Washing machine and control method thereof

a technology of washing machine and control method, which is applied in the field of washing machines, can solve the problems of wasting water in the washing process, pulsating machines, and relatively significant damage to the laundry, and achieves the effect of enhancing wash efficiency and reducing water was

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

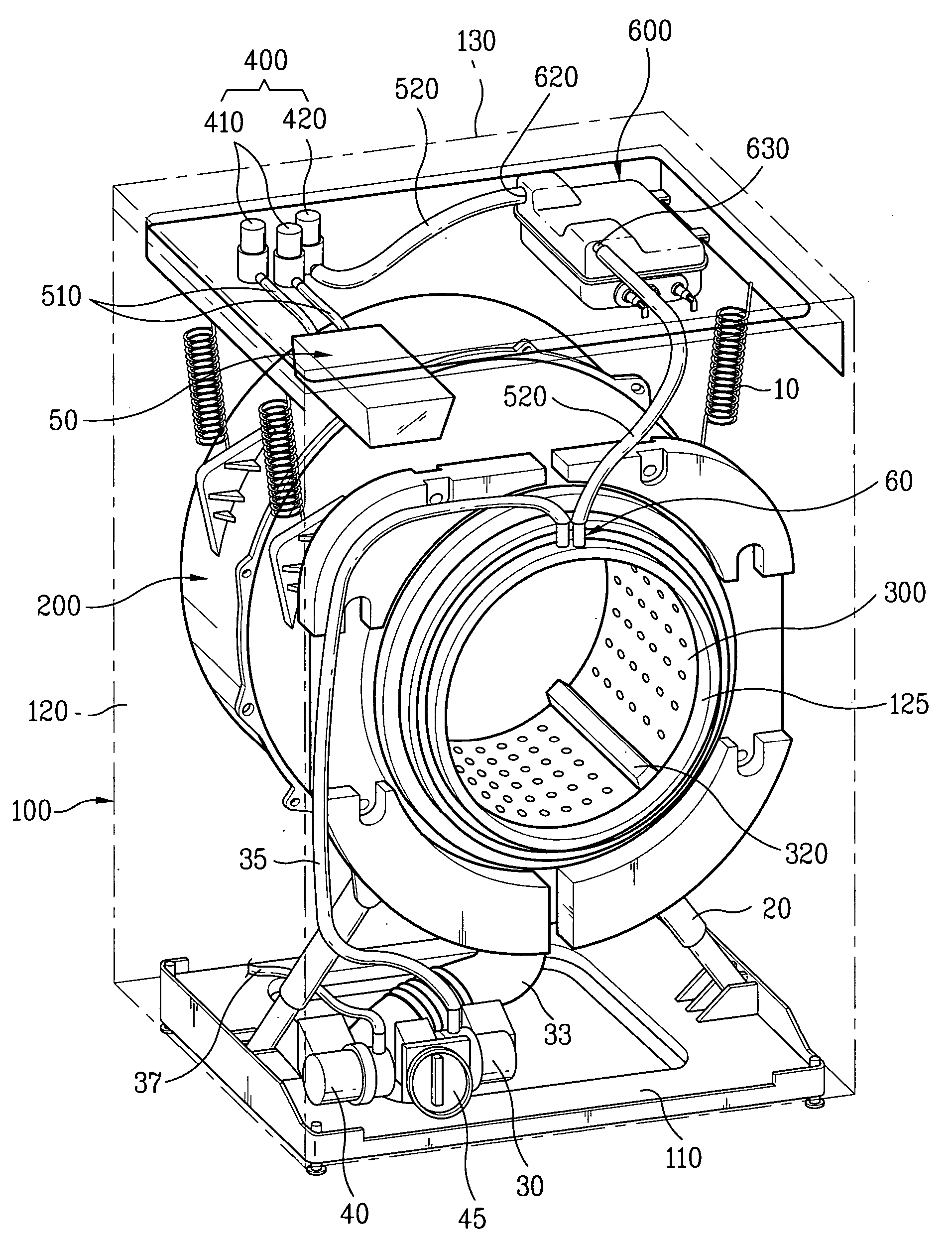

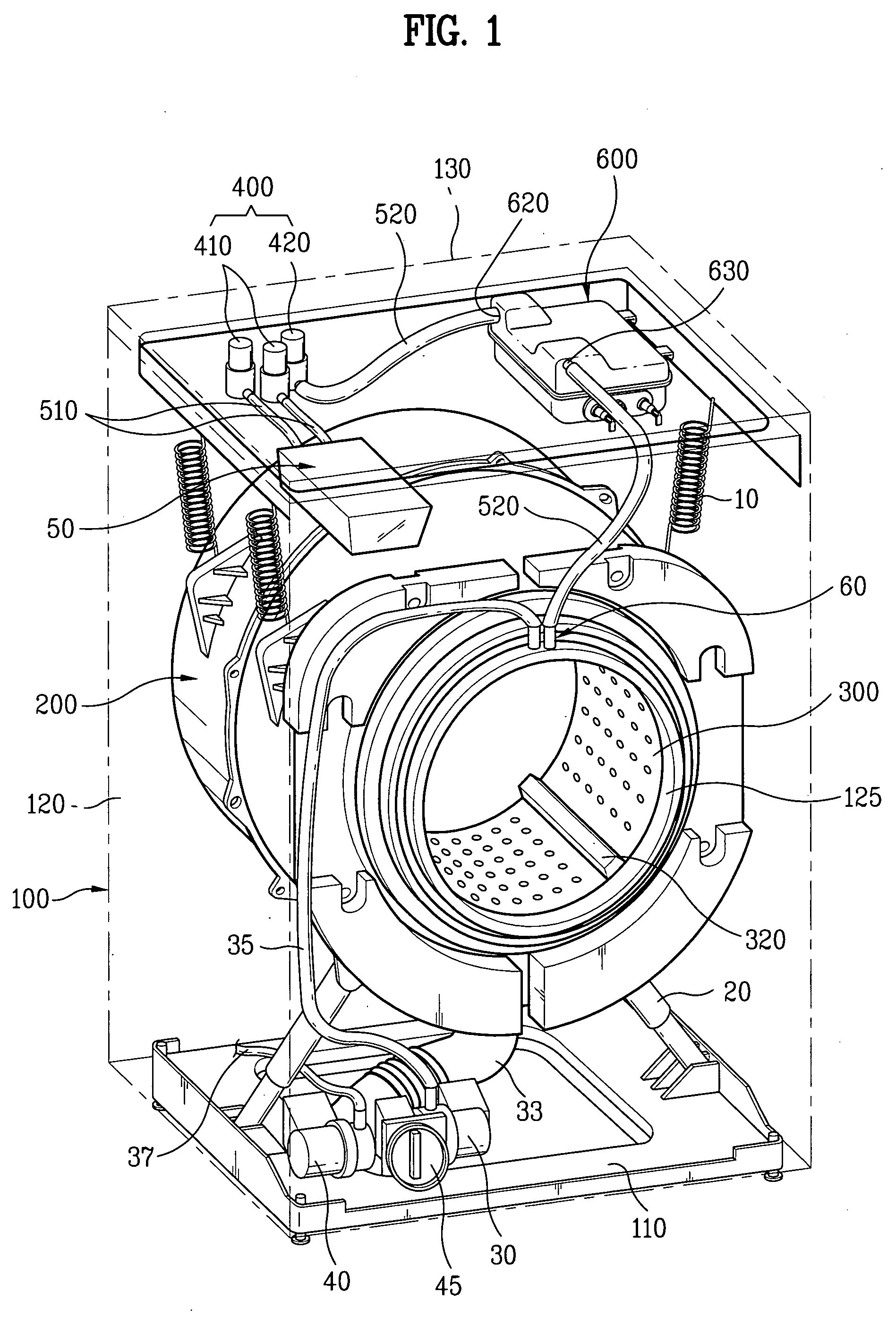

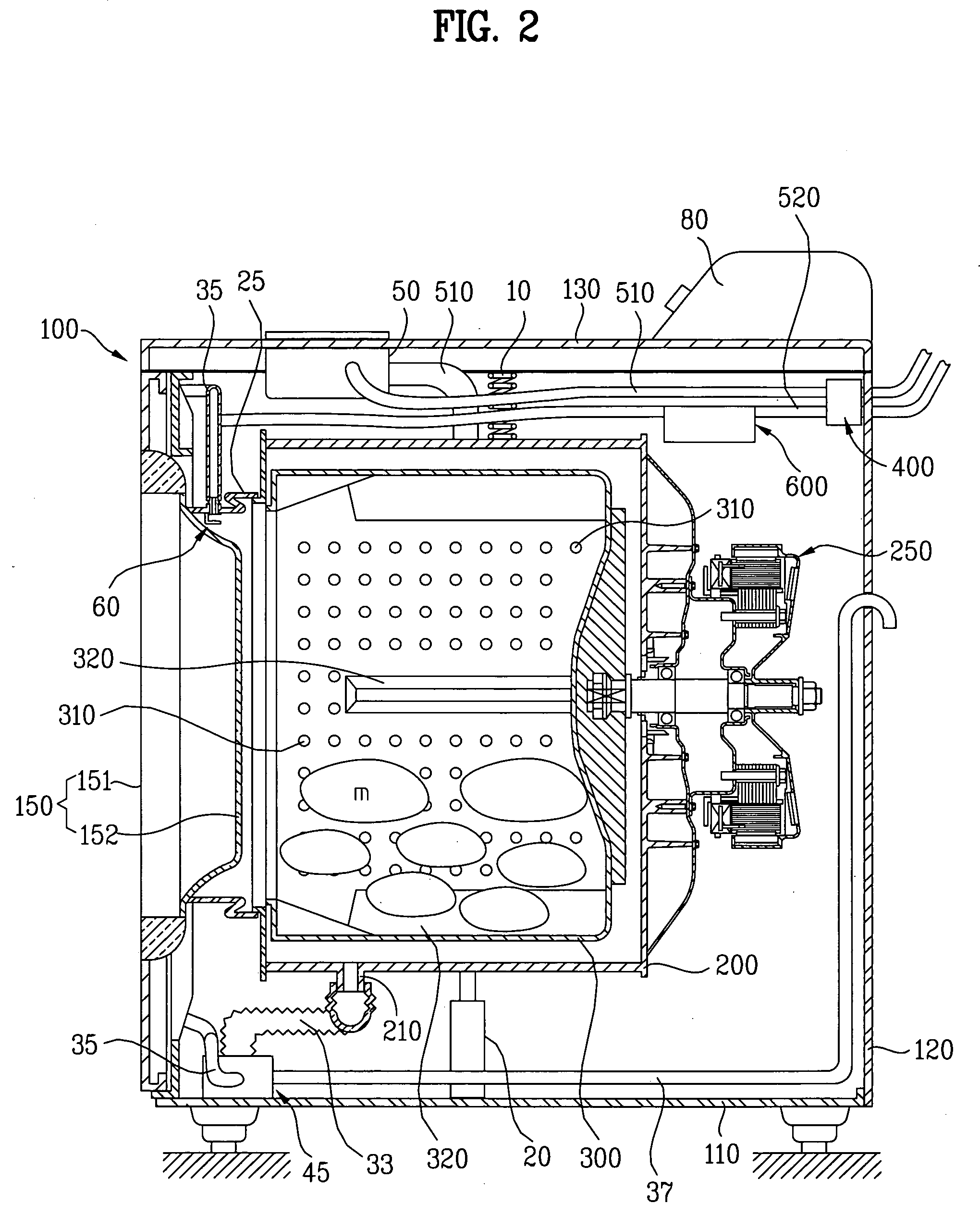

Image

Examples

first embodiment

[0080]FIG. 6 is a flowchart of a water supply method according to a first embodiment of the present invention.

[0081] Referring to FIG. 6, once a washing or rinsing cycle is selected and initiated, the temperature sensor 617 measures an inner temperature t0 of the steam generator 600 according to a command