Patents

Literature

2375 results about "Agitator" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An agitator is a device or mechanism to put something into motion by shaking or stirring. There are several types of agitation machines, including washing machine agitators (which rotate back and forth) and magnetic agitators (which contain a magnetic bar rotating in a magnetic field). Agitators can come in many sizes and varieties, depending on the application.

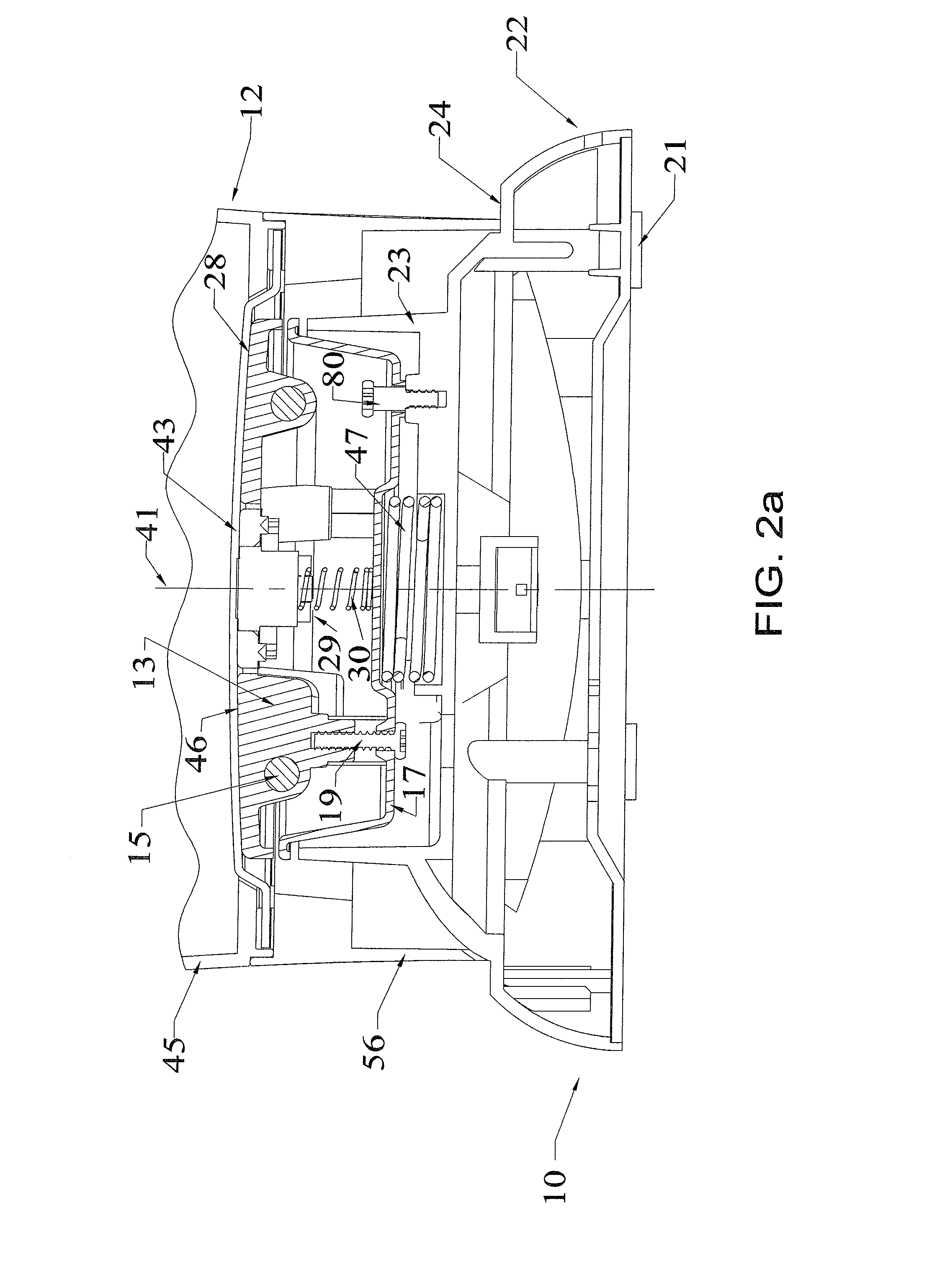

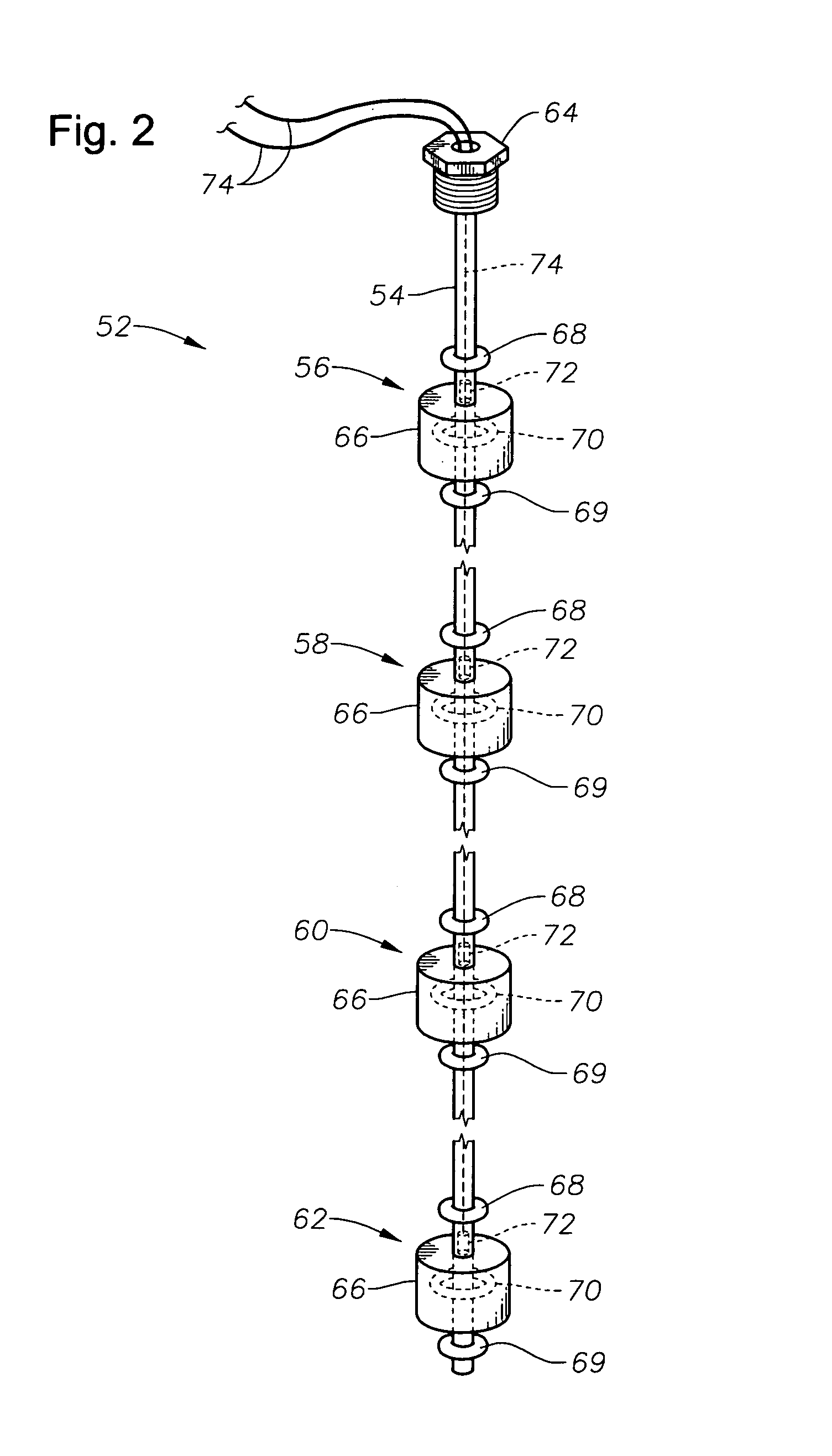

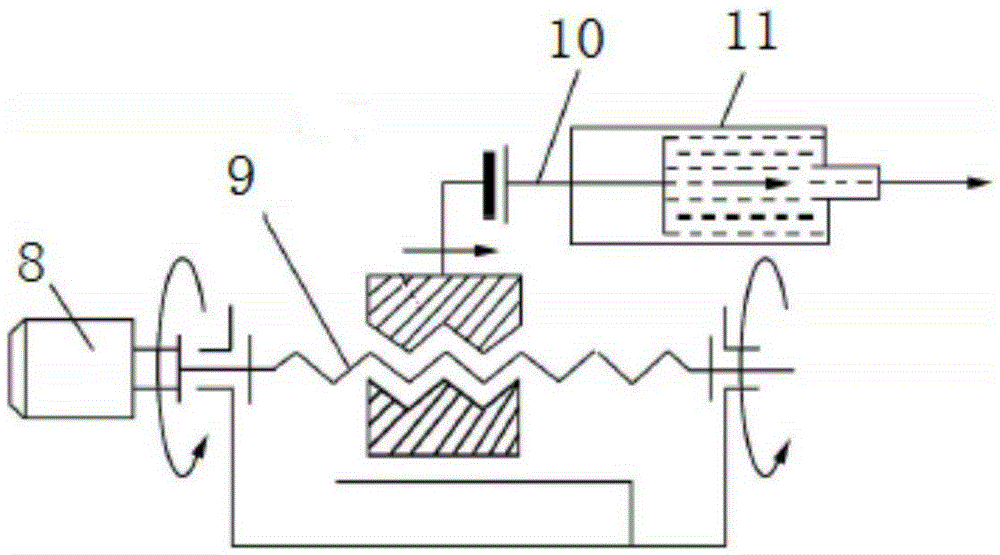

Small-scale mill and method thereof

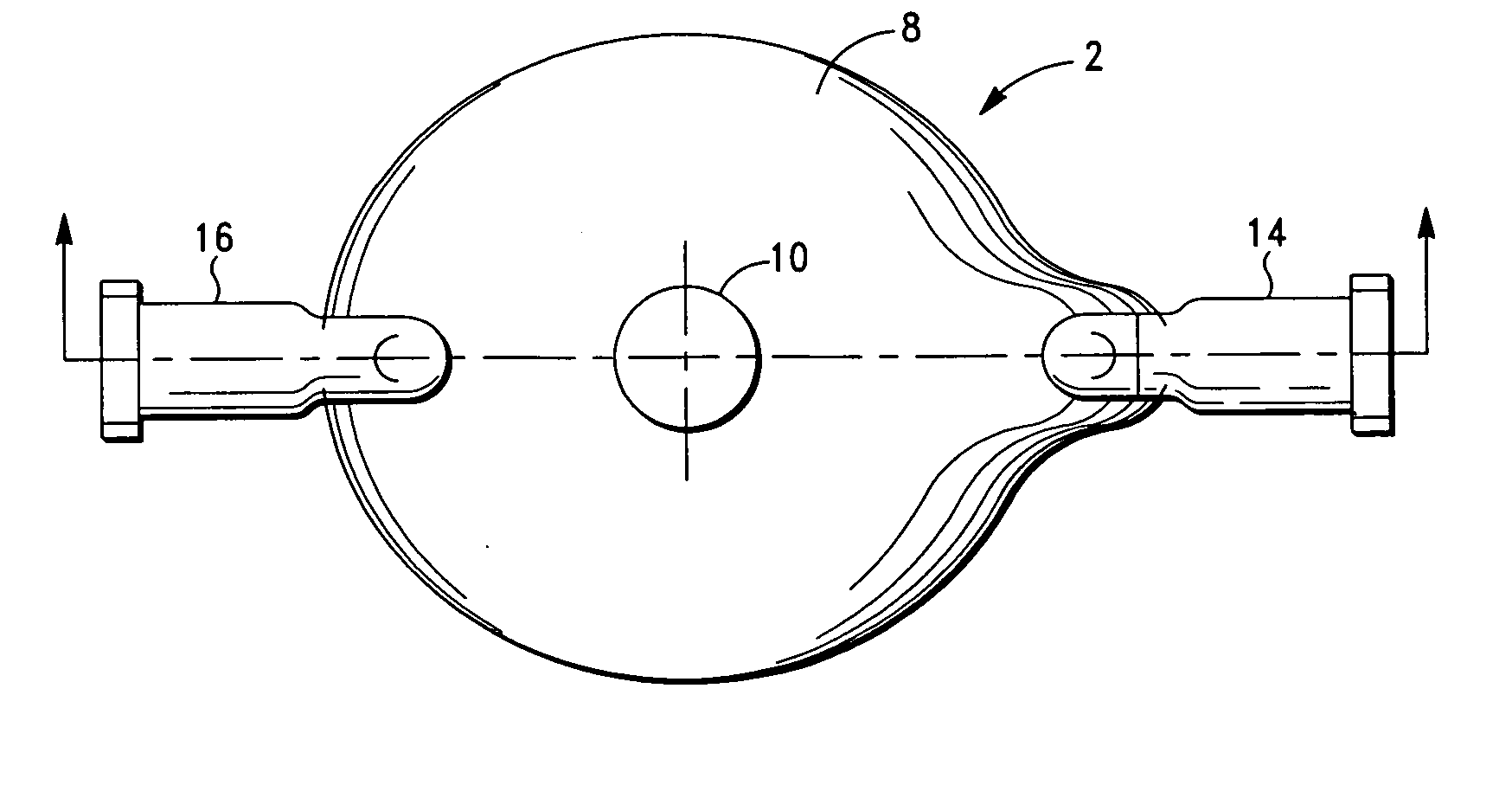

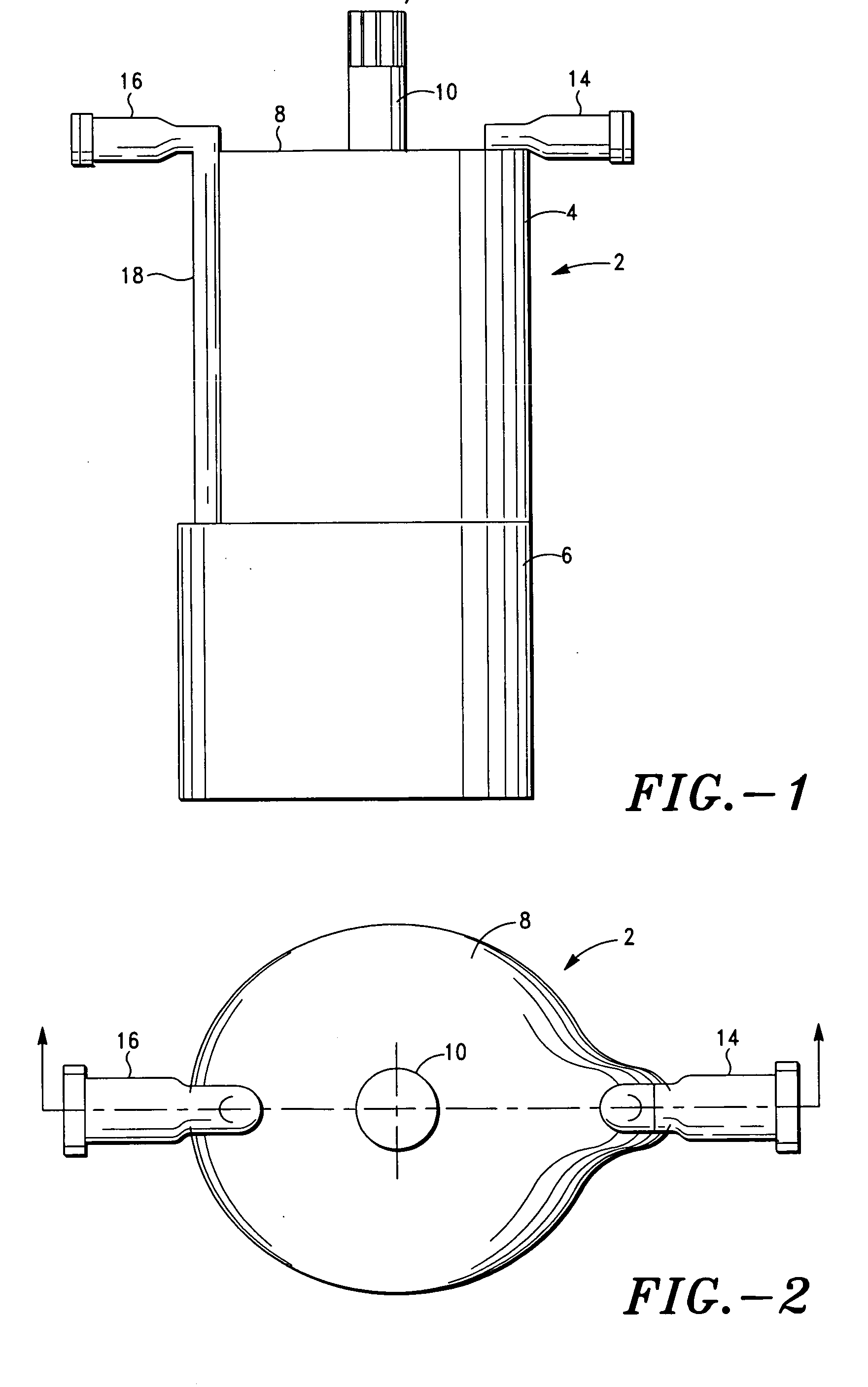

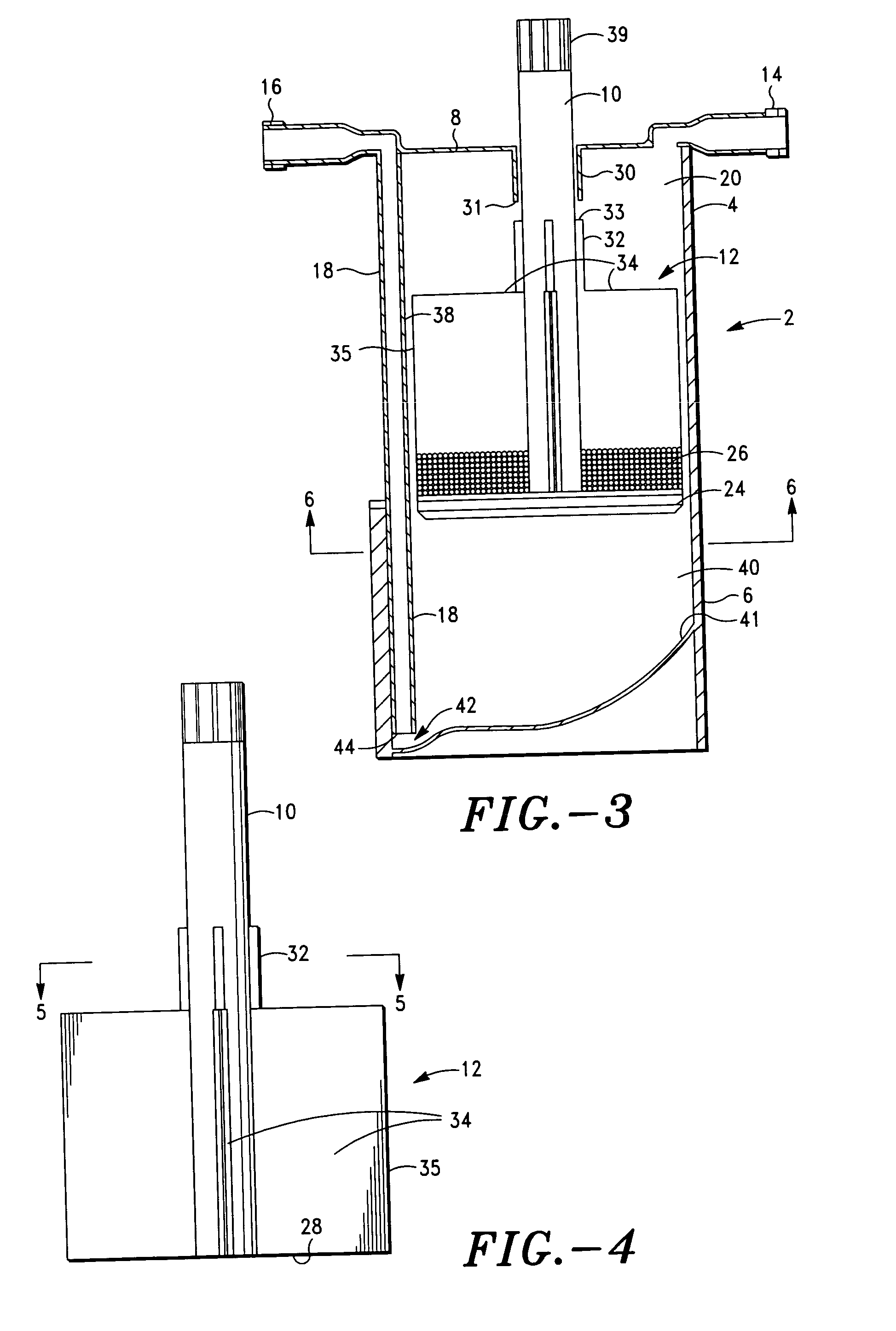

A small-scale or micro media-mill and a method of milling materials or products, especially pharmaceutical products, use a dispersion containing attrition milling media and the product to be milled. The milling media can be polymeric, formed of polystyrene or cross-linked polystyrene, having a nominal diameter of no greater than 500 microns. Other sizes include 200 microns and 50 microns and a mixture of these sizes. The mill has a relatively small vessel having an opening, an agitator, a coupling and a motor. The agitator can have a rotor and a shaft extending therefrom. The rotor can be cylindrical or have other configurations, and can have tapered end surfaces. The coupling can close the vessel opening, or attaching the coupling to the motor can close the opening. The coupling has an opening through which the rotor shaft extends into the motor. A sealing mechanism, such as a mechanical or lip seals the shaft while permitting the rotor shaft to rotate. The vessel can contain one or more ports for circulating the dispersion, where milling can be made in batches or recirculated through the milling chamber. The media can be retained in the vessel or recirculated along with the process fluid. The rotor is dimensioned so that its outer periphery is spaced with a small gap from an inner surface of the vessel. The vessel also can have a way of cooling the dispersion.

Owner:ALKERMES PHARMA IRELAND LTD

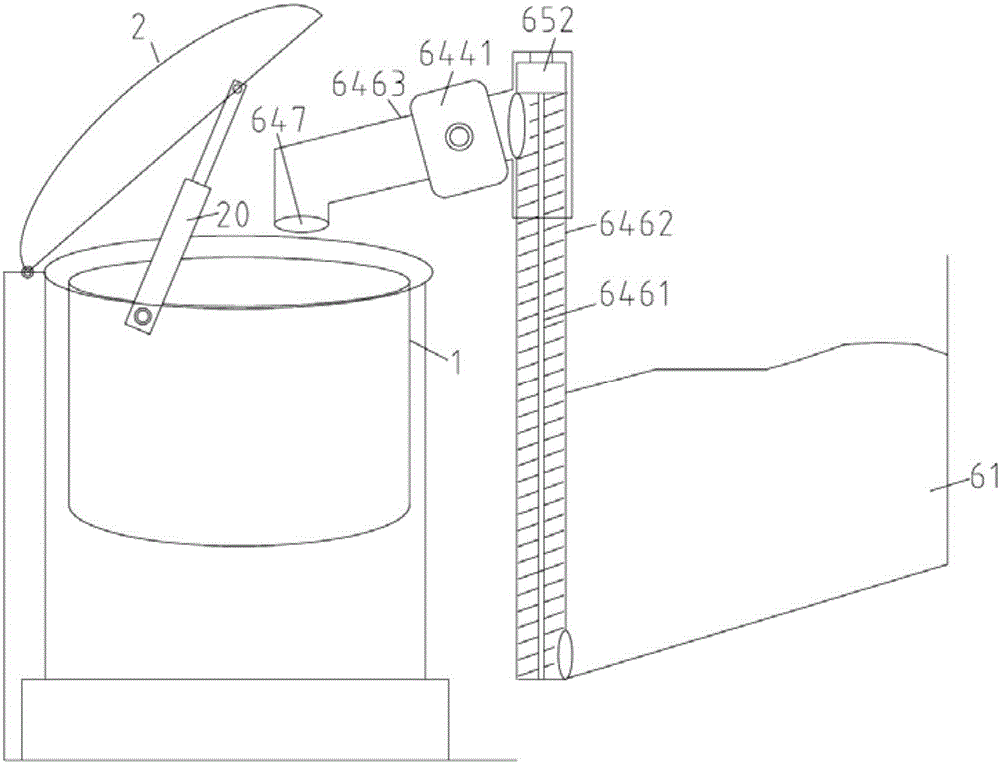

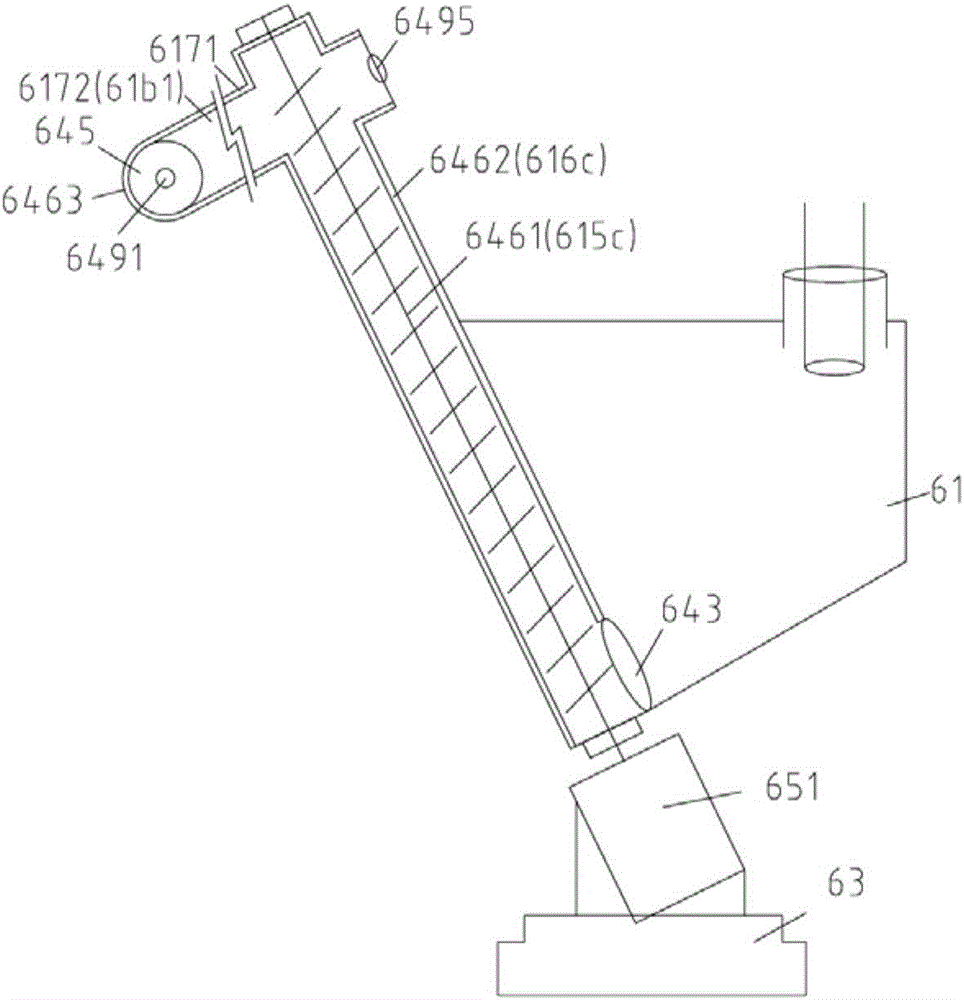

Supplying, dividing and feeding devices, cooking equipment and feeding method thereof

InactiveCN106419587ARealize feeding automationReduce labor workloadCooking-vessel lids/coversCooking vessel constructionsElectricityMating

According to the embodiment, the invention relates to the technical field of smart home, and discloses a feeding device of cooking equipment and the cooking equipment. The feeding device comprises a dividing device and a supplying device, wherein the dividing device adopts a worm or a disc provided with a charging groove; cooking raw materials in a storage box are supplied to a supplying device; and the dividing device and the supplying device are separated when the cooking raw materials are weighed. According to the supplying device, the cooking raw materials are conveyed into a pot body of the cooking equipment by virtue of a wind power device / vacuum device, or by virtue of a horizontal worm in a horizontal conduit and through self-gravity of the cooking raw materials, so that automatic feeding of the cooking equipment is achieved and workload of a user is reduced; a multipurpose mating device is provided for a plurality of intelligent home products, and a foundation is created for intelligent kitchen appliances or the smart home. The dividing device is applicable to such intelligent cooking equipment as an electric cooker, a bread maker, a frying machine, a soybean milk making machine, a bean curd machine, a stirrer, a coffee machine or a tea maker and the like.

