Patents

Literature

9565 results about "Purification methods" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The most common methods of water purification include heat, distillation, chemical treatment, UV light and filtration. In developing countries, where residents don't have access to safe sanitation and hygiene, alternative methods are often used.

Processes for production and purification of hydrofluoroolefins

ActiveUS20060106263A1High selectivityPreparation by hydrogen halide split-offHydrogen fluorideHydrogen fluoridePurification methods

Owner:THE CHEMOURS CO FC LLC

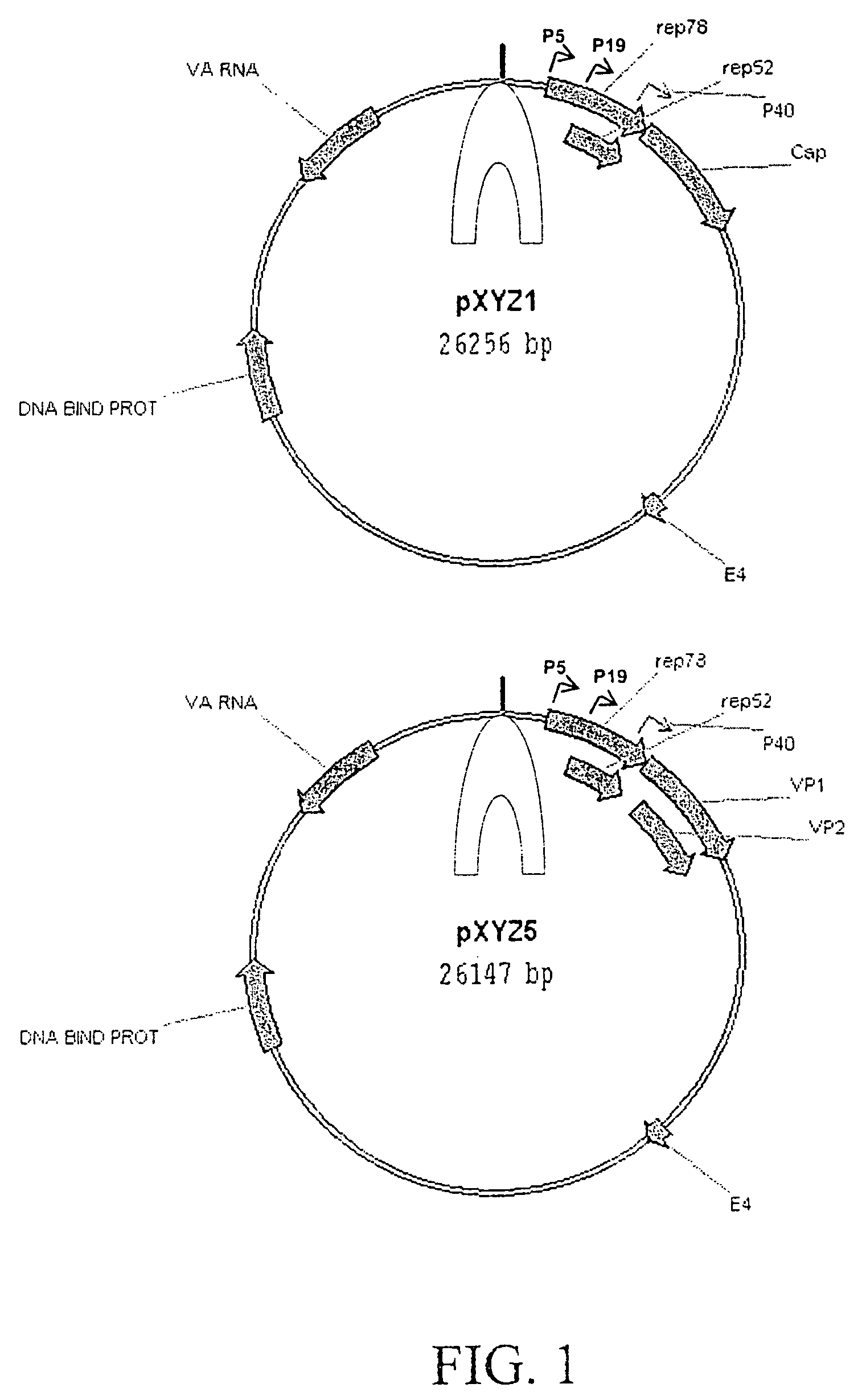

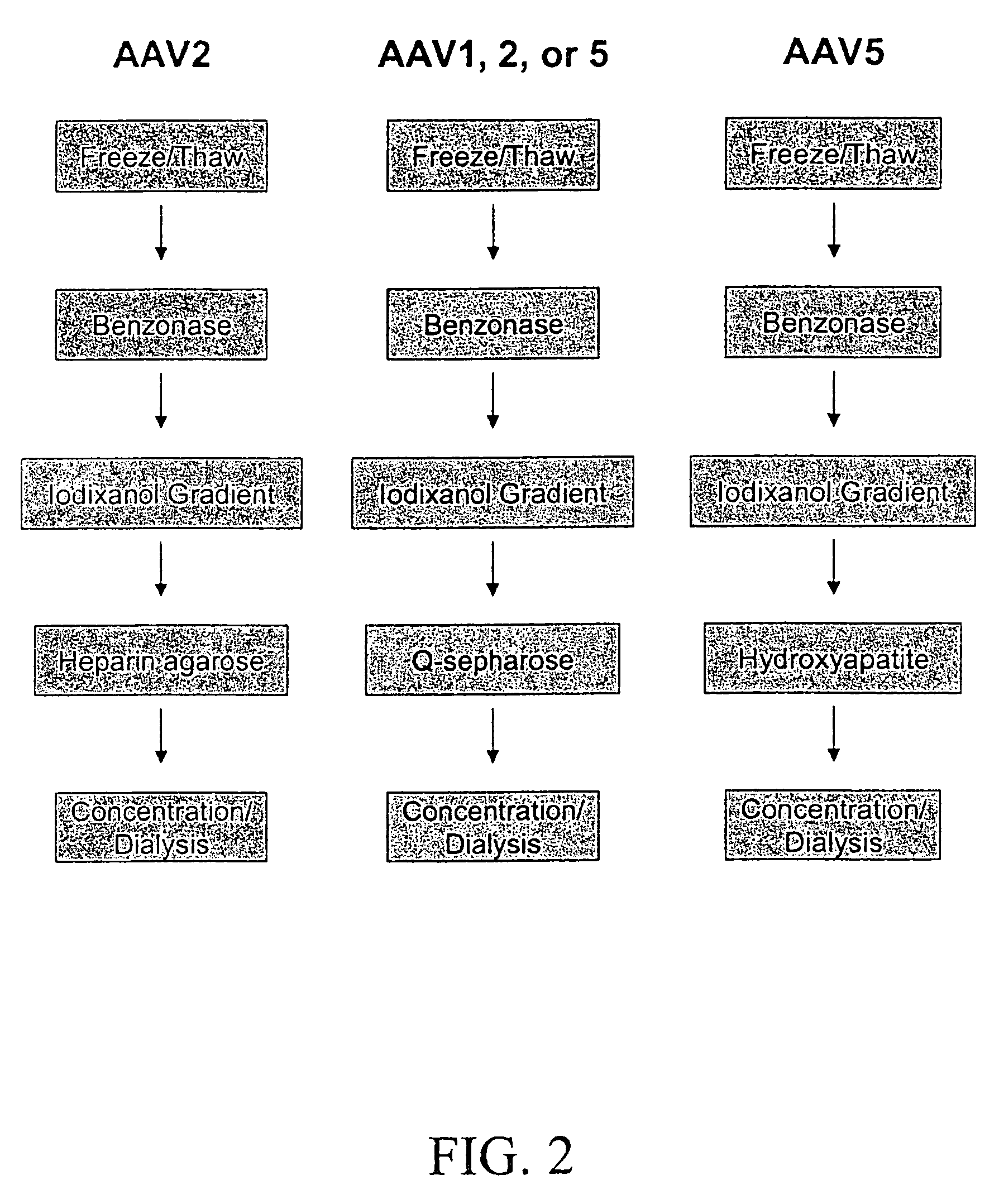

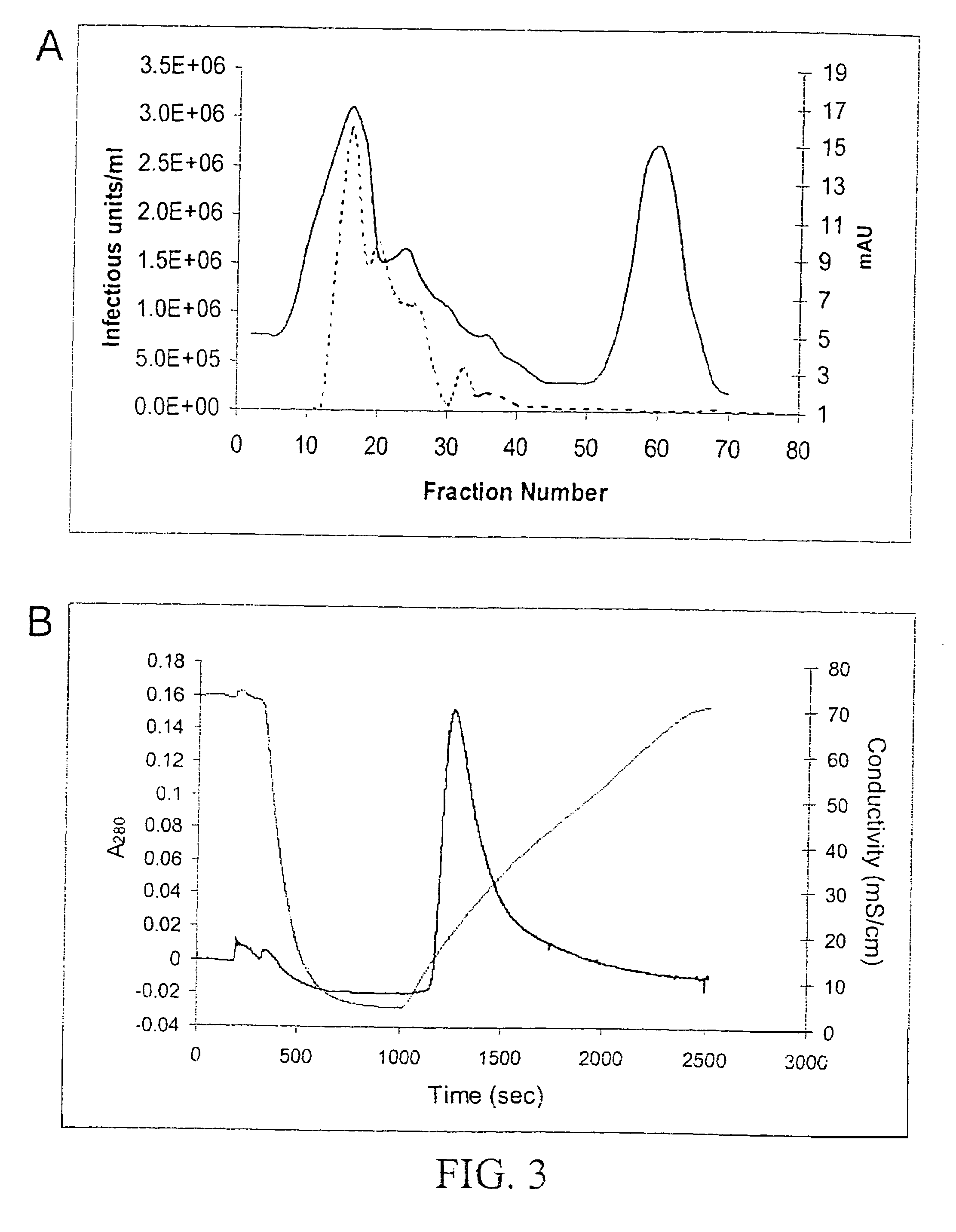

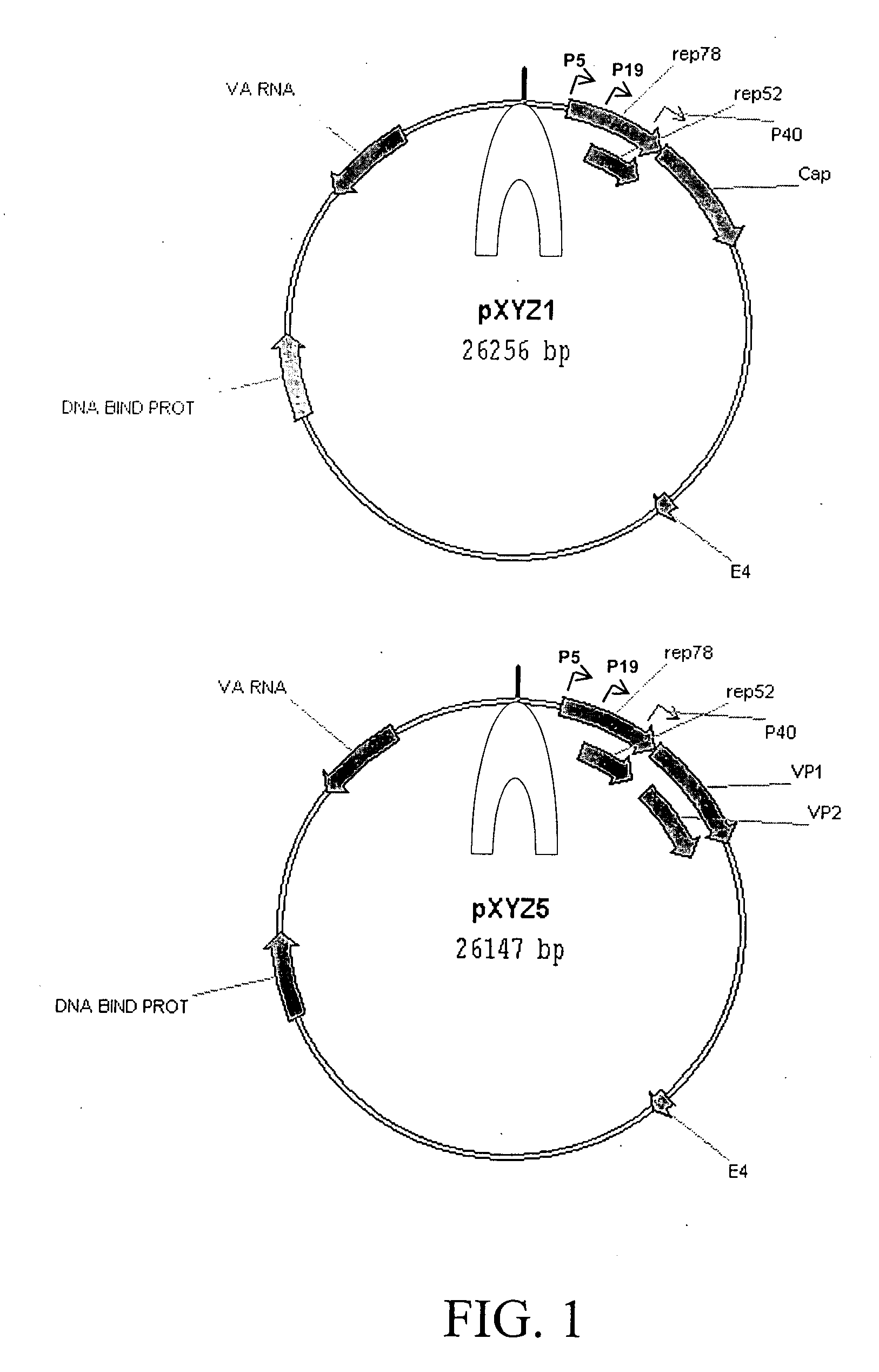

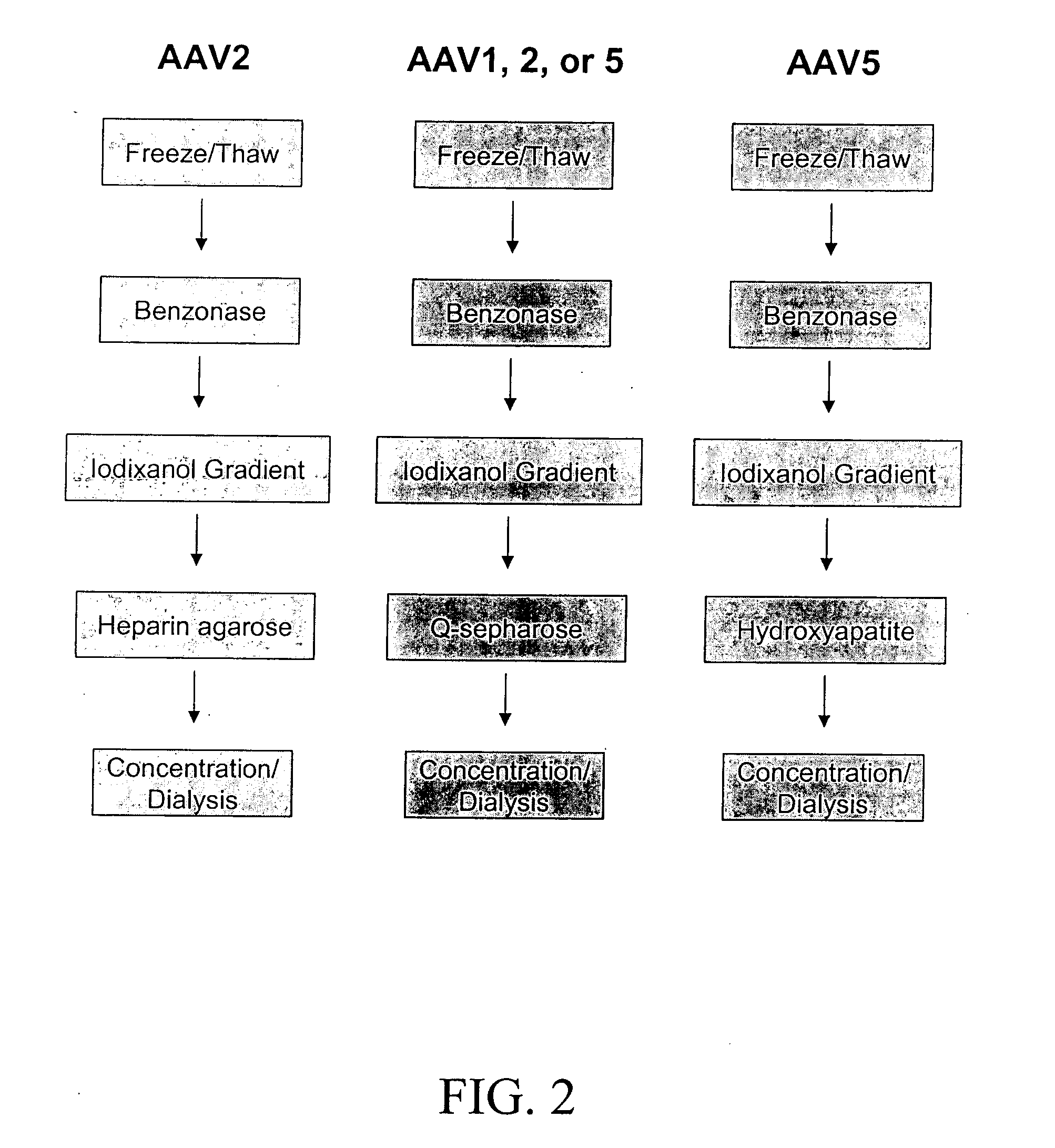

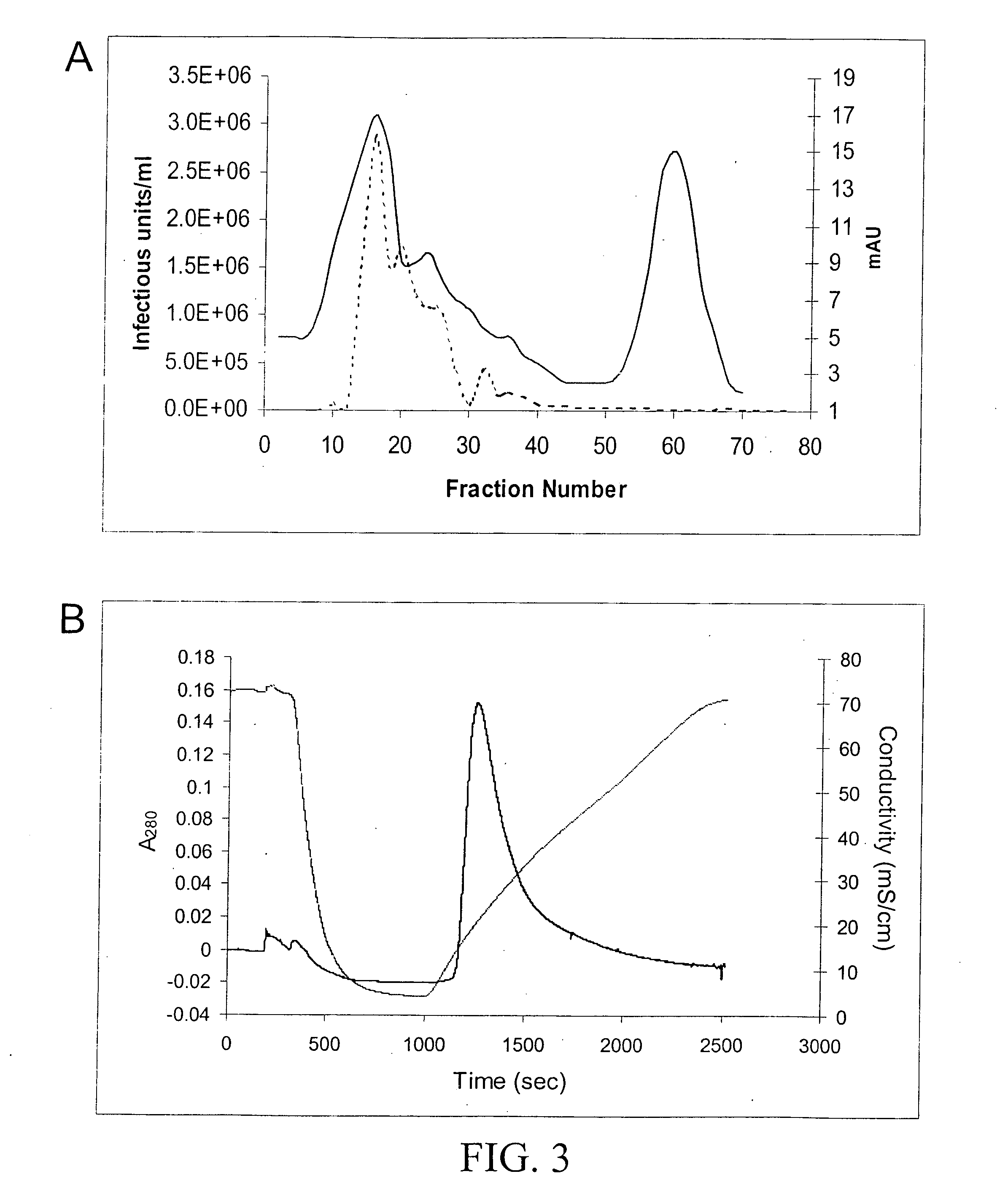

Production of pseudotyped recombinant AAV virions

InactiveUS7094604B2Highly purified and concentratedEfficient and large-scale productionVectorsSugar derivativesPurification methodsSerotype

Vectors that encode Adeno-Associated Virus (AAV) Rep and Cap proteins of different serotypes and Adenovirus transcription products that provide helper functions were used to produce pseudotyped recombinant AAV (rAAV) virions. Purification methods generated pseudotyped rAAV virion stocks that were 99% pure with titers of 1×1012–1×1013 vector genomes / ml.

Owner:UNIVIRSITY OF FLORIDA RES FOUND INC

Water purifier and method of making and using the same

ActiveUS20050139530A1Fully removedGeneral water supply conservationTreatment involving filtrationHigh concentrationPurification methods

