Patents

Literature

1044results about How to "Improve washing efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

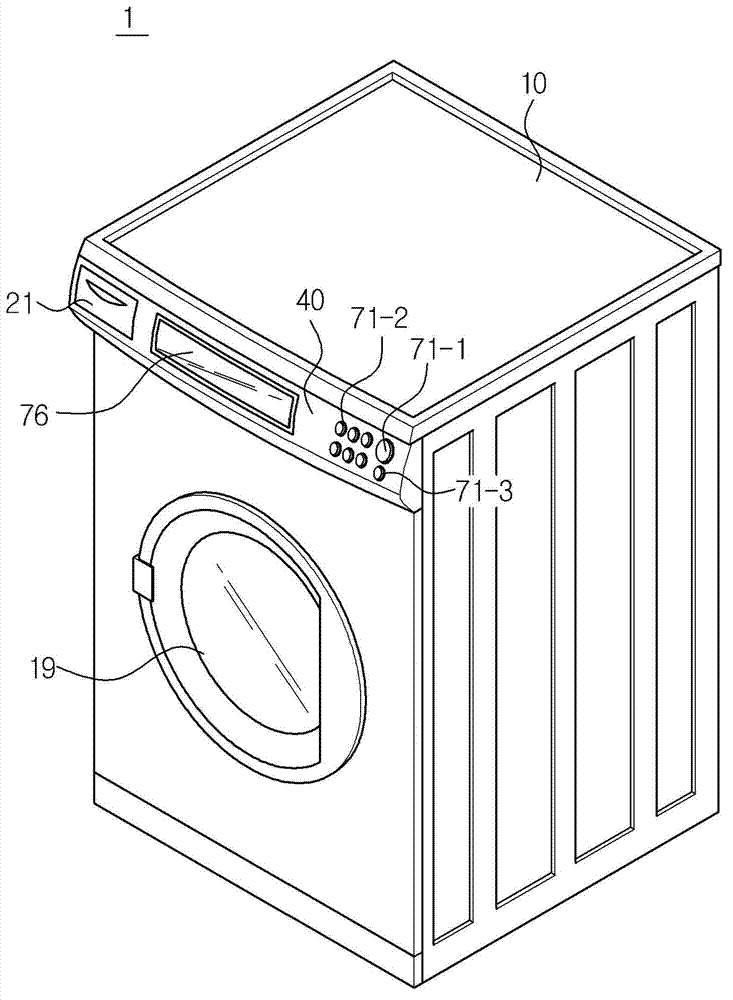

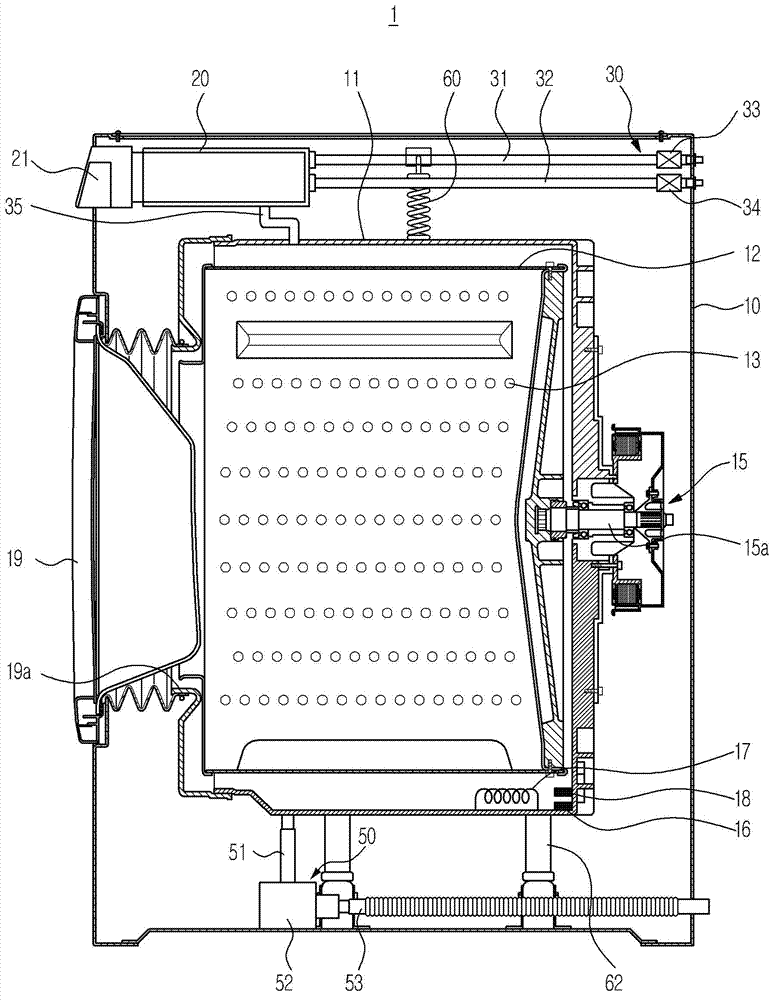

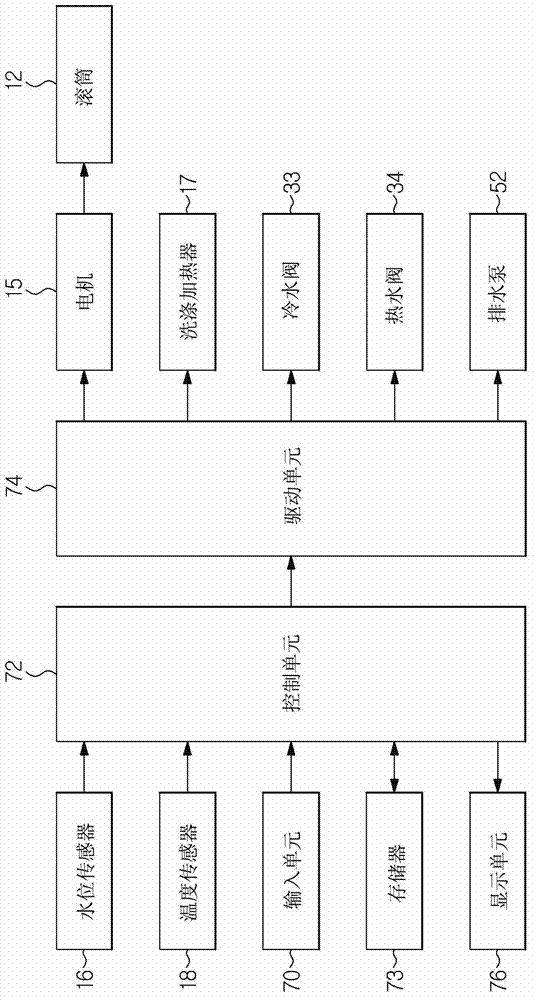

Washing machine and control method thereof

ActiveUS20060191077A1Reduce water wasteImprove washing efficiencyOther washing machinesControl devices for washing apparatusProcess engineeringTemperature difference

A washing machine and control method thereof are disclosed, by which water waste is reduced and by which an error or malfunction of the washing machine is detected and by which the detected error or malfunction of the washing machine is notified to a user. The present invention includes the steps of measuring an initial temperature of water supplied within a steam generator for providing steam to a drum, heating the water within the steam generator for a set time, measuring a temperature of the heated water within the steam generator, calculating a difference between the heated water temperature and the initial water temperature, and deciding a presence or non-presence of abnormality of the steam generator based on the calculated temperature difference.

Owner:LG ELECTRONICS INC

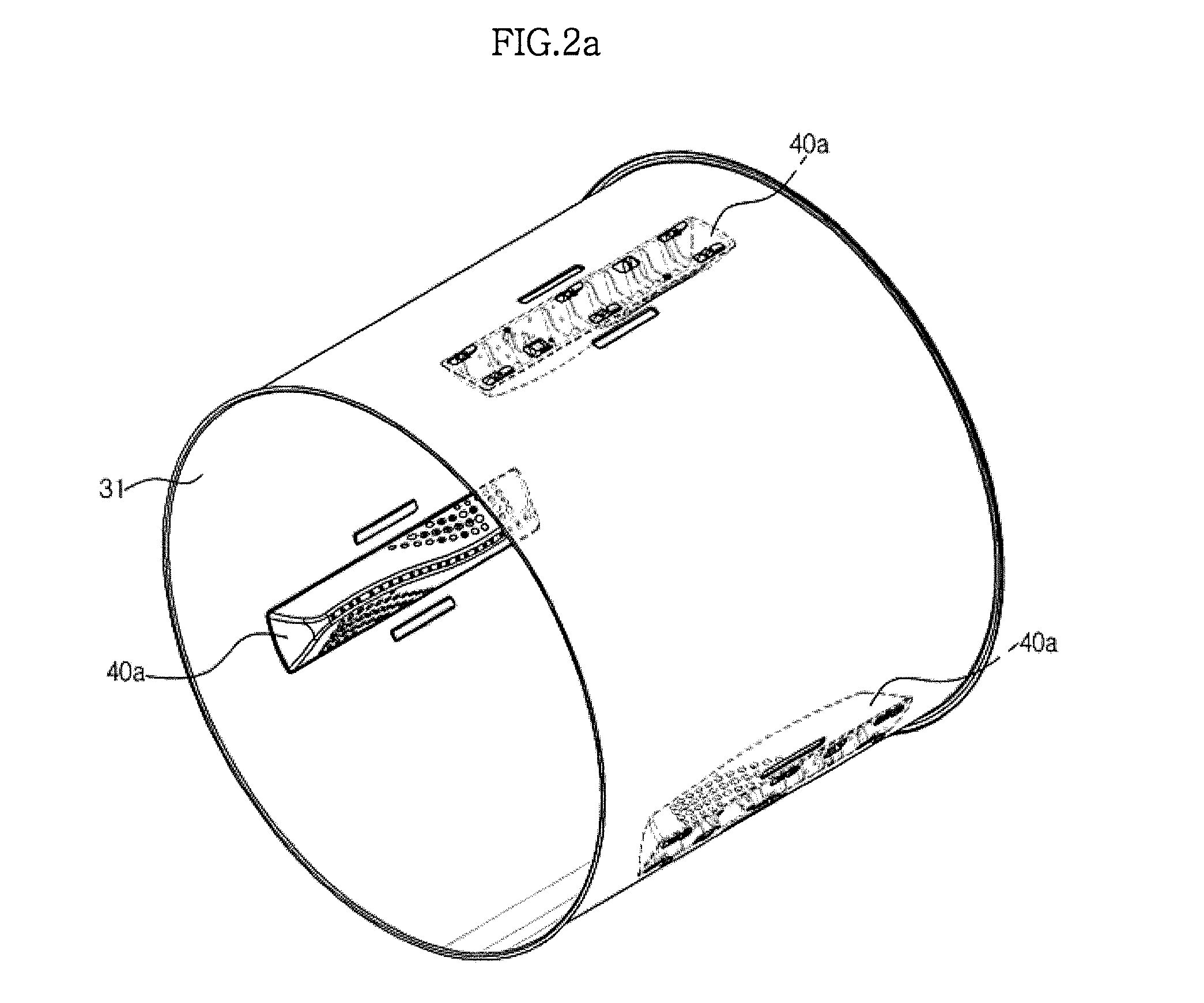

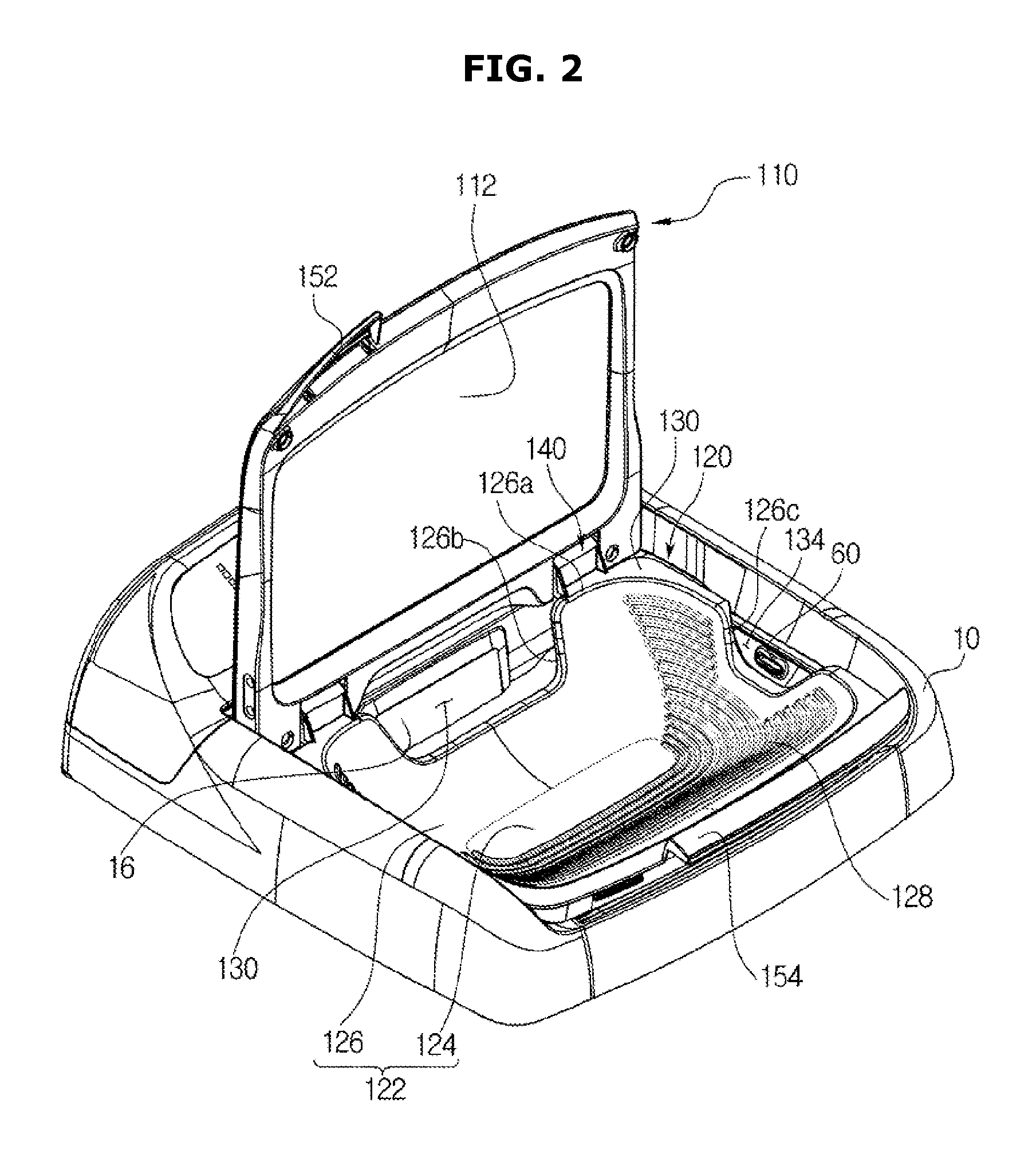

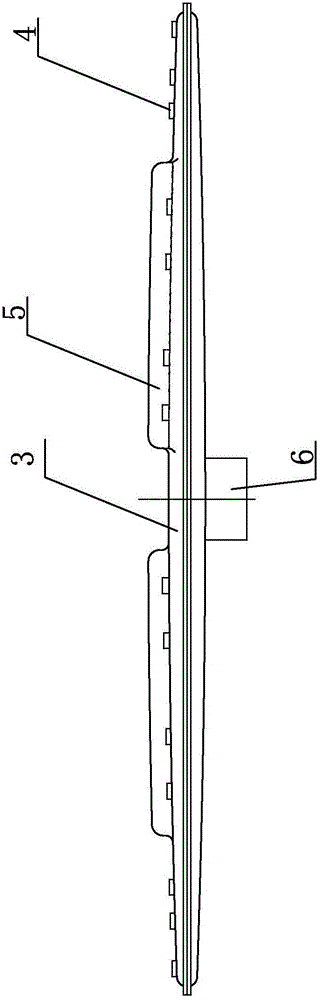

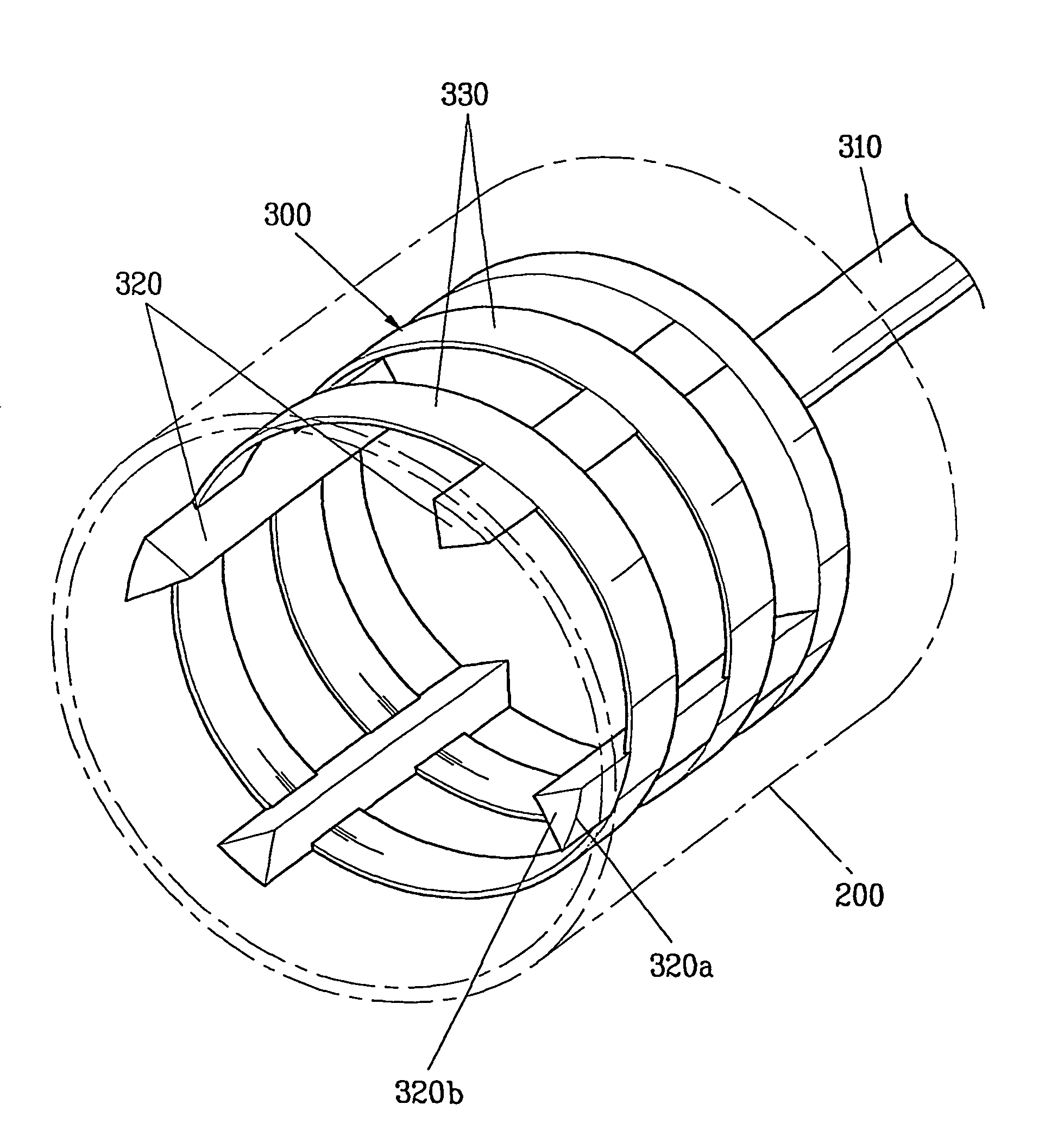

Lifter and washing machine having the same

InactiveUS20130081432A1Improve washing efficiencyImprove fastening forceOther washing machinesWashing machine with receptaclesLaundryMechanical engineering

A lifter simply mounted on a drum and a washing machine having the same. The washing machine includes a cabinet, a tub arranged within the cabinet, a drum arranged within the tub to accommodate laundry and rotated by rotary force transmitted from a driving source, and a plurality of lifters provided on the inner circumferential surface of the drum to move the laundry within the drum. Each of the plurality of lifters includes a plurality of hooks provided along a frame formed at the lower end of each of the plurality of lifters so as to allow each of the plurality of lifters to be hung to the drum, and at least one protrusion protruding from the lower end of each of the plurality of lifters so as to allow each of the plurality of lifters to be fixed to the inner circumferential surface of the drum.

Owner:SAMSUNG ELECTRONICS CO LTD

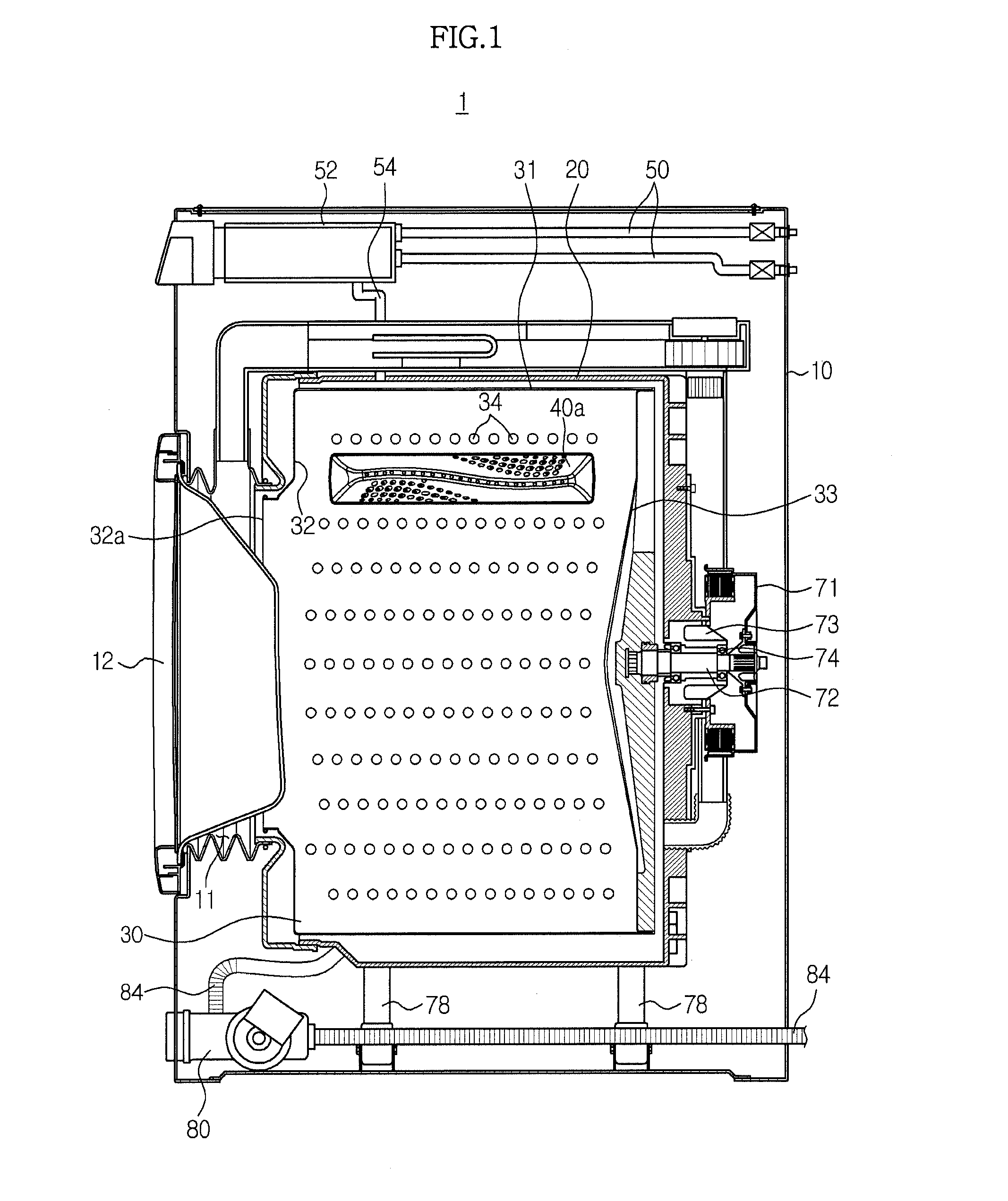

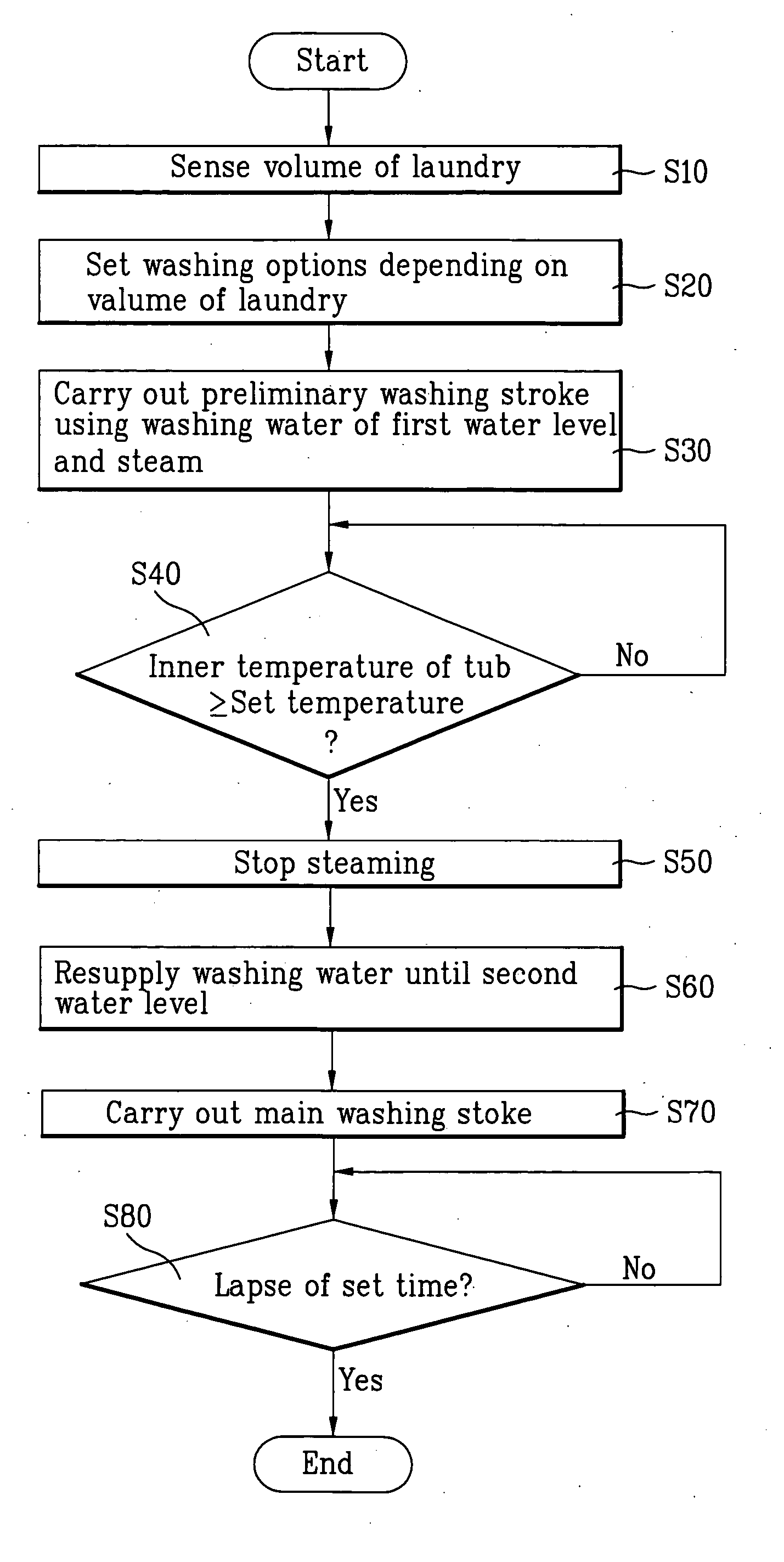

Washing machine and washing method

InactiveUS20060191078A1Reduce wasteImprove washing efficiencyOther washing machinesControl devices for washing apparatusProcess engineeringEngineering

A washing machine and a washing method thereof are disclosed, in which waste of washing water is reduced and washing efficiency is improved. The washing method includes the steps of determining the volume of laundry in a tub, setting a first water level for a preliminary washing stroke and a second water level for a main washing stroke based on the determined volume of laundry, carrying out the preliminary washing stroke using washing water of the first water level and steam, and converting the preliminary washing stroke into the main washing stroke based on washing water of the second water level depending on an inner temperature of the tub.

Owner:LG ELECTRONICS INC

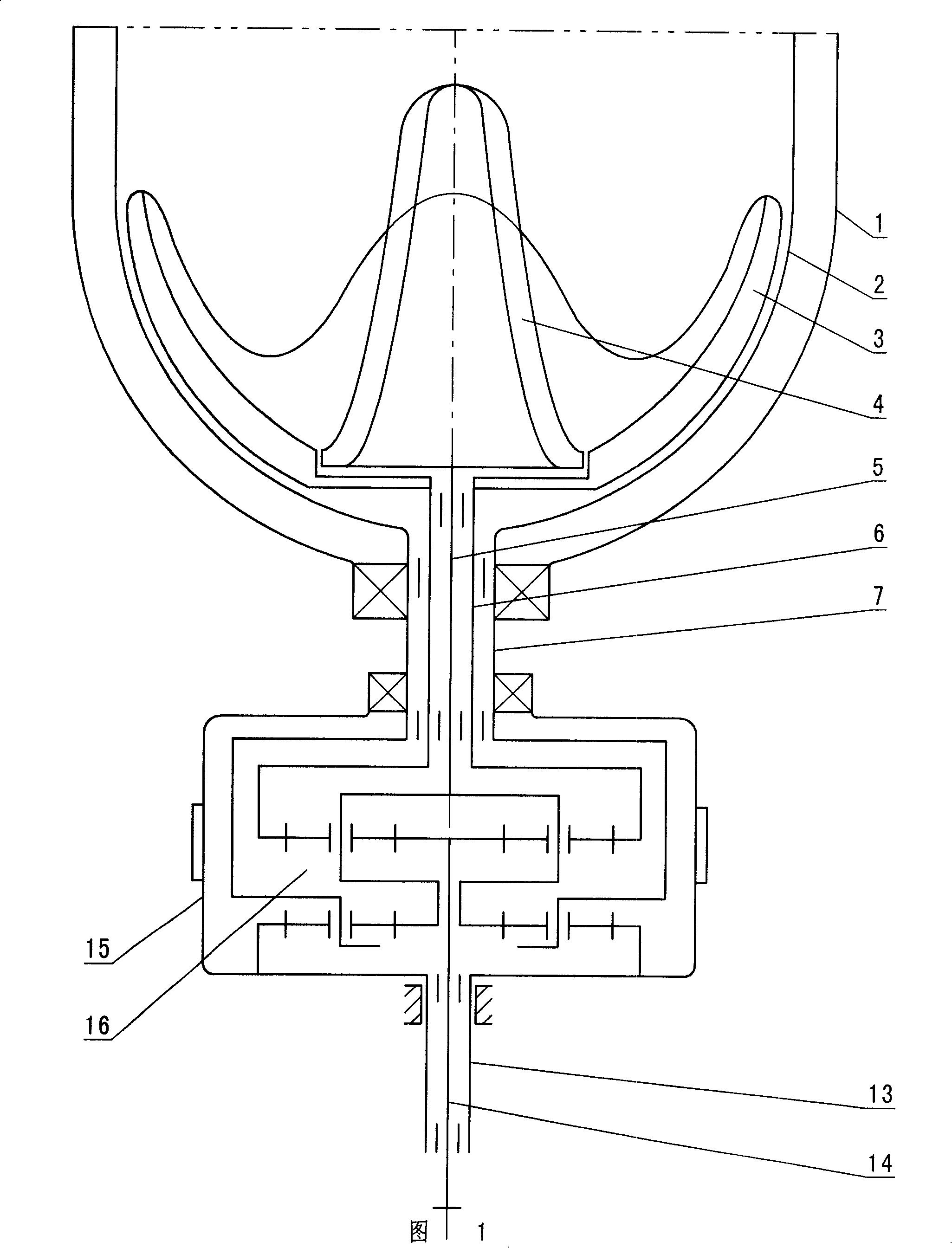

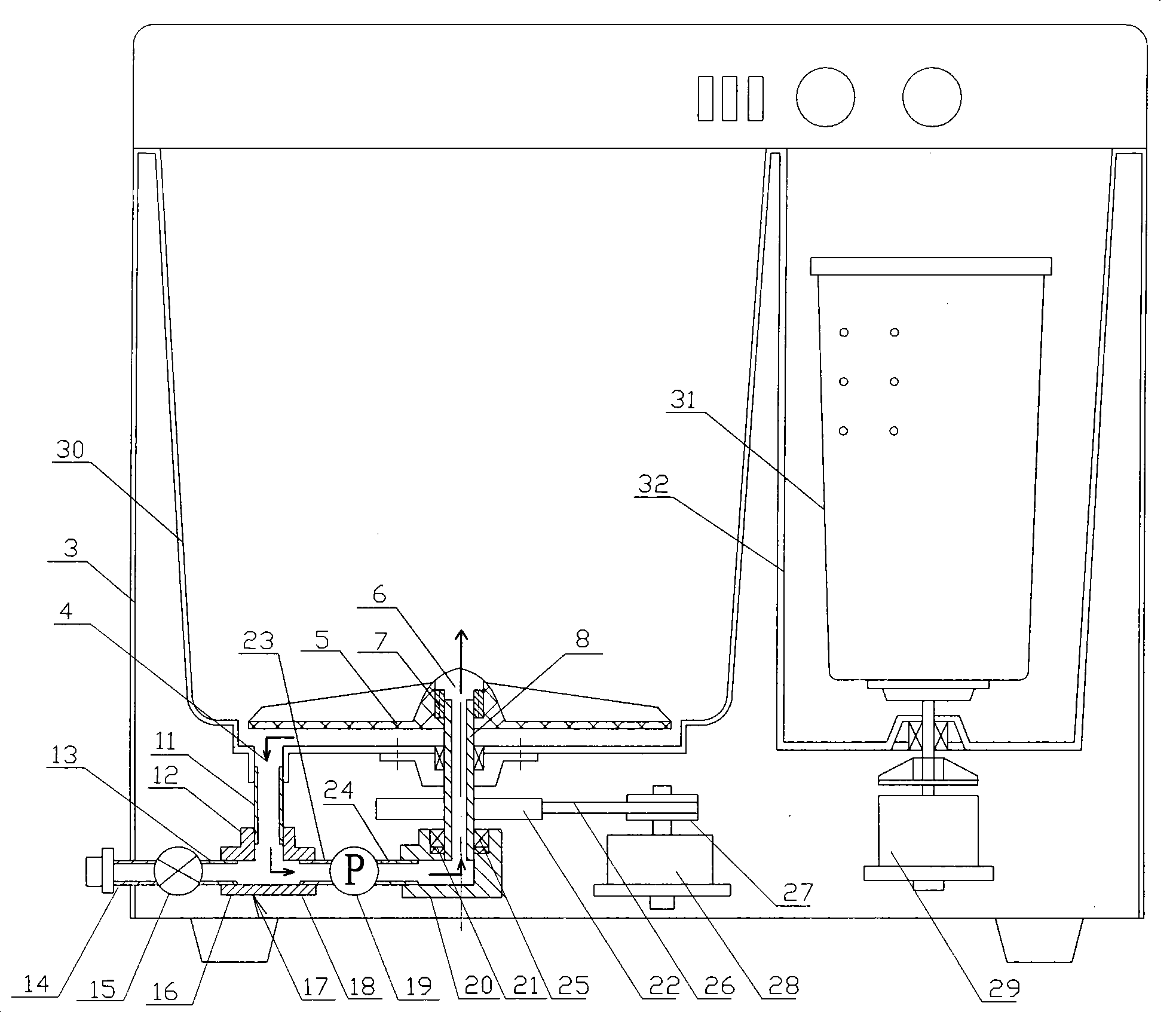

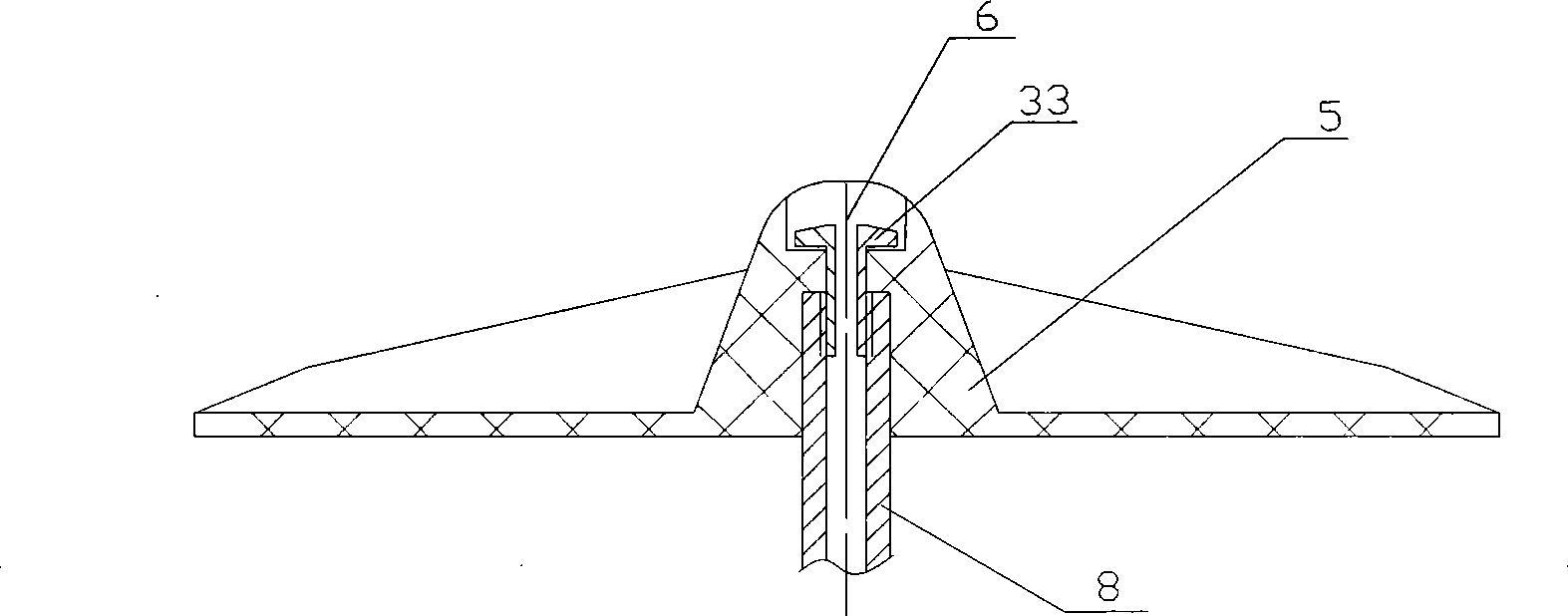

Washing machine deceleration clutch, washing machine and washing mode thereof

ActiveCN101210372ATumble fullImprove cleaning rateToothed gearingsOther washing machinesWater flowClutch

A decelerating clutch of a washer and the washer and a washing mode thereof relates to the technical field of washer. An output shaft of the decelerating clutch includes a small wave wheel shaft, a large wave wheel shaft and an inner barrel shaft, wherein the small wave wheel shaft is supported in the large wave wheel shaft, and the large wave wheel shaft is supported in the inner barrel shaft. By adopting the deceleration mechanism of the decelerating clutch, the invention can simultaneously drive a large wave wheel, a small wave wheel and an inner barrel to rotate. A washer manufactured by using the decelerating clutch comprises a small wave wheel and a large wave wheel, wherein the small wave wheel is fixedly arranged on the small wave wheel shaft and positioned at the middle portion of the large wave wheel; the large wave wheel is fixedly arranged on the large wave wheel shaft; and the inner barrel is fixedly arranged on the inner barrel shaft. The washer manufactured by using the decelerating clutch is operated in such a mode that the small wave wheel, the large wave wheel and the inner barrel make reciprocating rotation in mutually reverse directions at different speeds and different rotation angles by a ratio in two directions to produce complex and crossing shock water flow to scrub and clean the clothes, thus completely rotating the clothes, achieving strong scrubbing force and improving the cleaning rate.