Owner:李亚锐

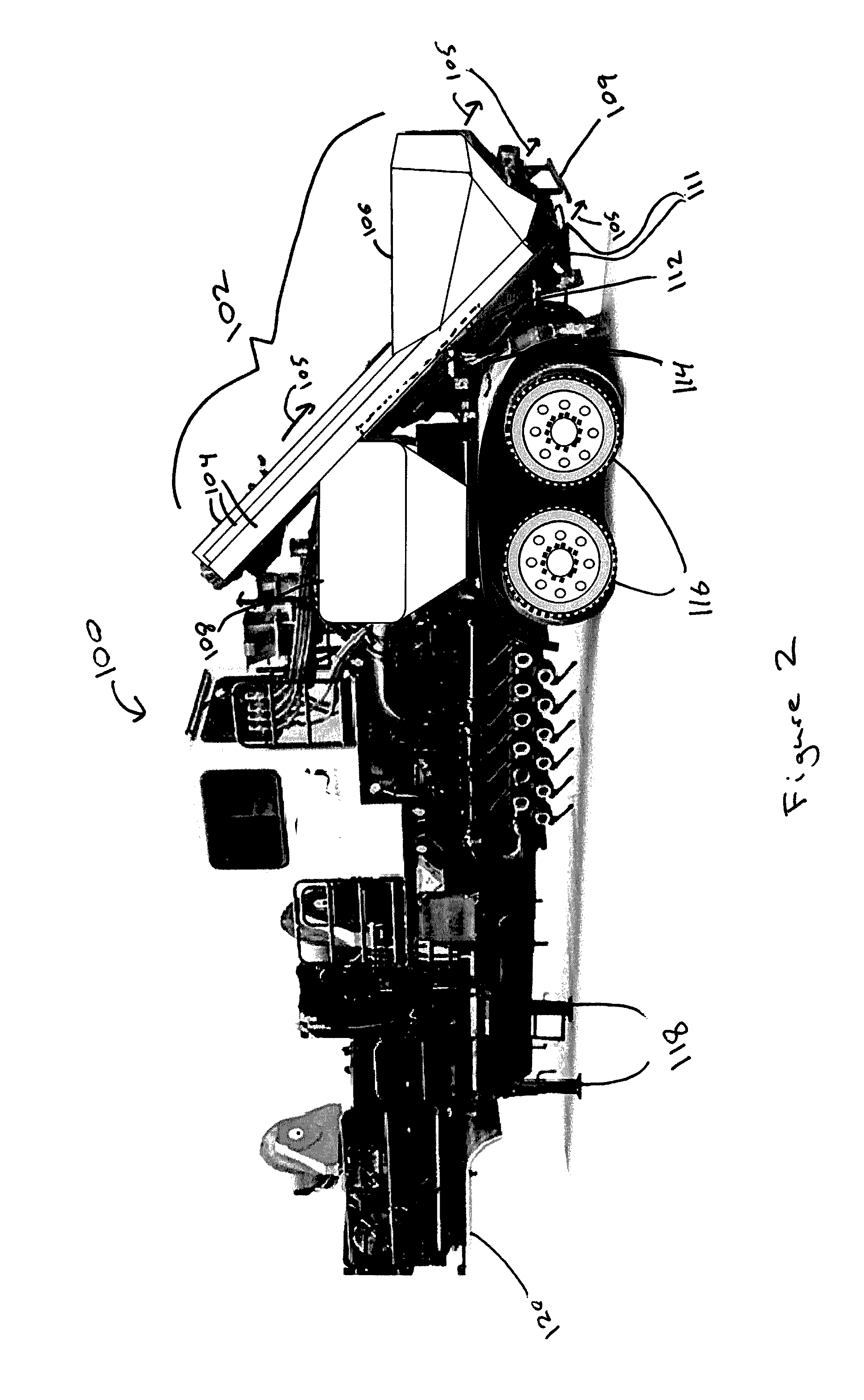

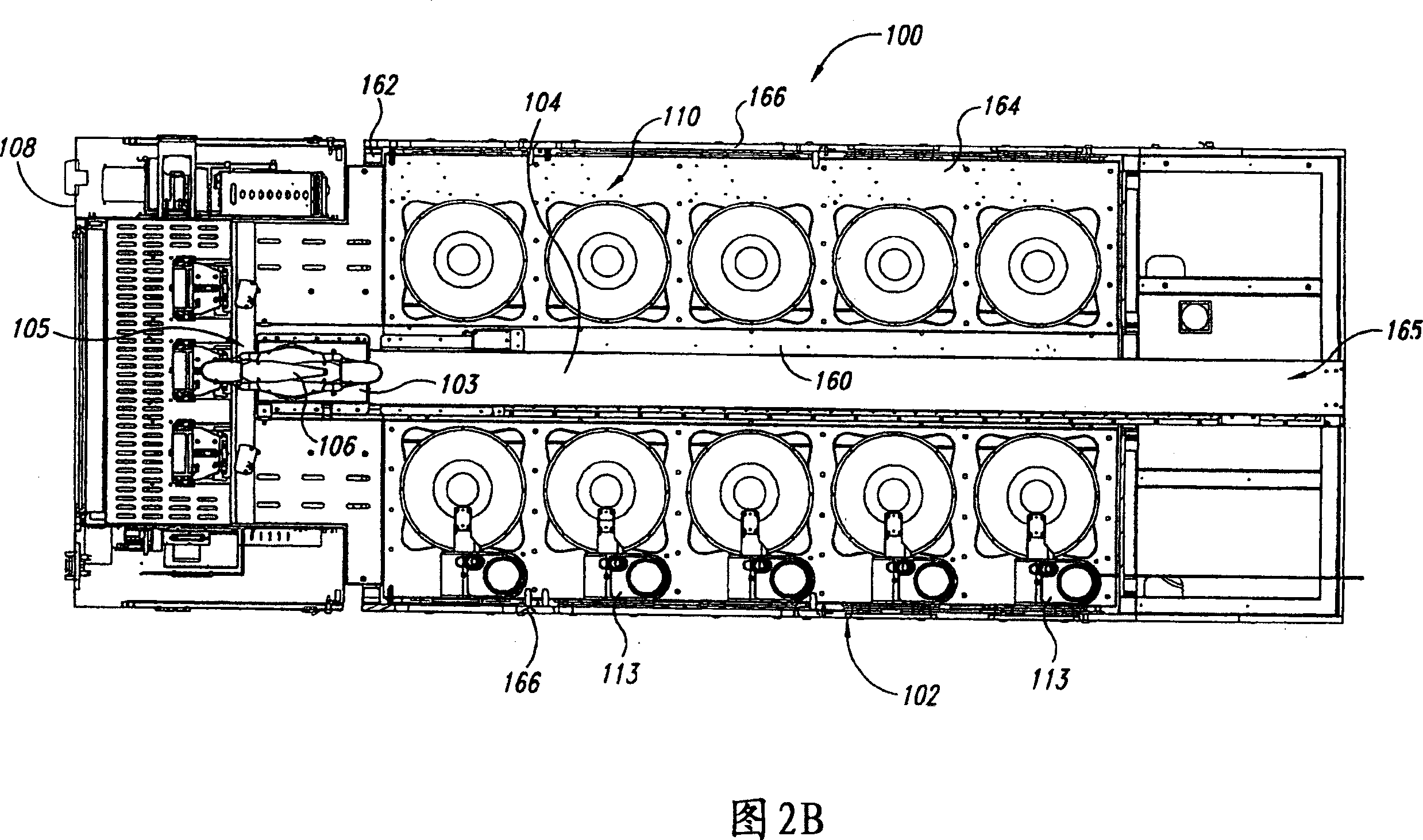

Independent control of auger and hopper assembly in electric blender system

Embodiments relate to a hydraulic fracturing system that includes a blender unit. The system includes an auger and hopper assembly to receive proppant from a proppant source and feed the proppant to the blender unit for mixing with a fluid. A first power source is used to power the blender unit in order to mix the proppant with the fluid and prepare a fracturing slurry. A second power source independently powers the auger and hopper assembly in order to align the hopper of the auger and hopper assembly with a proppant feed from the proppant source. Thus, the auger and hopper assembly can be stowed or deployed without use of the first power source, which is the main power supply to the blender unit.

Owner:US WELL SERVICS LLC

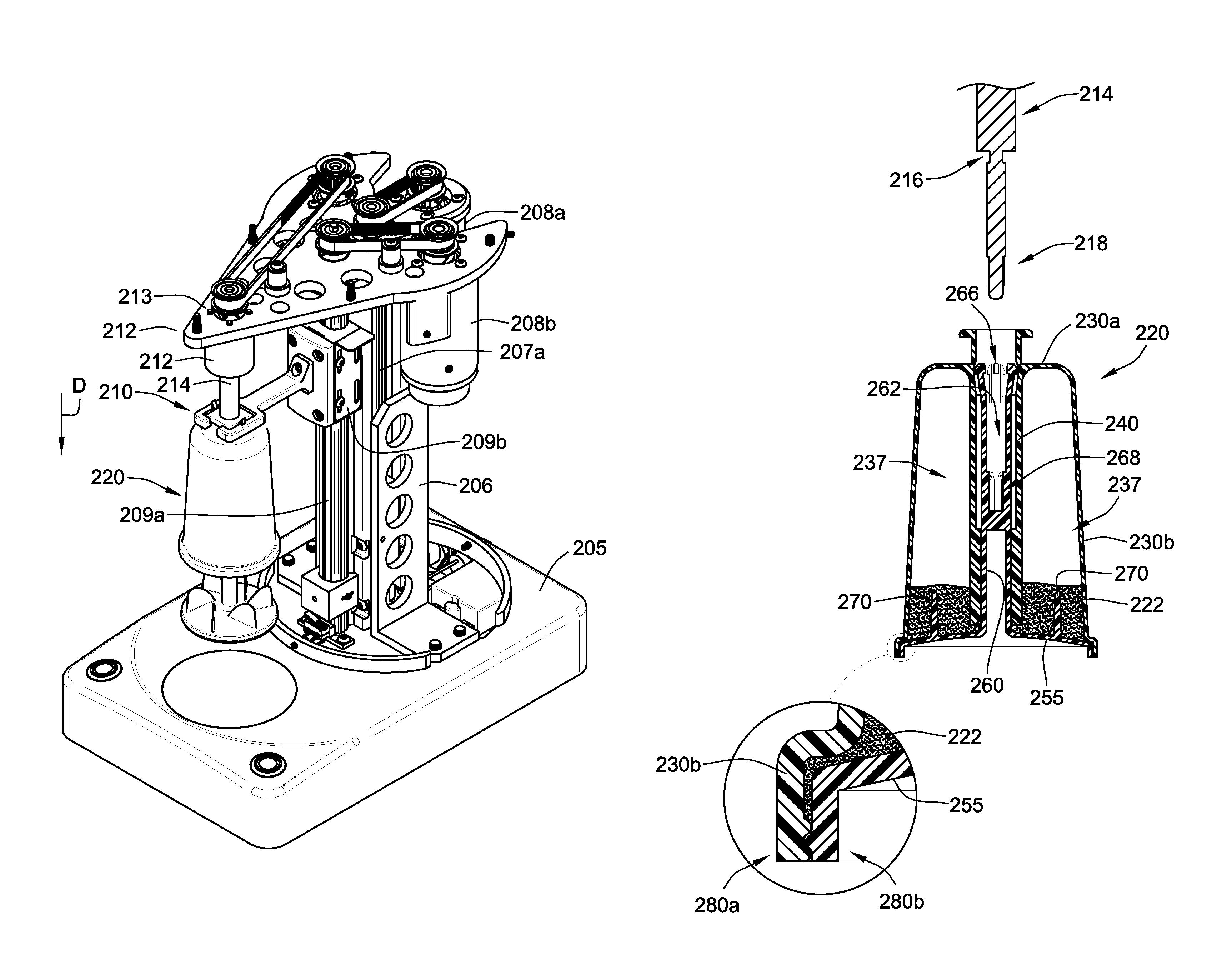

System for mixing beverages and method of doing the same

ActiveUS8960999B1Easily inserted intoEasy to removeDispensing apparatusRotary stirring mixersEngineeringMechanical engineering

A beverage mixing system includes a housing, a sealing feature, a locking feature, and an agitator. The housing has an opening separating inner and outer surfaces and a boss that extends through the housing such that part of the outer surface forms an inner bore of the boss having a terminus pointing toward the opening. The agitator has a base, a shaft, and a mixing element coupled to the base such that the base, in cooperation with the sealing feature, circumferentially seals the opening of the housing to form a cavity defined by the inner surface. The shaft passes through the inner bore. The locking feature when engaged permits independent or simultaneous translational and rotational movement of the shaft while an area between the terminus of the boss and the shaft remains mechanically sealed during the movement against liquid or powder encroachment into a clean area of the inner bore.

Owner:GUDPOD CORP

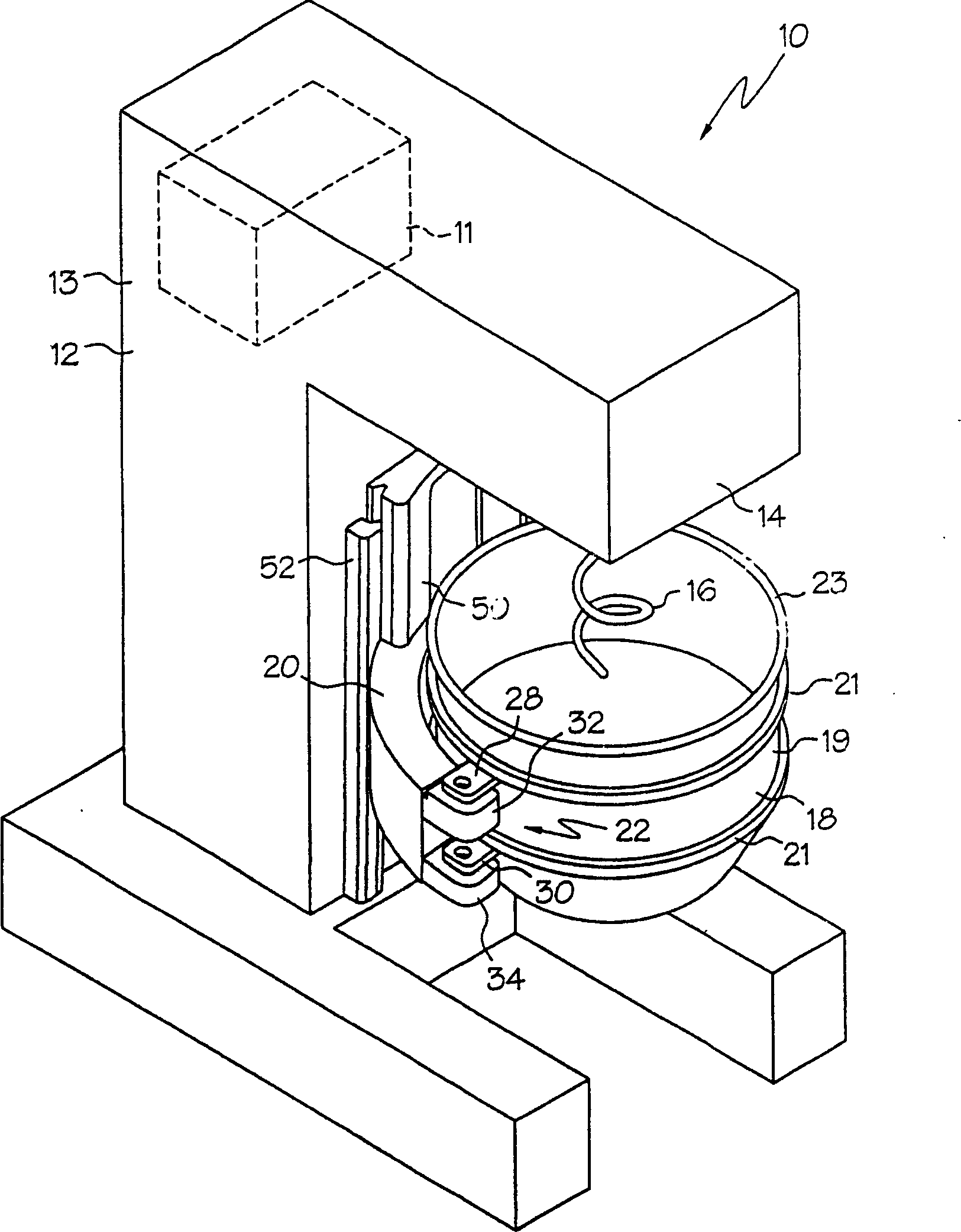

Plasma concentrator device

ActiveUS20060175268A1Reduce plasma polarizationSufficient amountWater/sewage treatment by centrifugal separationRotary centrifugesReciprocating motionBlood plasma

A plasma concentrator of this invention having a concentrator chamber, concentrator gel beads, a filter, and an agitator. The agitator has agitator blades extending outwardly from the lower end. The agitator end is positioned in the concentrator chamber and supported for rotation about its central axis and for reciprocal movement along its central axis. The concentrator has a top with an upper opening through which the upper end of the actuator stem extends, and a lower opening in which the filter is positioned. The concentrator chamber can have a cylindrical inner wall, and the agitator blades can have an outer edge in close proximity to the inner wall with the space between the outer edge and the inner wall being less than the diameter of the gel beads. The filter is selected to block effective flow of plasma therethrough under ambient gravity conditions and permit plasma and plasma concentrate flow therethrough under centrifugal forces of the separation gravity. The method concentrates plasma by removing water without significantly denaturing the fibrinogen in the plasma. The plasma is introduced into a concentration chamber containing a plurality of dehydrated concentrator gel beads and an agitator. Then water is removed from the plasma while stirring the beads to reduce plasma polarization and breaking up clumps of beads that form during the agitation. Then centrifugal force can be applied to the concentrated plasma in an amount sufficient to separate a substantial portion of the plasma concentrate from the beads.

Owner:HANUMAN +1

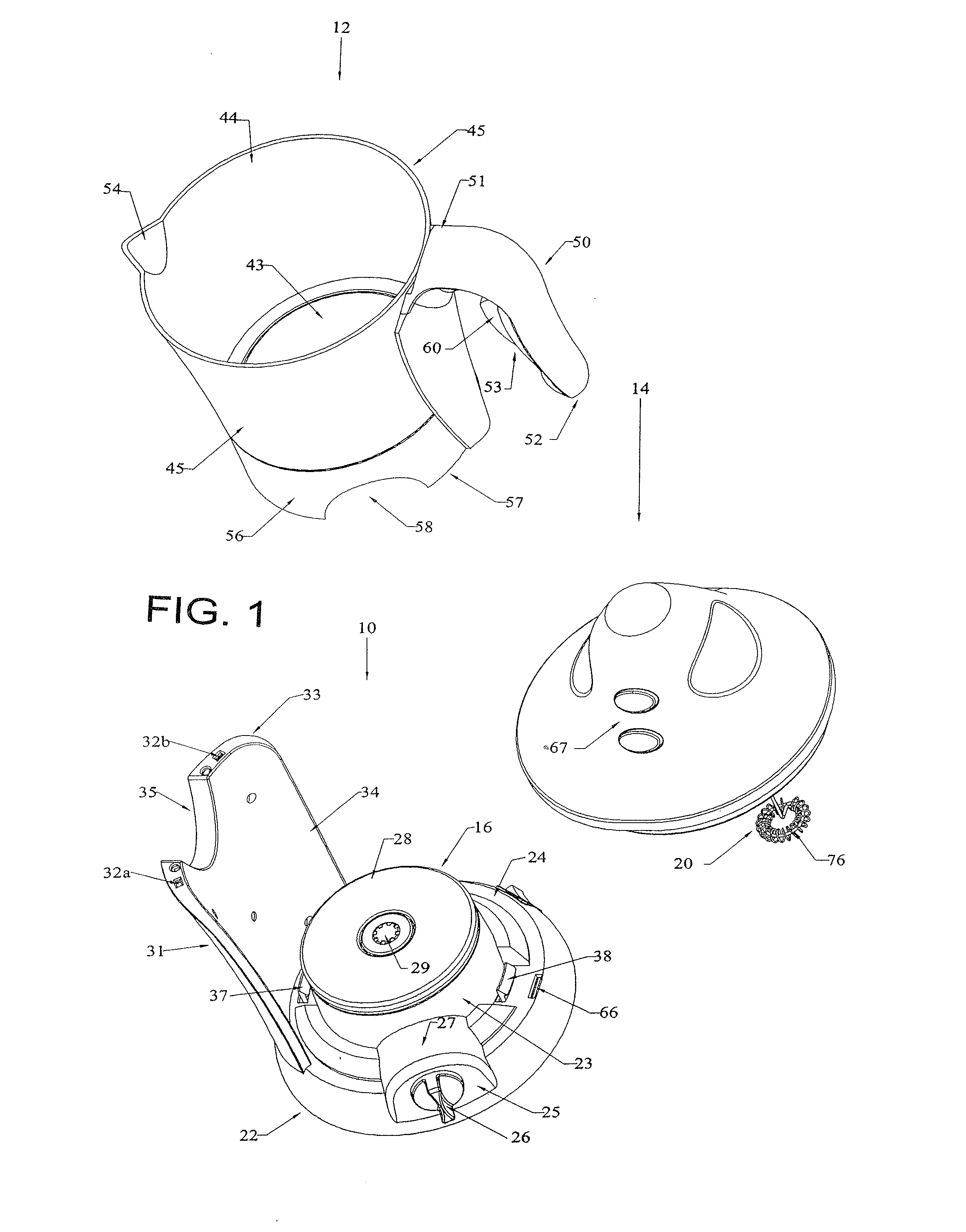

Appliance for simultaneous cooking and stirring

InactiveUS20130074700A1Effective and efficient in operational useVersatile convenient and safe to useRotary stirring mixersCooking-vessel lids/coversGear wheelAgitator

A cooking appliance includes a base upon which a pot is supported, with a stirrer configured as a lid, for closing an open top of the pot. A tool coupled to a motorized drive of the stirrer extends downwardly into the pot. A heating element is coupled to the base and resiliently biased outwardly from the base to engage the base of the pot. A latch mechanism is provided for releasably connecting the pot to the base. The motorized drive includes a planetary gear set mounted coaxially with a pot axis, and a tool coupling is connected to a planet gear of the planetary gear set to drive the stirring tool in an orbital motion.

