Patents

Literature

703 results about "Gas cabinet" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A gas cabinet is a metallic enclosure which is used to provide local exhaust ventilation system for virtually all of the gases used or generated in the Semiconductor, Solar, MEMS, NANO, Solar PV, Manufacturing and other advanced technologies.

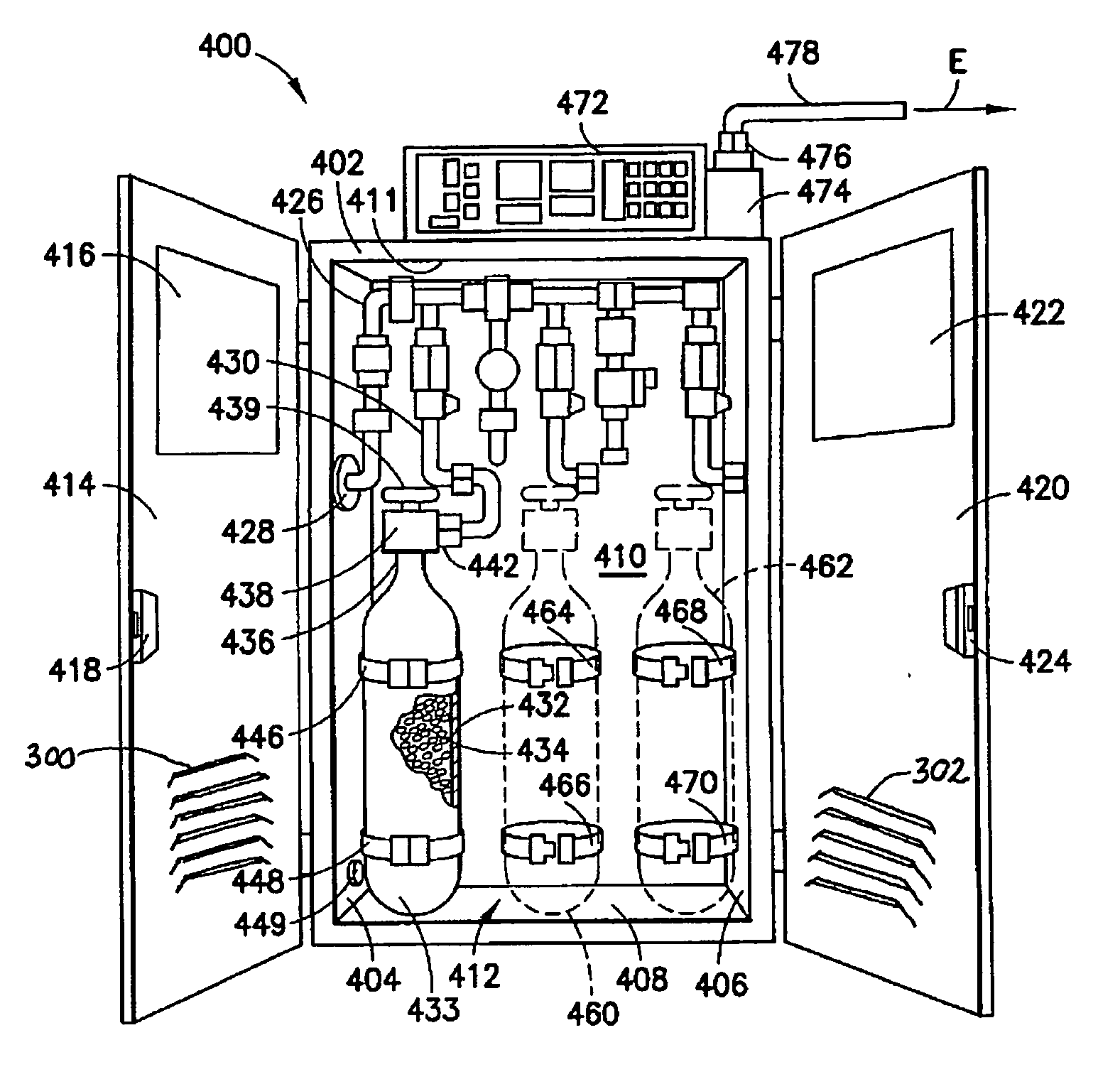

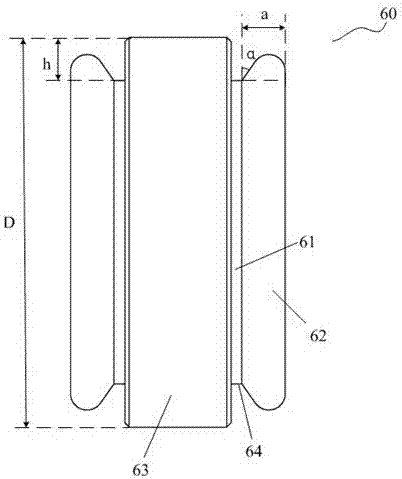

Rectangular parallelepiped fluid storage and dispensing vessel

InactiveUS6991671B2Reduced footprintReduce the burden onCombination devicesAuxillary pretreatmentSorbentChemical adsorption

Owner:ENTEGRIS INC

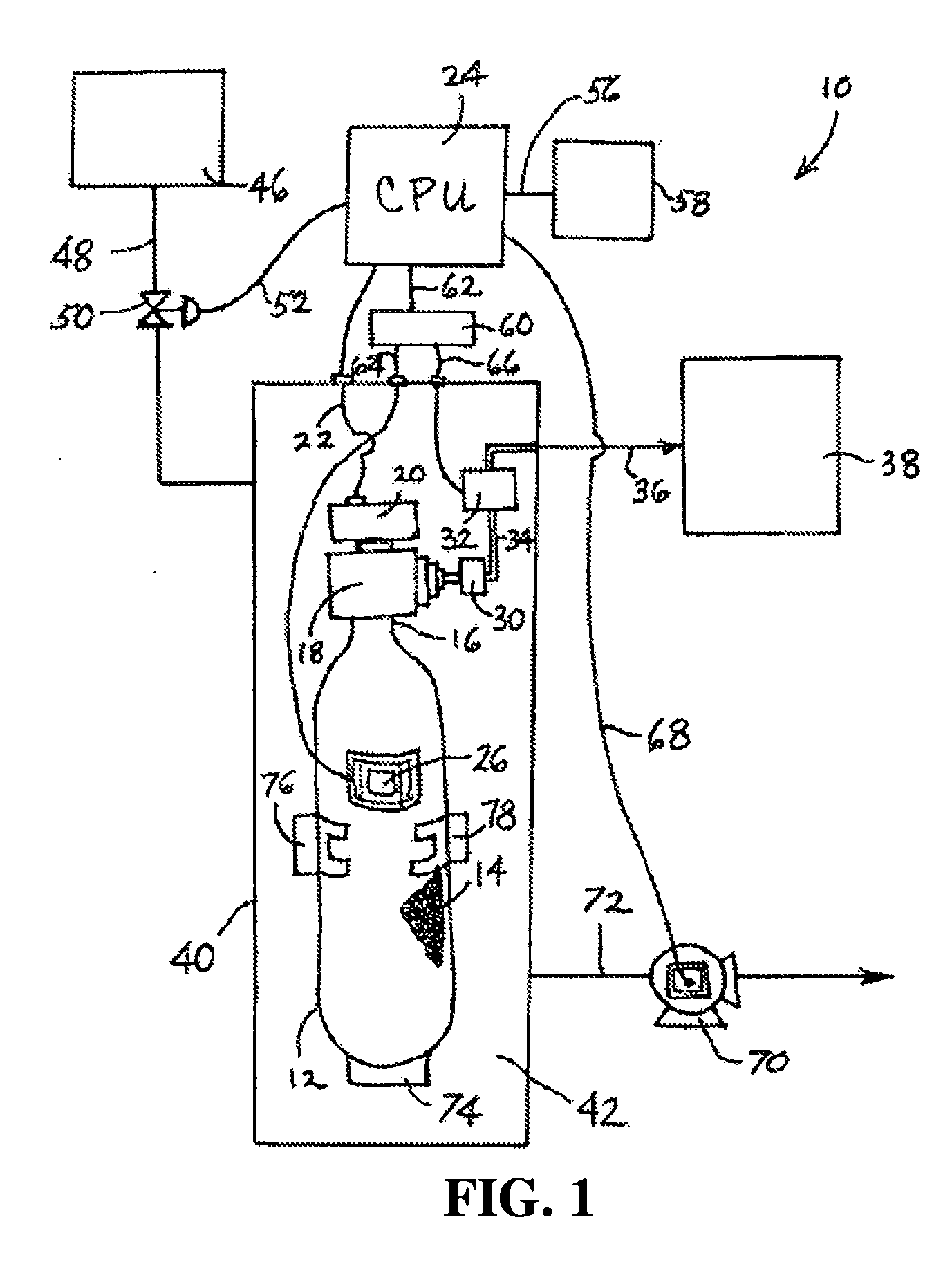

System and method for controlled delivery of liquified gases

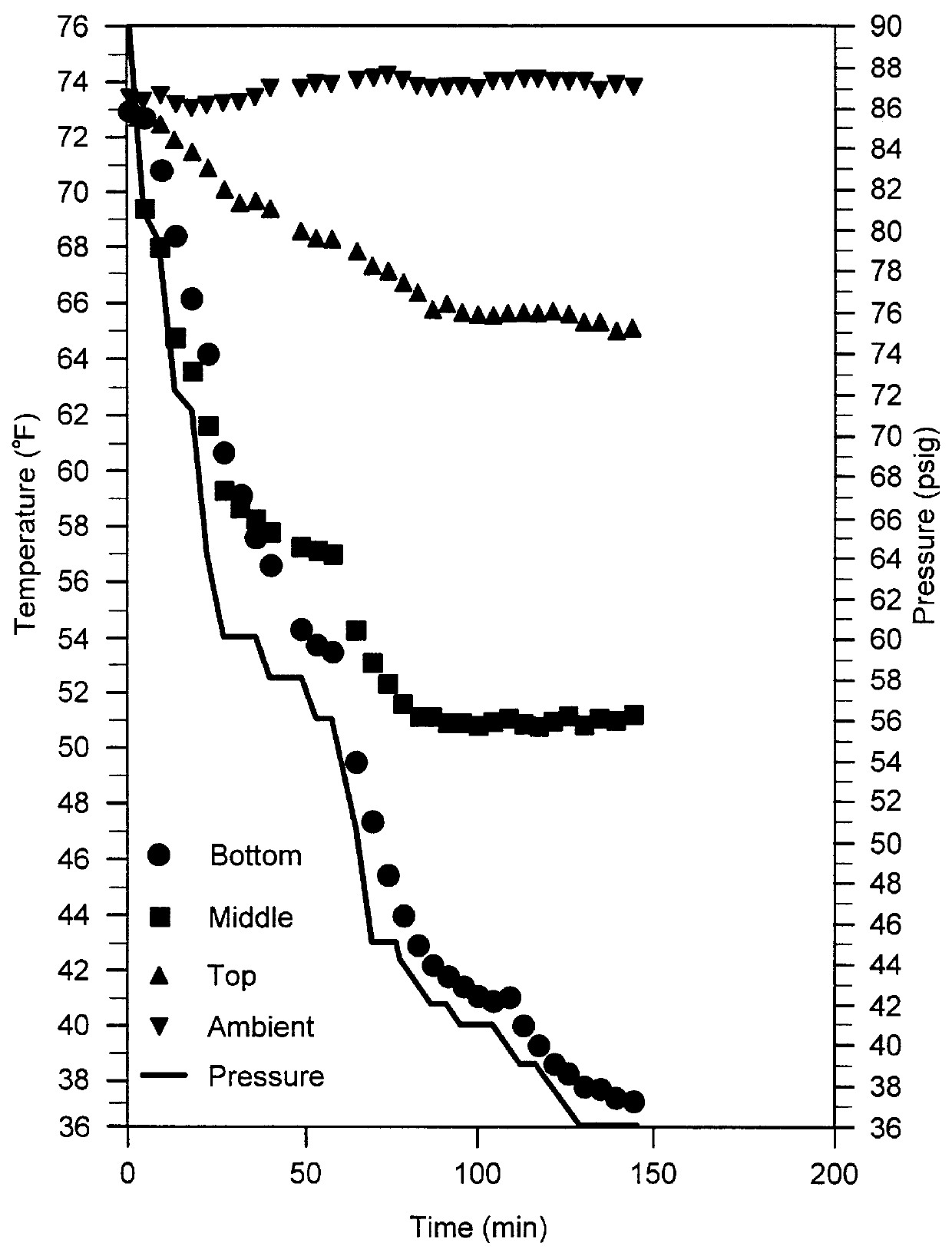

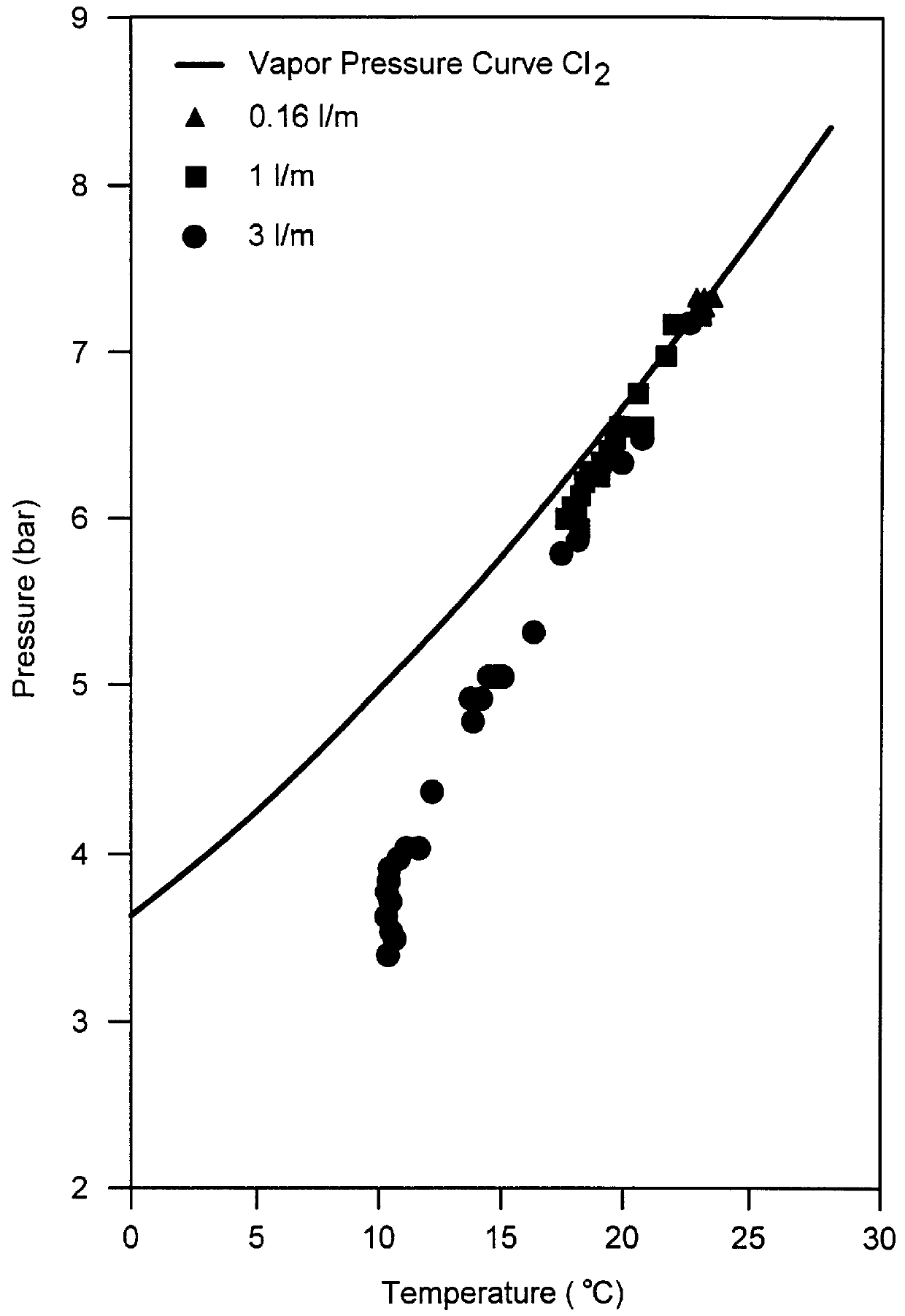

Provided is a novel system and method for delivery of a gas from a liquified state. The system includes: (a) a compressed liquified gas cylinder having a gas line connected thereto through which the gas is withdrawn; (b) a gas cylinder cabinet in which the gas cylinder is housed; and (c) means for increasing the heat transfer rate between ambient and the gas cylinder without increasing the temperature of the liquid in the gas cylinder above ambient temperature. The apparatus and method allow for the controlled delivery of liquified gases from gas cabinets at high flowrates. Particular applicability is found in the delivery of gases to semiconductor process tools.

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE +1

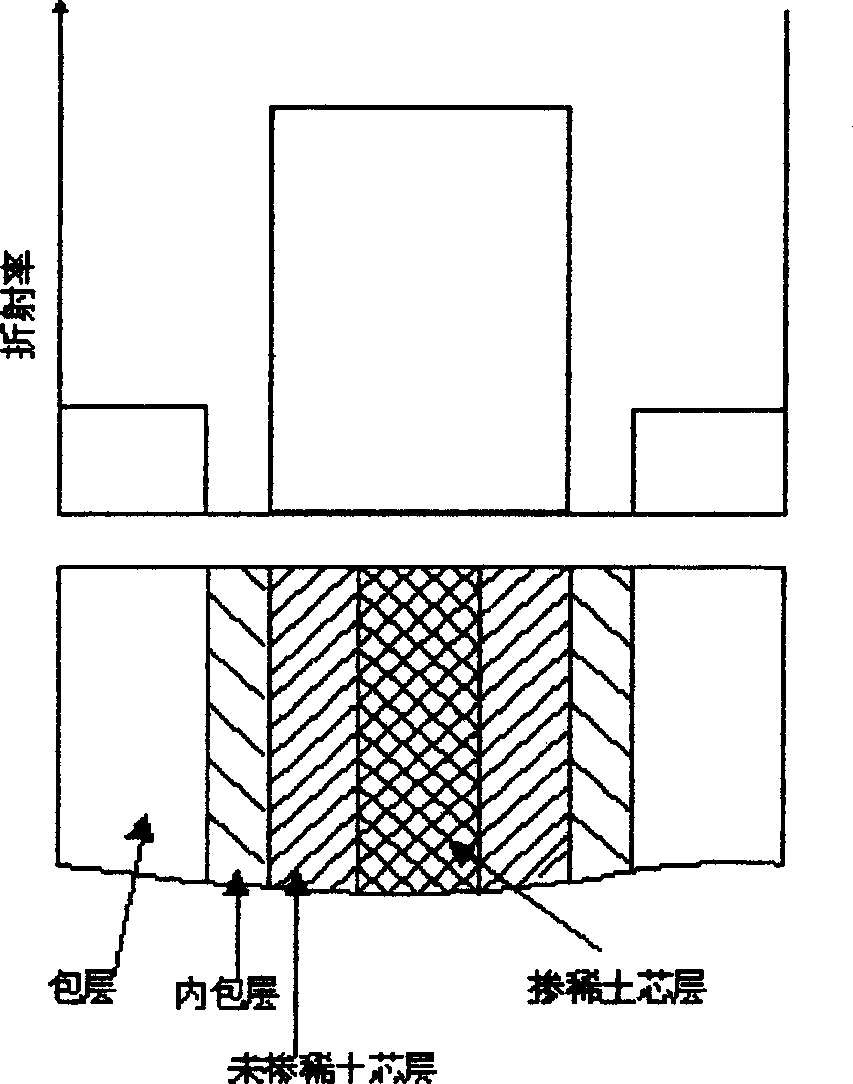

Method for manufacturing rare earth extended fibre-optical prefabricated bar

InactiveCN1490267APrecise control of doping amountImprove performanceGlass shaping apparatusGlass deposition burnersGas phaseRare earth

A process for preparing the prefabricated RE-doped optical-fibre rod features that the chemical gas-phase deposition of plasma is used to deposit the doped SiO2 layer on the inner surface of liner quartz tube and the evaporator is used to directly deliver the RE compound and other codoping agent into reaction tube for direct deposition without pollution.

Owner:FENGHUO COMM SCI & TECH CO LTD

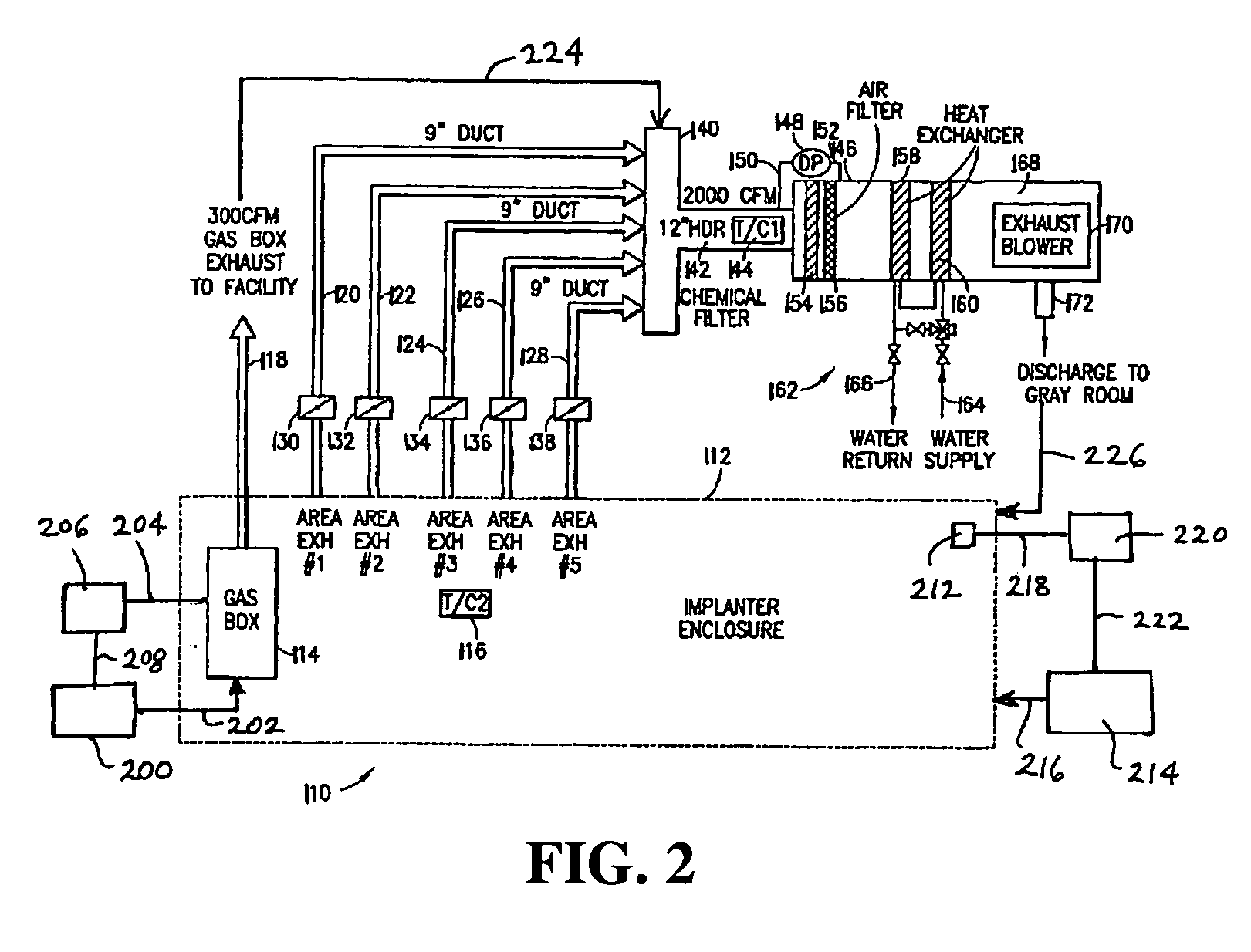

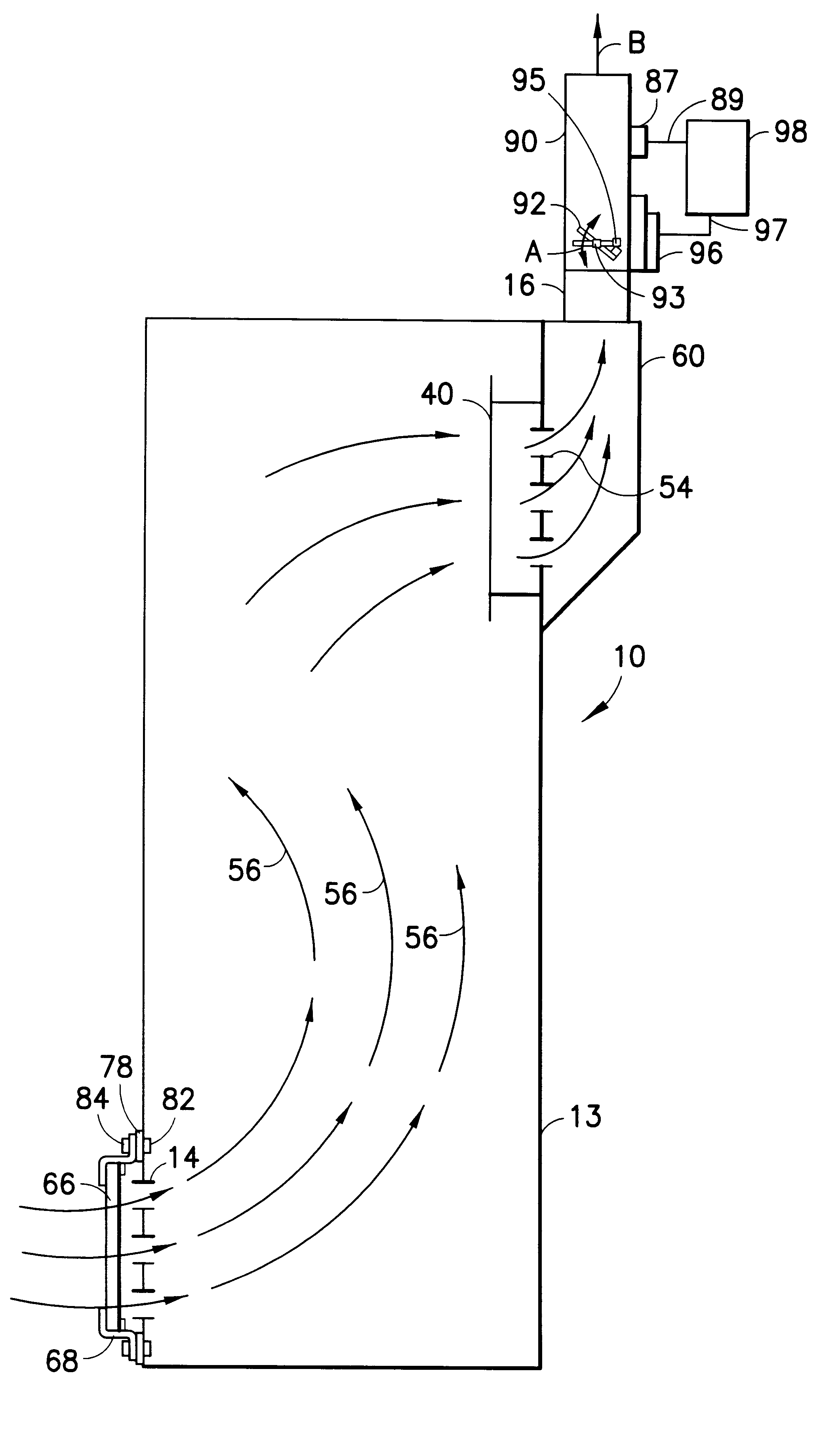

Ventilation gas management systems and processes

ActiveUS20120315837A1Lighting and heating apparatusContainer filling methodsThermodynamicsProcess engineering

