Patents

Literature

152results about How to "Reducing resource" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

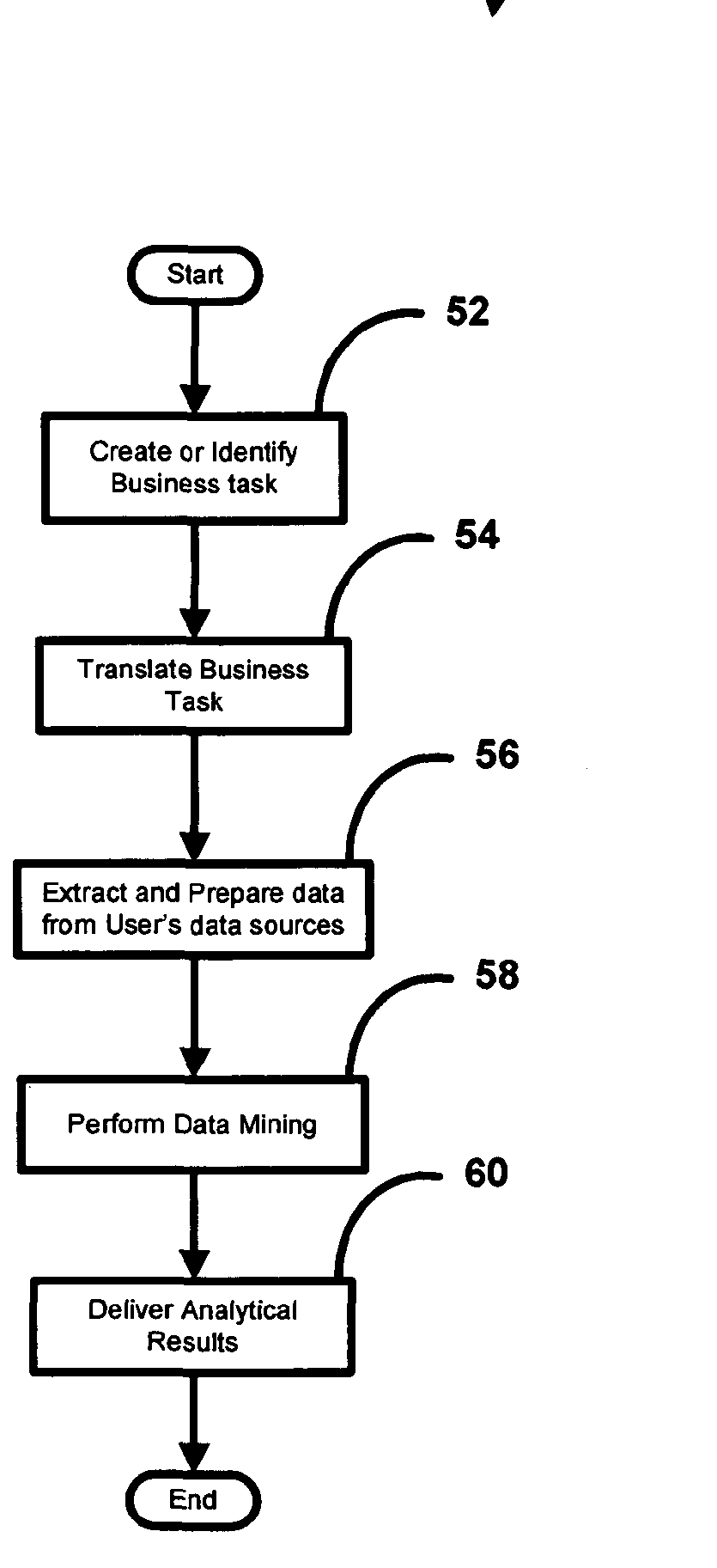

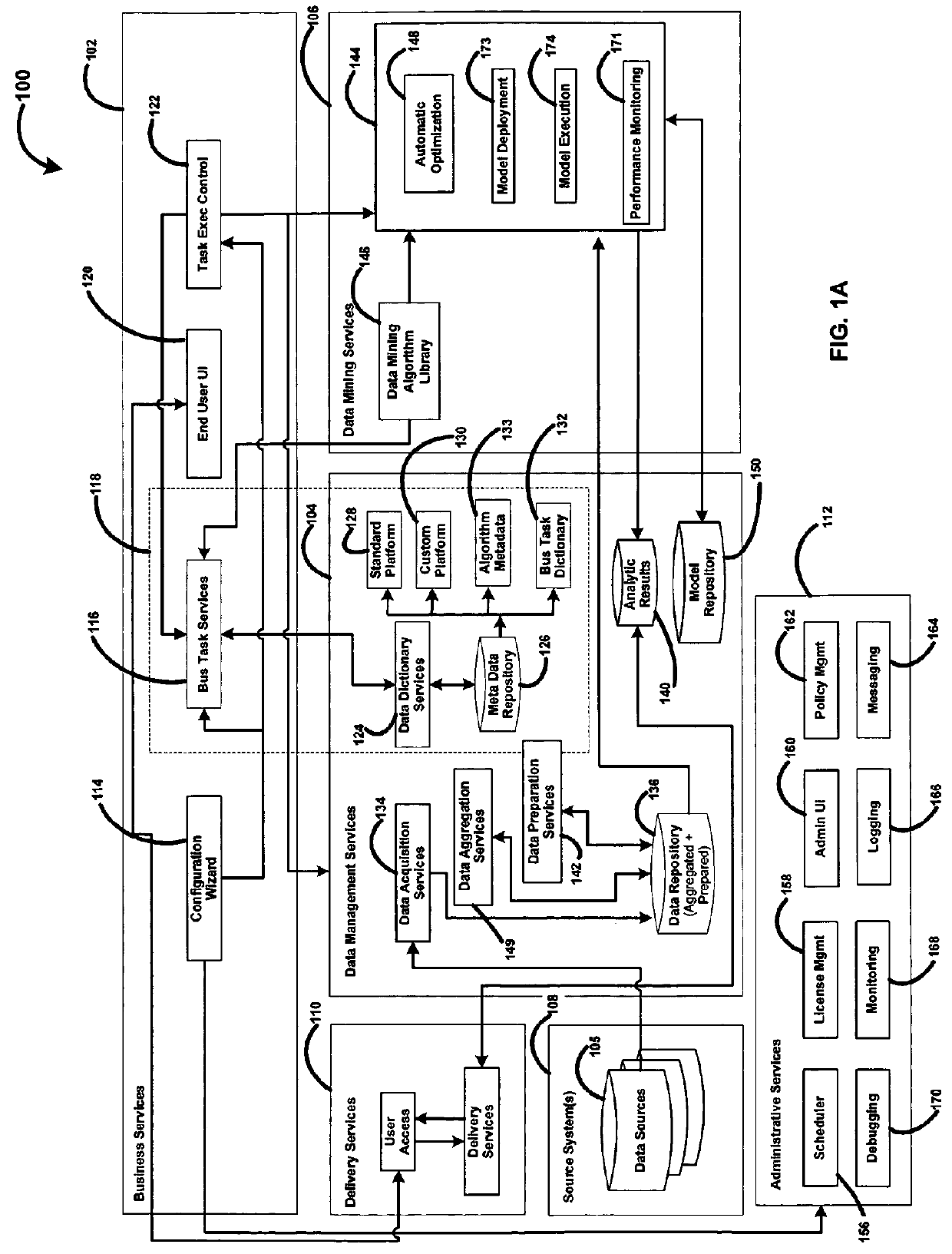

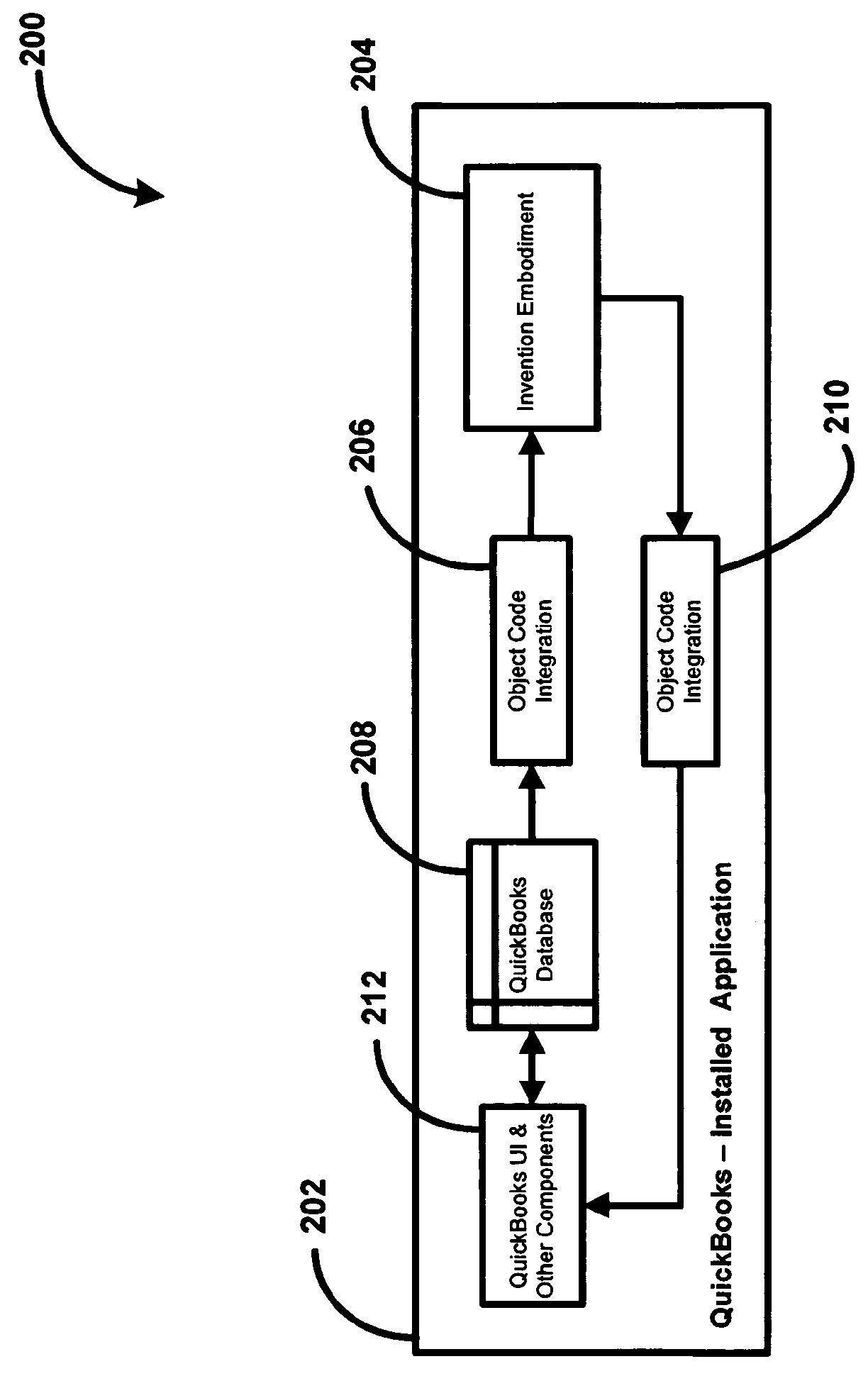

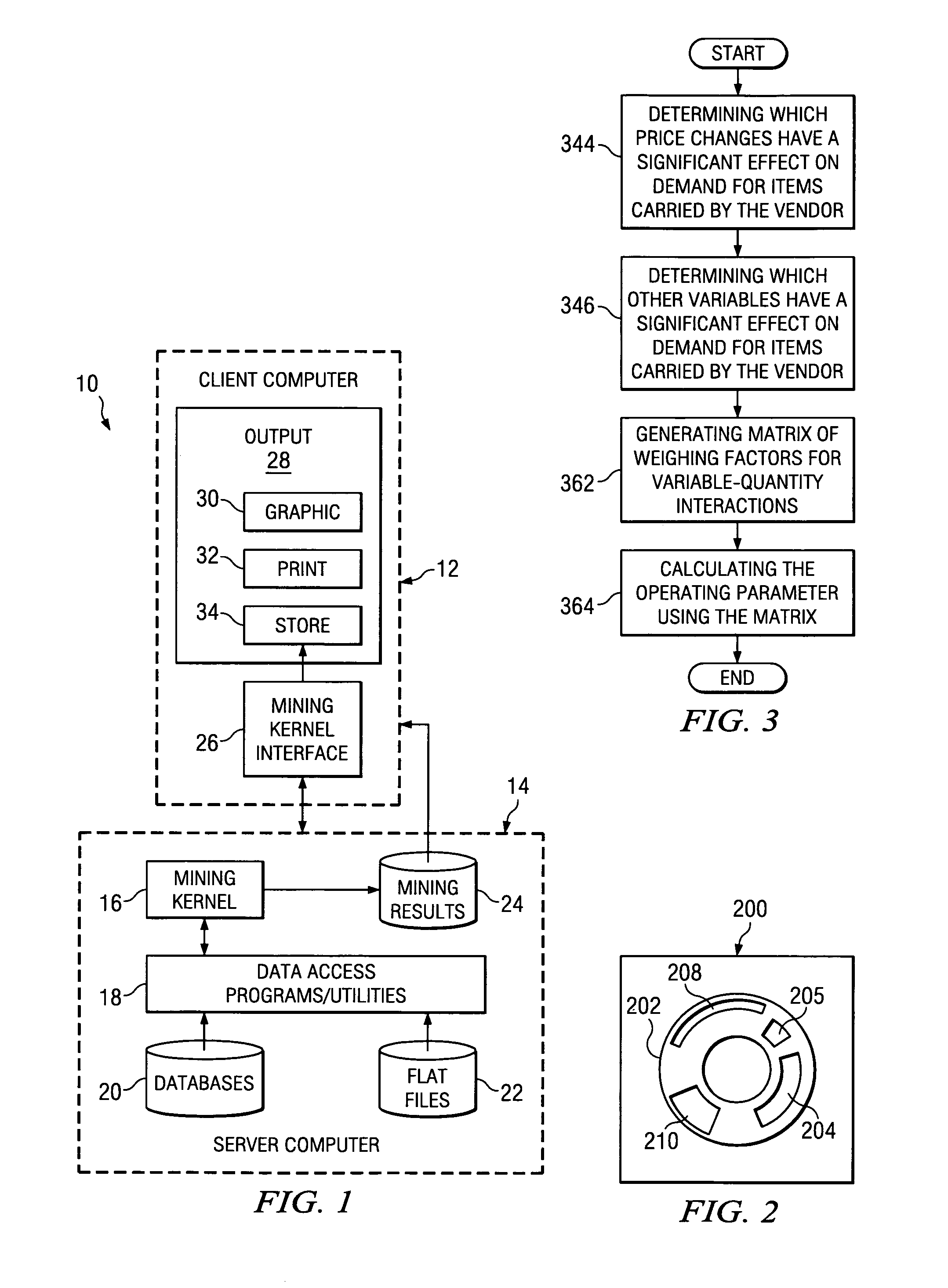

Platform independent plug-in methods and systems for data mining and analytics

ActiveUS8417715B1Lower barrierShorten cycle timeFinanceDigital data processing detailsData conversionSoftware

The present invention comprises methods, system, and apparatuses for generating and delivering analytic results for any simple or highly complex problem for which data exists that software or similar automated means can analyze. The present invention thus contemplates methods, systems, apparatuses, software, software processes, computer-readable medium, and / or data structures to enable performance of these and other features. In one embodiment, a method of the present invention comprises extracting and converting data using a data management component into a form usable by a data mining component, performing data mining to develop a model in response to a question or problem posed by a user.