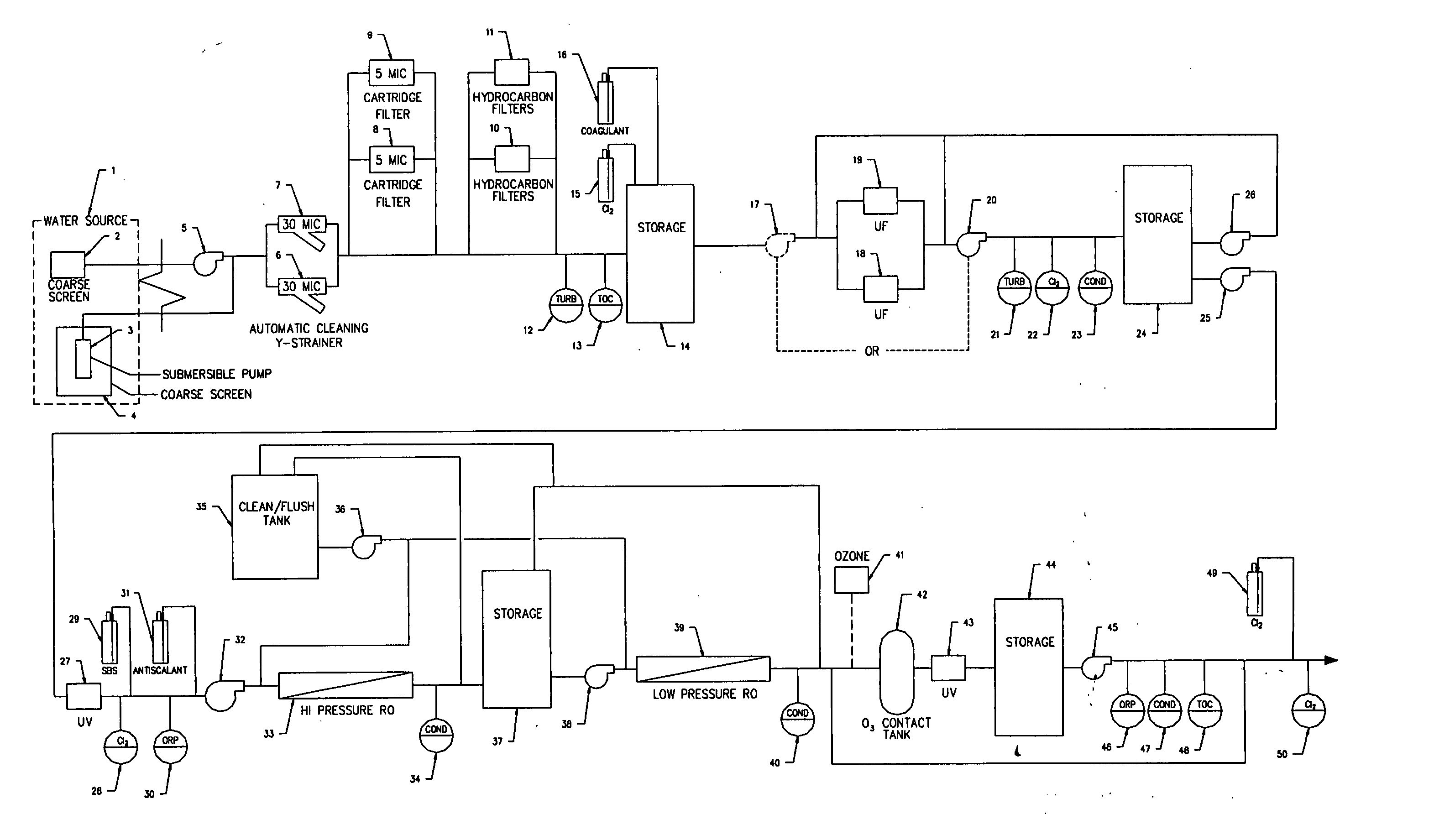

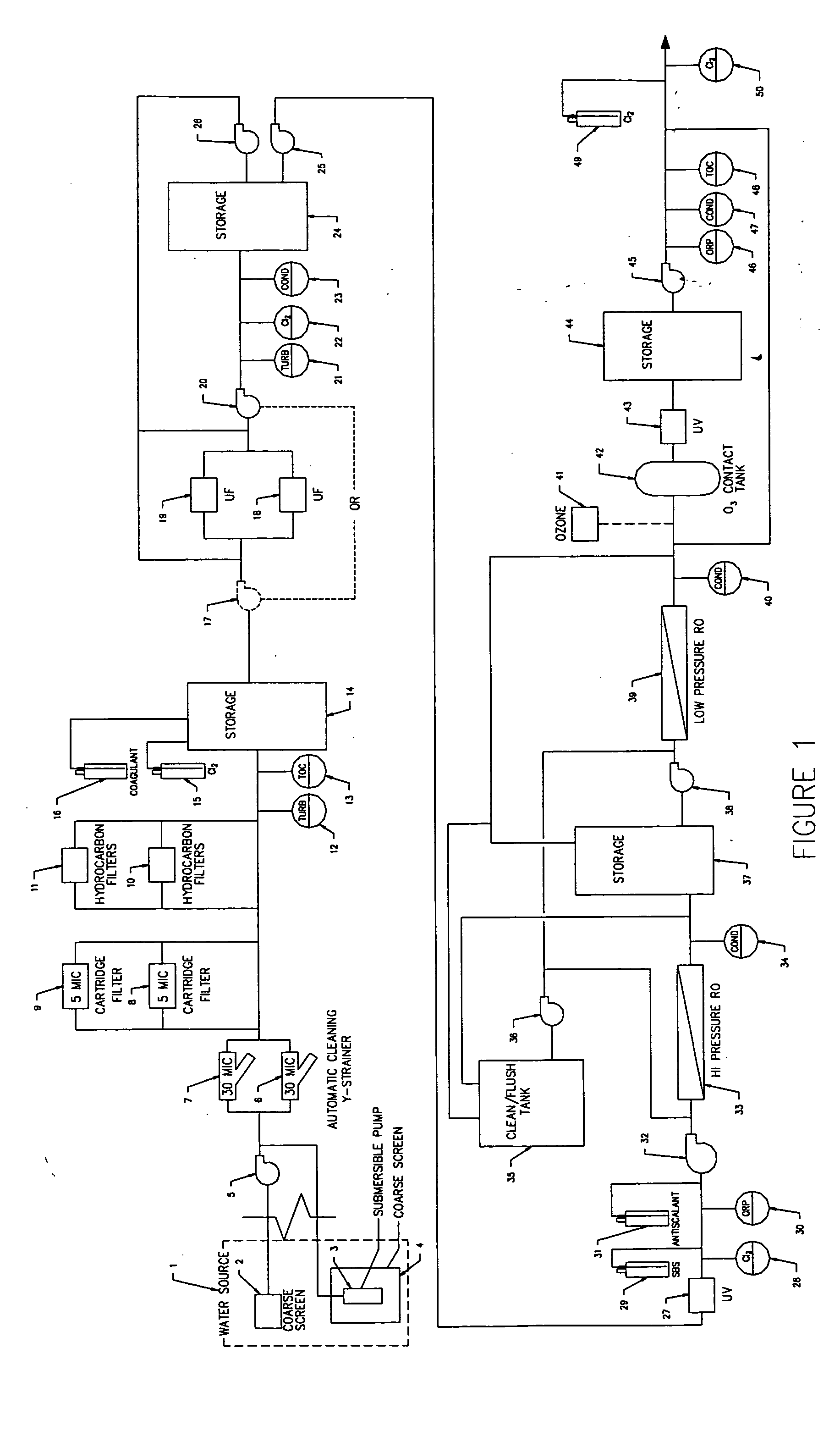

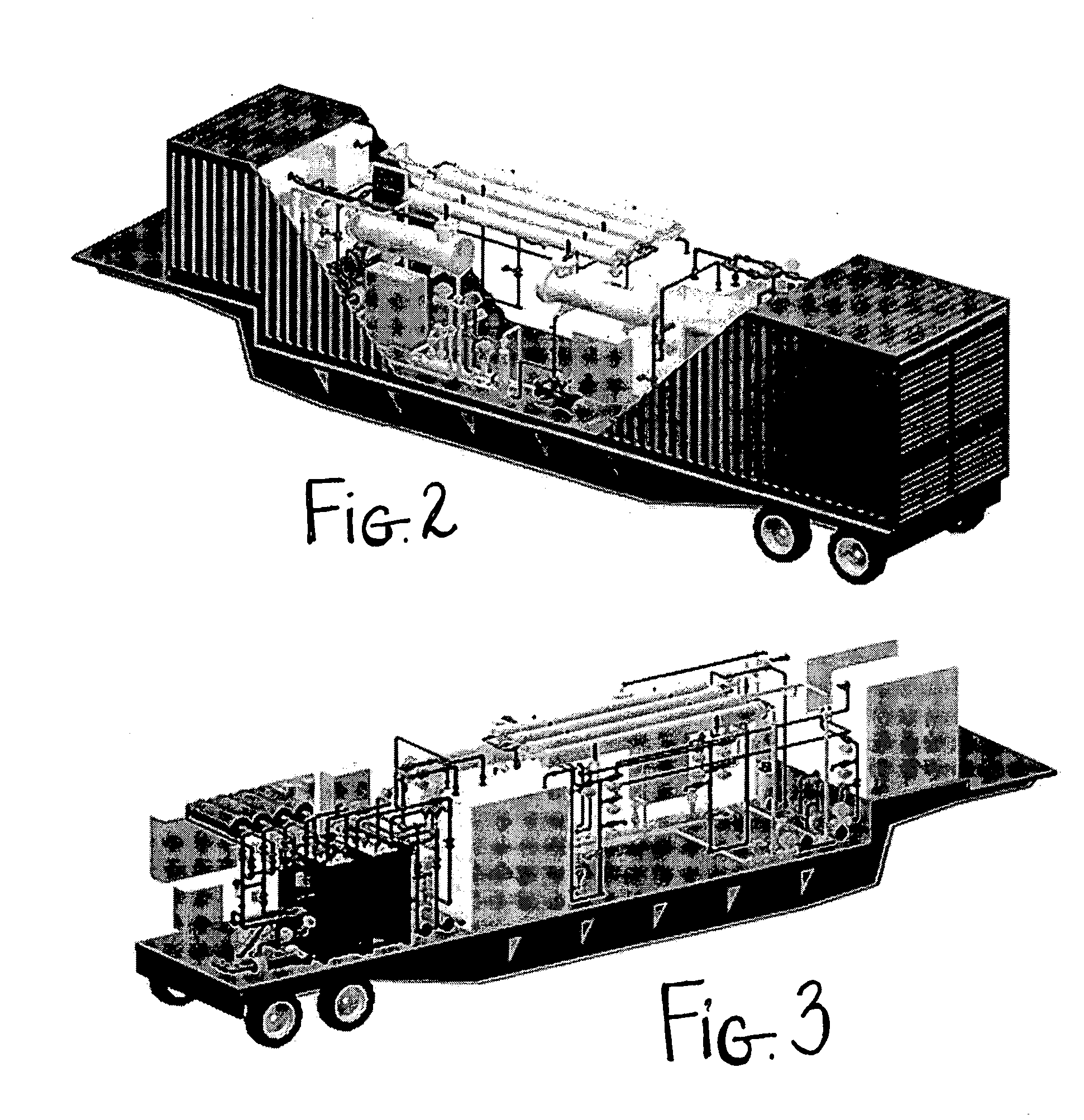

A method of producing safe drinking water from virtually any water source utilizing a water purification system is disclosed. The method includes a combination of water purification methods with a control system that evaluates water quality and functional processing parameters, such as pressure and flow. The control system determines what water processing methods to utilize and how most efficiently to operate them. The system is capable of treating highly contaminated water to the necessary degree to produce safe drinking water. Furthermore, the system regulates and cleans itself to maintain functionality despite receiving high concentrations of various contaminants from the feed water source.

Owner:HEISS CHRISTOPHER

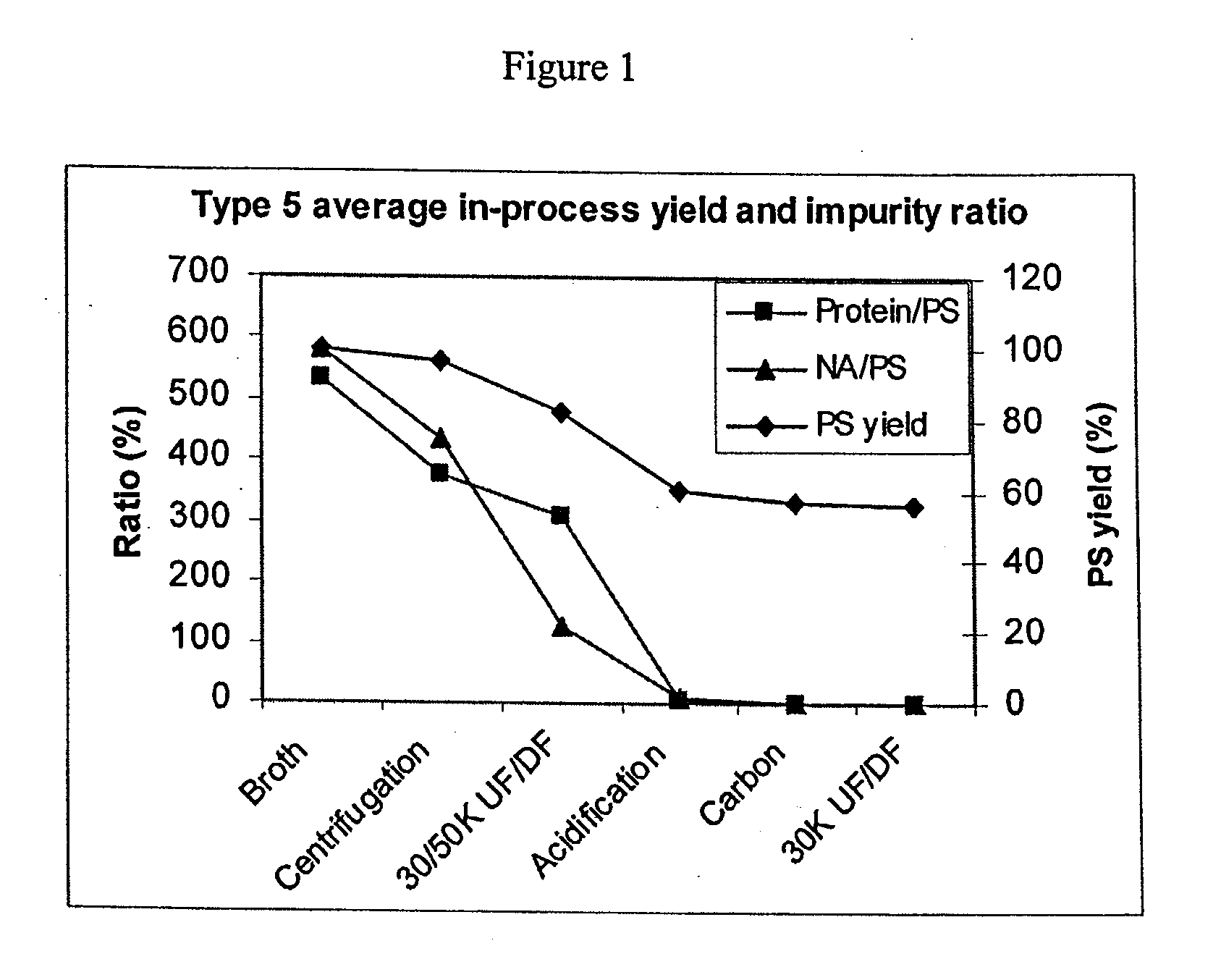

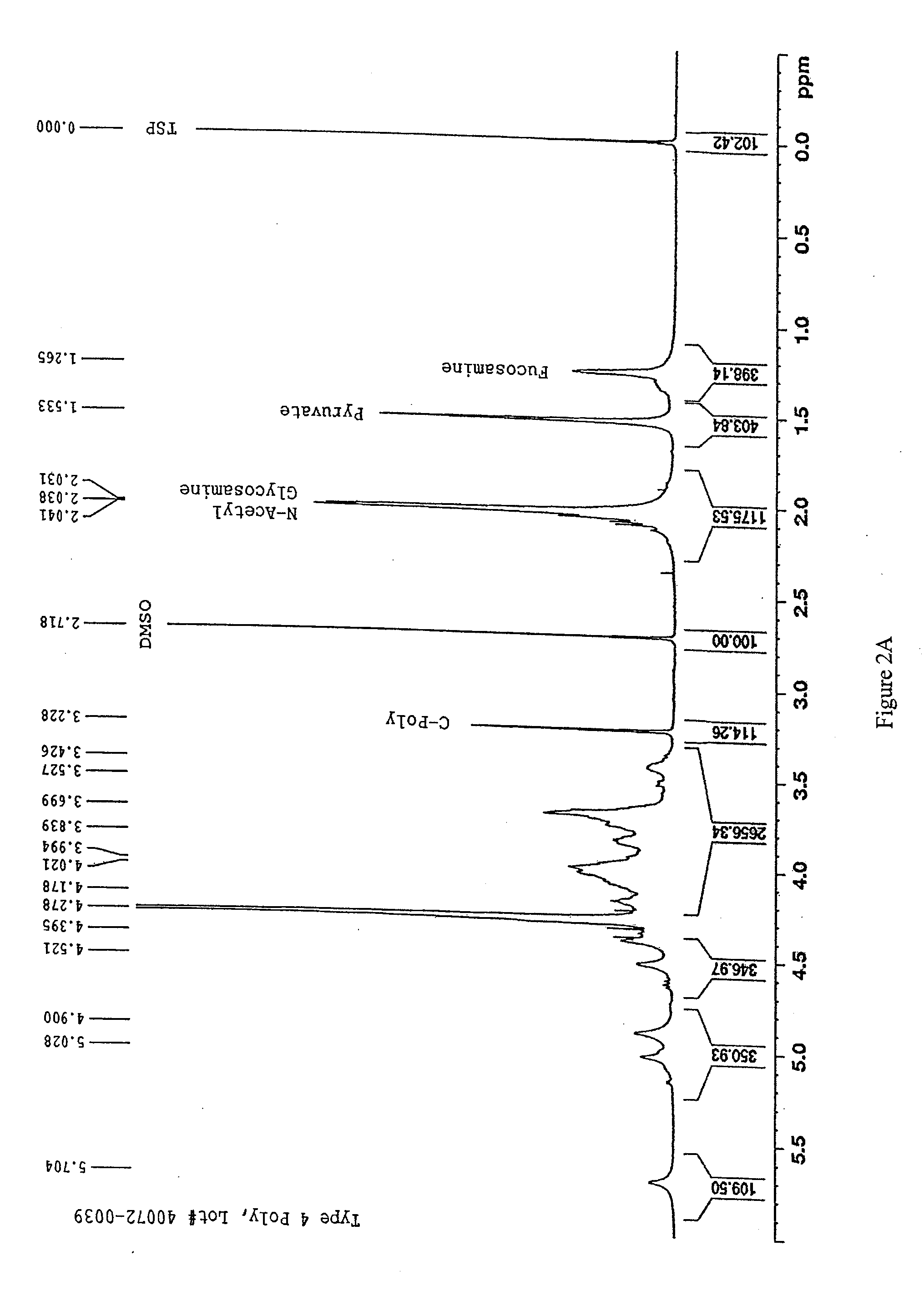

Shortened purification process for the production of capsular streptococcus pneumoniae polysaccharides

ActiveUS20080286838A1Increase polysaccharide concentrationReduce the presence of impuritiesAntibacterial agentsSugar derivativesPurification methodsActivated carbon filtration

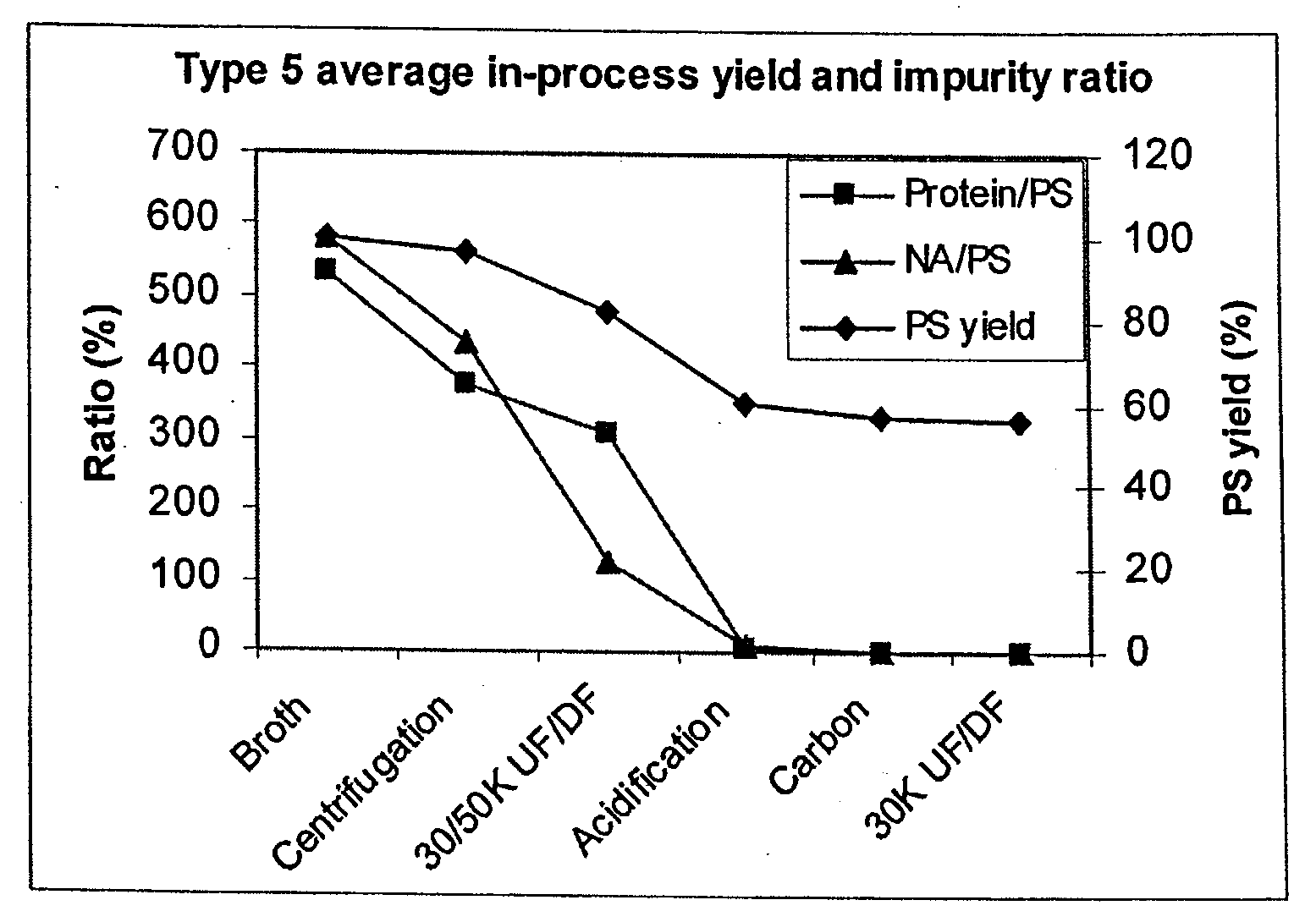

A shortened process for producing a solution containing substantially purified capsular polysaccharides from a cellular Streptococcus pneumoniae lysate broth is described. Ultrafiltering and diafiltering a clarified S. pneumoniae lysate followed by pH adjustment to less than 4.5, preferably about 3.5, precipitated at least 98% of the protein in the solution without seriously affecting polysaccharide yield. Furthermore, following ultrafiltration and diafiltration and acidification to a pH of less than 4.5, filtration using activated carbon precipitated at least 90% of remaining protein without seriously affecting polysaccharide yield. Exemplary, non-limiting S. pneumoniae serotypes that can be purified using the shortened process of the invention are 1, 4, 5, 6A, 6B, 7F, 9V, 14, 18C, 19A, 19F, and 23F. In one embodiment, the Streptococcus pneumoniae cells are lysed using deoxycholate sodium (DOC), while in another embodiment the lytic agent is a non-animal derived lytic agent such as N-lauryl sarcosine sodium (NLS).

Owner:WYETH LLC

Composite semipermeable membrane, processfor producing the same, and method of purifying water with the same

InactiveUS6406626B1Semi-permeable membranesWater/sewage treatment bu osmosis/dialysisPurification methodsHigh rate

The present invention relates to a composite semipermeable membrane which is characterized in that it is a composite semipermeable membrane in which there is formed by polycondensation on top of a microporous support membrane a crosslinked polyamide ultra-thin membrane layer from polyfunctional amine, polyfunctional acid halide and polyfunctional acid anhydride halide, and the flow of water permeate at an operating pressure of 0.3 MPa, a temperature of 25° C. and a pH of 6.5 lies in the range from 0.8 to 4.0 m3 / m2.day and, furthermore, the percentage humic acid removal is at least 98%; a method for the production thereof; and a water purification method employing same. With the composite semipermeable membrane obtained by means of the present invention it is possible, in particular, to recover drinking water at a high rate by permitting passage of silica and preventing deposition thereof at the membrane surface while selectively separating / removing the pollutants and trace quantities of harmful materials and their precursors, etc, contained in the raw water in water treatment plants.

Owner:TORAY IND INC

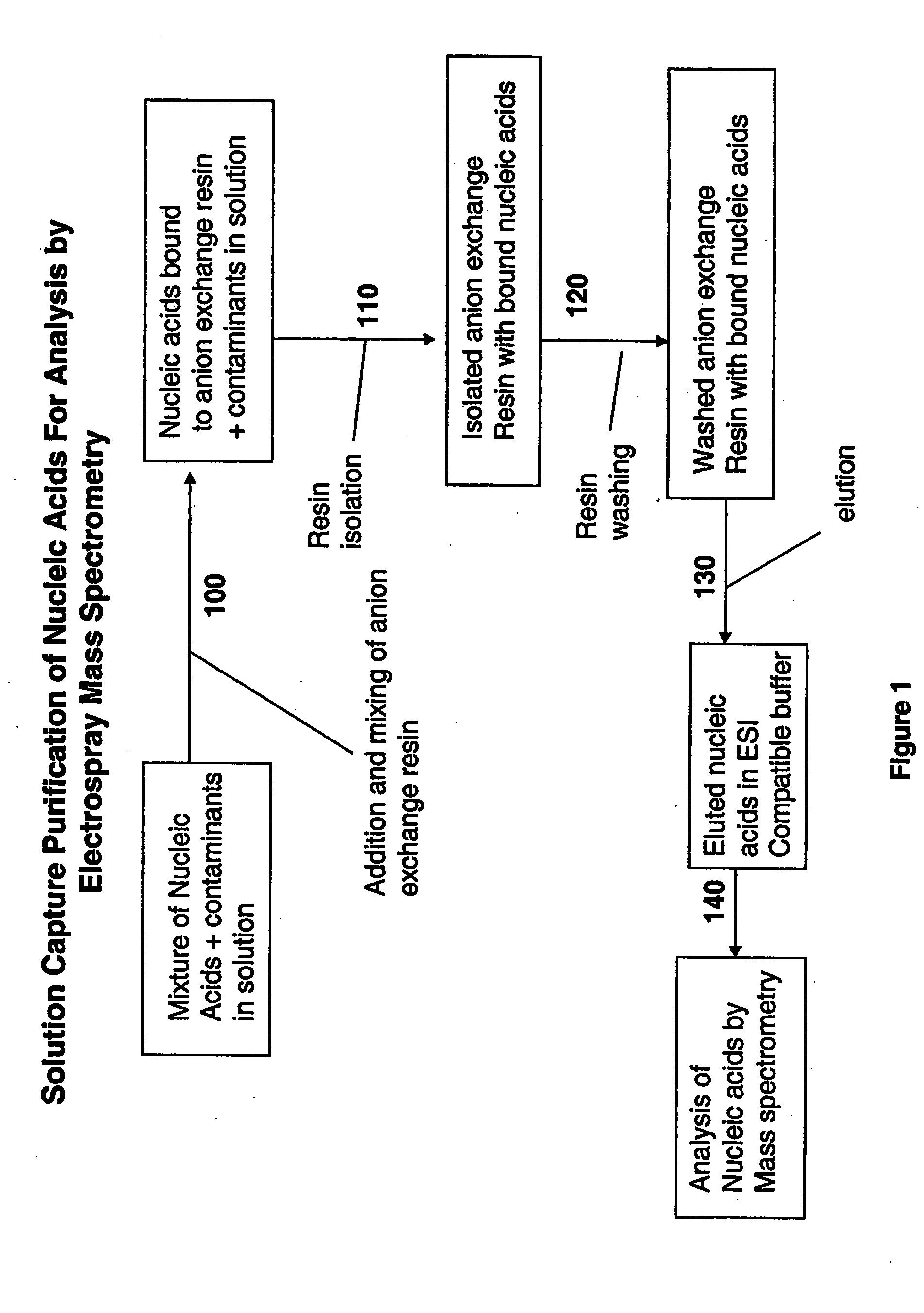

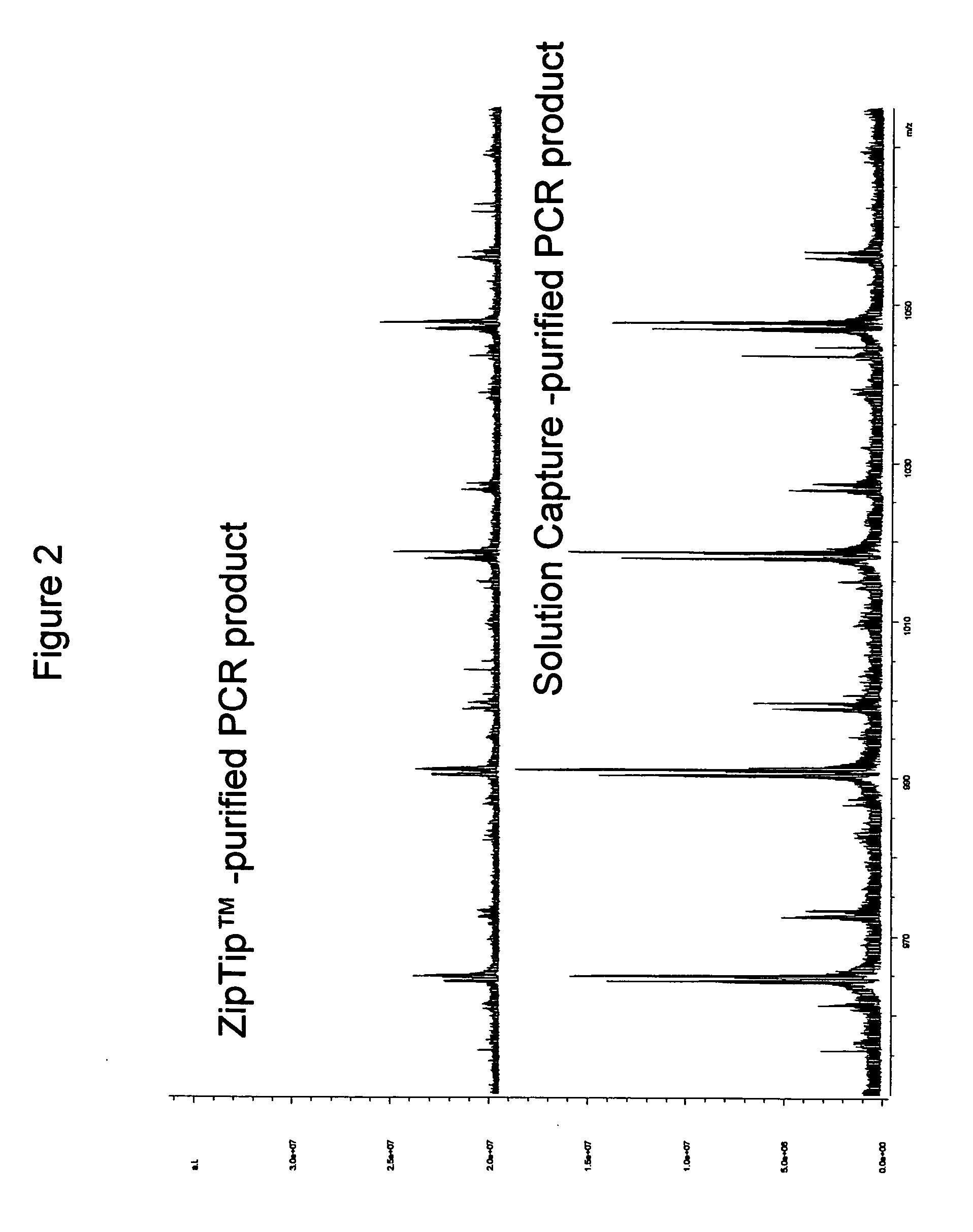

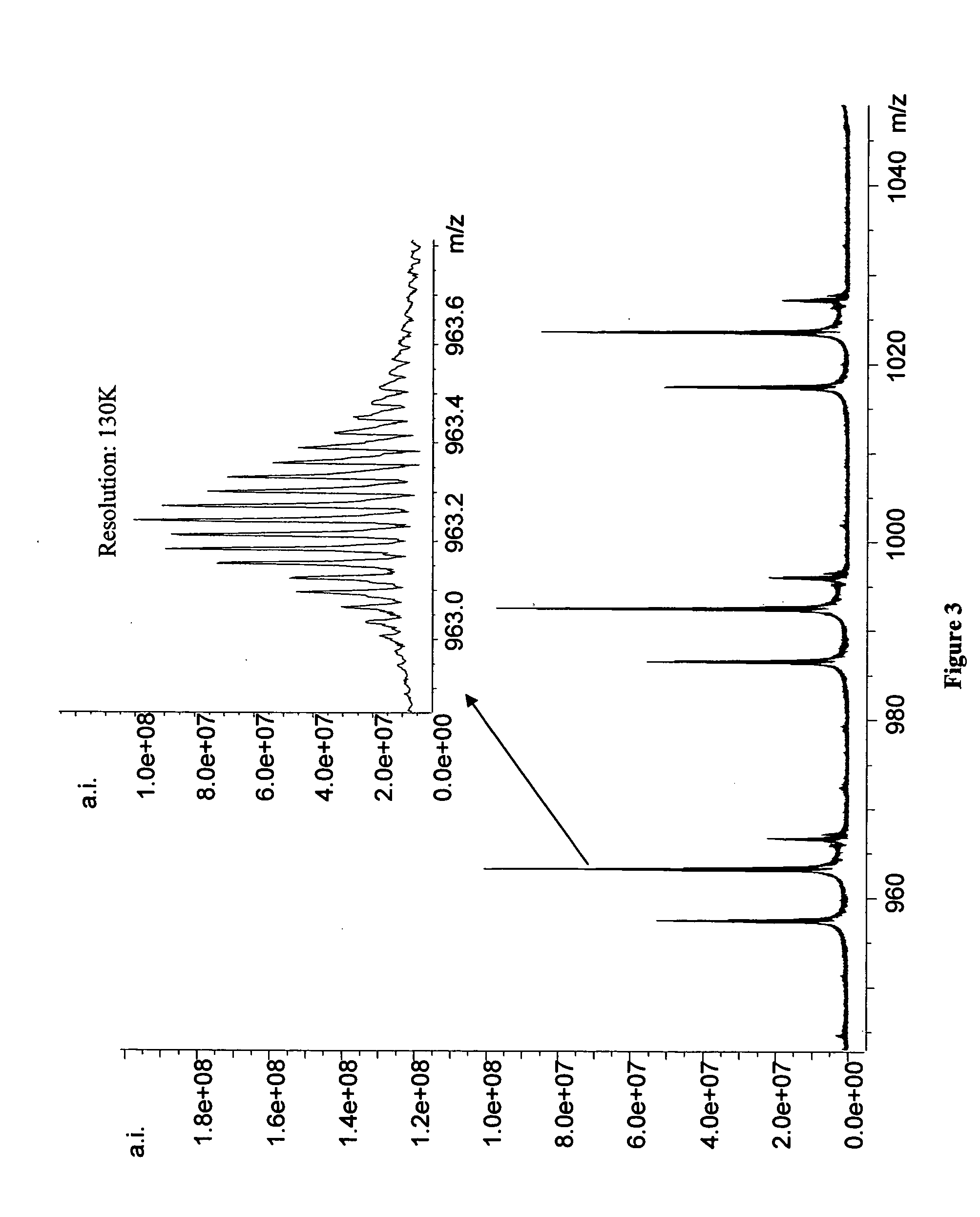

Methods for rapid purification of nucleic acids for subsequent analysis by mass spectrometry by solution capture

InactiveUS20050130196A1Sugar derivativesParticle separator tubesPurification methodsMass Spectrometry-Mass Spectrometry

The present invention provides a method for rapid solution capture purification of nucleic acids for subsequent analysis by electrospray mass spectrometry which is efficient and cost-effective relative to existing methods. The present invention also provides for kits useful for practicing rapid solution capture of nucleic acids so that purified samples are in condition for analysis by electrospray mass spectrometry.