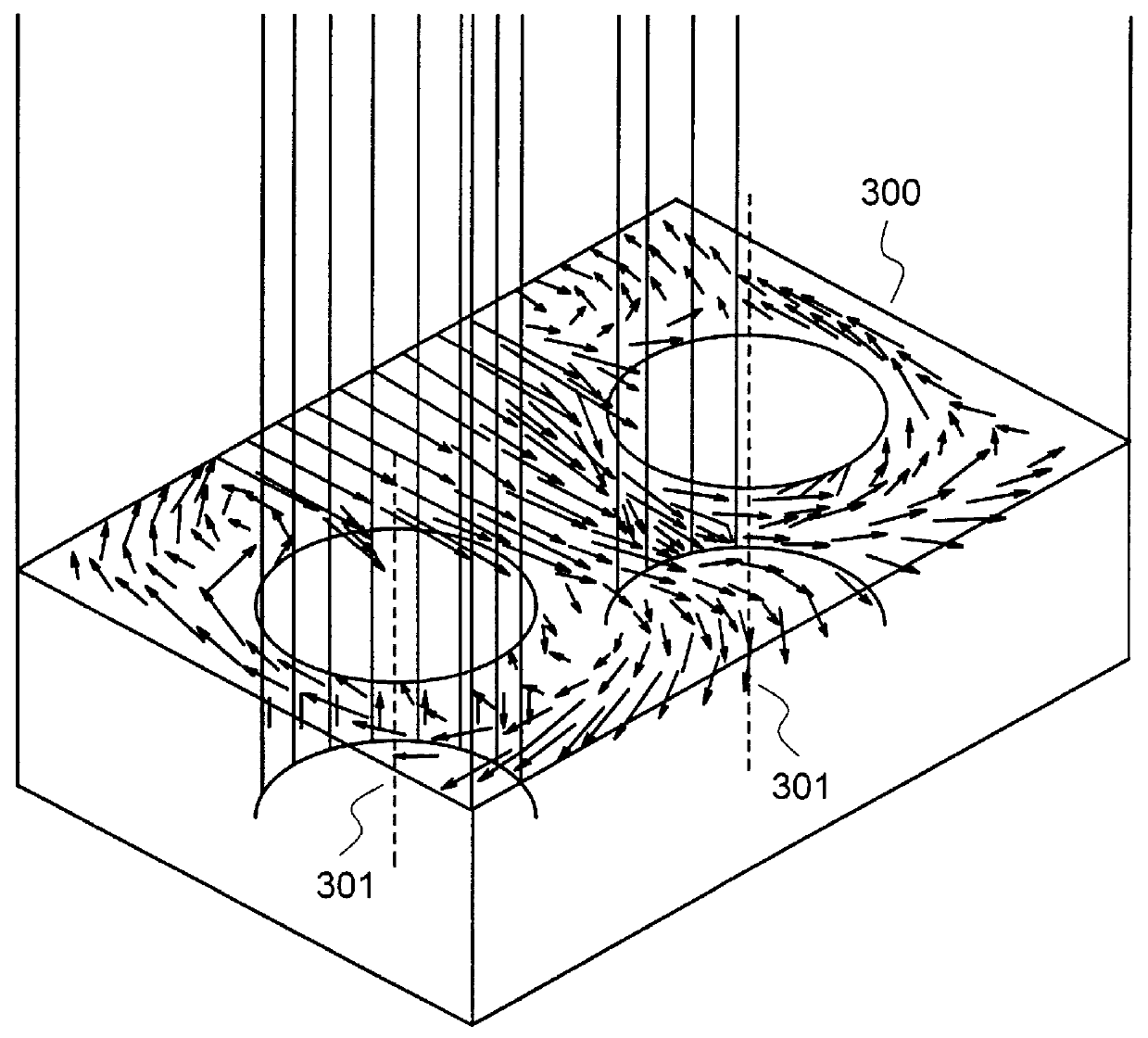

A ventilation gas management system and process for an enclosure adapted to contain fluid supply vessel(s) and through which ventilation gas is flowed to provide safe operation in the event of leakage of fluid from a vessel. Ventilation gas flow is modulated to accommodate various hazard levels associated with the deployment and operation of such enclosure containing fluid supply vessel(s), e.g., a gas box or gas cabinet in a semiconductor manufacturing facility, thereby achieving reduction in ventilation gas requirements otherwise required for such deployment and operation.

Owner:ENTEGRIS INC

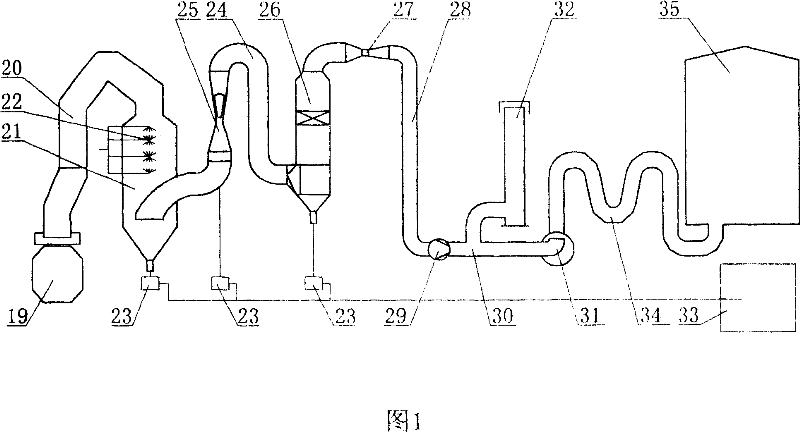

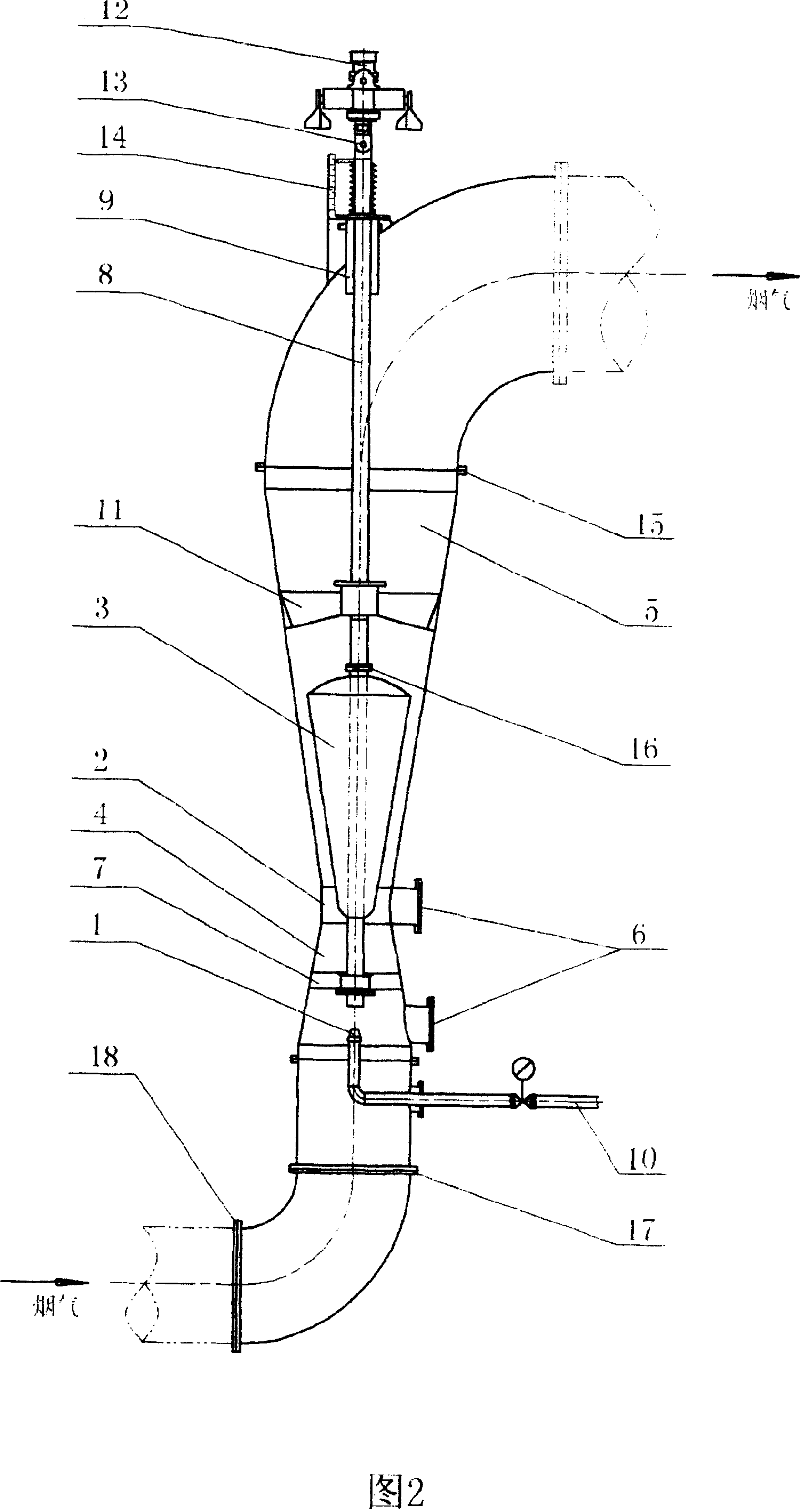

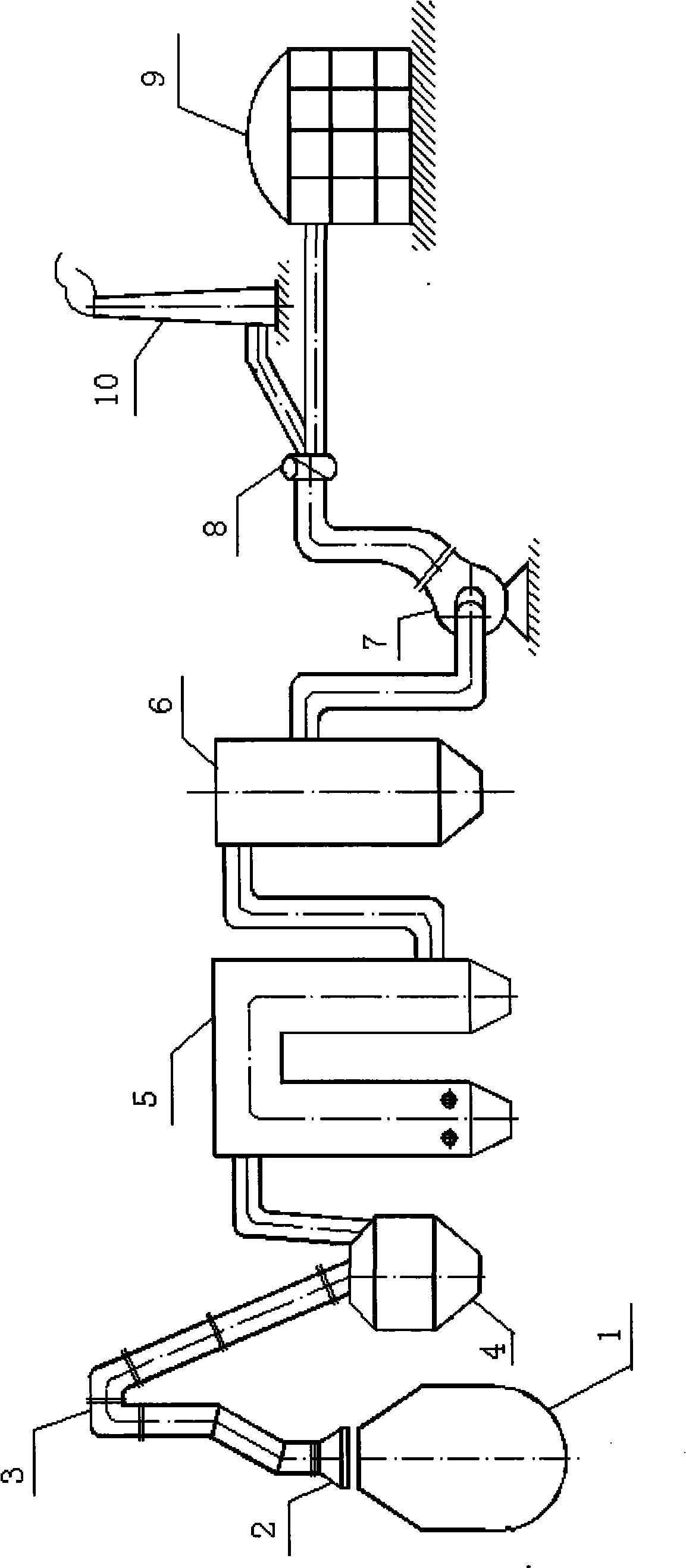

Device for purifying air by eliminating smoke and dust and the technique thereof

ActiveCN101036847AImprove purification effectImprove dust removal effectCombination devicesLighting and heating apparatusFlue gasTranspiration

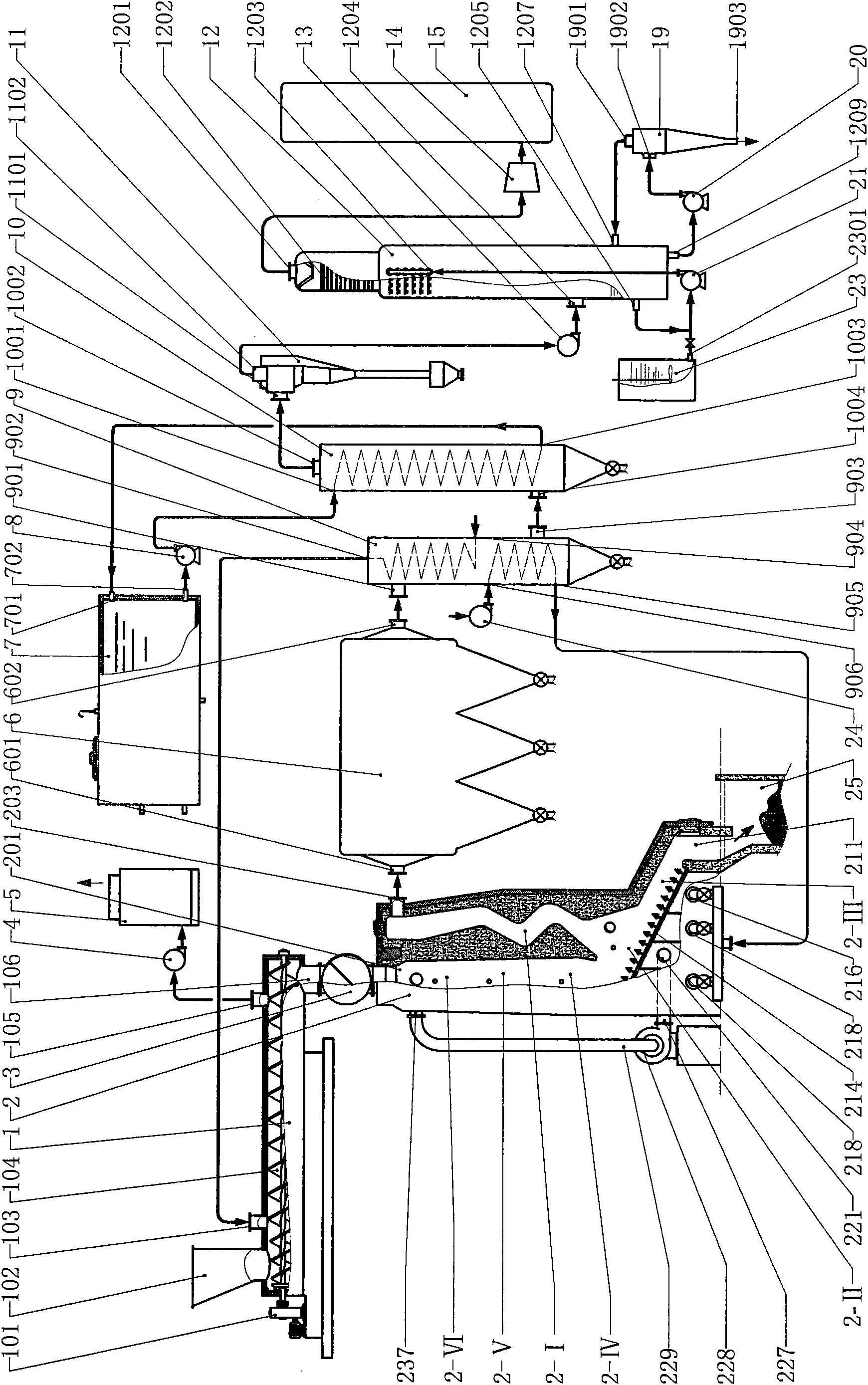

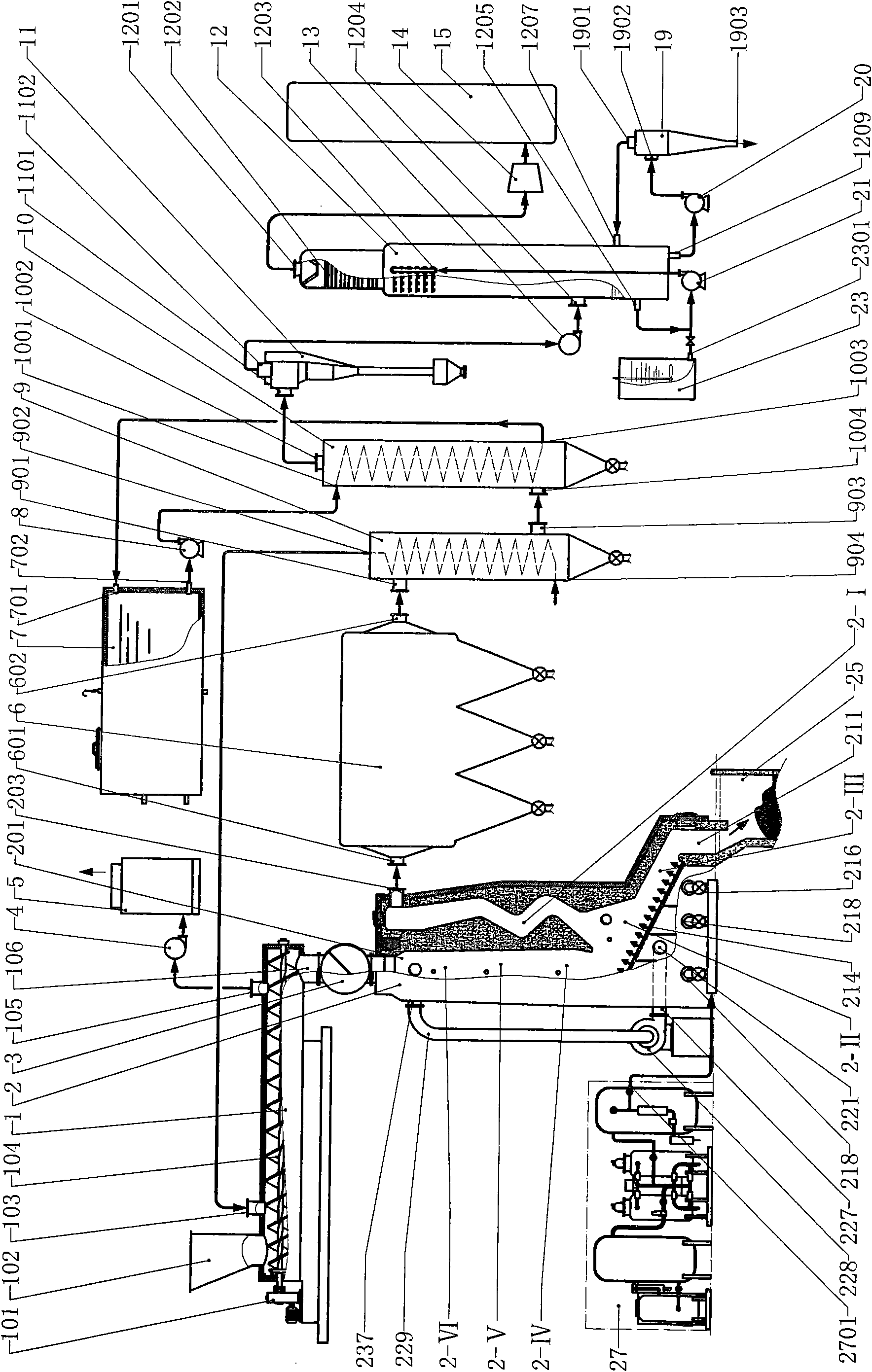

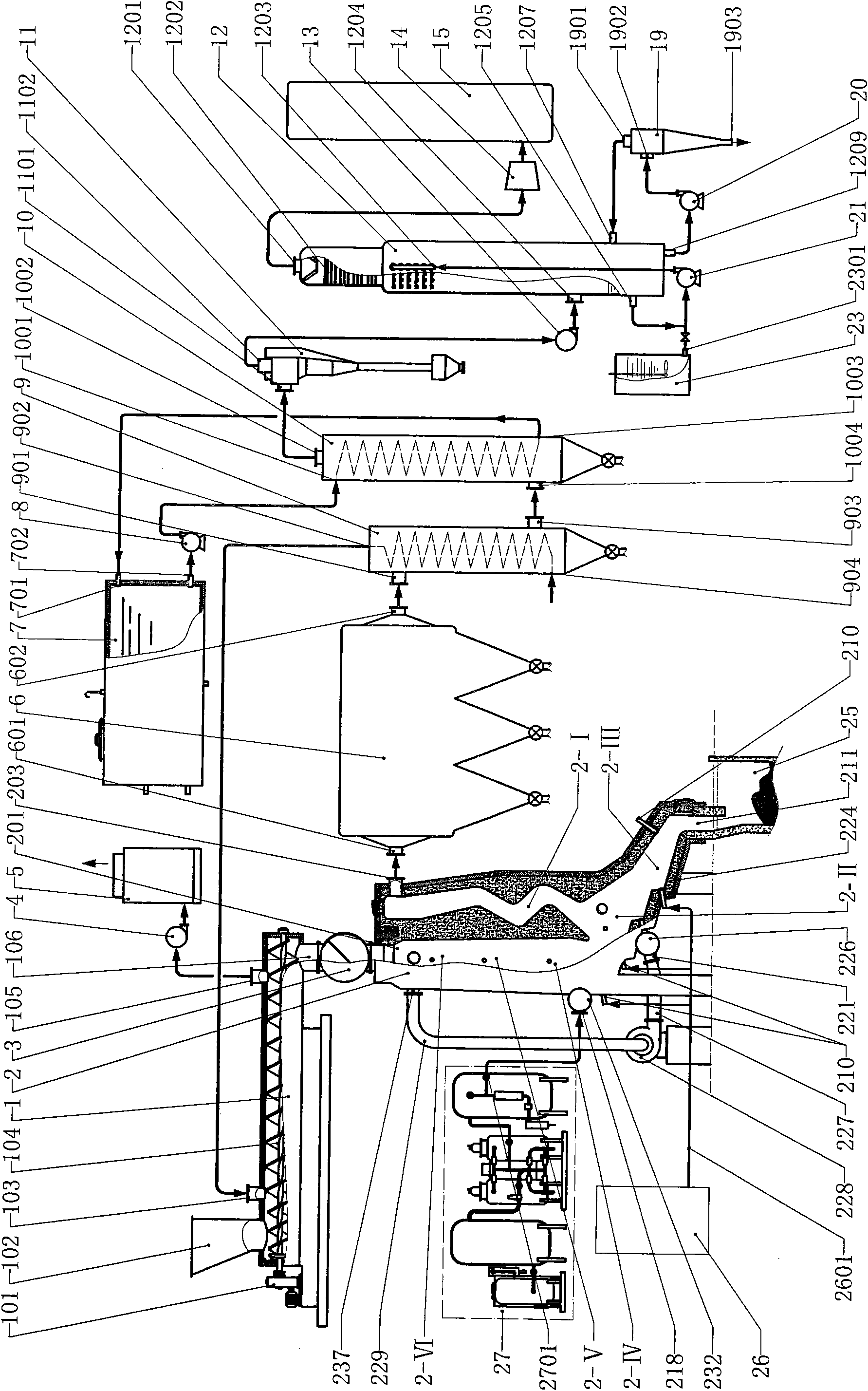

A flue gas purifying collector and process method thereof are provided. The flue gas purifying collector comprises a transpiration cooling flue, a water seal, a flue, a ring-seal Venturi tube, a dehydrator, a flowmeter, pipelines, a main air blower, a three-way valve, a rotary water seal, an irradiation flue pipe, a water treatment device, a U-shape water seal, a gas cabinet, etc, characterized in that the transpiration cooling flue is connected with a cooling washing tower with a nozzle arranged inside the cooling washing tower, the flue gas outlet on the lower part of the collector is connected to the flue gas inlet on the lower part of the ring-seal Venturi tube, the flue gas outlet of the ring-seal Venturi tube is connected to the dehydrator, and on the throat opening of the ring-seal Venturi tube and below the heavy iron are arranged a water supply pipe and a nozzle, and a heavy iron inversed cone is arrange inside the throat opening. An up-running type flue gas flowing manner and water supply below the heavy iron are employed in the process provided in the invention, redundant mechanical water can be directly reclaimed without passing through the throat opening of the ring-seal Venturi tube, water is atomized thoroughly and agglomerates with dust on the throat opening of the ring-seal Venturi tube, thereby improving dust purifying and dust collecting effect, facilitating the adjustment of the heavy iron, and preventing dust agglomeration below the heavy iron and dust deposit on the throat opening of the ring-seal Venturi tube.

