Patents

Literature

695 results about "Lip seal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

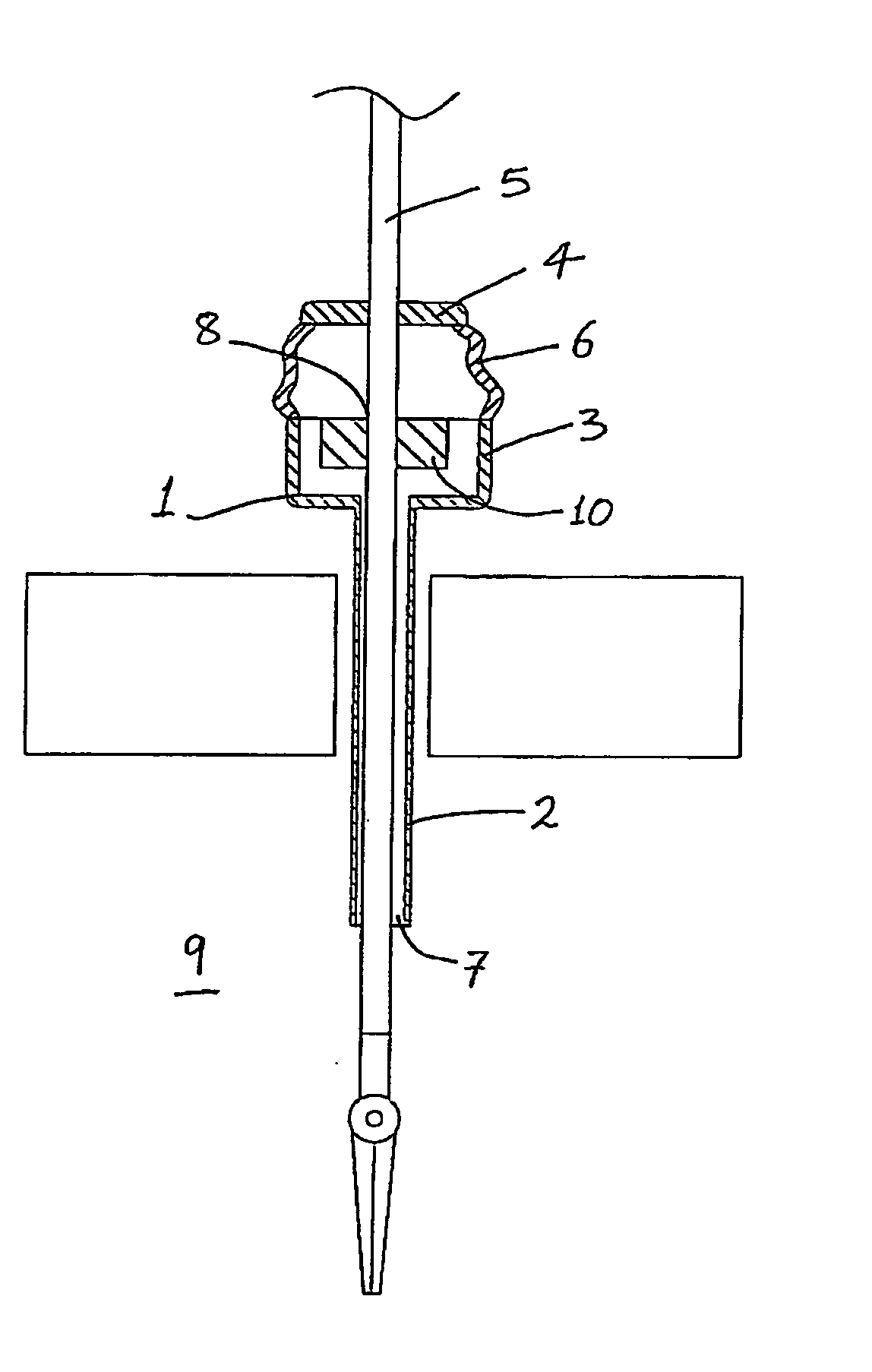

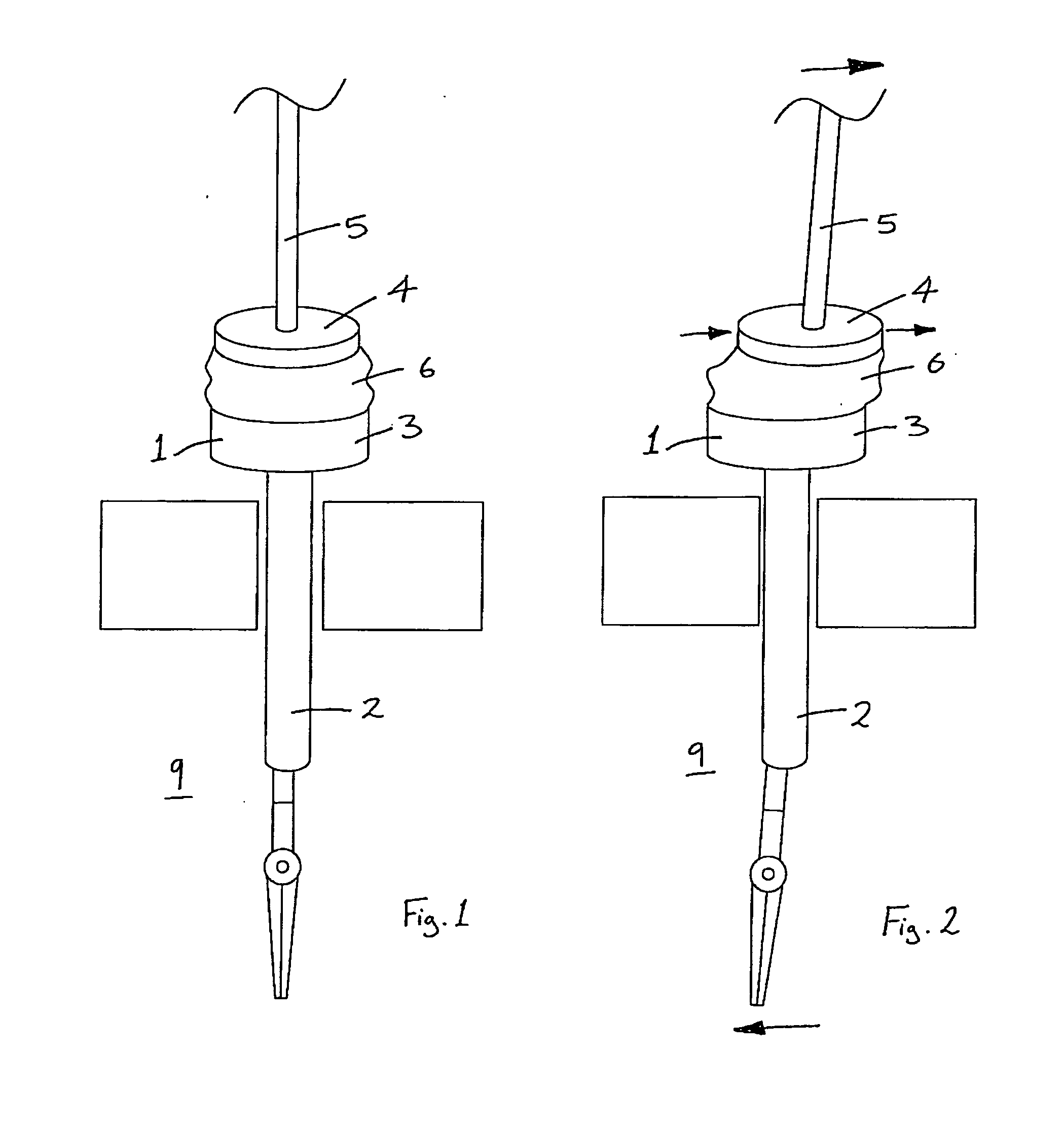

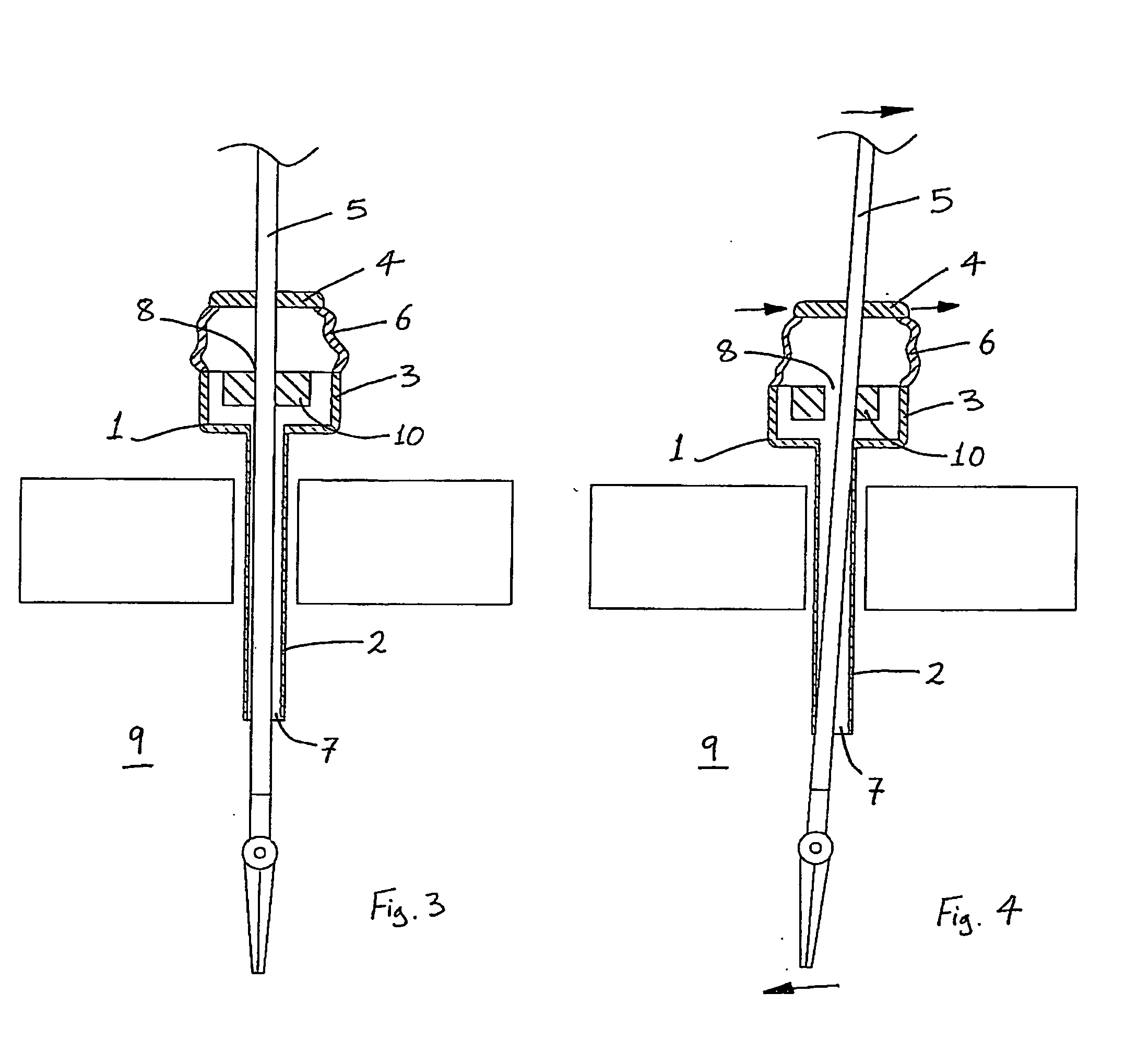

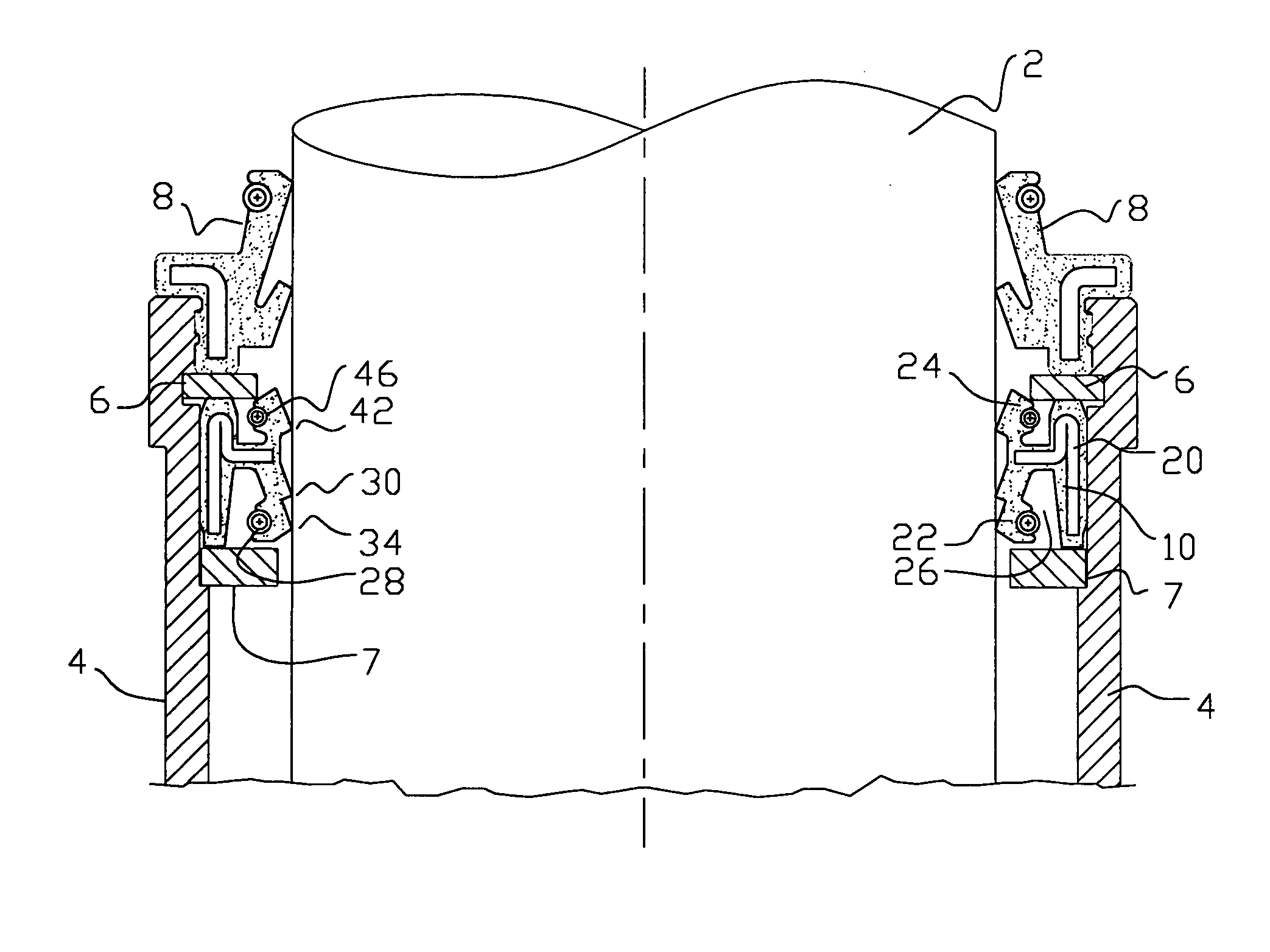

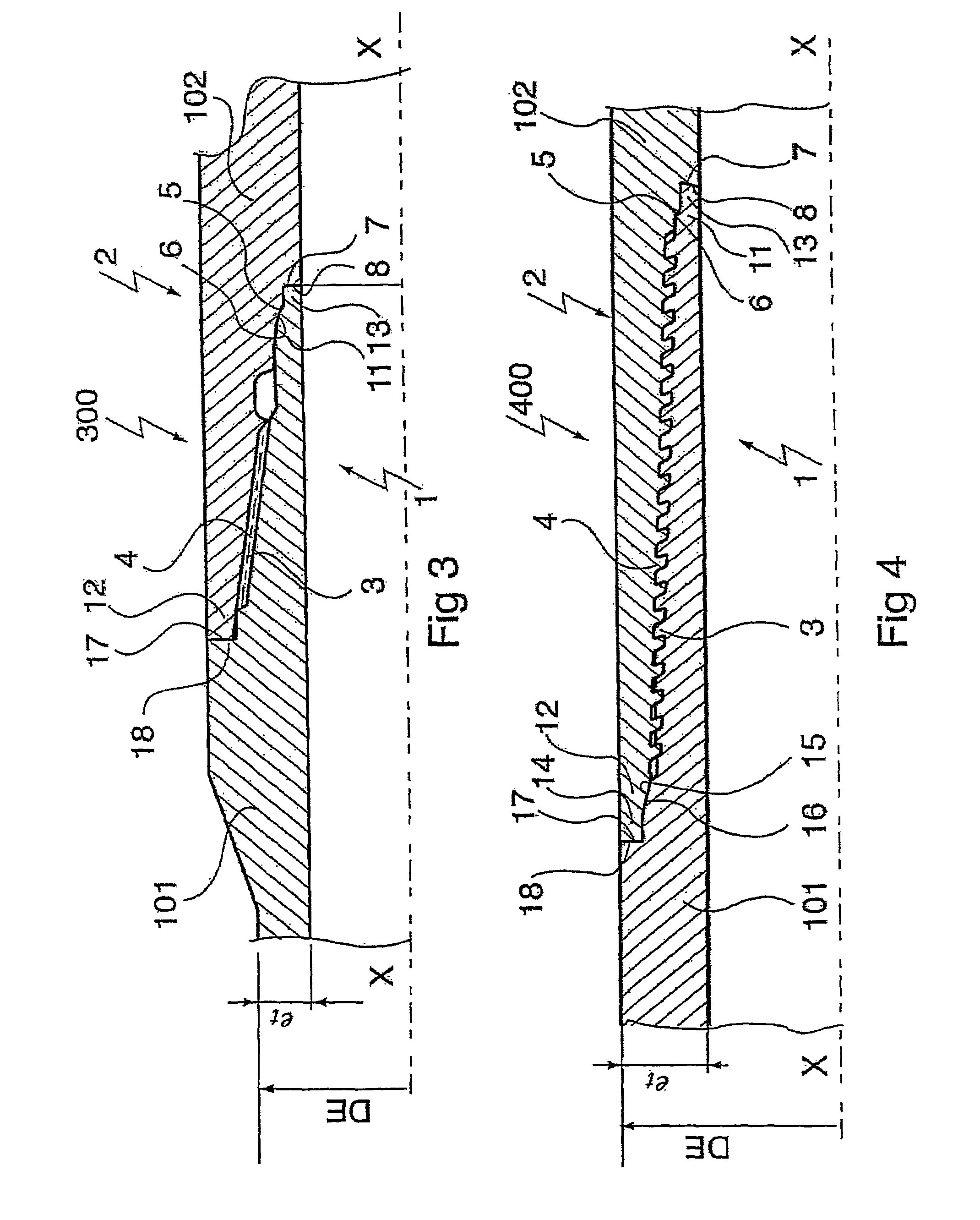

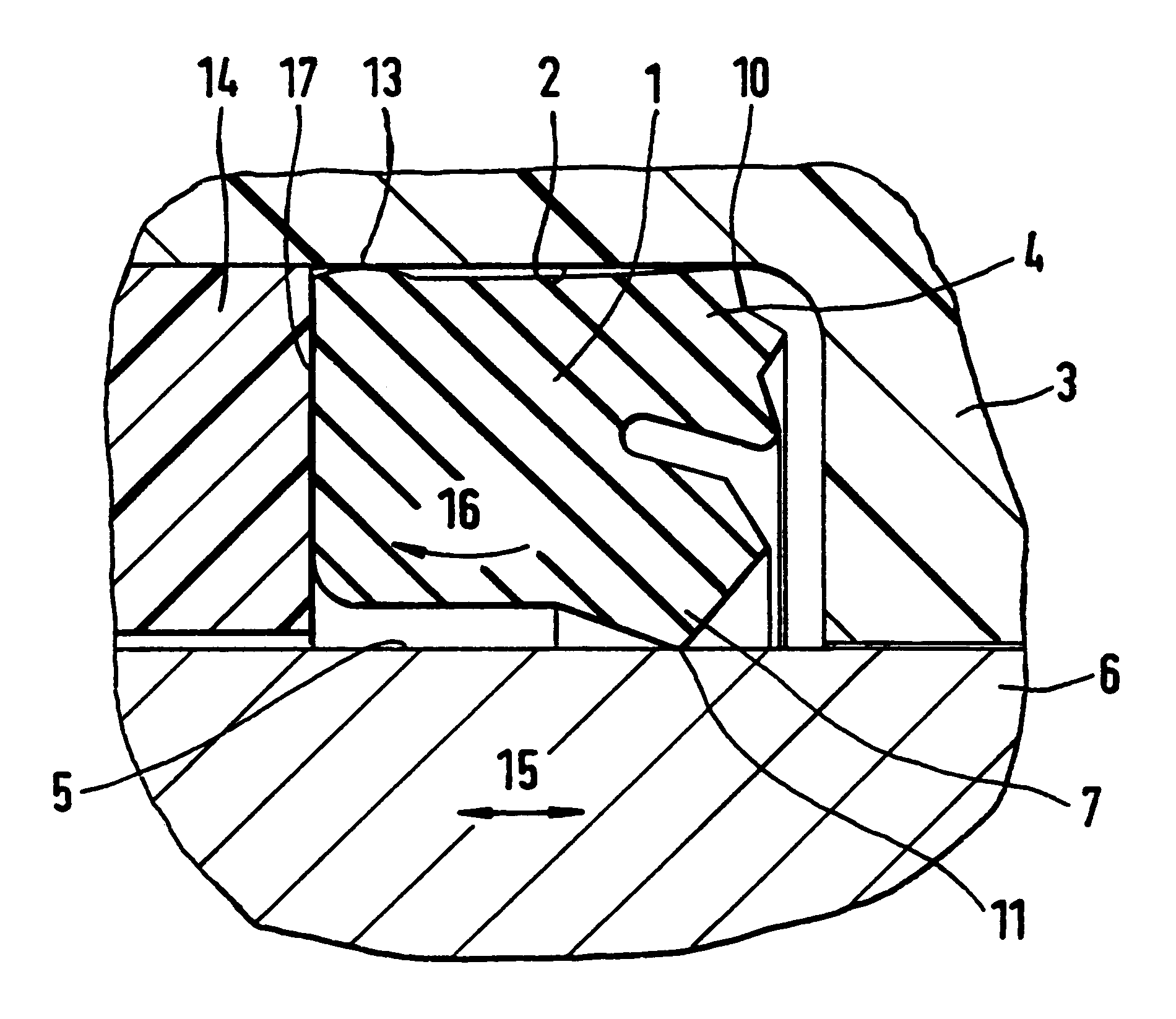

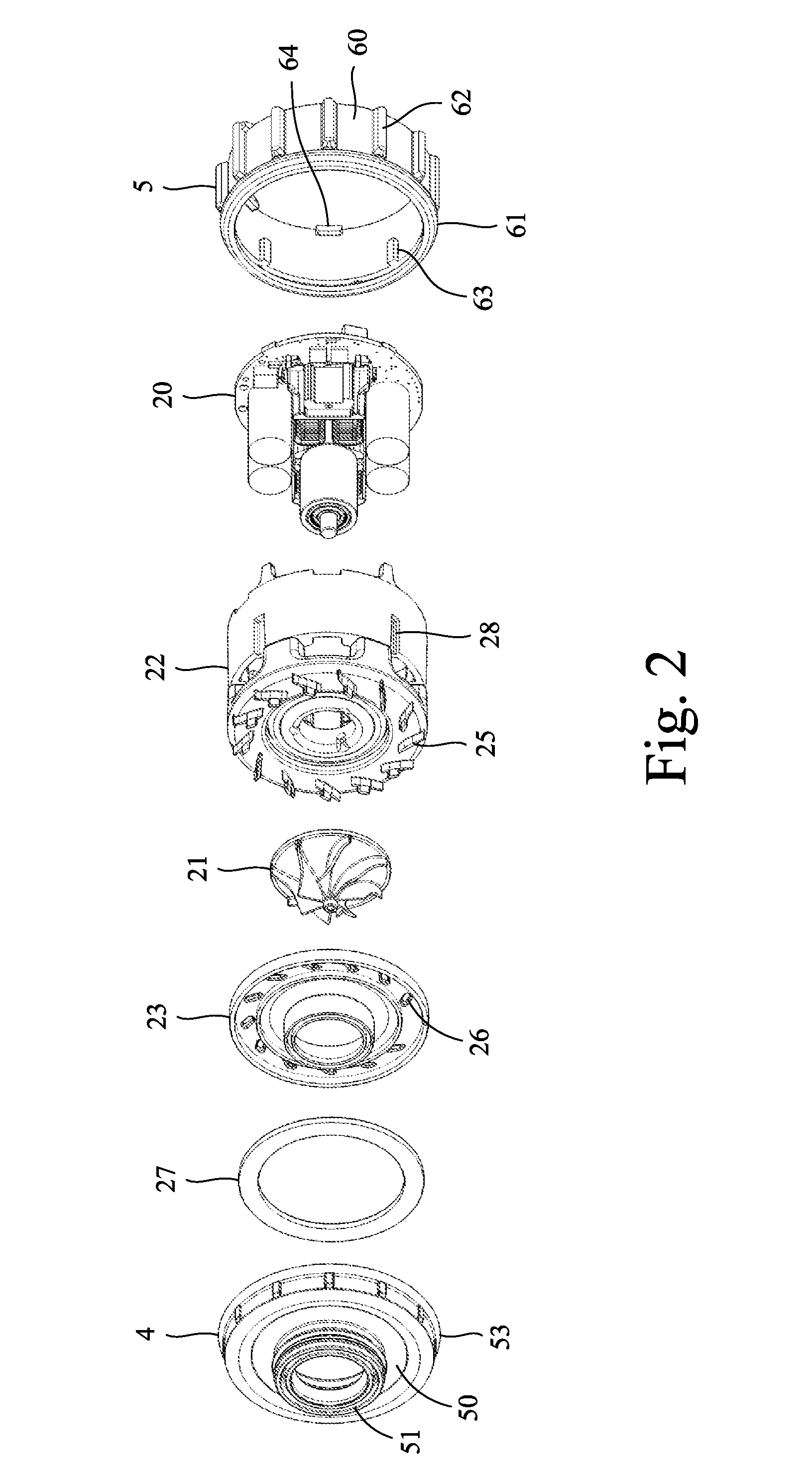

Seal for a cannula

A cannula (1) comprises a distal hollow tubular section (2), a proximal instrument insertion section (3), a lip seal (4) for sealingly engaging with an instrument shaft (5), and a duck-bill seal (10) also for sealingly engaging with the instrument shaft (5). The lip seal (4) is movably coupled to the proximal section (3) by a coupling section, provided in the form of a flexible tubular sheath section (6). The distal section (2) defines an access channel (7) for extension of the instrument shaft (5) therethrough. The proximal section (3) has a proximal opening (8) through which the instrument shaft (5) may be inserted into the proximal section (3). The distal end of the flexible section (6) is fixedly attached to the proximal section (3), and the proximal end of the flexible section (6) is fixedly attached to the lip seal (4). The flexible section (6) facilitates relative movement between the lip seal (4) and the proximal section (3) to accommodate lateral movement of the instrument (5) while maintaining the seal between the lip seal (4) and the instrument (5).

Owner:ATROPOS LTD

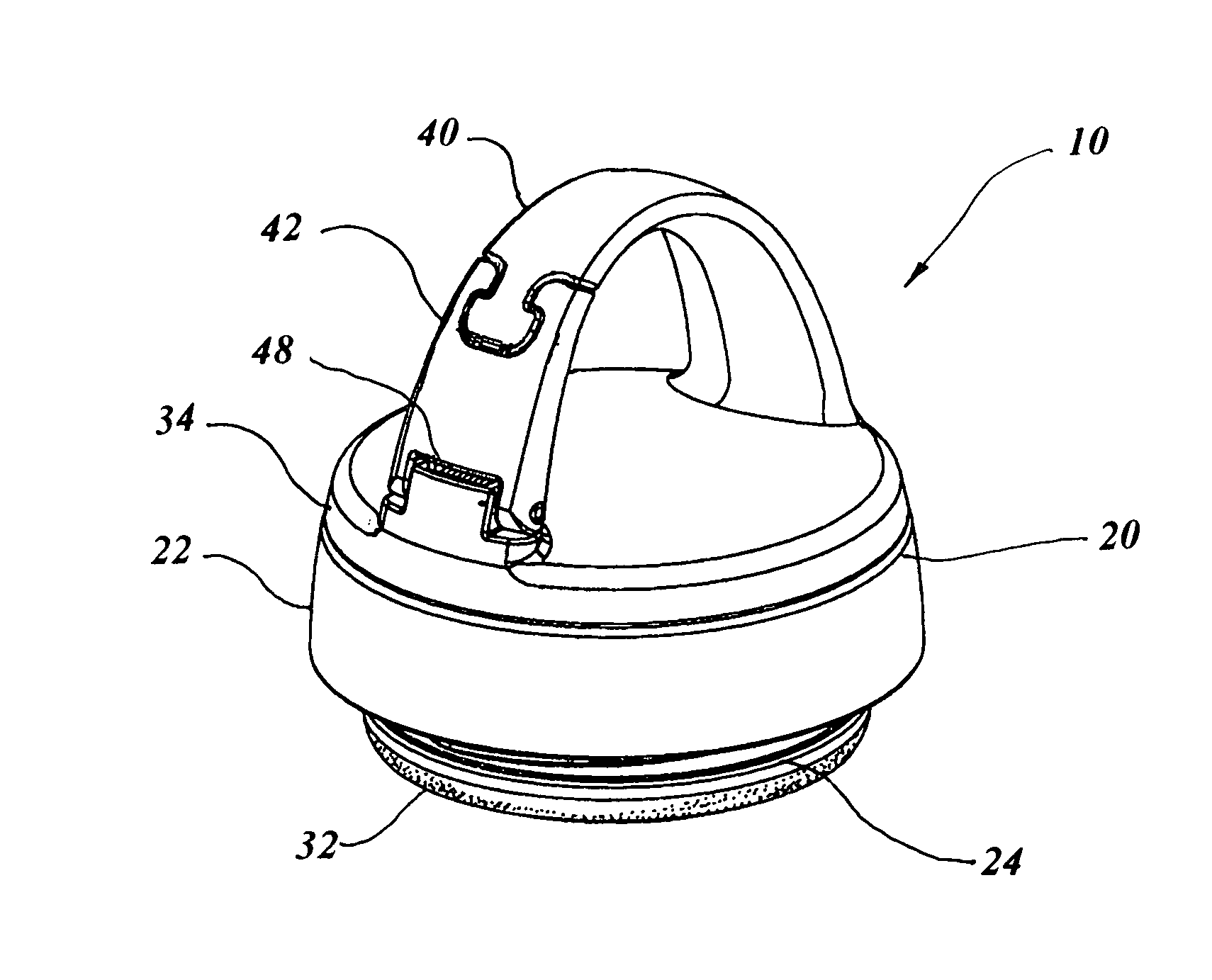

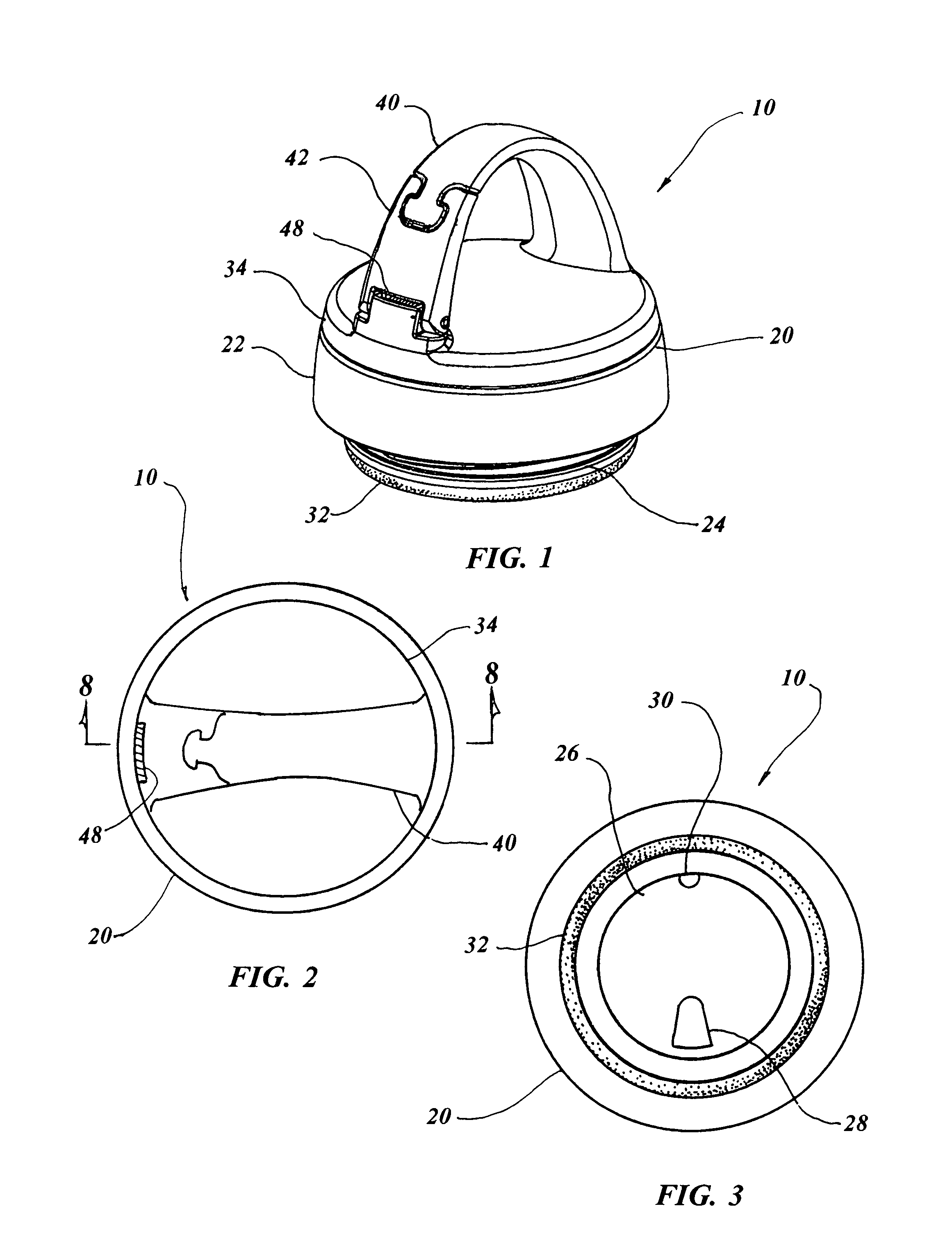

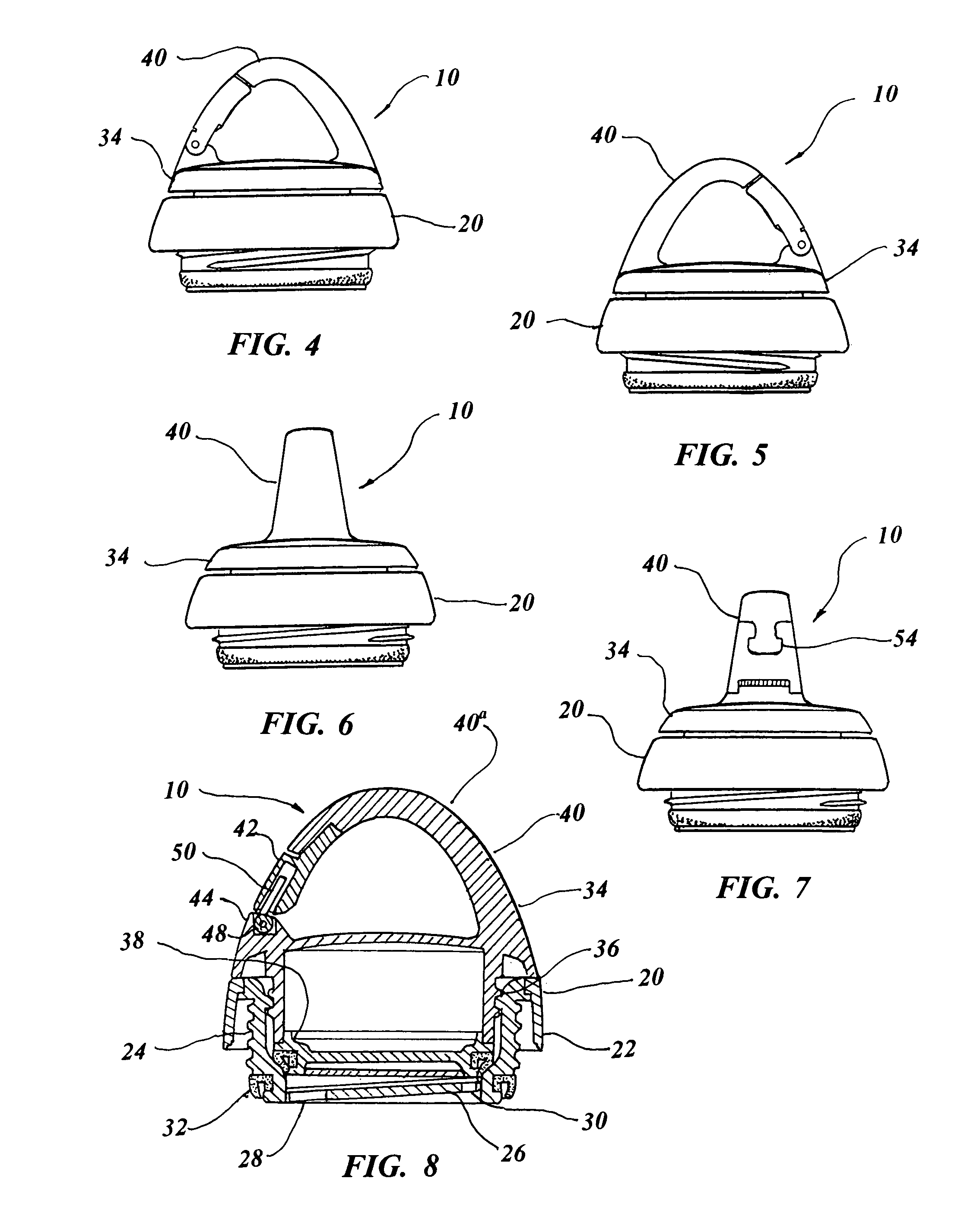

Latched handle container lid

A container lid with a latch handle is taught that incorporates a drinking lip, having a flared brim, configured to interface with a liquid container. A lip sealing ring is disposed on the drinking lip creating a watertight fit between the lip and the container. A lid body, having lid male threads, is configured to interface with container lid female threads, and the lid body includes a bottom cover which forms a dead air space for insulation purposes within the lid. The lid body incorporates a vertical arched handle with a snap-in hinged spring loaded latch for quick release attachment of the container lid and container securely to an object. A lid sealing ring is disposed on the lid body forming a watertight fit between the lid body and the container drinking lip.

Owner:LIN SHIN SHUOH

Small-scale mill and method thereof

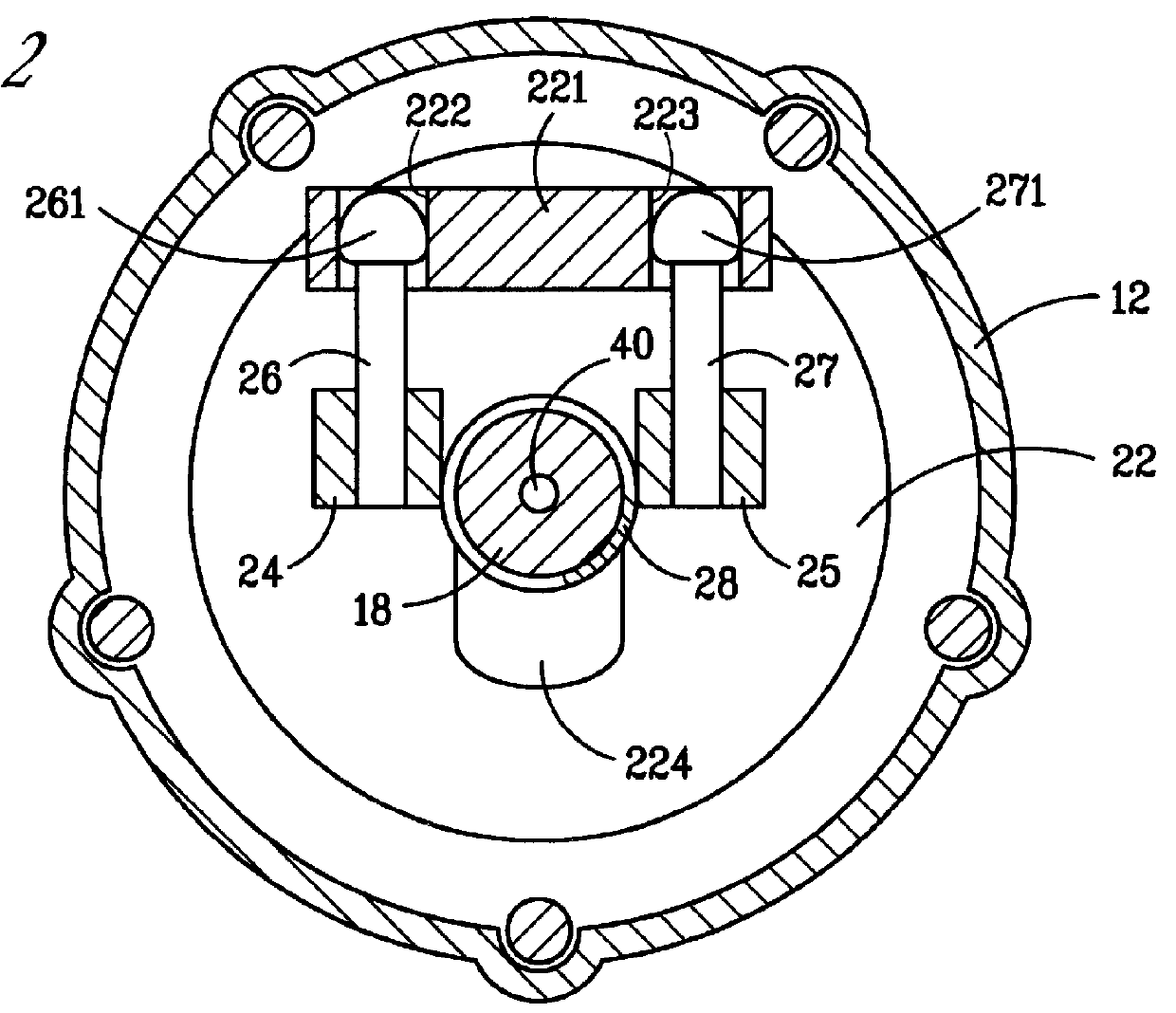

A small-scale or micro media-mill and a method of milling materials or products, especially pharmaceutical products, use a dispersion containing attrition milling media and the product to be milled. The milling media can be polymeric, formed of polystyrene or cross-linked polystyrene, having a nominal diameter of no greater than 500 microns. Other sizes include 200 microns and 50 microns and a mixture of these sizes. The mill has a relatively small vessel having an opening, an agitator, a coupling and a motor. The agitator can have a rotor and a shaft extending therefrom. The rotor can be cylindrical or have other configurations, and can have tapered end surfaces. The coupling can close the vessel opening, or attaching the coupling to the motor can close the opening. The coupling has an opening through which the rotor shaft extends into the motor. A sealing mechanism, such as a mechanical or lip seals the shaft while permitting the rotor shaft to rotate. The vessel can contain one or more ports for circulating the dispersion, where milling can be made in batches or recirculated through the milling chamber. The media can be retained in the vessel or recirculated along with the process fluid. The rotor is dimensioned so that its outer periphery is spaced with a small gap from an inner surface of the vessel. The vessel also can have a way of cooling the dispersion.

