Patents

Literature

5144 results about "Threaded pipe" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A threaded pipe is a pipe with screw-threaded ends for assembly.

Threaded pipe with surface treatment

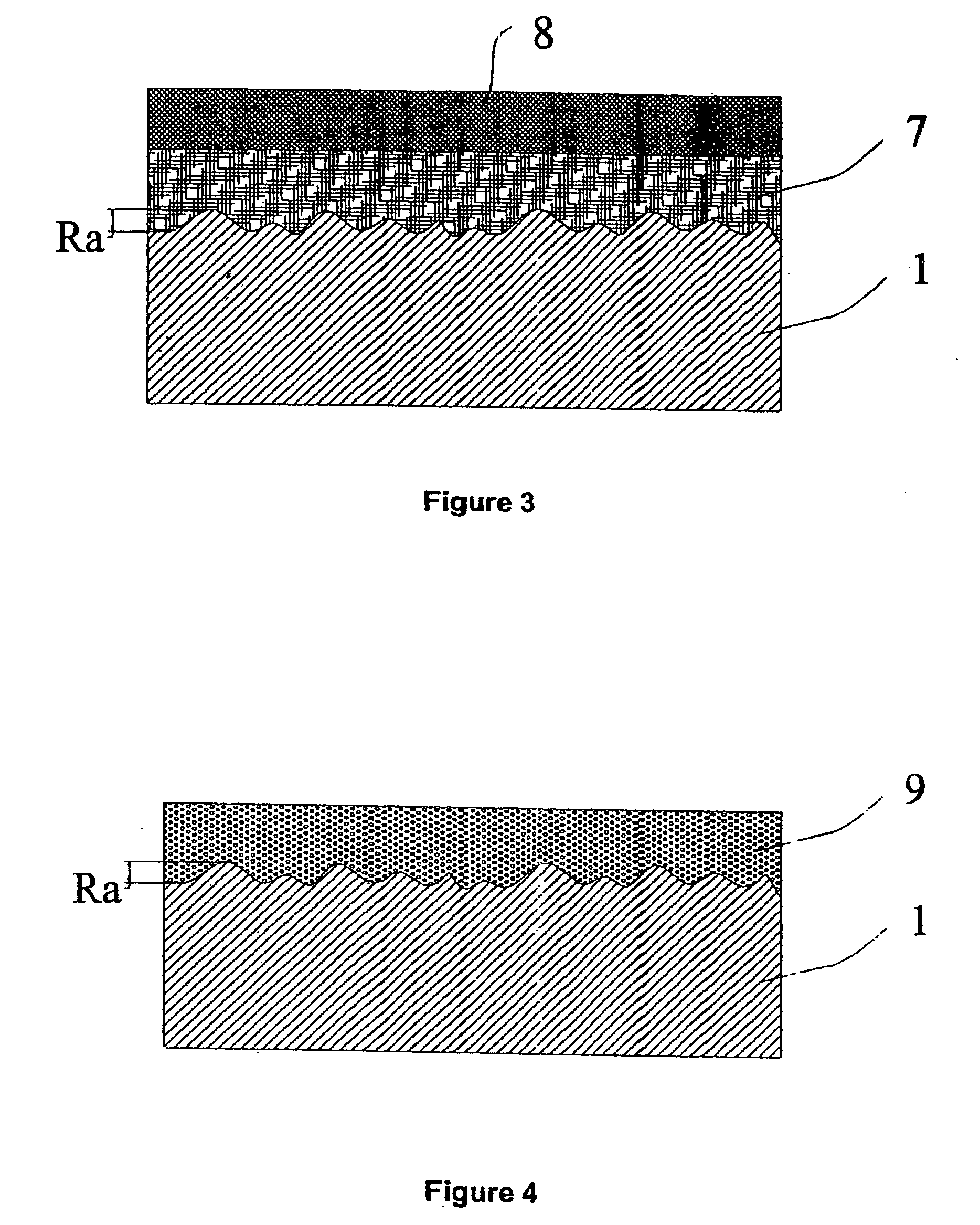

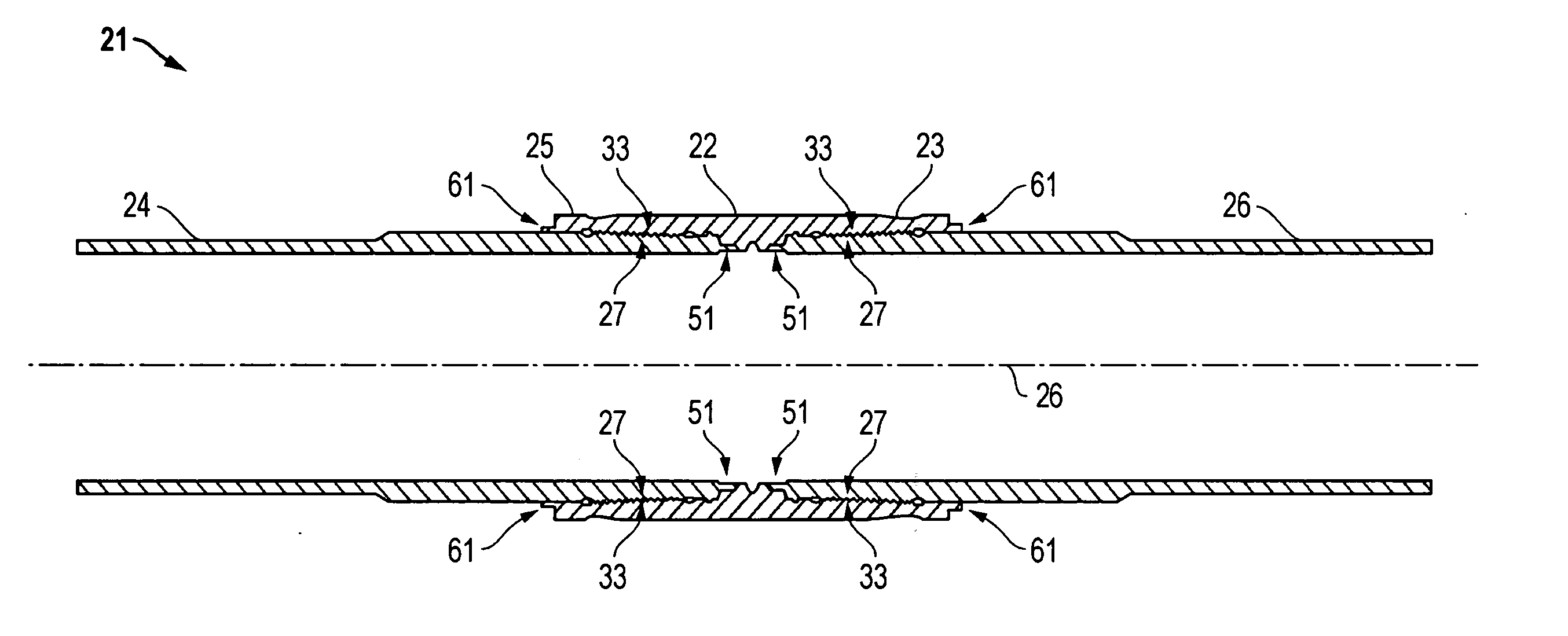

InactiveUS6971681B2Maintain good propertiesIncrease resistanceDrilling rodsPipe elementsThreaded pipeDry lubricant

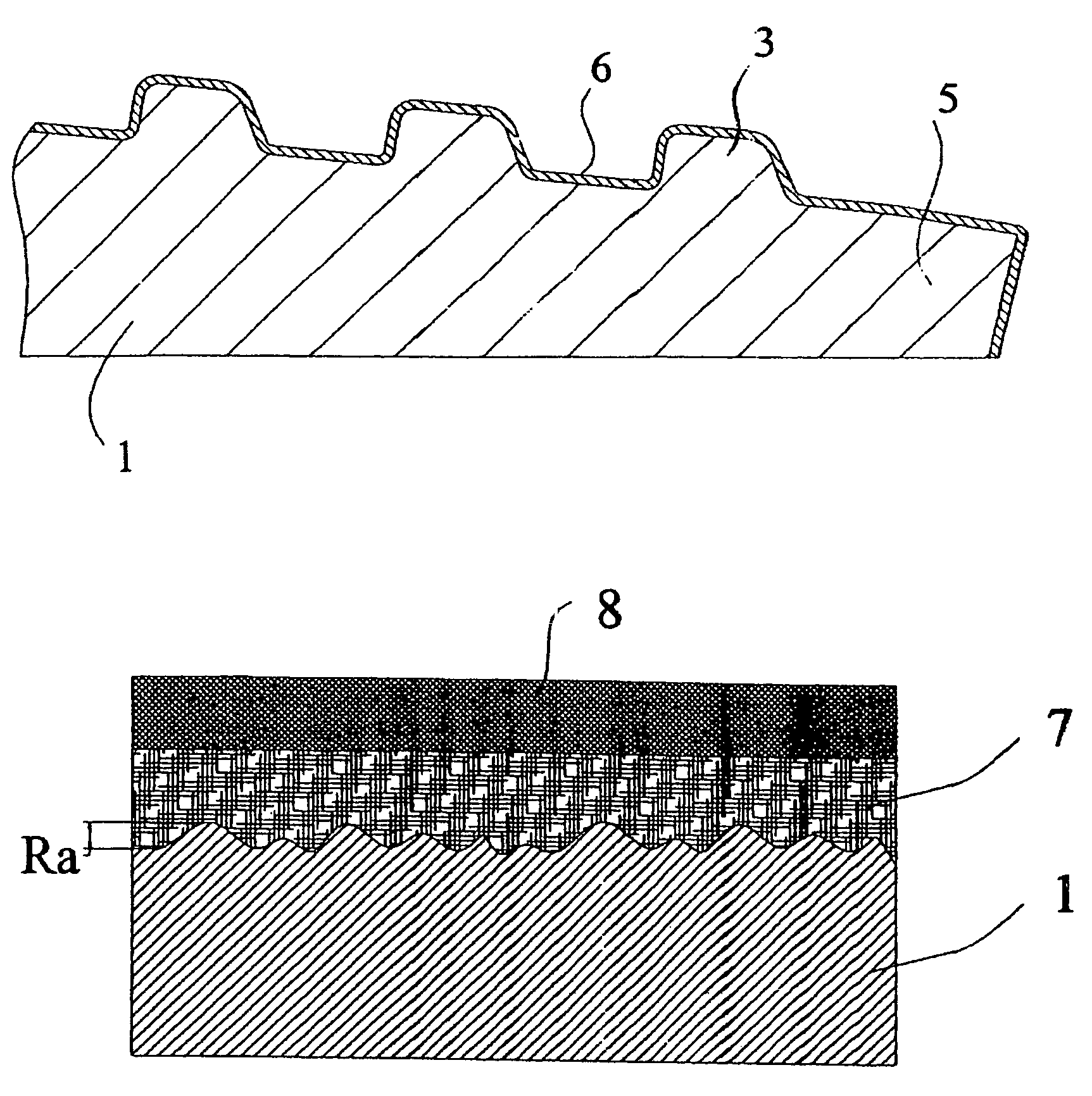

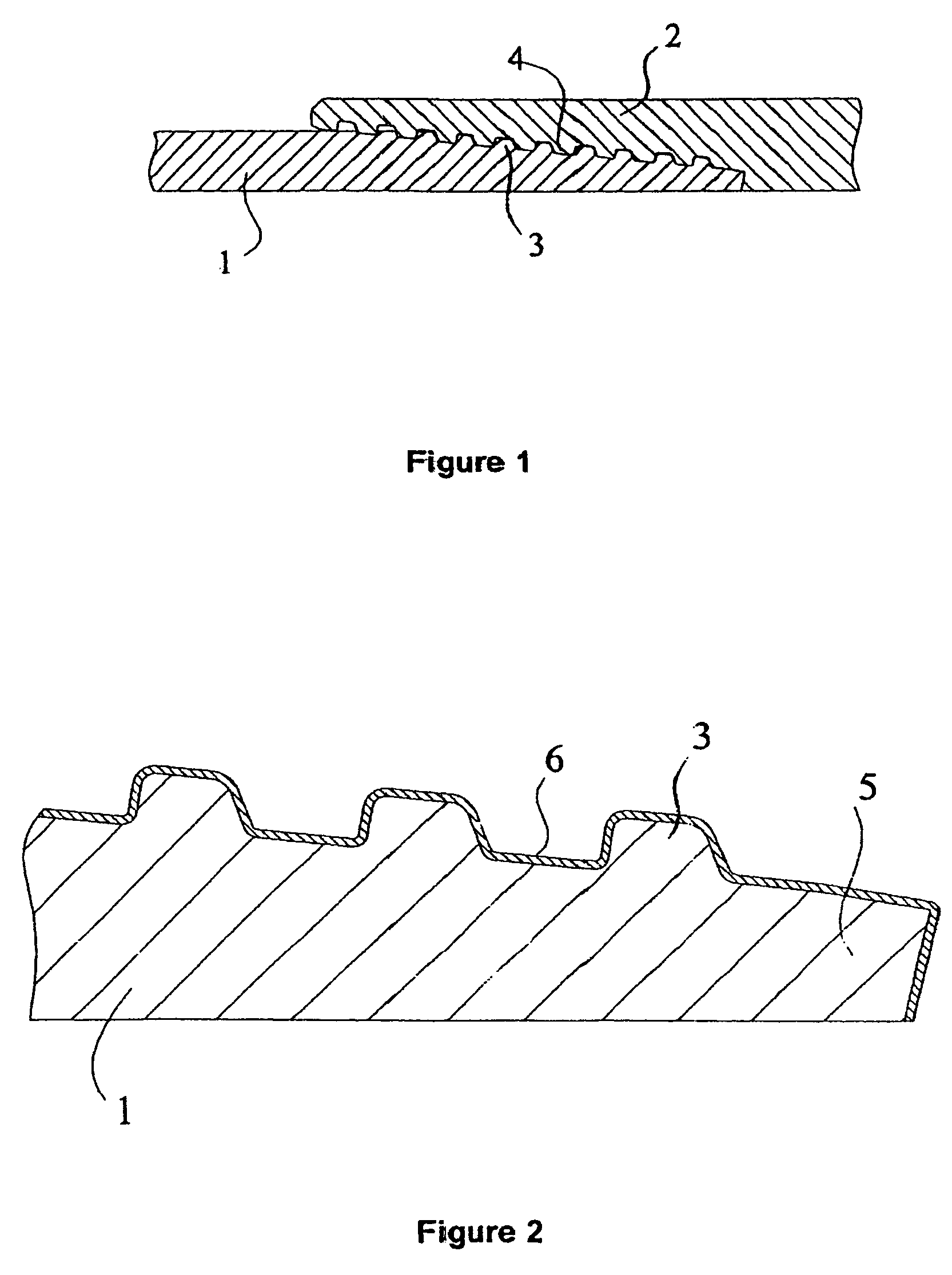

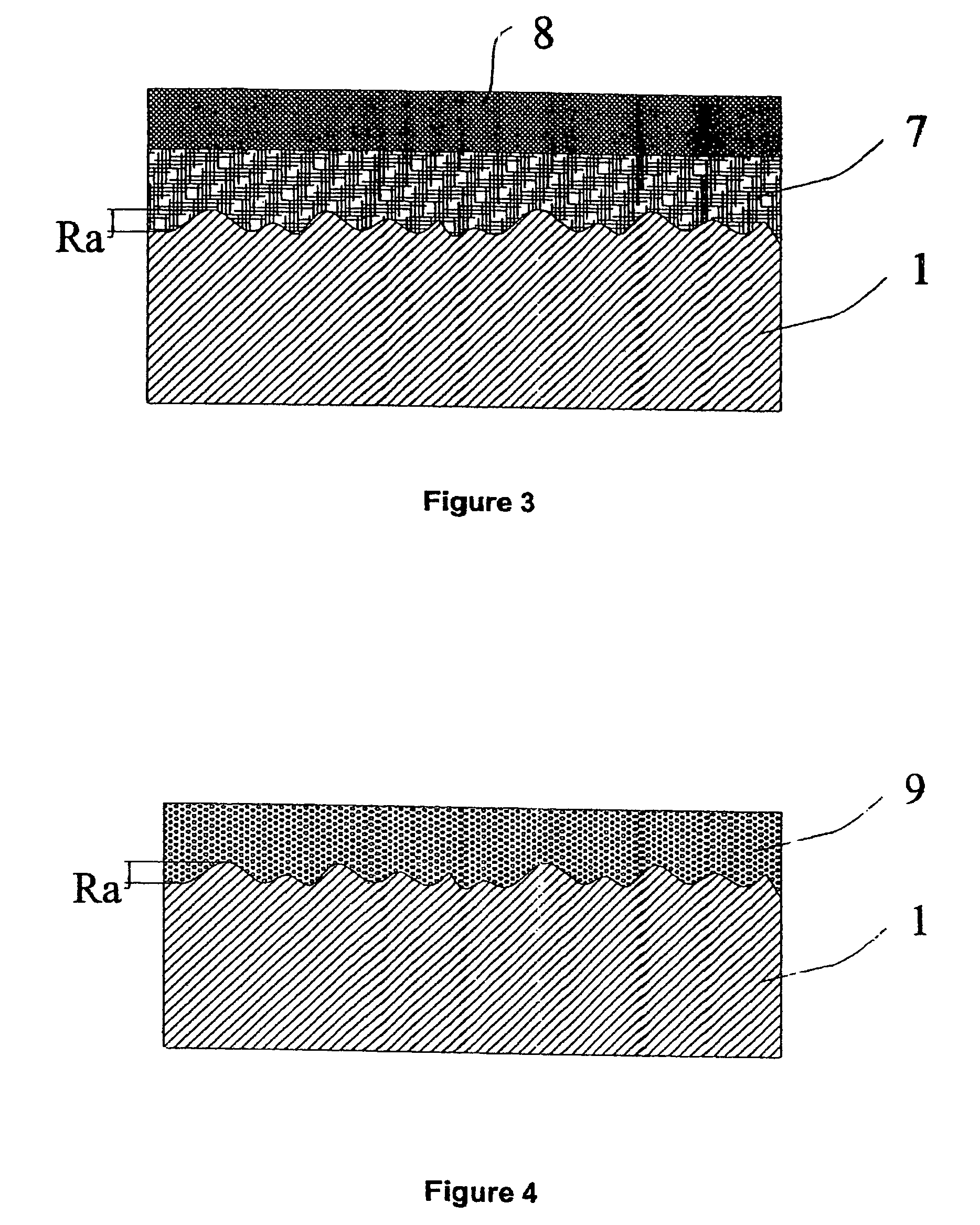

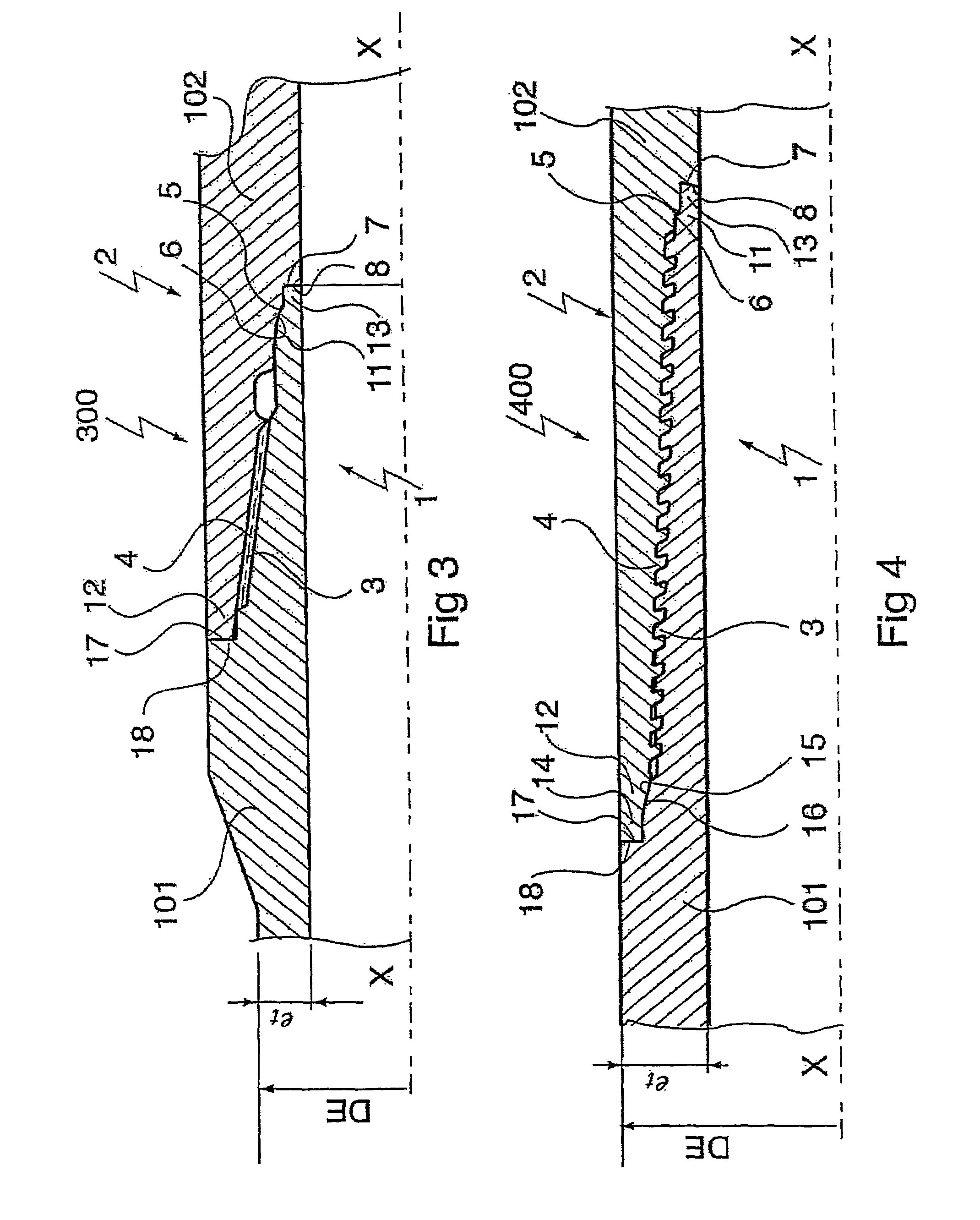

A threaded metallic pipe for oil extraction industry has a threaded end portion with treated surface in which the metal surface has a roughness (Ra) comprised of 2.0 μm and 6.0 μm, which is covered by a uniform layer (7) of a dry corrosion inhibiting coating and a second uniform layer (8) of dry lubricant coating. Alternatively the layers (8, 9) combined into one uniform layer (9) of a dry corrosion inhibiting coating containing a dispersion of particles of solid lubricant.

