Patents

Literature

64results about "Ammonium salt preparation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Recovery of inorganic salt during processing of lignocellulosic feedstocks

ActiveUS7585652B2Reduce inhibitionMeet cutting requirementsMagnesium fertilisersIon-exchanger regenerationCelluloseInorganic salts

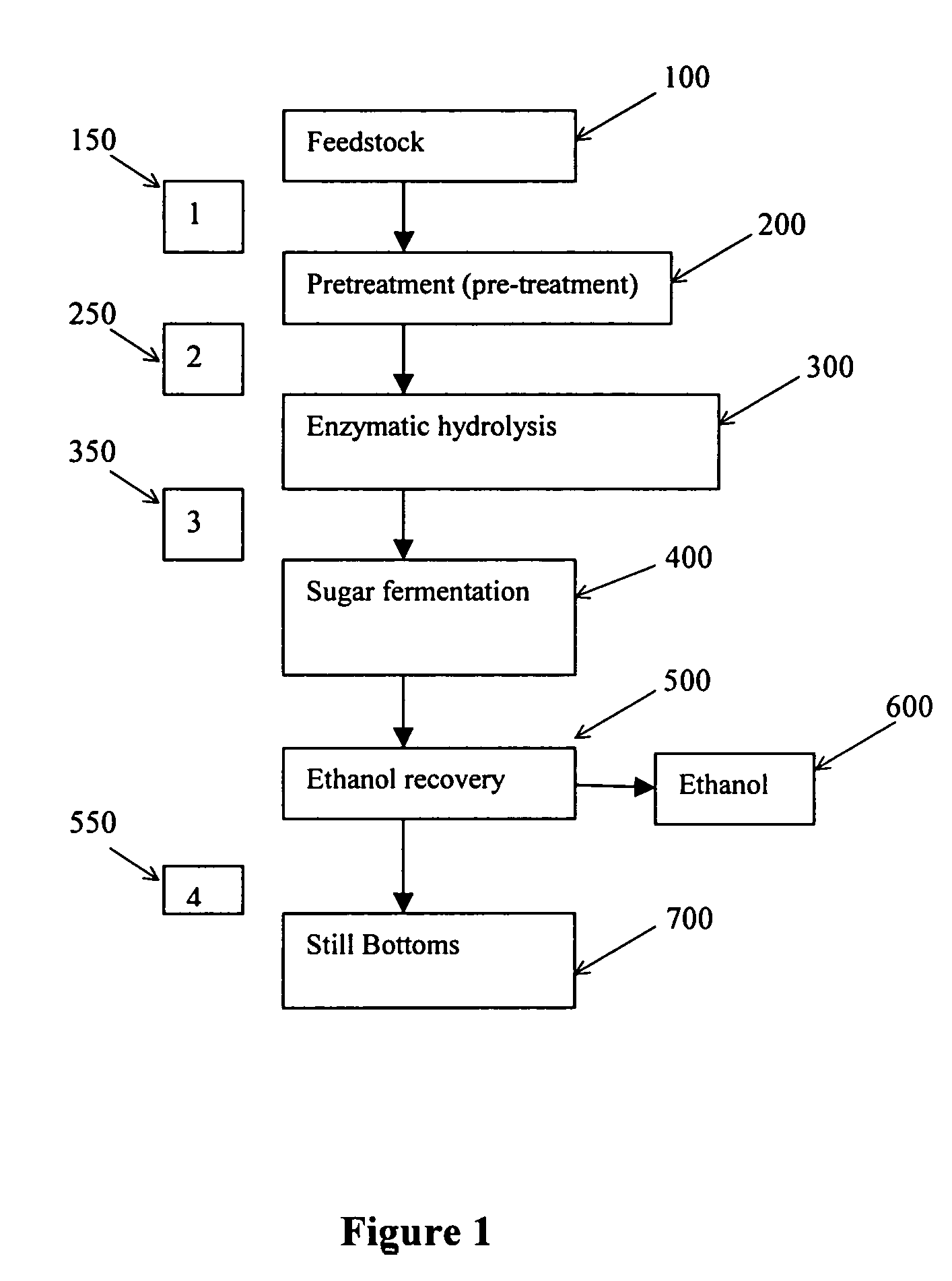

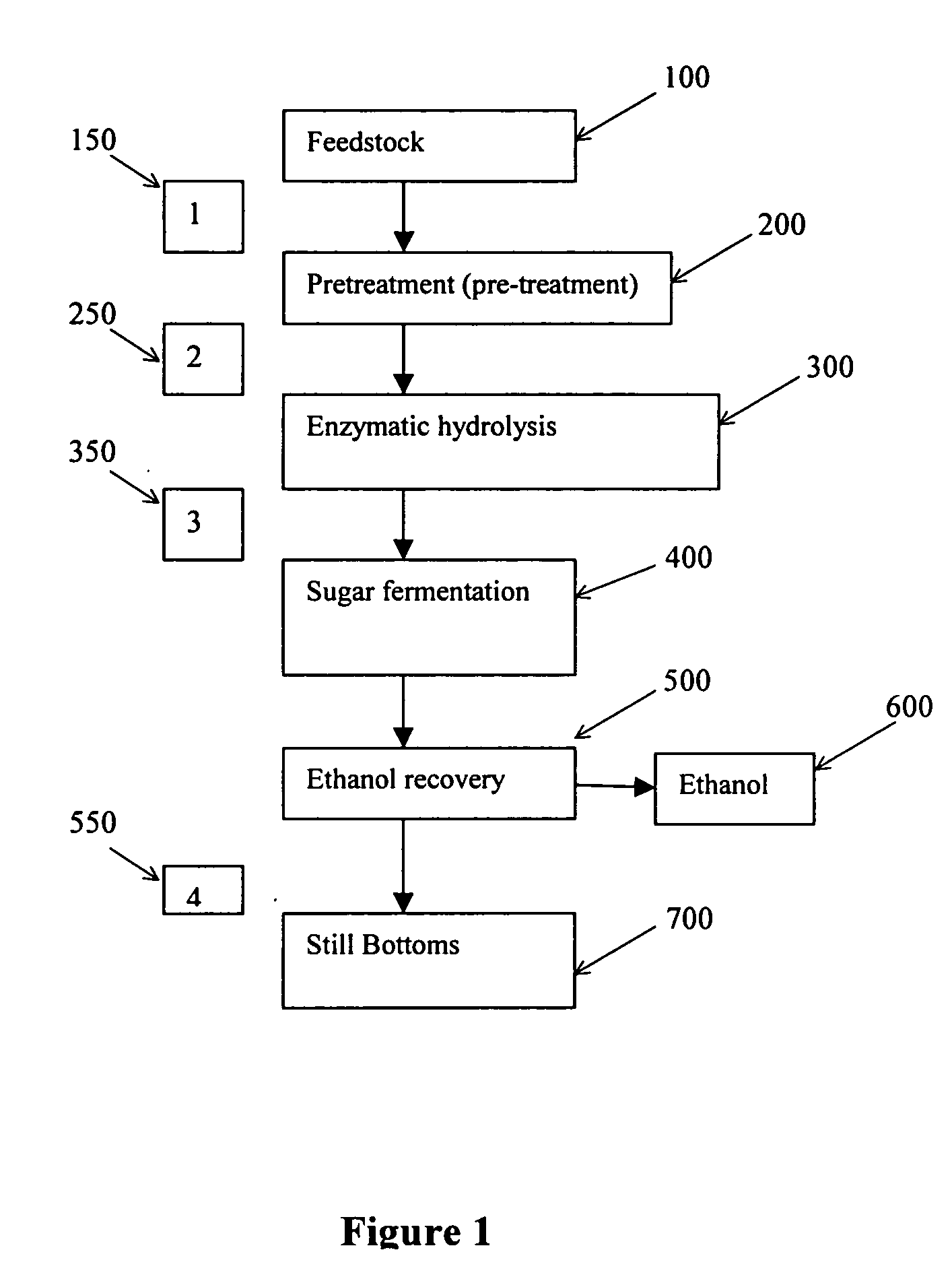

A method for recovering inorganic salt during processing of a lignocellulosic feedstock is provided. The method comprises pretreating the lignocellulosic feedstock by adding an acid to the feedstock to produce a pretreated lignocellulosic feedstock. A soluble base is then added to the pretreated lignocellulosic feedstock to adjust the pH and produce a neutralized feedstock. The neutralized feedstock is then enzymatically hydrolyzed to produce an enzyme hydrolyzed feedstock and a sugar stream. Inorganic salt is recovered from either a stream obtained from the lignocellulosic feedstock prior to the step of pretreating, a stream obtained from the pretreated lignocellulosic feedstock, a stream obtained from the neutralized feedstock, a stream obtained from the sugar stream, or a combination of these streams. The inorganic salt may be concentrated, clarified, recovered and purified by crystallization, electrodialysis drying, or agglomeration and granulation, and then used as desired, for example as a fertilizer.

Owner:IOGEN ENERGY CORP

Comprehensive utilization method of aluminum ash

ActiveCN105347361AHarmlessAvoid pollutionAmmonium salt preparationAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationAtmospheric dustAluminum industry

The invention belongs to the technical field of comprehensive utilization of waste resources from the aluminum industry and specifically discloses a comprehensive utilization method of aluminum ash. According to the comprehensive utilization method of aluminum ash, metallic aluminium is extracted from aluminum ash through an ore grinding method; the aluminum ash obtained after aluminium extraction undergoes catalytic deamination; the aluminum ash obtained after deamination is mixed with alkali and granulation forming is then carried out; and the granulation product is sintered and the sintered product is finally dissolved out. By the above method, useful components in the aluminum ash can be recovered to the maximum; ammonia gas which has been ignored for a long time is effectively recovered; components such as aluminium oxide, villiaumite and the like are recovered and utilized to the maximum; pollution of aluminum ash processing to the environment is avoided; atmospheric dust pollution is avoided; atmospheric pollution is also avoided due to ammonia gas recovery; pollution of aluminum ash stacking to underground water and soil is avoided due to extraction and recovery of fluoride salt; and environmental safety during the treating process is guaranteed.

Owner:湖南绿脉环保科技股份有限公司

Recovery of inorganic salt during processing of lignocellulosic feedstocks

ActiveUS20050244934A1Decreases acid requirementReduce inhibitionMagnesium fertilisersIon-exchanger regenerationCelluloseInorganic salts

A method for recovering inorganic salt during processing of a lignocellulosic feedstock is provided. The method comprises pretreating the lignocellulosic feedstock by adding an acid to the feedstock to produce a pretreated lignocellulosic feedstock. A soluble base is then added to the pretreated lignocellulosic feedstock to adjust the pH and produce a neutralized feedstock. The neutralized feedstock is then enzymatically hydrolyzed to produce an enzyme hydrolyzed feedstock and a sugar stream. Inorganic salt is recovered from either a stream obtained from the lignocellulosic feedstock prior to the step of pretreating, a stream obtained from the pretreated lignocellulosic feedstock, a stream obtained from the neutralized feedstock, a stream obtained from the sugar stream, or a combination of these streams. The inorganic salt may be concentrated, clarified, recovered and purified by crystallization, electrodialysis drying, or agglomeration and granulation, and then used as desired, for example as a fertilizer.

Owner:IOGEN ENERGY CORP

Process for scrubbing ammonia from acid gases comprising ammonia and hydrogen sulfide

The present invention provides a process for removing ammonia as an aqueous salt solution from an acid gas comprising ammonia and hydrogen sulfide. A strong acid, such as sulfuric acid, is used as a scrubbing agent to convert ammonia to an ammonium salt. Control of pH and stripping in combination with reboiler or evaporators reduces hydrogen sulfide concentration. The ammonium salt is produced as an aqueous solution, which may crystallized to form a solid product. The ammonium salt solution or solid may be used as a fertilizer.

Owner:EI DU PONT DE NEMOURS & CO

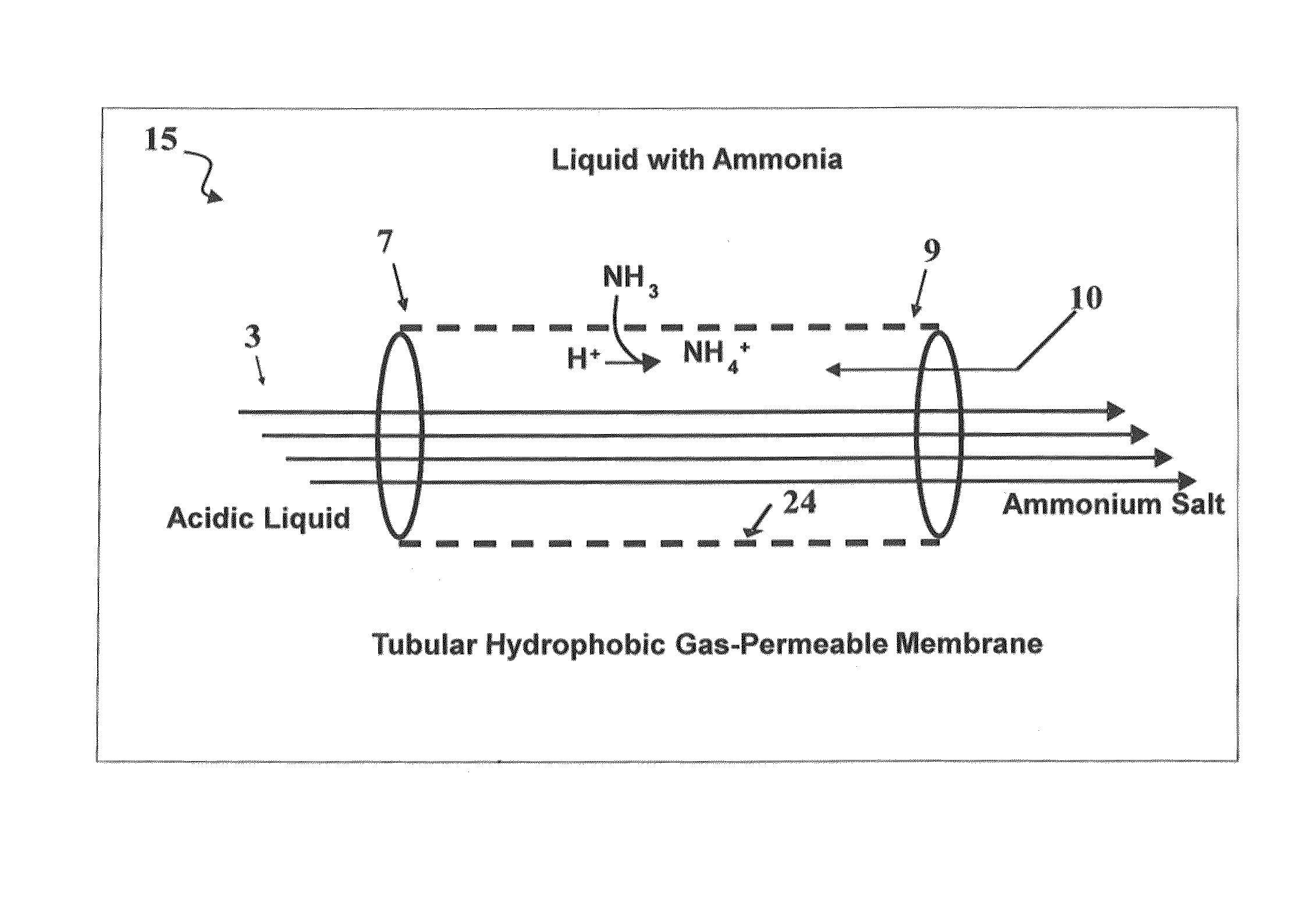

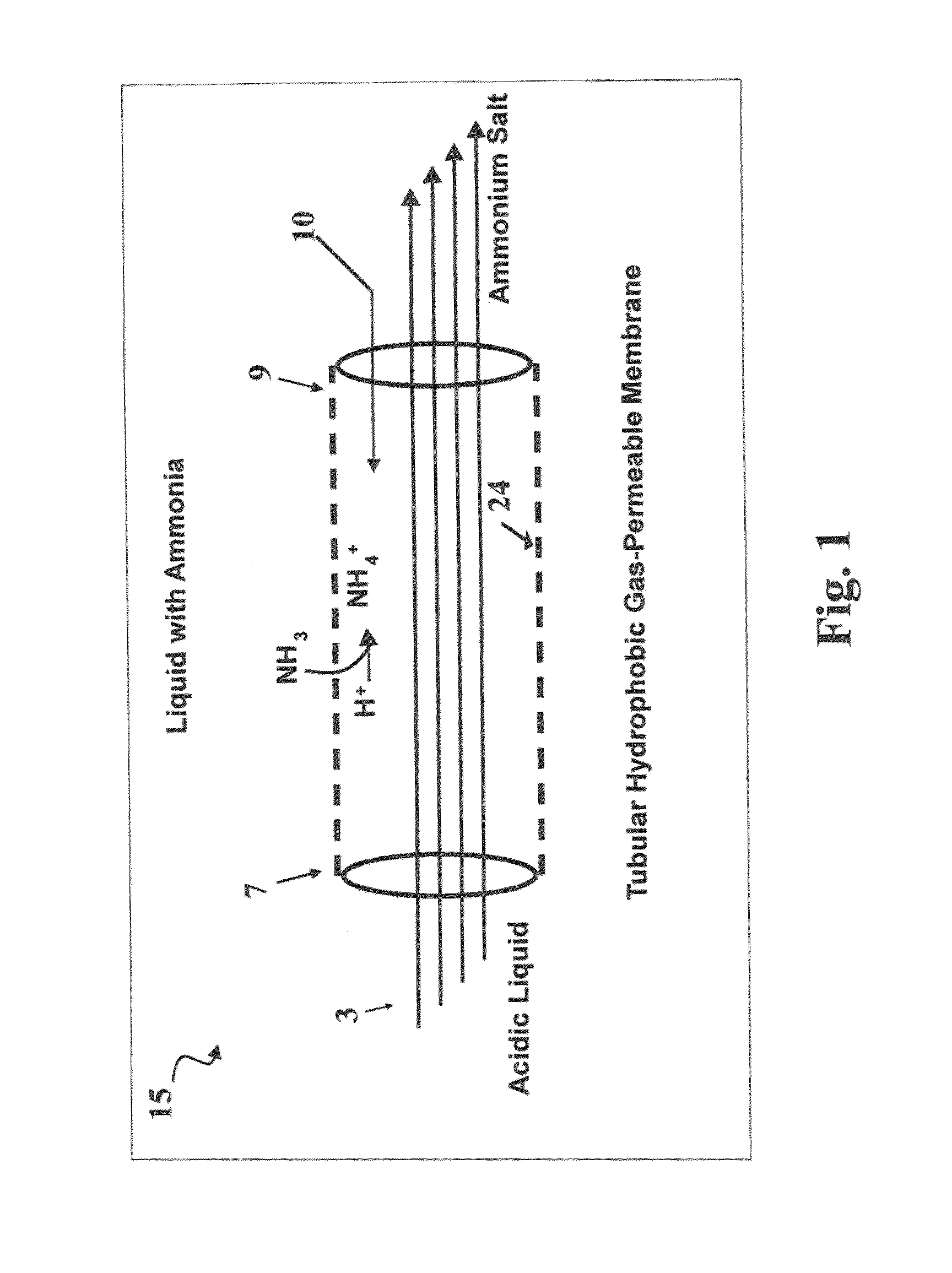

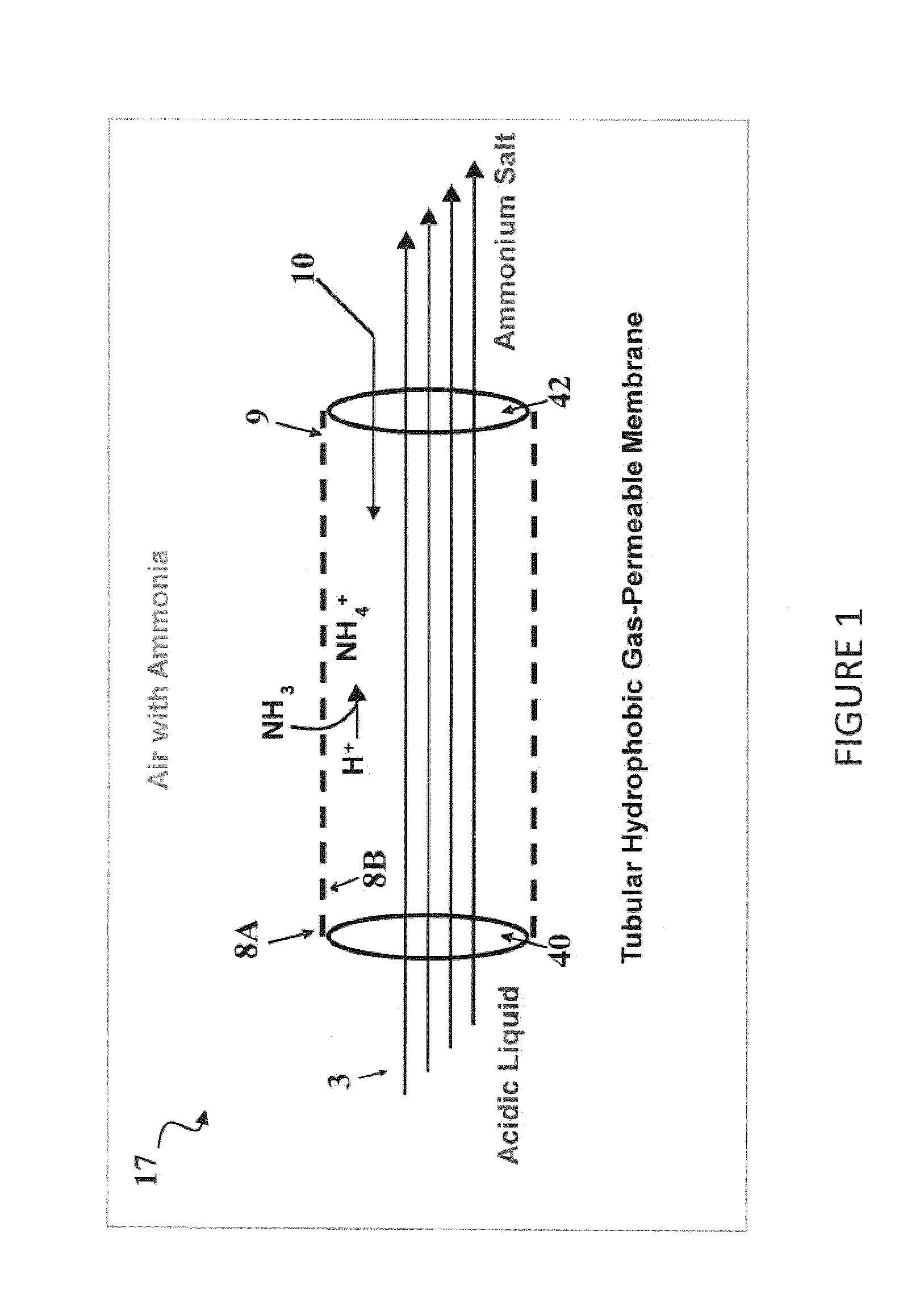

Systems and methods for reducing ammonia emissions from and for recovering the ammonia liquid effluents

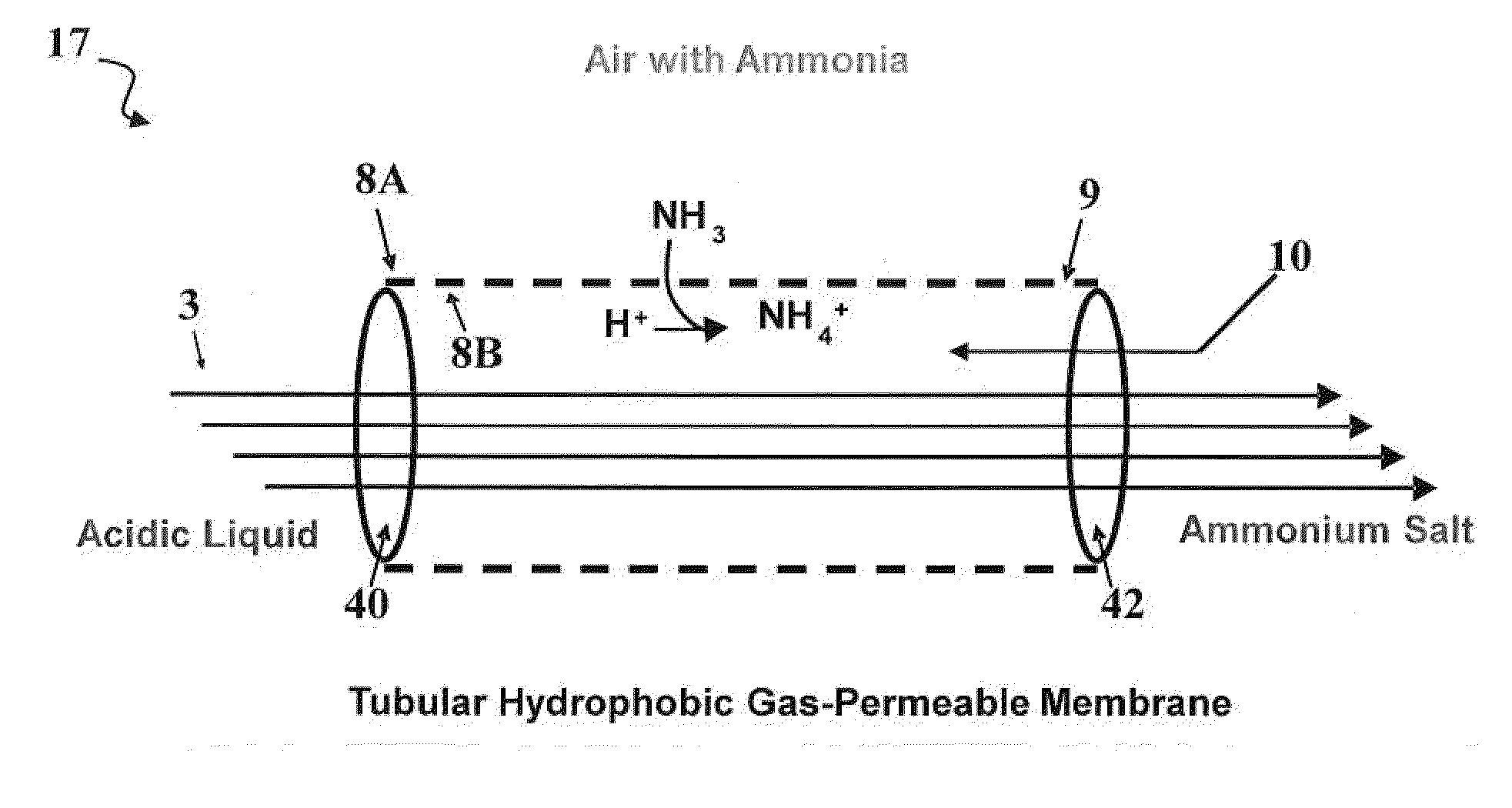

ActiveUS9005333B1Lower Level RequirementsLiquid degasificationWaste water treatment from animal husbandryNH3 compoundAmmonia emission

A system and method for passive capture of ammonia in an ammonia-containing liquid effluent. The invention allows for the passage of ammonia through microporous hydrophobic gas-permeable membranes and its capture in a circulated stripping solution with concomitant production of a concentrated non-volatile ammonium salt.

Owner:UNITED STATES OF AMERICA

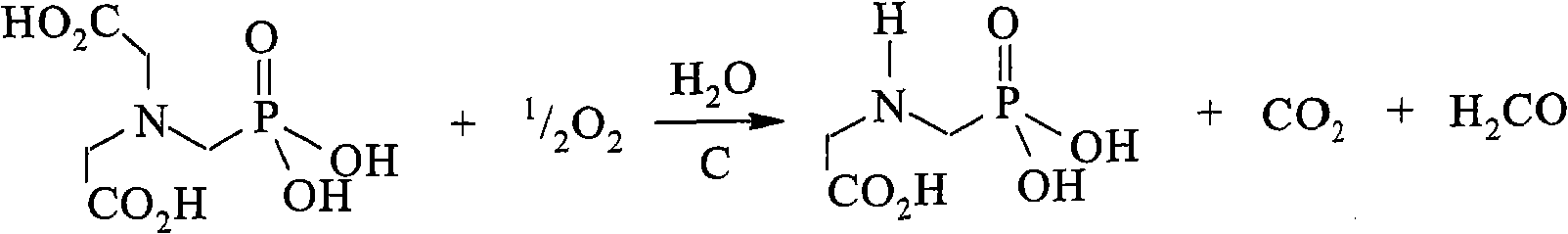

Comprehensive treatment method for glyphosate mother liquid

The invention relates to a comprehensive treatment method for mother liquid synthesized by oxidizing glyphosate by N-(Phosphonomethyl) iminodiacetic acid with an IDA (Iminodiacetic Acid) method. The mother liquid is treated by a condensed system to obtain condensed liquid and thin liquid, wherein the condensed liquid subjected to formaldehyde removal is used for preparing a gyphosate solution with high content or carrying out oxidation treatment, the treated thin liquid can be used for gyphosate production or biochemical treatment. The comprehensive treatment method not only recovers gyphosate, but also reduces the pollution to the environment.