Owner:BRUCKHAUS TILMANN +1

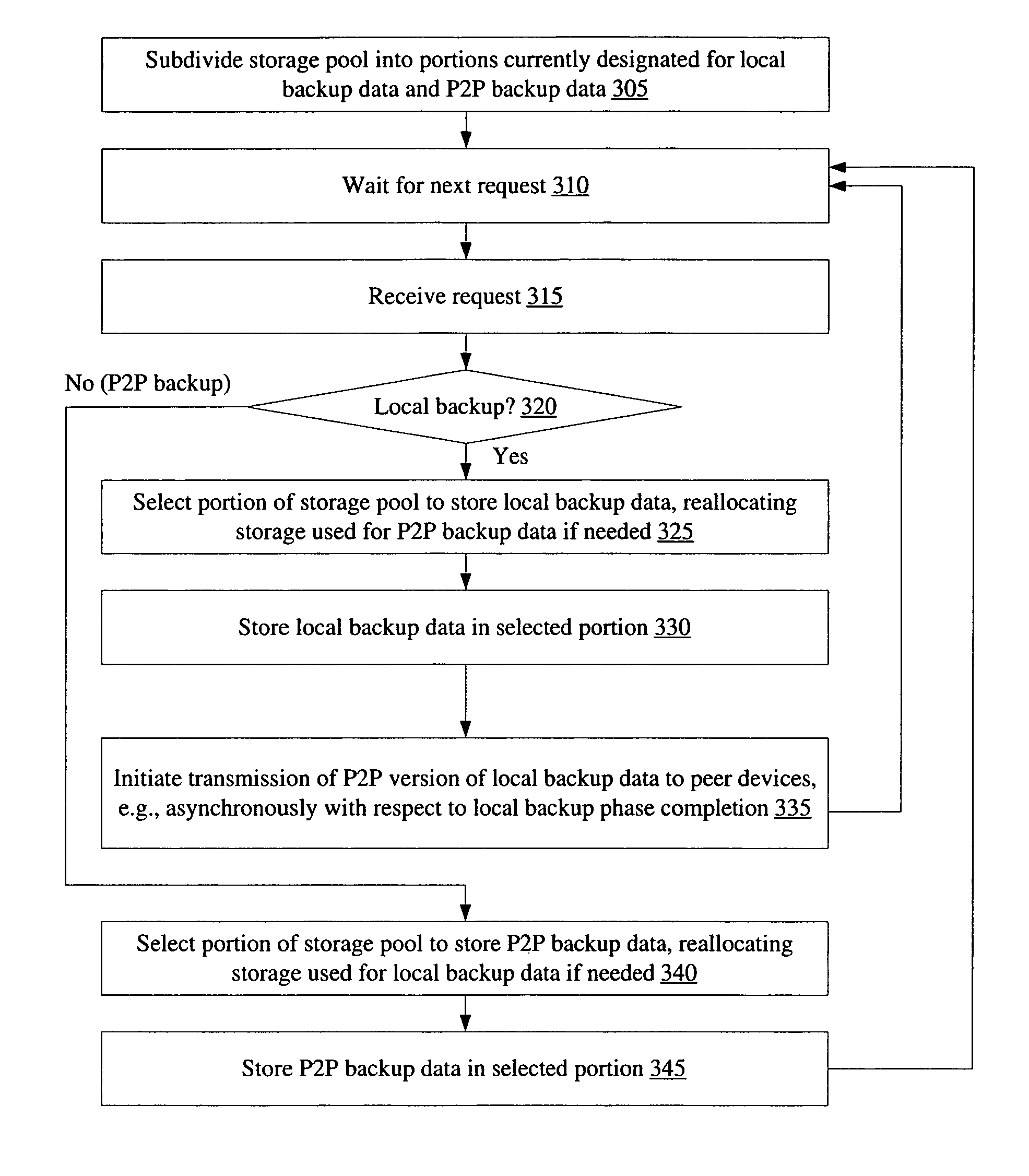

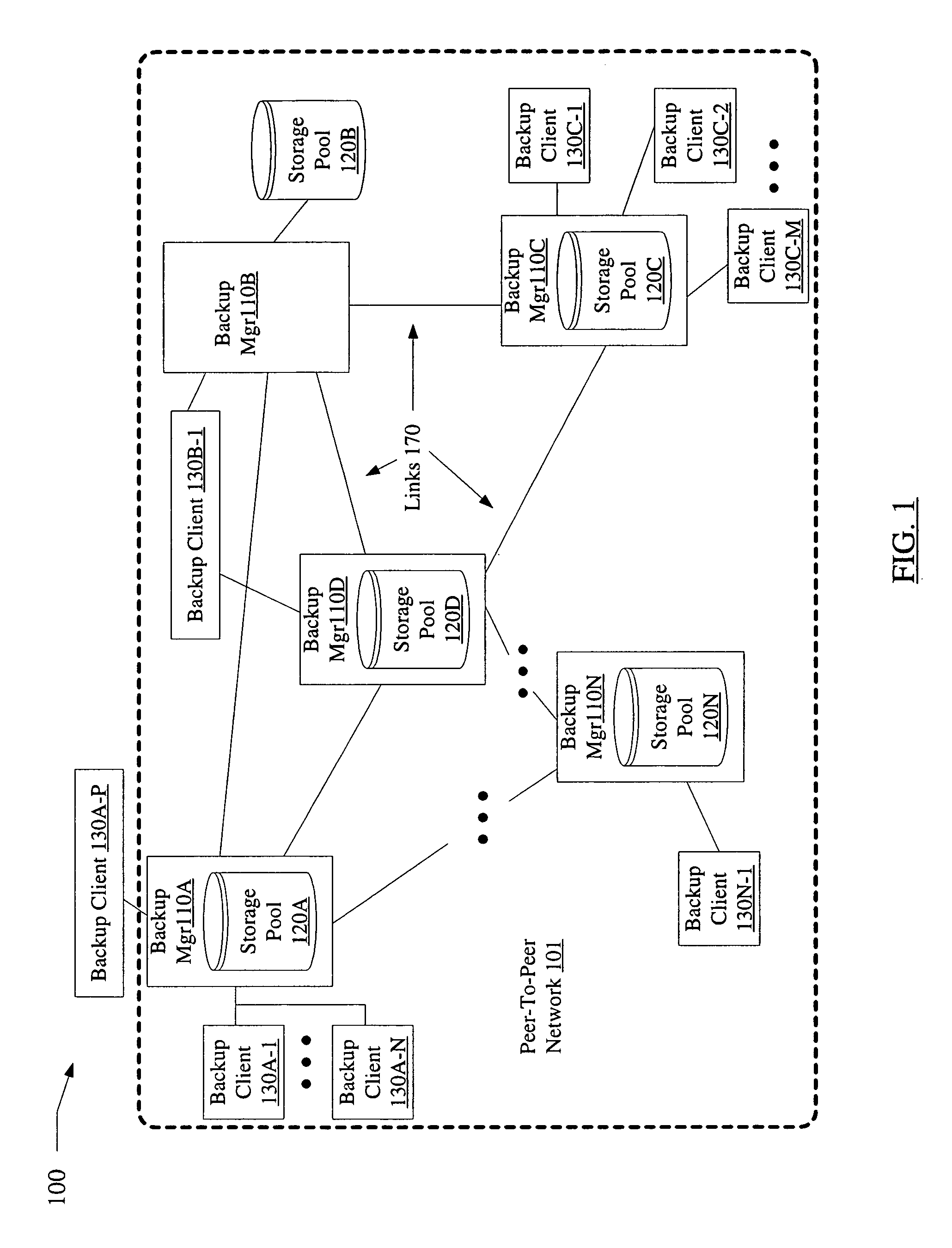

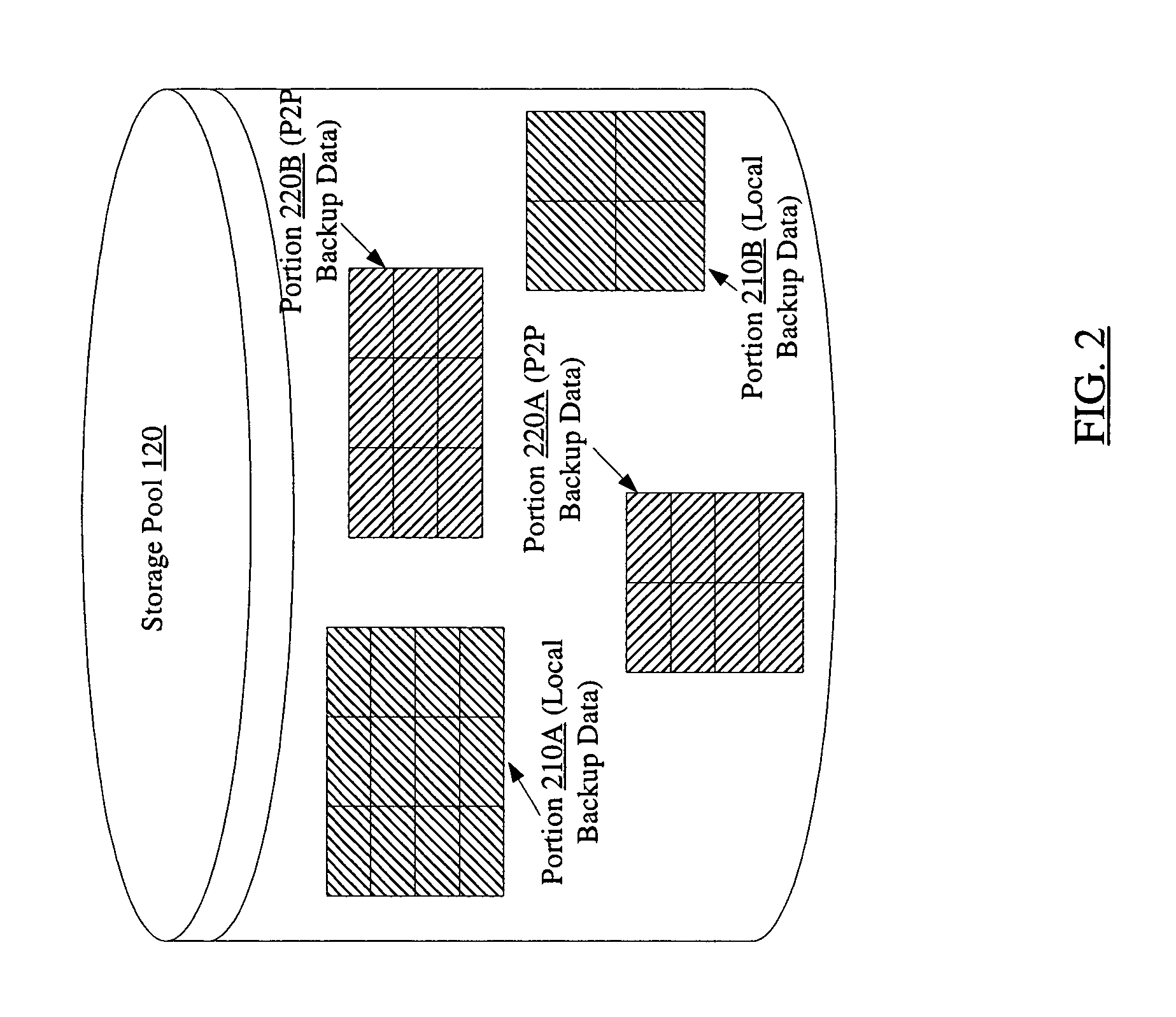

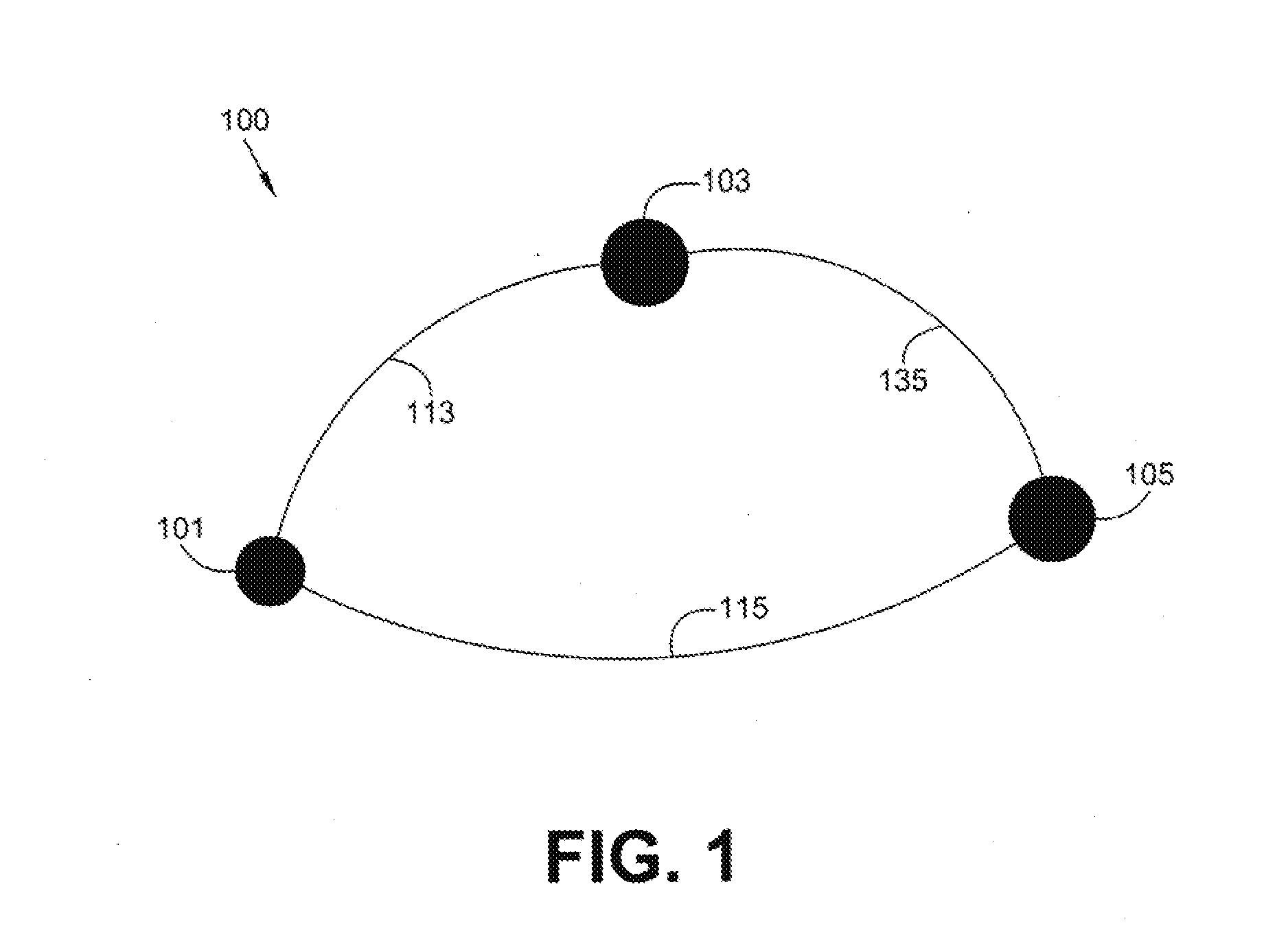

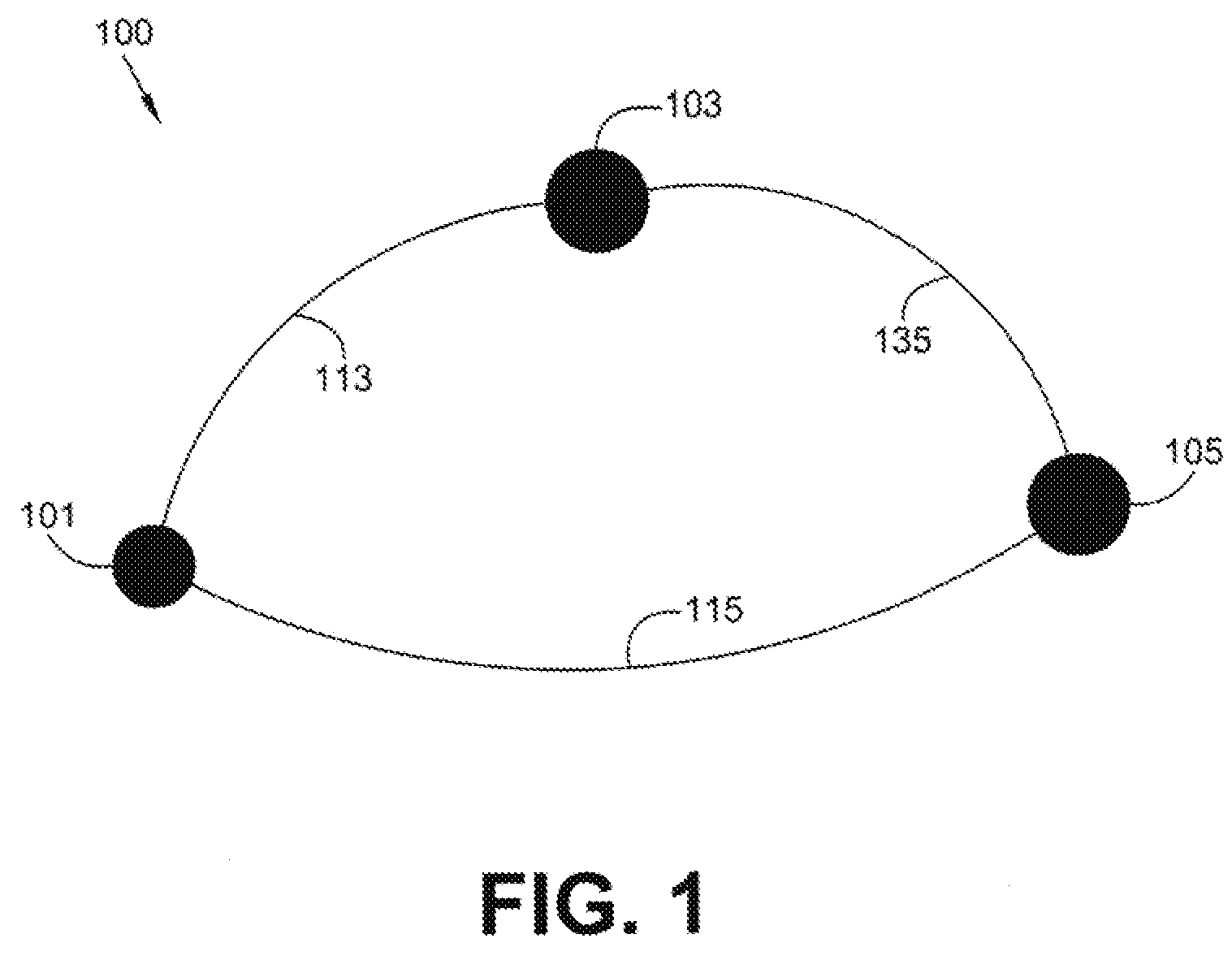

Efficient backups using dynamically shared storage pools in peer-to-peer networks

InactiveUS7529785B1Reduce storage requirementsEfficient backupError detection/correctionSpecial data processing applicationsClient-sideData store

A system for efficient backups using dynamically shared storage pools in peer-to-peer networks comprises one or more processors and memory coupled to the processors. The memory stores instructions executable by the processors to implement a backup manager configured to dynamically subdivide a storage pool into one or more portions of storage currently designated for local backup data and one or more portions of storage currently designated for peer-to-peer (P2P) backup data. In response to local backup data received from a backup client, the backup manager may store the local backup data in a portion of the storage pool that is currently designated for local backup data. The backup manager may then generate a P2P version of the local backup data, e.g., by encrypting and / or redundancy encoding the local backup data, and transmit parts of the P2P version to each of one or more peer devices in the P2P network.

