Patents

Literature

308 results about "Aluminum industry" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The aluminum industry in the United States in 2014 produced 1.72 million metric tons of primary aluminum, worth 3.97 billion dollars, at nine aluminum smelters. In addition, the US produced 1.70 million tons of secondary aluminum from old (post-consumer) scrap, and 1.93 million tons of aluminum from new (manufacturing) scrap.

Free flowing dry back-up insulating material

Disclosed is a free flowing dry back-up material which comprises:from 67 to 96% by weight of fly-ash;from 2 to 15% by weight of a heat sensitive binder such as boric acid;from 2 to 7% by weight of a non-wetting agent such as calcium fluoride;from 0 to 10% by weight of a heat expandable material, viz. a material expandable as a function of the temperature such as vermiculite or graphite; andfrom 0 to 1% by weight of a dust suppressant such as kerosene.This material which is useful in particular in the aluminum industry has the advantages of being water free and free flowing, such avoiding the use of vibrator to position it into a shell. It also has a low density and a low thermal conductivity. Moreover, it is organic free as compared to the existing materials which use an organic binder to ensure a low temperature set; and it sets at a temperature lower than 400° F.

Owner:LES PROD CHIMS INDS DE HAUTE TEMPERATURE PYROTEK

Comprehensive utilization method of aluminum ash

ActiveCN105347361AHarmlessAvoid pollutionAmmonium salt preparationAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationAtmospheric dustAluminum industry

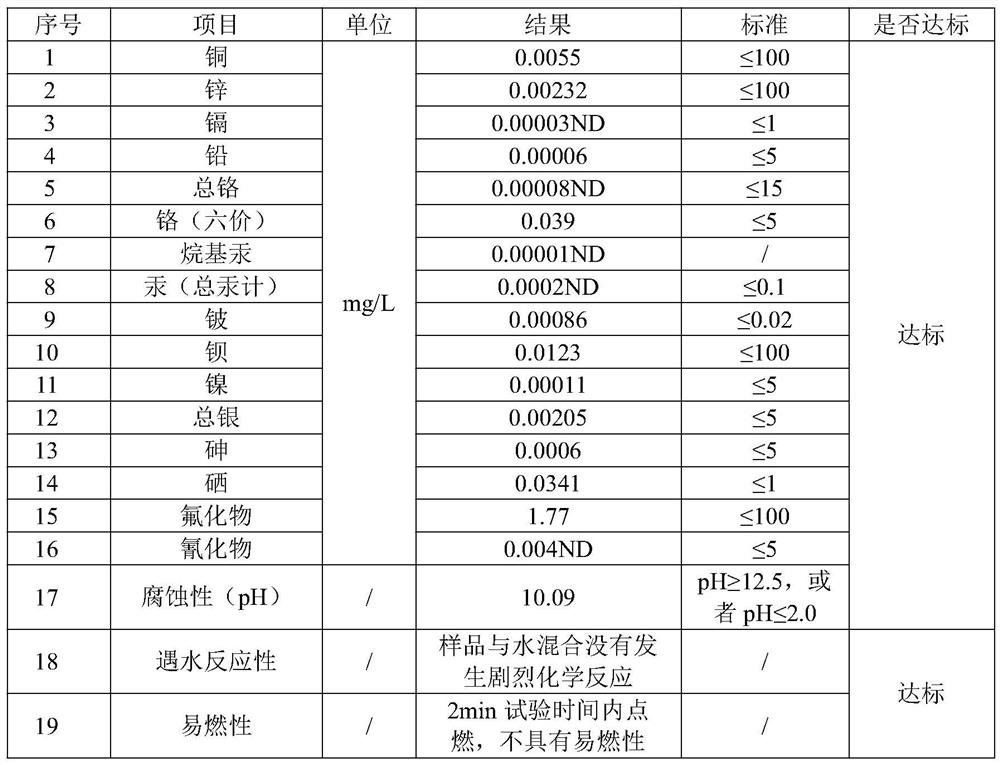

The invention belongs to the technical field of comprehensive utilization of waste resources from the aluminum industry and specifically discloses a comprehensive utilization method of aluminum ash. According to the comprehensive utilization method of aluminum ash, metallic aluminium is extracted from aluminum ash through an ore grinding method; the aluminum ash obtained after aluminium extraction undergoes catalytic deamination; the aluminum ash obtained after deamination is mixed with alkali and granulation forming is then carried out; and the granulation product is sintered and the sintered product is finally dissolved out. By the above method, useful components in the aluminum ash can be recovered to the maximum; ammonia gas which has been ignored for a long time is effectively recovered; components such as aluminium oxide, villiaumite and the like are recovered and utilized to the maximum; pollution of aluminum ash processing to the environment is avoided; atmospheric dust pollution is avoided; atmospheric pollution is also avoided due to ammonia gas recovery; pollution of aluminum ash stacking to underground water and soil is avoided due to extraction and recovery of fluoride salt; and environmental safety during the treating process is guaranteed.

Owner:湖南绿脉环保科技股份有限公司

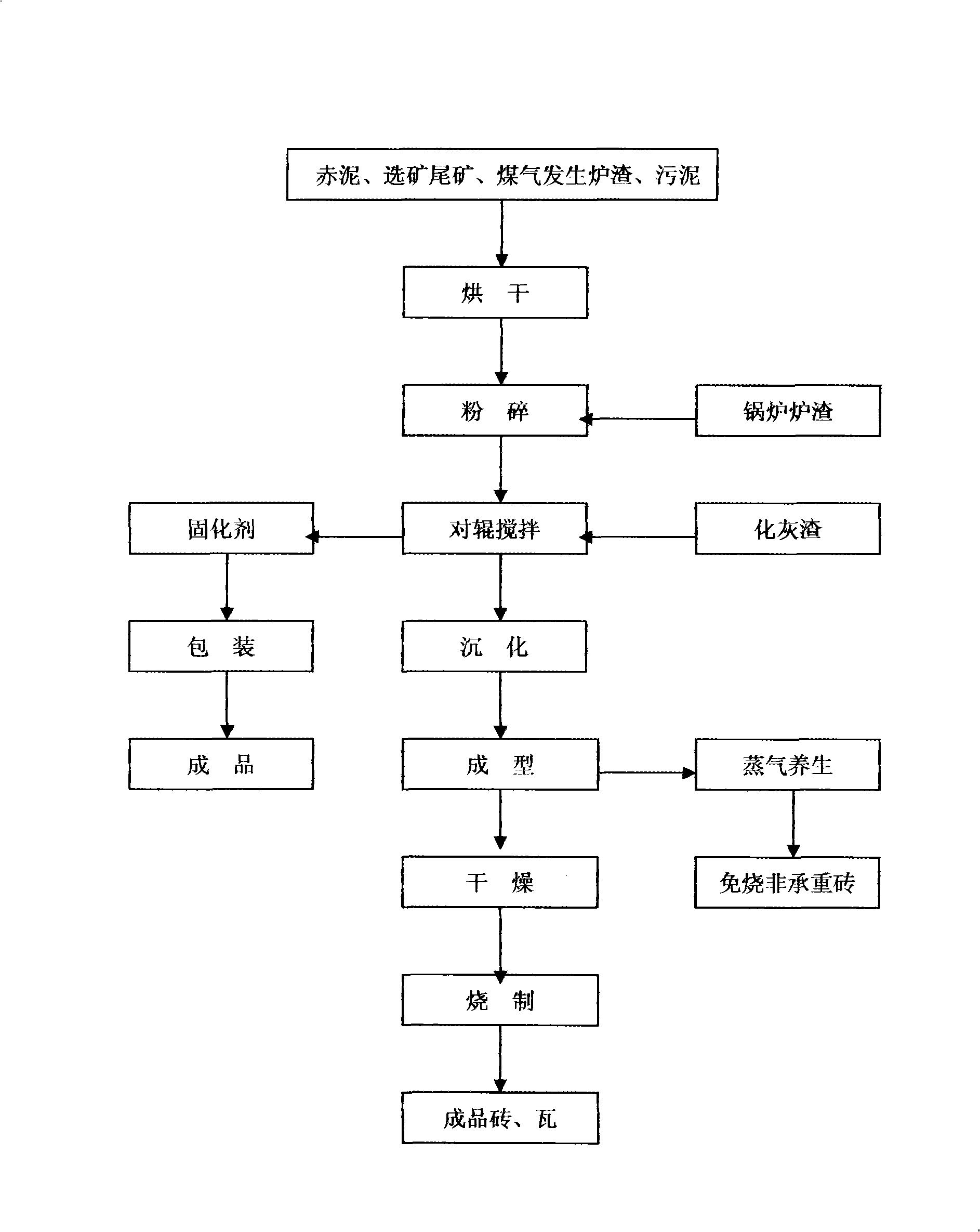

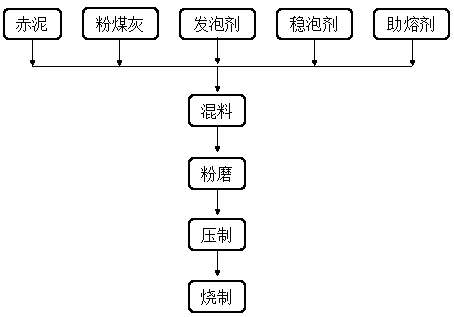

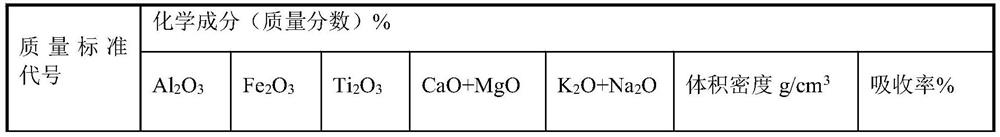

Process and method for converting waste slag wholly of aluminum industry into ecological building material

The invention belongs to a method for utilizing resources. The method utilizes the matter characteristics of solid wastes (six kinds of waste residues) such as red mud(the sintered method and the Bayer method), boiler slag, ore dressing tailings, ash and gas generation slag, which are generated during the manufacturing process in aluminum industry, and converts the solid wastes into a novel road material and construction walling material by the processes such as drying, crushing, reasonable proportioning, machine shaping(grinding and extrusion) and consolidation or sintering. The method is characterized in that the utilization ratio of the waste residues is 100 percent. The waste residues comprise the following compositions: (1) the produced road material-curing agent, which can be used to reinforce a highway subgrade and bases of road surface substrates(substrate and subbase) and buildings and completely replace cement, lime and sandstone materials, and the road material can meet prior national(industrial) standards and environmental protection standards in performance; and (2) the produced construction walling materials-non supporting brick, supporting brick, air brick, hollow building block, common tile, glazed roof tile and andorful tile, which are superior to the prior national standards in performance. The material obtained by the invention has the characteristics of energy conservation, thermal insulation, high strength, corrosion resistance, efflorescence resistance and no pollution.