Owner:ZHEJIANG XINAN CHEM INDAL GROUP

Process for scrubbing ammonia from acid gases comprising ammonia and hydrogen sulfide

Owner:EI DU PONT DE NEMOURS & CO

Method of separating multi-ammonium compound salt

InactiveCN101012065ANon-flammableNon-explosiveThiosulfates/dithionites/polythionitesThiocyanic acidAmmonium compoundsWastewater

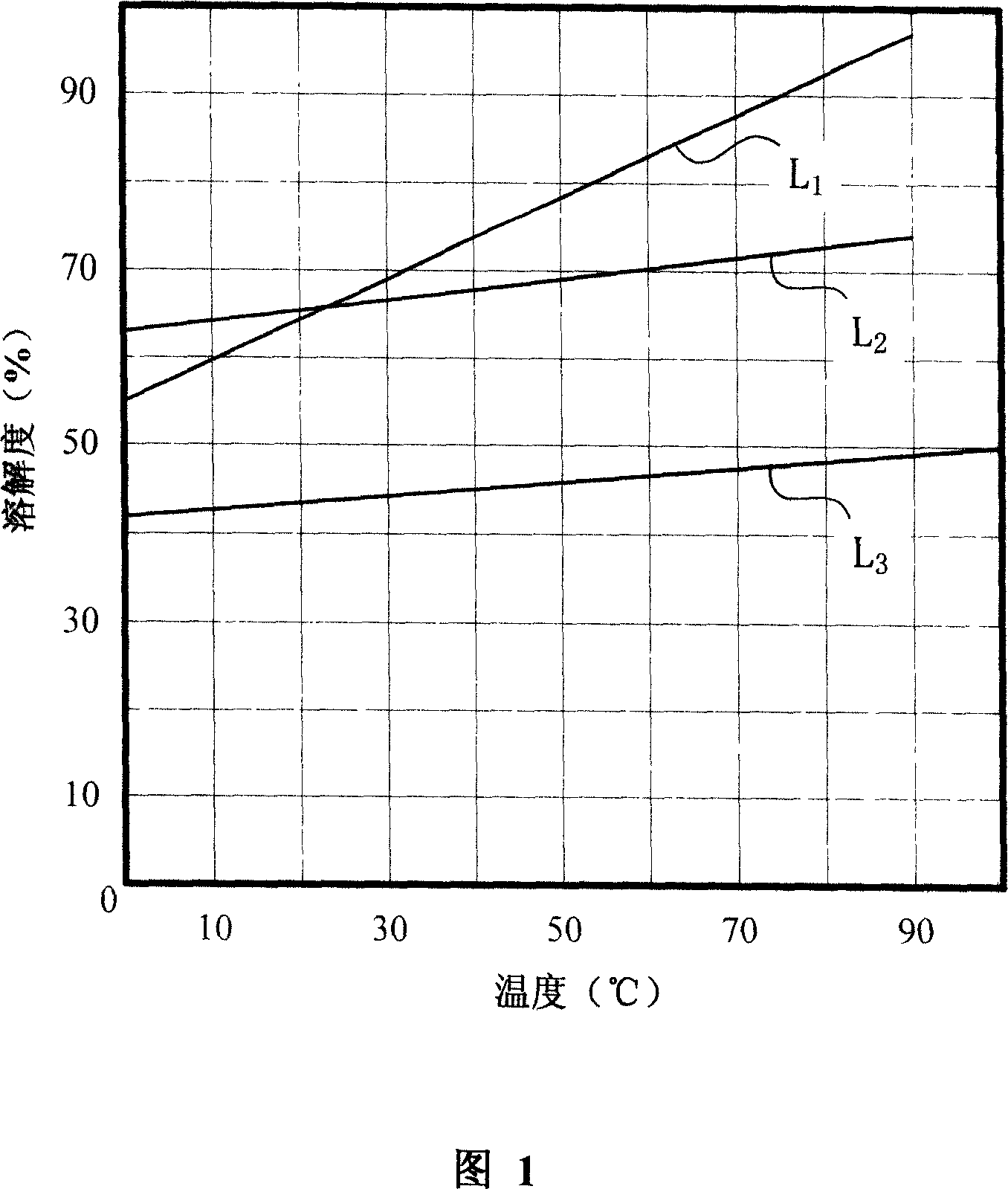

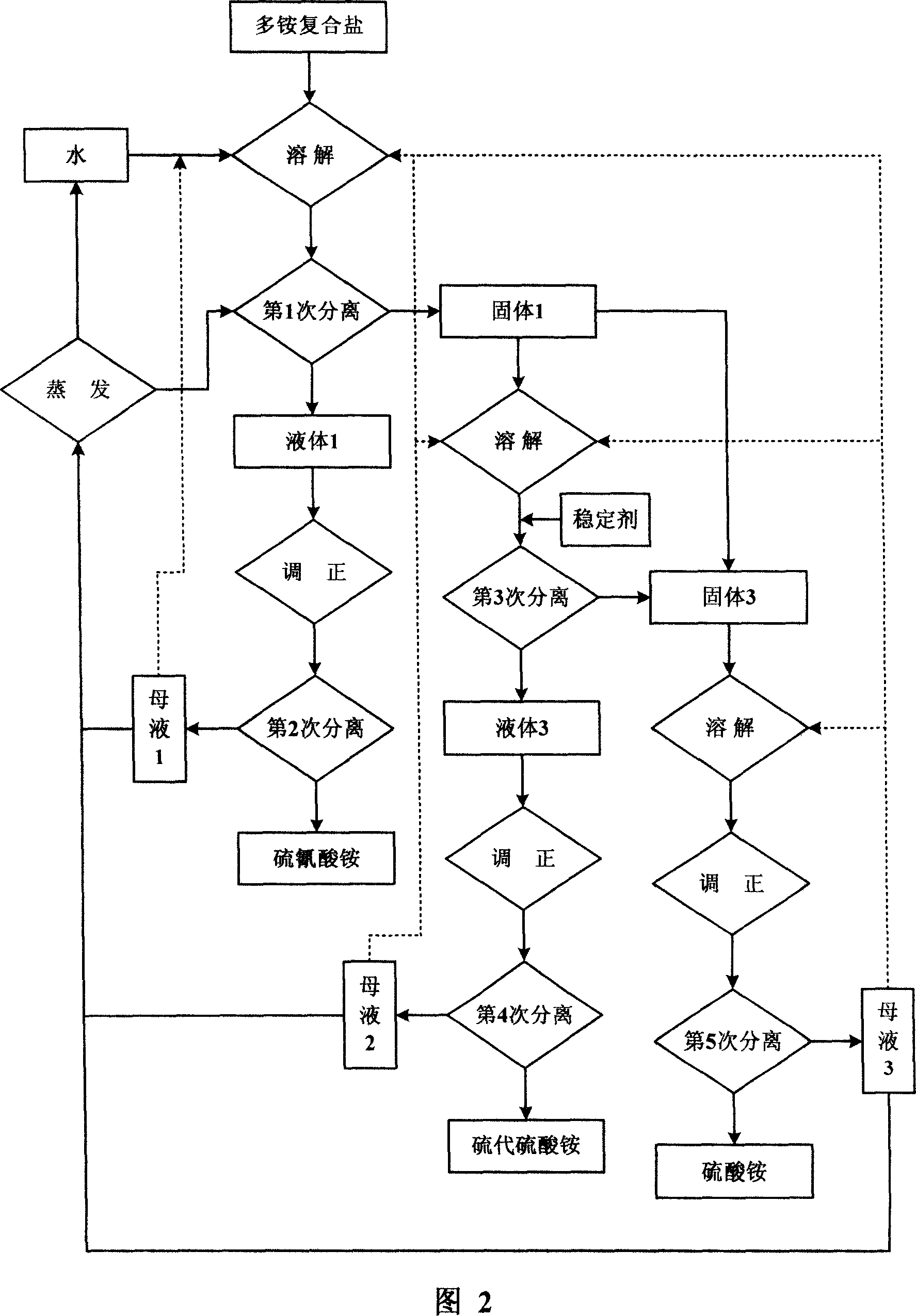

The invention discloses a separating method of multi-ammonia composite salt, which comprises the following steps: separating ammonia thiocyanate under low temperature (0-25 deg.c); enriching ammonium thiosulfate and ammonium sulfate under middle temperature (40-65 deg.c); separating ammonium sulfate under high temperature (80-90 deg.c); separating enriched ammonium thiosulfate at 20-40 deg.c; dissolving, crystallizing and separating solid from liquid for several times under different temperature to separate ammonium thiocyanate, ammonium thiosulfate and ammonium sulfate one by one.