Owner:HANG SHUN HING

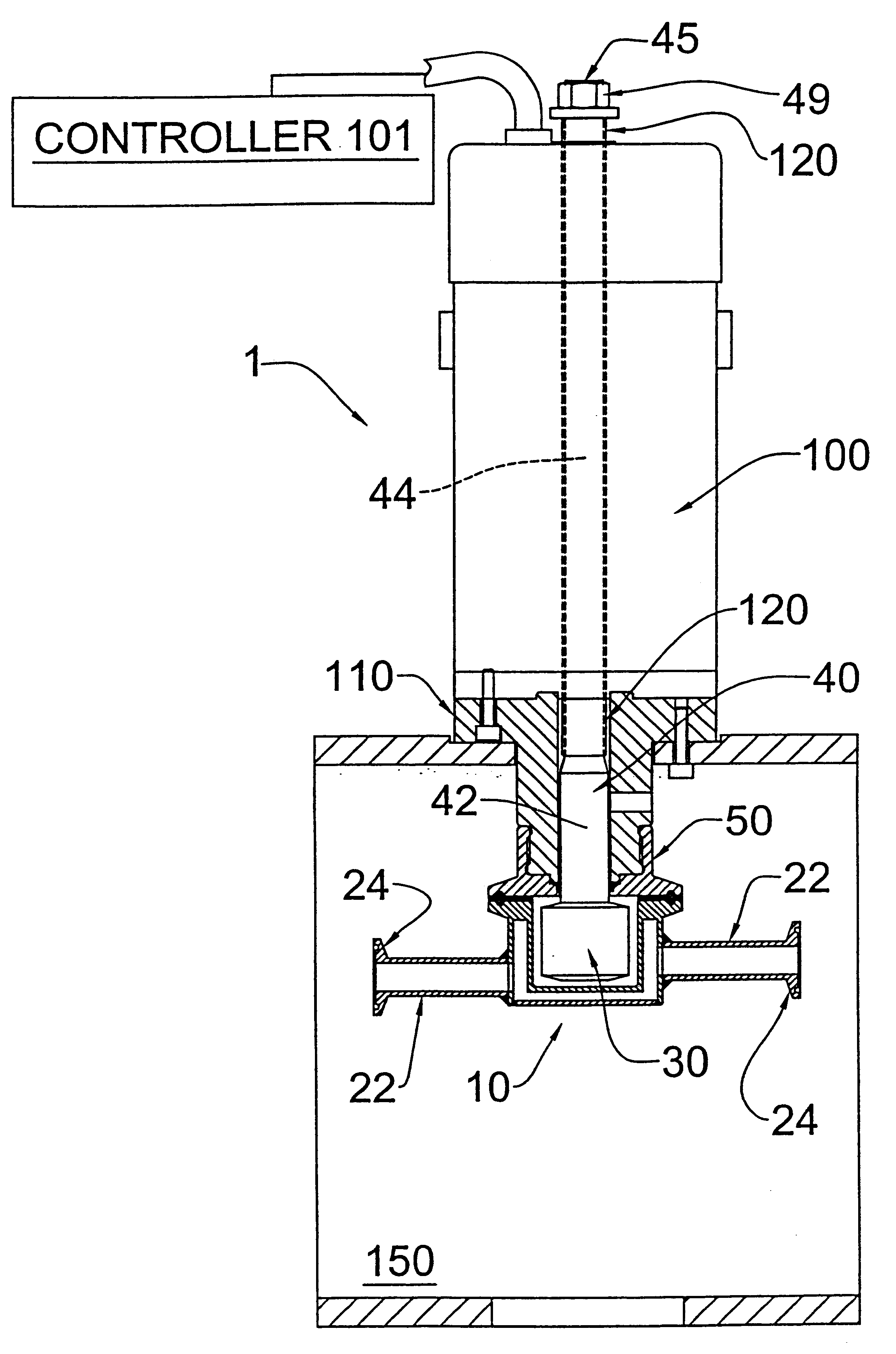

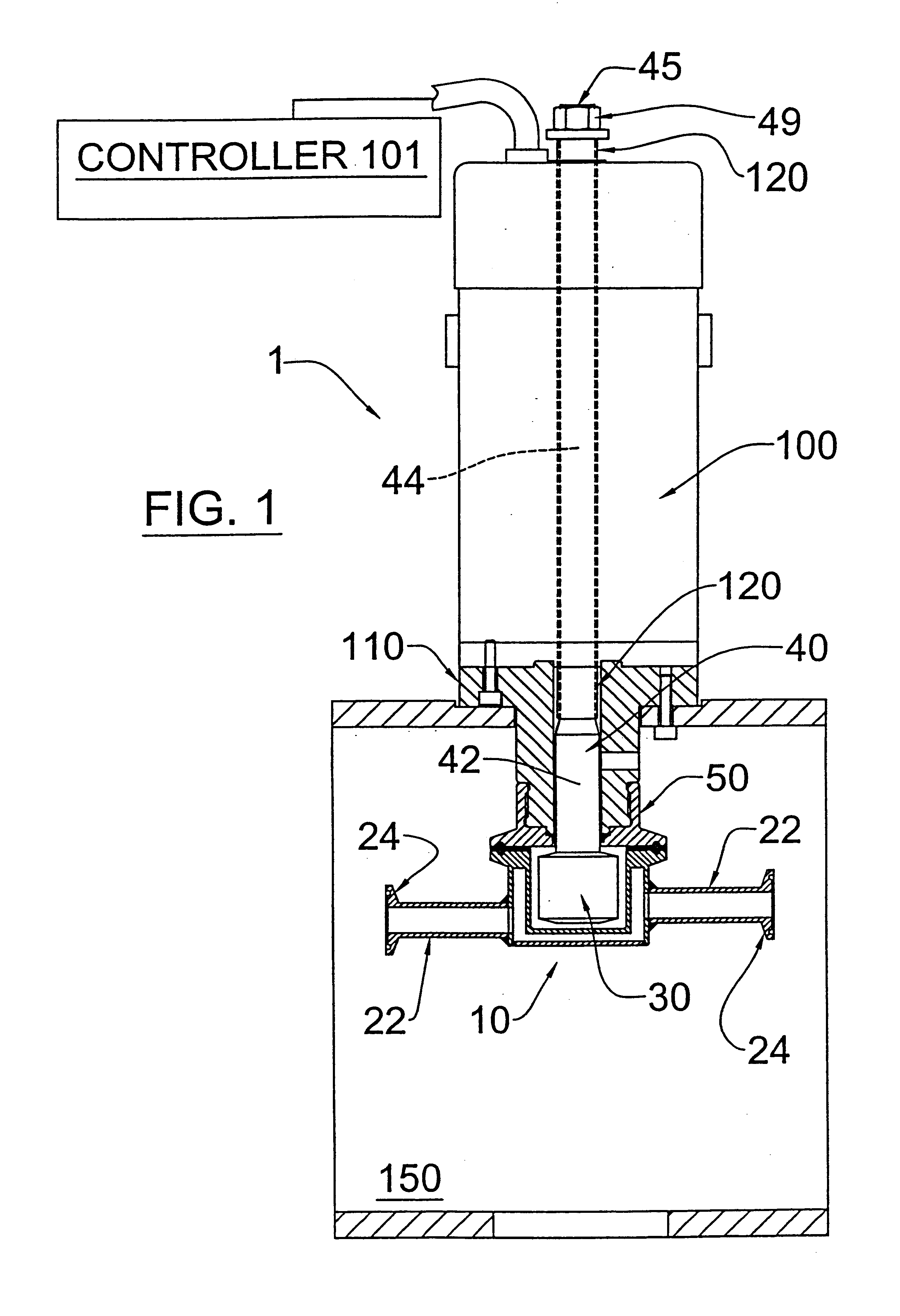

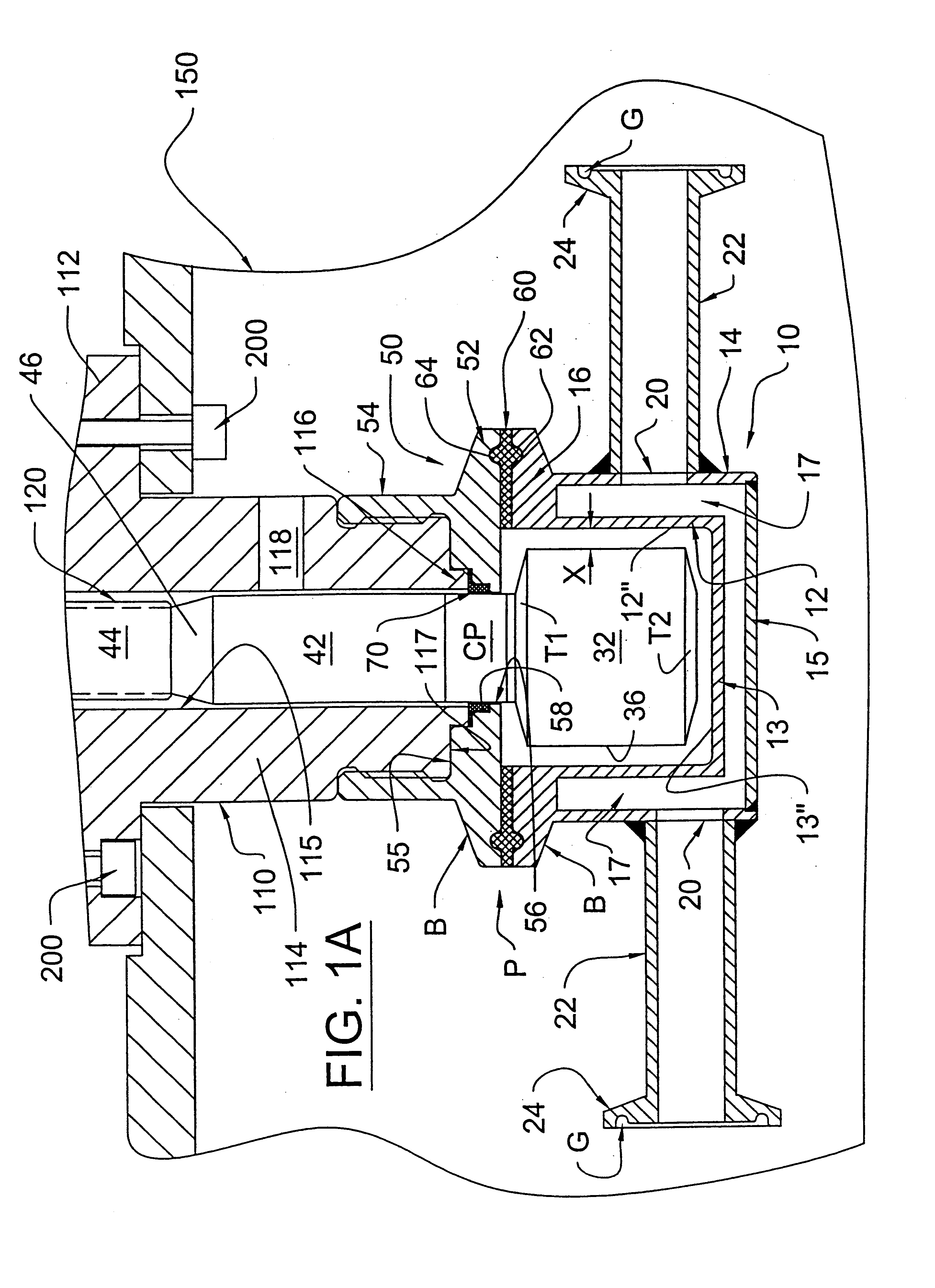

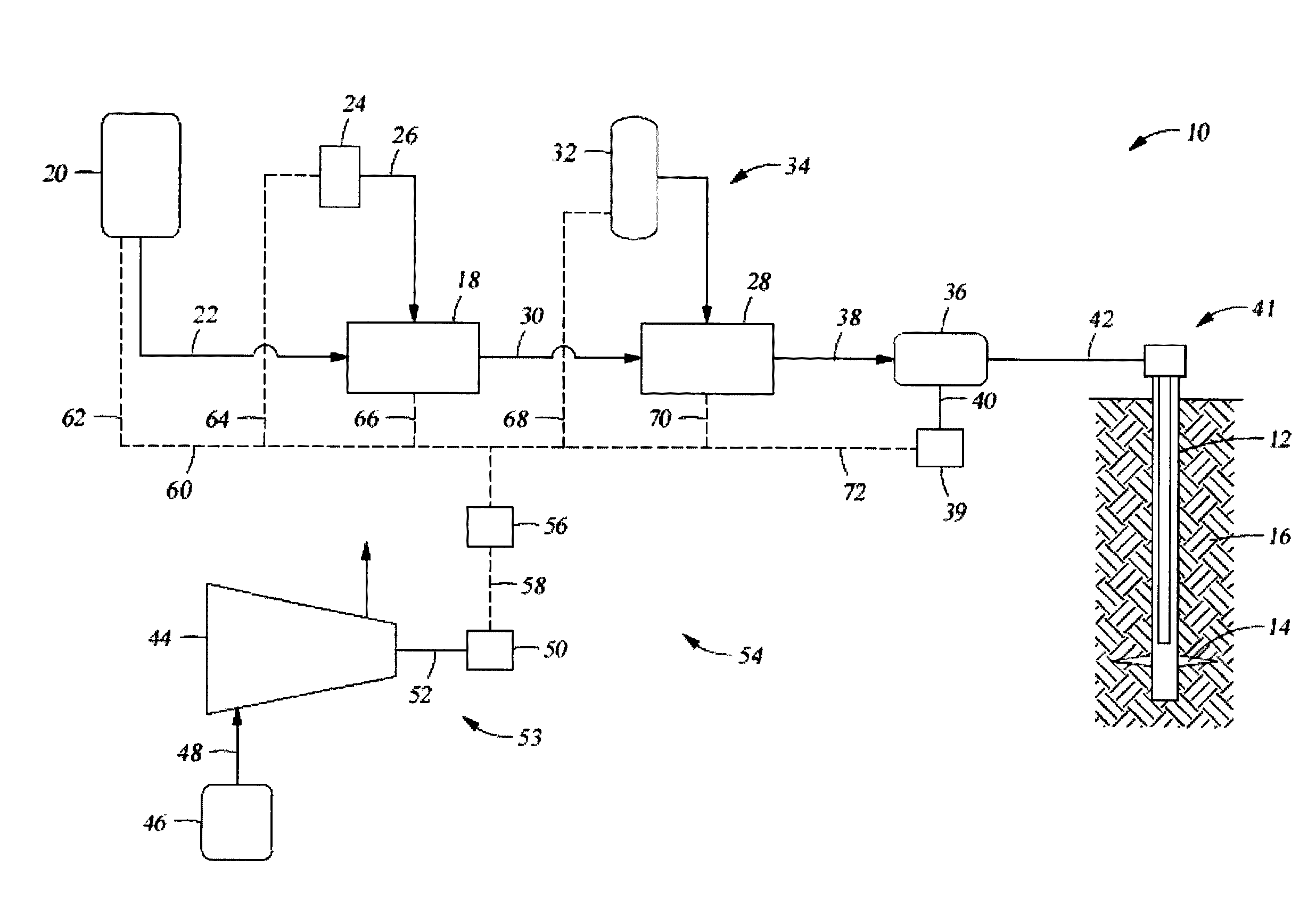

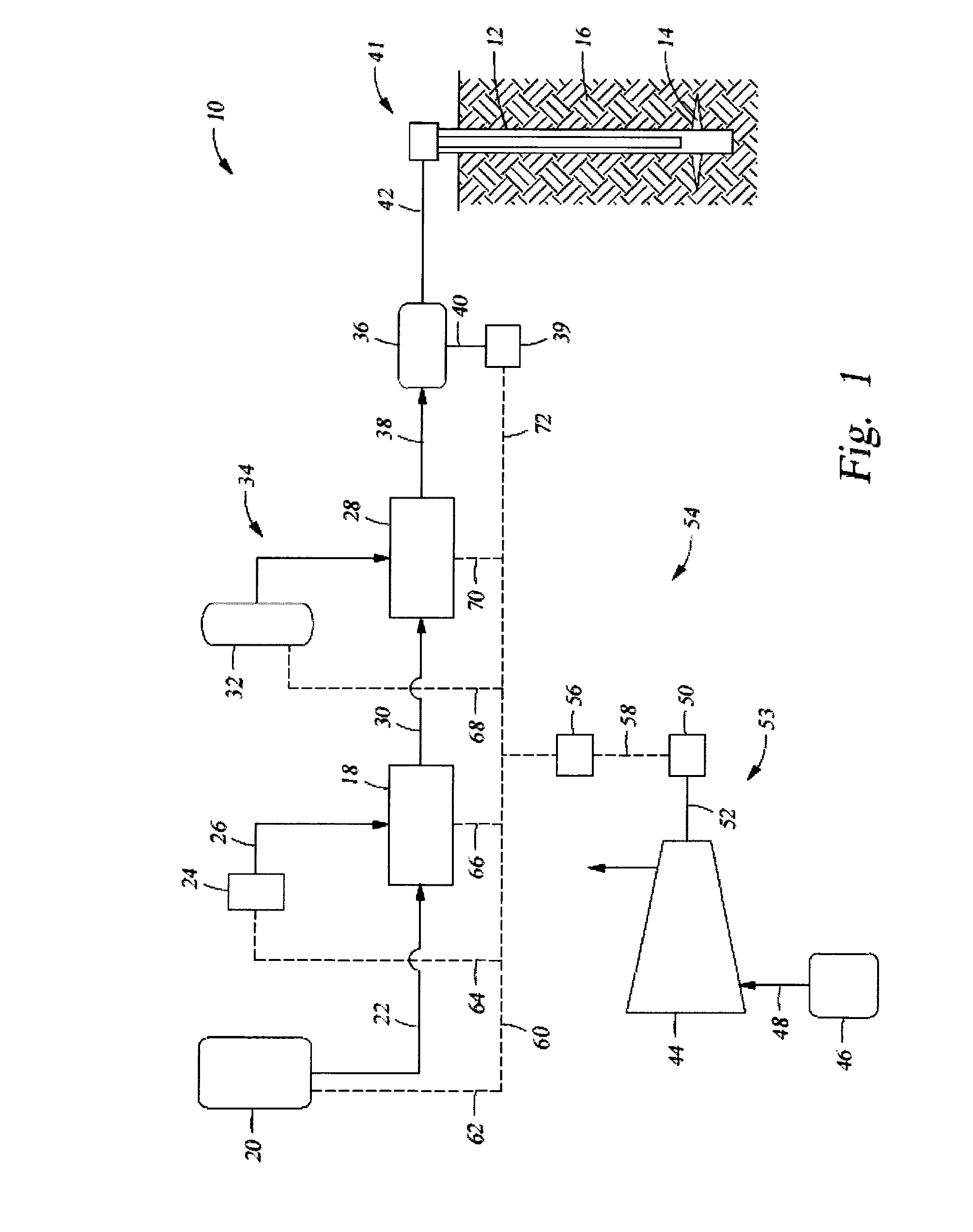

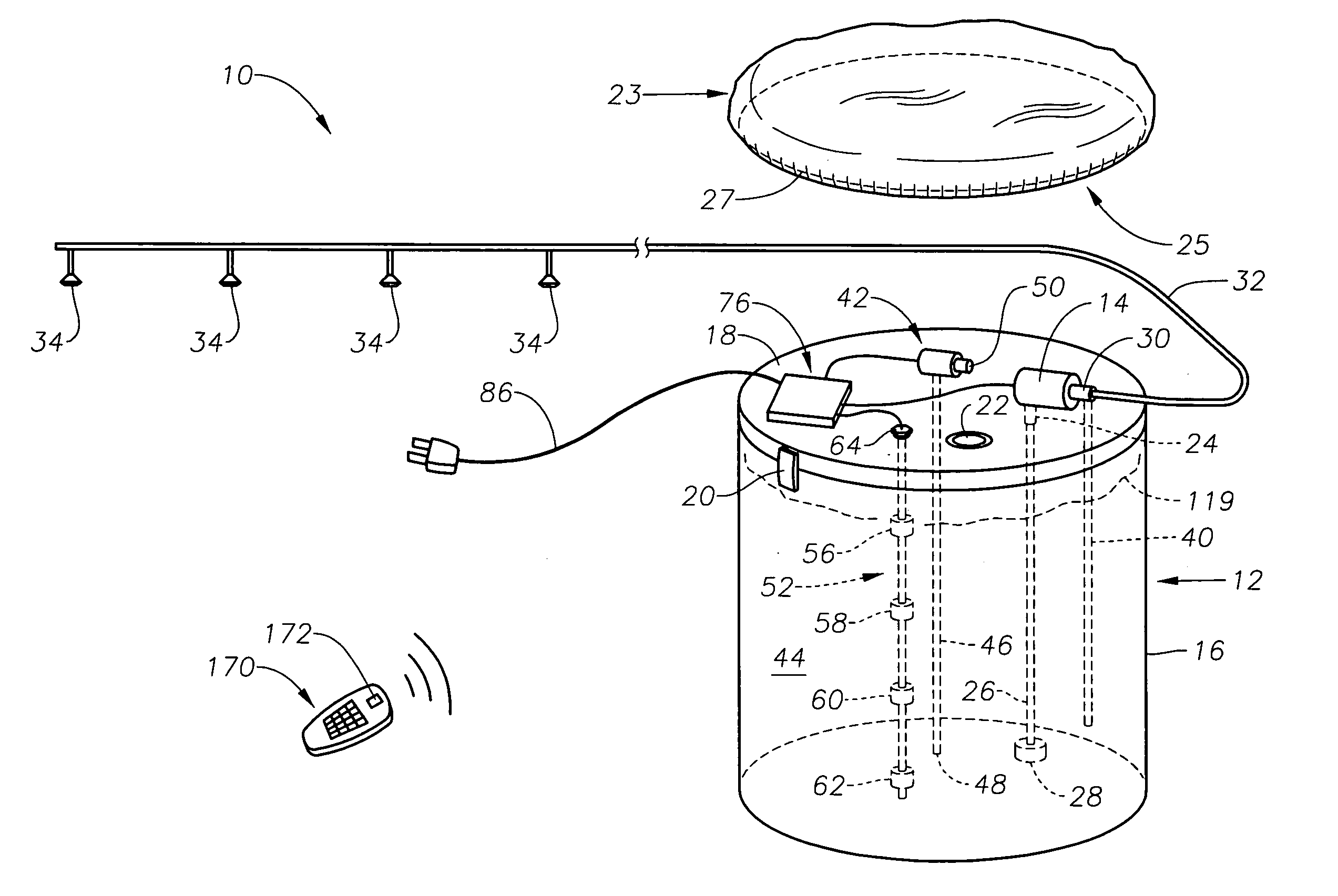

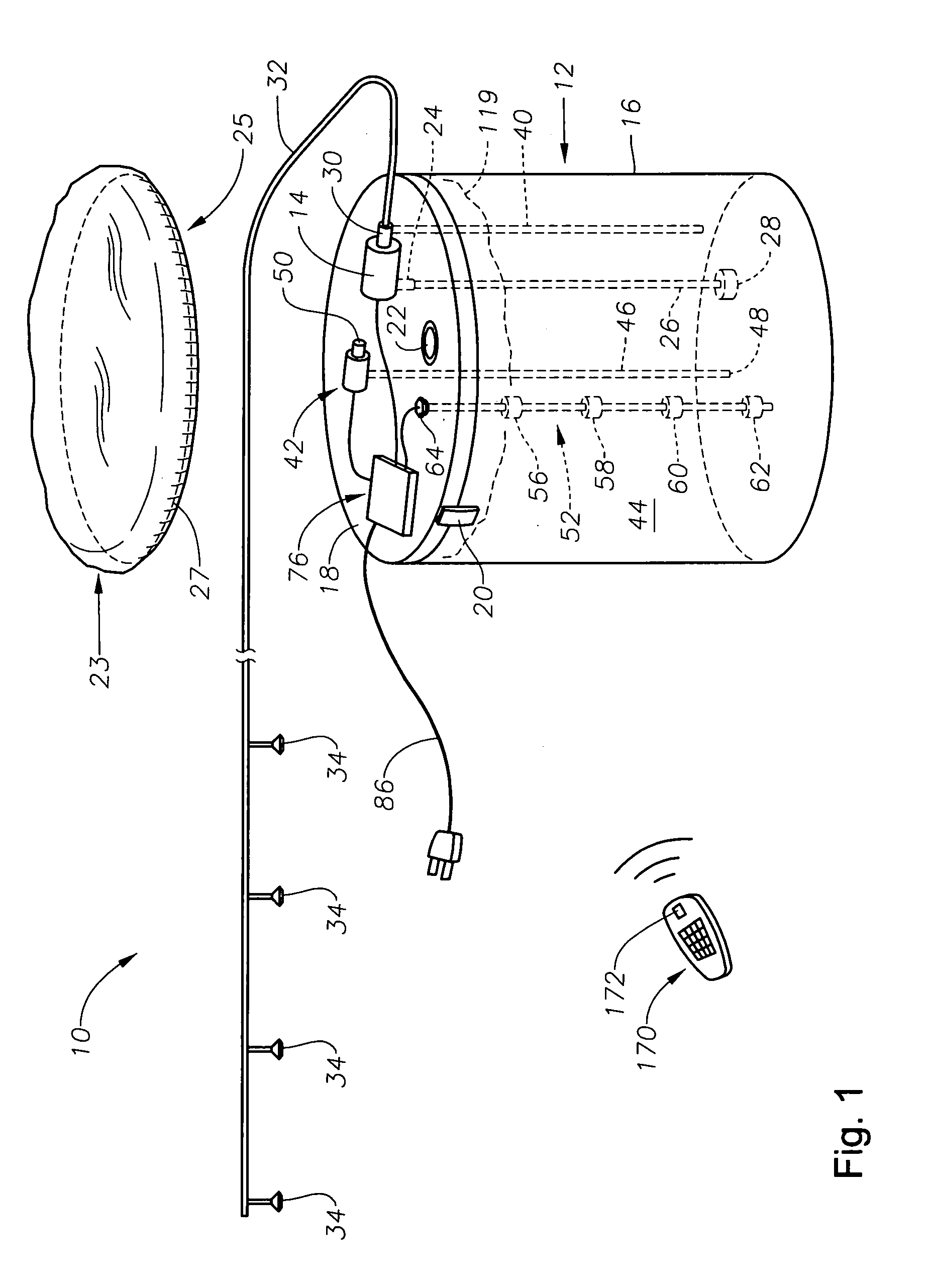

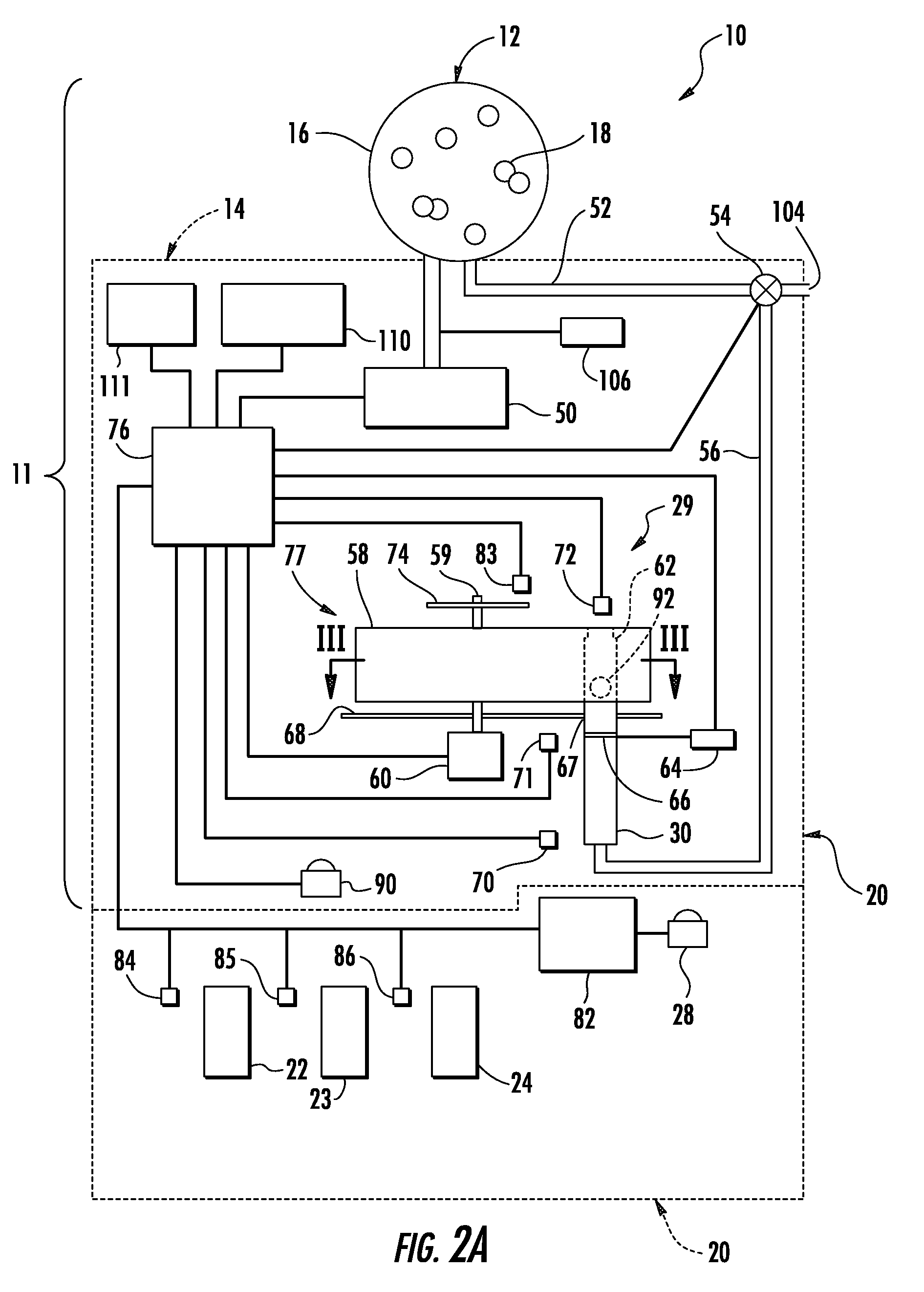

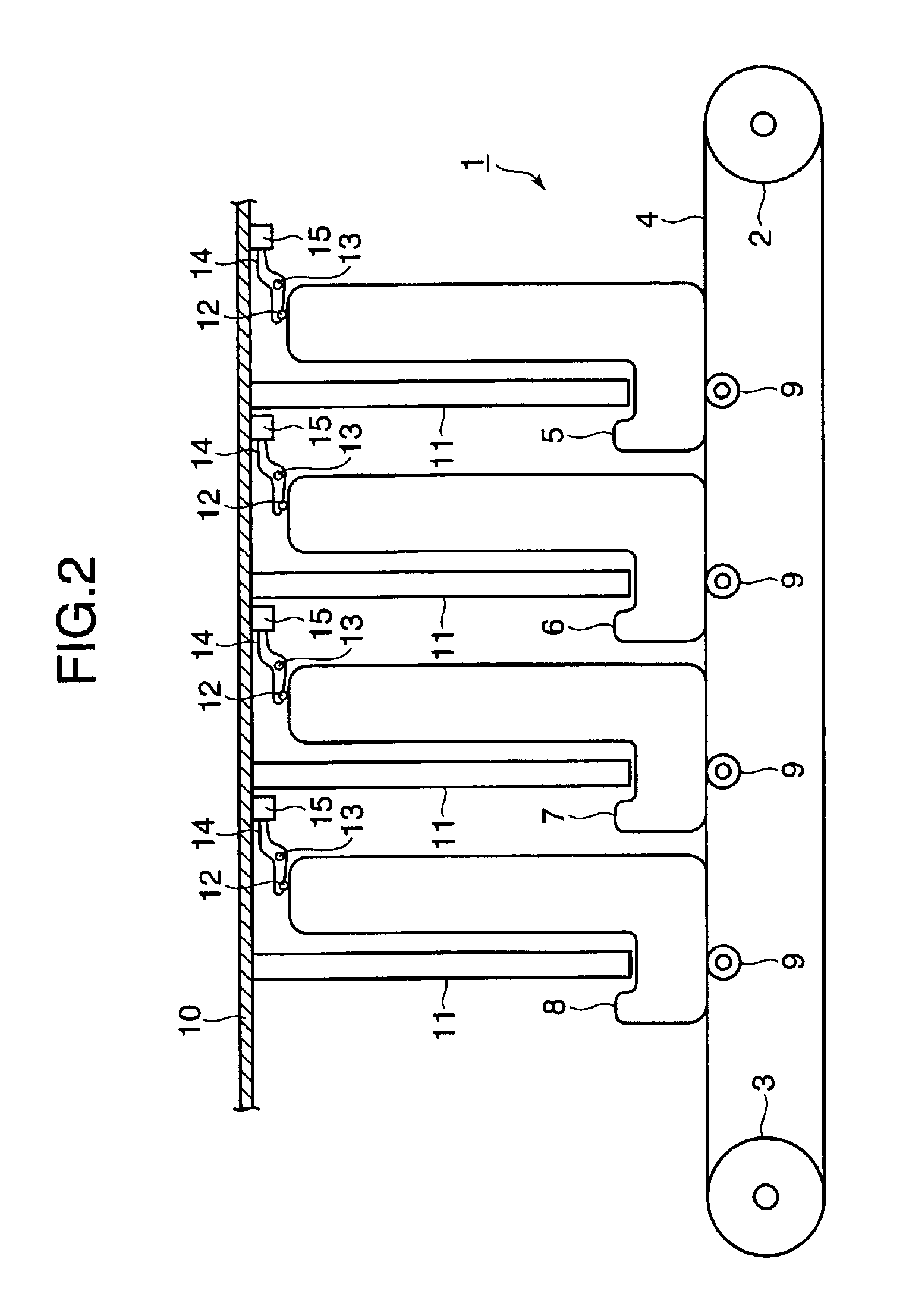

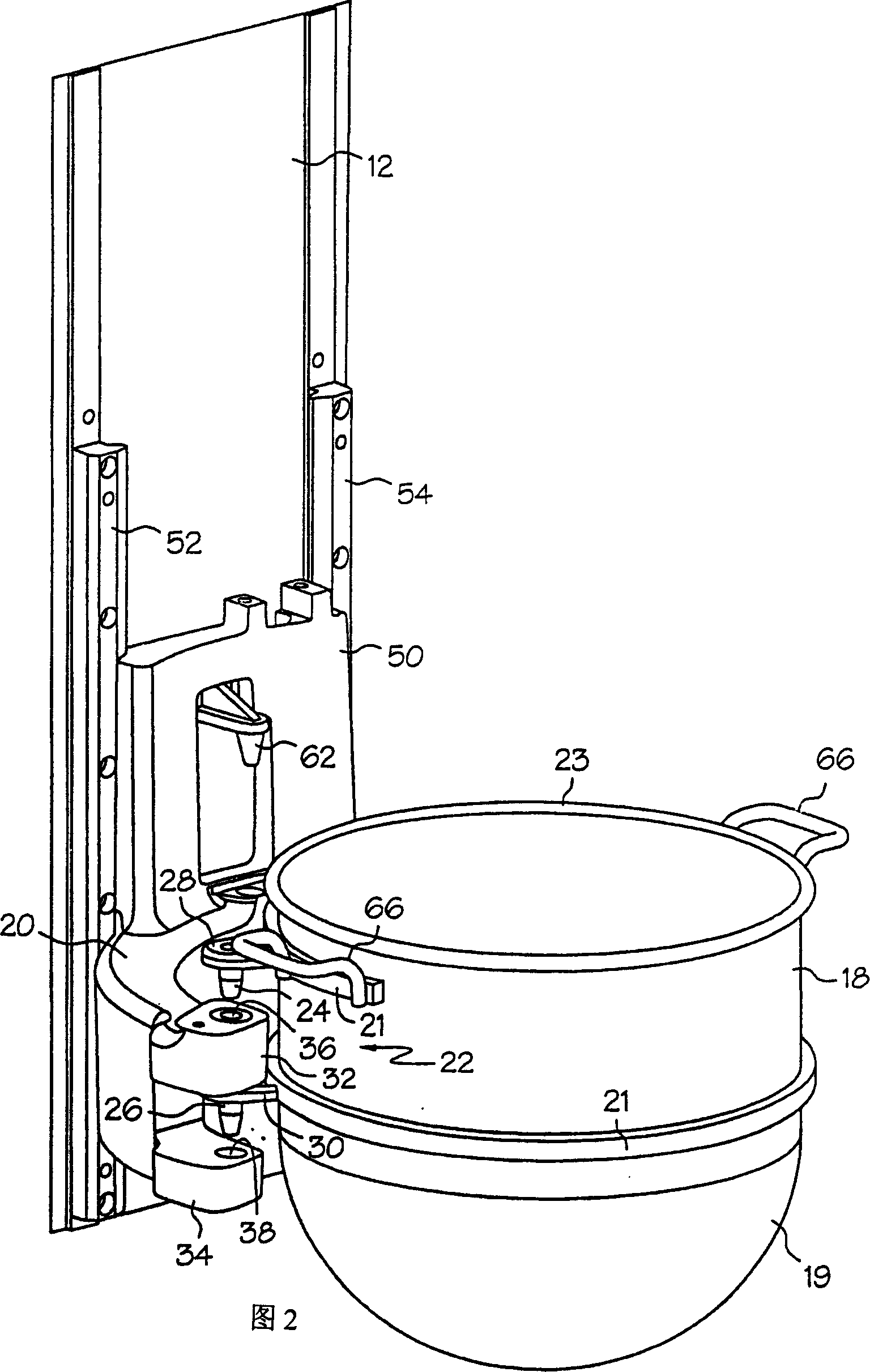

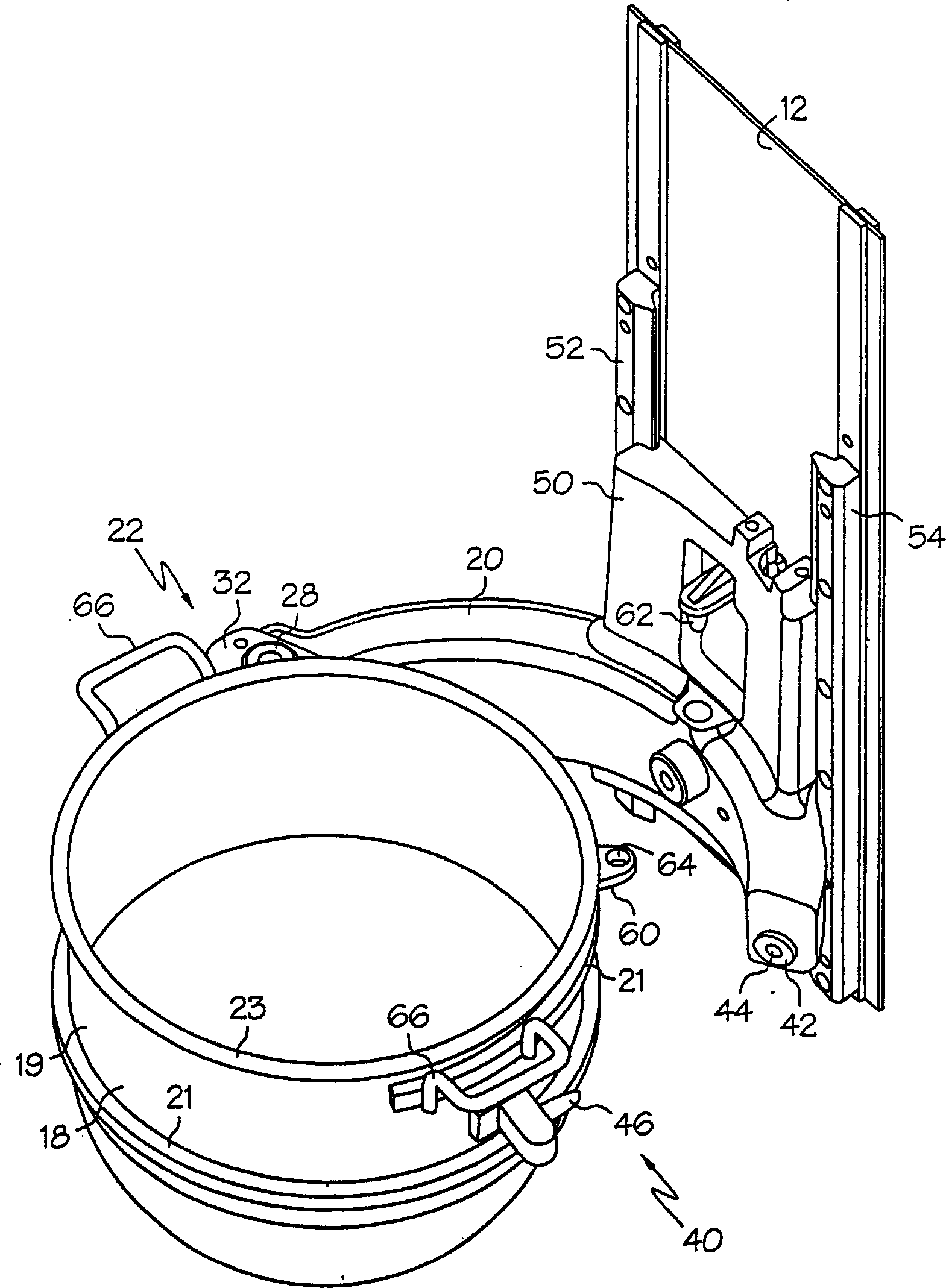

Mosquito misting system

InactiveUS7090147B2Stir wellAvoid flowSelf-acting watering devicesSpray nozzlesRemote controlEngineering

A mosquito misting system is described having a liquid reservoir that is operably associated with a fluid pump and motor and fluid conduits to transmit a fluid insecticide to one or more dispersal nozzles. A controller is used to control the frequency and duration of dispersal. An agitator device is preferably associated with the fluid reservoir to adequately agitate the insecticide mixture within the reservoir during or just prior to dispersal of the fluid insecticide. The controller is interconnected with a level sensor assembly to provide a graphic indication of the level of fluid insecticide remaining in the reservoir. Additionally, the misting system is provided with a fluid pressure switch that detects a rupture in the fluid conduit and prevents further flow of fluid from the reservoir. In further aspects, the system is provided with remote control and, optionally, a remote monitoring feature that allows improved service and maintenance for the system.

Owner:LOVETT ROD

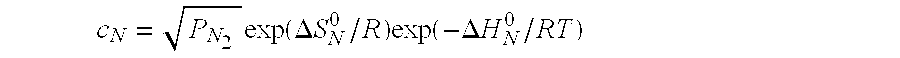

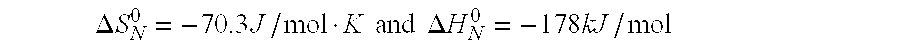

High purity niobium and products containing the same, and methods of making the same

InactiveUS20020072475A1Fine grain structureUniform textureCellsElectrolytic capacitorsNiobiumLog ratio

High purity niobium metals and alloys containing the same are described. The niobium metal preferably has a purity of at least 99.99% and more preferably at least 99.999%. In addition, niobium metal and alloys thereof are described, which either have a grain size of about 150 microns or less, or a texture in which a (100) intensity within any 5% increment of thickness is less than about 30 random, or an incremental log ratio of (111):(100) intensity of greater than about -4.0, or any combination of these properties. Also described are articles and components made from the niobium metal which include, but are not limited to, sputtering targets, capacitor cans, resistive film layers, wire, and the like. Also disclosed is a process for making the high purity niobium metal which includes the step of reacting a salt-containing niobium and a metal salt along with at least one compound capable of reducing the salt-containing niobium to niobium and in a reaction container. The reaction container or liner in the reaction container and the agitator or liner on the agitator are made from a metal material having the same or higher vapor pressure of melted niobium. The high purity niobium product preferably has a fine and uniform microstructure.