Owner:NINGGUO JULONG IND

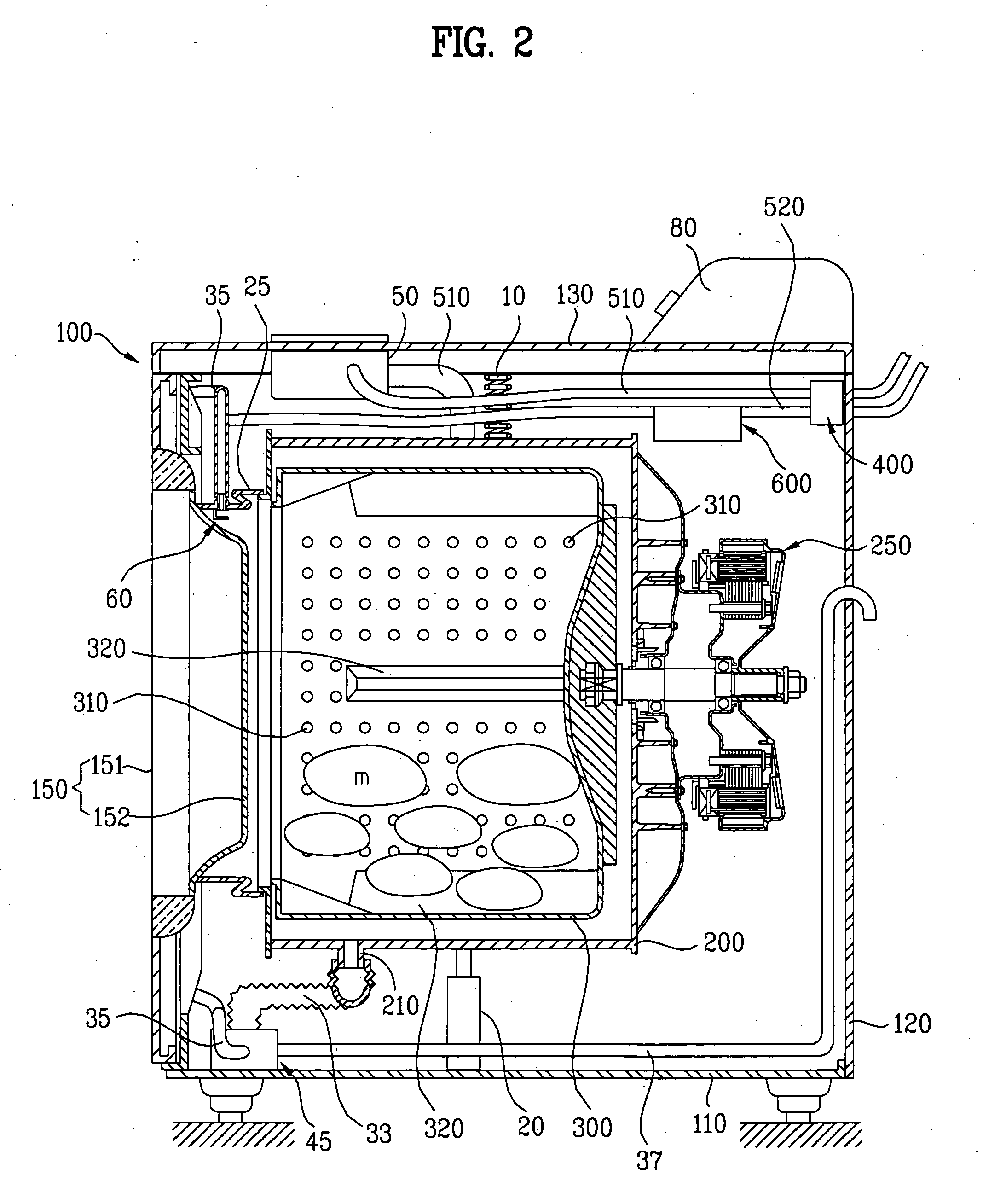

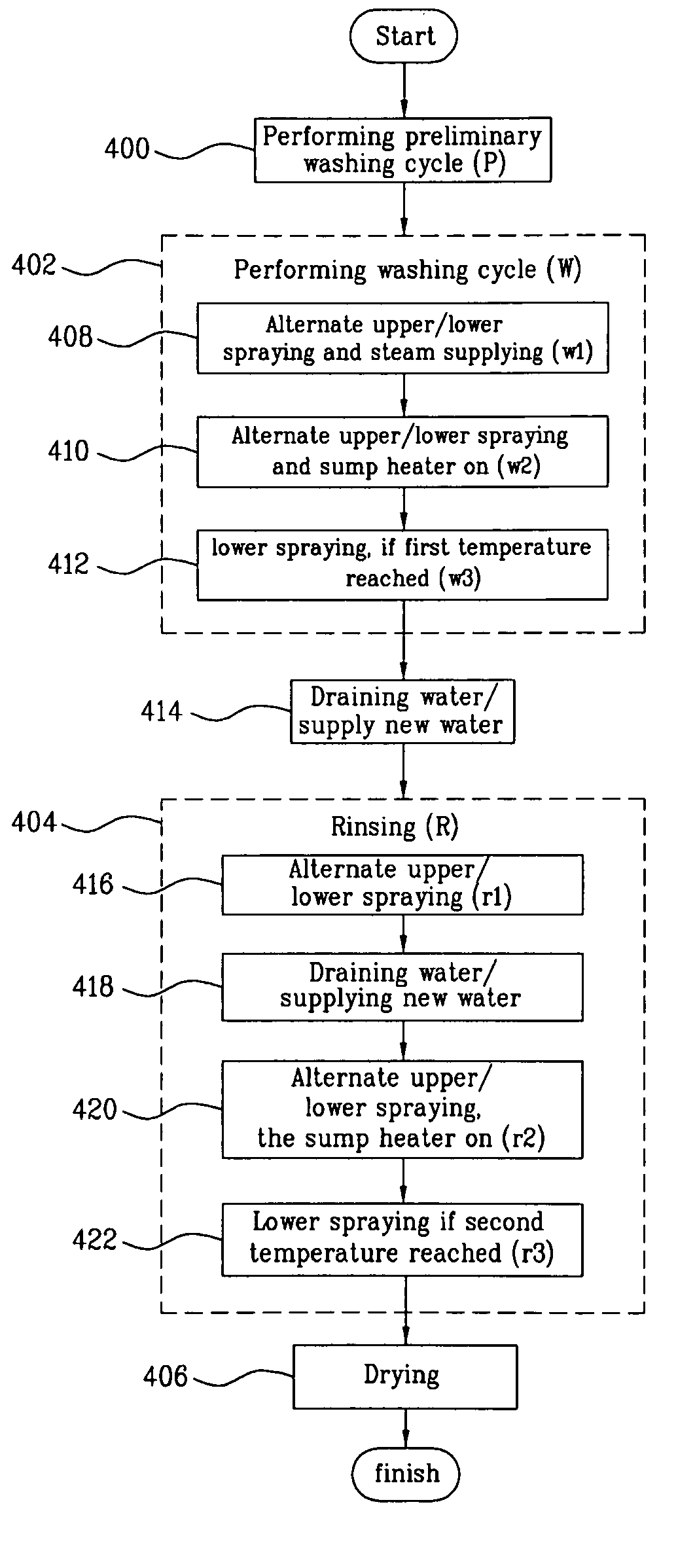

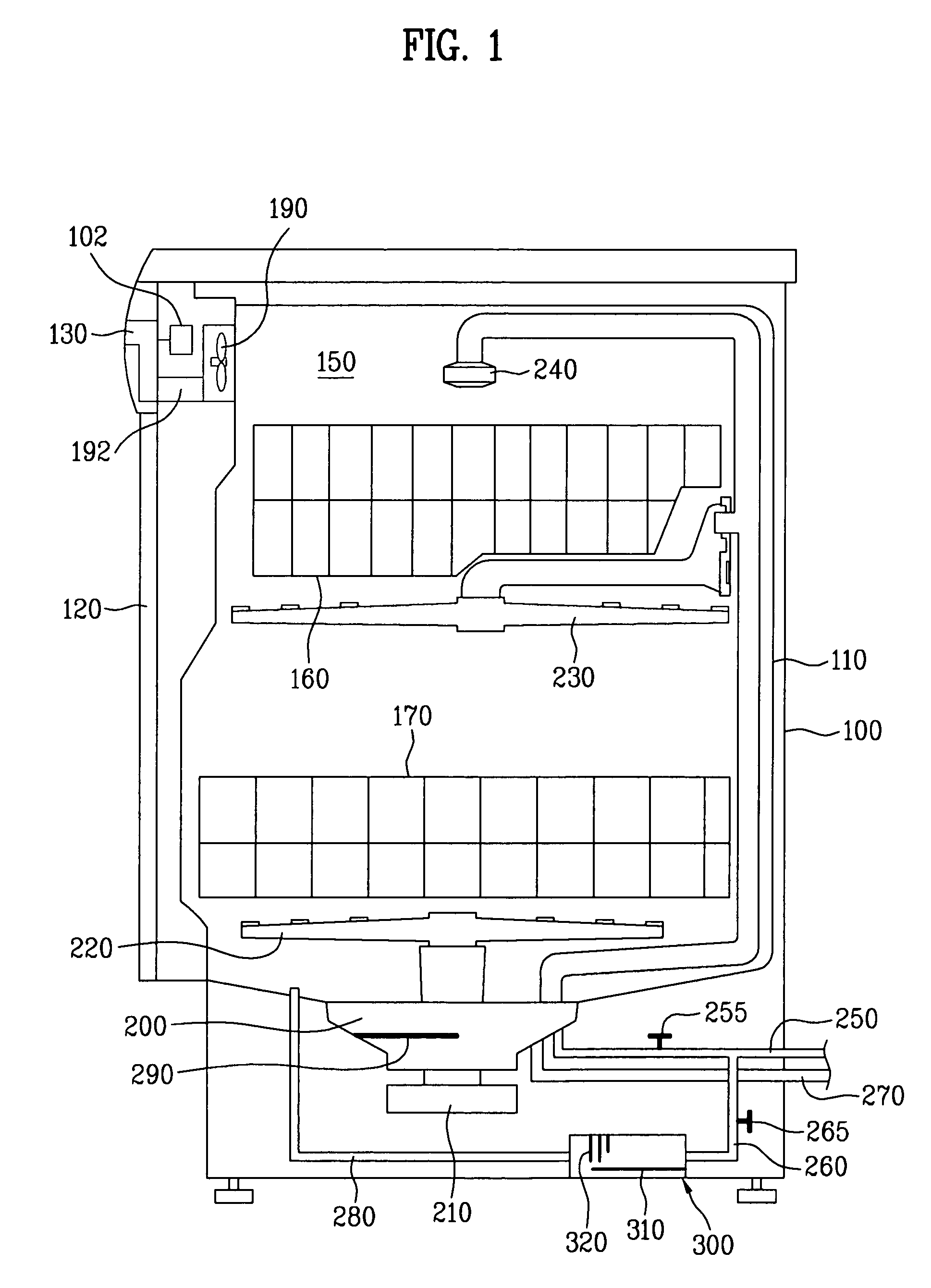

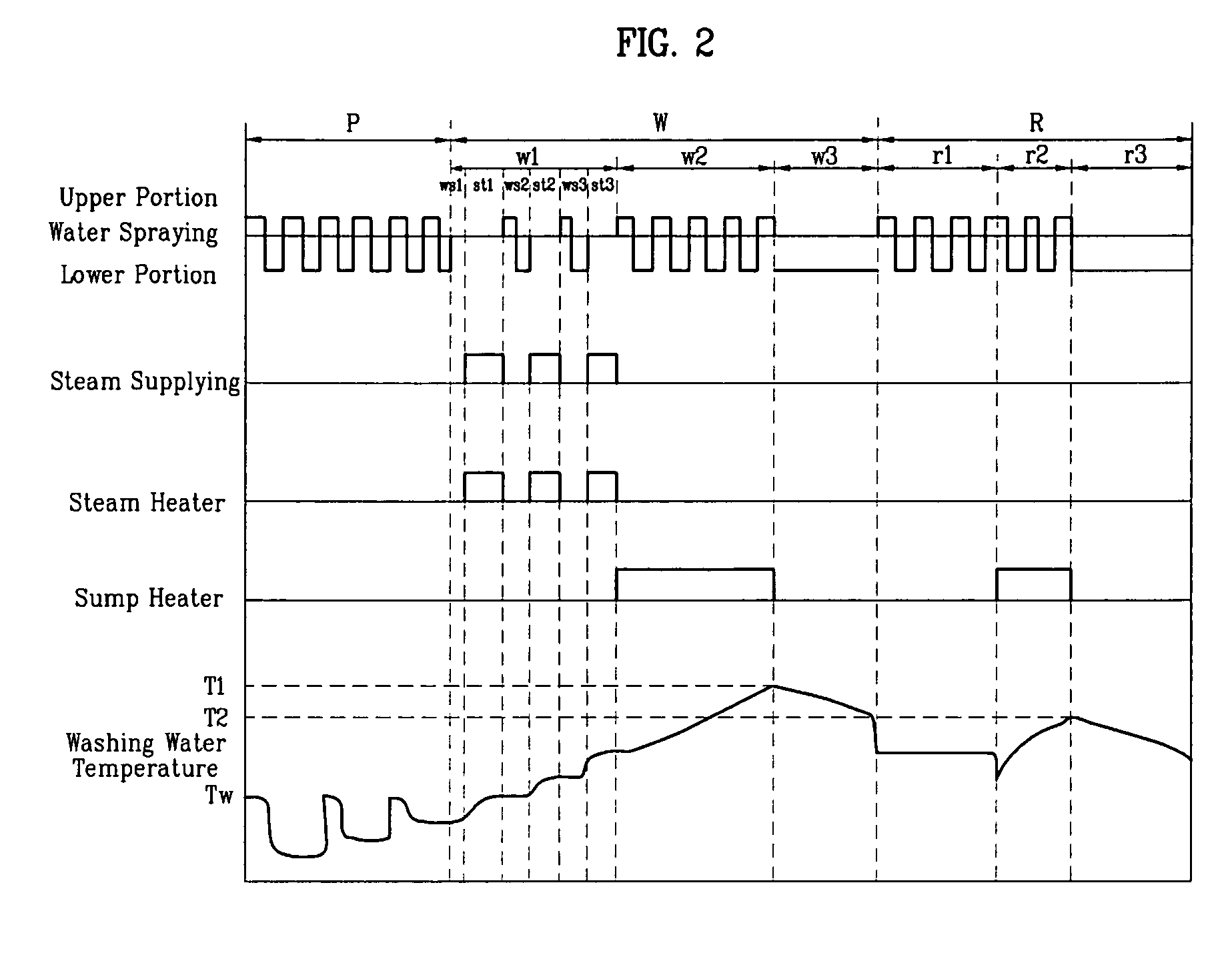

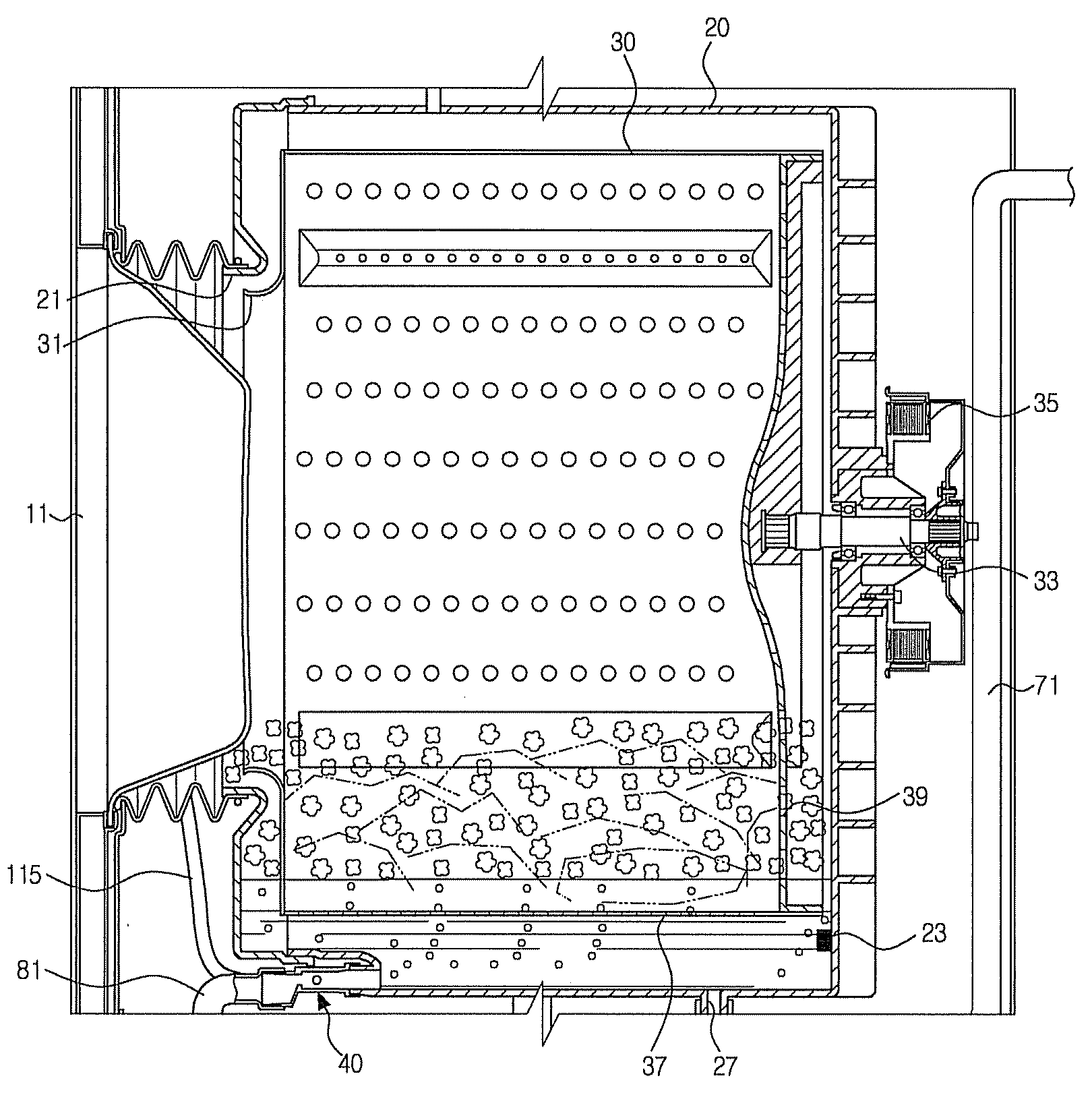

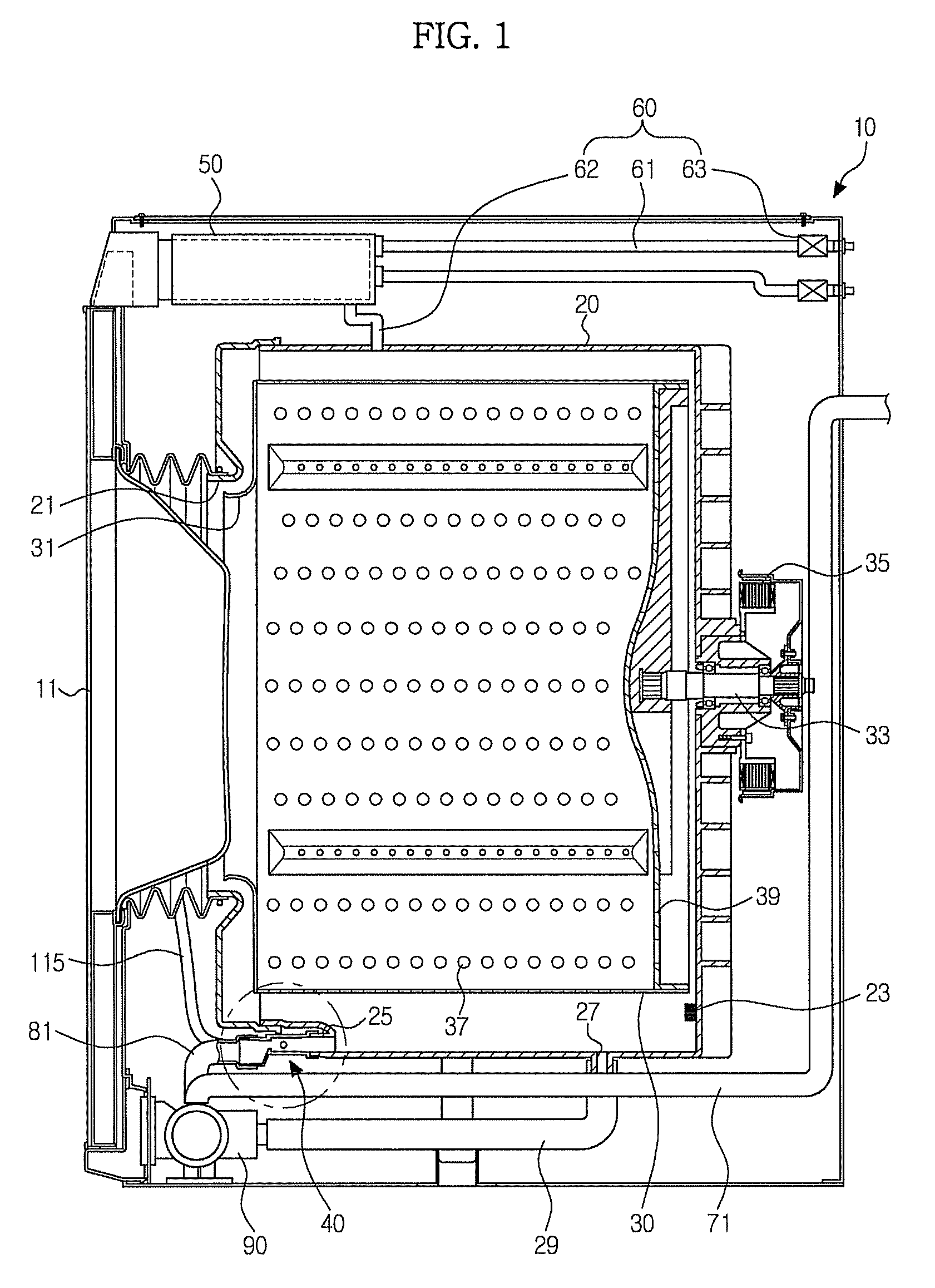

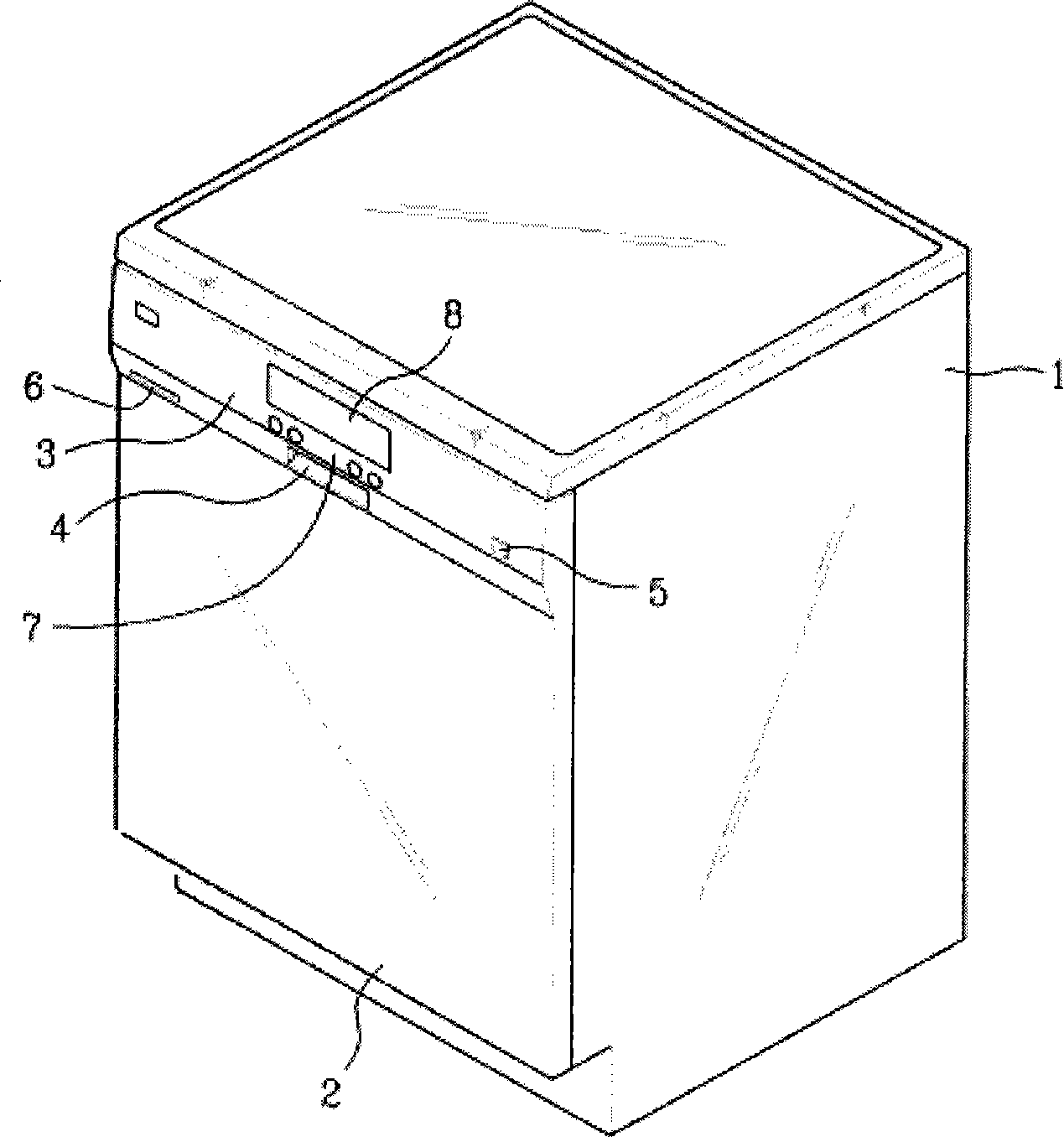

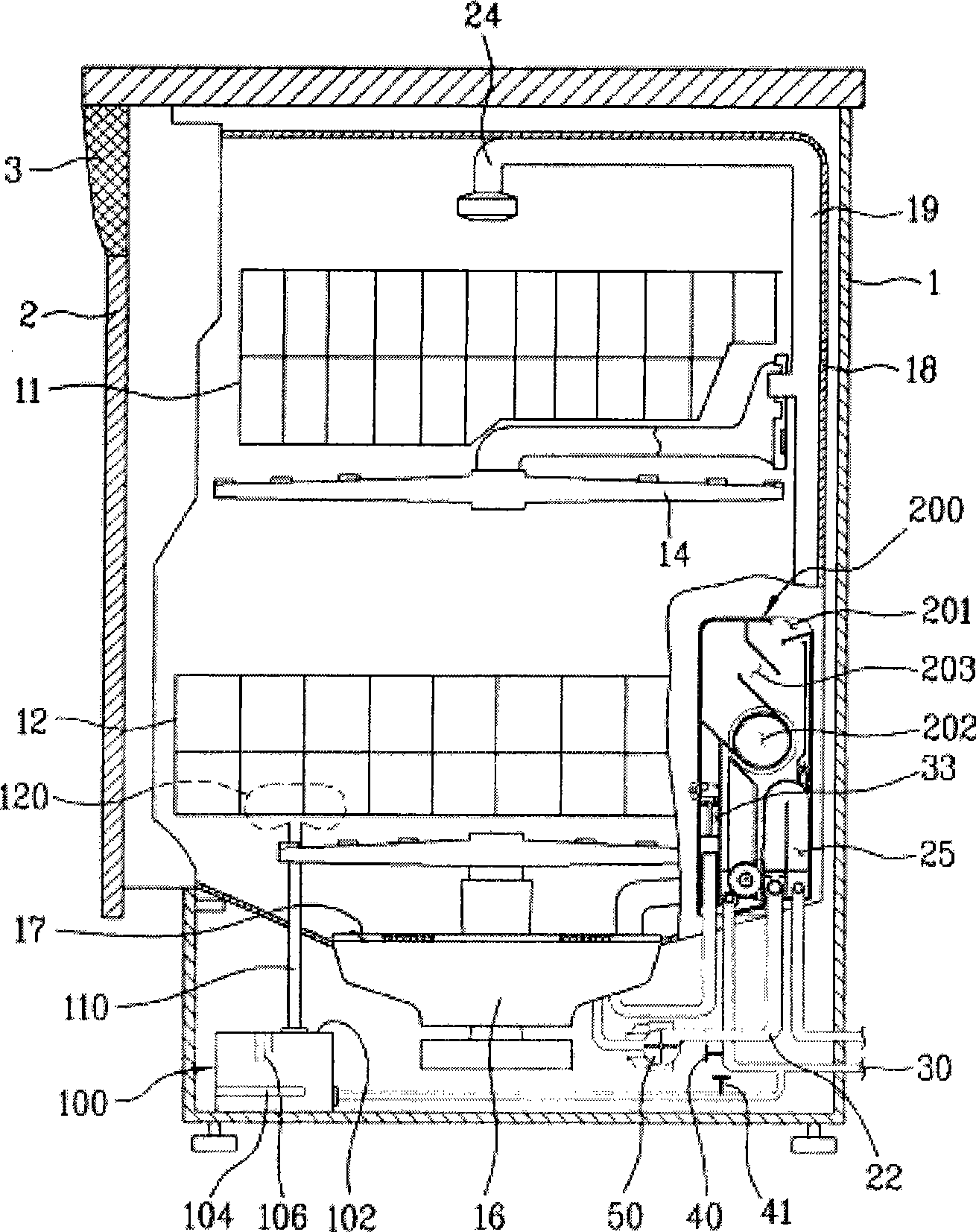

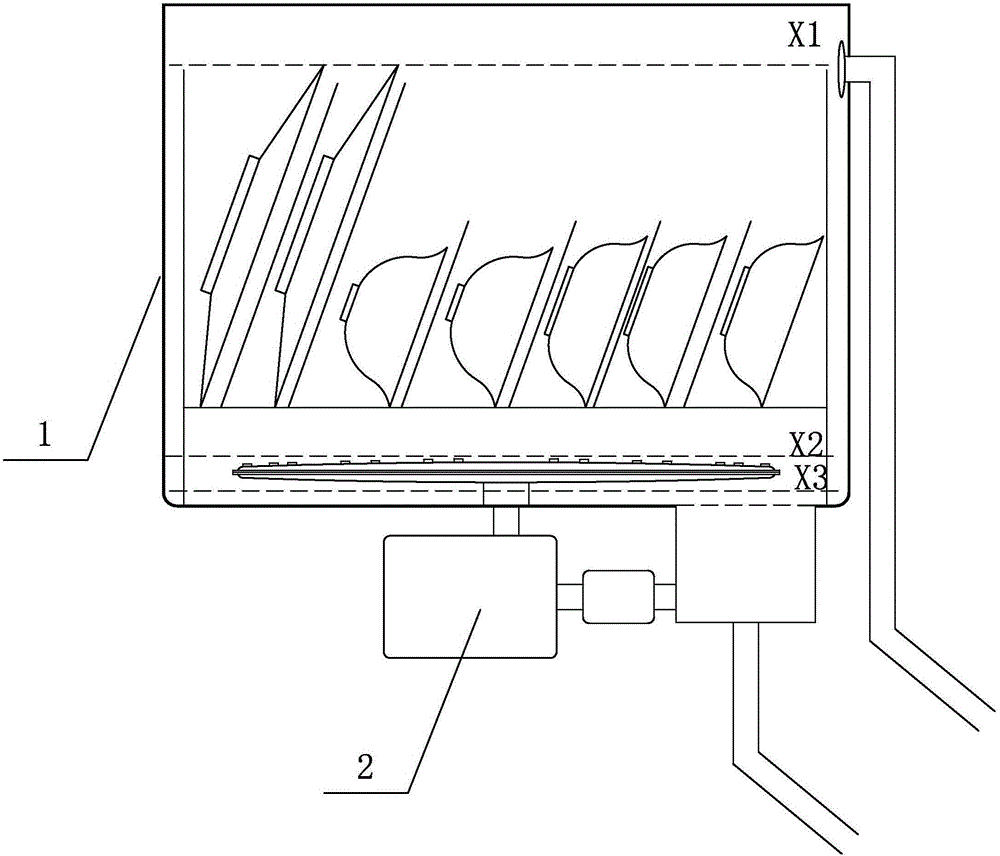

Diswasher and controlling method of the same

ActiveUS20100043828A1Improve washing efficiencyImprove operationTableware washing/rinsing machine detailsWashing processesProcess engineeringRunning time

Dishwashers and methods of control for operation of dishwashers are disclosed. The dishwasher may include an upper rack in an upper portion of a washing compartment configured to receive small dishes, such as a cup having a small washing load, and a lower rack in a lower portion of the washing compartment for placing large dishes, such as a dinner bowl having a large washing load. The operation of the dishwasher can include wash and rinse cycles having a plurality of sub-cycles. During the sub-cycles, the upper and lower racks can be selectively sprayed with water and steam can be supplied to the washing compartment based on configured conditions, such as a water temperature or operation time being reached. The operation of the dishwasher can reduce excessive washing of dishes having small washing loads and reduce power consumption of the dishwasher.

