Patents

Literature

2520 results about "Membrane bioreactor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

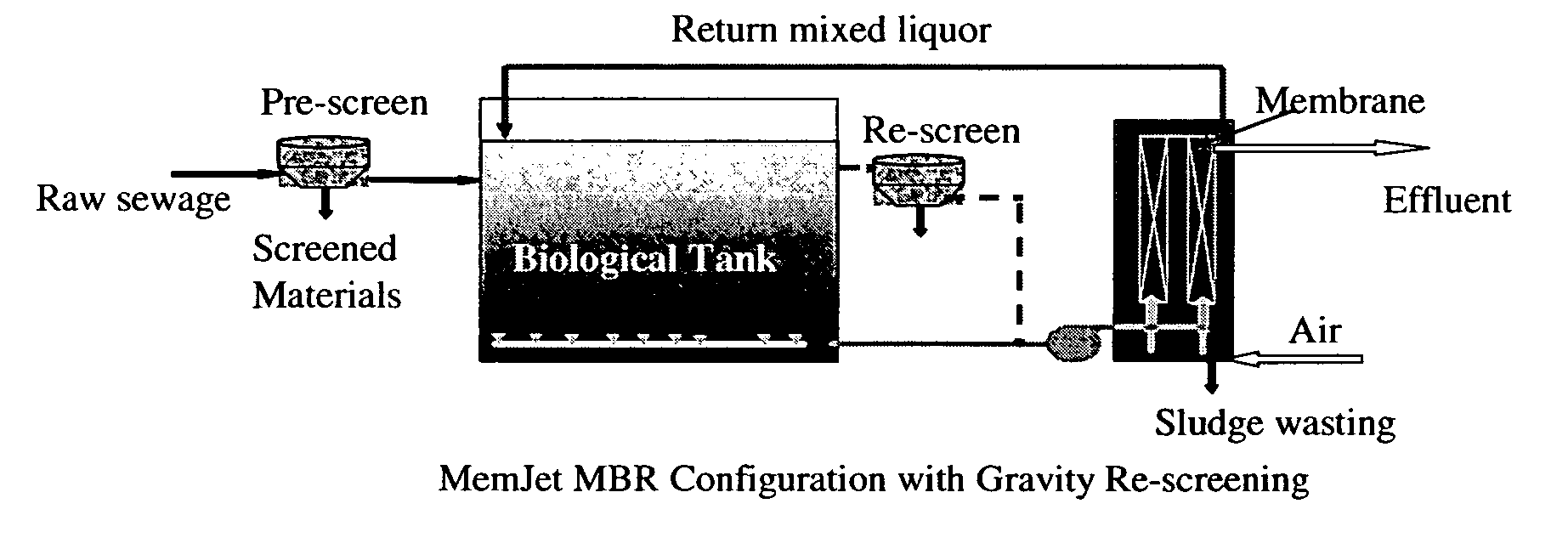

Membrane bioreactor (MBR) is the combination of a membrane process like microfiltration or ultrafiltration with a biological wastewater treatment process, the activated sludge process. It is now widely used for municipal and industrial wastewater treatment.

