Patents

Literature

11504 results about "Water circulation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

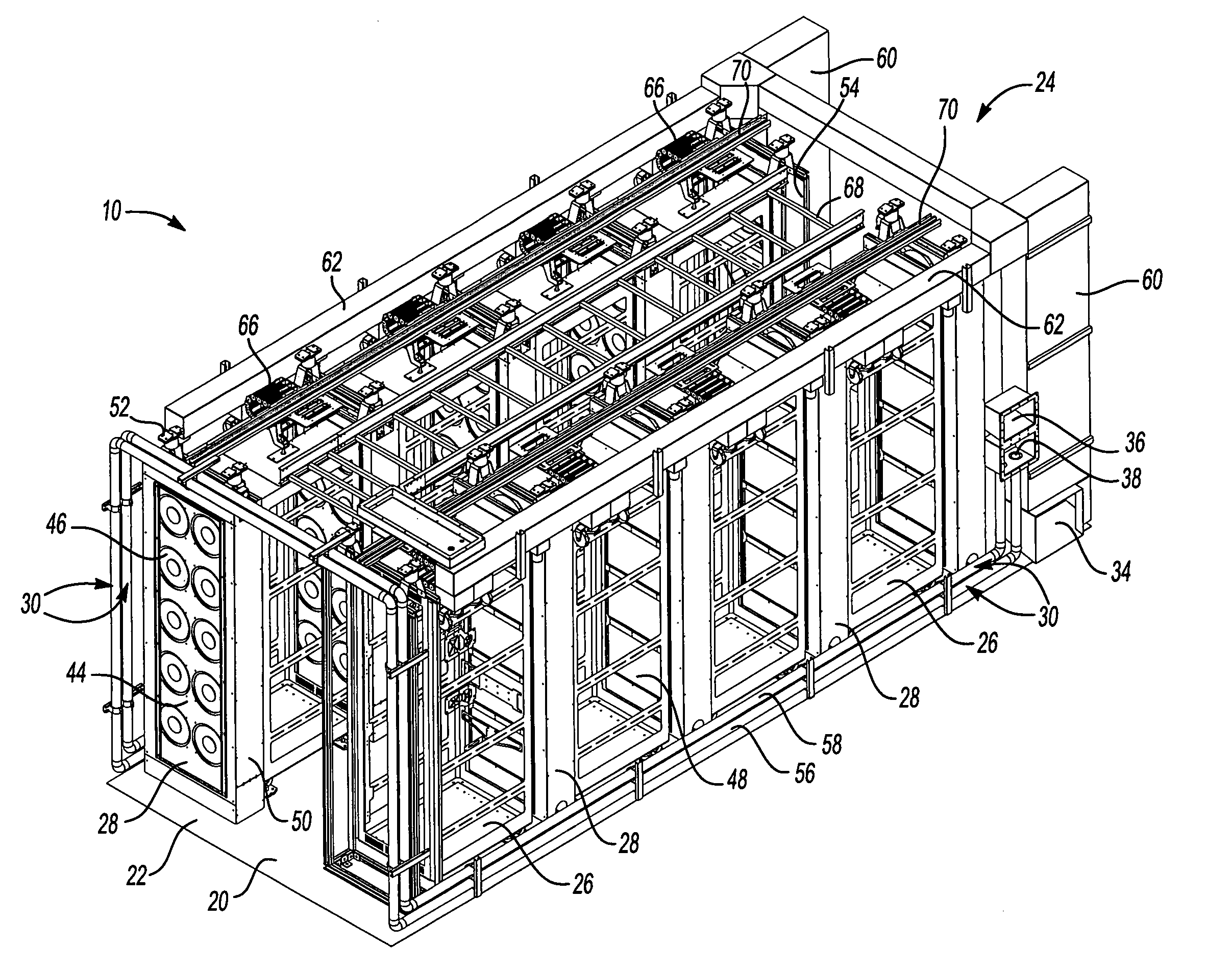

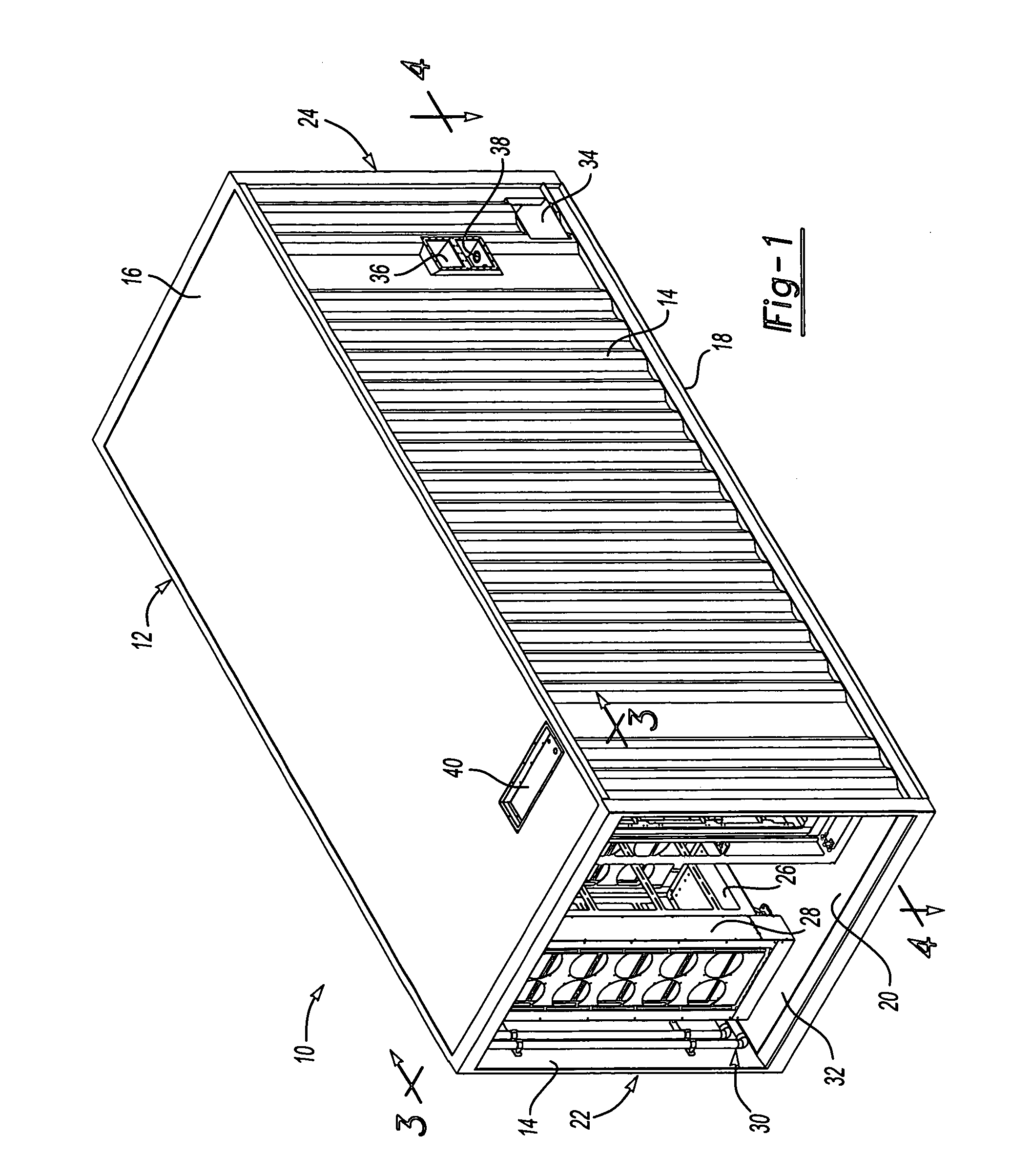

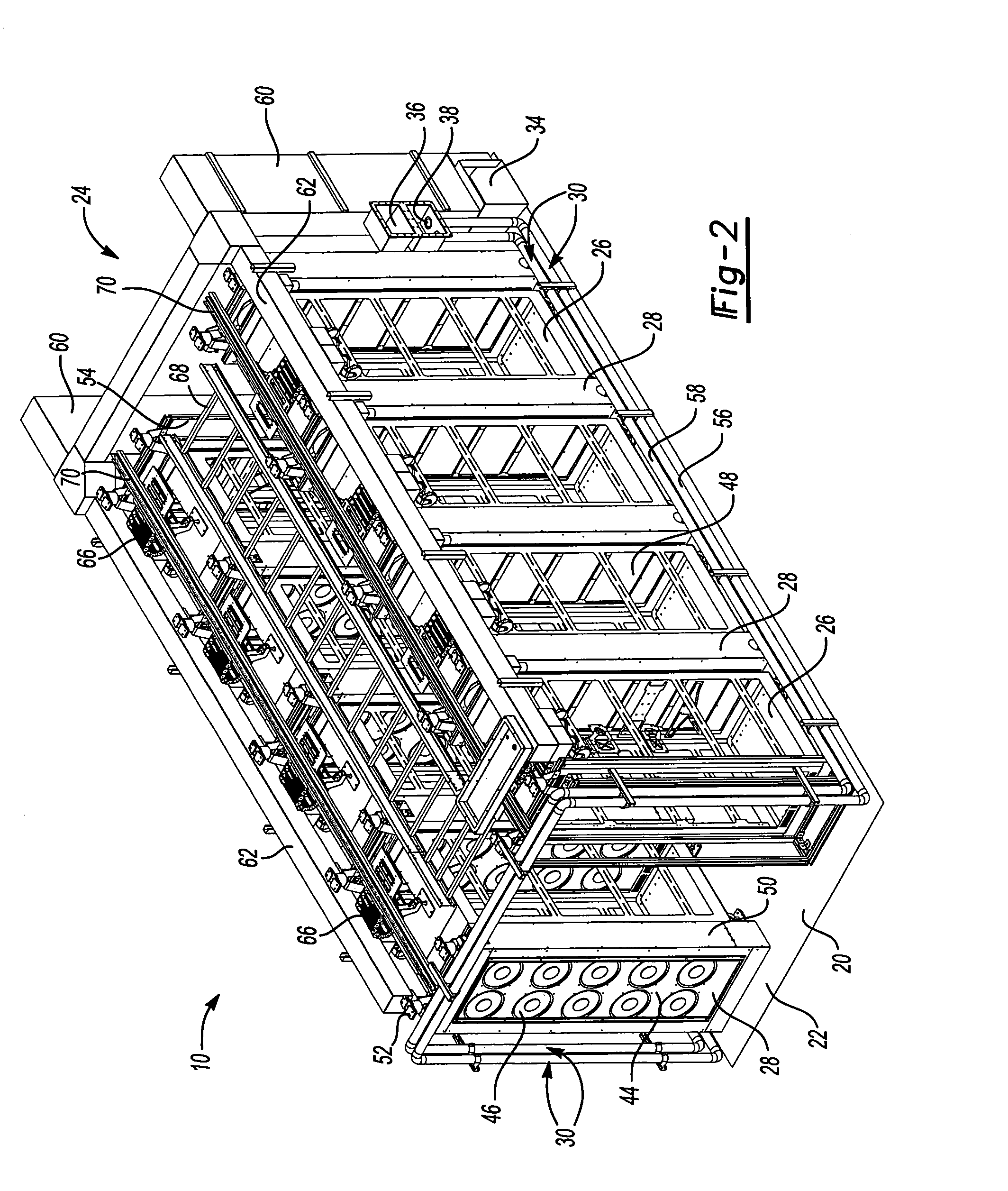

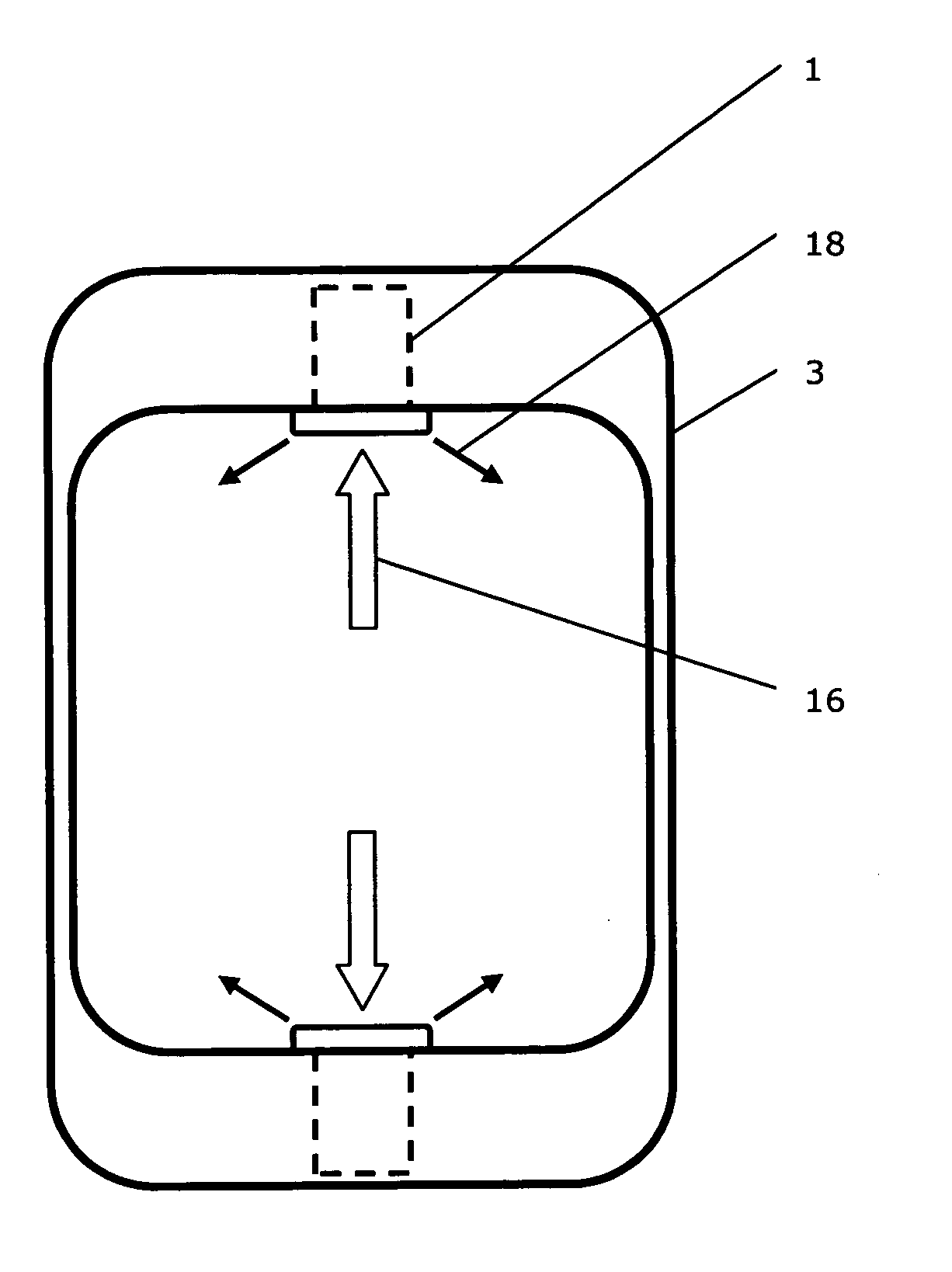

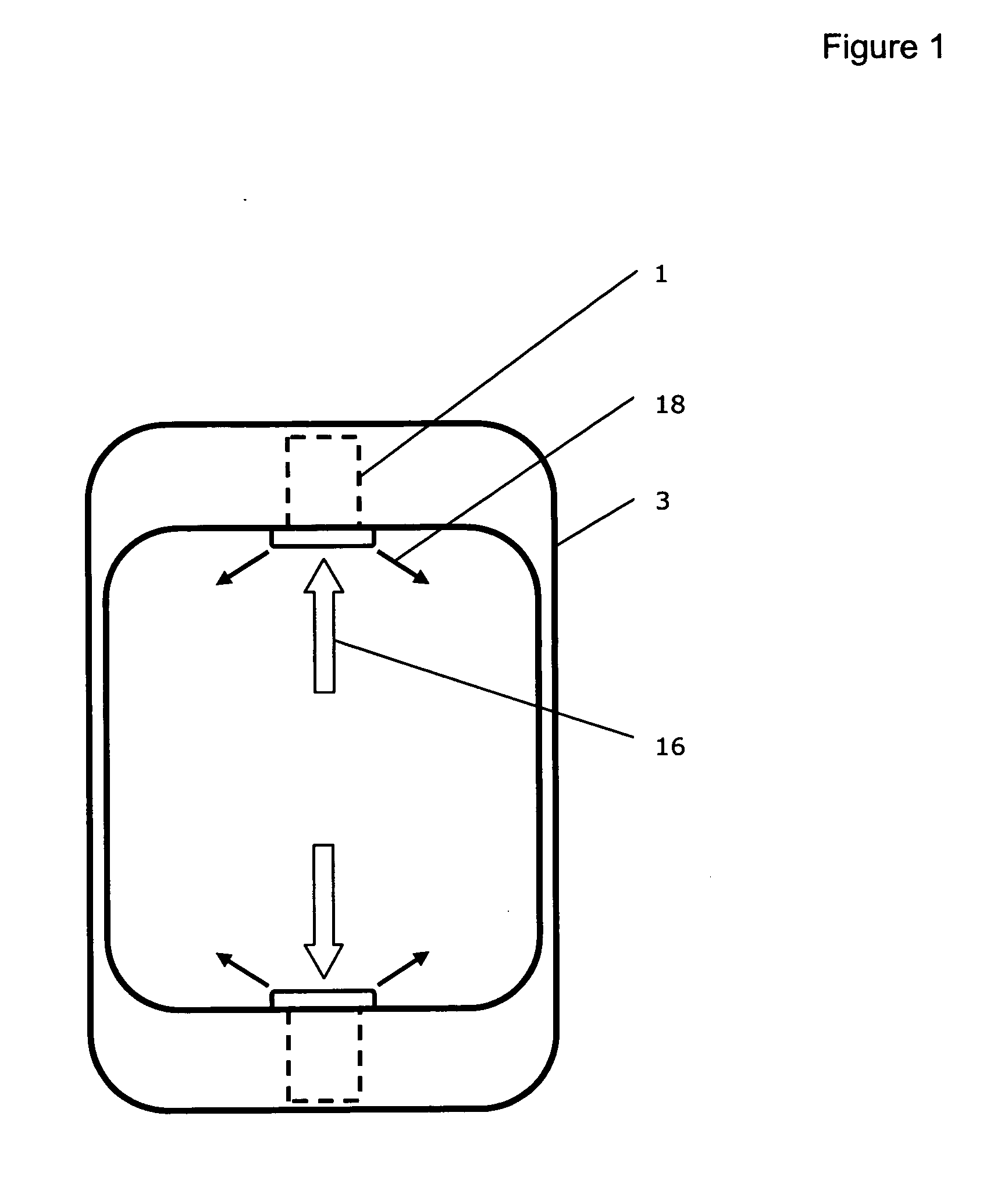

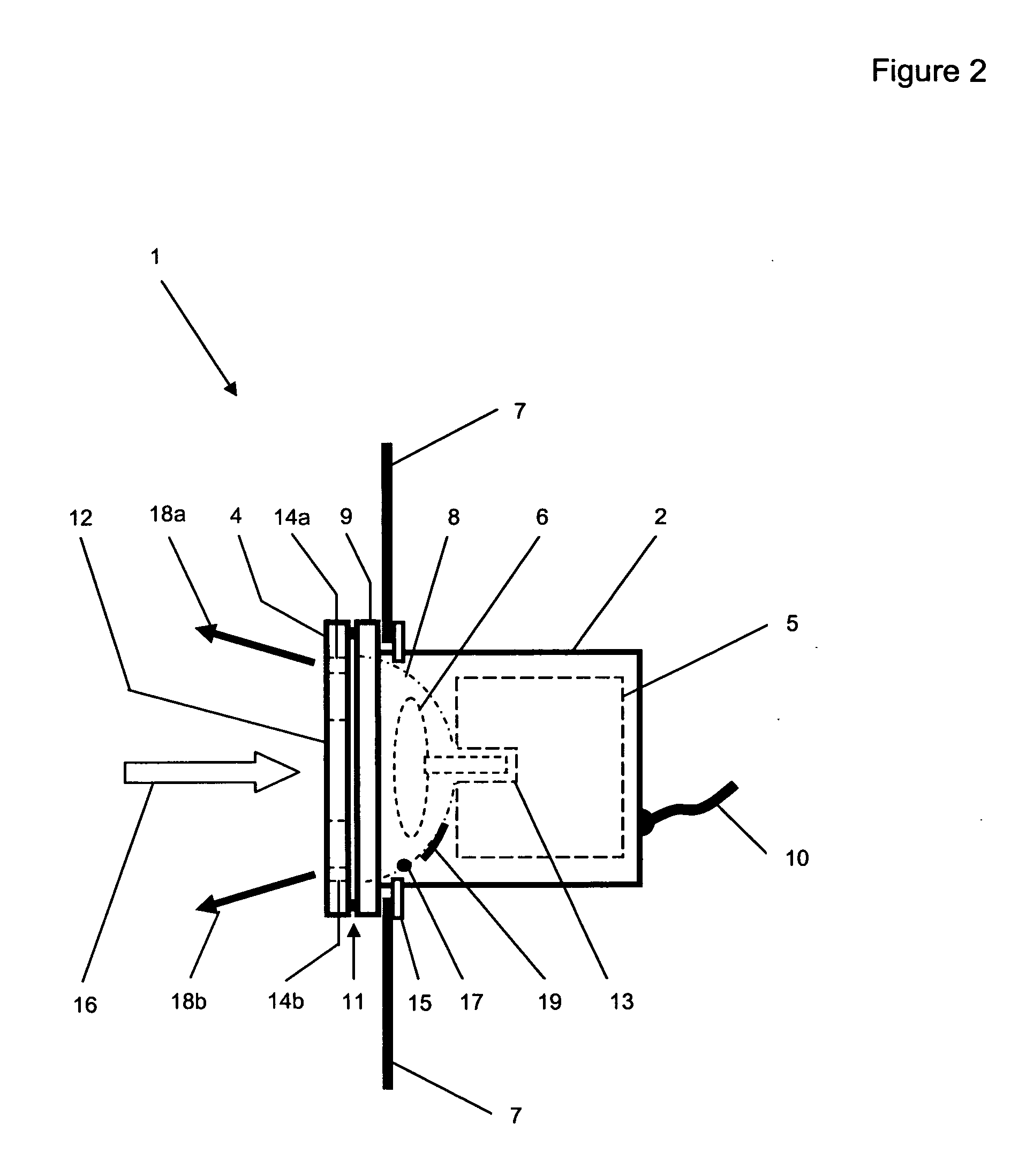

Balanced chilled fluid cooling system for a data center in a shipping container

ActiveUS7511960B2Improve heat transfer performanceServersDigital data processing detailsData centerWater source

A movable data center is disclosed that comprises a movable enclosure having partitions that define a closed-loop air flow path. A plurality of fans and a plurality of data processing modules are disposed in the air flow path. A pipe network is disposed within the enclosure that includes a chilled water supply pipe that receives chilled water from a source of chilled water. A water return pipe is provided that circulates water back to the source of chilled water. A plurality of heat exchange modules is installed in the enclosure in the air flow path. The heat exchange modules receive the chilled water from the chilled water supply pipe. Each of the heat exchange modules has a water circulation tube that connects the chilled water supply pipe to the return water pipe.

Owner:ORACLE INT CORP

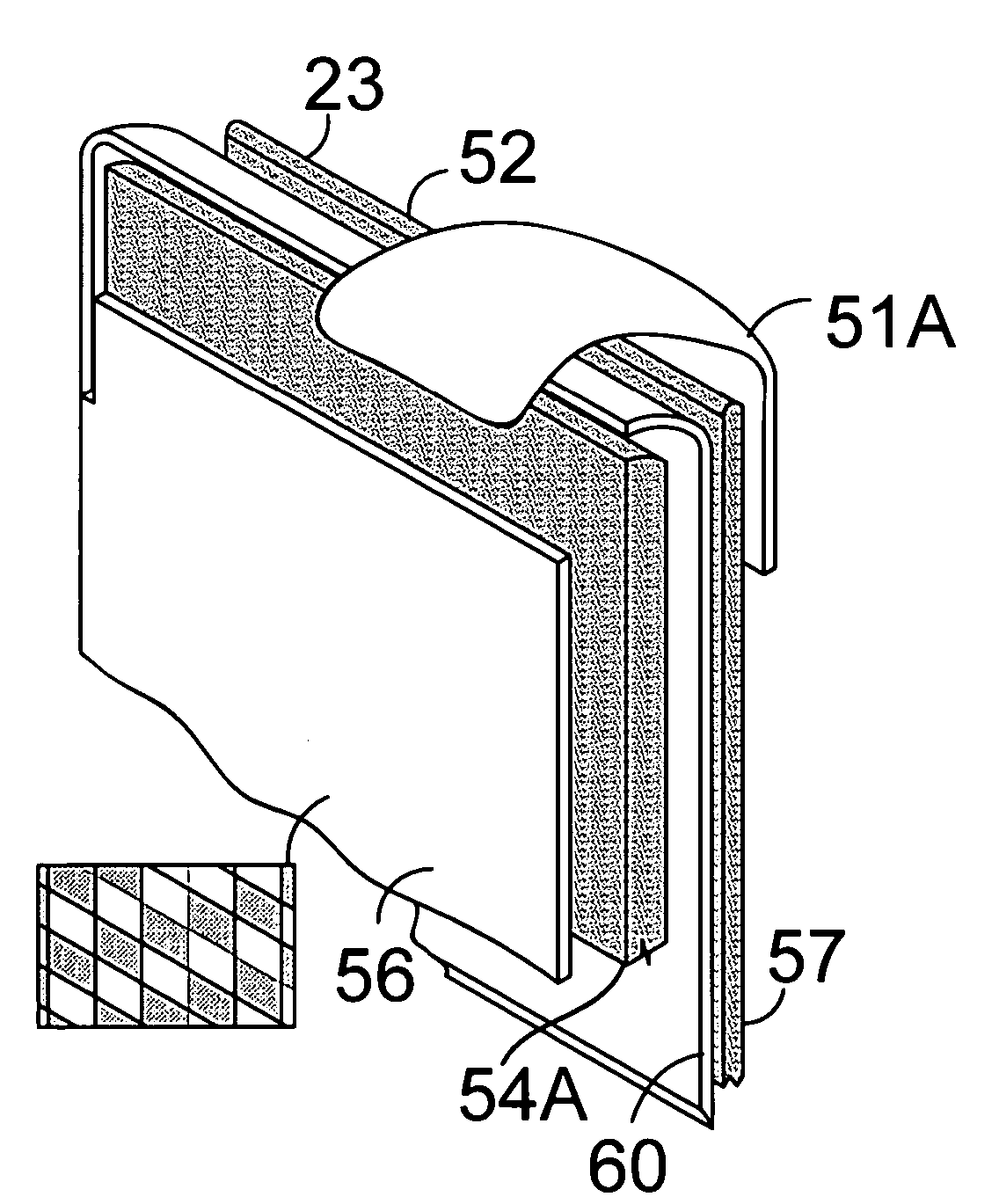

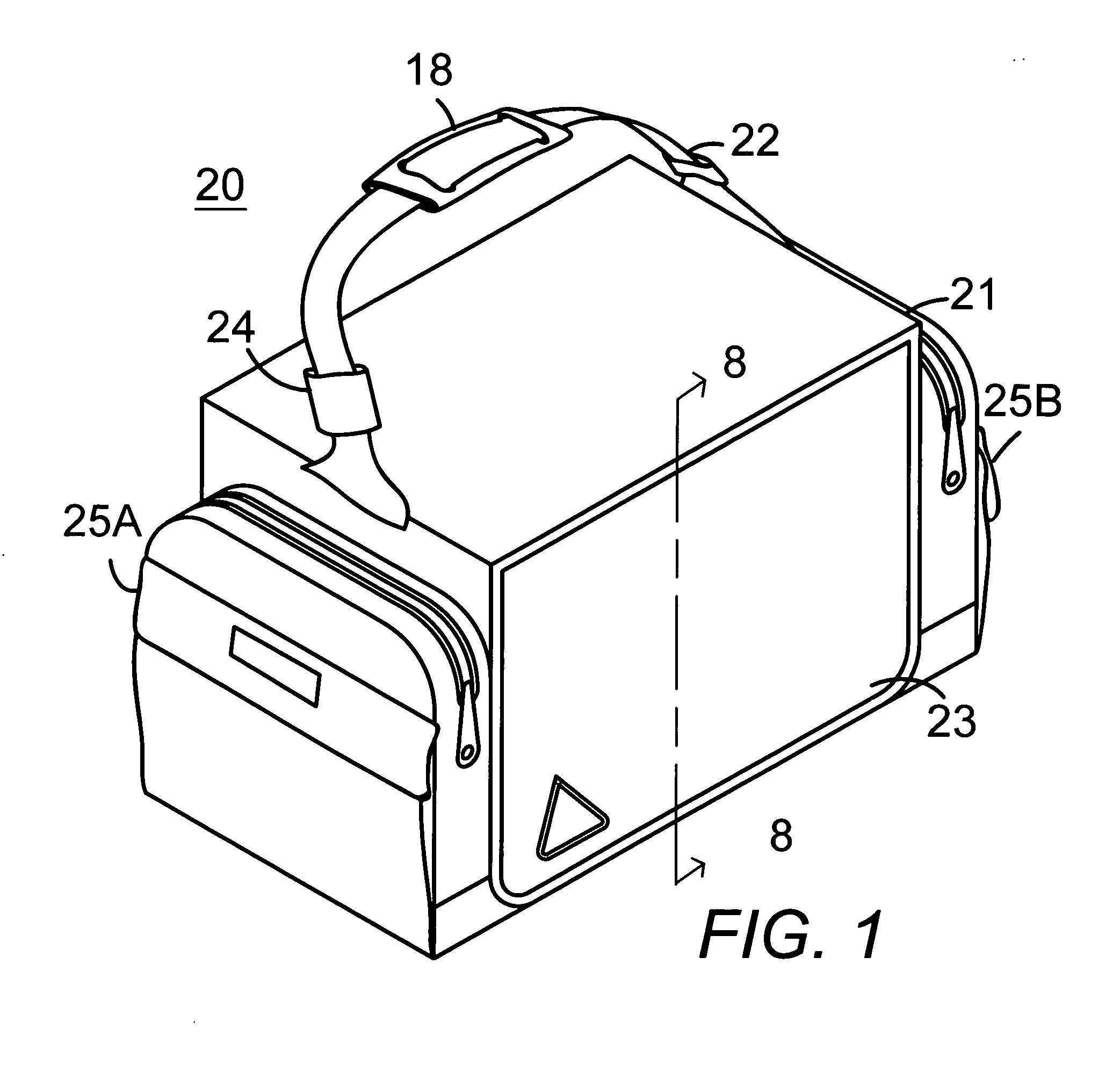

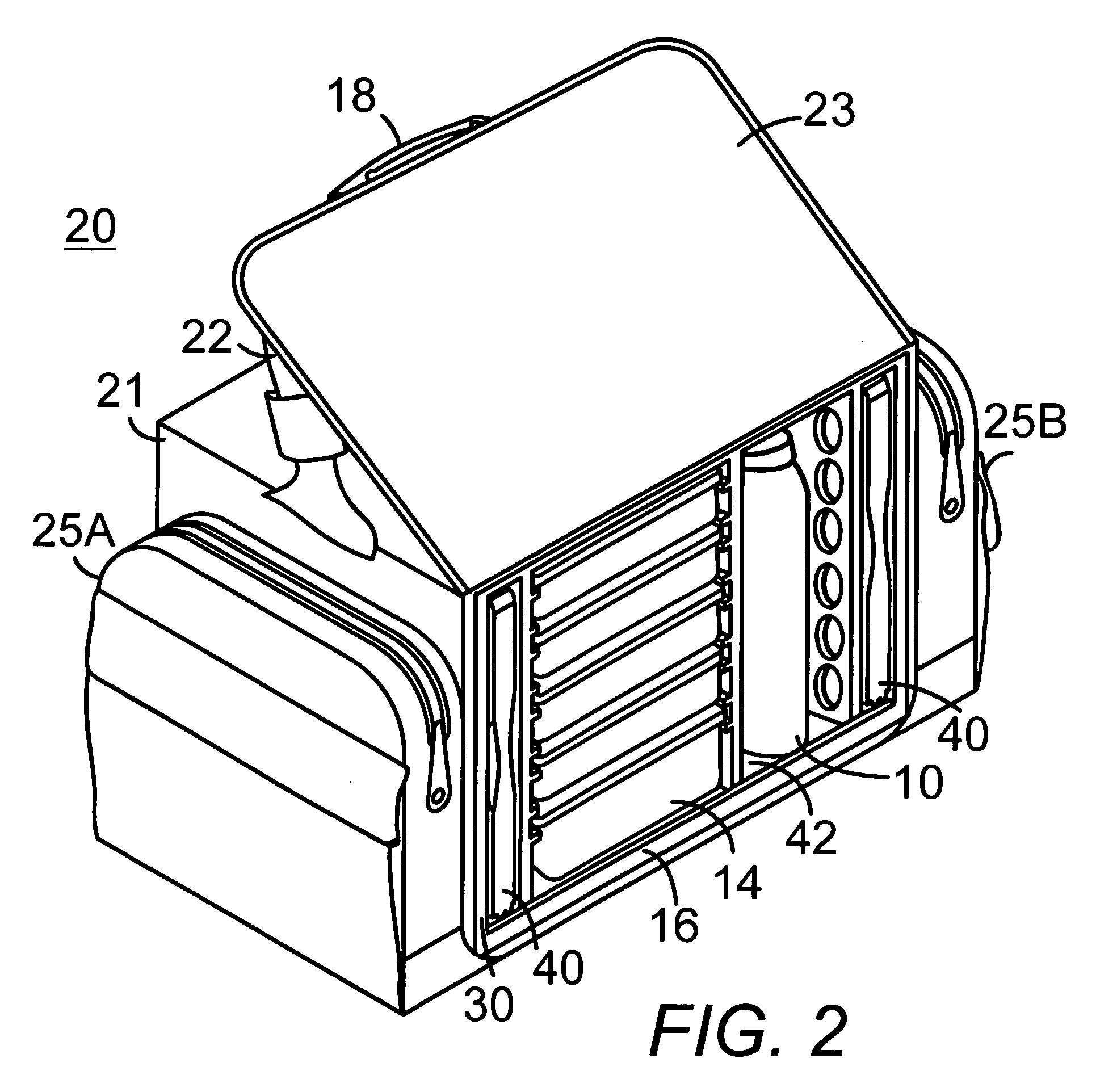

Portable soft shell cooler with compartmented rack for individual meal and beverage containers

InactiveUS7313927B2Easy to manageImprove cooling effectLighting and heating apparatusOther accessoriesWater circulationEngineering

A soft thermally insulated padded shell houses a rigid rack with a series of vertical walls forming compartments. One pair of walls has a series of mating horizontal tracks to receive slide-in meal containers in a spaced vertical array. Narrow side compartments house coolant containers. Another compartment houses beverage containers. Upper holes in the walls admit air flow between compartments. A vertical lip on the open front edge of the bottom of the rack forms a condensation basin beneath the elevated meal containers. An elevated floor section insertable in the beverage compartment serves as a beverage compartment condensation basin. Holes through the bottoms of the walls allow condensation water circulation between compartments.