Owner:ALKERMES PHARMA IRELAND LTD

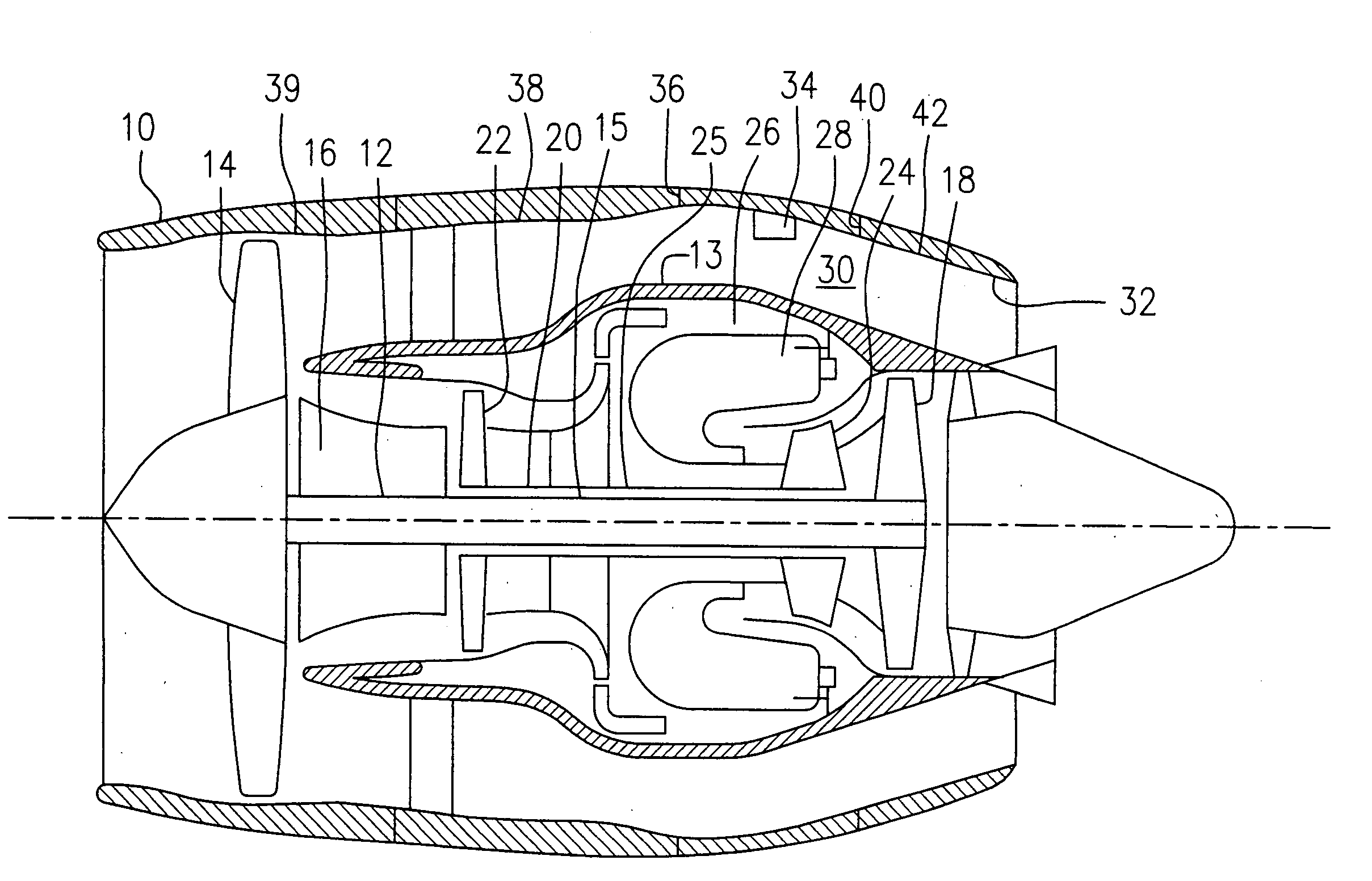

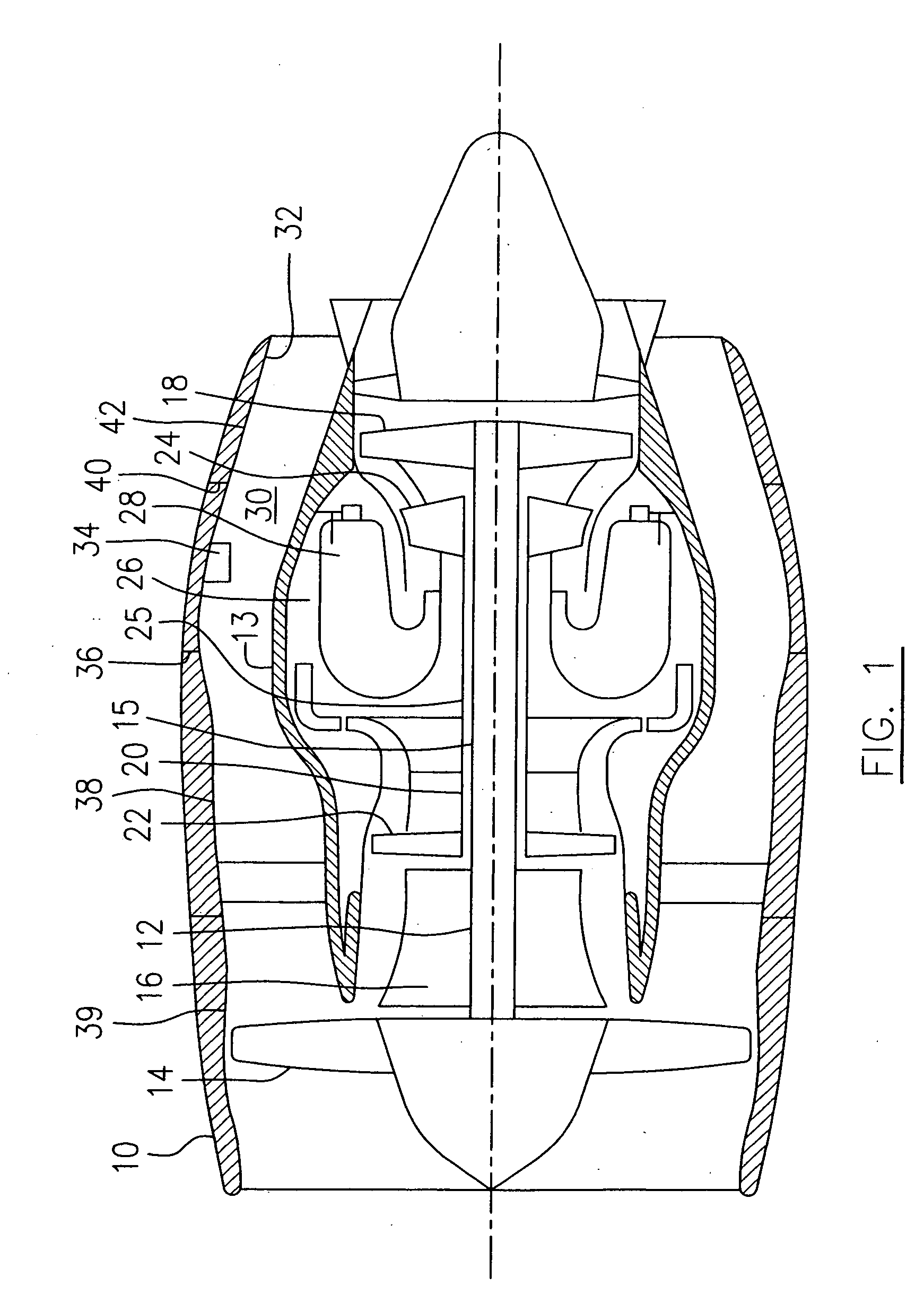

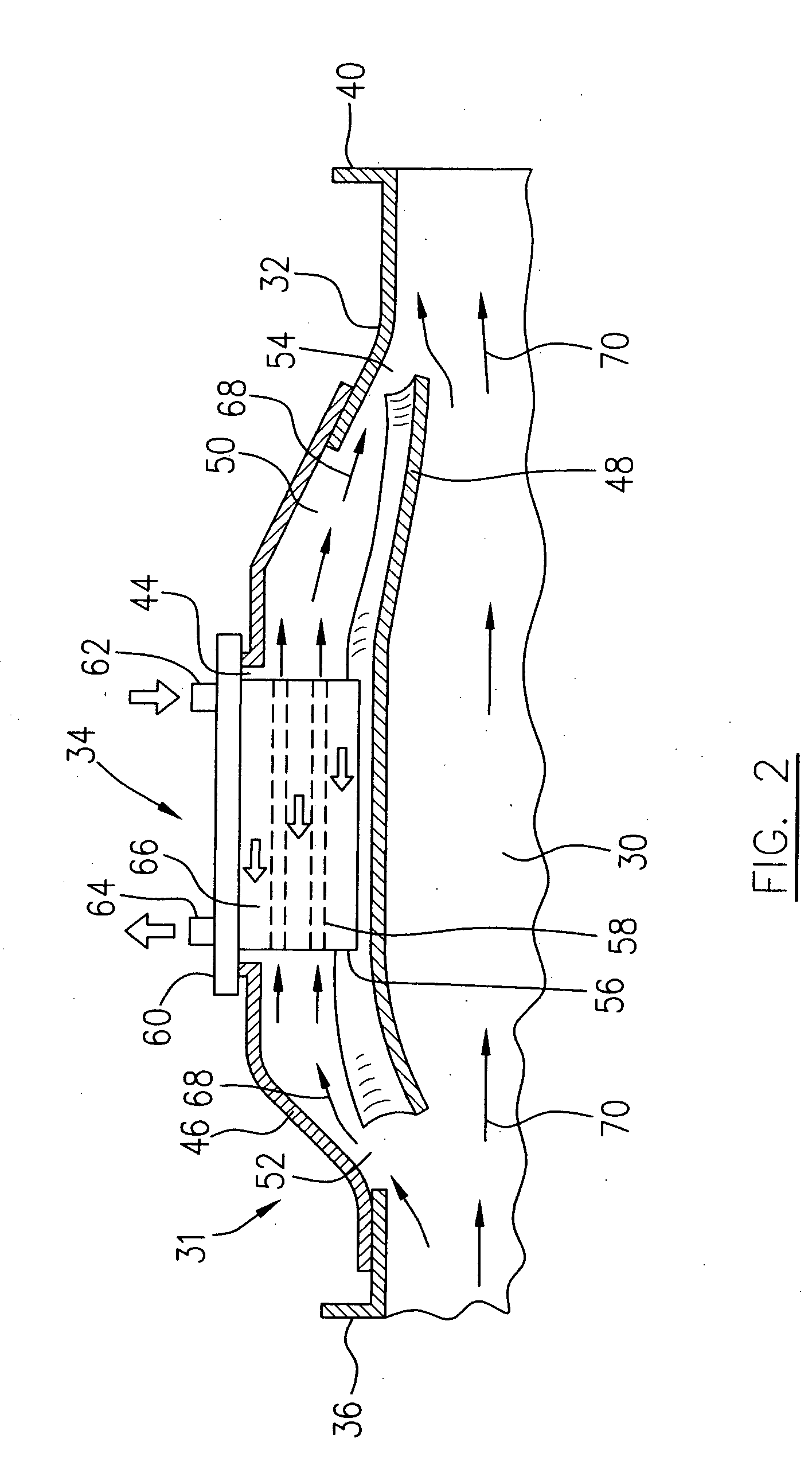

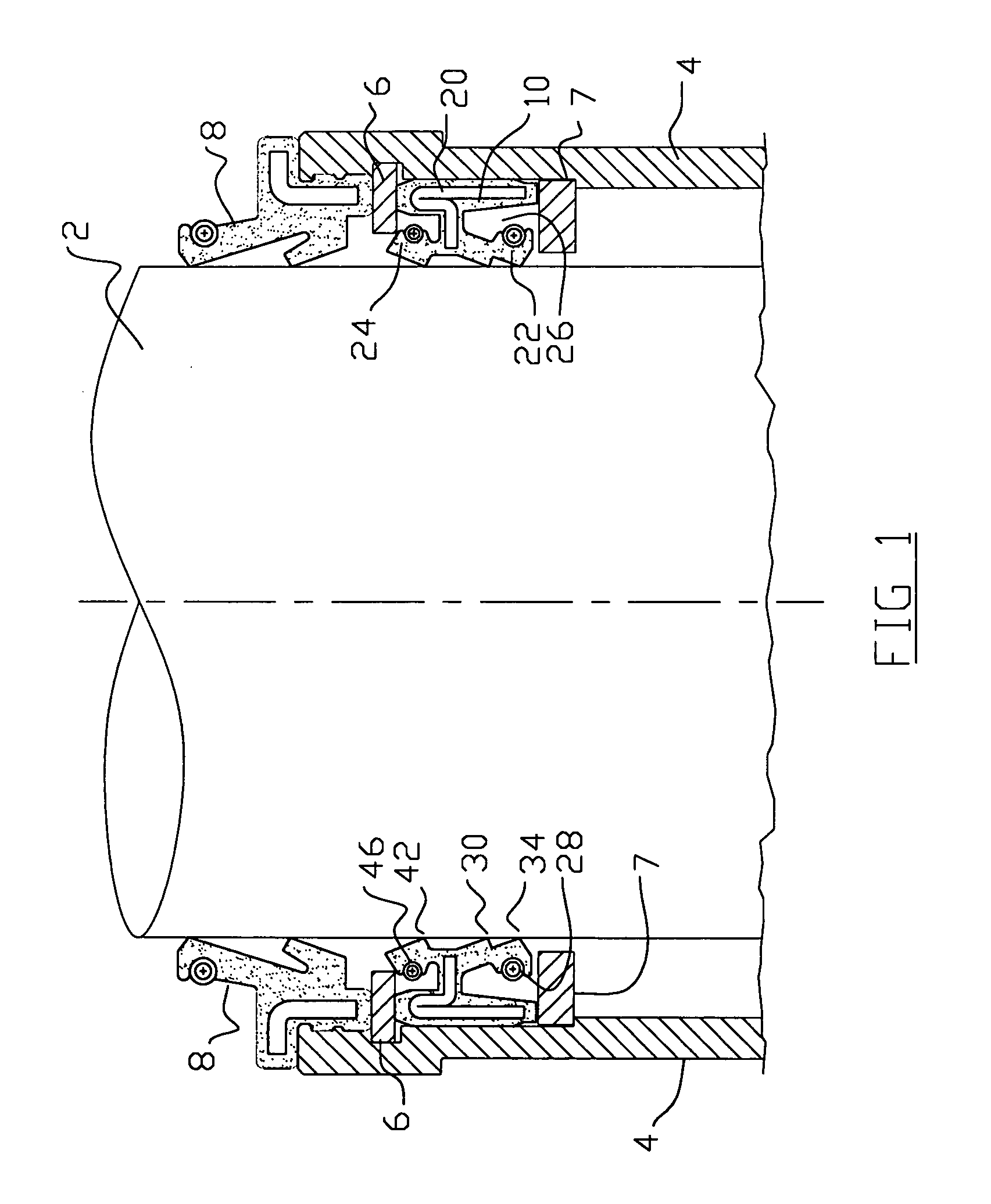

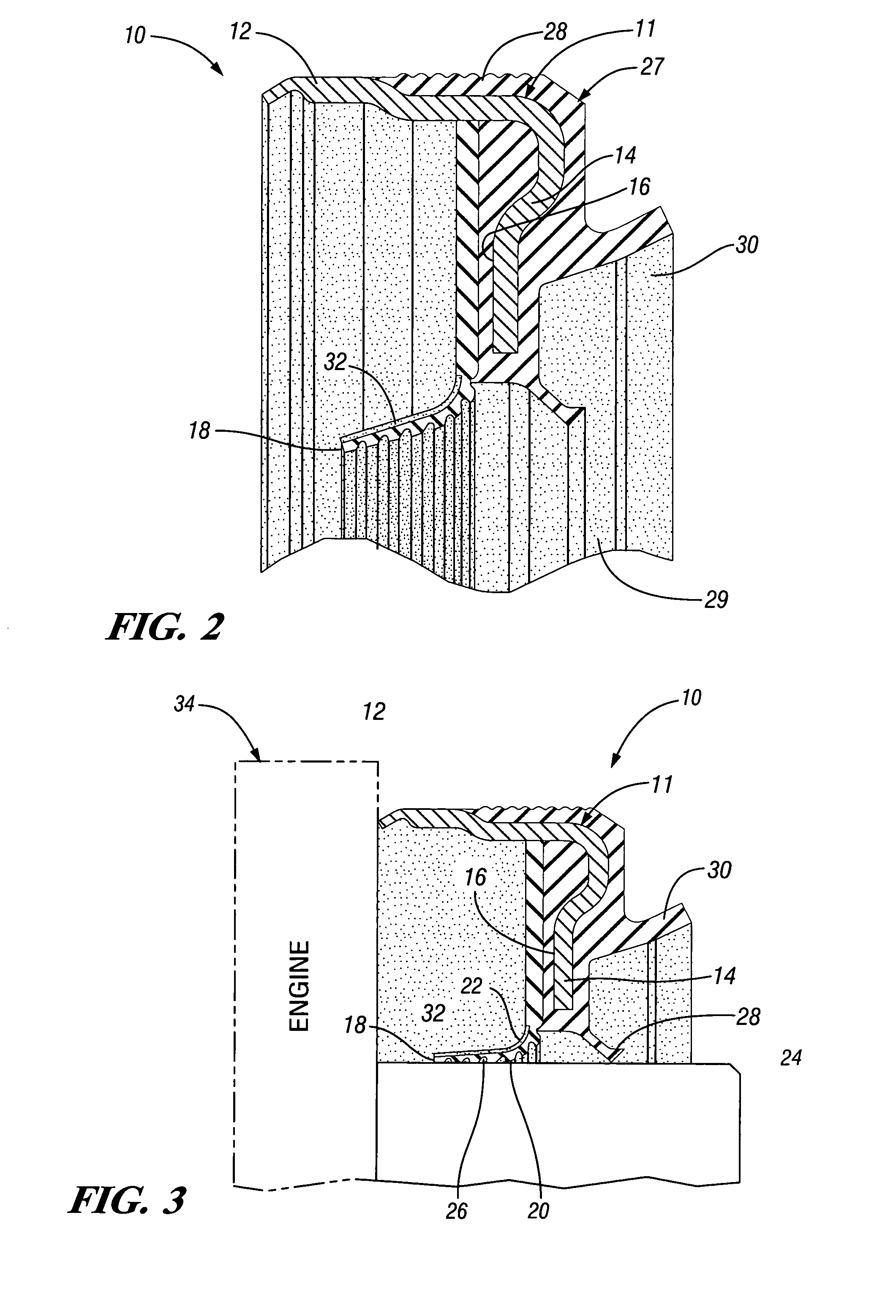

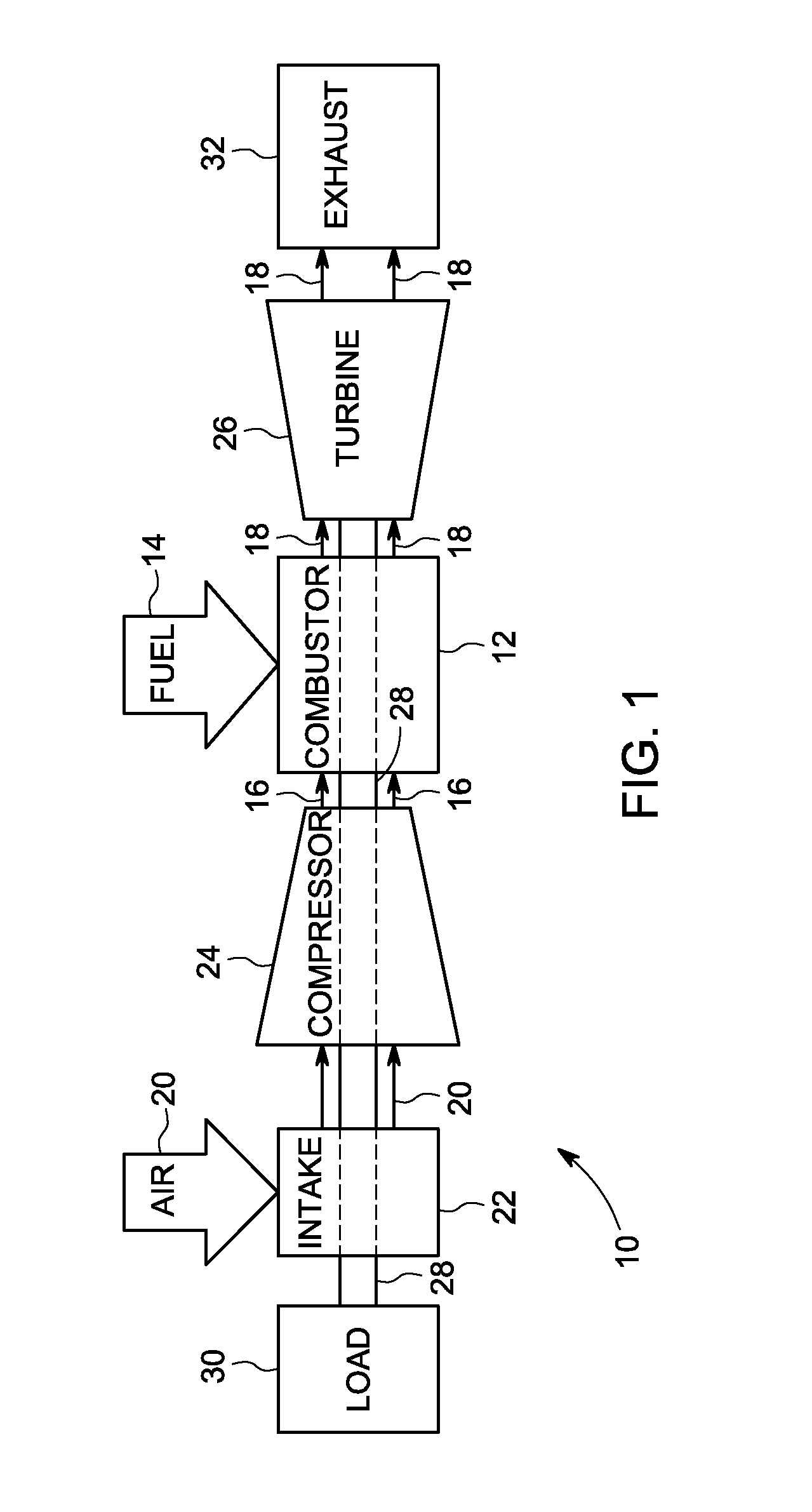

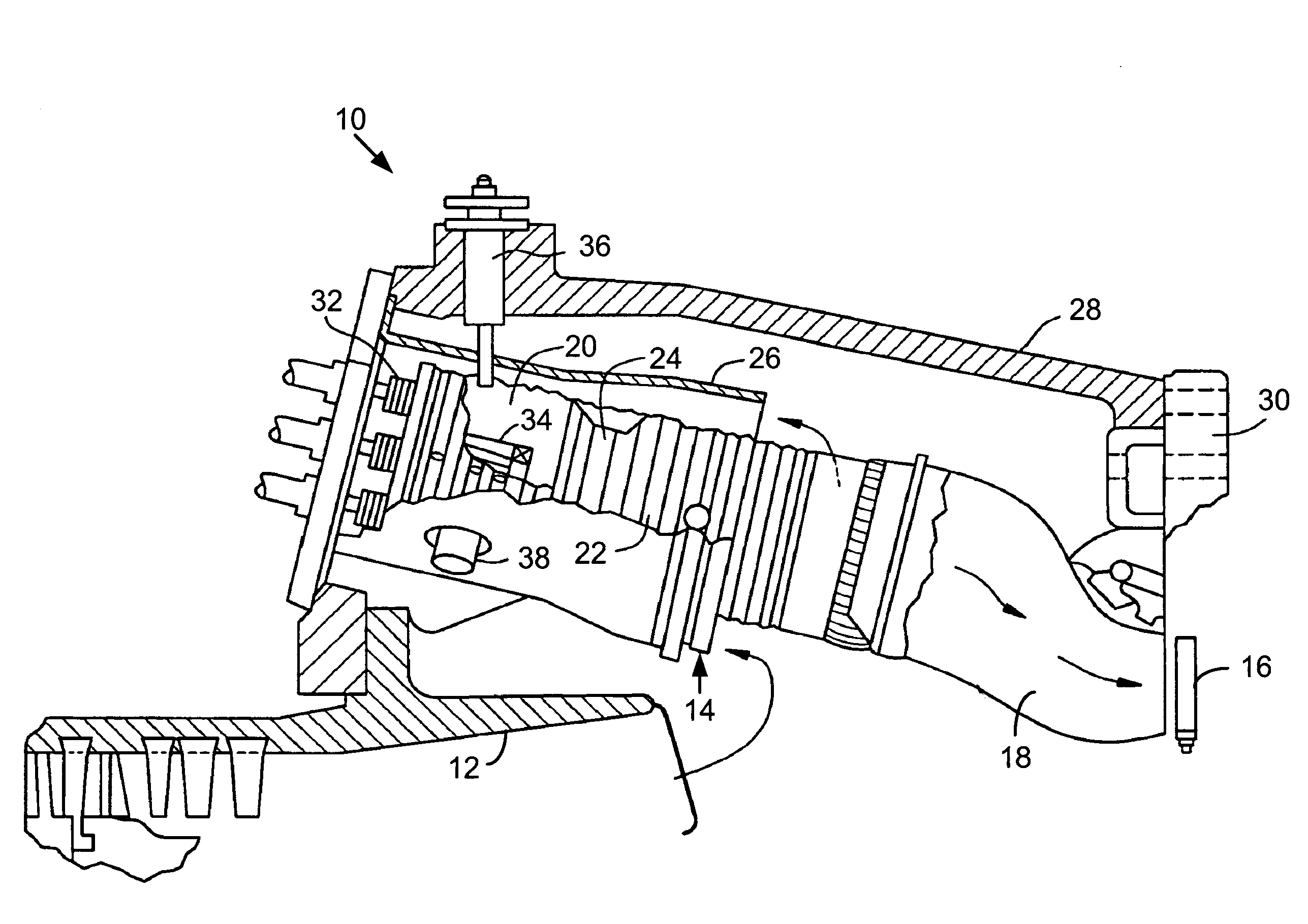

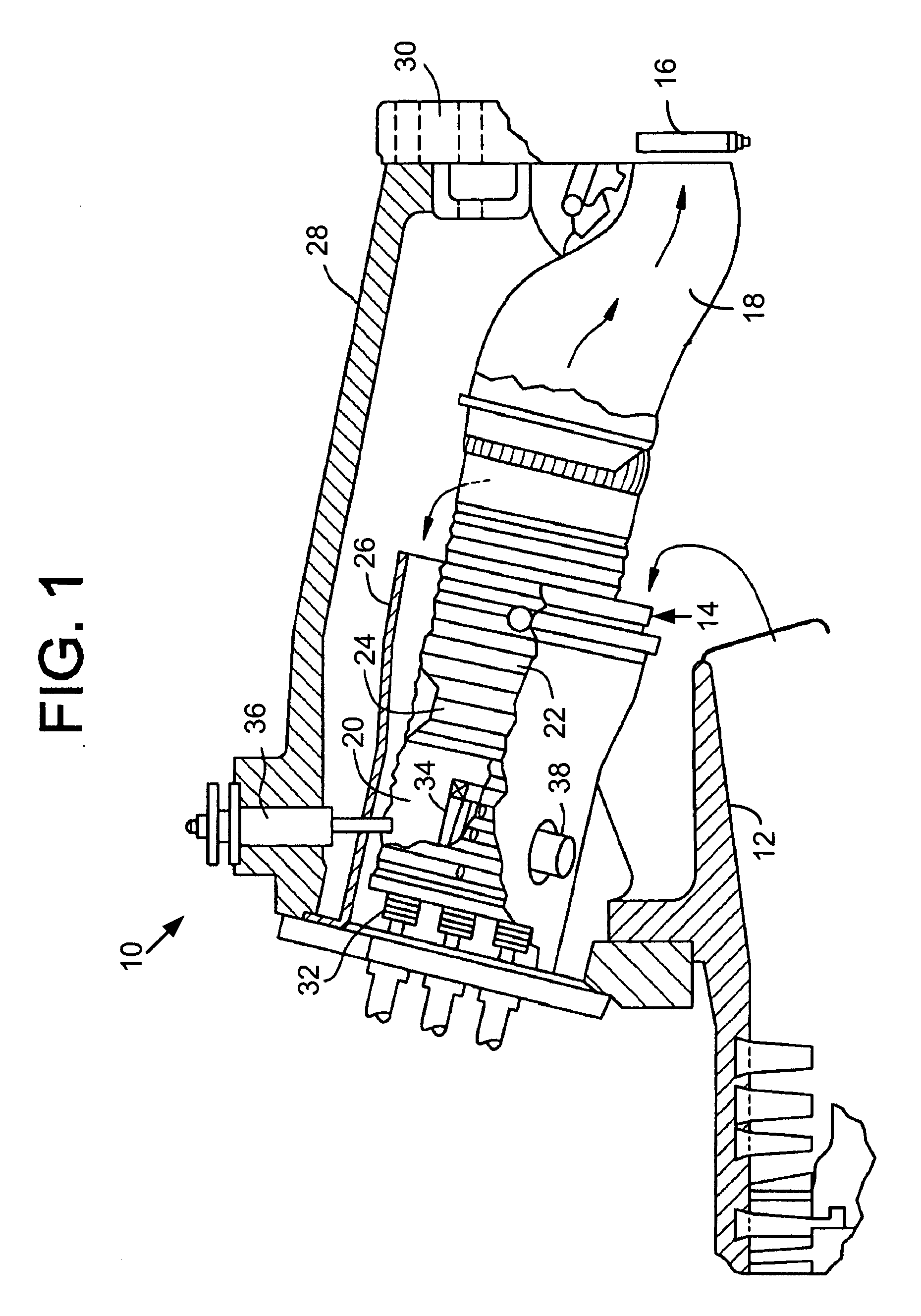

Bypass lip seal

InactiveUS20080053060A1Facilitate heat exchangeTurbine/propulsion engine coolingEfficient propulsion technologiesFlow dividerLip seal

A cooling apparatus for cooling a fluid in a bypass gas turbine engine comprises a heat exchanger disposed within a bypass duct and accommodated by a sub-passage defined by a flow divider affixed to an annular wall of the bypass duct. The sub-passage defines an open upstream end and an open downstream end to direct a portion of the bypass air flow to pass therethrough. A sealing assembly for the bypass duct is also provided.

