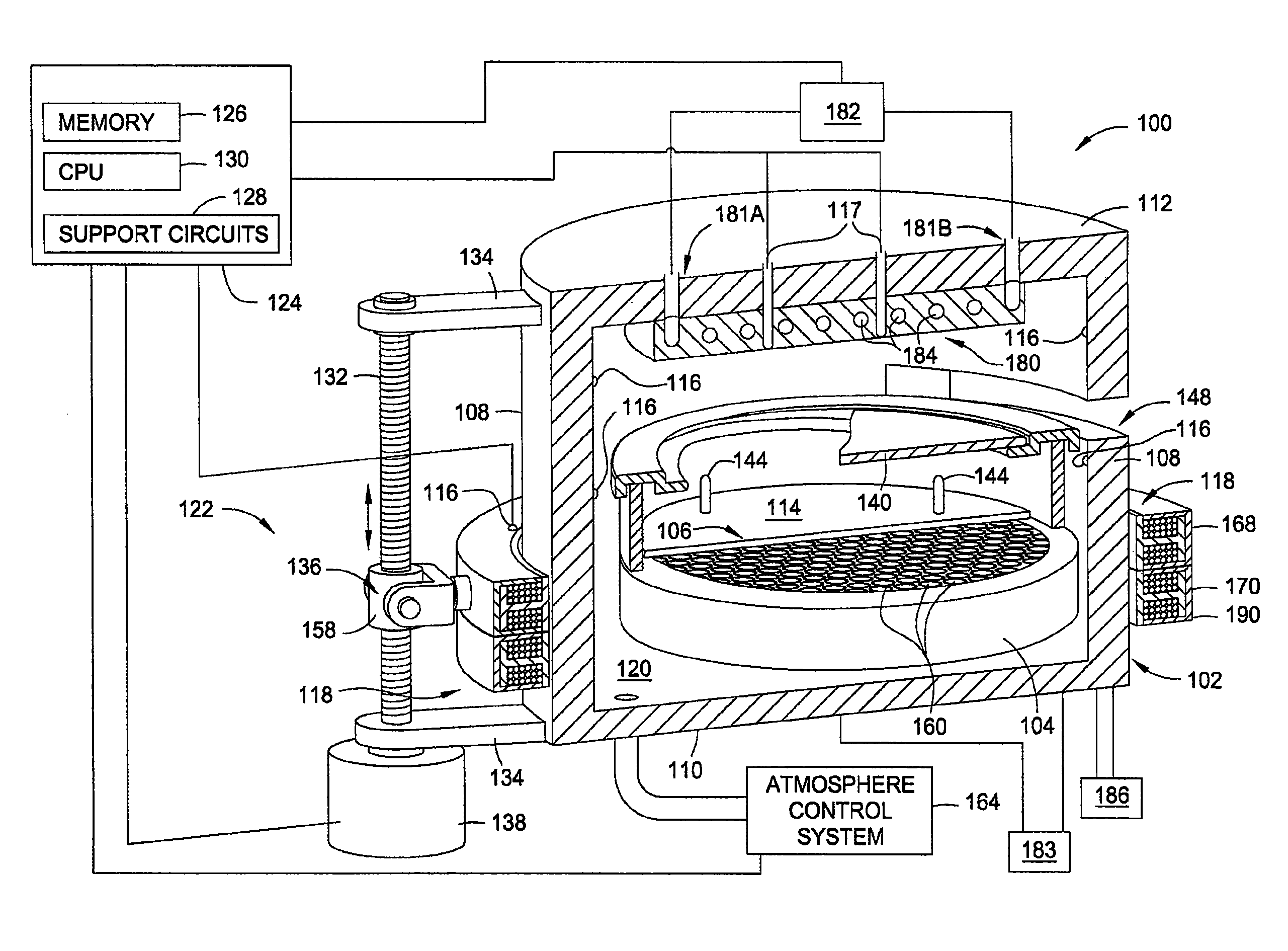

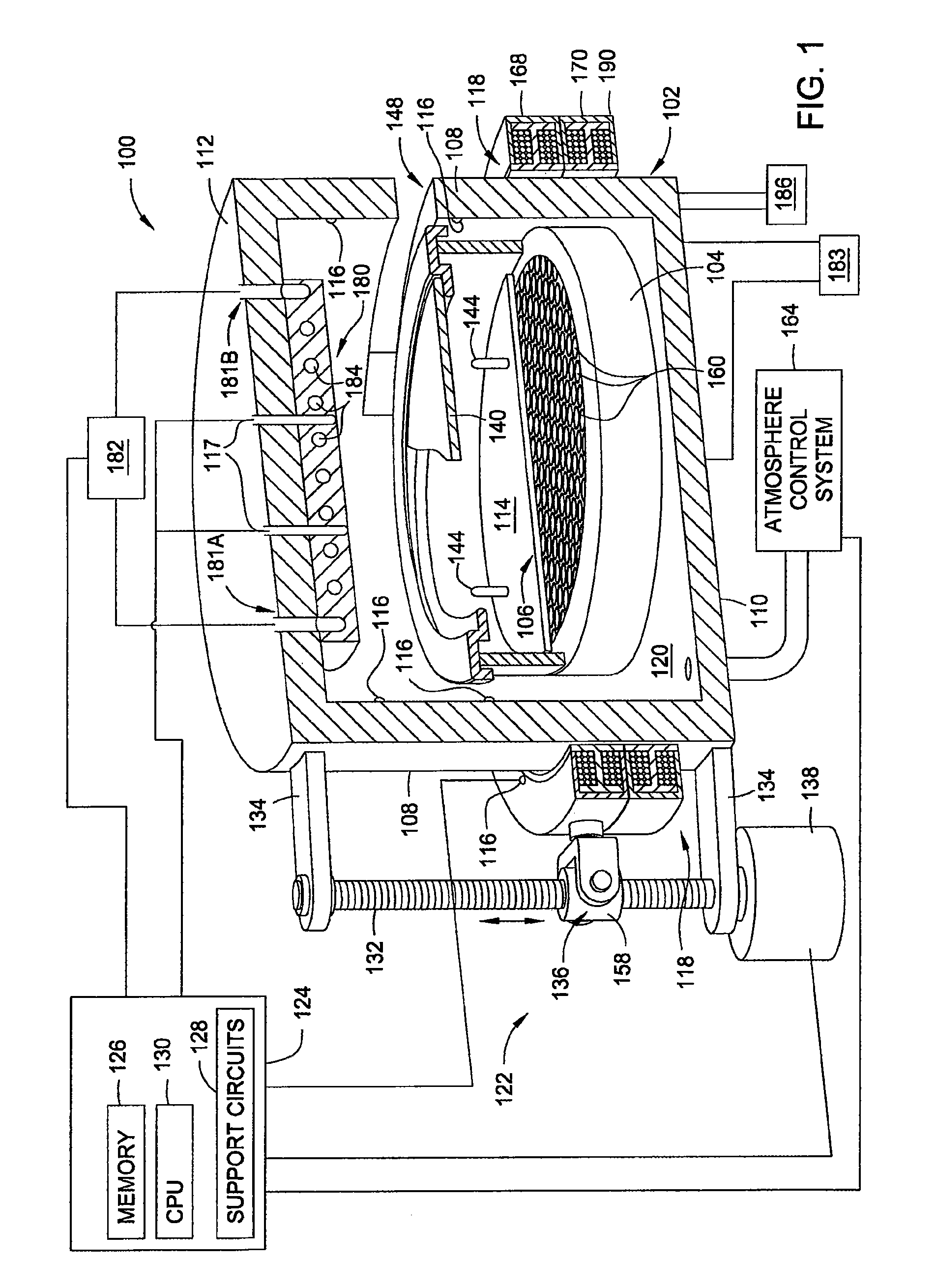

Rapid conductive cooling using a secondary process plane

A method and apparatus for thermally processing a substrate is described. The apparatus includes a substrate support configured to move linearly and / or rotationally by a magnetic drive. The substrate support is also configured to receive a radiant heat source to provide heating region in a portion of the chamber. An active cooling region comprising a cooling plate is disposed opposite the heating region. The substrate may move between the two regions to facilitate rapidly controlled heating and cooling of the substrate.

Owner:APPLIED MATERIALS INC

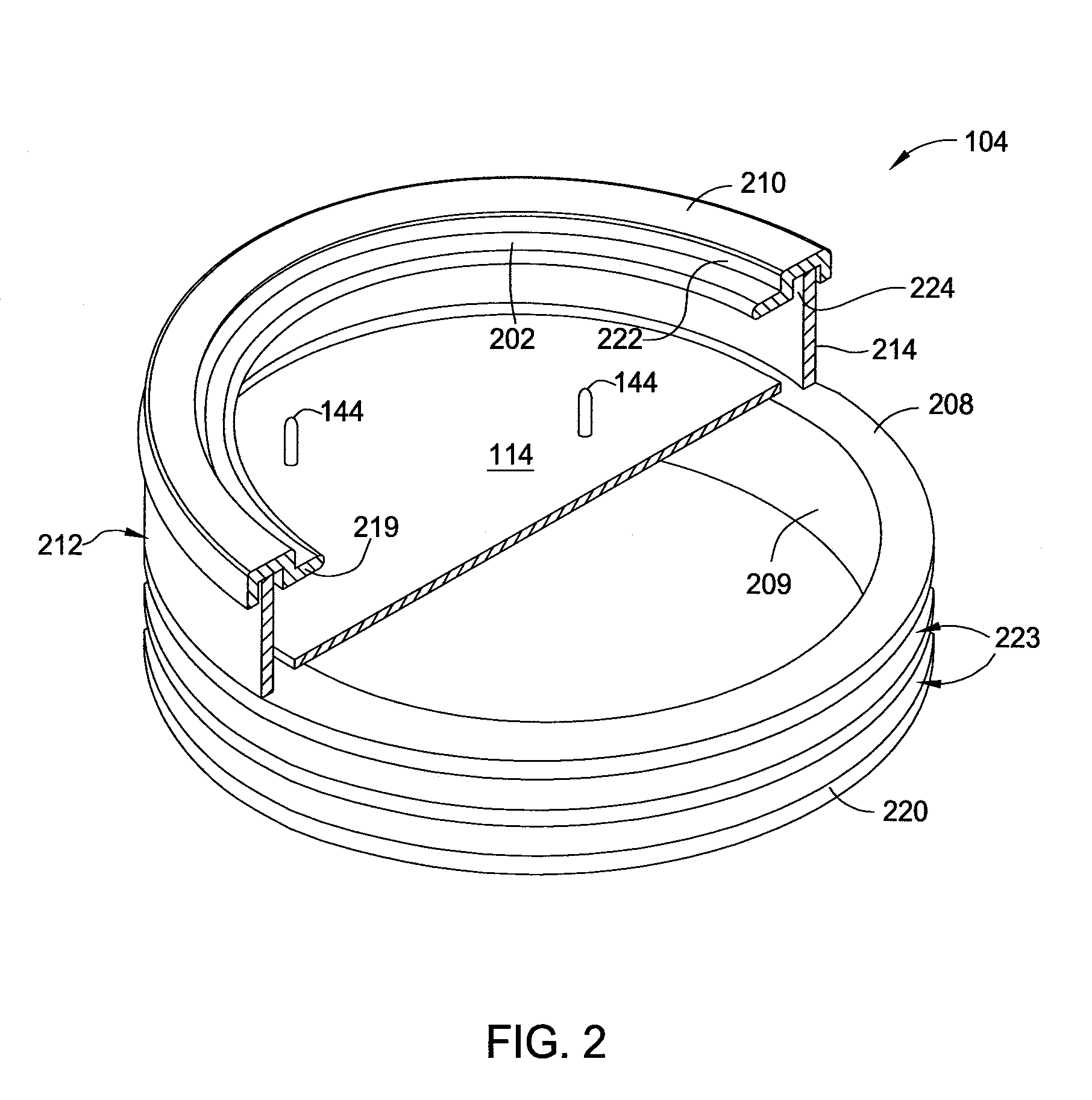

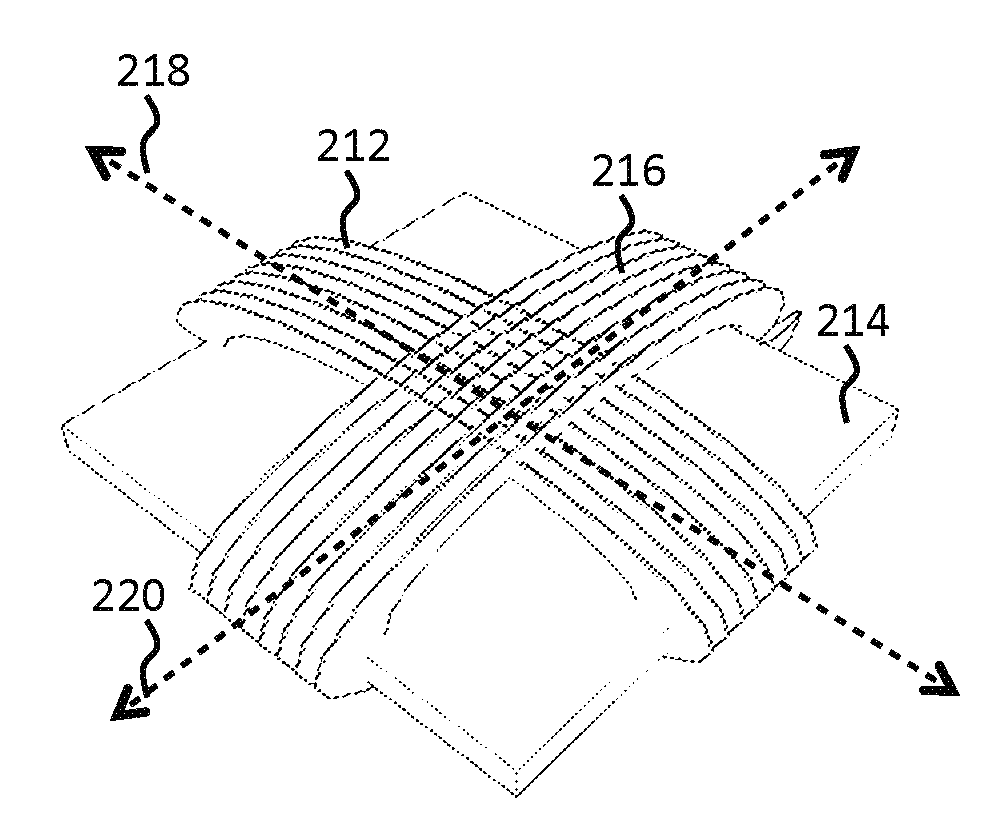

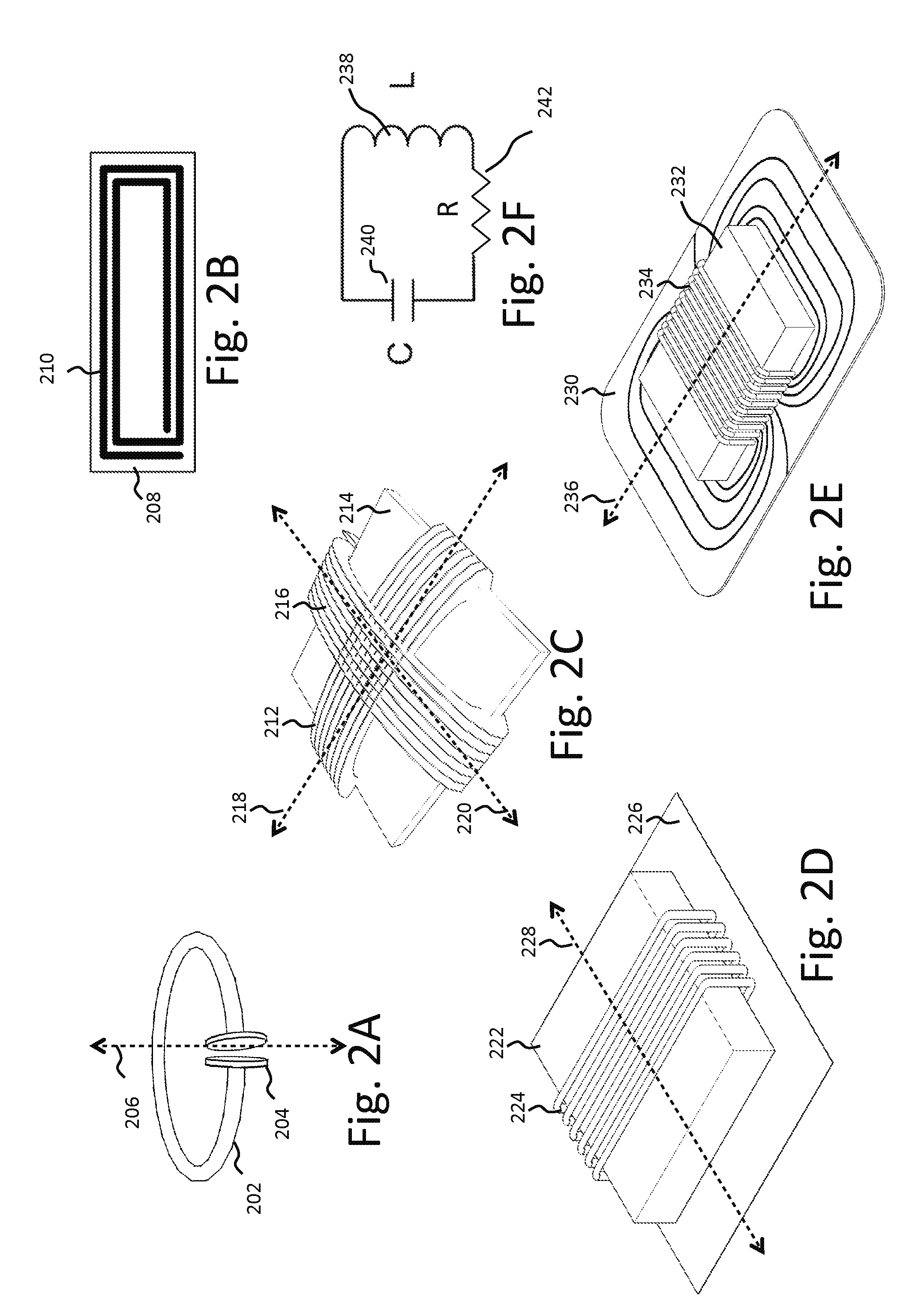

Wireless energy transfer resonator thermal management

ActiveUS20110121920A1Minimize the numberMultiple-port networksTransformers/inductances coolingResonatorThermal management of electronic devices and systems

Described herein are improved configurations for a wireless power transfer. Described are methods and designs to reduce and manage heating and heat dissipation in resonator structures. Configuration and orientation of magnetic material as well as heat sinking material with respect to the dipole moment of the resonator is used to reduce and control thermal properties of the resonator structure and reduce the effects of heating on the performance of wireless power transfer.

Owner:WITRICITY CORP

Thermal dissipation assembly and fabrication method for electronics drawer of a multiple-drawer electronics rack