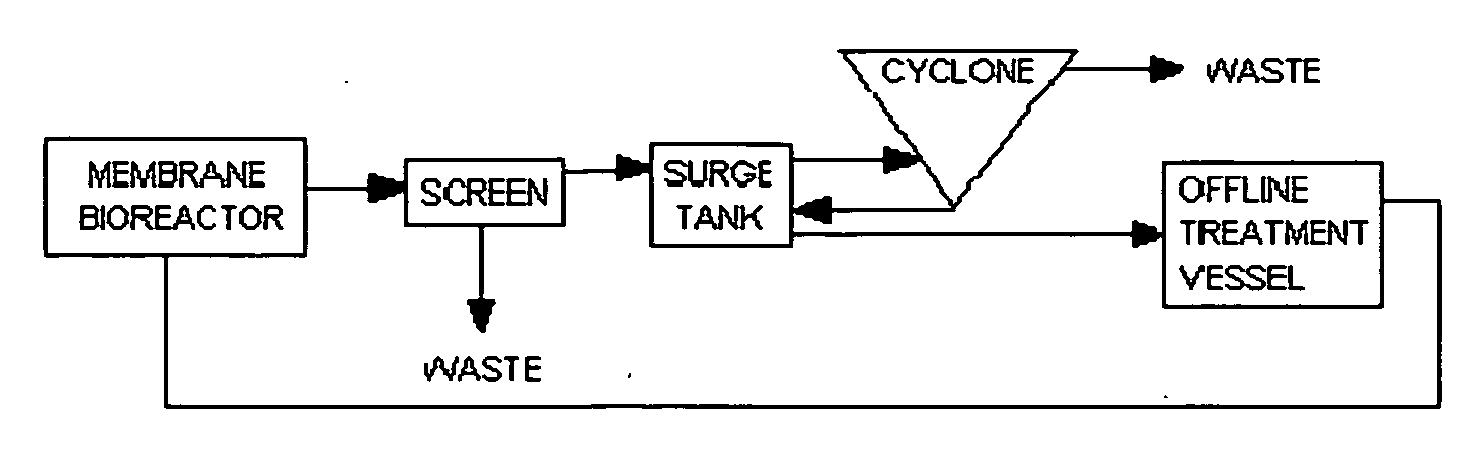

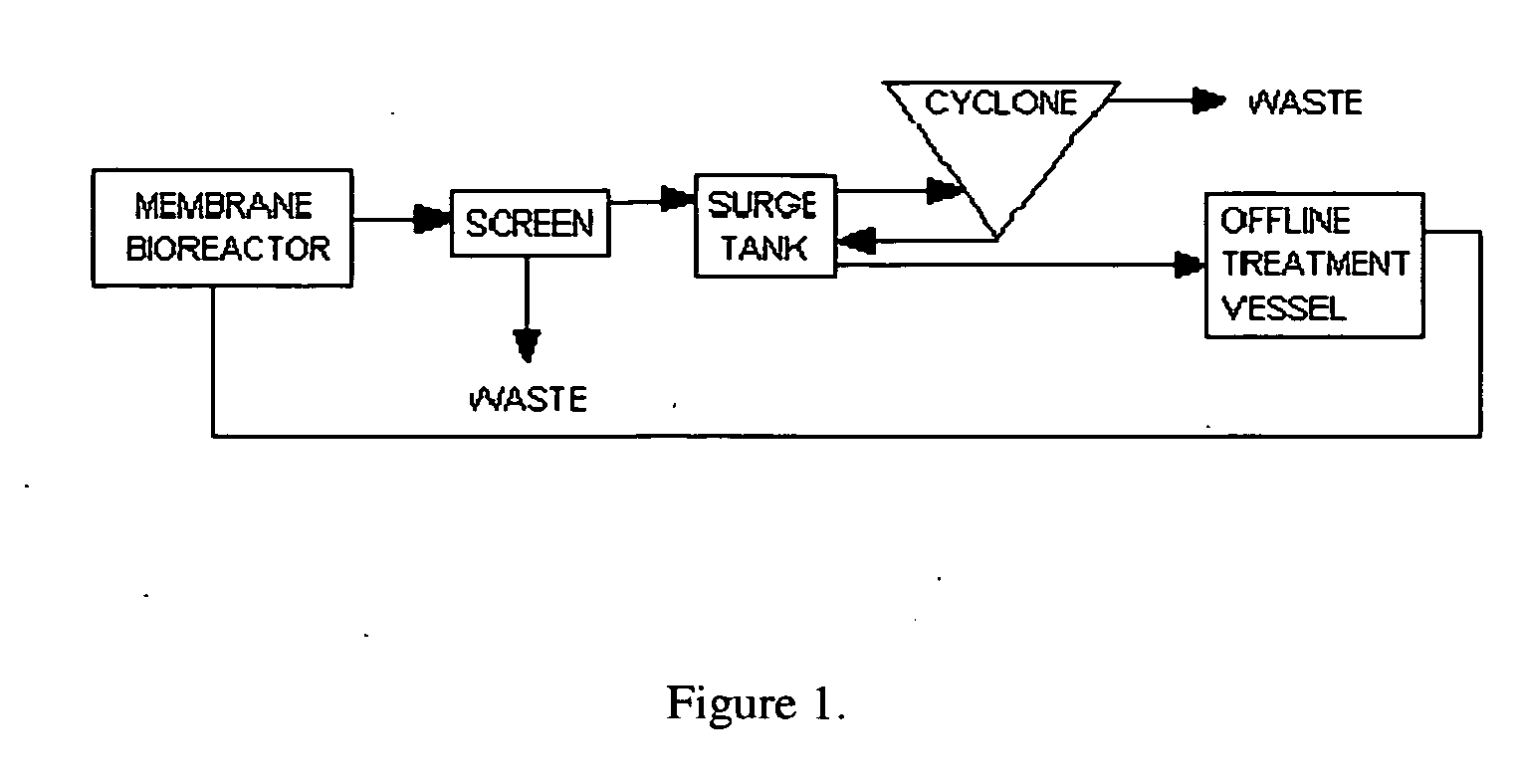

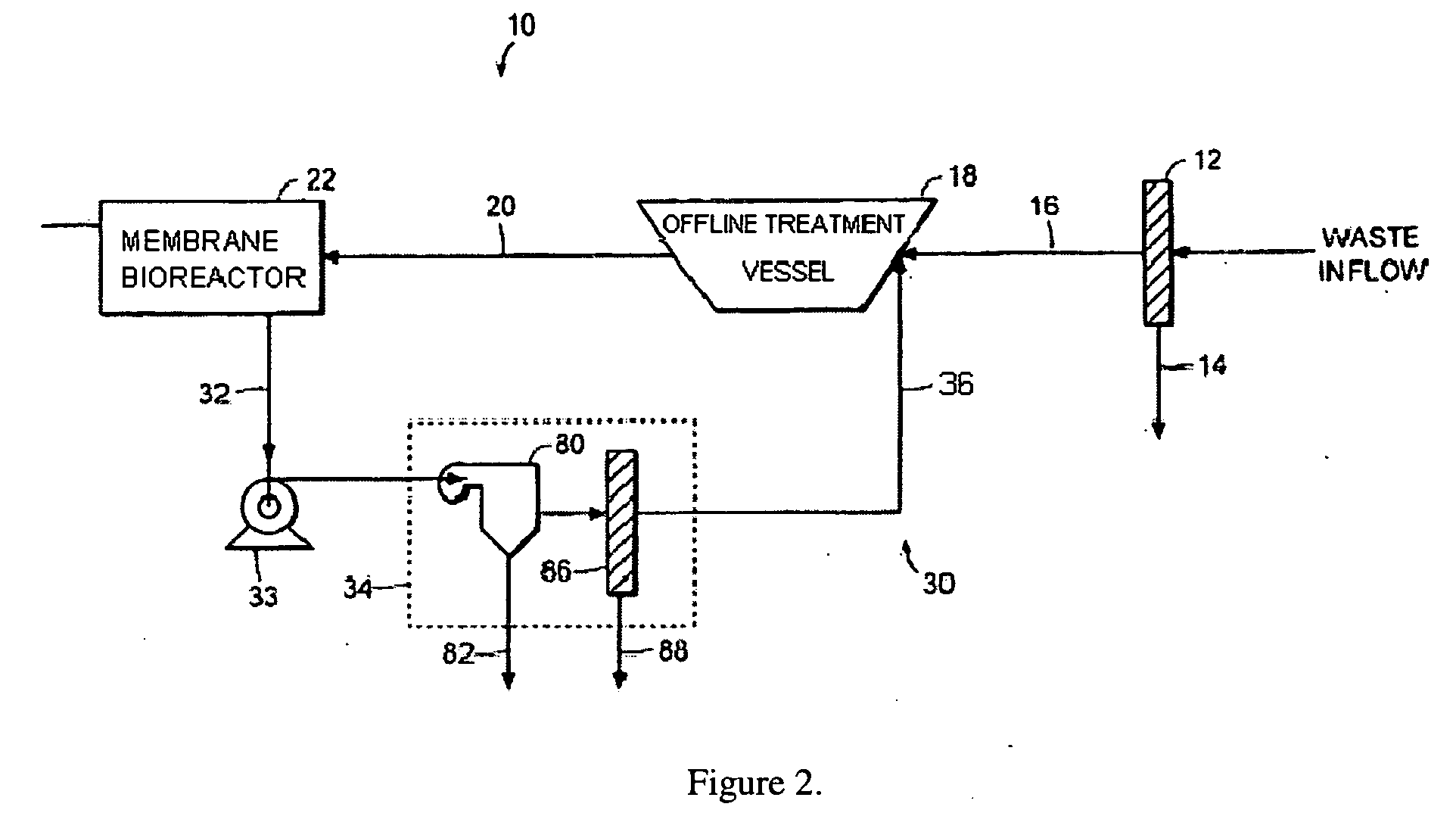

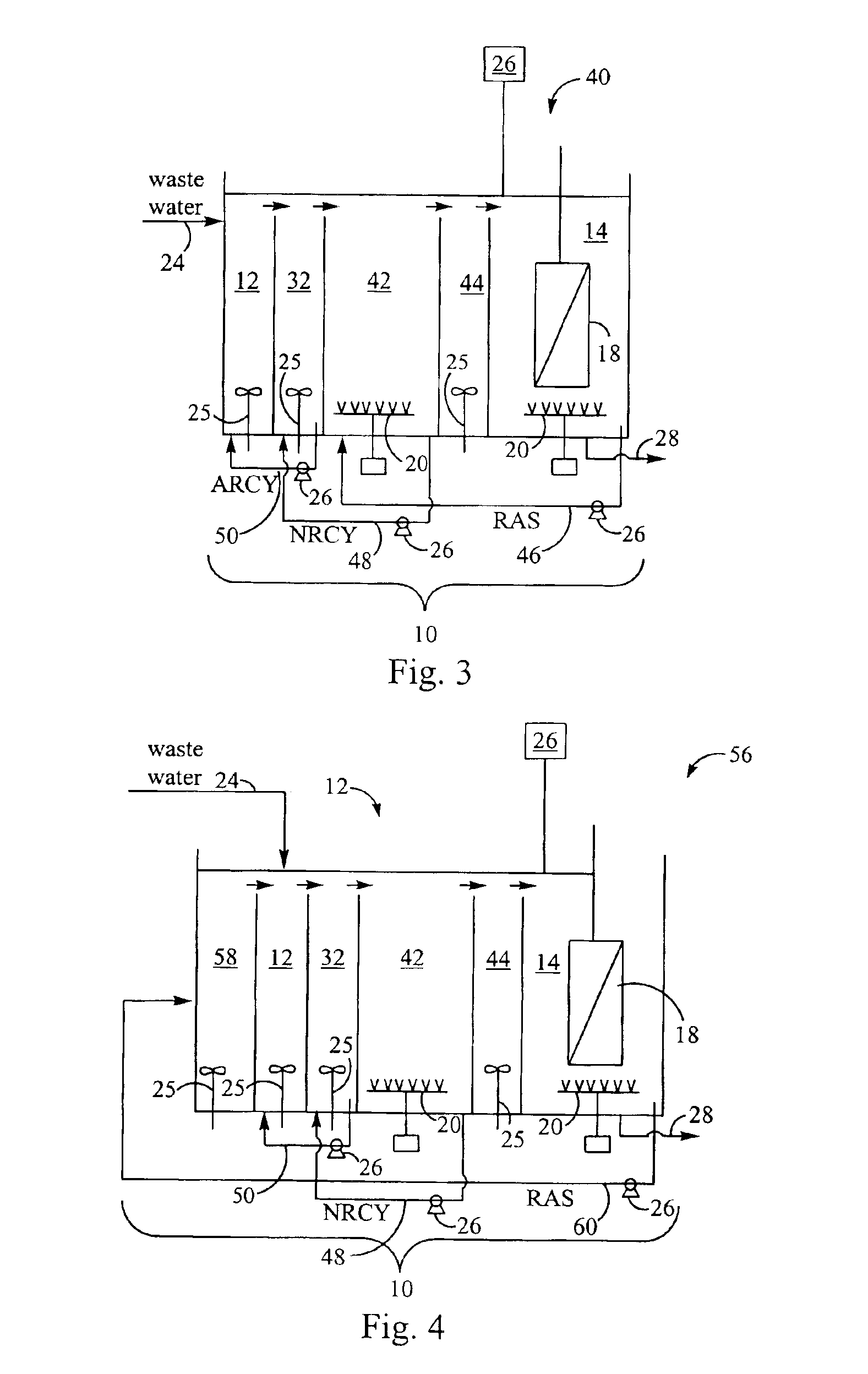

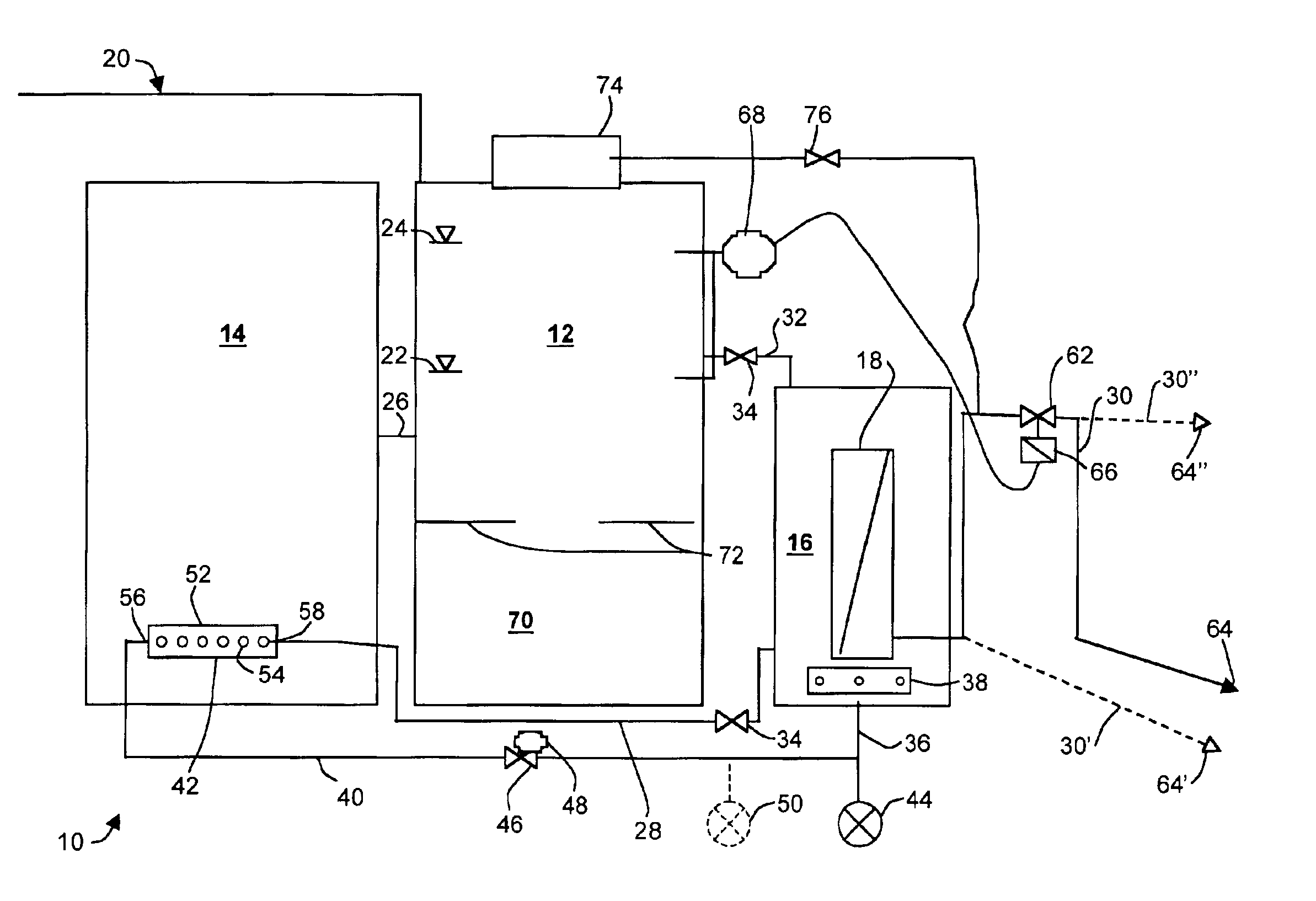

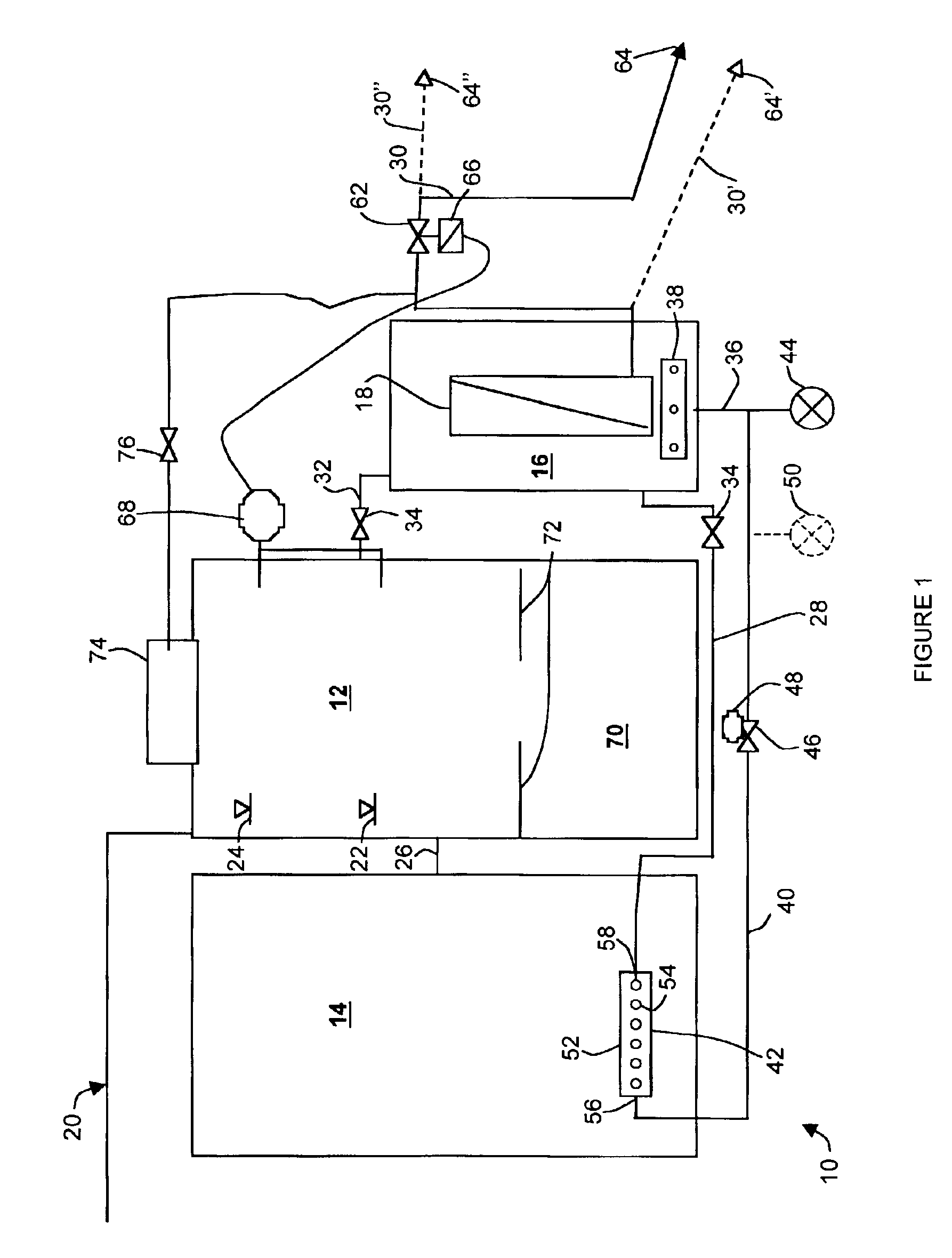

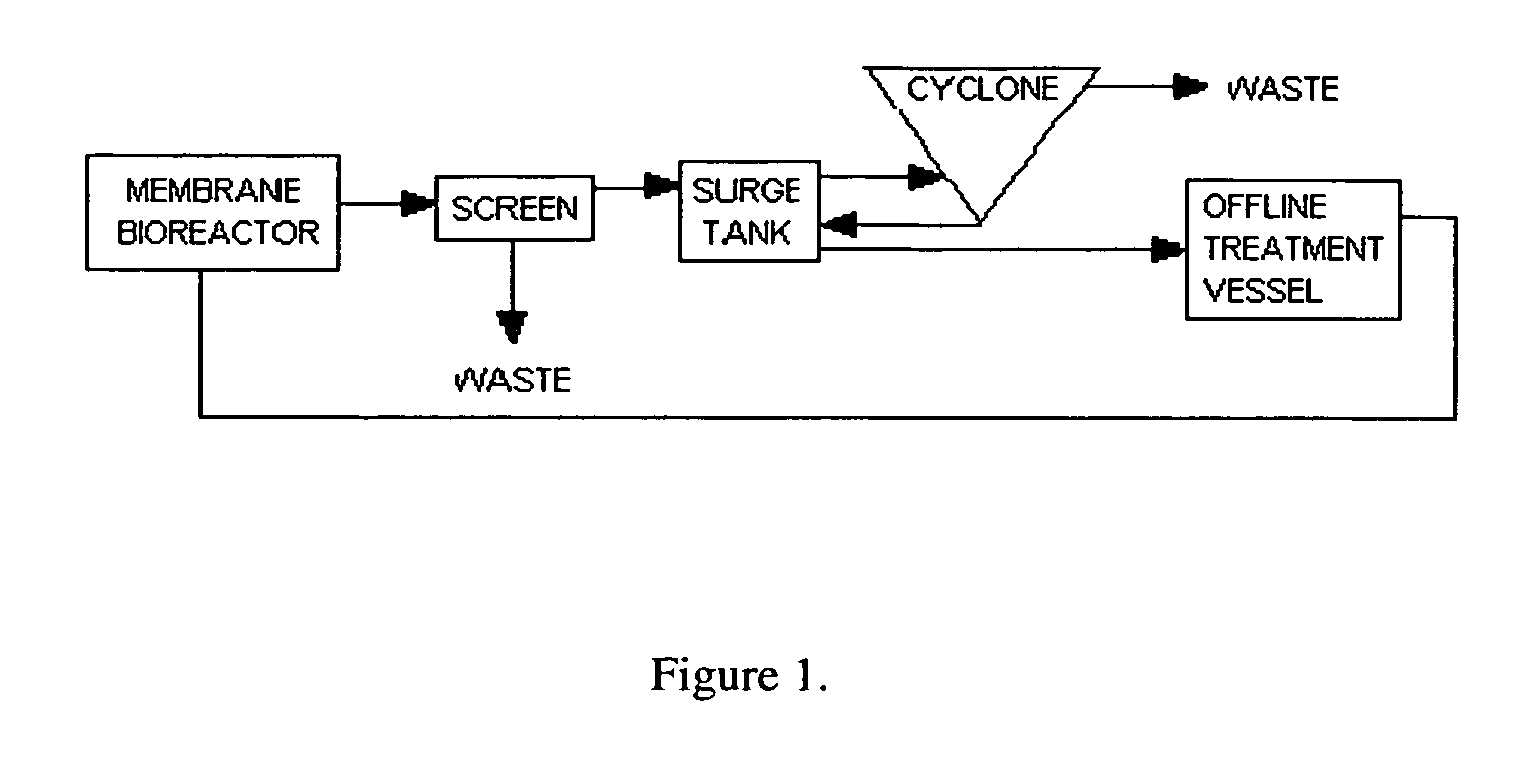

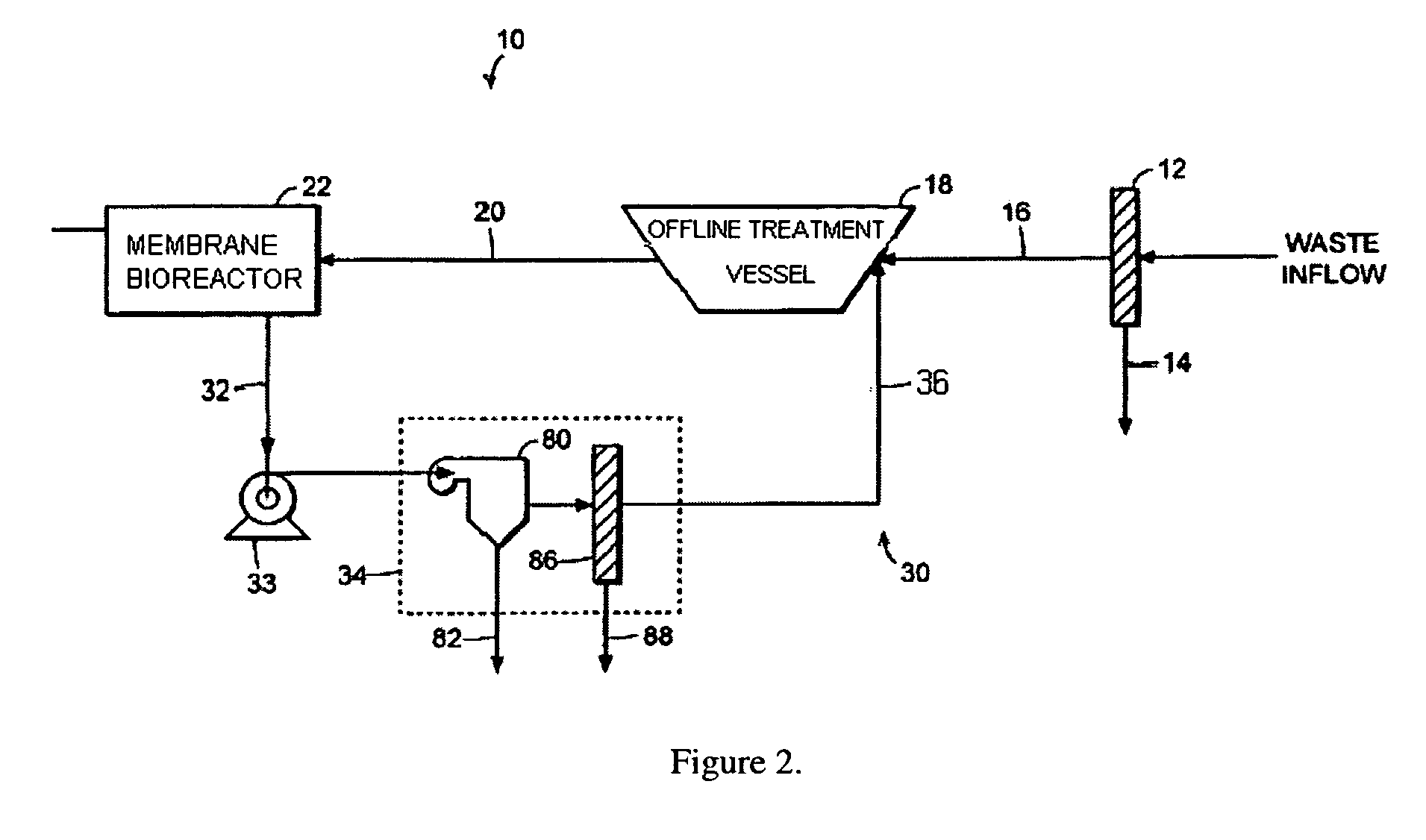

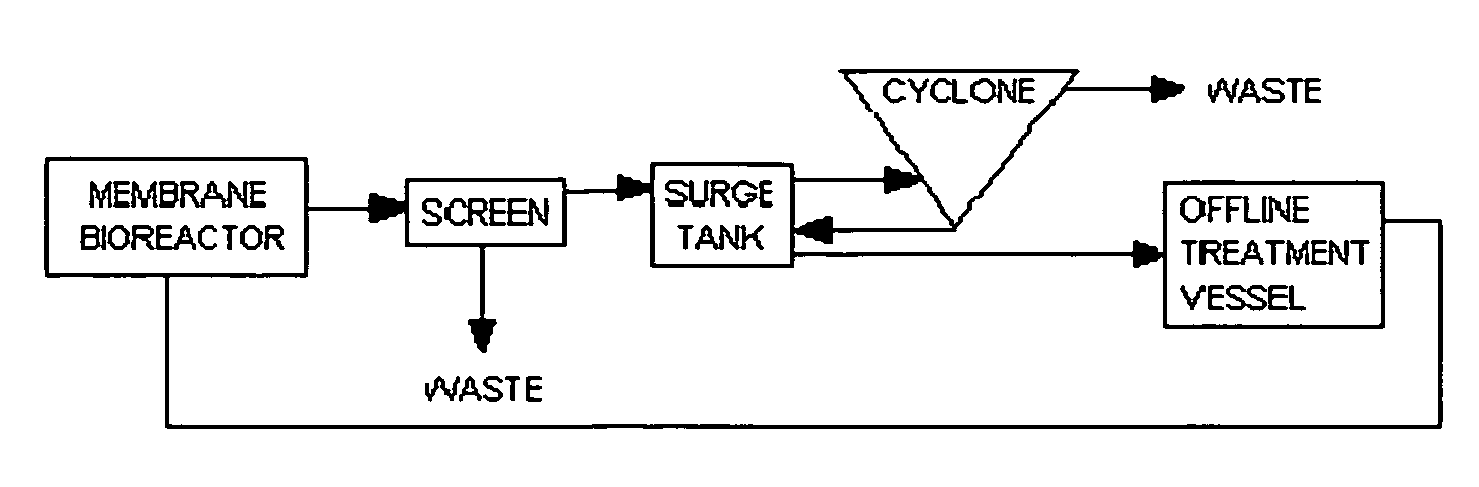

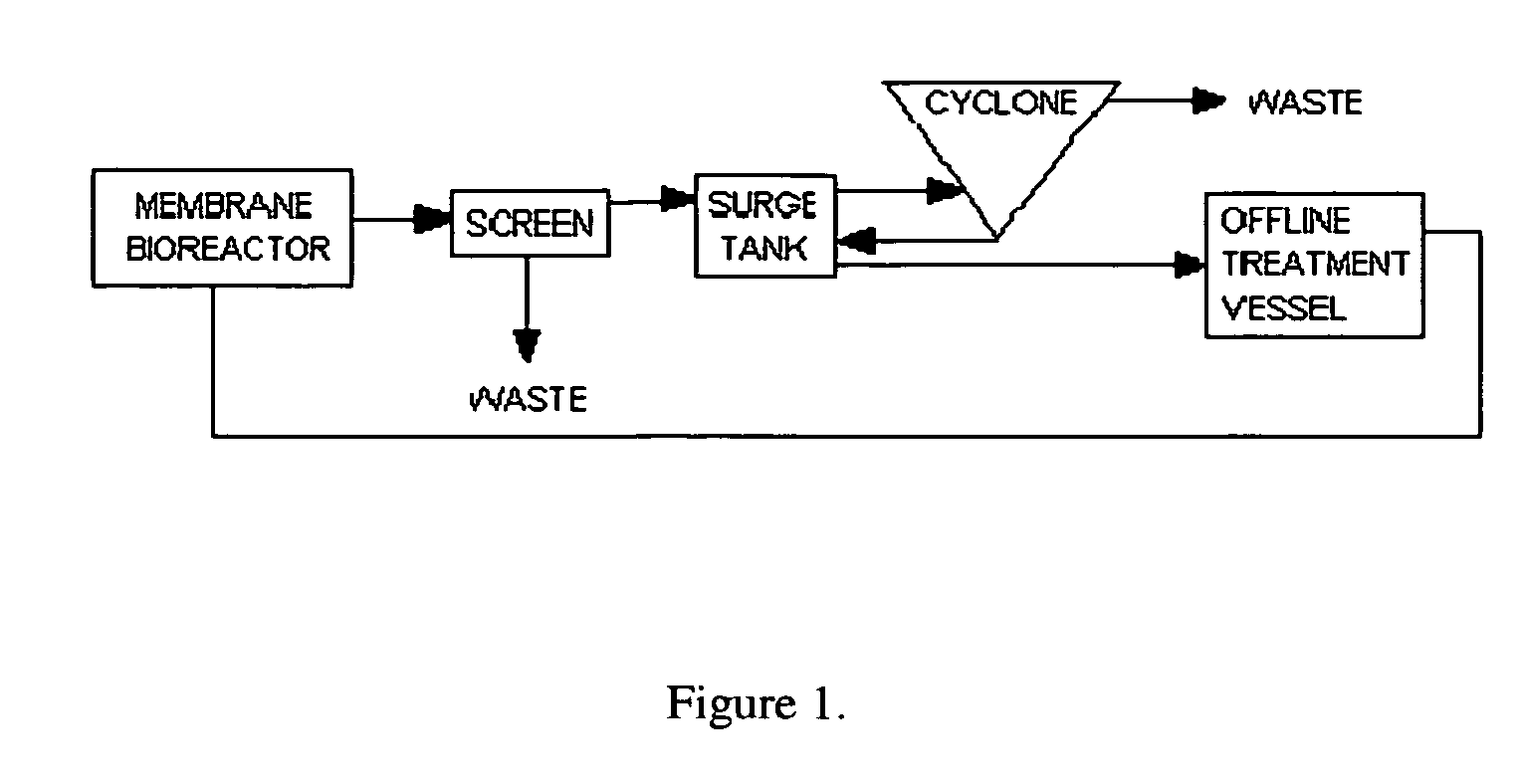

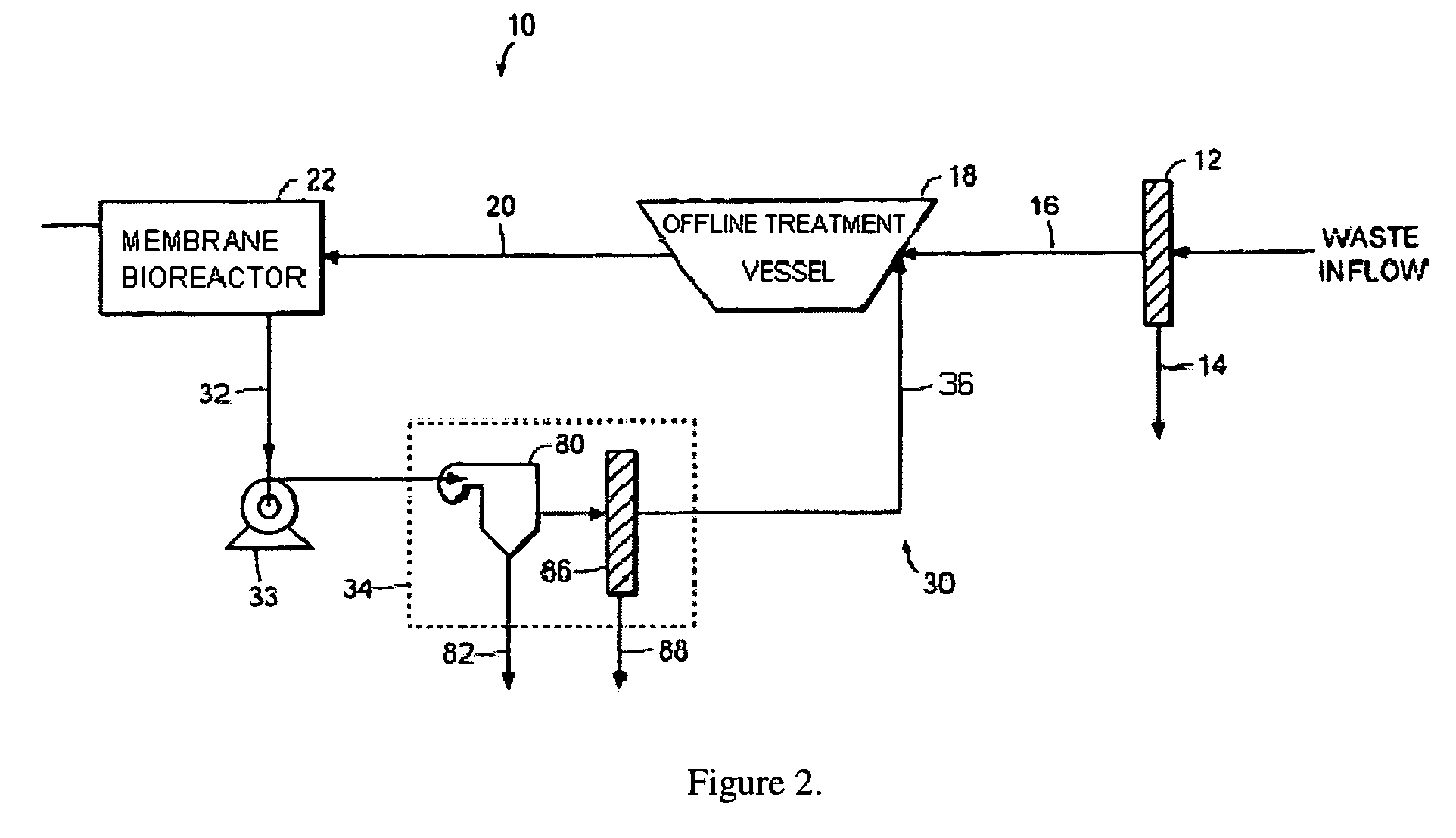

Filtration apparatus comprising a membrane bioreactor and a treatment vessel for digesting organic materials

InactiveUS20060201876A1Low costReducing resourceWater/sewage treatment by centrifugal separationWater treatment parameter controlFiltrationMembrane bioreactor

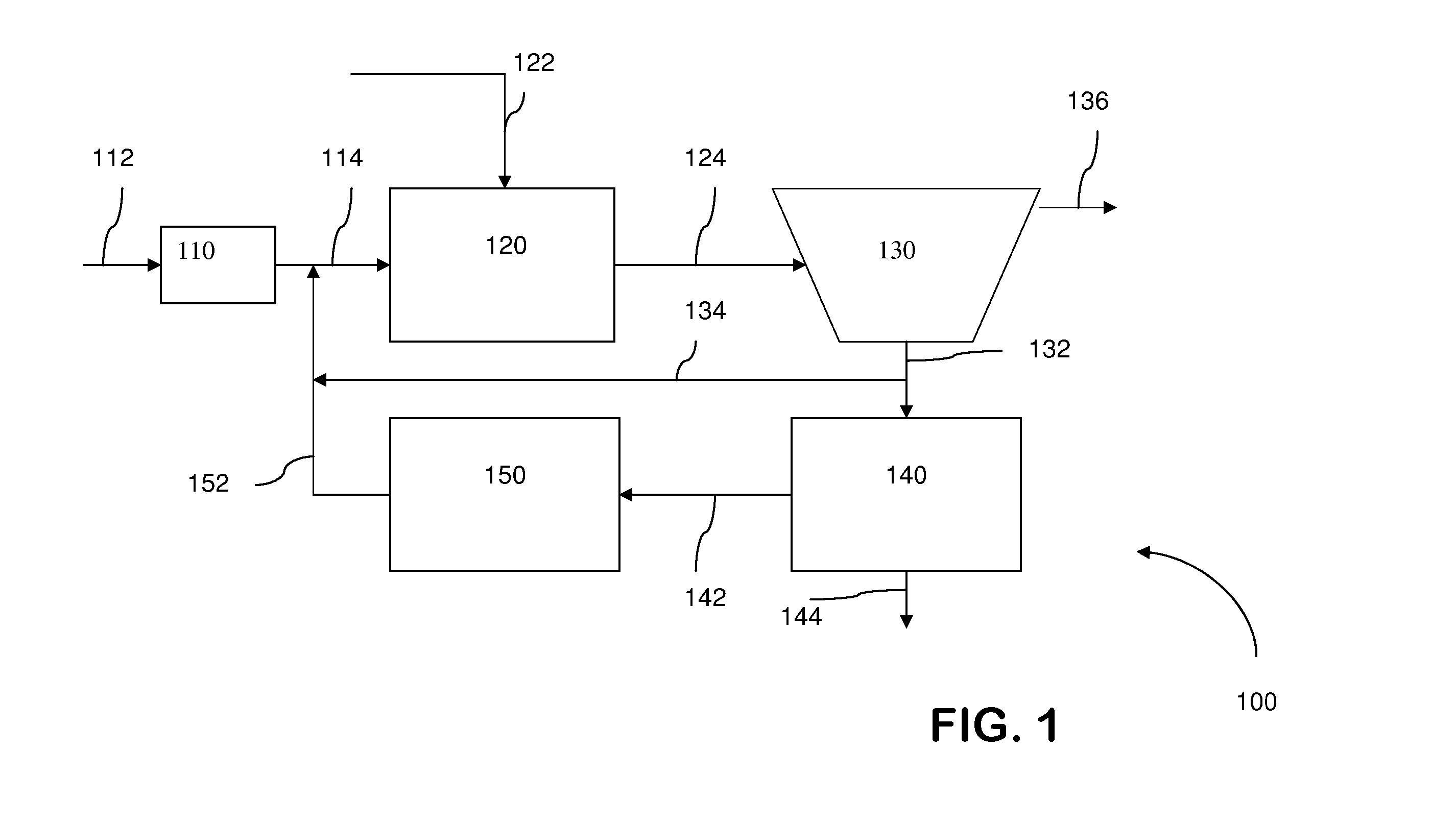

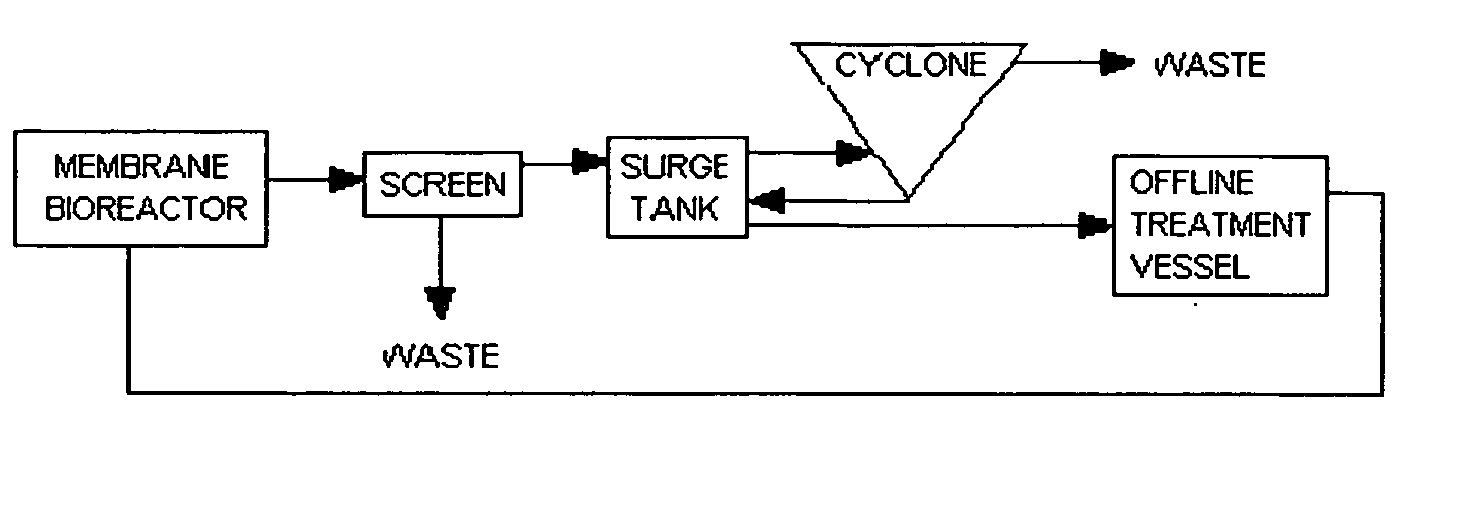

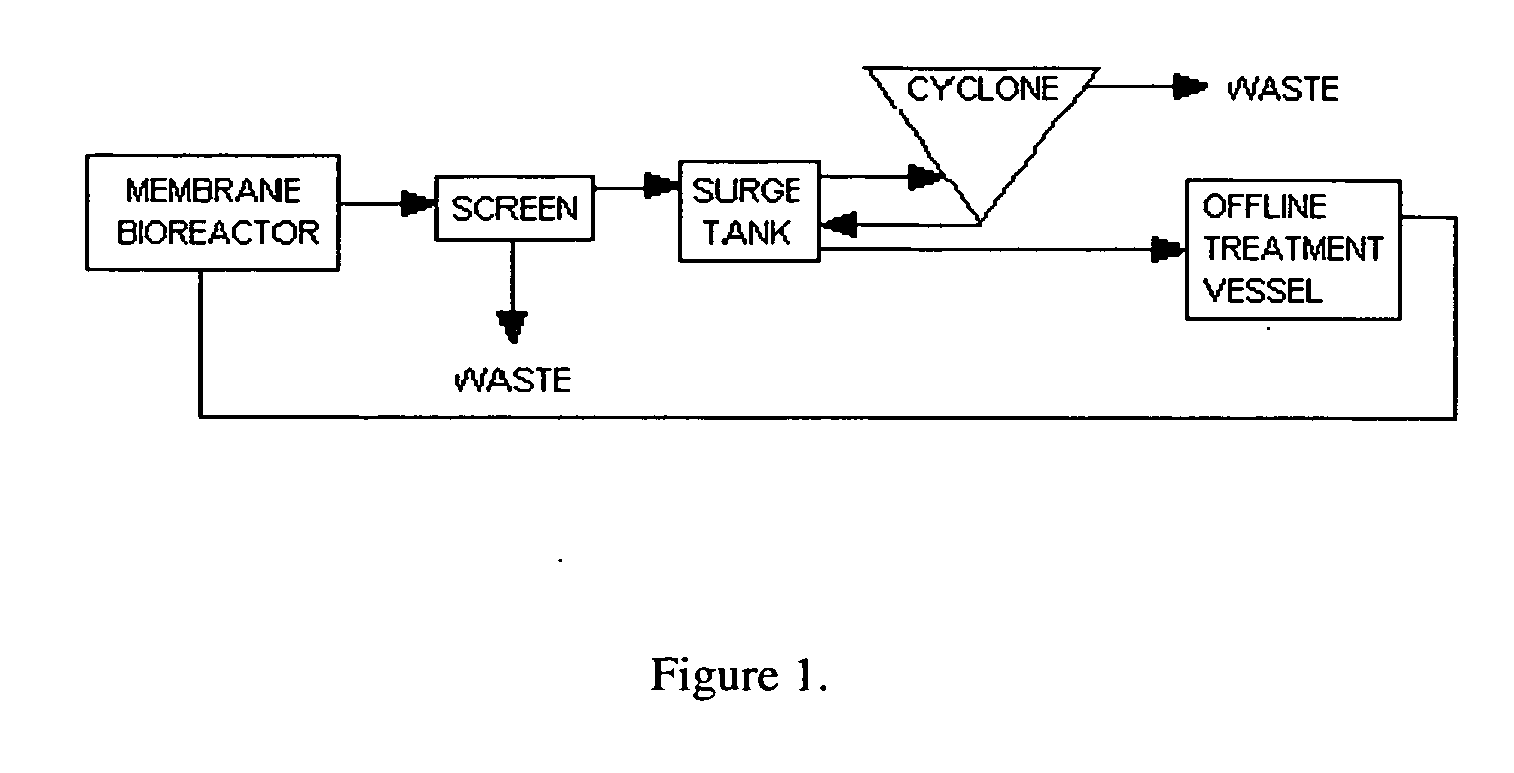

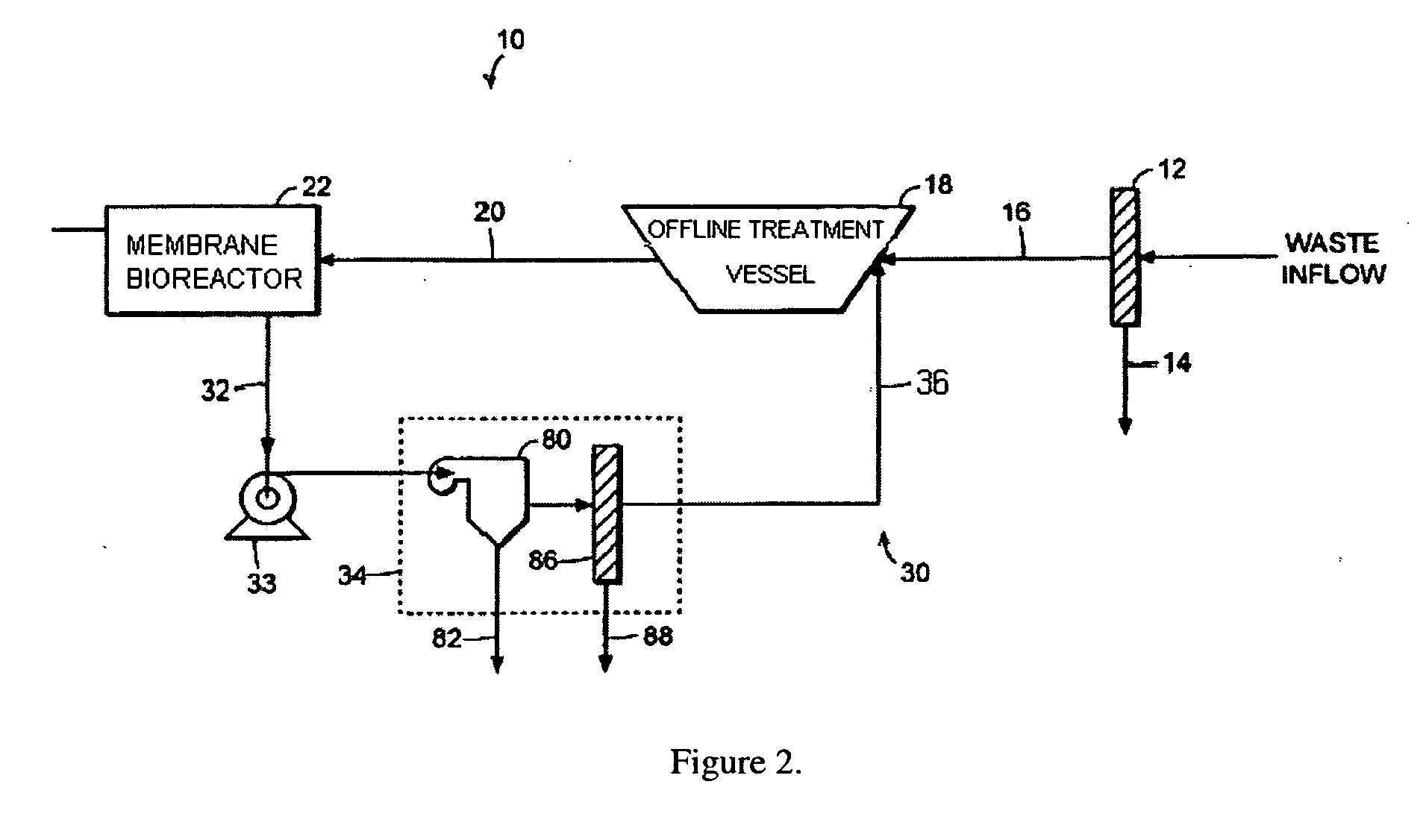

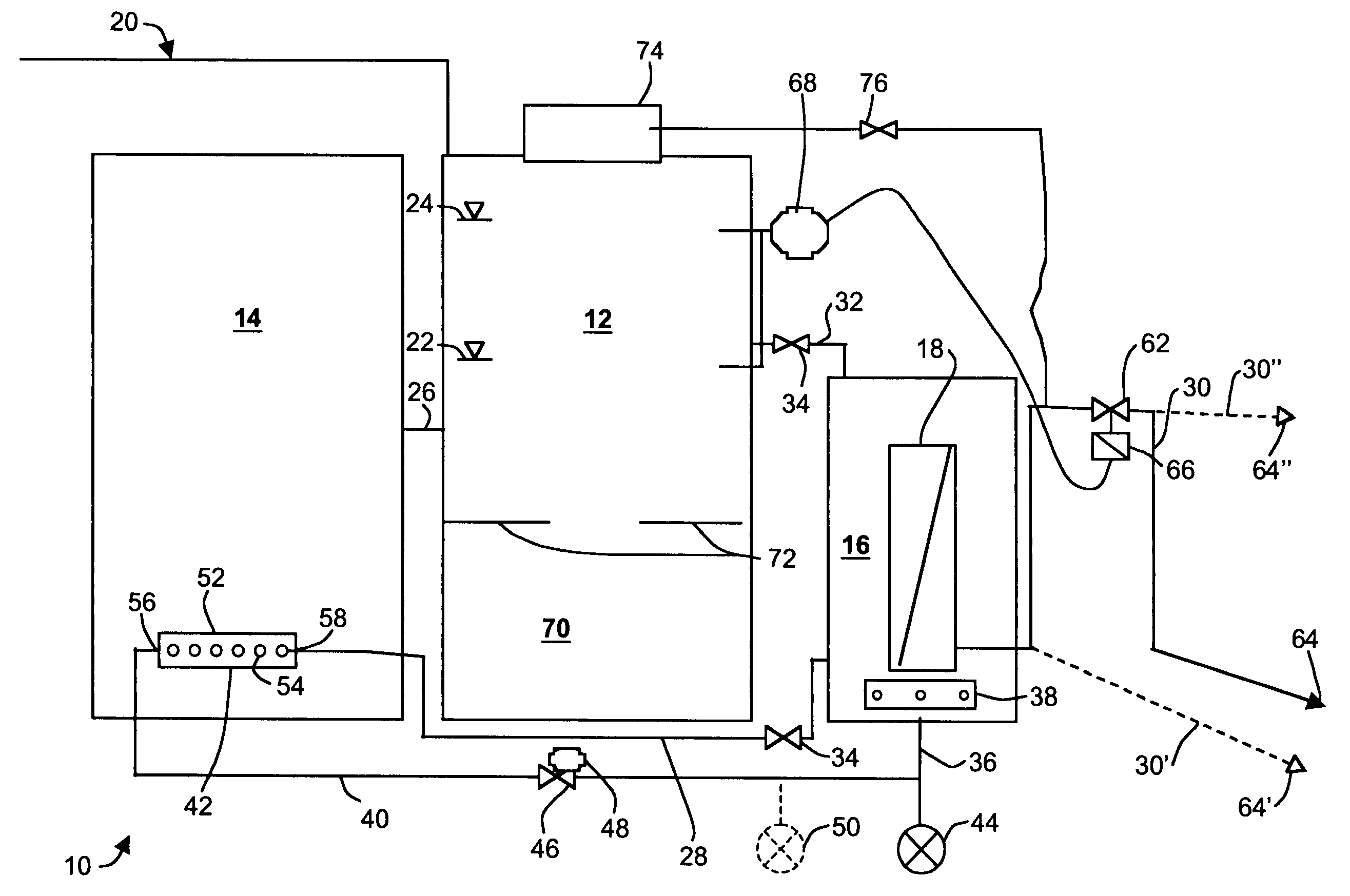

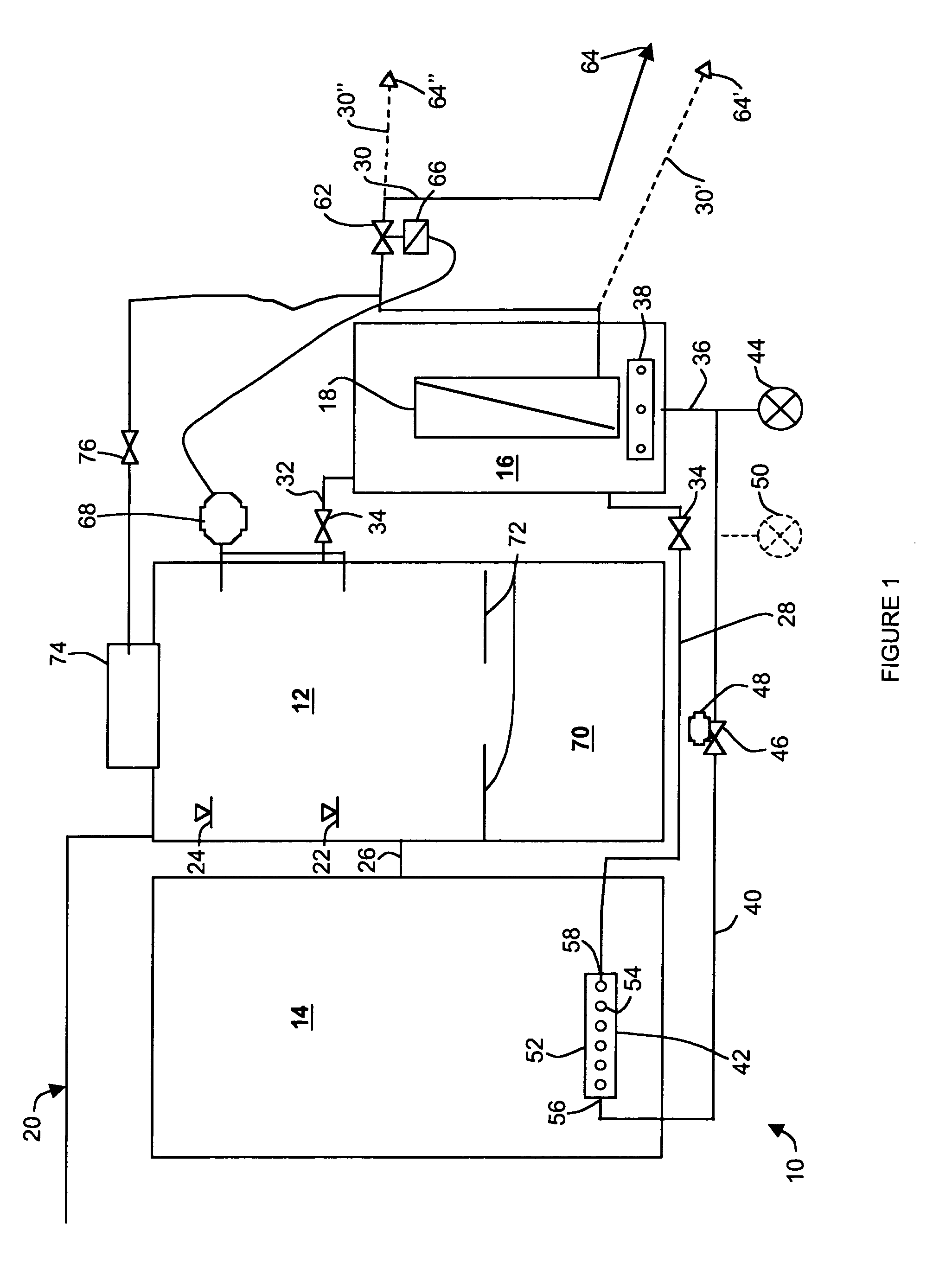

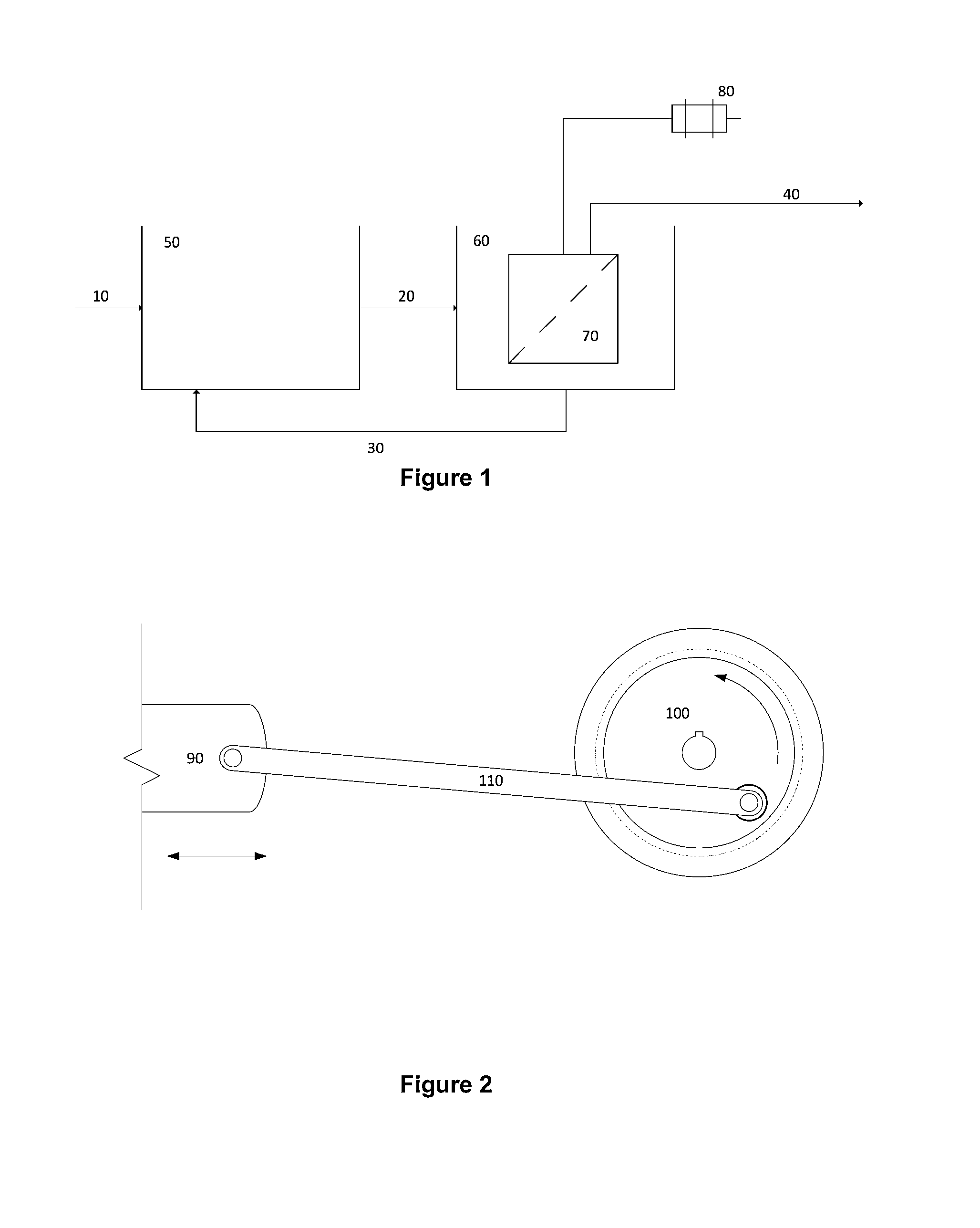

The invention relates to a membrane bioreactor process combined with an advanced biological sludge digestion process that provides significant improvements in sludge digestion by reducing the costs and resources required for disposing of digested sludge. The offline treatment vessel is used to solubilize the organic material by operating in a very low oxygen environment. Digested process fluid is transferred back to the membrane bioreactor. The processes and apparatus substantially reduce the production of waste sludge.

Owner:EVOQUA WATER TECH LLC

Wastewater treatment system and method

ActiveUS20070209999A1Treatment using aerobic processesTreatment involving filtrationActivated carbonWater treatment system

The invention is directed to a method and apparatus for treating wastewater. The wastewater treatment system includes a bioreactor including activated carbon and a first biological population. The wastewater treatment system may also include a membrane bioreactor and / or a wet oxidation unit.