Owner:IBIS BIOSCI

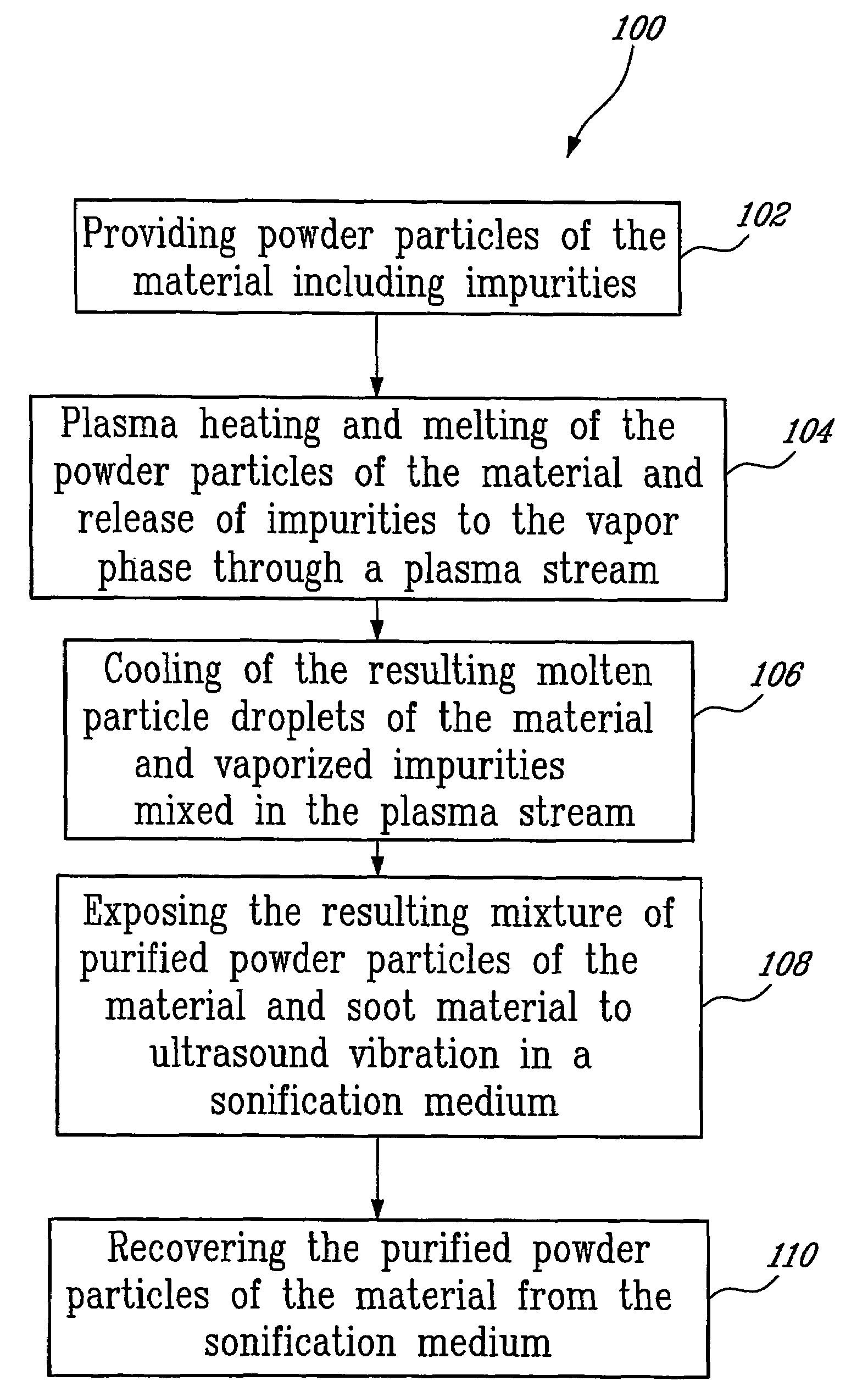

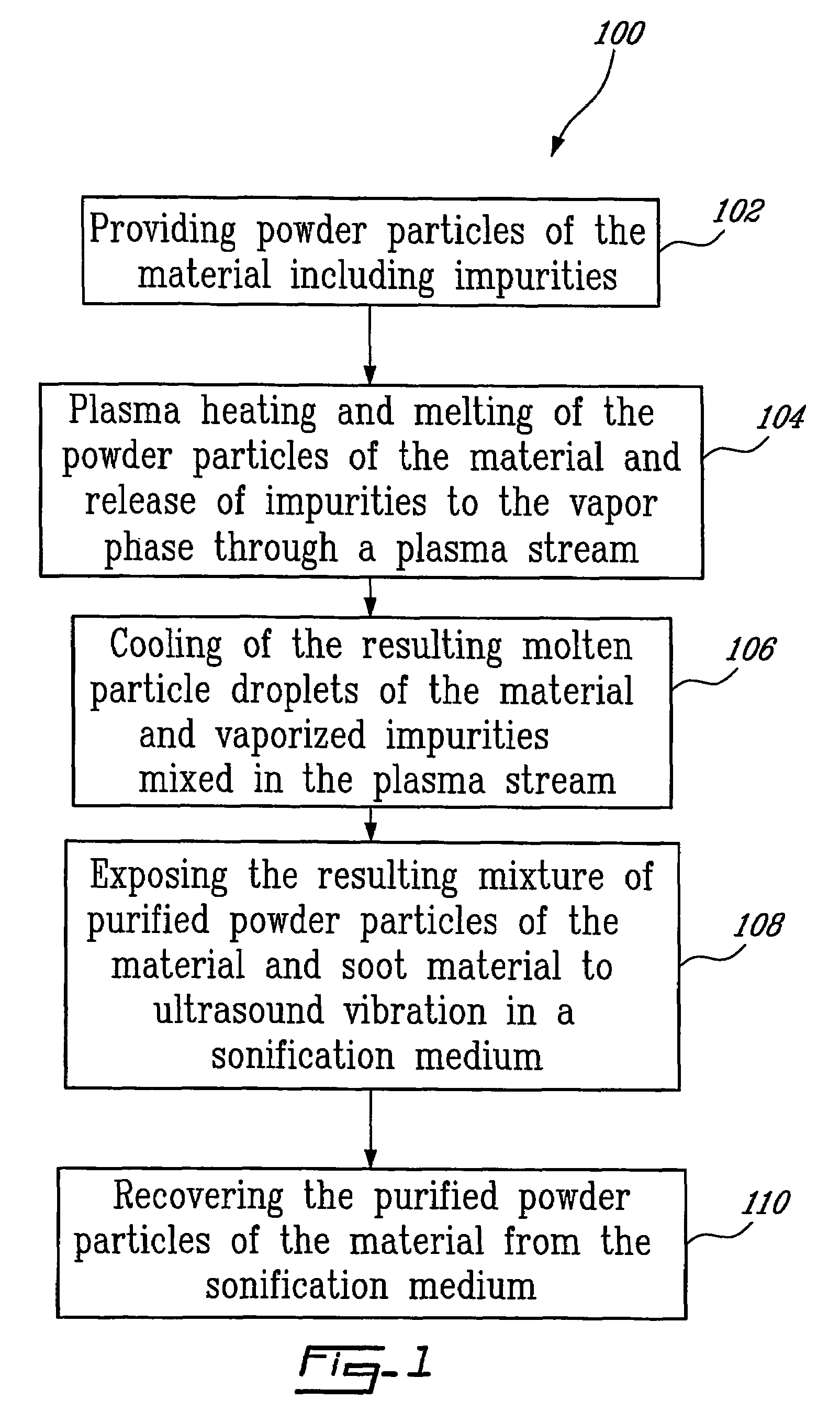

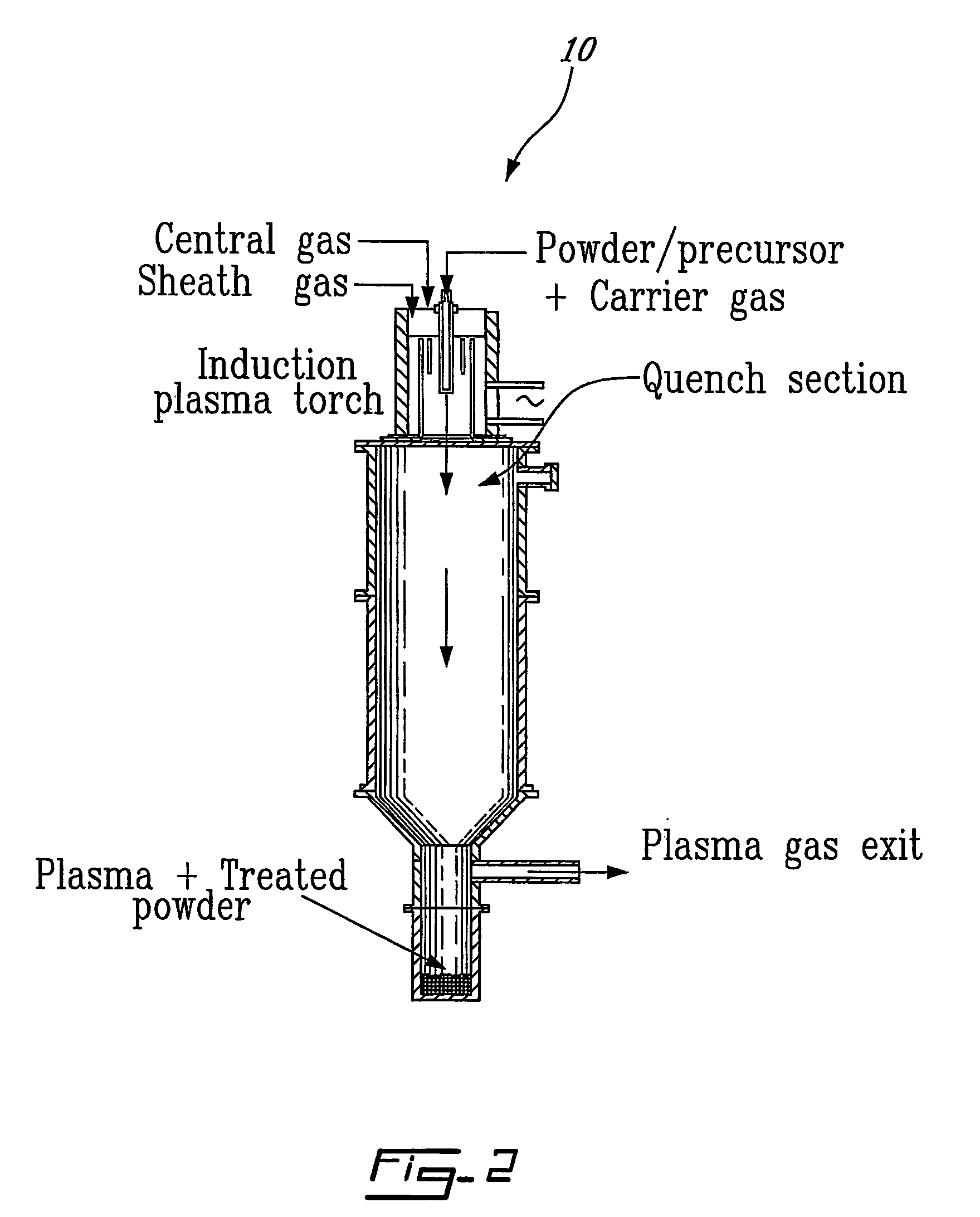

Process for the synthesis, separation and purification of powder materials

ActiveUS7572315B2Speed up the processTransportation and packagingMetal-working apparatusPurification methodsVaporization

Owner:TEKNA PLASMA SYST INC

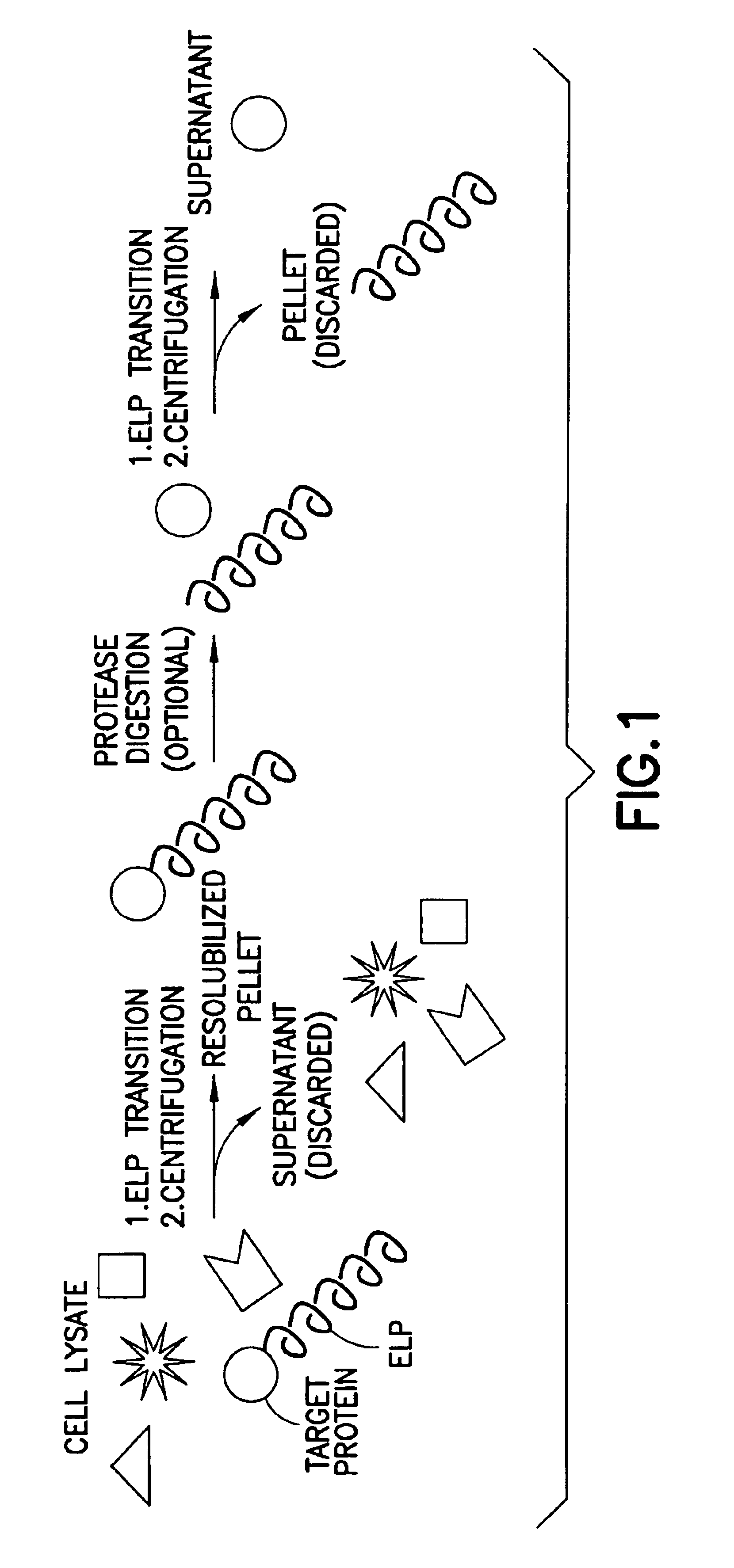

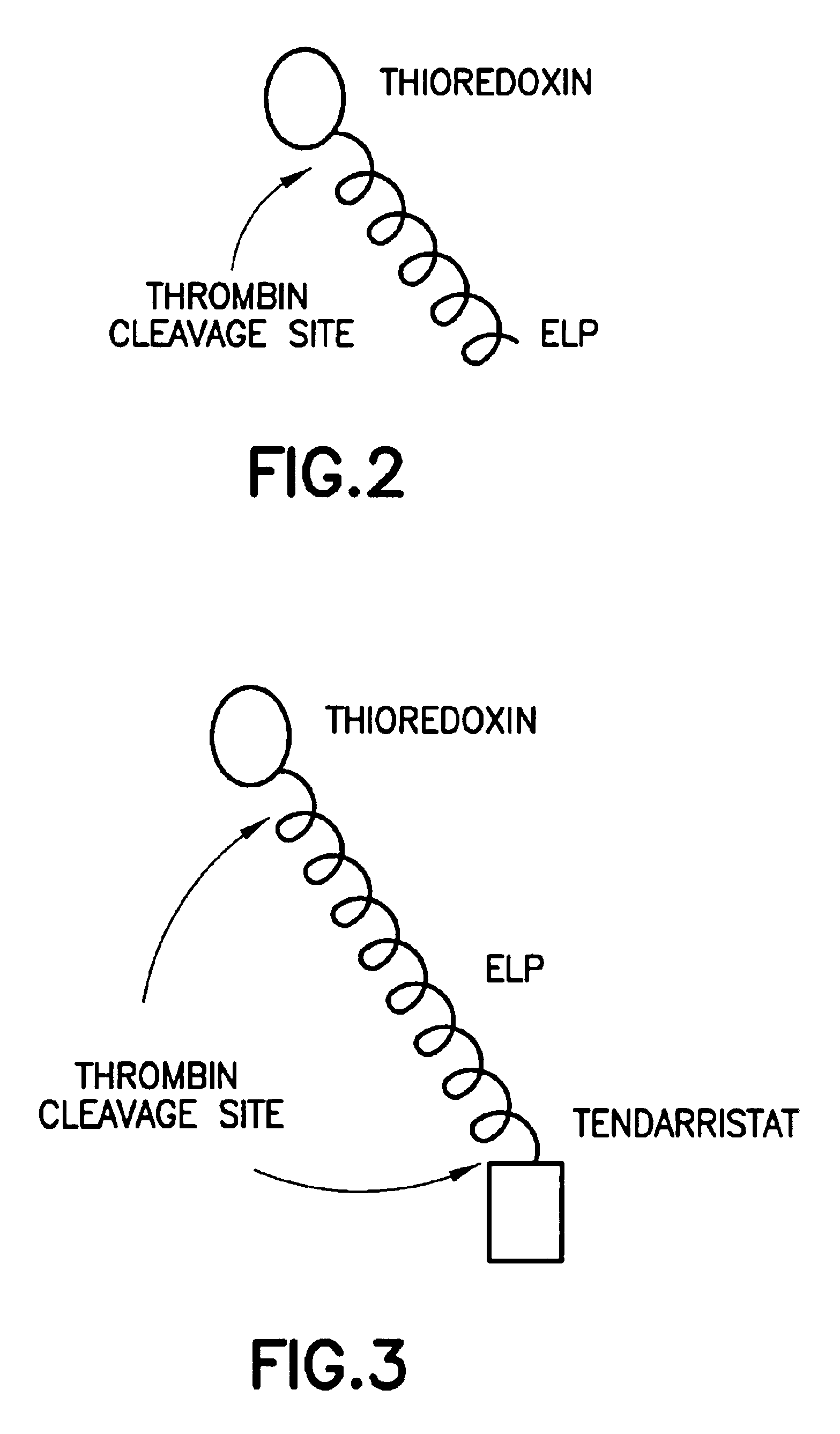

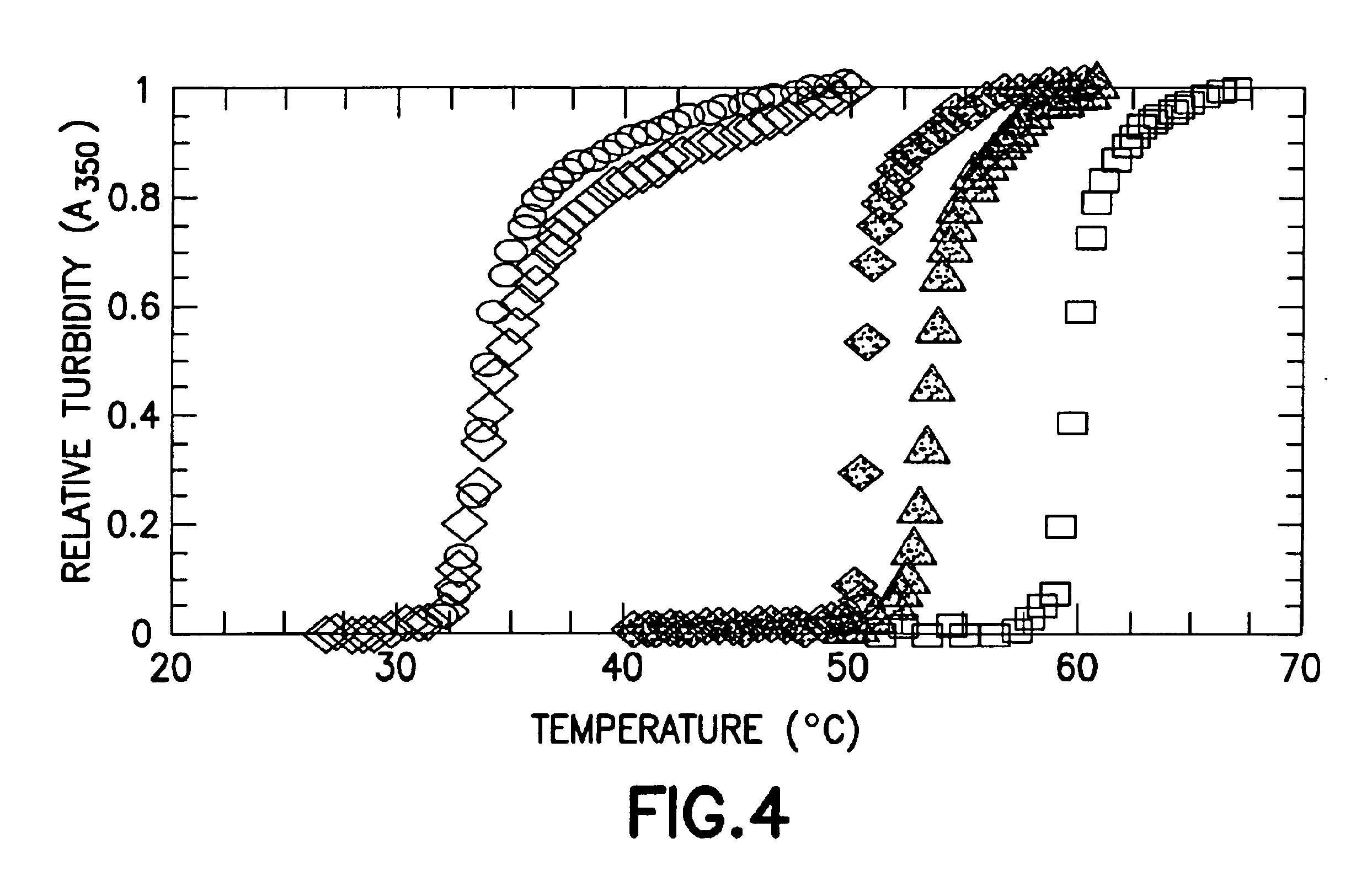

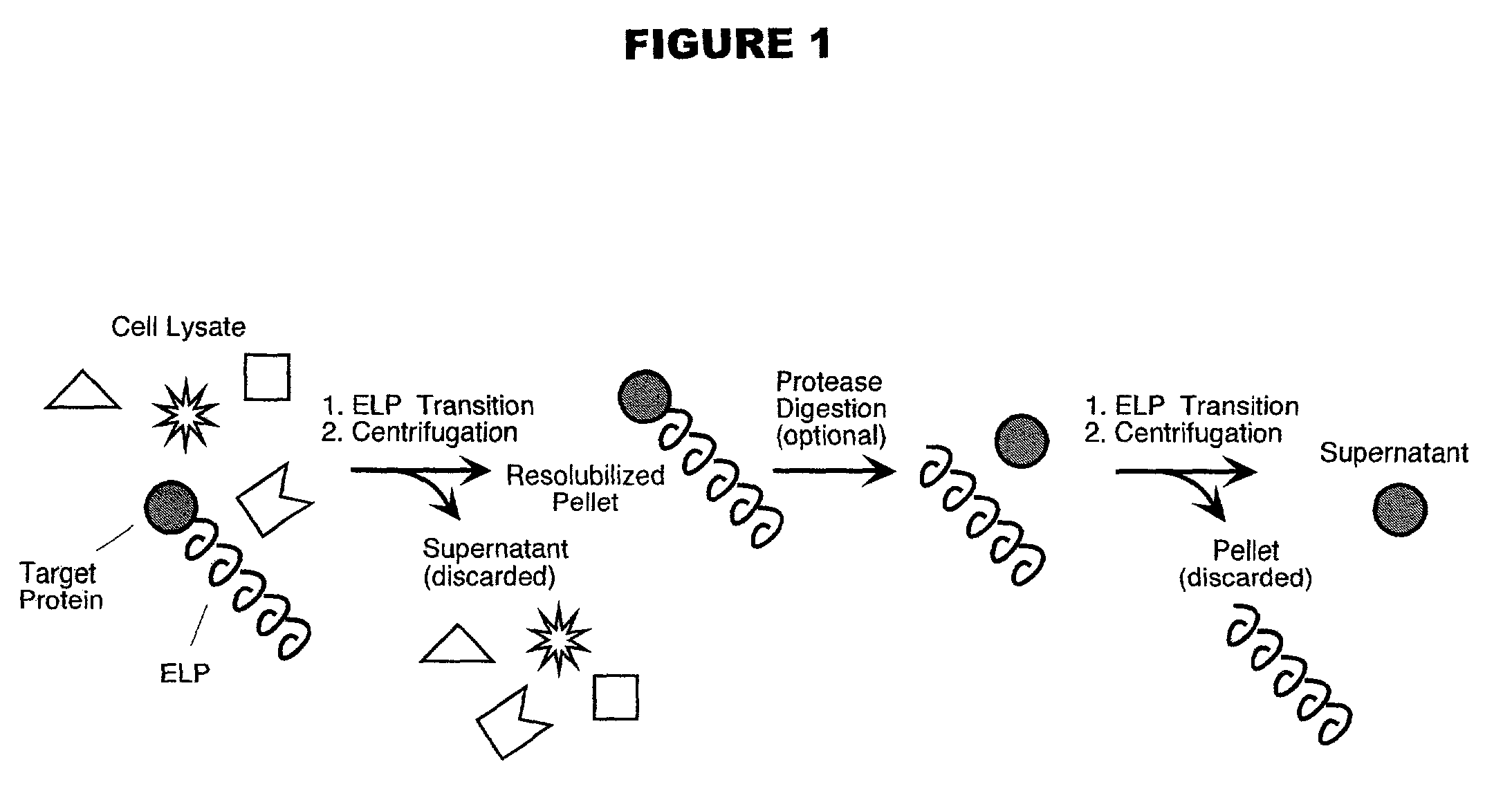

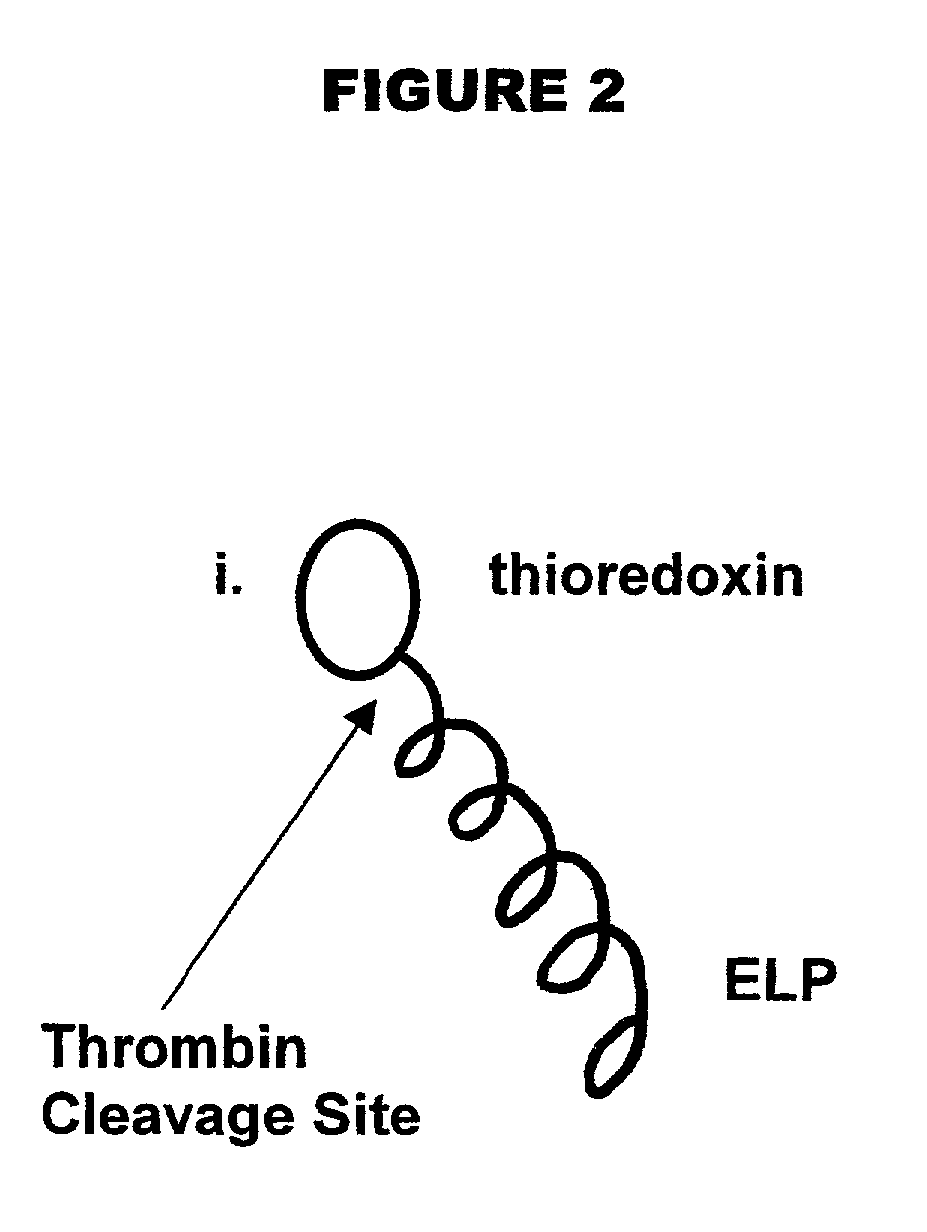

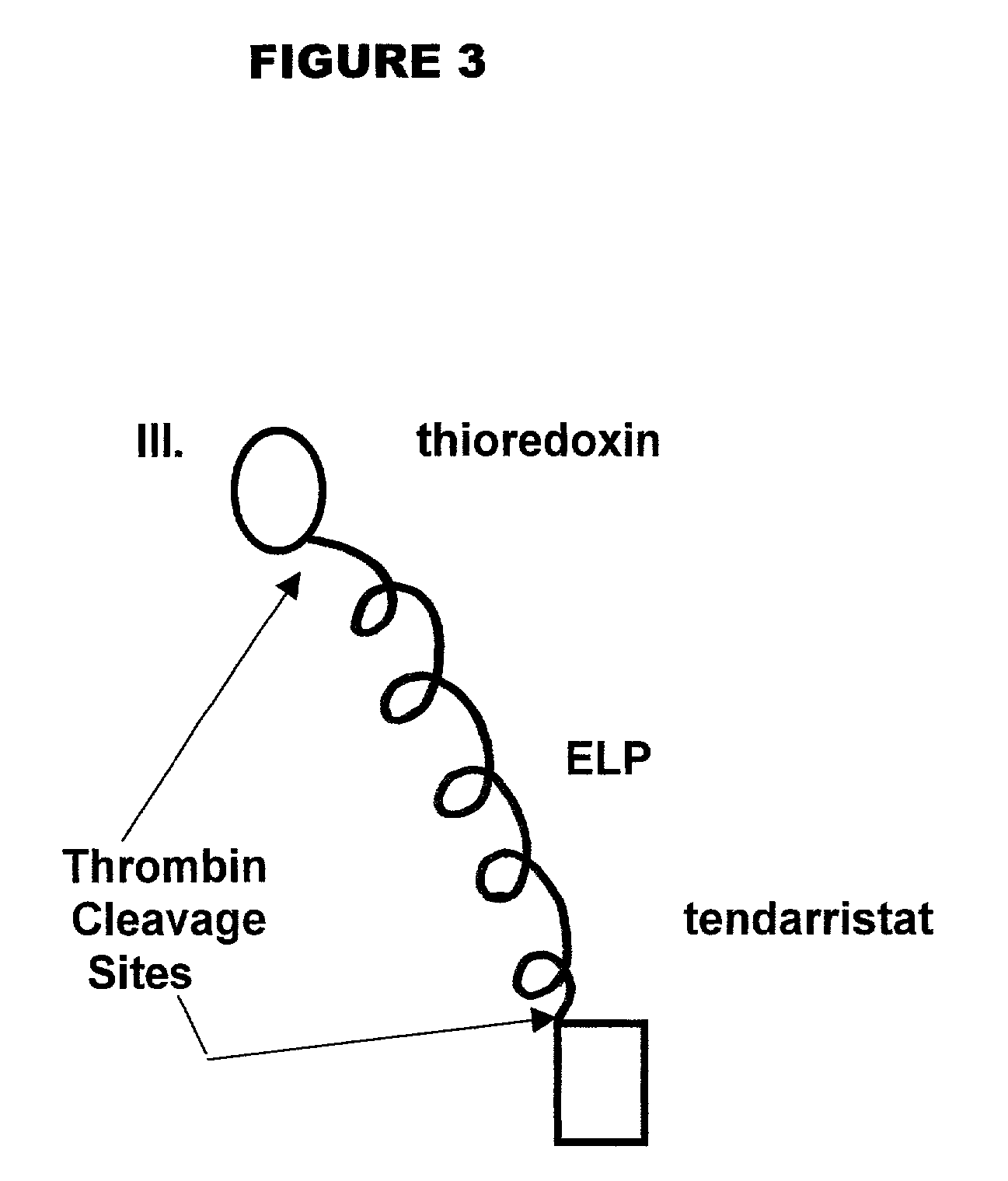

Fusion peptides isolatable by phase transition

Genetically-encodable, environmentally-responsive fusion proteins comprising ELP peptides. Such fusion proteins exhibit unique physico-chemical and functional properties that can be modulated as a function of solution environment. The invention also provides methods for purifying the FPs, which take advantage of these unique properties, including high-throughput purification methods that produce high yields (e.g., milligram levels) of purified proteins, thereby yielding sufficient purified product for multiple assays and analyses. The high throughput purification technique is simpler and less expensive than current commercial high throughput purification methods, since it requires only one transfer of purification intermediates to a new multiwell plate.