Owner:TENARIS CONNECTIONS

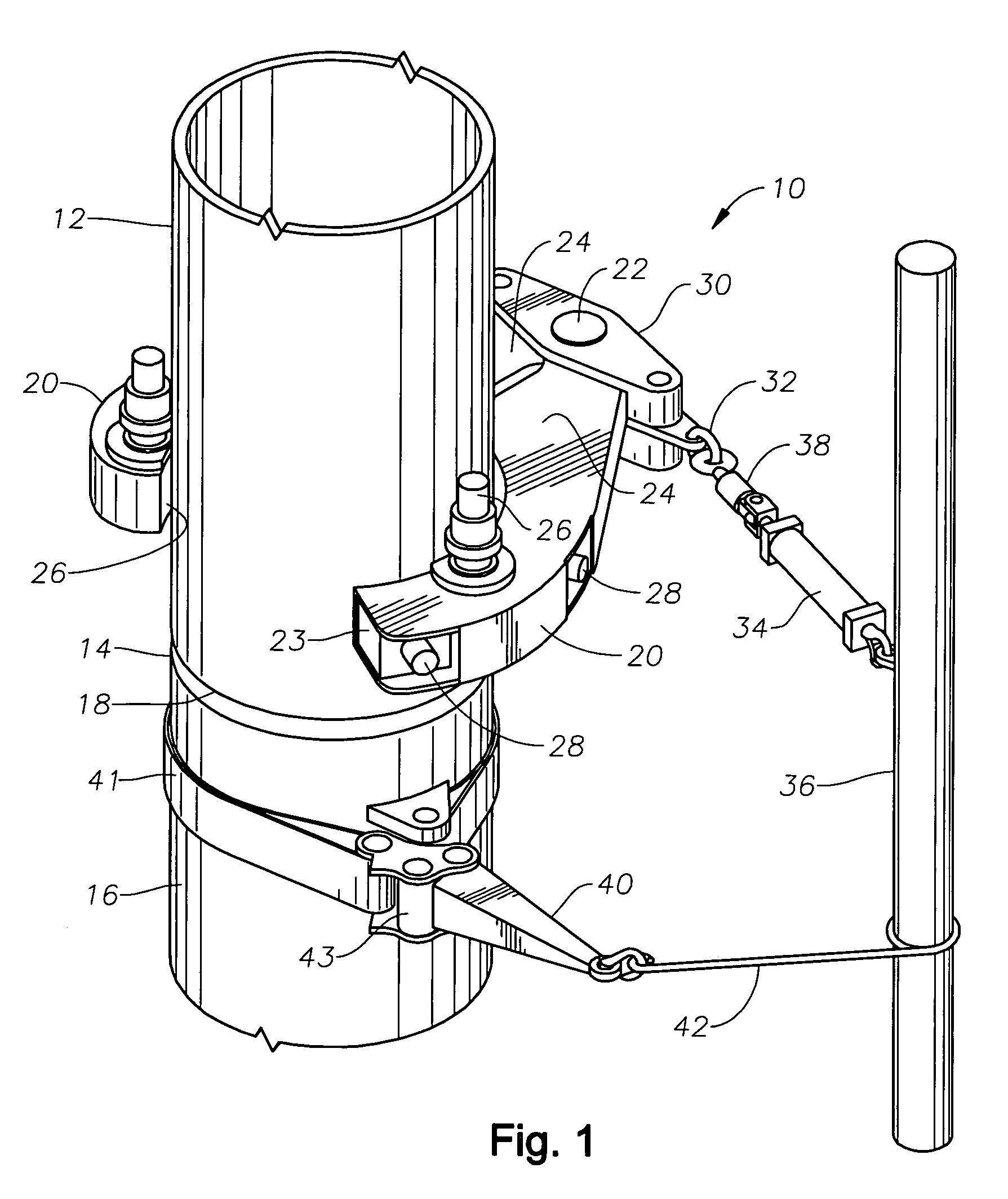

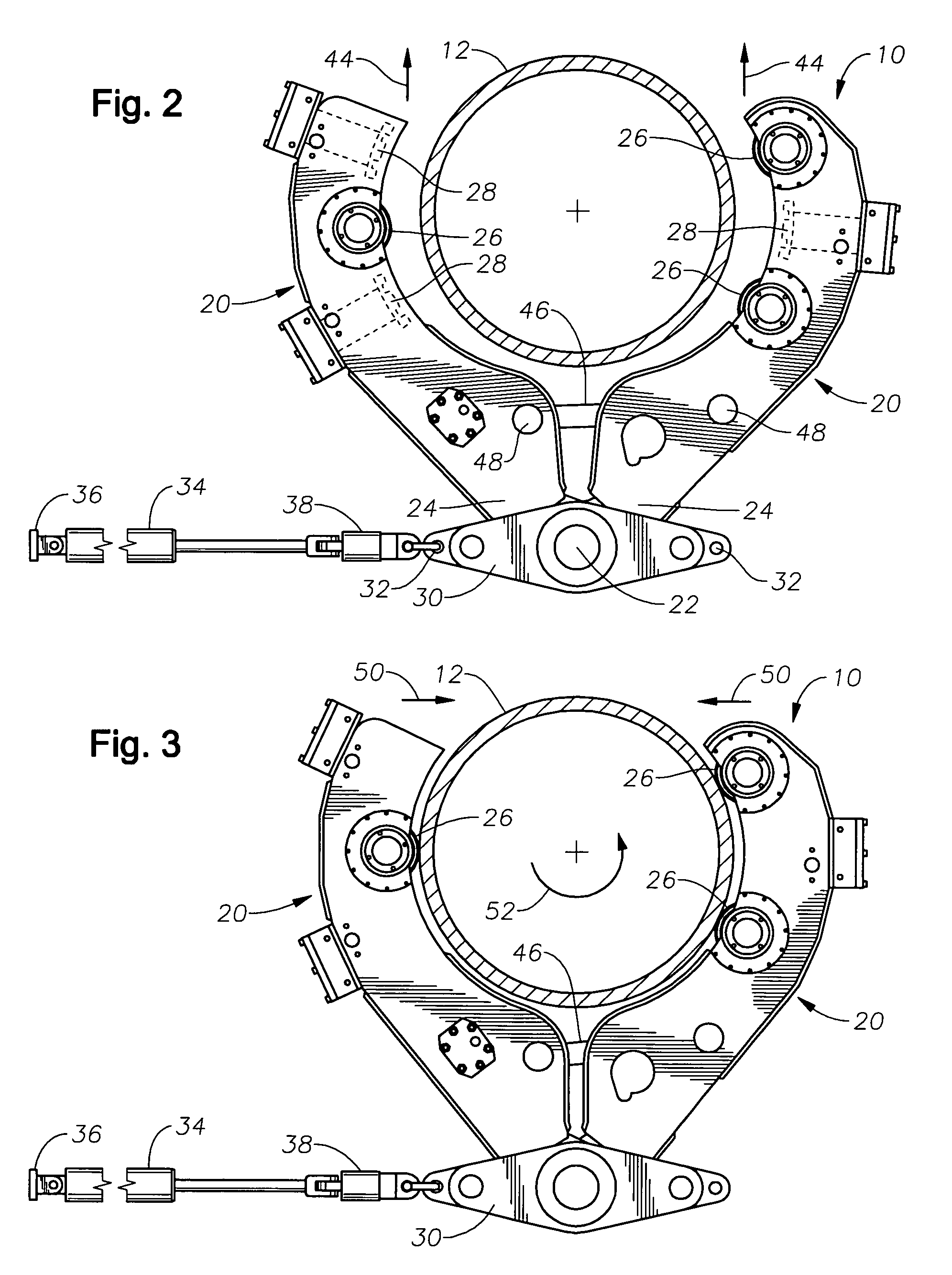

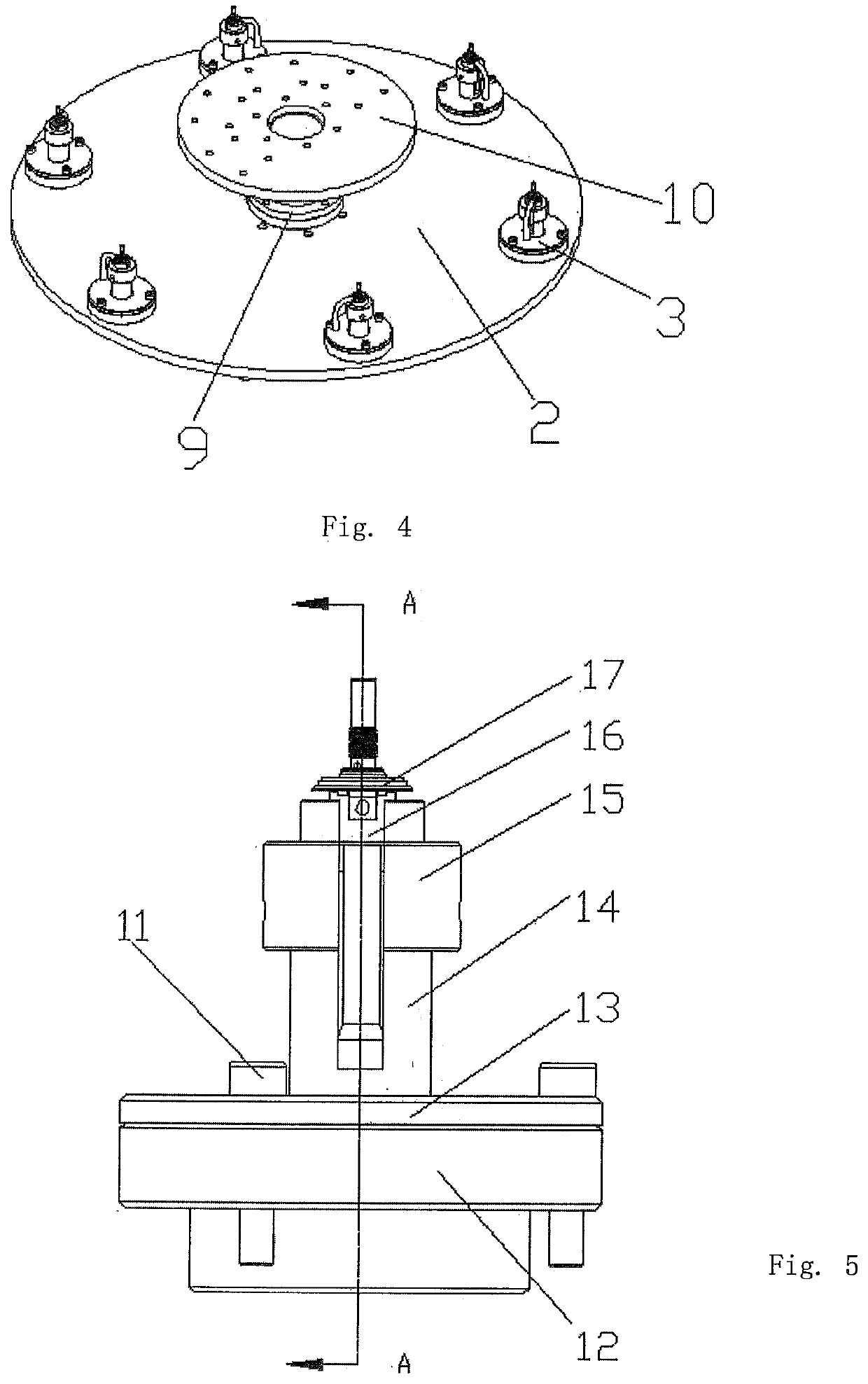

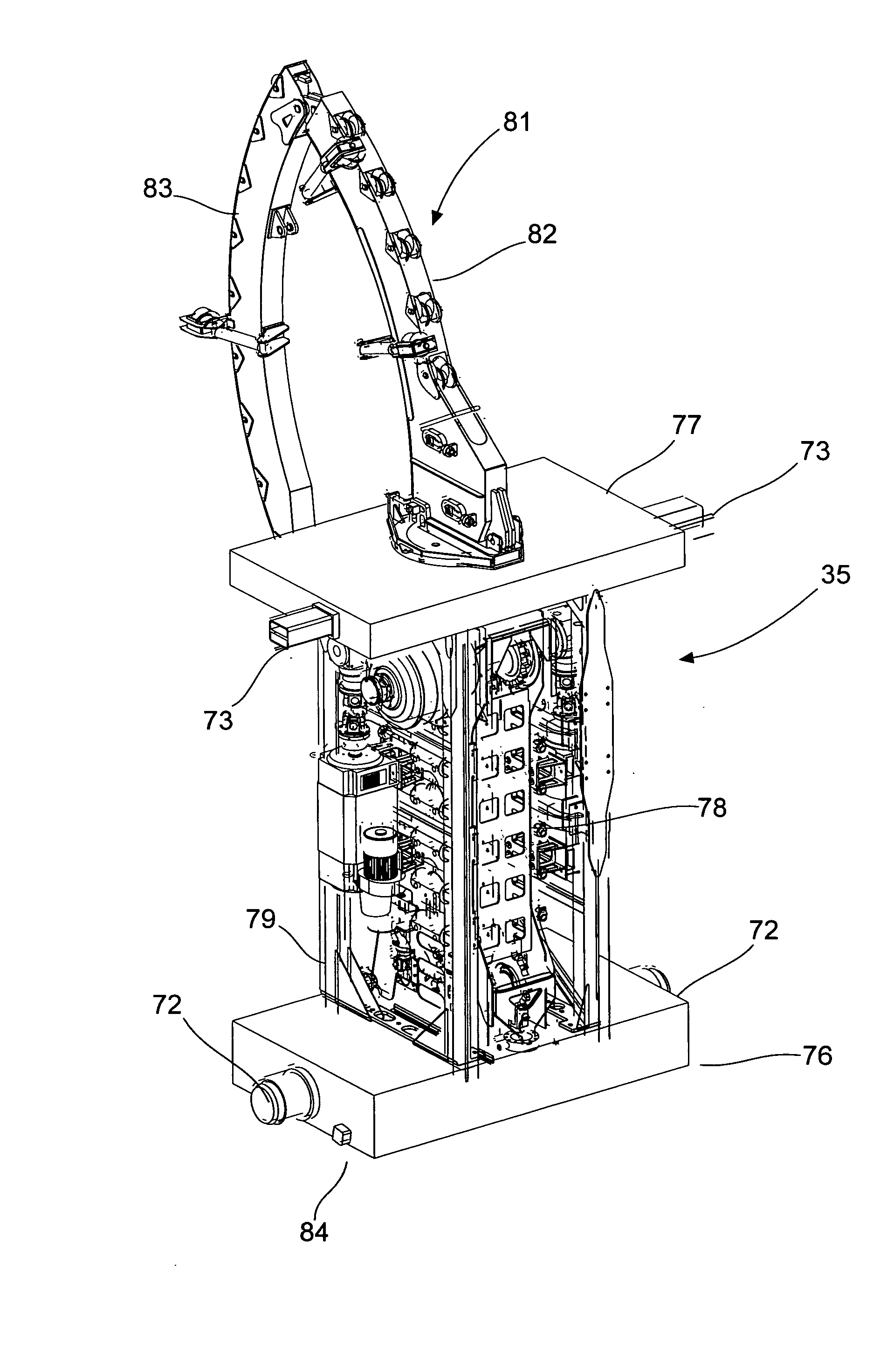

Method and apparatus for connecting and disconnecting threaded tubulars

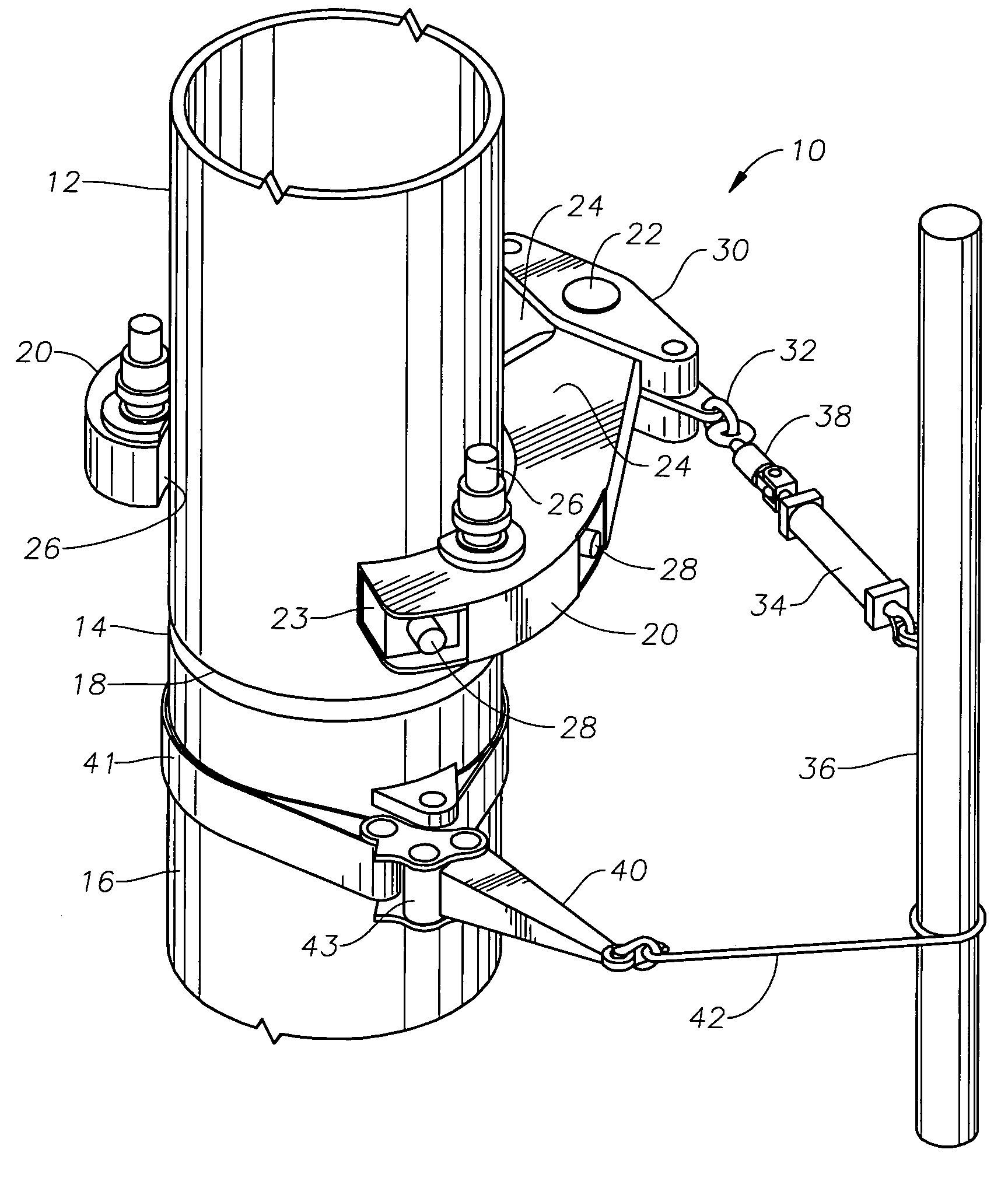

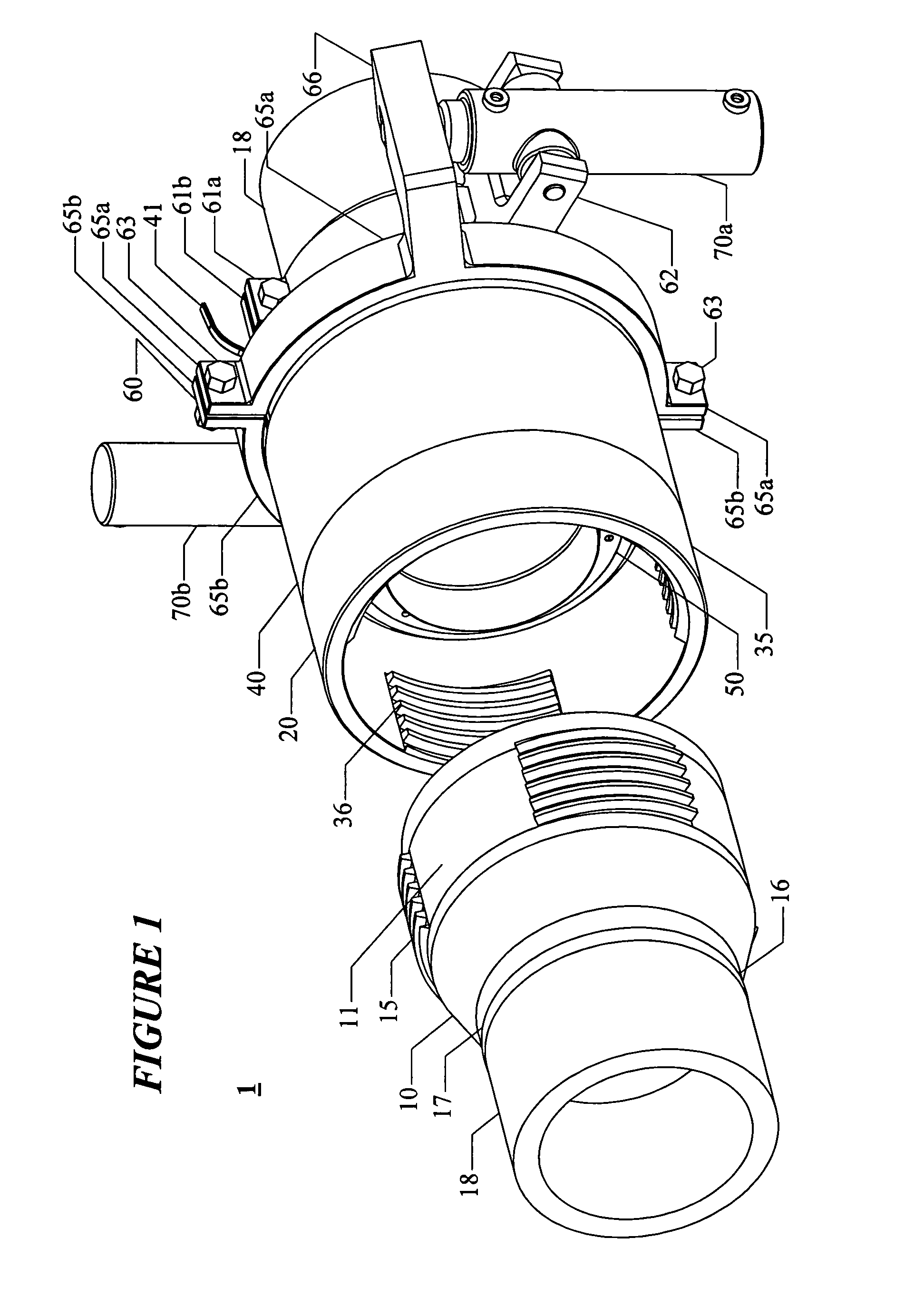

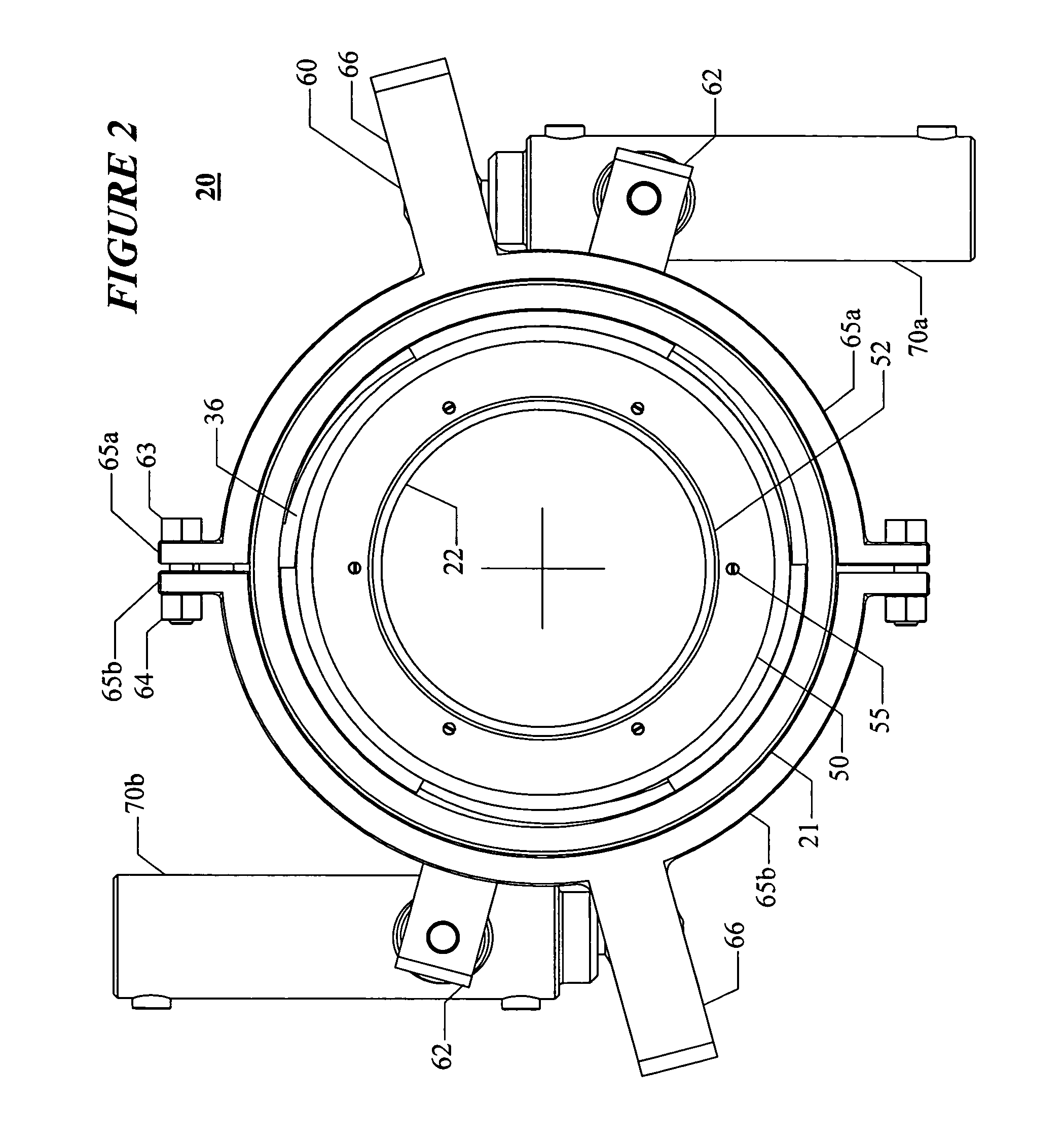

A system for screwing together threaded connections includes a pair of moveable arms which first grip the tubular to provide a contact force against three hydraulically powered drive rollers, that are contained within the arms. The three drive rollers will screw or “spin” the connection to an initial torque value. The moveable arms also contain a set of jaws (three) which extend radially inwardly to grip the tubular, so the connection can be made up to final torque by contracting a hydraulic cylinder. The hydraulic cylinder that is used to apply the final torque value is attached on one end, where the moveable arms are pinned together, and on the other end to something fixed, such a snub post or derrick leg. Rotation of the opposing connection is prevented by the use of standard equipment such as a manual chain tong.

Owner:FRANKS INT

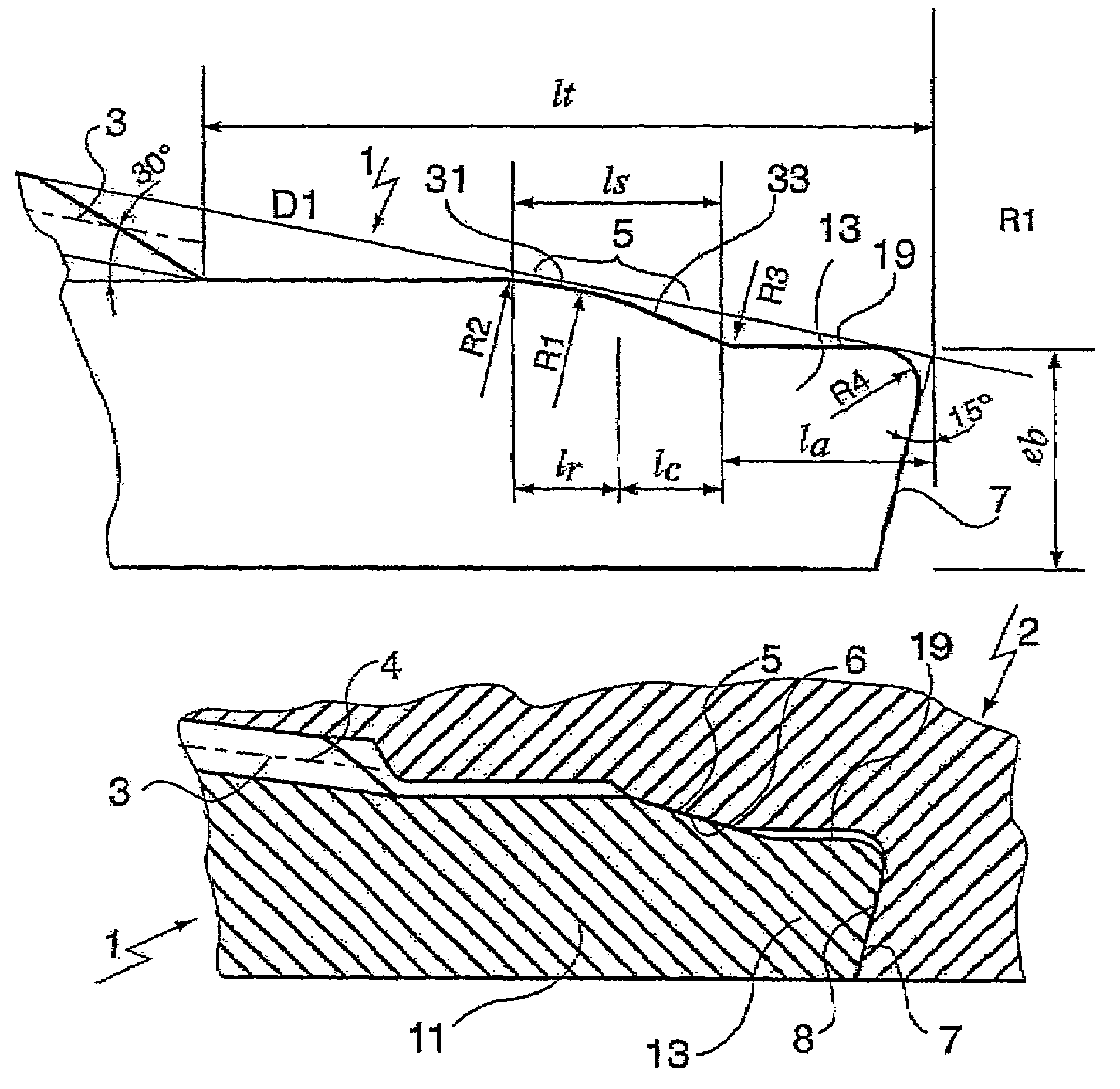

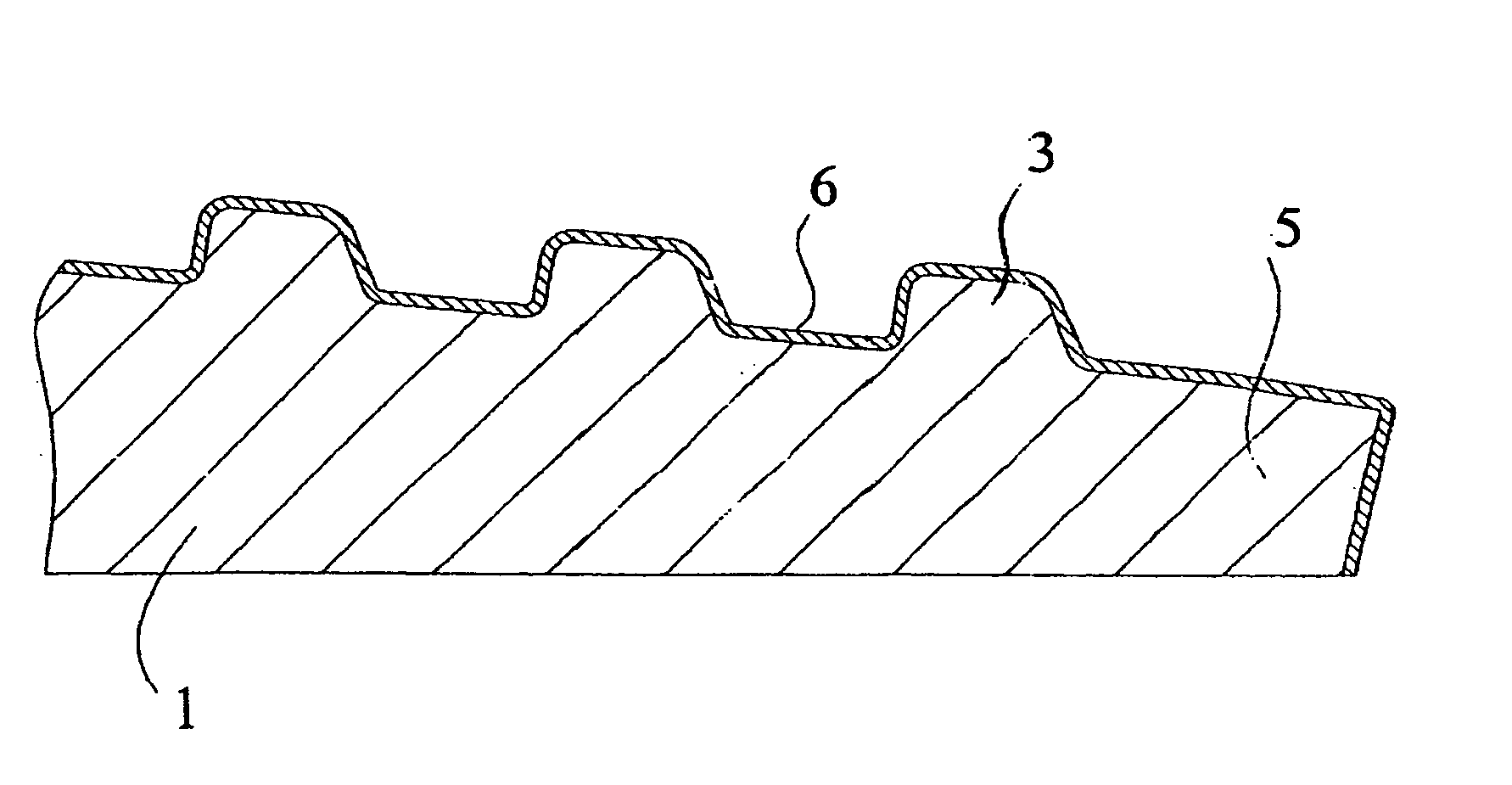

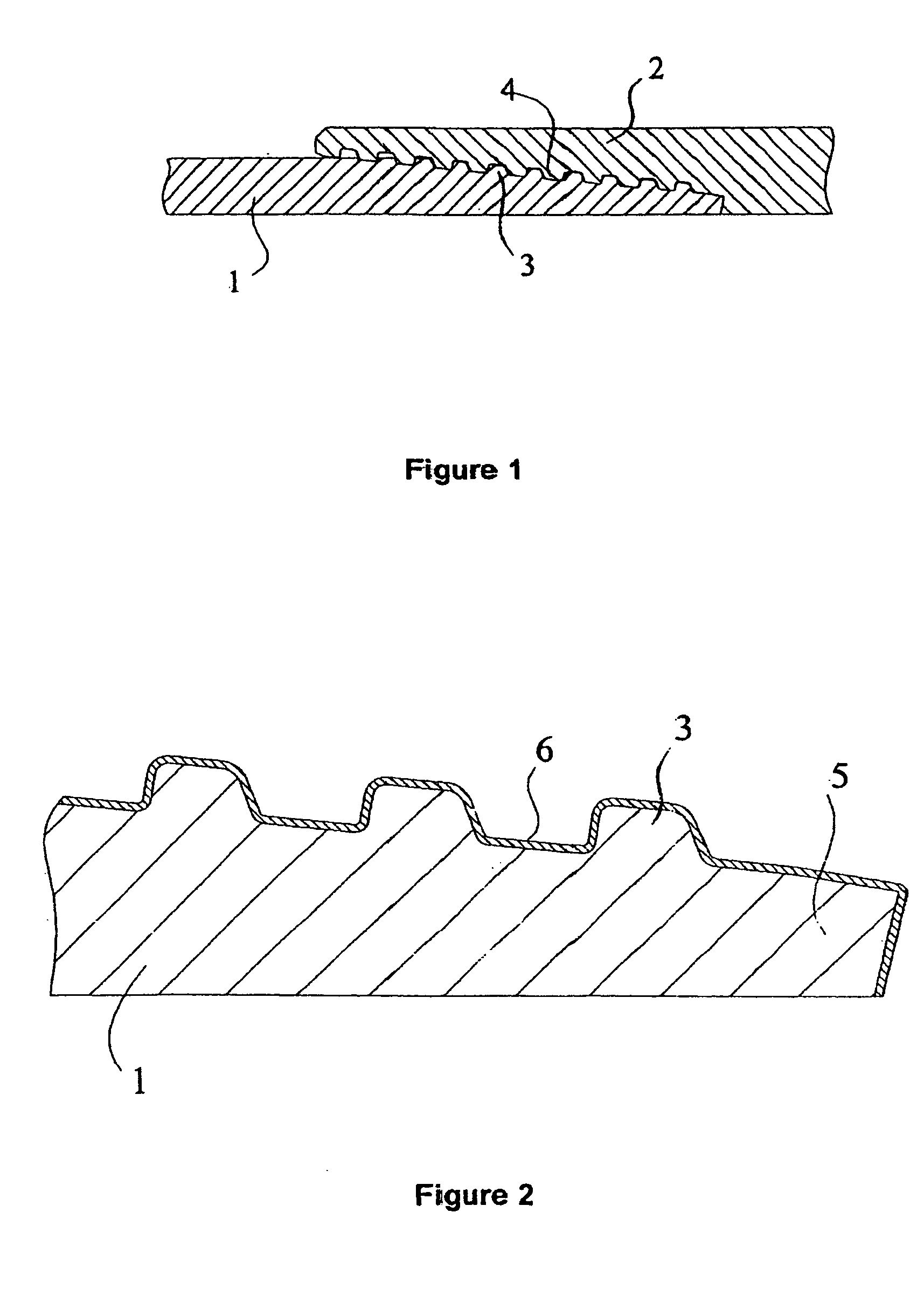

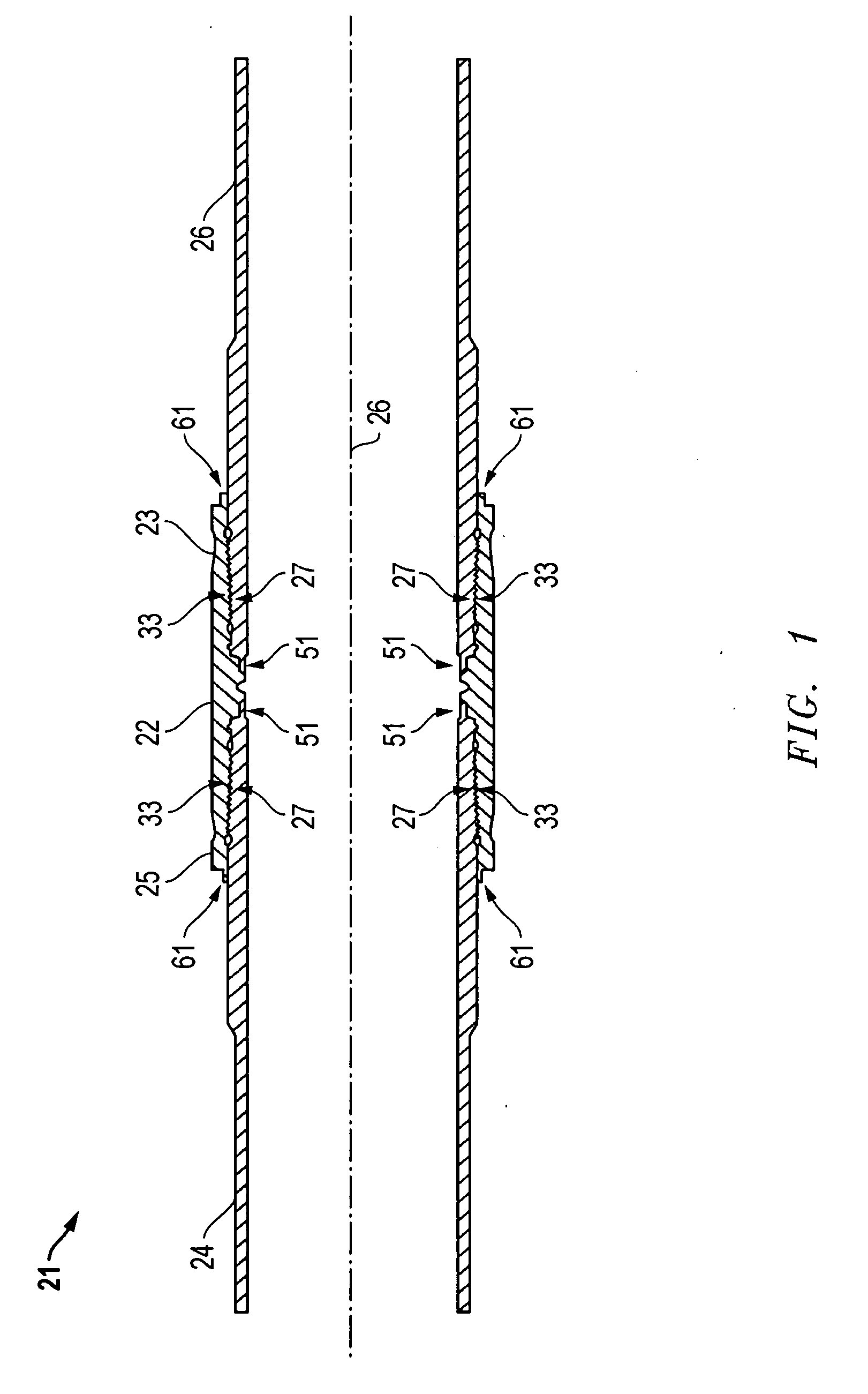

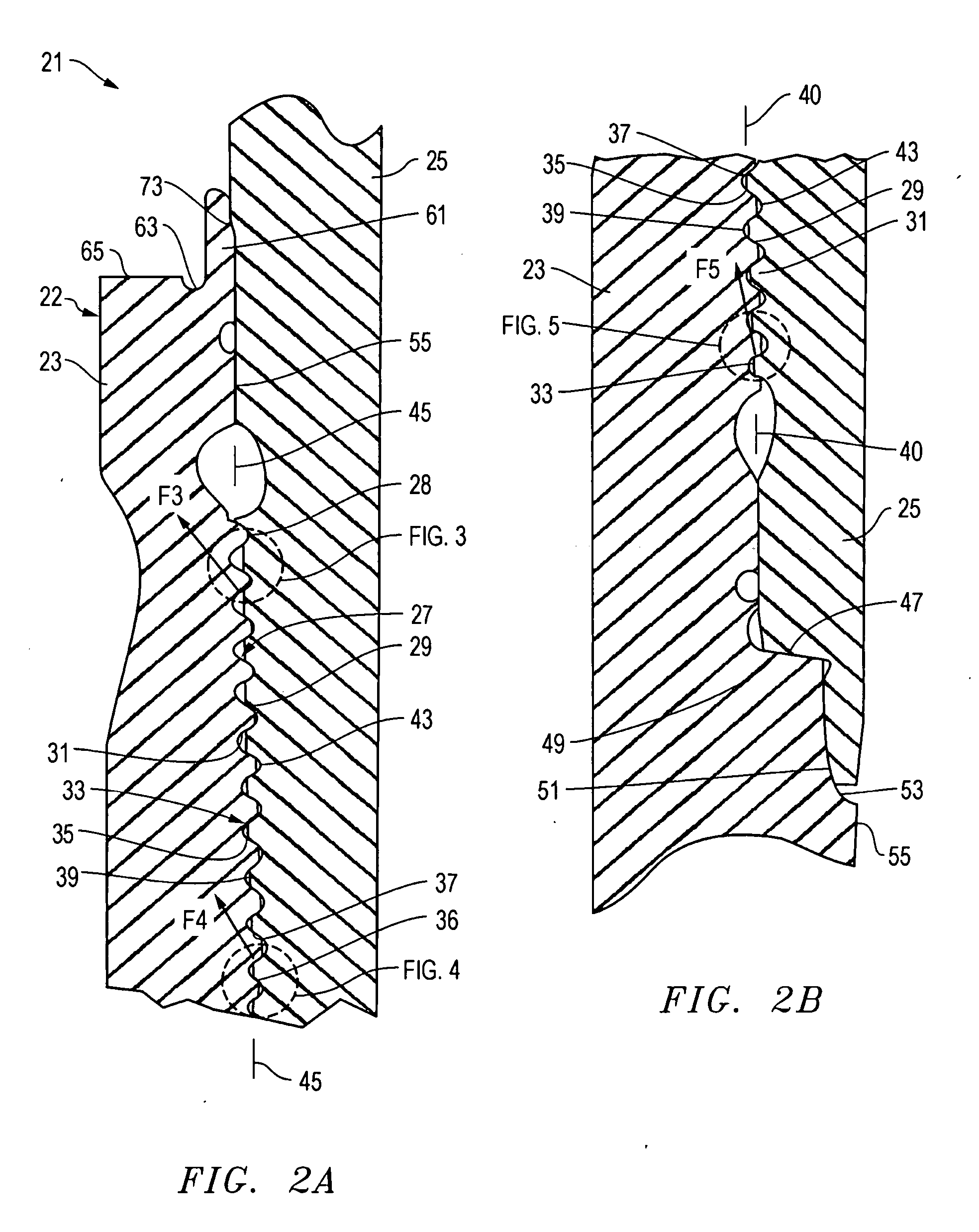

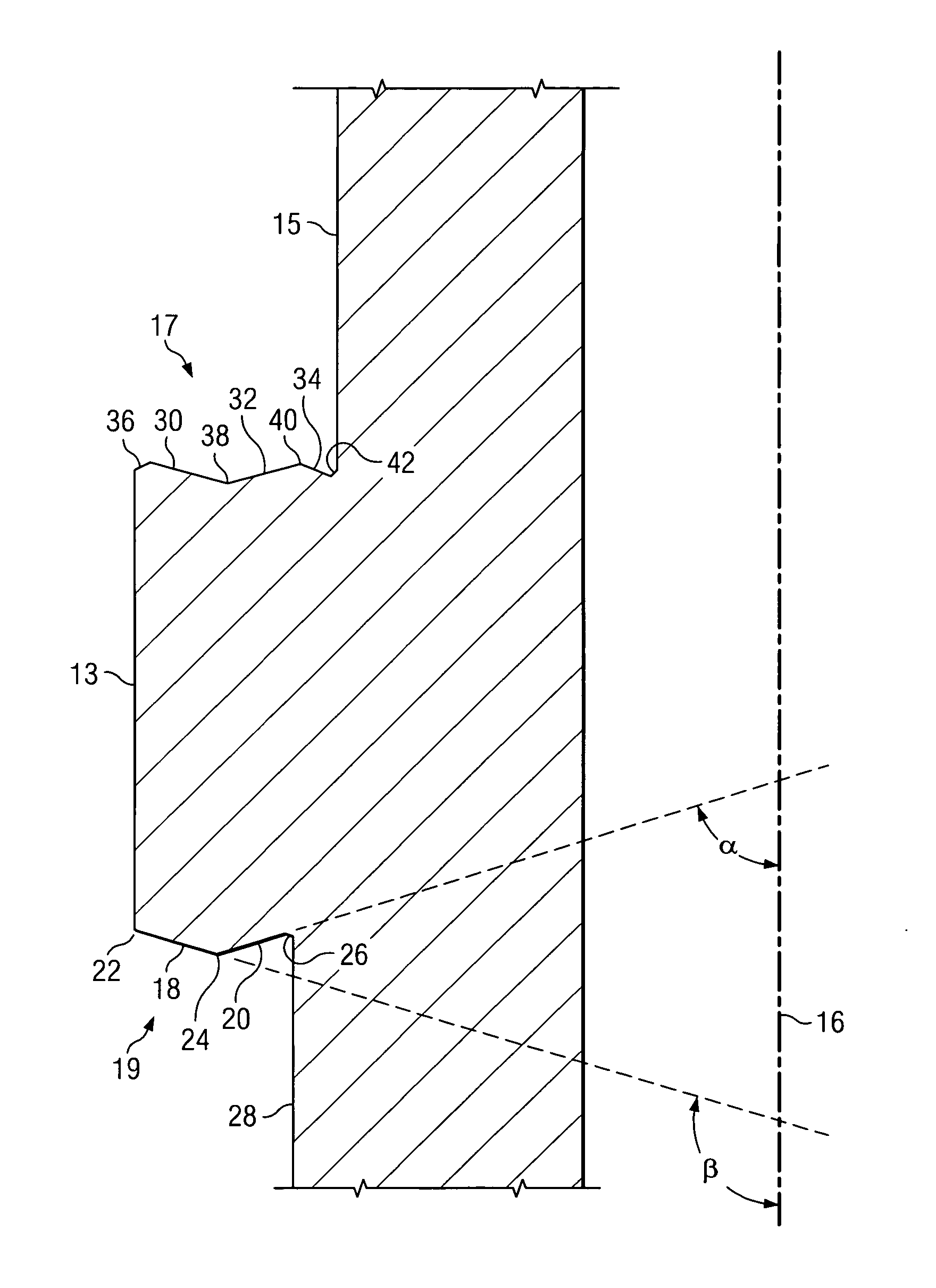

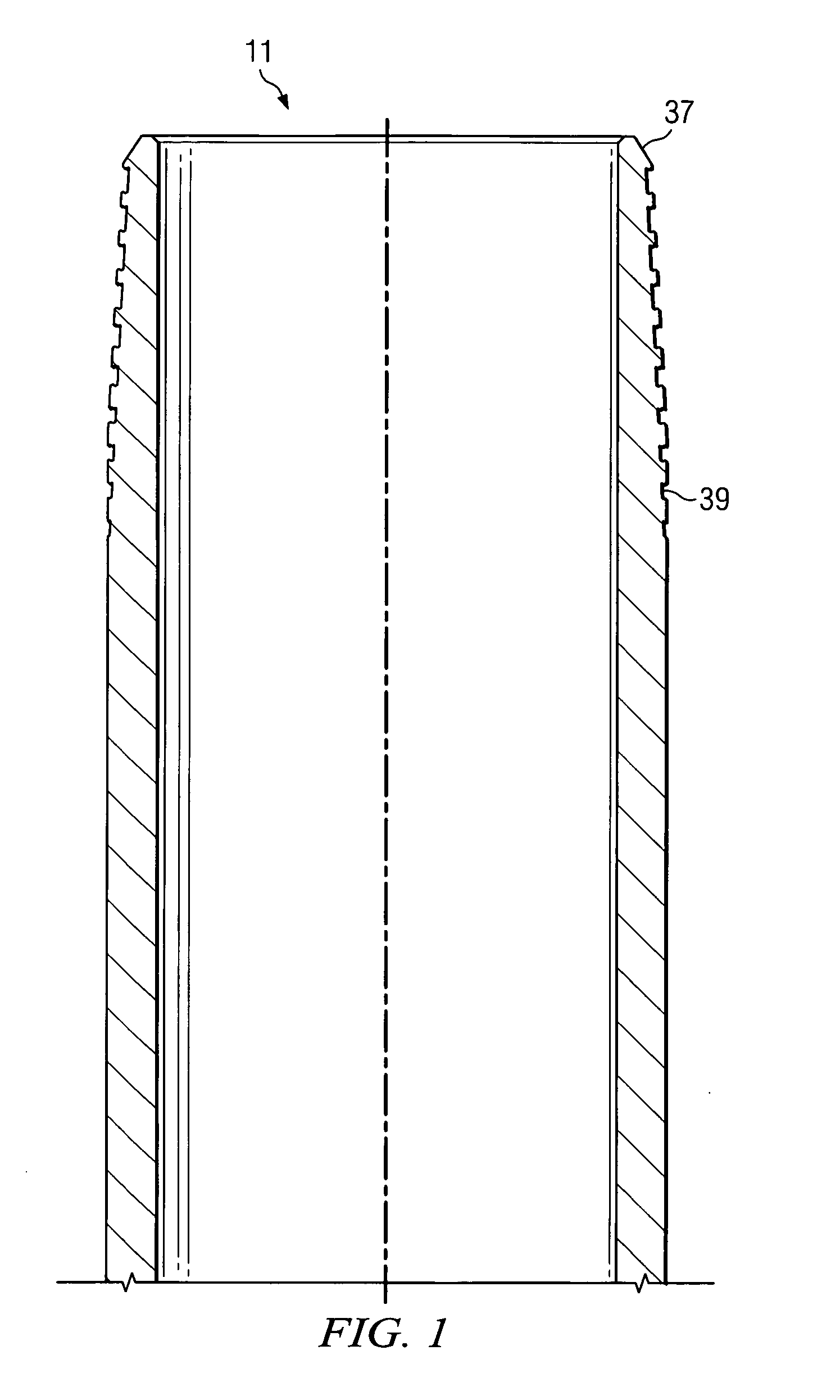

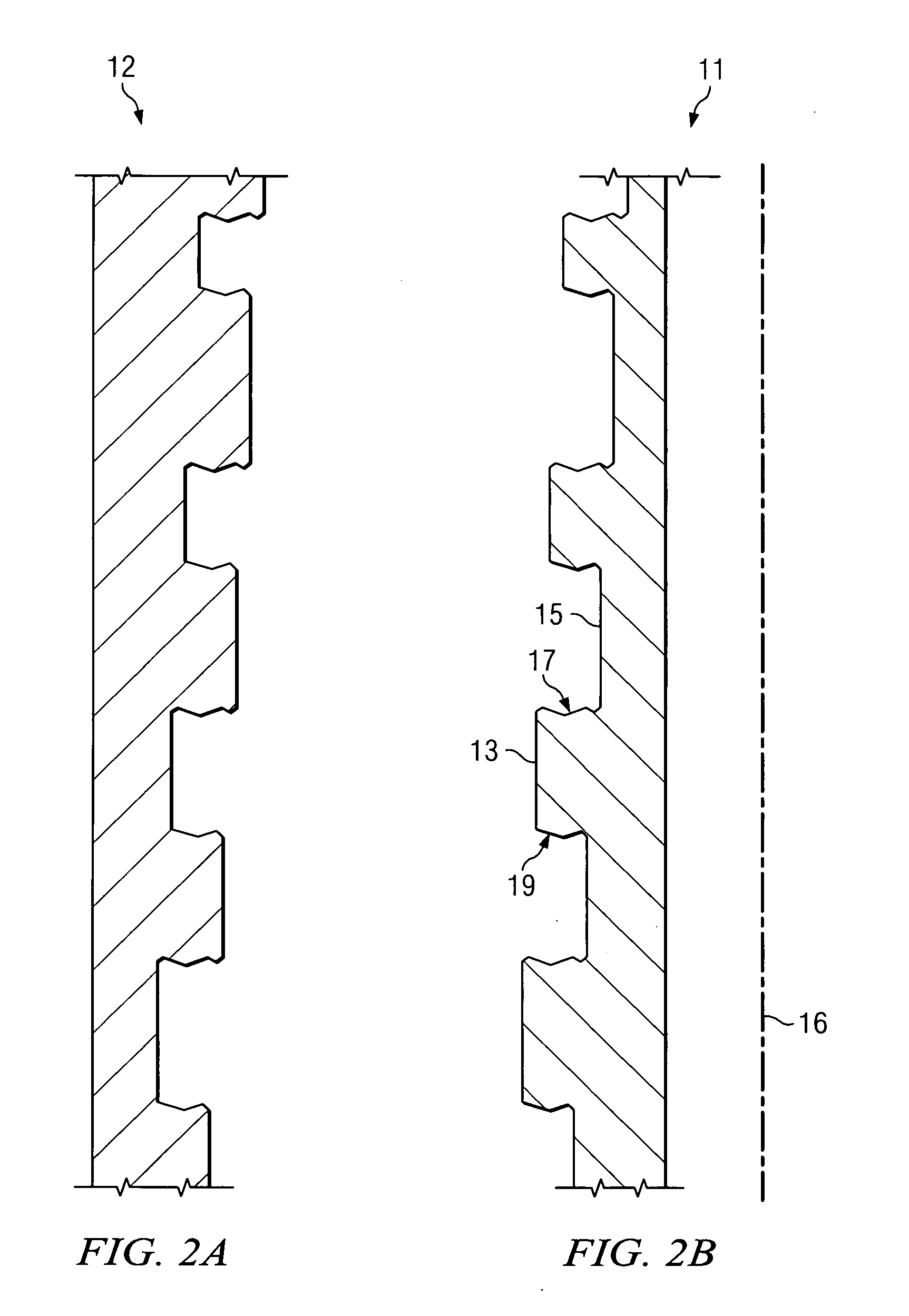

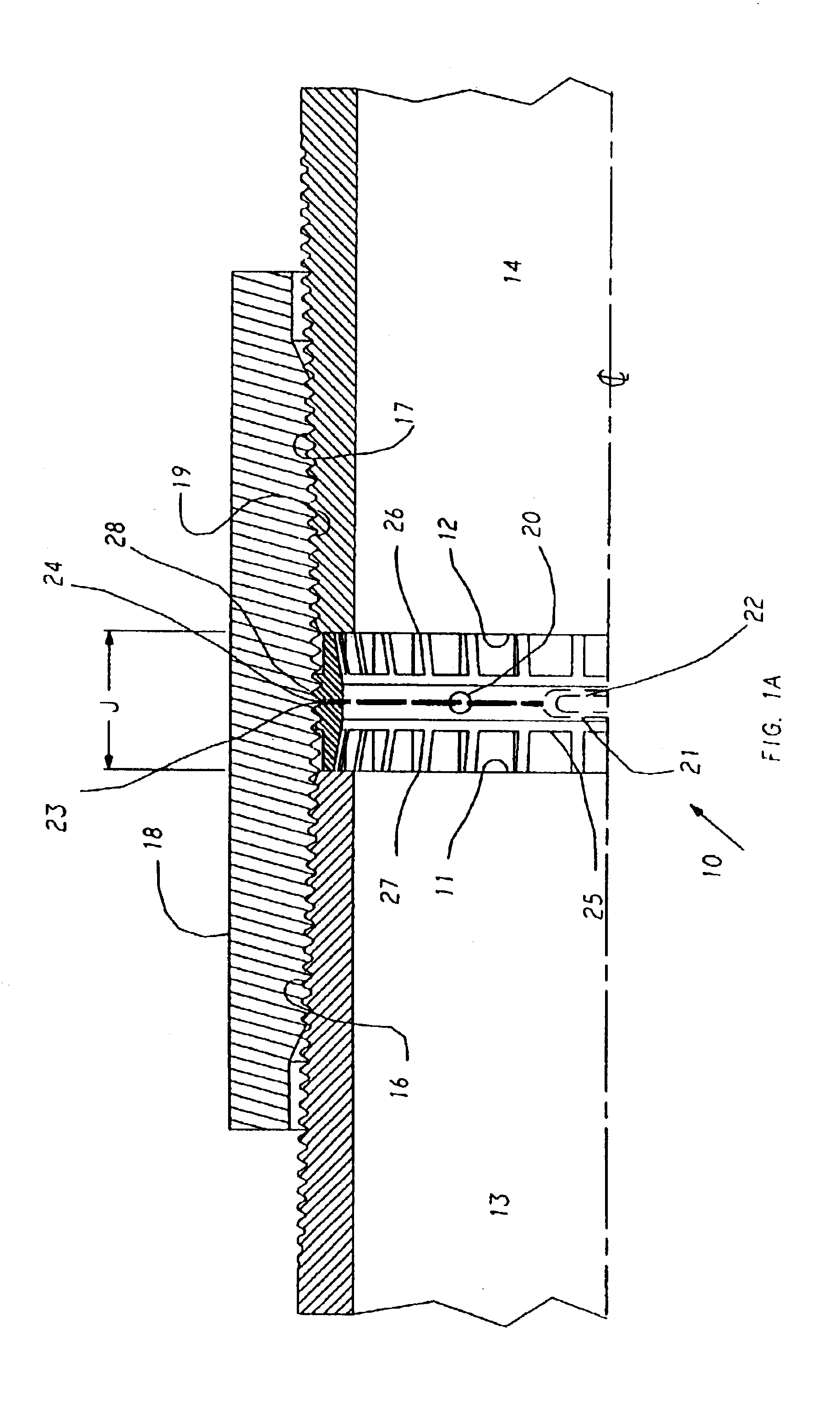

Premium threaded tubular joint comprising at least a threaded element with end lip

InactiveUS7334821B2Reduce axial stiffnessImprove elastic deformation abilityDrilling rodsFluid pressure sealed jointsThreaded pipeAxial compression

A premium threaded tubular connection including, on at least one threaded element, a distal abutment surface at the free end of a threaded element, and a lip sealing surface at a given distance from the threading. The lip includes an appendix that extends the lip towards its free end beyond the lip sealing surface so that the lip has both high radial stiffness and low axial stiffness. This results in enhanced performance as regards the seal of the threaded connection under pressure and / or under tension, and other advantages of precision of real makeup torque, mechanical strength in axial compression, a shock barrier effect, and tolerance in engaging the threaded elements.