Owner:BARKER GAREN S

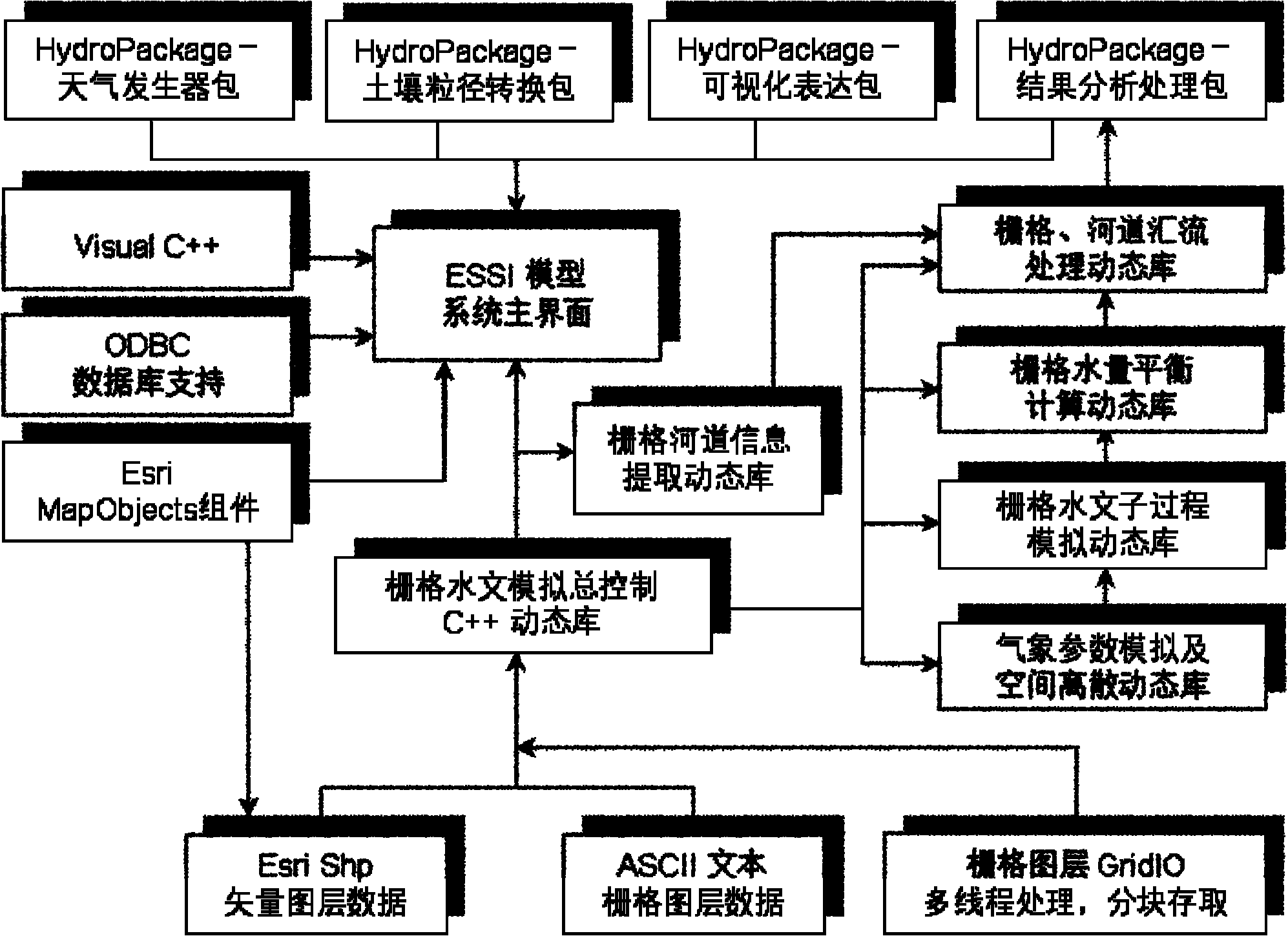

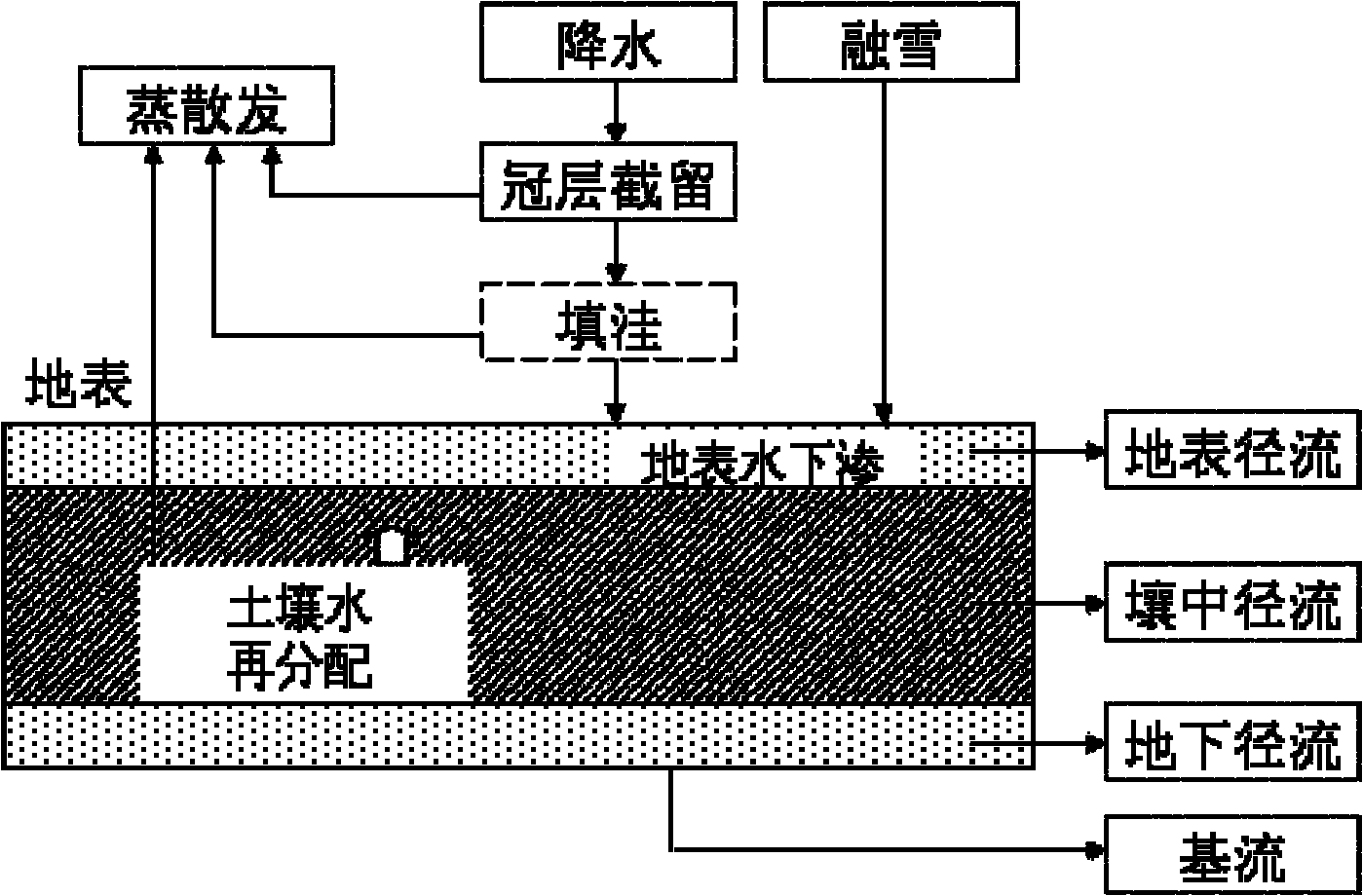

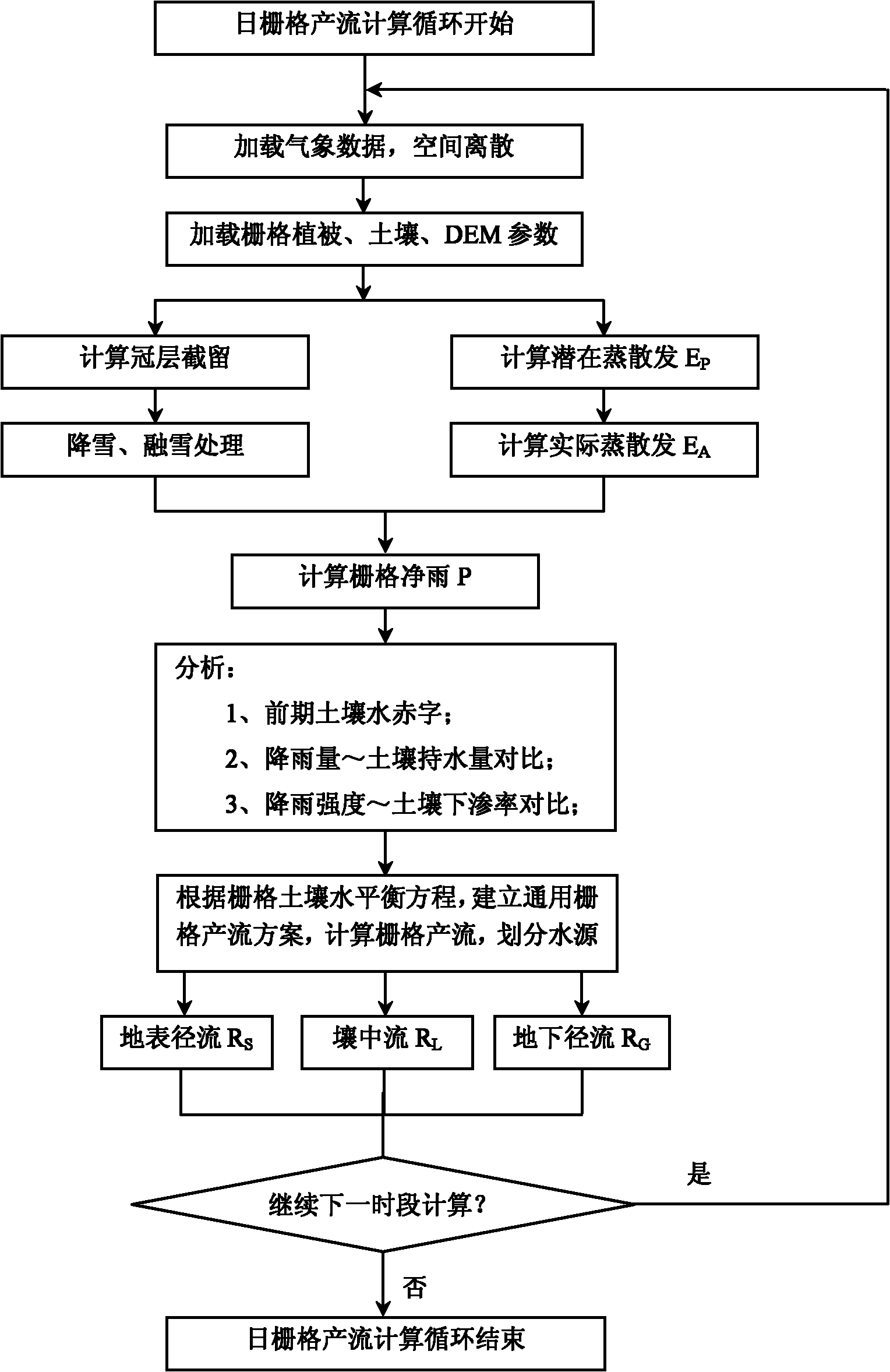

Design method for distributed hydrological model by using grid as analog unit

InactiveCN102034001AImprove scalabilityImprove execution efficiencyClimate change adaptationSpecial data processing applicationsAridRainfall runoff

The invention discloses a design method for a distributed hydrological model by using a grid as an analog unit, which is called as ESSI for short. The design method comprises the following steps of: obtainment of a distributed parameter: converting vector data into grid data; generalization of a watershed hydrological process: establishing a universal runoff generating type for the grid; design of a runoff generating process: respectively computing the water-quantity distributing condition of each part according to different prior-period soil water conditions; design of a flow collecting process: respectively designing a Muskingum-Cunge method, a delay algorithm and a riverway segmentation Muskingum method for the flow collecting process computation of the model under different conditions; and model development and integration. The invention not only can finish the watershed hydrological process simulation at an arid region and a humid region, but also can realize the short-term flood forecast and the long-term rainfall-runoff process simulation and prediction of a watershed by using modularization and integration ideas as means, thereby providing scientific reference bases for deeply learning about the physical mechanism of water circulation by people, reducing the drought and water-logging disasters and reasonably developing and utilizing water resources.

Owner:NANJING UNIV

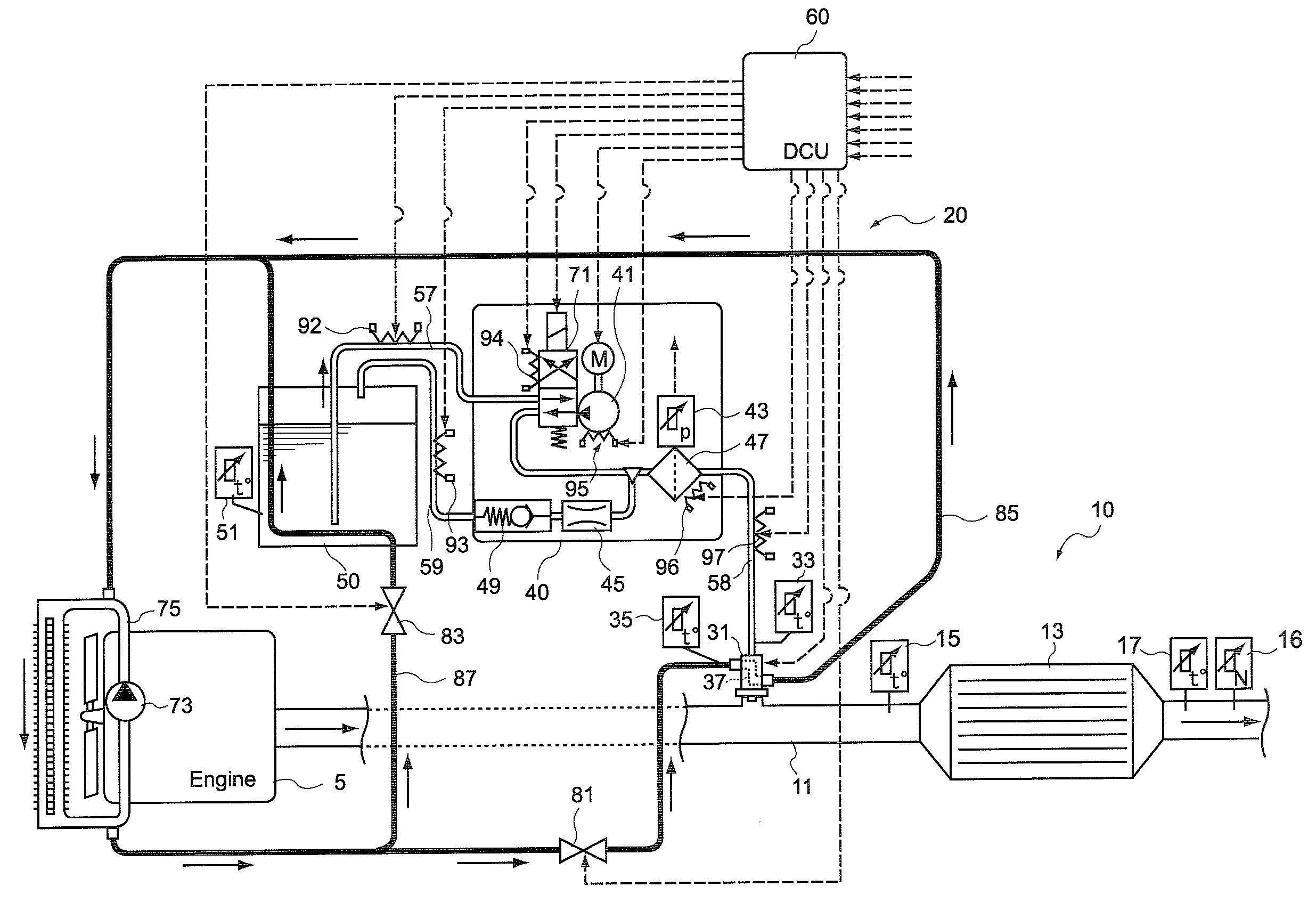

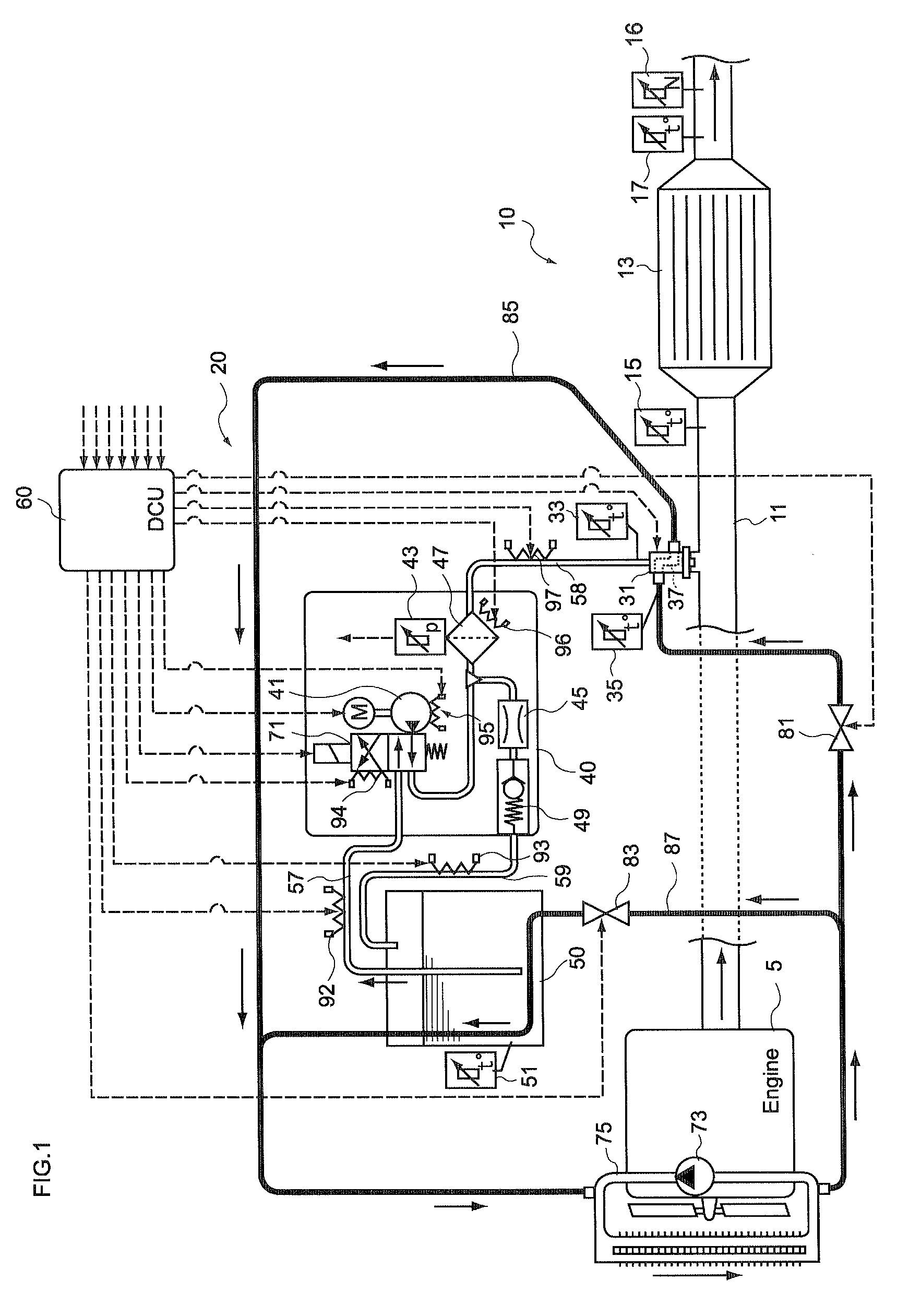

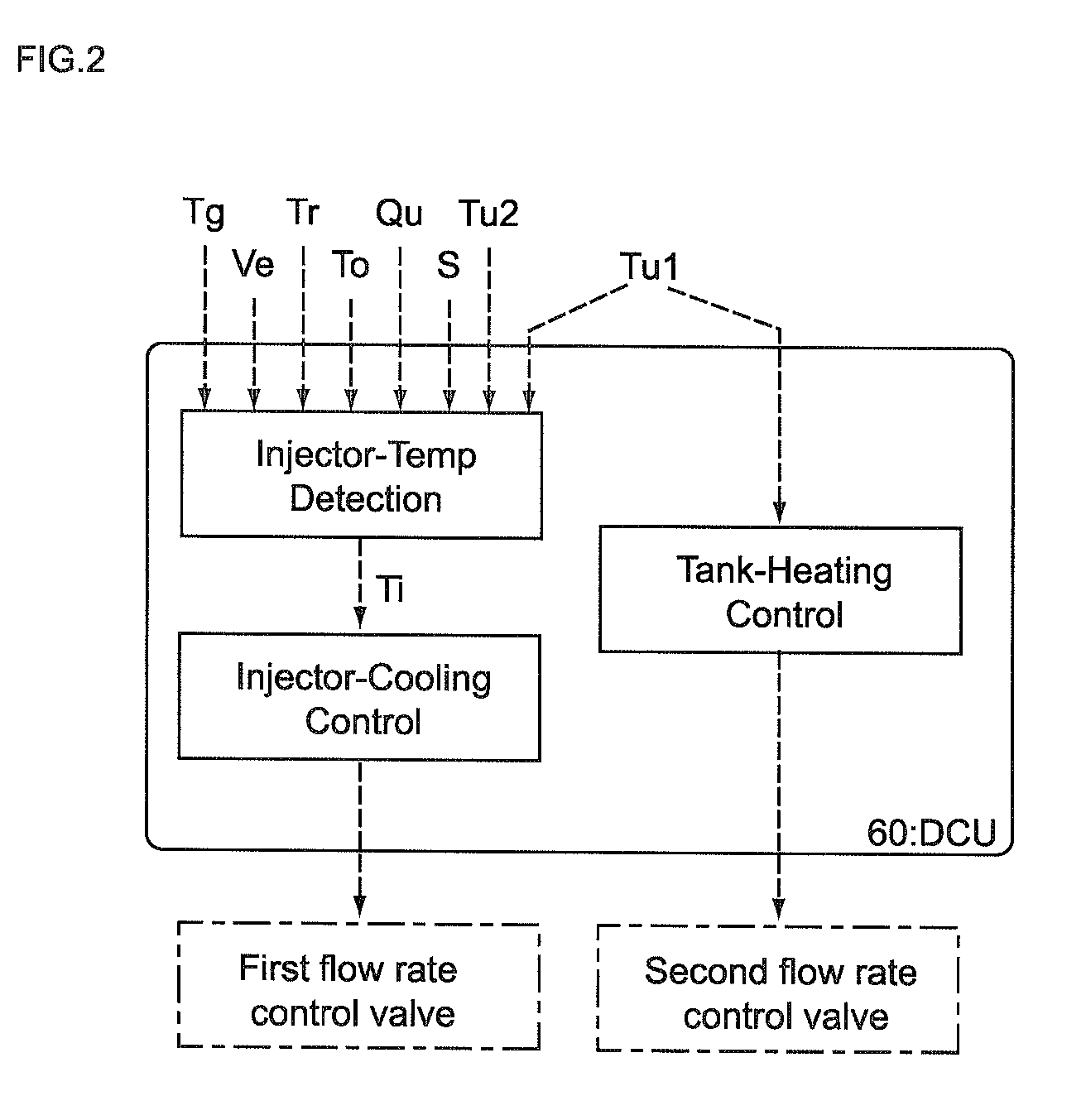

Control unit and control method for reductant supply device

InactiveUS20100242439A1Prevent overcoolingImprove cooling effectLiquid coolingInternal combustion piston enginesEngineeringWater circulation

There are provided a reductant supply device and a control method for the reductant supply device, which can prevent heat damage of a reductant injection valve, and also prevent crystallization of urea solution due to excessive cooling of the solution reductant.The reductant supply device which is used in an exhaust gas purification device that injects and supplies, as a reductant, a urea solution to an exhaust gas upstream side of a reduction catalyst disposed in an exhaust gas passage of an internal combustion engine, and that reduces and purifies nitrogen oxides contained in exhaust gas using the reduction catalyst, the reductant supply device having a reductant injection valve that is fixed to an exhaust pipe on the exhaust gas upstream side of the reduction catalyst, includes: a cooling water circulation passage that circulates at least part of cooling water of the internal combustion engine to cool the reductant injection valve; flow rate control means for adjusting a flow rate of cooling water flowing through the cooling water circulation passage; temperature detection means for detecting a temperature of the reductant injection valve; and control means for controlling the flow rate control means based on the temperature of the reductant injection valve.

Owner:BOSCH CORP

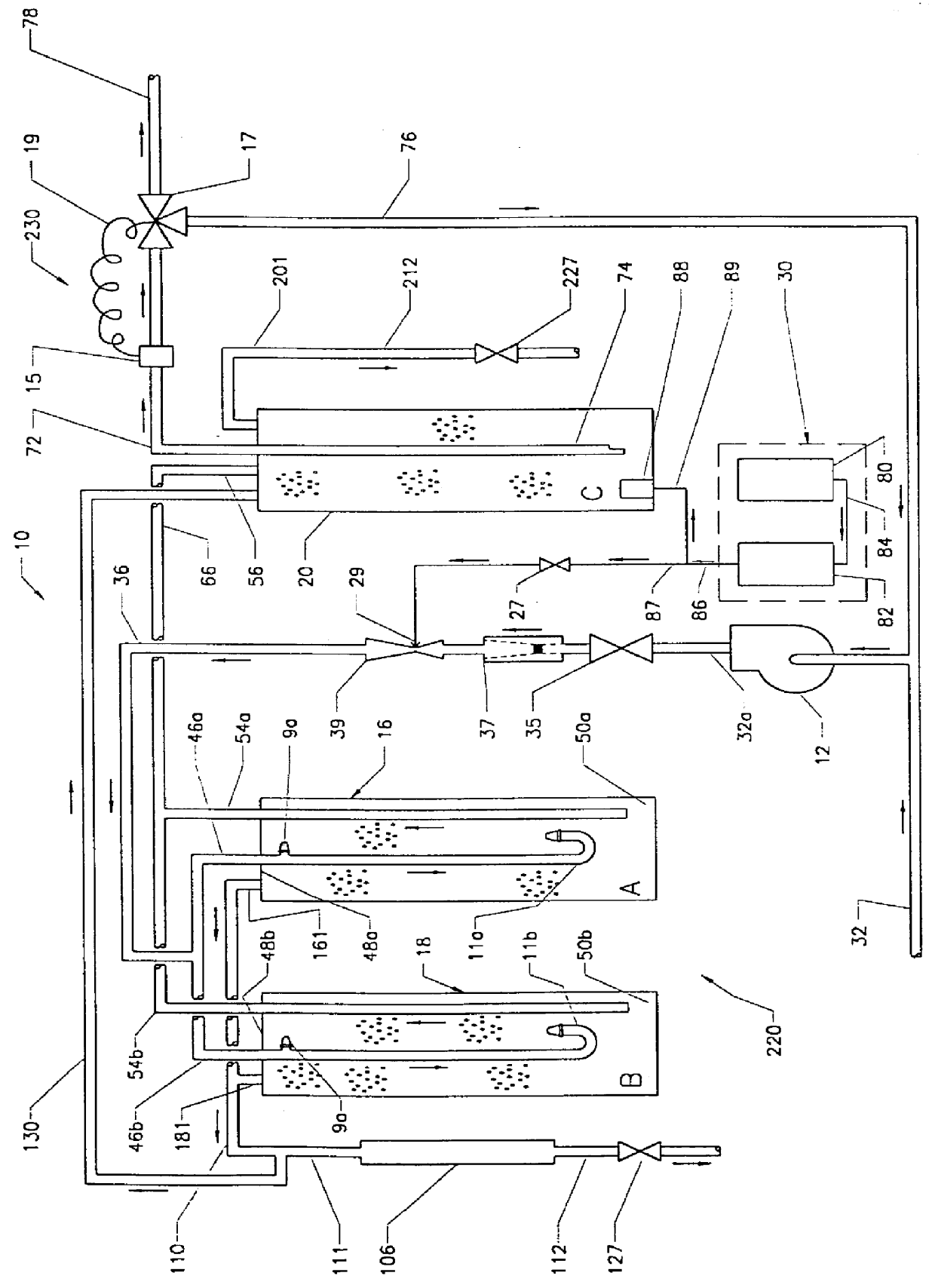

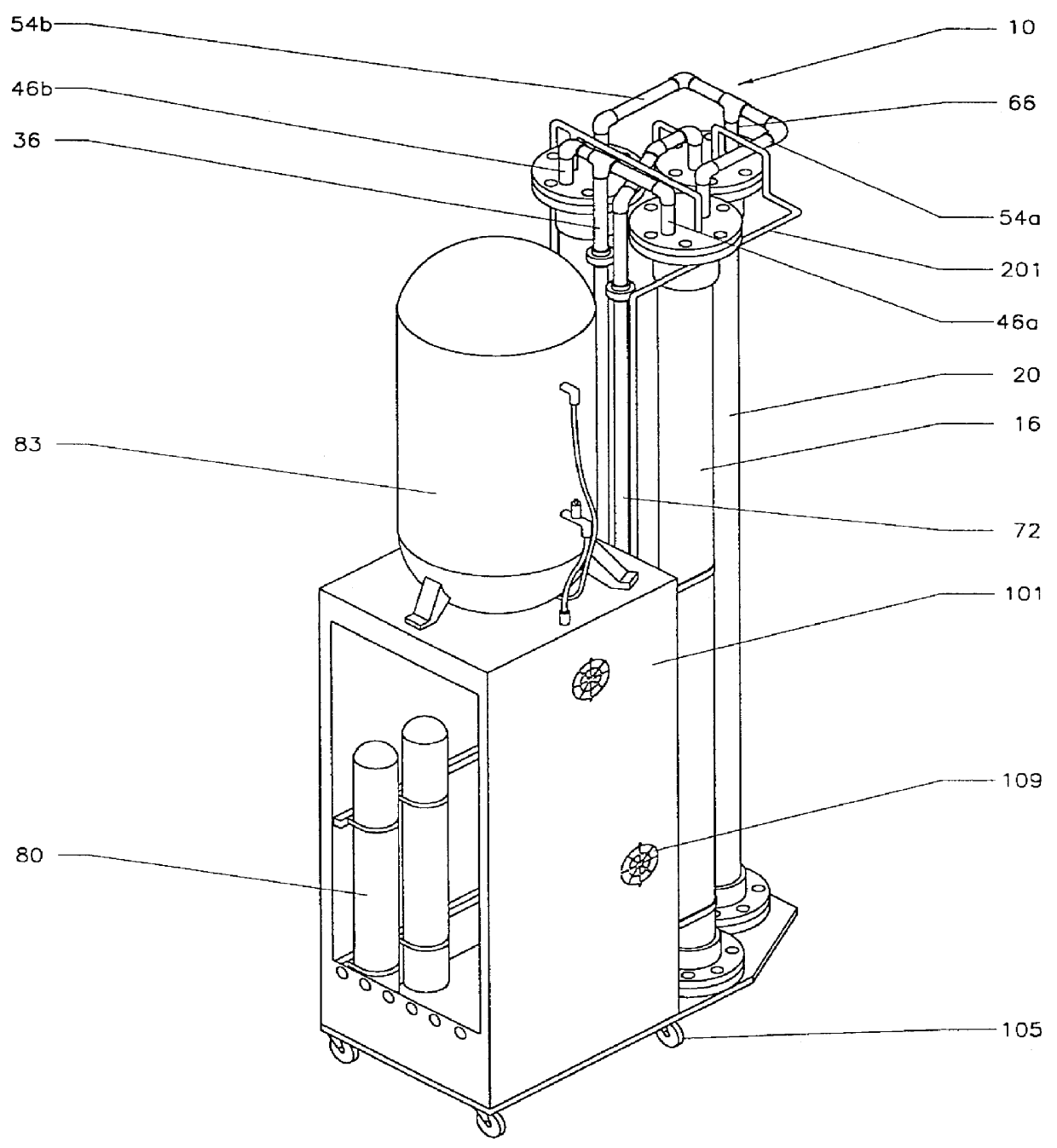

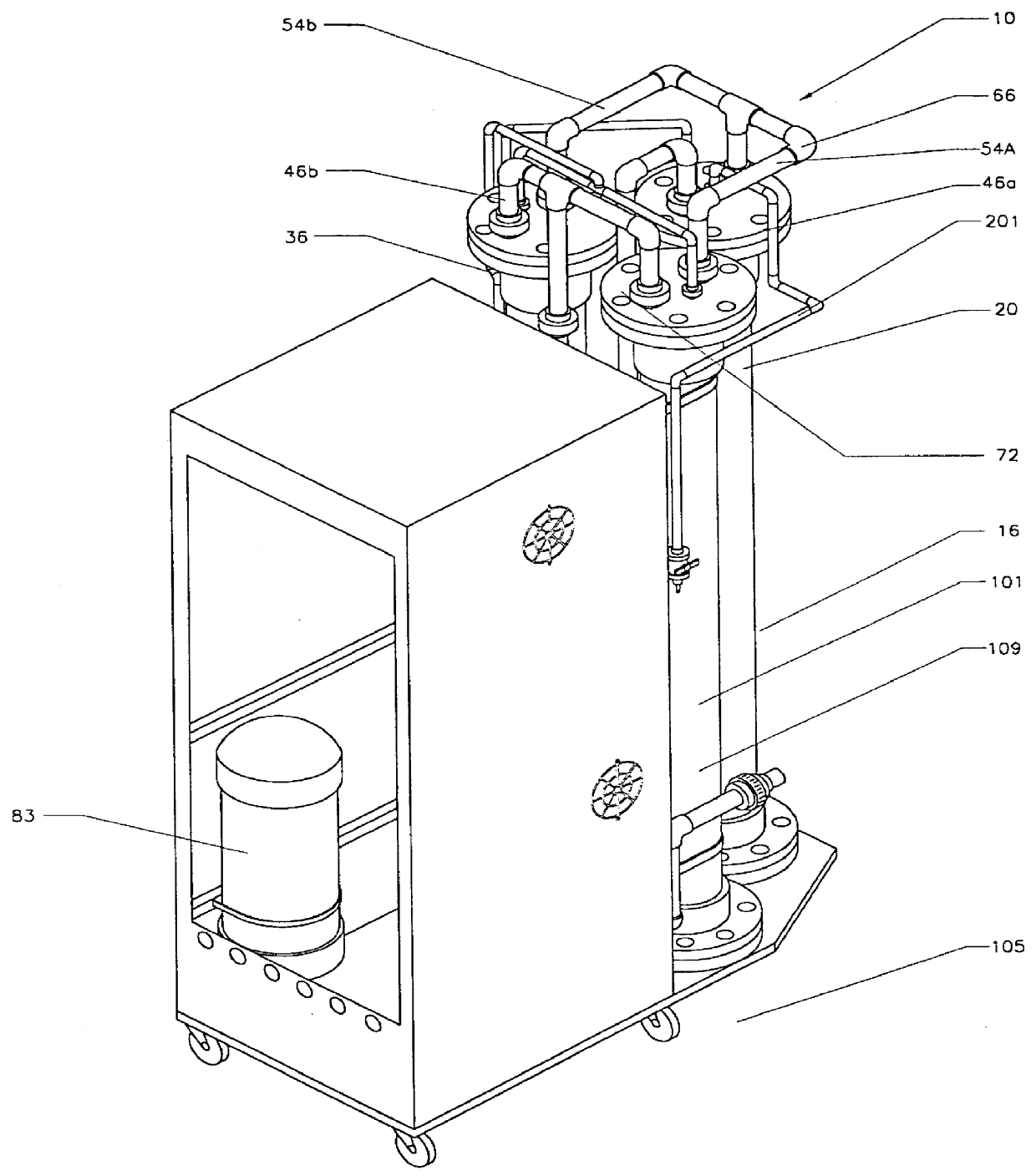

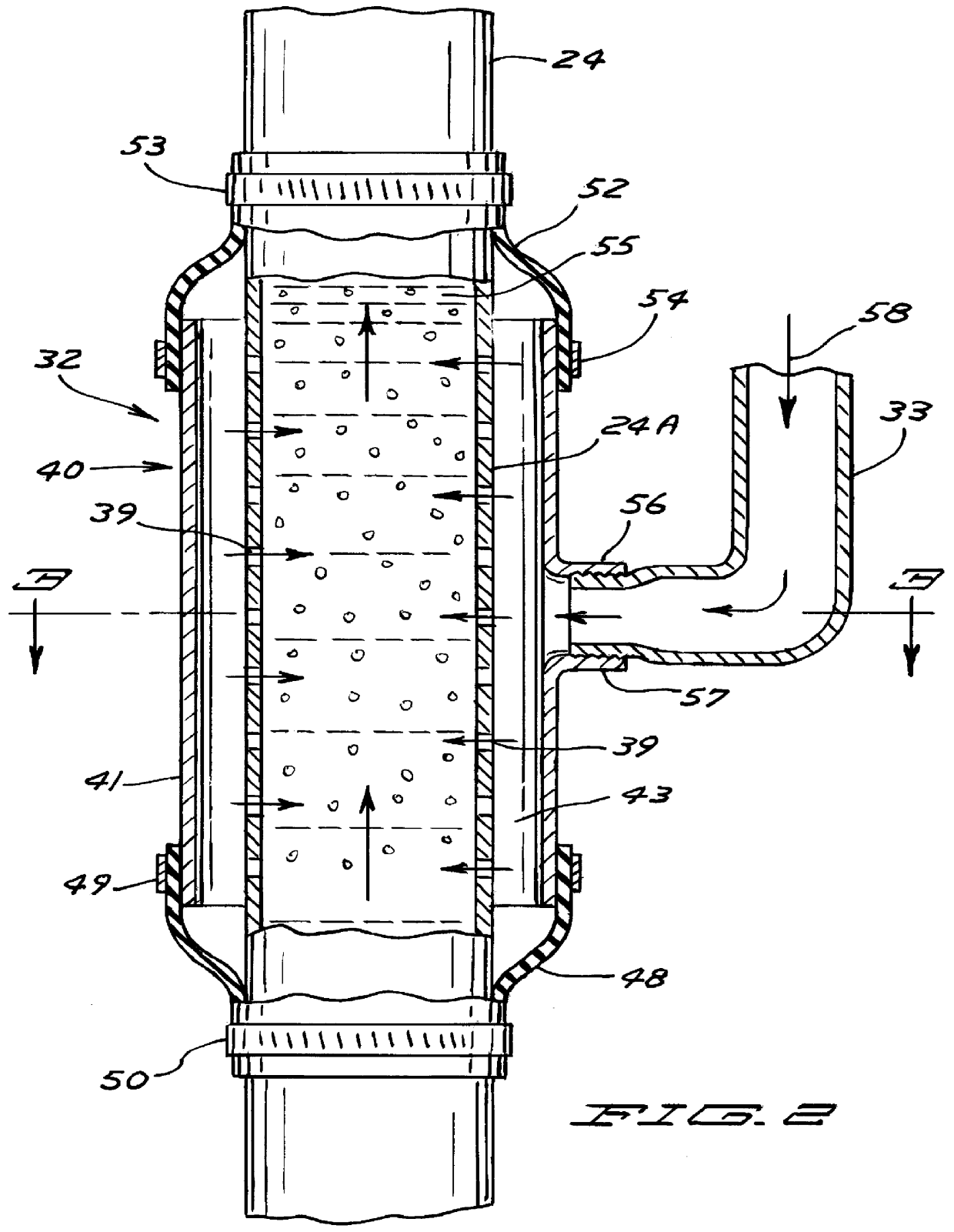

Apparatus for the purification of water and method therefor

InactiveUS6090294AComprehensive understandingSignificant utilityOther chemical processesIon-exchanger regenerationSolubilityGas phase

An apparatus and method for the purification of contaminated water whereby the contamination level of the wastewater is automatically monitored and treatment self-adjusted and continued until the desired level of purification is reached. Specifically, if upon treatment a pre-set purification level is not obtained a water recycle control means completely precludes the uptake of additional contaminated water and recycles wastewater within the apparatus until the desired level of purification is obtained. The present invention more particularly pertains to an efficient, turn key, economical, movable, automatic and compact apparatus and method for treating a fluid with ozone comprising multiple pressurized contact columns which are arranged in a hybrid parallel and series column configuration, which utilizes a unique water recycle control system and piping arrangement to improve the efficiency of the mass transfer of ozone into the water and increase its solubility by increasing the contact time between the water phase and the gas phase. The apparatus and method of the present invention has the further advantage that it requires minimal installation and may be used to fulfill the clean and safe water needs of any hotel, resort, restaurant, hospital, light industry, commercial business, apartment complex or small city.

