Patents

Literature

6642results about "Blast furnace details" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

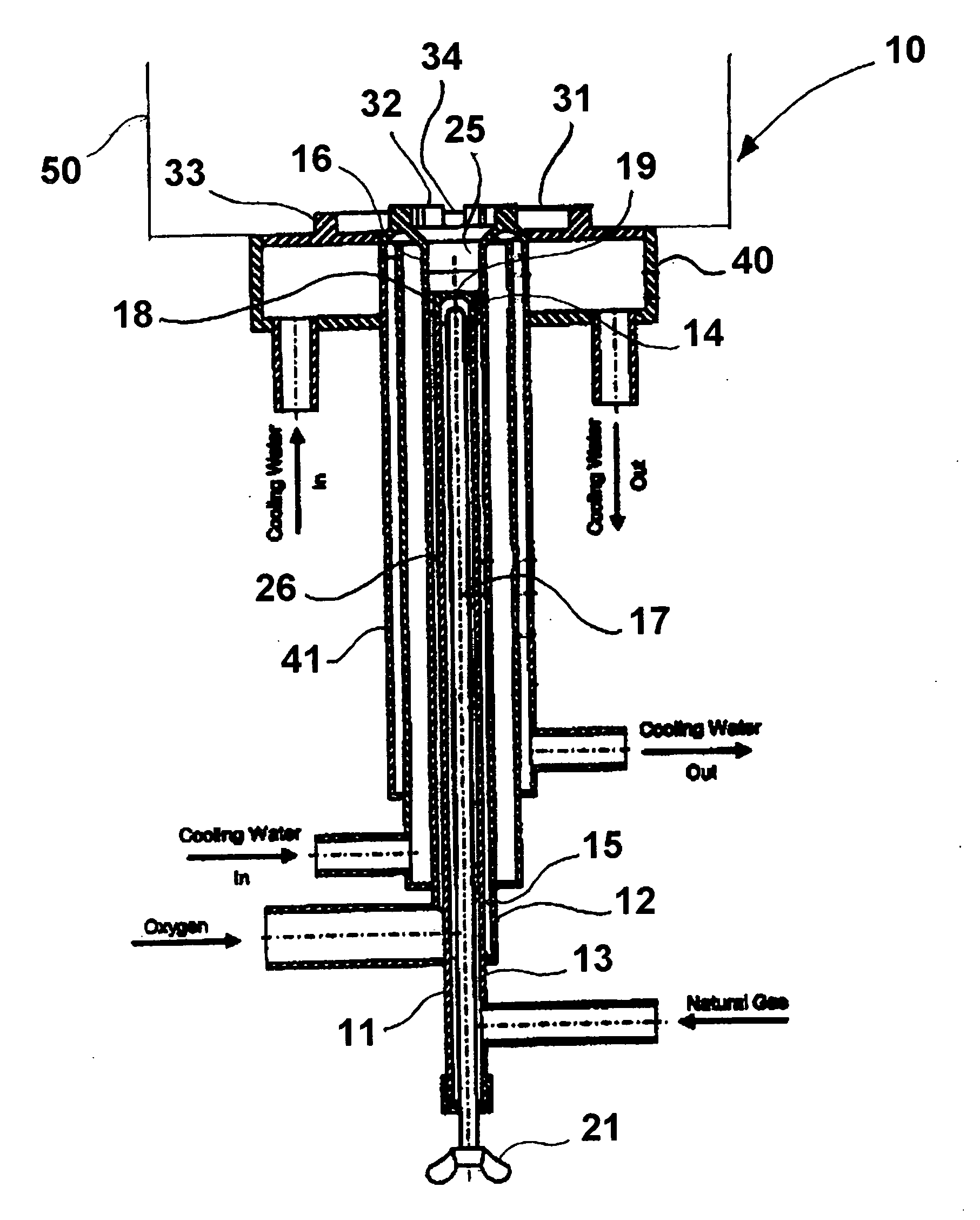

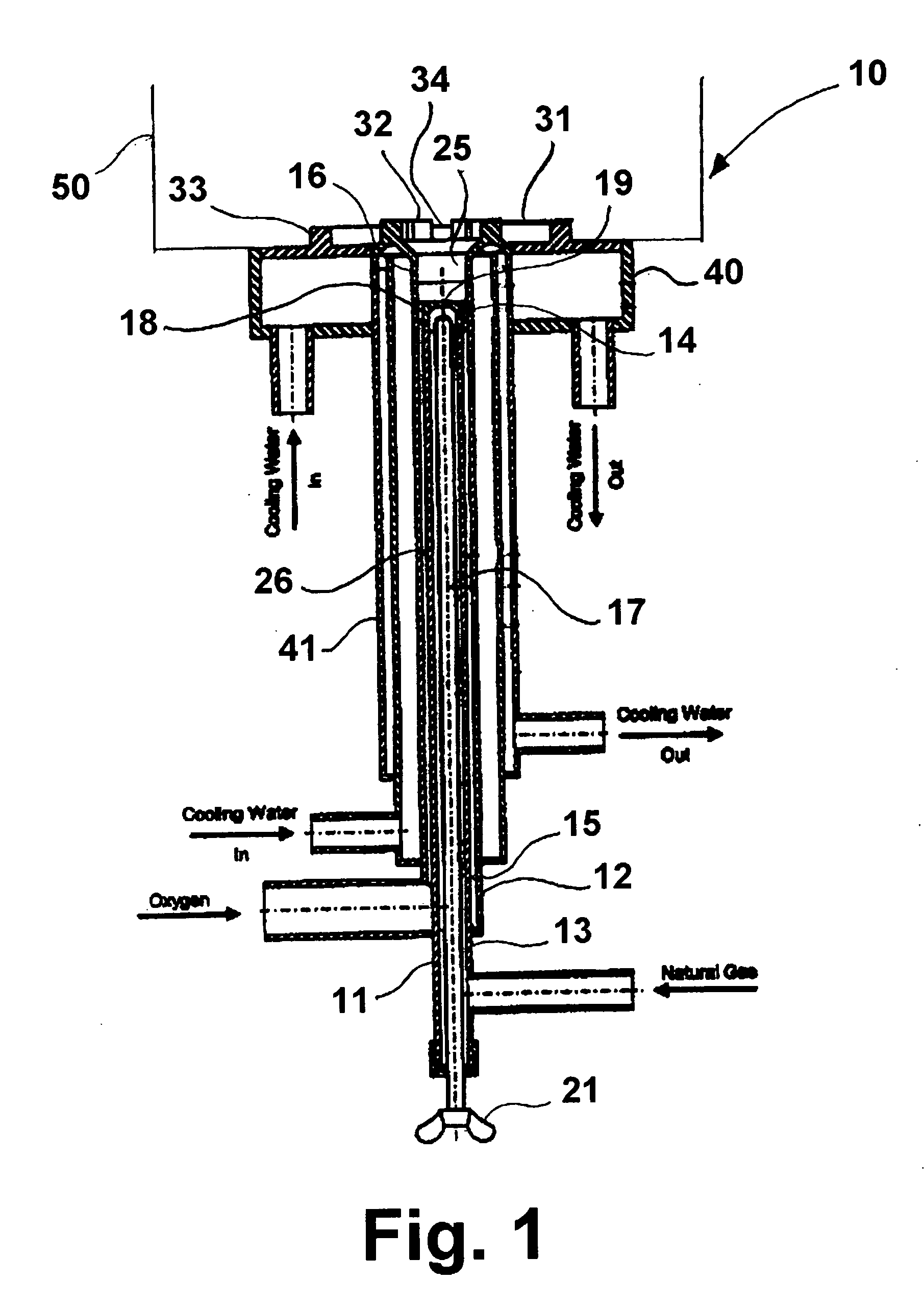

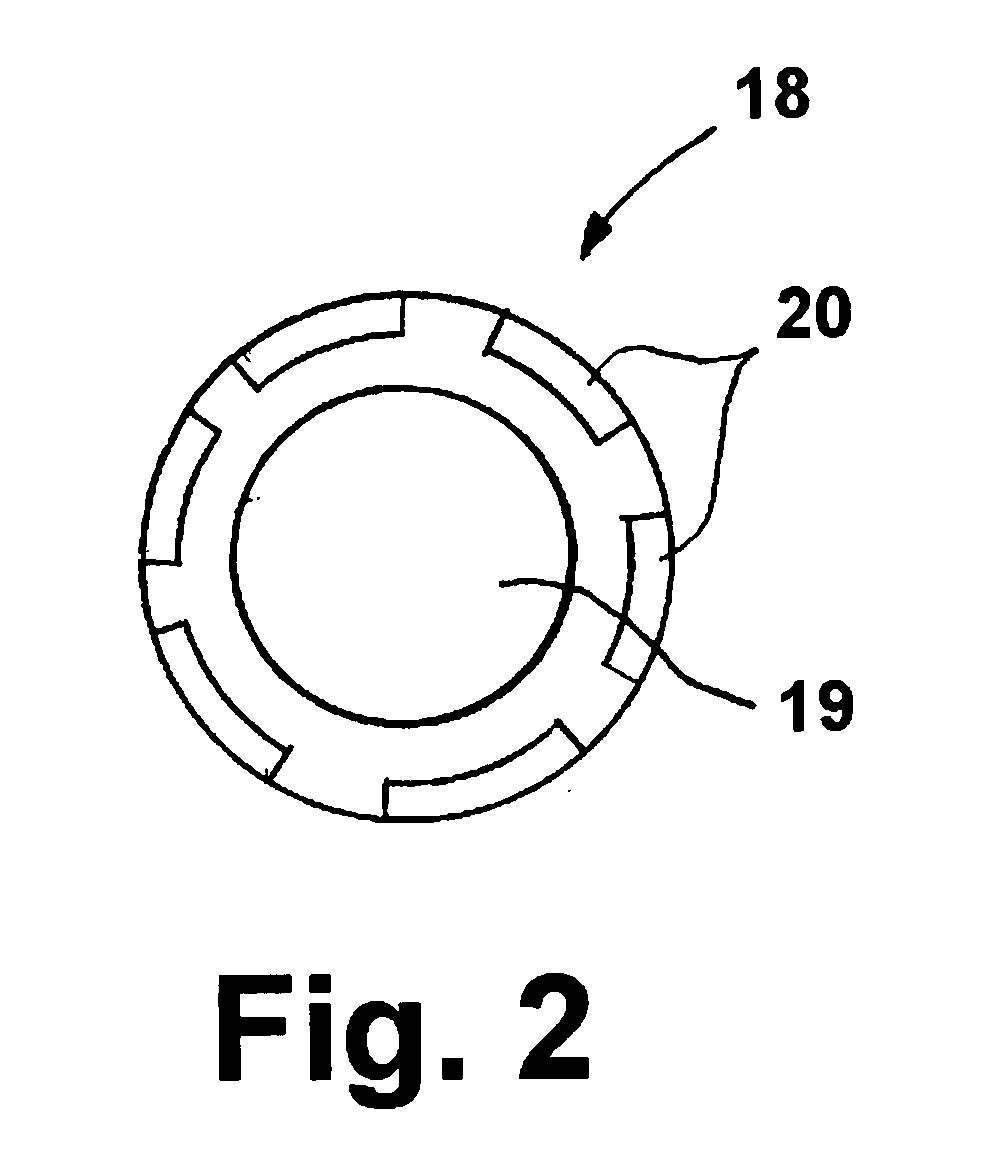

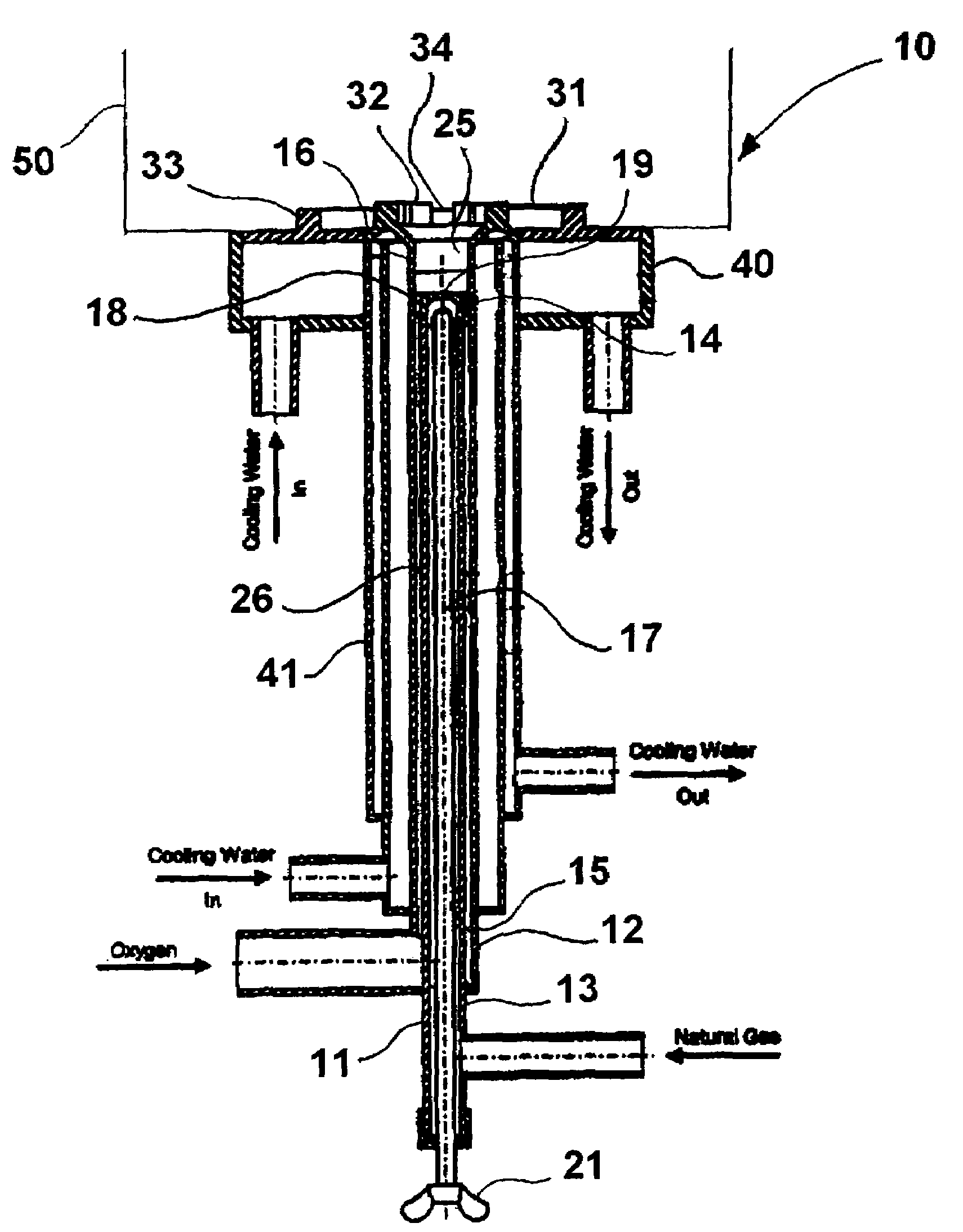

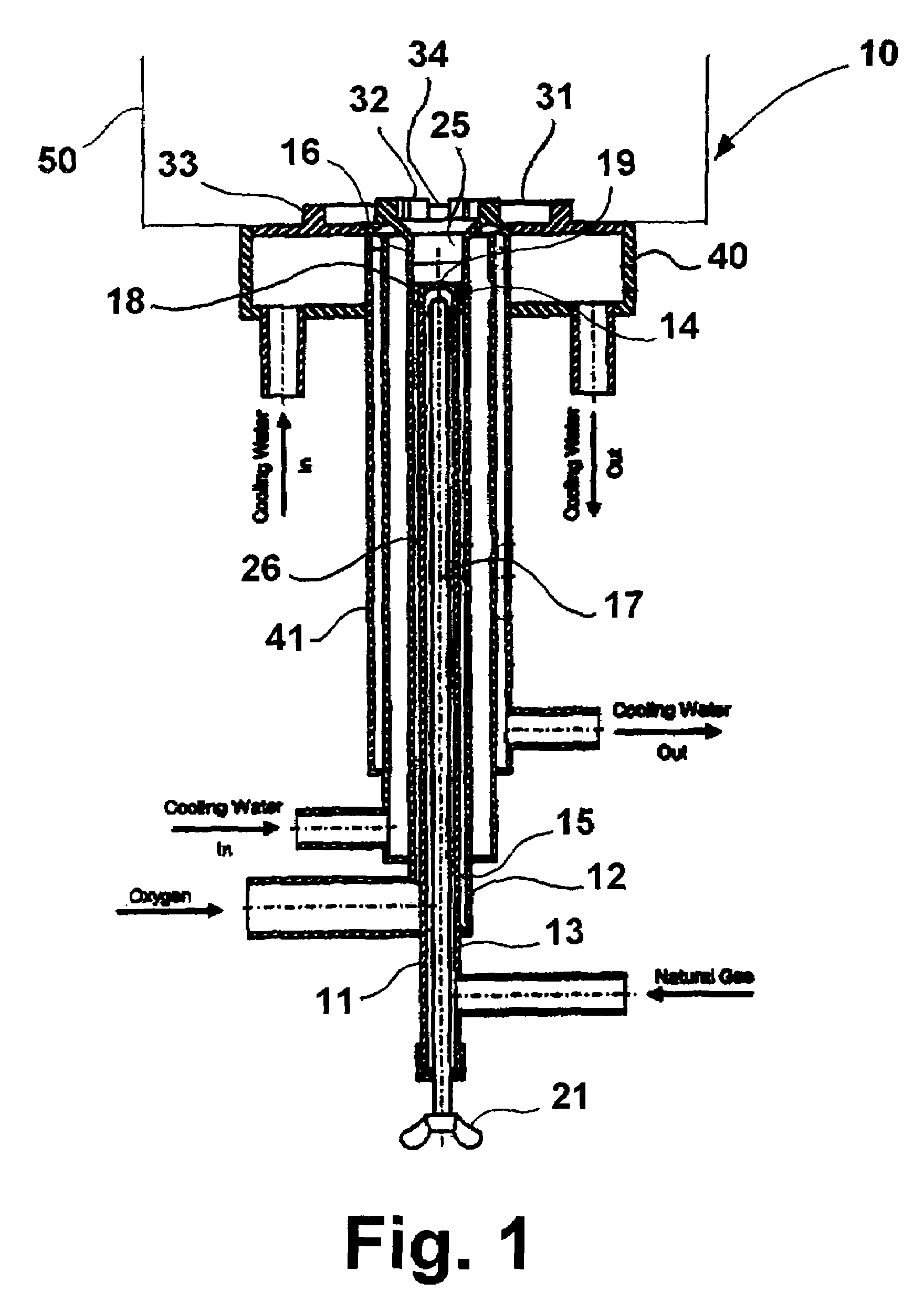

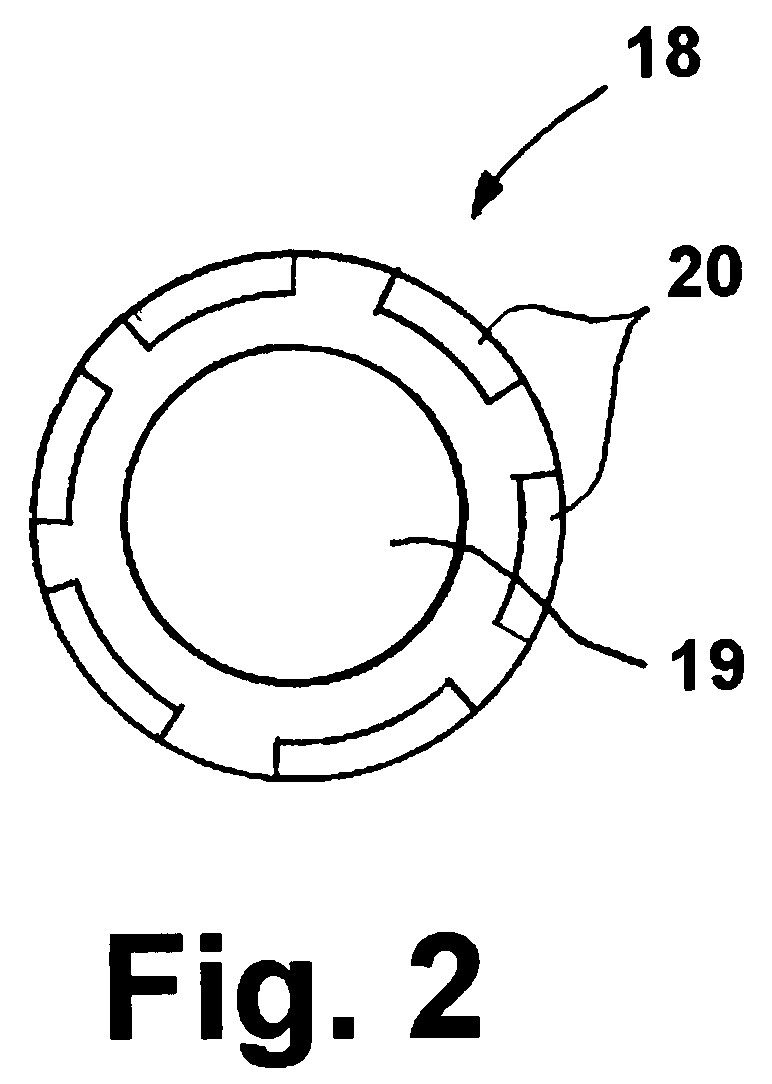

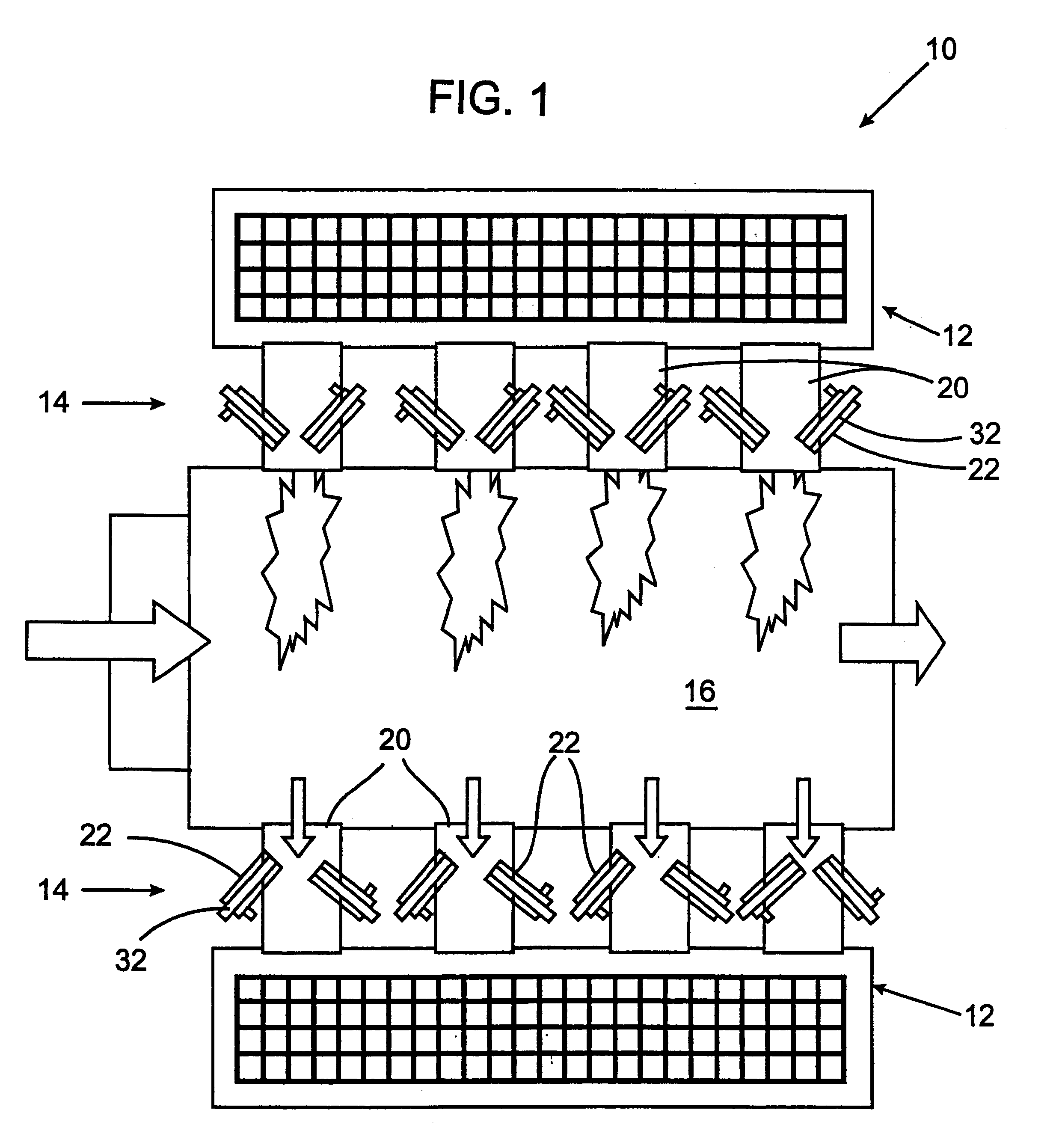

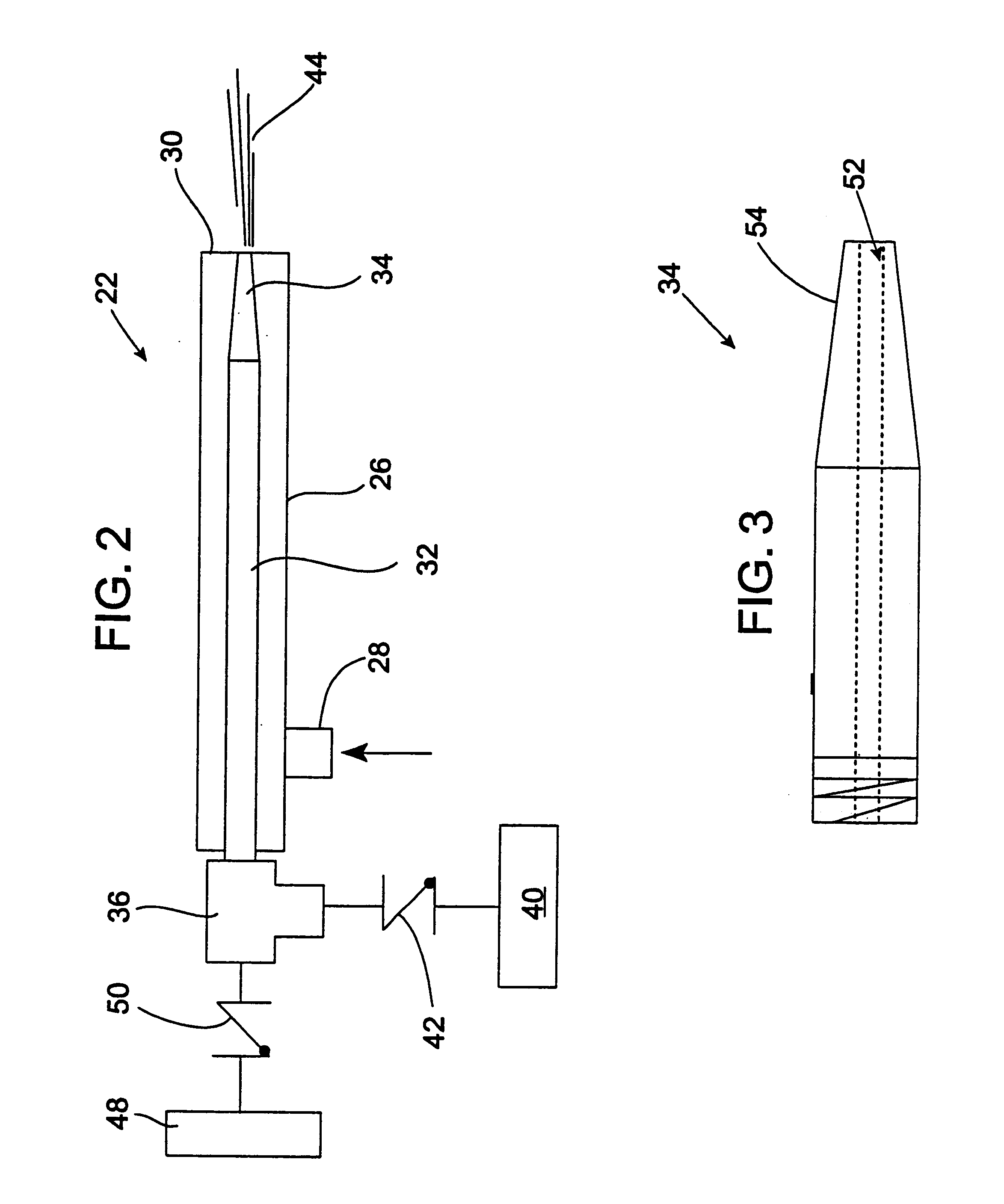

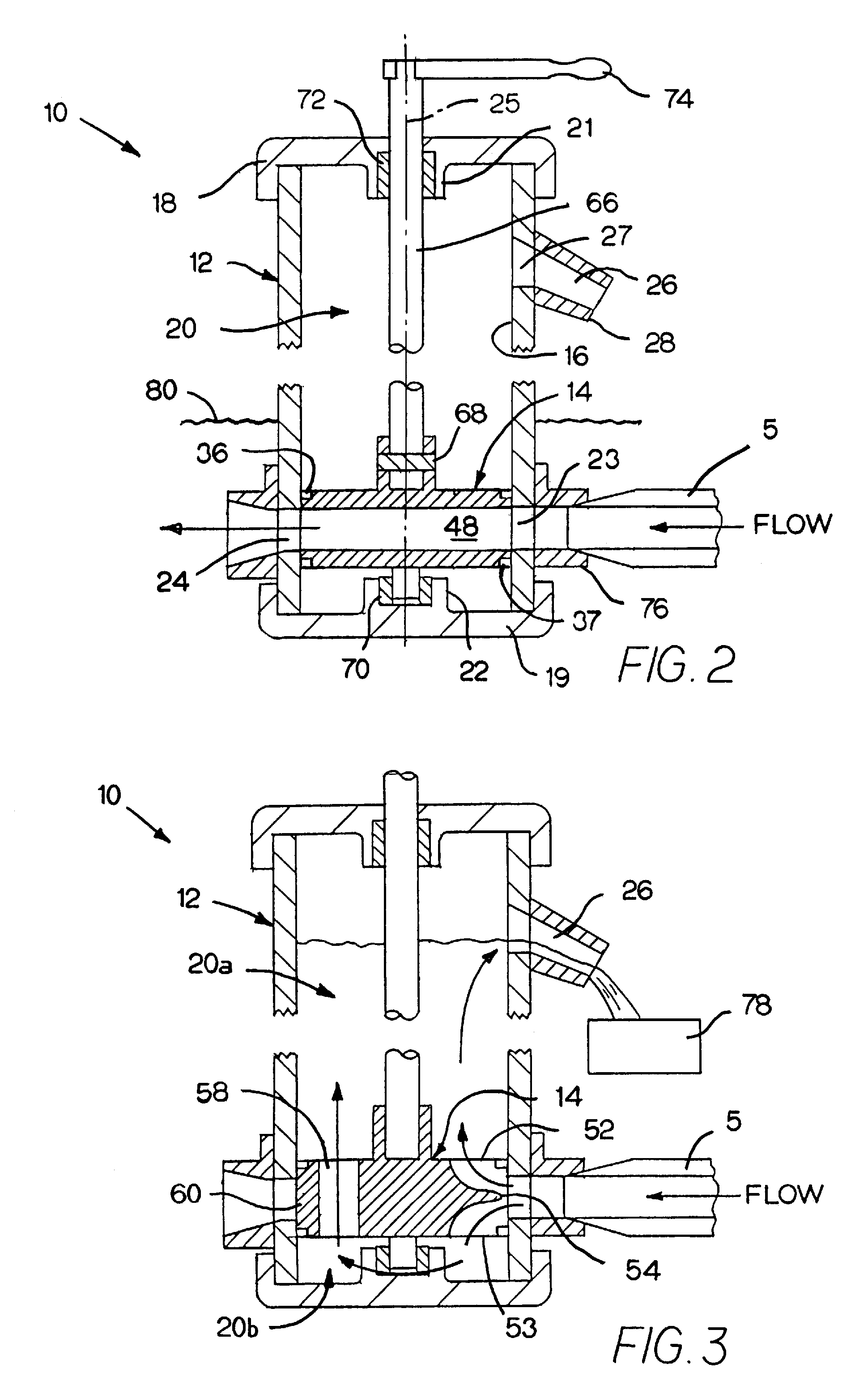

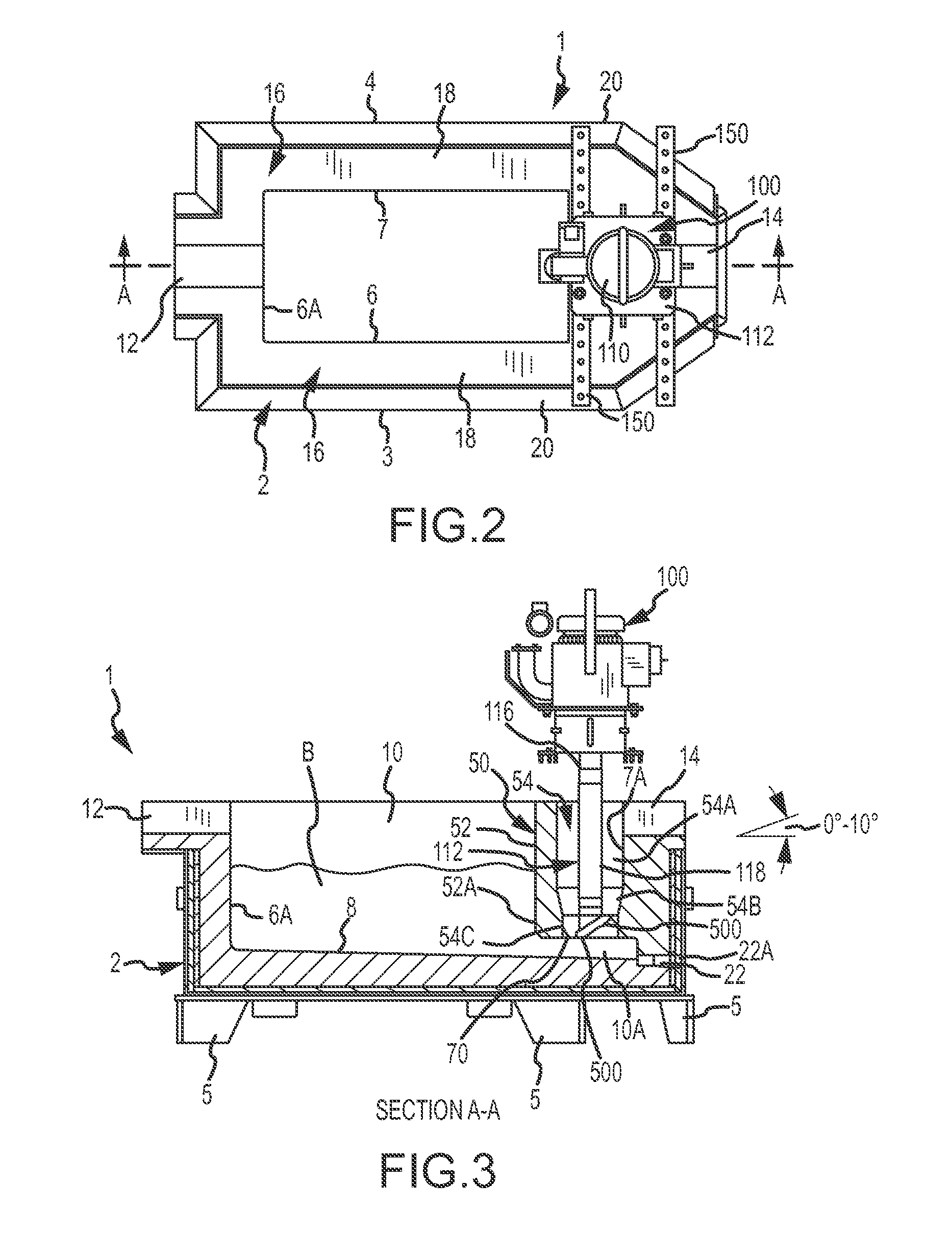

Process and apparatus for uniform combustion within a molten material

A submerged combustion burner having co-axial fuel and oxidant tubes forming an annular space therebetween, wherein the outer tube extends beyond the end of the inner tube. A burner nozzle having an outside diameter corresponding to the inside diameter of the outer tube is connected to the outlet end of the inner tube and forms a centralized opening in fluid communication with the inner tube and at least one peripheral longitudinally oriented opening in fluid communication with the annular space. In accordance with one embodiment, a longitudinally adjustable rod is disposed within the inner tube for adjustment of fluid flow therethrough, and a cylindrical insert having at least one flame stabilizer for stabilizing a flame produced by the burner is attached to the outlet end of the outer tube. In accordance with another embodiment, fluid flow through the inner tube is achieved by a flow control valve operably connected to the inner tube.

Owner:GAS TECH INST

Process and apparatus for uniform combustion within a molten material

A submerged combustion burner having co-axial fuel and oxidant tubes forming an annular space therebetween, wherein the outer tube extends beyond the end of the inner tube. A burner nozzle having an outside diameter corresponding to the inside diameter of the outer tube is connected to the outlet end of the inner tube and forms a centralized opening in fluid communication with the inner tube and at least one peripheral longitudinally oriented opening in fluid communication with the annular space. In accordance with one embodiment, a longitudinally adjustable rod is disposed within the inner tube for adjustment of fluid flow therethrough, and a cylindrical insert having at least one flame stabilizer for stabilizing a flame produced by the burner is attached to the outlet end of the outer tube. In accordance with another embodiment, fluid flow through the inner tube is achieved by a flow control valve operably connected to the inner tube.