Owner:NIPPON STEEL CORP

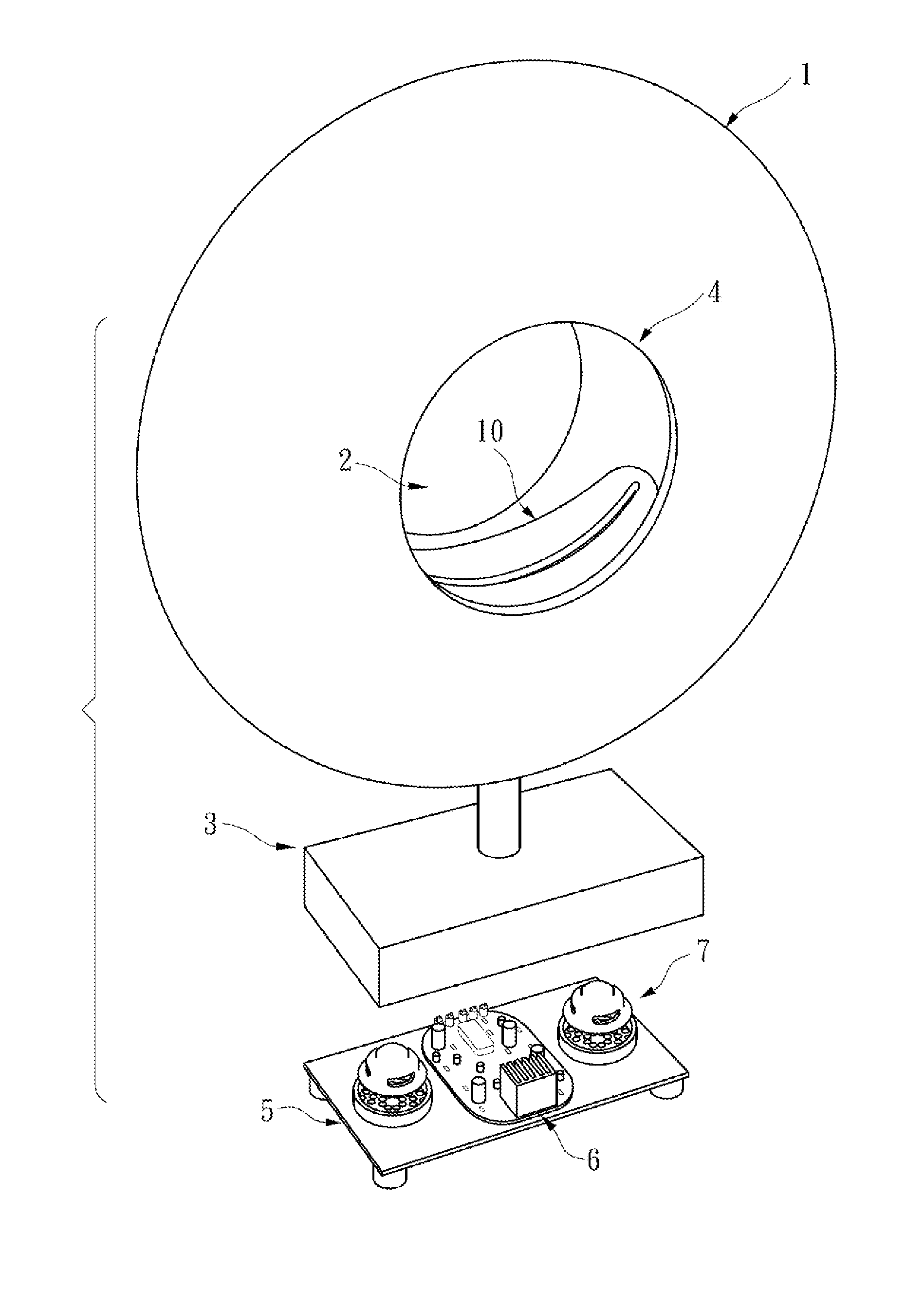

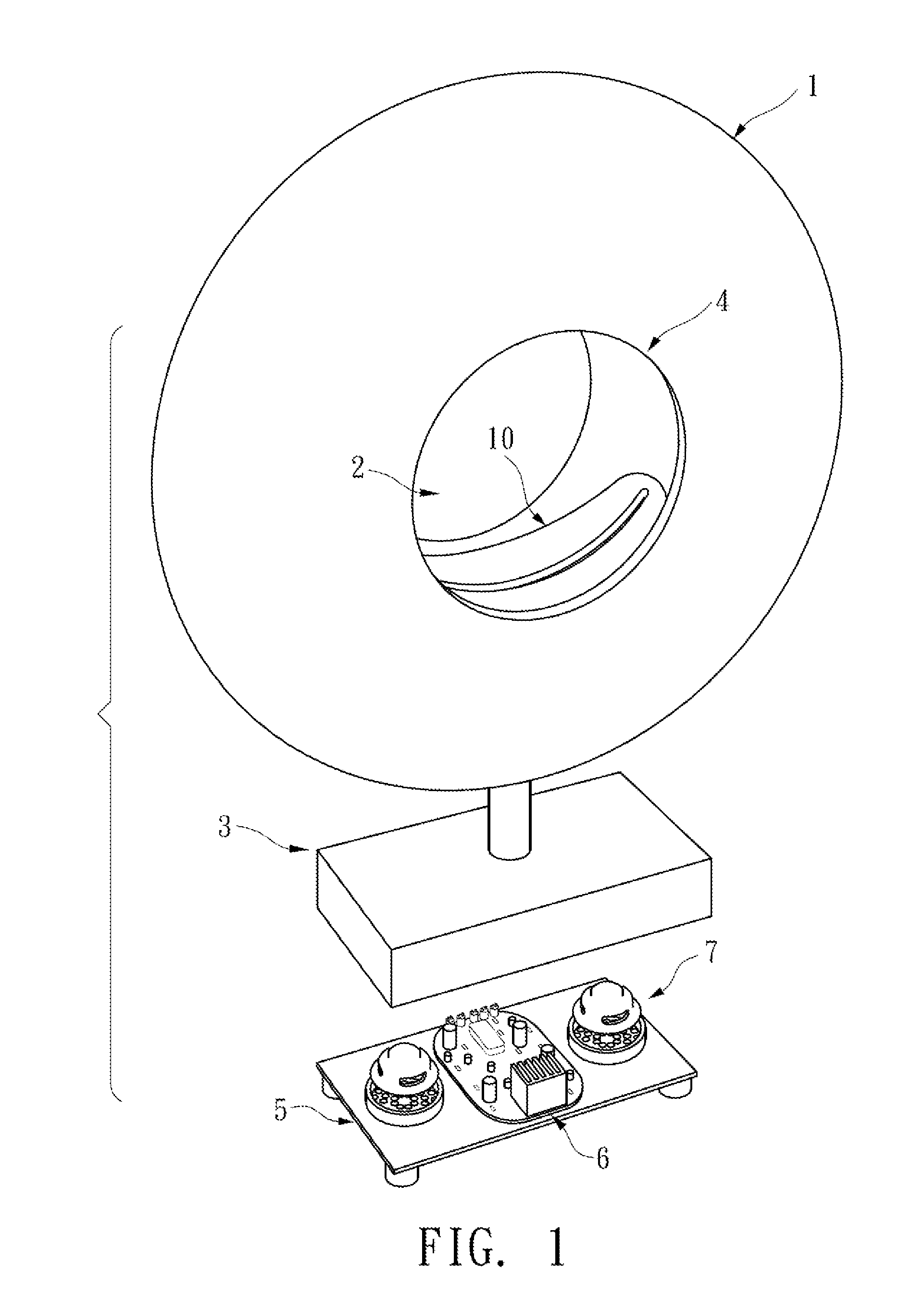

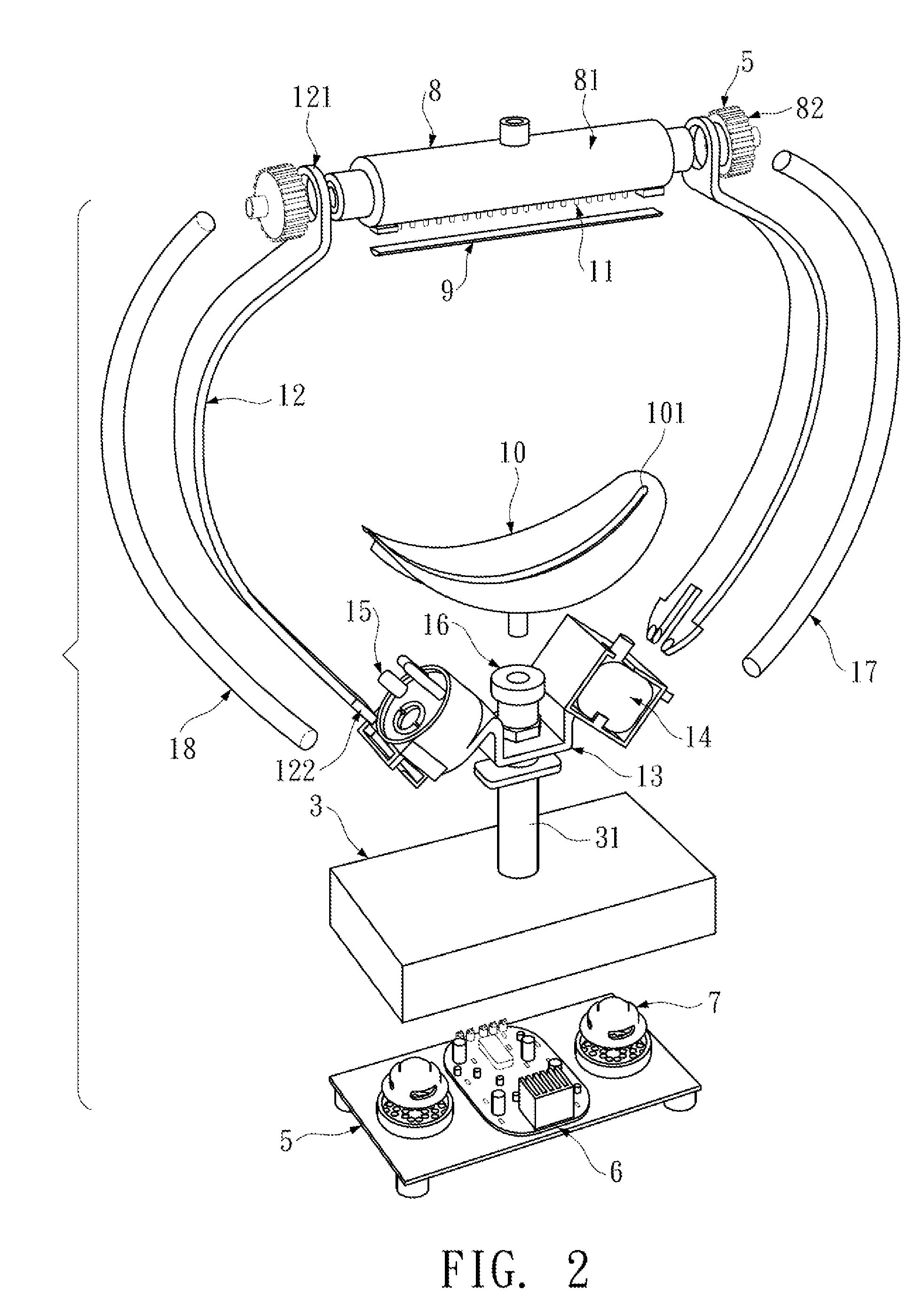

Wind-water ultrasonic humidifier

InactiveUS8113490B2Simple and fashioned decorationMechanical apparatusMixing methodsThreaded pipeWater circulation

Owner:CHEN HUI CHIN

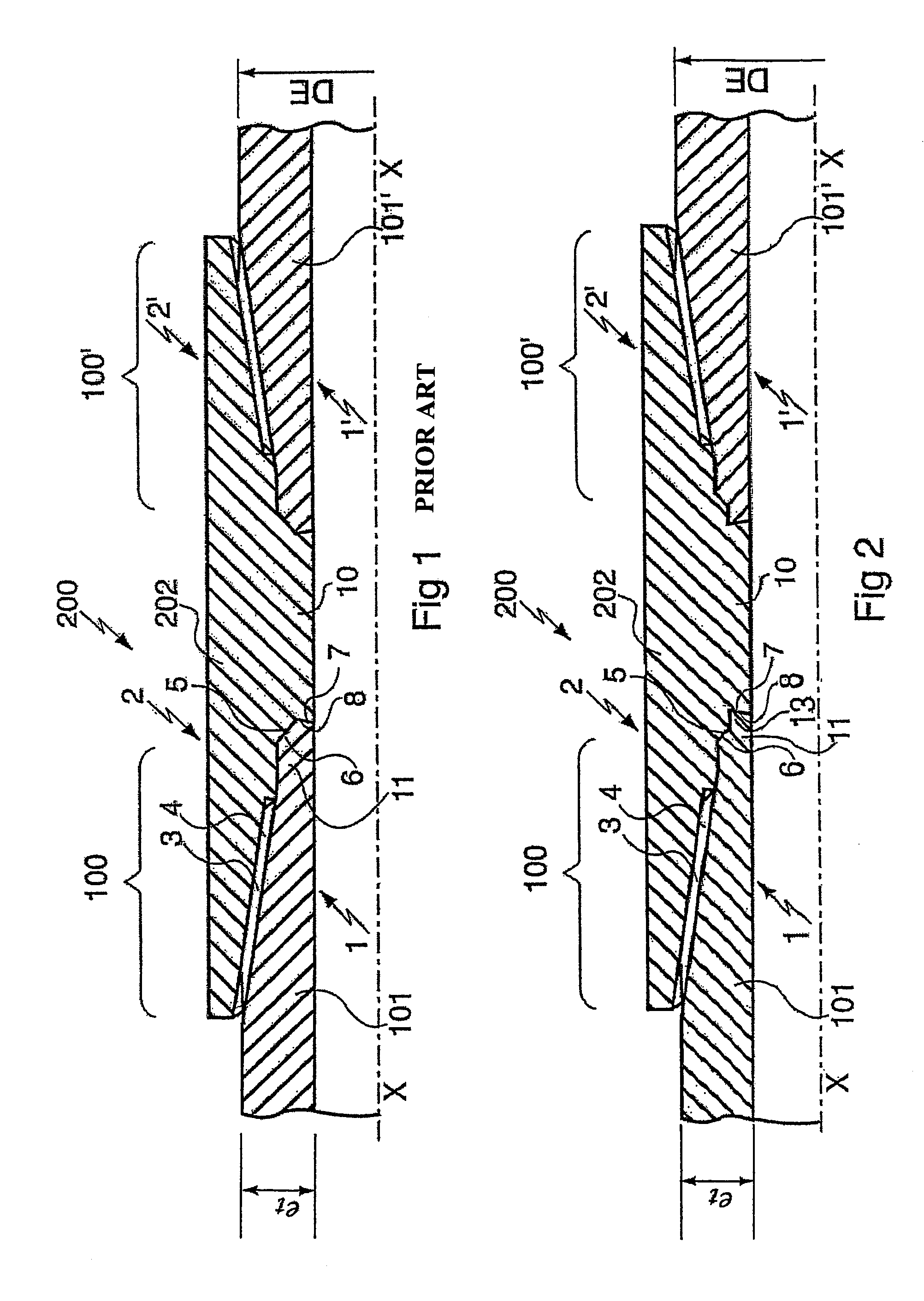

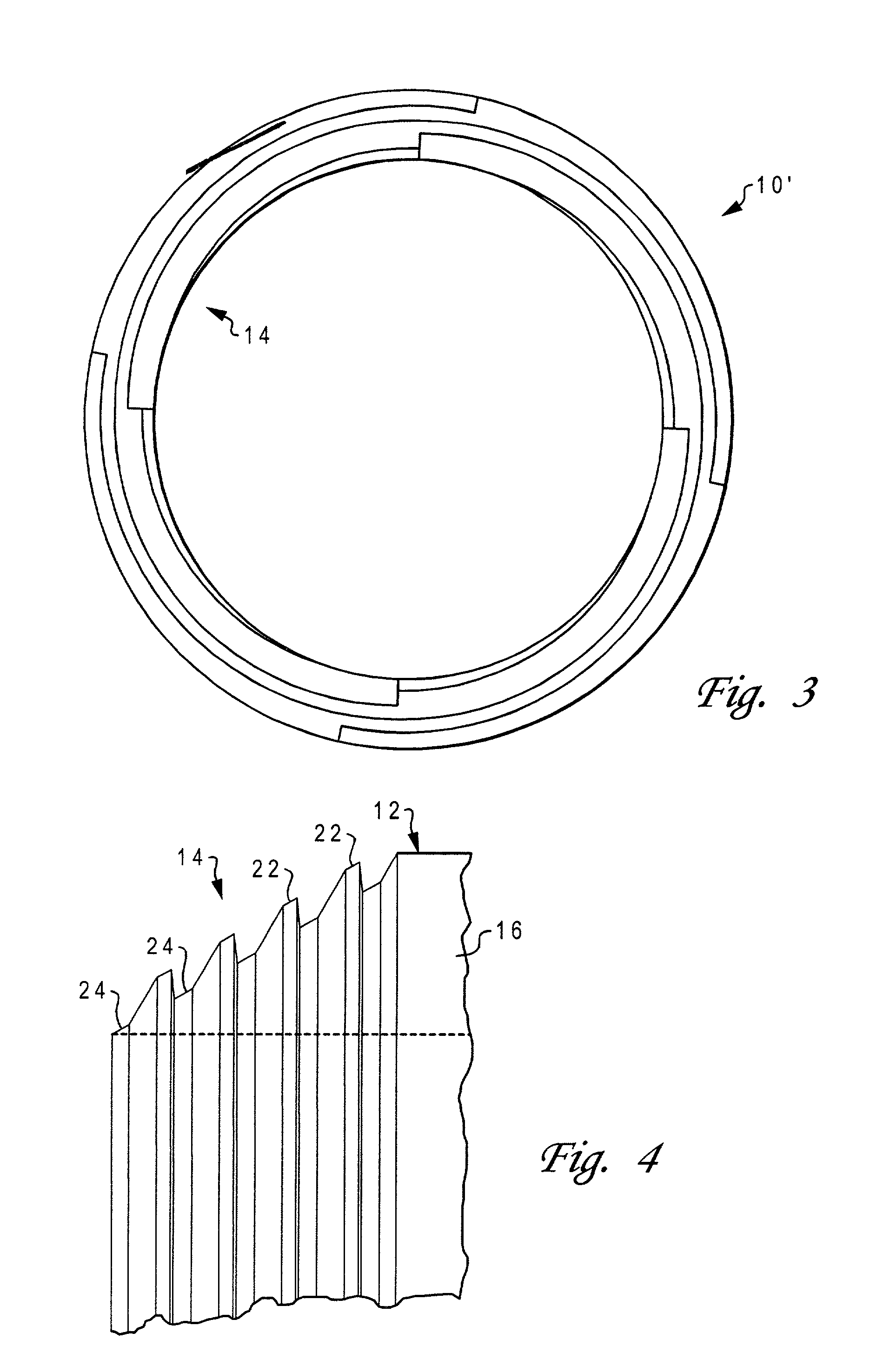

Threaded pipe joint

InactiveUS6905150B2Reduce pressureRaise the level of performanceHose connectionsScrew threaded jointsComing outThreaded pipe

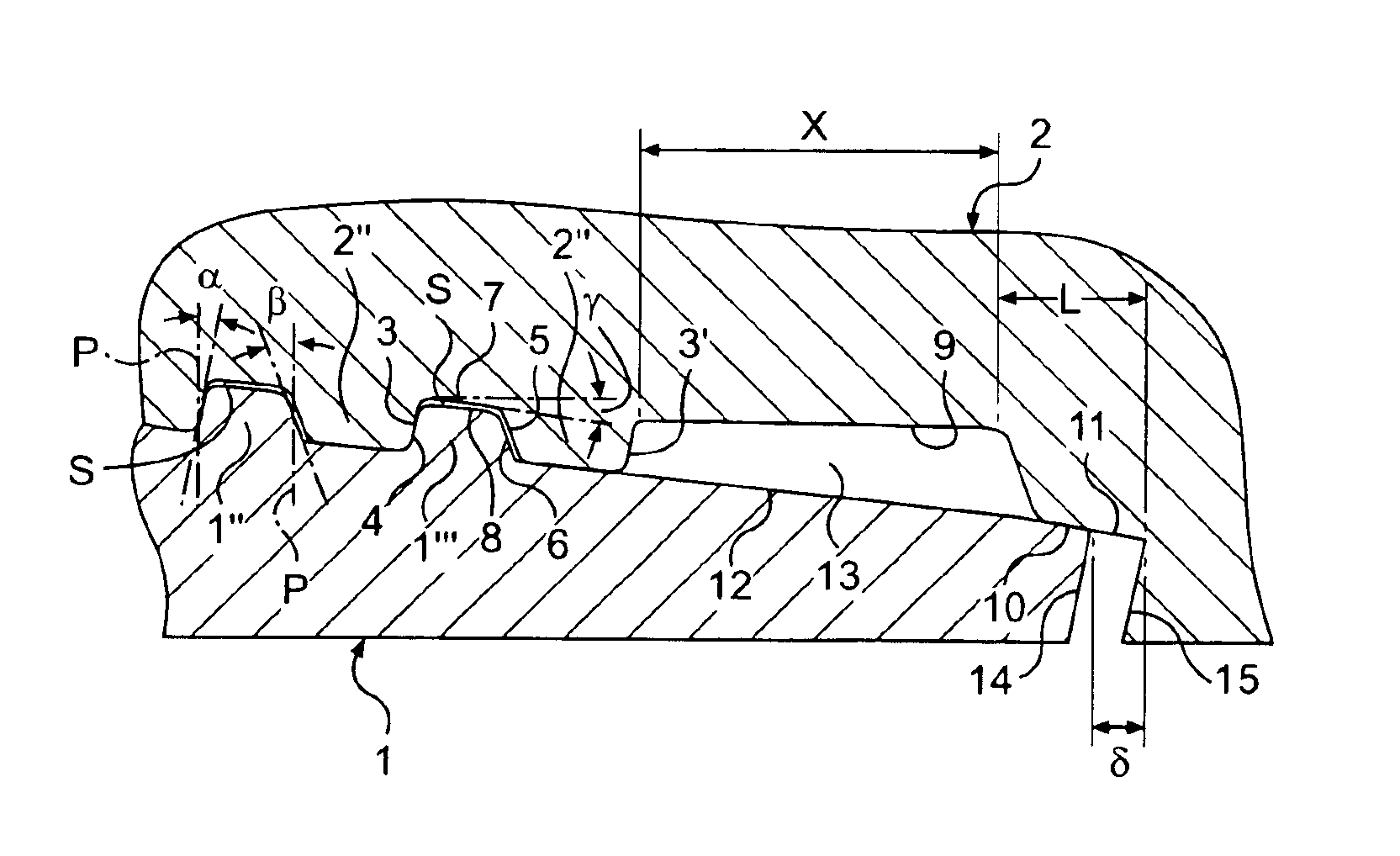

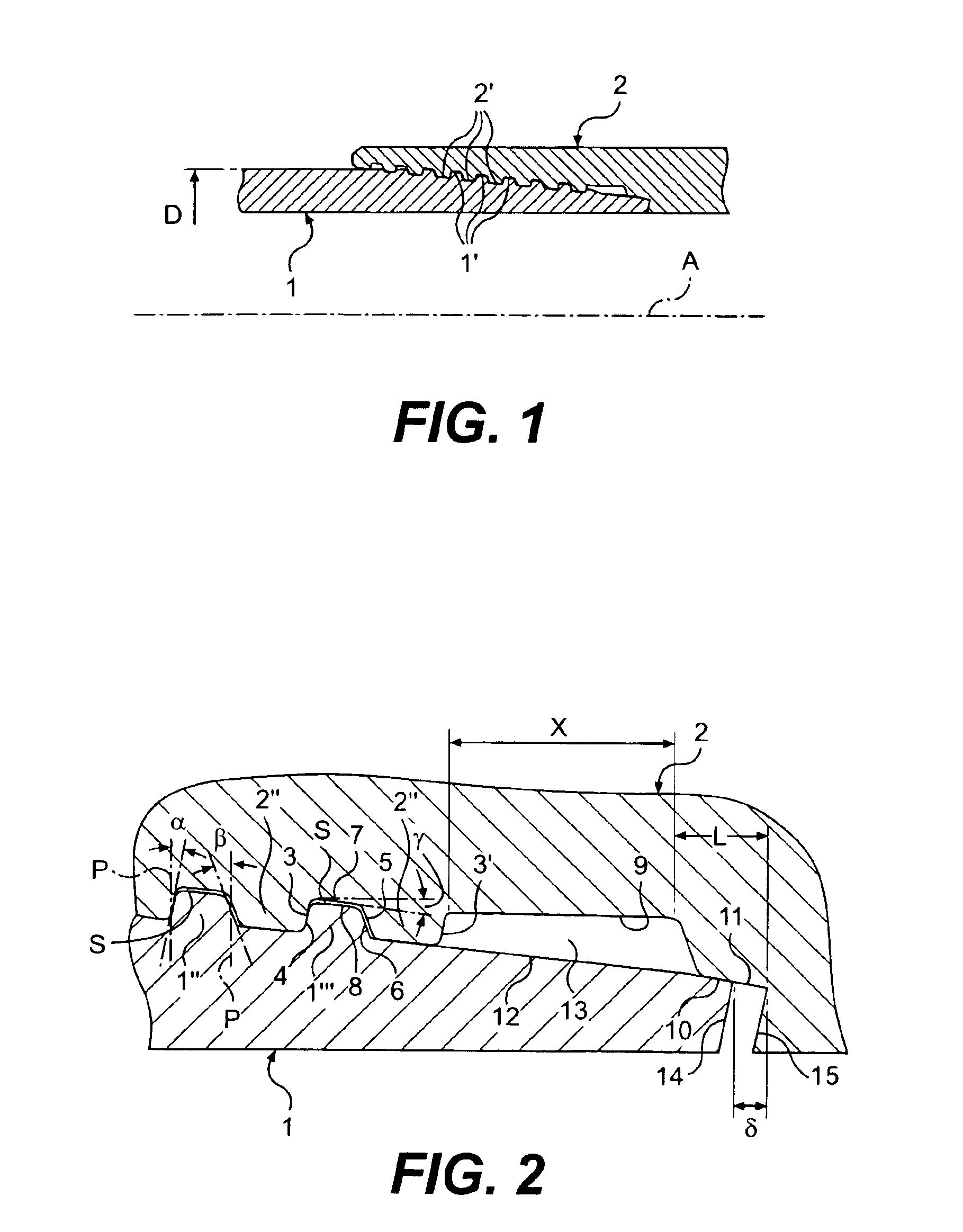

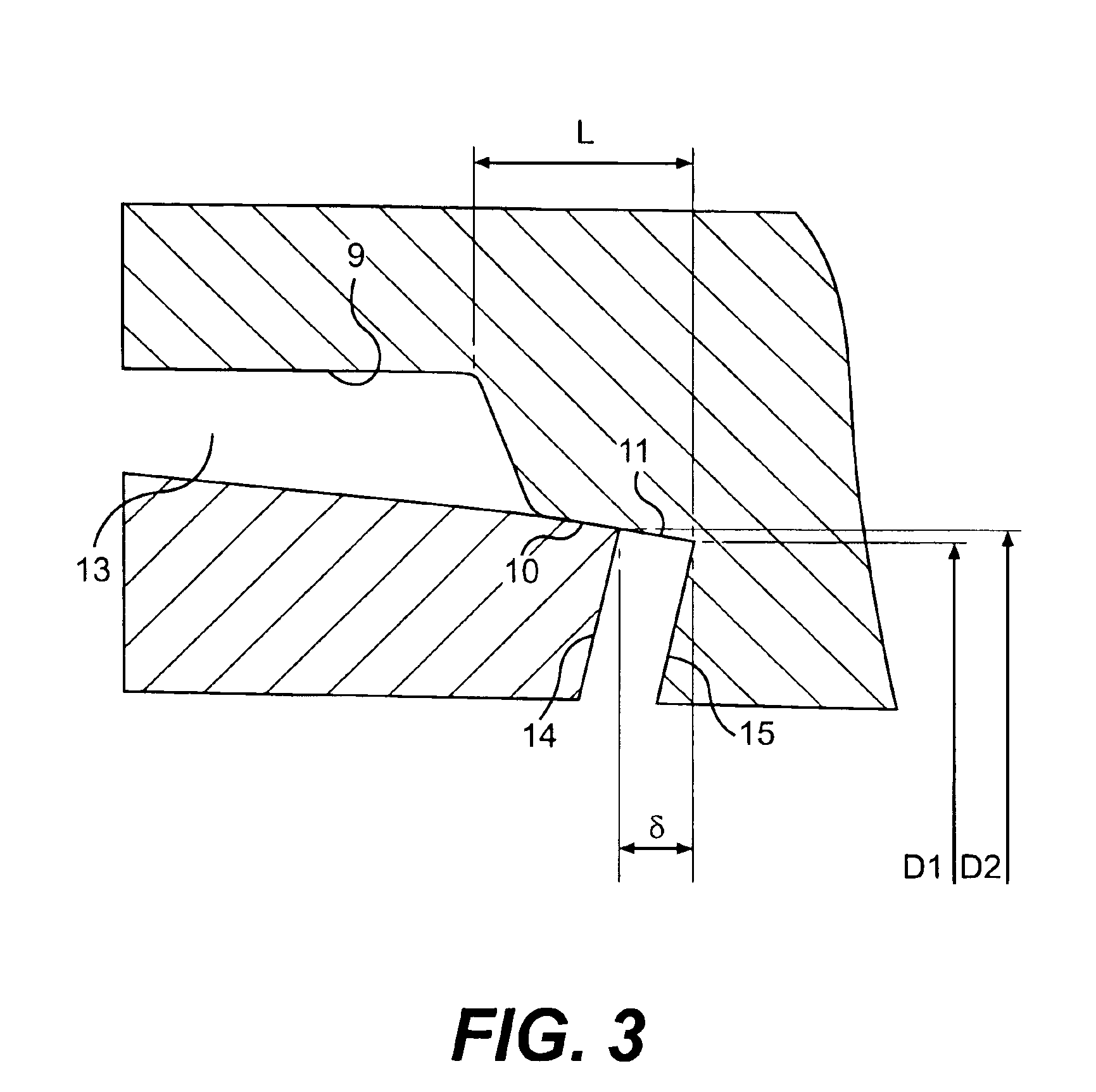

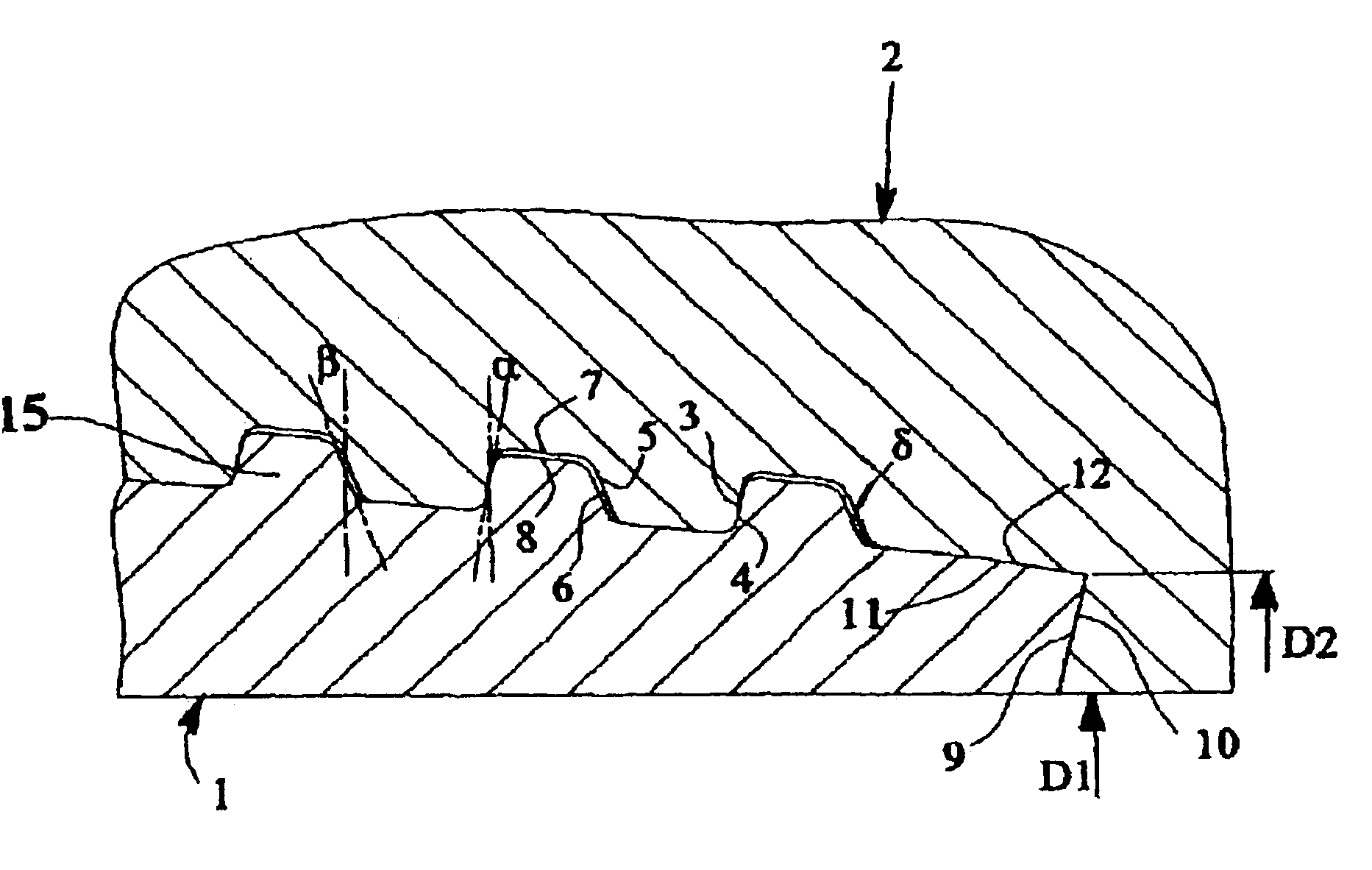

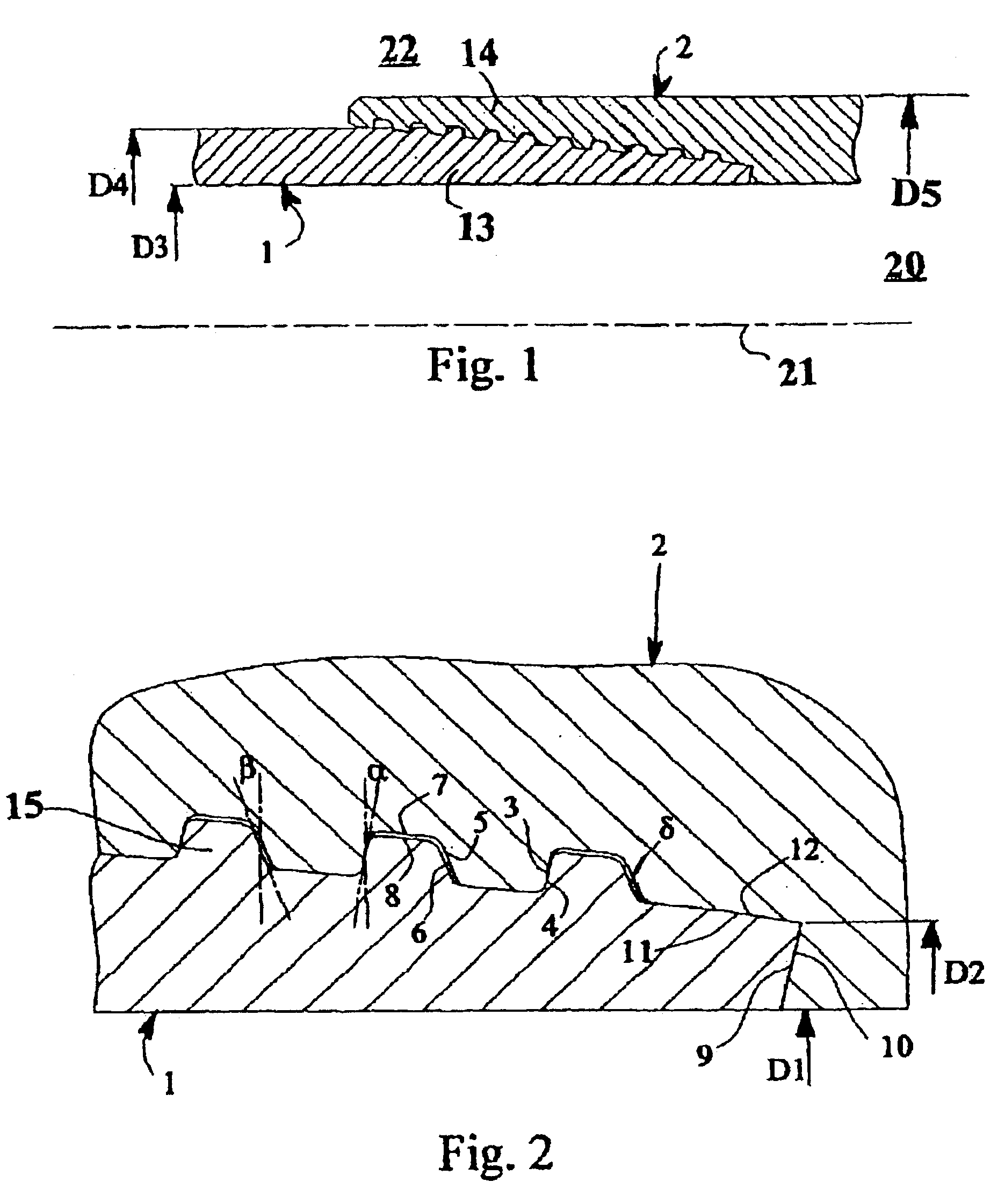

Threaded pipe joint comprising a male element (1) and a female element (2), threaded and provided with respective complementary sealing surfaces, which define, when screwed together, a notch (13) formed on the female element (2) of a predetermined length (X), and a space (7, 8) between the threads of predetermined section (S), forming reservoir to house the joint lubricant, which comes out of the volume between the threads of the female (2) and male (1) elements during the tightening of the joint.