Owner:SIEMENS ENERGY INC

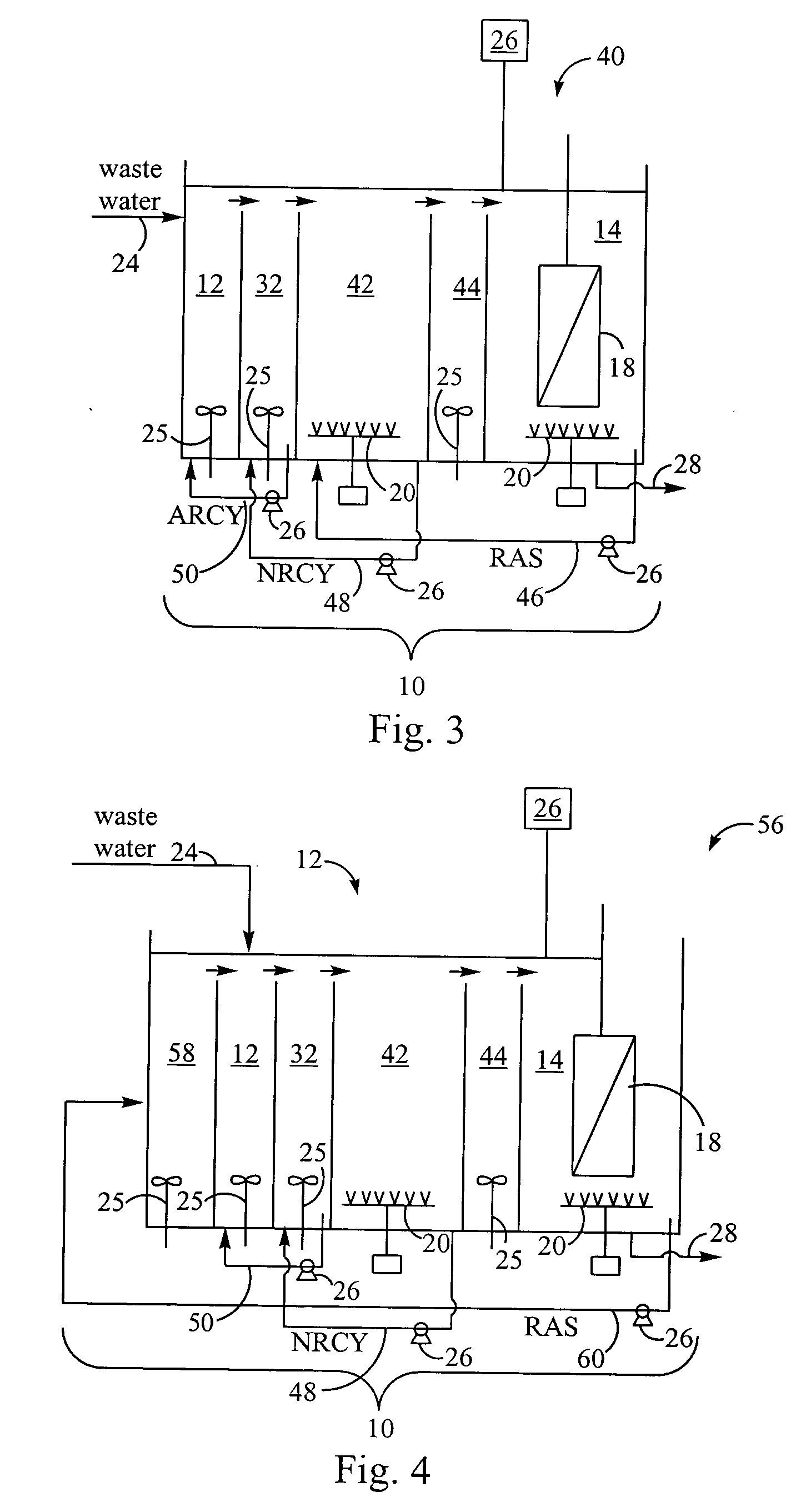

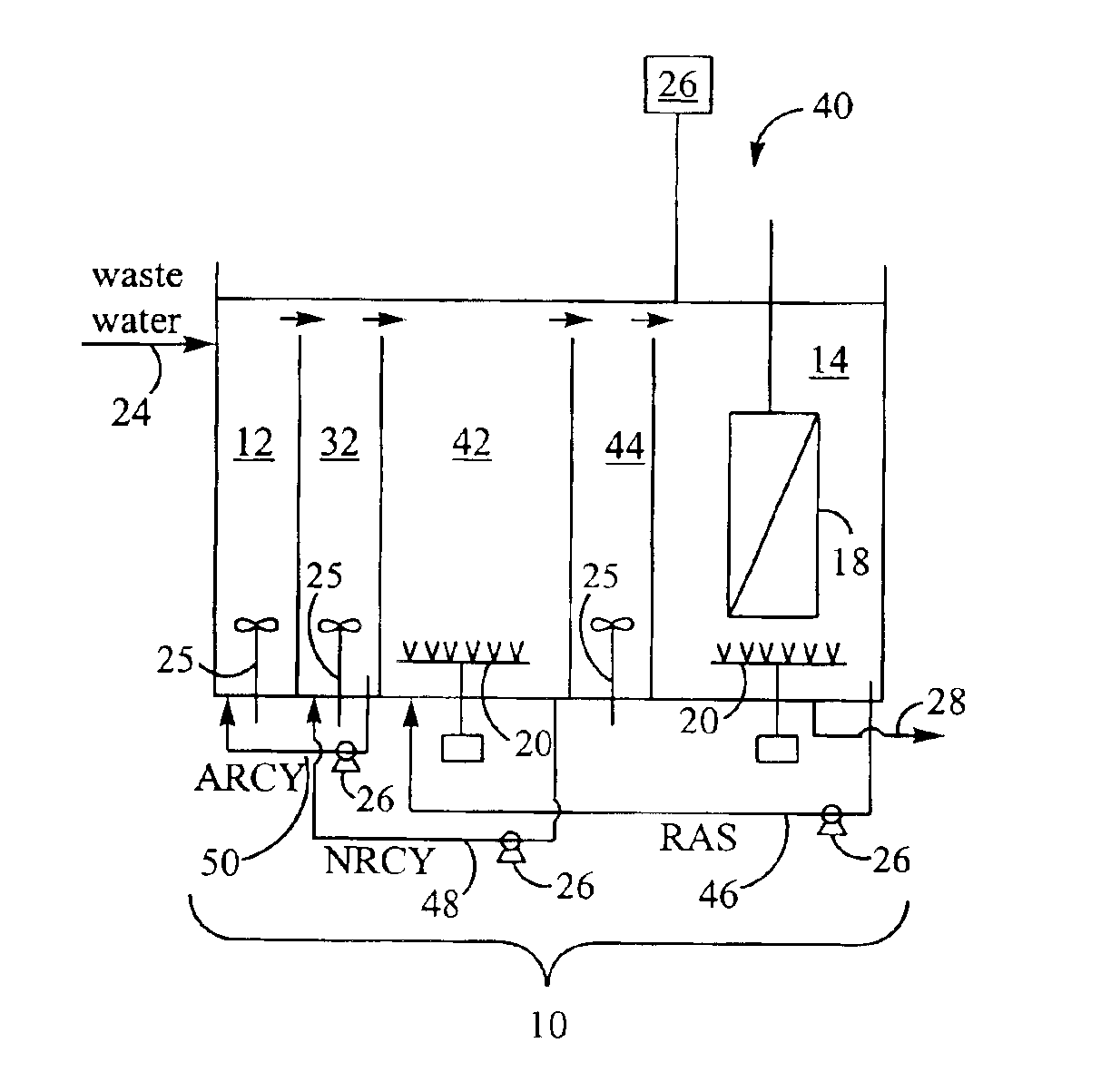

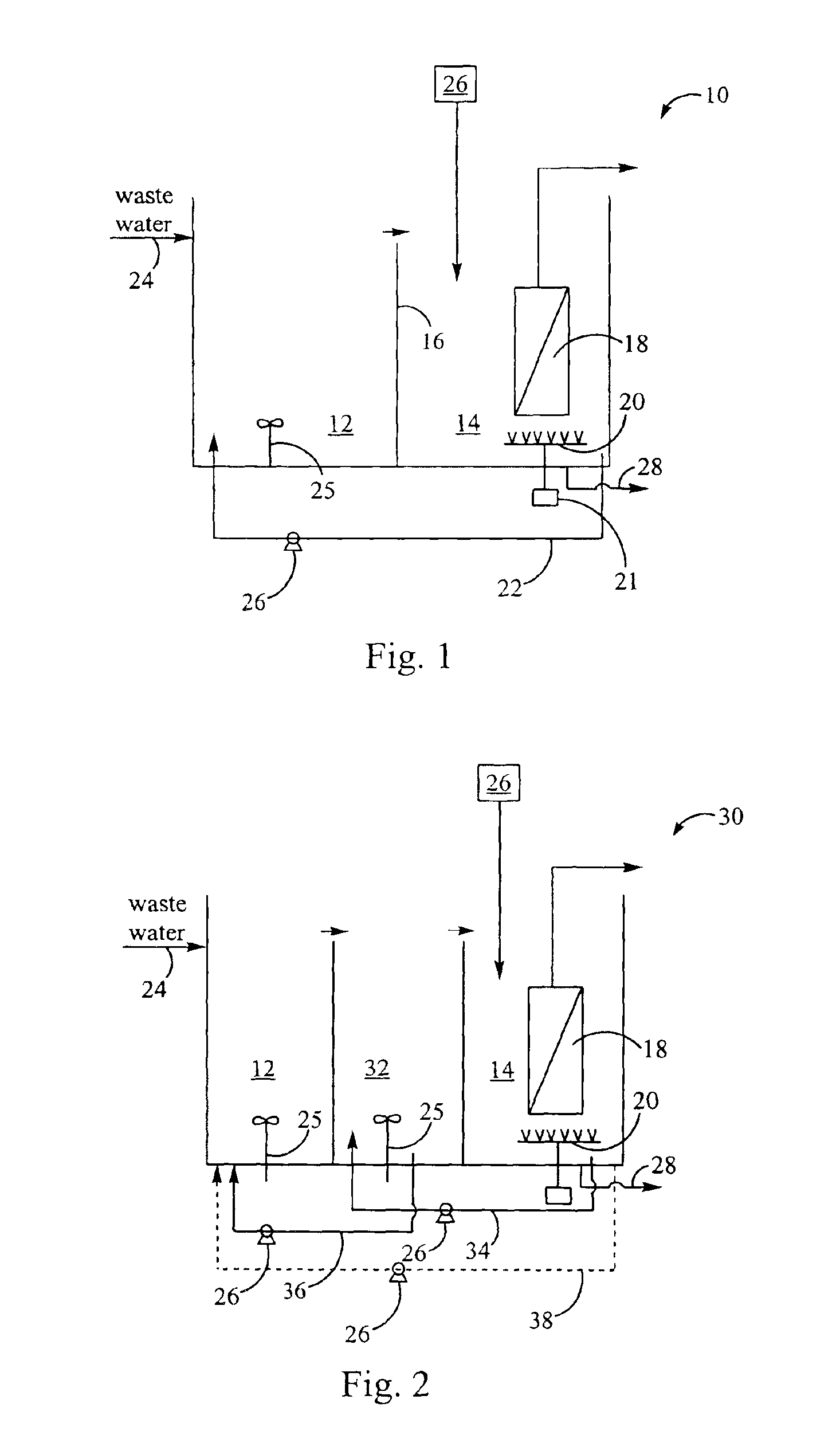

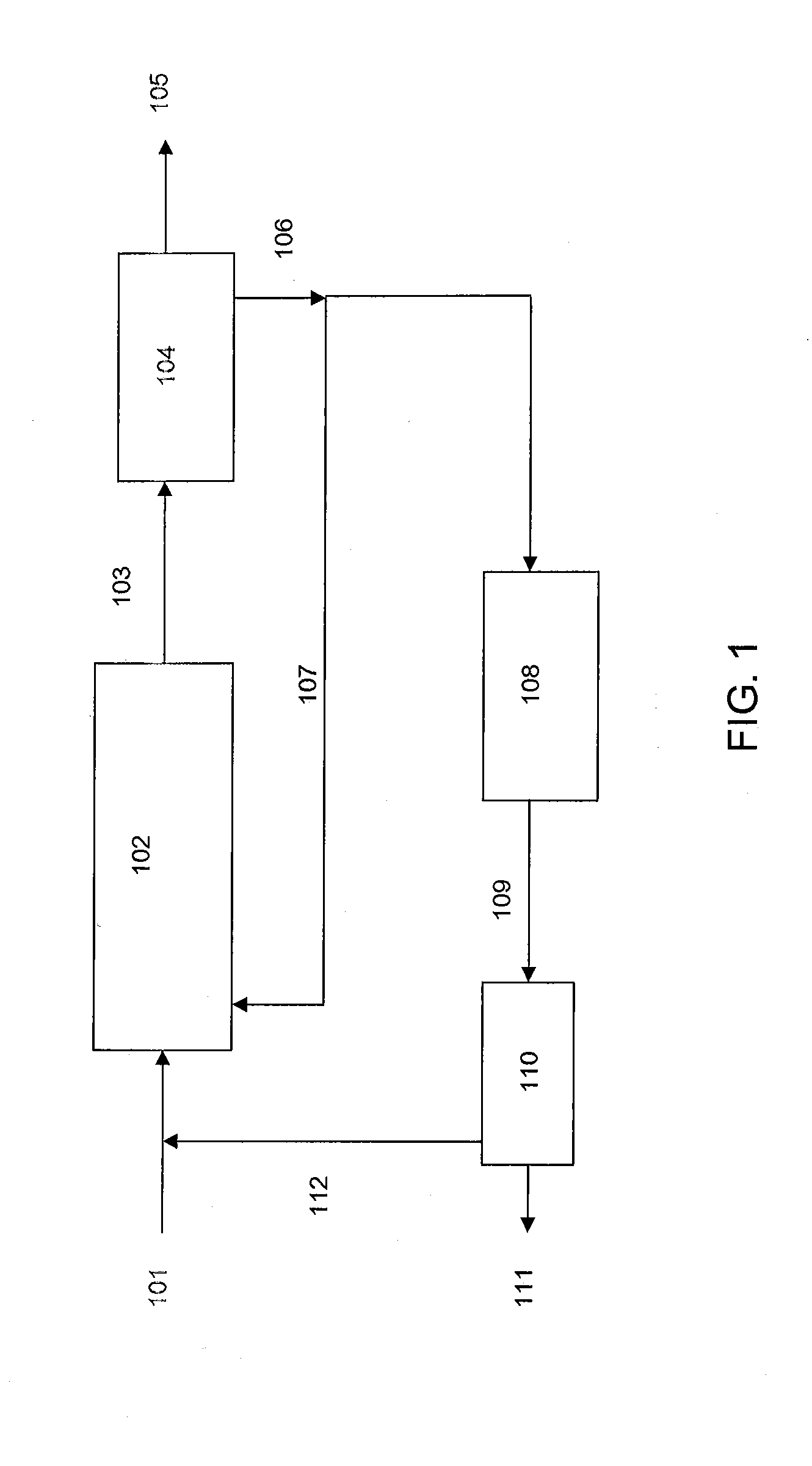

Method for treating wastewater in a membrane bioreactor to produce a low phosphorus effluent

ActiveUS20050045557A1Minimizing space requirementMinimizing attendant costTreatment using aerobic processesOther chemical processesActivated sludgeMembrane bioreactor

Removal of biological nutrients from a wastewater yielding a low phosphorous (e.g., less than 0.25 mg / L) output includes providing a serial multistage bioreactor containing activated sludge having in hydraulic series an anaerobic zone and a downstream aerobic zone, with each zone having an upstream inlet and a downstream outlet. The wastewater is provided to the anaerobic zone inlet. A quantity of chemical sufficient to precipitate soluble and particulate phosphorous is added to the downstream aerobic zone in an amount sufficient to yield a low phosphorous output. Treated water is separated from the activated sludge and precipitated phosphorous and a return activated sludge separated from the treated water is recycled to the anaerobic zone.

Owner:CH2M HILL

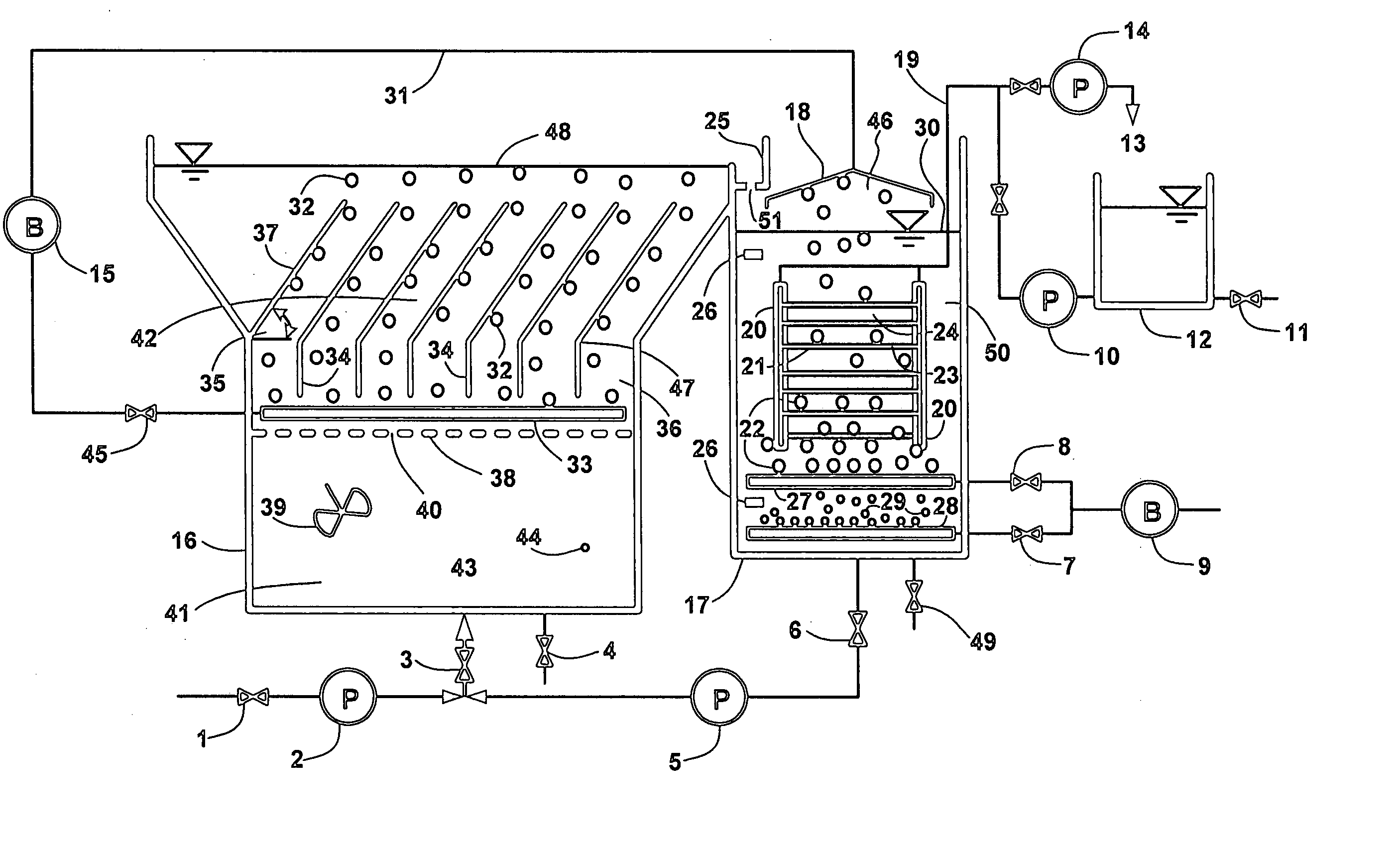

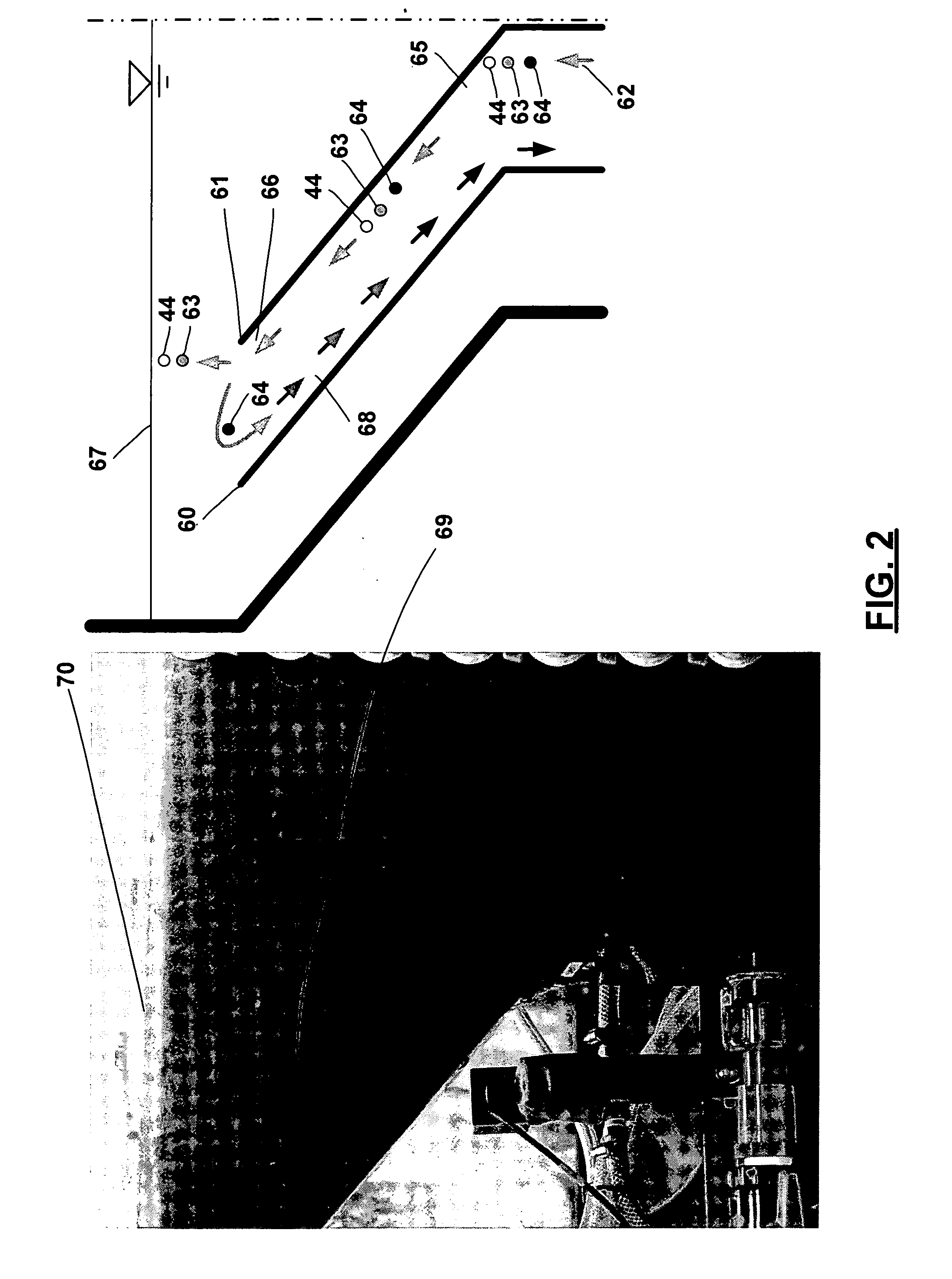

Zero excess sludge membrane bioreactor

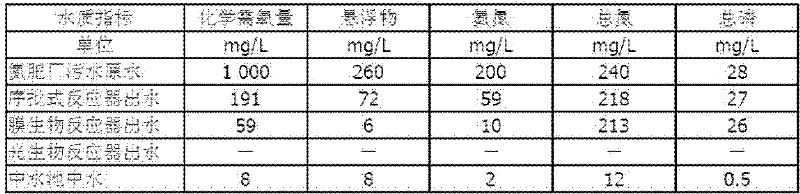

InactiveUS20050194310A1High yieldAcceptable levelTreatment using aerobic processesDialysis systemsChemical oxygen demandTotal nitrogen

An inclined plate coupled membrane bioreactor for treating feed water having excessive level of nutrients in particular chemical oxygen demand and total nitrogen and suspended solids has an aerobic bioreactor for nitrification and aerobic biodegradation in which membranes are submerged for permeate extraction, and an anoxic bioreactor for denitrification within which the inclined plates are outfitted to confine as much anoxic sludge as possible. An air oxygenating and an air scouring are continuously provided to the aerobic bioreactor to maintain a desired aerobic environment and to mitigate membrane fouling while an intermittent air blowing is provided to the anoxic bioreactor to blow out gaseous content generated through denitrification and to rectify the uniformed flow along the inclined plates. The aerobic sludge is recycled to the lower compartment of anoxic bioreactor and the supernatant of anoxic bioreactor is collected as weir effluent and delivered to the downstream aerobic bioreactor. Permeate is intermittently extracted from the membranes by a suction pump. There is no excess sludge withdrawn from the inclined plate coupled membrane bioreactor throughout the experiment.

Owner:YAMAMOTO KAZUO +1

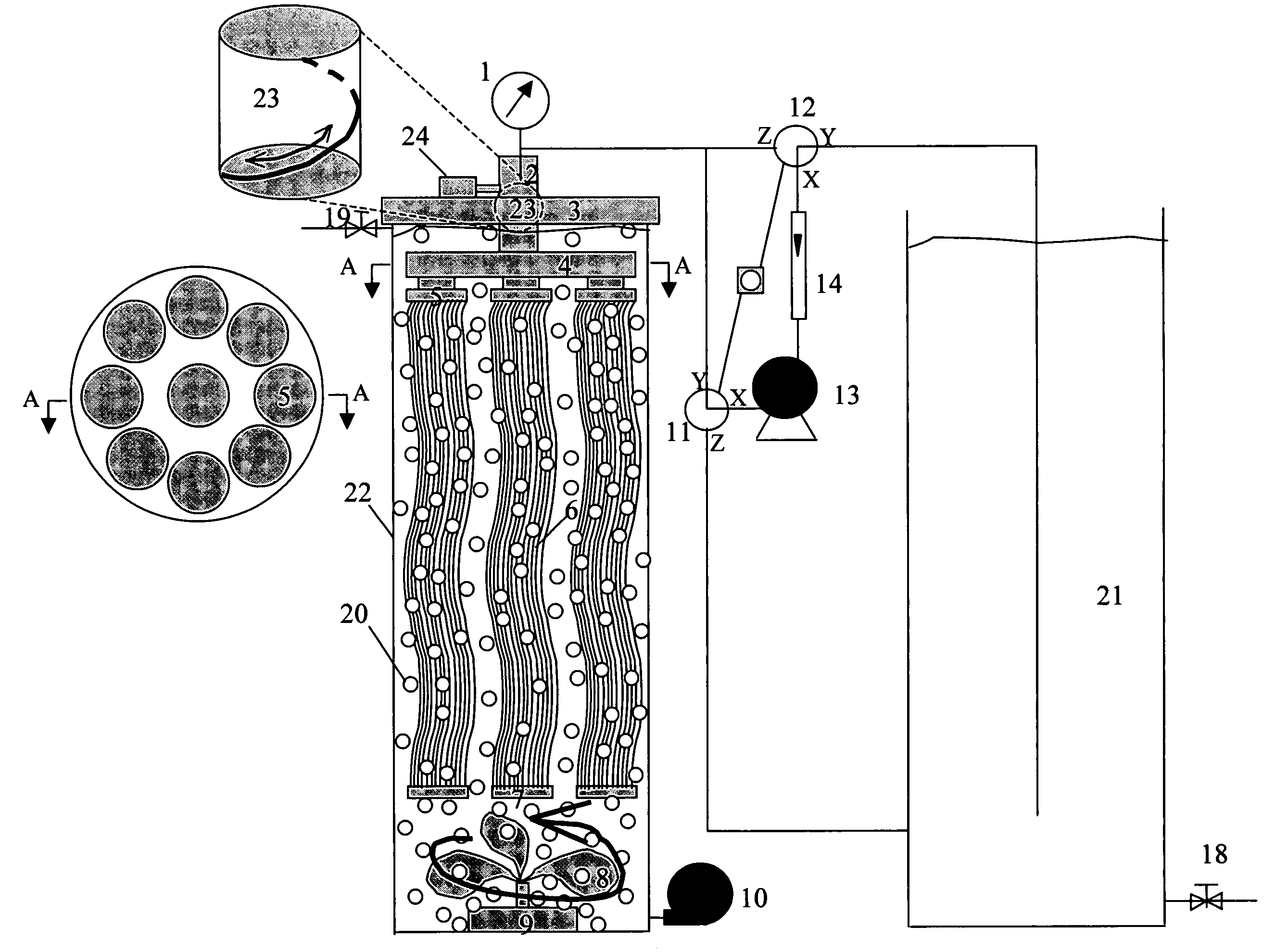

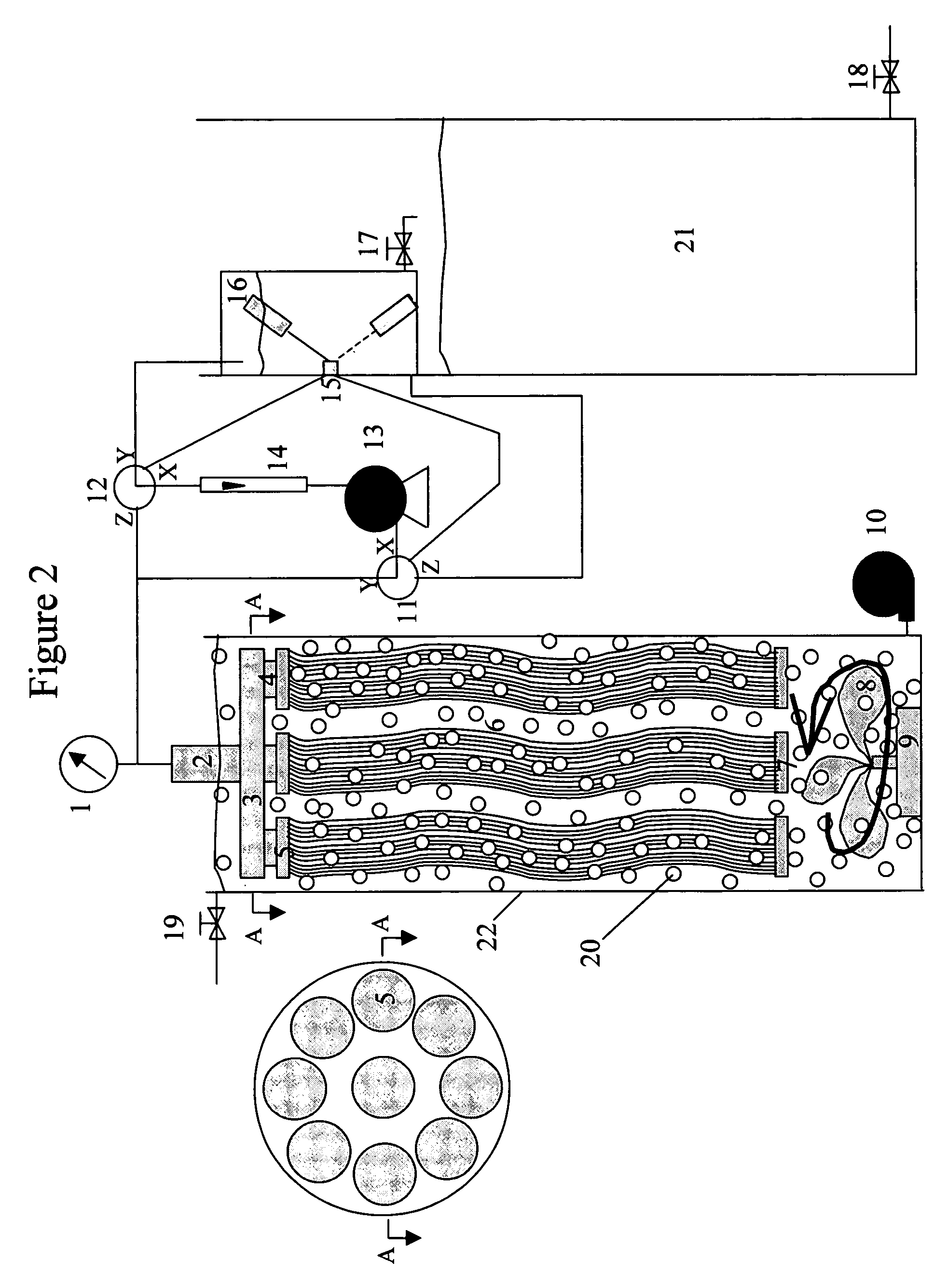

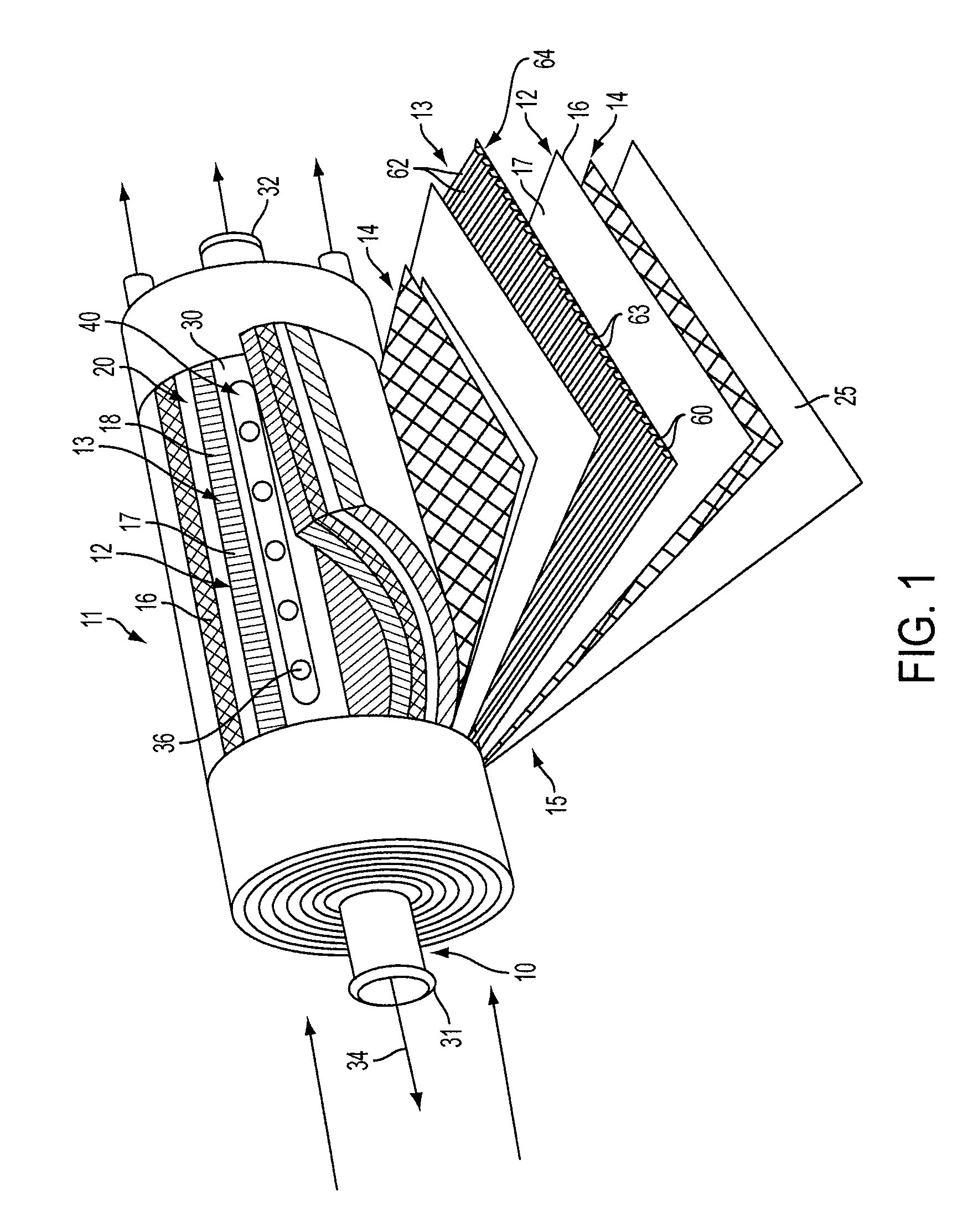

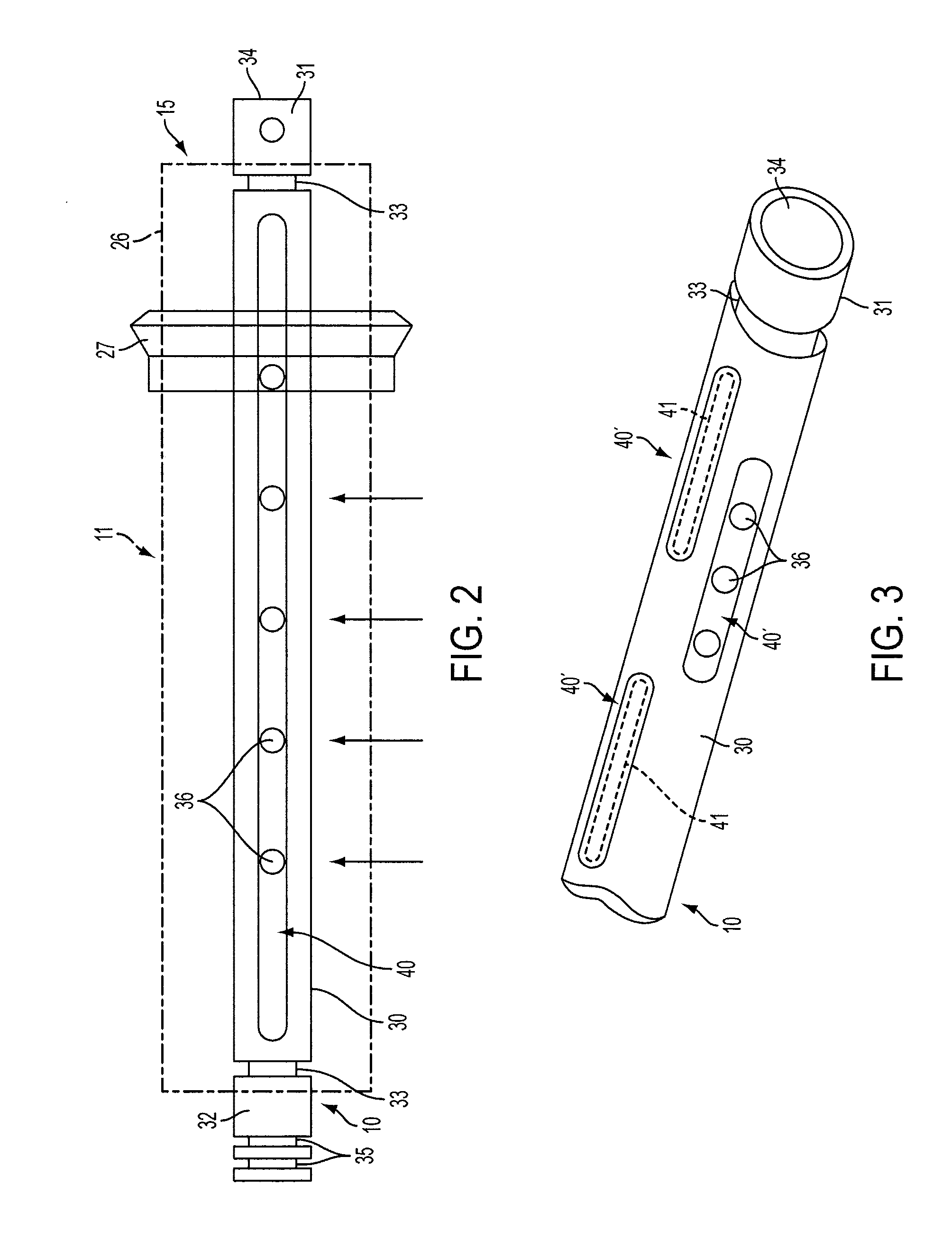

Advanced submerged membrane modules, systems and processes

Advanced submerged membrane systems are provided. Said submerged membrane systems have multiple membrane modules comprising of strips of flat sheet membrane, bundles of self-support hollow fiber membranes braided together for reinforcement, tubular membranes, and braid supported hollow fiber membranes. Said submerged membrane systems have alternating relay, or two-way floating switch or computer to control filtration and back flush / pulse cleaning. Said submerged membrane systems have an oscillating motor, and aerator which can generate liquid vortex (whirlpool) flow around membrane to keep membrane from fouling. The present invention provides advanced submerge membrane systems at very low cost for drinking water production, wastewater treatment and membrane bioreactors for biotech, pharmaceutical and other industries.