Owner:苏州久王环保科技股份有限公司

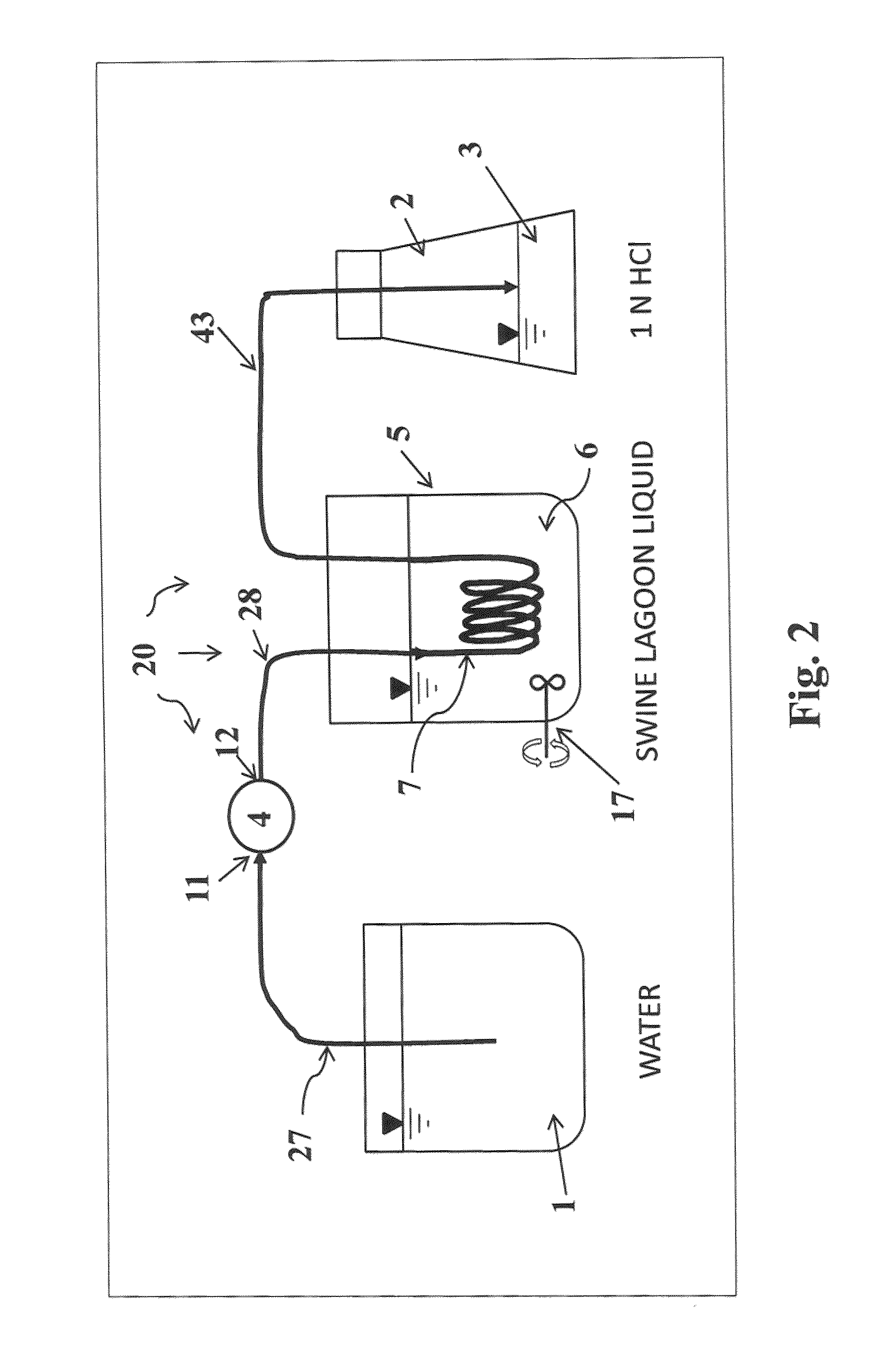

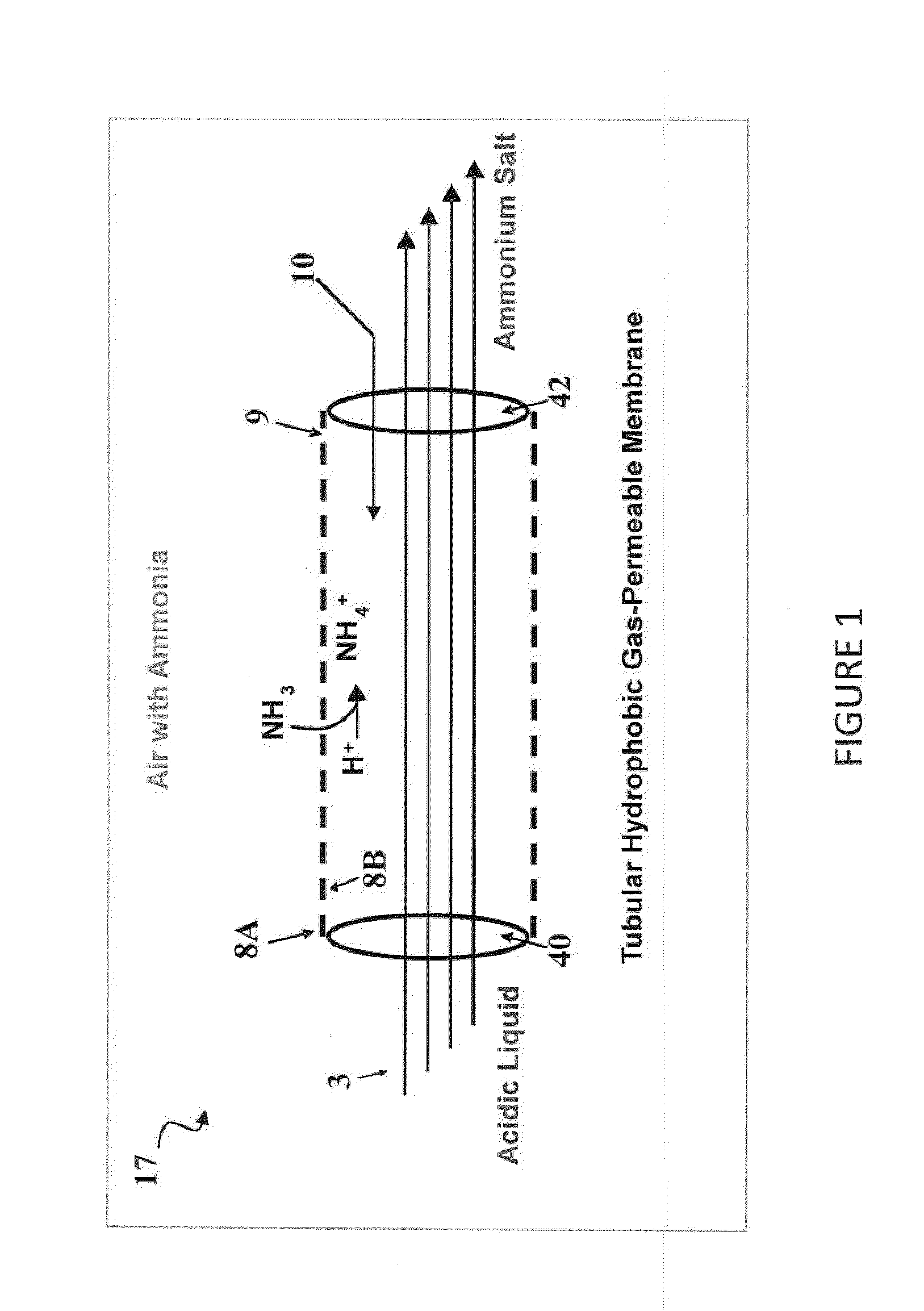

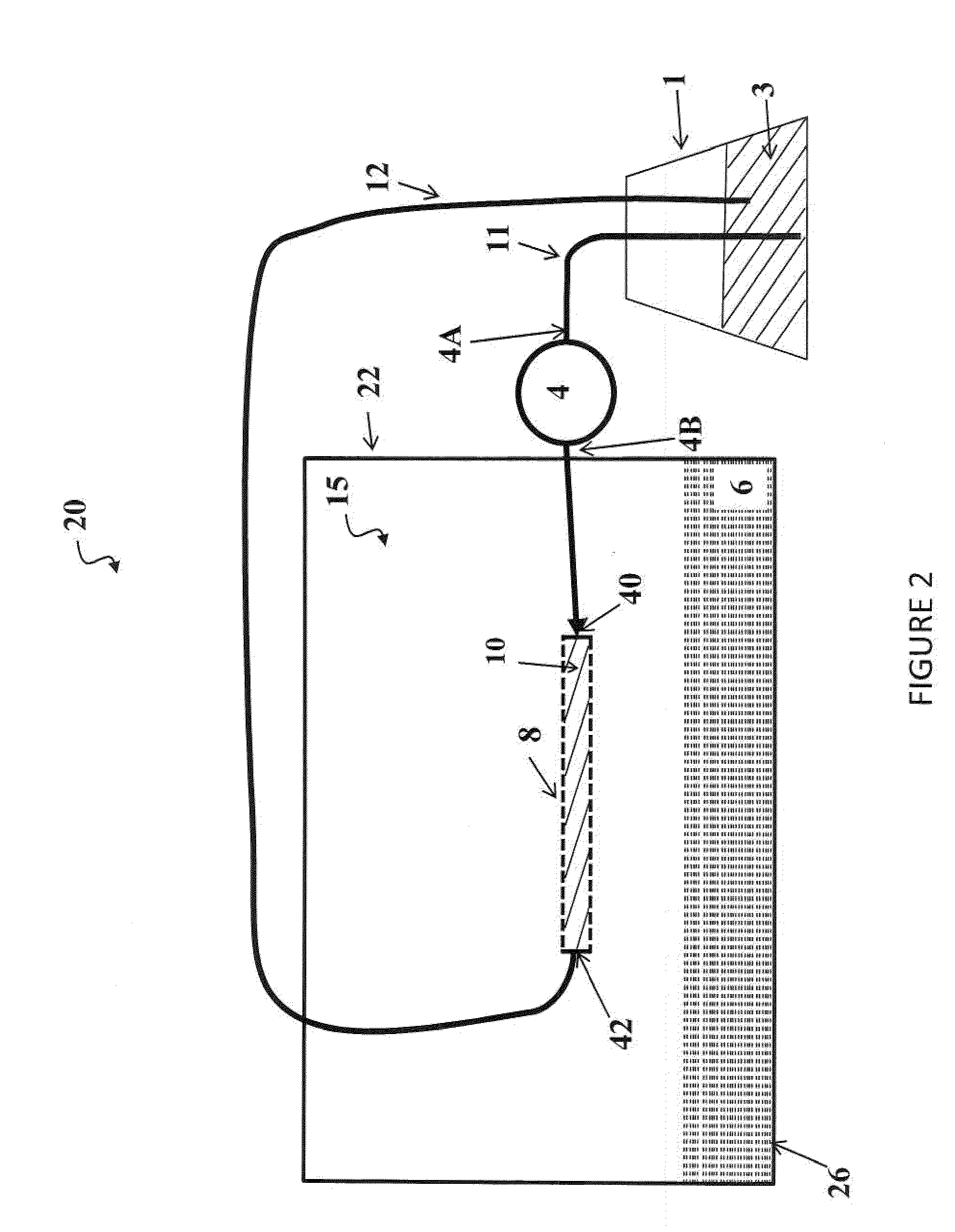

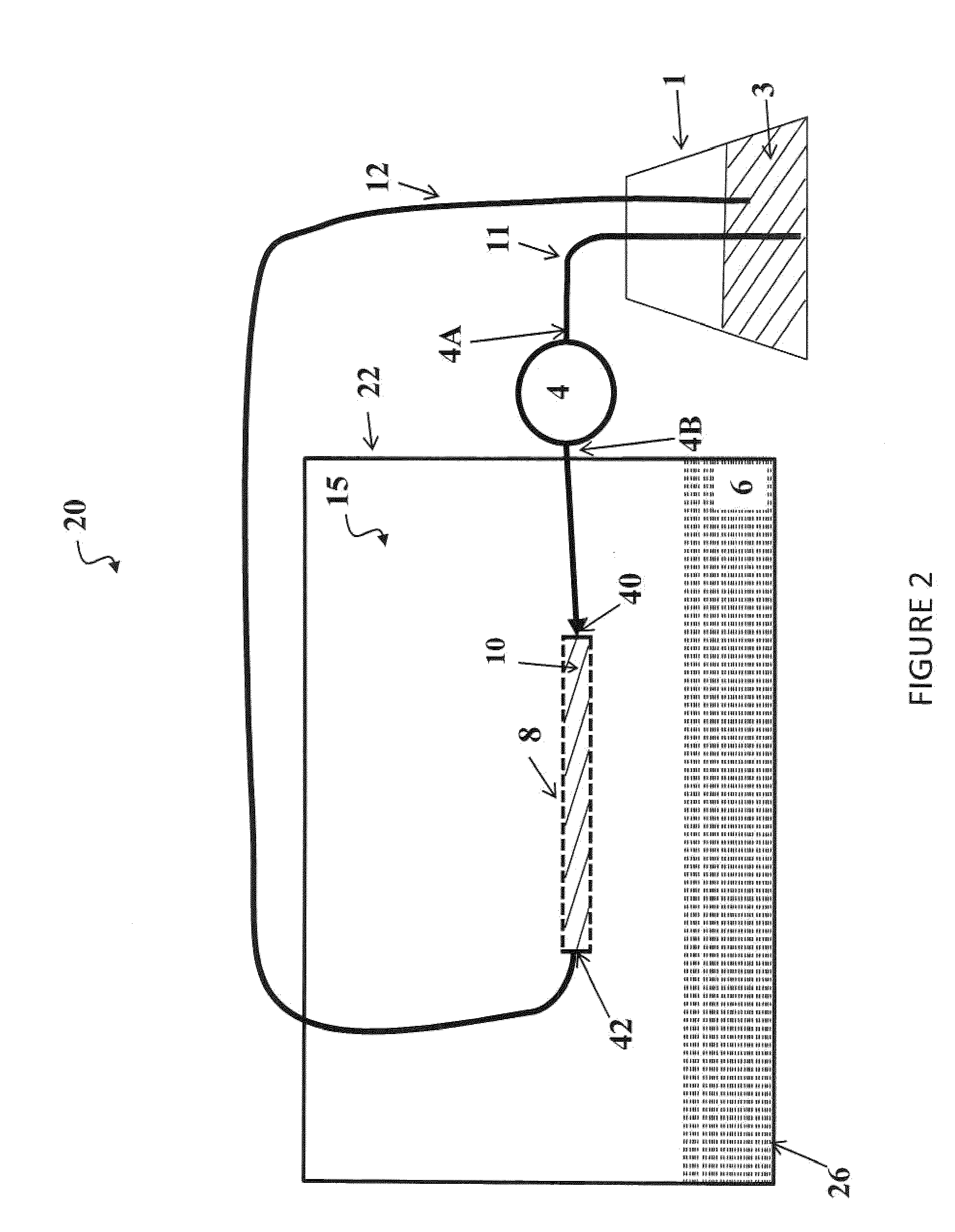

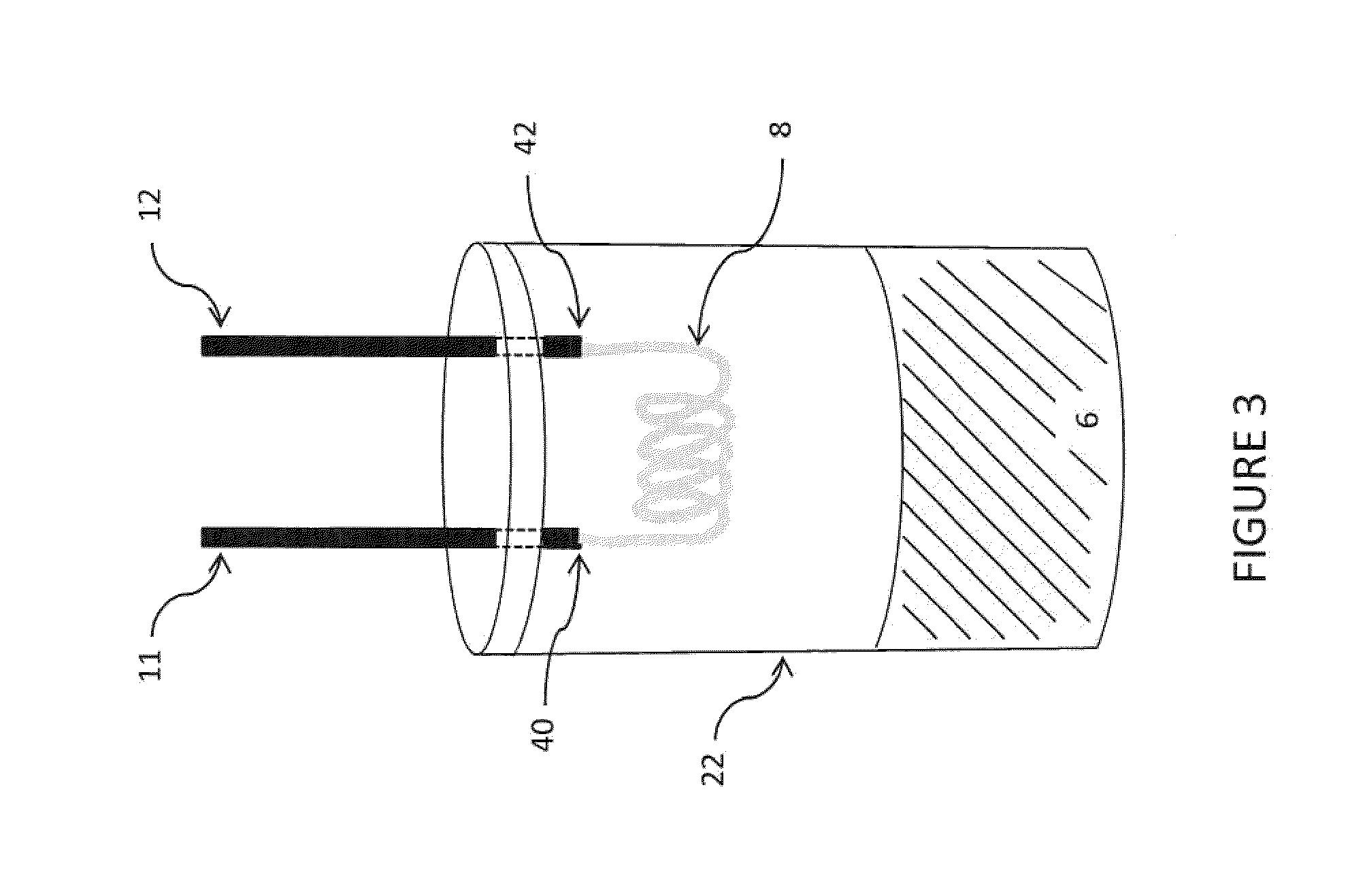

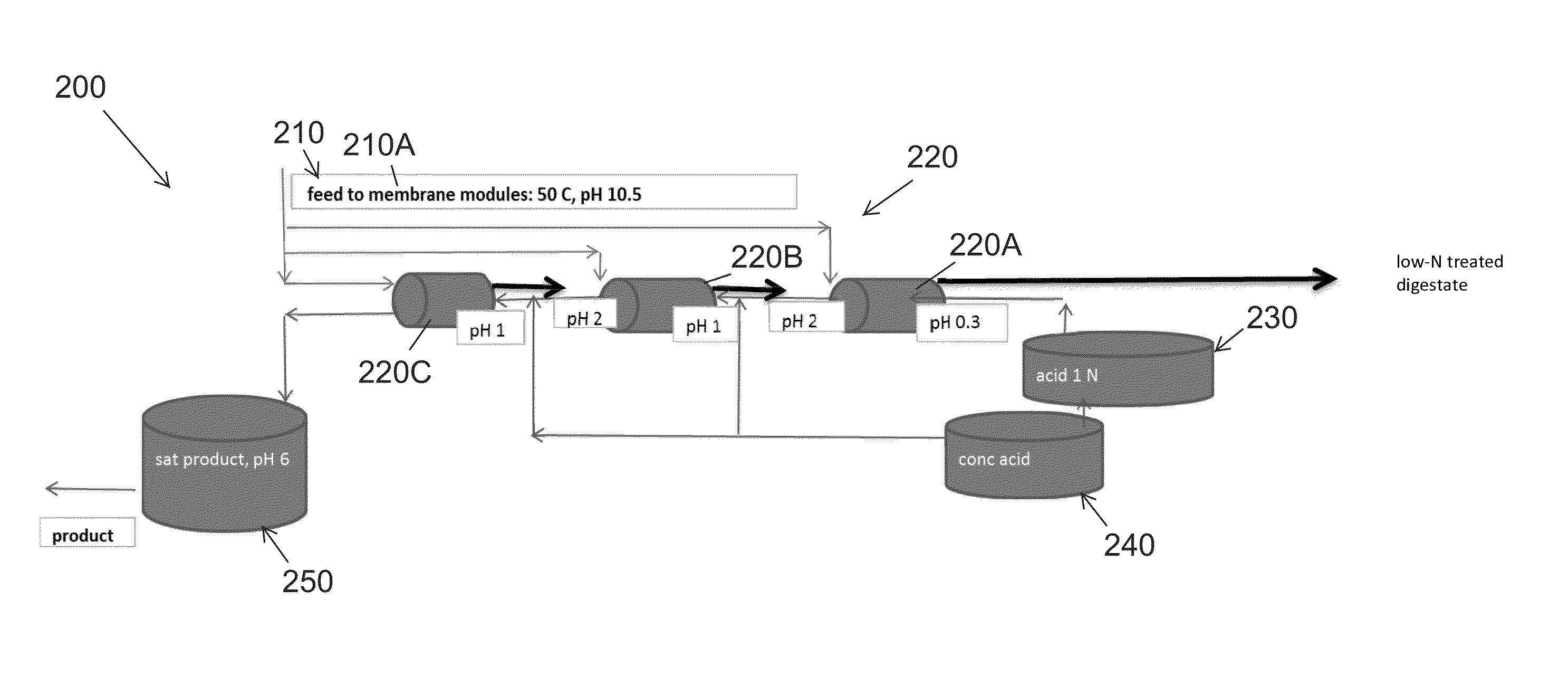

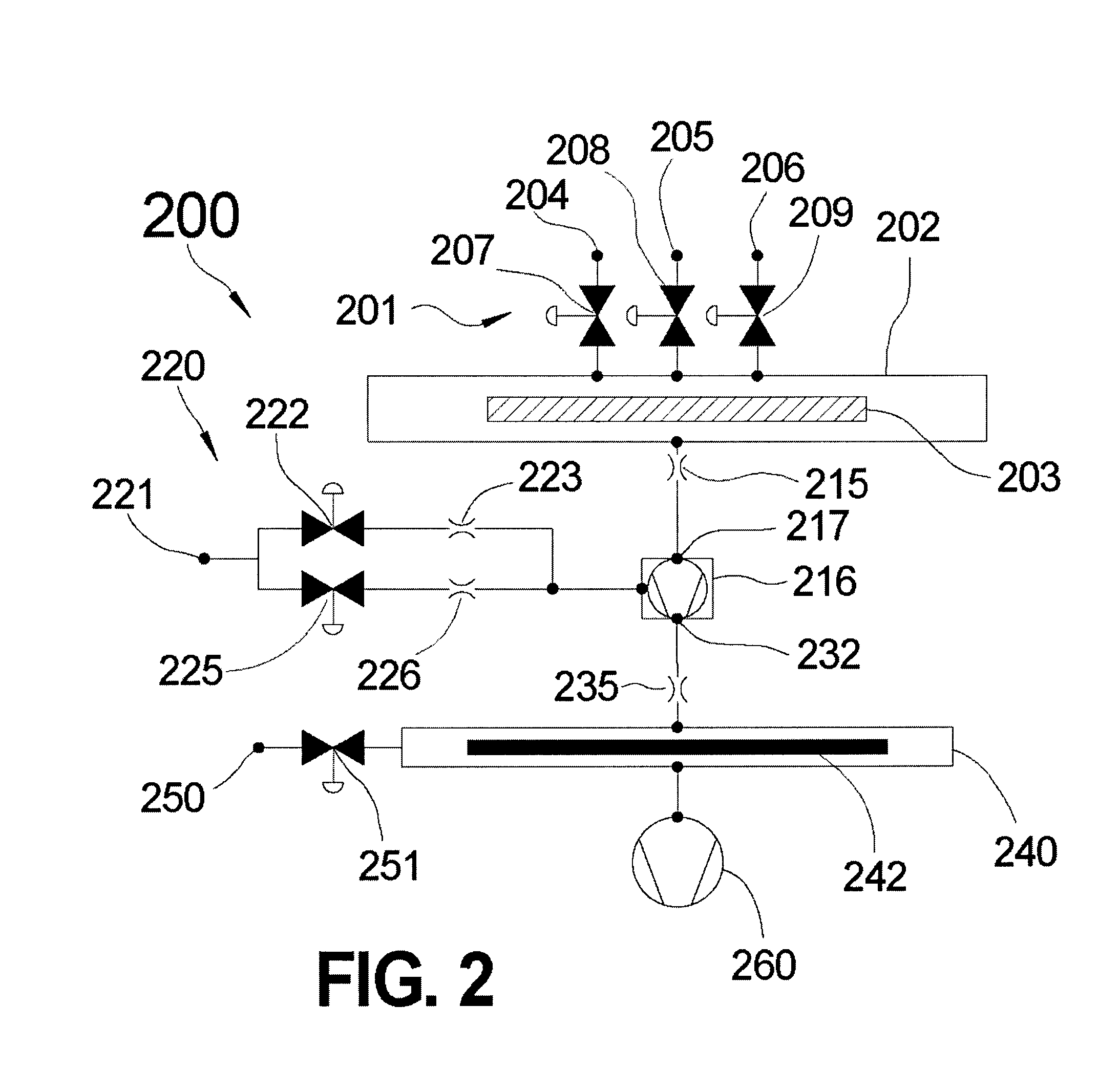

Ammonia capture recovery system

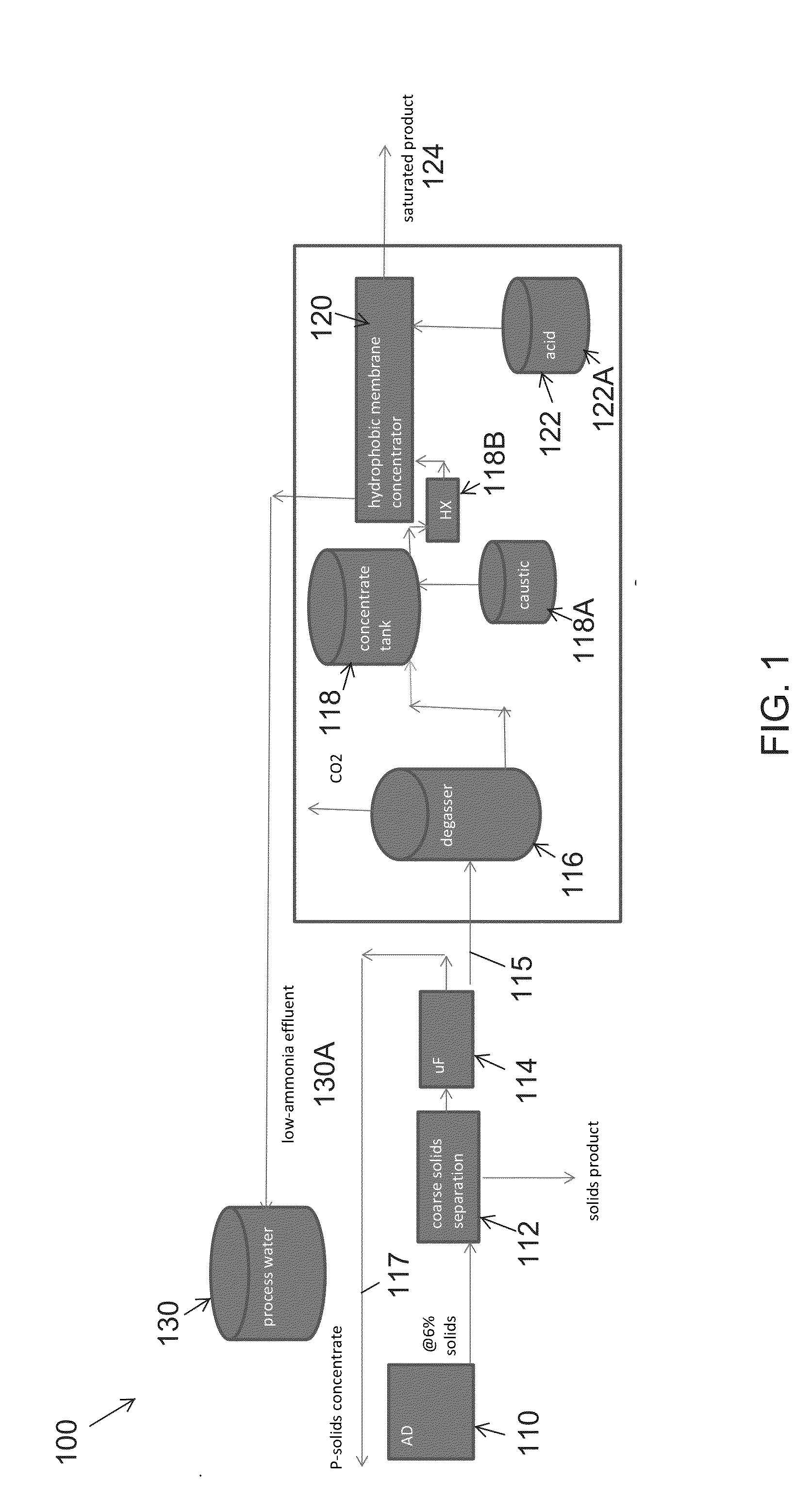

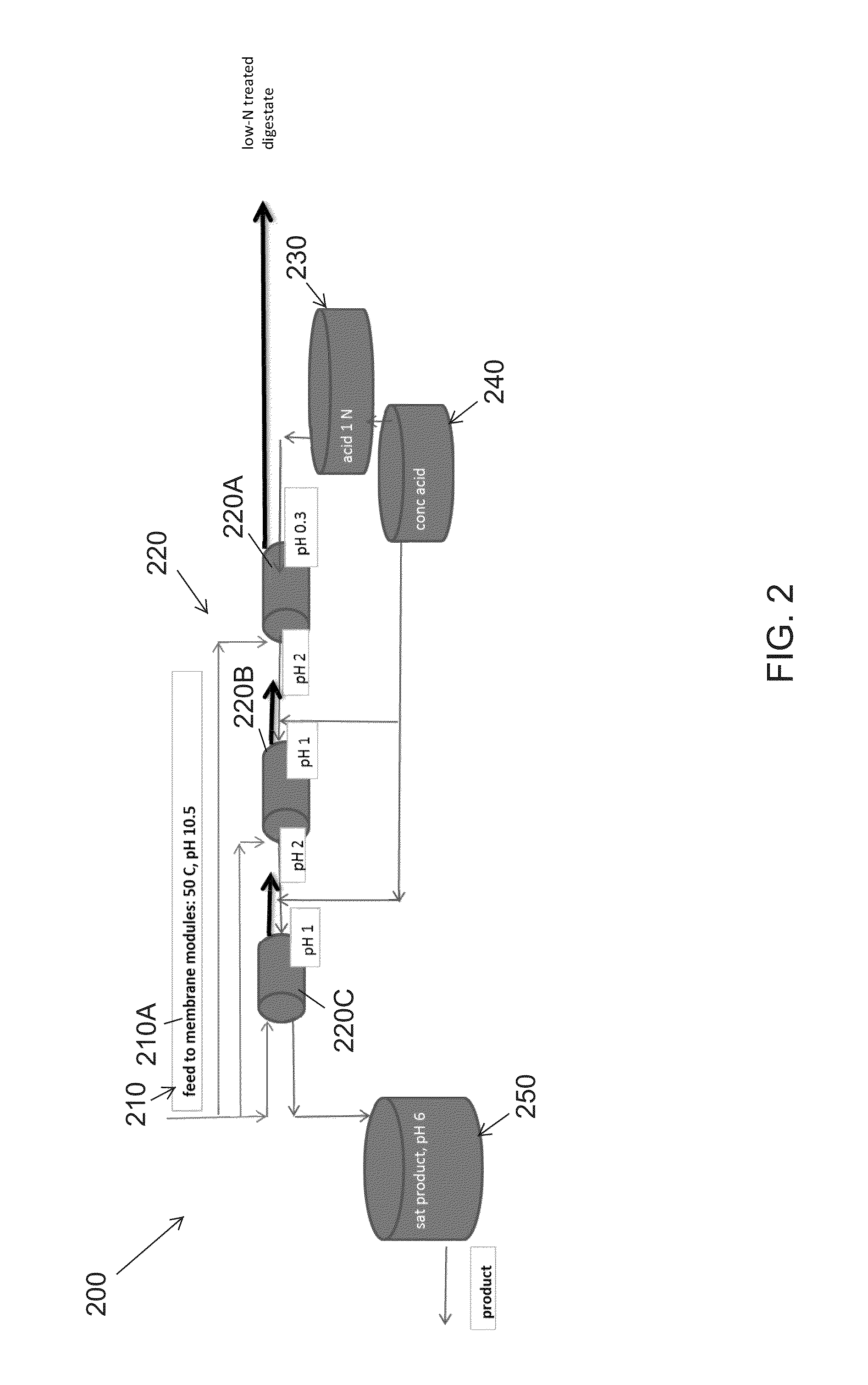

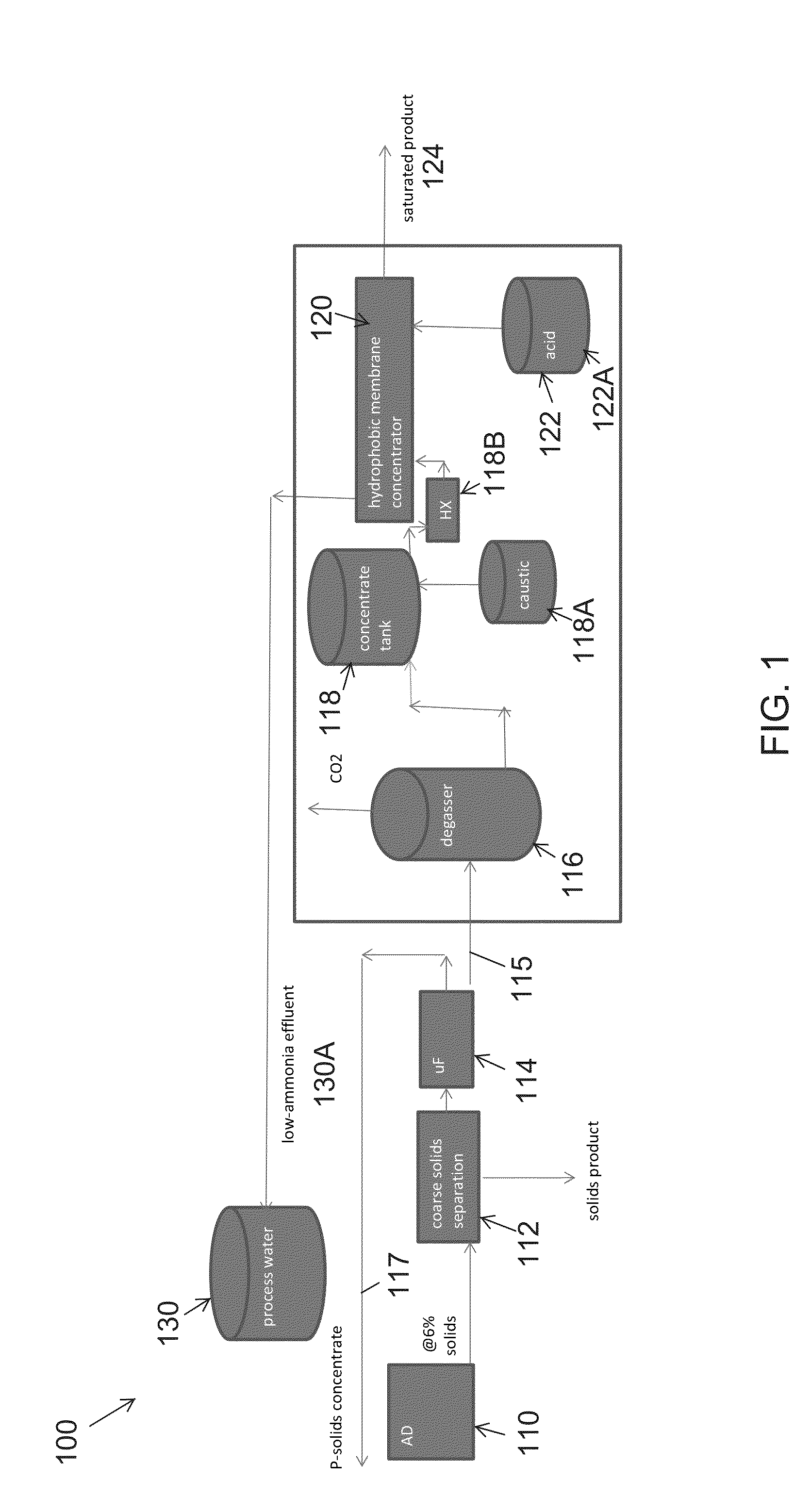

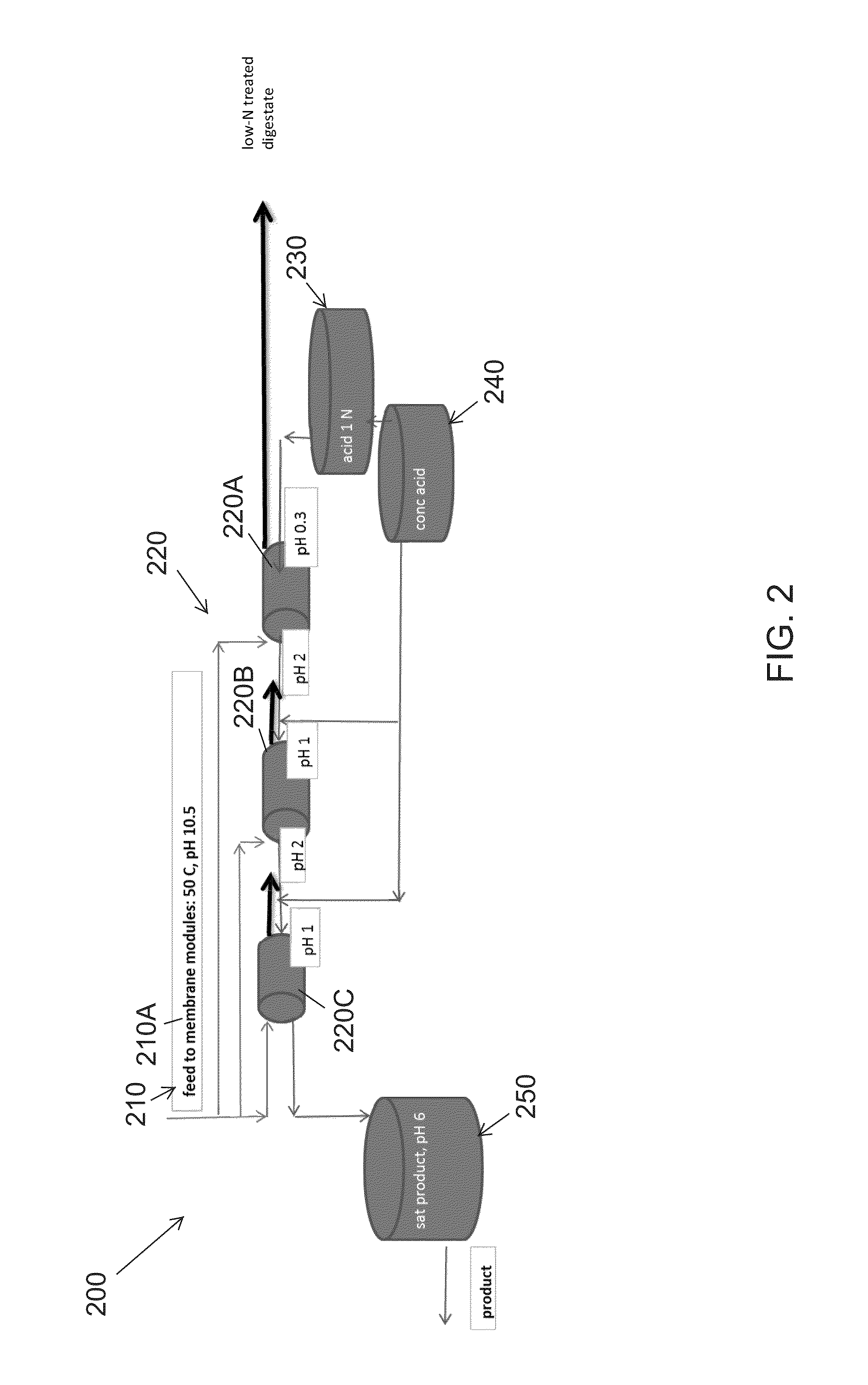

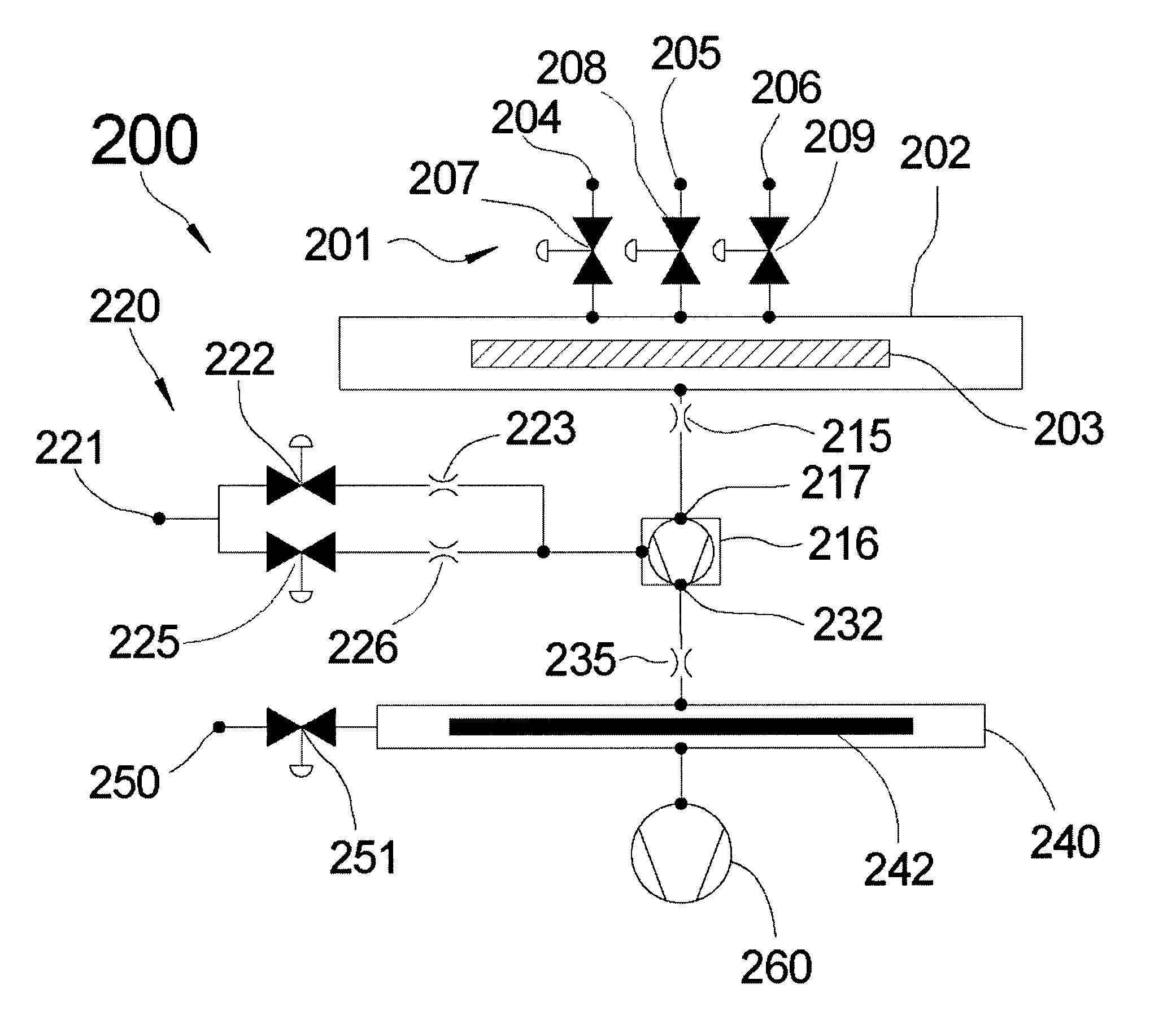

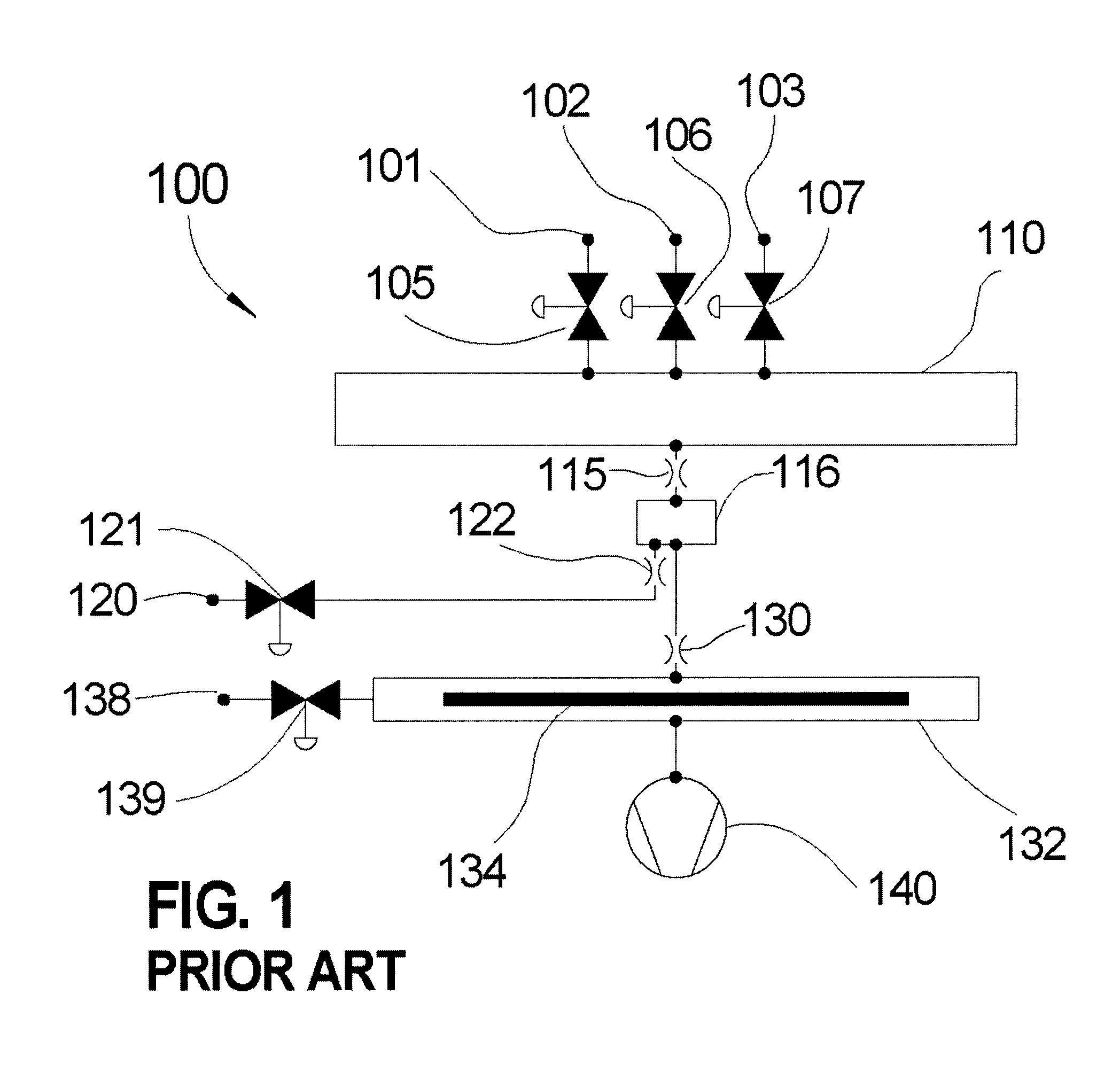

An ammonia capture recovery system is disclosed. The ammonia capture recovery system may include pretreatment with conventional solid removal devices and a single or a series of hydrophobic membrane concentrators receiving a heated ammonium containing influent either heated to a sufficient temperature to convert ammonia to ammonium or containing sufficient alkali to convert ammonia to ammonium in the influent. The heated ammonium containing liquid is pumped through the hydrophobic membrane concentrator and the hydrophobic membrane concentrator receives an acid. The acid then reacts with the extracted gaseous ammonia and ultimately forms a saturated ammonium salt product that is discharged from the hydrophobic membrane concentrator, the hydrophobic membrane concentrator includes a feed line, a plurality of hydrophobic membrane modules, a diluted acid source and a concentrated acid source and tanks to receive the saturated ammonium salt product and the low ammonia effluent.