Owner:北京中冶设备研究设计总院有限公司

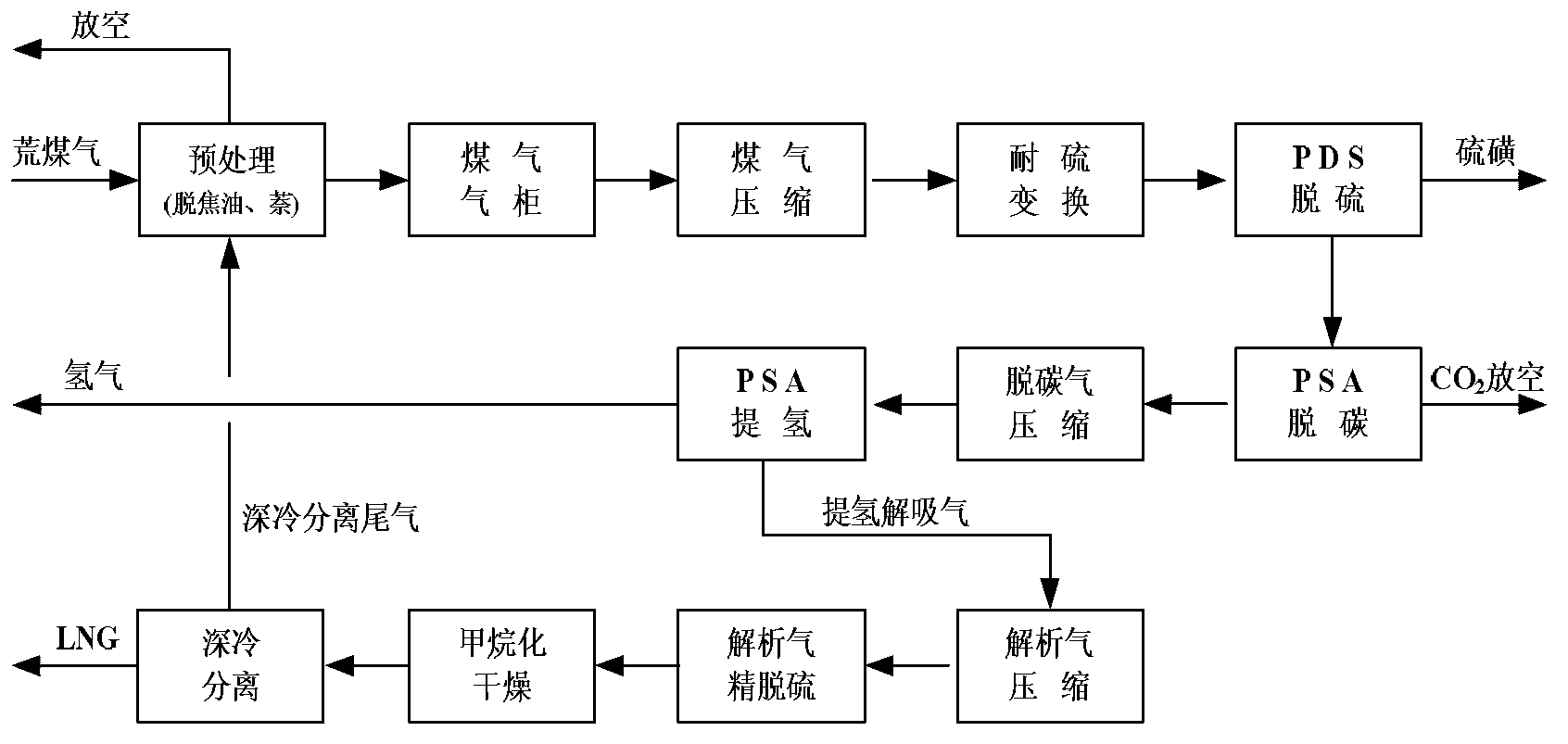

Method for preparing hydrogen and liquefied natural gas through using gas retort raw gas

ActiveCN103275777AImprove recycling efficiencyImprove utilization efficiencyHydrogenGaseous fuelsMethanationCoal pyrolysis

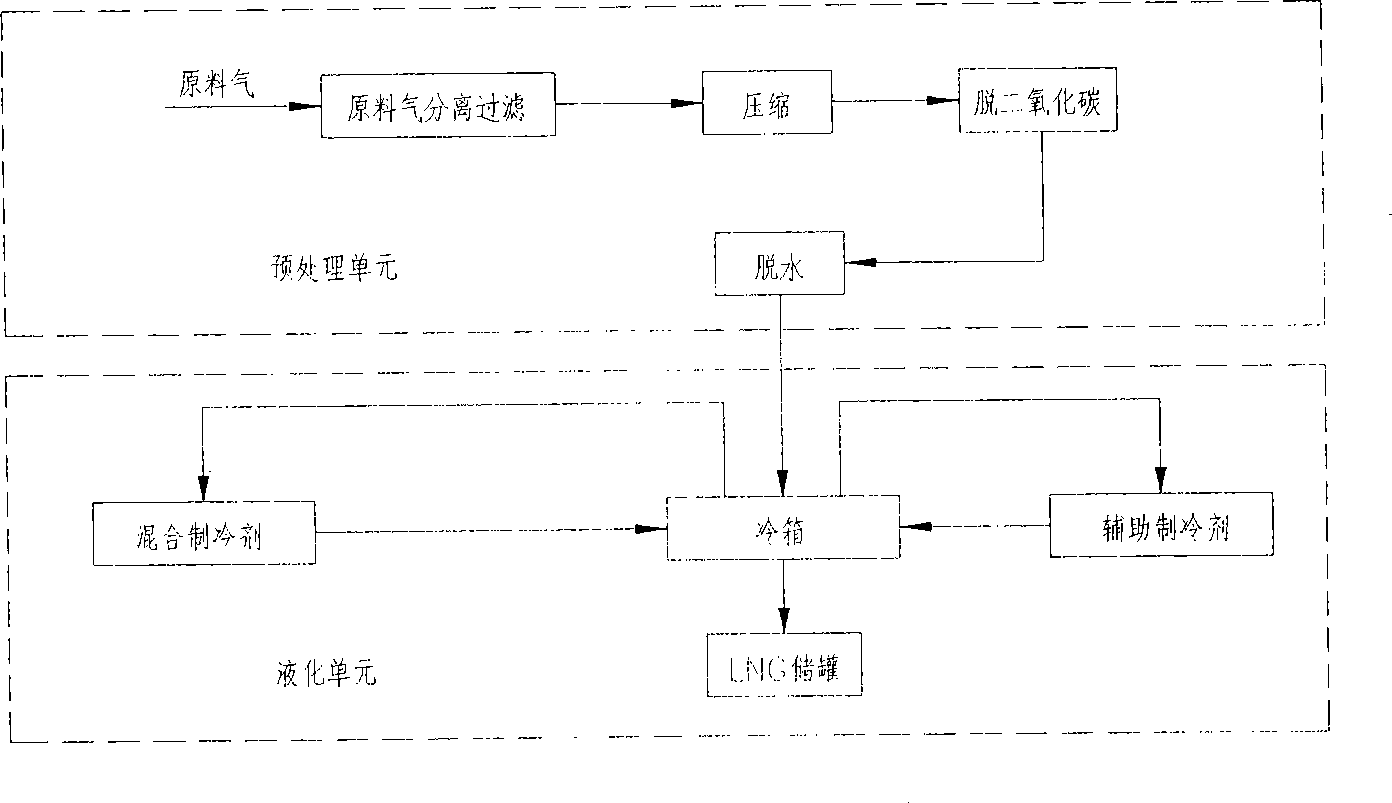

The invention discloses a method for preparing hydrogen and liquefied natural gas through using a gas retort raw gas. The method comprises the following steps: carrying out adsorbing pretreatment of the gas retort raw gas for removing tar and naphthalene in the gas retort raw gas, and allowing the obtained gas retort raw gas to enter a coal gas holder for buffering; pressurizing the buffered raw gas, allowing the pressurized raw gas to enter a sulfur-tolerant shift conversion reactor, and reacting carbon monoxide with steam to generate carbon dioxide and hydrogen; carrying out PDS wet desulphurization of the obtained shift conversion gas to obtain a byproduct sulfur, and regenerating a desulphurization liquid; carrying out a two-stage PSA (pressure swing adsorption) technology of the desulphurized shift conversion gas for carbon removal and hydrogen extraction; sending the obtained hydrogen to a tar hydrogenating apparatus as a raw material; carrying out pressurization and fine desulphurization of the obtained hydrogen extracted and desorbed gas, allowing the obtained gas to enter a methanation reactor, carrying out a methanation reaction of hydrogen in the desorbed gas, carbon monoxide and carbon dioxide to generate methane, drying the obtained generated gas, and allowing the generated gas to enter a cooling box; and liquefying methane through adopting a mixed refrigerating agent liquefying process to prepare the liquefied natural gas. The method increases the recycling efficiency of hydrogen and the comprehensive utilization efficiency of the raw material, and realizes the efficient and comprehensive utilization fo the coal pyrolysis raw gas.

Owner:HUADIAN HEAVY IND CO LTD

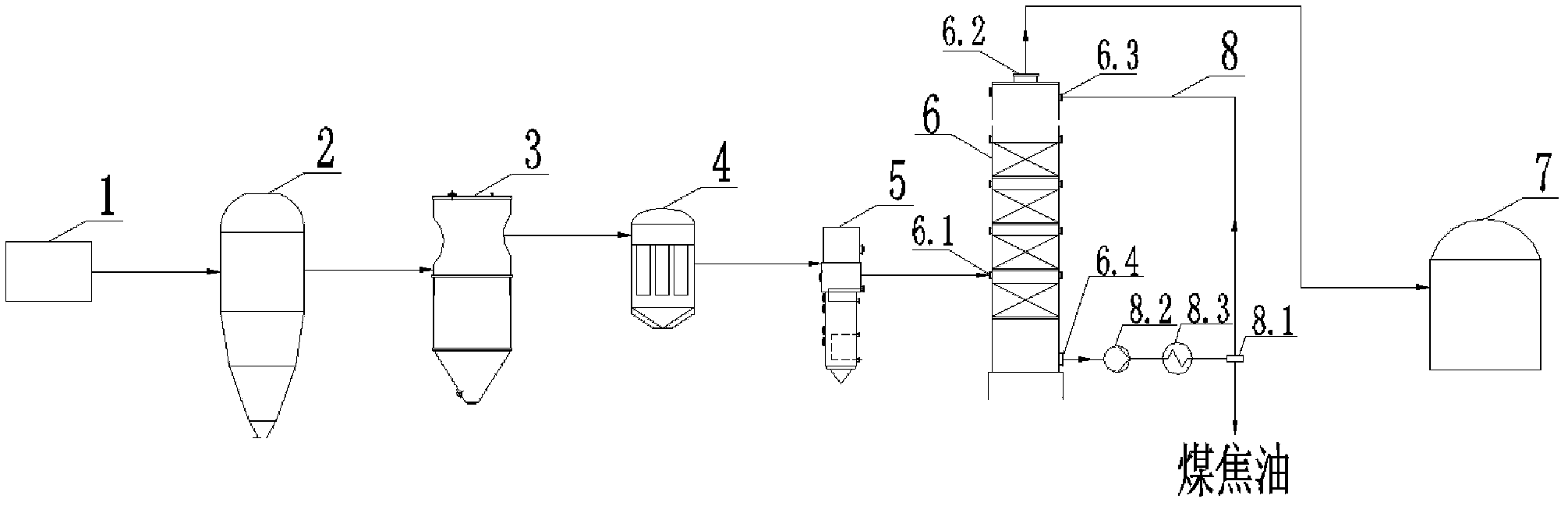

Gas purification process and system

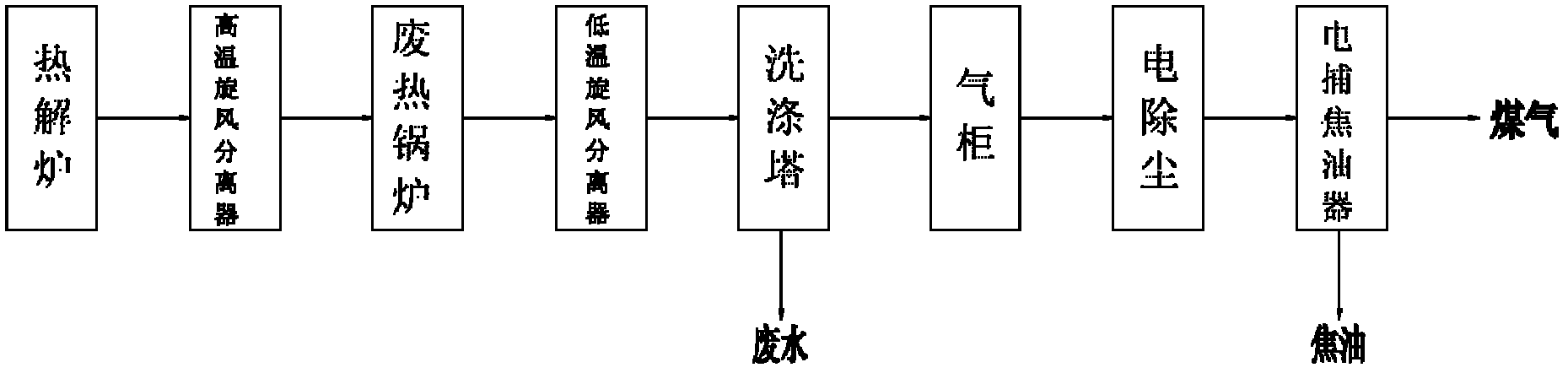

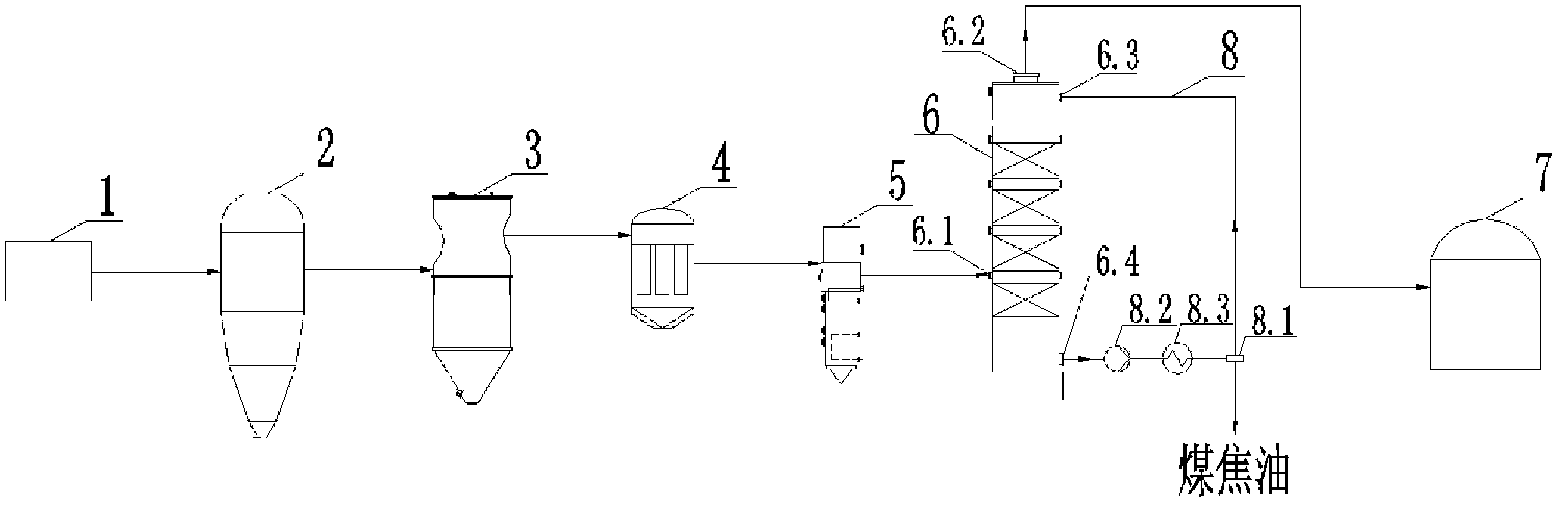

InactiveCN102492490AReduce moisture contentImprove qualityCoke ovensEnergy inputCycloneProcess engineering

The invention relates to a gas purification process and a system, which solve the problem that the existing gas purification process is complex in process, large in waste water amount, high in production cost, poor in dedusting effect and low in coal tar quality. The technical scheme is that raw material coal is predried in a dryer and then sent to a high temperature pyrolysis furnace for pyrolysis, untreated gas containing ash and coal tar and produced through pyrolysis is sent to a high temperature cyclone separator to remove ash in large particles, dedusting of the untreated gas after removing the ash in large particles is further carried out through a high temperature filter, gas is carried out waste heat recovery through a waste heat boiler after dedusting, the gas which exchanges heat to the temperature of 300-350 DEG C enters a chilling tower and is contacted with coal tar oil at the temperature of 40-80 DEG C in an adverse current mode so as to conduct washing and cooling, the coal tar contained in the gas enters the coal tar oil and is discharged from a tower bottom, the gas is washed and cooled to 40-100 DEG C at the tower top to obtain clean gas, and the clean gas is sent to a gas cabinet. The gas purification process and the device are simple, free of waste discharge, good in gas dedusting effect, high in byproduct coal tar quality and low in production cost.

Owner:WUHUAN ENG

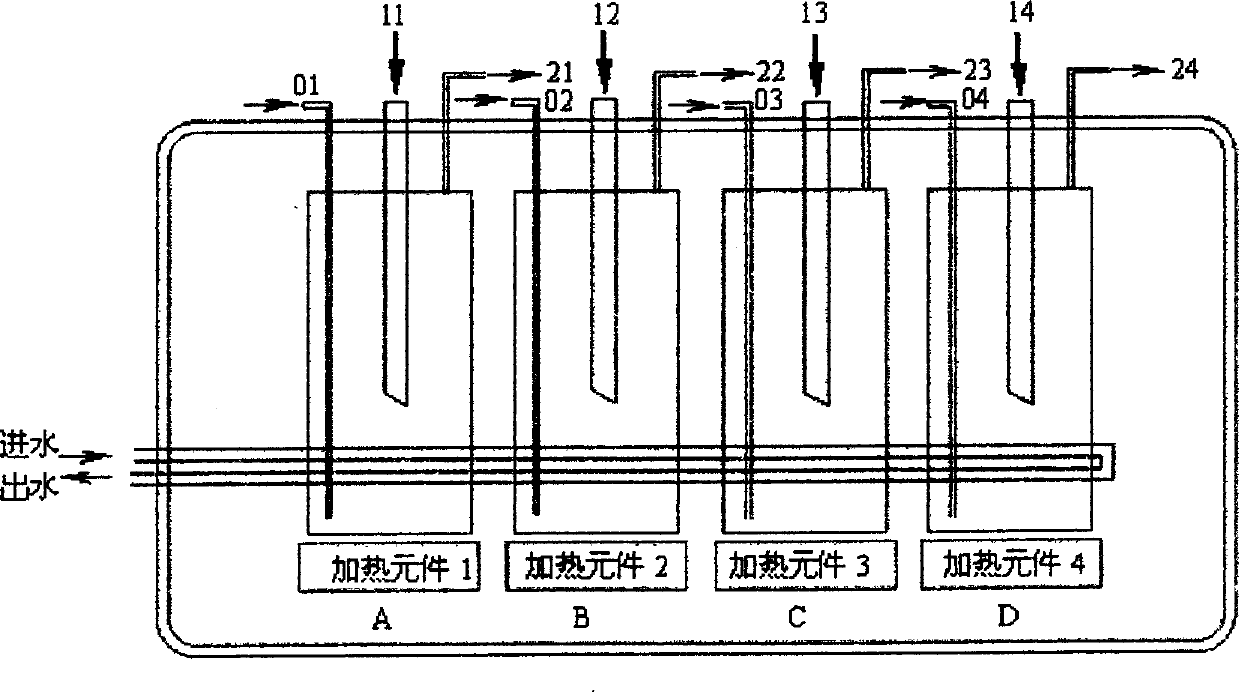

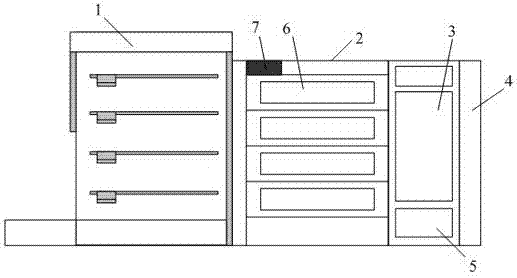

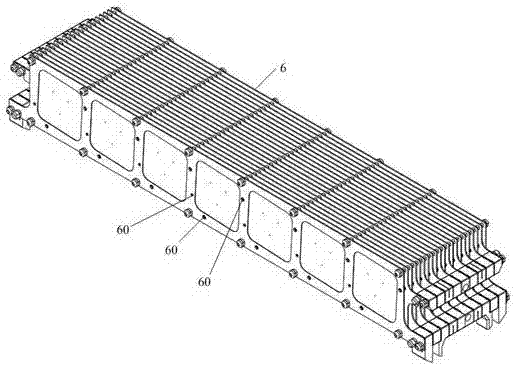

Coating equipment and method for tube-type PERC solar cells

ActiveCN107287579AReduce depthReduce gap sizeFinal product manufactureChemical vapor deposition coatingSilanesSolar cell

The invention discloses coating equipment for tube-type PERC solar cells. The coating equipment comprises a wafer loading region, a furnace body, a gas cabinet, a vacuum system, a heating system, a control system and a graphite boat; the gas cabinet is provided with a first gas pipeline for introducing silane, a second gas pipeline for introducing ammonia, a third gas pipeline for introducing trimethylaluminum, a fourth gas pipeline for introducing laughing gas and a fifth gas pipeline for introducing methane; the graphite boat is used for loading or unloading a silicon wafer; before being used or after being coated many times, the graphite boat needs to be subjected to pretreatment comprising the steps: drying the graphite boat; and coating at least one layer of silicon carbide film on the surface of the dried graphite boat. Correspondingly, the invention further discloses a coating method for tube-type PERC solar cells. By using the coating equipment and method, the pretreatment step of the graphite boat is simplified, the consumption of the silicon wafer is reduced, the silicon wafer is prevented from being scratched, and the EL yield of the cells is increased.

Owner:GUANGDONG AIKO SOLAR ENERGY TECH CO LTD +1

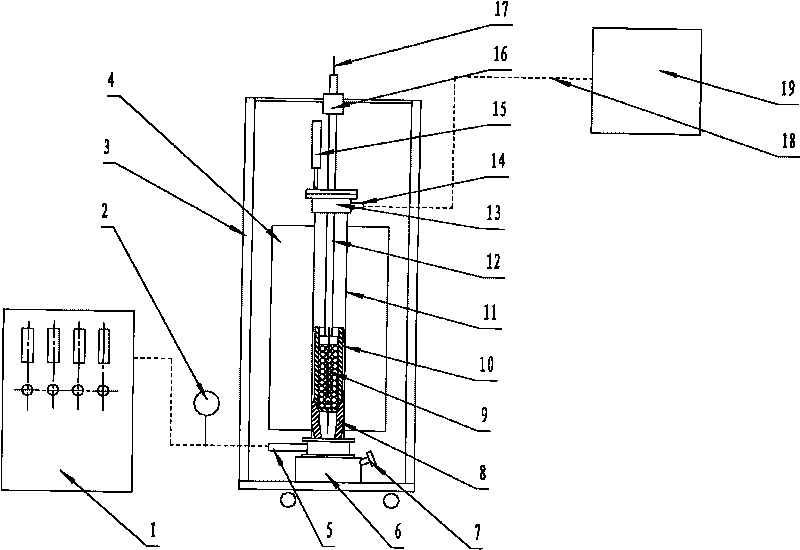

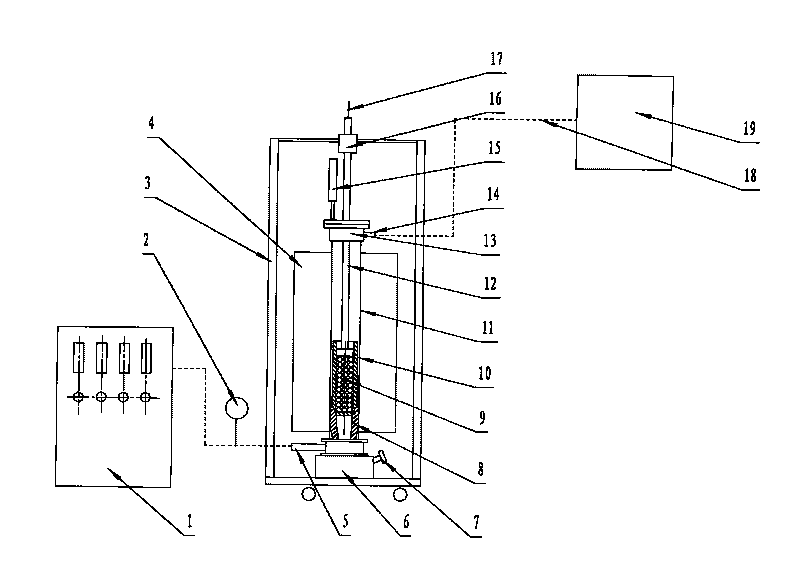

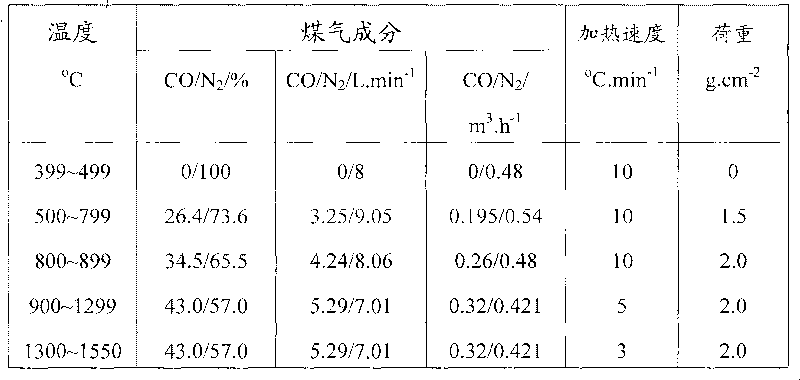

Blast furnace first slag experiment method and first slag experimental furnace

InactiveCN101701770ASimple structureReduce manufacturing costFuel testingFurnace typesElectric arc furnaceSlag

The invention relates to a blast furnace first slag experiment method and a first slag experimental furnace which solves the problem that the current experiment method can not well guide the optimization of furnace material structure for first slag can not be acquired. The first slag experimental furnace comprises an electric furnace and an air distribution cabinet, wherein the electric furnace is provided with a hearth pipe; a graphite crucible positioned on a graphite base is arranged in the hearth pipe; the upper end of the graphite crucible is provided with a center press rod, and the upper end of the center press rod penetrates through the hearth pipe and is provided with an inserted thermocouple; a material surface load readjusting device is arranged on the center press rod; the upper end of the hearth pipe is provided with an upper cover, an exhaust opening and a displacement sensor, and the lower end is provided with a material receiving box and communicated with the air distribution cabinet by a reducing gas inlet; and a pressure difference transmitter is arranged on a connecting pipeline of the reducing gas inlet and the air distribution cabinet. The experiment method obtains first slag by simulating the blast furnace condition through the first slag furnace, records all detecting data on line and carries out chemical analysis and microscopic detection on the first slag, thereby having important guide significance for optimizing the furnace material structure.