Owner:GAS TECH INST

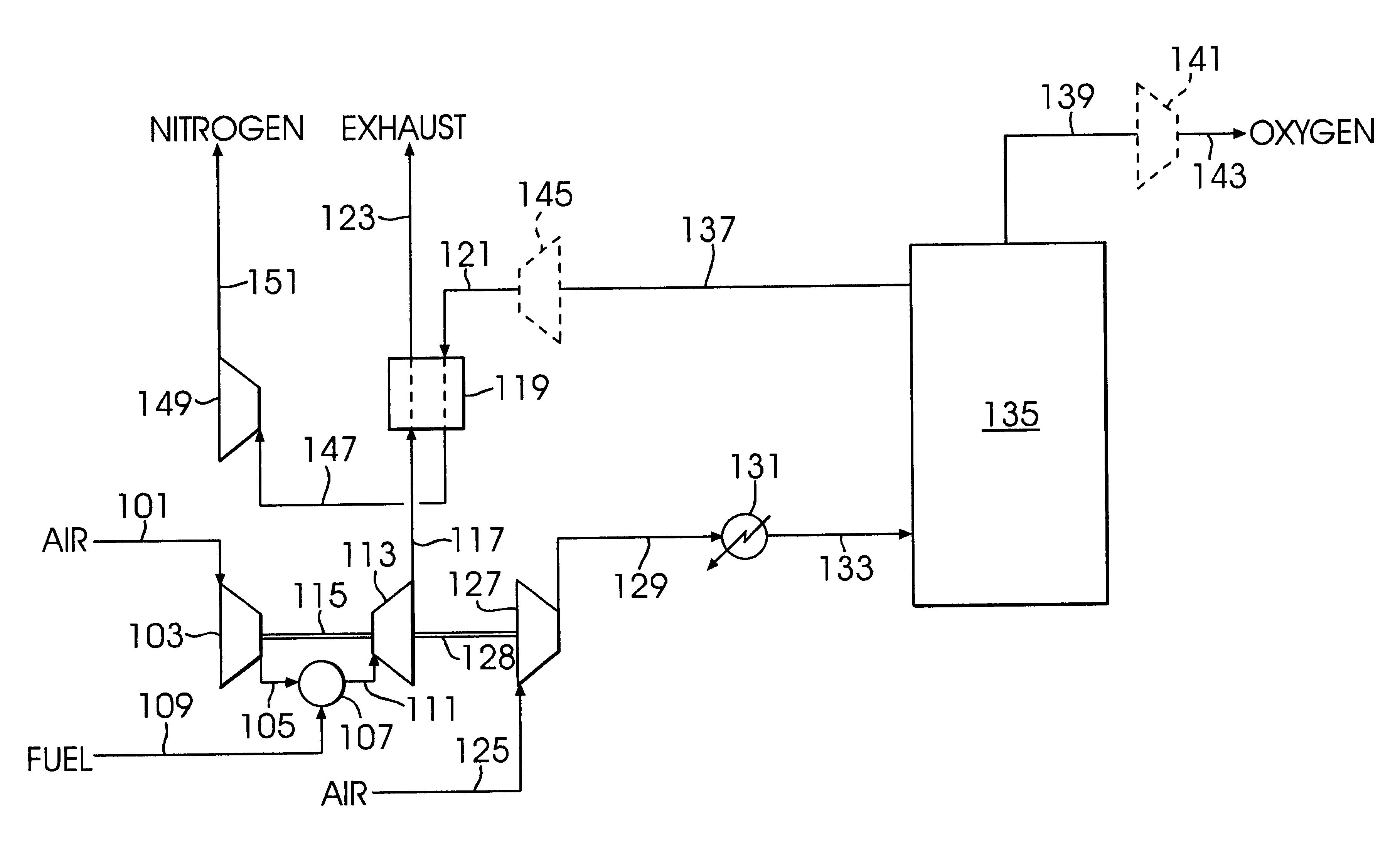

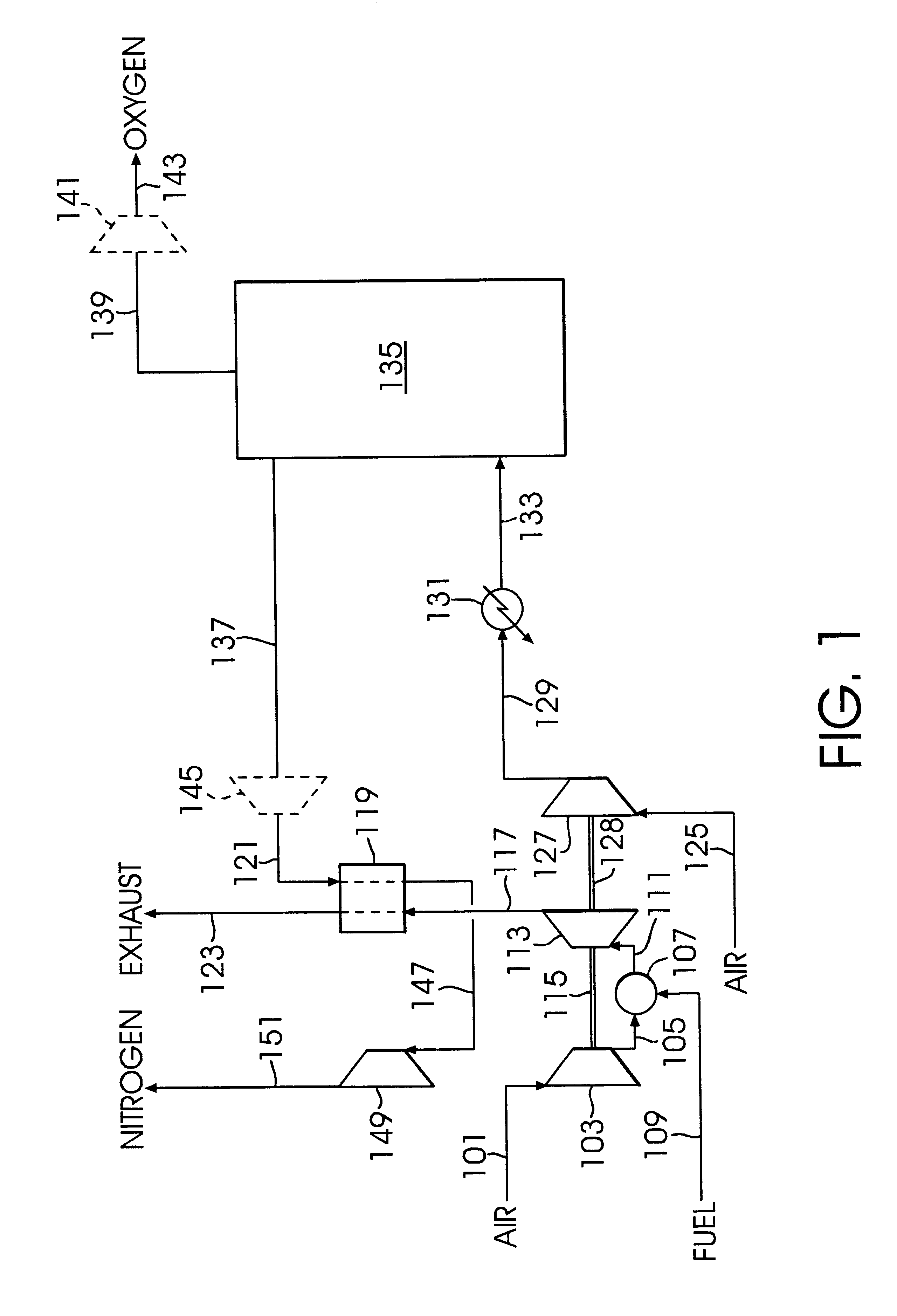

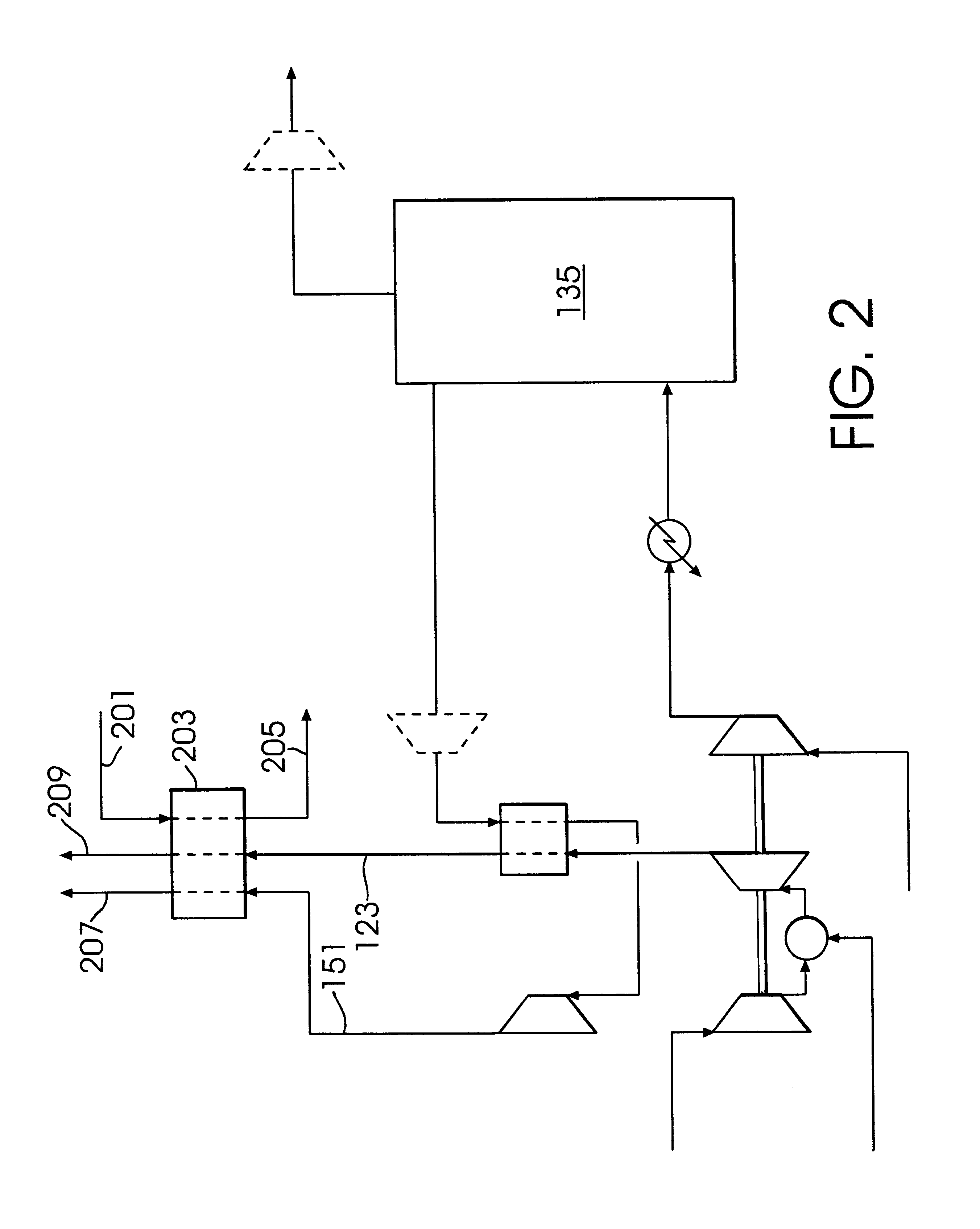

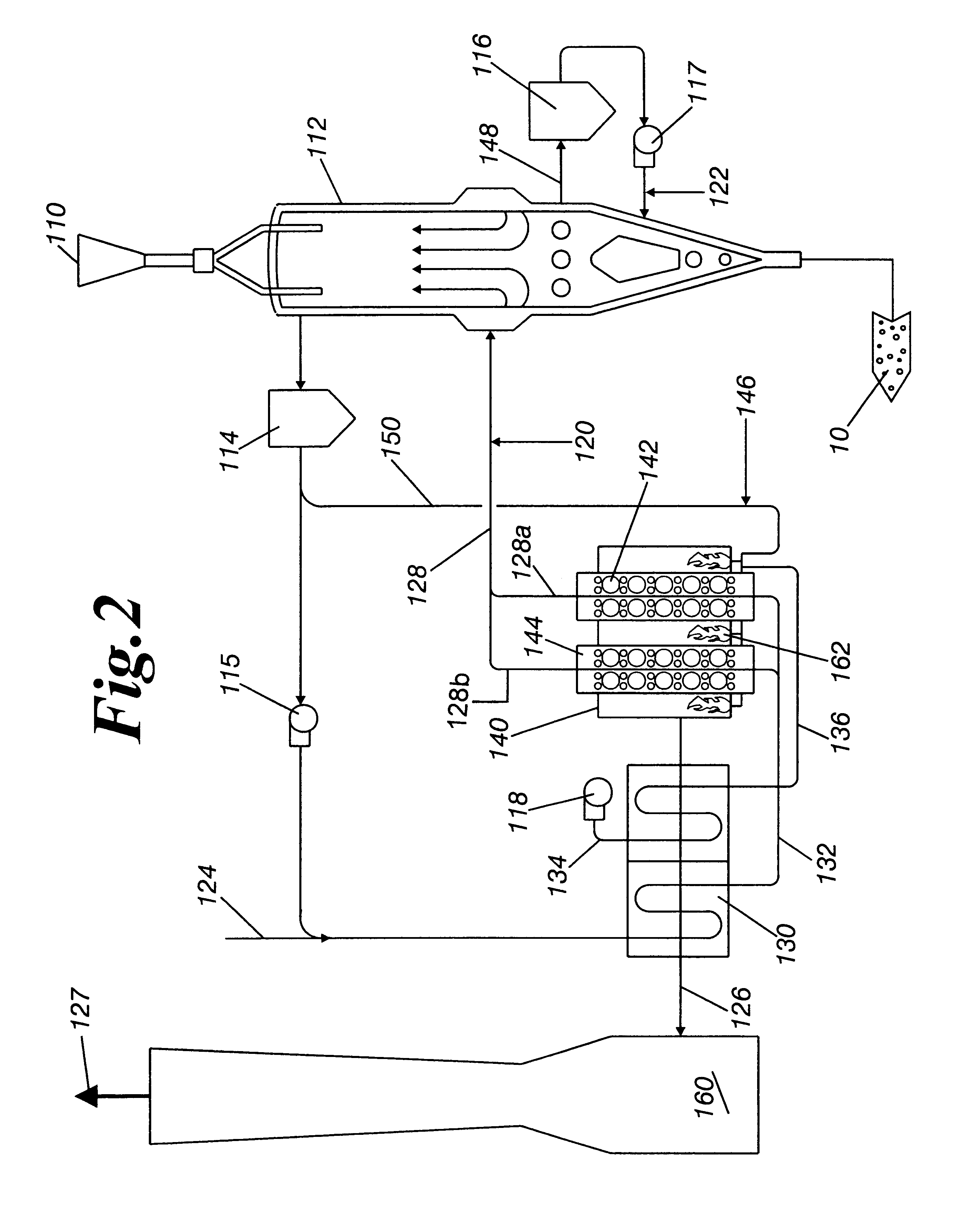

Air separation process integrated with gas turbine combustion engine driver

A method for the separation of a feed gas mixture comprising oxygen and nitrogen in which an oxidant gas and fuel are combusted in a combustion engine to generate shaft work and a hot exhaust gas, the feed gas mixture comprising oxygen and nitrogen is compressed, and the resulting compressed feed gas mixture is separated into two or more product gas streams with differing compositions. The shaft work of the combustion engine is utilized to provide at least a portion of the work required for compressing the feed gas mixture, one of the product gas streams by is heated by indirect heat exchange with the hot exhaust gas from the combustion engine, and the resulting heated product gas is work expanded to generate shaft work and yield an expanded product gas stream. The combustion engine may be a gas turbine combustion engine.

Owner:AIR PROD & CHEM INC

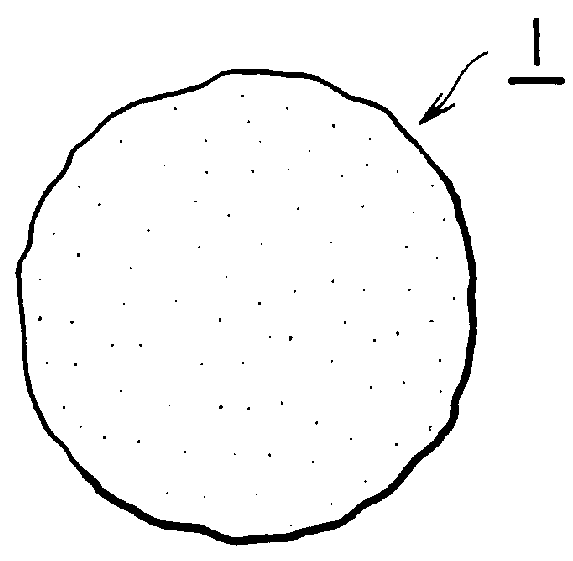

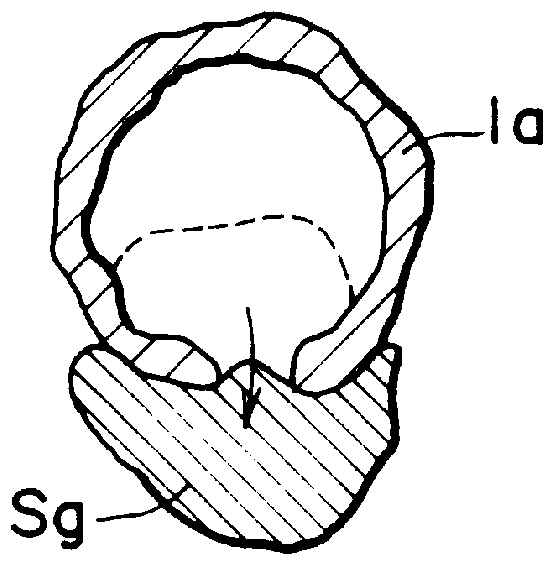

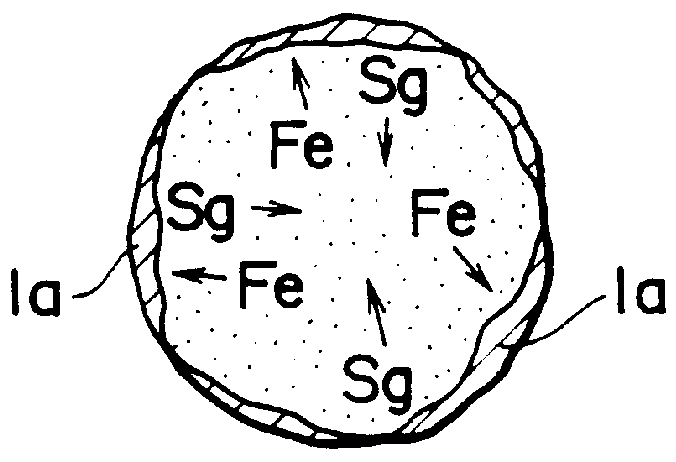

Method and apparatus for making metallic iron

InactiveUS6036744AHigh purityReadily and efficiently madeBlast furnace componentsRotary drum furnacesMolten slagCoal

A method of making metallic iron in which a compact, containing iron oxide such as iron ore or the like and a carbonaceous reductant such as coal or the like, is used as material, and the iron oxide is reduced through the application of heat, thereby making metallic iron. In the course of this reduction, a shell composed of metallic iron is generated and grown on the surface of the compact, and slag aggregates inside the shell. This reduction continues until substantially no iron oxide is present within the metallic iron shell. Subsequently, heating is further performed to melt the metallic iron and slag. Molten metallic iron and molten slag are separated one from the other, thereby obtaining metallic iron with a relatively high metallization ratio. Through the employment of an apparatus for making metallic iron of the present invention, the above-described method is efficiently carried out, and metallic iron having a high iron purity can be made continuously as well as productively not only from iron oxide having a high iron content but also from iron oxide having a relatively low iron content.

Owner:KOBE STEEL LTD

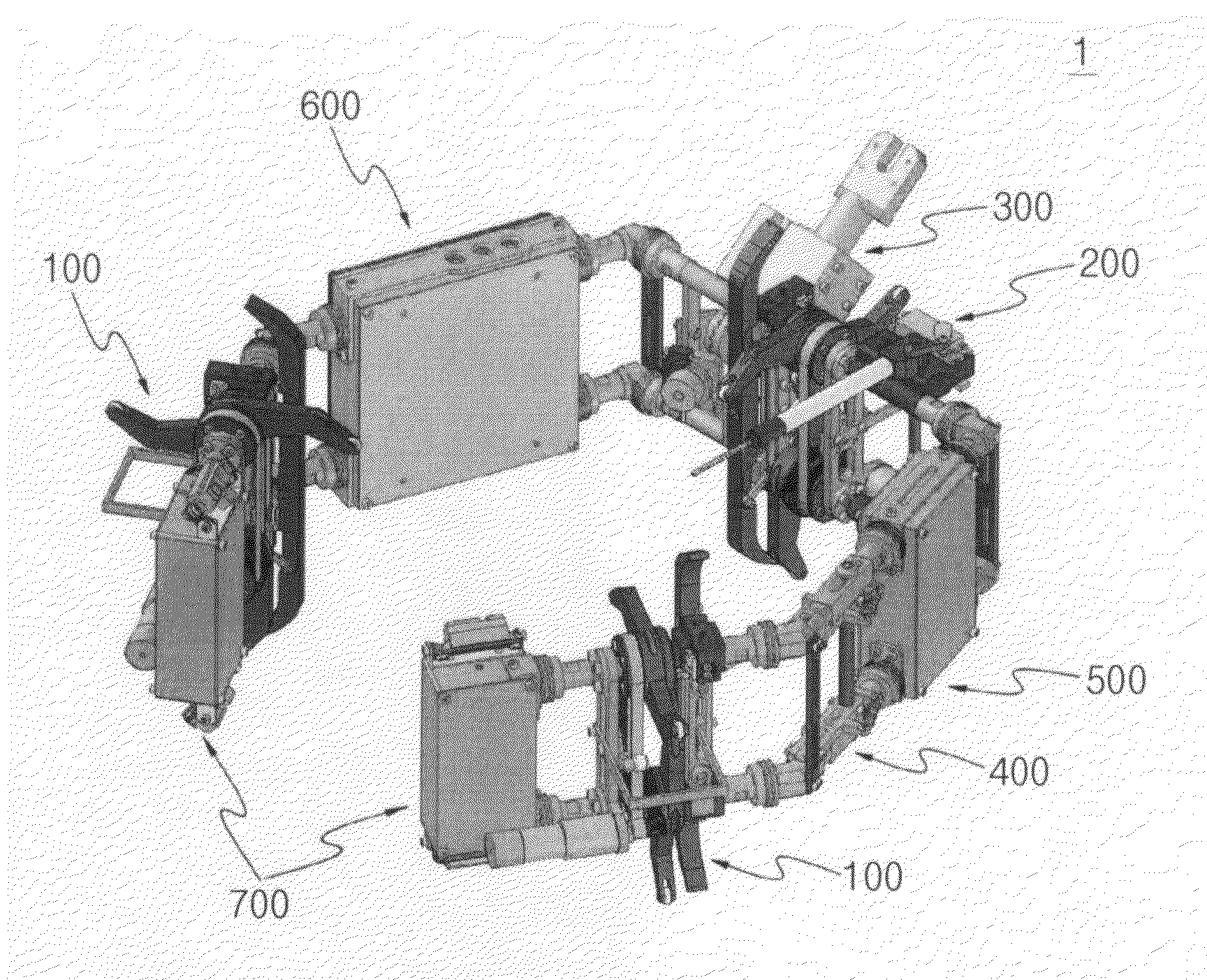

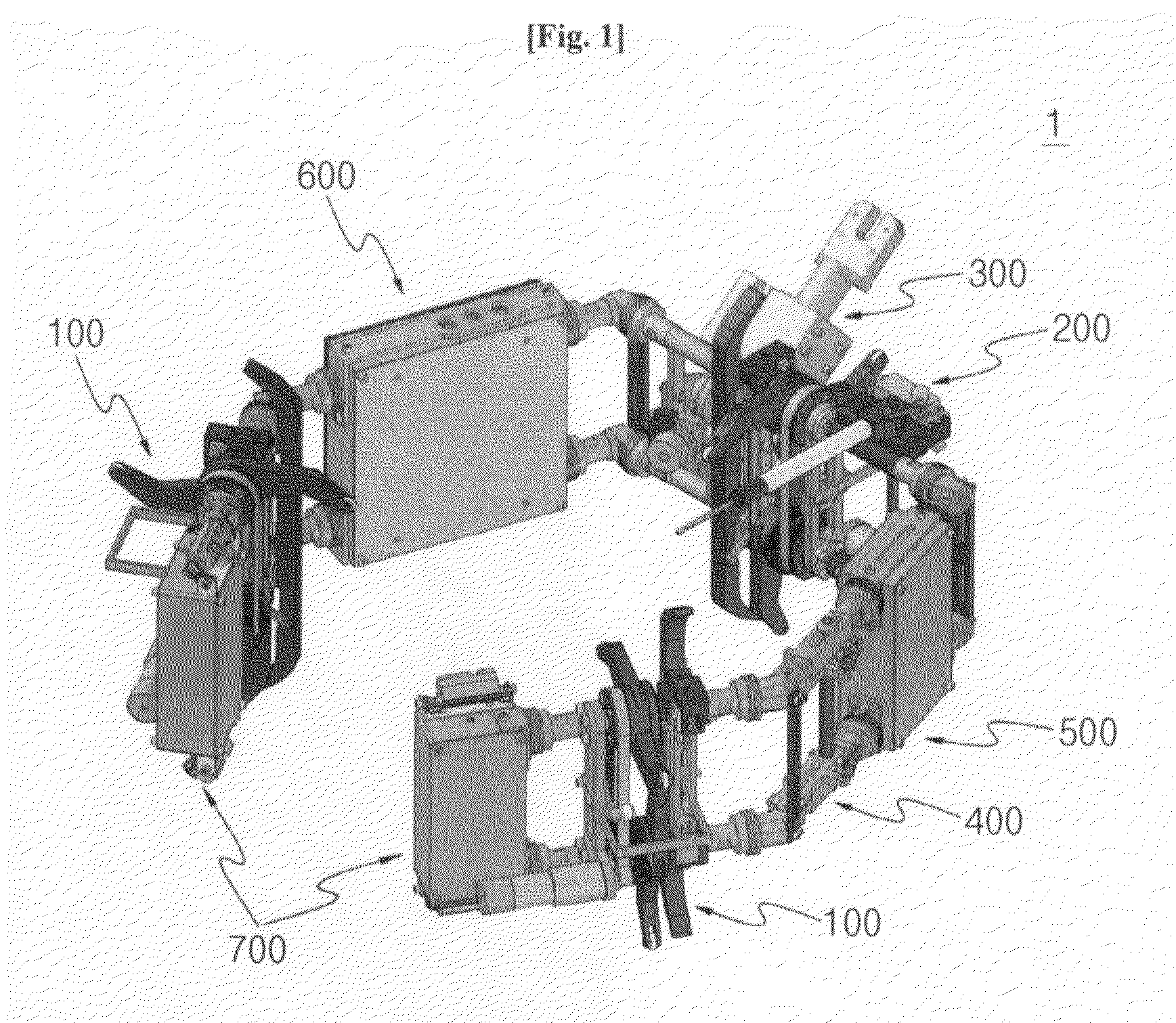

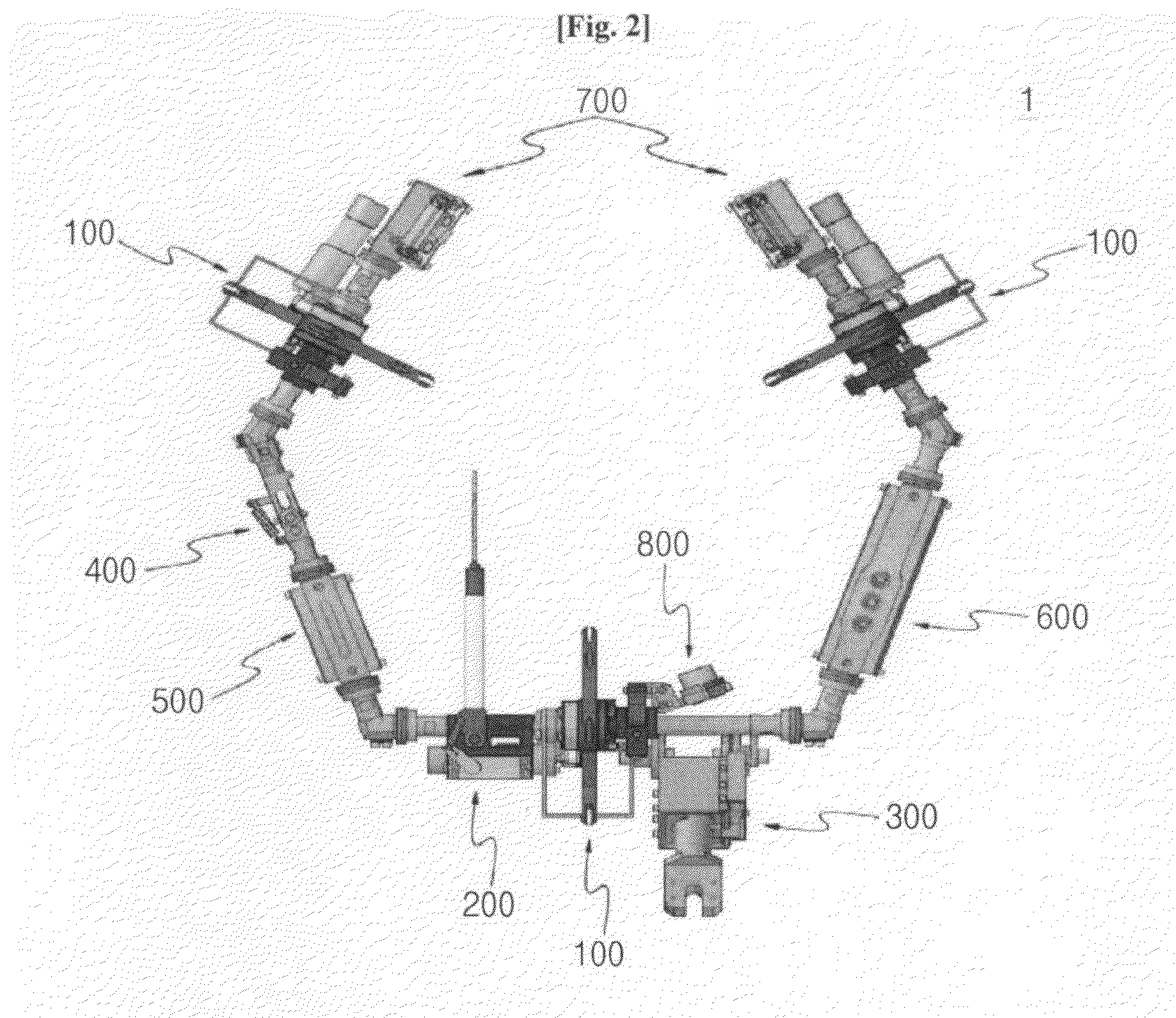

Robot mechanism for inspection of live-line suspension insulator string

ActiveUS20100100239A1Inspection is accurateProgramme controlVibration measurement in solidsControl theoryElectric wire

Disclosed herein is a robot mechanism for inspection of a live-line suspension insulator string. A robot body of the robot mechanism reciprocates along the live-line suspension insulator string and includes upper and lower robot frames configured to encircle the insulator string, a battery module provided to either end of the robot body, an actuation module for moving the robot body along the insulator string, an inspection module for electrically inspecting an insulator, a connection module for coupling the robot body to an installation / dismantlement mechanism, a wing opening / closing module for manually separating the robot body from the insulator string, a measurement module for measuring electrical properties of the insulator, a controller for controlling operation of the robot body, and a crack detection unit for detecting cracks formed in the insulator.

Owner:KOREA ELECTRIC POWER CORP

Free flowing dry back-up insulating material

Disclosed is a free flowing dry back-up material which comprises:from 67 to 96% by weight of fly-ash;from 2 to 15% by weight of a heat sensitive binder such as boric acid;from 2 to 7% by weight of a non-wetting agent such as calcium fluoride;from 0 to 10% by weight of a heat expandable material, viz. a material expandable as a function of the temperature such as vermiculite or graphite; andfrom 0 to 1% by weight of a dust suppressant such as kerosene.This material which is useful in particular in the aluminum industry has the advantages of being water free and free flowing, such avoiding the use of vibrator to position it into a shell. It also has a low density and a low thermal conductivity. Moreover, it is organic free as compared to the existing materials which use an organic binder to ensure a low temperature set; and it sets at a temperature lower than 400° F.

Owner:LES PROD CHIMS INDS DE HAUTE TEMPERATURE PYROTEK

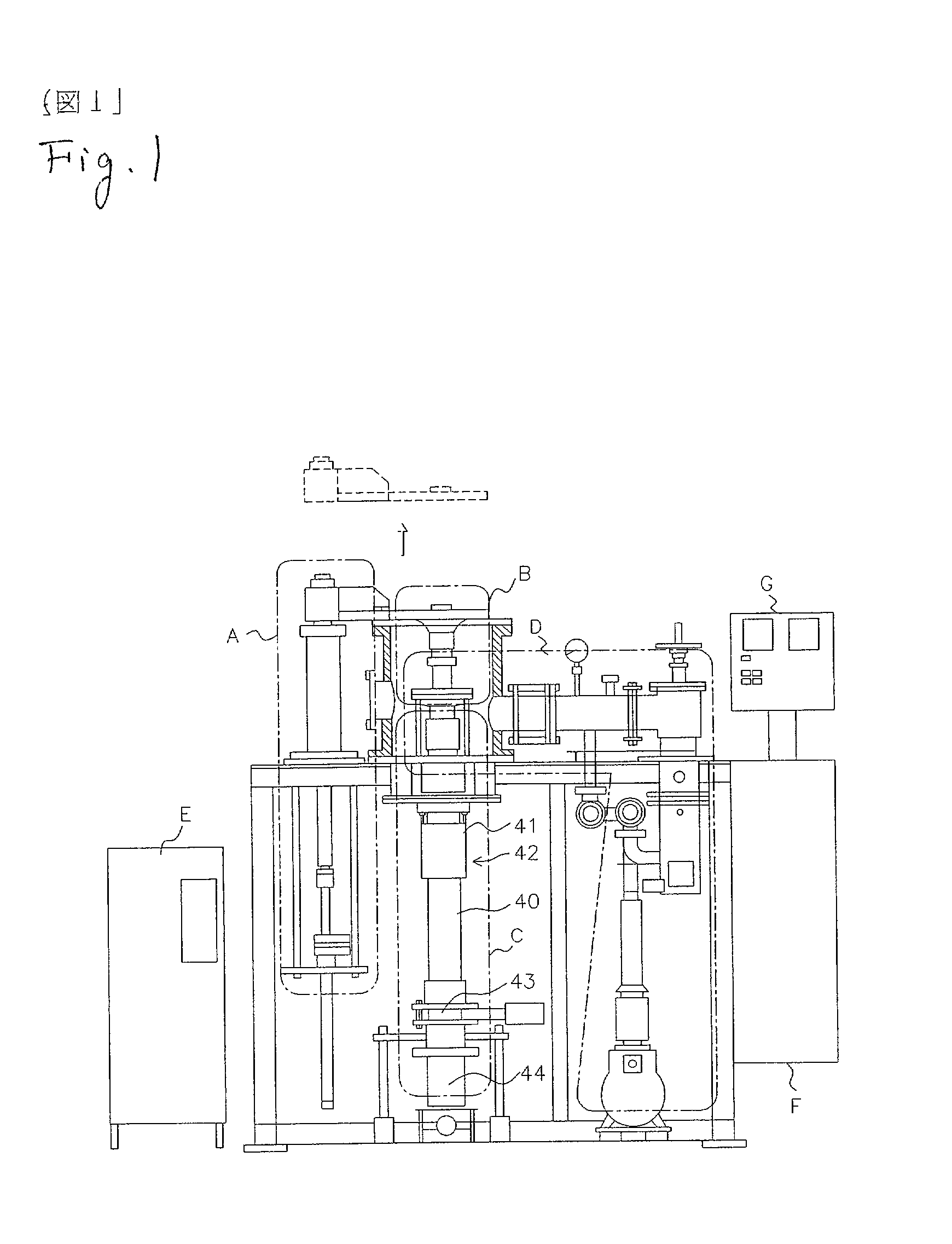

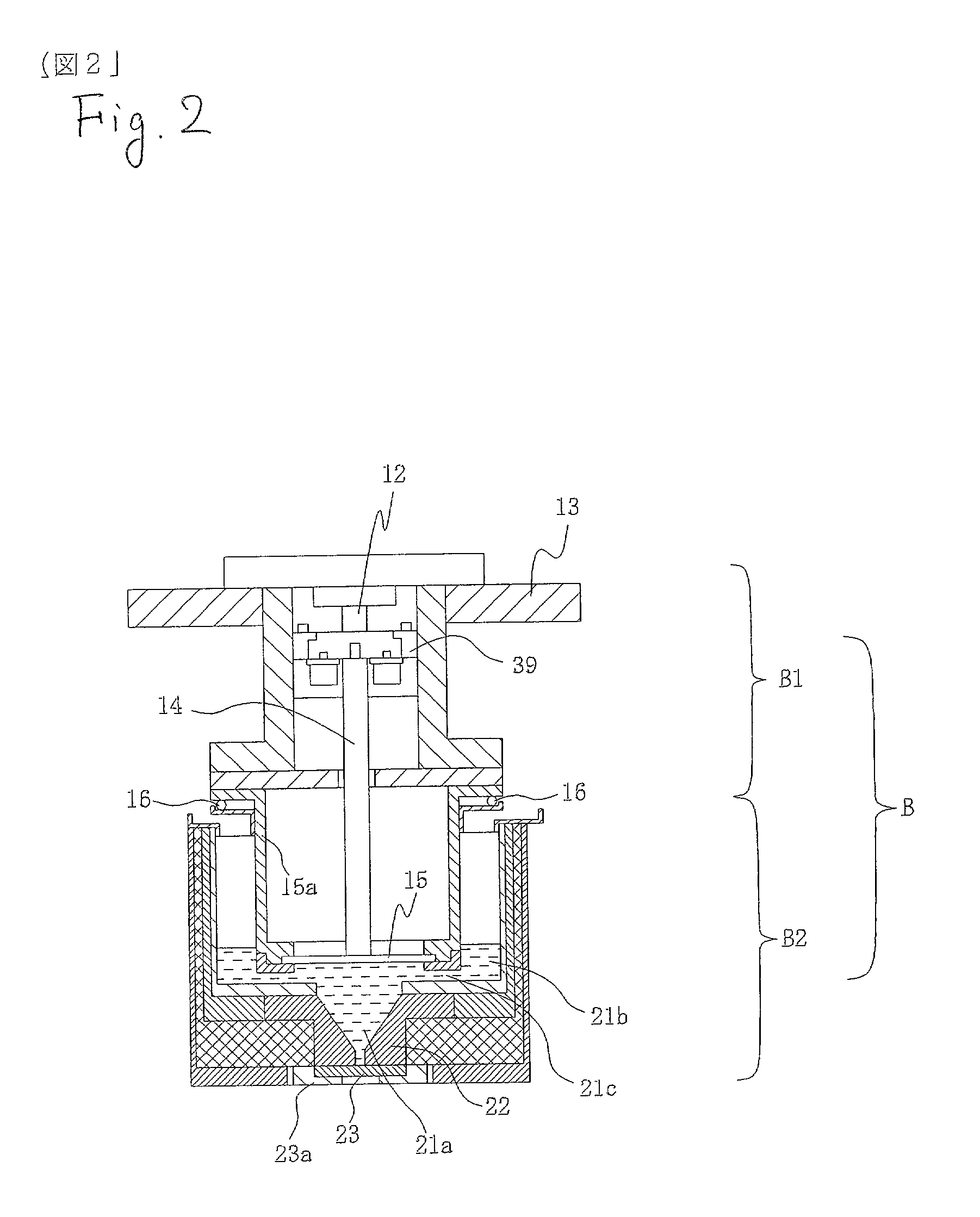

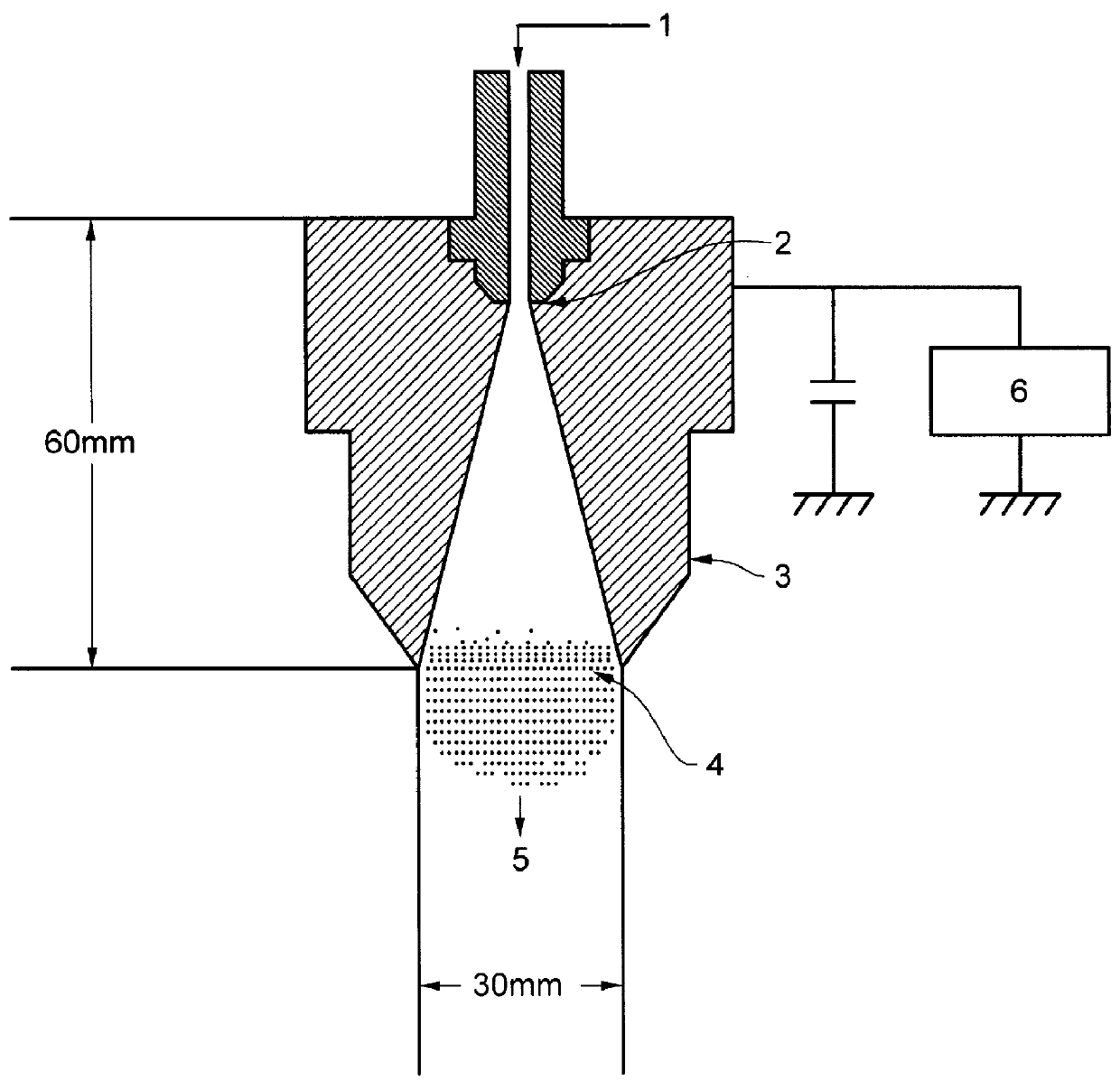

Production apparatus of monodisperse particle and production process of monodisperse particle and monodisperse particle produced by the process

InactiveUS20020089100A1Highly multi-purpose monodisperse particle industrially and cheaplyEasy to controlTransportation and packagingMetal-working apparatusMetallurgySlurry

It is the object to provide a production process of monodisperse particle in which monodisperse particle with uniform particle size (particle diameter) can be stably mass-produced, and monodisperse particle produced by this process, and its production apparatus. The supply pipe diameter deltaf is set to be greater than the orifice diameter deltao and the internal and external pressure of the slurry retention part b is controlled, and this allows to facilitate supply of the slurry through the supply pipe (21c), and continuously and efficiently supply the slurry, and then to produce monodisperse particle with uniform particle size (particle diameter).