Owner:LG ELECTRONICS INC

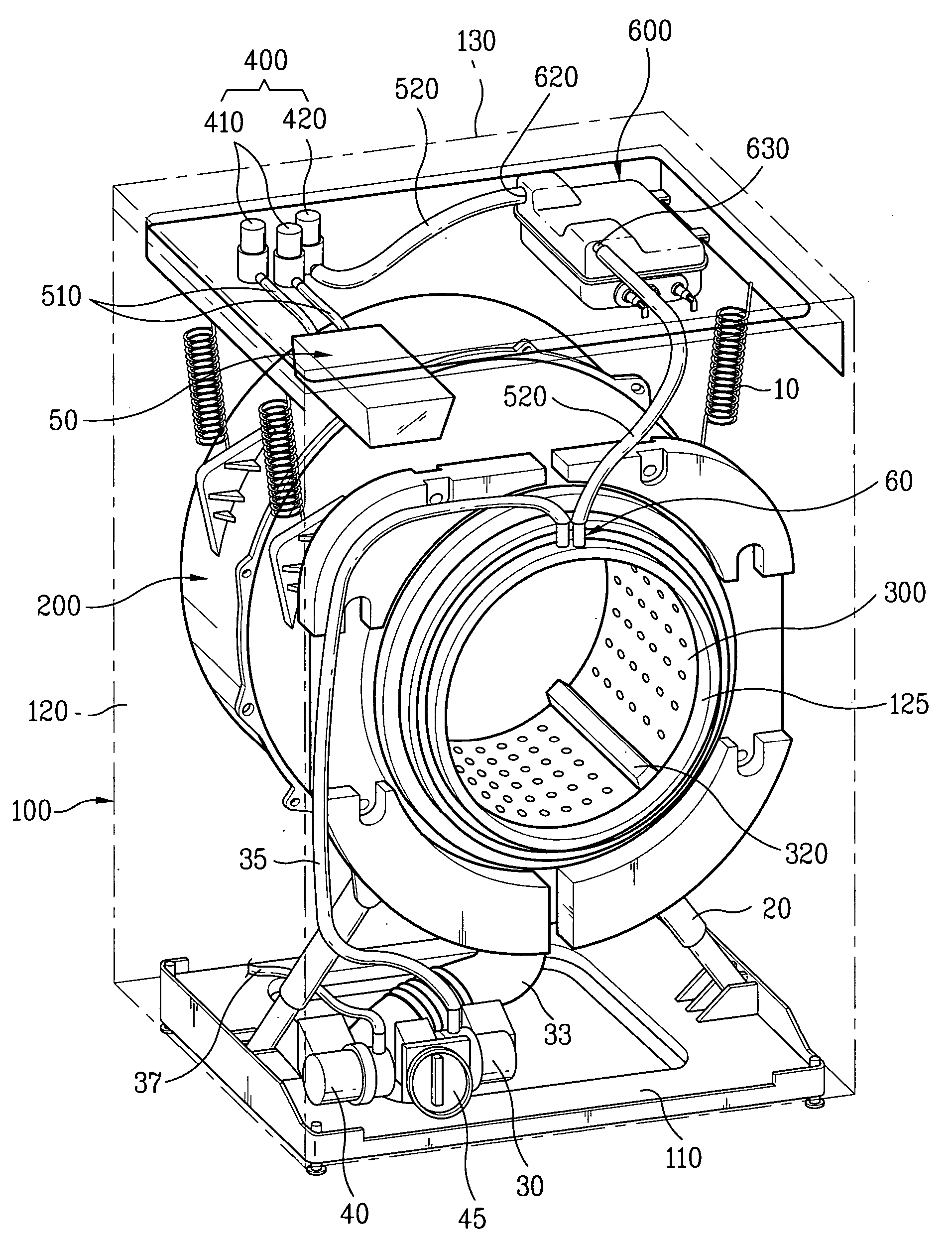

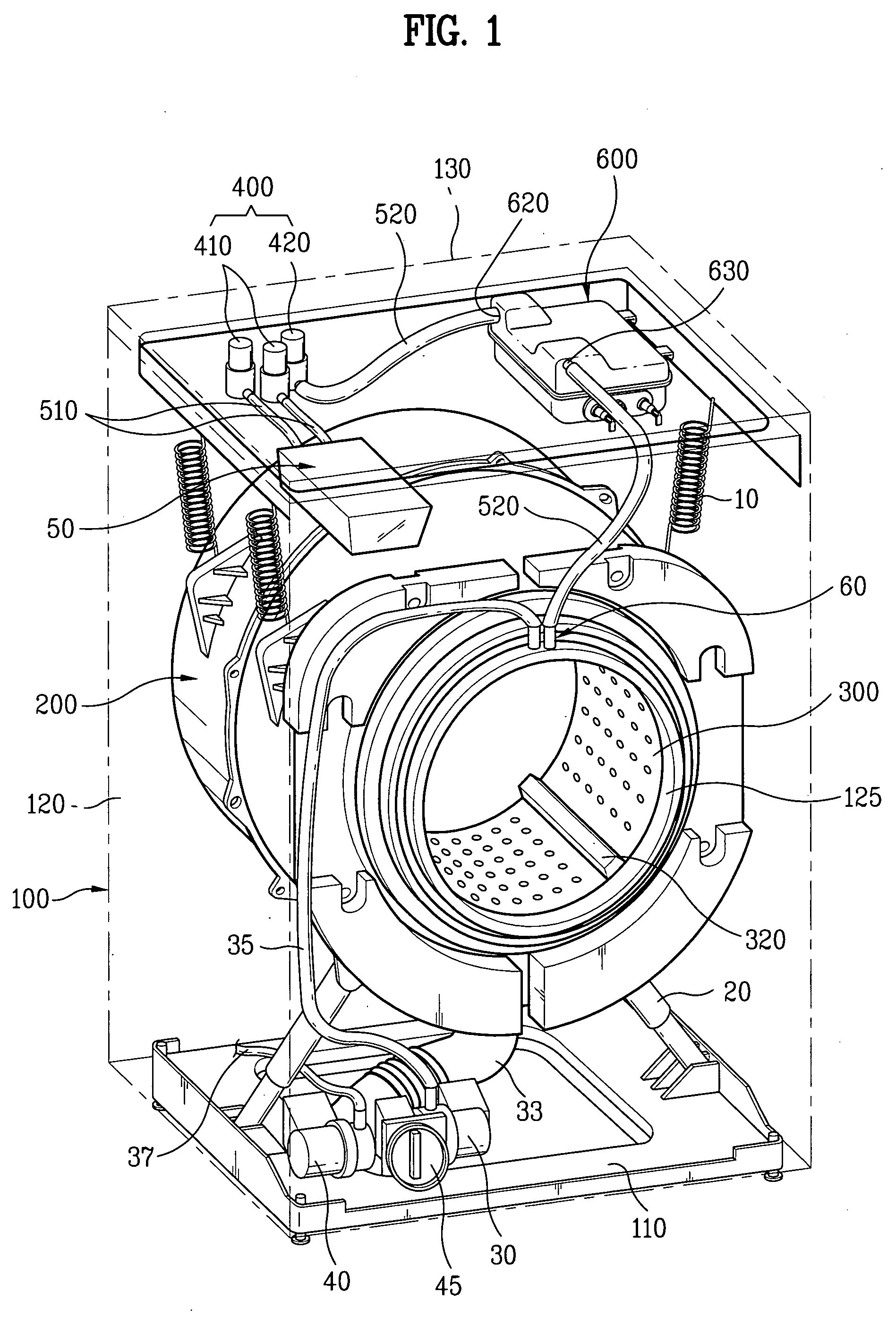

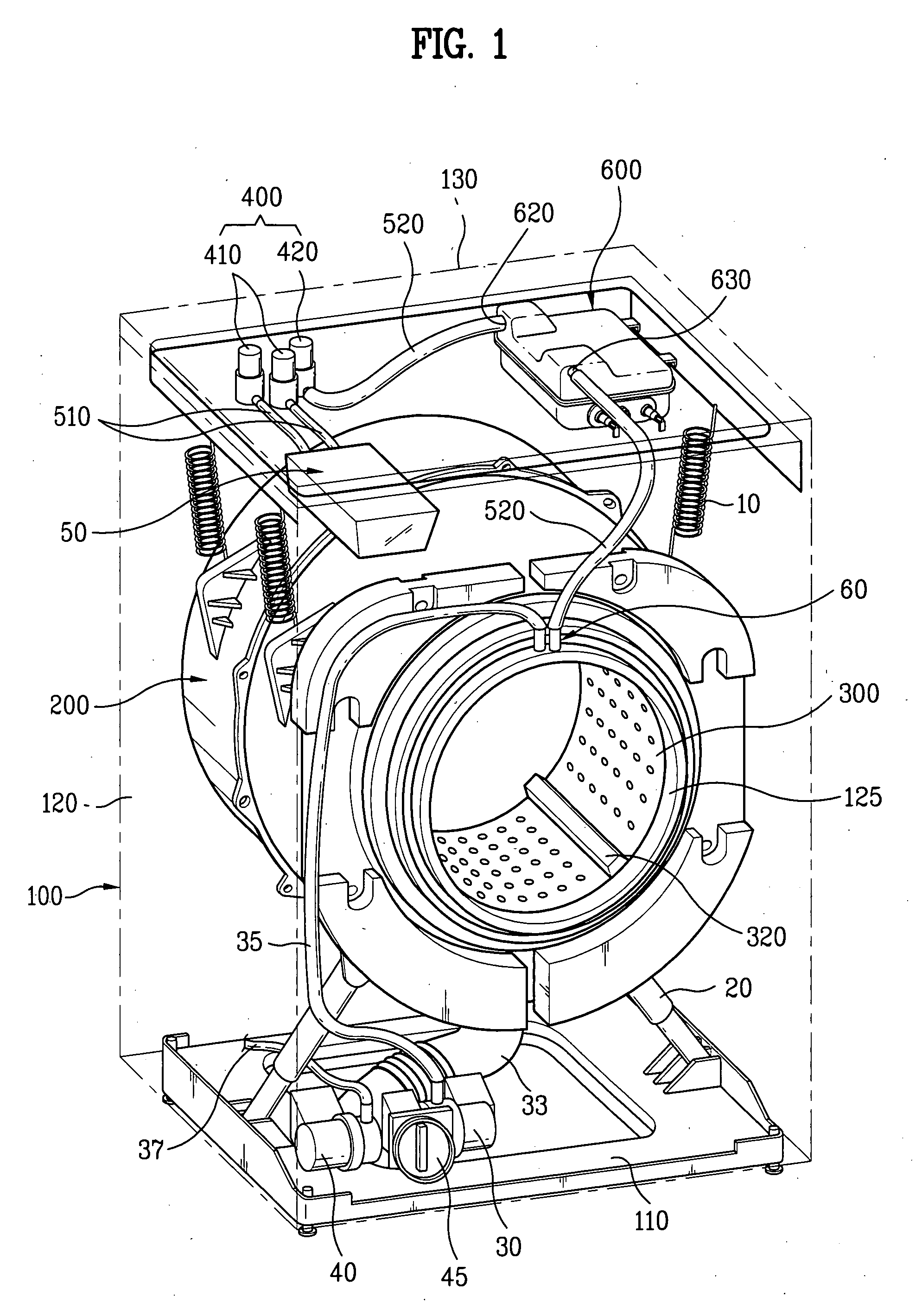

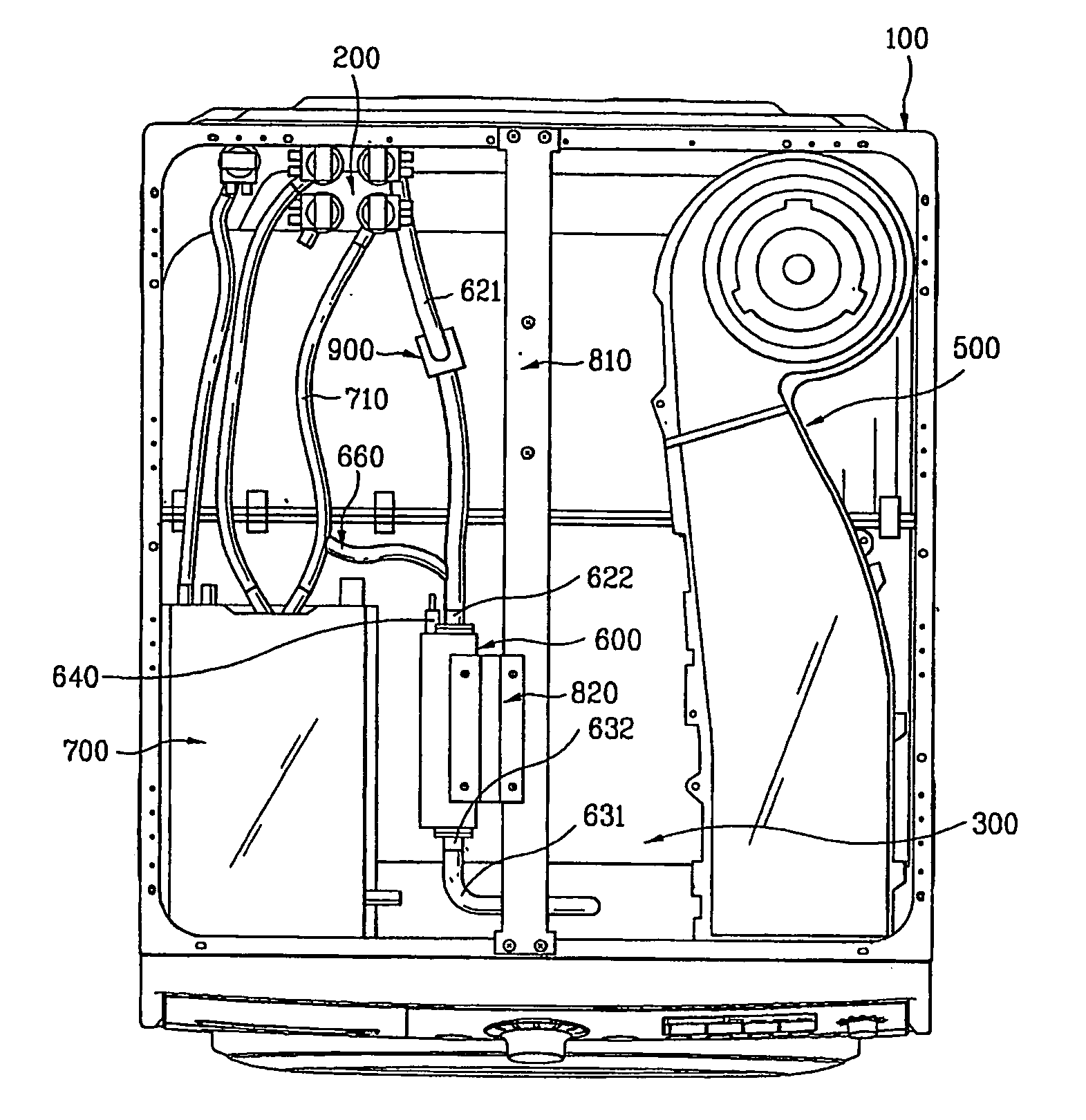

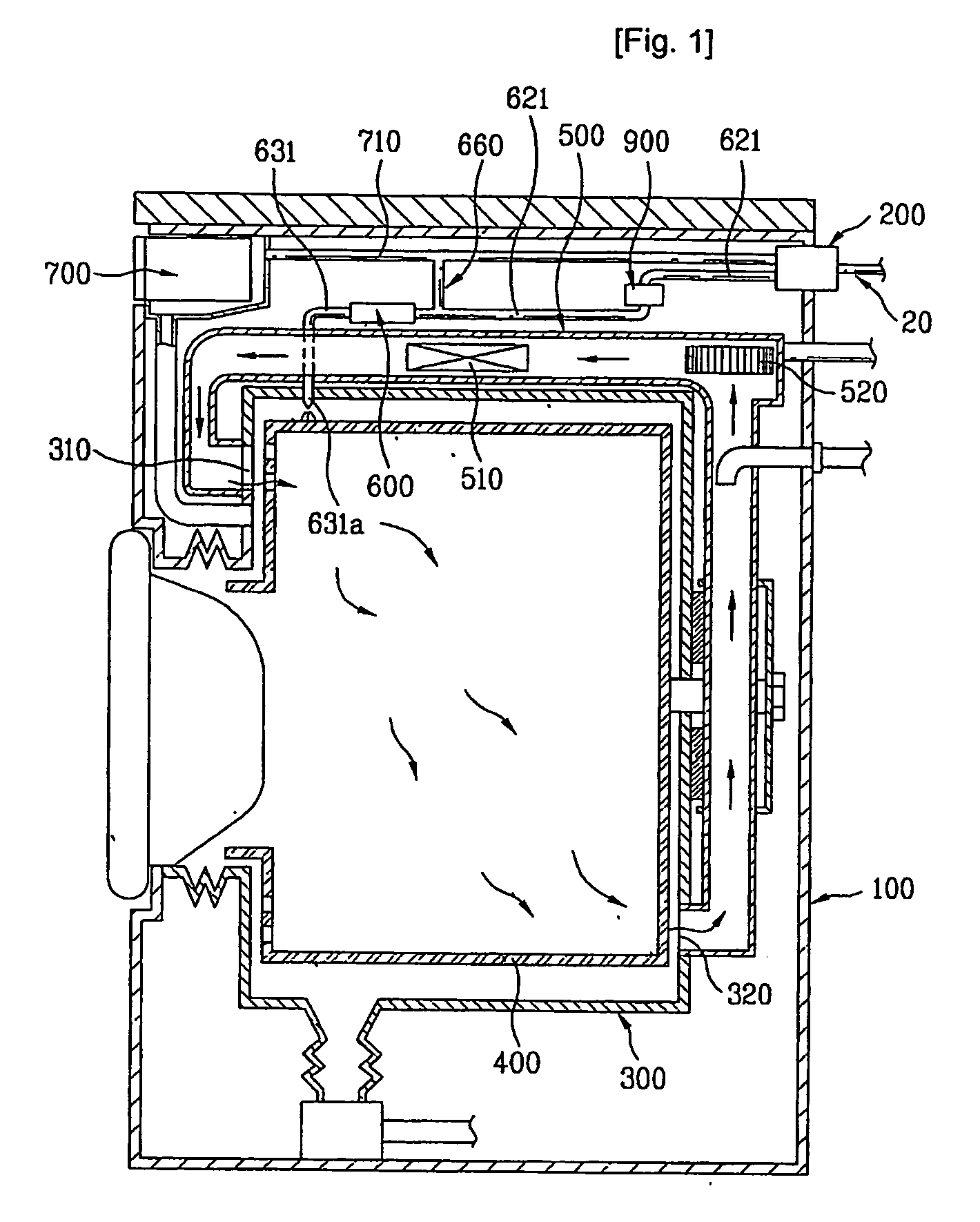

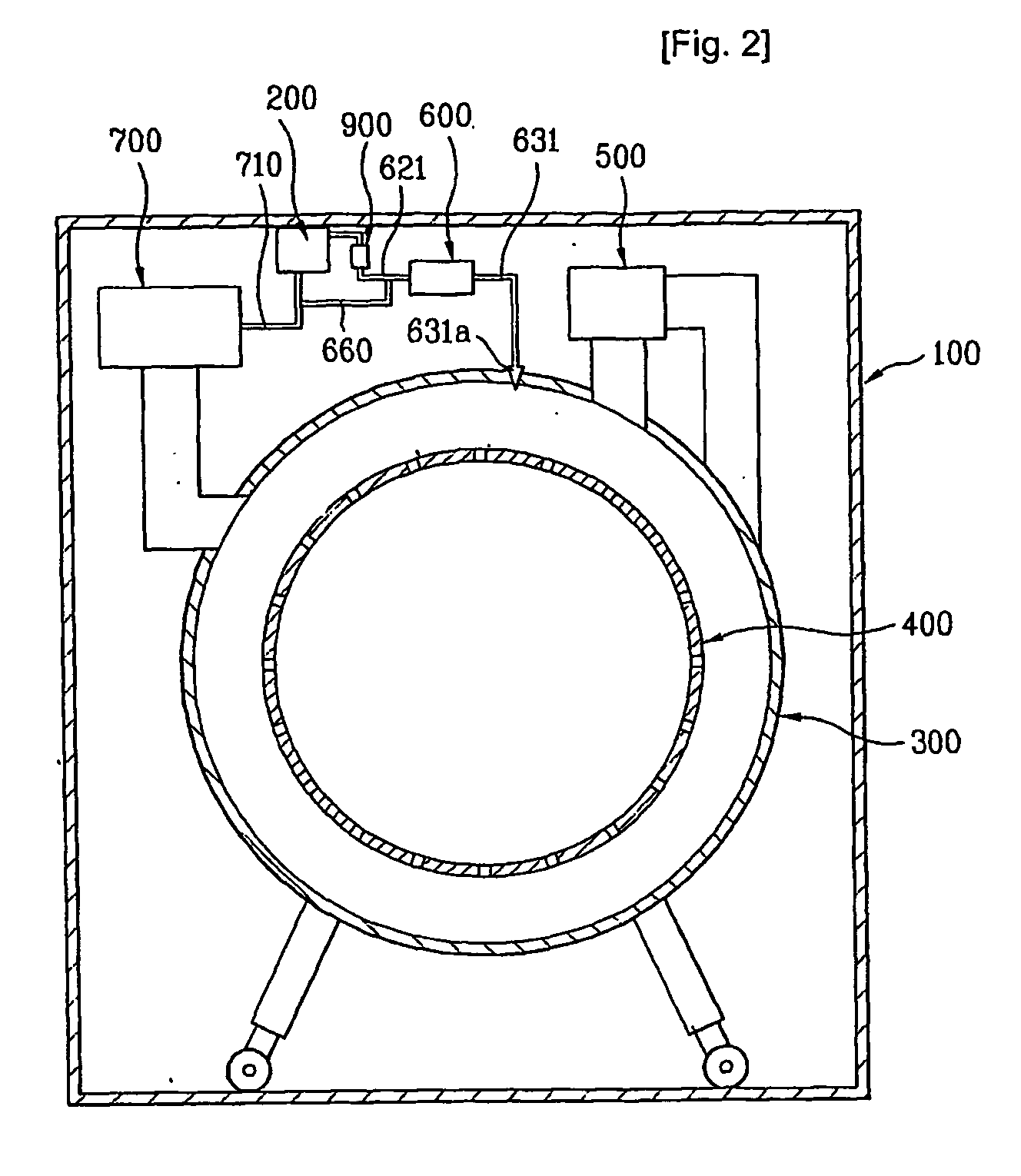

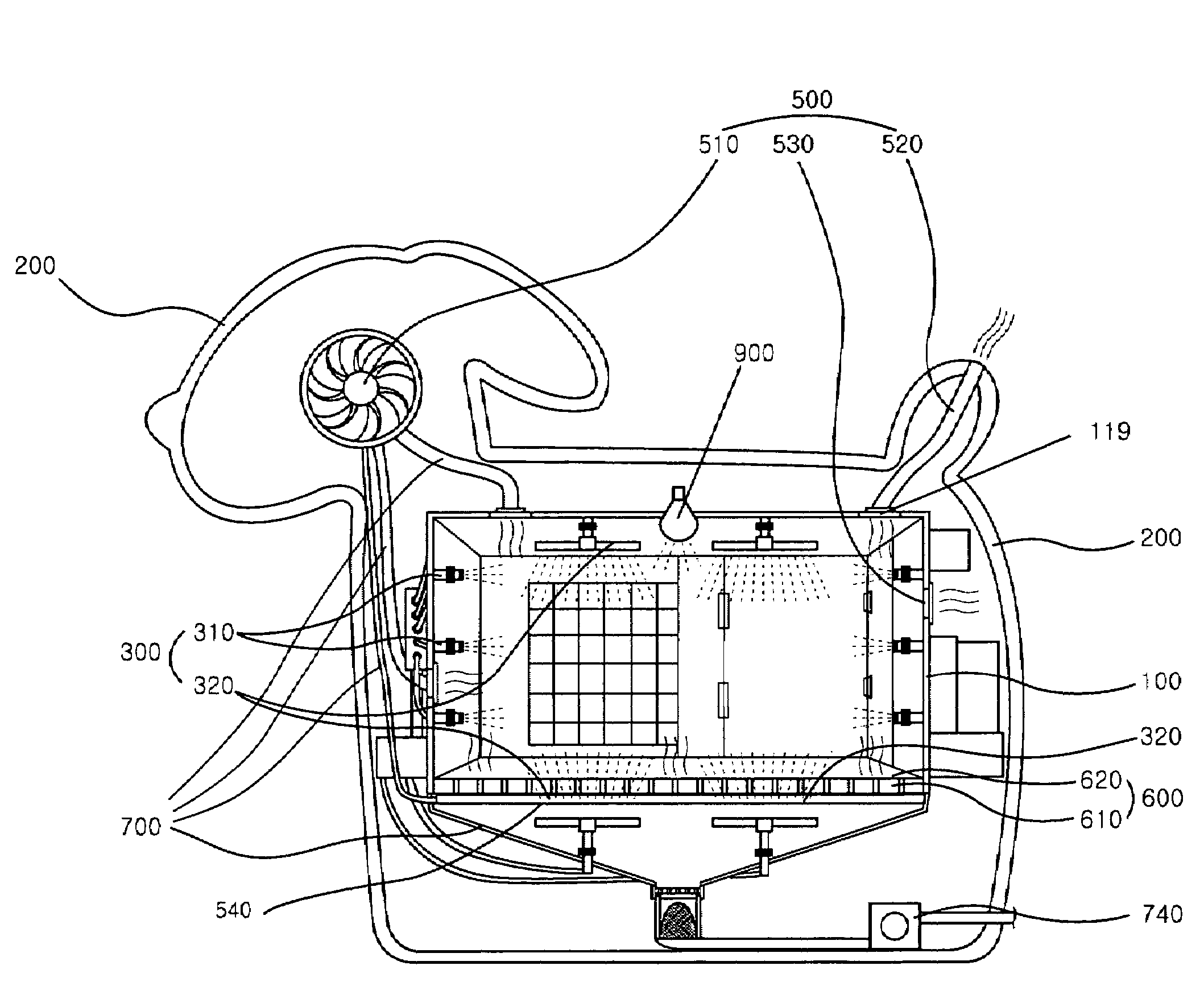

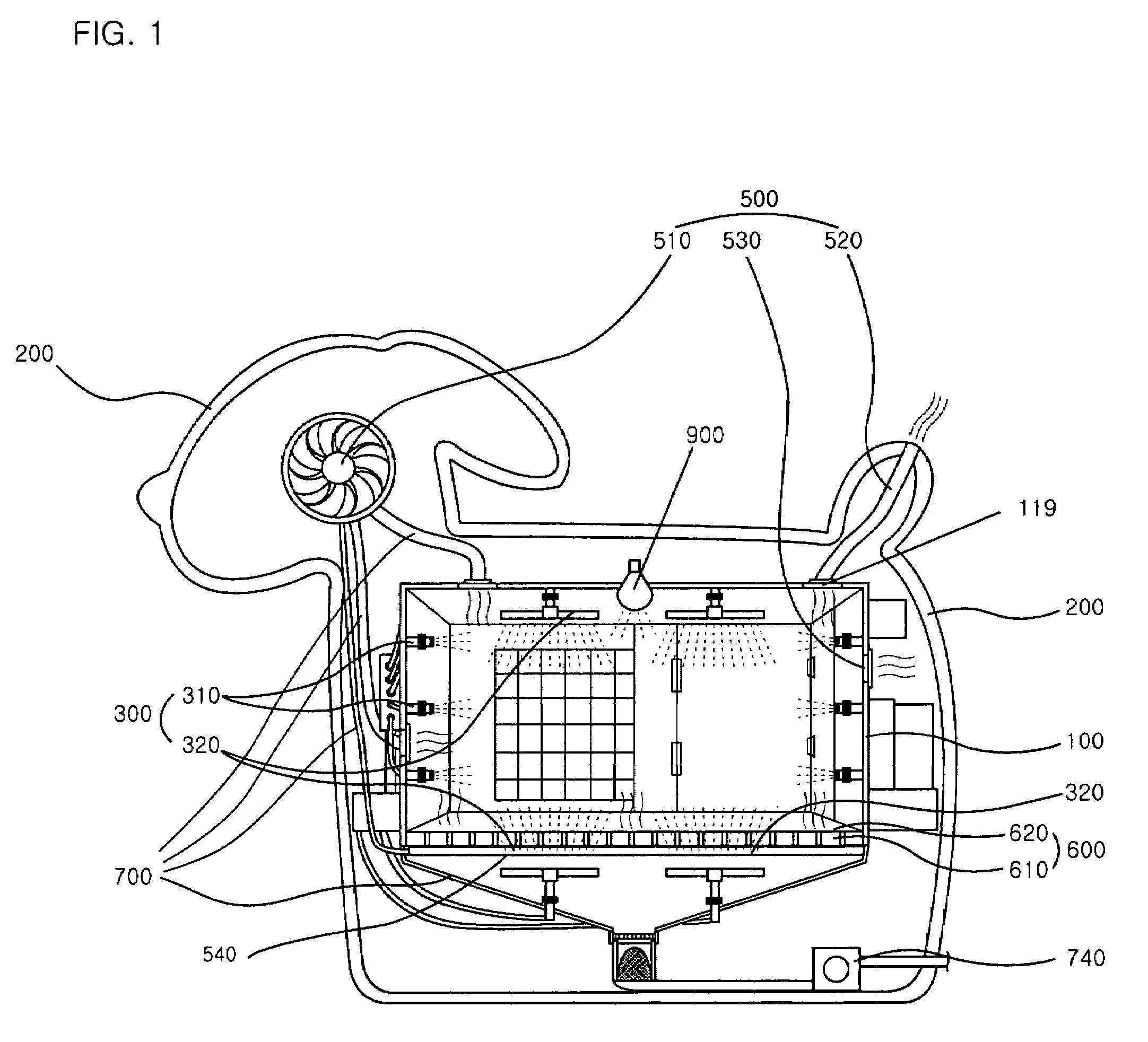

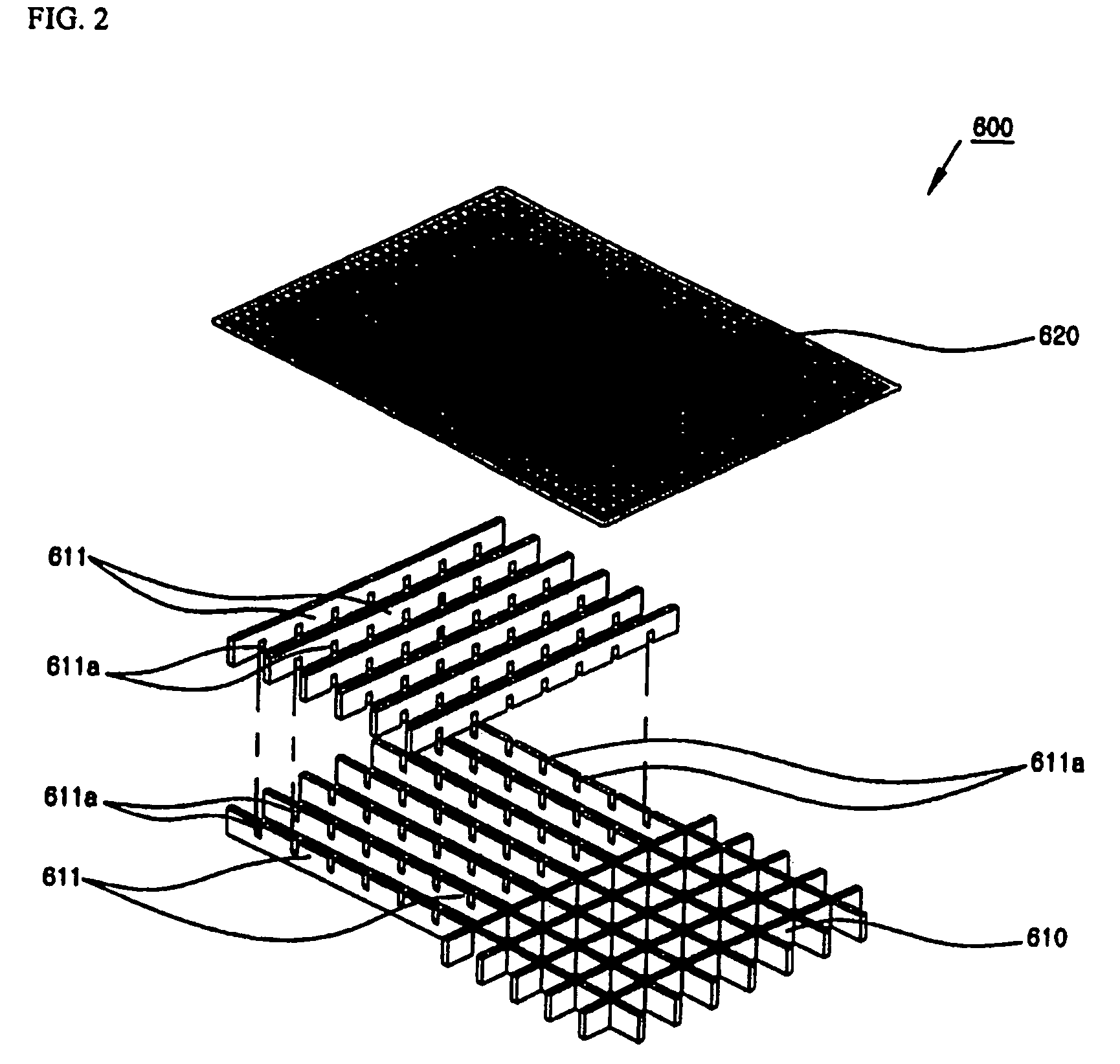

Laundry Machine

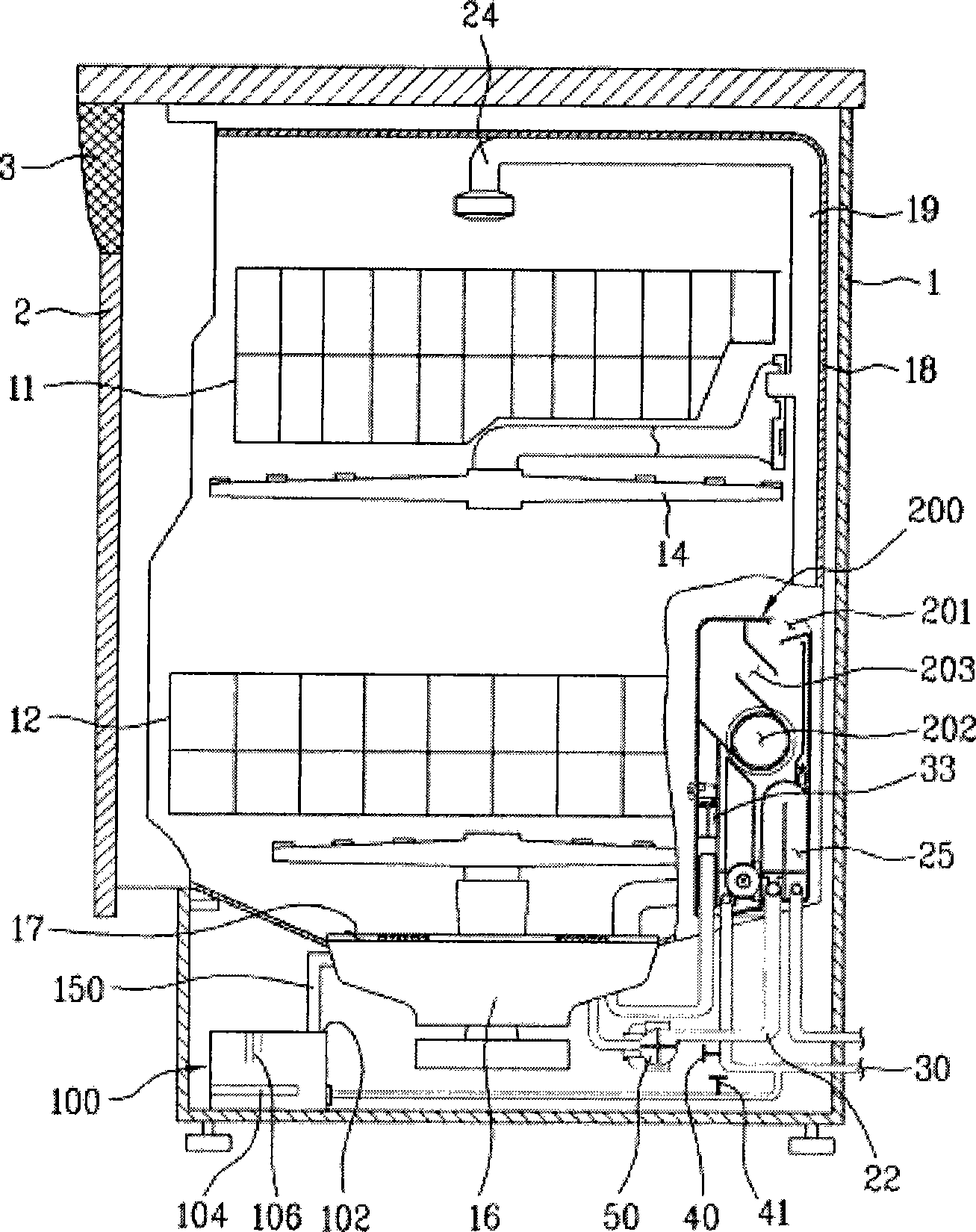

InactiveUS20080271500A1Improve washing efficiencyEconomizing in wash water in a washing cycleTextile treatment machine partsOther washing machinesProcess engineeringLaundry

A laundry machine is disclosed. A laundry machine includes a body (100) for defining an exterior, a water supply valve (200) provided in the body (100) and connected with an outer water supply device, a drum rotatably mounted within the body, at least one steam generator for supplying steam into the drum (600), and a water treatment apparatus (900) for treating water supplied to the steam generator (600). an object of the present invention is to provide a laundry machine which can perform washing and drying more quickly and efficiently as well as which has an effect of smoothing out wrinkles and sterilizing the laundry.