Owner:王文举

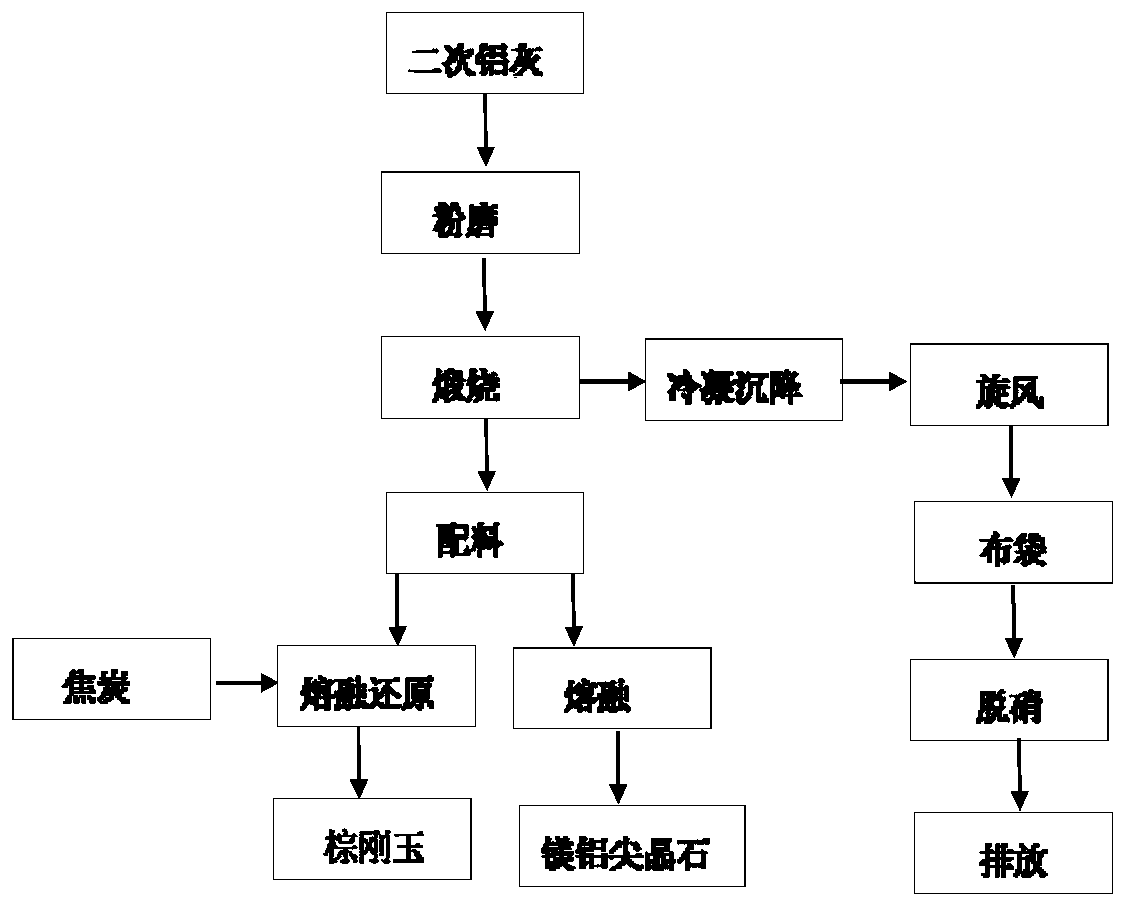

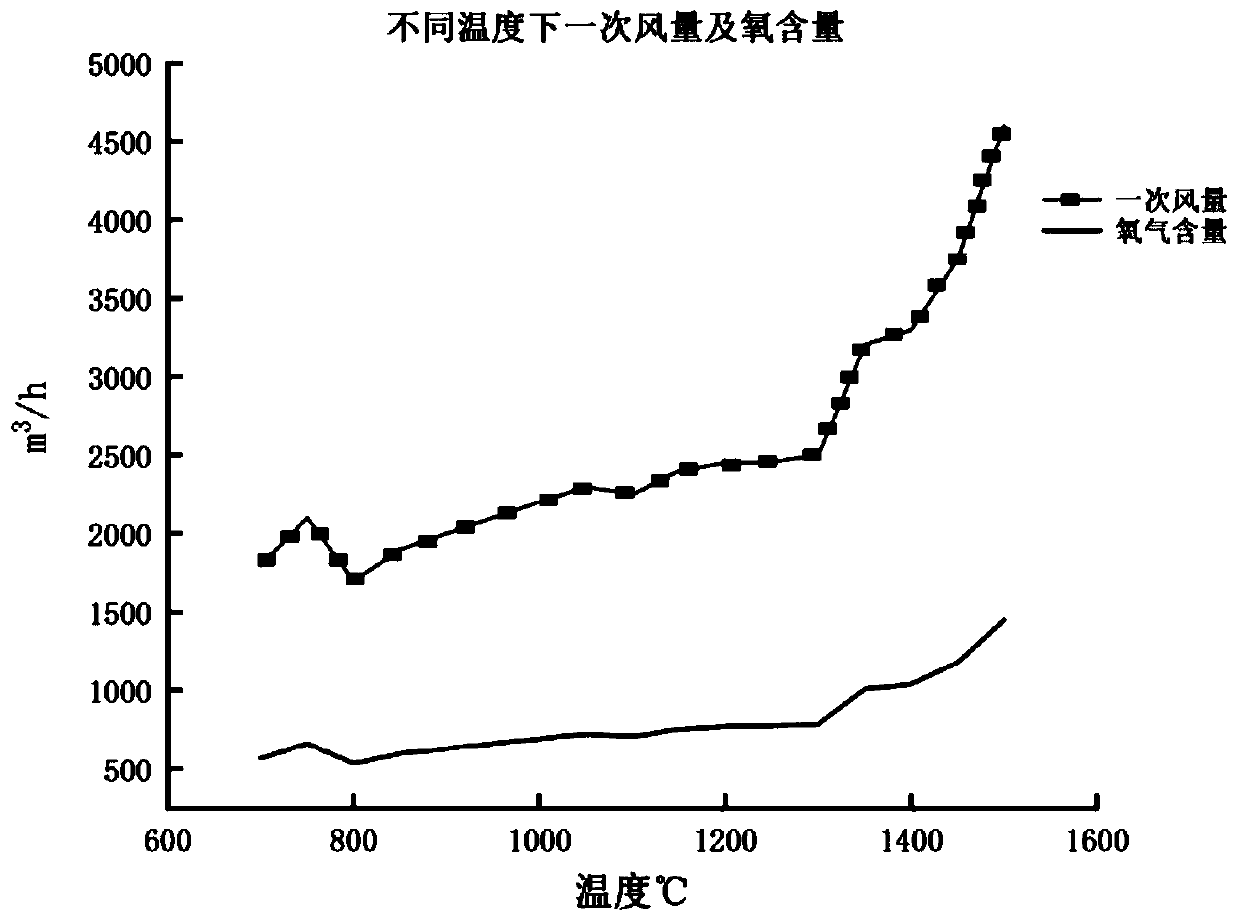

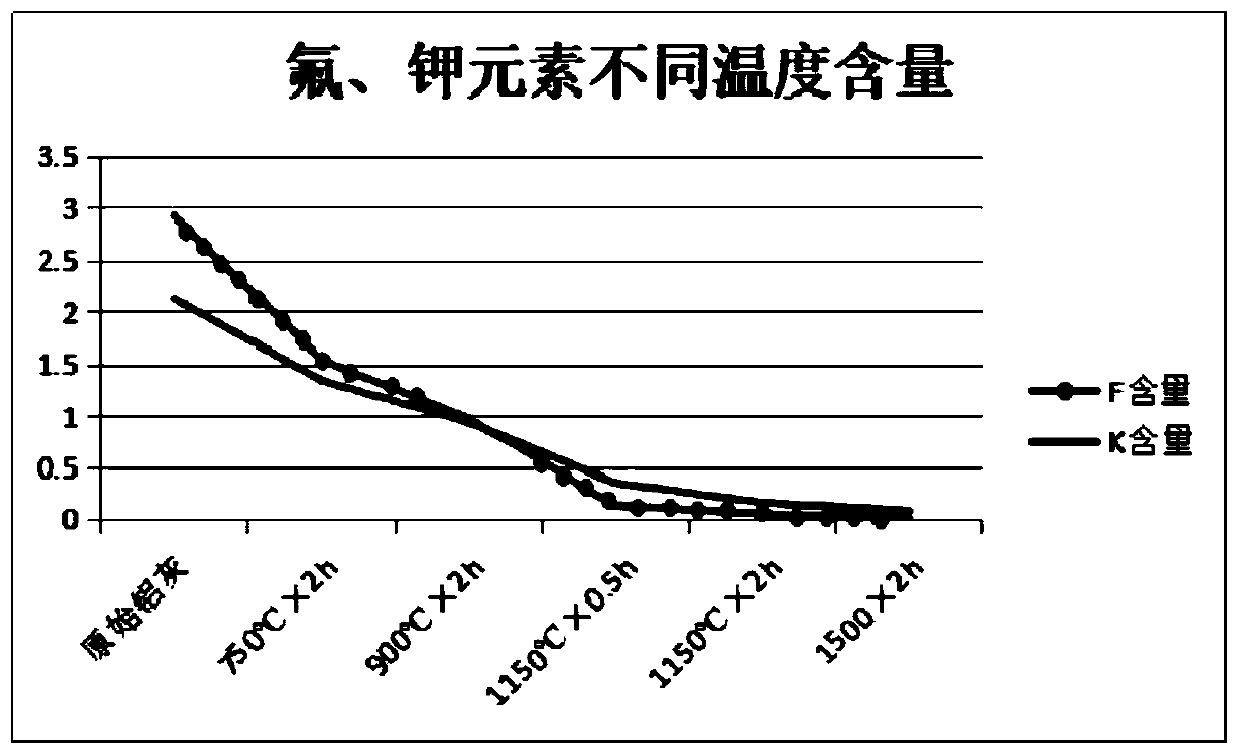

Method of manufacturing refractory material by innocent treatment of secondary aluminum ash

The invention discloses a method for manufacturing a refractory material by innocent treatment of secondary aluminum ash, and belongs to the field of aluminum industry. The method comprises the following steps: further grinding the secondary aluminum ash until 80% of the secondary aluminum ash passes through a screen with the pore diameter of 74 microns; and calcining the secondary aluminum ash for 0.5-4 hours at the temperature of 1150-1550 DEG C in an oxidizing atmosphere with the oxygen content of 12%-18% to convert metal aluminum, aluminum nitride and aluminum carbide in the secondary aluminum ash into aluminum oxide and volatilize the fluoride salt and chloride salt in the secondary aluminum ash, thereby producing a calcined oxide; cooling the waste flue gas containing fluoride salt and chlorate produced in the calcining process for recovery, and denitrifying and discharging the flue gas. The calcined oxide is independently prepared or mixed with an additive, and the aluminum-magnesium refractory material is prepared after electric arc melting. The preparation method can be used for preparing the refractory material with high purity.

Owner:BEIJING MINING & METALLURGICAL TECH GRP CO LTD

Regeneration method for waste composite paper film

A regeneration method for waste composite paper film material includes a separation step (1) and a separation step (2), wherein the separation step (1) mainly separates mostly paper fiber, and the separation step (2) further separates plastic film or / and plastic-aluminum composite film. The method including two steps can increase quality and quantity of regenerating paper, and reduce content of the plastic film and aluminum foil in the regenerating paper. The waste composite paper film material can be separated and regenerated without pollution, and can be used as raw material or auxiliary material for paper industry, rubber and plastic product industry and aluminum industry, wherein all kinds of recovery components are utilized.

Owner:吴宸 +1

Refining agent for smelting aluminum alloy and preparation method of refining agent

InactiveCN102181757AIncrease surface tensionImprove working environmentPotassium nitrateWorking environment

The invention relates to an aluminum smelting purifying agent, in particular to a refining agent for smelting an aluminum alloy and applied to purification treatment in a smelting furnace in the process of aluminum and aluminum alloy smelting, and a preparation method of the refining agent. The refining agent is prepared from the following raw materials in part by weight: 26 to 34 parts of sodium nitrate (NaNO3), 30 to 40 parts of potassium nitrate (KNO3), 15 to 22 parts of sodium aluminofluoride (Na3AlF6), 4 to 6 parts of calcium fluoride (CaF2), 6 to 12 parts of graphite (C), and 2 to 4 parts of sodium carbonate (Na2CO3). The preparation method of the refining agent comprises the following steps of: putting the raw materials of the sodium nitrate, the potassium nitrate, the sodium aluminofluoride, the calcium fluoride, the graphite and the sodium carbonate into a drying type rotary composite stirrer; stirring the raw materials for 60 to 90 minutes at 150 to 250 DEG C; and finally, preparing a powdery refining agent finished product. The refining agent has strong refining capability, has an obvious function in improving the quality of aluminum industry products, is low in cost and less in used amount, significantly saves the cost, improves the working environment of workers, and causes less environmental pollution.

Owner:湖南德利亨新材料科技股份有限公司

Environment friendly low-gas-content aluminum alloy ingot and production method thereof

The invention discloses an environment friendly low-gas-content aluminum alloy ingot which comprises the following components in percentage by weight: 1.6-3.3 percent of Cu, 9.8-11.8 percent of Si, 0-0.29 percent of Mg, 0-0.08 percent of Zn, 0-0.8 percent of Fe, 0-0.48 percent of Mn, 0-0.48 percent of Ni, 0-0.1 percent of Ti, 0-0.1 percent of Pb, 0-0.2 percent of Sn, 0-0.25 percent of other trace elements and the balance of aluminum. Meanwhile, the invention also discloses a production method of the environment friendly low-gas-content aluminum alloy ingot. The environment friendly low-gas-content aluminum alloy ingot has the advantages of low gas and dreg content, high aluminum liquid cleanness and good mechanical and machining properties. The production method has the advantages of low production cost and high efficiency and effectively solves the pollution problem of the secondary aluminum industry.

Owner:YE CHIU METAL RECYCLINGCHINALTD

High-purity stabilized aluminum alloy ingot and production method thereof

The invention discloses high-purity stabilized aluminum alloy ingot which comprises the following components in weight percent: 3.1-3.8% of Cu, 7.9-9.3% of Si, 0-0.1% of Mg, 0-2.3% of Zn, 0-0.9% of Fe, 0-0.5% of Mn, 0-0.5% of Ni, 0-0.35% of Sn, 0-0.1% of Ti, 0-0.25% of other trace elements and the balance of Al. The invention further discloses a production method of the high-purity stabilized aluminum alloy ingot. The high-purity stabilized aluminum alloy ingot of the invention has low gas and slag content, high cleanness of molten aluminum, uniform components of the product and thin crystal structure; and the production method has low production cost and high efficiency, and effectively solves the pollution problem of the secondary aluminum industry.