Owner:TENARIS CONNECTIONS

Threaded pipe joint

Threaded joint for pipes consisting of a male member (1) and a female member (2), which are provided on the outer and inner surfaces respectively with two threading portions presenting a lead-in flank β such that 10°≦β≦25°, an abutment surface (9) being present at the end of said male member for abutment to a corresponding annular abutment surface (10) of the female member. The lead-in flanks of the male (1) and the female (2) members, upon make-up and with unloaded joint leave a gap (in the direction parallel to the axis (21) of the joint) varying from 0.01 to 0.12 mm. The internal and external diameters D3 and D4 (of the pipe portion not involved in the coupling with the female member) of said male member, the inner and outer diameters D1 and D2 of the abutment surface of the female member are linked by the relationship: (D22−D12) / (D42−D32)≧0.5.

Owner:TENARIS CONNECTIONS BV A CO EXITING & ORGANIZED UNDER THE LAWS OF THE NETHERLANDS +1

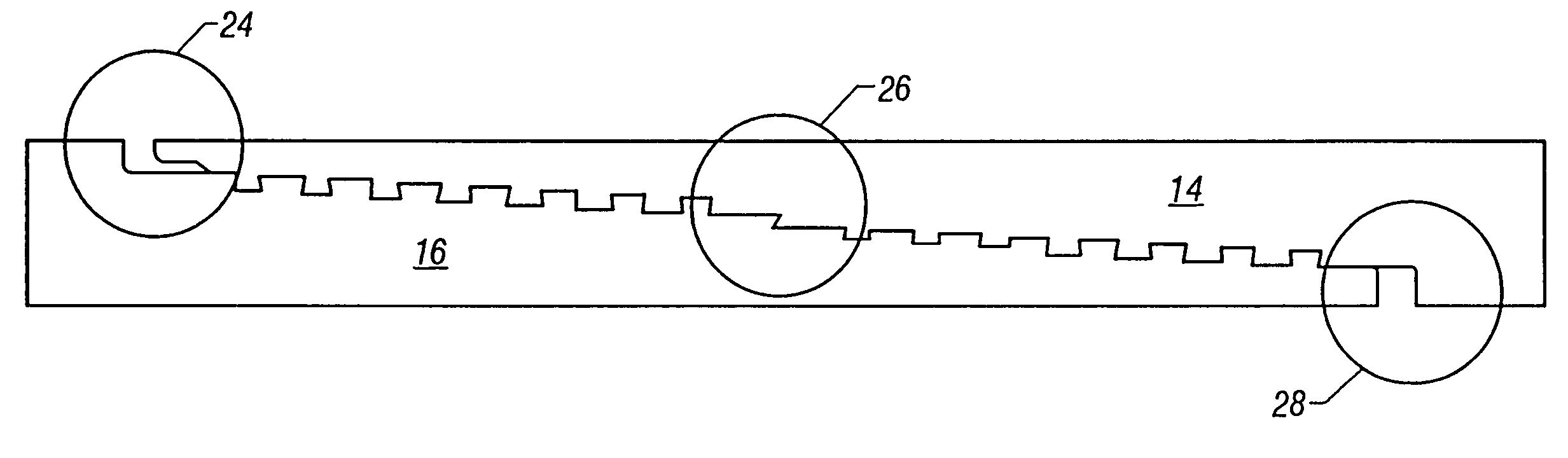

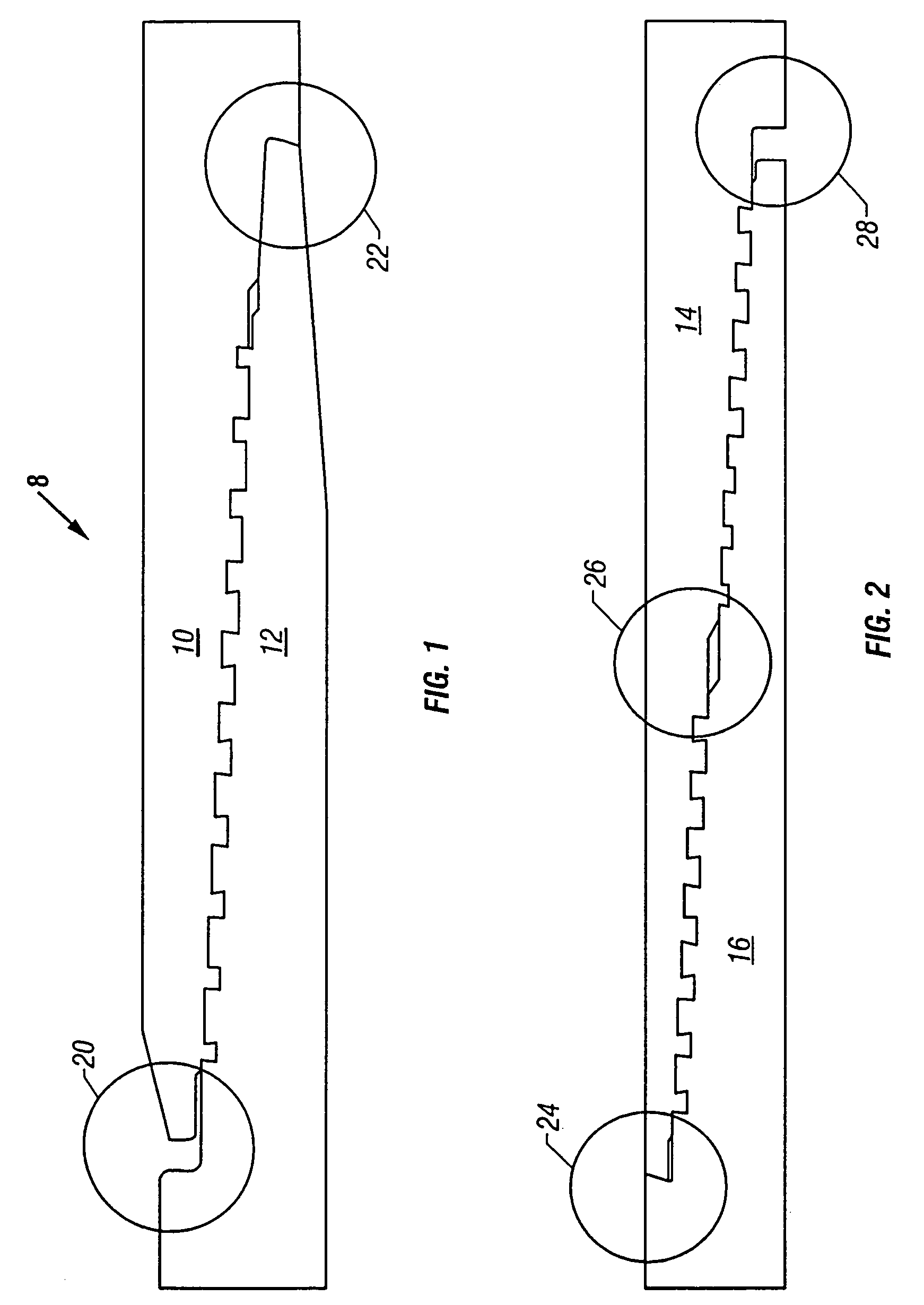

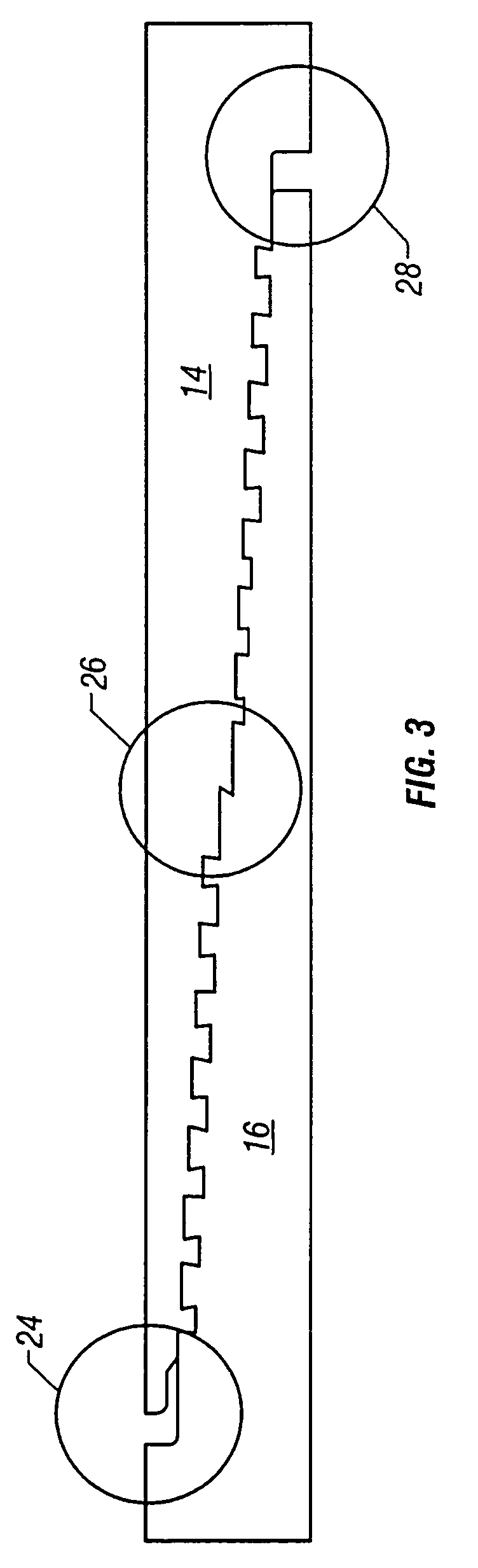

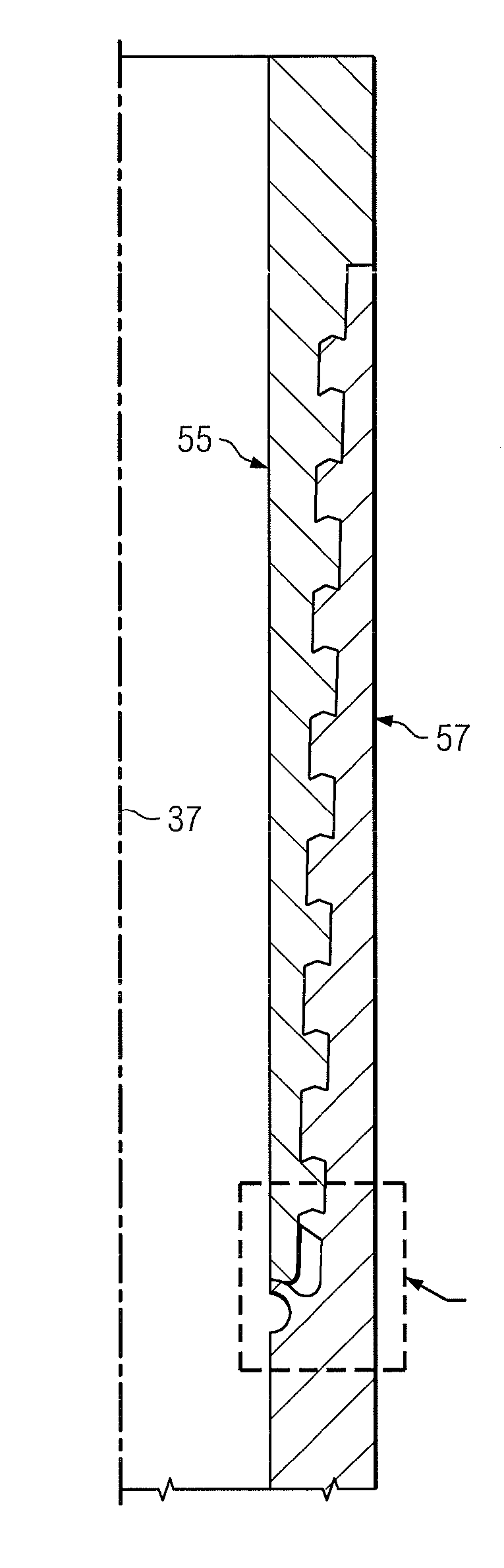

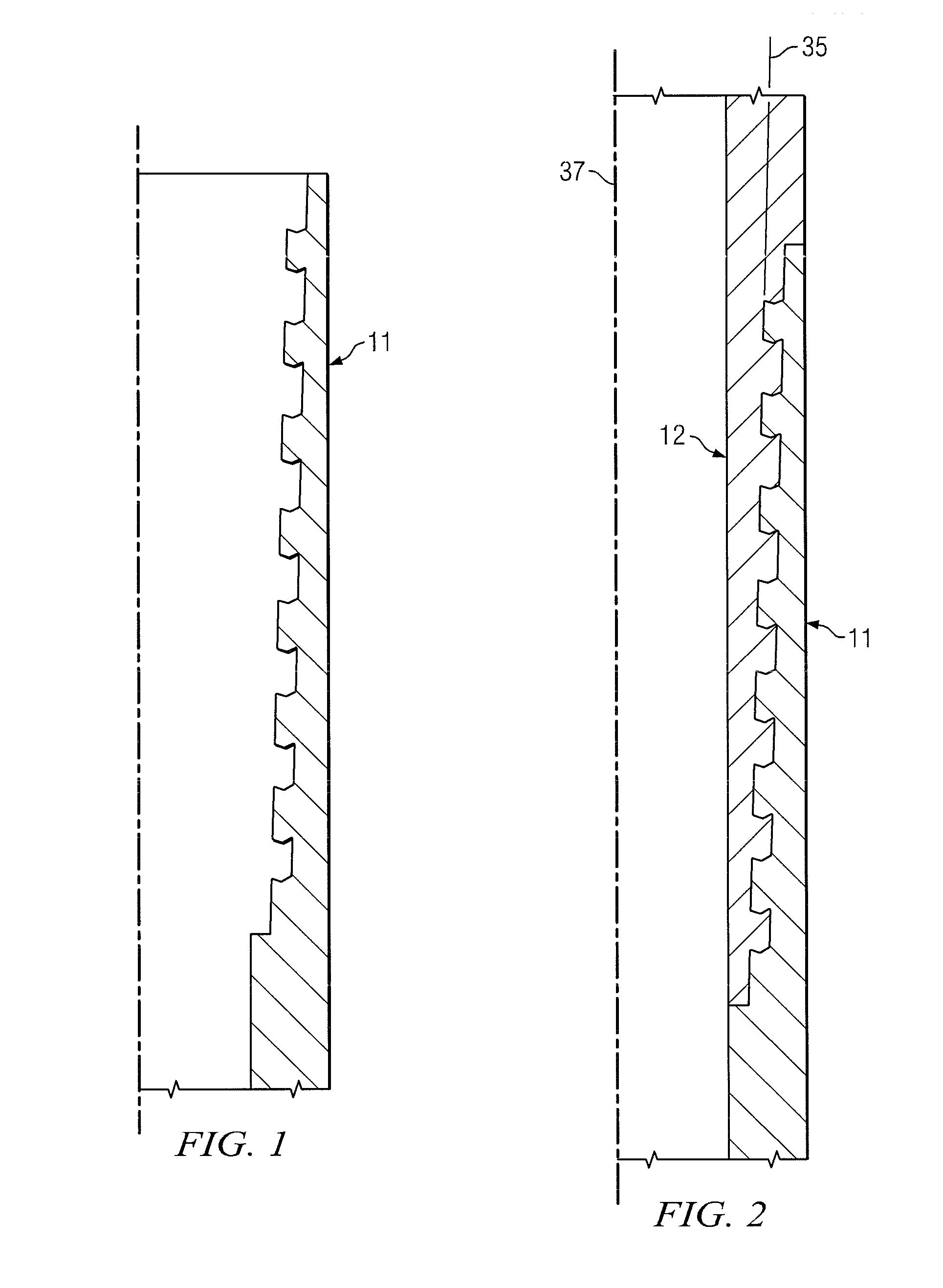

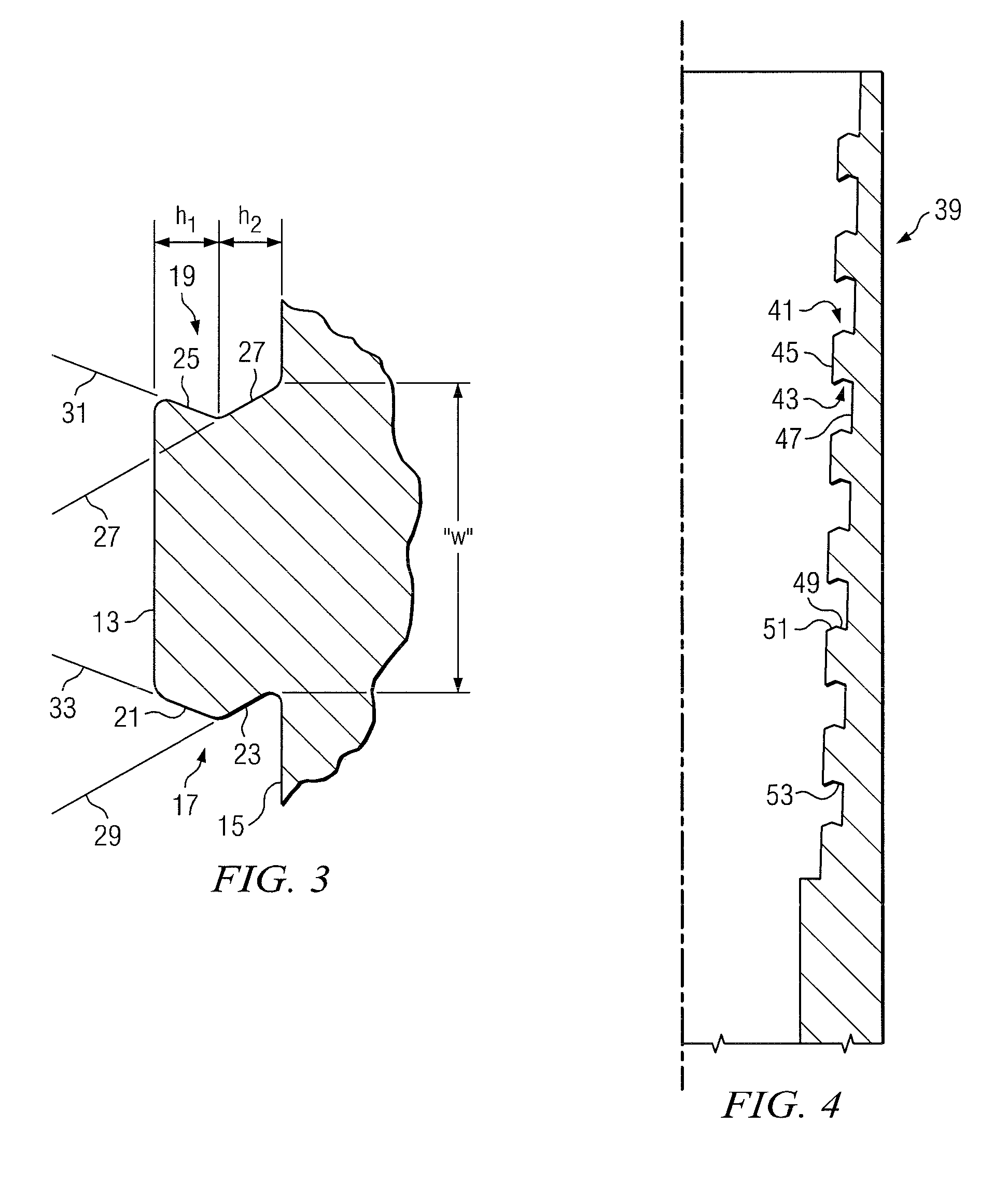

Hybrid threaded connection for expandable tubulars

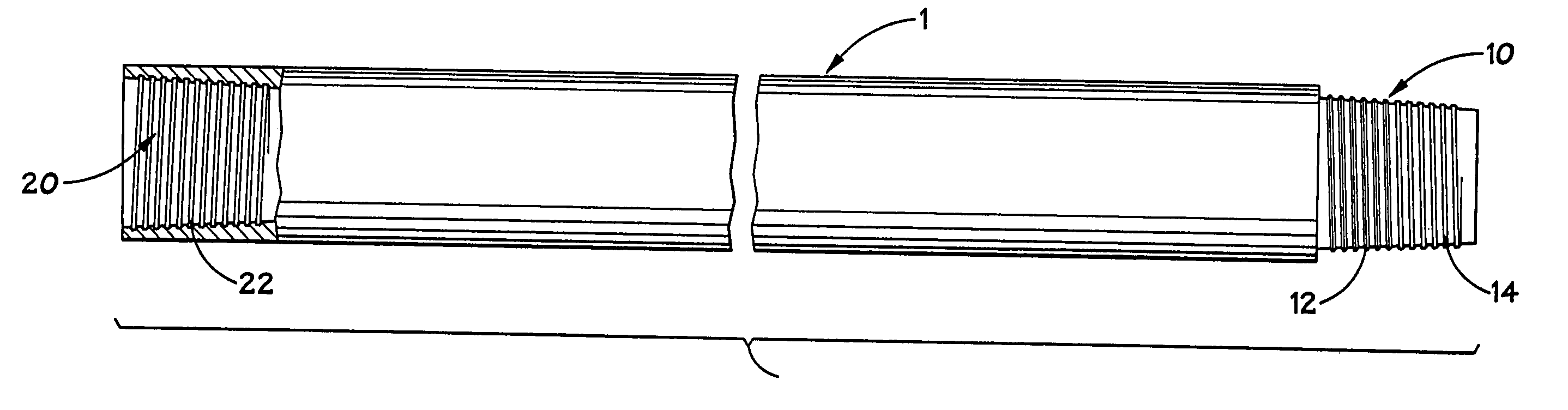

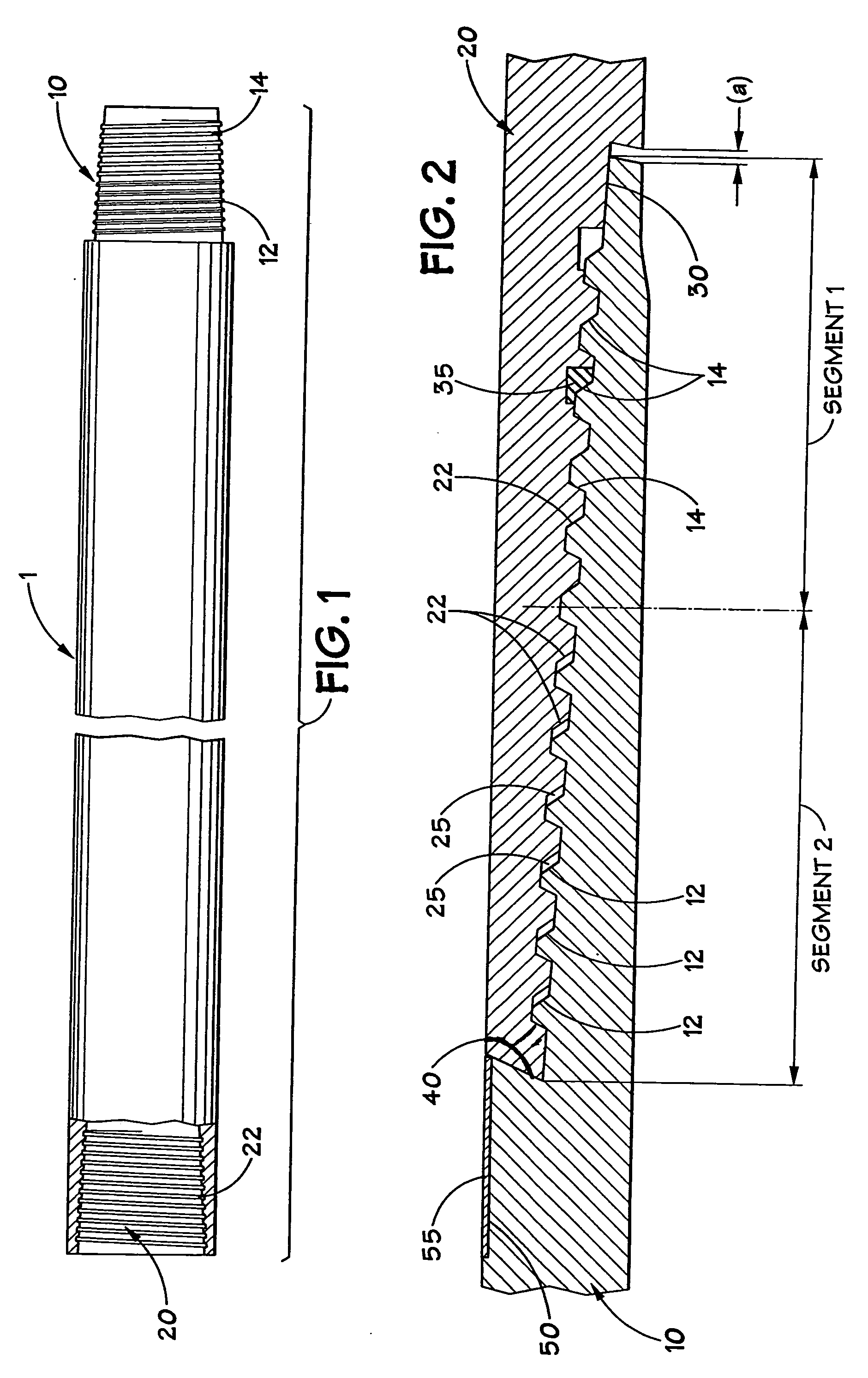

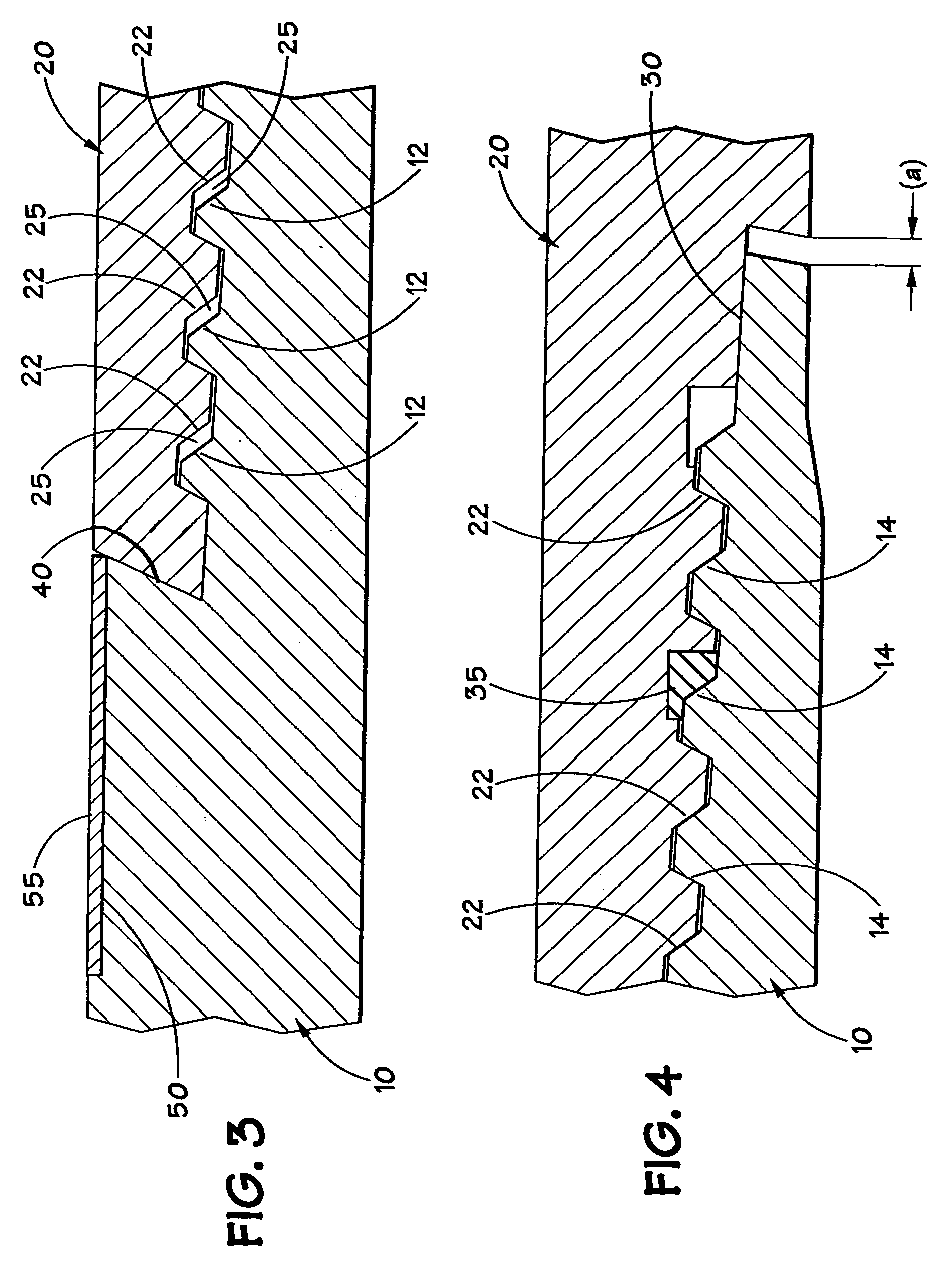

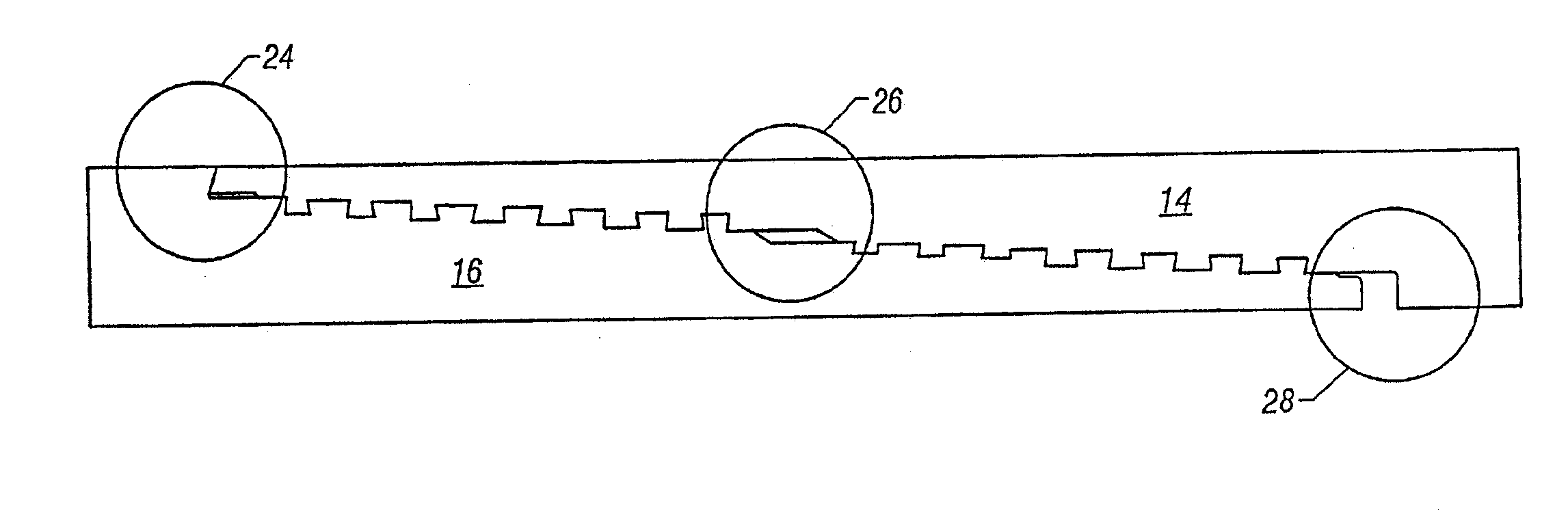

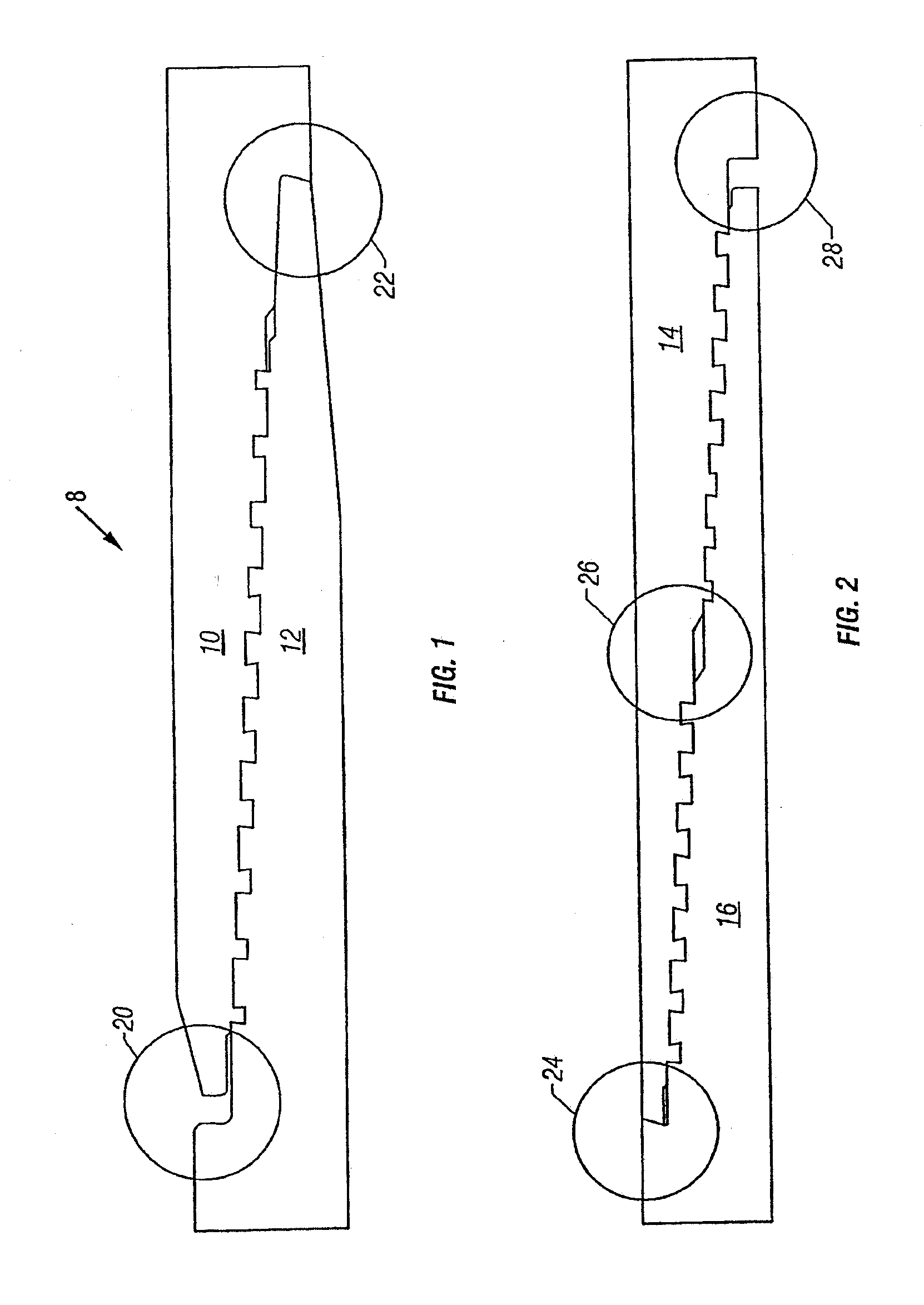

An expandable threaded connection between segments of expandable tubulars that allows the threaded tubular connection to withstand the stresses and deformations imposed on the connection by the tubular expansion process is disclosed. The present invention is a unique hybrid threaded connection that utilizes two complementary thread segments to form the expandable threaded connection. The first segment of the threaded connection utilizes standard box and pin threads such that the threads on the pin member in the area of the first segment fully engage the mating threads on the box member. The second segment of the threaded connection has the threads machined on the pin member in a manner such that material is removed from the stab flank of the pin threads to reduce the standard width of the pin threads. In contrast to the pin threads of the second segment, the box threads of the second segment are standard thread width and, thus, are the same thread width as the box threads in the first segment. The use of the reduced thread width in the pin threads of the second segment allows for a loose fit between the pin threads of the second segment and the box threads of the second segment. As the threaded connection is expanded, the loose fit between the pin and box threads of the second segment allows radial and axial movement between the pin and box threads of the second segments of the threaded connection without causing disengagement of the threaded connection. The disclosed hybrid threaded connection thus utilizes multiple thread segments in which the second thread segment accommodates the stresses and deformations generated by the radial expansion process while the threads of the first segment maintain the coupling strength and the pressure integrity of the threaded connection.

Owner:WEATHERFORD TECH HLDG LLC

Wedge thread with torque shoulder

A threaded pipe connection including a pin member having an external thread increasing in width in one direction, the external thread including load and stab flanks, a box member having an internal thread increasing in width in the other direction so that complementary internal and external threads move into engagement upon make-up of the connection, the internal thread comprising load and stab flanks, a positive stop torque shoulder, and wherein the width of the internal thread and external thread are selected to provide a selected clearance at least between the internal load and stab flanks and the external load and stab flanks upon initial engagement of the positive stop torque shoulder is disclosed.