Owner:LENOVO GLOBAL TECH INT LTD

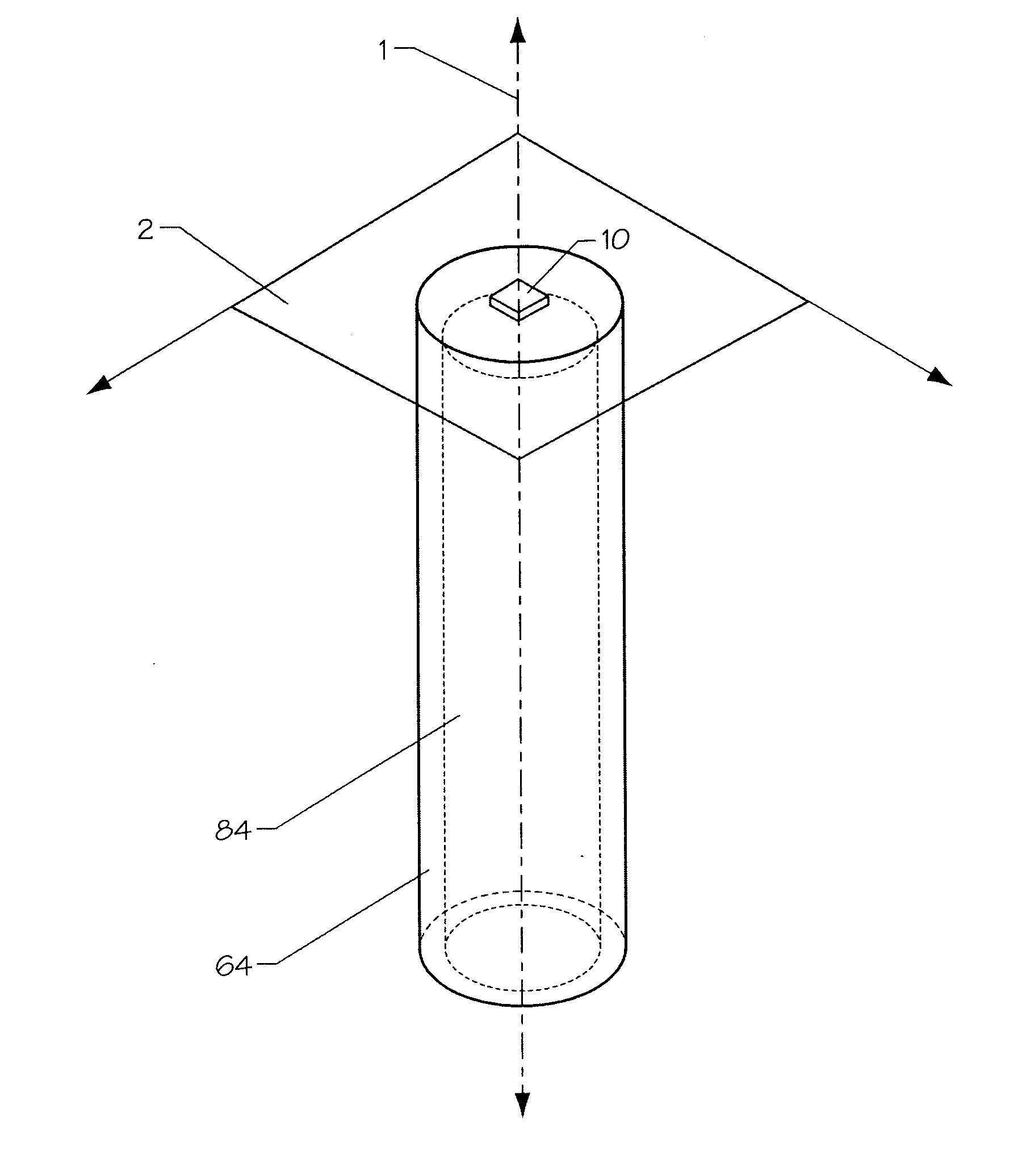

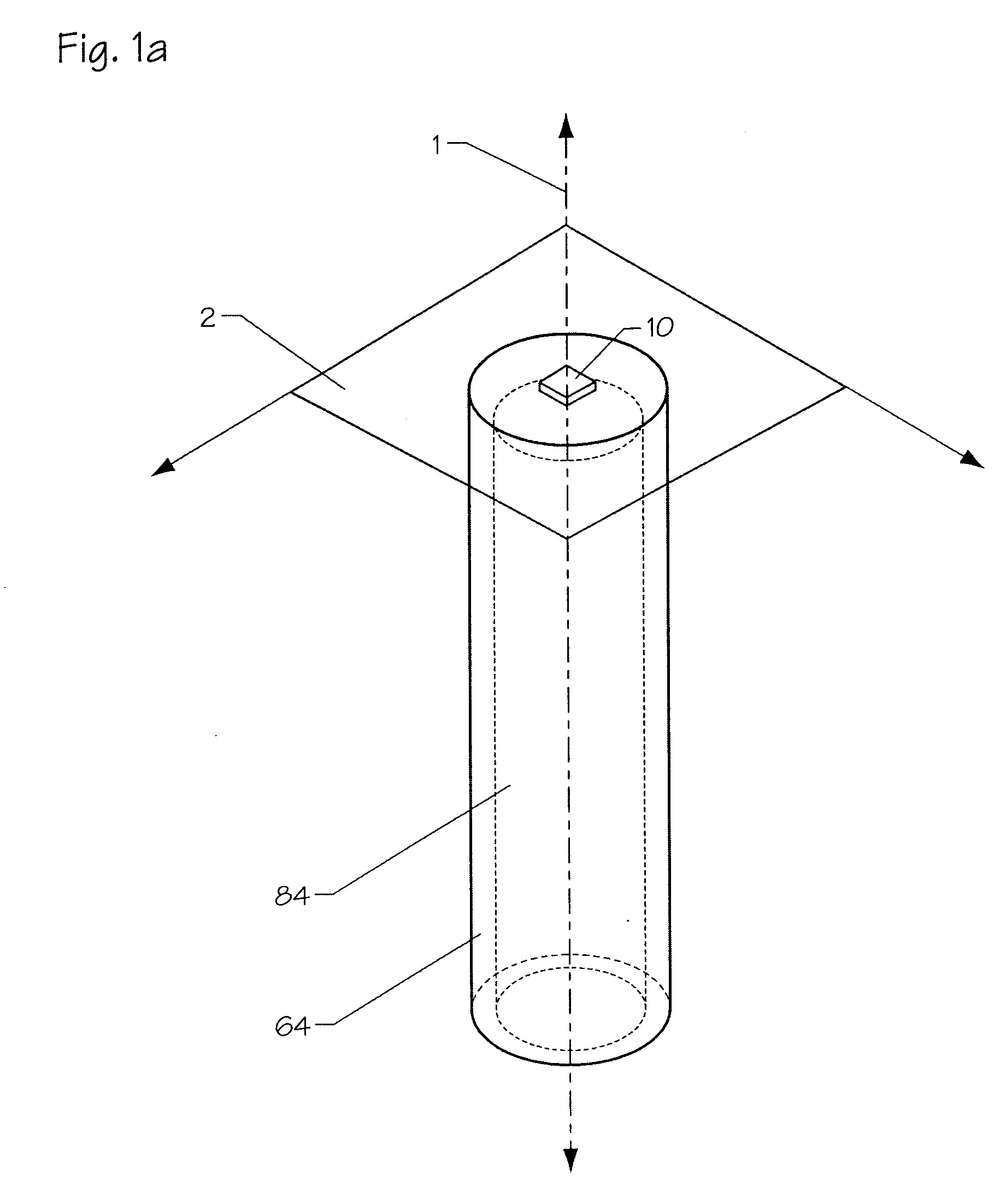

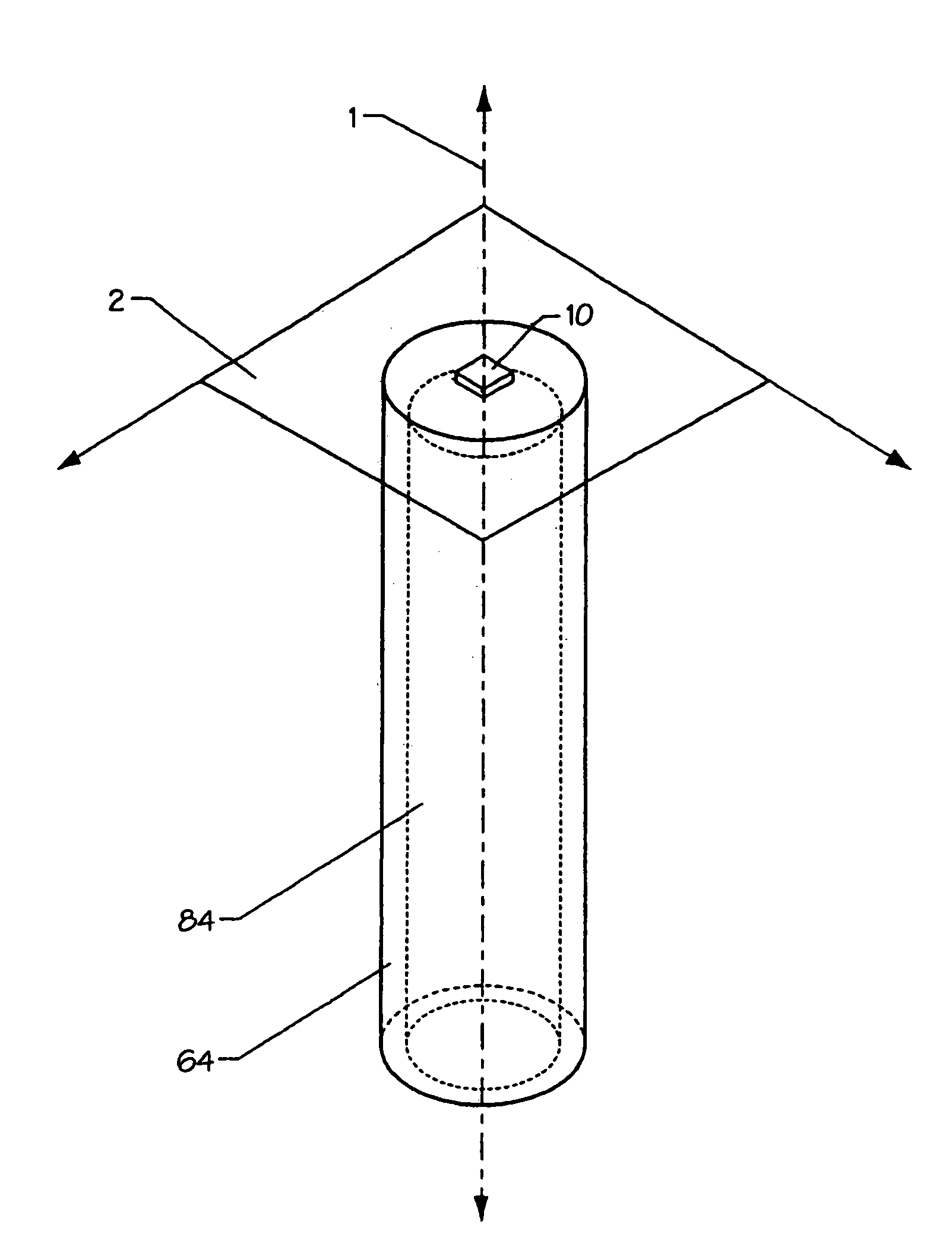

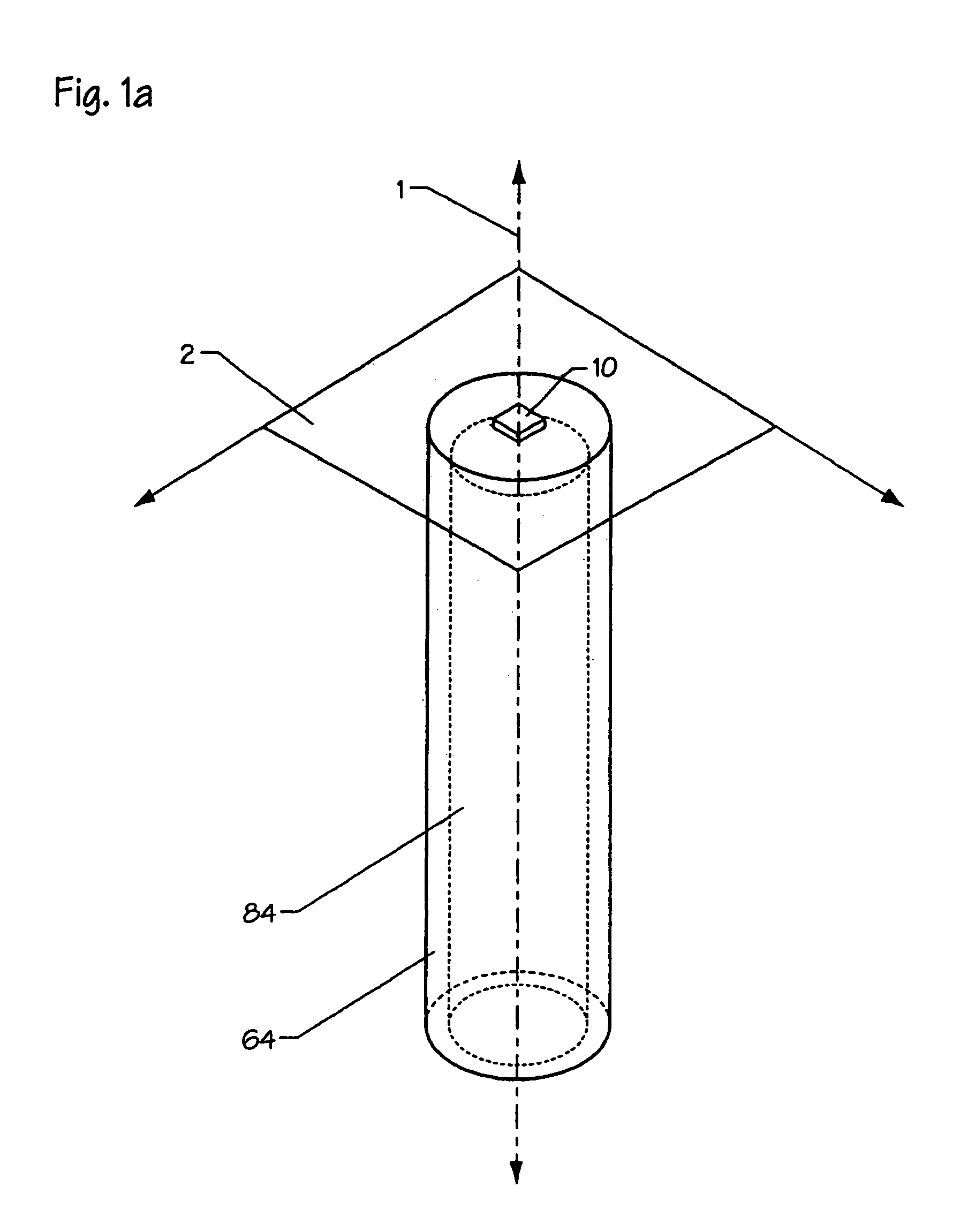

Method and apparatus for using light emitting diodes

InactiveUS20050231983A1Milk preservationLighting heating/cooling arrangementsThermal energyEngineering

The present invention provides a method and apparatus for using light emitting diodes for curing and various solid state lighting applications. The method includes a novel method for cooling the light emitting diodes and mounting the same on heat pipe in a manner which delivers ultra high power in UV, visible and IR regions. Furthermore, the unique LED packaging technology of the present invention utilizes heat pipes that perform very efficiently in very compact space. Much more closely spaced LEDs operating at higher power levels and brightness are possible because the thermal energy is transported in an axial direction down the heat pipe and away from the light-emitting direction rather than a radial direction in nearly the same plane as the “p-n” junction.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

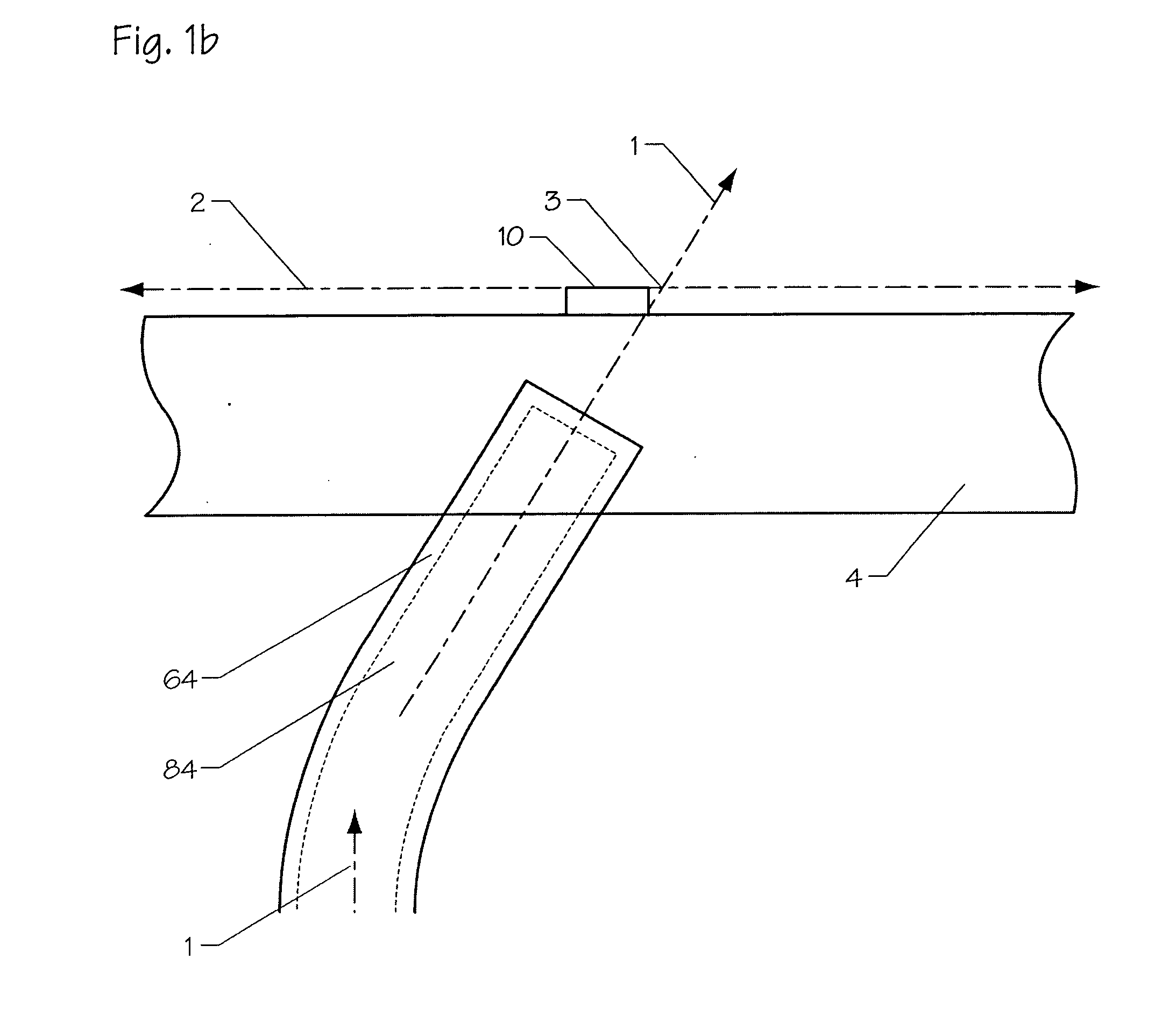

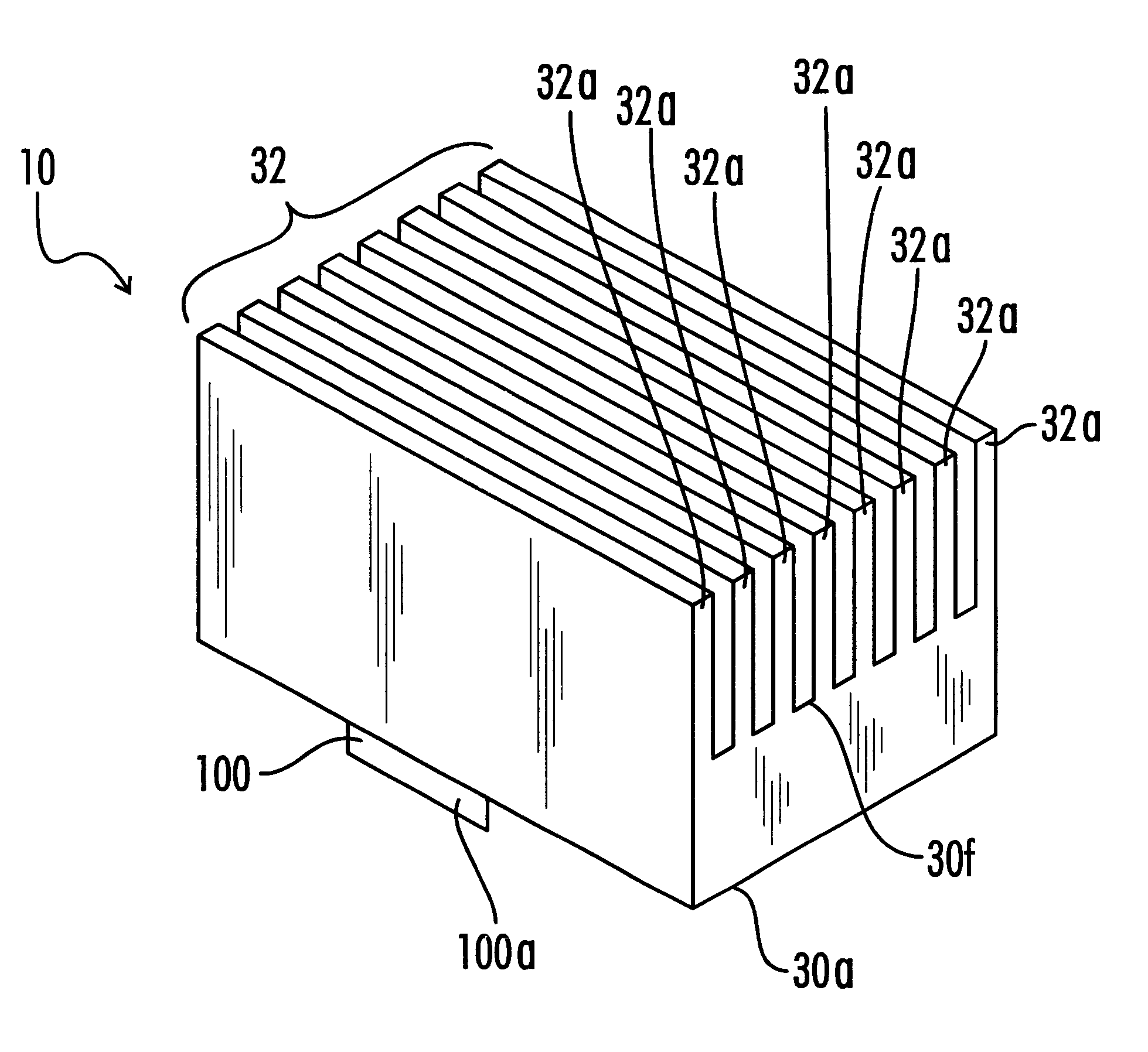

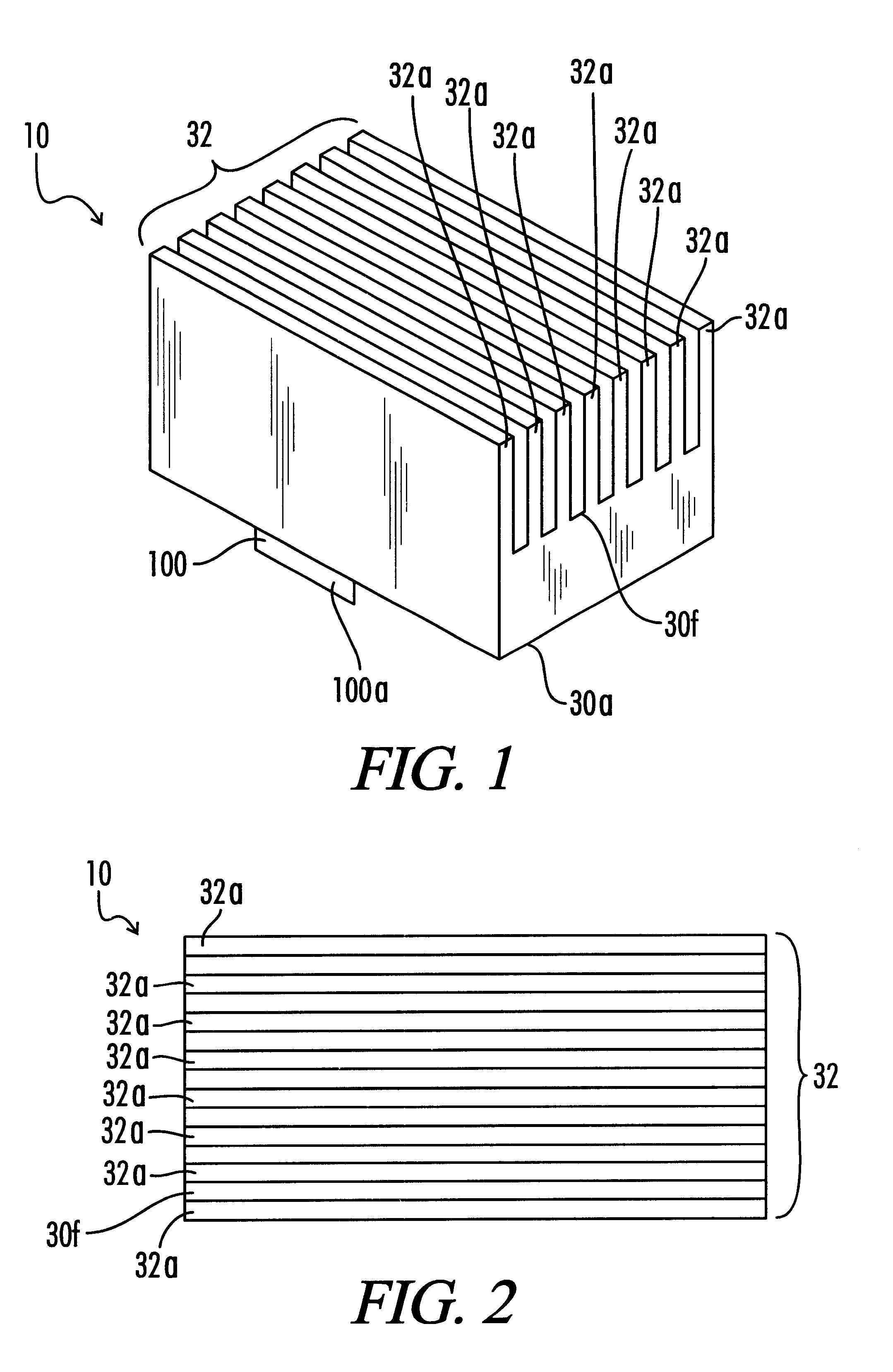

Graphite-based heat sink

InactiveUS6503626B1Improve cooling effectIncreased anisotropyLayered productsSemiconductor/solid-state device detailsNuclear engineeringGraphite

The present invention relates to a system for managing the heat from a heat source like an electronic component. More particularly, the present invention relates to a system effective for dissipating the heat generated by an electronic component using a heat sink formed from a compressed, comminuted particles of resin-impregnated flexible graphite mat or sheet.