Owner:YE CHIU METAL RECYCLINGCHINALTD

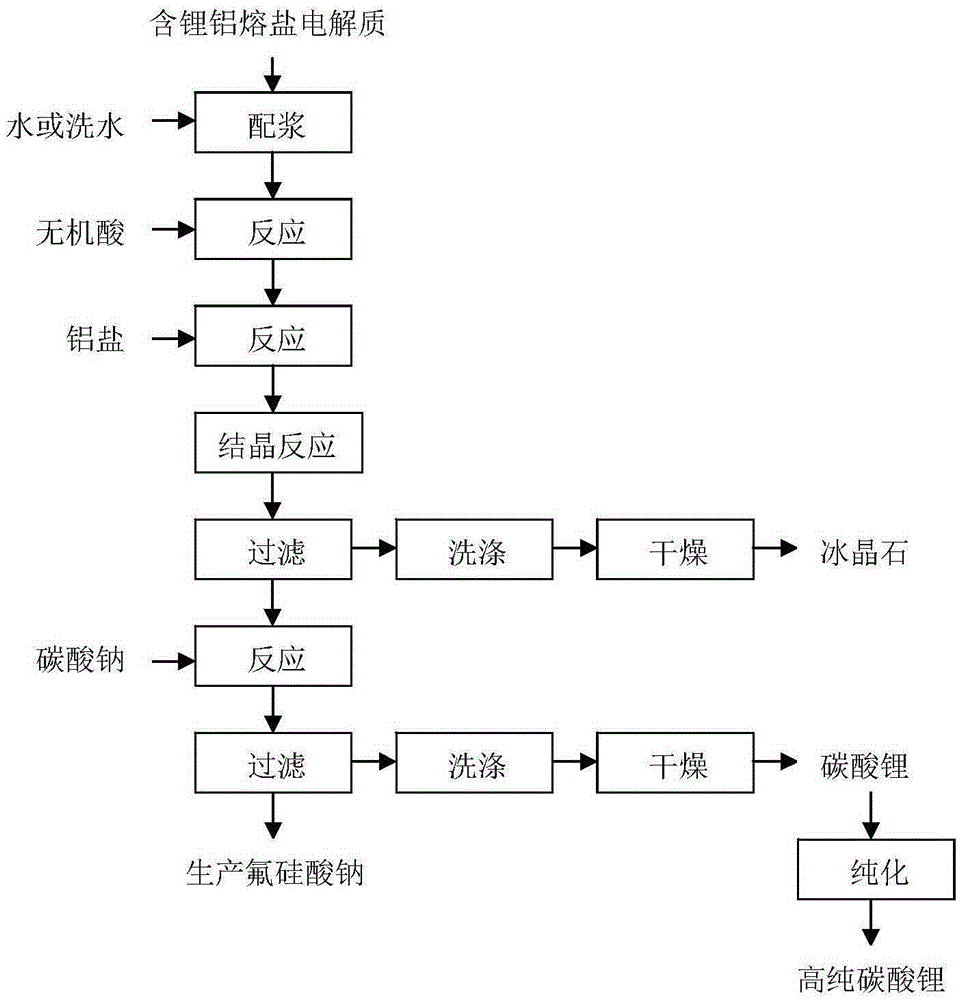

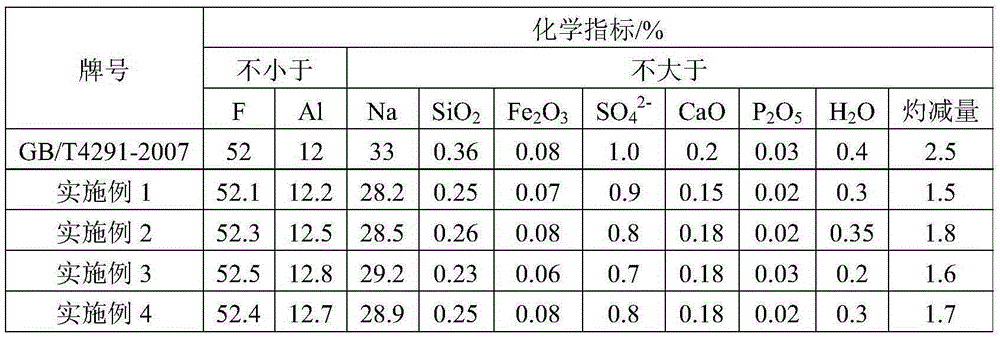

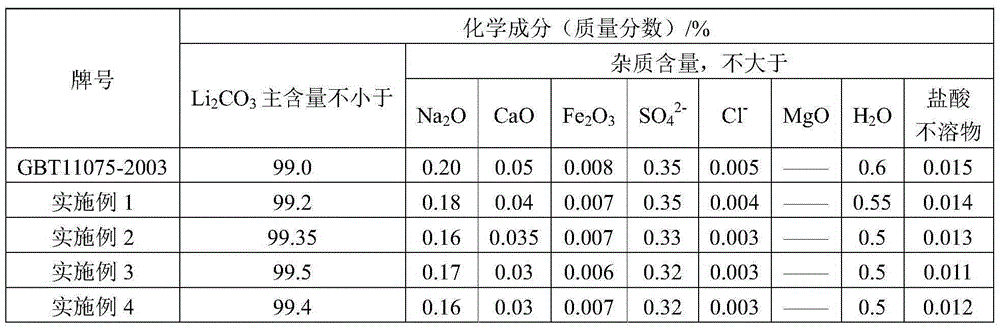

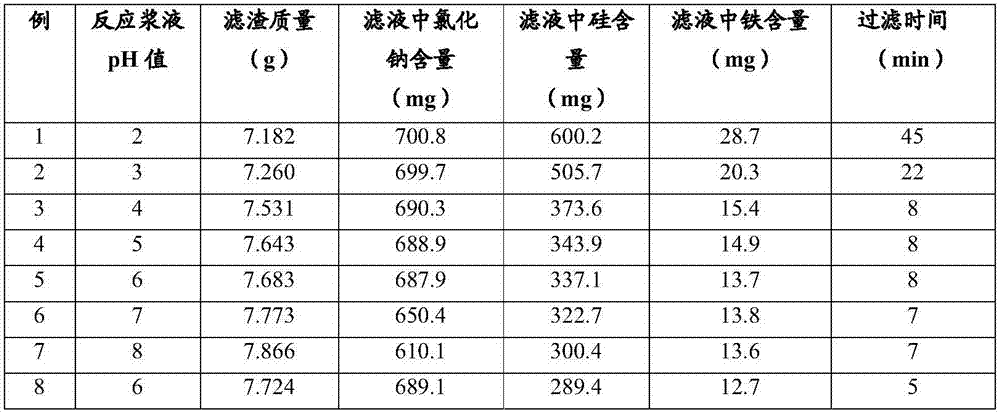

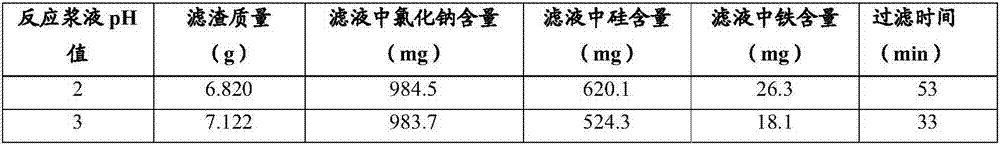

Lithium-aluminum-contained electrolyte comprehensive recycling method

ActiveCN105349786AImprove qualityRunning balance and stabilityProcess efficiency improvementLithiumSlurry

Owner:DO FLUORIDE CHEM CO LTD

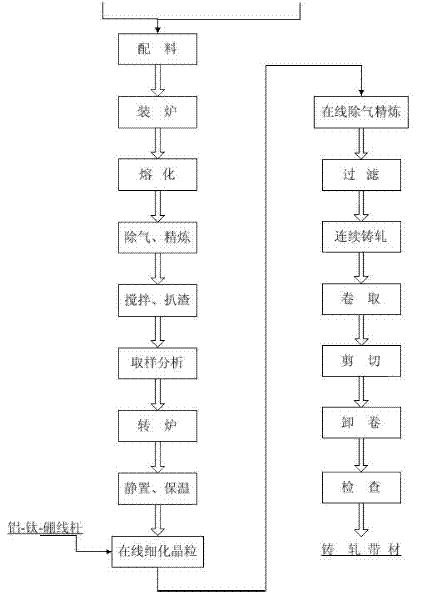

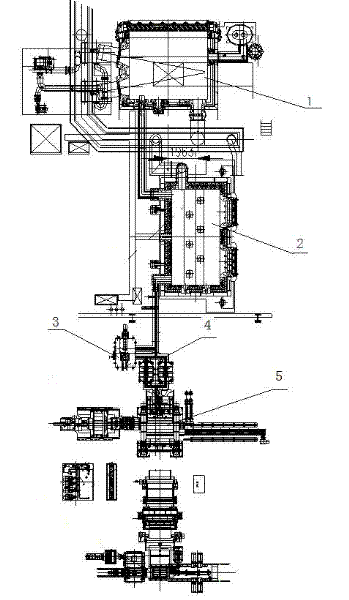

A continuous casting and rolling process for producing 5005 aluminum-plastic strip blanks

InactiveCN102266924AReduce burning lossReduce energy consumptionMetal rolling stand detailsMetal rolling arrangementsFoundryDual stage

The invention relates to the aluminum processing industry, in particular to a continuous casting and rolling process for producing 5005 aluminum-plastic strip blanks. The invention includes a holding furnace, an aluminum melting furnace, an on-line refining device, a two-stage filter item, and a continuous casting and rolling unit used in the production method. The process method includes the following steps: 1) batching step; 2) furnace loading step; 3 ) melting and stirring steps; 4) slag removal, sampling and analysis steps; 5) degassing refining, standing, heat preservation steps; 6) online melt processing steps; 7) continuous casting and rolling steps; 8) coiling and shearing steps ;9) Check the steps. The advantages of the method of the present invention: due to the use of 80% electrolytic aluminum liquid in the production process, the burning loss of aluminum is reduced to below 15‰, and the unit consumption of natural gas is reduced to below 80Nm3 / tAl, which is similar to the production of 3005 aluminum-plastic strips by using aluminum ingots for remelting Compared with the casting and rolling method of the billet, the burning loss and energy consumption of aluminum are reduced by 50%; the finished product rate reaches more than 99%. The invention discloses a continuous casting and rolling process for producing 5005 aluminum-plastic strip blanks, which is suitable for domestic and foreign aluminum and aluminum alloy casting industries.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

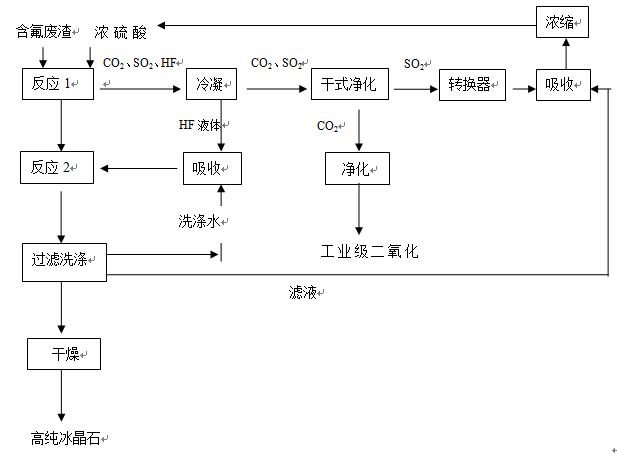

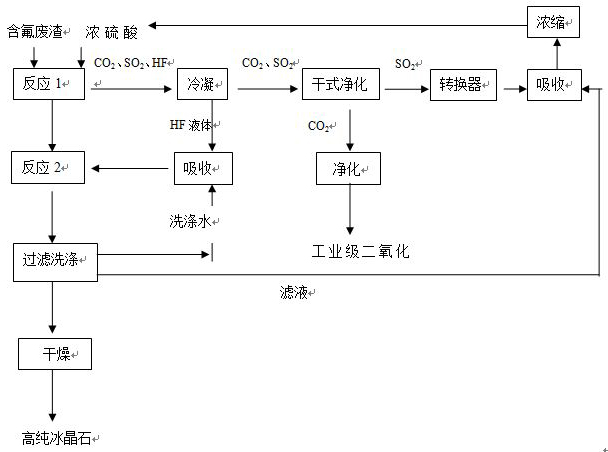

Method for producing cryolite by using fluorine-containing waste residues of electrolytic aluminium

ActiveCN102079534AQuality improvementReduce manufacturing costWaste processingSolid waste disposalPhysical chemistryEnvironmental engineering

The invention belongs to the technical field of aluminum industry smelting, and relates to a method for producing cryolite by using fluorine-containing waste residues of electrolytic aluminium. The technical scheme adopted by the invention is as follows: the fluorine-containing waste residues of the electrolytic aluminium and concentrated sulfuric acid are taken as raw materials to produce the cryolite. The method provided by the invention is used to improve the use ratio of the cryolite, prevent the waste of fluorine resources, and reduce the environmental pollution.

Owner:BAIYIN ZHONGTIAN CHEM

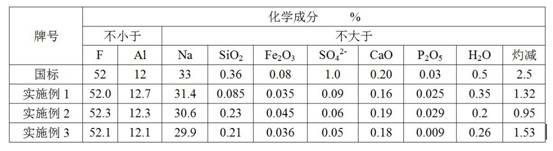

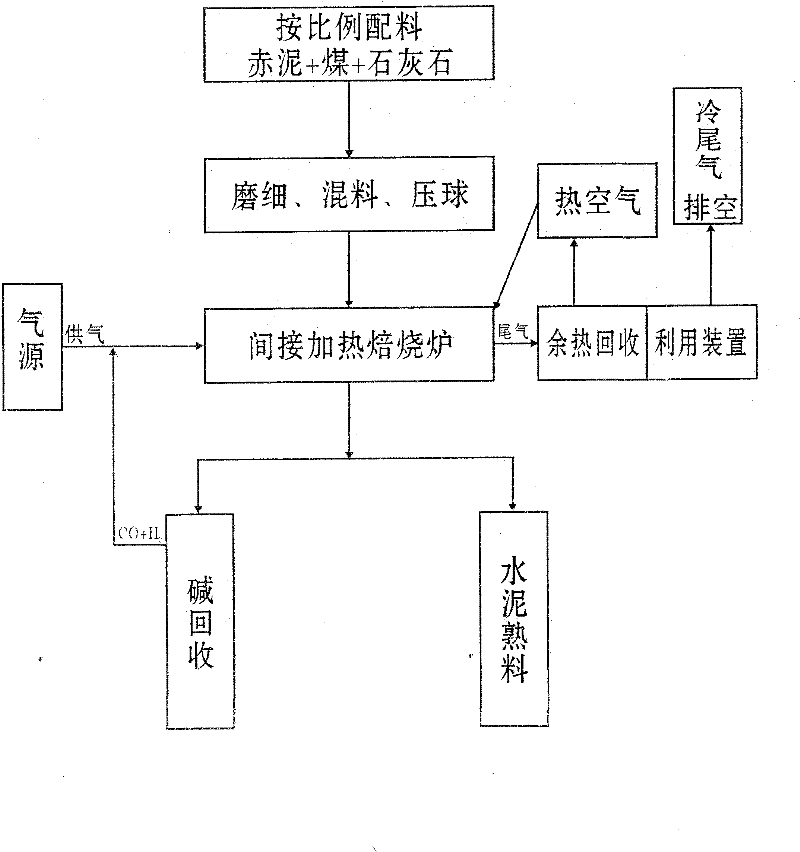

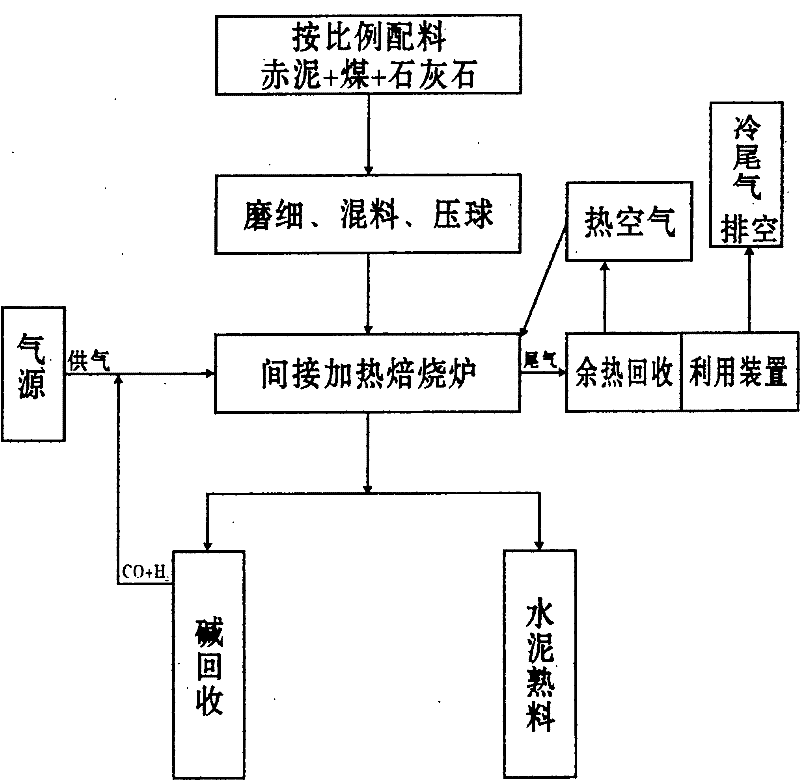

Process for recycling alkali and synchronously producing cement by roasting red mud