Owner:HYDRIL CO

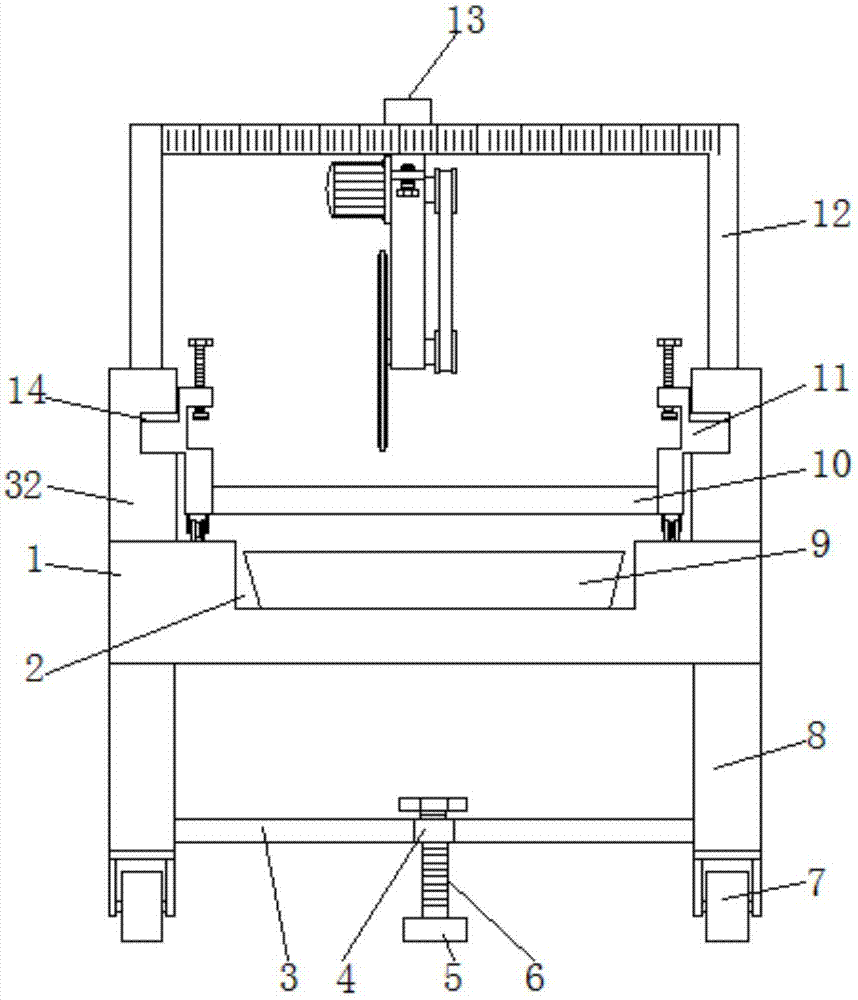

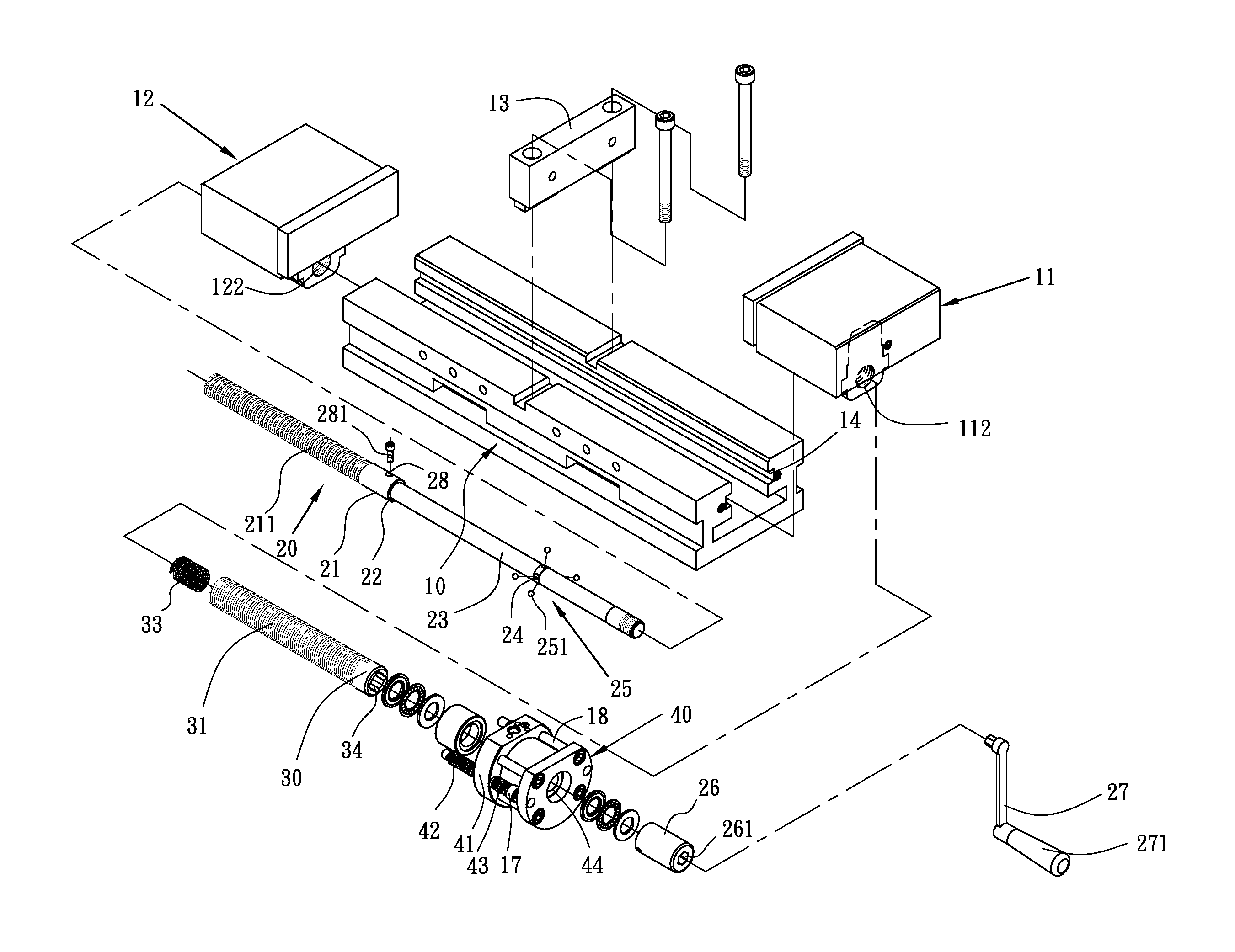

Plate cutting machine easy to adjust

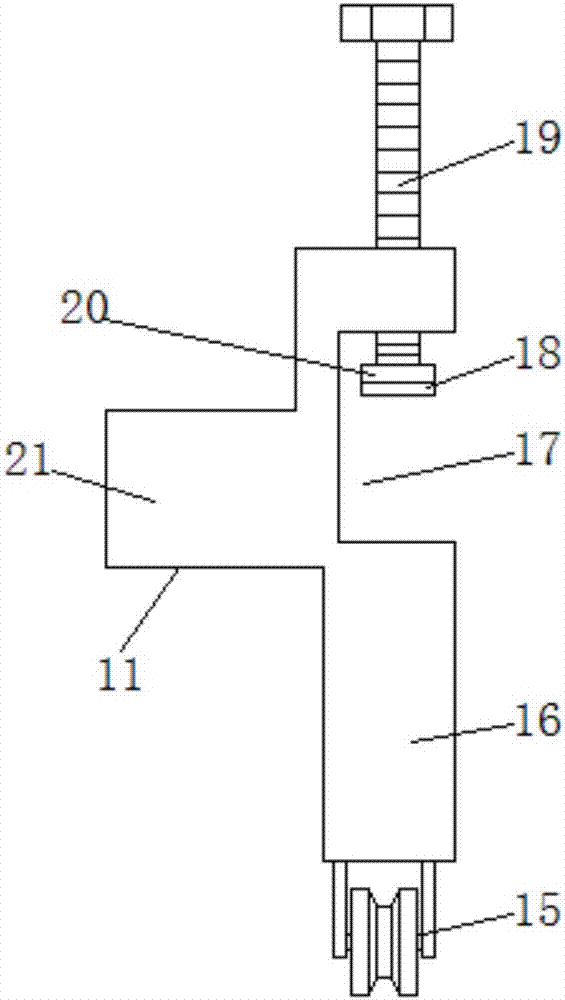

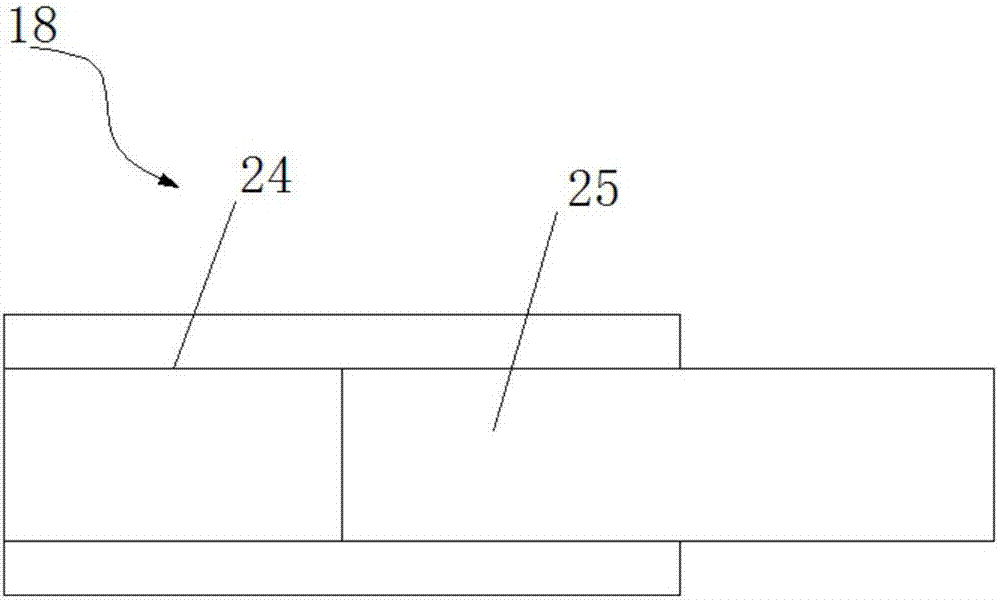

InactiveCN107214374AEasy to adjustEasy to fixShearing machinesMaintainance and safety accessoriesThreaded pipeEngineering

The invention discloses an easy-to-adjust plate cutting machine, which includes a workbench, the four corners of the bottom surface of the workbench are welded with supporting legs, and the bottom end of each supporting leg is equipped with rollers. Beams are welded, the middle of each beam is welded with a threaded pipe, the threaded pipe is threaded with a first screw, the bottom of the first screw is welded with a pad, and the upper surface of the workbench is provided with a groove. This easy-to-adjust board cutting machine uses the cooperation of two fixing mechanisms to fix the board, so that the board is fixed more firmly, and the walking wheel is installed on the bottom of the vertical board, and the rolling of the walking wheel on the workbench is convenient for the board. For placement and removal, since the fixing mechanism uses the slider to slide and connect with the first chute, the slider can be used to limit the position of the vertical plate, and the setting of the pole can strengthen the space between the two fixing mechanisms, improving the fixing institutional stability.

Owner:金陈敏

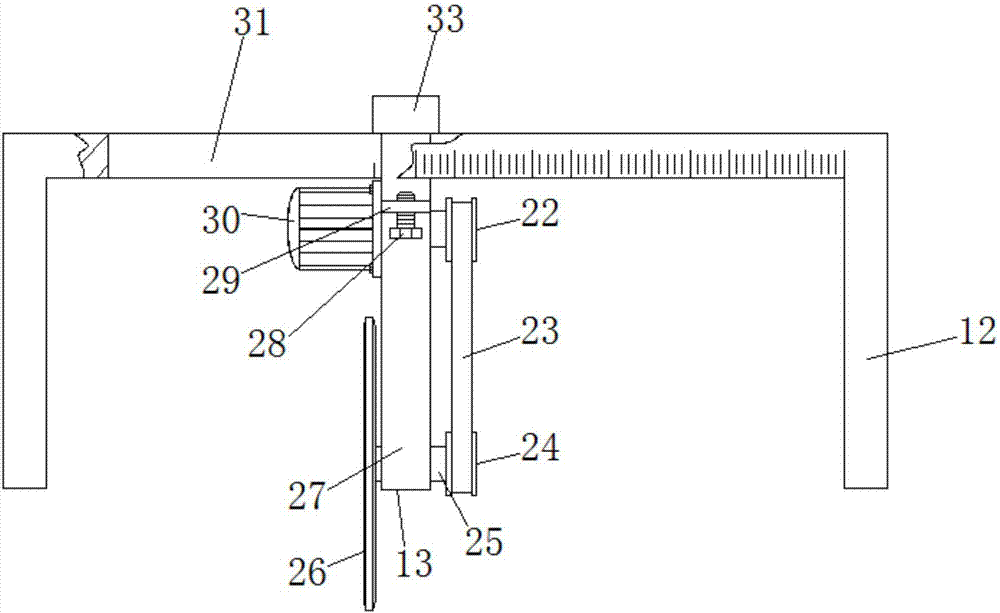

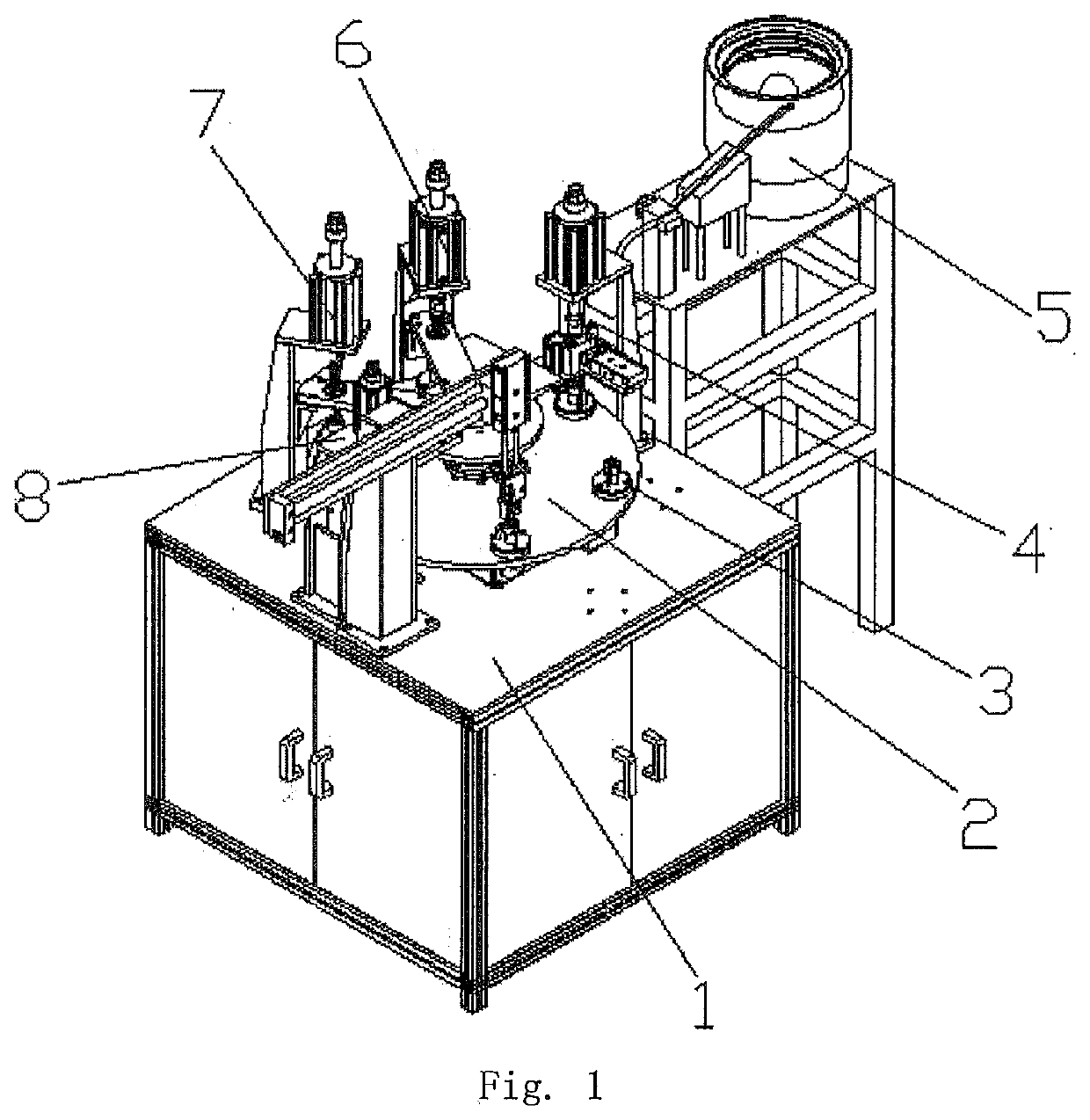

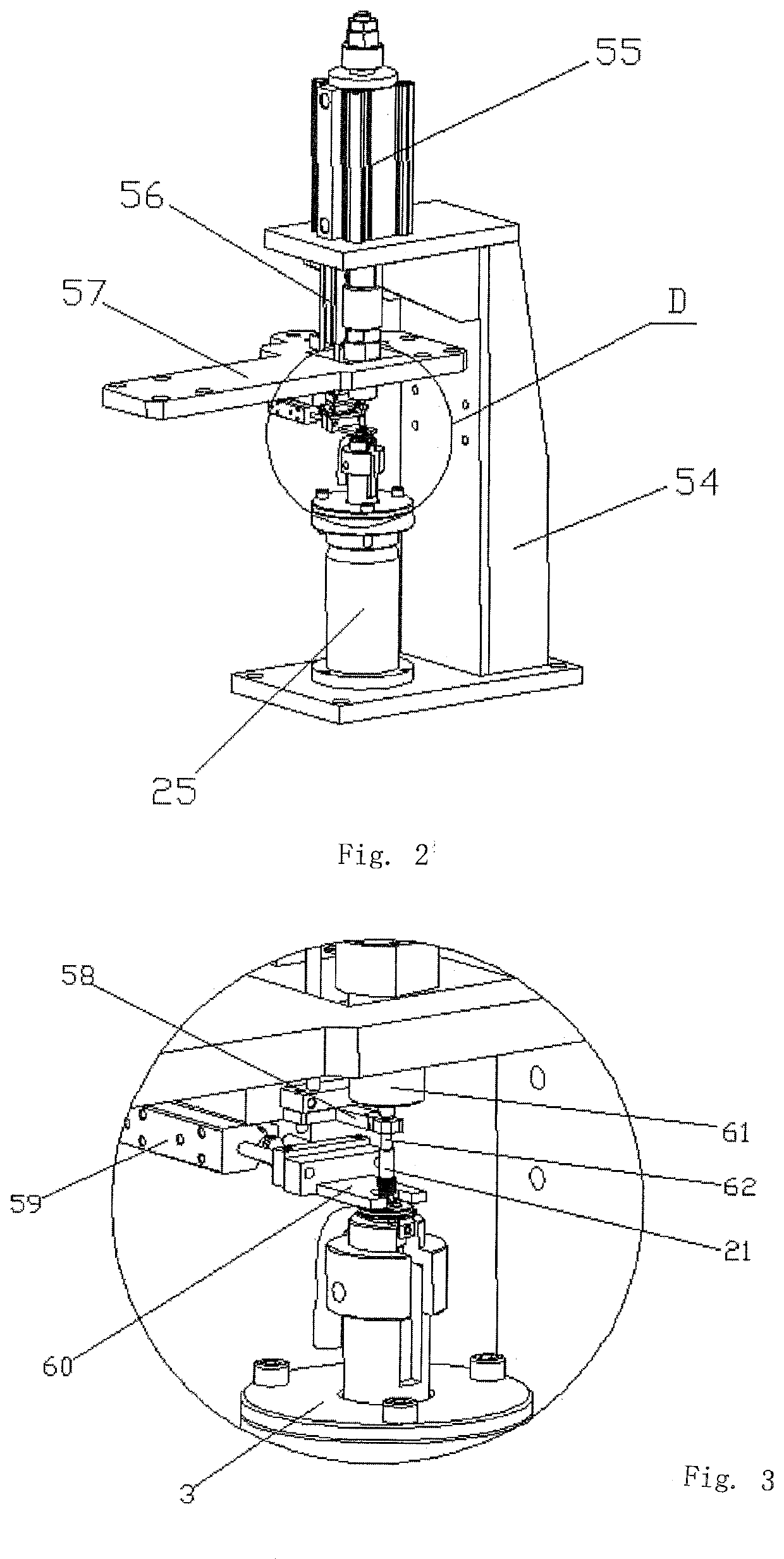

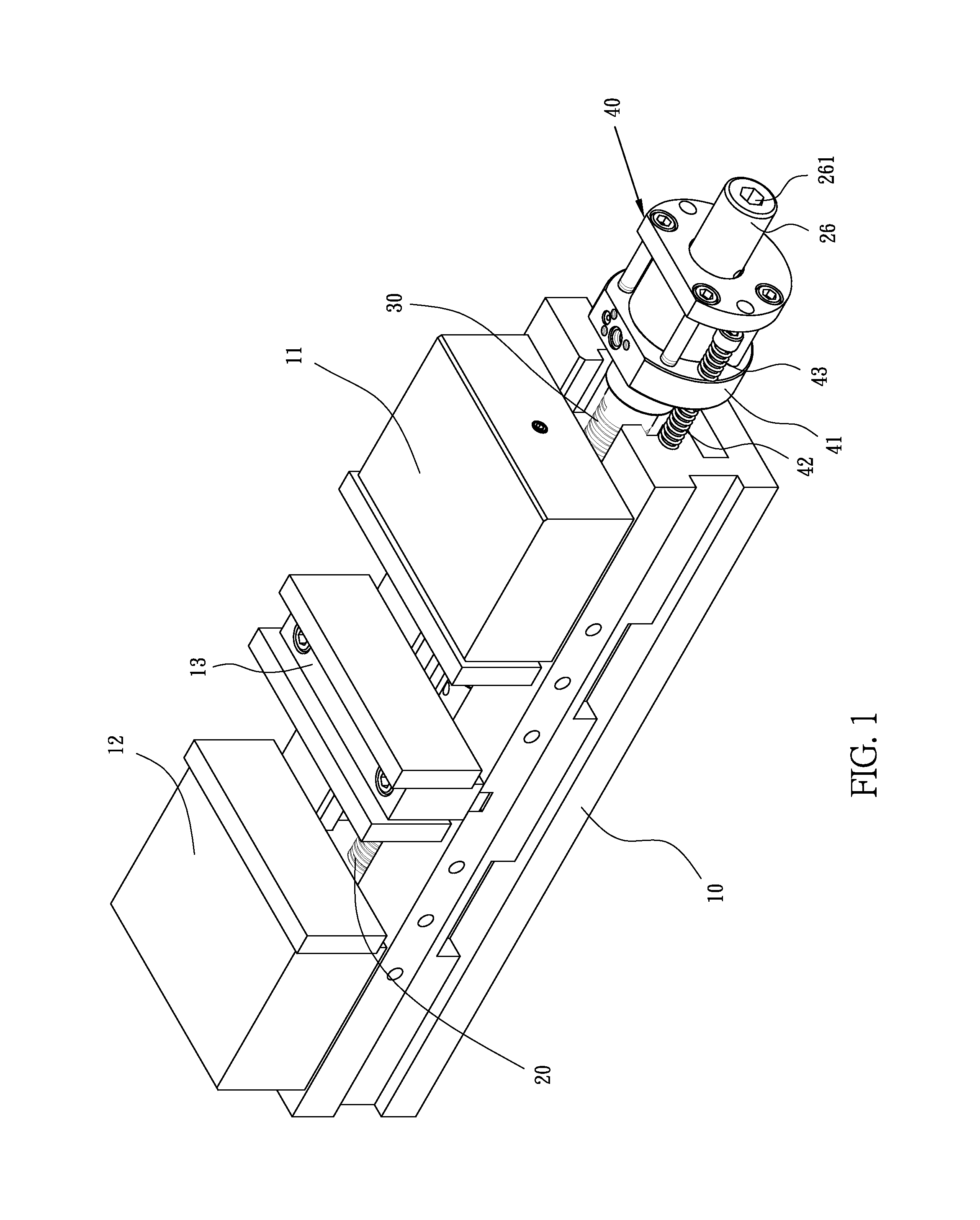

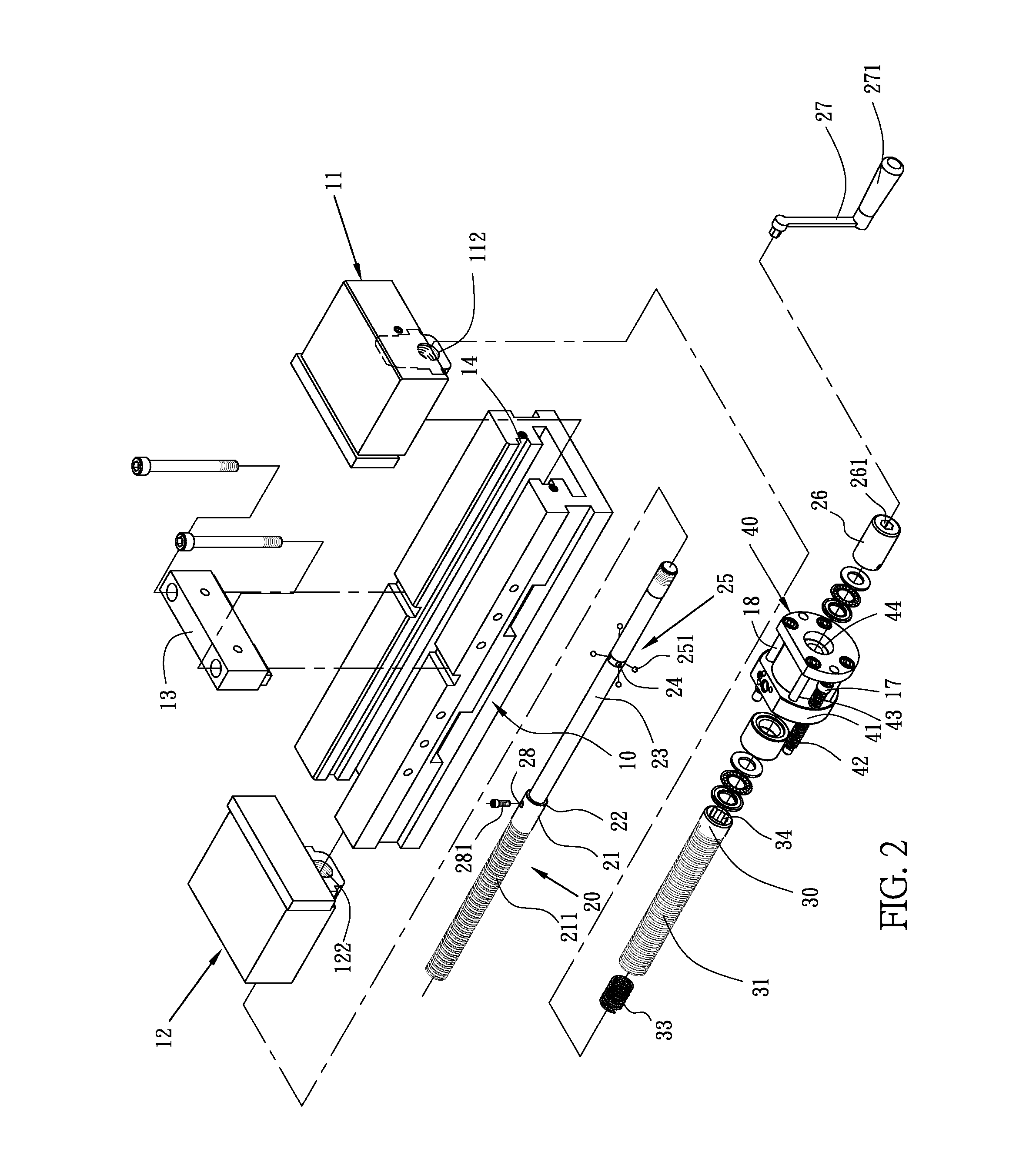

Riveting and grinding assembly for the nozzle of a screw shaft valve

ActiveUS20200038940A1High positioning accuracyEdge grinding machinesAssembly machinesThreaded pipeEngineering

The present invention generally relates to assembly equipment of valve body, especially to riveting and grinding assembly for nozzle of screw shaft valve. The invention may include a rack, a power control box, a turntable and a turntable divider. A carrier assembly which engages with the screw shaft valve body is installed on the edge of the turntable with uniform distribution. On the center part of the turntable, a support shaft which is installed on and fixed with the rack is vertically interposed and on the top of the support shaft, an upper supporting disc is installed. A valve pipe feeding device, a valve pipe preloading device, a valve pipe riveting device and a valve pipe grinding device which engage with the carrier assembly are installed on the said rack on the rotational direction of turntable. As the threaded pipe is put into the carrier assembly by valve pipe feeding device, the carrier assembly rotates counterclockwise along the turntable and rotates to the valve pipe feeding device to the press threaded pipe into the valve seat. Thereafter the carrier assembly rotates the valve pipe riveting device and rivets threaded pipe with a valve flange in order to finish assembling process. Finally, the carrier assembly rotates the valve pipe grinding device to grind nozzle of valve to finish grinding and riveting process of threaded pipe with high positioning accuracy of assembly and marvelous hermetic sealing.

Owner:DONGGUAN UNIV OF TECH

Plastic pipe adhesive joint

InactiveUS20030155768A1High strengthFluid pressure sealed jointsJoints with sealing surfacesThreaded pipeEngineering

A method of joining two pipe ends, by forming male threads on an end of a first pipe with a steep taper angle, forming matching female threads on an end of a second pipe, and applying adhesive material to the threads before twisting the pipes to fully engage the male and female threads, thereby spreading the adhesive material across adjacent load-bearing surfaces of the threads. The threads have multiple start locations for thread engagement so that the pipe ends may be twisted to achieve full engagement in less than one full relative rotation. The male and female threads are formed with a squeeze angle between matching surfaces of the threads between 0.5 and 5.0 degrees. The finished joint provides immediate leak-tightness, and immediate tensile, compressive and torsional strength and does not protrude outside of the pipe profile. The technique may also be used to join pipes constructed of dissimilar materials, particularly by using a coupler that has the appropriate threading, and securing the coupler to a non-threaded pipe end using any convenient means, such as a mechanical fit, or fusion bonding.

Owner:HOLLINGSWORTH ELMONT E +1

Threaded pipe with surface treatment

A threaded metallic pipe for oil extraction industry has a threaded end portion with treated surface in which the metal surface has a roughness (Ra) comprised of 2.0 mum and 6.0 mum, which is covered by a uniform layer (7) of a dry corrosion inhibiting coating and a second uniform layer (8) of dry lubricant coating. Alternatively the layers (8, 9) combined into one uniform layer (9) of a dry corrosion inhibiting coating containing a dispersion of particles of solid lubricant.

Owner:TENARIS CONNECTIONS

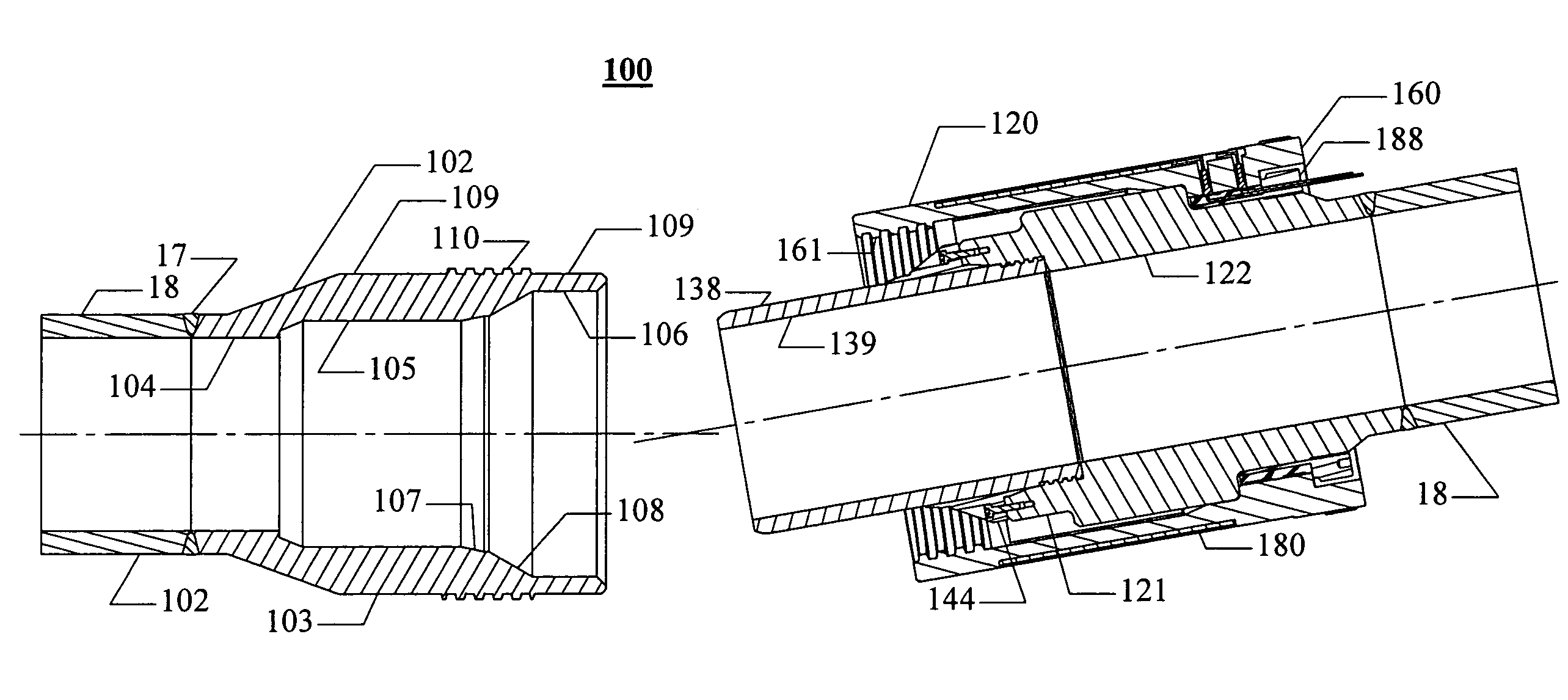

Threaded pipe connector

InactiveUS20070063517A1Protection from damageImprove interferenceHose connectionsScrew threaded jointsRadial positionThreaded pipe

A riser connector uses a box and upset pin connector threadform design having S-shaped load flanks that provide a variable load angles depending on the radial position along the engaged teeth. This design promotes a load path that changes with position along the axial length of the engaged thread, as well as increasing or decreasing external loads on the connector. The connector also varies radial distention of the pin from the box in a manner that is different from one thread to the next. The threadform uses a combination of thread cuts that vary in shape, pitch, and / or thread cone angle to provide load and stab flanks, as well as a load path, that vary from one axial end of the engaged thread to the other.

Owner:VETCO GRAY

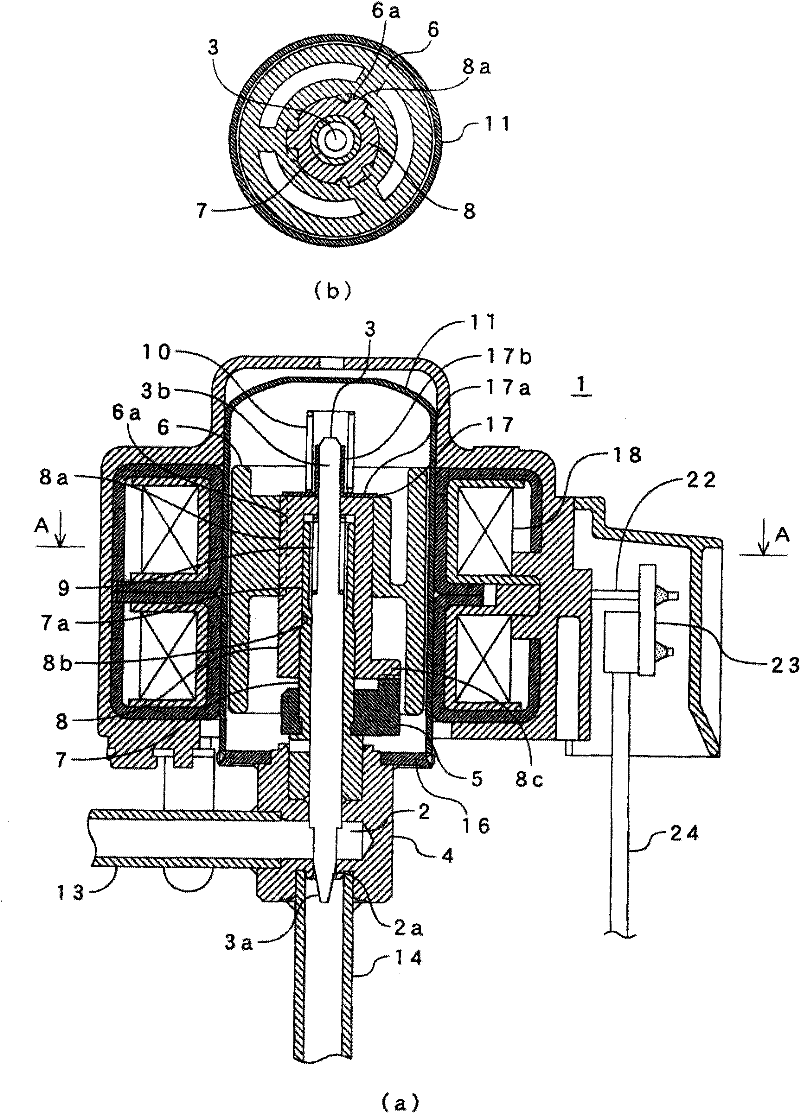

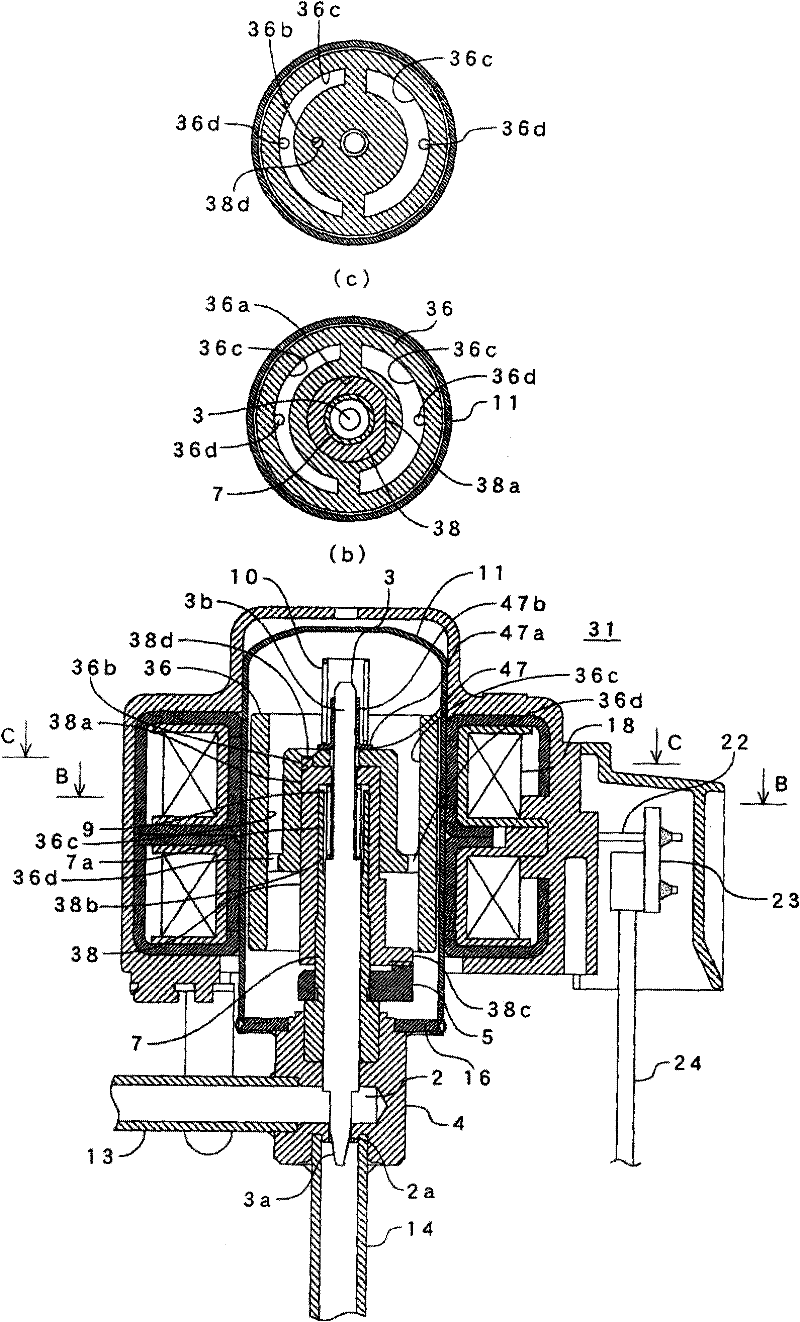

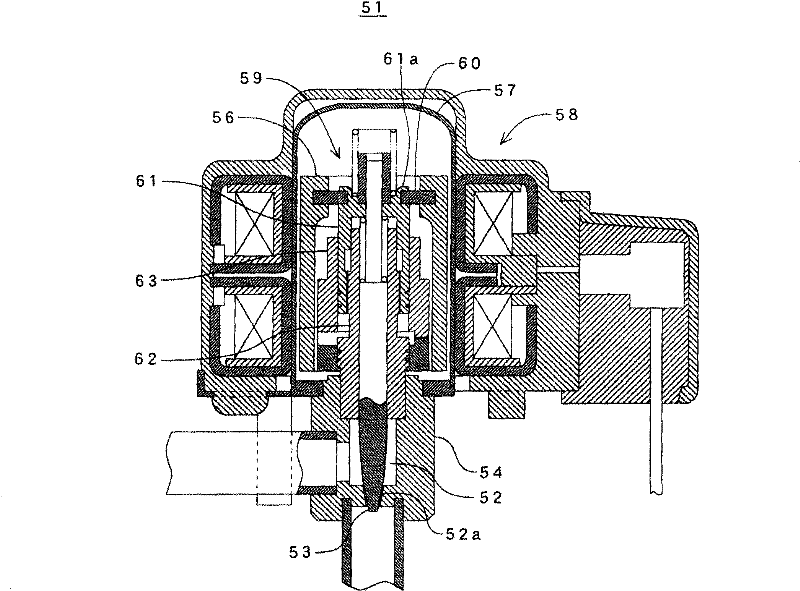

Motorized valve

ActiveCN102207224AReduce the number of piecesReduce manufacturing costOperating means/releasing devices for valvesFluid circulation arrangementThreaded pipeStator coil

The invention provides a motorized valve with a low manufacturing cost due to part number decrease and manufacturing process simplification. The motorized valve comprises a valve main body having a valve chamber and a valve hole formed in the valve chamber, a valve core for opening and closing the valve hole; a housing projecting from the valve main body; a stator coil equipped on the outer side of the housing; a resin rotor equipped on the inner side of the housing and performing rotation by means of the electrified excitation of the stator coil; a threaded pipe fixed on the valve main body; a resin valve rod frame configured in a way to rotate simultaneously with the rotor and making the valve core open and close the valve hole through a valve rod by means of the thread feeding motion between the valve rod frame and the threaded pipe; a valve-closing spring equipped between the valve rod frame and the valve rod and exerting force on the valve core through the valve rod towards the valve hole closing direction; and a limiter cooperating with the valve-closing spring for preventing relative motion of the valve rod frame and the rotor on the direction where the valve core opens and closes the valve hole.