Owner:AGRIMOND USA CORP

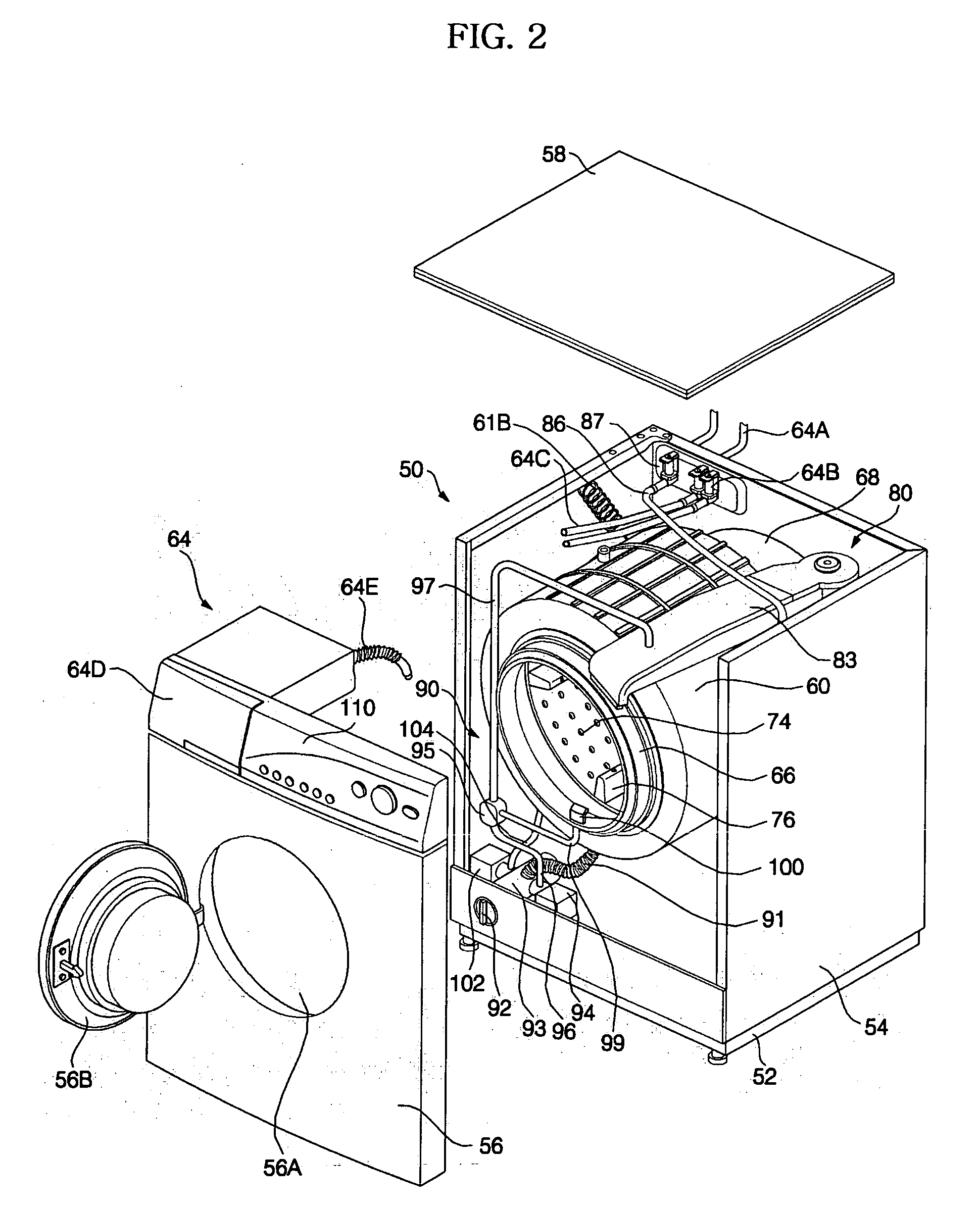

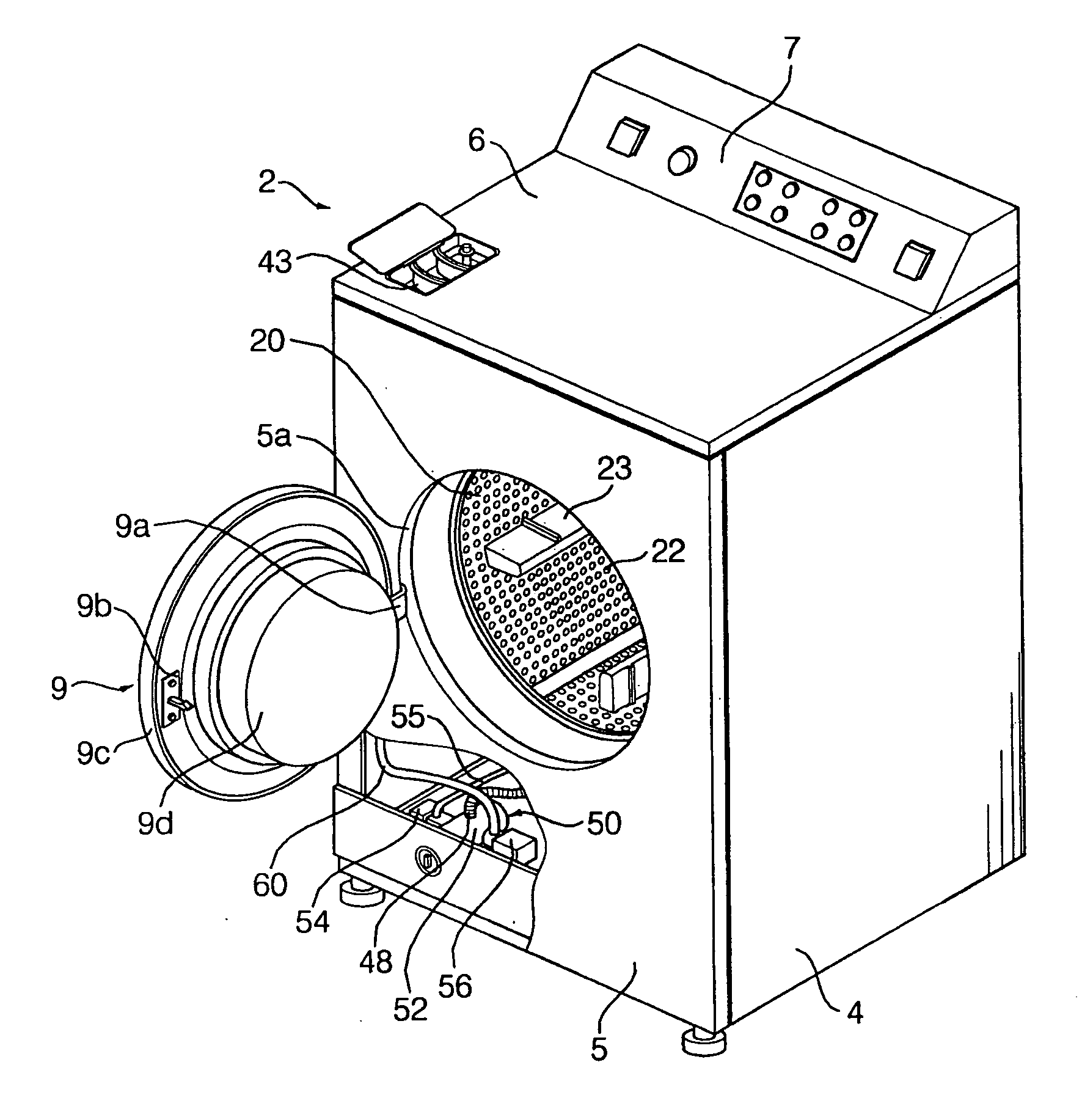

Washing machine having drying function and method for controlling the same

InactiveUS20050223504A1Easy to washIncreased rinse capacityOther washing machinesControl devices for washing apparatusWash waterEngineering

A washing machine having a drying function and a method for controlling the same. The washing machine includes a tub for containing wash water; a drum rotatably placed in the tub for containing laundry, and provided with through holes for circulating the wash water or air therethrough; a drying device provided with a circulation fan and a heater for drying the laundry in the drum; and a pumping device for pumping the wash water in the tub so that the wash water in the tub is circulated into the drum or heated by the air passing through the drying device, and is then circulated into the drum. The washing machine performs washing of laundry without any additional heater for heating the wash water, thereby having low production costs and a simple structure of the tub.

Owner:LG ELECTRONICS INC

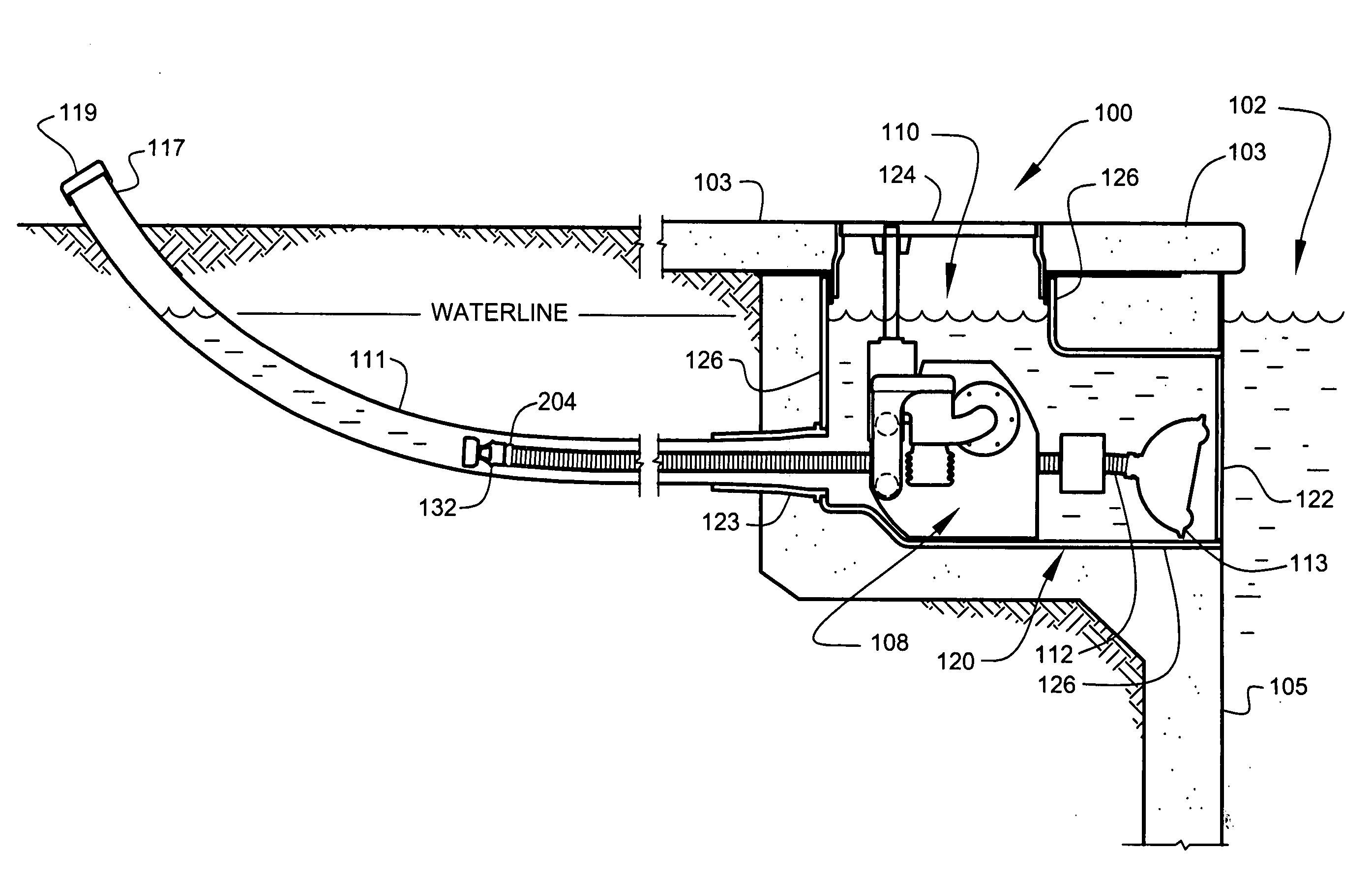

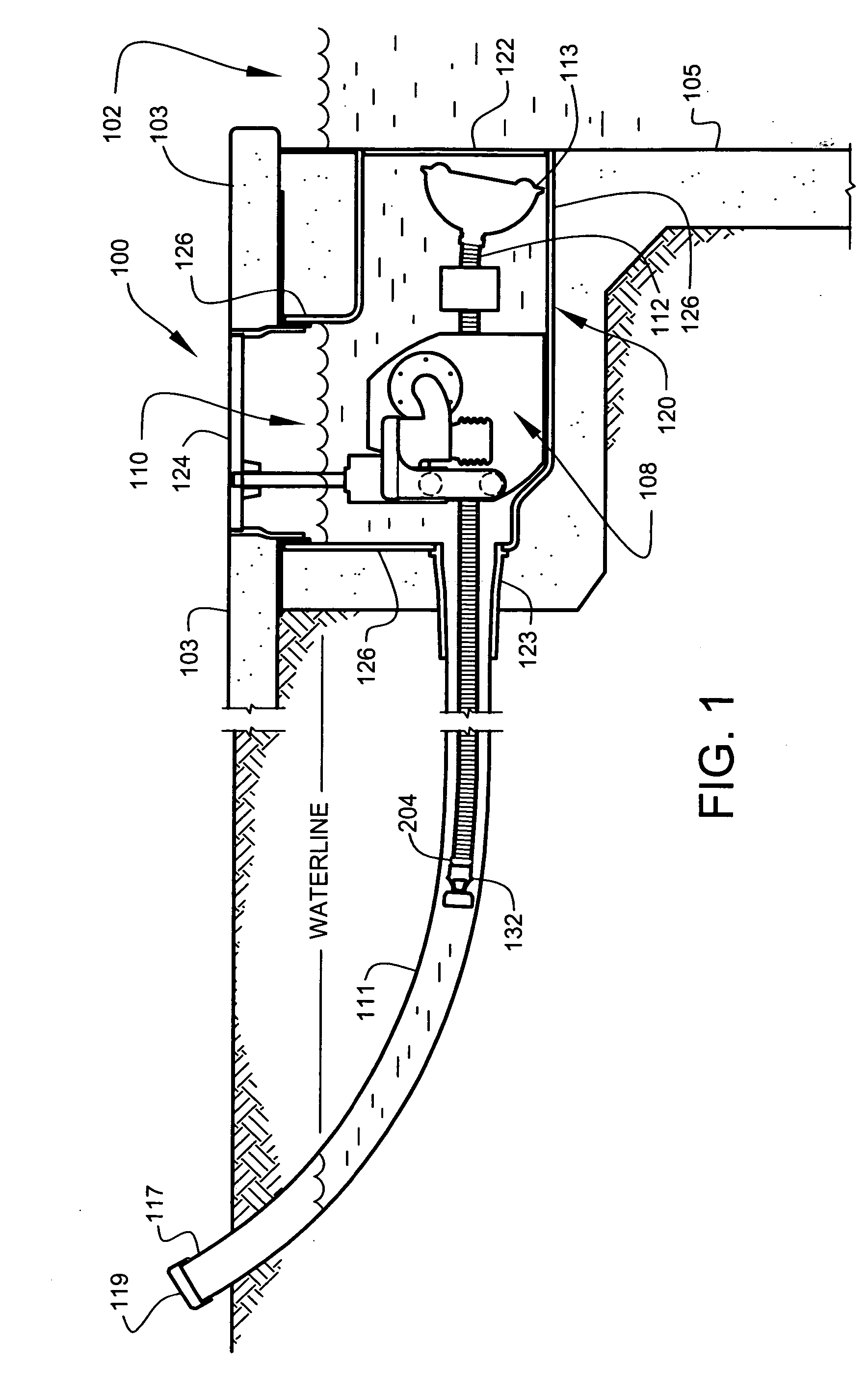

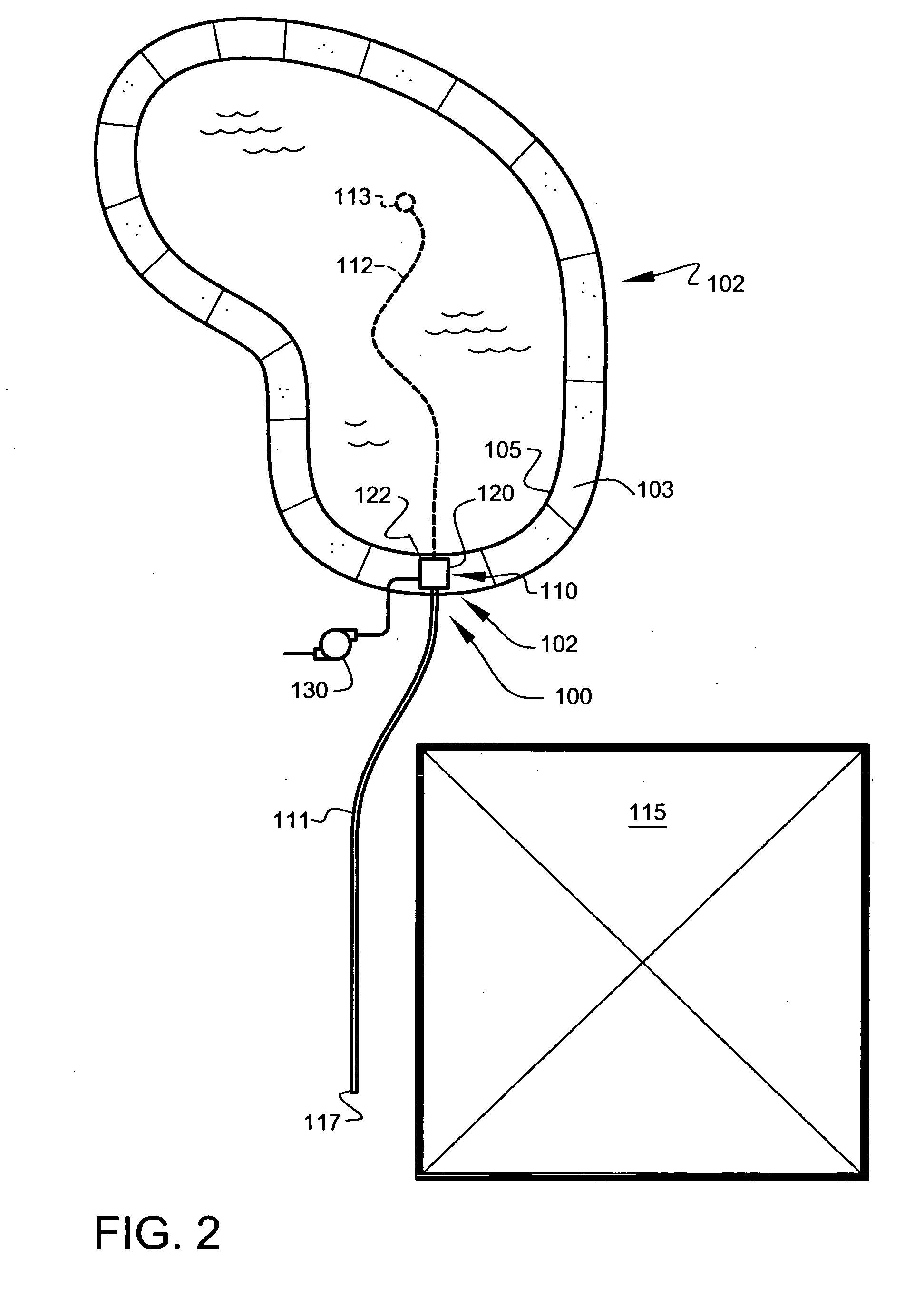

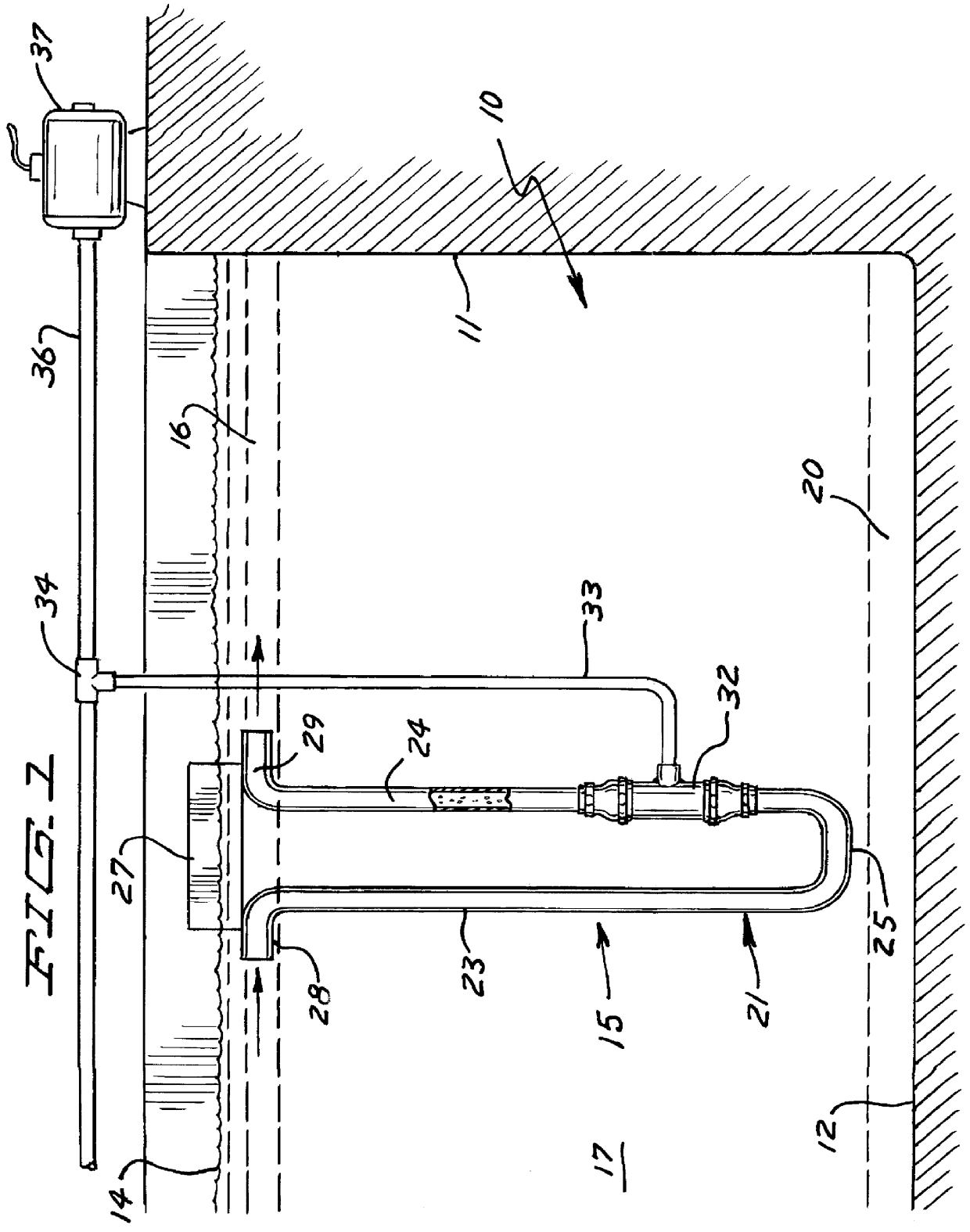

Concealed automatic pool vacuum systems

A vacuum pool-cleaning storage system that is housed in the side of a swimming pool substantially below the waterline. The pool vacuum cleaner automatically deploys to clean the pool when the central pool vacuum pump is activated, and automatically retracts to a stored position when the central pool vacuum pump is turned off. The system is adapted to store the vacuum hose in a substantially linear tube located substantially underground. A reel-type hose storage embodiment is also disclosed. The system is preferably powered by vacuum pressure generated by a water circulation pump of the pool plumbing system.

Owner:TORKELSON JOHN E

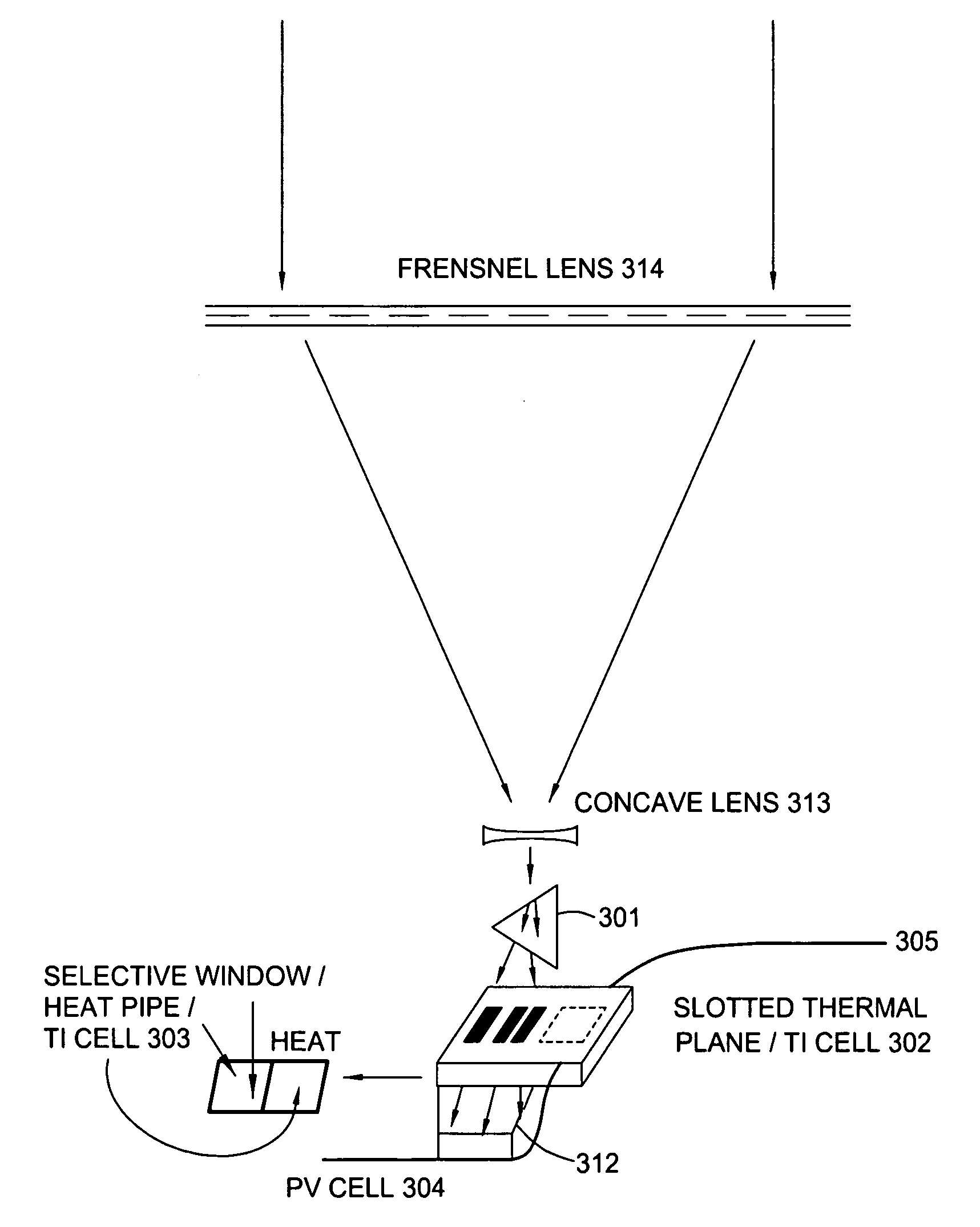

Integrated solar energy conversion system, method, and apparatus

InactiveUS20070289622A1Improve efficiencyEconomic return investmentSolar heating energySolar heat collector controllersWorking temperatureEngineering

A solar energy conversion package includes a photovoltaic (PV) cell, a thermionic or thermoelectric conversion unit and a thermal heating system. Solar radiation is concentrated by a lens or reflector and directed to the PV cell for electrical power conversion. A water circulation system maintains the PV cell at working temperatures. The thermionic or thermoelectric conversion cell is coupled between these cells in the thermal path to generate additional power. Additional efficiencies may be gained by partitioning the solar radiation with prisms or wavelength specific filters or reflective coatings into discrete spectrum segments optimized for each conversion unit for maximizing efficiency of electrical energy conversion and equipment design. Integrating all three of these conversion techniques produces a synergistic system that exceeds the performance conventional solar conversion systems.