Owner:SYMANTEC OPERATING CORP

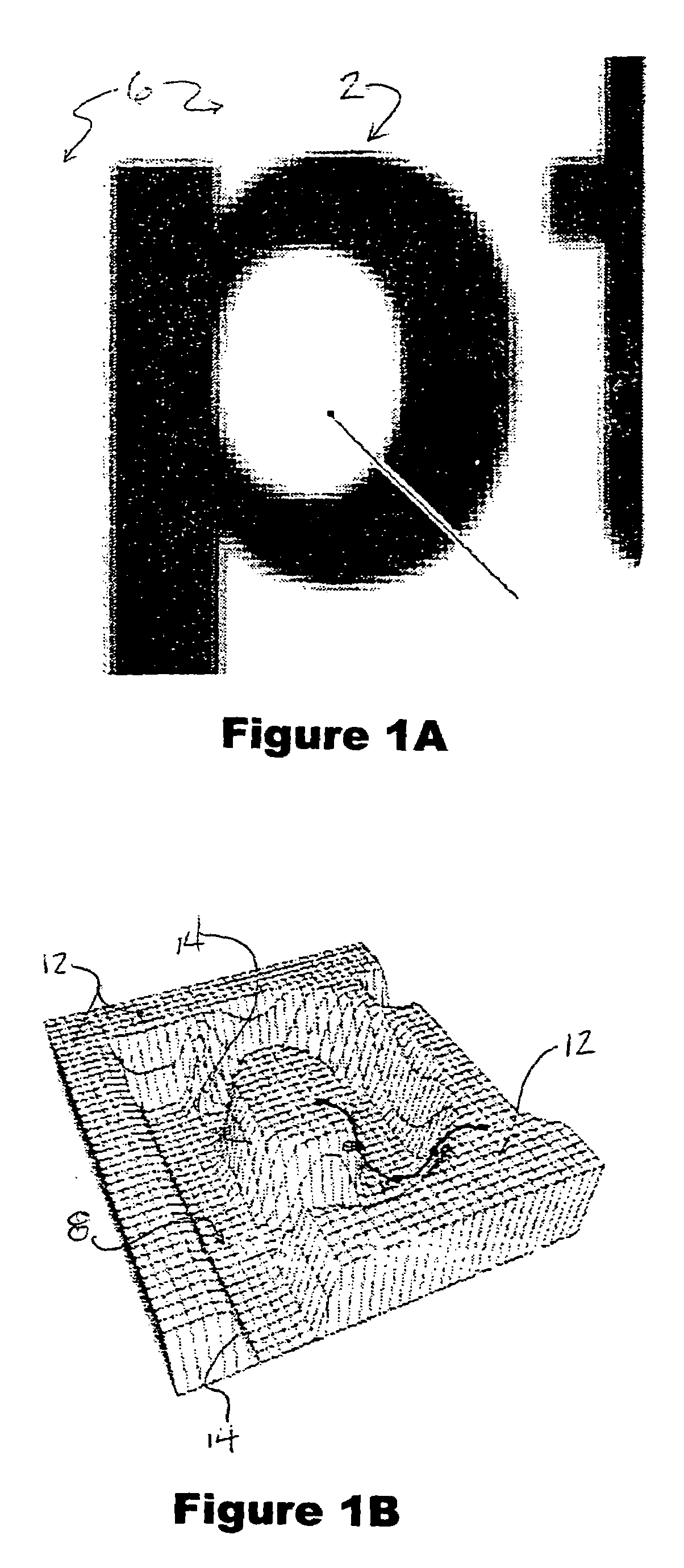

Methods and systems for text detection in mixed-context documents using local geometric signatures

InactiveUS7043080B1Quality andSpeed andCharacter and pattern recognitionVisual presentationGraphicsImaging processing

Embodiments of the present invention relate to methods and systems for detection and delineation of text characters in images which may contain combinations of text and graphical content. Embodiments of the present invention employ intensity contrast edge detection methods and intensity gradient direction determination methods in conjunction with analyses of intensity curve geometry to determine the presence of text and verify text edge identification. These methods may be used to identify text in mixed-content images, to determine text character edges and to achieve other image processing purposes.

Owner:SHARP KK

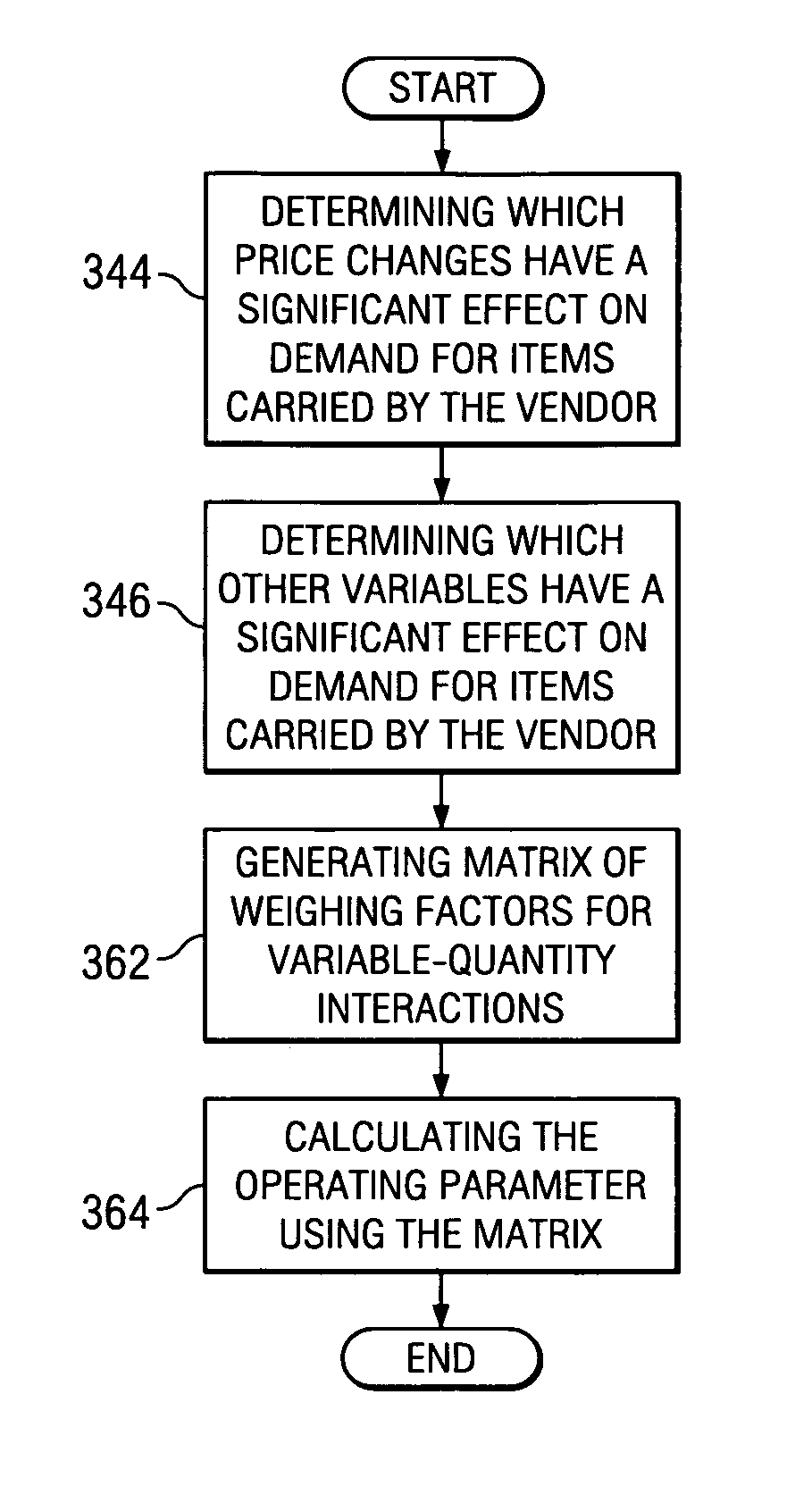

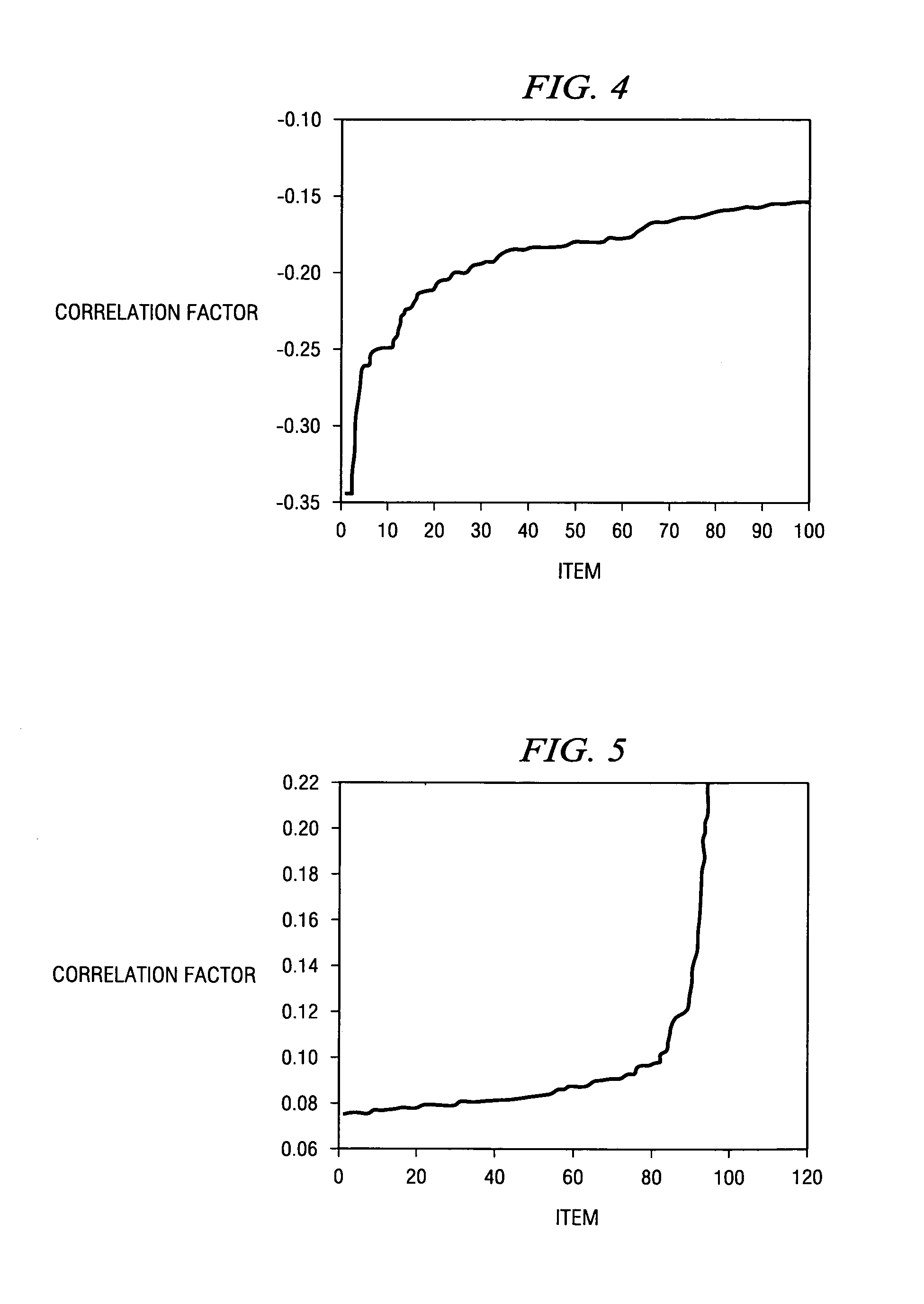

Method of modeling product demand subject to a large number of interactions

InactiveUS7197474B1Reduce computing timeReasonable operationMarket predictionsSpecial data processing applicationsData processing systemComputer science

A data processing system-implemented method or data processing system readable medium can be used to model operating parameter(s) for a vendor. Detailed analysis of the impact of prices or other variables, on the demand of each item, is performed. These allow us to prune large numbers of prices or other variables which have little or no impact on a given item. After determining which prices and other variables are significantly related to an item, a more in-depth examination of that small list of variables may be performed. This in-depth examination will result in a set of final weighing factors, quantifying the effect of each on the item. The weighing factors for all other variables can be assigned a value of zero. By limiting the number of non-zero weighing factors, the time needed to generate all the weighing factors for a matrix (or matrices) is reduced.