Owner:PRATT & WHITNEY CANADA CORP

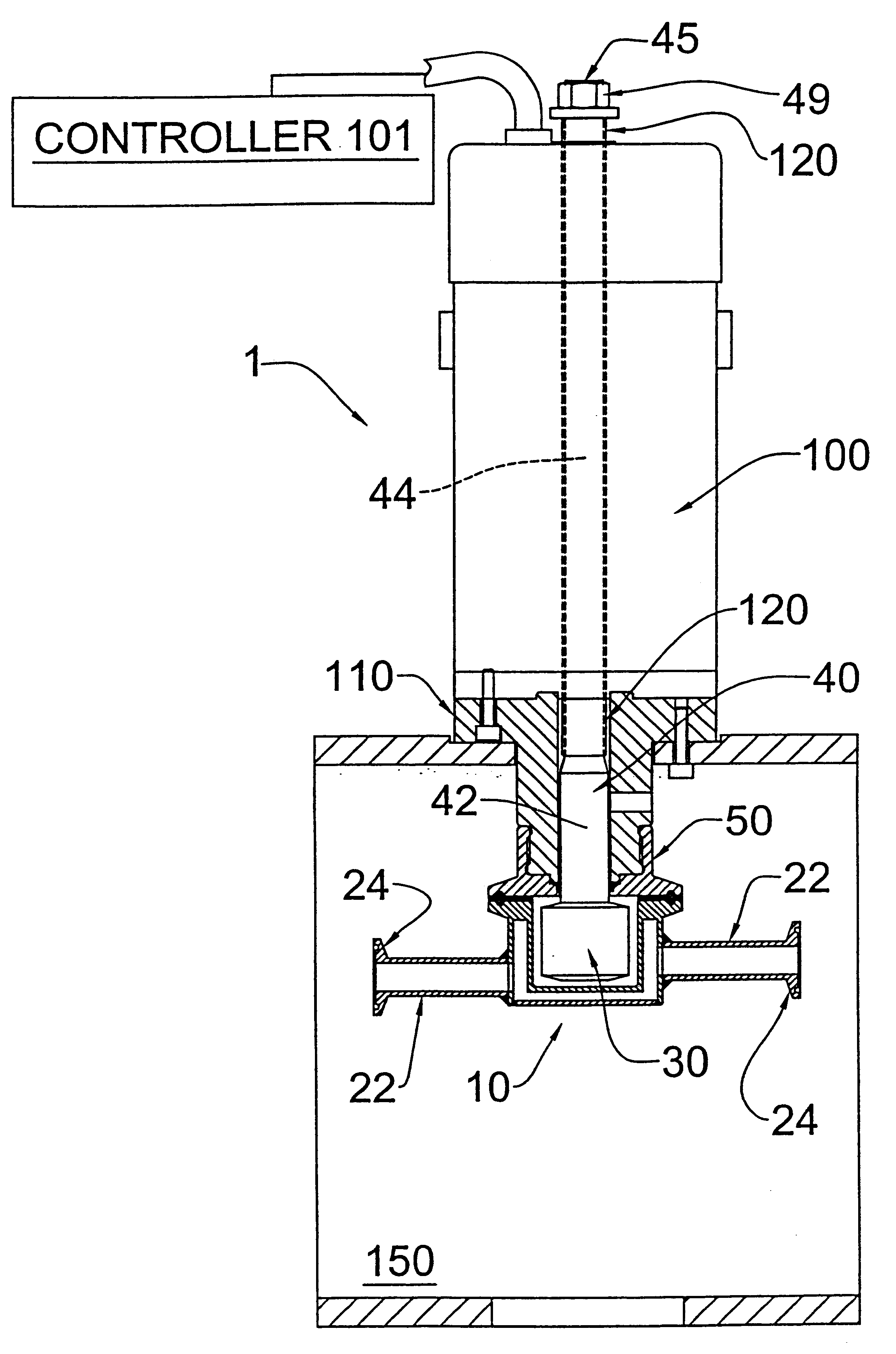

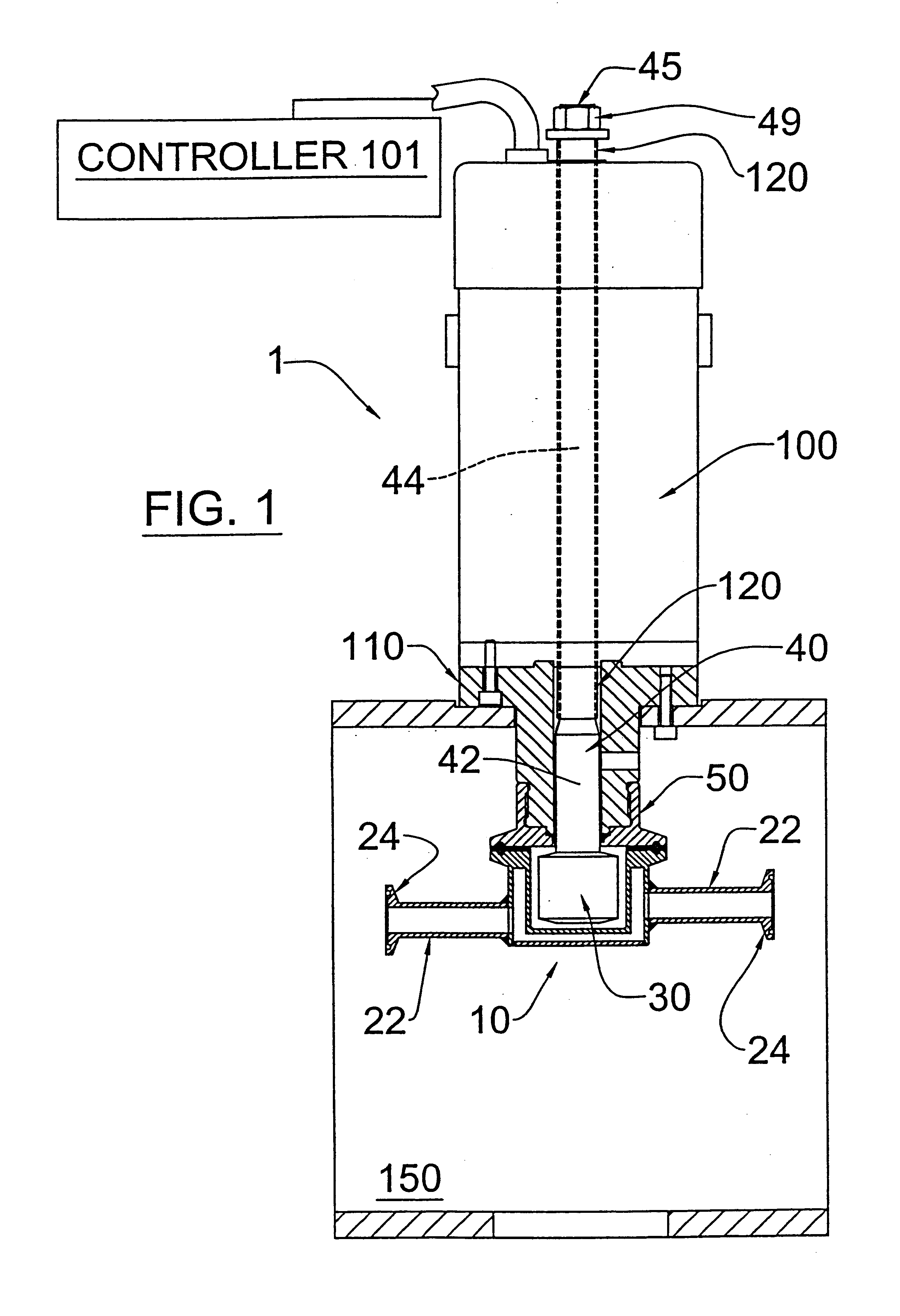

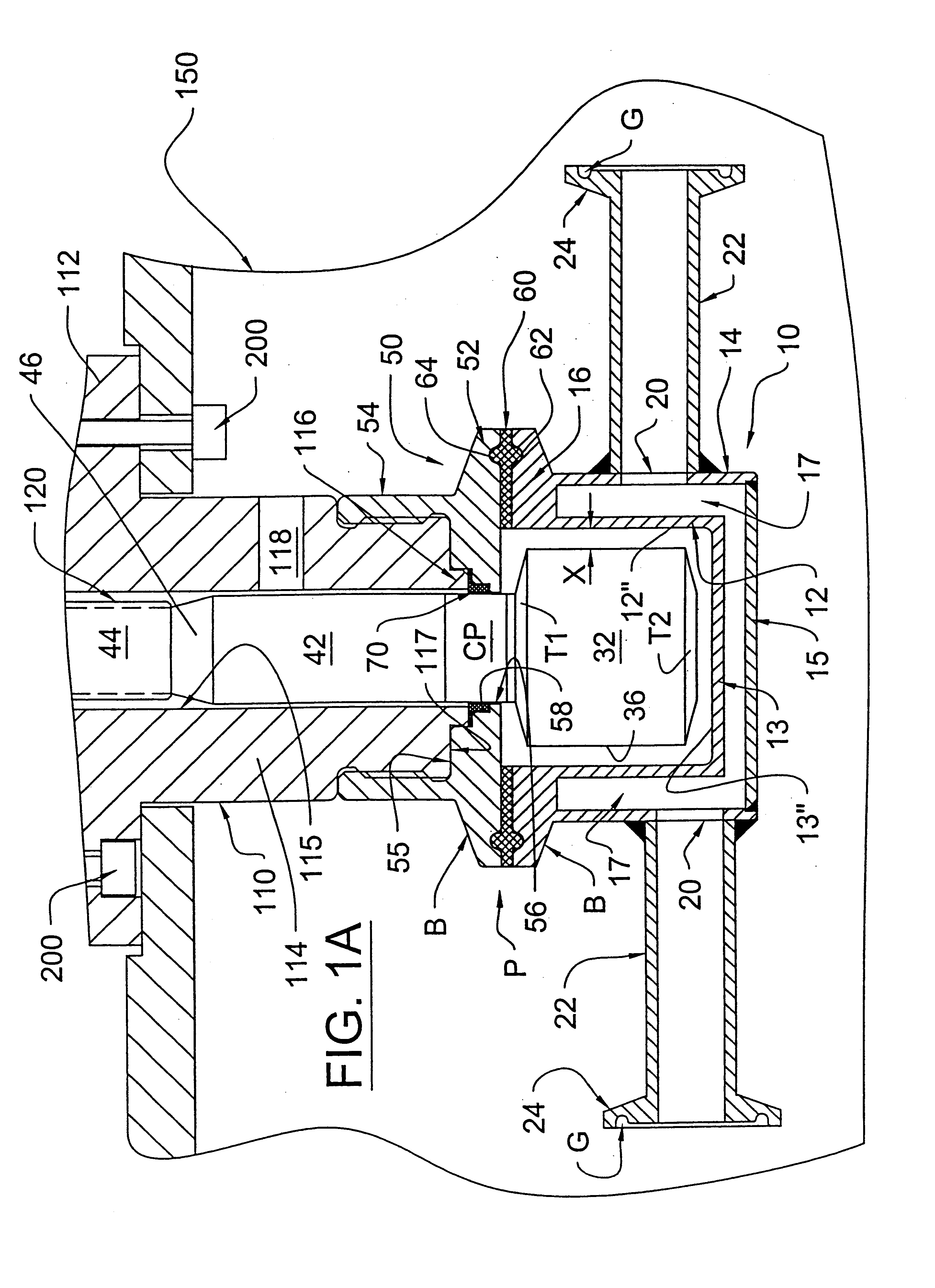

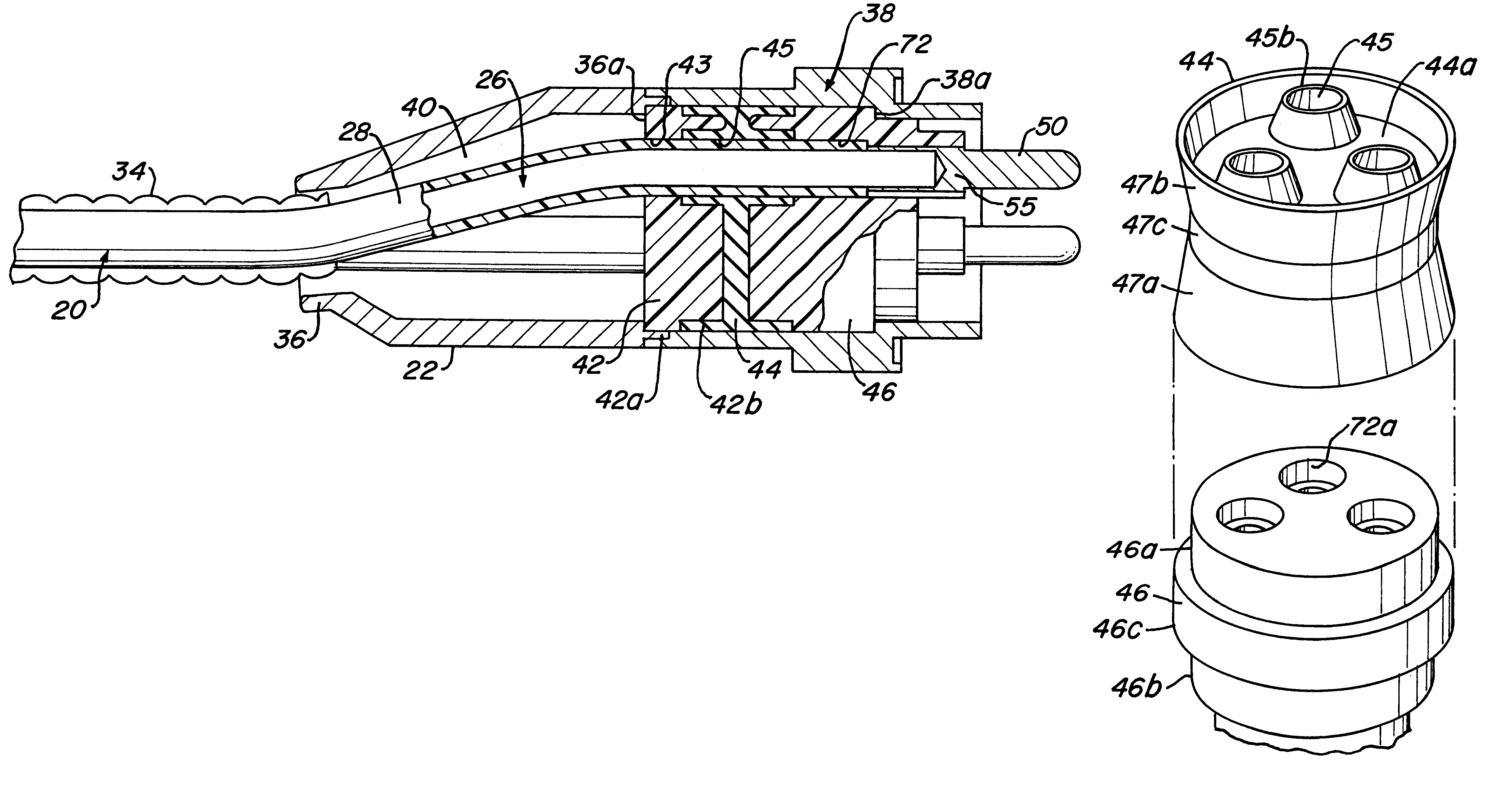

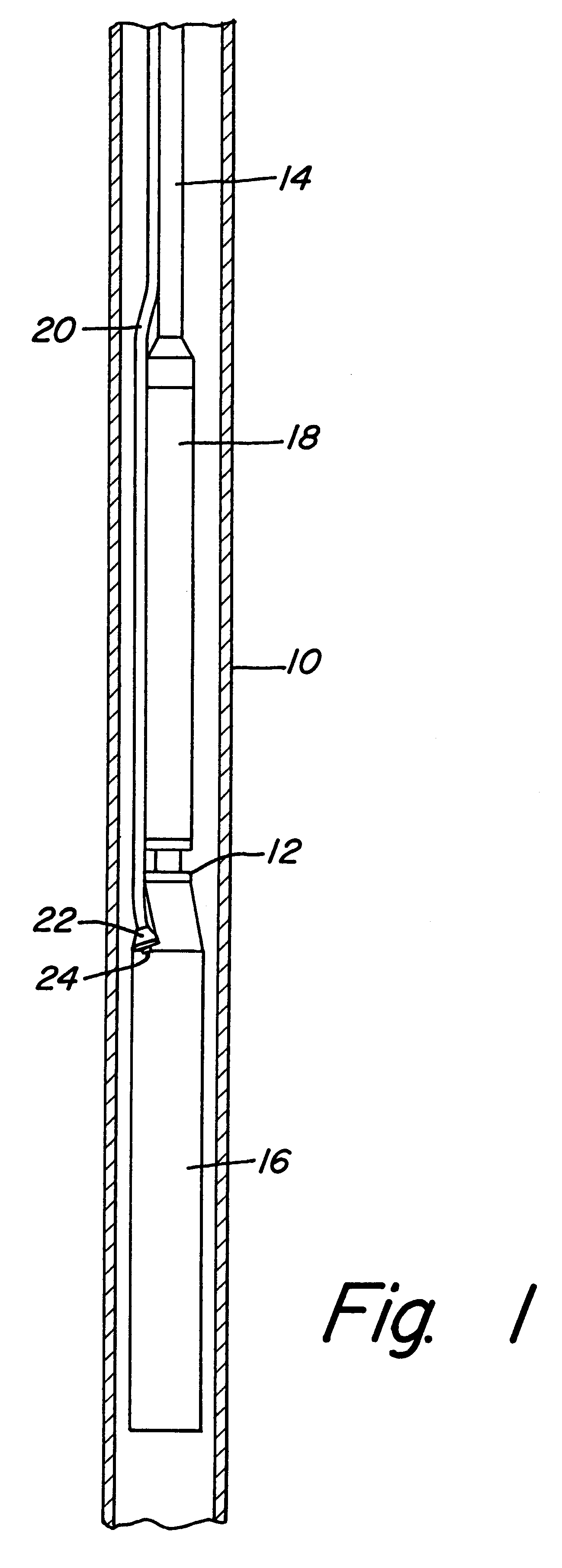

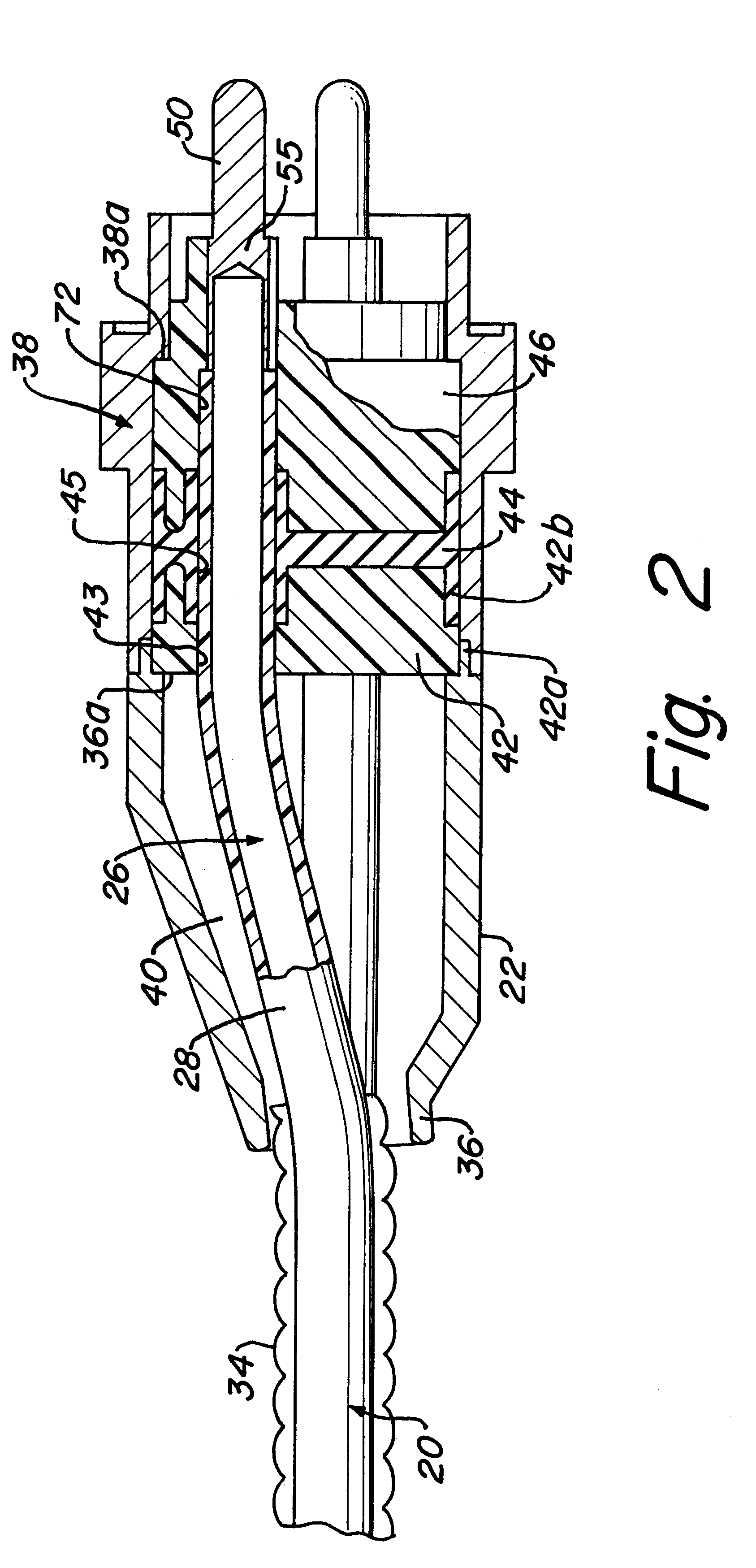

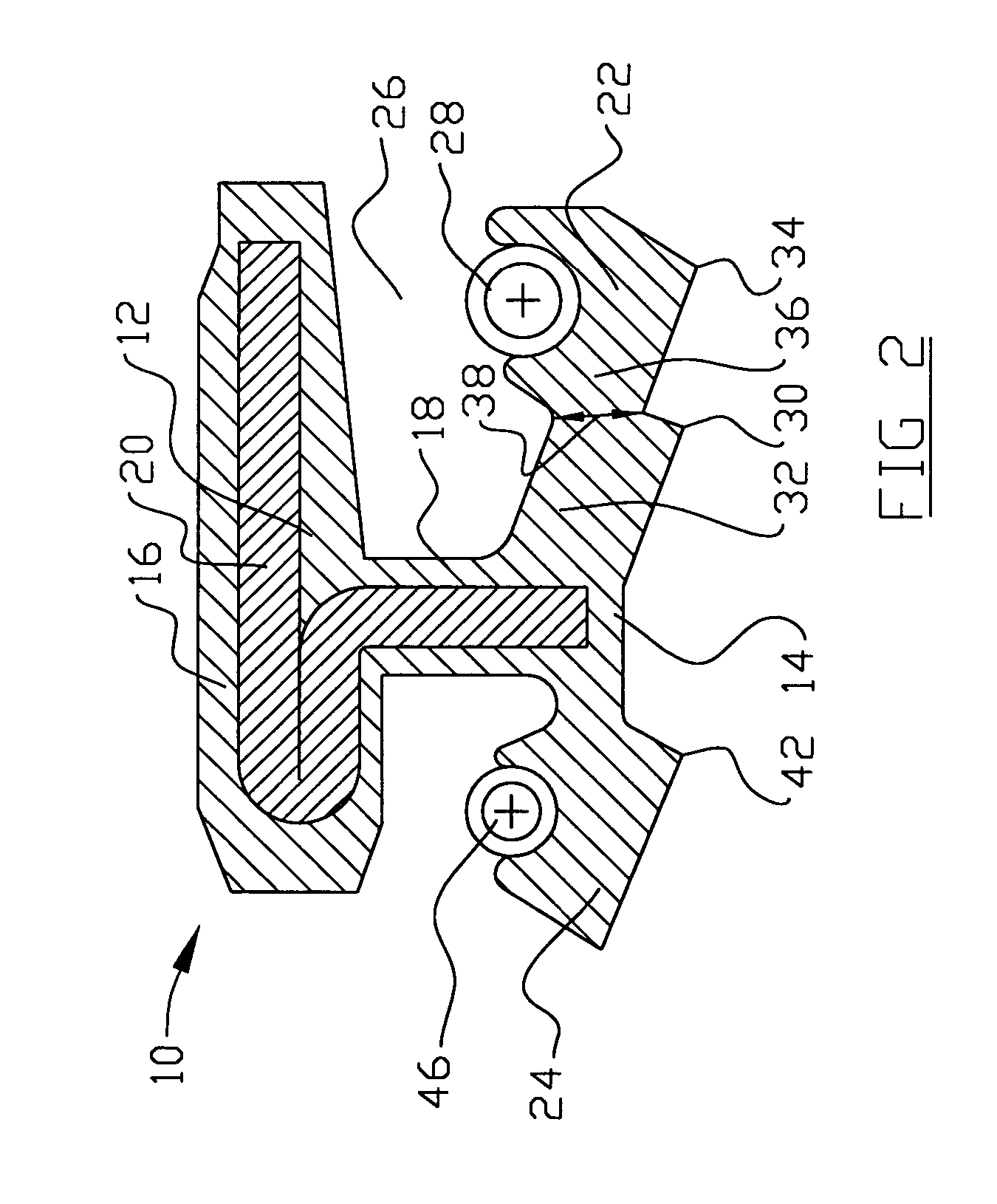

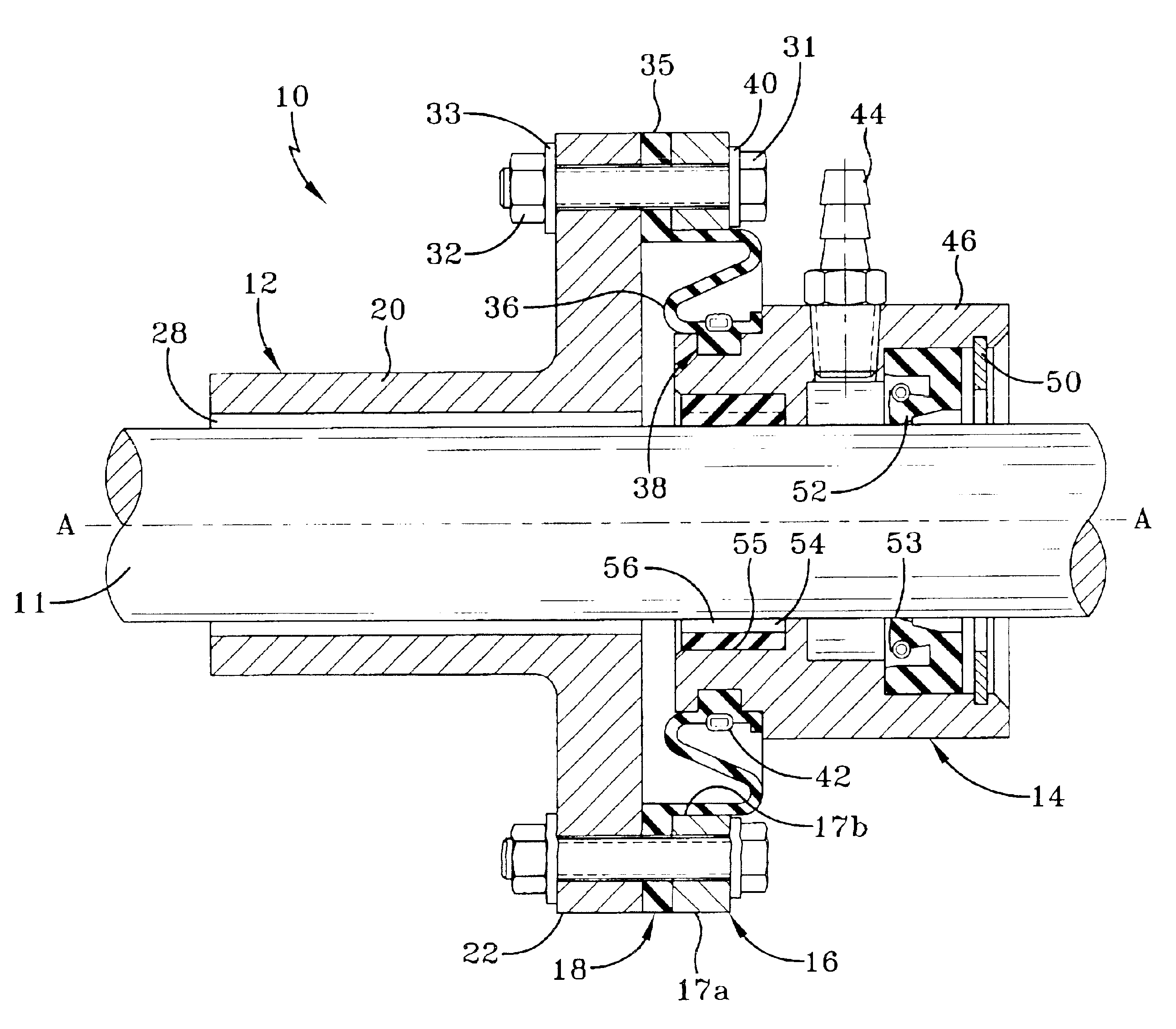

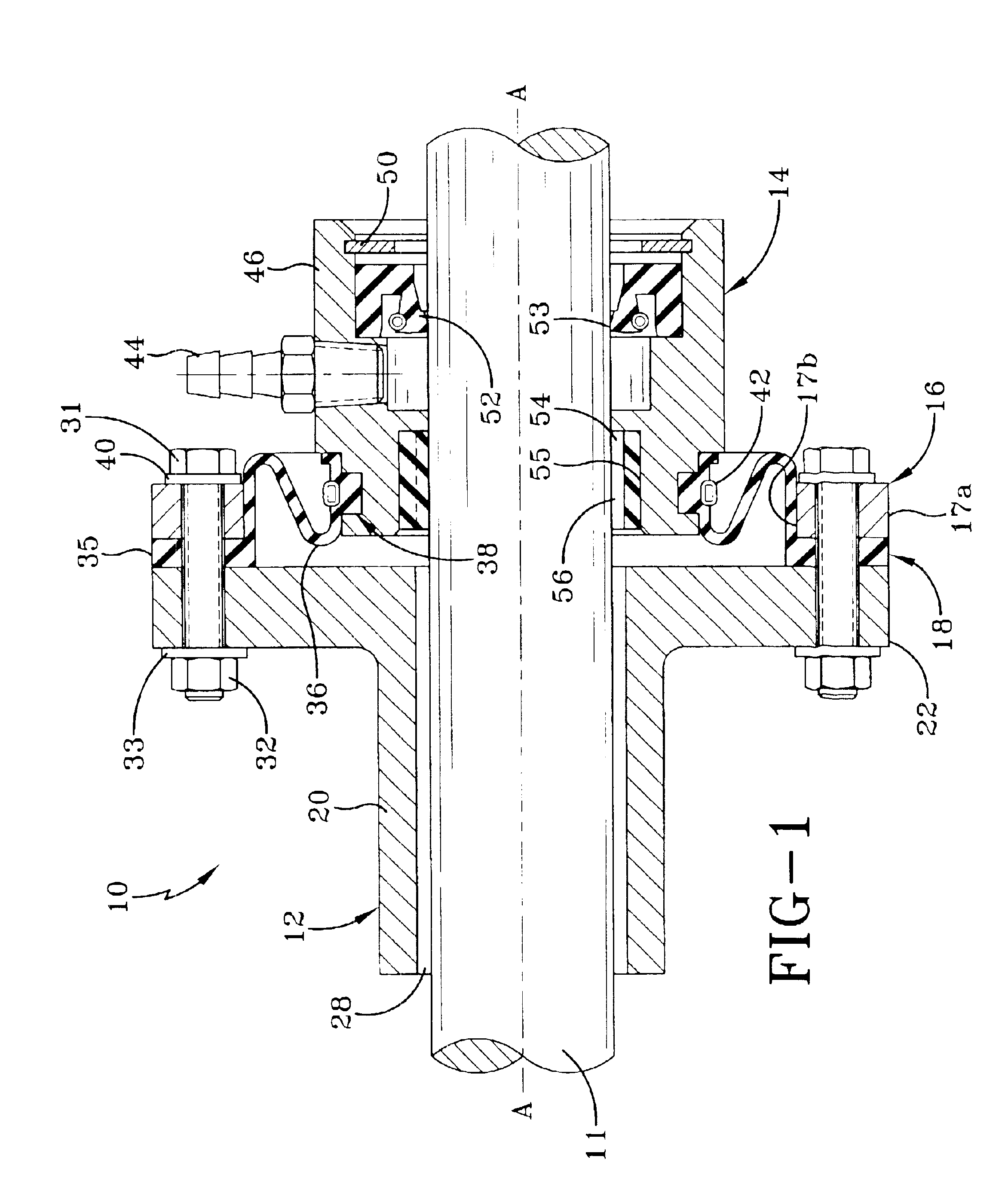

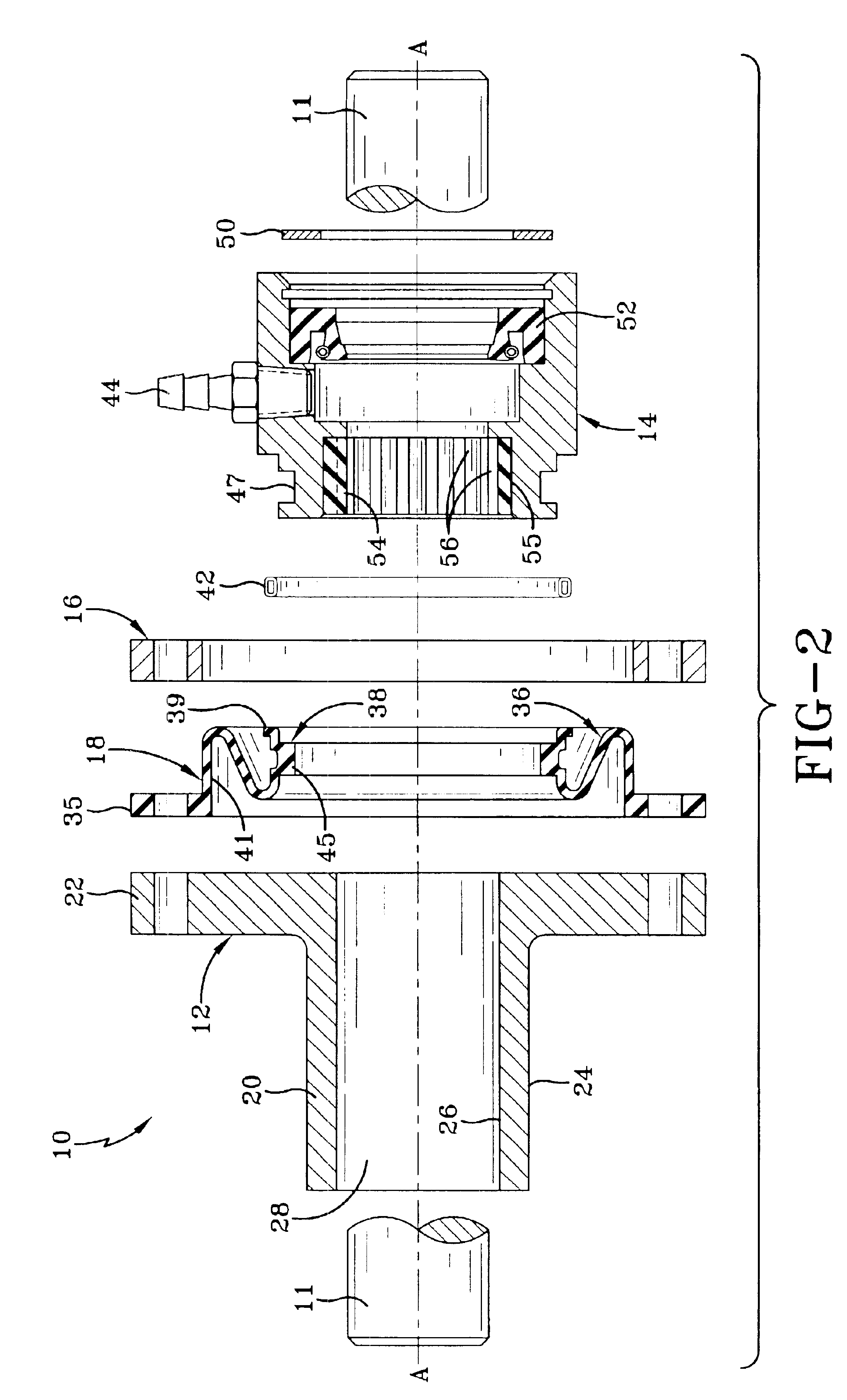

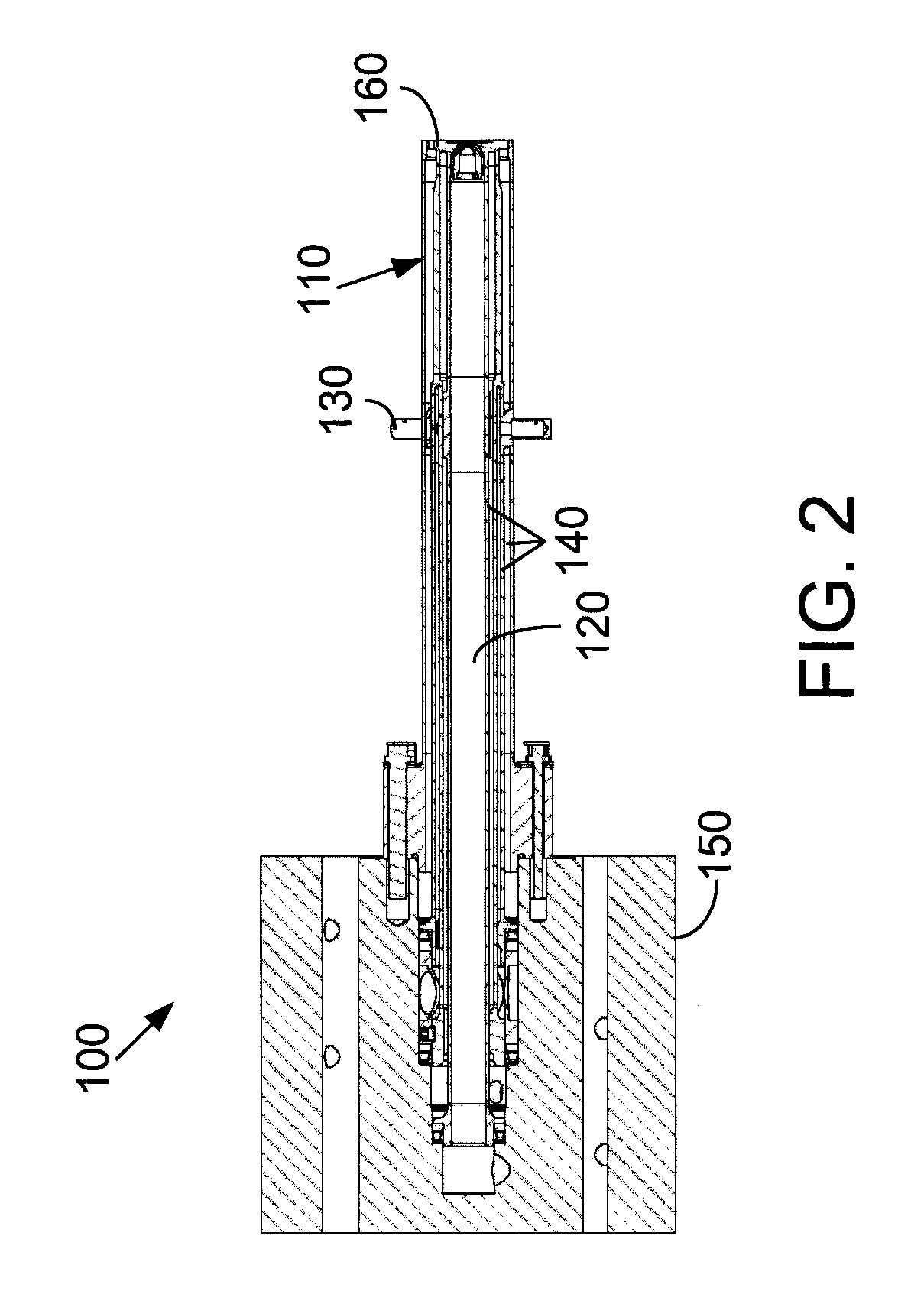

Pothead with pressure energized lip seals

InactiveUS6361342B1Sleeve/socket jointsFluid pressure sealed jointsElectrical conductorInsulation layer

An electric submersible pump is provided having a pothead connector for use to connect a downhole cable to an electric motor of the submersible pump. The pothead connector has a housing having an upper and a lower end. The downhole cable has electrical conductors which are separately covered by insulation layers. The downhole cable extends through the upper end and into the housing, and then is electrically connected to the electric motor through the lower end of the housing. Two insulating blocks are provided in the lower end of the housing for separating electrical conductors in alignment for mating with a connector mounted to the electric motor. A conductor pin is secured to the insulating block and to each of the conductors. An elastic sealing ring is disposed within the housing, intermediately between the two insulating blocks. An epoxy layer are disposed within the upper end of the housing.

Owner:BAKER HUGHES INC

Triple lip fork seal

InactiveUS20060103075A1Separation pointExtended service lifeEngine sealsPiston ringsReciprocating motionLip seal

A triple lip seal for reciprocating members, and especially for an inner cylindrical tube connected to a vehicle wheel and an off-road motorcycle or bicycle. The seal includes an oil side beam generally parallel to the axis of the reciprocating members and having at least two sealing lips for engaging the inner cylindrical tube and wherein the forces applied to the seal are balanced between the two lips to resist flattening of the sealing lips against the shaft and to enhance the service life of the seal. The seal also includes an air side beam having a third sealing lip engaging the inner cylindrical tube.

Owner:CLARK SEALS

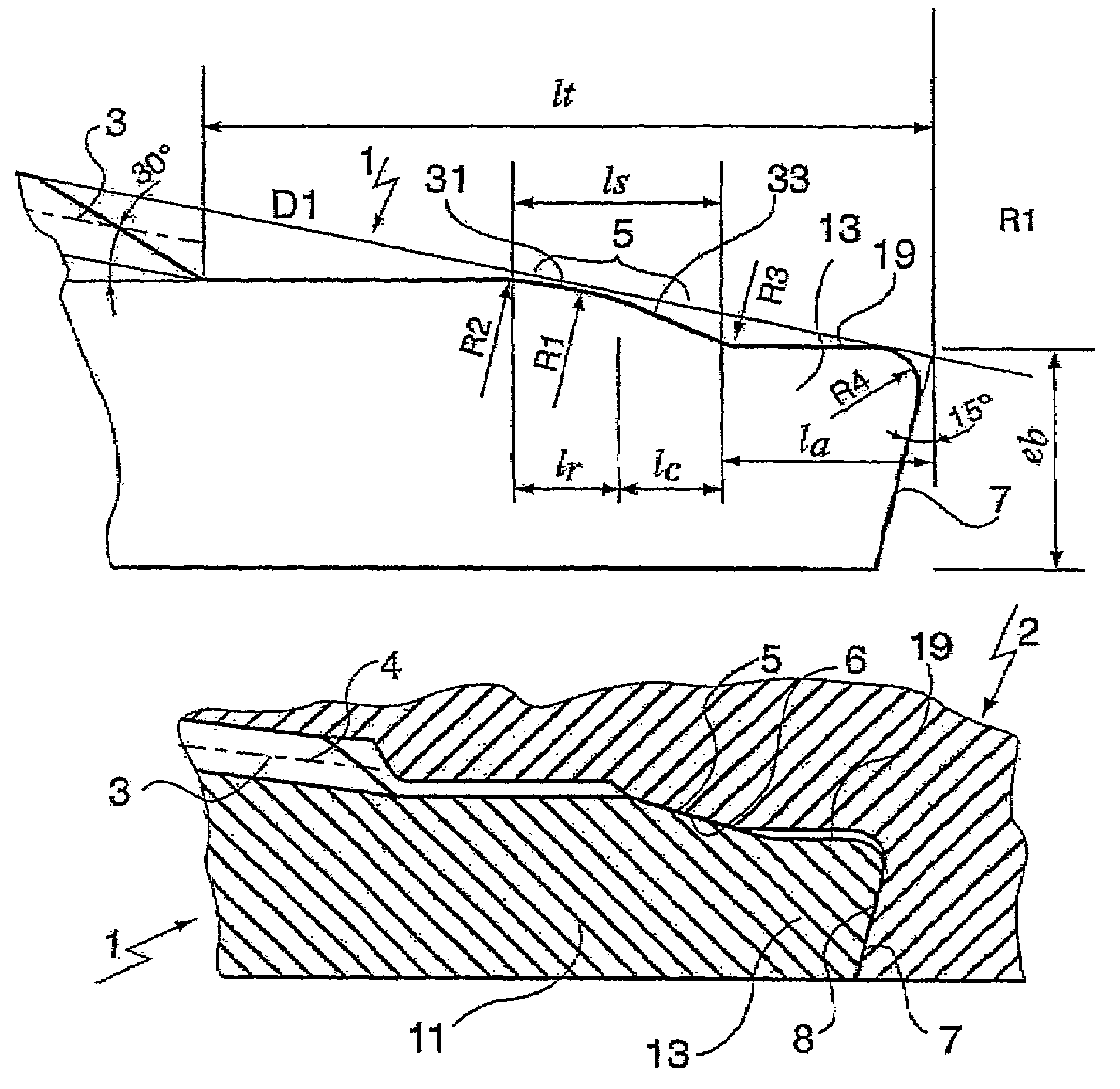

Premium threaded tubular joint comprising at least a threaded element with end lip

InactiveUS7334821B2Reduce axial stiffnessImprove elastic deformation abilityDrilling rodsFluid pressure sealed jointsThreaded pipeAxial compression

A premium threaded tubular connection including, on at least one threaded element, a distal abutment surface at the free end of a threaded element, and a lip sealing surface at a given distance from the threading. The lip includes an appendix that extends the lip towards its free end beyond the lip sealing surface so that the lip has both high radial stiffness and low axial stiffness. This results in enhanced performance as regards the seal of the threaded connection under pressure and / or under tension, and other advantages of precision of real makeup torque, mechanical strength in axial compression, a shock barrier effect, and tolerance in engaging the threaded elements.

Owner:NIPPON STEEL CORP

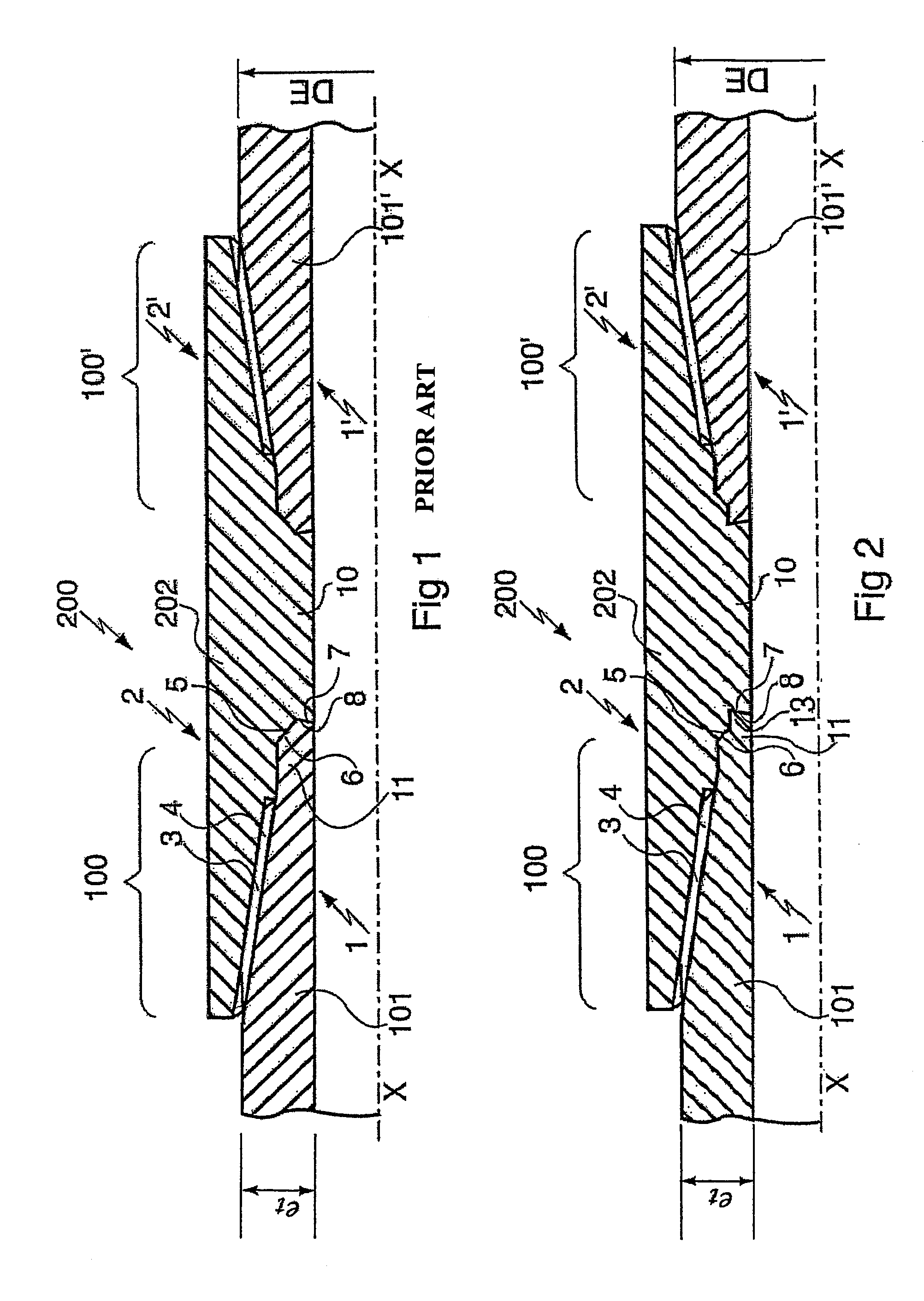

Seal ring having secondary sealing lips

InactiveUS6883804B2Economical and reliableFunctional integrationSleeve/socket jointsEngine sealsMachine partsActuator

Seal for the static or dynamic sealing of joints, machine parts or other components or structures such as may be found in choke, kill, or other auxiliary line strings for marine oil or gas well risers, hydraulic or pneumatic cylinders or other actuators. The seal may have a U-cup or solid geometry profile including a secondary sealing lip on both the inner and outer diameter thereof which functions as a wiper for the exclusion of outside contaminants, such as seawater, from joint sealed.

Owner:PARKER INTANGIBLES LLC

Marine shaft seal with lip seal, bearing and gasket

A sealing device for use with a drive shaft of a water vessel. The sealing device comprises a housing for a seal and bearing, a compression ring, a lip seal flange attachment and a diaphragm for tracking the movement of the shaft. The diaphragm is made of a resilient, flexible material and is operatively connected to the seal housing. In operation, the diaphragm tracks the motion of the drive shaft so that the drive shaft may move freely in the hull of the vessel. The diaphragm allows the rigid seal housing to also move in response to any axial, lateral or circular-axial (wobble-like) movement of the shaft so that a constant seal around the shaft is provided.

Owner:DURAMAX MARINE

Radial lip seal

A radial lip seal including an annular support with a radially extending portion having an inner periphery. An annular seal lip formed of elastomeric material such as polytetrafluoroethylene is connected to the inner periphery. The lip has an inner side adapted to seal a circumferential surface of a shaft and an outer side. The outer side of the lip has a plurality of grooves or protrusions to vary the diameter of the lip. The varied diameter creates a substantial leak between the outer side of the lip and the circumferential surface. The leak created is sufficient to be detected by a low-pressure air test.

