Patents

Literature

10954 results about "Biogas" patented technology

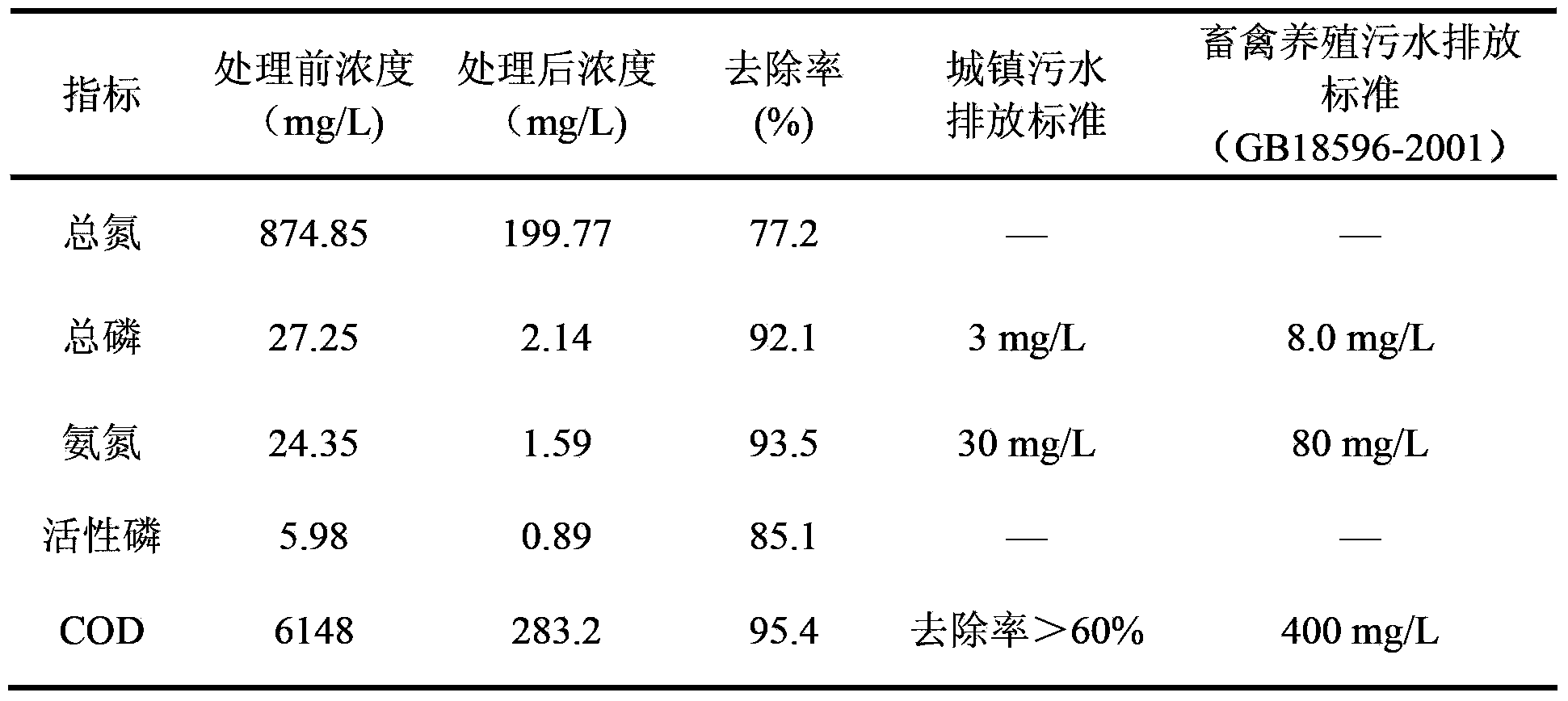

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Biogas is the mixture of gases produced by the breakdown of organic matter in the absence of oxygen, usually consisting of certain quantities of methane and other constituents. Biogas can be produced from raw materials such as agricultural waste, manure, municipal waste, plant material, sewage, green waste or food waste. Biogas is a renewable energy source. In India, it is also known as "Gobar Gas".

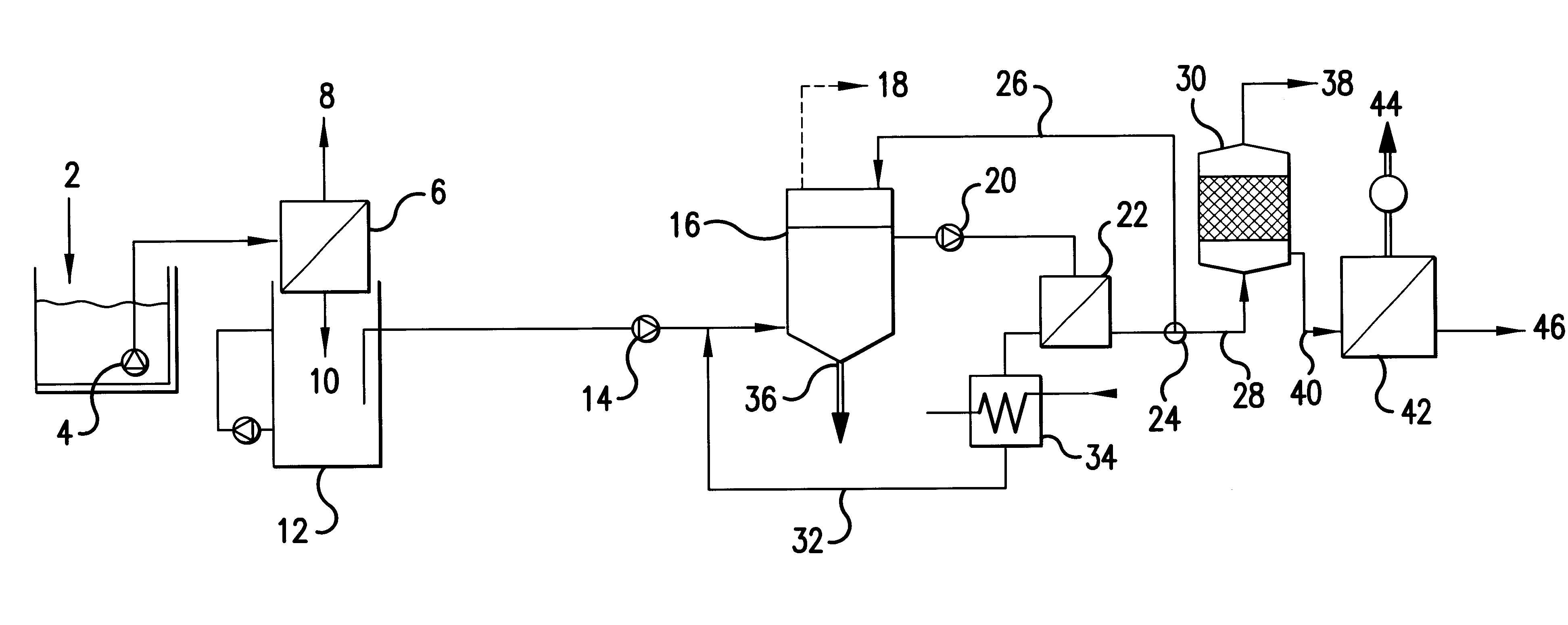

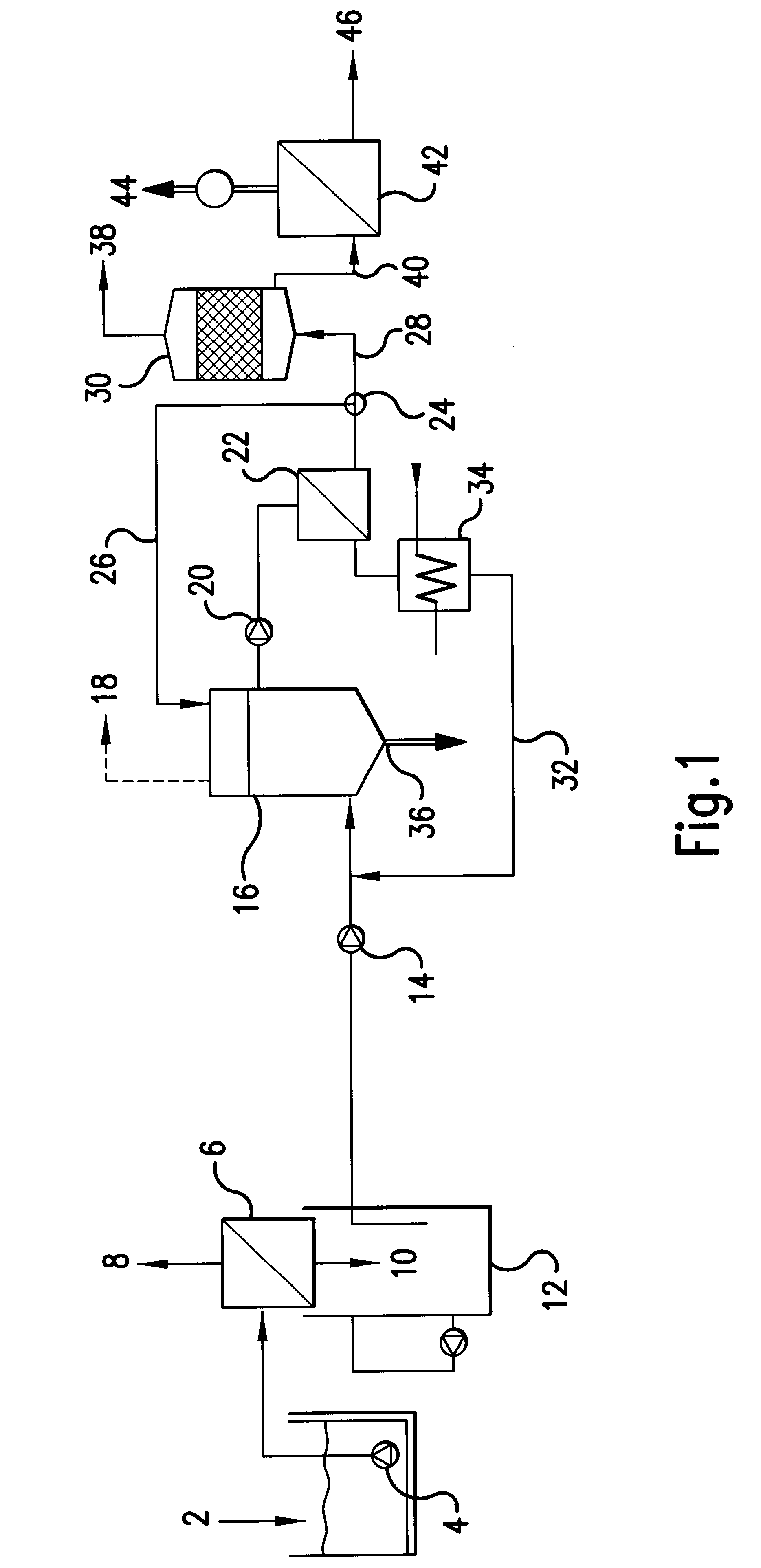

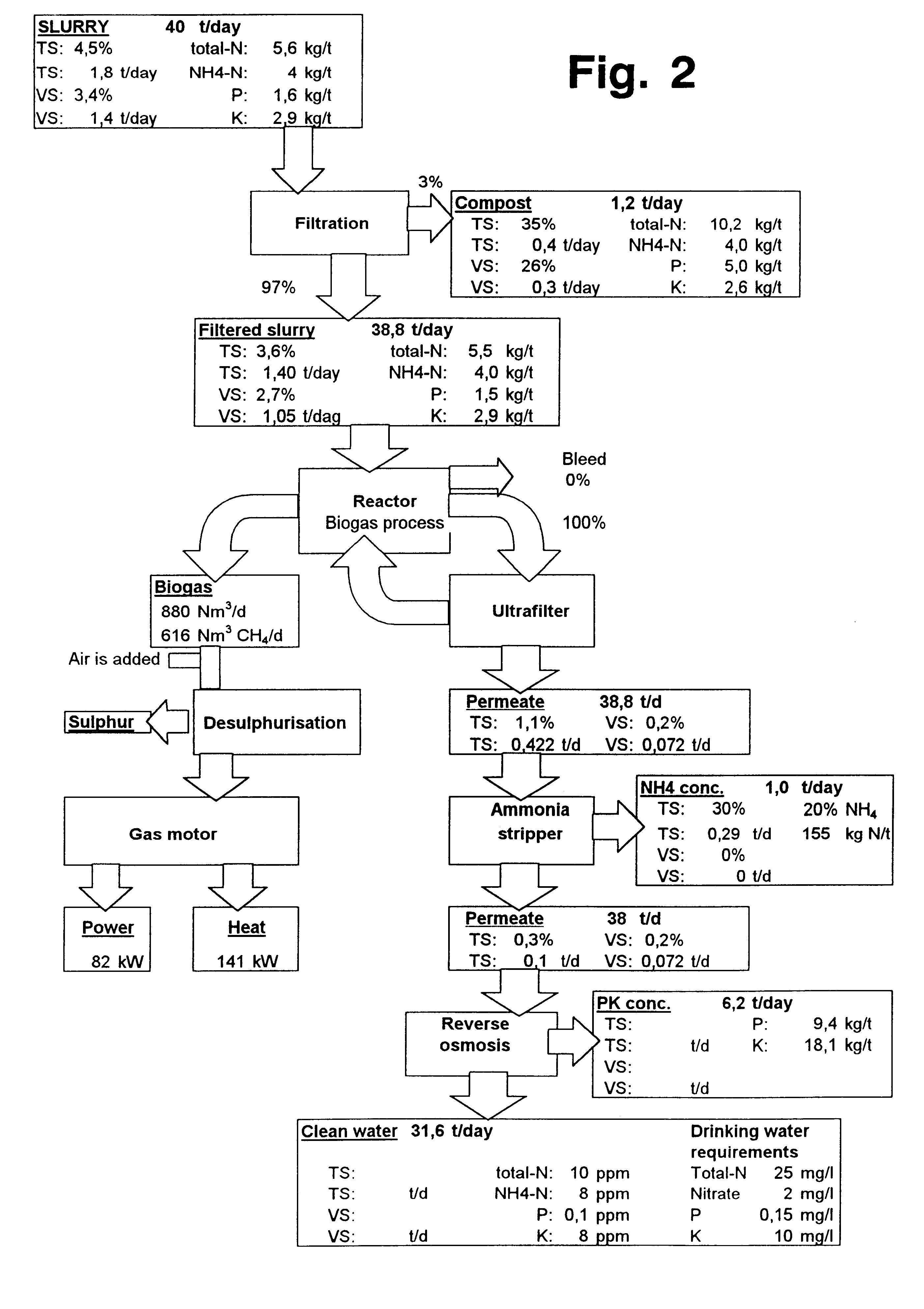

Method and plant for the treatment of liquid organic waste

InactiveUS6368849B1Increase profitReduce environmental impactBioreactor/fermenter combinationsBio-organic fraction processingFiberUltrafiltration

A method and plant for the treatment of an organic waste material in liquid form, e.g. liquid manure from livestock, the method comprising filtering fibres and particles from the liquid, subjecting the liquid to anaerobic fermentation in a biogas reactor, separating a substantially sterile and particle-free permeate stream from the biogas reactor, e.g. using ultrafiltration, subjecting the permeate stream to treatment with an ammonia stripper at an elevated temperature and preferably at reduced pressure to remove substantially all ammonia and carbon dioxide and to result in an ammonia fraction and a nutrient salt fraction, and separating the nutrient salt fraction into a fertiliser concentrate fraction and a water fraction, e.g. using reverse osmosis. The end products of the method are clean water, ammonia concentrate, fertiliser concentrate containing salts of P and K, compost and high-quality biogas with a high methane content.

Owner:GR BIOTECH

System and method for extracting energy from agricultural waste

InactiveUS7169821B2Reduce decreaseMinimize negative impactBioreactor/fermenter combinationsBio-organic fraction processingSyngasBiodiesel

Owner:BEST BIOFUELS LLC

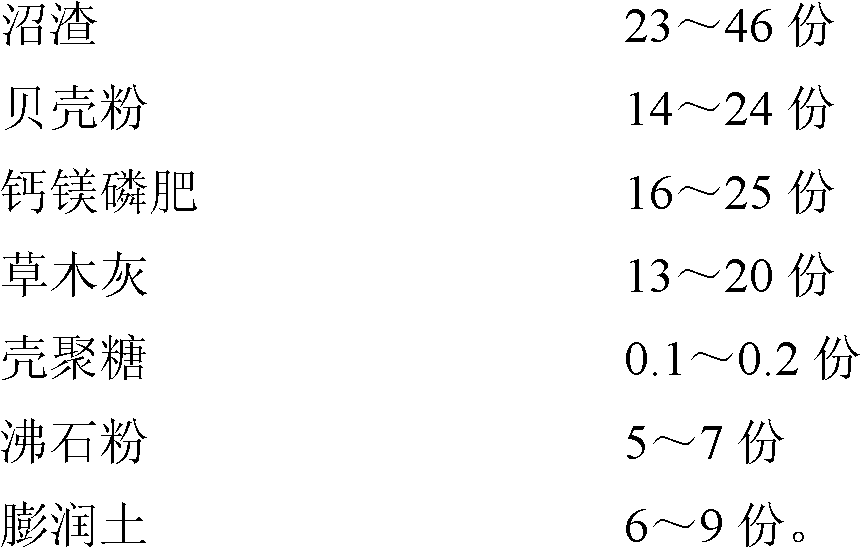

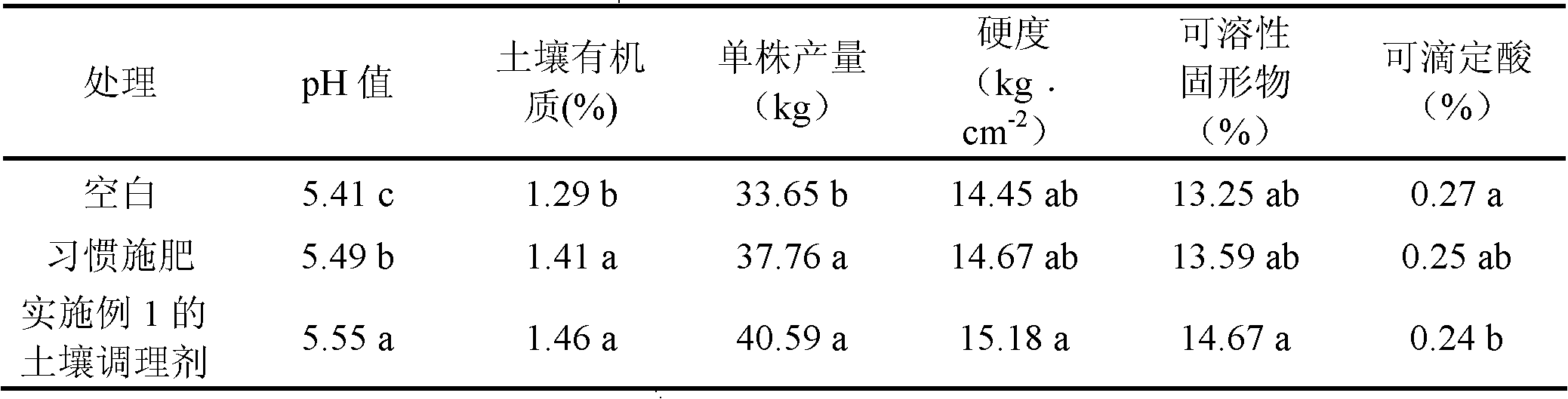

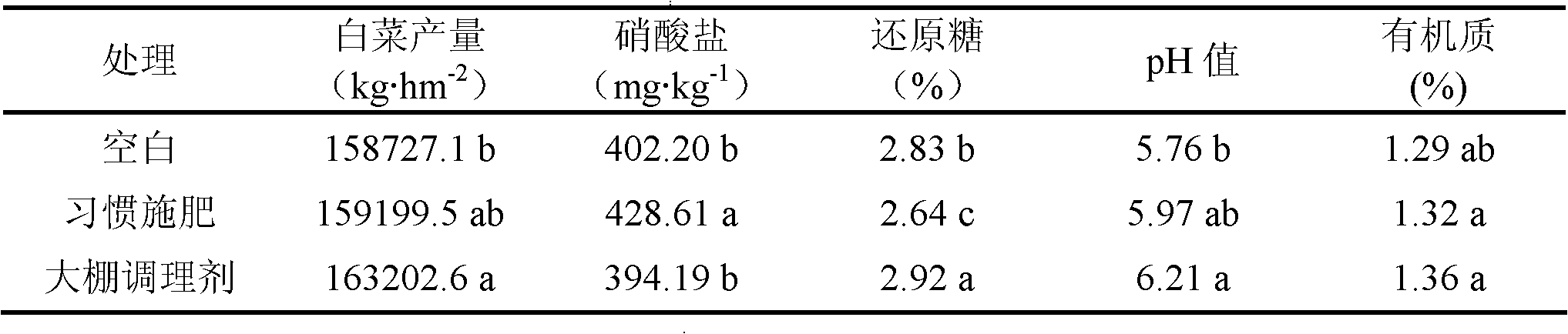

Organic environmentally-friendly soil conditioner for improving acidified or acid soil

ActiveCN102321484ARaw material safetyEfficient use ofOrganic fertilisersSoil conditioning compositionsSodium BentoniteHeavy metal poisons

The invention relates to an organic environmentally-friendly soil conditioner for improving acidified or acid soil and a preparation method thereof. The soil conditioner is prepared from the following raw materials in parts by weight: 23-46 parts of biogas residue, 14-24 parts of shell powder, 16-25 parts of calcium magnesium phosphate fertilizer, 13-20 parts of plant ash, 0.1-0.2 part of chitosan, 5-7 parts of zeolite powder and 6-9 parts of bentonite. The soil conditioner is prepared through pretreatment of the biogas residue, pretreatment of the shell powder and the like; through the produced soil conditioner, the pH value of soil can be increased; nutritive elements such as calcium, magnesium, phosphorus, potassium and the like in the soil are increased; the organic matter content in the soil is increased; the water retention and fertilizer retention capacity of the soil is improved; the physicochemical property of the soil is improved; the antiretroviral (diseases, pests, drought and the like) capacity of crops is improved; heavy metal poison is reduced; and the soil conditioner is convenient to apply, is not influenced by wind power and is suitable for mechanical working.

Owner:INST OF AGRI RESOURCES & ENVIRONMENT SHANDONG ACADEMY OF AGRI SCI

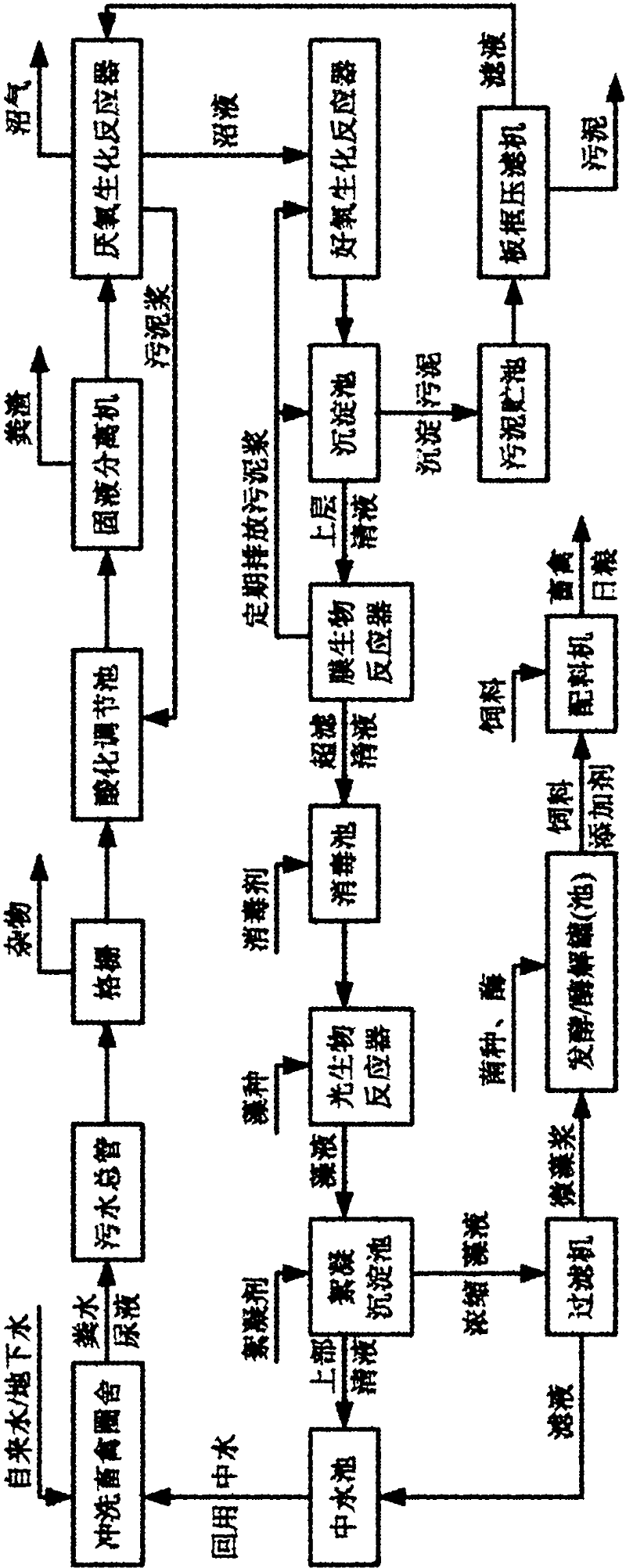

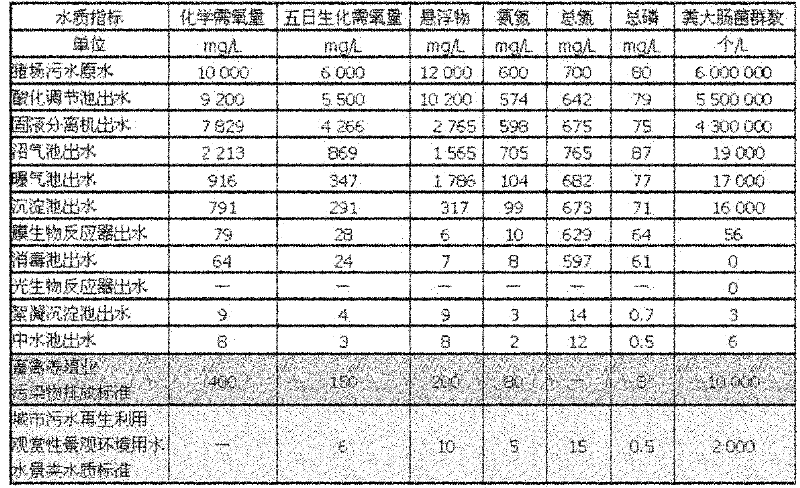

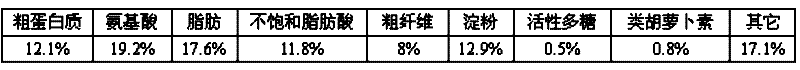

Method for producing feed additive from livestock and poultry breeding wastewater and purifying breeding wastewater to reclaimed water

InactiveCN102161550AReduce water consumptionAchieving zero emissionsWaste water treatment from animal husbandryAnimal feeding stuffUltrafiltrationSlurry

The invention relates to the fields of environmental technology and the breeding and processing of microalgae, in particular to a method for producing feed additive from livestock and poultry breeding wastewater and purifying breeding wastewater to reclaimed water. The method is characterized by comprising the following steps that: wastewater enters an acidification adjusting tank through a grille, and the acidified wastewater enters an anaerobic biochemical reactor for treatment and then enters an aerobic biochemical reactor; after the aerobic biochemical treatment, the obtained biogas slurry enters a settling tank for settling, the supernatant enters a membrane bioreactor for further aerobic treatment and is filtered by an ultrafiltration membrane, the generated ultrafiltration clear liquid is sterilized and neutralized and then enters a photobioreactor, algae are added into the photobioreactor to perform microalgae cultivation, and the algae liquid is discharged from the photobioreactor and then enters a flocculation and settling tank; and after flocculation and settling, the supernatant is used for water recycling, the concentrated algae liquid at the bottom enters a filter, and the separated microalgae slurry enters a fermentation / enzymolysis pot (tank) to perform fermentation / enzymolysis to be used as the feed additive. The invention has the advantages of high economic adaptability, zero discharge and the like.

Owner:蔡志武 +1

Porous metal organic framework material based on transition metal cobalt and preparation method thereof

InactiveCN102962036AGood application effectIncrease surface areaOther chemical processesGaseous fuelsMetal-organic frameworkCobalt

The invention relates to a porous metal organic framework material based on transition metal cobalt and a preparation method thereof. The metal organic framework material is a compound with supramolecular porous network structure and formed by self-assembly of metal ions and organic ligands through coordination complexation. The porous cobalt-based metal organic framework material contains one or more metal ions, and one or more organic ligands; and at least one of the metal ions is Co (II). The porous cobalt-based organic framework material has excellent selective adsorption on CH4 in a separation process of CH4 and N2; and the advantage of adsorption selectivity on CH4 is particularly evident under low pressure. The material is particularly suitable for development and recovery of oil field gas, coal bed methane and biogas.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

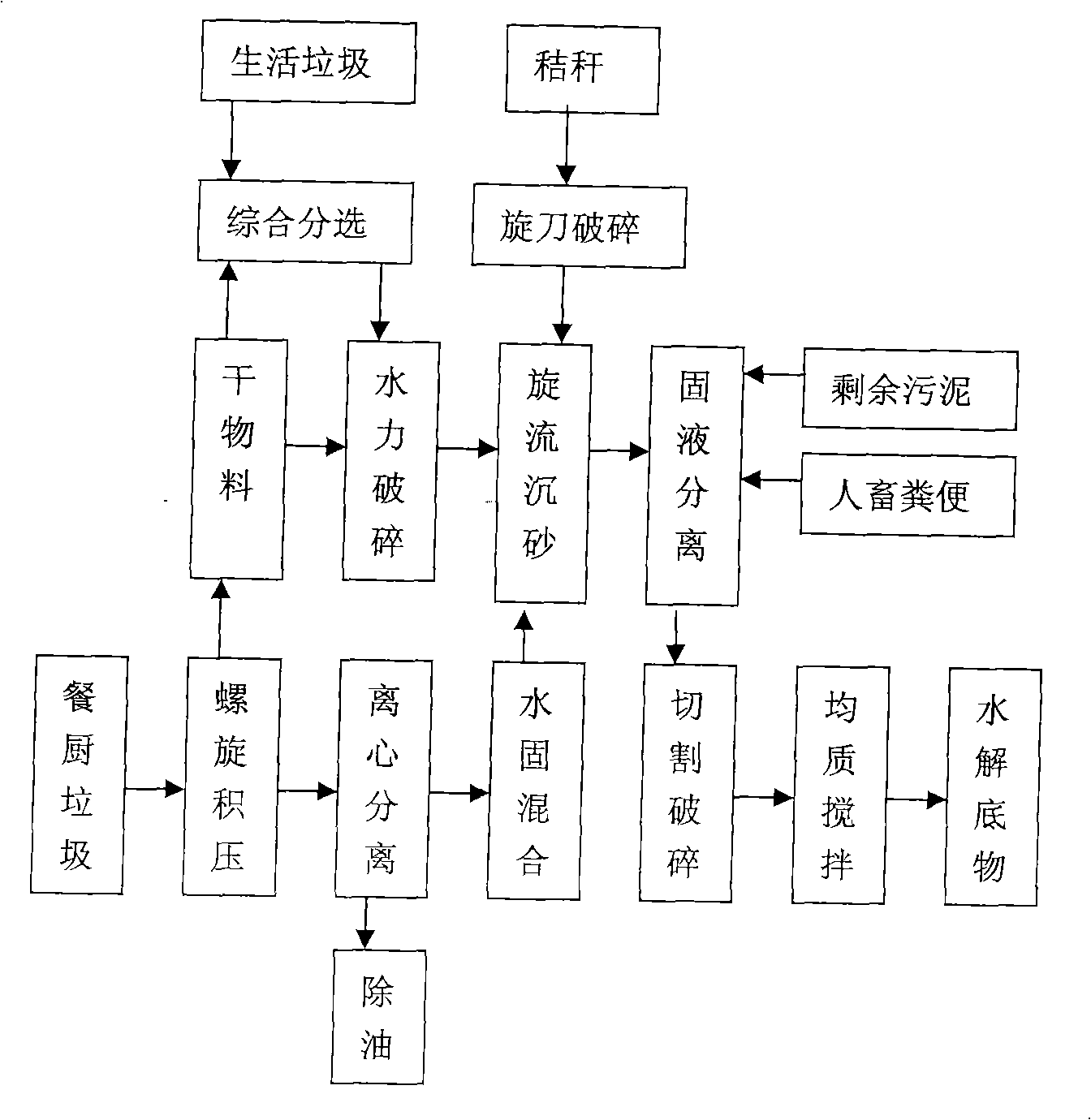

Combined anaerobic fermentation process for organic solid wastes

InactiveCN101337838AReduce consumptionImprove mass transfer efficiencyBio-organic fraction processingClimate change adaptationSludgeAnimal feces

The invention discloses a combined anaerobic fermentation method of organic solid wastes. The organic solid wastes used for the combined anaerobic fermentation include domestic wastes, excess sludge, feces, kitchen waste, straws, etc. The method comprises the following steps: carrying out different pre-processing processes to obtain organic materials with a granularity less than 5 mm; passing through a cutting pump, adjusting the C / N ratio, adjusting the water content, etc. to obtain a homogeneous fermentation substrate with a solid holdup of 2 to 10%; hydrolyzing and acidifying the fermentation substrate in the presence of a hydrolase; fermenting for a period of 15 to 25 days under the condition of stirring at a middle temperature of 32-38 DEG C to obtain biogas, which can be used for energy supply or output of a system; aging and desalting the biogas liquid to obtain a liquid humic acid fertilizer; and processing the biogas residues to a granular humic acid fertilizer. The fermentation substrate has proper C / N ratio to obviate feedback suppression of the substrate during the fermentation of a single material and simultaneously can enhance the hydrolysis effects of celluloses, lignin, hemicelluloses, etc. The method has the advantages of easy flow pattern control, low energy consumption, and no generation of sewages, and can obtain the high-quality biogas fluid and the high-quality granular humic acid fertilizer.