InactiveCN102234171ASludge treatment by thermal conditioningCement productionEcological environmentRed mud

The invention discloses a process for recycling alkali and synchronously producing cement by roasting red mud, belonging to the field of aluminum industry production. 1.2-2.1 tons of red mud as a byproduct is produced while 1 ton of aluminum oxide is produced, wherein the red mud contains 5-7% of alkali which is large in amount and harmful to the environment; and the alkali is a significant environmental pollution source for restraining the development of the aluminum industry and the comprehensive utilization of the red mud and damaging the ecological environment. At present, removing and recycling of the alkali in the red mud is still a difficult problem in the world. The invention solves the problem on removing and recycling the alkali in the red mud, and realizes that the cement is synchronously produced while the alkali is removed and recycled; therefore, the zero emission of solid waste residuals is realized for aluminum oxide production enterprises. The process is crucially characterized in that a condition of oxygen-free strong reduction is created for separating the alkali in the red mud, thereby a reducing / decomposing reaction of Na2O(solid)+C(solid)=2Na(gas)+CO(gas) can be performed successfully. According to the process provided by the invention, the red mud is indirectly heated and is decomposed under an air-insulated and oxygen-free strong reduction condition to generate Na metal atoms; and the Na metal atoms are led to the outside of the furnace together with a byproduct CO, and enter a recycling tower to synthesize alkali (NaOH) with water. After the alkali is separated and recycled, the residues are synchronously sintered into cement.