Owner:GRAFTECH INT HLDG INC

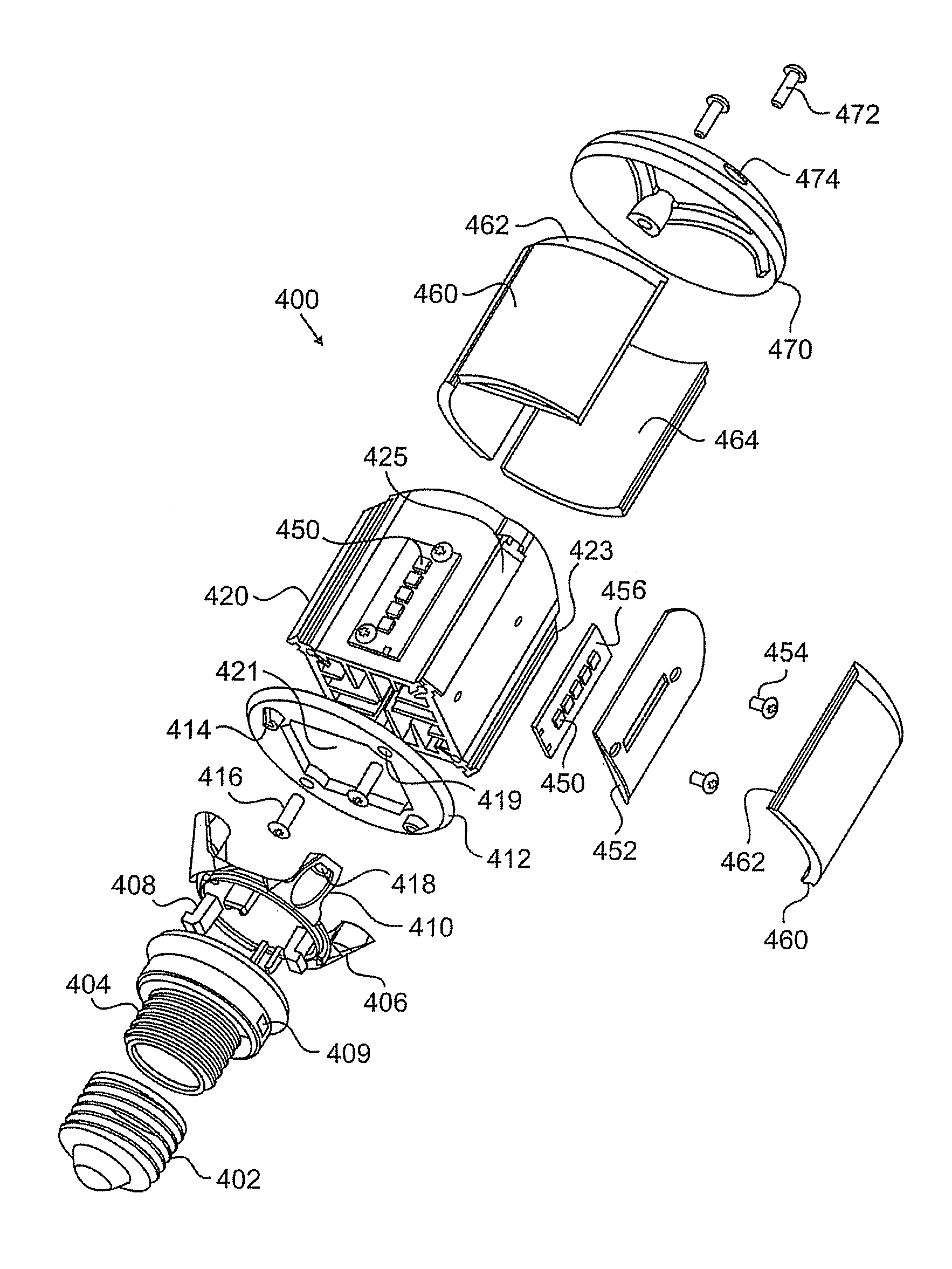

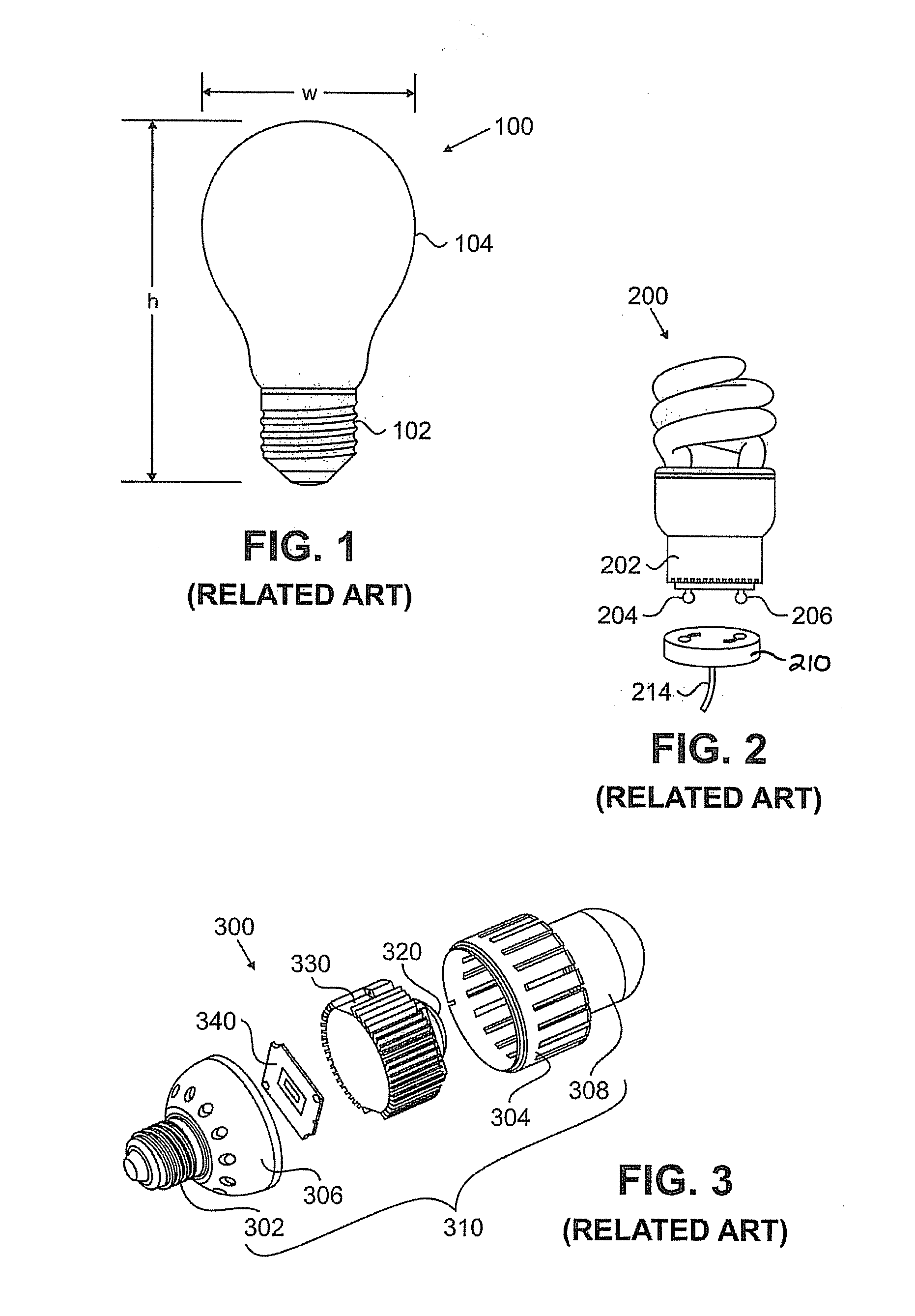

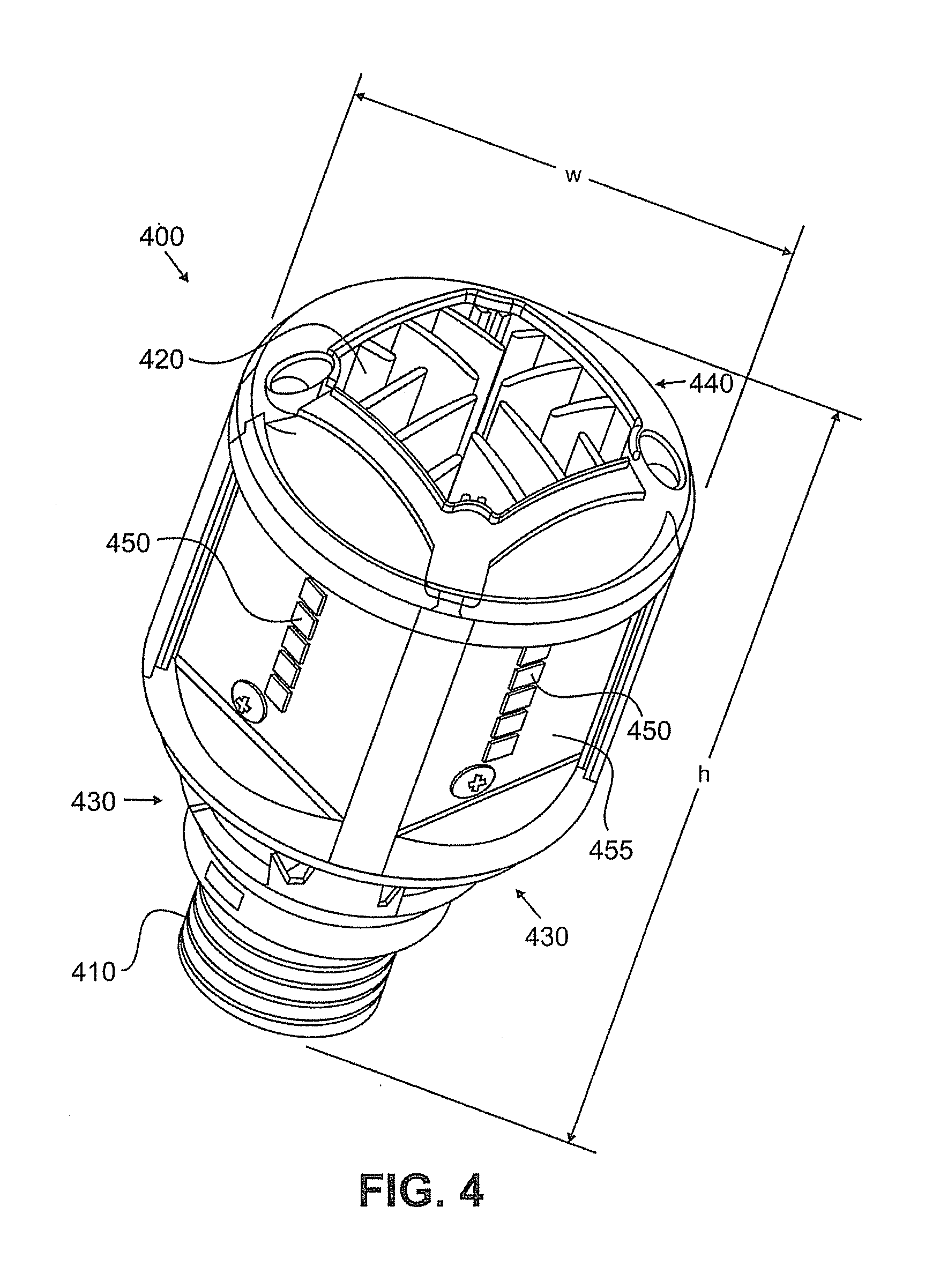

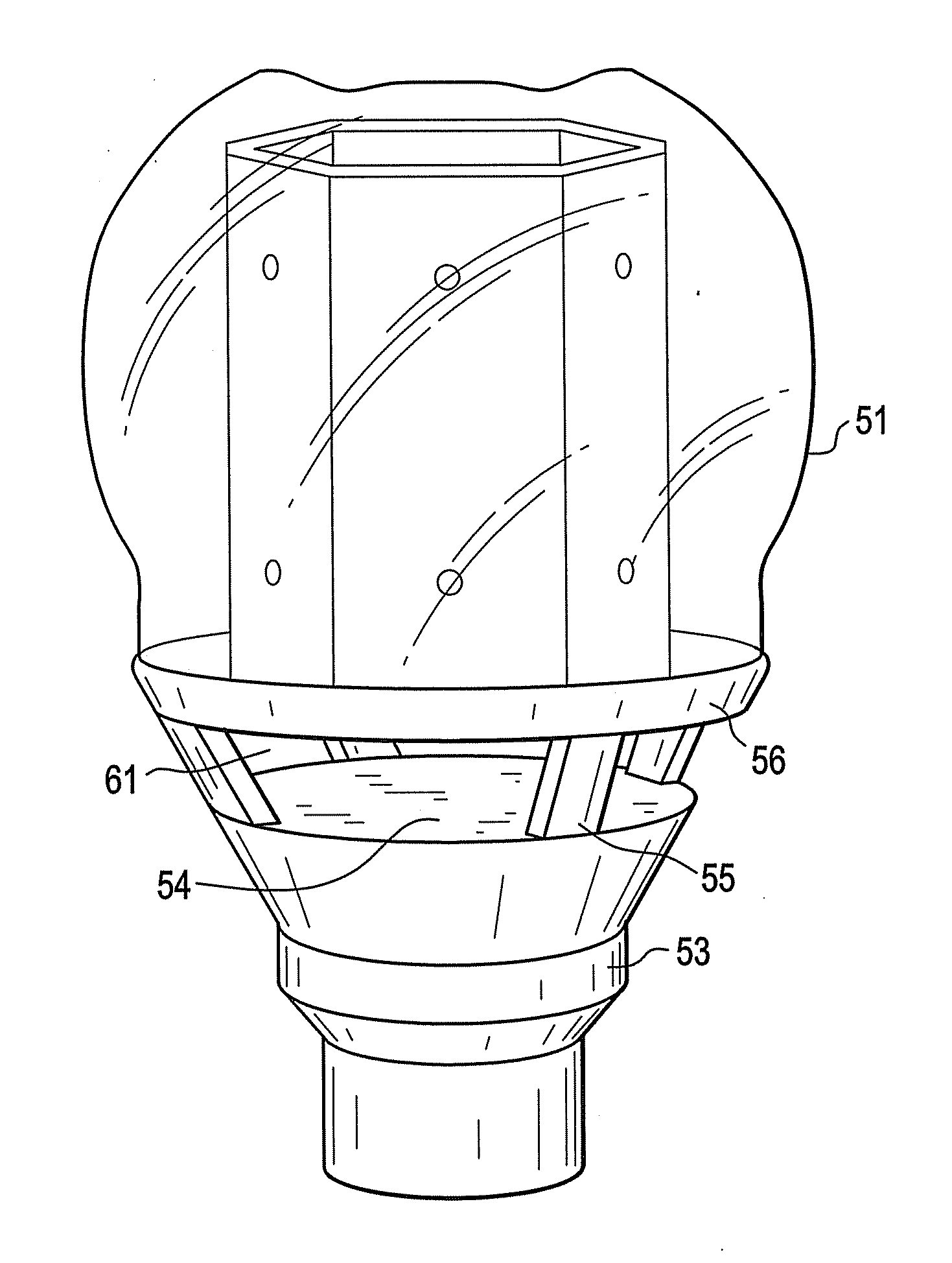

Heat sinks and lamp incorporating same

ActiveUS20110089830A1Improve efficiencyGood indexLight source combinationsPoint-like light sourceEngineeringSolid-state lighting

A lamp comprising a solid state light emitter, the lamp being an A lamp and providing a wall plug efficiency of at least 90 lumens per watt. Also, a lamp comprising a solid state light emitter and a power supply, the emitter being mounted on a heat dissipation element, the dissipation element being spaced from the power supply. Also, a lamp, comprising a solid state light emitter and a heat dissipation element that has a heat dissipation chamber, whereby an ambient medium can enter the chamber, pass through the chamber, and exit. Also, a lamp, comprising a light emissive housing at least one solid state lighting emitter and a first heat dissipation element. Also, a lamp comprising a heat sink comprising a heat dissipation chamber. Also, a lamp comprising first and second heat dissipation elements. Also, a lamp comprising means for creating flow of ambient fluid.

Owner:IDEAL IND LIGHTING LLC

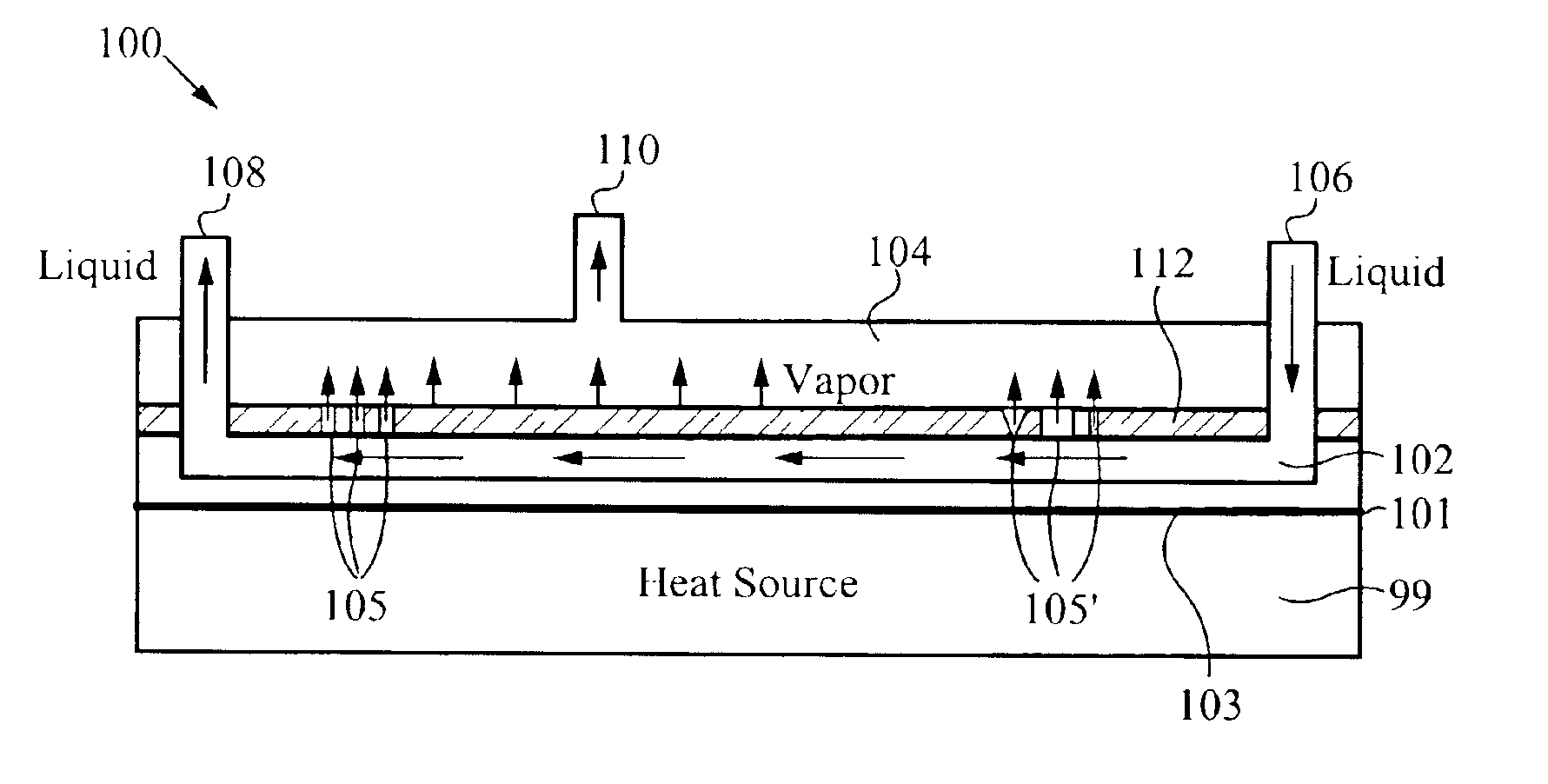

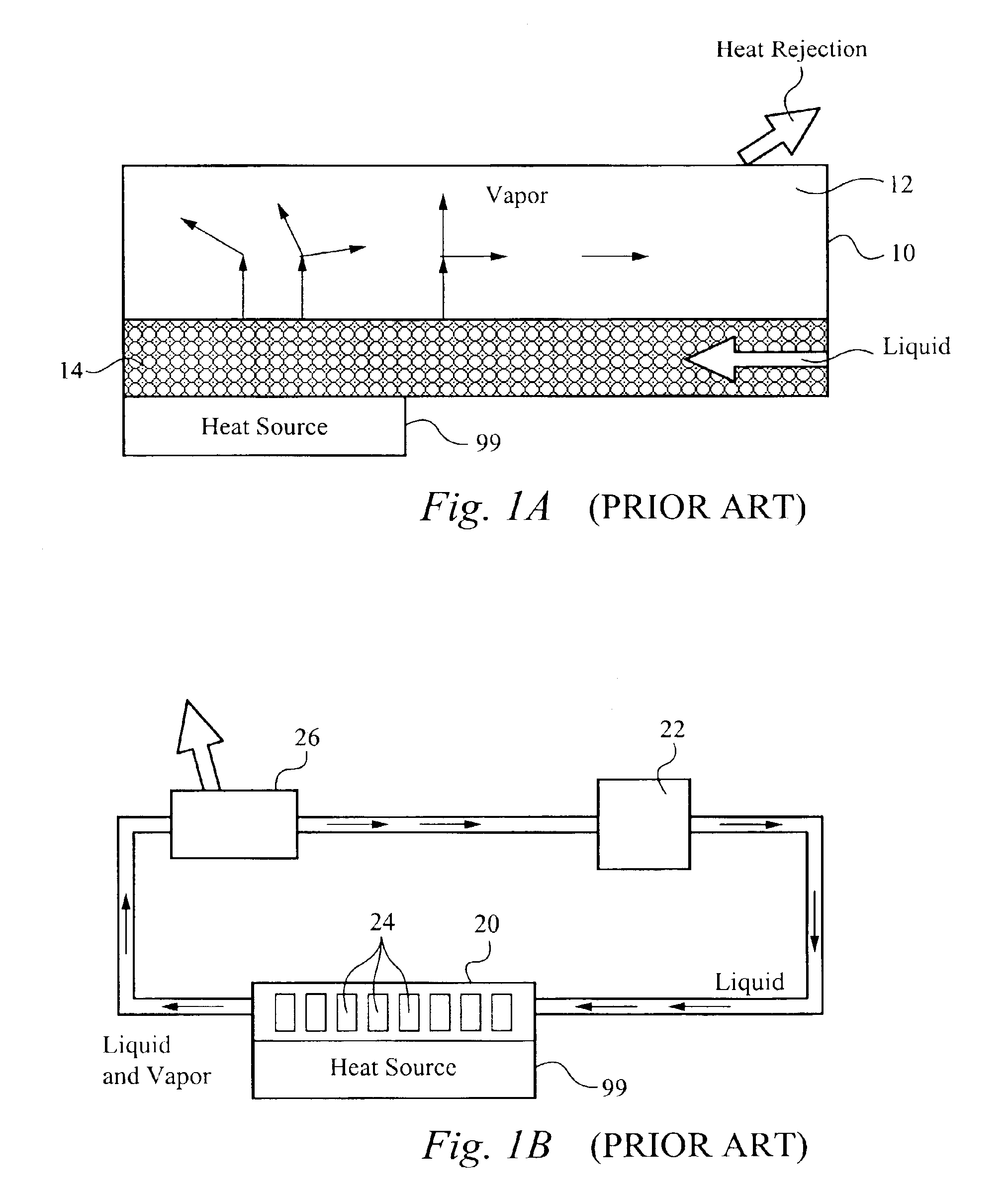

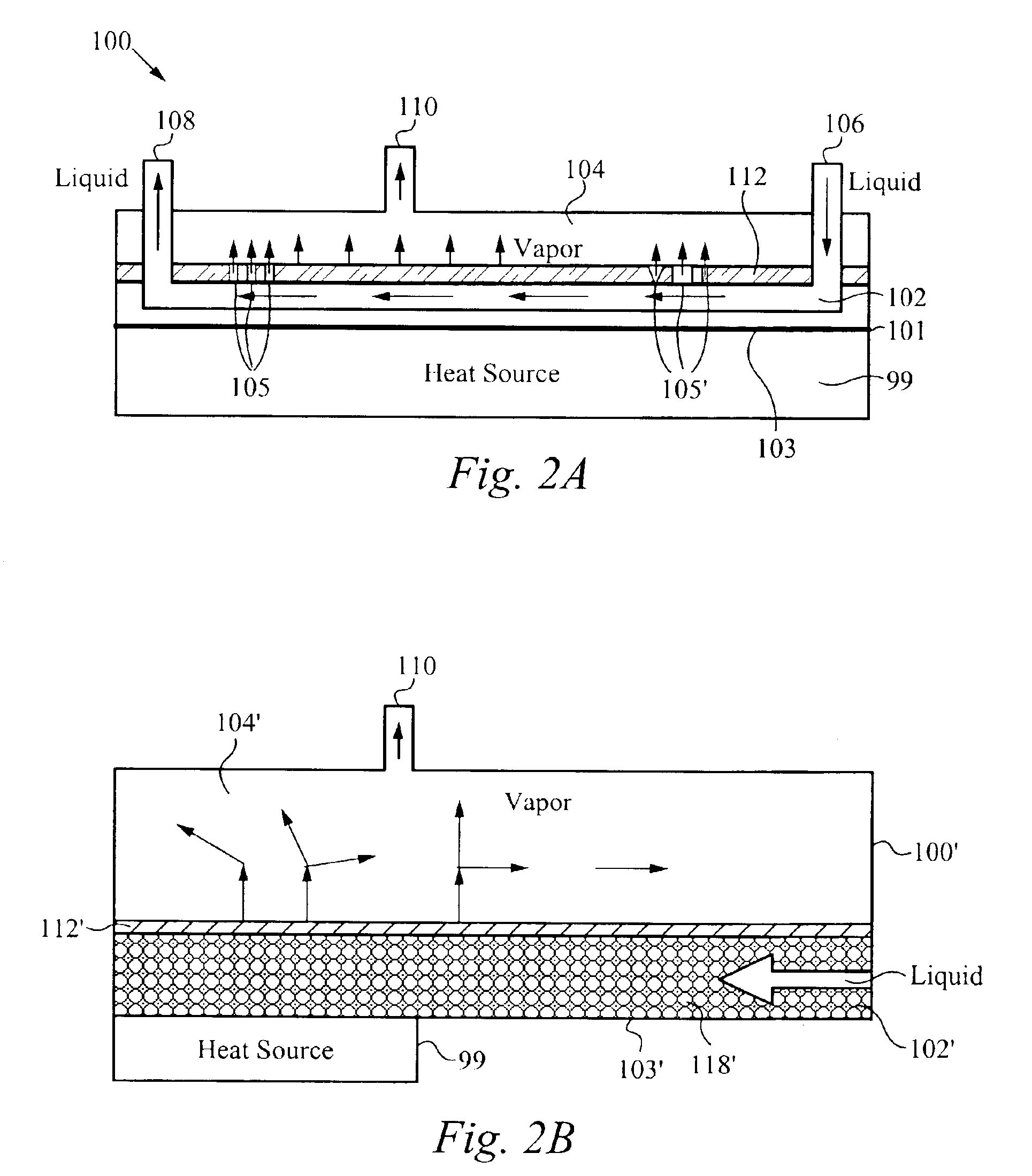

Vapor escape microchannel heat exchanger

InactiveUS6994151B2Semiconductor/solid-state device detailsSolid-state devicesHeat pipeHydrophobic surfaces