Owner:GM GLOBAL TECH OPERATIONS LLC +1

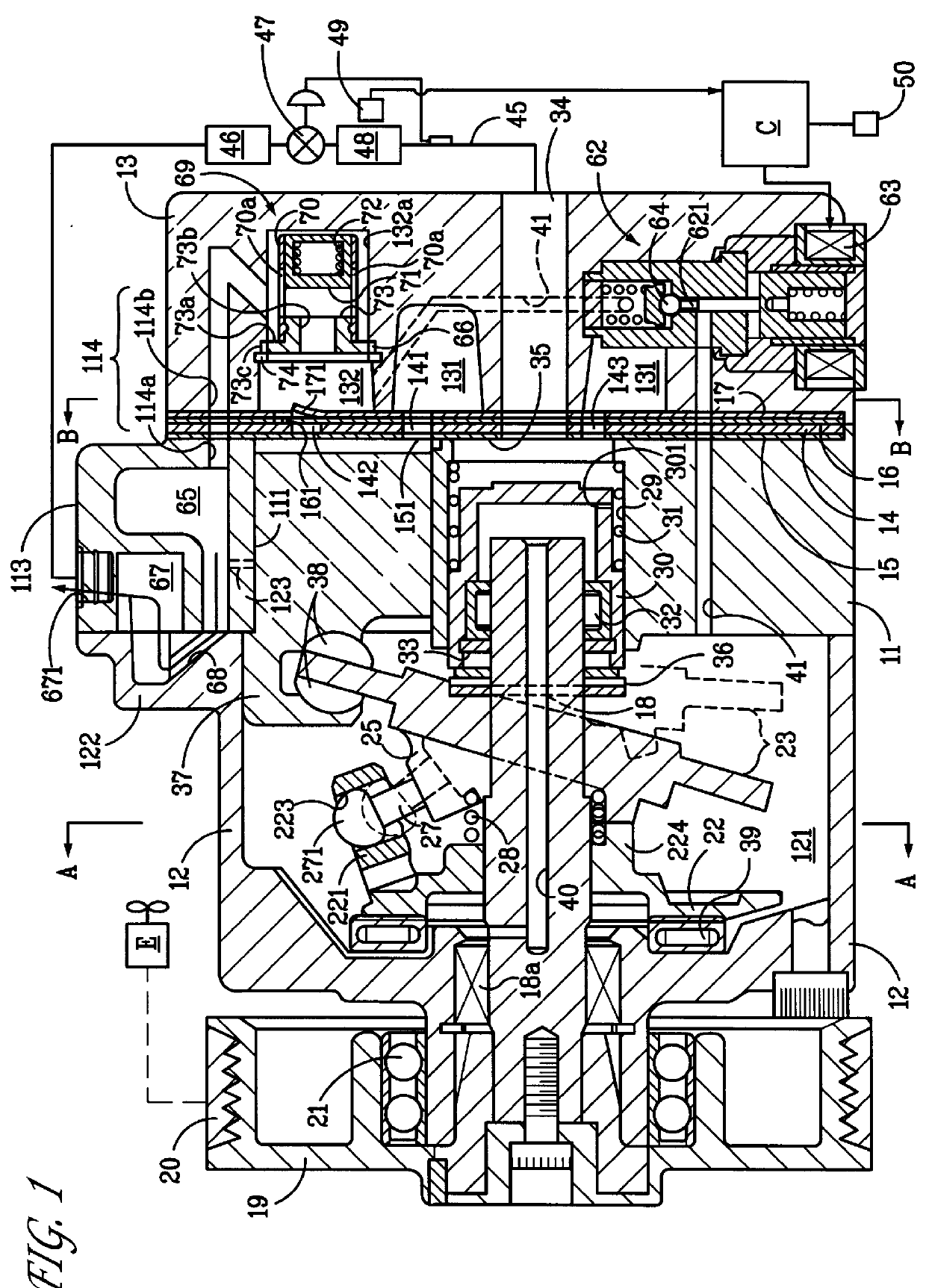

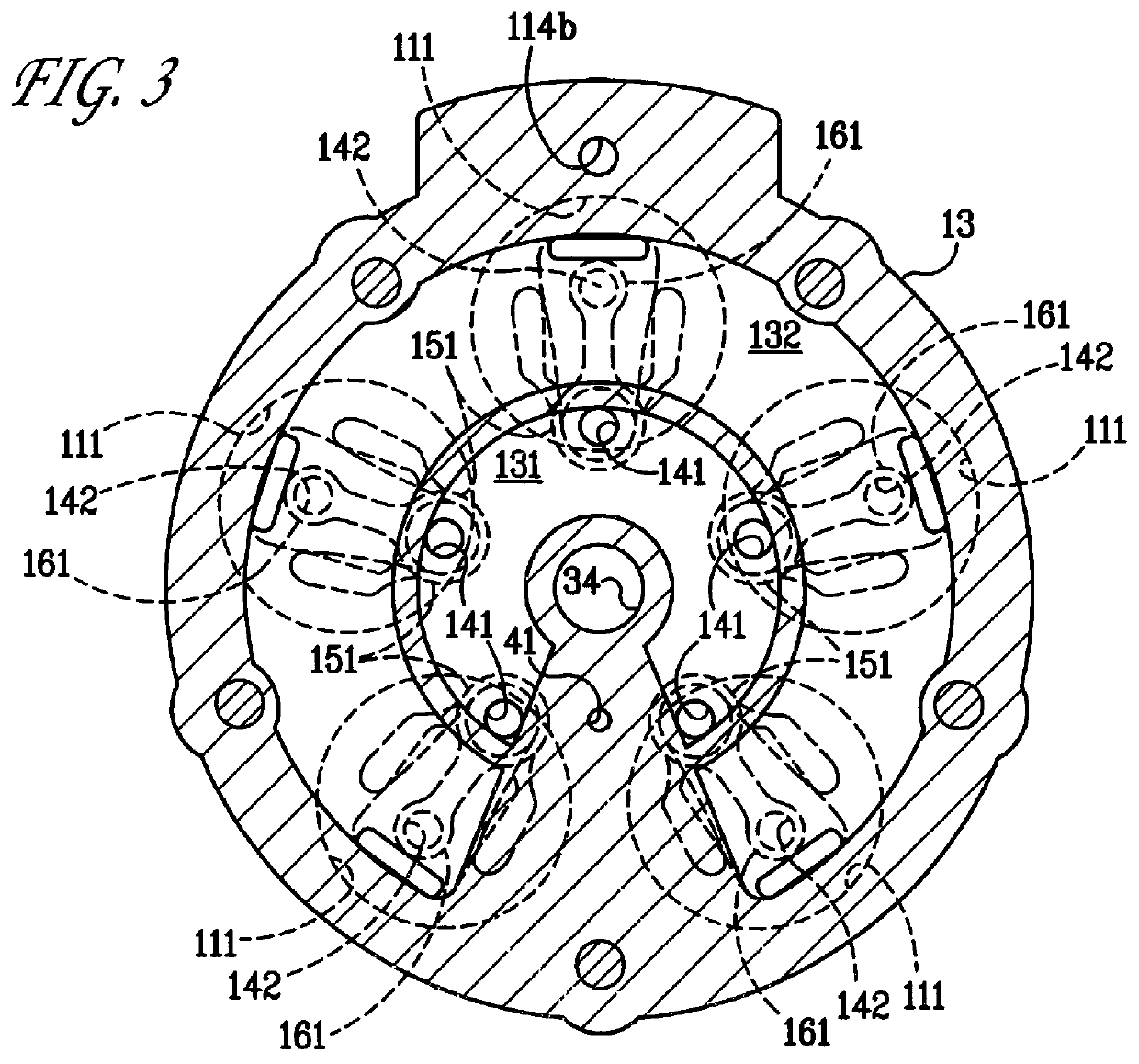

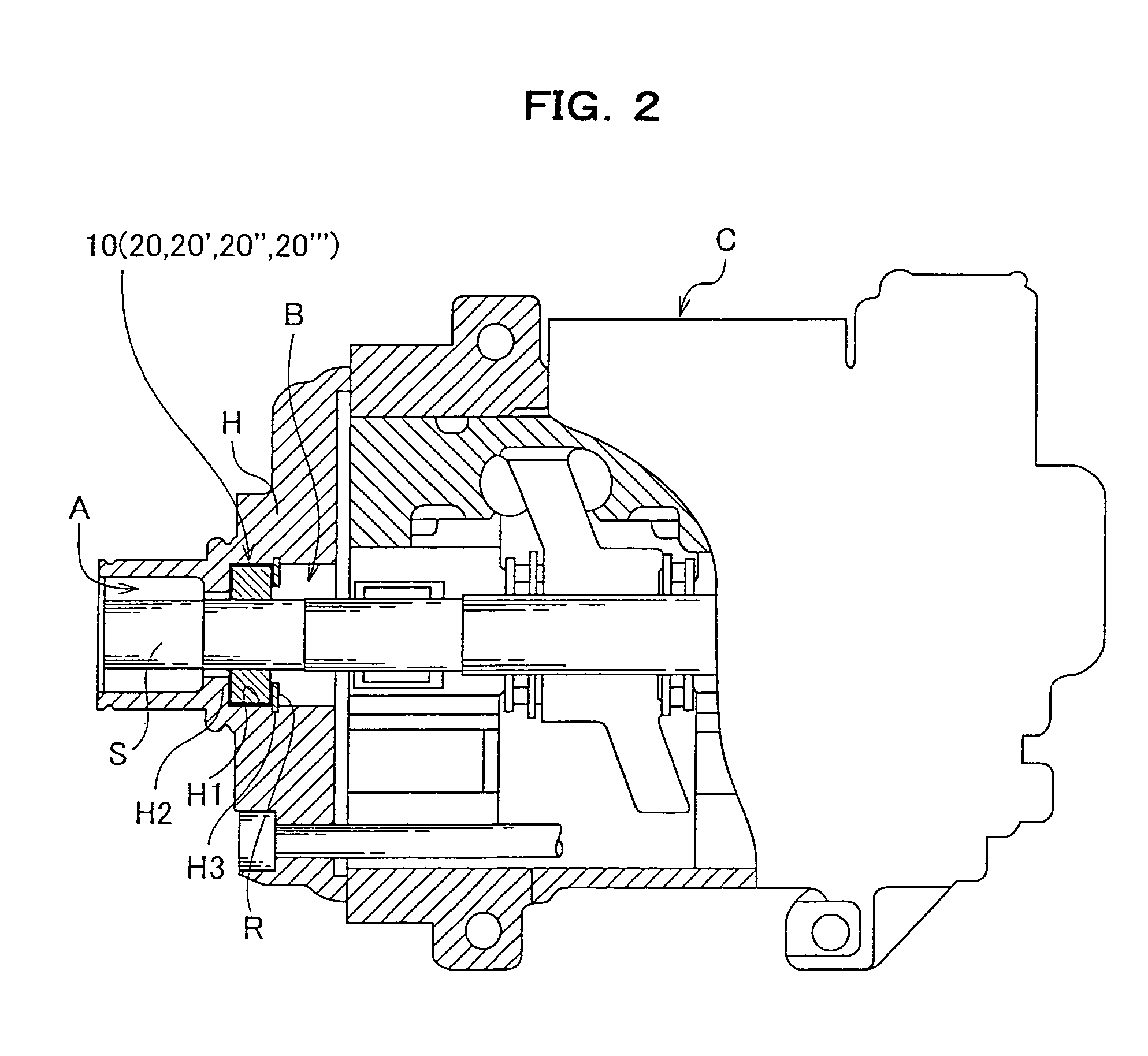

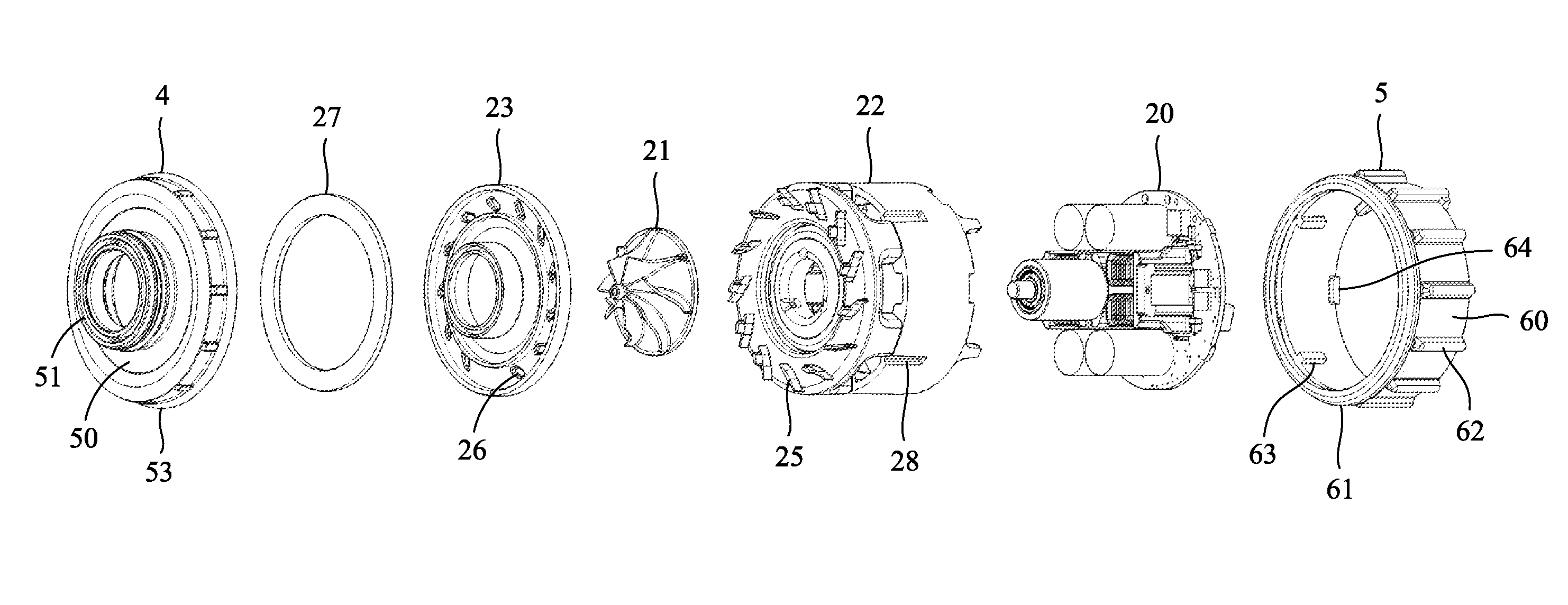

Pressure pulsations reducing compressor

InactiveUS6149397ASimplification of overall constructionPositive displacement pump componentsPump controlInternal pressureCrankcase

In a variable displacement compressor of the invention, cylinder bores (111) and a crankcase (121) are formed in a housing, single-ended pistons (37) are fitted in the cylinder bores (111), and a cam plate (23) is provided in the crankcase (121). The displacement capacity of the compressor is varied by controlling the angle of inclination of the cam plate (23) in accordance with the difference between the internal pressure of the crankcase (121) and an suction pressure present on both sides of each single-ended piston (37). A dampening or muffler chamber (65) is provided downstream of an output channel (114) through which a refrigerant gas discharged from the cylinder bores (111) passes. A check valve (69) which opens and closes in accordance with a pressure difference between upstream and downstream sides of the output channel (114) is provided in the output channel (114), upstream of the muffler chamber (65). The present invention reduces the effects of pressure pulsations caused by the compression motion of the compressor and caused by the valve body of the open / close device hunting, has no bad effects on the external refrigerant circuit connected to the compressor, and increases the reliability of the lip seal.

Owner:TOYOTA IND CORP

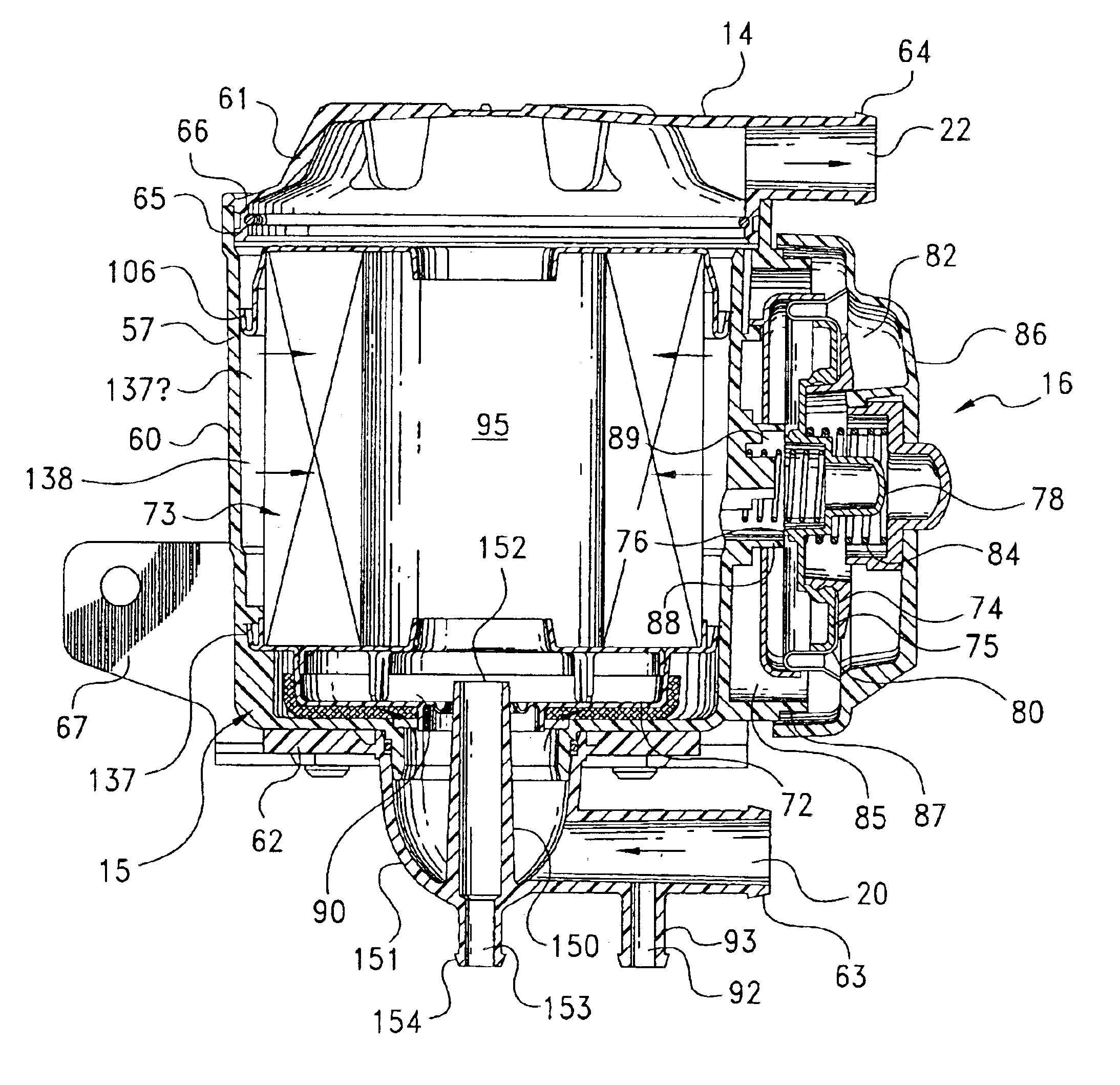

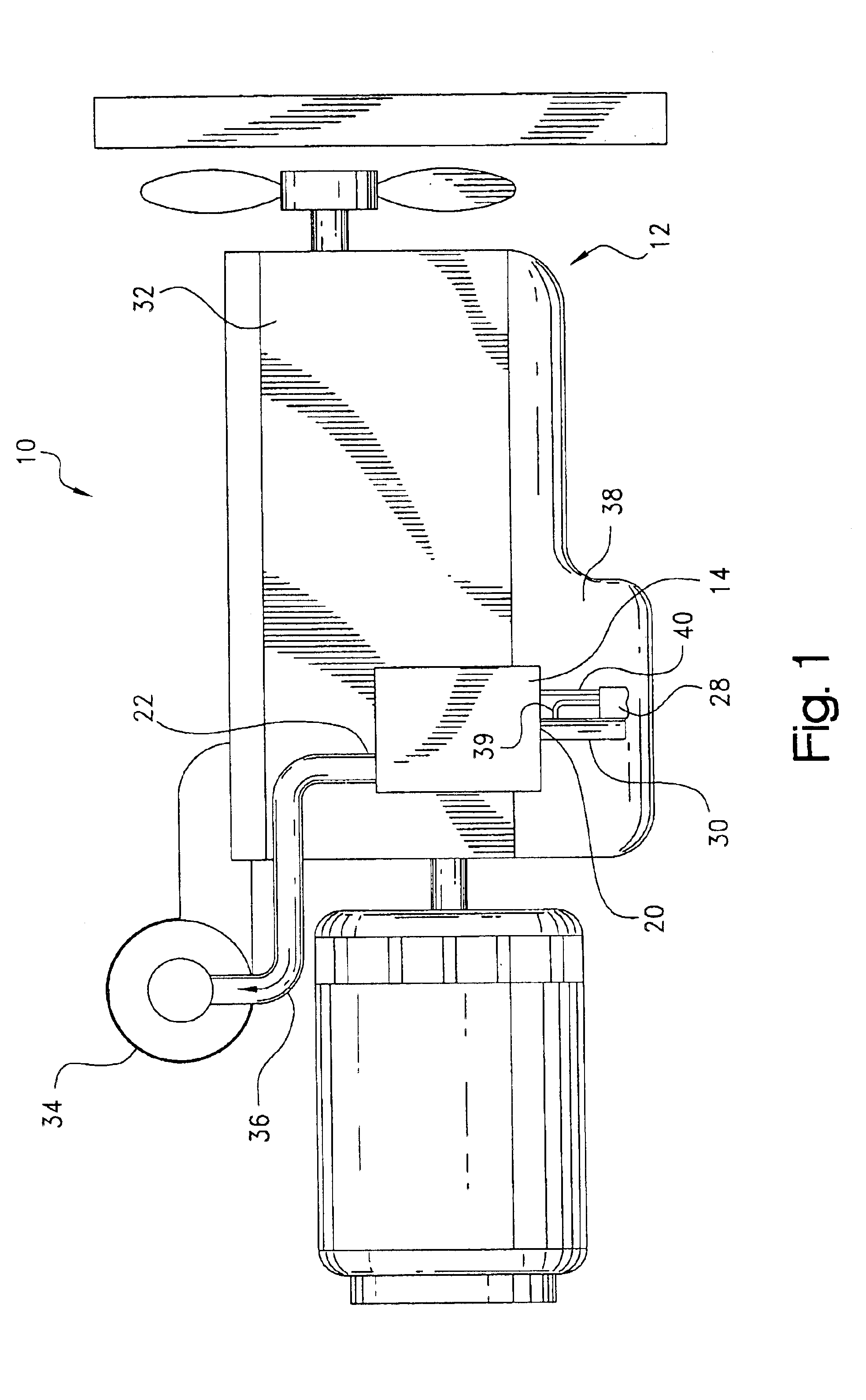

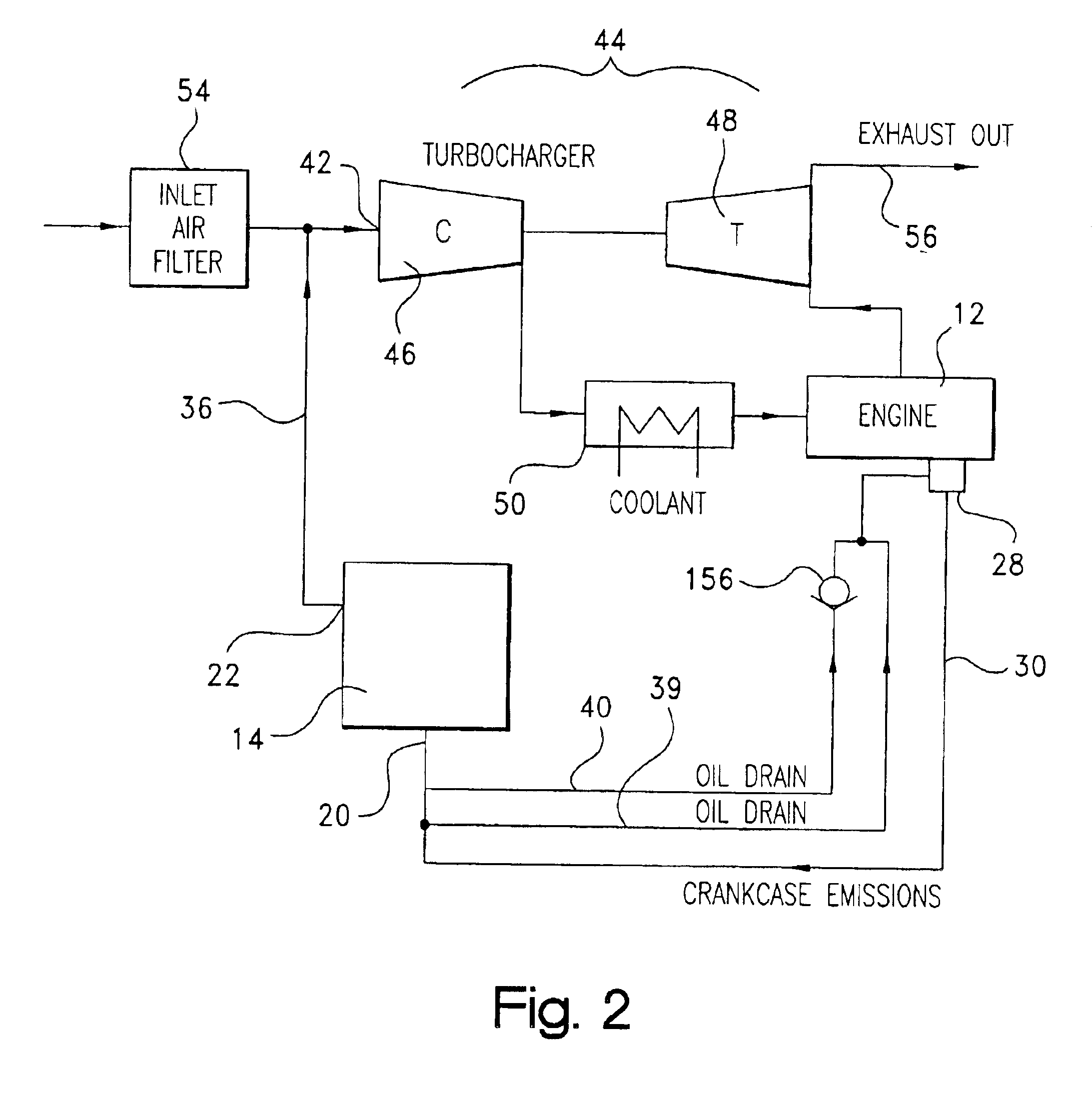

Filter element and assembly with continuous drain

ActiveUS6907869B2Simple and inexpensive to manufactureEasy to disassembleLiquid degasificationNon-fuel substance addition to fuelTurbochargerFilter media

A closed crankcase emission control assembly for an internal combustion engine includes a filter assembly comprising a housing and a replaceable filter element. The filter element includes a ring of filter media; a first annular end cap sealed to one end of the media ring; a second end cap sealed to another end of the media ring; a cup-shaped valve pan fixed to the second end cap and which together therewith defines a sump container; and an opening with a lip seal in the valve pan which closely receives a standpipe from the housing to allow continuous drainage of oil collected by the filter element. The filter housing includes an inlet port to receive blow-by gasses from the engine crankcase, and an outlet port to provide the substantially oil and particulate free gasses to an induction system (e.g. a turbocharger) and back to the engine crankcase.

Owner:PARKER INTANGIBLES LLC

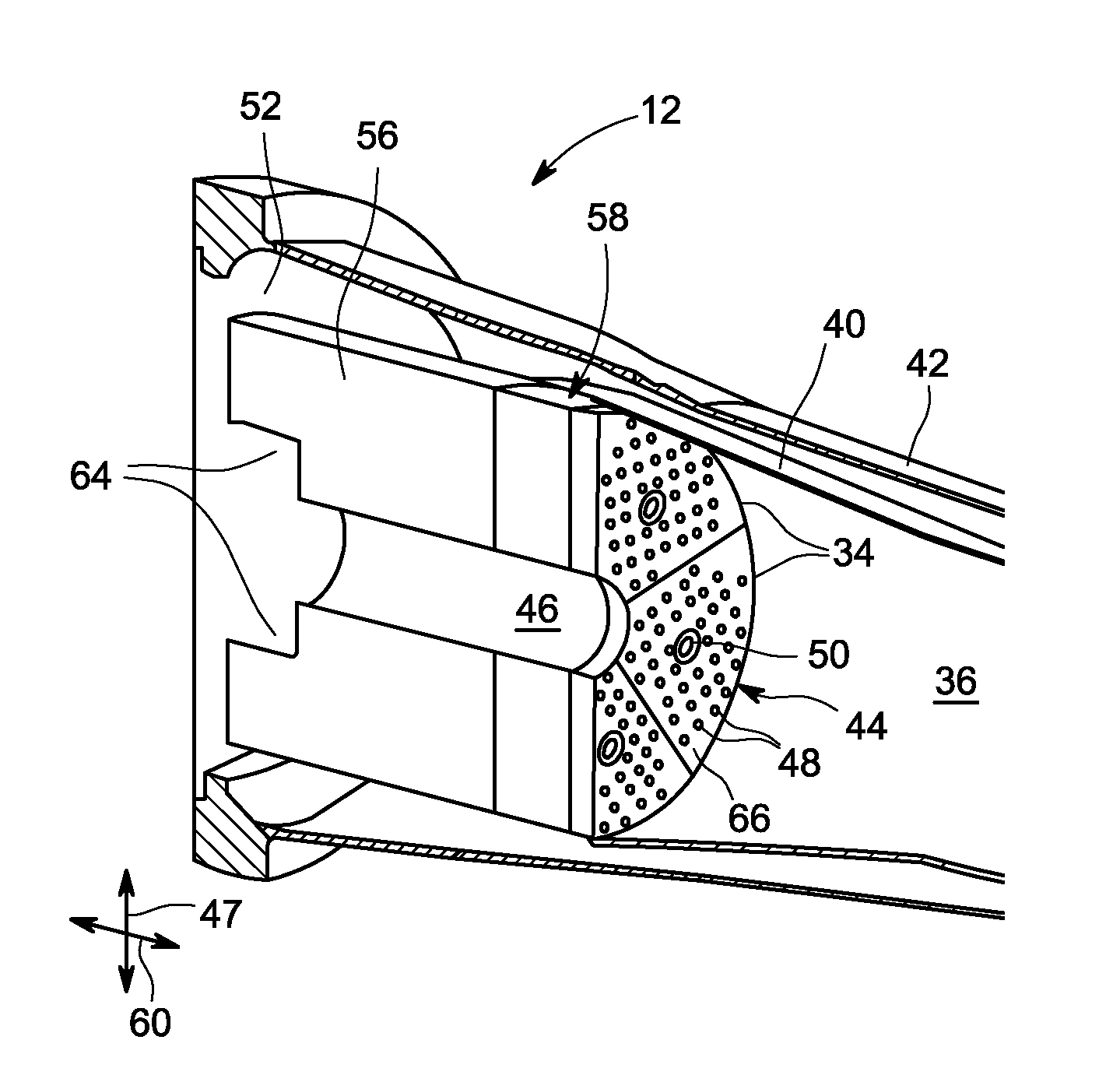

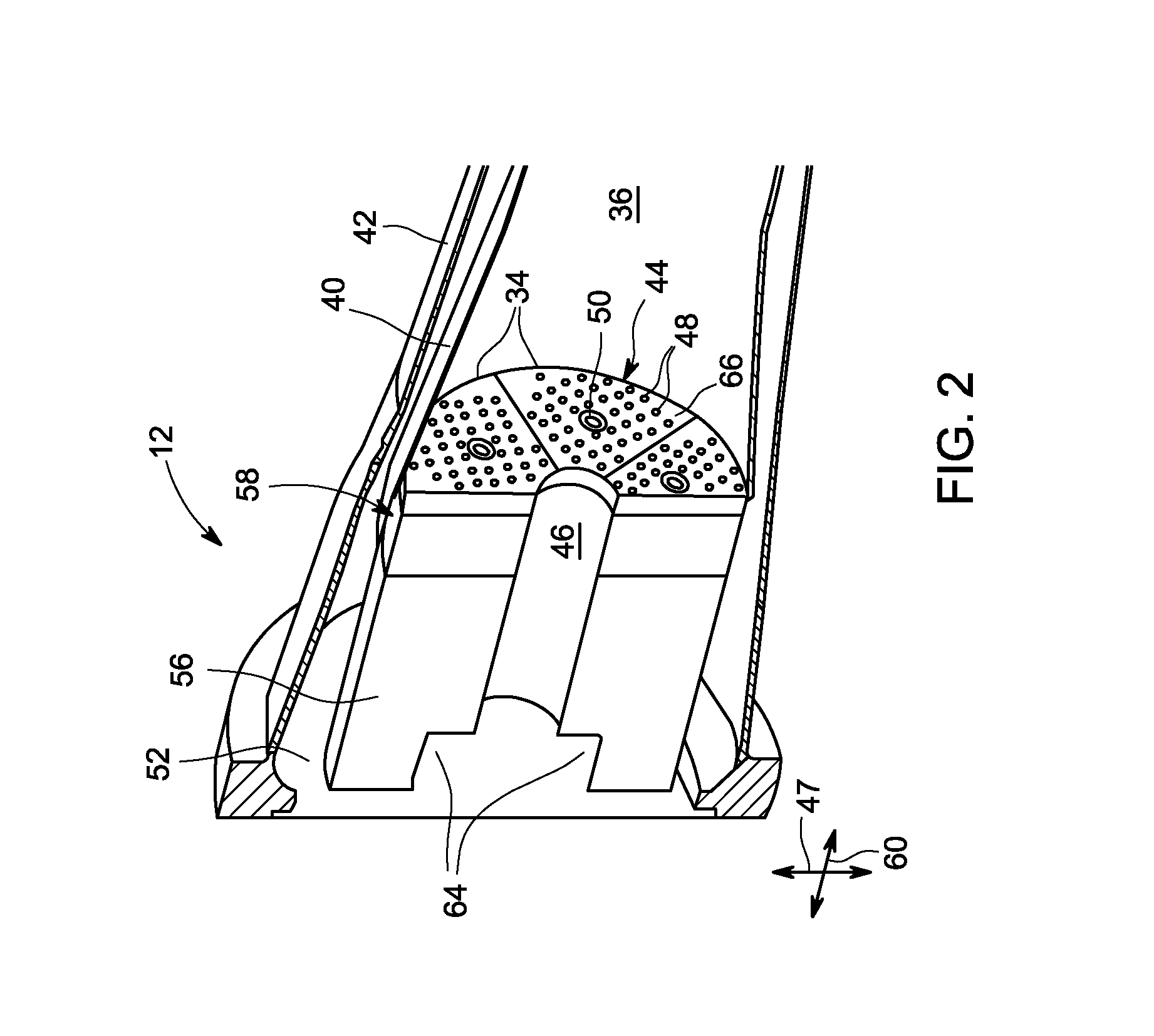

System for injecting fuel in a gas turbine combustor

ActiveUS20150076251A1Convenient inspectionPromote repairContinuous combustion chamberTurbine/propulsion fuel supply systemsCombustion systemCombustion chamber

A combustion system uses a fuel nozzle with an inner wall having a fuel inlet in fluid communication with a fuel outlet in a fuel cartridge. The inner wall defines a mounting location for inserting the fuel cartridge. A pair of annular lip seals around the cartridge outer wall on both sides of the fuel outlet seals the fuel passage between the fuel inlet and the fuel outlet.

Owner:GENERAL ELECTRIC CO

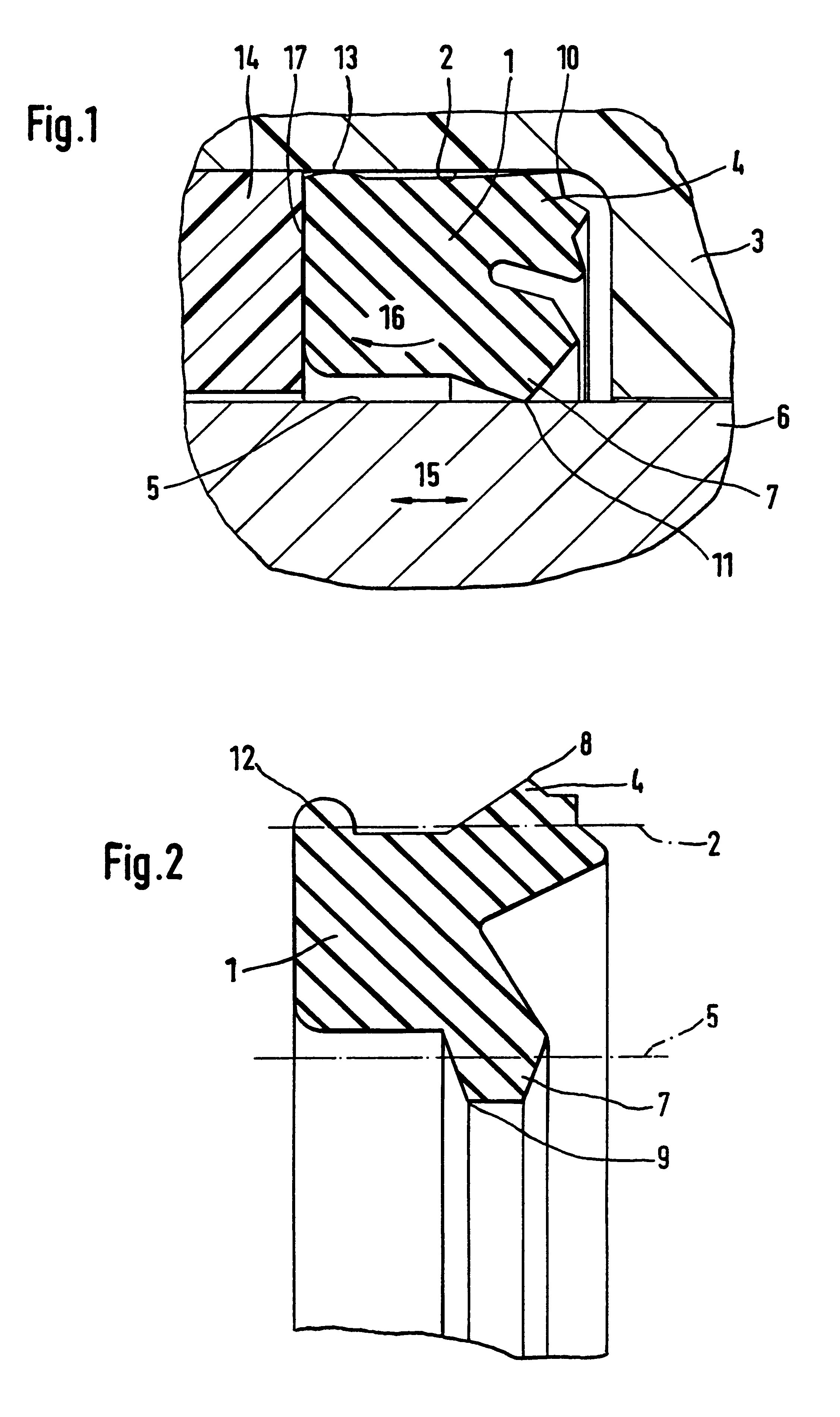

Lip seal for sealing cylindrical surfaces

A lip seal for sealing cylindrical surfaces of a cylindrical housing and a axially movable piston within the housing includes an annularly arranged supporting bead on its outer diameter to improve its tilting behavior around a central axis running annularly through the center of the lip seal. A first sealing lip of the lip seal forms a seal on the cylindrical surface of the housing and a second sealing lip forms a seal on the cylindrical surface of the piston. The supporting bead, in the installed state, forms a contact seal in the cylindrical part of the housing. Together with the contact seals of the first sealing lip and the second sealing lip, the supporting bead lends stability against tilting to the lip seal. Advantageously, a good sealing quality of the lip seal is maintained during an increased number of load changes.

Owner:MANNESMANN SACHS AG

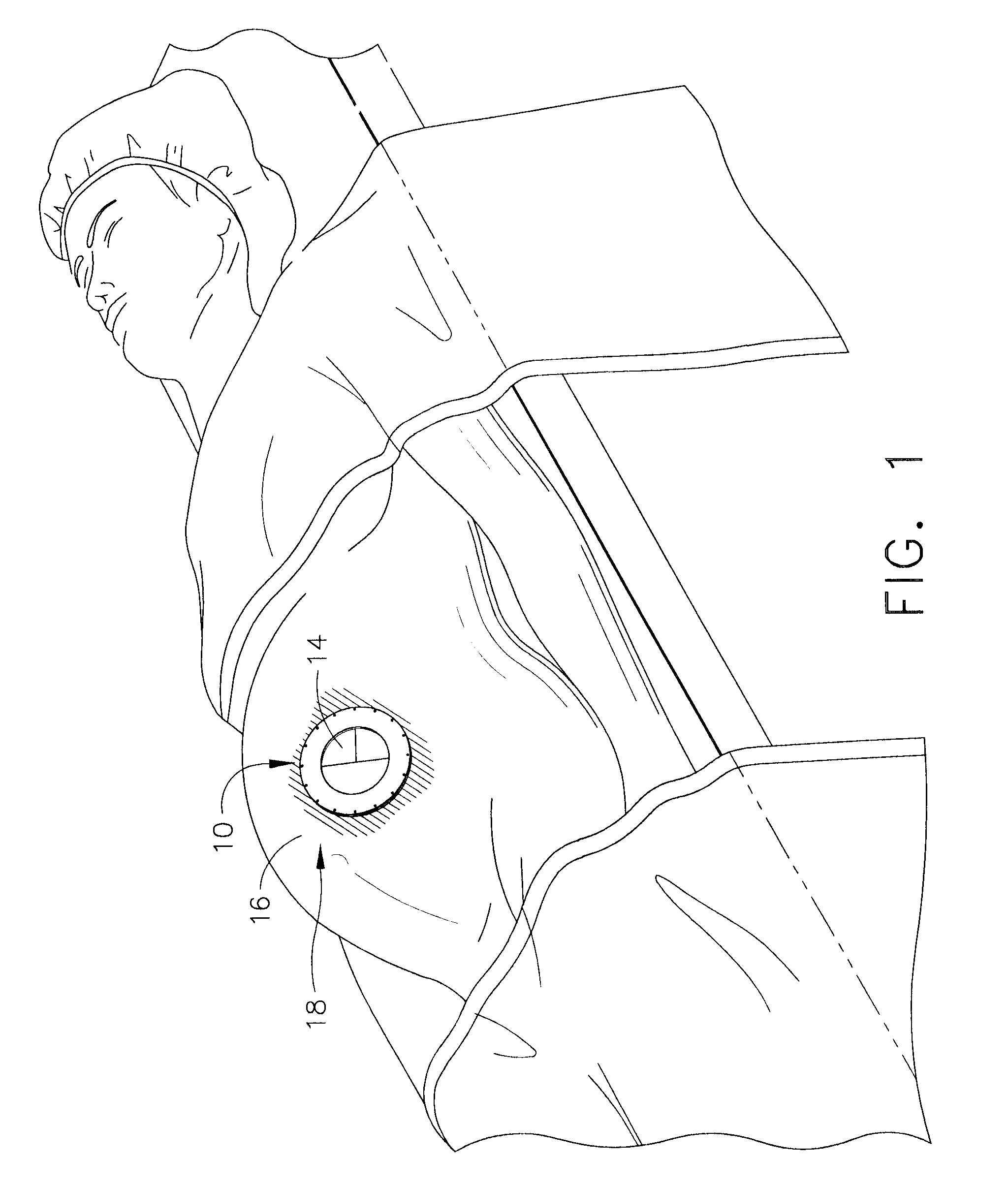

Sleep apnea prevention assembly

InactiveUS20130263865A1Avoid occlusionEasy to keepSnoring preventionNon-surgical orthopedic devicesOral applianceLip seal

A sleep apnea prevention assembly that includes an oral appliance that includes upper and lower members that are hingedly attached to one another and movable between an open position and a closed position. The upper and lower members cooperate to define a central opening when the oral appliance is in the closed position. A flexible lip seal extends between the upper and lower members and the assembly includes a main pipe assembly that comprises a main pipe and a mouth air vent. The main pipe is secured to one of the upper or lower members and extends through the central opening. The mouth air vent has a breathing opening at a proximal end of the main pipe assembly. The main pipe assembly includes an elbow receiver opening at a distal end thereof, and a mouth air path is defined between the breathing opening and the elbow receiver opening.