Owner:LG ELECTRONICS INC

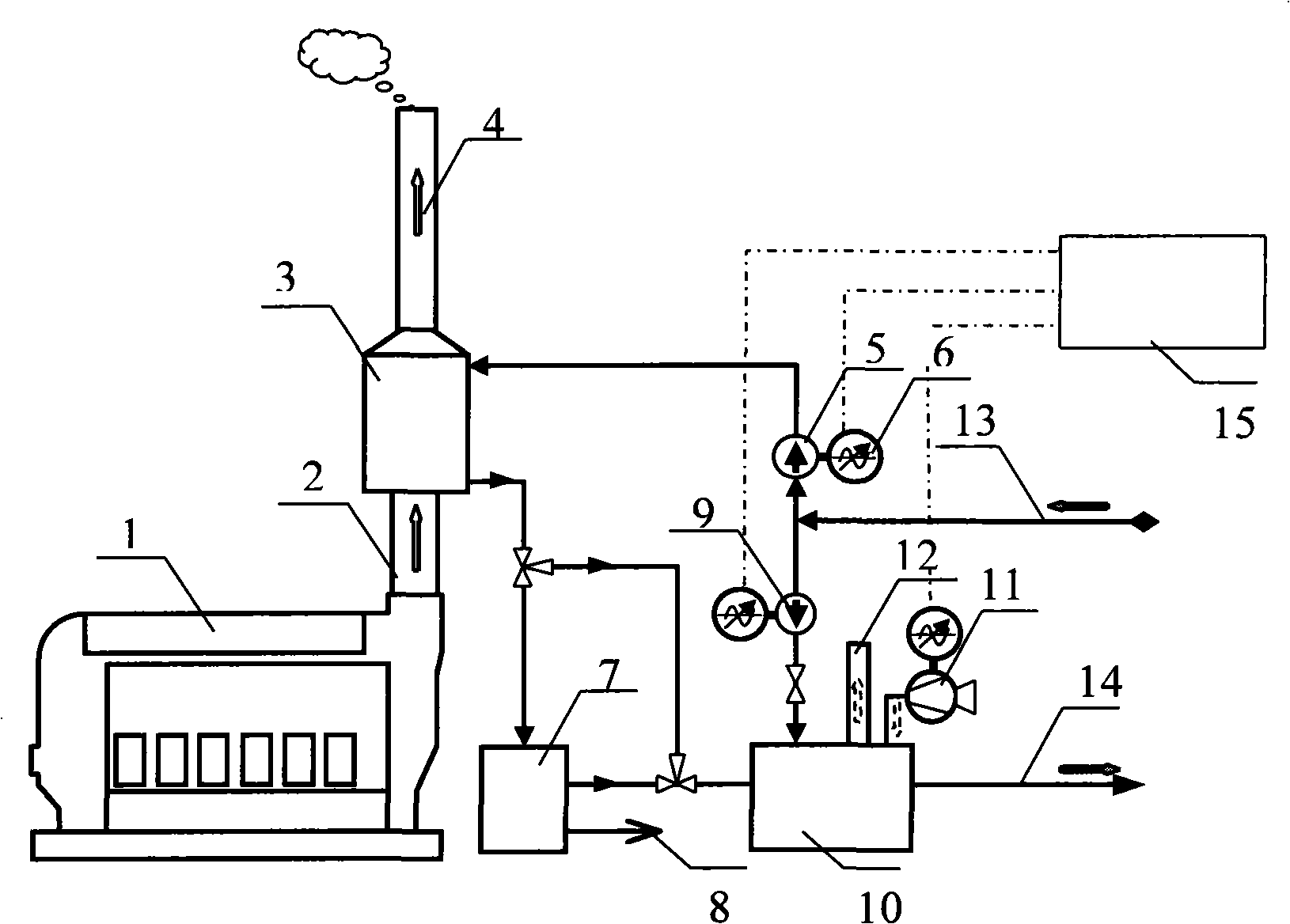

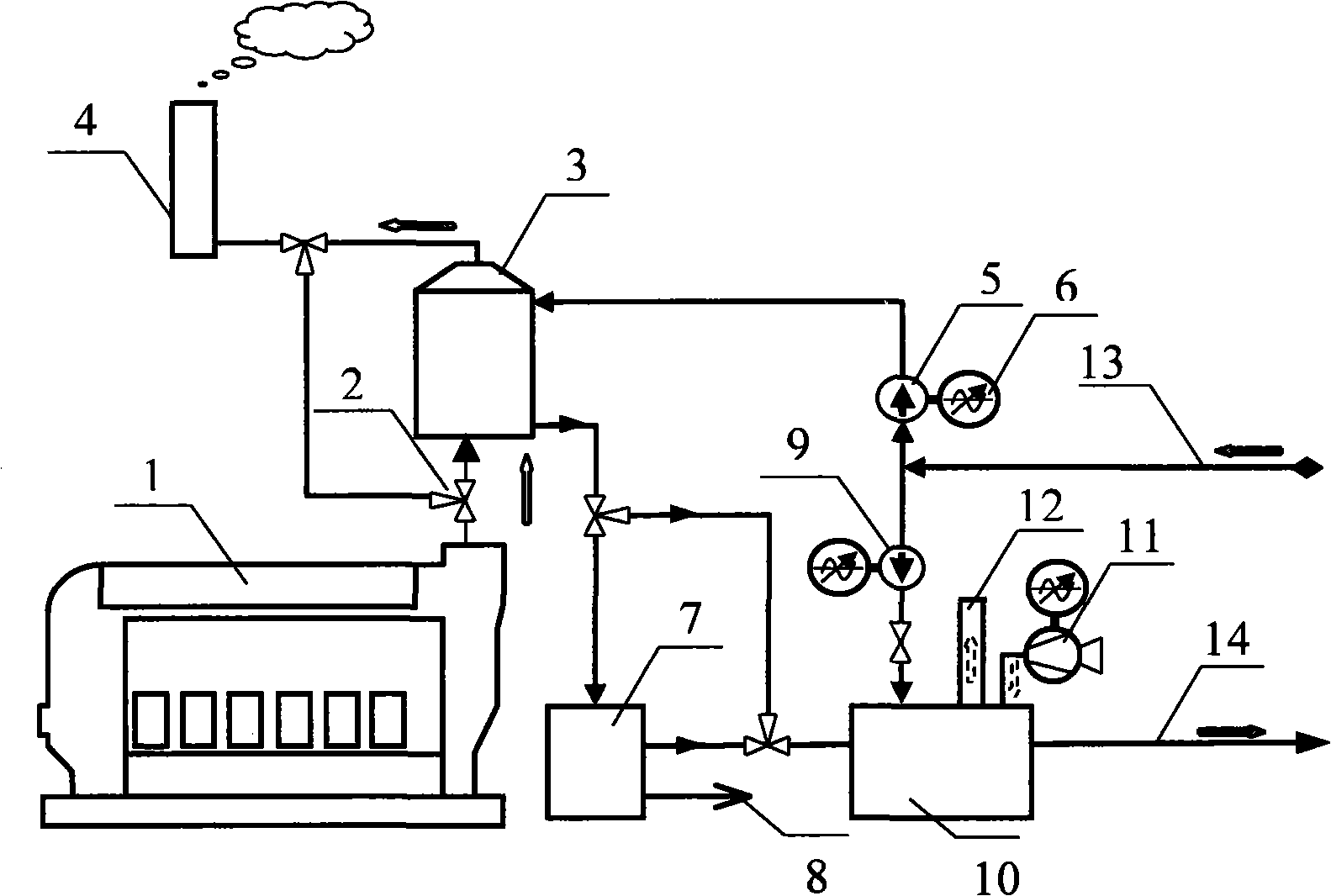

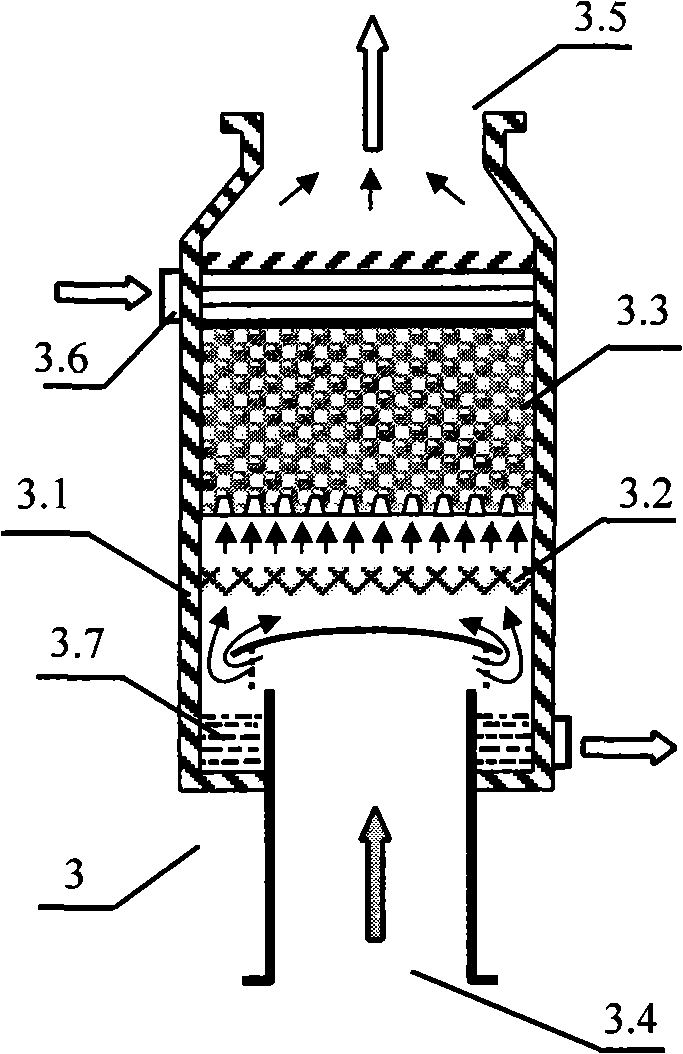

Method and apparatus for desulfurizing exhaust gas of seagoing vessel

InactiveCN101314106AGood technical effectImprove emission reduction efficiencyDispersed particle separationWater savingWater discharge

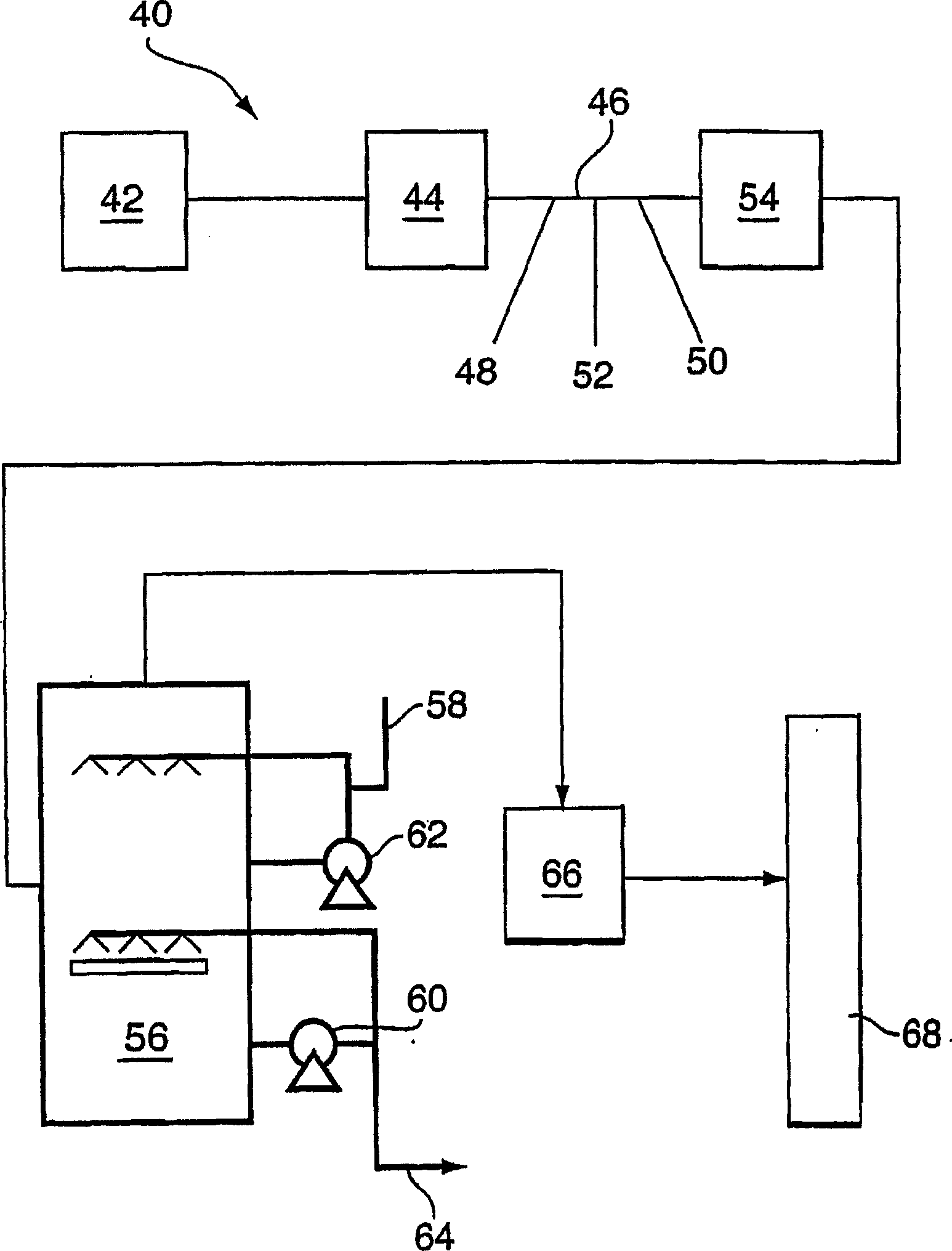

The invention relates to a method and a device for desulfurizing exhaust smoke of a sea-going ship, which uses sea water to reduce discharge of sulfur dioxide and other pollutants of the sea-going ship. The method comprises the following steps of: sea water scrubbing, acidic sea water transferring, acid separating treatment, water discharge and so on. The device comprises a scrubber and a water-saving acid separator, wherein, the upper part of the scrubber is provided with a scrubbing layer, and is communicated with a scrubbing sea water pump through a pipeline; the lower part of the scrubber is provided with a cooling layer; one end of the scrubber is communicated with a smoke exhaust pipe of a ship engine through a scrubbing inlet pipe, while the other end of the scrubber is connected with a scrubbing exhaust pipe; the lower part of the scrubber is communicated with the water-saving acid separator; and the water-saving acid separator is connected with a mixed sea water pump, a draught fan and a main discharge pipe for suitably discharging sea water which is subject to the acid separating treatment. The method and the device have the advantages of high desulfurizing efficiency, small sea water consumption, low equipment manufacturing cost and low running cost.

Owner:WUHAN SAFE ENVIRONMENTAL PROJECT TECH INC

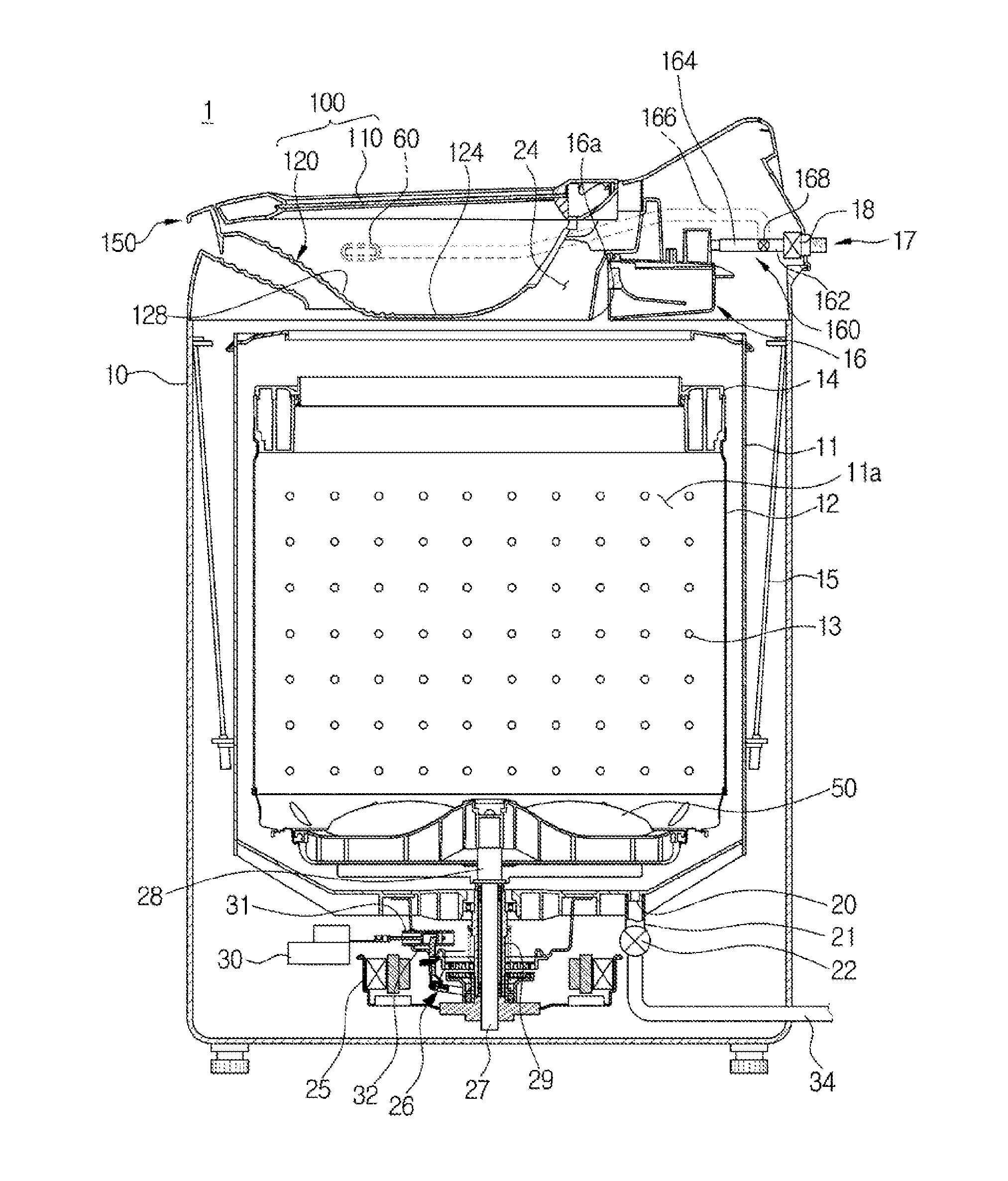

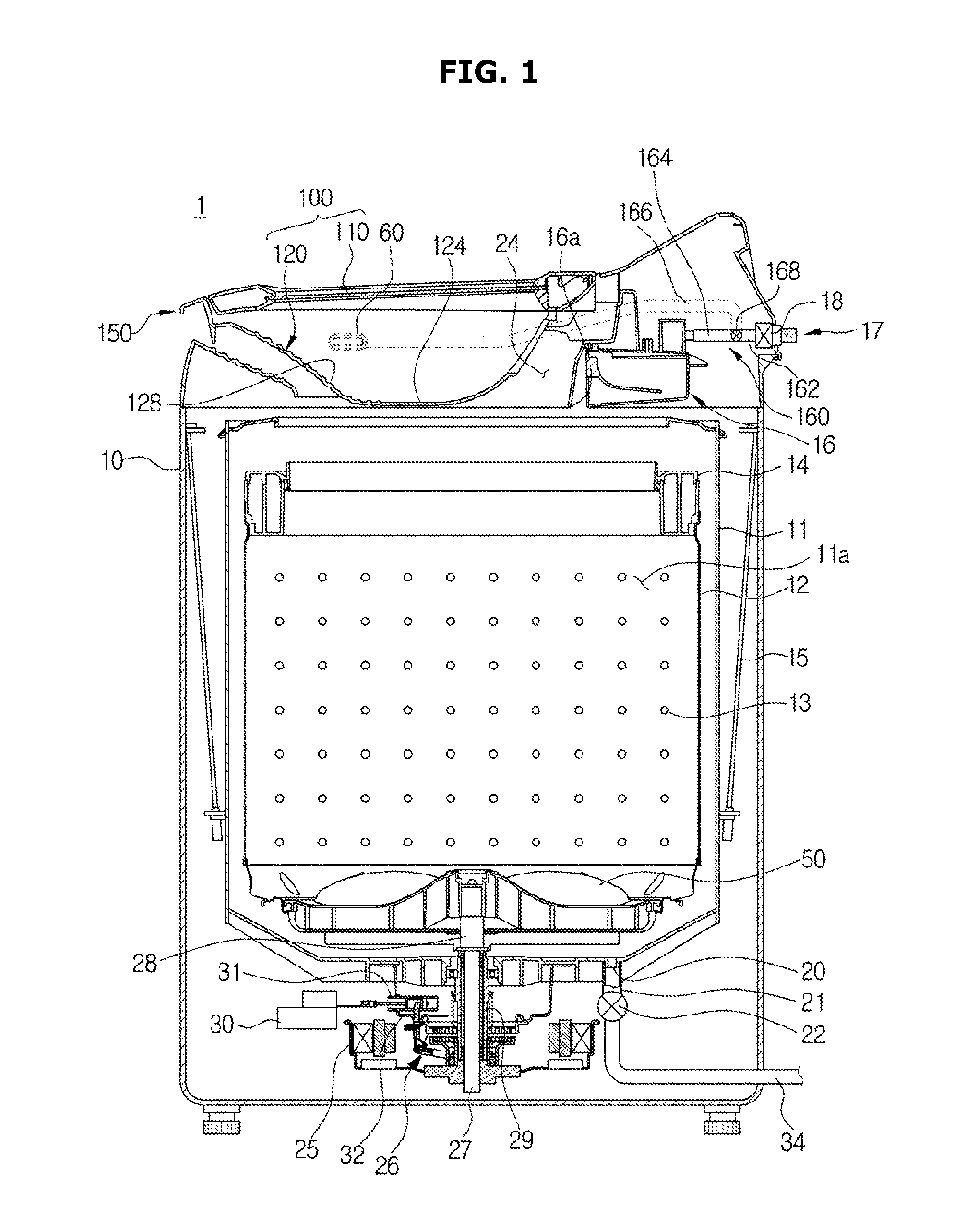

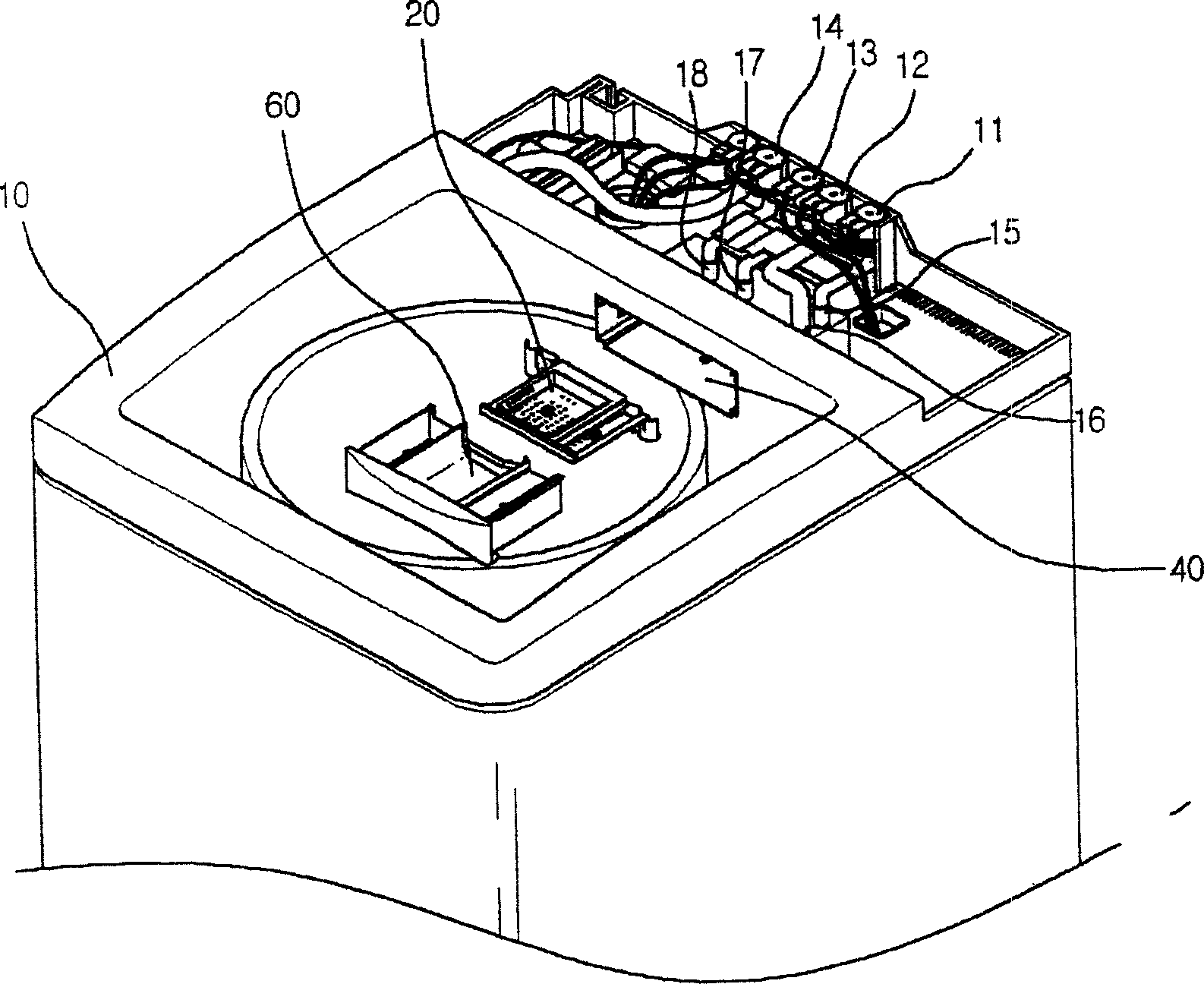

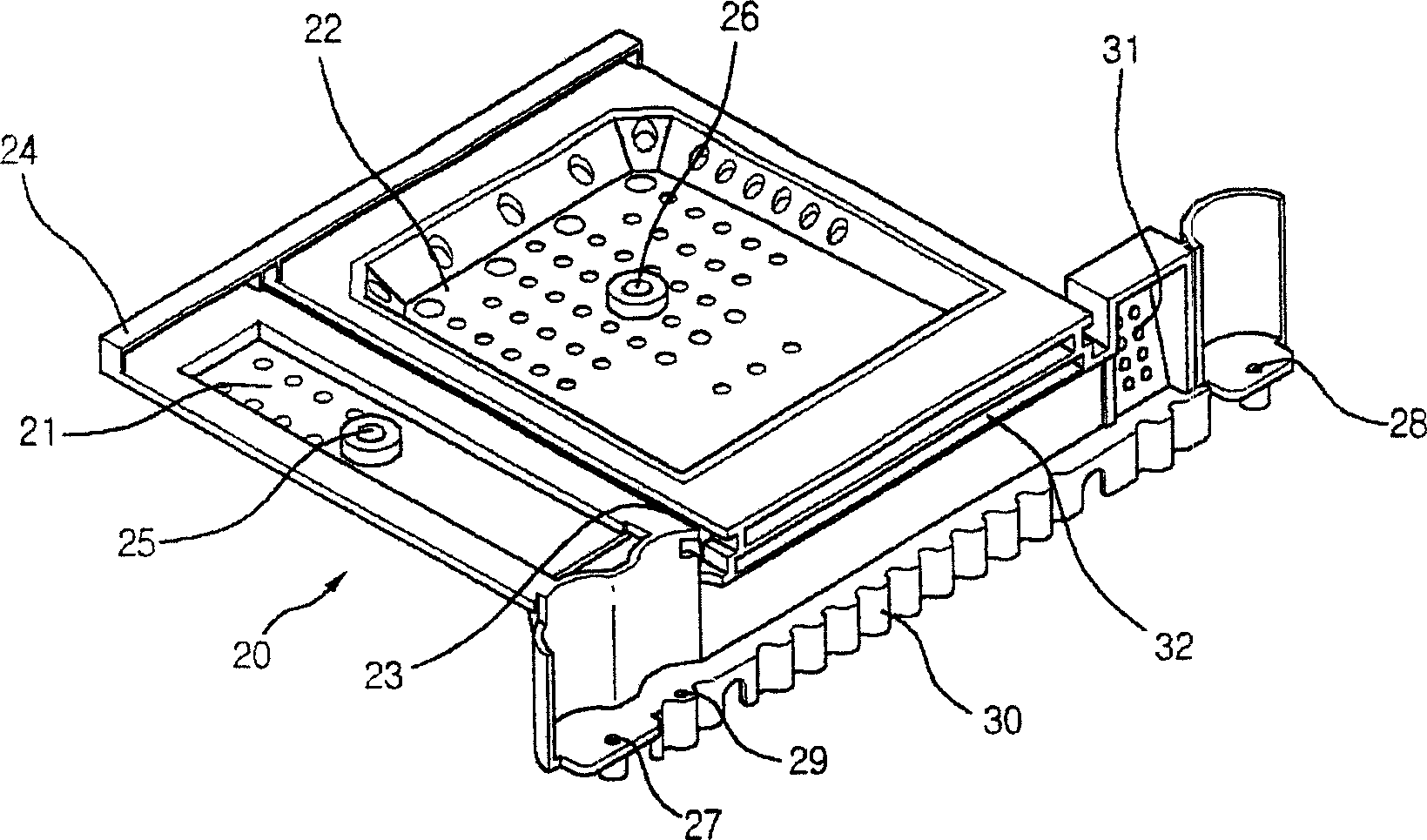

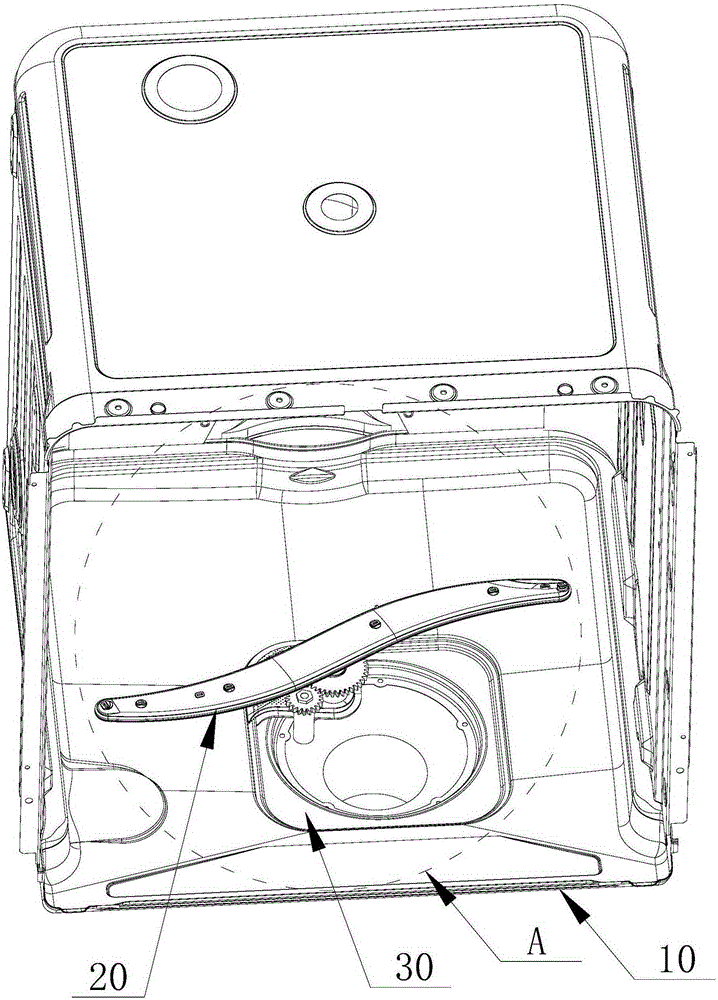

Washing machine having a manual washing unit

ActiveUS20150252508A1Improve washing efficiencyLimiting pivotal movementWashing receptaclesOther washing machinesEngineeringMechanical engineering

Disclosed is a washing machine capable of improving the efficiency of washing and product quality by improving a pivoting structure of a door assembly having a door and an auxiliary washing unit forming an auxiliary washing space. Also, the door and the auxiliary washing unit may be coupled by a locking part so that a user can open and close the door assembly conveniently when manual washing is not needed. When manual washing is needed, the user may release a locked state of the locking part to move the door and the auxiliary washing unit separately.