Owner:GLOBAL ADVANCED METALS USA

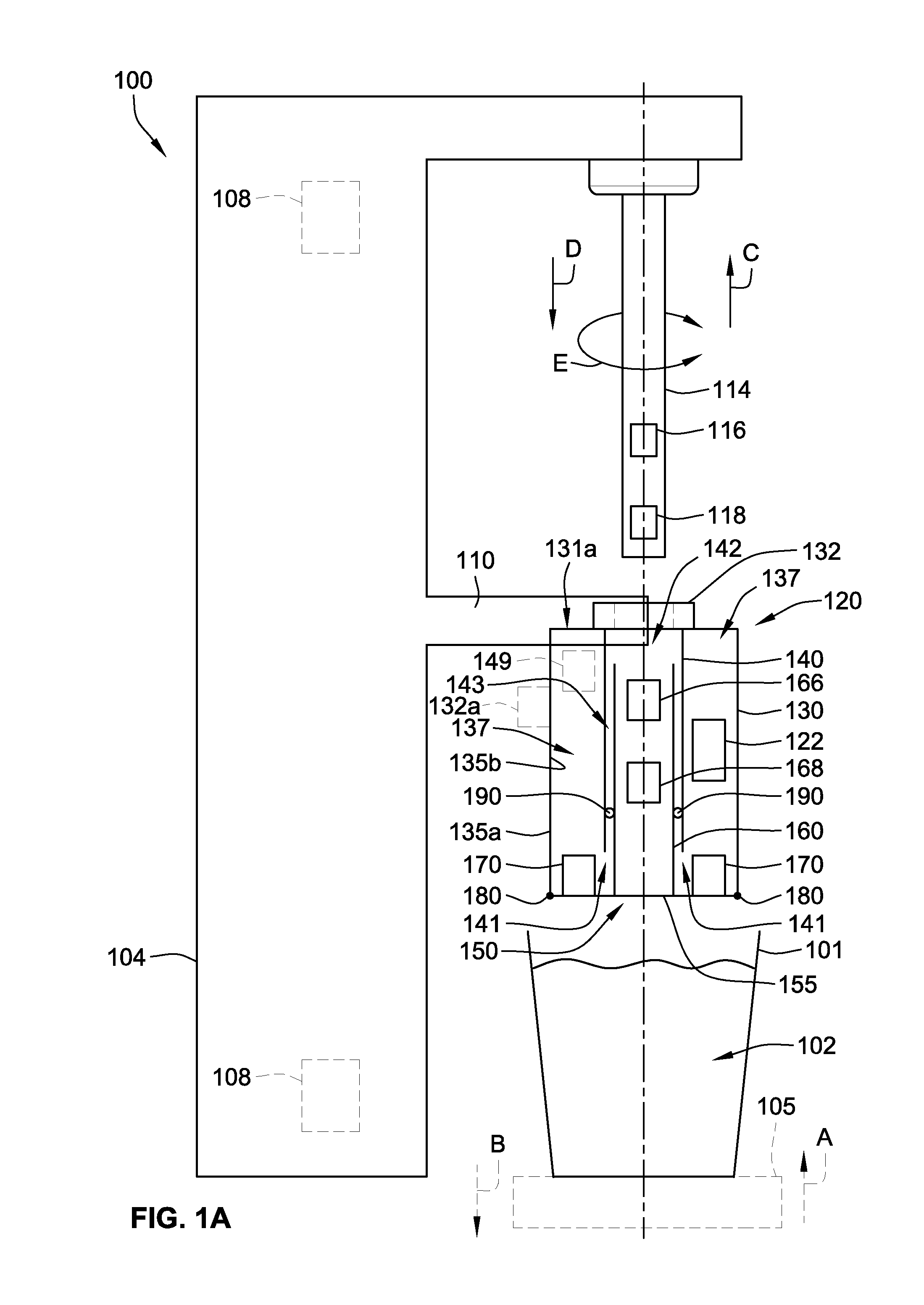

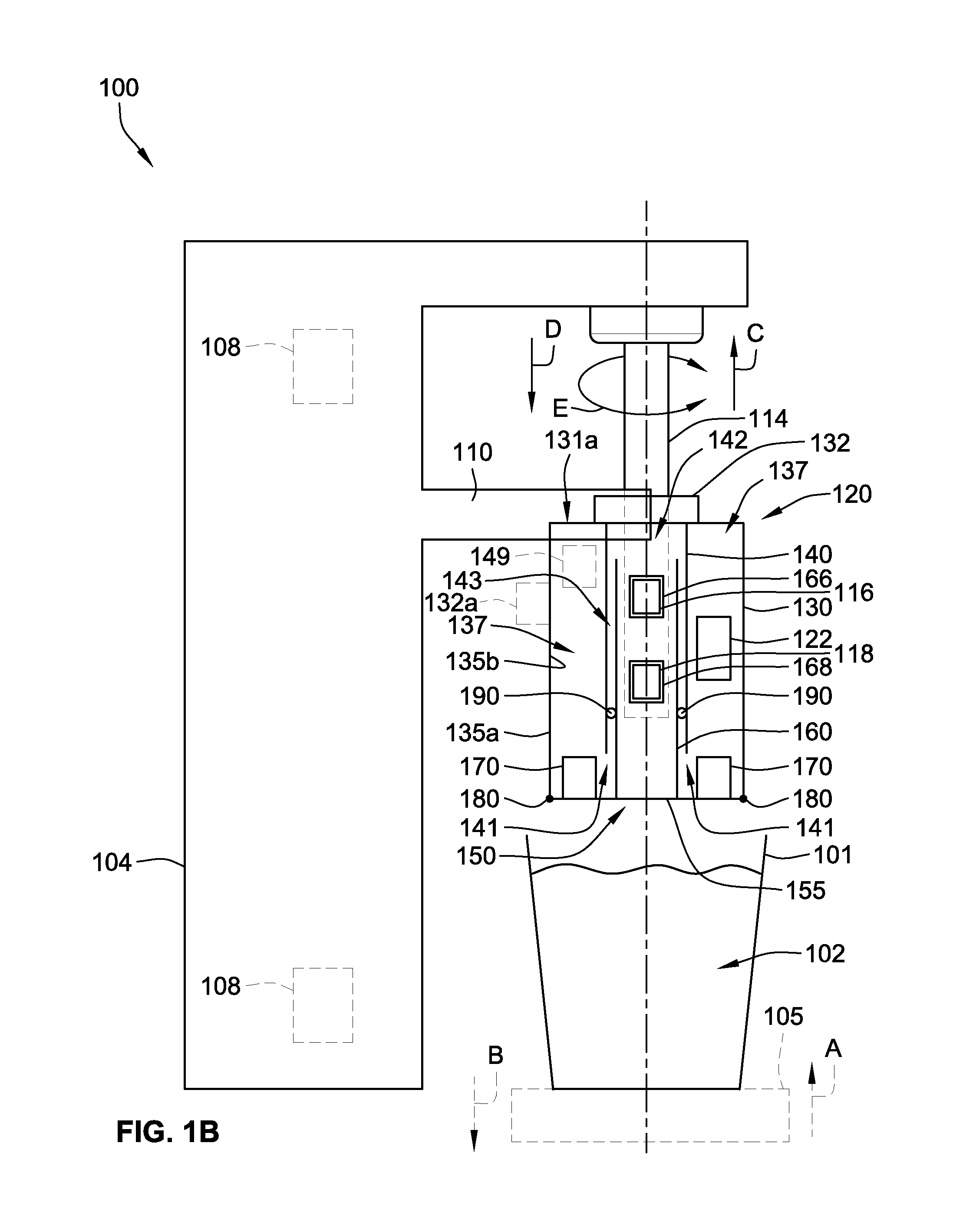

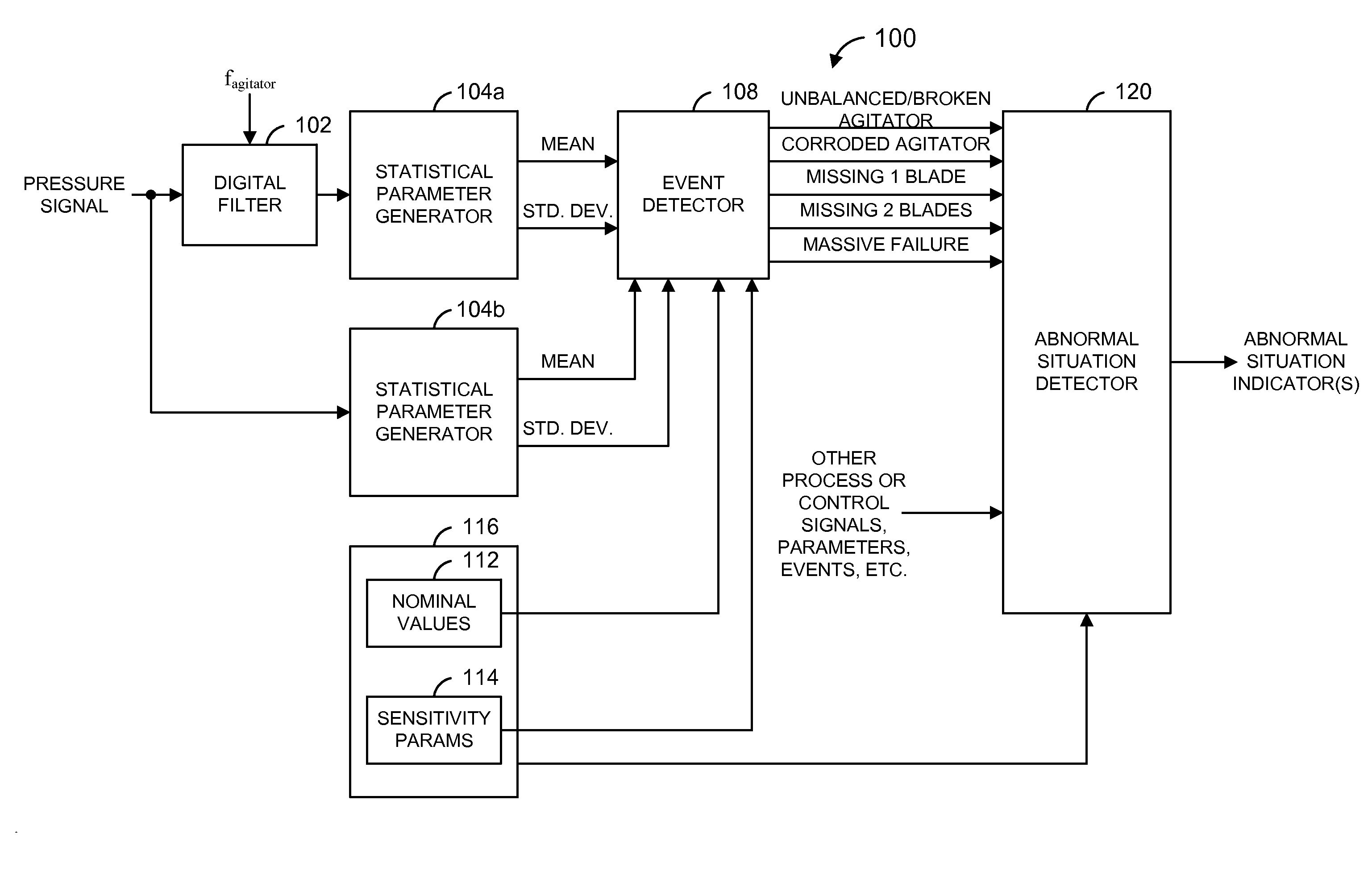

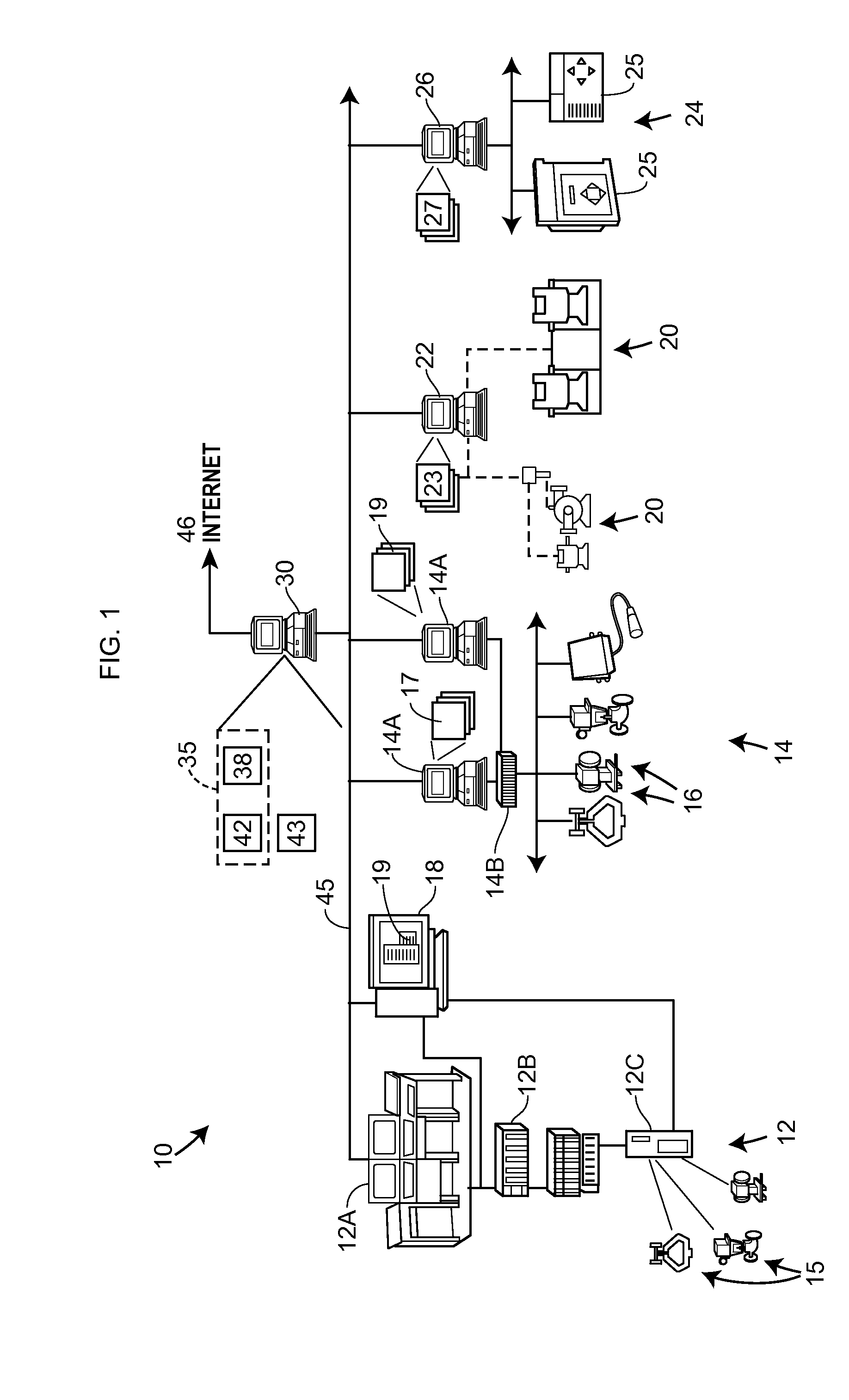

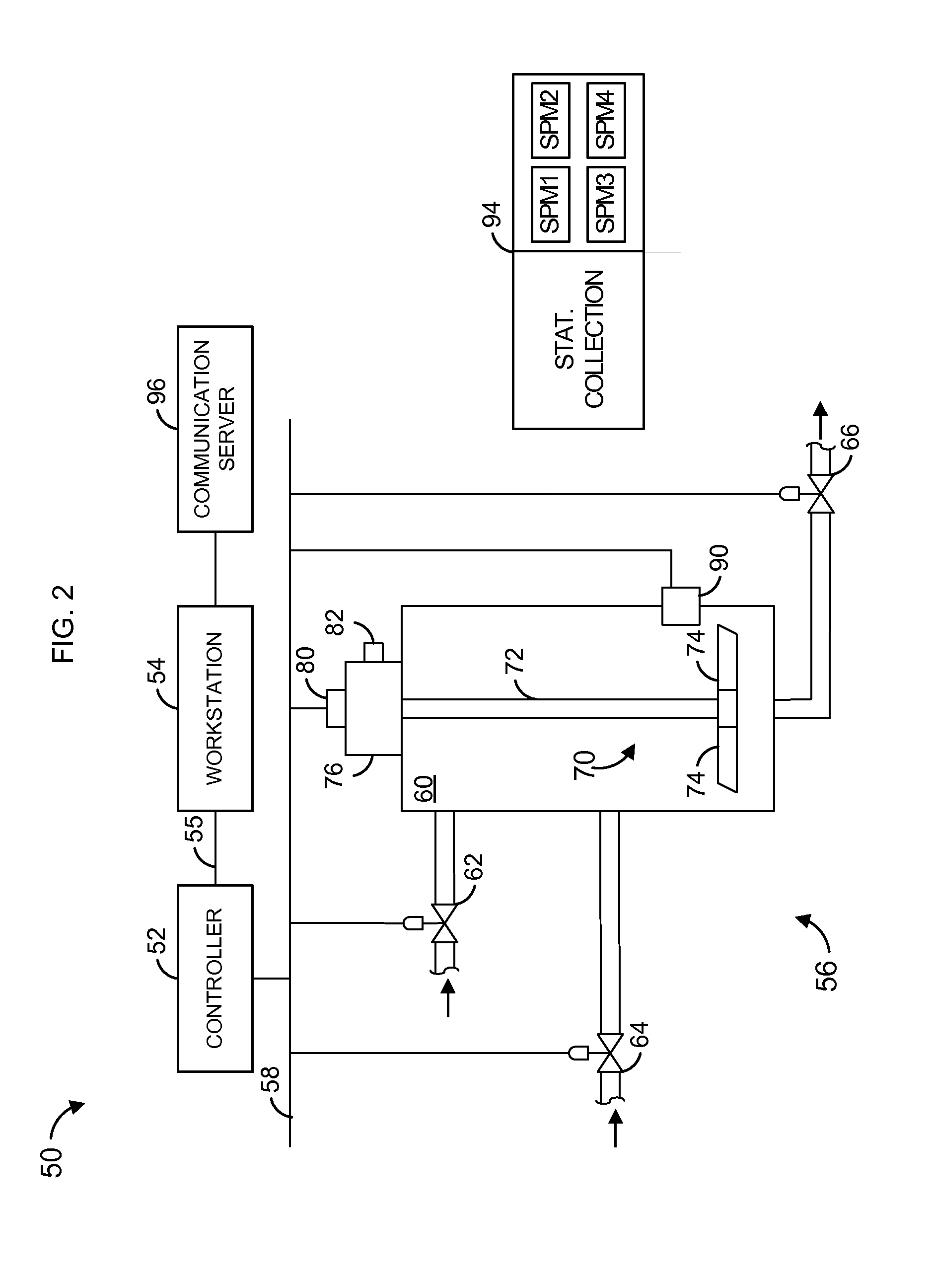

Method and system for detecting abnormal operation in a stirred vessel

ActiveUS20080082294A1Electronic circuit testingTesting/monitoring control systemsEngineeringDigital filter

A system and method for detecting abnormal situations associated with a stirred vessel in a process plant receives statistical data associated with a pressure within a stirred vessel. A pressure signal associated with the pressure in the vessel is filtered by a digital filter to isolate a frequency component corresponding to pressure changes caused by the movement of a blade of an agitator through a fluid. For example, a pressure sensor device disposed at least partially within the stirred vessel may generate the statistical data based on a pressure signal. The statistical data is analyzed to detect whether one or more abnormal situations associated with an agitator of the stirred vessel exist. For example, the statistical data may be analyzed to detect whether the agitator is broken / unbalanced, corroded, missing a blade or multiple blades, etc. If an abnormal situation is detected, an indicator of the abnormal situation may be generated.

Owner:FISHER-ROSEMOUNT SYST INC

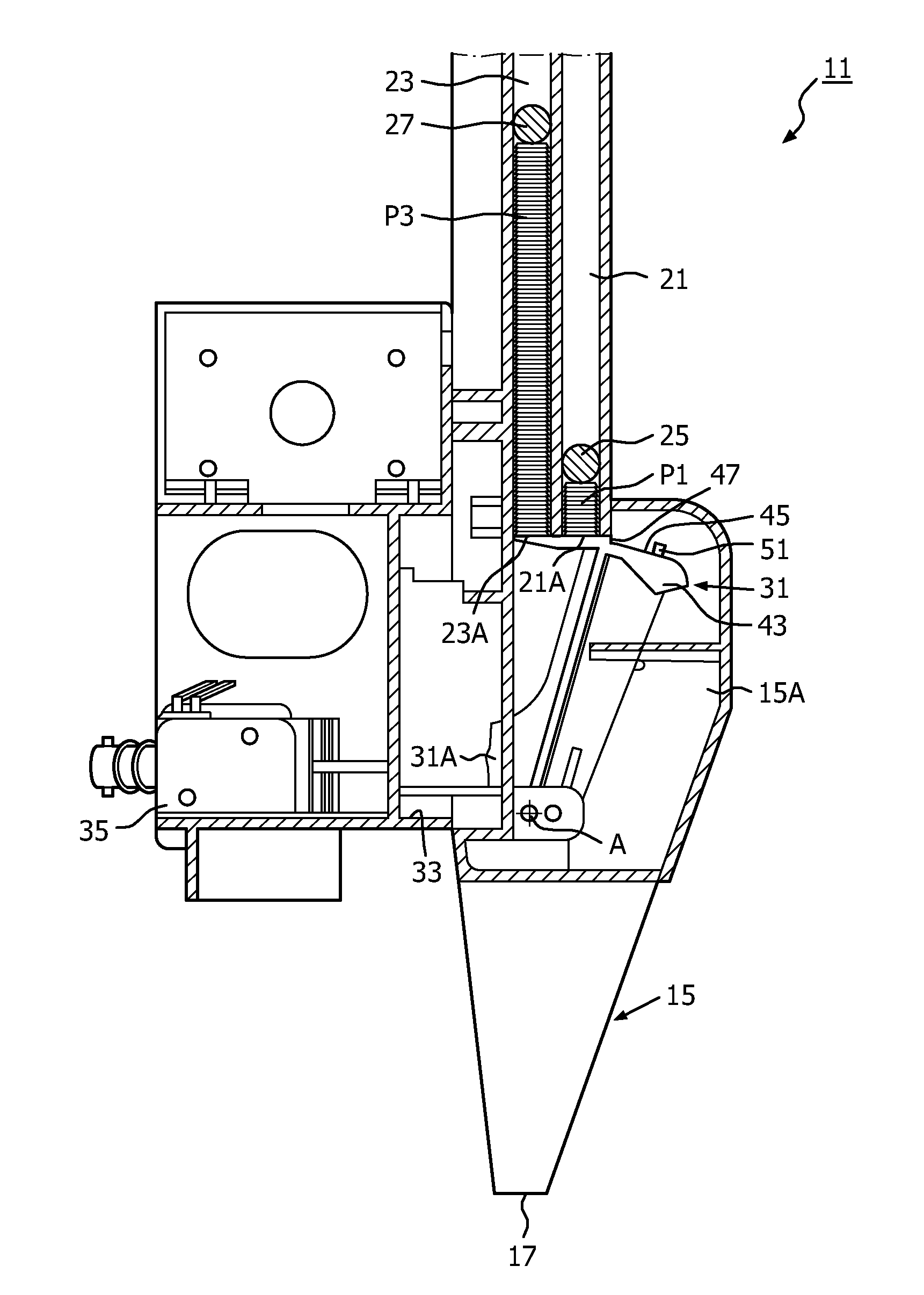

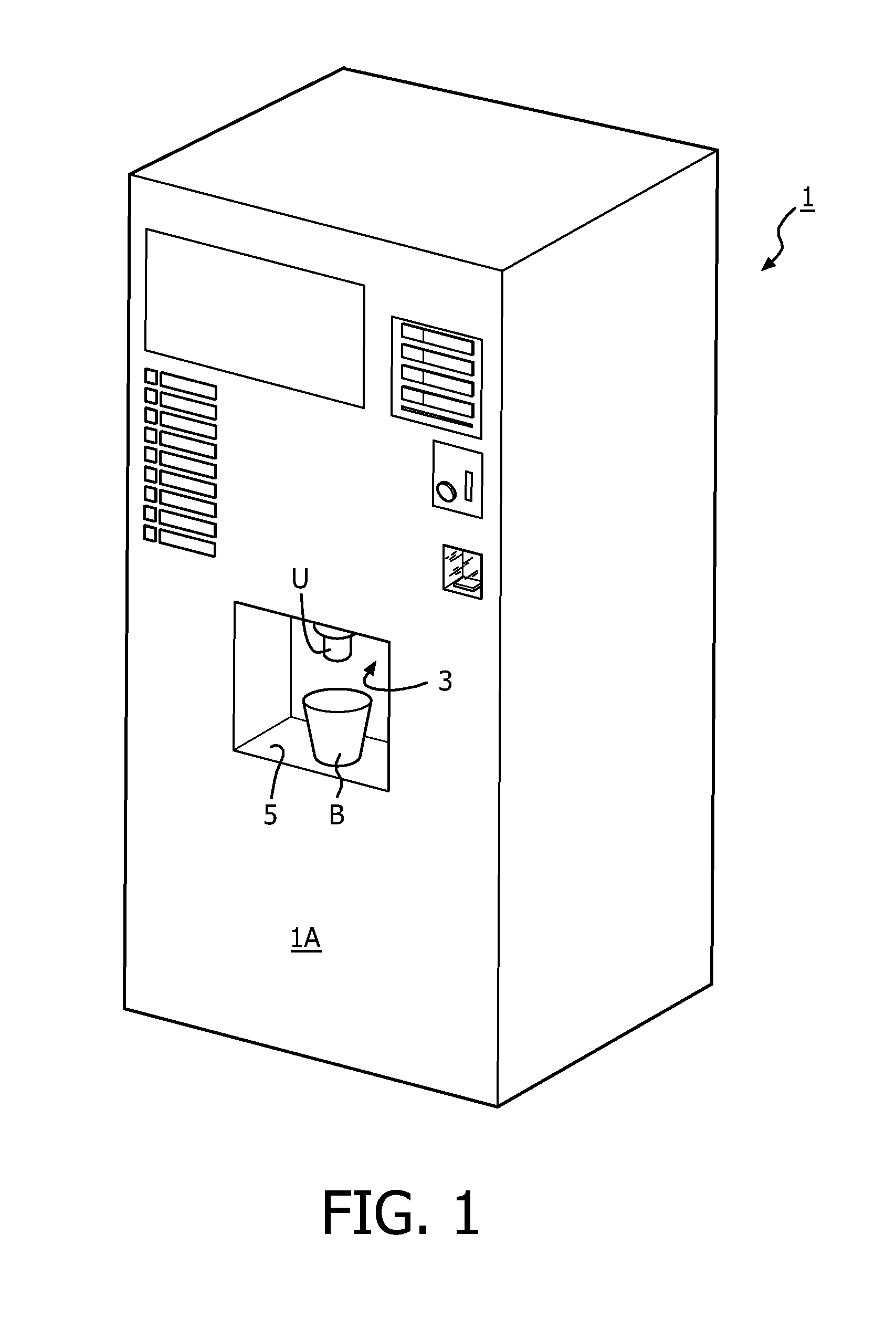

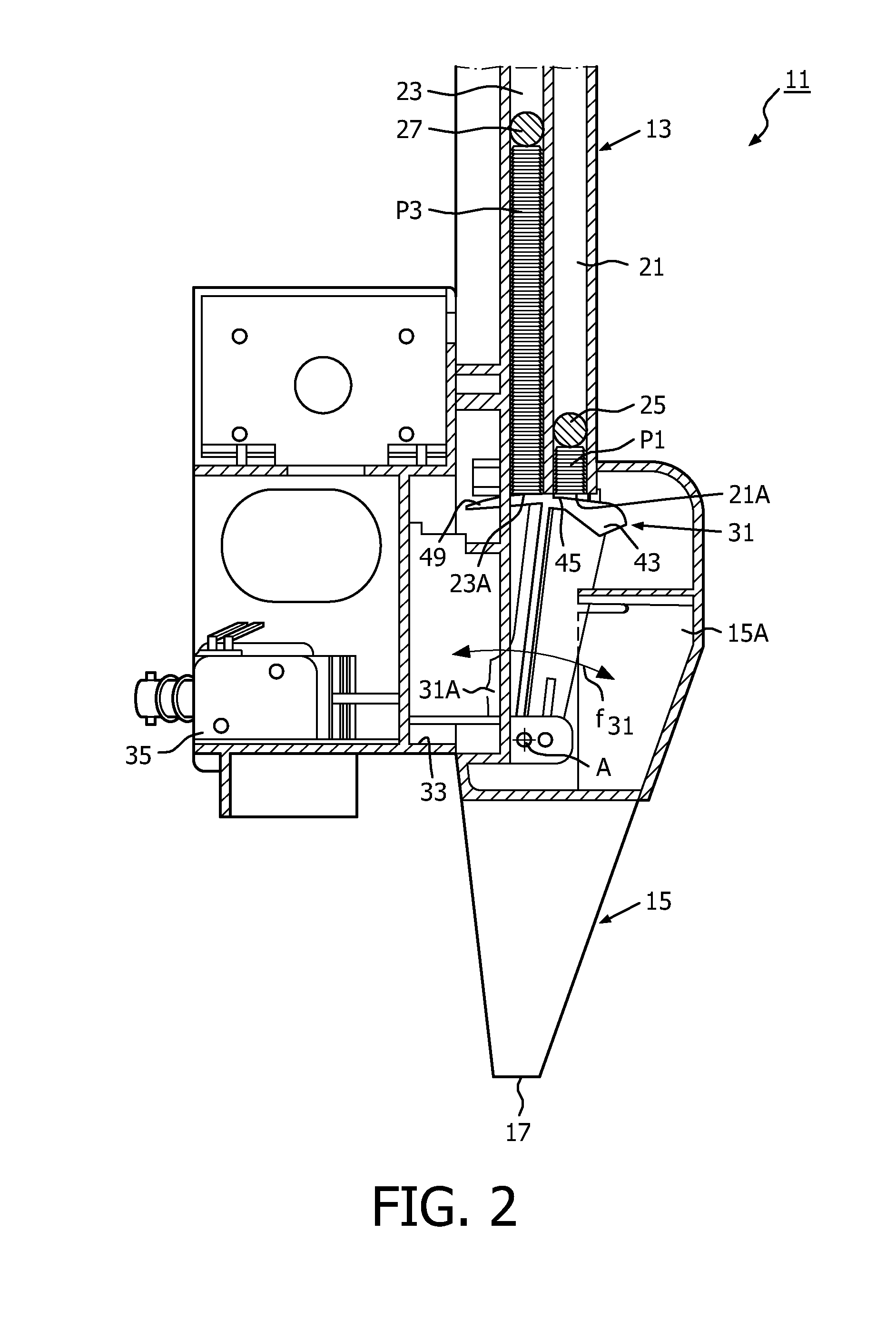

Stirrer or spoon dispenser for beverage dispensing machines

ActiveUS20130032609A1Simple and reliable structureMinimizes moving partRacksCoin-freed apparatus detailsElectrical and Electronics engineeringAgitator

The stirrer dispenser for beverage dispensing machines comprises a first channel (21) for containing a stack of stirrers (PI), which exhibits a first opening (21A), wherefrom single stirrers are extracted and ejected by an ejector (31) provided with an alternating movement (f31). The ejector to this end exhibits an engagement member (45, 47) wherewith single stirrers (PI, P3) are engaged and ejected from said opening at each stroke of said ejector. The dispenser, moreover, exhibits at least a second channel (23) next to the first channel (21) and exhibiting a second opening (23A). The two openings (21A; 23A) are side by side along the movement direction of the ejector (31). Moreover, there is provided a stroke delimiter (51) that limits the stroke of the ejector (31) when at least one stirrer (PI) is present in the first channel (21), so that the ejector (31) picks up the stirrers from the second channel (23) only when the first channel (21) is empty.