Owner:LOCKHEED MARTIN CORP

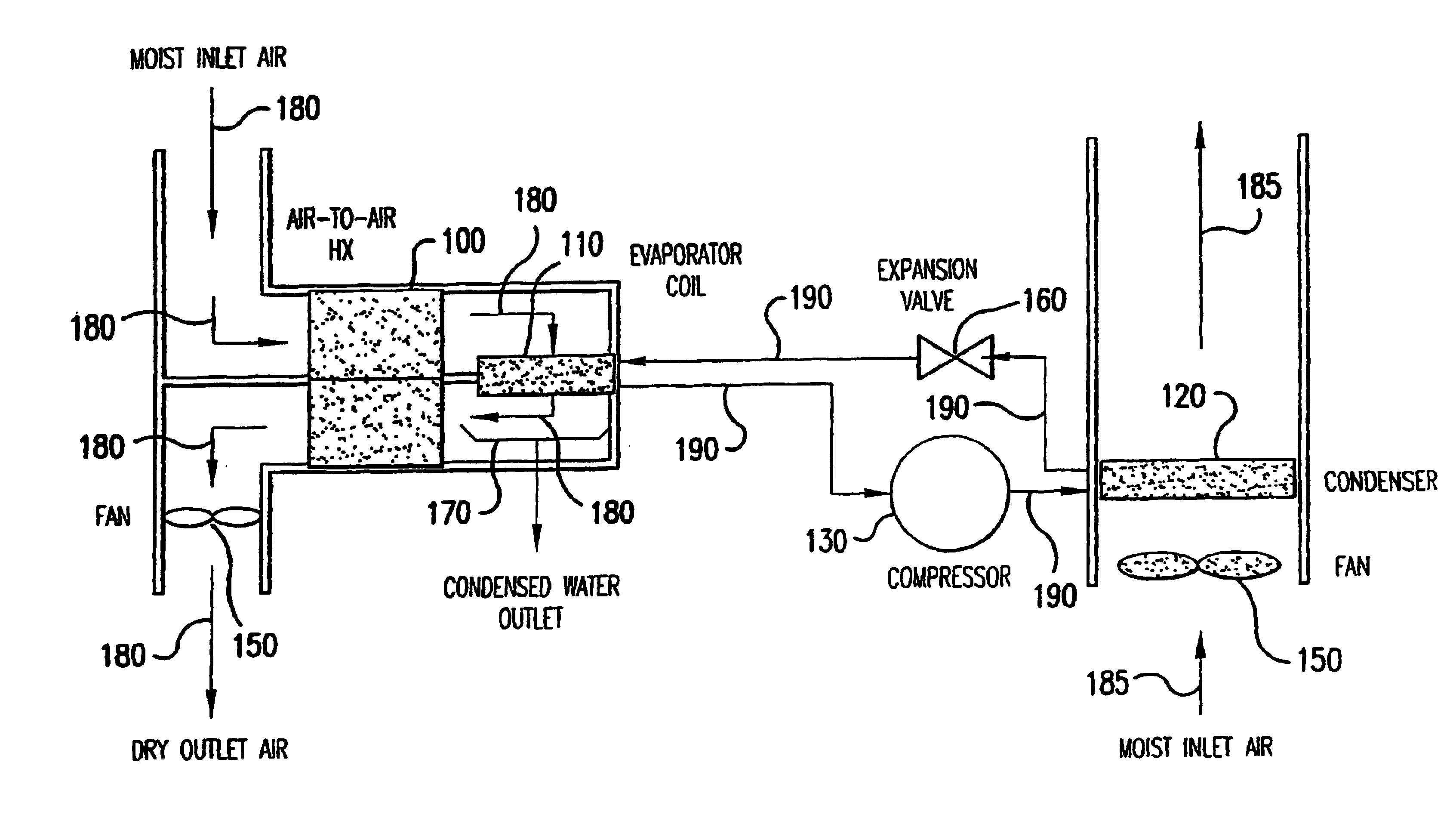

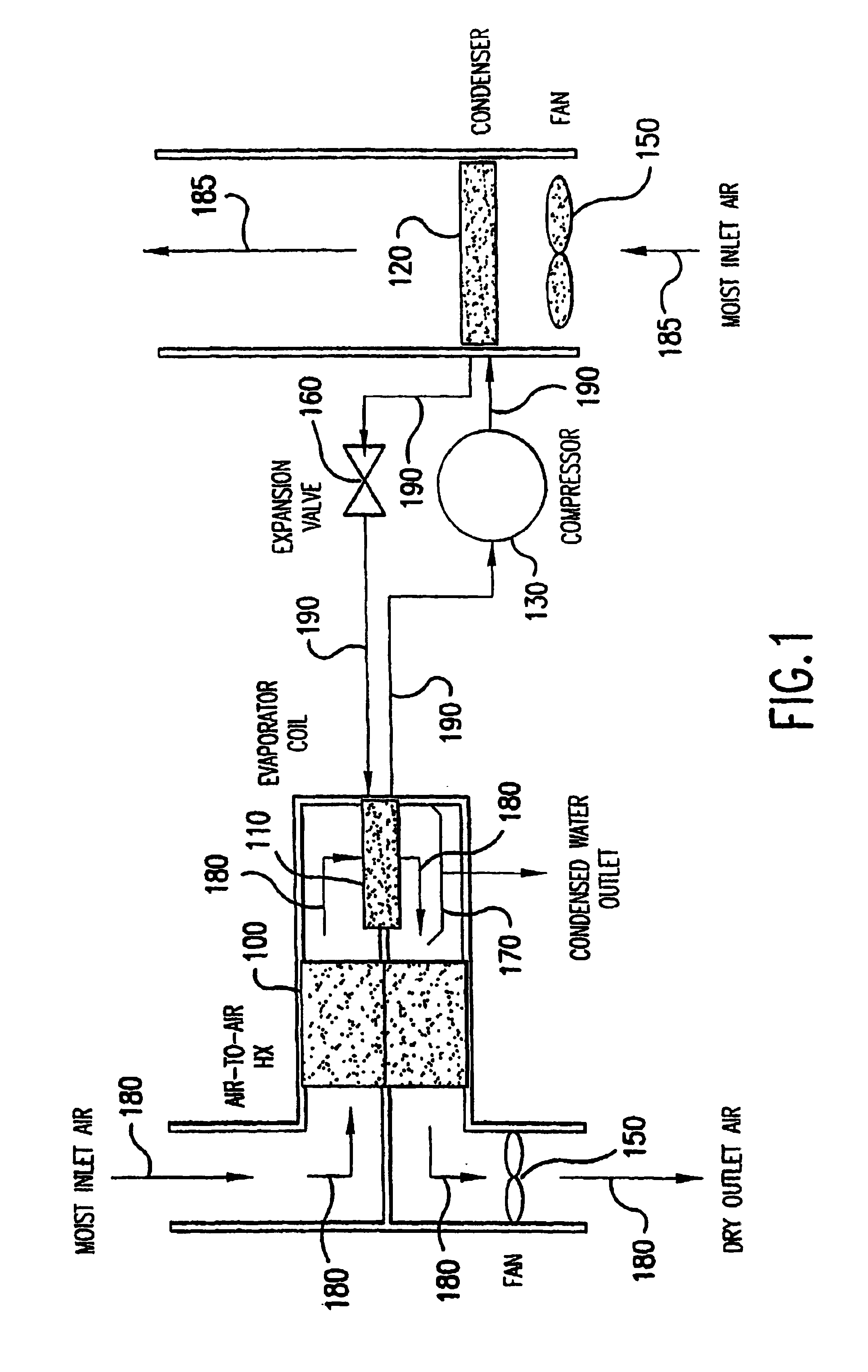

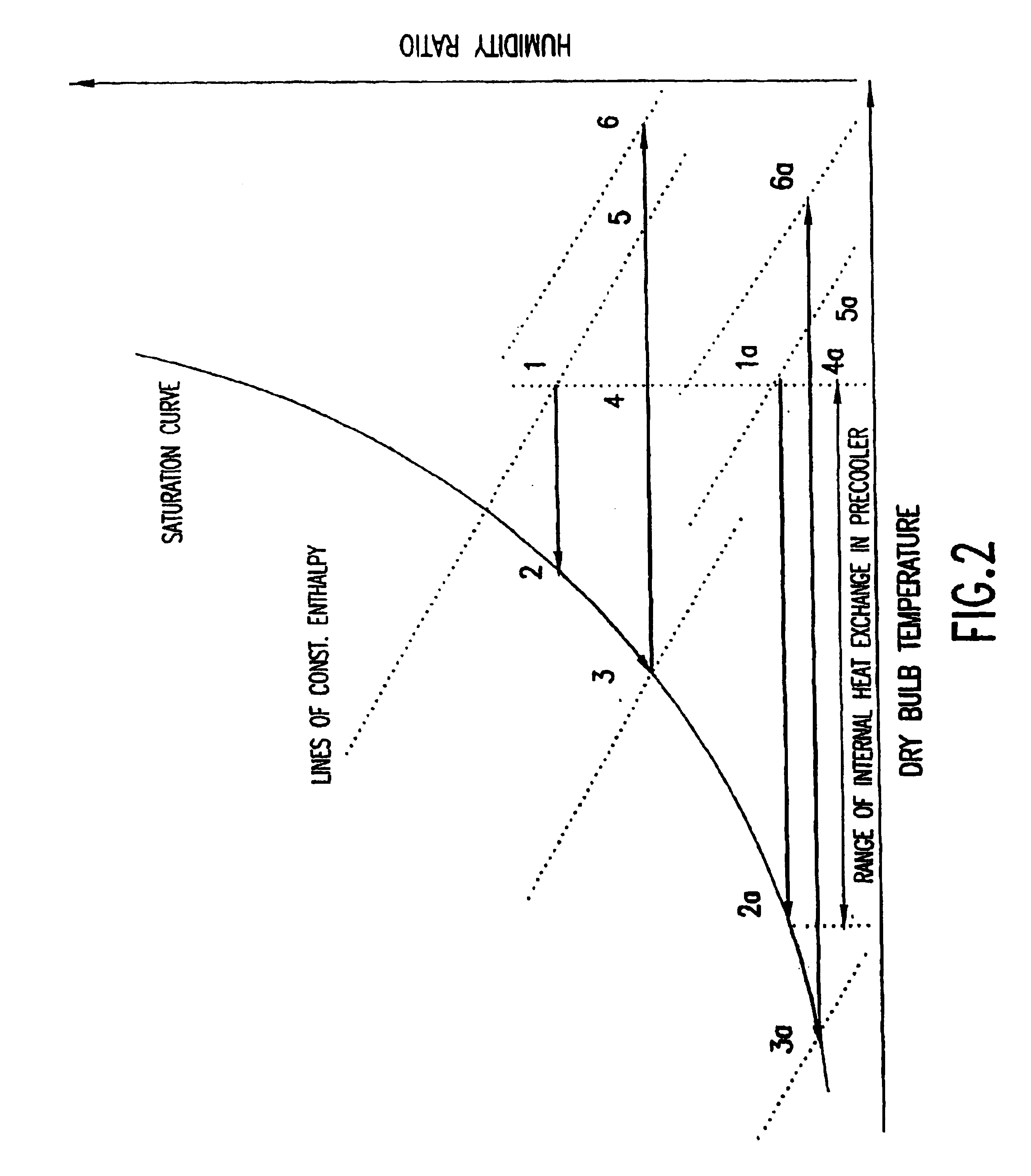

Device for collecting water from air

The present invention is directed to a water making device that collects the moisture contained in the atmosphere and condenses it into high purity water. In one embodiment, moist air entering the water making / water cooling system flows across an air filter, then a precooler heat exchanger (where the air stream is cooled to or close to its dew point) and then a water extraction heat exchanger, where the air stream is cooled further and water is extracted. The water that leaves water extraction heat exchanger is collected in a water collection device and passes from there through a primary water filter into a water storage tank. The air stream then passes across a reheat heat exchanger and exhausted to the outside. A water circulation pump extracts water from the water storage tank and circulates the water stream through an evaporator of a vapor compression refrigeration system, where the water stream is chilled, then through the water extraction heat exchanger and precooler, where the incoming air stream is chilled by removing heat to the water stream. The water stream is then circulated through the reheat heat exchanger, where the water stream is again cooled by removing heat to the cool dry air exiting the water extraction heat exchanger. Finally, the cooled water stream is circulated through the water filter to a three way valve, that directs water flow either to a dispenser or back to the water storage tank.

Owner:UNIV OF MARYLAND

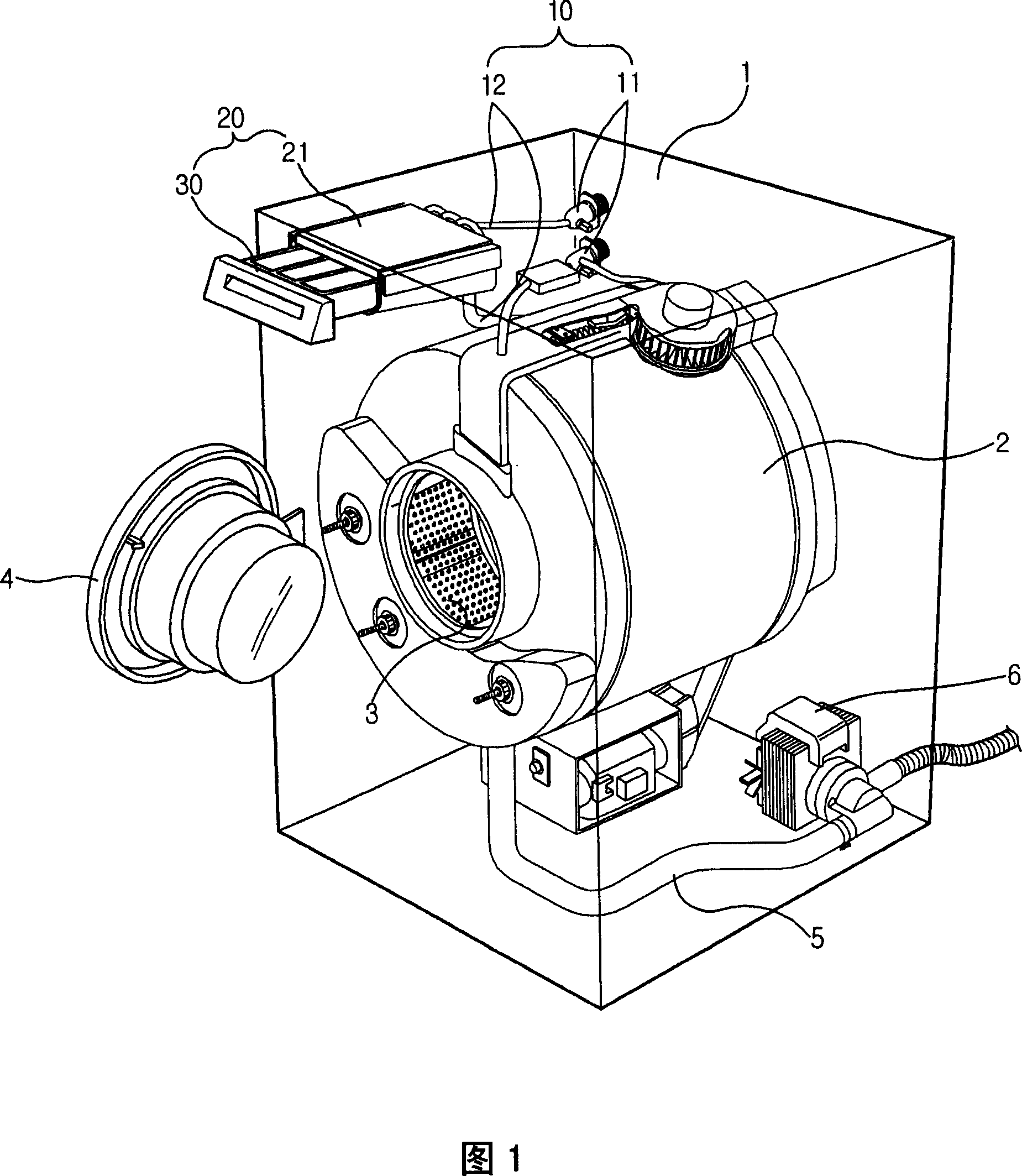

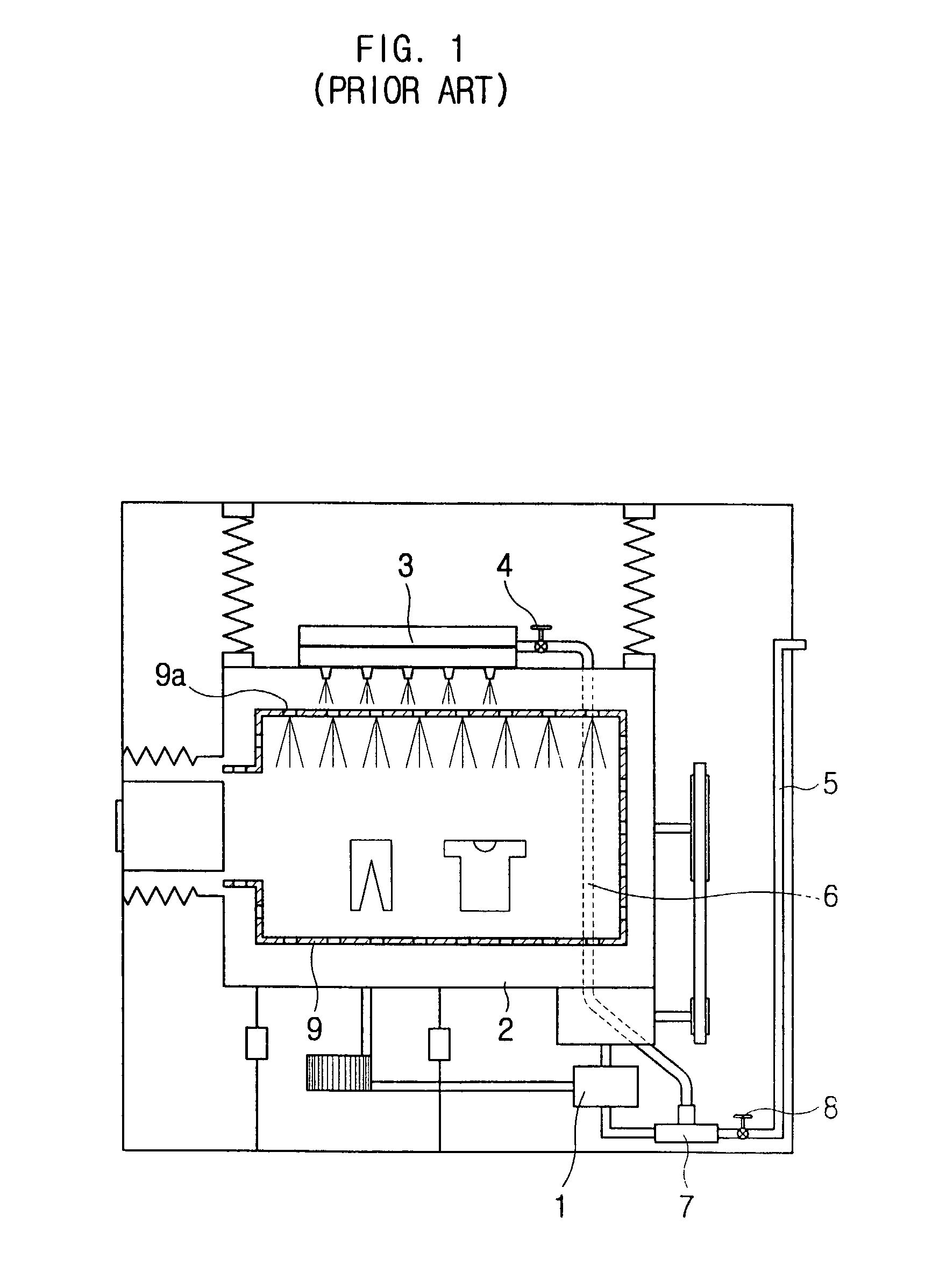

Washing machine

InactiveUS20050028564A1Reduce in quantityImprove efficiencyOther washing machinesSpray nozzlesElectric machineryEngineering

Disclosed is a washing machine provided with a nozzle for spraying washing water into a drum at a broadened angle, thus improving washing efficiency and rinsing efficiency and reducing a quantity of the washing water consumed. The washing machine comprises a tub for containing washing water, a drum rotatably arranged in the tub for accommodating laundry, a motor for rotating the drum, and a washing water-circulating device for circulating the washing water so that the washing water in the tub is sprayed into the drum, wherein the washing water-circulating device includes a nozzle having a vertical water-spraying angle in the range of 30° to 40°.

Owner:LG ELECTRONICS INC

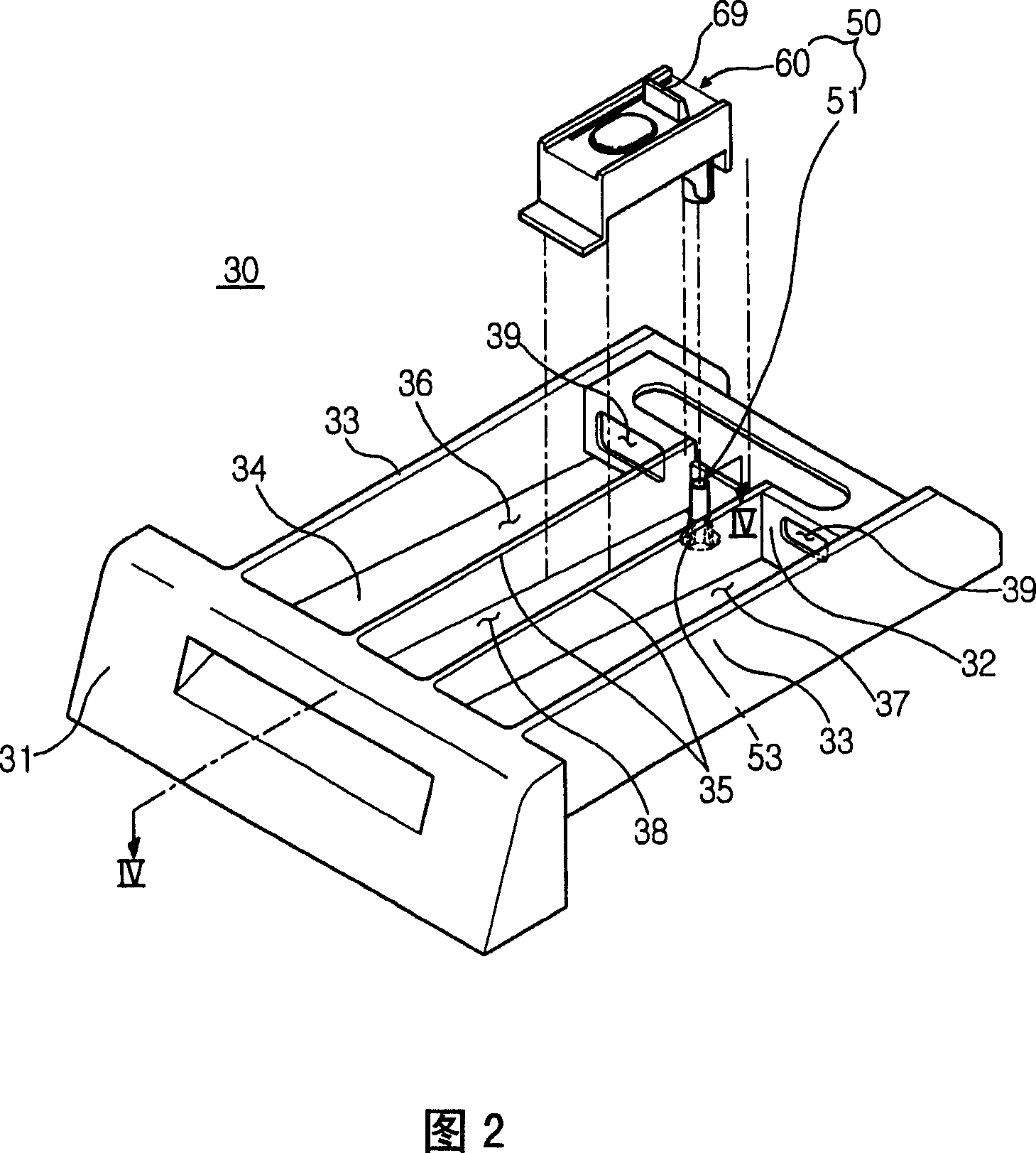

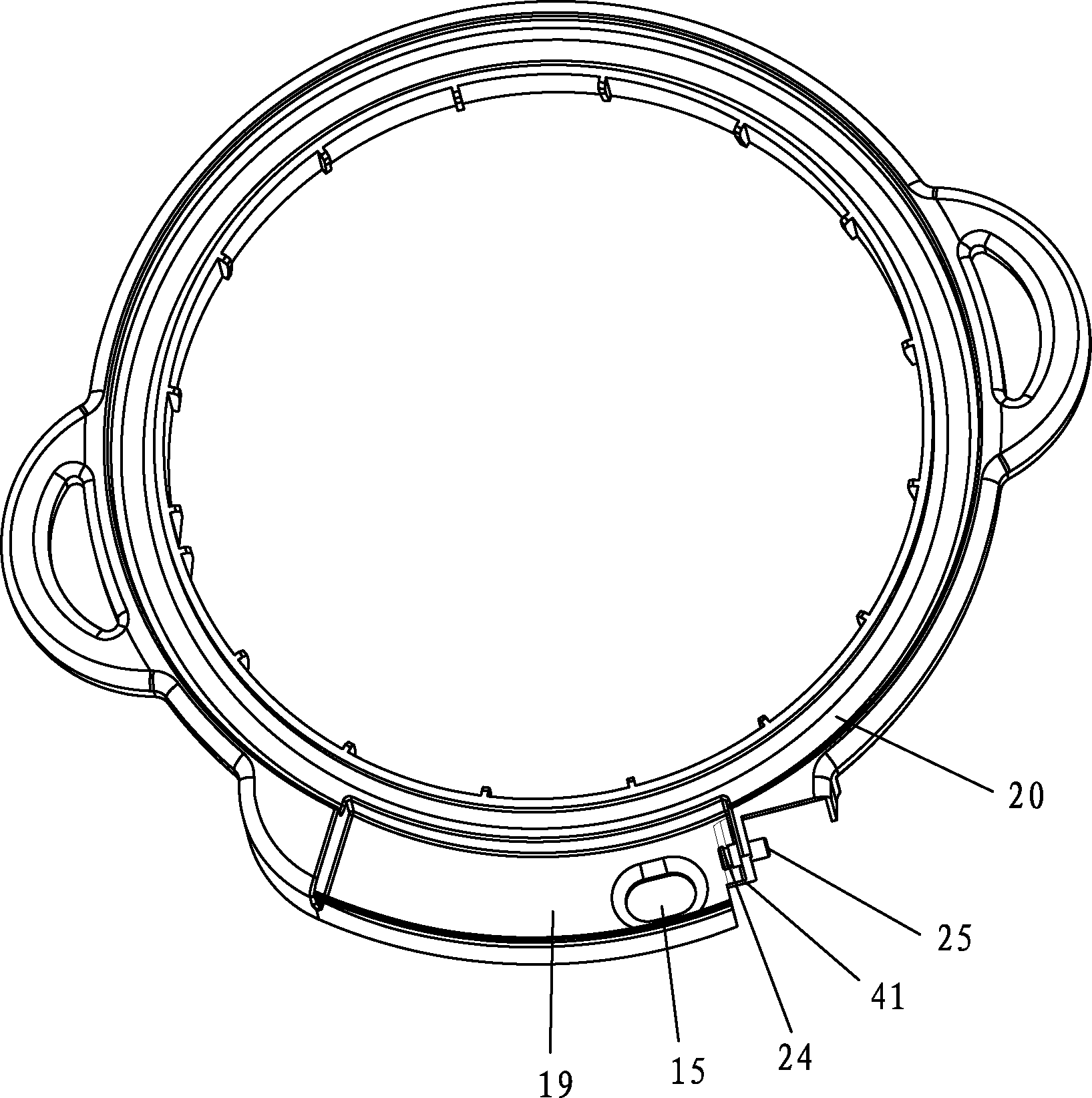

Detergent supply apparatus of washing machine

A detergent supply apparatus for a washing machine, which prevents water, which is not discharged from a detergent tub through a siphon unit, from overflowing the detergent tub and being discharged to the outside of the washing machine. The siphon unit includes a siphon pipe formed on a bottom of a chamber of the detergent supply apparatus, and a cover member installed above the siphon pipe. The cover member includes a siphon cap surrounding an outer circumferential surface of the siphon pipe so that a siphon channel is provided between the siphon pipe and the siphon cap, and a bypass channel for circulating water overflowing the siphon channel to the siphon channel.

Owner:SAMSUNG ELECTRONICS CO LTD

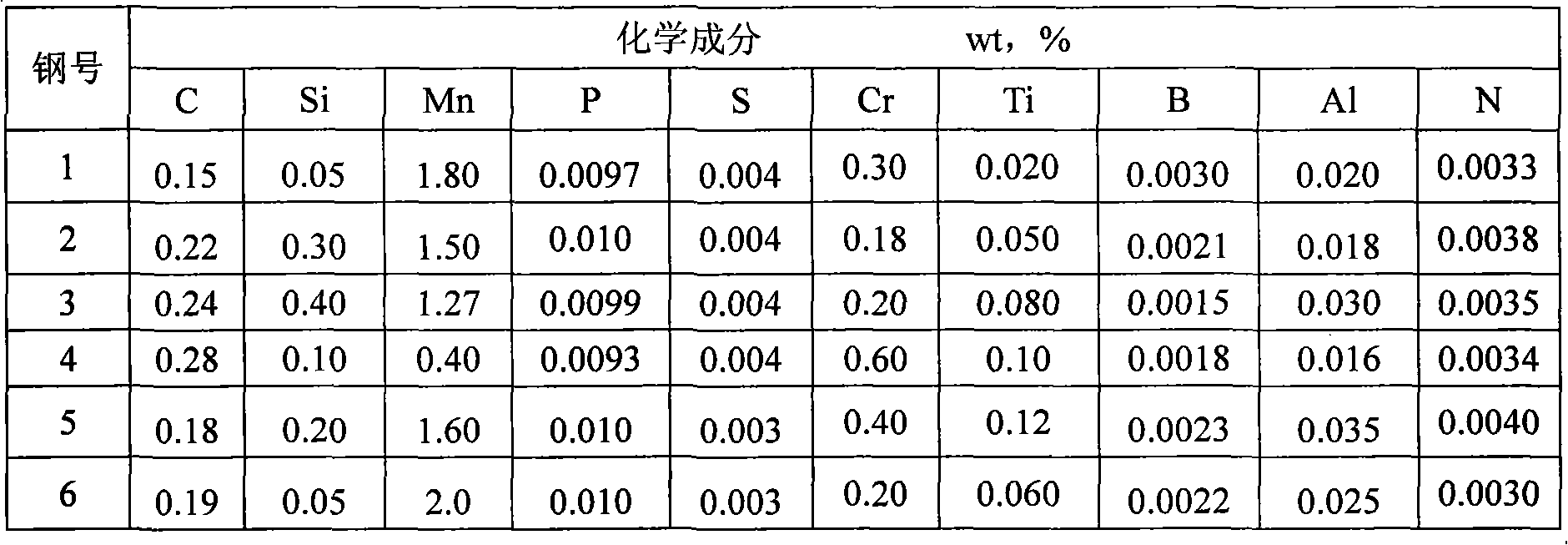

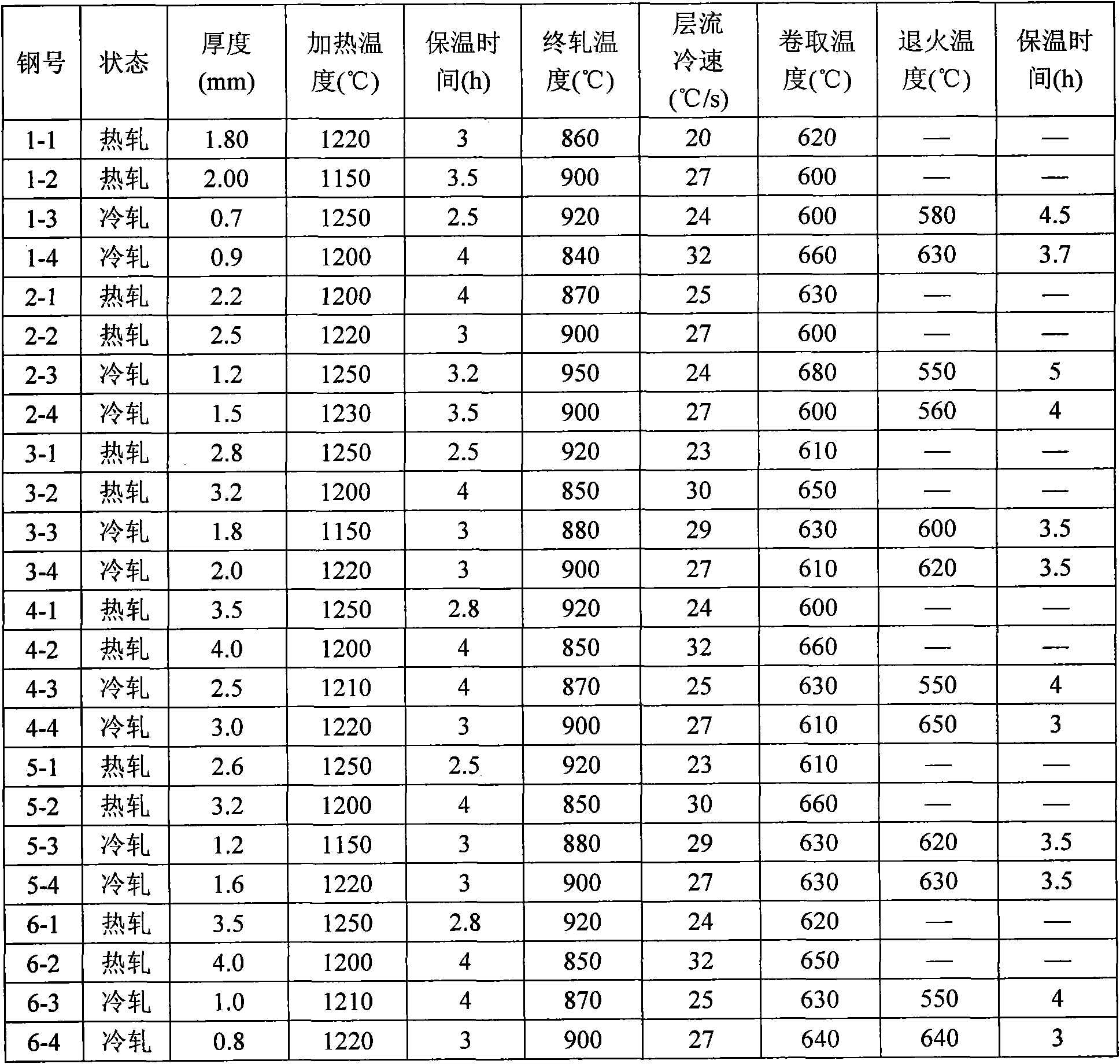

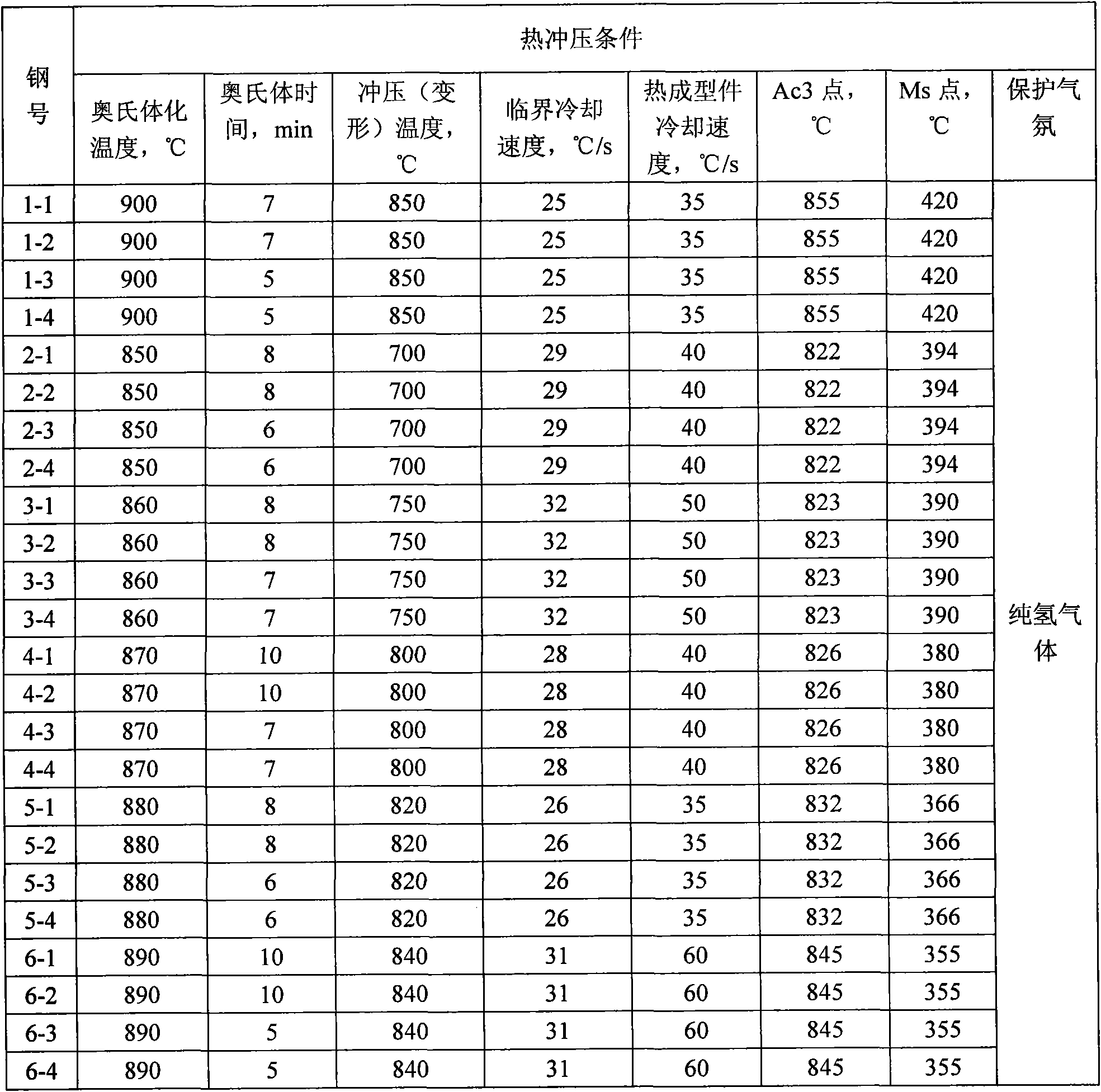

Steel plate for stamping and quenching and thermoforming method of steel plate

ActiveCN102031456ASimple compositionPlay the effect of weight reduction and energy savingHot stampingSimple component

The invention discloses a steel plate for stamping and quenching and a thermoforming method of the steel plate. The steel plate comprises the following chemical components in percentage by weight: 0.14-0.28% of C, less than 0.40% of Si, 0.4-2.0% of Mn, less than or equal to 0.010% of P, less than or equal to 0.004% of S, 0.016-0.040% of Al, 0.15-0.8% of Cr, 0.015-0.12% of Ti, 0.0001-0.005% of B, less than or equal to 0.005% of N, and the balance of Fe and inevitable impurities. The thermoforming method comprises the following steps: blanking by shearing the steel plate, and heating at Ac3 to (Ac3+80) DEG C to carry out austenization; after insulating for 5-10 minutes in the heating furnace, immediately transferring the steel plate to a metal mold the inside of which is cooled by introducing water, and stamping at the high temperature of 650-850 DEG C; cooling the formed workpiece in the closed mold, and cooling the mold by water circulation in the mold, wherein the cooling rate is greater than the critical cooling rate when austenite forms martensite, and the temperature of the workpiece leaving the hot stamping production line is below 150 DEG C; and carrying out air-cooling to room temperature. The steel plate has the advantages of simple component system and favorable hardenability; and the substrate tissues, which are ferrite and pearlite, are processed by hot stamping andquenching to obtain the all martensitic structure. The tensile strength of the steel plate can be higher than 1300 N / mm<2>.