Owner:PHASE BIOSCIENCE INC

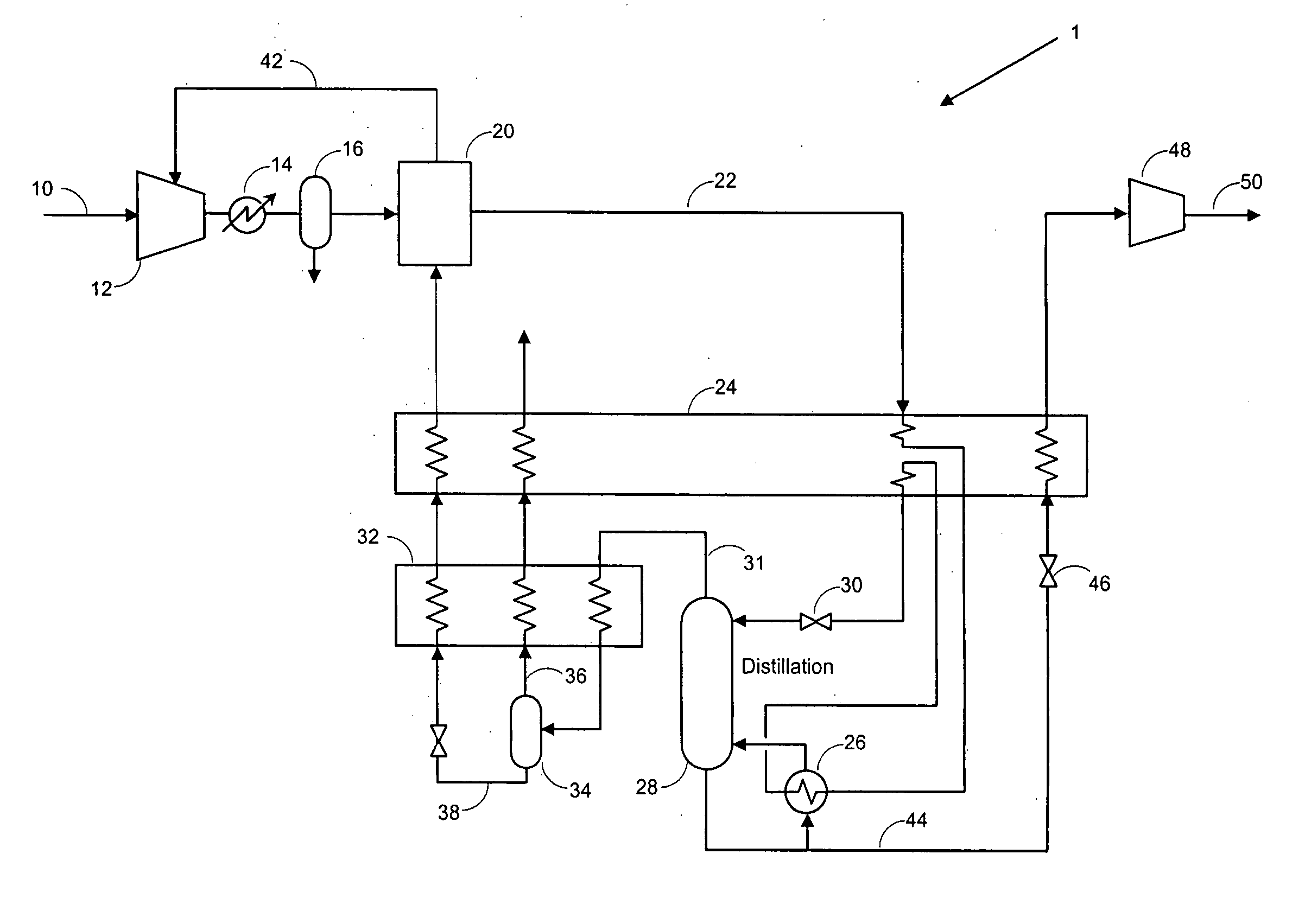

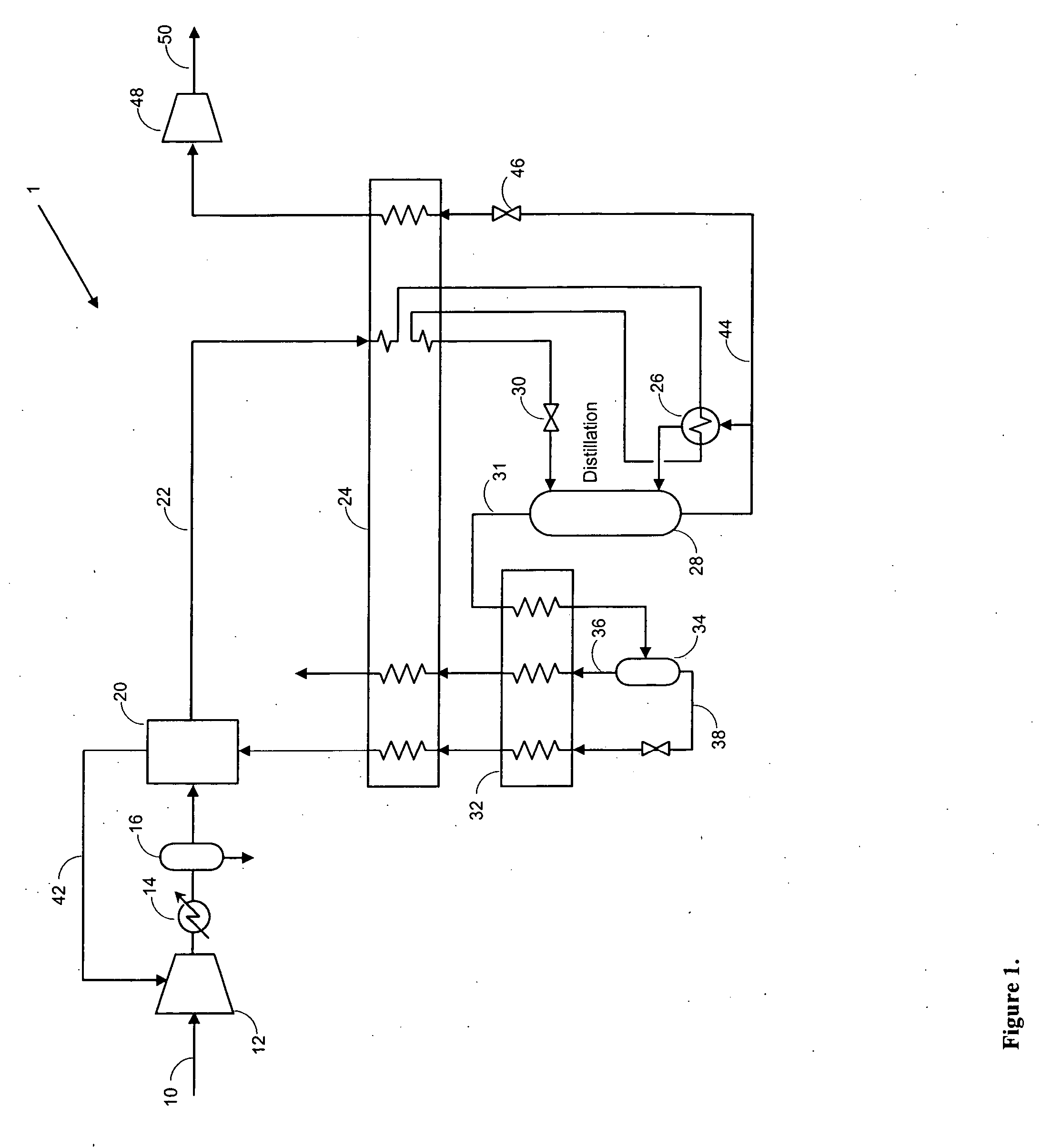

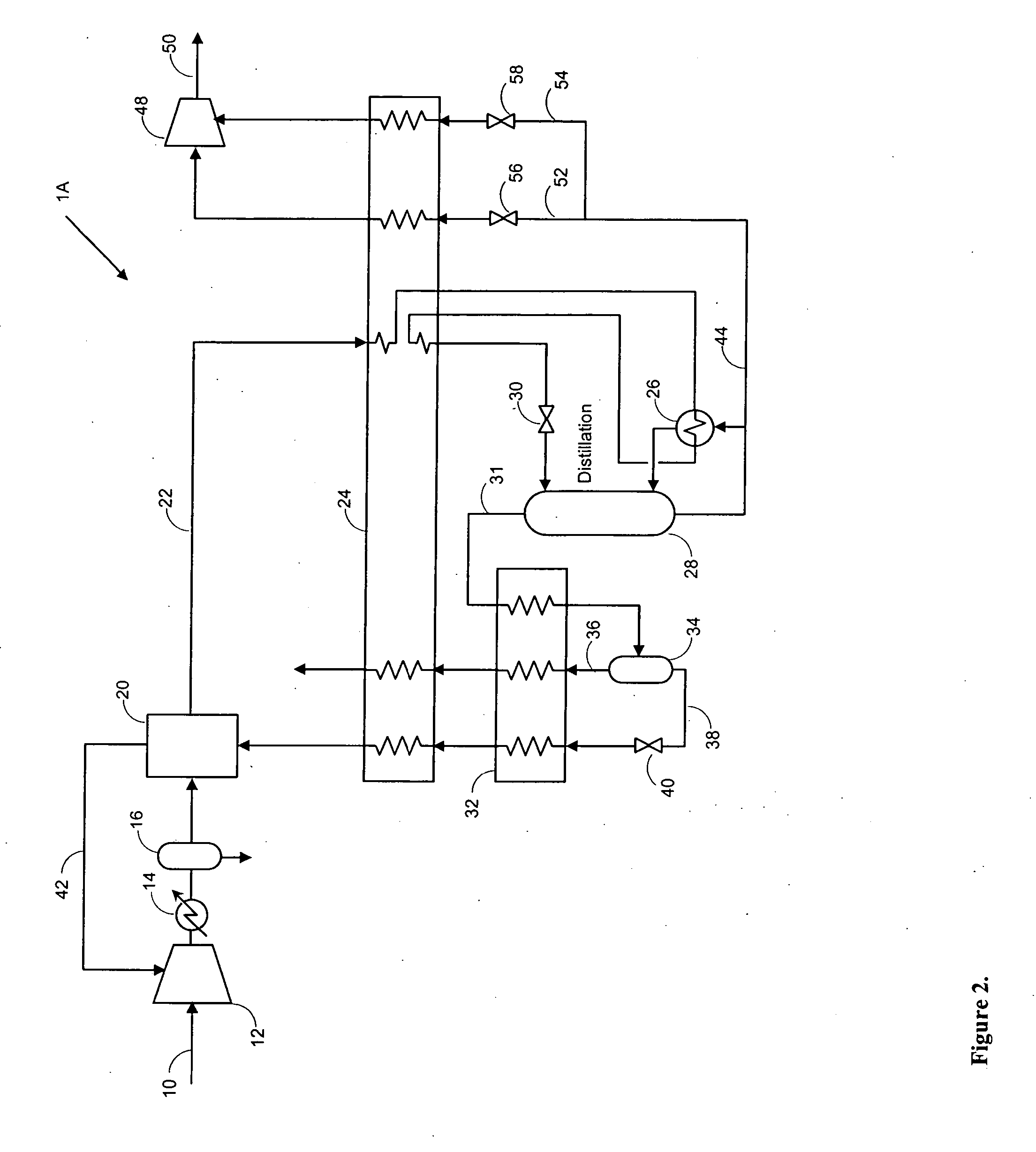

Carbon dioxide purification method

InactiveUS20070231244A1Lower energy requirementsLess refrigerationSolidificationLiquefactionPurification methodsRefrigeration

Method of purifying a feed stream containing carbon dioxide wherein the feed stream after having been compressed and dried is partly cooled and then used to reboil a stripping column. Thereafter, the feed stream is further cooled and expanded to a lower operational temperature of the stripping column. A carbon dioxide product stream composed of the liquid column bottoms of the stripping column is expanded at one or more pressures to generate refrigeration, then fully vaporized within the main heat exchanger and compressed by a compressor to produce a compressed carbon dioxide product. Refrigeration is recovered in the main heat exchanger from a column overhead stream extracted from the stripping column within the main heat exchanger either directly or indirectly by auxiliary processing in which carbon dioxide is further separated and optionally recycled back to the main compressor used in compressing the feed stream.

Owner:PRAXAIR TECH INC

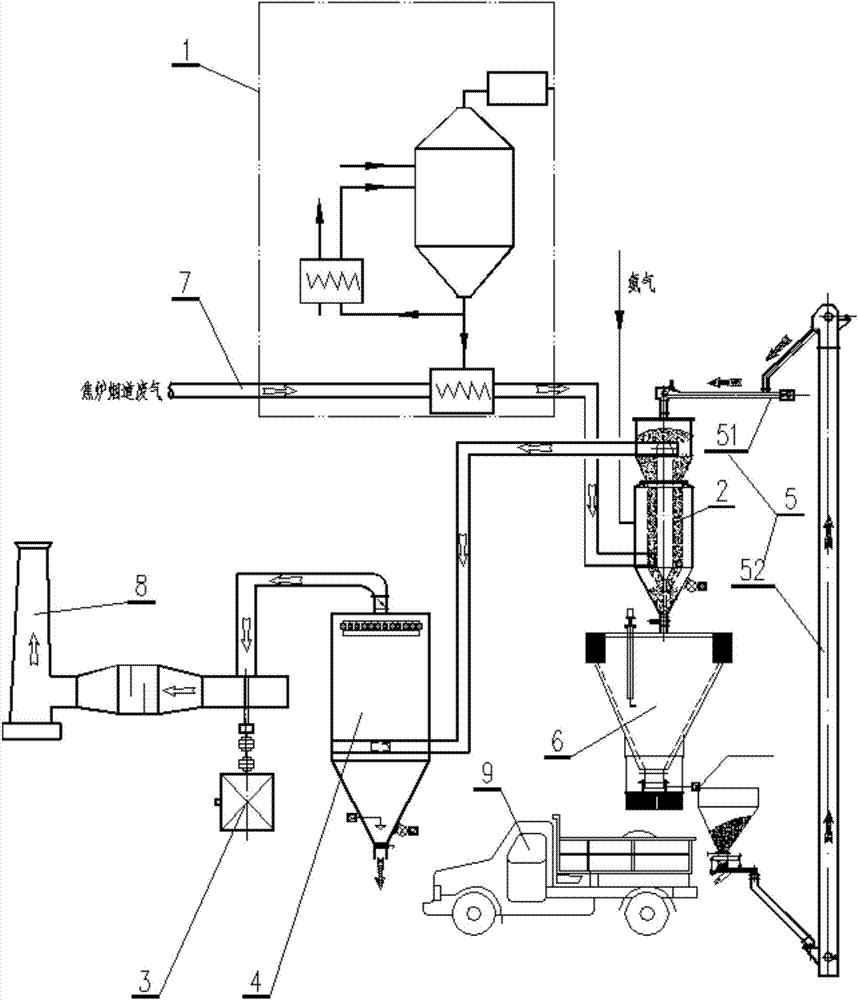

Coke oven flue gas waste heat utilization and purification method

ActiveCN103877856AReduce consumptionEfficient governanceDispersed particle separationPurification methodsCoking plant

The invention relates to the technical field of coke oven flue gas integrated utilization and pollution treatment and in particular relates to a coke oven flue gas waste heat utilization and purification method. The method is characterized in that flue gas waste heat is recovered by utilizing a flue gas waste heat recovery device, the temperature of the flue waste gas is reduced, and integrated desulfurization and denitration of the flue waste gas is realized by utilizing the activated adsorption capacity and low-temperature denitration catalytic capability of the coke. Compared with an existing process, the method has the beneficial effects that the flue waste gas desulfurization and denitration is performed under low-temperature working conditions, an additional heating system is not needed, and the energy consumption is reduced. In order to realize the desulfurization and denitration under low-temperature working conditions, the flue waste gas is cooled through the waste heat recovery device, so that the waste heat of the flue waste gas is fully utilized. The coke serves as a main catalyst for desulfurization and denitration and comes from a coking plant, the source is sufficient, and waste loss is avoided. The method disclosed by the invention can be widely applied to pollution treatment and integrated utilization of coke oven heated flue waste gas in coking production enterprises.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

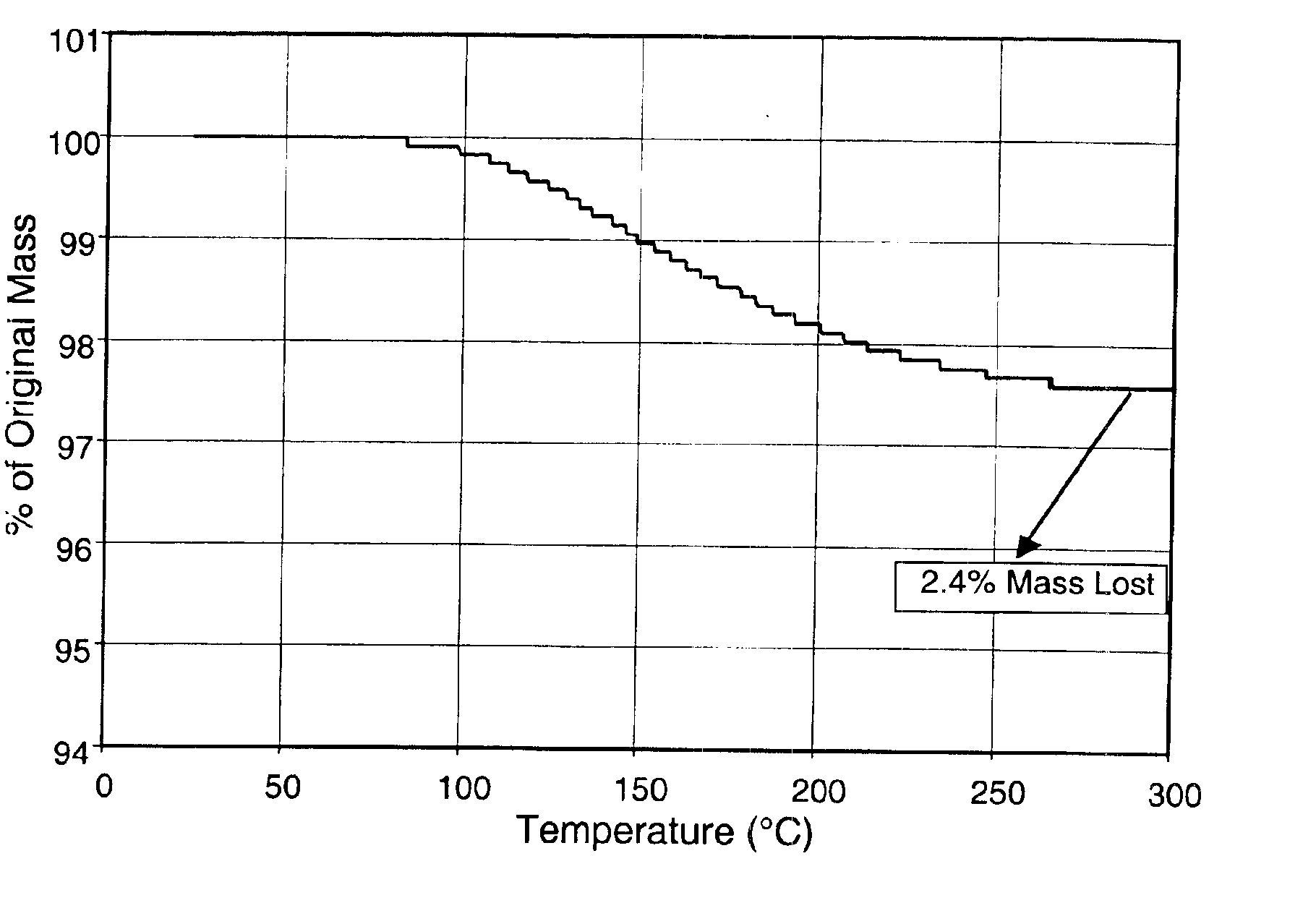

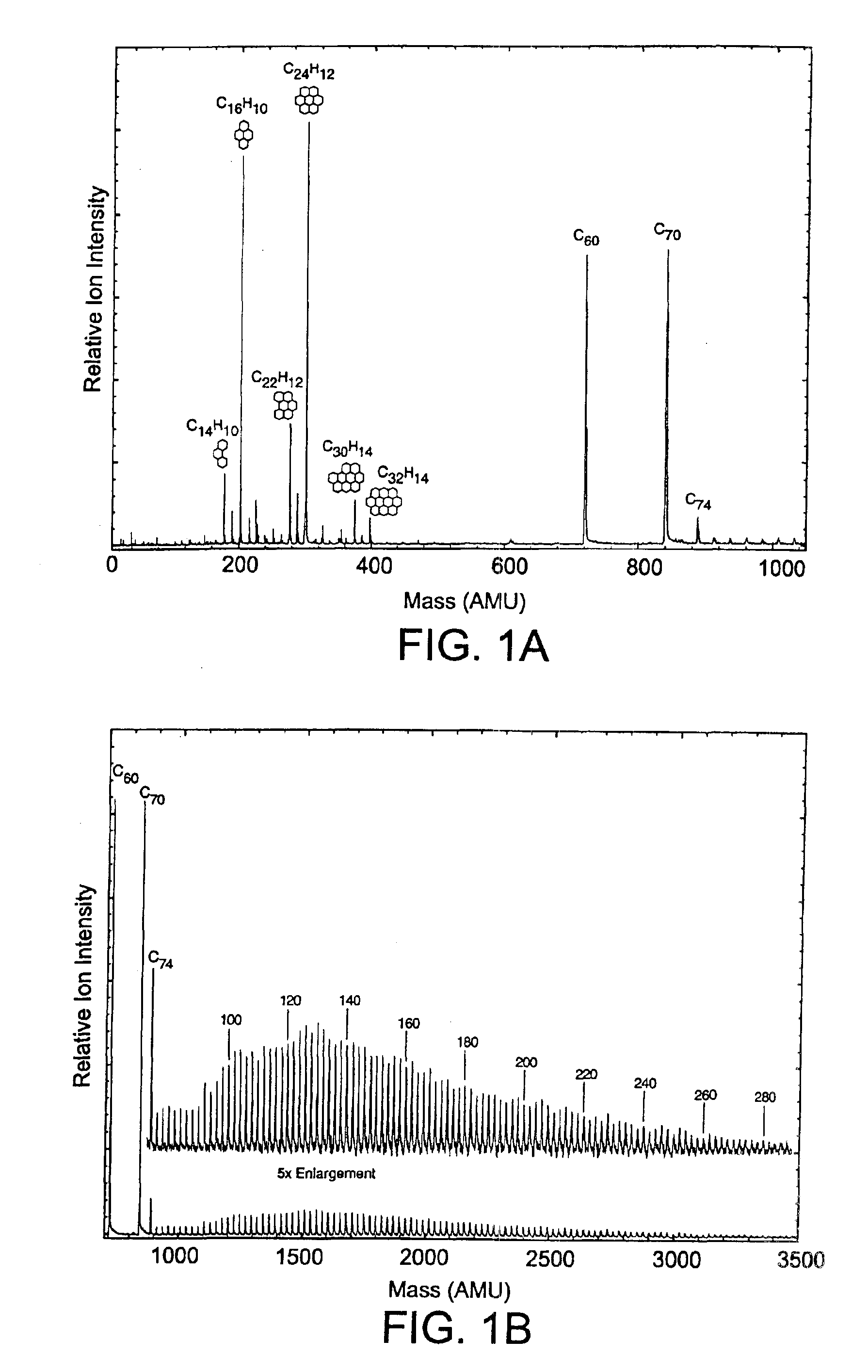

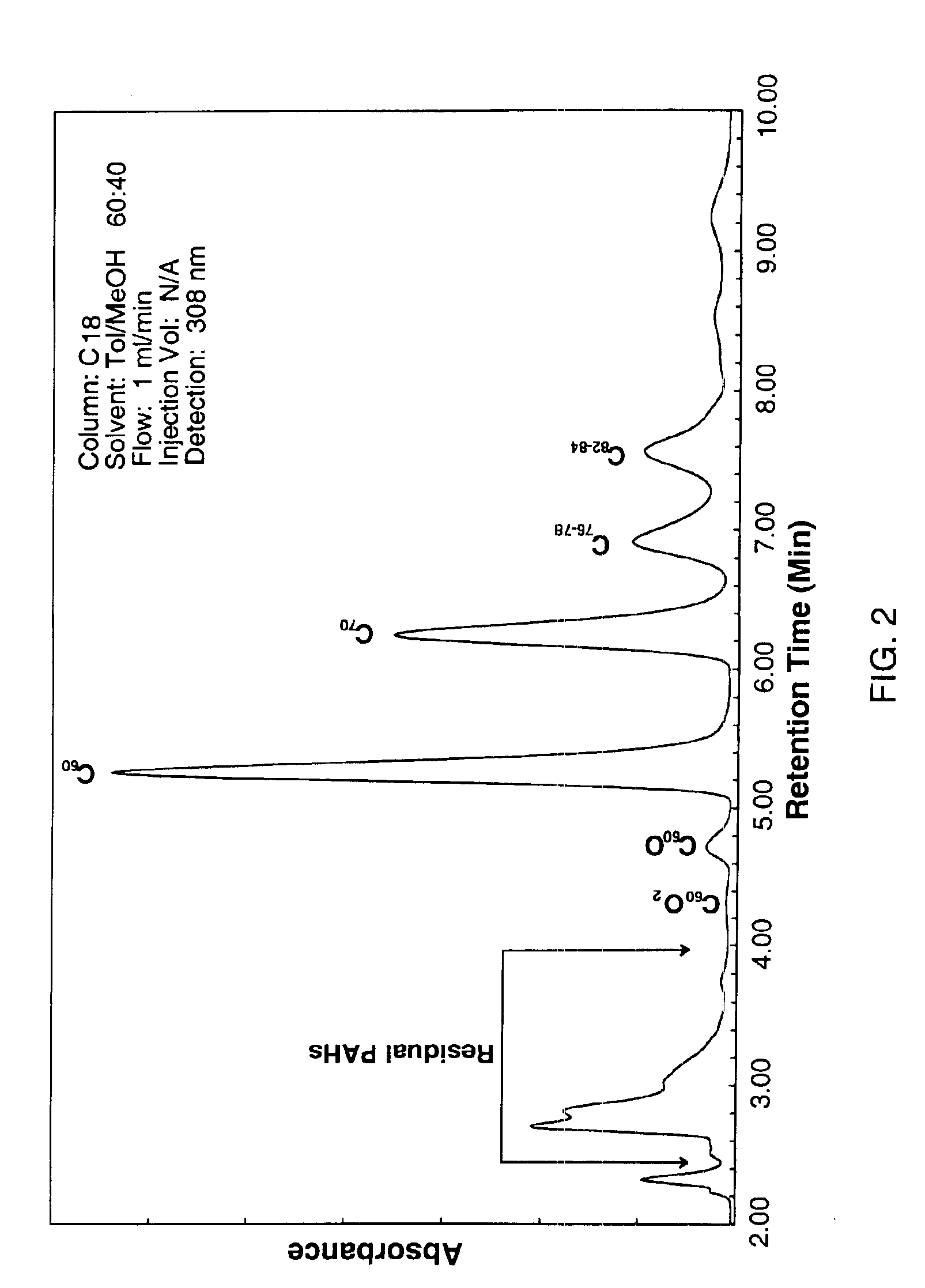

Process for the removal of impurities from combustion fullerenes

InactiveUS6923915B2Without incurring undo costEfficient removalMaterial nanotechnologyFullerenesO-XylenePurification methods

The invention generally relates to purification of carbon nanomaterials, particularly fullerenes, by removal of PAHs and other hydrocarbon impurities. The inventive process involves extracting a sample containing carbon nanomaterials with a solvent in which the PAHs are substantially soluble but in which the carbon nanomaterials are not substantially soluble. The sample can be repeatedly or continuously extracted with one or more solvents to remove a greater amount of impurities. Preferred solvents include ethanol, diethyl ether, and acetone. The invention also provides a process for efficiently separating solvent extractable fullerenes from samples containing fullerenes and PAHs wherein the sample is extracted with a solvent in which both fullerenes and PAHs are substantially soluble and the sample extract then undergoes selective extraction to remove PAHs. Suitable solvents in which both fullerenes and PAHs are soluble include o-xylene, toluene, and o-dichlorobenzene. The purification process is capable of treating quantities of combustion soot in excess of one kilogram and can produce fullerenes or fullerenic soot of suitable purity for many applications.