Owner:SAGA COFFEE SPA

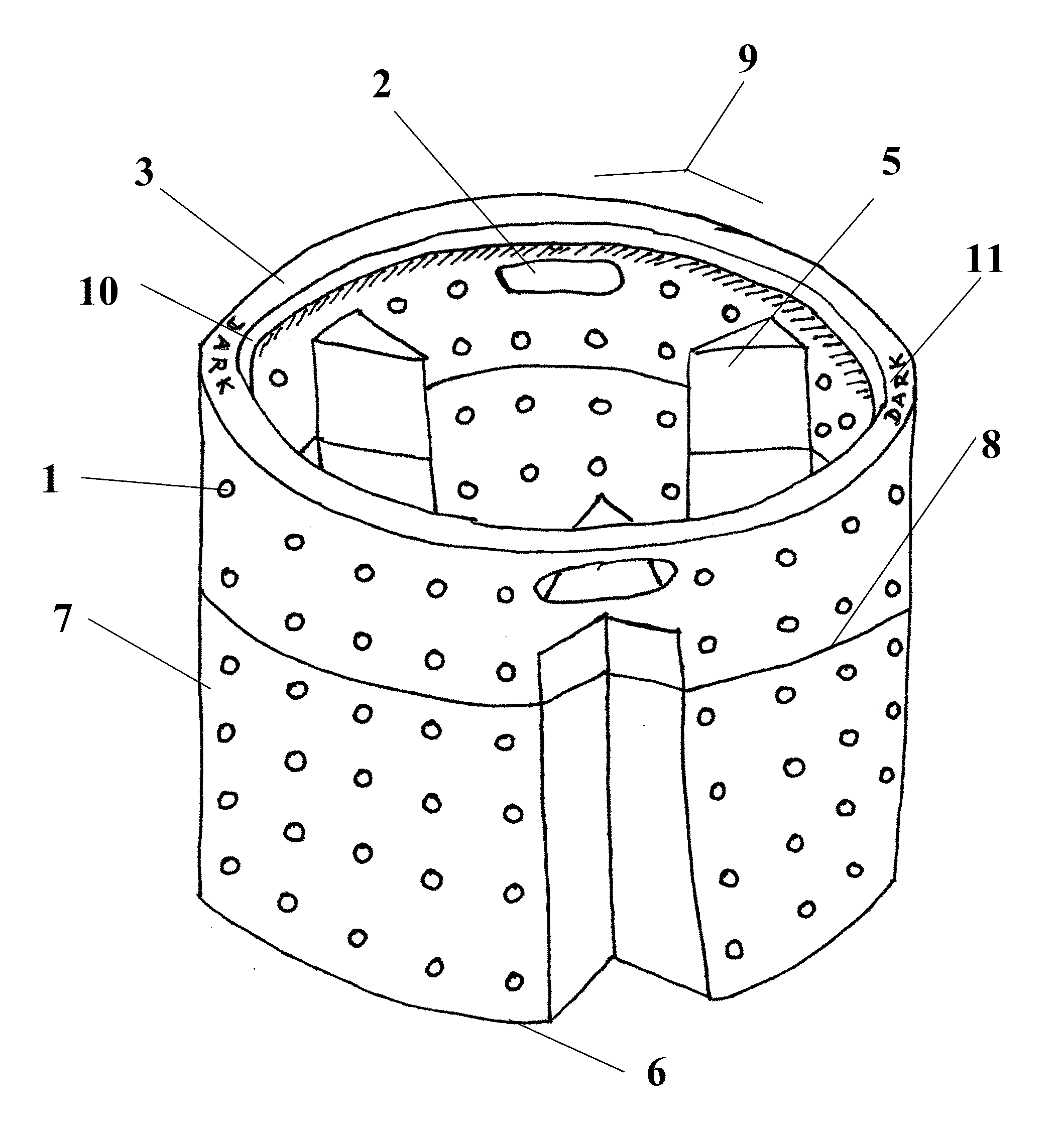

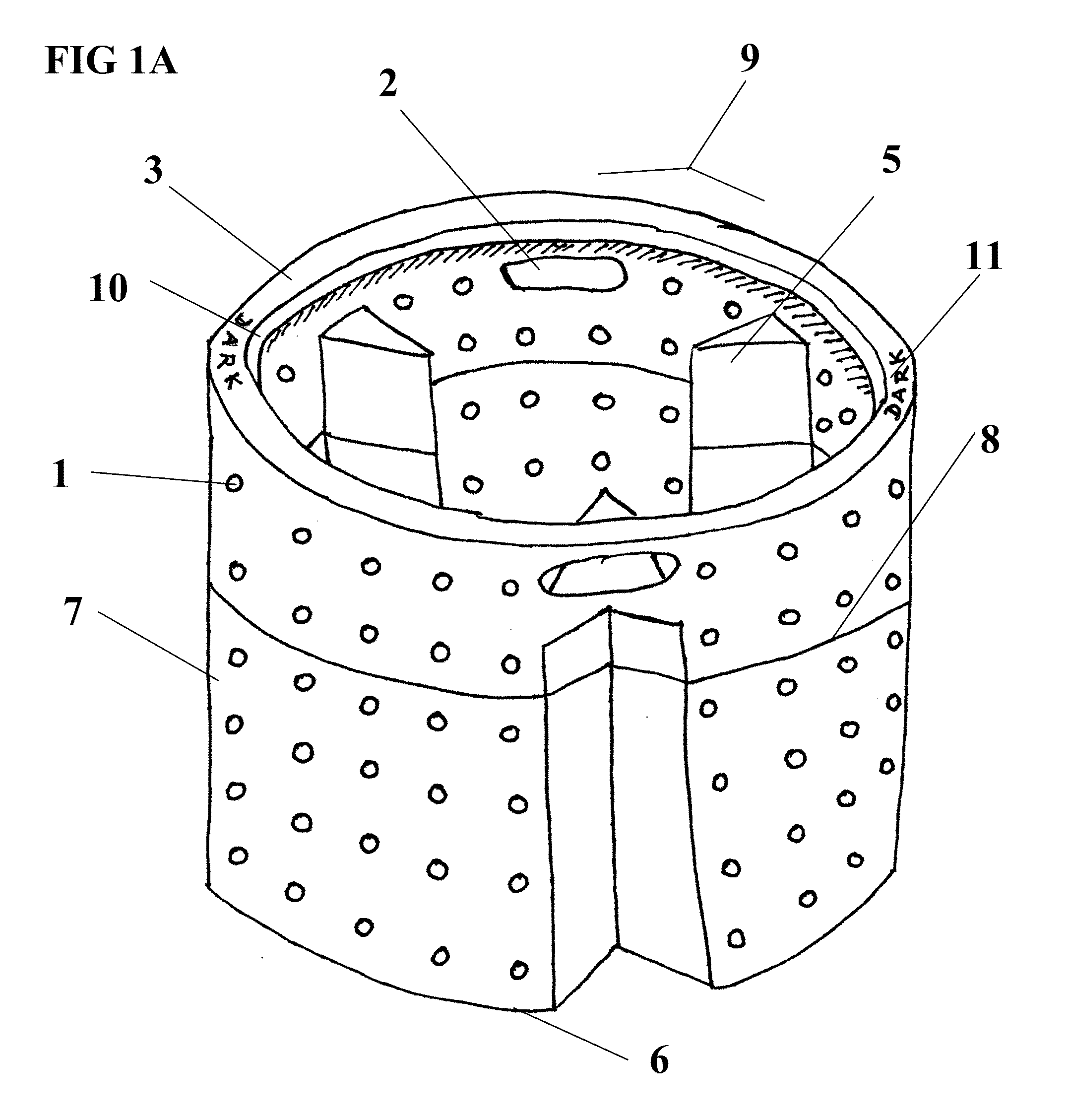

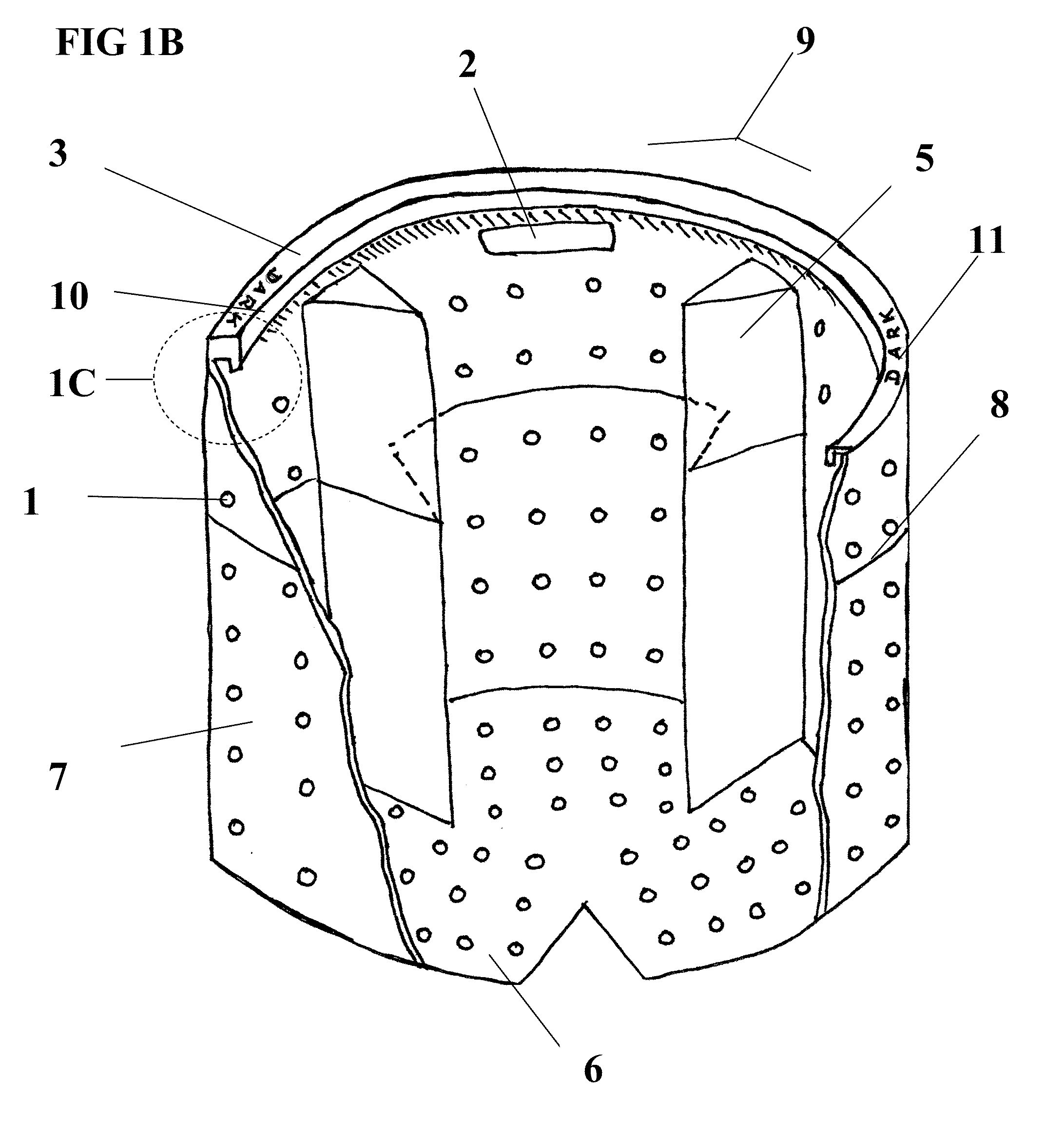

Laundry Hamper For Insertion Into Clothes Washers And Dryers

InactiveUS20110094902A1Easy to transportHand rubbing apparatusContainer/bottle contructionEngineeringLaundry

One embodiment of a hamper for the insertion into conventional consumer and commercial clothing washers and dryers. The article is cylindrical shaped article to fit inside typical front load and top load commercial or consumer clothing washer and dryer. This embodiment of our hamper has cut out transport handles 2 in the side of the cylinder and handles in the top lip of the cylinder 3. In addition, the base 6 and cylinder sides contain the apertures 1 for liquid drainage during the washing cycle and ventilation during the drying cycle. The cylinder sides may contain recessed baffles 5 along the cylinder walls to fit over the baffles of existing front load washer and dryers or concavities originating in the base to fit over agitators of top load washers.

Owner:DELEHEY JACK MURPHY +5

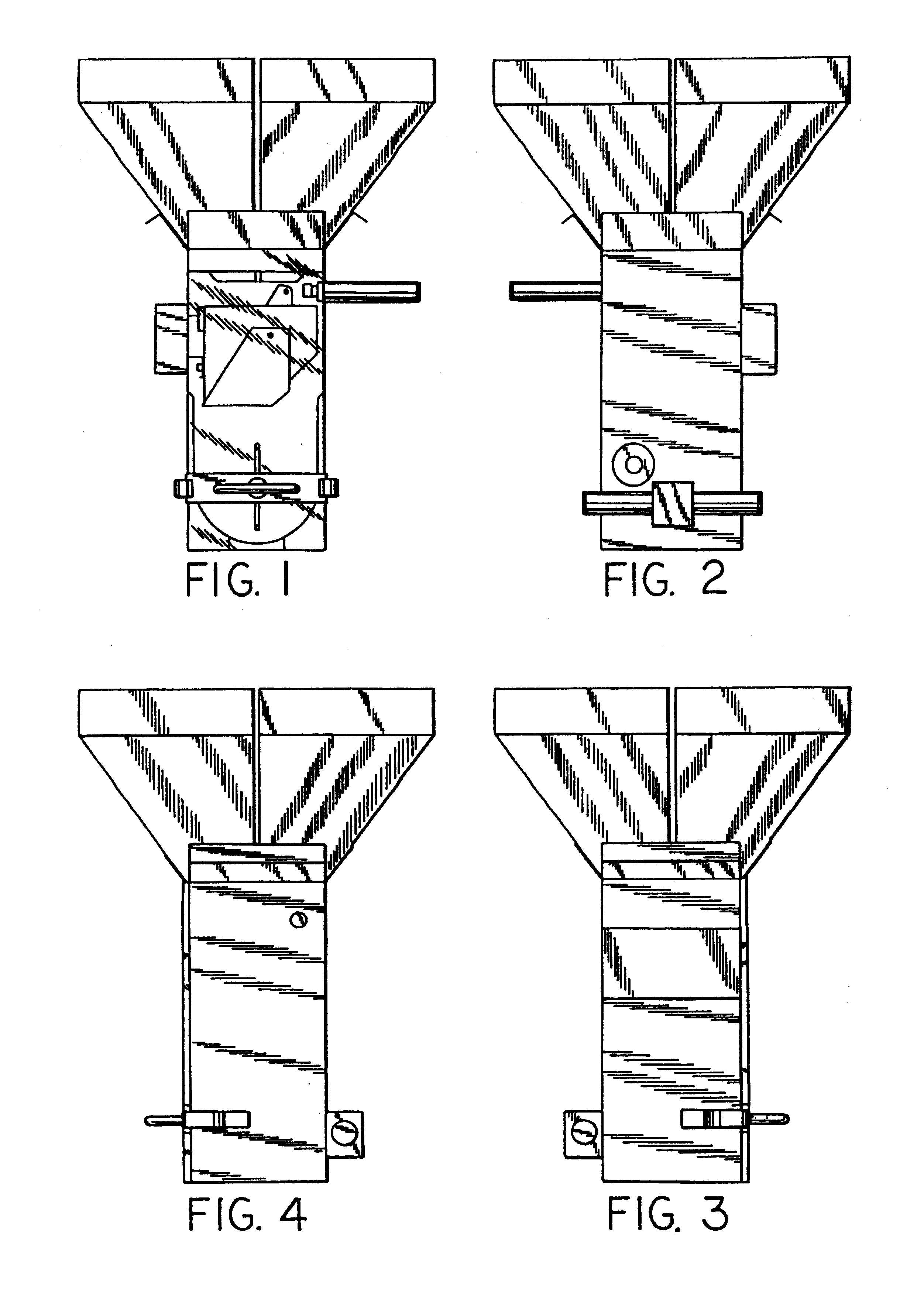

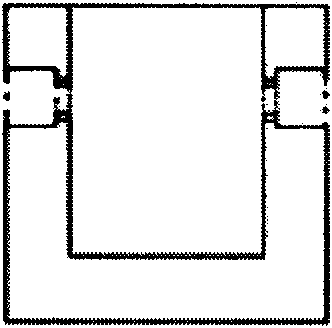

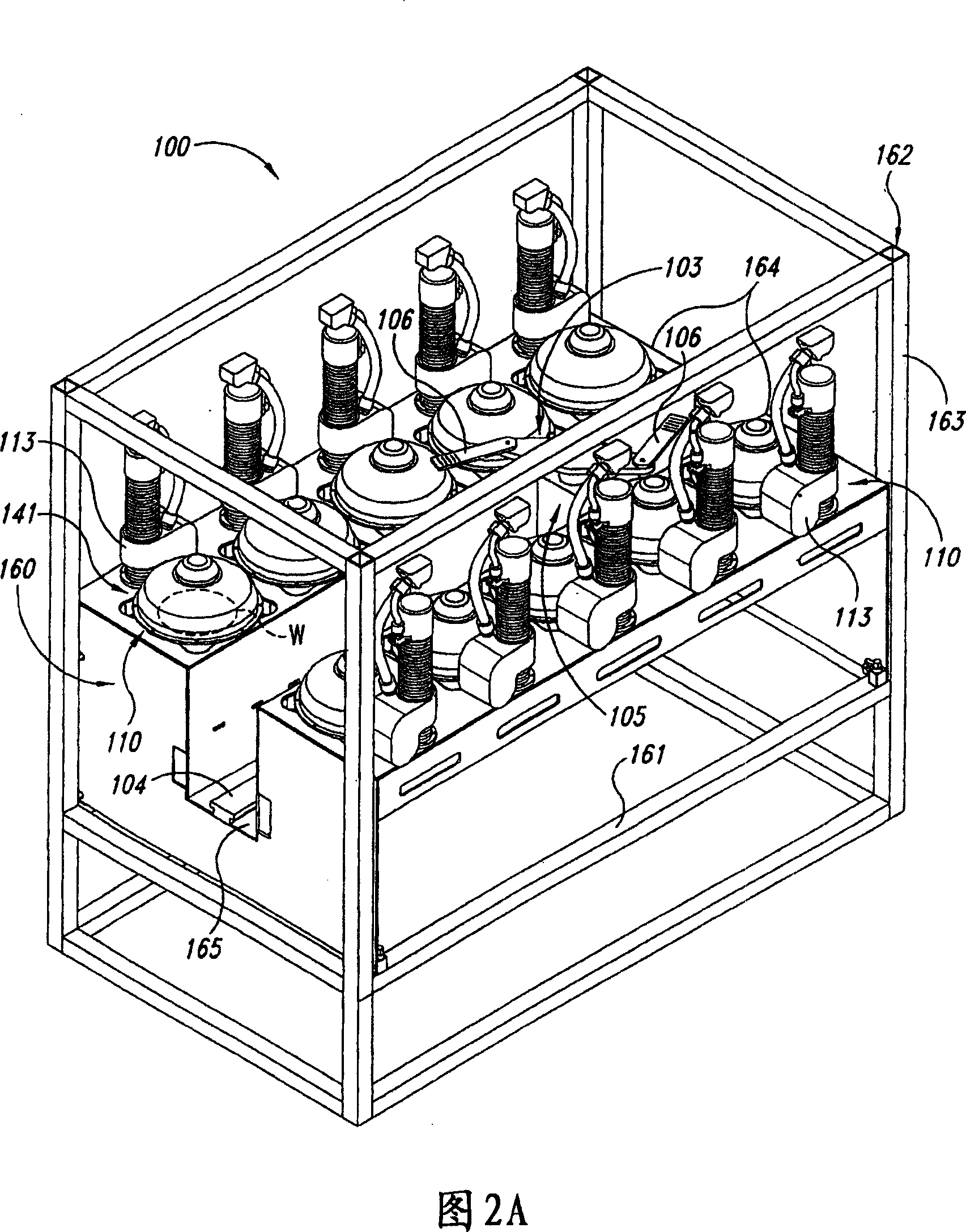

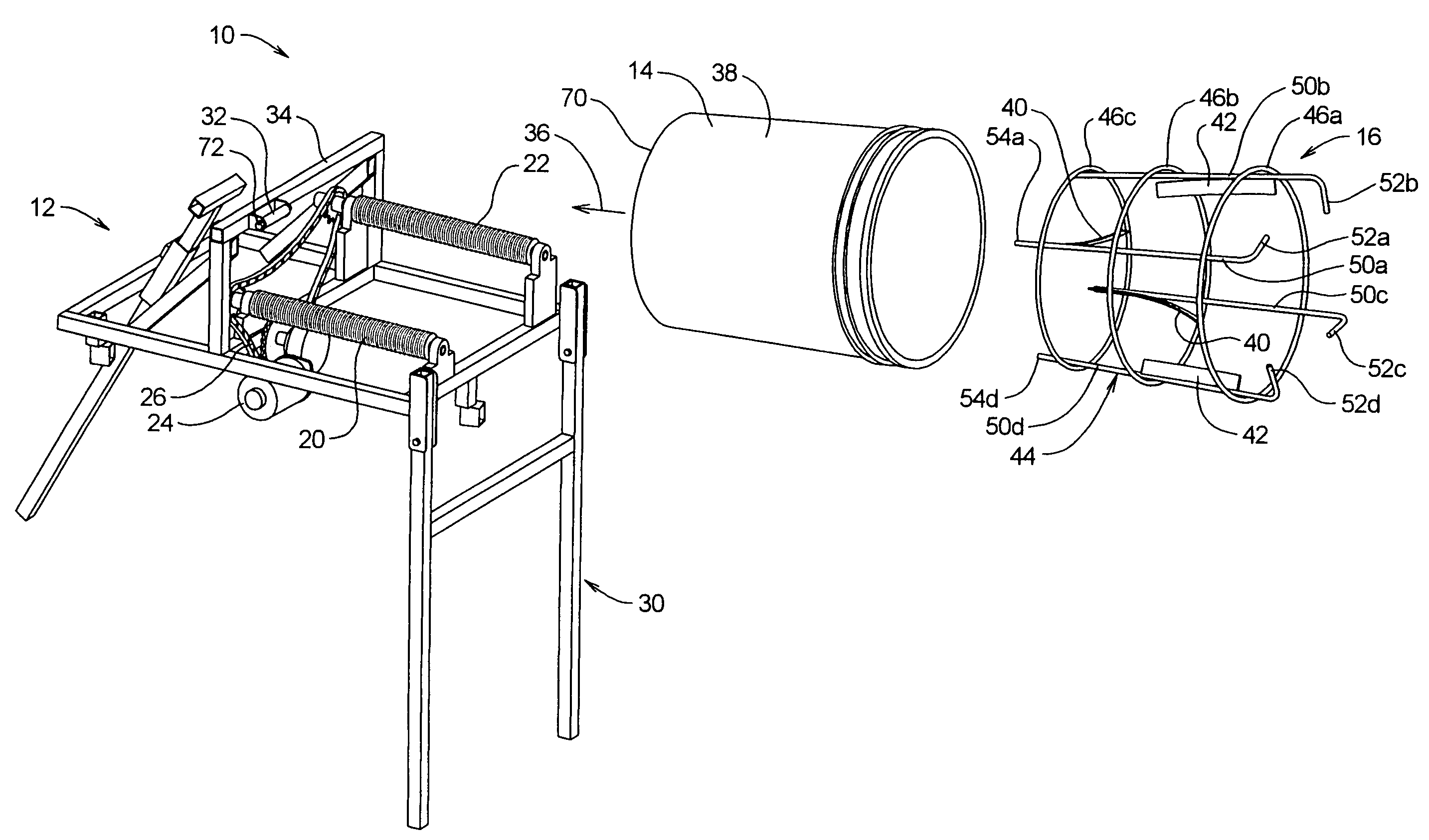

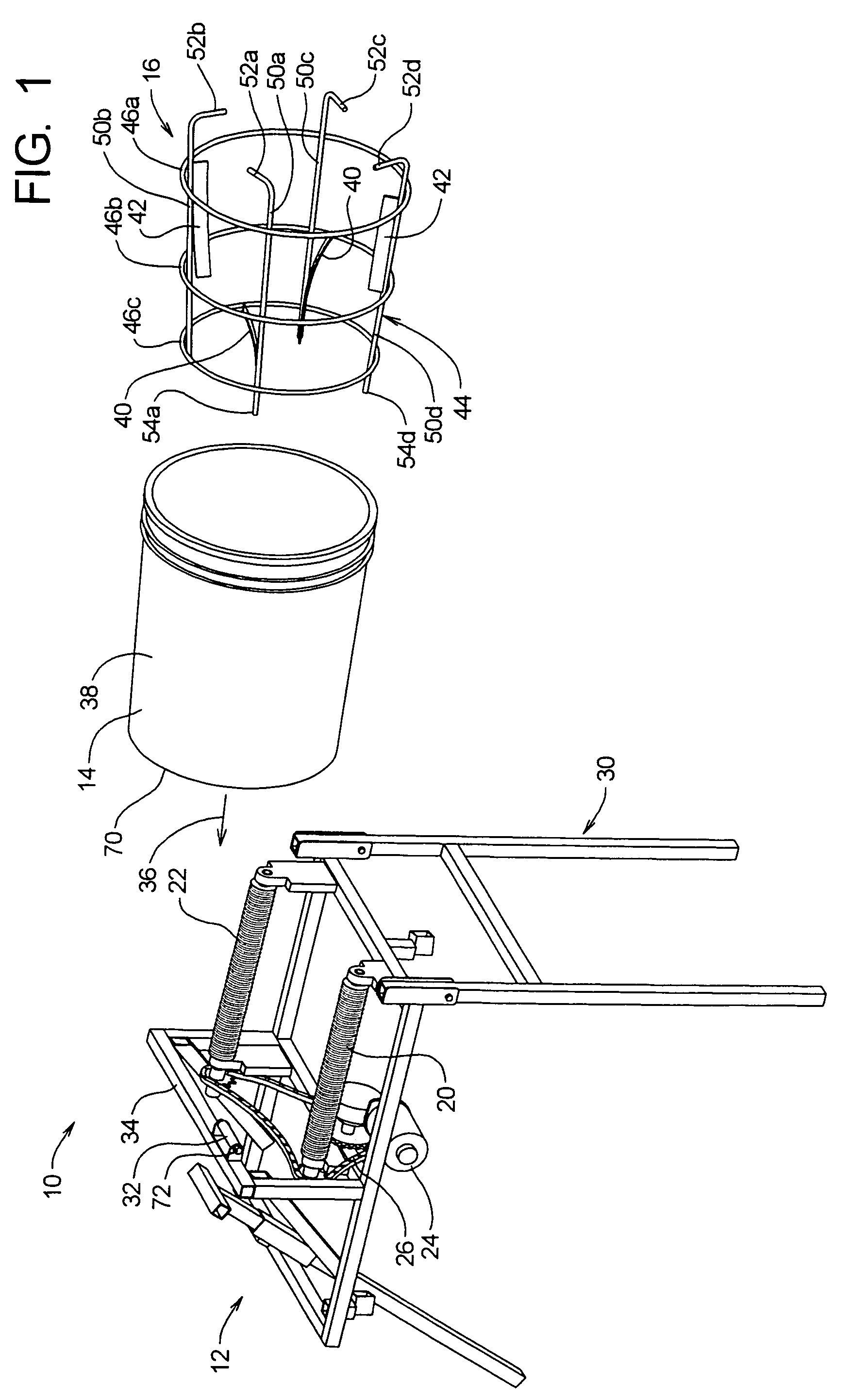

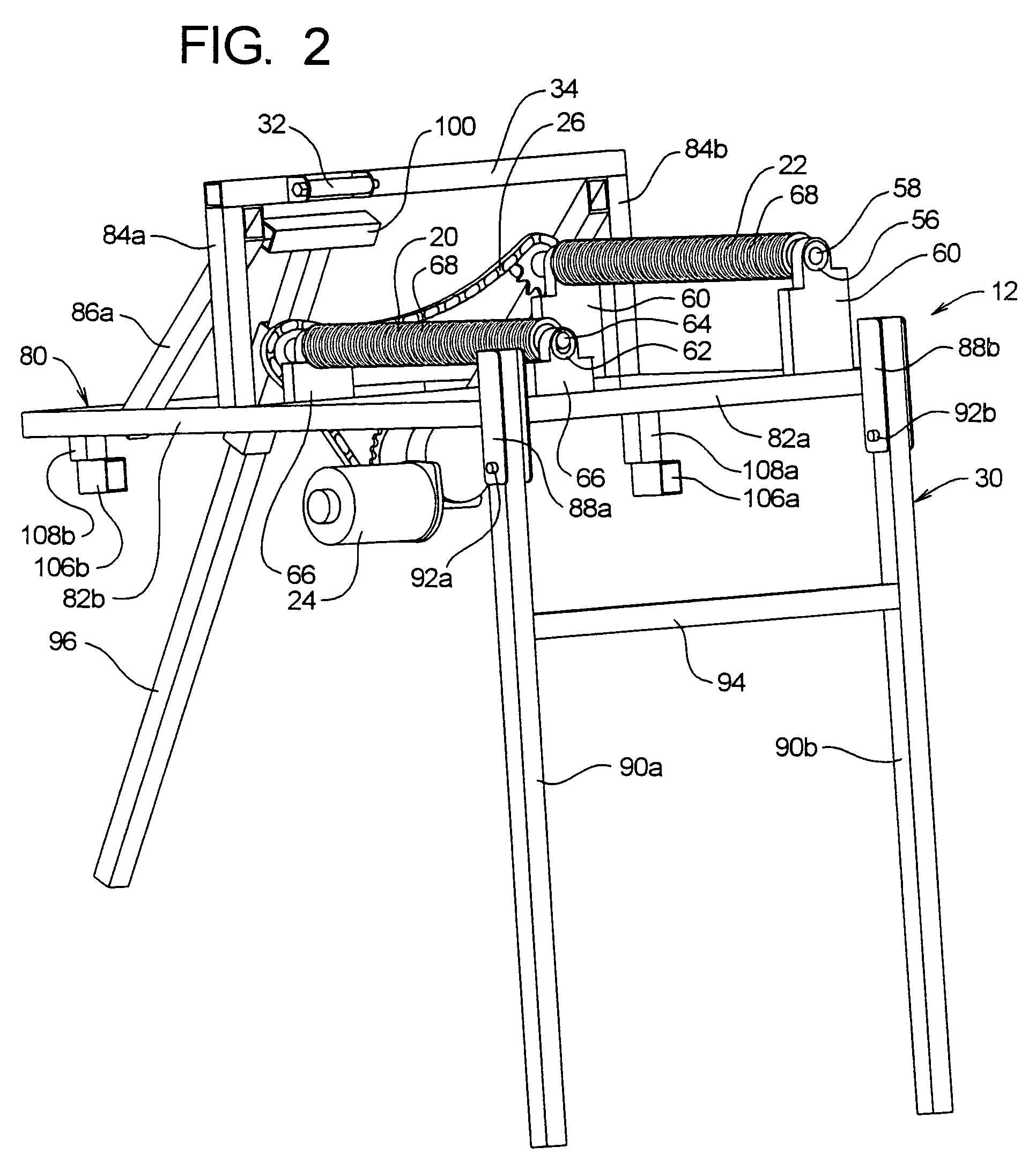

Reduced size gravimetric blender

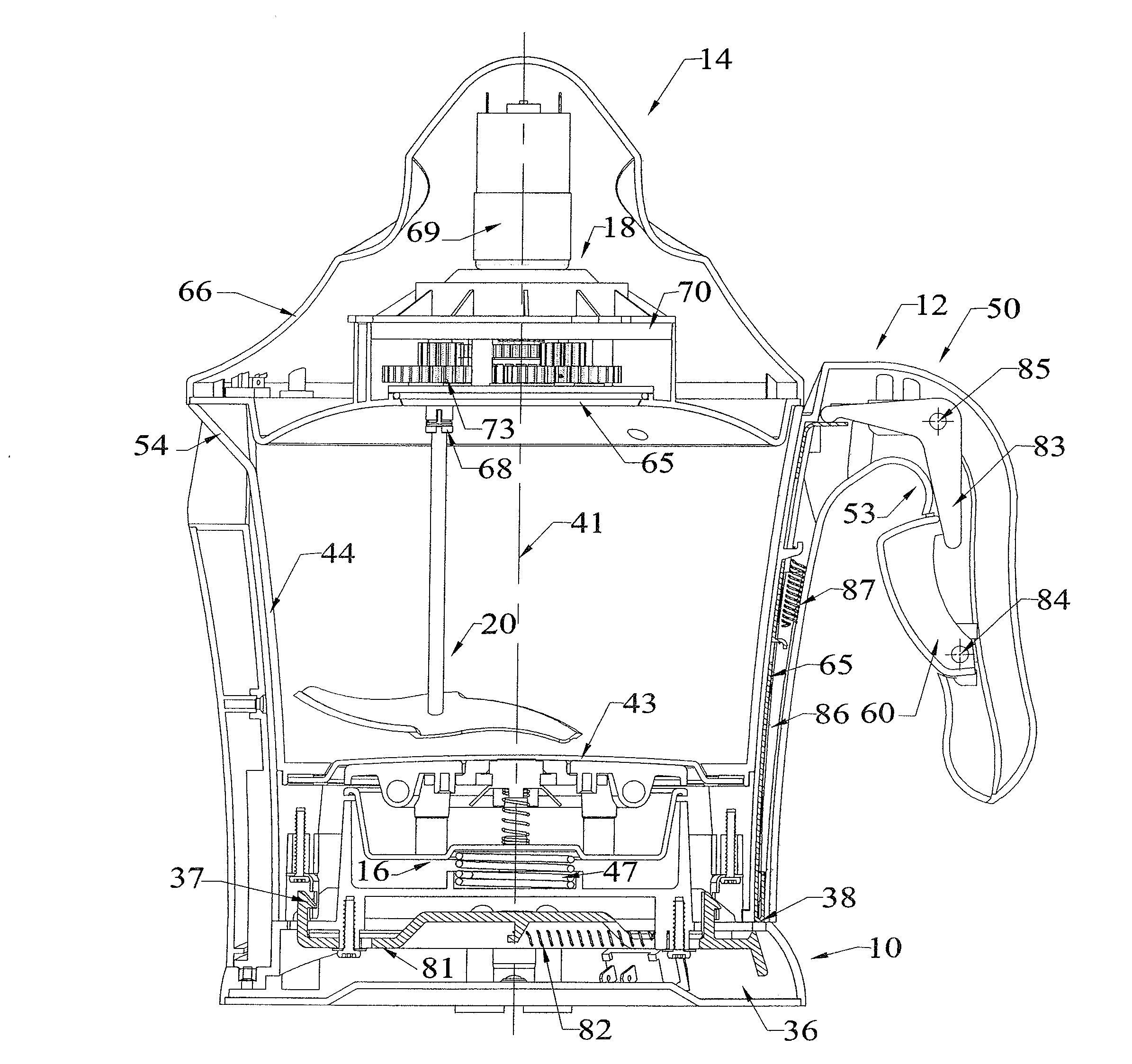

InactiveUS6467943B1Controlling ratio of multiple fluid flowsRotary stirring mixersMolding machineReduced size

A gravimetric blender of a reduced size mounted to be directly over the feed trough of small molding machines or extruders. The blender has an upright hollow rectangular frame with a transparent panel. The top of the frame forms a cradle for removably supporting a plurality of hoppers having a bottom discharge controlled by a valve mechanism. The valve mechanism is mounted on each hopper and is connected to a control station having a quick-disconnect fitting on the hopper. The hoppers discharge sequentially into a weigh bin supported on a load cell connected to the control station of the blender. The weigh bin has an openable bottom portion pivotally mounted thereon for actuation by the control station when the appropriate weight is registered by the load cell. The weigh bin discharges into a mixing chamber having an agitator or mixer removably mounted therein. The mixer is journaled for rotation in the transparent panel which is removable so that when the panel is removed, the mixer agitator is disengaged from its drive and removed with the panel.