Owner:鄂尔多斯市城市矿产研究开发有限责任公司

Thermoplastic composite material, and preparation method and application thereof

The invention belongs to the field of polymer composite materials, and discloses a thermoplastic composite material, and a preparation method and an application thereof. The composite material is composed of the components of, by weight: 1-99 parts of a prepreg and 1-99 parts of a thermoplastic composition or thermoplastic resin. The preparation method comprises the steps that: the 1-99 parts of thermoplastic composition or thermoplastic resin is added into a feeding hopper of an injection molding machine, and is mixed with the 1-99 parts of prepreg already in an injection mold; and injection molding is carried out. The invention also discloses an application of the thermoplastic composite material in car bumpers, car door inner panels, car bumper beams, cars toe-boards, car hood, car rear lift door, building templates, biogas digesters, train sidings, train wall panels, or train roof panels. The composite material provided by the invention has the advantages of smooth outer surface, high gloss, good appearance, excellent mechanical performance, high strength, and good impact resistance.

Owner:HEFEI GENIUS NEW MATERIALS

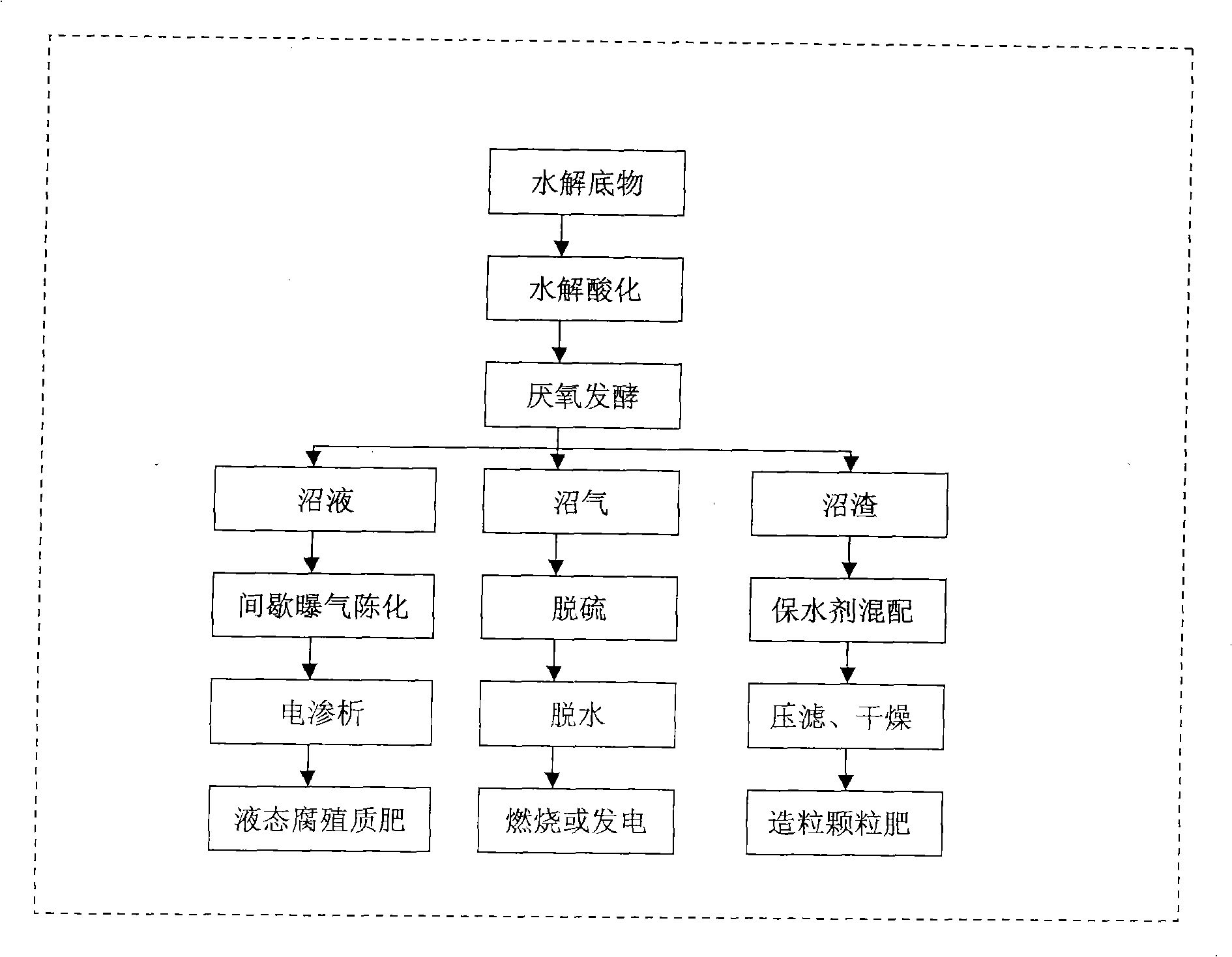

Anaerobic digestion handling method for restaurant garbage

ActiveCN101224999AHarmlessRealize resource processingBio-organic fraction processingClimate change adaptationSlurryOxygen

The invention provides a method for resourceful treatment of restaurant garbage, which is characterized in that the restaurant garbage is completely degraded after treatment with the working procedures of oil separating, preliminary selecting, mechanical crushing, hydraulic pulping, slurry blending, anaerobic fermentation and oxygen-control composting, finally the marsh gas is decomposed via anaerobic digestion and is utilized as energy after desulfurization treatment; the high-quality organic manure is produced from the biogas residues via oxygen-control composting; the separated oil can be recycled as the regenerated industrial raw oil; the wastewater generated in the treatment process can be recycled, and finally the redundant wastewater reaching the standard is discharged after biochemical treatment; and the odor generated by the garbage in the treatment process is directly discharged after reaching the standard via biofiltration treatment, thus the restaurant garbage can be transformed into the clean regenerated energy of electric power and the pollution-free organic manure to completely realize resourceful treatment of restaurant garbage. The resourceful treatment of restaurant garbage has the advantages of innocuity, no peculiar smell, no secondary pollution during the treatment process and realization of harmless and resourceful treatment of restaurant garbage.

Owner:宝林

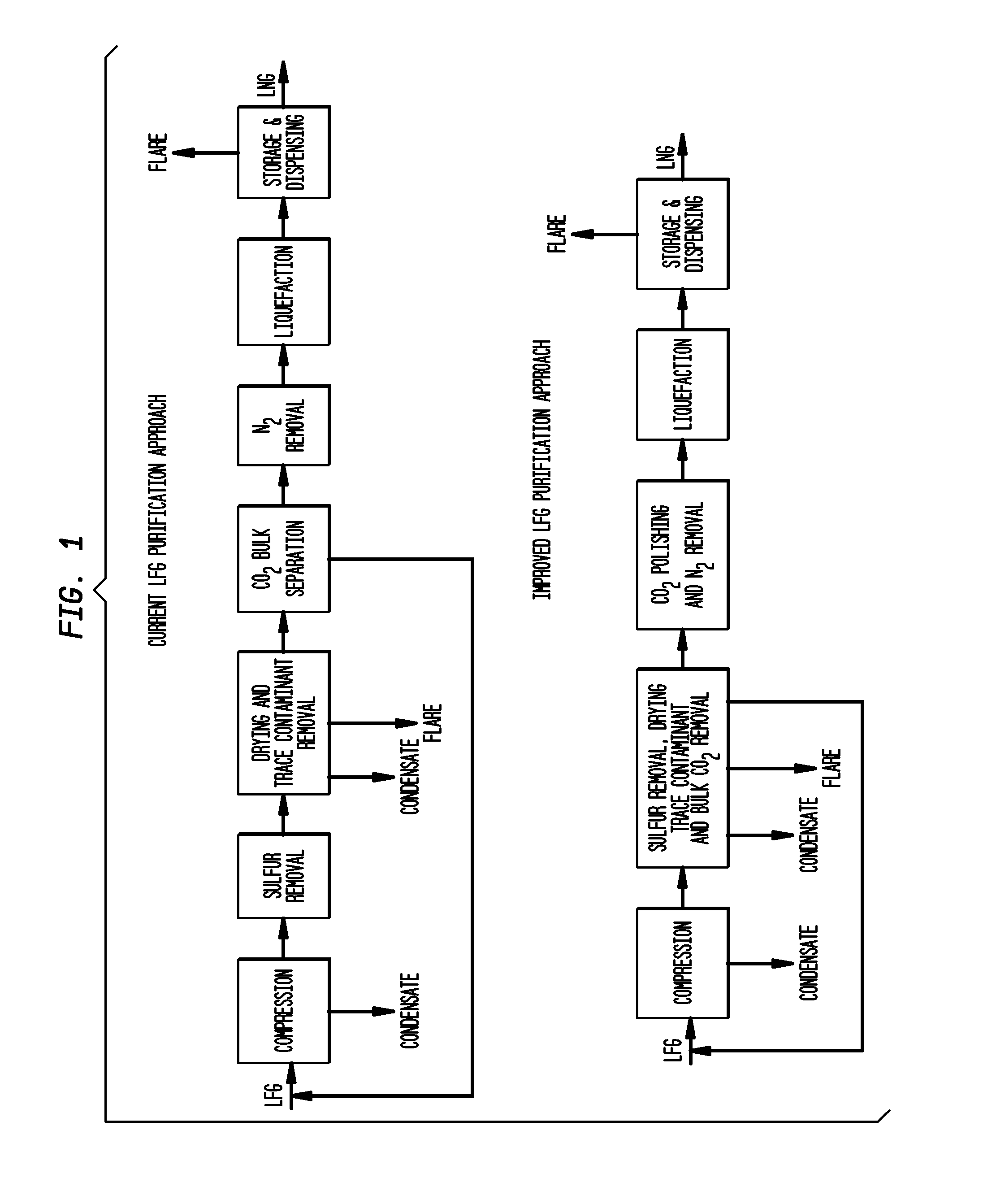

Novel sorbents and purification and bulk separation of gas streams

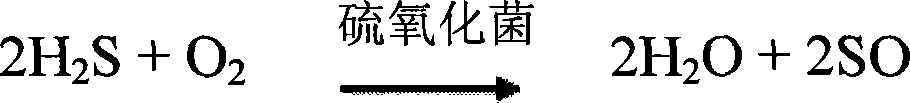

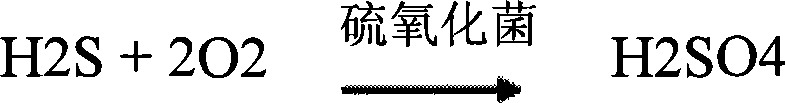

InactiveUS20080264254A1Large capacityLittle and no corrosive effectNitrous oxide captureGas treatmentSorbentDesorption

Porous-material-supported polymer sorbents and process for removal of undesirable gases such as H2S, COS, CO2, N2O, NO, NO2, SO2, SO3, HCl, HF, HCN, NH3, H2O, C2H5OH, CH3OH, HCHO, CHCl3, CH2Cl2, CH3Cl, CS2, C4H4S, CH3SH, and CH3—S—CH3 from various gas streams such as natural gas, coal / biomass gasification gas, biogas, landfill gas, coal mine gas, ammonia syngas, H2 and oxo-syngas, Fe ore reduction gas, reformate gas, refinery process gases, indoor air, fuel cell anode fuel gas and cathode air are disclosed. The sorbents have numerous advantages such as high breakthrough capacity, high sorption / desorption rates, little or no corrosive effect and are easily regenerated. The sorbents may be prepared by loading H2S—, COS—, CO2—, N2O, NO—, NO2—, SO2—, SO3—, HCl—, HF—, HCN—, NH3—, H2O—, C2H5OH—, CH3OH—, HCHO—, CHCl3—, CH2Cl2—, CH3Cl—, CS2—, C4H4S—, CH3SH—, CH3—S—CH3-philic polymer(s) or mixtures thereof, as well as any one or more of H2S—, COS—, CO2—, N2O, NO—, NO2—, SO2—, SO3—, HCl—, HF—, HCN—, NH3—, H2O—, C2H5OH—, CH3OH—, HCHO—, CHCl3—, CH2Cl2—, CH3Cl—, CS2—, C4H4S—, CH3SH—, CH3—S—CH3-philic compound(s) or mixtures thereof on to porous materials such as mesoporous, microporous or macroporous materials. The sorbents may be employed in processes such as one-stage and multi-stage processes to remove and recover H2S, COS, CO2, N2O, NO, NO2, SO2, SO3, HCl, HF, HCN, NH3, H2O, C2H5OH, CH3OH, HCHO, CHCl3, CH2Cl2, CH3Cl, CS2, C4H4S, CH3SH and CH3—S—CH3 from gas streams by use of, such as, fixed-bed sorbers, fluidized-bed sorbers, moving-bed sorbers, and rotating-bed sorbers.

Owner:PENN STATE RES FOUND +1

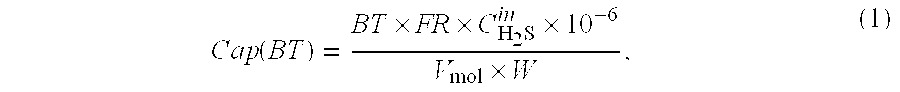

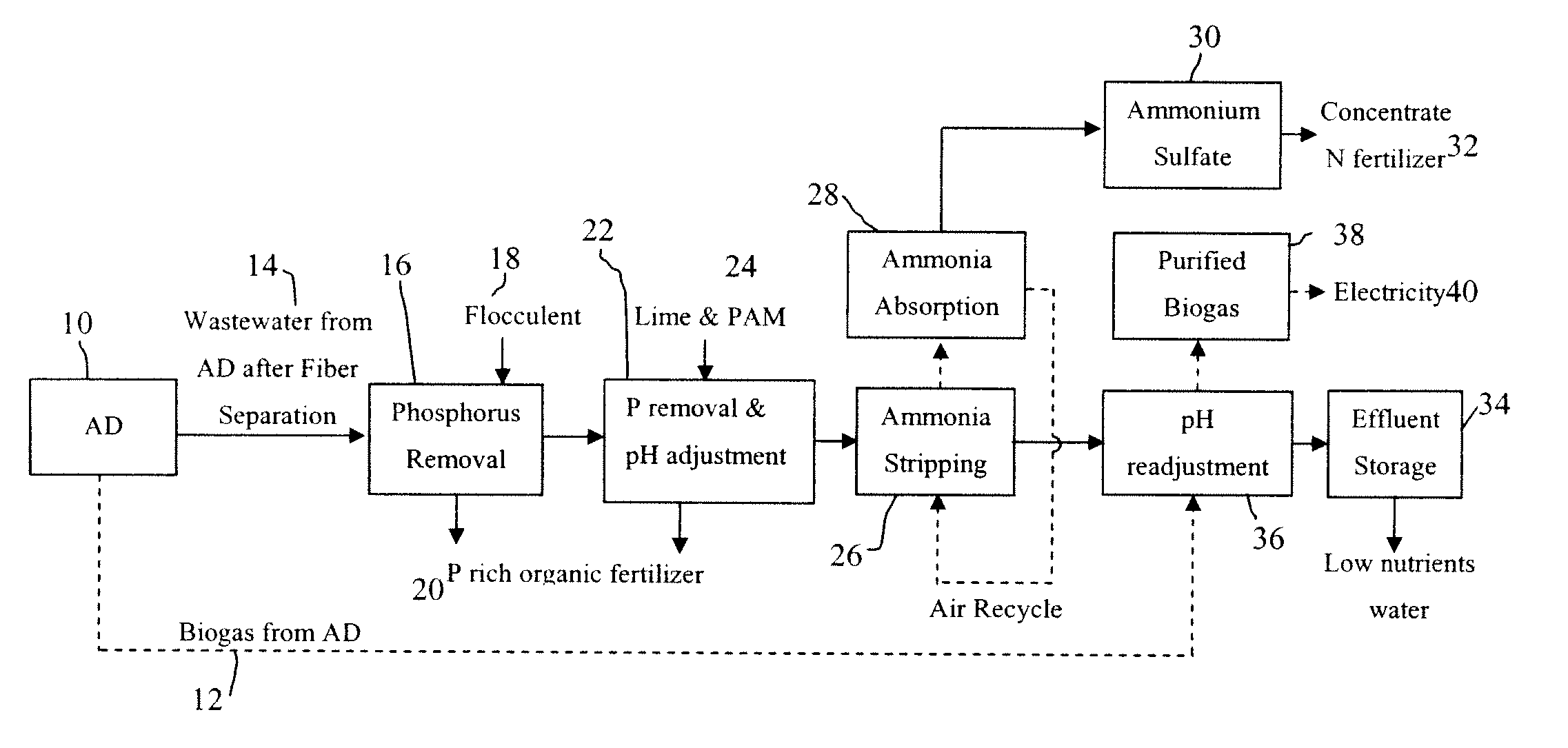

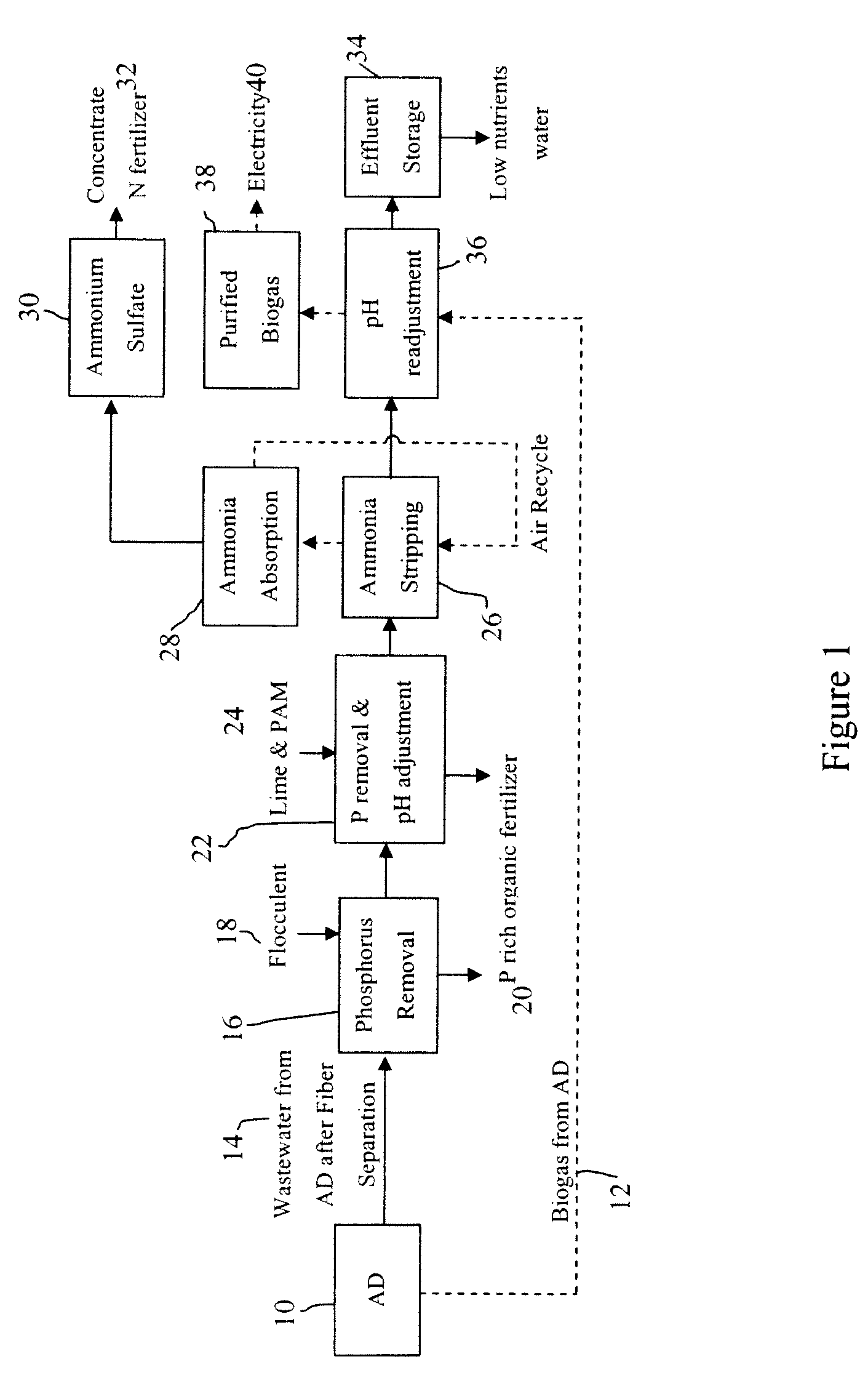

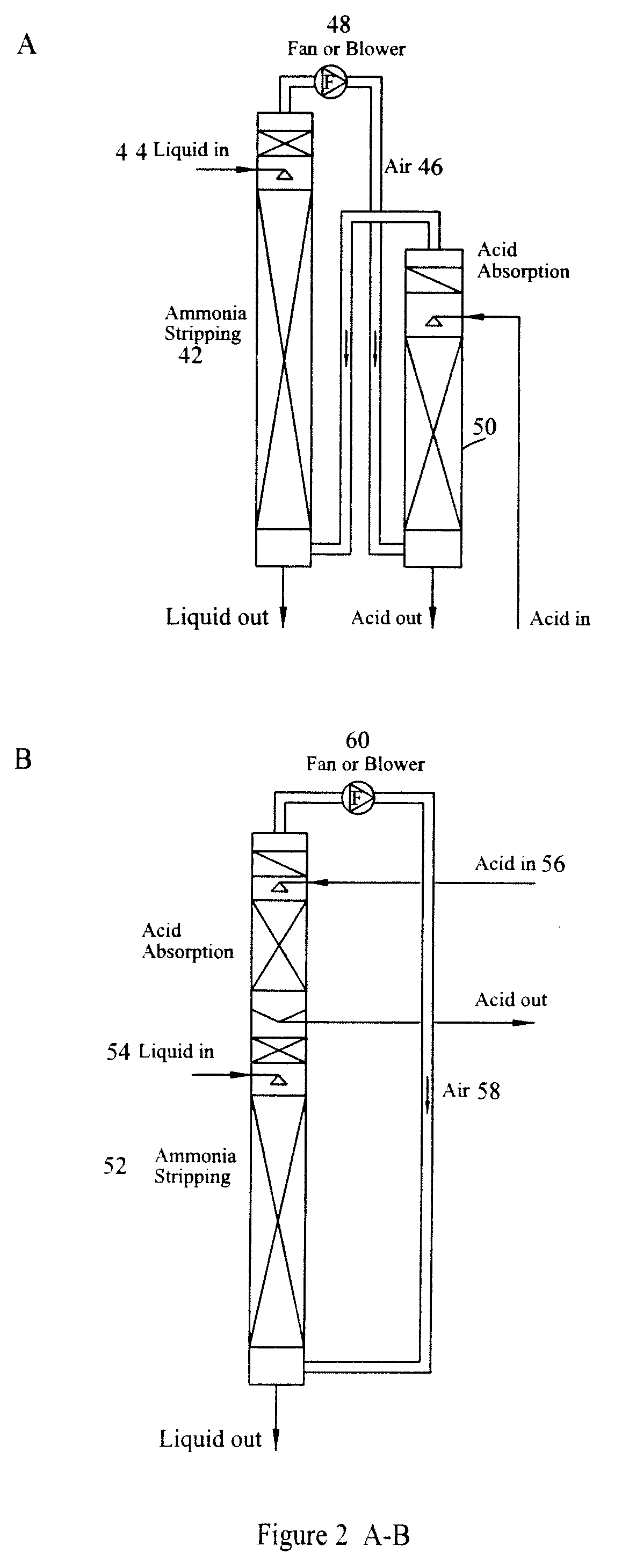

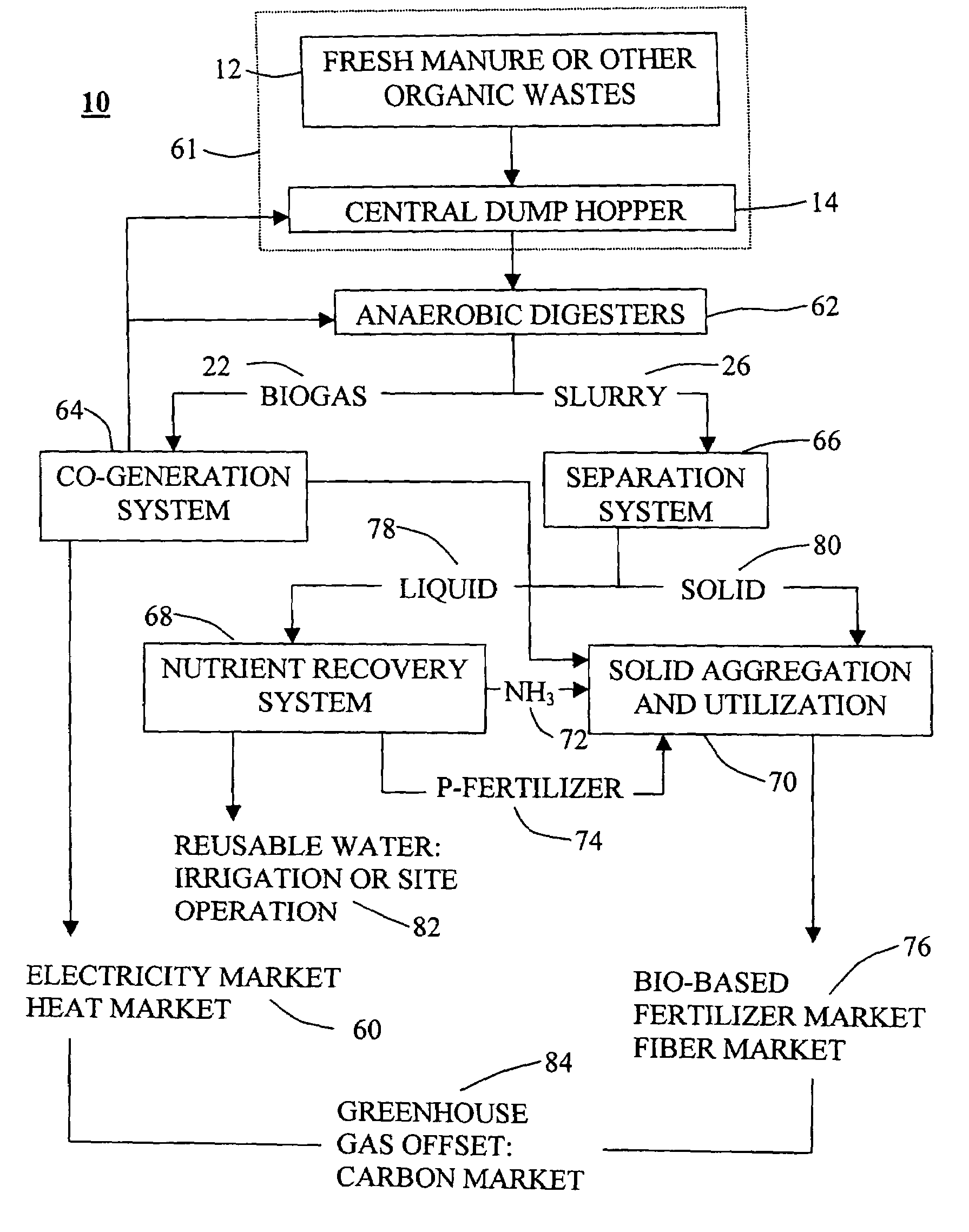

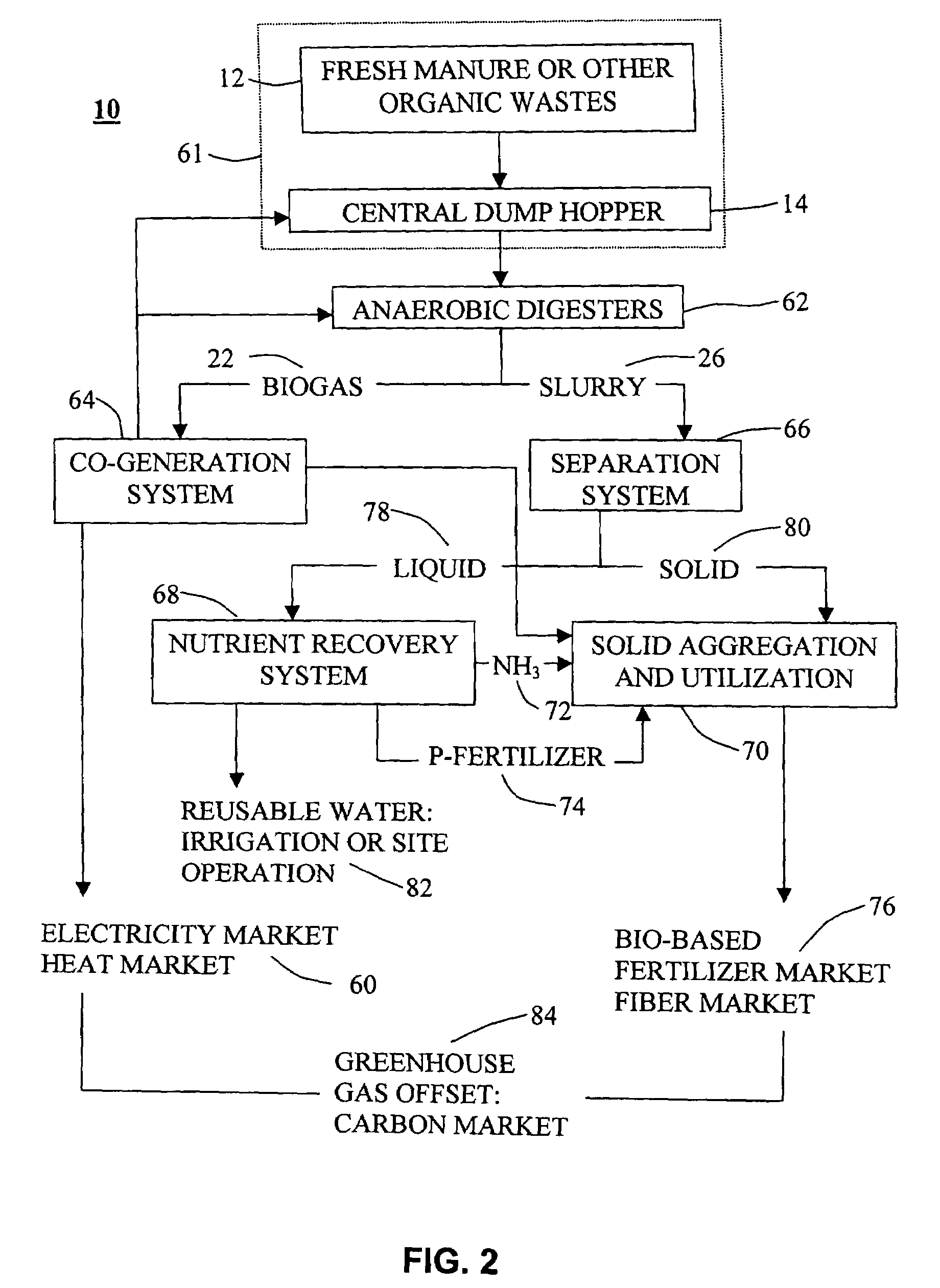

Combined nutrient recovery and biogas scrubbing system integrated in series with animal manure anaerobic digester

InactiveUS20090206028A1Inherent flexibilityIncrease flexibilityBio-organic fraction processingBiological substance pretreatmentsFecesNitrogen

An economical, integrated system works in series with anaerobic digestion of animal waste to recover nitrogen and phosphorous, while also scrubbing the produced biogas.