Owner:SAMSUNG ELECTRONICS CO LTD

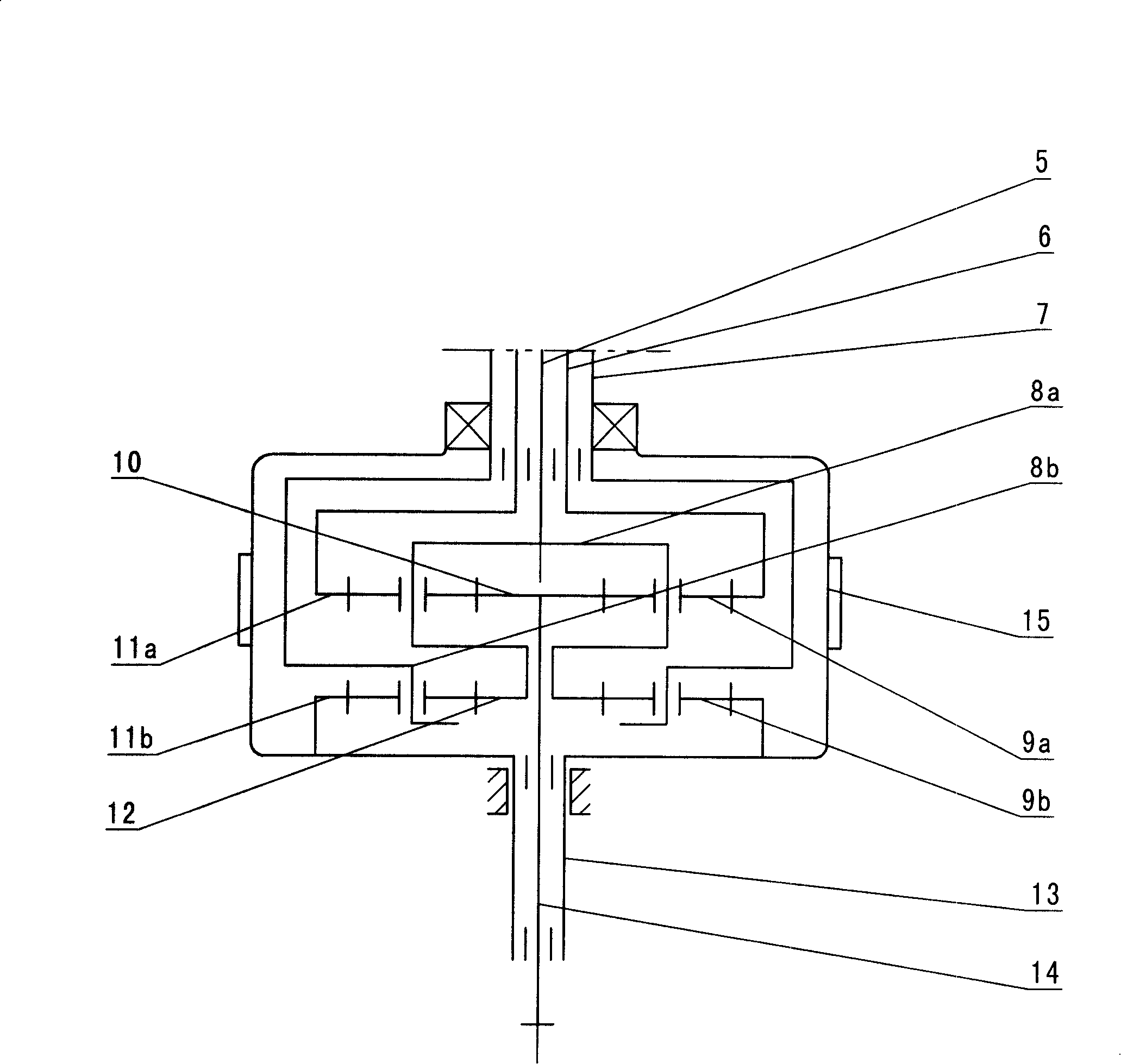

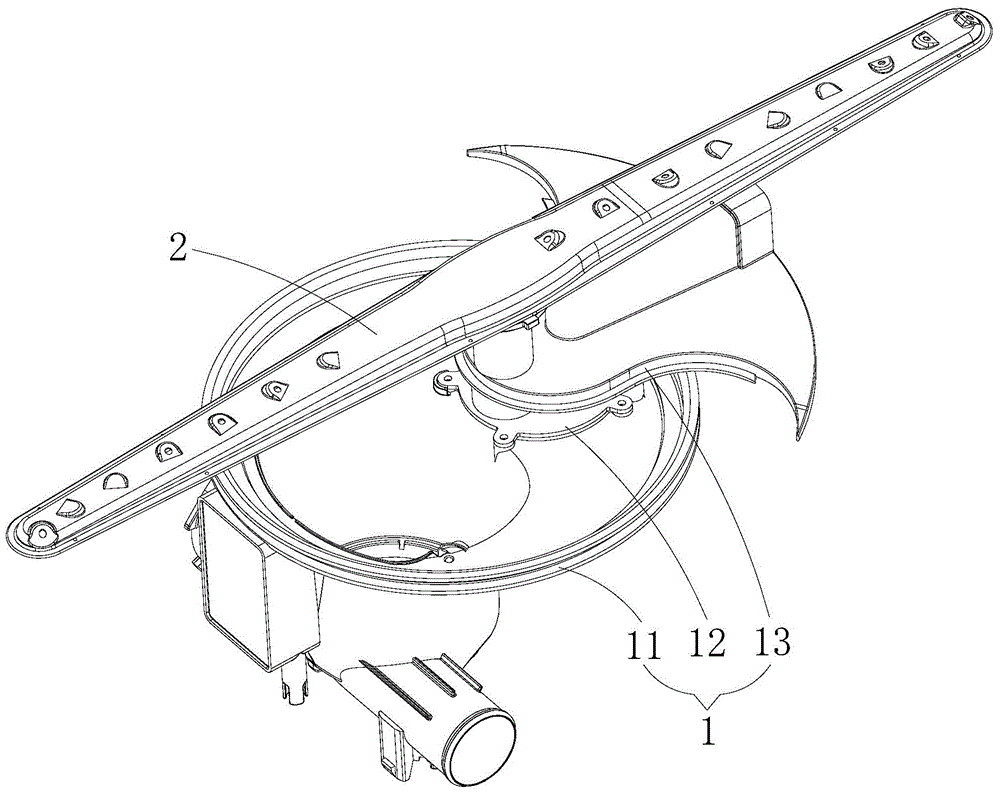

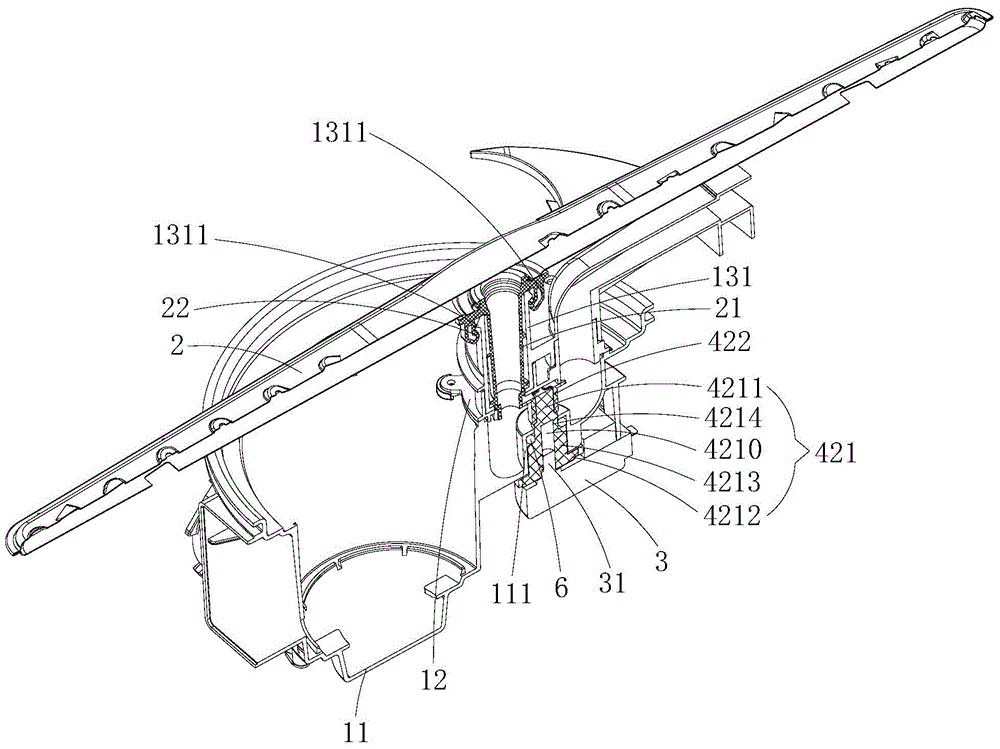

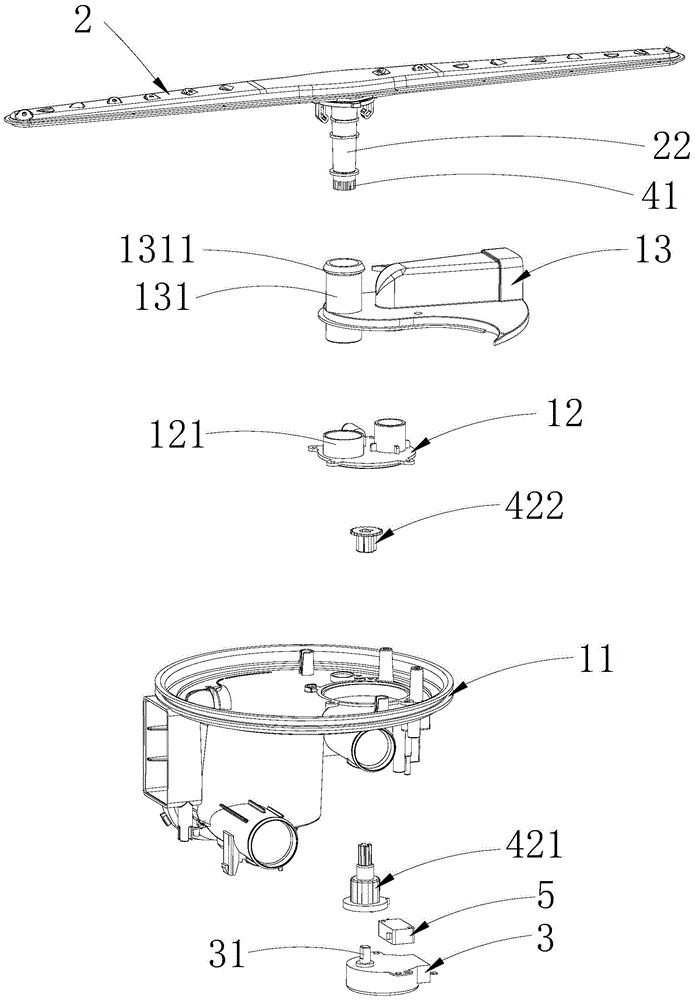

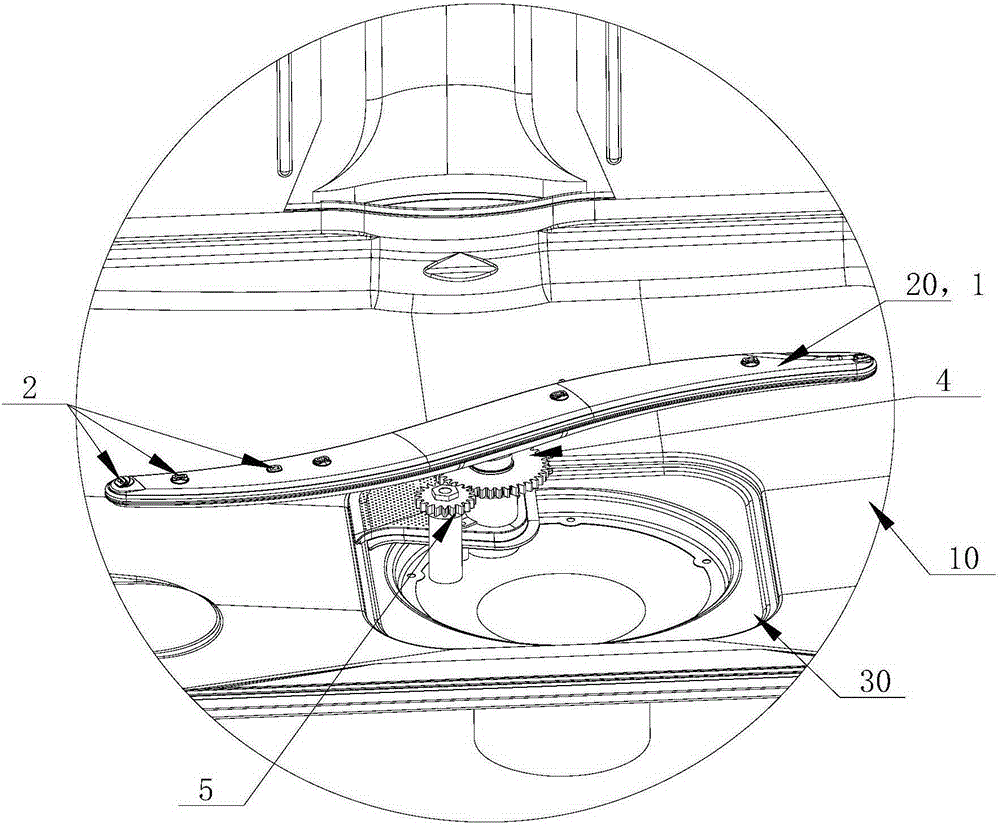

Spraying arm device and dish washing machine

ActiveCN104523208AGuaranteed stabilityImprove controllabilityTableware washing/rinsing machine detailsWater resourcesEngineering

The invention is applicable to the field of dish washing machines and discloses a spraying arm device and a dish washing machine. The spraying arm device comprises a spraying arm base assembly, a motor, a transmission structure and a spraying arm installed on the spraying arm base assembly, wherein a water cavity is formed in the spraying arm base assembly, a first connection pipe is arranged on the spraying arm in a protruding mode, penetrates through the spraying arm assembly and is communicated with the water cavity, the motor is installed on the spraying arm base assembly, and the transmission structure is connected between the first connection pipe and the motor in a transmission mode. Due to the fact that the motor and the transmission structure are matched to drive the spraying arm to rotate, the controllability of the rotational movement of the spraying arm is achieved, the spraying arm can stop at a certain position to perform reinforced washing by controlling starting and stop of the motor in the washing process, tableware which is high in fouling degree and difficult to clean can be subjected to independent prolonged washing, the washing efficiency and the washing effect of the tableware are improved, and electric energy and water resources can be saved easily; meanwhile, due to the fact that driving of the motor is stable, stability of rotation of the spraying arm is guaranteed.

Owner:WUHU MIDEA SMART KITCHEN APPLIANCE MFG CO LTD

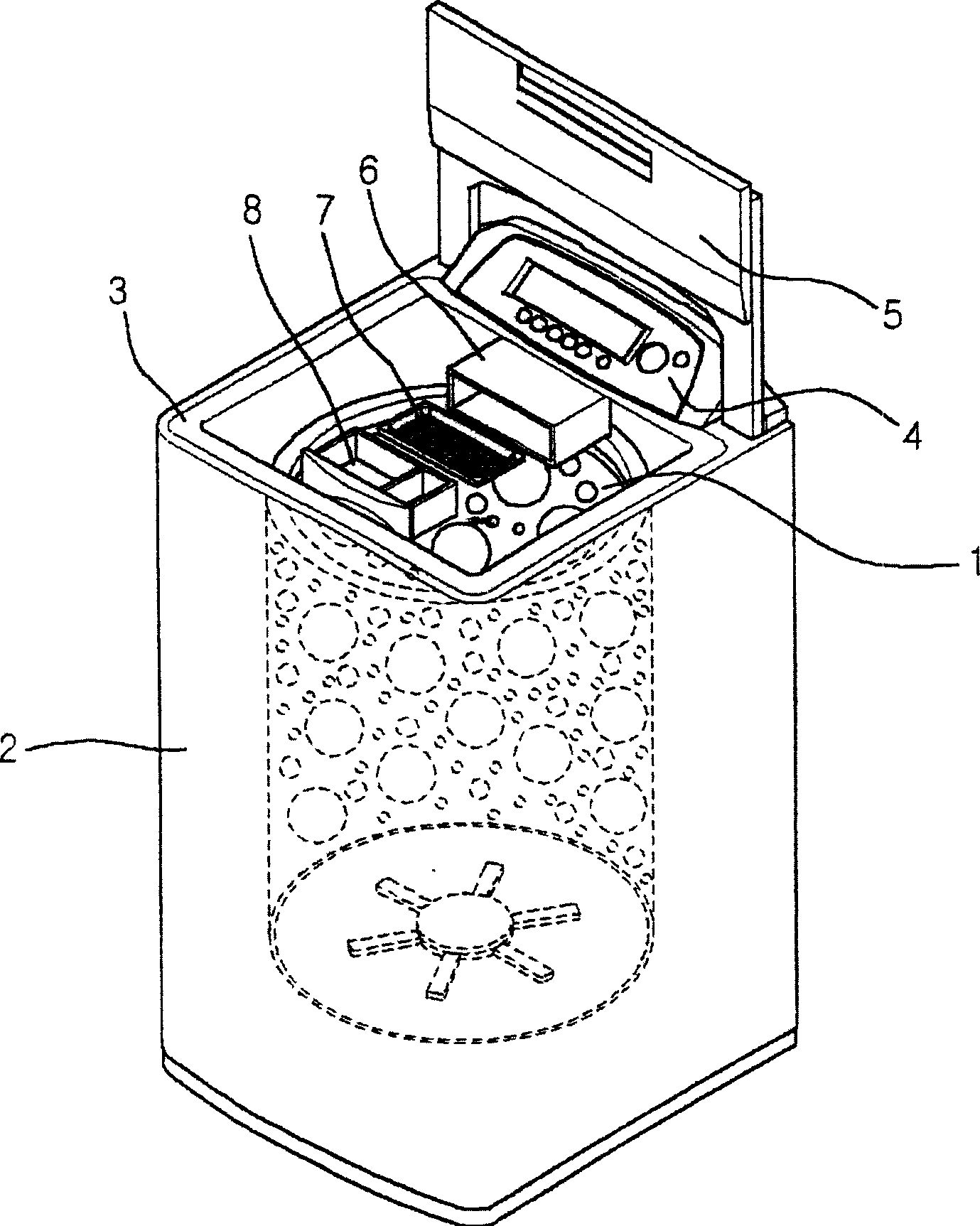

Washing machine

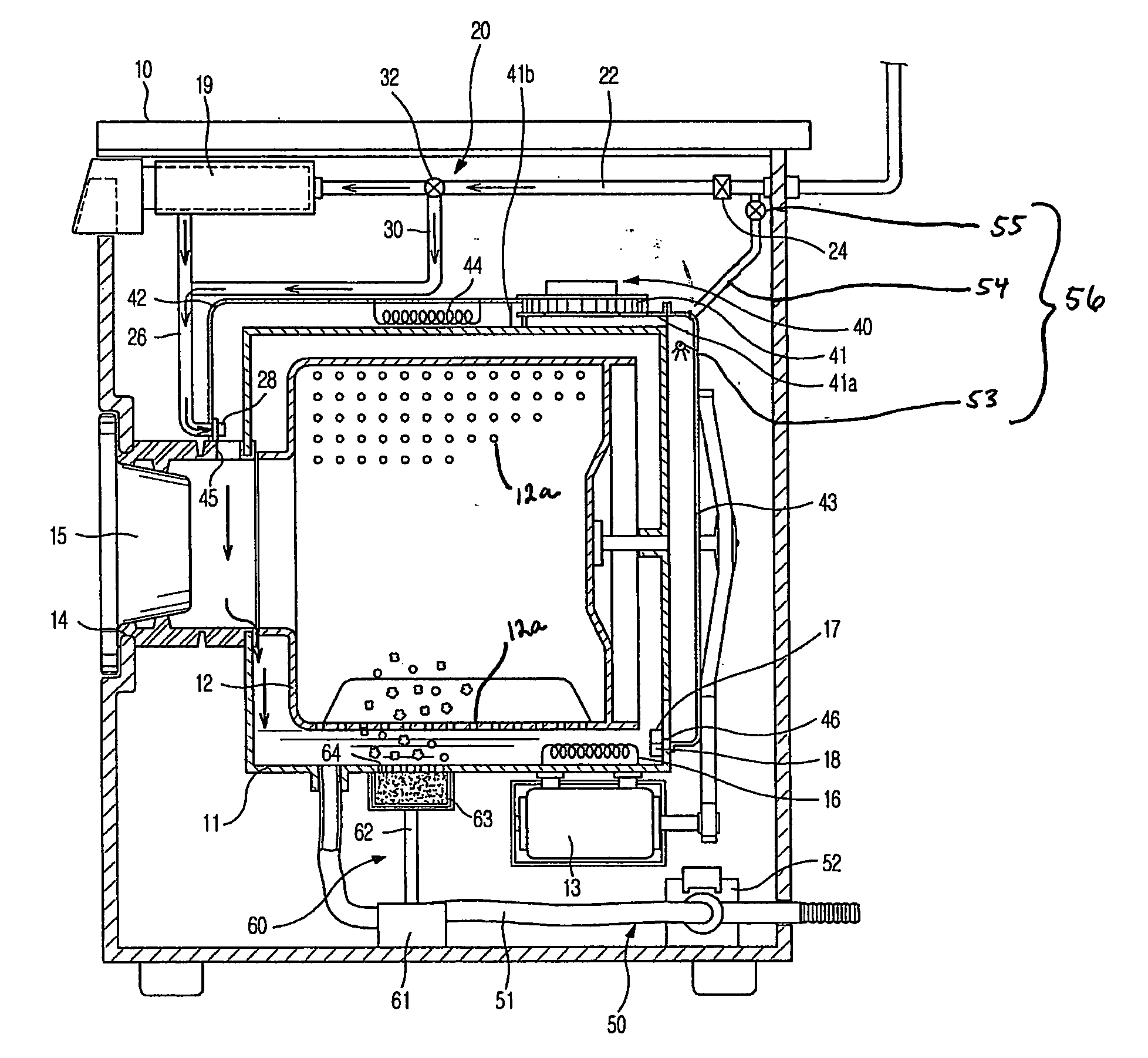

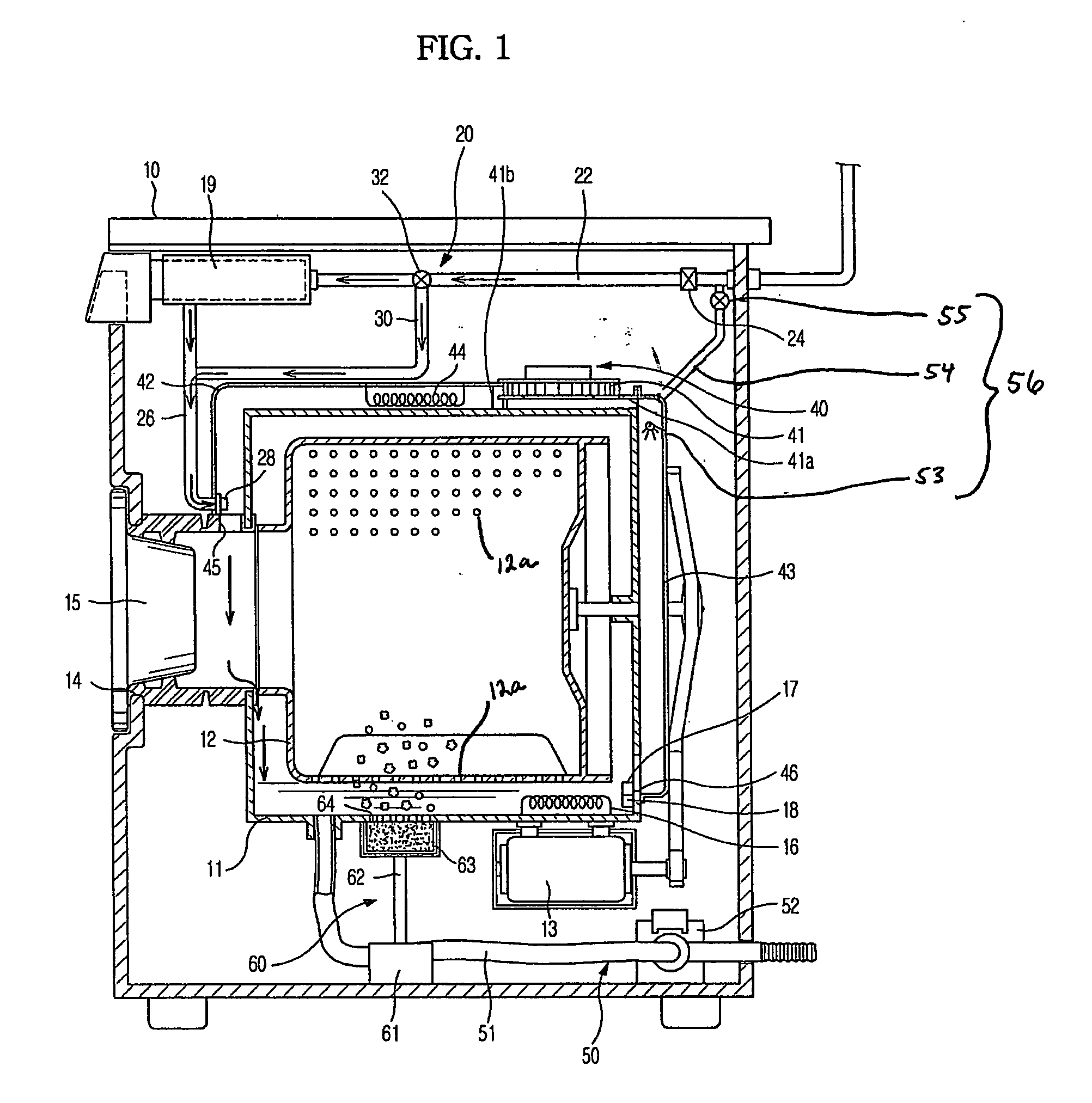

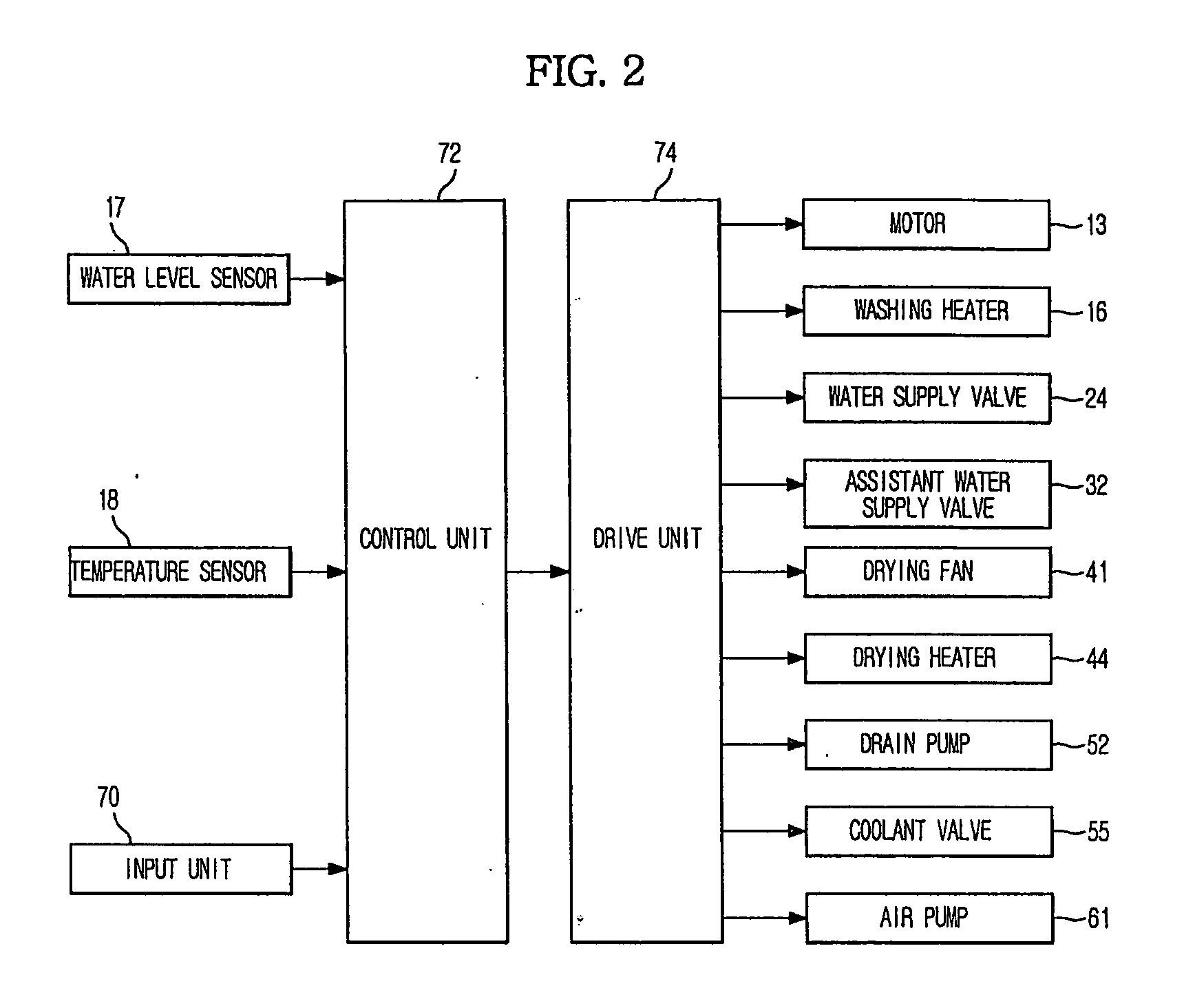

ActiveUS20100263410A1Reduce sizeImprove washing efficiencyOther washing machinesControl devices for washing apparatusWater useAir bubble

Disclosed herein is a washing machine that performs washing using bubbles. The washing machine may include an air bubble unit to generate air bubbles in detergent water using external air naturally introduced thereinto by pressure difference caused when the detergent water passes therethrough, a water tub having an introduction port to allow the detergent water containing the air bubbles to be introduced thereinto, and a washing tub rotatably provided in the water tub, the washing tub having a plurality of through-holes having a size less than the introduction port such that the air bubbles rise to a surface of the detergent water contained in the water tub.

Owner:SAMSUNG ELECTRONICS CO LTD

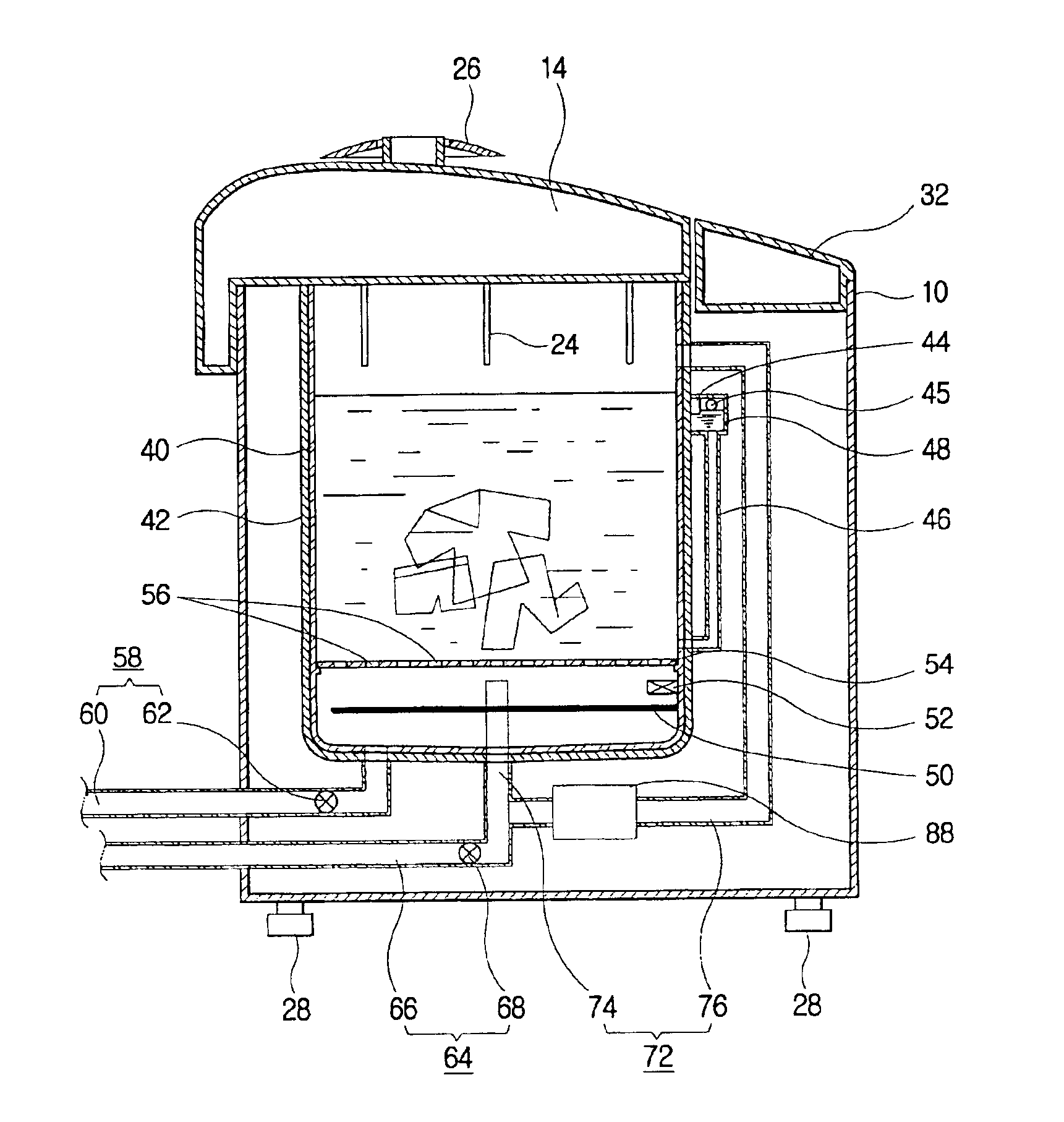

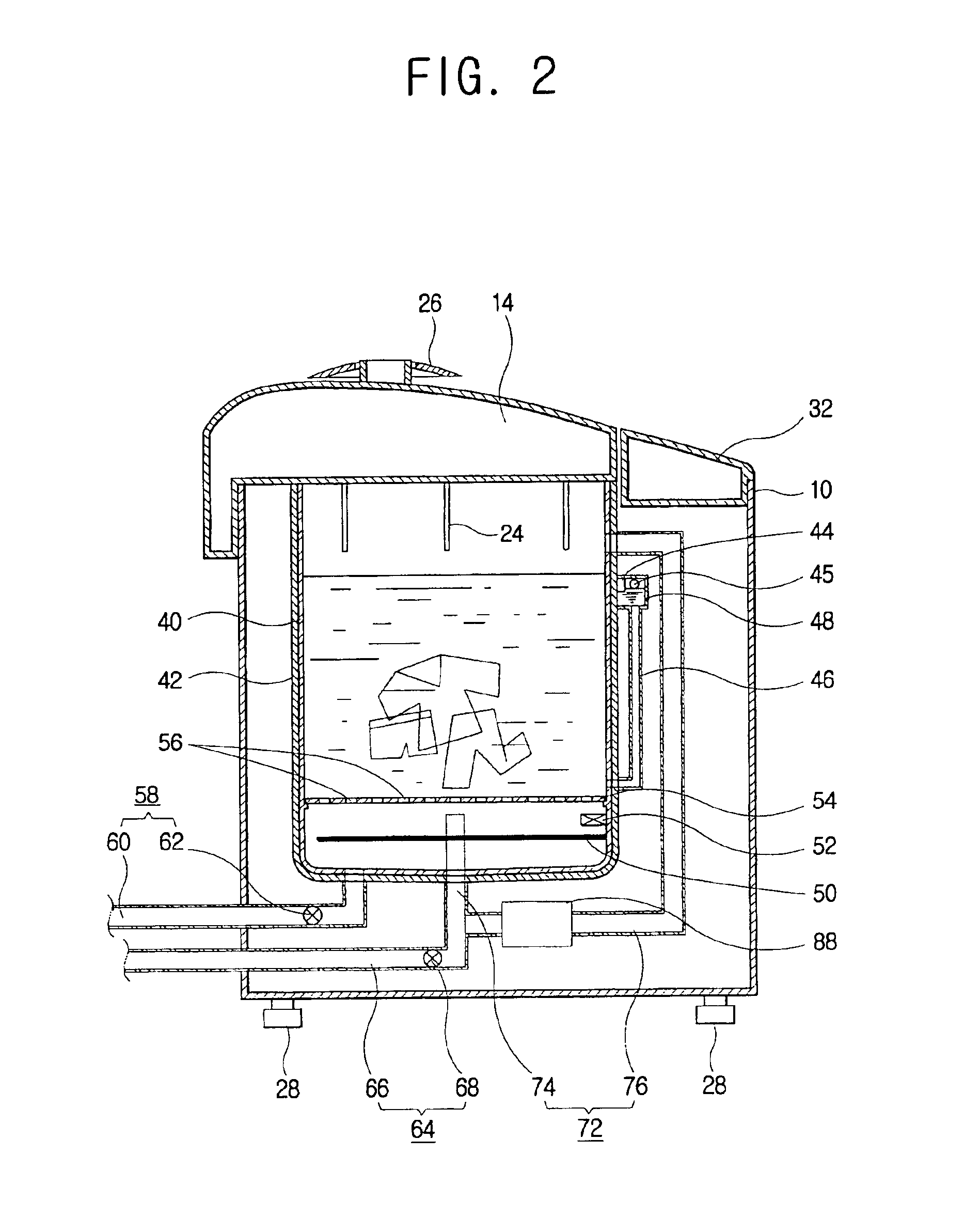

Washing machine and controlling method thereof

InactiveUS6874191B2Improve washing efficiencyPrevent oxidationOther washing machinesWashing machine with receptaclesCirculator pumpProcess engineering

Disclosed is a washing machine comprising a heating tank accommodating the washing and washing water; a heating part heating the washing water in the heating tank; and a circulation pump circulating the washing water in the heating tank. With this configuration, the present invention provides the circulation pump circulating washing water in the heating tank, thereby preventing the washing from oxidizing, improving a washing efficiency especially improving a washing efficiency according to washing material, and saving washing water. Further, water supply and drain can be easily performed.