Owner:OMIDI JULIAN

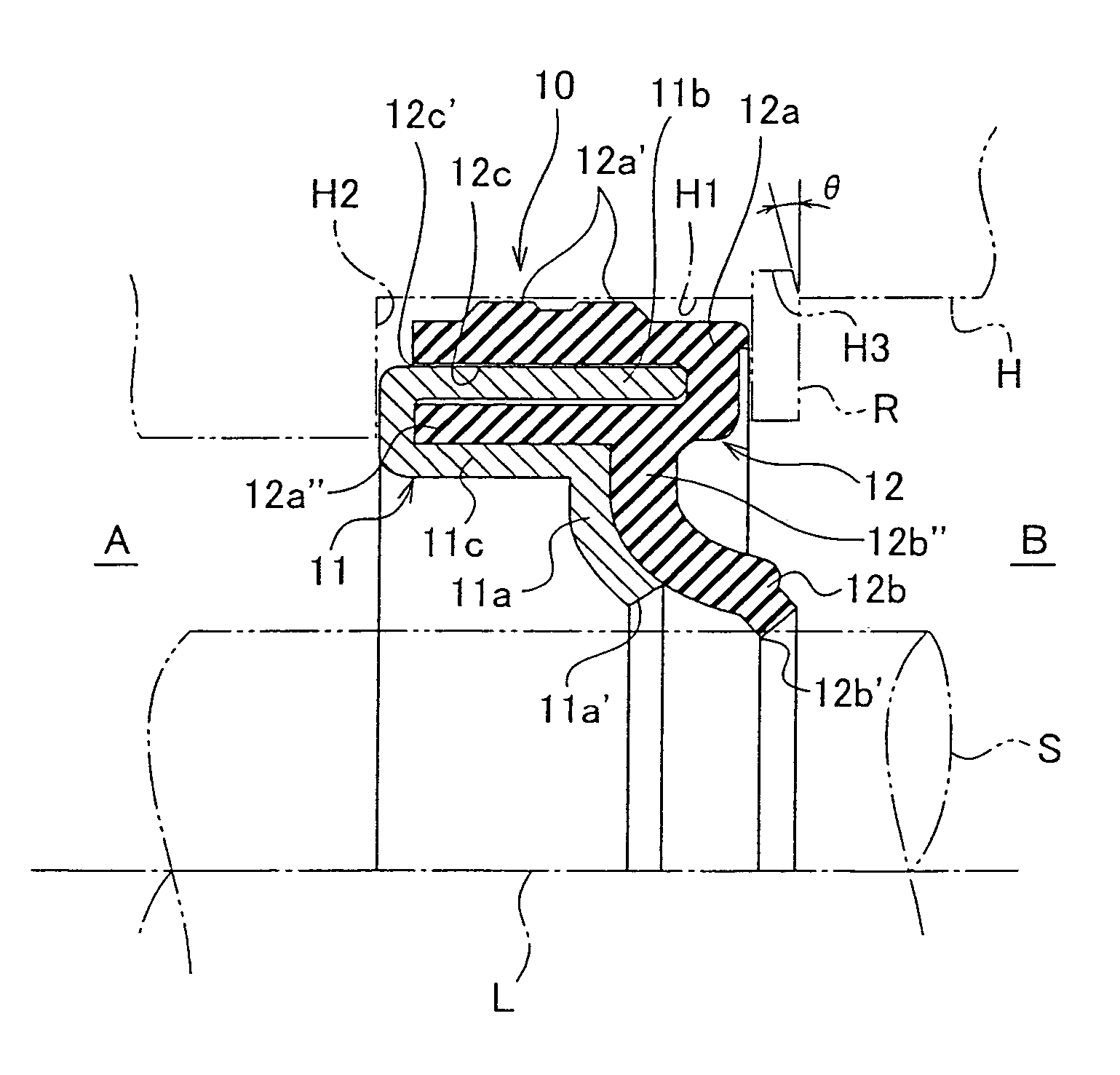

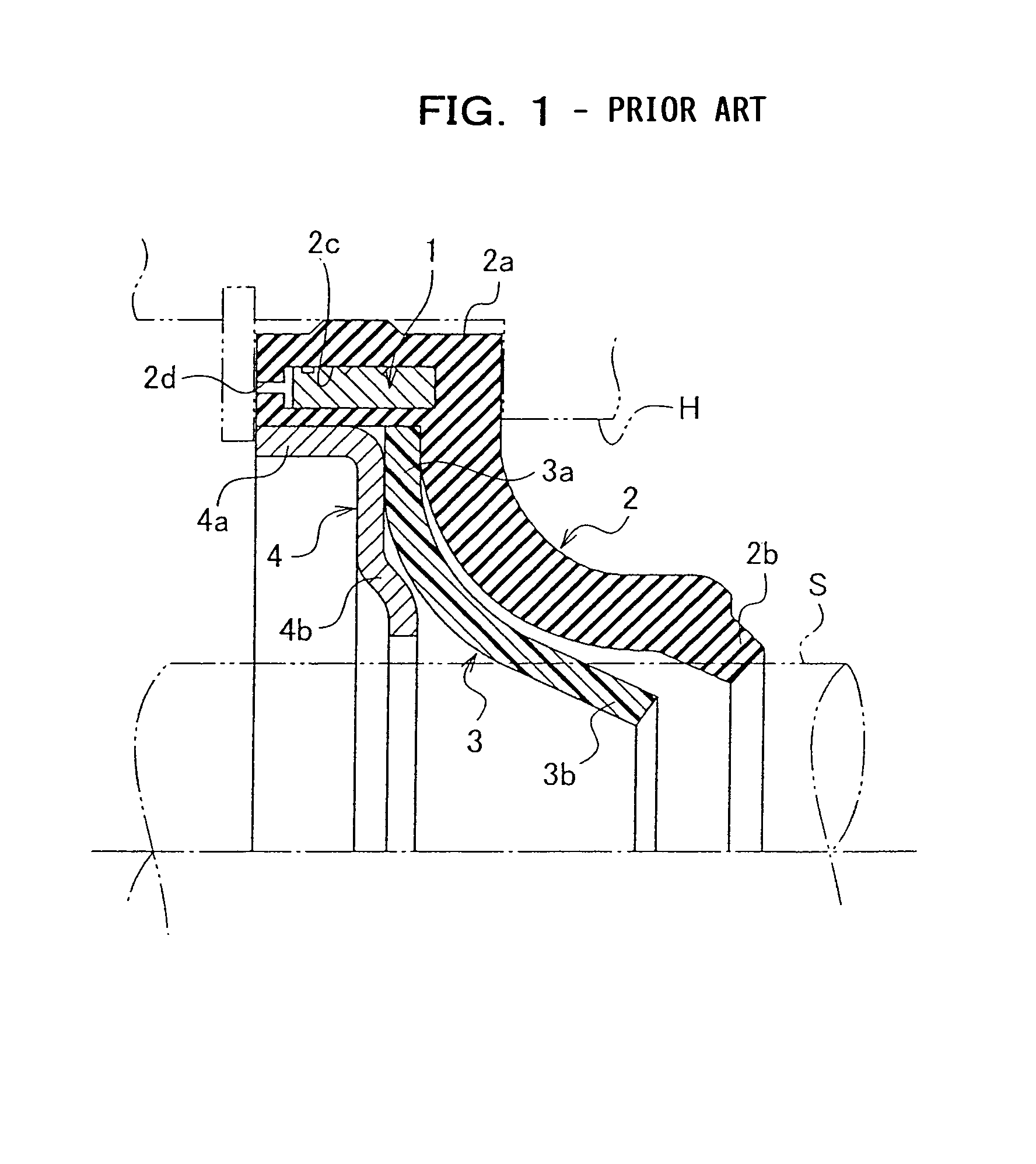

Lip-type seal

Owner:EAGLE INDS

Vibration isolation mount

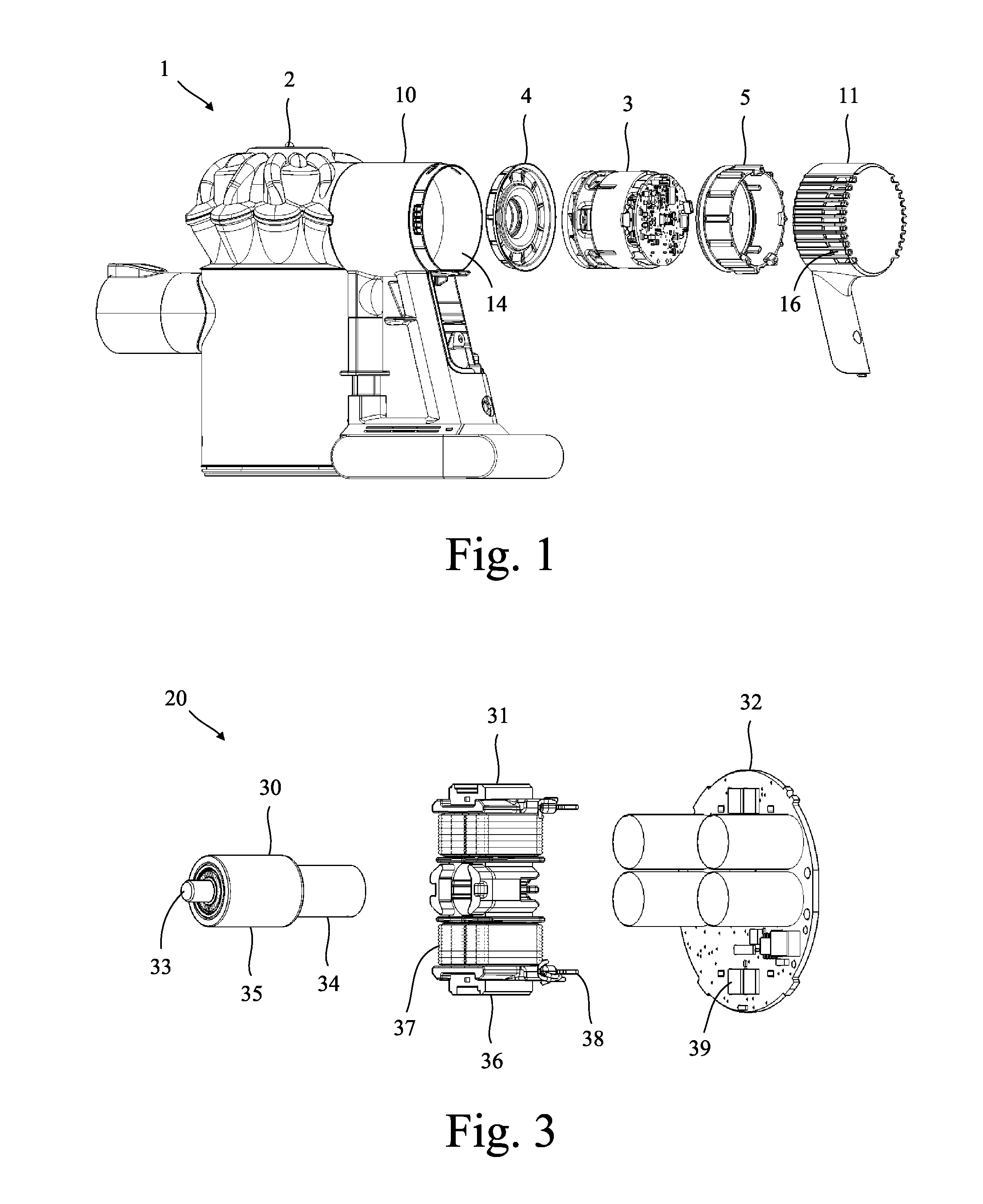

ActiveUS20140328670A1Compact compressorReduce traffic lossPump componentsMotor fan assembly mountingEngineeringVibration isolation

A vibration isolation mount for a compressor that is formed of an elastomeric material and includes a sleeve, tapered studs or axial ribs spaced around the sleeve, and a lip seal extending around the sleeve. The mount is intended to be located between a compressor and a housing. The studs or ribs then deform to isolate the housing from radial vibration of the compressor, and the lip seal creates an annular seal between the housing and the compressor.

Owner:DYSON TECH LTD

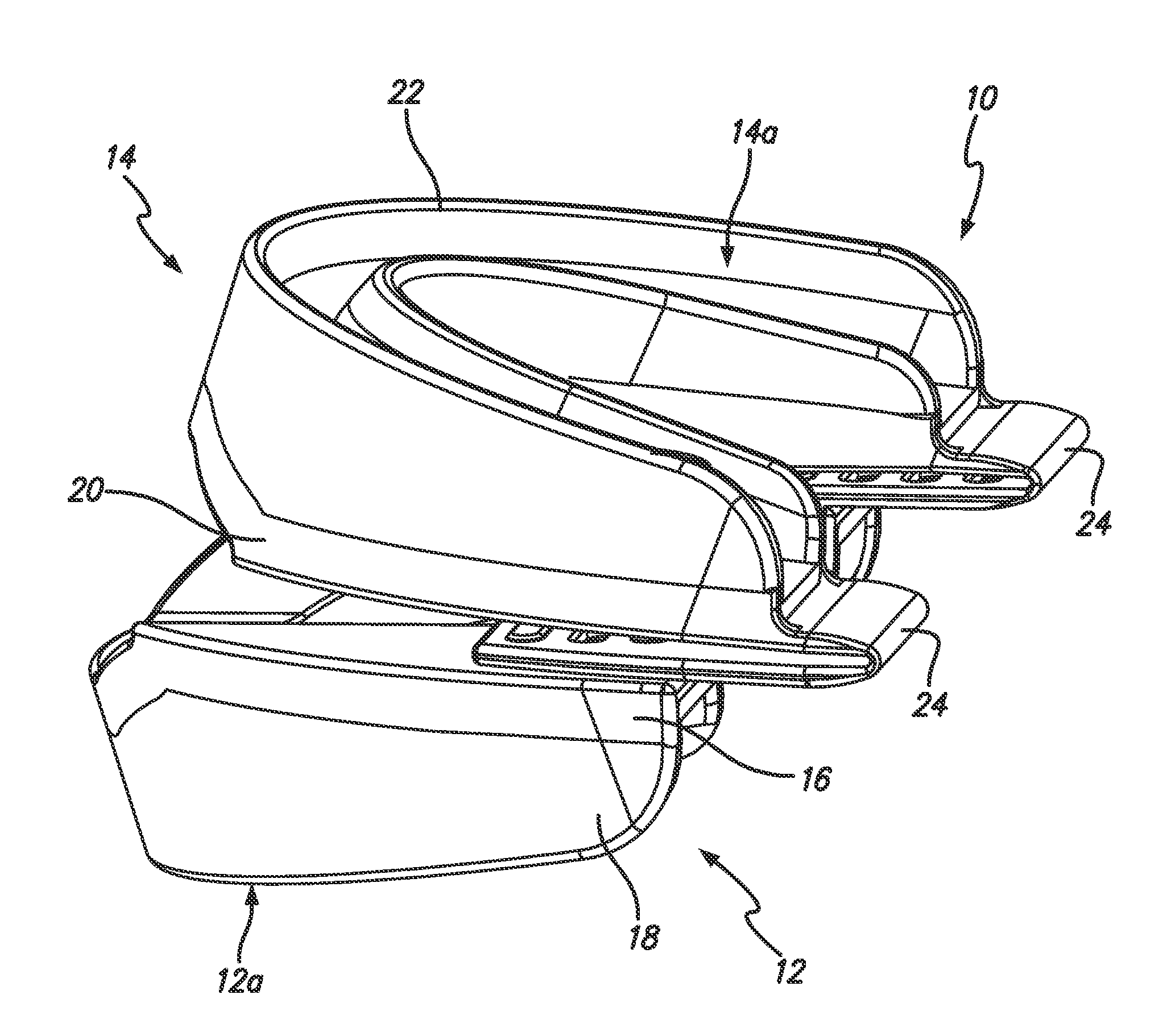

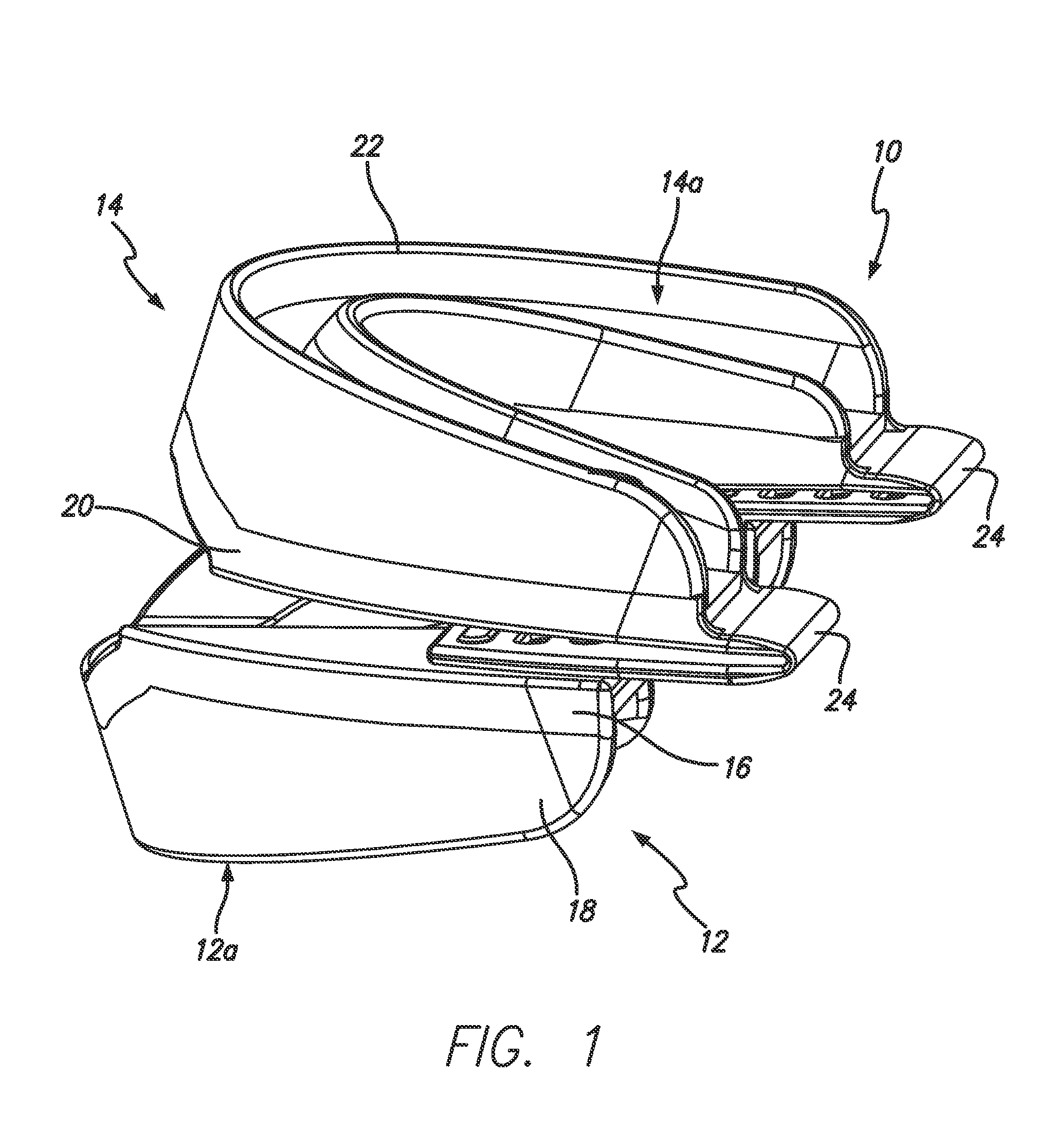

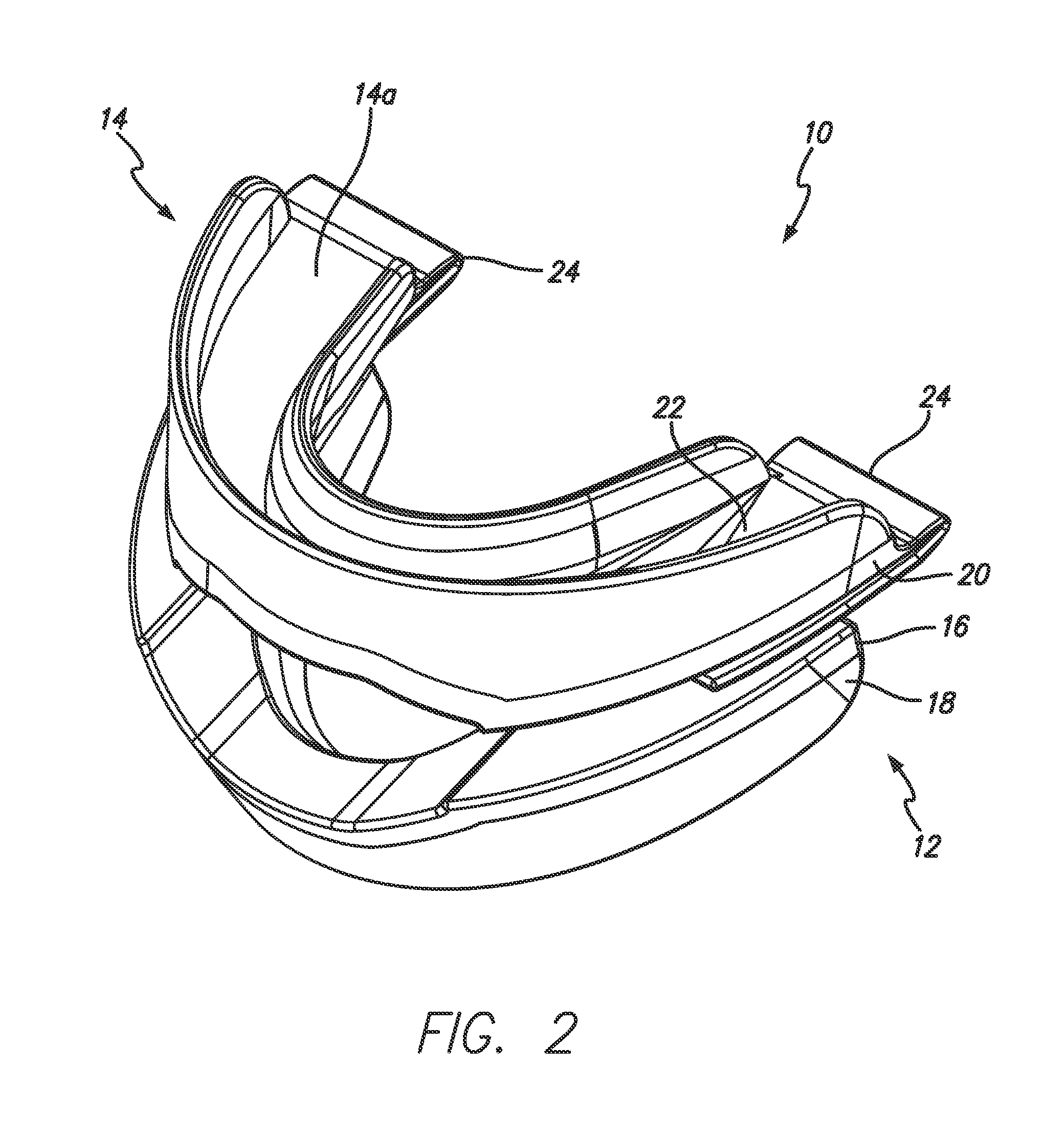

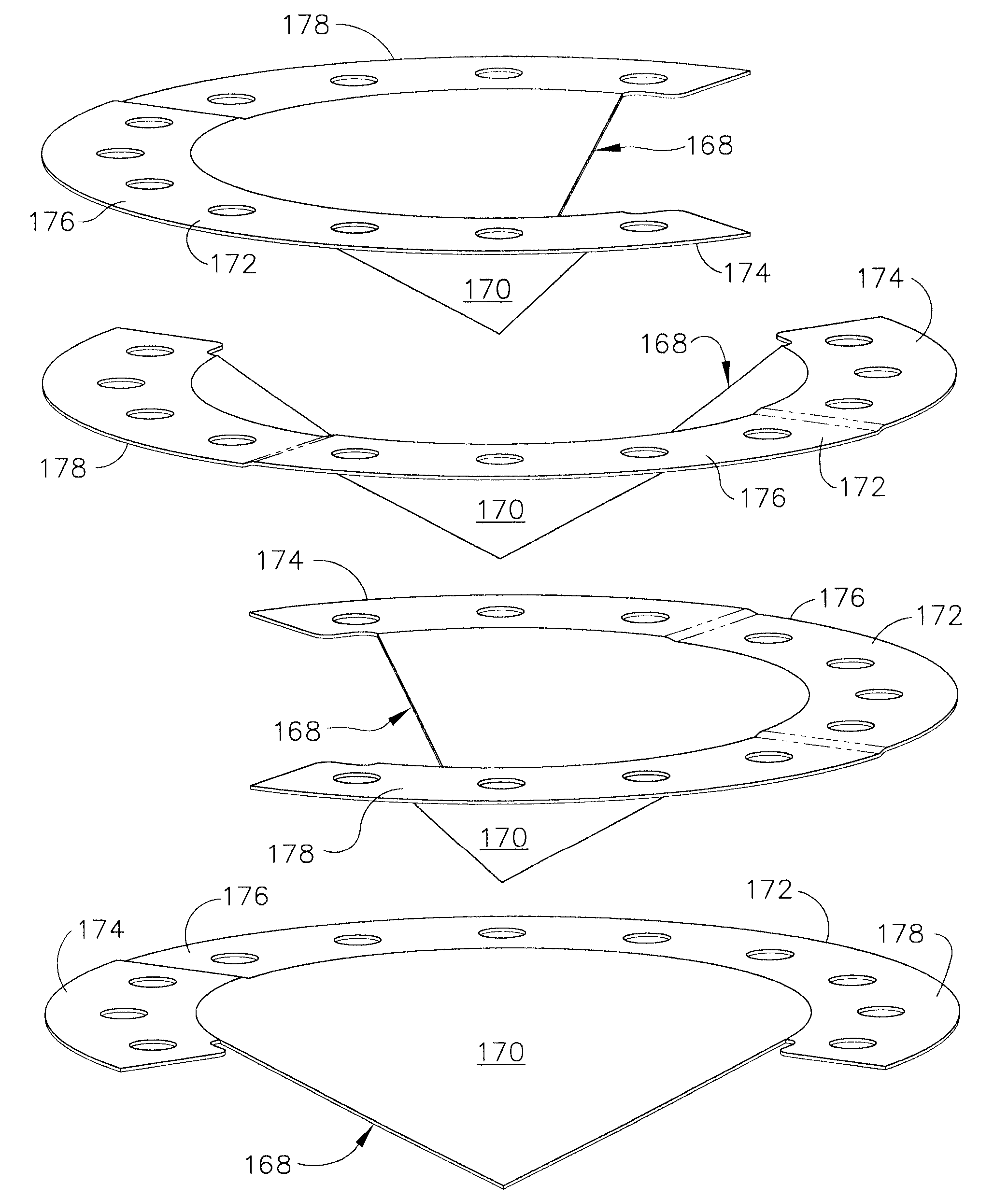

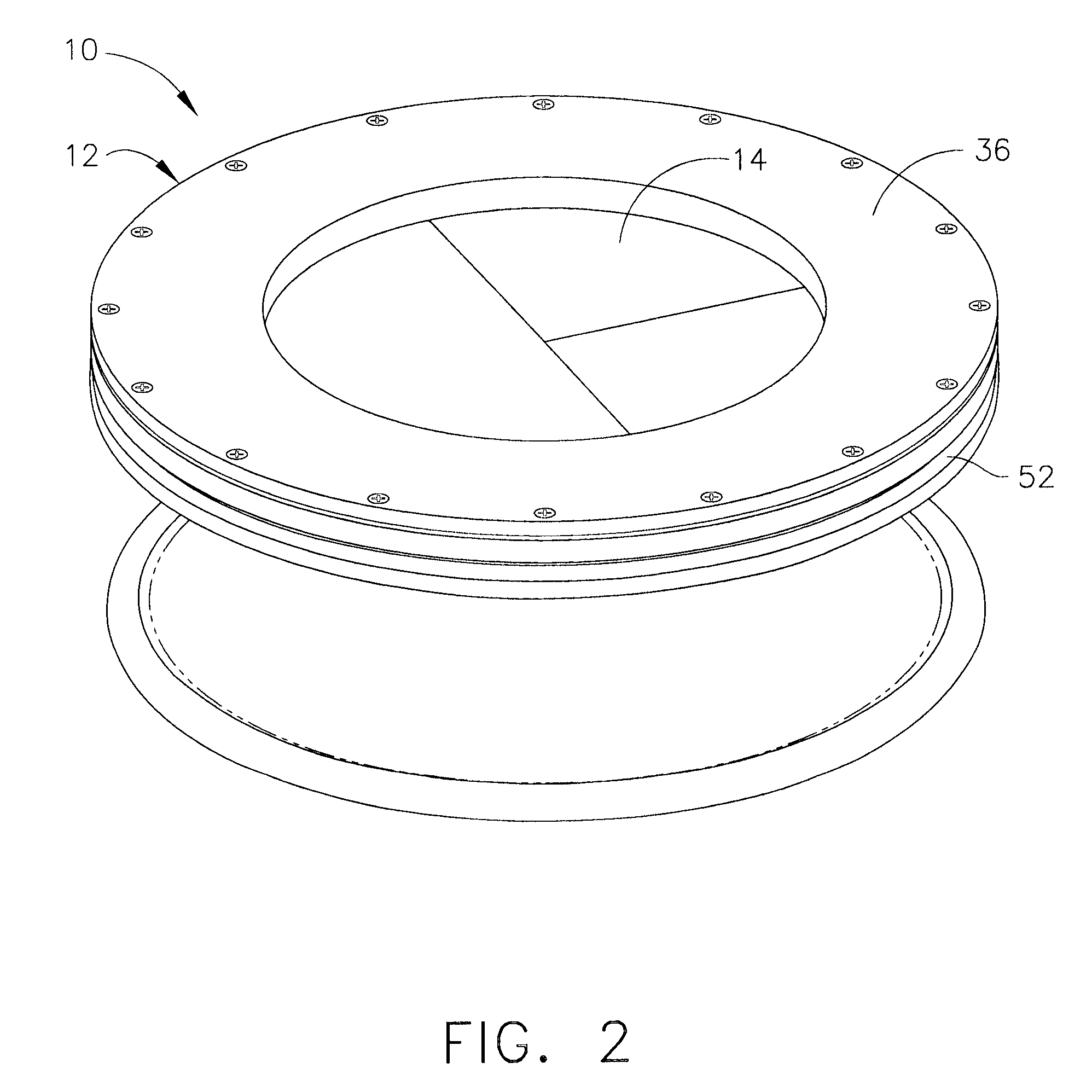

Handoscopy Interwoven Layered Seal Laparoscopic Disk

A laparoscopic disk assembly, which includes an interwoven gasket seal, either flat or conical, comprised of four gasket sections, forms a seal without anything inserted or in the presence of a laparoscopic instrument or surgeon's hand, approximating an opening of a single through hole of a lip seal providing the same sealing as a lip seal. By breaking the seal through hole into multiple pieces, the direction and amount of strain applied to any section is less than the strain applied by the simple change in diameter. The layers form contact zones with the inserted probe or hand. The sum of the array of contact zones provides contact around the full diameter of the inserted tool or hand. Additionally, the hoop stress of the seal is reduced, thereby reducing the drag force on the instrument or the hand and wrist of the doctor.