Owner:KAWASAKI CORP KK

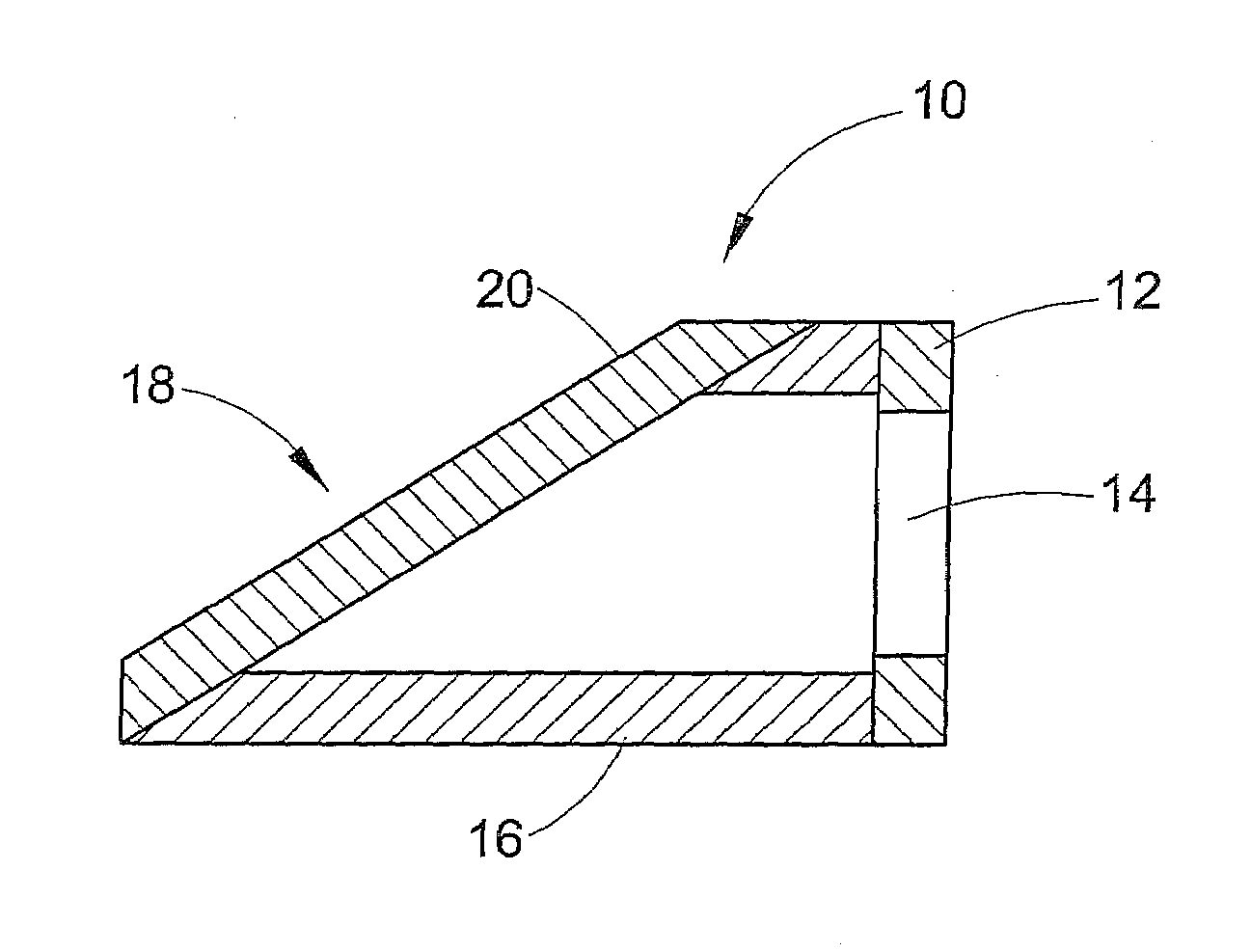

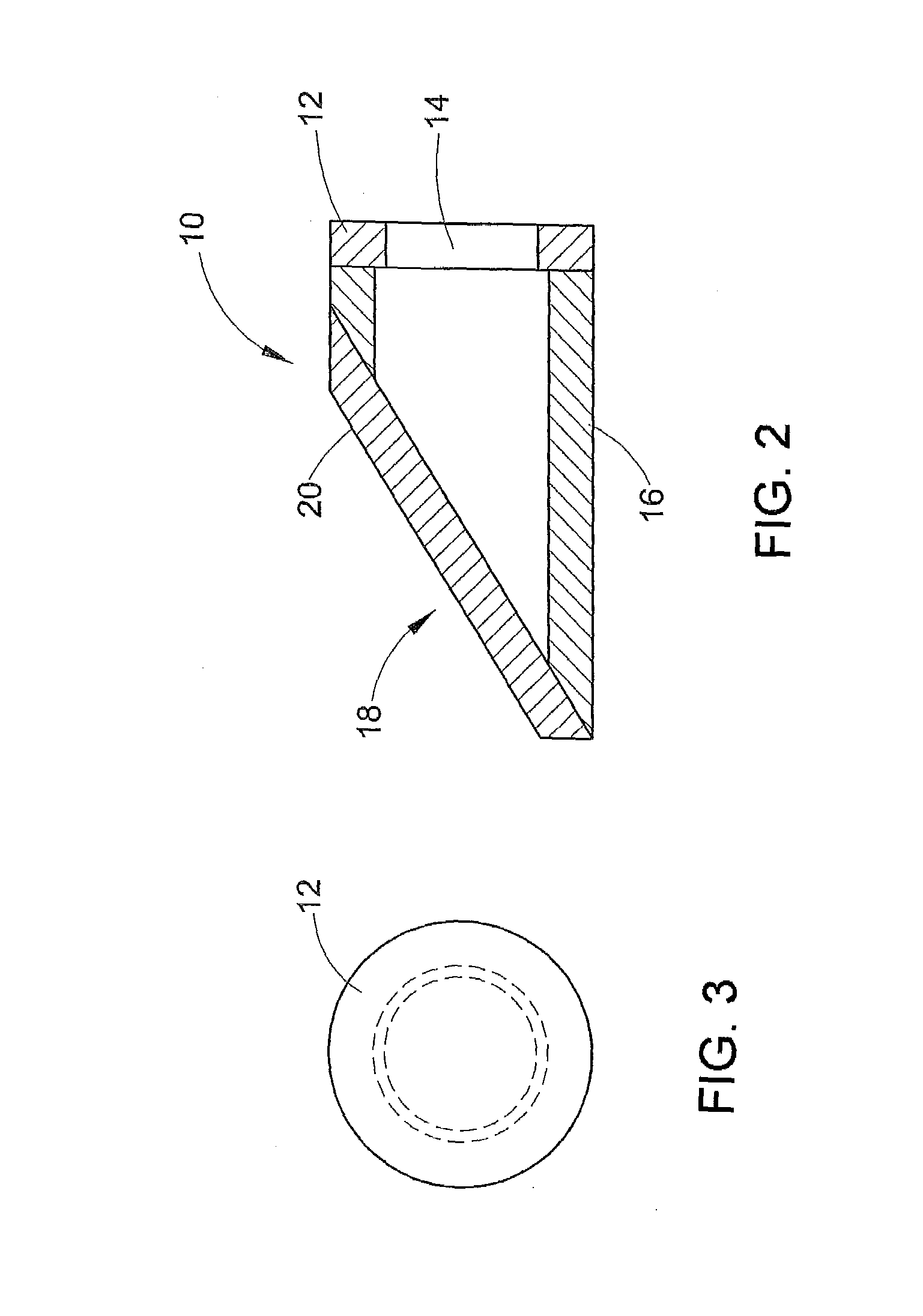

Bonded particle filters

InactiveUS7157043B2Significant portionMelt-holding vesselsMolten metal pouring equipmentsMolten metalMaterials science

An apparatus for filtering molten metal held in a vessel before the metal enters the dosing tube. The filtering apparatus includes an attachment portion that mounts to the dosing tube, a filter body connected to the attachment portion and a planar surface attached to an end of the filter body opposite the attachment portion. The filter body can include a beveled end opposite the attachment portion where the planar surface is attached. The apparatus can be made from a bonded-particle material made from silicon carbide or aluminum oxide held together by an aluminum-resistant binder.

Owner:METAULLICS SYST +1

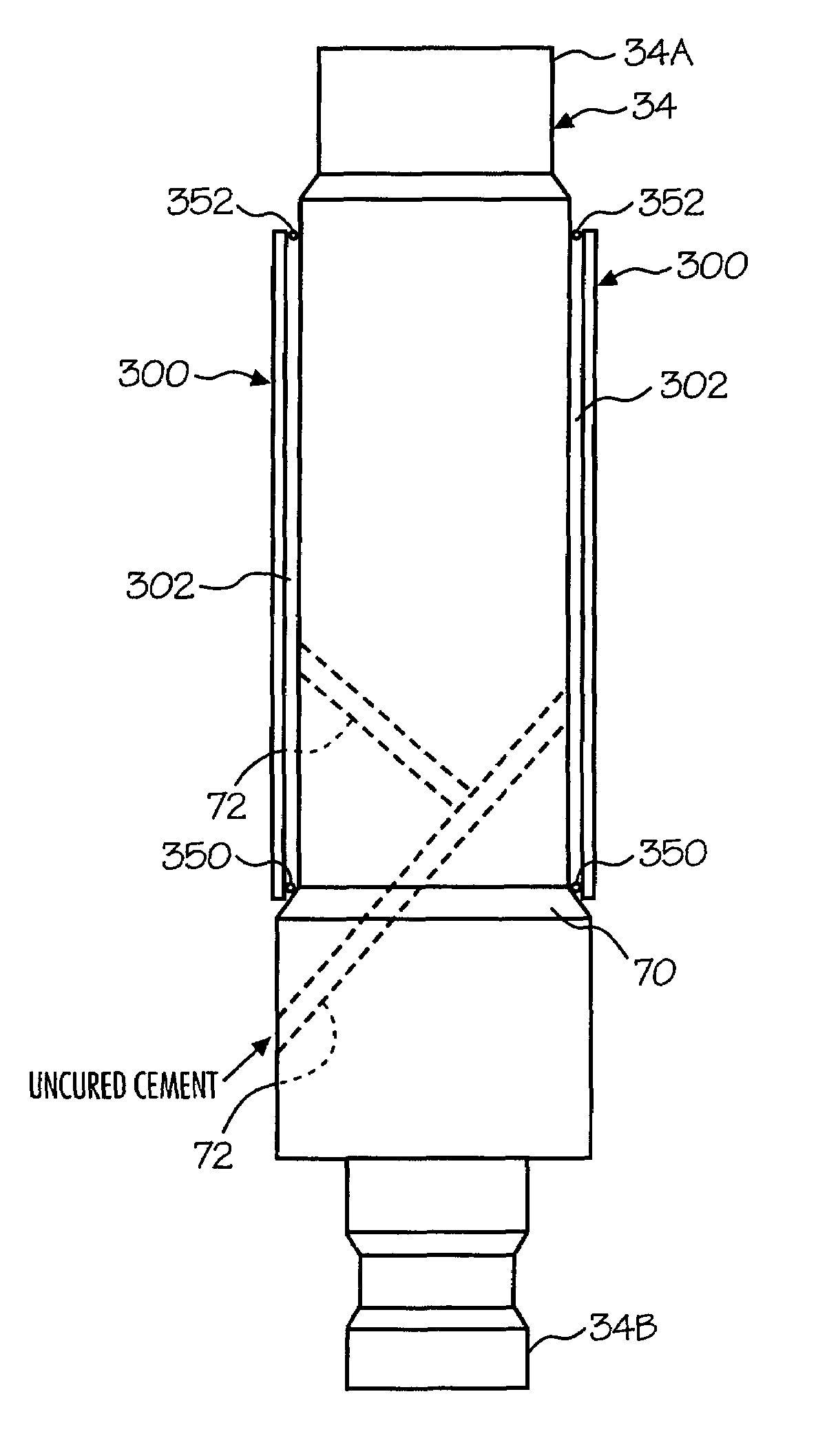

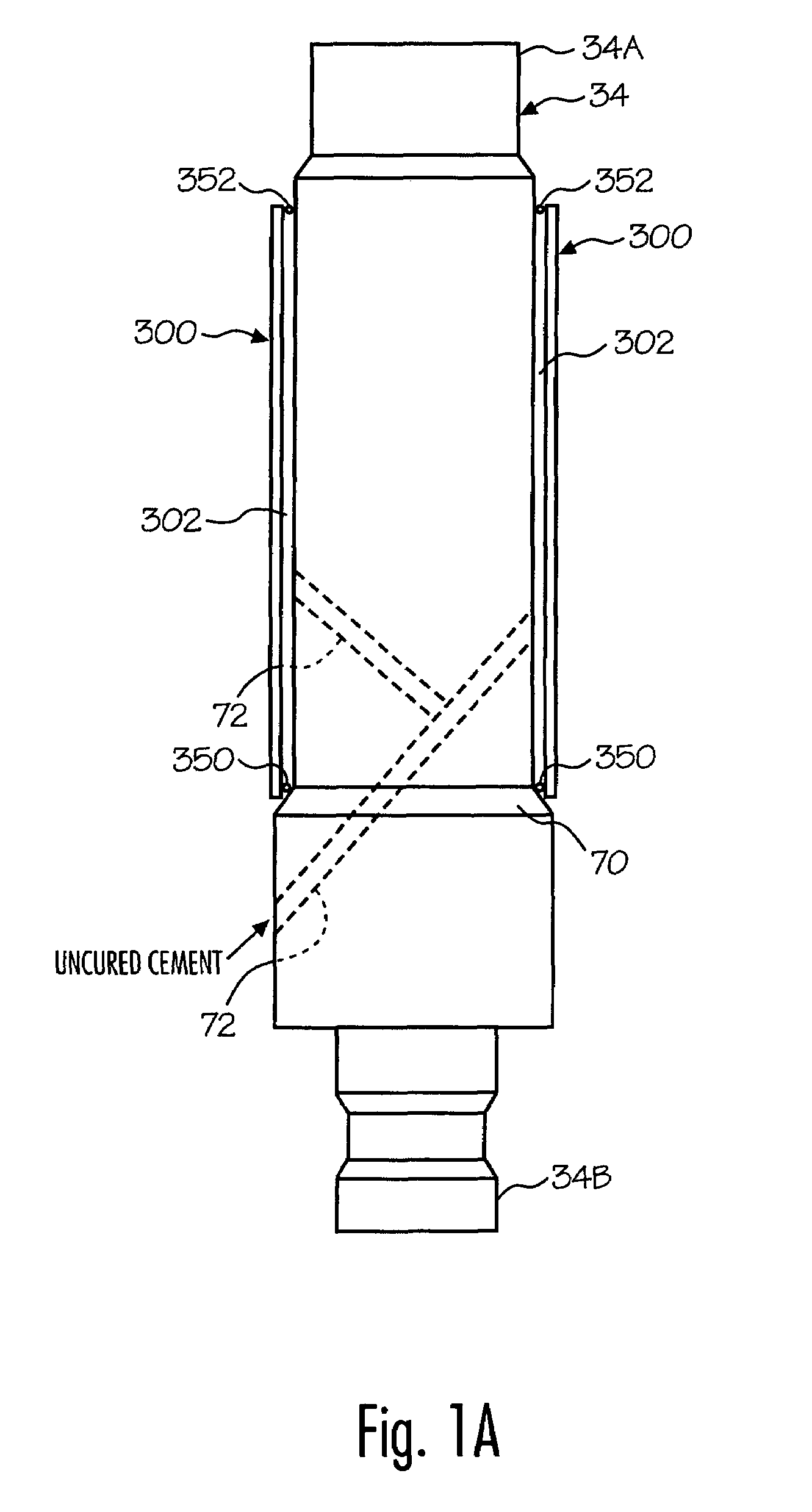

Protective coatings for molten metal devices

ActiveUS7507367B2Reduce componentsPrecise positioningSpecific fluid pumpsPump componentsMolten metalCoating

Disclosed are components covered with a protective coating for use in a molten metal bath (or comparable environment) and devices including such components. The protective coating is preferably a ceramic sleeve adhered to a non-coated component by cement. A component with the protective coating is more resistant to degradation in molten metal than is the component without the coating, and may be manufactured by the process of (a) placing the protective coating over the non-coated component, and (b) injecting cement into the space between the non-coated component and protective coating, wherein at least some of the cement is injected through a passage in either the non-coated component or the protective coating.

Owner:MOLTEN METAL EQUIP INNOVIATIONS LLC

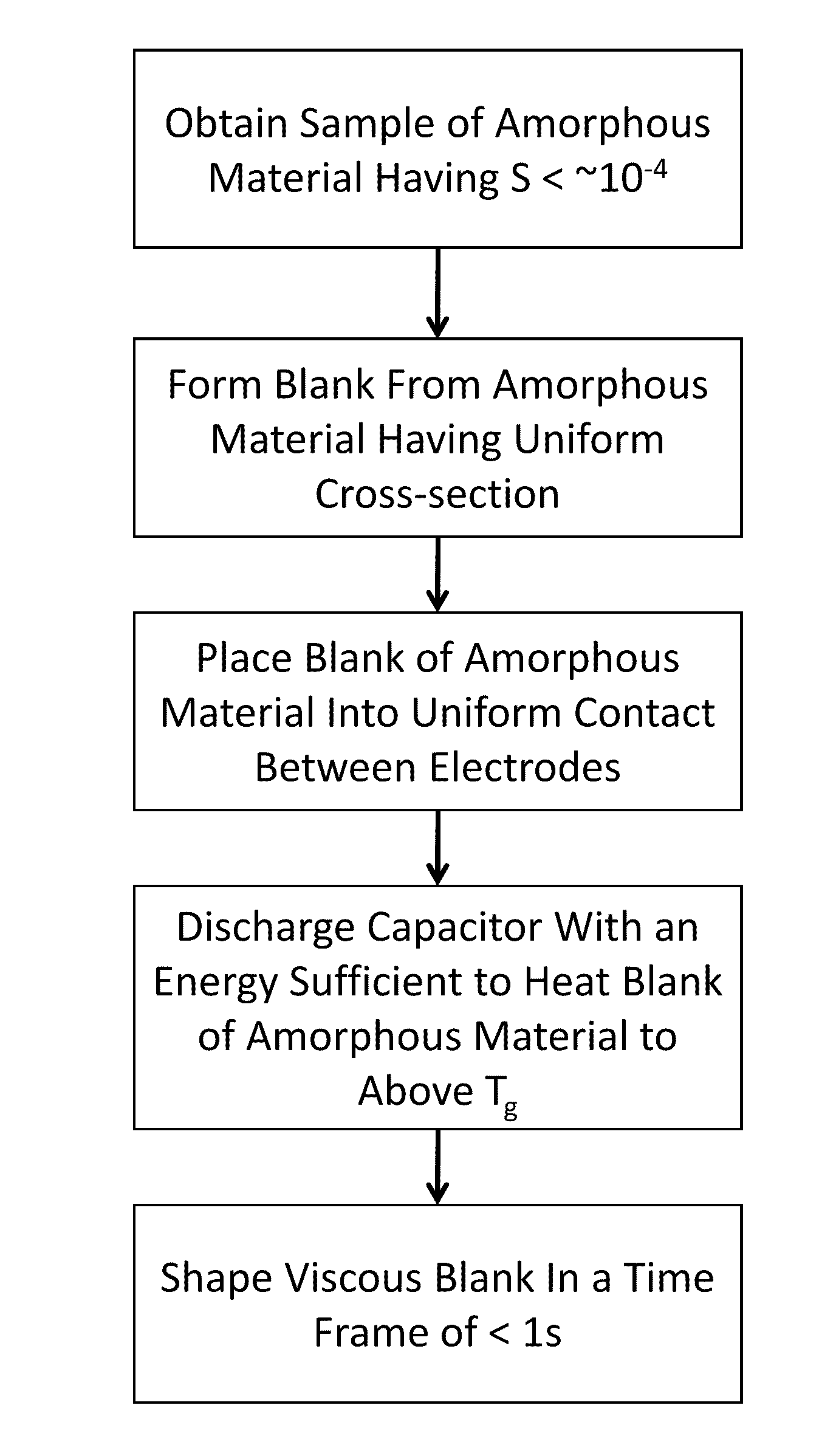

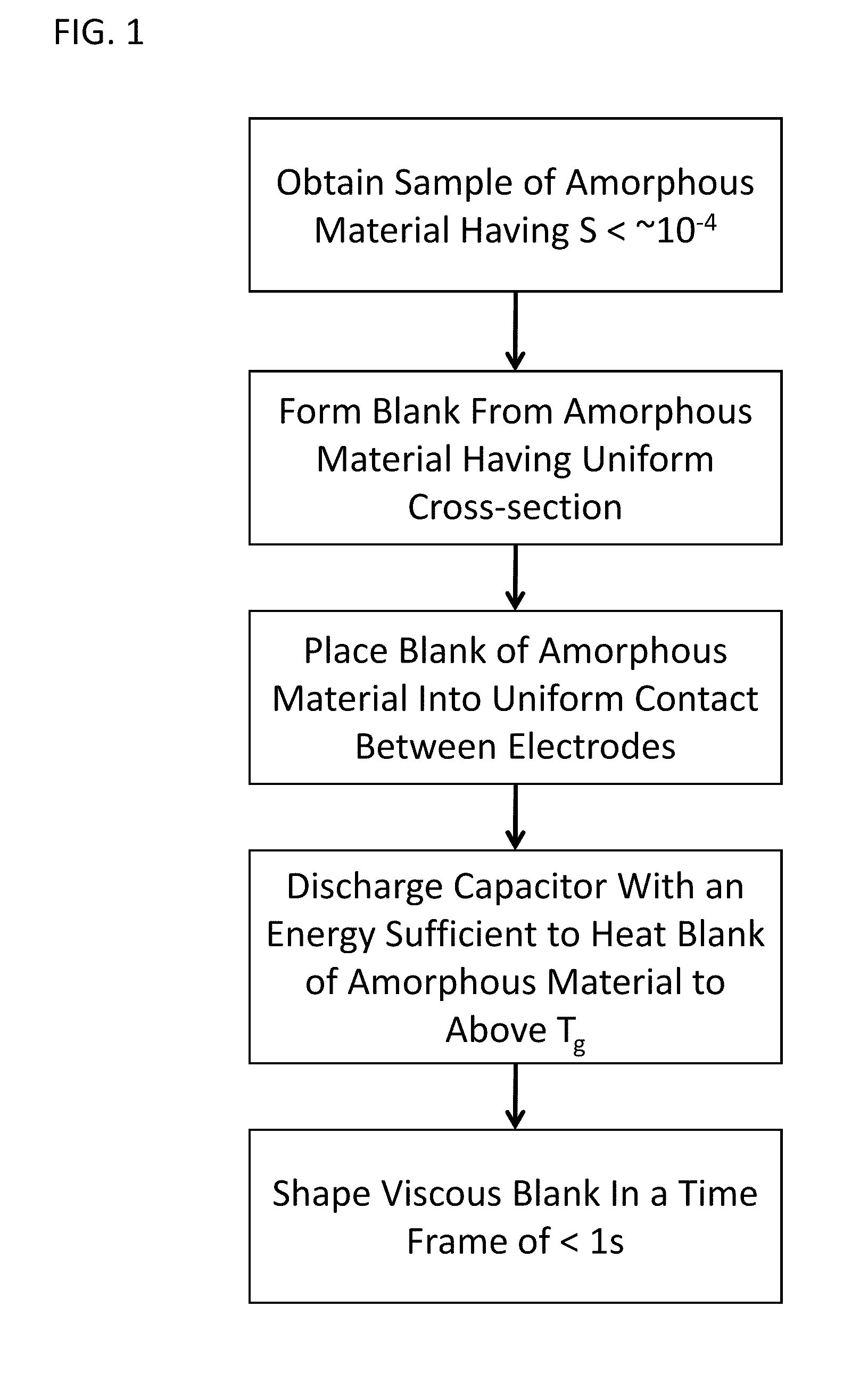

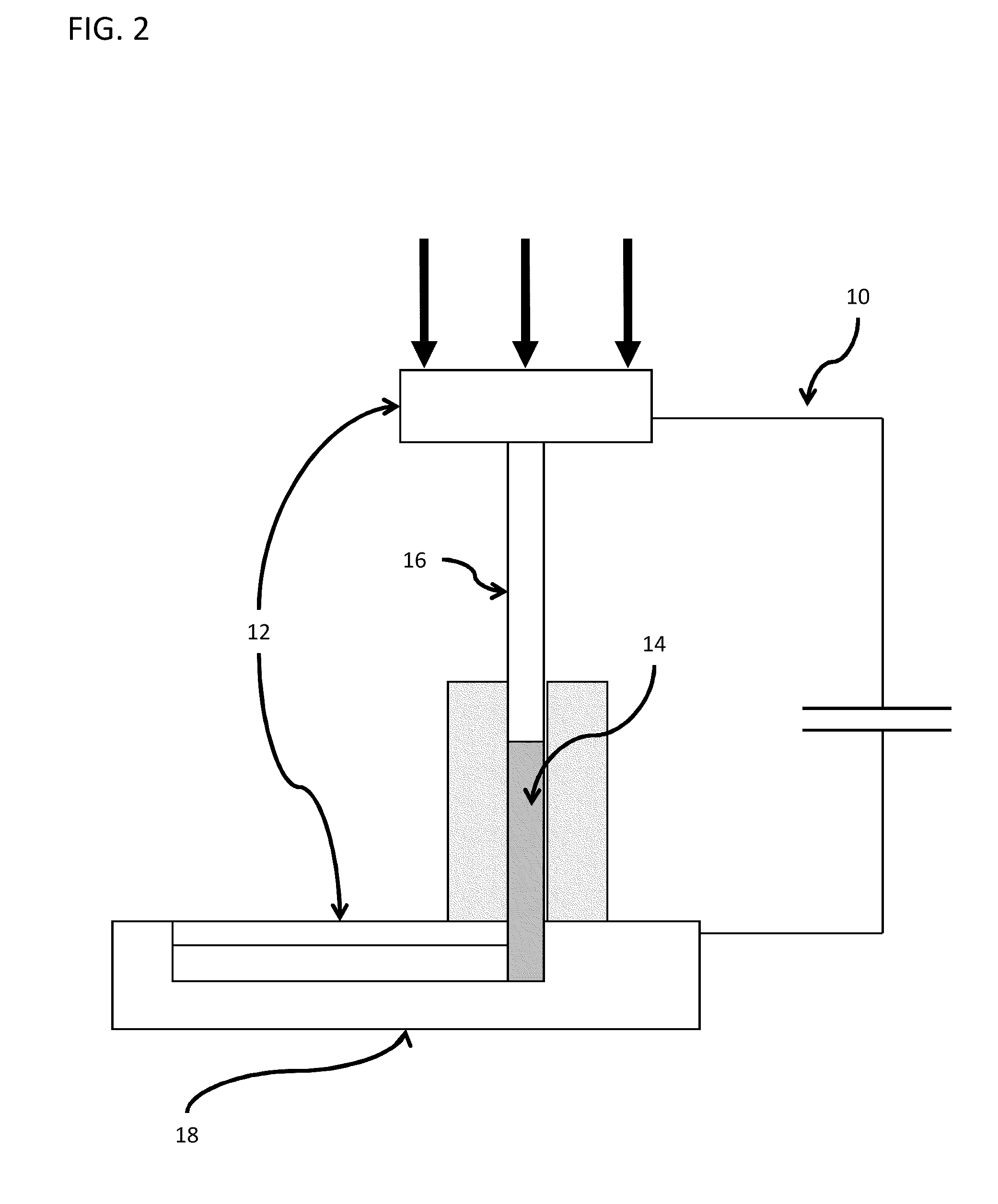

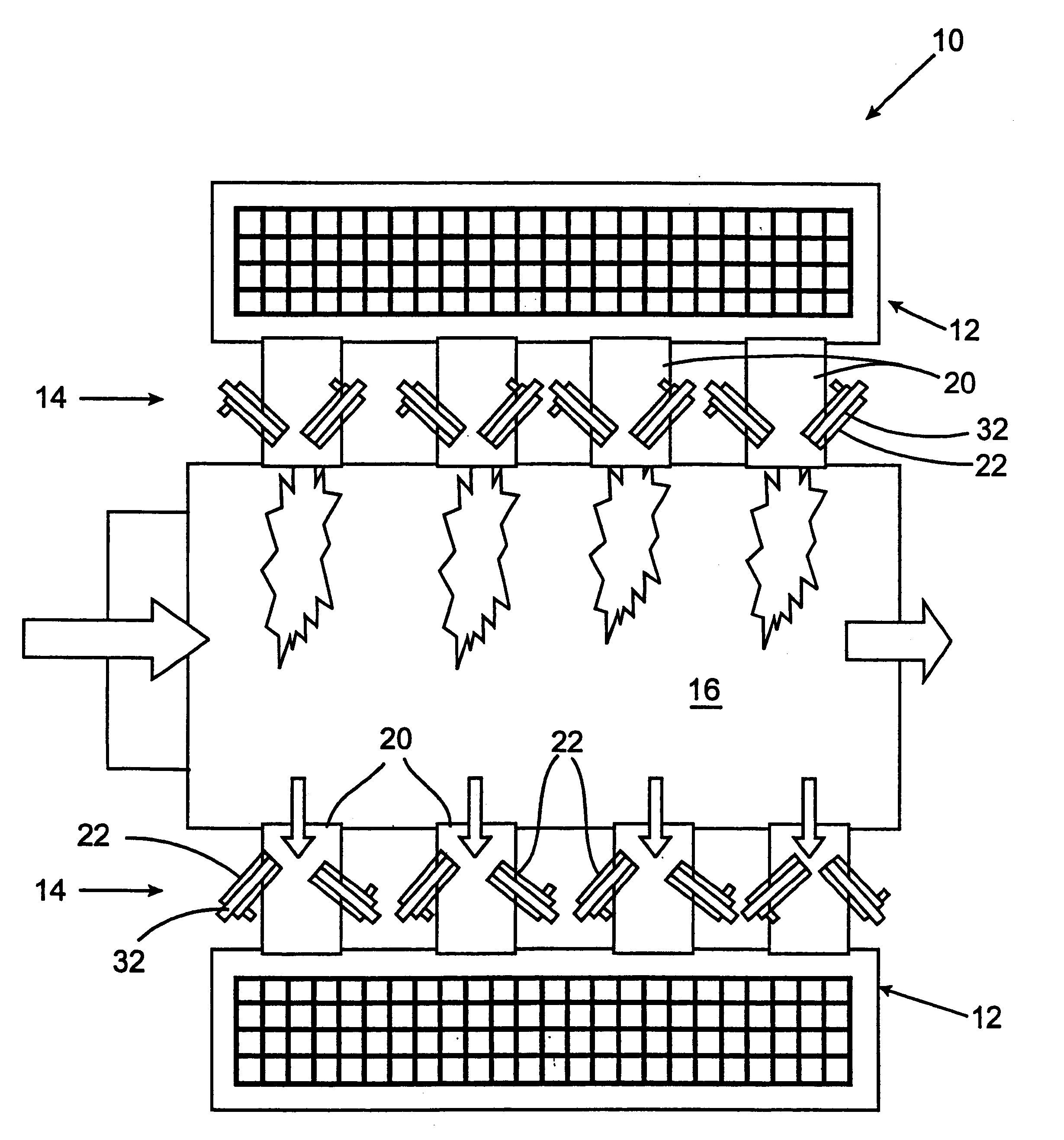

Forming of metallic glass by rapid capacitor discharge

ActiveUS20090236017A1Avoid failureAvoid thermal transport and development of thermalDielectric heatingShaping toolsAlloyGlass transition

An apparatus and method of uniformly heating, rheologically softening, and thermoplastically forming metallic glasses rapidly into a net shape using a rapid capacitor discharge forming (RCDF) tool are provided. The RCDF method utilizes the discharge of electrical energy stored in a capacitor to uniformly and rapidly heat a sample or charge of metallic glass alloy to a predetermined “process temperature” between the glass transition temperature of the amorphous material and the equilibrium melting point of the alloy in a time scale of several milliseconds or less. Once the sample is uniformly heated such that the entire sample block has a sufficiently low process viscosity it may be shaped into high quality amorphous bulk articles via any number of techniques including, for example, injection molding, dynamic forging, stamp forging, and blow molding in a time frame of less than 1 second.

Owner:CALIFORNIA INST OF TECH

Method of retrofitting a furnace to provide oxygen enrichment

An oxygen enrichment system is provided which uses the existing air / fuel burners of a regenerative furnace to distribute additional oxygen to the burners for increased efficiency, and reduced nitrous oxide emissions. The centrally positioned cooling air lances in the burners of a regenerative furnace are modified to deliver oxygen when the burners are firing for oxygen enrichment. During the burmer firing cycle, oxygen is delivered from an oxygen supply through the oxygen lance to provide a central oxygen jet. The fuel is delivered concentrically around the oxygen jet. During the non-firing cycle of the burner, cooling air or other cooling fluid is delivered from the cooling air supply through the oxygen jet for cooling the offside of the furnace.