Owner:JI JIANG

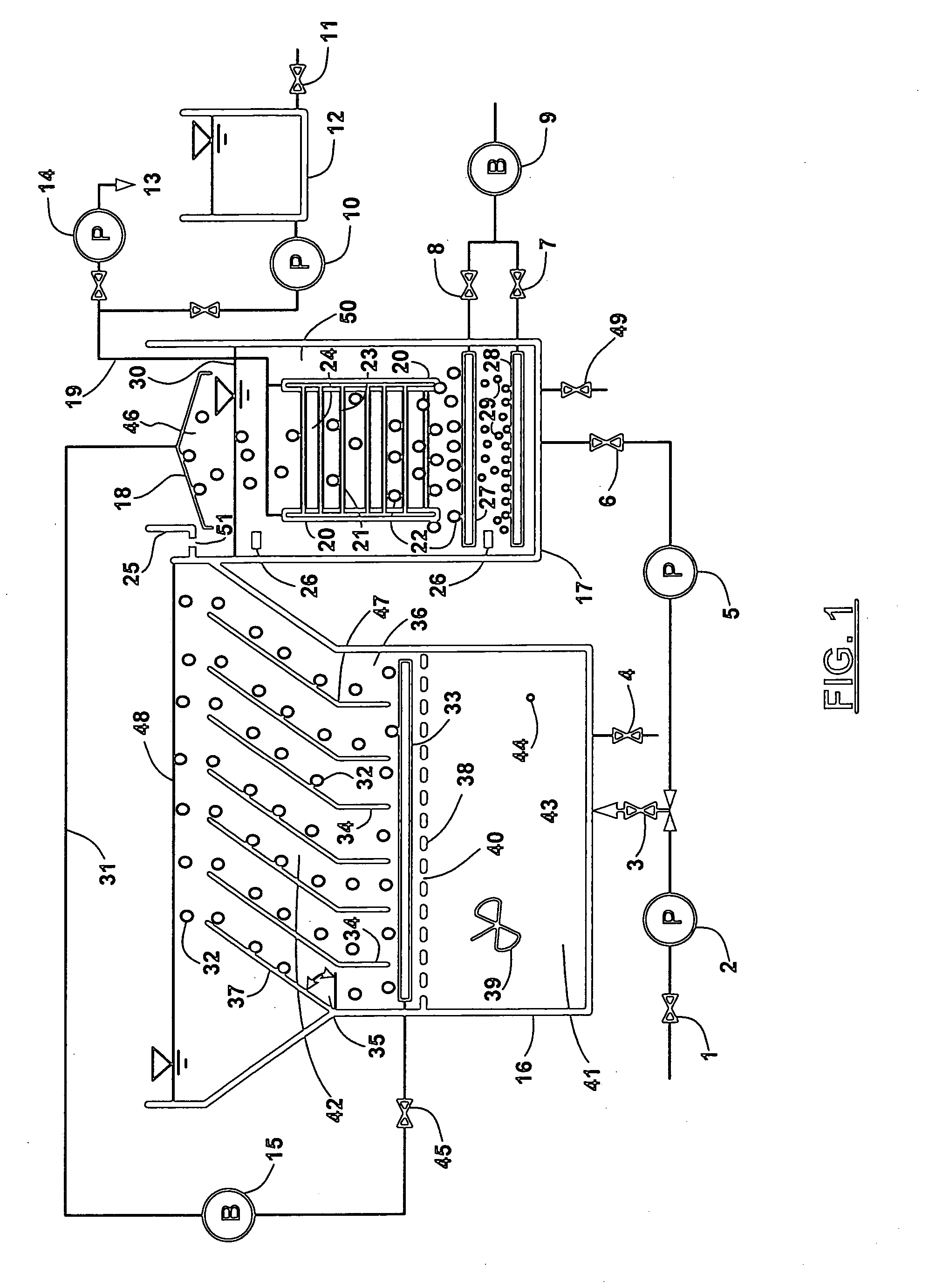

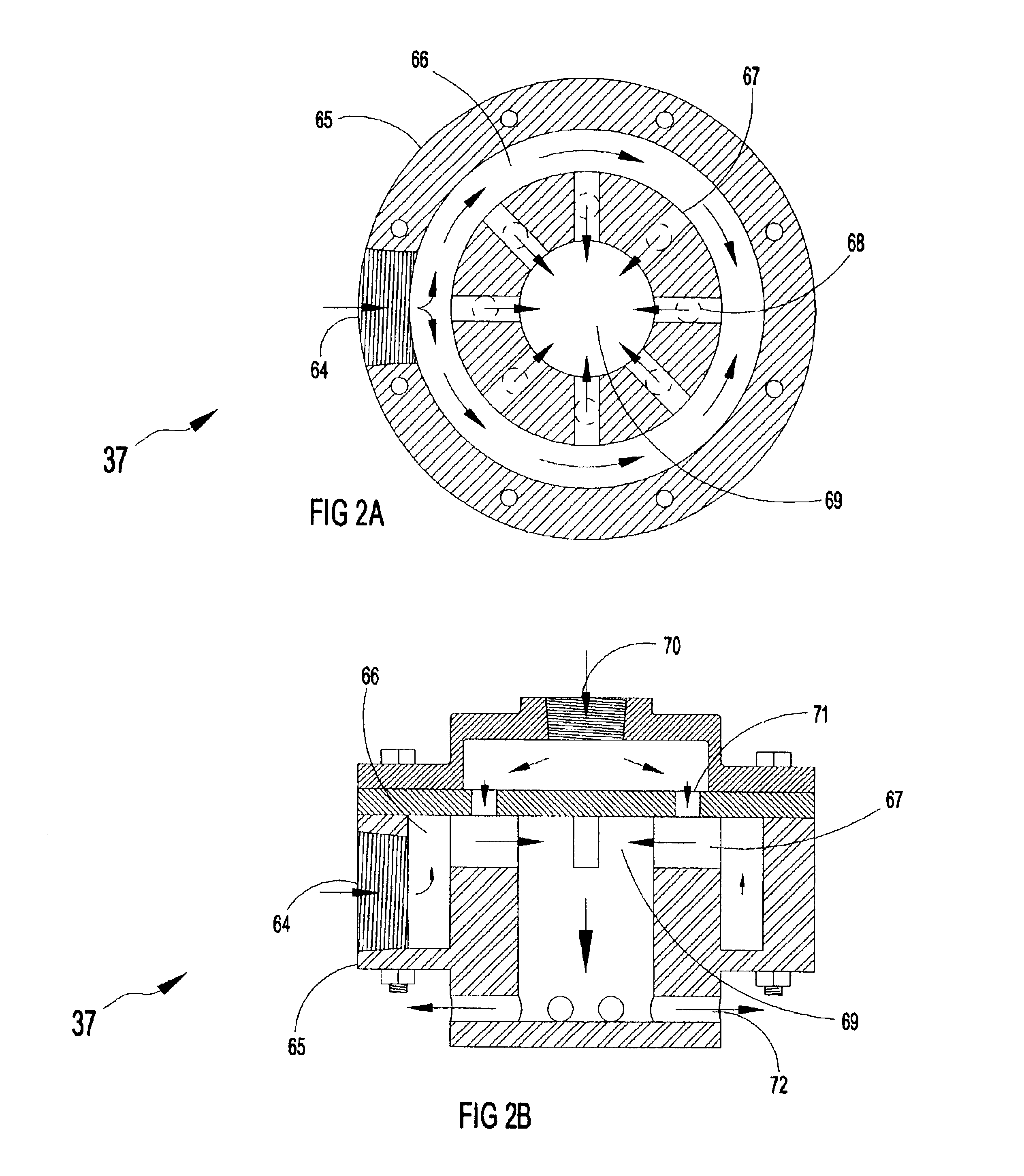

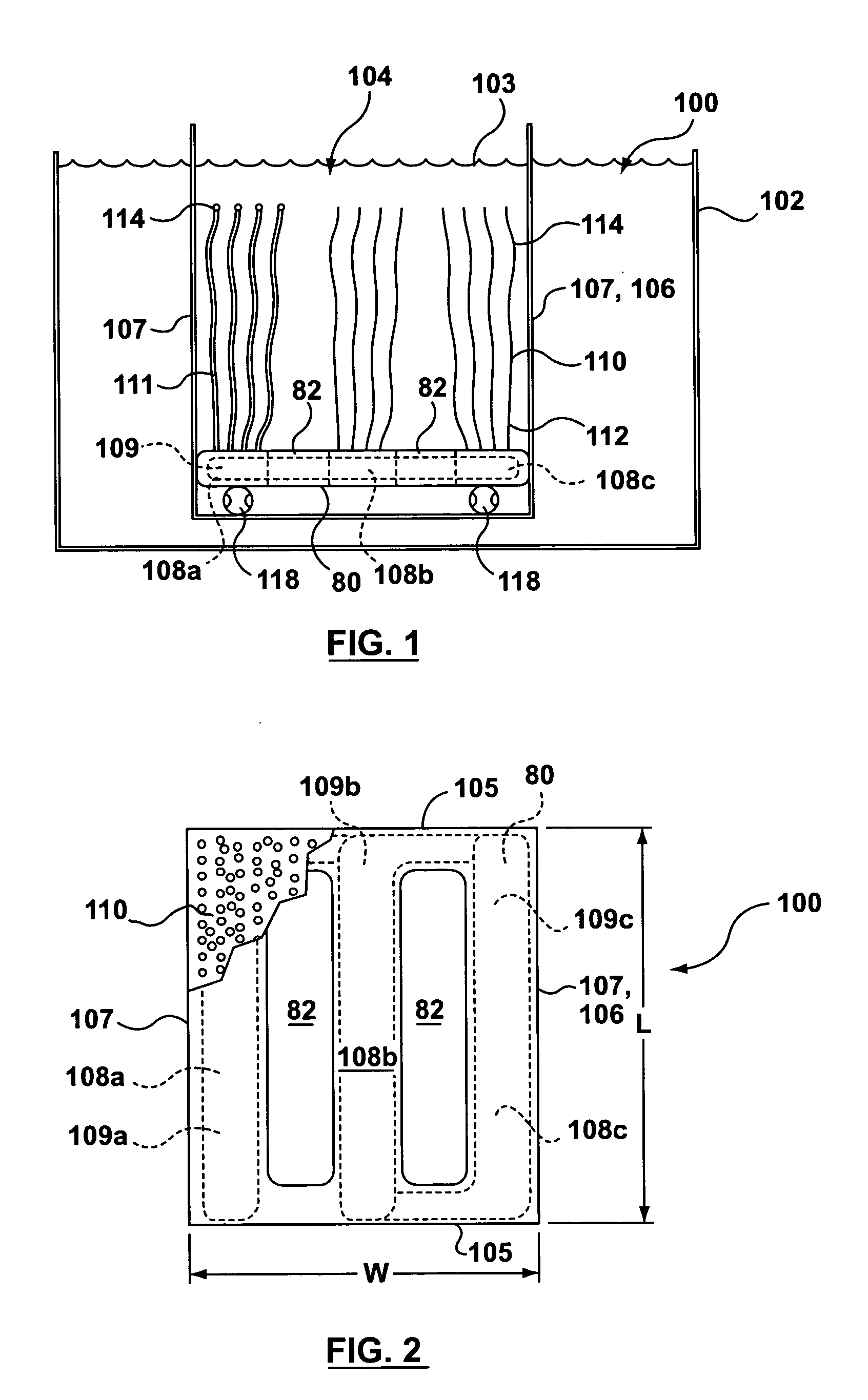

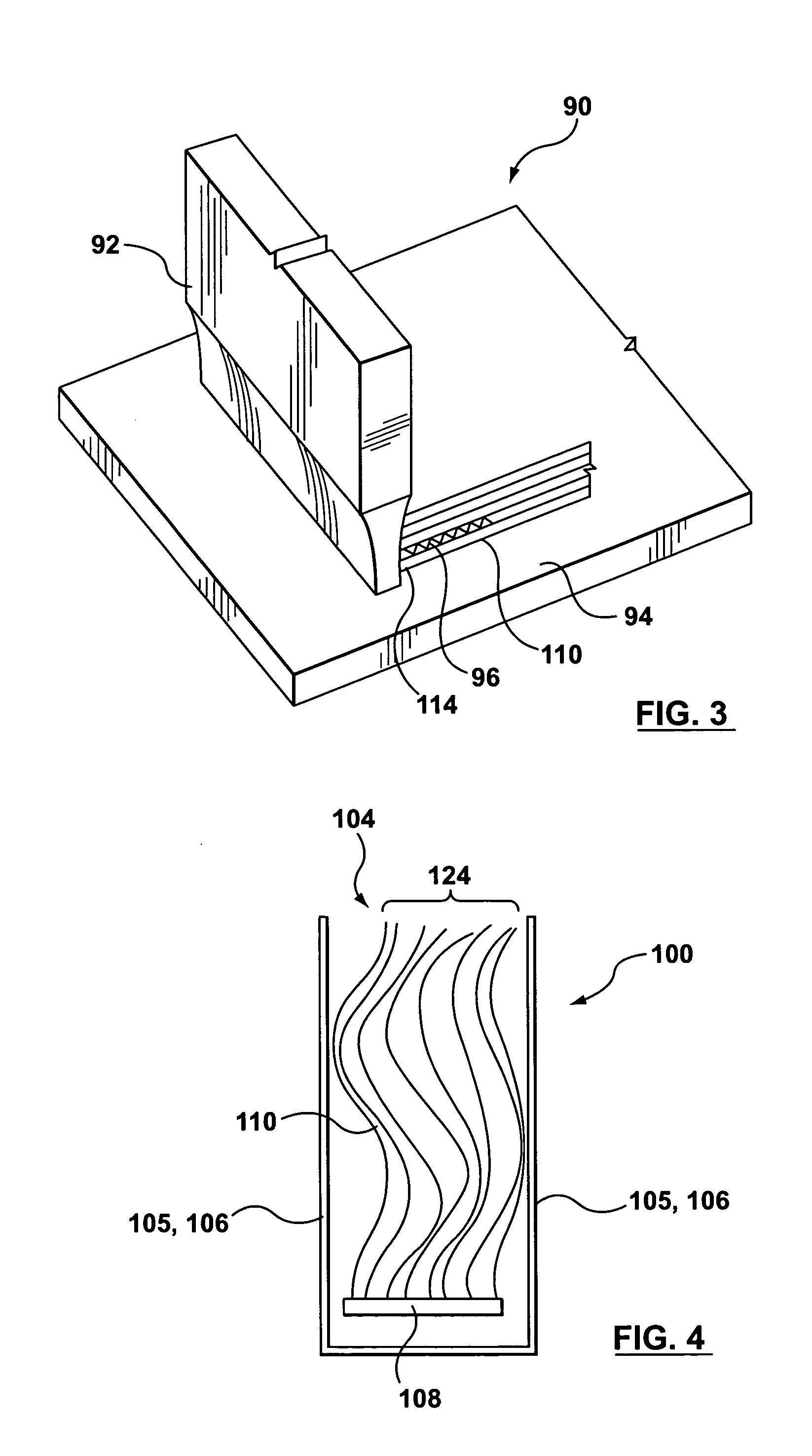

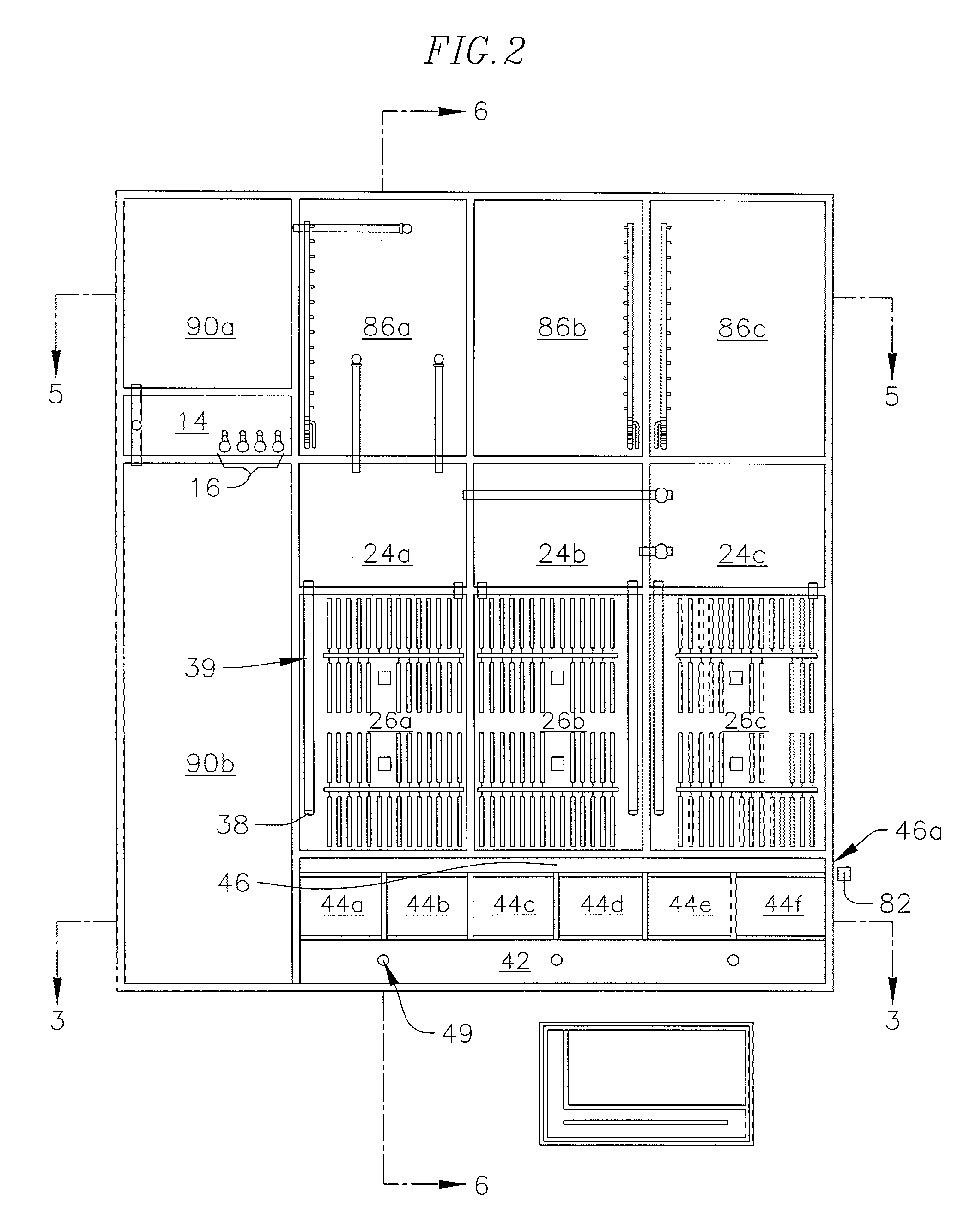

Method and apparatus for treatment of wastewater employing membrane bioreactors

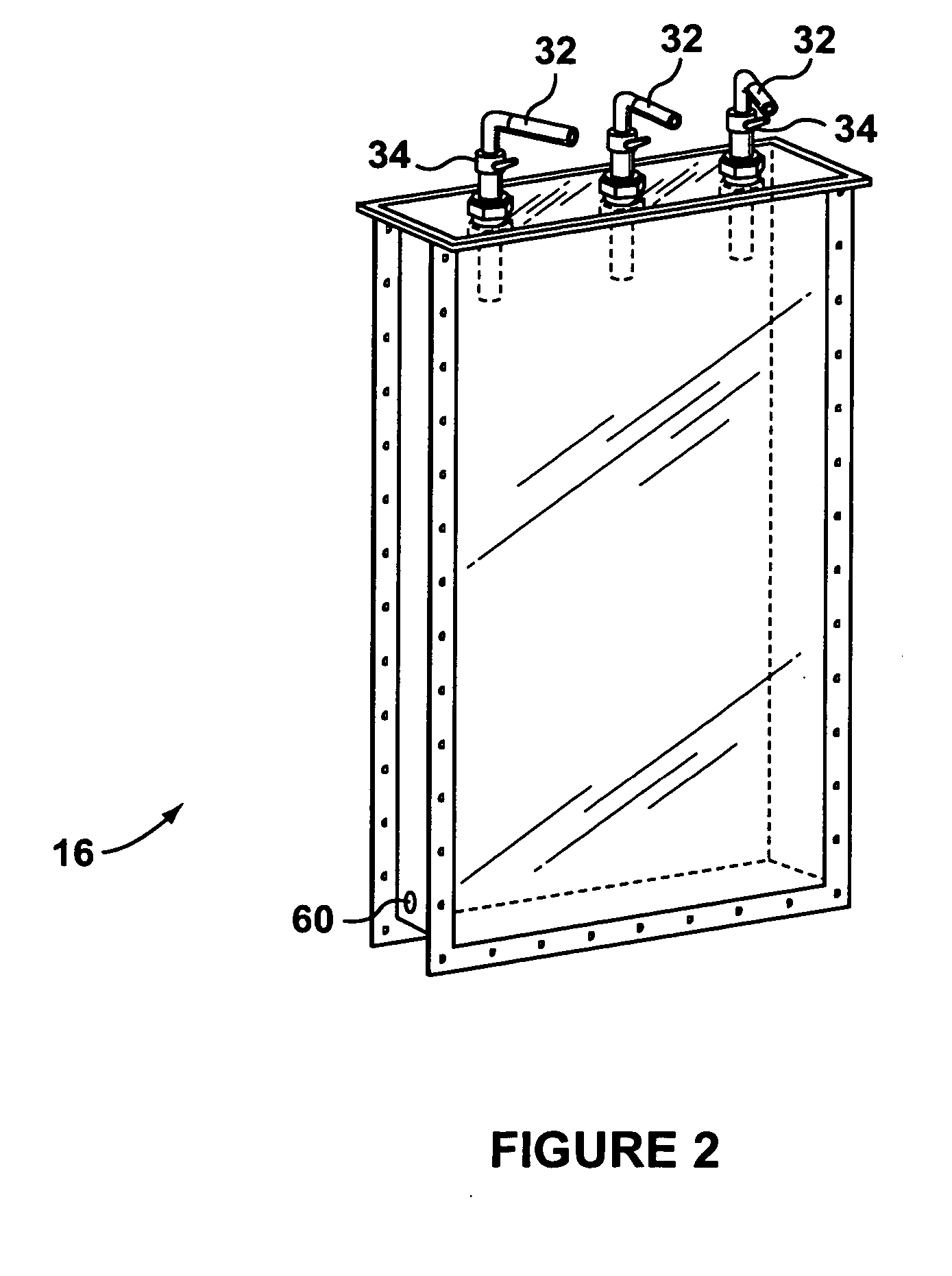

InactiveUS6805806B2Accelerates the biodegradation processAvoid cloggingLiquid separation auxillary apparatusTreatment using aerobic processesAeration systemFiltration

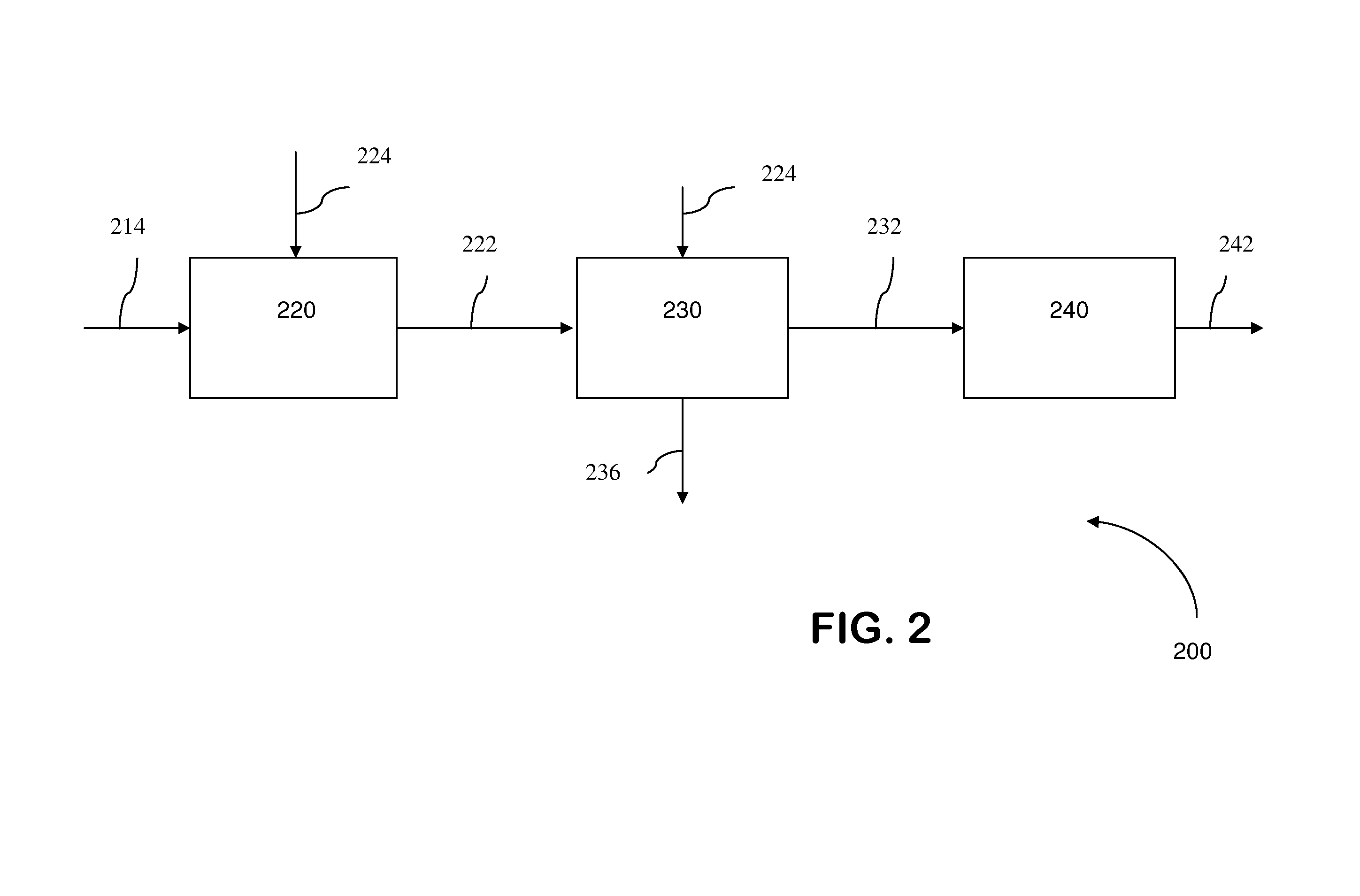

Methods and apparatus employing membrane filtration in biodegradation processes for treatment of wastewater are described. A bioreactor system is described having an equalization system, a membrane bioreactor system, and a controller. Aeration systems for a membrane bioreactor, such as a mixer, and an ultrafilter subsystem are also described, as is a rotary membrane ultrafilter.

Owner:HYDROTREAT

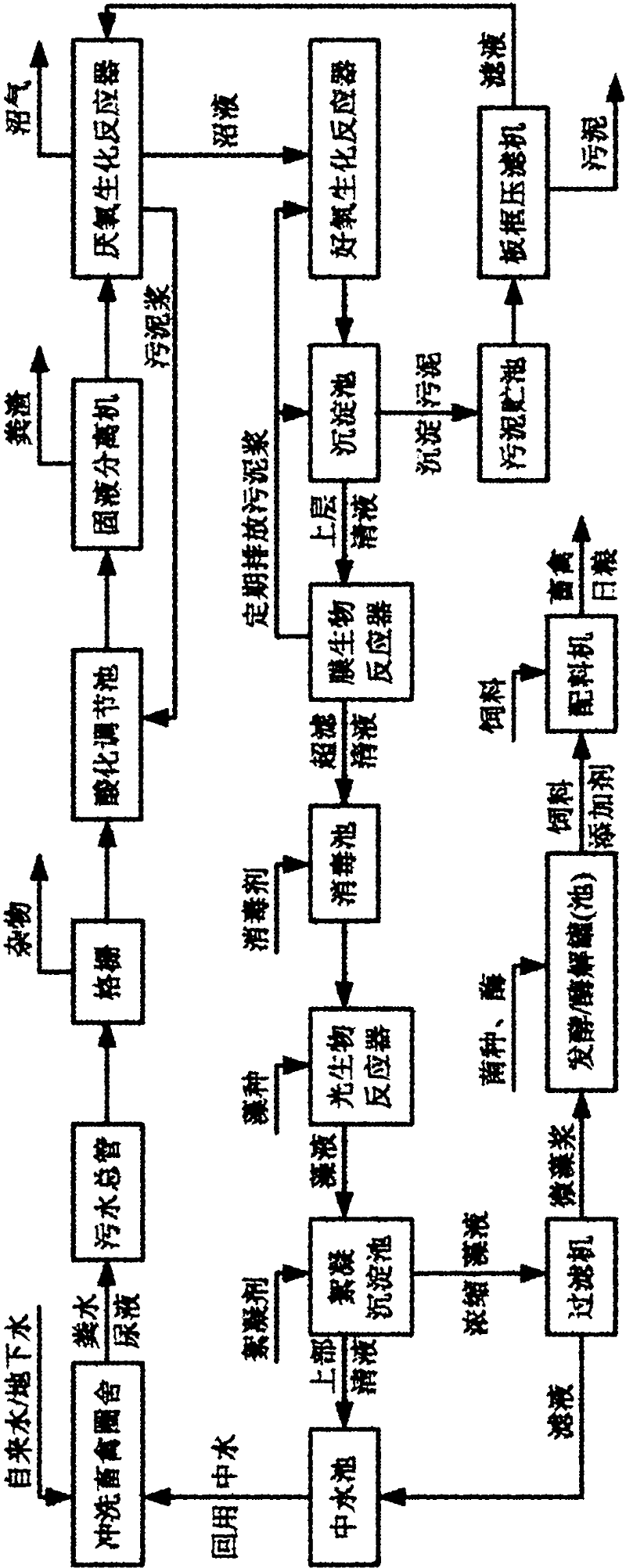

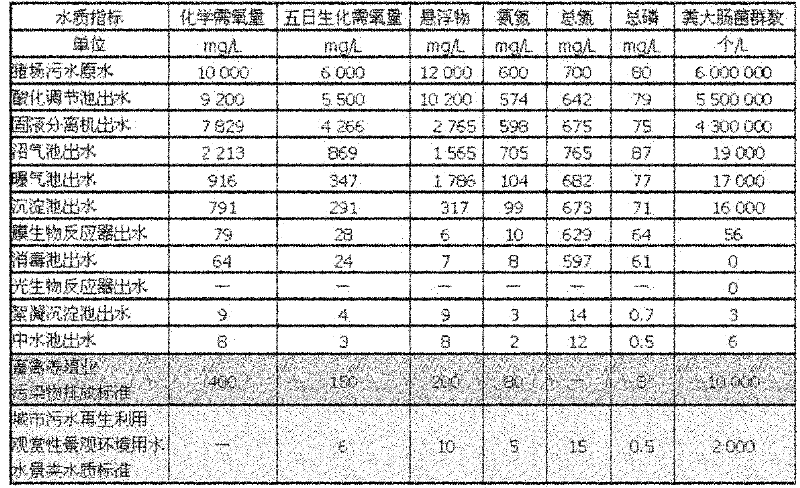

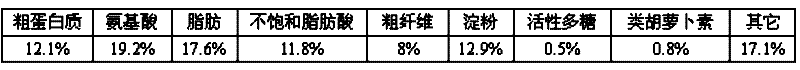

Method for producing feed additive from livestock and poultry breeding wastewater and purifying breeding wastewater to reclaimed water

InactiveCN102161550AReduce water consumptionAchieving zero emissionsWaste water treatment from animal husbandryAnimal feeding stuffUltrafiltrationSlurry

The invention relates to the fields of environmental technology and the breeding and processing of microalgae, in particular to a method for producing feed additive from livestock and poultry breeding wastewater and purifying breeding wastewater to reclaimed water. The method is characterized by comprising the following steps that: wastewater enters an acidification adjusting tank through a grille, and the acidified wastewater enters an anaerobic biochemical reactor for treatment and then enters an aerobic biochemical reactor; after the aerobic biochemical treatment, the obtained biogas slurry enters a settling tank for settling, the supernatant enters a membrane bioreactor for further aerobic treatment and is filtered by an ultrafiltration membrane, the generated ultrafiltration clear liquid is sterilized and neutralized and then enters a photobioreactor, algae are added into the photobioreactor to perform microalgae cultivation, and the algae liquid is discharged from the photobioreactor and then enters a flocculation and settling tank; and after flocculation and settling, the supernatant is used for water recycling, the concentrated algae liquid at the bottom enters a filter, and the separated microalgae slurry enters a fermentation / enzymolysis pot (tank) to perform fermentation / enzymolysis to be used as the feed additive. The invention has the advantages of high economic adaptability, zero discharge and the like.