Owner:CILAG GMBH INT

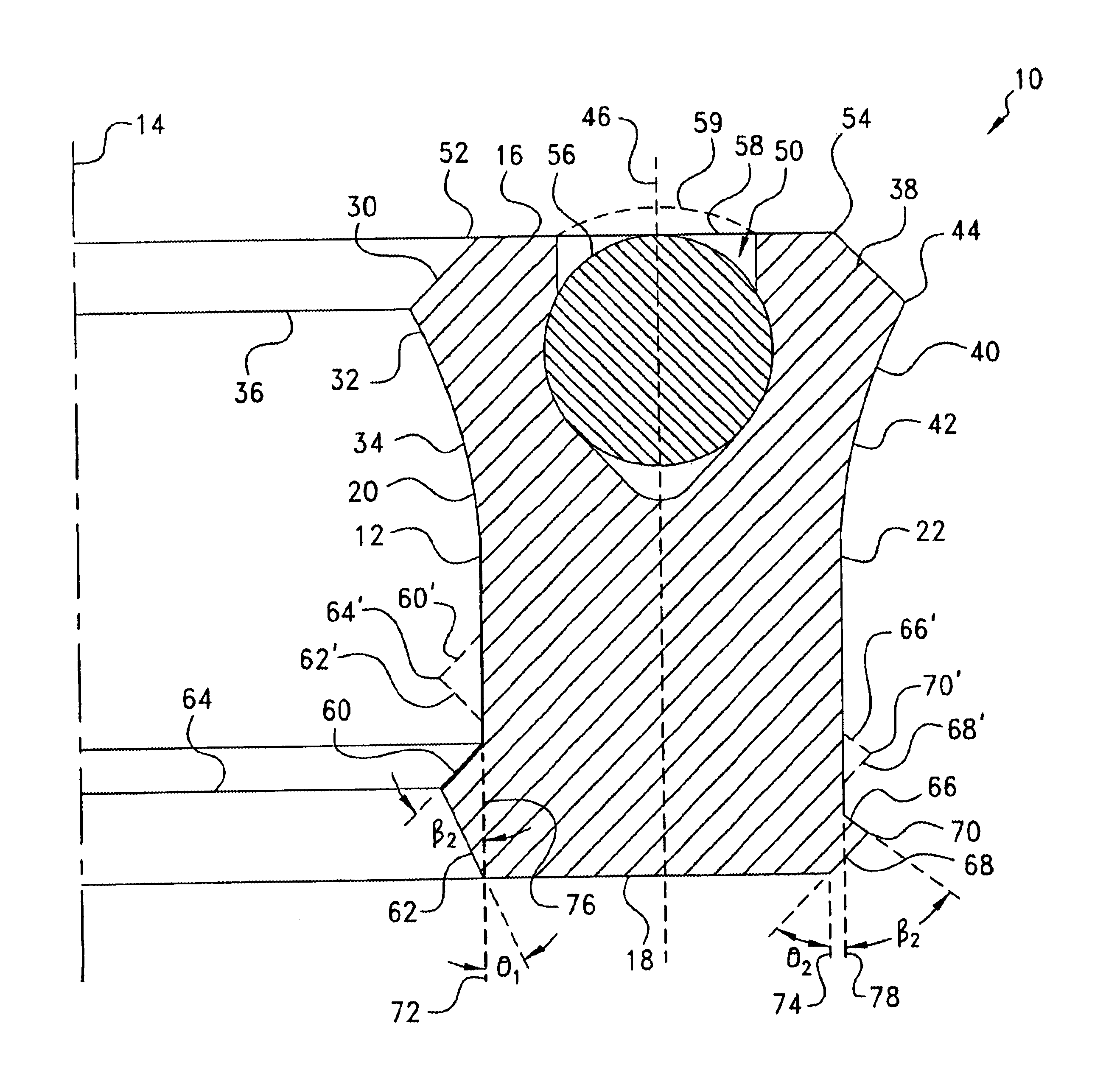

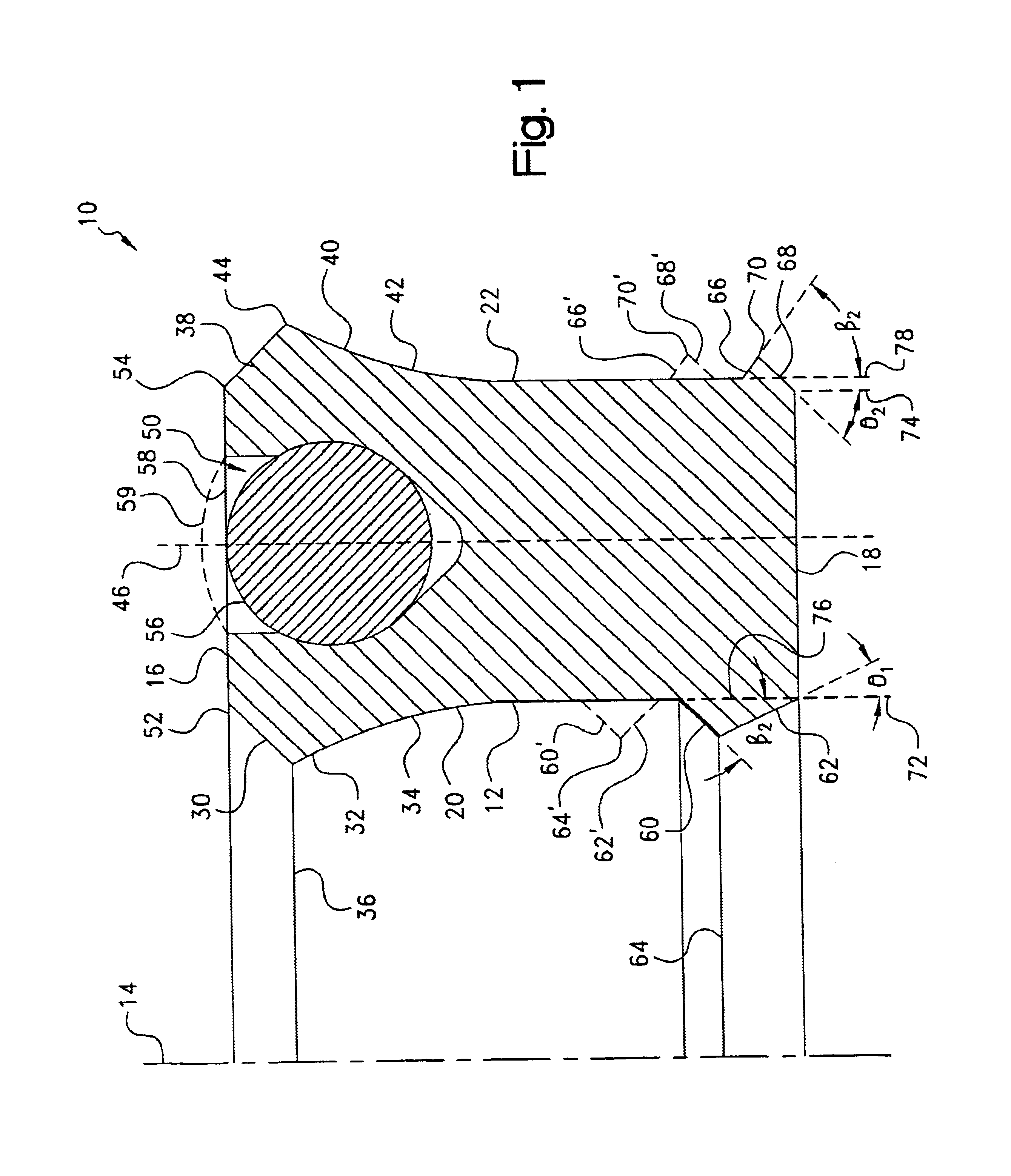

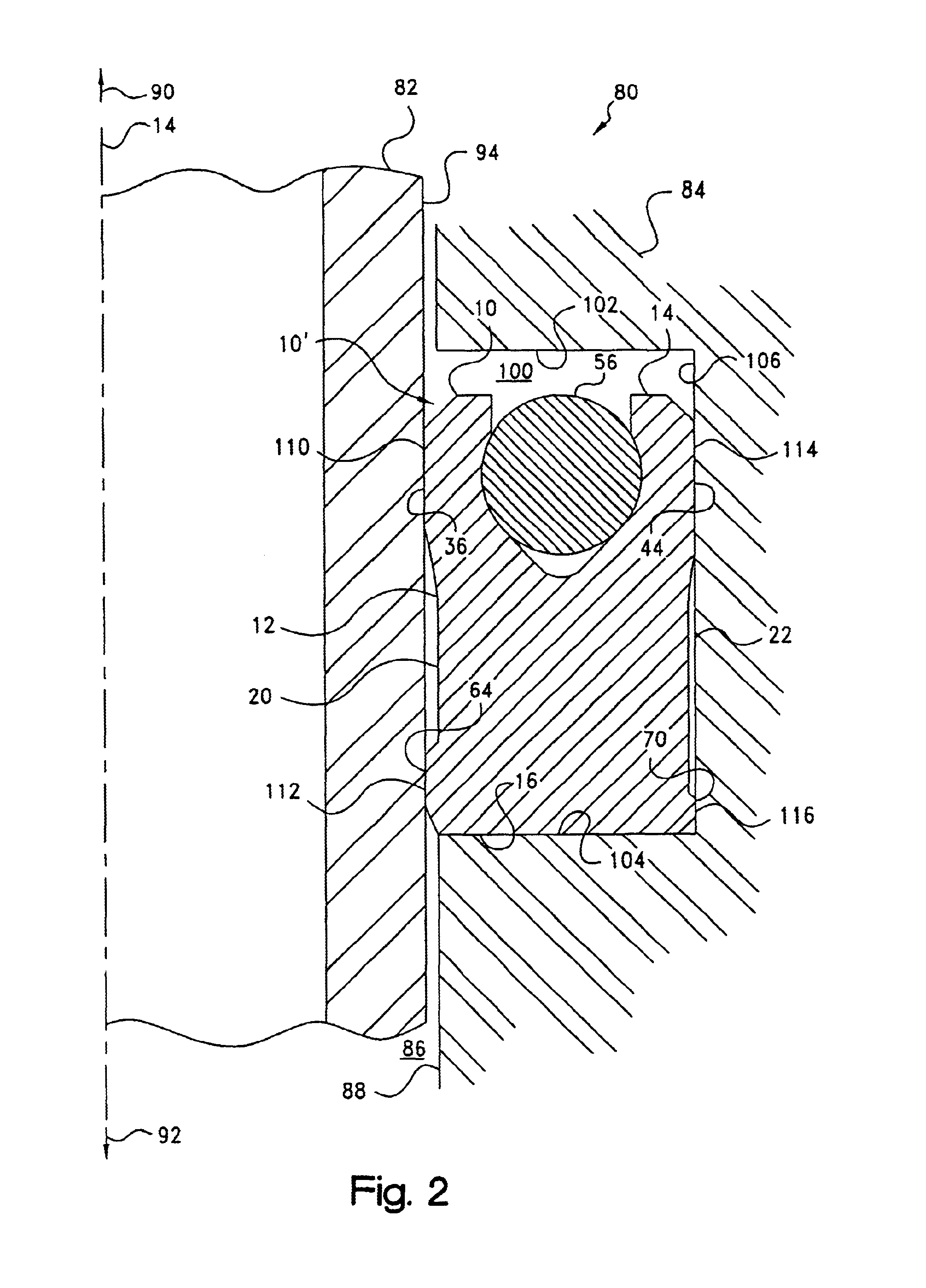

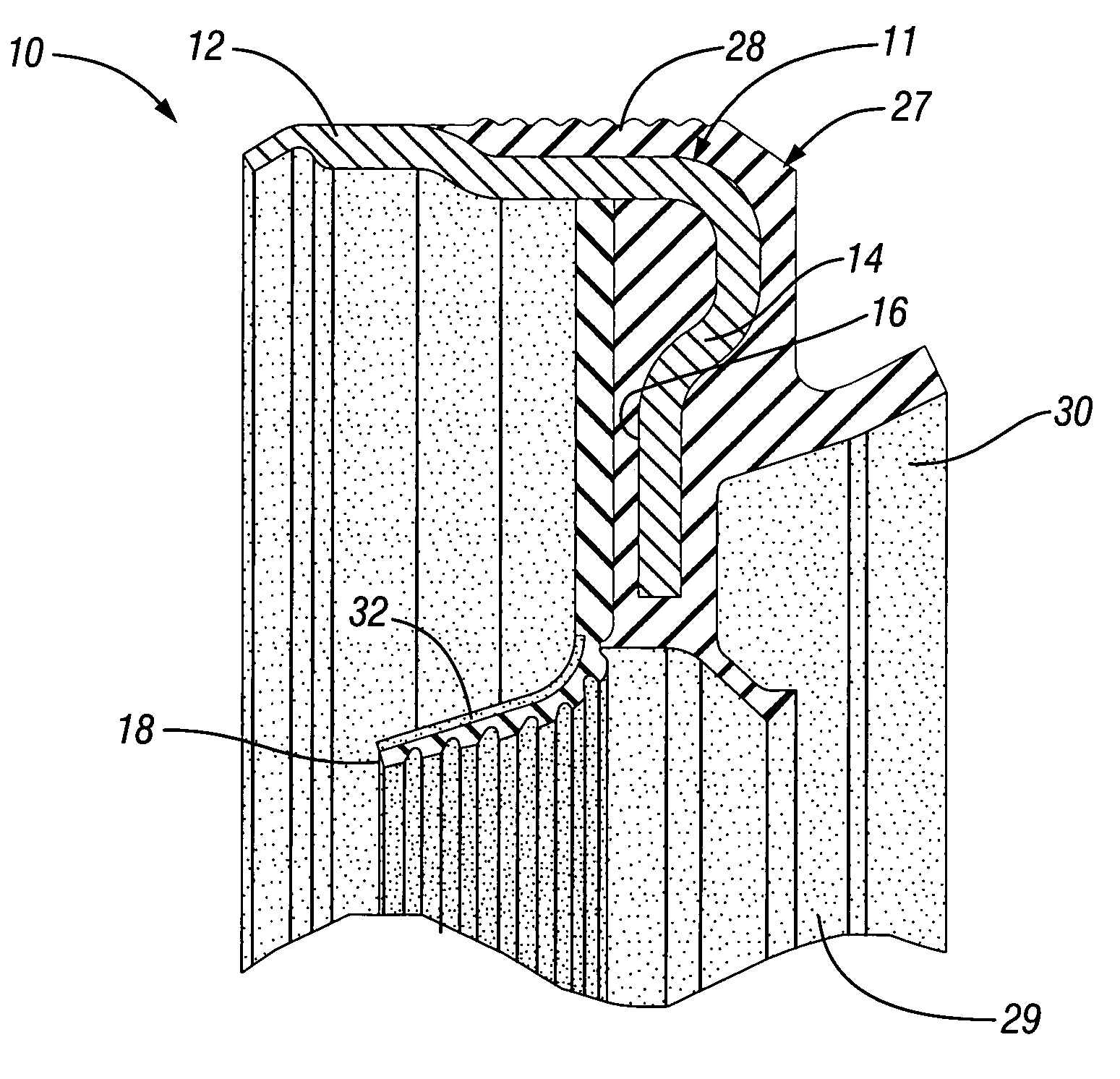

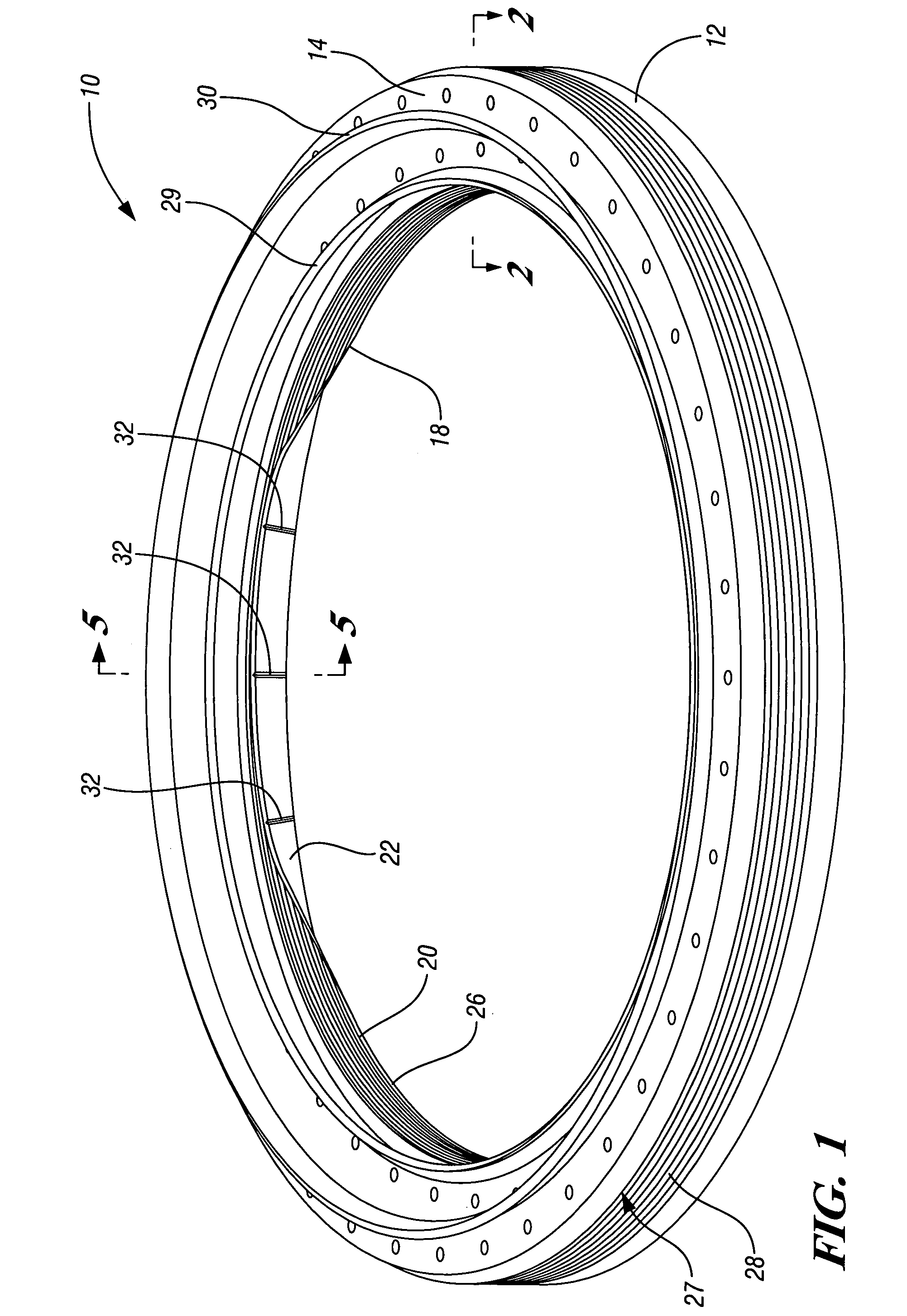

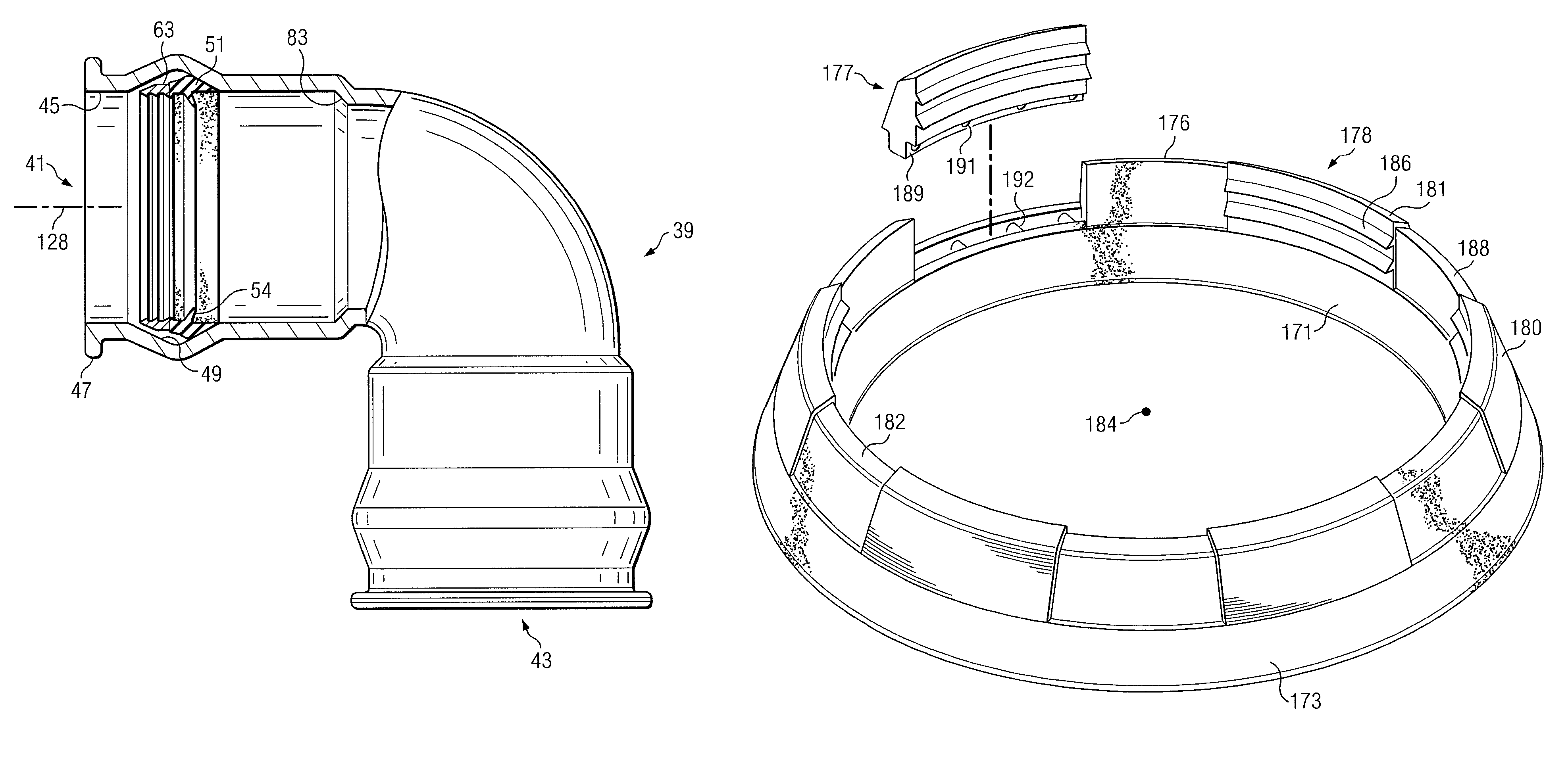

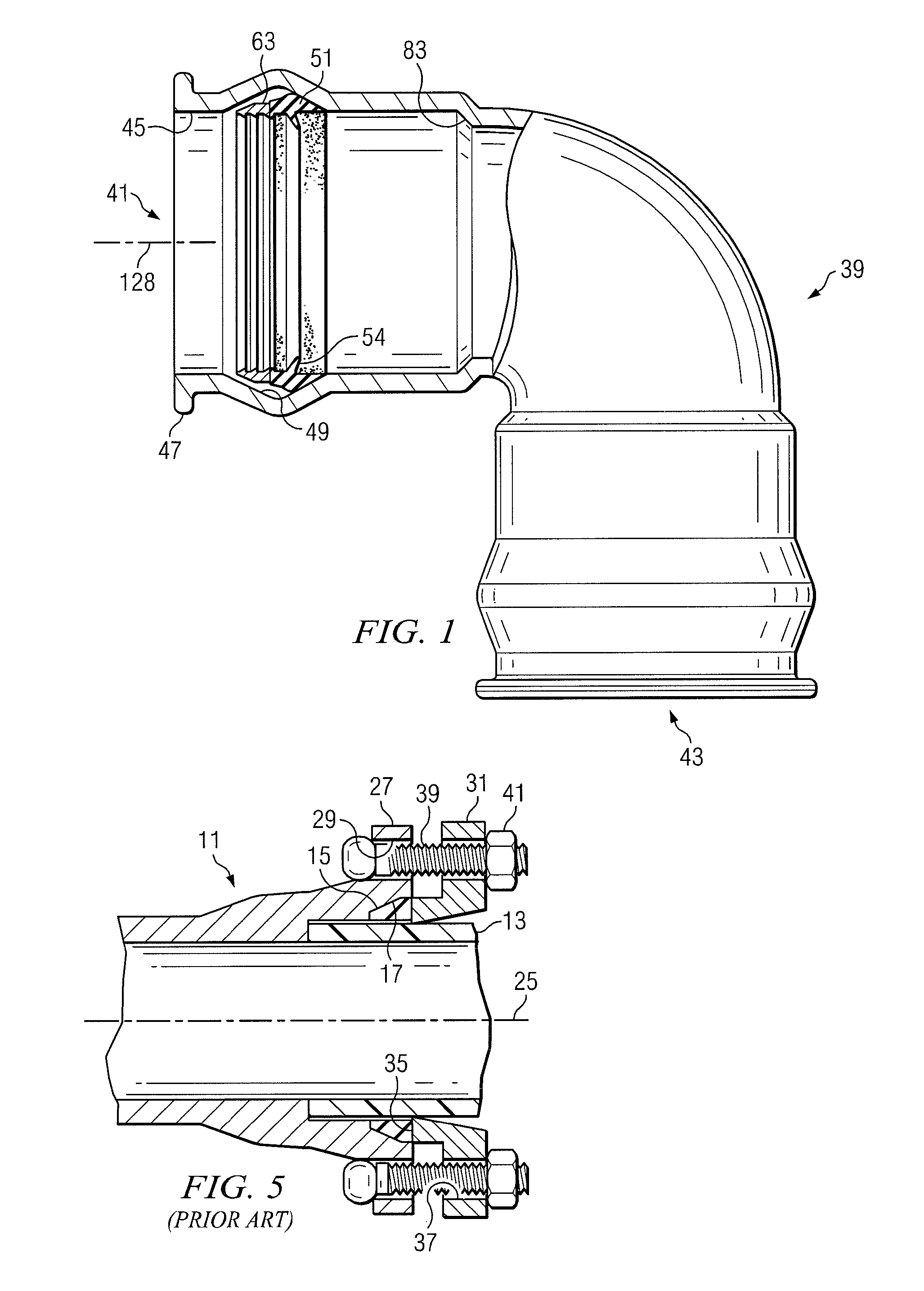

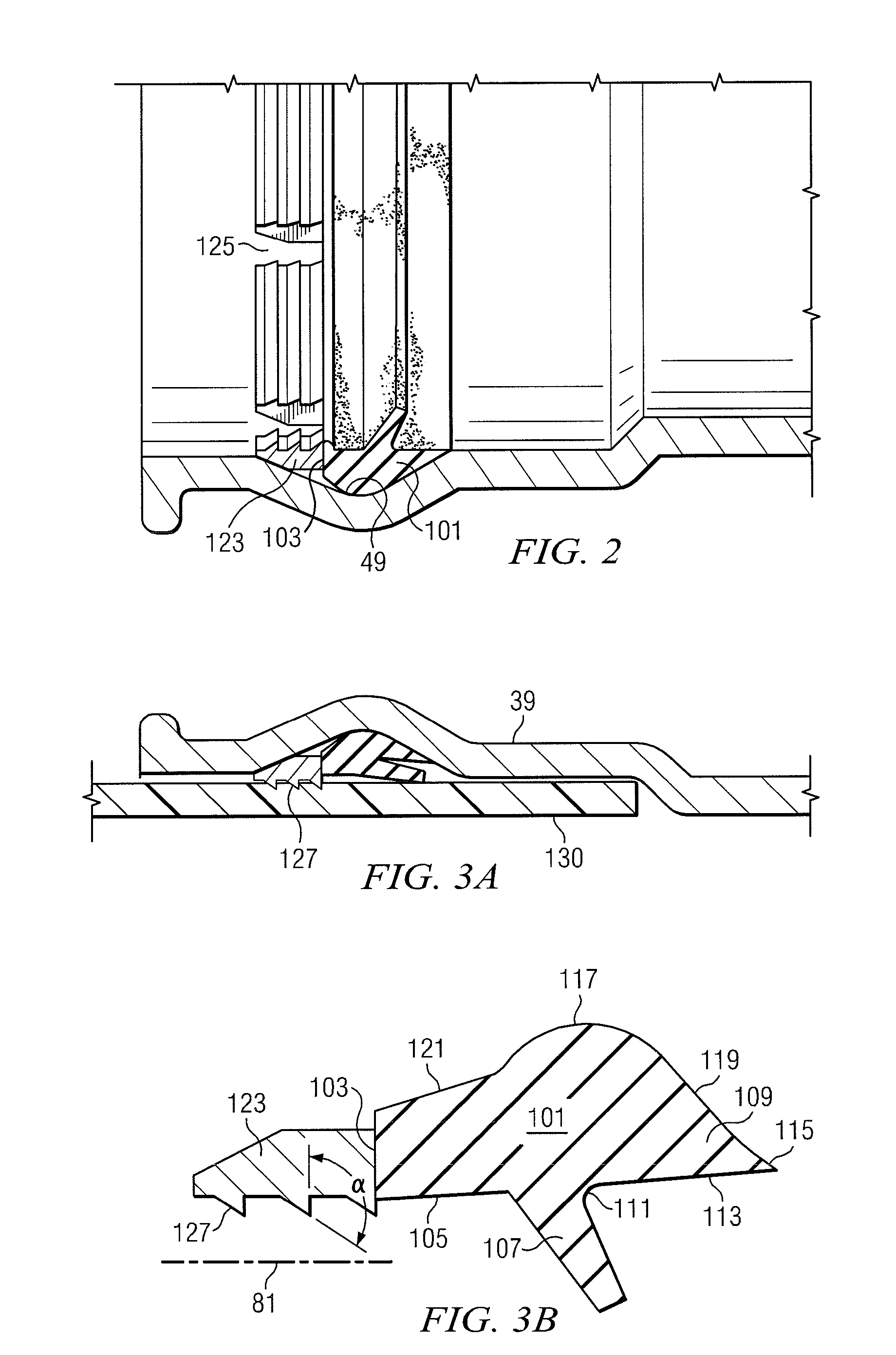

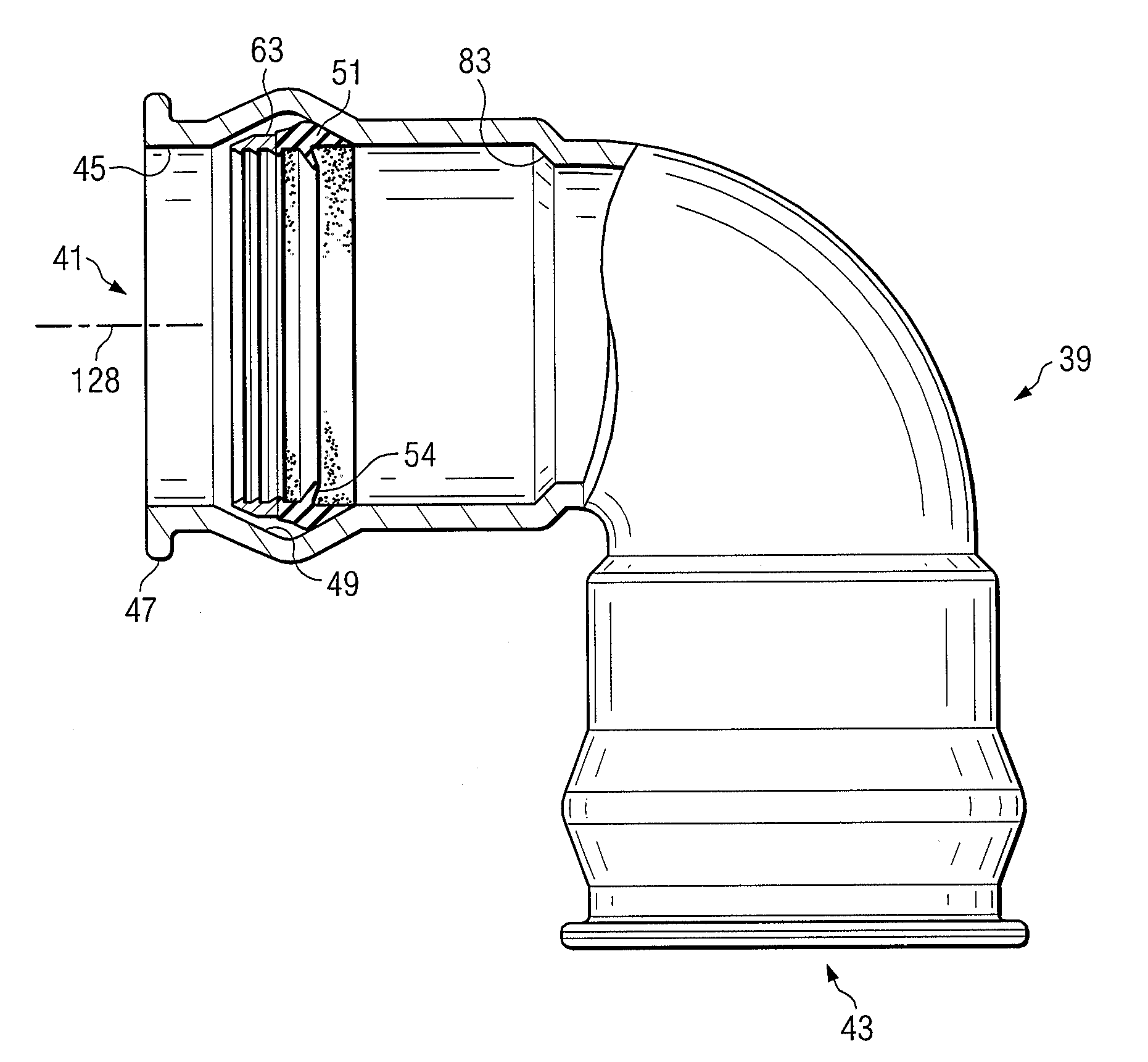

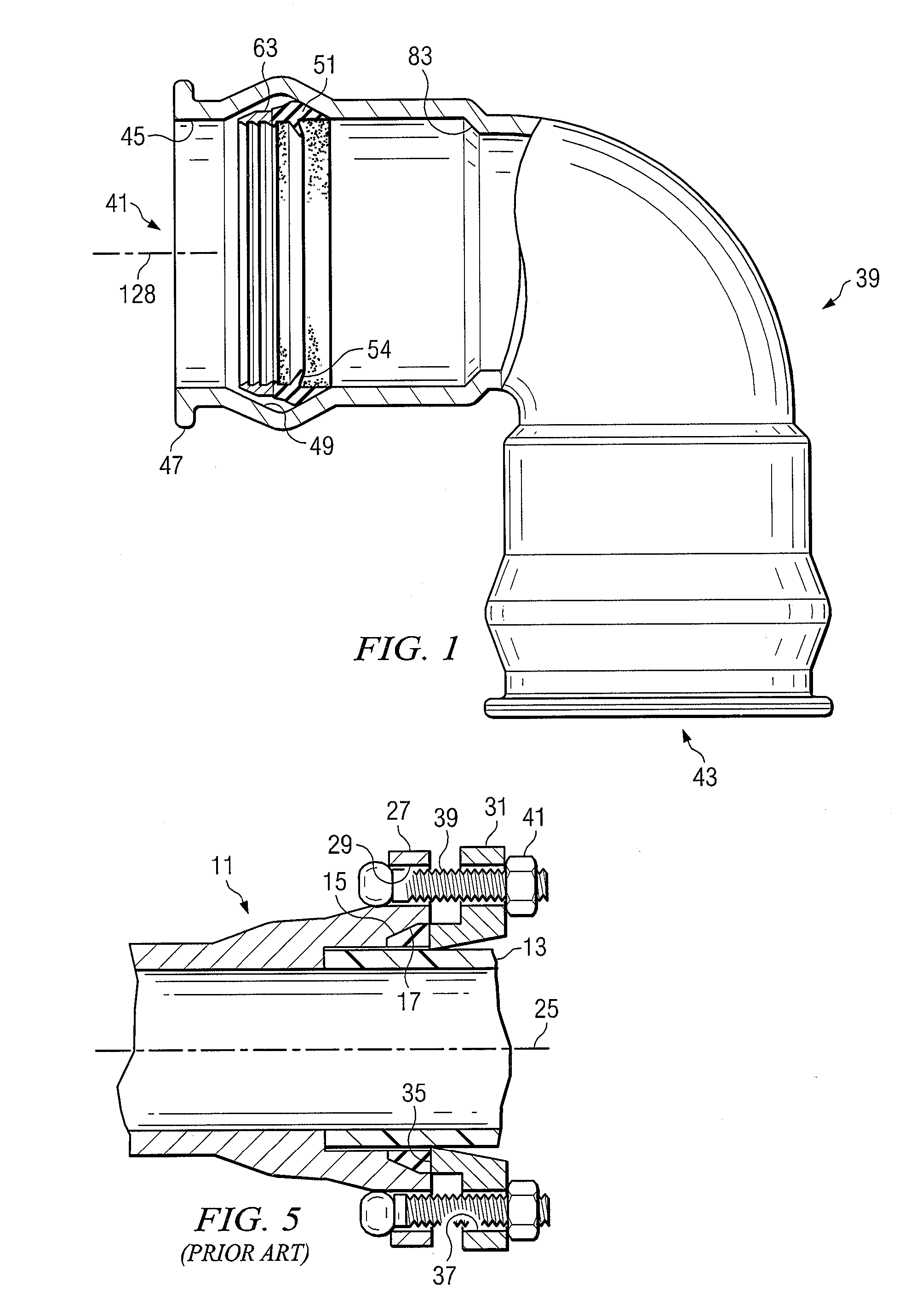

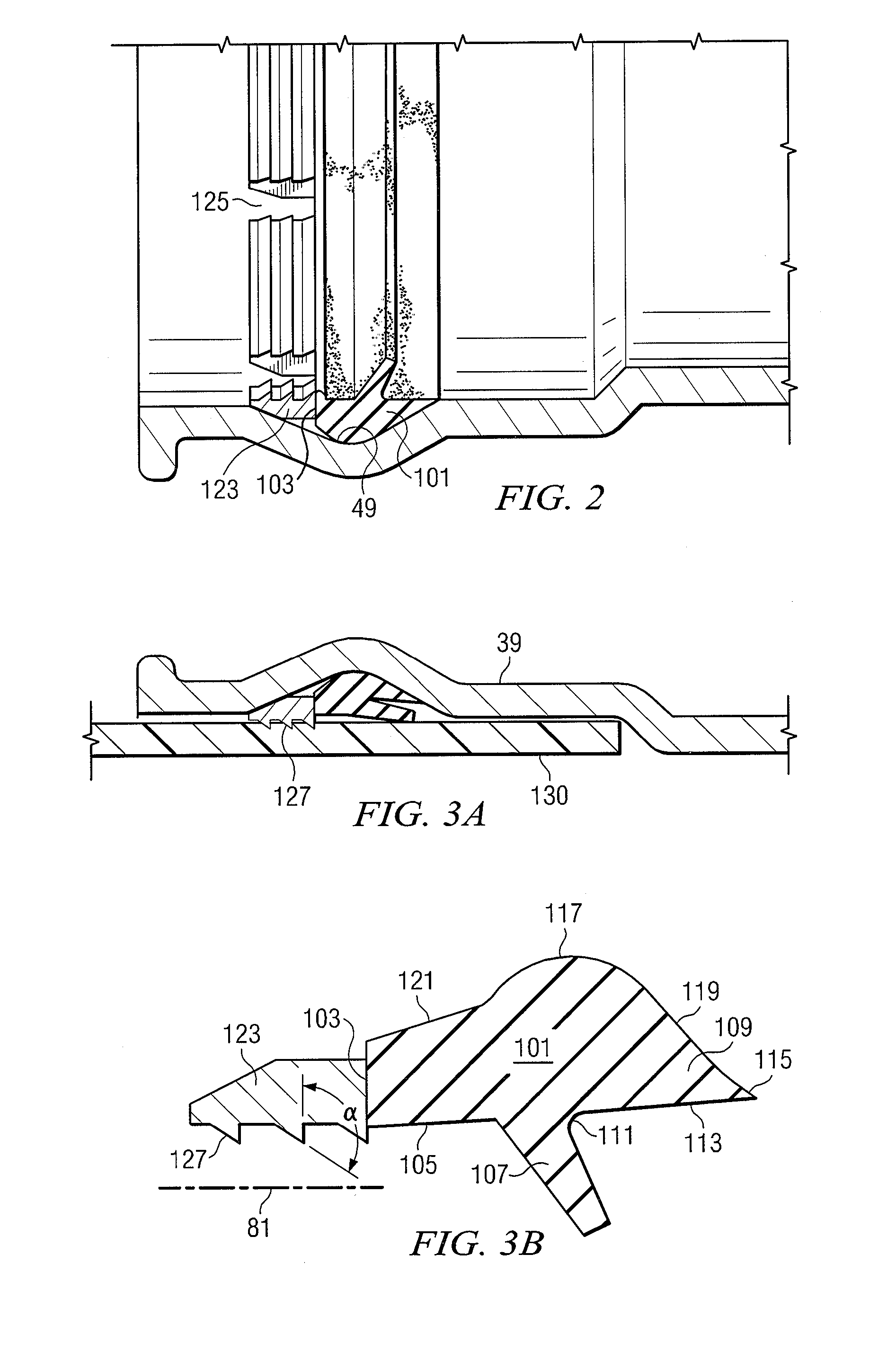

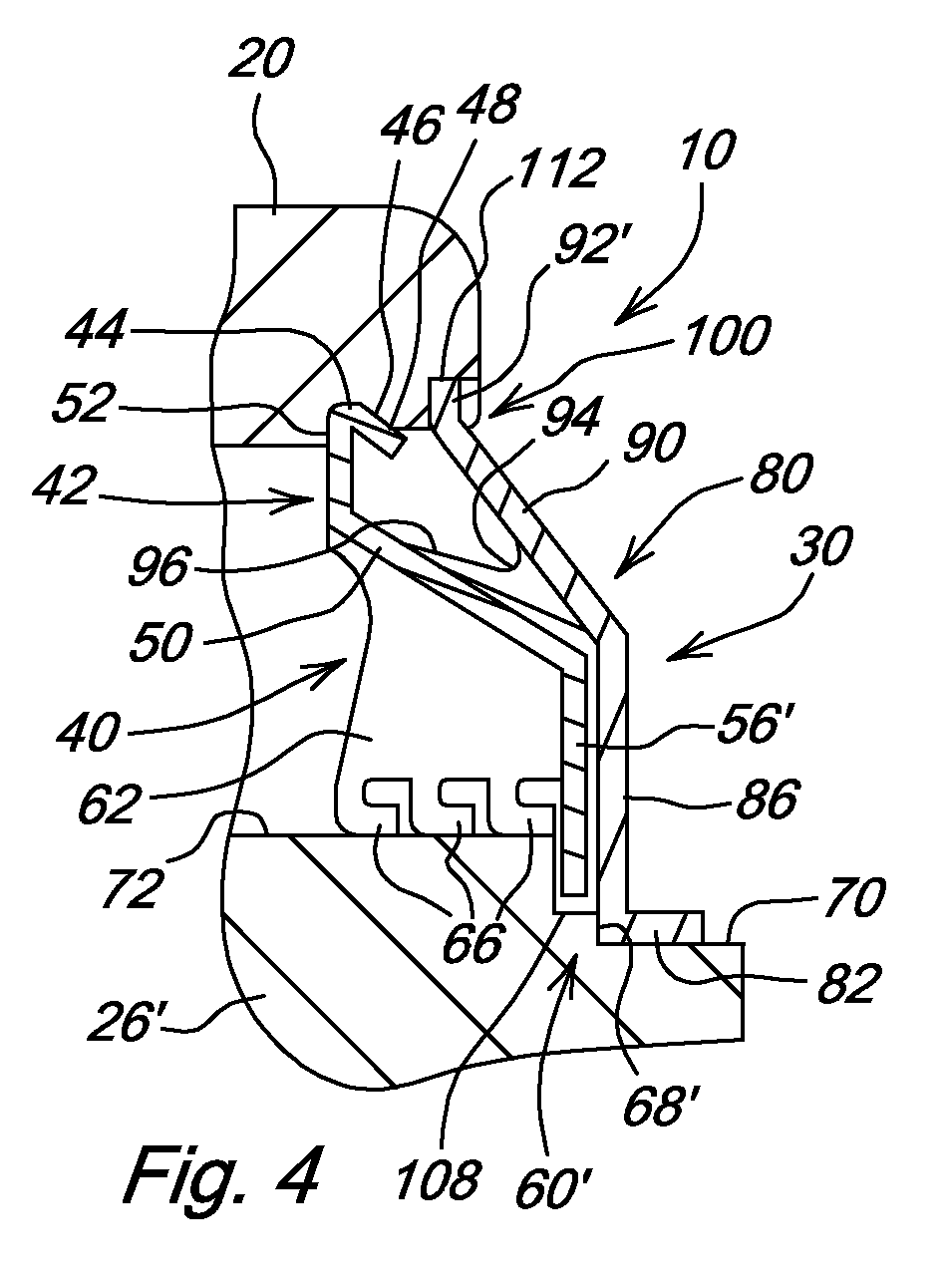

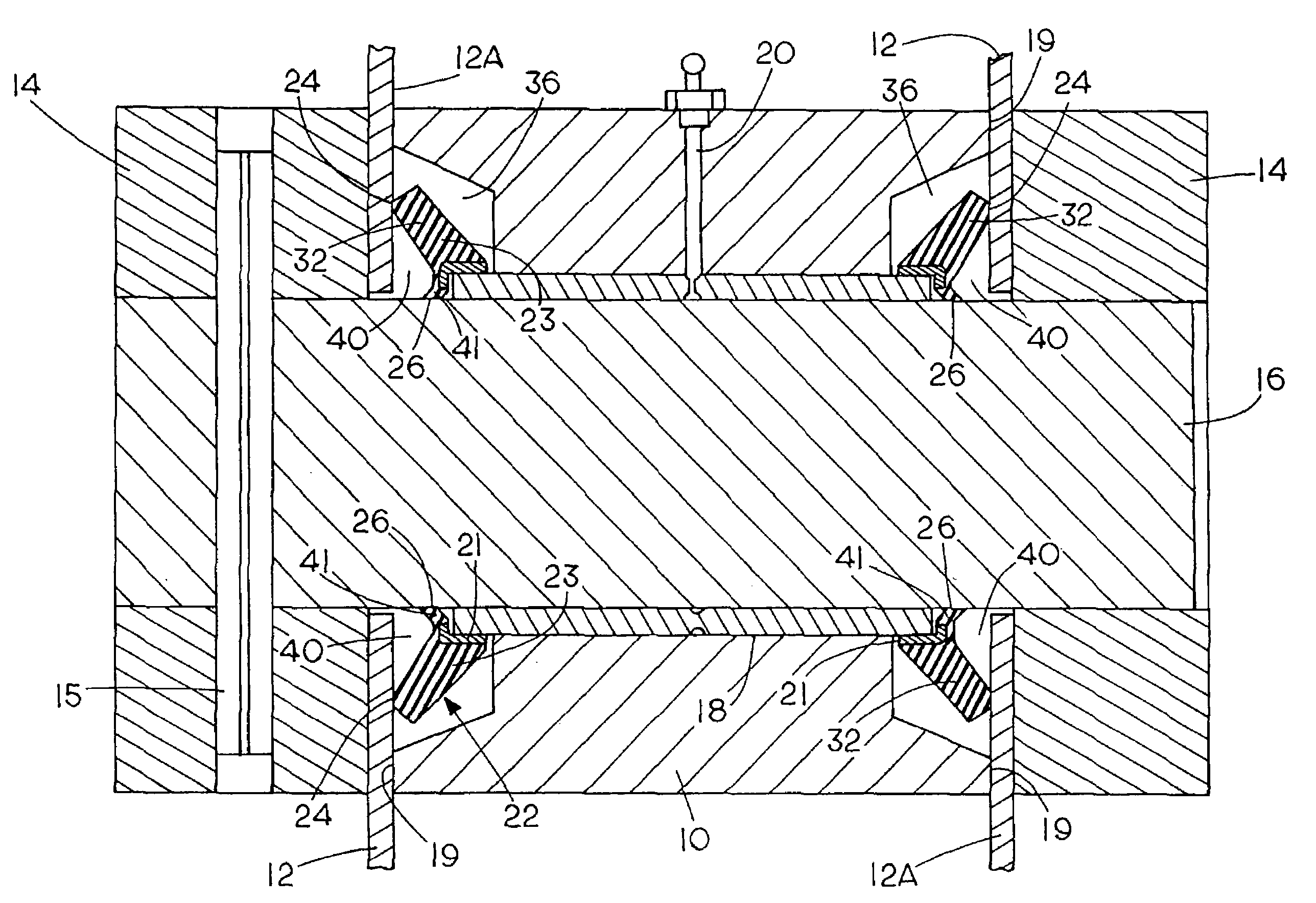

Self restrained ductile iron fitting

A combination sealing and restraint system for an as-cast ductile iron fitting is shown for both sealing and preventing separation of an iron pipe fitting and a mating male pipe. A ring-shaped body is installed within a mating groove provided in a mouth region of the as-cast fitting after the fitting has been cast at the manufacturing plant. The ring-shaped body is formed of an injection molded elastomeric material and carries a series of gripping segments which have teeth on an inner surface thereof which are designed to engage an outer surface of a mating male pipe. The teeth are oriented to allow movement of the male pipe in a first direction relative to an end opening of the fitting during assembly, but to resist movement in a opposite direction after the fitting joint has been assembled. The gripping segments have shelf regions which are mechanically secured to the elastomeric body of the gasket. The ring-shaped body also includes a relatively flexible portion formed of an elastomer which forms a lip seal region with the mating male pipe.

Owner:S & B TECHN PRODS

Self Restrained Ductile Iron Fitting

A combination sealing and restraint system for an as-cast ductile iron fitting is shown for both sealing and preventing separation of an iron pipe fitting and a mating male pipe. A ring-shaped body is installed within a mating groove provided in a mouth region of the as-cast fitting after the fitting has been cast at the manufacturing plant. The ring-shaped body is formed of an injection molded elastomeric material and carries a series of gripping segments which have teeth on an inner surface thereof which are designed to engage an outer surface of a mating male pipe. The teeth are oriented to allow movement of the male pipe in a first direction relative to an end opening o f the fitting during assembly, but to resist movement in a opposite direction after the fitting joint has been assembled. The gripping segments are mechanically bonded to the elastomeric body of the gasket during the injection molding operation. The ring-shaped body also includes a relatively flexible portion formed of an elastomer which forms a lip seal region with the mating male pipe.

Owner:S & B TECHN PRODS

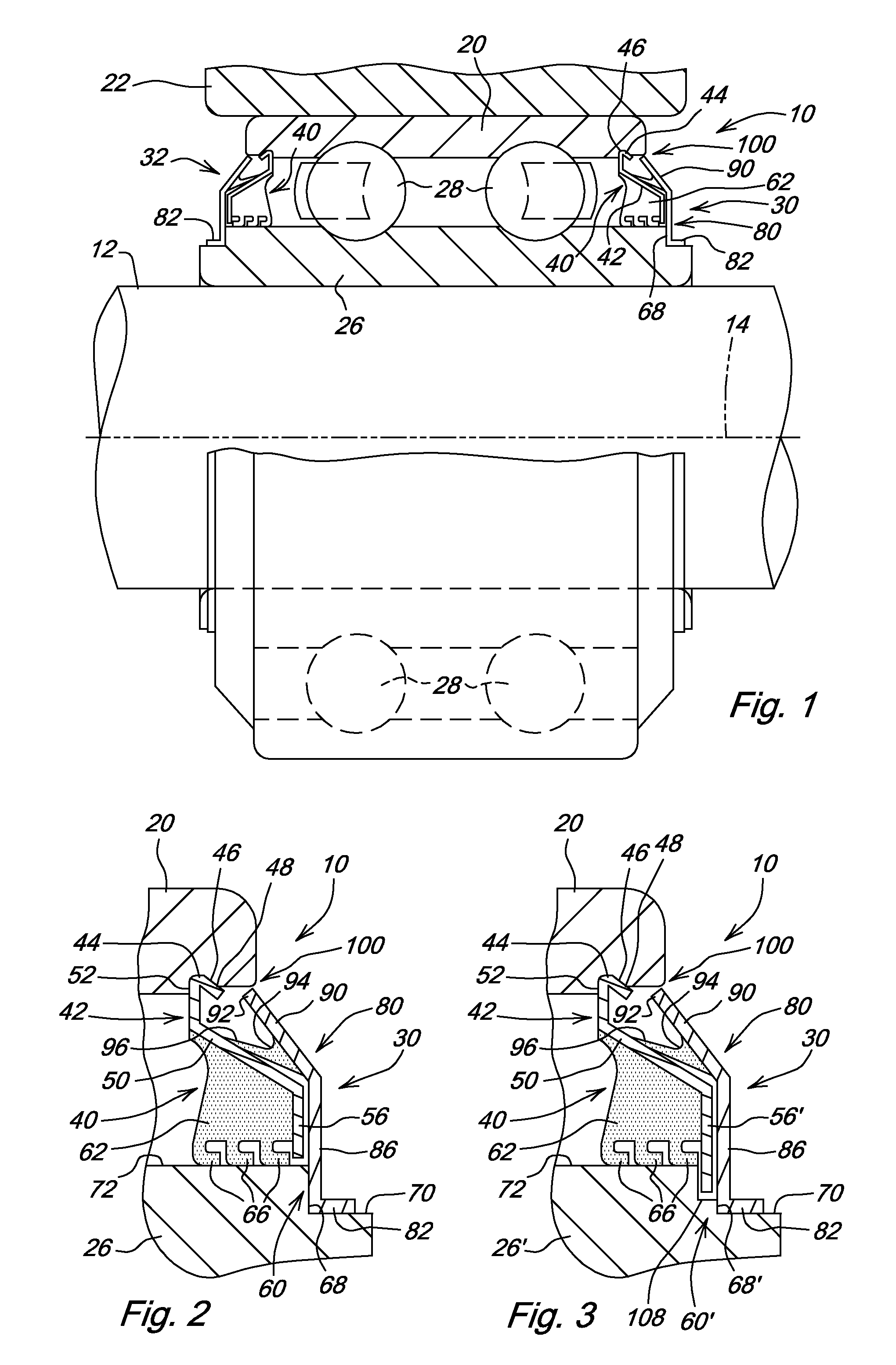

Bearing seal assembly for agricultural applications

ActiveUS7258491B2Overcome problemsEliminate the problemBall bearingsBearing componentsEngineeringLip seal

A contaminant-resistant bearing assembly includes a multi-lip seal with an extended shroud supported from the outer ring and projecting adjacent a stepped inner ring shoulder. A steel slinger supported from the inner ring is offset outwardly adjacent the shroud and includes a radially outer edge terminating closely adjacent the connection of the seal shroud to the outer ring. The slinger includes an outer portion angled inwardly from the radial direction and supporting a lip seal which contacts an angled portion of the seal shroud at a central location between the rings. A primary step machined on the inner ring prevents the slinger from being pushed into the seal.