Owner:AIR LIQUIDE AMERICA INC

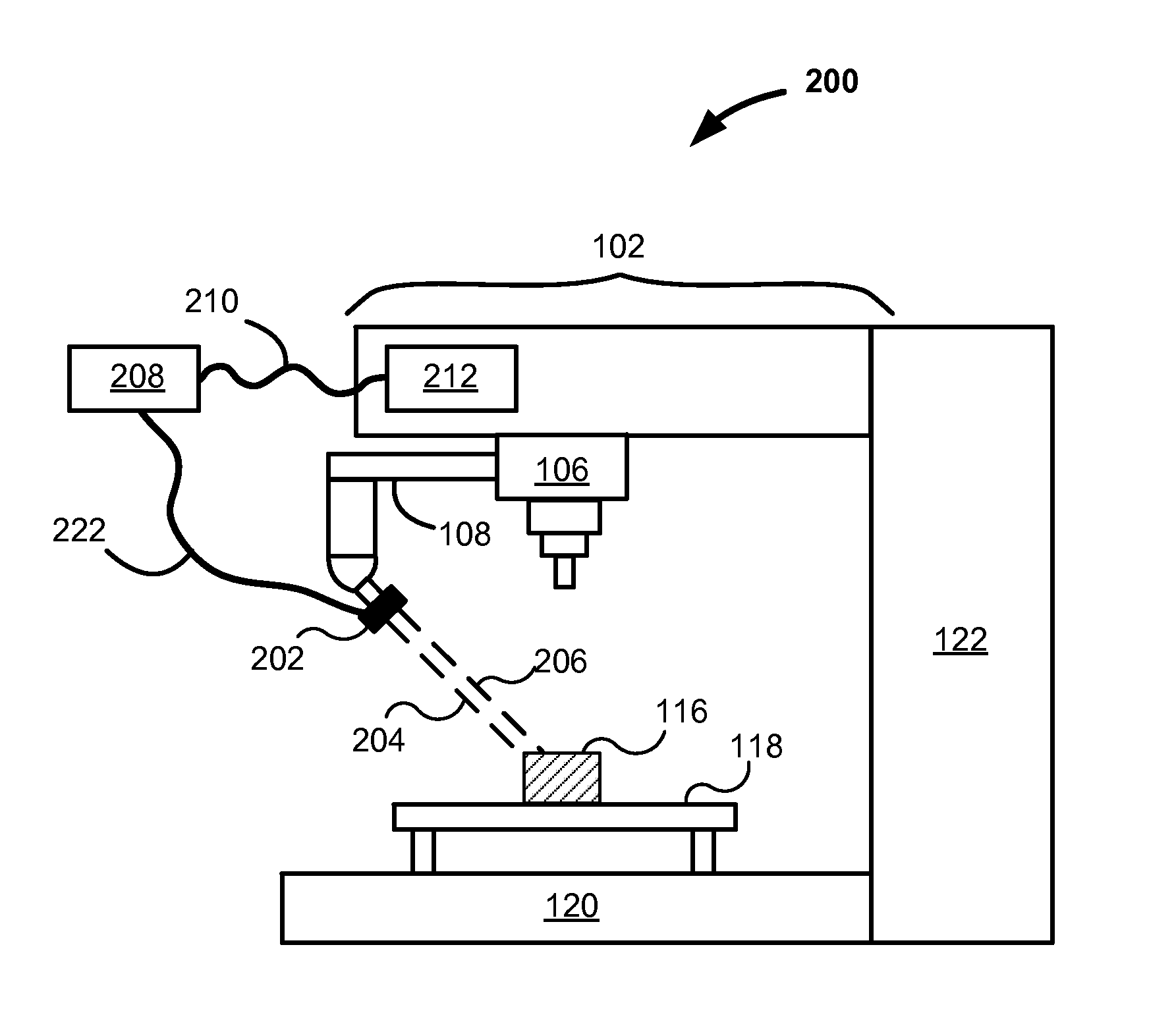

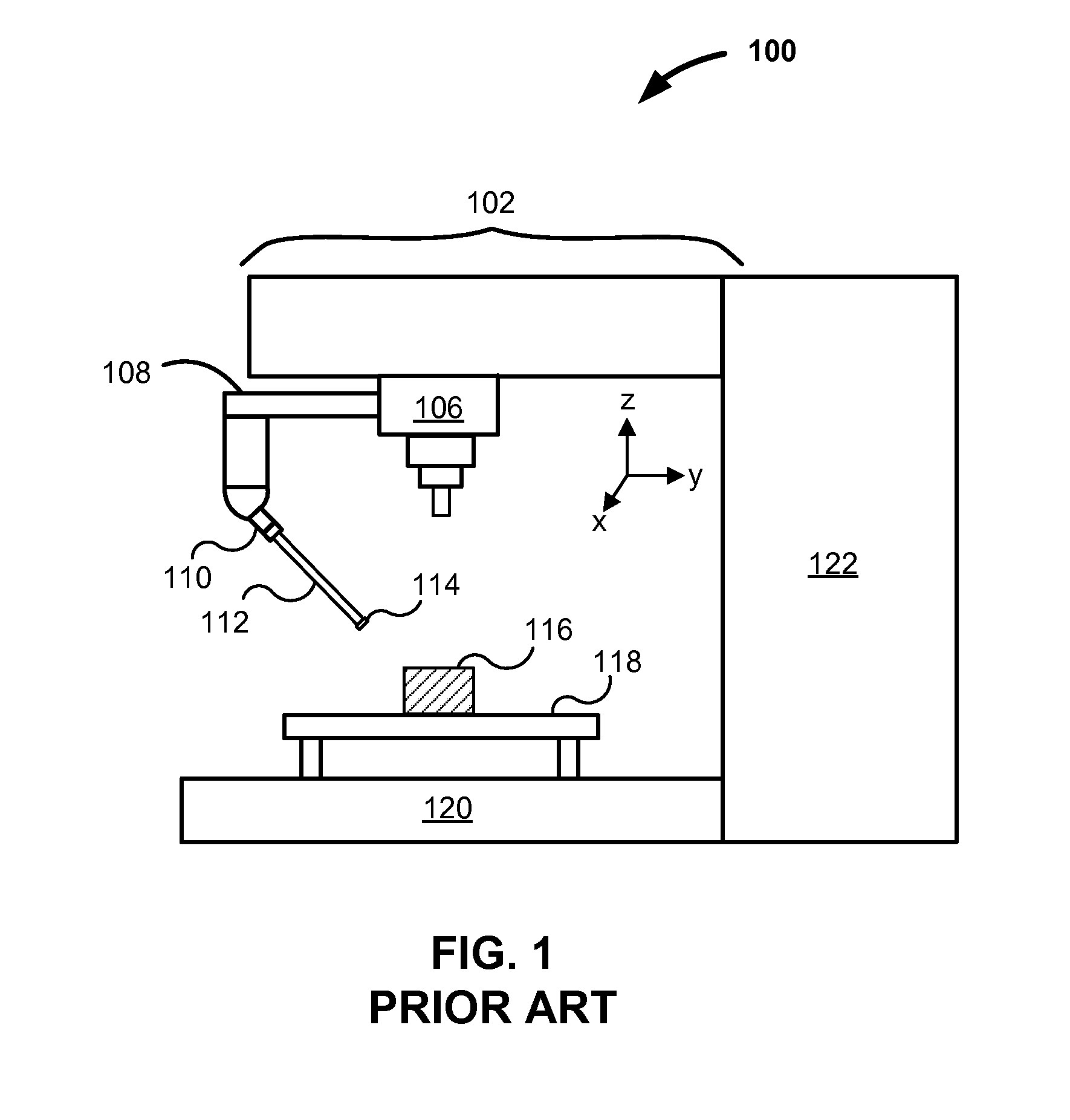

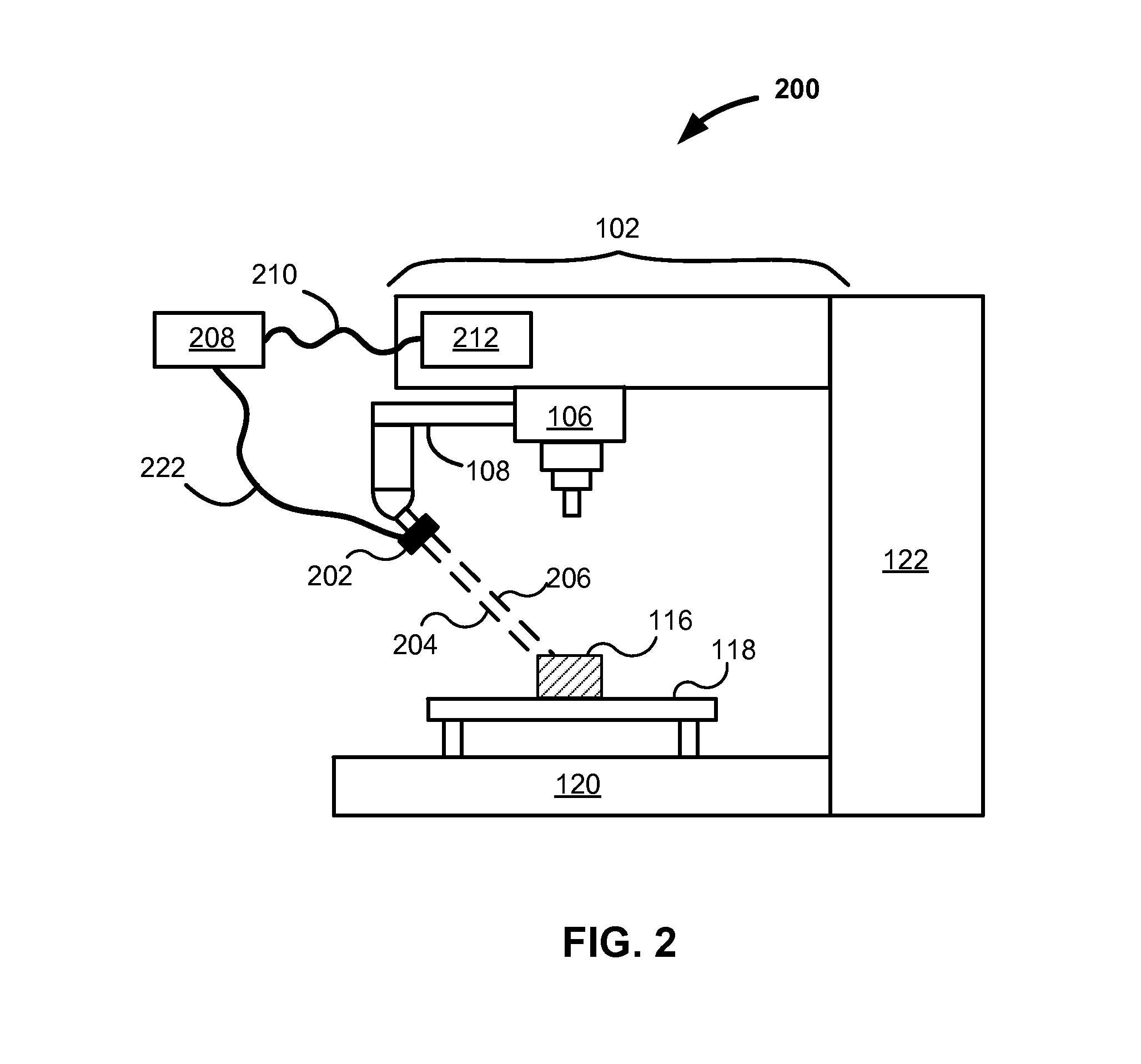

High Speed Metrology with Numerically Controlled Machines

ActiveUS20140157610A1Accurate verificationTight stack-up toleranceVibration measurement in solidsAnalysing solids using sonic/ultrasonic/infrasonic wavesNumerical controlMetrology

Systems, apparatuses and methods are described for integrating an electronic metrology sensor with precision production equipment such as computer numerically controlled (CNC) machines. For example, a laser distance measuring sensor is used. Measurements are taken at a relatively high sample rate and converted into a format compatible with other data generated or accepted by the CNC machine. Measurements from the sensor are synchronized with the position of the arm of the machine such as through the use of offsets. Processing yields a detailed and highly accurate three-dimensional map of a workpiece in the machine. Applicable metrology instruments include other near continuously reading non-destructive characterization instruments such as contact and non-contact dimensional, eddy current, ultra-sound, and X-Ray Fluorescence (XRF) sensors. Various uses of measurements include: multiple component matching, correction of machine drift, closed loop control of machines, and verification of product tolerances via substantially complete serialized dimensional quality control.

Owner:GRALE TECH

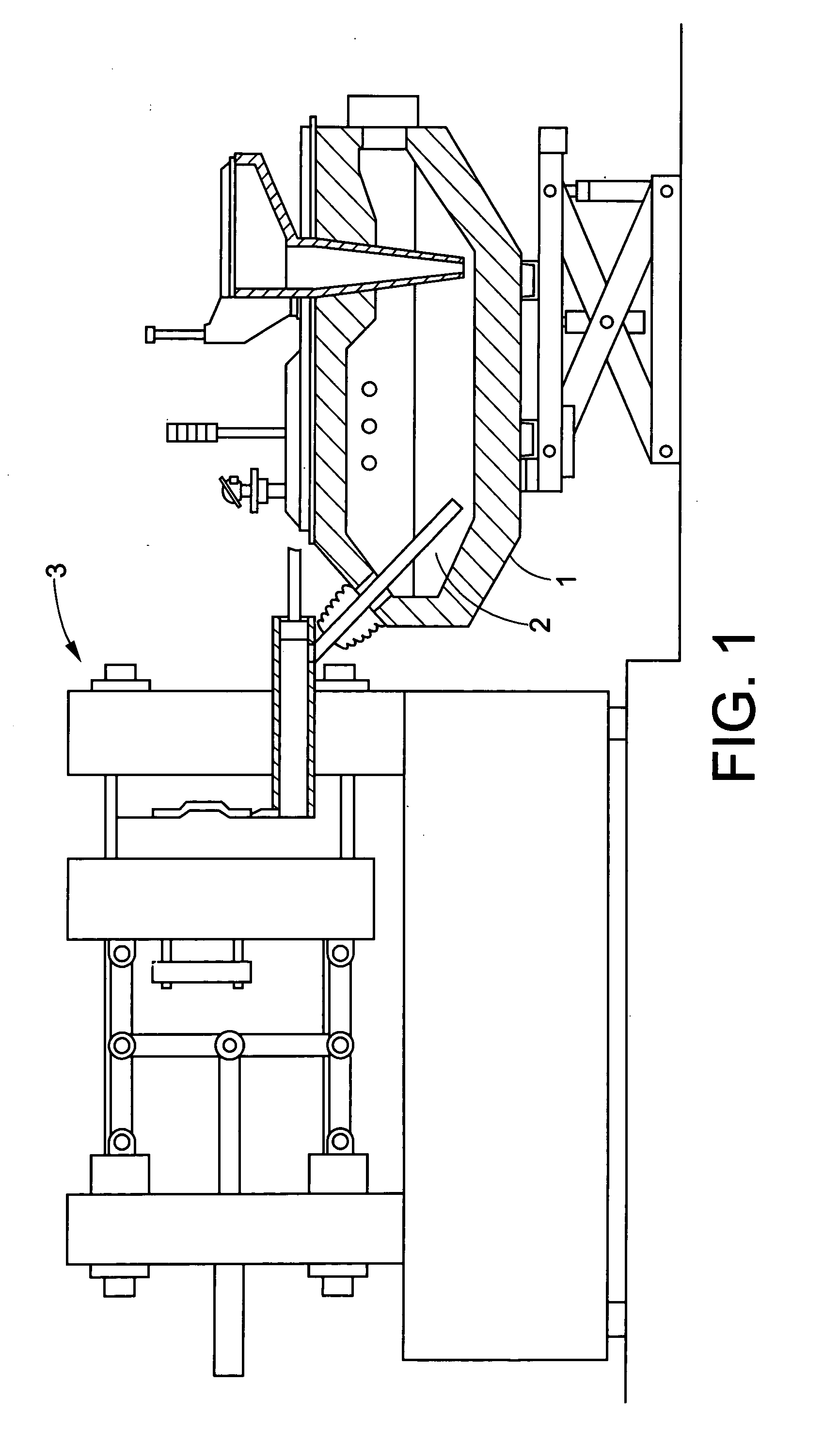

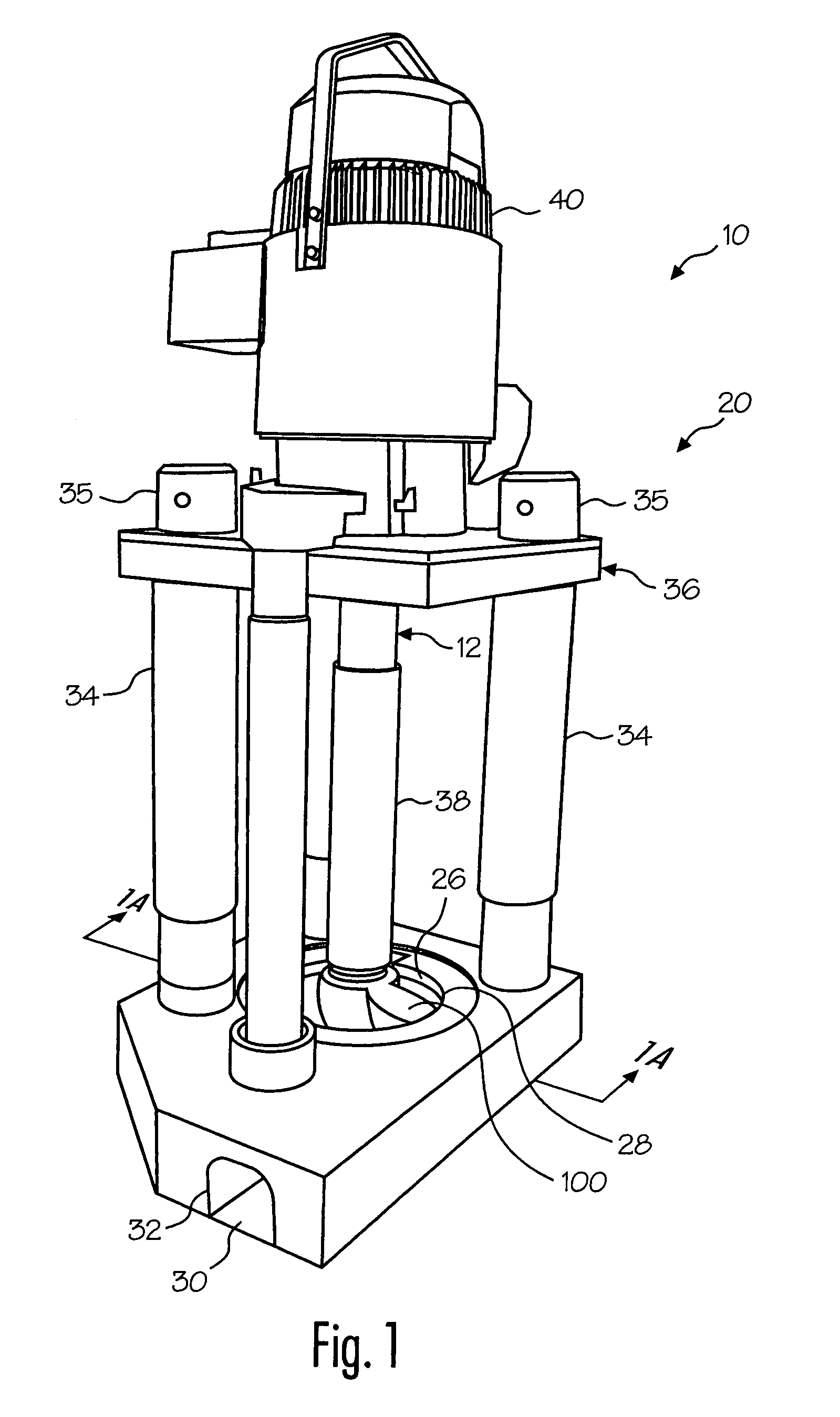

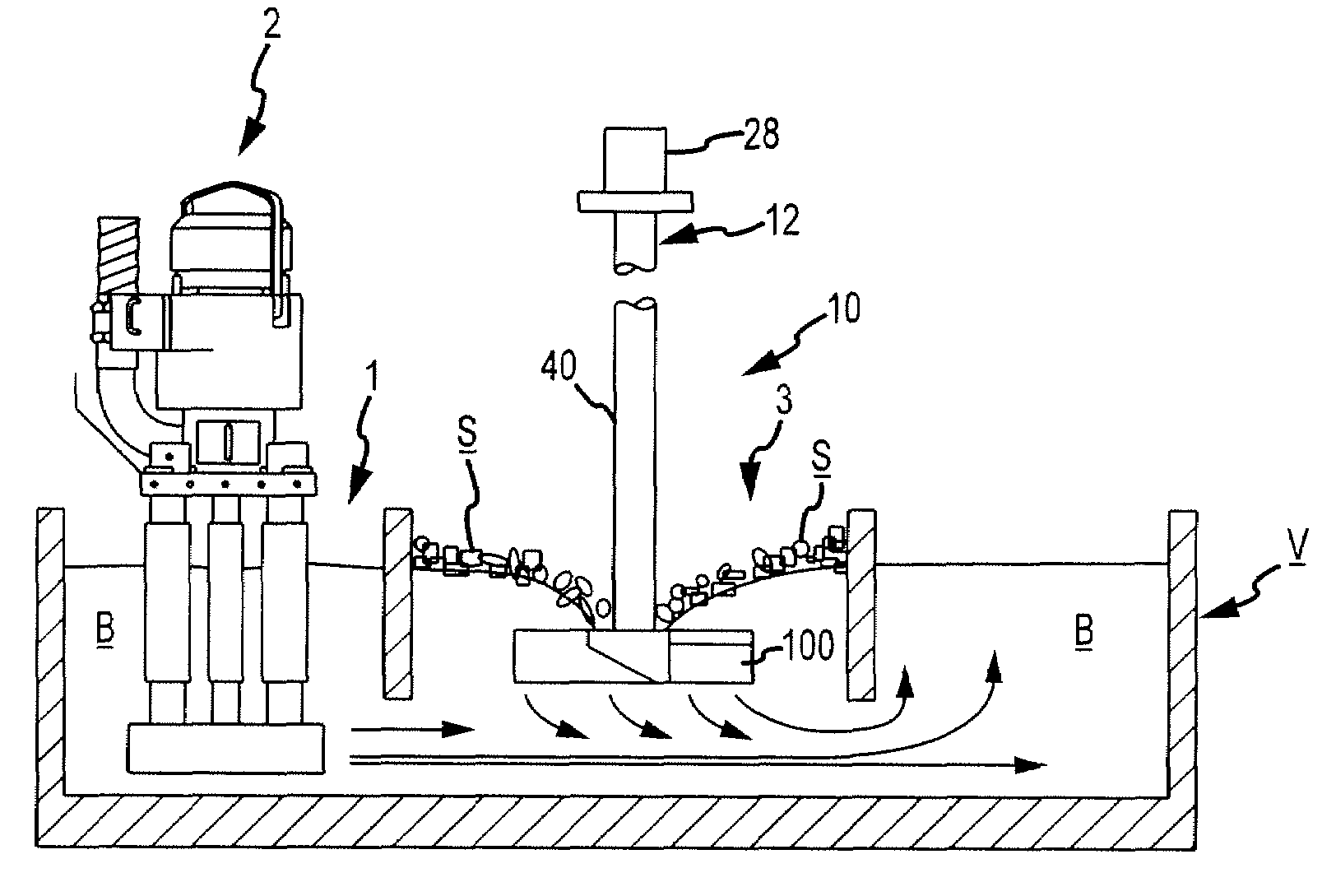

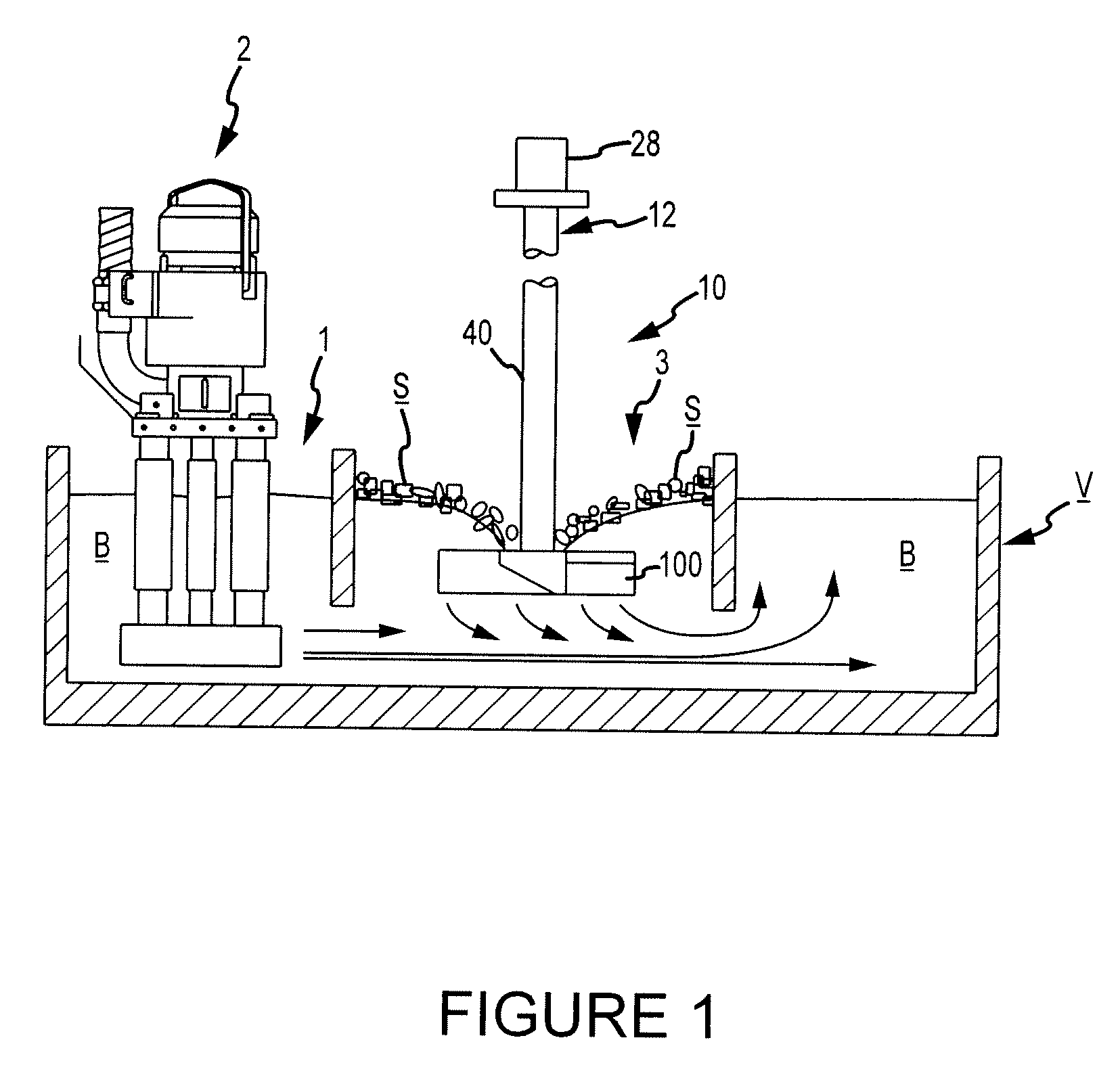

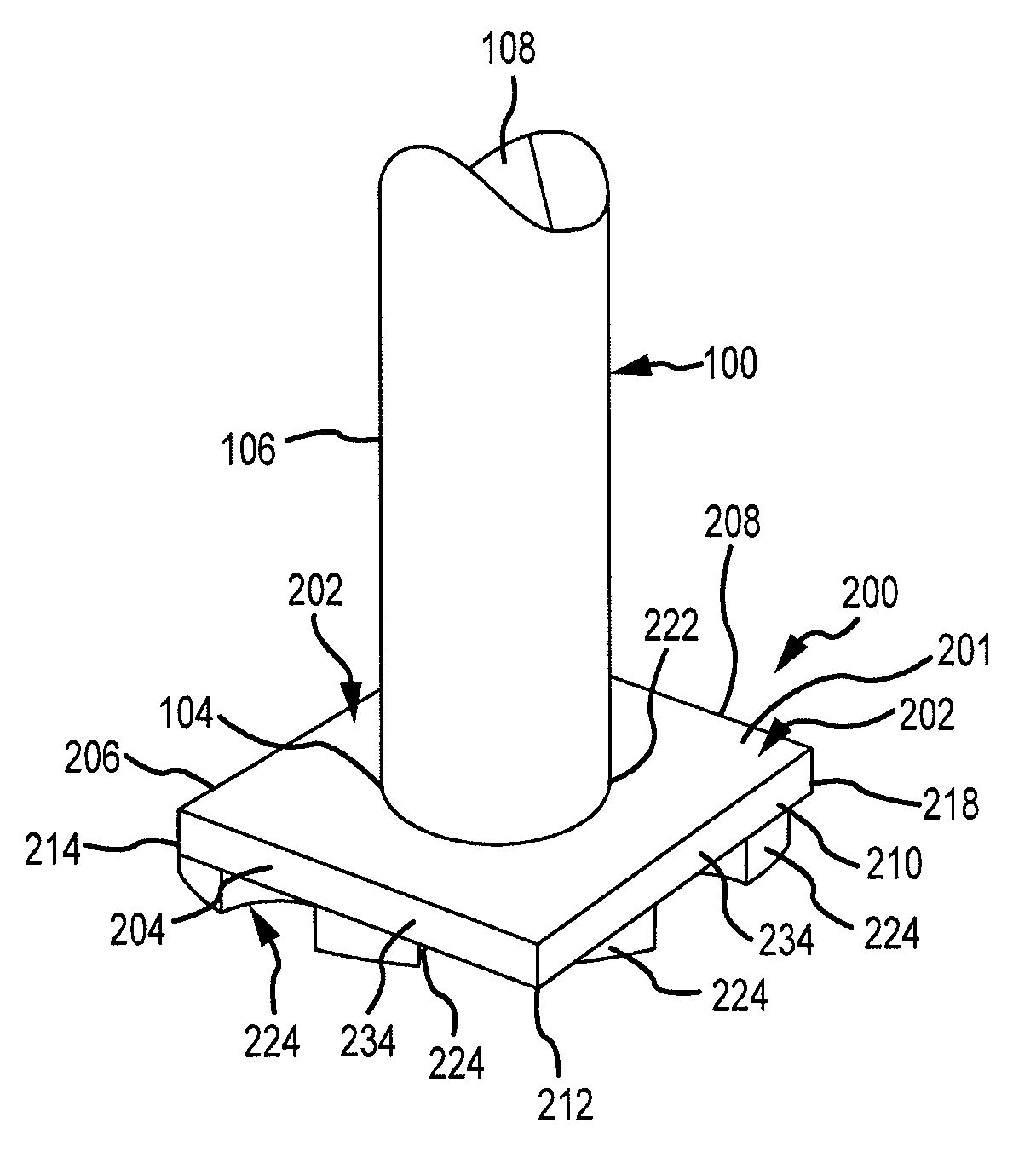

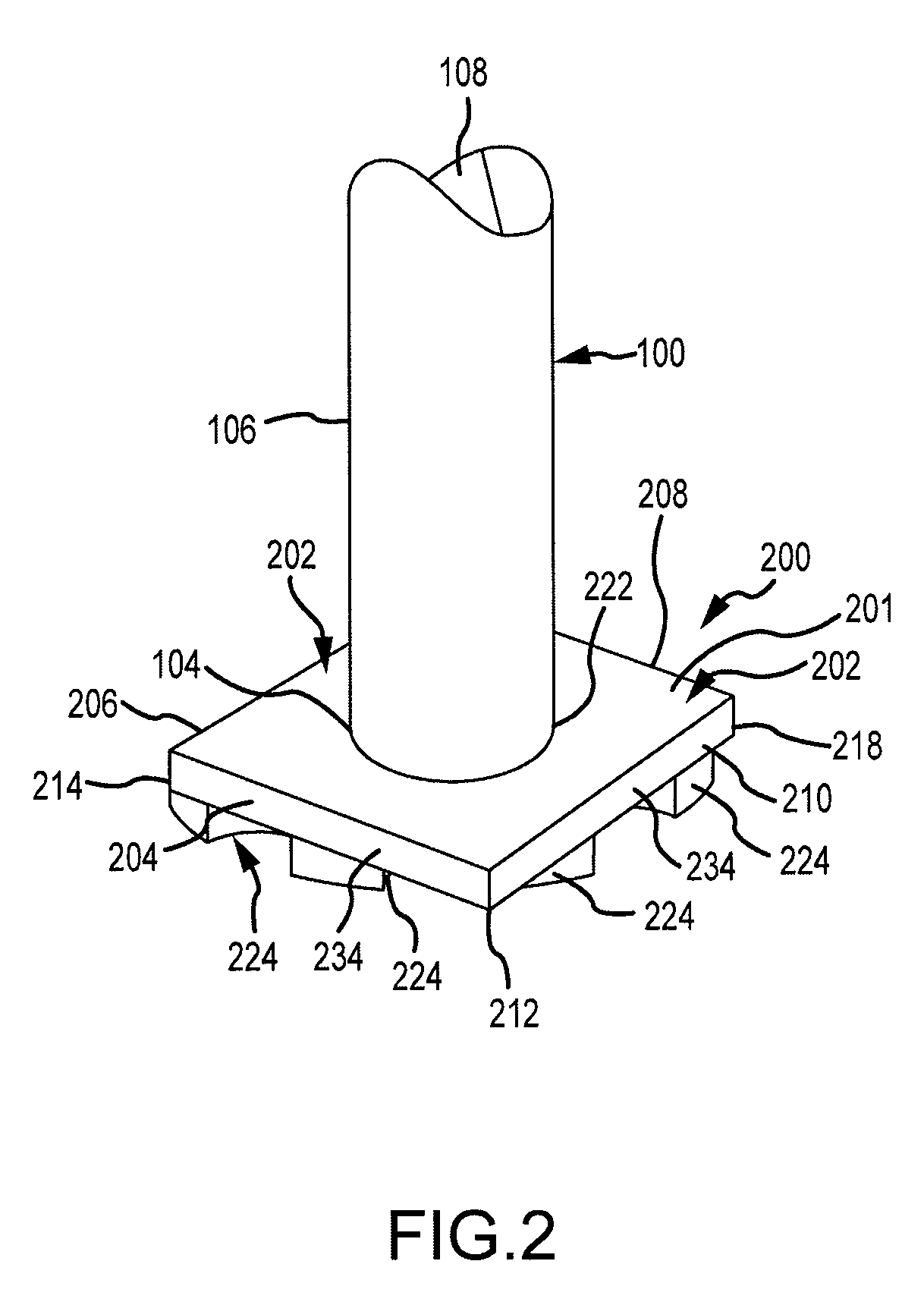

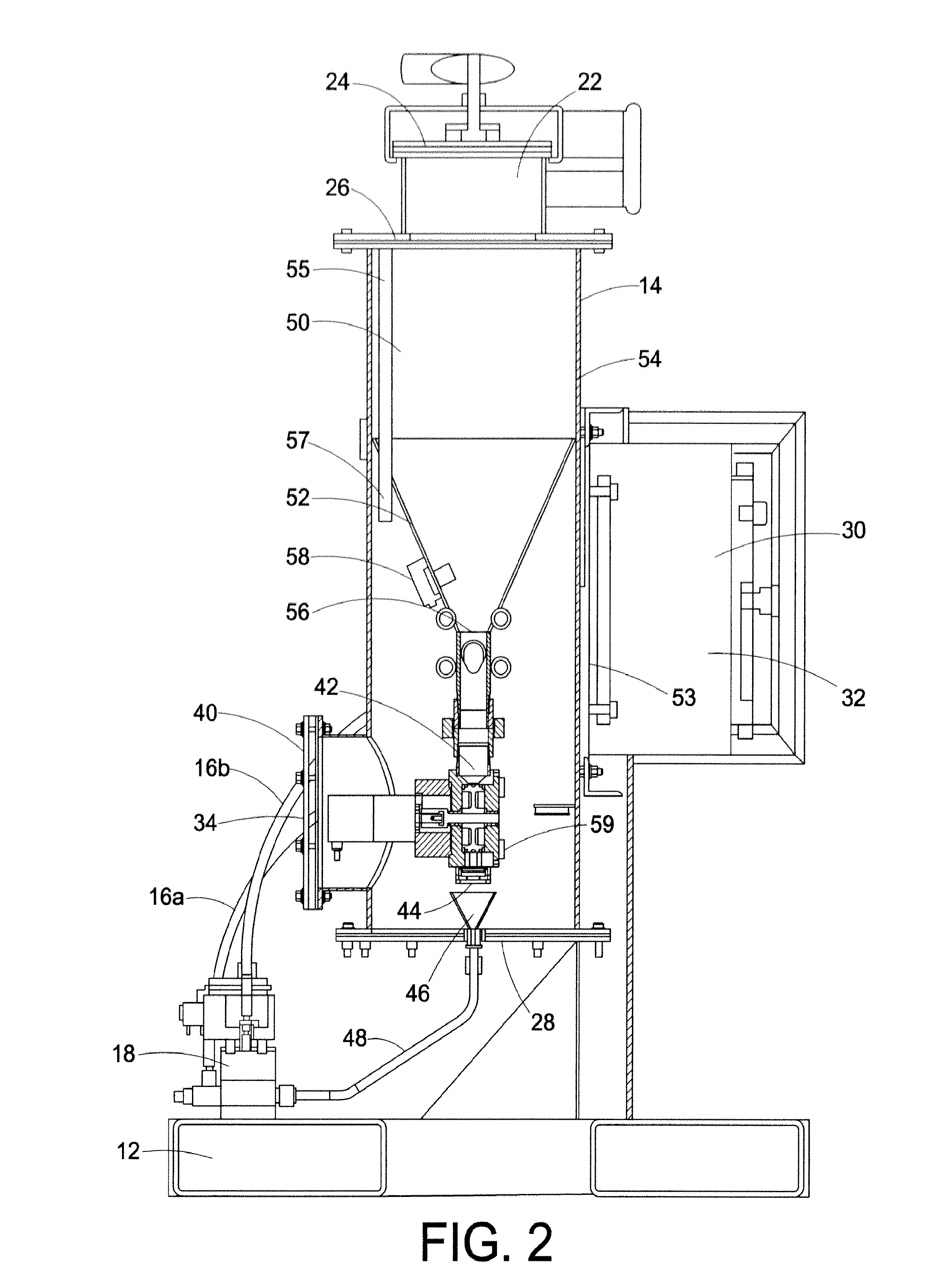

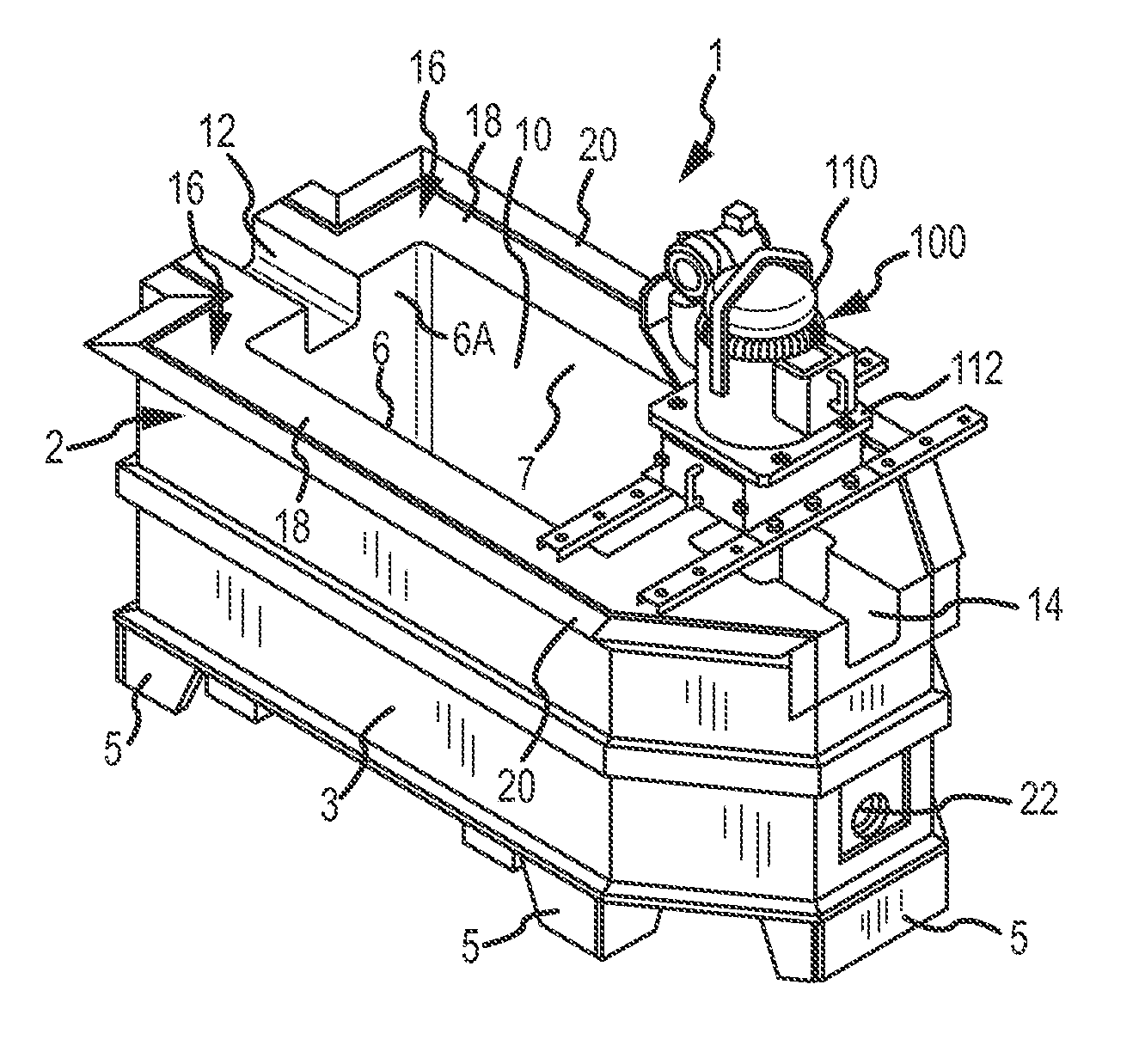

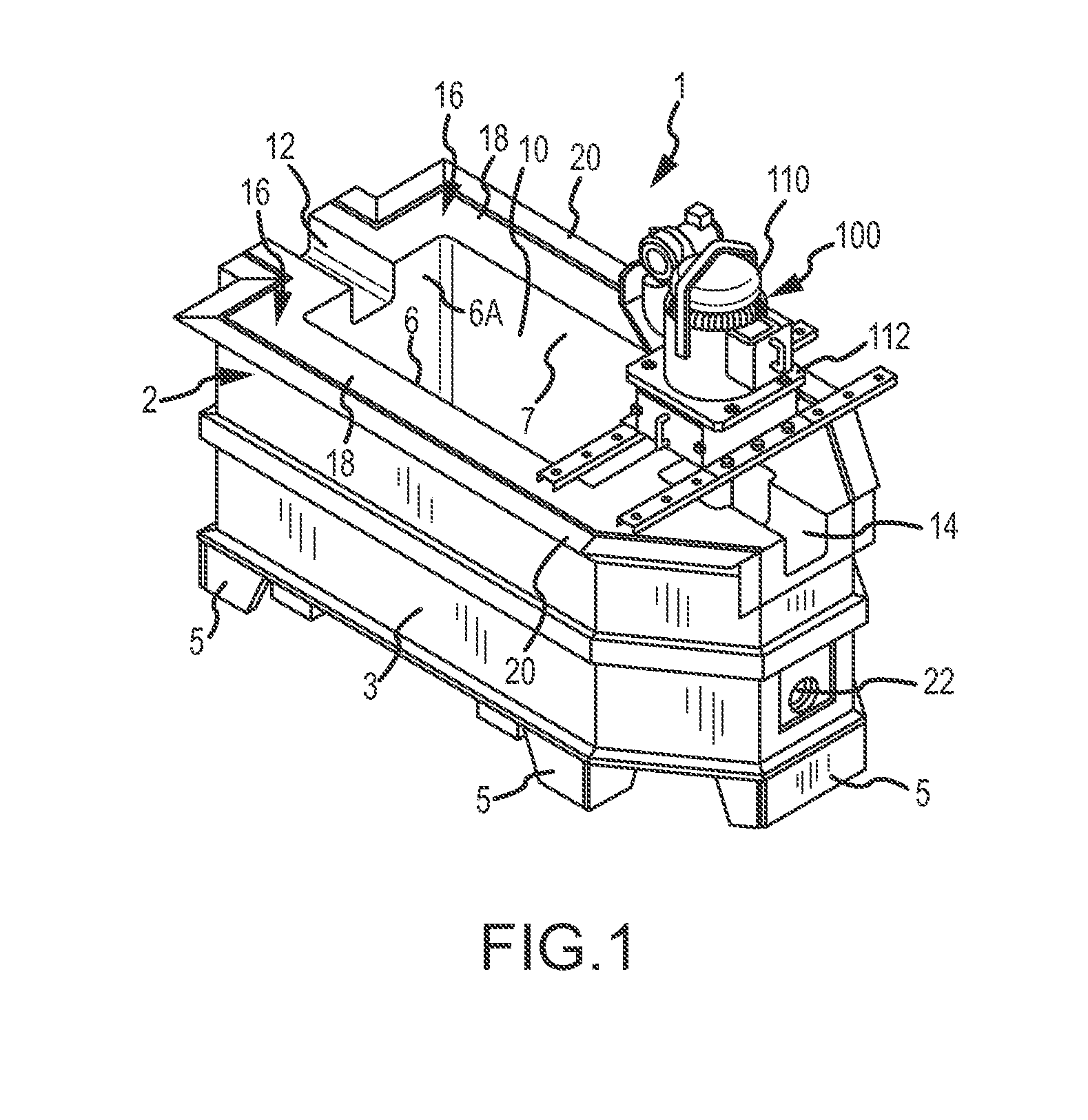

Scrap melter and impeller therefore

InactiveUS20080230966A1Reduce jammingReduce cloggingMelt-holding vesselsStirring devicesImpellerDrive shaft

A device for submerging scrap metal includes: (a) a drive source, (b) a drive shaft having a first end and a second end, the first end being connected to the drive source, and (d) an impeller connected to the second end of the drive shaft, the impeller preferably having two or more outwardly-extending blades. Preferably, each of the blades has a portion that directs molten metal at least partially downward. The impeller design leads to lower operating speeds, lower vibration, longer component life and less maintenance. Additionally, the impeller preferably has a connective portion. The connective portion is used to connect the impeller to the shaft and preferably comprises a nonthreaded, tapered bore extending through the impeller.