Owner:SAMSUNG ELECTRONICS CO LTD

Pet bathing apparatus

InactiveUS7497188B2Improve washing efficiencyOther apparatusTaming and training devicesSpray nozzleCompanion animal

Owner:PETABCARE

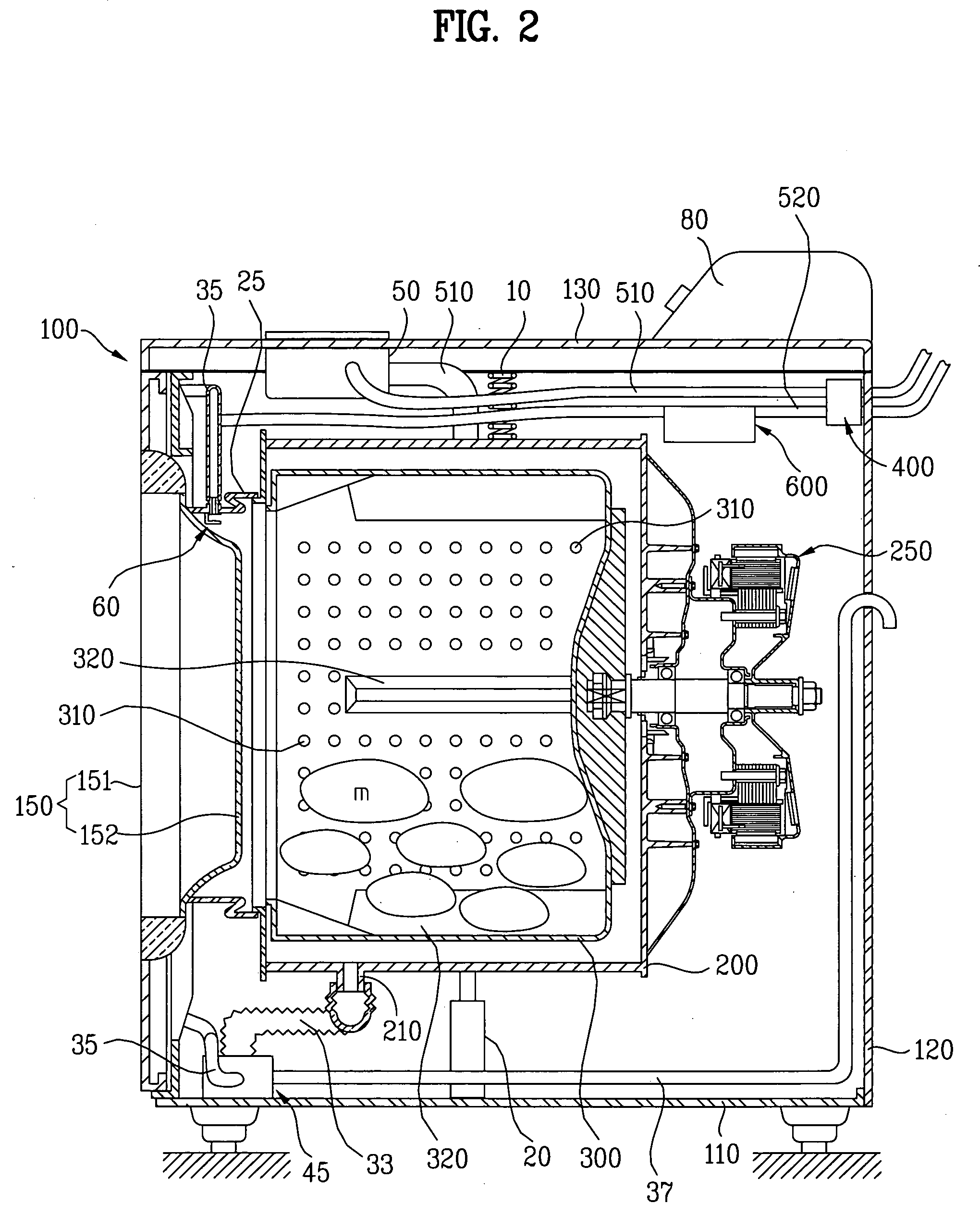

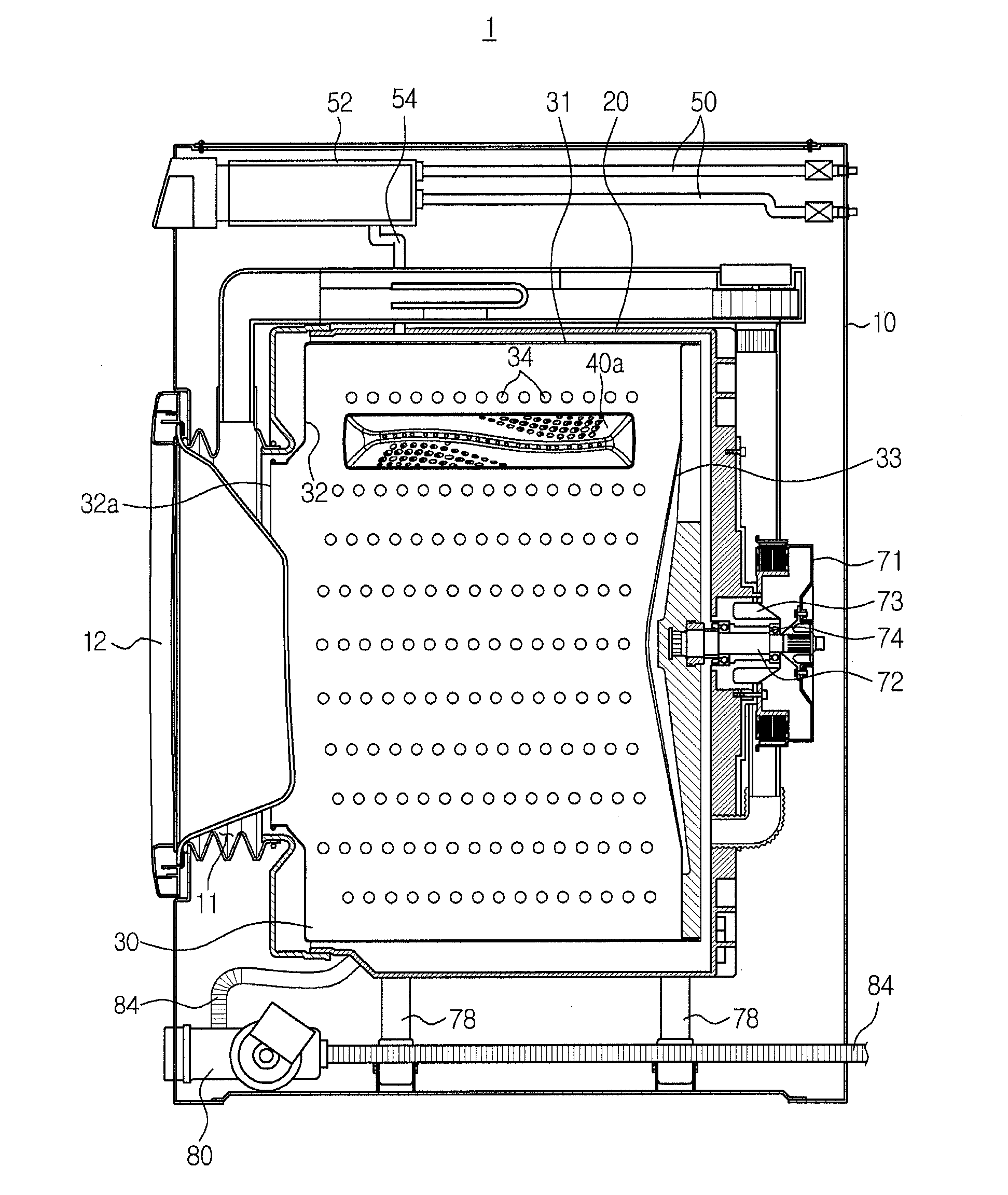

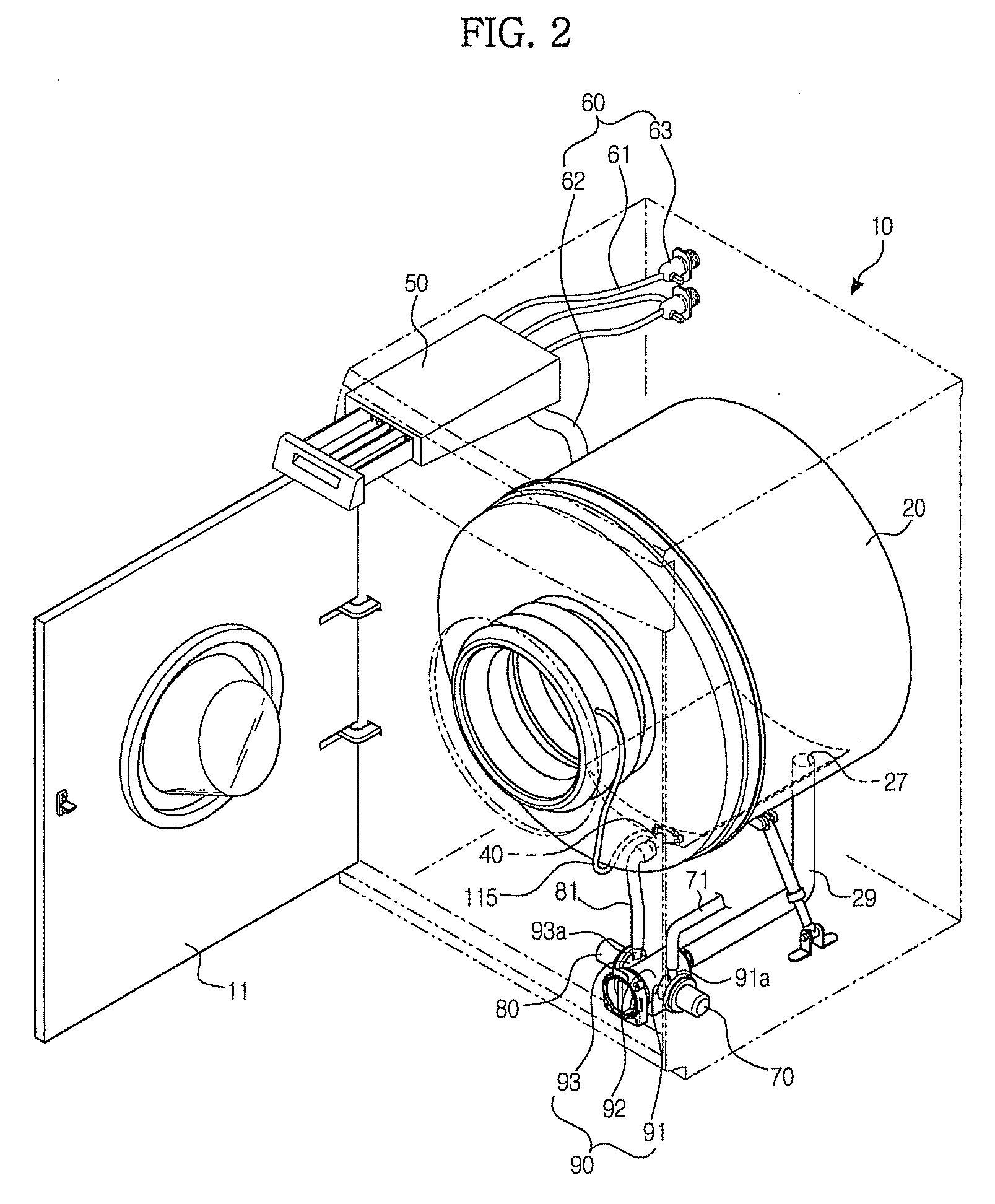

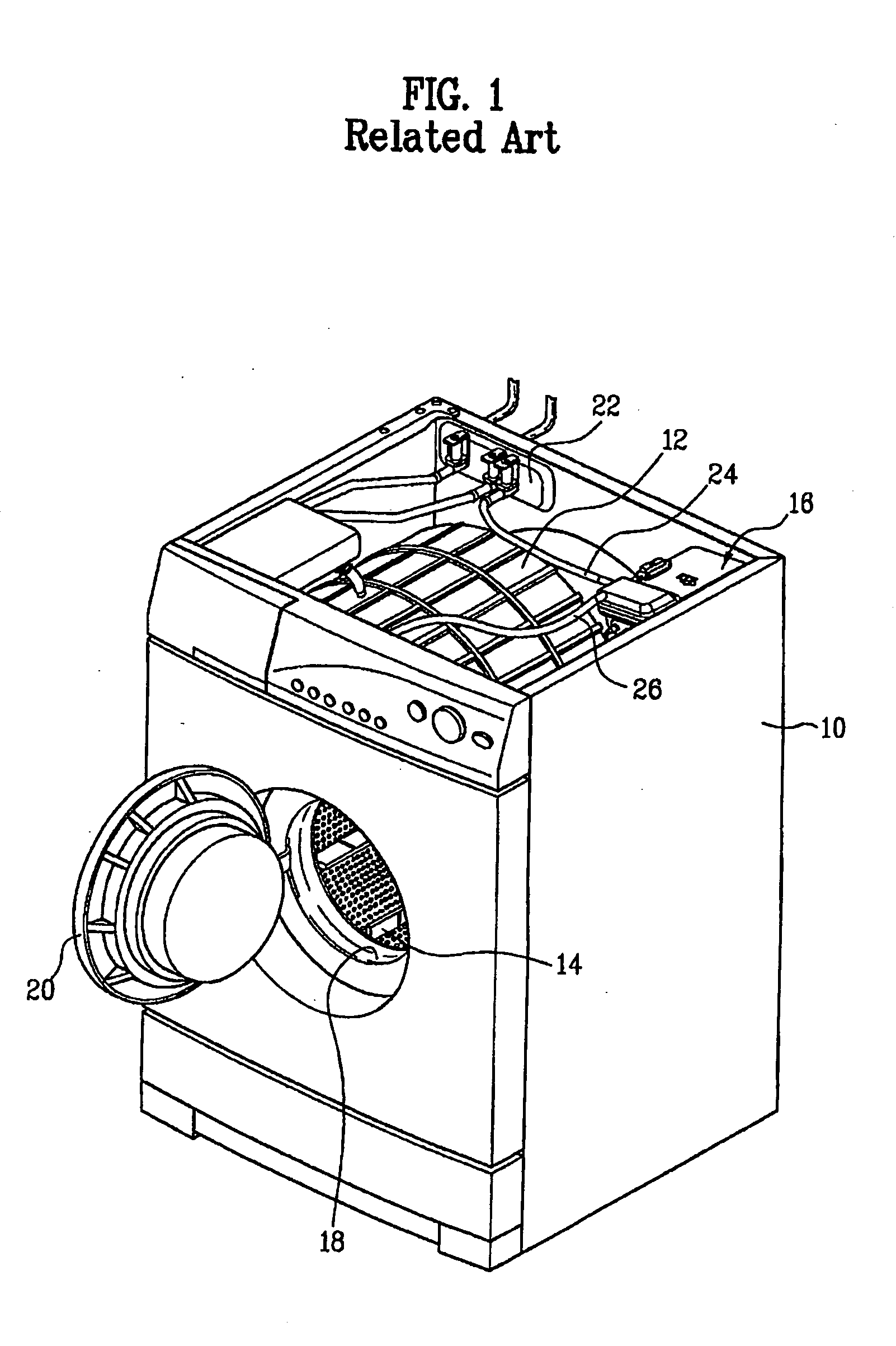

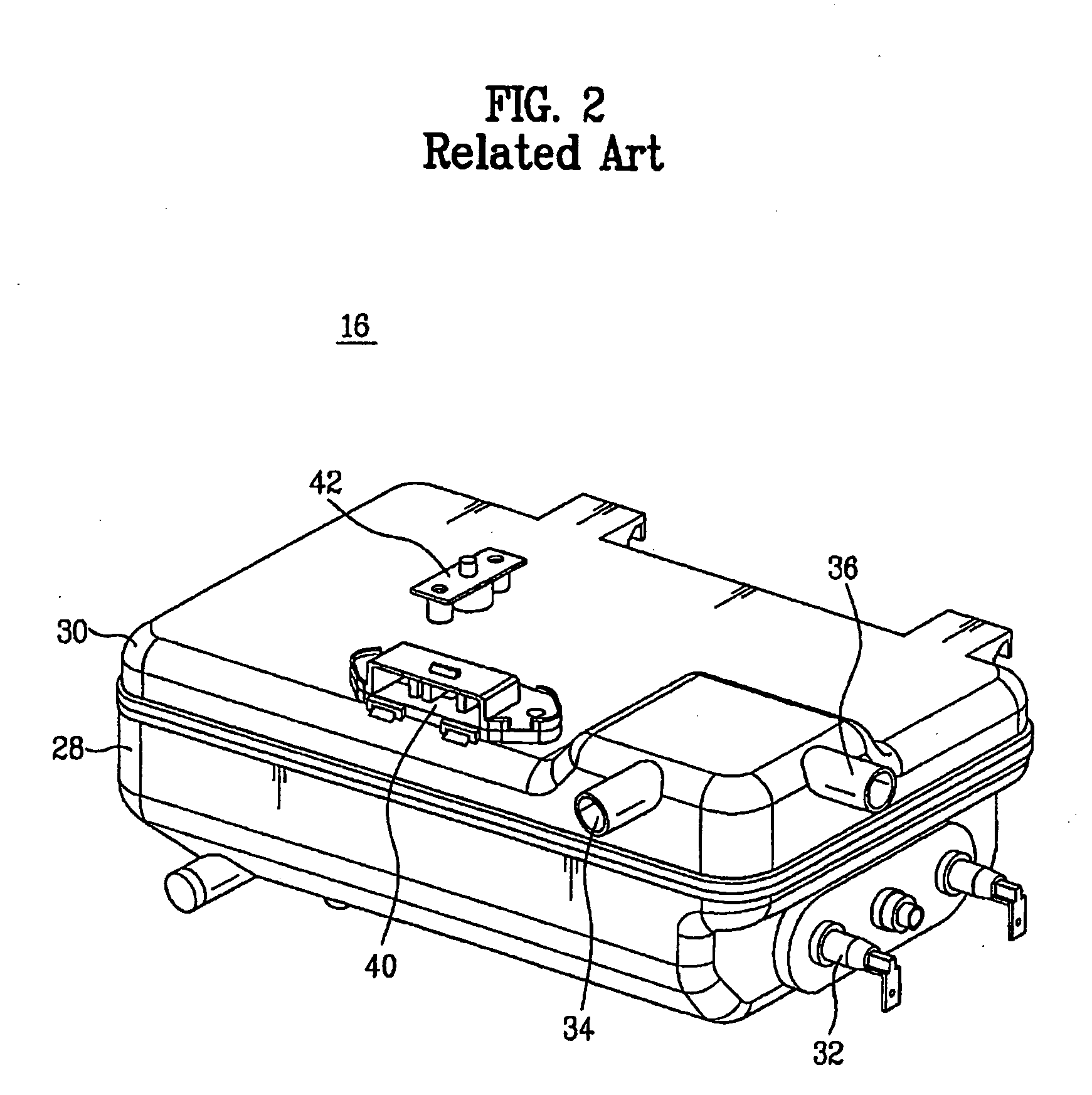

Steam generator and drum type washing machine with the same

InactiveUS20070199353A1Compact designImprove steam generation efficiencySteam generation heating methodsOther washing machinesEngineeringControl theory

The present invention relates to a steam generator. More particularly, the present invention relates to a steam generator which has a compact design to enhance efficiency, and to a drum-type washing machine with this steam generator. The steam generator includes a heater that heats water to generate steam; a lower case that holds water for steam generation, having a heater holding part in which the heater is vertically oriented in the heater holding part, and an upper case coupled to an upper portion of the lower case to form a predetermined space.

Owner:LG ELECTRONICS INC

Dishwasher

InactiveCN101444412AImprove washing efficiencySimple structureTableware washing/rinsing machine detailsSpray nozzlesWater flowEngineering

The present invention relates to a dishwasher equipped with a steam generating device, including a dish-washing drum for holding the dish; a water collection tank for receiving the washing water and equipped with a washing water flow path for supplying the washing water to the dish-washing flow path; a steam generating device, for generating the steam supplied to the dish-washing drum; and a steam flow path for supplying the steam generated in the steam generating device to the dish-washing drum through the washing water flow path.

Owner:NANJING LG PANDA APPLIANCES

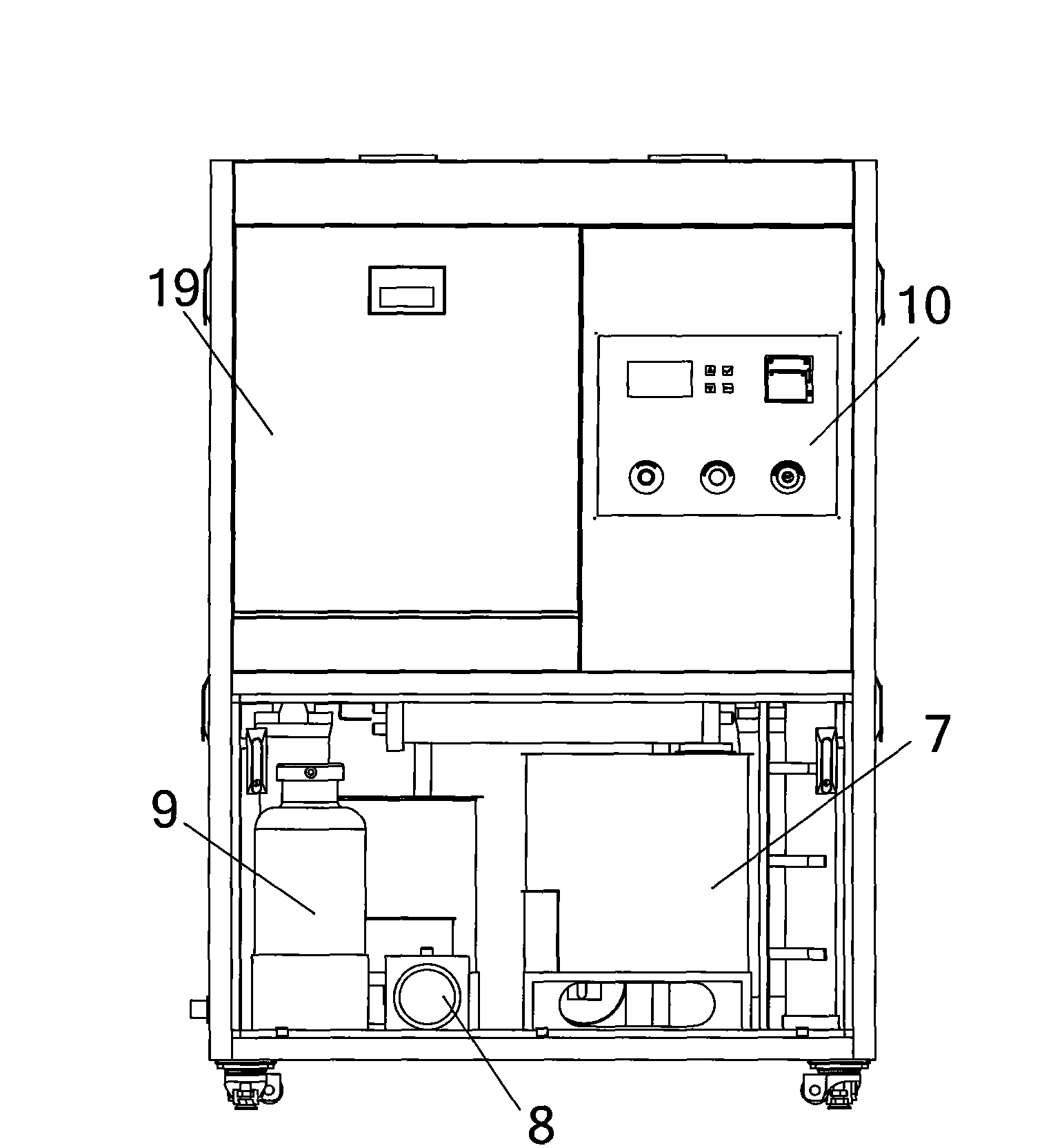

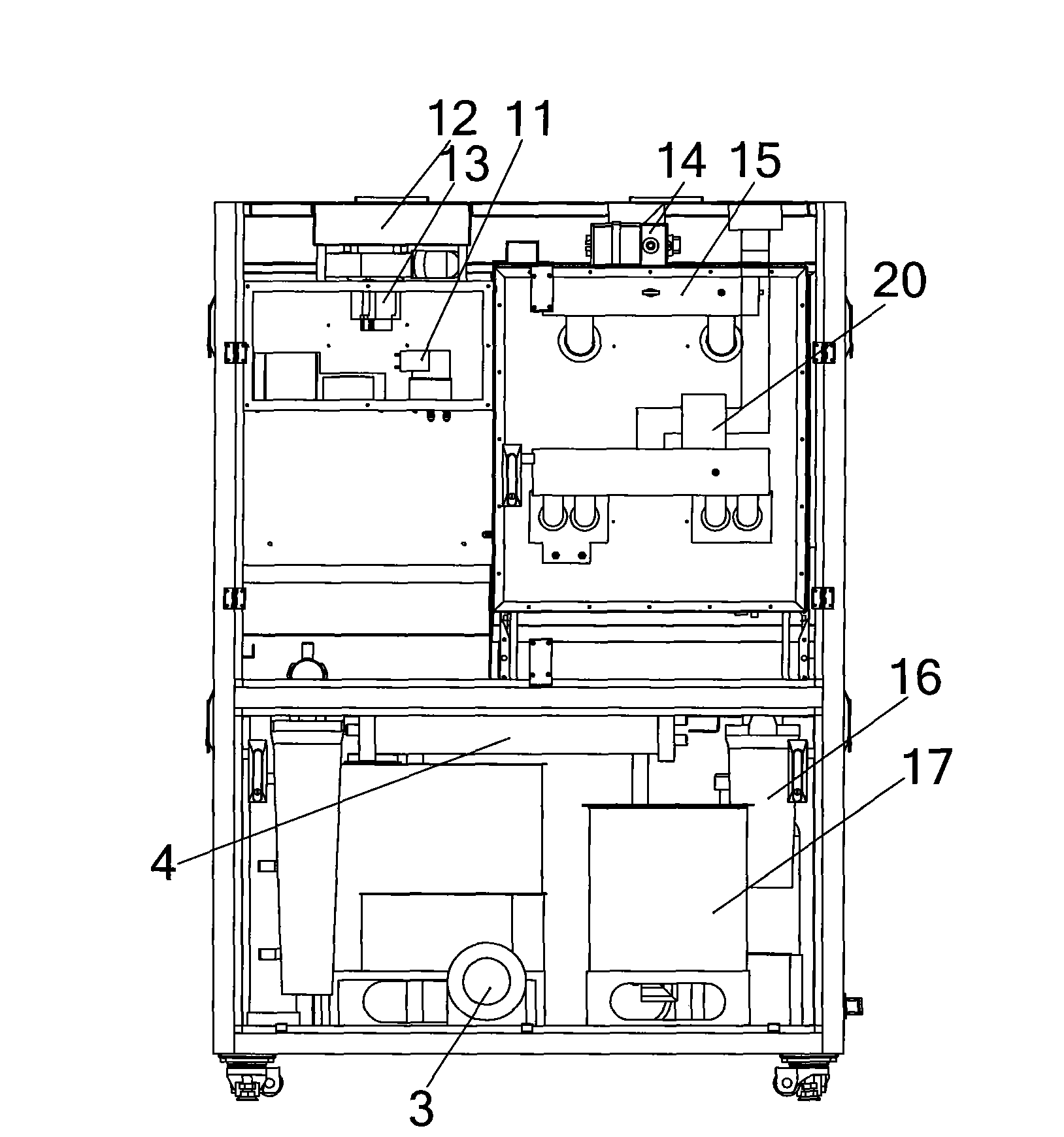

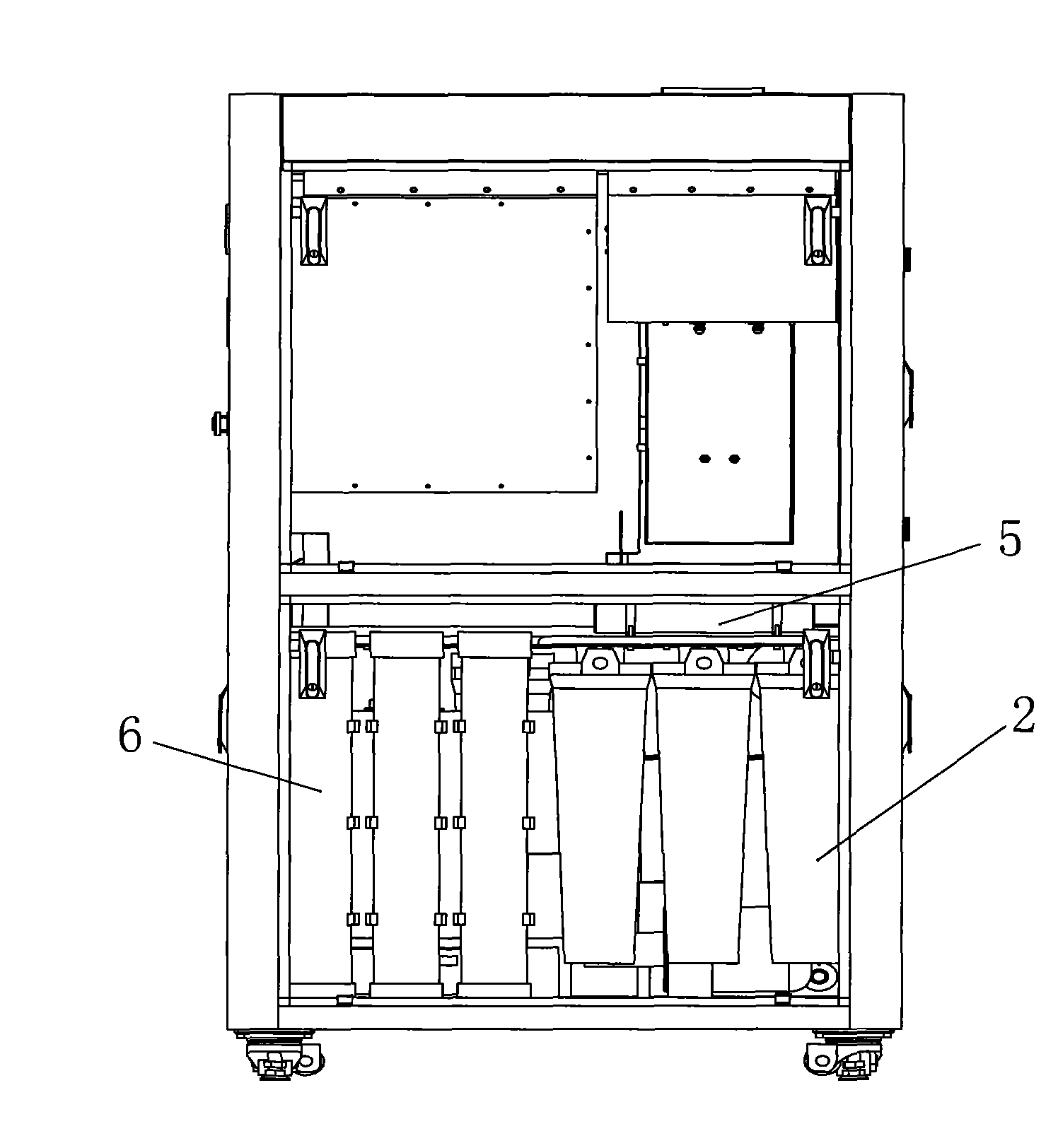

Printed circuit board cleaning machine

InactiveCN101583246AImprove washing efficiencyGood washing effectWater/sewage treatment by irradiationWater/sewage treatment bu osmosis/dialysisElectricityWater saving

The embodiment of the invention provides a printed circuit board cleaning machine, belonging to the technical field of printed circuit cleaning. The cleaning machine comprises a chassis, a master control system, a backing water treatment system, a cleaning system, a drying system, a waste water treatment system and a water detection system; the systems are all arranged in the chassis, the main control system is electrically connected with other systems and controls the operation of other systems; wherein, a water inlet and a water outlet are arranged on the backing water treatment system, the water outlet of the backing water treatment system is connected with the cleaning system, and the water outlet of the cleaning system is connected with the waste water treatment system; the drying system is connected with an air inlet of the cleaning system; the detection ends of the water detection system are respectively arranged on the water outlet ends of the backing water treatment system and the cleaning system, which are used for detecting the effluent water of the backing water treatment system and the cleaning system. The cleaning machine has the advantages of high cleaning efficiency, good cleaning effects, cleaning water saving and environmental protection.

Owner:常州至易环保科技有限公司

Detergent injection device for washing machine

InactiveCN1516764AWork around limitationsEasy to useOther washing machinesTextiles and paperLaundry washing machineWarm water

A laundry aid dispenser for a washing machine includes a top cover disposed above a washtub for receiving clothes, a receiving cavity defined by an upper wall, a bottom wall, opposing sidewalls, and an inner wall that are formed by indenting a portion of the top cover, a shower member comprising a shower portion coupled on the upper wall defining the receiving cavity and a warm water guide portion defined by a rear wall of the shower portion with the inner wall defining the receiving cavity, and a laundry aid container for storing laundry aids, the laundry aid container being inserted in the receiving cavity under the shower member. The laundry aid container has at least two chambers each for storing a different laundry aid.

Owner:LG ELECTRONICS INC

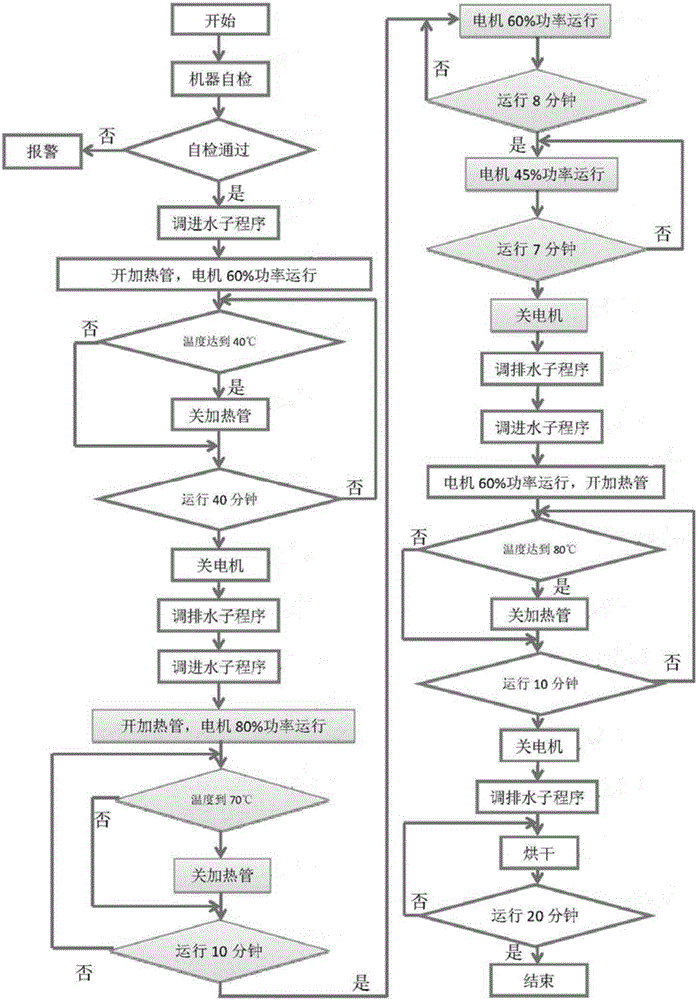

Washing method for water tank type dish washer

ActiveCN104983379AAvoid collisionIncrease flushing powerTableware washing/rinsing machinesHome appliance efficiency improvementElectricityPulp and paper industry

The invention discloses a washing method for a water tank type dish washer. The method includes the following steps that firstly, at the prewashing stage, water is injected, heating is started when the amount of injected water reaches a preset water amount, a circulating water pump starts running at the power accounting for 50% to 60% of the rated power, and eddy stirring is conducted through fins arranged on the upper surfaces of rotating spraying arms; secondly, at the main washing stage, the amount of injected water is controlled to be the preset water amount below the rotating spraying arms, heating is started, and the rotating spraying arms are driven to conduct spraying of different spraying strengths and different spraying angles in a segmented mode by setting the rated power of the circulating water pump in a segmented mode and setting the execution time in a segmented time; thirdly, at the rinsing stage, the amount of injected water is controlled to be the preset water amount below the rotating spraying arms, heating is started, and the rotating spraying arms are driven to conduct rinsing spraying. The washing method for the water tank type dish washer can solve various problems of Chinese style dishes, the washing efficiency can be effectively improved, more water and electricity are saved, and a mixing program is obtained.

Owner:NINGBO ZHONGWU DONGFANG OPTOELECTRONICS TECH CO LTD

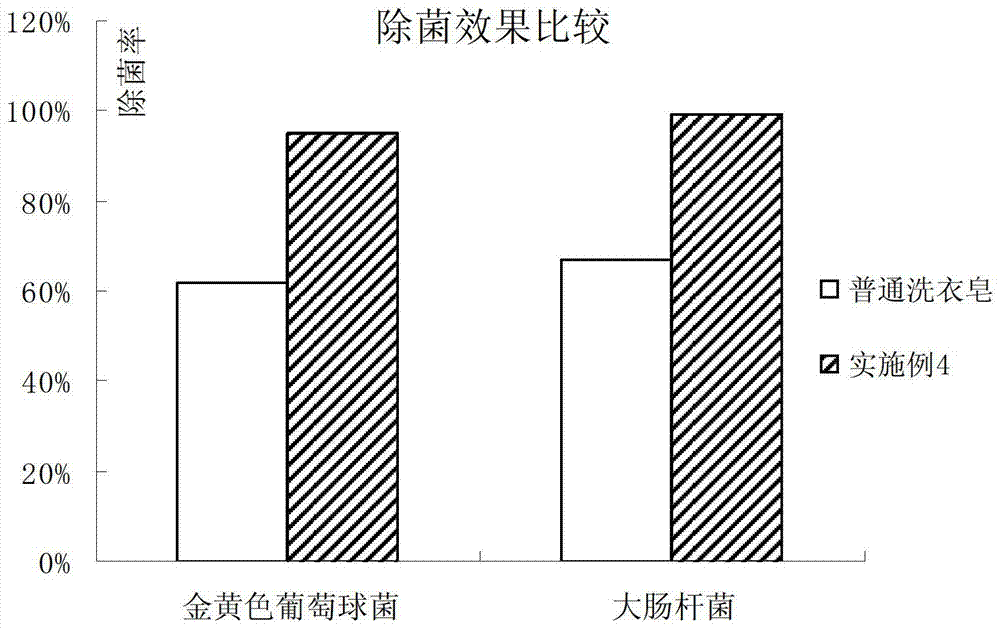

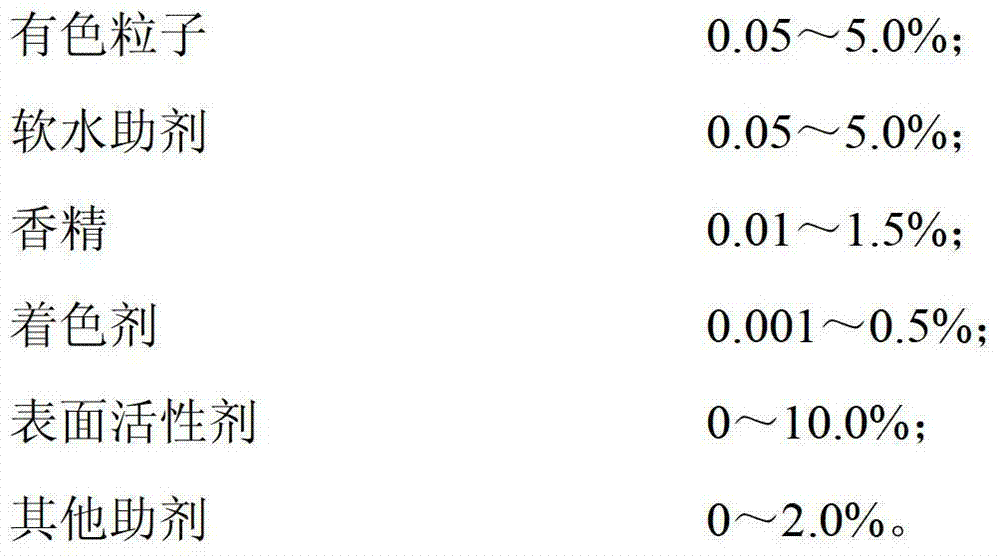

Washing soap with functional colored granules and production method thereof

ActiveCN103242992AGive full play to special effectsEfficient combinationSoap detergent compositionsSoft waterSURFACTANT BLEND

The invention discloses a washing soap with functional colored granules and a production method thereof. The washing soap is formed by mixing the following components by weight percent: 60.0-99.0% of soap granules, 0.05-5.0% of colored granules, 0-10% of a surfactant, 0.05-5.0% of a soft water additive, 0.01-1.5% of essence, 0.001-0.5% of a colorant and 0-2.0% of other additive. Due to the adoption of the washing soap, the appearance acceptance and the visual beauty of a washing soap product can be improved; and due to the addition and application of the functional colored granules, the washing functionality of the washing soap can be improved, the washing effect of the washing soap can be enhanced, and the integrated effect of the washing performance of the washing soap product can be achieved.

Owner:GUANGZHOU LIBY

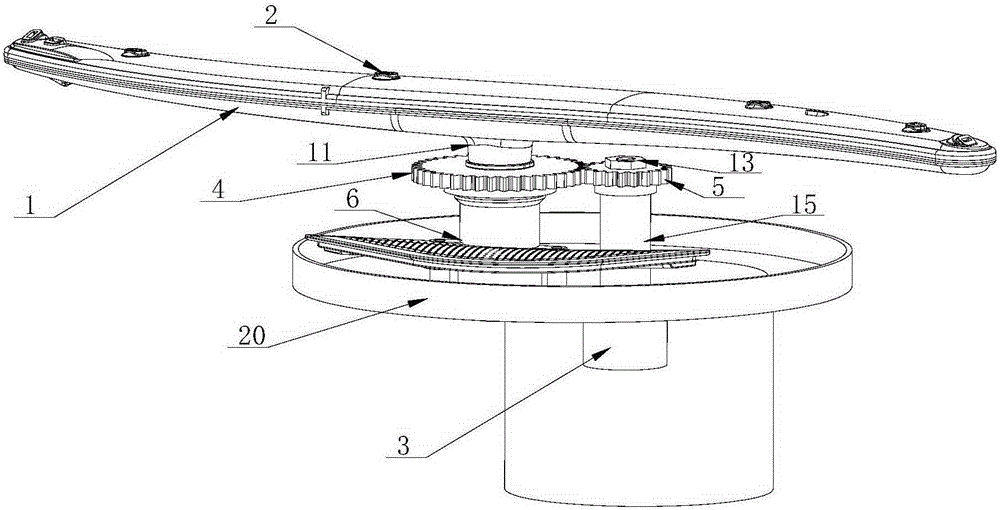

Dish-washing machine spray thrower, dish-washing machine provided with the spray thrower and control method

InactiveCN106618429AReduce water consumptionImprove washing efficiencyTableware washing/rinsing machine detailsWater flowEngineering

The invention relates to a dish-washing machine spray thrower. The dish-washing machine spray thrower comprises a spray arm arranged horizontally, at least one spray hole is formed in the spray arm, the spray arm is connected with a motor in a meshed mode directly or through a transmission mechanism, and driven by the motor, and the spray arm rotates or sways in the horizontal plane. The invention further provides a dish-washing machine provided with the spray thrower and a control method. Driven by the motor, the spray arm sways back and forth at a certain angle and therefore the sprayed water radiates to the whole or part area of the dishing-washing machine and articles in the area are washed. Thus, the sprayed water flow does not need to be used for driving the spray arm to rotate and is all used for washing the articles to reduce water consumption; at the same time, the spray arm conducts swaying back and forth in a certain area and achieves the purpose of reinforced washing or specific washing for the certain area and fulfills the purpose of increasing the washing efficiency of the washing machine. Meanwhile, the dish-washing machine spray thrower and the dish-washing machine provided with the spray thrower are simple in structure, obvious in effect and suitable for popularization and use.