A vapor escape membrane for use in a heat exchanging device, including a heat pipe or heat sink that runs liquid into a cooling region positioned adjacent to the heat producing device, the vapor escape membrane comprising: a porous surface for removing vapor produced from the liquid in the cooling region, the membrane configured to confine the liquid only within the cooling region. The vapor escape membrane transfers vapor to a vapor region within the heat exchanging device, wherein the membrane is configured to prevent liquid in the cooling region from entering the vapor region. The membrane is configured to include a hydrophobic surface between the membrane and the cooling region, wherein the liquid in the cooling region does not flow through the porous surface. The vapor escape membrane includes a plurality of apertures for allowing vapor to transfer therethrough, each of the apertures having a predetermined dimension.

Owner:VERTIV CORP

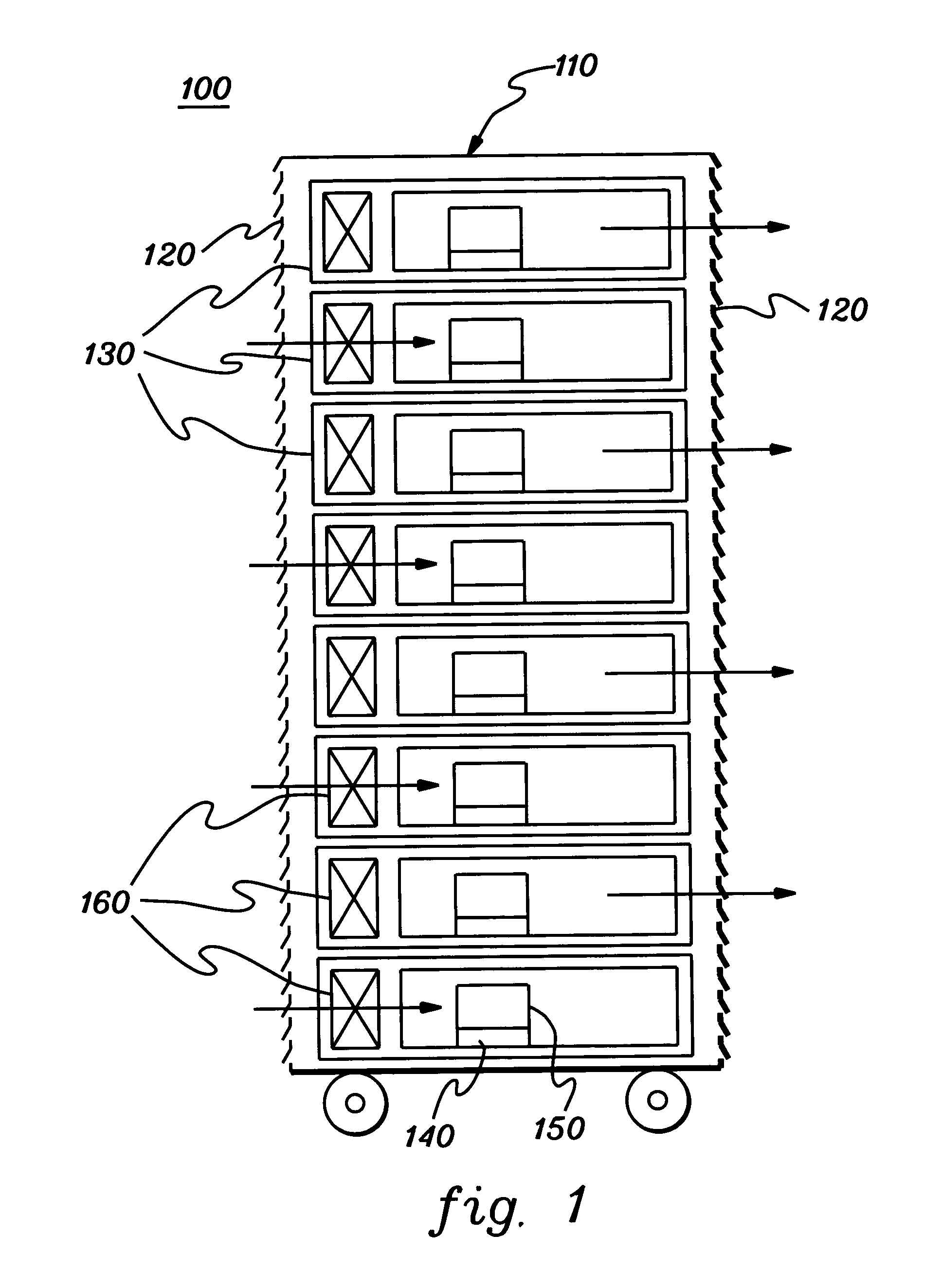

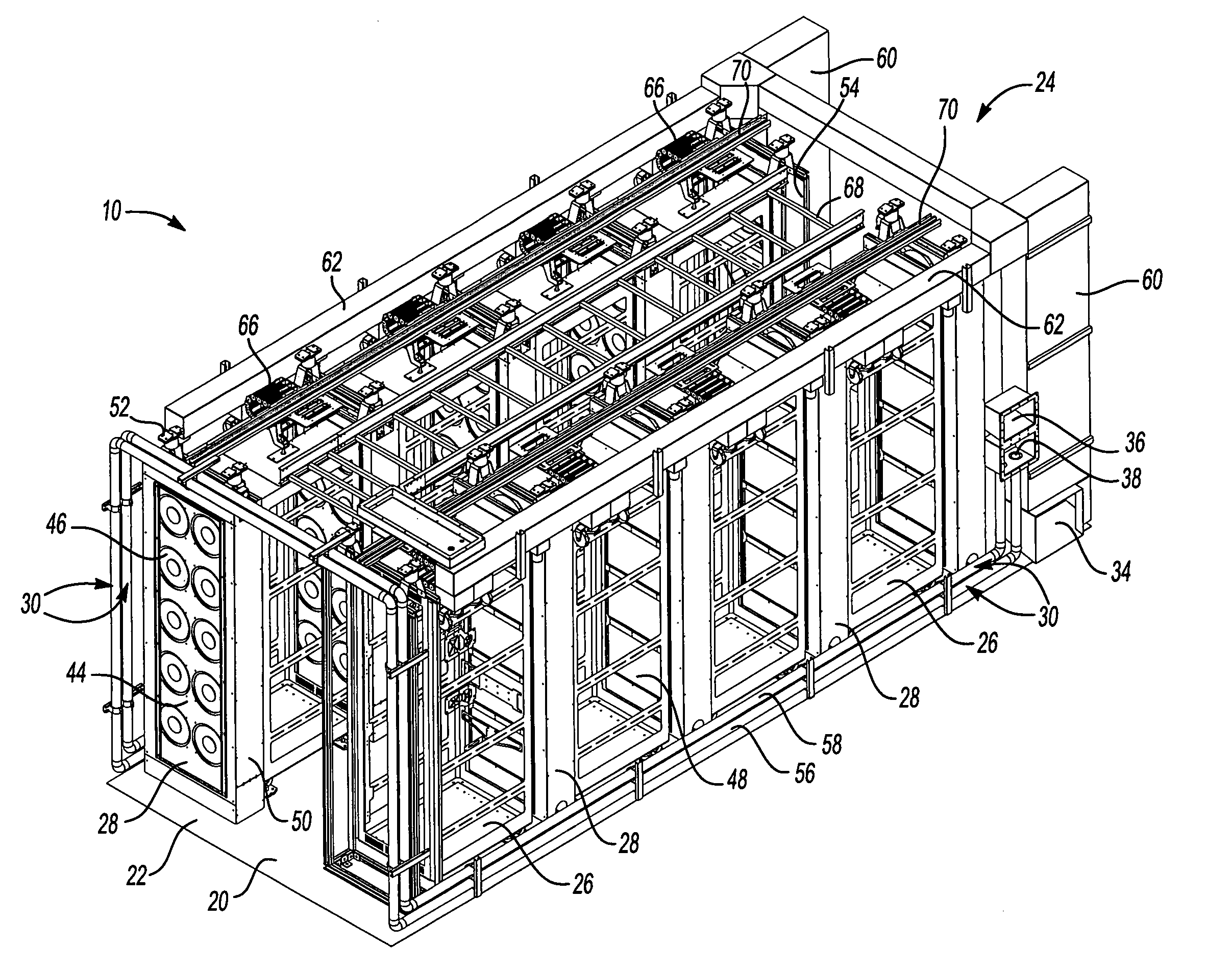

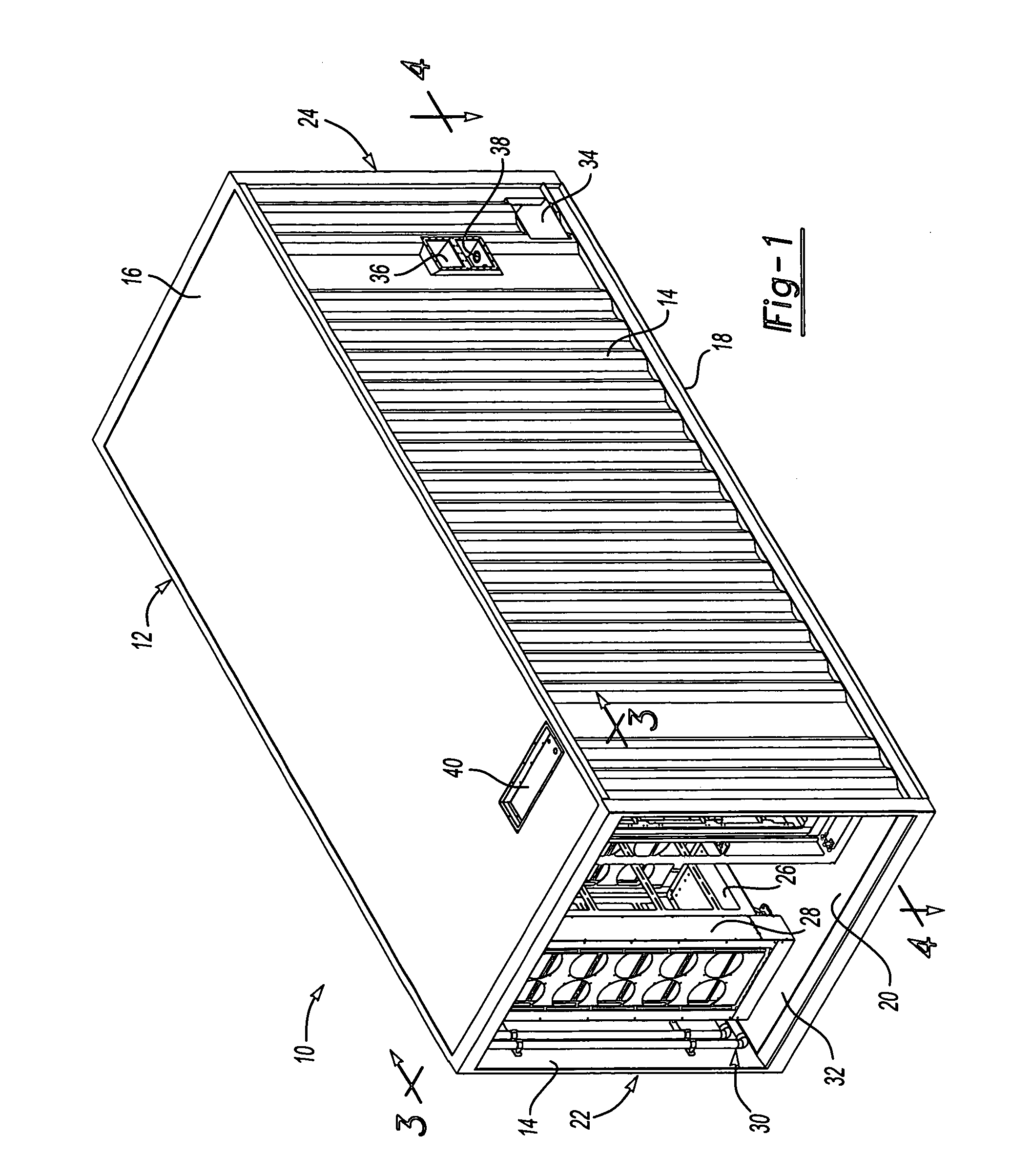

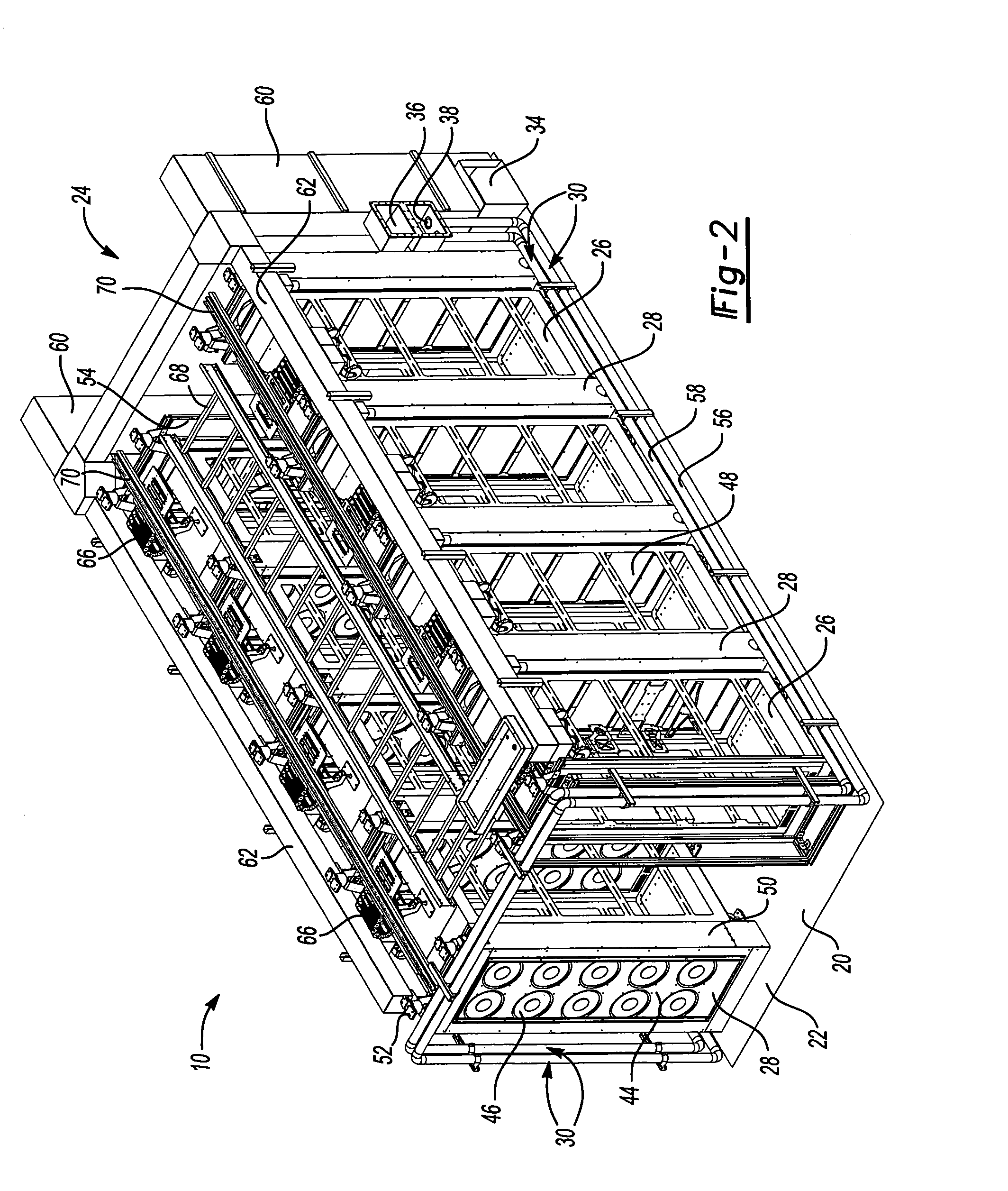

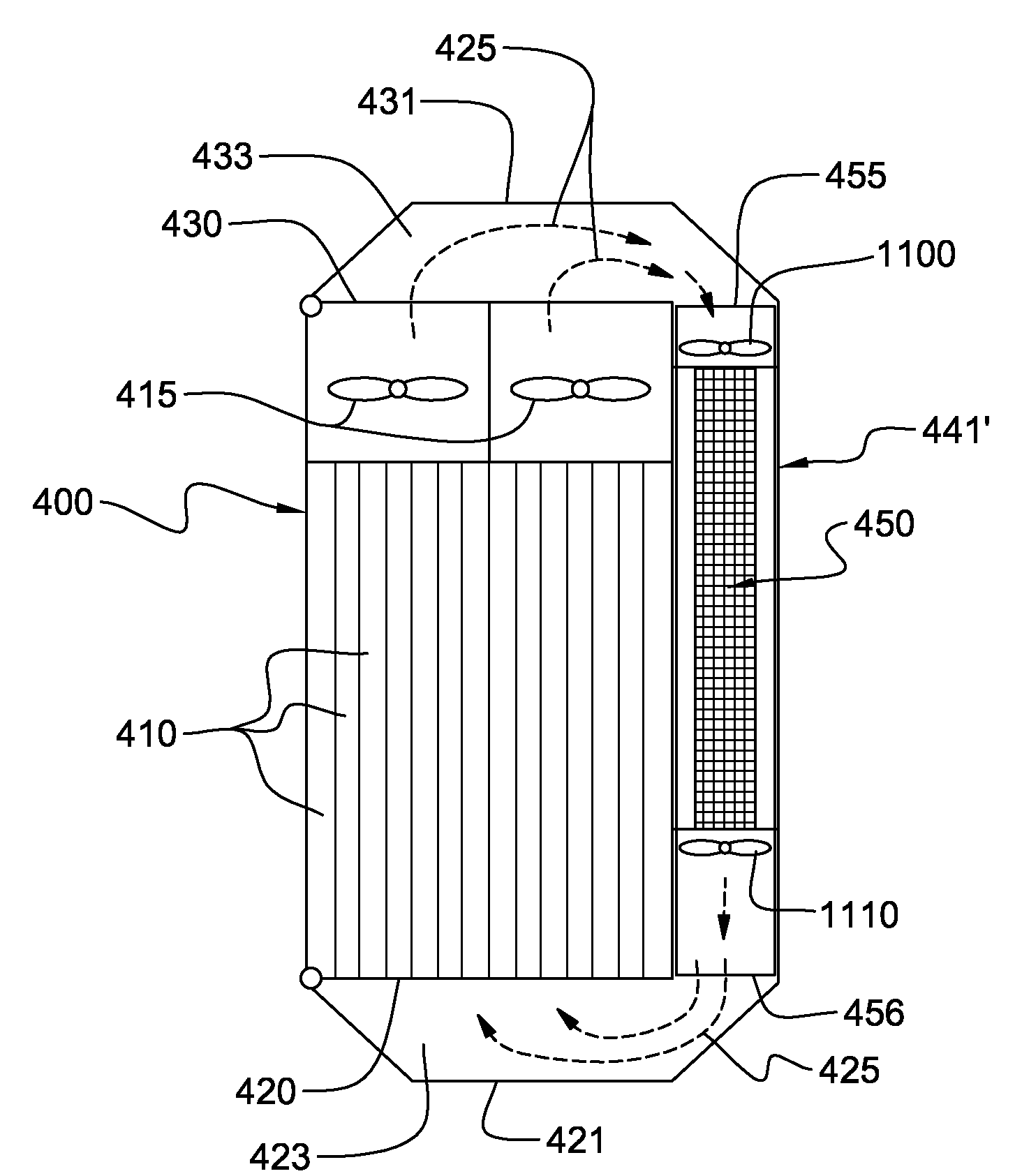

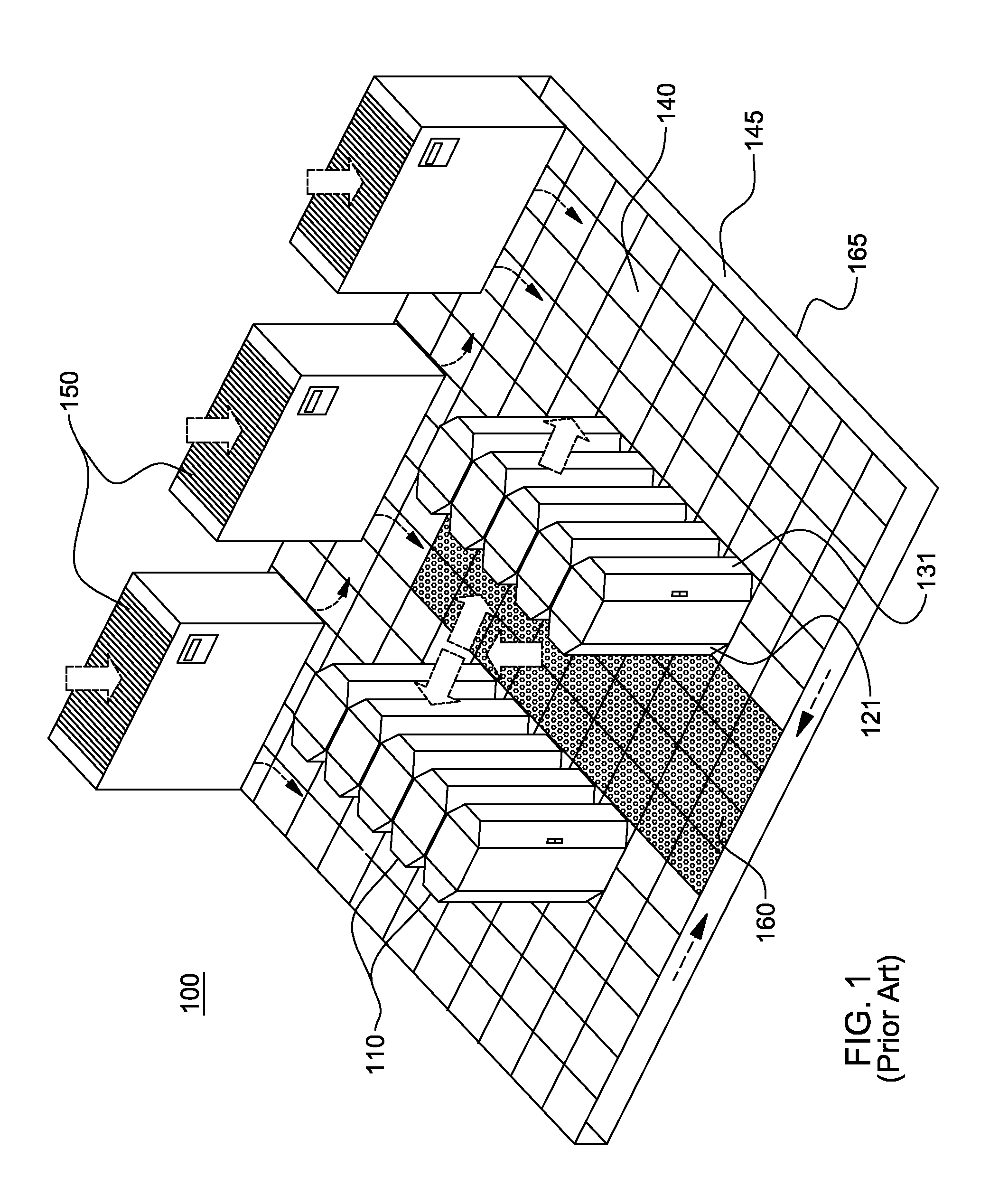

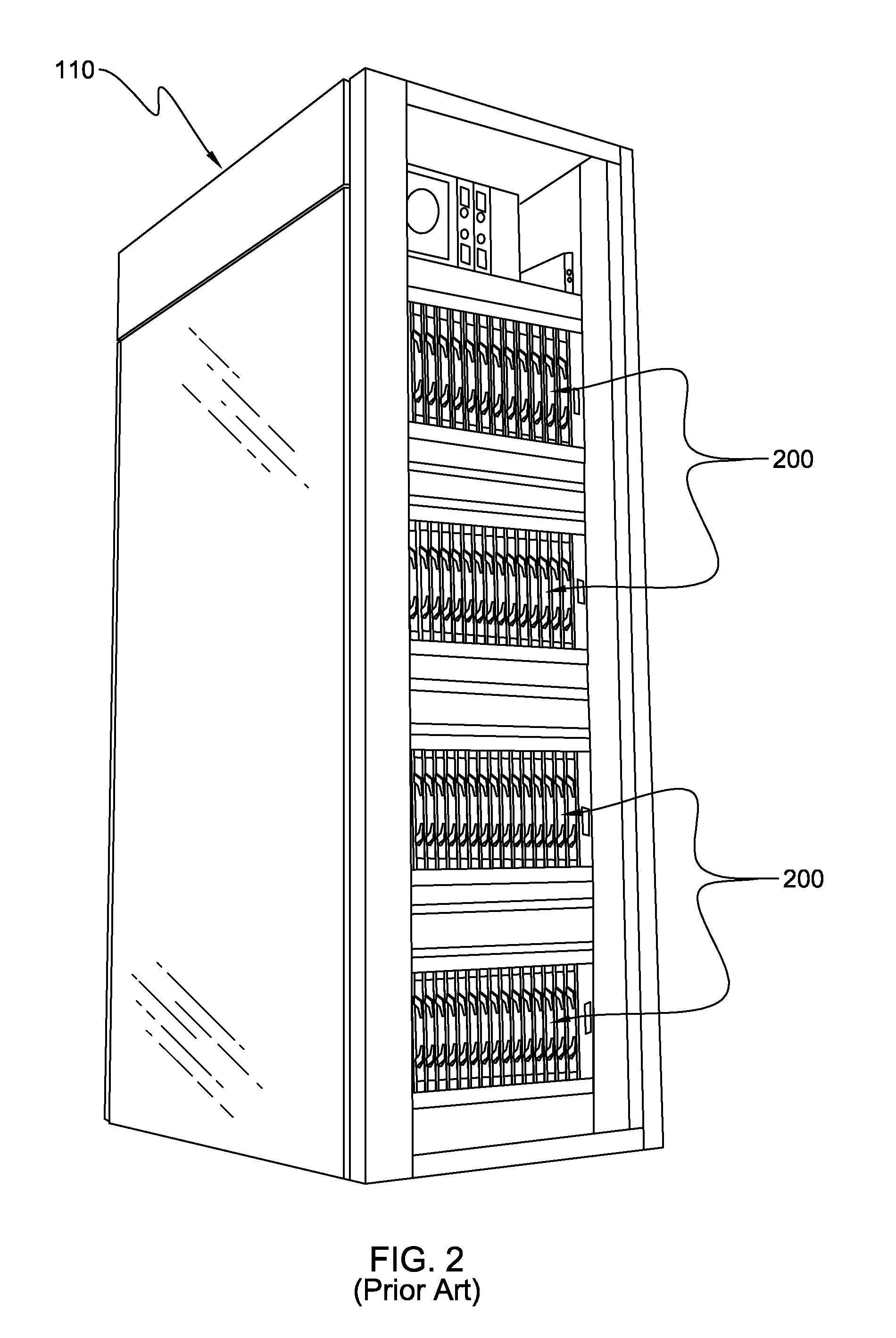

Balanced chilled fluid cooling system for a data center in a shipping container

ActiveUS7511960B2Improve heat transfer performanceServersDigital data processing detailsData centerWater source

A movable data center is disclosed that comprises a movable enclosure having partitions that define a closed-loop air flow path. A plurality of fans and a plurality of data processing modules are disposed in the air flow path. A pipe network is disposed within the enclosure that includes a chilled water supply pipe that receives chilled water from a source