of the control unit 700 (S10). In doing so, it is preferable that a temperature of an air within the steam generator 600 is measured. Alternatively, it is also possible to measure a temperature of water in case that a small quantity of the water remains within the steam generator 600.

[0082] Subsequently, a predetermined quantity of water is supplied to the tub 200. For this, the control unit 700 turns on the first valve 410 to supply water of the water supply source to the tub 200 via the water supply hose 510. The water supply hose 510, as mentioned in the foregoing description, passes through the detergent box 600. Hence, in case that the detergent box 600 is supplied with the ...

second embodiment

[0089]FIG. 7 is a flowchart of a water supply method according to a first embodiment of the present invention.

[0090] Referring to FIG. 7, once a washing course or cycle is selected, the control unit 700 turns on the first valve 410 to supply water to the tub 200 and also turns on the second valve 420 to supply water to the tank 610 (S21).

[0091] A user can previously select either a steam mode for using steam or a non-steam mode for not using steam. Alternatively, the control unit 700 can automatically select either the steam mode or the non-steam mode. The control unit 700 measures a temperature t0 of water introduced into the tank 610 using the temperature sensor 617 (S22) and then selects either the steam mode or the non-steam mode based on the measured water temperature (S23). For instance, if the temperature of the water introduced into the tank 610 is lower than a set temperature, the control unit 700 selects the steam mode. If the temperature of the water introduced into the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com