Owner:蔡志武 +1

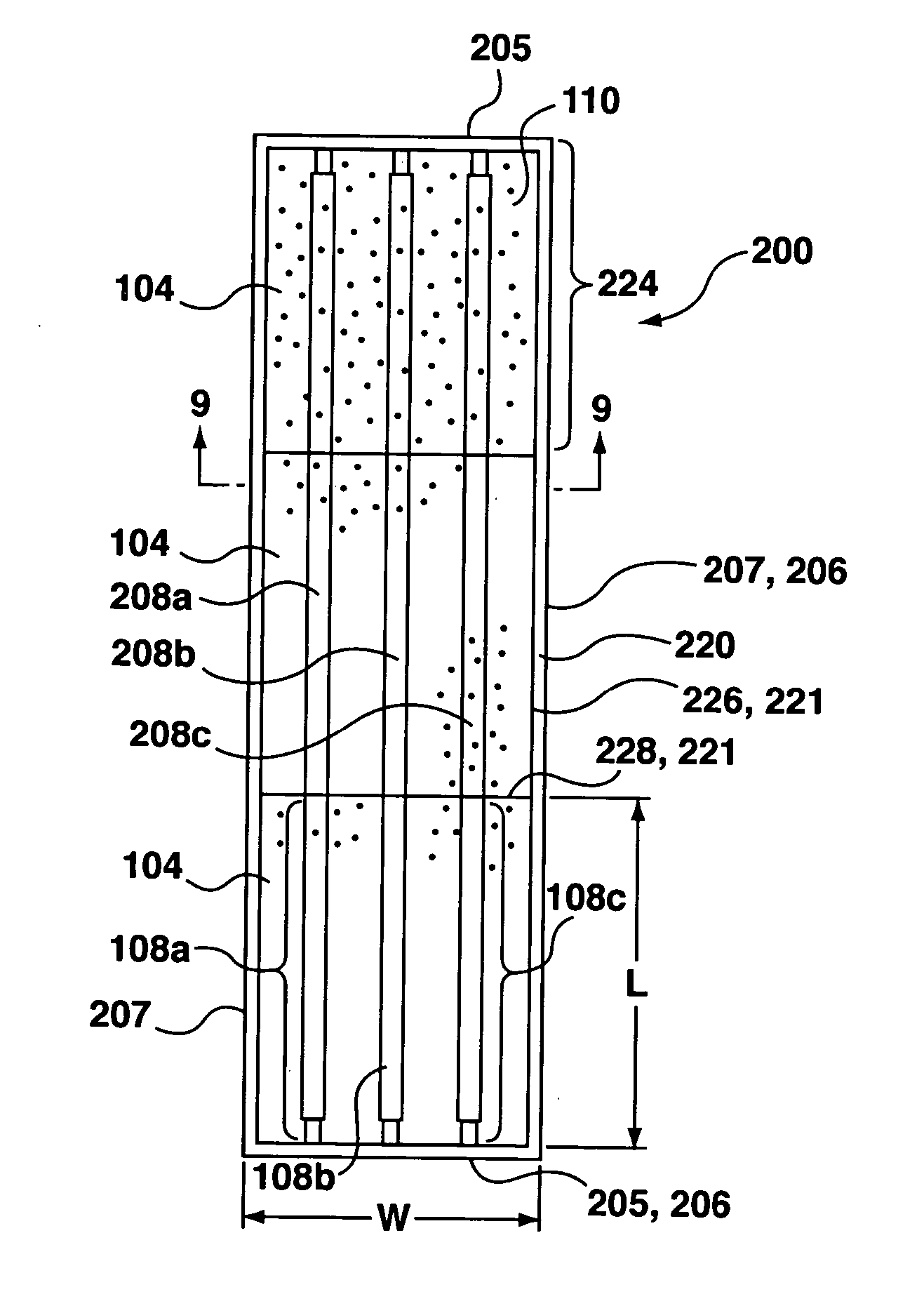

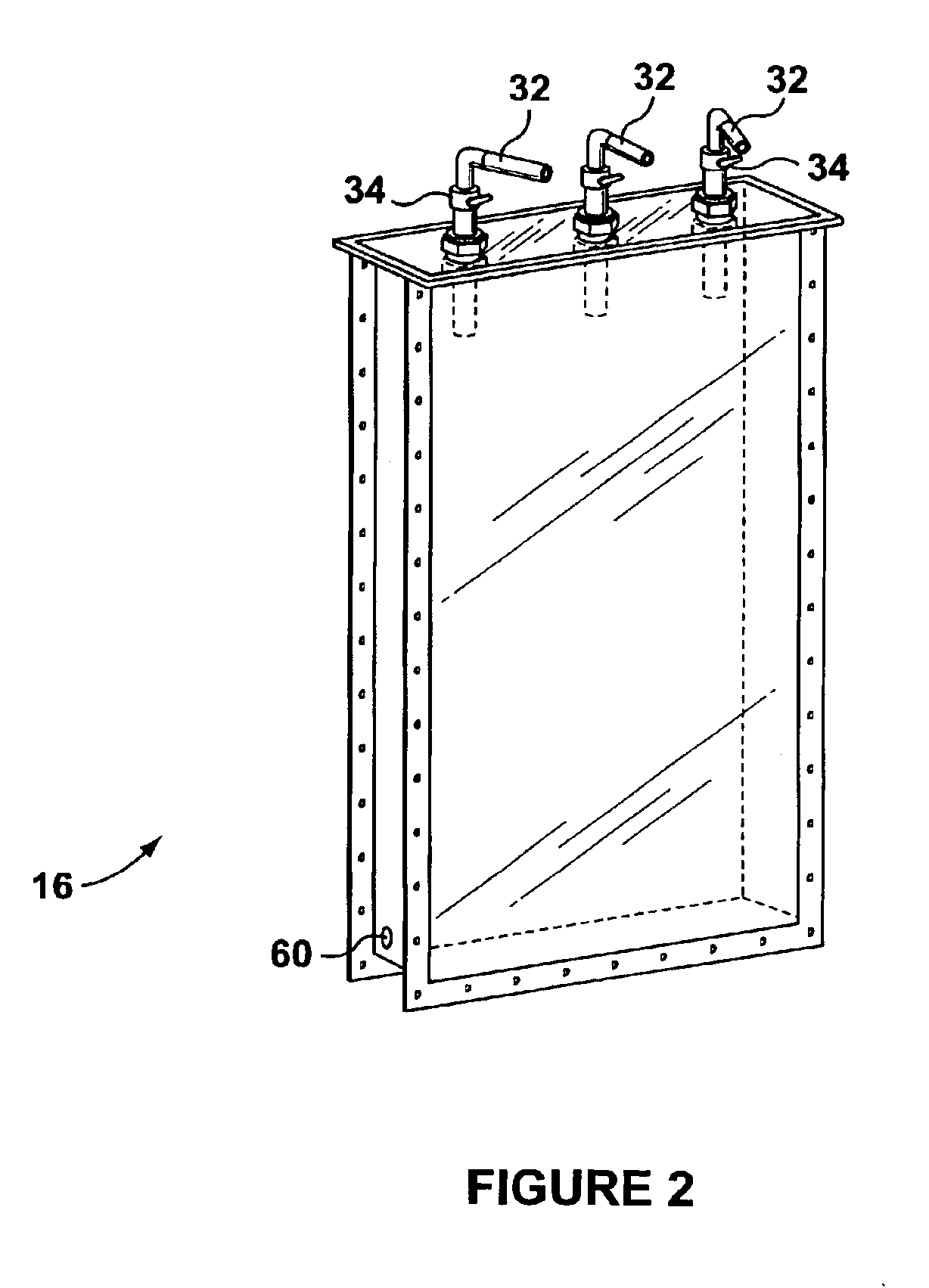

Membrane bioreactor having single header membrane module

A filtration apparatus for filtering liquid has a filtration cell having generally vertical front and rear panels spaced apart to define a cell length, and generally vertical side panels extending between the front and rear panels and spaced apart to define a cell width. A plurality of header segments are provided in the cell, each header segment having a permeate channel. A plurality of hollow fiber membranes are associated with each header segment and extend generally upright between the cell panels, each membrane having a lumen in flow communication with the permeate channel of the associated header segment and a lower end secured to the associated header segment and a loose upper end.

Owner:ZENON ENVIRONMENTAL INC

Method for treating wastewater in a membrane bioreactor to produce a low phosphorus effluent

InactiveUS6946073B2Reduce outputPromoting robust nutrient uptakeTreatment using aerobic processesOther chemical processesActivated sludgeMembrane bioreactor

Removal of biological nutrients from a wastewater yielding a low phosphorous (e.g., less than 0.25 mg / L) output includes providing a serial multistage bioreactor containing activated sludge having in hydraulic series an anaerobic zone and a downstream aerobic zone, with each zone having an upstream inlet and a downstream outlet. The wastewater is provided to the anaerobic zone inlet. A quantity of chemical sufficient to precipitate soluble and particulate phosphorous is added to the downstream aerobic zone in an amount sufficient to yield a low phosphorous output. Treated water is separated from the activated sludge and precipitated phosphorous and a return activated sludge separated from the treated water is recycled to the anaerobic zone.

Owner:CH2M HILL

Membrane bioreactor, process and aerator

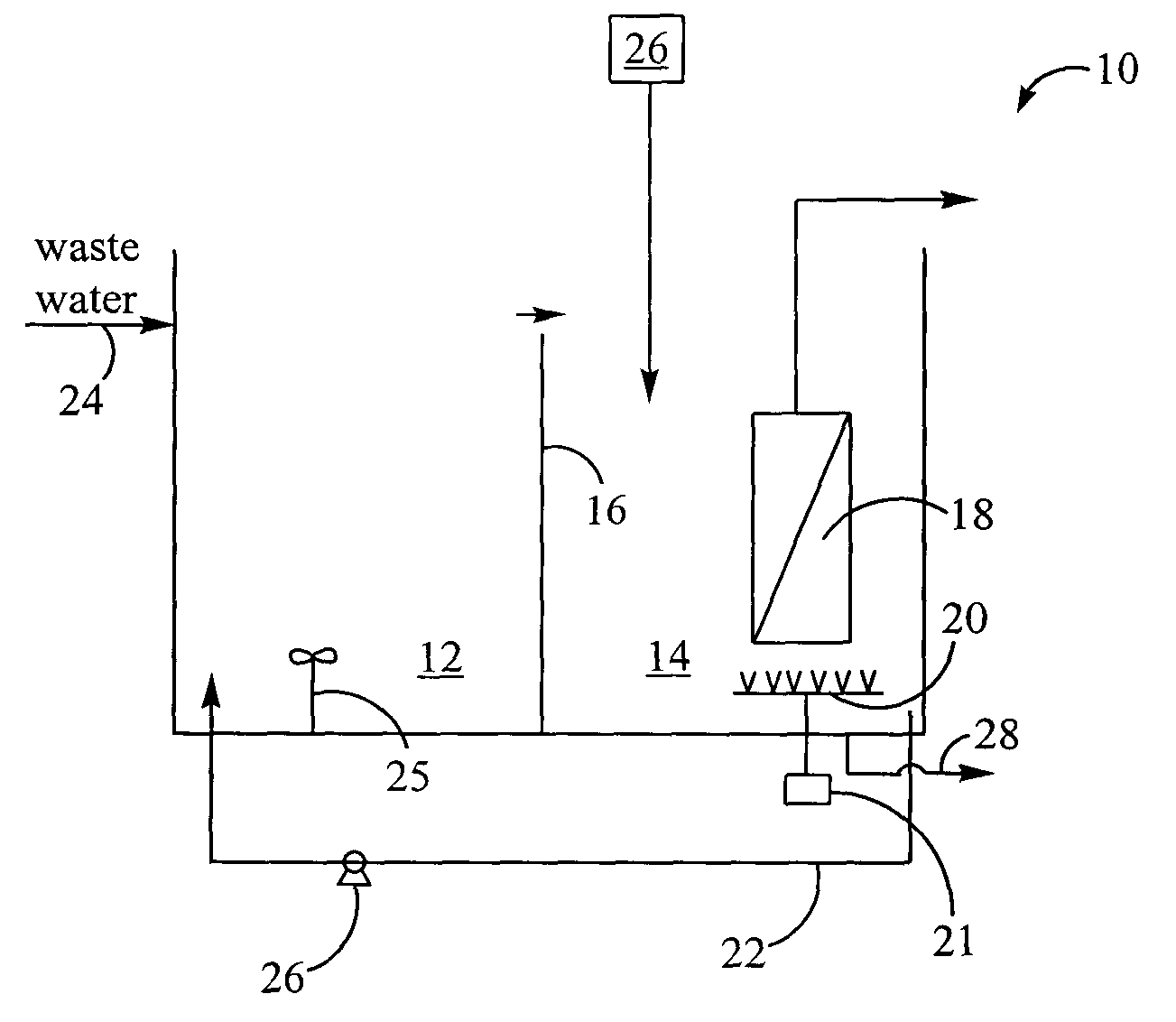

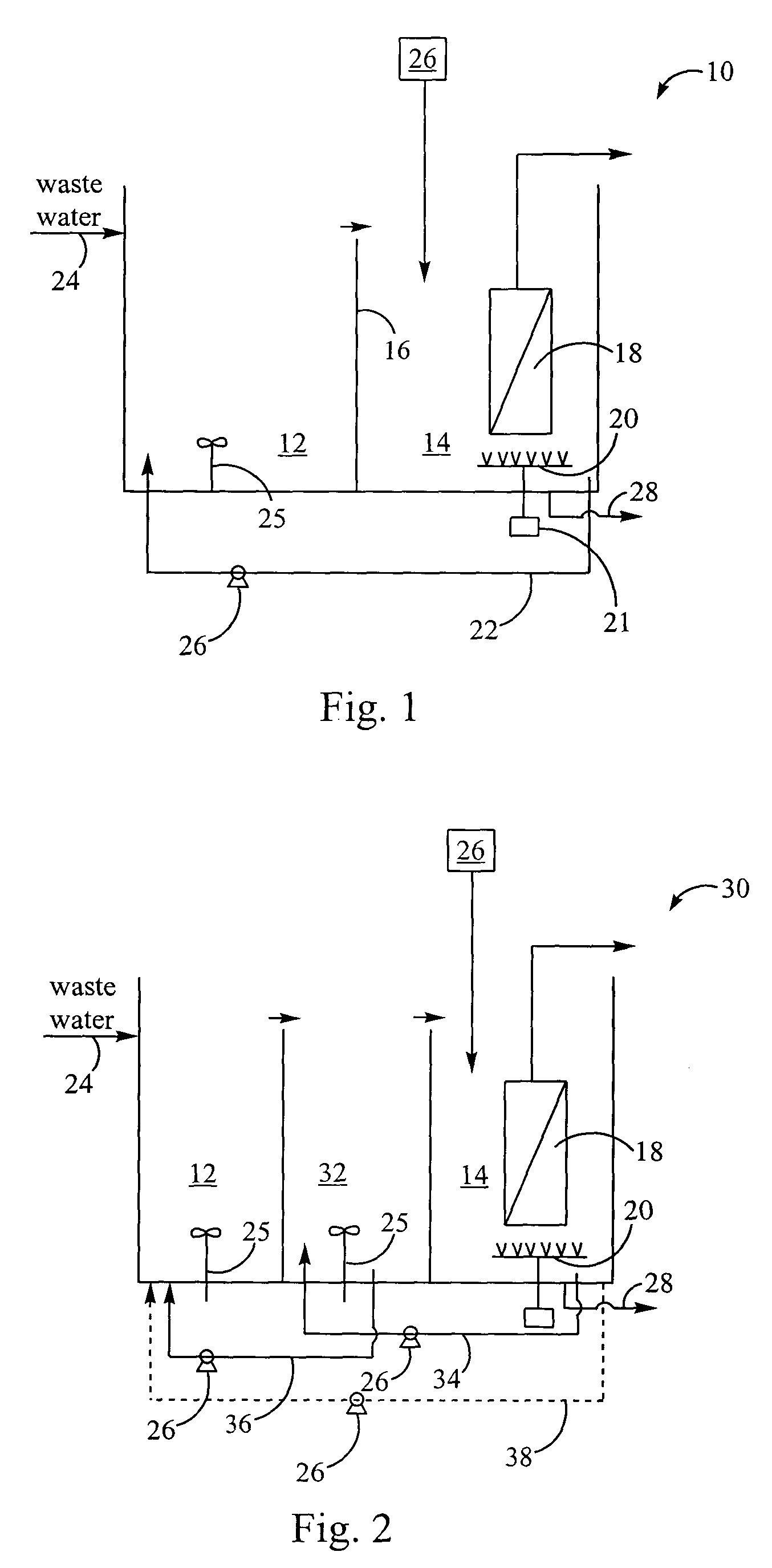

InactiveUS6863817B2Increase pressureEasy to moveTreatment using aerobic processesUsing liquid separation agentSiphonGravity flow

A reactor has an aerobic tank, an anoxic tank and a sealed membrane tank with conduits for circulating mixed liquor between them. Permeation starts when the mixed liquor reaches a high level and stops when the mixed liquor reaches a low level. A sensor, for detecting the mixed liquor level, may stop and start permeation. Pressure builds in the membrane tank when membrane air is on. Transmembrane pressure is also provided by gravity flow or siphon. Membrane air generates an air lift which drives the mixed liquor circulation. The total amount of air provided by an air source is divided and varied in time between the membrane aerator and the process aerator. The process aerator acts as a screening inlet to the conduit to the membrane tank. Chemical maintenance cleaning is provided by gravity flow.

Owner:ZENON TECH PARTNESHIP

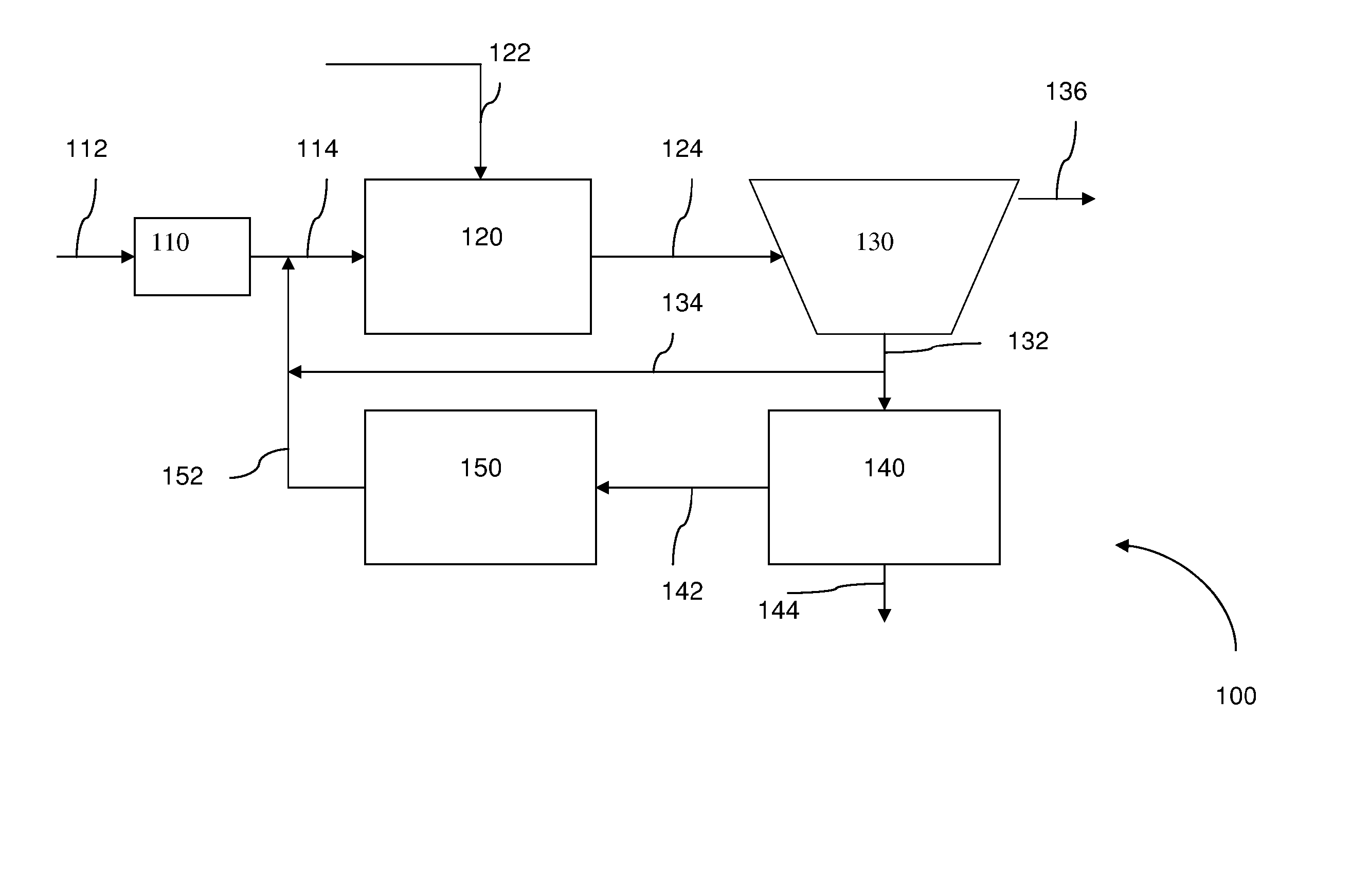

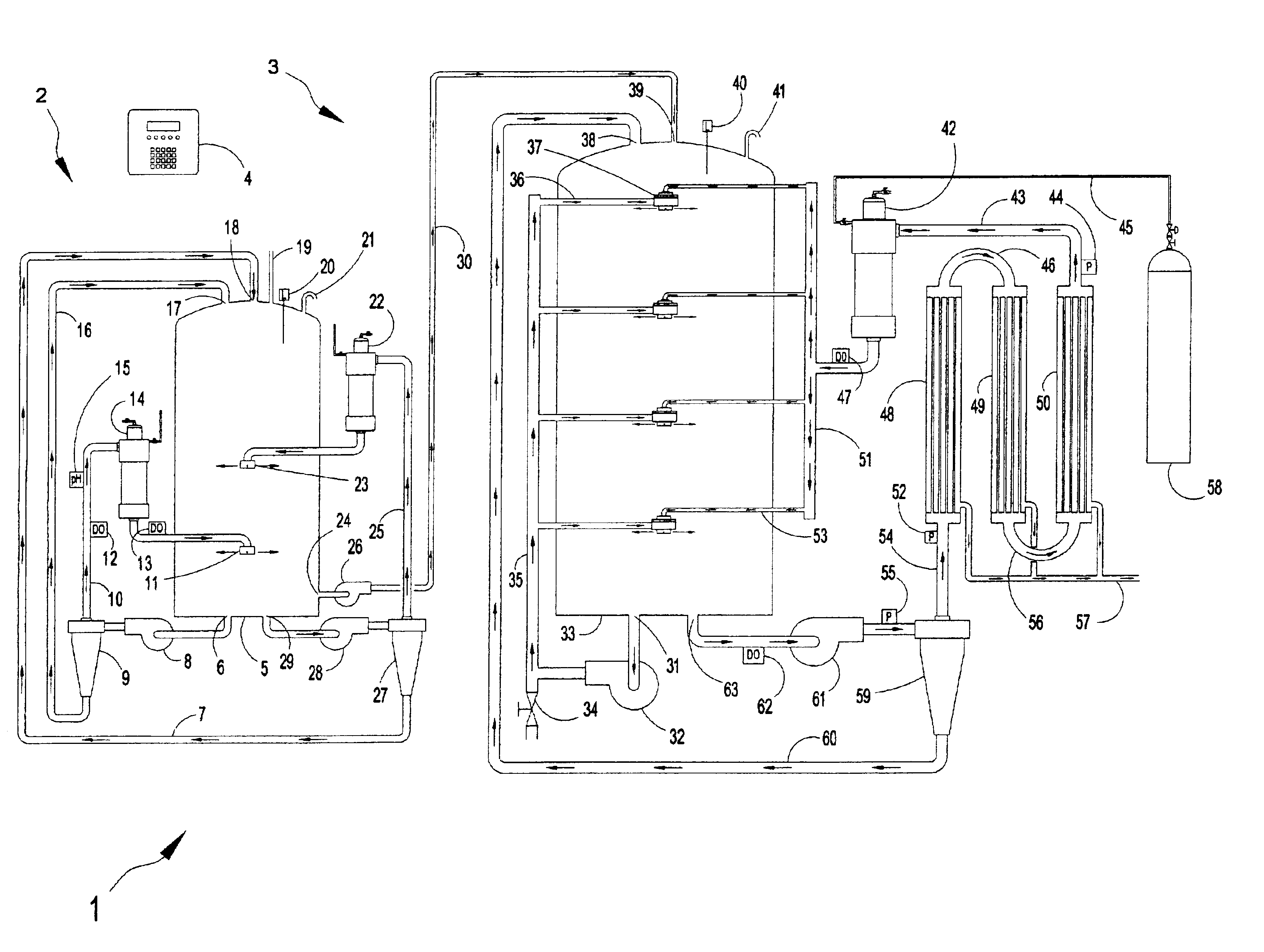

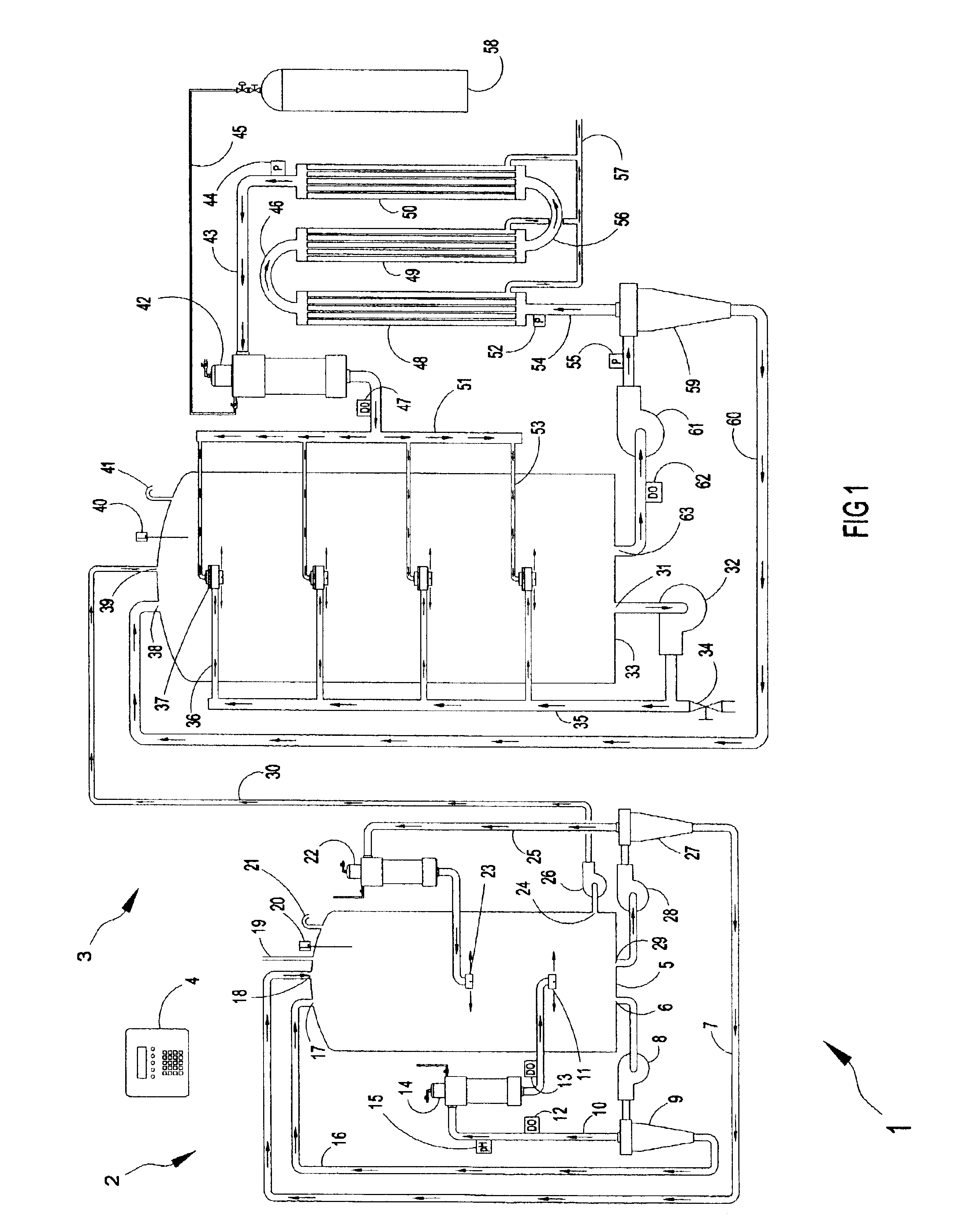

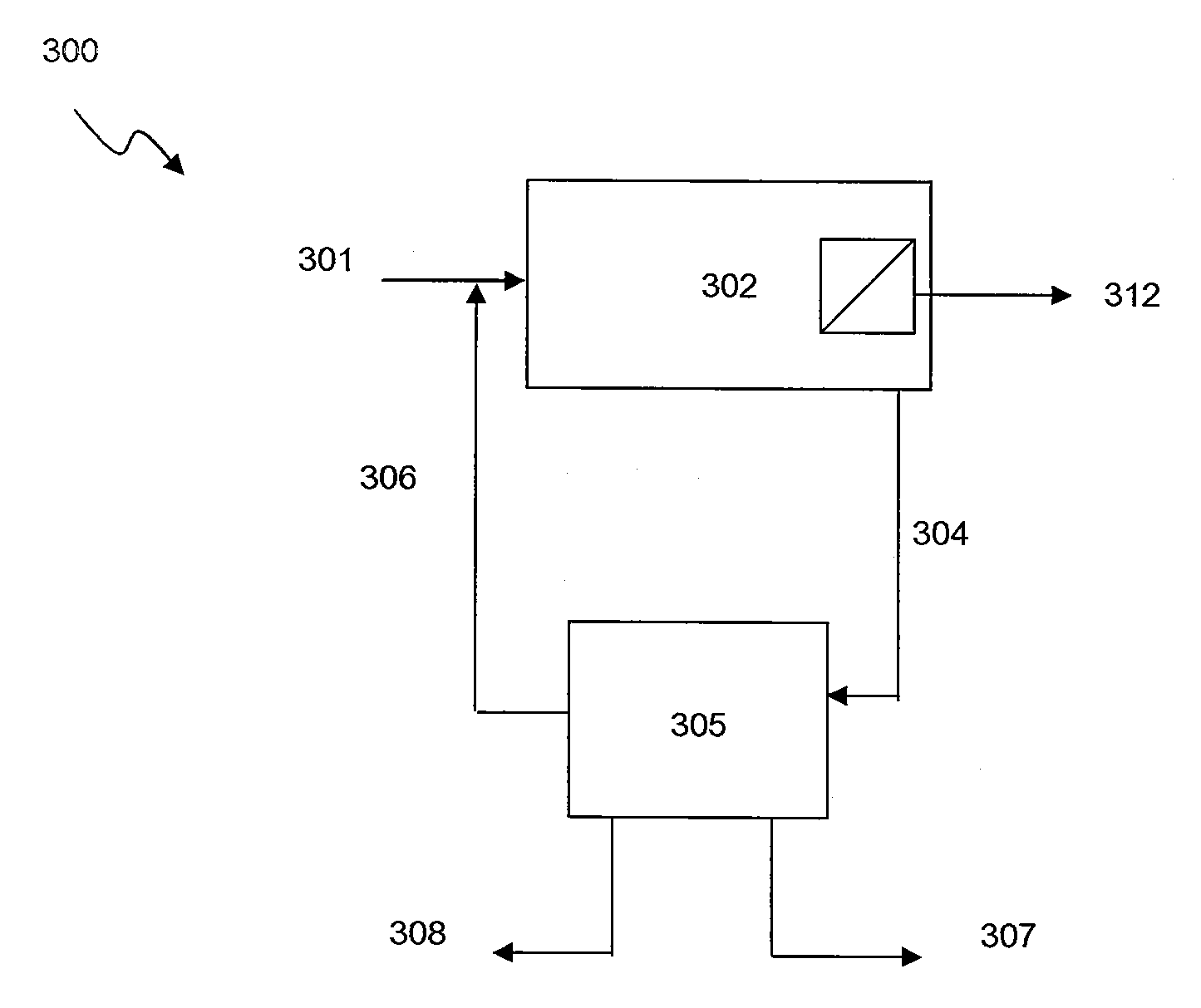

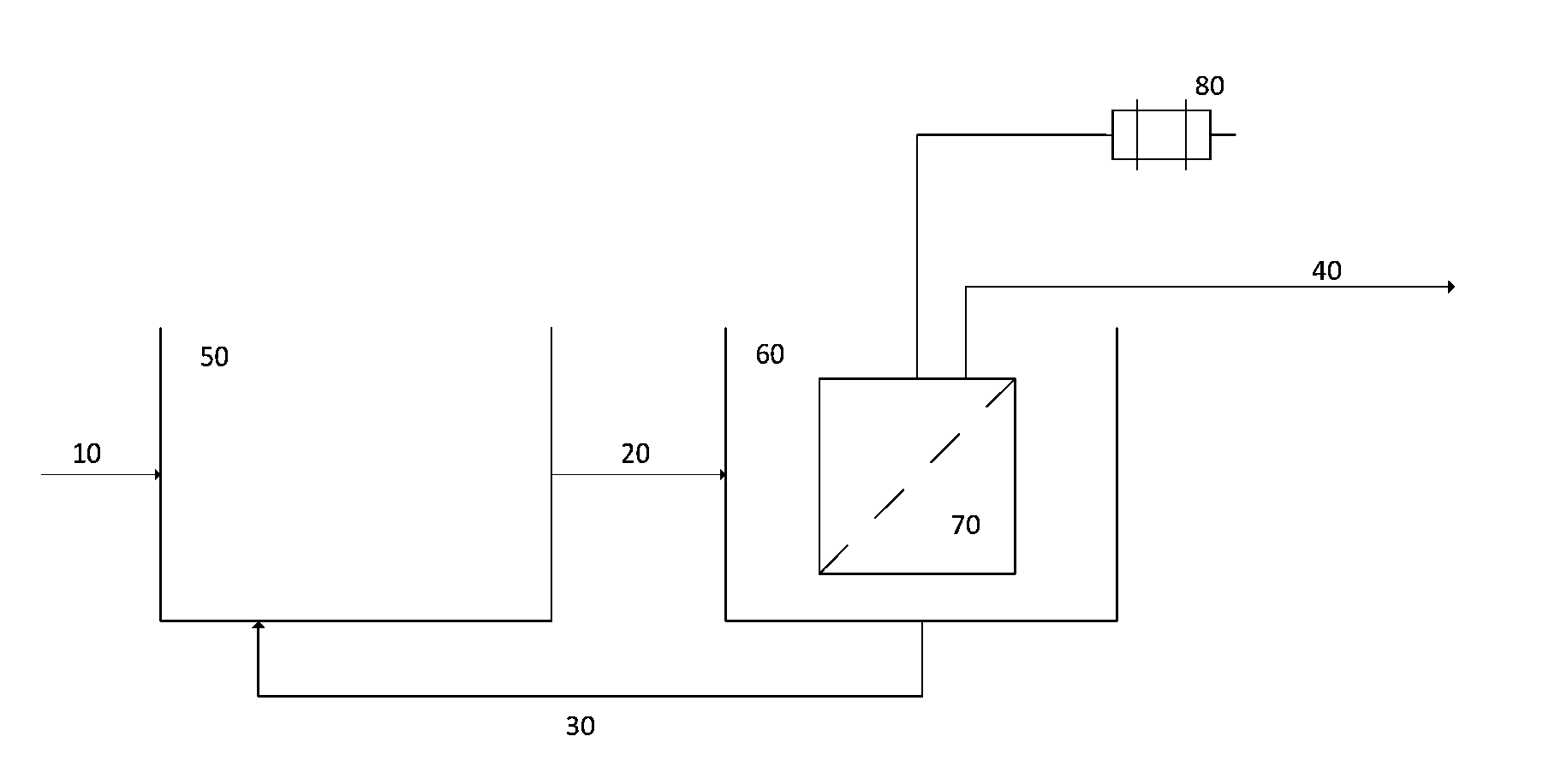

High performance, energy efficient system and method for wastewater treatment with resource recovery and reduced residual solids generation