Owner:WASHINGTON STATE UNIV RES FOUND INC

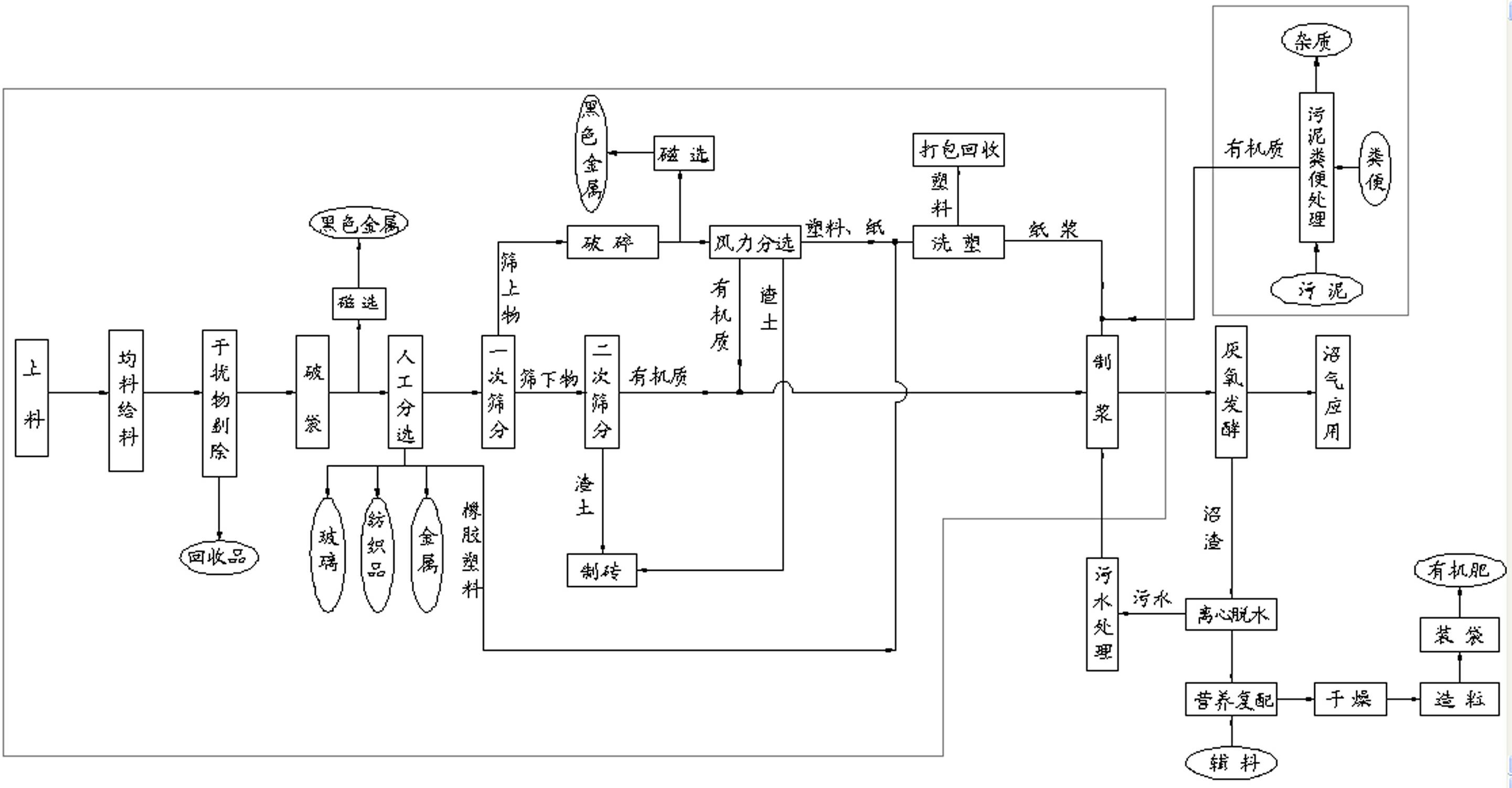

Comprehensive treating system for domestic wastes

InactiveCN102527701AIncrease productionImprove qualityBio-organic fraction processingWaste processingSludgeOrganic manure

The invention discloses a comprehensive treating system for domestic wastes. Reutilizing comprehensive treatment for mixed wastes is realized by the system according to a comprehensive sorting technology and a combined anaerobic fermentation technology, wherein the advanced sorting techniques, such as, crushing, magnetic separating, sieving, air classifying, and the like, are adopted in the comprehensive sorting technology; reutilized products, such as metal, plastics, organic matters, and the like, are screened out; the screened organic matters are prepared into slurry together with sludge and excrements and are then subjected to the combined anaerobic fermentation; the reutilized products, such as methane, organic fertilizer, and the like, can be produced under the action of anaerobic fermentation; and after the methane is purified, the methane is used for generating power, domestic fuel or vehicle-mounted fuel. According to the technology, the intensified treatment for organic wastes, such as domestic wastes, sludge, excrements, kitchen wastes, and the like, can be realized. The comprehensive treating system is high in mechanical and automated degree. Compared with the prior art, the comprehensive treating system has the advantages of simplification, effectiveness, less labor power, and the like.

Owner:BEIJING HAOHAI TIANJI TECH +1

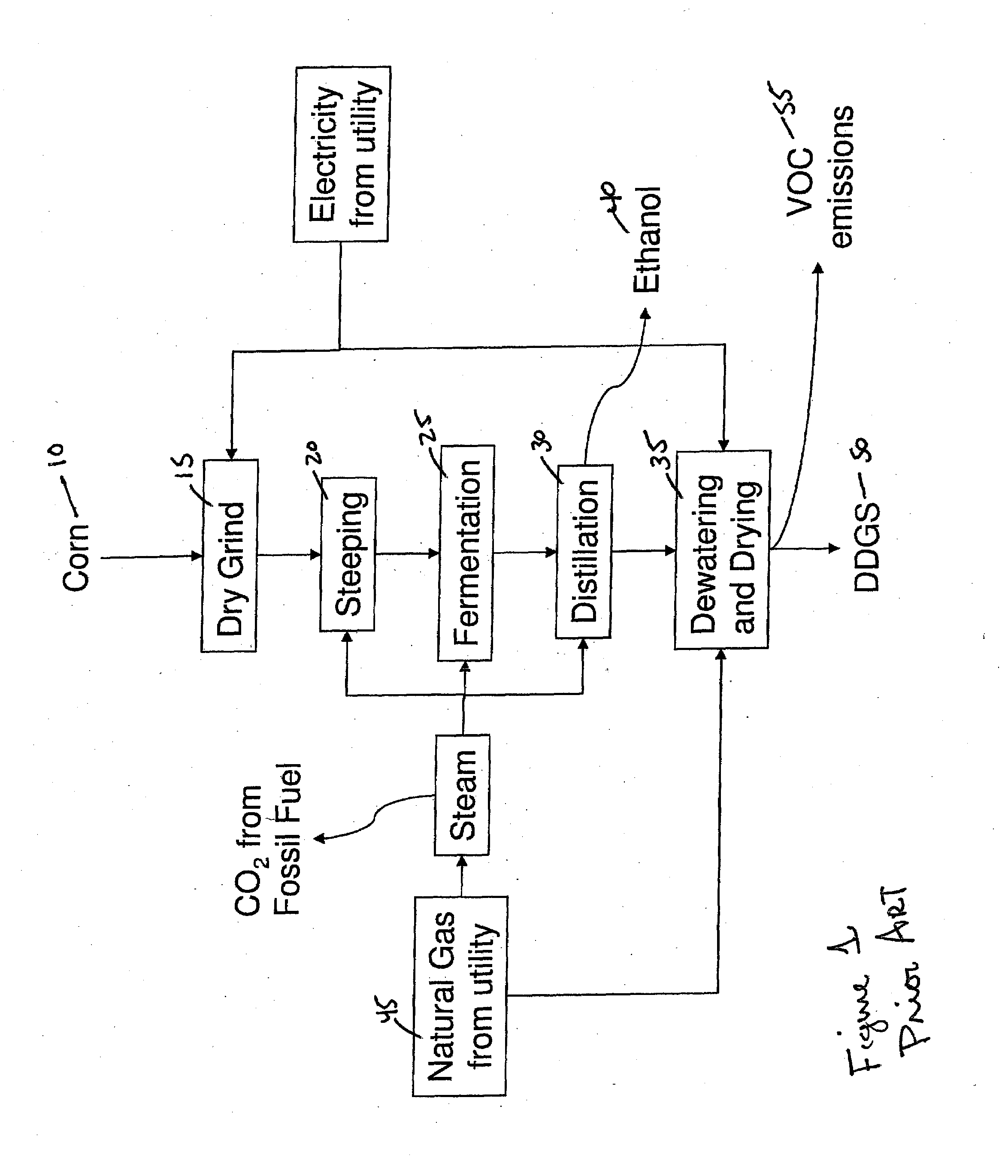

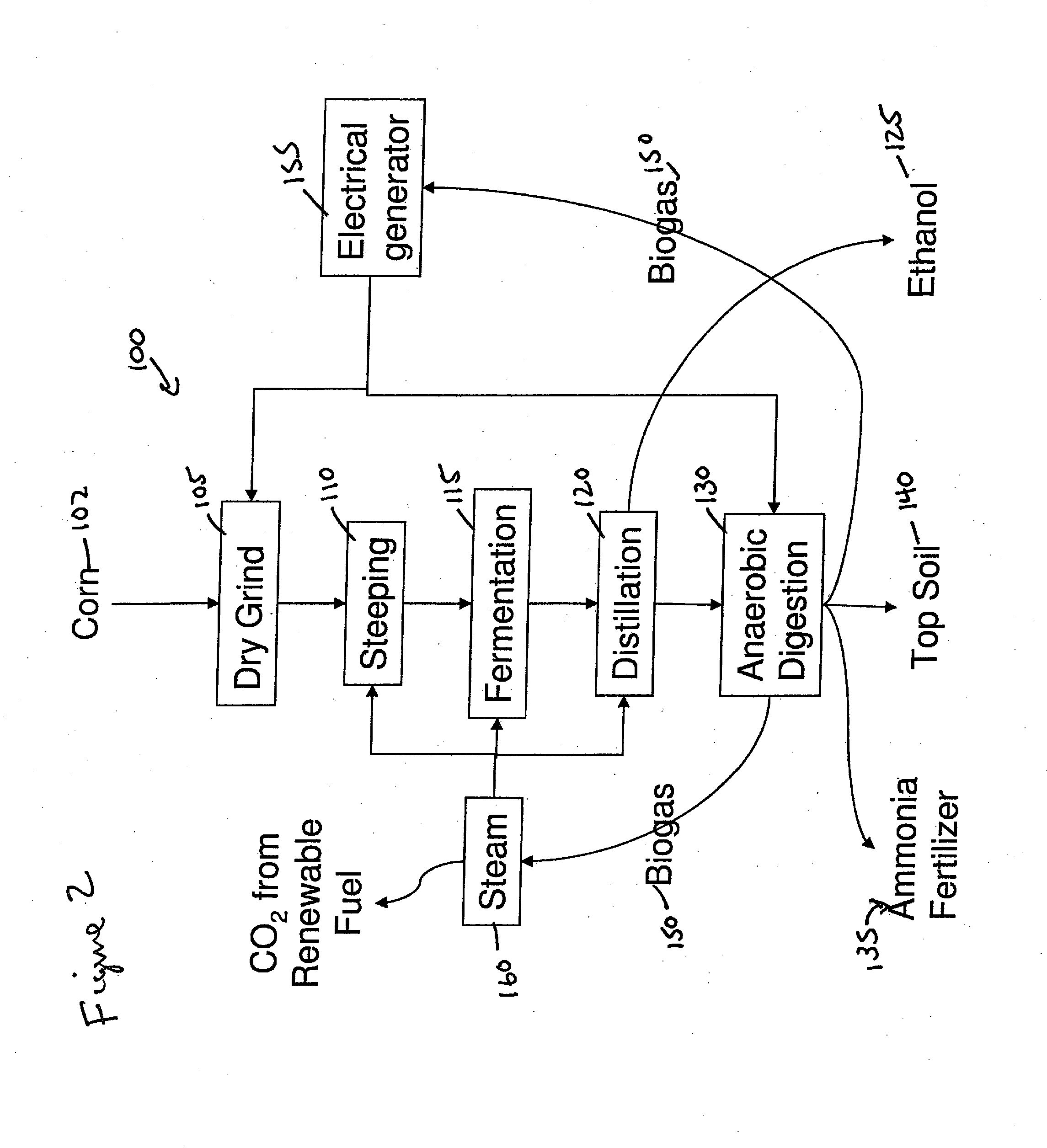

Process for producing ethanol and for energy recovery

InactiveUS20070141691A1Increasing net energy valueReducing the reliance of the ethanol industryBioreactor/fermenter combinationsBio-organic fraction processingElectricityDistillation

The present invention is directed to a process for the production of ethanol and energy. The process includes the steps of fermenting a corn mash in an aqueous medium to produce a beer. Next, the beer is distilled to produce ethanol and a whole stillage. The whole stillage is anaerobically digested to produce a biogas and a residue. The biogas is combusted to produce electricity and steam. The electricity and steam are used during the fermentation and distillation process. The residue may further be separated into a liquid fertilizer and top soil residue.

Owner:STANLEY CONSULTANTS

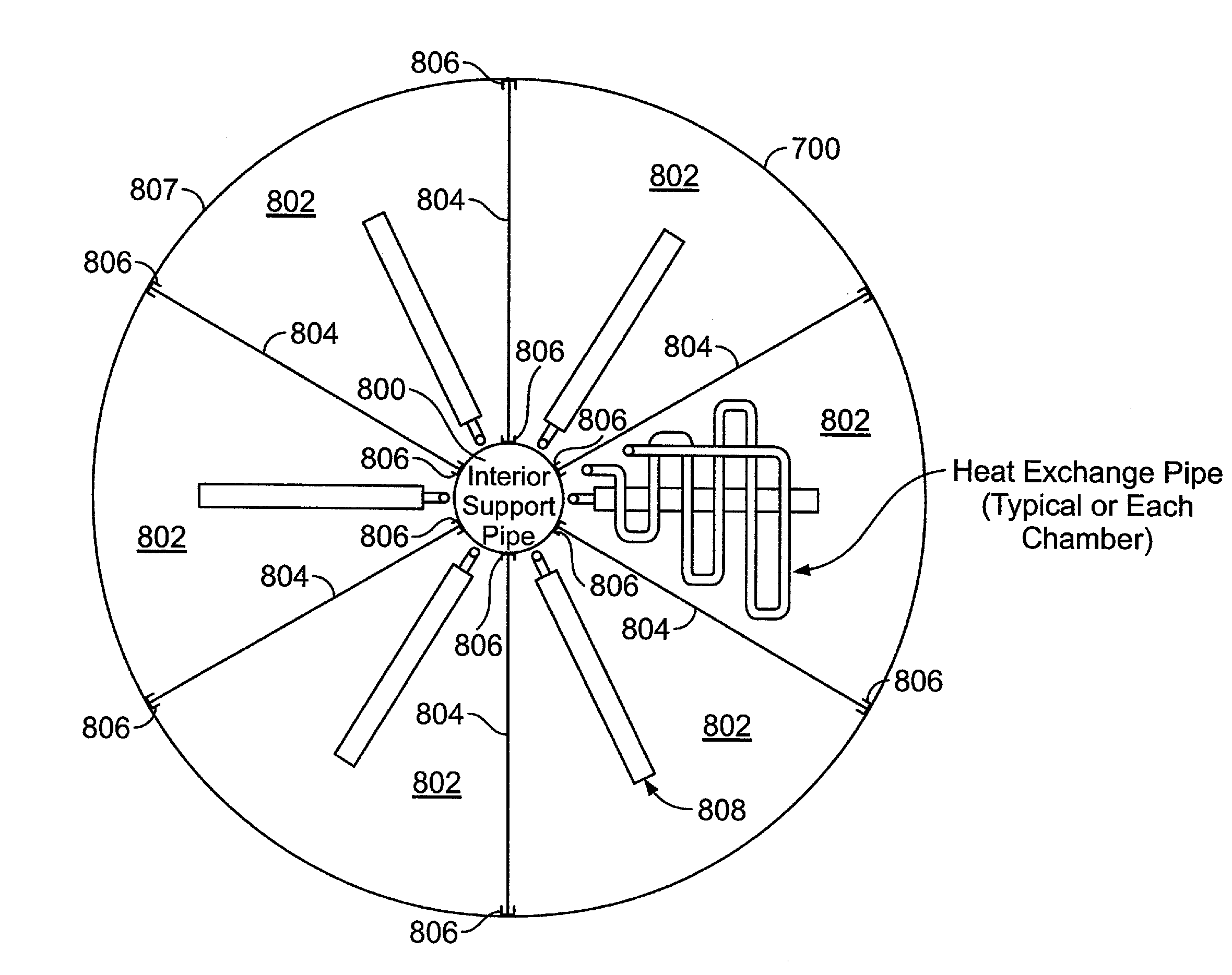

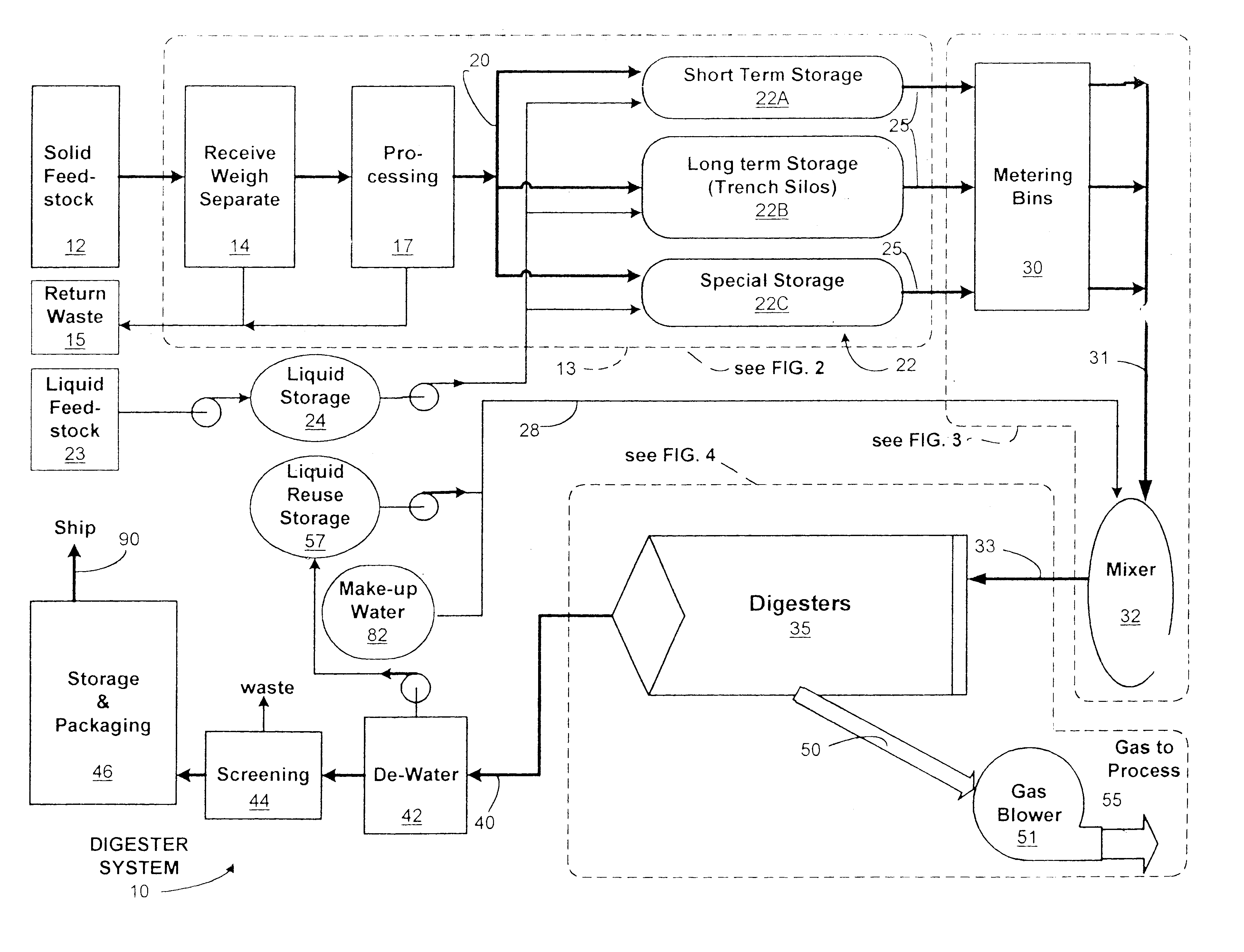

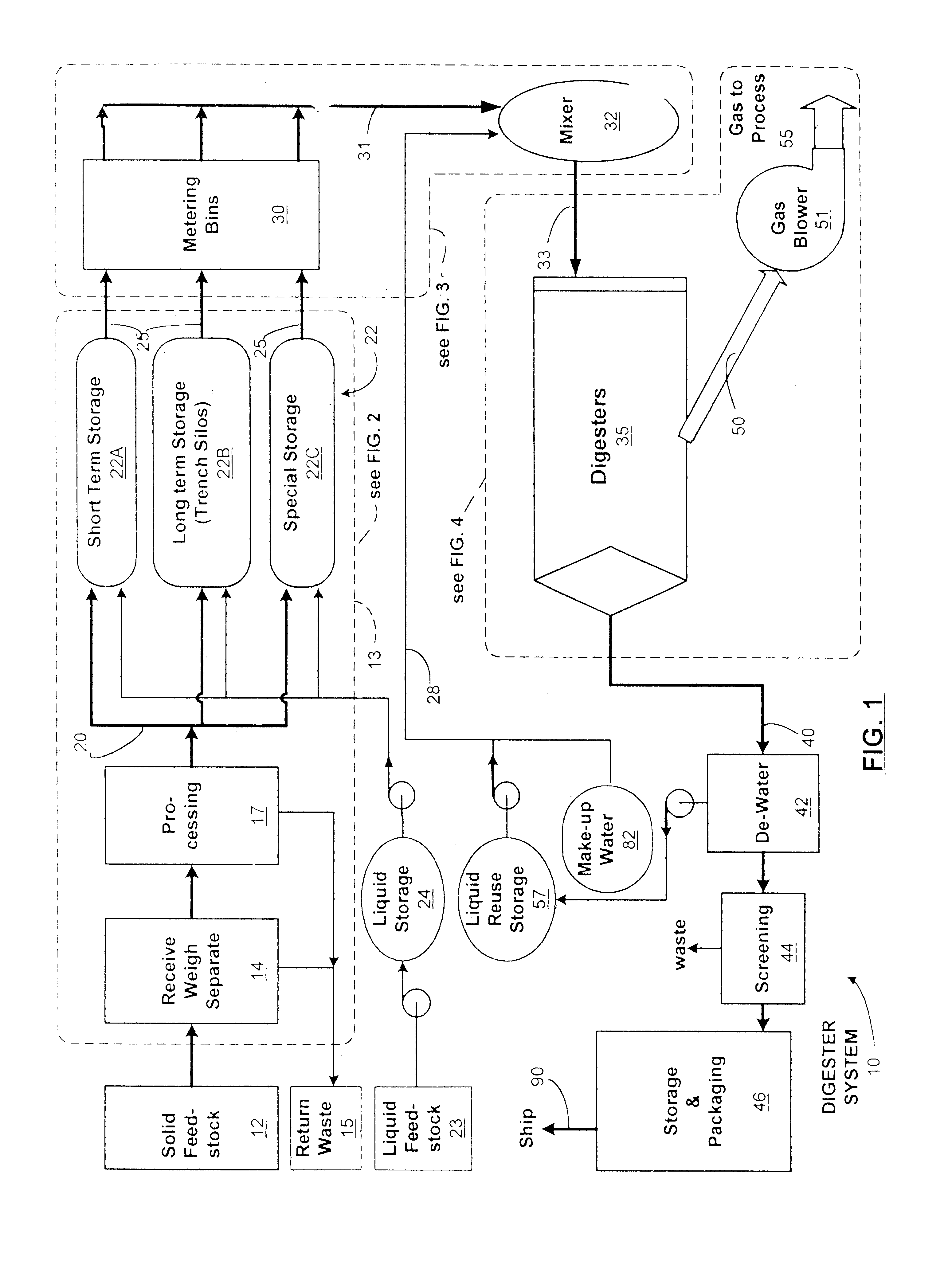

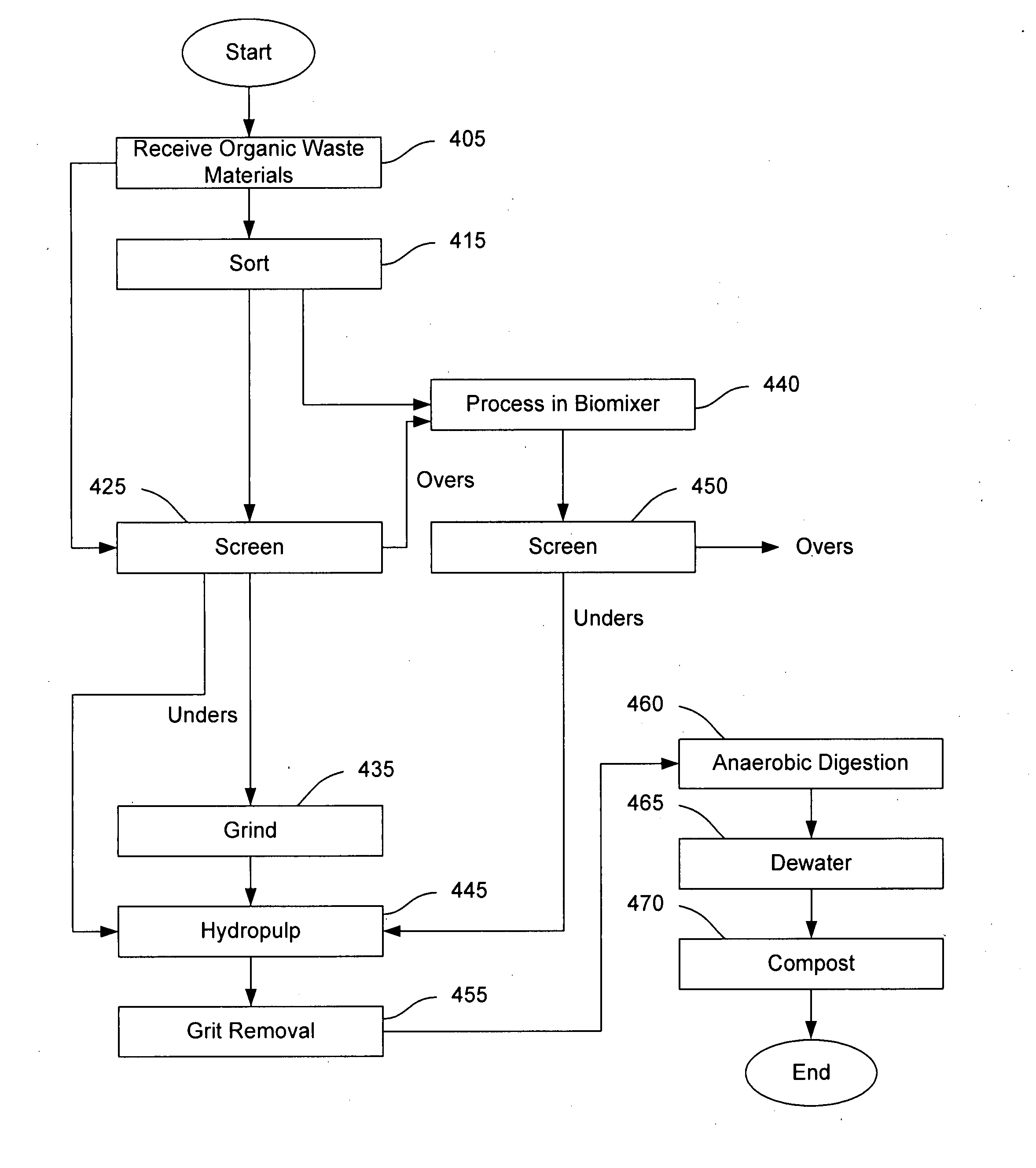

Anaerobic digester system

InactiveUS6296766B1Easy to monitorEasy to controlData processing applicationsBiological treatment regulationGrowth plantEnvironmental engineering

A method for an anaerobic digester system is provided that employs a cumulative data base to better monitor and control the anaerobic process, as compared with conventional anaerobic digester systems. The method includes the storing and ensiling of a feedstock, preferably a biomass, to form a digester feed material, which then processed by a digester. The process evolves a biogas and forms a digested material. The process is monitored, to collect a plurality of digester data from all stages of the process. These individual points or elements of the data are telemetered to a cumulative data base for storage and eventual retrieval and the cumulative data base is mined to compile predictive, feed forward controls and construct feedstock correlations between the metabolic activity within the digesters and an analysis of the feedstocks into the digesters. The method further includes the production of a high quality plant growth media from the digested mash, and recovery of the biogas generated within the digester. The biogas is collected with the aid of a biogas recovery system. The biogas is predominantly methane, and the anaerobic digester system is preferably operated to maximize the quantity and quality of methane generated.