Owner:FUJIKOKI MFG CO LTD

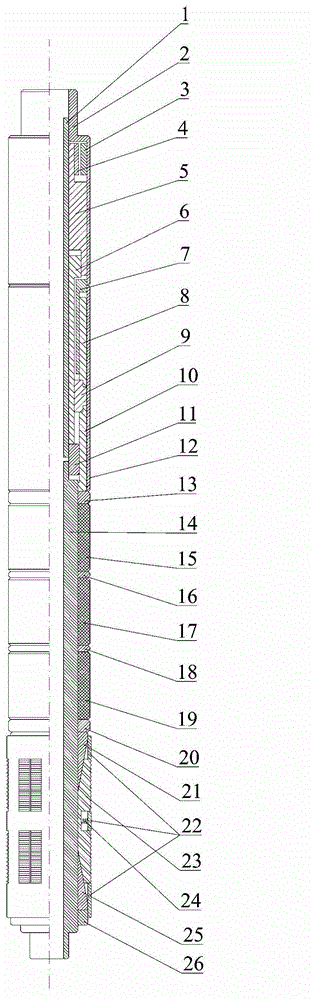

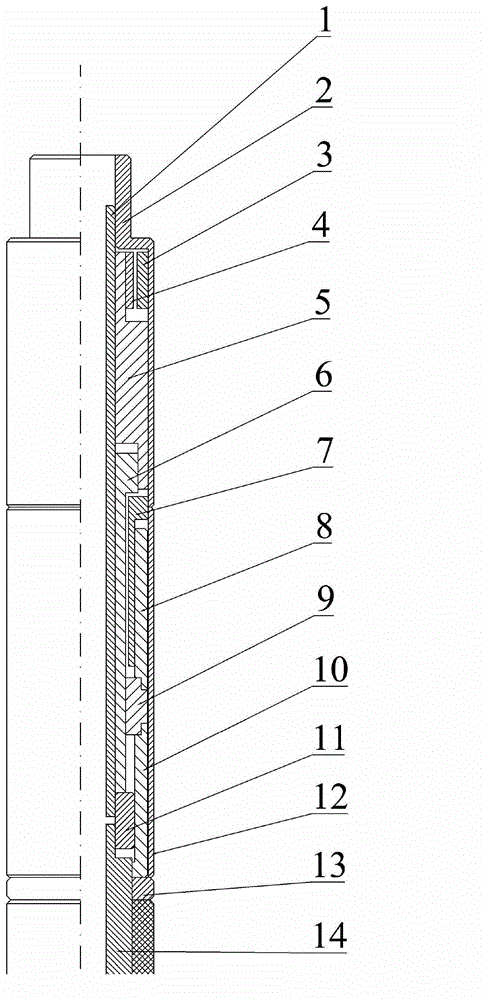

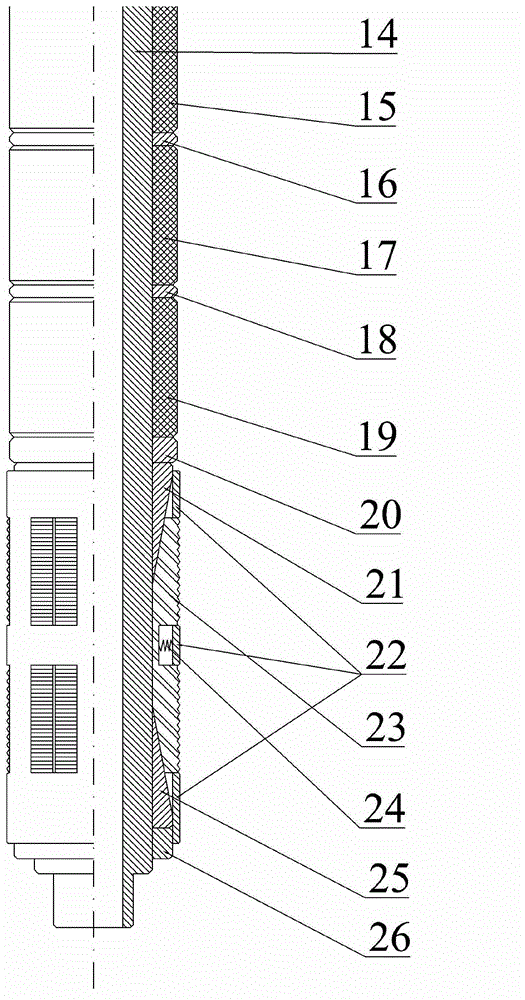

Downhole electric control compression type packer

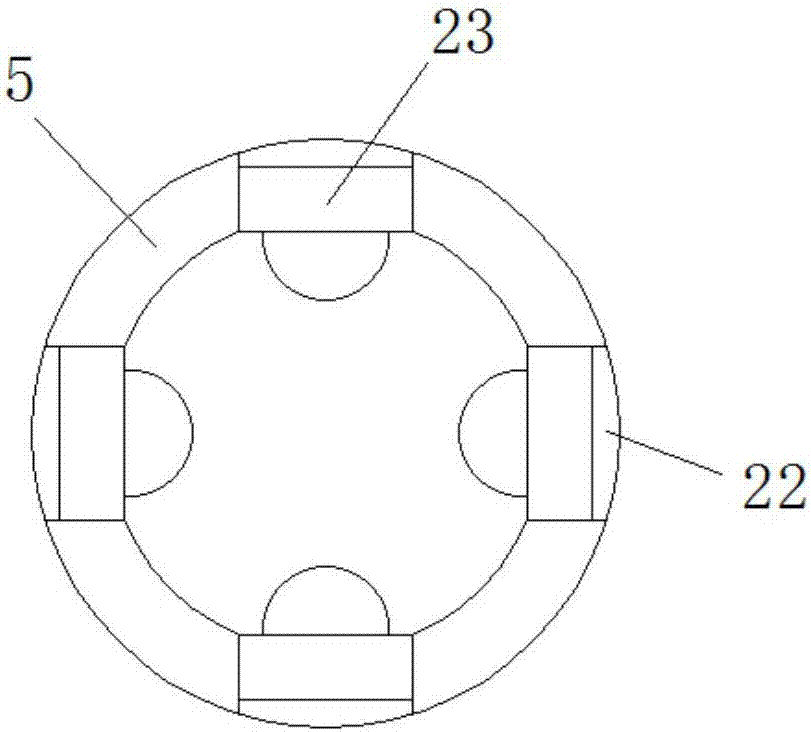

ActiveCN102979477AAchieving tightnessAccurate data feedbackSealing/packingThreaded pipeElectric machine

The invention provides a downhole electric control compression type packer, which comprises a base pipe, a motor, a speed reduction device, a transmission device and a packing device, wherein the motor, the speed reduction device, the transmission device and the packing device are sheathed on the base pipe, the motor comprises a circular motor output shaft, the circular motor output shaft is rotatably sheathed on the base pipe, the speed reduction device comprises a circular NN-shaped planetary gear speed reducer with small teeth difference (5), the circular NN-shaped planetary gear speed reducer with small teeth difference (5) comprises a circular input shaft and a circular output shaft, the input shaft of the circular NN-shaped planetary gear speed reducer with small teeth difference (5) is connected with the circular motor output shaft, and the transmission device comprises a thread pipe (6), a transmission nut sleeve (9) and a lower sleeve (10).

Owner:PETROCHINA CO LTD

Thread form for tubular connections

ActiveUS20080277933A1Improved design characteristicImprove performanceDrilling rodsHose connectionsThreaded pipeEngineering

A thread form is shown which is used to make a threaded pipe connection capable of being screwed together and subsequently unscrewed. A pin member is provided having external threads with stab flanks and load flanks and flat crests and roots for mating with the mating internal threads of a box member to make up a pipe connection. One of the stab or load flanks is made up of two facets and three radii. The other selected flank is made up of three facets and four radii, giving it irregular features forming a complex geometric profiles. The thread form can be used to form a premium threaded connection which is used with such tubulars as casing and tubing for oil, gas, water and waste disposal wells.

Owner:U S STEEL TUBULAR PROD

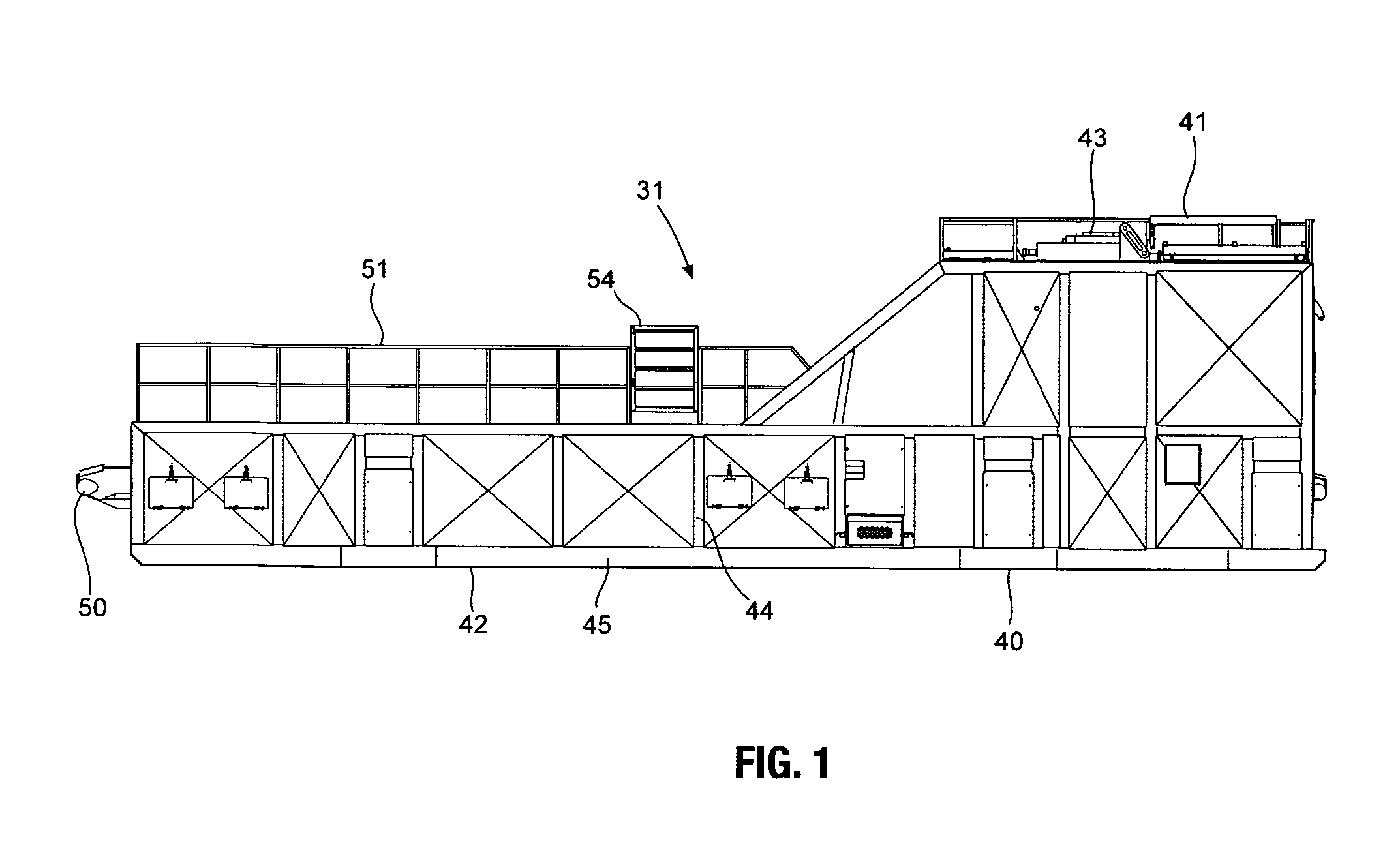

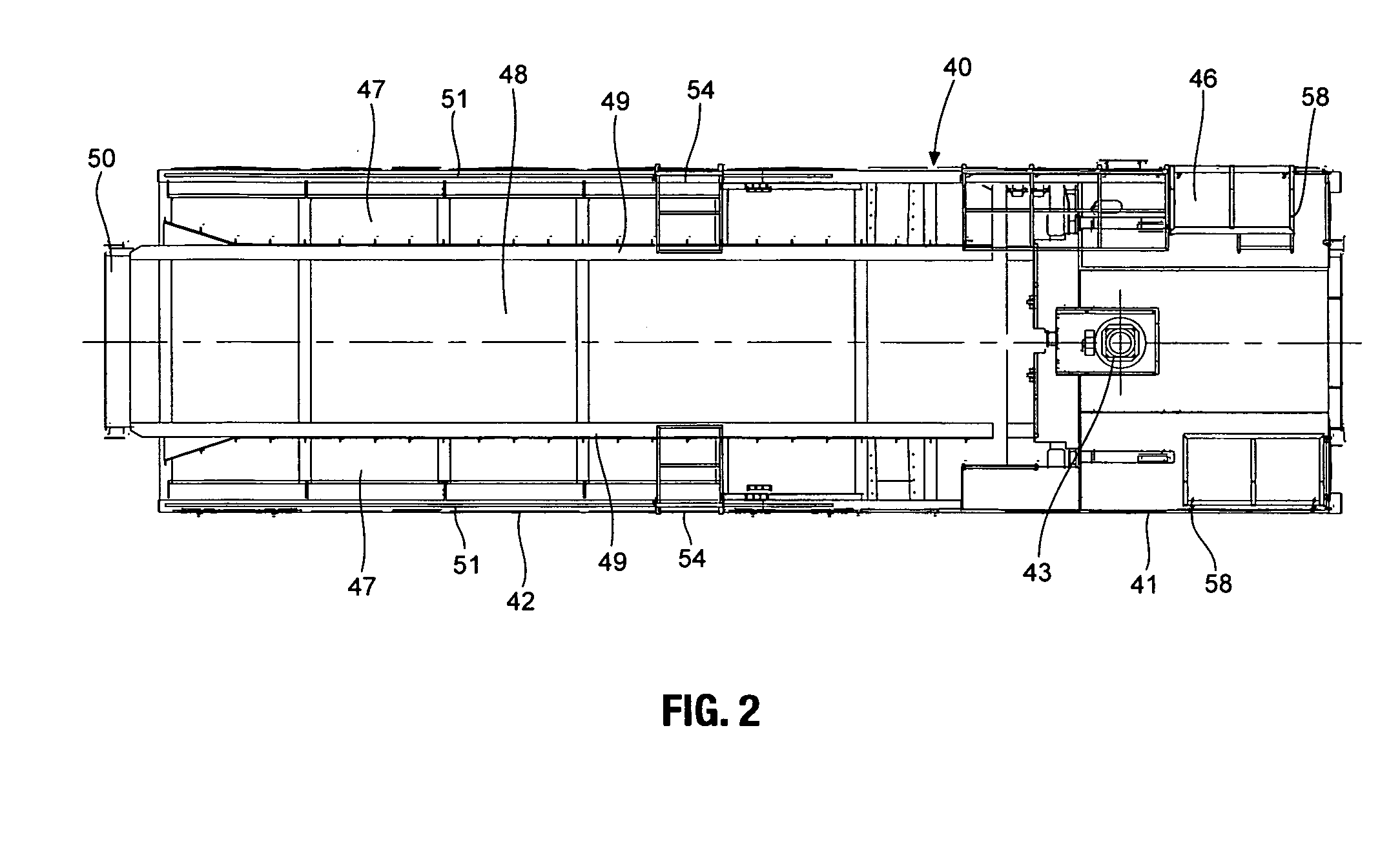

Modular coiled tubing and sectional pipe drilling rig

A drilling rig for use in both coiled tubing injection and rigid threaded pipe operations, and consisting of a number of separably transportable modules which are assembled on site for carrying out the operations. Included in the modules are a substructure component, a mast component and an injector component. In setting up for operation, the mast component is combined on site with the substructure component which supports the assembled rig over the borehole. The mast component in location provides a loading area to support the injector component in a position for ready loading of an injector included in the injector component into the mast when required for a coiled tubing operation.

Owner:FOREMOST INDS

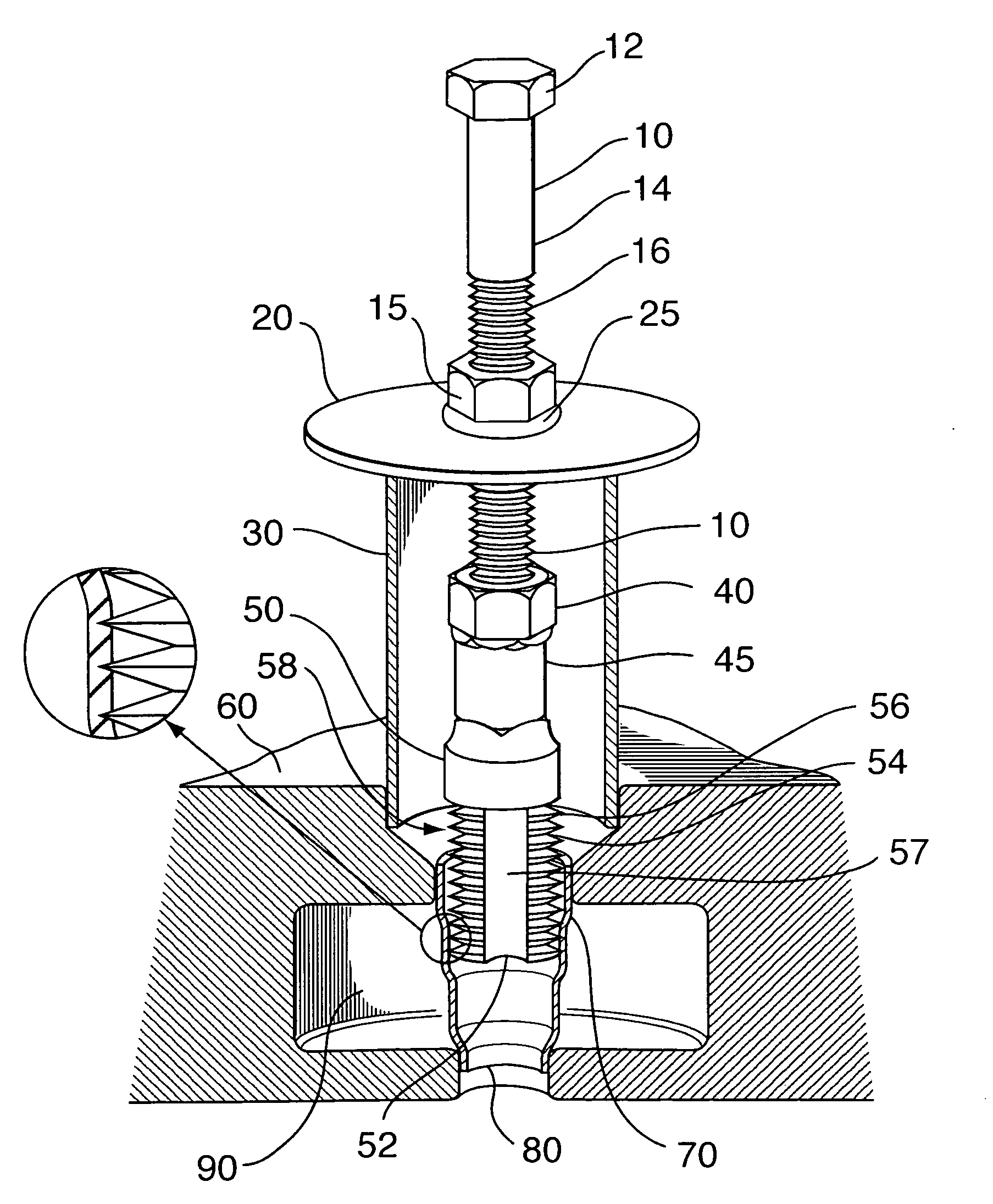

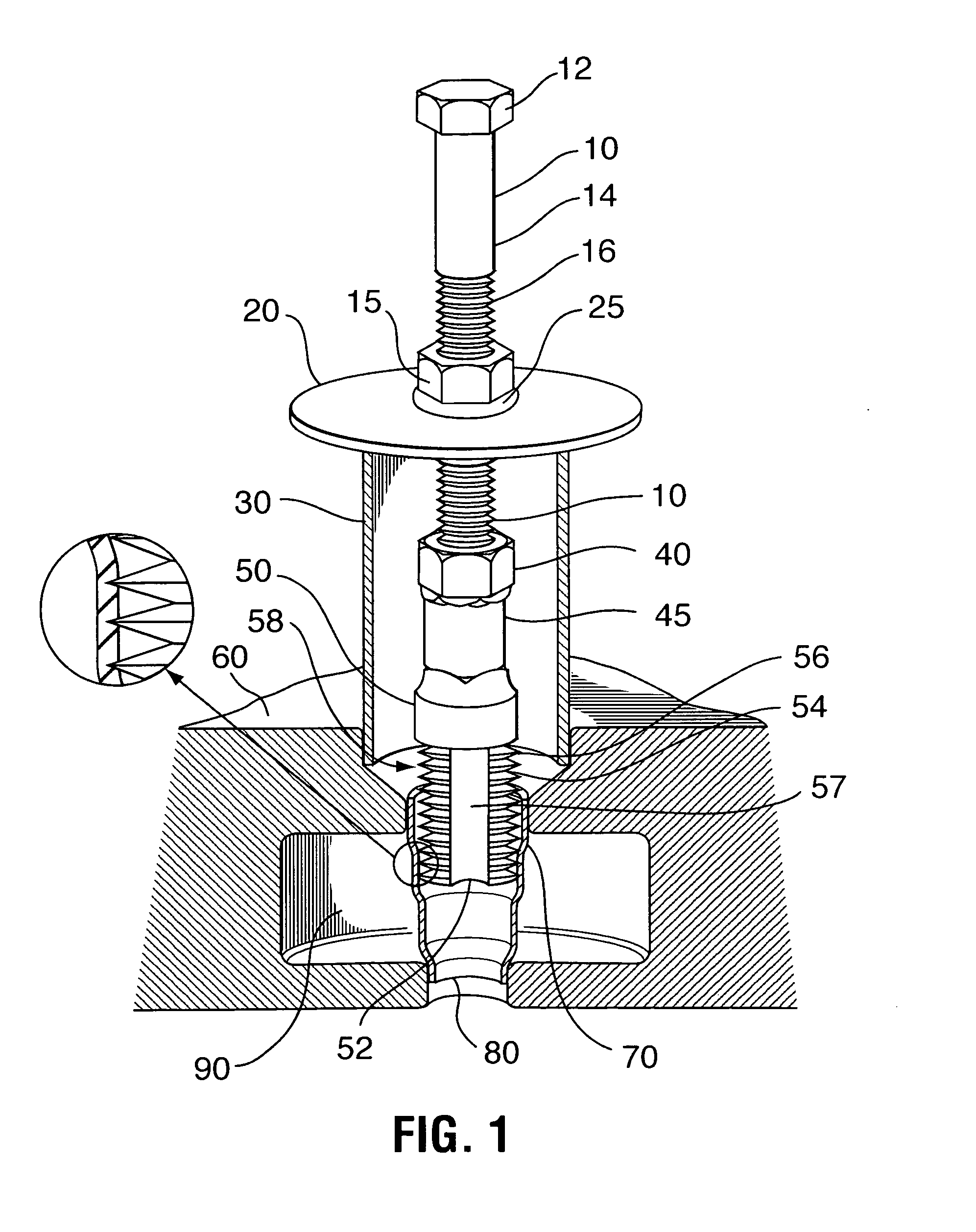

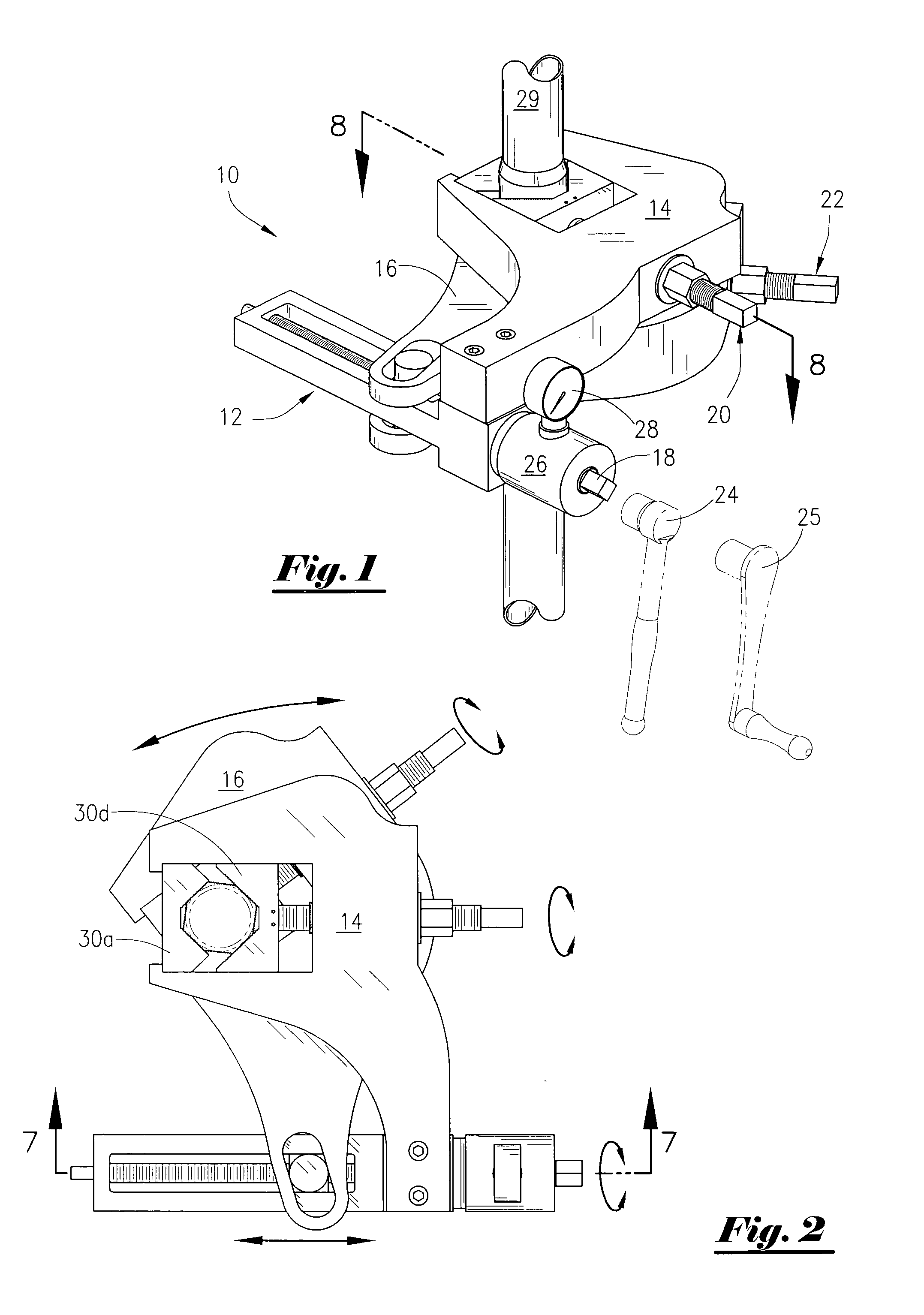

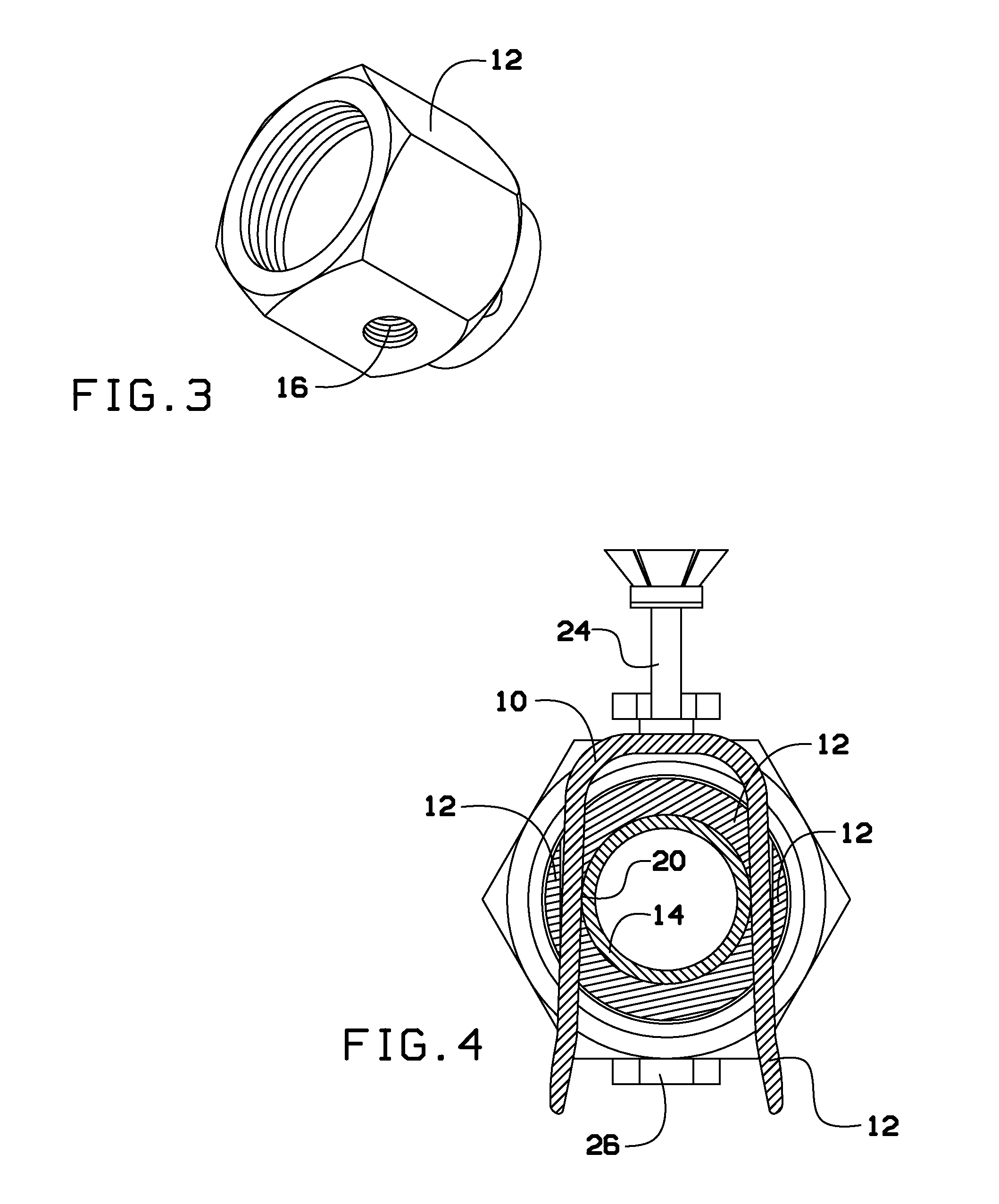

Injector sleeve removal tool

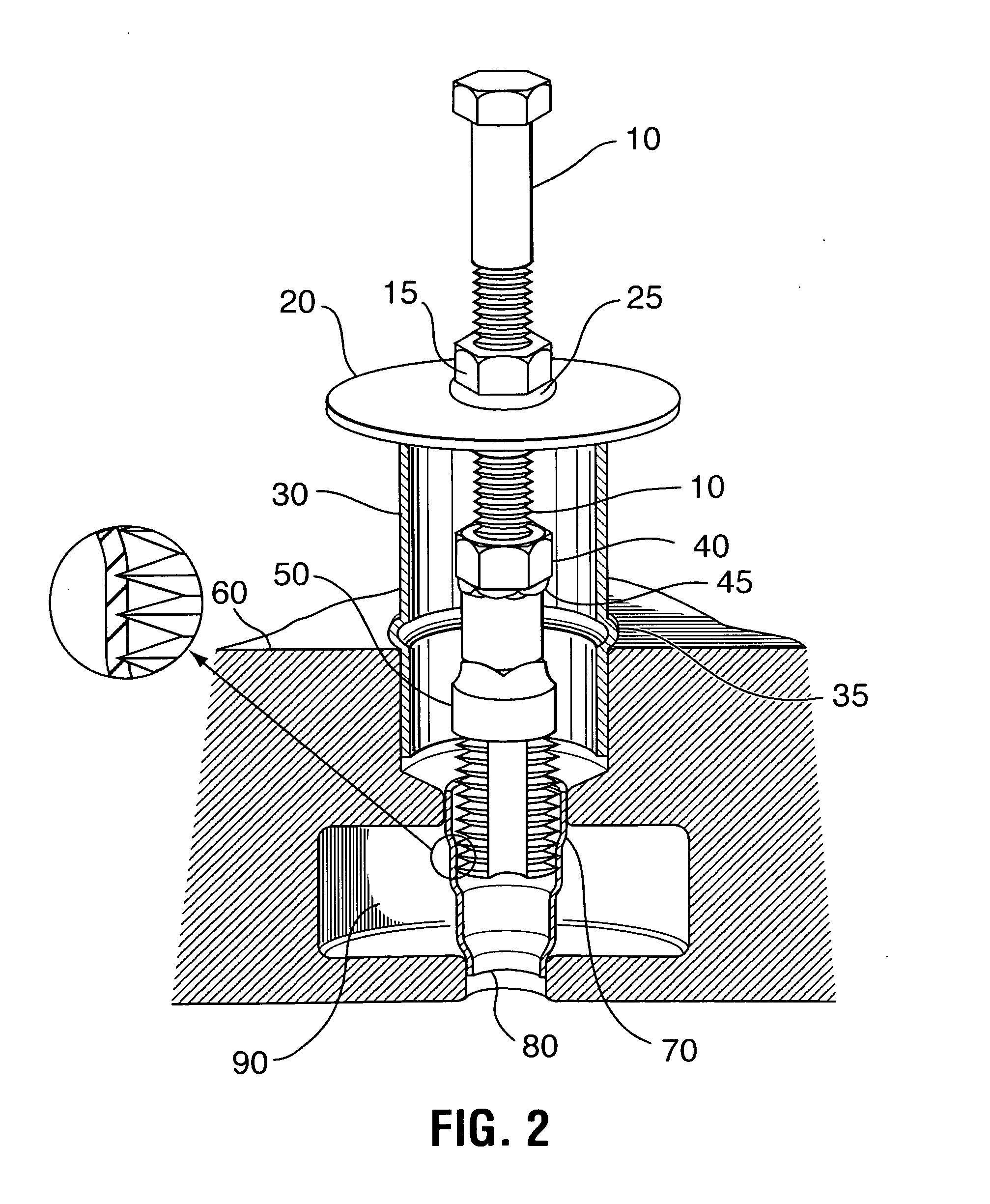

ActiveUS20100095500A1Stable and powerfulImprove securityMetal working apparatusMetal-working hand toolsThreaded pipeCylinder head

A tool is disclosed herein used for removing an injector sleeve from the cylinder head of a diesel engine between the rocker arms while the head remains mounted to the engine block within the vehicle. The devices includes a tap having a longitudinal body has a thread cutting head at one end and an axial threaded bore at the opposing end. A drive member comprises a bolt having a head at one distal end and a threaded shaft body portion. An extraction nut is threaded onto the threaded shaft of the drive member followed by a bearing surface member such as a spacer. A washer having an axial hole sized for movable engagement on the threaded shaft is disposed on the threaded shaft after the spacer. A hollow cylinder or support sleeve having an internal diameter greater than the injector sleeve to be removed and an external diameter less than the diameter of the sleeve bore includes a shoulder member projecting outwardly from the exterior of the support sleeve at a selected point. Moreover, a washer having a center hole is disposed onto the threaded end of a bolt having a holding nut threaded thereon spaced apart a selected distance from the threaded distal end. The threaded distal end of the bolt is inserted into and threadably engages threads of the tap nut so that the bolt is fastened to the tap. The end of the injector sleeve removal tool defining the tap assembly is passed through a hollow cylinder of a selected diameter sized so that the end edges of the tube rest on the surface of the cylinder head surrounding the injector sleeve to be removed. The washer is selected having an outer diameter large enough to provide a bottom surface for resting on the top edge of the hollow cylinder. The holding nut rests upon the top surface of the washer above the hollow cylinder. The head of the bolt opposite the tap assembly is rotated with a tool, whereby the distal end having the tap assembly turns to cut threads into the interior surface of the injector sleeve securing same. The head of the bolt is held in a stationary position and the holding nut is then turned and moved downwardly biasing the bottom surface of the washer against the top edges of the hollow cylinder pulling the injector sleeve upward and out of the cylinder head in order that a replacement injector sleeve can be pressed into place in the cylinder head.