Owner:DEERE & COMPANY & PEER BEARING

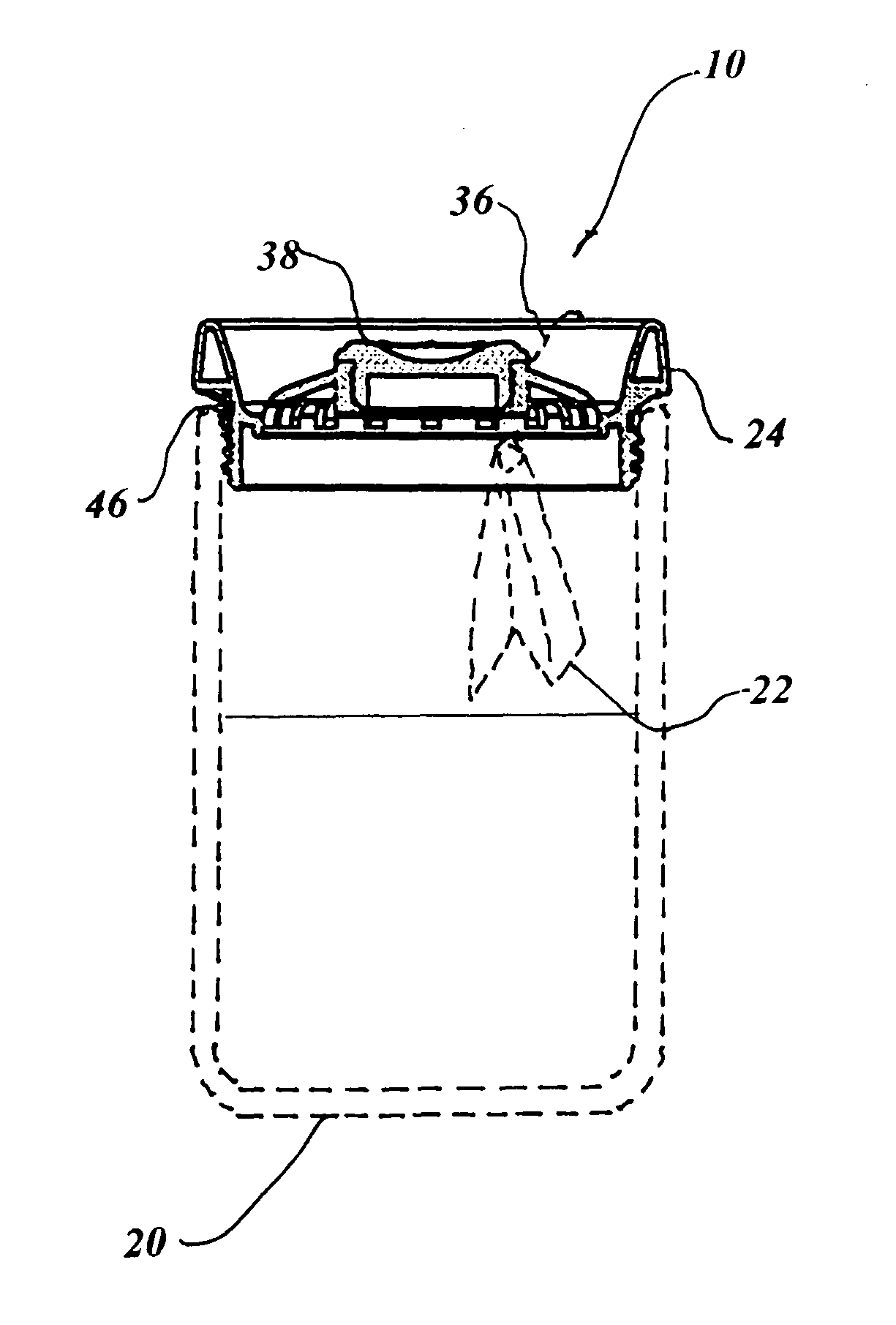

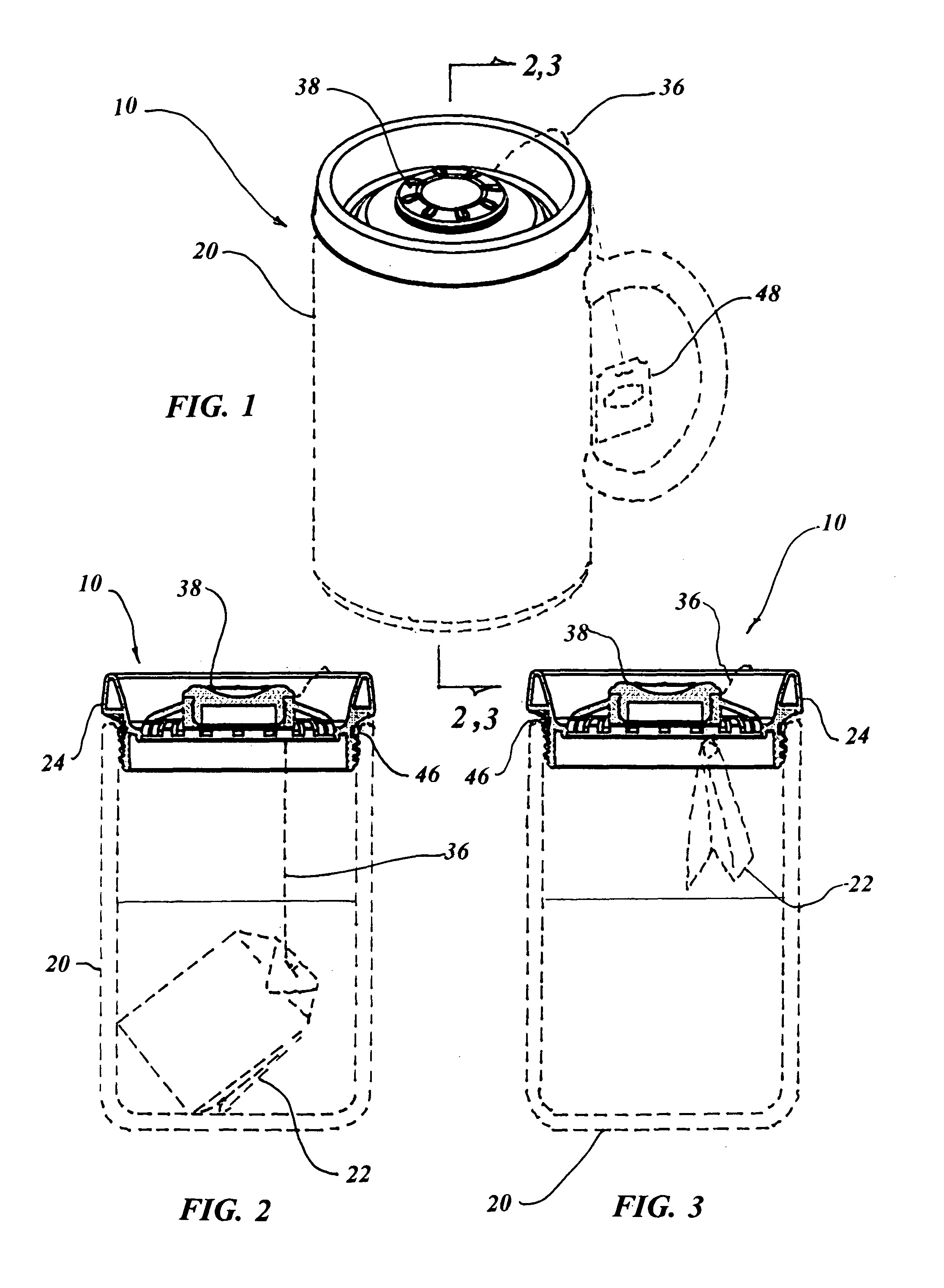

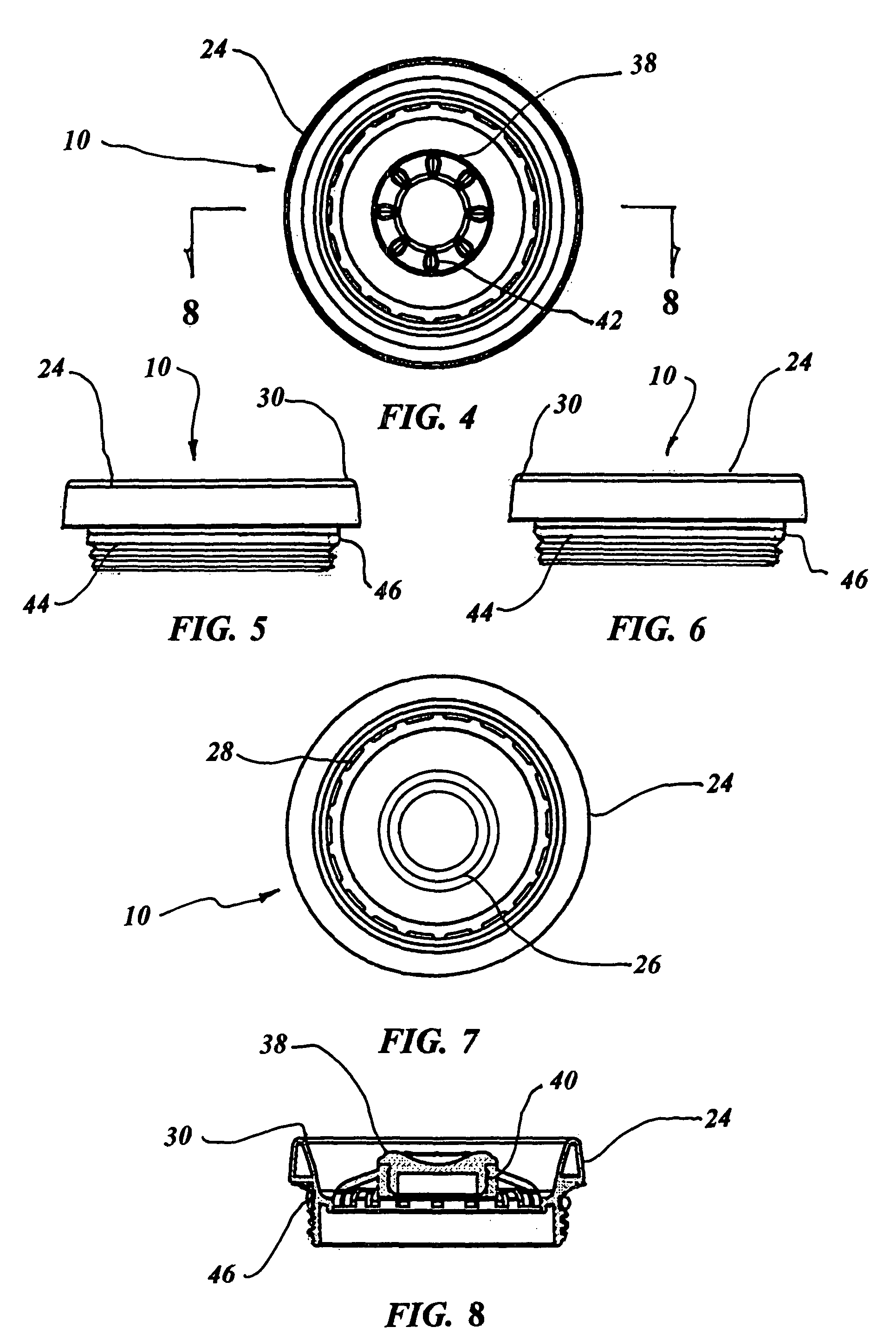

Tea bag cup lid

InactiveUS7806044B2Prevents accidental spillageSimple methodClosuresBeverage vesselsEngineeringLip seal

Owner:LIN SHIN SHUOH

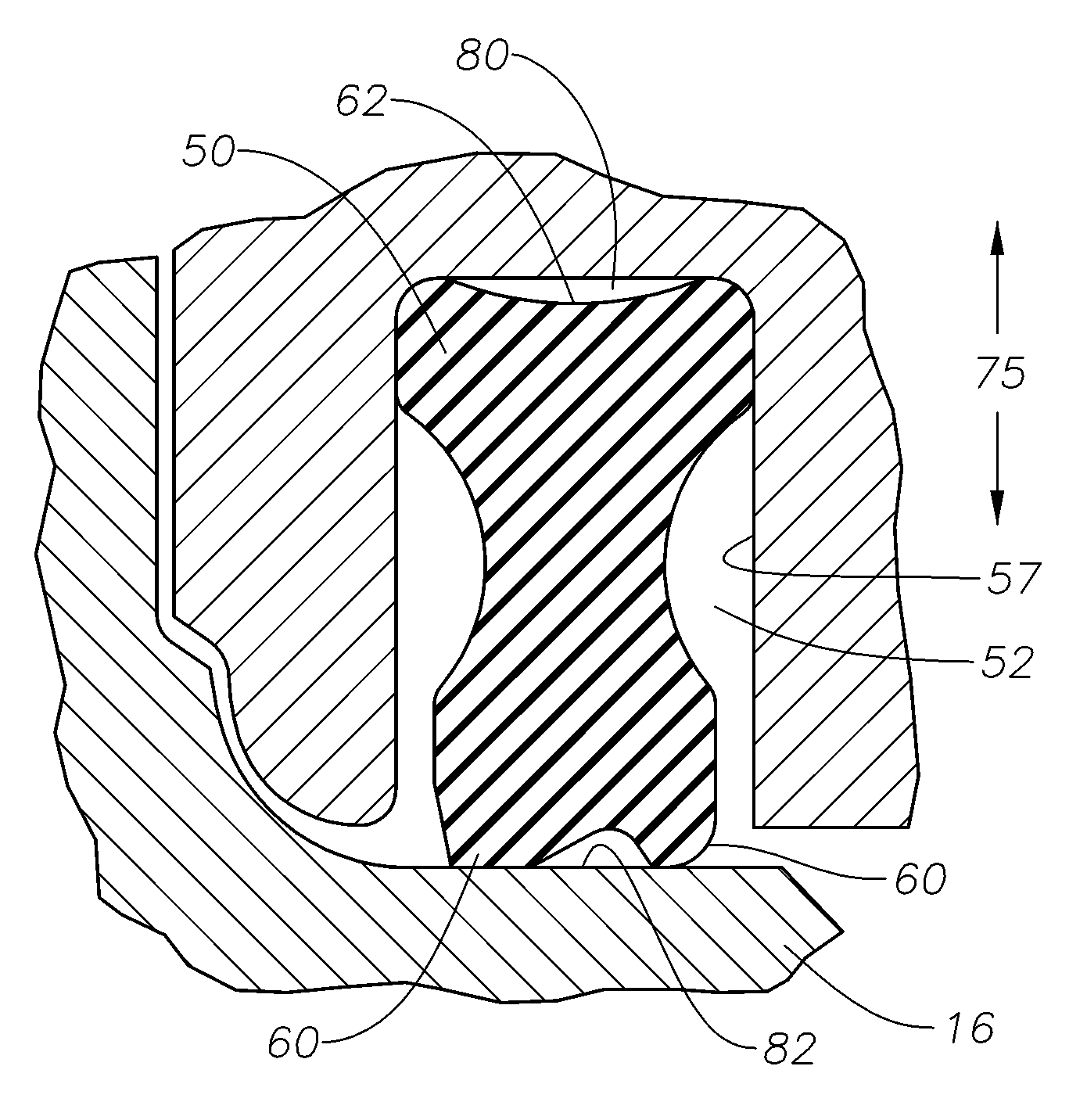

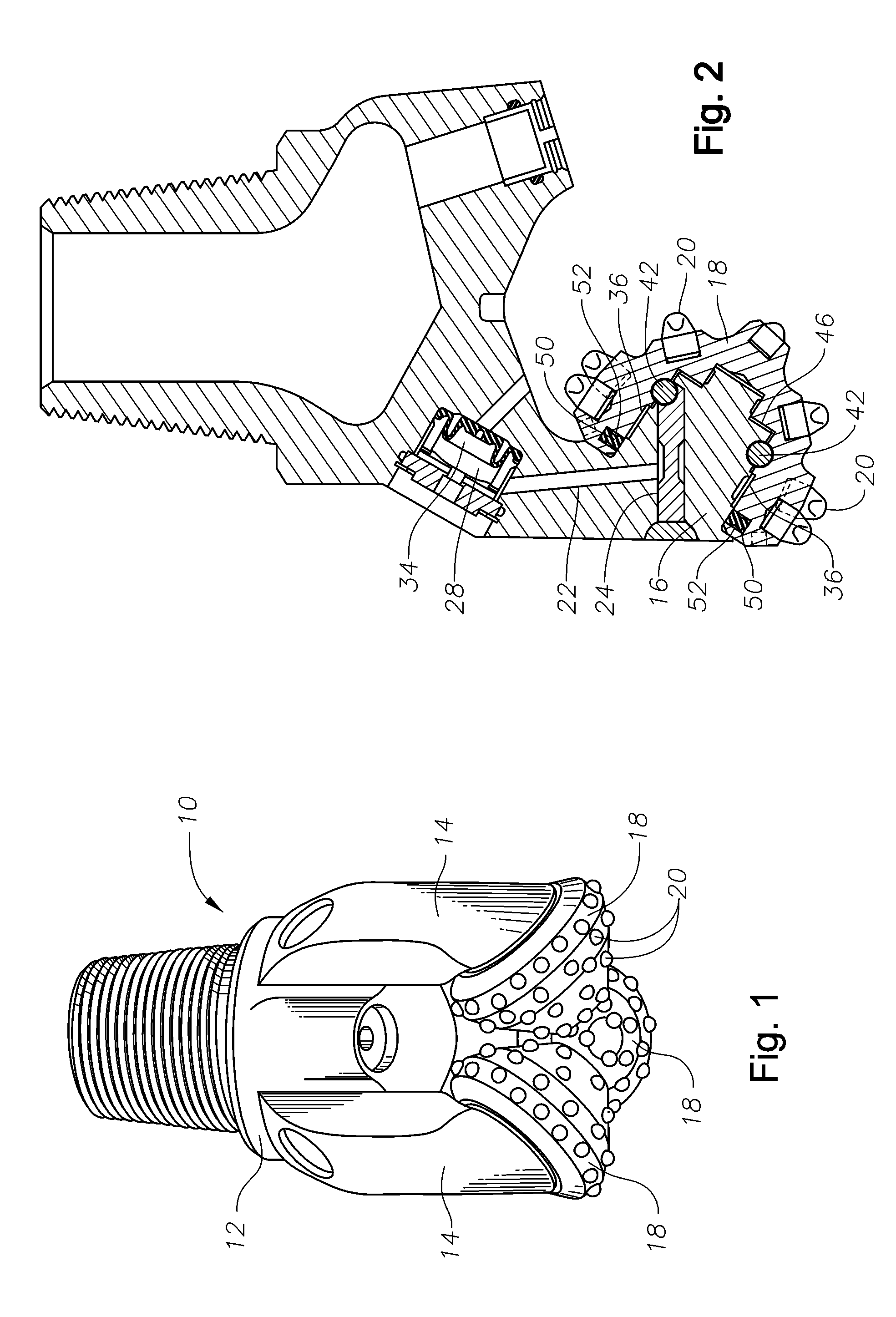

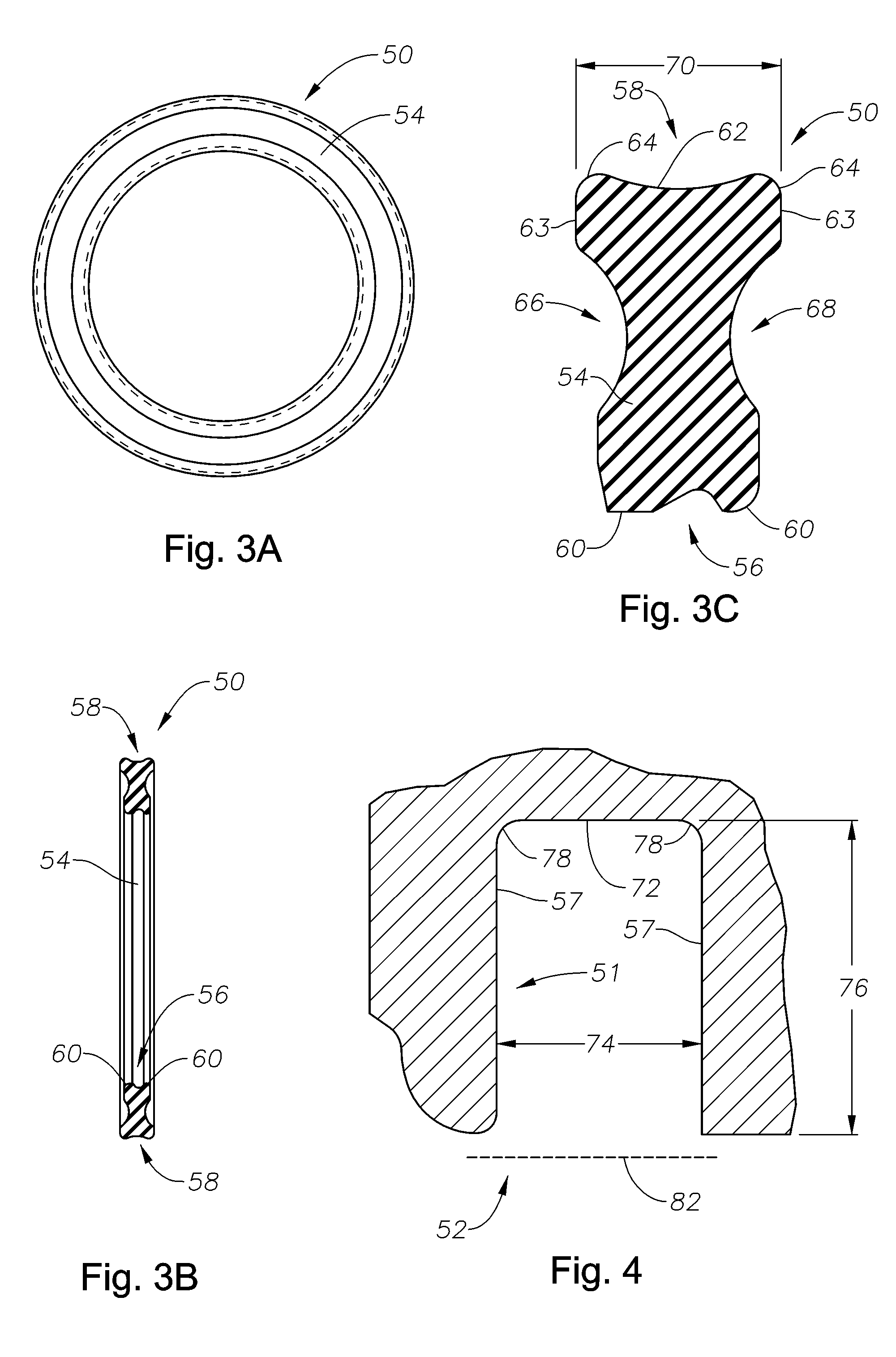

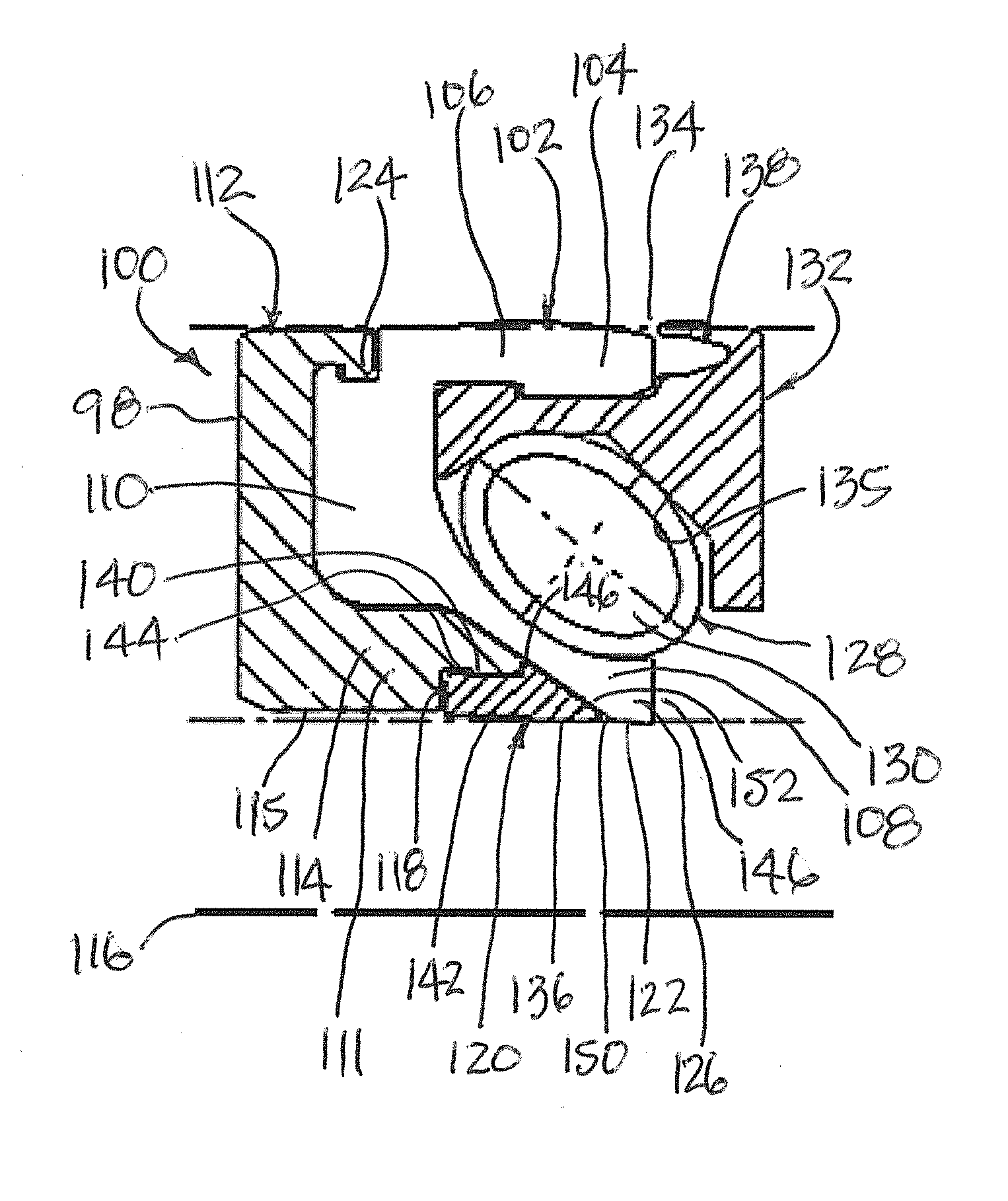

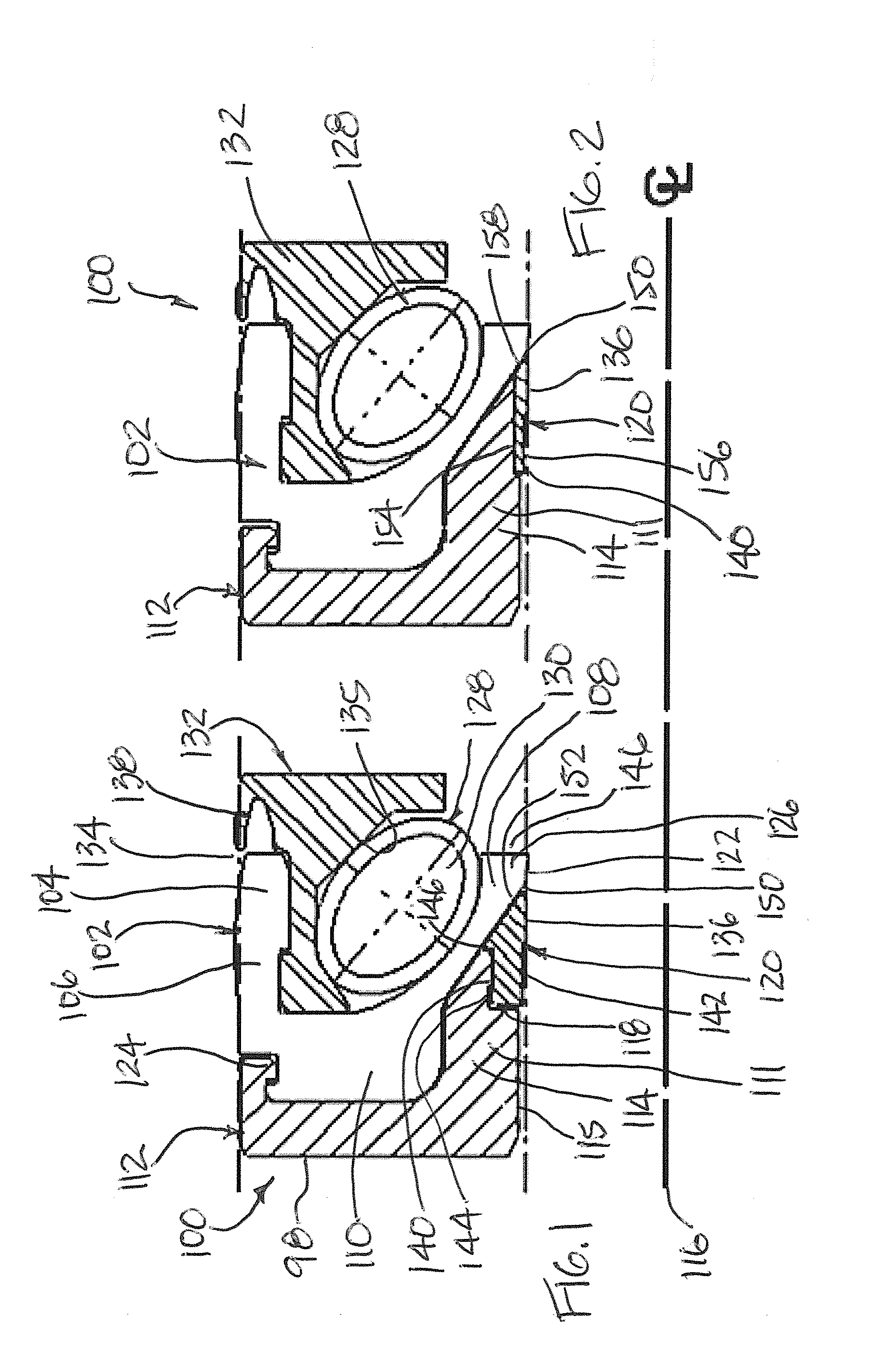

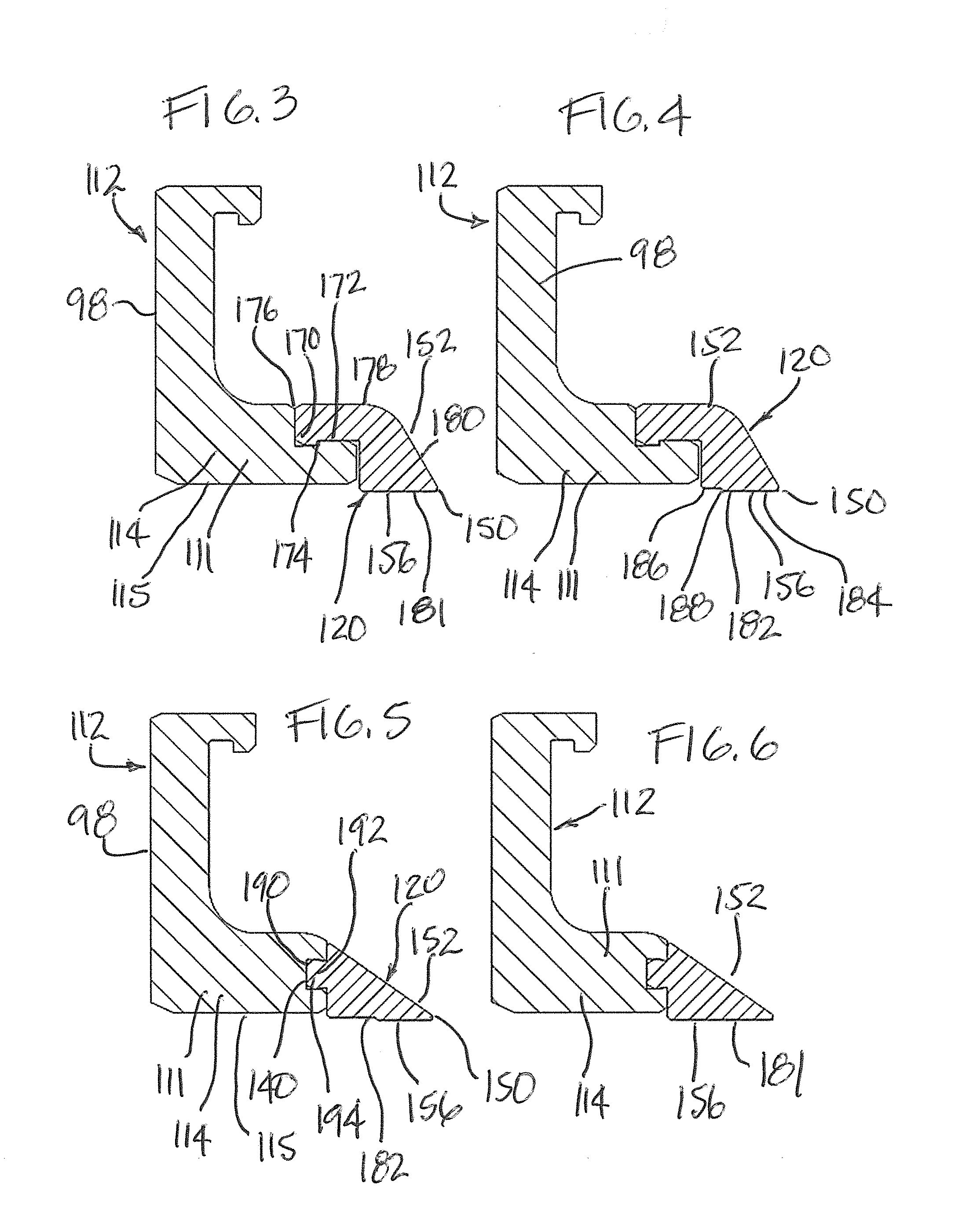

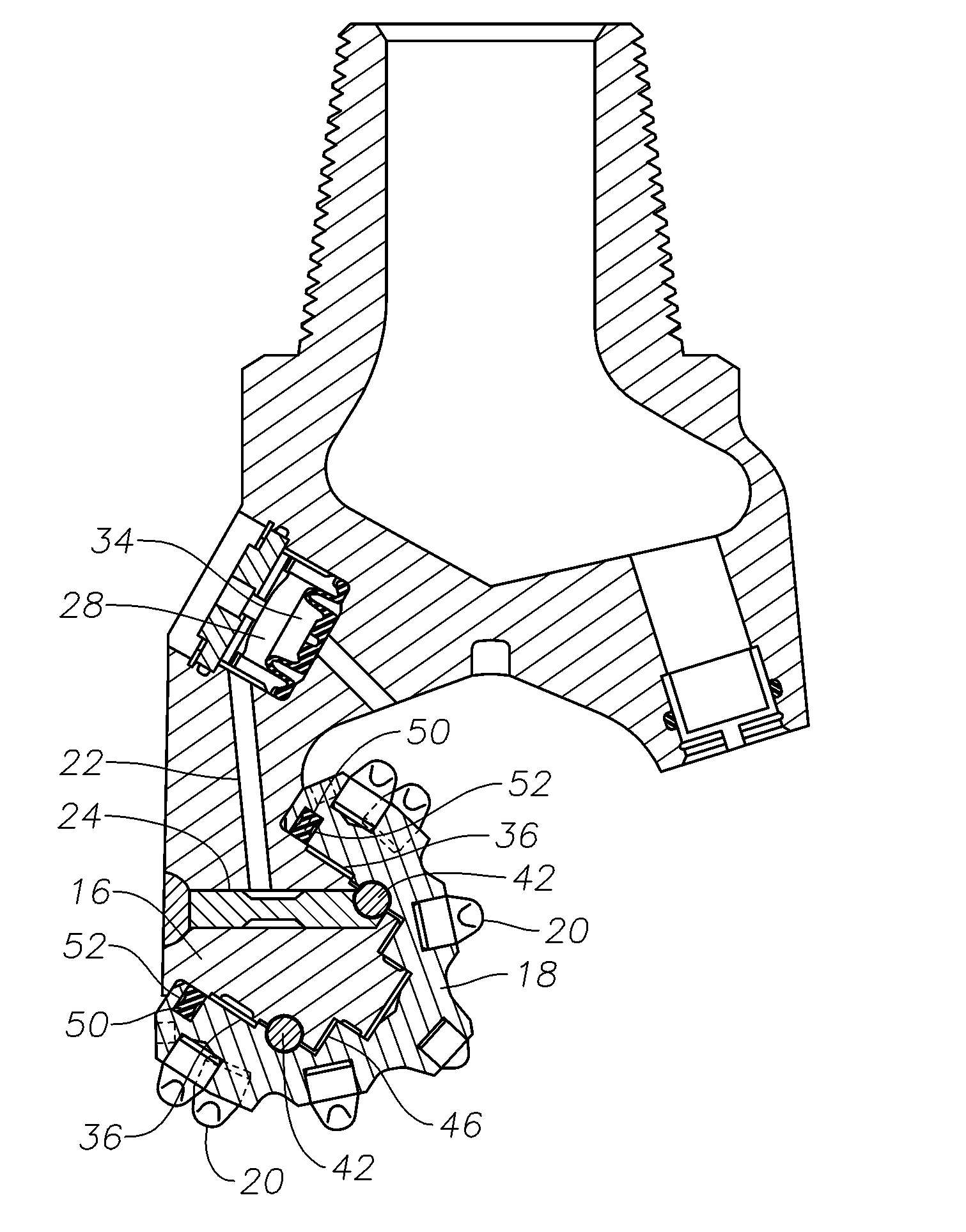

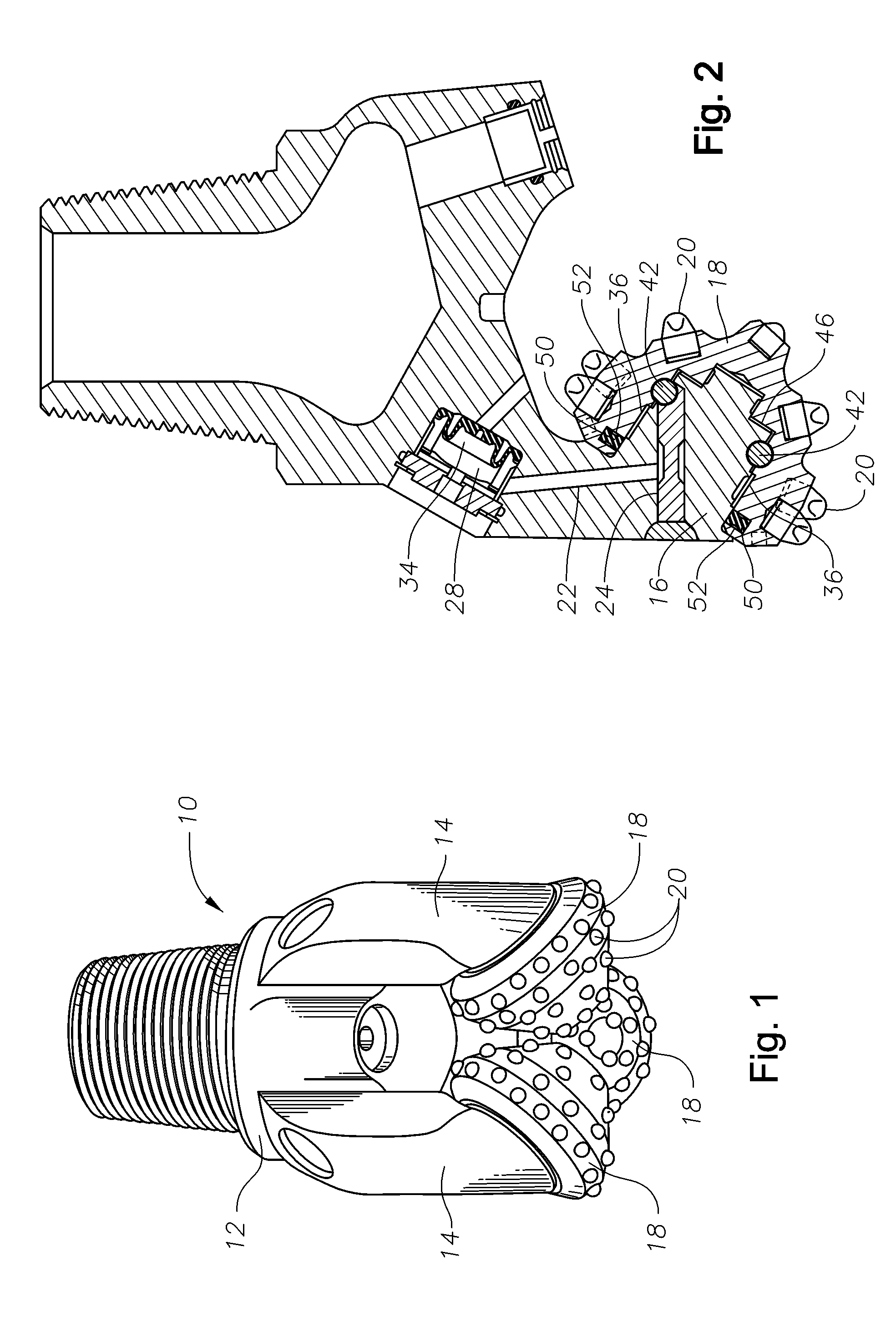

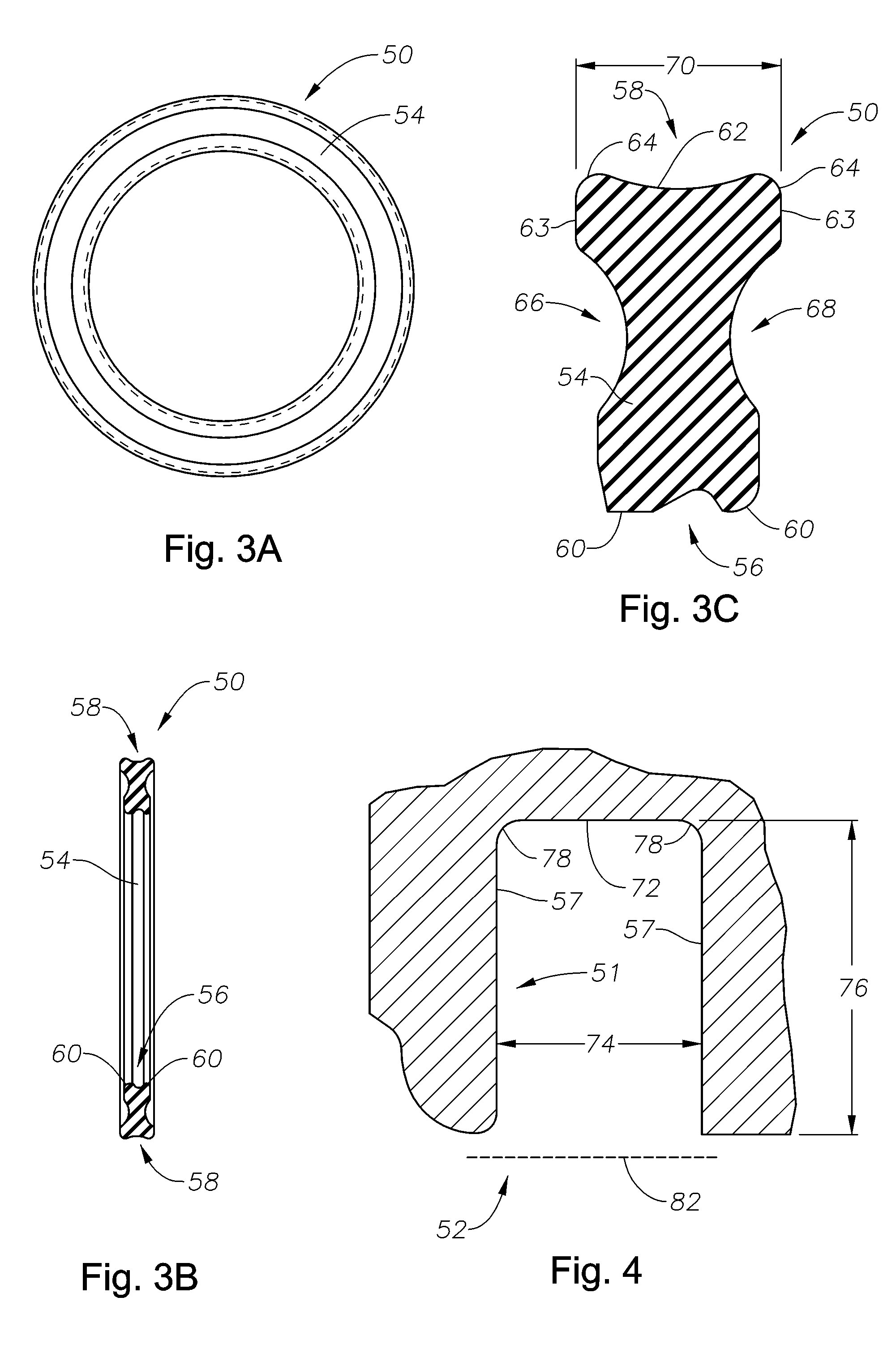

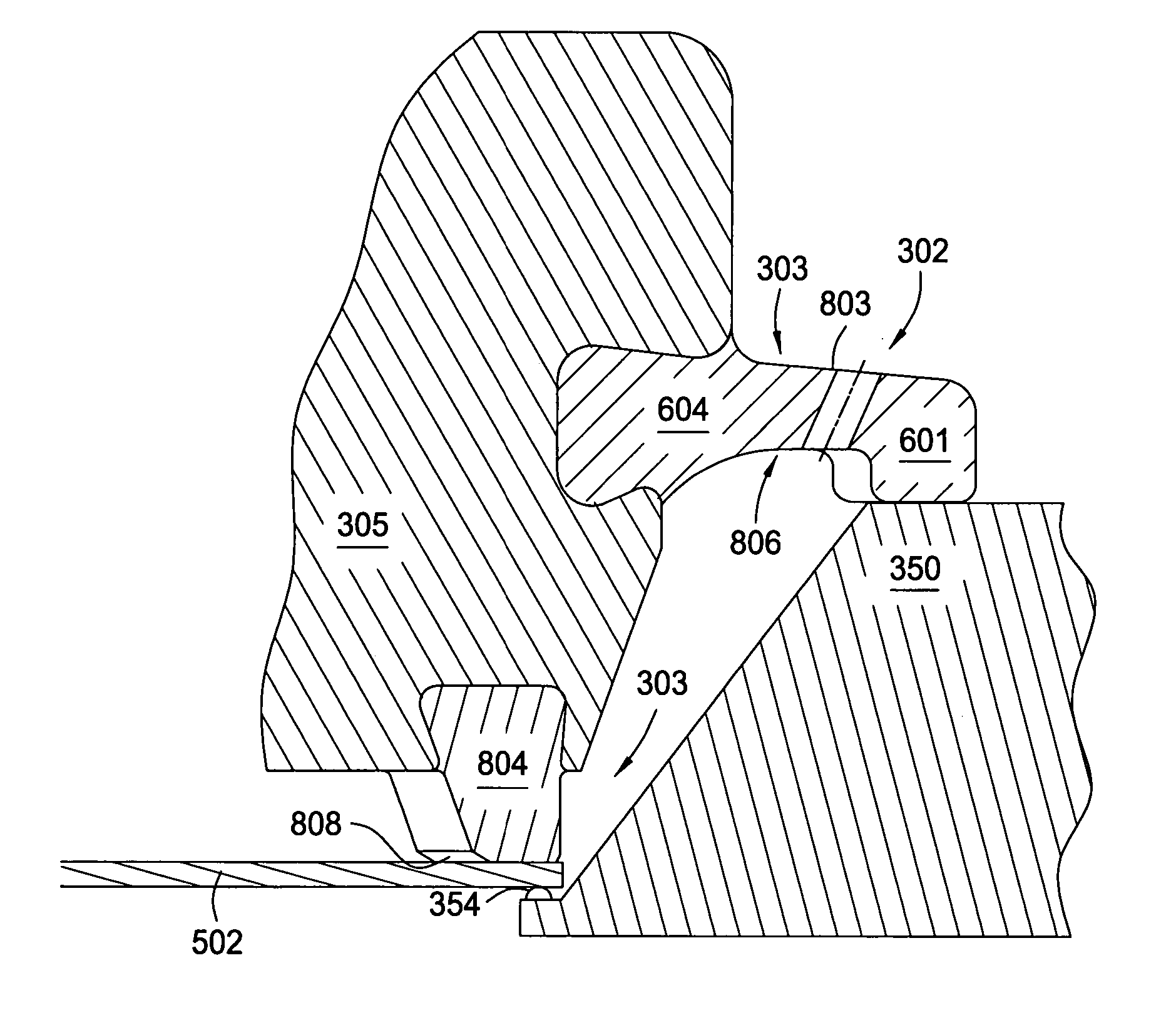

Lip seal for roller cone drill bit

A radial lip seal for use with roller cone drill bits is at least partially collapsed and held in place when the drill bit is subjected to hydrostatic pressure in the well bore when performing drilling operations. The drill bit and seal cooperate to form at least one void intentionally established between the outer surface of a seal recess in the bit and the outer surface of the lip seal. The drill bit has a spindle and a rolling cutter positioned around the spindle. The seal recess is formed in the rolling cutter and has an outer surface to carry the lip seal.