Owner:OPEN TEXT SA ULC

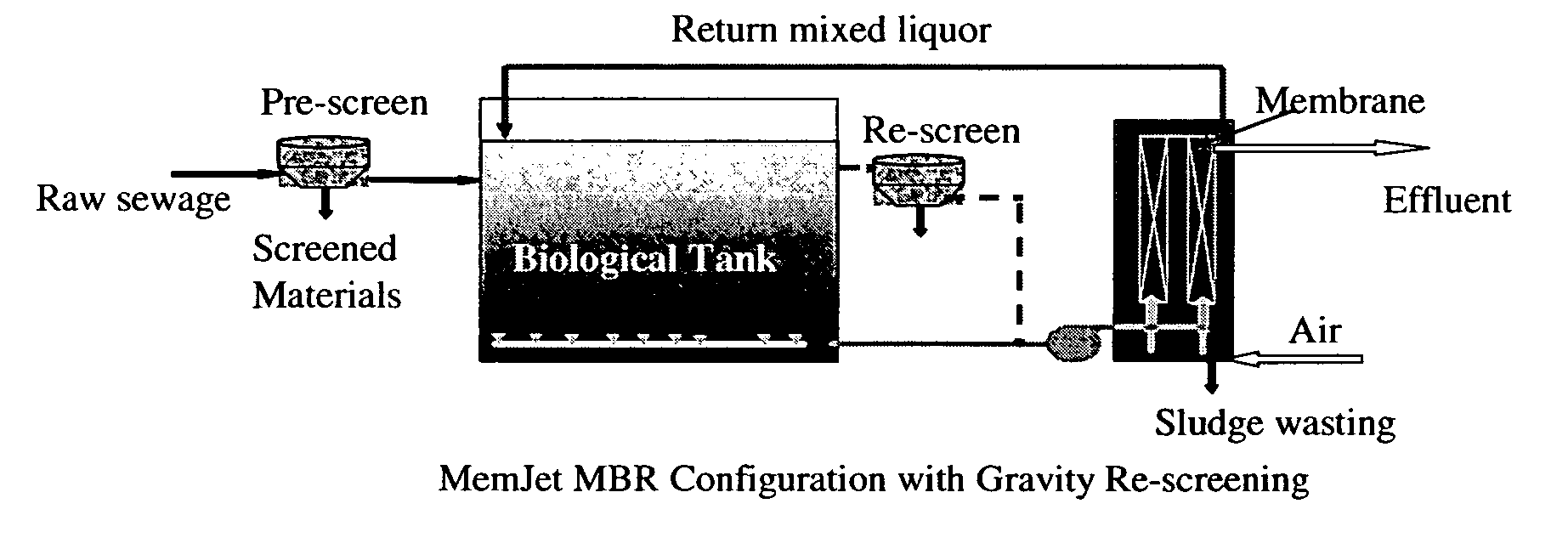

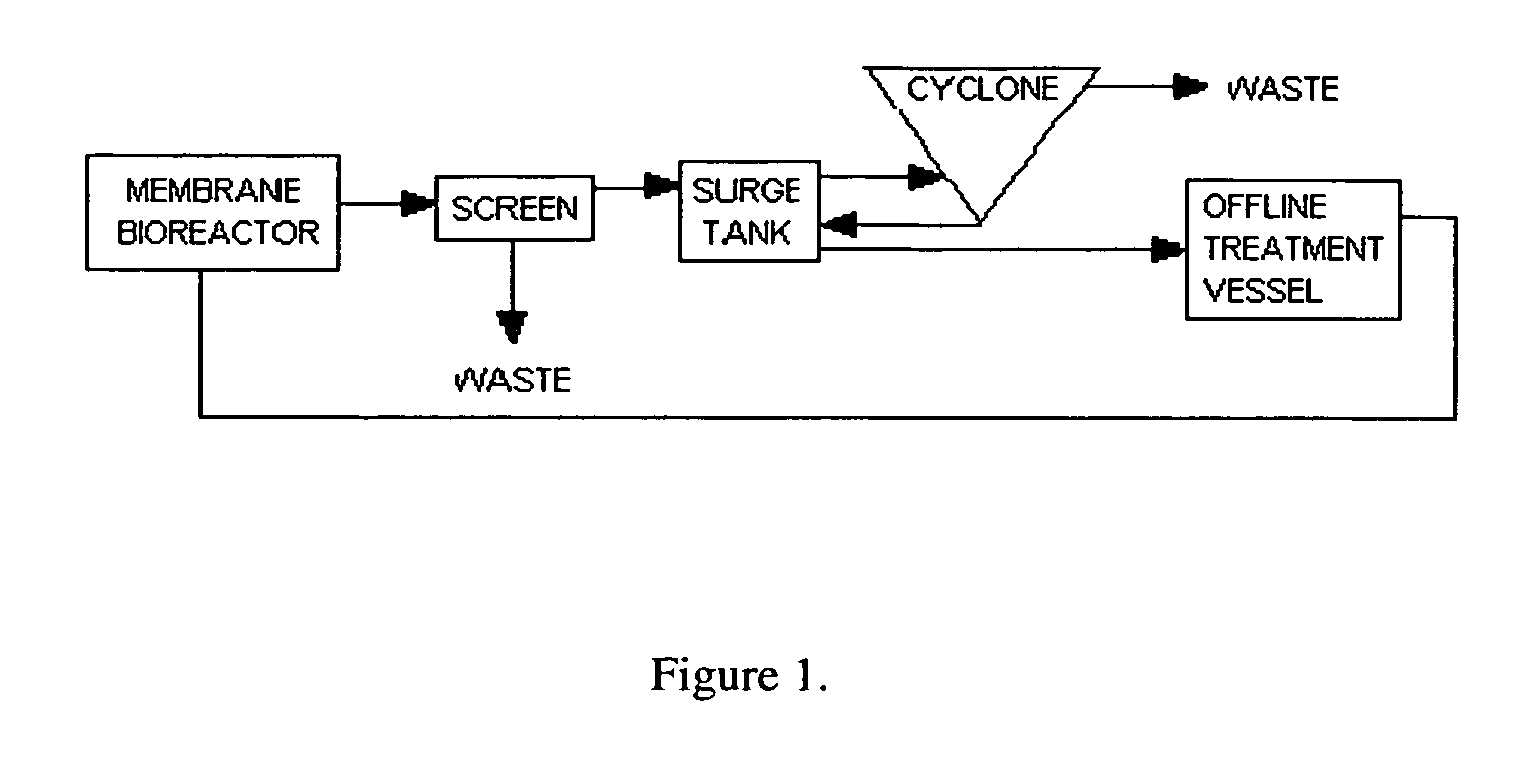

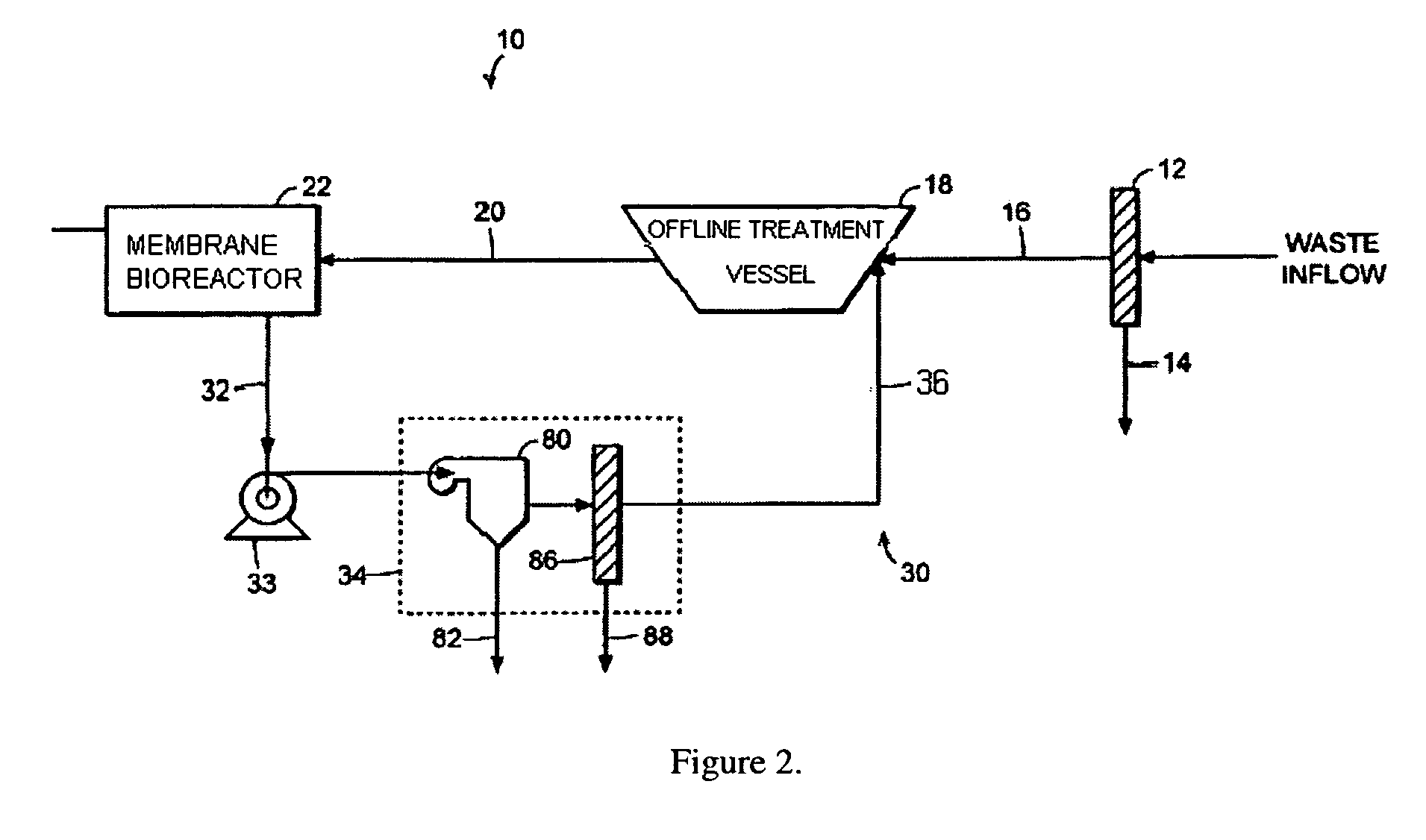

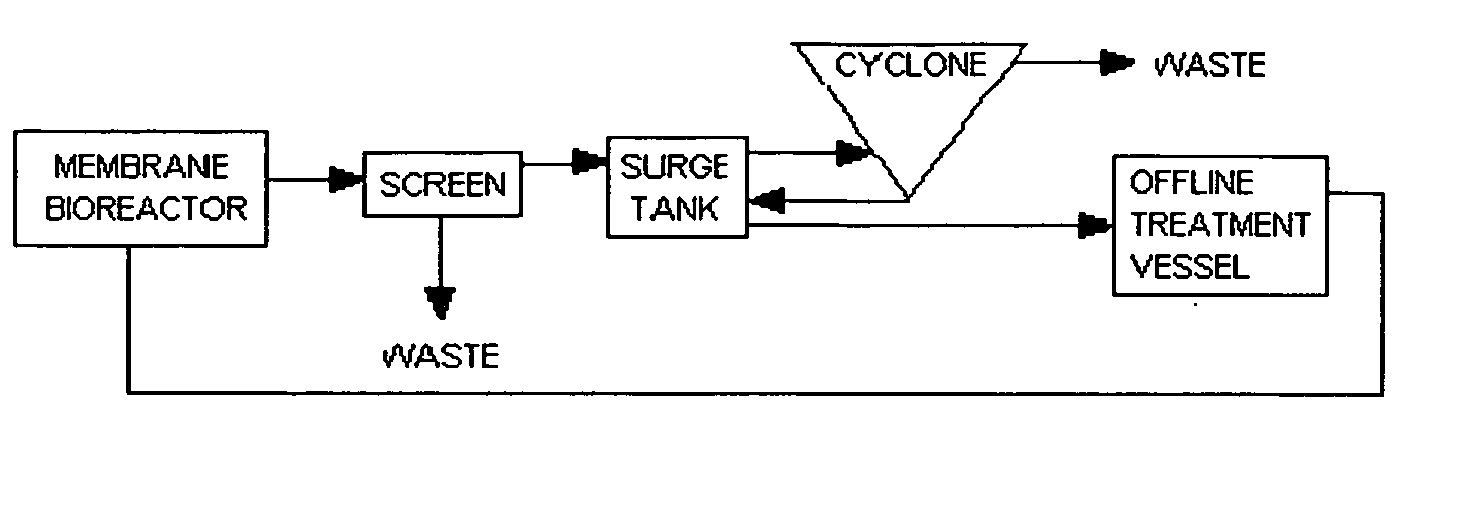

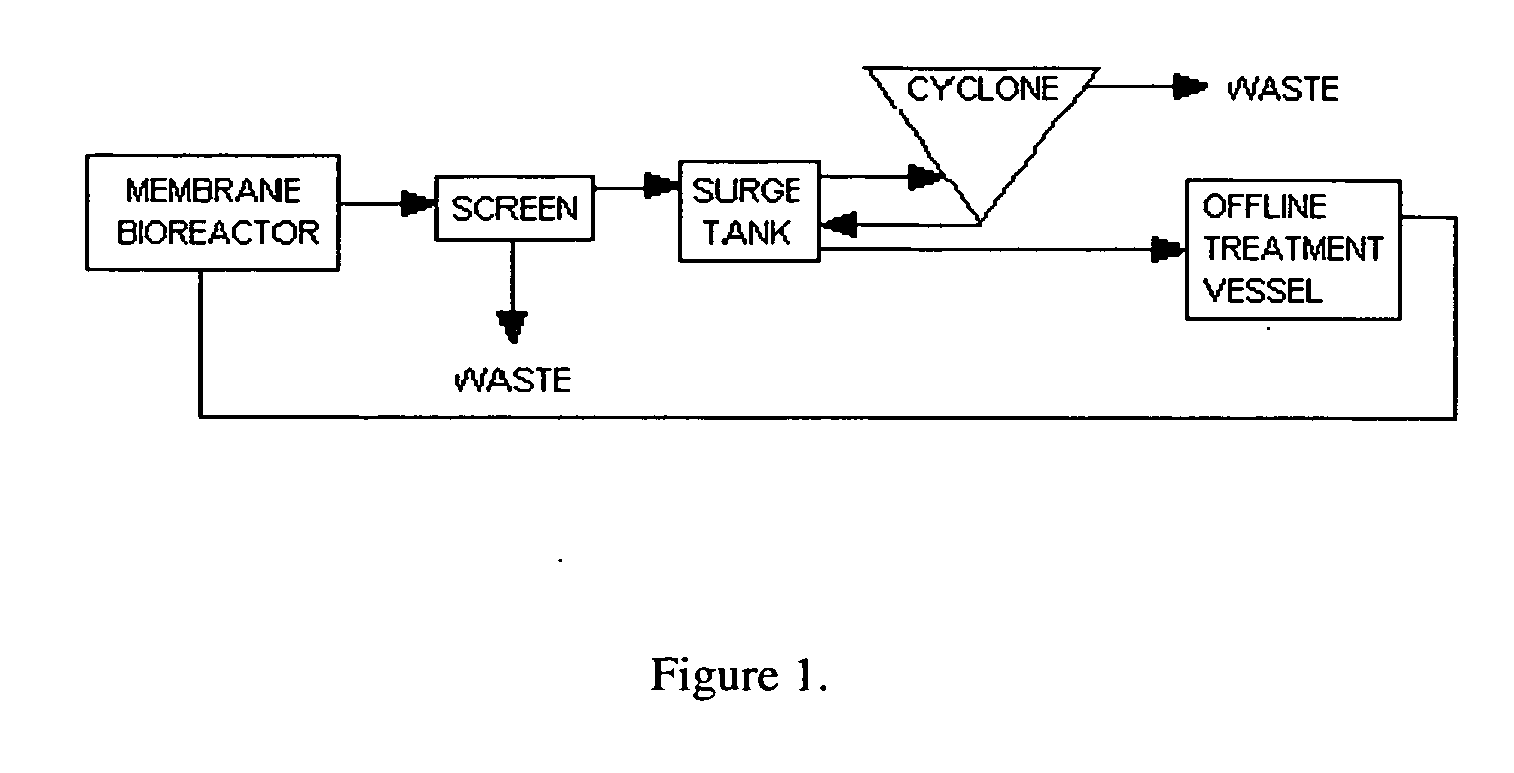

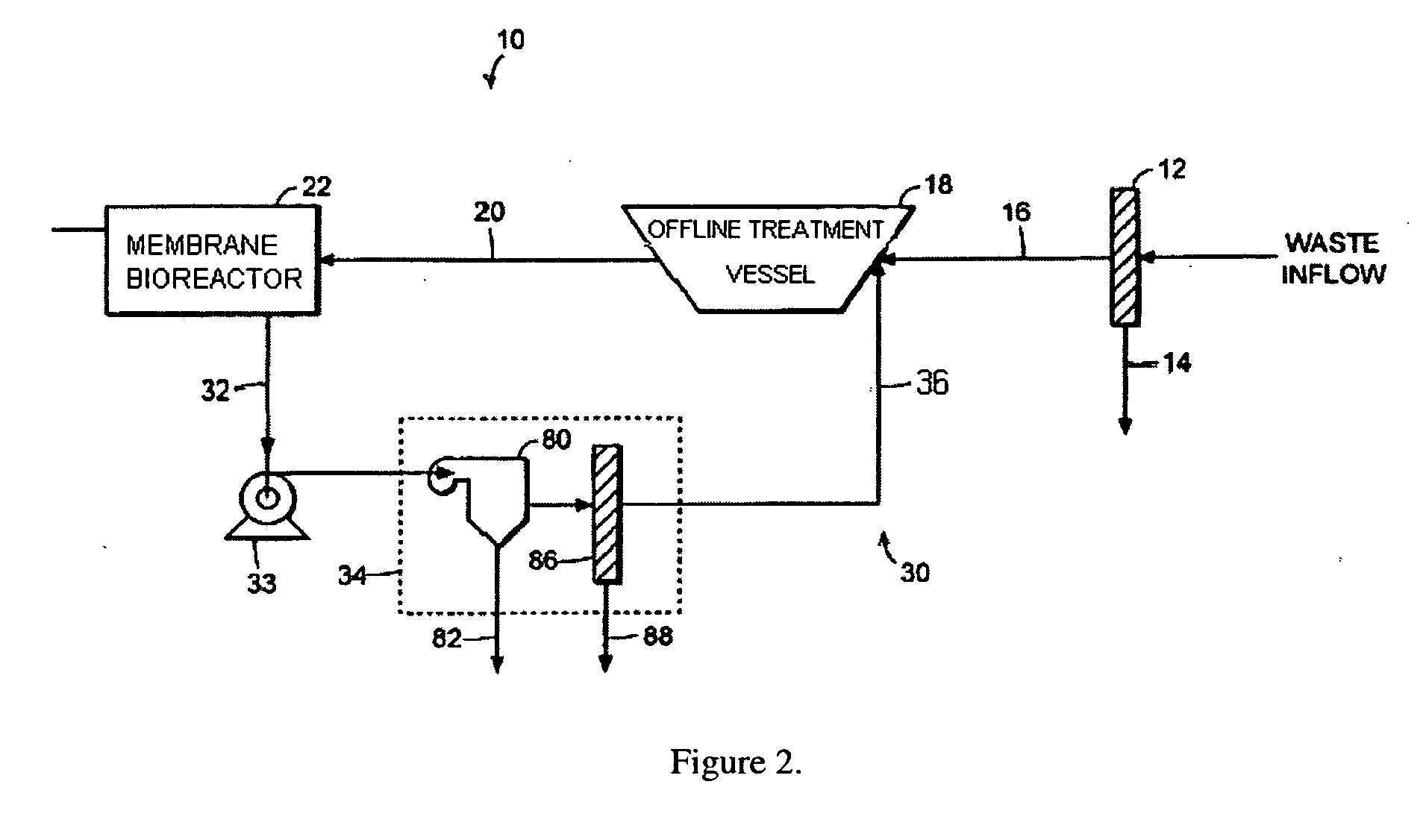

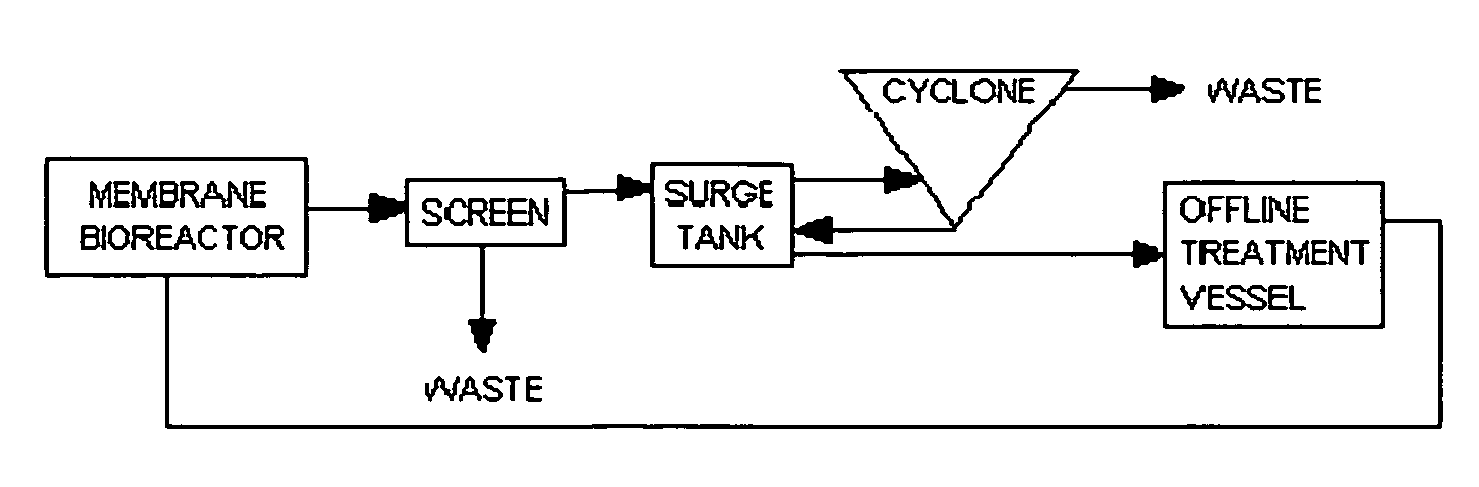

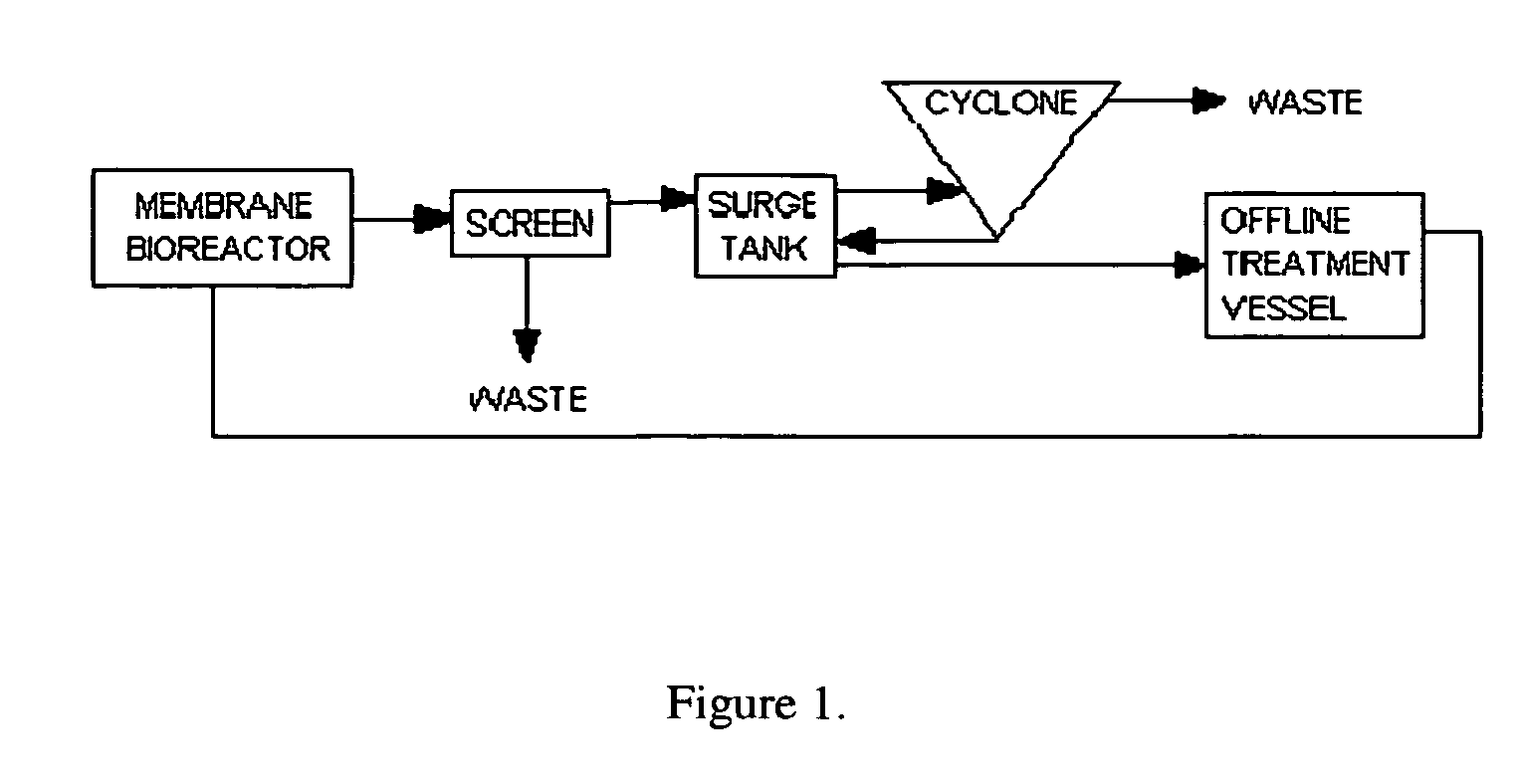

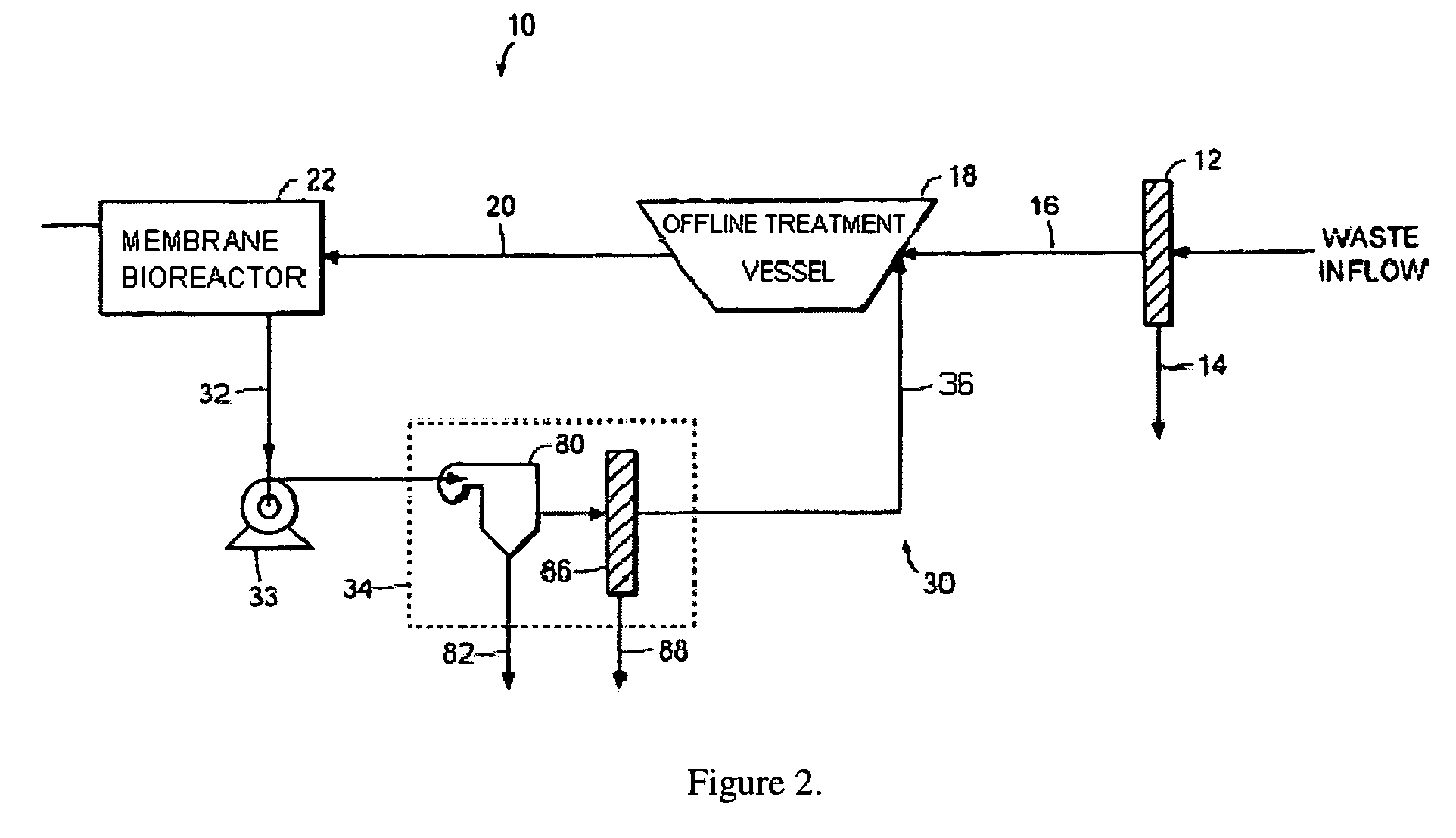

Grease and scum removal in a filtration apparatus comprising a membrane bioreactor and a treatment vessel for digesting organic materials

InactiveUS7329344B2Significant comprehensive benefitsLow costMembranesUltrafiltrationFiltrationMembrane bioreactor

The invention relates to a membrane bioreactor process combined with an advanced biological sludge digestion process that provides significant improvements in sludge digestion by reducing the costs and resources required for disposing of digested sludge. The offline treatment vessel is used to solubilize the organic material by operating in a very low oxygen environment. Digested process fluid is transferred back to the membrane bioreactor. The processes and apparatus substantially reduce the production of waste sludge. The device includes one or more weirs operable to remove grease and scum.