Owner:WHITAKER TOOLS

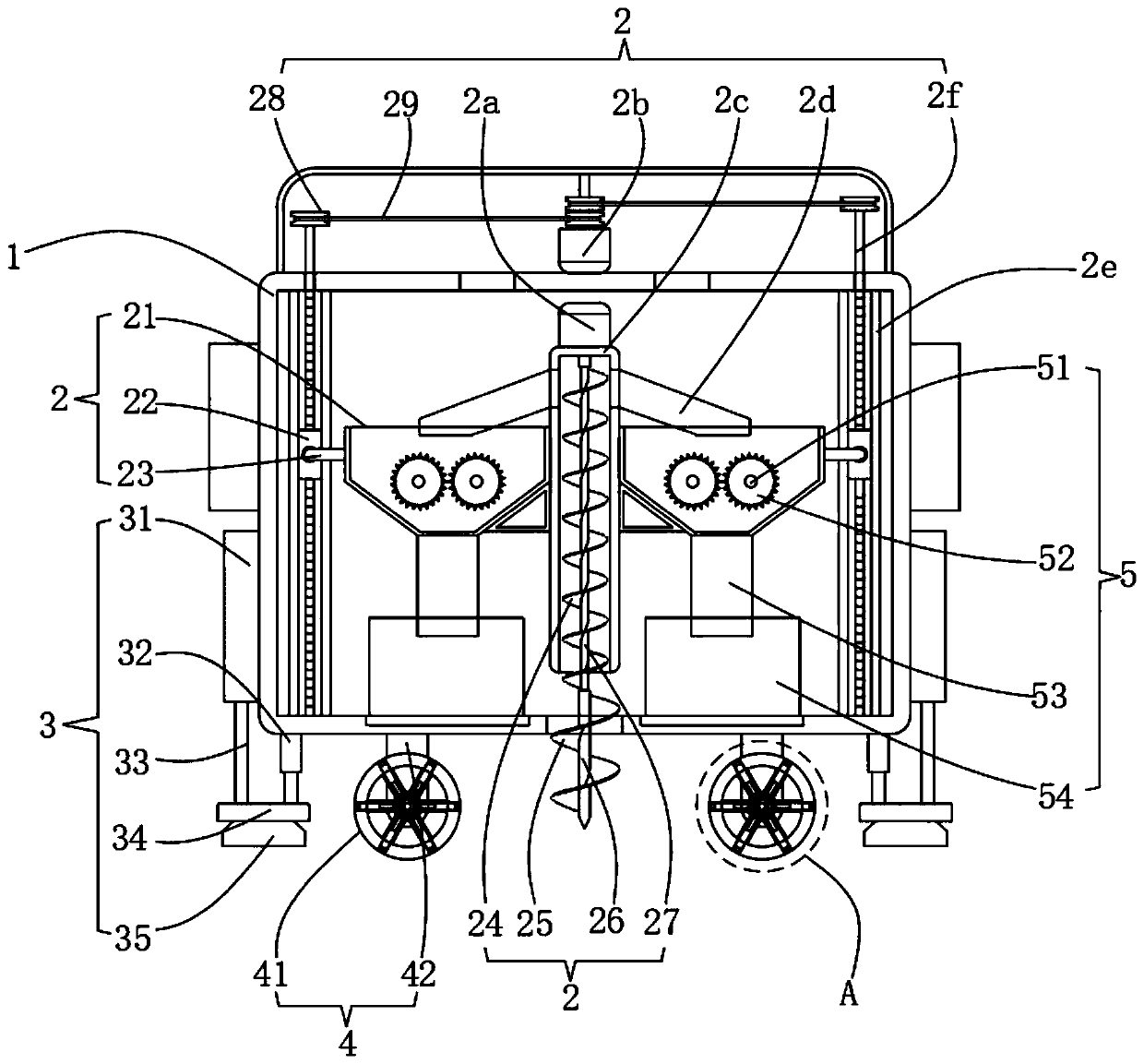

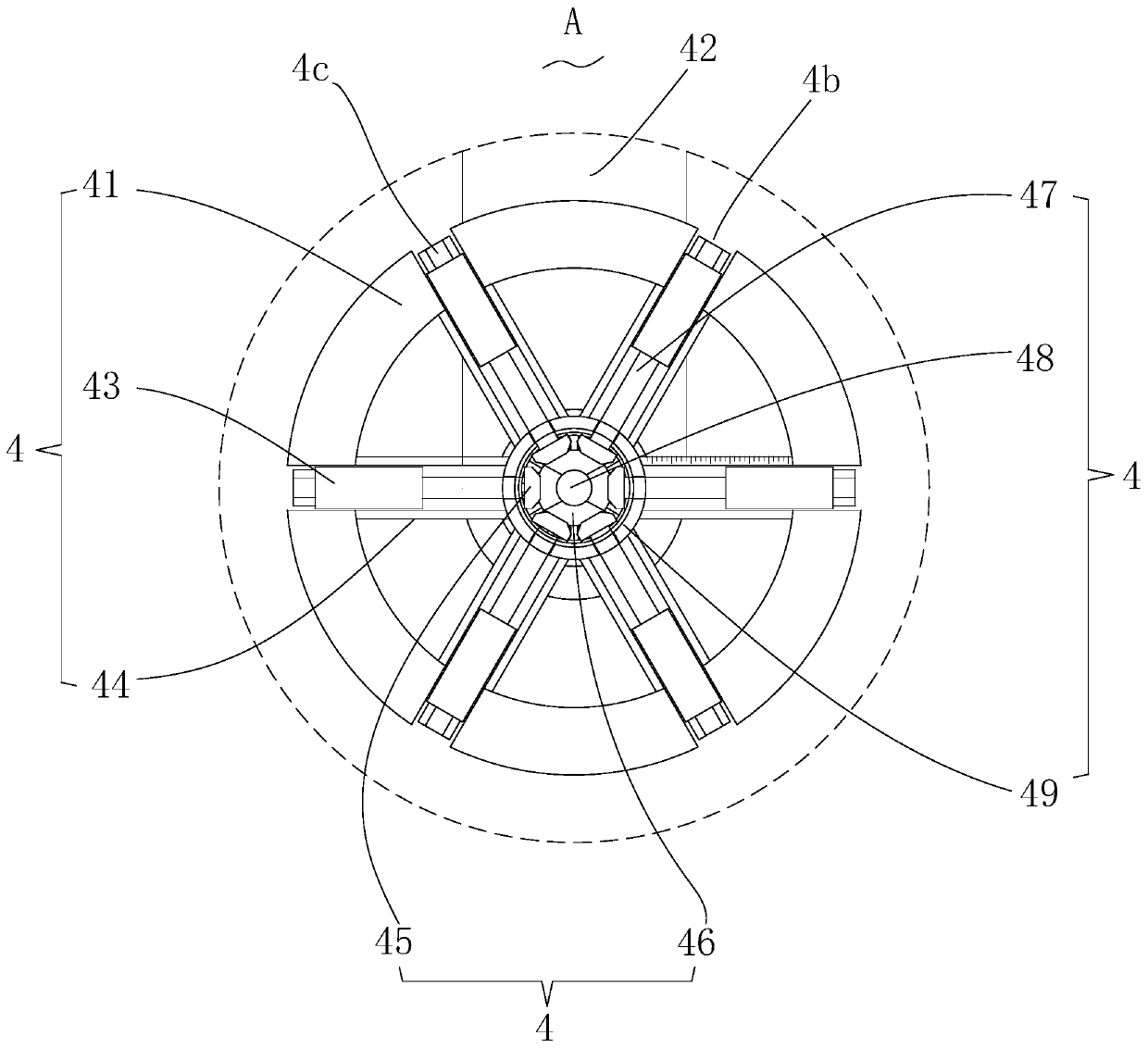

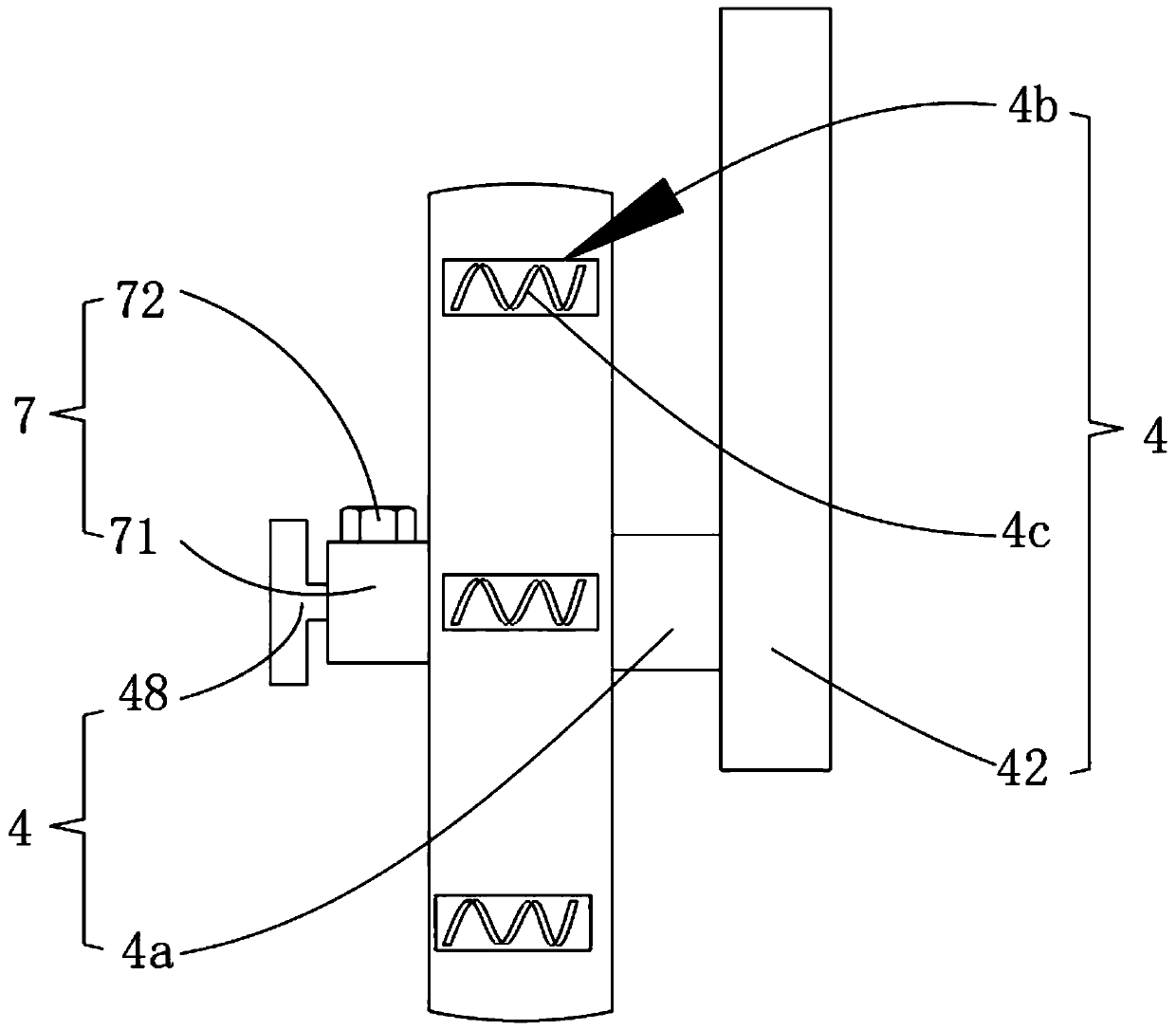

Soil sampling and detecting device

InactiveCN111537273AImprove gripIncrease contact frictionWithdrawing sample devicesPreparing sample for investigationAgricultural scienceThreaded pipe

The invention provides a soil sampling and detecting device. The soil sampling and detecting device comprises a box body, a soil sampling mechanism, a supporting adjusting mechanism, a movable adjusting mechanism, a crushing and detecting mechanism, an auxiliary operating mechanism and a limiting mechanism. The movable adjusting mechanism suitable for adjusting and transferring different road surfaces is connected with the bottom of the box body and comprises a hub, a supporting plate, a rectangular inner threaded pipe, a rectangular sleeve, a first bevel gear, a second bevel gear, an outer threaded rod, a T-shaped rotating rod, a circular box, a third rotating shaft and a bent plate. According to the soil sampling and detecting device provided by the invention, the form of the corresponding hub needs to be adjusted in the transferring process for pushing and transferring; the device can be suitable for rolling of different types of road surfaces; and when the road condition of the soil conveying road surface is poor, transferring can be conducted in a manual carrying mode; time and labor are saved in the operation process; the working efficiency is improved; the device is suitablefor transferring of two kinds of road surfaces; and the application range of the transferring process is widened.

Owner:苏波

Threaded Pipe Connection with a Pressure Energized Flex Seal

InactiveUS20110101684A1Improved design characteristicImprove performanceHose connectionsScrew threaded jointsThreaded pipeEngineering

A threaded pipe connection is shown which features a pressure energized flex-seal structure. The connection includes a first box member having a box end, the box end having an end opening defining an interior surface with internal threads, the internal threads being defined by crests and roots and opposing flanks. A second, mating pin member has a pin end with a pin nose, the pin end having an exterior surface with mating external threads, the external threads also having crests and roots and opposing flanks, at least selected ones of which move into engagement with the internal threads of the box when the connection is made up. A flex-seal region is located on the box end interior surface which is designed to engage a cooperating energizing surface on the mating pin end to thereby form a primary containment seal upon make up of the connection.

Owner:GANDY TECH

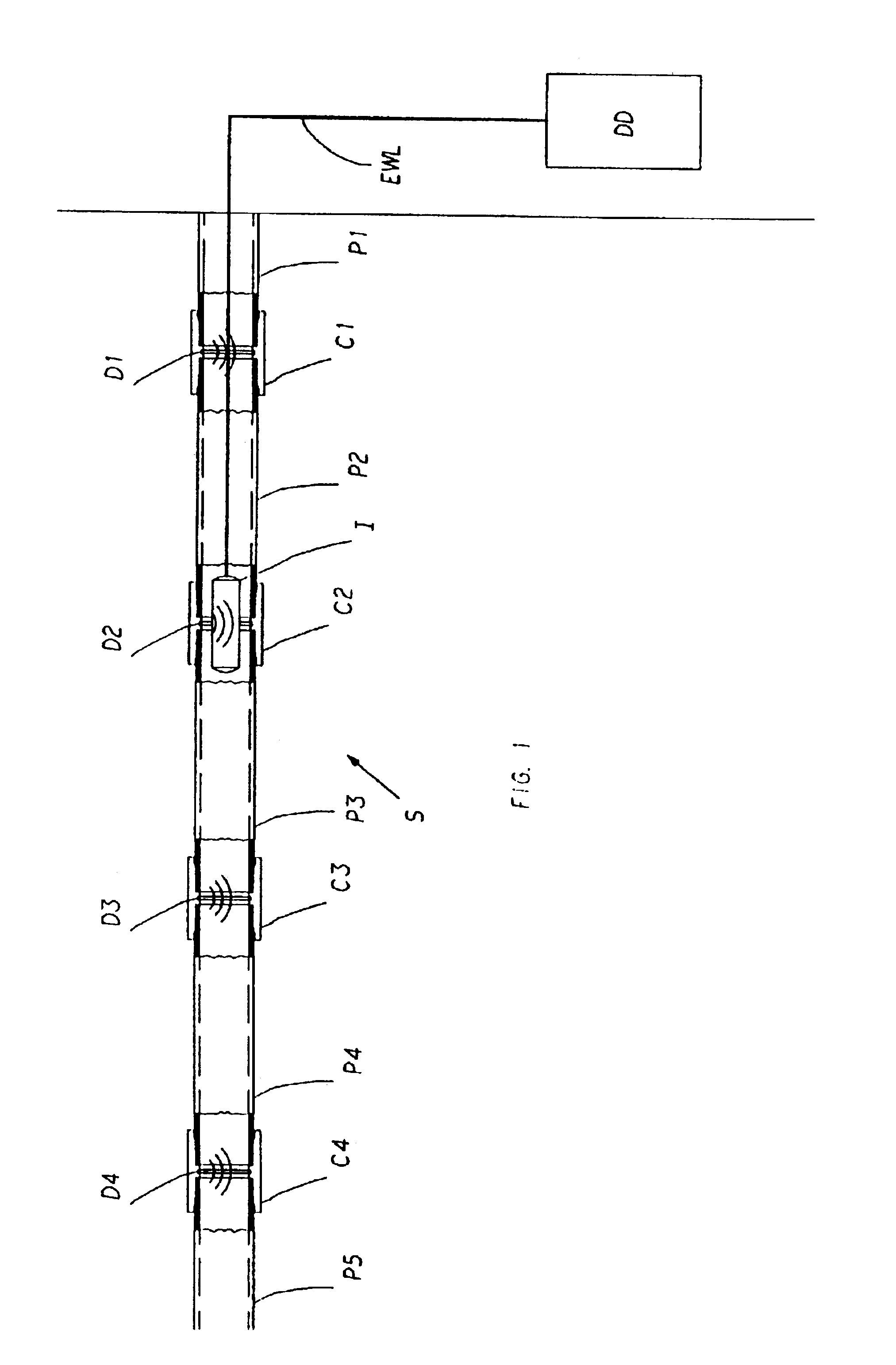

Pressure-containing tubular connections for remote operation

InactiveUS7431351B2Rapid and reliable and accurateReduce the amount requiredSleeve/socket jointsFluid pressure sealed jointsElectricityControl manner

Owner:RUSSELL LARRY R

Wedge thread with torque shoulder

A threaded pipe connection includes a pin member having an external thread increasing in width in one direction, a box member having an internal thread increasing in width in an opposite direction so that complementary internal and external threads move into engagement upon make-up of the connection, and at least one contact zone in which the pin member and box member are in sealed contact.

Owner:HYDRIL CO

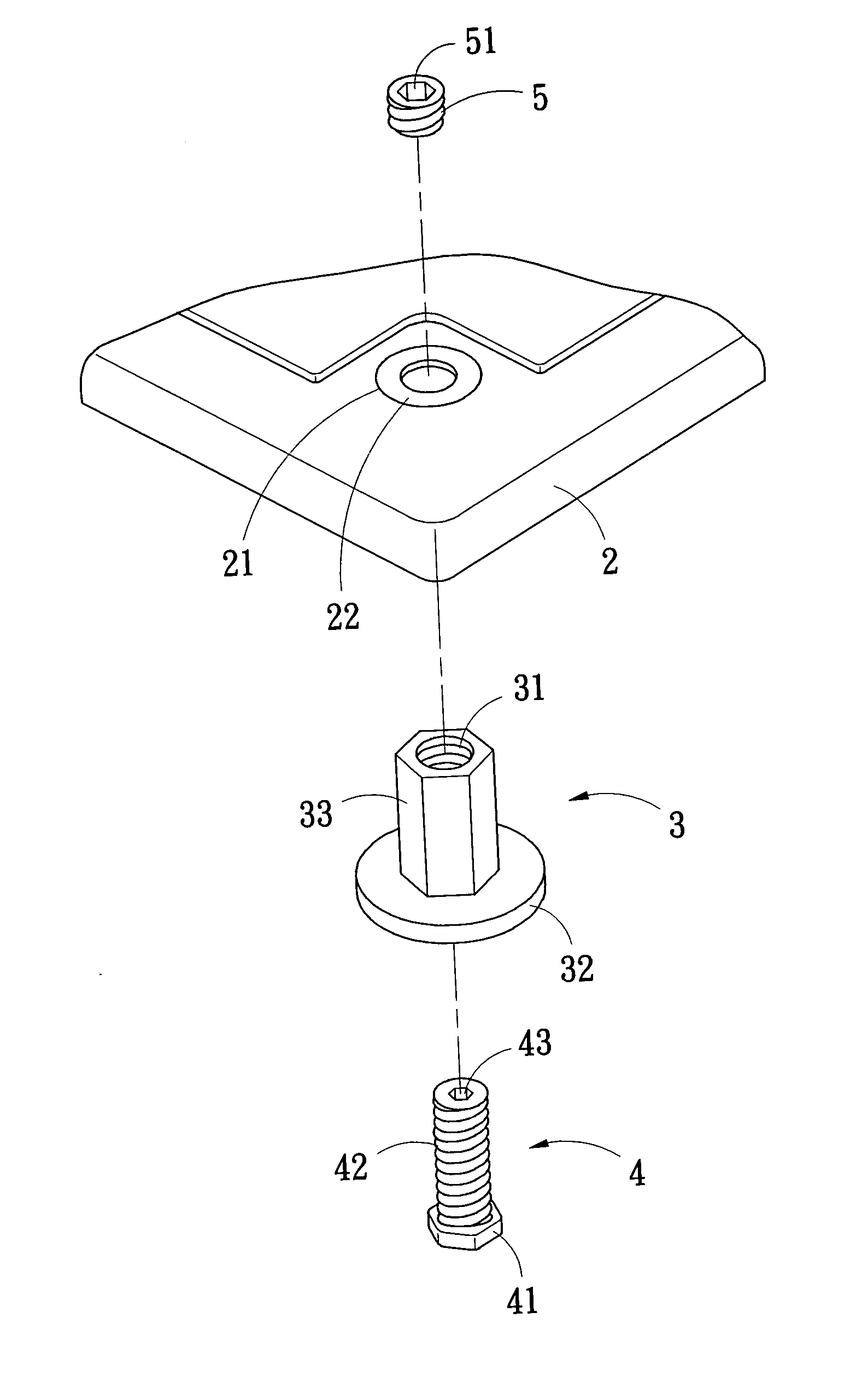

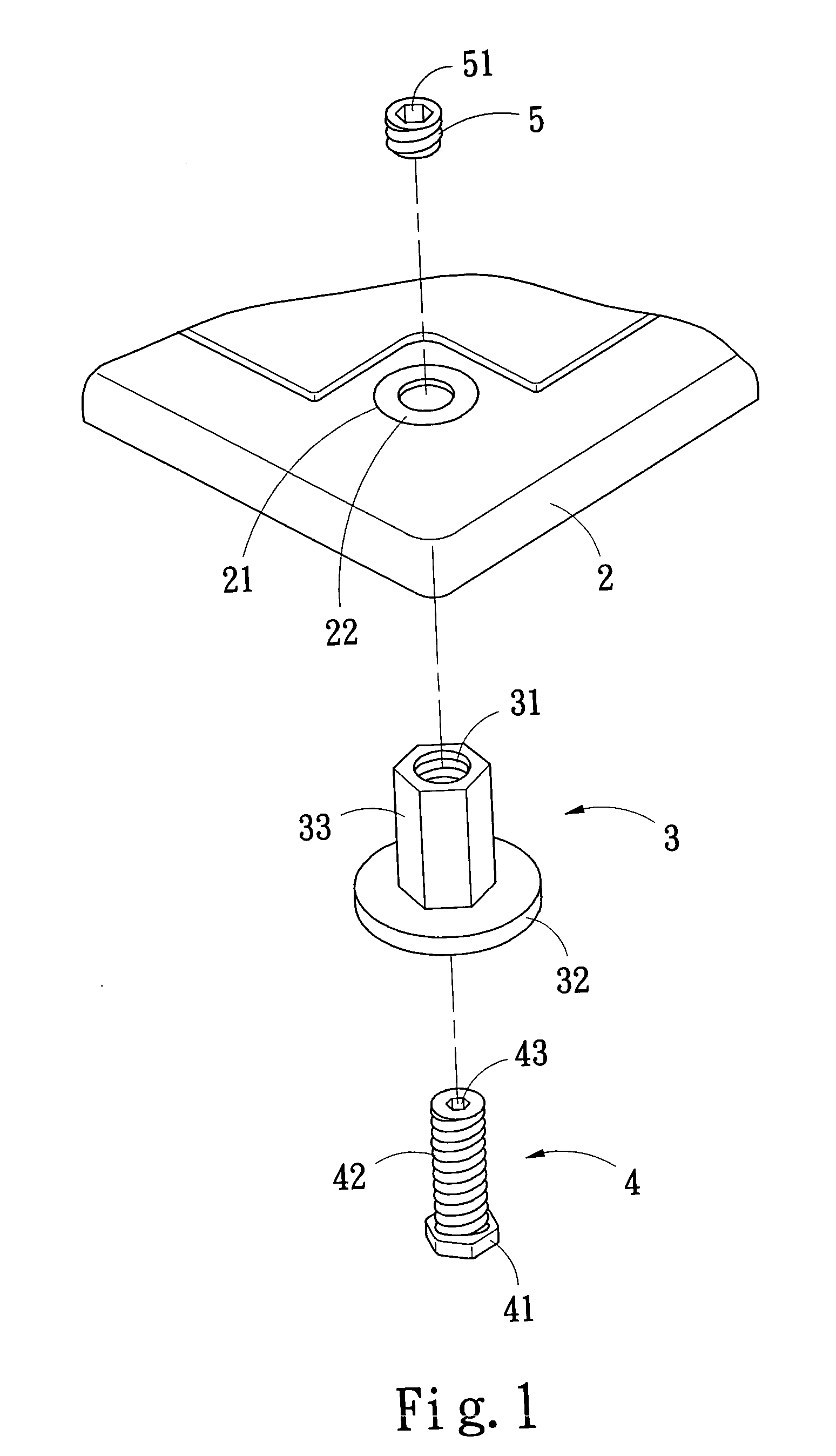

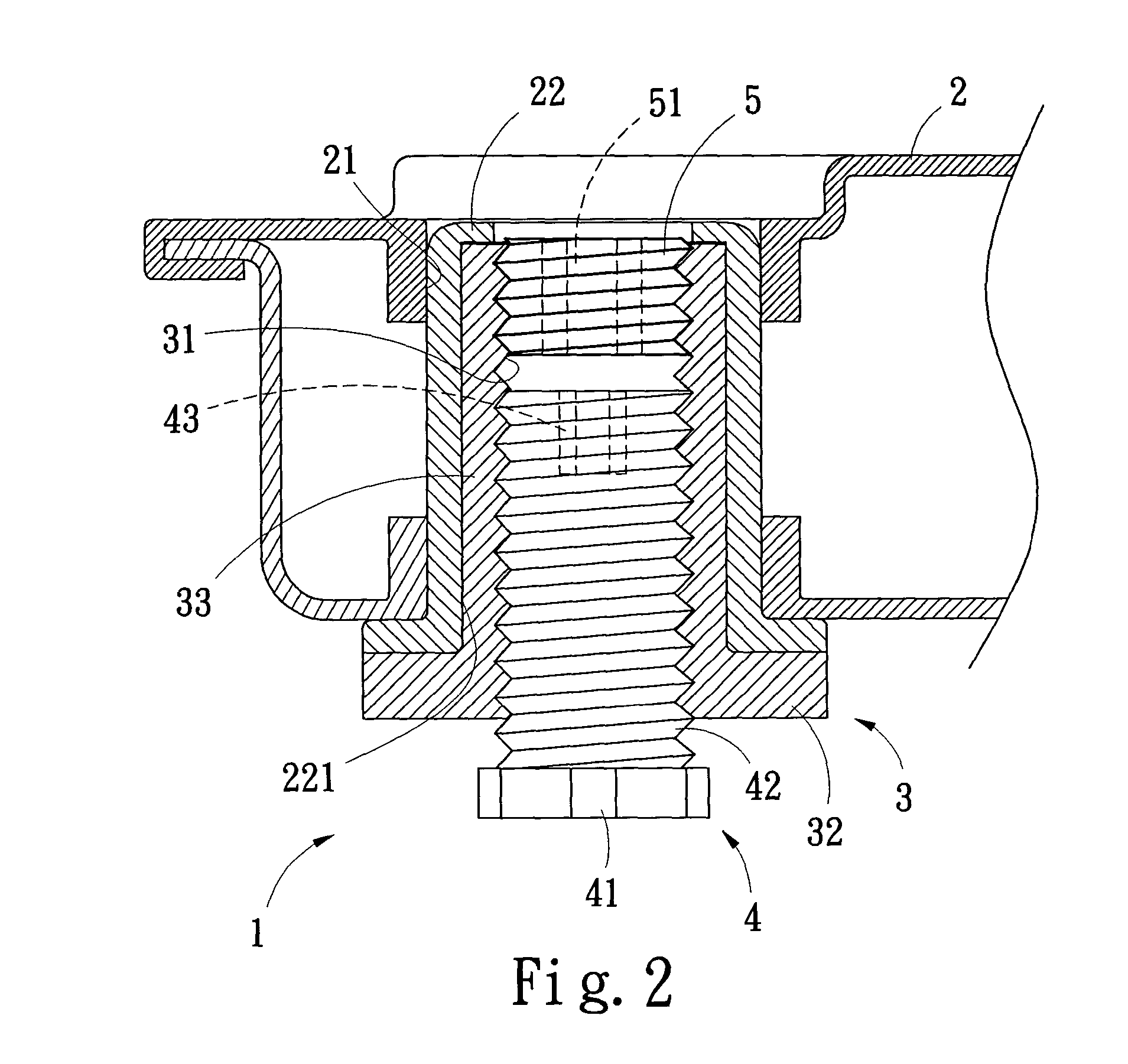

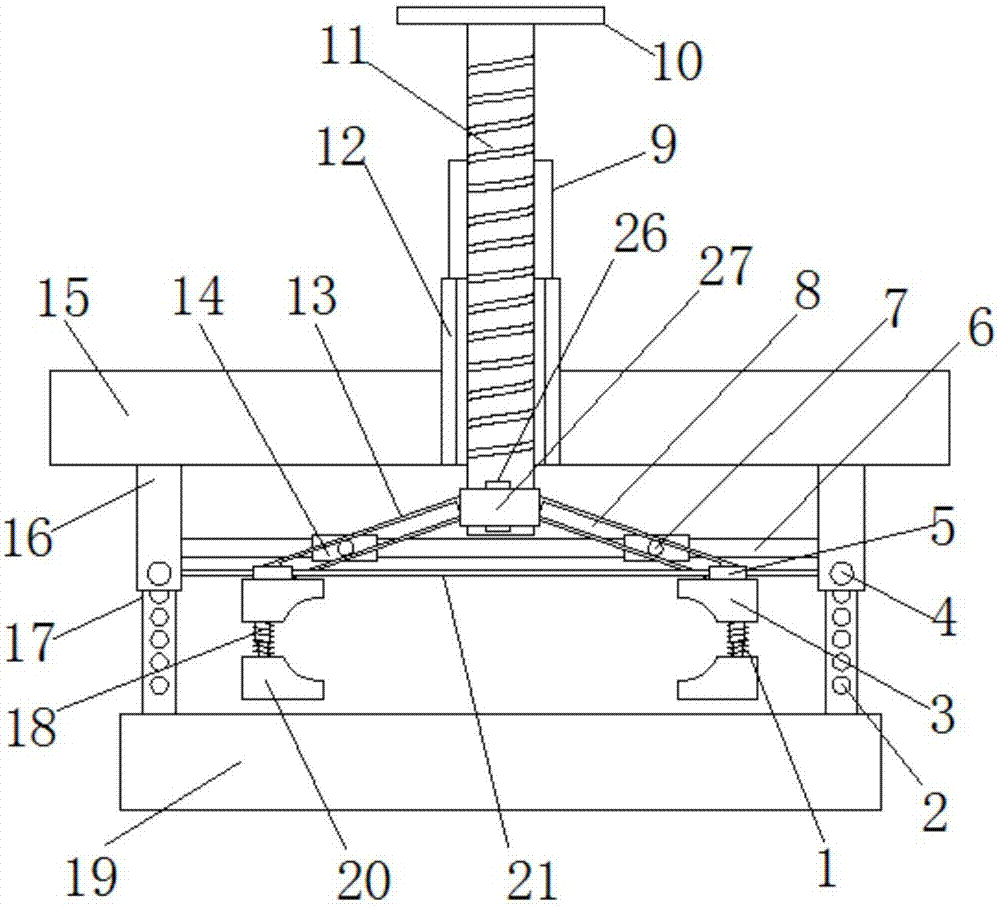

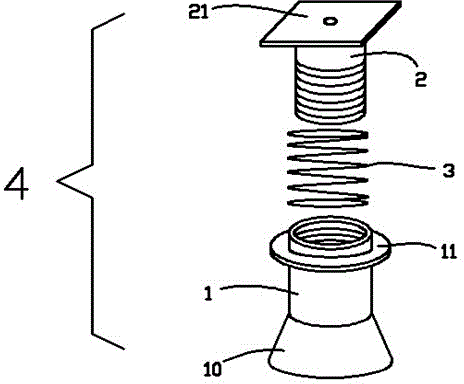

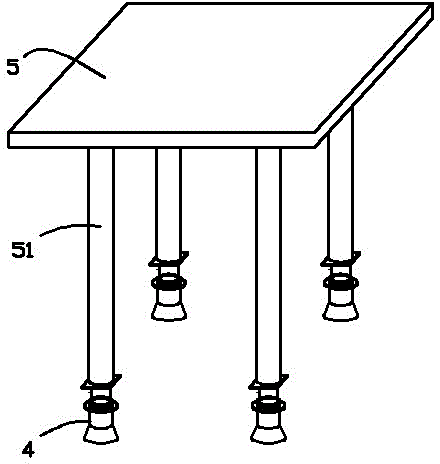

Adjuster for elevated floor

An adjuster for an elevated floor comprises a threaded pipe having an inner thread for connecting with a connecting hole which is on the elevated floor, and the threaded pipe is thread connected therein with a footing seat and a fixing screw mounted above the footing seat. The footing seat has an adjustment hole on its upper end, the fixing screw has a through hole extended from top to bottom, which is larger than the adjustment hole of the footing seat, so that the adjustment tool can be extended through the through hole and inlaid in the adjustment hole for adjusting the displacement of the threaded pipe relative to the footing seat. The adjuster can effectively reduce the gross height of the elevated floor and reduce waste of space. Further, it is suitable for use in new and old buildings.