Owner:骆群

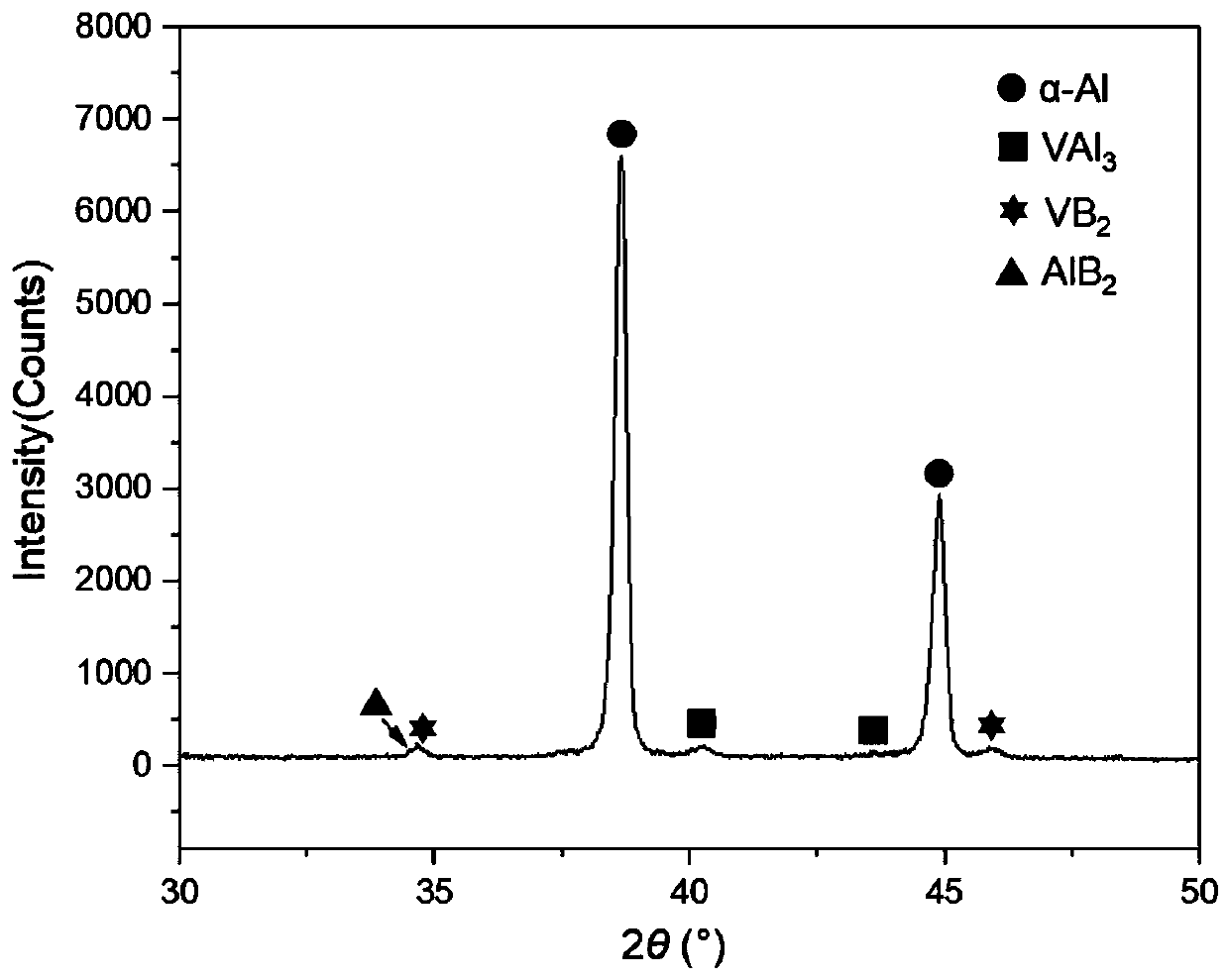

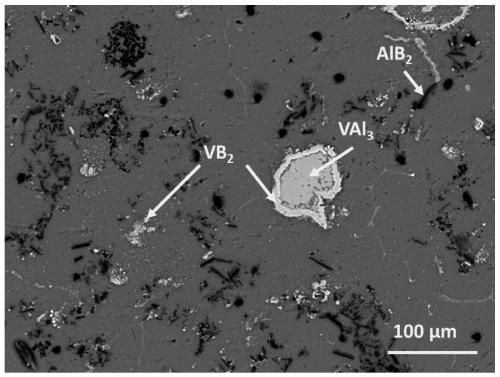

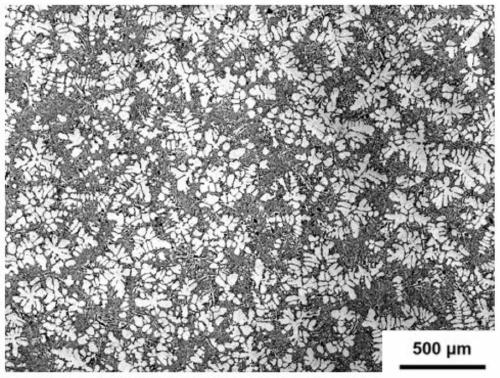

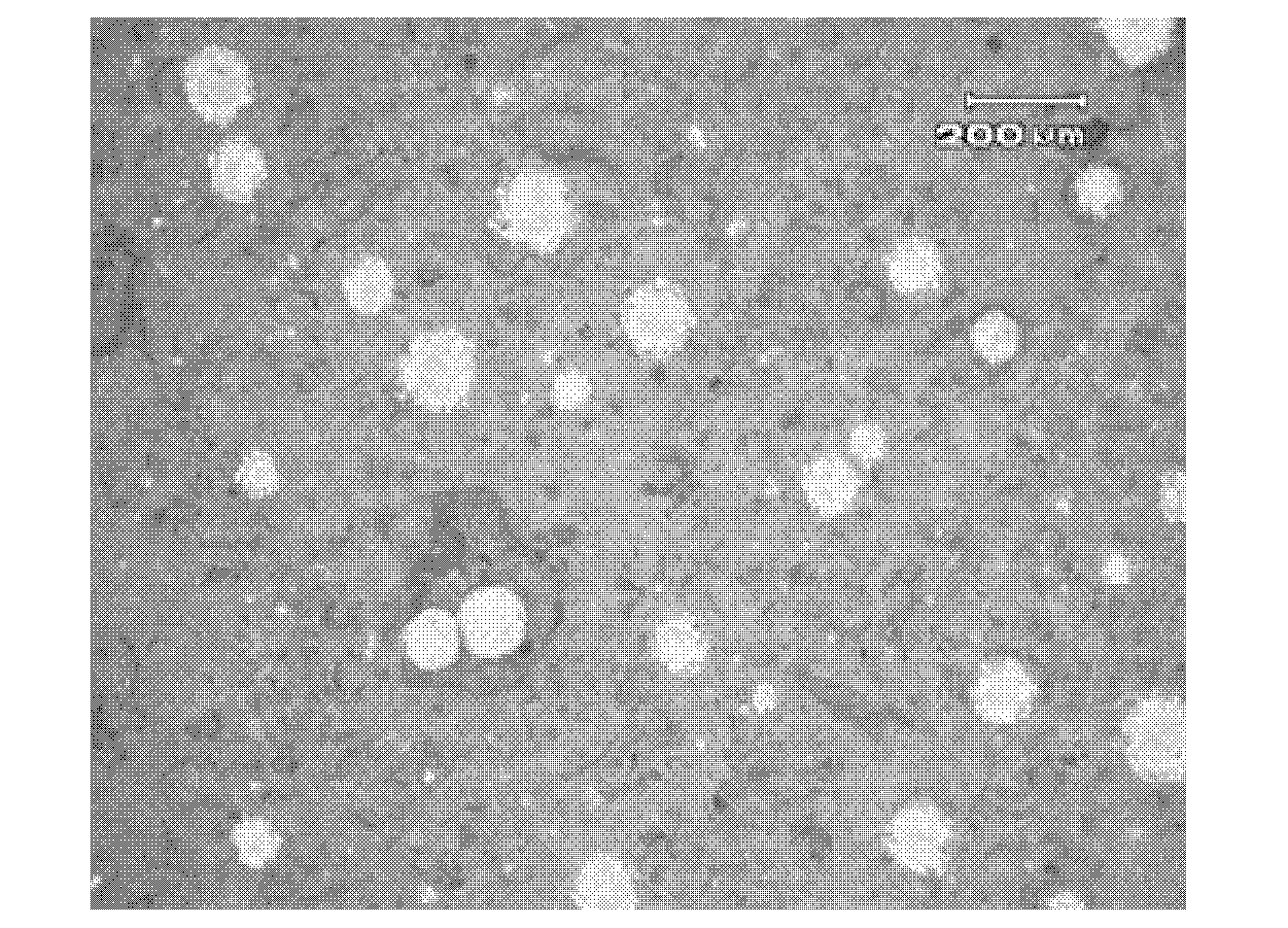

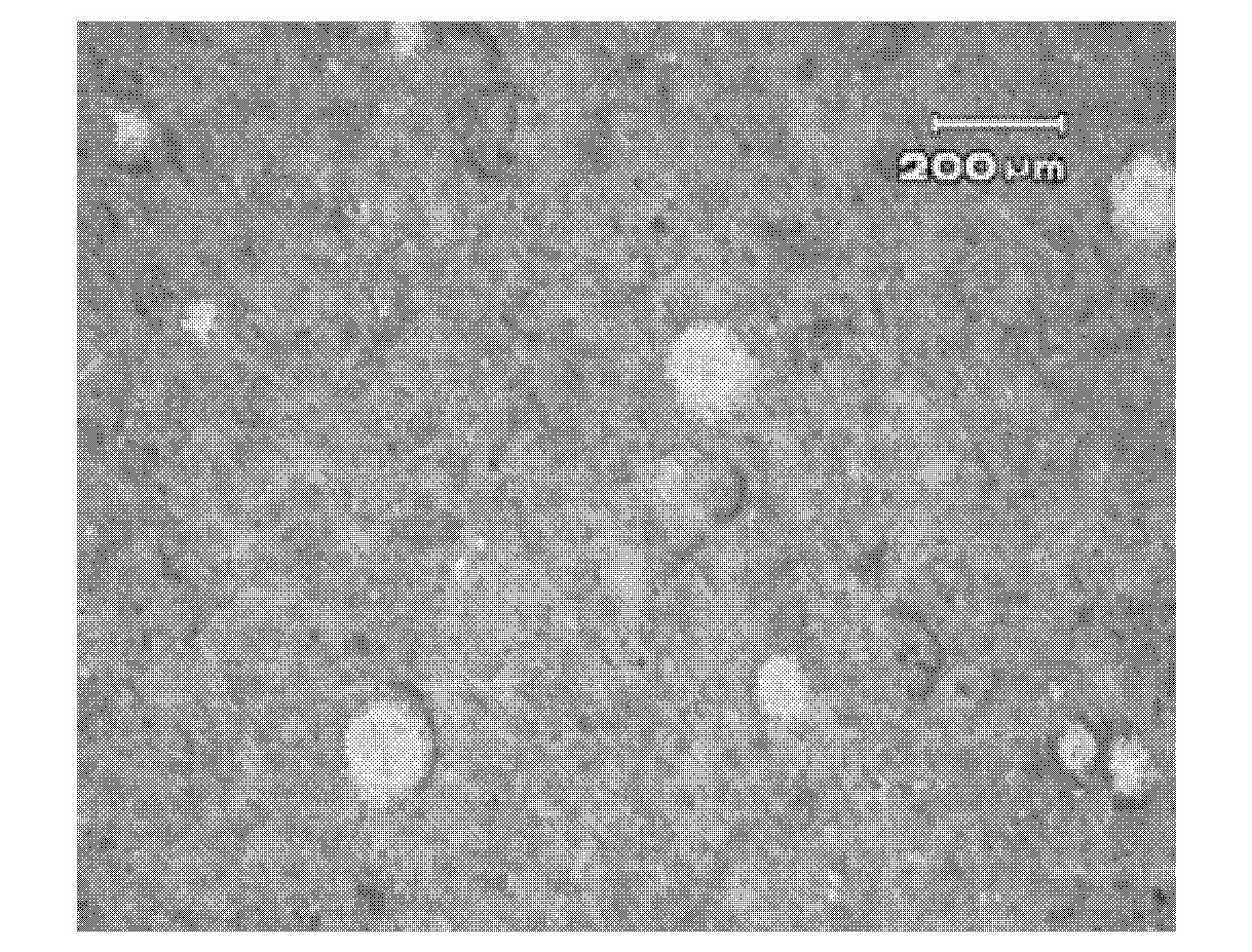

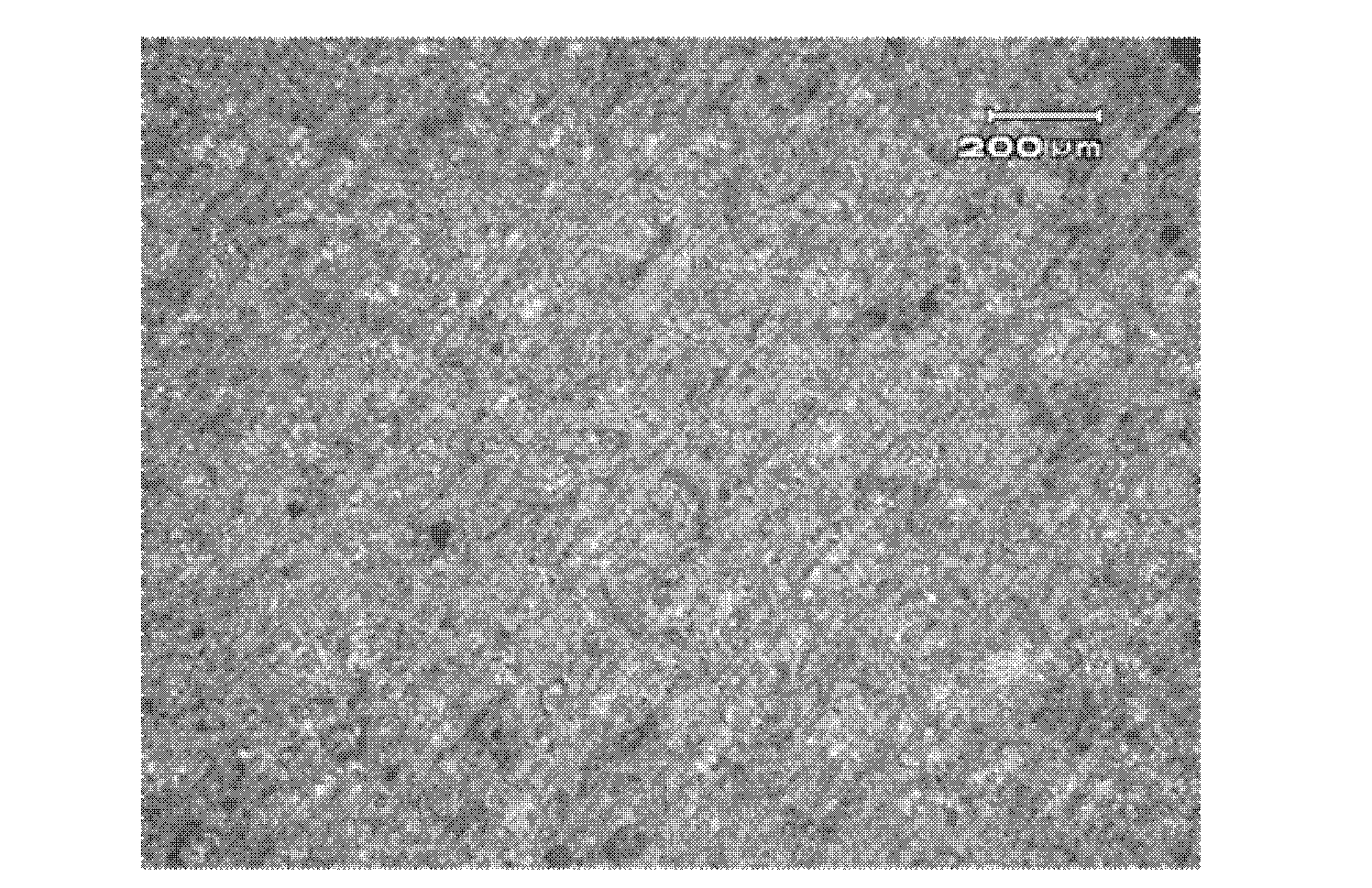

Al-V-B refining agent for cast aluminum-silicon alloy, preparation method and application thereof

ActiveCN110157935AImprove refinementMeets Aluminum Industry Acceptance StandardsSilicon alloyChemical element

The invention discloses an Al-V-B refining agent for cast aluminum-silicon alloy, a preparation method and application thereof. The Al-V-B refining agent comprises the following chemical elements of,in percentage by mass, 80.0%-95.8% of aluminum, 2.1%-10.0% of vanadium and 2.1%-10.0% of boron; the phase composition of the refining agent is composed of an aluminum solid solution alpha-Al acting asa matrix and particle particles with the particle size of 2-100 microns. The phase of each particle particle comprises a VAl3 phase, a VB2 phase and an AlB2 phase at the same time. In the casting aluminum-silicon alloy application, the grain size of the alpha-Al in the cast aluminum-silicon alloy is refined to be 220 microns or below. The preparation method of the refining agent adopts a villiaumite method and comprises the following steps of weighing raw materials; and smelting the Al-V-B alloy. According to the Al-V-B refining agent, the refining effect can reach 184 microns, and the requirement of the aluminum industry approved standard of less than or equal to 220 microns are met; and the preparation method is simple and convenient, and is suitable for large-scale industrial production.

Owner:SHANGHAI UNIV

Method for recovering aluminum hydroxide and sodium hydroxide from liquid waste of aluminum industry alkali waste

InactiveCN108069449AAvoid manual cleaning difficultiesRestore production capacityAlkali metal hydroxidesAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationLiquid wasteAluminum Ion

Disclosed is a method for recovering aluminum hydroxide and sodium hydroxide from liquid waste of aluminum industry alkali waste. The method comprises the following steps of (1) obtaining liquid wastecontaining free alkali and aluminum ions at a ratio of 3.0-3.5; (2) adding seed crystal inside the liquid waste; (3) precipitating aluminum hydroxide; (4) performing solid-liquid separation on the liquid waste to recovering the aluminum hydroxide as well as alkali liquor containing sodium hydroxide. The method for recovering the aluminum hydroxide and the sodium hydroxide from the liquid waste ofthe aluminum industry alkali waste can effectively recover the aluminum hydroxide meeting national standard to achieve high-value resource reutilization of waste aluminum, to reduce the scaling riskof recovery equipment and to greatly prolong the maintenance period, and meanwhile, can on line recycle the alkali liquor containing the sodium hydroxide to reduce the production cost of mold boilingand further to achieve zero emission of liquid waste and waste residue of a mold boiling workshop.

Owner:FOSHAN SANSHUI XIONGYING INNOVATION CENT FOR ALUMINUM SURFACE TECH

Anode, a process for the manufacture thereof and a process for the production of aluminum

InactiveUS6235184B1Frequent problemNon-metal conductorsElectric discharge heatingLithiumElectrolysis

The present invention refers to an anode composition comprising as binding agent the sugar cane molasses instead of the conventional electrolytic pitch. The composition may optionally include additives based on lithium, fluorine, aluminum, boron and sulfur, and is used in a process for the manufacture of anodes for the primary aluminum industry. The invention also refers to a process for the manufacture of said anode and the application thereof to the primary aluminum industry.

Owner:ALBRAS ALUMINIO BRASILEIRO

Method for recycling and utilizing electrolytic aluminum fluorine-containing resources

The invention relates to the technical field of recycling and utilization of fluorine-containing resources in the electrolytic aluminum industry, in particular to a method for recycling and utilizingelectrolytic aluminum fluorine-containing resources. The method for recycling the electrolytic aluminum fluorine-containing resources comprises the step of leaching electrolytic aluminum fluorine-containing waste residues, and the step of leaching the electrolytic aluminum fluorine-containing waste residues is: mixing the electrolytic aluminum fluorine-containing waste residues with a leaching agent, and adding water to prepare a mixed reaction solution with a solid content of 3 to 60%, and performing leaching reaction on the mixed reaction solution at 10 to 150 DEG C to obtain a mixed leaching solution. The method for recycling and utilizing the electrolytic aluminum fluorine-containing resources, which is provided by the invention, mainly uses the leaching agent to leach fluorides in theelectrolytic aluminum fluorine-containing waste residues, and transfers valuable elements fluorine and aluminum in the electrolytic aluminum fluorine-containing waste residues to a liquid phase; thesum of the mass percentages of the fluorine element and the aluminum element in filtrate obtained by filtration is 1 to 50%. The method for recycling and utilizing the electrolytic aluminum fluorine-containing resources, which is provided by the invention, provides a possibility for further treatment to obtain fluorine-containing and aluminum-containing products.

Owner:湖南绿脉环保科技股份有限公司

Method for preparing foam microcrystalline glass through red mud

The invention relates to a preparing method for foam microcrystalline glass, in particular to a method for preparing the foam microcrystalline glass through red mud. The preparing method aims at preparing the foam microcrystalline glass with the industrial solid waste red mud, the low energy consumption and the excellent performance. The preparing method includes the following steps that (1) industrial waste residues, fluxing agent, foaming agent and foam stabilizer are mixed to be even according to the weight ratio to form a batch mixture; (2) the mixed batch mixture is put into a ball mill and powdered; (3) the powdered batch mixture is put into a grinding tool and pressed and formed; (4) a pressed sample is put into a reacting furnace and fired. The method has the advantages that the problems that in aluminum industry of China, the discharging quantity of waste residues is large, waste residues are difficult to treat are solved, the comprehensive utilization level of the industrialwaste is improved, sustainable development of building materials in China can be achieved, and social economical benefits can be remarkably improved.

Owner:UNIV OF JINAN

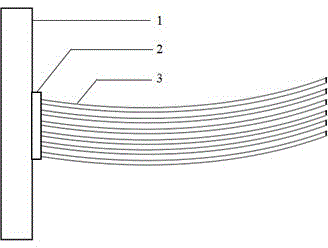

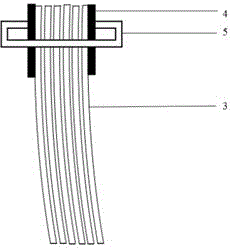

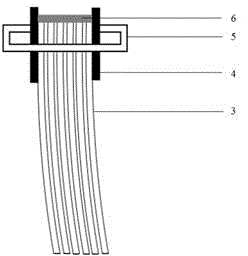

In-situ power-cut-free welding method for soft mother belts and aluminum bus of cathode of aluminum electrolysis cell

ActiveCN104972220ASolve technical problemsAvoid the defect that exothermic welding cannot be used directlyWelding/cutting media/materialsSoldering mediaExothermic weldingEconomic benefits

The invention relates to the electrolytic aluminum industry, in particular to an in-situ power-cut-free welding method for soft mother belts and an aluminum bus of the cathode of an aluminum electrolysis cell. The method comprises the following steps of 1 in-situ grinding, 2 in-situ fixing, 3 in-situ fusion, 4 pre-welding treatment, 5 preheating, 6 exothermic welding and 7 post-welding treatment. By means of the method, in-situ connection between the soft mother belts and the aluminum bus is directly completed through exothermic welding, the defect that the soft mother belts of a sheet type structure cannot be directly welded in a magnetic field is overcome, the economic benefits of an aluminum electrolysis enterprise are increased, and repairing of the soft mother belts for the aluminum electrolysis enterprise is realized. The operation can be completed under the condition that serial aluminum electrolysis cells are powered all the time, and the repairing purpose can be achieved on the promise of not affecting production of the serial aluminum electrolysis cells. The method is suitable for welding of the soft mother belts and the aluminum bus in various cell types, and is good in universality, easy to operate and high in welding repair efficiency.