Owner:ANGANG STEEL CO LTD

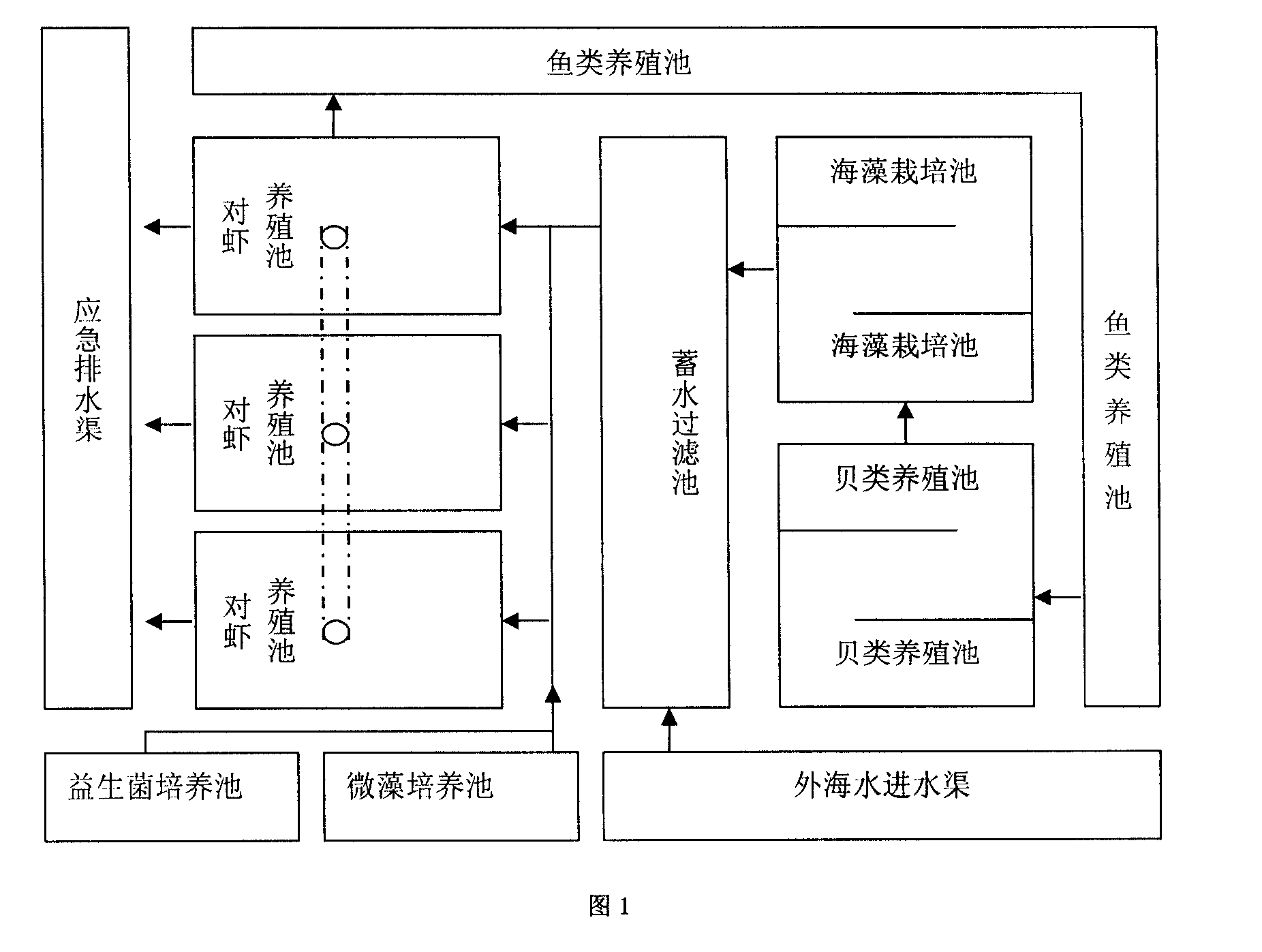

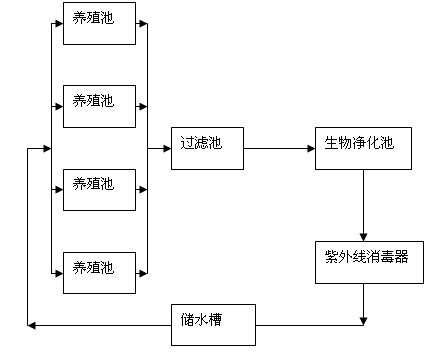

Shrimp-fish-shellfish-algae multiple cultivation and water quality biological regulate and control system thereof

InactiveCN101248766AAvoid direct competitionReduce mutual harmClimate change adaptationMultistage water/sewage treatmentMacrocystis pyriferaWater quality

The invention provides a shrimp-fish-shellfish-alga multi-unit culture and aquatic organism regulation system thereof. A shrimp culture zone, a fish culture zone, a shellfish culture zone, a large scale alga cultivation zone, a probiotics and microalga culture zone, a water processing zone and an emergency drainage system are arranged in a closed water circulation culture system, wherein the culture water circulates in different culture and water processing units. As the water circulates in different culture units and is utilized in multiple levels by various aquatic organisms of different trophic level and ecological niche, the system gives the various aquatic organisms full play to the positive bait resource complementarity, prevents the aquatic organisms from directly competing on living space and dissolved oxygen and reduces the mutual damage caused by organic remains and metabolic waste, achieves the 'self-modification' and 'biomanipulation' of the culture environment, enables the environment itself to recover from the pollution in culture process, and decontaminates the seawater culture environment.

Owner:GUANGDONG OCEAN UNIVERSITY

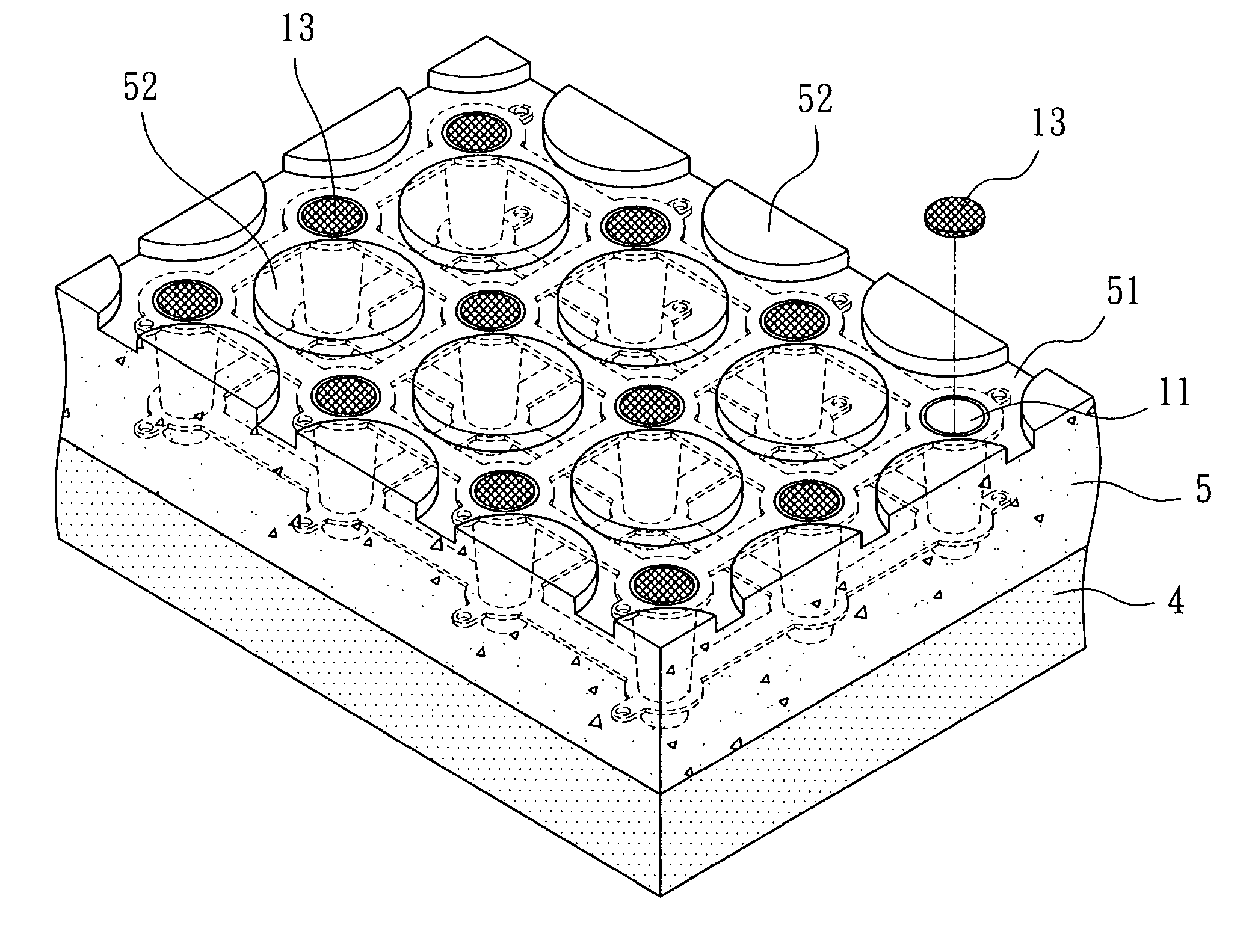

Washing machine

InactiveUS20090249838A1Uniform supplyWash evenlyOther washing machinesWashing machine with receptaclesSpray nozzleEngineering

A circulatory washing machine, in which water stored in the bottom of a tub is circulated and supplied to a drum. The washing machine includes a tub for containing washing water; a drum rotatably installed in the tub; a circulation unit for circulating the washing water stored in the tub to the upper portion of the drum; and a spray nozzle for spraying the washing water, circulated by the circulation unit, to the rear portion of the inside of the drum.

Owner:LG ELECTRONICS INC

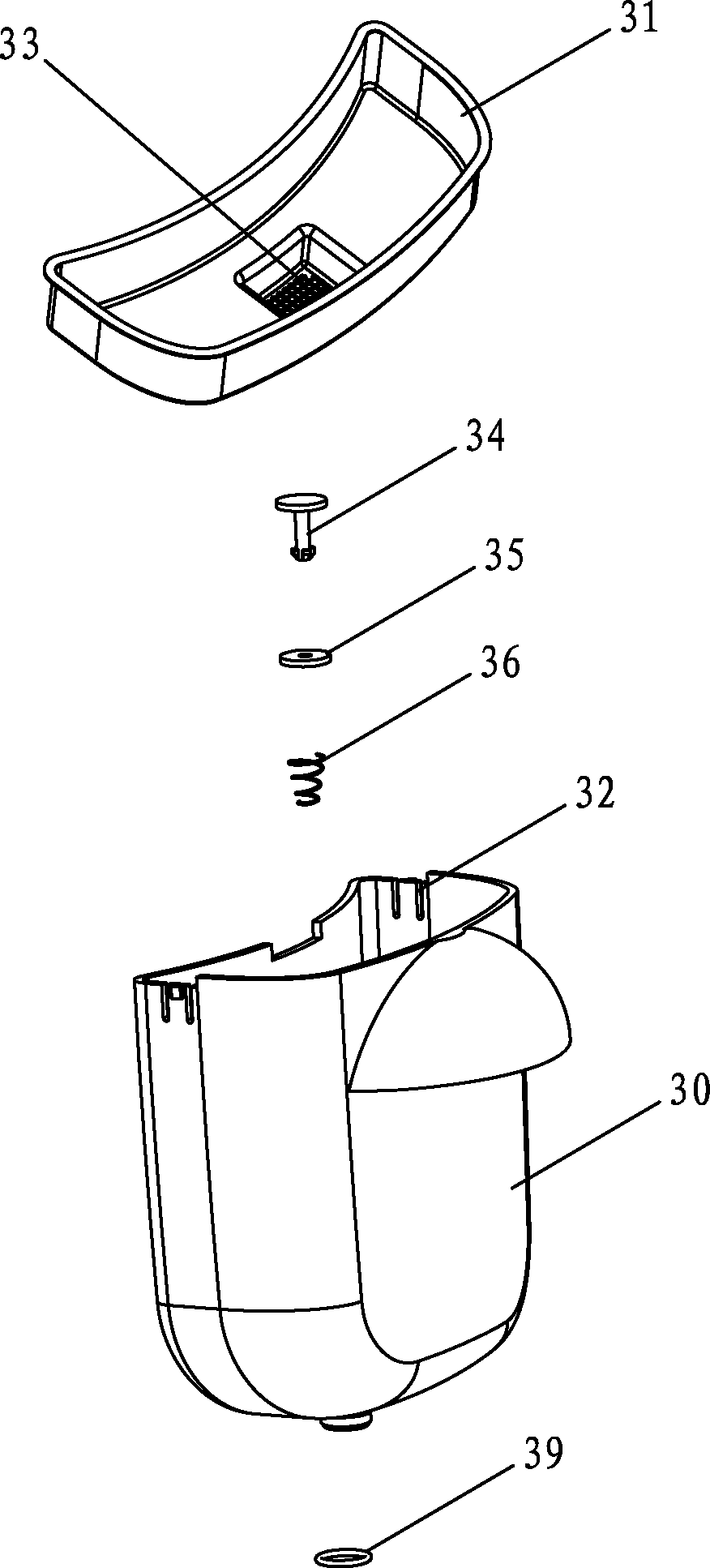

Electric pressure cooker with rapid pressure relief function

The invention relates to an electric pressure cooker with a rapid pressure relief function. The electric pressure cooker comprises a cooker cover and a cooker body, wherein the cooker cover comprises a plastic surface cover and a stainless steel cover; the cooker body comprises an upper gasket seat and a plastic shell; the electric pressure cooker also comprises a water pump and a water tank, wherein the water pump is arranged inside the cooker body, and the water tank is arranged on the lateral surface of the cooker body; the cooker cover is provided with a water spraying structure which is used for shunting water to the upper surface of the stainless steel cover; the upper gasket seat is provided with a water collecting structure which is used for receiving water flowing from the upper surface of the stainless steel cover; the bottom surface of the water collecting structure is provided with a water drainage hole; the upper end of the water tank is provided with an opening; the opening of the water tank is positioned below the water drainage hole; the water inlet of the water pump and the water outlet of the water tank are communicated; and the water outlet of the water pump and the water spraying structure are communicated. According to the electric pressure cooker disclosed by the invention, the water pump, the water tank, the water spraying structure and the water collecting structure are matched to realize circular temperature reduction of water; and the electric pressure cooker has the advantages of convenience for operation, water resource saving, good safety and high speed of temperature reduction and pressure relief.

Owner:GUANGDONG LUBY ELECTRONICS

Composite water permeable brick and composition for producing the same

The invention disclosed a composite permeable brick comprising a permeable surface layer and a permeable base layer. The surface layer and the permeable base layer, which respectively comprise an aggregate and a binder adhering to the aggregate, are closely combined together. The binder in the permeable surface layer at least comprises a hydrophilic binder. The permeable brick according to the invention has a good permeability and is of low cost, because of the compact and permeable surface of the brick. The invention also discloses a mixture for preparing the composite permeable brick, comprising an aggregate and a binder adhering to the aggregate. The binder at least comprises a hydrophilic binder, and the binder / aggregate ratio is from 1:100 to 20:100 by mass. The composite permeable brick and the mixture of the invention may be used for road surfacing, water circulation, water filtration and water purification, promoting the full utilization of rainwater resources and improving the urban water circulation.

Owner:BEIJING RECHSAND SCI & TECH GRP

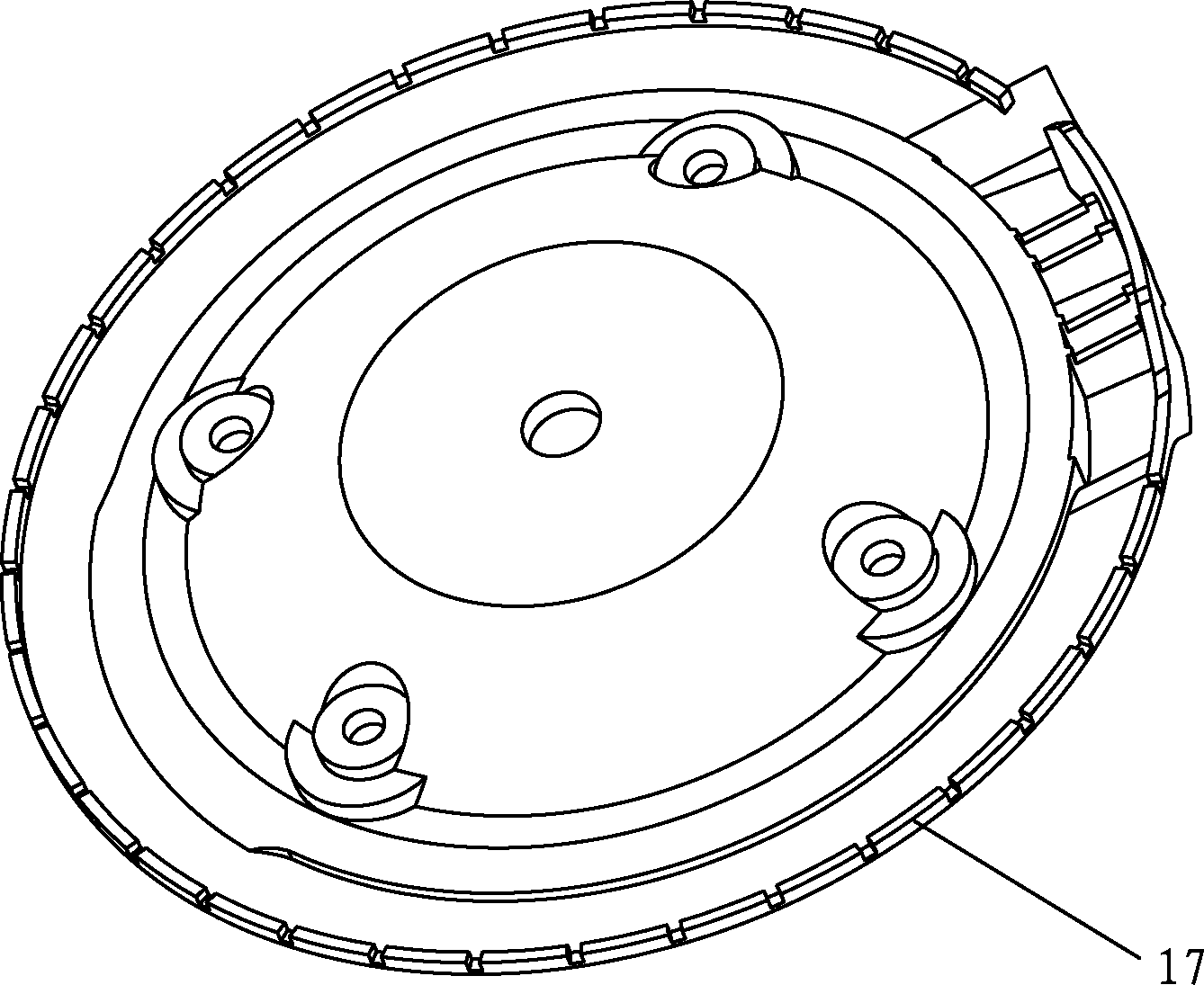

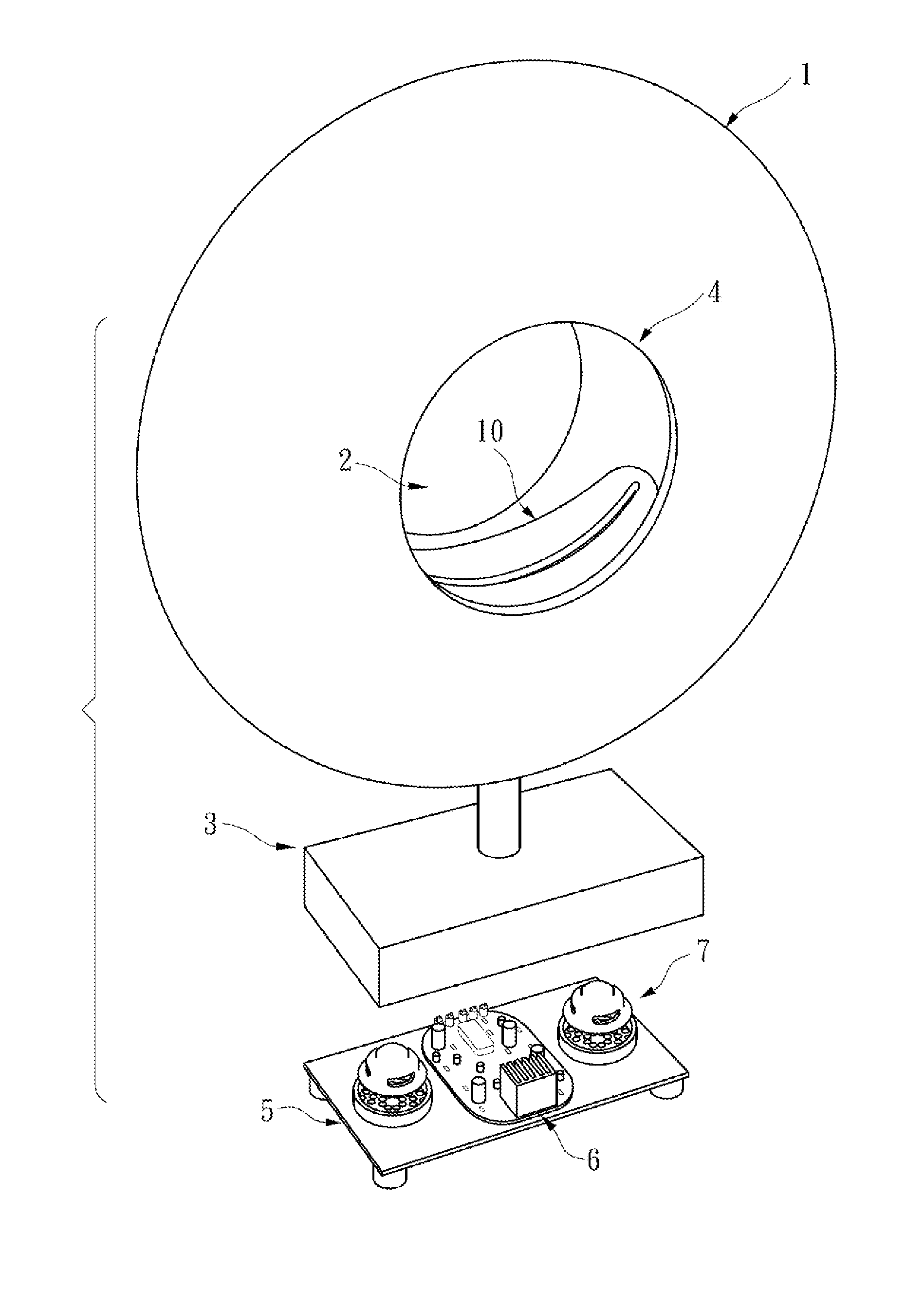

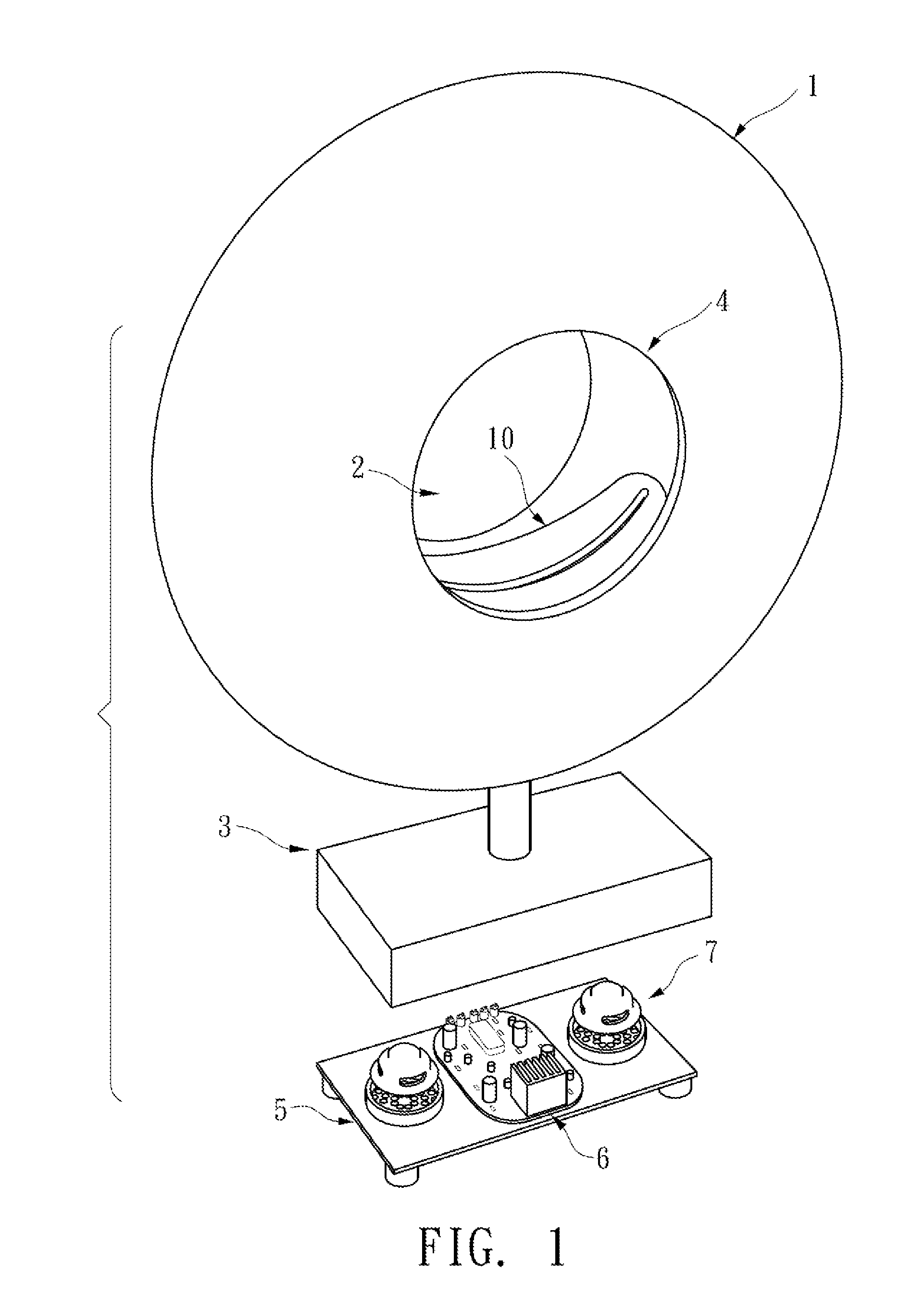

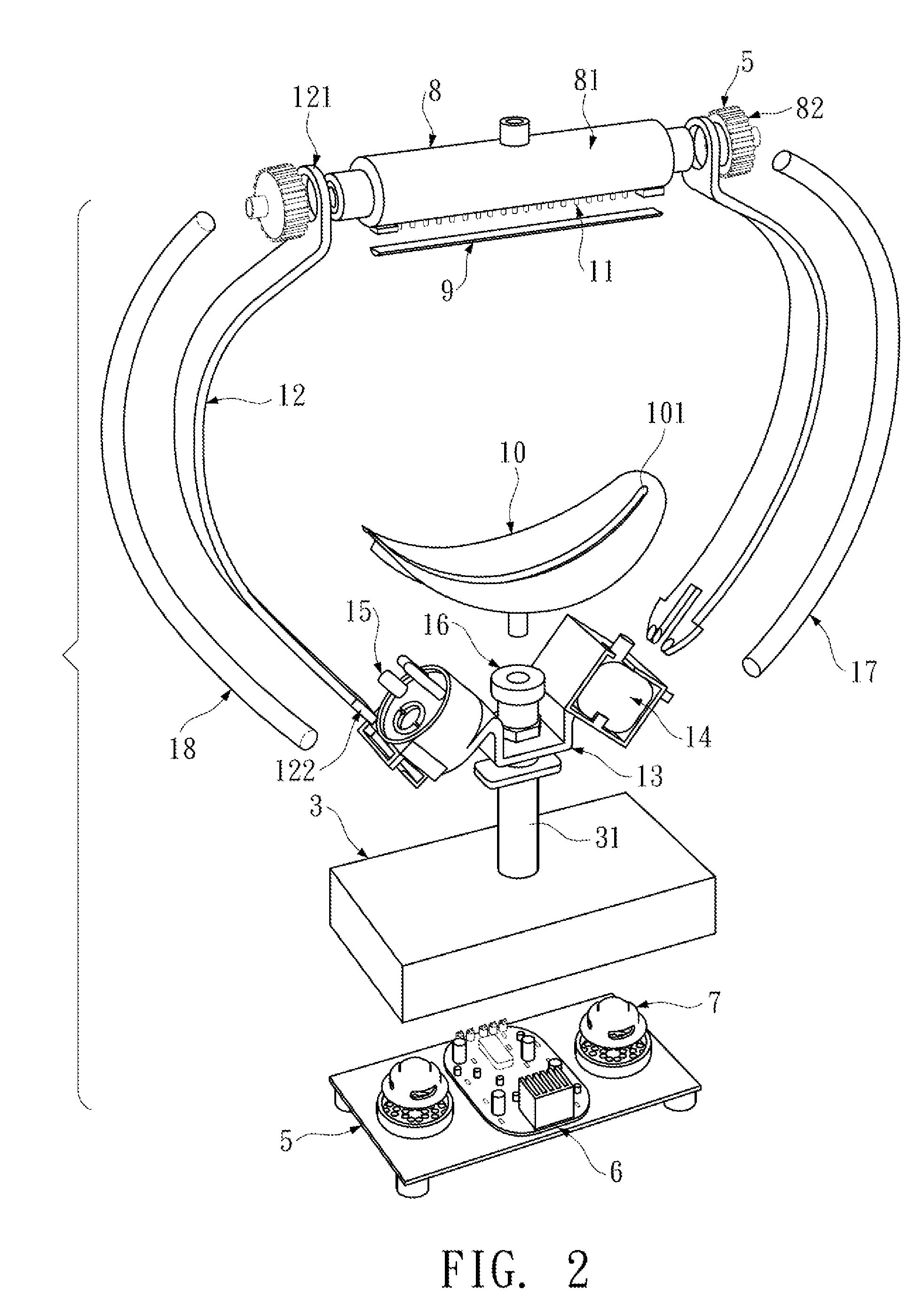

Wind-water ultrasonic humidifier

InactiveUS8113490B2Simple and fashioned decorationMechanical apparatusMixing methodsThreaded pipeWater circulation

Owner:CHEN HUI CHIN

Vehicle air-conditioner system with battery heat management function

InactiveCN105539067AEffective coolingFully meet cooling needsAir-treating devicesVehicle heating/cooling devicesElectricityHeat management

A vehicle air-conditioner system with a battery heat management function comprises a compressor, a condenser, a first expansion valve and an evaporator. The compressor, the condenser, the first expansion valve and the evaporator are connected in the first flowing direction of a refrigerant to form an air-conditioner refrigeration circulation loop. The vehicle air-conditioner system further comprises a plate heat exchanger, a second expansion valve, an air-water heat exchanger, a fan, a water pump, an electric heater and a battery pack built-in heat exchanger. The fan is arranged on the air inlet side of the air-water heat exchanger. The compressor, the condenser, the second expansion valve and the plate heat exchanger are connected in the second flowing direction of the refrigerant to form a battery cooling low-temperature medium circulation loop. The battery pack built-in heat exchanger, the water pump, the plate heat exchanger, the air-water heat exchanger and the electric heater are connected in the water circulation direction to form a battery temperature adjusting medium circulation loop. According to the vehicle air-conditioner system, uniform management of the temperature inside a vehicle and the temperature of a battery is achieved, a battery pack is in the better temperature environment all the time during working, and it is ensured that the good refrigeration effect is achieved inside the vehicle.