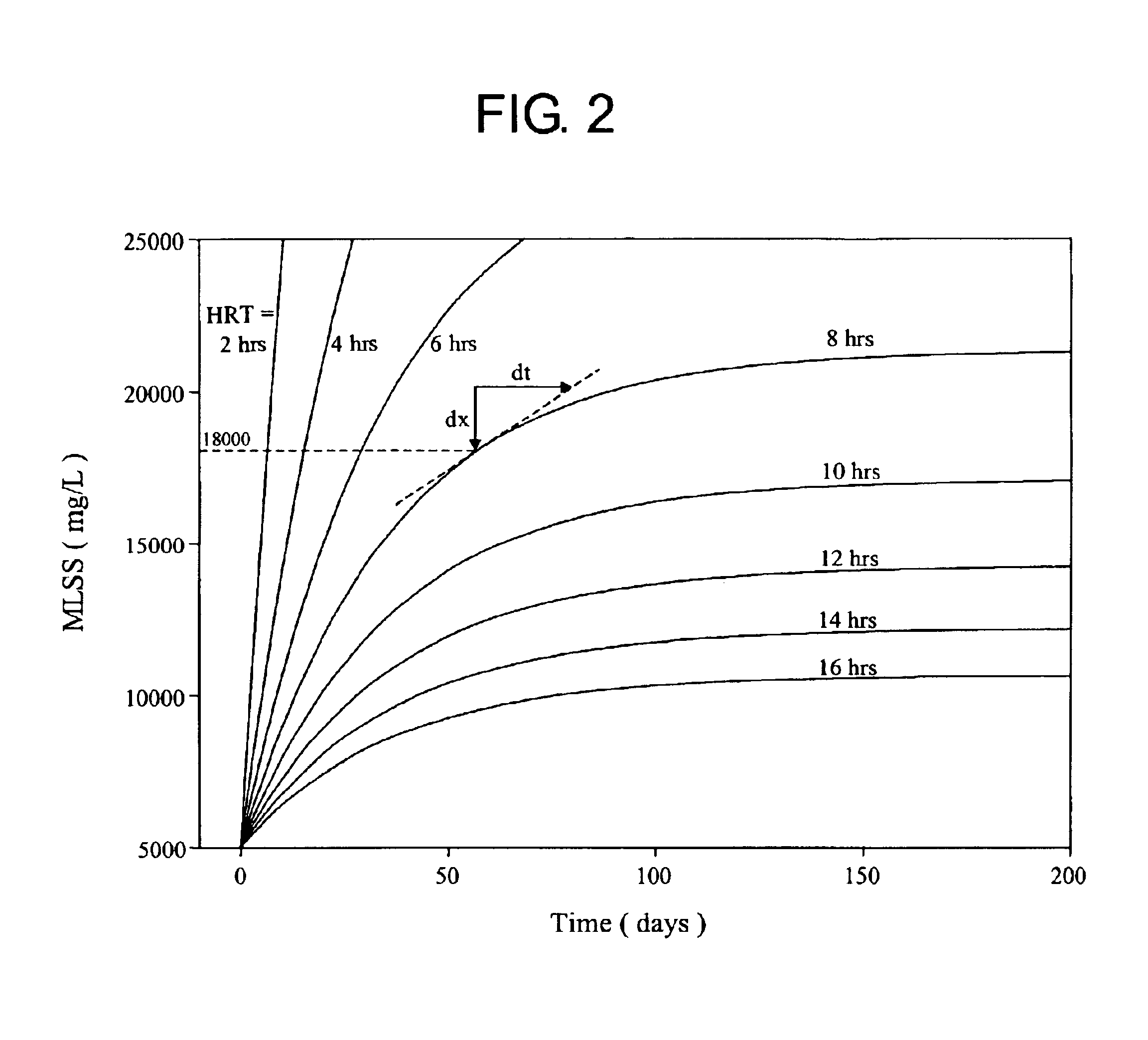

ActiveUS20080223783A1Treatment with anaerobic baffled reactorsWater treatment parameter controlRetention timeCell mass

A wastewater treatment system is provided including an aerobic membrane bioreactor and an anaerobic digester system connected to receive wasted solids continuously from the aerobic membrane bioreactor and also connected to return effluent from the anaerobic digester system continuously to the aerobic membrane bioreactor. Further, a process is provided for treating wastewater including the step of wasting a volume fraction of organic cell mass from an aerobic membrane bioreactor to an anaerobic digester system and maintaining a solids retention time (SRT) in the bioreactor that is (1) greater than a time needed to achieve growth of organisms suitable for converting carbonaceous biochemical oxygen demand (CBOD) into cell mass and (2) less than a time at which substantial decay of the organisms occurs. The system and process may further include optional pretreatment and / or phosphorus and / or nitrogen removal downstream of the membrane bioreactor system.

Owner:HSBC BANK

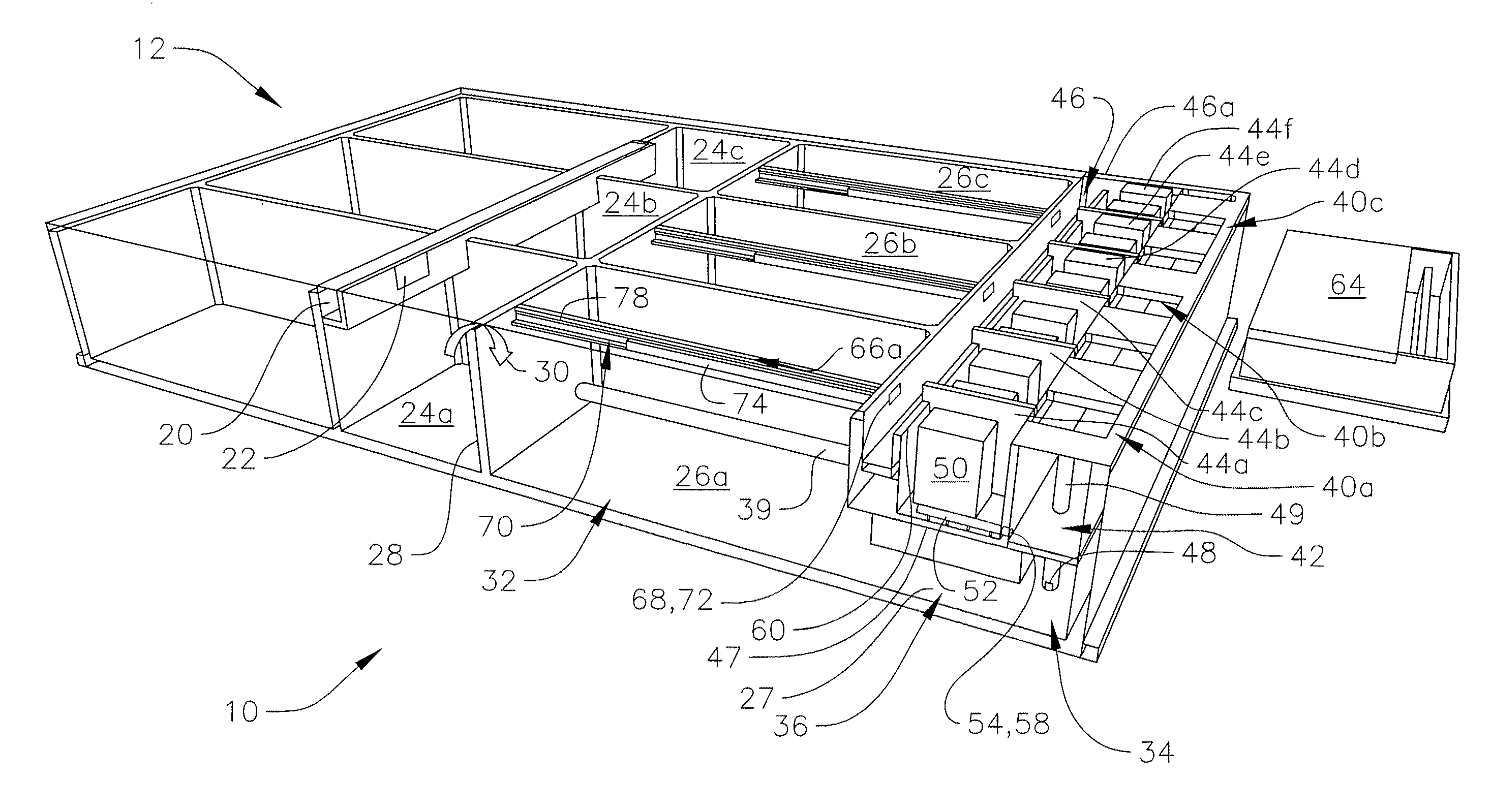

Grease and scum removal in a filtration apparatus comprising a membrane bioreactor and a treatment vessel for digesting organic materials

InactiveUS7329344B2Significant comprehensive benefitsLow costMembranesUltrafiltrationFiltrationMembrane bioreactor

The invention relates to a membrane bioreactor process combined with an advanced biological sludge digestion process that provides significant improvements in sludge digestion by reducing the costs and resources required for disposing of digested sludge. The offline treatment vessel is used to solubilize the organic material by operating in a very low oxygen environment. Digested process fluid is transferred back to the membrane bioreactor. The processes and apparatus substantially reduce the production of waste sludge. The device includes one or more weirs operable to remove grease and scum.

Owner:EVOQUA WATER TECH LLC

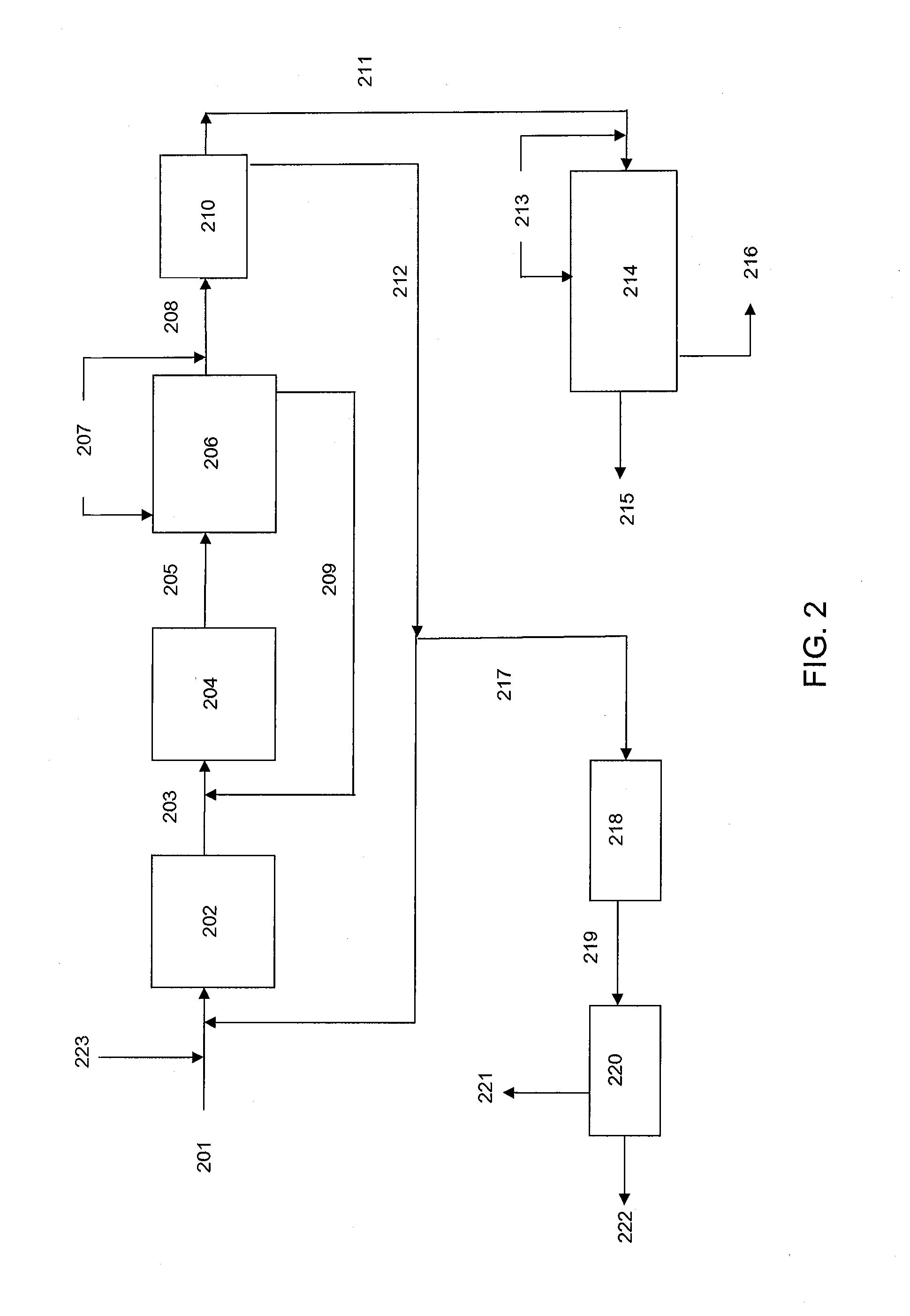

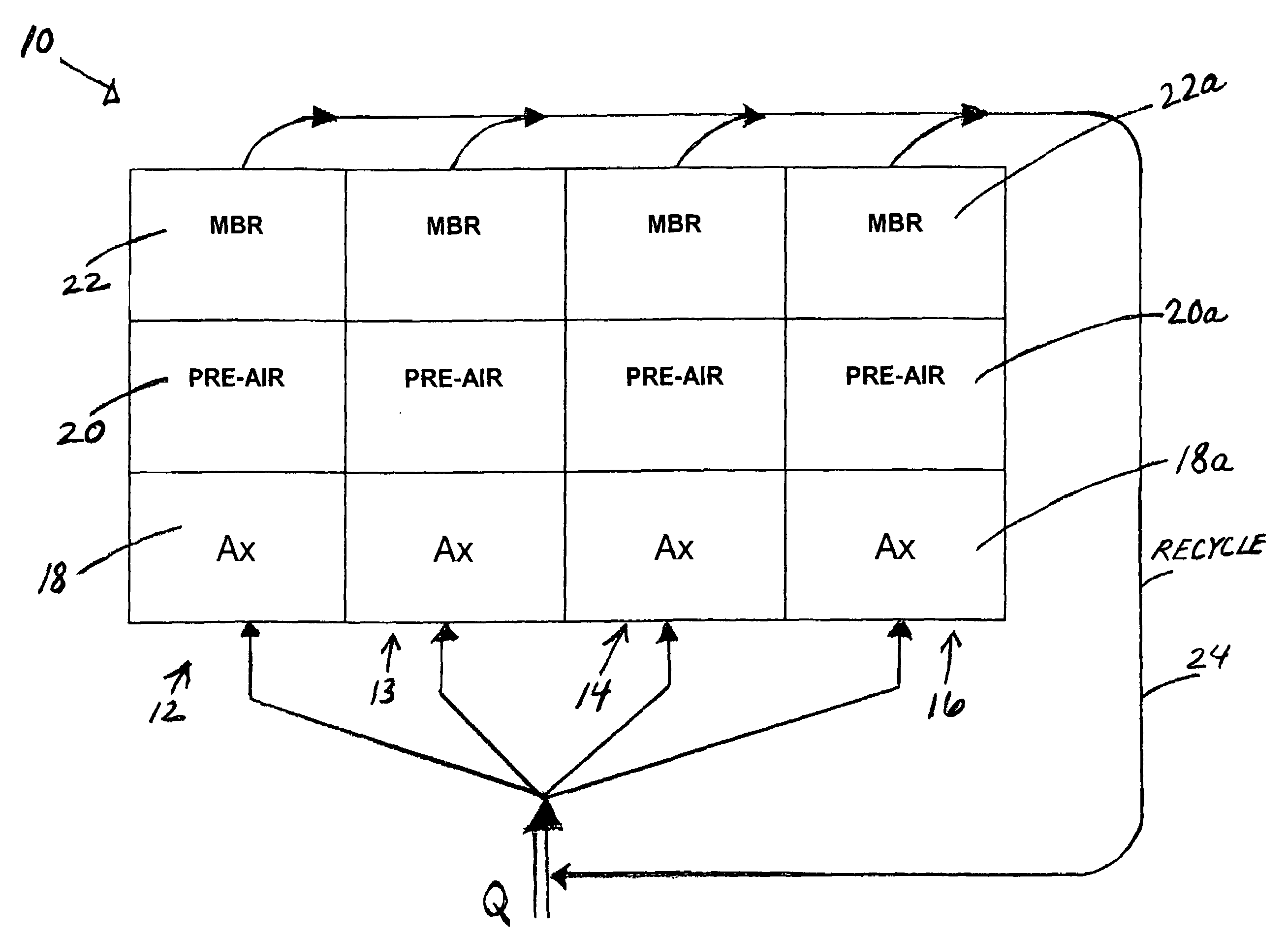

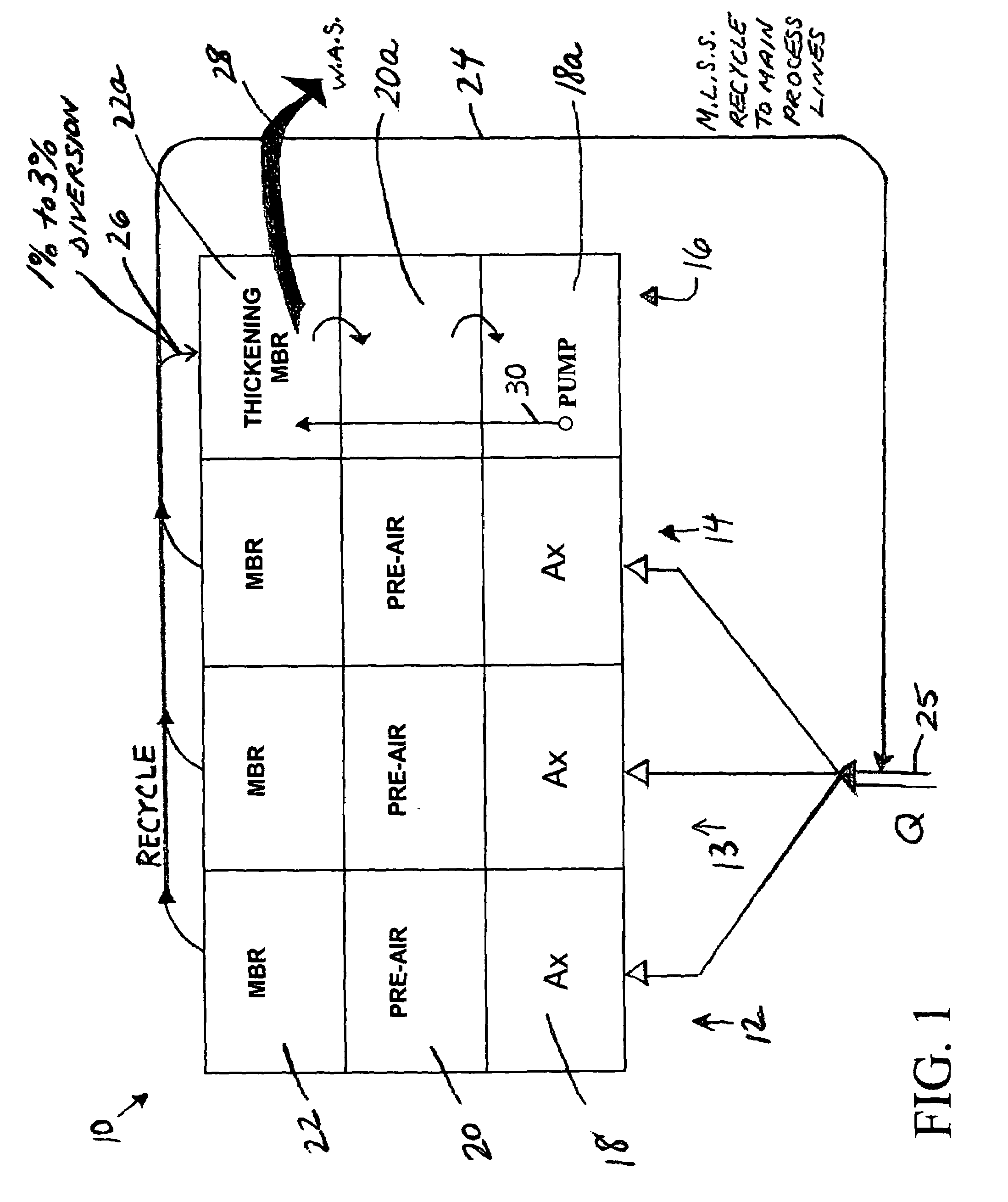

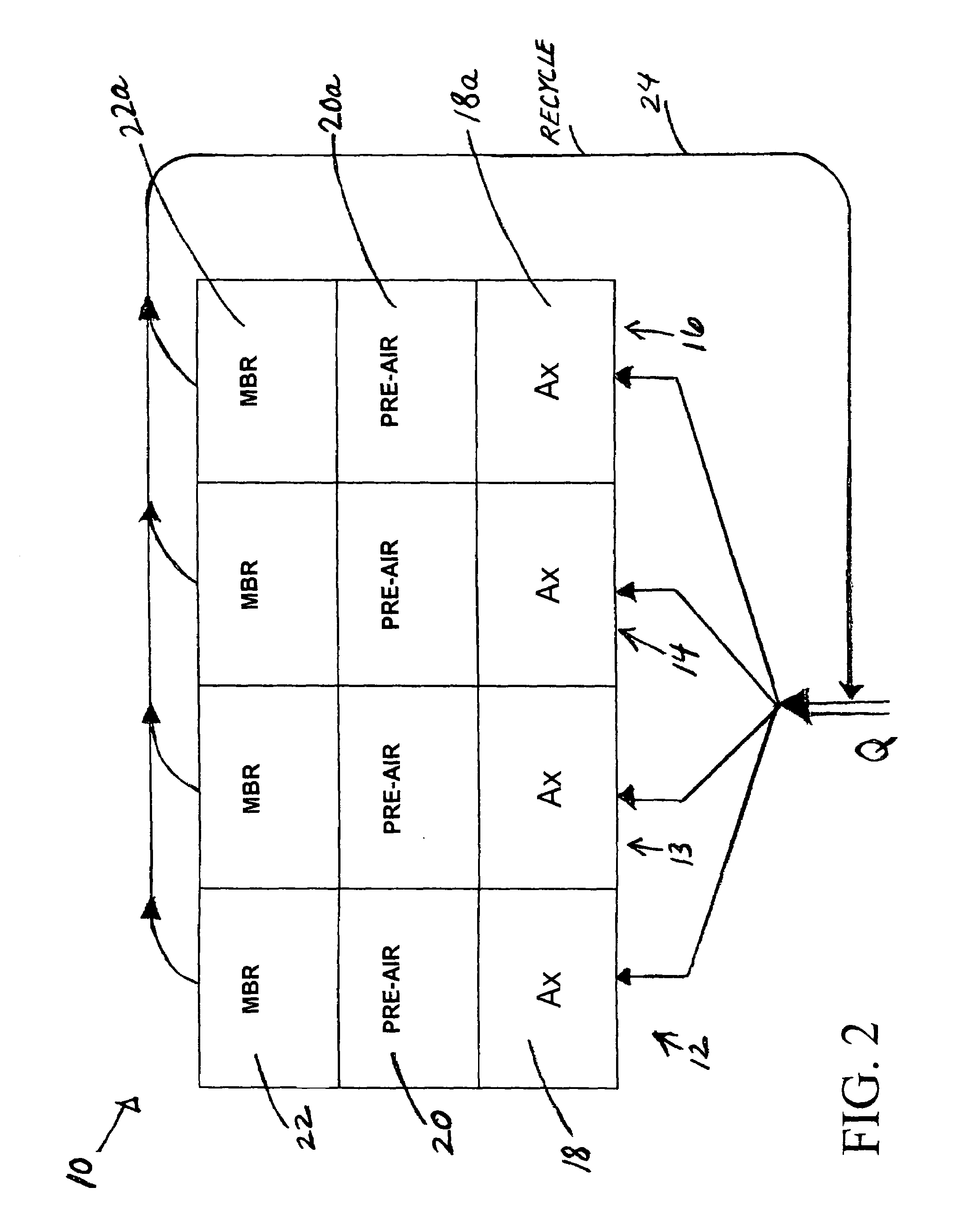

Wastewater treatment system with membrane separators and provision for storm flow conditions

ActiveUS7147777B1Increase biomassTreatment using aerobic processesTreatment with aerobic and anaerobic processesStreamflowTreatment system

In a wastewater treatment system and process utilizing membrane bioreactors (MBRs), multiple, parallel series of tanks or stages each include, an MBR stage. Under conditions of normal flow volume into the system, influent passes through several parallel series of stages or process lines, which might be, for example, an anoxic stage, an aeration stage and an MBR stage. From the MBR stages a portion of M.L.S.S. is cycled through one or more thickening MBRs of similar process lines, for further thickening and further processing and digesting of the sludge, while a majority portion of the M.L.S.S. is recycled back into the main process lines. During peak flow conditions, such as storm conditions in a combined storm water / wastewater system, all of the series of stages with their thickening MBRs are operated in parallel to accept the peak flow, which is more than twice normal flow. M.L.S.S. is recycled from all MBR stages to the upstream end of each of all the parallel process lines, mixing with influent wastewater, and the last one or several process lines no longer act to digest the sludge. Another advantage is that with the thickened sludge in the last process line of basins, which ordinally act to digest the sludge, there is always sufficient biomass in the system to handle peak flow, the biomass being available if needed for a sudden heavy flow or an event that might bring a toxic condition into the main basins.

Owner:OVIVO INC

Composite thermotropic phase separation film-making method

The invention relates to a composite thermotropic phase isolated membrane preparation method which is characterized in that used composite diluent is the mixture of water-soluble good solvent and water-soluble additive of polymers. The membrane forming separation is a composite process which mainly takes the thermotropic membrane phase separation as the dominant role and non-solvent induced phaseseparation as the subsidiary role. The membrane prepared through the method has the advantages of high abruption strength, high abruption elongation and high water flux. The method is applicable to the preparation of membranes which are made of a plurality of polymers, including polyvinylidene fluoride, polysulfone, polyether sulfone, polyvinyl chloride and polyacrylonitrile. The performances of the membranes are improved greatly. Thus, the membranes can be widely applied to the fields of drinking water advanced treatment, pretreatment before reverse permeation, membrane bioreactor wastewatertreatment, reclaimed water reuse, etc.

Owner:湖南坎普尔环保技术有限公司

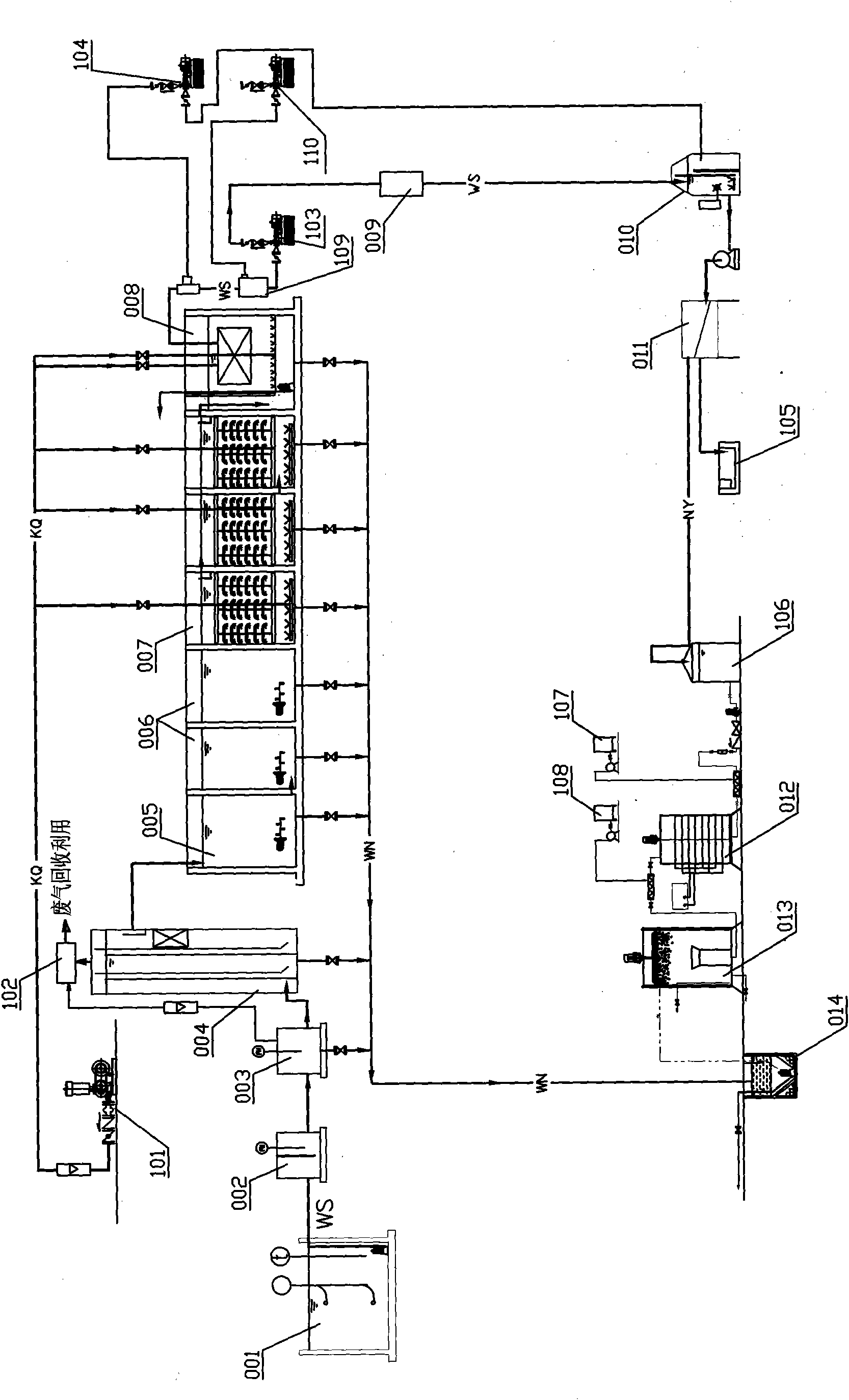

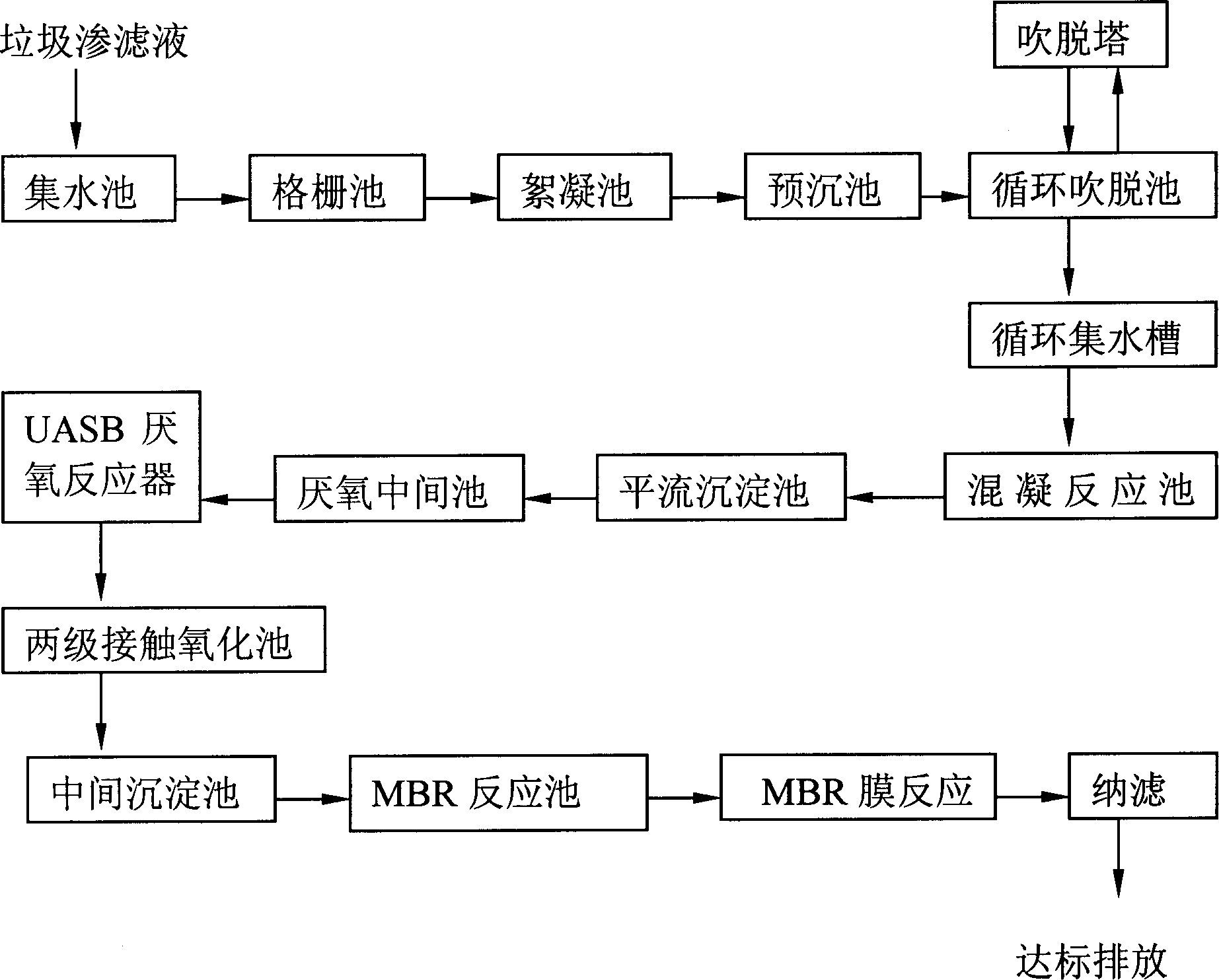

Ultrasonic combined waste water treatment process and system of refuse leachate

InactiveCN102139990ASimple processCompact structureWater/sewage treatment with mechanical oscillationsMultistage water/sewage treatmentEmission standardCatalytic oxidation

The invention relates to an ultrasonic combined waste water treatment process of refuse leachate, relating to the technical field of waste water treatment and recycling of resources and environmental protection. The ultrasonic combined waste water treatment process of the refuse leachate comprises the following steps of: enabling waste water to enter a regulating pond; treating colloids, amphoteric substances and heavy metals in a coagulation sedimentation pond; eliminating ammonia nitrogen in an ultrasonic catalytic oxidation pond; sequentially sedimentating through biological treatment in an ABR (Acrylate Butadience Rubber) baffle plate anaerobic pond, a hydrolytic pond, a facultative pond and an aerobic pond; filtering in a CMBR (Chatter Membrane Bioreactor); eliminating waste gases and stench in a carbon filter pond; disinfecting in a contact disinfection pond; and filtering in an RO (Reverse Osmosis) membrane reverse osmosis system so as to obtain water meeting the requirements for emission standards. The invention also provides a treatment system for the ultrasonic combined waste water treatment process. The ultrasonic combined waste water treatment process and system can obtain the outflow water with stable quality by treating the refuse leachate; the treatment system has the advantages of small size and occupying area, high efficiency, low energy consumption and easy realization for mechanical-electrical integration control and management; and in addition, the invention is beneficial to the protection of the original landscapes of a construction party by adopting a non-buried type structure and also reduces the influence of the operation of the treatment system on an office area.