Owner:WUHAN UNIV

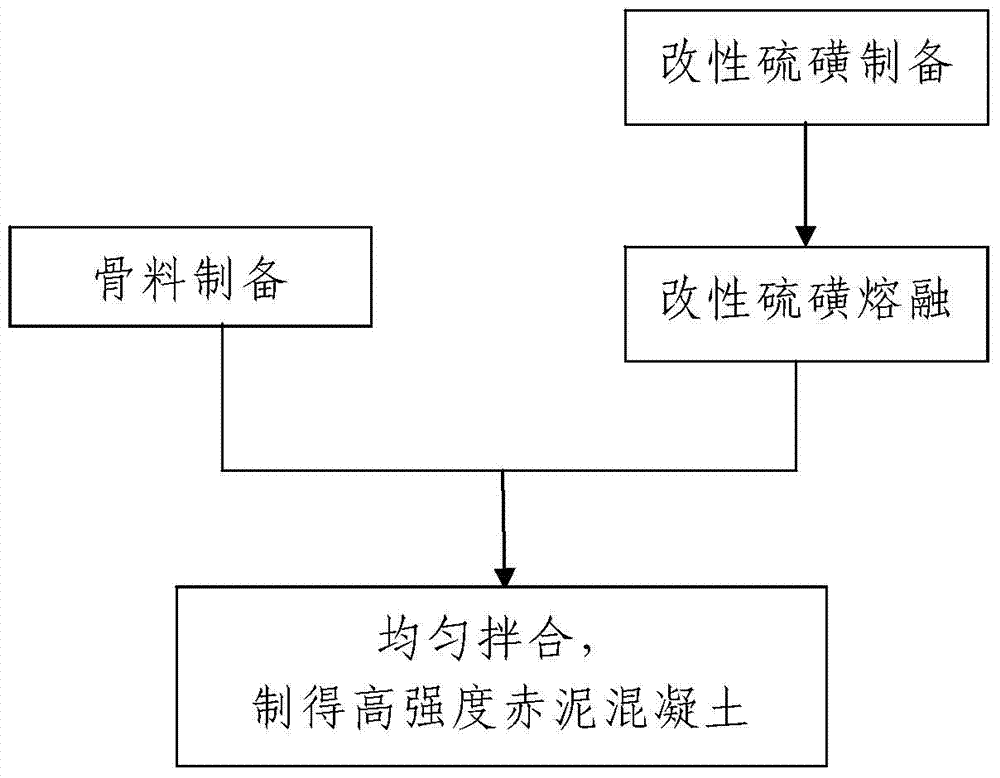

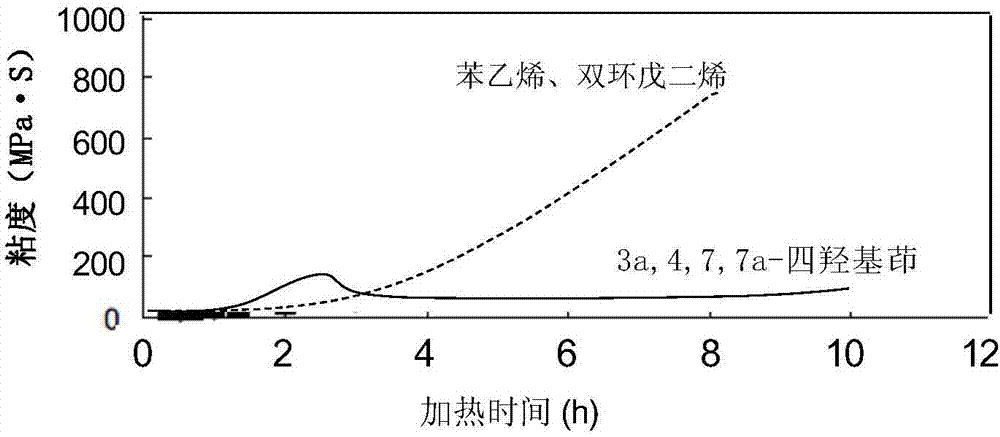

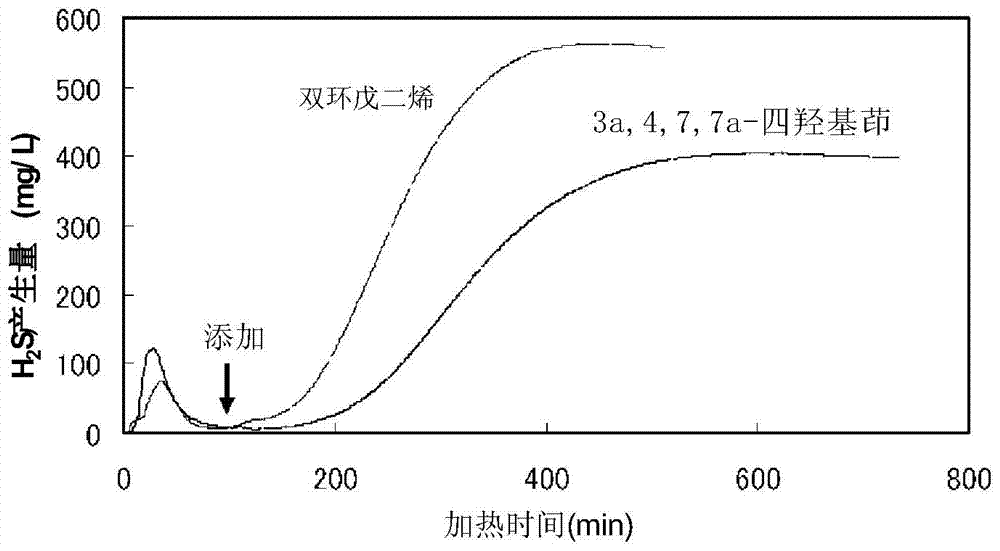

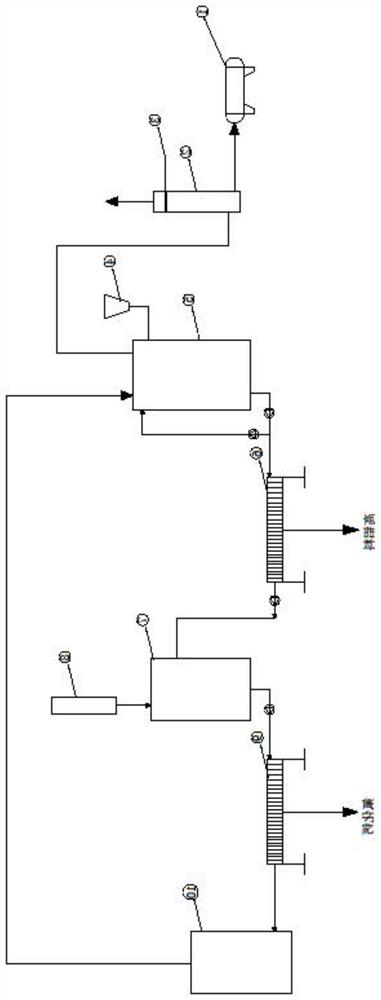

Low-emission high-strength red-mud concrete, and industrial production method and application thereof

The invention discloses a low-emission high-strength red-mud concrete and an industrial production method and application thereof. The high-strength red-mud concrete comprises, by weight, 21 to 40% of modified sulphur, 25 to 60% of red mud particles and 54 to 0% of steel slag, is prepared through uniform blending of the modified sulphur, the red mud particles and steel slag particles and has compressive strength of no less than 50 MPa. The industrial production method comprises the following steps: 1, preparation of the modified sulphur; 2, preparation of aggregate and fusion with the modified sulphur; and 3, uniform blending. Application of the high-strength red-mud concrete is as follows: the high-strength red-mud concrete is poured into a casting molding die so as to obtain molded red mud stone. The industrial production method has the advantages of simple process steps, short production flow, low investment cost, easy operation, convenient implementation, capacity of effective utilization of the waste material red mud in the aluminum industry and discharge of low concentration sulfur-containing gas during production and casting; and a produced red mud concrete structural member has excellent performance.

Owner:嘉兴如运建筑科技有限公司

Method for preparing high-strength foam glass by utilizing red mud and waste glass

The invention relates to foam glass manufacturing method, in particular to a method for preparing high-strength foam glass by utilizing red mud and waste glass. The invention aims at providing a preparation method for high-strength red mud foam glass which utilizes solid wastes and reduces the foam glass production cost. According to the technical scheme, the method for preparing high-strength foam glass by utilizing red mud and waste glass comprises the steps: firstly mixing red mud, waste glass and foam agent, carrying out ball milling to obtain powder batch mixture, and then conducting foaming and annealing treatment to obtain high-strength red mud foam glass product, wherein the red mud is polluting waste slag exhausted when the aluminum oxide is extracted in aluminum industry. The method has the beneficial effects of massively applying solid wastes red mud and waste glass, being environment-friendly and energy-saving, and changing wastes into valuables, thereby having good social benefits and economic benefits.

Owner:刘立强

Harmless treatment method for secondary aluminum ash

PendingCN113578927AAvoid explosionAvoid mixingSolid waste disposalCalcium/strontium/barium fluoridesCalcinationChemistry

A harmless treatment method for secondary aluminum ash comprises the following five process steps: (1) preparing raw materials, namely preparing the secondary aluminum ash; (2) carrying out hydrolysis in a hydrolytic tank; (3) carrying out filter pressing by using a filter press and washing; (4) fixing fluorine by using calcium hydroxide; and (5) washing ammonia gas generated by reaction in a third-stage leaching tower. The method disclosed by the invention has the following advantages: firstly, aiming at the ammonia gas and hydrogen gas generated in a secondary aluminum ash hydrolysis process, a hydrolytic tank sealing form is adopted to prevent air from being mixed in, and a continuous feeding form and a continuous discharging form are adopted, so that explosion accidents of a large amount of ammonia gas and hydrogen gas generated instantly are effectively avoided, and the method is a safe and reliable recovery process; secondly, the whole technological process consumes less equipment, so that the energy consumption is low; the production cost of the method is lower than that of calcination, acid leaching and other processes, the product high-aluminum material, the by-product fluorite calcium fluoride and dilute ammonia water can be comprehensively utilized, and the economic benefit is high. The method is suitable for treating aluminum ash by-products in the electrolytic aluminum industry.

Owner:邵冰 +1

Method for preparing foam glass ceramics by utilizing red mud and waste glass

The invention relates to foam glass ceramic manufacturing method, in particular to a method for preparing foam glass ceramics by utilizing red mud and waste glass. The invention aims at providing a preparation method for preparing environment-friendly and energy-saving foam glass ceramics. According to the technical scheme, the method for preparing foam glass ceramics by utilizing red mud and waste glass comprises the steps: firstly mixing red mud and waste glass, carrying out ball milling to obtain powder batch mixture, and then conducting foaming and annealing treatment to obtain foam glass ceramics, wherein the red mud is polluting waste slag exhausted when the aluminum oxide is extracted in aluminum industry. The method has the beneficial effects of being simple in preparation technique and low in sintering temperature, lowering the production cost of foam glass ceramics, and obtaining higher economic benefits while solving the environment-friendly problem.

Owner:SHANDONG JIANZHU UNIV

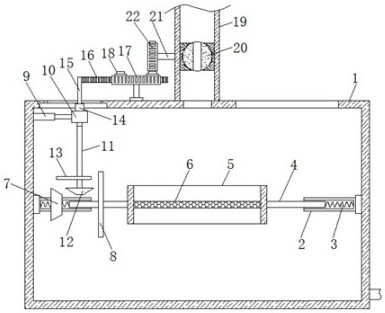

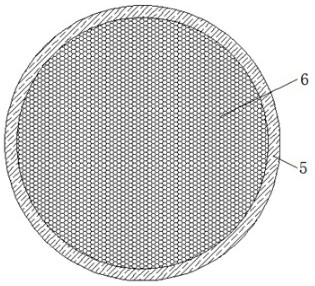

Wastewater recovery treatment equipment for aluminum industry production

InactiveCN111892105AHEPA filterAvoid contactSpecific water treatment objectivesTreatment involving filtrationCircular discFiltration

The invention discloses wastewater recovery treatment equipment for aluminum industry production, and relates to the technical field of aluminum production. In the prior art, one side of an existing filter screen is in contact with impurities, so that meshes are easily blocked by the impurities; and when the filter screen is cleaned, a worker needs to manually shut down wastewater feeding. A purpose of the invention is to solve the problems in the prior art. According to the technical scheme, the equipment comprises a box body, the inner walls of the two sides of the box body are rotationallyconnected with telescopic mechanisms, the sides, close to each other, of the two telescopic mechanisms are fixedly connected with a fixing frame, a filter screen is fixedly connected to the interior of the fixing frame, a first bevel gear and a disc are fixedly arranged outside the telescopic mechanism located on the left side in a sleeving mode, the disc is located on the right side of the firstbevel gear, a push rod motor is fixedly connected to the top of the inner wall of the left side of the box body, and a driving motor is fixedly connected to the output shaft of the push rod motor. According to the invention, vibration and turnover of the filter screen are conveniently controlled, efficient filtration of the filter screen is guaranteed, and wastewater feeding can be automatically stopped during turnover.

Owner:安徽亿智新材料科技有限公司

Low-temperature melting permeation continuous separation method for aluminum industry carbon-based hazardous wastes, and product obtained through the method

ActiveCN107285354AWon't enterLess investmentGas treatmentDispersed particle filtrationPerformance indexPermeation

The invention provides a low-temperature melting permeation continuous separation method for aluminum industry carbon-based hazardous wastes, and a product obtained through the method. The method includes the steps of: S1) performing crushing and iron removal pretreatment to the aluminum industry carbon-based hazardous wastes; S2) after the pretreatment, performing low-temperature electric calcination to the hazardous wastes at 1050-1200 DEG C so that fluoride salts are molten and are separated through permeation; S3) performing permeation impurity removal to the remained low-fluorine carbon granules, and feeding the carbon granules into a high-temperature electric calcination furnace to perform high-temperature electric calcination, thereby producing high-purity carbon products. The invention also provides a low-temperature melting permeation continuous separation system for the aluminum industry carbon-based hazardous wastes. By means of the method, harmless treatment and recycling utilization of three hazardous wastes, including fluoride salt containing anode scraps, anode carbon residues and wasted cathodes, in aluminum industry can be carried out with low cost and high efficiency. A fluoride salt product recovered through the continuous low-temperature melting permeation impurity removal and separation method is high in whiteness and purity, wherein all performance indices are higher than that of second-stage products in national standard.

Owner:唐红艳

Preparation method of reclaimed 7075 aluminum alloy containing rare earth

The invention discloses a preparation method of reclaimed 7075 aluminum alloy containing rare earth. The invention belongs to the technical field of materials. the method comprises steps that: surface impurities are removed from waste 6063 aluminum; smelting material alloys are prepared; metal aluminum is heated until melted; a mixed salt is added to the melted aluminum; the waste 6063 aluminum is added to the mixture, and the mixture is melted; metal silicon, Al-30Cu alloy, Al-10Mn alloy, Al-2Cr alloy and Al-3Ti alloy are pressed in the mixture and are melted; Al-RE alloy, metal magnesium and excess metal magnesium and metal zinc are added to the mixture; the mixture is melted and heated; mixed gas of argon and nitrogen is delivered into the mixture; the mixture is settled and used for casting; a cast ingot is subject to preheating and hot rolling; the rolled material is subject to a solid solution treatment and water quenching; then the material is subject to an aging treatment for 15-20h under a temperature condition of 110-115 DEG C. With the method, the consumption of industrial pure aluminum is reduced, waste aluminum is cyclically utilized, and sustainable development of aluminum industries can be realized. The method has advantages of high recovery rate, low cost, and low pollution.