Owner:FRONTIER CARBON CORP

Production of pseudotyped recombinant AAV virions

InactiveUS20070015238A1Highly purified and concentratedEfficient and large-scale productionVectorsTissue culturePurification methodsSerotype

Vectors that encode Adeno-Associated Virus (AAV) Rep and Cap proteins of different serotypes and Adenovirus transcription products that provide helper functions were used to produce pseudotyped recombinant AAV (rAAV) virions. Purification methods generated pseudotyped rAAV virion stocks that were 99% pure with titers of 1×1012−1×1013 vector genomes / ml.

Owner:SNYDER RICHARD O +12

Use of human plasma hyaluronidase in cancer treatment

InactiveUS7148201B2Control of level of activityQuick filterBiocidePeptide/protein ingredientsPurification methodsScreening method

Owner:RGT UNIV OF CALIFORNIA

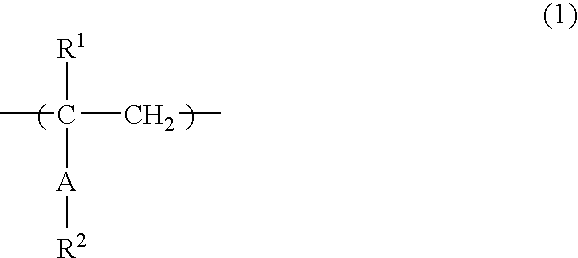

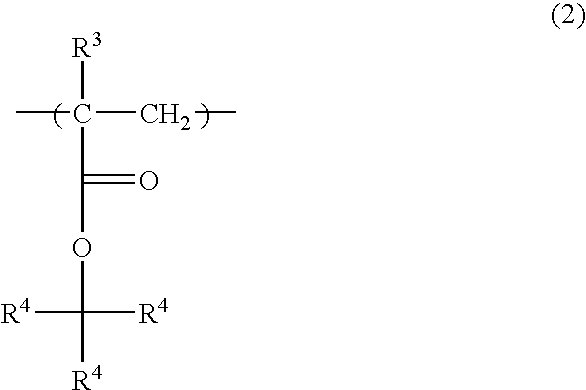

Fluorine-containing polymer, purification method, and radiation-sensitive resin composition

ActiveUS20090202945A1Great depth of focusQuantity minimizationPhotosensitive materialsSemiconductor/solid-state device manufacturingPurification methodsNitrogen

An object of the present invention is to provide a novel fluorine-containing polymer, a radiation-sensitive resin composition for liquid immersion lithography which contains the fluorine-containing polymer, which leads to a pattern having an excellent shape and excellent depth of focus, wherein the amount of an eluted component in a liquid for liquid immersion lithography such as water that comes in contact with the resist during exposure in liquid immersion lithography is little, and which provides a larger receding contact angle between the resist film and the liquid for liquid immersion lithography such as water, and a method for purifying the fluorine-containing polymer. The present resin composition comprises a novel fluorine-containing polymer (A) containing repeating units represented by the general formulae (1) and (2) and having Mw of 1,000-50,000, a resin (B) having an acid-unstable group, a radiation-sensitive acid generator (C), a nitrogen-containing compound (D) and a solvent (E).

Owner:JSR CORPORATIOON

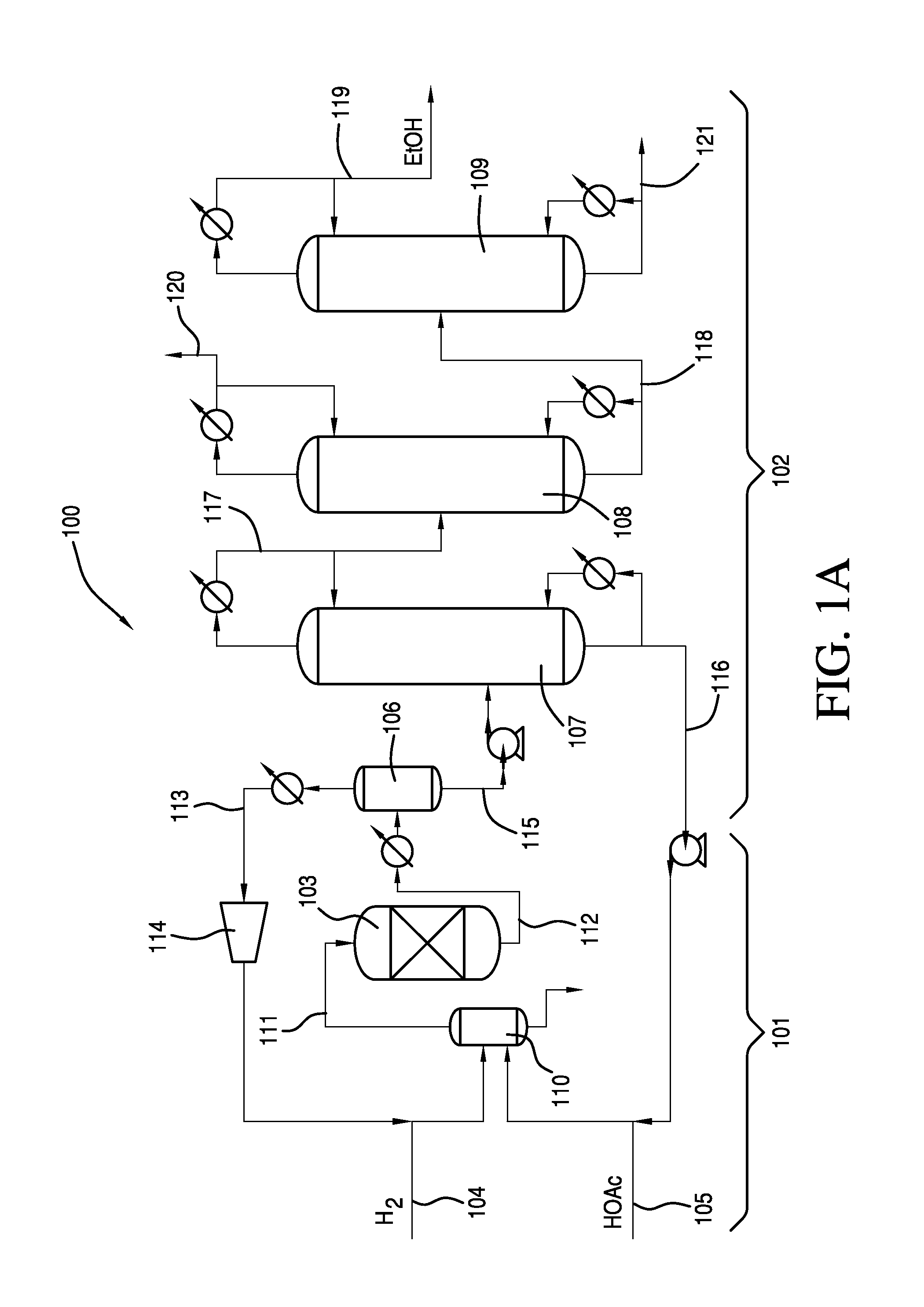

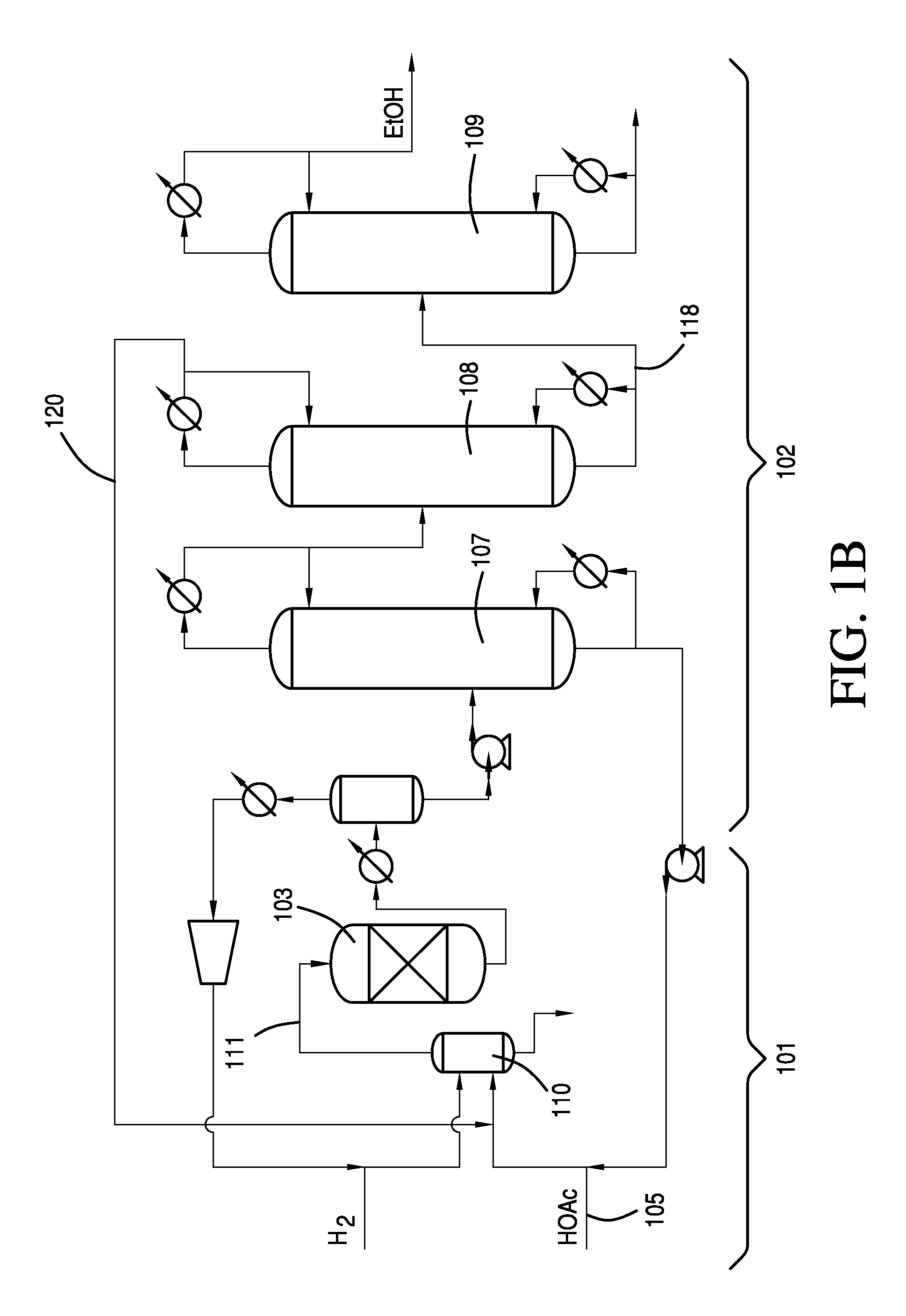

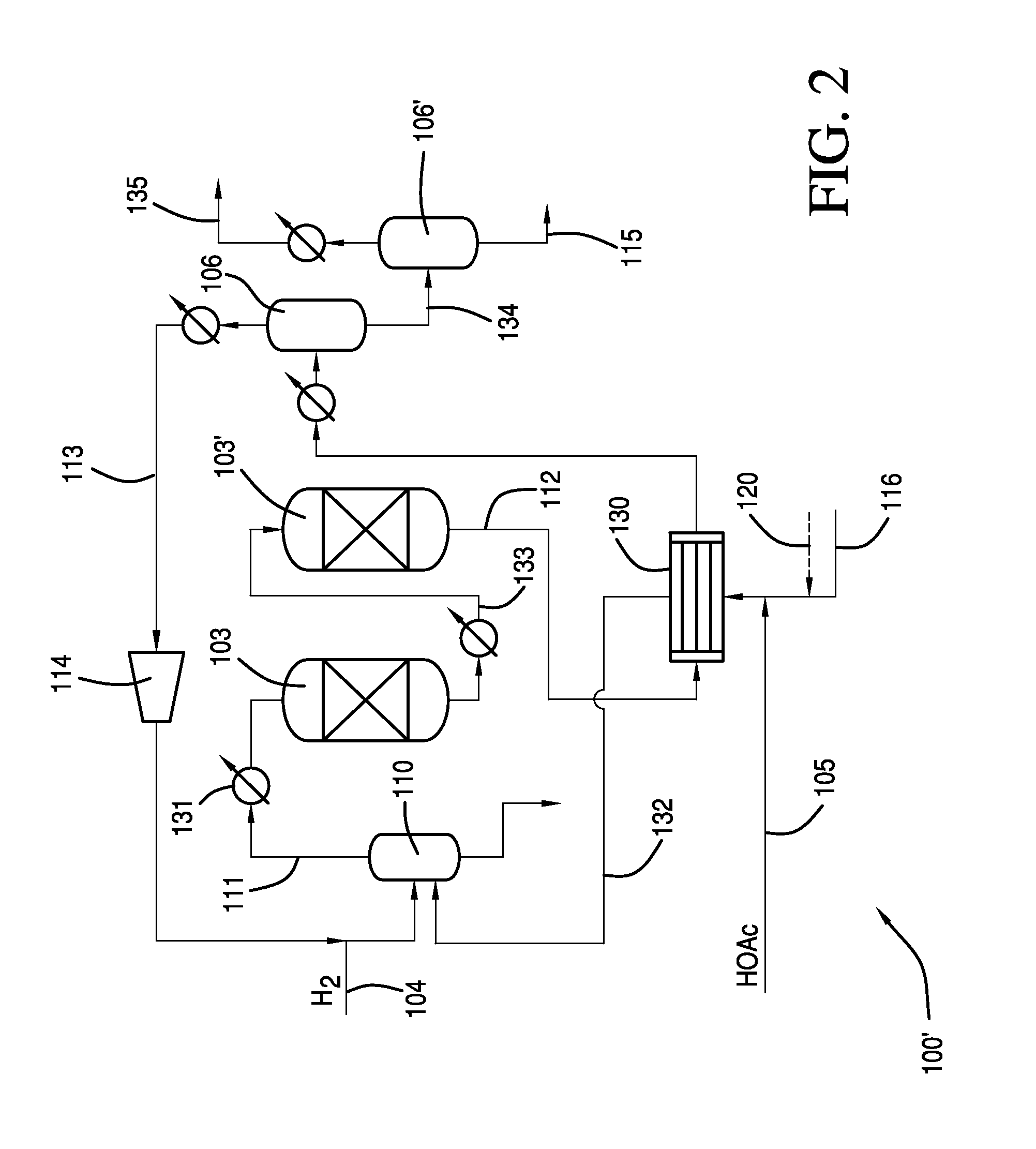

Process for recovering ethanol

InactiveUS20110190547A1Organic compound preparationOxygen compounds preparation by reductionAcetic acidPurification methods

Owner:CELANESE INT CORP

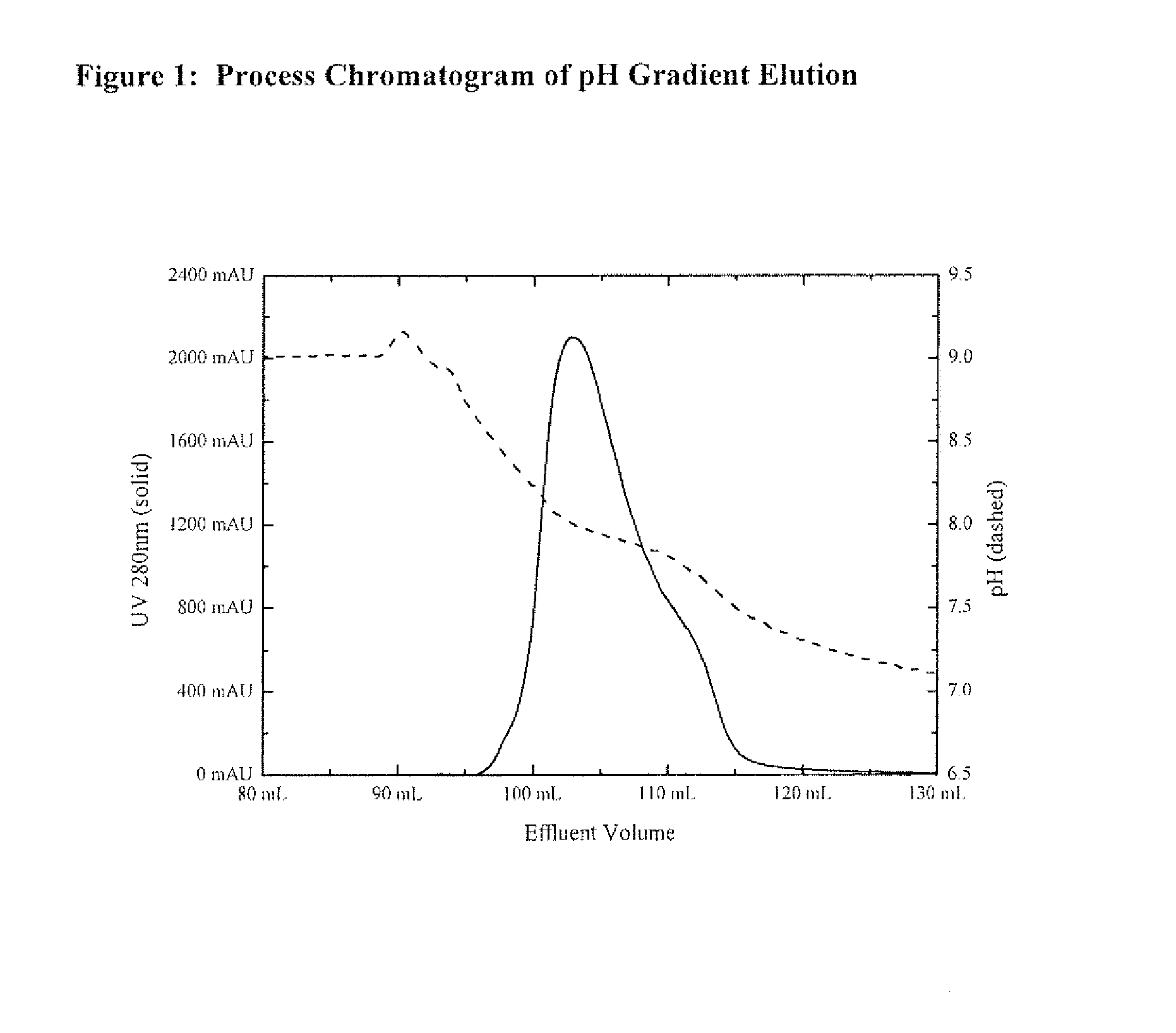

Purification methods for oligonucleotides and their analogs

InactiveUS20060035224A1Rapid and simplified and efficient and methodReduce the number of stepsSugar derivativesMicrobiological testing/measurementPurification methodsIon exchange

The present invention discloses methods for separating oligonucleotides from impurities. In the methods of the invention, a target oligonucleotide, in a mixture comprising the target oligonucleotide and an impurity, is separated from the impurity using a titratable anion exchange composition. The target oligonucleotide is bound to the titratable anion exchange composition and an eluting solution which increases in pH over time is passed through the titratable anion exchange composition with the target oligonucleotide bound thereon. Preferably, the eluting solution does not substantially increase its salt concentration. The target oligonucleotide is eluted and thereby separated from the impurity which either elutes at a lower pH or a higher pH than the target oligonucleotide.

Owner:AVECIA BIOTECH LTD

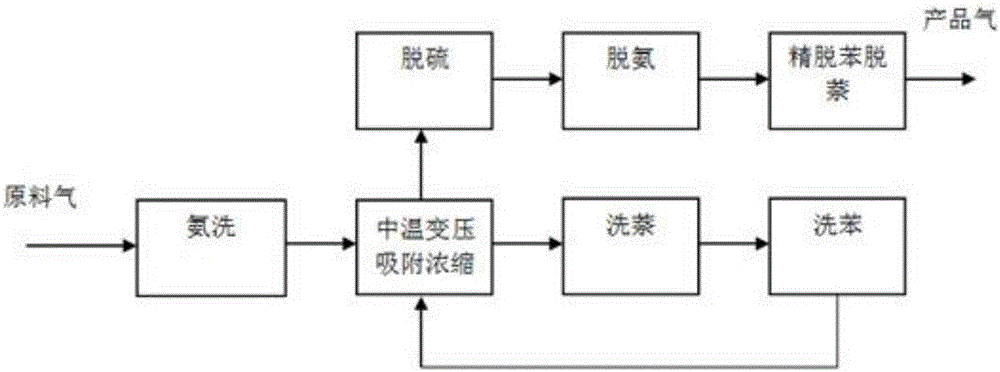

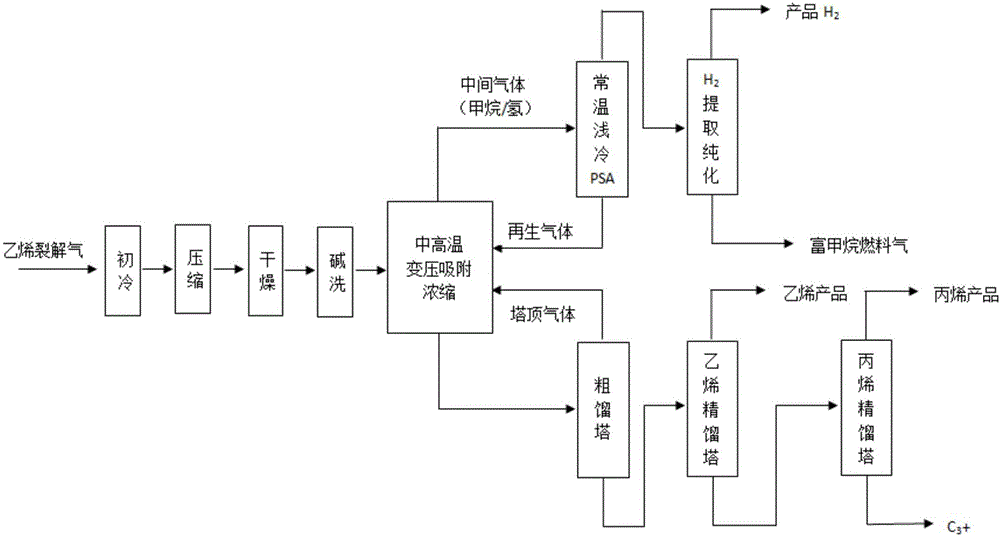

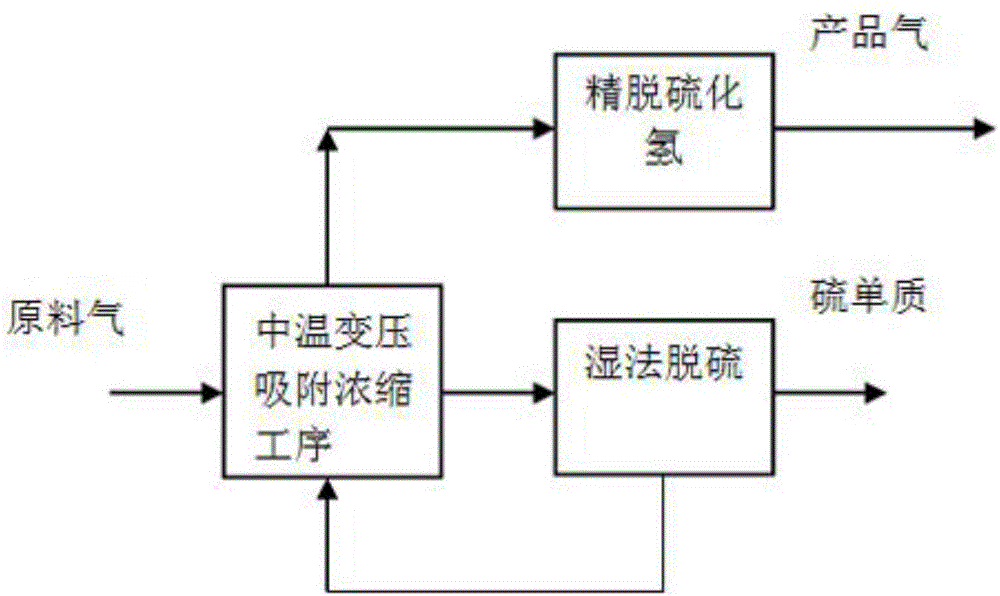

Full-temperature-range pressure swing adsorption gas separation, refinement and purification method

ActiveCN105749699AReduce energy consumptionBroaden the scope of adsorption separation applicationsSolidificationLiquefactionEnergy gradientPurification methods

The invention discloses a full-temperature-range pressure swing adsorption gas separation, refinement and purification method.By means of the difference of the temperatures and pressures of different raw material gases and the difference of the adsorption separation coefficients and physical chemistry properties of all components in the raw material gases in the temperature range of 80-200 DEG C and the pressure range of 0.03-4.0 MPa, the adsorption or desorption regeneration operation of the pressure swing adsorption circulation process is adjusted by coupling all separation methods, the adsorption theory that the pressure or temperature swing adsorption separation process is only limited to the adsorption and desorption regeneration circulation operation through pressure or temperature changes is expanded, and therefore all raw material gases are separated, refined and purified by achieving the energy gradient utilization in the gas separation, refinement and purification process and achieving the circulation operation, where adsorption, desorption and regeneration are easily matched and balanced, in the moderate to low cold and moderate to high temperature pressure swing adsorption separation process, and it is changed that a traditional adsorption method is only limited to the auxiliary effect of refinement and purification, and adsorption becomes the basic separation unit operation just as important as refinement, absorption and extraction separation.