Owner:COOPER PAUL V

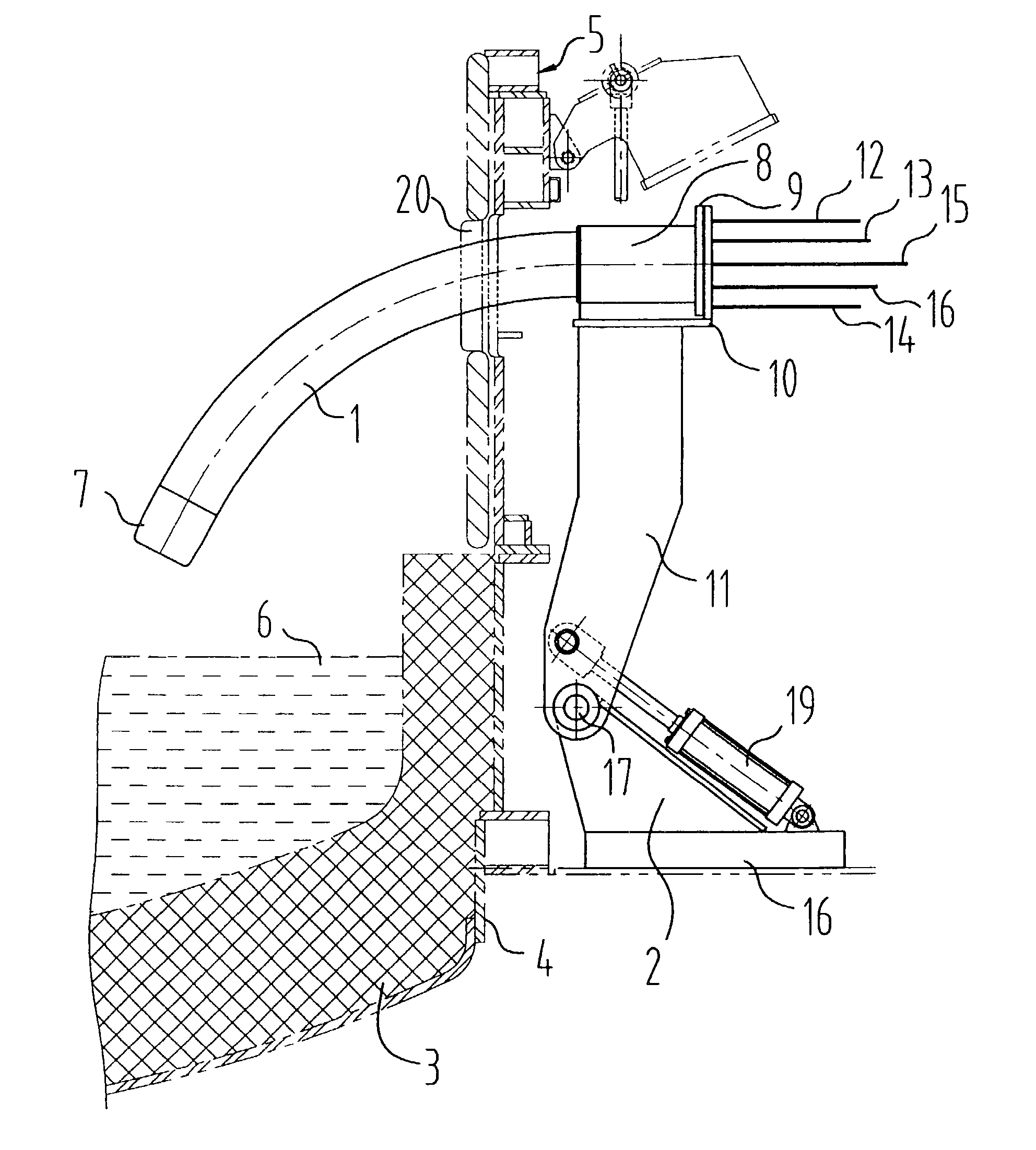

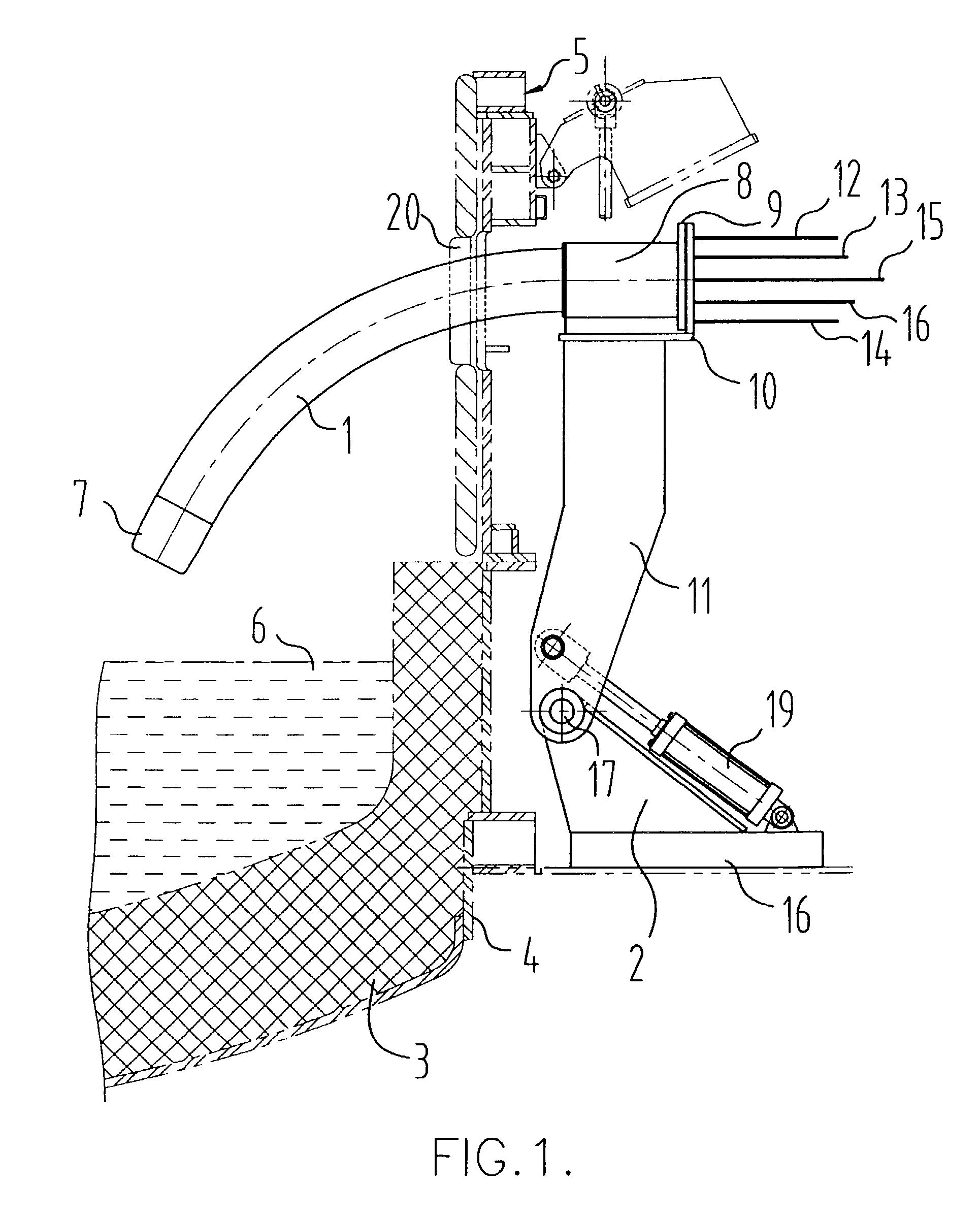

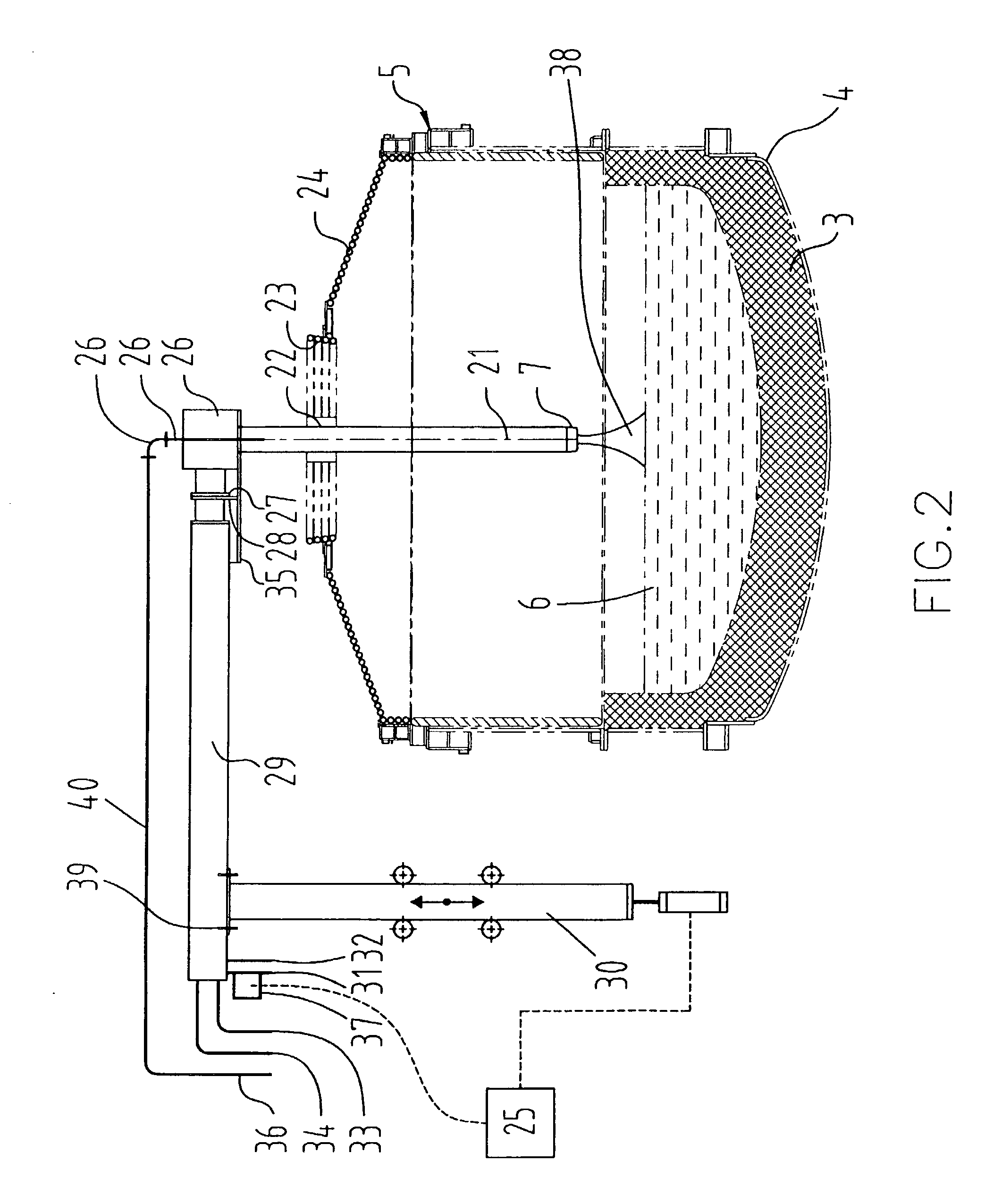

Multi-purpose, multi-oxy-fuel, power burner/injector/oxygen lance device

InactiveUS20030075843A1Reduce the numberSmall sizeTuyeresCharge manipulationSteelmakingLiquid medium

A multi-purpose, multi-oxy-fuel High Temperature Power Burner / Injector / Oxygen Lance, Mechanical System Apparatus Device, for steelmaking from recycled scrap and / or virgin ferrous charge, which can be employed in multi-oxy-fuel (natural gas; pulverized carbonaceous matter; heavy oil), especially by Oxygen Combusted mixture of Natural Gas / Pulverized Carbonaceous Matter in High Temperature Power Burner Mode, for efficient and rapid melting of solid ferrous charge (cold or preheated) in a special steelmaking Metallurgical Furnace or Open Hearth Furnace, Tandem Furnace, BOF, EAF, as its augmenting or only source of thermal energy; more than one Device in Oxygen-Natural Gas / Pulverized Carbonaceous Matter Power Burner Mode, can be employed as the only source of thermal energy in a modified, originally Electric Arc Furnace, as total replacement of Graphite Electrodes and Electric Arc System, the replacement being noticeably more primary energy efficient than the thermal energy provided by Graphite Electrode / Arc System; it also can be employed in an Solid Particles Injector Mode, for injecting of adequately granulated carbonaceous materials or lime into the molten steel for its carburizing or for foamy slag control; further it can be employed in a natural gas shrouded, pulsating oxygen stream, for vertically to the charge oriented soft blow supersonic Oxygen Injection Lance Mode, for decarburization of the molten metal contained in the hearth of the metallurgical furnace and foamy slag control; in one of the embodiments-generally arcuate-pivotally mounted, liquid media cooled composite body, is pivoted into and out of a furnace vessel through a small opening in the shell wall for auto-regulated constant optimal positioning of the Composite Body Tip against solid or molten charge, in each and all multi-purpose modes; furthermore, when inserted into the furnace vessel, the arcuate composite body can be rotated about its longitudinal axis for directing the oxy-fuel high temperature flame towards unmolten charge in the furnace; in an other-generally linear-embodiment, the liquid cooled composite body is attached to the mast type carrier allowing vertical movement of the composite body which enters the furnace vessel through a small opening in the furnace roof; the bimetallic, liquid cooled special tip assembly of both-arcuate and linear embodiments-of the composite body includes easy replaceable, independent, multi-opening nozzles, mounted in a protective, retracted position inside of the liquid cooled special tip assembly.

Owner:EMPCO (CANADA) LTD

Iron coke for blast furnace and preparing method thereof

InactiveCN103468289AEnsure Strength IndexBest heating speedCoke ovensBlast furnace detailsCoke ovenUltimate tensile strength

The invention relates to iron coke for a blast furnace and a preparing method thereof. The iron coke comprises 5wt%-20wt% of iron ore powder and 80wt%-95wt% of mixed coal; the mixed coal is formed by mixing 25wt%-29wt% of one third of coking coal, 40wt%-44wt% of coking coal, 7wt%-11wt% of lean coal, 6wt%-10wt% of gas-fat coal and 12wt%-16wt% of fat coal; the iron ore powder and the mixed coal are mixed uniformly with water and tamped before entering the blast furnace, and are placed into the blast furnace when the temperature is 800 DEG C, the temperature is increased at the speed of 2 DEG C per minute to 3 DEG C per minute, the iron ore powder and the mixed coal are discharged from the blast furnace when the temperature is 950-1050 DEG C, and the iron coke is obtained by adopting a wet way of quenching the coke. According to the iron coke and the preparing method, the performance, the ratio, the particle size and the composition and the like of the iron ore powder and the mixed coal are optimized, and the strength and the reactivity of the iron coke can meet the requirement of the blast furnace process under the circumstance of not adding binding agents.