Owner:EVOQUA WATER TECH LLC

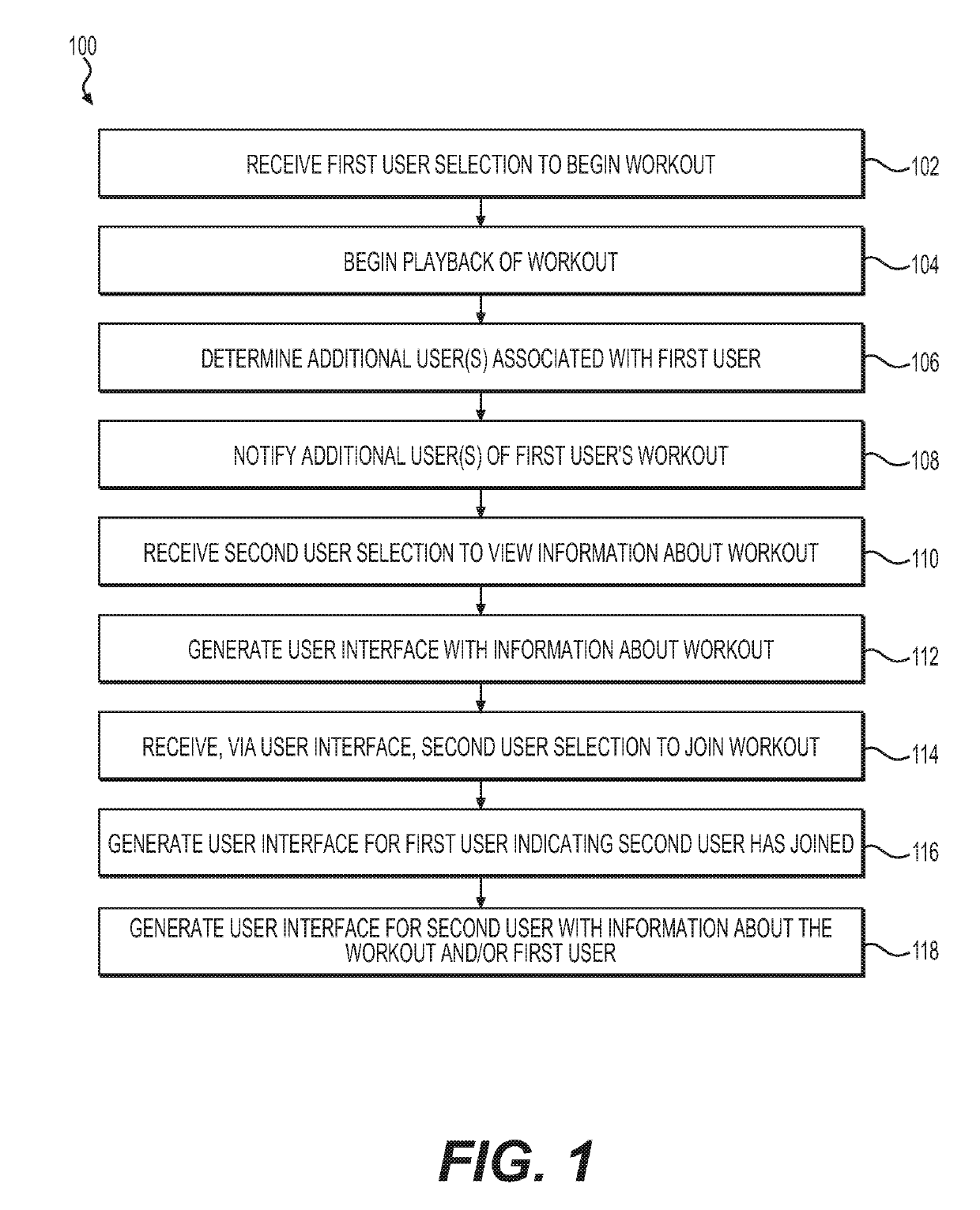

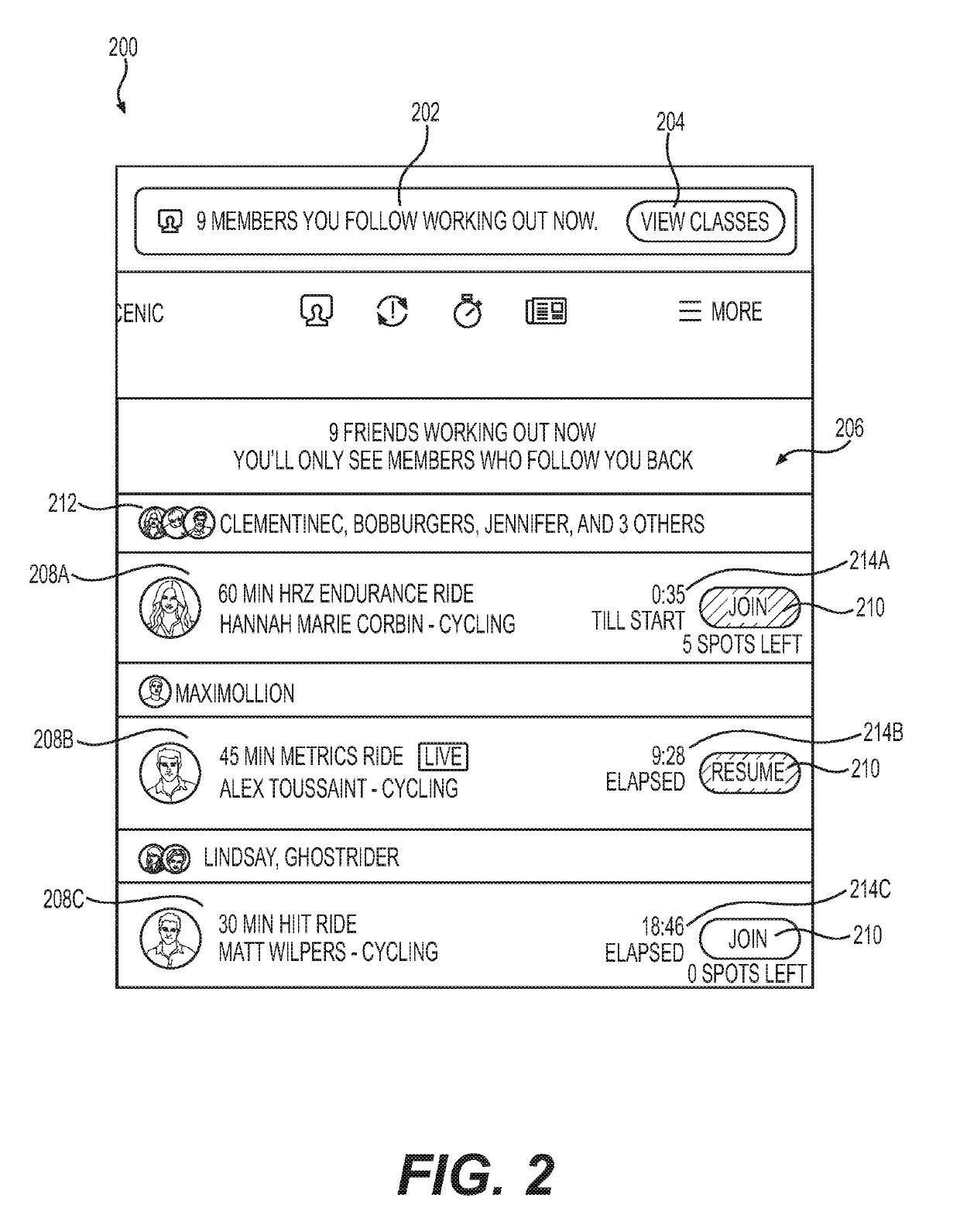

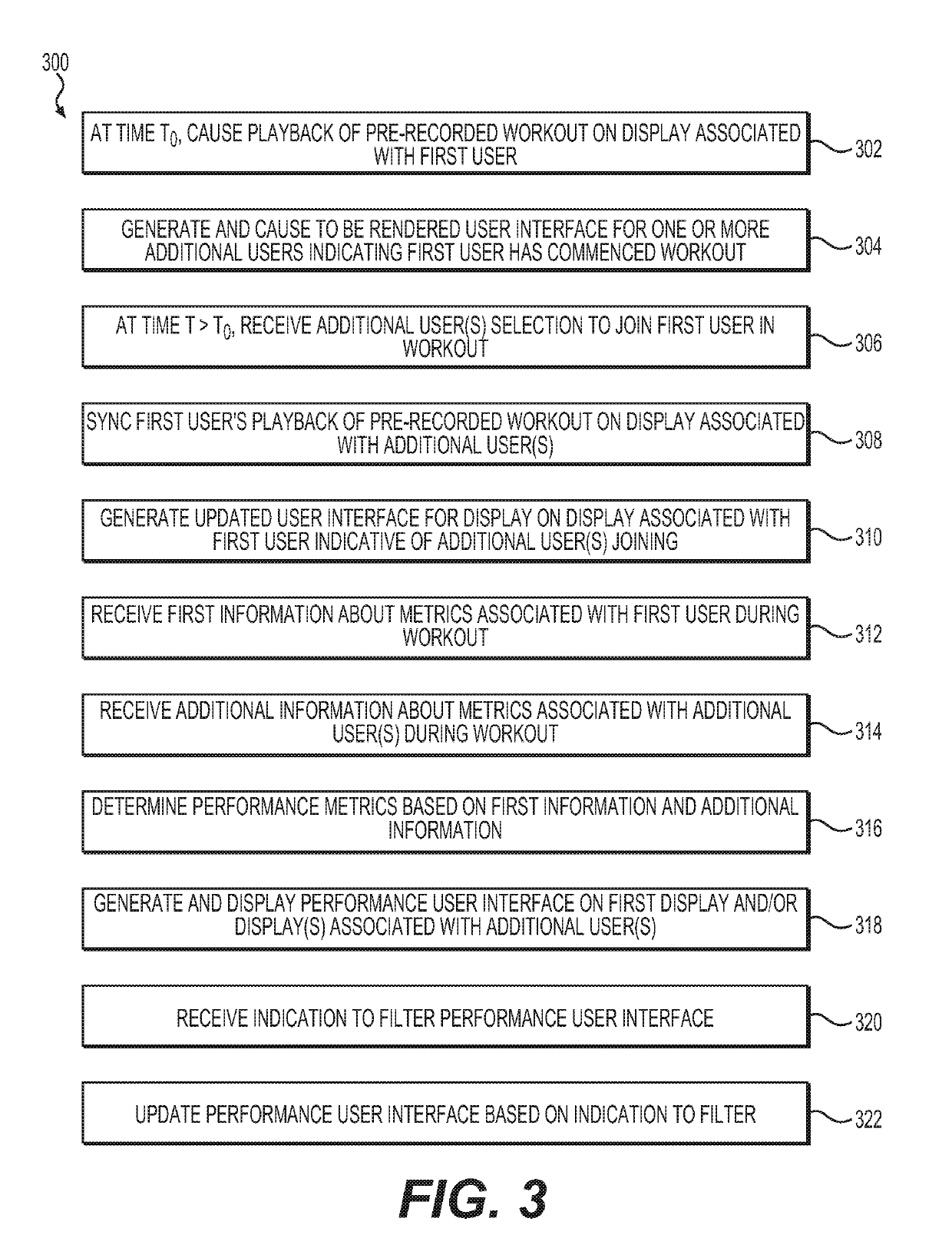

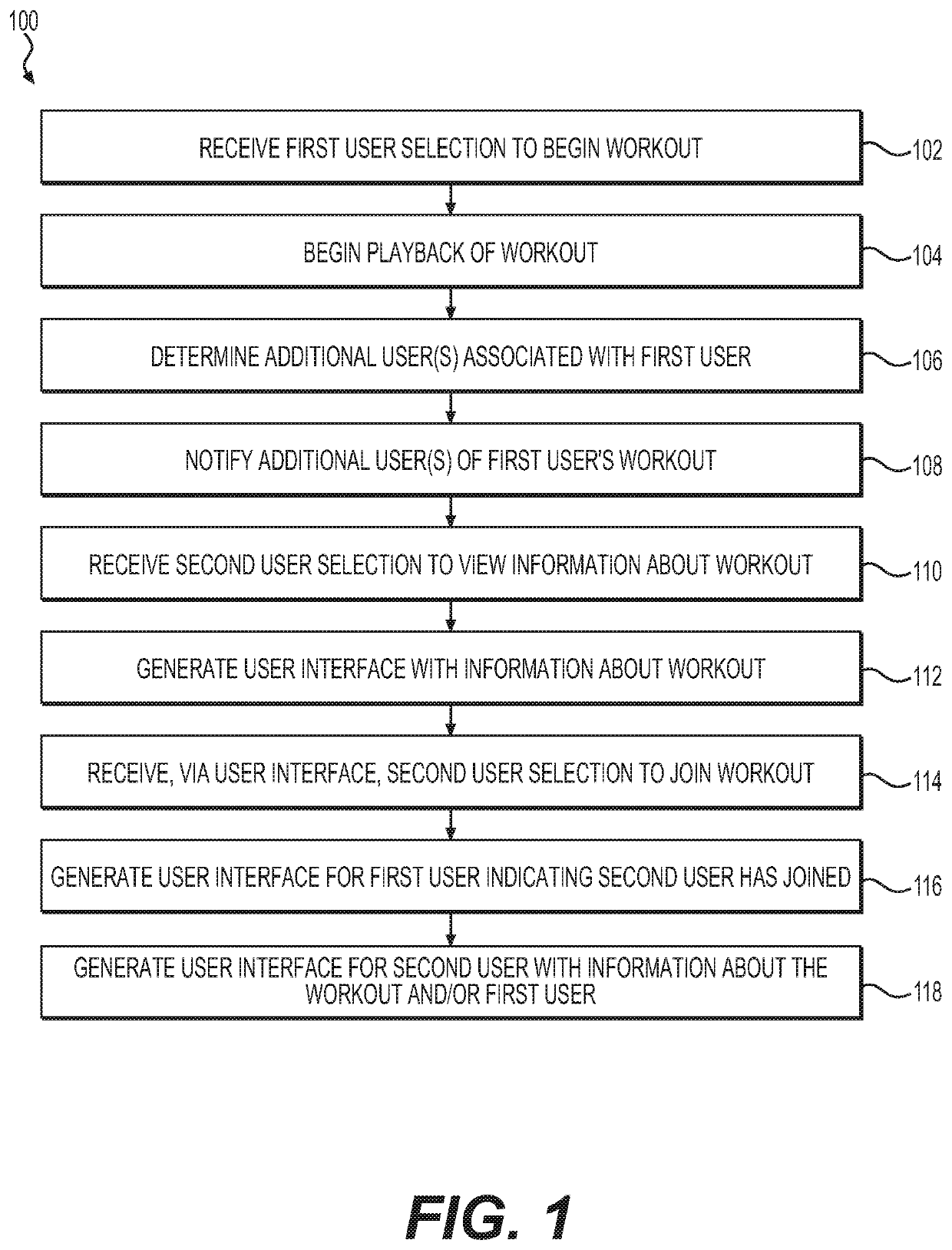

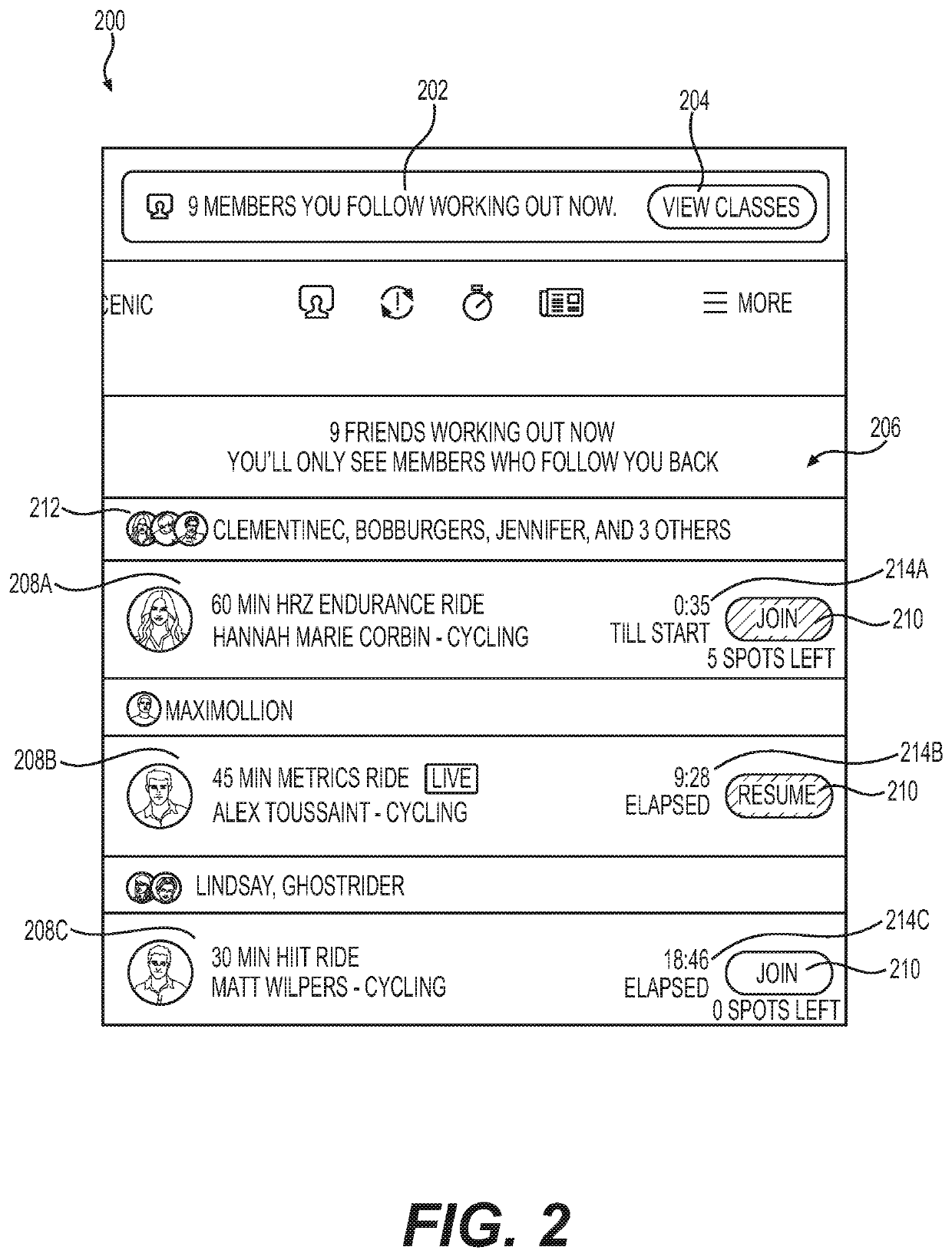

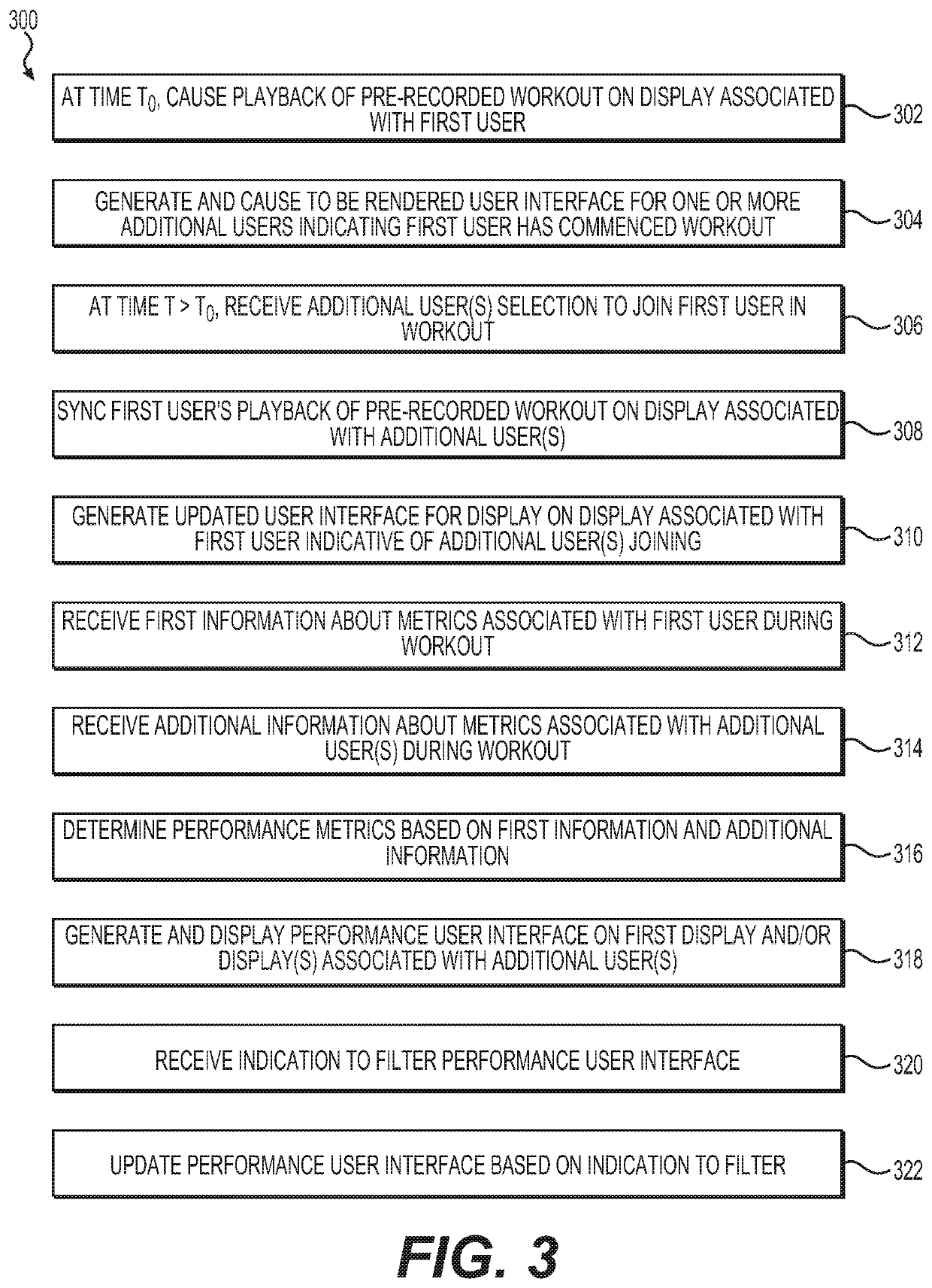

Coordinating workouts across remote exercise machines

ActiveUS20190184234A1Reduce traffic problemsEmission reductionTeaching apparatusInput/output processes for data processingFile synchronizationDisplay device

A method includes receiving, with a processor in communication with a first exercise machine, a first request for an exercise class, the first request being provided by a first user of the first exercise machine. The method also includes providing a video file associated with the exercise class to the first exercise machine, providing a notification to a second user indicating that the first user has chosen to participate in the exercise class, and receiving a second request for the exercise class provided by the second user. The method further includes providing the video file to a second exercise machine of the second user via the network. In such a method, display of the video file via a display of the second exercise machine is synchronized with display of the video file via a display of the first exercise machine.