Owner:NORTHEASTERN UNIV

Red mud comprehensive utilization treatment method

InactiveCN107879367ALow equipment requirementsLower requirementAluminium hydroxide preparationAlkali metal hydroxidesRed mudSlurry

The invention belongs to the technical field of aluminum industry waste residue treatment, and specifically discloses a comprehensive utilization treatment method of red mud produced in production ofalumina. According to the red mud comprehensive utilization treatment method, red mud acidification treatment is performed, specifically, a hydrochloric acid solution is employed, appropriate pH value, temperature and reaction time are specifically controlled, the pH value is controlled to be 4 to 7, a reaction is carried out at 0 to 100 DEG C for 0.5 to 50 hours; after the reaction, solid-liquidseparation is easily performed on the slurry, the separated solid phase is a weak acidic alkali-removed red mud residue, and the obtained liquid phase can be used as a mother liquor for preparing caustic alkali; and the weak acidic alkali-removed red mud residue is classified to obtain a fine-grained product and a coarse-grained product, wherein fine-grained product is used as a filler, and the coarse-grained product is used as a building material or an iron-selecting material. The red mud comprehensive utilization treatment method provided by the invention effectively solves the problems of land occupation and pollution of ground surfaces and groundwater caused by red mud accumulation.

Owner:湖南绿脉环保科技股份有限公司

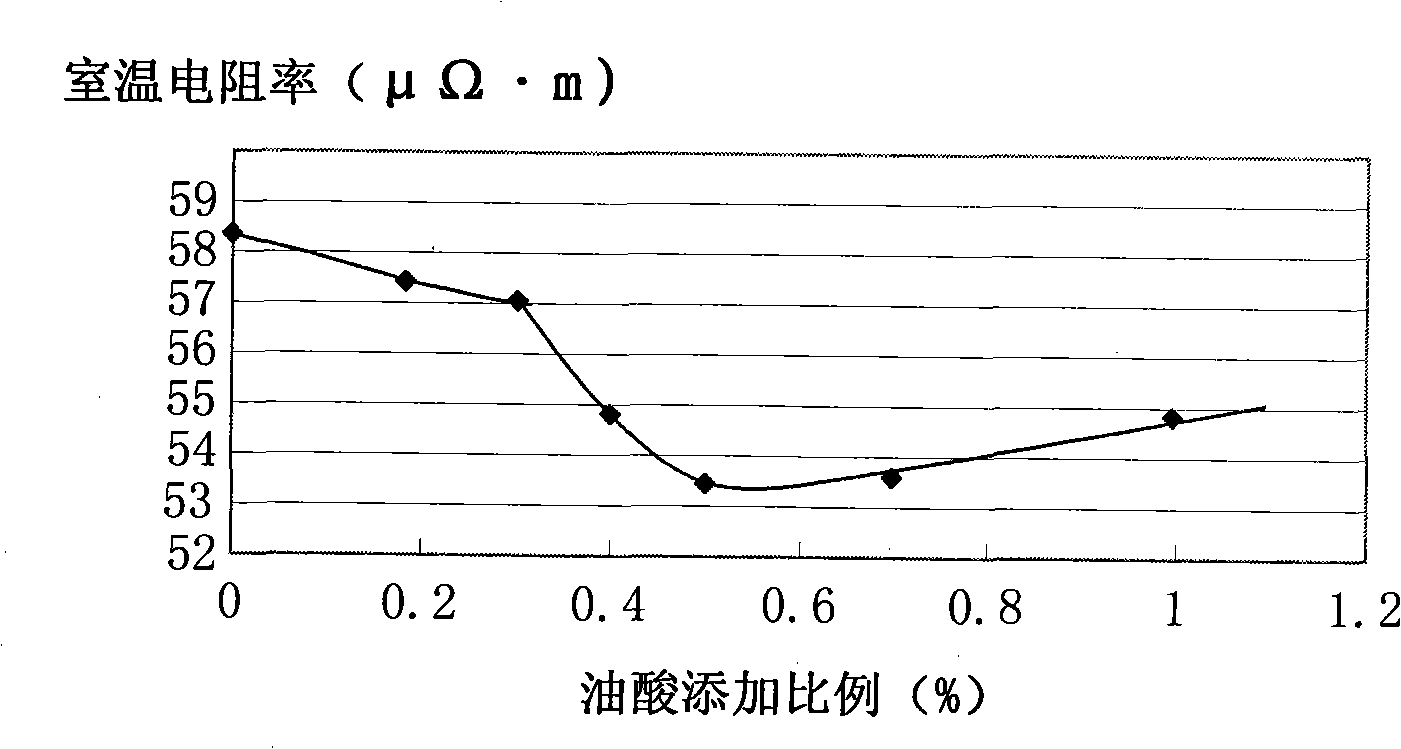

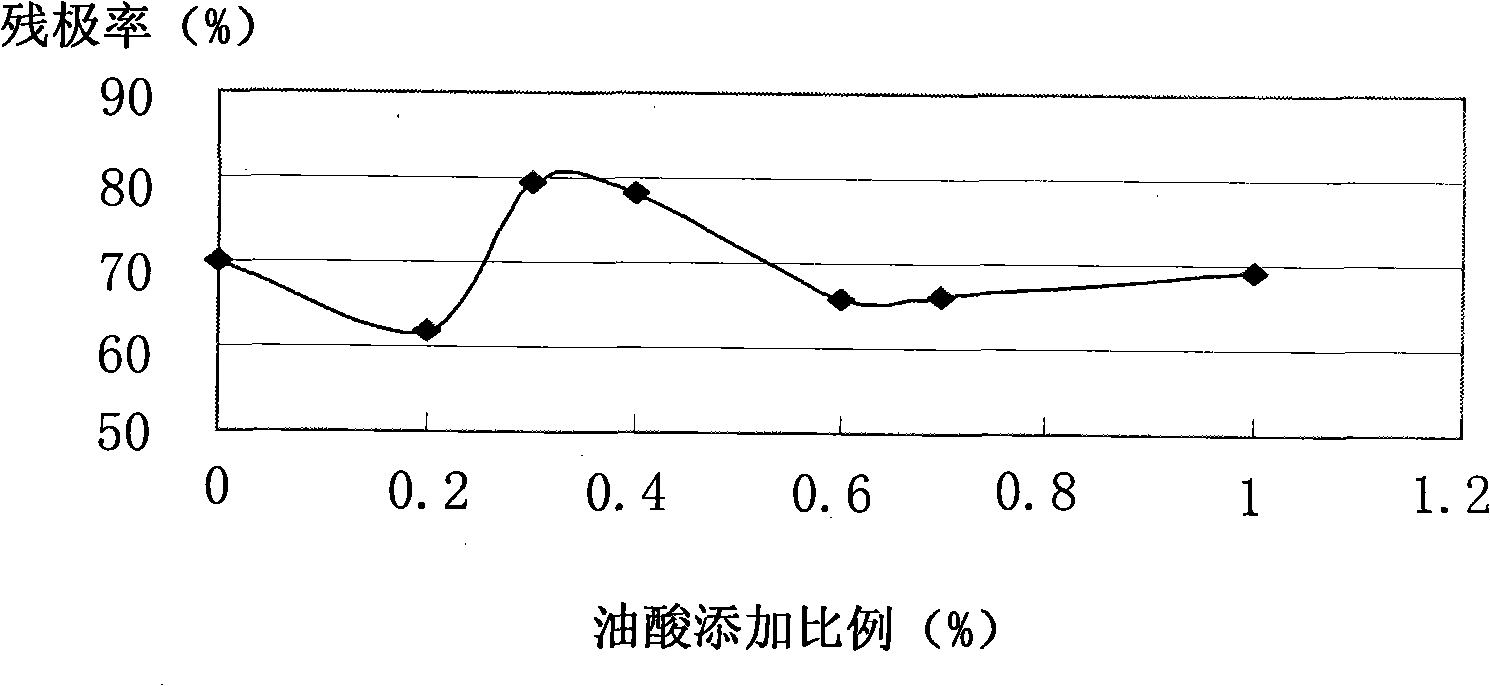

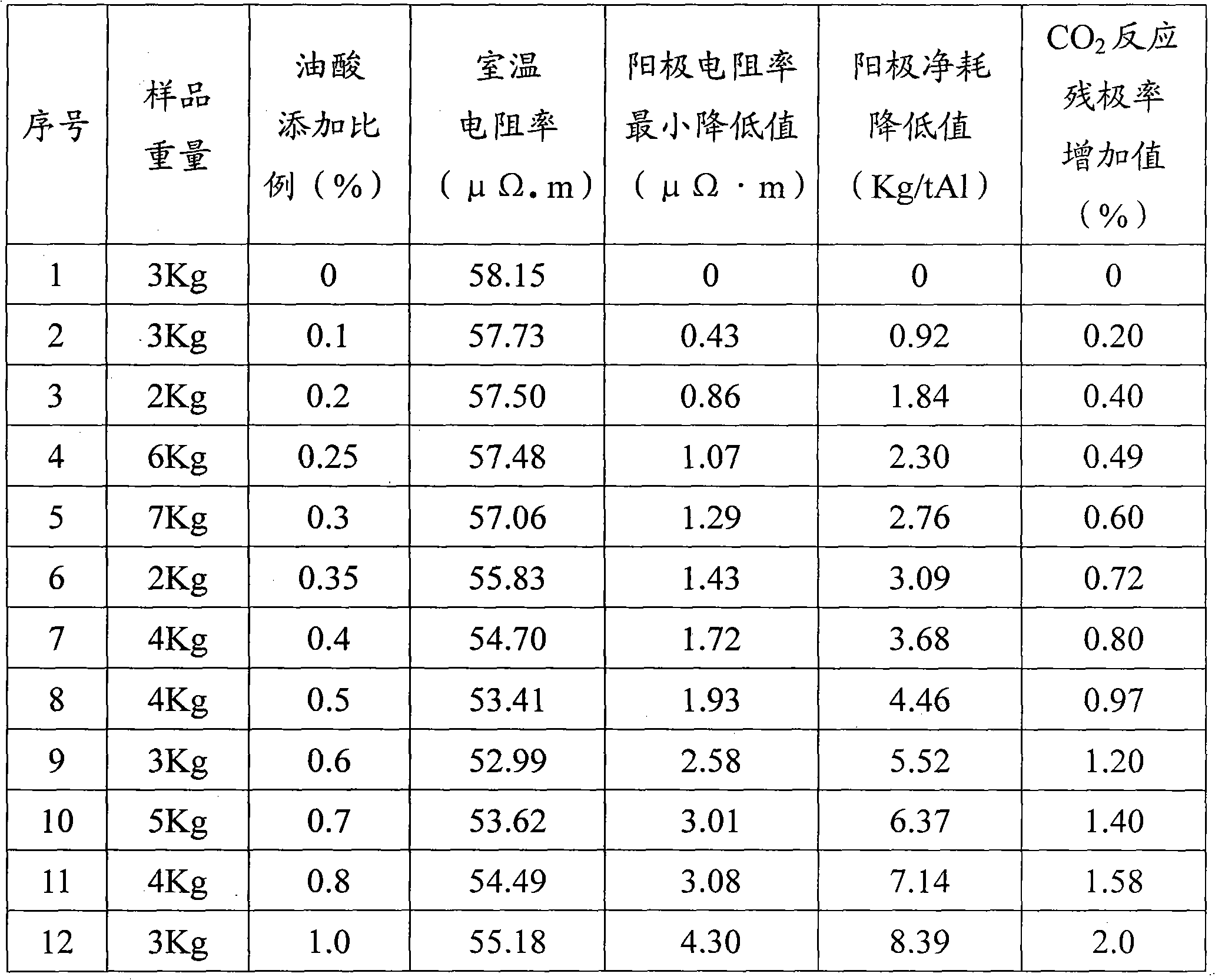

Anode paste and carbon anode made from same

The invention discloses an anode paste and a carbon anode made from the same. The invention has the technical scheme as follows: the carbon anode paste used in electrolytic aluminum industry comprise oleic acid which is 0.1-1 wt% of the paste, and the anode paste is used in the carbon anode preparation process. The viscosity of liquid asphalt, and the interfacial tension of aggregate and asphalt in the anode paste and the carbon anode are effectively reduced, thereby reducing the wetting angle between asphalt and aggregate and greatly enhancing the plasticity and lubricating property of the anode paste. In addition, the materials adopted in the invention can increase the adhesive strength of the anode, greatly reduce the resistivity, enhance the capability of resisting CO2 oxidation, reduce the anode net consumption and lower the production cost of electrolysis.

Owner:HUNAN CHUANGYUAN ALUMINUM IND

Method for preparing Al-Ti-B intermediate alloy refining agent for aluminum

The invention discloses a method for preparing an Al-Ti-B intermediate alloy refining agent for aluminum, relates to a method for preparing an aluminum alloy refining agent, and aims to solve the technical problems of large harmful gas discharge amount of a fluoride salt method and high preparation temperature and low reaction speed of an oxide method in the conventional method for preparing the Al-Ti-B alloy refining agent. The preparation method comprises the following steps of: uniformly mixing pure Ti powder, boric acid, potassium fluoborate and potassium chlorate, adding a pure aluminum block, heating until the pure aluminum block is melted, degassing, slagging-off, and pouring to obtain the Al-Ti-B intermediate alloy refining agent for the aluminum. The production process is simple, the raw material source is wide, harmful gas discharged in the reaction process is greatly reduced, the prepared Al-Ti-B alloy refining agent has a good effect, and the method is applied to the field of aluminum industry.