of chilled water. A water return pipe is provided that circulates water back to the source of chilled water. A plurality of heat exchange modules is installed in the enclosure in the air flow path. The heat exchange modules receive the chilled water from the chilled water supply pipe. Each of the heat exchange modules has a water circulation tube that connects the chilled water supply pipe to the return water pipe.

Owner:ORACLE INT CORP

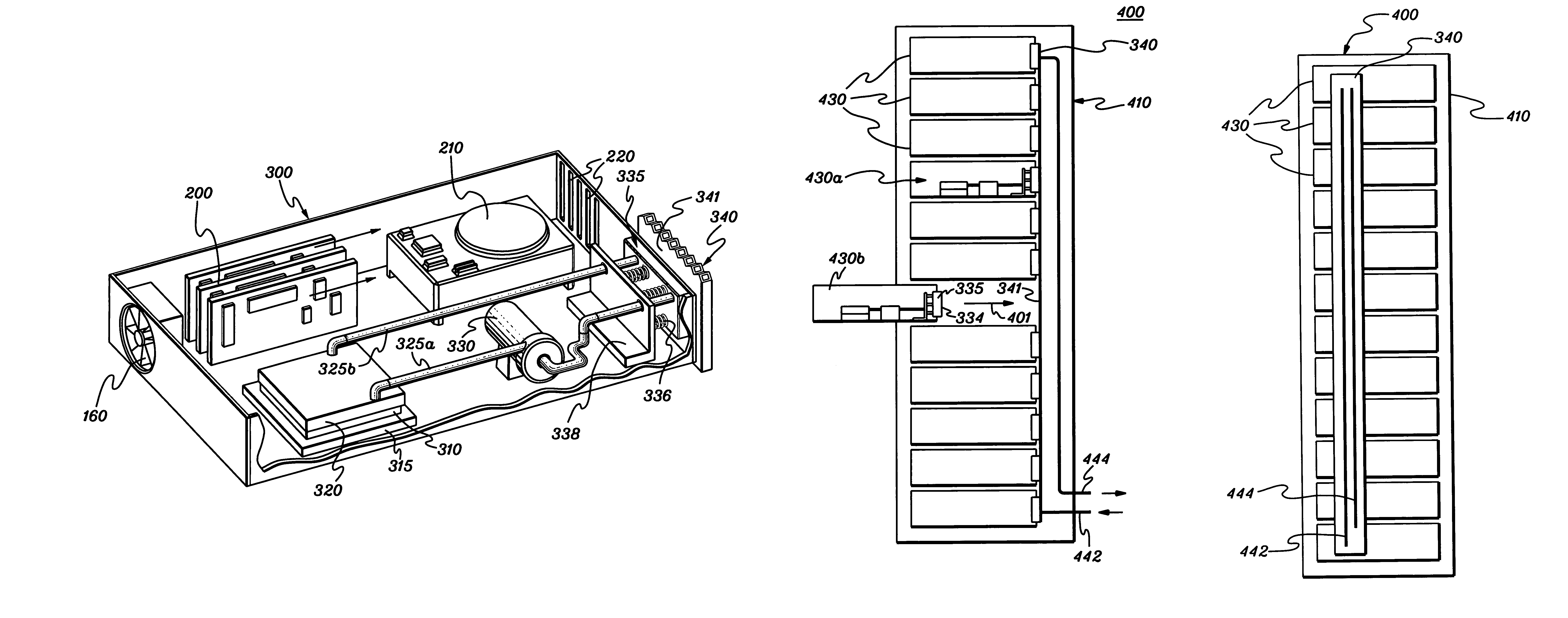

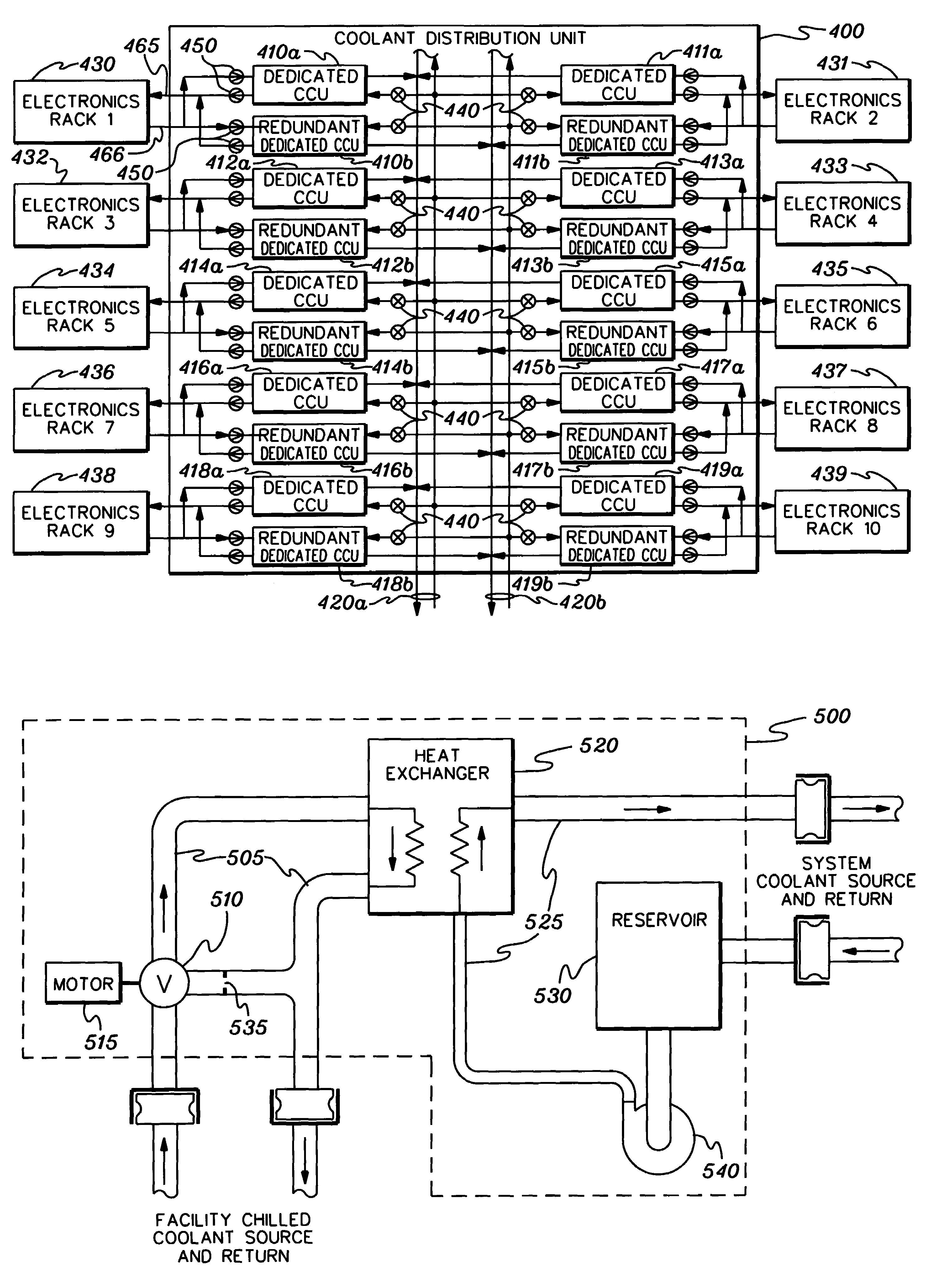

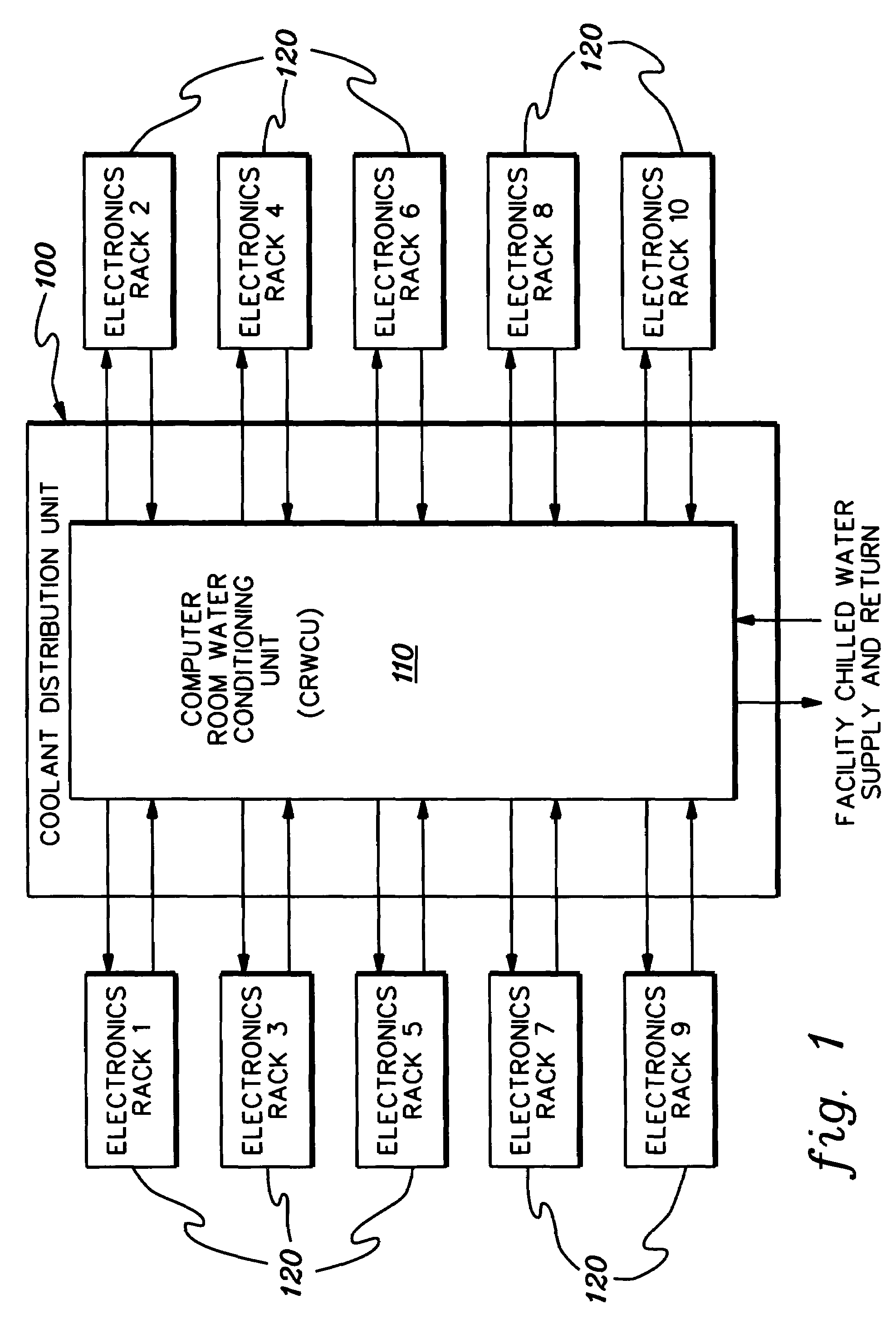

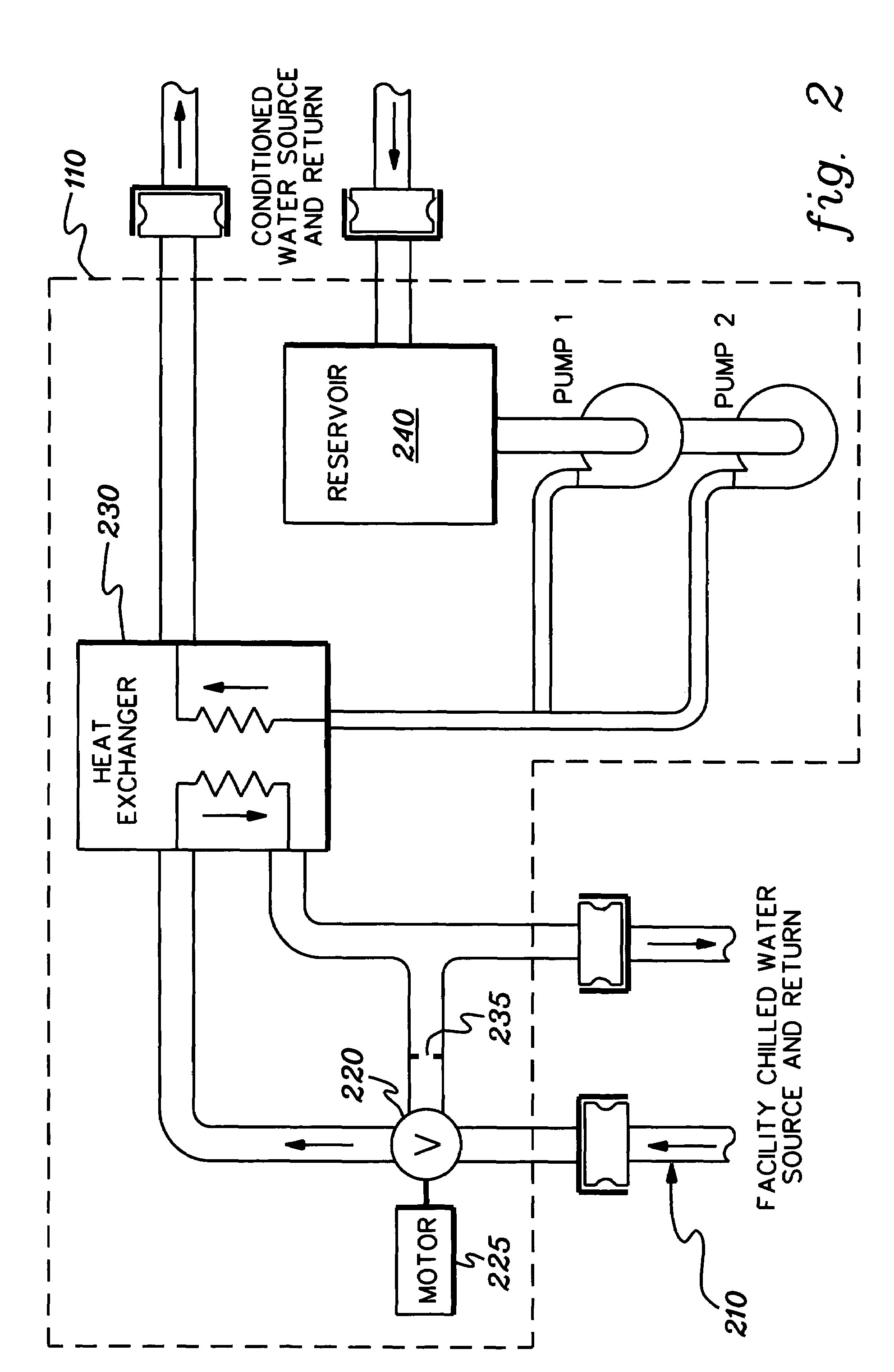

Cooling system and method employing multiple dedicated coolant conditioning units for cooling multiple electronics subsystems

InactiveUS7106590B2Superconductors/hyperconductorsDomestic cooling apparatusCoolant flowNuclear engineering

A cooling system is provided employing multiple coolant conditioning units (CCUs). Each CCU, which is coupled to a different, associated electronics rack of multiple electronics racks to be cooled, includes a heat exchanger, a first cooling loop with a control valve, and a second cooling loop. The first cooling loop receives chilled facility coolant from a source and passes at least a portion thereof via the control valve through the heat exchanger. The second cooling loop provides cooled system coolant to the associated electronics rack, and expels heat in the heat exchanger from the electronics rack to the chilled facility coolant in the first cooling loop. The control valve allows regulation of the facility coolant flow through the heat exchanger, thereby allowing independent control of temperature of the system coolant in the second cooling loop. Various CCU and associated component redundancies of the cooling system are also provided.