Owner:WUHAN UNIV OF SCI & TECH

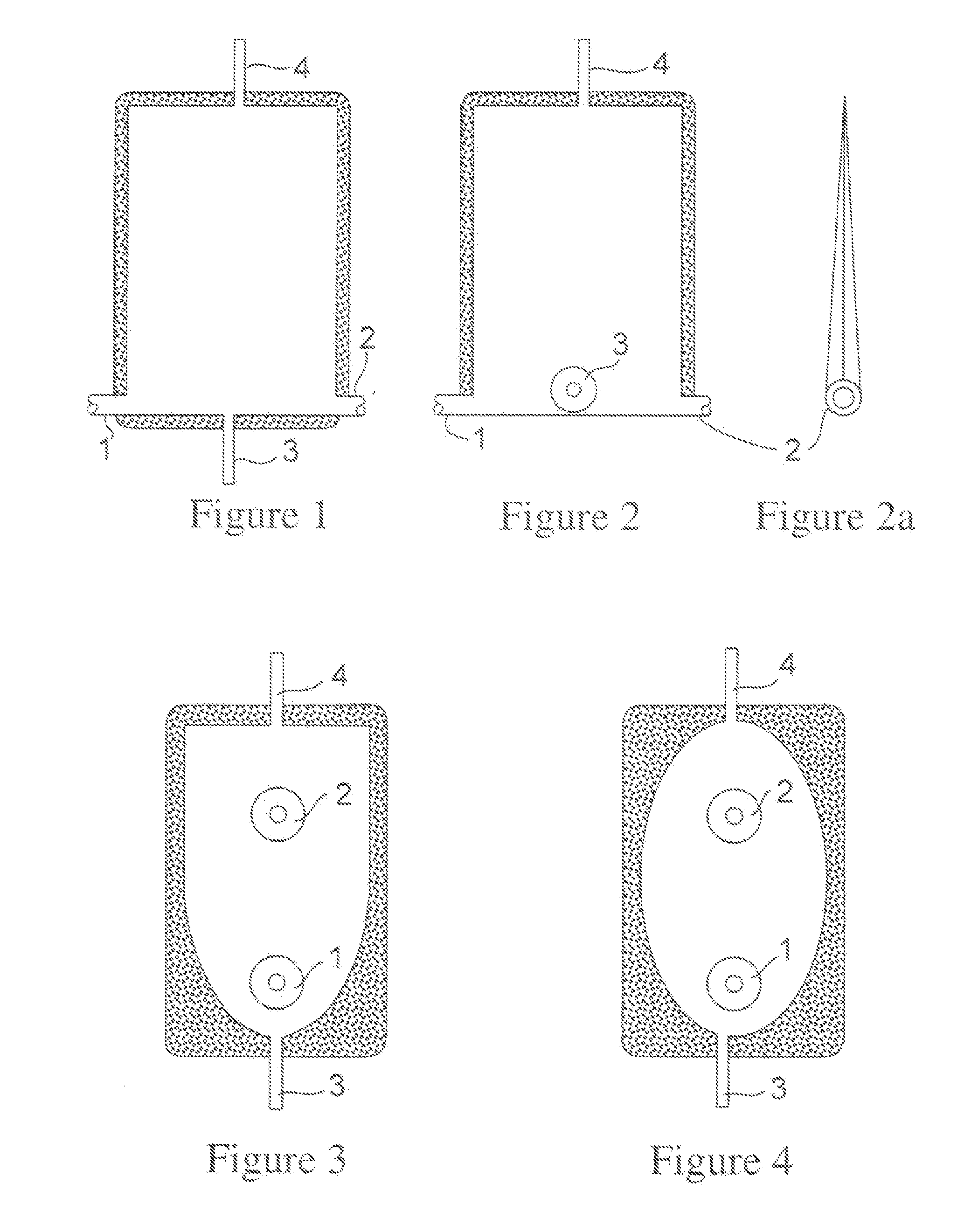

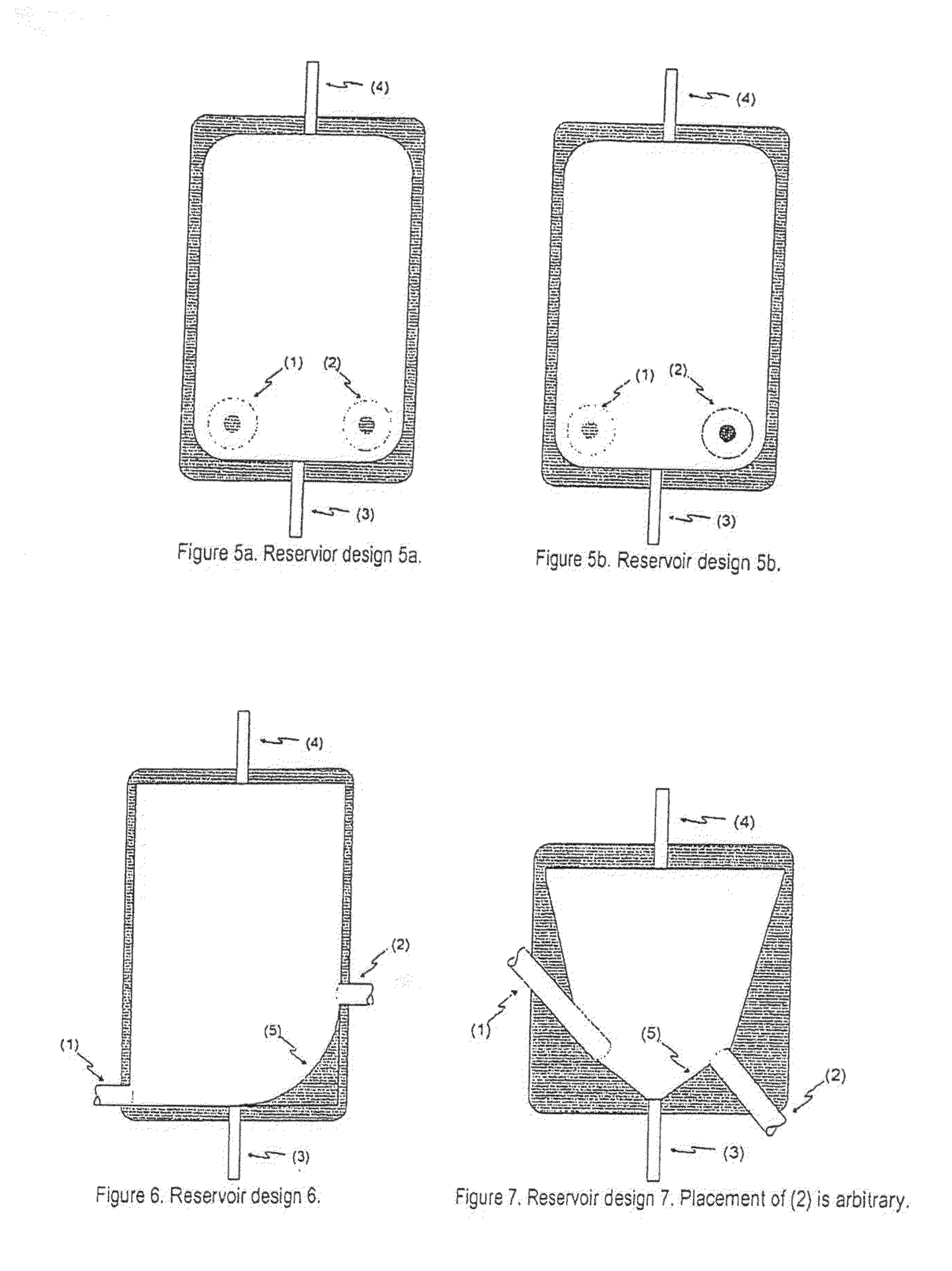

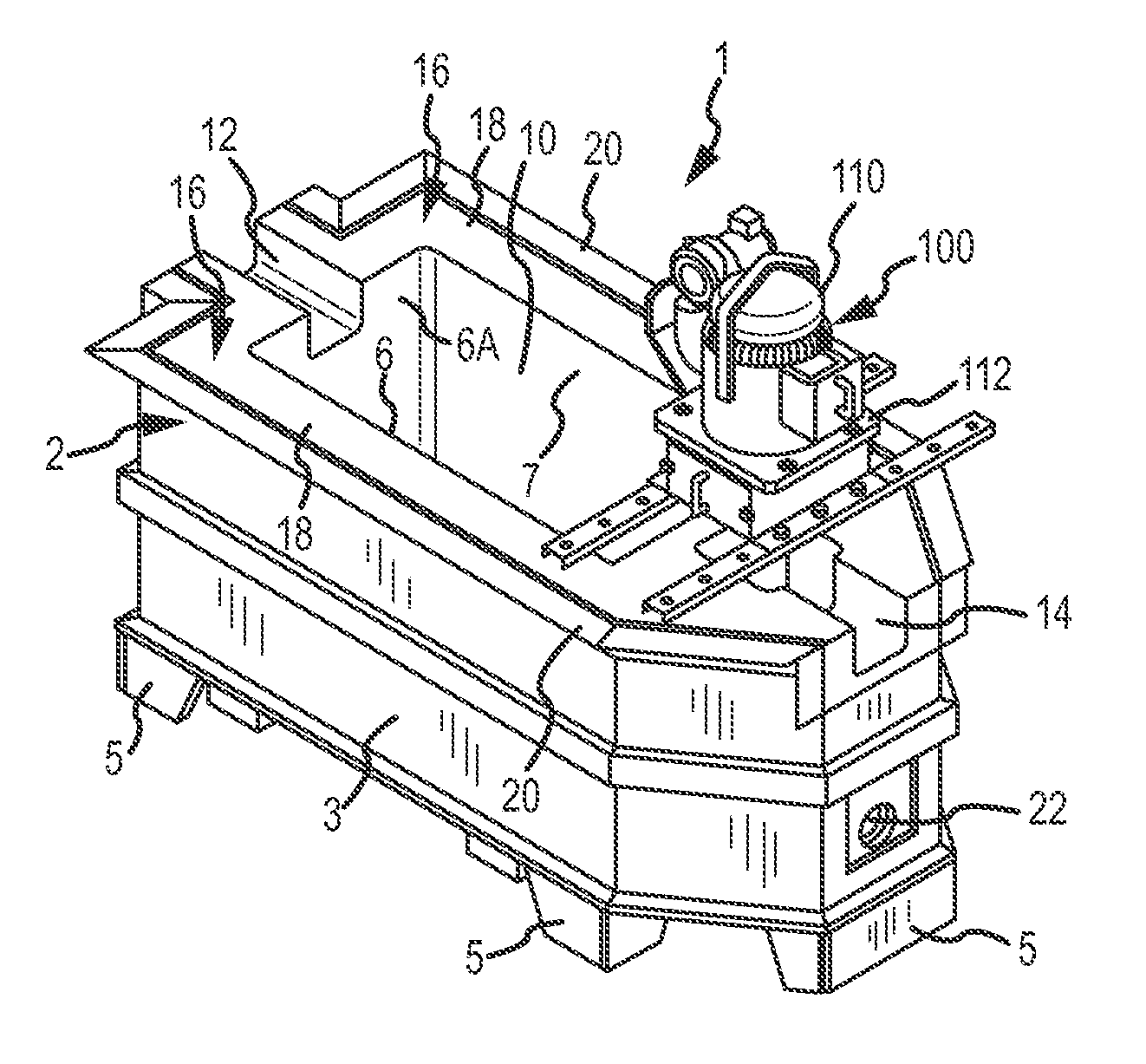

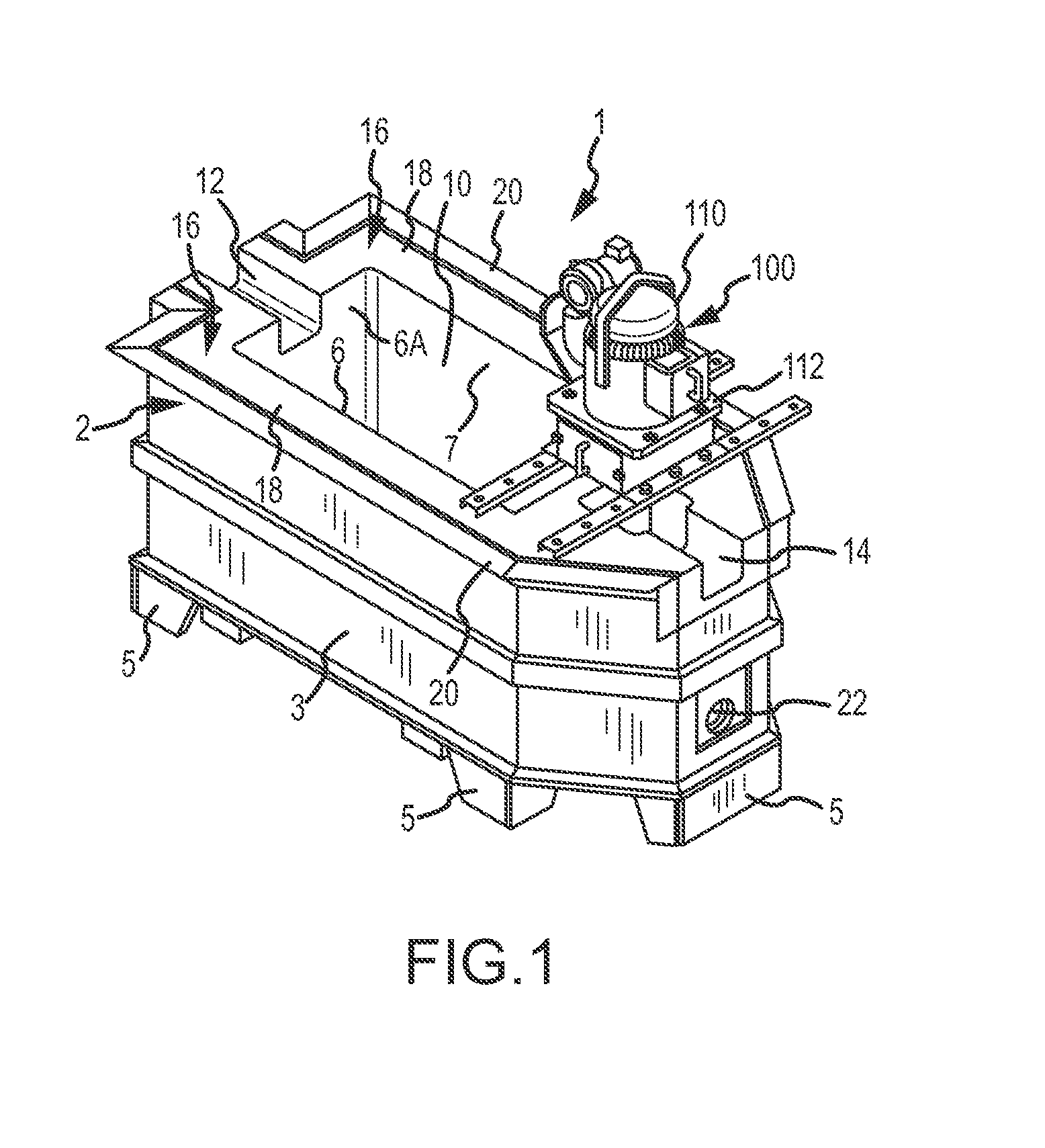

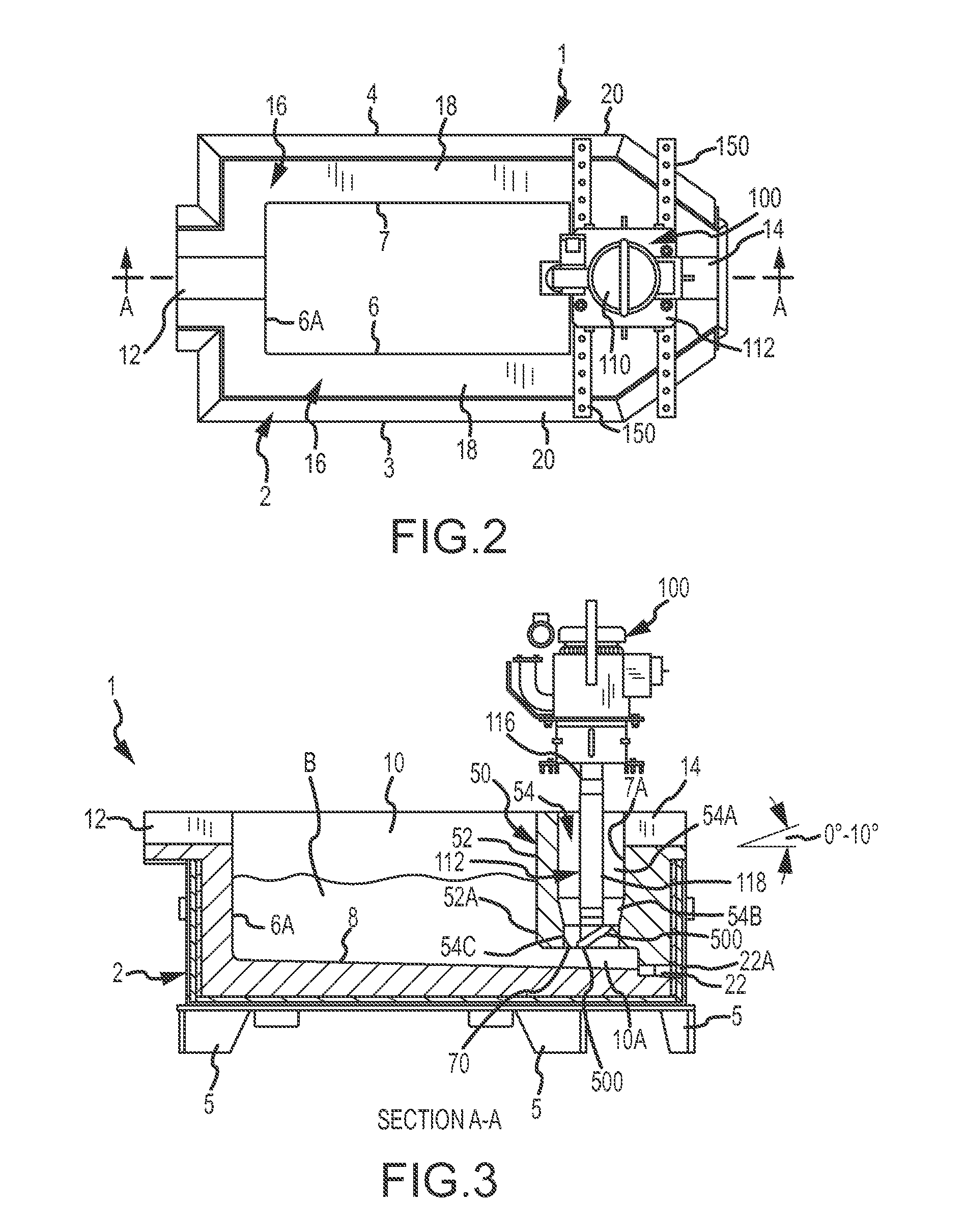

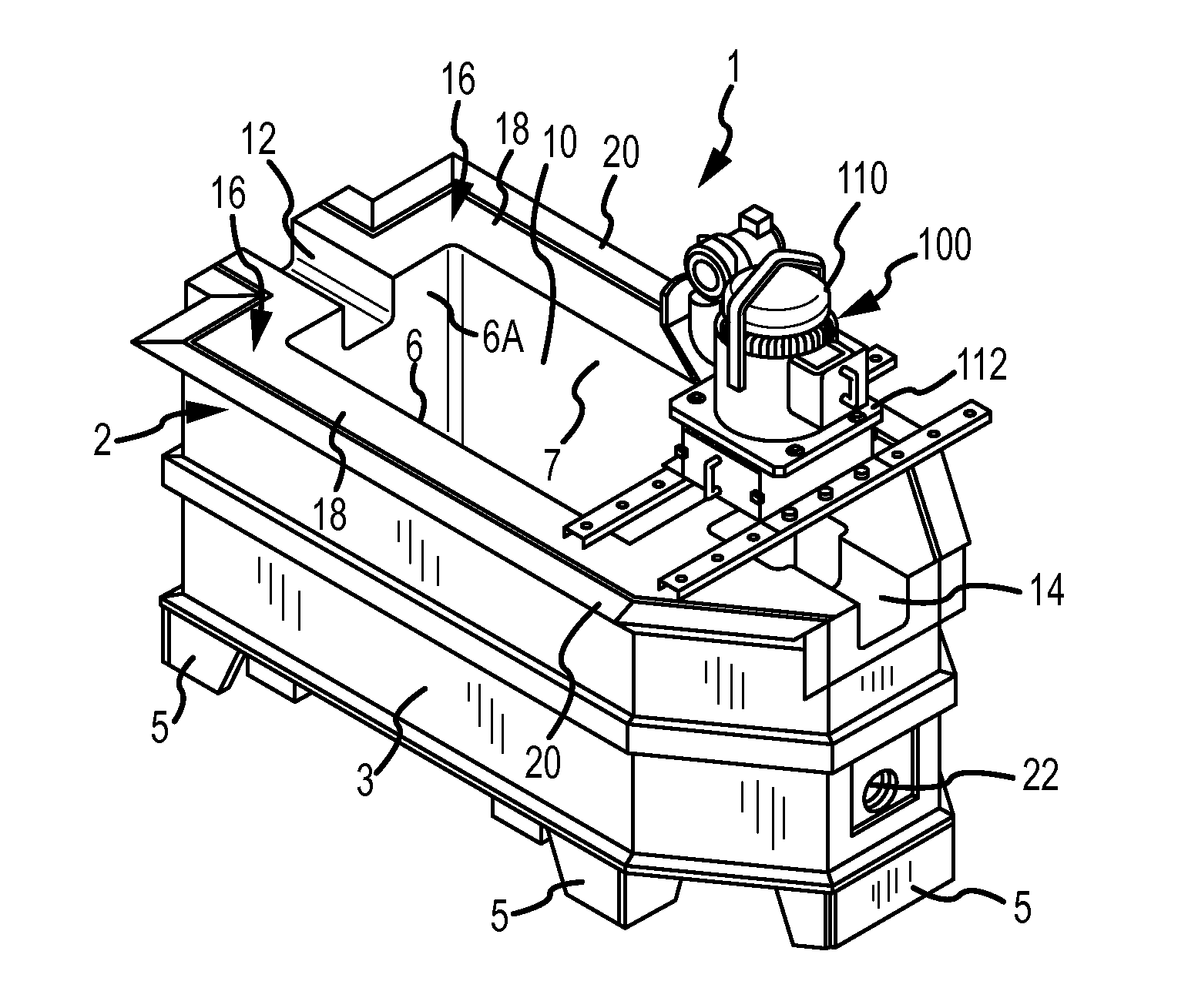

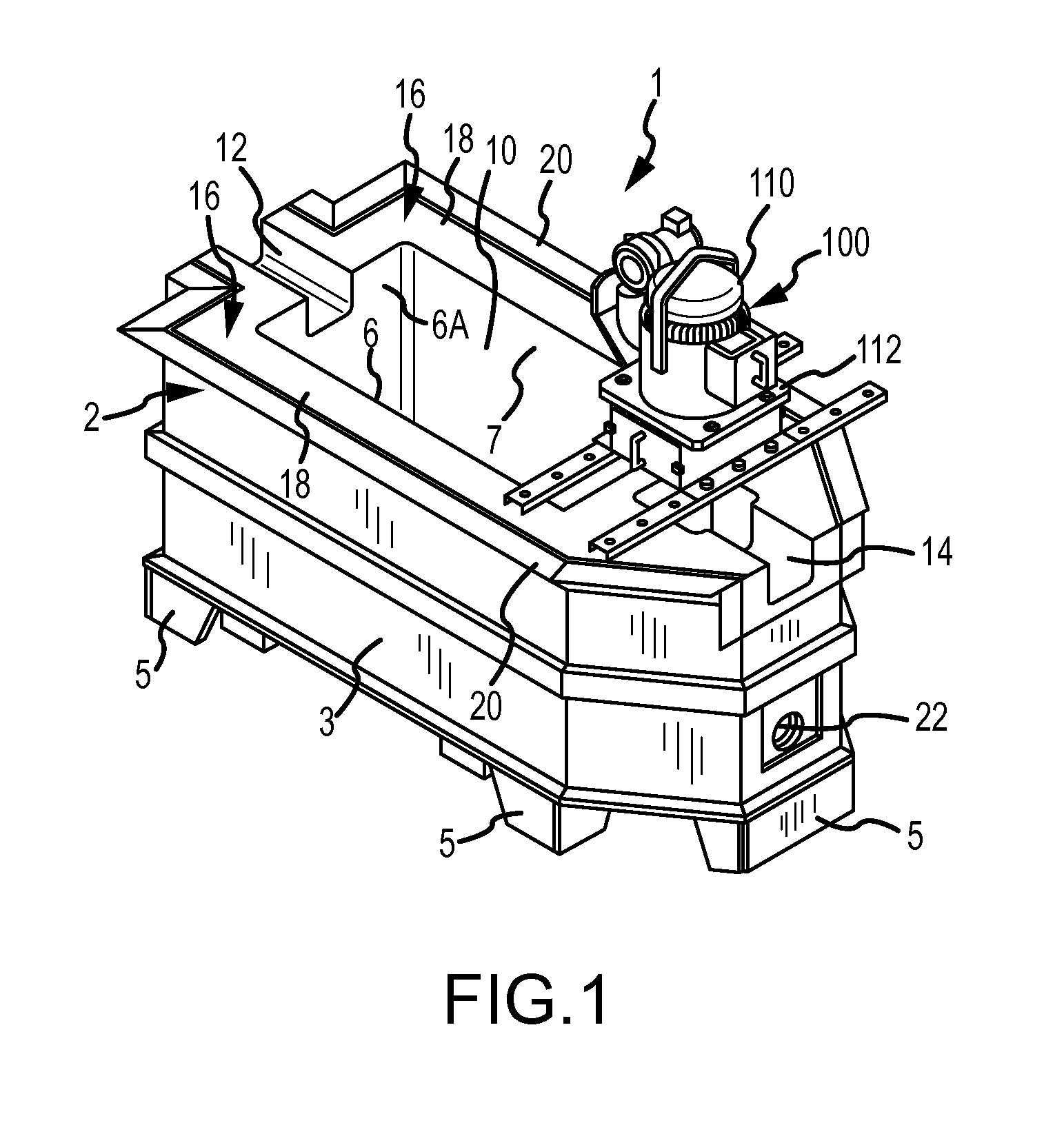

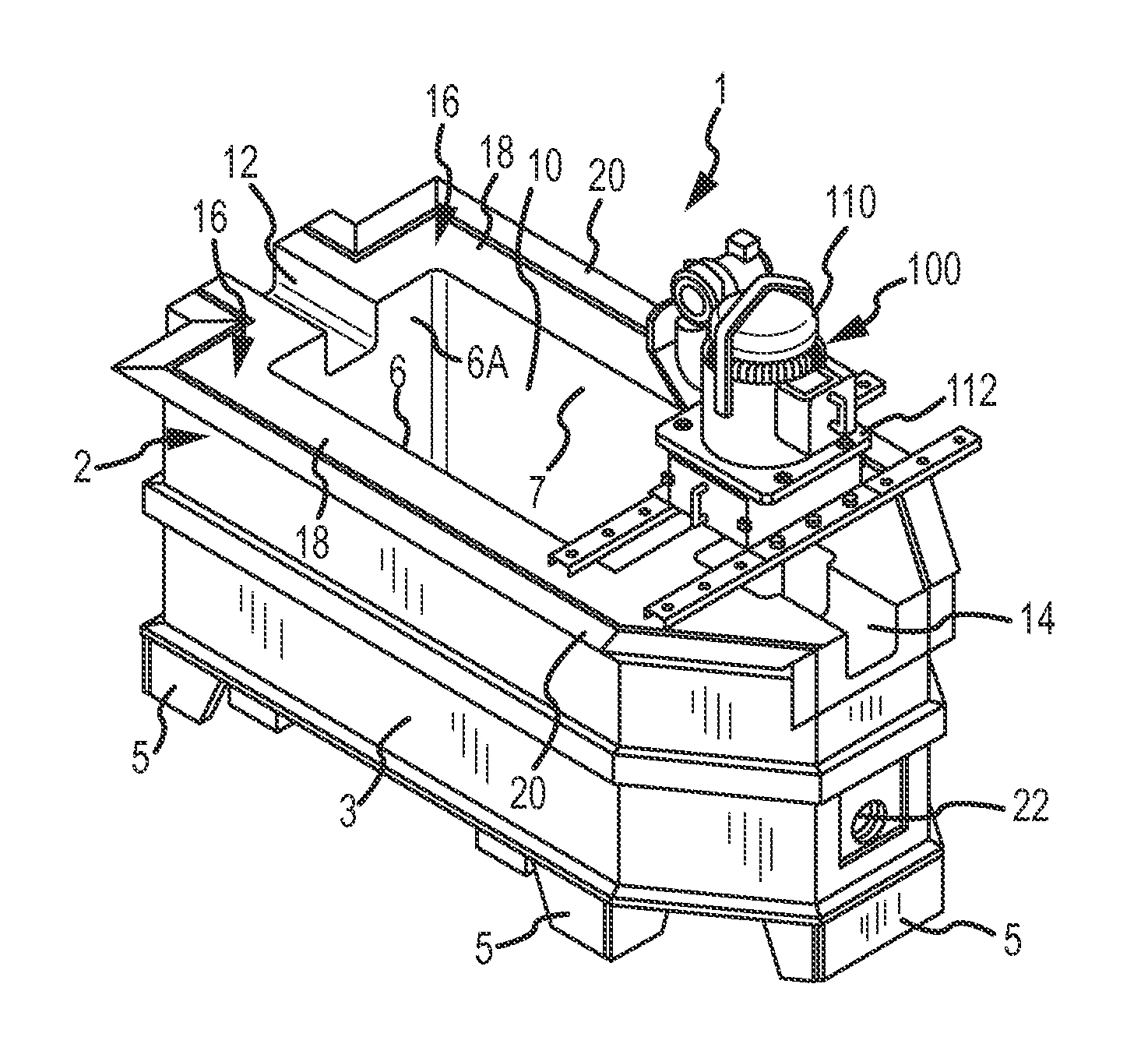

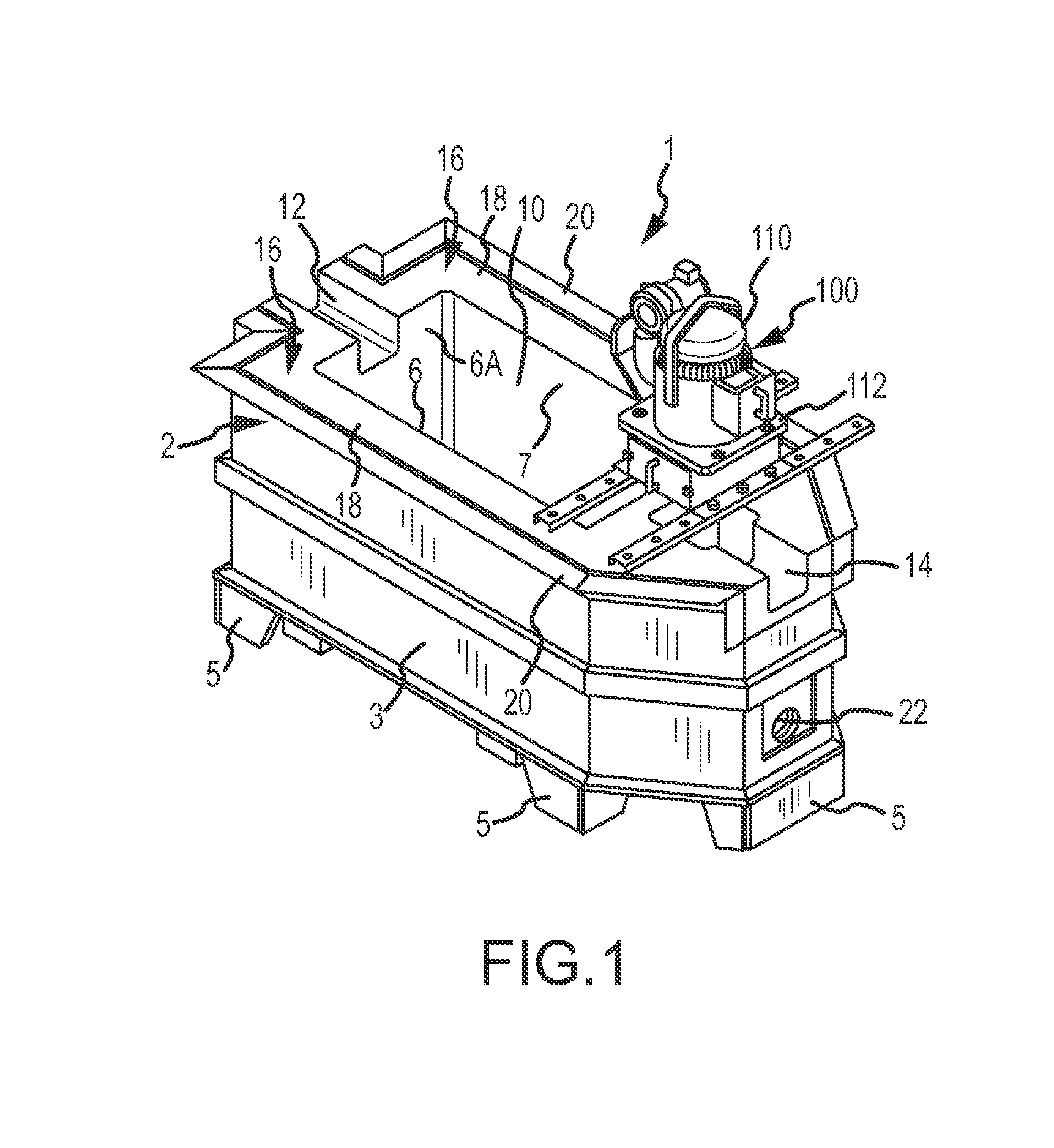

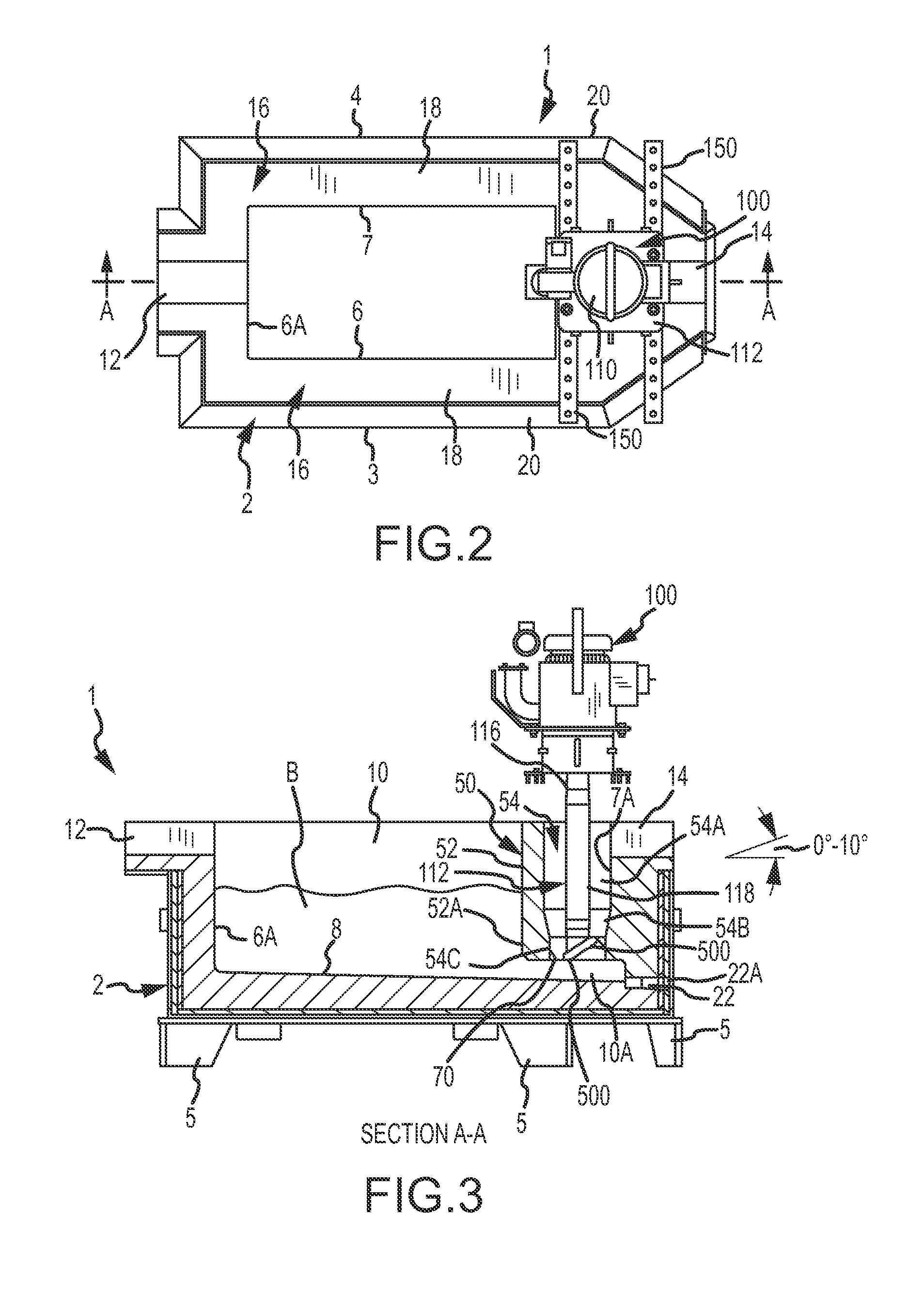

Reservoir For Liquid Dispensing System With Enhanced Mixing

InactiveUS20110120565A1Minimize any fluid dead zonesSuitable for installationBlast furnace detailsManufacturing convertersSystems designEngineering

Reservoir for a dispense system designed to maintain a suspending fluid flow within the reservoir. The fluid dispense system is particularly well suited to be manufactured in a single-use format comprising a fluid reservoir and fill tube assembly, particularly comprising a reservoir, tubing, fittings and connectors, and a needle. The system ensures uniformity within the liquid by moving the fluid through the product reservoir such as with a continuous or pulsating flow, and is designed to maintain the fluid in motion in order to maintain a homogenous solution. The reservoir is designed to minimize any fluid dead zones.

Owner:MILLIPORE CORP

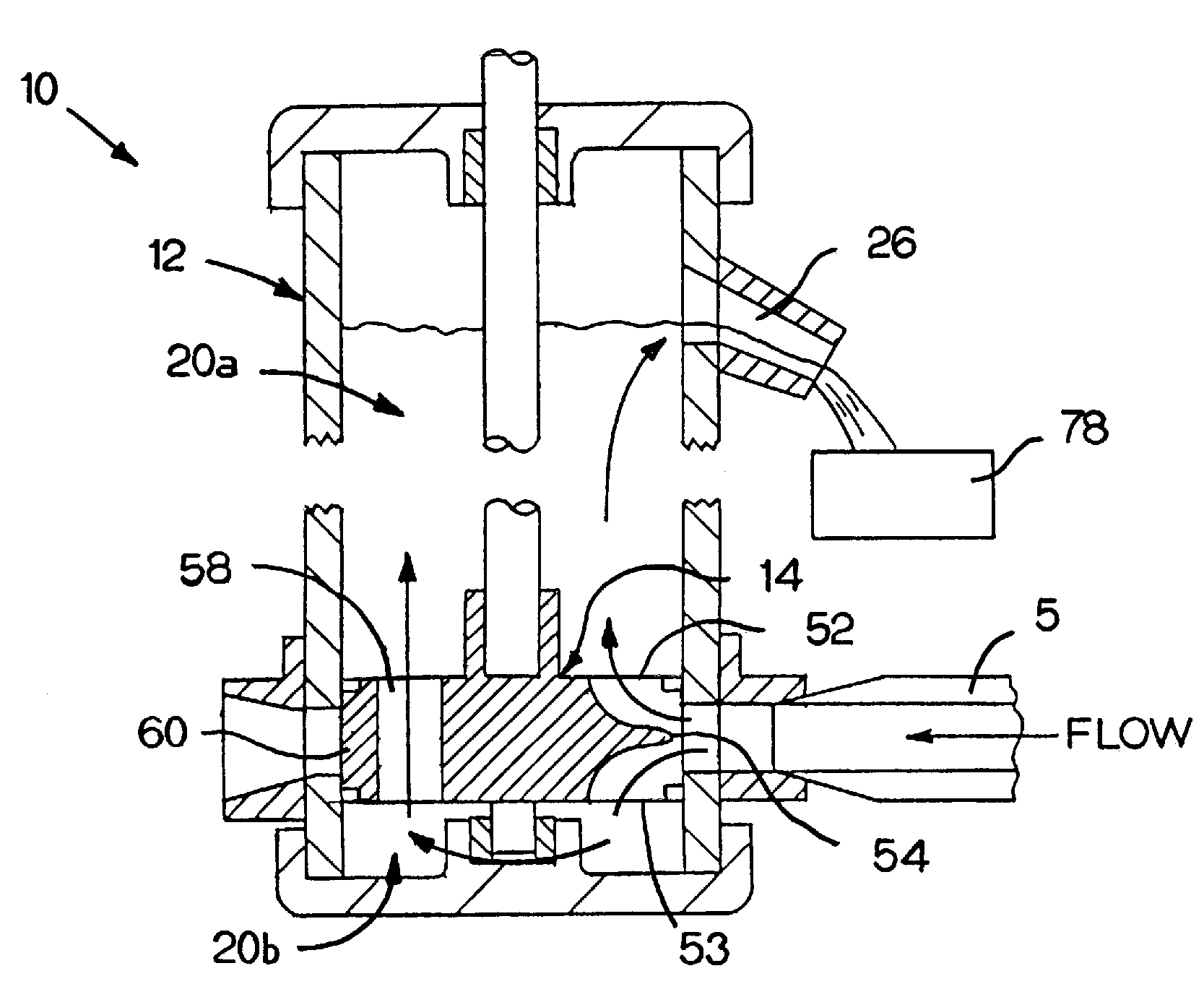

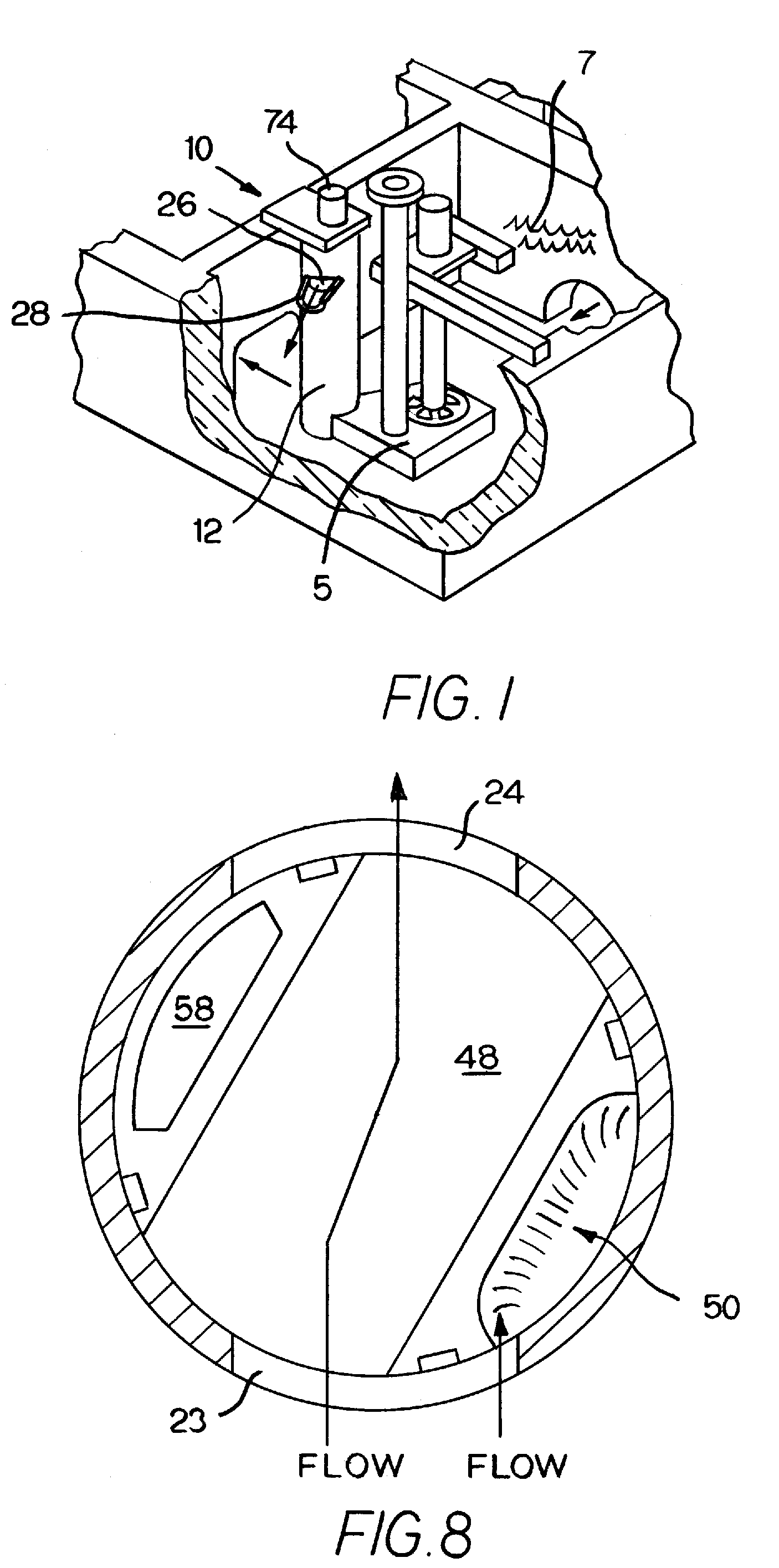

Dual recycling/transfer furnace flow management valve for low melting temperature metals

InactiveUS7543605B1Eliminate needIncrease flow rateMelt-holding vesselsMolten metal pouring equipmentsControl valvesFlow management

A furnace flow control valve for use within a bath of molten metal. The flow control valve includes a vertically-disposed elongated tubular stator, which is configured to receive flow from a molten metal pump. The valve has a rotor which is sealing rotatable within the stator between: a full re-circulation position, where flow from the pump passes un-hindered through the valve; a full transfer position, where flow from the pump is redirected into the vertically disposed stator and out of the valve; and a partial re-circulation / partial transfer position where flow from the pump both passes through the valve and is transferred up and out of valve through the stator.

Owner:MORANDO JORGE A

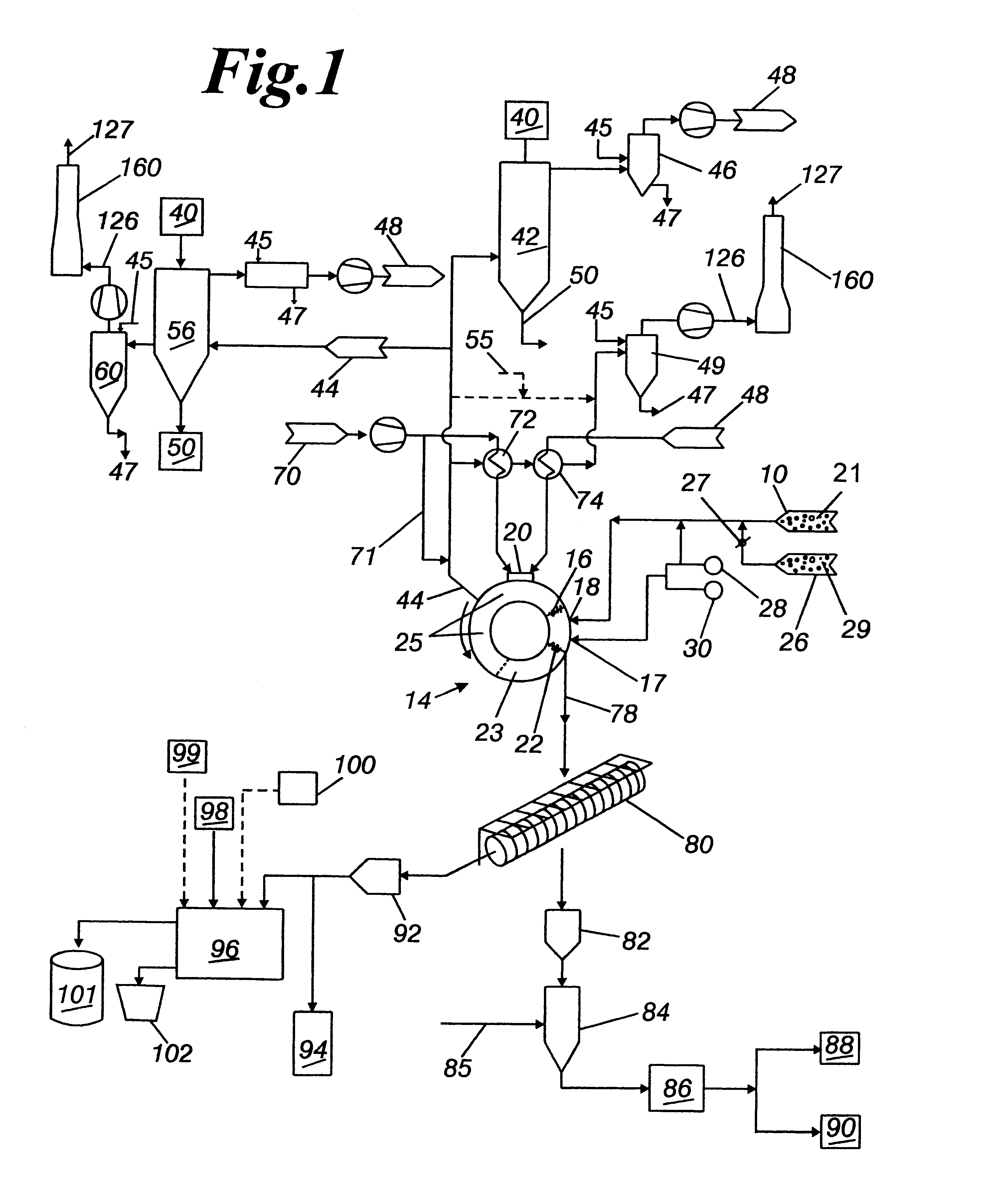

Method of direct iron-making / steel-making via gas or coal-based direct reduction and apparatus

The invention is a method and apparatus for iron-making / steel-making using a modified rotary hearth furnace, that is a finisher-hearth-melter (FHM) furnace. In the method the refractory surface of the hearth is coated with carbonaceous hearth conditioners and refractory compounds, where onto said hearth is charged with pre-reduced metallized iron. The pre-reduced metallized iron is leveled, then heated until molten, and then reacted with the carbon and reducing gas burner gases until any residual iron oxide is converted to iron having a low sulfur content. Nascent slag separates from the molted iron forming carburized iron nuggets. The nuggets are cooled, and then the iron nuggets and the hearth conditioners, including the refractory compounds, are discharged onto a screen, which separate the iron nuggets from the hearth conditioner. The hearth conditioner is recycled, and the iron nuggets are either prepared for sale or for additional treatment, such as alloying, in a final melter, where the final melter is preferably an electric furnace. Exhaust gases from the FHM furnace are recovered for calcining coal into fuel gases and coke.

Owner:KOBE STEEL LTD

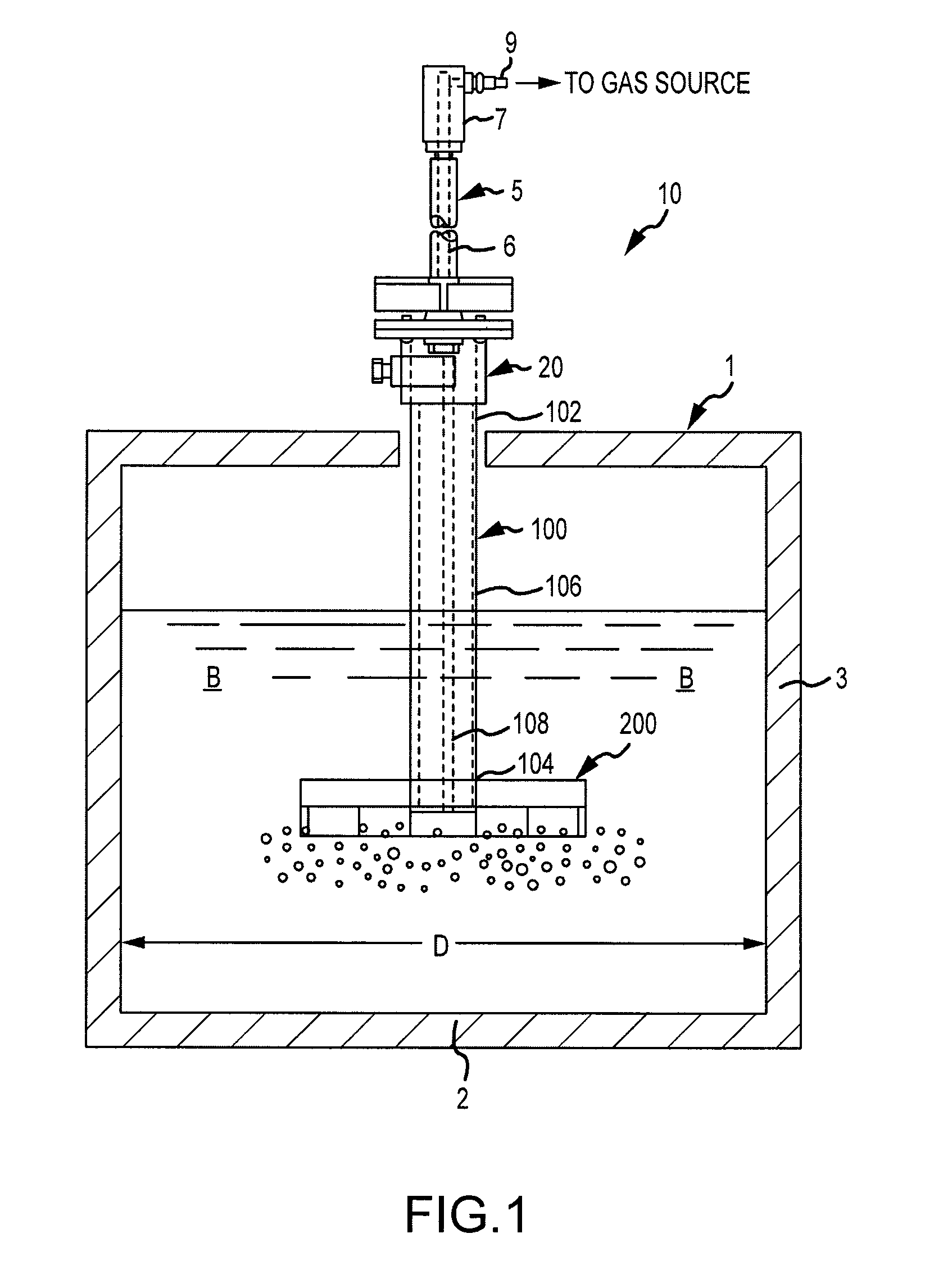

Rotary degasser and rotor therefor

ActiveUS8535603B2Efficiently circulatedWell mixedMelt-holding vesselsStirring devicesImpellerDegasser

A device for dispersing gas into molten metal includes an impeller, a drive shaft having a gas-transfer passage therein, and a first end and a second end, and a drive source. The second end of the drive shaft is connected to the impeller and the first end is connected to the drive source. The impeller includes a first portion and a second portion with a plurality of cavities. The first portion covers the second portion to help prevent gas from escaping to the surface without entering the cavities and being mixed with molten metal as the impeller rotates. When gas is transferred through the gas-transfer passage, it exits through the gas-release opening(s) in the bottom of the impeller. At least some of the gas enters the cavities where it is mixed with the molten metal being displaced by the impeller. Also disclosed are impellers that can be used to practice the invention.