Owner:TECHN INFORMATION

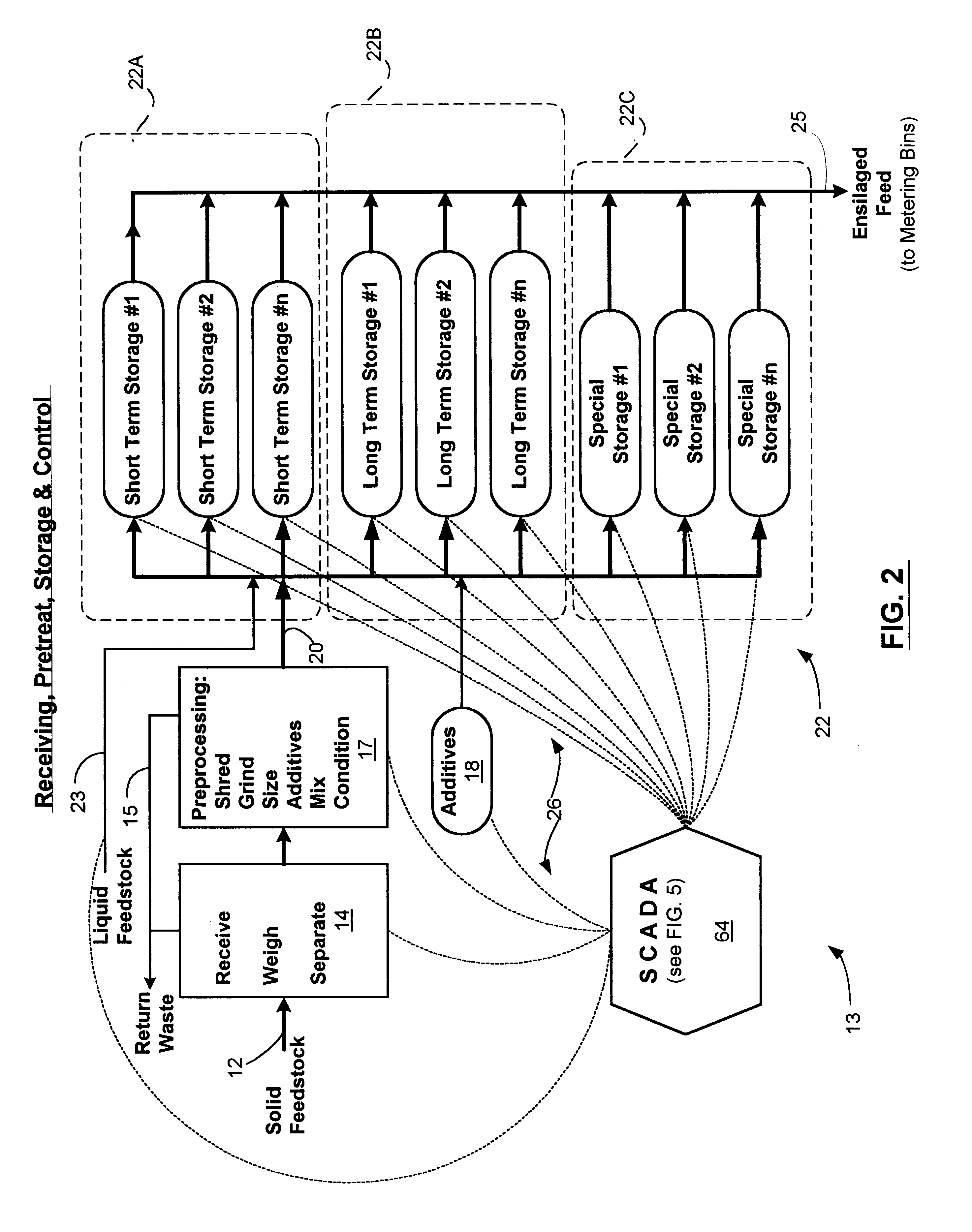

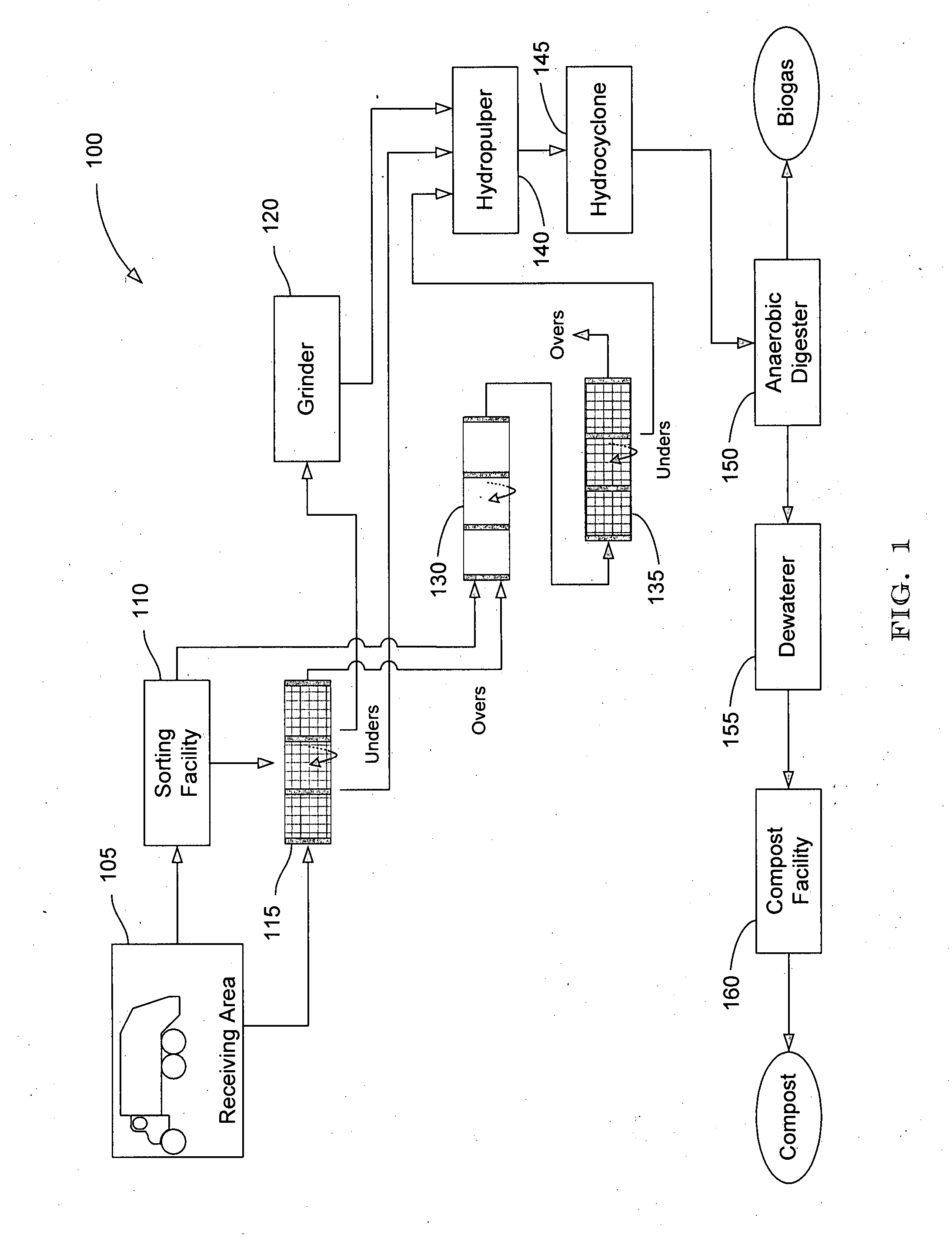

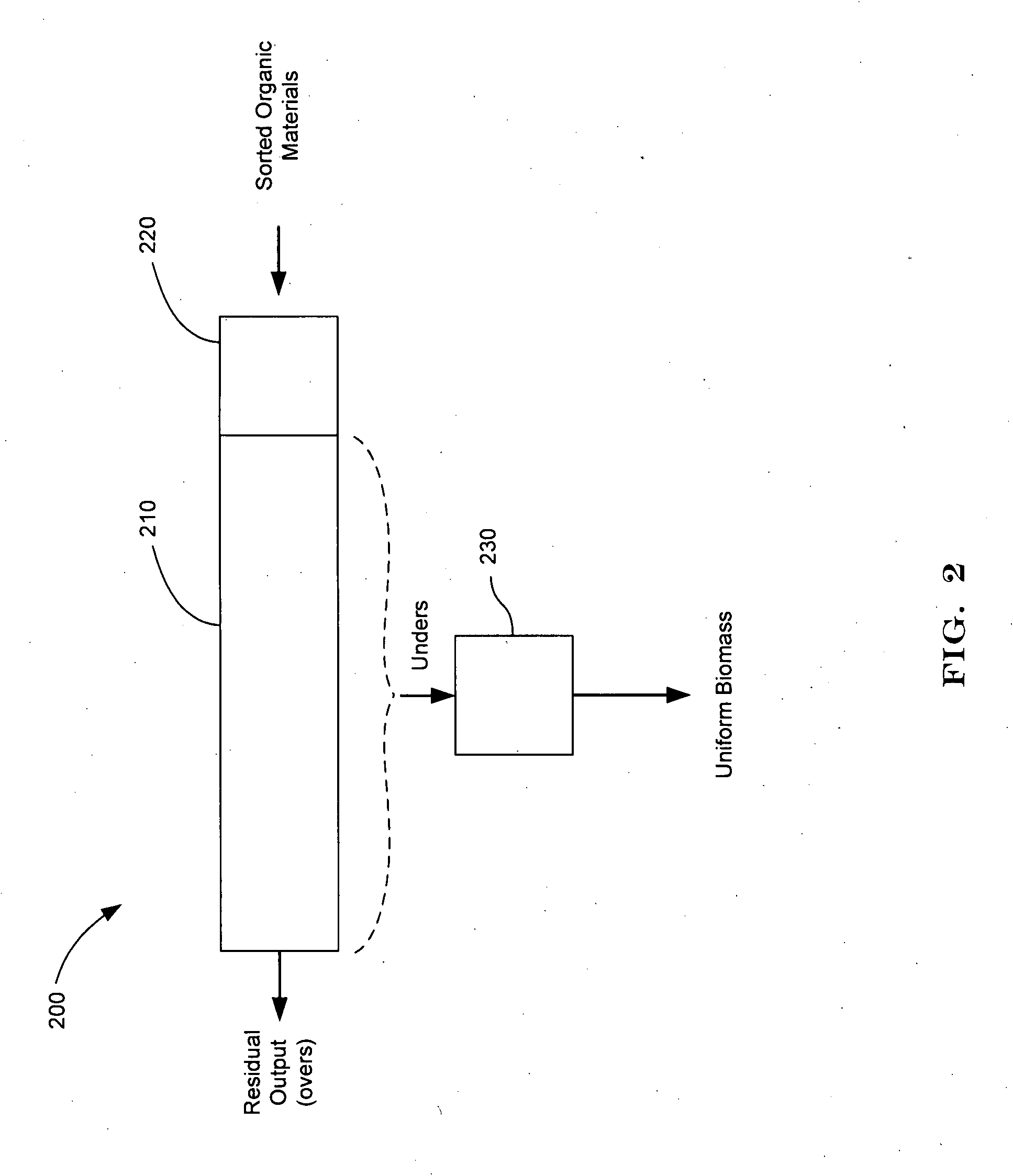

Systems and methods for converting organic waste materials into useful products

ActiveUS20080020456A1Bioreactor/fermenter combinationsBio-organic fraction processingOrganic fractionProduct system

Systems and methods are provided for converting organic waste materials from a municipal waste stream to useful products. Organic waste materials having a wide range of compositions such as, for example, yard waste, food waste, paper, and the organic fraction of municipal solid waste are converted into a uniform biomass that is suitable for conversion to useful products, such as fuels. Through the use of a biomixer and a hydropulper, as well as through sorting and screening, the organic waste materials are progressively reduced in size and cleaned of contamination. The resulting uniform biomass is suitable for anaerobic digestion to produce biogas and a residual solid that is suitable for producing a high quality compost.

Owner:RECOLOGY

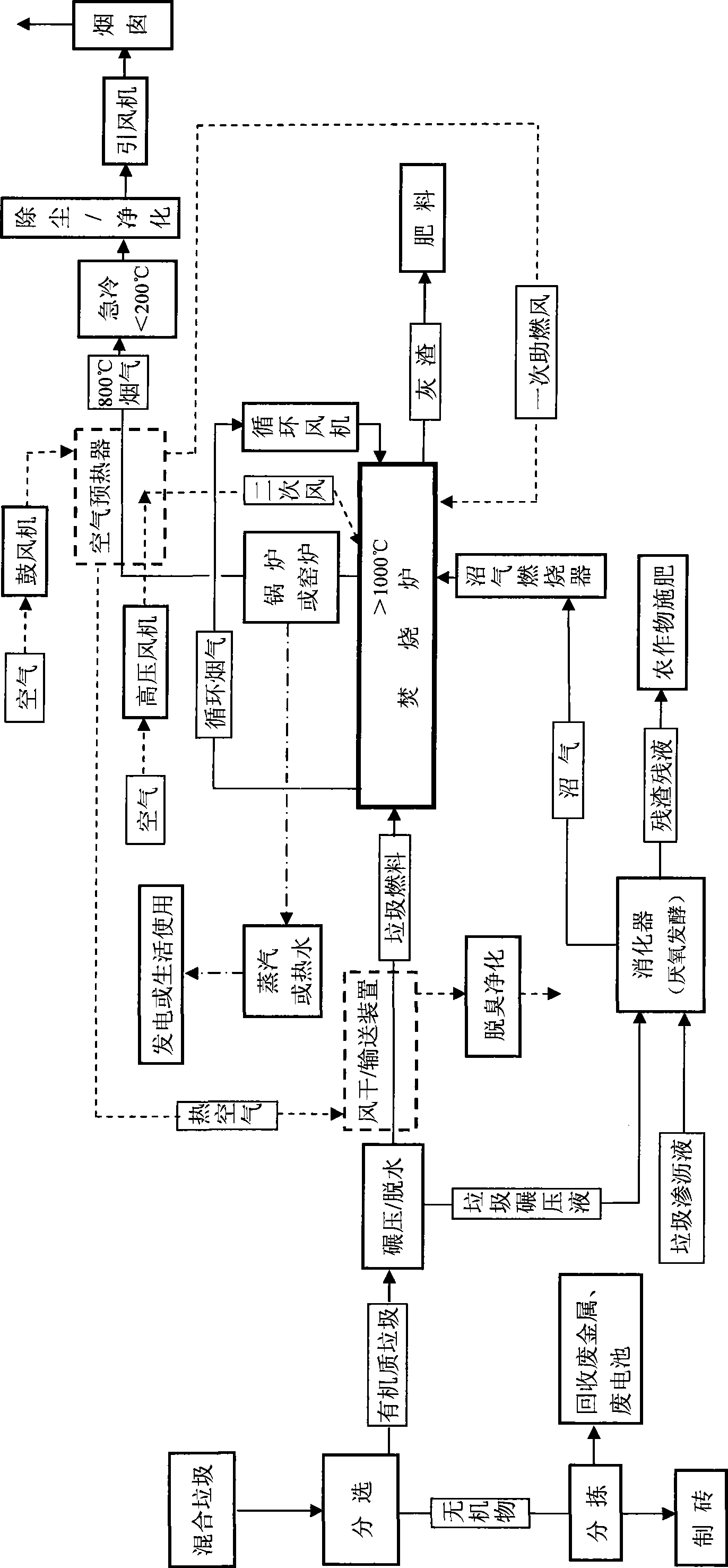

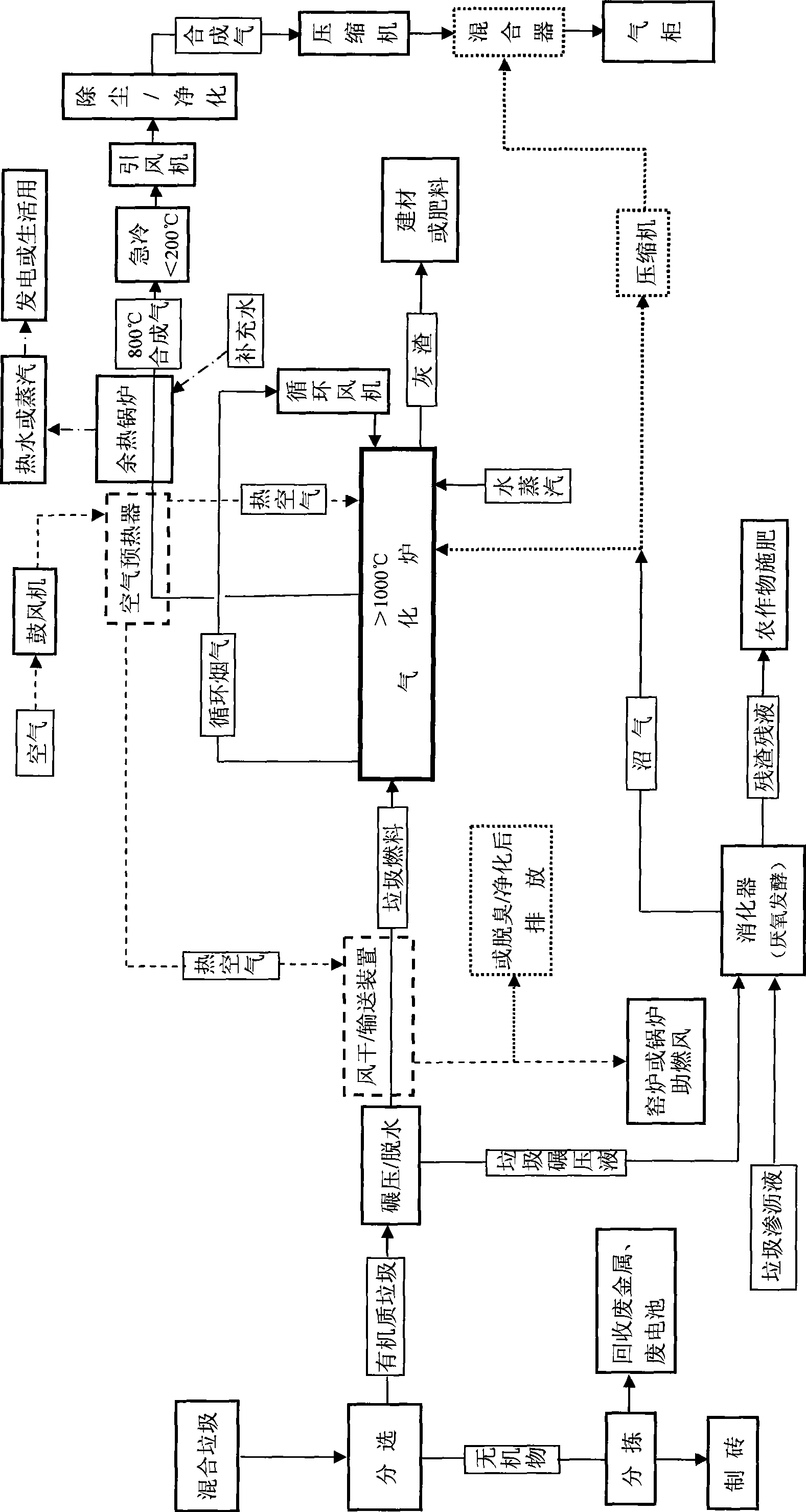

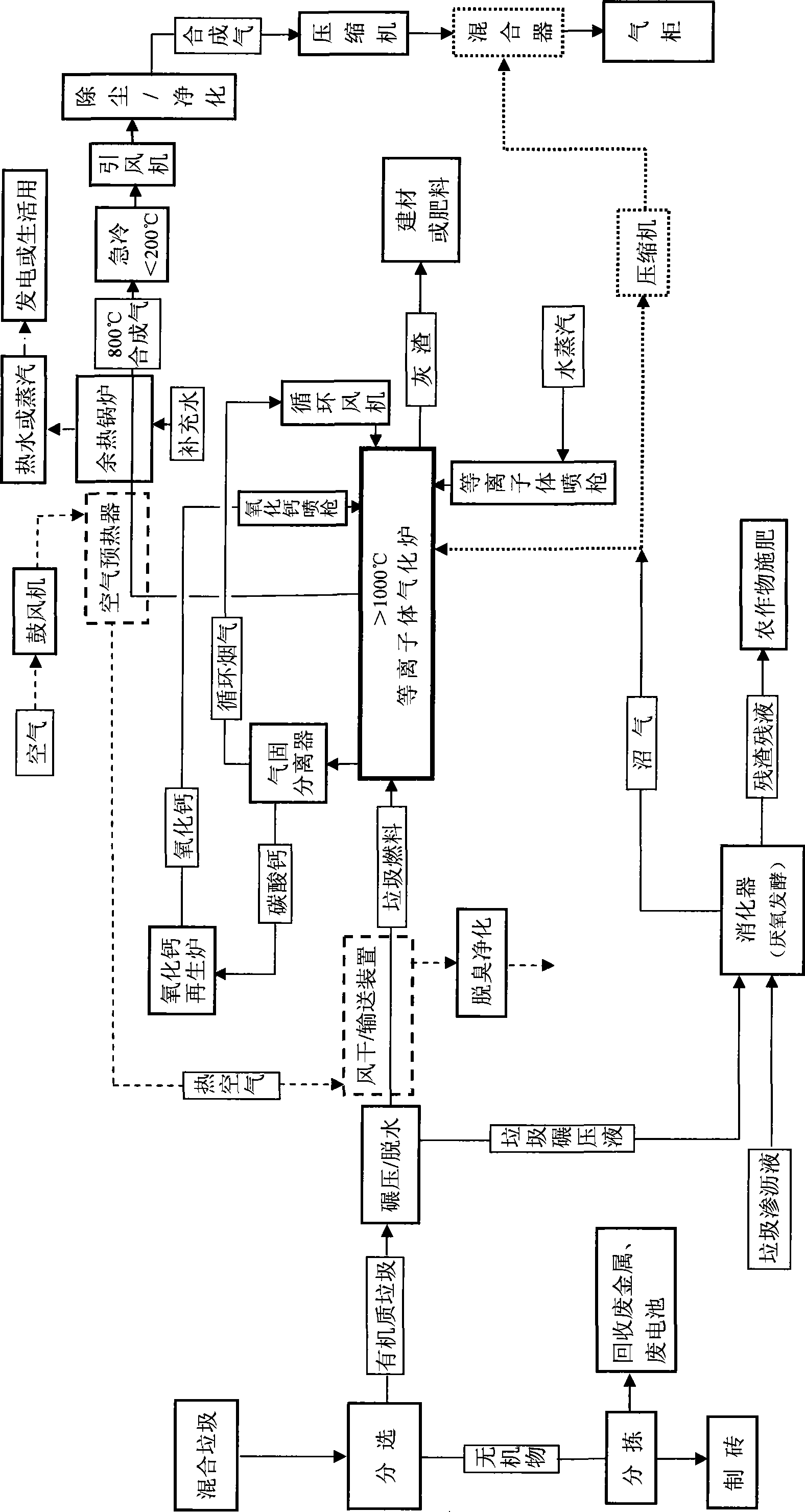

Domestic garbage transformation technique, system and apparatus without conventional fuel for combustion supporting

InactiveCN101468789AReduce pollutant contentLow investment costBio-organic fraction processingSolid waste disposalBrickClean energy

The invention provides a process, a system and equipment for converting household garbage without support combustion of the prior fuels, which relates to a process and equipment for processing garbage. The process is characterized in that the household garbage is sent into a gasification furnace or an incinerator after separating, dehydrating by rolling compaction and air-drying treatment; garbage fuel is converted in the furnace by a mode of gasification or incineration, and is subjected to baking, pyrogenation, gasification and carbon residue burn-out in the furnace; the converted synthesis gas is used for cleaning energy; waste heat of incineration is absorbed by heat-exchange equipment for reclamation; garbage rolling liquid is sent into a digesting machine for anaerobic fermentation so as to produce biogas, the biogas is used as auxiliary fuel of the incinerator, and the digested residue and residual liquid are used for fertilizing crops; and inorganic substances separated from the garbage are used as raw materials to manufacture bricks, and clinker discharged from the incinerator or the gasification furnace is used for producing cement or fertilizer. The process, the system and the equipment comprehensively utilize the garbage so as to achieve complete dissolving treatment, and the equipment has a simple structure and low investment cost, and is easy to popularize..

Owner:周开根

Lightweight ecological nutrient soil for roof greening and method for preparing lightweight ecological nutrient soil

InactiveCN102875227AMeet the requirements of green environmental protectionUltra-thin soil layerFertilizer mixturesSlagMushroom

The invention relates to lightweight ecological nutrient soil for roof greening and a method for preparing the lightweight ecological nutrient soil. The nutrient soil is made of dry basis raw materials including 10-20% of biogas residues, 5-15% of slag, 10-20% of loess, 25-35% of rice hulls, 15-25% of mushroom residues and 15-30% of pine needle soil, and living earthworms accounting for 0.2-1% of the total mass of the dry basis raw materials. The nutrient soil is light in load, low in volume weight, free from hardening, resistant to trampling, fine in moisture and fertility preserving performance, pollution-free, extensive in source of raw materials, low in cost, simple in production process and easy to popularize.

Owner:HENAN XIFANGE GREENING PROJECT

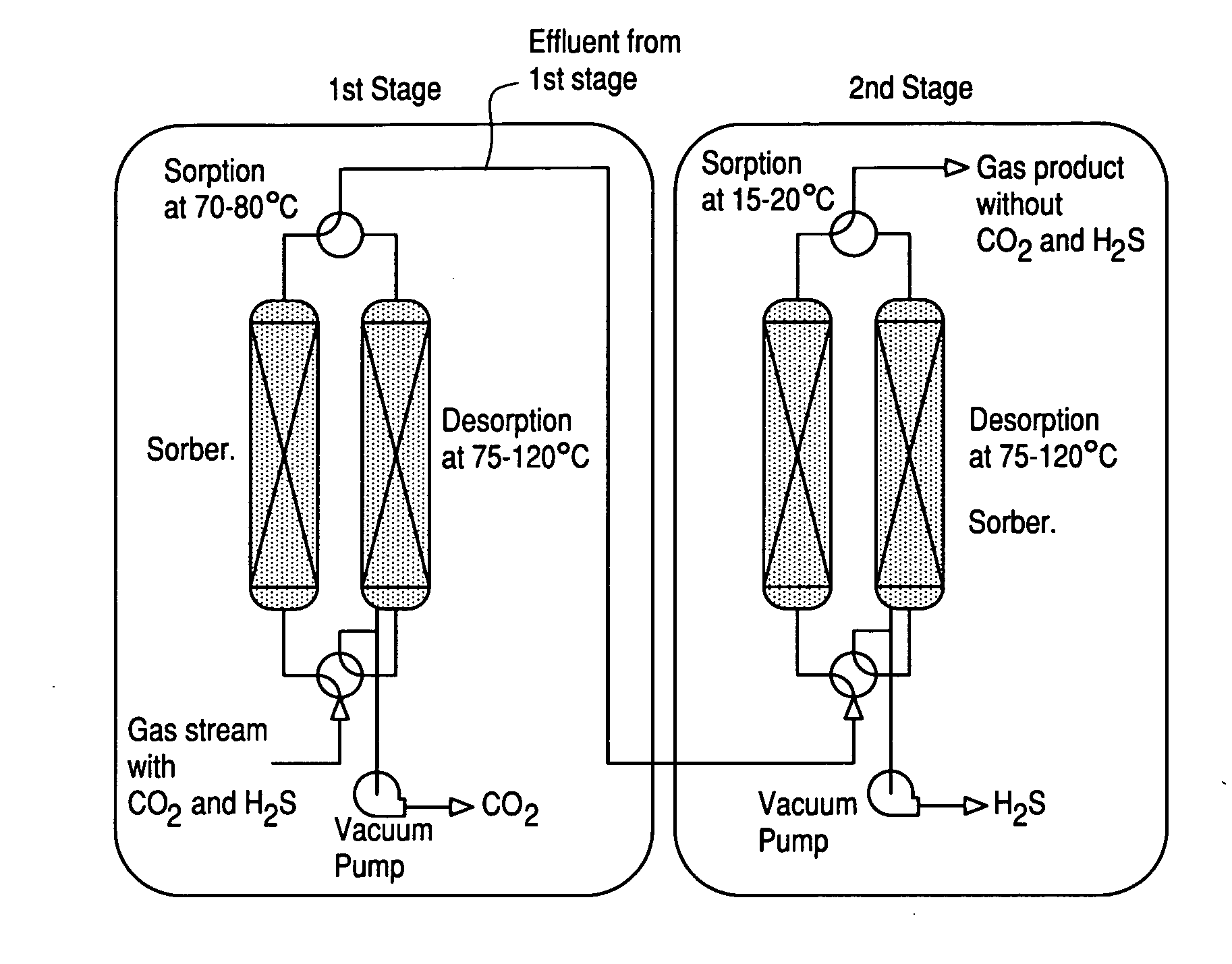

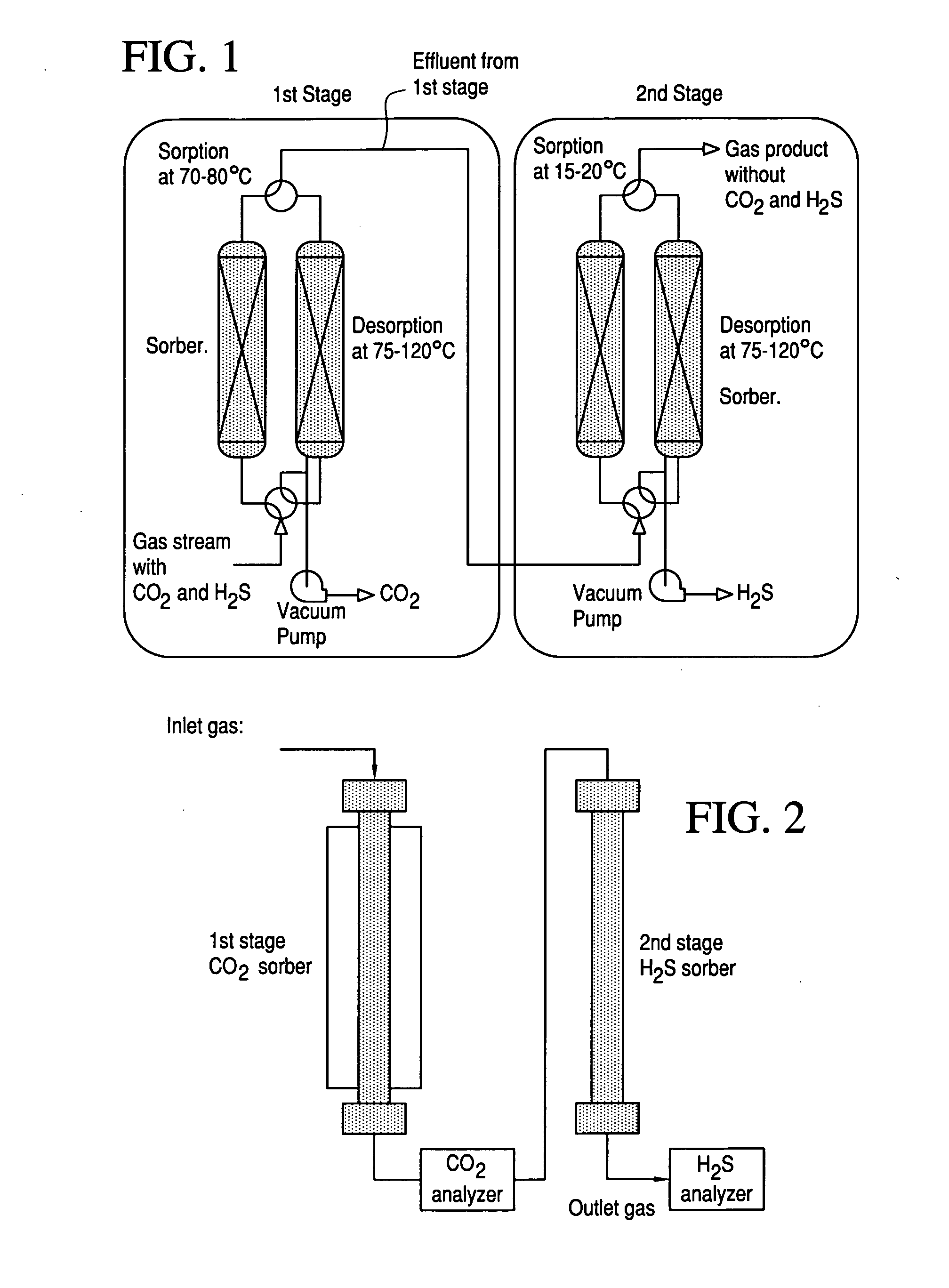

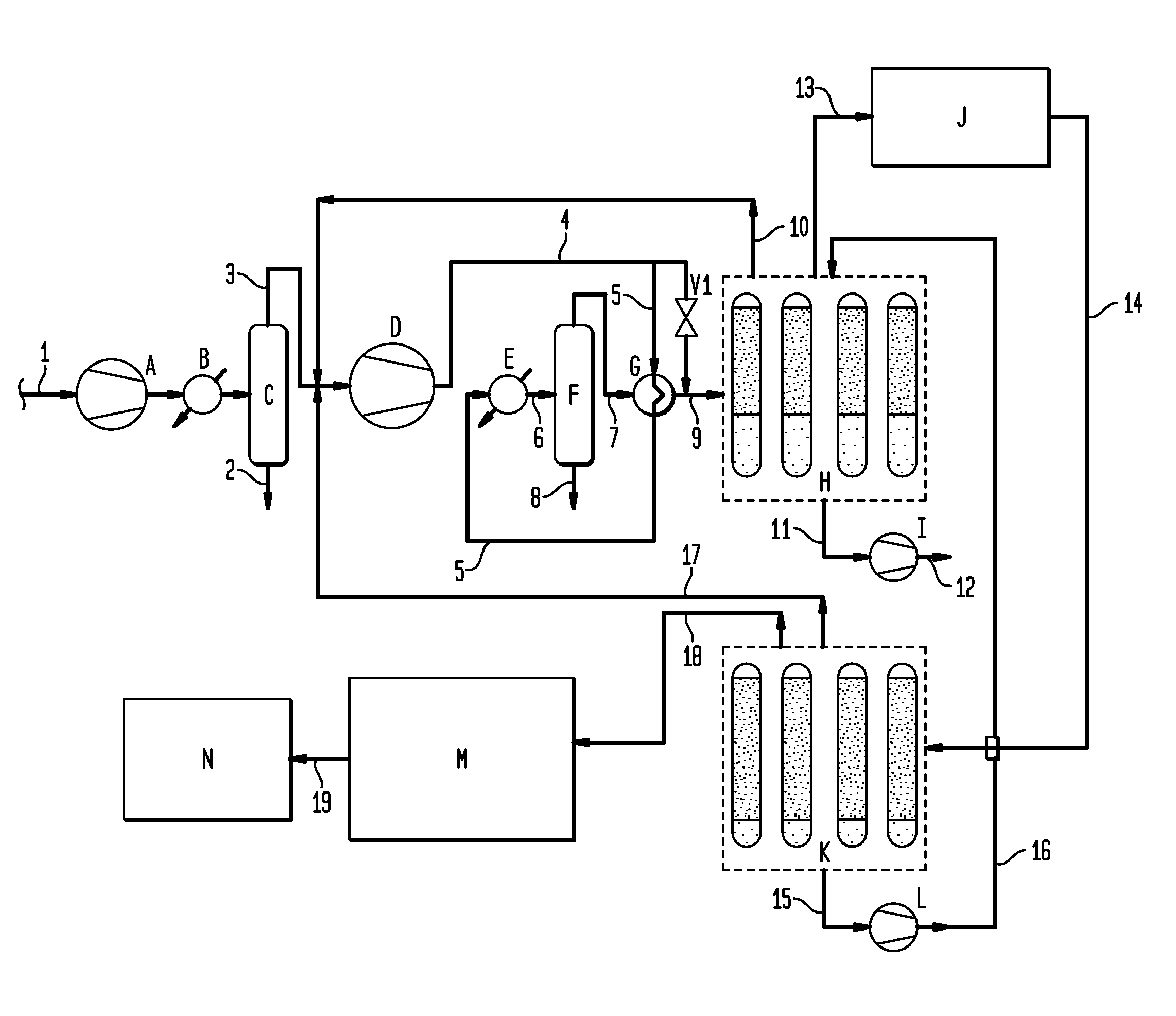

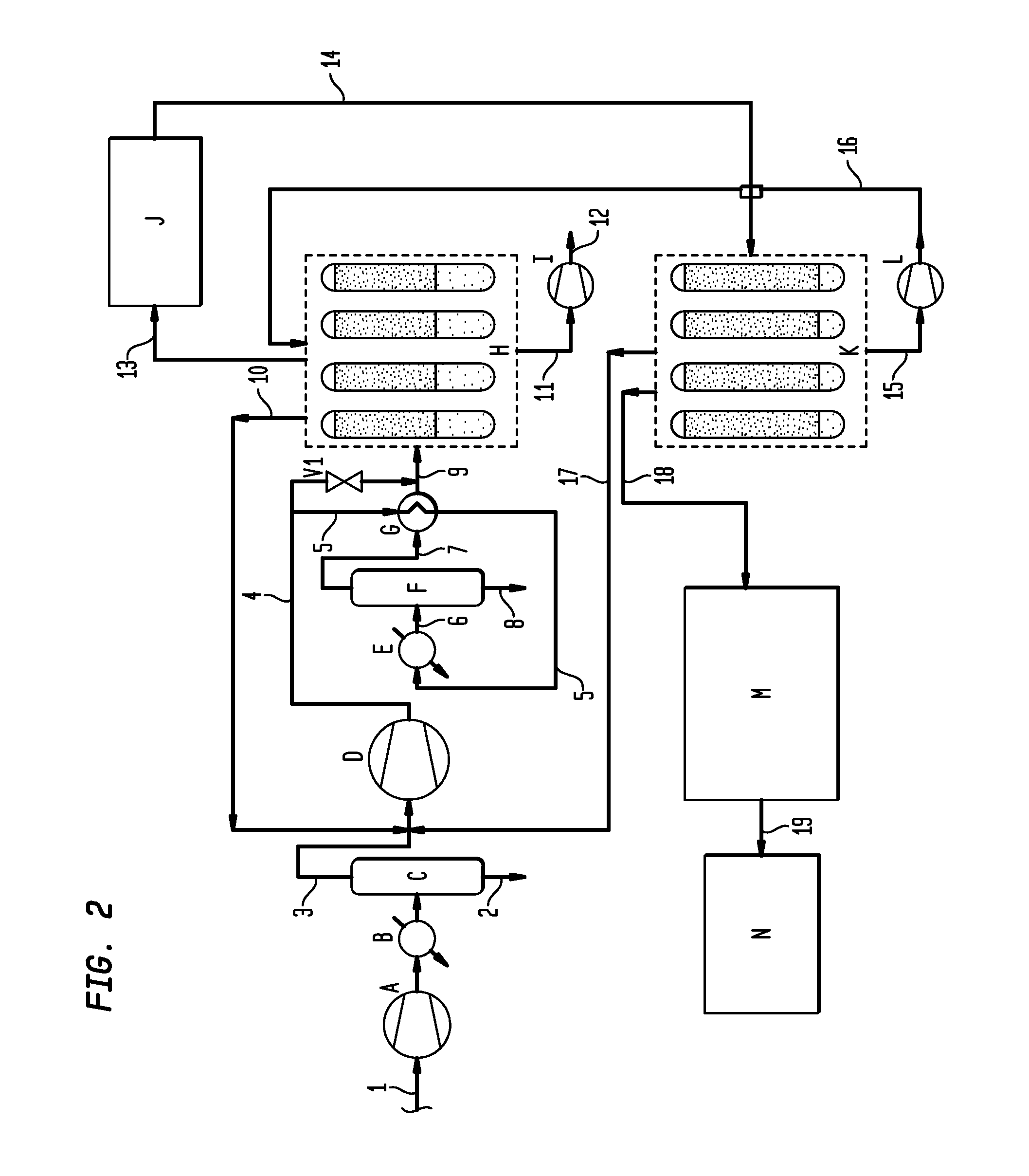

Gas purification processes

InactiveUS20110185896A1Reduce and eliminate needEasy to controlGas treatmentGaseous fuelsVacuum levelAir purification

A method for removing contaminants from a natural gas stream such as a biogas / landfill gas stream. The natural gas stream is fed to a first adsorption unit for removal of certain contaminants and then to a second adsorption unit for the removal of additional contaminants. Alternatively, a membrane stage may be employed between the adsorption units. The method utilizes the external purge to enhance pressure swing adsorption working capacity so that the vacuum level required for regeneration is not as high.