Owner:INT BUSINESS MASCH CORP

High density memory module using stacked printed circuit boards

ActiveUS7254036B2Semiconductor/solid-state device detailsPrinted circuit aspectsHigh densityComputerized system

Owner:NETLIST INC

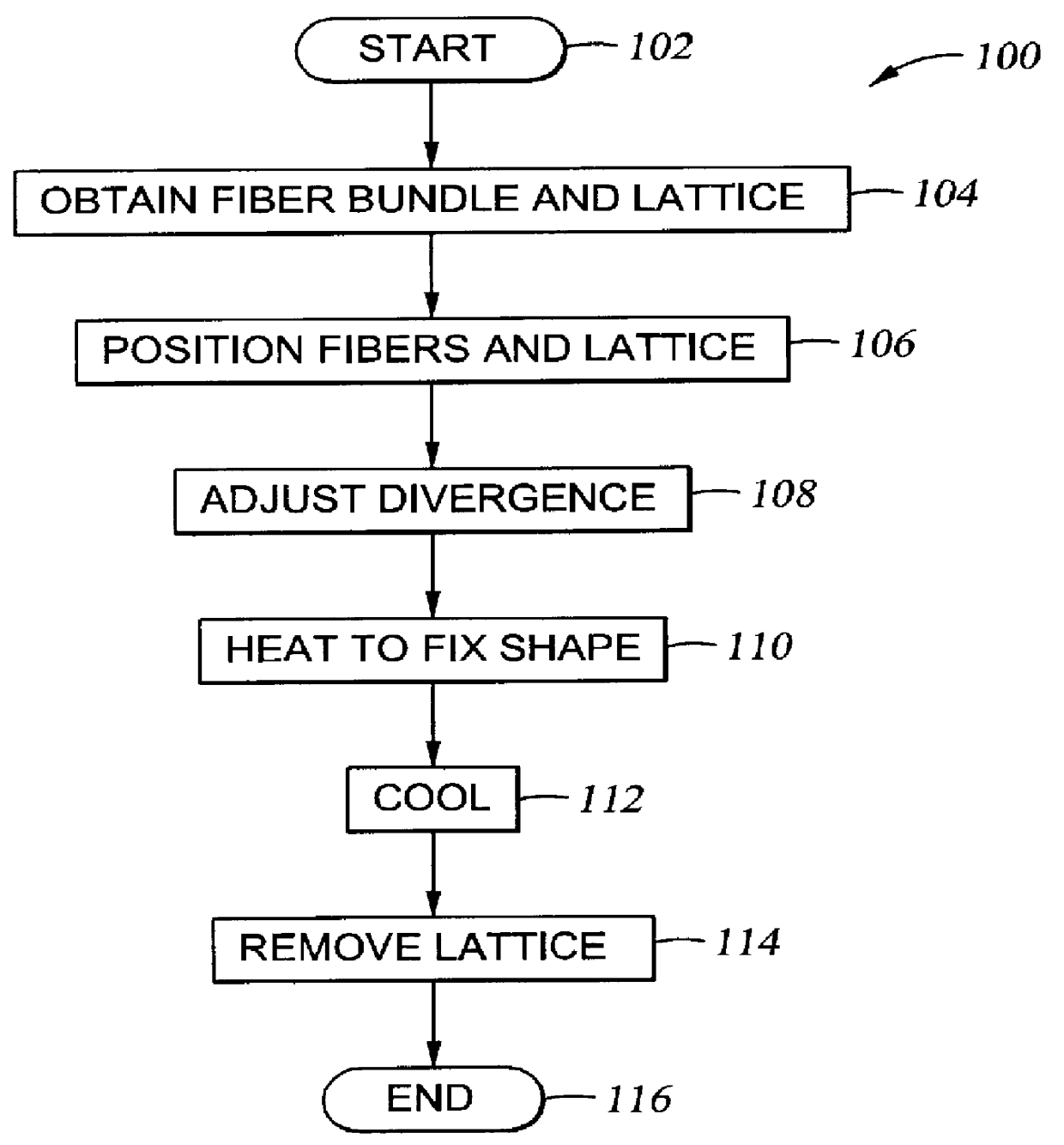

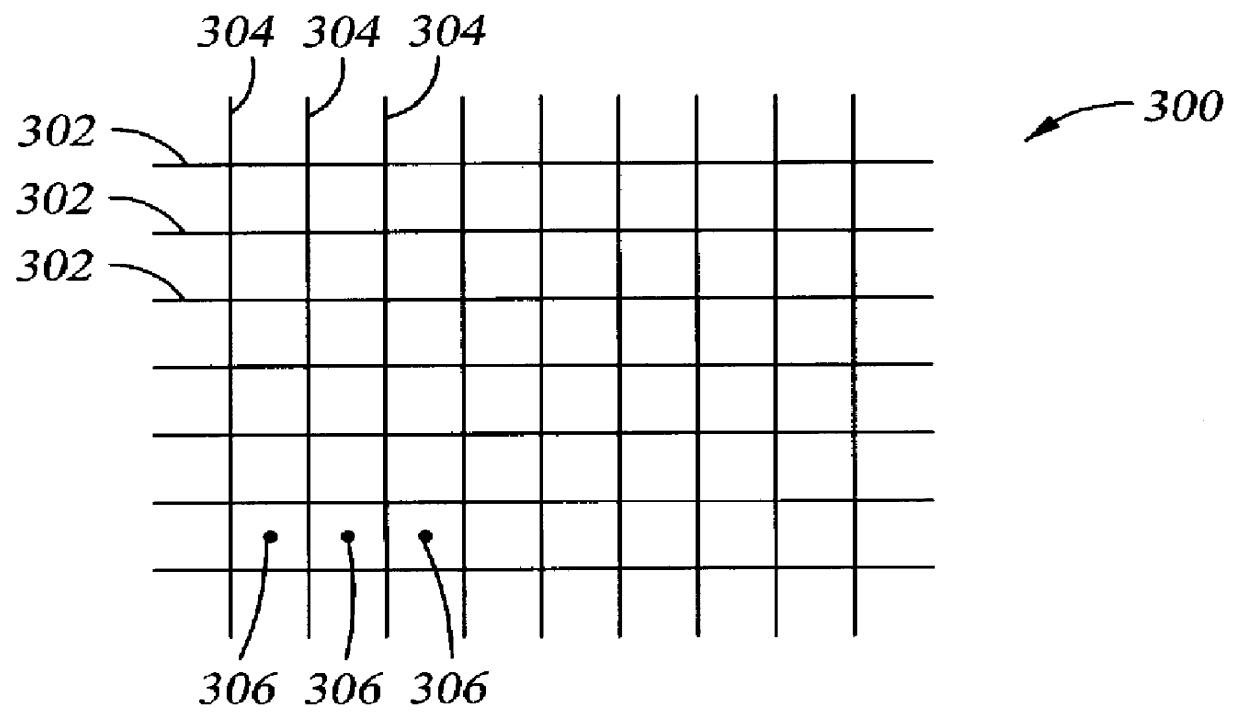

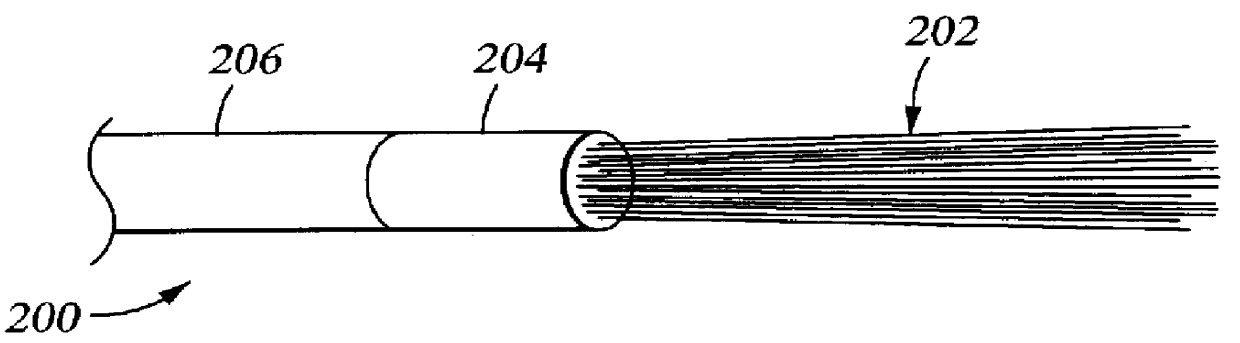

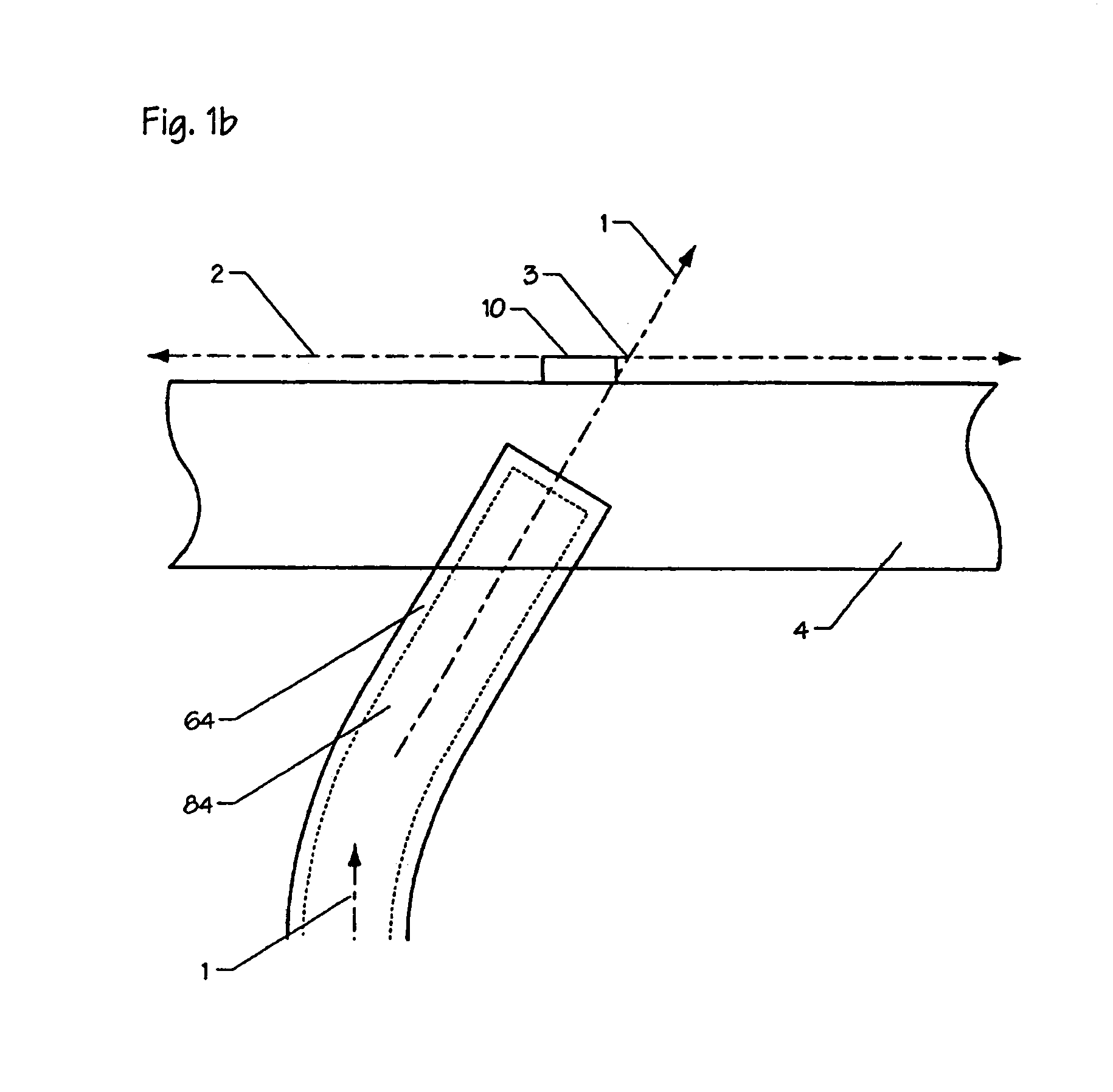

Method of selectively shaping hollow fibers of heat exchange catheter

A group of multiple hollow fibers may be shaped to introduce angular divergence among the fibers, or to introduce a selected longitudinal oscillation into the fibers. In one shaping technique, the fibers are held in parallel while upper and lower crimping assemblies of parallel crimping bars are drawn together on opposite sides of the parallel fibers. When bars of the opposing assemblies draw sufficiently close, they sandwich the fibers in between them, causing each fiber to assume a shape that oscillates as the fiber repeatedly goes over and then under successive bars. Since the crimping bars are aligned at oblique angles to the fibers, the peaks and troughs of successive fibers are offset. While in this position, the fibers are heated and then cooled to permanently retain their shapes. A different shaping technique utilizes a lattice of crisscrossing tines defining multiple apertures. In this technique, the lattice and fibers are positioned so that each fiber passes through one of the apertures. Then, the lattice and / or the fibers are slid apart or together until the lattice holds the fibers in a desired configuration, where the fibers have a prescribed outward divergence relative to each other. While in this position, the fibers are heated and then cooled to permanently retain this angular divergence.

Owner:ZOLL CIRCULATION

Flat plate heat pipe cooling system for electronic equipment enclosure

InactiveUS6148906ARemove heatDigital data processing detailsSemiconductor/solid-state device detailsEngineeringElectron

A cooling system for an electronic equipment enclosure employs a flat plate heat pipe to deliver heat from the interior of the enclosure through a connector to a removable external heat sink. The heat pipe includes a metallic bottom plate having a depression therein containing a set of rods evenly spaced from one another. A top plate covers the bottom plate with the rods compressed therebetween. Channels formed between adjacent rods are partially evacuated and injected with an evaporative fluid. The fluid and its vapor circulate in the channels to convey heat from a warm end of the heat pipe to a cool end. The heat sink is of similar construction.

Owner:SCIENTECH

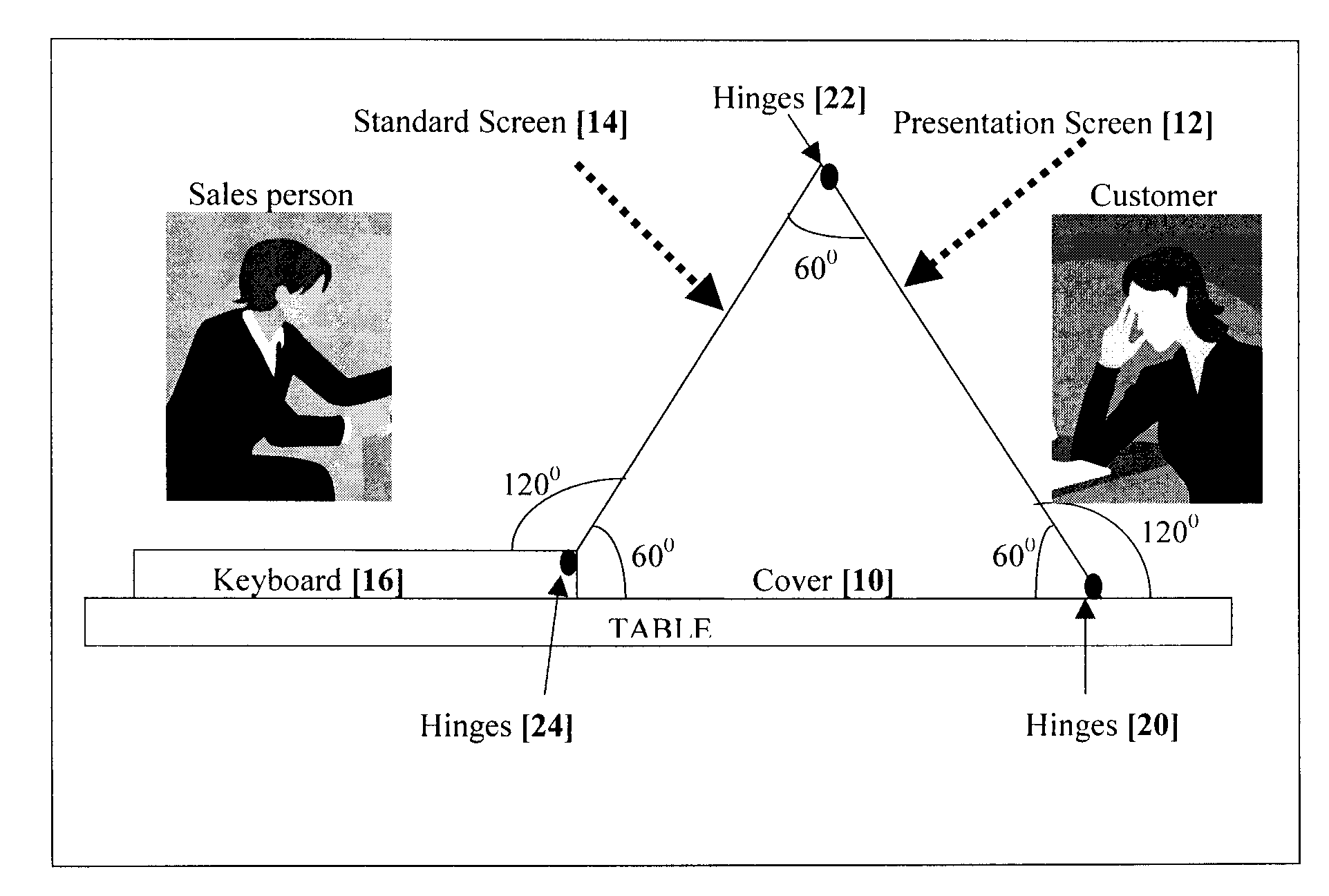

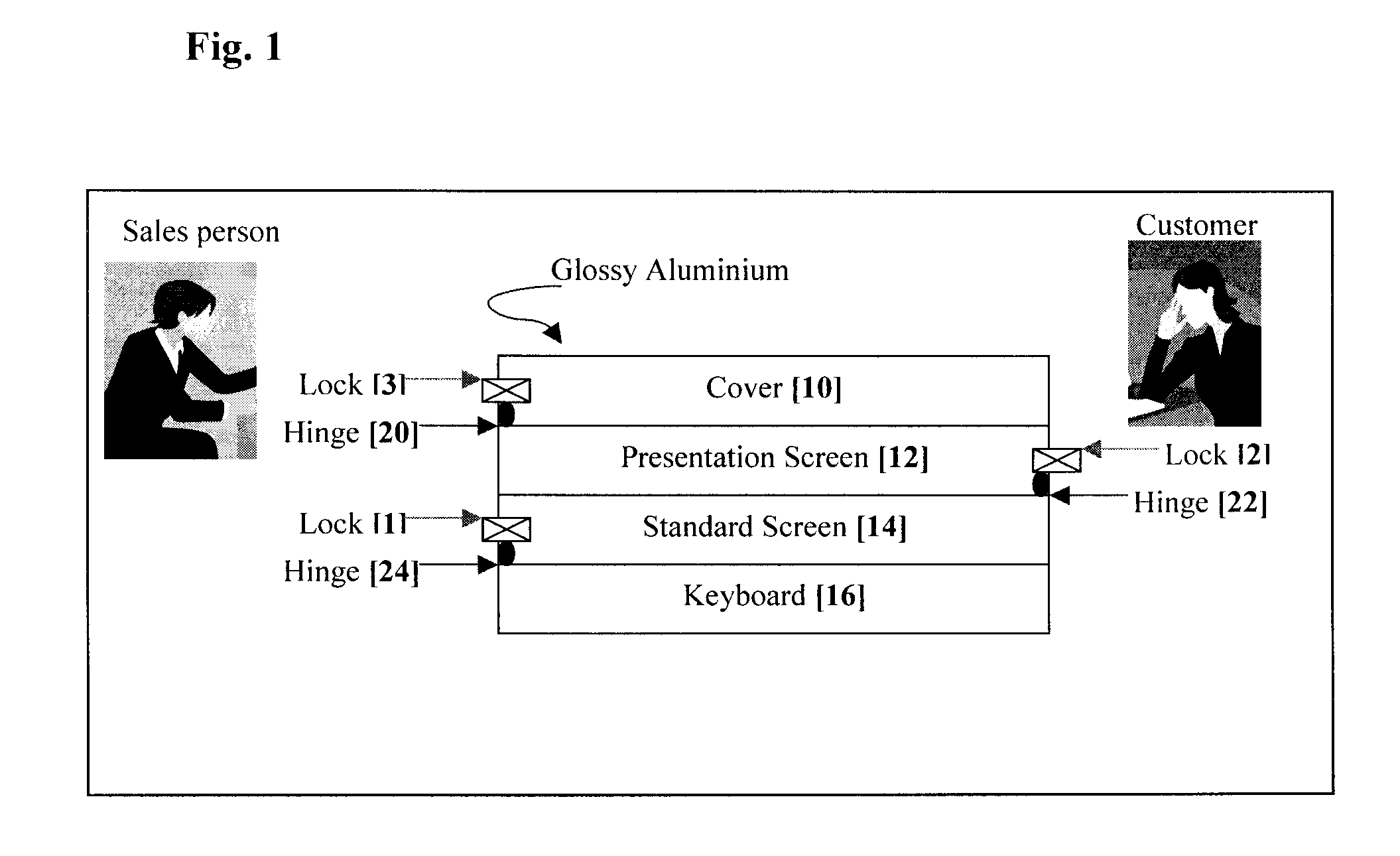

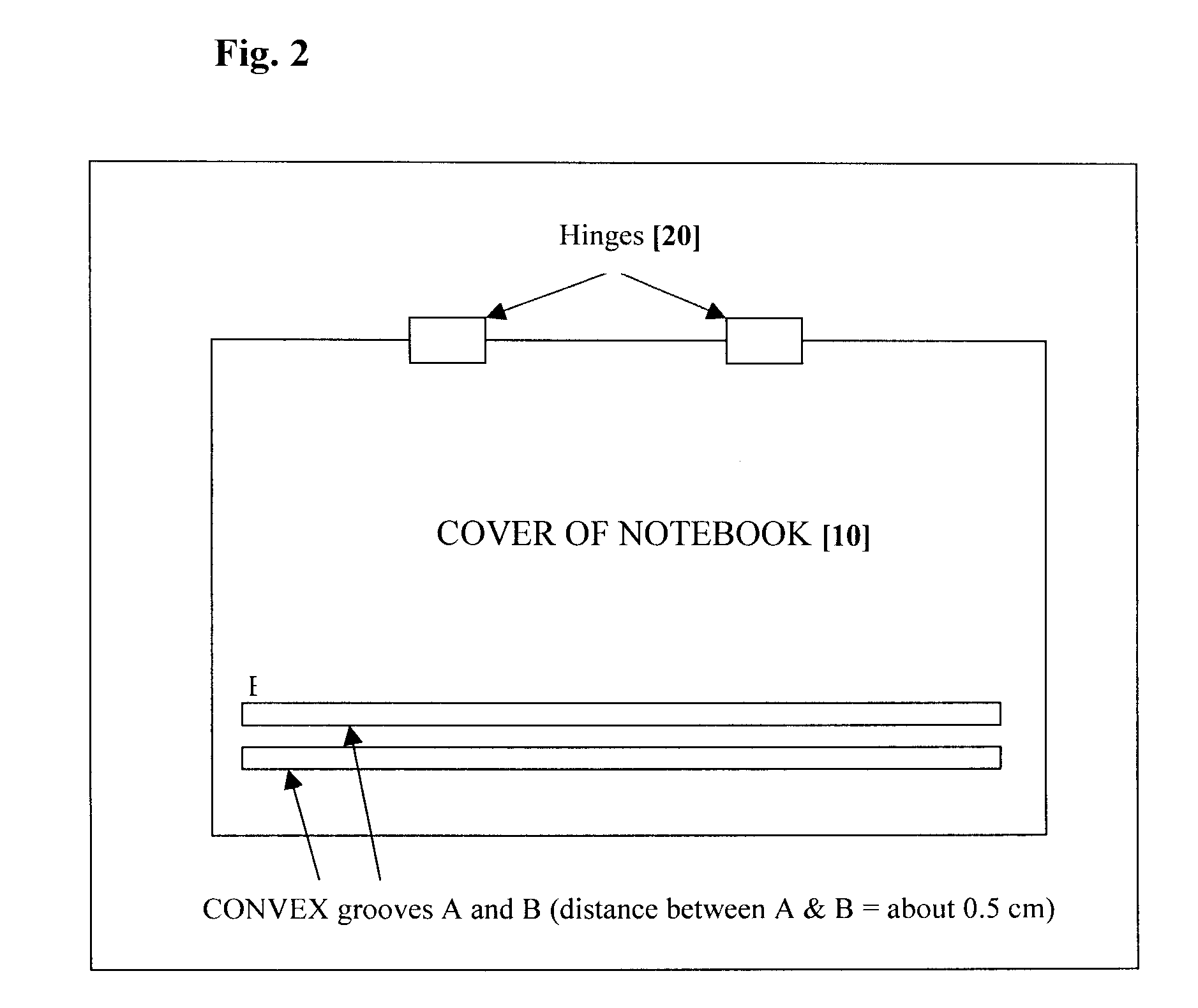

Dual screen presentation notebook computer

InactiveUS20090296331A1Easy to useDelayed closureInput/output for user-computer interactionEnergy efficient ICTTablet computerComputer graphics (images)

A dual screen presentation notebook having components that are integrally connected together to allow easy viewing of presentation materials without the users having to sit side by side craning their necks close together facing the same direction but instead can face opposite one another. When the dual screen presentation notebook is switched on, users can either (i) view identical or mirror images of the presentation materials or (ii) different images on the two monitor screens. The dual screen presentation notebook can be easily converted into a tablet computer and can also be used for other applications such as viewing electronic book, electronic photograph and images, videos, movies, etc.