Owner:QINGDAO HAIER DISHWASHER

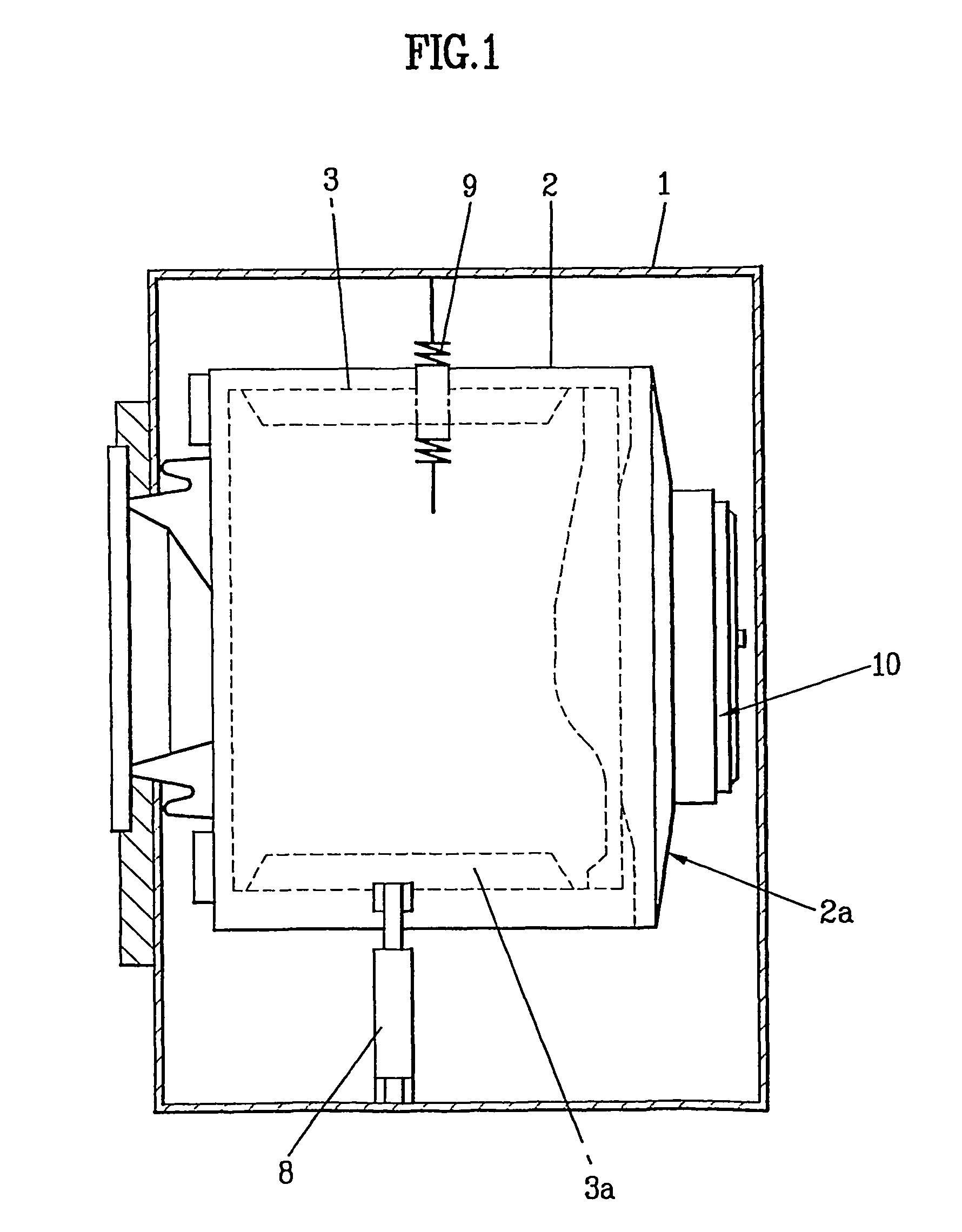

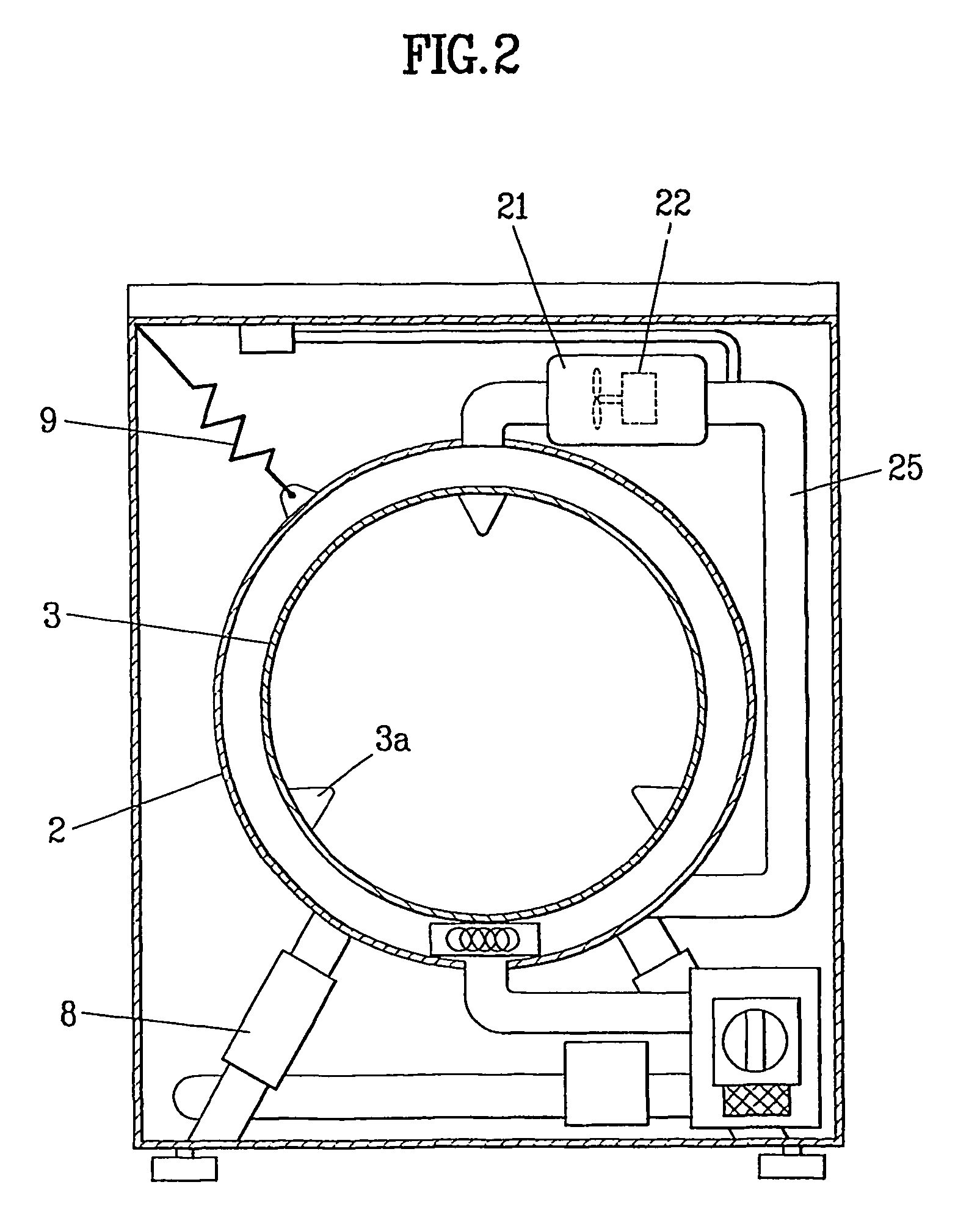

Drum type washing machine with rotatable baffle

InactiveUS7441422B2Increase frictionEnhanced efficiencyRotating receptacle mixersOther washing machinesEngineeringMechanical engineering

Drum type washing machine with a rotatable baffle including a tub fitted in a cabinet, a drum in a tub to be rotatable as rotation force is received from a motor part, and the baffle fitted in the drum to be rotatable in a direction opposite to a direction of rotation of the drum, thereby enhancing a washing efficiency because the baffle increases a friction to the laundry as the baffle and the drum rotate in opposite directions, and improving a laundry drying performance because spun laundry is taken off from an inside surface of the drum before drying the laundry, and preventing formation of wrinkles on dried laundry.

Owner:LG ELECTRONICS INC

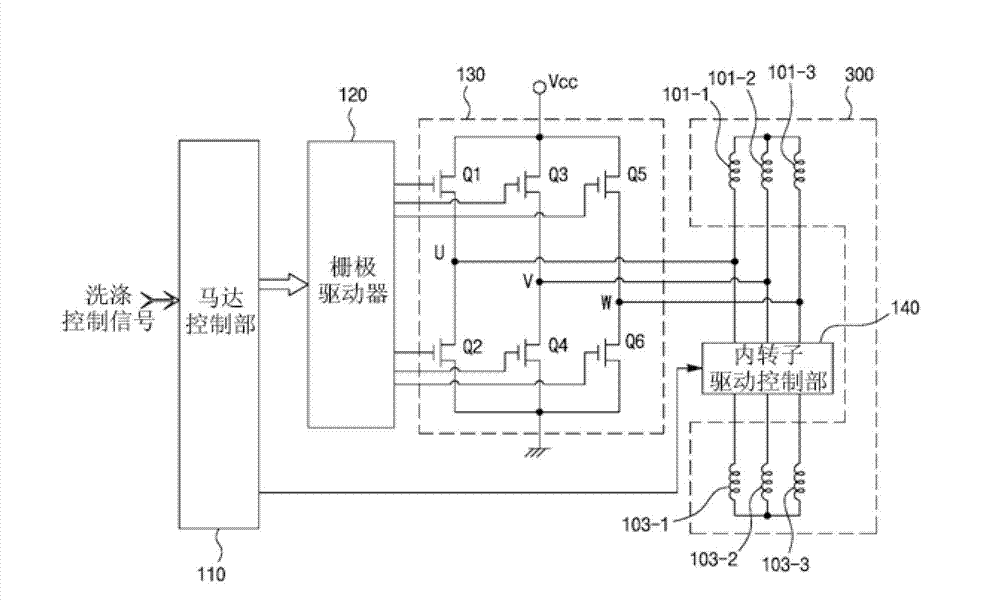

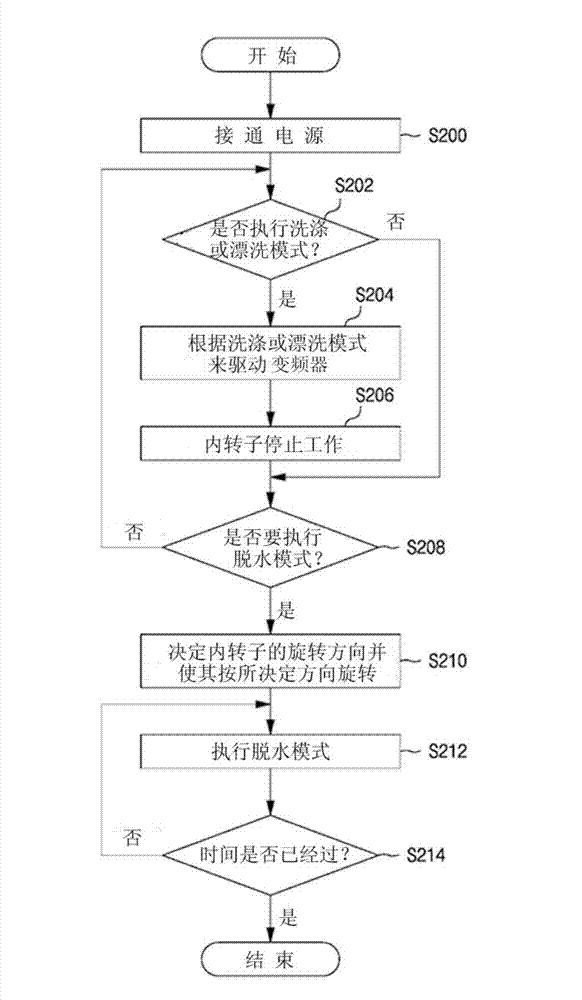

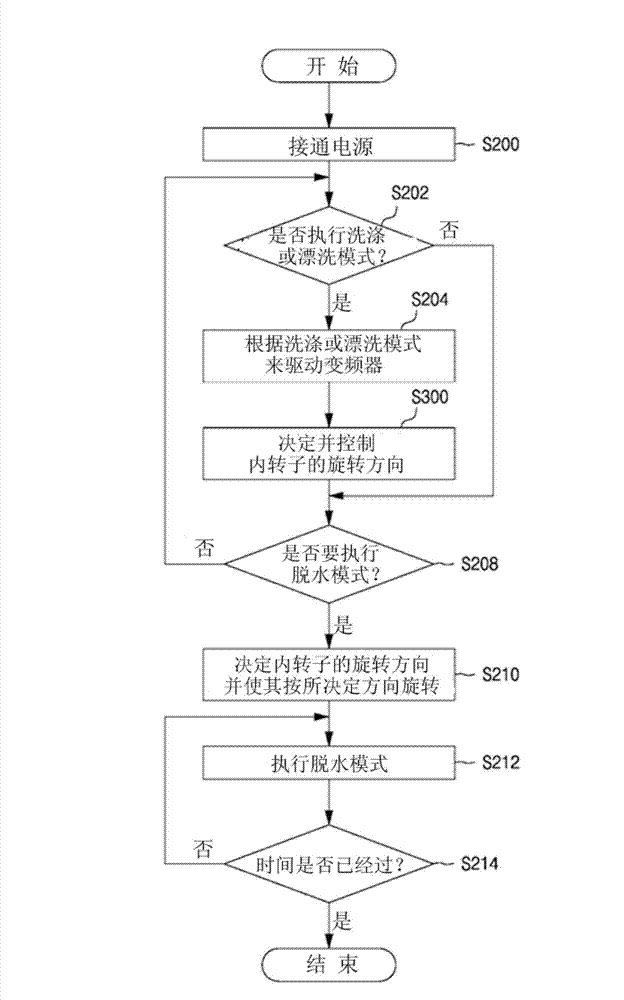

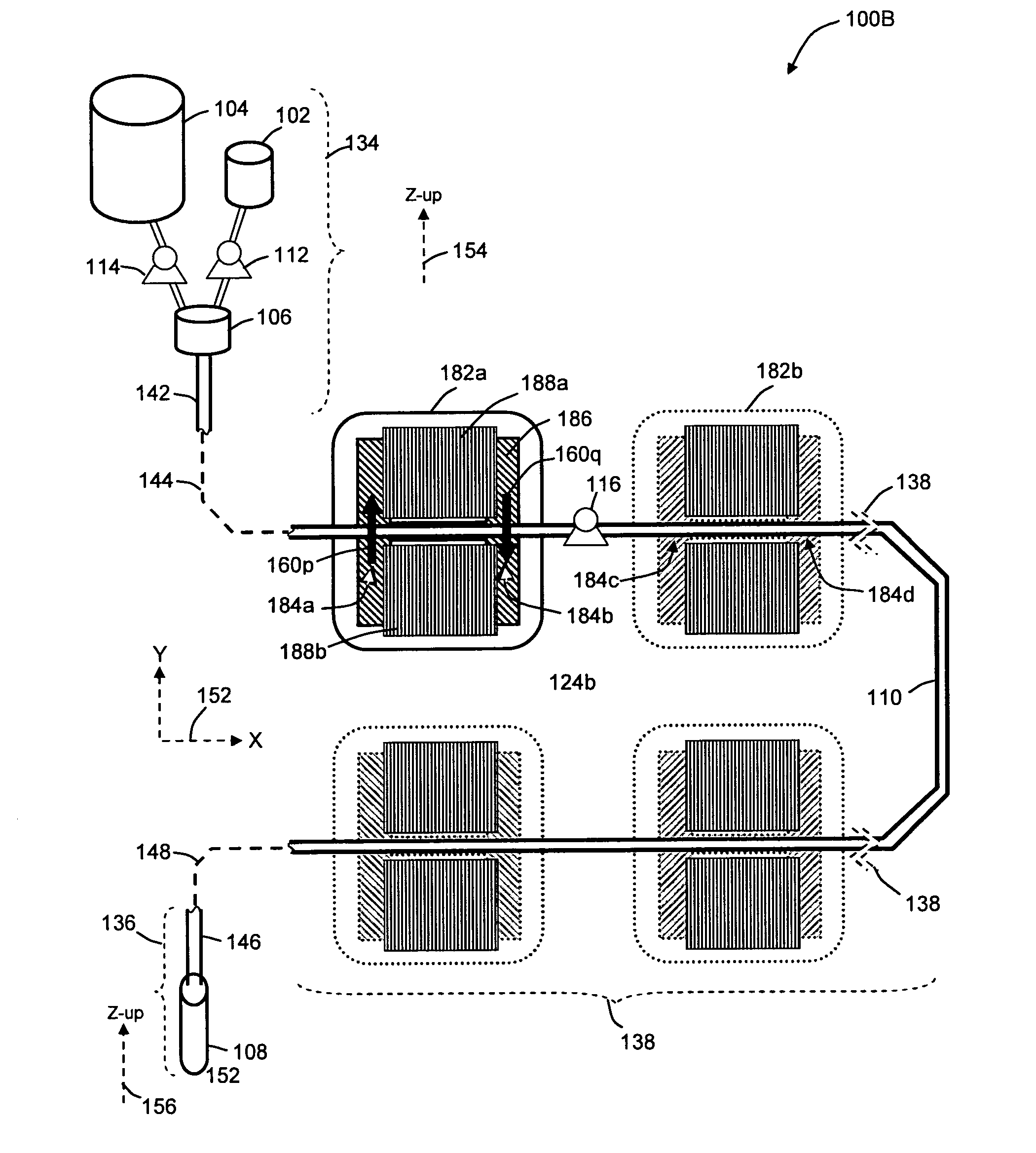

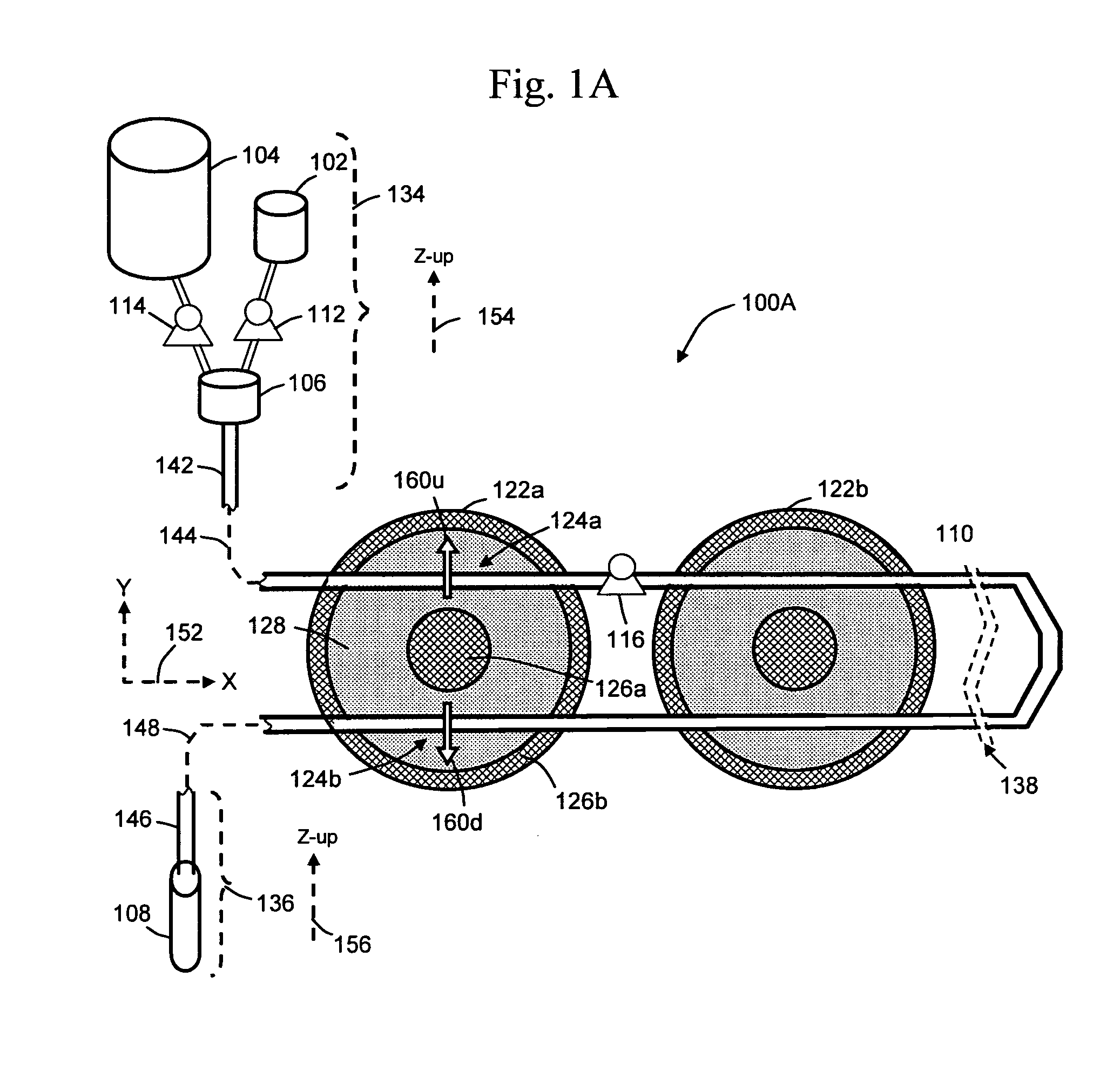

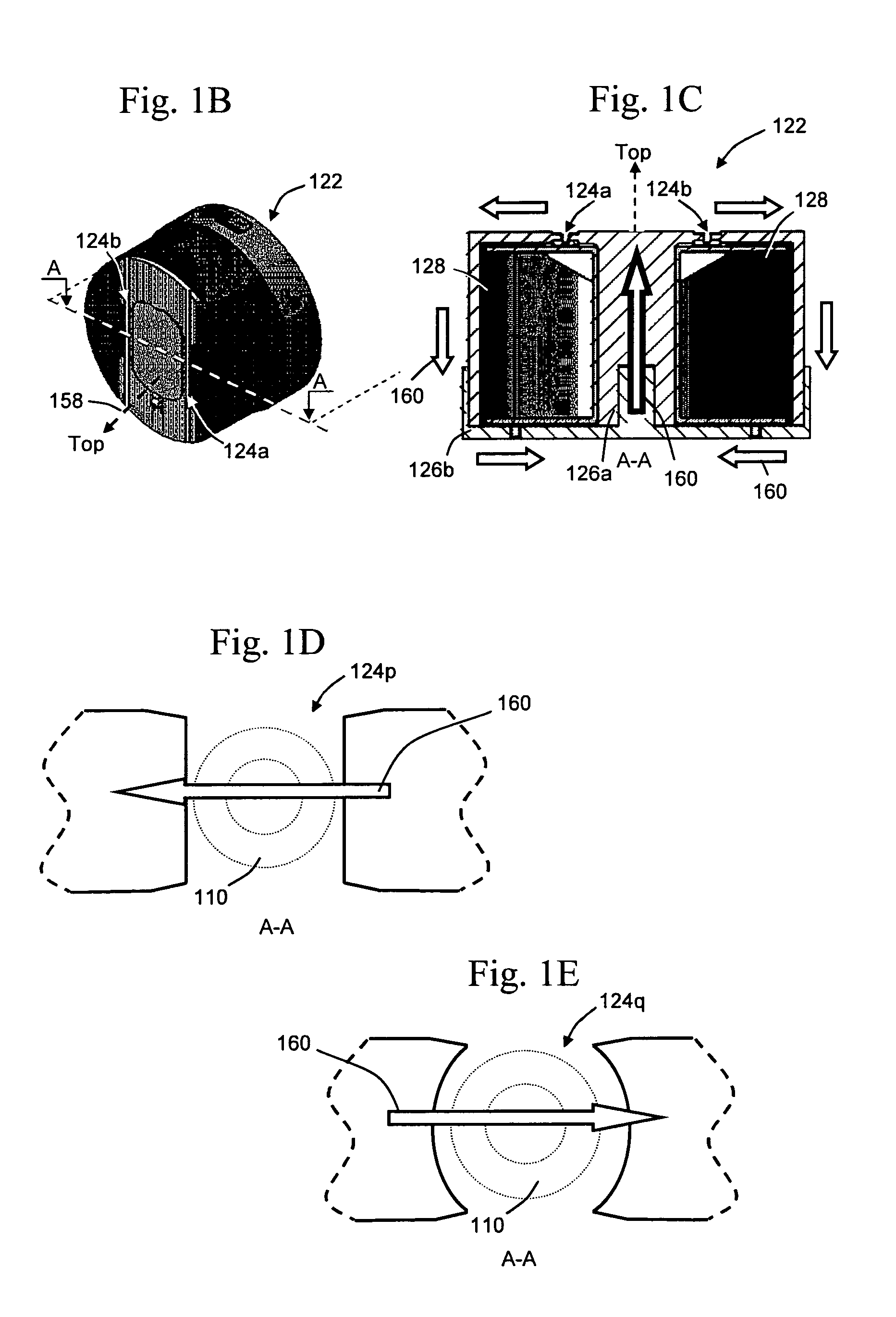

Motor driving device and driving method for washing machine

ActiveCN103051284AImprove washing efficiencyImprove dehydration efficiencyWashing controlling processesAC motor controlFrequency changerImpeller

The invention relates to a motor driving device and a driving method for driving the motor for a washing machine with a dual rotor-dual stator structure. The motor for a washing machine with a dual rotor-dual stator structure is provided with no independent clutch, and an impeller and a dewatering tank are selectively used. The invention includes the components as following: a motor control portion, a driving signal is generated according to a washing control signal, and the motor for the washing machine is controlled to be driven; a transducer, a three-phase alternating current is generated under the control of the motor control portion, and the three-phase alternating current is output to the thirteenth phase stator coil for driving the outer rotor of the motor to rotate and output to the twenty-third phase stator coil for driving the inner rotor of the motor to rotate; and a first rotor driving control portion, which is arranged between the transducer and the twenty-third phase stator coil and used for blocking or permitting the three-phase alternating current to pass under the control of the motor control portion, and the rotation direction of the inner rotor is controlled.

Owner:AMOTECH

Magnetic separation of rare cells

ActiveUS20120295302A1Rapid high qualitative and quantitative magnetic separationKeep activeBioreactor/fermenter combinationsBiological substance pretreatmentsRare cellNatural abundance

A magnetic separation system configured to separate with high qualitative and quantitative yield magnetized cells from cell mixtures, comprising at least one electromagnet structured to generate a magnetic field flux about a plurality of separation zones and sufficient to attract a majority of the magnetized cells in the mixture, and a pump to drive the cell mixture at a controlled flow rate through a tube disposed within the zones thereby separating a majority of the magnetized cells from the mixture. The system is particularly useful to retrieve rare cells from a fluid mixture of cells having low abundance of the rare cells relative to the rest of the cells while sustaining viability of the cells.

Owner:BIOCEP LTD

Direct production of electron grade high purity trimangnese tetraoxide from ores

InactiveCN1644513AImprove resource utilizationImprove product qualityManganese oxides/hydroxidesOxygenManganese oxide

Production of electronic high purity manganic manganous oxide by manganese oxide ore is characterized by taking manganese oxide ore as materials, immersing manganese from manganese oxide ore under ordinary pressure and temperature by sulfur dioxide, removing iron, copper, nickel, lead heavy metal ion in manganese sulfate mother liquid, obtaining purified manganese sulfate solution, coordinating the ammonia water and ammonium acid carbonate, depositing manganese, obtaining hydrated manganic hydroxide and manganese carbonate mixture, high temperature roasting the mixture, cooling washing for 3-5 times, drying to obtain manganic manganous oxide or inducing directly the purified manganese sulfate solution into ammonia water, regulating pH value 8-10 with solution temperature 50-70deg.C, inducing the dried air or oxygen for 6-9hrs, washing 3-5 times, filtering, drying to obtain manganic manganous oxide . It achieves low cost, high utilizing rate and product purity.

Owner:UNIV OF SCI & TECH BEIJING

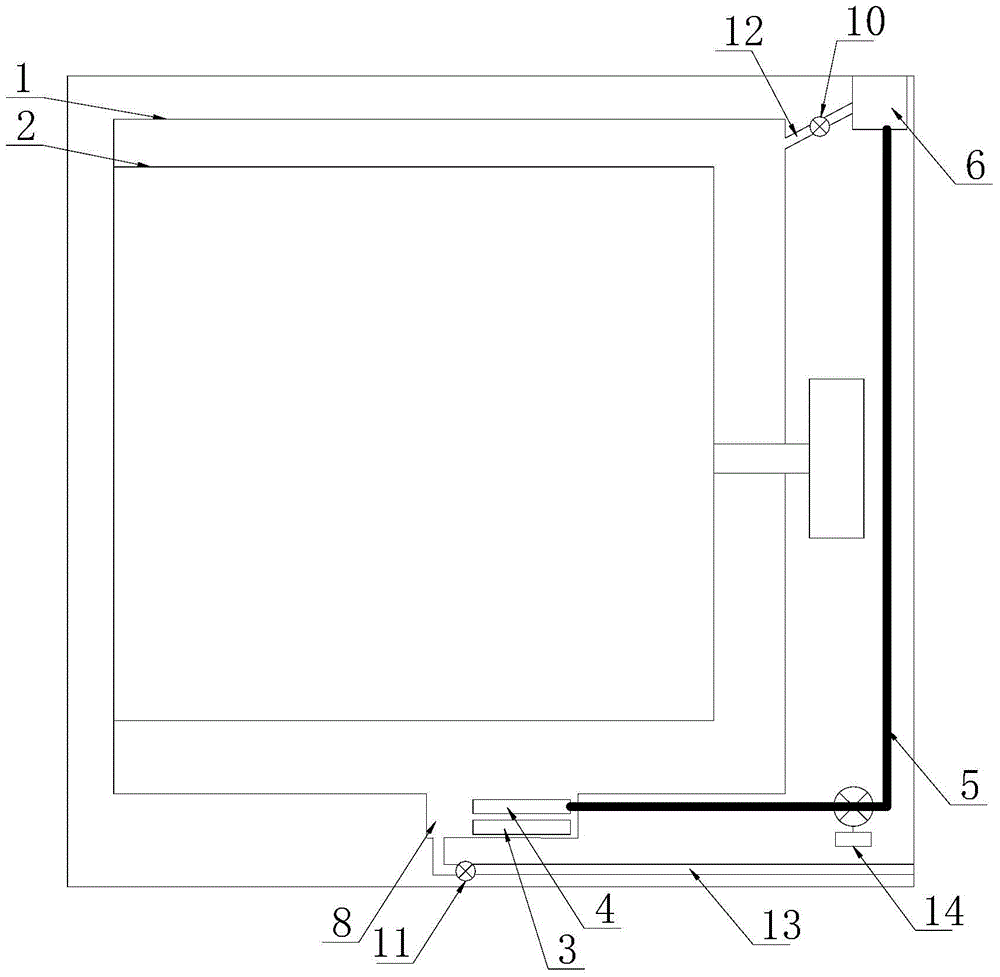

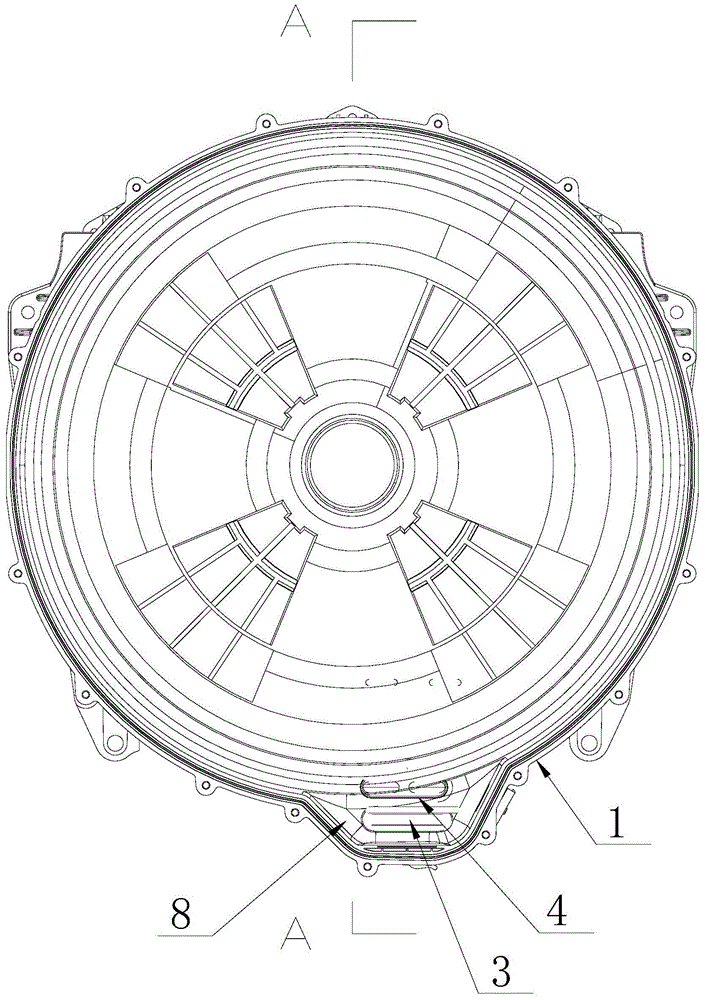

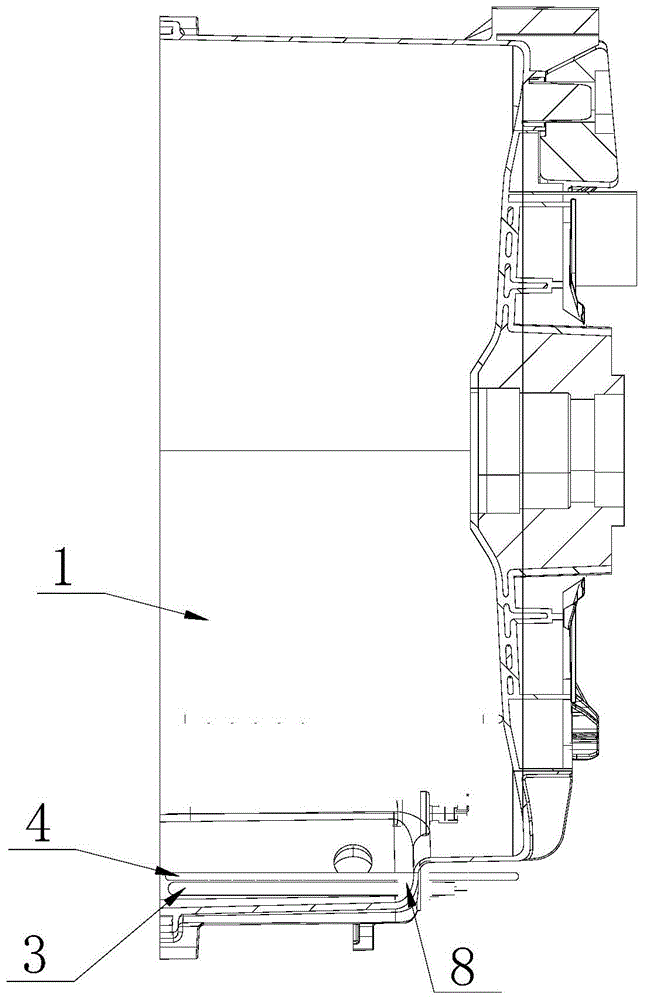

Washing machine with steam-washing function and control method

ActiveCN106283532ARealize generationGood effectOther washing machinesControl devices for washing apparatusSprayerProcess engineering

The invention relates to a washing machine with a steam-washing function and a control method. The washing machine comprises an outer barrel (1), and a heater (3) is arranged inside the outer barrel (1); the washing machine further comprises a sprayer (4) for spraying water to the heater (3), and the heater (3) performs heating to vaporize the water sprayed to the surface to form high-temperature steam. The sprayer for spraying the water to the heater is arranged on the heater, in this way, the heater under the heating state can rapidly heat and vaporize the sprayed water to form a large amount of steam, the steam generated inside the outer barrel can be utilized for heating and wetting clothes inside an inner barrel, and the washing machine has the functions of steam washing, clothes drying, sterilizing and disinfecting, deodorizing, ironing and others and is remarkable in effect. Meanwhile, the washing machine is simple in structure, remarkable in effect and suitable for utilization and popularization.