Owner:MOLTEN METAL EQUIP INNOVIATIONS LLC

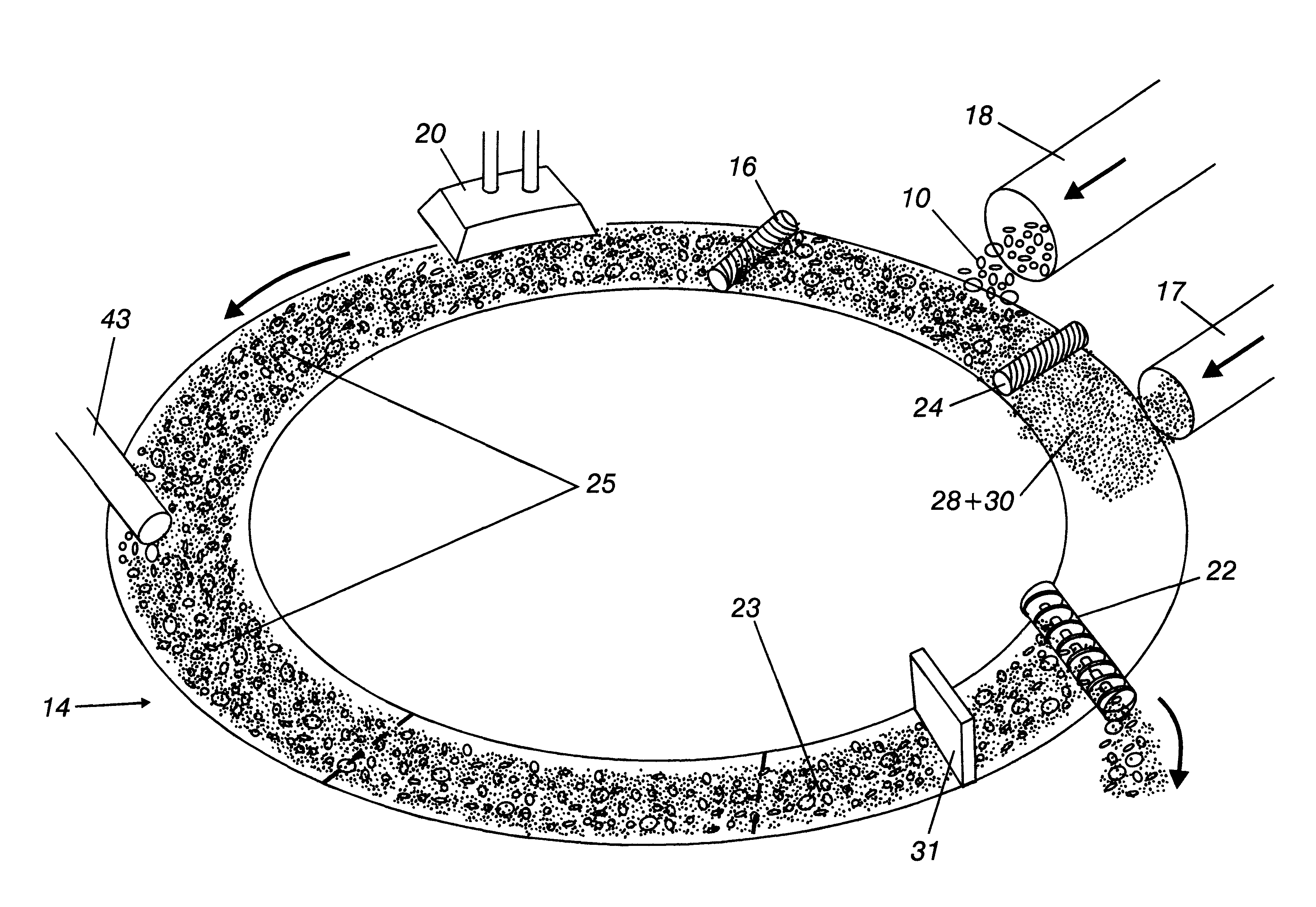

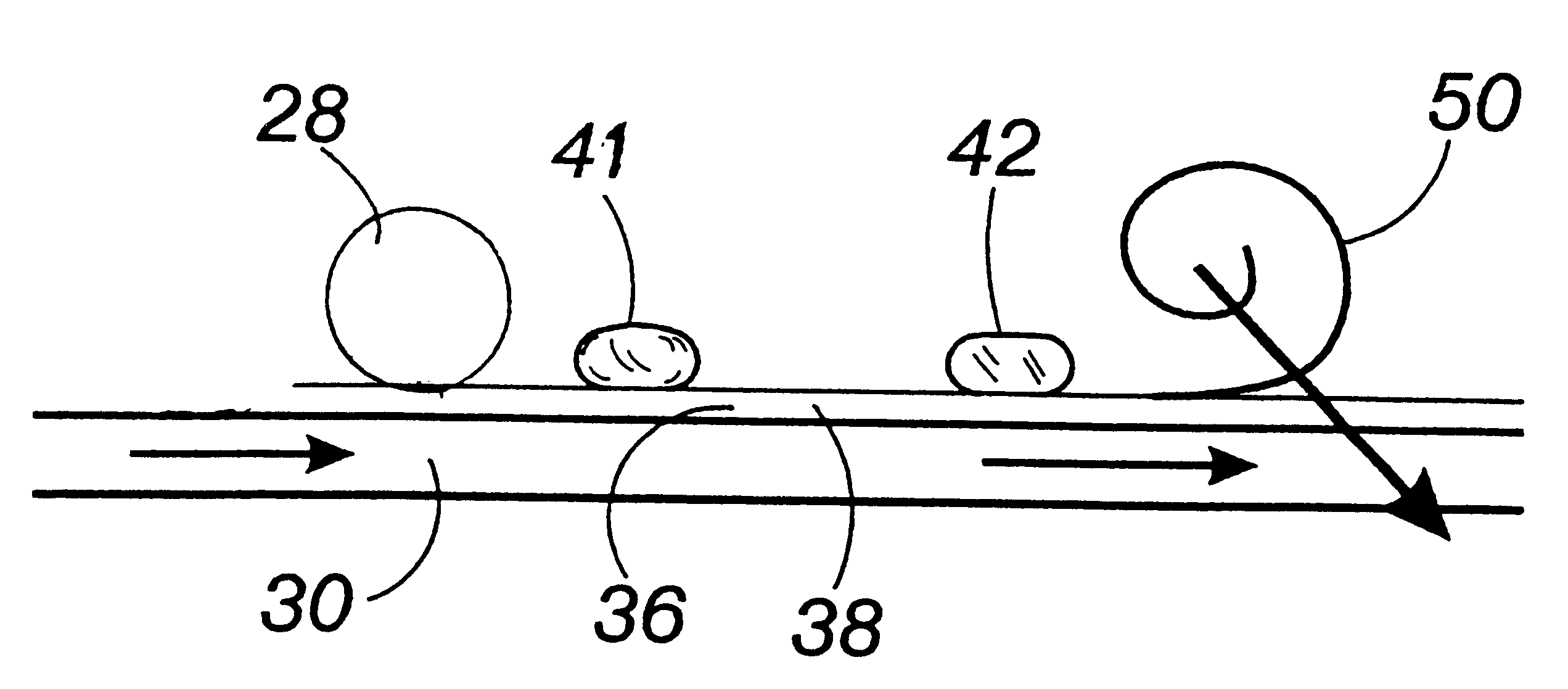

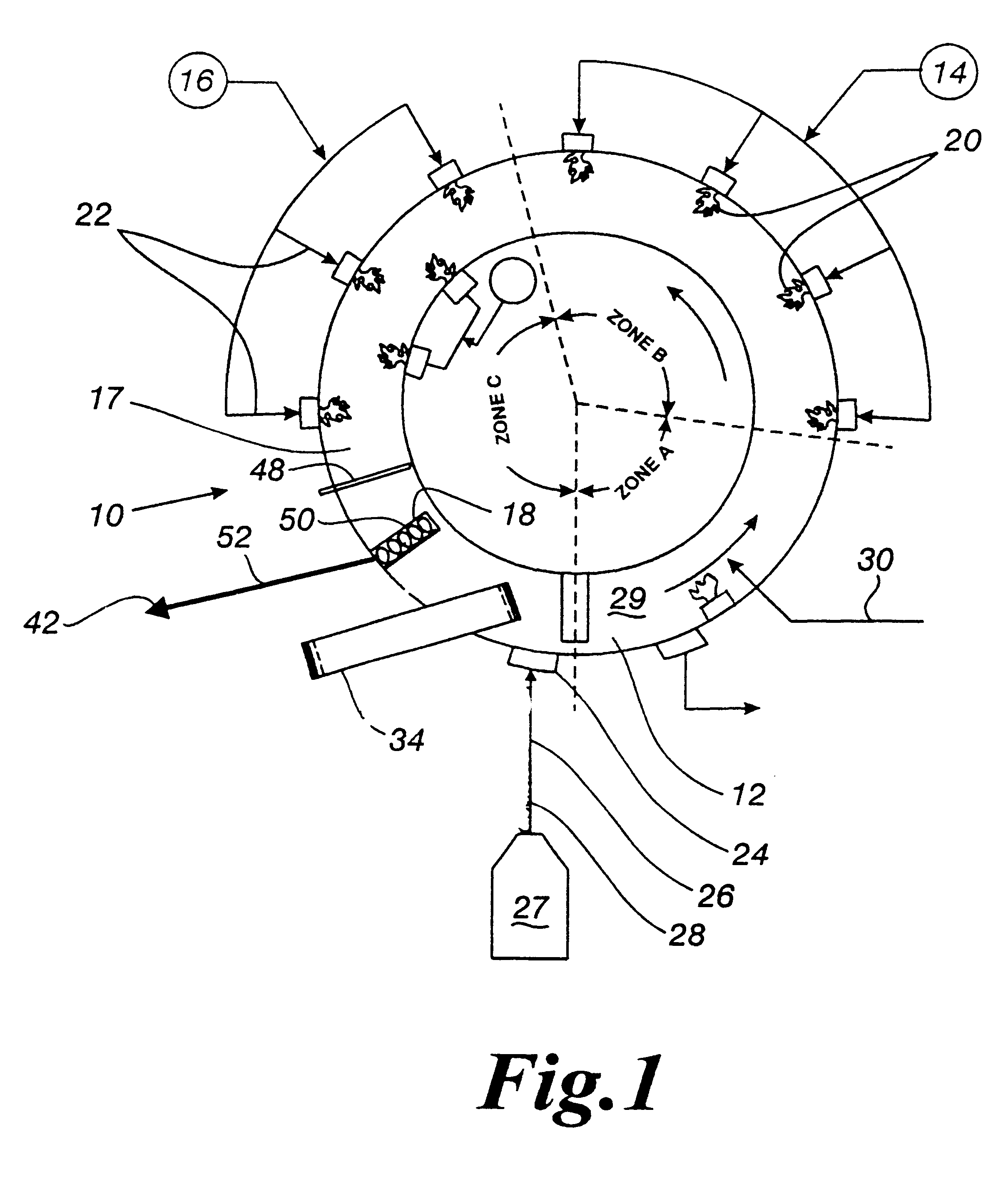

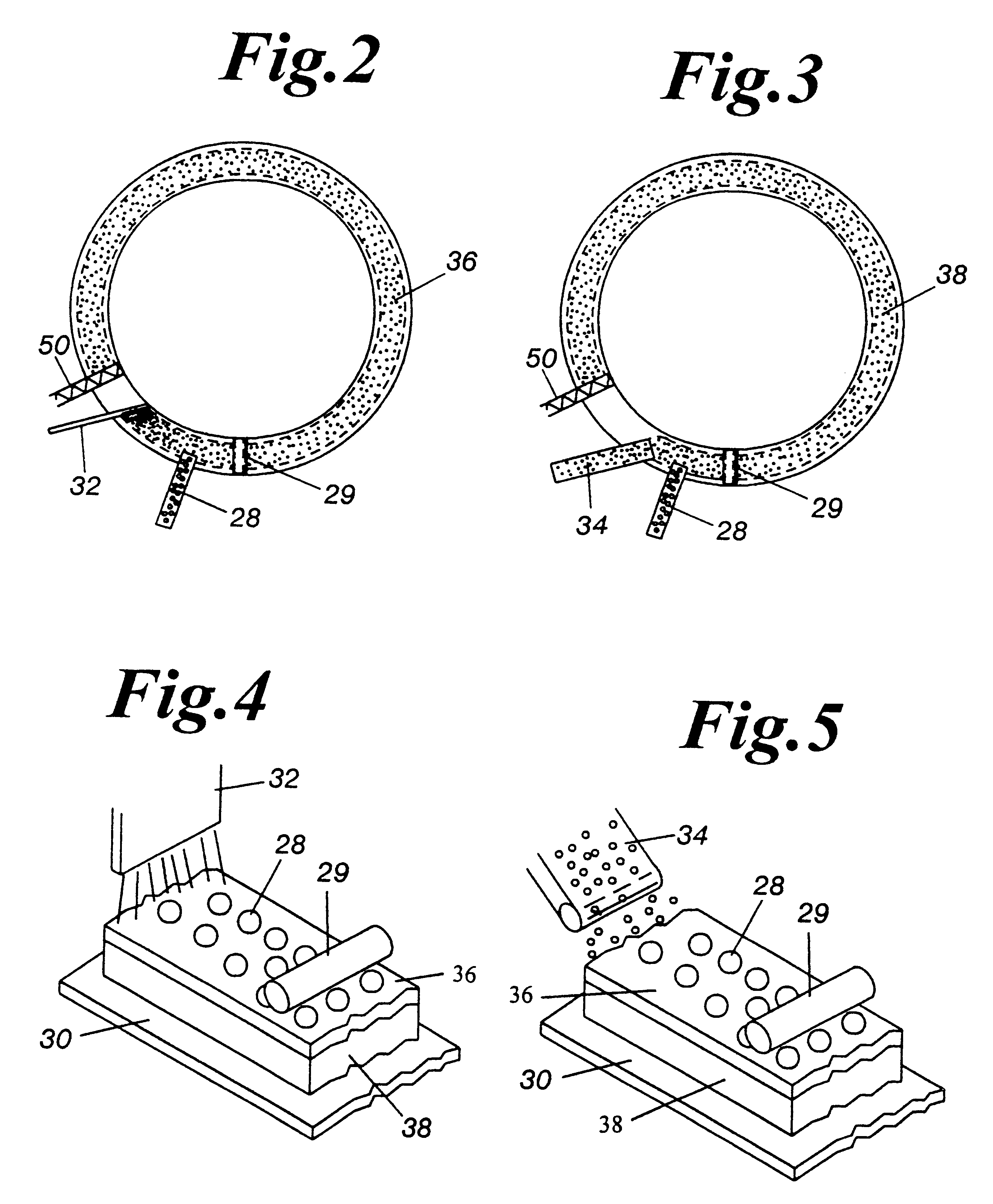

Iron production method of operation in a rotary hearth furnace and improved furnace apparatus

The present invention is an apparatus and method for the direct reduction of iron oxide utilizing a rotary hearth furnace to form a high purity carbon-containing iron metal button. The hearth layer may be a refractory or a vitreous hearth layer of iron oxide, carbon, and silica compounds. Additionally, coating materials may be introduced onto the refractory or vitreous hearth layer before iron oxide ore and carbon materials are added, with the coating materials preventing attack of the molten iron on the hearth layer. The coating materials may include compounds of carbon, iron oxide, silicon oxide, magnesium oxide, and / or aluminum oxide. The coating materials may be placed as a solid or a slurry on the hearth layer and heated, which provides a protective layer onto which the iron oxide ores and carbon materials are placed. The iron oxide is reduced and forms molten globules of high purity iron and residual carbon, which remain separate from the hearth layer. An improved apparatus includes a cooling plate that is placed in close proximity with the refractory or vitreous hearth layer, cooling the molten globules to form iron metal buttons that are removed from the hearth layer. The improvements due to the present apparatus and method of operation provide high purity iron and carbon solid buttons, which are separate from slag particulates, and discharged without significant loss of iron product to the interior surfaces of the furnace.

Owner:MIDREX INT B V ROTTERDAM

Flux injection assembly and method

ActiveUS20140083253A1Safely store and measureAvoid pollutionCharge manipulationBlast furnace detailsEngineeringInjector

A flux injector apparatus and method adapted to distribute a predetermined amount of flux to an associated pool of molten aluminum. The flux injector apparatus includes a pressurized tank adapted to store and feed the flux under pressure. A feed mechanism operative to discharge a predetermined amount of flux to an outlet and a controller for monitoring and operating the apparatus. The feed mechanism includes a housing having an inner wall defining a cavity with an inlet and an outlet. A feed wheel is positioned within the cavity and operative to receive a predetermined amount of flux from the inlet, translate the flux within the cavity and discharge the predetermined amount of flux through the outlet of the pressurized tank.

Owner:PYROTECK INC

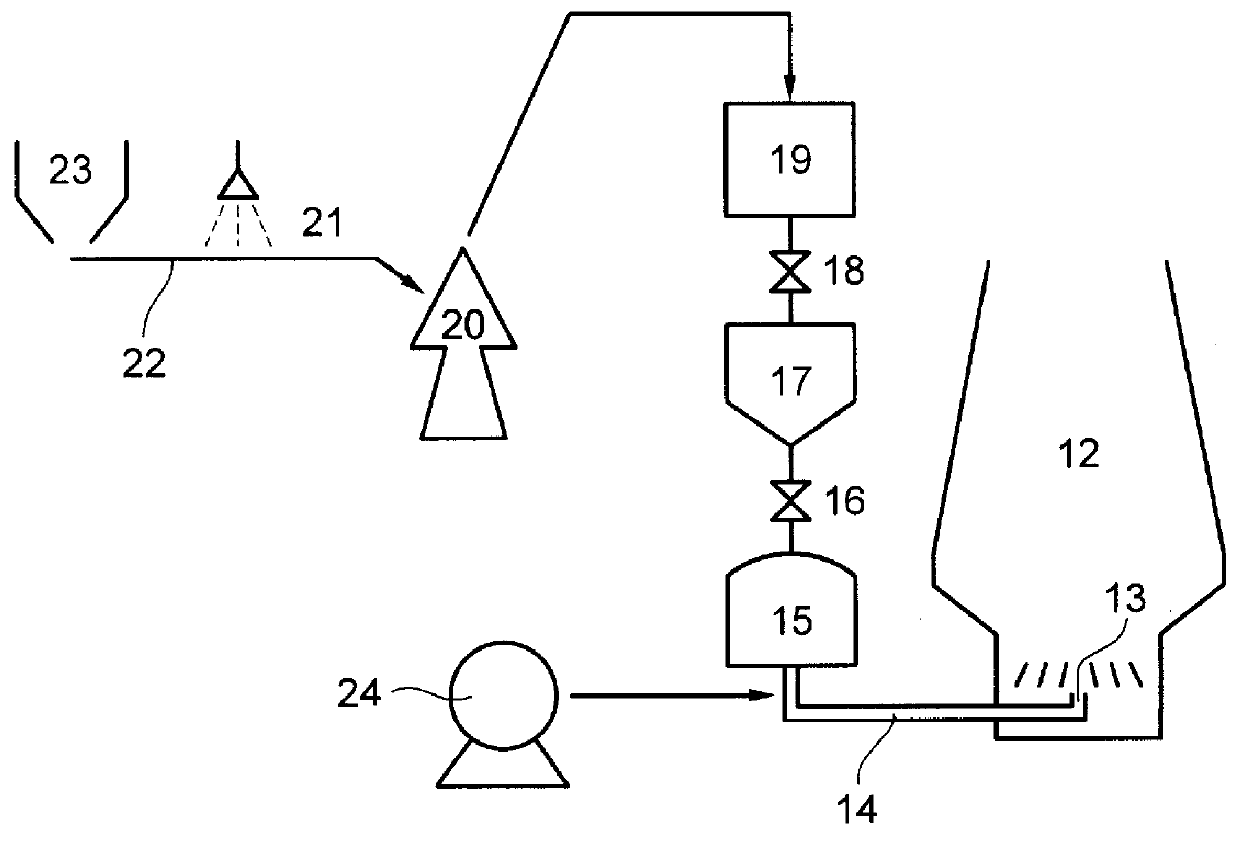

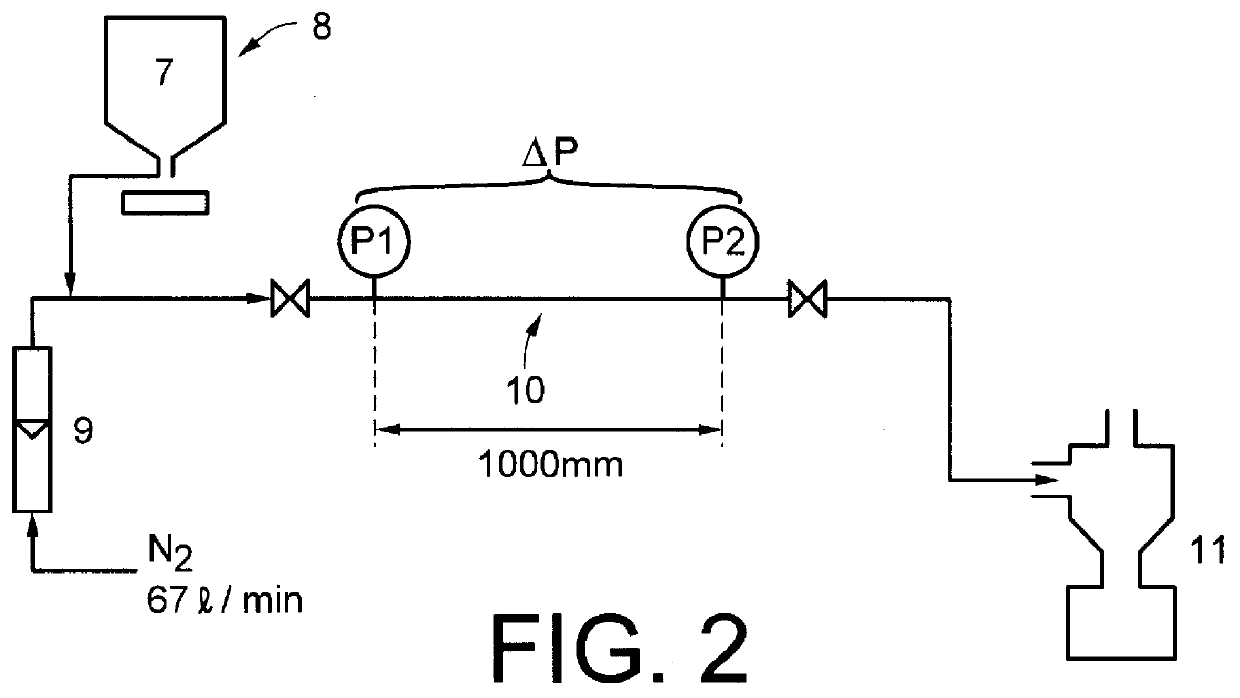

Pulverized coal carriability improver

InactiveUS6083289AGreat varietyImprove liquiditySolid fuel pretreatmentSolid fuelsInorganic saltsCombustion

PCT No. PCT / JP97 / 00668 Sec. 371 Date Sep. 25, 1998 Sec. 102(e) Date Sep. 25, 1998 PCT Filed Mar. 5, 1997 PCT Pub. No. WO97 / 36009 PCT Pub. Date Oct. 2, 1997The use of pulverized coal as the fuel to be injected into metallurgical or combustion furnace becomes possible enabled by improving the transportability thereof. Further, a pulverized coal is provided, which is inhibiting from bridging or channeling in a hopper, or piping choking. A water-soluble inorganic salt having a polar group is made to adhere to pulverized coal which is prepared from raw coal having an average HGI of 30 or above and which is in a dry state at the injection port of a metallurgical or combustion furnace, The inorganic salt is selected from among BaCl2, CaCl2, Ca(NO2)2, Ca(NO3)2, Ca(ClO)2, K2CO3, KCl, MgCl2, MgSO4, NH4BF4, NH4Cl, (NH4)2SO4, Na2CO3, NaCl, NaClO3, NaNO2, NaNO3, NaOH, Na2S2O3, Na2S2O5, HNO3, H2SO4, H2CO3, and HCl.

Owner:KAO CORP

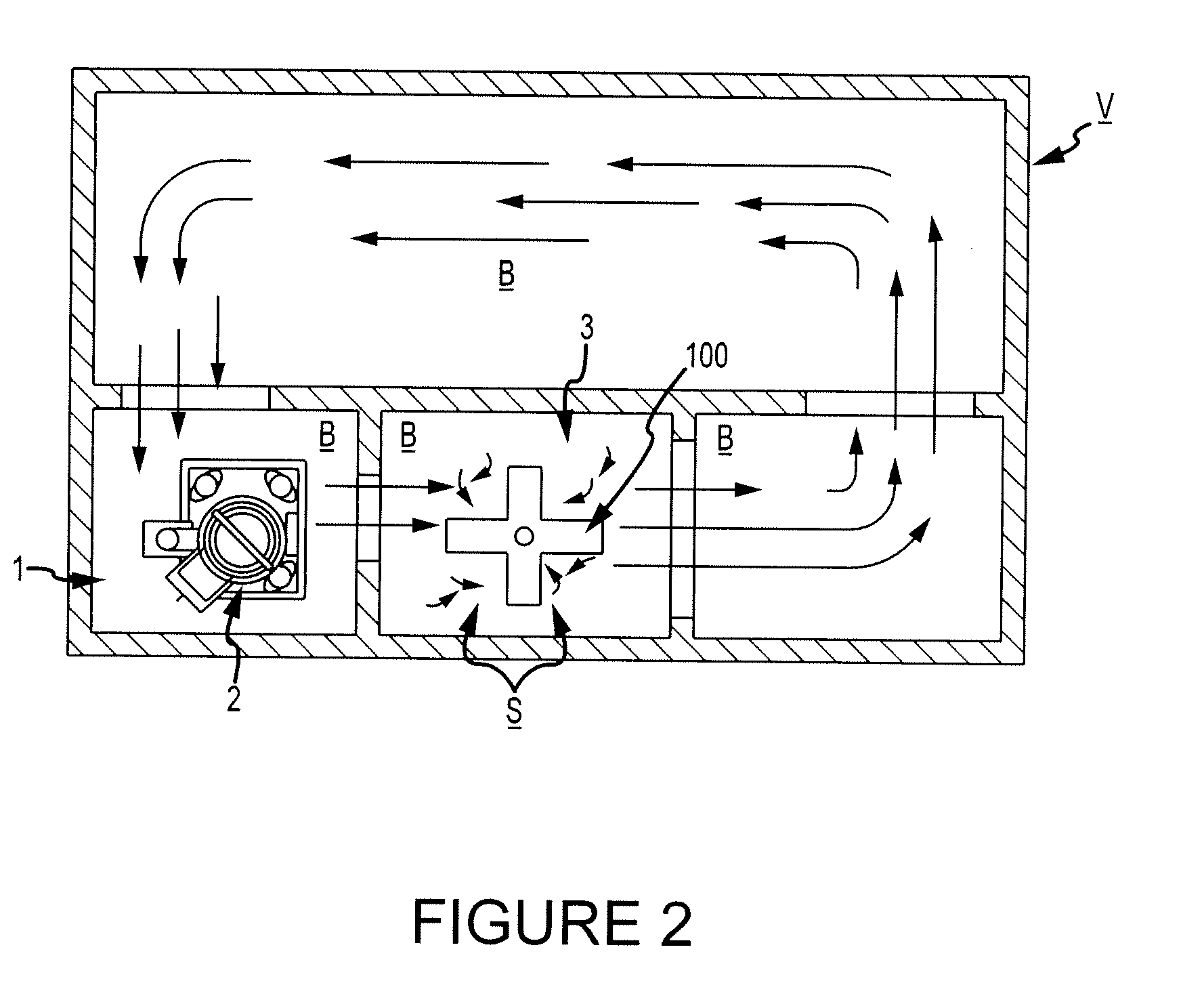

Transfer well system and method for making same

ActiveUS20130292426A1Melt-holding vesselsMolten metal pouring equipmentsMarine engineeringMolten metal

The invention relates to systems for transferring molten metal from one structure to another. Aspects of the invention include a transfer chamber constructed inside of or next to a vessel used to retain molten metal. The transfer chamber is in fluid communication with the vessel so molten metal from the vessel can enter the transfer chamber. A powered device, which may be inside of the transfer chamber, moves molten metal upward and out of the transfer chamber and preferably into a structure outside of the vessel, such as another vessel or a launder.

Owner:MOLTEN METAL EQUIP INNOVIATIONS LLC

Molten metal transfer system and rotor

The invention relates to systems for transferring molten metal from one structure to another. Aspects of the invention include a transfer chamber constructed inside of or next to a vessel used to retain molten metal. The transfer chamber is in fluid communication with the vessel so molten metal from the vessel can enter the transfer chamber. A powered device, which may be inside of the transfer chamber, moves molten metal upward and out of the transfer chamber and preferably into a structure outside of the vessel, such as another vessel or a launder.

Owner:MOLTEN METAL EQUIP INNOVIATIONS LLC

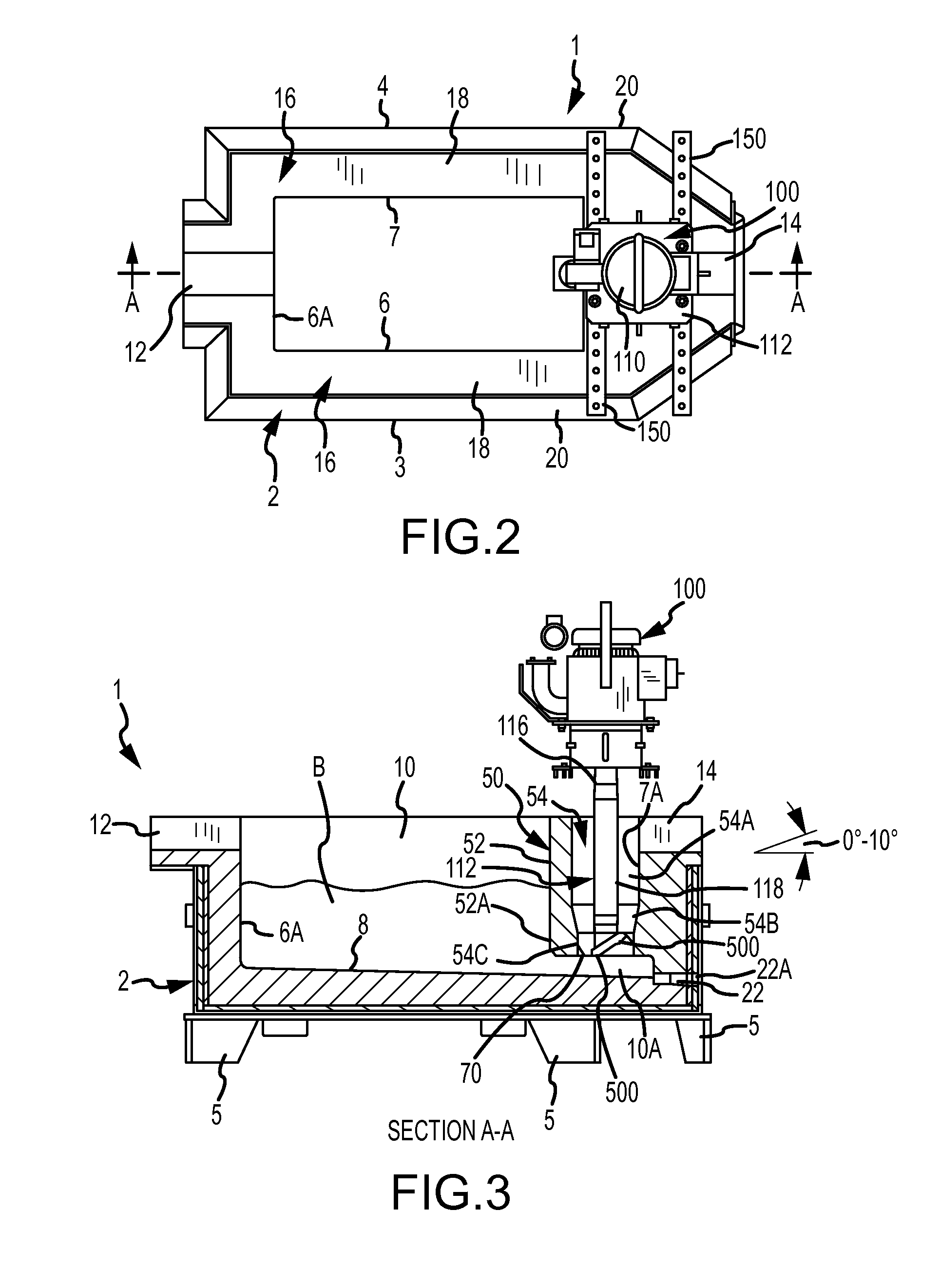

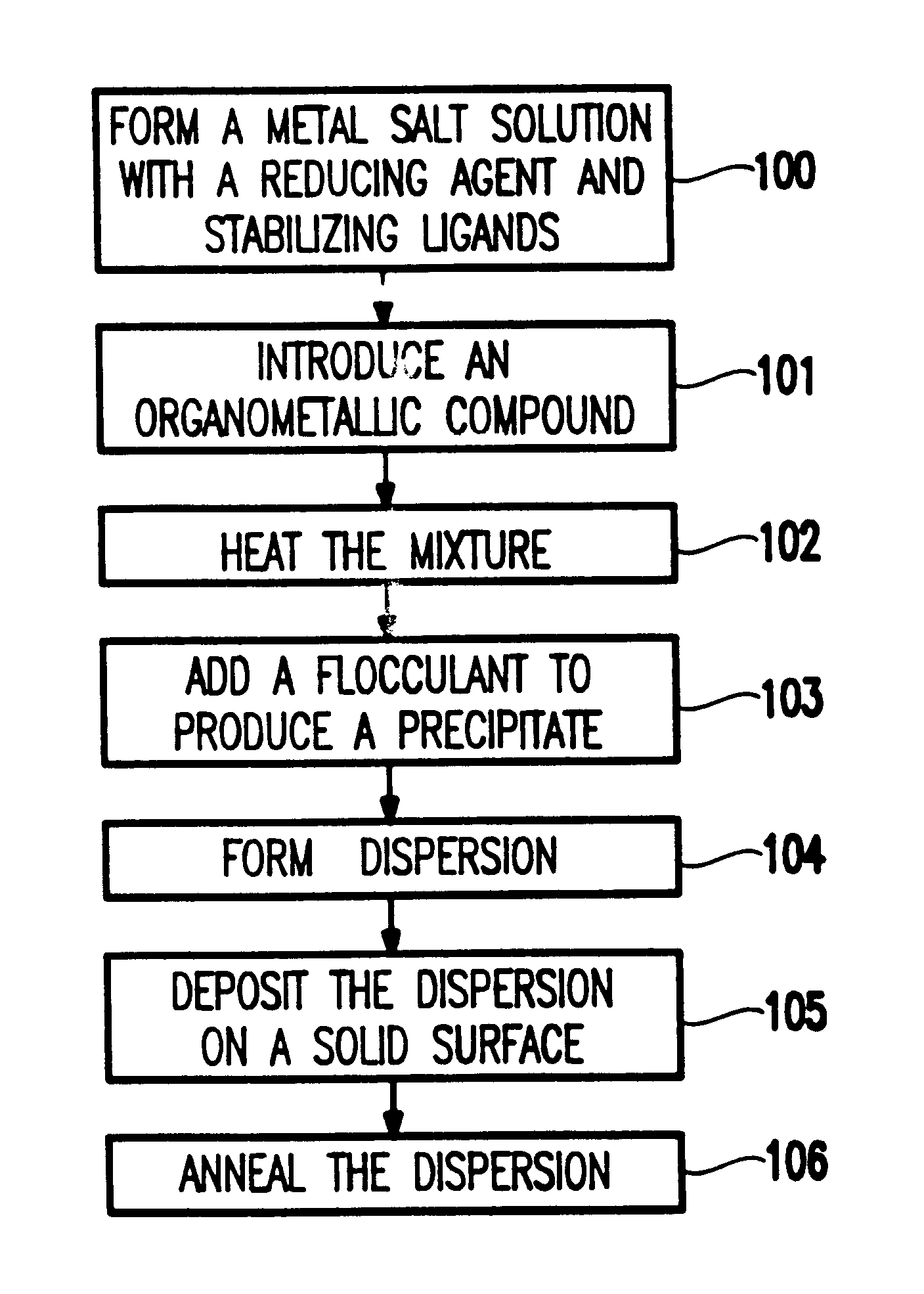

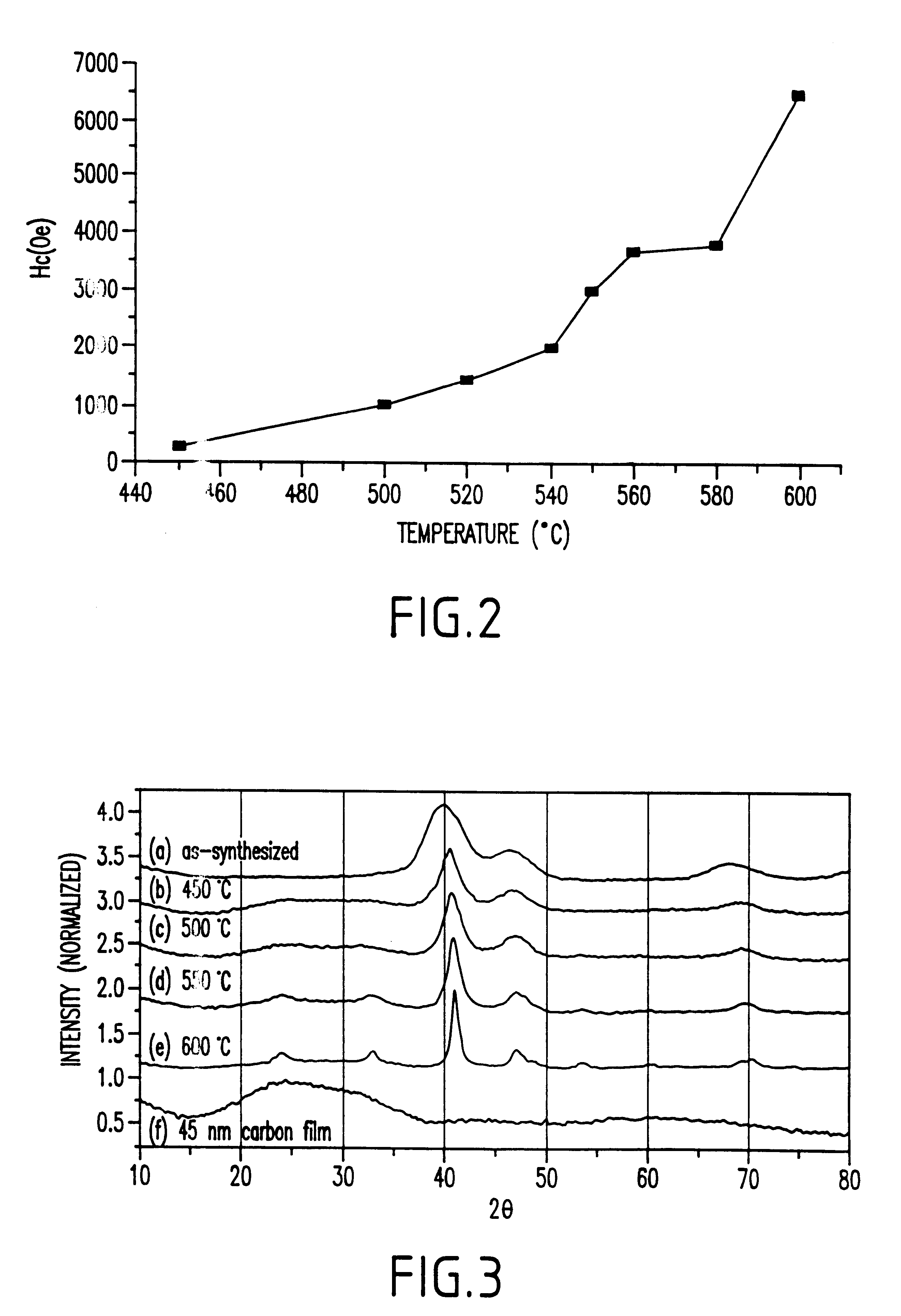

Chemical synthesis of monodisperse and magnetic alloy nanocrystal containing thin films