Owner:CHEN YAO CHUNG +1

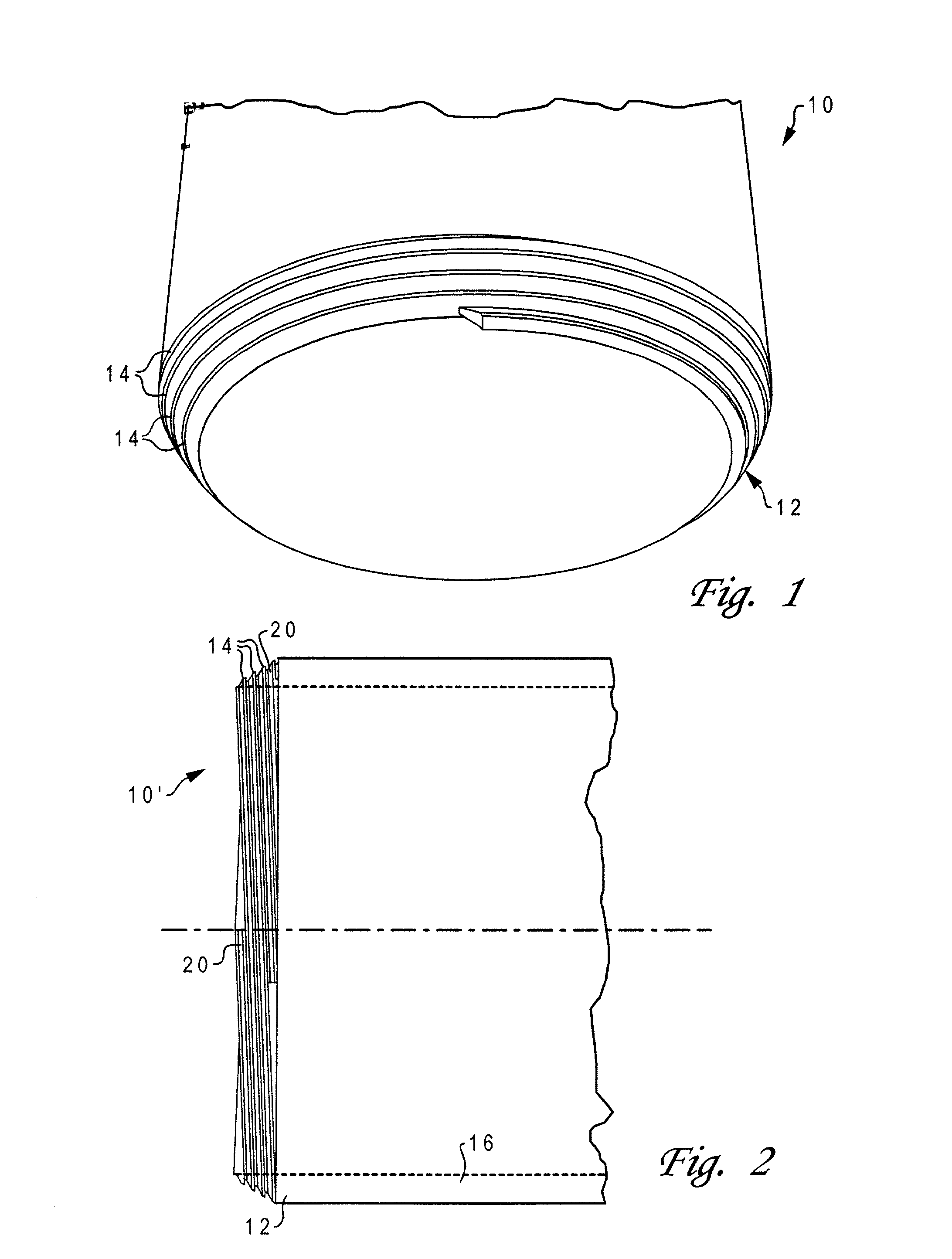

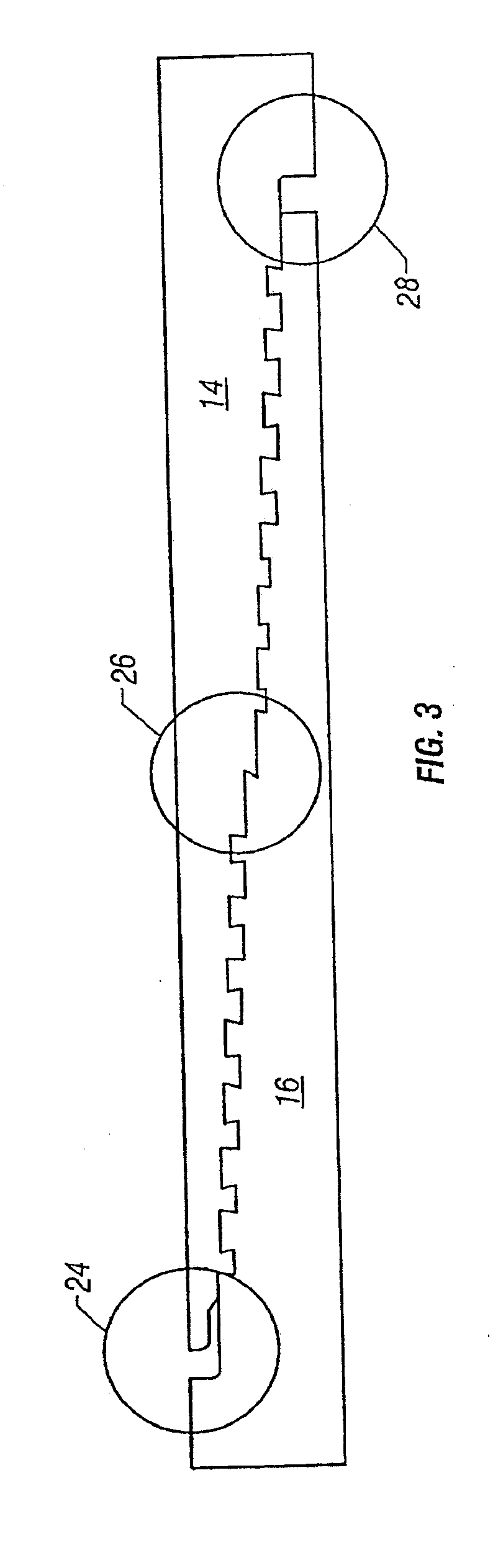

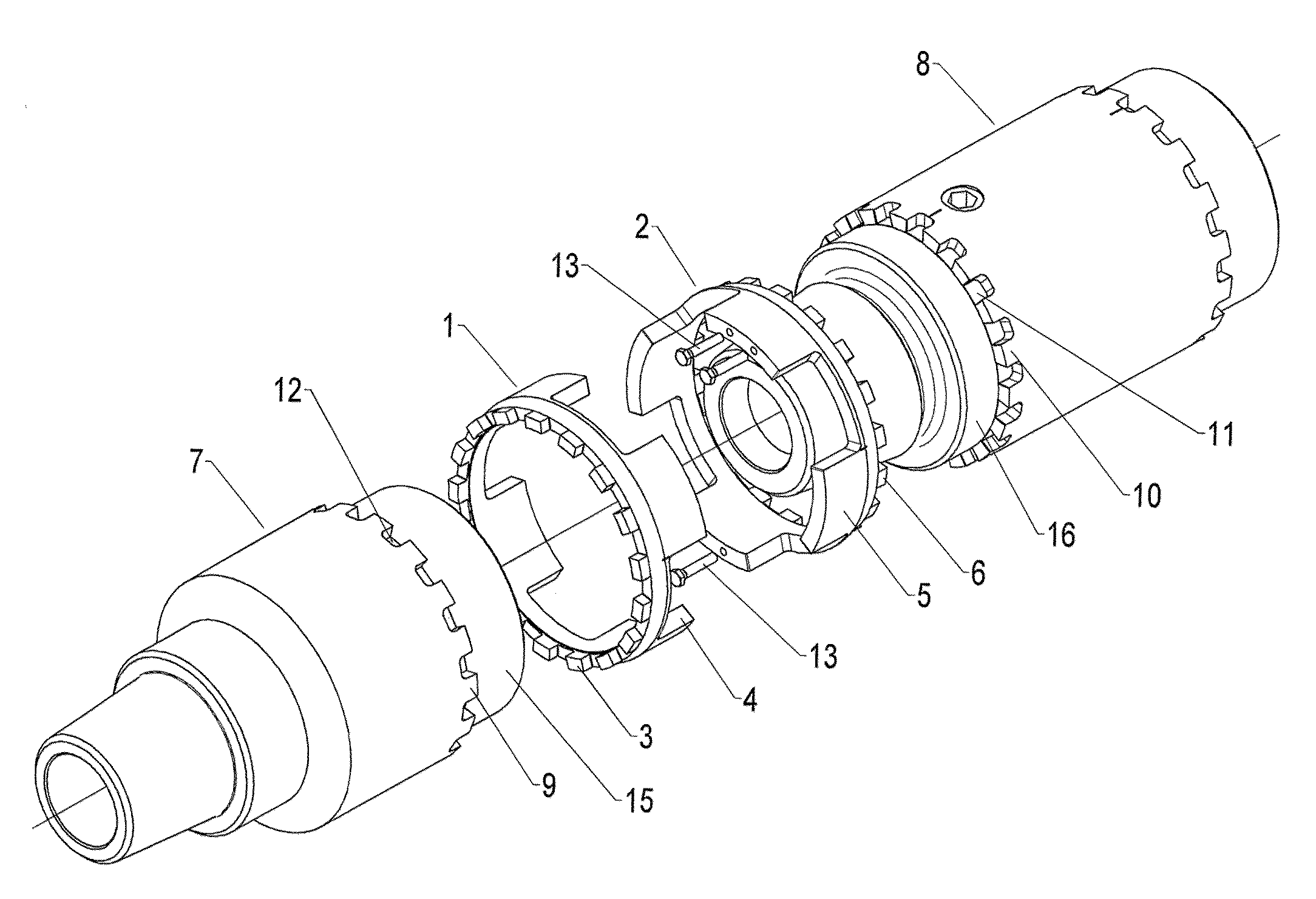

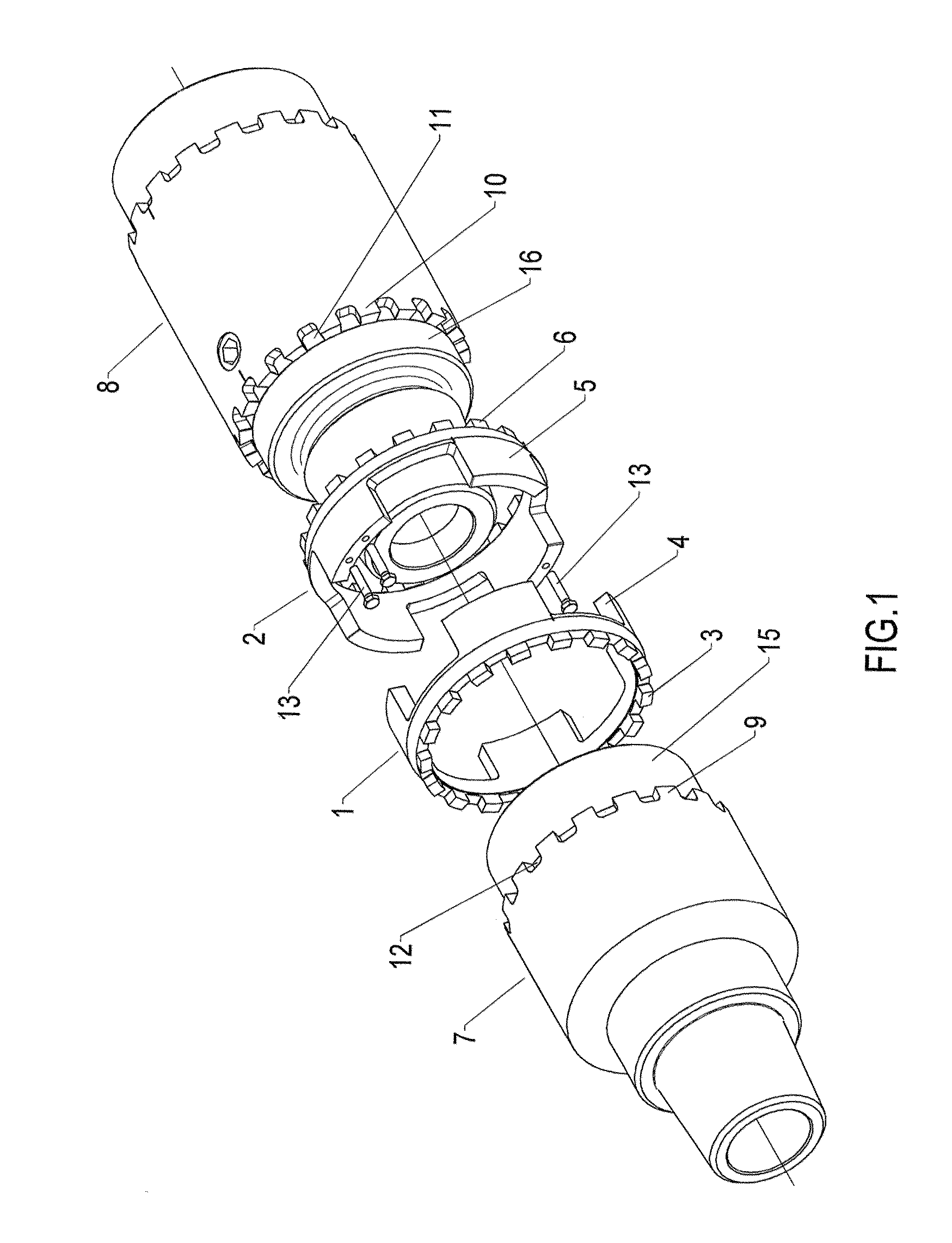

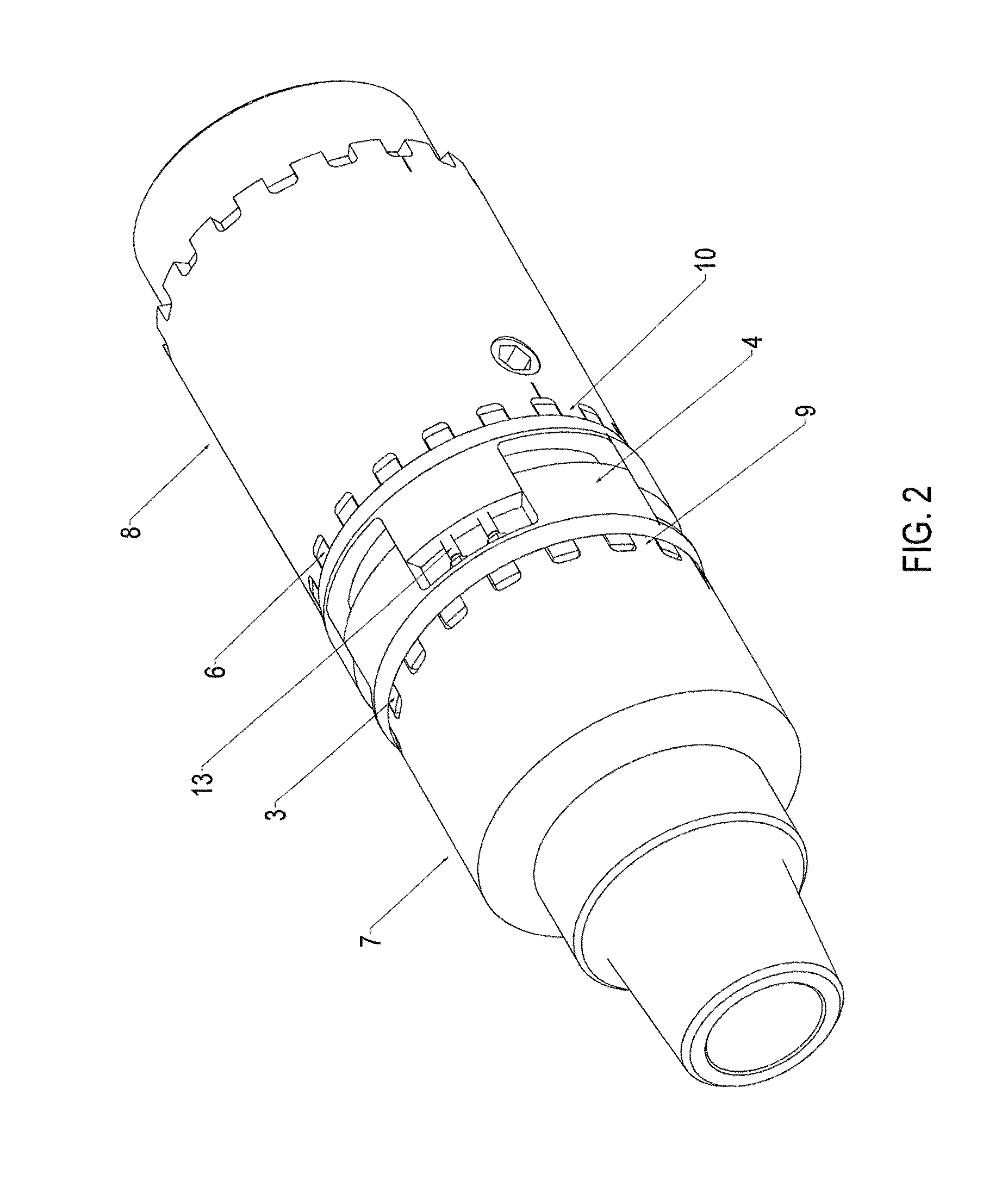

Locking device for built pipe connections

ActiveUS7887098B2Reliable lockingSafe and fast operationSleeve/socket jointsEngine sealsThreaded pipeEngineering

A locking device for locking a threaded pipe connection where two threaded connection units are screwed together. The locking device includes two locking rings which engage each other with corresponding teeth and notches on their first sides. Each of the two rings has a different number of teeth and notches on their second side. The two second sides, which face the connection units, are formed to engage a corresponding number of notches and teeth formed on the shoulder of the connection unit's opposite side, after the rings have been spread apart in an axial direction, while maintaining the engagement between the first and the second ring.

Owner:NAT OIL WELL NORWAY

Clamping device for machining

ActiveCN107042418AImprove work efficiencyEasy to adjustPositioning apparatusMetal-working holdersThreaded pipePipe fitting

The invention relates to the technical field of machining, in particular to a clamping device for machining. The clamping device comprises a base; a fixing plate is arranged above the base; the fixing plate and the base are connected through two telescopic devices; a second sliding rod and a first sliding rod are arranged between the two telescopic devices; a first metal pipe fitting is arranged at the top of the fixing plate in a penetrating mode; a threaded pipe is arranged at the top end of the first metal pipe fitting; internal threads are connected with a screw; a mounting plate is arranged at the top end of the screw; the bottom end of the screw penetrates through the first metal pipe fitting and extends to the position below the fixing plate; the bottom end of the screw is connected with an annular part in a sleeved mode; and limiting blocks are arranged on and under the annular part. The clamping device is simple in structure and convenient to use, a workpiece can be clamped in an adjustment mode according to the size of the workpiece, meanwhile, the waste of time can be greatly reduced, and therefore the working efficiency of machining can be improved.

Owner:宁夏飞天科技有限公司

Adjustable supporting leg

The invention provides an adjustable supporting leg which relates to the field of furniture; the adjustable supporting leg comprises a section of an external thread pipe with a contact plate on the upper end, and a section of an internal thread pipe which is matched with the external thread pipe; a screw hole is arranged in the center of the contact plate; and an elastic foot pad is fixedly arranged on the lower end of the internal thread pipe. The adjustable supporting leg can be fixedly arranged below an ordinary desk leg or a chair leg, the supporting heights of all desk legs or chair legs can be adjusted according to different environments whenever and wherever possible, so that a stable and reliable horizontal desktop or a chair top is provided, not only is the use convenient, but also an effect is excellent.

Owner:吴贝尔

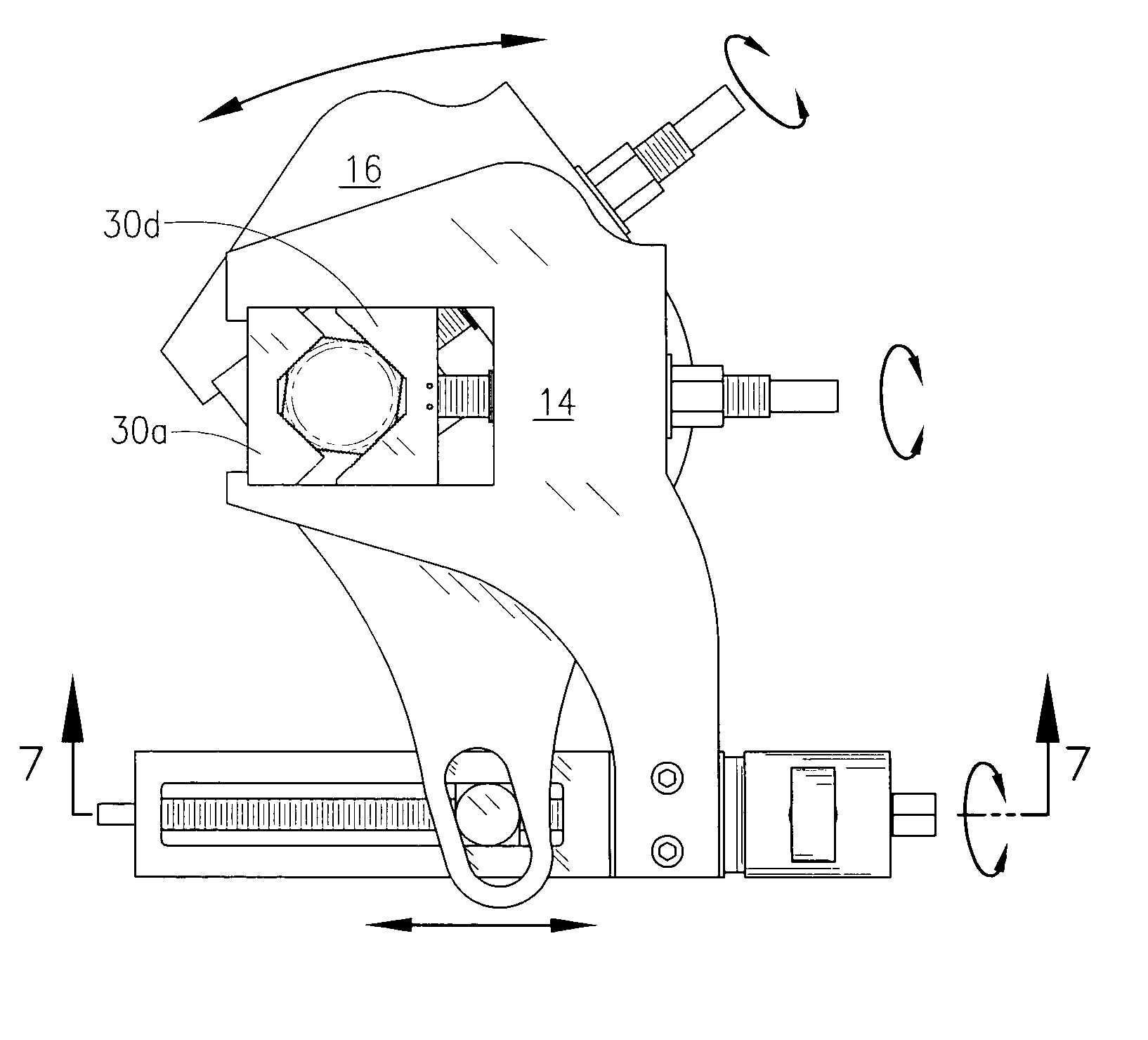

Double clamp vise

The vise includes a seat body having two movable jaws separately with two inner threads, a fixed jaw and a rail. A screwing rod has a rear portion and a front portion whose diameter is less than the rear portion. A first outer thread is formed on the rear portion. A step is formed between the front portion and the rear portion. A screwing tube telescopically and unrotatably sheathes the front portion of the screwing rod and has a second outer thread. The two movable jaws are separately engaged with the screwing tube and screwing rod by screwing the outer threads and the inner threads. A spiral direction of the first outer thread is contrary to the second outer thread. A main spring is nipped between the screwing rod and screwing tube. A crank is axially connected to the front portion of the screwing rod for rotating the screwing rod.

Owner:WANG WEN FENG

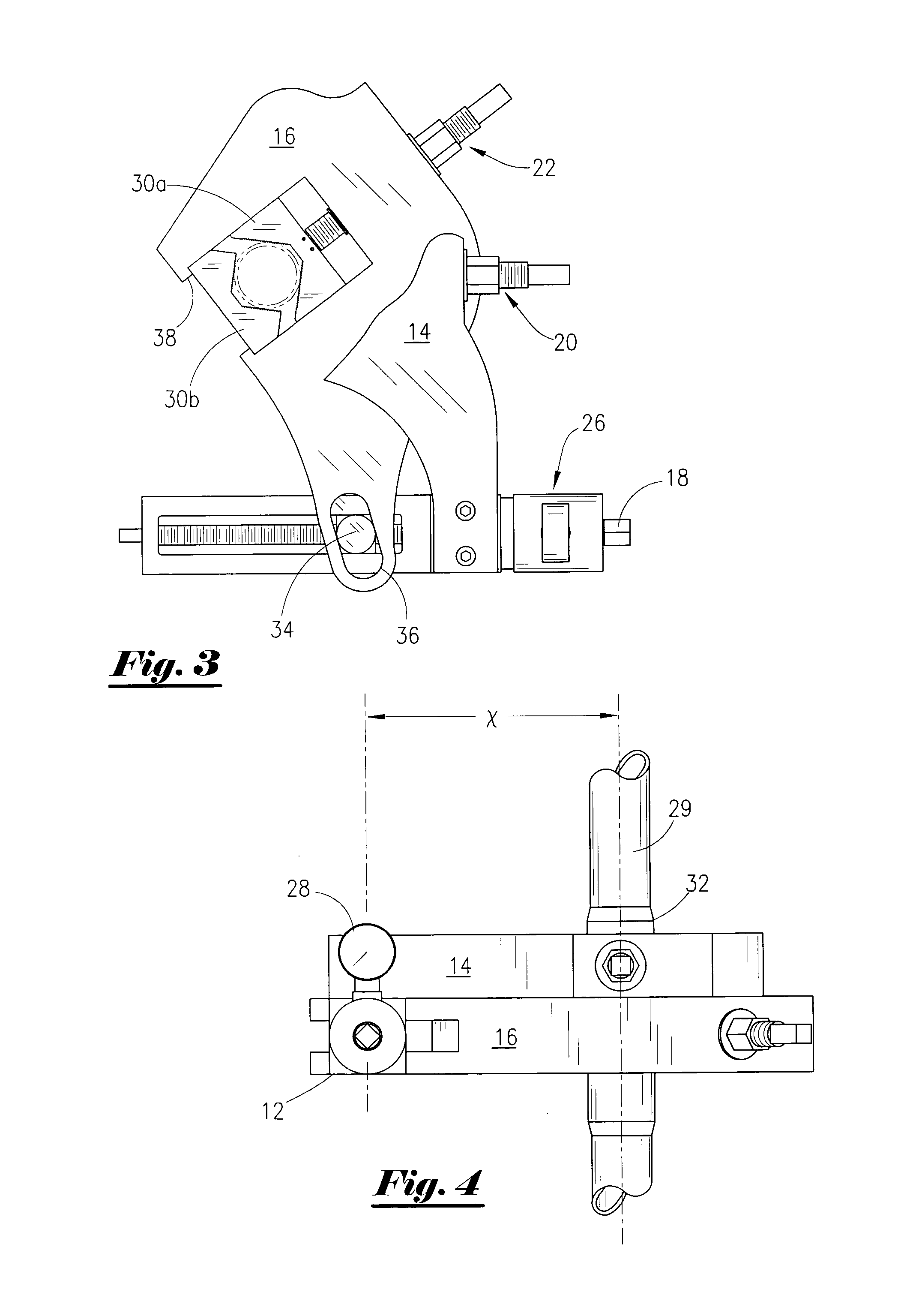

Portable pipe tong and method of use

InactiveUS6931965B1The right amountQuickly applying torqueDrilling rodsSpannersThreaded pipeEngineering

A relatively compact portable tong assembly utilizing adaptable jaws for gripping the threaded box and pin ends of adjacent pipe joints without the use of an external support and thus applying final make-up torque or applying initial breakout torque to threaded pipe joints using only a spanner, socket and ratchet or other such hand tools for quickly applying torque to at least one of the tong jaws. An integral means is also provided for accurately measuring the amount of torque being applied to the joints.

Owner:FANGUY ROBERT P

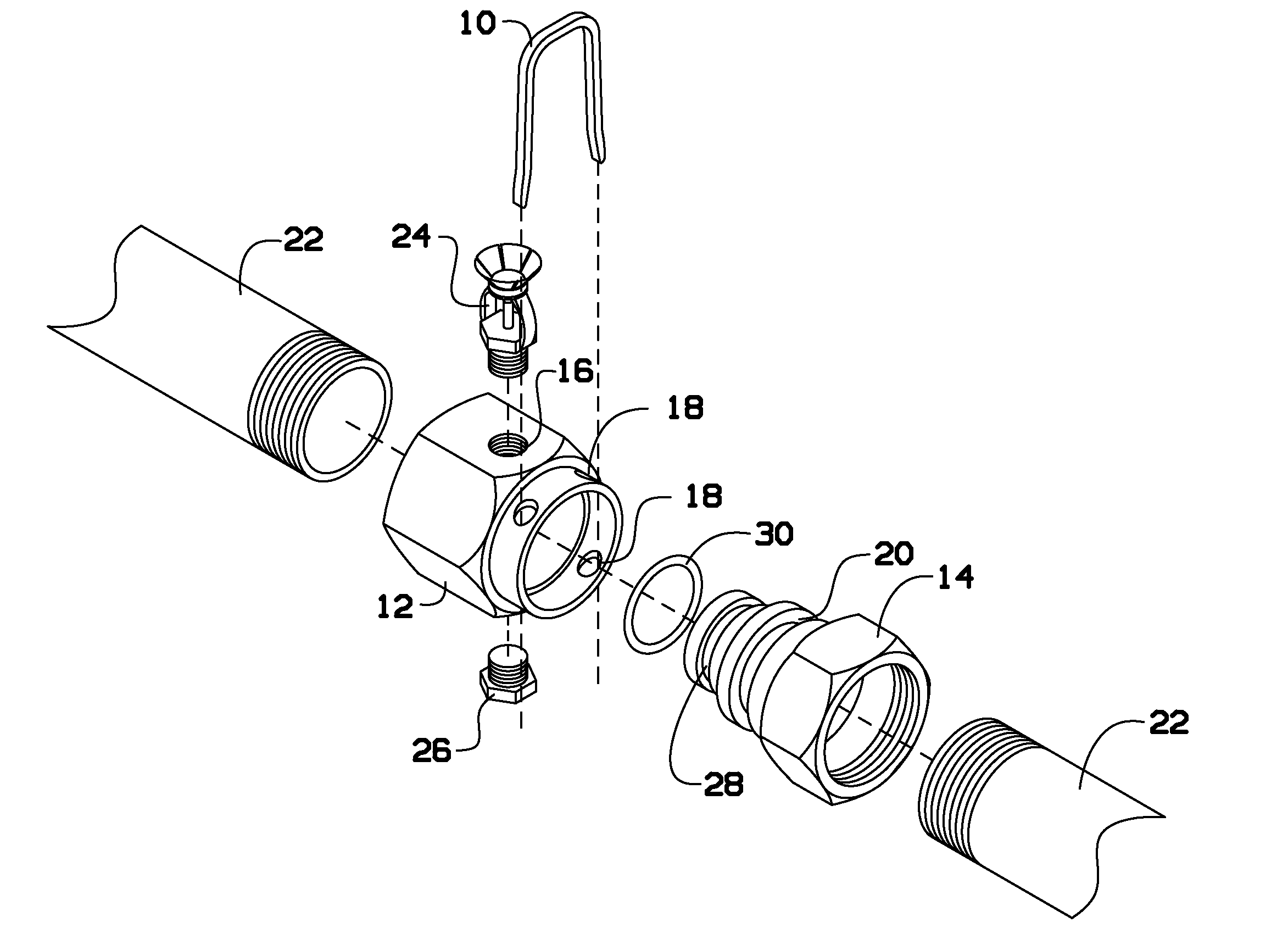

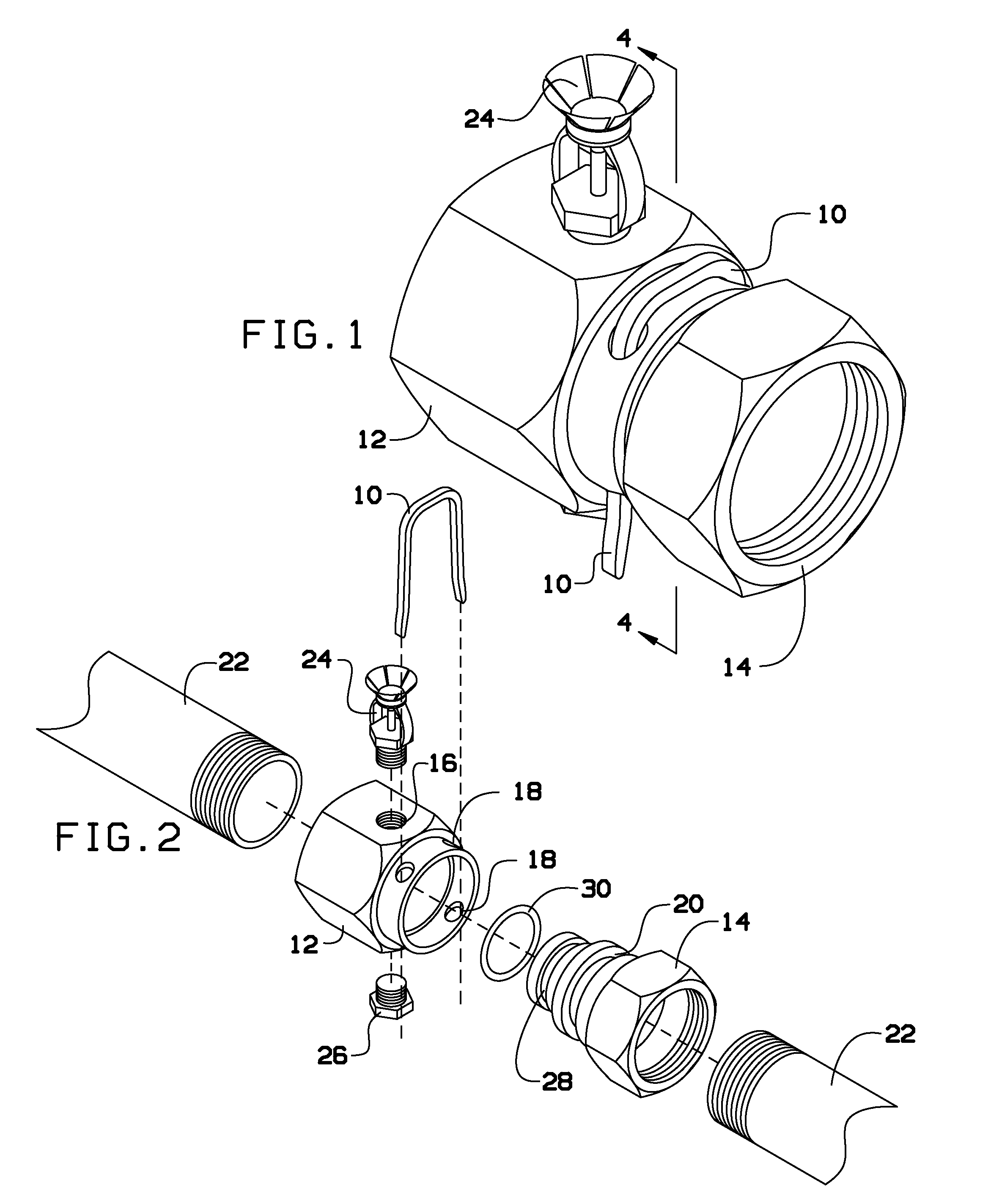

Quick connect fire and dust suppression system

A quick connect system for the assembly of underground mining dust and fire suppression systems can eliminate the need for threading pipe with couplings during the installation, reducing installation times approximately 75%. The quick connect system results in the quick and easy coupling and positioning of sprays along the water line. The quick connect system typically uses galvanized, brass and stainless steel components to reduce the need for replacement and to provide for quick adjustment of fittings with sprays using pliers. The system is simple to maintain and reduces high installation and maintenance labor costs. The system uses male and female ported fittings and horseshoe pins. Pendant style or deluge style sprays can be used in the system and can be pre-installed prior to delivery and installation of the system.

Owner:PORTA FR T

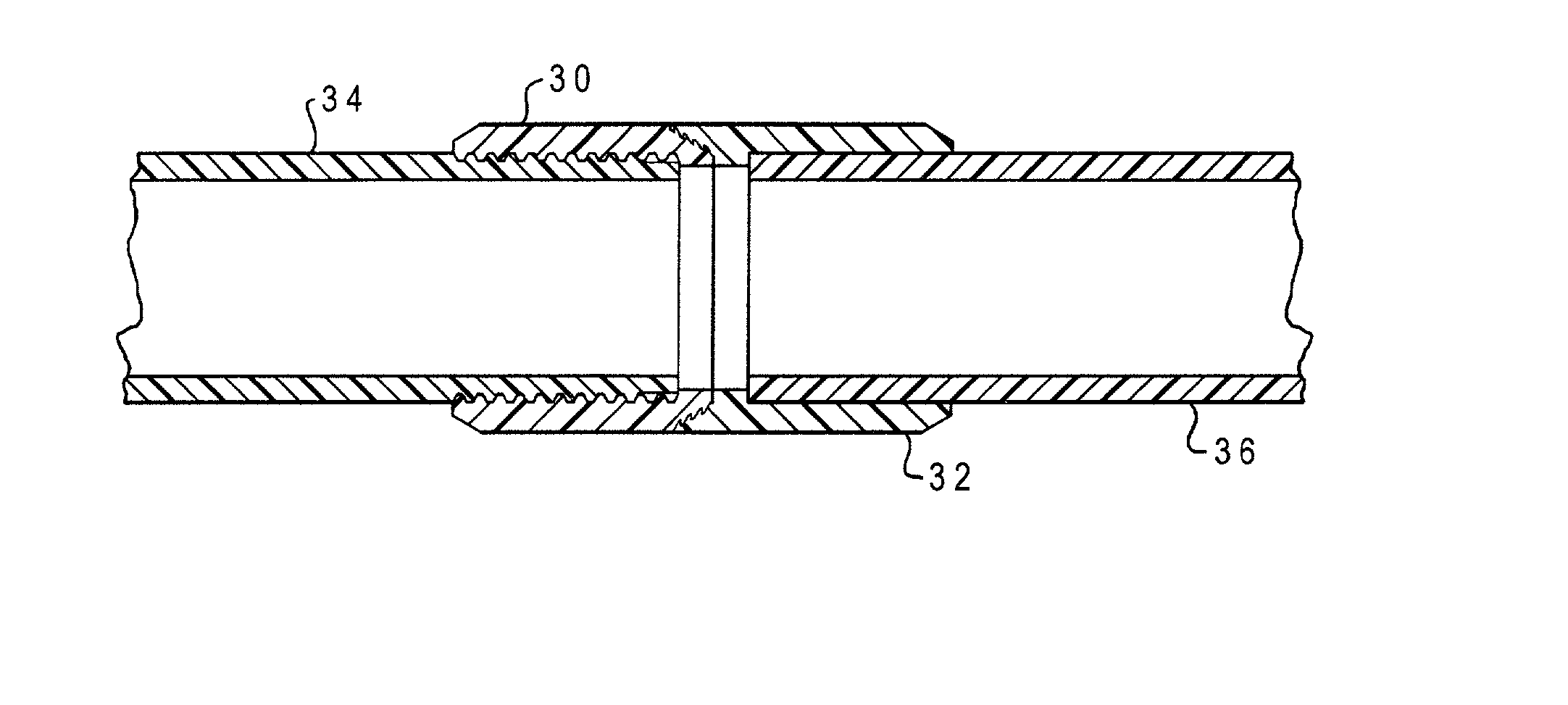

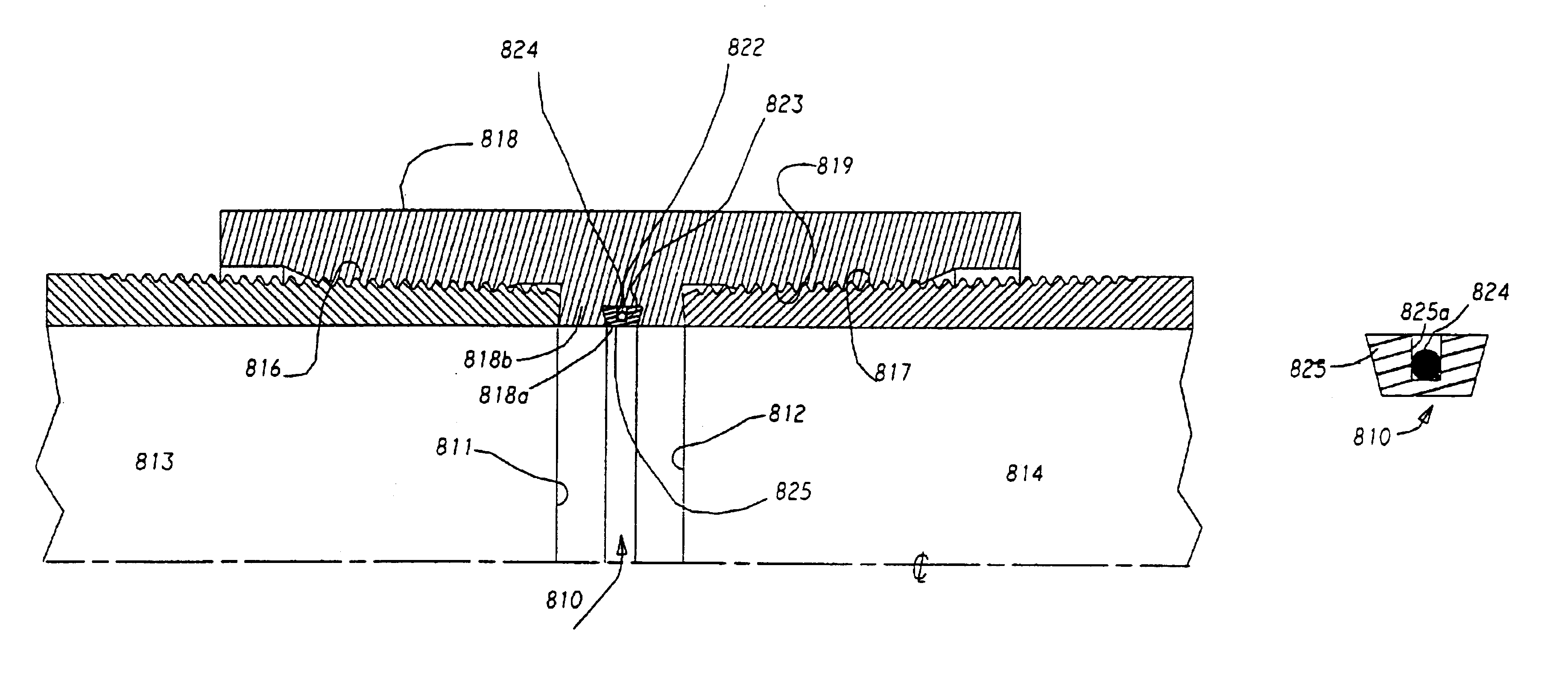

System, method and apparatus for deploying a data resource within a threaded pipe coupling

A data resource specific to a pipe coupling centrally positioned within the coupling, intermediate the coupling ends. Multiple couplings are employed to connect together a string of well pipe. The data resource is adapted to be deployed at the coupling center in the space formed between the abutting ends of pipe made up into the coupling. The data resource provides information regarding the physical characteristics and locations of the coupling, the attached string pipe or the environment within which the coupling is disposed. The data resource may be a read-only component or it may be a readable and writeable component. The resource communicates with an instrument movable through the pipe and coupling. The data resource may be removably positioned at the center of the coupling or it may be permanently cemented in place. The data resource may take on the form of an annular ring with a crushable structure and suitable recesses for holding a data resource module. A circular communication antenna may be carried in the ring. A preferred form of the data resource is an externally threaded Teflon(R) ring equipped with axially extending resilient fingers. The resilient fingers are deformable upon engagement with the rotating ends of the pipe sections so that advancing the pipe sections beyond their optimum depth into the coupling deforms the fingers without rotating and thus displacing the ring. The body of the ring remains in the gap between the pipe and where it is protected from crushing.

Owner:GRANT PRIDECO LP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com