Owner:深圳市万山红环保实业有限公司

Grease and scum removal in a filtration apparatus comprising a membrane bioreactor and a treatment vessel for digesting organic materials

InactiveUS20070084791A1Significant comprehensive benefitsLow costMembranesUltrafiltrationFiltrationMembrane bioreactor

The invention relates to a membrane bioreactor process combined with an advanced biological sludge digestion process that provides significant improvements in sludge digestion by reducing the costs and resources required for disposing of digested sludge. The offline treatment vessel is used to solubilize the organic material by operating in a very low oxygen environment. Digested process fluid is transferred back to the membrane bioreactor. The processes and apparatus substantially reduce the production of waste sludge. The device includes one or more weirs operable to remove grease and scum.

Owner:EVOQUA WATER TECH LLC

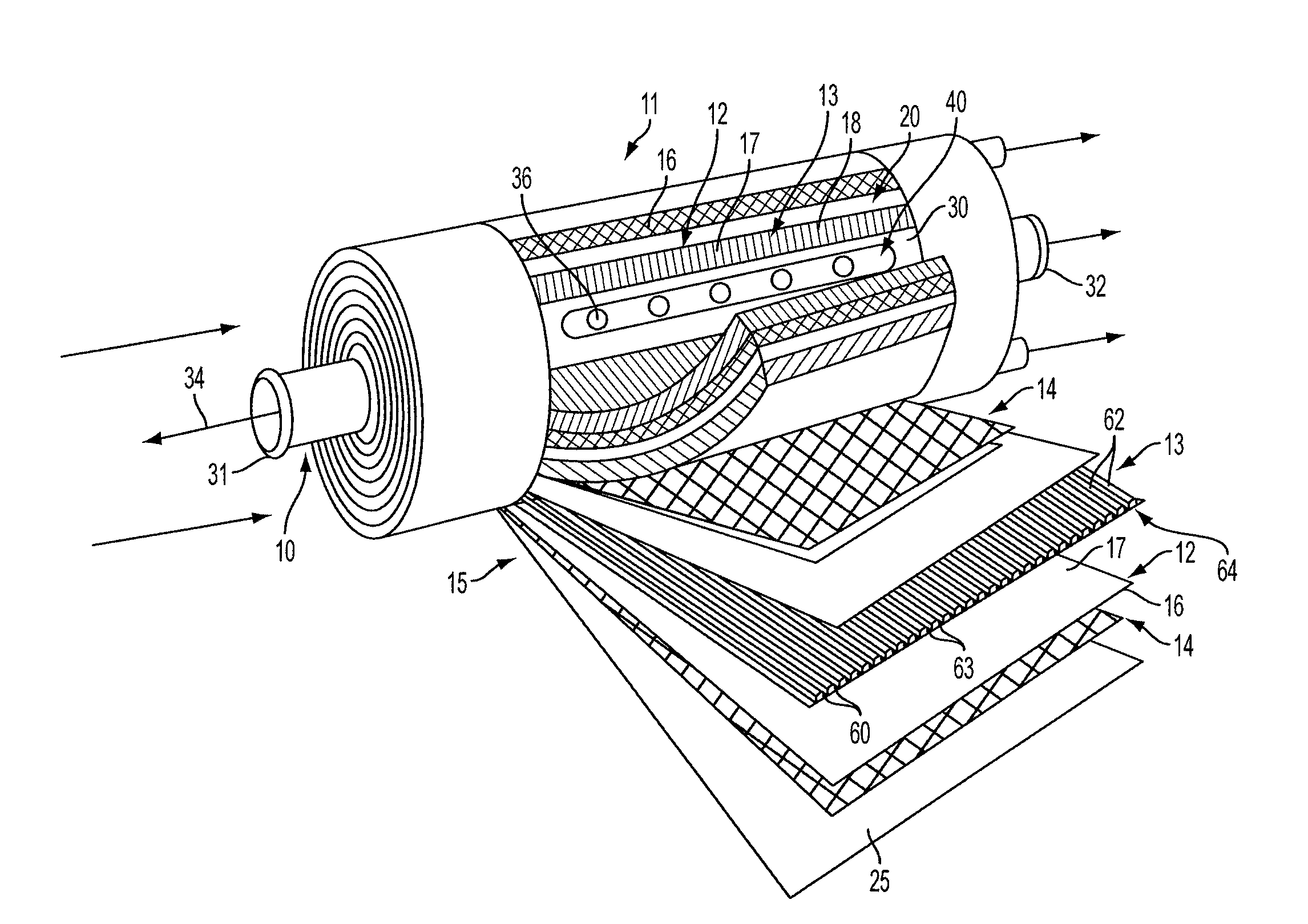

Filter element for fluid filtration system

InactiveUS20120261333A1Improve configurationEasy to controlSemi-permeable membranesMembranesYarnMembrane bioreactor

A filter element for use in a reverse osmosis, nano-filtration, membranes and spacers membrane-bioreactor, forward osmosis, or other filtration system, includes a permeate carrier substrate having a wrapped core tube. The permeate carrier includes a series of spaced ribs. The ribs are formed by application of yarns, strings or resinous or polymeric materials to a membrane substrate. The ribs define channels for passage of a liquid or gas permeate therealong. The permeate is received at the core tube which has one or more elongated flow recesses therealong to facilitate collection of the permeate.

Owner:GFD FABRICS

Method of using water soluble polymers in a membrane biological reactor

InactiveUS6926832B2Amount of timeLower cost of capitalMembranesTreatment using aerobic processesMembrane foulingWater soluble

A method of conditioning mixed liquor in a membrane biological reactor comprising adding to the mixed liquor an effective coagulating and flocculating amount of one or more water soluble cationic, amphoteric or zwitterionic polymers, or combination thereof and methods of reducing membrane fouling, enhancing membrane flux and reducing sludge production.

Owner:ECOLAB USA INC

Membrane bioreactor, process and aerator

InactiveUS20050061725A1Easy to moveIncrease pressureWater treatment parameter controlMembranesSiphonEnvironmental engineering

A reactor has an aerobic tank, an anoxic tank and a sealed membrane tank with conduits for circulating mixed liquor between them. Permeation starts when the mixed liquor reaches a high level and stops when the mixed liquor reaches a low level. A sensor, for detecting the mixed liquor level, may stop and start permeation. Pressure builds in the membrane tank when membrane air is on. Transmembrane pressure is also provided by gravity flow or siphon. Membrane air generates an air lift which drives the mixed liquor circulation. The total amount of air provided by an air source is divided and varied in time between the membrane aerator and the process aerator. The process aerator acts as a screening inlet to the conduit to the membrane tank. Chemical maintenance cleaning is provided by gravity flow.

Owner:ZENON ENVIRONMENTAL INC

Filtration apparatus comprising a membrane bioreactor and a treatment vessel for digesting organic materials

InactiveUS7387723B2Significant comprehensive benefitsLow costWater/sewage treatment by centrifugal separationMembranesFiltrationMembrane bioreactor

The invention relates to a membrane bioreactor process combined with an advanced biological sludge digestion process that provides significant improvements in sludge digestion by reducing the costs and resources required for disposing of digested sludge. The offline treatment vessel is used to solubilize the organic material by operating in a very low oxygen environment. Digested process fluid is transferred back to the membrane bioreactor. The processes and apparatus substantially reduce the production of waste sludge.

Owner:EVOQUA WATER TECH LLC

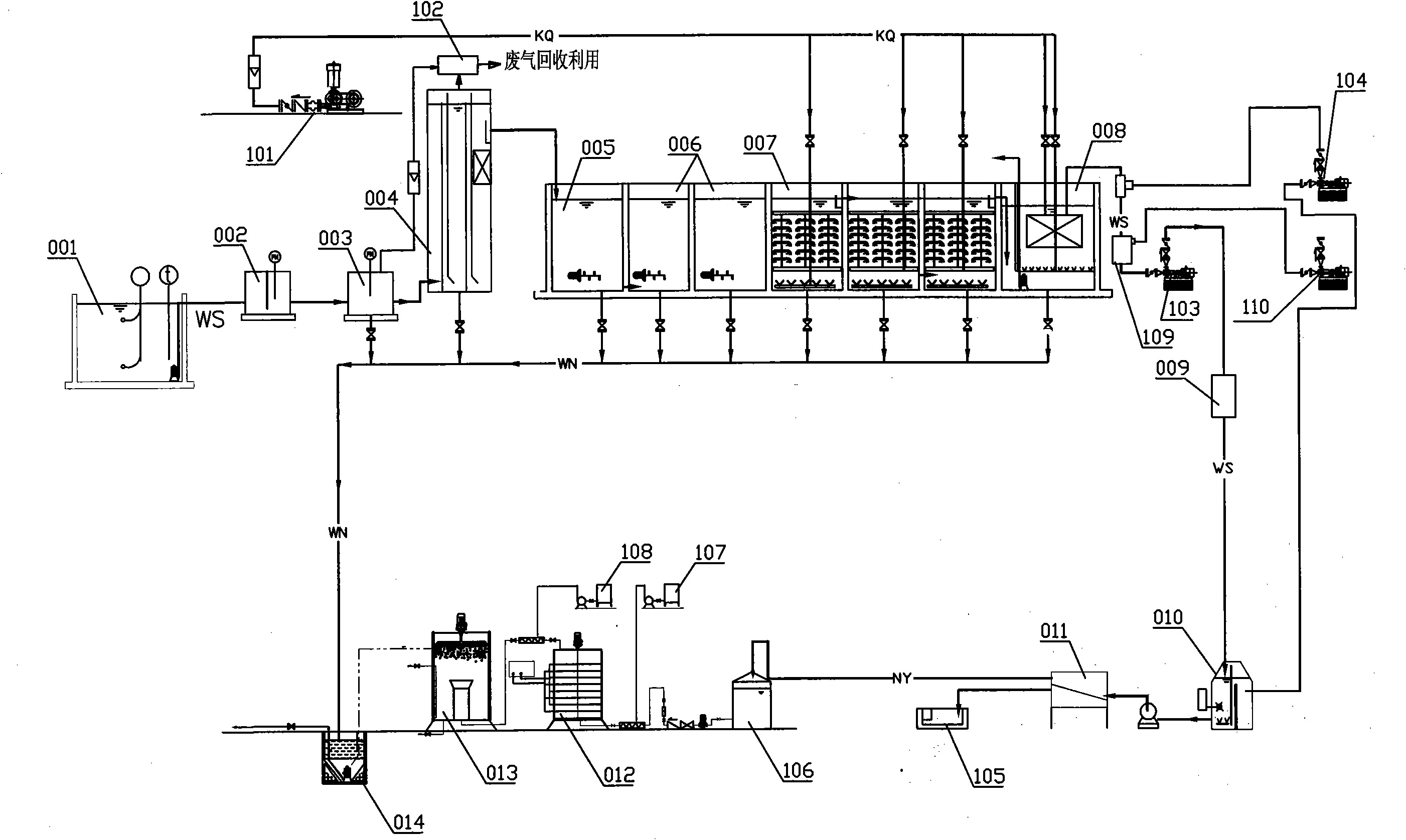

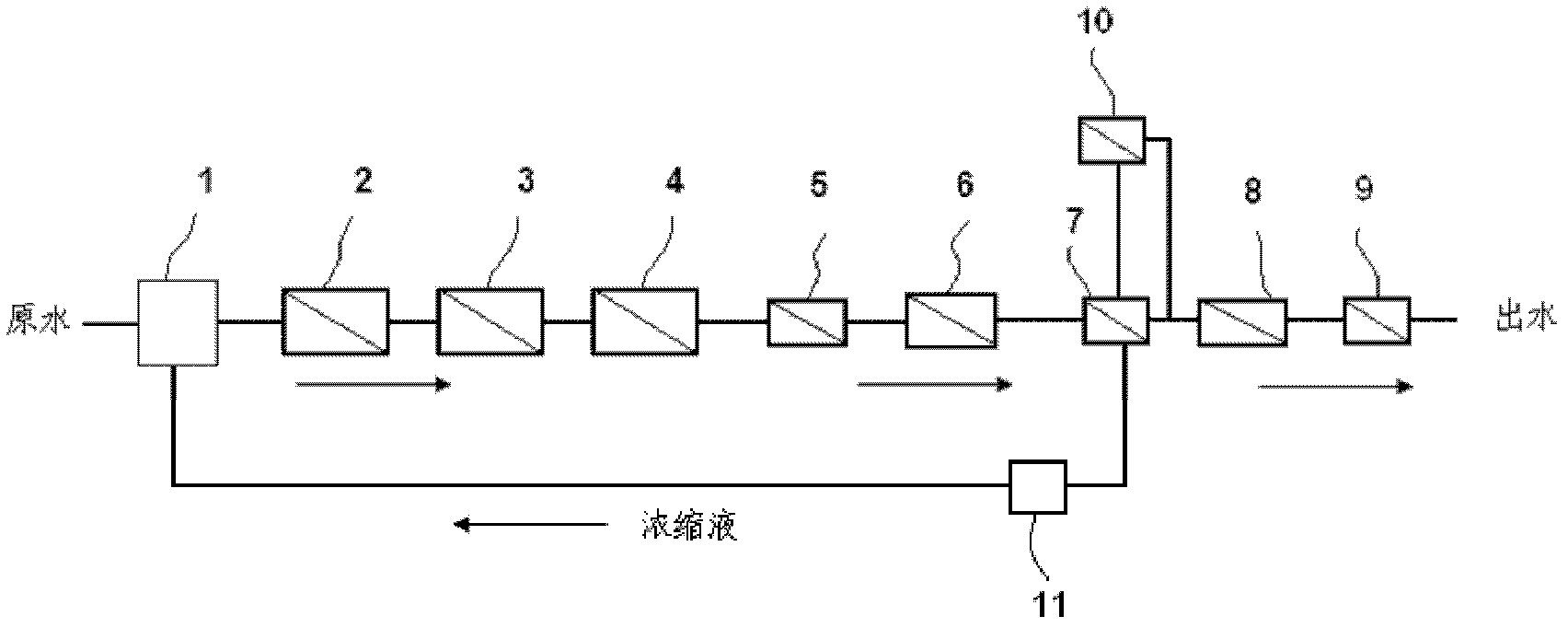

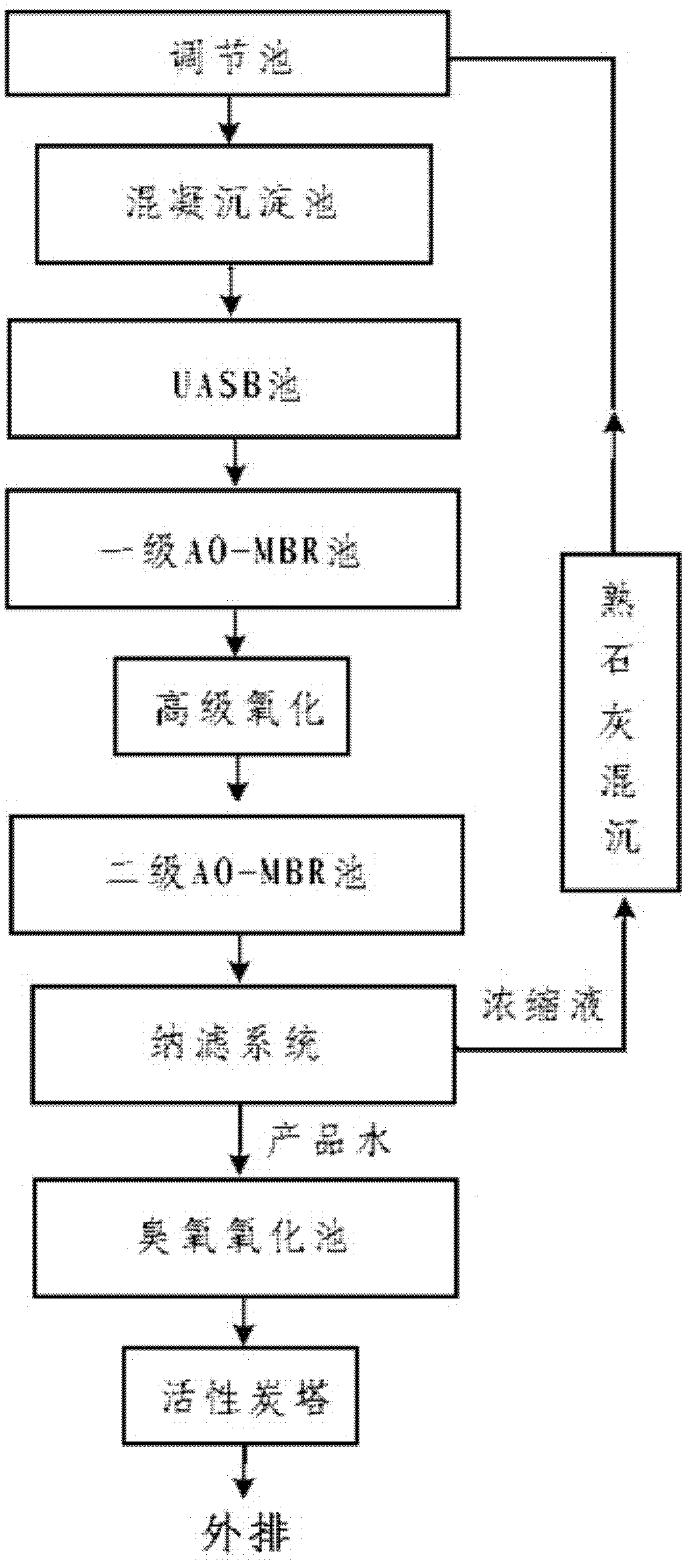

Advanced treatment system and method for high-concentration percolate in comprehensive garbage disposal plant

InactiveCN102503046AEasy to handleRequirements to meet emission concentration limitsMultistage water/sewage treatmentActivated carbon filtrationReverse osmosis

The invention discloses an advanced treatment system and method for high-concentration percolate in a comprehensive garbage disposal plant, belonging to the field of industrial waste water treatment. The system is formed by connecting a regulating tank, a coagulative precipitation tank, an upflow anaerobic sludge bed reaction tank, a primary anoxic and aerobic membrane bioreactor, advanced oxidation treatment equipment, a secondary anoxic and aerobic membrane bioreactor, nanofiltration membrane treatment equipment, an ozone contact tank and an active carbon filtering tower in sequence. According to the system, garbage percolate can be treated comprehensively, different pollutants in garbage percolate are treated in a classified way by combining physical, chemical and biological treatment,advanced treatment of garbage percolate is realized, and classified treatment for removing pollutants such as organic matters, heavy metals, ammonia, nitrogen and the like is performed, so that treated effluent strictly reaches the requirement of water pollution discharge degree limit in the Household Garbage Landfill Pollution Control Standard, the system runs stably for a long time, and treatment cost is lower than that of a secondary disc pipe reverse osmosis membrane process.

Owner:BEIJING YIPU INT WATER AFFAIRS

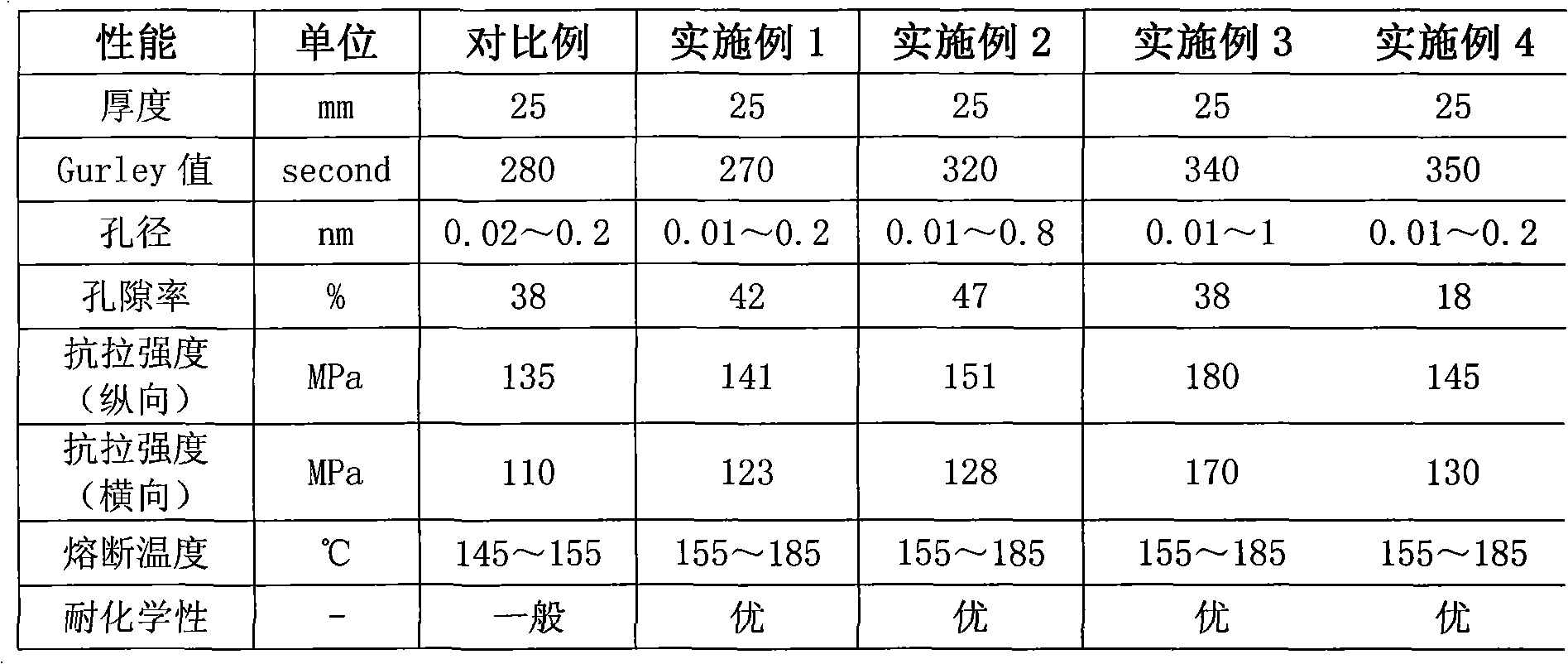

Crosslinking polyolefin microporous membrane and preparation method thereof

ActiveCN102134342AHigh mechanical strengthOutstanding chemical resistanceSemi-permeable membranesCell component detailsPolyolefinPolymer science

The invention discloses a crosslinking polyolefin microporous membrane and a preparation method thereof. Materials for making the membrane mainly comprise 28.8 to 48.8 parts by weight of polyolefin, 30 to 50 parts by weight of cosolvent, 0.1 to 2 parts by weight of peralcohol, 1 to 5 parts by weight of silane, and 0.1 part by weight of antioxygen, and further comprise 0 to 20 parts by weight of ultrafine filler. By the crosslinking of polyolefin, the mechanical strength, the thermal resistance and the tolerance to strong base and chlorine-oxygen compound and other severe chemical environmentsof the polyolefin microporous membrane can be improved, and in practical application, such as an isolating membrane of a lithium ion battery or a filtering membrane in a membrane bioreactor, the service life of the polyolefin microporous membrane can be greatly prolonged.

Owner:HANGZHOU FUMO NEW MATERIAL TECH

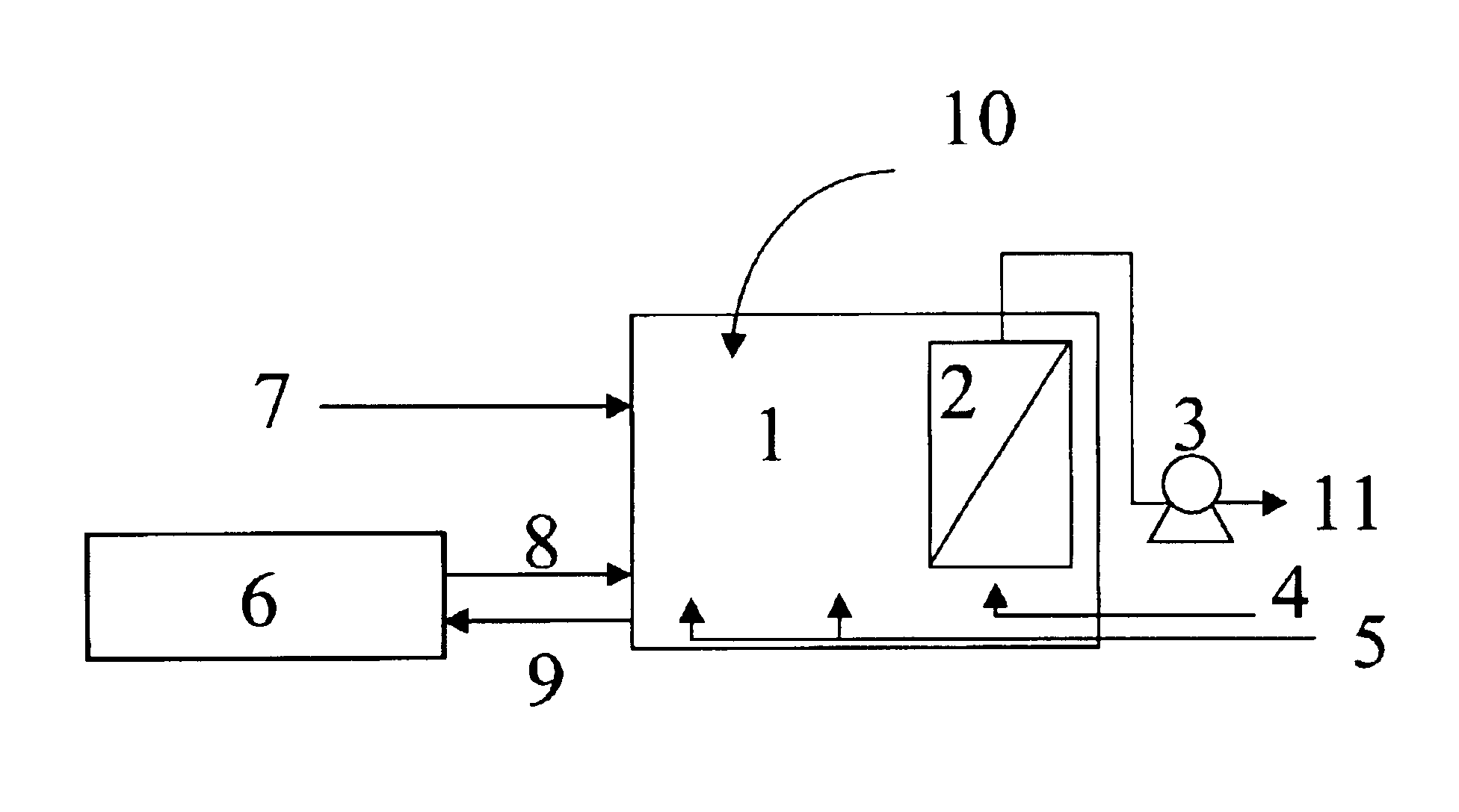

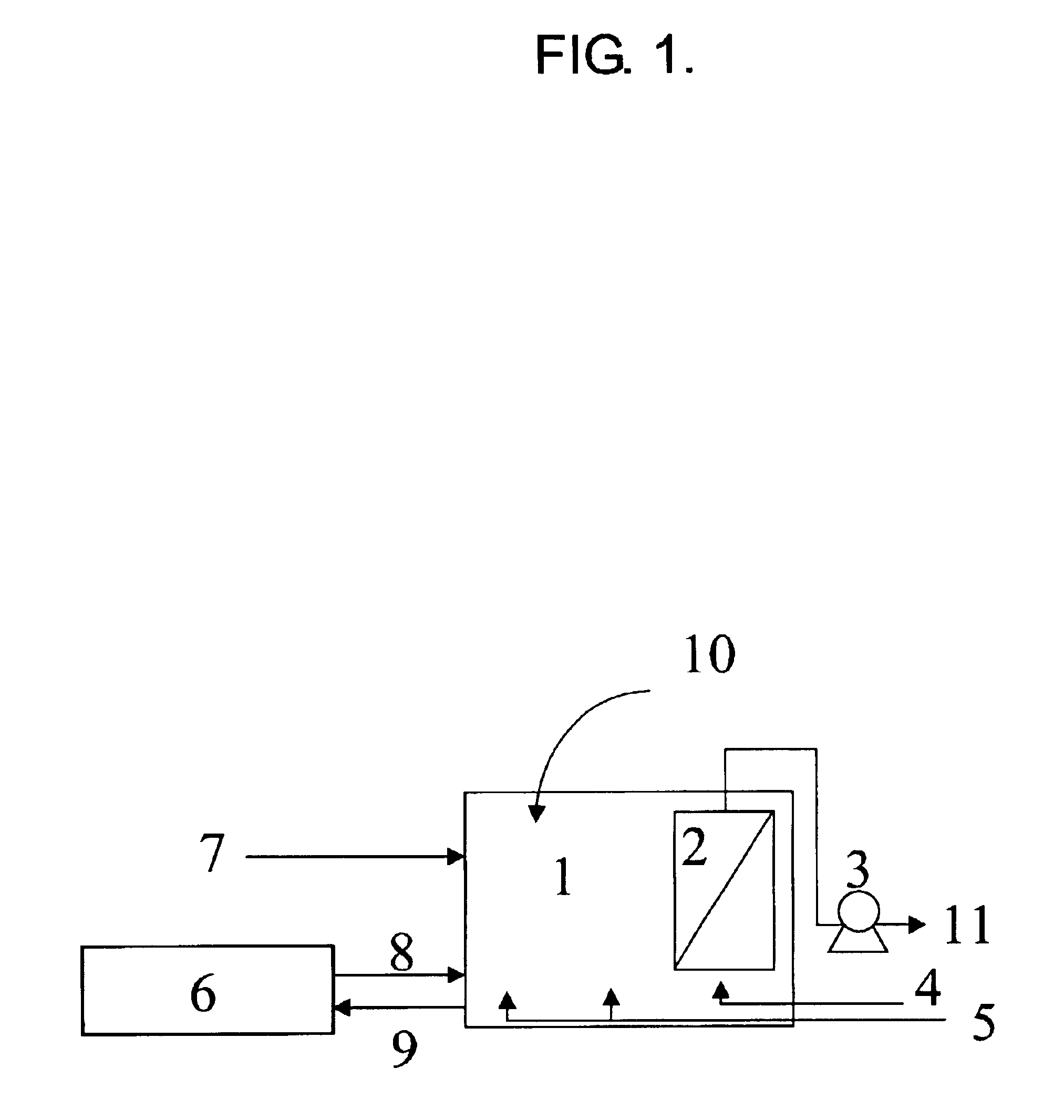

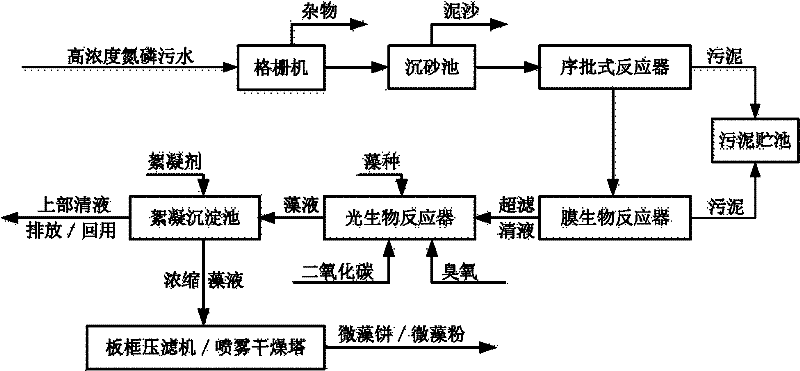

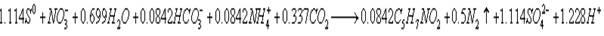

Nitrogen-phosphorus wastewater treating method by sequencing batch reactor coupled photobioreactor

ActiveCN102336498AWater quality varies widelyMultistage water/sewage treatmentSequencing batch reactorHigh concentration

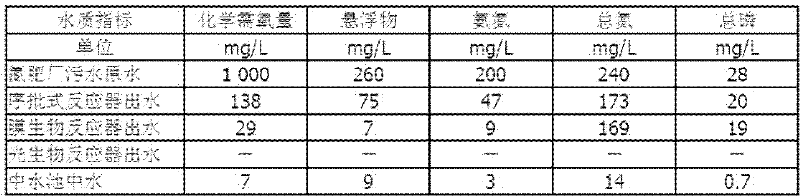

The invention relates to the field of environmental wastewater treatment, specifically to a nitrogen-phosphorus wastewater treating method by a sequencing batch reactor coupled photobioreactor. The method provided by the invention is characterized in that it comprises the following steps of: removing impurities and sediments of high concentration nitrogen-phosphorus wastewater and then treating the wastewater by using active sludge in the sequencing batch reactor, decanting a supernatant from the sequencing batch reactor, adding the supernatant into a membrane bioreactor for further aerobic treatment, filtering by ultrafiltration membrane in the membrane bioreactor to remove micro-suspension and bacteria, adding a generated ultrafiltration supernatant into a photobioreactor, disinfecting by ozone and adding algae filament as well as a few necessary nutrient salt, filling with carbon dioxide waste gas to perform microalgae cultivation, discharging a algae liquid after a microalgae growth cycle and adding the algae liquid into a flocculating settling pool for sedimentation, standardly discharging or reusing a supernatant liquor, compressing the concentrate algae liquid at the bottominto a microalgae cake by a plate and frame filter press. The invention has advantages of wide range of treated nitrogen-phosphorus wastewater water quality variation and production of economical microalgae with the utilization of nitrogen and phosphorus nutrients in wastewater as more as possible.