Owner:LINDE AG

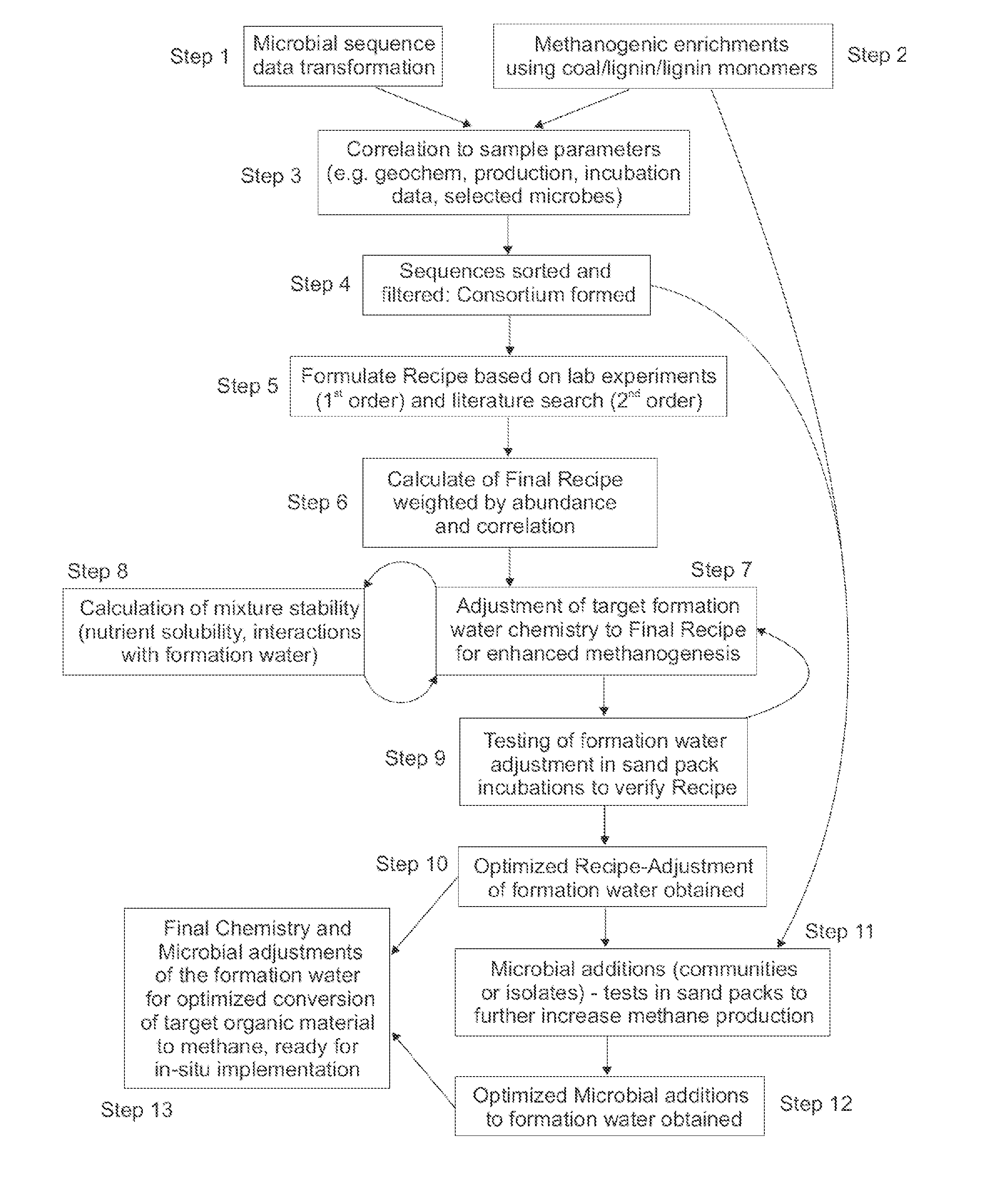

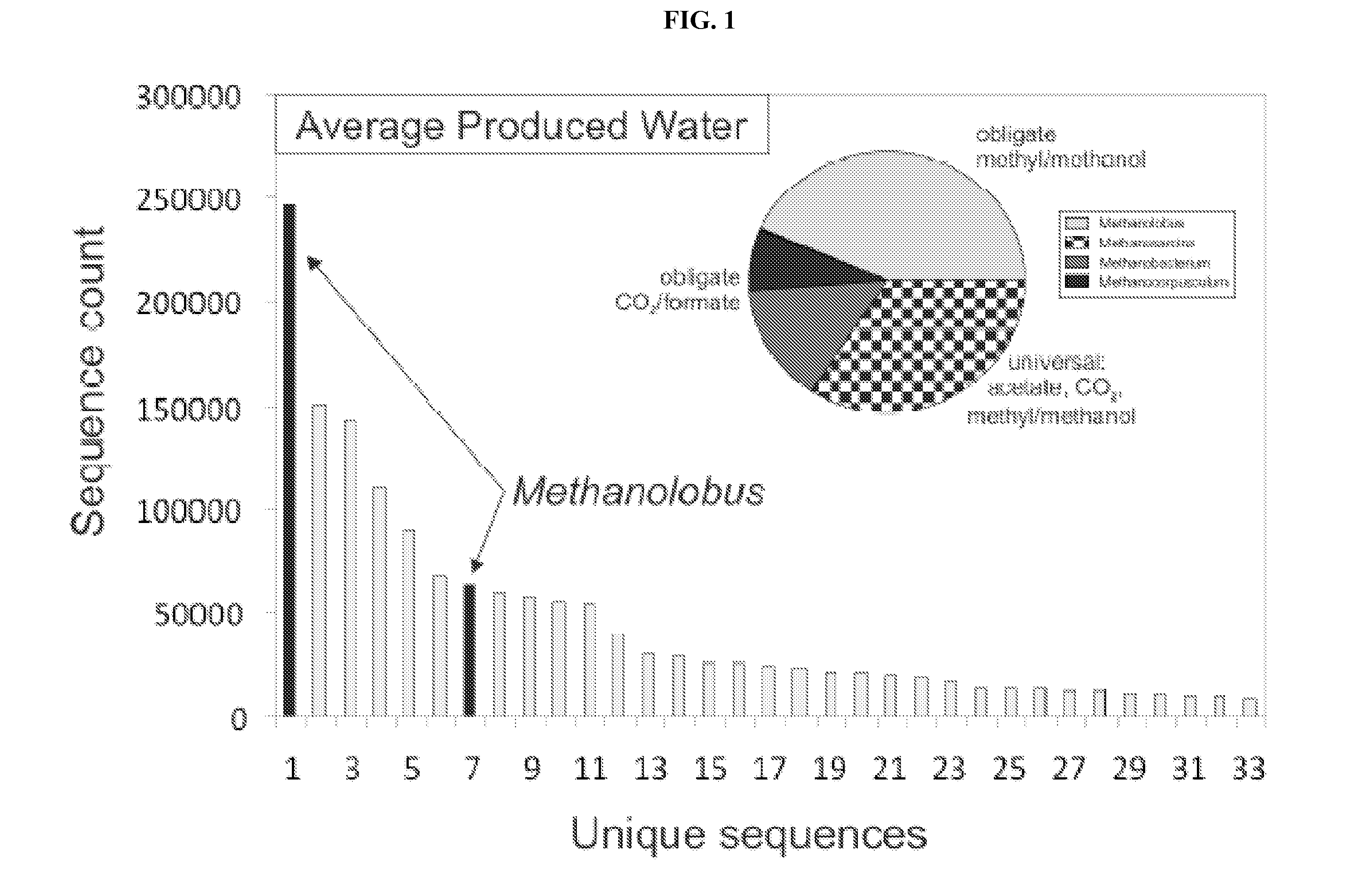

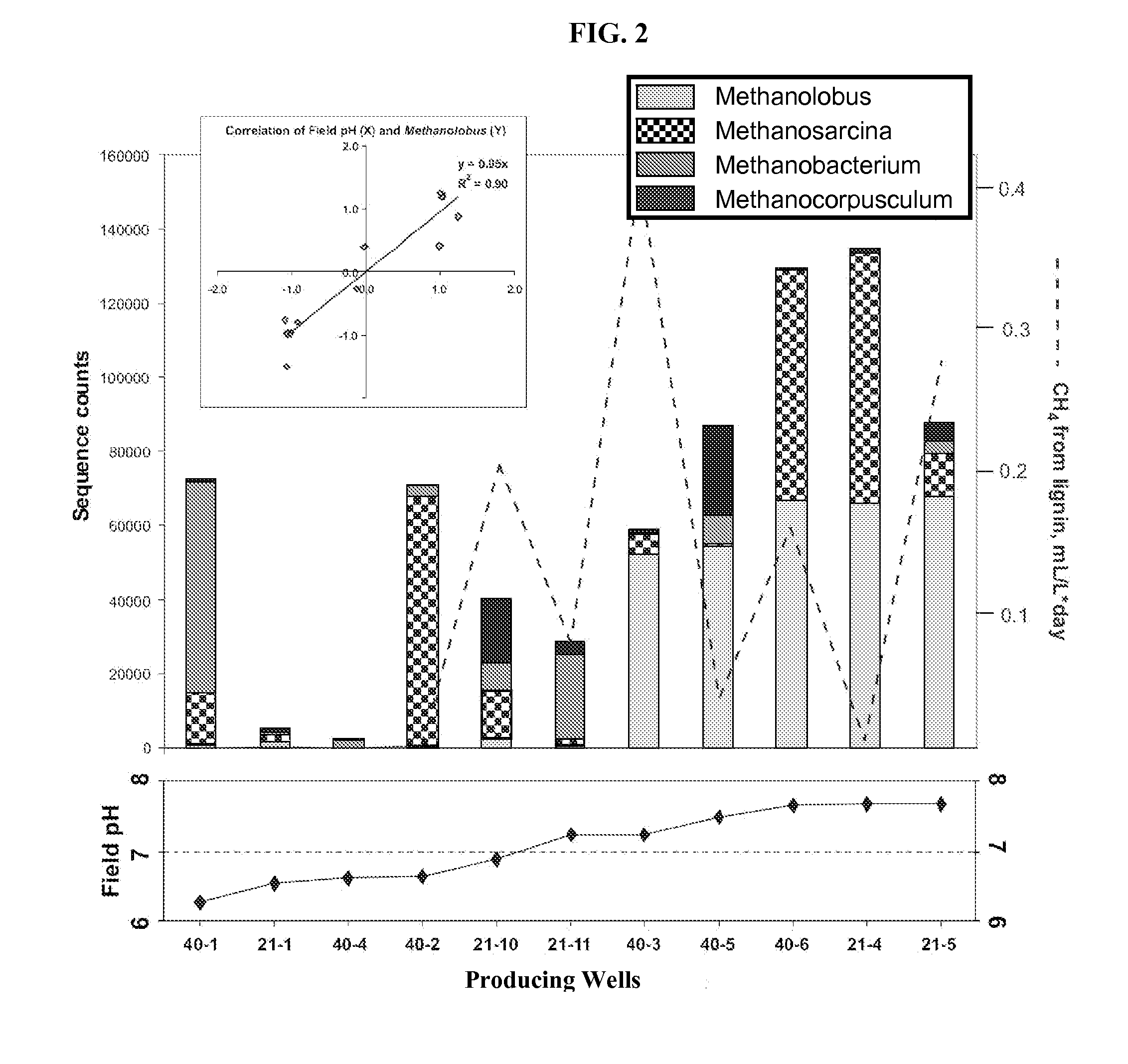

In situ methanogenesis modeling and risk analysis

ActiveUS20110308790A1Enhancing methanogenic rateEnhance methanogenic degradationSurveyBacteriaComputational modelMicrobiome

This invention generally relates to natural gas and methylotrophic energy generation, bio-generated fuels and microbiology. In alternative embodiments, the invention provides nutrient amendments and microbial compositions that are both specifically optimized to stimulate methanogenesis, or “methylotrophic” conversion. Additionally, the invention provides methods to develop nutrient amendments and microbial compositions that are both specifically optimized to stimulate methanogenesis in a given reservoir. The invention also provides methods for the evaluation of potentially damaging biomass formation and scale precipitation resulting from the addition of nutrient amendments. In another embodiment, the invention provides methods for simulating biogas in sub-surface conditions using a computational model.

Owner:CONOCOPHILLIPS CO

Novel method for innocent treatment and utilization of dead livestock and poultry

InactiveCN101182247ASave energyNo secondary pollutionBio-organic fraction processingInternal combustion piston enginesSlagSludge

The invention discloses a novel method of the harmless treatment and utilization of livestock and poultry which died of disease according to the steps as follows: firstly, various kinds of the animal bodies of the livestock and the poultry which died of disease are collected; secondly, the animal bodies are crushed; thirdly, the crushed animal bodies are sterilized under high temperature and highpressure and separated for filtering, the material of oil and fat flows into a cooling pool, and the material of hair and bone is dried; fourthly, the material of hair and bone after drying is carbonized; fifthly, the material of oil and fat after cooling is added with catalyst, high-efficiency compound microorganism, trash, organic wastewater and sludge; sixthly, the mixed organic material is put into an anaerobic tower to be fermented, and then biogas, biogas slurry and biogas slag are processed for three-phase separation; seventhly, the biogas is used for burning and generating electricity; eighthly, the biogas slurry inside a fertilizer storing pool is used as farmland fertilizer; ninthly, the biogas slag is added with the high-efficiency compound microorganism and the catalyst for secondary ferment; tenthly, the material after the secondary ferment is made into agricultural high-efficiency organic fertilizer. The invention solves the problem of the environmental pollution caused by the livestock and poultry which died of disease and change the waste livestock and poultry which died of disease into valuables.

Owner:浙江威尔斯生物能源开发有限公司

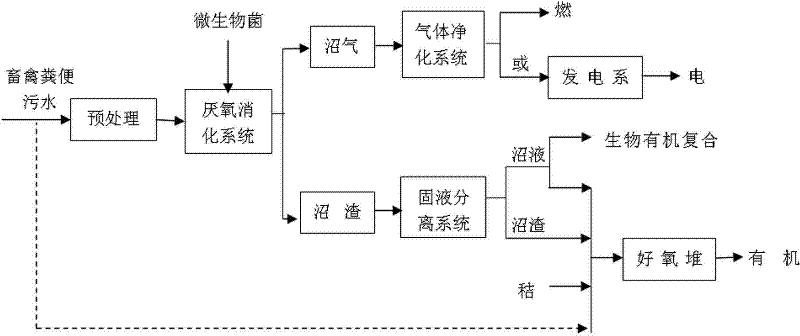

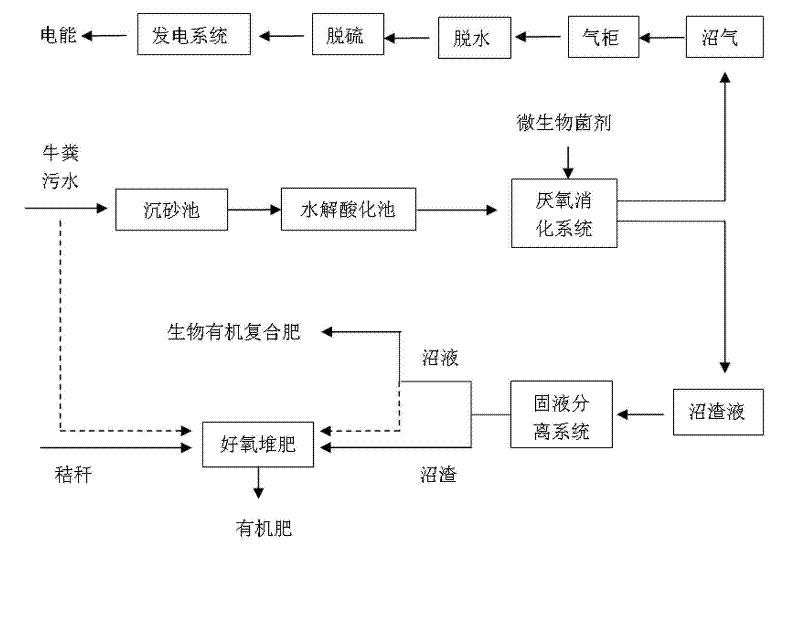

Method for comprehensively recycling fecal sewage of large-scale livestock and poultry farms and farmland crop straws

InactiveCN102173507AOvercome the problem of insufficient productionIncrease gas productionBio-organic fraction processingWaste based fuelFecesSlurry

The invention relates to a method for comprehensively recycling the fecal sewage of large-scale livestock and poultry farms and farmland crop straws, which comprises the following steps of: (1) performing anaerobic digestion, namely regulating the solid content of the fecal sewage of livestock and poultry to be between 5 and 10 percent, adding anaerobic digestion inocula, and performing the anaerobic digestion to generate methane; (2) performing energy utilization on the methane, namely purifying the methane obtained in the step (1) to be used as fuel gas or allowing the purified methane to be used for power generation to perform energy utilization; (3) performing solid-liquid separation, namely performing the solid-liquid separation on biogas residues and biogas slurry which are obtainedin the step (1) to obtain the biogas slurry and the biogas residues of which the moisture content is about 60 percent; (4) preparing a biological organic compound fertilizer from the biogas slurry, and mixing the biogas residues and part of biogas slurry with the straws and part of excrement to perform aerobic compost; and (5) mixing and performing the aerobic compost, namely mixing part of biogas slurry obtained in the step (3) and the crushed straws, regulating the moisture content of the mixture to be between 50 and 60 percent, and performing the aerobic compost. In the method, clean resources are recovered by the anaerobic digestion, and the biogas slurry is used for producing the biological organic compound fertilizer with a high additional value.

Owner:江苏加德绿色能源有限公司

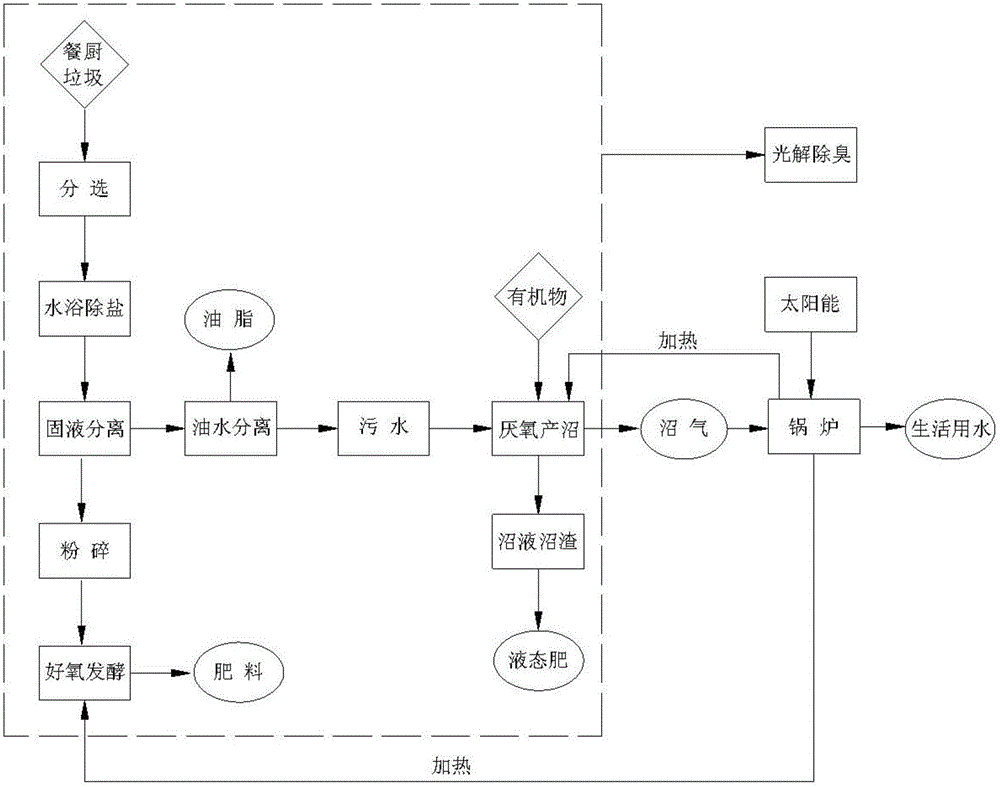

Resource-based and harmless treatment method for kitchen waste

InactiveCN104030738AEfficient removalGrowth inhibitionBio-organic fraction processingClimate change adaptationWater bathsLiquid waste

Relating to the technical field of resource recovery and recycling, the invention discloses a resource-based and harmless treatment method for kitchen waste. The method is directed at the problems of high salt content in fertilizer products, easy cause of soil salinization, and large equipment investment for anaerobic fermentation of total waste in existing kitchen waste treatment methods. The method comprises the steps of: (a) kitchen waste sorting; (b) water bath desalting: adding water, and conducting heating and stirring to dilute salt; (c) solid-liquid separation: dehydrating the waste; (d) solid material aerobic fermentation: crushing the dehydrated solid material into small particles, and conducting aerobic fermentation and drying treatment to obtain an organic fertilizer; and (e) waste liquid anaerobic fermentation: conducting oil-water separation on the waste liquid, recovering grease, subjecting sewage to anaerobic fermentation, making the produced biogas residue and biogas slurry into a liquid fertilizer, and taking the produced biogas as the fuel of a biogas boiler. The method provided by the invention is particularly suitable for resource-based and harmless treatment of kitchen waste.

Owner:习建华 +1

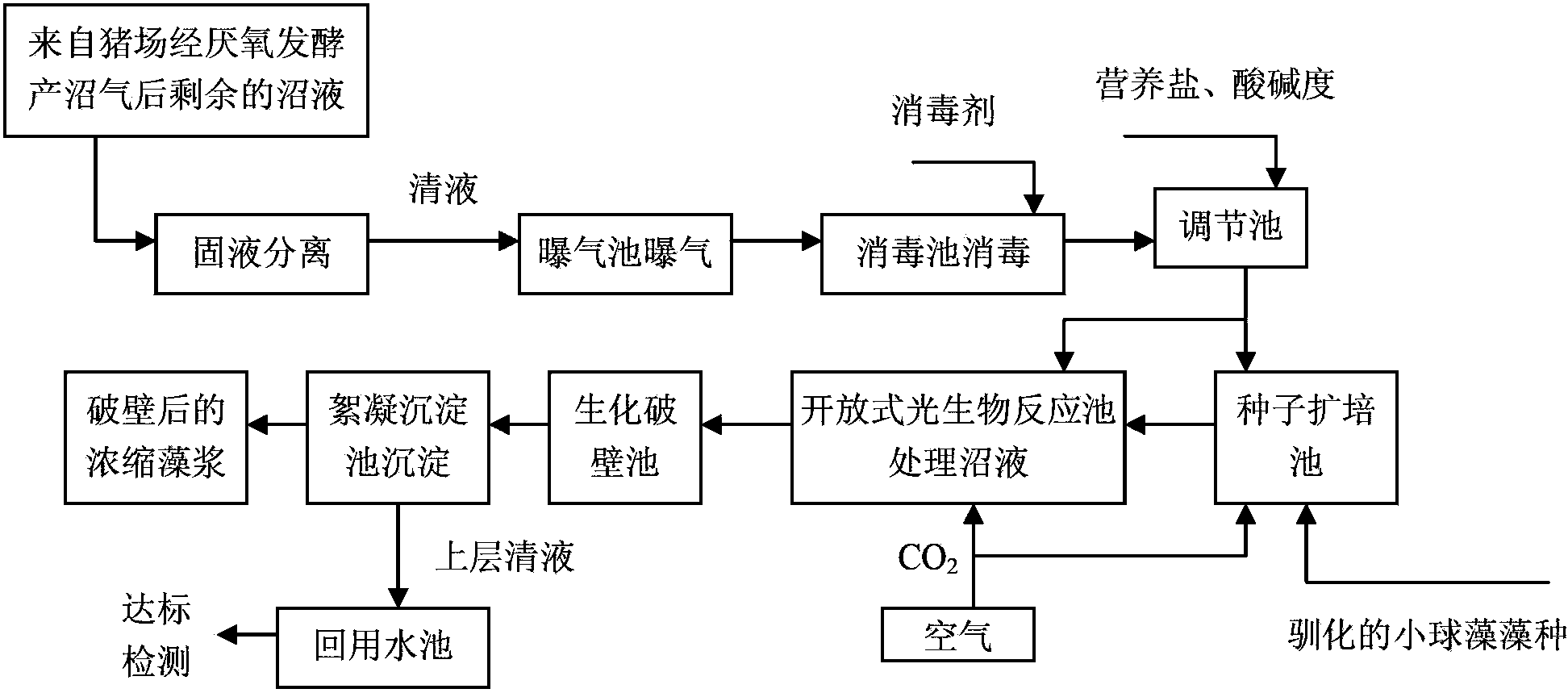

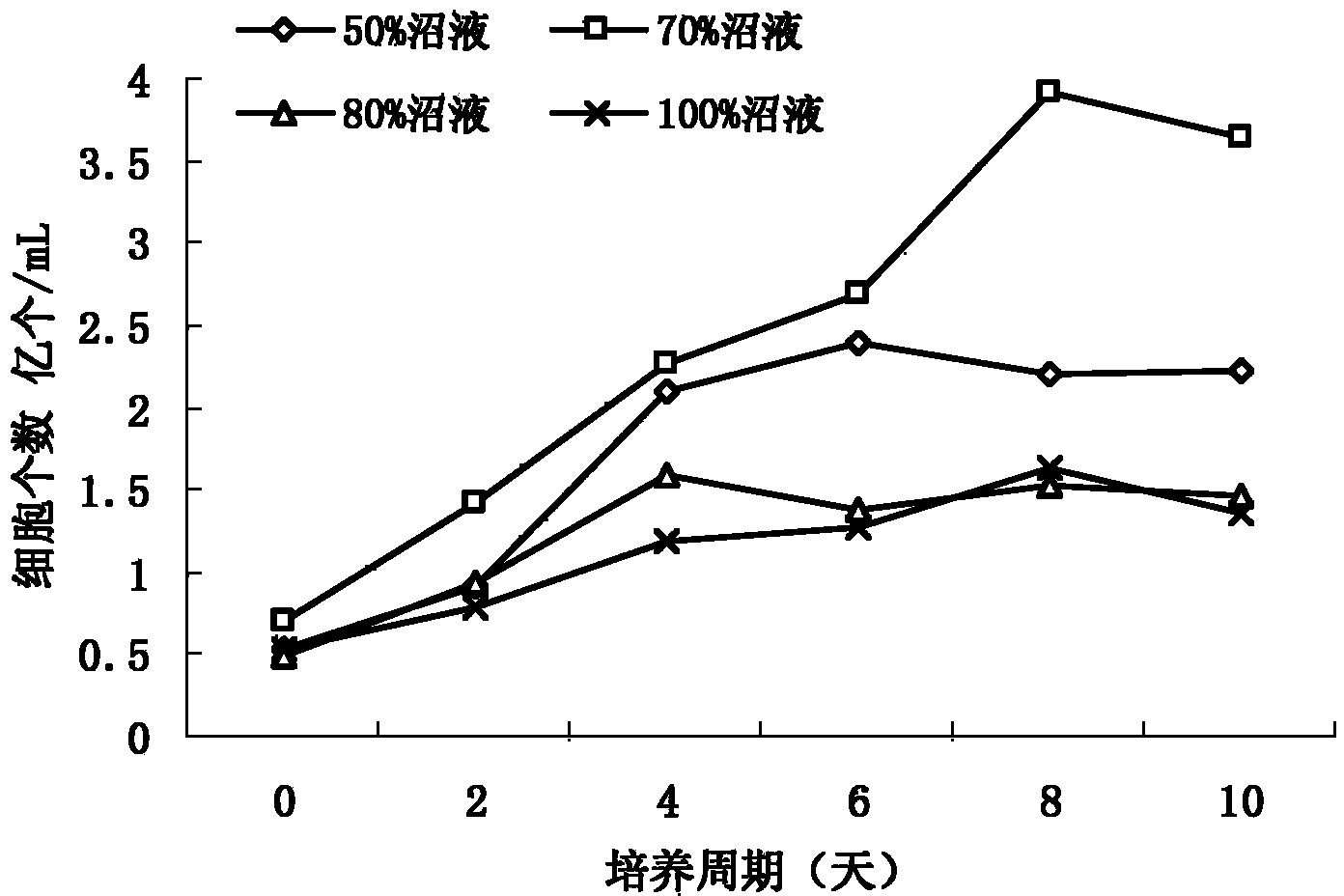

Biogas slurry ecological purification method based on microalgae cultivation

ActiveCN103396950AImprove photosynthetic efficiencyFast growthUnicellular algaeMicroorganism based processesSocial benefitsPurification methods

The invention discloses a biogas slurry ecological purification method based on microalgae cultivation. The method comprises the following steps: (1) biogas slurry pretreatment; (2) habituated culture of autotrophic microalgae, namely, obtaining algae strains capable of rapidly growing in 70%-100% biogas slurry; (3) preparation of a seed solution; (4) a biogas slurry purification method during growing of microalgae, namely, after expanded cultivation, inoculating the habituated algae species into an open photobioreactor for cultivation, obtaining chlorella biomass growing by high density through a semi-continuous culture method and optimized methods such as fed-batch cultivation, and purifying the biogas slurry; (5) biochemical breaking of microalgae cell walls, namely, introducing the microalgae cells into a biochemical wall breaking pool, putting freshwater fish into the pool, and obtaining algae slurry subjected to wall breaking; and (6) collection of the microalgae cells and recycling of the biogas slurry. According to the method, not only is a method provided for purifying the biogas slurry, but also the obtained algae cells and the biogas slurry can be recycled, so that ecologicalization treatment of the biogas slurry is realized, the environment is improved, and furthermore, the economic and social benefits are produced.