Owner:QINGDAO HAIER DRUM WASHING MACHINE +1

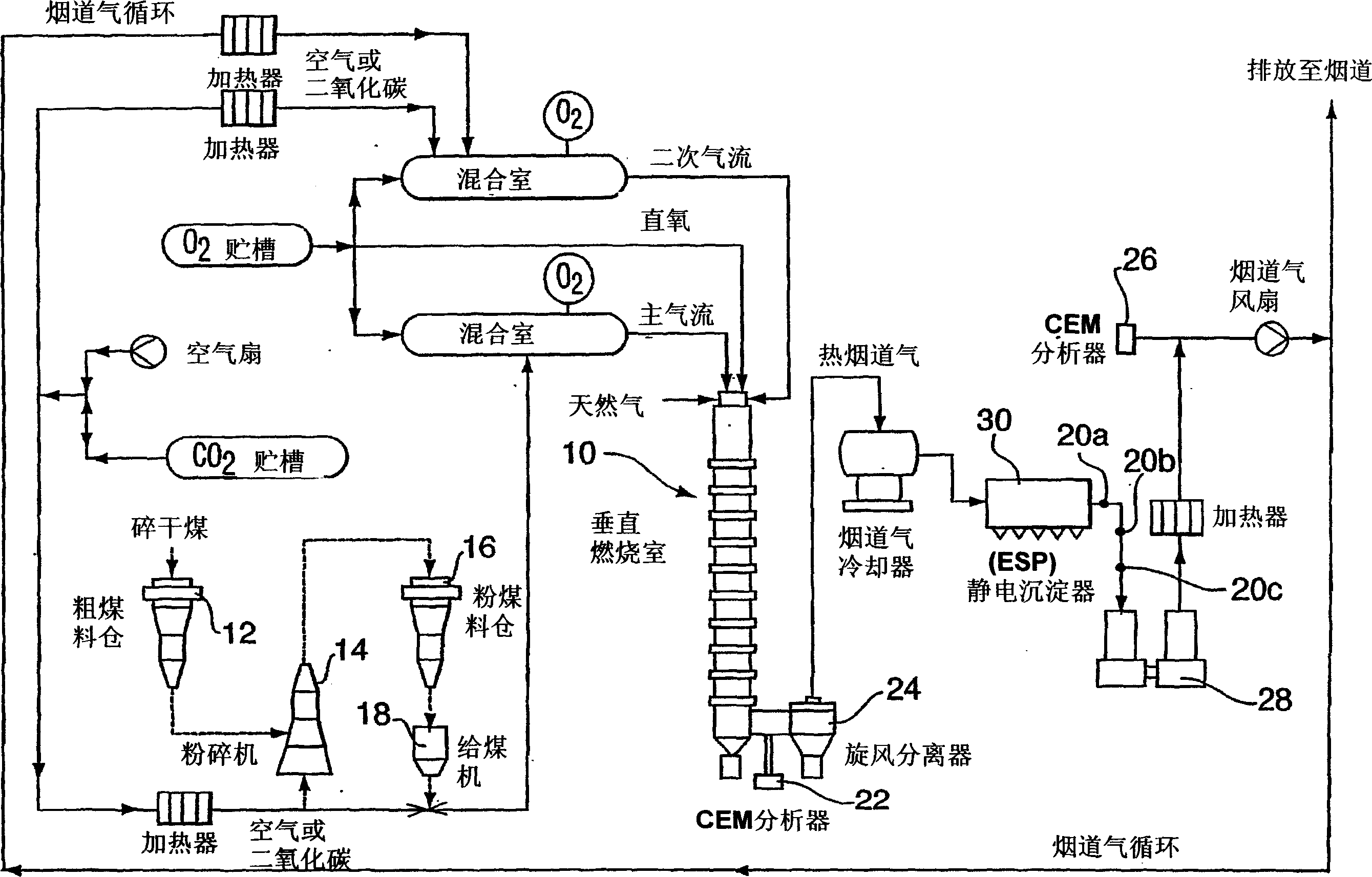

Flue gas purification method

InactiveCN1720091AEfficient capturePromote oxidationDispersed particle separationAir quality improvementPurification methodsSorbent

The present invention provides a method of scrubbing SOx, NOx compounds and other air toxins from a flue gas stream. In the method, two distinct unit operations are amalgamated to scrub SOx, NOx and other air toxins compounds from a flue gas stream. More specifically, there is a dry scrubbing operation and a wet scrubbing operation. The dry injection scrubbing operation involves contacting a flue gas stream containing SOx and NOx compounds with a sorbent for removing substantially all of the SOx and NOx compounds present in the stream. The second wet scrubbing operation involves contacting the stream to remove any residual SOx, NOx compounds, and other air toxins remaining in the stream.

Owner:AIRBORNE CLEAN ENERGY

Washing machine and controlling method

ActiveUS20090064421A1Reduce water consumptionImprove washing efficiencyOther washing machinesControl devices for washing apparatusProcess engineering

Disclosed are a washing machine and a controlling method, capable of maintaining an optimal temperature for efficient generation of foam to perform foam washing that uses a large amount of foam in washing laundry, thereby accomplishing optimal washing efficiency. The controlling method for the washing machine according to the present invention comprises supplying washing water with detergent required to generate foam, generating foam using detergent water which is a mixture of the washing water and the detergent, transmitting heat to the generated foam by heating the detergent water, and washing laundry using the foam.

Owner:SAMSUNG ELECTRONICS CO LTD

Washing machine and control method thereof

ActiveCN102965882AImprove washing efficiencyReduce consumptionOther washing machinesControl devices for washing apparatusElectric machineryProcess engineering

A method of detecting weight of laundry contained in a washing machine (1). A calibration mode is provided that is performed separately from a washing mode such that a detection error of the weight of laundry, which occurs due to external environment factors, is calibrated when the weight of laundry is detected using a motor (15). The calibration mode is provided to find the weight detection offset data of the washing machine based on external environment factors, and to store the weight detection offset data found. When the weight of laundry is detected in a next washing mode, the weight of laundry is calibrated by use of the weight detection offset data of the washing machine, so that the weight of laundry accommodated in the washing machine is precisely detected.

Owner:SAMSUNG ELECTRONICS CO LTD

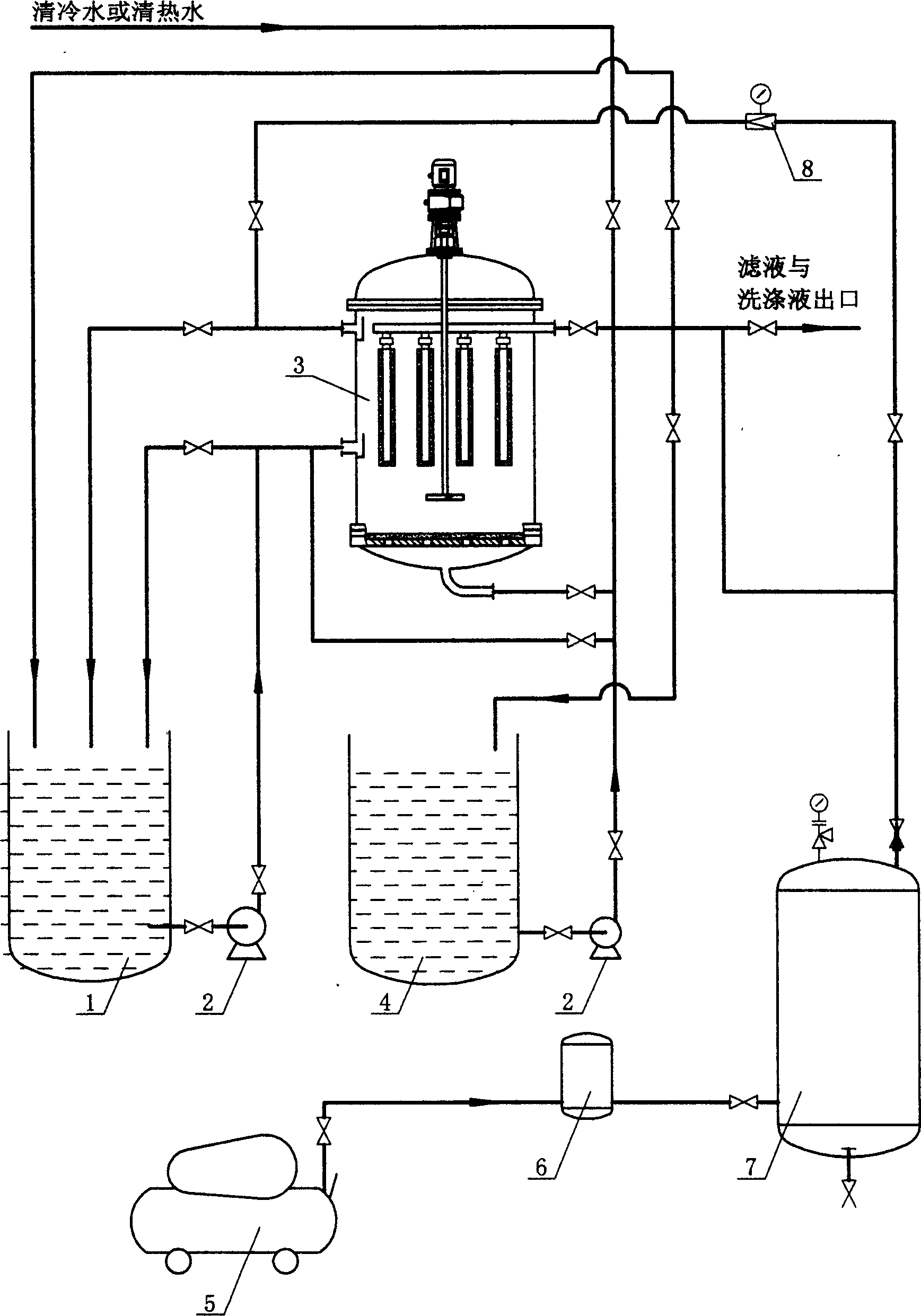

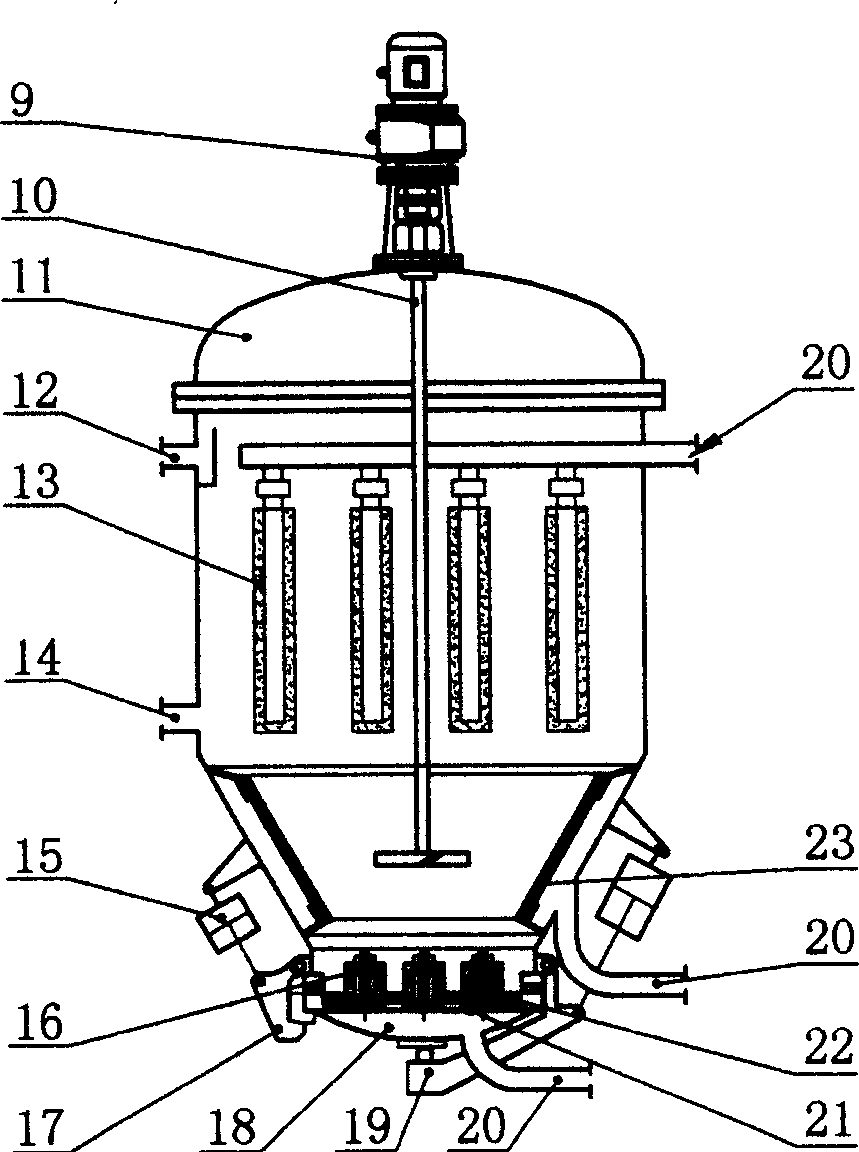

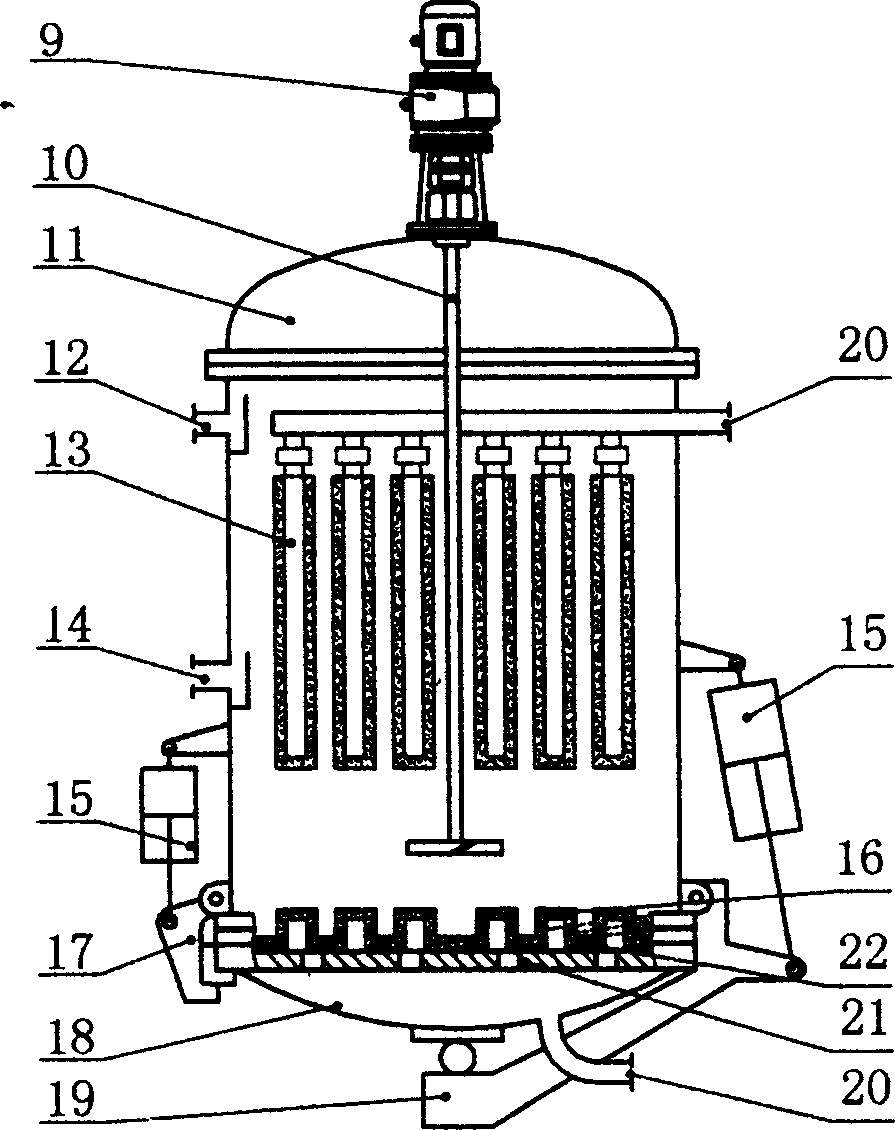

Filtration and washing technology in preparing metal or non metal fine granular powder

ActiveCN1686593AOvercome the disadvantages of filtrationHigh yieldFiltration circuitsEngineeringSpherical form

A filtering and washing process for preparing the metallic or non-metal fine particles includes filtering, washing, blow-drying of filtered cake, discharging and cleaning filter. Said filtering step features use of the precise millipore filter with at least two filter regions for respective filtering. Said washing step includes reversely blowing the washing liquid to drop the filtered cake onto filter plate, instantaneously reversely blowing compressed air several times, and stirring the mixture of filtered cake and washing liquid.

Owner:ZHEJIANG DONGOU FILTERING MASCH MFG CO LTD

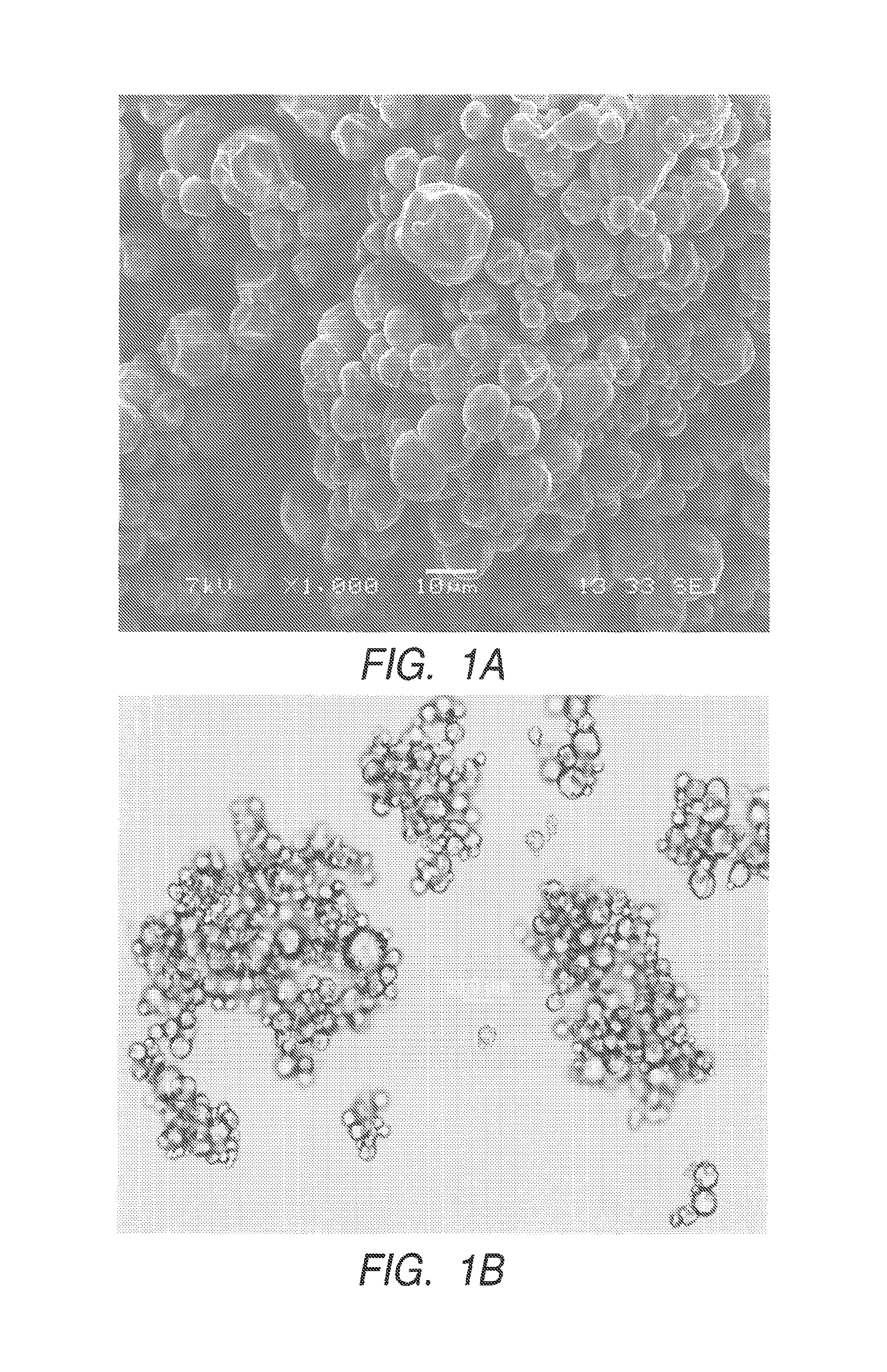

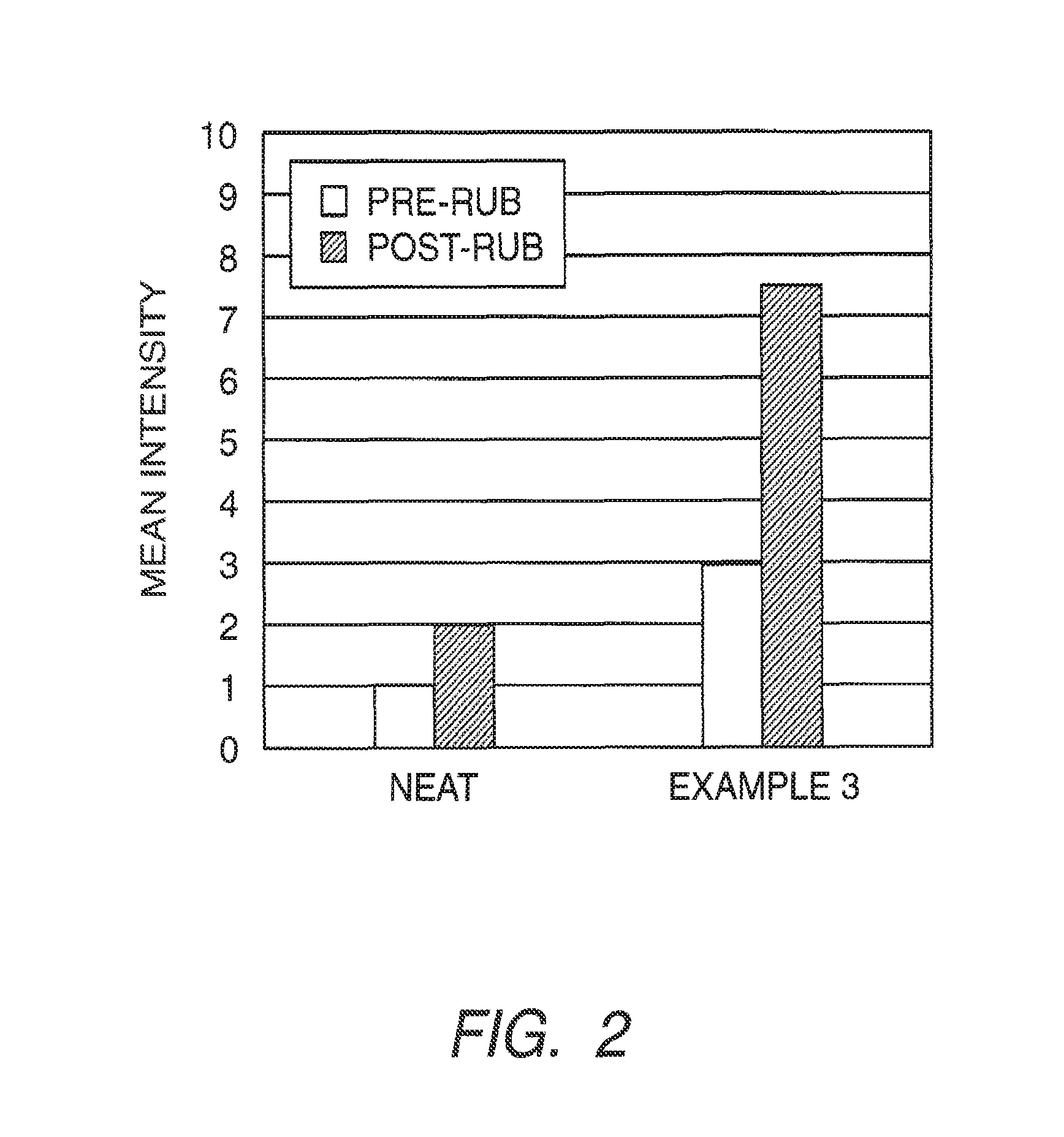

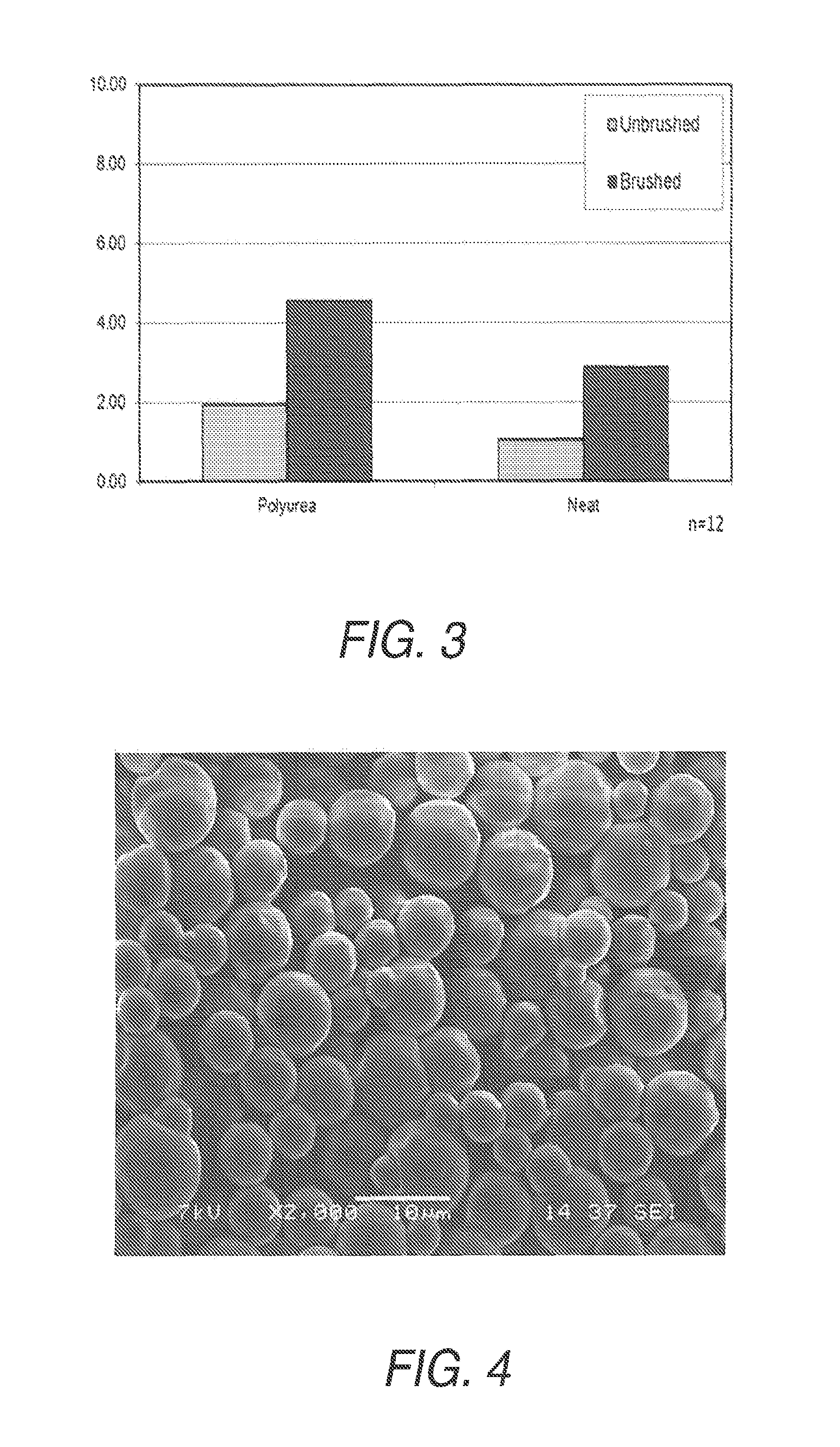

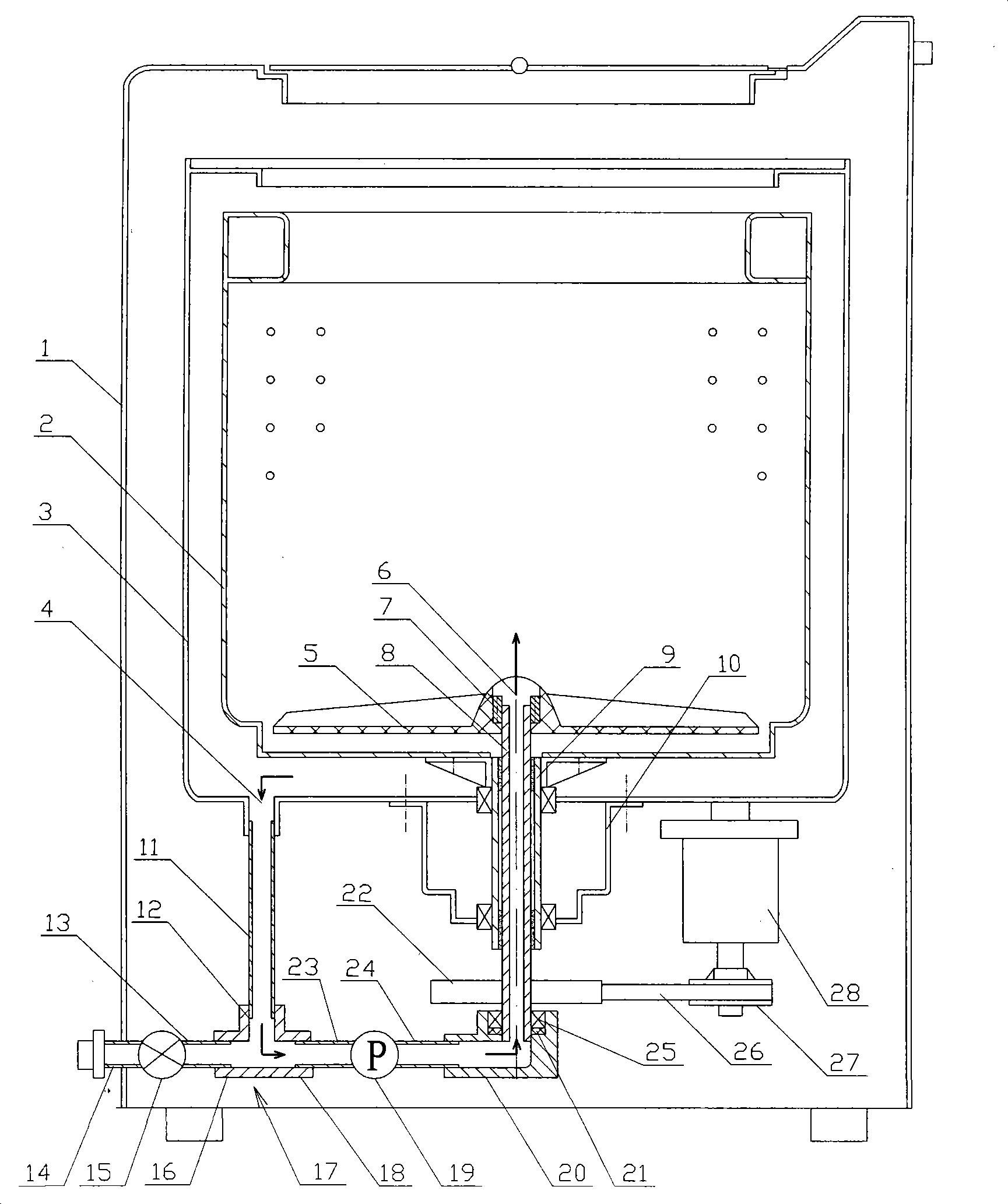

Polyurea or polyurethane capsules

ActiveUS20160193122A1High perceived olfactory intensityImprove stabilityCosmetic preparationsToilet preparationsCross-linkPolyurea

Poiyurea or polyurethane capsule compositions. A subset of these compositions contain a plurality of capsules and a capsule formation aid, in which each of the capsules contains a poiyurea or polyurethane wall and an oil core; the poiyurea or polyurethane wall is formed of a reaction product of a polyisocyanate and a cross-linking agent in the presence of the capsule formation aid; and the oil core contains an active material. The polyisocyante, cross-linking agent, and capsule formation aids are described herein. Also disclosed are methods of preparing poiyurea and polyurethane capsule compositions, as well as consumer products containing one of these compositions.

Owner:INTERNATIONAL FLAVORS & FRAGRANCES

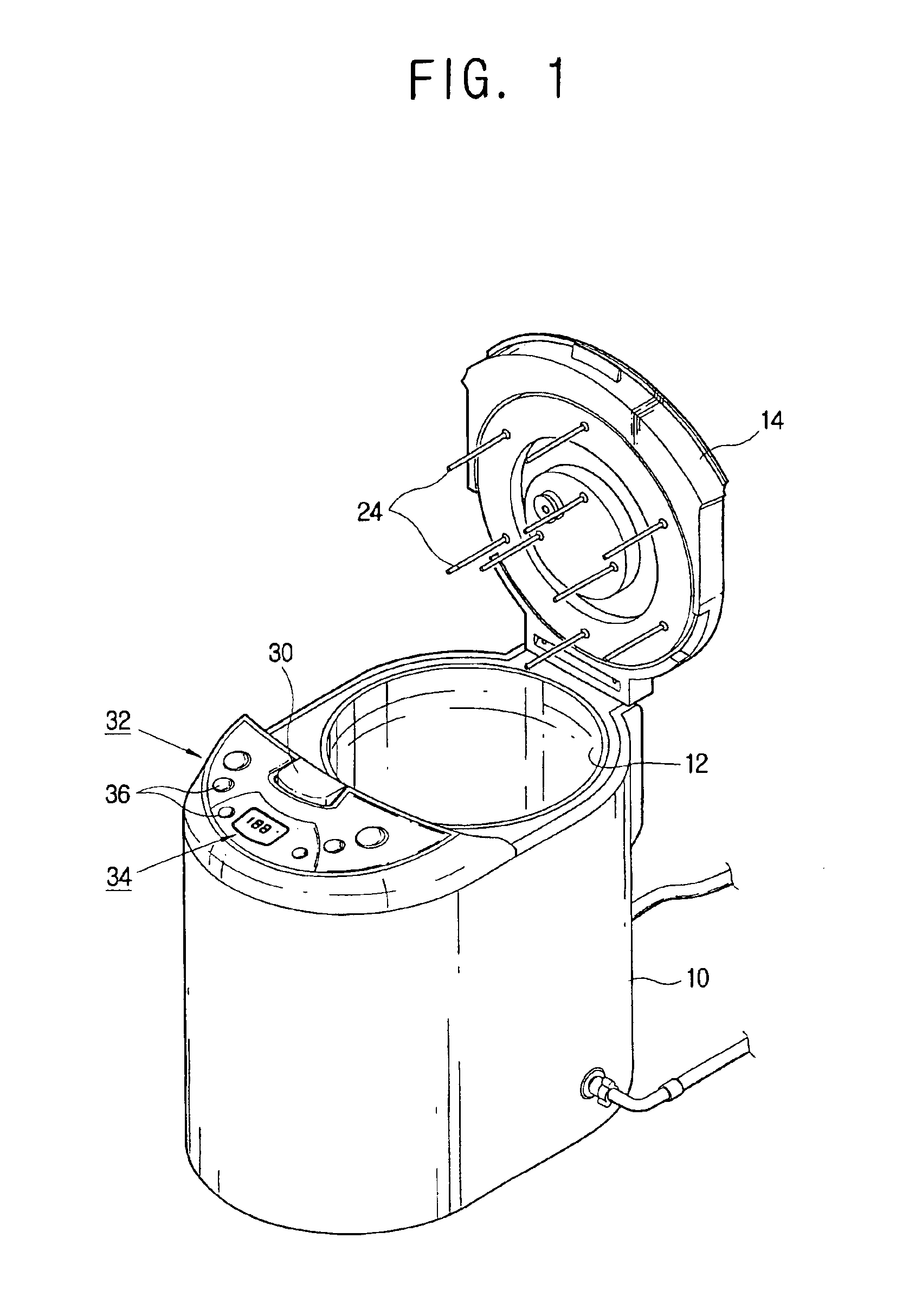

Washing method of washing machine and washing machine thereof

InactiveCN101381935AReduce wear rateReduce wearOther washing machinesWashing machine with receptaclesWater storageLow noise

The invention provides a washing method for washing machines, as well as a washing machine thereof. The washing method is characterized in that while a stirrer rotates during wash, a drainage pump pumps washing water out from a water storage bucket and jets the washing water upwards through a hollow stirrer shaft and a hollow core hole of the stirrer so as to lift washed clothes. During wash, as the drainage pump pumps the high-pressure water out from the hollow stirrer shaft and the hollow core hole of the stirrer so as to spray and lift the washed clothes, the washed clothes are effectively prevented from receiving the long-term wear of a stirrer vane, and the washed clothes are allowed to receive the wash and rinse of high-pressure water flow, the stir of the stirrer and the wash in various washing forms at the same time. The invention has the advantages of low wear, low intertwining, low noise, high cleaning rate, high washing efficiency and the like.

Owner:宁小静

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com