Treatment method of biogas liquid

A treatment method and biogas slurry technology, which is applied in the field of livestock and poultry breeding biogas slurry treatment, can solve the problems of large-scale livestock and poultry farms without environmental impact assessment, ammonia nitrogen utilization, and biogas slurry not comprehensively utilized.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

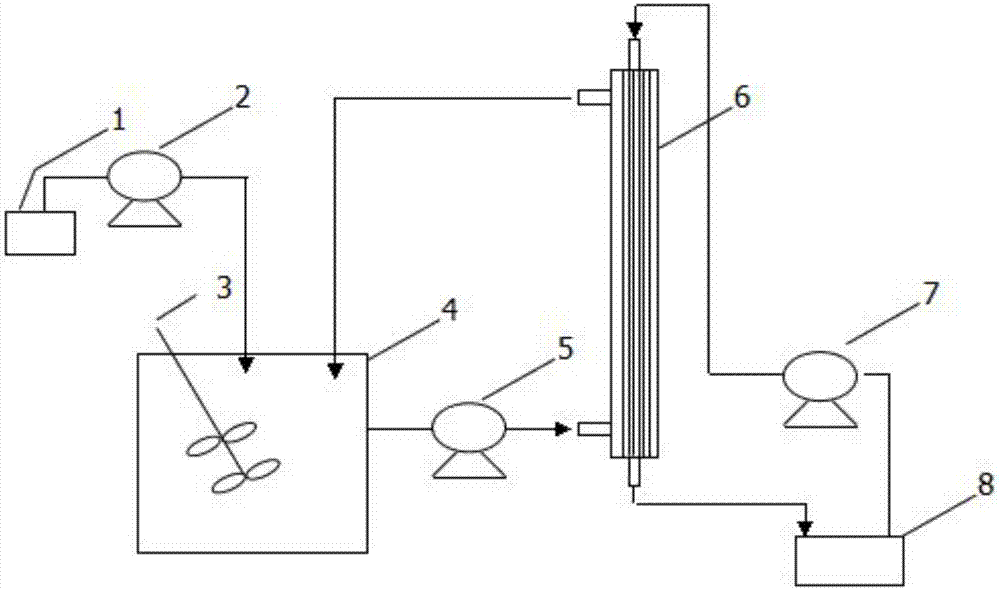

Embodiment 1

[0049] A lye dosing pump and agitator are installed in the biogas slurry storage tank of a dairy farm. The pollutant concentration in the biogas slurry is: TP 10mg / L, ammonia nitrogen 300mg / L, COD 900mg / L, pH 6-8. Use 0.2mol / L sodium hydroxide solution to adjust the pH value of the biogas slurry to 10, and use a biogas slurry circulation pump to make the biogas slurry flow through the hollow fiber membrane module (membrane area 3m2) at a speed of 6cm / s 2 ) shell side flow; use 0.1mol / L sulfuric acid solution to flow in the tube side of the hollow fiber membrane module at a speed of 7cm / s, and the biogas slurry and sulfuric acid solution circulate for 2 hours at the same time, and the biogas slurry passes through the hollow fiber membrane module through the circulation pump. Shell side, and then return to the biogas slurry storage tank, but when the ammonia nitrogen concentration in the biogas slurry drops to 50mg / L, the contact absorption cycle is stopped, the wastewater treatm...

Embodiment 2

[0052] A lye dosing pump and agitator are installed in the biogas slurry storage tank of a pig farm. The concentration of pollutants in the biogas slurry is: TP35mg / L, ammonia nitrogen 700mg / L, COD 550mg / L, pH 6-8. Use 0.3mol / L sodium hydroxide solution to adjust the pH value of the biogas slurry to 11, and use a biogas slurry circulation pump to make the biogas slurry flow through the hollow fiber membrane module (membrane area 3m2) at a speed of 5.5cm / s 2 ) shell-side flow; use 0.2mol / L sulfuric acid solution to flow in the tube-side of the hollow fiber membrane module at a speed of 6.5cm / s, and circulate for 5 hours.

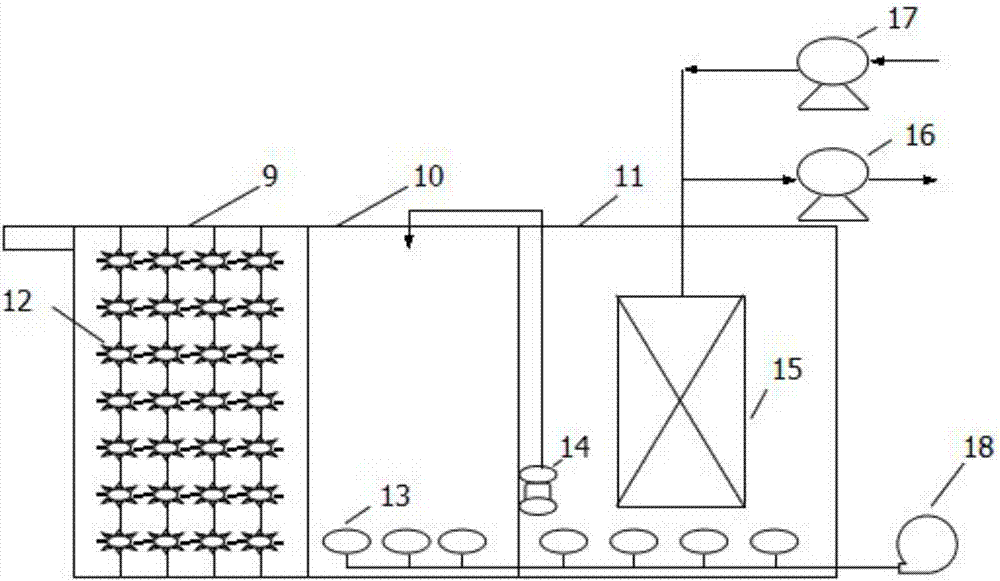

[0053] Use a 50L / H lift pump to transport the biogas slurry after contact absorption treatment to the membrane bioreactor, first to the anaerobic zone (9, specification Φ0.7×0.25m), and then to the facultative zone (10, Specification Φ0.7×0.25m), and finally flow to the aerobic zone (11, specification Φ0.7×0.8m). The suction capacity of the inner membrane of...

Embodiment 3

[0055] A lye dosing pump and agitator are installed in the biogas slurry storage tank of a pig farm. The pollutant concentration in the biogas slurry is: TP 70mg / L, ammonia nitrogen 1000mg / L, COD 1500mg / L pH 6-8. Use 0.3mol / L sodium hydroxide solution to adjust the pH value of the biogas slurry to 11, and use a biogas slurry circulation pump to make the biogas slurry flow through the hollow fiber membrane module (membrane area 3m2) at a speed of 8cm / s 2 ) shell-side flow; use 0.3mol / L sulfuric acid solution to flow in the tube-side of the hollow fiber membrane module at a speed of 10cm / s, and circulate for 10 hours.

[0056] Use a 50L / H lift pump to transport the biogas slurry after contact absorption treatment to the membrane bioreactor, first to the anaerobic zone (9, specification Φ0.7×0.25m), and then to the facultative zone (10, Specification Φ0.7×0.25m), and finally flows to the MBR area (11, specification Φ0.7×0.8). The suction capacity of the inner membrane of the mem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com