Owner:湖南瑞藻生物科技有限公司

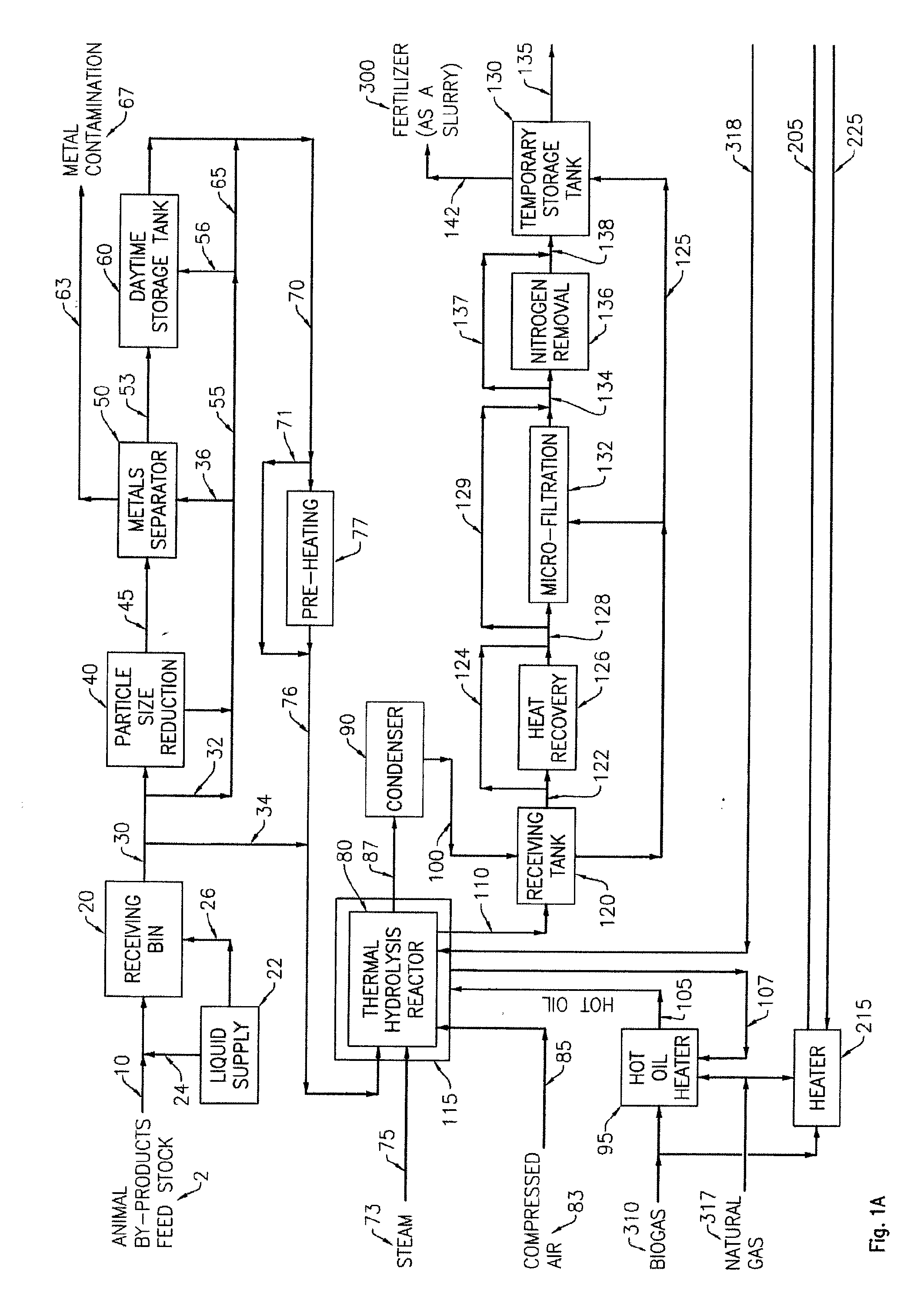

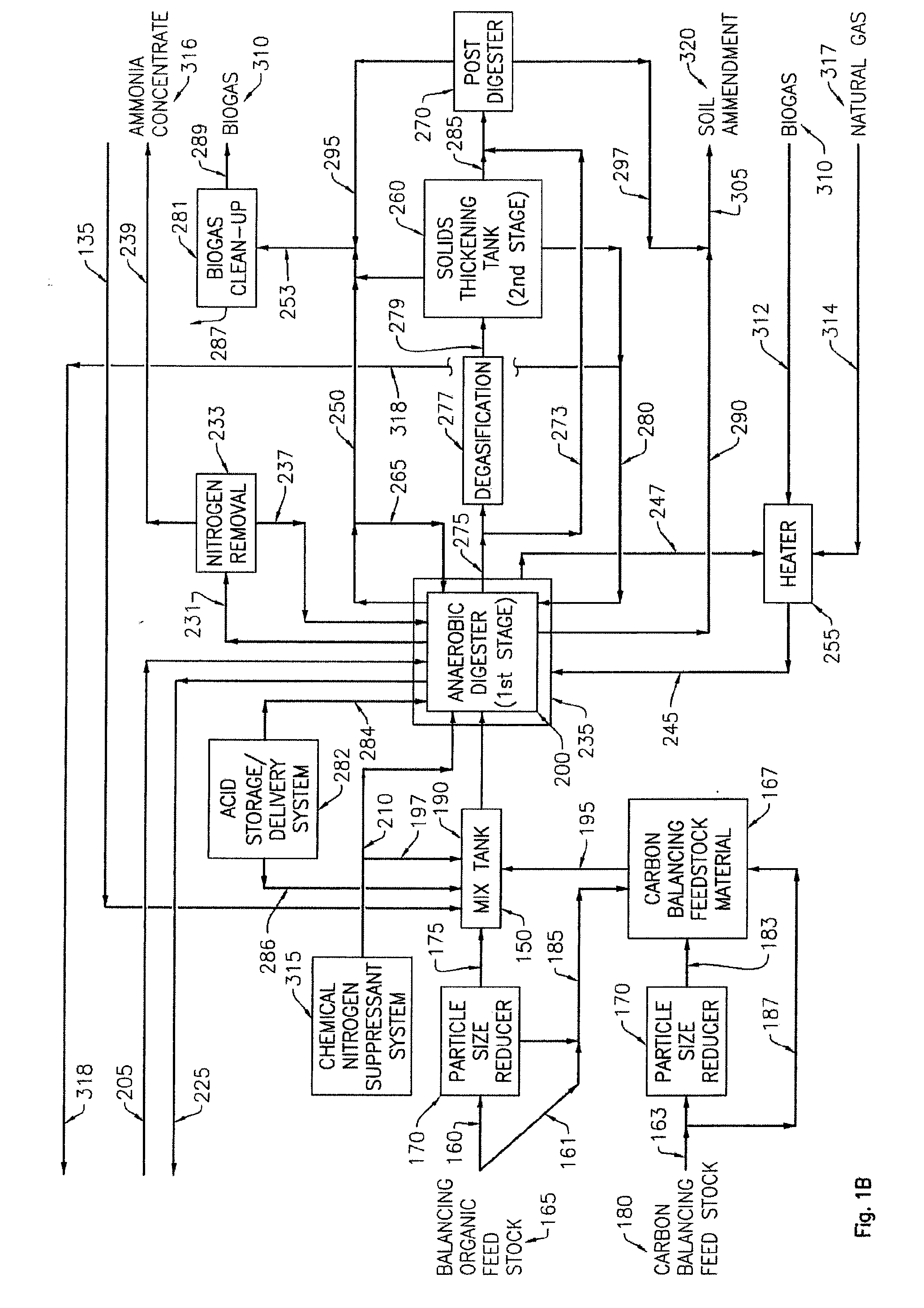

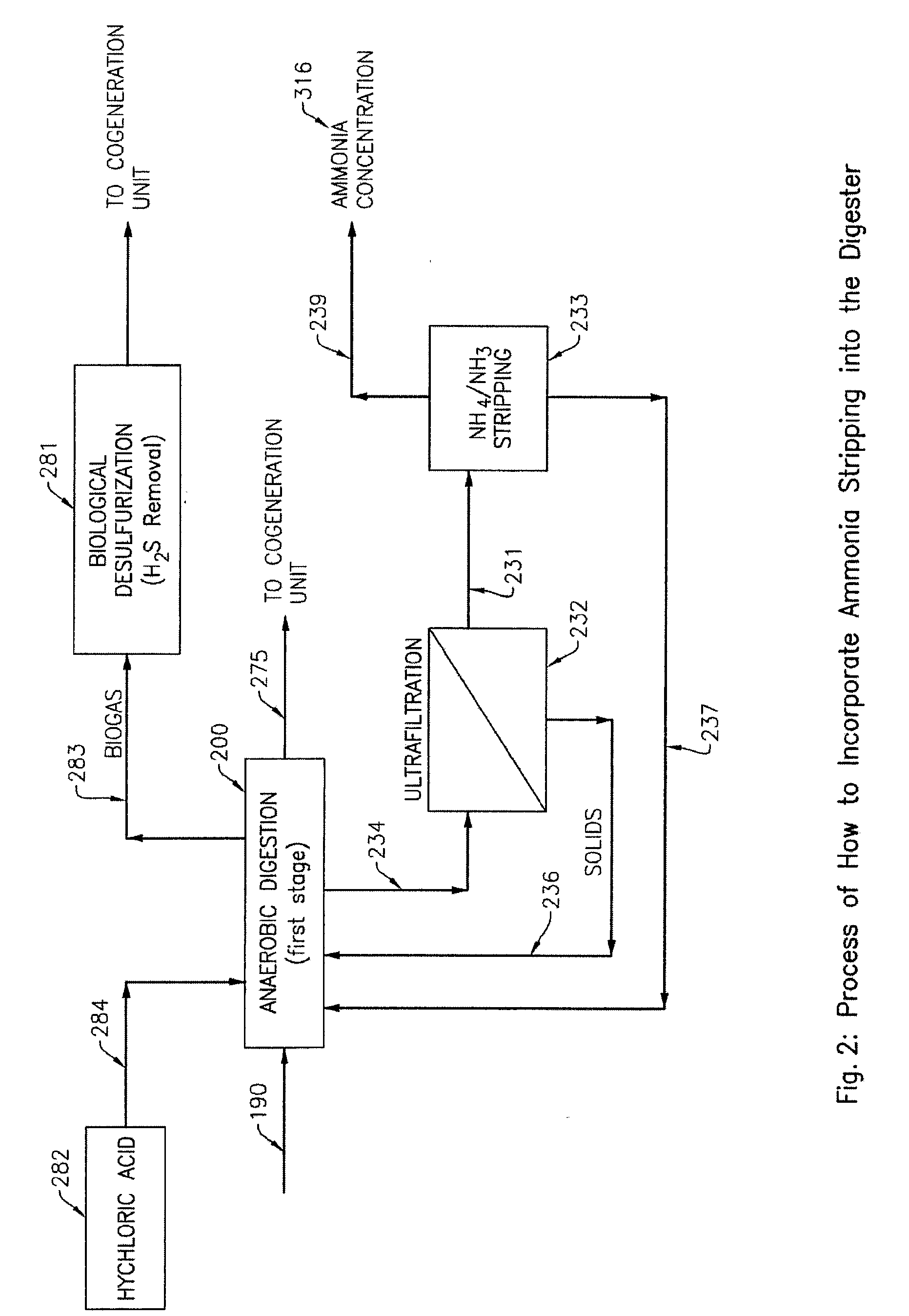

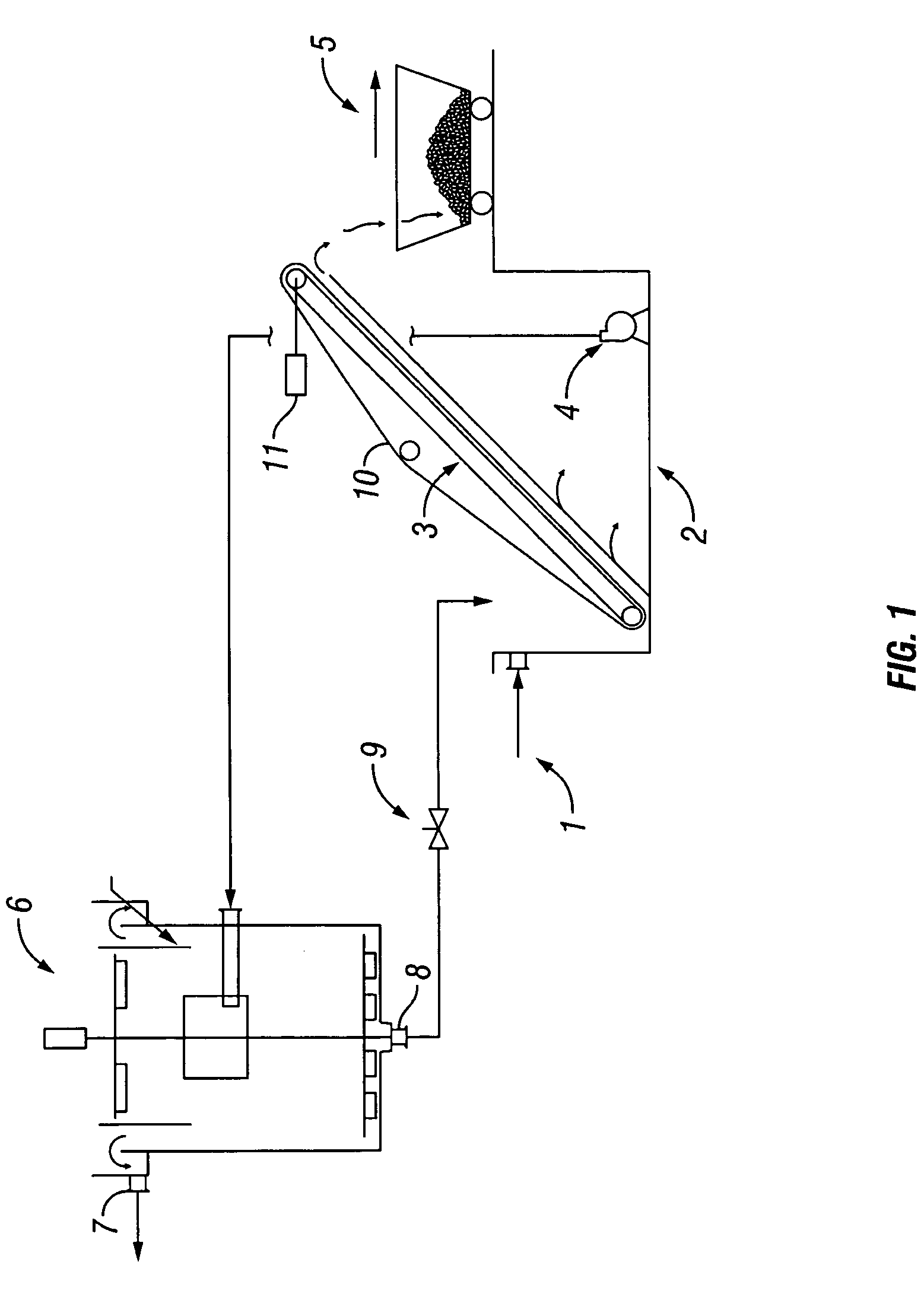

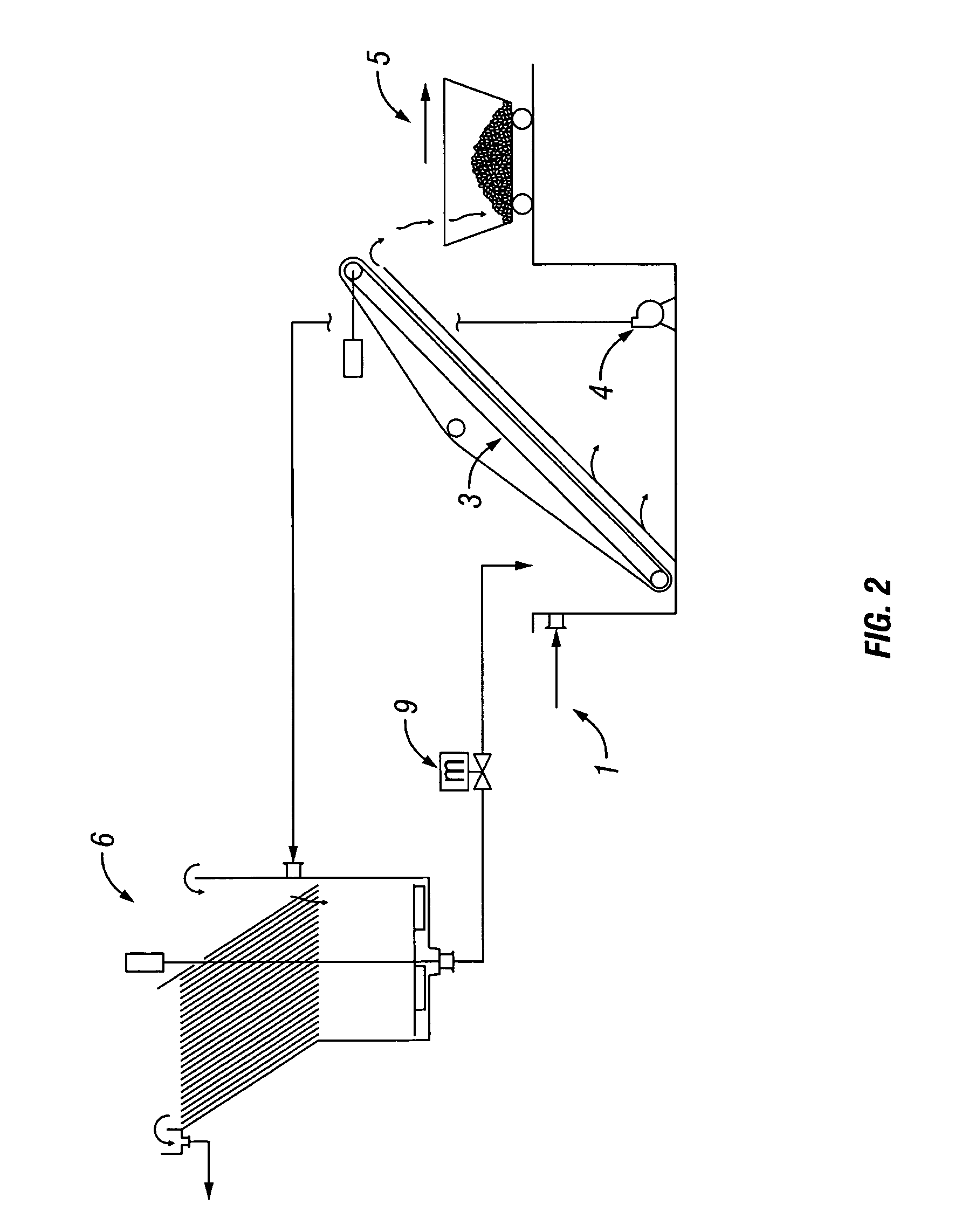

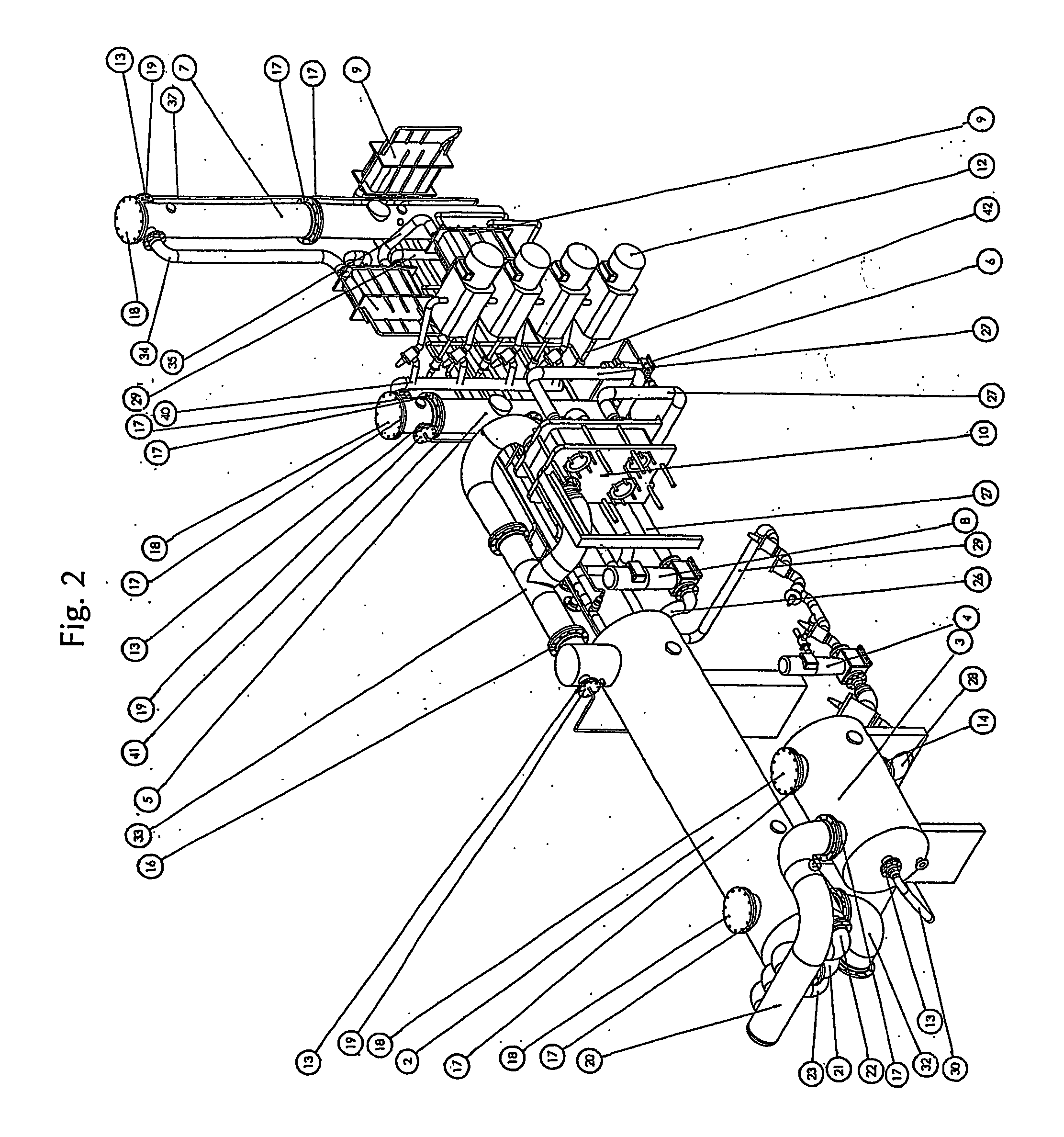

Apparatus and Process for Production of Biogas

ActiveUS20100021979A1Quick conversionDigesting retention timeBioreactor/fermenter combinationsBiological substance pretreatmentsHydrolysateSolid fraction

A process and an apparatus for the manufacture of biogas and a solids fraction from an organic waste feedstock is provided. The process involves thermal hydrolysis of the organic waste feedstock at a temperature from about 100 to about 220° C., a pressure from about 5 to about 20 bars, for a period of time from about 15 minutes to 4 hours, to produce a hydrolysate. The hydrolysate undergoes anaerobic digestion at a temperature from about 25 to 60° C., for a period of time from about 1 to 35 days to produce a biogas stream and a digestate. The digestate is separated into a solids fraction and a liquid fraction, and a portion of the solids fraction is recycled for further anaerobic digestion. The biogas stream, characterized as having a methane content from between 55 to 80% by volume, and the solids fraction, are recovered. The apparatus includes a receiving bin for receiving and supplying organic waste feedstock to a thermal hydrolysis reactor. The thermal hydrolysis reactor for processing the organic waste feedstock at a temperature from about 100 to about 220° C., a pressure from about 5 to about 20 bars, for a period of time from about 15 minutes to 4 hours to produce a hydrolysate. An anaerobic digester for processing the hydrolysate at a temperature from about 25 to 60° C., for a period of time from about 1 to 35 days to produce the biogas and a digestate, and a solids thickening tank for separating the digestate into the solid fraction, a liquid fraction and a secondary biogas fraction.

Owner:GEMINI CORP

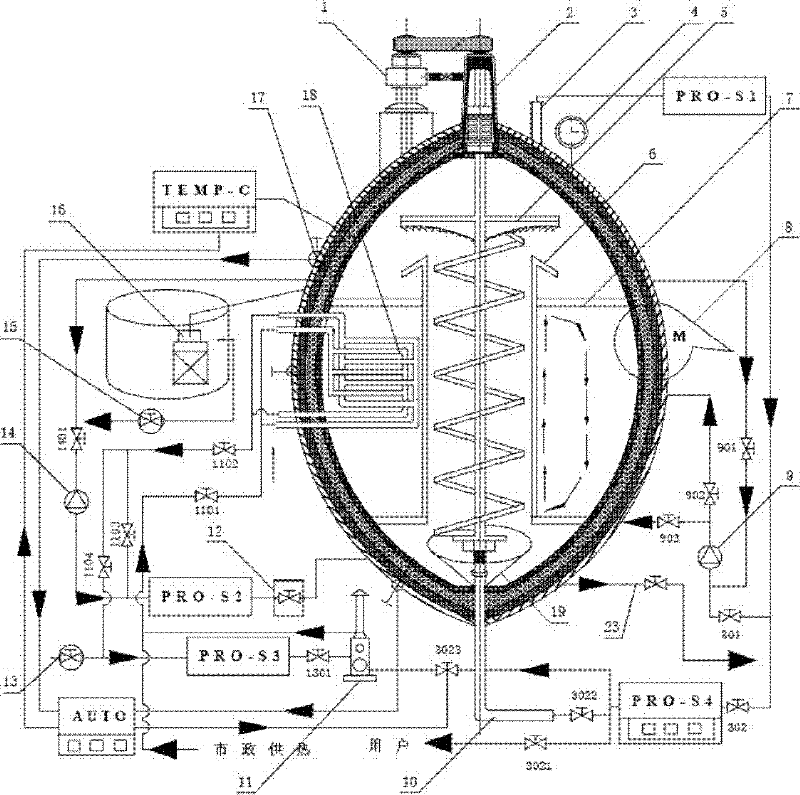

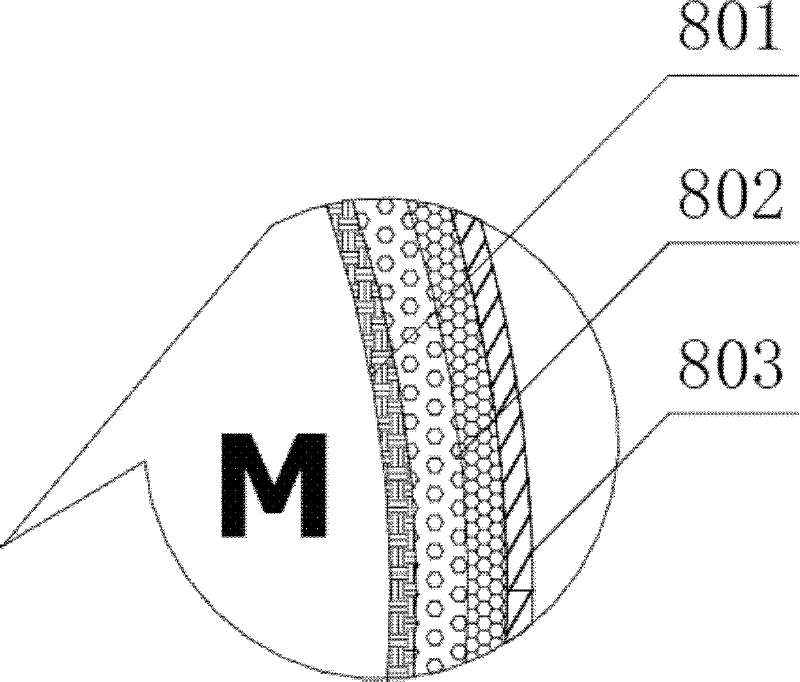

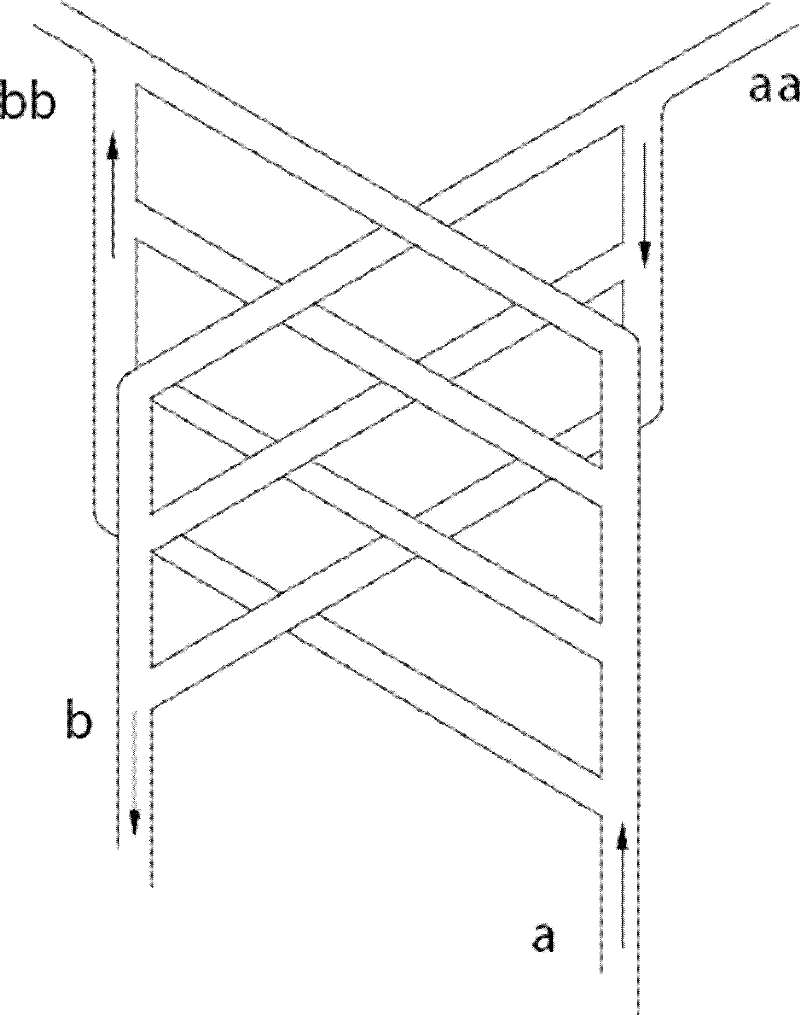

Multi-cycle stirring egg-shaped anaerobic fermentation system

ActiveCN102517199ASimple structureReasonable designBioreactor/fermenter combinationsBiological substance pretreatmentsAgricultural engineeringSlurry

The invention discloses a multi-cycle stirring egg-shaped anaerobic fermentation system. The system comprises a fermentation tank body and a driving device arranged on the fermentation tank body, wherein the fermentation tank body is egg-shaped, the center of the inner cavity of the fermentation tank body is provided with an inner barrel type spiral stirrer, the outside of the inner barrel type spiral stirrer is provided with a stirrer inner barrel, a temperature heating device is arranged between the wall of the fermentation tank body and the stirrer inner barrel, the bottom of the inside ofthe tank is provided with an umbrella-shaped gas flow distribution device; the upper part of the fermentation tank body is provided with a vent pipe and a pressure control device, the bottom of the fermentation tank body is provided with an umbrella-shaped gas flow distribution device gas inlet pipe and a mud-discharging and sand-discharging outlet; and the side wall of the fermentation tank bodyis communicated with a biogas circulation system, a biogas slurry circulation system, a gas-liquid circulation system, a heating system, a temperature control system and a biogas residue and biogas slurry storage pool respectively. The multi-cycle stirring egg-shaped anaerobic fermentation system adopts multi-cycle stirring to increase the stirring efficiency of the system; and the anaerobic fermentation environment is improved, the fluid is mixed evenly, the temperature difference slightly fluctuates, the energy consumption of the system is low, the fermentation rate is high and the system is suitable for popularization and application.