Owner:ORENTLICHER MORTON +1

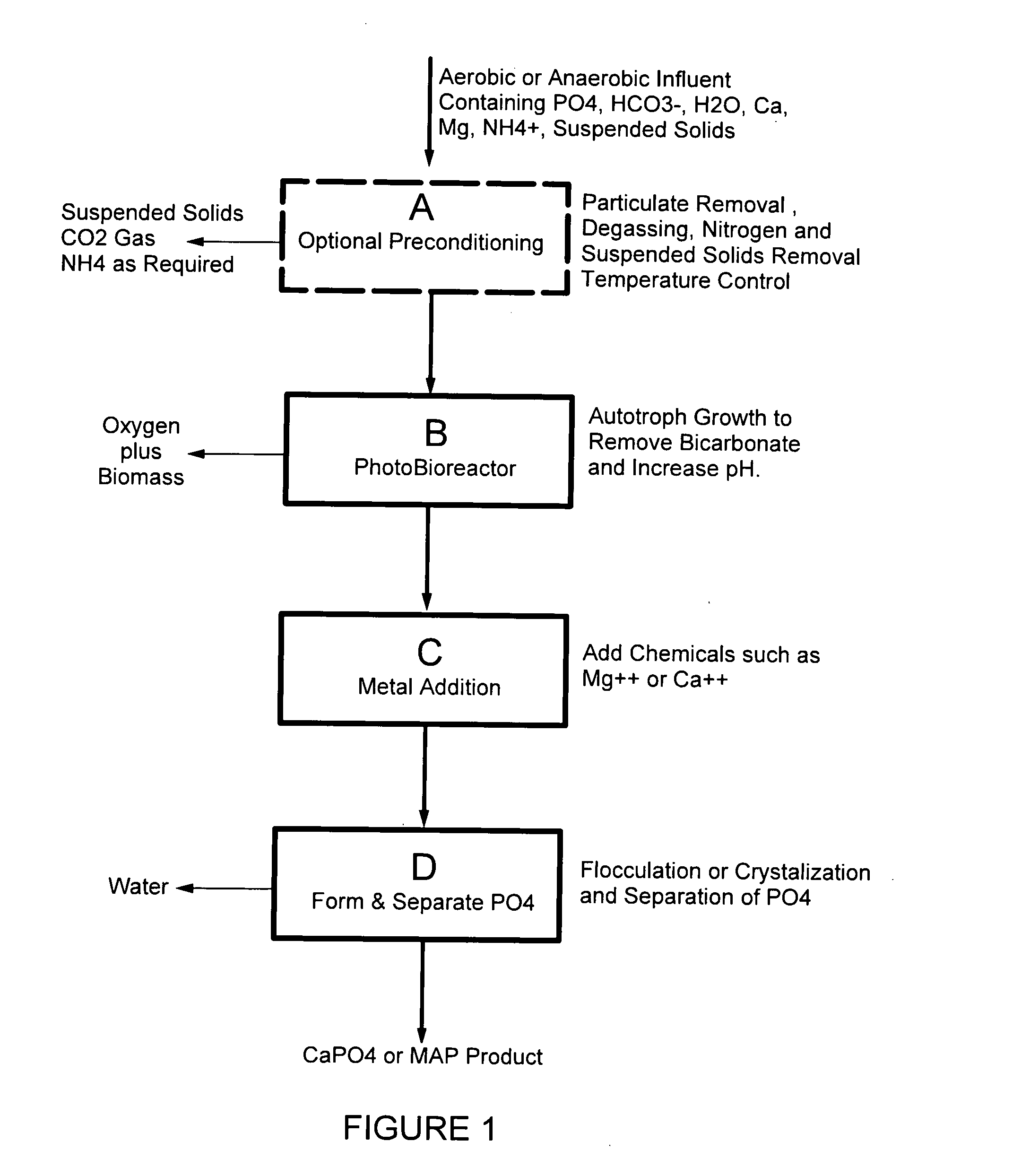

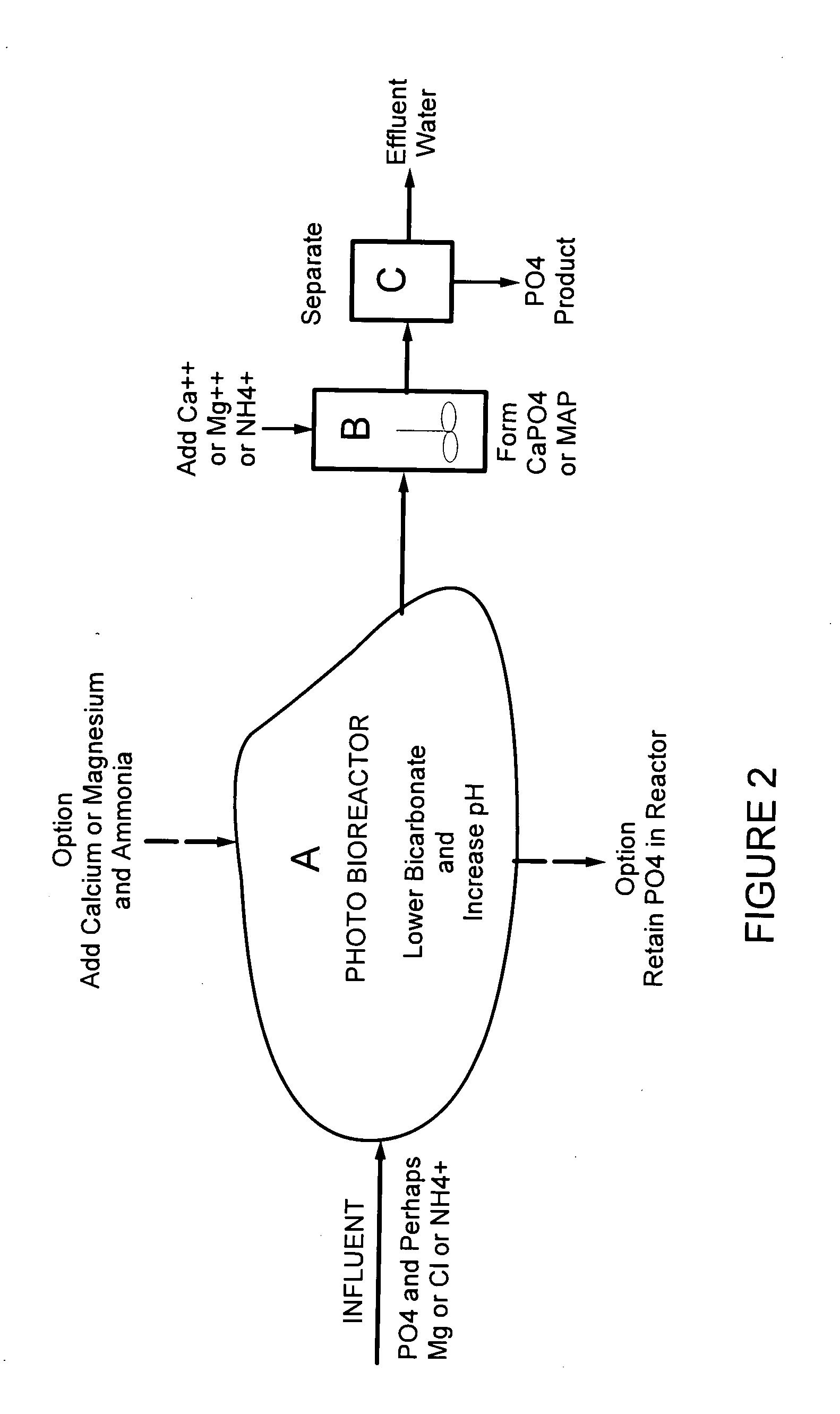

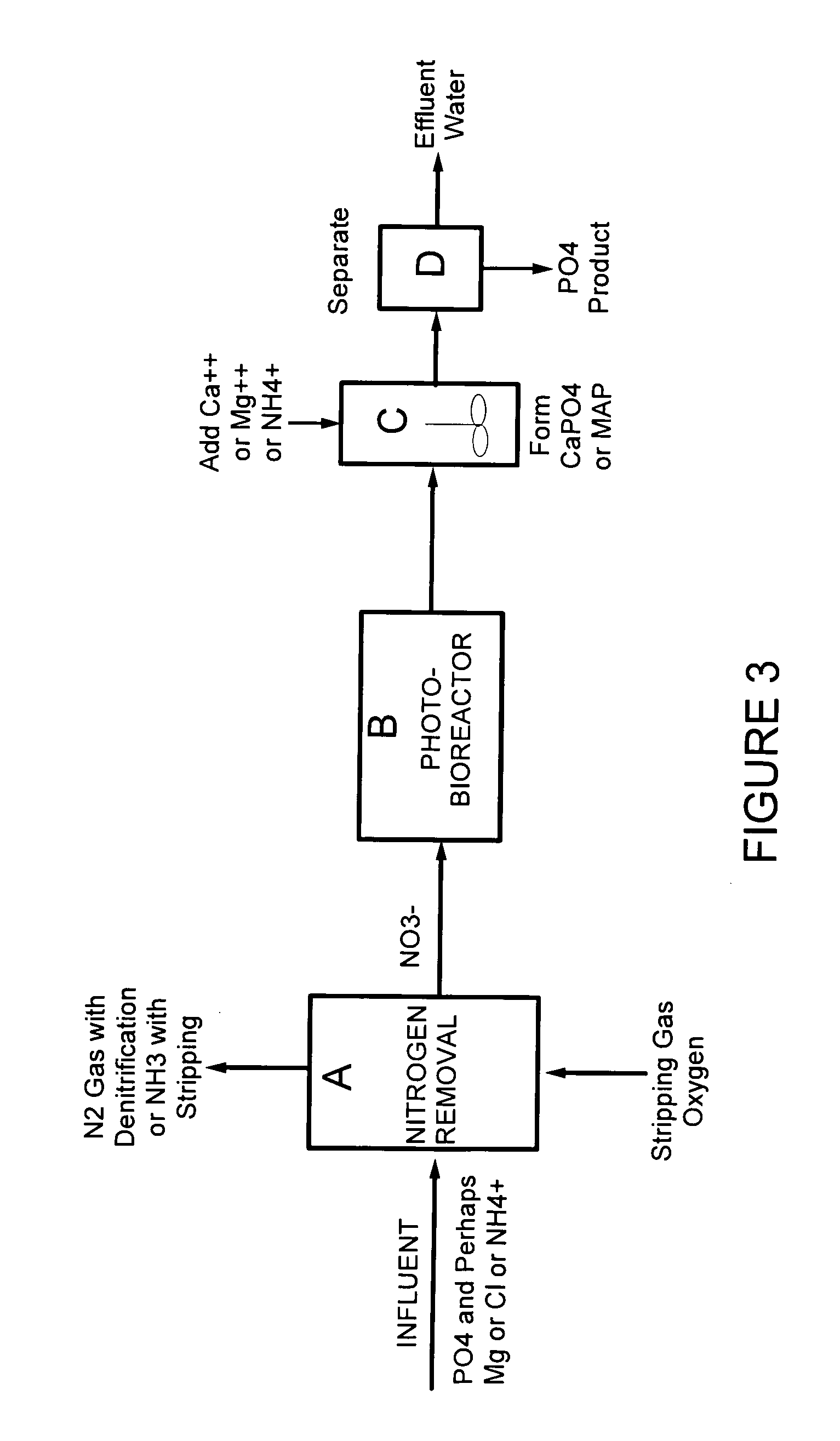

Removal and recovery of phosphate from liquid streams

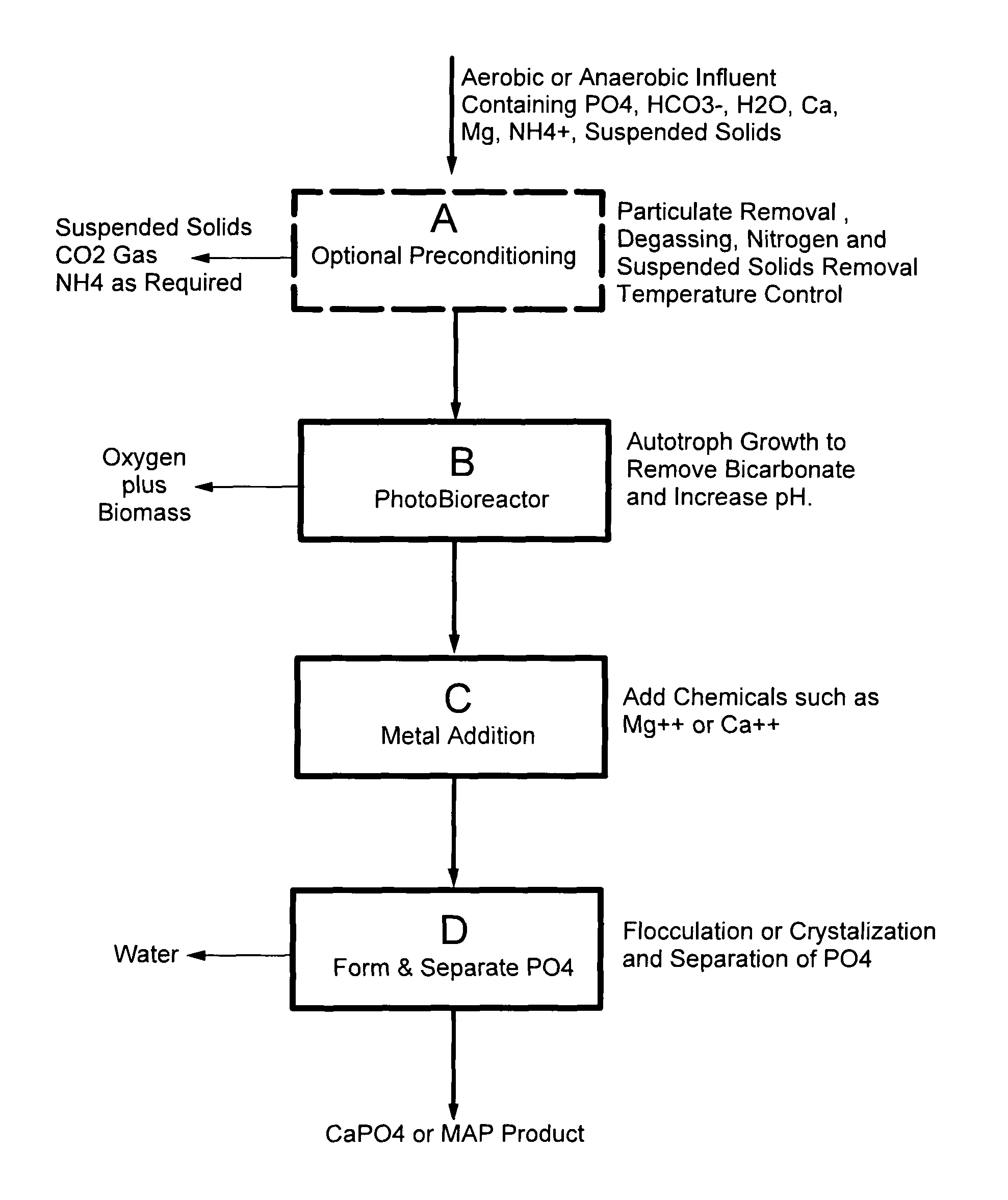

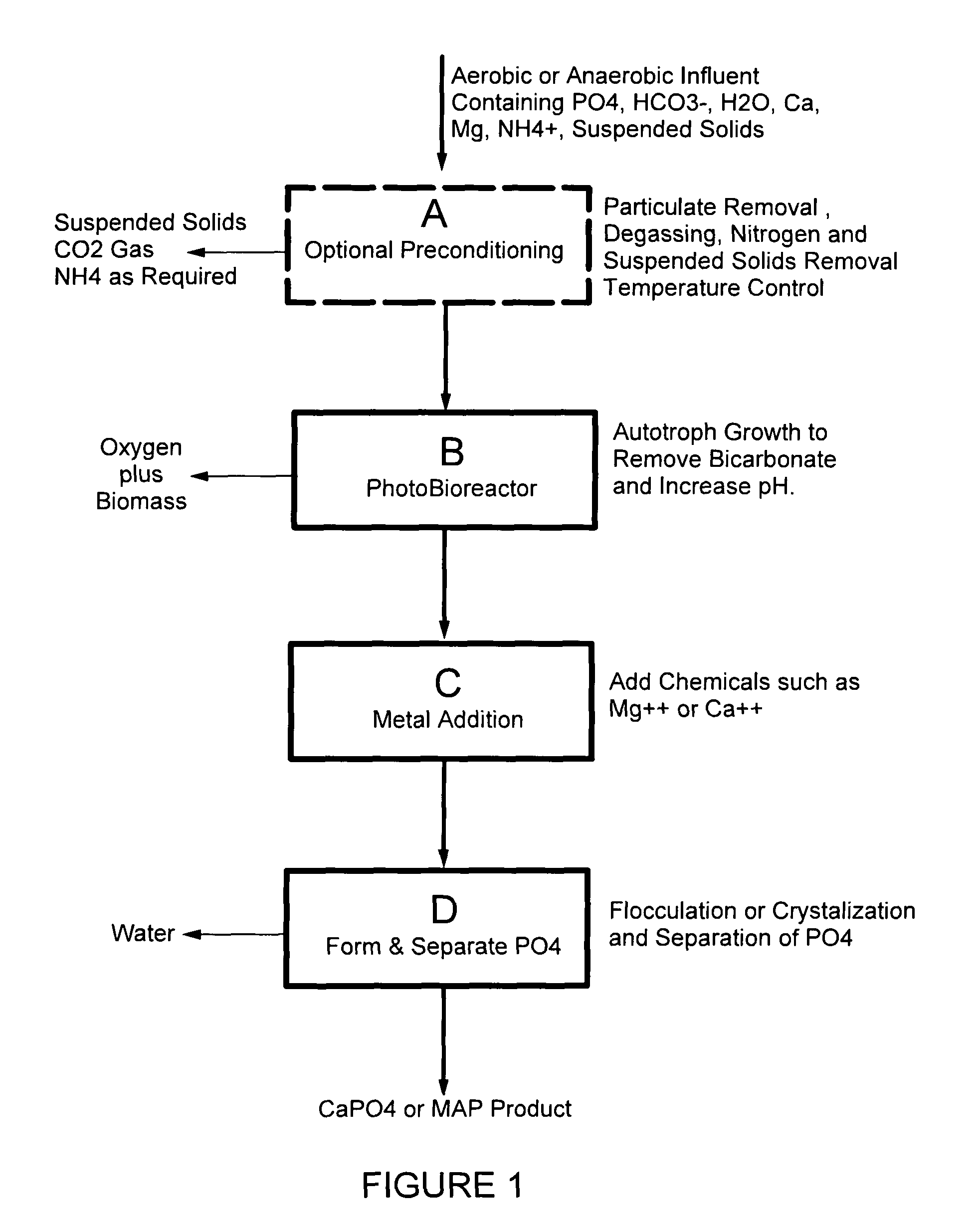

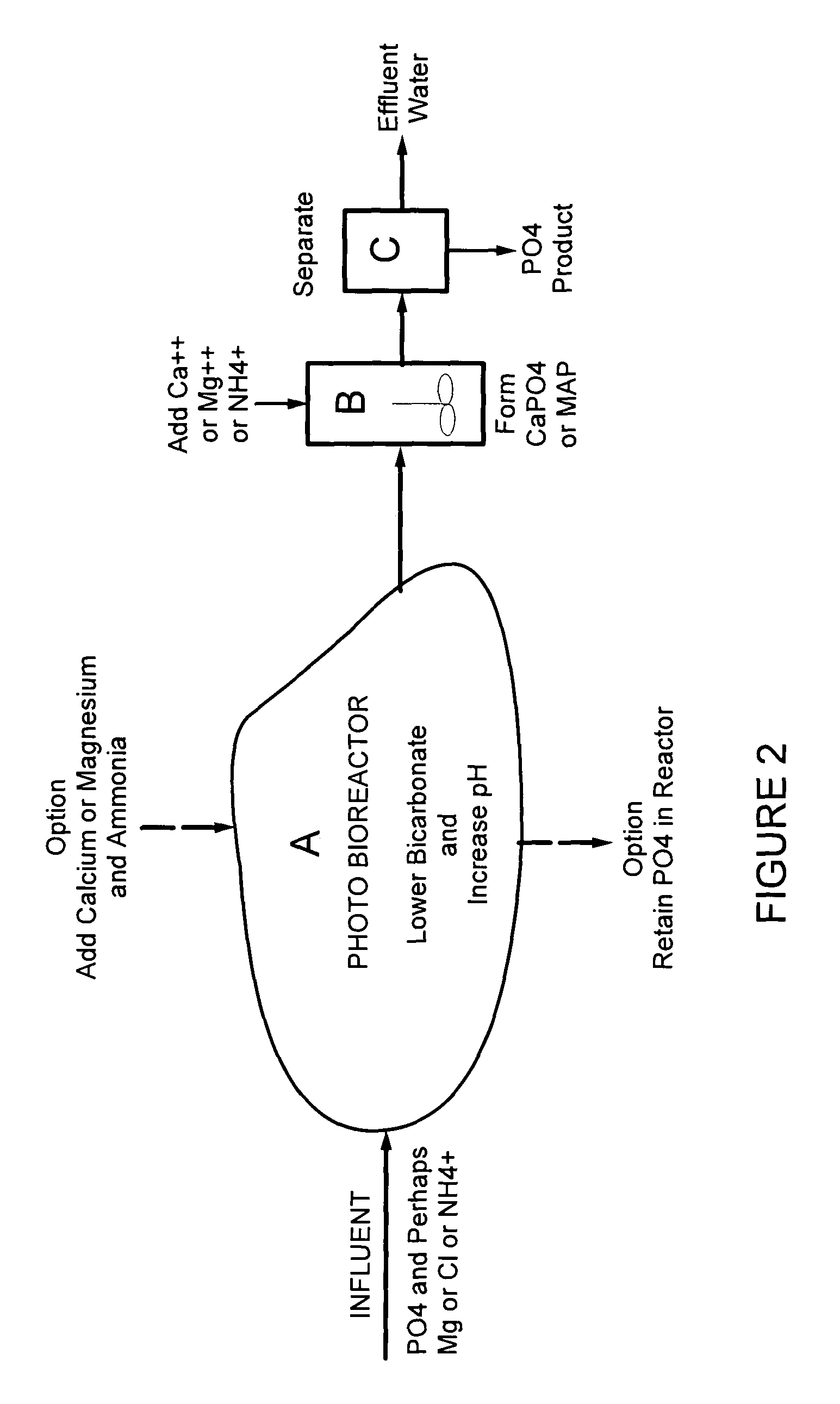

ActiveUS20150336830A1Chemical cost reductionImprove efficiencyLiquid degasificationEnergy based wastewater treatmentChemical treatmentMagnesium ammonium phosphate

An economical method for recovering phosphate or phosphate and nitrogen from liquid streams. A liquid containing phosphate is introduced into a culture of autotrophic microorganisms in the presence of natural or artificial light, thereby producing a liquid effluent with elevated pH and reduced alkalinity. The alkalinity is reduced through the consumption of bicarbonate / carbonate by the autotrophic microorganisms. The effluent is then chemically treated with low-cost chemicals to provide Ca++ or Mg++ ions necessary to form a phosphate precipitate such as calcium phosphate or magnesium-ammonium-phosphate (MAP). The autotrophic microorganisms can be cultivated in ponds, lagoons, or photobioreactors. The pH of the culture is adjustable within a preferred range of 7.5 to 10.5 by adjusting the photobioreactor operation. The process includes an economical flotation separator for solid, liquid, gas separation and a means of concentrating ammonia nitrogen that may also be removed during the process of phosphate reclamation.