Owner:MAGUIRE PROD

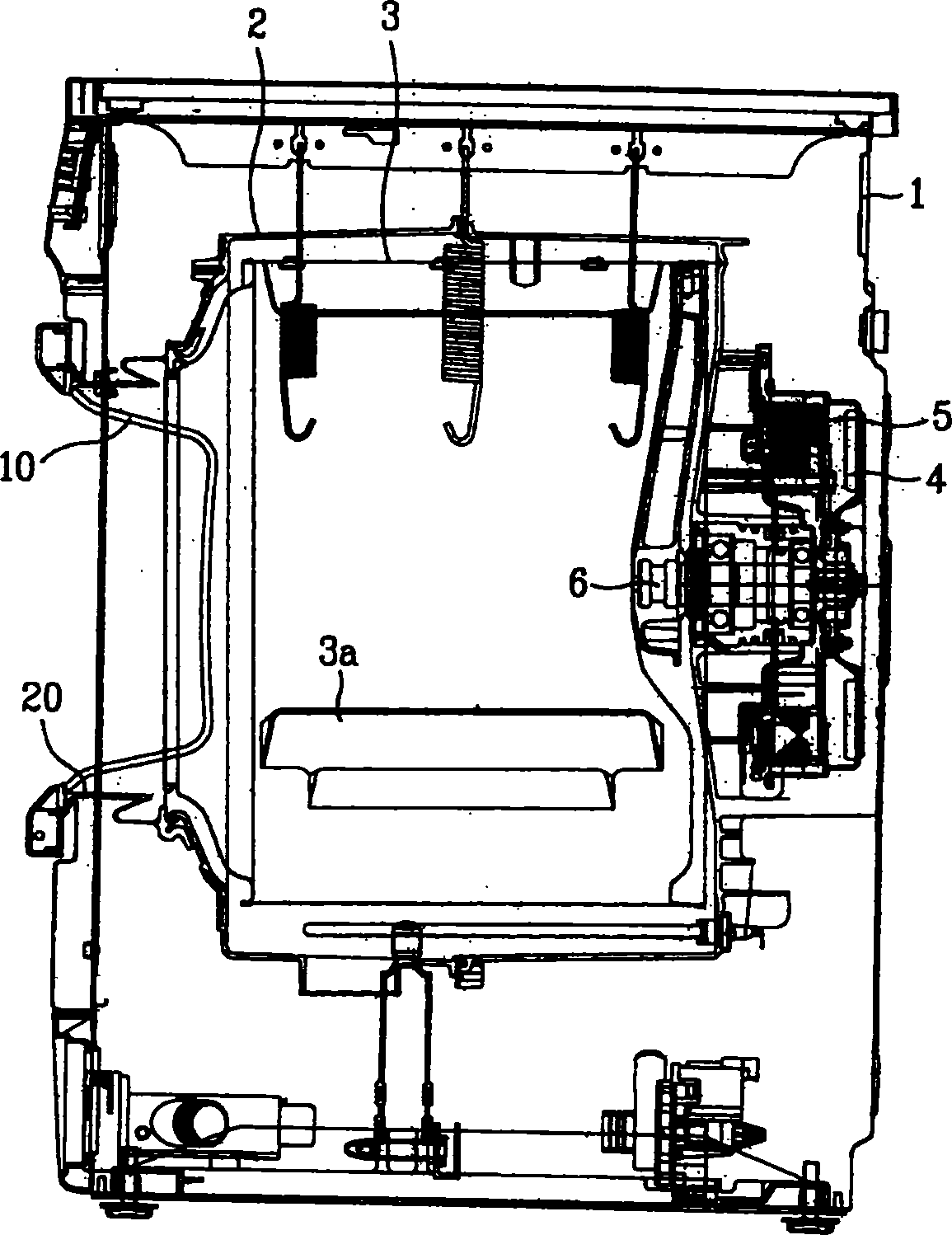

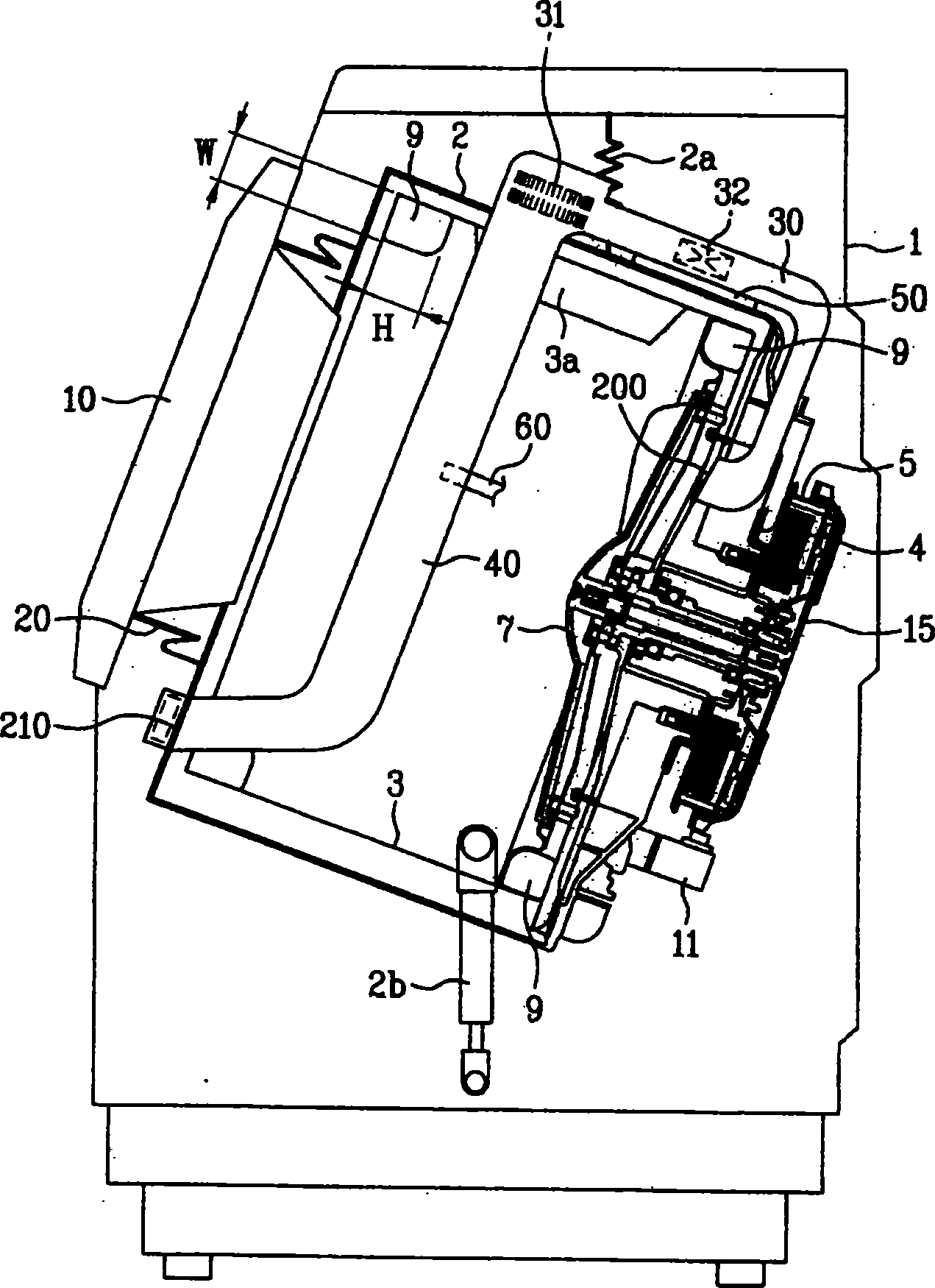

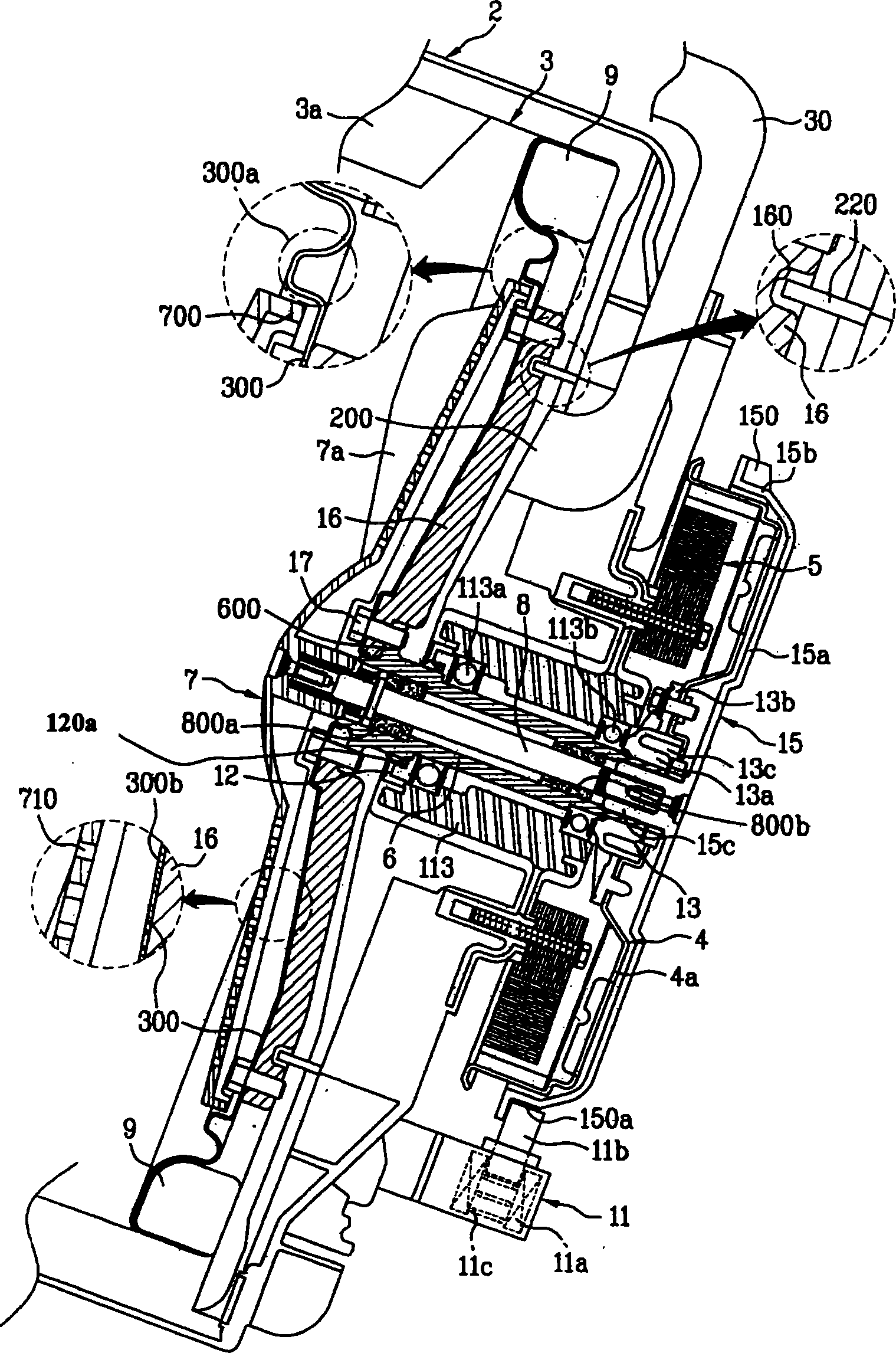

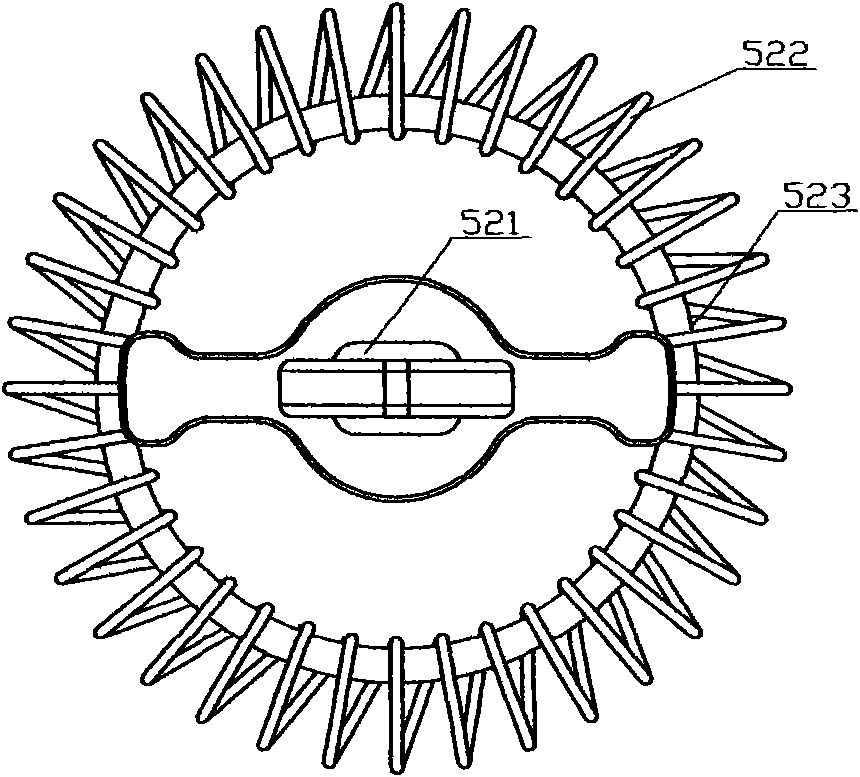

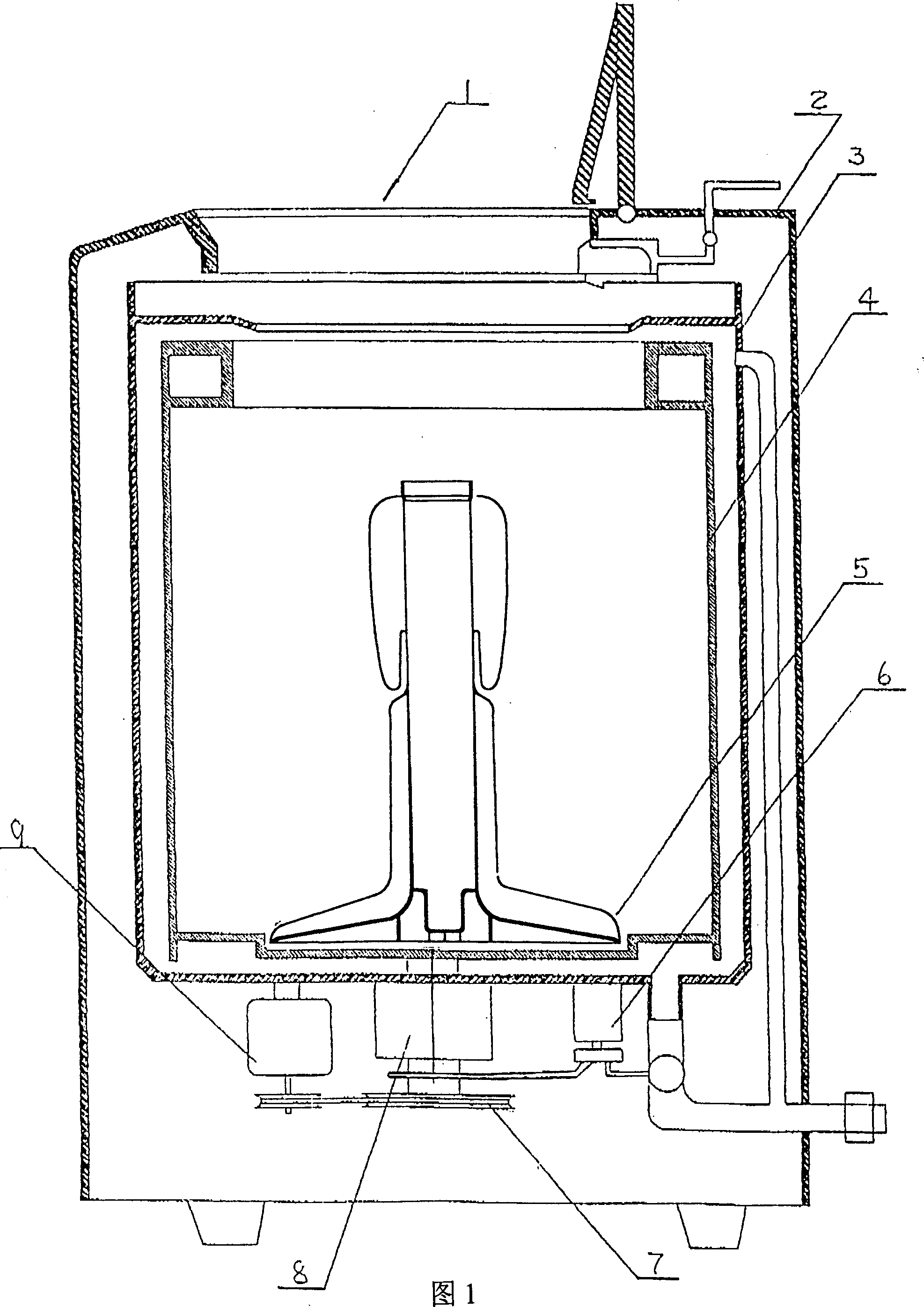

Inclined rotary drum washing machine with pulsating wheel and drying function and control method thereof

InactiveCN1888202AEasy to put inEasy to take outOther washing machinesWashing machine with receptaclesFixed frameEngineering

The present invention relates to a kind of inclined drum washing machine with agitator and drying function and its control method. Said washing machine includes the following several portions: inclined washing tub, drum, hollow drum shaft, bearing, bearing cover, stator, rotor, agitator, agitator shaft, fixed frame and constraining device. Besides, said invention adopts a new drying system capable of making hot air be flowed along central axis of said drum and formed into central hot air flow so as to raise drying efficiency.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

Method and device for preparing ordered porous alumina template

The invention relates to a method and a device for preparing an ordered porous alumina template, thereby being capable of realizing large-scale preparation of the ordered porous alumina templates with low cost. The method comprises the steps of: 1) removing stains and an oxide film on an aluminum sheet and polishing; and 2) using the aluminum sheet as an anode, adopting a base metal as a cathode and adopting the secondary anode oxidation method for preparing the nano-ordered porous alumina template. The cathodes and the anodes are multiple and are respectively connected in parallel by adopting guide wires, thereby controlling the anode oxidation of the aluminum sheets. The device is a cuboid groove structure, a plurality of pairs of small holes are formed on two sides and used for containing the cathodes and the anodes which are connected with a power supply, and electrolyte is contained in the groove. An magnetic stirrer and other stirring equipment can be adopted for carrying out stirring on the electrolyte during the anode oxidation process. The method and the device can realize the low-cost, large-scale and rapid preparation of a nano-pore path array with high order degree and adjustable pore size.

Owner:TONGJI UNIV

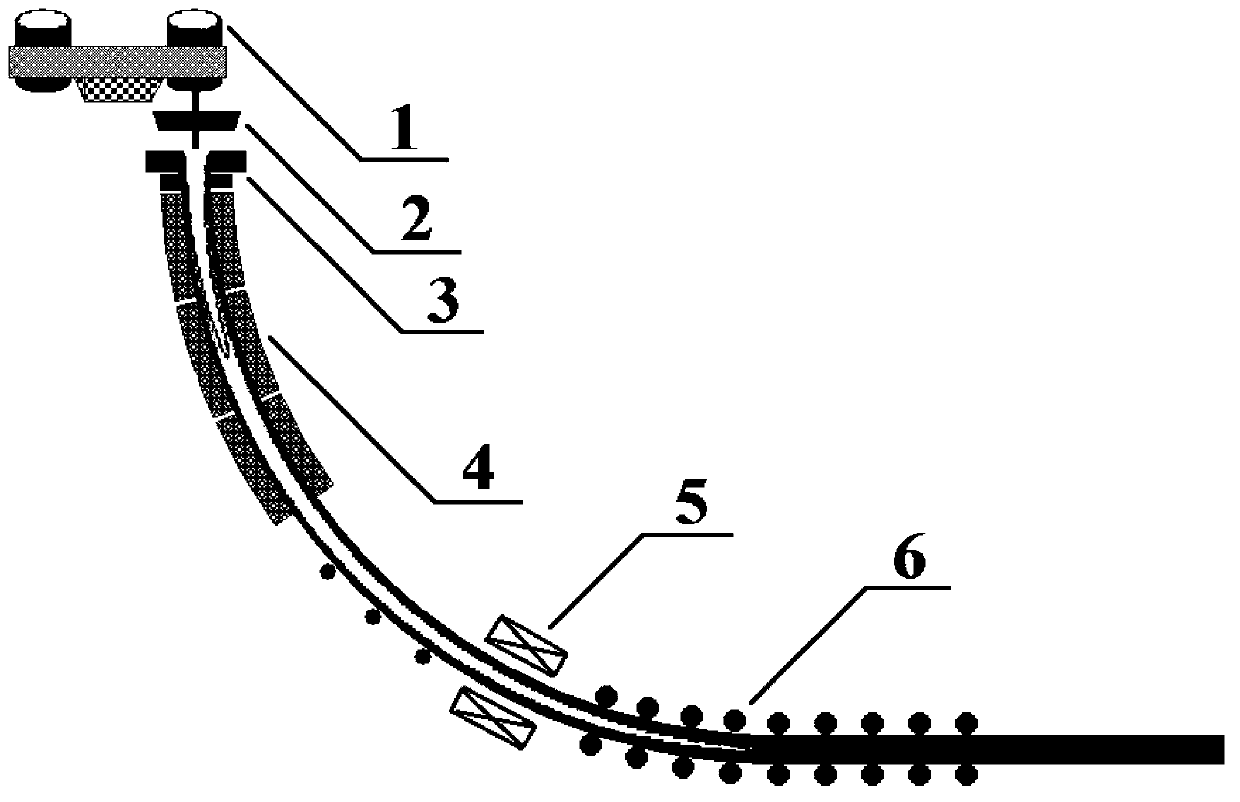

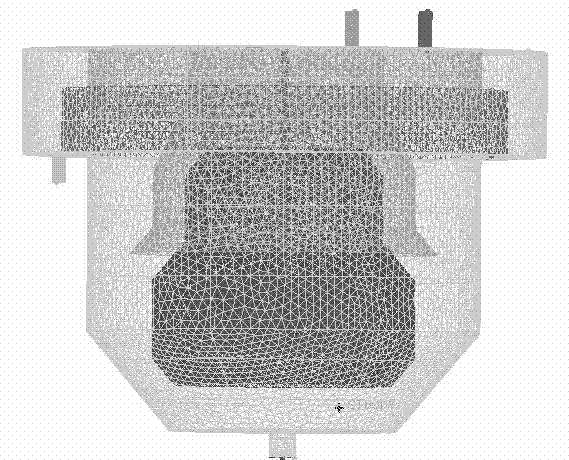

Continuous casting bloom soft press technology based on tail end electromagnetic stirring

ActiveCN103121092AReduce dependenceThe effect of electromagnetic stirring is greatThermodynamicsHeat transmission

The invention provides a continuous casting bloom soft press technology based on tail end electromagnetic stirring and belongs to the field of metal casting. The continuous casting bloom soft press technology based on the tail end electromagnetic stirring is characterized in that after a tail end electromagnetic stirring device is arranged on a second cooling area, a previous air cooling area is straightened. The thickness of a liquid core controlling the position of the stirring device occupies 30% to 55% of the thickness of a casting blank through a solidification heat transmission mathematical model. Stirring current of the tail end electromagnetic stirring device is 350A to 750A and stirring frequency is 3Hz to 8Hz. When soft press and straightening are conducted simultaneously, complete solidification of liquid phase among columnar crystals is guaranteed and meanwhile total press amount of a press intersection is controlled to be 10mm to 25mm, liquid steel superheat degree of a tundish is 20 DEG C to 30DEG C, dragging speed of a continuous casting machine is 0.35m / min to 0.75m / min, and therefore internal quality of a continuous casting bloom is remarkably improved and high quality rolled metal is guaranteed. Continuous casting bloom bearing steel manufactured through the technology is continuously manufactured for over 10 boilers, occurrence of internal cracks is avoided, a central organization is dense and even, the rate that a center contracting hole <=1.0 reaches 97.54%, center C segregation is controlled to be under 1.06 and thus the internal quality of the bearing steel is remarkably improved.