Owner:TIANJIN SANDEN AUTO AIR CONDITIONING

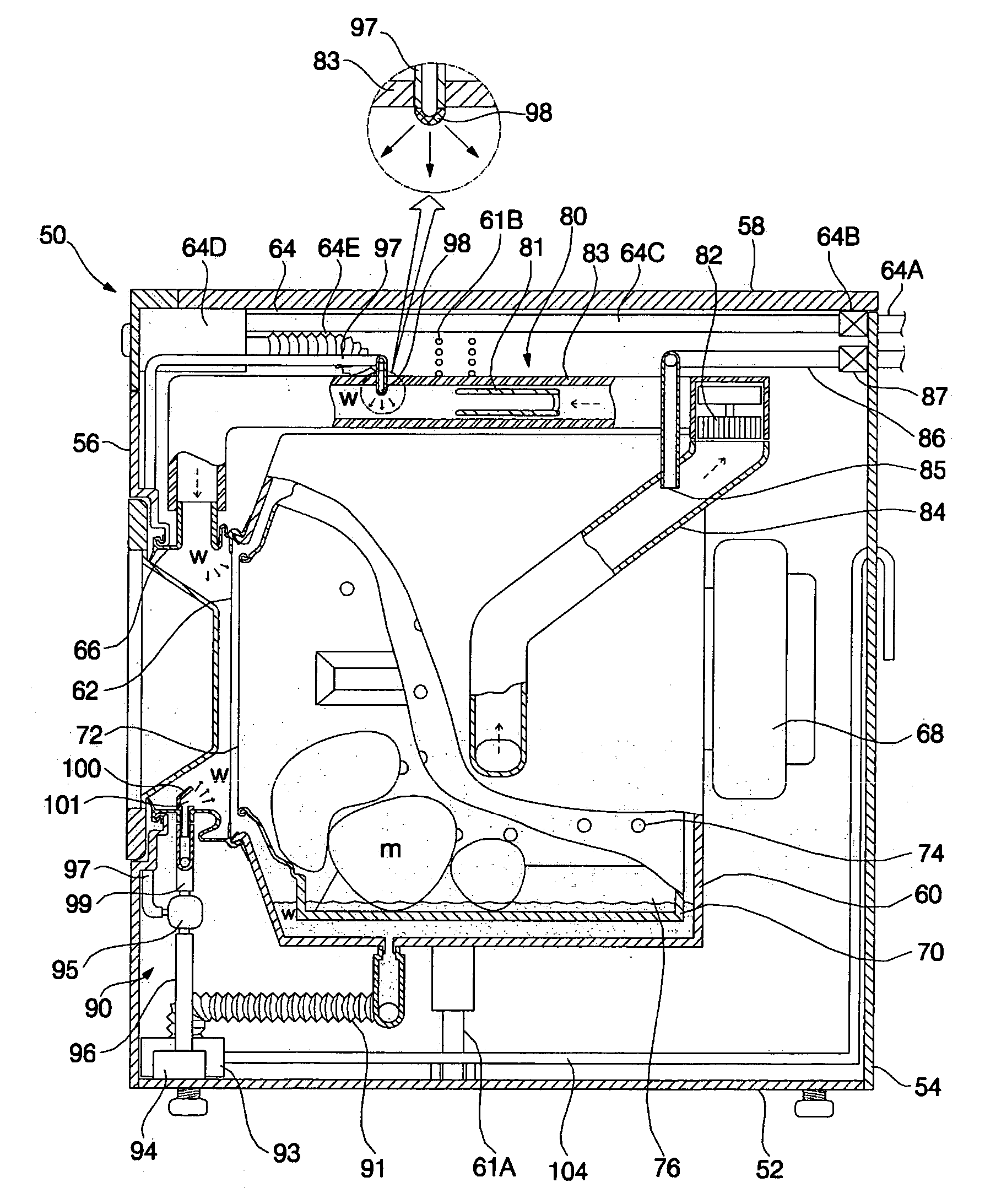

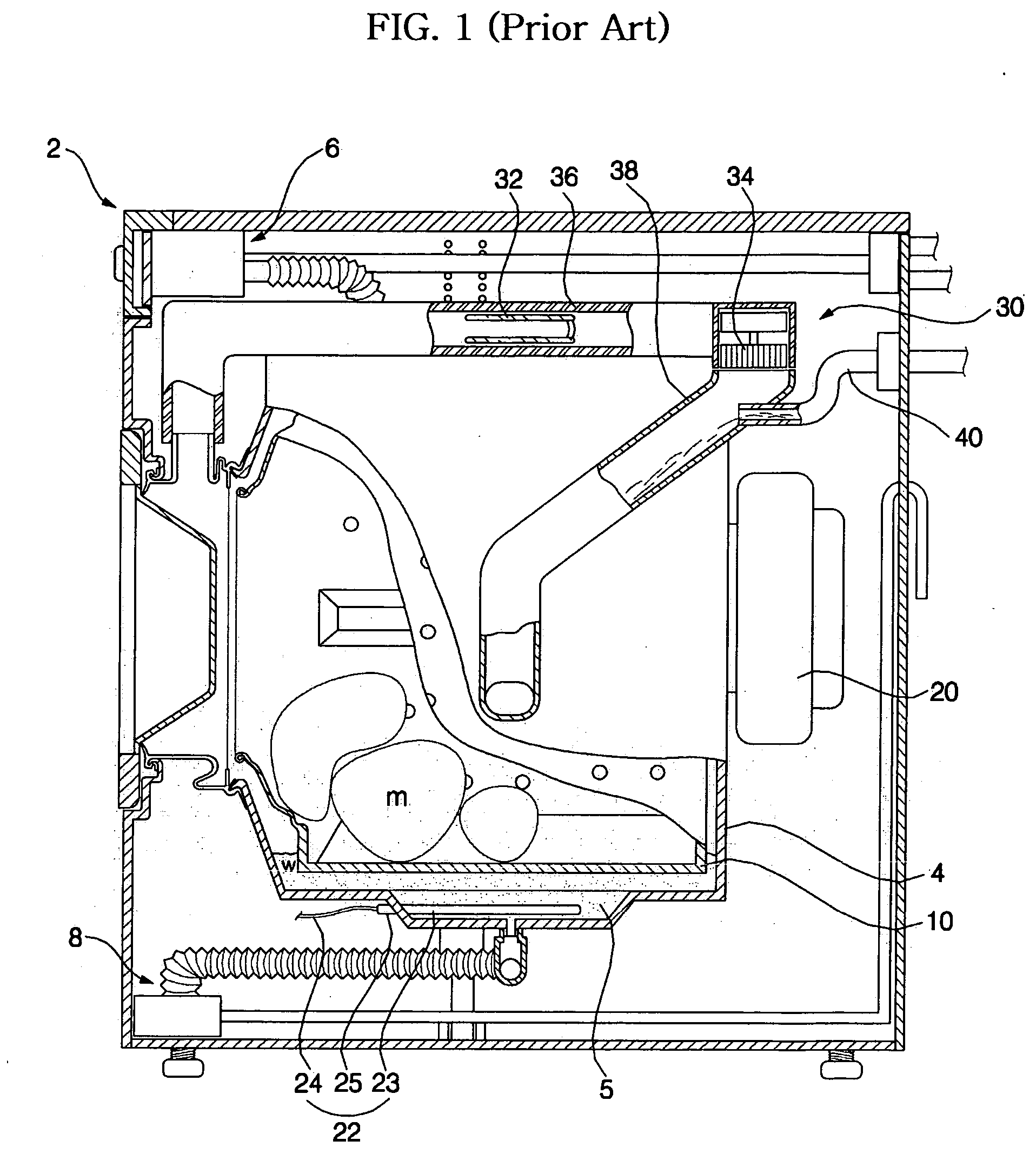

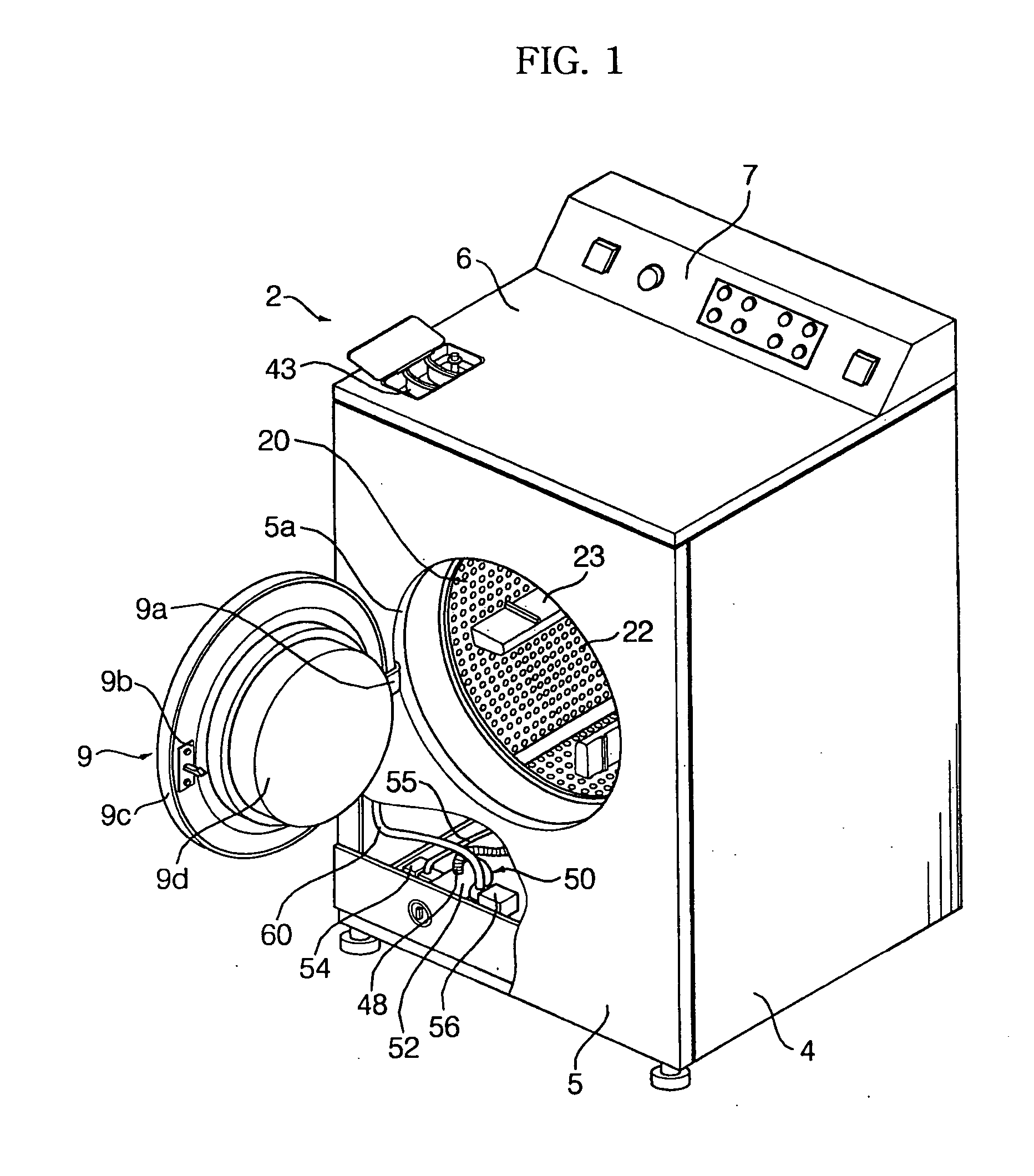

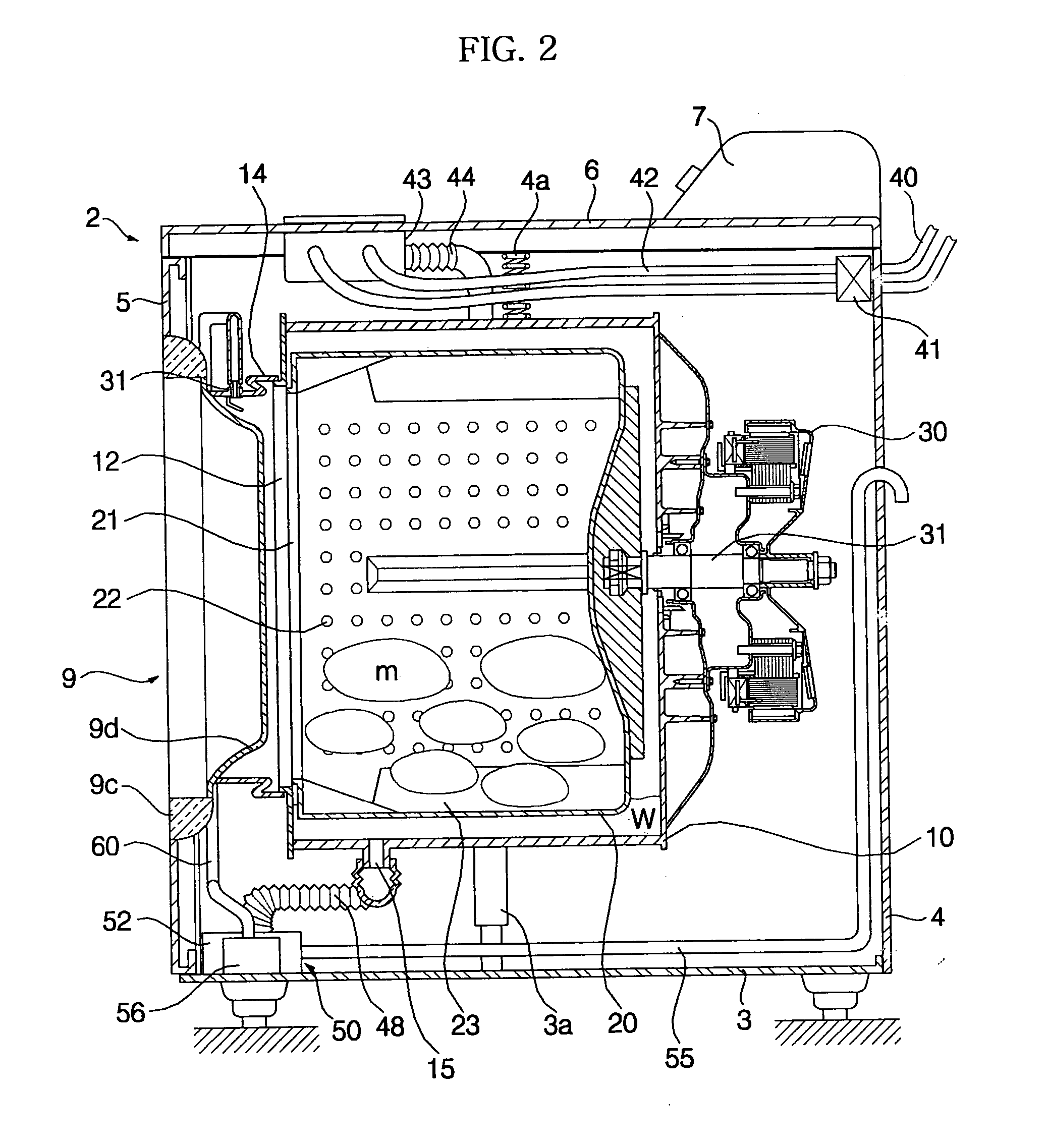

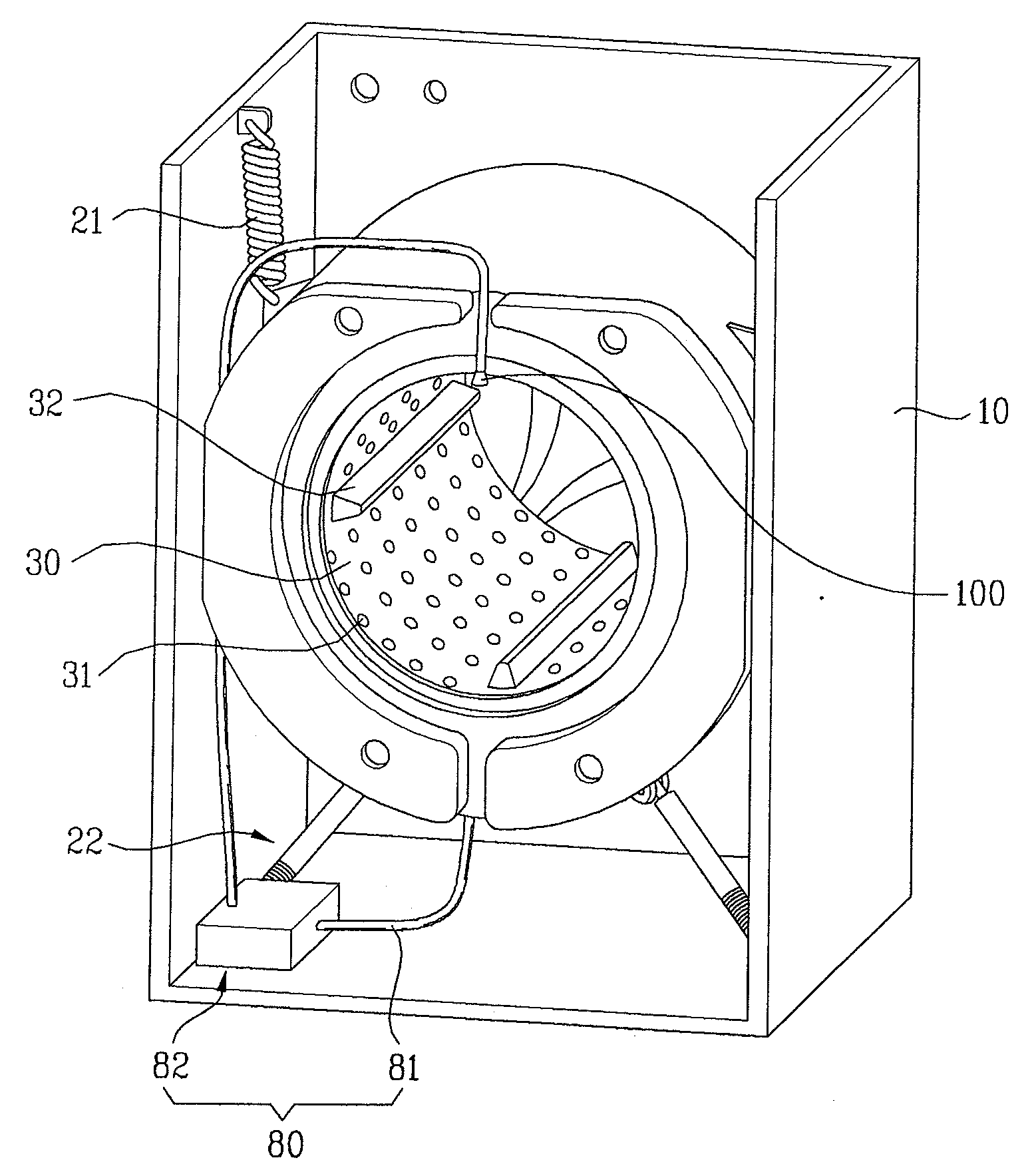

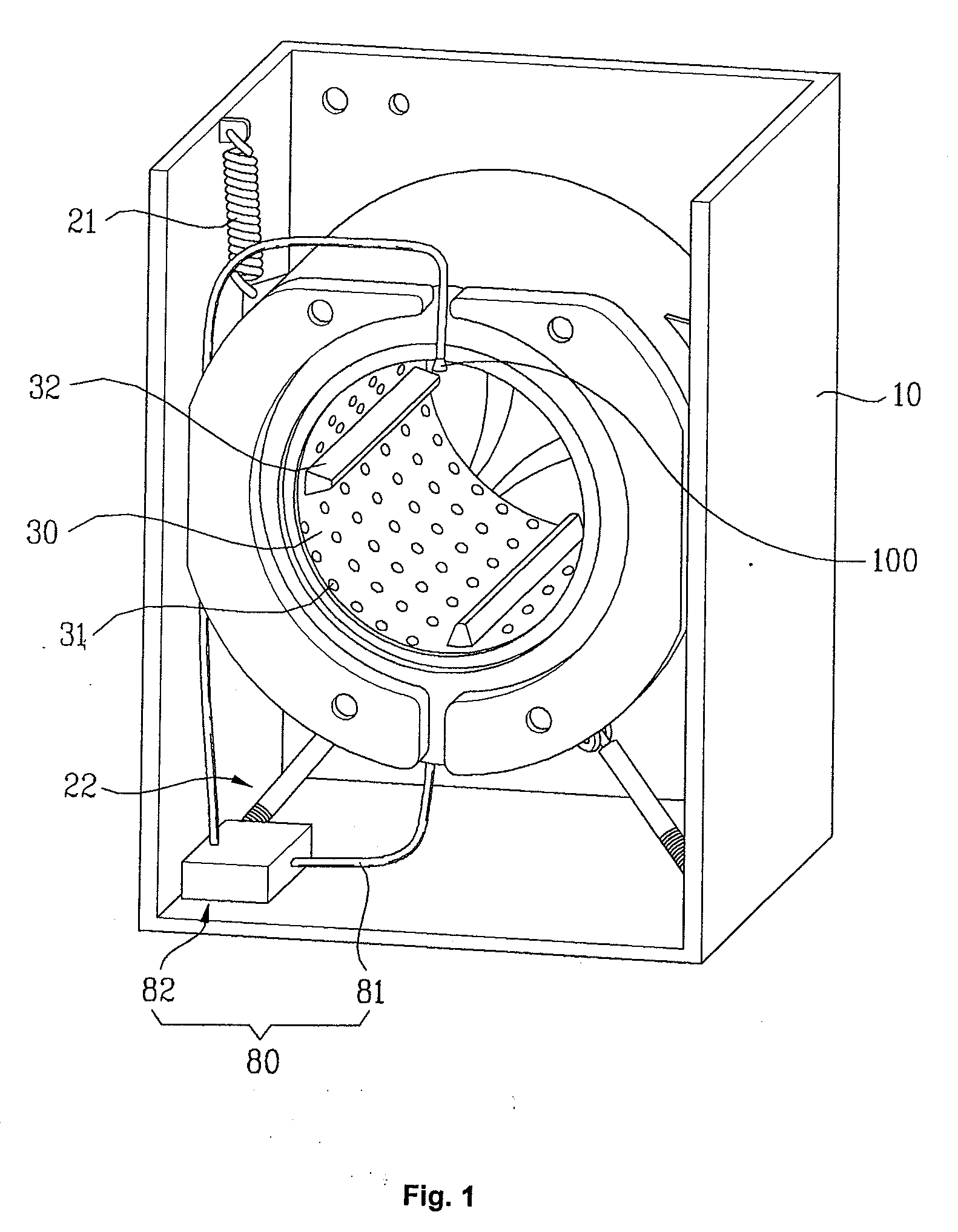

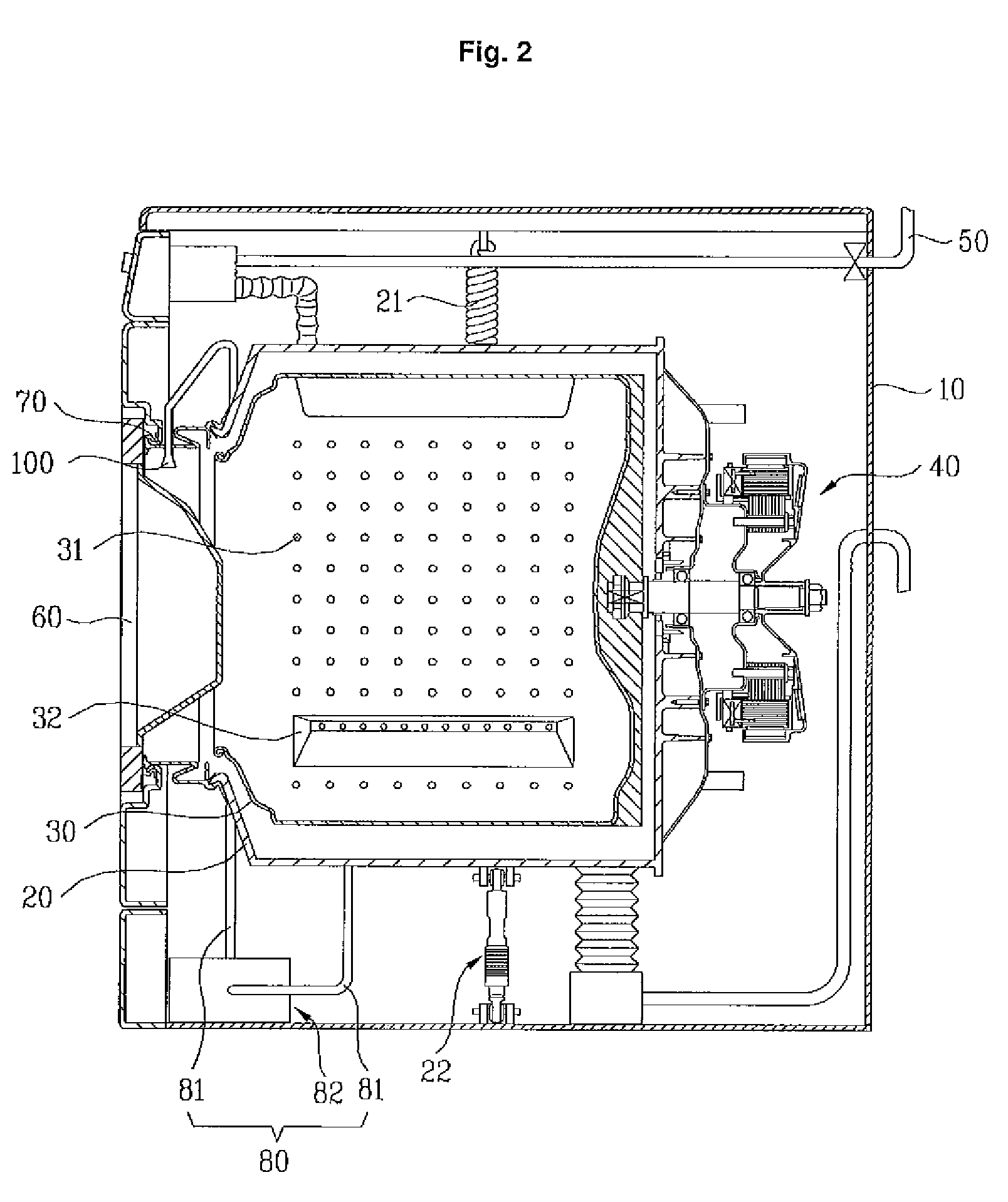

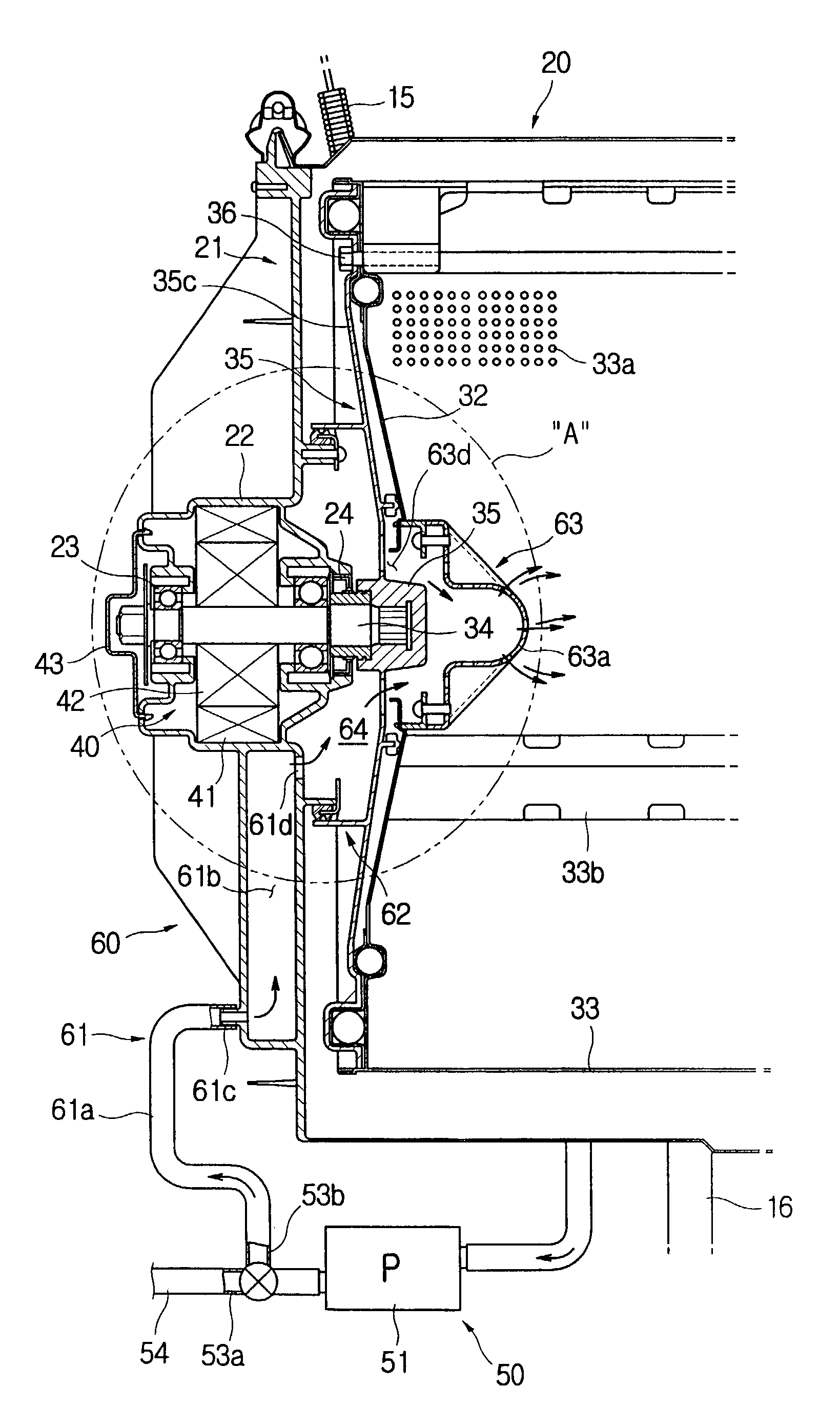

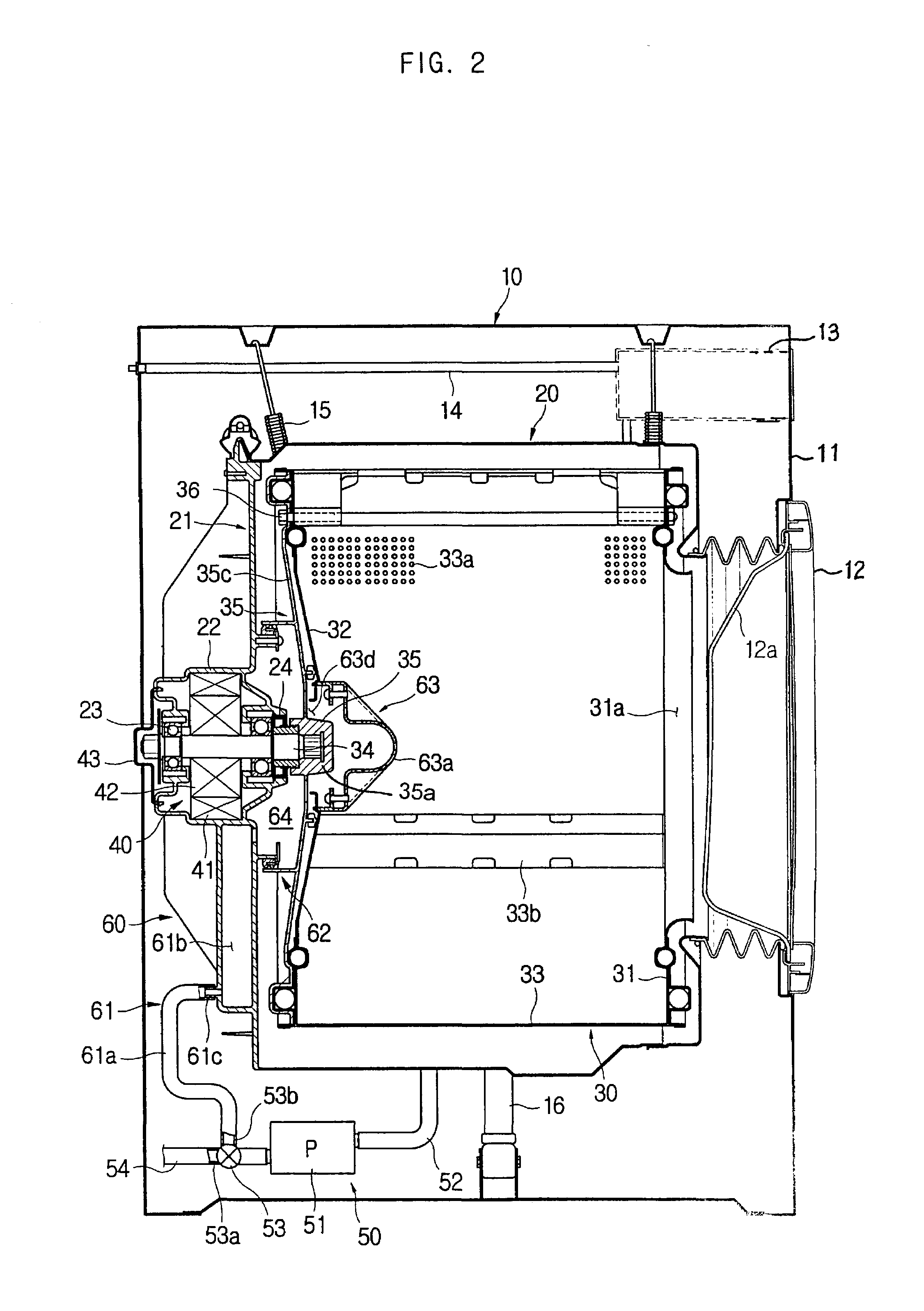

Drum type washing machine

InactiveUS6981395B2Promote water circulationImprove efficiencyTextile treatmentOther washing machinesWash waterWater circulation

A drum type washing machine includes a cabinet, a fixed drum set in the cabinet to contain wash water therein, a rotary drum rotatably set inside the fixed drum, a pump which forcibly pumps out the wash water contained in the fixed drum, and a water circulation device which feeds the wash water pumped by the pump into the rotary drum in a washing operation. The water circulation device includes a storing unit and a spraying unit. The storing unit defines a space which temporarily holds the wash water pumped by the pump, and is provided between rear panels of the fixed drum and the rotary drum. The storing unit guides the wash water to the rear panel of the rotary drum. The spraying unit is provided at the rear panel of the rotary drum, and sprays the wash water contained in the storing unit into the rotary drum.

Owner:SAMSUNG ELECTRONICS CO LTD

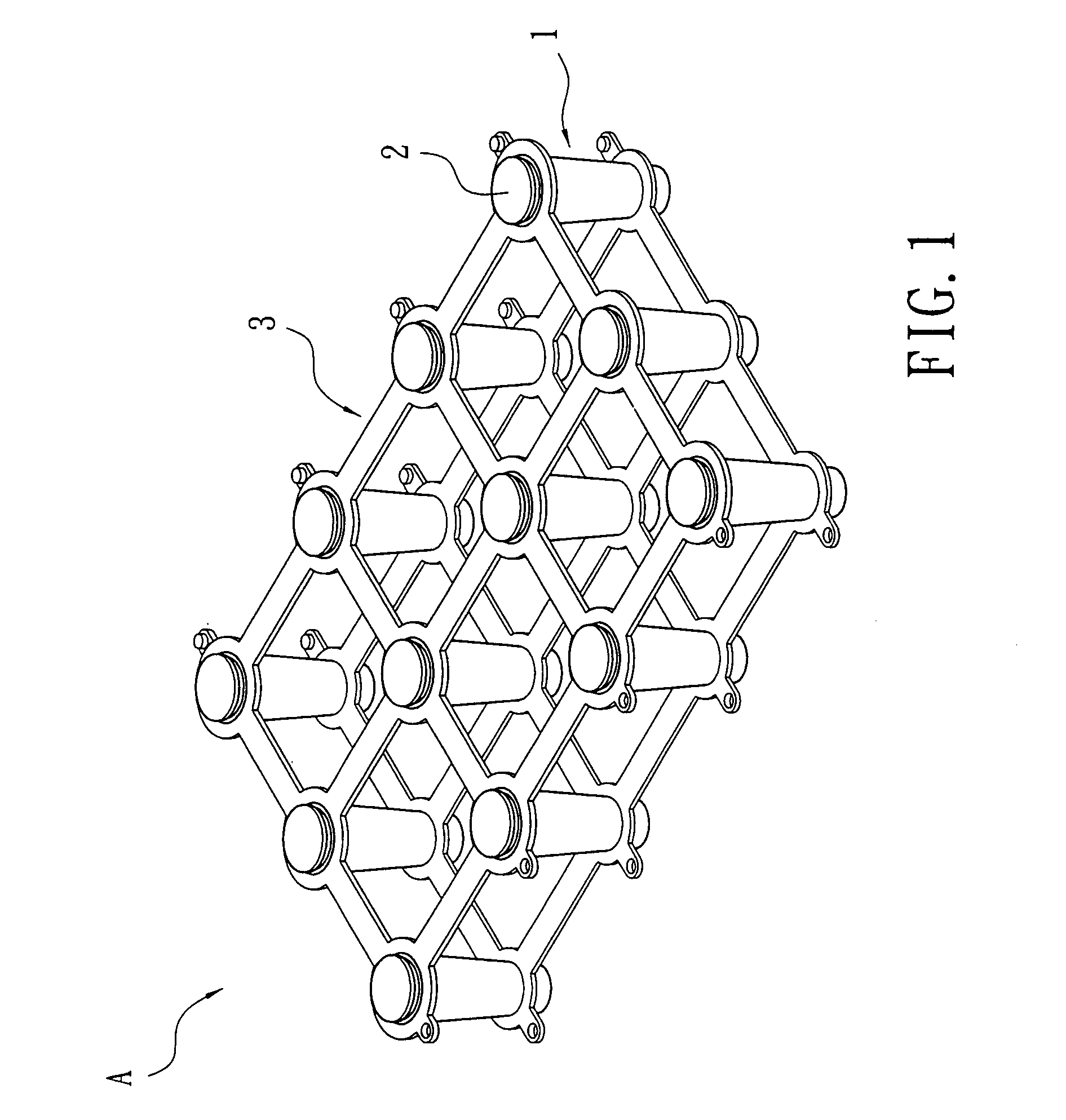

Method for constructing a water resource recycling system

ActiveUS6962464B1Reduce chanceImprove permeabilityGround-workGeneral water supply conservationWater resourcesEngineering

An environmental water resource recycling system of the invention comprises pluralities of drainpipes units, which includes pluralities of drainpipes engaged in pluralities of holder holes formed by coupled frame strips, and sealing lids covering the opening at one end of the drainpipes. An instant water-absorbing sand layer is applied on the soil layer exposed on the ground surface before inserting the lower end of the drainpipes held in the drainpipe unit into the sand layer. Concrete is poured onto the ground to be constructed such that the concrete can integrally cover the drainpipe units. The sealing lids can be removed from the openings on the upper end of the drainpipes after the concrete is solidified, thereby accomplishing a permeable paving and instantly draining the rain on the permeable paving to the sand layer and further to the underground for being recycled as water resource for further utilization.