Owner:武钢集团有限公司 +1

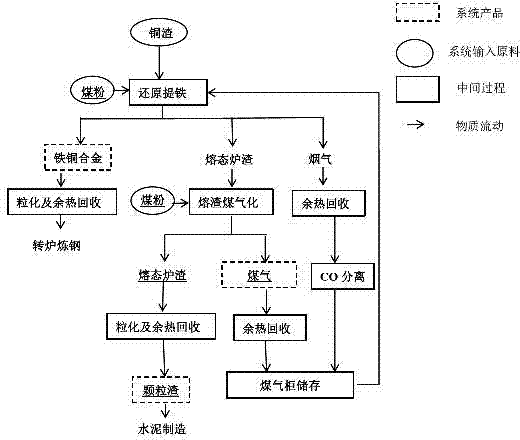

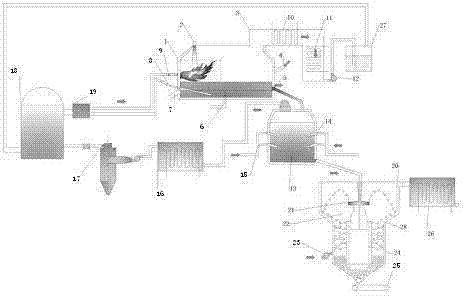

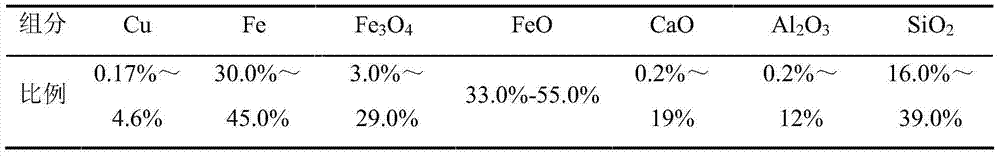

System and method for recovering iron and waste heat from molten copper residues respectively through step-by-step reduction and coal gasification

ActiveCN104846209AReduce consumptionSave resourcesIncreasing energy efficiencyRecycling and recovery technologiesCopperCyclonic spray scrubber

The invention discloses a system and a method for recovering iron and waste heat from molten copper residues respectively through step-by-step reduction and coal gasification, belonging to the fields of resources and environments. The system comprises a reductive iron extraction furnace, a coal gasification furnace, a granulating and waste heat recovering device, a gas heat exchanger, a gas separating and dust collecting device, a waste heat boiler, a cyclone dust collector, a gas cabinet and a transportation device. The method comprises the following three steps of step-by-step reductive iron extraction and coal gas recovery; coal gasification and coal gas recovery; and granulation and waste heat recovery. By using the system and method disclosed by the invention, the link of a dry-process copper residue granulation and waste heat recovery process and a copper residue valuable metal extracting process is realized, iron in copper residues can be effectively recovered, the recovery rate of the iron is up to more than 90%, and CO gases generated in the recovery process can be recycled, so that the environment is protected, resources are saved, and meanwhile a series of problems existing in the high-temperature copper residue treating process are solved.

Owner:NORTHEASTERN UNIV

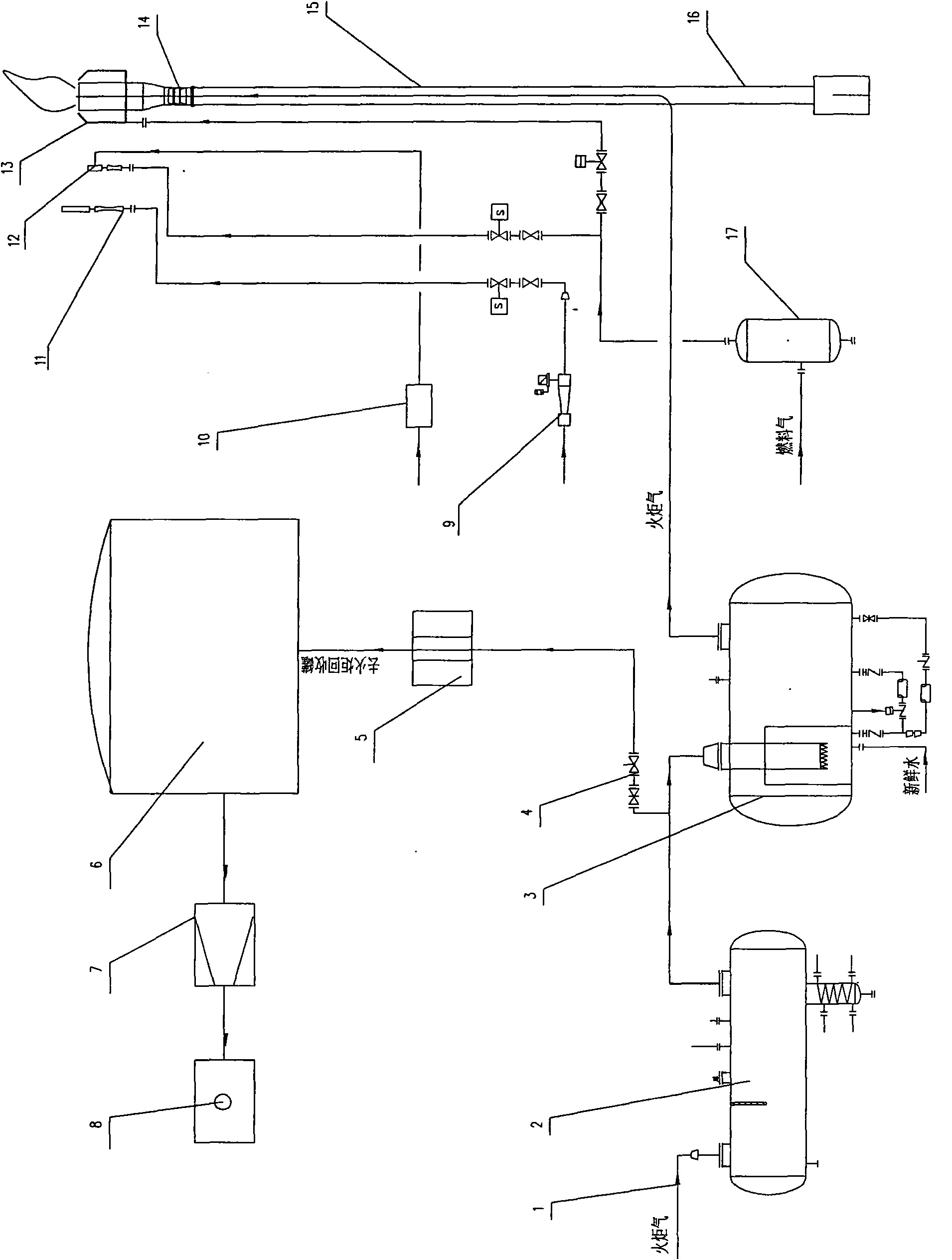

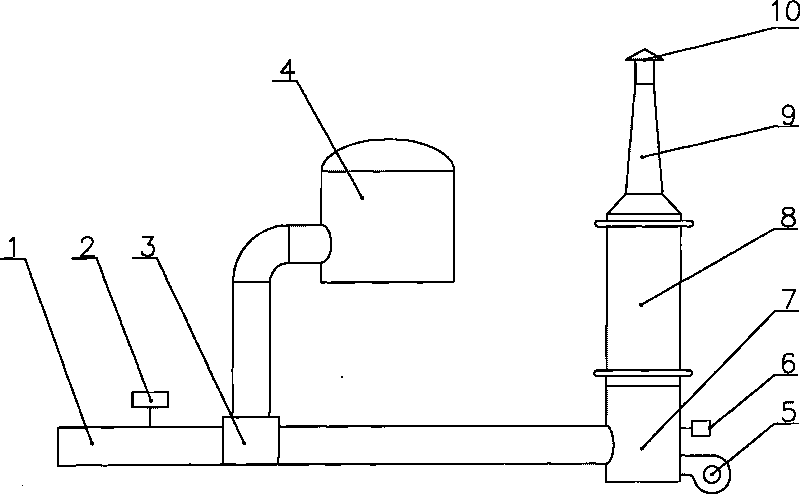

Flare gas safe recovery and discharge system

ActiveCN101672478ARealize automatic controlSafe recyclingIncinerator apparatusAutomatic controlProcess engineering

The invention provides a flare gas safe recovery and discharge system, which comprises a flare gas delivery flask (2), an automatic control water-sealed valve (3), a gas holder (6) and a flare tip (13) and is characterized in that the gas inlet end of the flare gas delivery flask (2) is connected with a flare gas source by a flare gas main pipe (1); one path of the output end of the flare gas delivery flask (2) is connected with a gas torch (6), and the other path thereof is connected with the flare tip (13) via the automatic control water-sealed valve (3); an automatic control valve (4) and aflare gas filtering tank (5) are mounted on the pipeline connecting the flare gas delivery flask (2) with the gas torch (6); the output end of the gas torch (6) is connected with a compressor (7); and the output end of the compressor (7) is connected with a gas appliance (8). The invention has the advantages of simple system structure, convenient manufacturing and installation and safe usage; andthe invention also has the characteristics of being favor of preventing environment, saving energy and the like.

Owner:JIANGSU SUNPOWER TECH

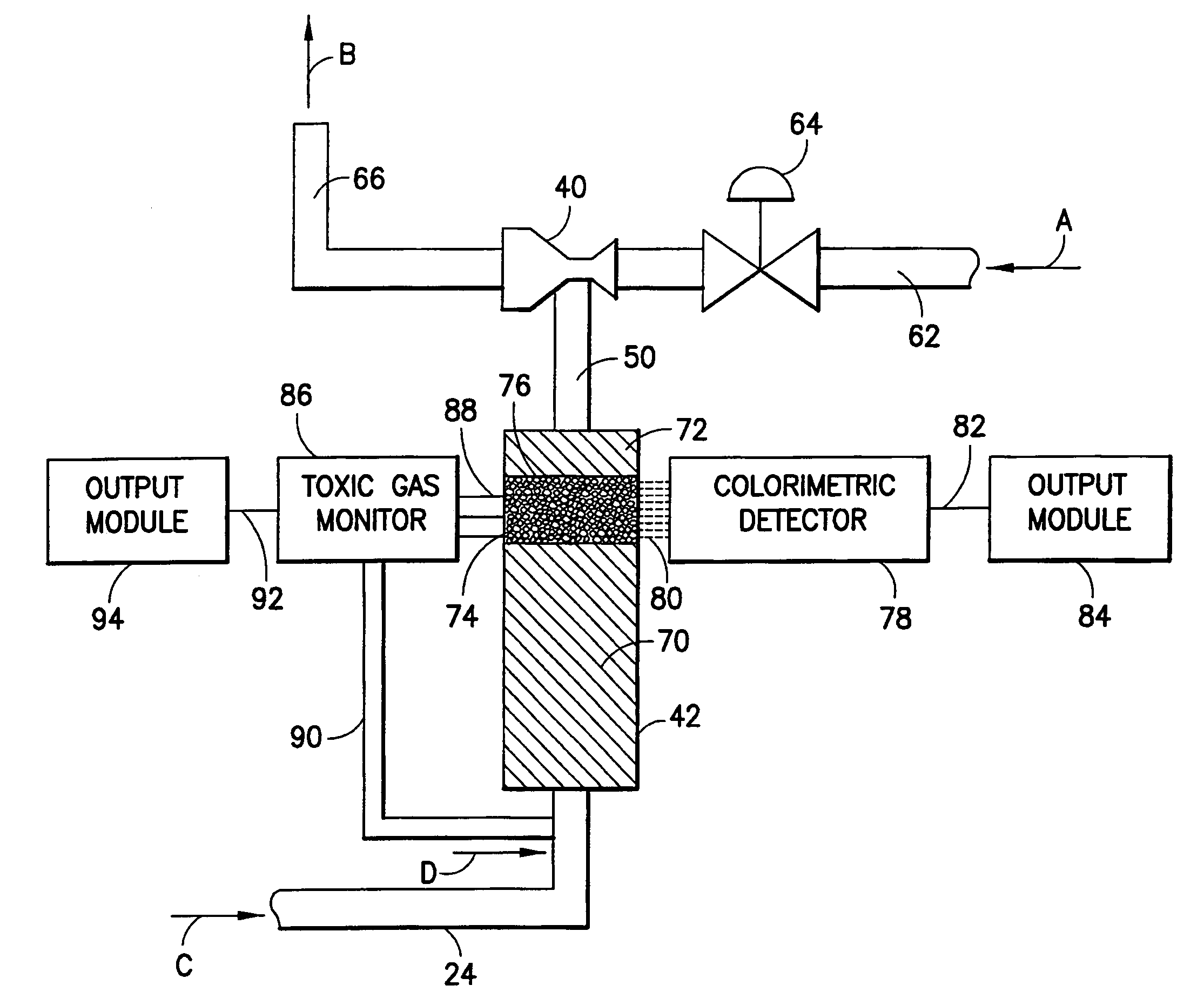

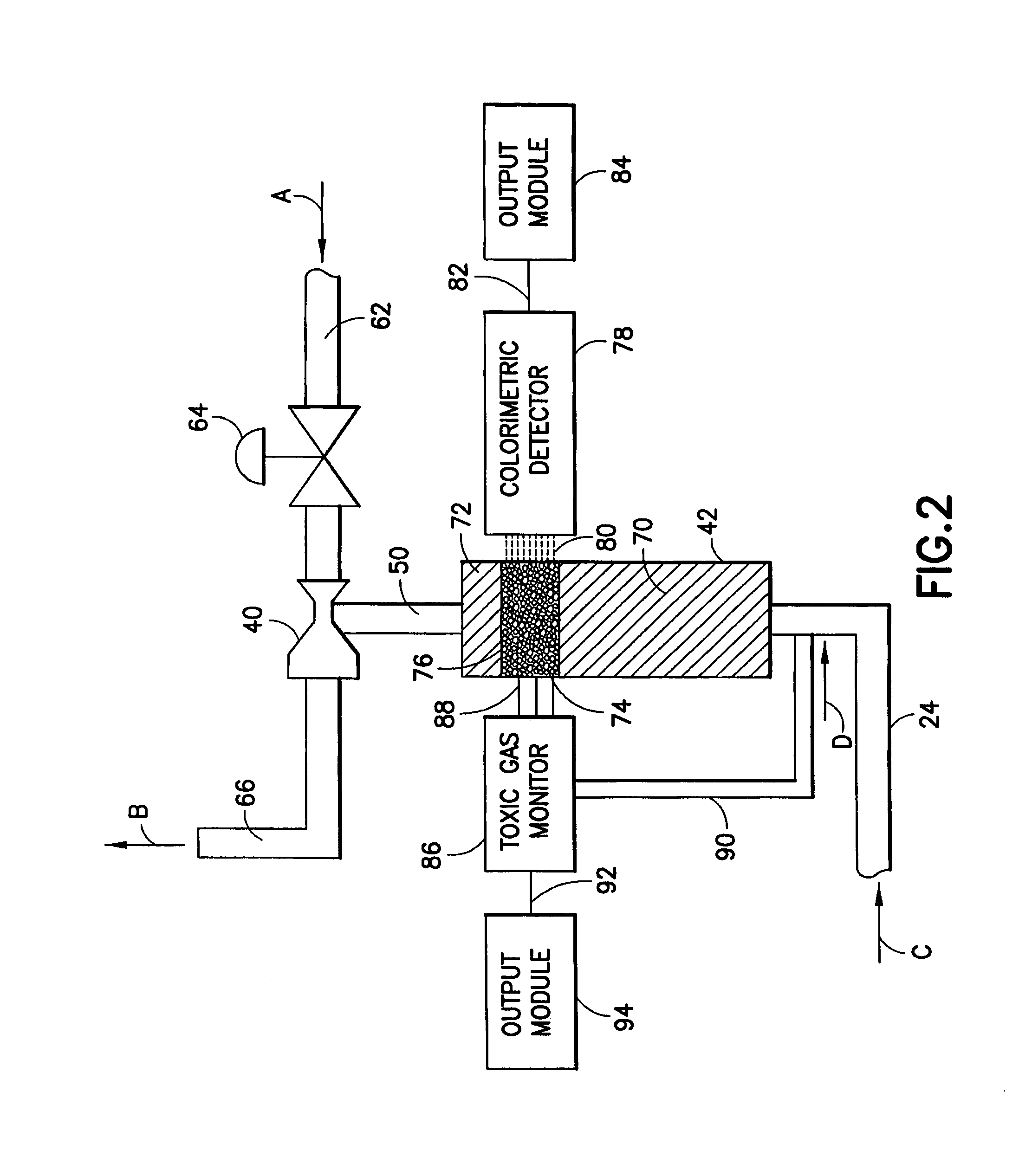

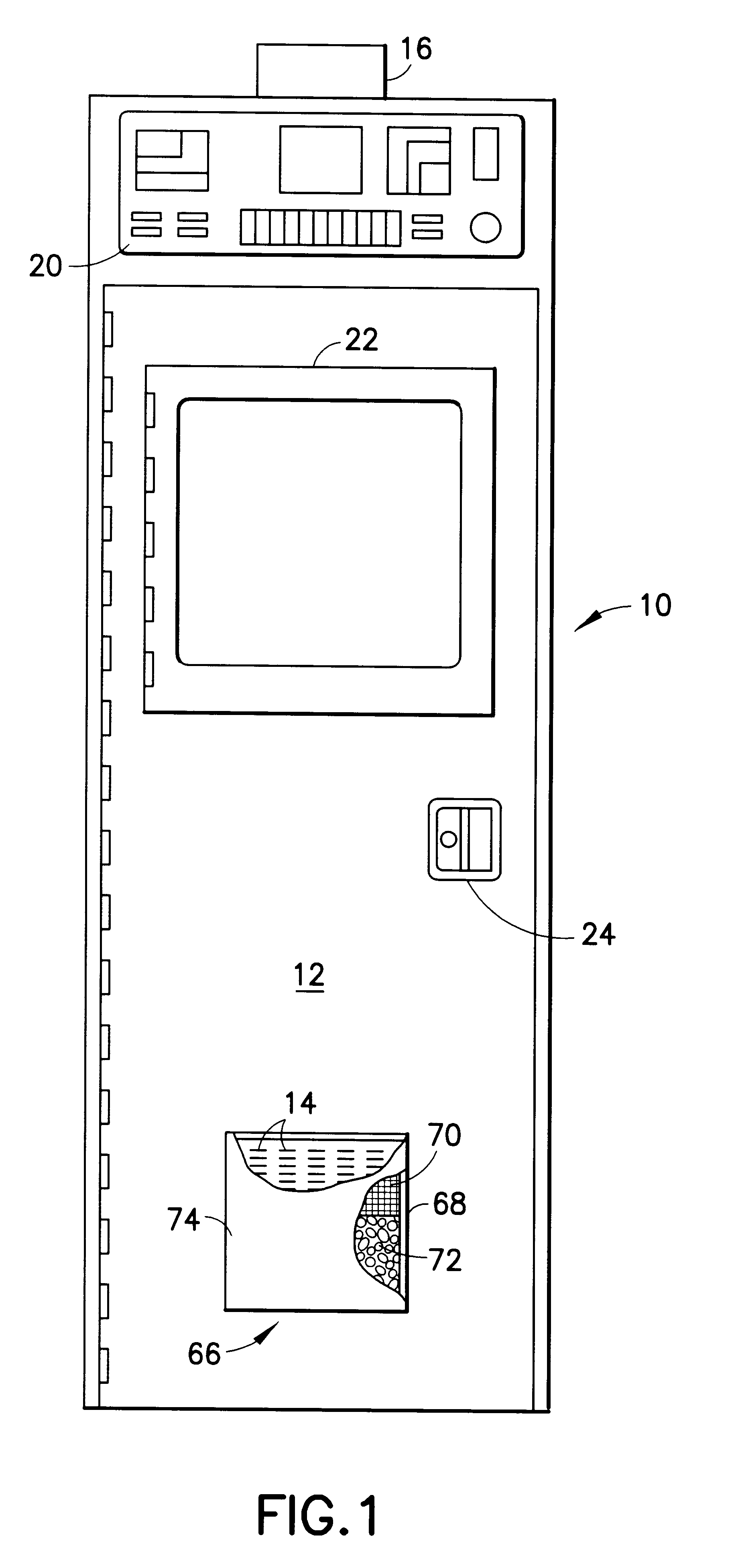

Gas cabinet including integrated effluent scrubber

InactiveUS7018448B2Minimizing vent gas abatement issuesEfficient removalCombination devicesGas treatmentToxic gasSewage

A gas cabinet assembly for dispensing of gas to a process facility such as a semiconductor manufacturing tool. A purge gas dry scrubber is integrated with the gas flow circuitry and a venturi pump in the gas cabinet. Purge gas is flowed through the flow circuitry in the gas cabinet subsequent to on-stream dispensing of process gas through such flow circuitry, and forms a purge effluent including the residual process gas. The purge effluent is flowed through a dry scrubber unit to sorptively remove the process gas species from the purge effluent. The resultant process gas-depleted purge effluent is vented from the gas cabinet, e.g., into the ducting of the house exhaust system of the process facility. Monitoring of the relative depletion of the dry scrubbing medium in the dry scrubber may be carried out with endpoint detection, e.g., using colorimetric change techniques, toxic gas monitor devices, or PLC / CPU arrangements.

Owner:ADVANCED TECH MATERIALS INC

Full dry purification and residual heat utilization equipment and method for converter gas

InactiveCN101492756ALess dustLess waterIncreasing energy efficiencyManufacturing convertersSuperheated steamMoisture

The invention provides devices for purifying converter gas by dry process and using afterheat of the converter gas and a method thereof. In a converting period, waste gas exhausted from the converter is cooled by a movable gas hood and a vaporizing cooling duct, then is sent into a gravity dust collector to reduce dust content thereof, is conducted into a flue and then to an afterburning afterheat boiler; the afterburning afterheat boiler generates overheated vapor by using large quantity of sensible heat of the converter gas and sends the converter gas after being cooled into a bag dust collector through the flue to purify; the purified converter gas is sent to a draft fan to be pressurized through the flue, then passes through a three-way valve, and is sent to a converter gas cabinet; in a non-blowing period of the converter, converter gas is not generated; afterburning afterheat boiler burns a certain amount of blast furnace gas to stabilize load thereof and vapor yield. The three-way valve is switched to cause the afterheat boiler waster gas exhausted from the draft fan to flow to a waste gas discharging chimney. The converter gas processed by the method and devices has very low dust and moisture contents and is an ideal purified gas. During the operation process, large quantity of industrial water is saved, and large quantity of secondary energy is recycled.

Owner:袁长胜

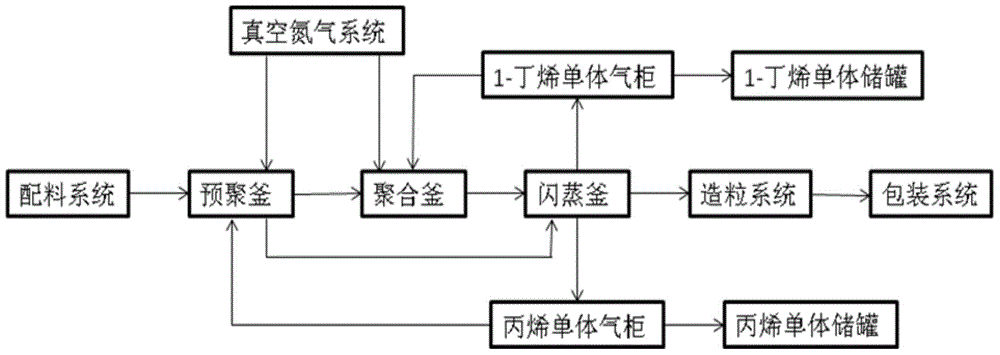

Industrial production method and device for highly isotactic polybutylene alloy

The application discloses an industrial production method and device for a highly isotactic polybutylene alloy. The production method comprises the following steps: firstly polymerizing propylene in a prepolymerization kettle at -20 to 90 DEG C to form polypropylene particles loaded with active centers, carrying out reduced pressure recovery on the unreacted propylene monomer into a propylene monomer gas cabinet, putting polypropylene loaded with active centers and 1-butene monomer into the polymerization kettle and polymerizing at -10 to 80 DEG C to obtain a granular polybutene alloy, removing partial unreacted monomer under reduced pressure, feeding the materials in the prepolymerization kettle into a flash kettle to further remove unreacted 1-butene, sequentially introducing nitrogen into the flash kettle for replacing air, discharging the granular isotactic polybutene alloy from a discharge valve arranged at the bottom of the kettle, extruding and packaging. The production device comprises a batching system, a polymerization system, a post-treatment packaging system, a vacuum nitrogen system, a degassing flash system and a utility system. By the method and the device, the industrialized synthesis of the polybutylene alloy can be achieved and the method has the advantages of no organic solvent and no waste emissions and belongs to the scope of environment-friendly clean production.