Owner:SICHUAN TECHAIRS

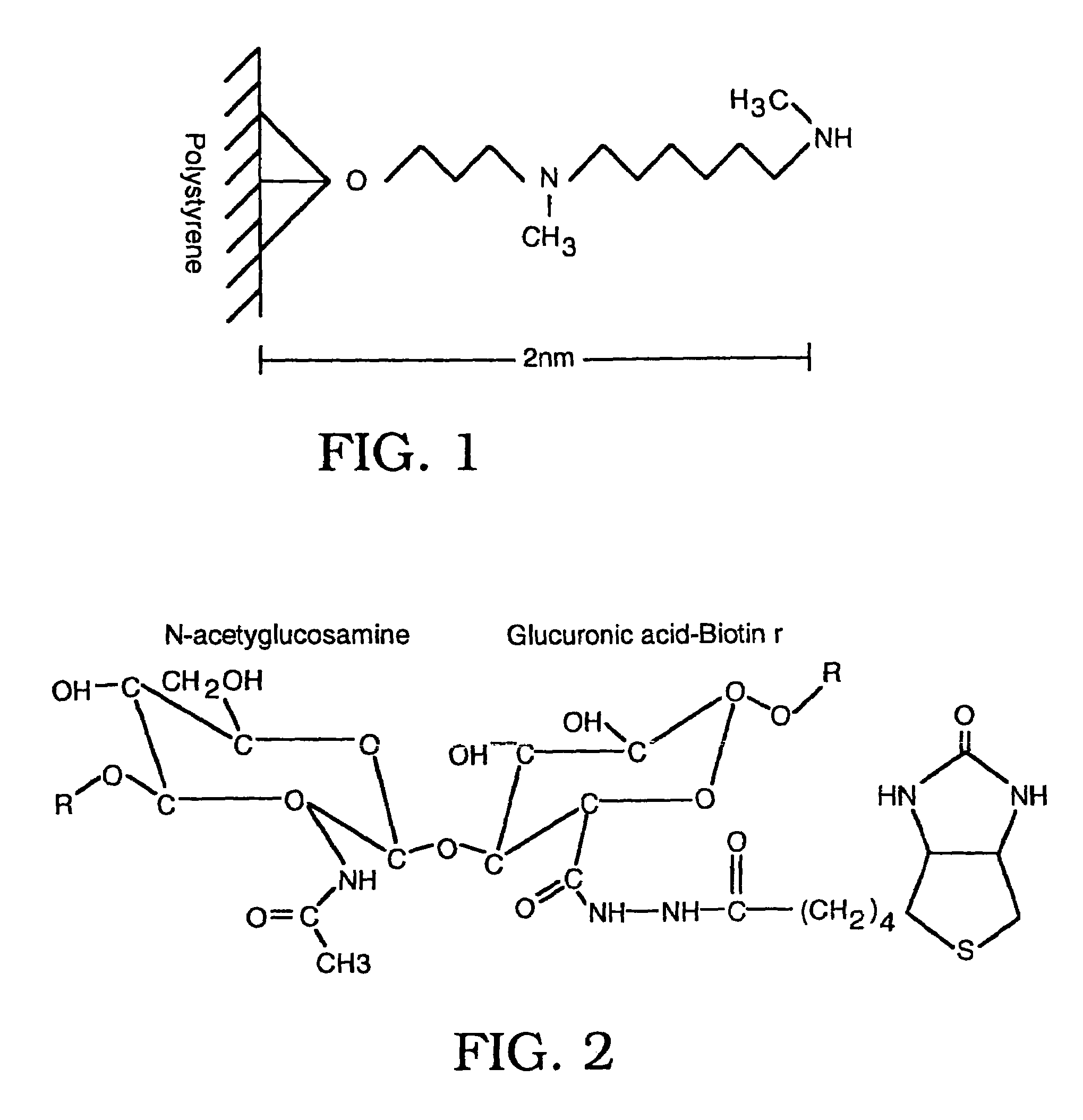

Human plasma hyaluronidase

InactiveUS7105330B2Less likely to induceControl of level of activityPeptide/protein ingredientsMicroorganism based processesPurification methodsScreening method

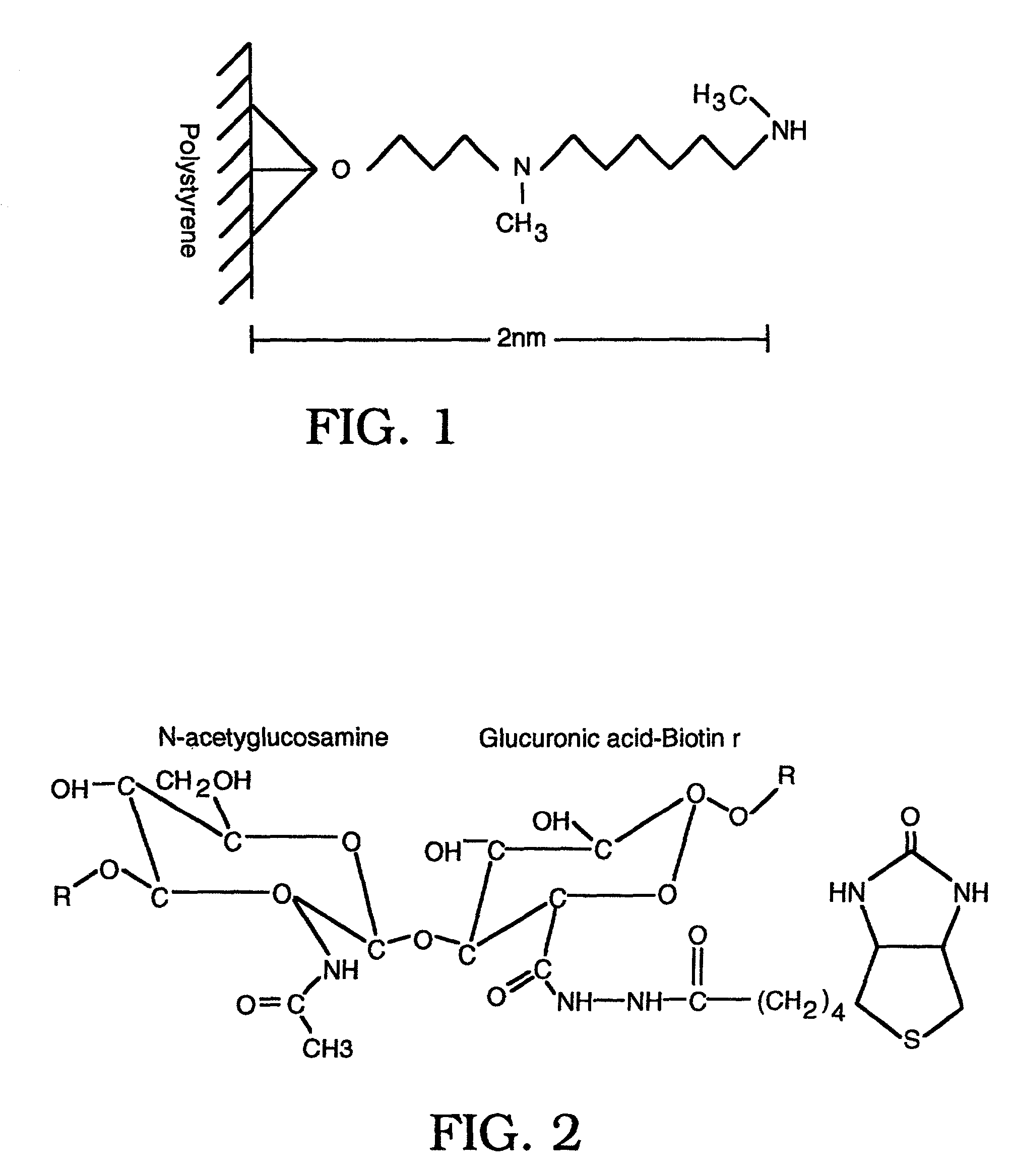

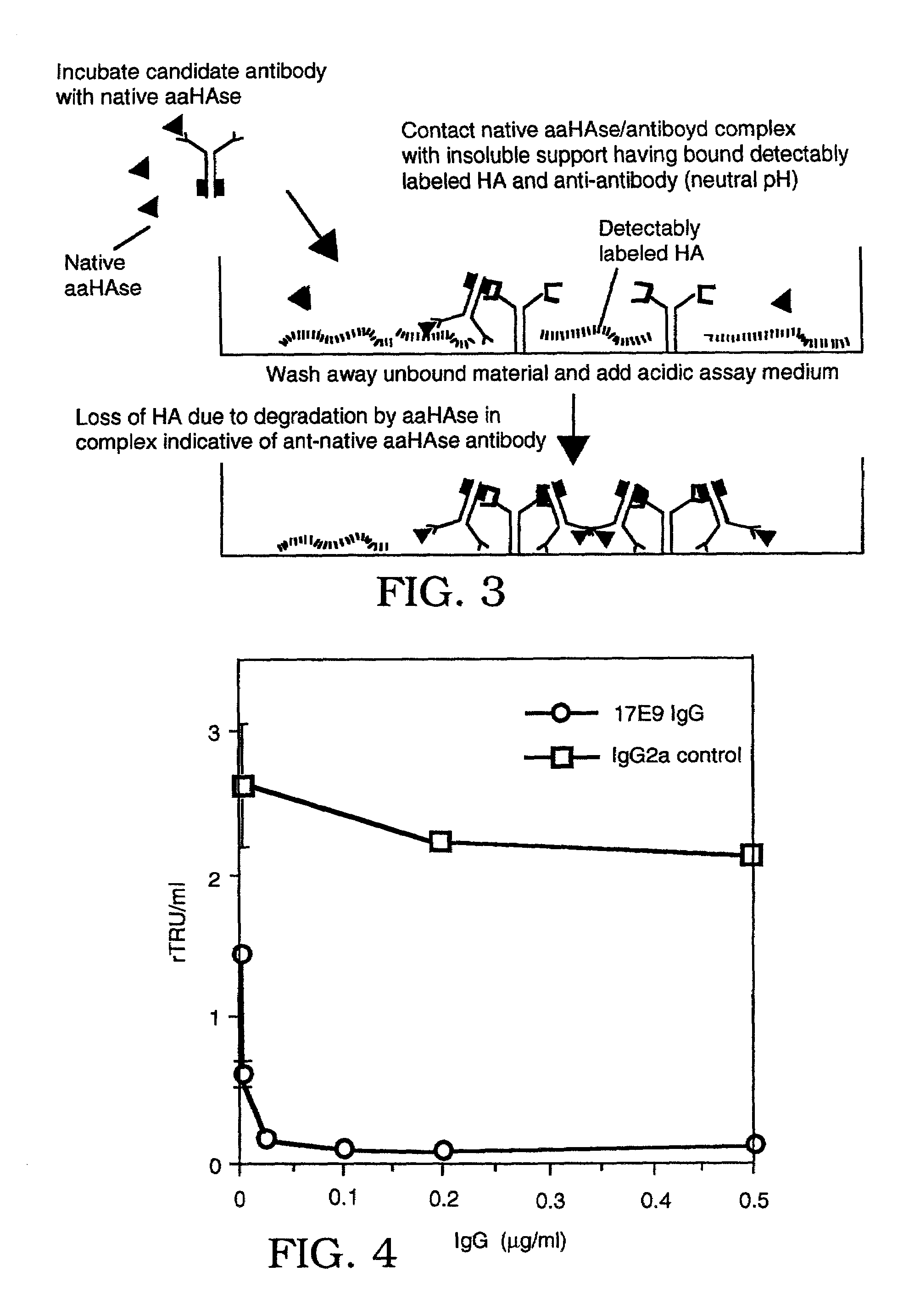

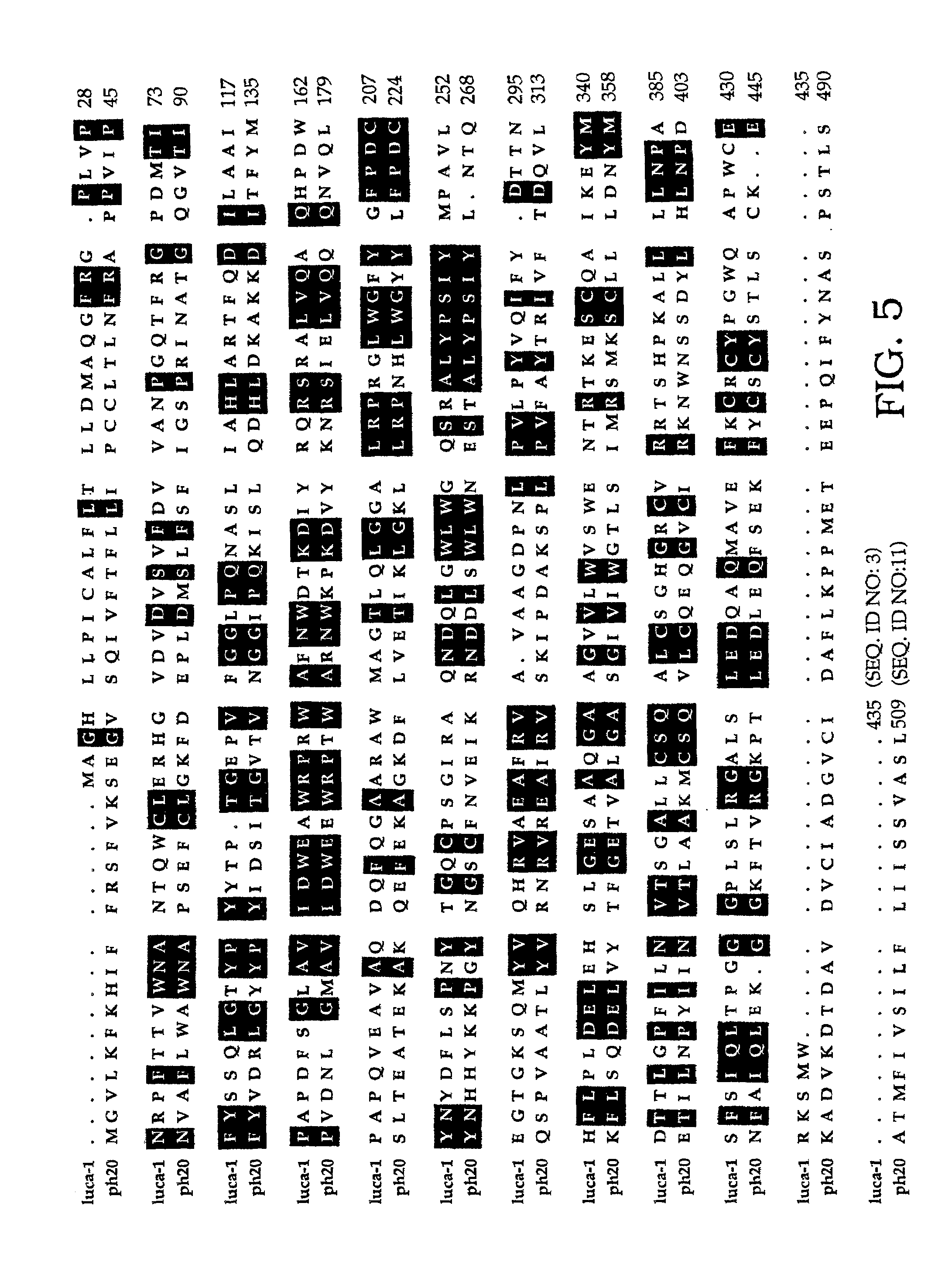

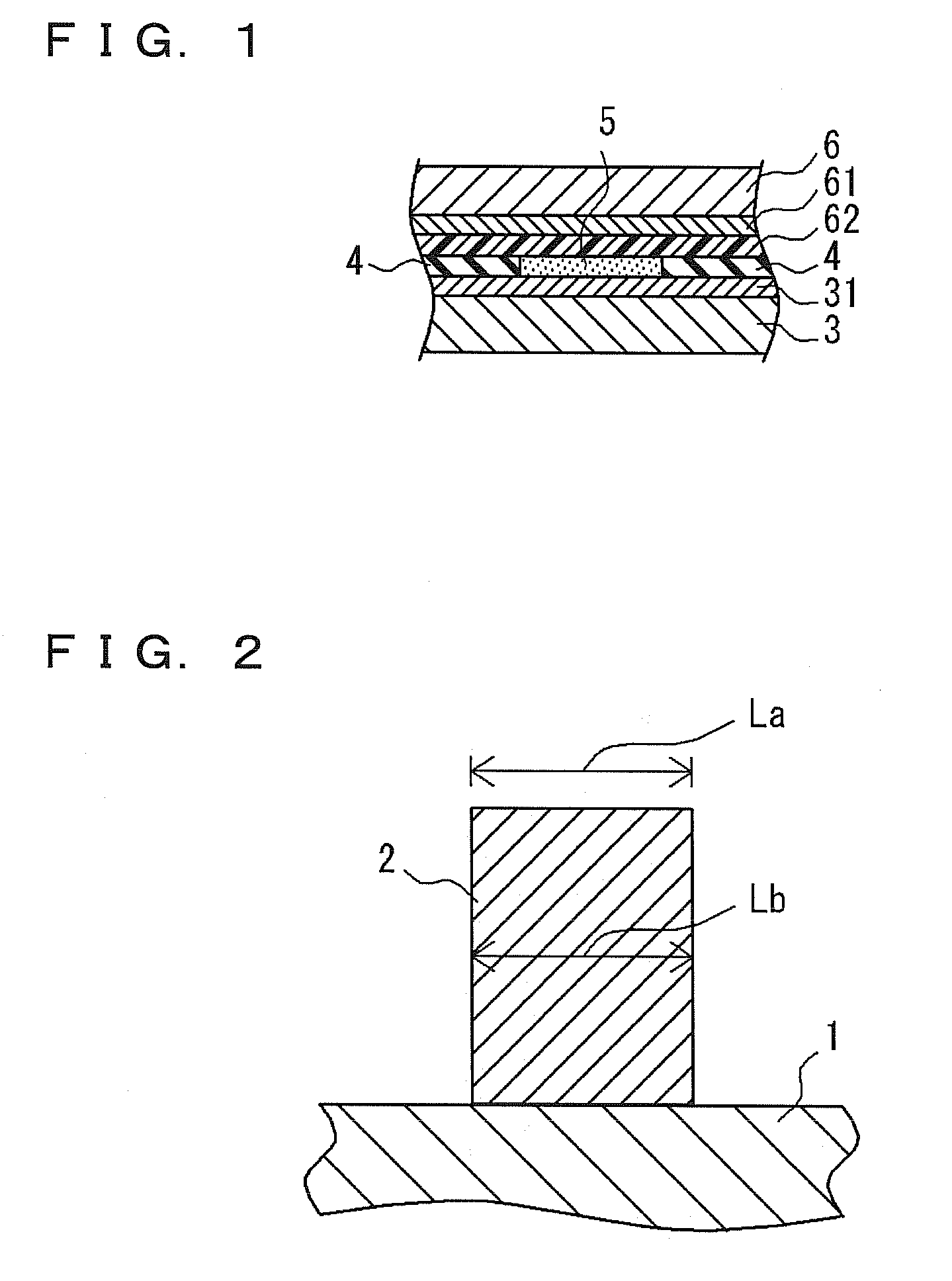

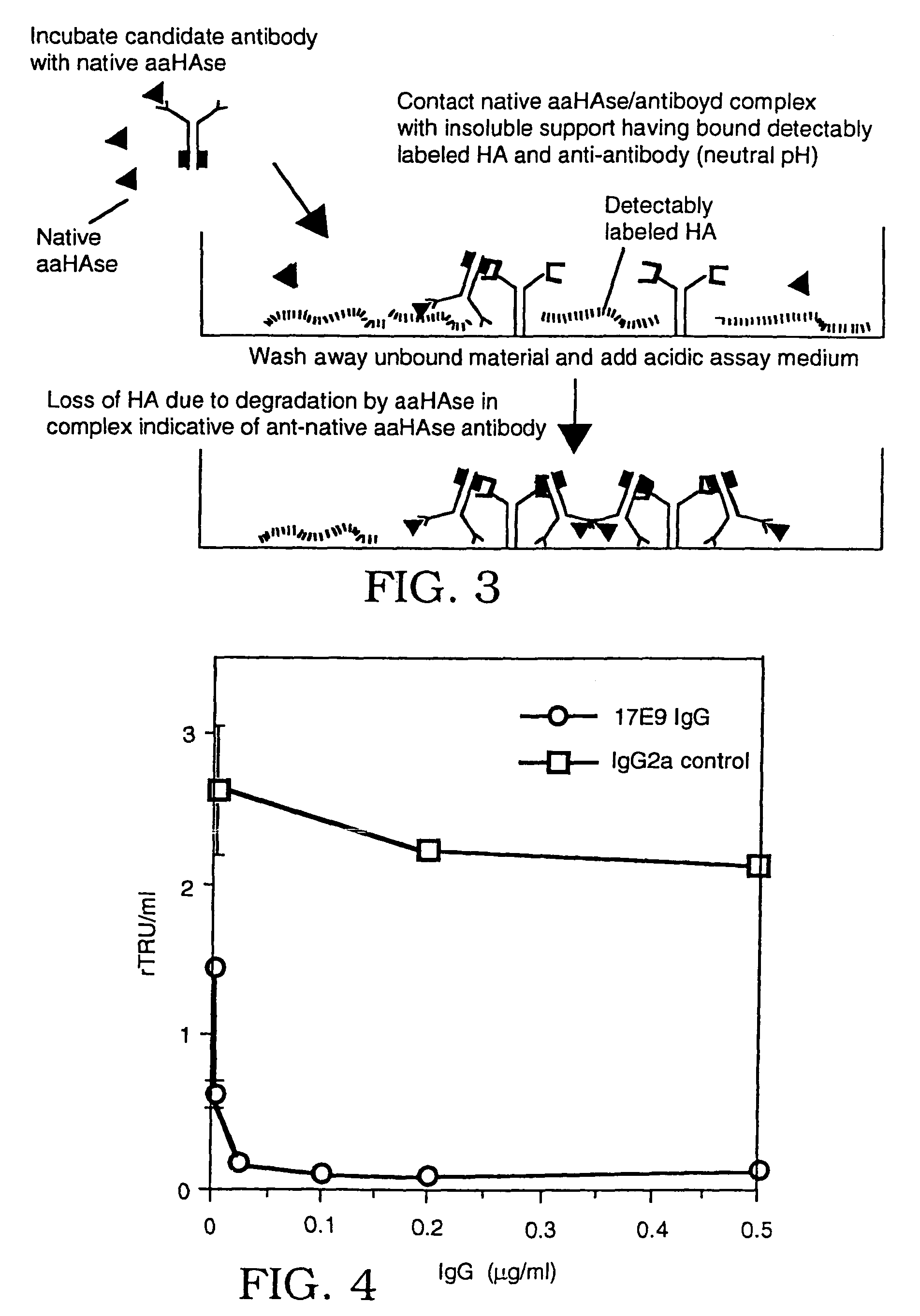

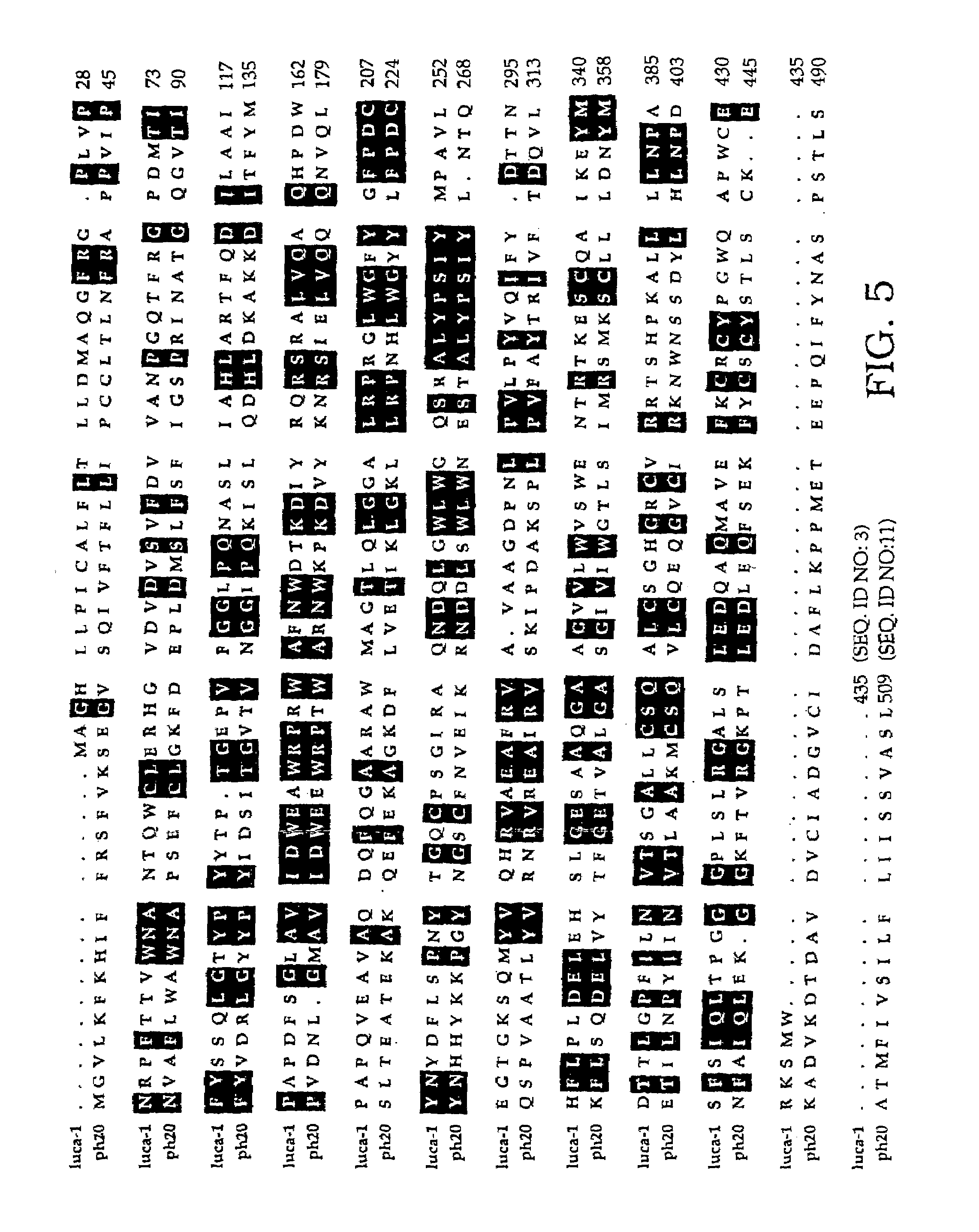

The invention is based on the discovery of methods for purification of an acid active hyaluronidase found in human plasma (hpHAse), including both biochemical and immunoaffinity purification methods. The method of immunoaffinity purification of the invention is based on the discovery of a method for identifying antibodies that specifically bind native hpHAse (anti-native hpHAse antibodies), and anti-native hpHAse antibodies identified by this screening method. The invention also features an assay for sensitive detection of HAse activity using biotinylated hyaluronic acid (bHA). Purification and characterization of hpHAse lead to the inventors' additional discovery that hpHAse is encoded by the LuCa-1 gene, which gene is present in the human chromosome at 3p21.3, a region associated with tumor suppression. The invention additionally features methods of treating tumor-bearing patients by administration of hpHAse and / or transformation of cells with hpHAse-encoding DNA.

Owner:RGT UNIV OF CALIFORNIA

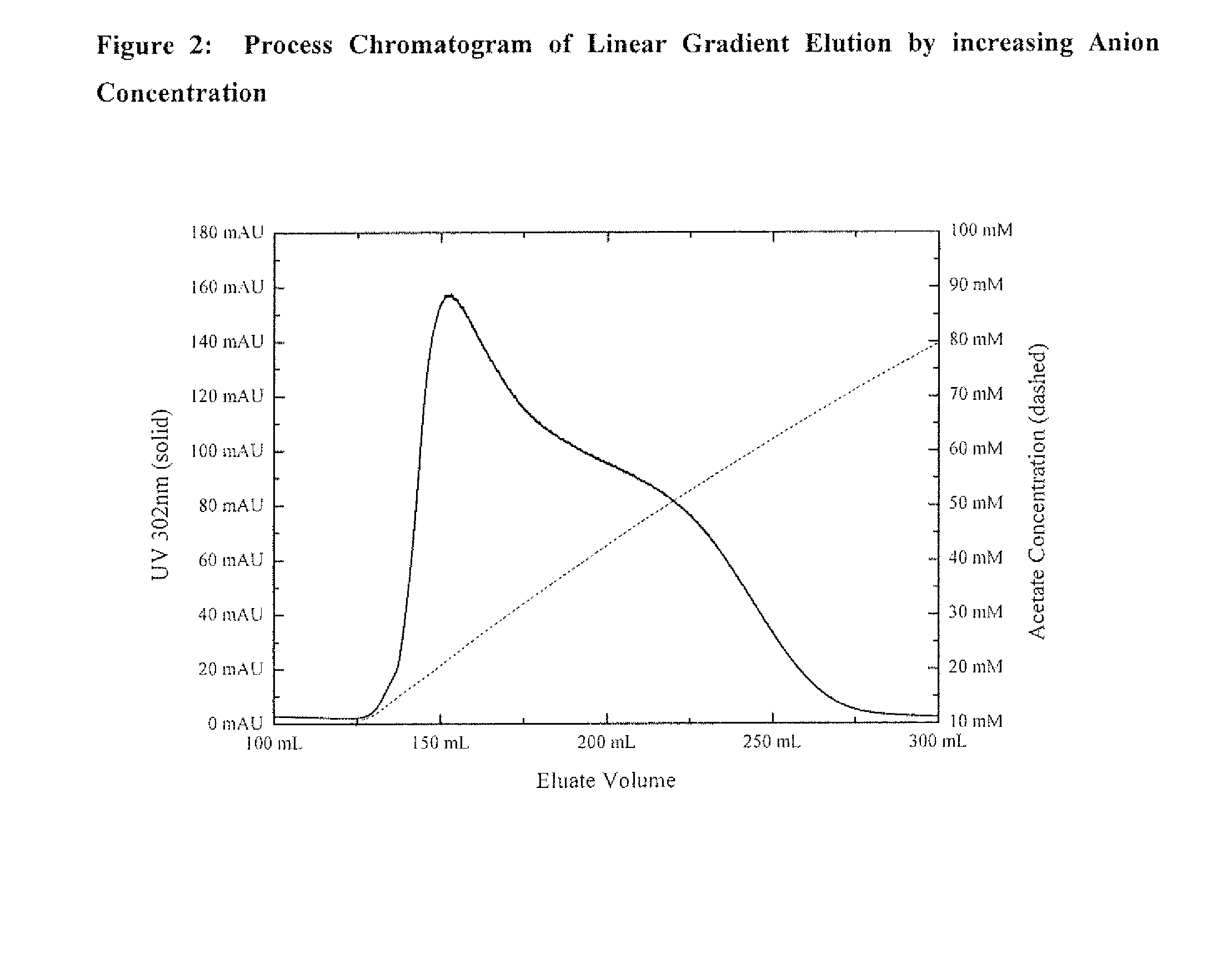

Protein purification methods to reduce acidic species

ActiveUS20130338344A1Reduce the amount requiredImmunoglobulins against cytokines/lymphokines/interferonsPeptide preparation methodsPurification methodsProtein purification

The instant invention relates to the field of protein production and purification, and in particular to compositions and processes for controlling the amount of charge variants, aggregates, and fragments of a protein of interest, as well as host cell proteins, present in purified preparations by applying particular chromatography conditions during such protein purification.

Owner:ABBVIE INC

Method for the purification of ionic polymers

InactiveUS6168719B1Efficient removalReduce the amount requiredSolid sorbent liquid separationSeparation devicesPurification methodsUltrafiltration

To provide a method for purification of the ionic polymer compound comprising efficiently removing low-molecular impurities, for example, ionic remaining monomers, which are charged identically to the ionic polymer compound from the ionic polymer compound in a shorter period of time. A method for purification of an ionic polymer compound, characterized by removing low-molecular impurities, such as ionic remaining monomers, by the use of an ultrafiltration membrane and / or a reverse osmosis membrane from an aqueous solution containing the ionic polymer compound and low-molecular impurities which are charged identically to the ionic polymer compound, under conditions that a concentration of the ionic polymer compound is from 7 to 20% by weight, and that an amount of charges of the ionic polymer compound in the aqueous solution is 0.30 gram-equivalent / liter or more.

