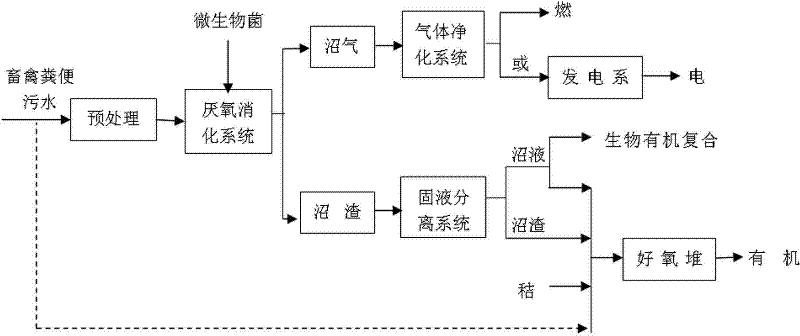

Method for comprehensively recycling fecal sewage of large-scale livestock and poultry farms and farmland crop straws

A technology for fecal sewage and farmland crops, which is applied in the field of renewable energy development and utilization and environmental protection, can solve problems such as environmental pollution and waste of biomass resources, and achieve the effects of increasing gas production, shortening fermentation cycle, and overcoming insufficient biogas production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

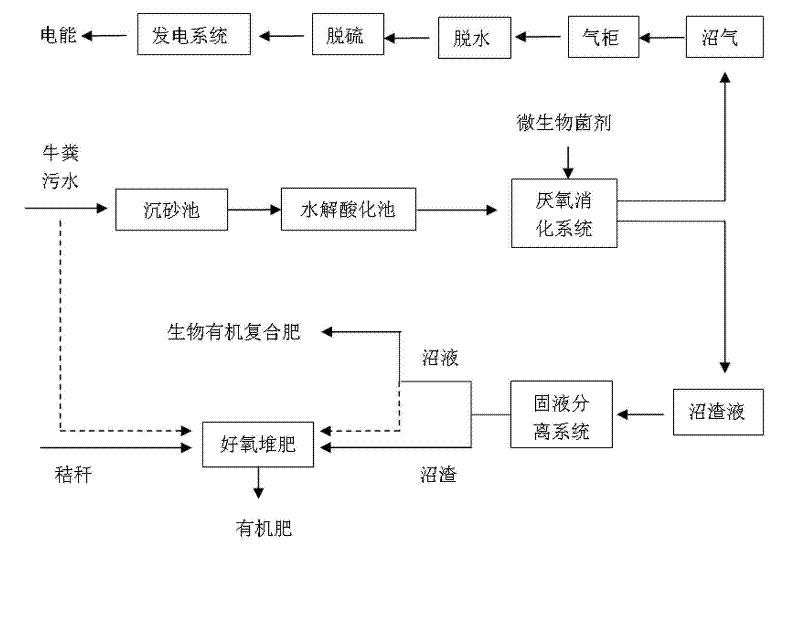

[0031] Taking the biogas project of a ten thousand dairy cow farm as an example, the specific implementation is as follows:

[0032] (1) Pretreatment: Collect cow dung and its flushing water, enter the grit chamber to remove sand at a ratio of 1:4, and adjust the pH to 6.8~7.2 through the hydrolysis and acidification tank.

[0033] (2) Anaerobic digestion: The pretreated fecal sewage is added to the anaerobic digestion tank, and the inoculum (anaerobic digestion sludge or sludge in a normal biogas digester) is added for inoculation and mixing. The amount of inoculum added is 10%~30% of the dry weight of the fermented product, adjust the total solid content TS load in the reactor (anaerobic digestion tank) at 5%~10%. The reaction temperature is controlled at 35~40°C, and the material is stirred by a stirring device during the digestion process.

[0034] (3) Biogas utilization: The generated biogas is collected by the gas cabinet, dehydrated, desulfurized and purified for power...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com