Owner:QINGDAO UNIV OF SCI & TECH +2

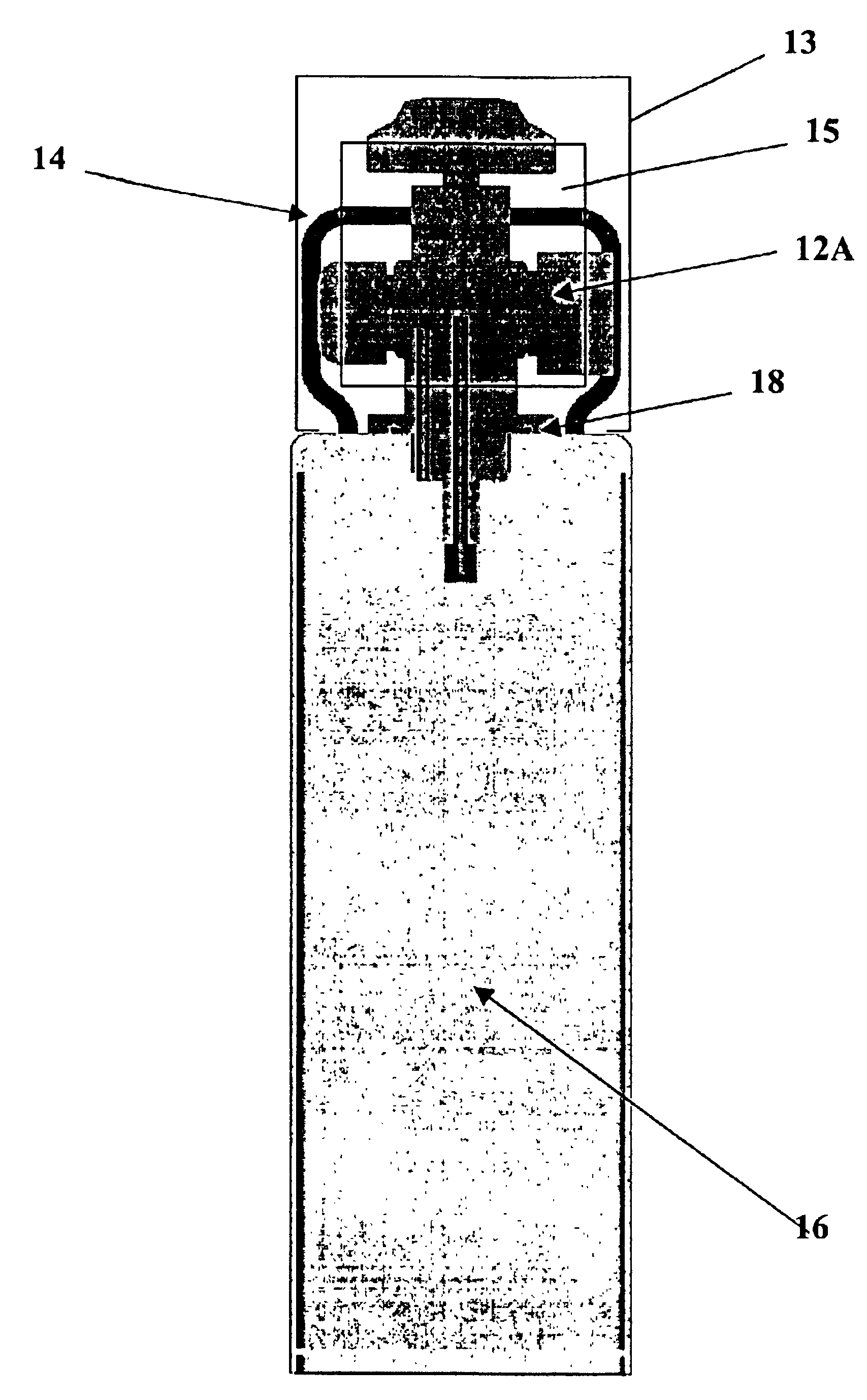

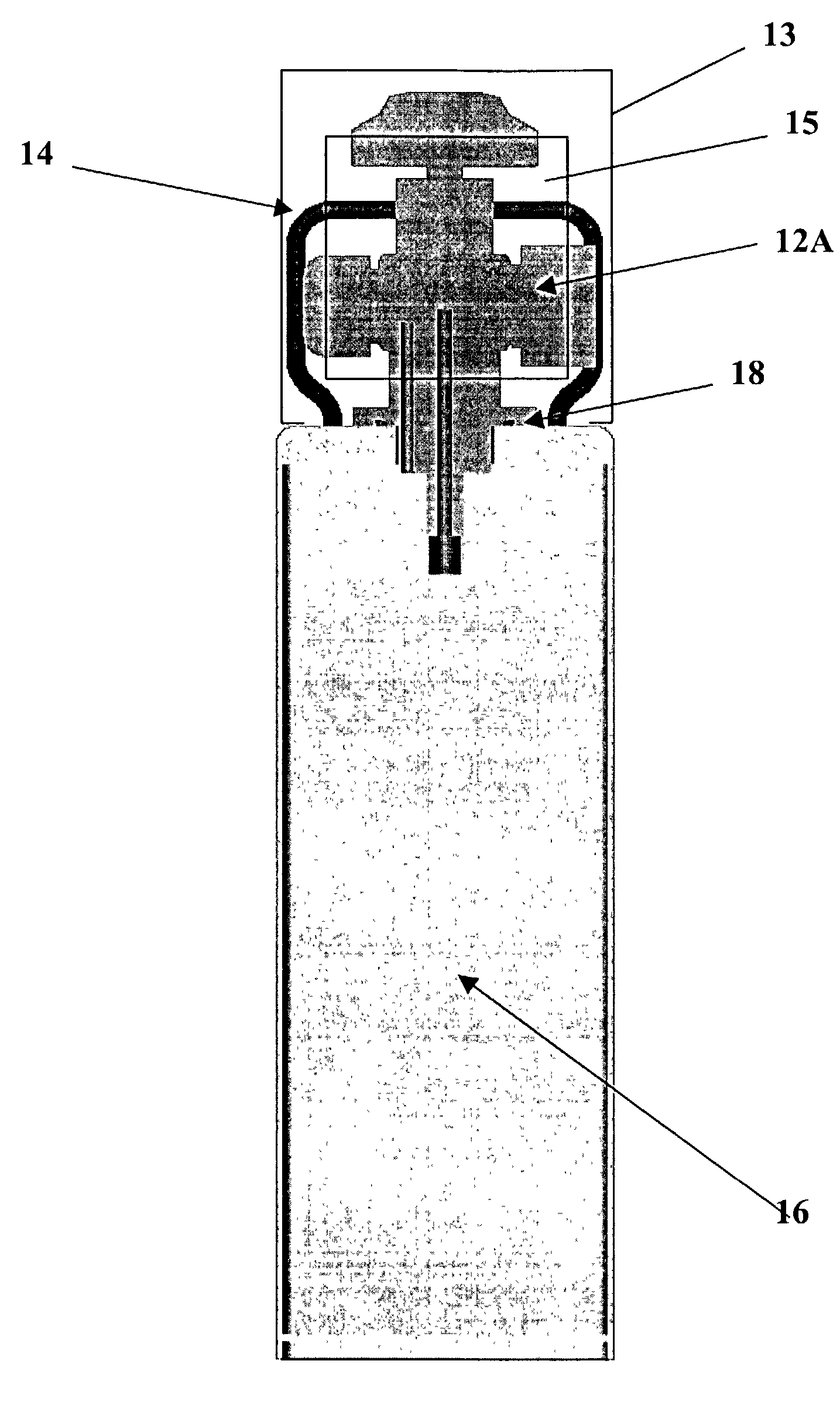

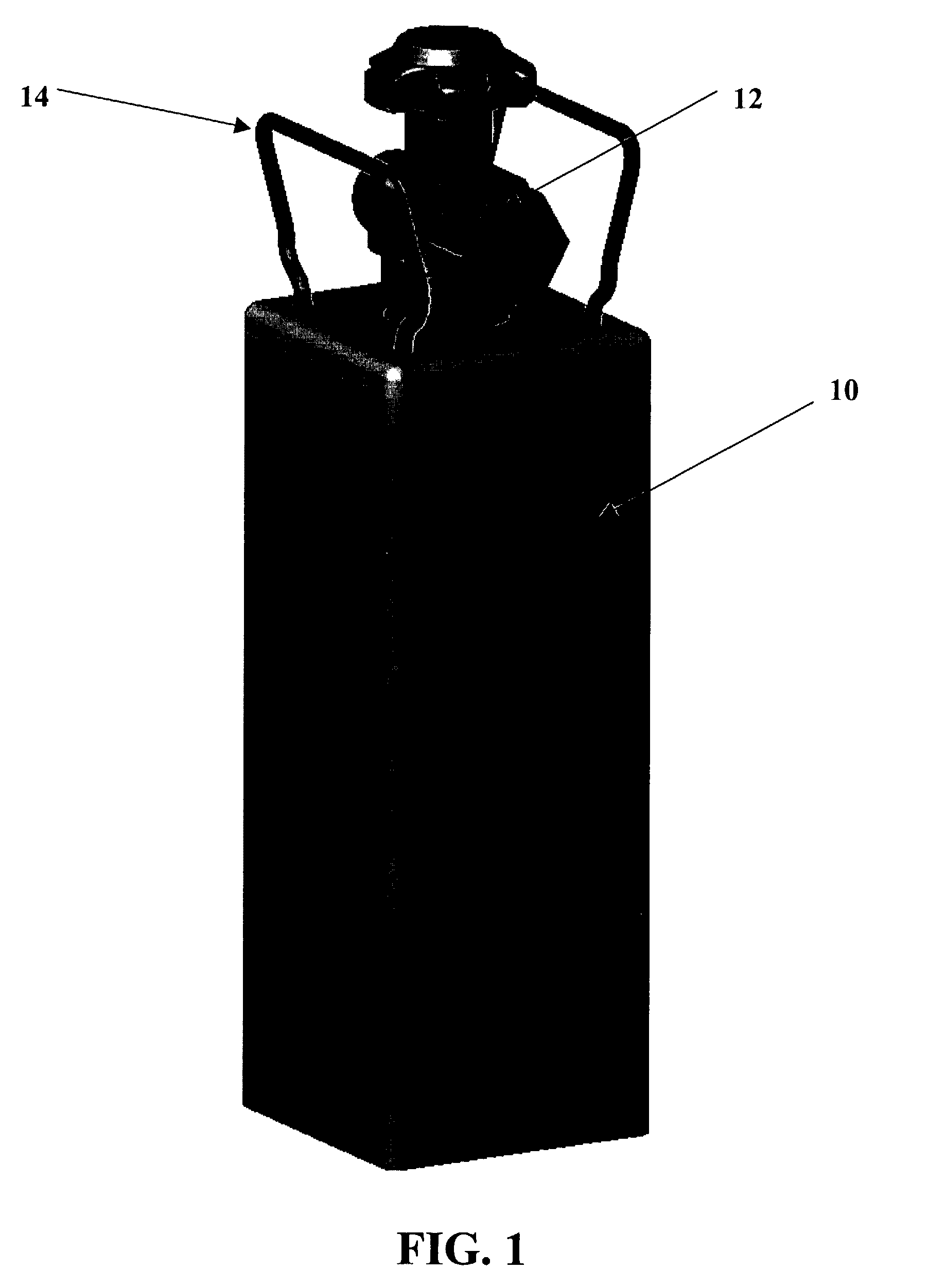

Rectangular parallelepiped fluid storage and dispensing vessel

A fluid storage and dispensing apparatus including a fluid storage and dispensing vessel having a rectangular parallelepiped shape, and an integrated gas cabinet assembly including such fluid storage and dispensing apparatus and / or a point-of-use ventilation gas scrubber in the vented gas cabinet. By the use of physical adsorbent and chemical sorbent media, the gas cabinet can be enhanced in safety of operation, e.g., where the process gas supplied from the gas cabinet is of a toxic or otherwise hazardous character.