Owner:PELOTON INTERACTIVE INC

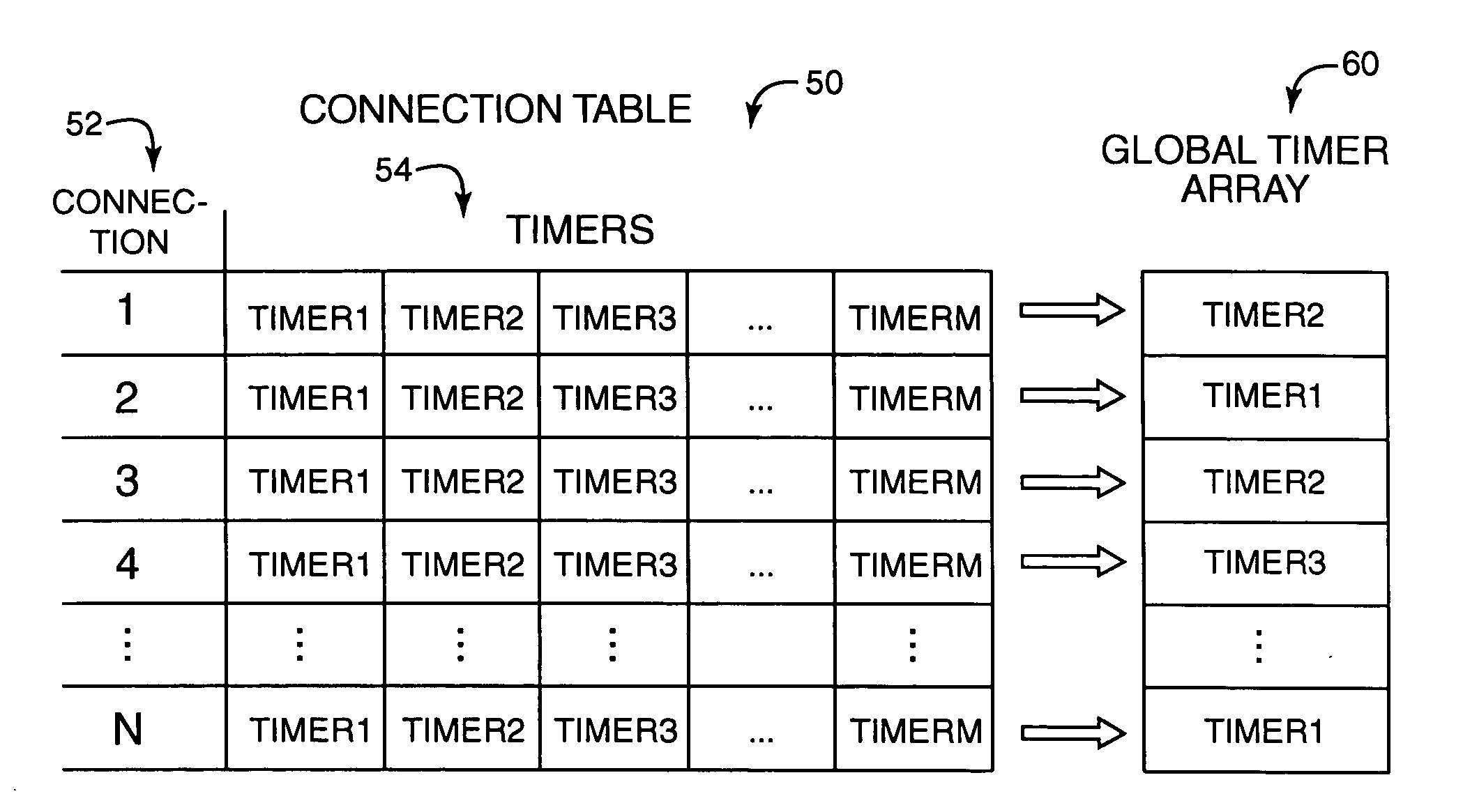

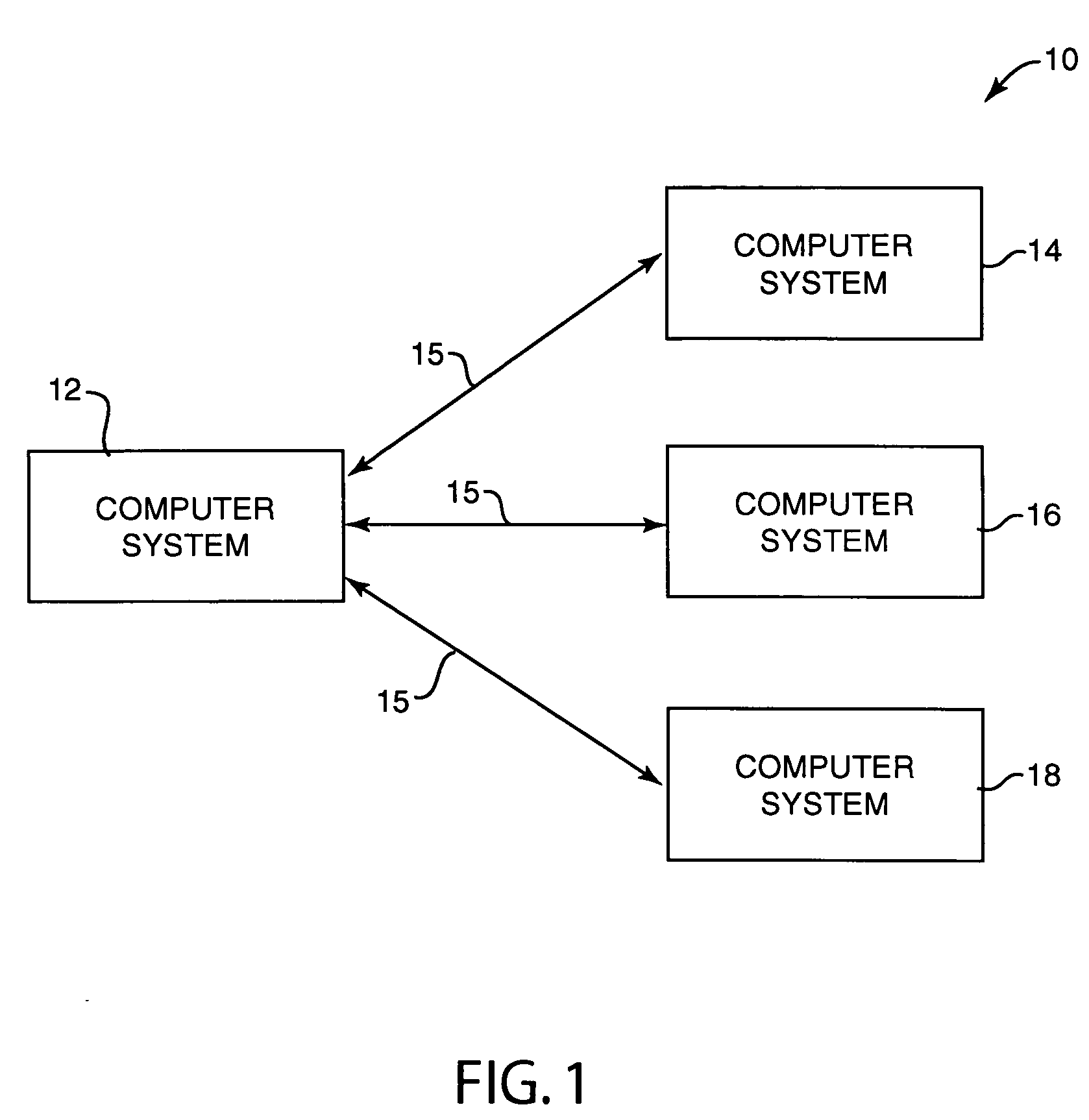

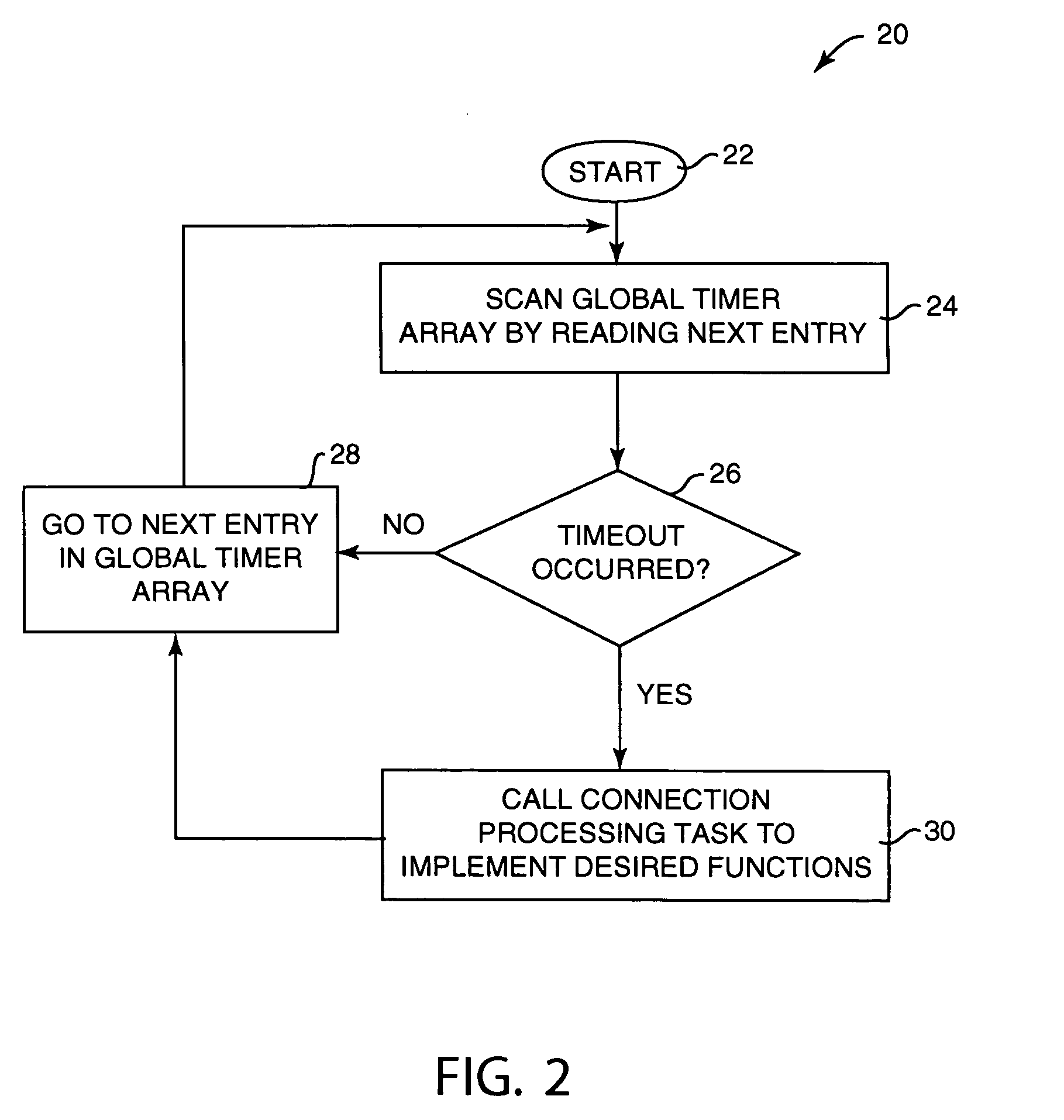

Method and system for maintaining and examining timers for network connections

InactiveUS20050209804A1Shorten the timeReduces processing resourceTime indicationDigital data processing detailsConnection tableNetwork connection

System and method for maintenance and examination of timers for a computer system having connections in a networking system. Timer values in a connection table each indicate a timeout for a timer for a connection, where each connection has multiple timers, and one of the timer values is written to a global timer array for each connection such that the global timer array can be scanned to determine when timeouts occur for active connections. Sparse restart of a timer includes restarting the timer if data is communicated with a connected computer before the timeout occurs and after a predetermined time interval after timer start, and not restarting the timer if data is communicated before the timeout occurs and within the predetermined interval after timer start.

Owner:IBM CORP

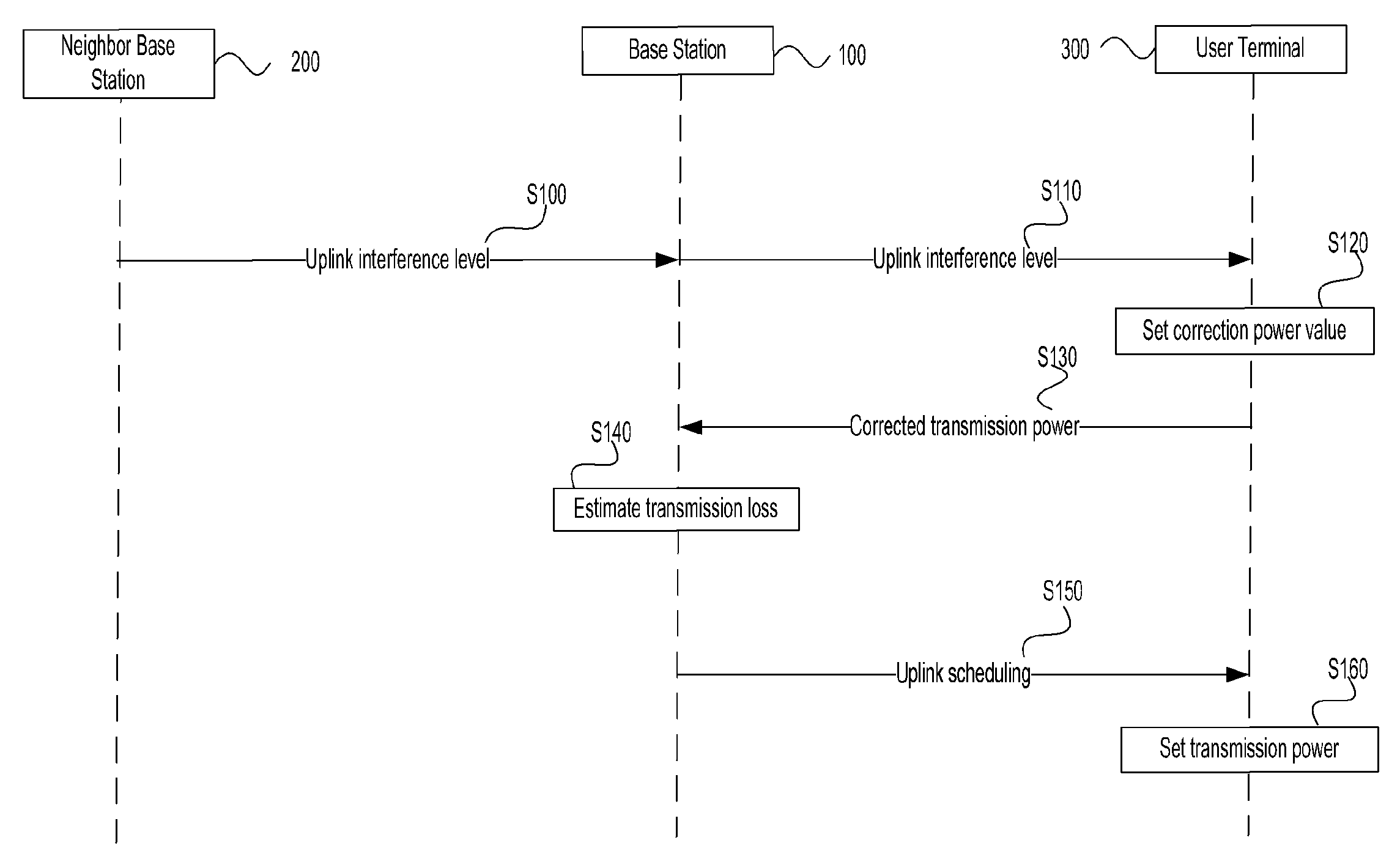

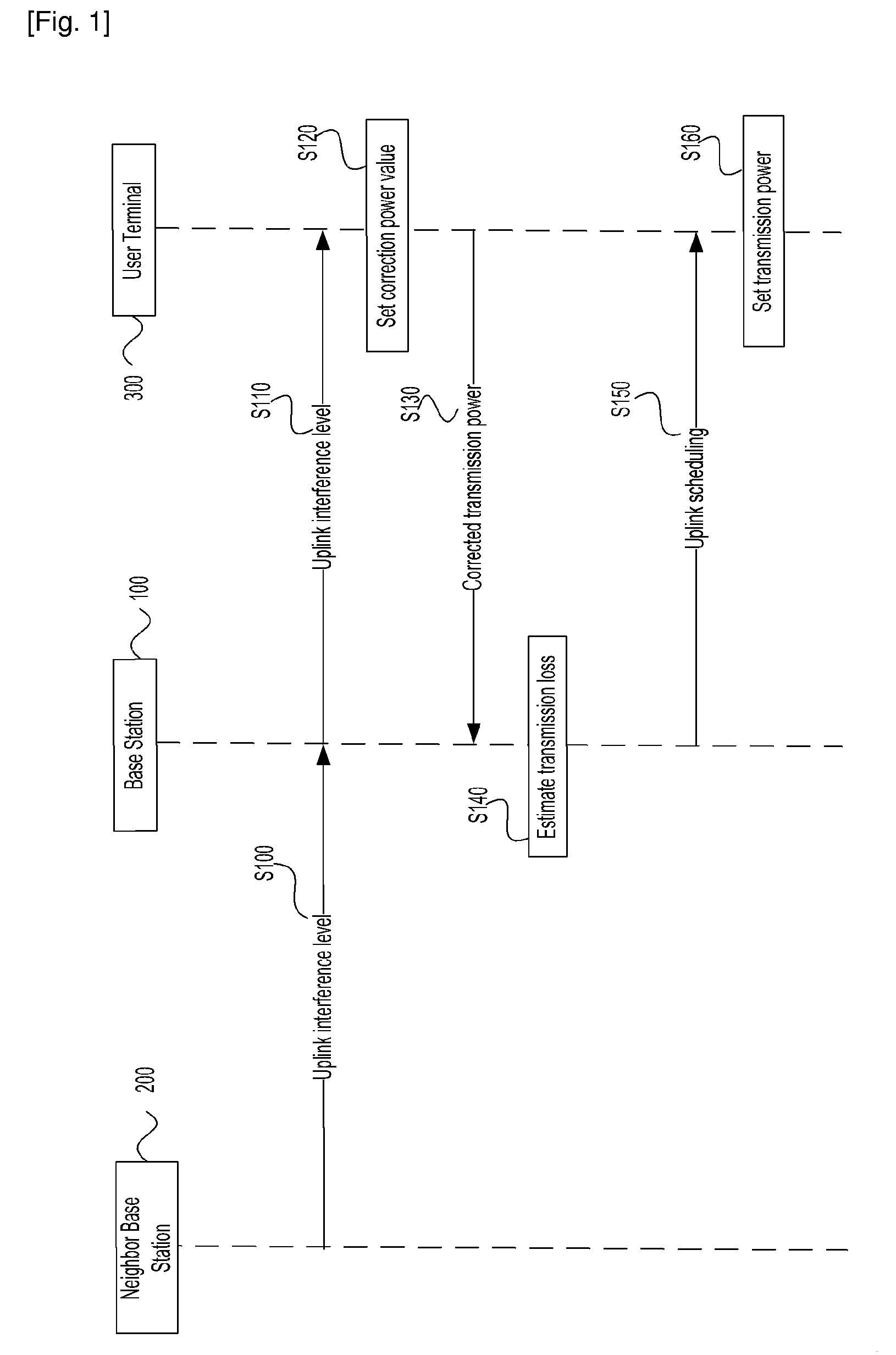

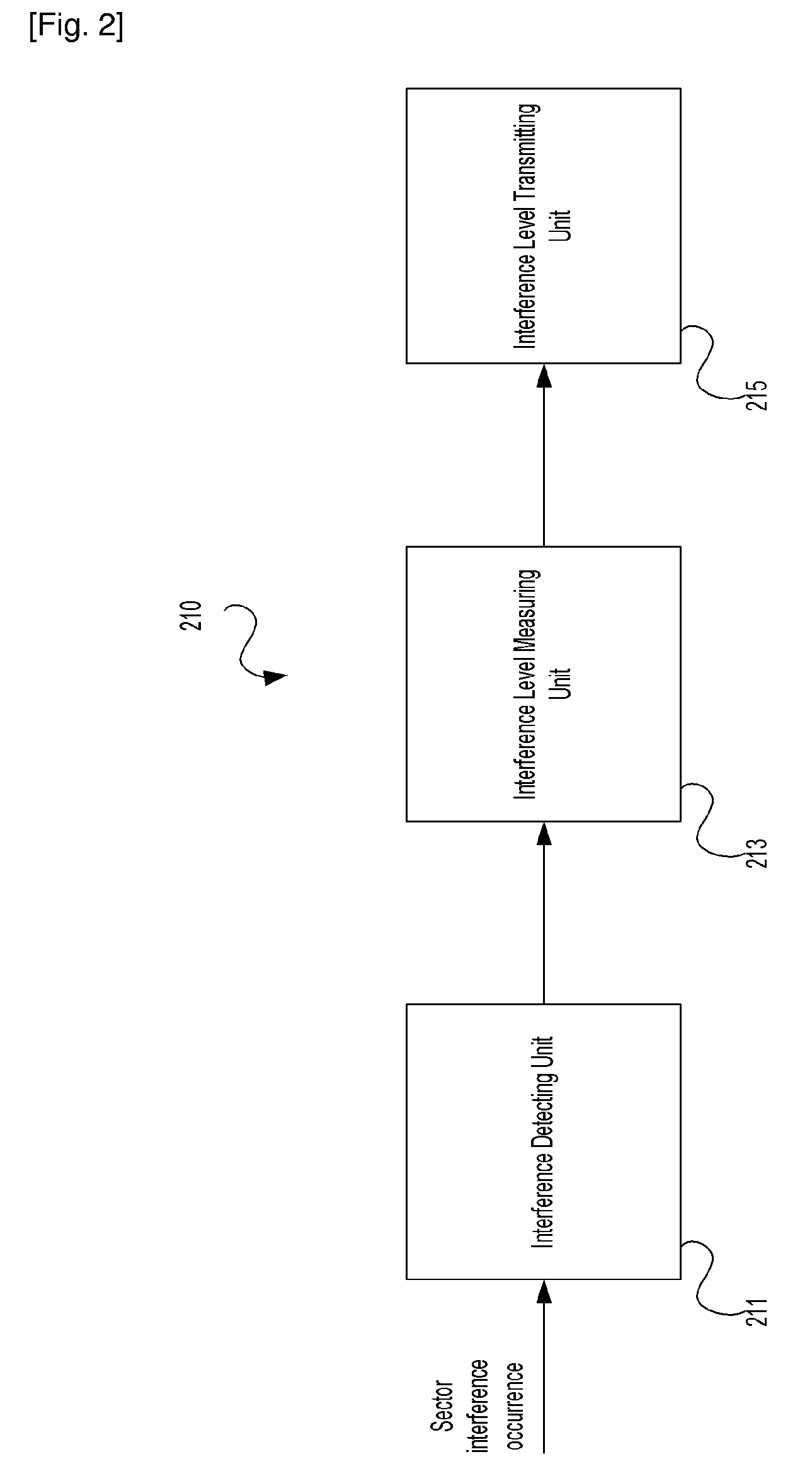

Power control and scheduling method in consideration of interference levels between neighbor sectors in communication system

ActiveUS20090196192A1Improving function of userFunction increasePower managementError preventionPower controlBase station

In order to perform uplink scheduling for a terminal, a base station receives information on uplink interference due to the terminal from neighbor base stations, transmits the information on the uplink interference to the terminal, receives information on transmission power of a feedback channel from the terminal through the feedback channel, compares the transmission power of the feedback channel and reception power of the feedback channel so as to estimate transmission loss, and performs uplink scheduling for the terminal by reflecting the transmission loss.