Owner:UNIV OF SCI & TECH BEIJING

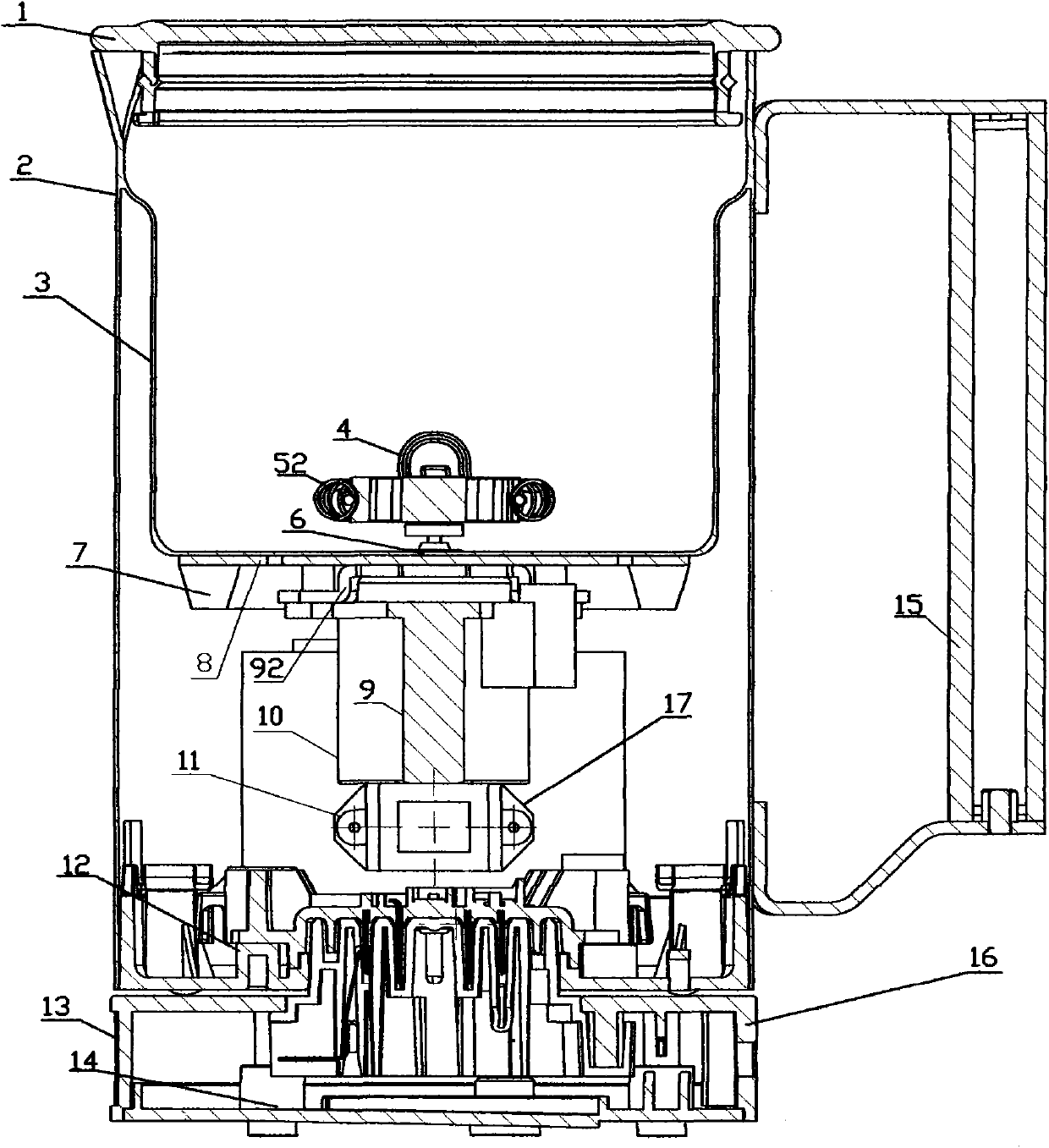

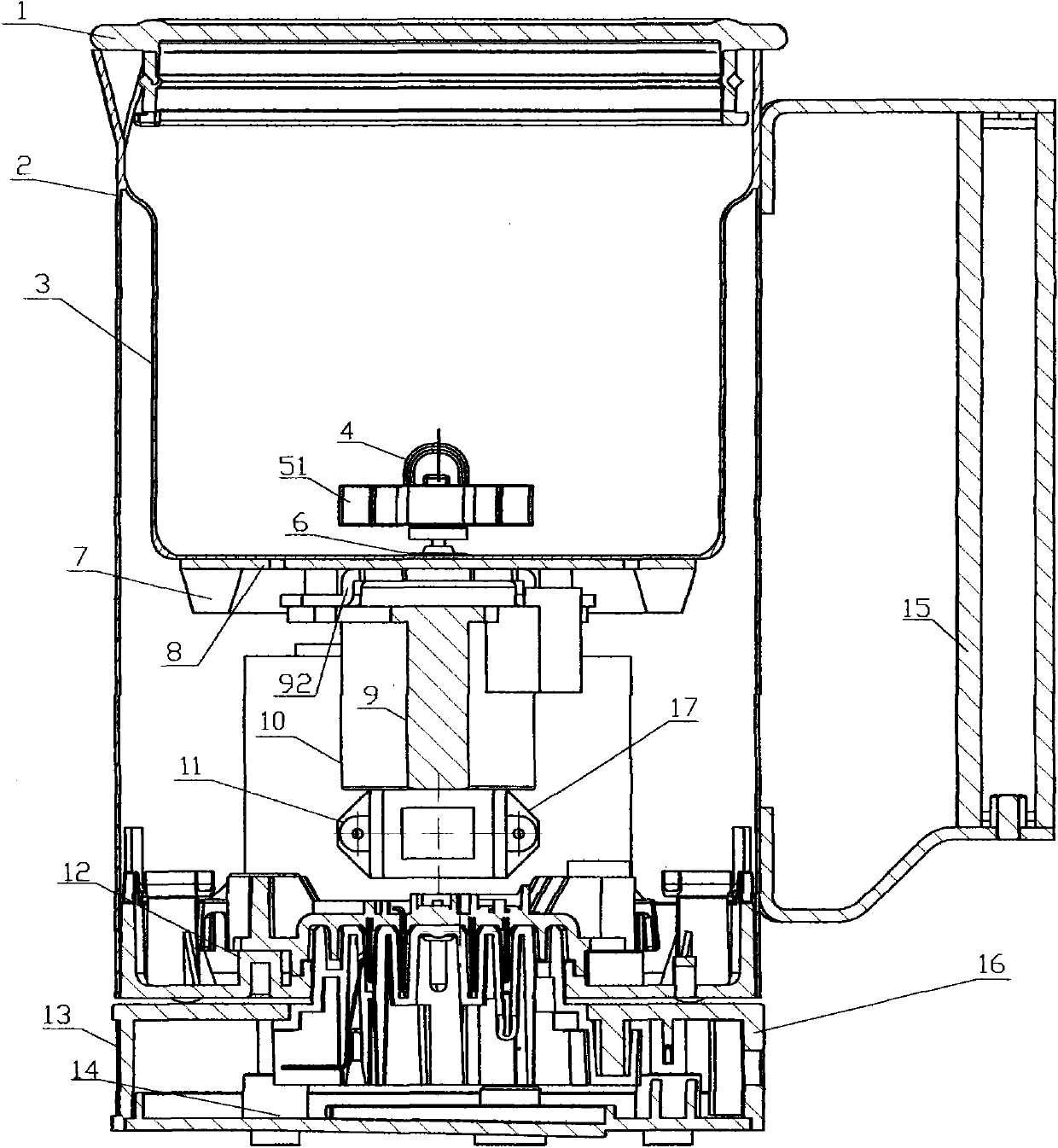

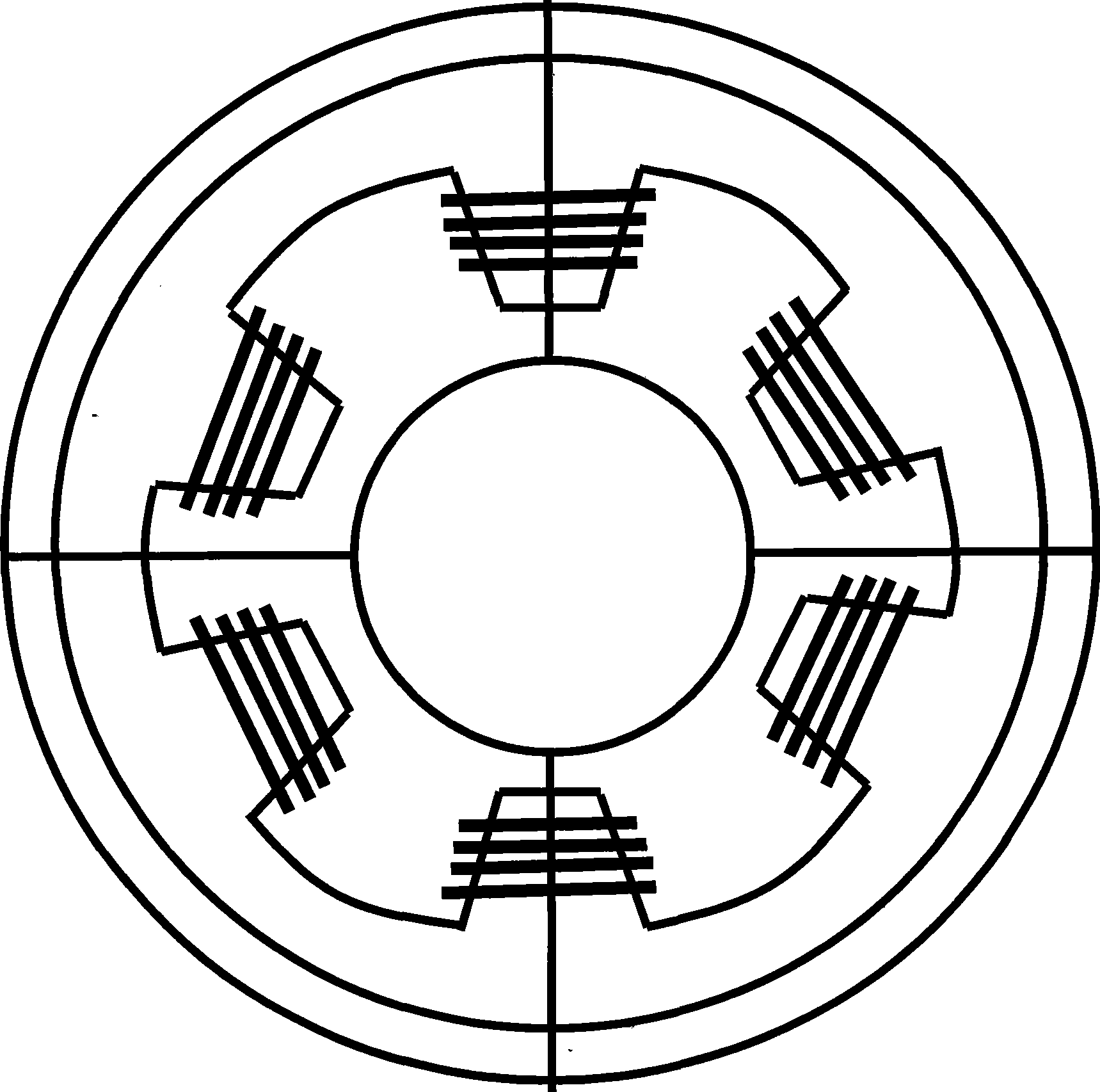

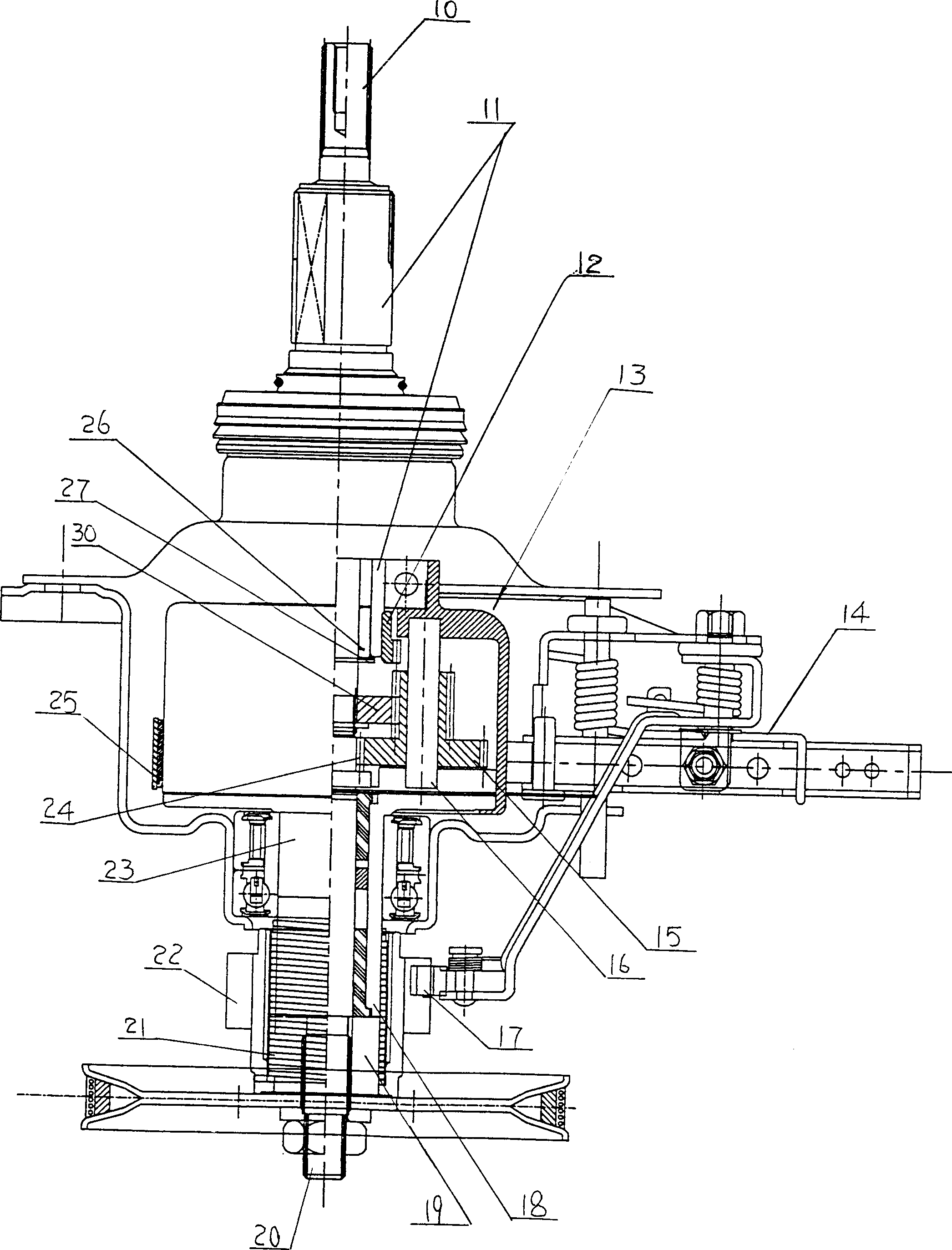

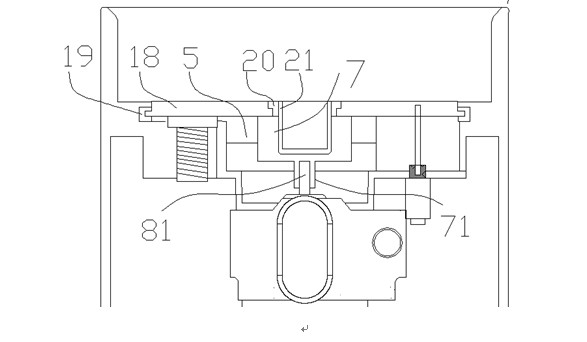

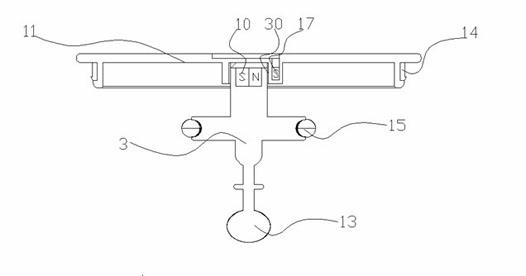

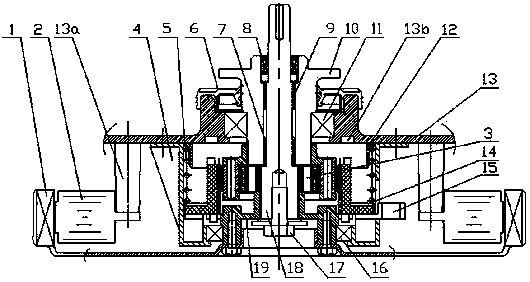

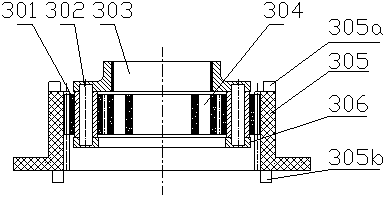

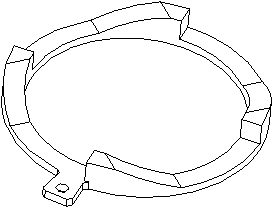

Milk foam machine directly driven by motor

ActiveCN101904700ASimple structureGood shaft seal performanceKitchen equipmentElectric machineLiquid state

Owner:GUANGDONG MASTER ELECTRICAL APPLIANCE CO LTD

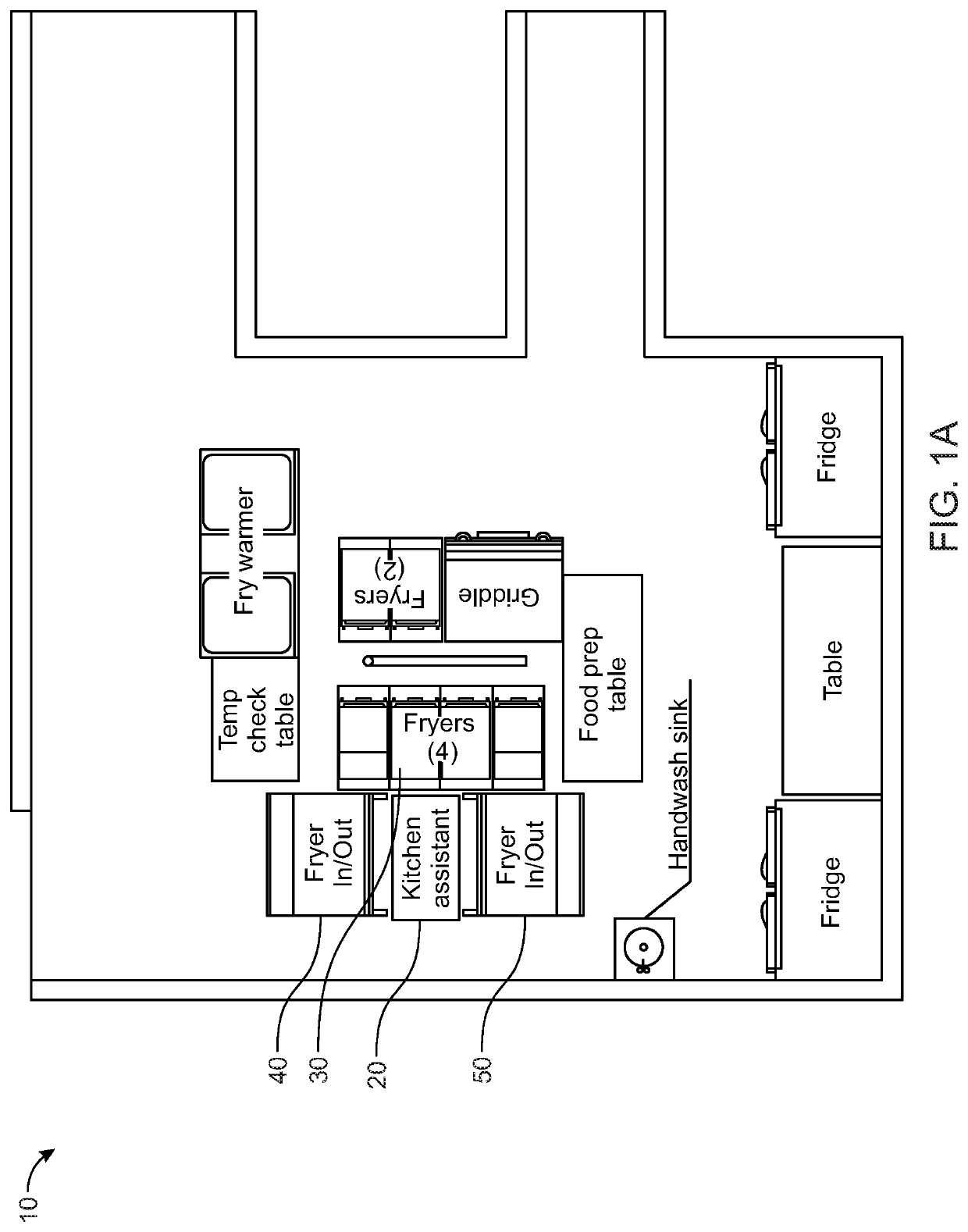

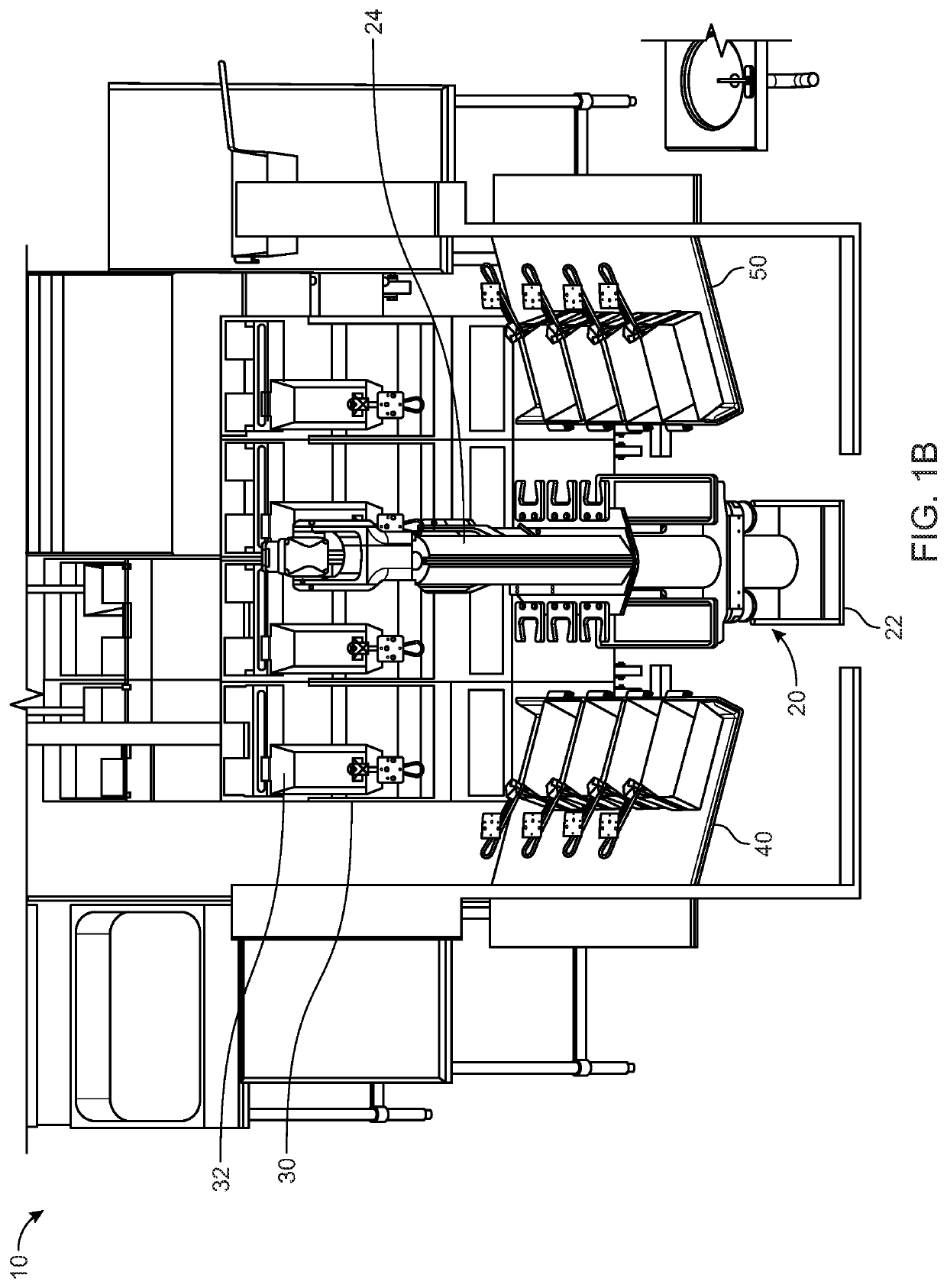

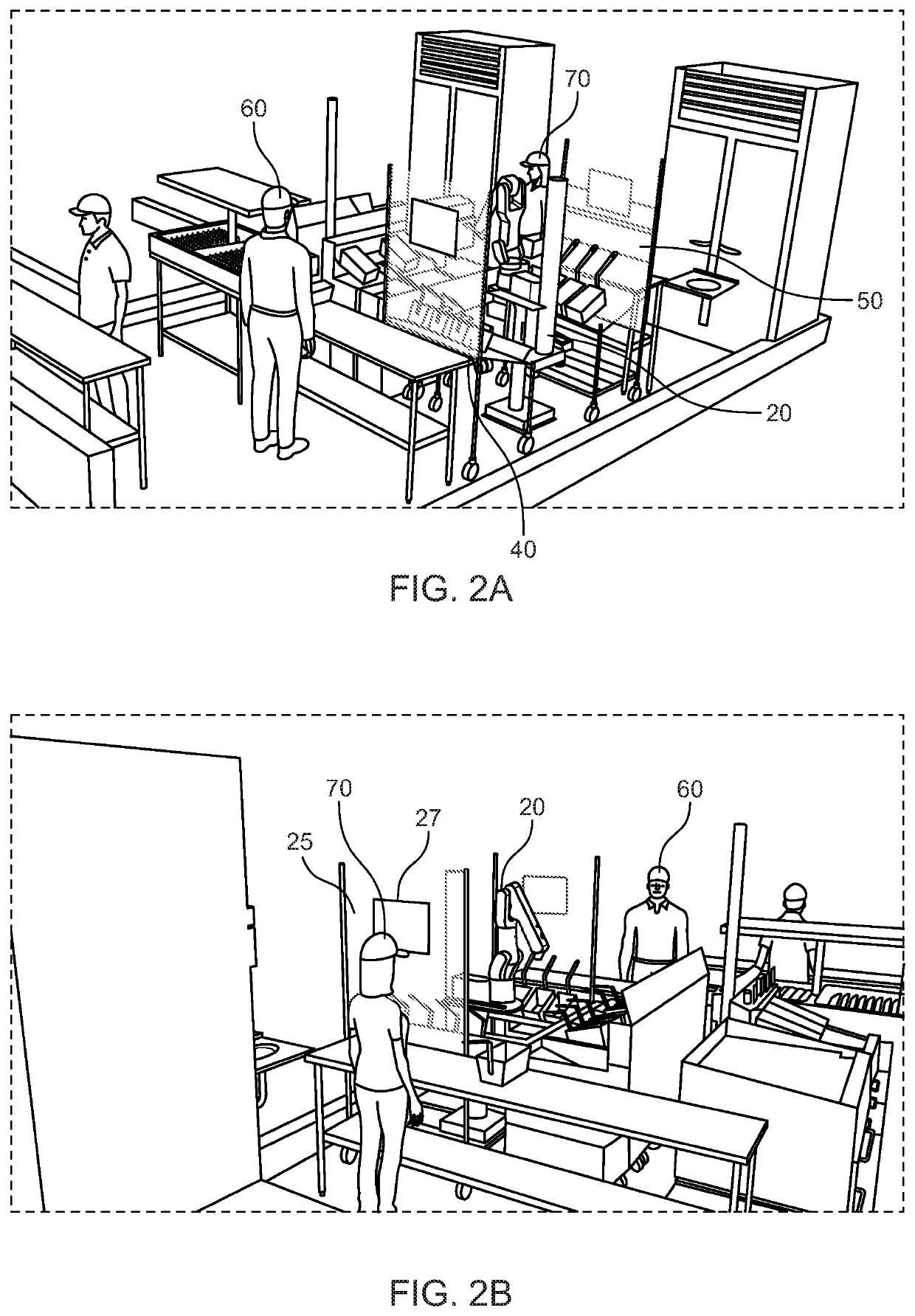

Robotic kitchen assistant including universal utensil gripping assembly

ActiveUS20200047349A1Maximize effectivenessMaximize efficiencyProgramme-controlled manipulatorGripping headsRobotic armEngineering

A robotic kitchen assistant for frying includes a robotic arm, a fryer basket, and a robotic arm adapter assembly allowing the robotic arm to pick up and manipulate the fryer basket. The robotic arm adapter includes opposing gripping members to engage the fryer basket. A utensil adapter assembly is mounted to the handle of the fryer basket, and the opposing gripper members are actuated to capture a three-dimensional (3D) feature of the utensil adapter assembly. The robotic arm adapter assembly can include an agitator mechanism to shake the fryer basket or another utensil as desired. Related methods are also described.

Owner:MISO ROBOTICS INC

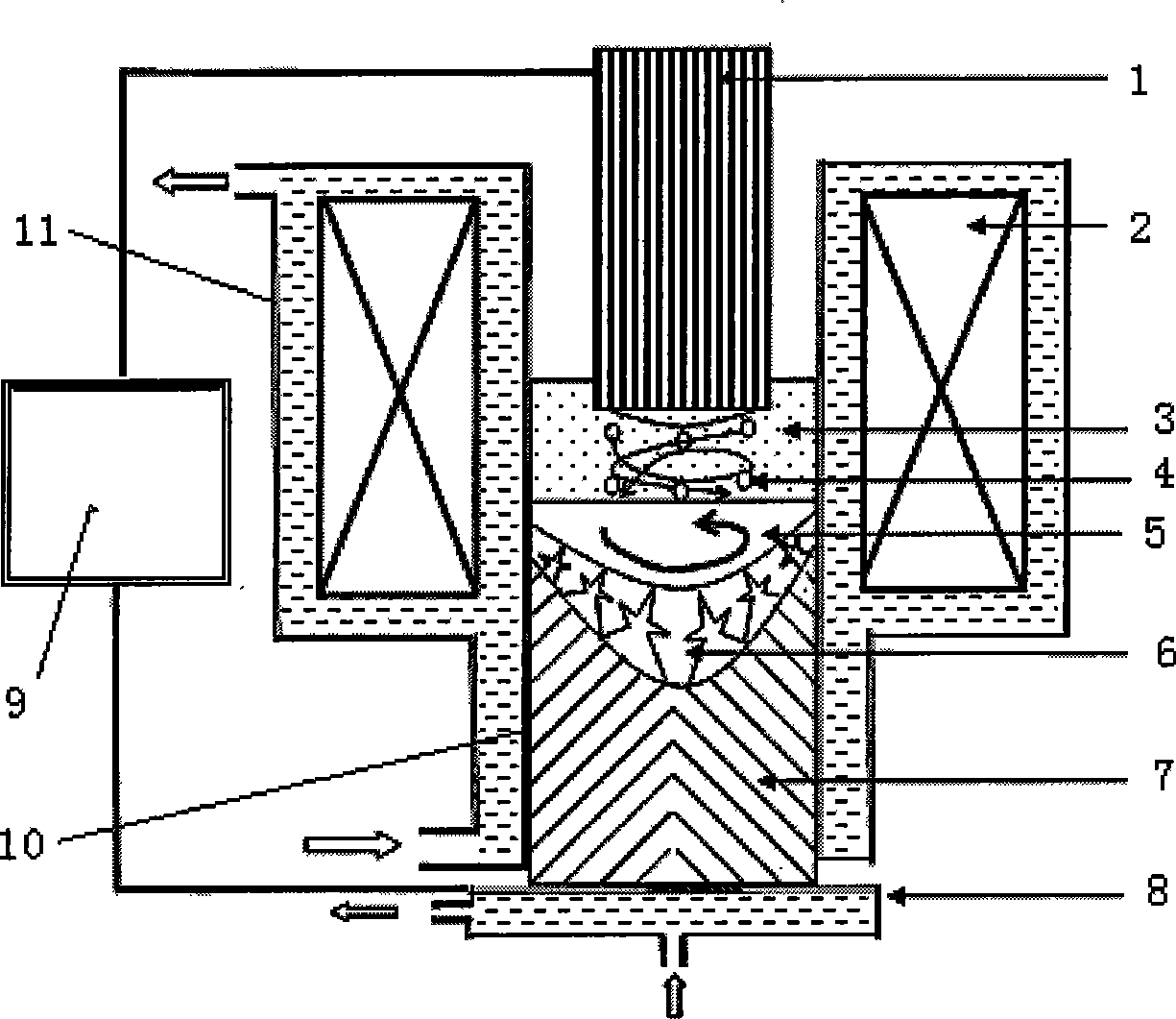

Electroslag smelting casting device with additional electromagnetic stirring and method

The invention relates to an electroslag casting device additionally provided with electromagnetic stirring and a method thereof. The electroslag casting device belongs to the technical field of special steel electroslag metallurgy and comprises a crystallizer, a crystallizer water jacket and an electromagnetic stirrer; an annular magnet is sleeved on the outer wall of the crystallizer and positioned at the middle-upper part of the crystallizer, a loop is wound on an iron core of the annular magnet, an electromagnetic stirrer water jacket is arranged at the periphery of the annular electromagnet, and the electromagnetic stirrer water jacket is communicated with the crystallizer water jacket; a melting consumable electrode forms molten steel drops which then enter a slag layer; the molten steel drops fall down in a spiral line way in the slag layer under the action of the rotary electromagnetic field and then enter a steel ingot liquid tank; the steel ingot liquid tank raises continuously and also enters into an effective magnetic field action region of the electromagnetic stirrer; and meanwhile, electric current in the molten steel is acted with the rotary magnetic field to produce the electromagnetic force which then drives the molten steel to rotate. The invention has simple equipment, and has the obvious functions of improving the surface quality, the subsurface quality and the solidifying tissue of a casting blank and the isometric crystal ratio, and lightening the internal defects, such as the center segregation, the center looseness, and the like.

Owner:NORTHEASTERN UNIV

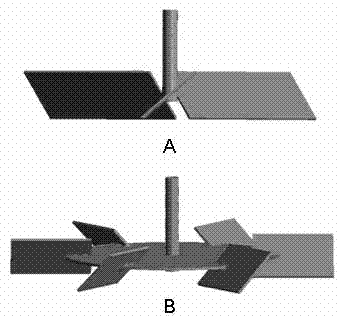

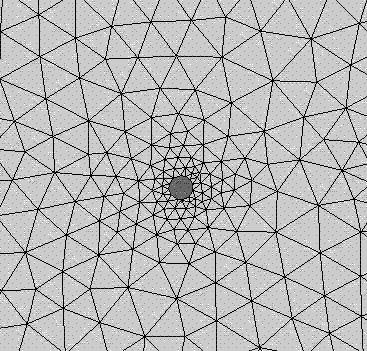

Optimization design method of anaerobic continuous flow agitator bath type biological hydrogen production reactor

InactiveCN102855342ASimple designSolve engineering problemsSpecial data processing applicationsContinuous flowAgitator

The invention belongs to the field of environment protection, and in particular relates to an optimization design method of an anaerobic continuous flow agitator bath type biological hydrogen production reactor. The method comprises the following steps: researching reactor internal flow field characteristics of different types of stirring paddles under the conditions of different paddle-bath diameter ratios and different agitating speeds and influence on hydrogen production process, by using a numerical simulation software based on computational fluid mechanics technology; obtaining detailed flow field information, such as velocity field, turbulence energy and dissipation rate thereof, biogas integration rate and shearing rate distribution by adopting a two-phase flow model, and analyzing and comparing different flow field information obtained through simulation according to influence on hydrogen production process by the various flow field information, thereby determining an optimal stirring paddle style and agitating speed combination, and providing an effective method for the optimization design of the agitator bath reactor. The optimization design method of the anaerobic continuous flow agitator bath biological hydrogen production reactor is mature in technology, avoids the blindness of hydraulic design of the reactor using an empirical or semiempirical association method, and has the advantages of being visual in optimization cycle effect and short in optimization cycle, saving cost, and the like.

Owner:TONGJI UNIV

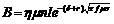

Dynamic control method for slab continuous casting electromagnetic stirrer

InactiveCN102554172AMeet the requirements of segregationImprove internal qualityThermodynamicsEngineering

The invention provides a dynamic control method for a slab continuous casting electromagnetic stirrer, which includes: acquiring and processing field production process data by the aid of a primary continuous casting computer and a secondary continuous casting computer to obtain related numerical values of non-solidification rate of molten steel in a casting blank, mushy zone width and the like; substituting selected, set and measured data into a magnetic induction density B calculation formula to obtain corresponding frequency values or current density values; and adjusting and controlling the electromagnetic stirrer in real time according to the values. The dynamic control method can be used for continuously calculating the related data of the non-solidification rate of the casting blank, the mushy zone width and the like according to change of field process conditions, automatically adjusting electromagnetic stirring current and frequency, enabling electromagnetic stirring effects to be more stable, and meeting the requirements of various steel types on segregation, so that the casting blank has no defects of cracks, needle holes, bubbles, scab, inclusion and the like, the isometric crystal rate of the casting blank reaches 55%, and central segregation degree is blow C1.0.