Owner:ENTEGRIS INC

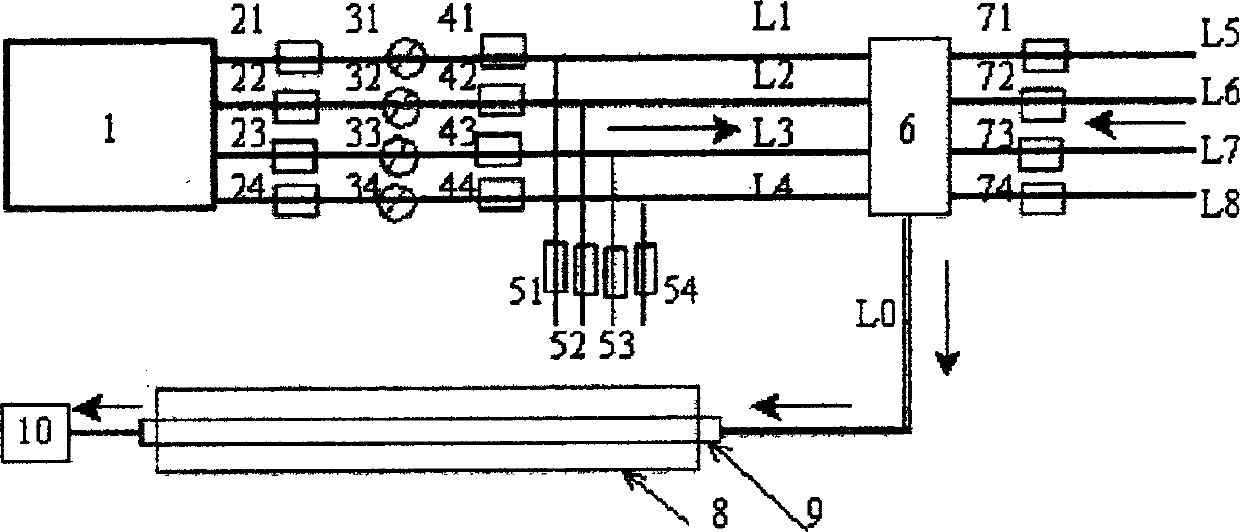

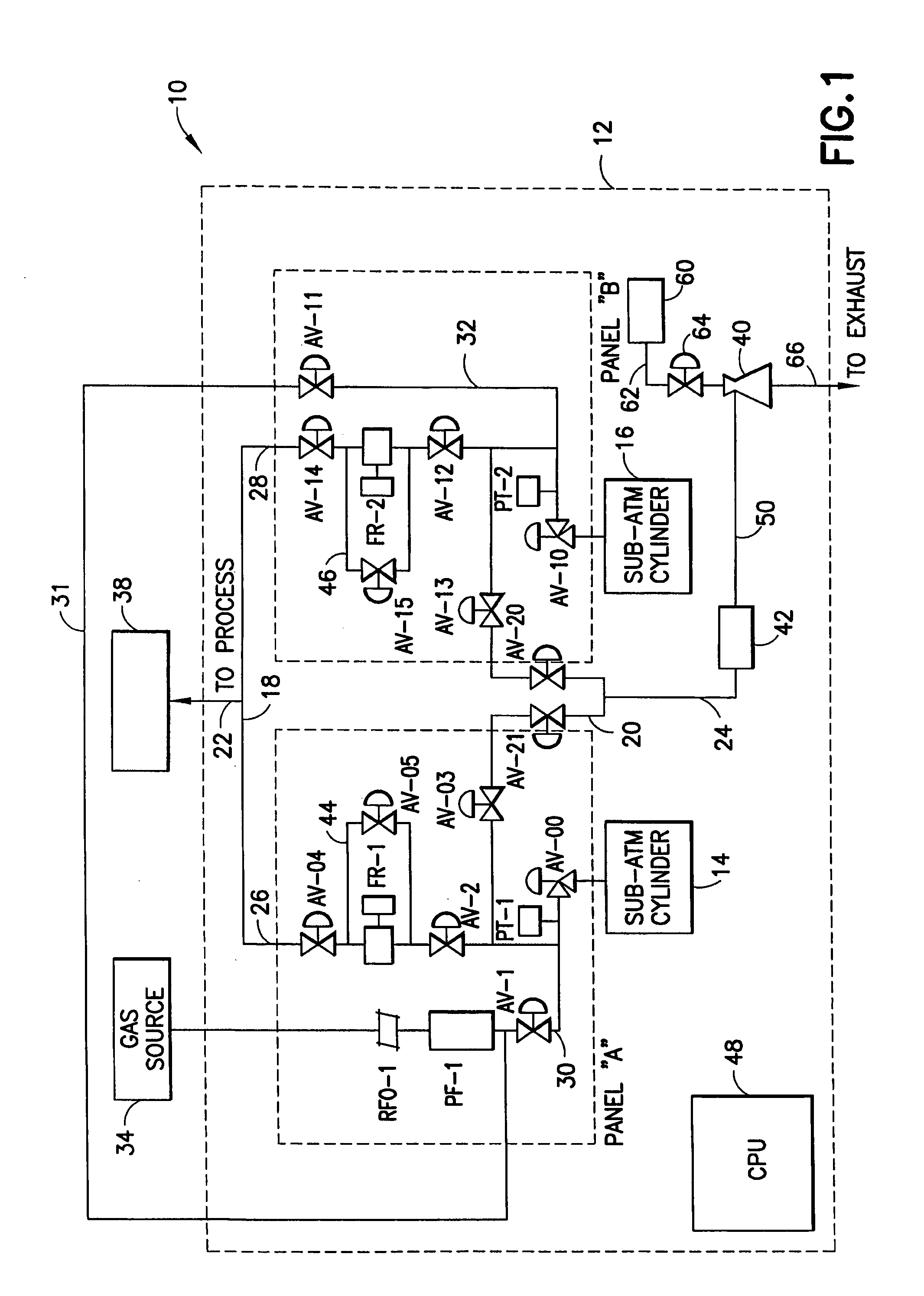

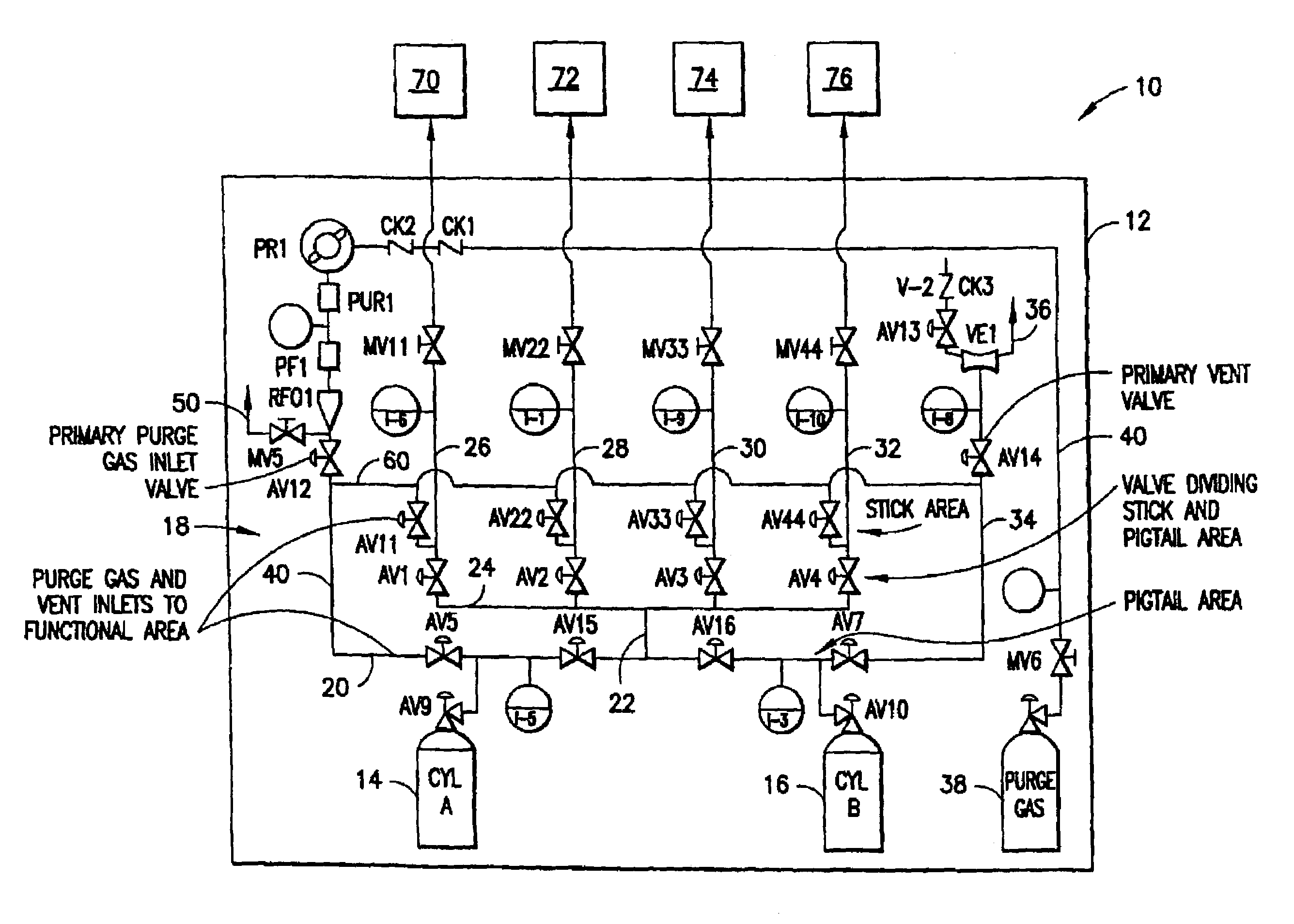

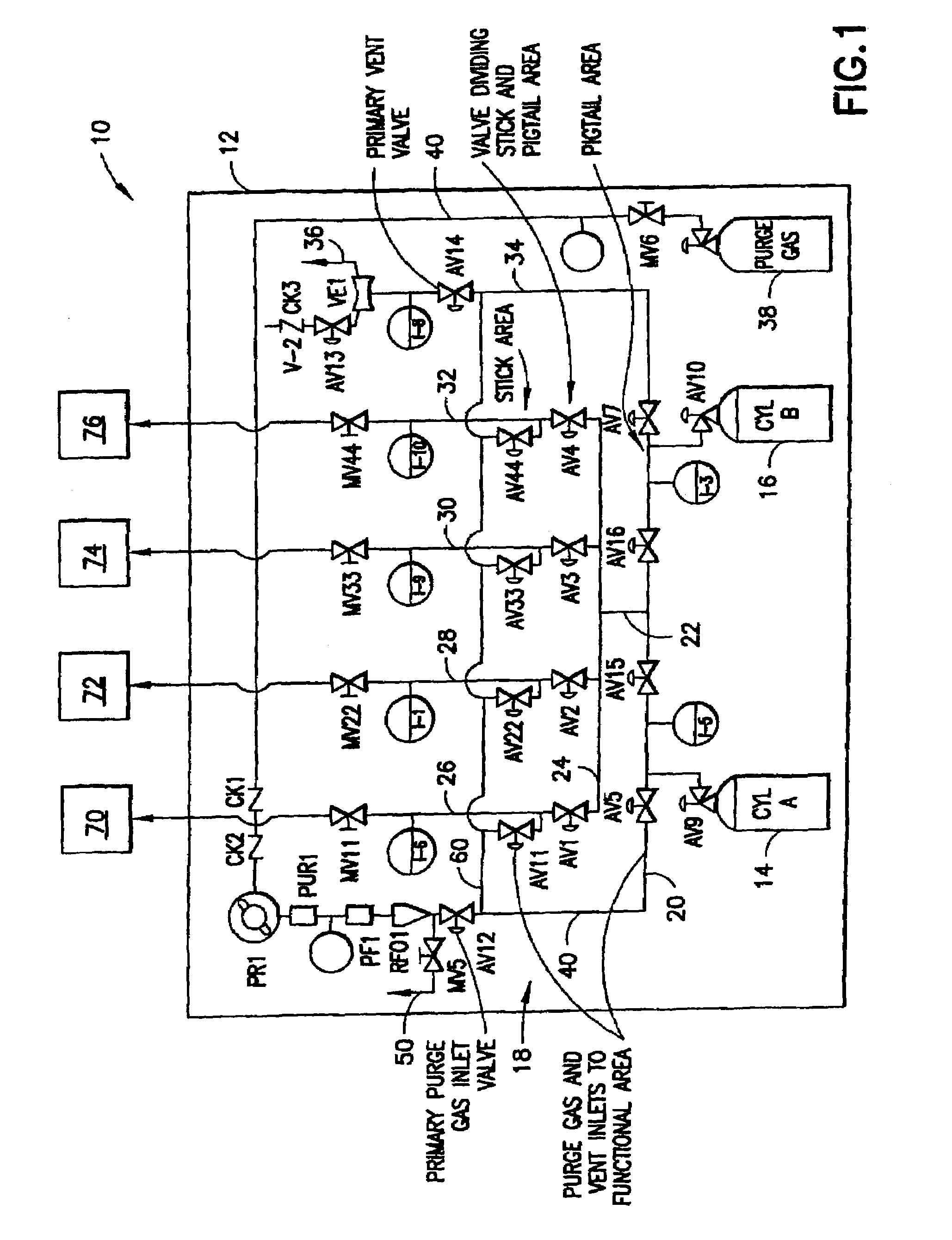

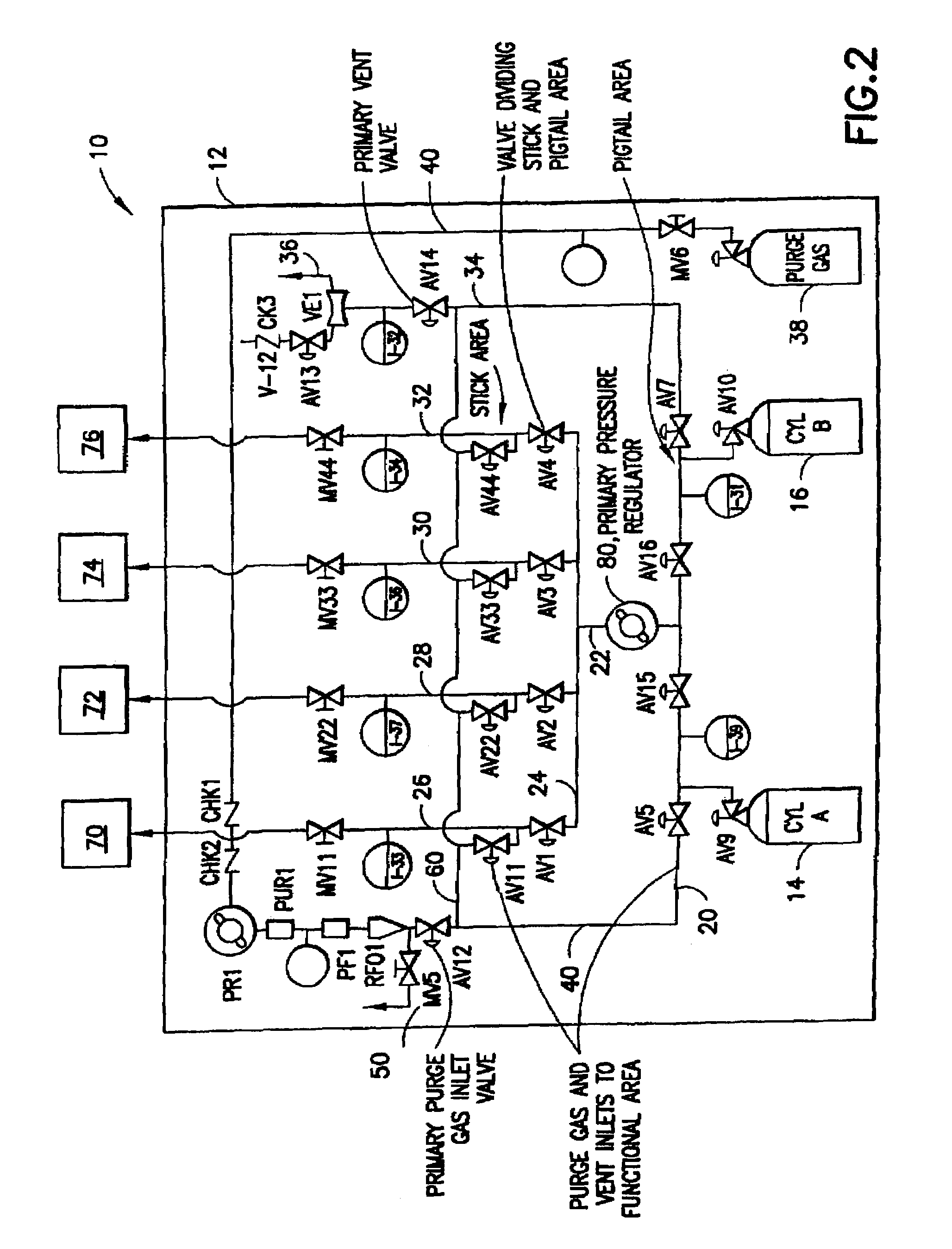

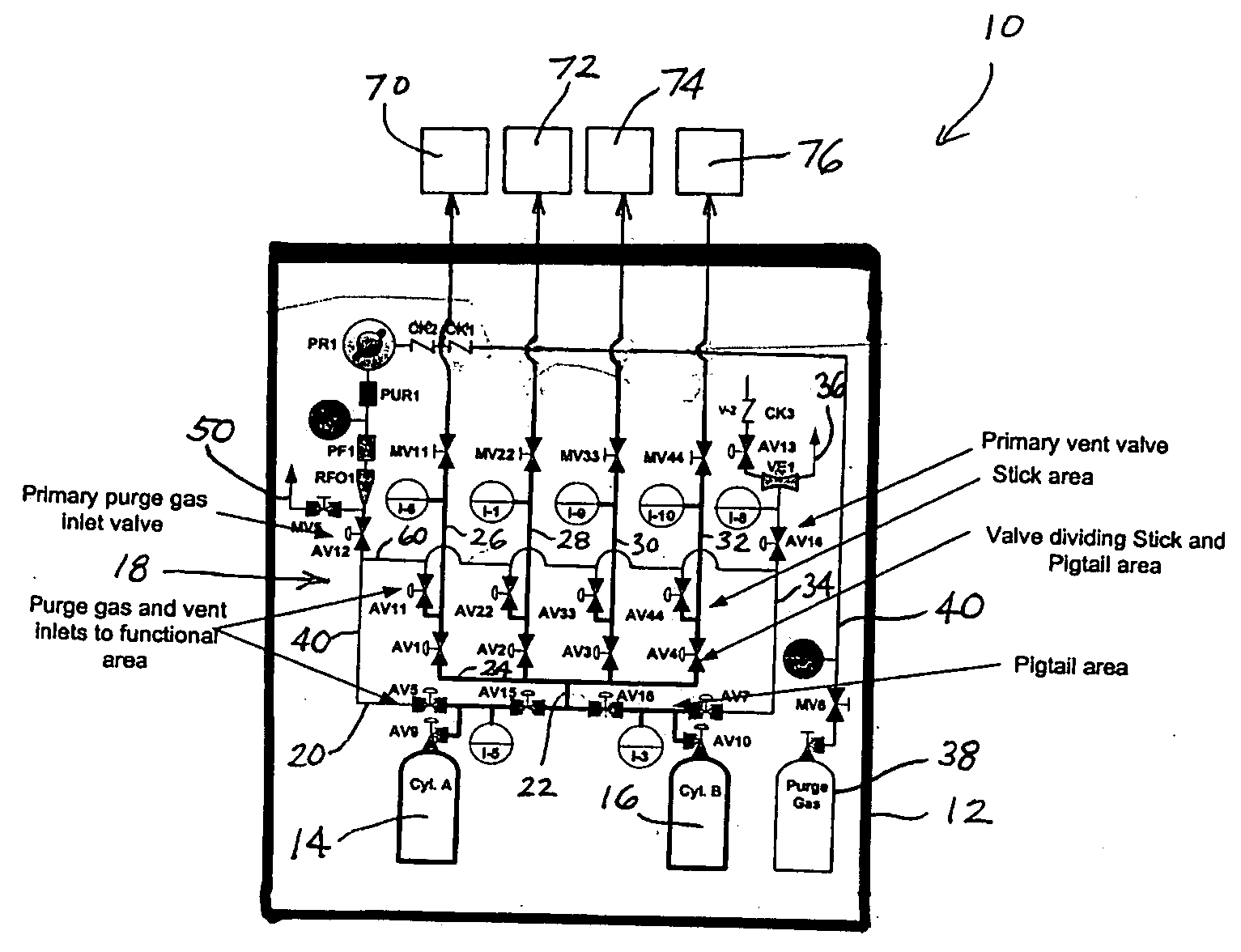

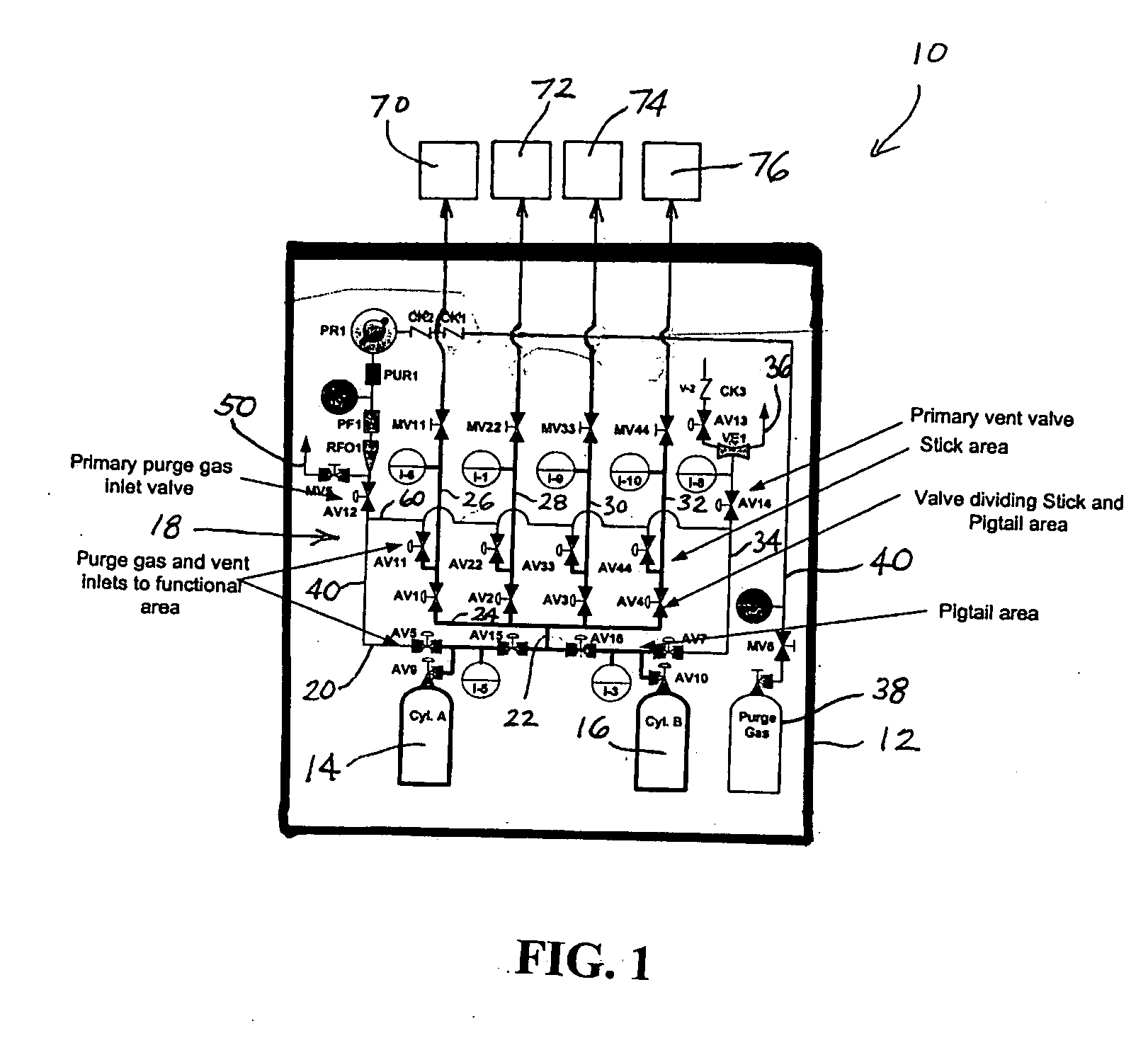

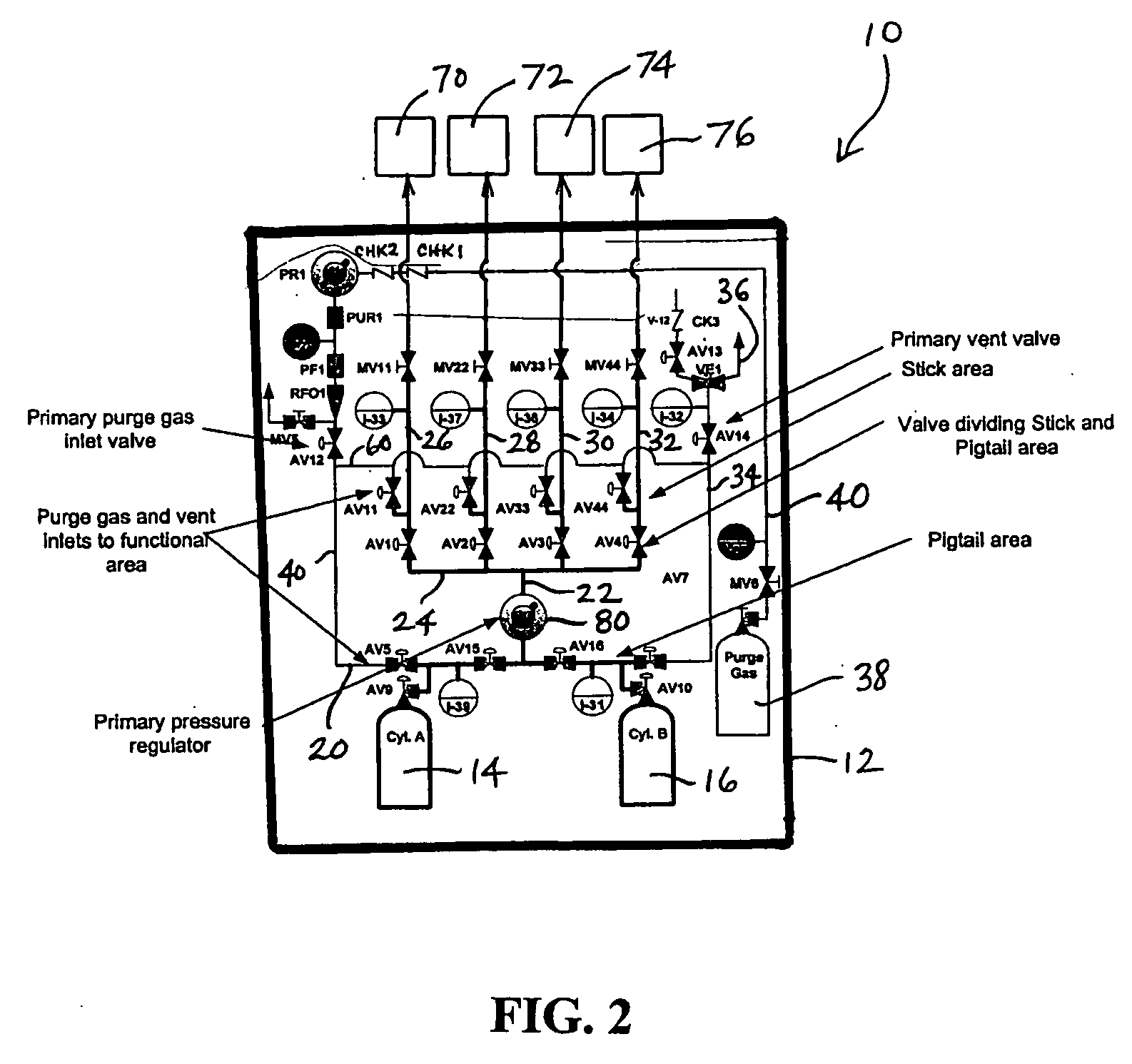

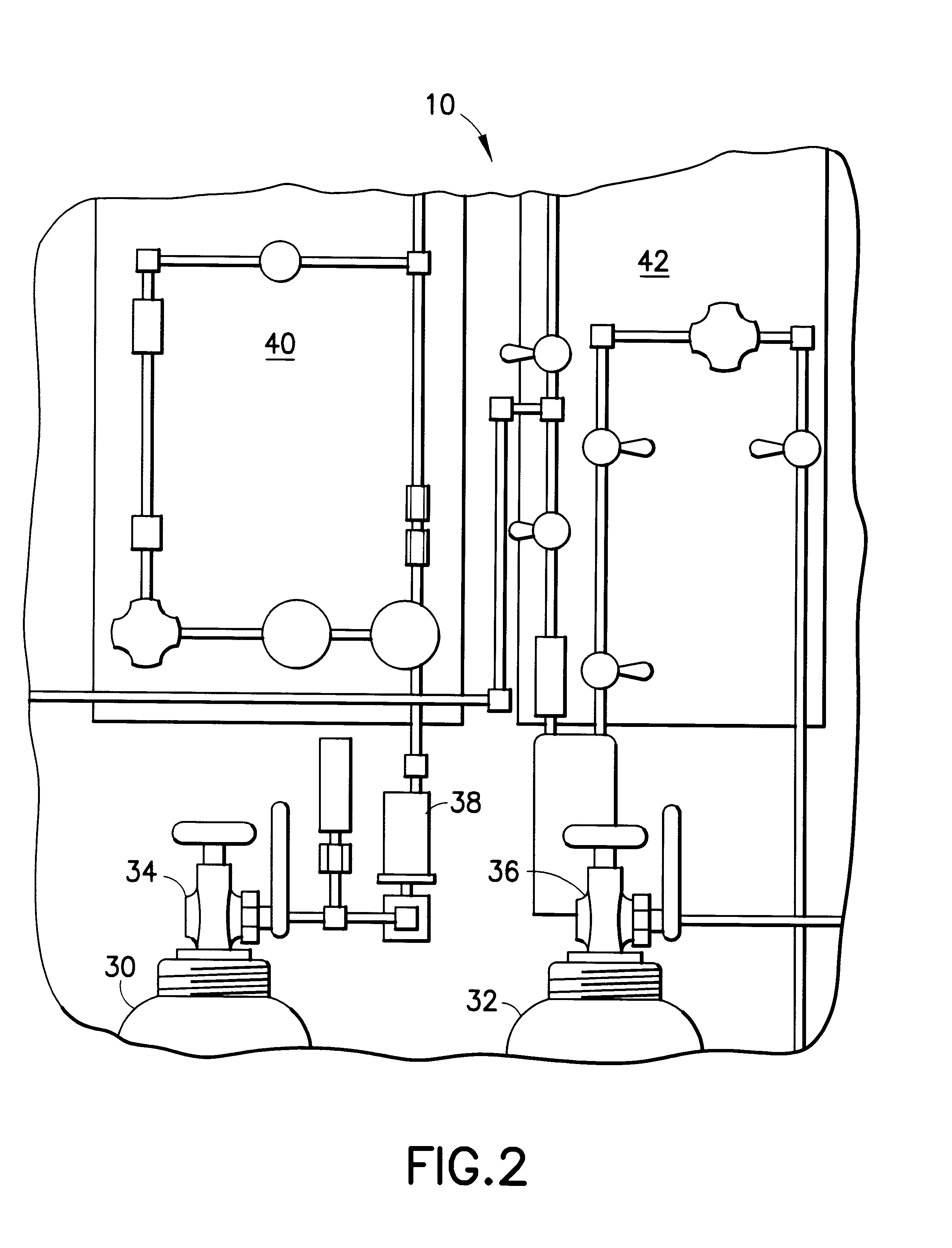

Gas delivery system with integrated valve manifold functionality for sub-atmospheric and super-atmospheric pressure applications

A gas cabinet including an enclosure containing at least one gas supply vessel and flow circuitry coupled to the gas supply vessel(s). The flow circuitry is constructed and arranged to flow dispensed gas from an on-stream gas supply vessel to multiple sticks of the flow circuitry, with each of the multiple sticks being joined in gas flow communication to a respective gas-utilizing process unit. The flow circuitry is valved to enable sections of the flow circuitry associated with respective ones of the multiple sticks to be isolated from other sections of the flow circuitry, so that process gas can be flowed to one or more of the sticks, while other sticks are being evacuated and purged, or otherwise are closed to dispensed gas flow therethrough.

Owner:ADVANCED TECH MATERIALS INC

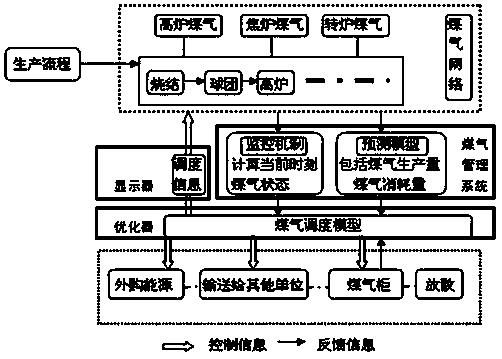

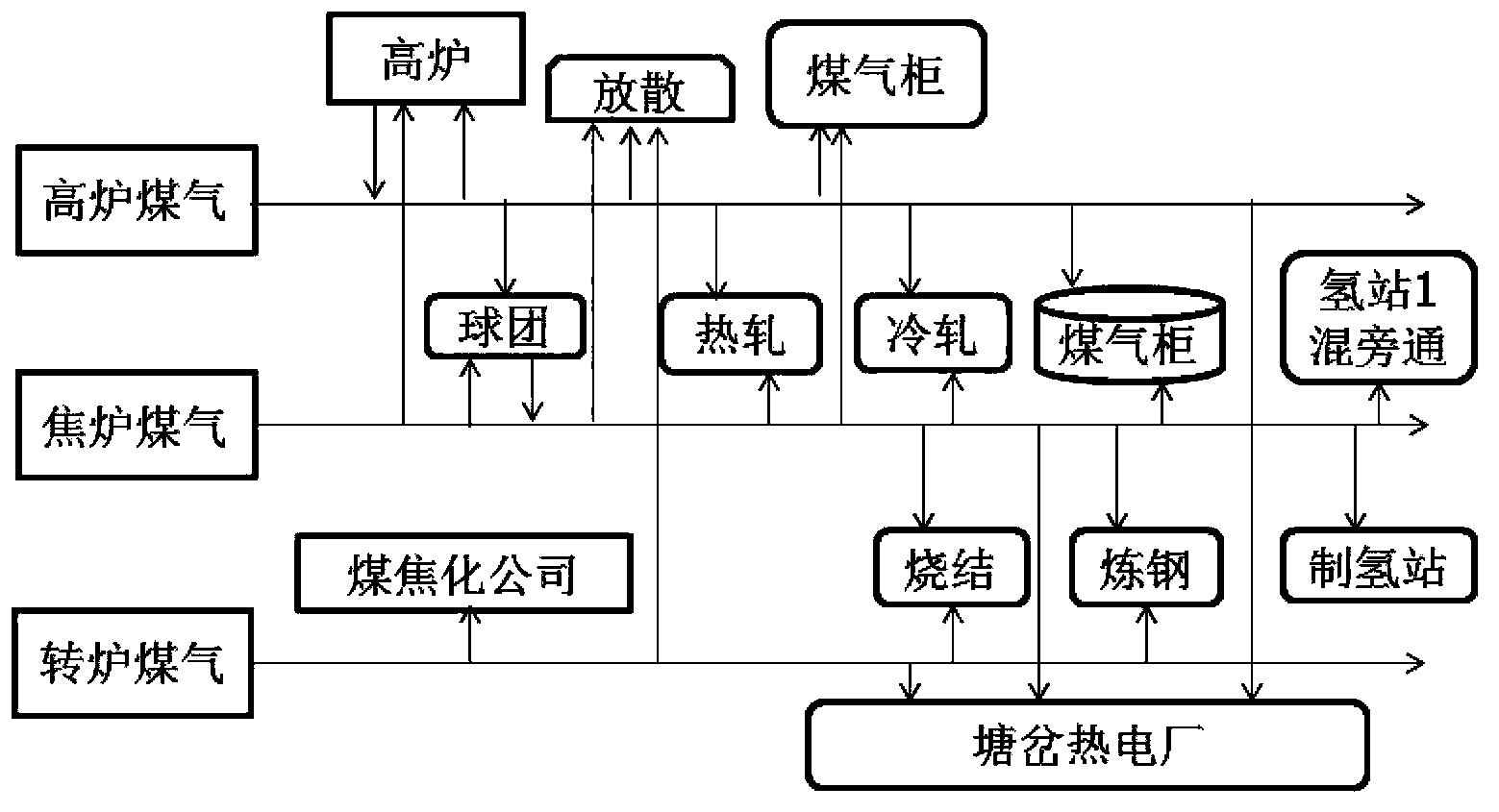

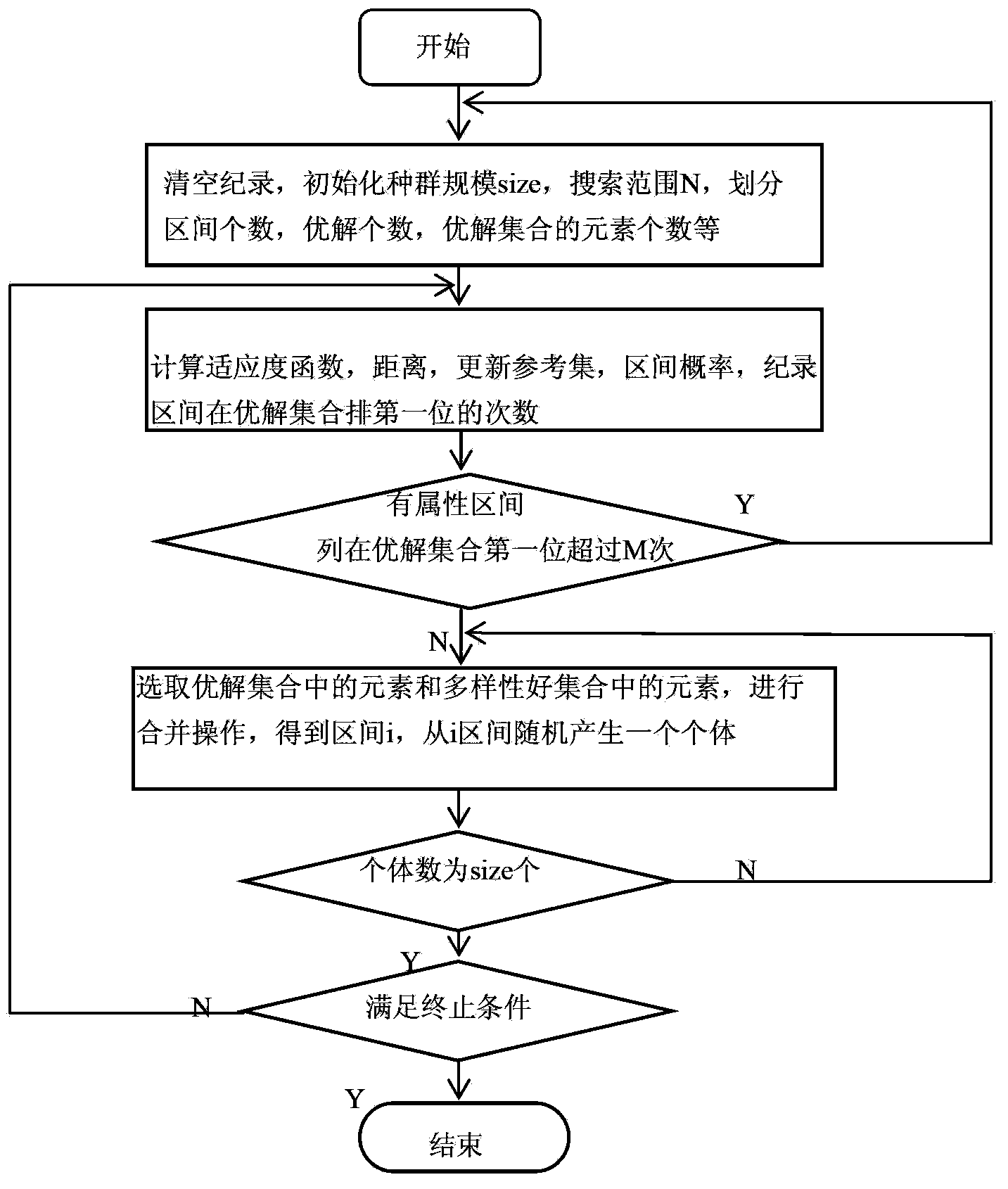

Gas optimization scheduling device of iron and steel enterprise

InactiveCN103439926AEmission reductionReduce purchasesEnergy industryTotal factory controlDisplay devicePurchasing

The invention relates to a gas optimization scheduling device of an iron and steel enterprise. The scheduling device is connected with an energy management system and comprises a gas managing device, an optimizing device and a display device, wherein the gas managing device, the optimizing device and the display device are sequentially connected. The gas managing device acquires gas consumption amount historical data, gas generation amount historical data and storage amount data of a gas cabinet in each procedure through the energy management system of the enterprise to predict the production amount and the consumption amount of gas at present or in future; on the basis of the predicted data, the optimizing device adopts improved distribution estimation algorithms to optimize distribution of the gas, and the optimization principle aims to make the scattering amount smallest and the purchasing amount largest; the display device displays the gas distribution scheme obtained by the optimizing device for reference of users, so that the gas can be reasonably distributed. Compared with the prior art, the gas optimization scheduling device has the advantages of reducing the scattering amount and the purchasing amount of the gas and the like.

Owner:TONGJI UNIV

Safe and high-efficiency recovery method for converter gas

ActiveCN101812562ALower oxygen levelsGuaranteed oxygen contentManufacturing convertersRecovery methodGranularity

The invention relates to a safe and high-efficiency recovery method for converter gas. The converter gas generated in the smelting process of a converter is subjected to temperature reduction and dust extraction and enters a gas storage cabinet, wherein when the converter gas is recovered, a carbon material is blown into a vaporization cooling flue through a spray gun or is blown between the converter and the vaporization cooling flue; blown carrier gas is nitrogen, the flow rate of the nitrogen is 0.1 to 0.25 m<3> / kg of carbon material, and the blowing amount of the carbon material is 0.04 to 0.08 kg / m<3> of the converter gas; and the carbon material is pulverized anthracite or coke powder of which the granularity is below 300 meshes. The method has the advantages of improving the yield and quality of the recovered converter gas obviously, increasing the recovery volume of the gas per ton by 10 to 17 percent, improving the unit heat value by 14 and 20 percent and reducing oxygen content by 40 to 80 percent, along with strong practicability, safety, reliability, stable control and broad market prospects.