Owner:KAO CORP

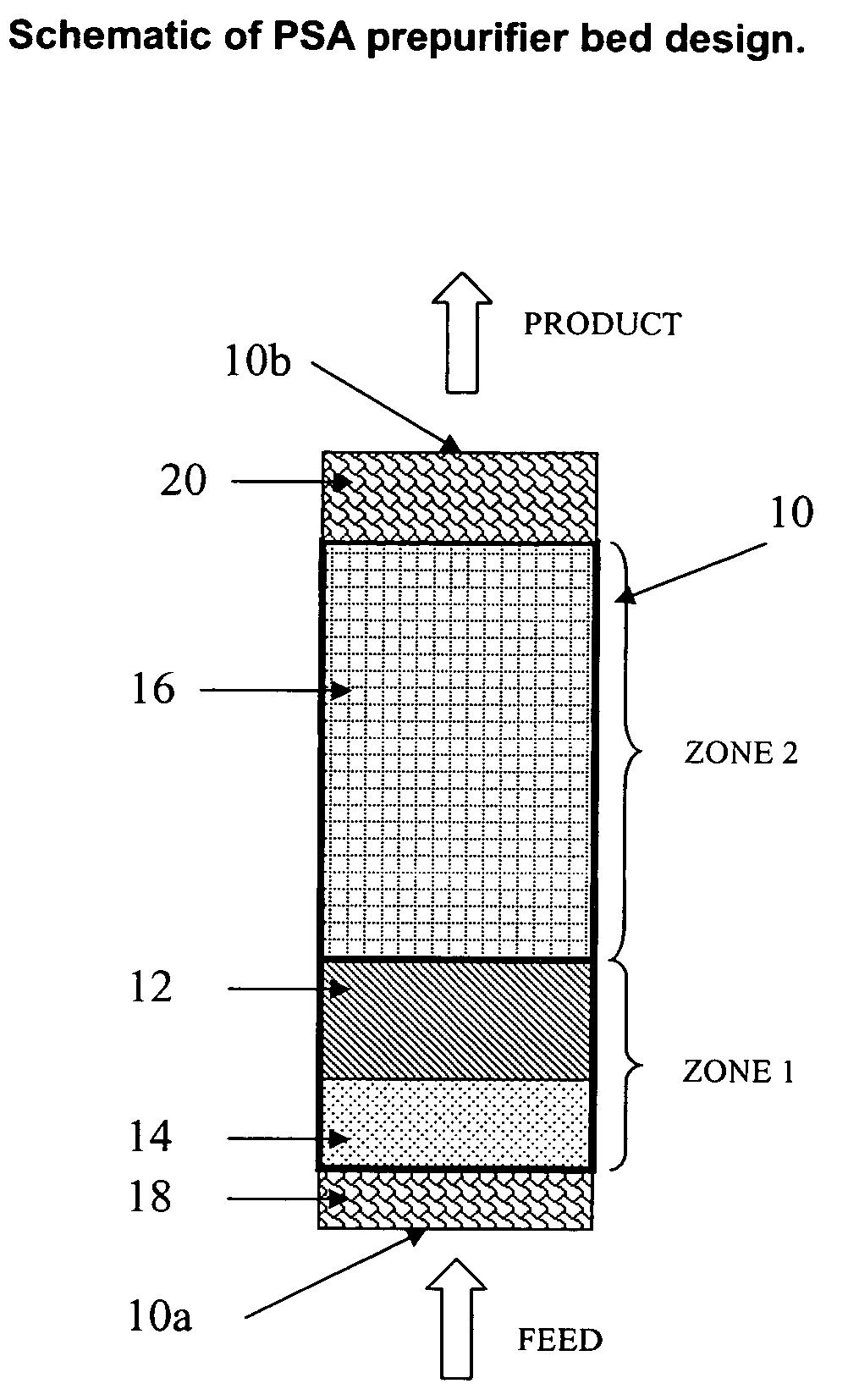

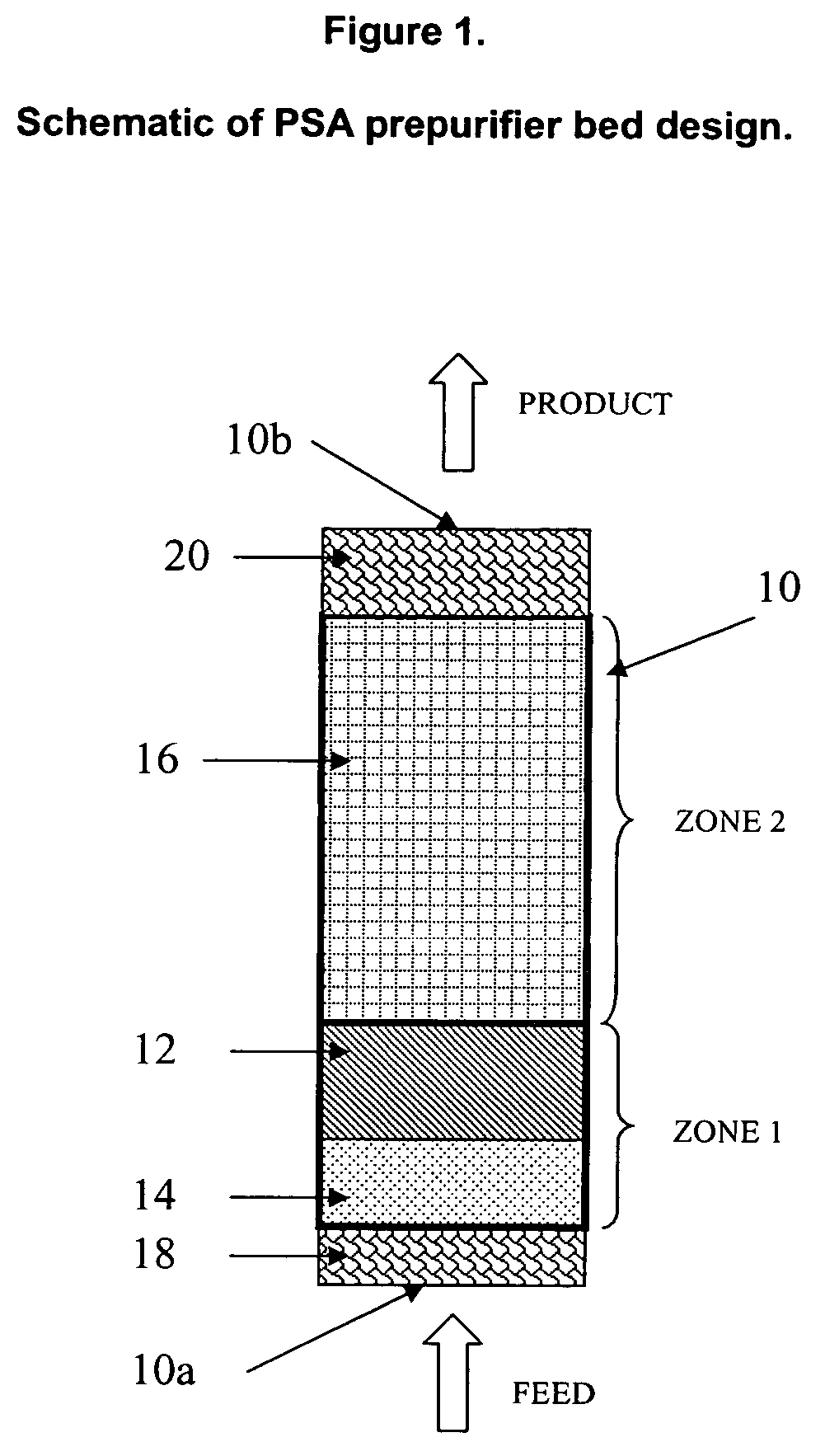

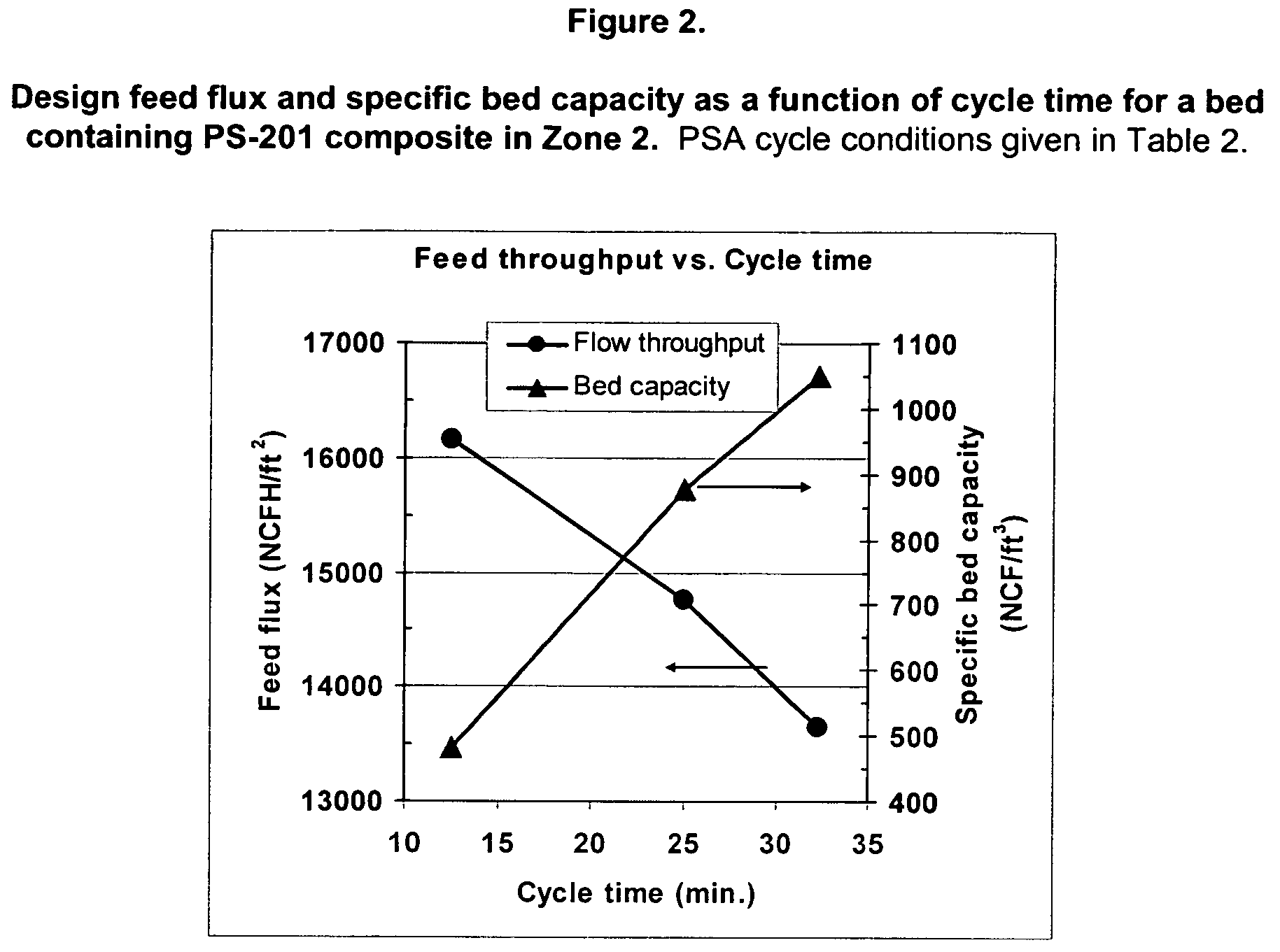

Adsorbents for pressure swing adsorption systems and methods of use therefor

InactiveUS7713333B2Reduce frequencyMaintain purityGas treatmentIsotope separationPurification methodsSorbent

The present invention relates generally to adsorbents for use in pressure swing adsorption (PSA) prepurification processes. The invention more particularly relates to the design of adsorbent zones to be used in PSA prepurification processes that are expected to provide for extensions in PSA cycle time, thereby reducing blowdown loss and operating costs associated with the process. One particular embodiment of the present invention includes a first adsorption zone containing activated alumina and a second adsorption zone of an alumina-zeolite mixture or composite adsorbent in which the volume of the first zone does not exceed 50% of the total volume of the first and second zone.

Owner:PRAXAIR TECH INC

Viral purification methods

The present invention is directed to an improved method of purifying virus, particularly reovirus. Infectious virus can be extracted from a cell culture with a detergent to produce high titers of virus, and the virus can then be purified by simple steps such as filtration and column chromatography. Viruses and compositions comprising the viruses prepared according to the present invention are also provided.

Owner:ONCOLYTICS BIOTECH

Thermostable strong acid cation resin catalyst and its preparing method

ActiveCN1569334ARaise the partial pressure of the gas phaseImprove uniformityOrganic-compounds/hydrides/coordination-complexes catalystsAlkanePurification methods

The present invention solves the problem that the existing strong acid resin catalyst has bad high temperature mechanical intensity and complex hole purification technics, brings forward a simple preparing method for pressurization polymerization and hole purification method, the pressurization polymerization improves the uniformity of polymer bead body structure and the high temperature mechanical stability for resin, the extraction is executed by solvent naphtha first and the boiling is executed by halogeno-alkane, the hole purification method is simplified. The prepared strong acid cation resin catalyst has high temperature resistant and excellent catalytic activity and its high temperature stability is better than same kind of product.

Owner:KAIRUI ENVIRONMENTAL PROTECTION TECH

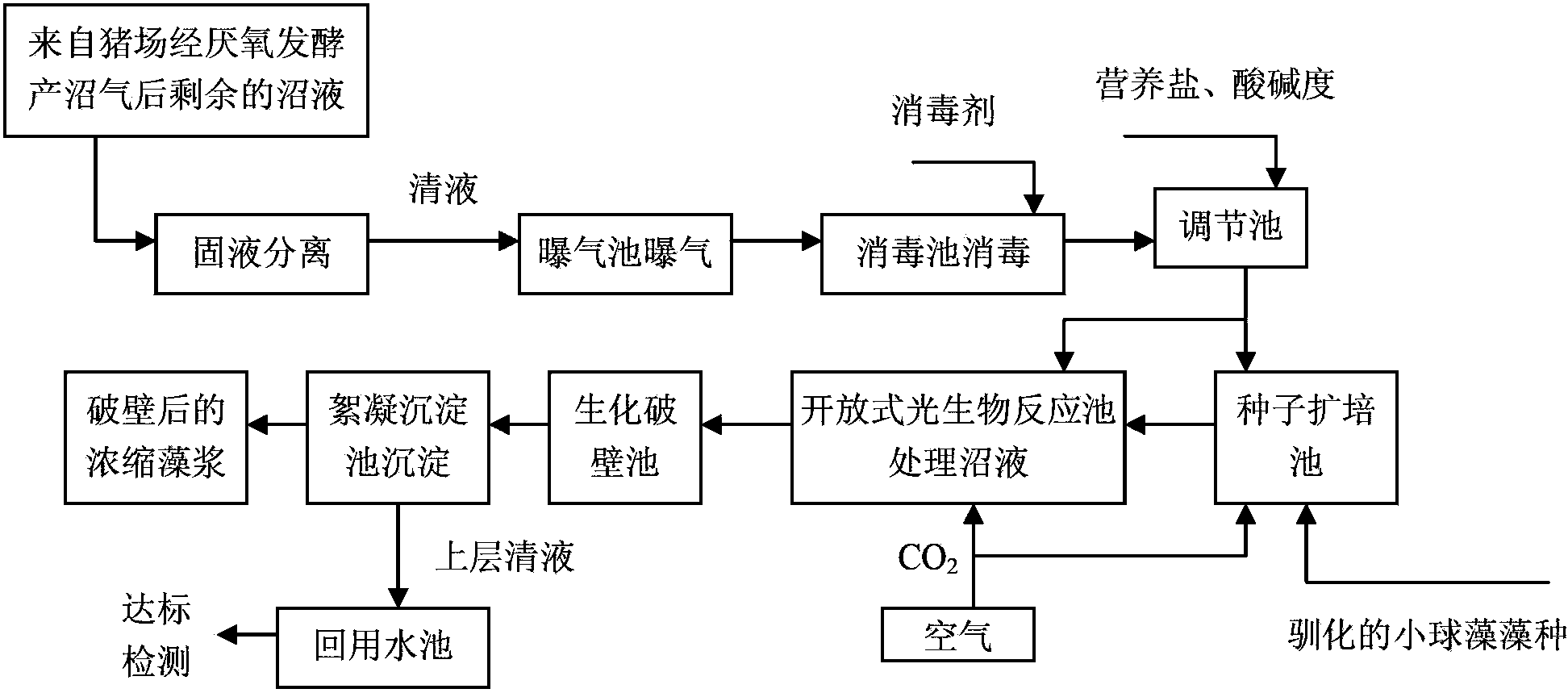

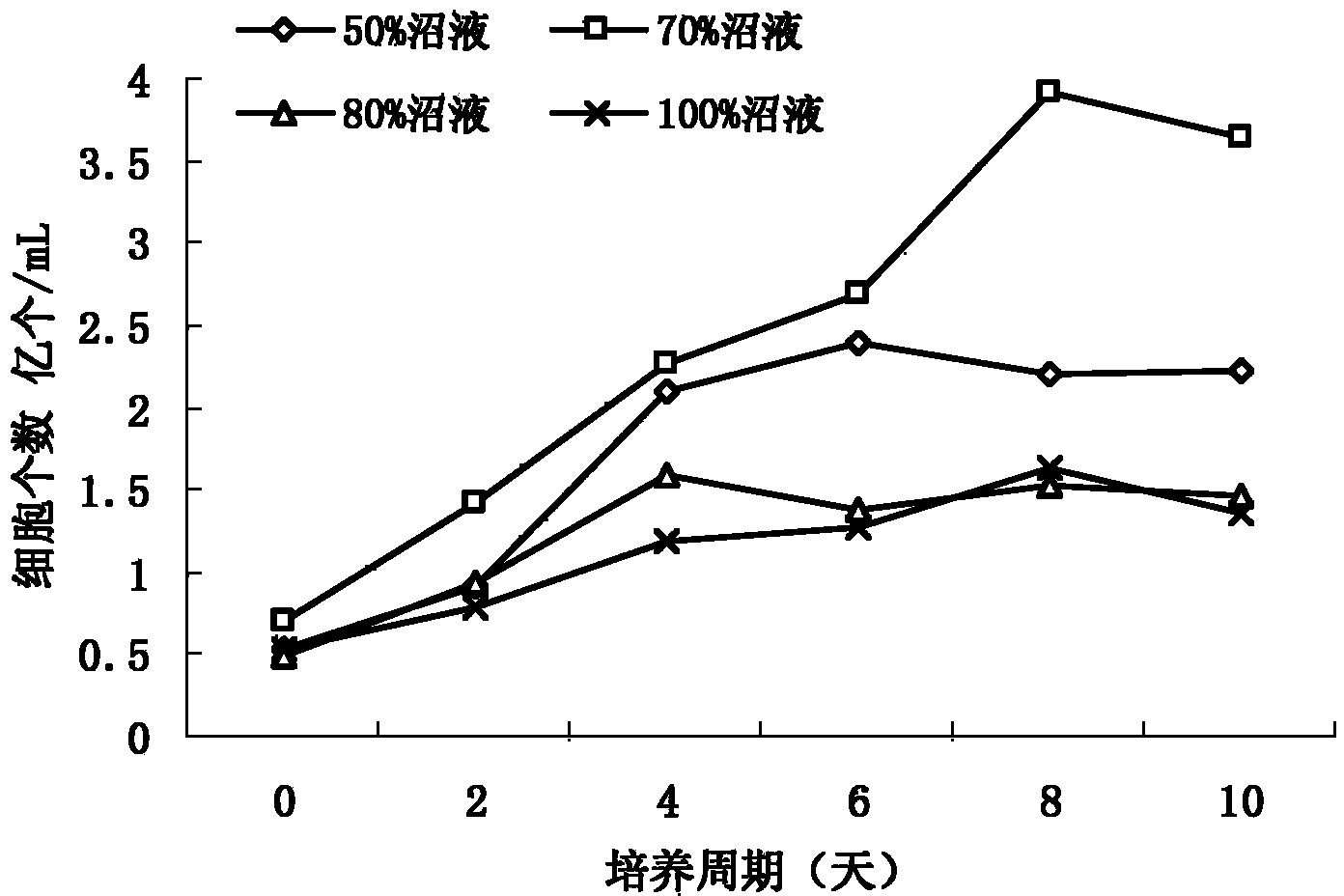

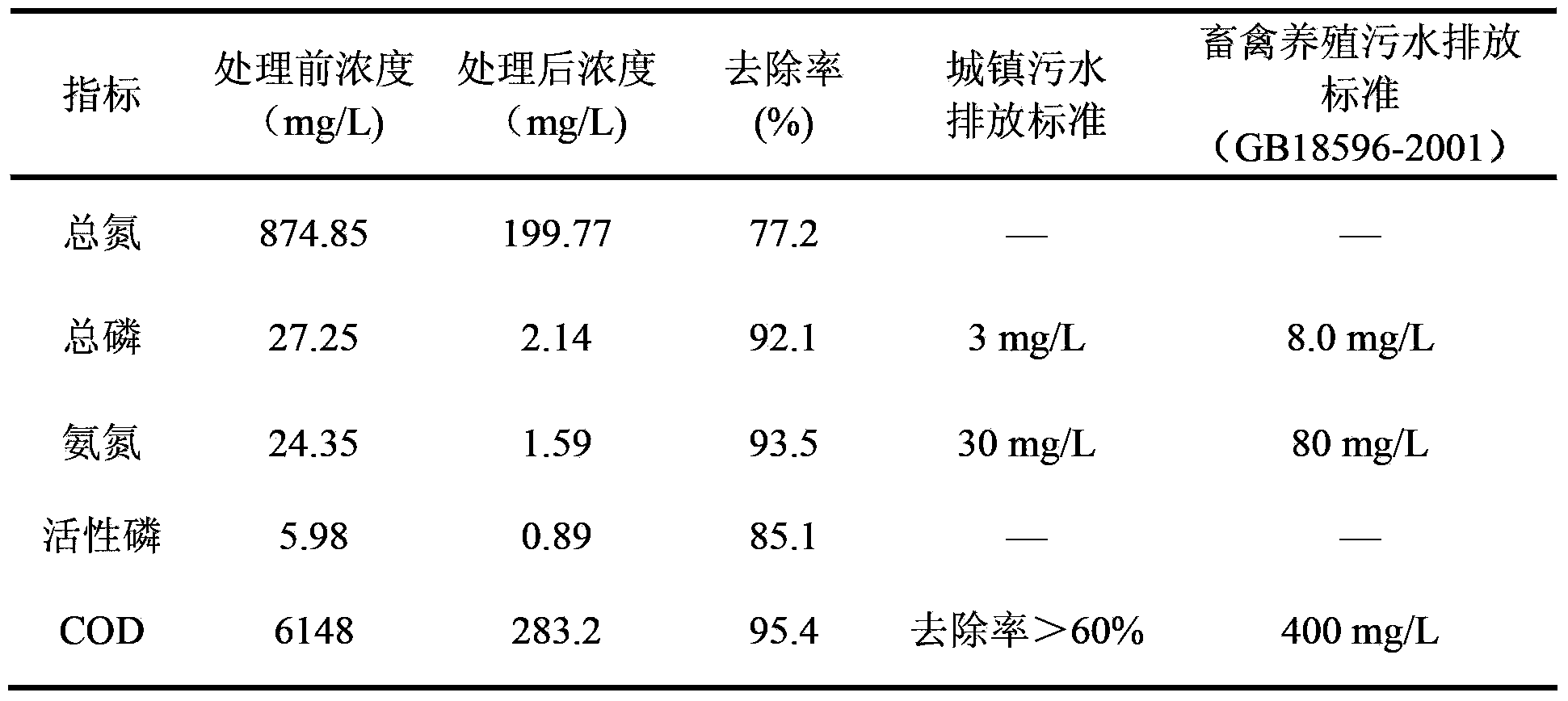

Biogas slurry ecological purification method based on microalgae cultivation

ActiveCN103396950AImprove photosynthetic efficiencyFast growthUnicellular algaeMicroorganism based processesSocial benefitsPurification methods

The invention discloses a biogas slurry ecological purification method based on microalgae cultivation. The method comprises the following steps: (1) biogas slurry pretreatment; (2) habituated culture of autotrophic microalgae, namely, obtaining algae strains capable of rapidly growing in 70%-100% biogas slurry; (3) preparation of a seed solution; (4) a biogas slurry purification method during growing of microalgae, namely, after expanded cultivation, inoculating the habituated algae species into an open photobioreactor for cultivation, obtaining chlorella biomass growing by high density through a semi-continuous culture method and optimized methods such as fed-batch cultivation, and purifying the biogas slurry; (5) biochemical breaking of microalgae cell walls, namely, introducing the microalgae cells into a biochemical wall breaking pool, putting freshwater fish into the pool, and obtaining algae slurry subjected to wall breaking; and (6) collection of the microalgae cells and recycling of the biogas slurry. According to the method, not only is a method provided for purifying the biogas slurry, but also the obtained algae cells and the biogas slurry can be recycled, so that ecologicalization treatment of the biogas slurry is realized, the environment is improved, and furthermore, the economic and social benefits are produced.

Owner:湖南瑞藻生物科技有限公司

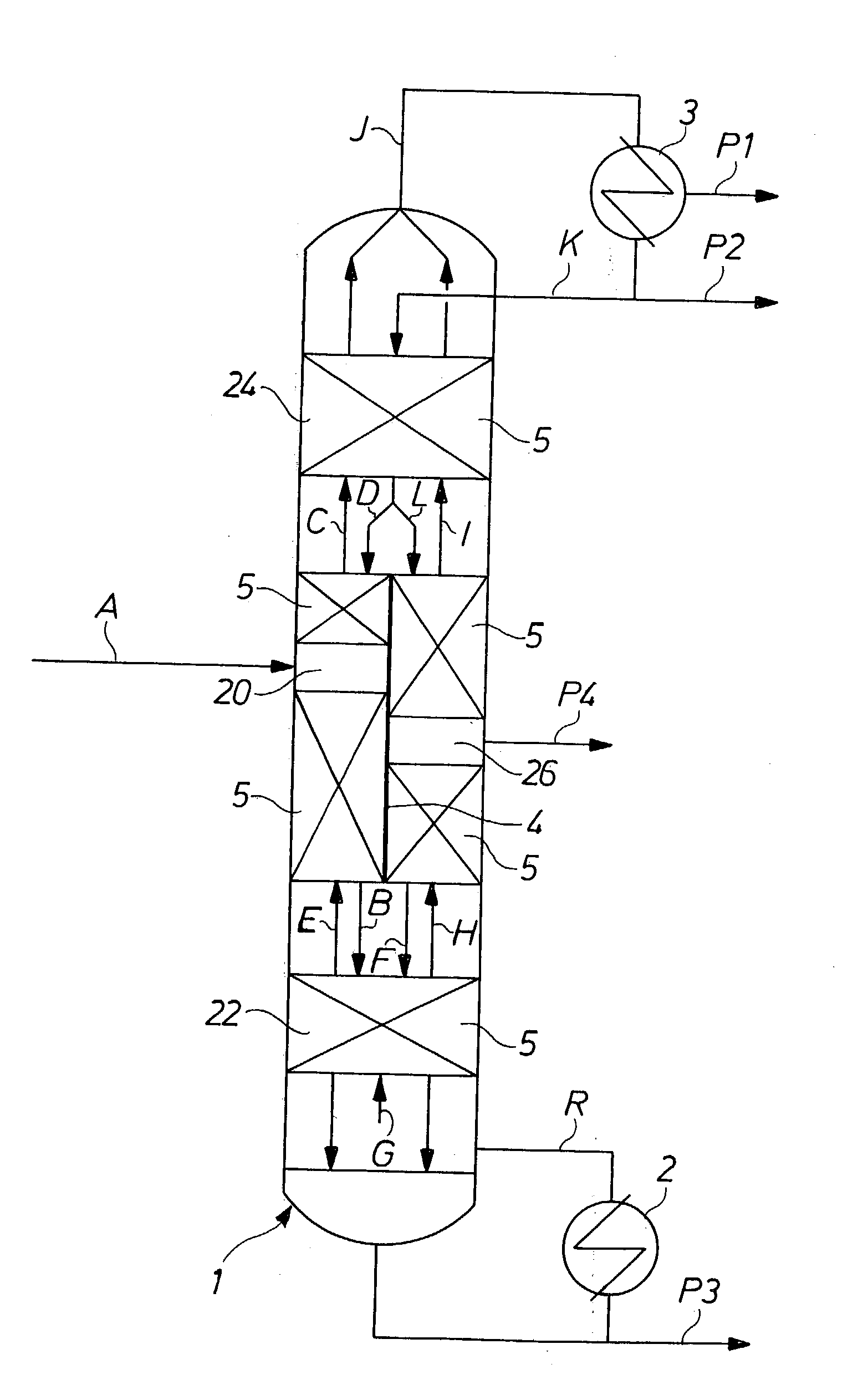

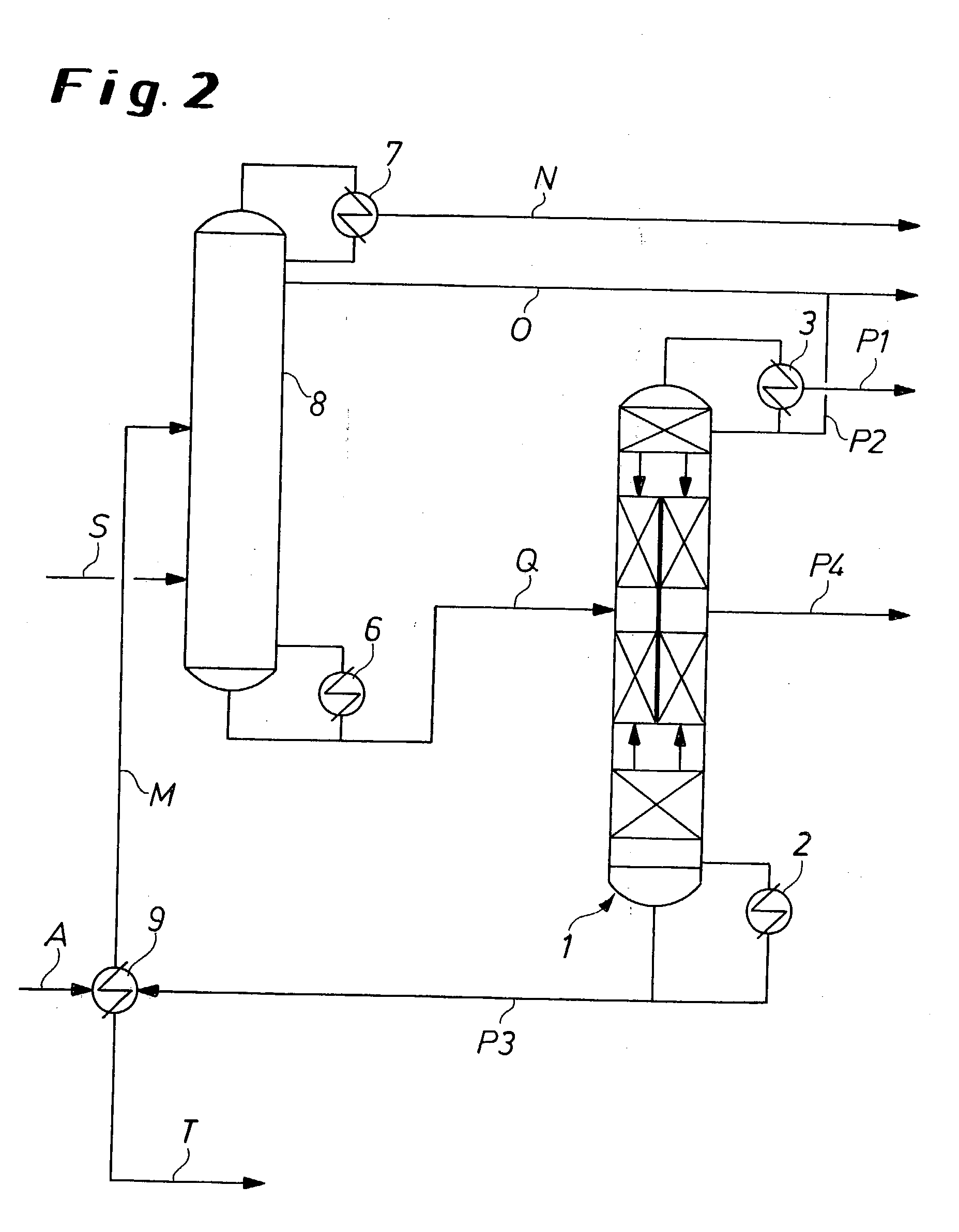

Process for the purification of mixtures of toluenediisocyanate incorporating a dividing-wall distillation column

InactiveUS20030230476A1Weaken energyLow investment costThermal non-catalytic crackingOrganic compound preparationPurification methodsOrganic solvent

Process for the purification of toluenediisocyanate from a crude distillation feed comprising toluenediisocyanate, an organic solvent and less than 2% by weight phosgene by separating the crude distillation feed in a dividing-wall distillation column into at least four product fractions P1-P4. P1 is a phosgene enriched low-boiler product, P2 is a solvent-enriched product, P3 is a high boiler enriched bottoms and P4 is a toluenediisocyanate product stream.