Owner:ANGANG STEEL CO LTD

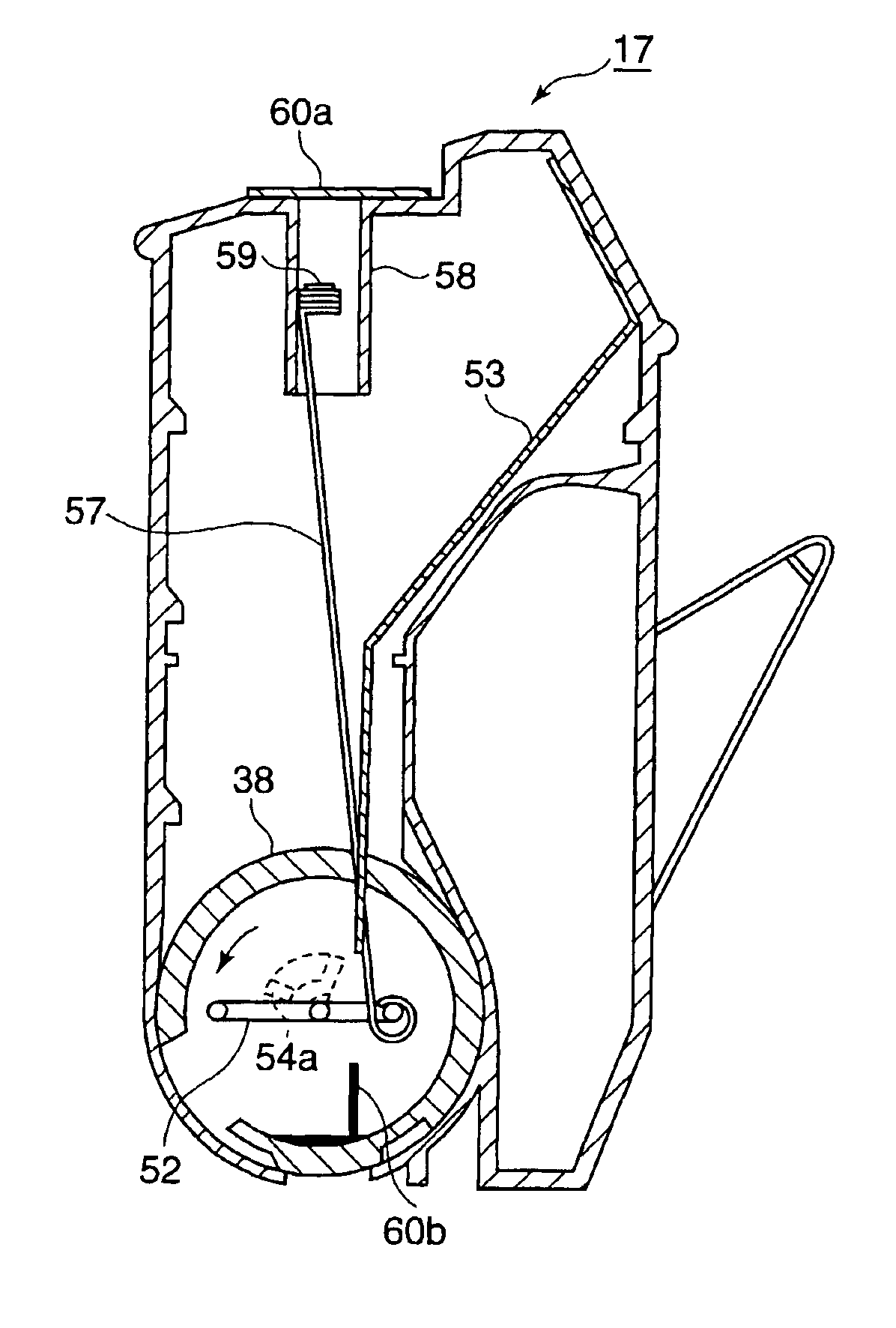

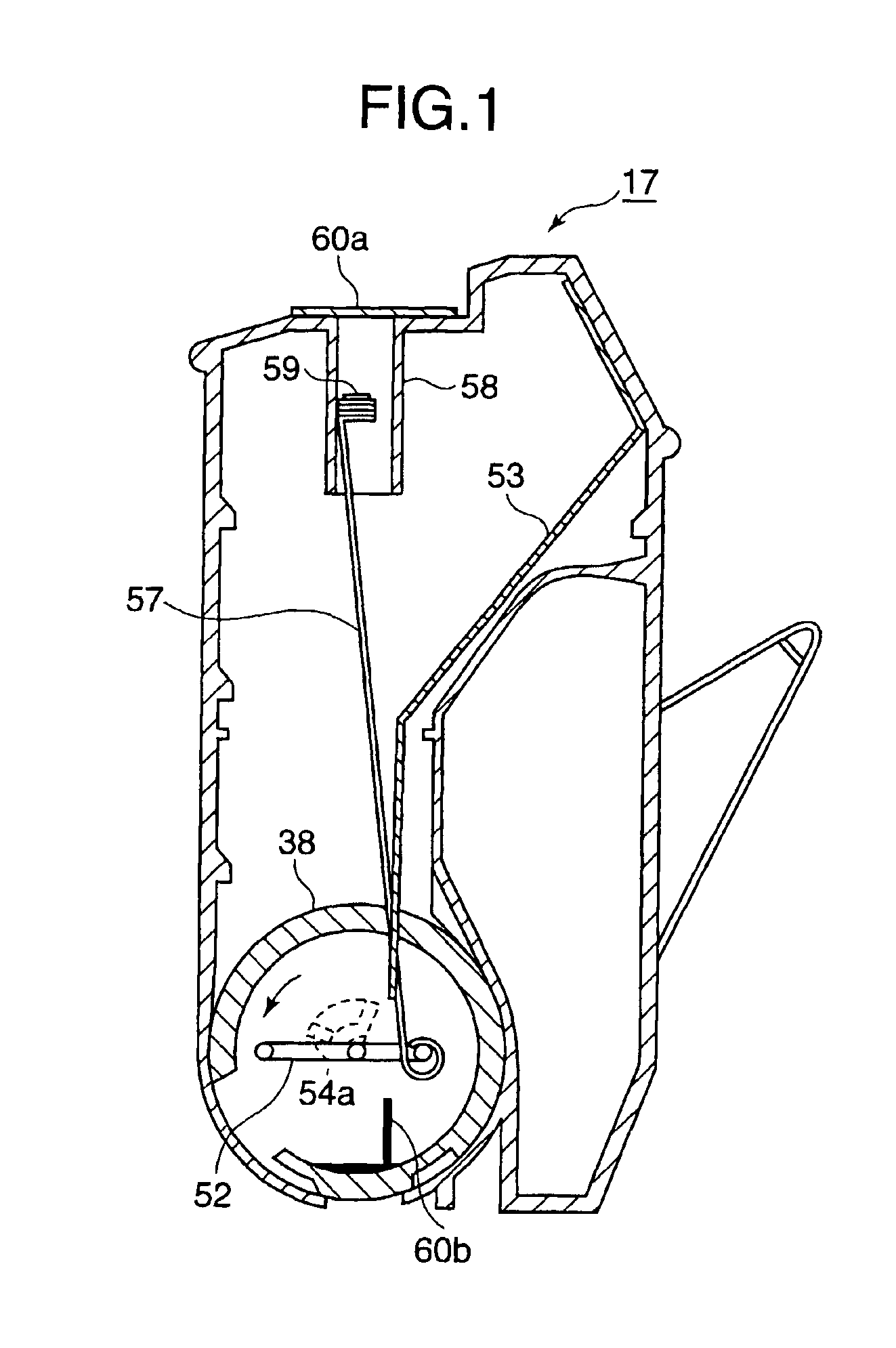

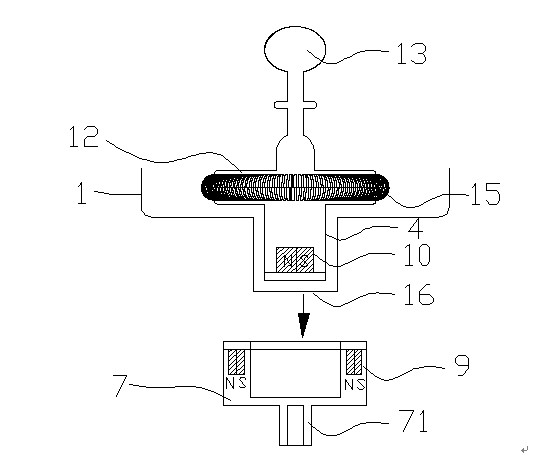

Toner cartridge having a toner agitator and a reciprocally moving member coupled to the agitator, and an image forming apparatus

InactiveUS6892036B2Normally performanceElectrographic process apparatusReciprocating motionImaging equipment

A toner cartridge has a toner-agitating member that agitates the toner to be supplied to a developing unit. The toner cartridge has at least a part of a detecting mechanism that transmits the motion of the agitating member to detect an amount of the remaining toner in the toner cartridge. The detecting mechanism has a sensor rod. The sensor rod has one end that rotatably engages the agitating member and the other end to which a detector is attached. At least a part of the motion-transmitting section is made of a material that when the part receives a pressure greater than a predetermined value, the part absorbs the pressure.

Owner:OKI DATA CORP

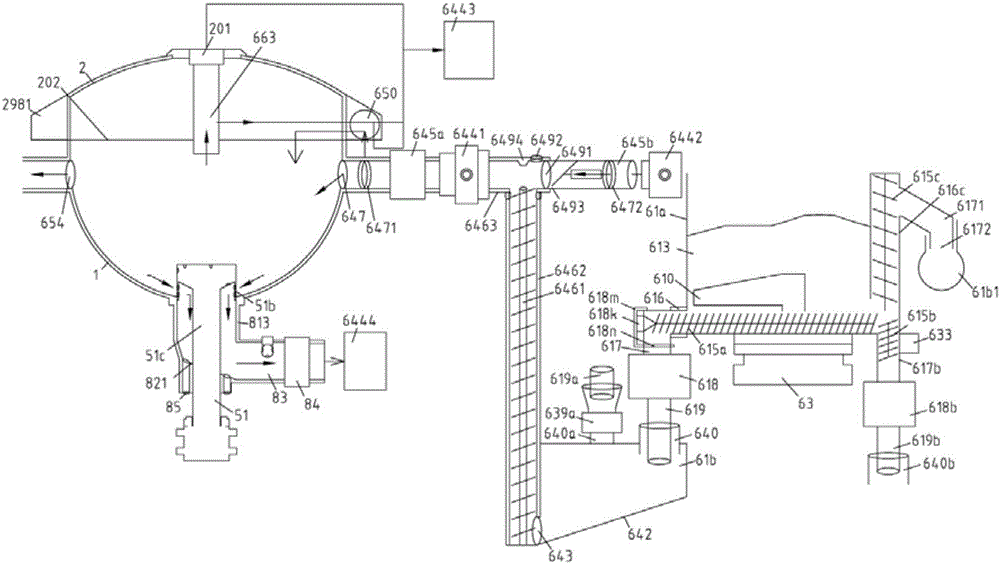

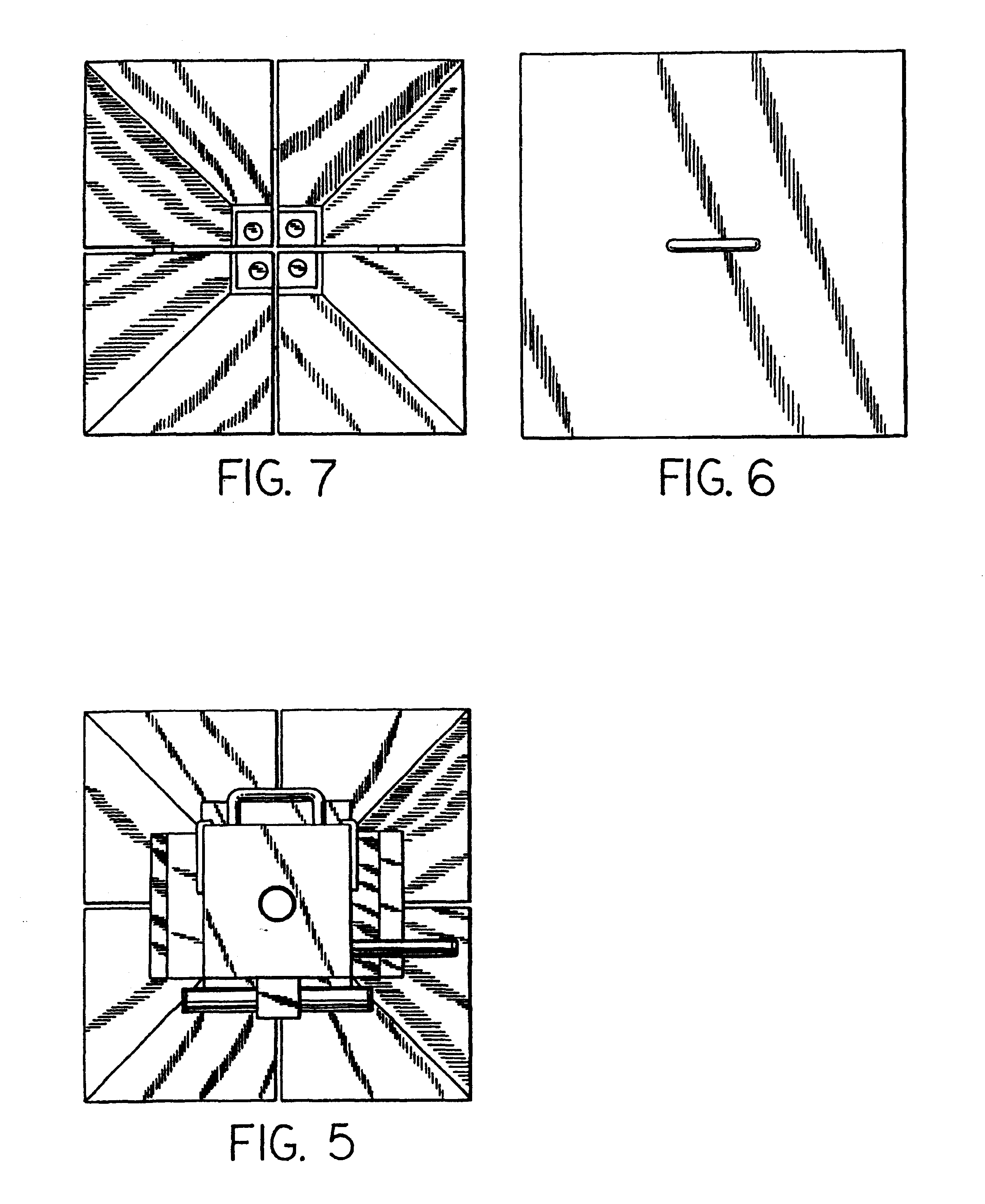

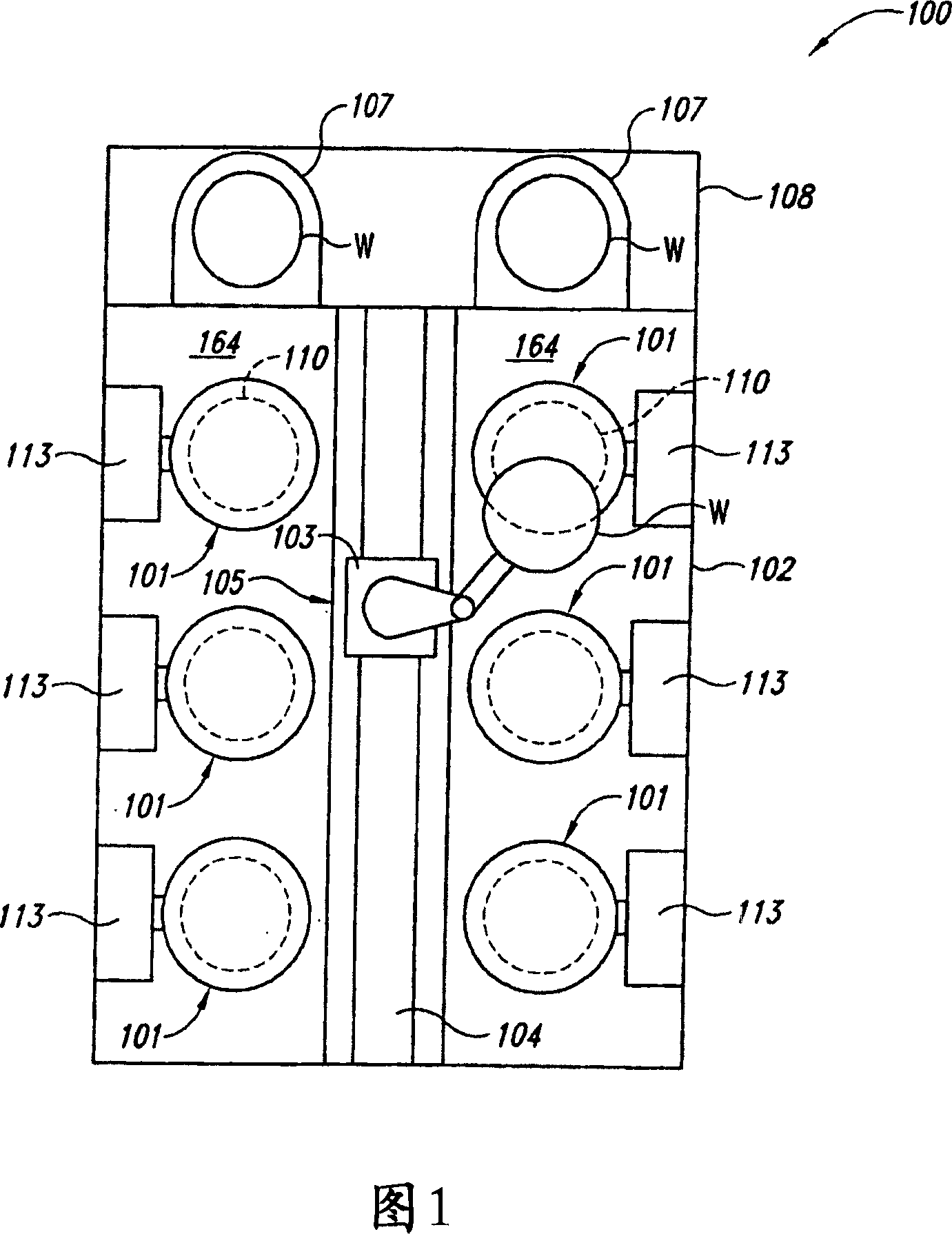

Methods and systems for processing microfeature workpieces with flow agitators and/or multiple electrodes

InactiveCN1960799AEnhanced agitationImprove quality transfer effectShaking/oscillating/vibrating mixersTanksElectricityComputer module

A tool with installation module is disclosed. The installation module has an aligning system and comprises a positioning element for precise positioning the reactor and the workpiece transferring device which moves the workpiece into and out of the reactor. The module is fixed at the relative position between the positioning elements of the reactor, therefore, the workpiece transferring device do not need to be re-marked when the reactor is detached and changed by another one. The reactor includes an agitator for agitating the treating fluid on the treated surface of the workpiece. The agitator, the reactor and the electrodes in the reactor is configured to reduce the probability of generating electric shadow by the agitator, and the 3-D effect to electric field, when the beater and / or workpiece receiver move relatively, is considered.

Owner:塞米用具公司

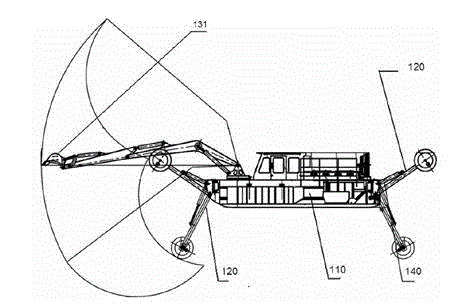

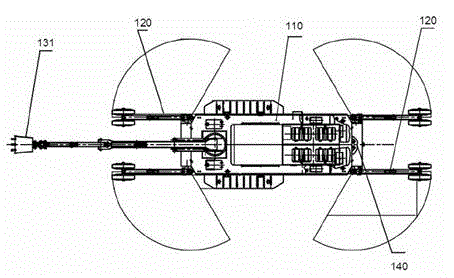

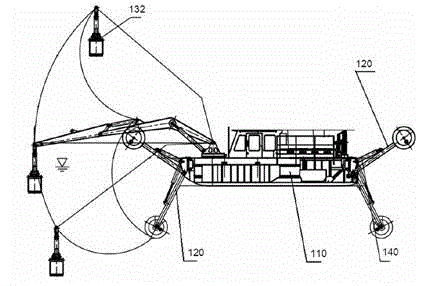

Processing system and processing technology for removing river pollution bottom silt in central urban area

ActiveCN103334469AEasy to cleanImprove water qualitySludge treatment by de-watering/drying/thickeningSoil-shifting machines/dredgersLand resourcesUrban area

The invention discloses a processing system and processing technology for removing river pollution bottom silt in a central urban area. The processing system comprises a multi-functional desilting vessel, a silt storage and transportation vessel and a silt dehydrating and drying vessel, wherein the multi-functional desilting vessel, the silt storage and transportation vessel and the silt dehydrating and drying vessel are communicated through pipelines. The multi-functional desilting vessel comprises a machine body, wheel-type supporting legs, a coarse garbage collection tool / reamer tool arranged at one end of the machine body and a first hydraulic system used for driving the coarse garbage collection tool / reamer tool. The silt storage and transportation vessel comprises a storage and transportation vessel body, positioning piles and a silt cabin, wherein a plurality of stirrers are further arranged in the silt cabin, the silt cabin is connected to the silt dehydrating and drying vessel through a pipeline. The silt dehydrating and drying vessel comprises a dehydrating and drying vessel body, positioning piles, a second hydraulic system, a stirring cabin, a chemical feed device and a drying device. According to the processing technology, a mobile processing station is adopted, all the devices are arranged aboard for operation, and therefore land resources are not occupied. Moreover, a processing method is simple, a processing period is short, the silt processing is thorough, and operability is high.

Owner:SHANGHAI HONGCHENG IND DEV

Washing method of agitatory washer and its washer

InactiveCN1381634AReduce entanglementIncrease the strength of the currentOther washing machinesWashing machine with receptaclesWater flowEngineering

Owner:HAIER GRP CORP +1

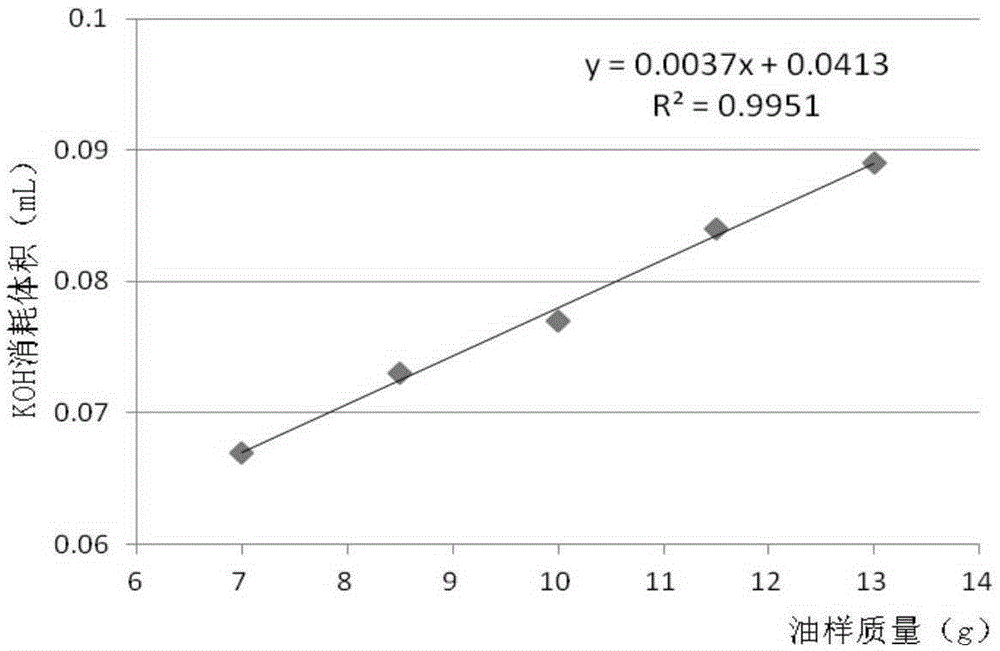

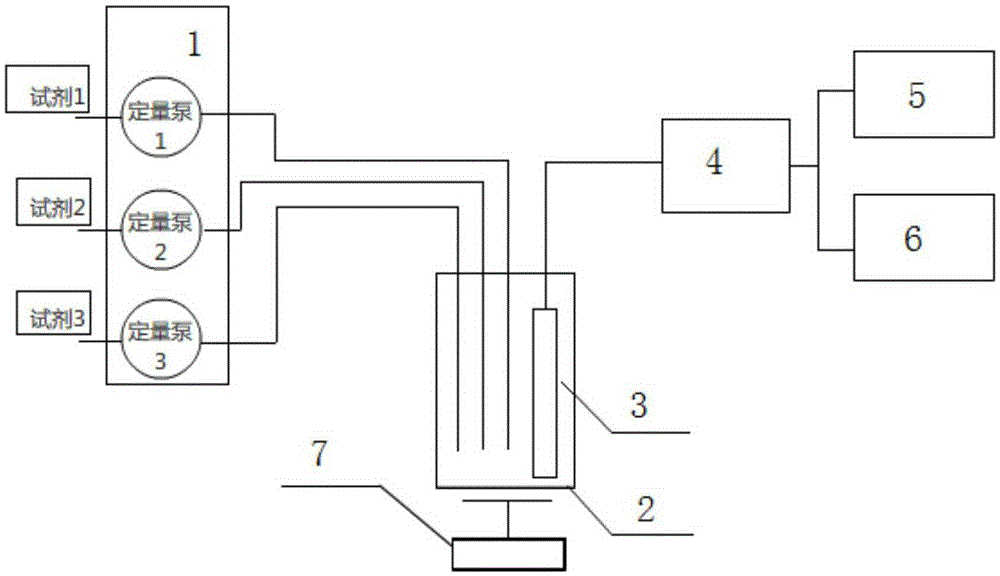

System and method for automatically detecting oleic acid value

ActiveCN105242002ARapid determinationSave human effortChemical analysis using titrationAcid valueMagnetic stirrer

The invention discloses a system and method for automatically detecting the oleic acid value. The method includes the steps that firstly, oil samples to be detected are added into a titration pool, then an extraction solvent and a temperature indicating agent are injected into the titration pool through quantitative pumps respectively, solutions in the titration pool are fully mixed through a magnetic stirrer, and a temperature sensor in the titration pool ceaselessly measures the temperature of mixed liquid in the titration pool; secondly, titration reagents are injected into the titration pool through a third metering pump, and the magnetic stirrer performs continuous stirring; thirdly, a signal processing device connected with the temperature sensor is used for displaying heat absorbed in reaction and heat released in reaction in real time, the number of the consumed titration reagents is determined through reaction inflection points, and the acid value of the oil samples to be detected is calculated through the consumption of the titration reagents. According to the system and method, the method for automatically detecting oleic acid in a non-aqueous solution is put forwards at the first time, the acid value of oil products can be fast measured, measurement of one oil sample can be completed within 3 min or so, manpower is greatly saved, and high economic value is achieved.

Owner:ELECTRIC POWER RESEARCH INSTITUTE OF STATE GRID SHANDONG ELECTRIC POWER COMPANY +1

Milk foam kettle

ActiveCN102670097AEasy to storeStorage hygieneVessels with intergral heatingElectric machineryEngineering

The invention relates to household appliances, in particular to a milk foam kettle for heating, foaming and stirring liquid food. The milk foam kettle comprises a cup body and a base, wherein a stirrer and a positioning sleeve are arranged on the cup body; a heater, a heat-transfer plate and a fixed sleeve are arranged on the base; the positioning sleeve is sleeved in the fixed sleeve on the base; a driving device for driving the stirrer to rotate is arranged under the heater; and a driving motor is connected with the driving device. According to a magnetic force principle, an upper cup body for containing liquid milk is fully separated from a working circuit for driving a stirring device, a heating device and the driving device; during a use process, the liquid milk is free from seeping into the base to influence the circuit and a lubricant of the driving motor cannot flow into the cup body to contaminate the liquid milk as well, so that the milk foam kettle is hygienic and safe; pole directions of a driving magnet and a driven magnet are both horizontally arranged, so that the space is saved; the stirrer is driven by a magnetic force, thereby being hygienic and safe; and the stirrer is only located in the cup body, so that the stirrer can be more conveniently disassembled and cleaned.

Owner:YUYAO SUNBOY ELECTRIC APPLIANCE

Portable mixing apparatus

InactiveUS7229204B2Easy to transportRotating receptacle mixersTransportation and packagingMotor driveSlope angle

Owner:HASKELL GEORGE L

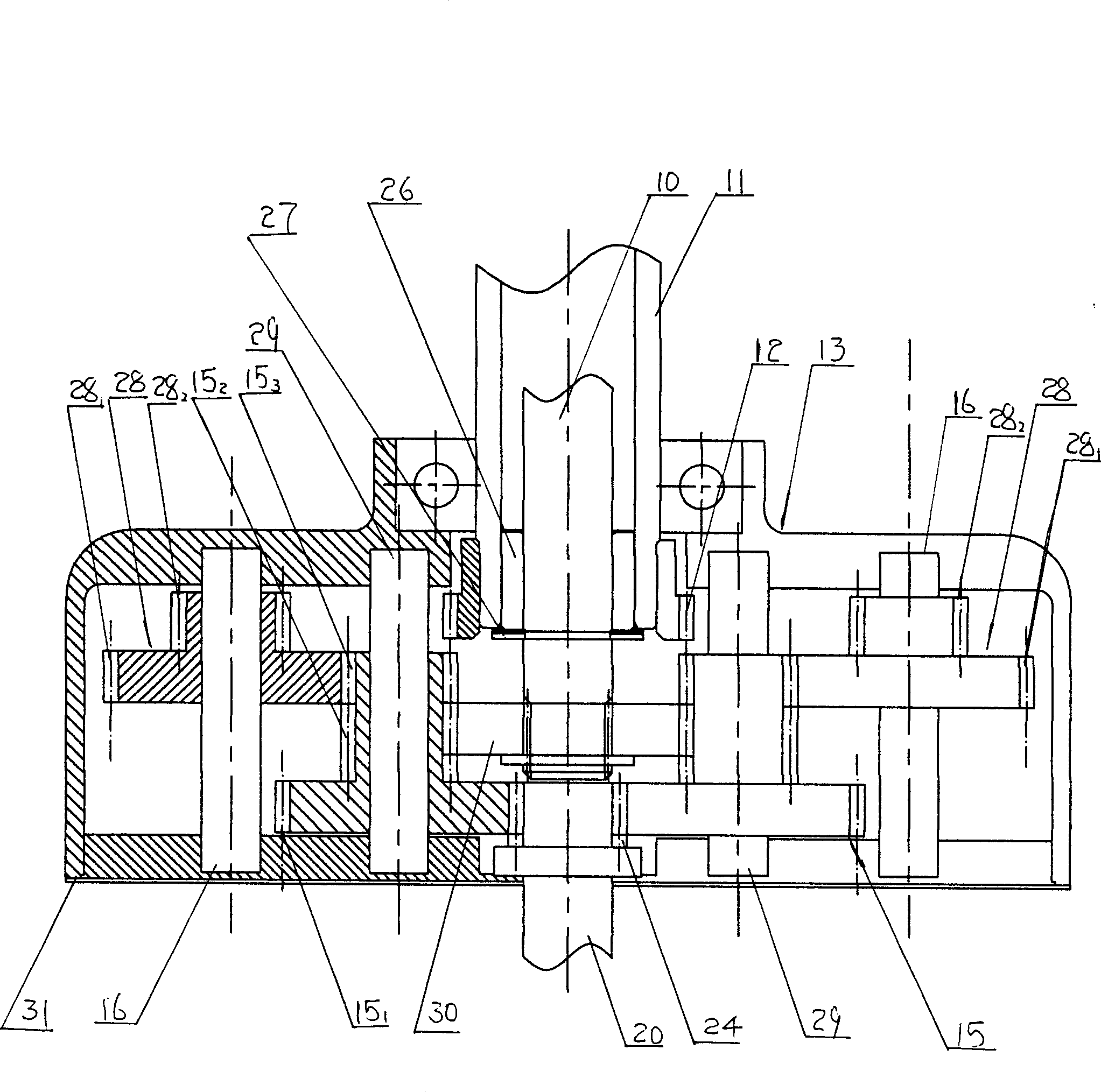

Dual-output washing machine drum speed reducing clutch and washing machine

ActiveCN104032542AEasy to operateImprove washing efficiencyOther washing machinesTextiles and paperEngineeringClutch

The invention discloses a dual-output washing machine drum speed reducing clutch and a washing machine, relates to the technical field of washing machines and overcomes the defect of unexpected washing effect of an existing washing machine. The dual-output washing machine drum speed reducing clutch comprises an internal drum shaft and is characterized by further comprising an input shaft arranged in the internal drum shaft and a gear set component arranged between the internal drum shaft and the input shaft; the input shaft is concentrically mounted in the internal drum shaft through a lower lining sleeve and an upper lining sleeve; the input shaft is of a first output and is connected to a rotor through a rotor mounting plate; the internal drum shaft is of a second output and is connected to the input shaft through the gear set component; a stirrer of the washing machine is mounted in an internal drum and is connected to the input shaft. Thus, washing efficiency is improved, the axial size is saved, the stirrer and the internal drum are the same in rotating direction and are different in rotating speed, dual-power washing is implemented, stirring and rolling actions is added when clothing is tossed, beat, and tossed again, cleaning ratio is increased, heating is omitted, and power is saved.

Owner:NINGGUO JULONG IND

Mixer with pivotable bowl container

A mixer system including a bowl for receiving a material to be mixed, a mixer body having a rotatable output component, and a hinge. The bowl is pivotable about the hinge relative to the mixer body such the bowl can be pivoted between a loading / unloading position and a closed position relative the mixer body. The mixer system further includes a locking mechanism located at least partially on one of the bowl or the mixer body, the locking mechanism being normally biased into a locking position. At least a portion the bowl or the mixer body interacts with the locking mechanism to move the locking mechanism toward the release position to allow the bowl to move to the closed position, the locking mechanism being movable back toward the locking position when the bowl is in the closed position to retain the bowl in the closed position.

Owner:PREMARK FEG L L C

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com