Owner:武汉市赟巨科技有限公司

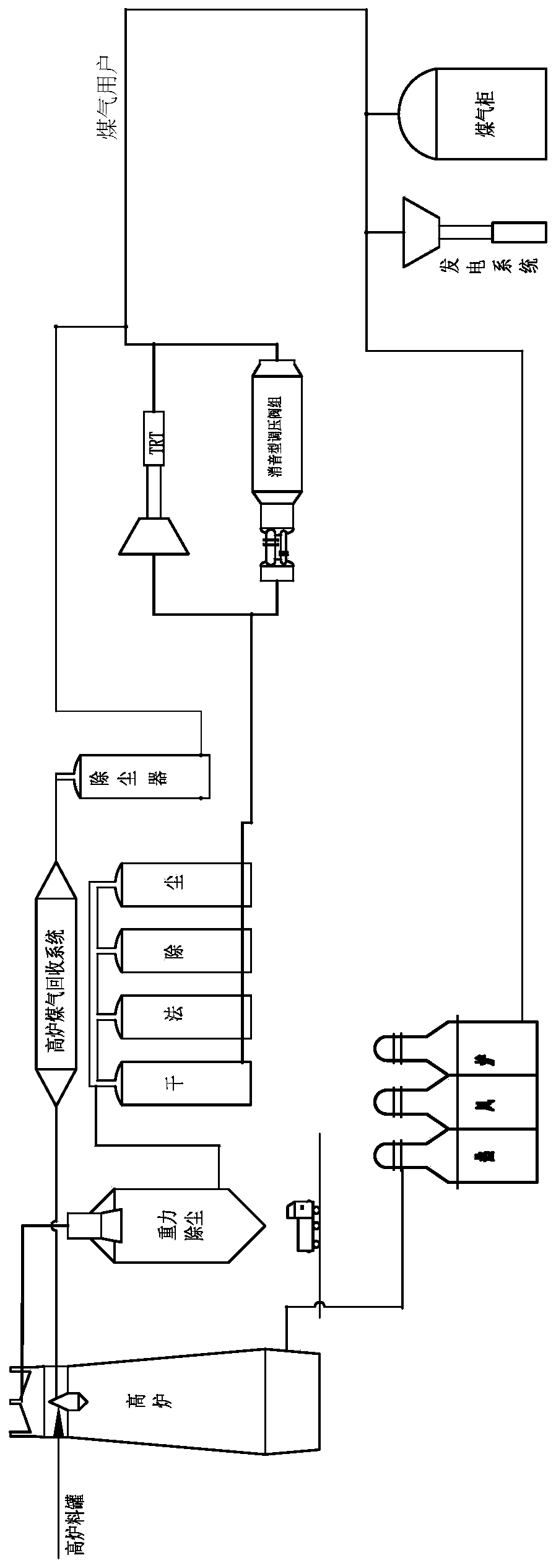

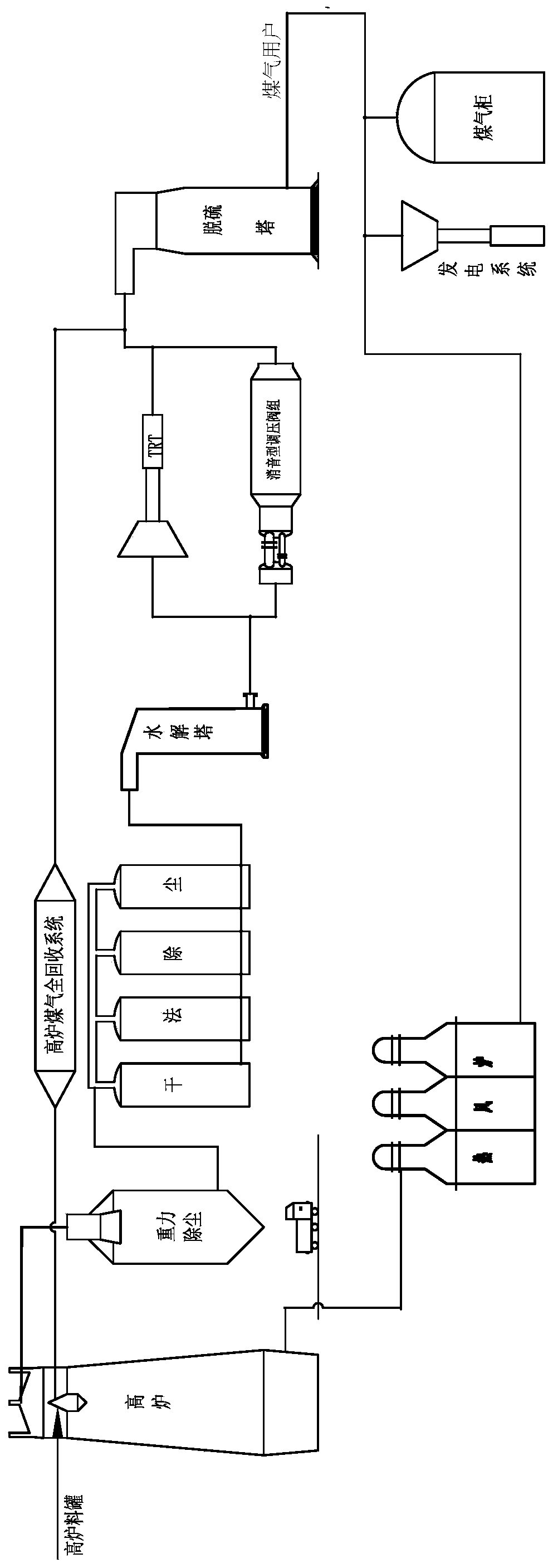

System and technology for environmentally-friendly comprehensive treatment of iron making blast furnace gas

PendingCN110452744AEfficient removalGroundbreakingBlast furnace detailsDust arrestersFull recoveryMetallurgy

The invention provides a system and a technology for environmentally-friendly comprehensive treatment of iron making blast furnace gas. The system comprises a blast furnace top uniform pressure gas full-recovery system, a gravity deduster and a dry bag filter, and further comprises a blast furnace gas hydrolysis tower and a blast furnace gas desulfurization tower. The blast furnace gas goes through the gravity deduster and the dry bag filter, and then is conveyed into the blast furnace gas hydrolysis tower, COS in the blast furnace gas is hydrolyzed by the blast furnace gas hydrolysis tower toform H2S; the treated blast furnace gas goes through a TRT / or pressure regulating valve group, and then is conveyed into the blast furnace gas desulfurization tower, and the blast furnace gas desulfurization tower desulfurizes and dechlorinates H2S and Cl<-> in the blast furnace gas; and the treated blast furnace gas is conveyed into a blast furnace gas user or is stored in a gas cabinet througha gas pipe network. The integral treatment technology which integrates blast furnace gas desulfurization, dechlorination and blast furnace top uniform pressure gas recovery has a high integration degree, and can run stably and reliably.

Owner:LOFON CONTROL EQUIP BEIJING

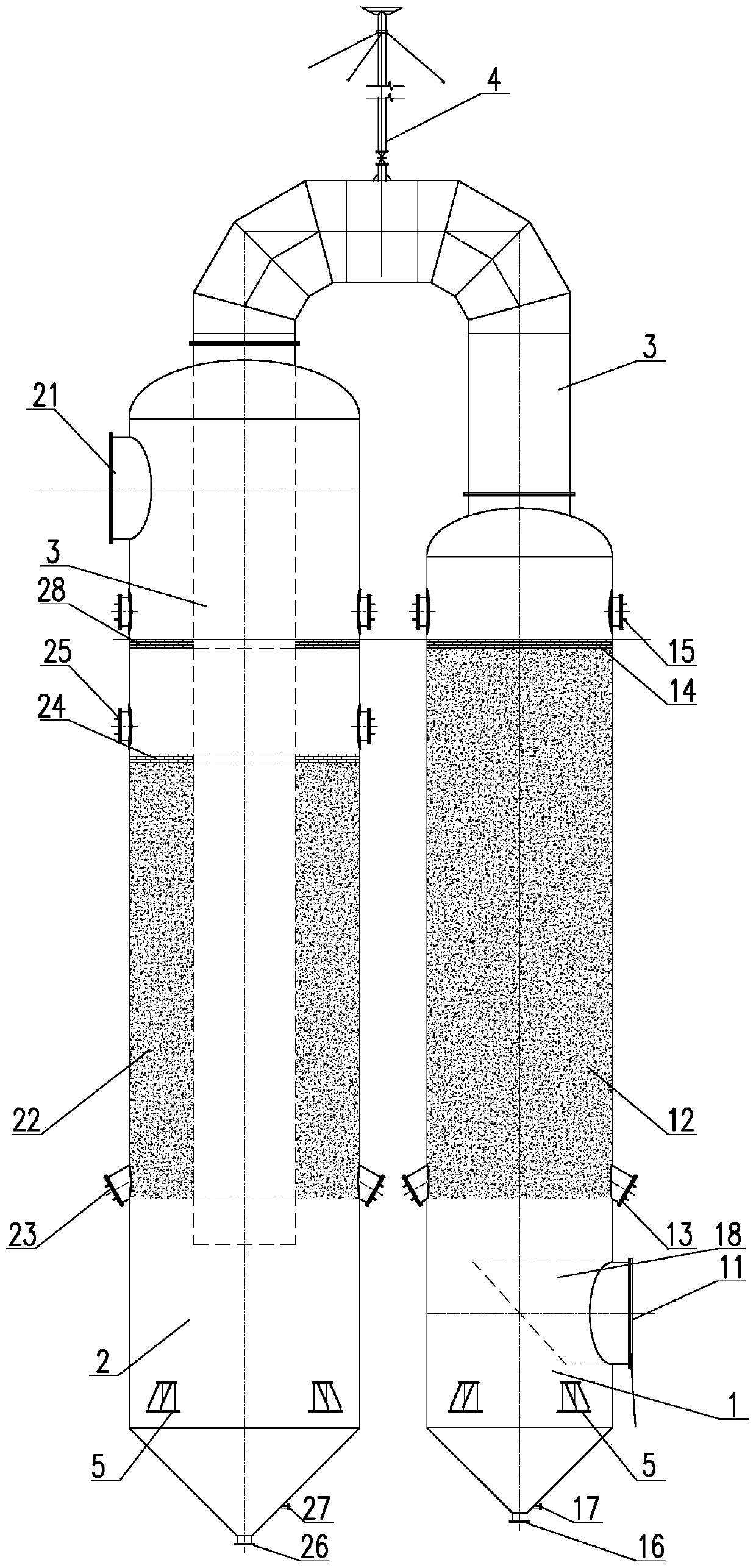

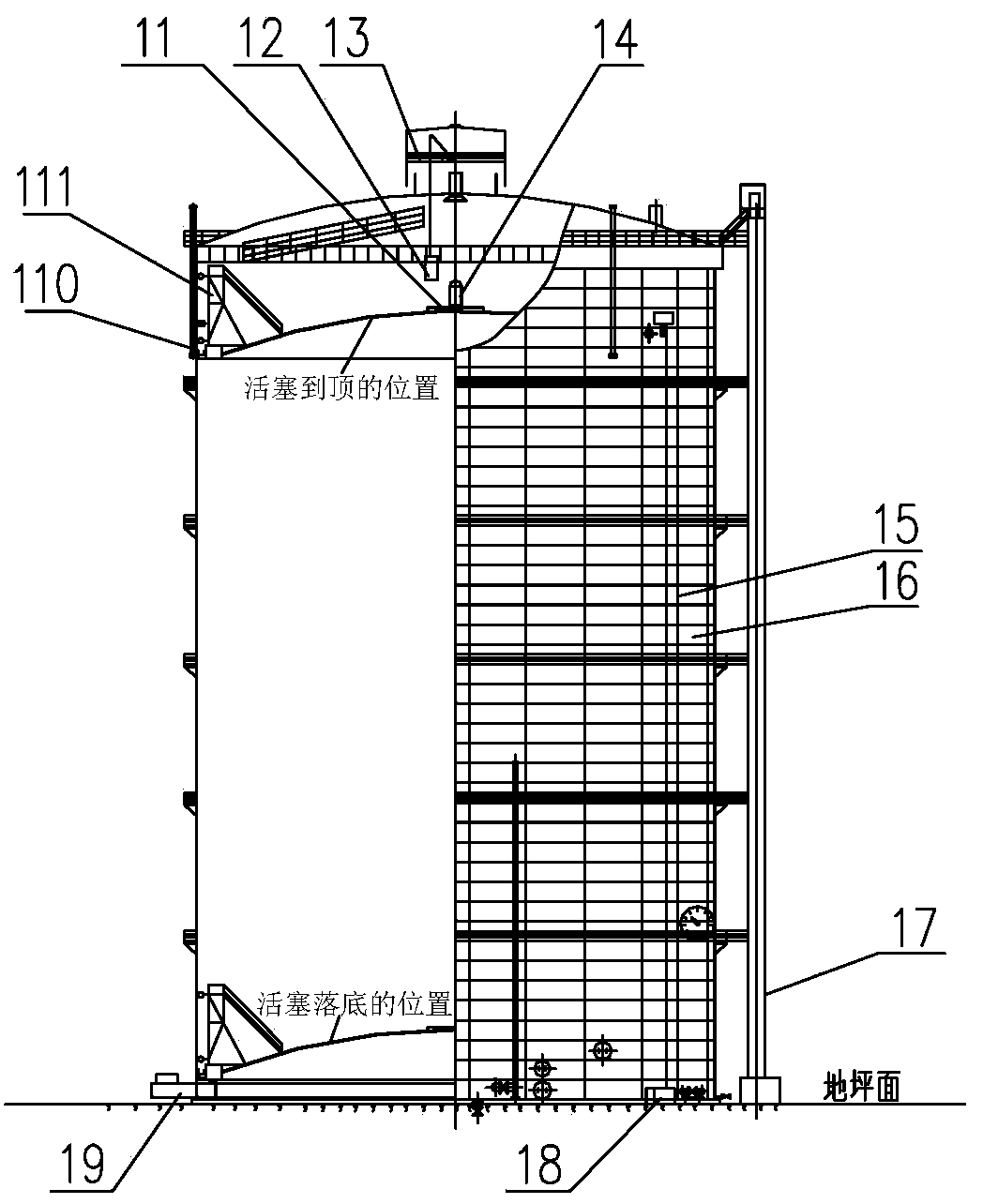

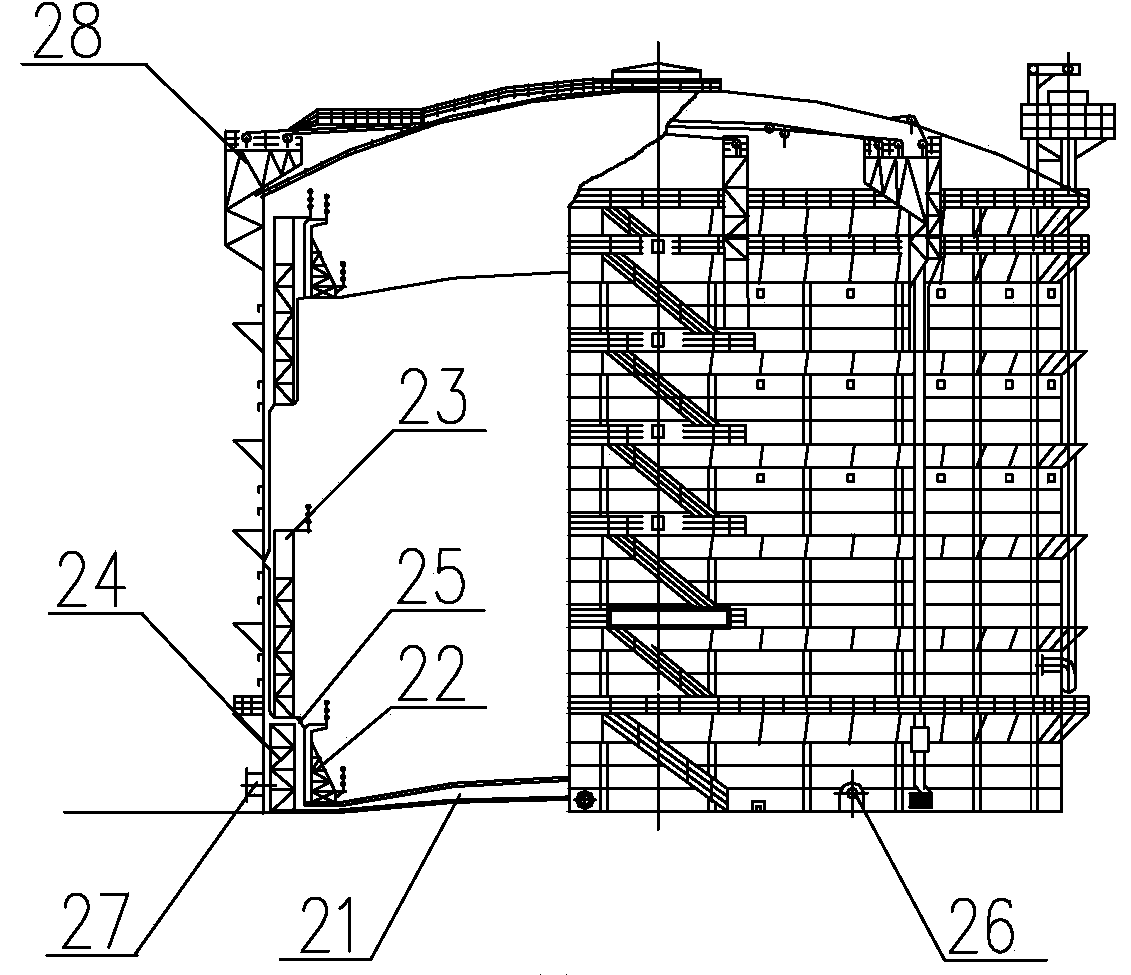

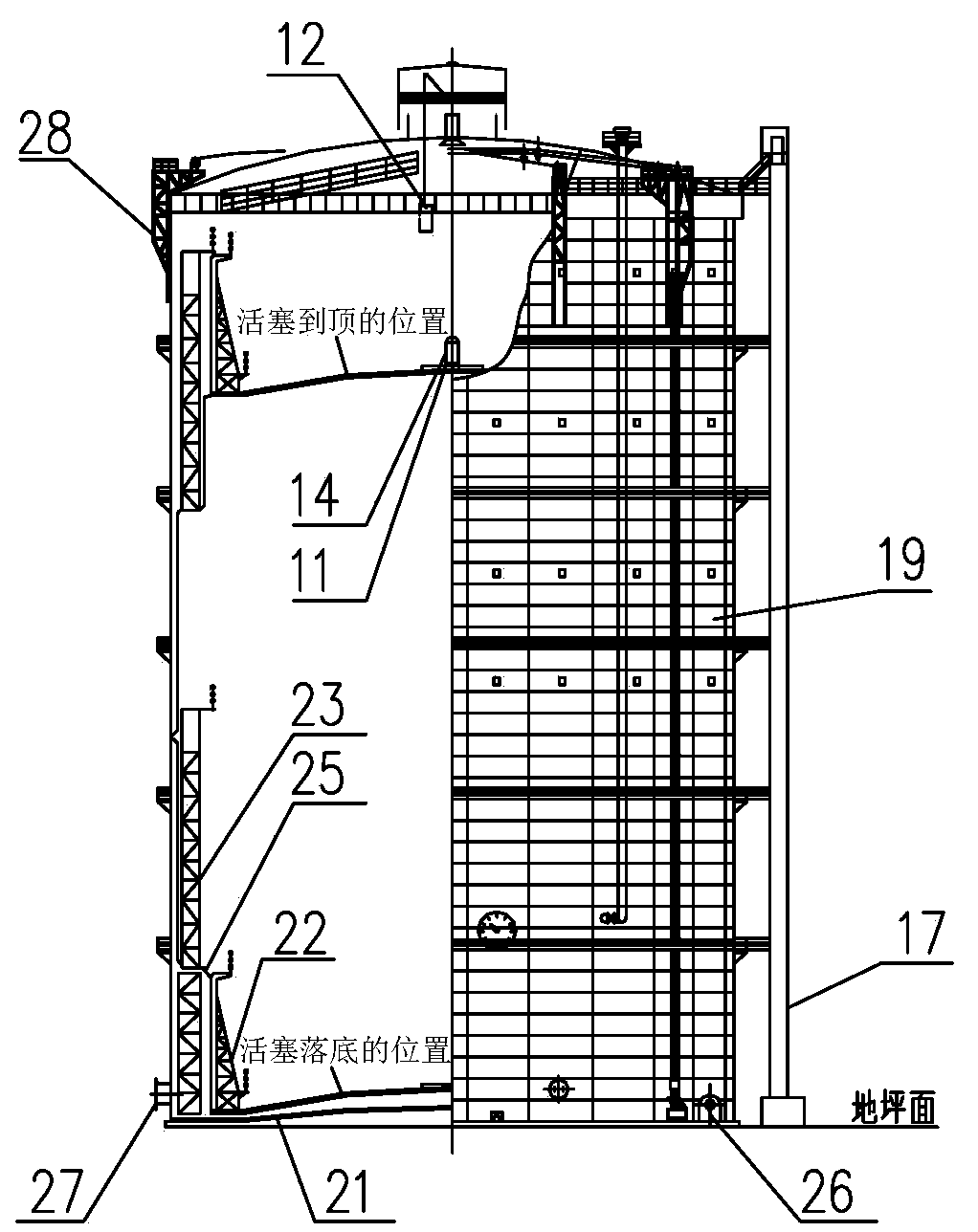

Reconstructing method for round dry and thin oil sealed dry type gasholder

ActiveCN104006287AGood effectSave engineering costVariable capacity gas holdersUltimate tensile strengthStructural stability

The invention discloses a reconstructing method for a round dry and thin oil sealed dry type gasholder. The reconstructing method is to reconstruct the round dry and thin oil sealed dry type gasholder into a rubber film sealed dry type gasholder, and comprises the steps of: 1, tearing down gasholder accessories inside the round dry and thin oil sealed dry type gasholder; 2, reconditioning the foundation into a structure suitable for the rubber film sealed dry type gasholder by regarding the diameter of the round dry and thin oil sealed dry type gasholder as the benchmark; 3, mounting a structural parts in the round dry and thin oil sealed dry type gasholder. The reconstructing method for the round dry and thin oil sealed dry type gasholder greatly saves engineering cost and engineering time, and compared with common gasholders of the same type, the reconstructed rubber film sealed dry type gasholder is higher in structural stability and intensity.

Owner:WISDRI ENG & RES INC LTD

Gas delivery system with integrated valve manifold functionality for sub-atmospheric and super-atmospheric pressure applications

A gas cabinet including an enclosure containing at least one gas supply vessel and flow circuitry coupled to the gas supply vessel(s). The flow circuitry is constructed and arranged to flow dispensed gas from an on-stream gas supply vessel to multiple sticks of the flow circuitry, with each of the multiple sticks being joined in gas flow communication to a respective gas-utilizing process unit. The flow circuitry is valved to enable sections of the flow circuitry associated with respective ones of the multiple sticks to be isolated from other sections of the flow circuitry, so that process gas can be flowed to one or more of the sticks, while other sticks are being evacuated and purged, or otherwise are closed to dispensed gas flow therethrough.

Owner:ADVANCED TECH MATERIALS INC

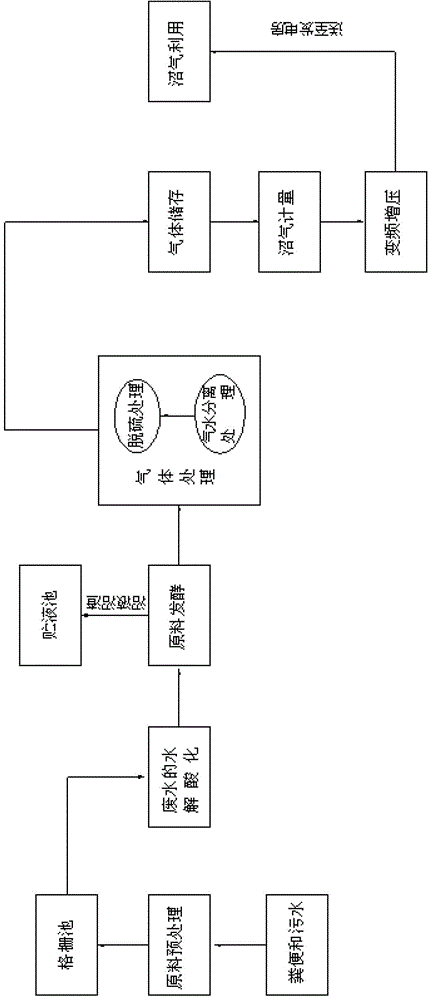

Method for producing biogas in large biogas project

InactiveCN103145308AImprove sanitationEmission reductionWaste based fuelMultistage water/sewage treatmentChemical oxygen demandHydrolysis

The invention discloses a method for producing biogas in a large biogas project, and relates to the field of biogas projects. The method specifically comprises the following steps of: (1) conveying pig manure and wastewater to a wastewater treatment station, and filtering sands and suspensions in pig manure through a grating tank; (2) conveying treated pig manure and wastewater to a hydrolysis acidification pool to dilute and stir so as to improve the biodegradability of wastewater and removing COD (Chemical Oxygen Demand) in wastewater; (3) conveying raw materials treated by the step (2) to a fermenting chamber through a feeding pump to hermetically ferment so as to product biogas; (4) treating biogas produced by the step (3) through a gas-water separator and a desulfurizing tower device; (5) collecting biogas treated by the step (4) to a gas storage cabinet; and (6) metering biogas stored by the step (5) through a biogas flowmeter, pressurizing by a frequency conversion pressurizing device, conveying the biogas to a generator room to generate electricity so as to solve electricity for production and living in farms. The method provided by the invention has the advantages of saving the energy resource, improving the environment, enhancing the fertilizer effect, improving the soil, accelerating the development of breeding industry, saving the labor force and the like, so that the method is an energy-saving and environmental-friendly green project.

Owner:ANHUI YU WANG CULTURE

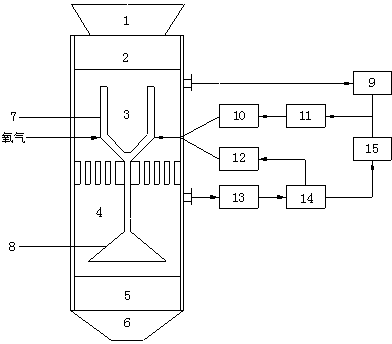

Gasification system of garbage and organic waste and device thereof

InactiveCN101560408AEliminate pollutionIncrease the low calorific valueWaste based fuelCombined combustion mitigationHydrogenGas phase

The invention discloses a gasification system of garbage and organic waste and a device thereof, and relates to a garbage treatment device. The gasification system mainly consists of a blast drier, a gas phase circulation gasification furnace, a dusting / purification device, a compressor, a gas receiver and connection pipelines, wherein, the gasification furnace is equipped with a baking zone, a pyrolysis zone, a first gasification zone, a second gasification zone, a burnout zone and a heat storage chamber, a recirculating blower and a recirculating wind pipeline form a gas phase circulation loop outside the furnace. In the system, a discharge port of the blast drier is connected to a feed inlet of the gasification furnace, a synthesis gas output interface of the gasification furnace is connected to the dusting / purification device by an induced draft fan, the dusting / purification device is connected to the compressor, and the compressor is connected to the gas receiver. The system utilizes a technical measure of arranging the heat storage chamber in a gas phase circulation gasification furnace to enhance gasification rate and quality of refuse fuel and decompose dioxin with severe toxicity and eliminate coke tar, convert garbage and organic waste into secondary clean energy which comprises producer city coal gas, hydrogen, methanol and dimethyl ether liquefied gas.

Owner:周开根

Waste heat recovery system of exhaust gas of metallurgical converter

InactiveCN101694352ASmooth circulationRaise the discharge heightManufacturing convertersIncreasing energy efficiencyWaste heat recovery unitCombustion chamber

The invention discloses a waste heat recovery system of exhaust gas of a metallurgical converter, which comprises a CO detector, a three-way valve, a burning chamber, a burner and an exhaust smokestack and is characterized in that a waste heat recovery boiler is arranged between the exhaust smokestack and the burning chamber. In the system, when the gas concentration of the converter is lower than 30% and the gas cannot enter a gas cabinet, exhaust energy is recovered; by arranging the waste heat recovery boiler on the bottom of an exhaust chimney as well as heating softened water by heat generated by burning the gas, the heat valve of the gas of the converter is fully recovered, and the generated saturated steam can be used for production and life.