Owner:COVESTRO DEUTSCHLAND AG

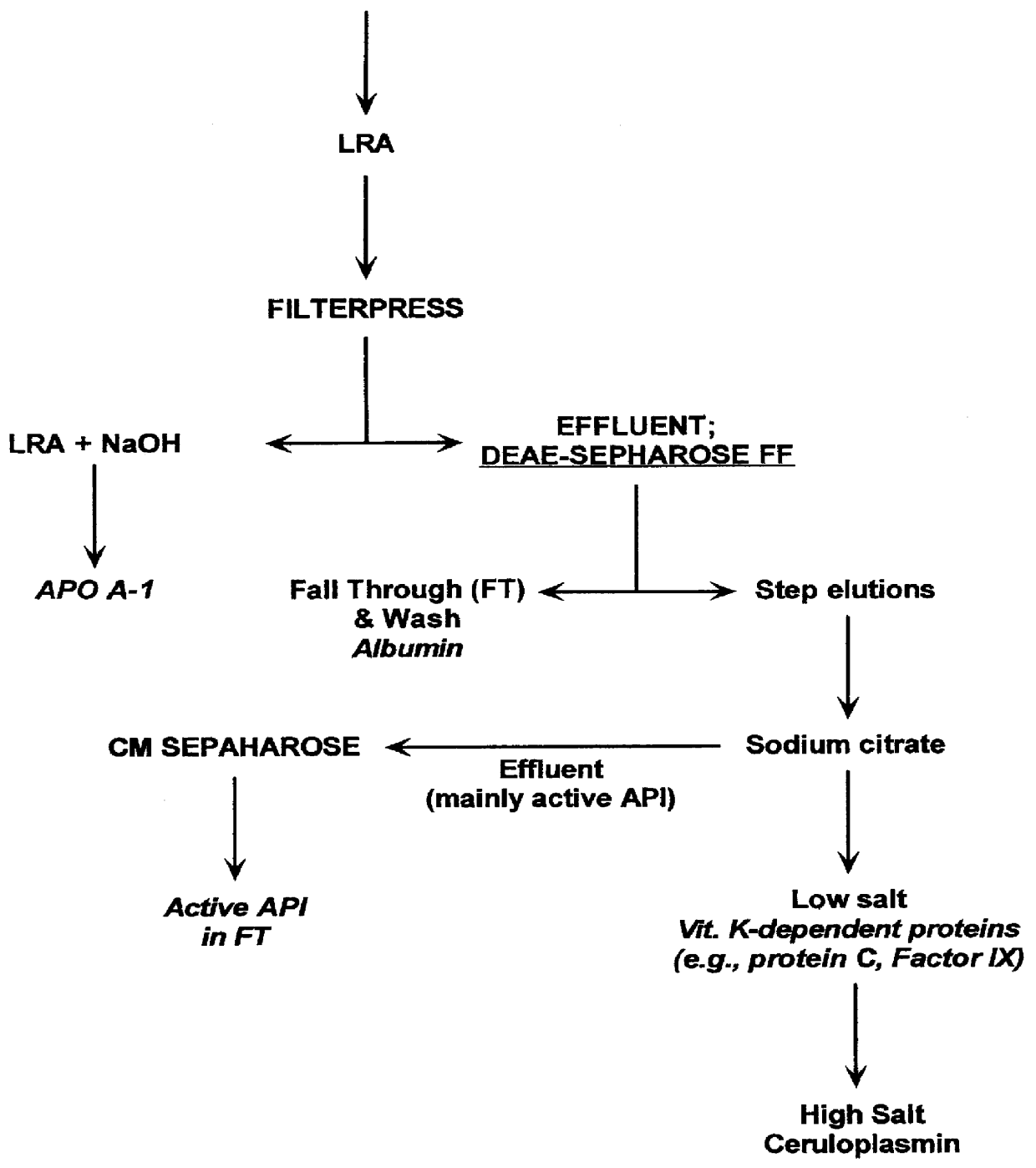

Method for purification of alpha-1 proteinase inhibitor

InactiveUS6093804AHigh yield isolationAchieve separationPeptide/protein ingredientsMammal material medical ingredientsPurification methodsEnzyme inhibitor

The methods of the present invention provide a simple means for separating active and inactive Alpha Proteinase Inhibitor (API). The methods further provide means for purifying API at high yield (>70%), and at levels of purity (>90%) and activity (>90%) not heretofore available. Moreover, the methods of the present invention are simple (i.e., two chromatographic steps) and efficient; and are thus especially suitable to large scale purification processes. These methods will contribute substantially to alleviating the unmet demand for API for therapeutic purposes.

Owner:KAMADA

Fusion peptides isolatable by phase transition

InactiveUS20010034050A1Small sizePeptide/protein ingredientsHydrolasesPurification methodsThroughput

Genetically-encodable, environmentally-responsive fusion proteins comprising ELP peptides. Such fusion proteins exhibit unique physico-chemical and functional properties that can be modulated as a function of solution environment. The invention also provides methods for purifying the FPs, which take advantage of these unique properties, including high-throughput purification methods that produce high yields (e.g., milligram levels) of purified proteins, thereby yielding sufficient purified product for multiple assays and analyses. The high throughput purification technique is simpler and less expensive than current commercial high throughput purification methods, since it requires only one transfer of purification intermediates to a new multiwell plate.

Owner:PHASE BIOSCIENCE INC

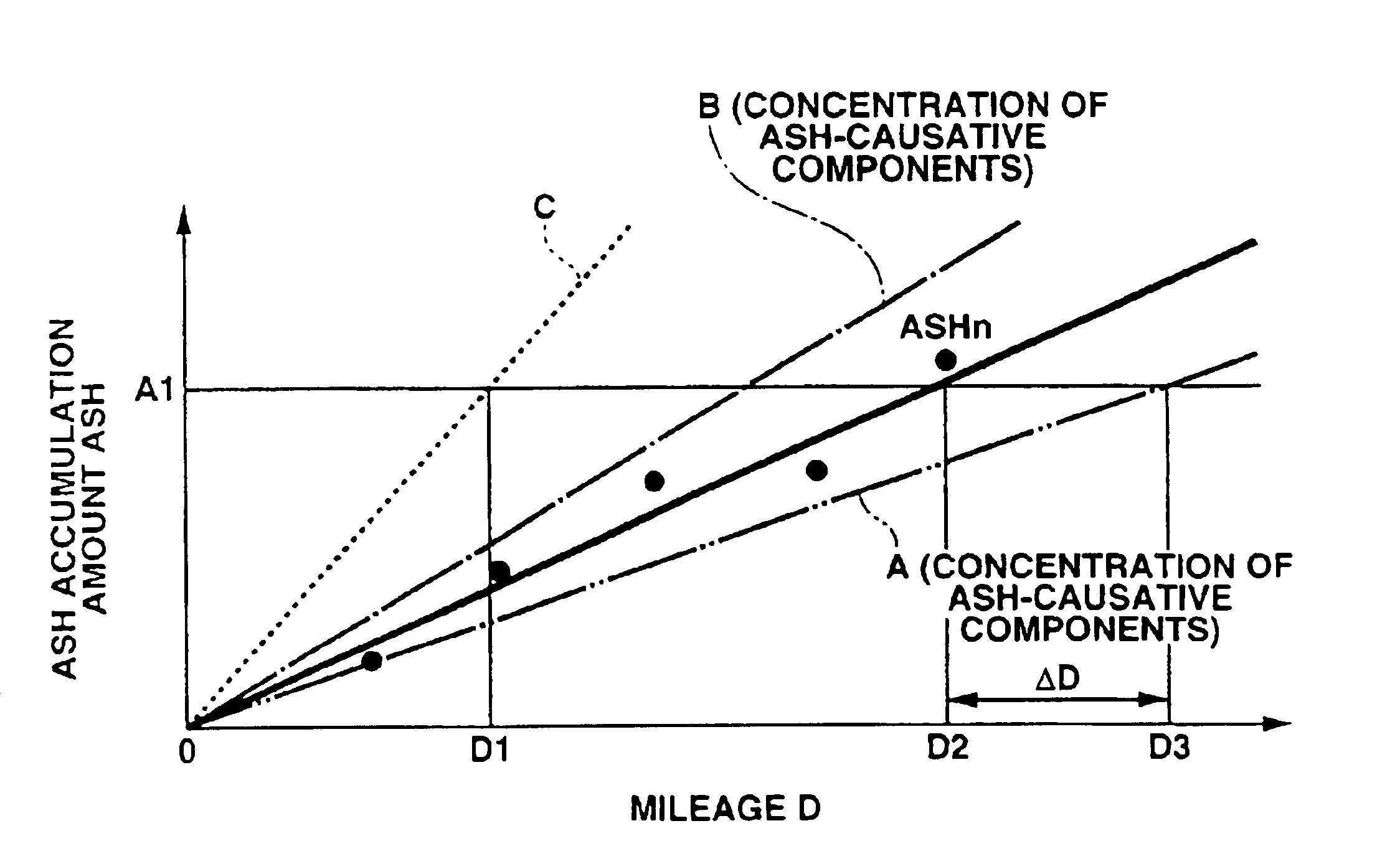

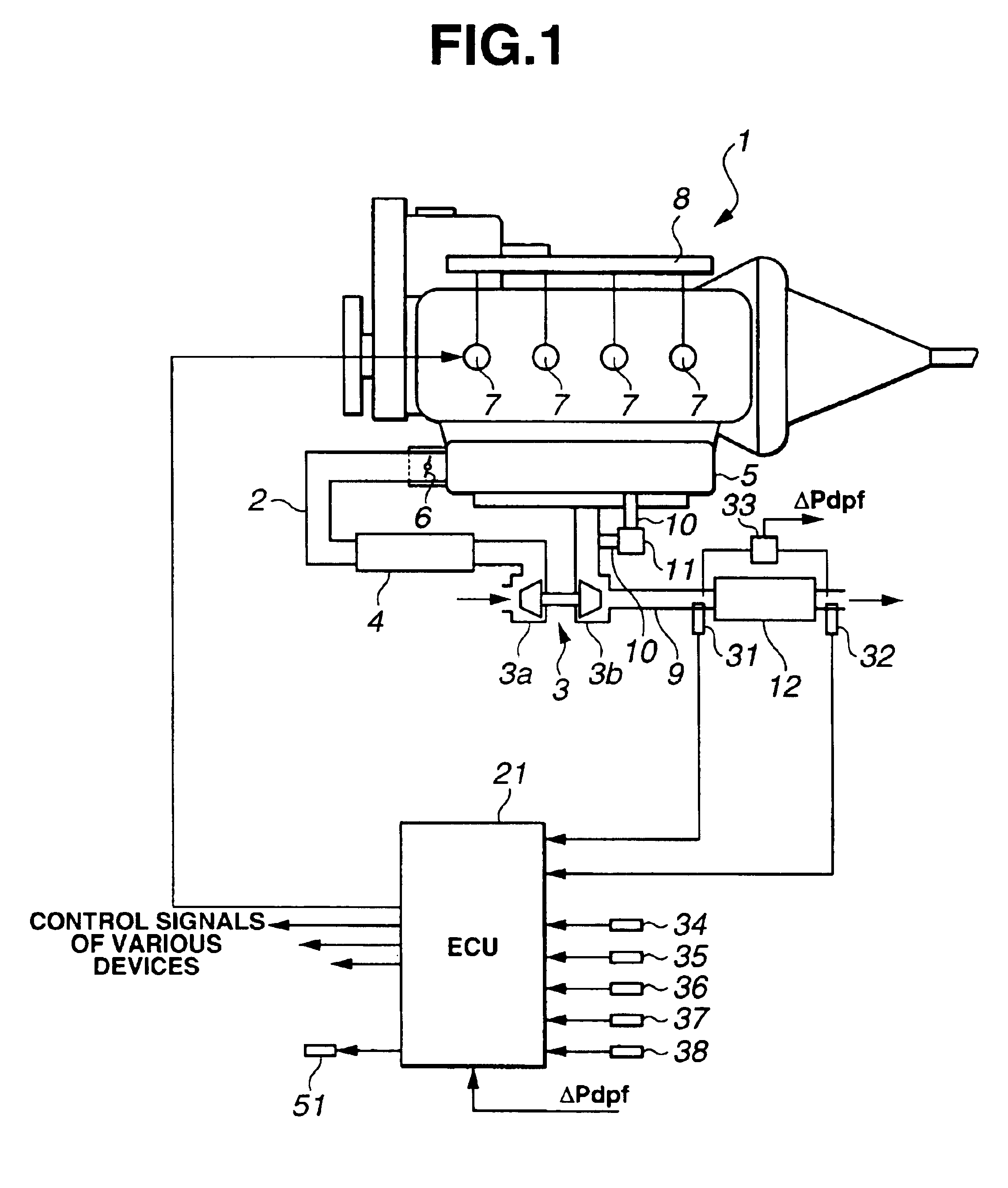

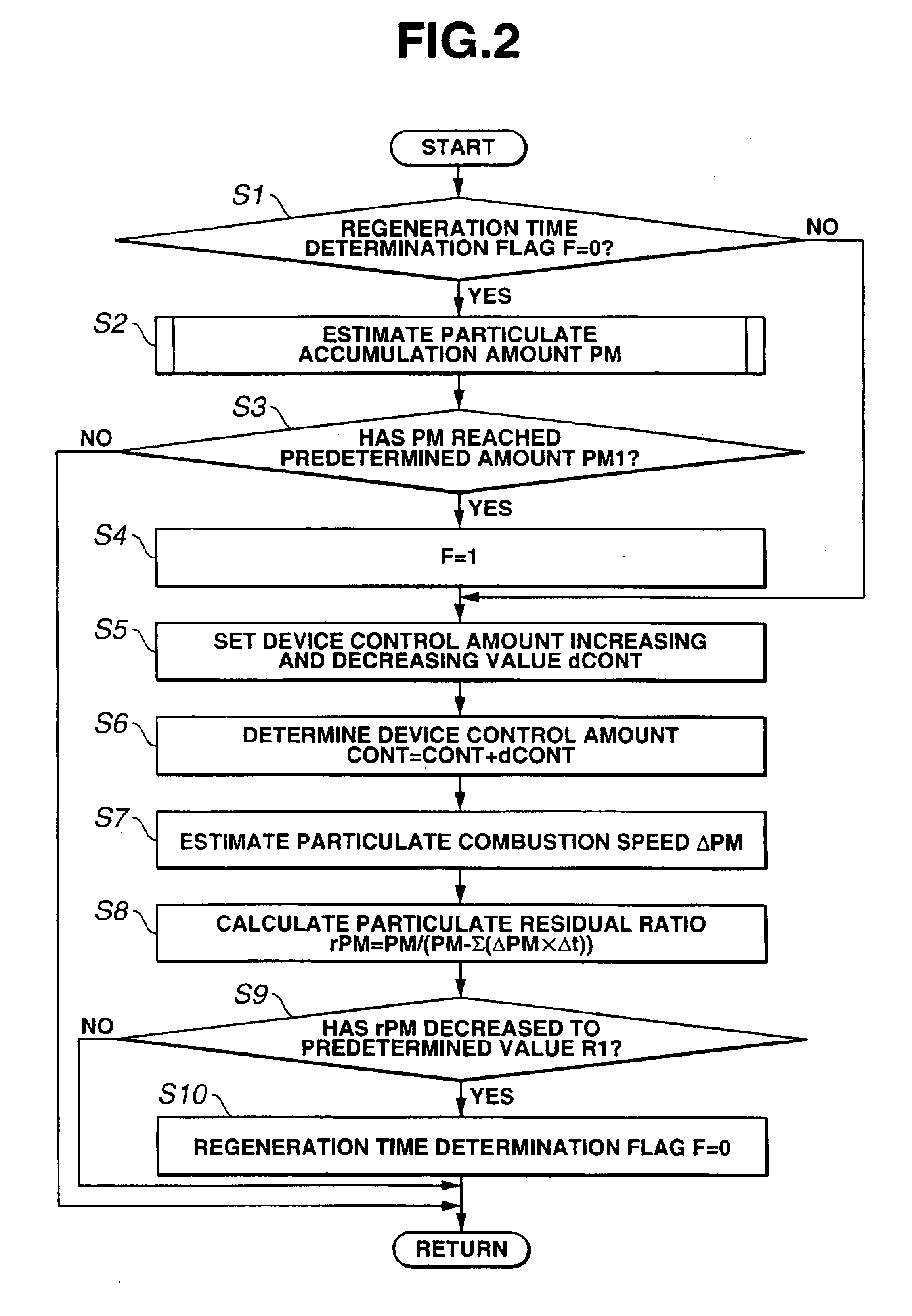

Exhaust gas purification system and method

ActiveUS6928809B2Easily and accurately amountEstimate easily and accuratelyElectrical controlInternal combustion piston enginesParticulatesPurification methods

An exhaust gas purification system includes a particulate filter, a sensor that detects a filter differential pressure and a controller that controls regeneration of the particulate filter. The controller is programmed to execute a control for burning particulate accumulated on the particulate filter, determine whether regeneration of the particulate filter is completed, detect, in cooperation with the sensor, a filter differential pressure immediately after it is determined that regeneration of the particulate filter is completed, and estimate an ash accumulation amount based on the detected filter differential pressure. An exhaust gas purification method is also provided.

Owner:NISSAN MOTOR CO LTD

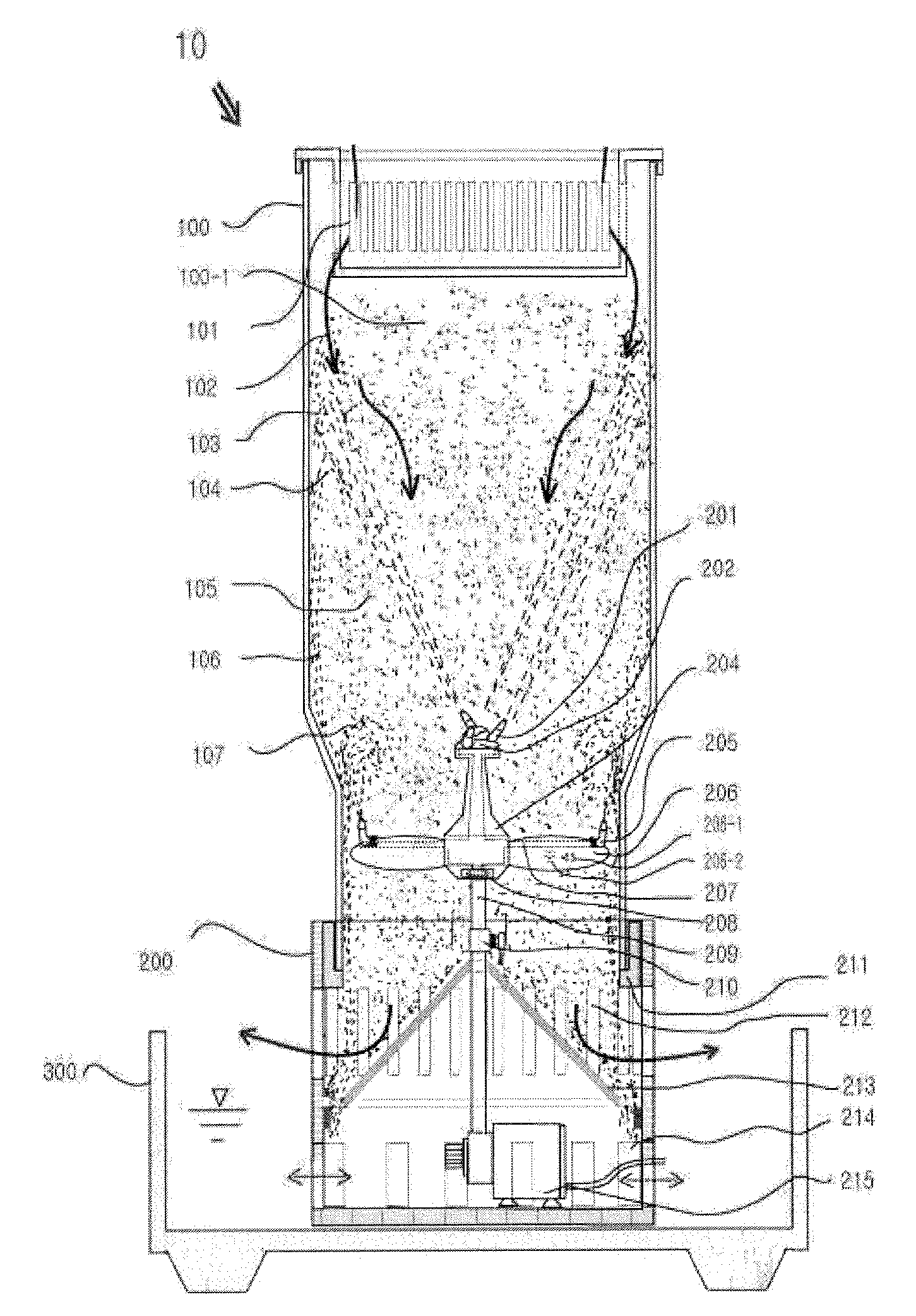

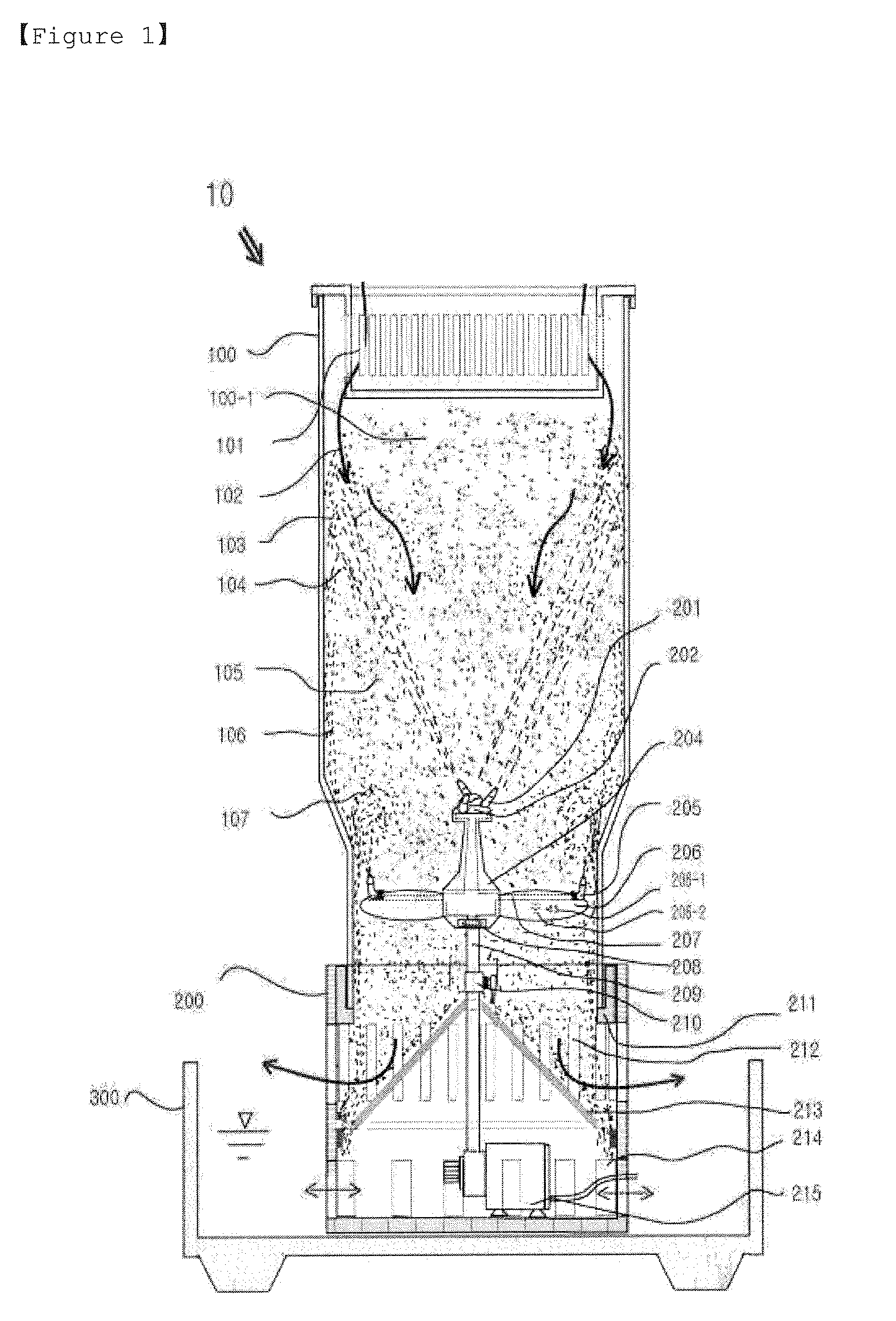

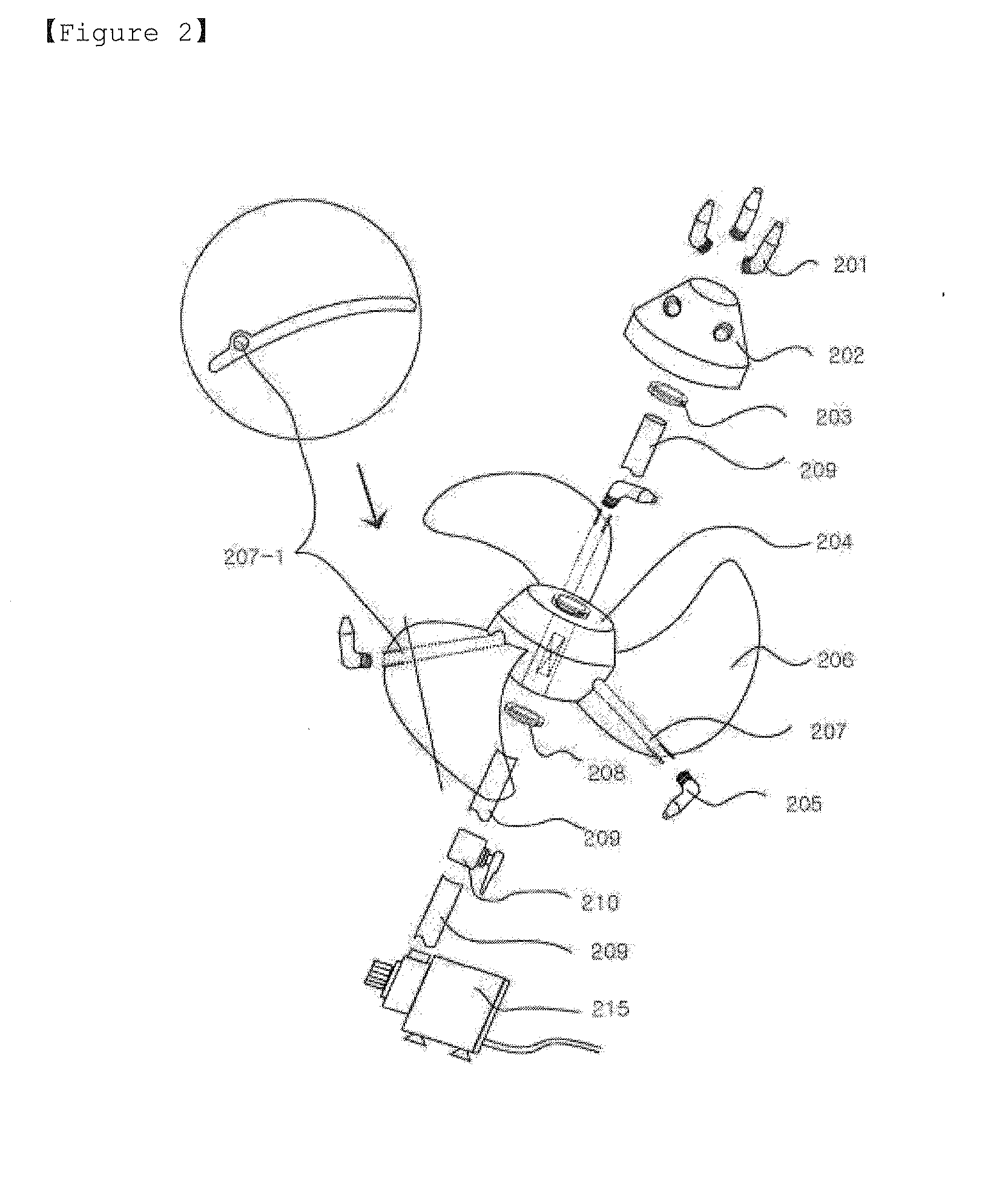

Air Purifier Employing A Water Jet-Type Fan System, and Purification Method Thereof

InactiveUS20110139005A1Reduce manufacturing costSolve the real problemDispersed particle filtrationLighting and heating apparatusAir cyclePurification methods

The present invention relates to an air purifier employing a water jet-type fan system having a simple structure, in which water is pumped by a water pump and sprayed and scattered by the water jet-type fan system in which a plurality of spray nozzles are mounted on a fan having a flow channel, in order to purify contaminants. The fan system rotates by the principle of action and reaction using the spraying force of water. The air purifier of the present invention performs an air purification process and an air circulation function at the same time by spraying and scattering water so as to use the adsorption power of water, instead of using a motor fan for circulating air. The present invention also relates to a purification method of the air purifier.

Owner:KWON YONG JOON

Viral purification methods

ActiveUS7223585B2Simple methodViral antigen ingredientsGenetic material ingredientsPurification methodsFiltration

The present invention is directed to an improved method of purifying virus, particularly reovirus. Infectious virus can be extracted from a cell culture with a detergent to produce high titers of virus, and the virus can then be purified by simple steps such as filtration and column chromatography. Viruses and compositions comprising the viruses prepared according to the present invention are also provided.

Owner:ONCOLYTICS BIOTECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com