Owner:INNER MONGOLIA HUAMENG KECHUANG ENVIRONMENTAL PROTECTION TECH ENG CO LTD

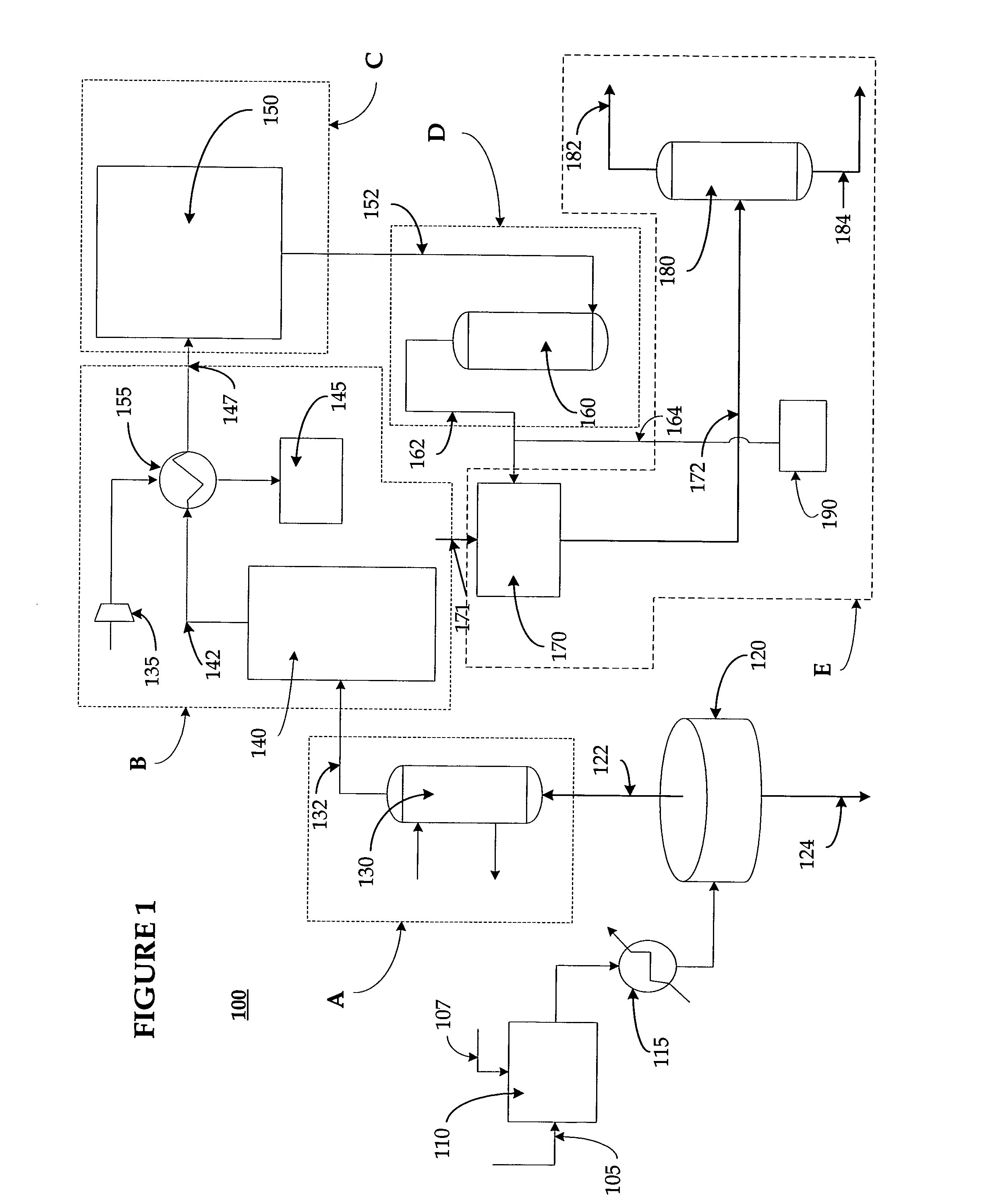

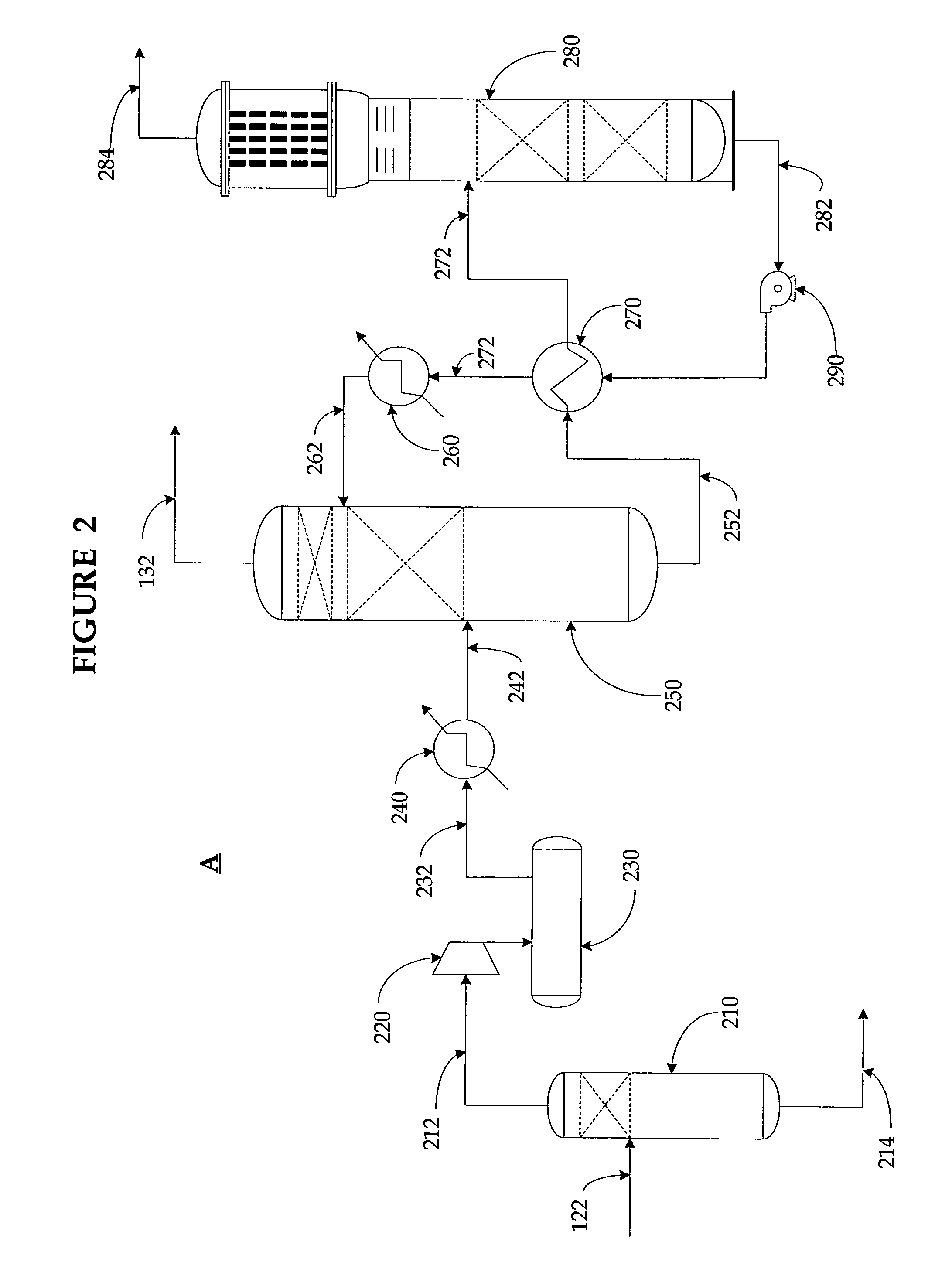

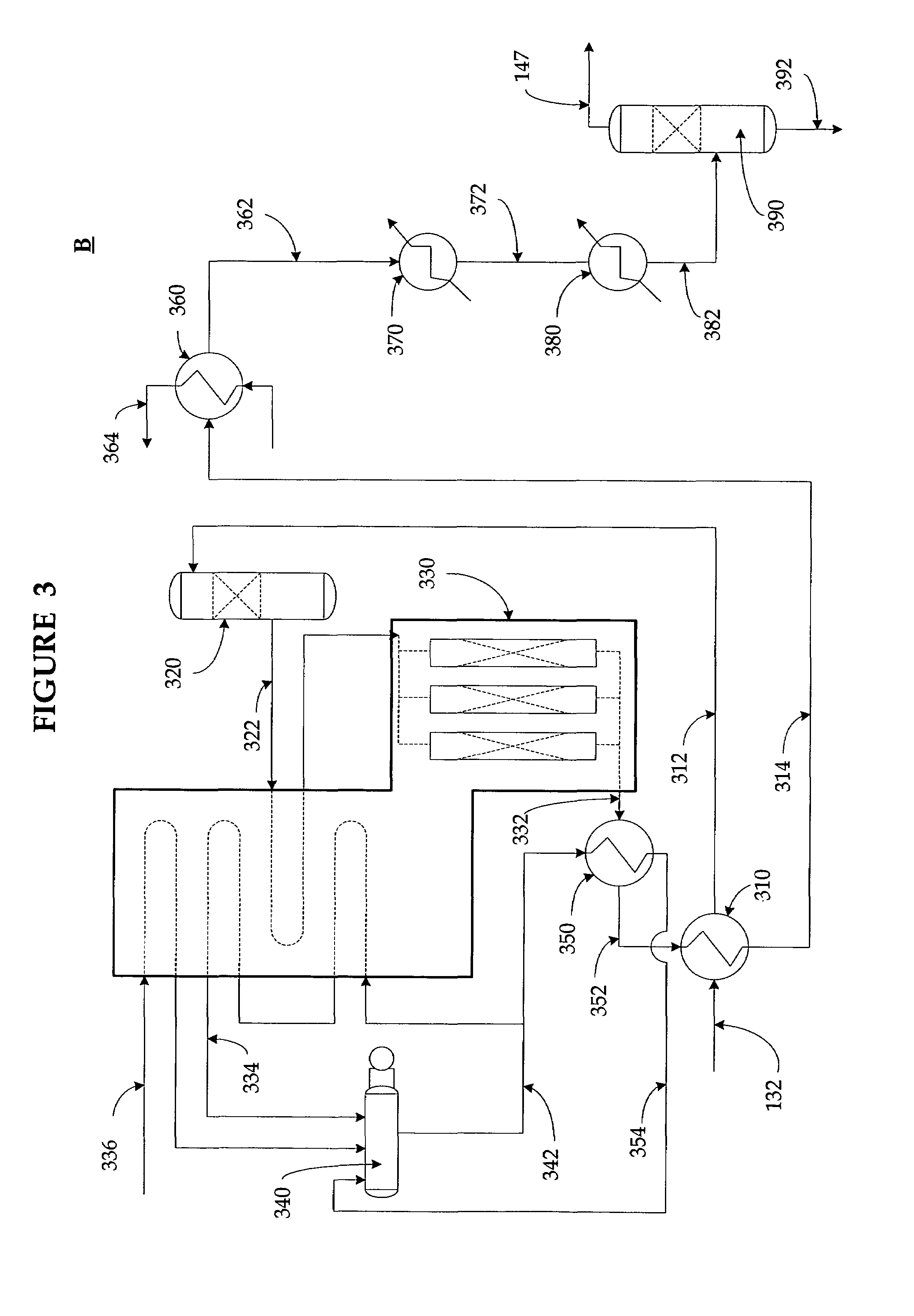

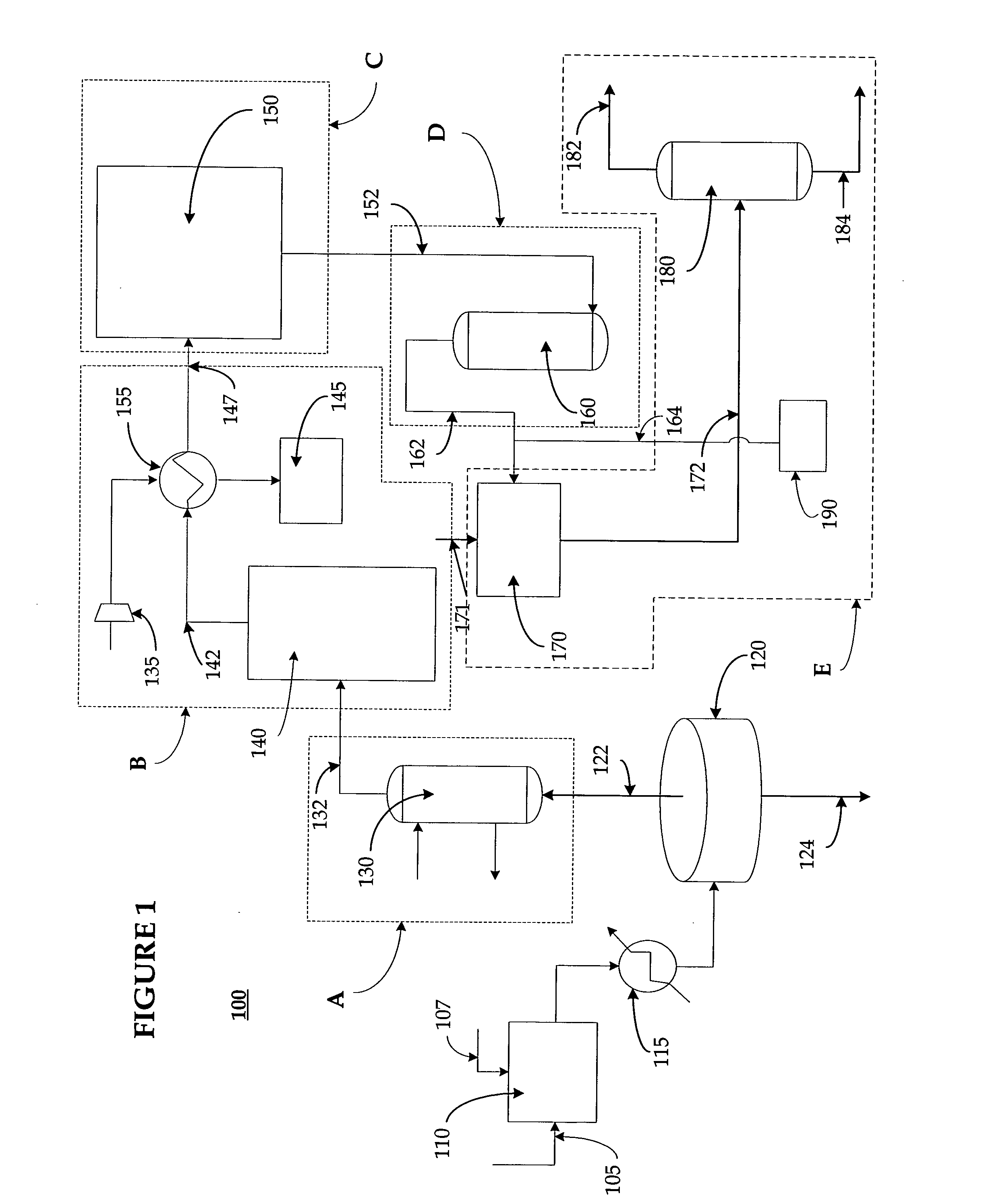

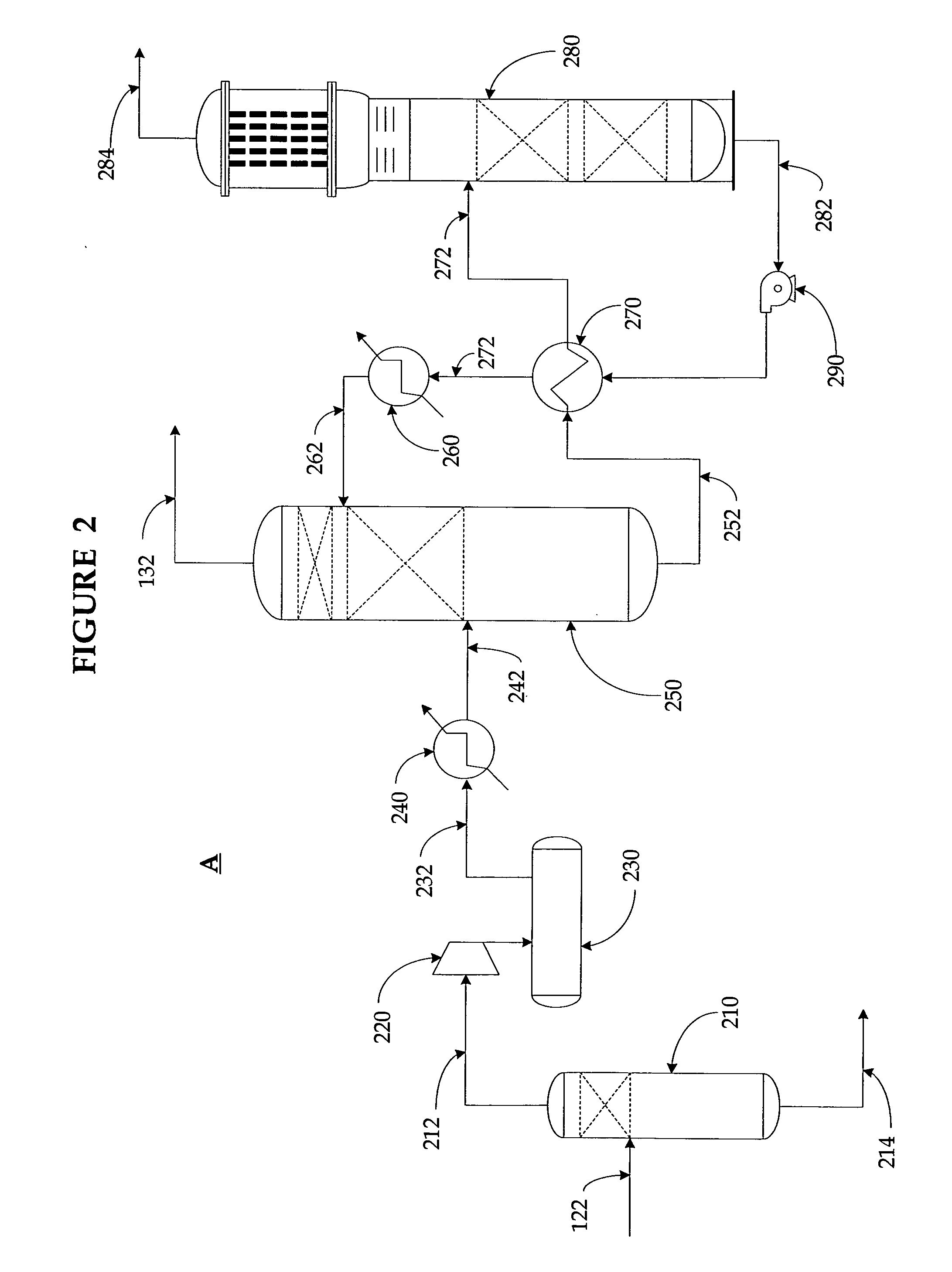

System and method for extracting energy from agricultural waste

InactiveUS20050113467A1Reduce decreaseMinimize negative impactBioreactor/fermenter combinationsBio-organic fraction processingSyngasBiodiesel

The present invention relates to a process and apparatus for processing agricultural waste to make alcohol and / or biodiesel. The agricultural wastes are subjected to anaerobic digestion which produces a biogas stream containing methane, which is subsequently reformed to a syngas containing carbon monoxide and hydrogen. The syngas is converted to an alcohol which may be stored, sold, used, or fed directly to a reactor for production of biodiesel. The solids effluent from the anaerobic digester can be further utilized as slow release, organic certified fertilizer. Additionally, the wastewater from the process is acceptable for immediate reuse in agricultural operations.

Owner:BEST BIOFUELS LLC

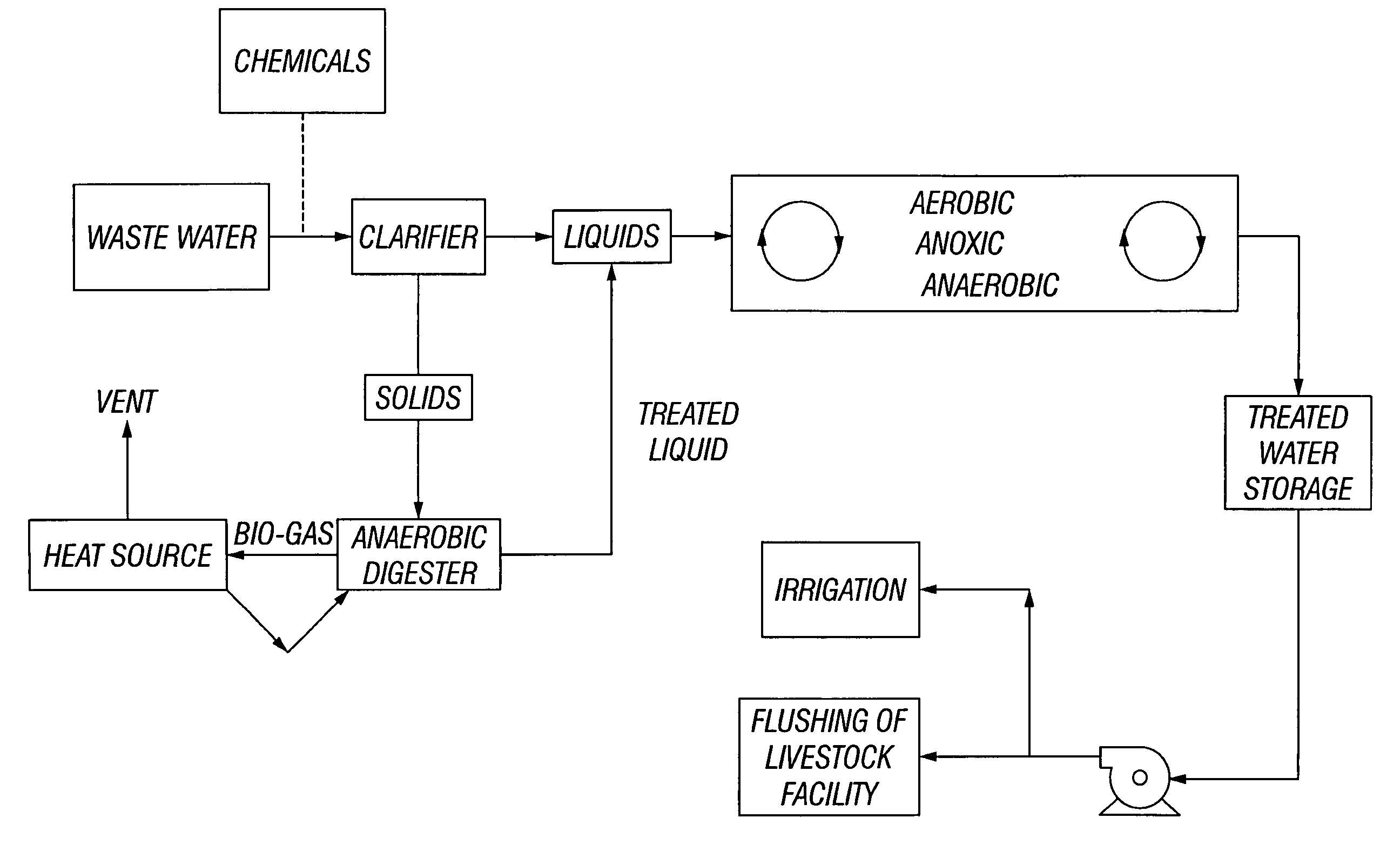

Method and apparatus for treating animal waste and wastewater

InactiveUS7005068B2Treatment using aerobic processesWaste water treatment from animal husbandryBiogasFlare

Novel methods and apparatuses are disclosed for the treatment of wastewater to reduce often associated offensive odors by promoting aerobic conditions through decreasing the amount of oxygen required to maintain aerobic cultures and / or aerobic biological activity in the wastewater. Also, the wastewater is screened or otherwise separated the wastewater to remove or concentrate the solids which are anaerobically digested. By concentrating the solids, a smaller digester can be used. The anaerobic digestion produces biogas that may be collected and used, or burned by a flare or oxidized by a semipermeable membrane to deodorize the biogas. The heat produced from the biogas may have a variety of uses, including raising the temperature of the anaerobic digester and the bacterial metabolism. The wastewater is also clarified to remove nitrogenous and organic carbon wastes.

Owner:HOFFLAND ROBERT O

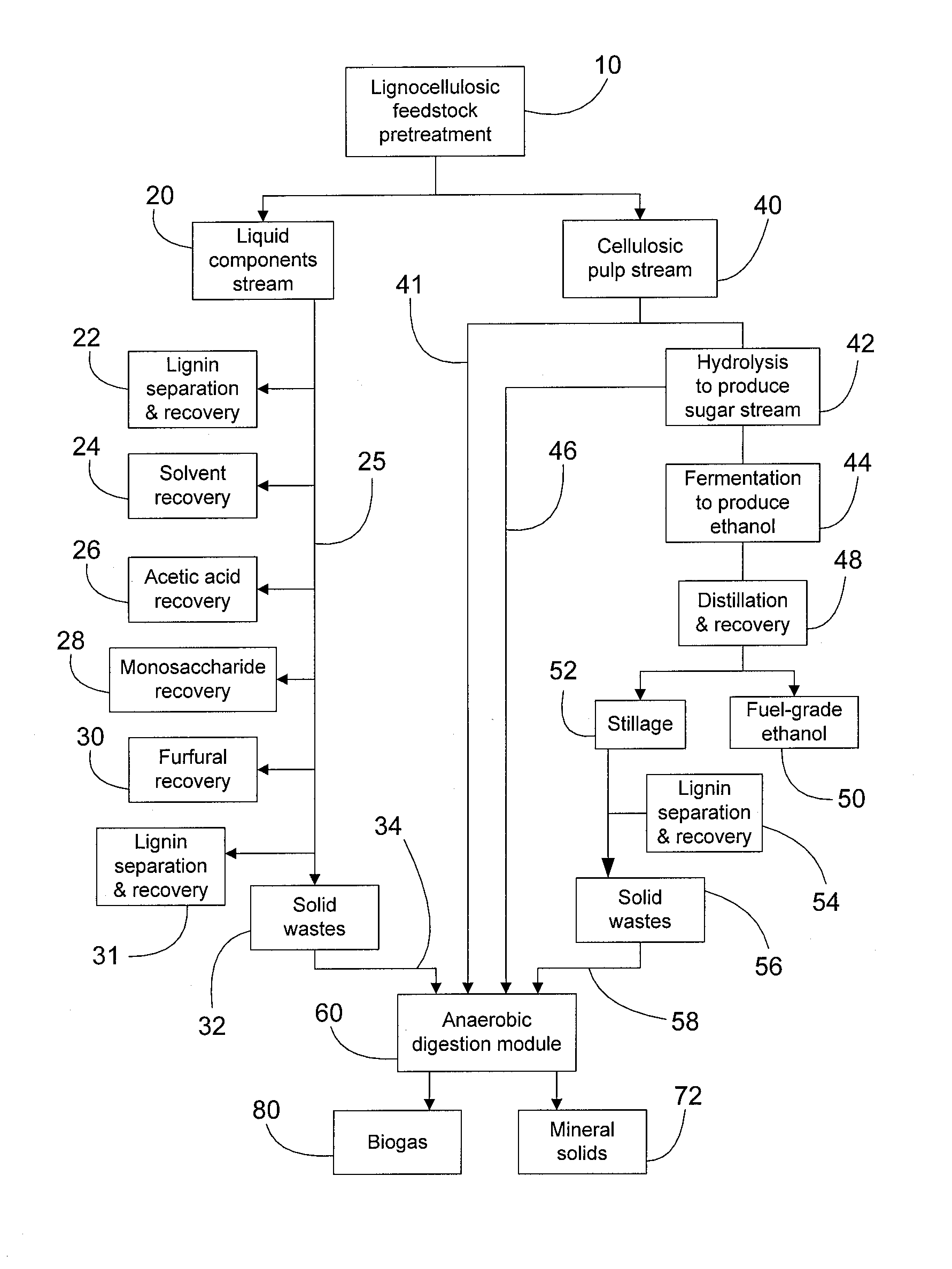

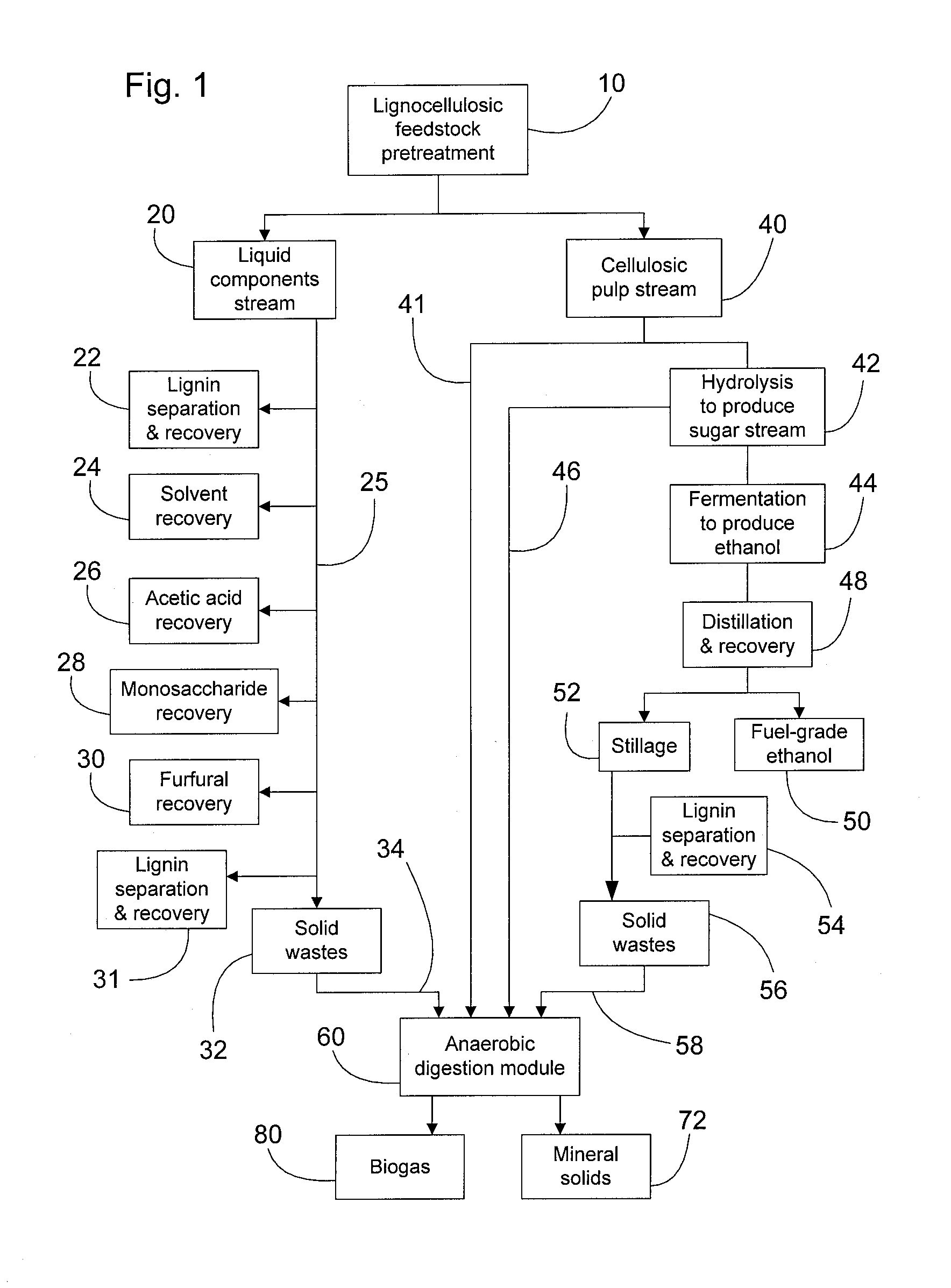

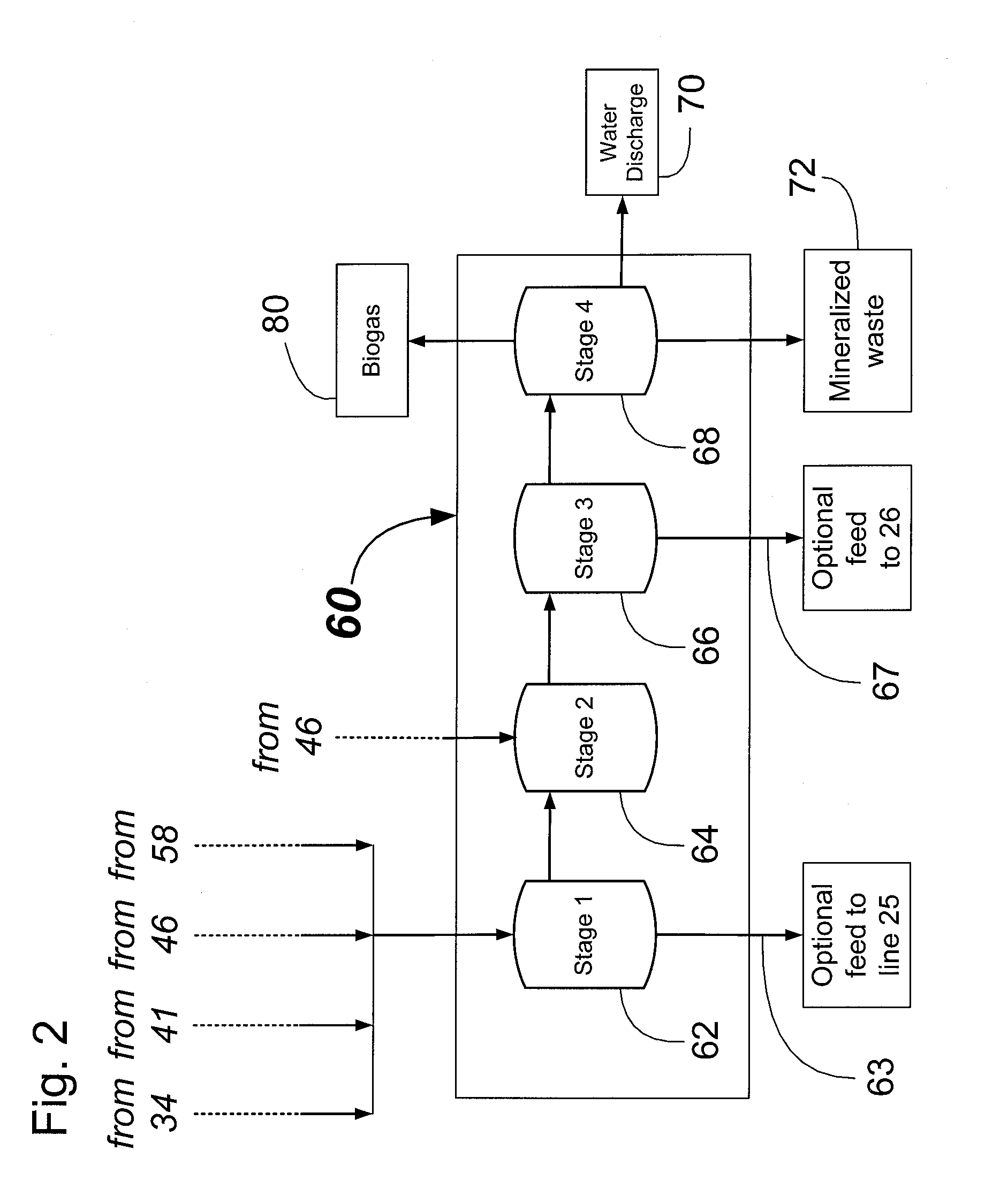

Concurrent Anaerobic Digestion and Fermentation of Lignocellulosic Feedstocks

InactiveUS20110236946A1Bioreactor/fermenter combinationsBiological substance pretreatmentsAlcoholSemi solid

A process for concurrent production of lignins, fuel alcohol, and biogas from lignocellulosic feedstocks. The process comprises: (1) pretreating a lignocellulosic feedstock to produce a solubilised liquid components stream comprising lignins, lignin-derived compounds, and a cellulosic pulp stream, (2) separating the liquid stream from the cellulosic pulp stream, (3) processing the liquid stream to separate and recover at least lignins, lignin-derived compounds, and semi-solid waste material, (b) processing the cellulosic pulp stream to saccharify and ferment the cellulose pulp to produce a beer which is then separated into fuel-grade alcohol and a waste stillage material, (4) anaerobically digesting the semi-solid waste material from the liquid stream and the waste stillage material to produce a biogas. The rate of anaerobic digestion can be manipulated by controllably supplying a portion of the monosaccharides produced from the cellulosic pulp. The cellulosic pulp stream may also be anaerobically digested.