Owner:CHEN JUI WEN

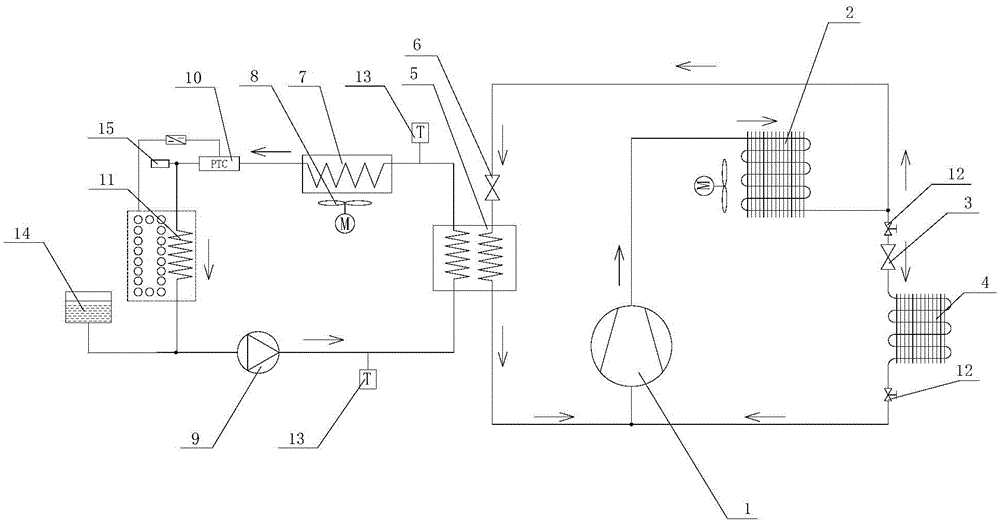

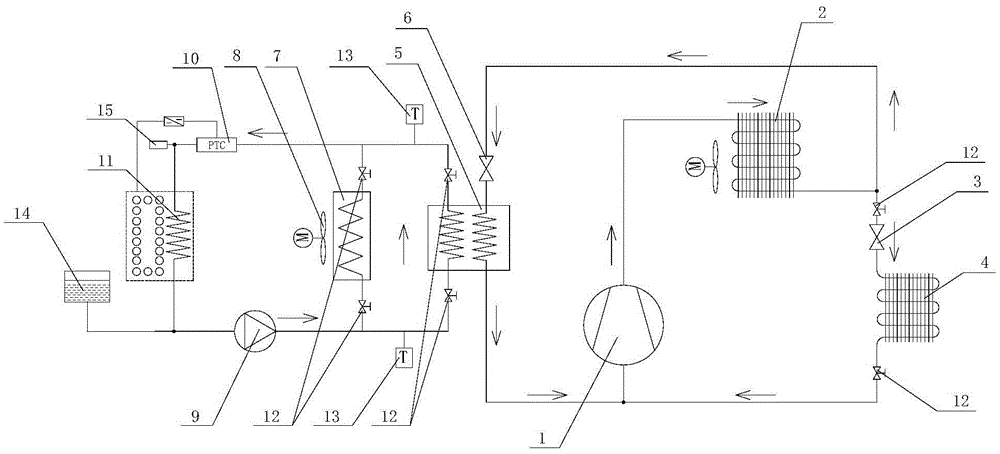

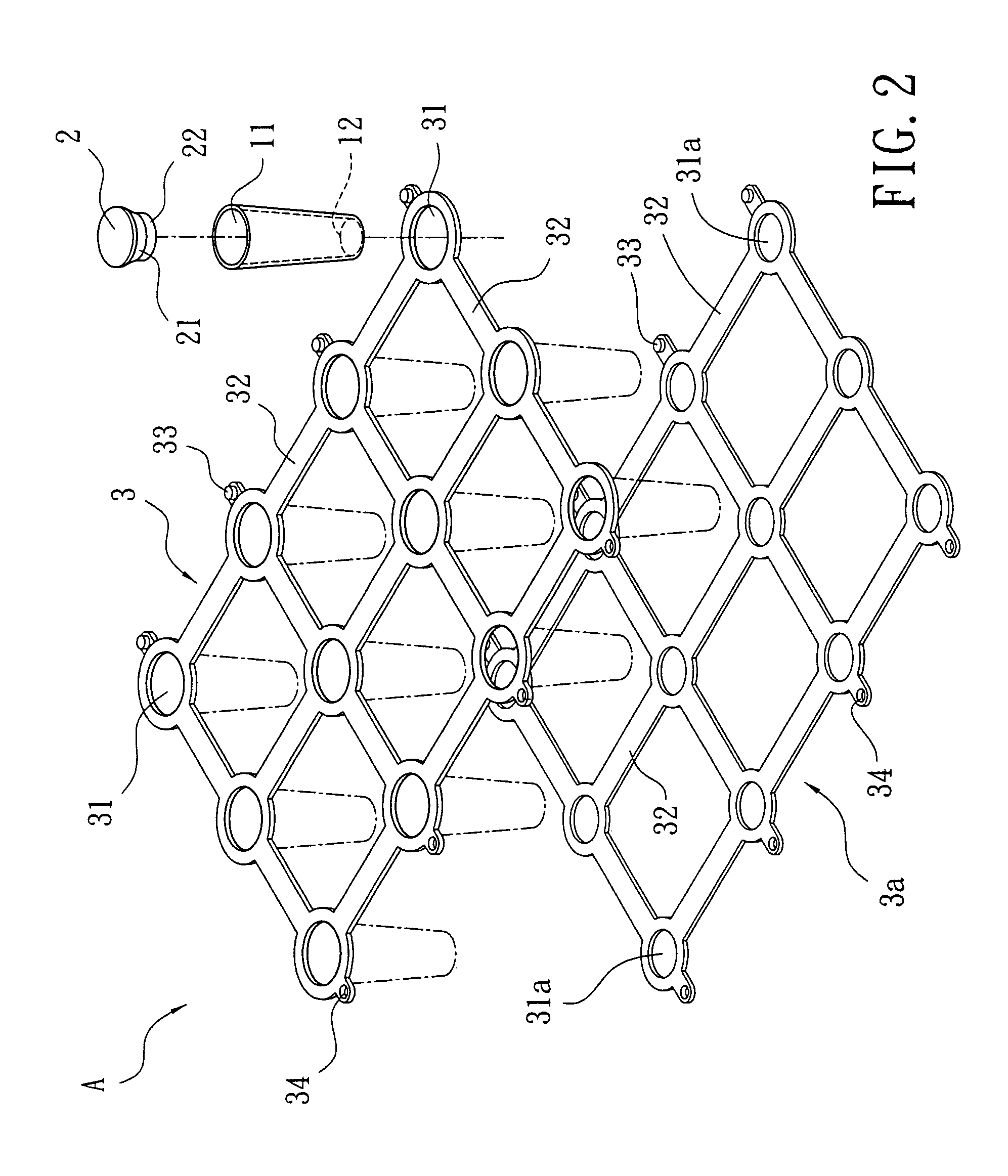

Temperature control dehumidification system and temperature control dehumidification method for fresh air of radiation air conditioner

ActiveCN104329759ASolve the disadvantages of inability to dehumidify and easy condensationSimple structureMechanical apparatusSpace heating and ventilation safety systemsEvaporationEngineering

The invention discloses a temperature control dehumidification system and a temperature control dehumidification method for the fresh air of a radiation air conditioner. The system comprises an air duct system, a radiation water circulation system and a cooling system, wherein the air duct system comprises a fresh return air treatment air duct and an exhaust air heat recovery air duct, which are independent; a pre-cooler / pre-heater and a temperature control heat exchanger are integrated corrugated finned type internally-threaded coiled pipes, and are connected with a radiation water inlet / outlet pipeline to form the radiation water circulation system; one stage of evaporator is used for direct evaporation, and two stages of condensers are connected in parallel to form a double-stage condensation cooling compression system. The system can be combined with the radiation air conditioner to independently control temperature and humidity, and besides a conditioning treatment function of a conventional dehumidification system, the system also has an exhaust air heat recovery function; a household compression cooling air conditioner is combined with the dehumidification system to realize cooling in summer, heating in winter and humidification in transition seasons; the running energy consumption is greatly lowered, and the shortcomings of dehumidification incapability and high condensation rate of the radiation air conditioner are overcome.

Owner:UNIV OF SHANGHAI FOR SCI & TECH +1

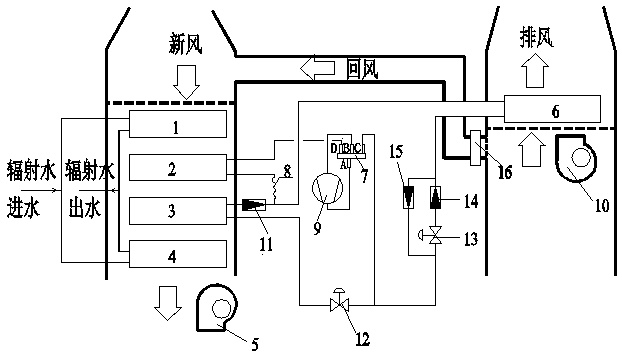

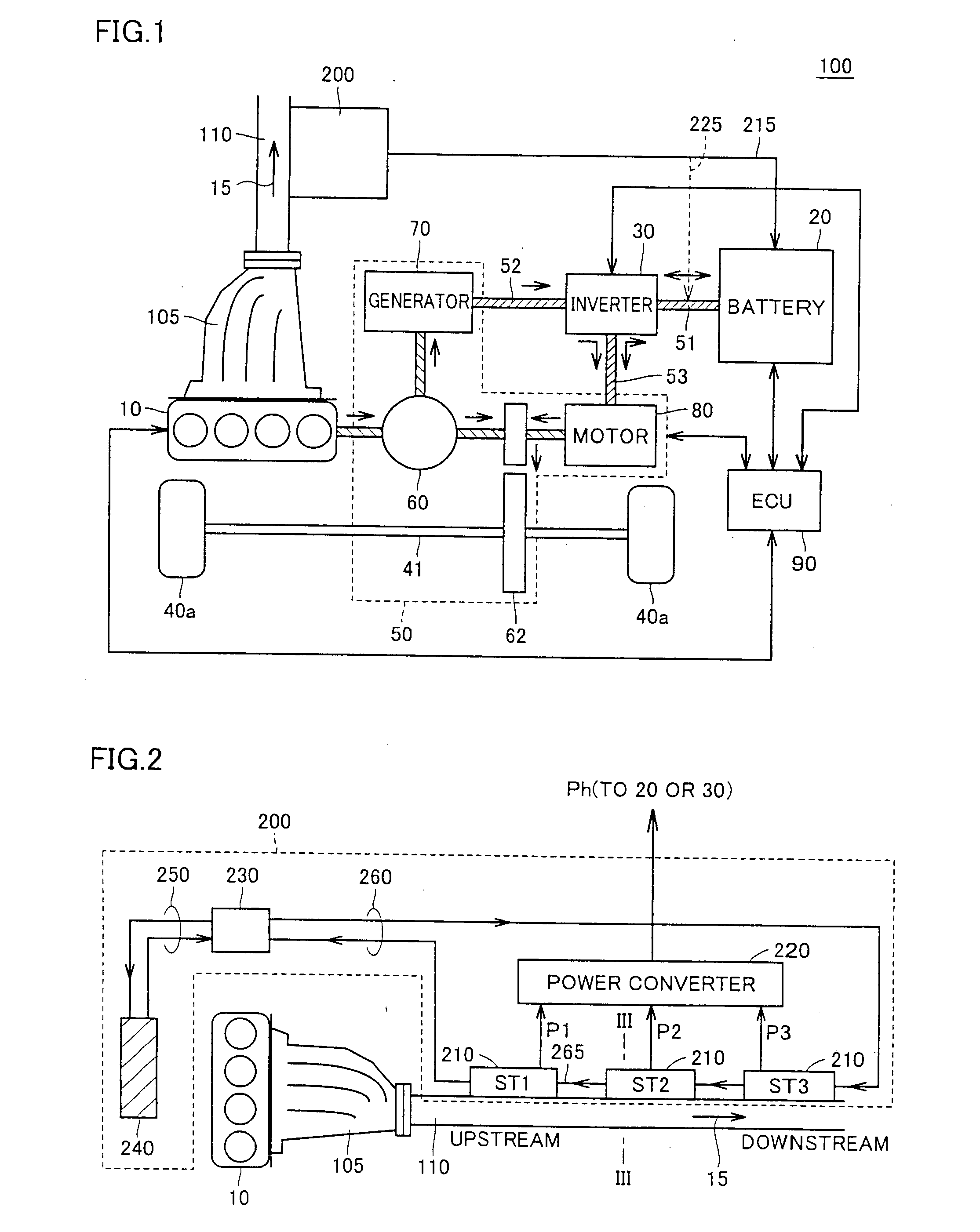

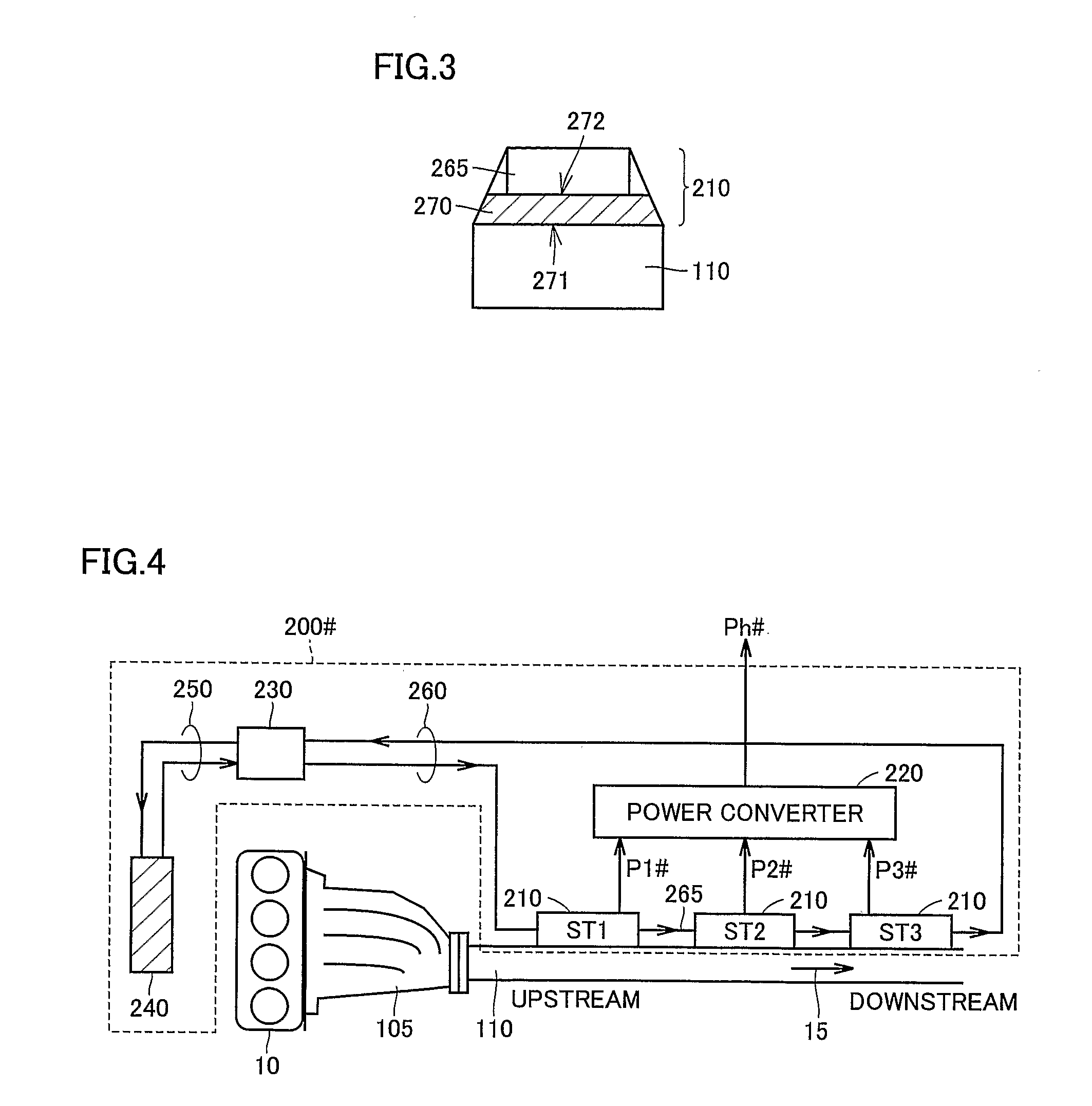

Exhaust heat recovery power generation device and automobile equipped therewith

InactiveUS20070193617A1Low efficiencyHigh power outputHybrid vehiclesInternal combustion piston enginesExhaust fumesEngineering

An engine exhausts gas which is in turn exhausted through an exhaust pipe in a prescribed direction. A cooling water pump supplies cooling water to circulate a refrigerant through each of cooling water circulation paths. The cooling water circulation path includes a cooling water pipe arranged along the exhaust pipe to pass the cooling water. At stacks a plurality of thermoelectric power generation elements are attached to the exhaust pipe and the cooling water pipe successively in a direction from the upstream toward downstream of the exhaust gas. The cooling water pipe and the exhaust pipe pass the cooling water and the exhaust gas, respectively, in opposite directions so that the downstream stack has an increased difference in temperature between the exhaust pipe and the cooling water pipe, and the stacks provide power outputs having a reduced difference, and hence an increased total power output. Thus an exhaust heat recovery power generation device can provide increased thermoelectric conversion efficiency without complicated piping.

Owner:TOYOTA JIDOSHA KK

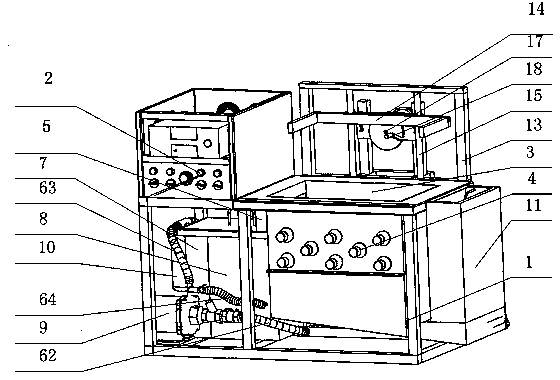

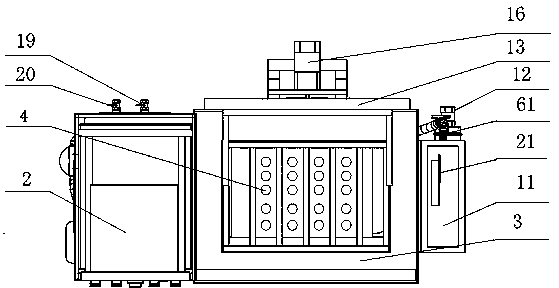

Ultrasonic cleaner

ActiveCN103878143AConsistent cleanlinessReduce replacement cycleCleaning using liquidsFiltrationWater storage tank

The invention discloses an ultrasonic cleaner and belongs to the field of mechanical equipment cleaning. The ultrasonic cleaner solves the problems that cleaning fluid in an existing ultrasonic cleaner cannot remove impurities in time, and the cleaning fluid is wasted. The ultrasonic cleaner comprises a rack (1), an ultrasonic generator (2), a cleaning tank (3) and ultrasonic vibrators (4). A water circulation device is arranged on the outer side of the cleaning tank (3) and comprises an overflow tank (5) arranged on one side of the cleaning tank (3). The water circulation device further comprises the overflow tank, an oil contamination tank (7), a water storage tank (8), a water pump (9), a filter (10) and a water injection tank (11). The bottom of the water injection tank (11) is communicated with the cleaning tank (3). The bottom of the cleaning tank (3) is an inclined plane. The ultrasonic cleaner integrates the functions of heating, ultrasonic waves, circulating filtration, oil-water separation and article movement, the cleaning speed is high, and the cleaning effect is good; besides, the ultrasonic cleaner is multifunctional, low in energy consumption and capable of prolonging the replacement cycle of the cleaning fluid and reducing environmental pollution, thereby being wide in application range.

Owner:台州鸿辰机械制造有限公司

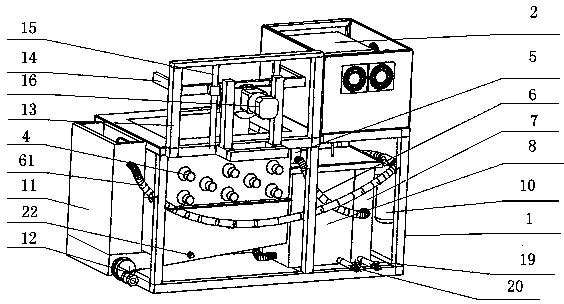

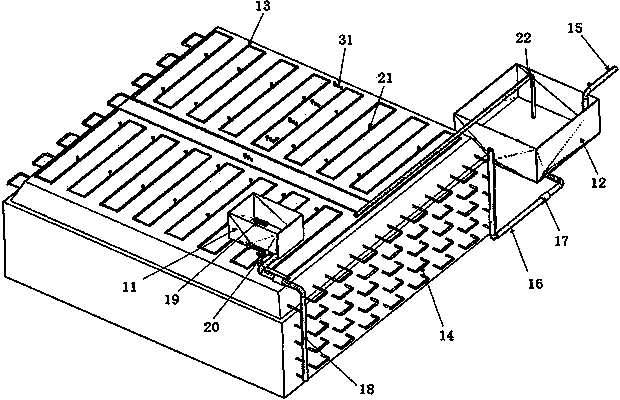

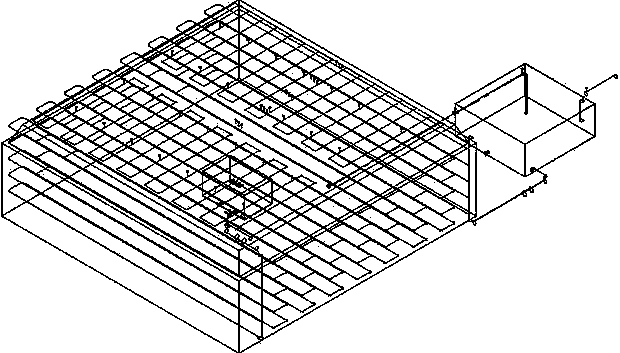

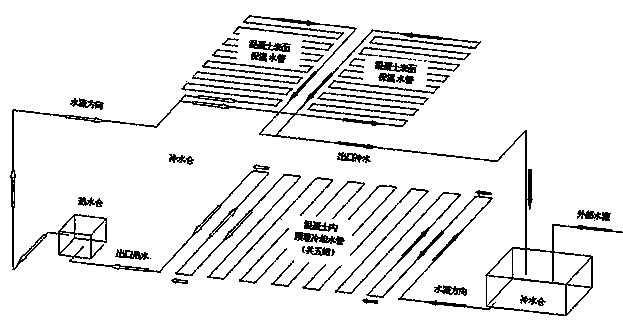

Large-sized concrete automatic temperature control and maintenance device and method

ActiveCN103526761AIncrease surface temperatureTemperature monitoring and automatic adjustmentFoundation engineeringTemperature controlSprayer

The invention discloses a large-sized concrete automatic temperature control and maintenance device and method, wherein the temperature control device comprises a water circulation system, a temperature measuring device and a temperature control system. The water circulation system comprises a hot water cabin, a cold water cabin, a heat-preservation water tube and a cooling water tube, the cold water cabin is arranged outside a concrete foundation, the cooling water tube is buried inside the concrete, the hot water cabin is arranged at the top of the concrete foundation, and a heater is arranged in the hot water cabin. The heat preservation water tube is buried in the upper portion of the concrete foundation in advance and is respectively communicated with the hot water cabin and the cold water cabin, and a sprayer is arranged on the heat preservation water tube. The temperature measuring device is buried inside the concrete foundation in advance and is connected with the temperature control system. The temperature control system is connected with the water circulation system, and the water circulation of the water circulation system is controlled according to the temperature measured by the temperature measuring system. According to the large-sized concrete automatic temperature control and maintenance device and method, the monitoring and automatic adjustment of the temperature, the flowing speed and pressure of the cooling water and heat-preservation water are achieved through the temperature control system, and the timing automatic spraying and maintenance function can also be achieved.

Owner:CHINA FIRST METALLURGICAL GROUP

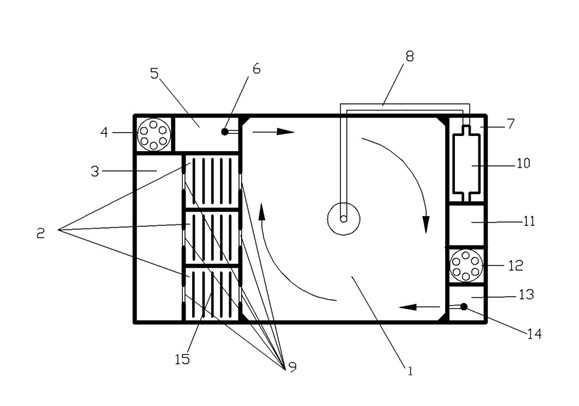

Water circulation system and method for breeding marine fishes inland

ActiveCN101933489AActivates and strengthens osmoregulatory mechanismsImprove adaptabilityClimate change adaptationPisciculture and aquariaJuvenile fishFresh water organism

The invention relates to a water circulation system and a method for breeding marine fishes inland, and mainly solves the technical problems of complex process, large investment, high operating cost, large limitation of breeding varieties, low survival rate, slow growth and the like in the process of breeding the marine fishes in fresh water or low salinity salt water at present. A technical scheme comprises the following steps of: a, establishing the water circulation system; b, performing domestication on juvenile fishes of the marine fishes in the low salinity salt water in a gradient mode, namely breeding the juvenile fishes which are bred in the seawater in the brackish water temporarily, formulating a domestication strategy of slowing salinity gradually, and performing domesticationon the juvenile fishes of the marine fishes through three gradients, namely the brackish water phase, the low salinity phase and the ultra-low salinity phase; c, adding a physiological salt preparation, namely adding metal ions which play a key role in osmoregulation into the water or a feed; and d, managing the breeding, namely providing a preference temperature, illumination intensity and a daily illumination period. The water circulation system and the method are mainly used for breeding the marine fishes inland.

Owner:SUZHOU FISHSEEDS BIOLOGICAL TECH CO LTD

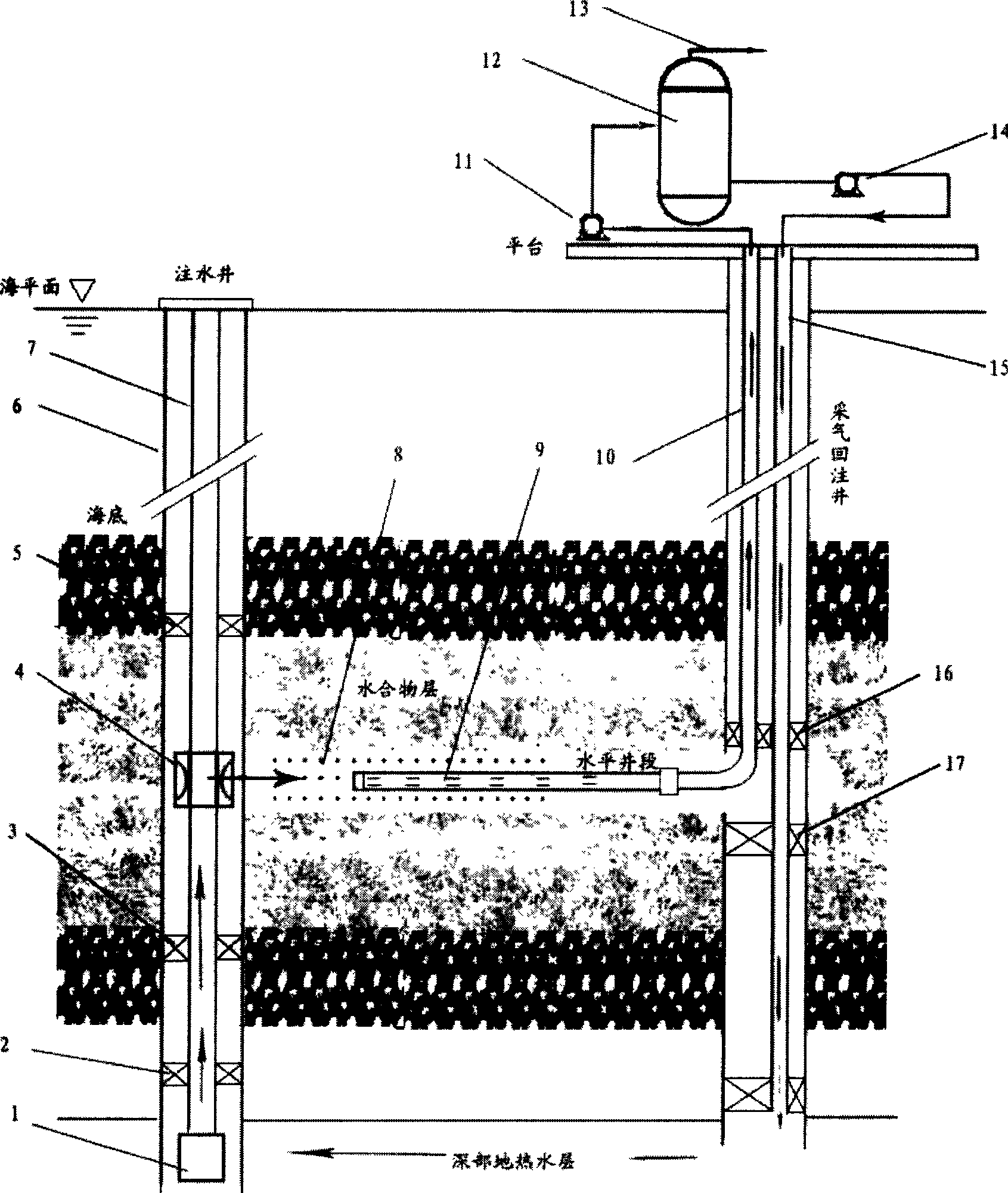

Method for extracting hydrate on bottom of sea by deep earth heart water circulation

InactiveCN1786416AEasy to operateAvoid sewageConstructionsMineral miningOcean bottomWater circulation

The invention offers a method of exploiting seabed hydrate. It includes the following steps: using at least two well arrays to form a injecting exploiting well array; using horizontal or deflected section to connect with water injection well and gas production well at hydrate layer; transferring carried heat quantity to hydrate to make it decompose; exploiting the decomposed natural gas; separating gas and water; injecting the separated water to deep part geothermal water layer. The invention combines heating and decompression. The invention has the advantages of simple equipment, convenient operation, and environmental protection. It can apply in large scale exploiting seabed hydrate.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