Owner:DALIAN DAKAI SEWAGE TREATMENT

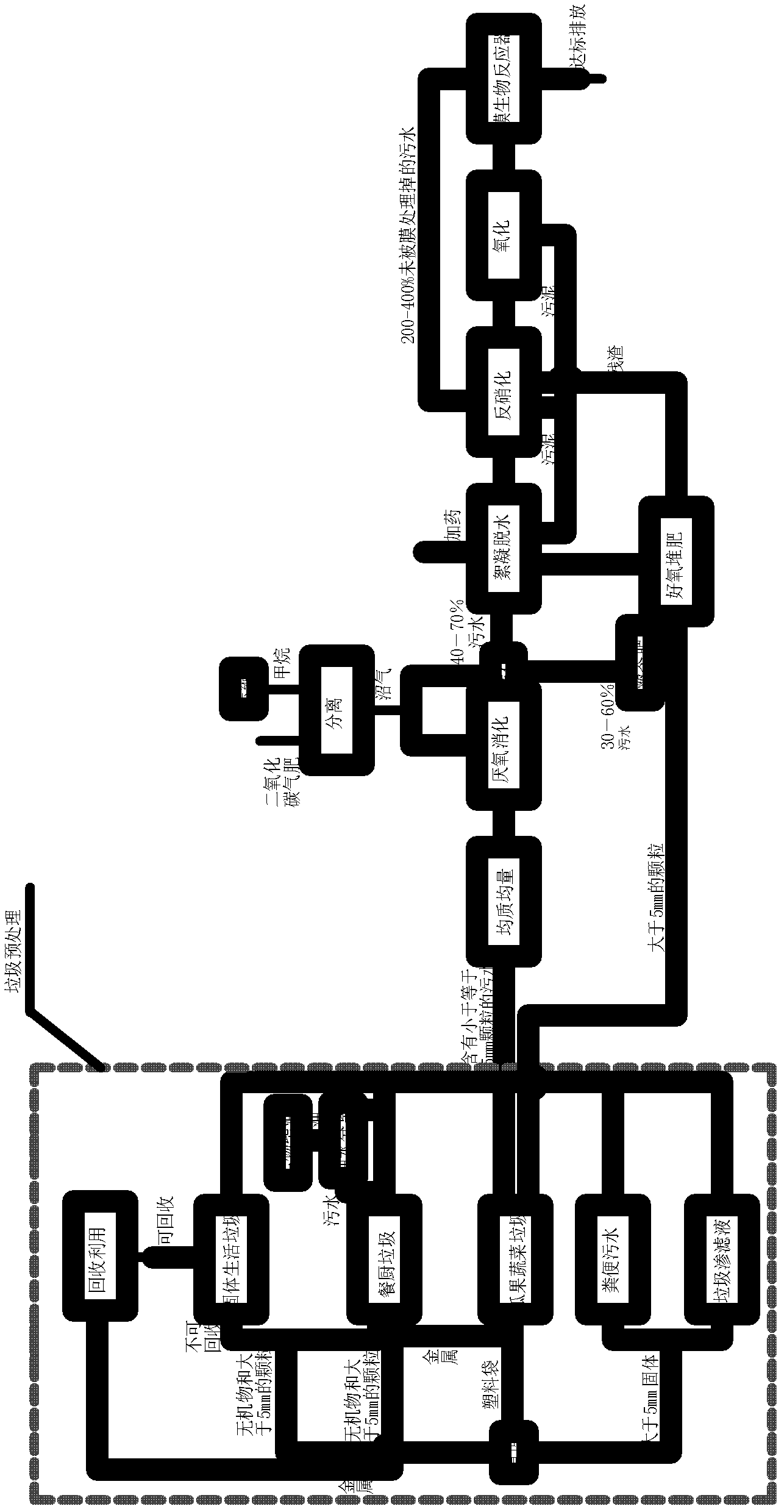

Method for jointly treating different garbage

ActiveCN102531295ASave processing powerProportional balanceBio-organic fraction processingWaste processingFlocculationBiodiesel

The invention discloses a method for jointly treating different garbage. In the implementation process, different garbage is subjected to pretreatment, homogenization, anaerobic digestion, flocculation dewatering, denitrification, oxidation treatment, membrane bioreactor treatment, aerobic composting and biodiesel production, treated sewage can reach the third grade Standard of Water Pollutants Discharge of DB11 / 307-2005, the process flow is greatly shortened, the cost is reduced, and methane generated in the treatment process and the recovered waste oil are subjected to deep processing to beutilized as green energy.

Owner:北京昊业怡生科技有限公司

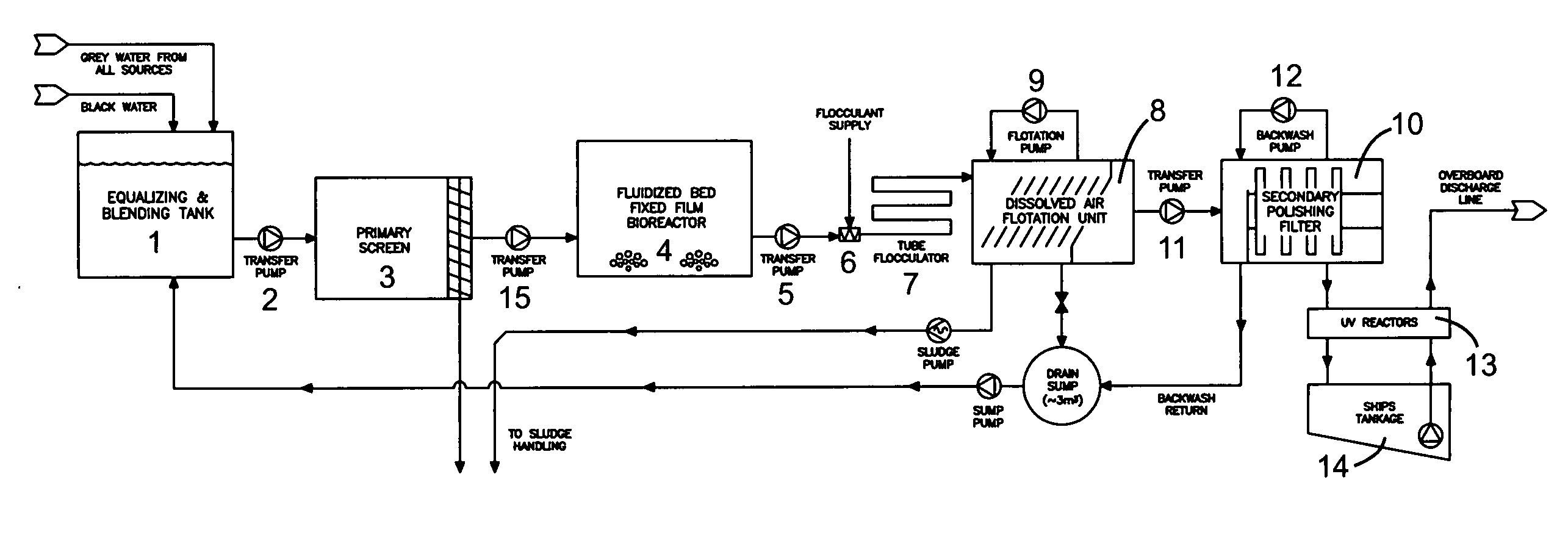

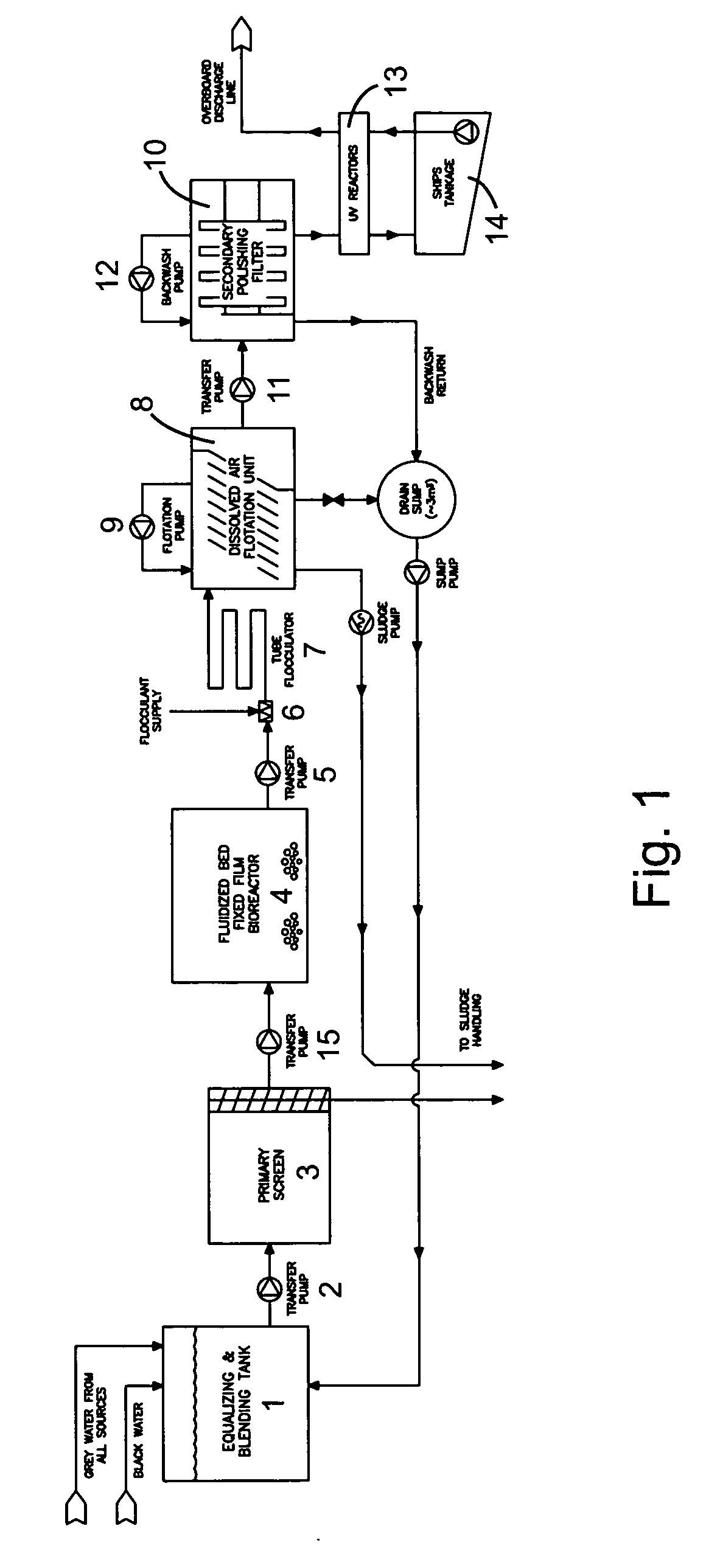

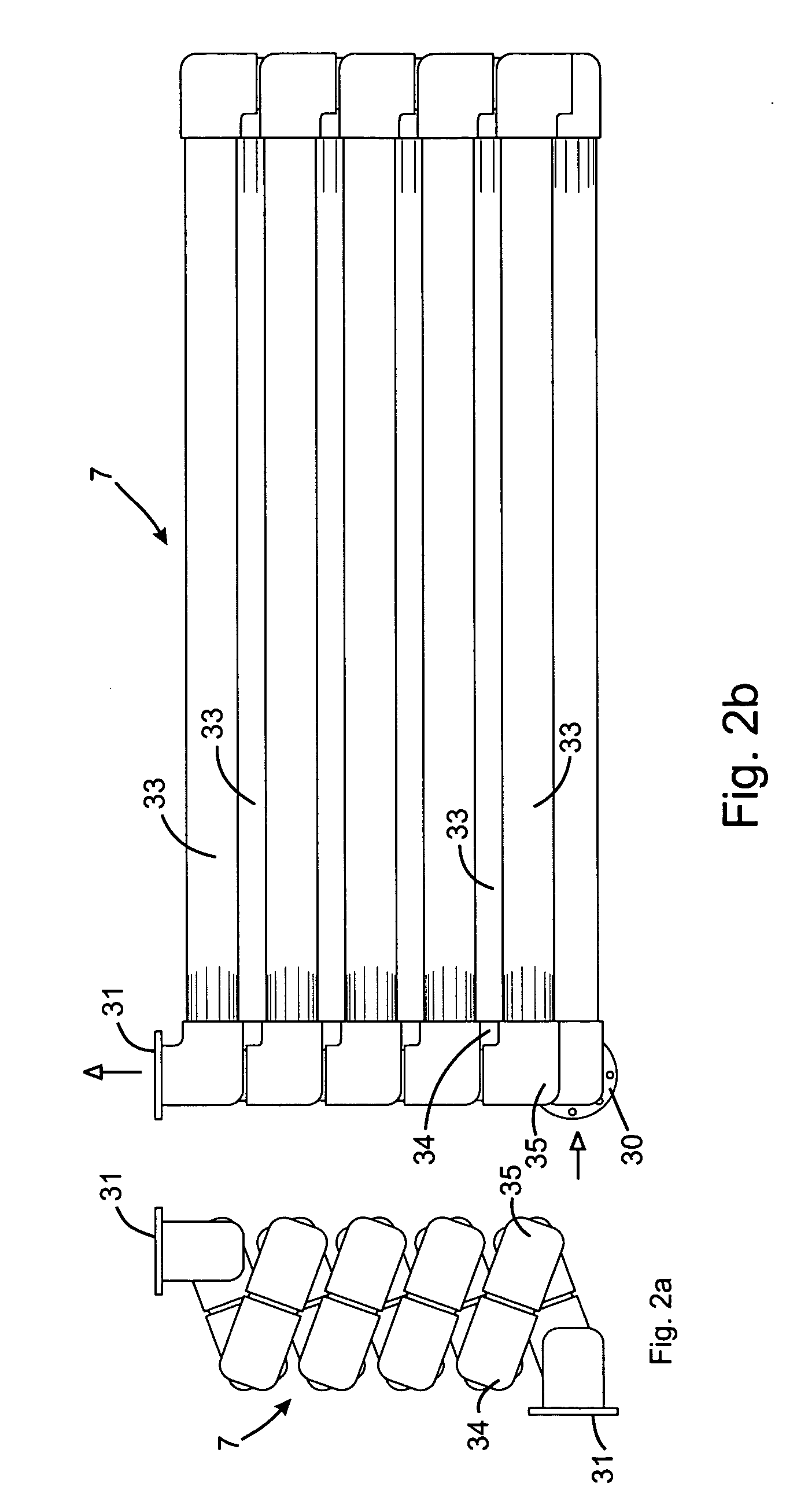

Wastewater treatment system for a marine vessel

InactiveUS20070114182A1Reduce movementAvoid erratic movementTreatment using aerobic processesTreatment involving filtrationCompound (substance)Membrane bioreactor

A wastewater treatment system for use on a marine vessel comprising an aerobic fixed film biological reactor, a tubular flocculator and a dissolved air flotation (DAF) unit. The process units desirably include means for reducing erratic movement of the wastewater due to sea-induced movement of the marine vessel. The DAF unit includes a plurality of inclined baffles arranged to create a plurality of parallel inverted U-shaped flow paths that effect combined co-current and counter-current flotation separation while reducing erratic movement of the wastewater. The selection of process units and operating conditions advantageously reduces the footprint of the wastewater treatment system and reduces cost and complexity associated with the handling of wastewater treatment chemicals.

Owner:HYDROXYL SYST

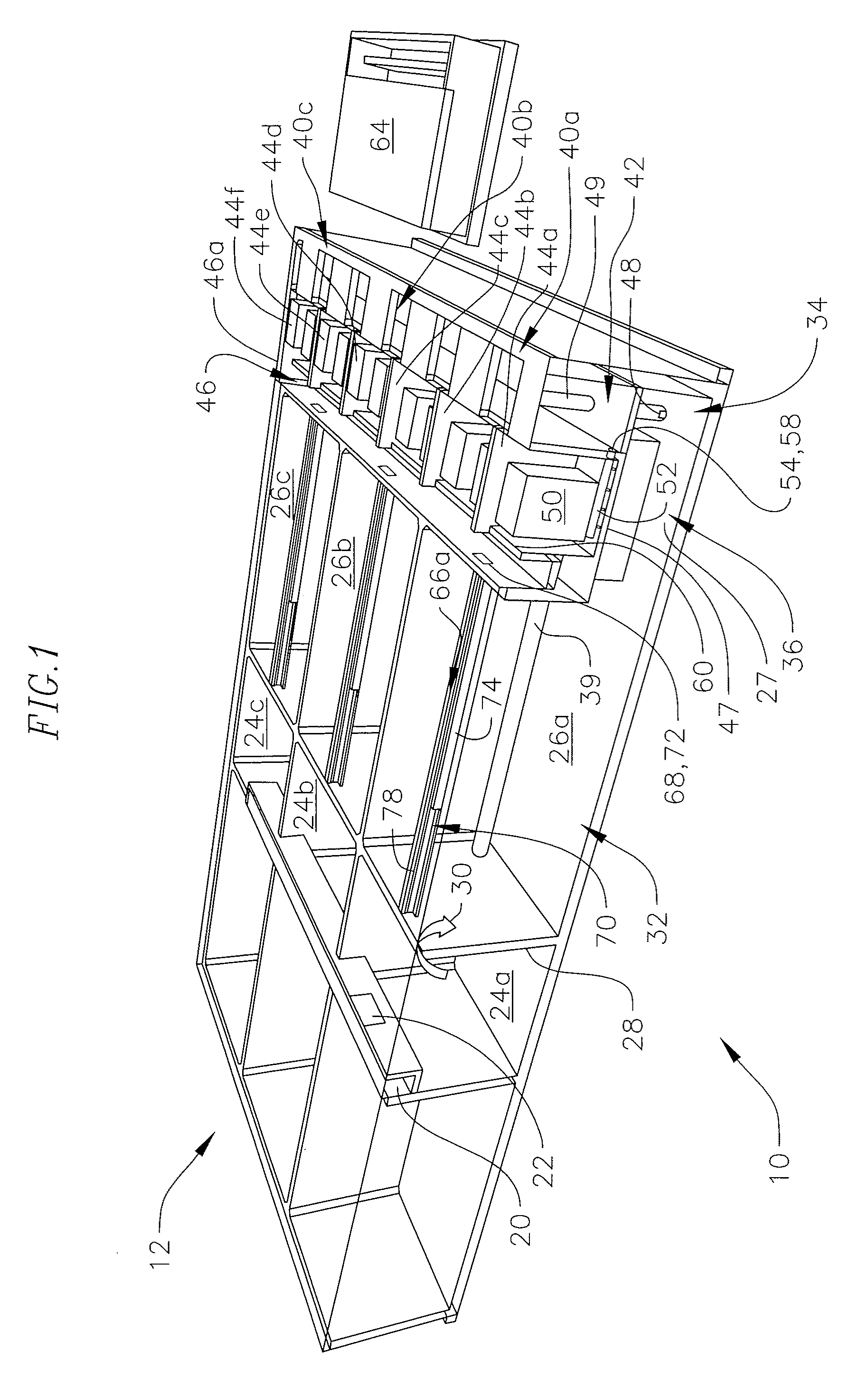

Membrane bioreactor

The present invention relates to wastewater treatment facilities, and more particularly to an improved membrane bioreactor for treatment of wastewater. In one embodiment, a membrane bioreactor for treatment of wastewater includes first and second anoxic basins for anoxic treatment of such wastewater, and first and second aerobic basins for aerobic treatment of such wastewater. The bioreactor also includes a first flow path connecting the first anoxic basin and the first aerobic basin, and a second flow path connecting the second anoxic basin and the second aerobic basin, for flow of the wastewater from the respective anoxic basin into the respective aerobic basin. The bioreactor also includes a membrane chamber with a plurality of membrane tanks, the membrane chamber being arranged in series with the aerobic basins, and the membrane tanks being arranged in parallel with each other, and third and fourth flow paths connecting the membrane chamber to the first and second aerobic basins. The membrane chamber may extend into the aerobic basin.

Owner:NICK JUERGEN T +2

Membrane Bioreactor System Using Reciprocating Membrane

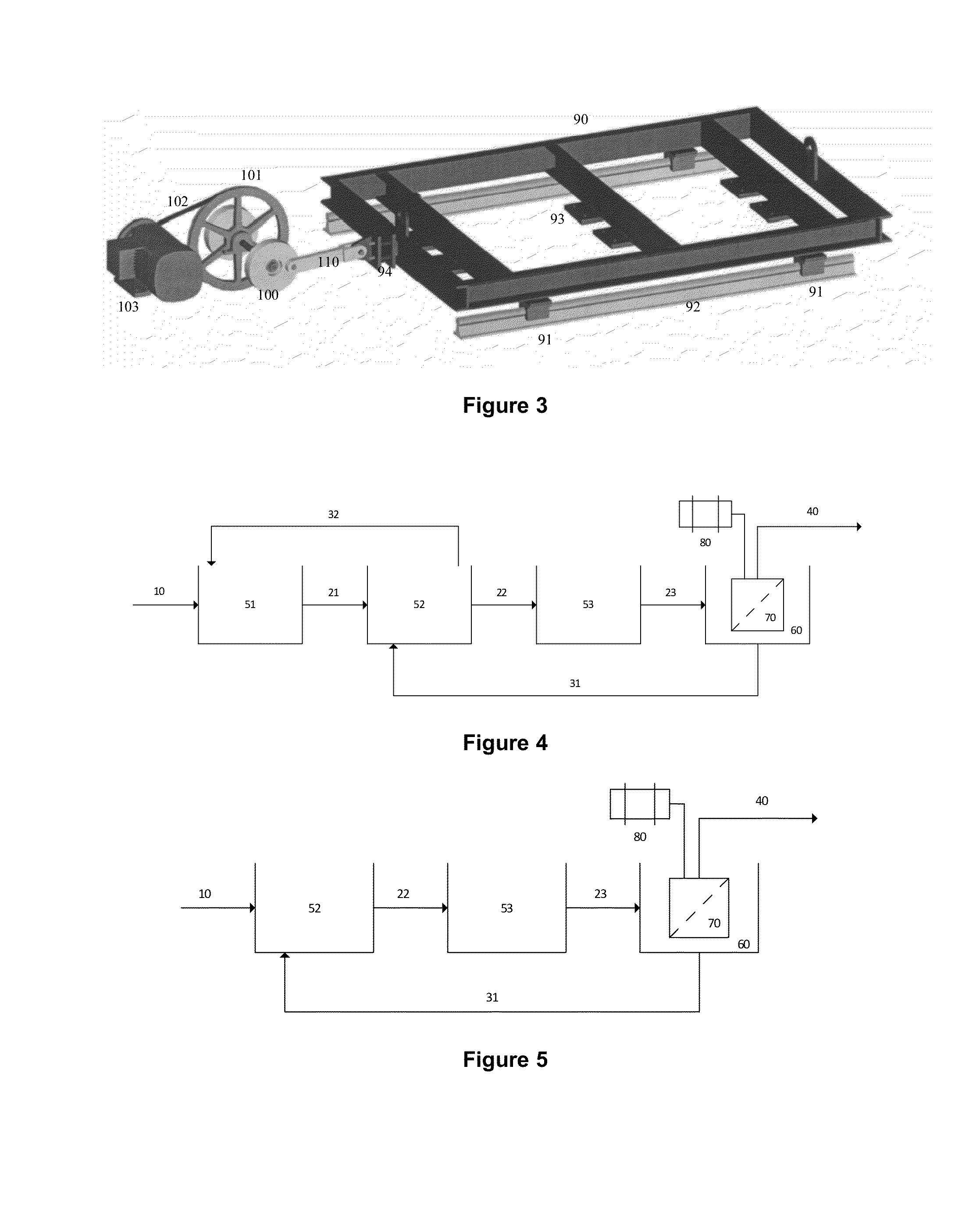

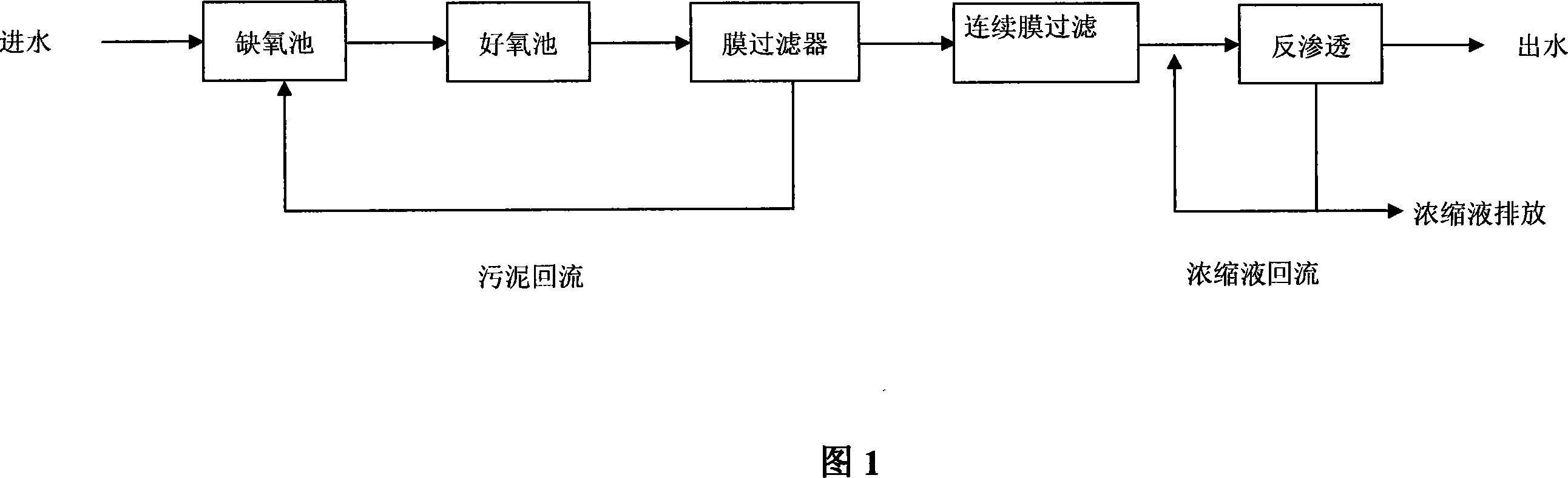

ActiveUS20140097132A1Reduce and eliminate membrane foulingReduce eliminateSemi-permeable membranesMembranesReciprocating motionHigh flux

The present invention relates to membrane bioreactor (“MBR”) system that includes a mechanical membrane reciprocation system to reduce or eliminate membrane fouling. The disclosed MBR system can be operated with higher flux and lower fouling than MBR systems using air scouring. Furthermore the system can remove nitrogen and phosphorous with one RAS and one or no internal recirculation line. The membrane can be reciprocated by a low RPM motor connected to a pulley via belt to rotate rotor to convert rotational motion into reciprocating motion of membrane. Various mechanical means can also be employed to create the reciprocating motion.

Owner:DOOSAN HEAVY IND & CONSTR CO LTD

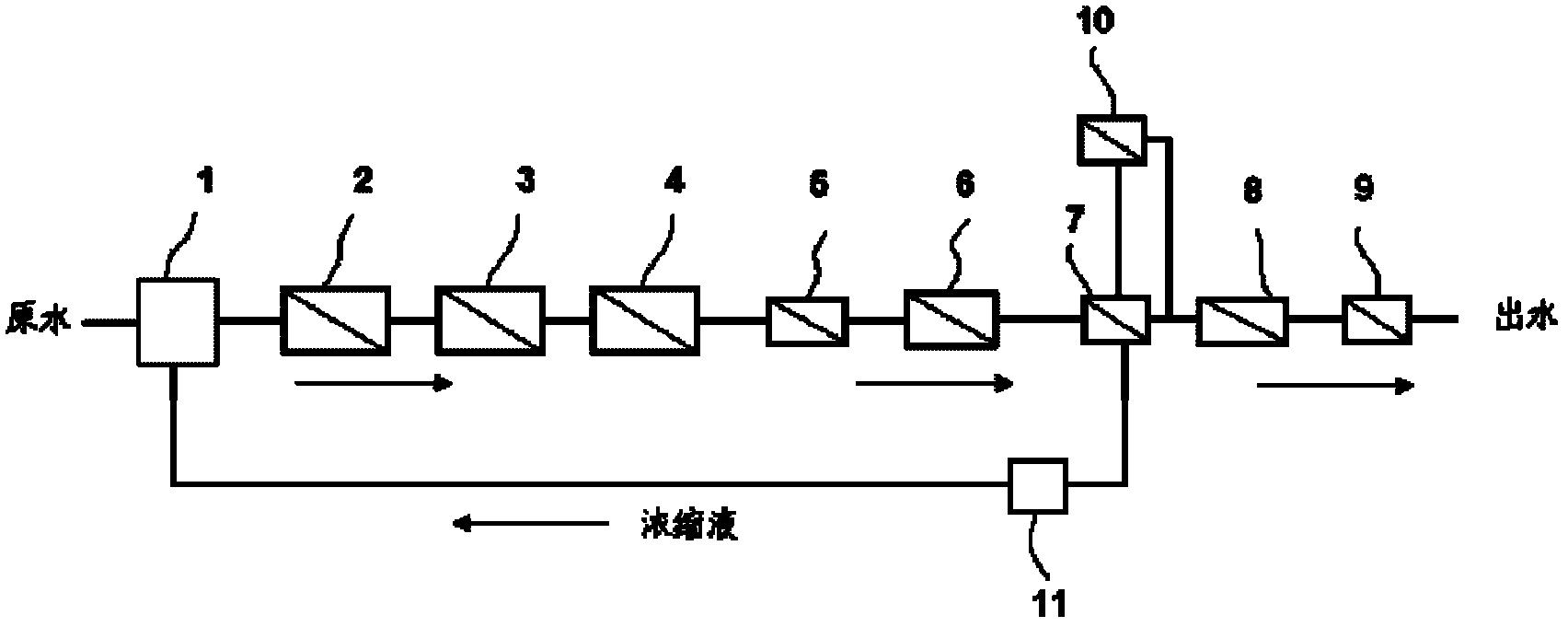

Technological process of treating papermaking effluent for reuse based on membrane integrating technique

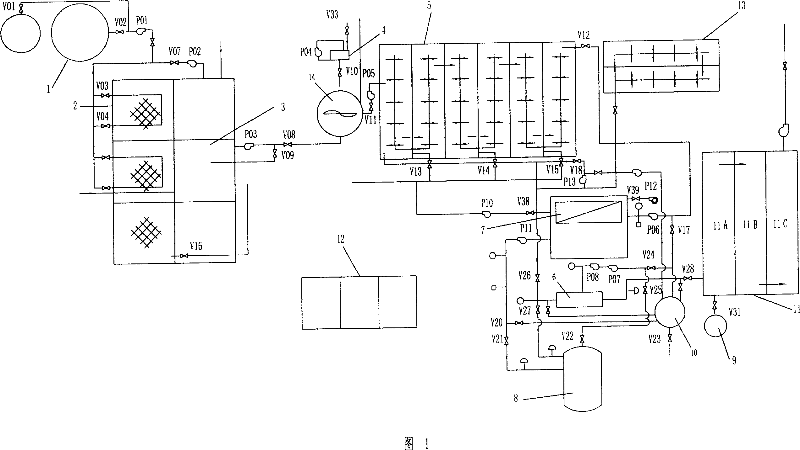

ActiveCN101088941AAchieve recyclingEfficient deep processingWater/sewage treatment bu osmosis/dialysisTreatment with aerobic and anaerobic processesReverse osmosisPapermaking

The technological process of treating papermaking effluent for reuse based on membrane integrating technique has membrane bioreactor, continuous membrane filter and reverse osmosis unit integrated for high efficiency treatment of papermaking effluent. The papermaking effluent treating process includes drum filtering and flocculating deposition to eliminate most suspended matter and colloid matter, anaerobic and aerobic biochemical treatment, filtering in membrane separating element, continuous membrane filtering, and treating with reverse osmosis membrane to reach the papermaking water standard. The present invention is especially suitable for treating hard-to-treat papermaking effluent.

Owner:安徽森诺膜技术有限公司 +1

Printing and dyeing waste water treatment method based on film technology

ActiveCN101041532AOvercome costsUnsatisfactory processing effectWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentTextile printerWater based

The invention discloses a disposing method of textile printing waste water based on film technology involving a waste water disposing method, which comprises the following steps: adjusting pH and COD value of integrated waste water; pumping into flocculate tank; adding into flocculant; pumping into flocculating setting vessel; getting clarified solution; pumping into membrane biological reactor; proceeding biological treatment; getting dialysate; pumping into counter osmotic separating system; proceeding counter osmotic separation; getting reverse osmosis dialysate; recycling; making concentrated liquid flow into oxide adsorbing tank; refluxing into flocculating setting disposal process; proceeding twice flocculating setting dispose; reaching to two grade emission standard; discharging the eligible reverse osmosis dialysate; adding ClO2 to oxide ineligible reverse osmosis dialysate; adsorbing with activated char; adjusting pH value with alkali liquor; depositing in storing tank.

Owner:SUNTAR MEMBRANE ENVIRONMENT TECH

Infiltration method for treating garbage

InactiveCN1872745AEasy to handleEasy to manageTreatment with aerobic and anaerobic processesWater/sewage treatment bu osmosis/dialysisFlocculationAfter treatment

This invention discloses a method for treating the leachate of garbage. The method comprises: (1) adding flocculant to the leachate of garbage under a basic condition, and performing flocculation and preprecipitation; (2) performing partial denitrification in a circulatory aeration tank and an aeration column; (3) performing anaerobic treatment in an upflow anaerobic sludge bed reactor; (4) performing aerobic treatment by two-step contact oxidation; (5) treating the leachate in a membrane bioreactor; (6) performing nanofiltration. Water after treatment has a COD value not higher than 10 mg / L, and electrical conductivity not higher than 1000 mus cm, and can satisfy the standard for domestic water.

Owner:深圳市百斯特环保工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com