Owner:HARBIN UNIV OF SCI & TECH

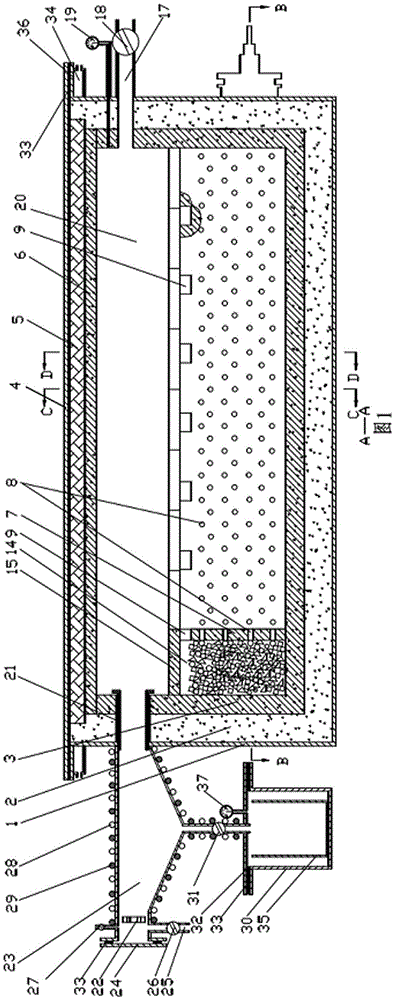

Aluminum industry solid waste recovery/petroleum coke high-temperature desulphurization device and using method thereof

InactiveCN105603216AEfficient use ofEasy to recycleProcess efficiency improvementTar working-up by thermal treatmentPetroleum cokePetroleum

The invention discloses an aluminum industry solid waste recovery / petroleum coke high-temperature desulphurization device and a using method thereof, and belongs to the technical field of metallurgy environmental protection. The device comprises a furnace body, a low-melting-point matter crystallizer at the rear end of the furnace body, and a liquid low-melting-point matter collector below the low-melting-point matter crystallizer. A main material chamber in the furnace body is used for containing aluminum electrolysis cell waste cathode carbon broken blocks or petroleum coke used as a resistance heating body. A sleeve is arranged at the rear end of the furnace body to be communicated with the low-melting-point matter crystallizer. The bottom of the low-melting-point matter crystallizer is communicated with a liquid collector through a valve. The using method mainly comprises the steps that the resistance heating body is placed into the main material chamber, vacuumizing is carried out, cooling water is introduced, the resistance heating body is powered on and heated, vacuumizing and heating are stopped after vacuum high-temperature separation, argon is introduced, and materials coagulated by the low-melting-point matter crystallizer are heated to be molten to enter the liquid low-melting-point matter collector. According to the device and the method, operation is easy, energy is saved, and pollution is reduced.

Owner:SHENYANG BEIYE METALLURGIGAL TECH CO LTD

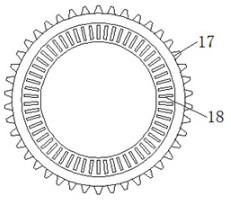

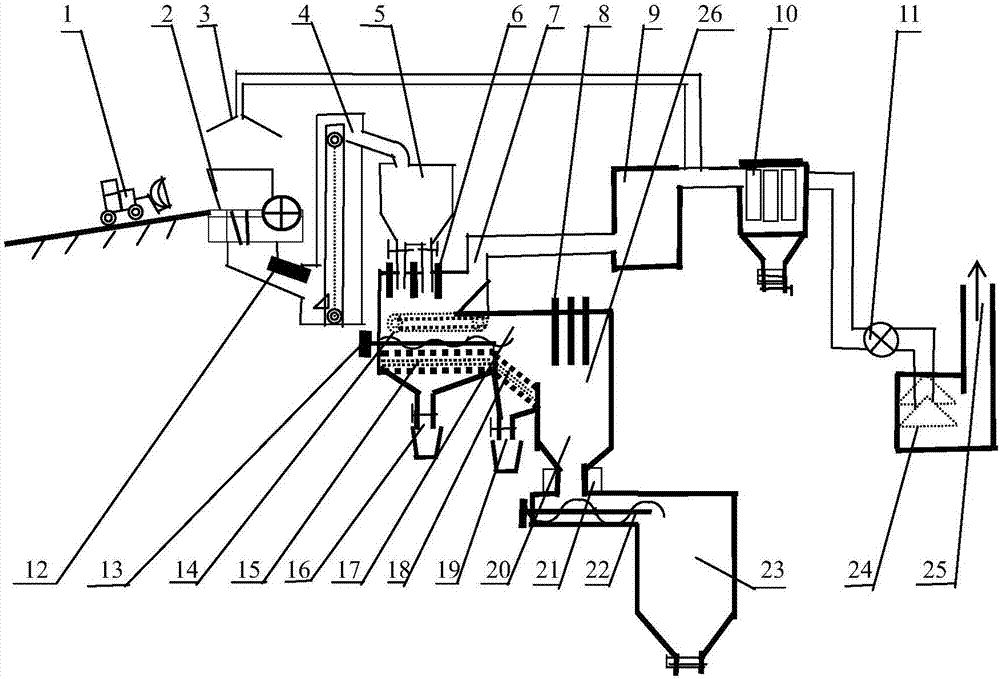

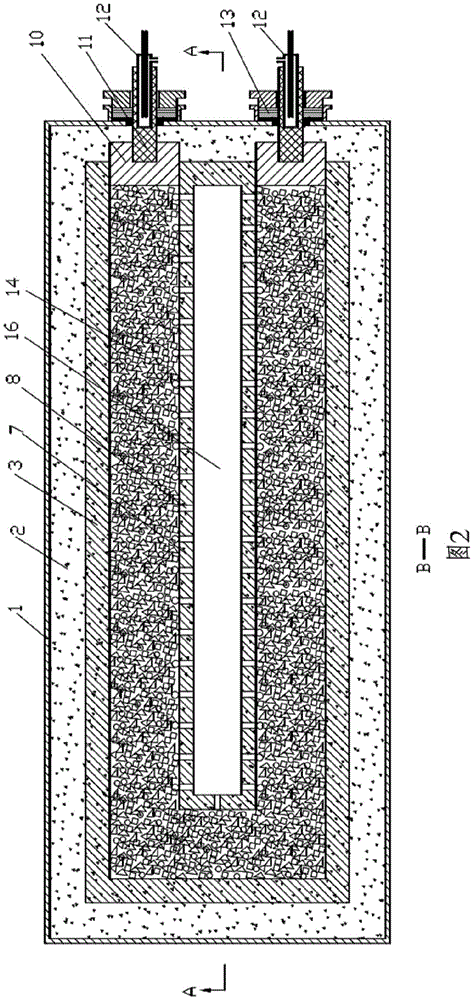

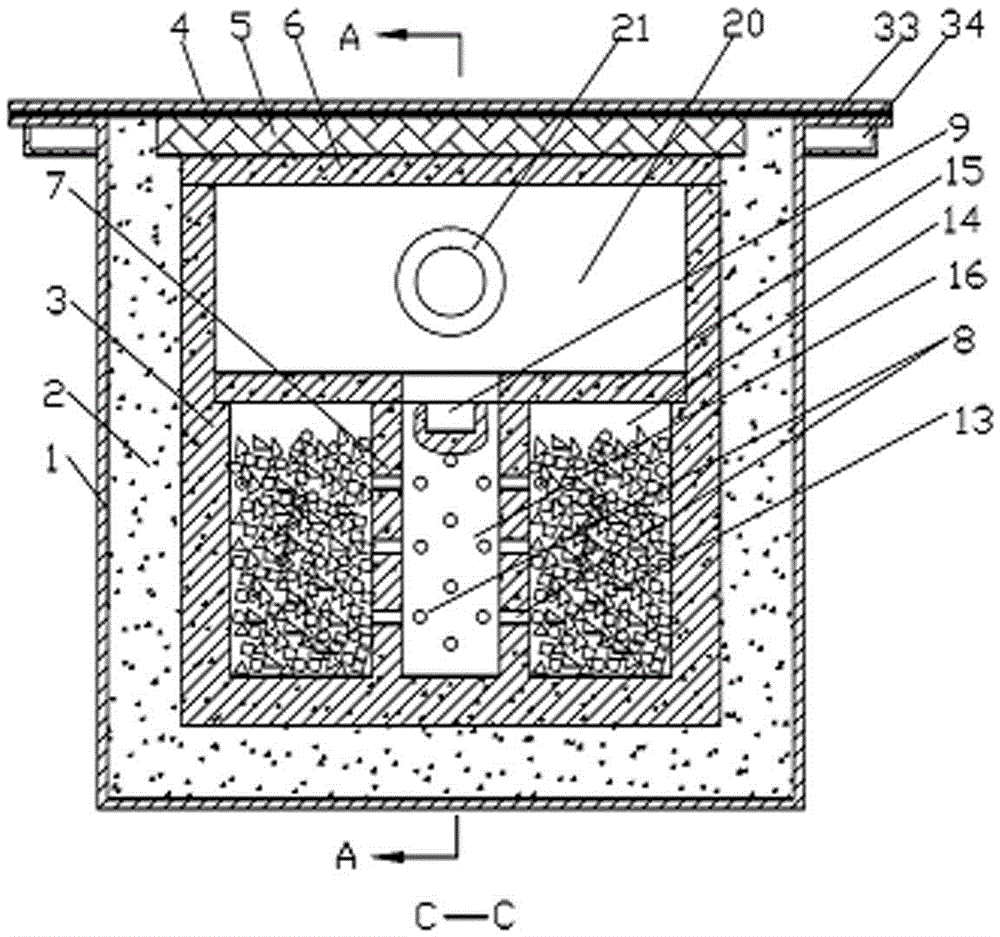

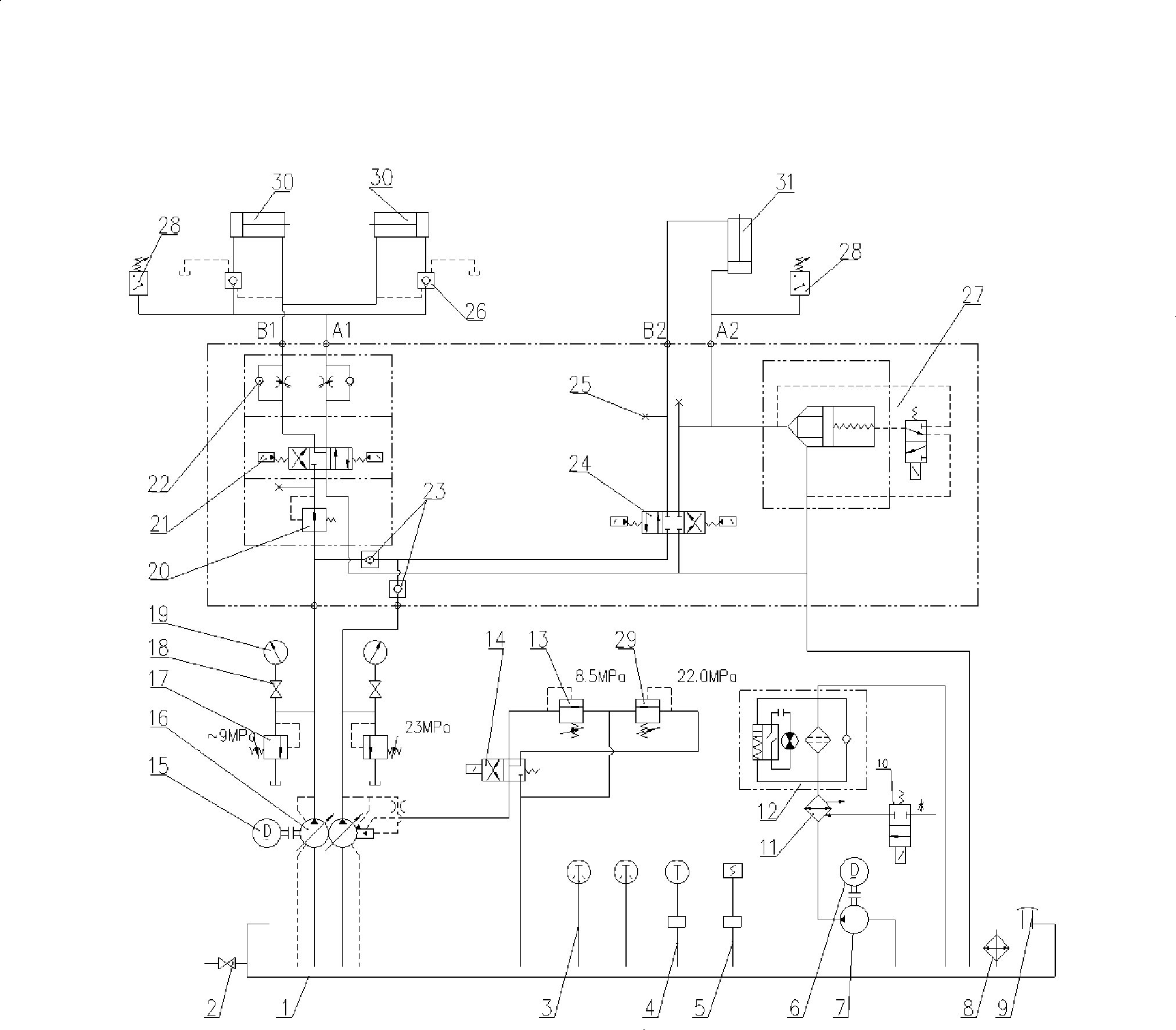

Hydraulic system of press stripper

ActiveCN101444887ASimple and fast operationLarge pressure release forceMetal working apparatusGear pumpFiltration

The invention discloses a hydraulic system of a press stripper dedicated for press stripping of a ferrophosphorus ring on an anode rod in a carbon plant in the electrolytic aluminum industry. The system consists of a clipping circuit, an ejection circuit and a heat dissipation and filtration circuit. A front pump, that is, a constant pressure pump of a twin pump (16) in the clipping circuit is sequentially connected with a pressure reducing valve (20), an electro-hydraulic directional control valve (21), a one-way throttle valve (22), a hydraulic control one-way valve (26), a pressure relay (28) and a clipping oil cylinder (30); the front pump (the constant pressure pump) and a rear pump (a remote constant pressure pump) of the twin pump (16) in the ejection circuit are sequentially connected with two stages of pilot overflow valves (13, 14, 29), two one-way valves (23), an electro-hydraulic directional control valve (24), an electromagnetic unloading valve (27), the pressure relay (28) and an ejection cylinder (31); and a gear pump (7) in the heat dissipation and filtration circuit is connected with a cooler (11) controlled by an electromagnetic water valve and a filter (12) with a bypass back pressure valve and a blocking warning device.

Owner:GUIYANG AL-MG DESIGN & RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com