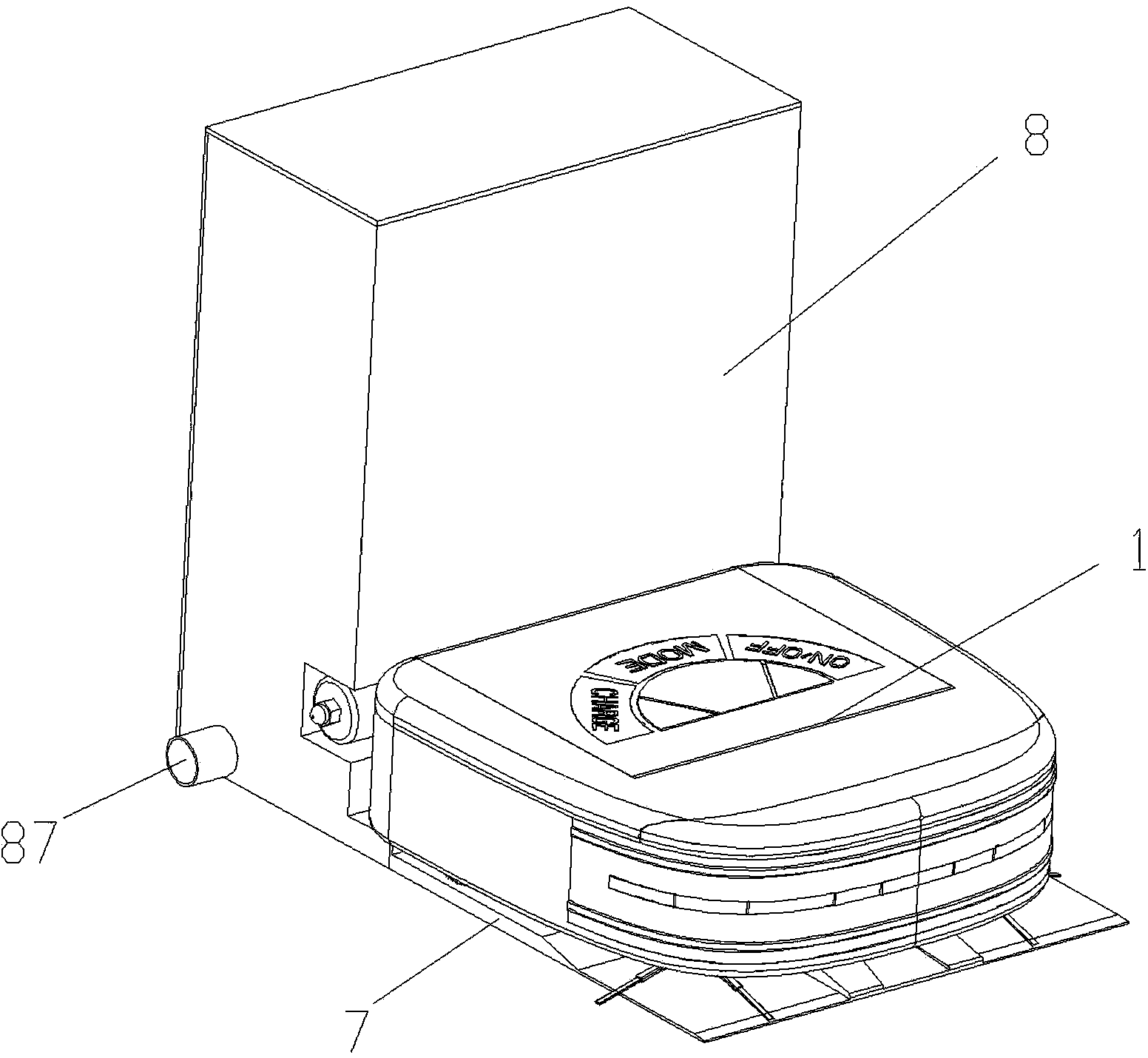

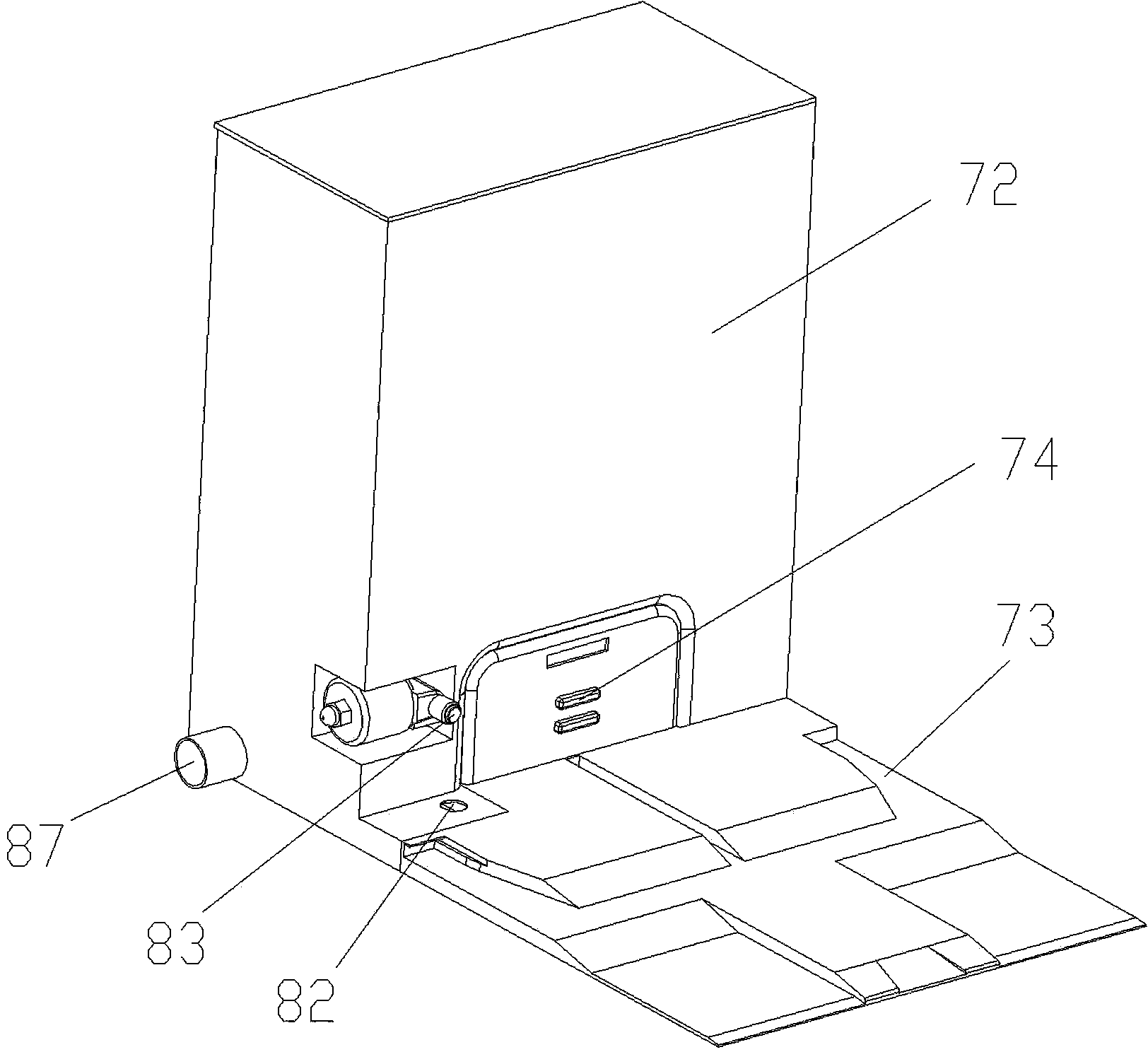

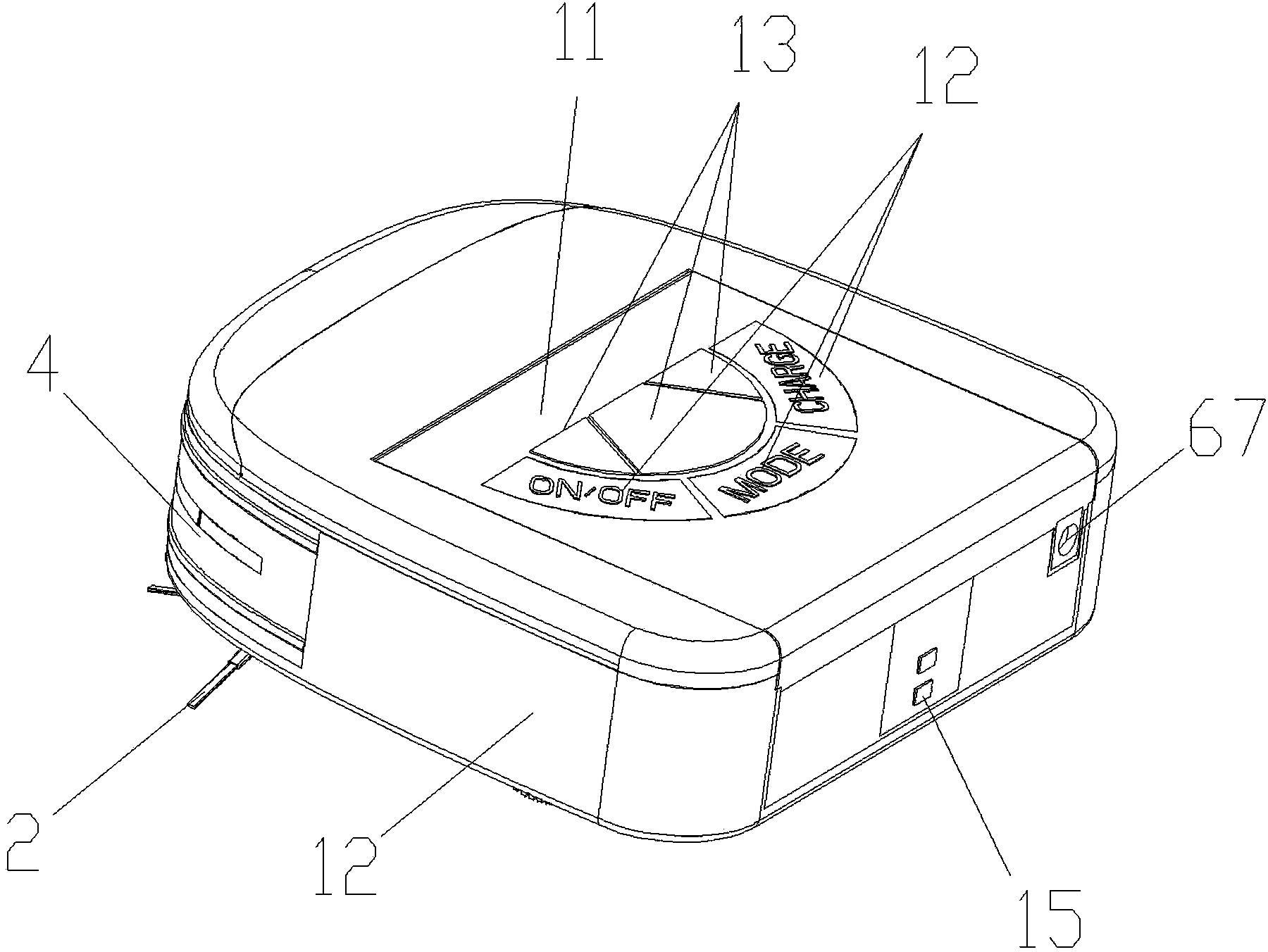

Intelligent mopping machine

ActiveCN104257330ARealize high intelligenceMeet the needs of automatic cleaning indoor sanitationMachine detailsFloor-scrubbing machinesDrive wheelControl system

The invention discloses an intelligent mopping machine. The intelligent mopping machine comprises a main machine and a recharging station for automatically recharging the main machine, a sweeping component, a driving wheel component, an obstacle avoiding device, a mopping component, a power system and a control system are arranged inside the main machine, the mopping component comprises a wiping unit and an internal water tank, and the recharging station is also provided with an external water tank which can automatically exchange water with the internal water tank. When the main machine returns to the recharging station for recharging, the control system opens the water exchange between the internal water tank and the external water tank. The intelligent mopping machine can achieve automatic recharging through the recharging station, achieve automatic water circulation through the internal water tank and the external water tank, achieve automatic and synchronous sweeping and mopping through the sweeping component and the mopping component, truly achieve intelligent control of the mopping machine in combination with the driving wheel component and the obstacle avoiding device arranged inside the main machine and meet the demand for automatic indoor cleaning by machines.

Owner:陈国英

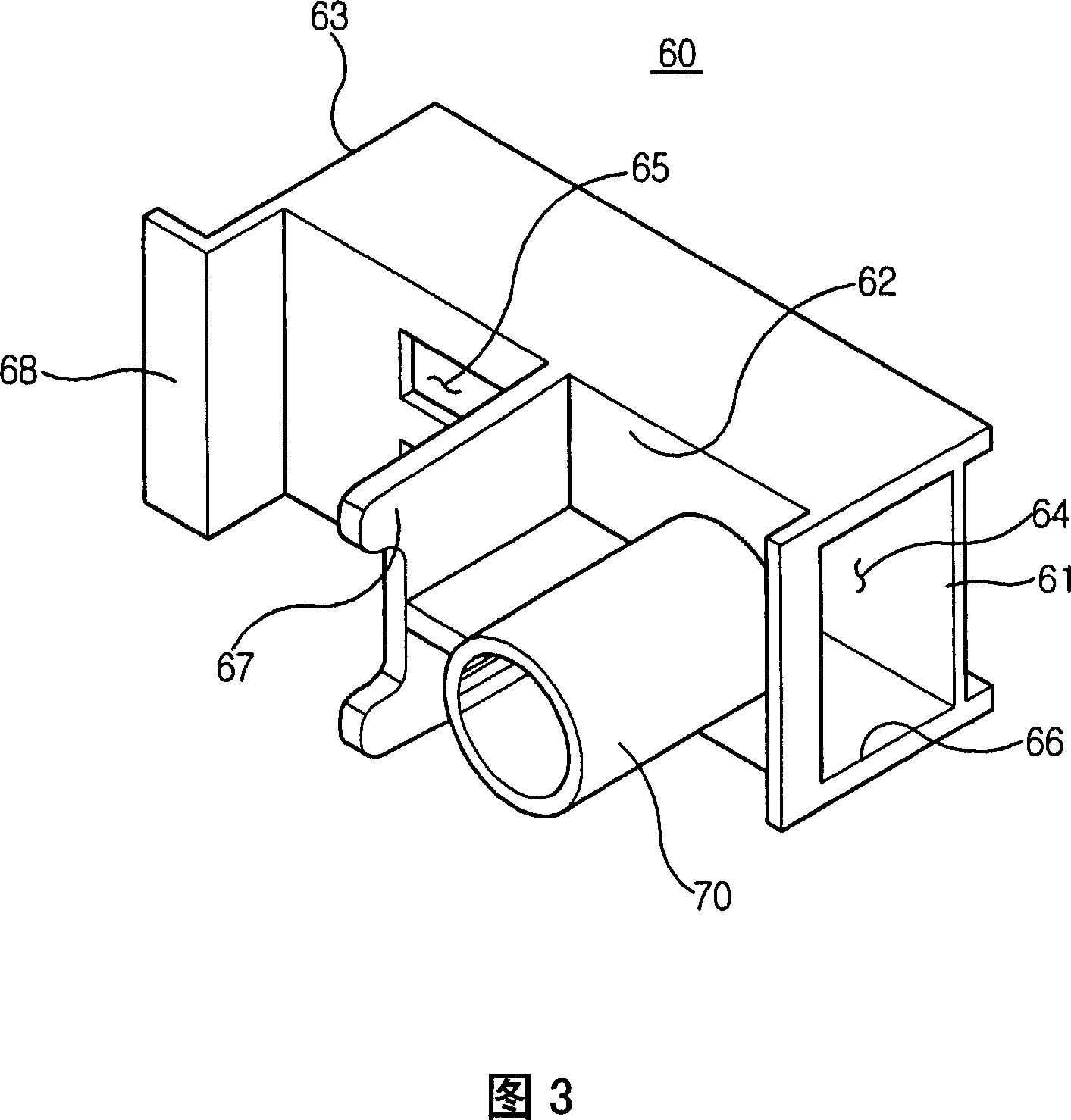

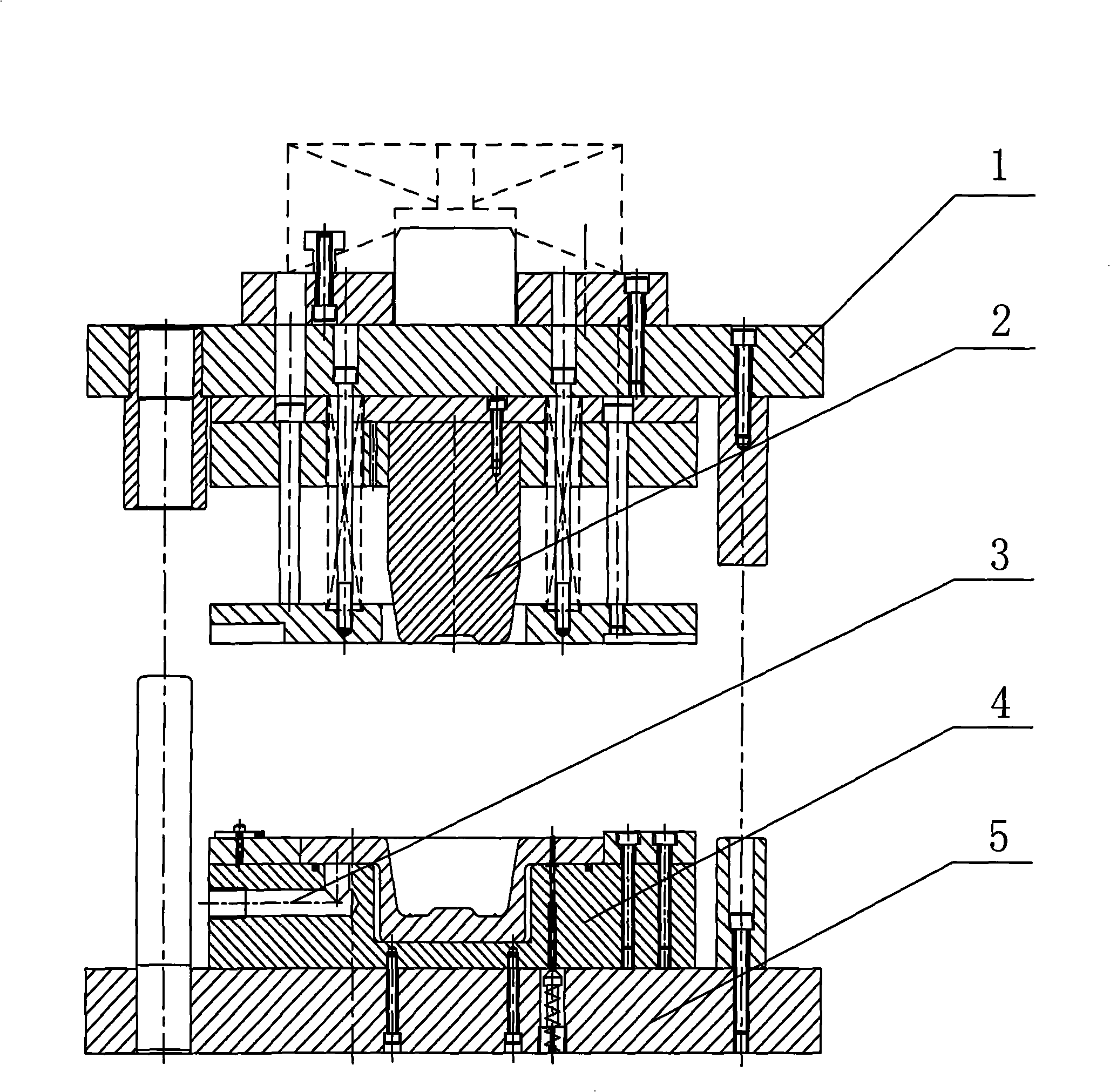

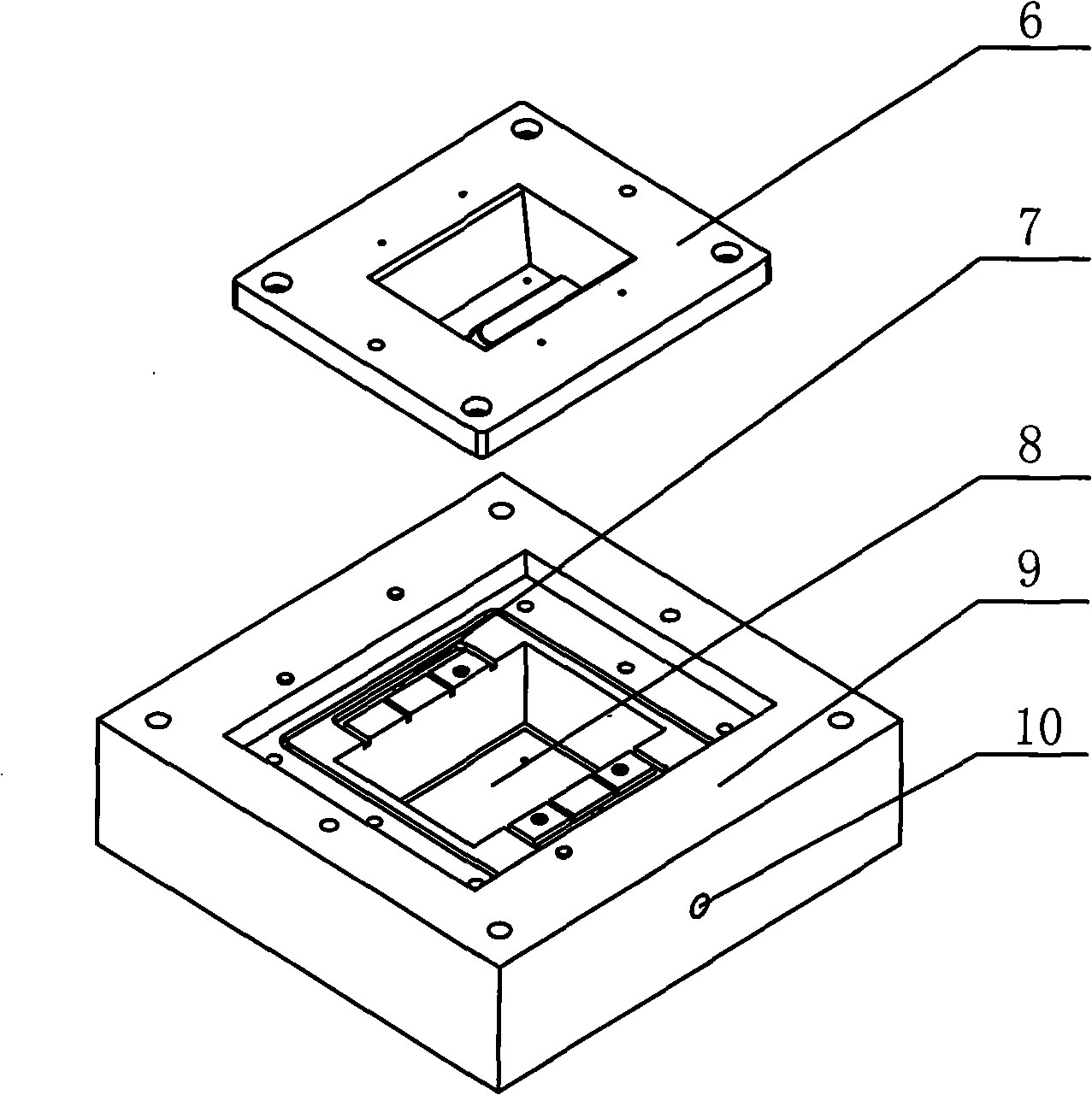

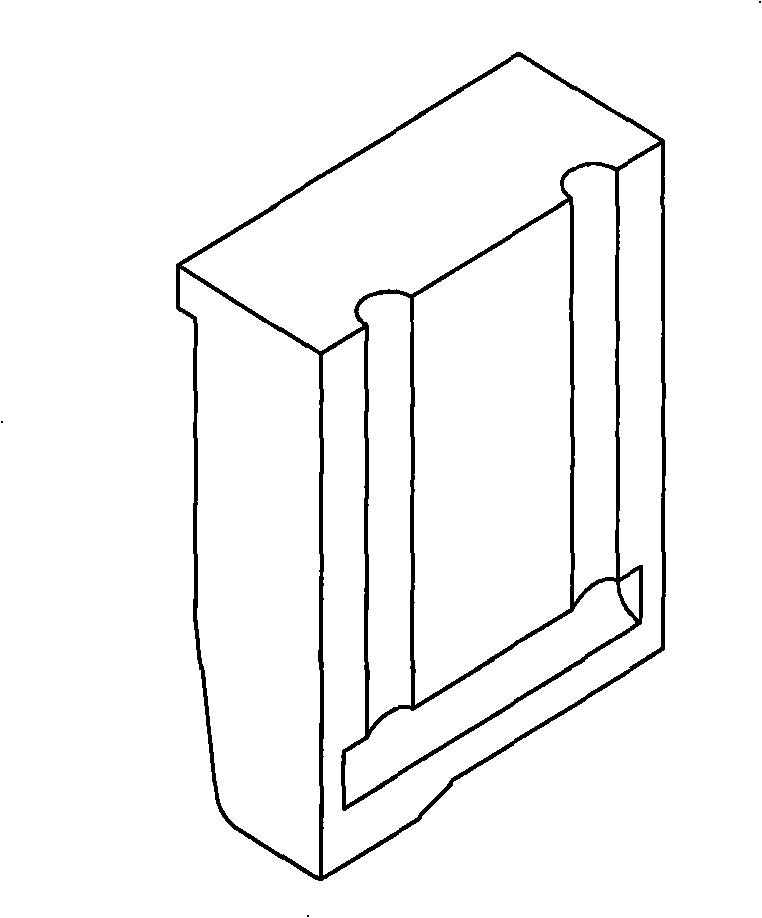

Ultra-high strength steel hot stamping forming die

The invention discloses an ultra-high strength steel plate thermal die cutting and forming die, comprising an upper die seat and a convex die which is fixed on the upper die seat, a lower die seat and a concave die that is fixed on the lower die seat; the concave die is internally provided with a cooling water passage which is connected with a cooling water circulation system. More particularly, the concave die is compose of a trough-shaped concave die seat and a cavity body; the concave die seat is provided with a water inlet and a water outlet; the cavity body is arranged in the concave trough of the concave die seat; a gap is arranged between the cavity body and the concave die seat; the gap is communicated with the water inlet and the water outlet. The die improves cooling speed, ensures the uniformity of cooling, has simple and practical structure, and fast cools the die and the punching parts in the die by the water cooling system of the die, so as to achieve the effect of quenching. As the process is completed under the pressure preservation process of the die, the workpiece has extremely small deformation and the dimension precision of the punching part can be excellently ensured.

Owner:SAIC VOLKSWAGEN AUTOMOTIVE CO LTD +1

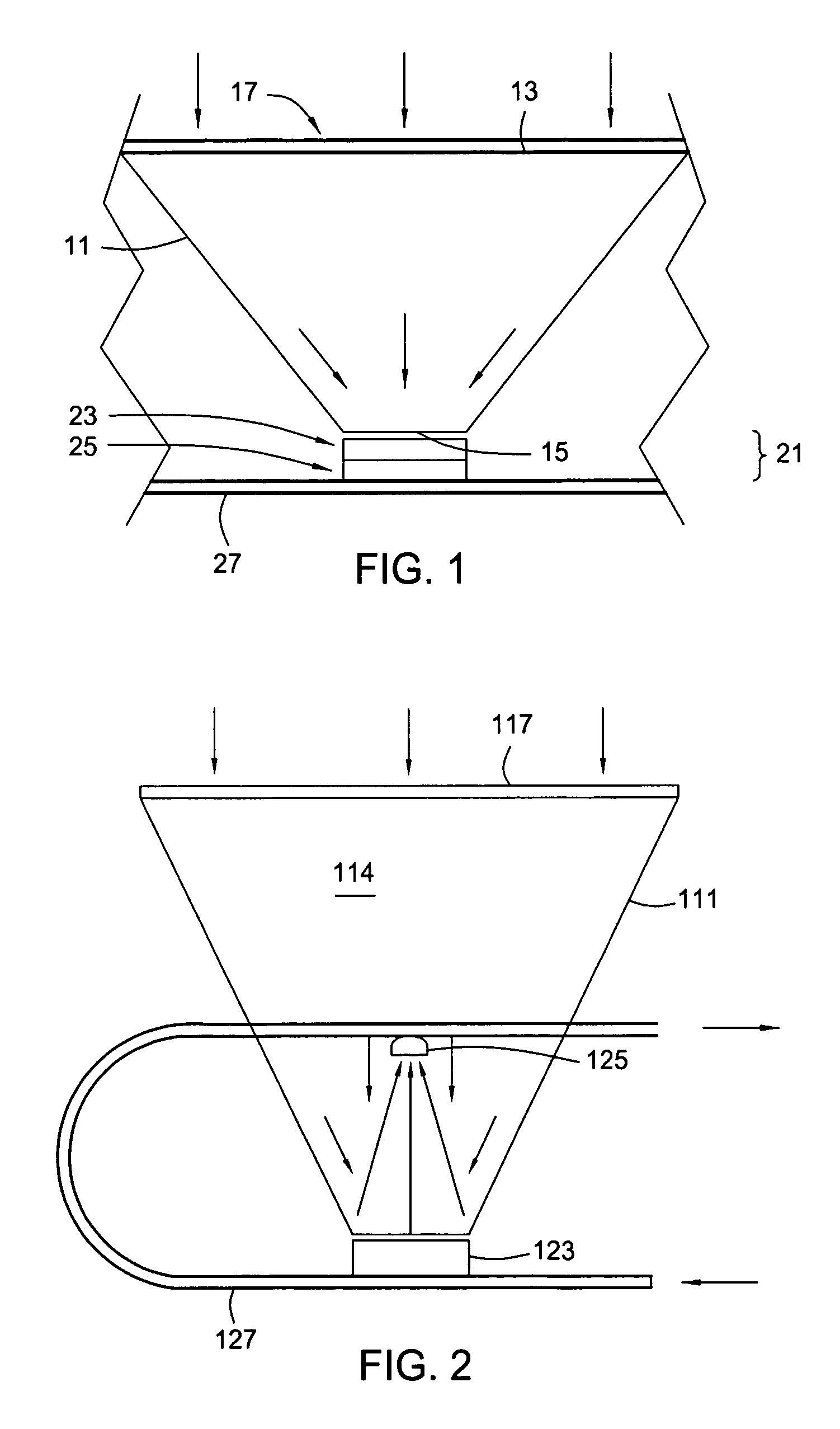

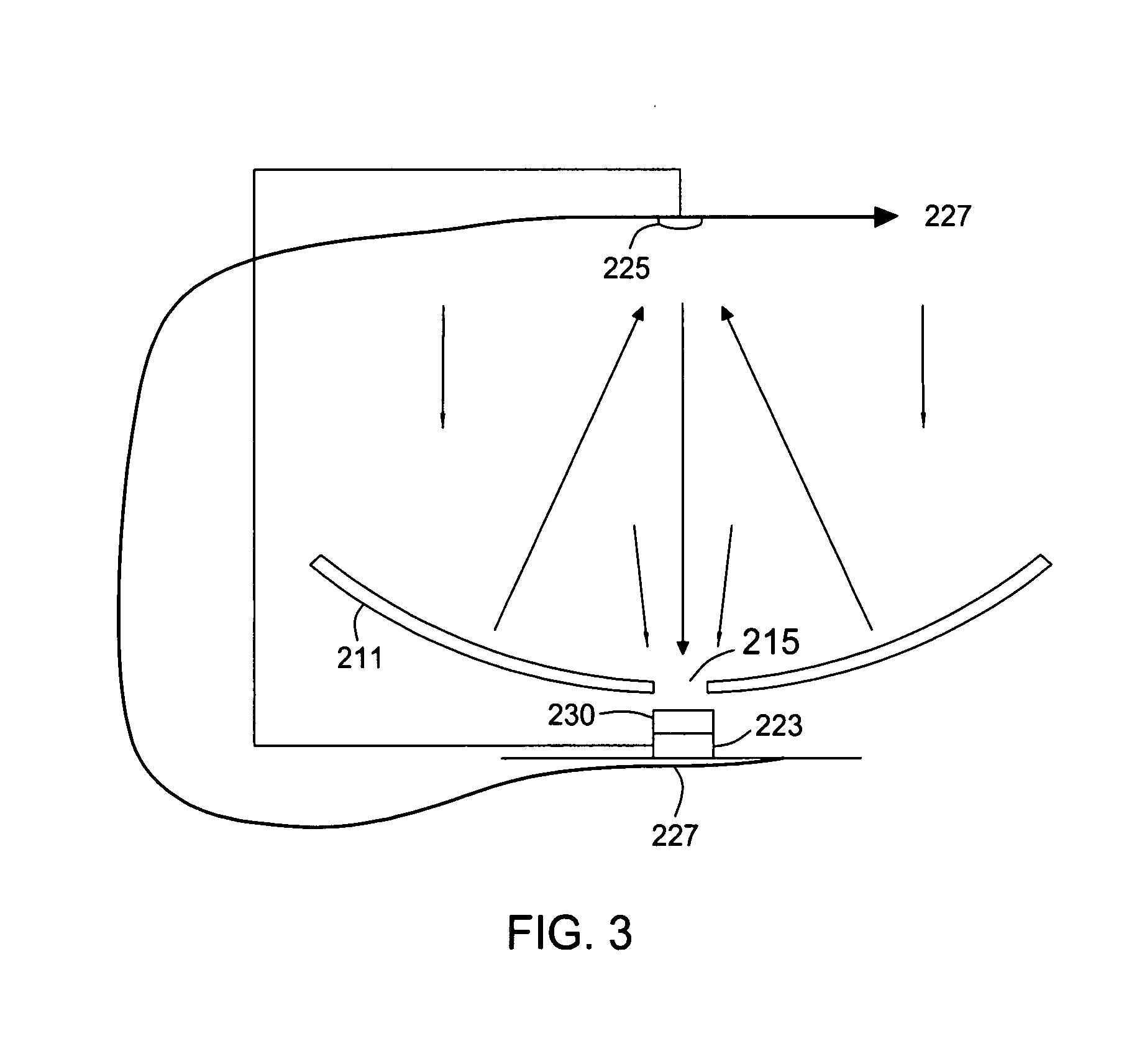

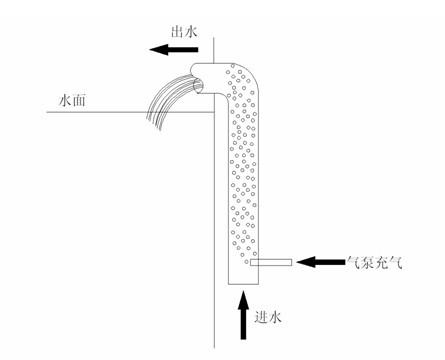

Aeration device and method for creating and maintaining facultative lagoon

InactiveUS6103123ATreatment using aerobic processesFlow mixersFacultative lagoonEnvironmental engineering

A facultative lagoon, an airlift aerator for such a lagoon, and a method of operating such a lagoon. The aerator includes a U-shaped body with a down flow leg and an airlift leg and a float. The float sustains the U-shaped body with respect to the surface of polluted material contained in the lagoon. The upper ends of the legs are submerged slightly beneath the surface of the material in the lagoon. The down flow leg has a water inlet and the airlift leg has the water outlet. A bubble generator is connected to a lower portion of the airlift leg. Air supplied under pressure to the bubble generator introduces bubbles into the airlift leg which establishes a water circulation through the U-shaped body. Bubbles transfer oxygen to the passing water which is disbursed through the water outlet. The dissolved oxygen is used in the biodegradation of the hazardous and odorous gases of the waste material that would otherwise be emitted into the atmosphere.

Owner:GANTZER CHARLES J

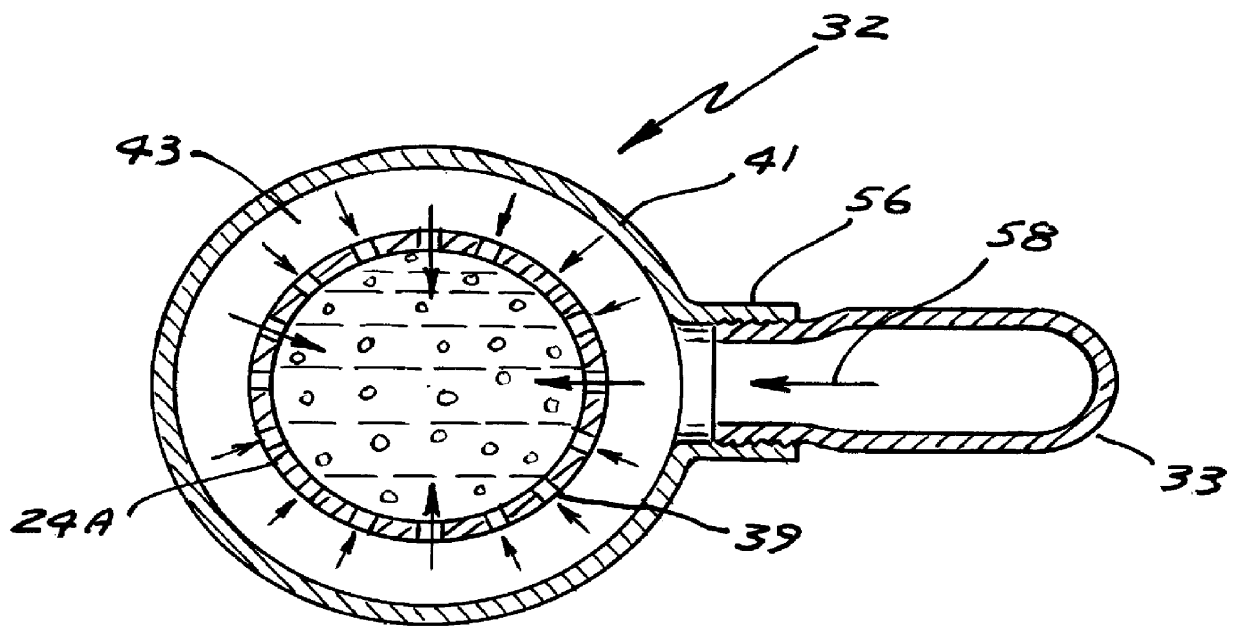

Hydrotherapy circulation and cleaning system

InactiveUS20050120473A1Reduce riskEasy to disassembleBathing devicesEnvironmental engineeringWater circulation

A spa, whirlpool or hot tub hydrotherapy system comprised of a unitized pump and motor assembly to provide a pipeless water circulation and air injection system that is easy to clean. The system can optionally provide an ionization device, which injects a stream of silver, copper and zinc ions into the water to kill bacteria, mold and algae, and solid-state lighting.

Owner:MCDOUGALL EUGENE MR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com