Owner:无锡市东方环境工程设计研究所有限公司

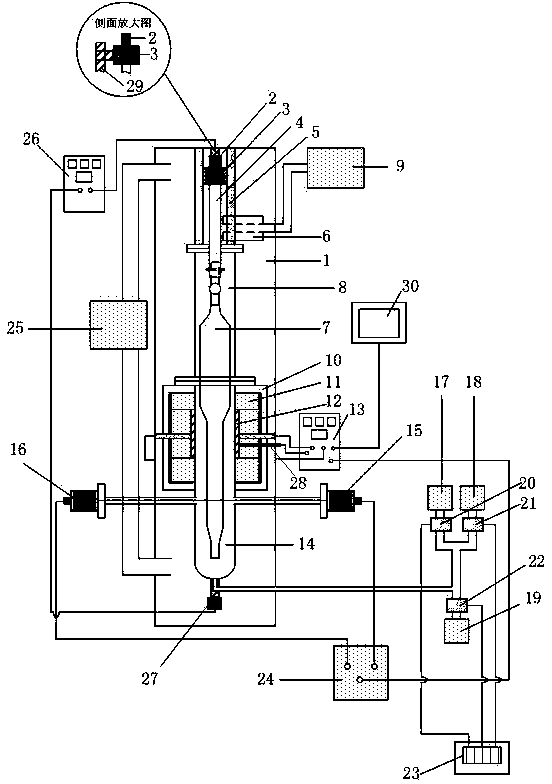

Sintering method of optical fiber preform and equipment thereof

ActiveCN103739194AReal-time access to transparencyTransparency can be adjusted online in real timeGlass making apparatusLaser transmitterLoop control

The invention relates to a sintering method of optical fiber preform and equipment thereof. The invention relates to the field of optical fiber perform sintering, and particularly relates to a method and equipment which utilize a laser feedback control system for adjusting the temperature of a sintering furnace in a sintering process in real time so as to realize the closed-loop control over the sintering process. The equipment comprises a tower body, a motor I, a chuck, a quartz derrick, a guide rail, a gas suction port, powder perform, a quartz chamber, a washing tower, a furnace body, a heat insulation material, a heating body, a temperature control cabinet, a quartz furnace core pipe, a laser transmitter, a laser receiver, a Cl2 gas holder, a He gas holder, an N2 gas holder, a Cl2 mass flow controller, a He mass flow controller, an N2 mass flow controller, an MFC (Microfunction Circuit) flow control cabinet, a laser control cabinet, an air exhaust and supply controller, a motor control cabinet, a motor II, a thermocouple, a lead screw and a control computer.

Owner:ZHONGTIAN TECH ADVANCED MATERIALS CO LTD +2

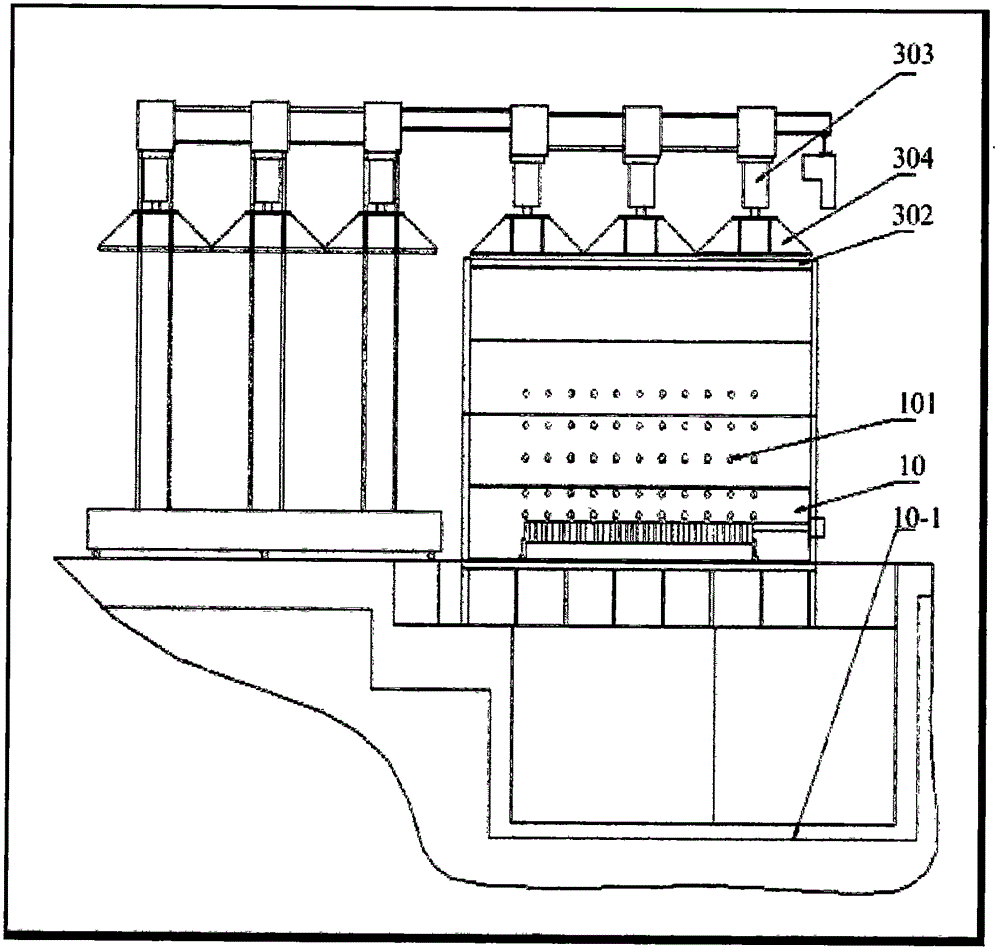

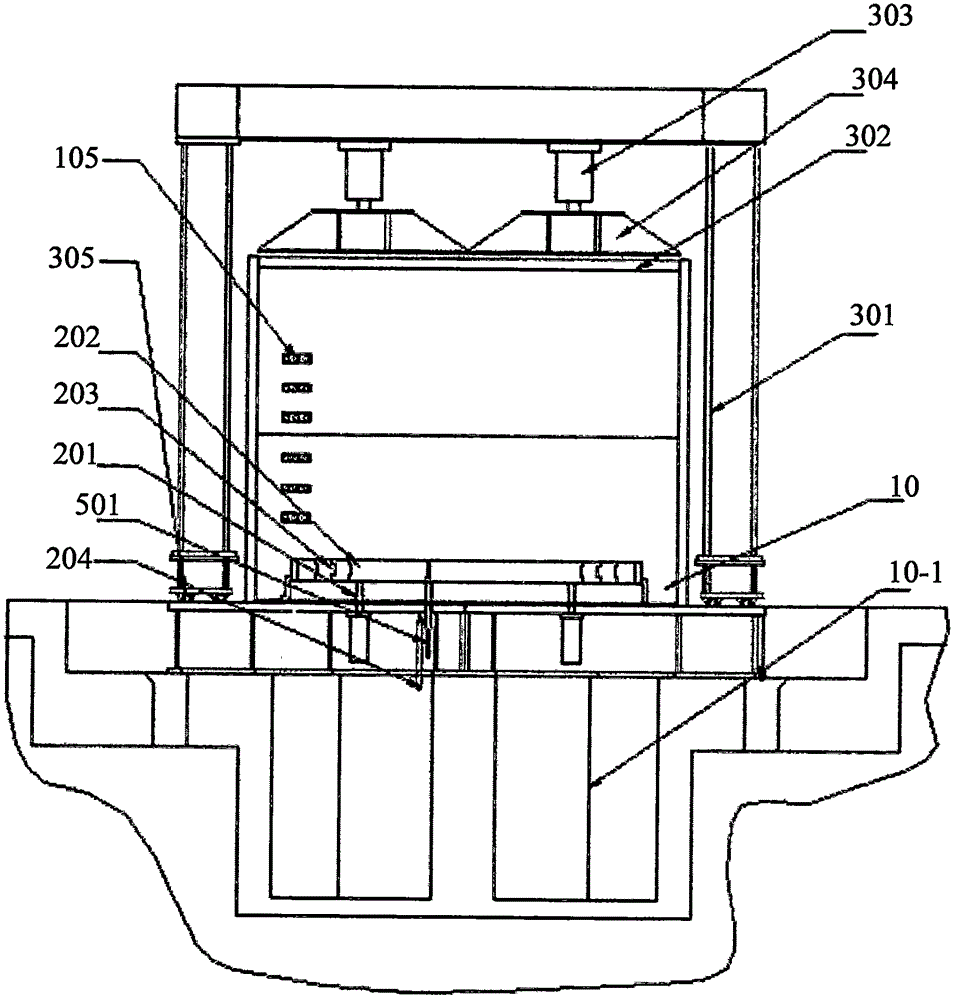

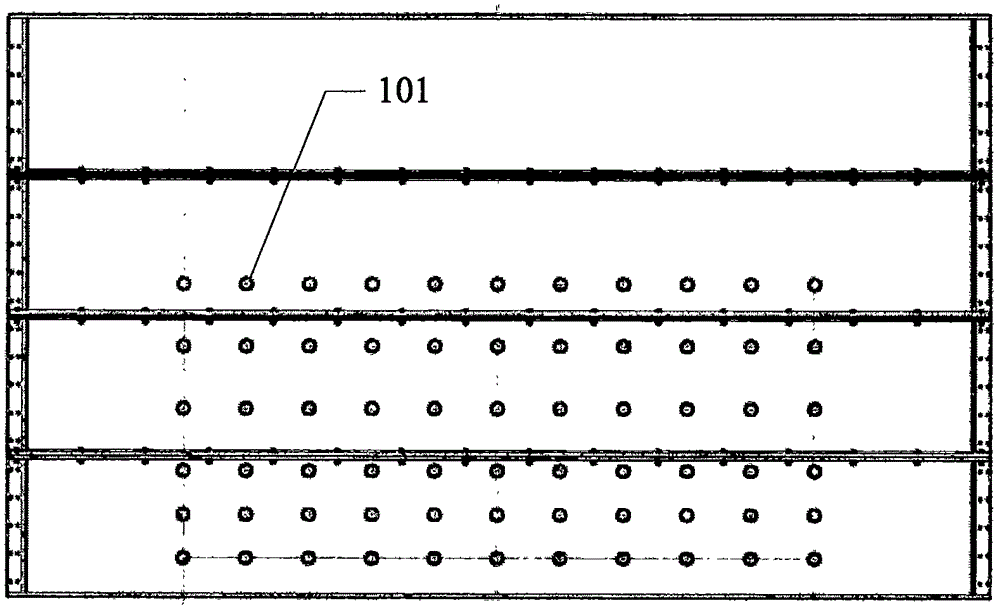

Coal and gas co-mining three-dimensional physical simulation comprehensive experiment system

The invention discloses a coal and gas co-mining three-dimensional physical simulation comprehensive experiment system, and belongs to the technical field of coal and gas safe co-mining. The system comprises a box, a hydraulic mining unit, a hydraulic loading unit, a ventilation roadway unit, a gas injection control unit, and a test unit. The first surface and third surface, which is opposite to the first surface, of the box are both provided with a gas testing hole. The second surface of the box is provided with an air inlet hole and an air return hole. The fourth surface of the box is provided with a wire outlet hole. The hydraulic mining unit comprises parallelly arranged hydraulic cylinders and support steel bars, and two hydraulic cylinders and the bottom of the box connect and support one steel bar. The hydraulic loading unit comprises a loading frame, which is arranged on the guide rails of the box. The guide rails are arranged on two sides of the box. The ventilation roadway comprises a roadway and a ventilating machine. A high pressure steel bottle in the gas injection control unit is communicated with a multi-way air distribution cabinet through an air distribution pipe, the air distribution pipe is communicated with a sub-pipeline; and the test unit comprises a gas testing unit, a stress testing unit, and a slight shock testing unit.

Owner:XIAN UNIV OF SCI & TECH

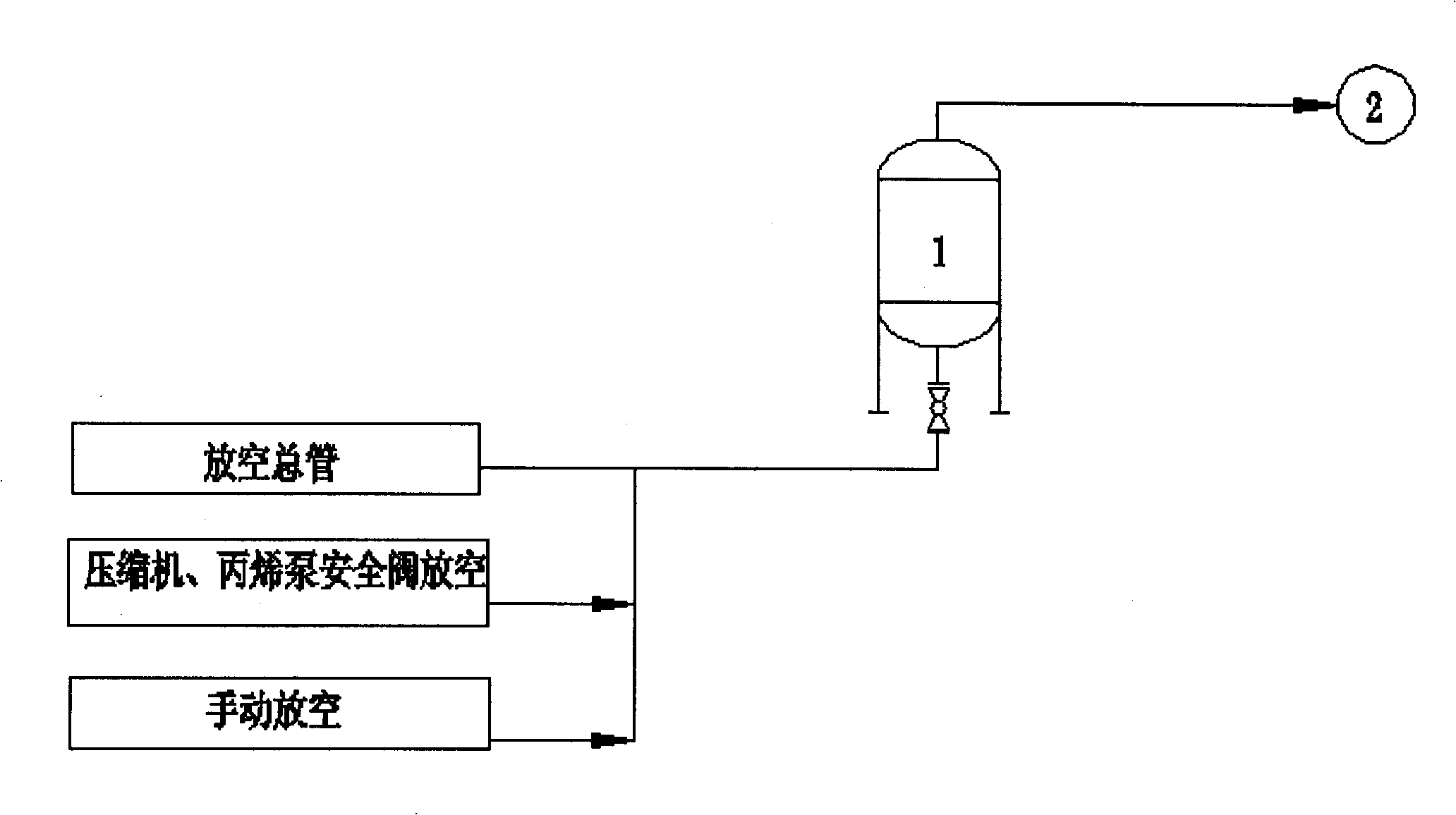

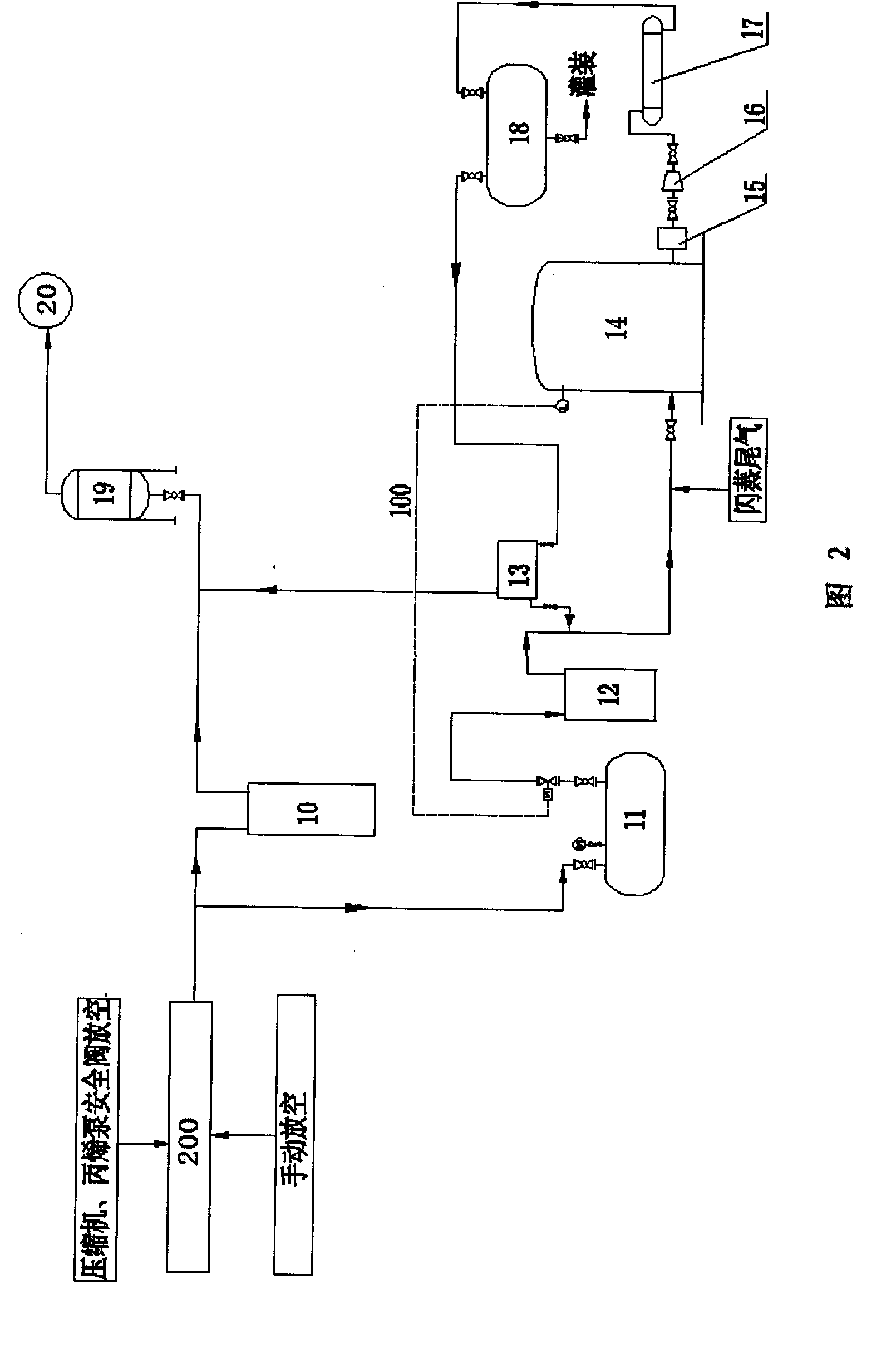

Flare gas recovering technique during producing polypropylene using interval liquid-phase substantial method

ActiveCN101357289ASave resourcesEmission reductionHydrocarbon purification/separationDispersed particle separationHigh concentrationLiquid storage tank

The invention discloses a flare gas recovery process in the production process of polypropylene by an intermittent liquid-phase entity method. The flare gas is collected in a vent line (200); polypropylene particles are removed by a dust collector (15); and then the flare gas is input to a tail gas cabinet (14) for storage; after being compressed by a compressor (16) and condensed by a condenser (17), the tail gas enters a liquid storage tank (18); and non-condensable gas passes through a membrane separation system (13), the high-concentration propylene gas obtained by separation enters the tail gas cabinet (14); and extremely small amount of the lean propylene gas is discharged to a flare (20) by a flare gas vent buffer tank (19), thus actually reducing flare gas emission or even emitting no flare gas; when the content of the propylene at a primary membrane outlet is more than 30%, the flare gas enters a secondary membrane separation system, and a linkage program (100) is designed between a trip valve of a recovery buffer tank and the tail gas cabinet (14). The flare gas recovery process has the advantages of effectively recovering the propylene, environmental protection, saving resources and having positive popularization significance.

Owner:南京金陵塑胶化工有限公司

Process for producing active carbon by cyclic utilization of high temperature flue gas

InactiveCN103224234AEfficient use ofQuality improvementCarbon compoundsEnergy inputThermal insulationCarbonization

The invention relates to a process for producing active carbon by cyclic utilization of high temperature flue gas. The process comprises that: high temperature mixing gas of a thermal insulation gas cabinet is introduced into a pure oxygen burner arranged in a carbonization activation furnace; a carbonization reaction is performed by controlling a temperature; the generated high temperature steam, the generated carbon dioxide, and a downflow carbonization material are subjected to an activation reaction through a downstream gas distributor, and active carbon after the activation reaction enters a cooling chamber, and then is discharged; high temperature flue gas discharged from a carbonization chamber and an activation chamber enters the pure oxygen burner again to be burned; and the generated high temperature steam and the generated carbon dioxide are adopted as mixing activation gas, the mixing activation gas and the downflow carbonization material are subjected to the activation reaction through the downstream gas distributor again, and the process is cyclically and continuously performed to prepare the active carbon. According to the process, the high temperature flue gas produced through carbonization and activation is adopted to cyclically produce the active carbon so as to save steam energy source, reduce cost, achieve continuous production, and effectively avoid environment pollution.

Owner:TAIYUAN UNIV OF TECH

Gas cabinet assembly comprising back migration scrubber unit

InactiveUS6471750B1Combination devicesDispersed particle filtrationEnvironmental engineeringGas supply

A gas containment assembly including a containment enclosure defining an enclosed interior volume, with an exhaust inlet and an exhaust outlet for flow of exhaust gas into the enclosed interior volume through the exhaust inlet and flow from the containment enclosure through the exhaust outlet. A gas supply vessel and / or gas flow circuitry is provided in the interior volume of the containment enclosure. A back-migration scrubber unit overlies and is sealed to the exhaust inlet so that back-flow migration of gas from the gas supply vessel and / or gas flow circuitry in the interior volume of the containment enclosure is sorptively taken up by sorbent material in the scrubber unit and prevented from passing into an ambient environment in which said gas containment assembly is deployed. This arrangement permits significant reduction in the flow rate of exhaust gas through the gas containment enclosure without compromising the safety of the gas containment assembly.

Owner:ENTEGRIS INC

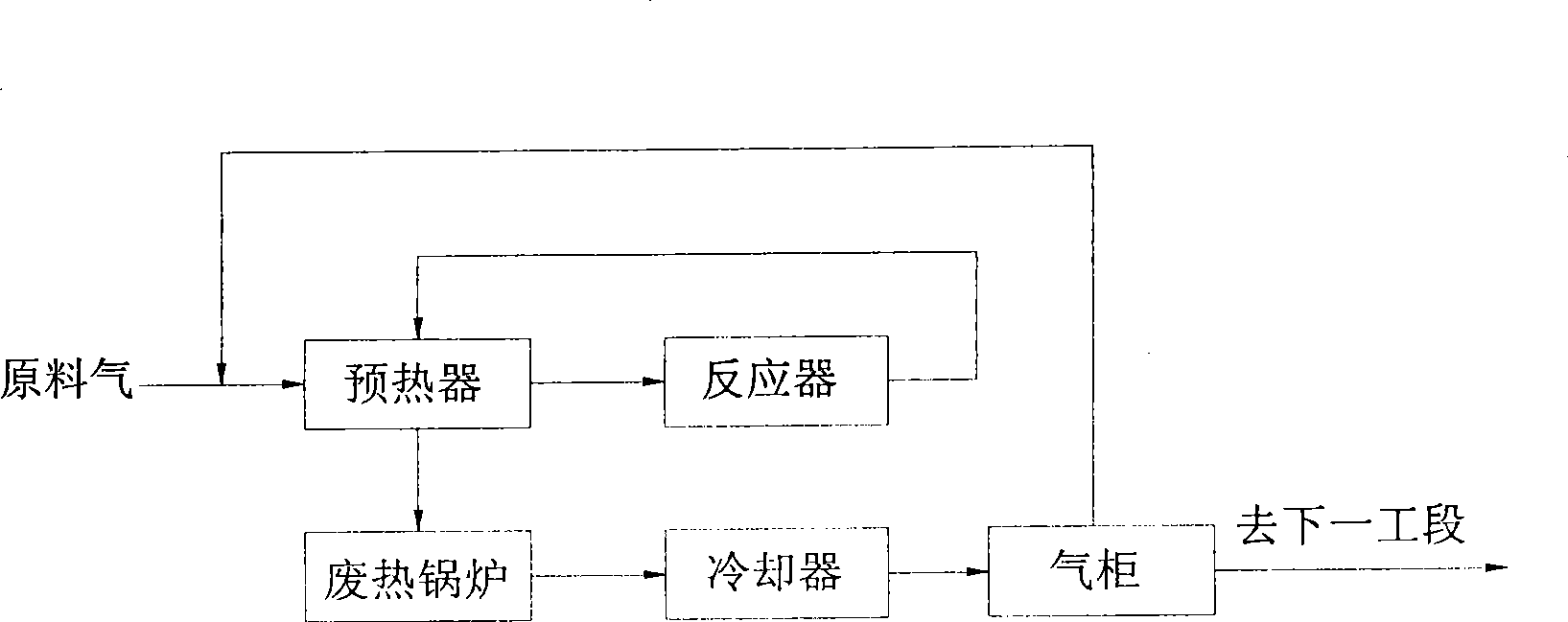

Method for purifying and liquefying coalbed gas

InactiveCN101445755AImprove extraction utilizationReduce pollutionSolidificationLiquefactionSulfurOxygen

The invention relates to a method for purifying and liquefying coalbed gas, the method is used for purifying and liquefying the exhausted oxygen-containing mixed coalbed gas of worked-out areas and mining areas, and the method is mainly realized through the following process: raw material coalbed gas-deoxidation-pressure boosting-decarburization-dehydration-denitrification-storage and transportation, wherein, the dioxidation is carried out as follows: the sulfur-tolerant catalytic deoxidation process mixes the raw material coalbed gas with part of deoxidizing circulating gas in a gas cabinet at 70KPa, the mixed gas enters a reactor after pre-heating by a pre-heater, methane and oxygen are reacted in a catalyst bed within a certain temperature range to generate CO2 and H2O; then the pressure boosting is carried out, the MEA plus MDEA decarburization process is adopted for decarburization, the physical absorption method is utilized for dehydration, the mixed refrigerant process is adopted for denitrification, and the storage and the transportation are carried out according to the standards. The method solves the problems that the deoxidization after pressure boosting is unsafe and the daily processing capacity of the raw material layer for production is small of the prior art. The method can be widely used for purifying and liquefying the exhausted oxygen-containing mixed coalbed gas of the worked-out areas and the mining areas.

Owner:CNPC GREATWALL DRILLING ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com