Owner:CHOY HENG KAH

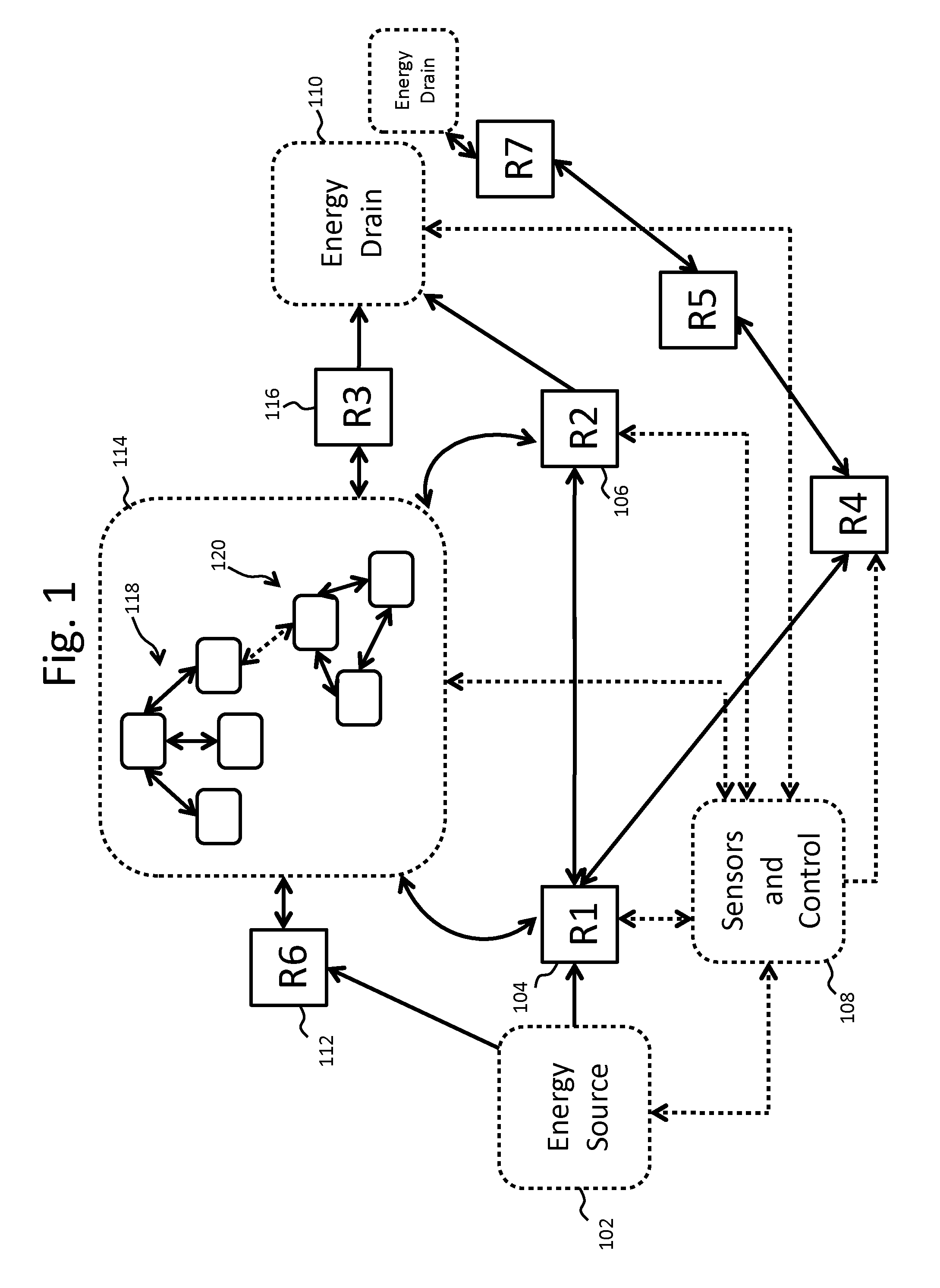

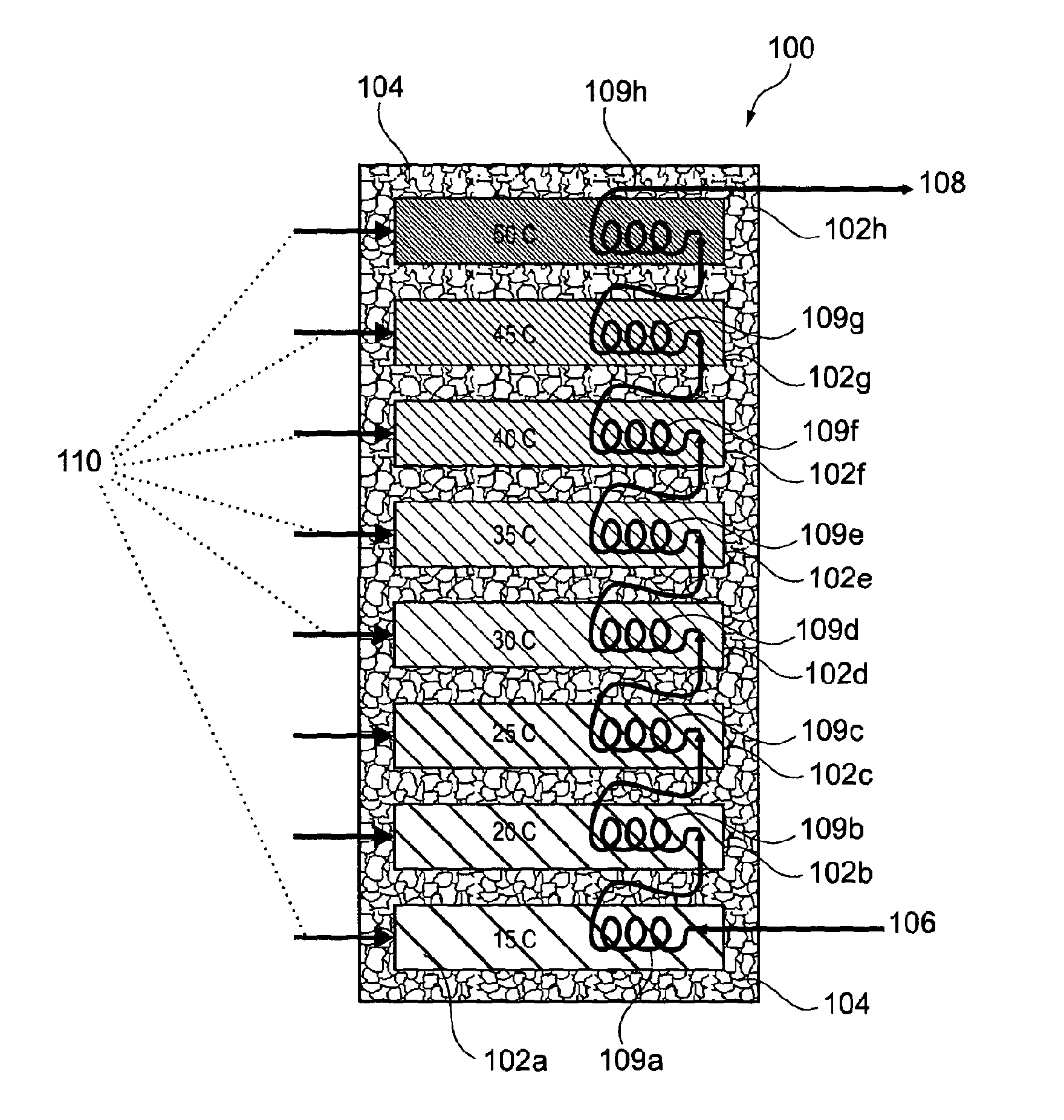

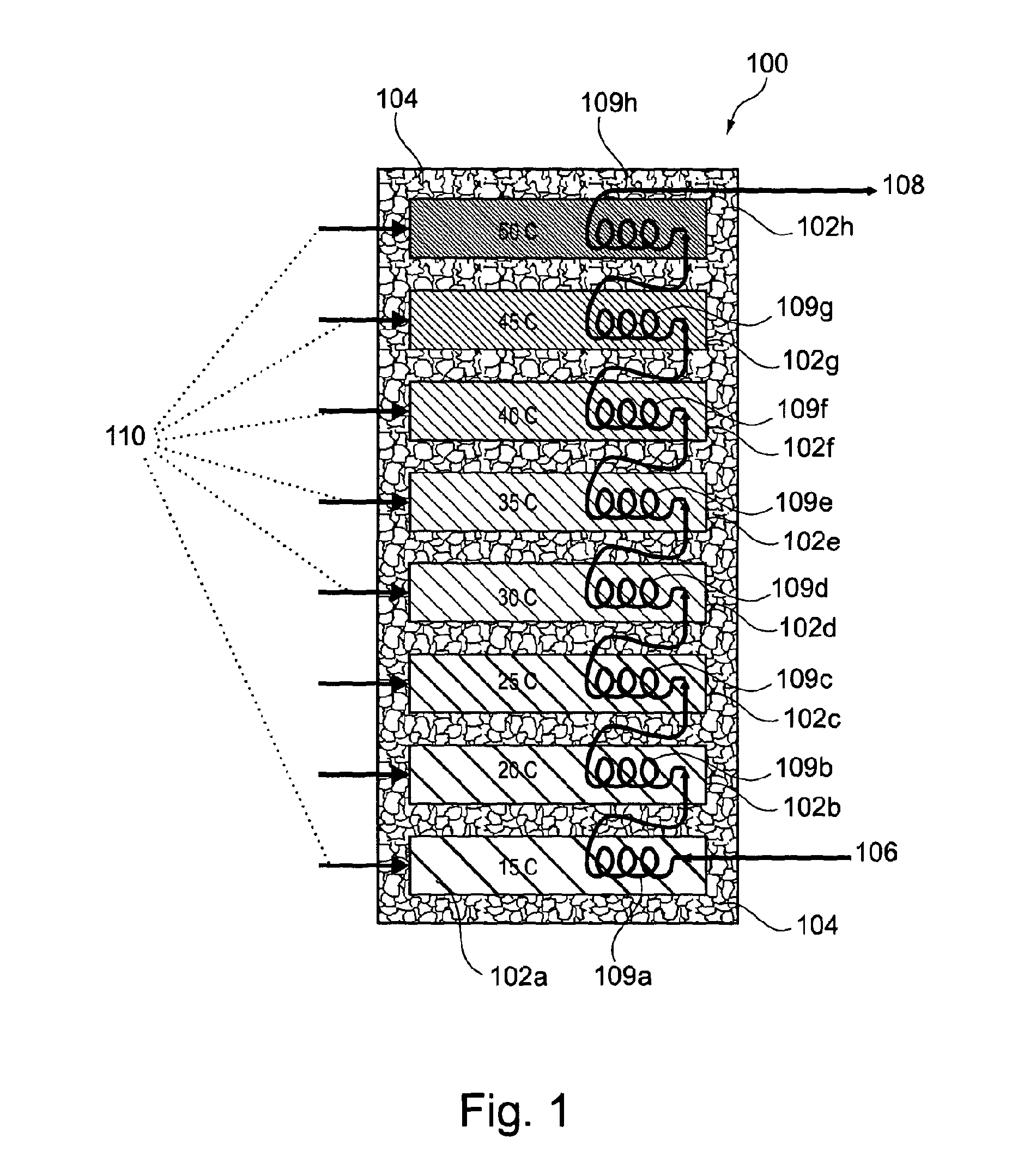

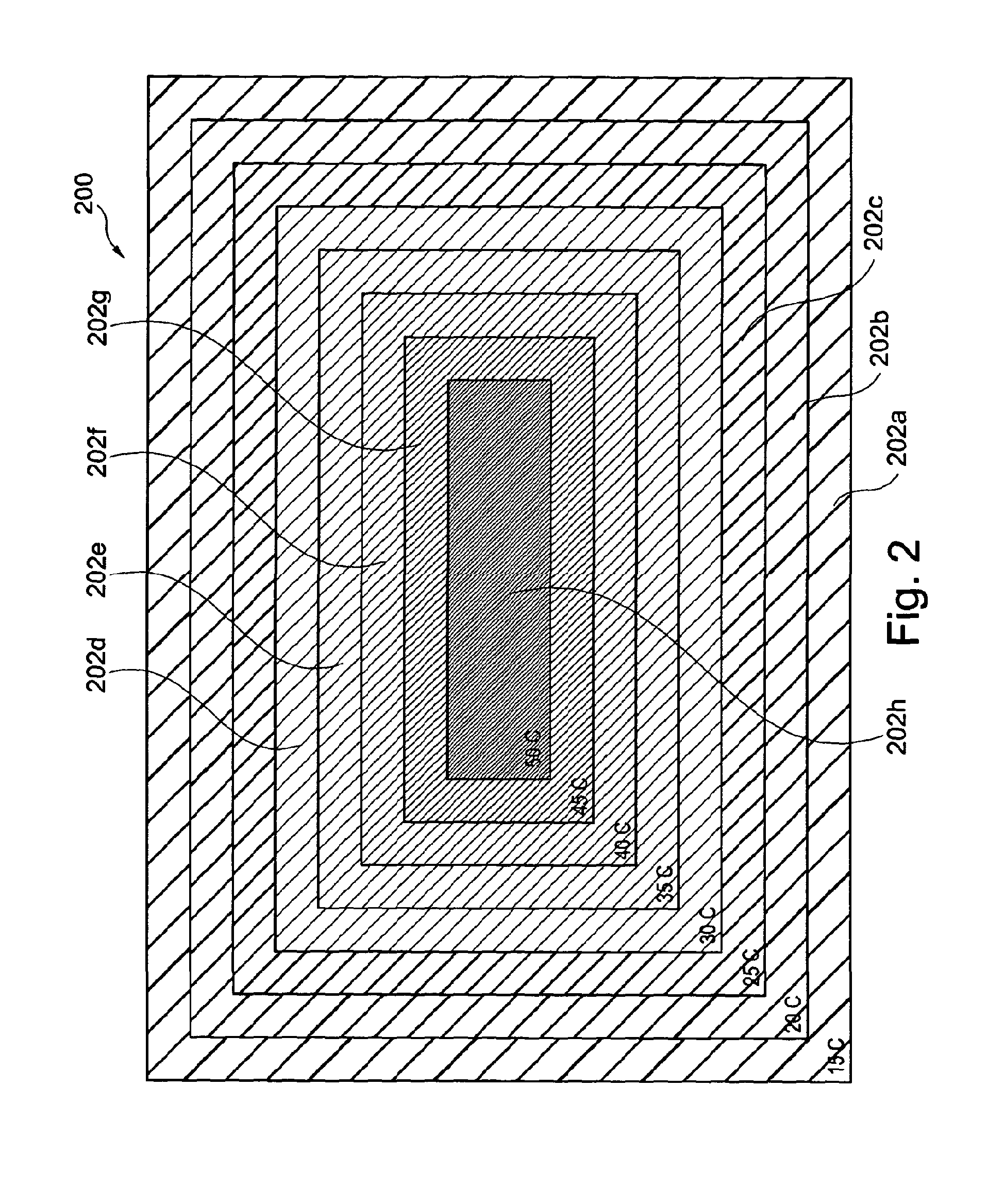

Energy storage systems

InactiveUS20120227926A1Low costReduce usageSolar heating energySolar heat devicesThermal energyThermal energy storage

There is herein described energy storage systems. More particularly, there is herein described thermal energy storage systems and use of energy storable material such as phase change material in the provision of heating and / or cooling systems in, for example, domestic dwellings.