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

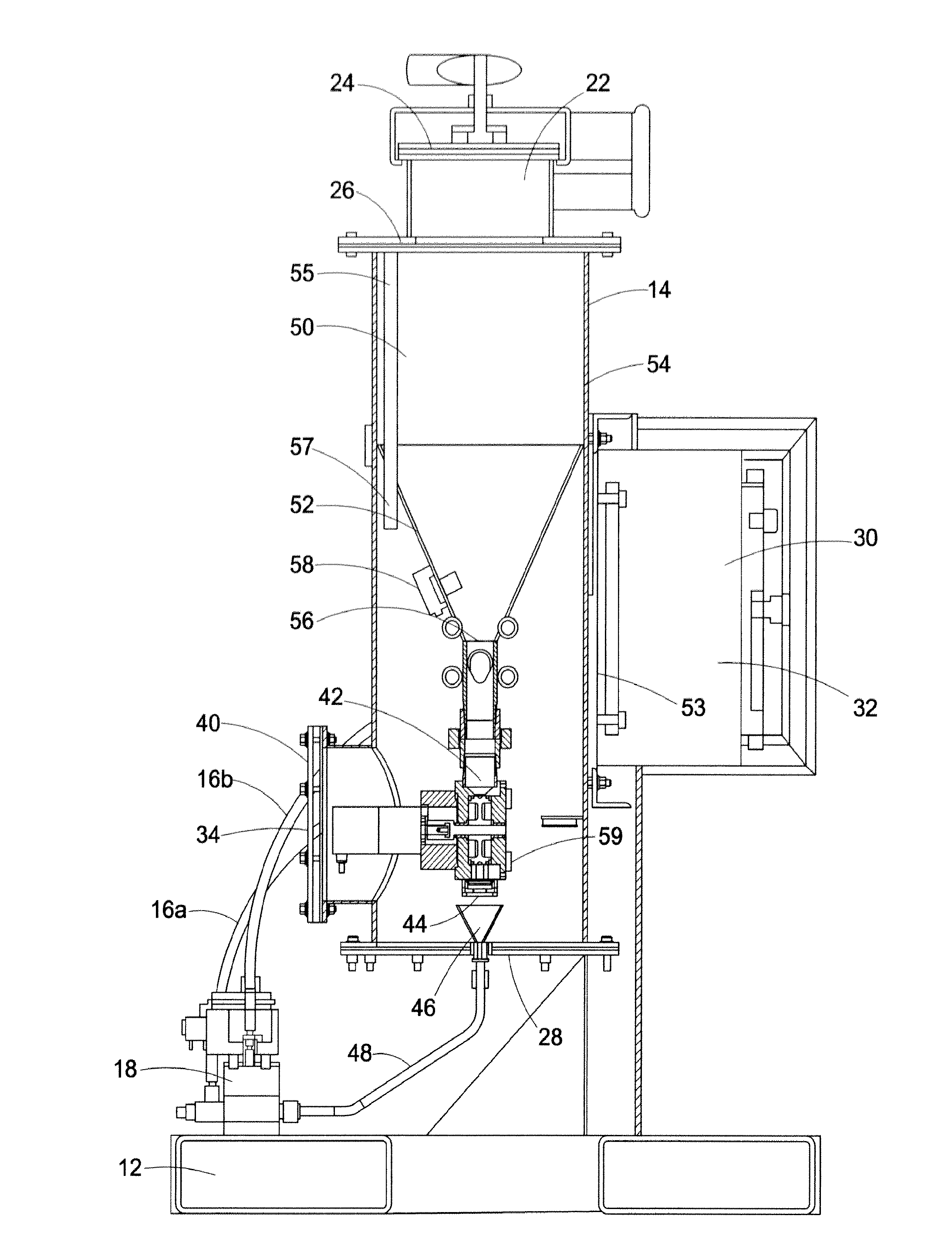

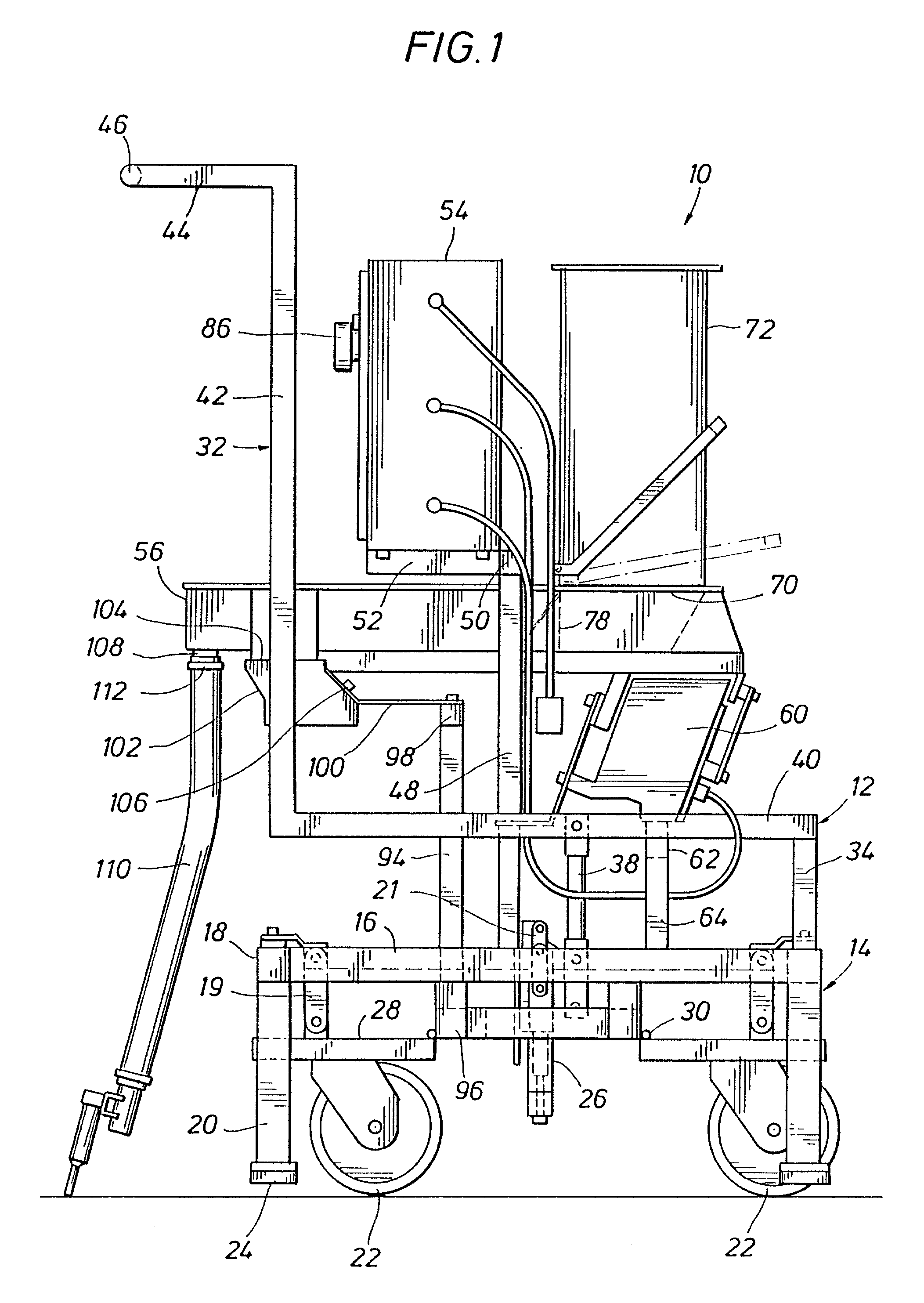

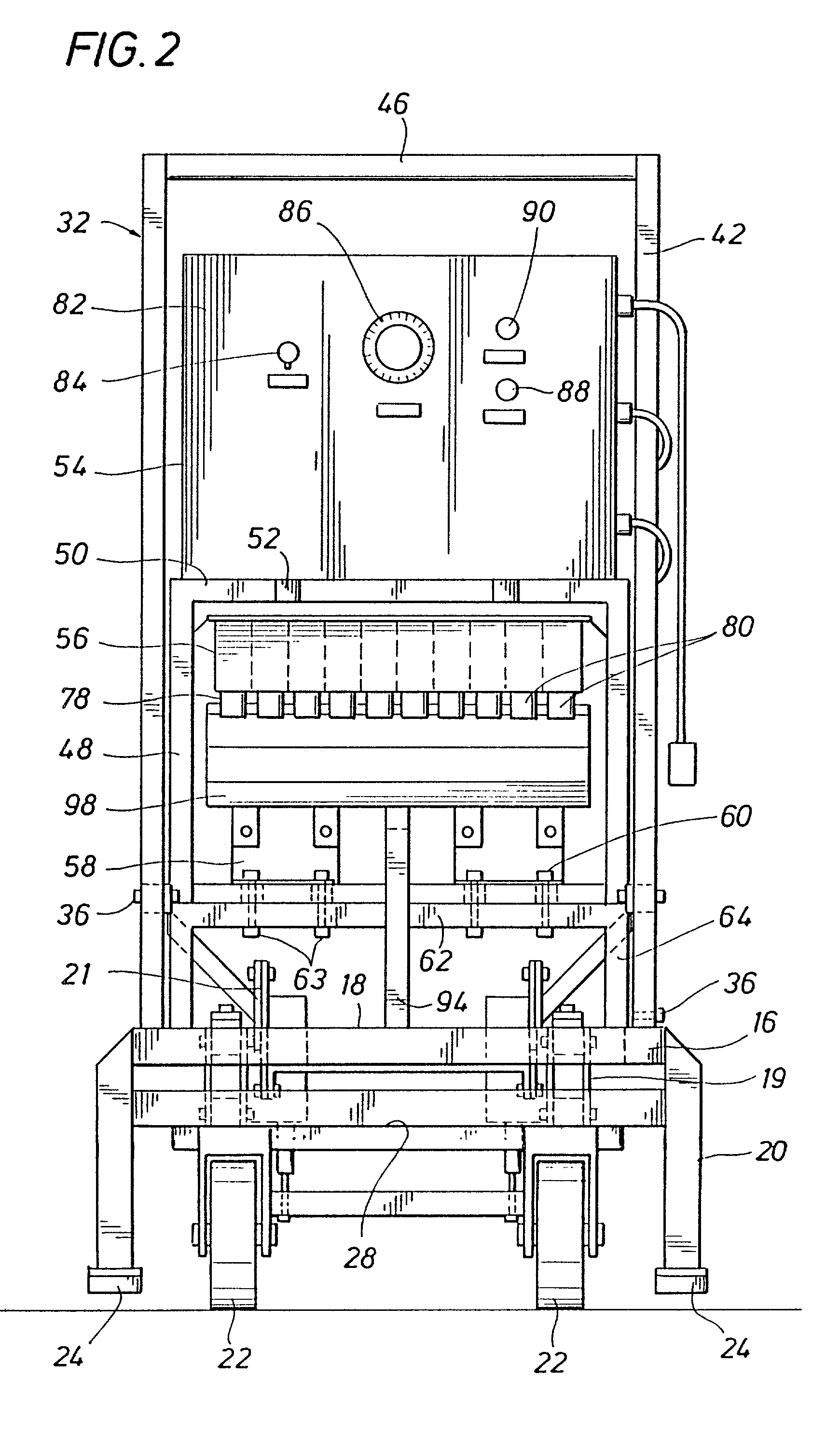

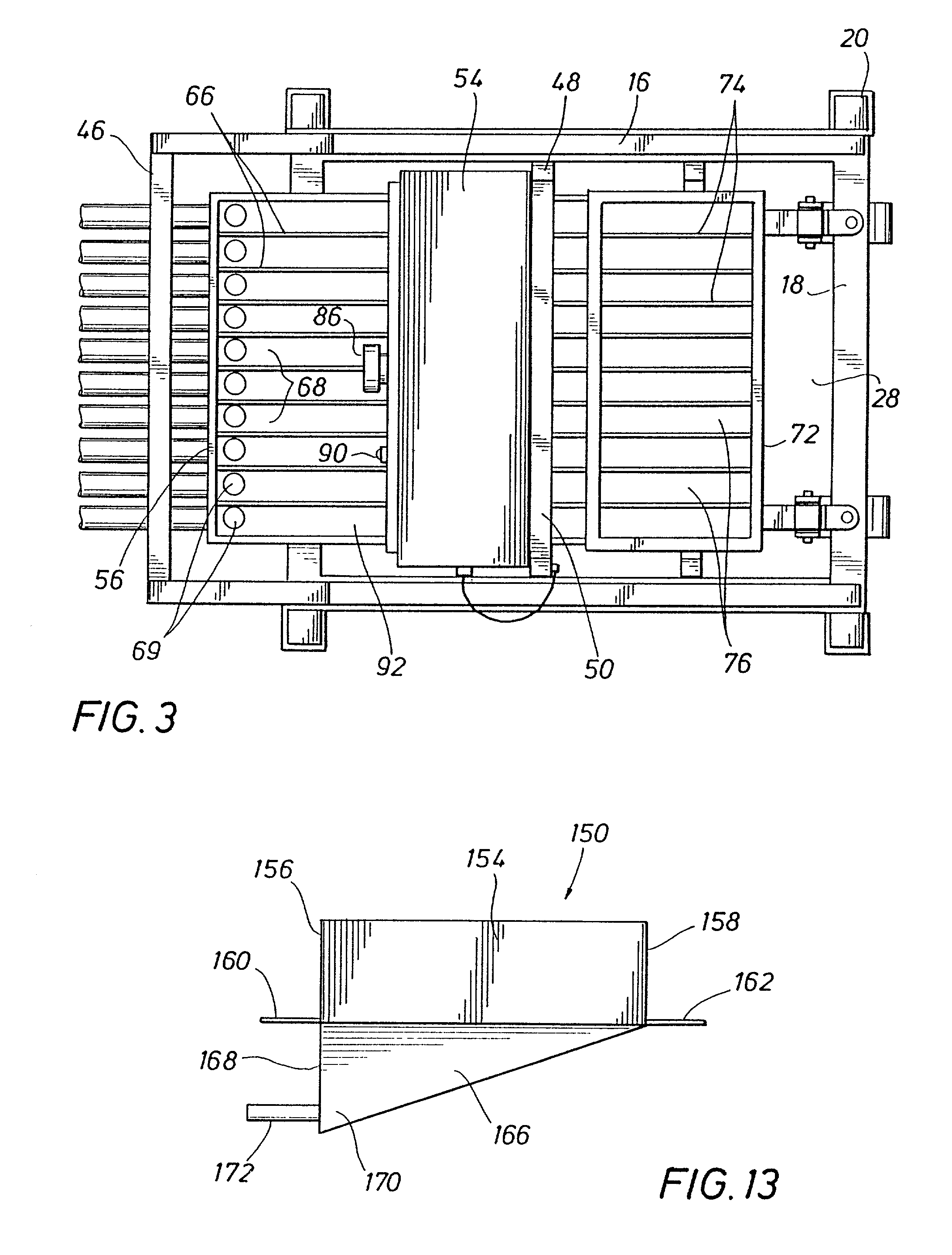

Catalytic reactor charging system and method for operation thereof

InactiveUS20010041117A1Permit accuracyPermit efficiencyTank vehiclesBell-and-hopper arrangementPtru catalystControl system

A catalyst loading system for utilizing catalyst from a bulk supply located adjacent but not on the upper tube sheet of a catalytic reactor and for mechanized measuring of multiple identical quantities of catalyst and for mechanized loading of catalyst pellets into the reaction tubes of the reactor to achieve even drop rate, compaction and outage of the reaction tubes. From the bulk supply, multi-compartment catalyst charging hoppers are individually filled in rapid and accurately measured fashion by mechanized filling equipment having a predetermined sequence of operation that ensures accuracy of volumetric catalyst measurement. The charging hoppers are used for delivery of measured volumes of catalyst of a reactor tube loading mechanism which may take the form of a mobile cart framework being selectively positionable relative to the upper tube sheet and reaction tubes of a catalytic reactor to be charged with catalyst pellets. A pair of electronic vibrators are mounted to the cart framework and provide for support and vibratory movement of a vibratory tray having a catalyst feed hopper adapted to feed catalyst pellets to a plurality of generally parallel catalyst transfer troughs along which catalyst pellets are moved by vibration of the vibratory tray to a plurality of drop tubes. A compartmented hopper is fixed to the vibratory tray and controllably feeds catalyst pellets into respective catalyst transfer troughs. A plurality of charging tubes are connected to respective drop tubes by a plurality of elongate flexible tubes and are maintained in fixed, spaced relation by a structural element so as to define a charging manifold for simultaneous, timed delivery of catalyst pellets into a plurality of reactor tubes. The charging manifold has locator pins which are inserted into selected reactor tubes for orienting the charging tubes of the charging manifold with respect to a selected group of reaction tubes. A system is also provided for raising and lowering the charging manifold for efficiency of reactor tube charging operations. An electronic control system is effective for controlling the vibrators to achieve even drop rate from each of the catalyst transfer troughs and to control the vibrators responsive to catalyst weight to achieve even catalyst drop rate during an entire catalyst charging cycle.

Owner:COMARDO MATHIS P

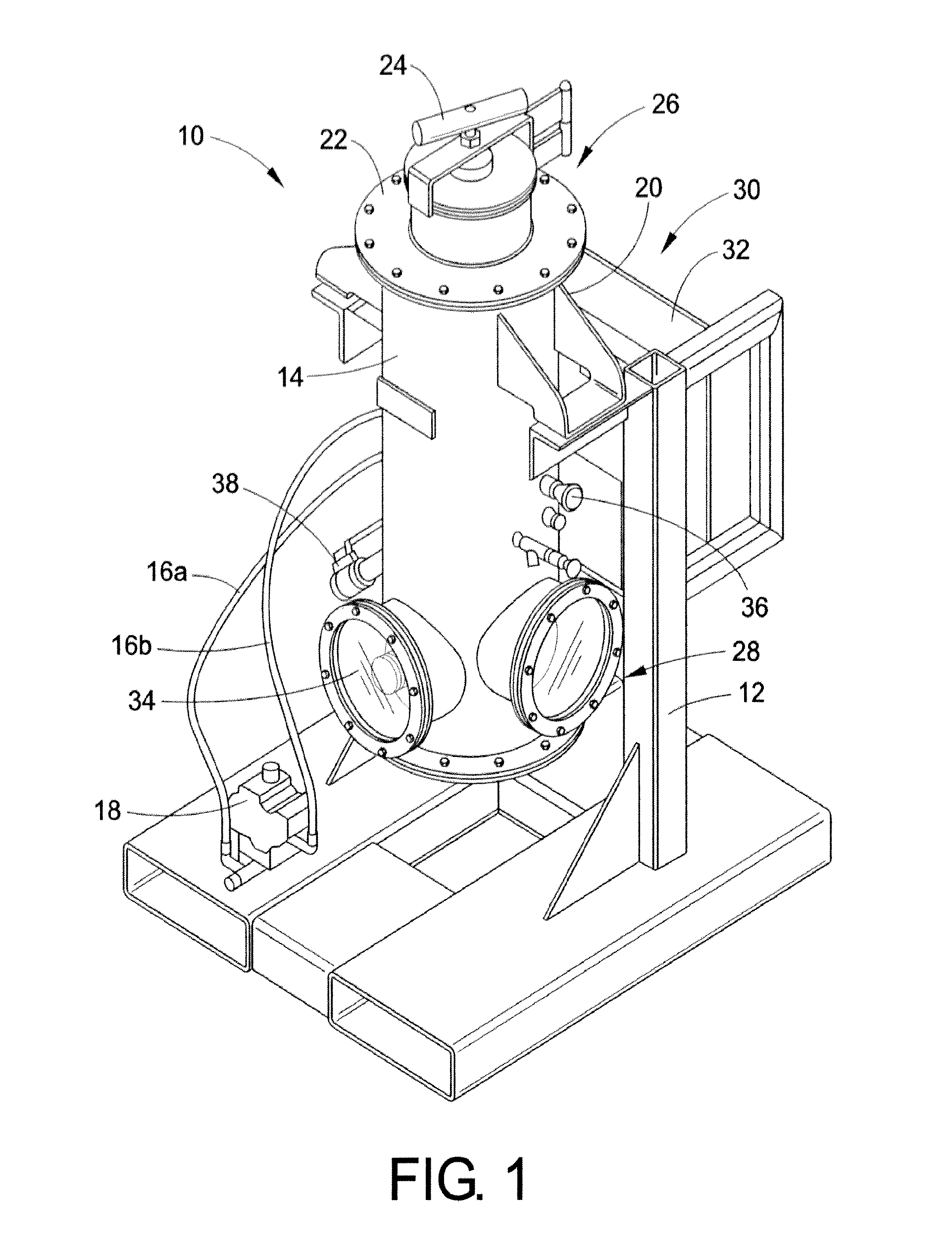

Molten metal transfer and degassing system

ActiveUS20130306687A1Keep the flowReduce the possibilityMelt-holding vesselsMolten metal pouring equipmentsEngineeringMolten metal

Aspects of the invention include a transfer chamber constructed inside of or next to a vessel used to retain and degas molten metal. The transfer chamber is in fluid communication with the vessel so molten metal from the vessel is pulled through the vessel by the pump as it is degassed. This helps maintain a generally constant flow of molten metal through the degassing vessel. Other aspects relate to a system and method for efficiently performing maintenance on components positioned in a vessel.

Owner:MOLTEN METAL EQUIP INNOVIATIONS LLC

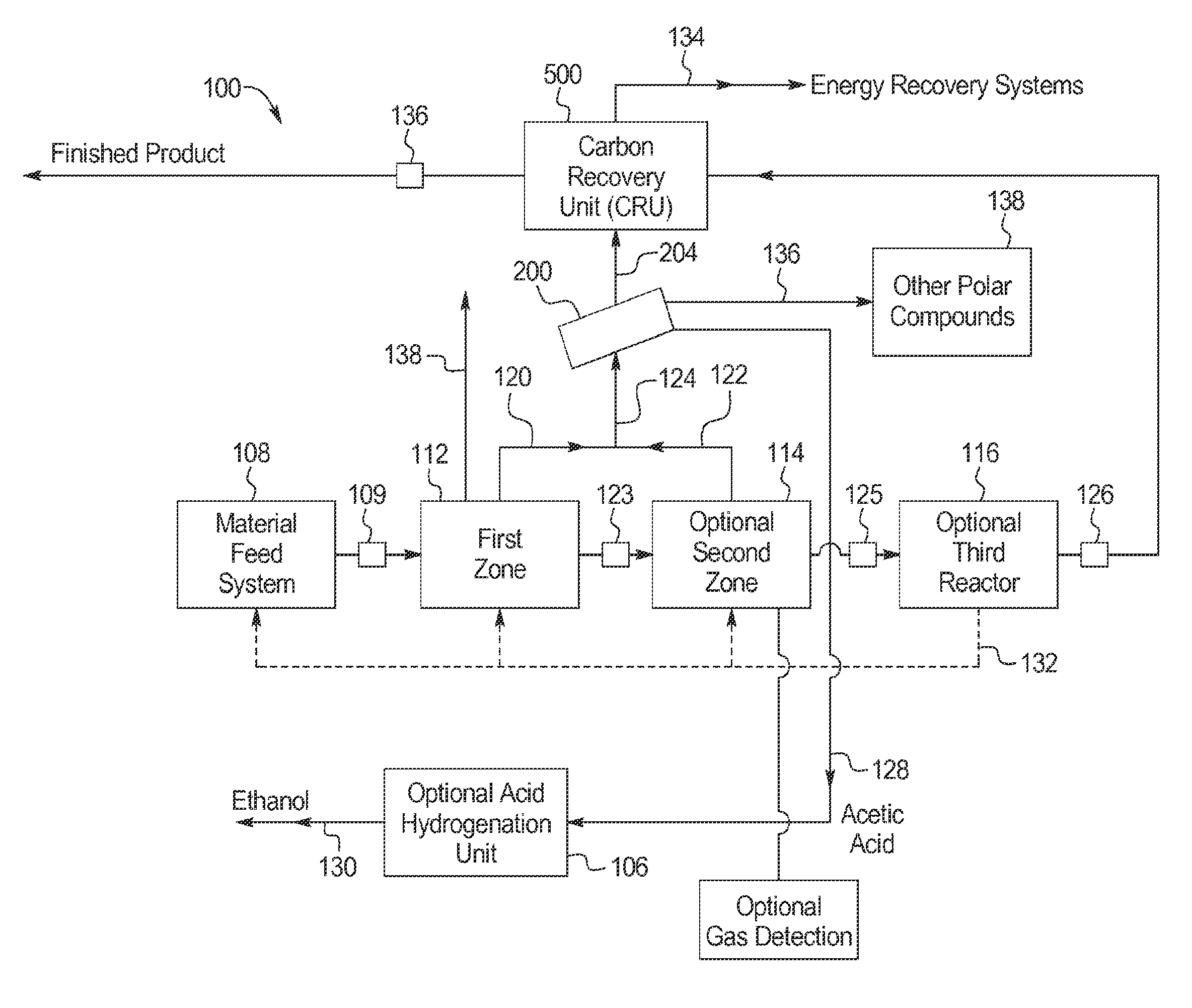

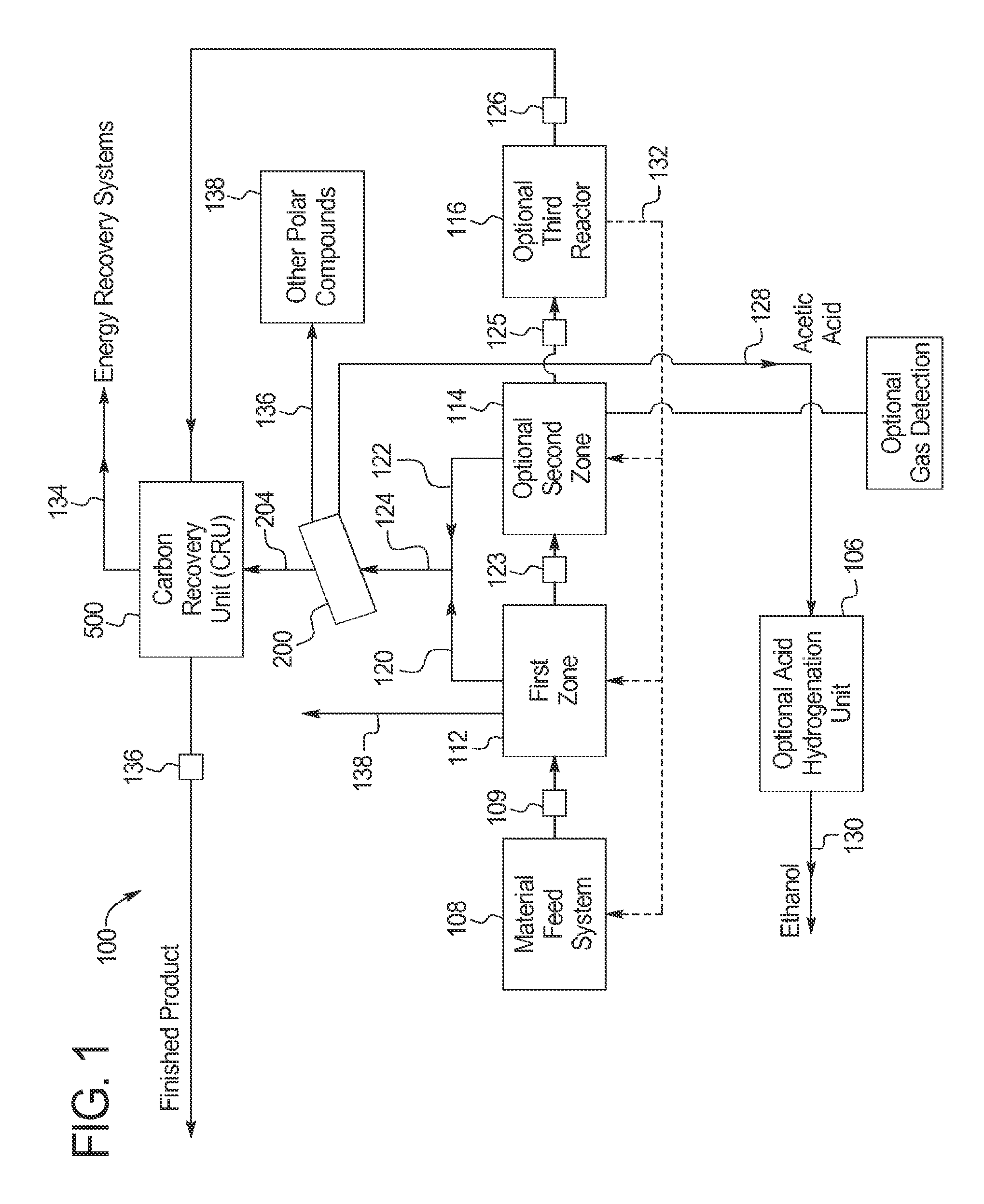

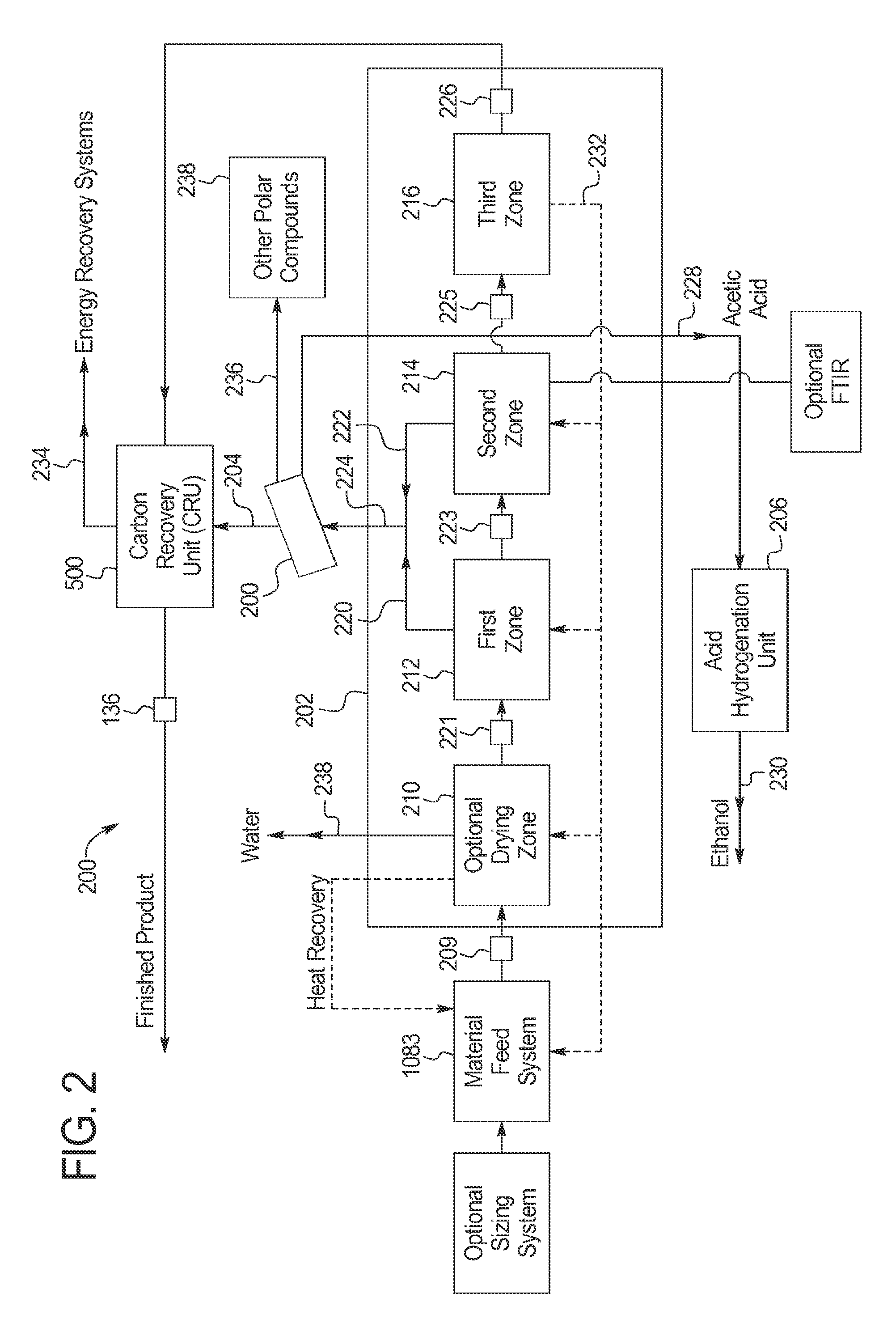

High-carbon biogenic reagents and uses thereof

ActiveUS20120285080A1High carbon contentImprove energy efficiencyCoke quenchingCoke oven safety devicesHigh carbonReagent

This invention provides processes and systems for converting biomass into high-carbon biogenic reagents that are suitable for a variety of commercial applications. High carbon biogenic reagents are also provided.

Owner:CARBON TECH HLDG LLC

Transfer well system and method for making same

The invention relates to systems for transferring molten metal from one structure to another. Aspects of the invention include a transfer chamber constructed inside of or next to a vessel used to retain molten metal. The transfer chamber is in fluid communication with the vessel so molten metal from the vessel can enter the transfer chamber. A powered device, which may be inside of the transfer chamber, moves molten metal upward and out of the transfer chamber and preferably into a structure outside of the vessel, such as another vessel or a launder.

Owner:MOLTEN METAL EQUIP INNOVIATIONS LLC

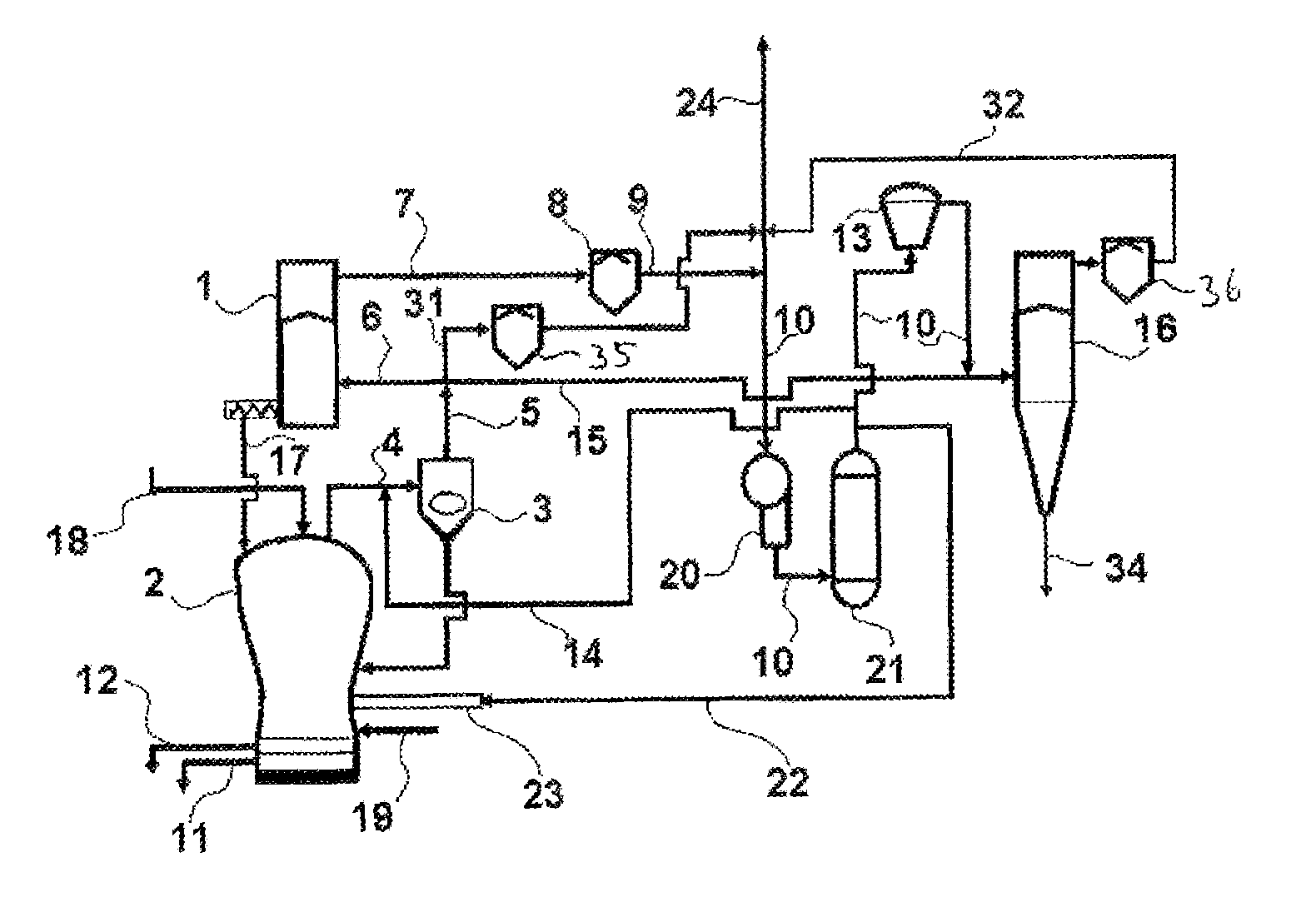

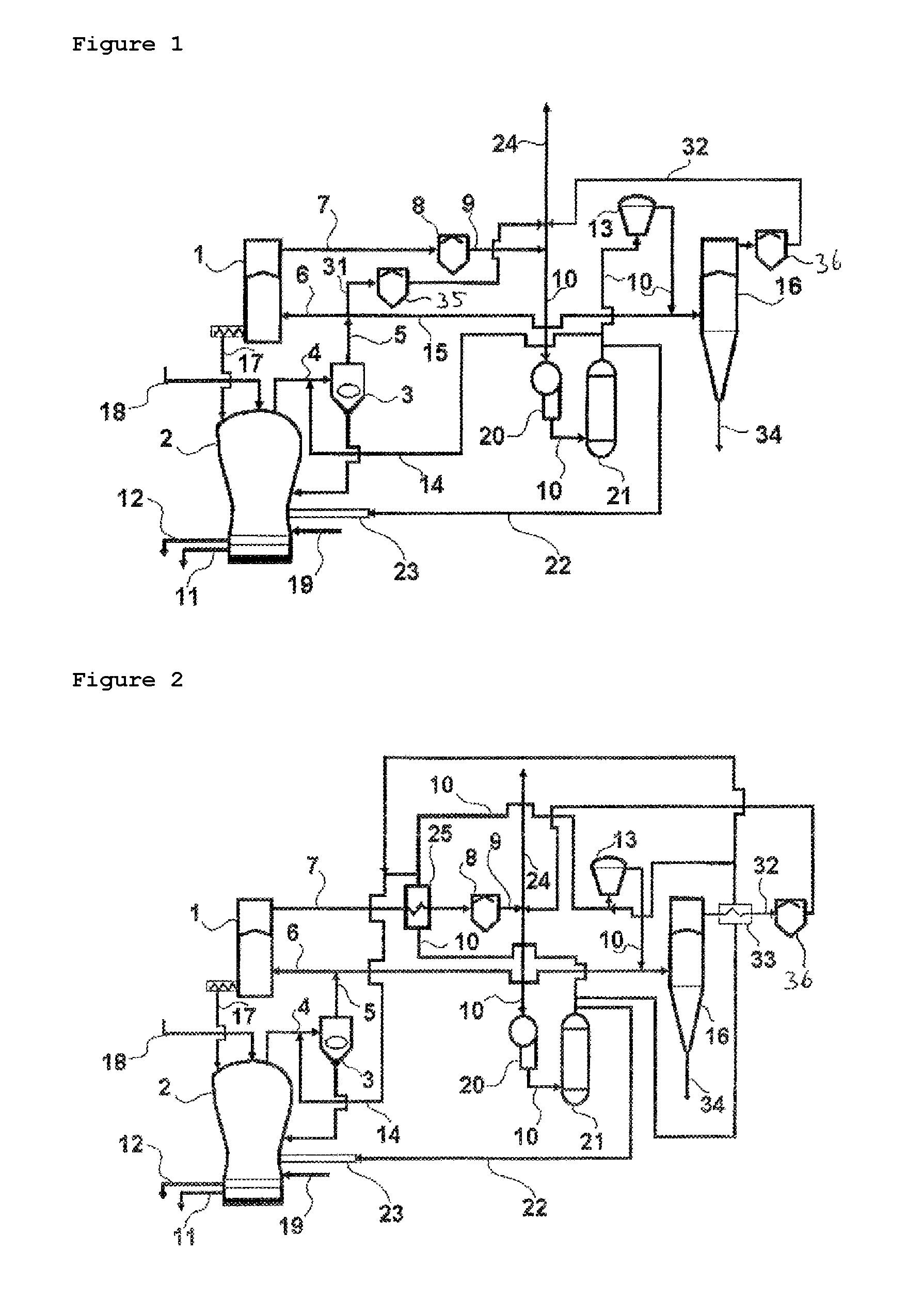

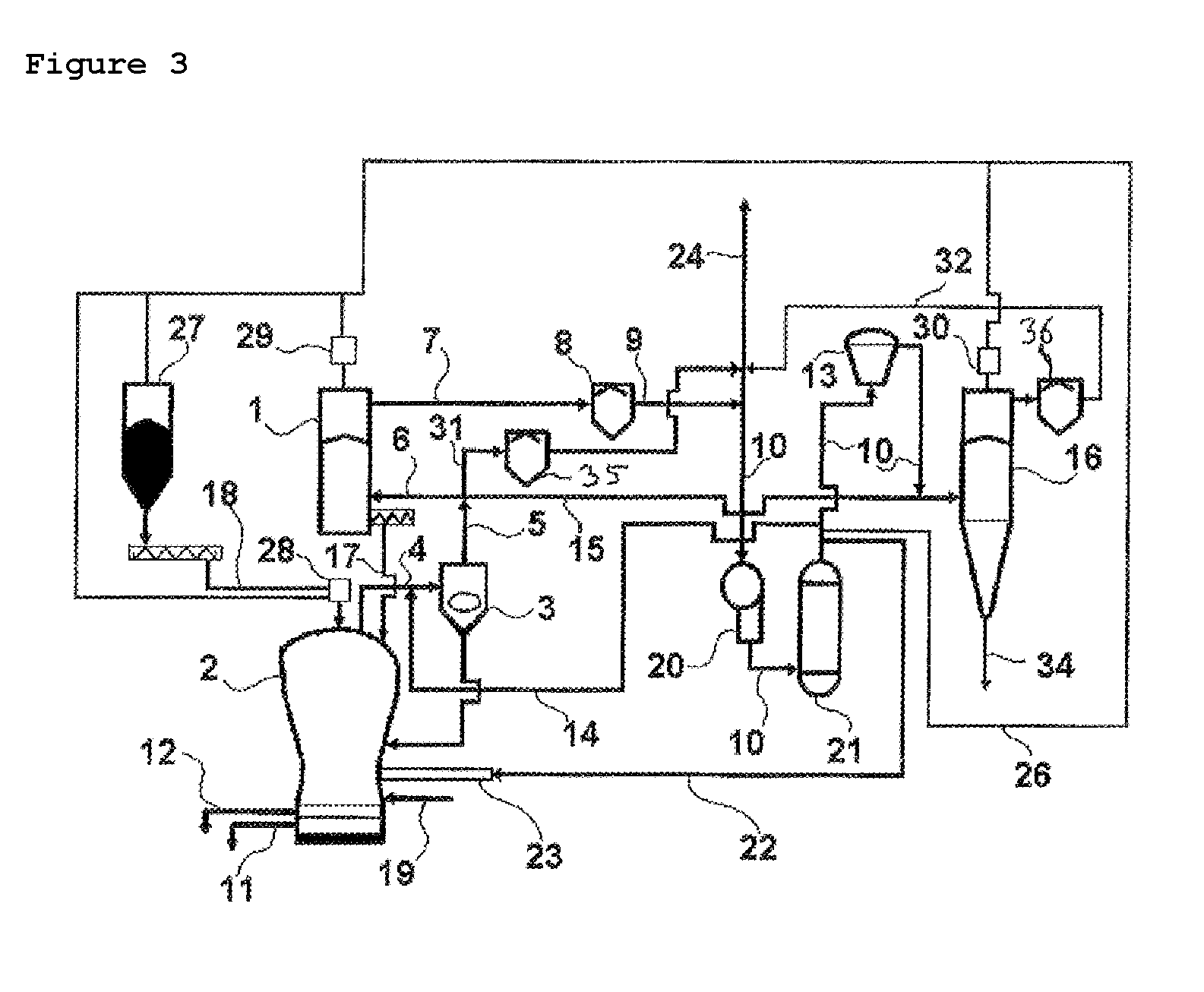

Method and system for energy-optimized and CO2 emission-optimized iron production

InactiveUS8419825B2Emission reductionIncrease profitBlast furnace detailsExhaust gas handlingProcess engineeringProduct gas

A process for energy- and emission-optimized iron production and an installation for carrying out the process. A first partial amount of a generator gas produced in a melter gasifier is used as a first reducing gas in a first reduction zone. A second partial amount is fed to at least one further reduction zone as a second reducing gas. In addition, after CO2 scrubbing, a partial amount of top gas removed from the first reduction zone is admixed with the generator gas after the latter leaves the melter gasifier, for cooling the generator gas.

Owner:PRIMETALS TECH AUSTRIA GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com