Owner:COYNE BRIAN J

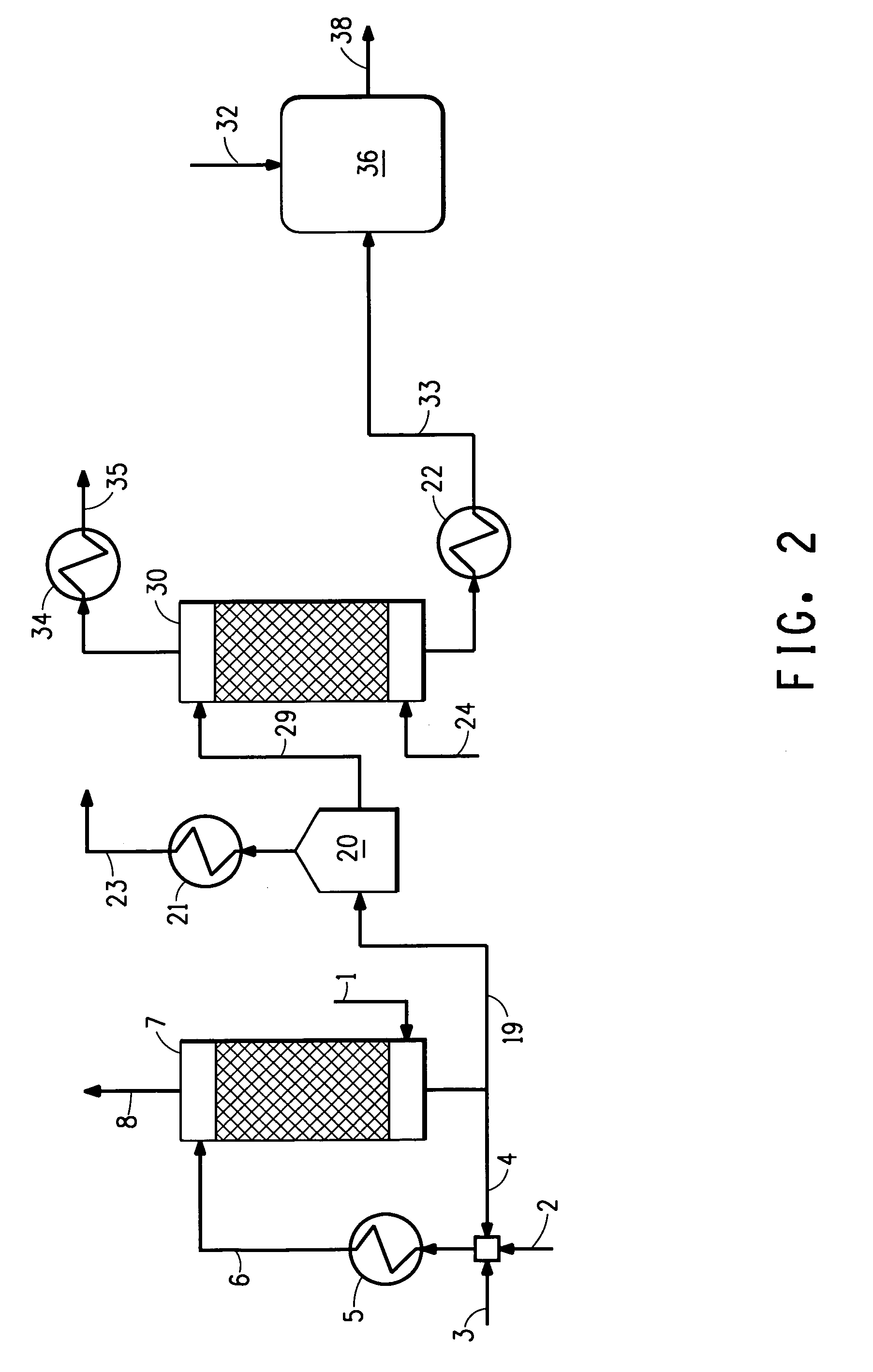

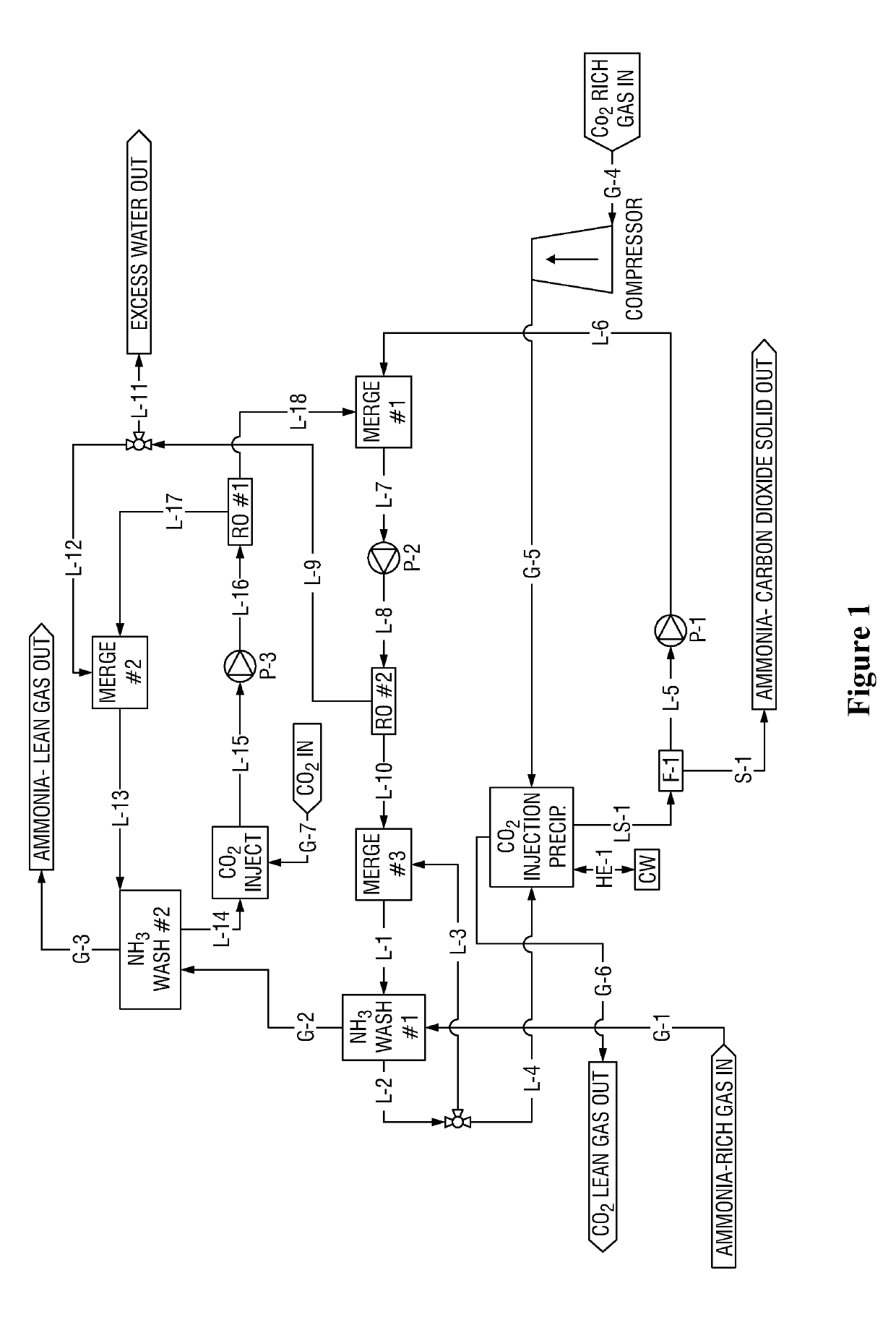

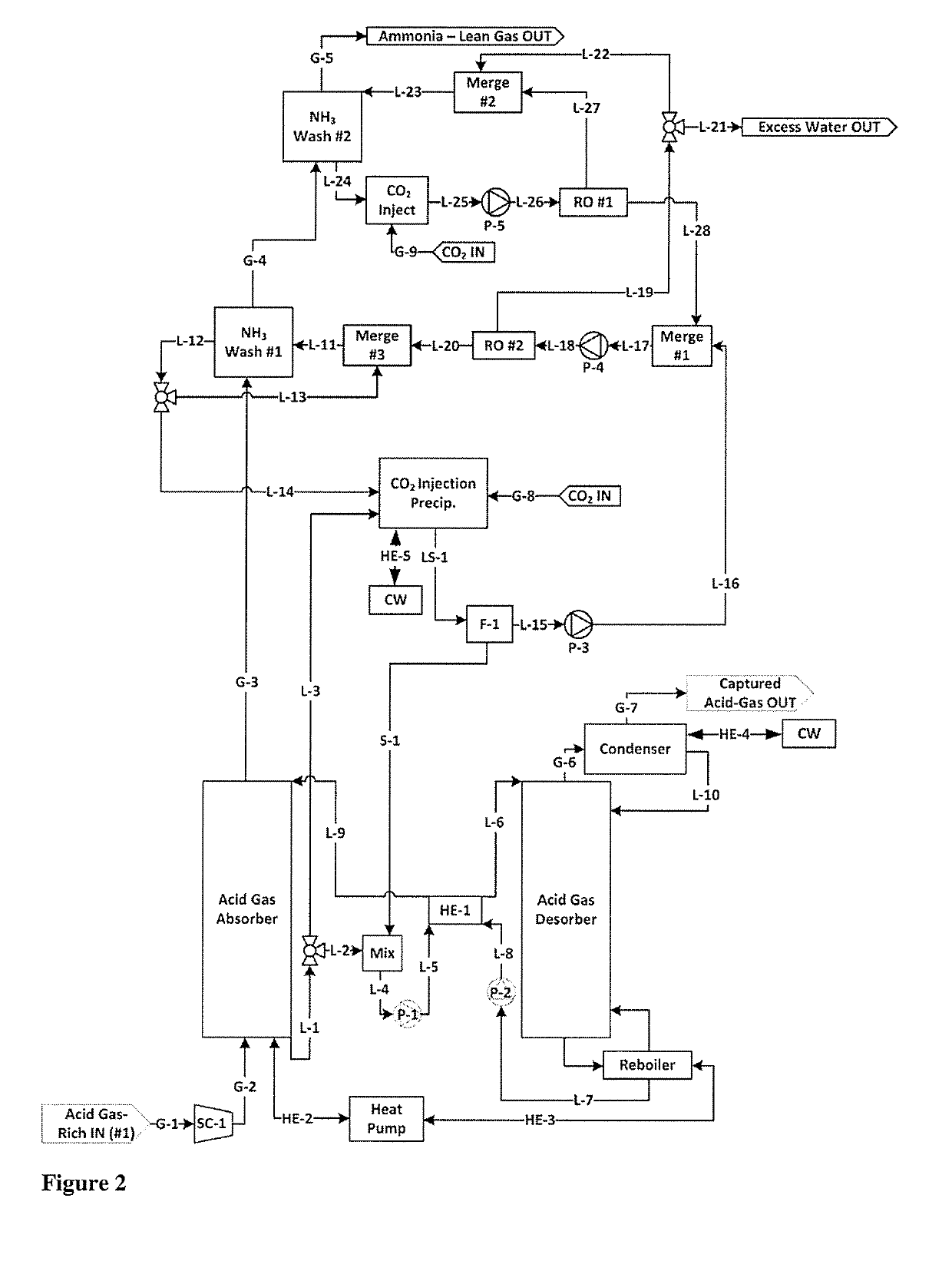

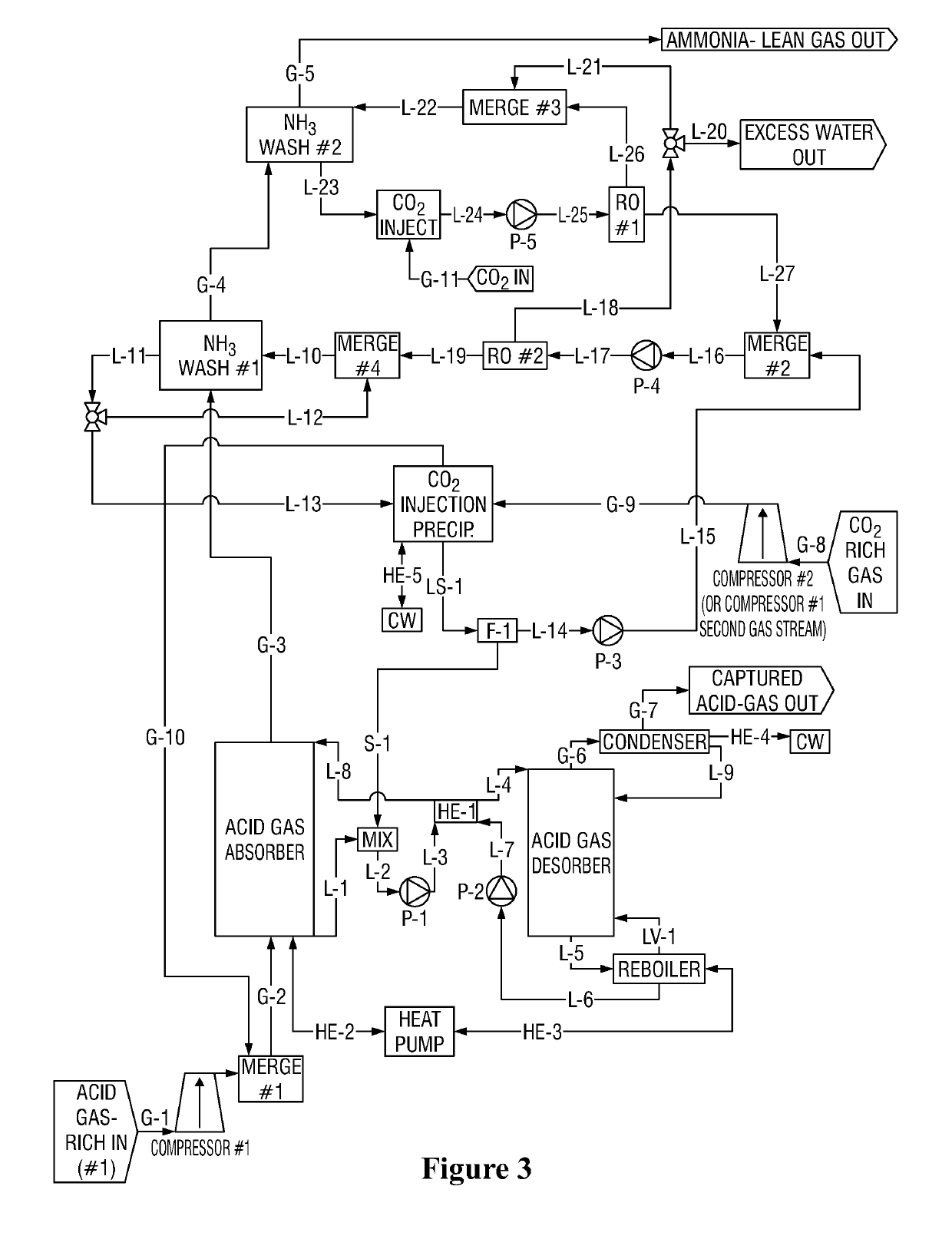

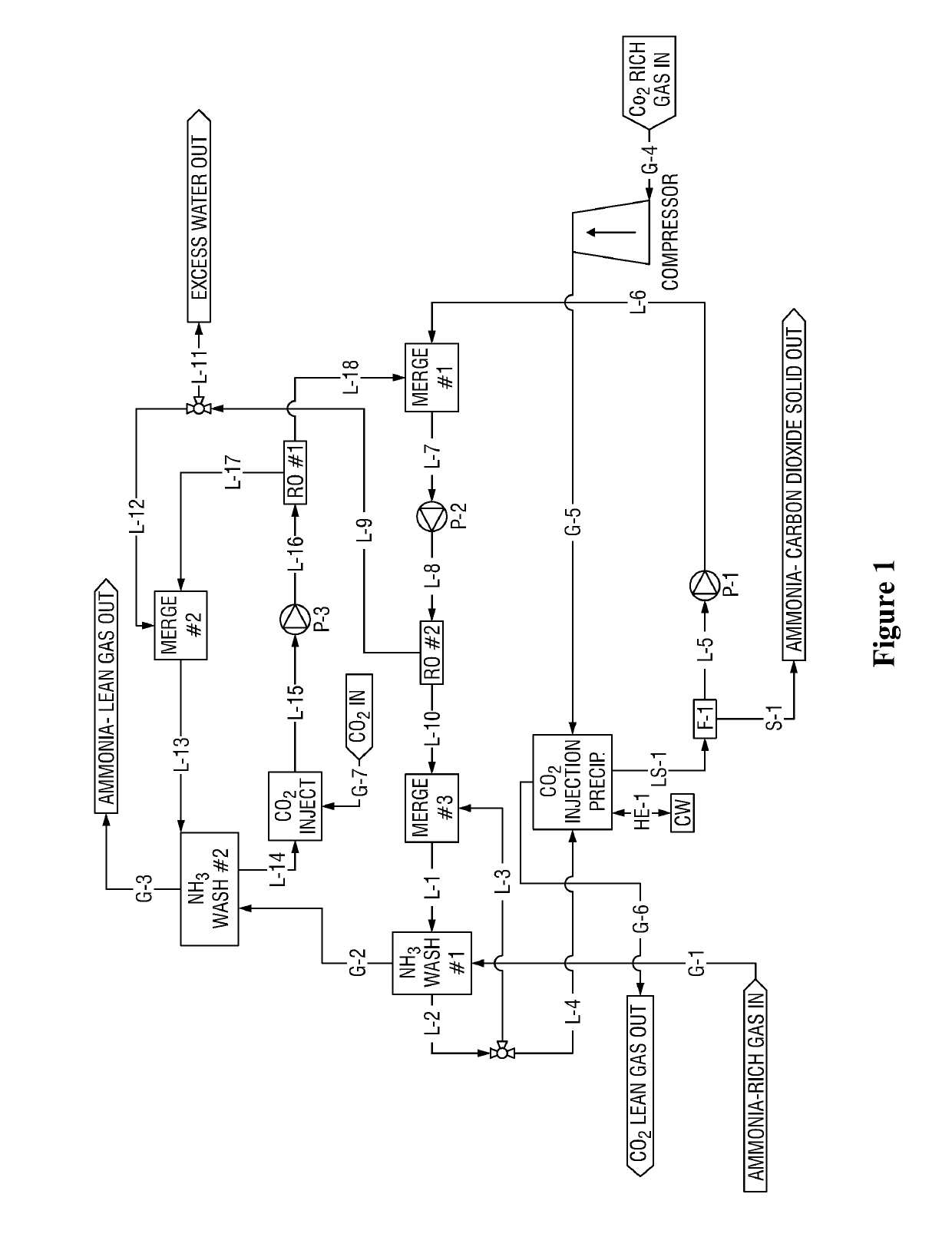

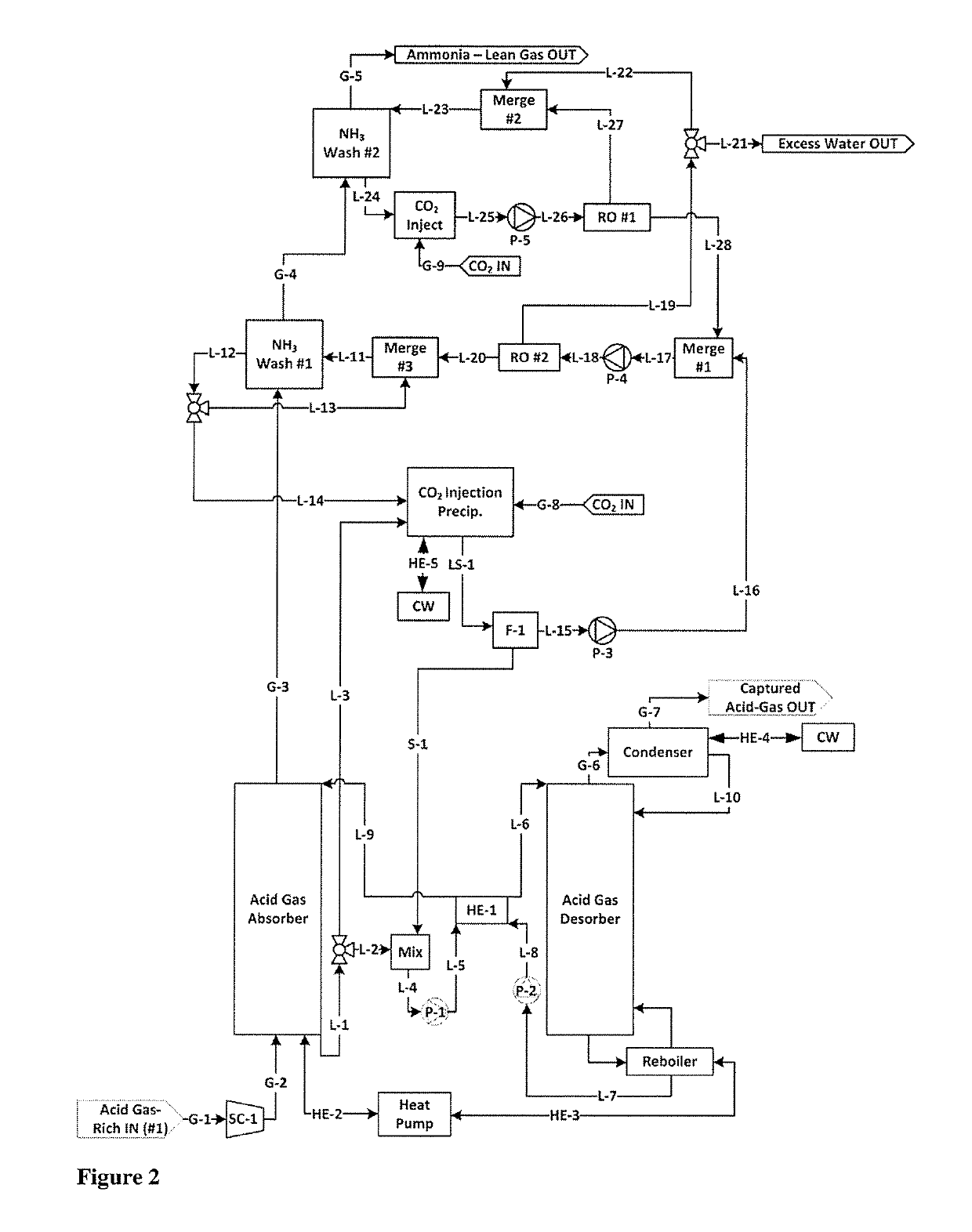

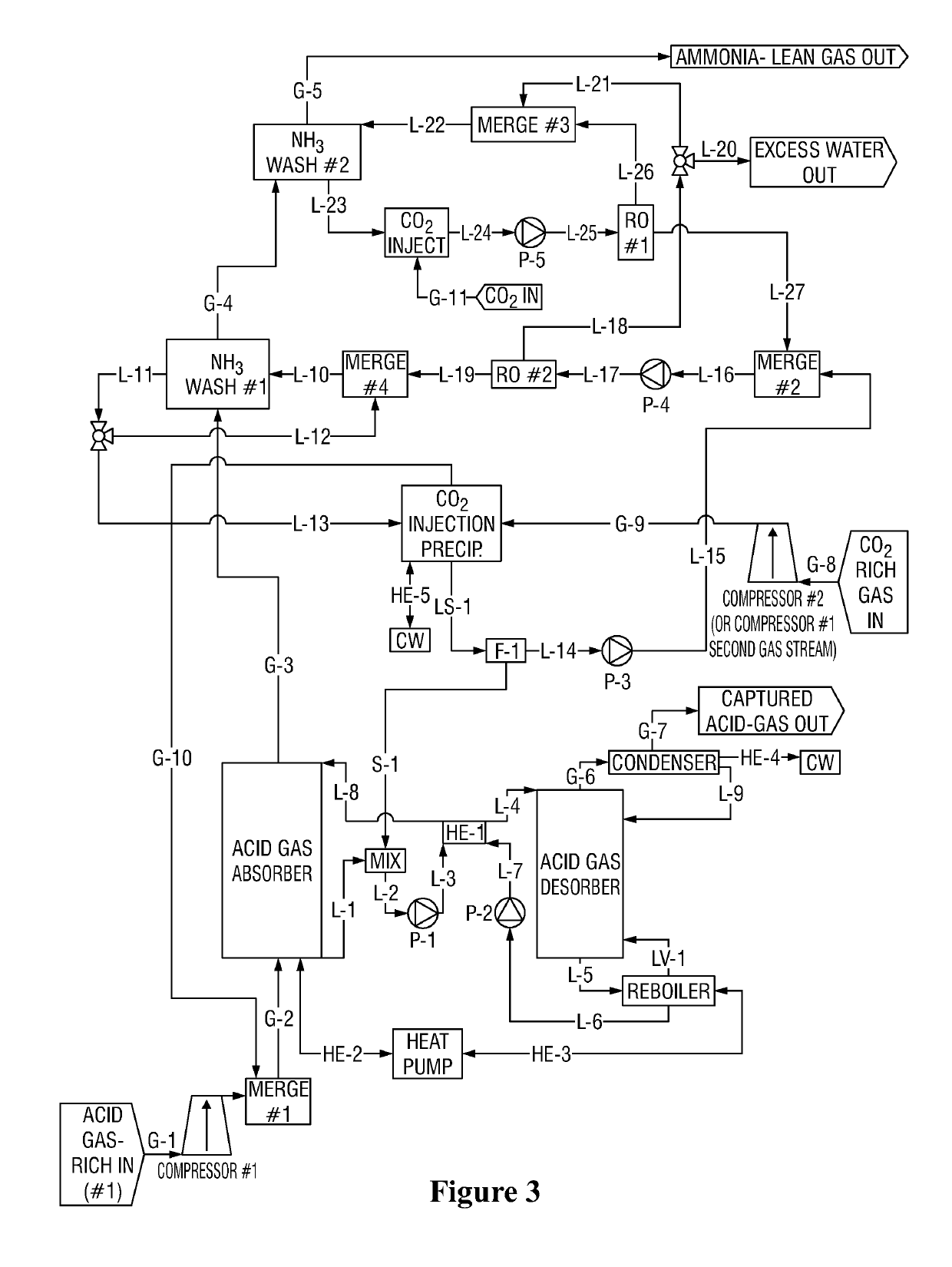

Systems and methods for ammonia recovery, acid gas separation, or combination thereof

ActiveUS20190233296A1Reduce and eliminates challengeFast absorptionProductsMembranesDesorptionReverse osmosis

The present invention relates to processes and systems for ammonia recovery and / or acid-gas separation. In some embodiments, a system for acid gas separation may be integrated with an ammonia abatement cycle employing a high temperature absorber. In some embodiments, a system for acid gas separation may employ a higher temperature absorber due to the lower energy consumption and cost of the integrated ammonia abatement cycle. Advantageously, heat may be recovered from the absorber to power at least a portion of any acid gas desorption in the process. Reverse osmosis or other membranes may be employed.

Owner:INNOVATOR ENERGY LLC

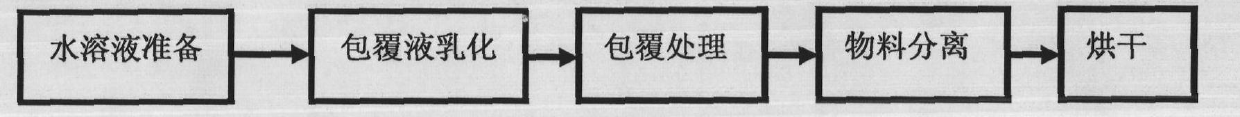

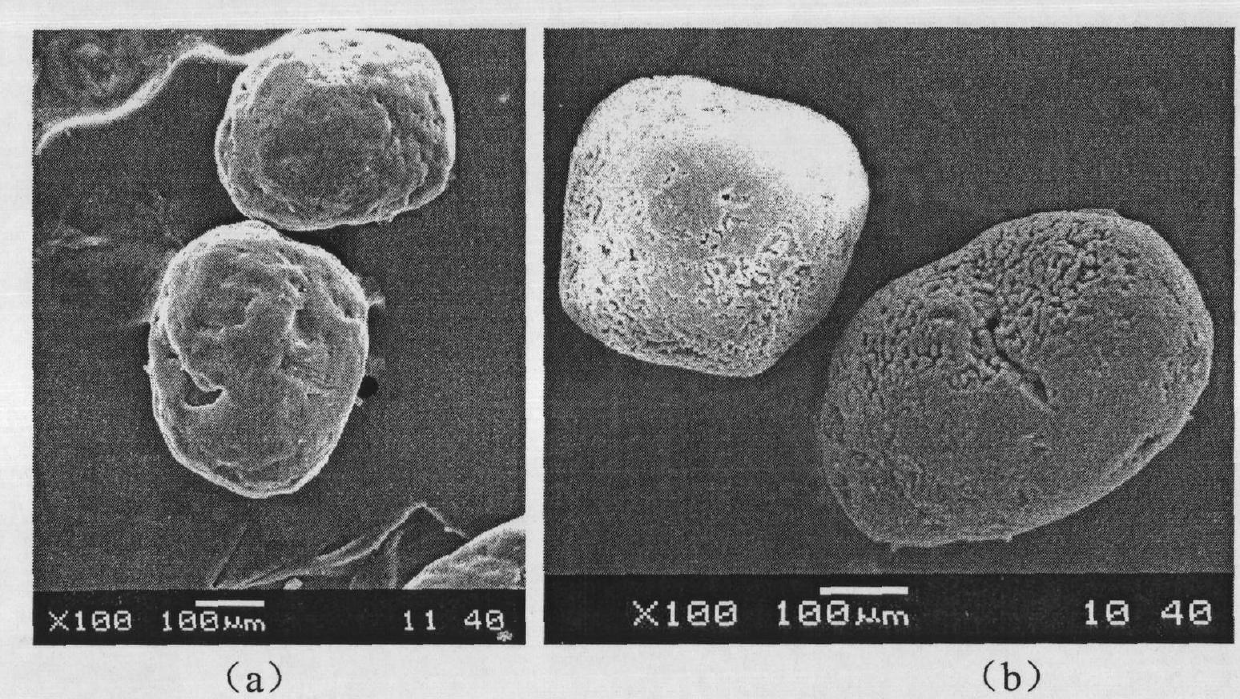

Surface coating method of ammonium salts

InactiveCN102198951AImprove bindingLow moisture absorptionAmmonium salt preparationCoatingsDispersed mediaWater insoluble

The invention relates to a surface coating method of ammonium salts. The method comprises emulsifying a mixture of a disperse medium, an aqueous formaldehyde solution and a silicate solution through a conventional emulsification method to obtain a water in oil type emulsion or a water in oil type microemulsion, adding ammonium salt particles, which need to be coated, into the emulsion or the microemulsion, mixing the ammonium salt particles and the emulsion or the microemulsion at a normal temperature to make a surface of each one of the ammonium salt particles be coated with a uniform and dense coating layer, and treating the resulting products by separating and drying processes to make surfaces of the ammonium salt particles be coated with water-insoluble silica coating layers. Comparedwith other physical coating methods, the method provided by the invention has the characteristics of uniform and dense coating layer, no agglomeration between particles and controllability of a coating thickness, and a moisture rate of a sample coated through the method provided by the invention is far lower than moisture rates of samples coated through other methods.

Owner:NANJING UNIV OF SCI & TECH

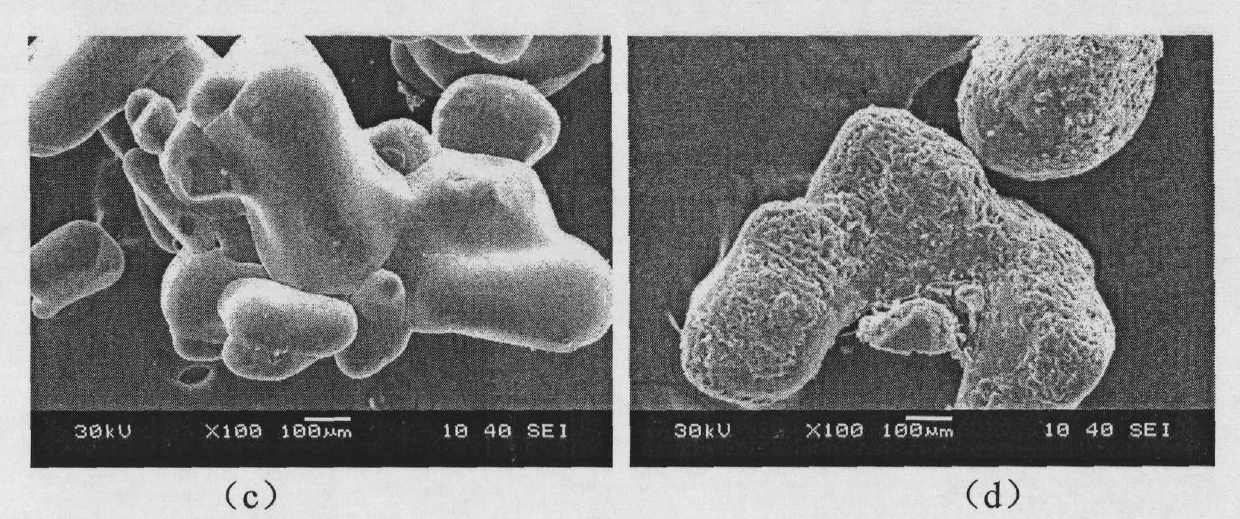

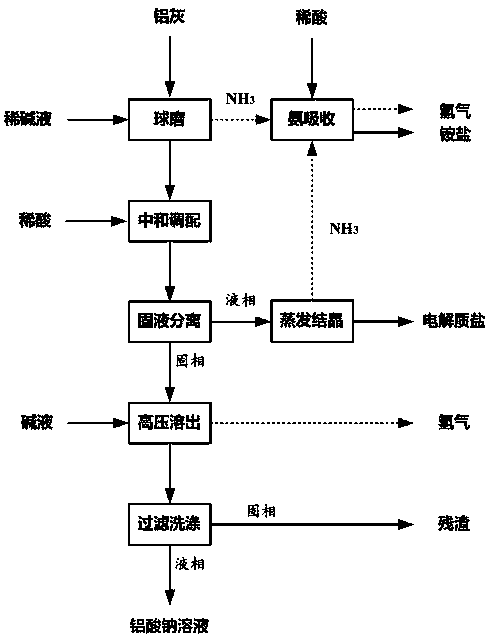

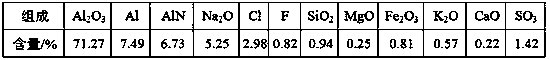

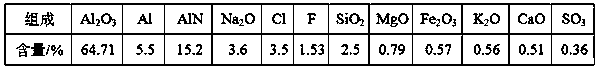

Method for efficiently recycling valuable element in aluminum ash

ActiveCN110217810AEasy to separateEfficient recyclingAmmonium salt preparationHydrogen productionSodium aluminateSlurry

The invention discloses a method for efficiently recycling valuable elements in aluminum ash. The method comprises the following steps: carrying out wet grinding on aluminum ash and water or sig water, adjusting the pH value of slurry to be neutral, and carrying out solid-liquid separation so as to respectively obtain desalting deamination aluminum ash and a salt solution; carrying out evaporationcrystallization treatment on the salt solution so as to obtain an electrolyte salt product, adding the desalting deamination aluminum ash and an alkali liquid into a high-pressure reaction kettle according to a certain liquid-solid ratio, and carrying out a hydrothermal reaction, wherein a certain amount of hydrogen is generated in the reaction process; carrying out solid-liquid separation on theobtained slurry, so as to obtain a sodium aluminate solution and dissolved residues, wherein the sodium aluminate solution can be adopted to product an aluminum oxide or aluminum hydroxide product, and the residues can be used as a construction raw material. Due to desalting deamination treatment on the aluminum ash, nitrogen and electrolyte salt components in the aluminum ash can be sufficientlyrecycled, an inert aluminum oxide component in the aluminum ash can be efficiently dissolved in a high-pressure dissolution mode, efficient recycling of valuable elements in the aluminum ash is achieved, and a novel way is created for recycling of solid wastes such as the aluminum ash generated in industries such as electrolyte aluminum and aluminum processing.

