Biogas slurry ecological purification method based on microalgae cultivation

A technology of ecological purification and biogas slurry, applied in the direction of microorganism-based methods, biochemical equipment and methods, chemical instruments and methods, etc., can solve the problems of poor denitrification and phosphorus removal, biogas slurry pollution of the environment, and difficulty in popularization. Achieve the effects of easy promotion, high photosynthetic efficiency, and increased economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

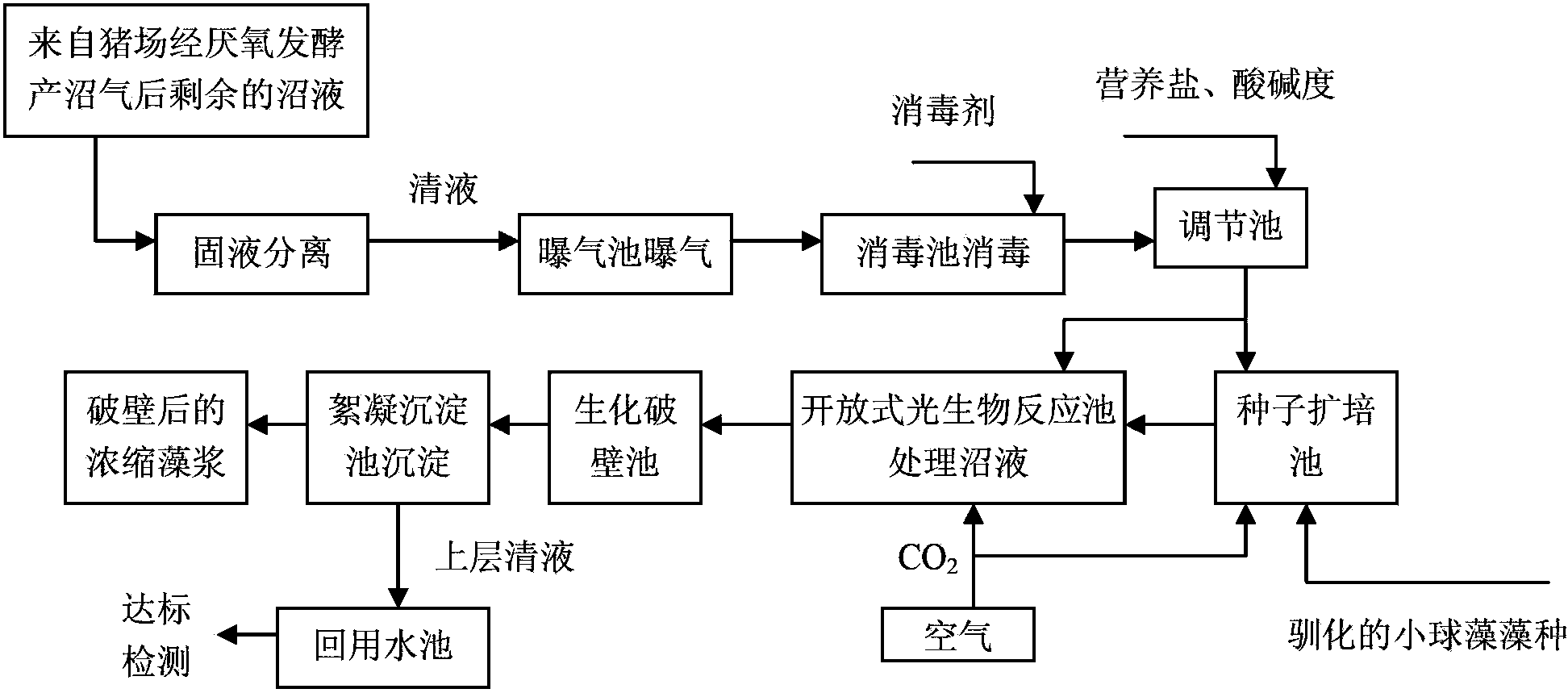

[0033] Such as figure 1 , the biogas slurry ecological purification method based on microalgae cultivation of the present invention comprises the following steps:

[0034] 1. Biogas slurry pretreatment: The biogas slurry after anaerobic fermentation is aerated, and the aerated biogas slurry is separated by a solid-liquid separator and then enters a disinfection tank. The concentration of 8%-10% sodium hypochlorite is 1-3mL / L disinfection, neutralization by sodium thiosulfate of the same concentration; adjustment of nutrient composition in the adjustment pond refers to the supplementary adjustment of biogas slurry concentration, pH and nutrient composition; the water in the adjustment pond is introduced into the seed expansion pond and Open photobioreaction tank.

[0035] Add 0.3-0.5‰ quicklime in the aeration process, continue aeration for 24 hours and then continue aeration for another 24 hours at an interval of 3 hours; the adjustment measures match the microalgae cultivat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com