Owner:SUNAMP

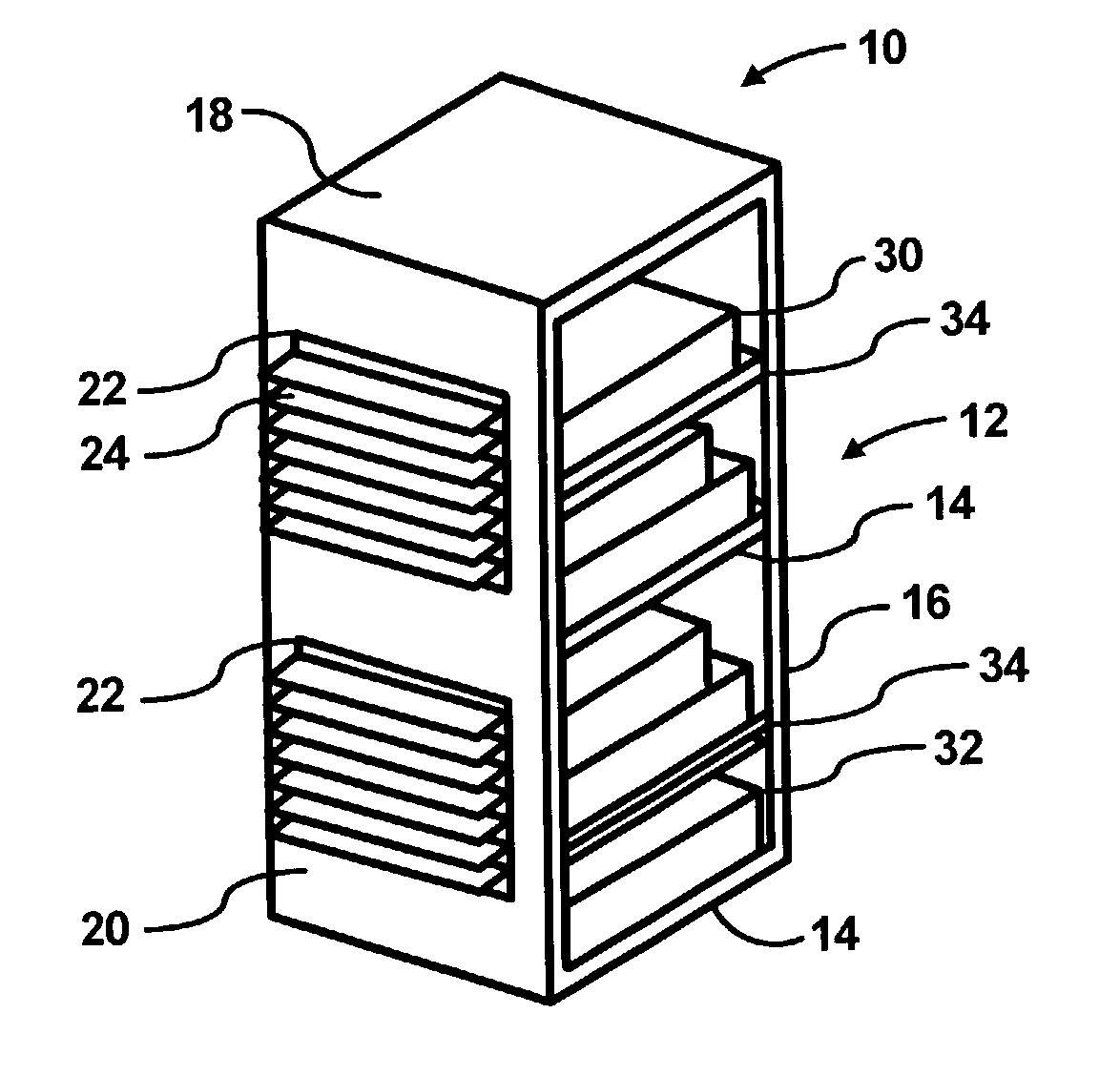

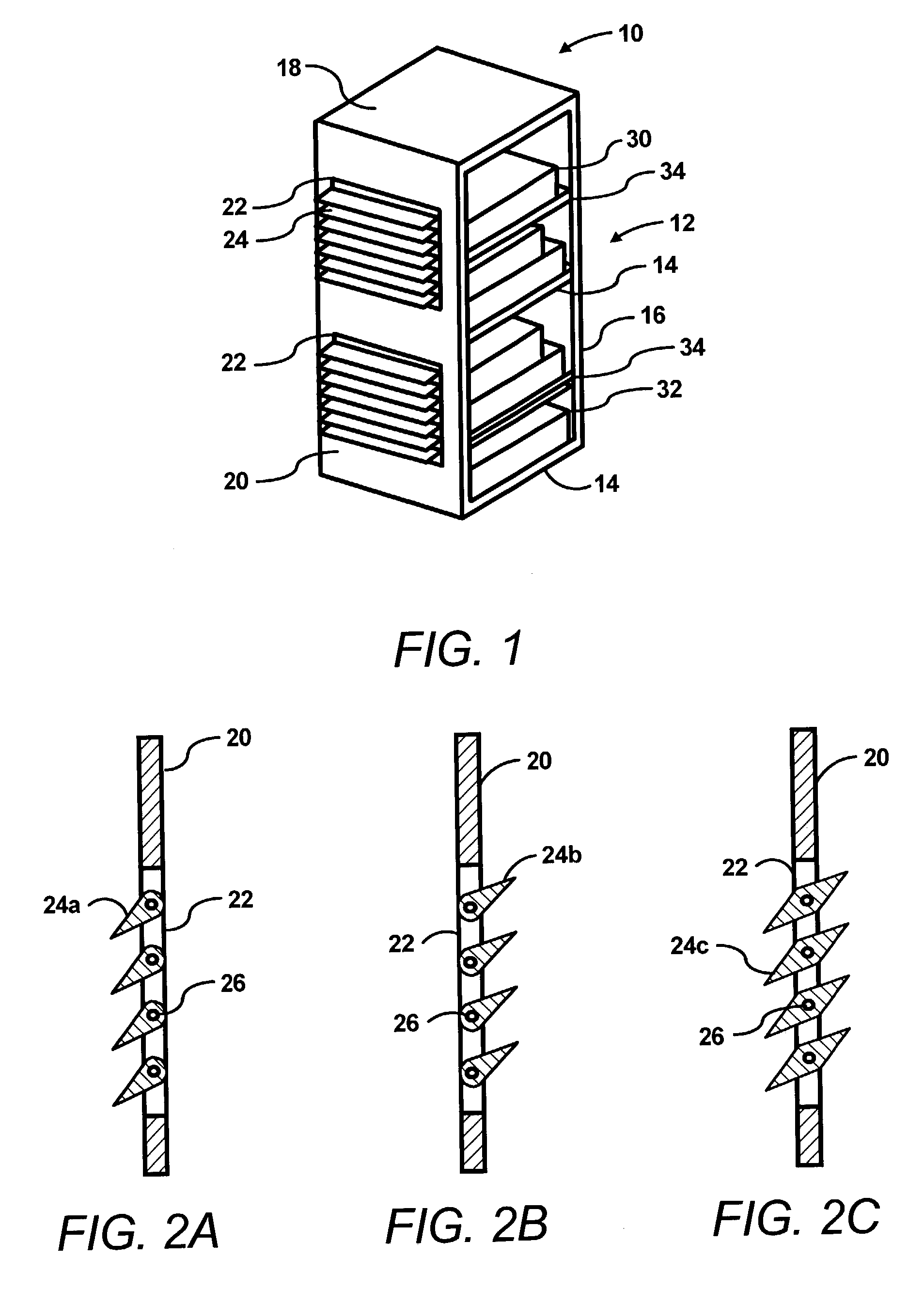

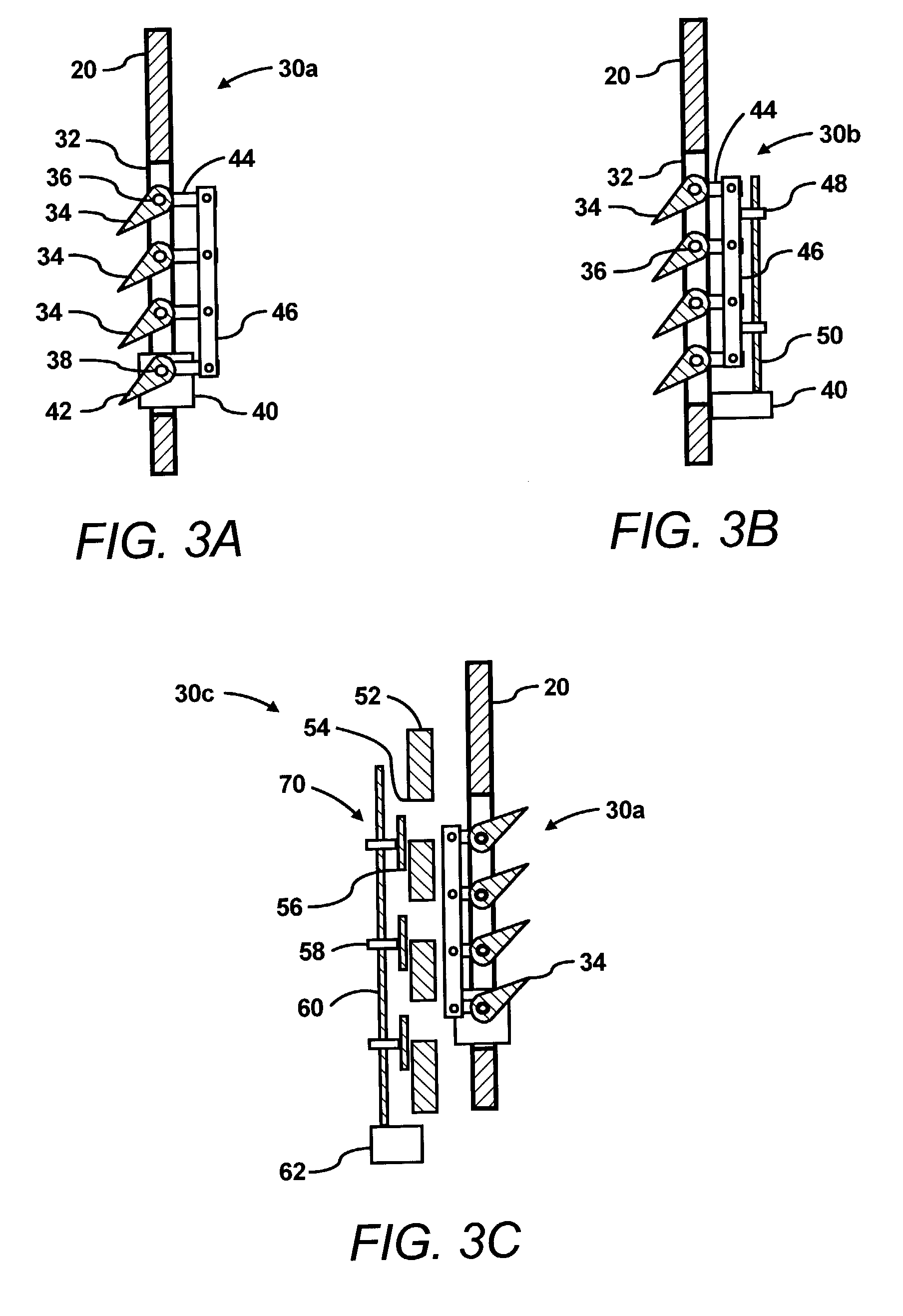

Louvered rack

A rack has a frame for supporting one or more electronic components. A front panel and a rear panel are attached to the frame. At least one of the front panel and the rear panel comprises a vent having at least one movable louver configured to vary airflow through the vent.

Owner:HEWLETT PACKARD DEV CO LP

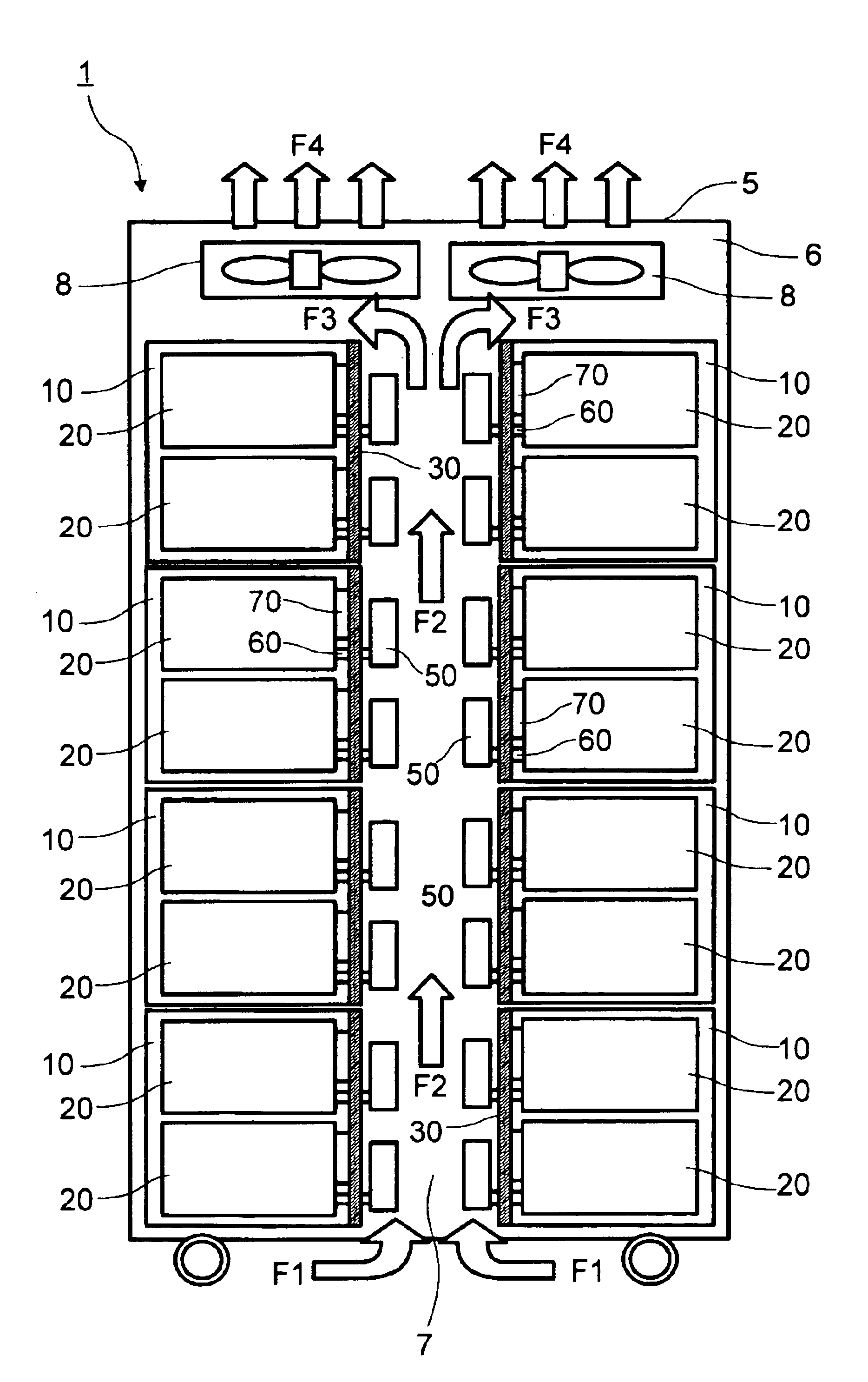

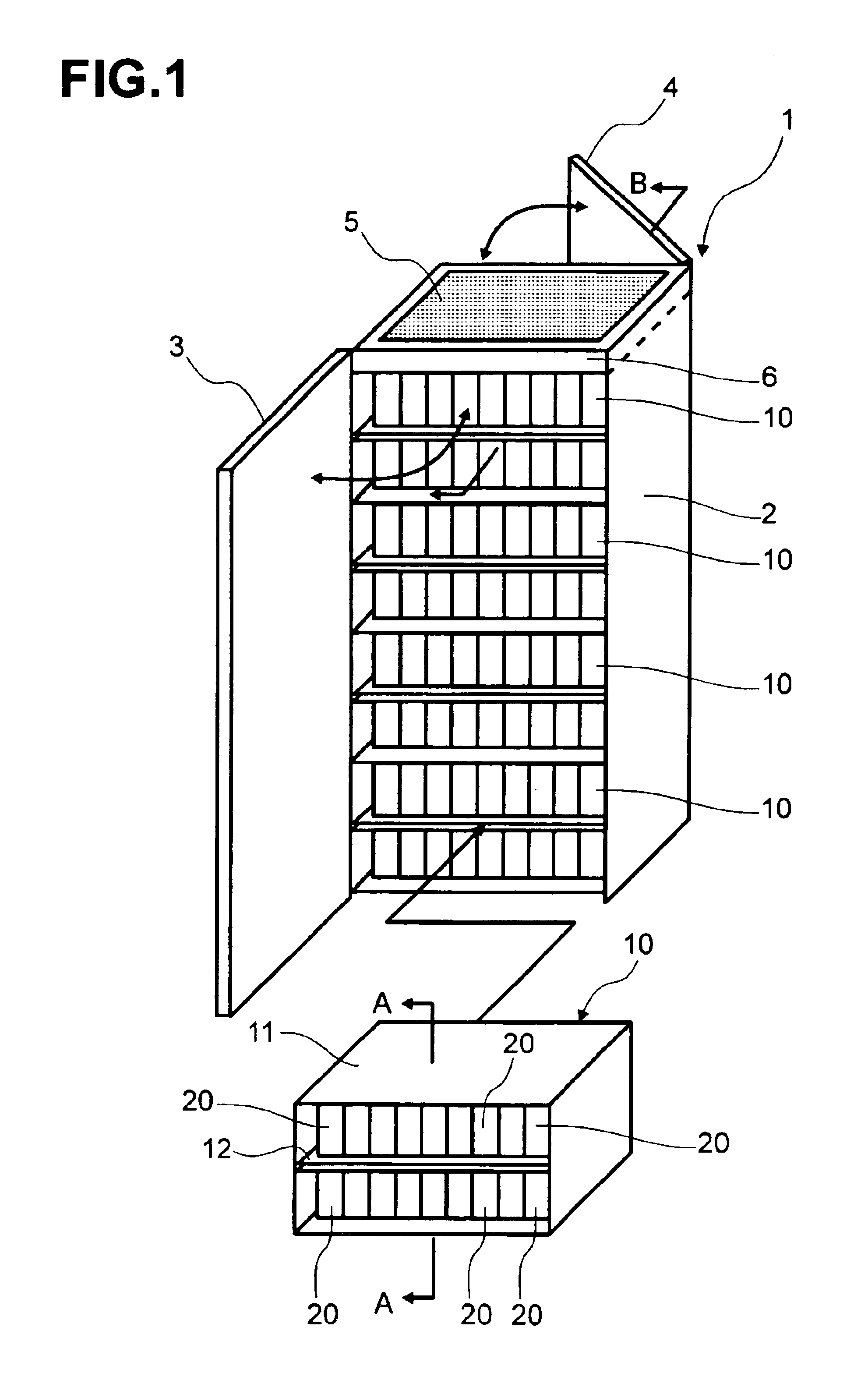

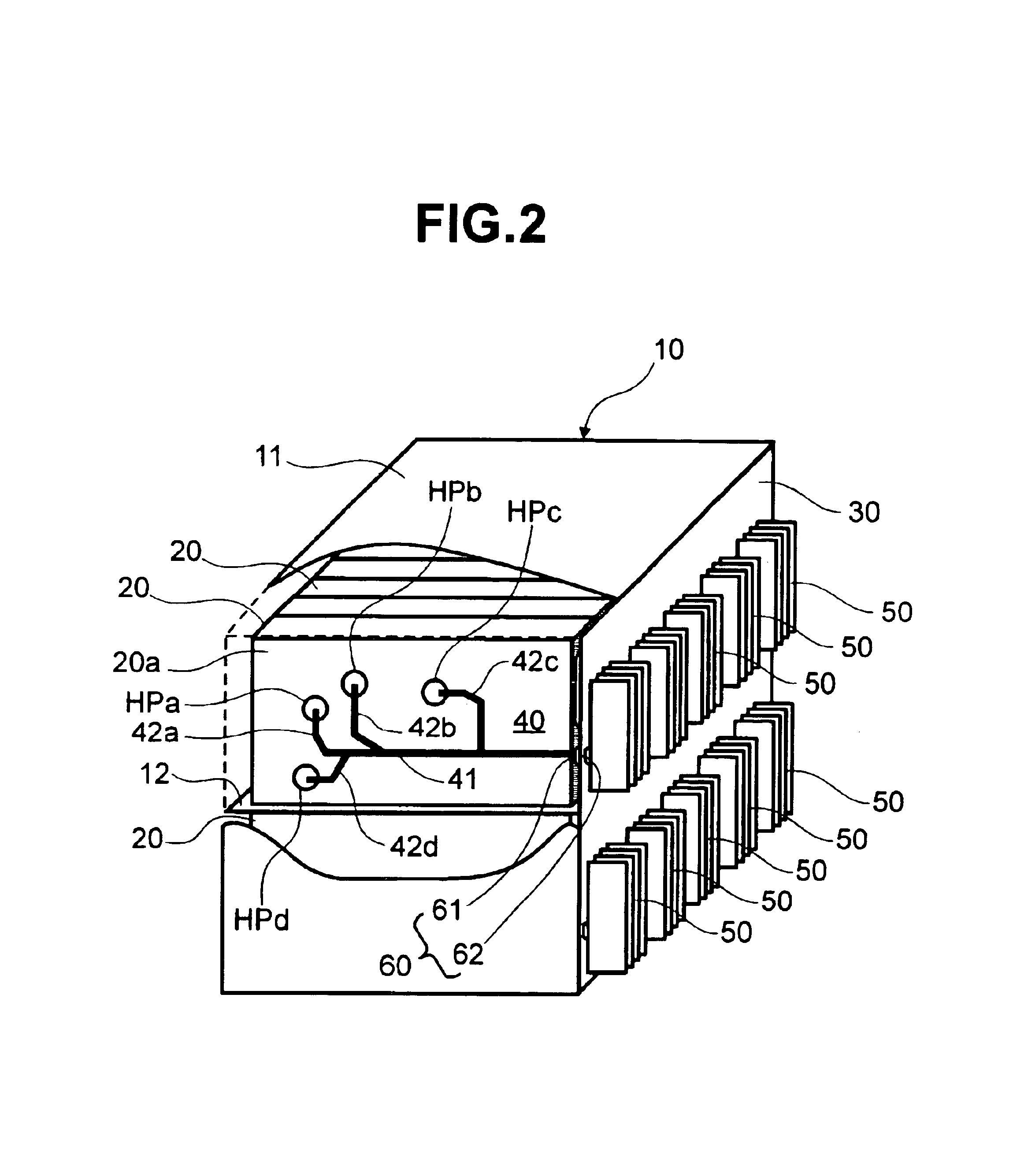

Cooling structure for disk storage device

ActiveUS6927980B2Increase freedomImprove cooling effectReducing temperature influence on carrierDomestic cooling apparatusEngineeringSize reduction

A disk drive box 10 accommodates a plurality of disk drives 20 within a case 11. A side face of each of the drives 20 is provided with a heat-absorbing part 40 including a heat pipe, corresponding to heat producing area HP. The heat taken away by the heat-absorbing part 40 is transmitted to a heat sink 50 of the rear of a backboard 30 via a heat connector 60. The heat sink 50 is cooled by cooling air flowing through an air duct 7. By cooling the drive 20 with the heat pipe, clearances between the drives 20 can be substantially eliminated, and it is made unnecessary to form an opening for air cooling in the backboard 30. Thus, size reduction is possible, and it is possible to increase the degree of freedom for a wiring pattern formed on the backboard 30.

Owner:GOOGLE LLC

Computer rack heat extraction device

InactiveUS6412292B2More revenueExcessive coolingDucting arrangementsDigital data processing detailsAppliance componentEngineering

An air conditioning cooling apparatus and method which includes the steps of supplying cooling air generated from a cooling apparatus into an air passageway formed below a floor; guiding the cooling air within the air passageway into an equipment assembly disposed on the floor through an opening located in the floor; communicating the cooling air introduced into the equipment assembly into a plenum and introducing the air released from within the equipment into the plenum and communicating the released air through the cooling apparatus for cooling the released air. The method permits temperature differential between the air supplied to the air passageway and the air introduced into the plenum from the equipment assembly to be 45.degree. F. to substantially 40.degree. F. so as to reduce the power necessary for operating on the fan of the blowing apparatus. The equipment assembly utilizes an air flow control mechanism so as to substantially evenly distribute cooling air to the equipment.

Owner:EATON INTELLIGENT POWER LIMITED

Light emitting apparatus

The present invention provides a method and apparatus for using light emitting diodes for curing and various solid state lighting applications. The method includes a novel method for cooling the light emitting diodes and mounting the same on heat pipe in a manner which delivers ultra high power in UV, visible and IR regions. Furthermore, the unique LED packaging technology of the present invention utilizes heat pipes that perform very efficiently in very compact space. Much more closely spaced LEDs operating at higher power levels and brightness are possible because the thermal energy is transported in an axial direction down the heat pipe and away from the light-emitting direction rather than a radial direction in nearly the same plane as the “p-n” junction.

Owner:KONINK PHILIPS ELECTRONICS NV

Heat sink structures, lighting elements and lamps incorporating same, and methods of making same

ActiveUS20120268936A1Improve efficiencyGood indexLighting support devicesPoint-like light sourceFlexible circuitsEngineering

In some embodiments, a lighting element comprising at least first and second solid state light emitters, a first heat sink structure with a fold region between first and second heat sink regions, and at least one light emitter on each of the heat sink regions, and methods of making. In some embodiments, a lighting element, comprising plural heat sink regions on respective regions of a flexible circuit board, and plural light emitters on respective regions of the flexible circuit board, and methods of making. In some embodiments, heat sink structures comprising plural heat sink regions and a circuit board with plural regions, and lighting elements comprising them. In some embodiments, a heat sink structure, comprising plural heat sink regions and an internal flow guide structure, and lighting elements comprising same. Also, other lighting elements, lamps and heat sink structures.

Owner:IDEAL IND LIGHTING LLC

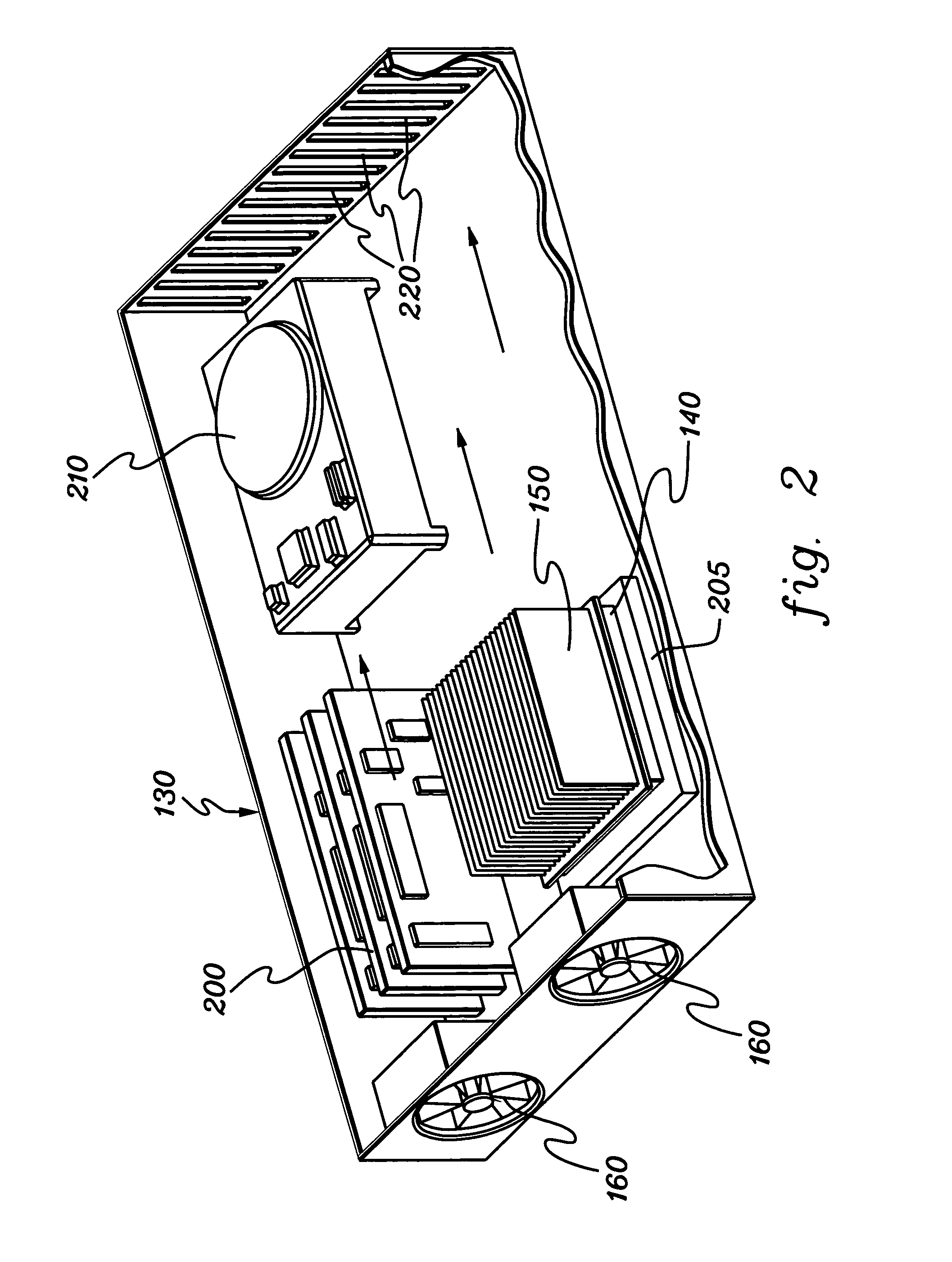

Apparatus and method for facilitating cooling of an electronics system

ActiveUS20090154096A1Overcomes shortcomingEnhanced advantageDigital data processing detailsCompression machines with non-reversible cycleElectronic systemsClosed loop

Apparatus and method are provided for facilitating air-cooling of an electronics system employing a vapor-compression heat exchange system, and front and back covers. An evaporator housing of the heat exchange system is mounted to a system housing of the electronics system and extends at least partially between air inlet and outlet sides of the system housing. The evaporator housing includes air inlet and outlet openings, and an evaporator. The front cover is mounted to the system or evaporator housing adjacent to the air inlet side or air outlet opening, and the back cover is mounted to the system or evaporator housing adjacent to the air outlet side or air inlet opening. Together, the system housing, back cover, evaporator housing and front cover define a closed loop airflow path passing through the system housing and evaporator housing, with the vapor-compression heat exchange system cooling air circulating therethrough.

Owner:IBM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com