Owner:郑州中科新兴产业技术研究院 +1

Integral treatment method for waste water of acephate producing process

InactiveCN101215063AEmission reductionReasonable processAmmonium salt preparationMultistage water/sewage treatmentTemperature controlAcetic acid

The invention relates to a sewage water treating method, in particular to a comprehensive treatment method of sewage water of n-acetoacetyl methylamine production. The invention is characterized in that adding acid into the sewage water of n-acetoacetyl methylamine production with the temperature controlled between 0-100 DEG C, adjusting pH value to 0.5-9, then distilling and crystallizing at the temperature between 50-150 DEG C and separating out dilute acetic acid and inorganic ammonium salt. The invention has the advantages of reasonable process flow, convenient operation and low disposal cost. Employing the invention technique can increase benefit, also can reduce the discharging capacity of the contaminant and meet the environmental protection need of clean production and energy saving and discharge reducing, thereby the invention has important value of popularization and application.

Owner:荆州沙隆达控股有限公司

Gaseous Ammonia Removal System

ActiveUS20110229403A1Lower Level RequirementsGas treatmentOrganic compound preparationGaseous ammoniaNH3 compound

A system and method for passive capture of ammonia in an enclosure containing material that gives off ammonia. The invention allows for the passage of gaseous NH3 through microporous hydrophobic gas-permeable membranes and its capture in a circulated acidic solution with concomitant production of a concentrated non-volatile ammonium salt.

Owner:US SEC AGRI

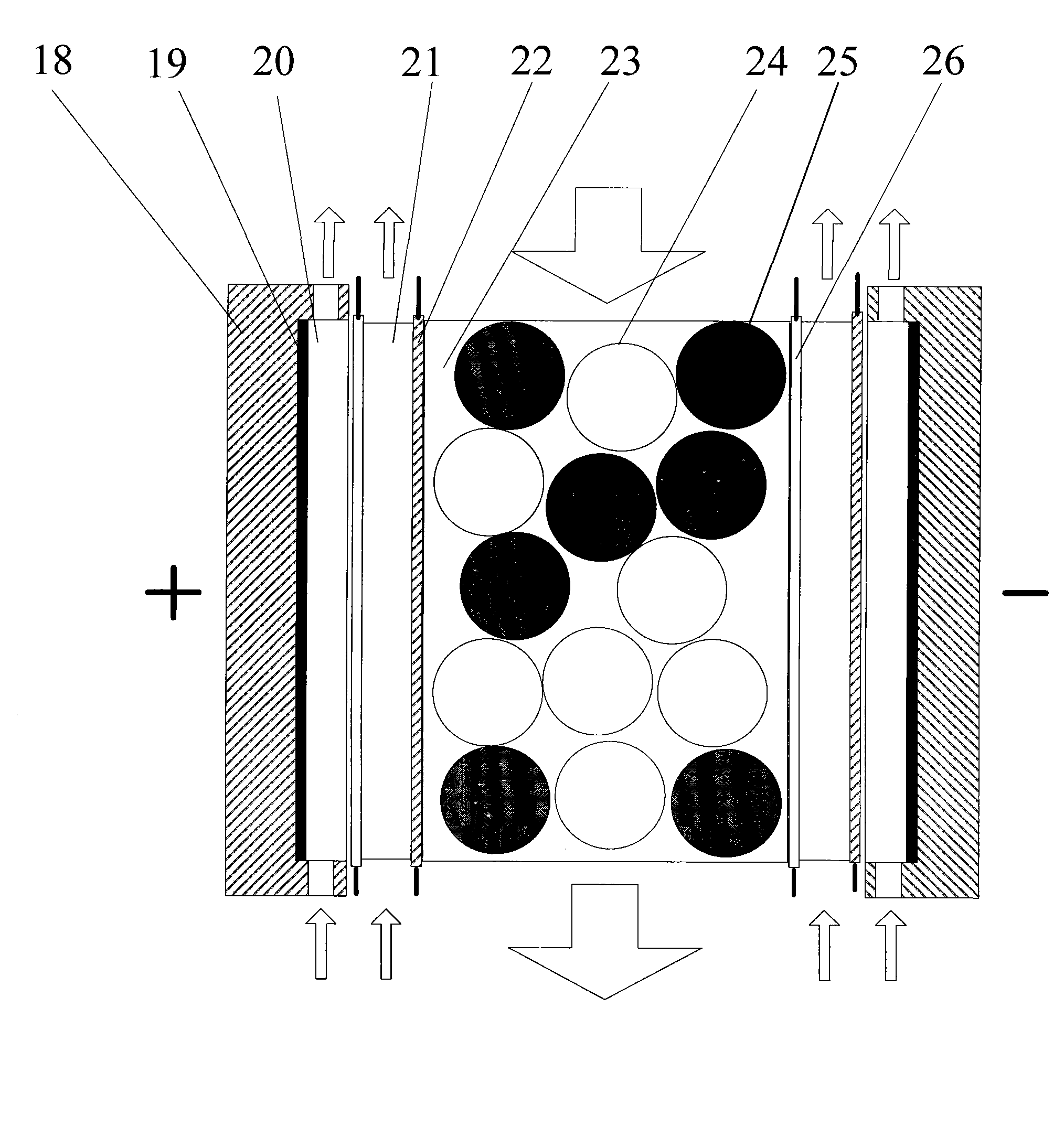

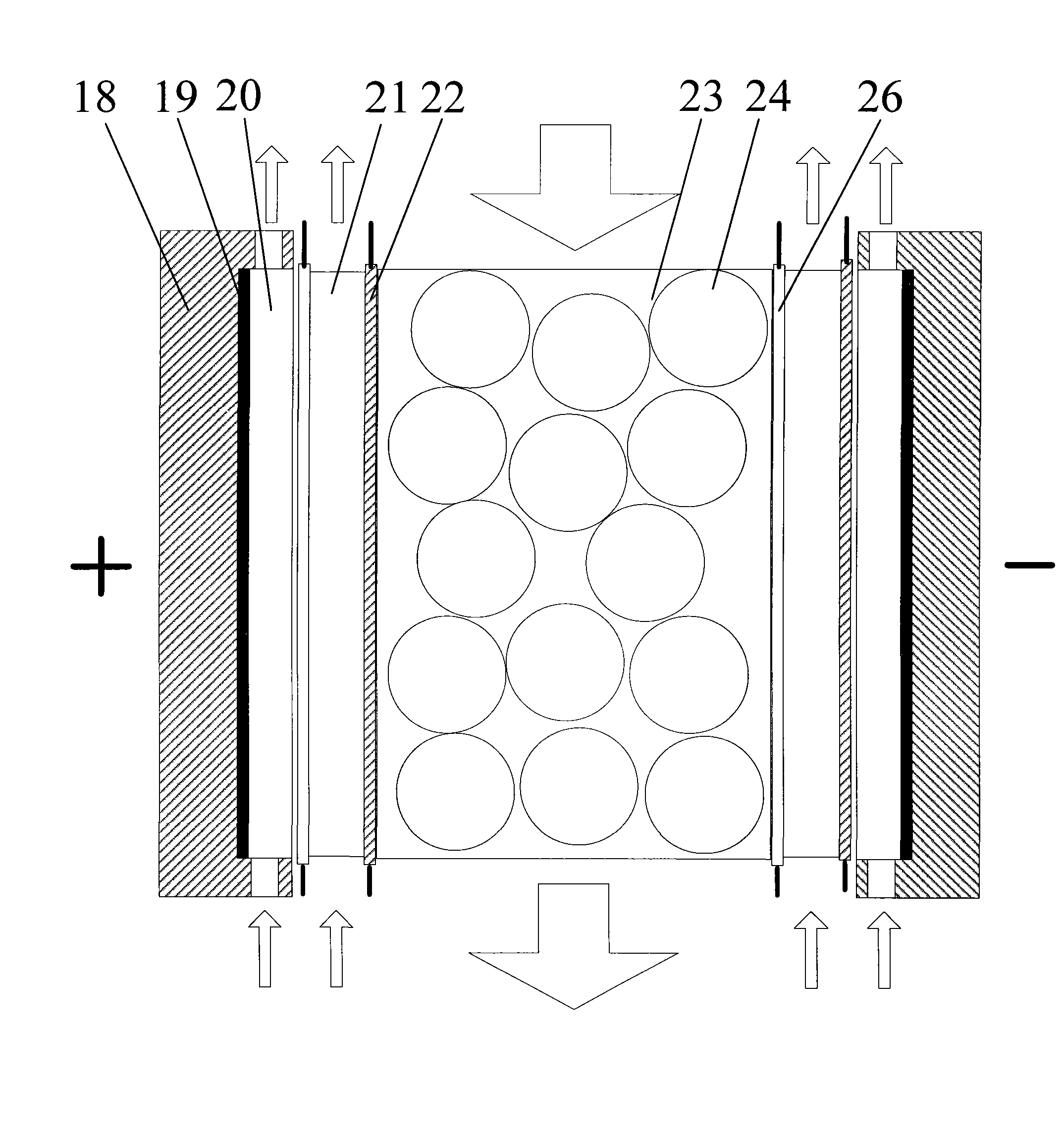

Electro-deionization method and electro-deionization device for recycling ammonia nitrogen waste water

ActiveCN101648738ASimple processReduce processing costsDispersed particle separationAmmonium salt preparationAmmoniacal nitrogenEnvironmental engineering

The invention discloses an electro-deionization method and an electro-deionization method for recycling ammonia nitrogen waste water, wherein the electro-deionization method comprises the following steps: a plurality of modules which are connected in series or in parallel are selected to form a set of electro-deionization device according to the water quantity of waste water to be processed and the mass concentration of ammonium salt of the waste water, wherein inlet water of the device is ammonia nitrogen waste water that is preprocessed and accordant with requirements, producing water is process pure water, does not contain nitrogen-containing compounds and can be recycled; in addition, ammonium salt thickening solution is obtained by a thick water circulated thickening method, and the mass concentration of the ammonium salt reaches an expected requirement of 1-25 percent; and the thickening solution is evaporated, concentrated and crystallized to obtain the solid ammonia nitrogen product. The invention not only can reach the zero emission requirement of the system, but also simultaneously recycle the ammonium salt thickening solution and the process pure water. The invention hasadvanced process, low cost, low energy consumption and simple operation.

Owner:王方

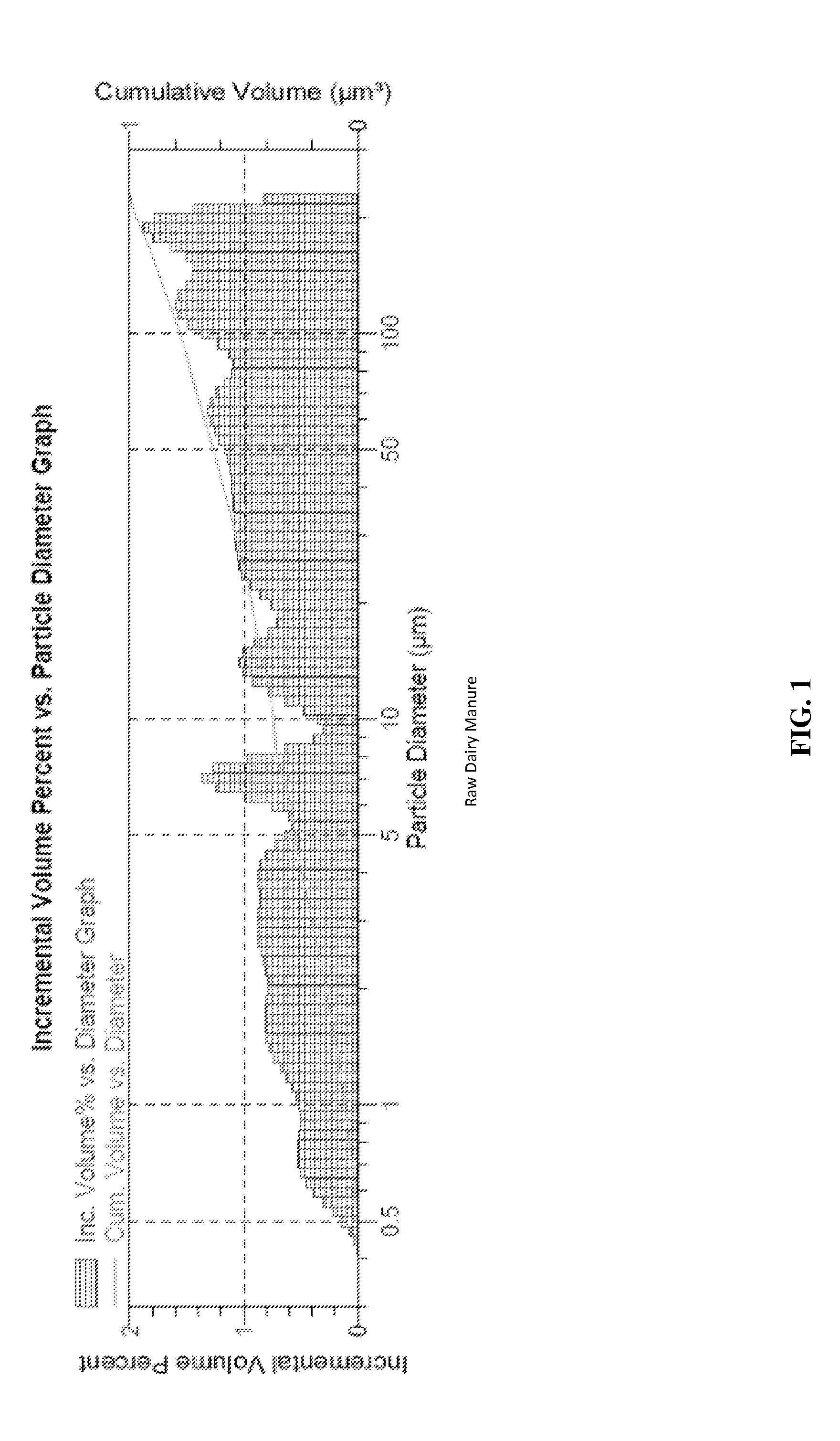

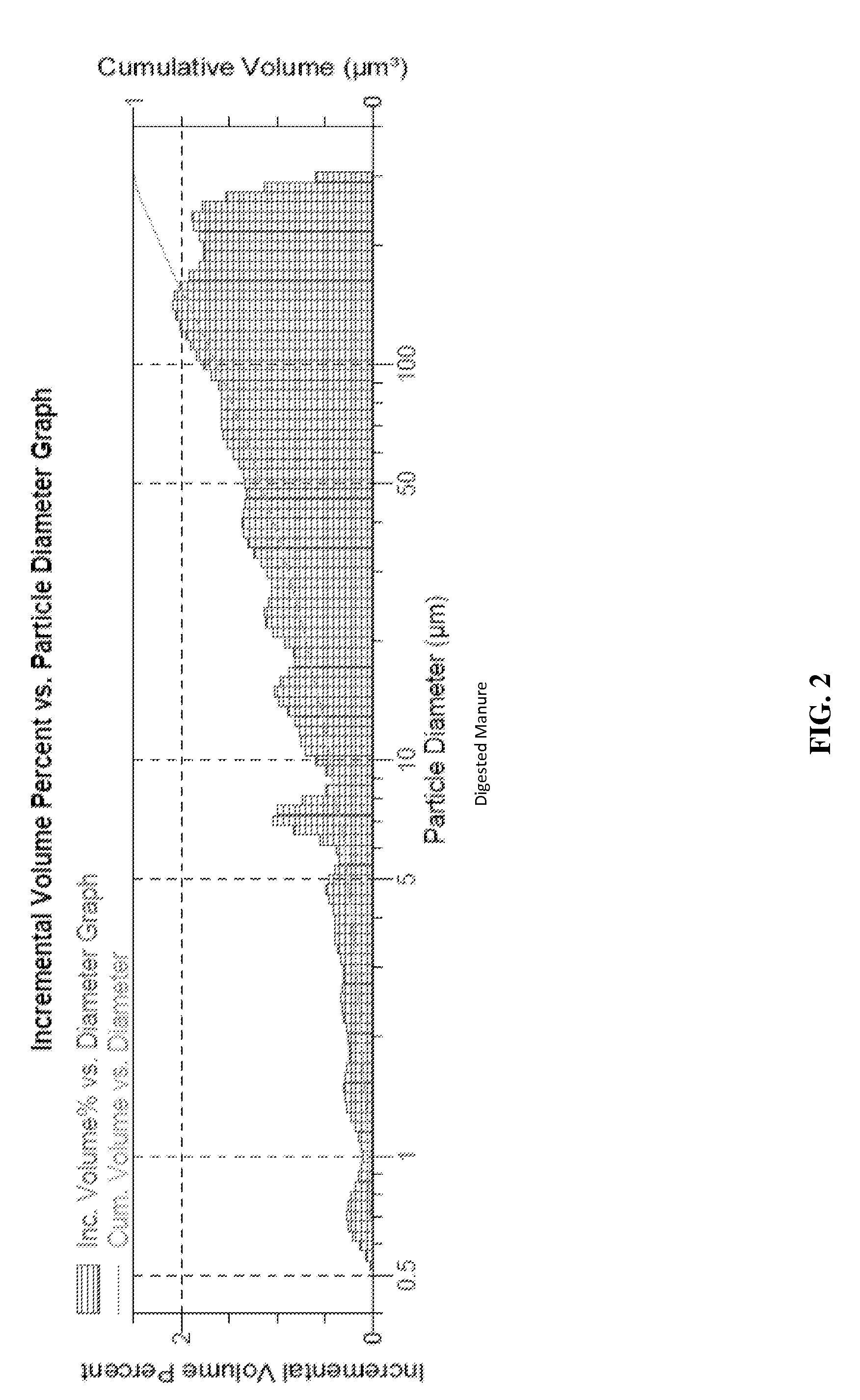

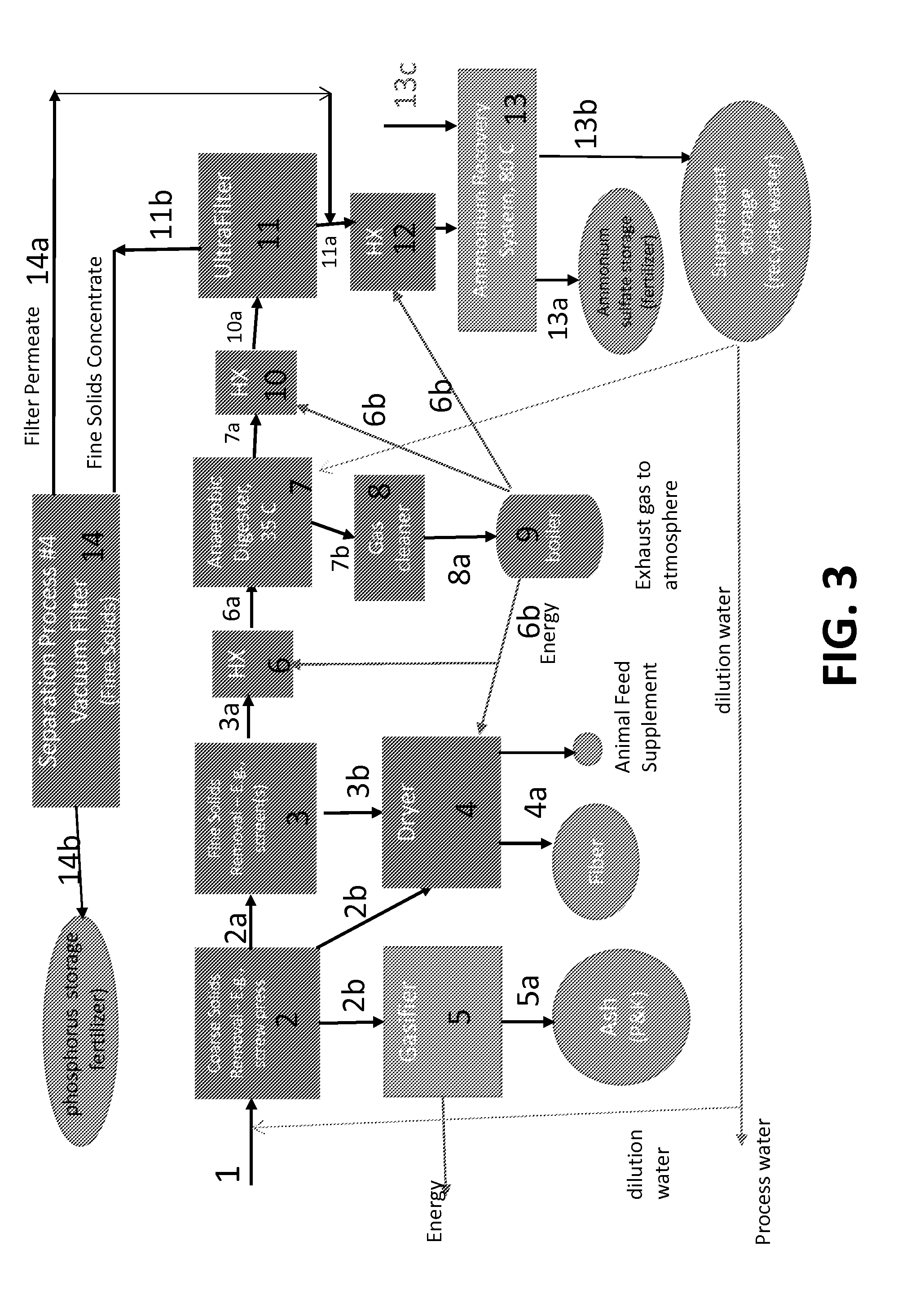

Wastewater treatment using controlled solids input to an anaerobic digester

InactiveUS20150008181A1Accelerated destructionEasily damagedExcrement fertilisersWaste water treatment from animal husbandryChemical treatmentDisposal waste

The present invention is a system and process for livestock waste management that operates more efficiently than existing technologies with less maintenance and with less chemical process components (and thus chemical handling) with recovery of useful end products. The invention comprises solids separation of the waste to remove solids in excess of about 0.50 mm in size prior to anaerobic digestion followed directly by solids separation preferably using an ultra filter and then ammonia recovery.