Owner:LIGNOL INNOVATIONS

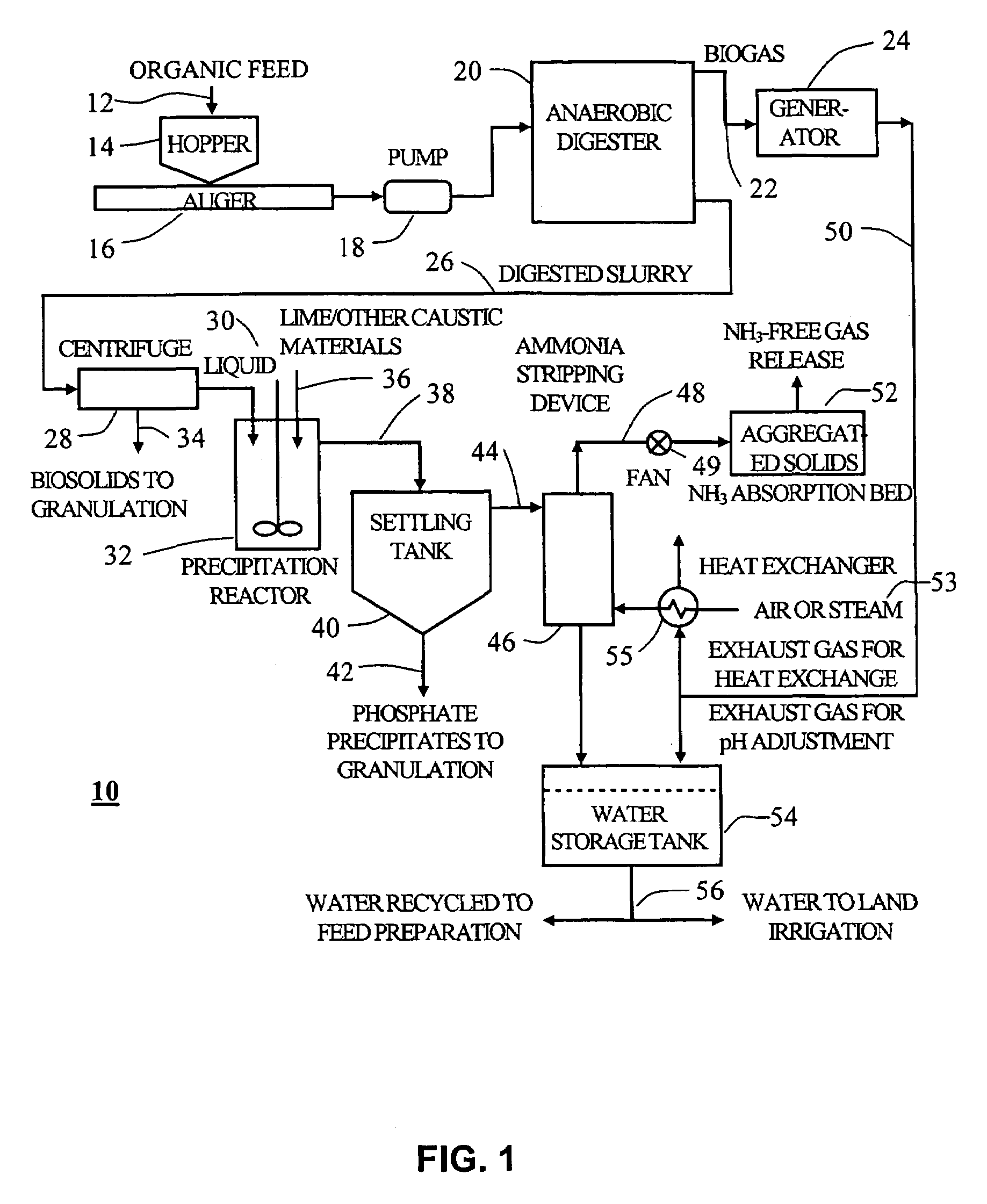

Process for removal and recovery of nutrients from digested manure or other organic wastes

InactiveUS7014768B2Eliminate the effects ofIncrease temperatureBioreactor/fermenter combinationsBio-organic fraction processingCogenerationNitrogen gas

A process for removal and recovery of nutrients and recycling of water from digested manure or other organic wastes. A first step involves separating waste from an anaerobic digester into digested liquids, digested solids, and biogas. A second step involves precipitating solids from the digested liquids. A third step involves stripping ammonia from the digested liquids. A fourth step involves injecting an exhaust stream of carbon dioxide drawn from the co-generator into the digested liquids to reduce the pH and raise the temperature of the digested liquid. A fifth step involves recycling the digested liquids back to the anaerobic digester for use in diluting in coming solid wastes. A sixth step involves passing the excess ammonia stripped from the digested liquid through the digested solids to recover nitrogen through aborption with the resultant digested solids being usable as a biofertilizer with a high nitrogen content. A seventh step involves capturing the biogas for use in a co-generation system.

Owner:HIGHMARK RENEWABLES RES PARTNERSHIP

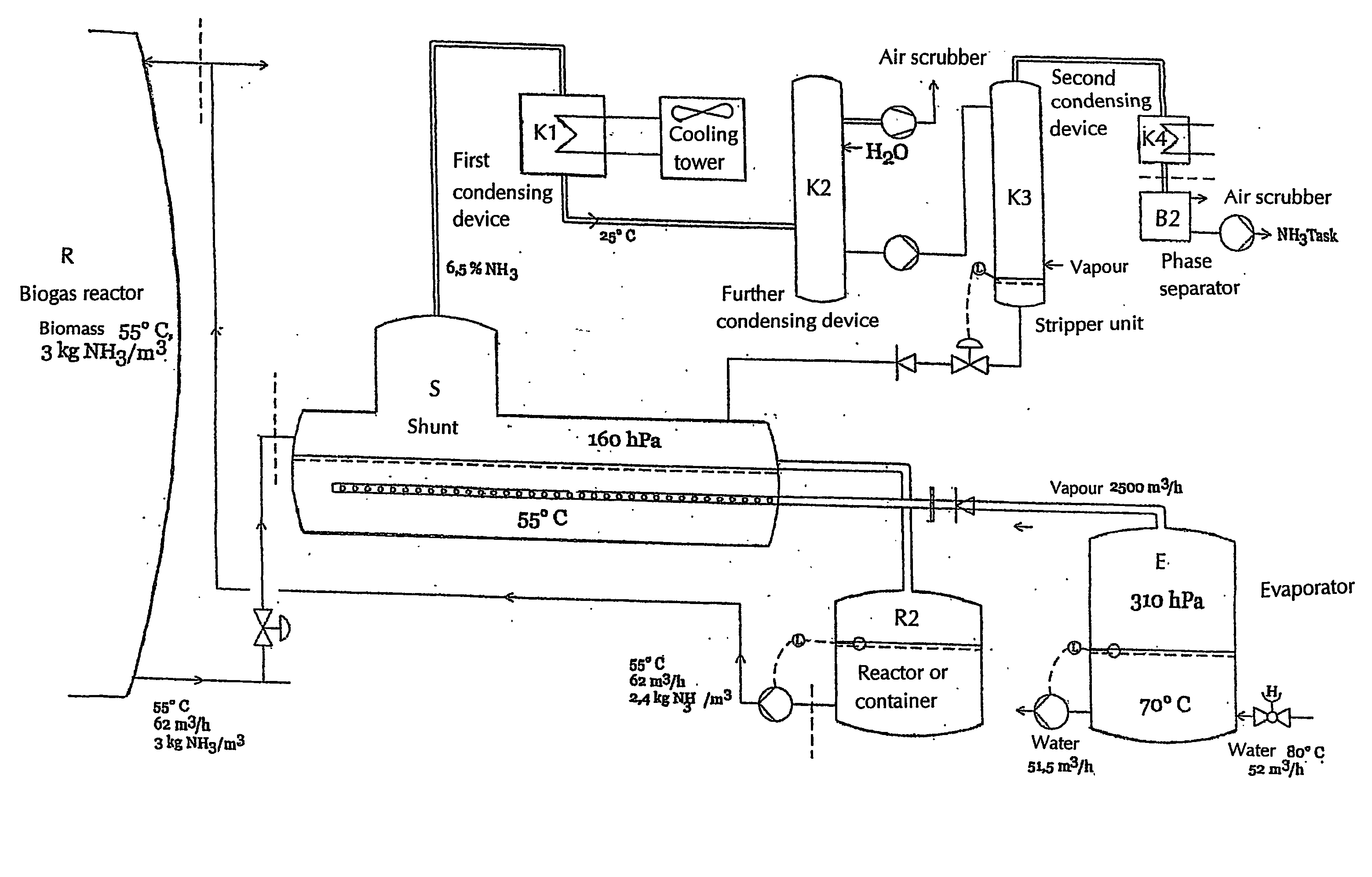

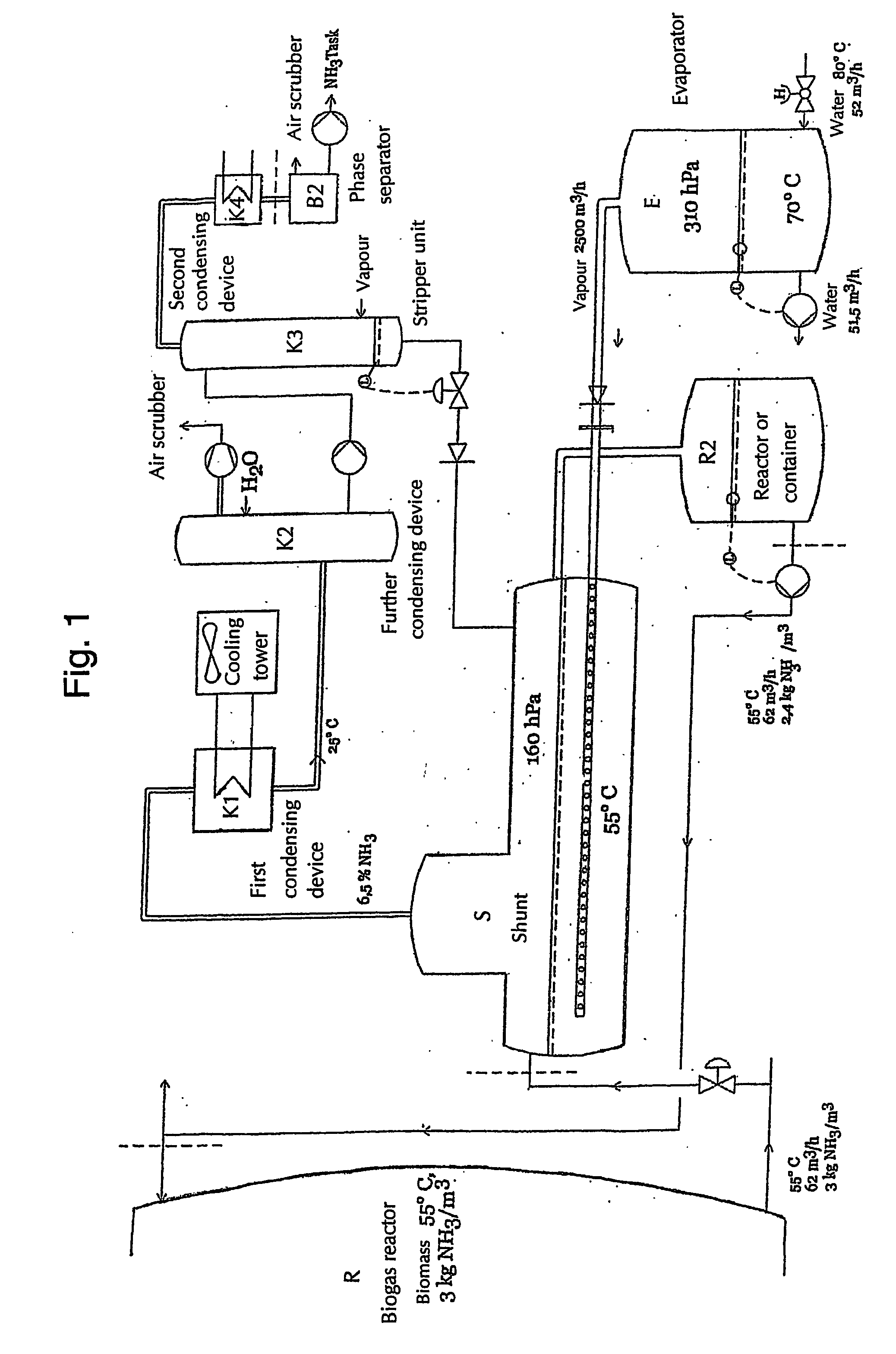

Method and device for stripping ammonia from liquids

InactiveUS20060006055A1Simple and economic in operationLow-valuedBioreactor/fermenter combinationsBiological substance pretreatmentsLiquid mediumHigh pressure

The present invention in a first aspect provides a method and a system for stripping volatile compounds such as ammonia from e.g. fermentation liquids. Part of the ammonia is stripped from the liquid in a stripper system comprising a shunt through which liquid such as e.g. fermentation medium comprising a biomass can be diverted in the form of a side stream in liquid contact with a main fermentor(s). The stripper system is connected to an evaporator. In the evaporator aqueous liquid is heated at a pressure below atmospheric pressure whereby vapour is developed at a temperature below 100° C. The vapour from the evaporator is directed to the liquid medium comprising ammonia and this results in ammonia being stripped from the liquid and transferred to the vapour phase. The vapour phase is condensed in a first condenser at a low pressure, e.g. a pressure well below 1 bar, and the liquid thus obtained is further treated in a stripper unit at a higher pressure, such as e.g. a pressure at or above 1 bar, to obtain a more concentrated solution of ammonia. When stripped for at least part of the ammonia the liquid initially obtained from the biogas reactor and diverted to the shunt can be returned to the reactor.

Owner:GFE PATENT AS

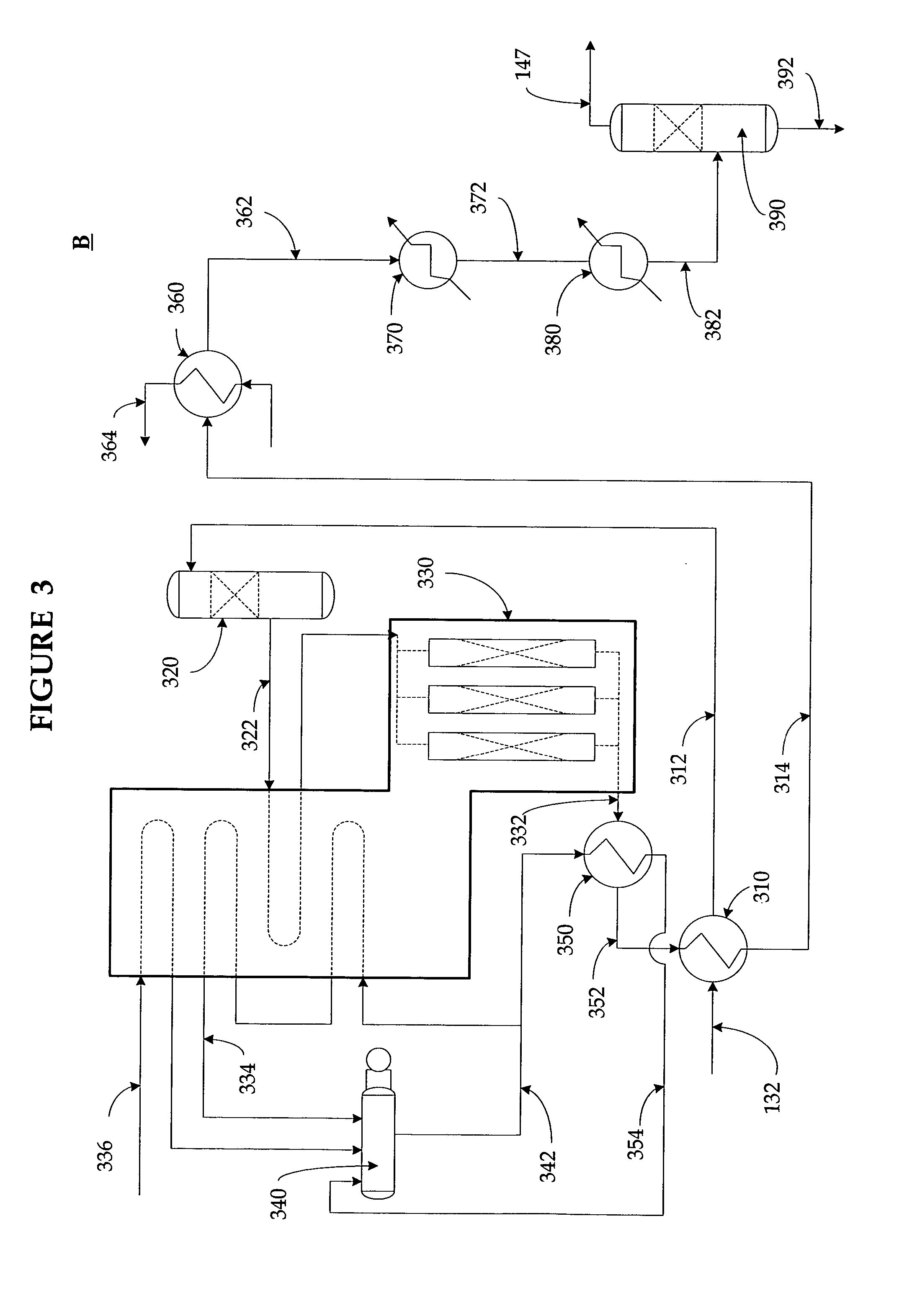

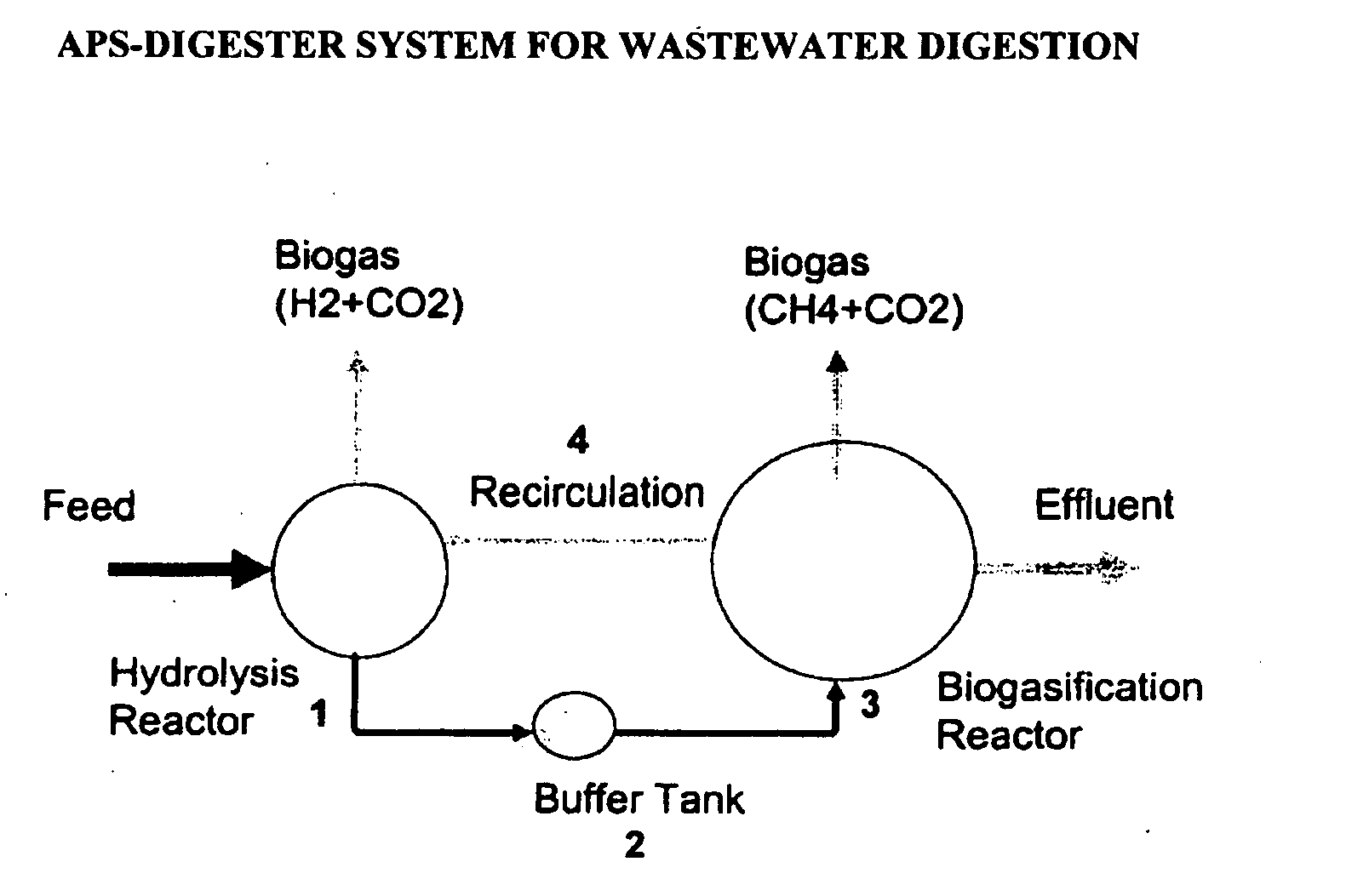

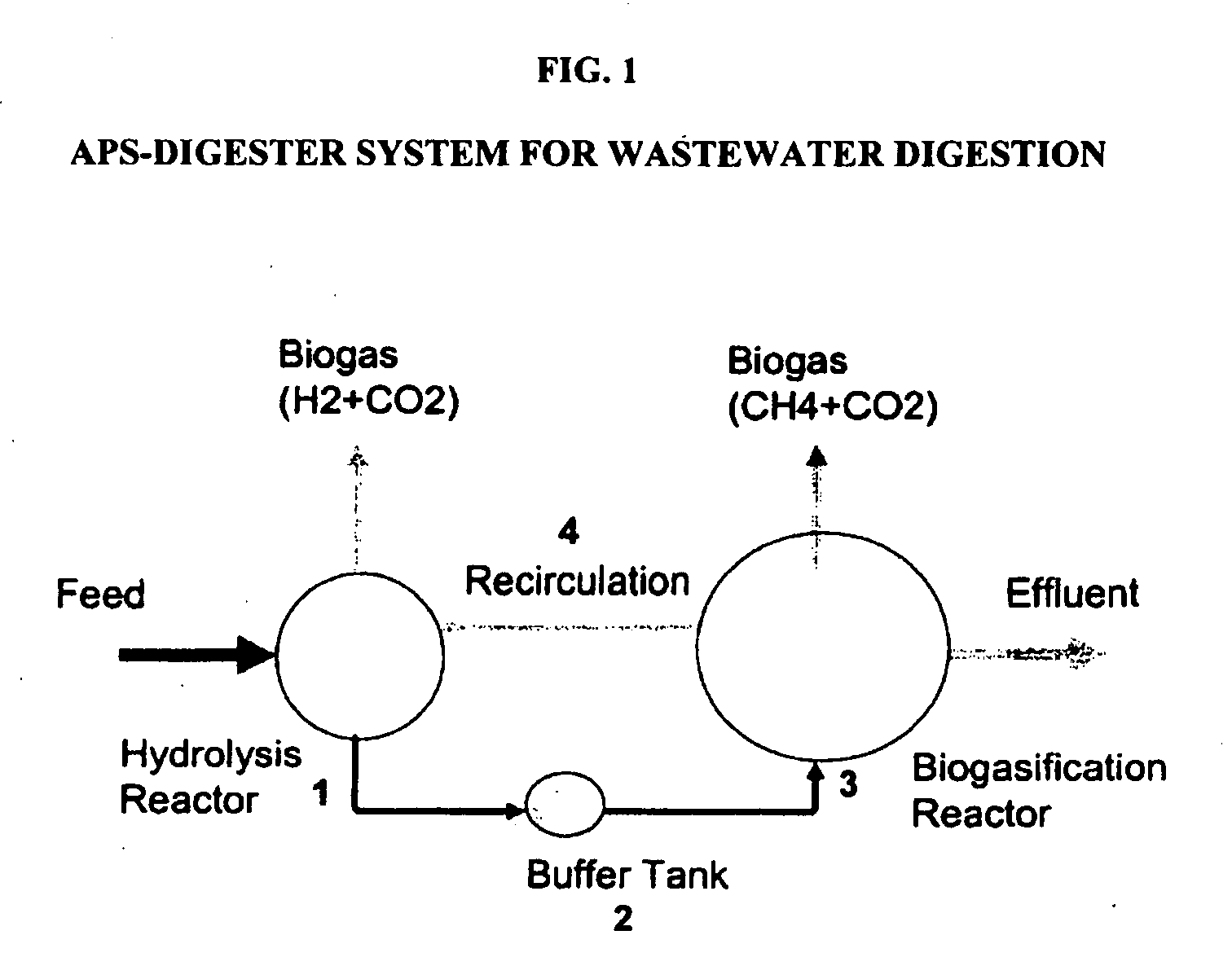

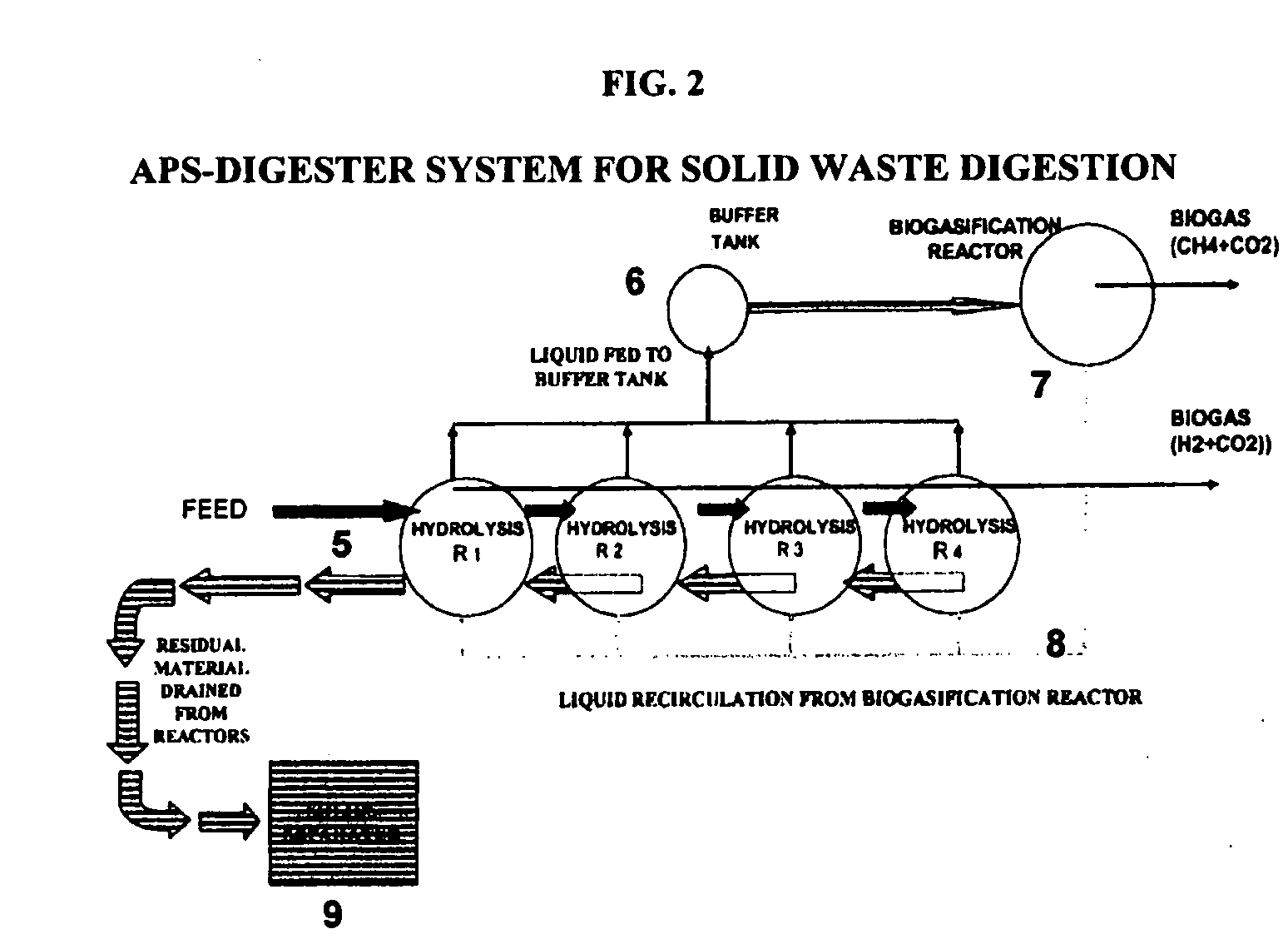

Anaerobic phased solids digester for biogas production from organic solid wastes

InactiveUS20070158264A1Improve energy conversion efficiencyLess air emissionLiquid degasificationBiological substance pretreatmentsHigh rateBuffer tank

The present invention provides methods for the generation of methane by a two phase anaerobic phase system (APS) digestion of organic substrates. Also provided is a device for practicing the methods of the invention. The APS-digester system is a space-efficient, high-rate solids digestion system. The APS-digester system consists of one or more hydrolysis reactors, a buffer tank and one biogasification reactor.

Owner:RGT UNIV OF CALIFORNIA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com