Owner:GP USA HLDG LLC

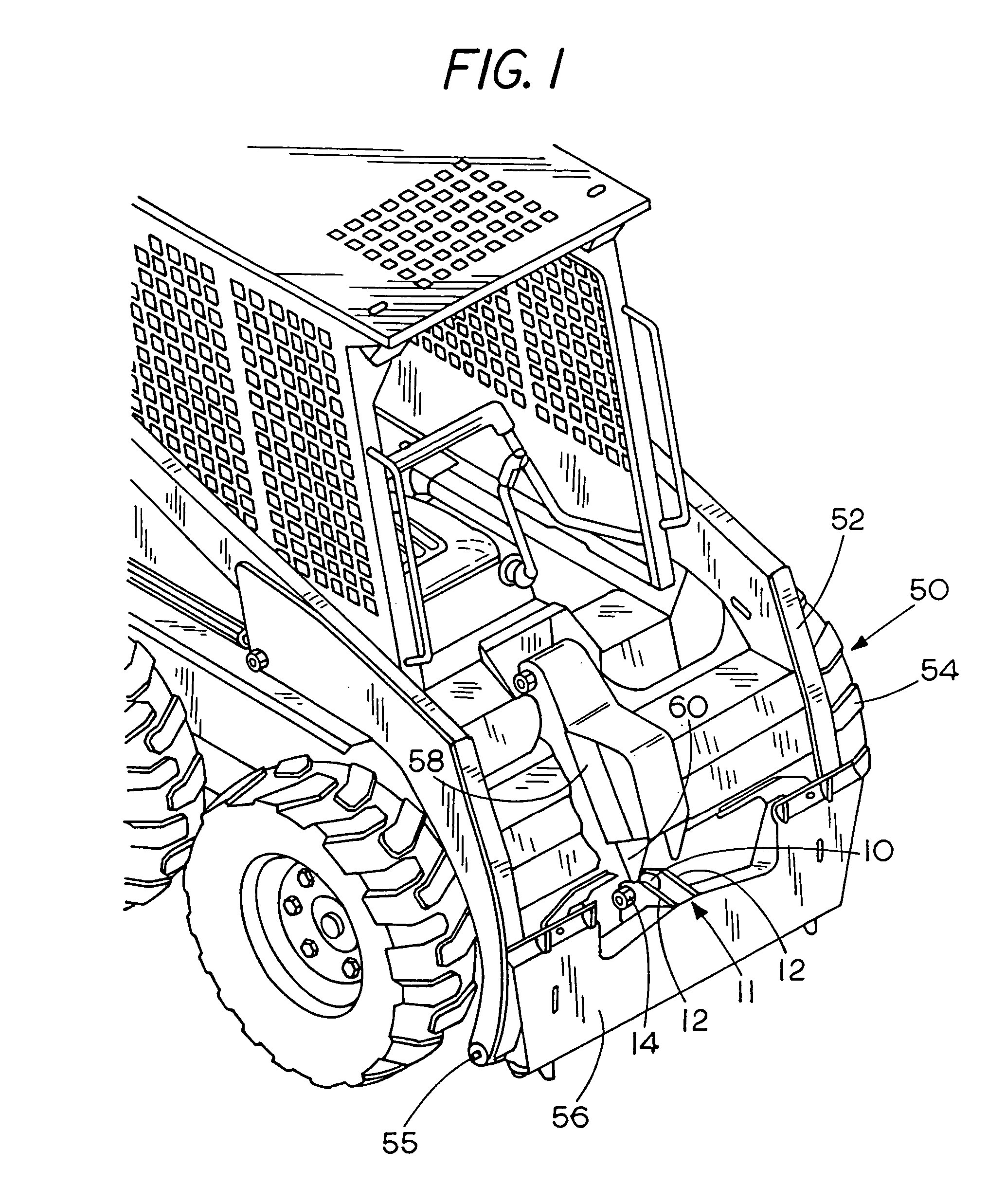

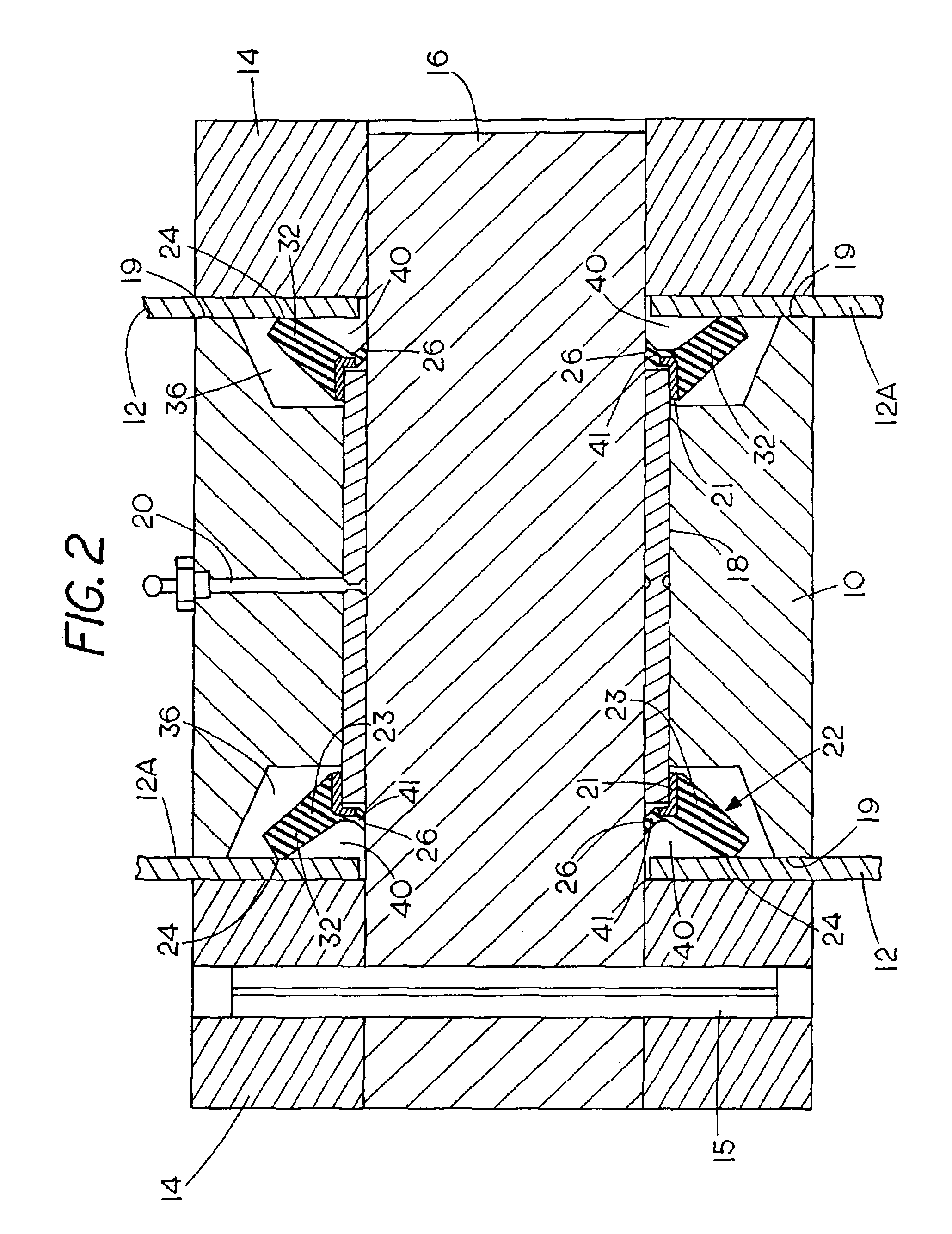

Two component seal

Owner:DOOSAN BOBCAT NORTH AMERICA INC

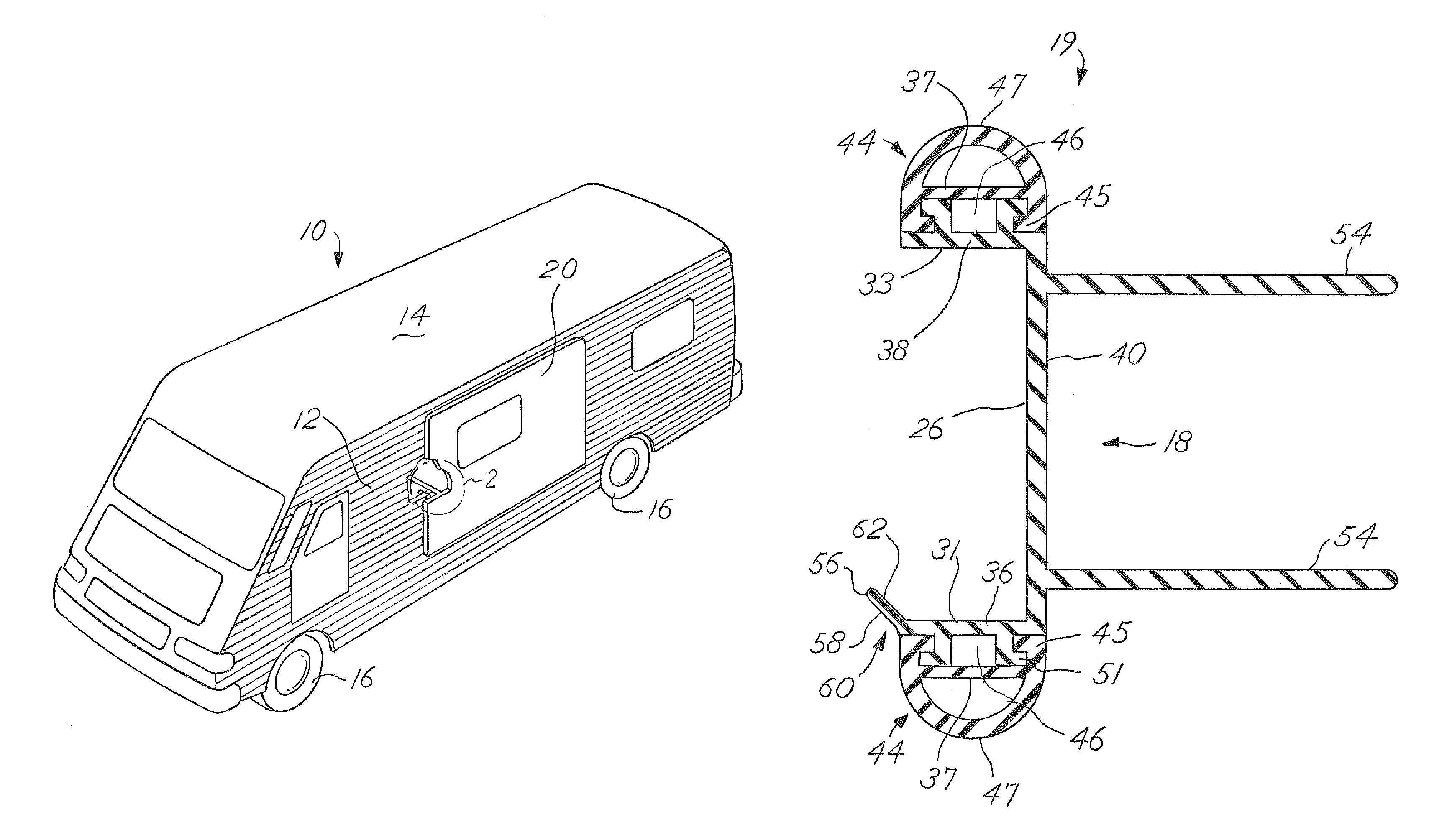

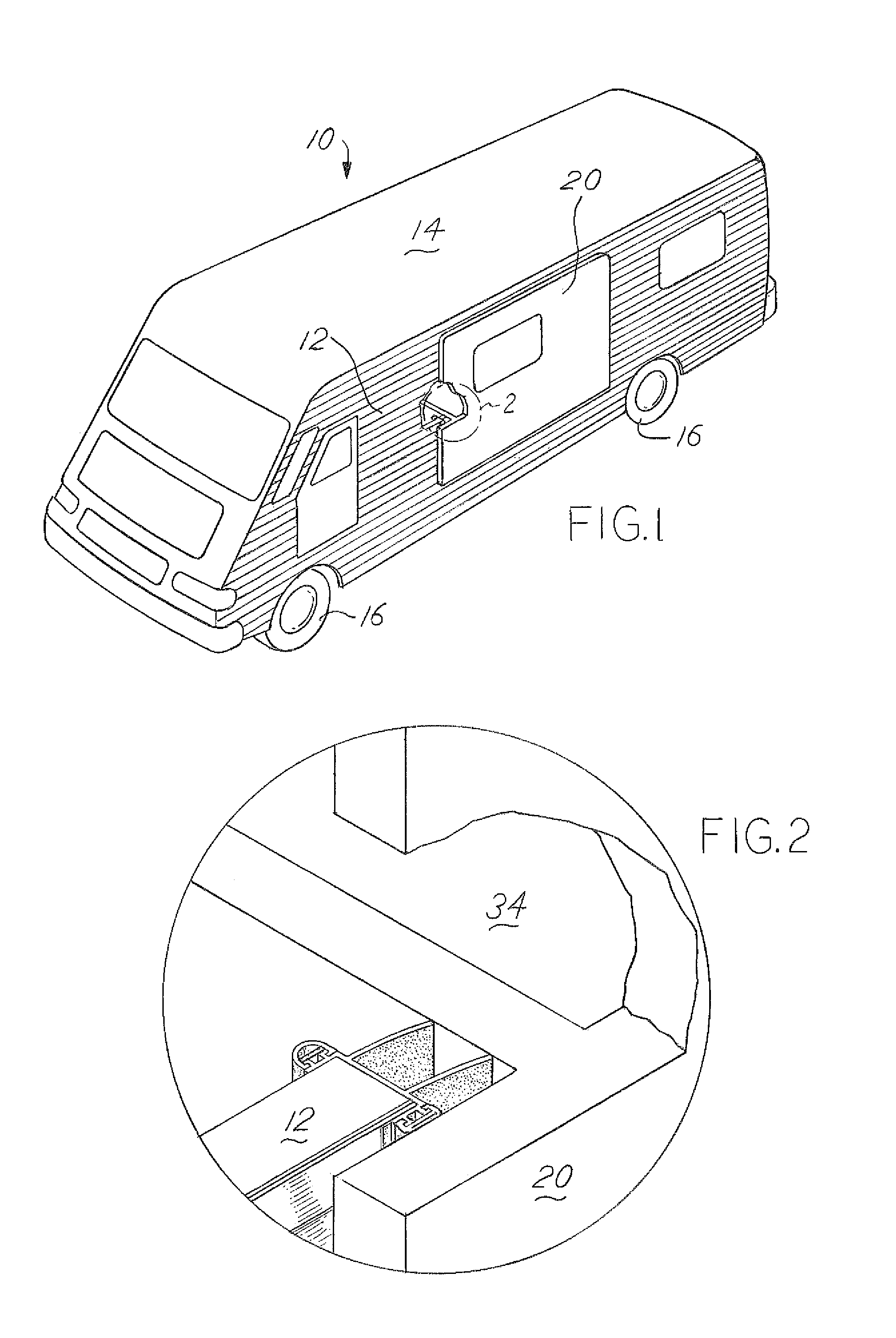

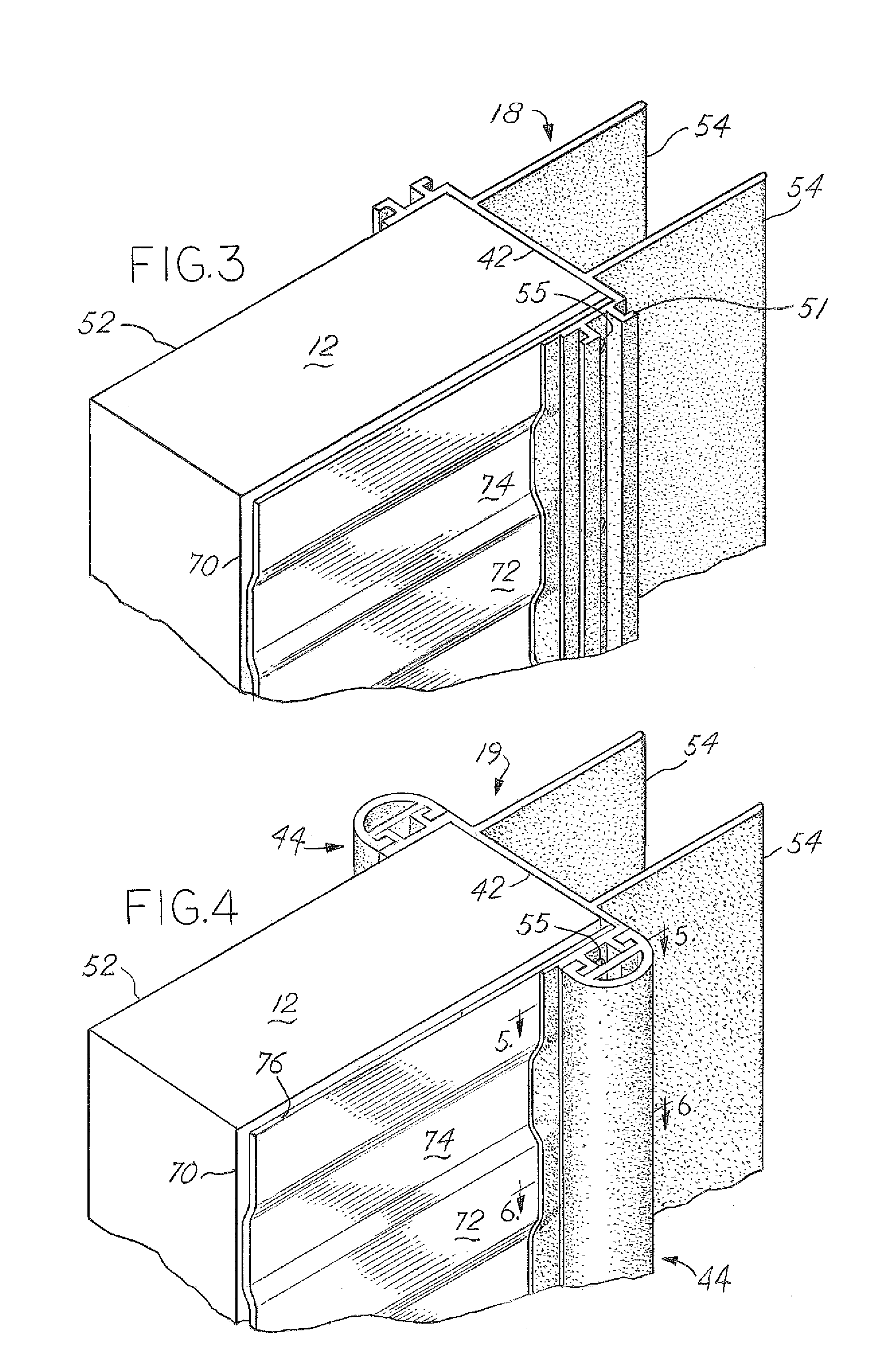

Edge seal with sidewall seal

A resilient seal for mobile living quarters around a slide out room that includes a pair of mounting portions extending along the inside and outside surfaces of the main living area wall at an aperture through which the slide out room moves and further includes a connecting member extending between the attaching members and along the edge of the wall defining the aperture. A wiper seal extends from the connecting member to flex against the walls of the slide out room, and the mounting portion further includes a lip seal for accommodating walls of different thicknesses.

Owner:LIFETIME INDS

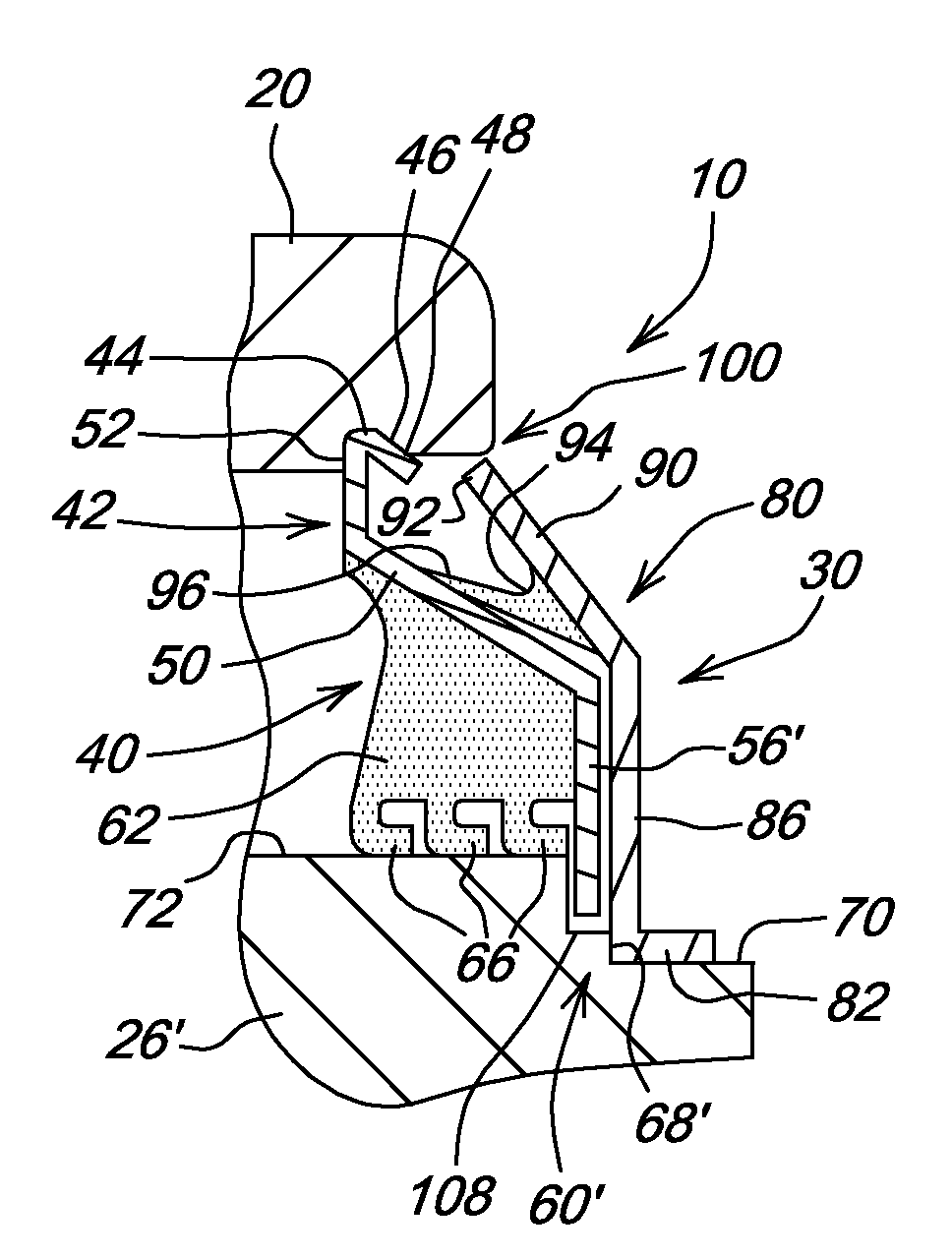

High pressure lip seals with Anti-extrusion and Anti-galling properties and related methods

ActiveUS20140265139A1High modulus materialReduce the possibilityEngine sealsEngineeringHigh pressure

Sealing assemblies to provide sealing between a shaft and a housing comprising a sealing component comprising a body section as well as an outer flange and an inner flange both extending from said body section; a supporting component receiving said sealing component and comprising a relatively thick inner arm projecting into said sealing component and providing a supporting area spanning an inner portion of said body section and a portion of said inner flange; an anti-extrusion component engaged with said relatively thick inner arm; the minimum clearance between said anti-extrusion component and said shaft being less than the minimum clearance between said relatively thick inner arm and said shaft; said inner flange comprising a sealing area; wherein said sealing assembly is to be received in a cavity in said housing or on said shaft.

Owner:BAL SEAL ENG LLC

Lip seal for roller cone drill bit

The present invention is generally directed to various embodiments of a radial lip seal for use with roller cone drill bits. In one illustrative embodiment, a drill bit is disclosed that is comprised of a spindle, a rolling cutter positioned around the spindle, the rolling cutter having a seal recess formed therein, the seal recess having an outer surface, and a lip seal positioned in the seal recess and around the spindle, wherein at least one void is intentionally established between the outer surface of the seal recess and the outer surface of the lip seal. In another illustrative embodiment, the method comprises providing a drill bit comprised of a spindle, a rolling cutter positioned around the spindle, the rolling cutter having a seal recess formed therein, the seal recess having an outer surface, and a lip seal positioned in the seal recess and around the spindle, wherein at least one void is intentionally created between the outer surface of the seal recess and the outer surface of the lip seal. The method further comprises positioning the drill bit in a well bore, wherein the at least one void is at least partially collapsed when the drill bit is subjected to hydrostatic pressure in the well bore, and performing drilling operations with the drill bit.

Owner:GP USA HLDG LLC

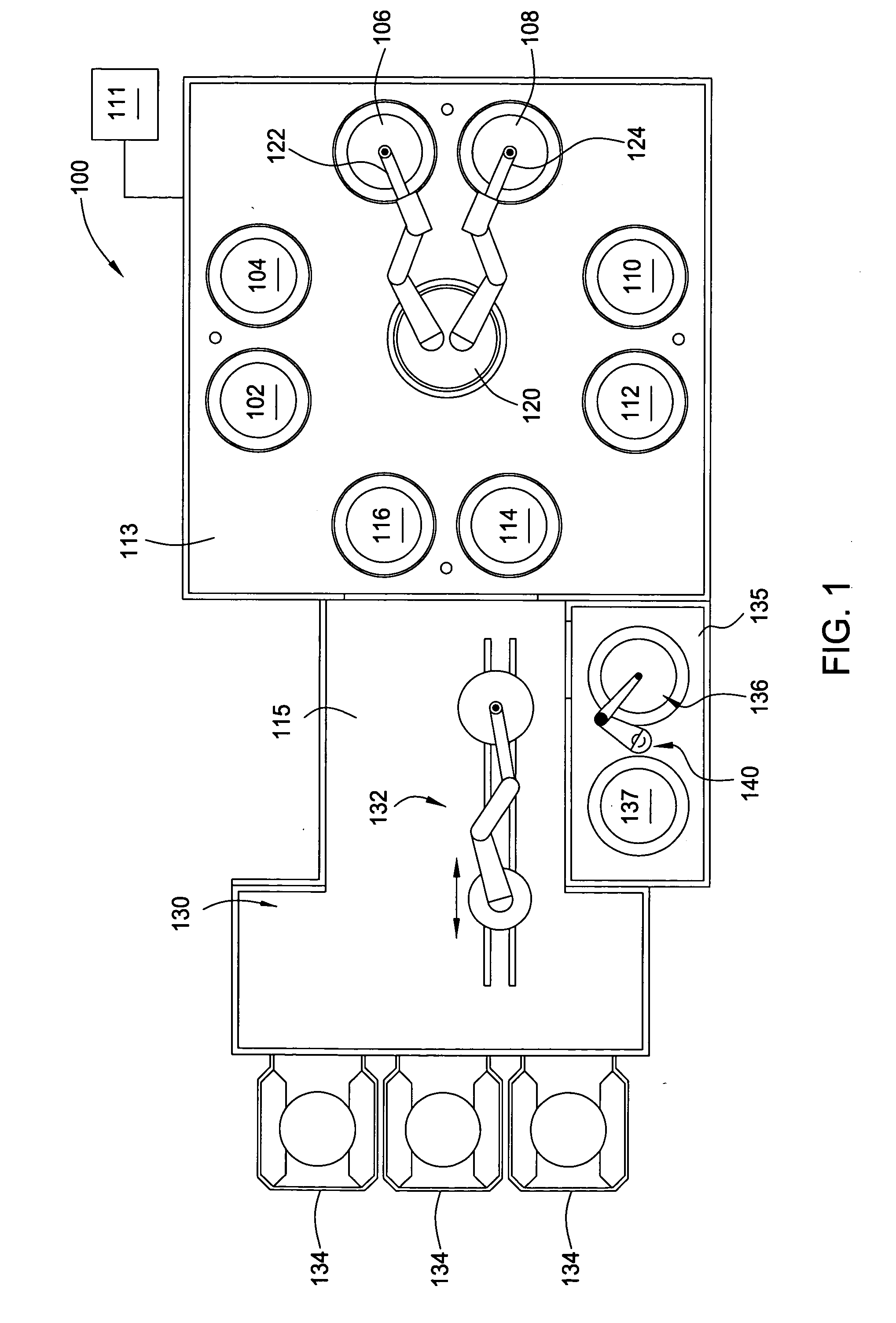

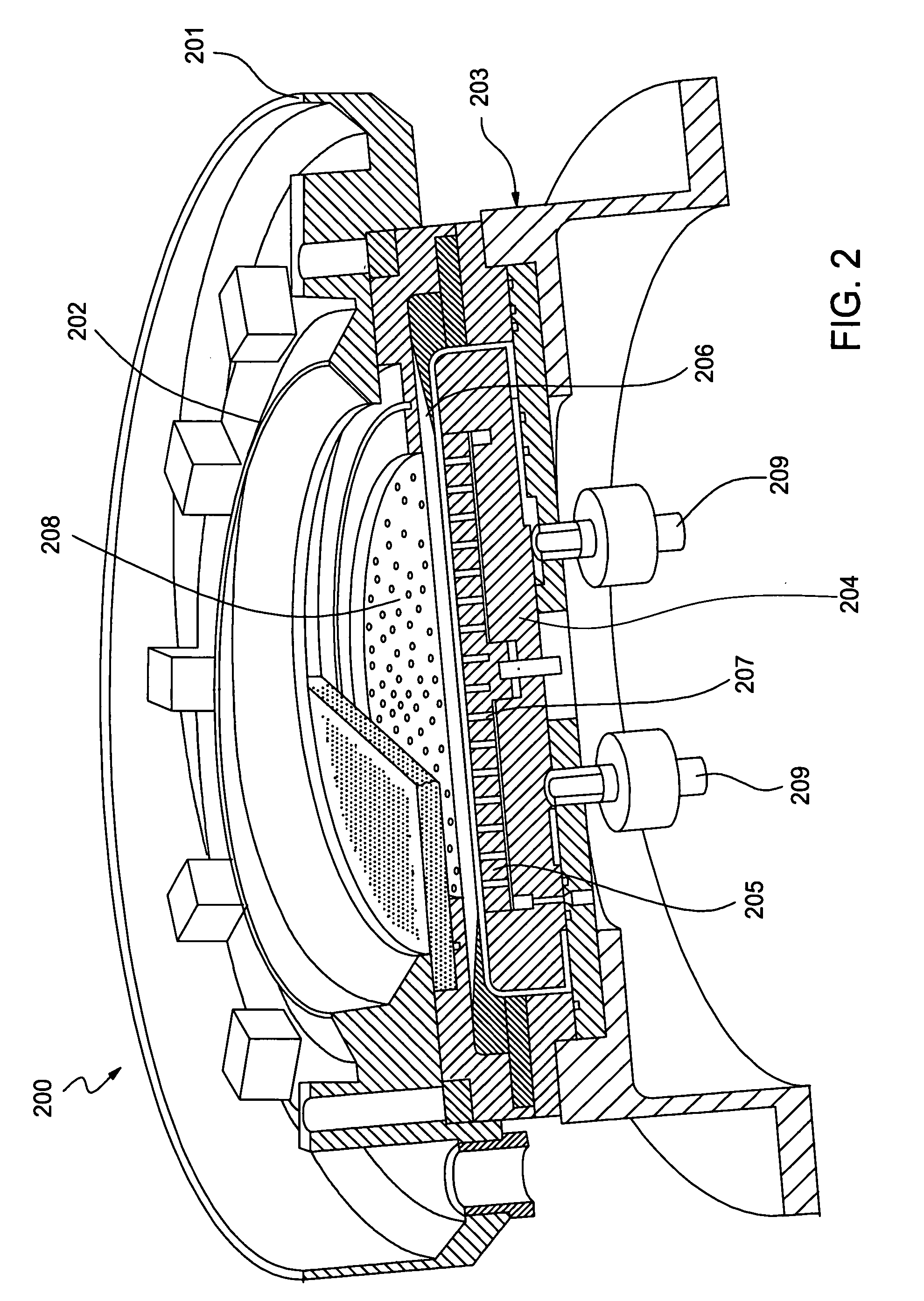

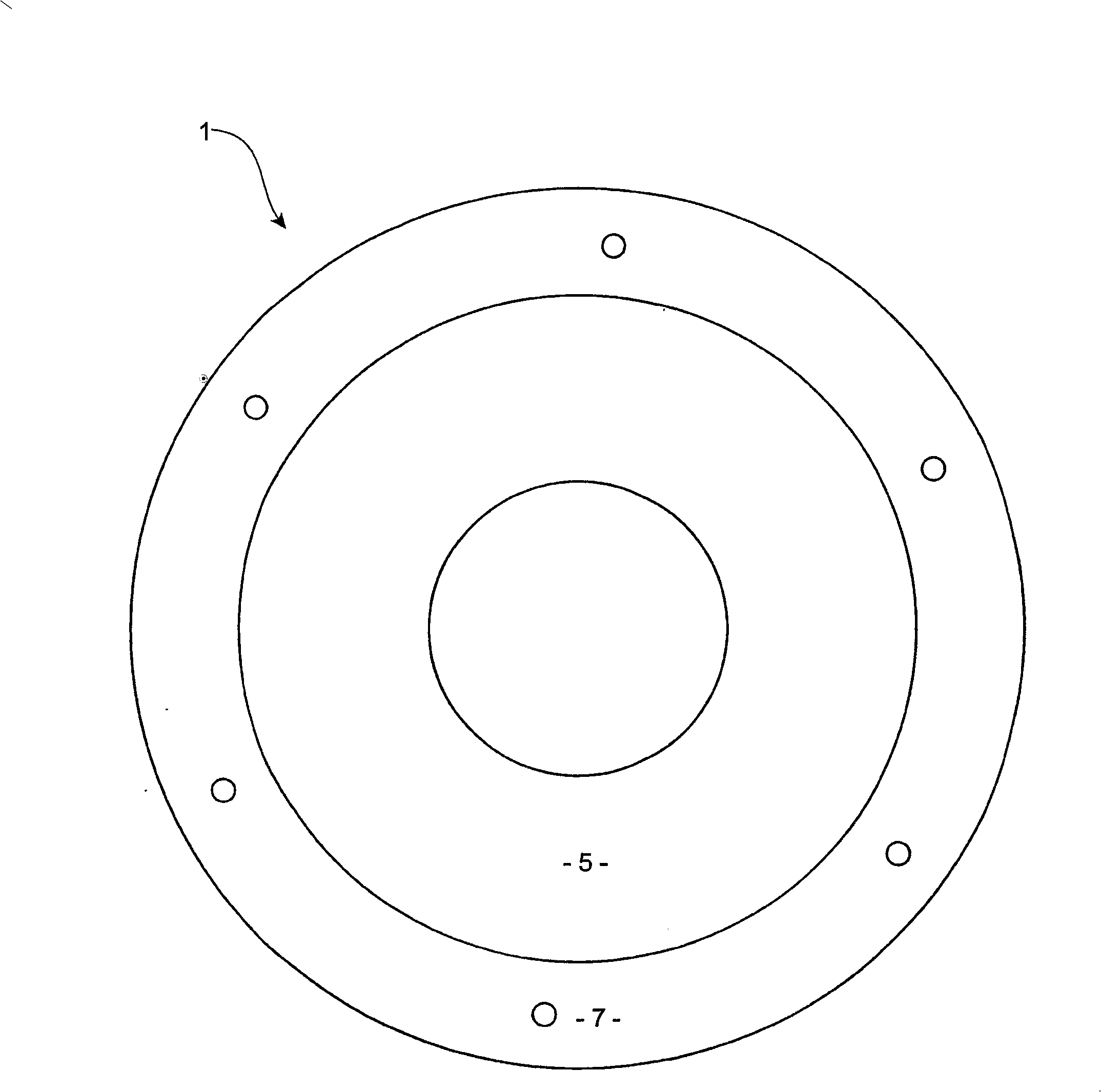

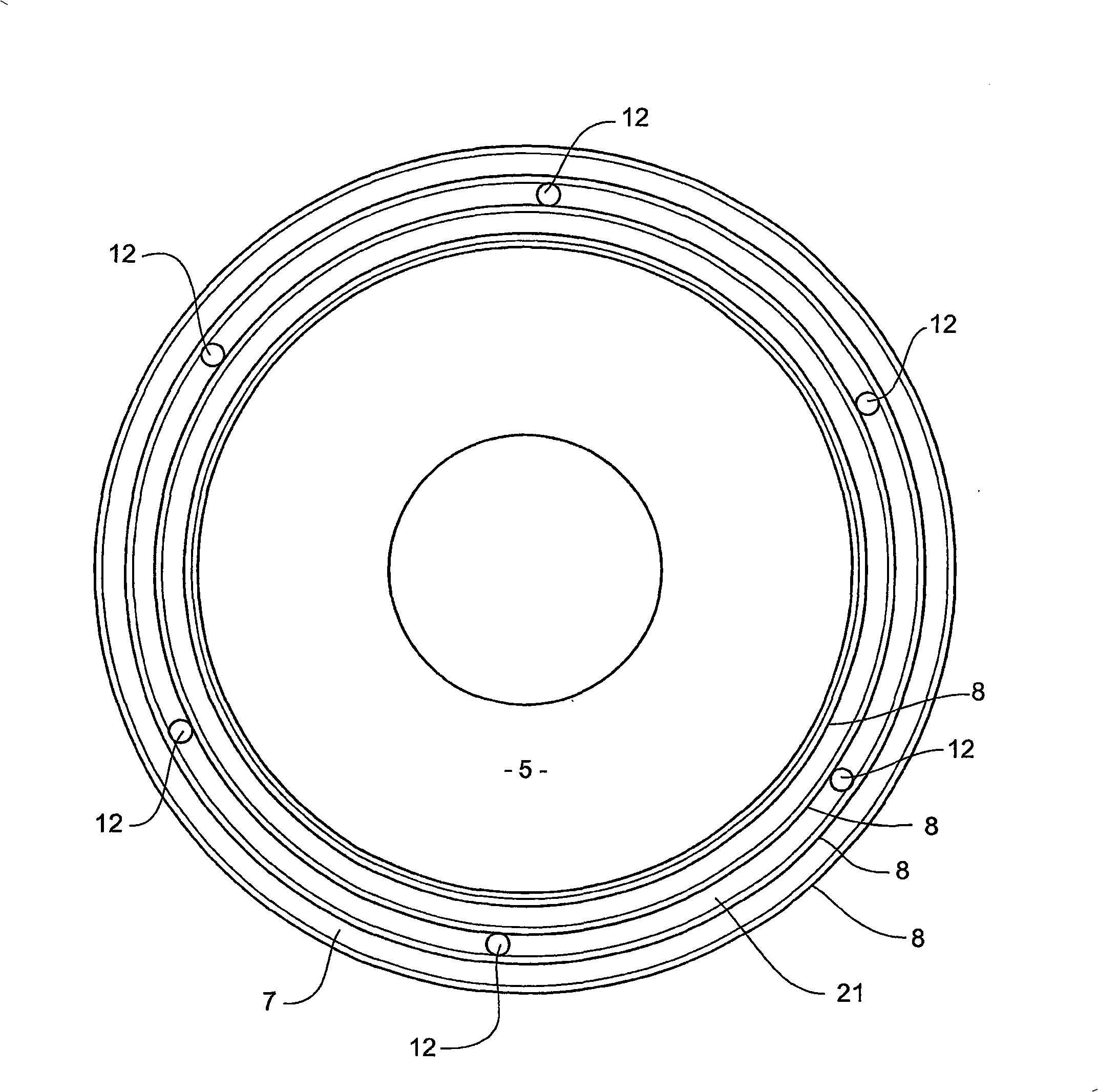

Electric field reducing thrust plate

A method and apparatus for an electrochemical processing cell that is configured to minimize bevel and backside deposition. The apparatus includes a contact ring assembly for supporting a substrate, a thrust plate movably positioned to engage a substrate positioned on the contact pins, and a lip seal member positioned to contact the thrust plate and the contact ring to prevent fluid flow therebetween. The lip seal includes a at least one bubble release channel formed therethrough. The method includes positioning an electric field barrier between a backside substrate engaging member and a frontside substrate supporting member to prevent electric field from traveling to the bevel and backside of the substrate. The electric field barrier including at least one bubble release channel formed therethrough.

Owner:APPLIED MATERIALS INC

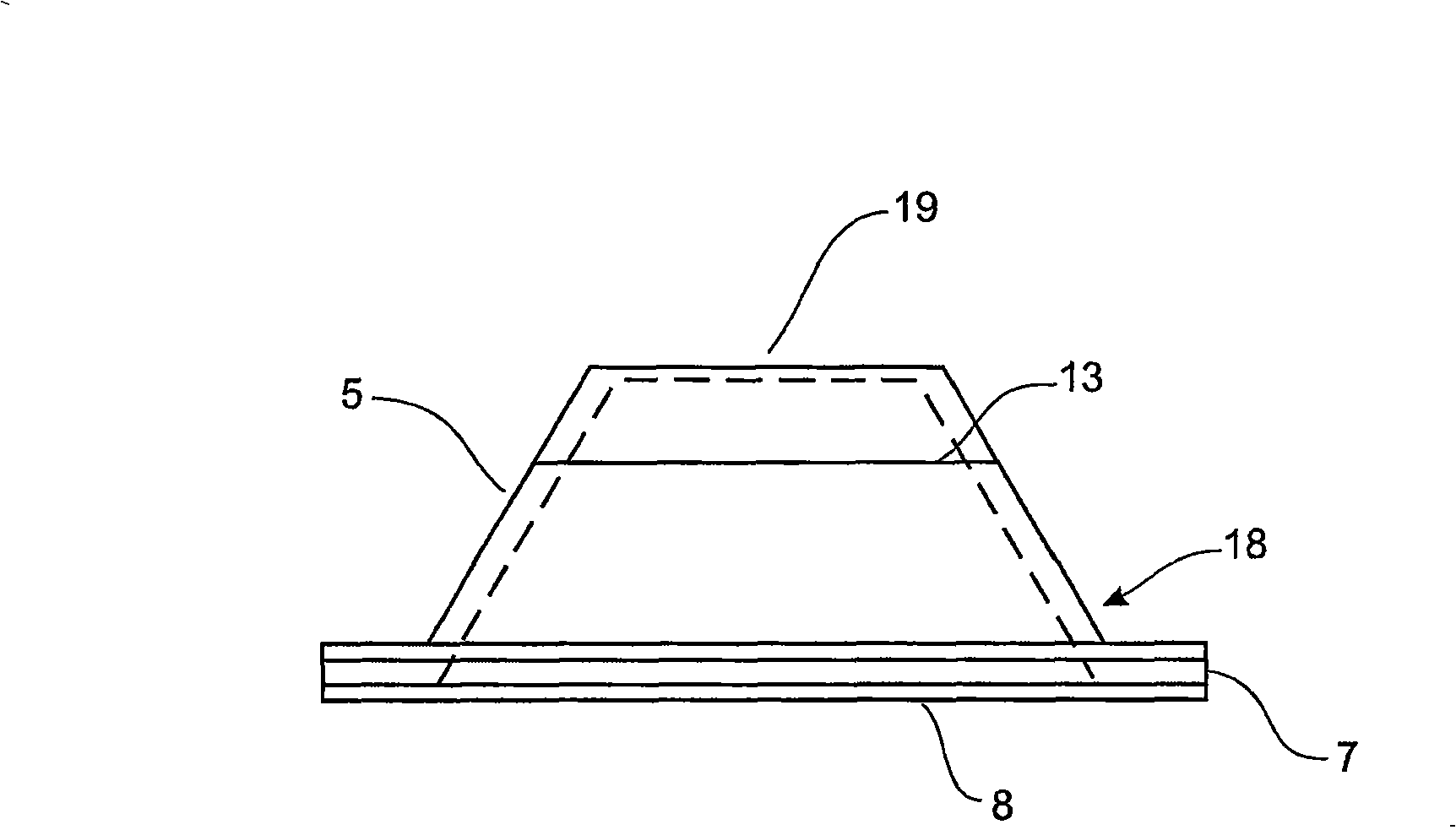

A peripheral sealing gland for elongate objects passing through a surface or beyond a pipe end

The disclosure relates to a peripheral sealing gland to form a seal, between an elongate member and a substantially flat surface. The gland has an at least in part tapered skirt or frustoconical shaped skirt through which the elongate member is to pass and defining at the upper periphery of the skirt and deformable upper seal to deform about and seal to a periphery of said elongate member. A flange depends from the lower periphery of the skirt including on its outward from the skirt presented surface, at least one endless lip to seal when brought into contact, against said substantially flat surface. A compression ring is able to bear on said flange, to be fastened to said substantially flat surface to capture the flange therebetween. In an alternative embodiment a planar flange with at least one endless lip seal is disclosed, and a further alternative embodiment combines this with the frusto-conical shaped skirt.

Owner:LAKE PROD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com