Owner:BION ENVIRONMENTAL TECH

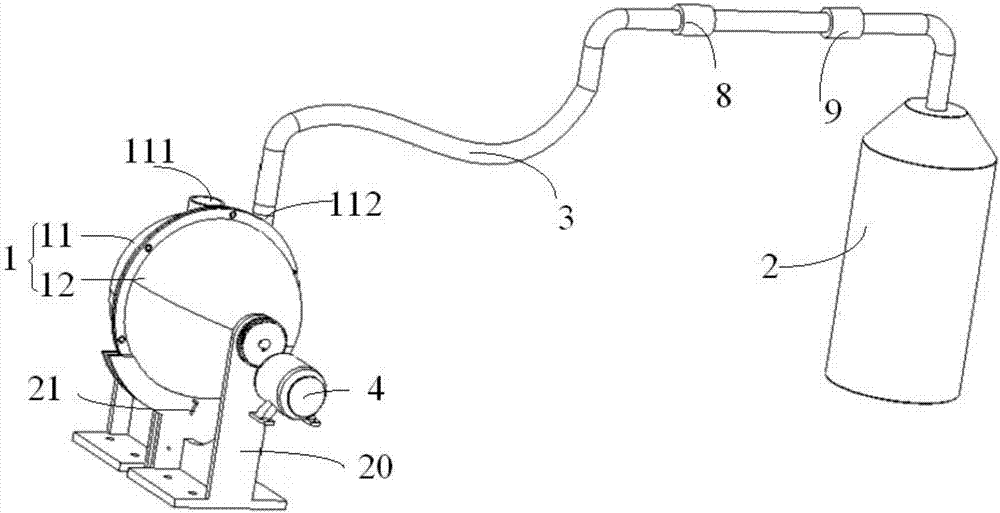

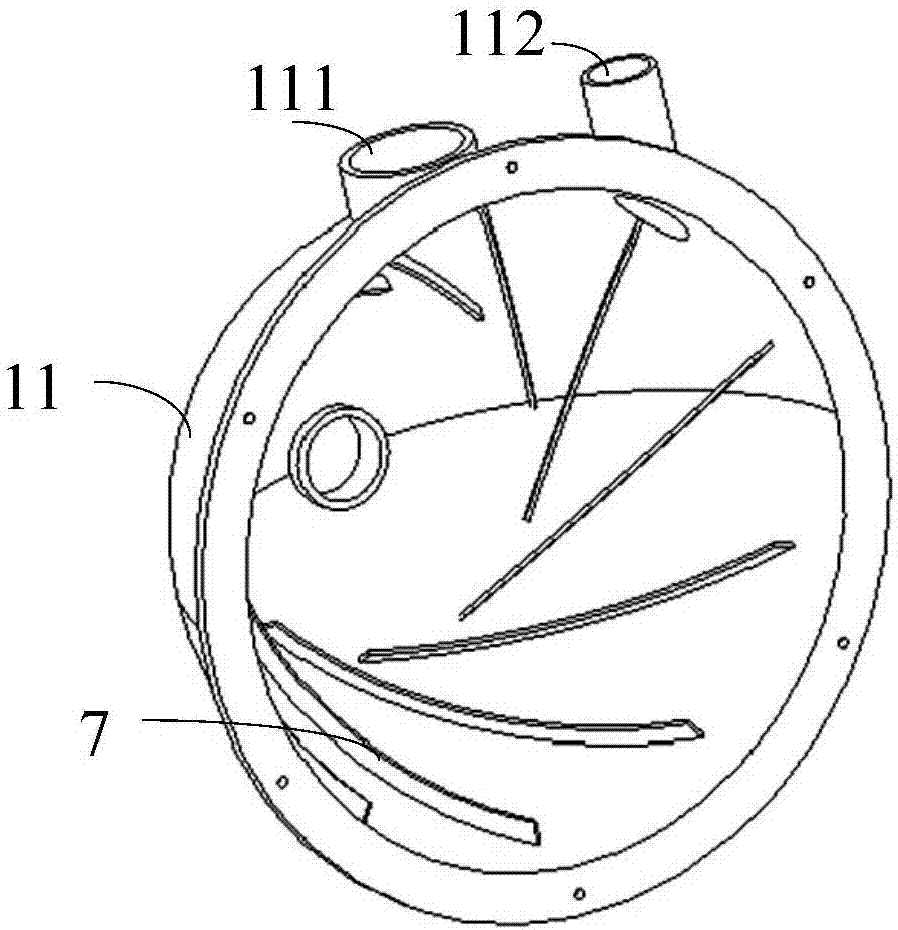

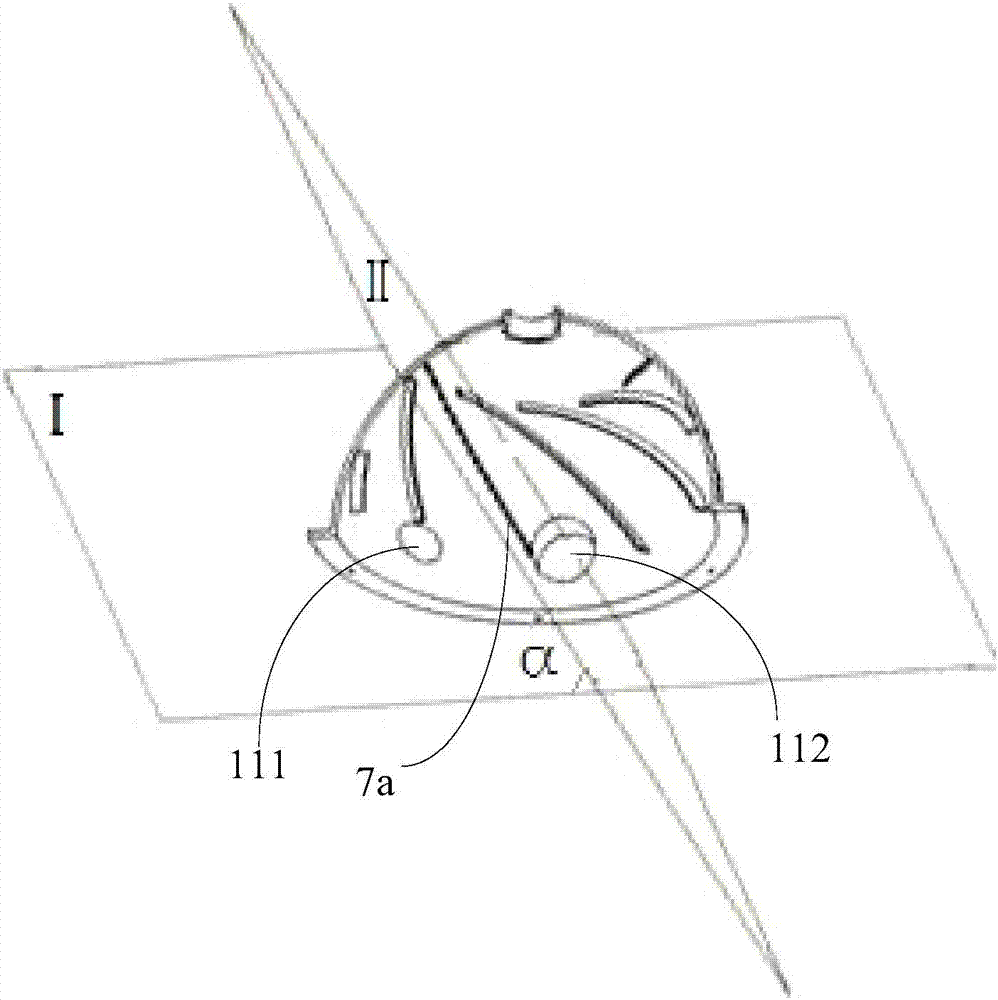

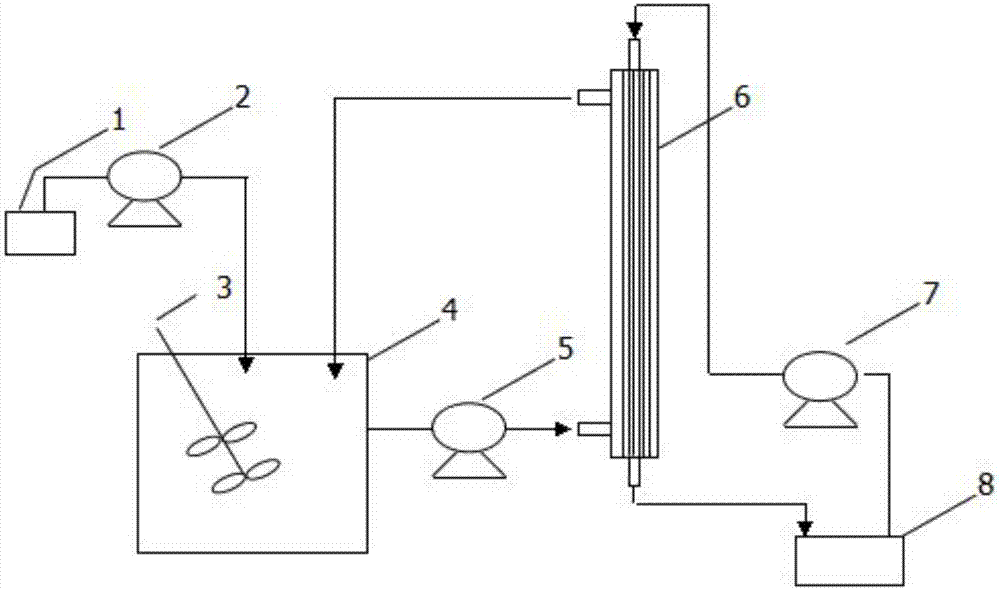

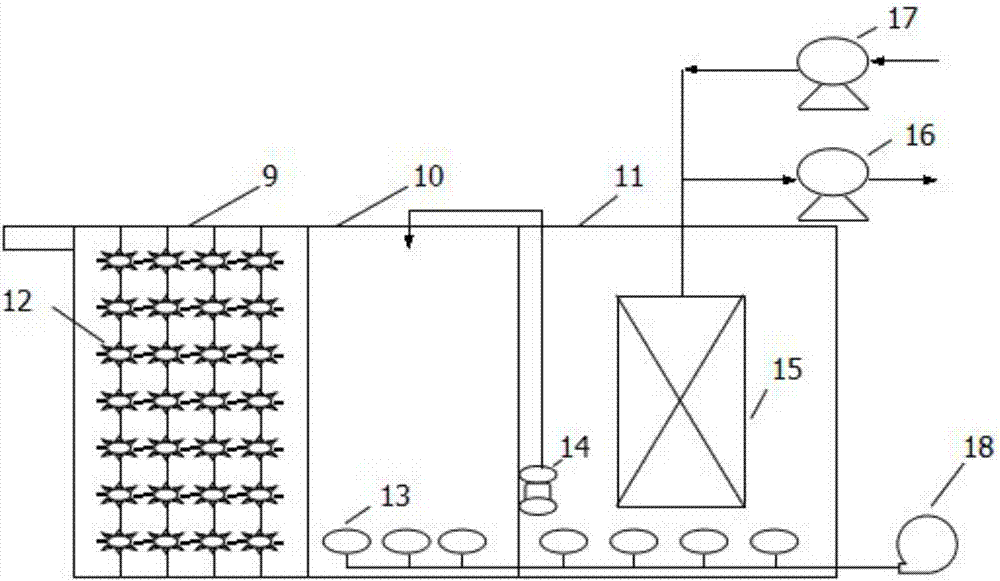

Device for recovering nitrogen element in aluminum ash

ActiveCN106861581ASolve the problem of irritating odorEfficient recyclingDispersed particle separationAmmonium salt preparationNitrogenProcess engineering

The invention discloses a device for recovering nitrogen element in aluminum ash. The device comprises a reaction kettle and an absorption tower, wherein the reaction kettle communicates with the absorption tower by means of a pipe for collecting ammonia gas. The device for recovering nitrogen element in aluminum ash, provided by the invention, is characterized in that: the aluminum ash is hydrolyzed in the reaction kettle to generate ammonia gas, and the ammonia gas is transported via a pipe and collected by the absorption tower, so that the nitrogen element in the aluminum ash is recovered to an utmost extent, pollution of the aluminum ash on the environment in the later processing course is avoided, and harmless, recycled and beneficial treatment of the aluminum ash is achieved.

Owner:NANTONG UNIVERSITY

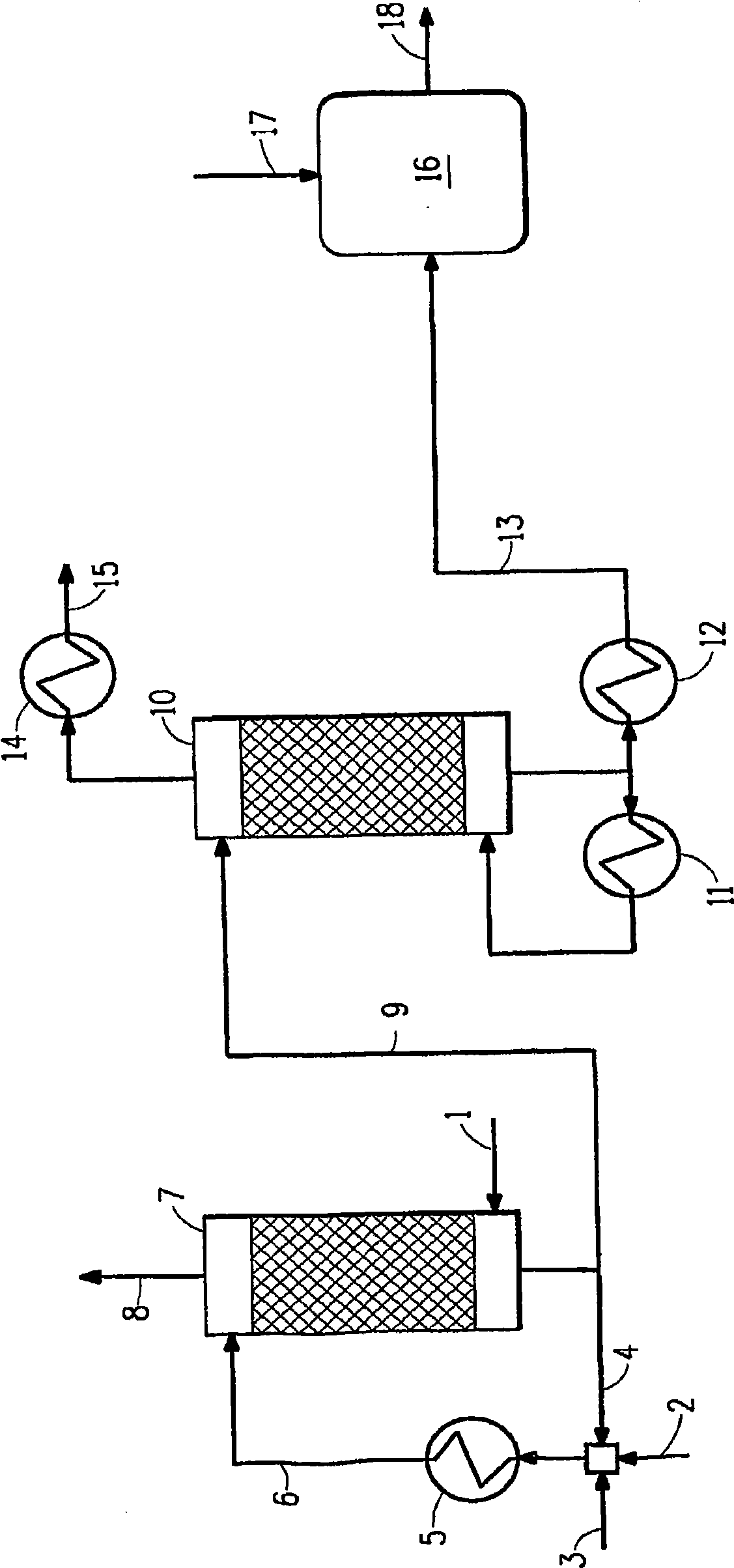

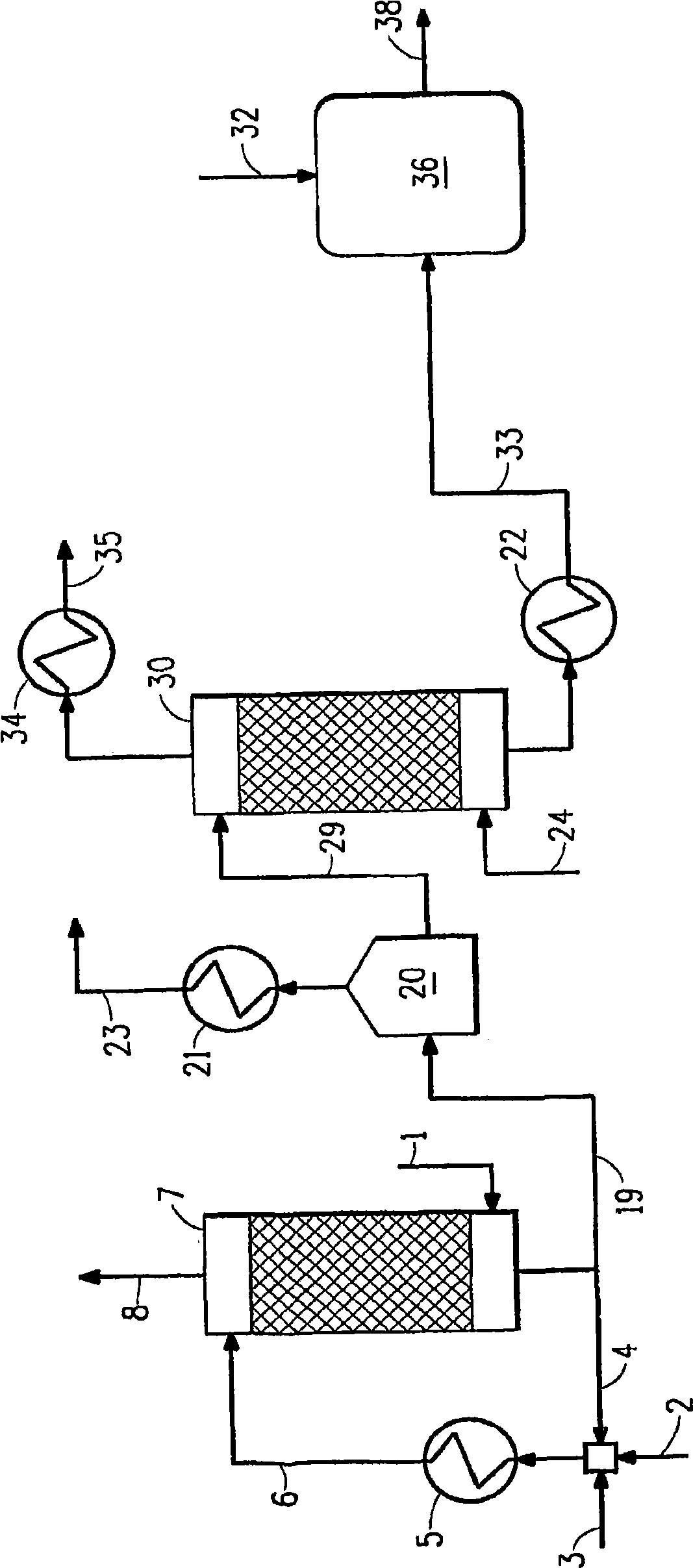

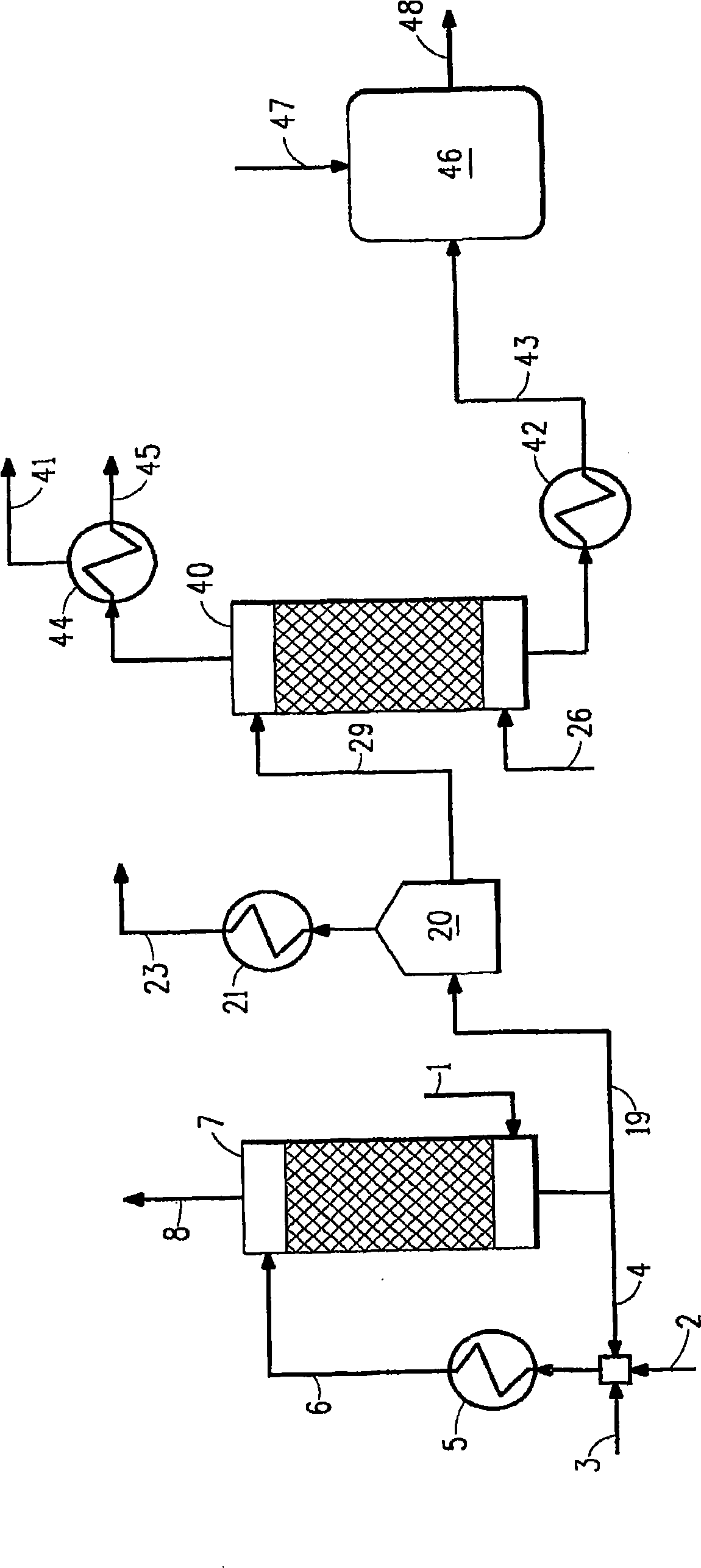

Treatment method of an aqueous solution containing urea, ammonia and carbon dioxide and treatment equipment therefor

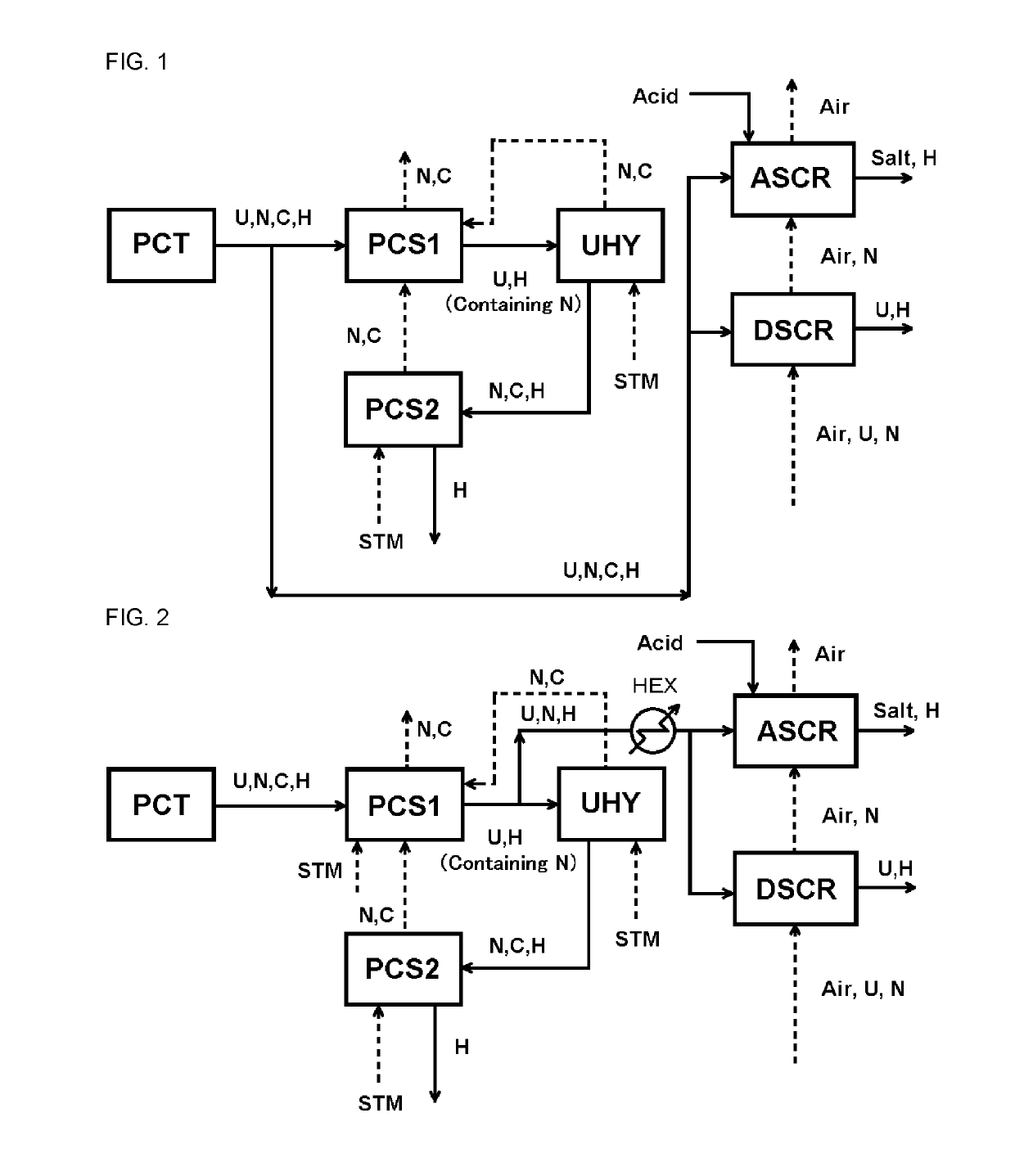

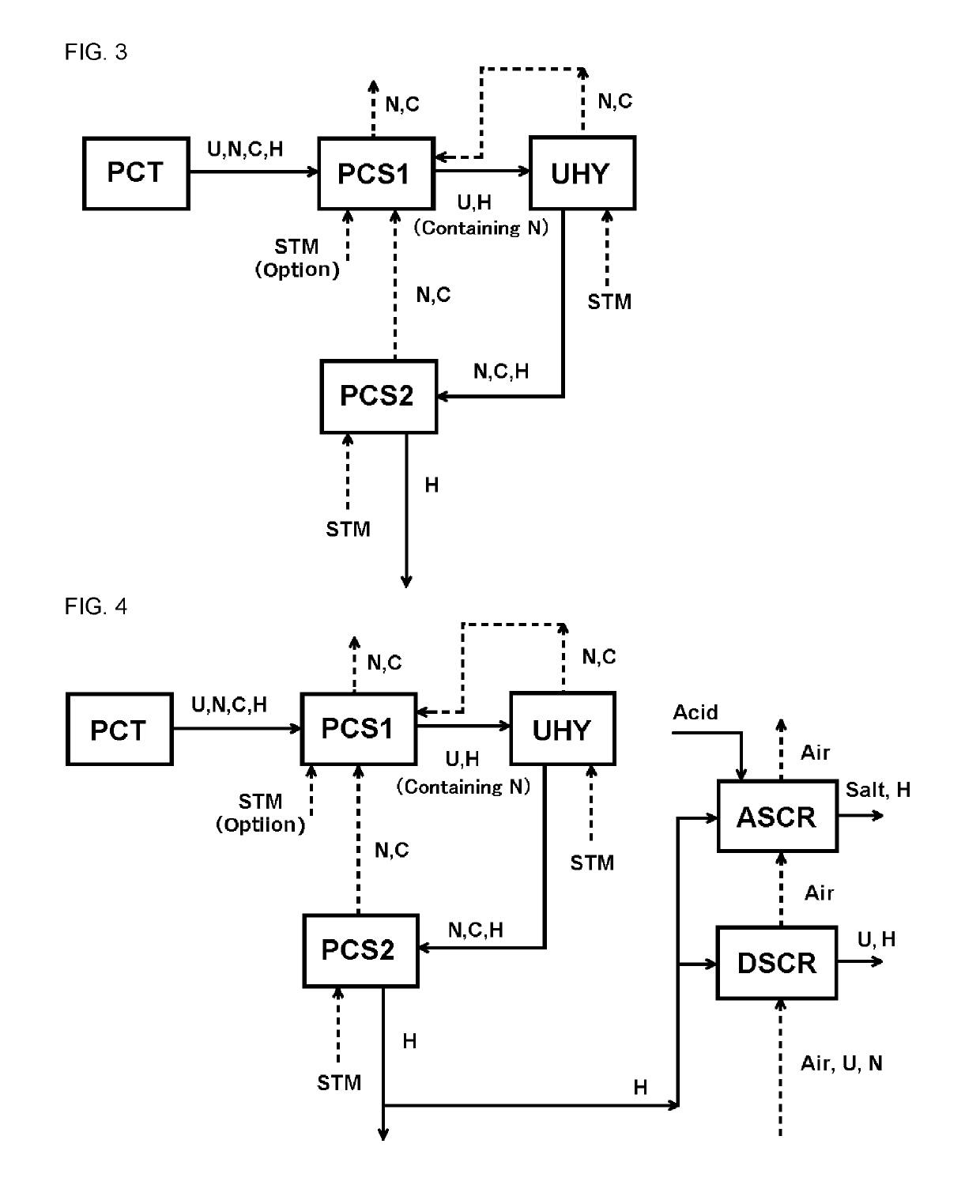

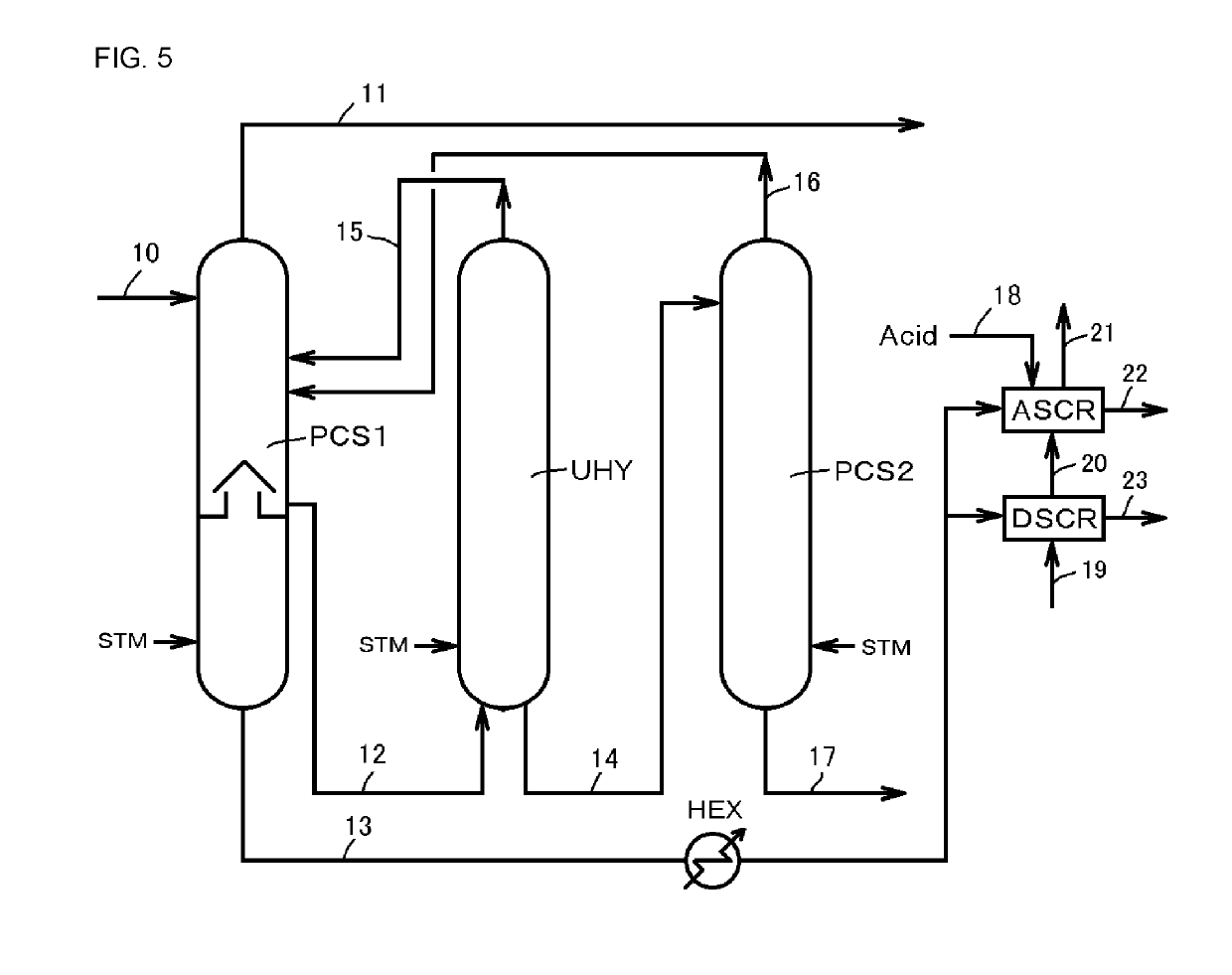

ActiveUS20190177180A1Reduce loadAmount of heating steam supplied to the urea hydrolyzer can be savedUrea derivatives preparationLiquid degasification with auxillary substancesAqueous solutionAmmonia

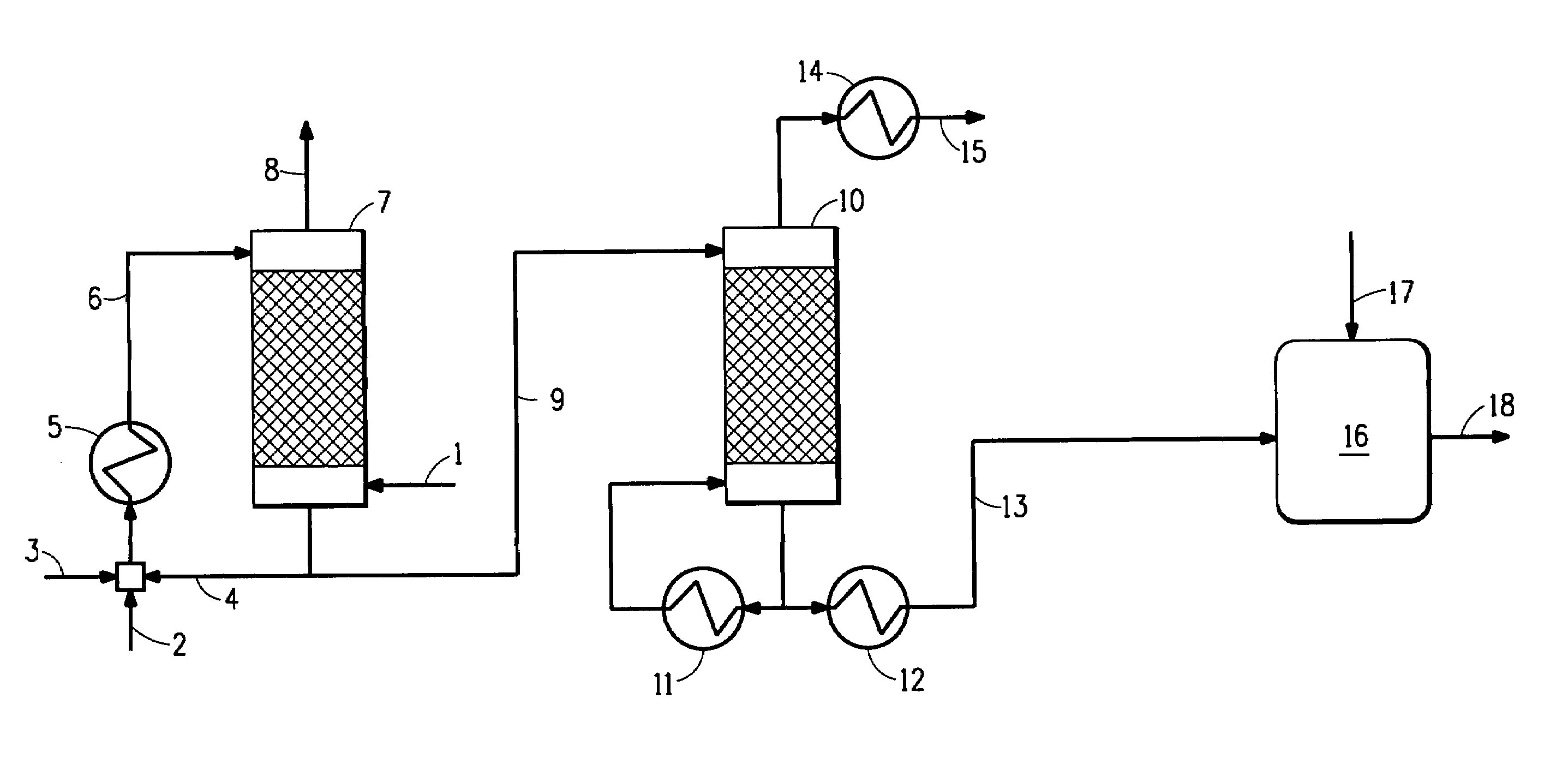

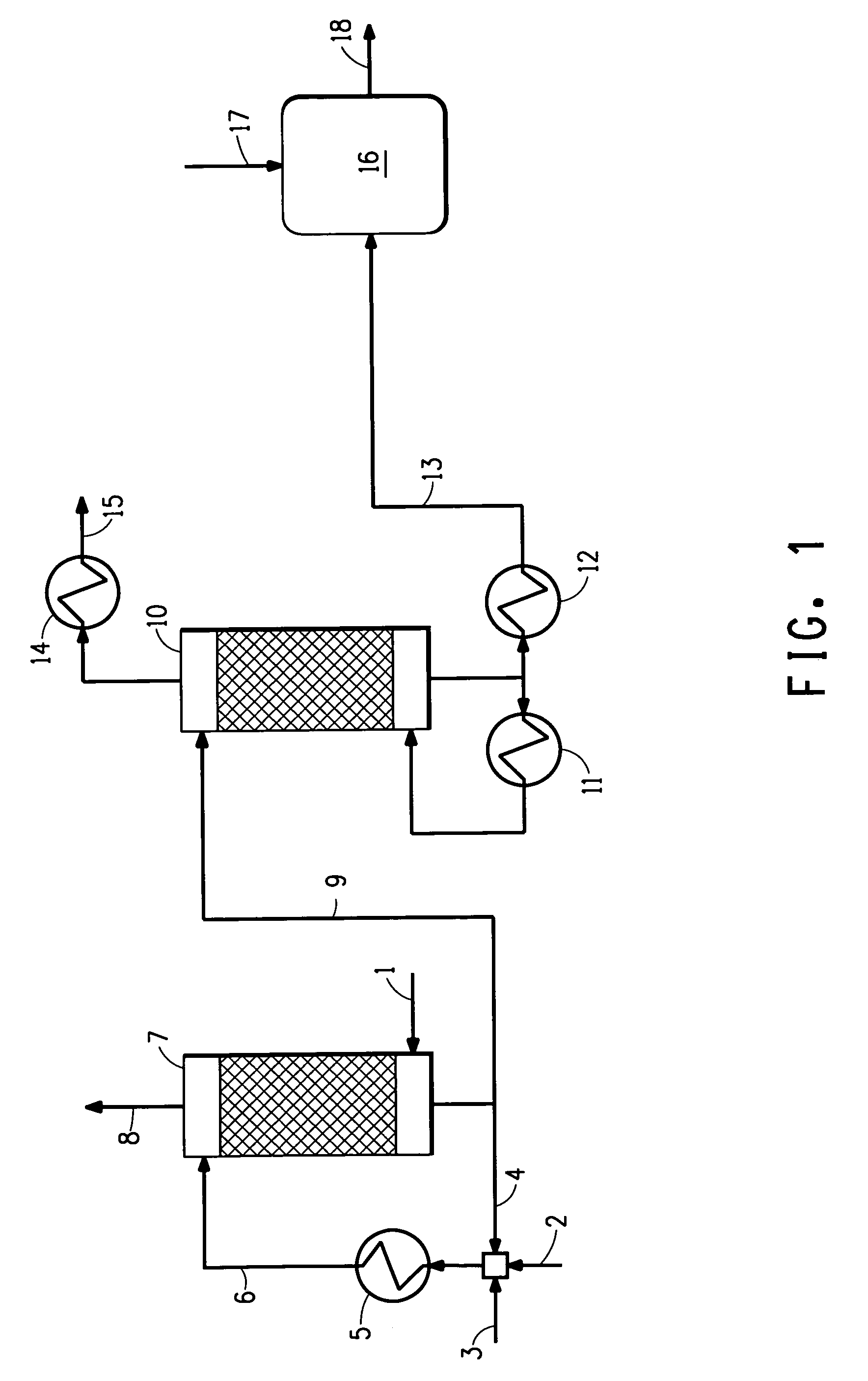

Disclosed are: a treatment method comprising (1) a step in which an aqueous solution containing urea, ammonia and carbon dioxide is introduced into a first stripper (PCS1) and subjected to stripping, and the aqueous solution after stripping is introduced into a urea hydrolyzer (UHY), (2) a step in which urea in the aqueous solution is hydrolyzed in the urea hydrolyzer (UHY), and the aqueous solution after hydrolysis is introduced into a second stripper (PCS2), (3) a step in which the aqueous solution is subjected to stripping in the second stripper (PCS2), and (4) a step in which a part of the aqueous solution before being stripped in the first stripper (PCS1), and / or, a part of the aqueous solution after being stripped in the first stripper (PCS1) but before being hydrolyzed in the urea hydrolyzer (UHY) is introduced into an exhaust gas treatment equipment equipped with an ammonia scrubbing equipment (ASCR); and a treatment equipment therefor.

Owner:TOYO ENG CORP

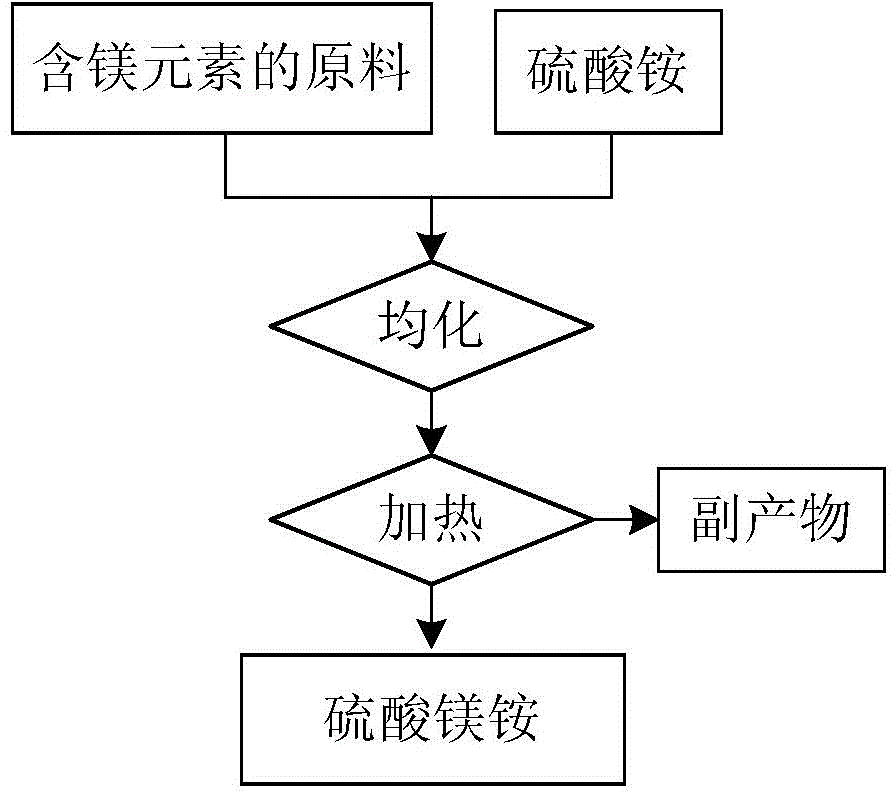

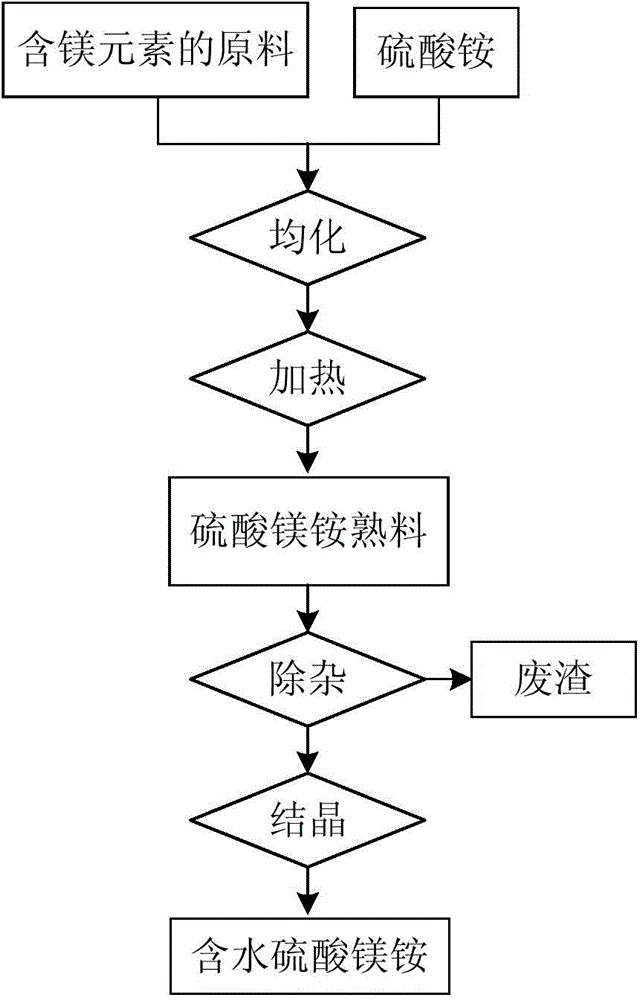

Ammonium magnesium sulfate preparation method

InactiveCN104803400AOmit the water removal stepShort reaction processAmmonium carbonates/bicarbonatesAmmonium salt preparationThermal insulationImpurity

The present invention relates to an ammonium magnesium sulfate preparation method, which comprises: mixing a magnesium-containing raw material and ammonium sulfate, heating, carrying out thermal insulation, and reacting to obtain the ammonium magnesium sulfate, optionally, carrying out impurity removing, crystallization and other steps after completing the reaction to obtain the ammonium magnesium sulfate. The present invention provides a solid-phase ammonium magnesium sulfate preparation method, wherein the reaction process is performed without water, such that the water consumption is saved, the water removing step is eliminated, and the new way for preparing the ammonium magnesium sulfate is provided.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

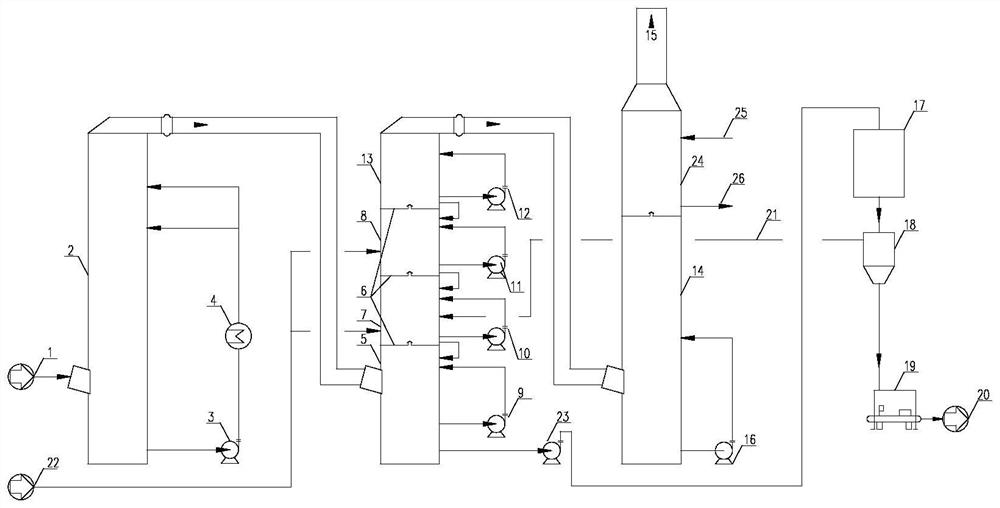

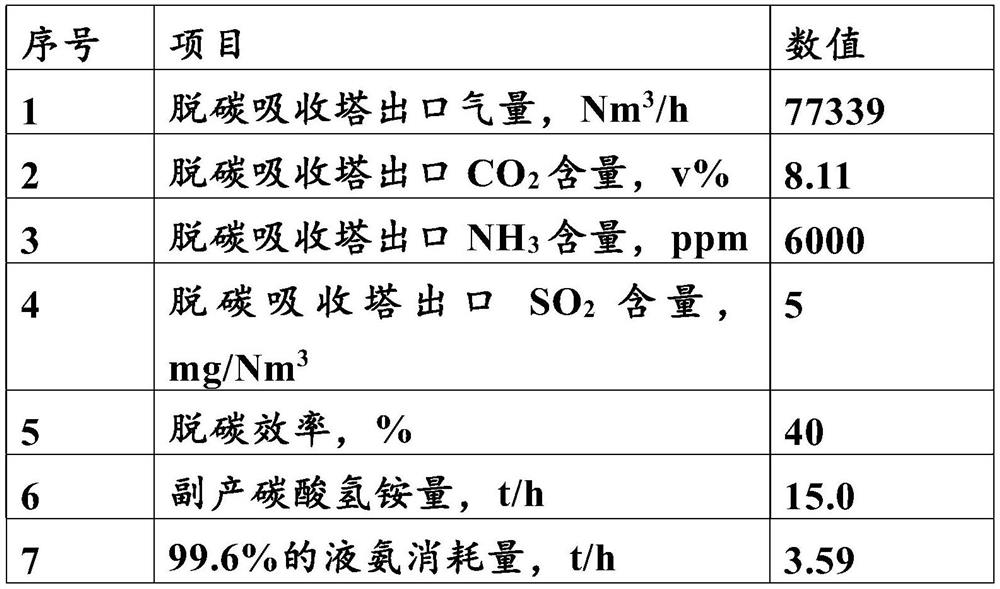

Method and device for producing ammonium bicarbonate by ammonia process decarbonization system

The device and the method are characterized in that the device comprises a cooling functional area, an ammonium bicarbonate generation area, a carbon dioxide absorption area and an ammonia removal functional area, the cooling functional area is used for removing heat of the decarbonization system, the ammonium bicarbonate generation area is used for generating ammonium bicarbonate, and the carbon dioxide absorption area is used for absorbing carbon dioxide. The carbon dioxide absorption area is used for absorbing carbon dioxide in process gas and adopts multi-stage absorption, the ammonia removal functional area is used for removing ammonia in the decarburized process gas, and the absorbent ammonia for removing the carbon dioxide is mainly added from the carbon dioxide absorption area. Through zoned control of ammonium bicarbonate generation, CO2 absorption and ammonia removal, the decarburization absorption efficiency is improved, ammonia escape is reduced, and meanwhile, carbon dioxide in flue gas can be used for producing ammonium bicarbonate which can be used as a nitrogen fertilizer.

Owner:JIANGSU NEW CENTURY JIANGNAN ENVIRONMENTAL PROTECTION +1

Treatment method of biogas liquid

InactiveCN106957133AReduce concentrationLow costWaste water treatment from animal husbandryAmmonium salt preparationFiberChemical oxygen demand

The invention provides a treatment method of biogas liquid. According to the treatment method, after the pH (potential of Hydrogen) value of original biogas liquid is adjusted, ammonia nitrogen in the biogas liquid is subjected to preliminary recovery by adopting acidic absorption liquid through a way of absorption by a hollow fibrous membrane component; afterwards, the biogas liquid obtained by contact absorption is subjected to an anaerobic reaction, a facultative reaction and an aerobic reaction in sequence. By using the method provided by the invention, the ammonia nitrogen in the biogas liquid can be converted into an ammonium salt to carry out recycling; the concentration of the ammonia nitrogen in the biogas liquid is decreased; the subsequent biological denitrification and dephosphorization are facilitated. The treatment method is simple in process and low in cost. In the method provided by the invention, the concentration of the ammonia nitrogen in the biogas liquid subjected to the contact absorption is decreased to 20mg / L to 50mg / L; in the biogas liquid subjected to whole-course treatment, the TP (Total Phosphorus) index is 6mg / L to 8mg / L, the concentration of the ammonia nitrogen is 10mg / L to 30mg / L, the COD (Chemical Oxygen Demand) is 50mg / L to 220mg / L, and the pH value is 7 to 9; the national Discharge Standard of Pollutants for Livestock and Poultry Industry (GB18596-2001) is met.

Owner:NANCHANG HANGKONG UNIVERSITY

Gaseous ammonia removal system

A system and method for passive capture of ammonia in an enclosure containing material that gives off ammonia. The invention allows for the passage of gaseous NH3 through microporous hydrophobic gas-permeable membranes and its capture in a circulated acidic solution with concomitant production of a concentrated non-volatile ammonium salt.

Owner:US SEC AGRI

Removal and recovery of phosphate from liquid streams

ActiveUS9328006B2Low costImprove efficiencyTreatment with aerobic and anaerobic processesEnergy based wastewater treatmentChemical treatmentMagnesium ammonium phosphate

An economical method for recovering phosphate or phosphate and nitrogen from liquid streams. A liquid containing phosphate is introduced into a culture of autotrophic microorganisms in the presence of natural or artificial light, thereby producing a liquid effluent with elevated pH and reduced alkalinity. The alkalinity is reduced through the consumption of bicarbonate / carbonate by the autotrophic microorganisms. The effluent is then chemically treated with low-cost chemicals to provide Ca++ or Mg++ ions necessary to form a phosphate precipitate such as calcium phosphate or magnesium-ammonium-phosphate (MAP). The autotrophic microorganisms can be cultivated in ponds, lagoons, or photobioreactors. The pH of the culture is adjustable within a preferred range of 7.5 to 10.5 by adjusting the photobioreactor operation. The process includes an economical flotation separator for solid, liquid, gas separation and a means of concentrating ammonia nitrogen that may also be removed during the process of phosphate reclamation.

Owner:COYNE BRIAN J

Ammonia capture recovery system

ActiveUS9452938B2Low costReduce alkalinityBio-organic fraction processingWaste based fuelGaseous ammoniaAmmonium

An ammonia capture recovery system is disclosed. The ammonia capture recovery system may include pretreatment with conventional solid removal devices and a single or a series of hydrophobic membrane concentrators receiving a heated ammonium containing influent either heated to a sufficient temperature to convert ammonia to ammonium or containing sufficient alkali to convert ammonia to ammonium in the influent. The heated ammonium containing liquid is pumped through the hydrophobic membrane concentrator and the hydrophobic membrane concentrator receives an acid. The acid then reacts with the extracted gaseous ammonia and ultimately forms a saturated ammonium salt product that is discharged from the hydrophobic membrane concentrator, the hydrophobic membrane concentrator includes a feed line, a plurality of hydrophobic membrane modules, a diluted acid source and a concentrated acid source and tanks to receive the saturated ammonium salt product and the low ammonia effluent.

Owner:ORENTLICHER MORTON +1

Deposition method and apparatus

ActiveUS20110070141A1Speed up the gas flowIncrease pressureNitrogen compoundsTantalum compoundsEnvironmental geology

Owner:SUNDEW TECH

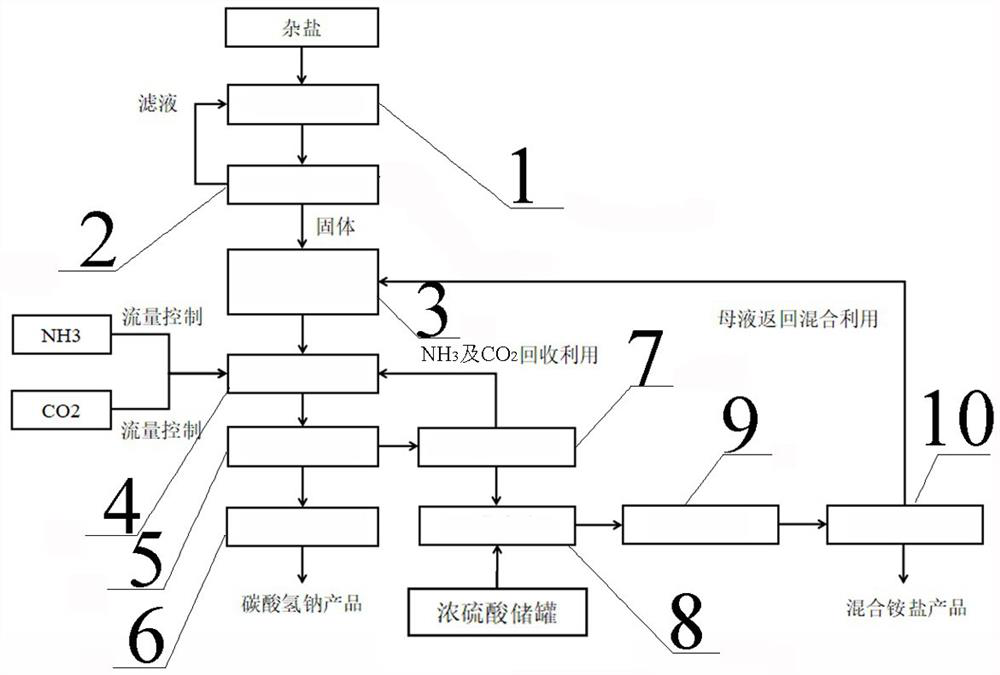

System and method for treating and recycling carnallite in coal chemical industry

ActiveCN113636576ARealize resource utilizationBig market demandProductsReagentsSodium bicarbonateChemical products

The invention discloses a system and a method for treating and recycling carnallite in the coal chemical industry. The system comprises a carnallite pretreatment unit, a double decomposition reaction unit, a sodium bicarbonate separation unit, an NH3 and CO2 recovery unit and an ammonium salt separation unit; the carnallite is treated by equipment such as a carnallite pretreatment unit, a double decomposition reaction unit, a sodium bicarbonate separation unit, an NH3 and CO2 recovery unit and an ammonium salt separation unit to obtain ammonium chloride, ammonium sulfate and sodium bicarbonate products. According to the method, the sodium sulfate / sodium chloride waste salt, NH3 and CO2 are used as raw materials, the final products obtained after reaction are ammonium chloride, ammonium sulfate, sodium bicarbonate and other bulk chemical products, the market demand is large, resource utilization of the waste salt is achieved, and economic benefits and environmental benefits are remarkable.

Owner:BEIJING GUODIAN LONGYUAN ENVIRONMENTAL ENG +1

Systems and methods for ammonia recovery, acid gas separation, or combination thereof

ActiveUS10427948B2Reduce and eliminates challengeFast absorptionProductsMembranesDesorptionReverse osmosis

The present invention relates to processes and systems for ammonia recovery and / or acid-gas separation. In some embodiments, a system for acid gas separation may be integrated with an ammonia abatement cycle employing a high temperature absorber. In some embodiments, a system for acid gas separation may employ a higher temperature absorber due to the lower energy consumption and cost of the integrated ammonia abatement cycle. Advantageously, heat may be recovered from the absorber to power at least a portion of any acid gas desorption in the process. Reverse osmosis or other membranes may be employed.

Owner:INNOVATOR ENERGY LLC

A kind of comprehensive utilization treatment method of aluminum ash

ActiveCN105347361BHarmlessAvoid pollutionAmmonium salt preparationAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationAtmospheric dustAluminum industry

The invention belongs to the technical field of comprehensive utilization of waste resources from the aluminum industry and specifically discloses a comprehensive utilization method of aluminum ash. According to the comprehensive utilization method of aluminum ash, metallic aluminium is extracted from aluminum ash through an ore grinding method; the aluminum ash obtained after aluminium extraction undergoes catalytic deamination; the aluminum ash obtained after deamination is mixed with alkali and granulation forming is then carried out; and the granulation product is sintered and the sintered product is finally dissolved out. By the above method, useful components in the aluminum ash can be recovered to the maximum; ammonia gas which has been ignored for a long time is effectively recovered; components such as aluminium oxide, villiaumite and the like are recovered and utilized to the maximum; pollution of aluminum ash processing to the environment is avoided; atmospheric dust pollution is avoided; atmospheric pollution is also avoided due to ammonia gas recovery; pollution of aluminum ash stacking to underground water and soil is avoided due to extraction and recovery of fluoride salt; and environmental safety during the treating process is guaranteed.

Owner:湖南绿脉环保科技股份有限公司

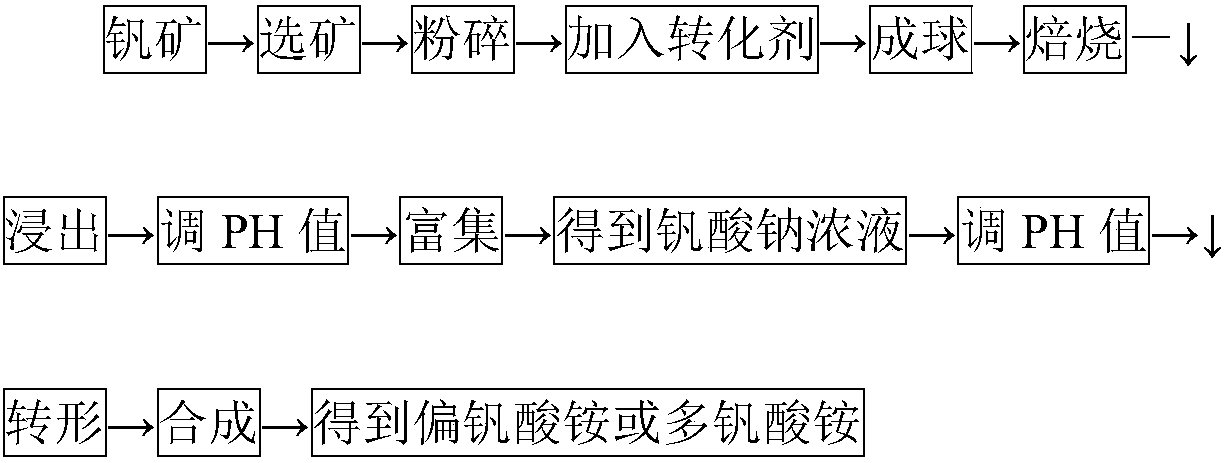

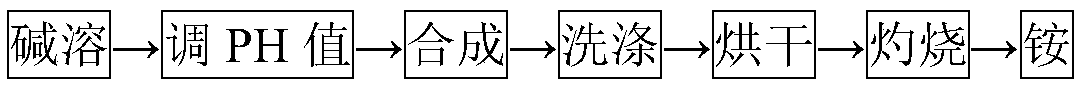

Process for recycling ammonia gas for vanadium preparation to prepare ammonium and recycling wastewater

InactiveCN109081375AEnsure normal dischargeEasy to handleAmmonium salt preparationVanadium oxidesFlocculationWastewater

The invention discloses a process for recycling ammonia gas for vanadium preparation to prepare ammonium and recycling wastewater. Conventional vanadium extraction processes are complex in procedure and most difficult in control of ammonia gas emission and wastewater treatment. By the process, ammonium metavanadate and ammonium polyvanadate can be directly extracted starting from mining and smelting; in the process of using ammonium metavanadate or ammonium polyvanadate to prepare high-purity vanadium pentoxide, all discharged ammonia gas can be bundled to prepare ammonium for use, so that zero emission of waste gas is realized; polyacid ester flocculation technology is adopted, all wastewater generated in the above process is effectively treated, so that zero emission and recycling of wastewater are ensured, and purity of all products reaches 99.5-99.99%.

Owner:ZHONGFANLIAN TECH DEV CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com