Owner:ELECTRONICS & TELECOMM RES INST +1

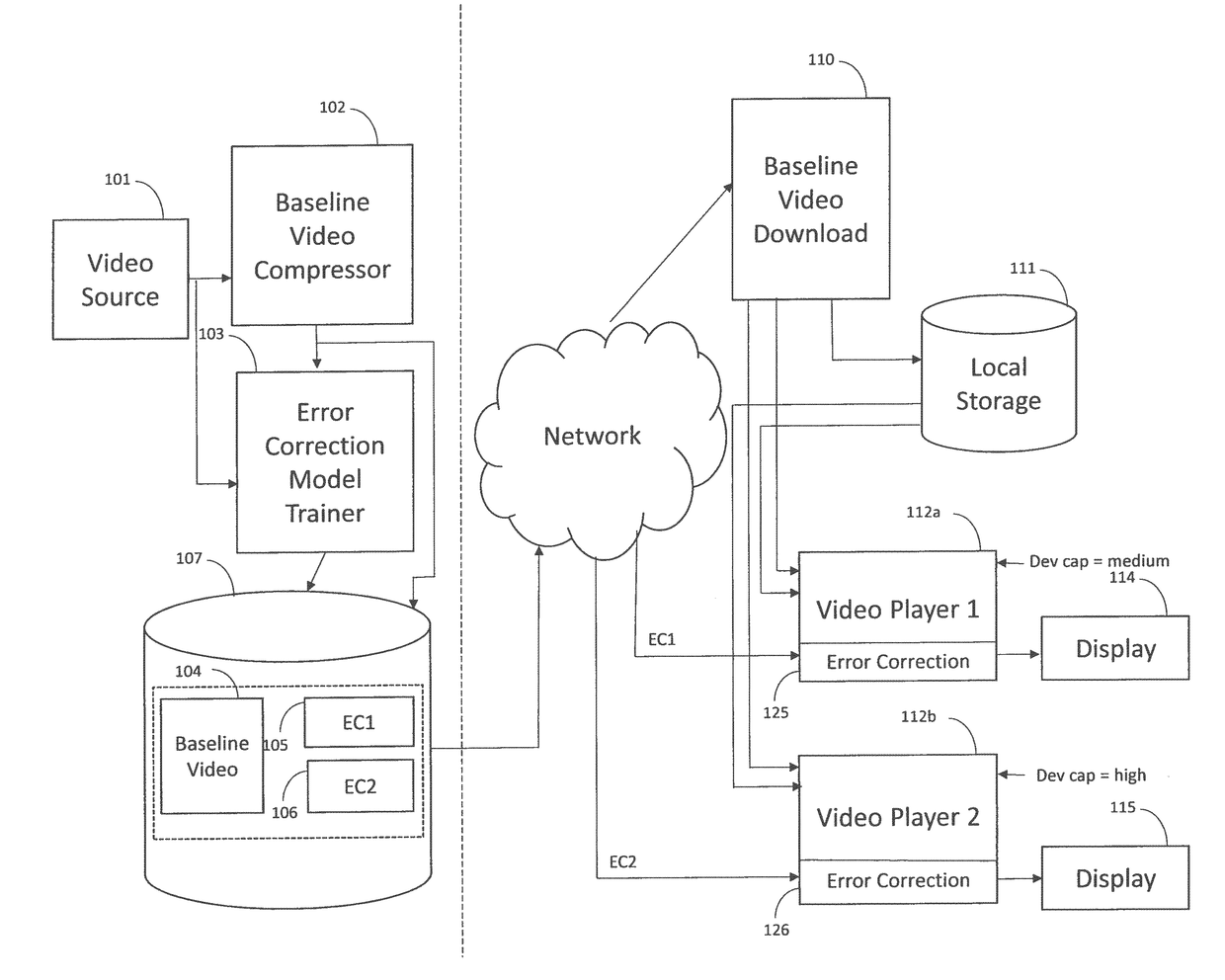

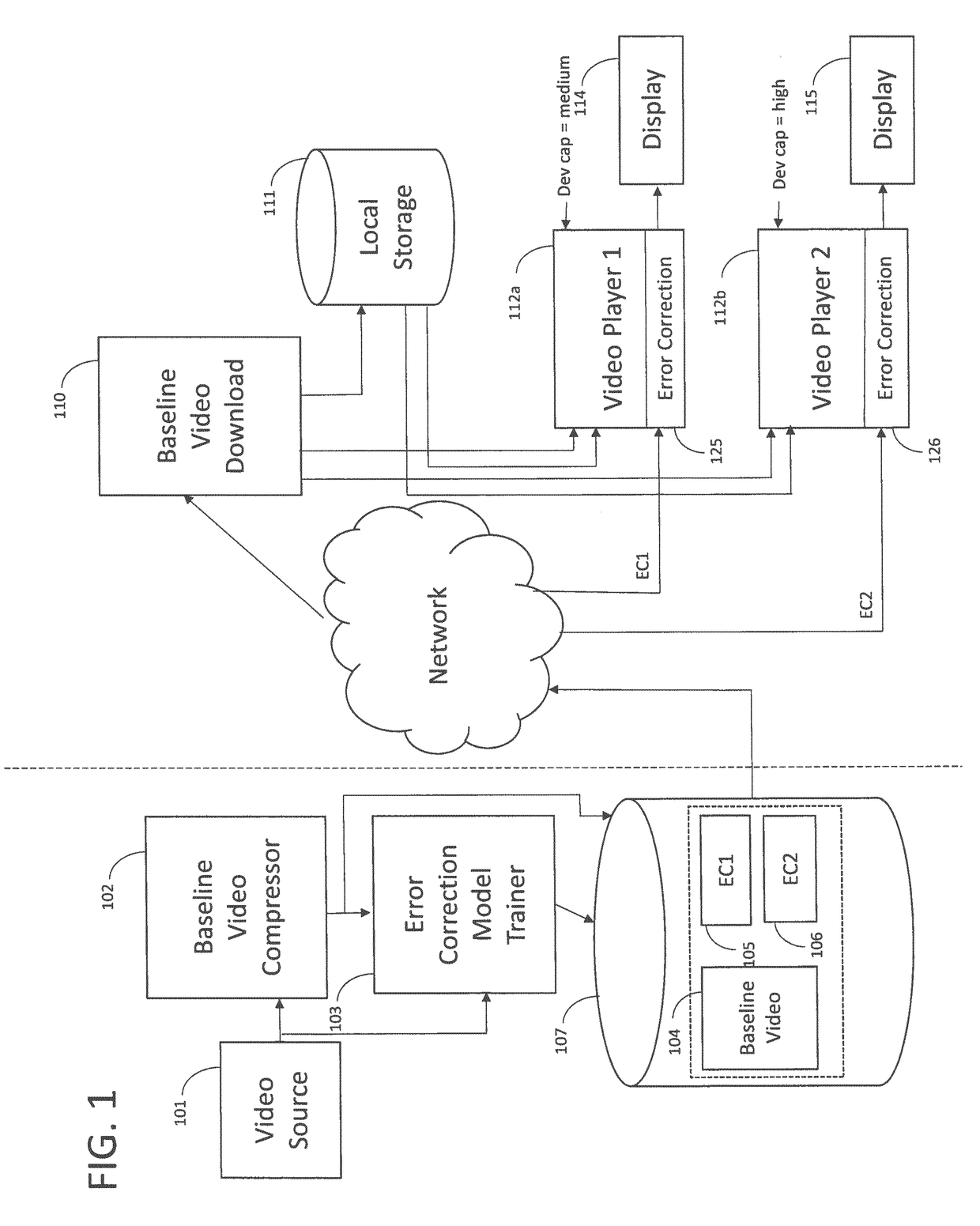

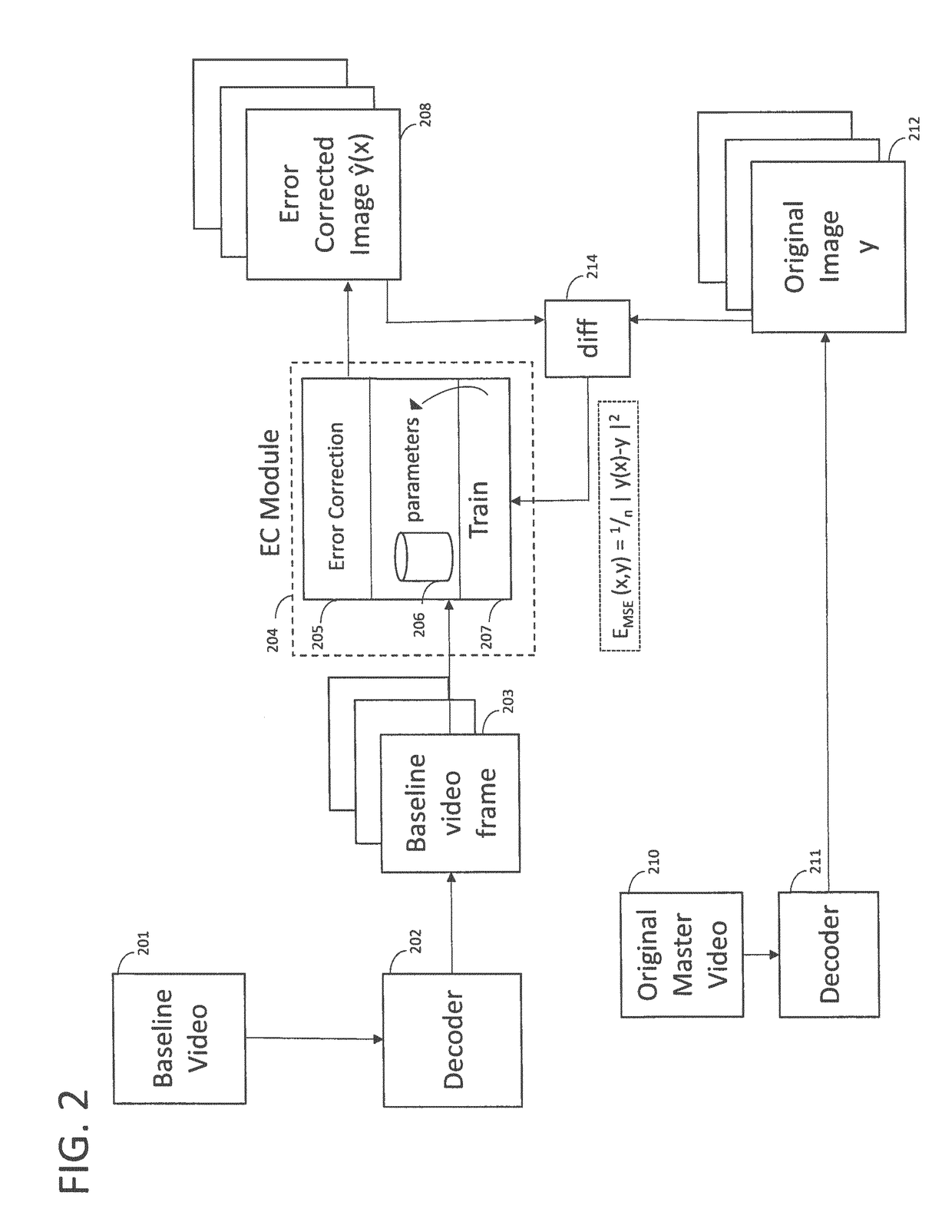

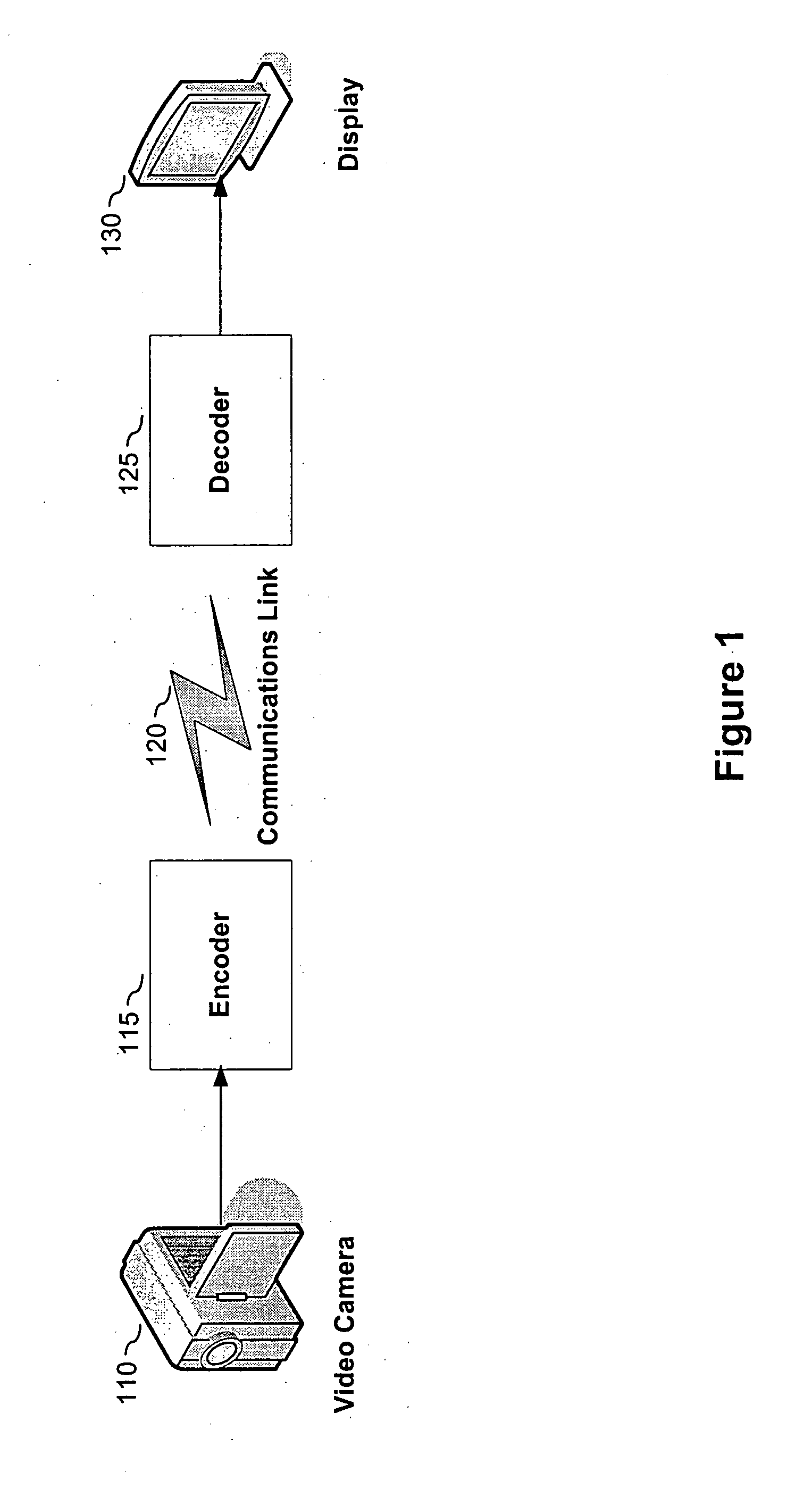

Improved video stream delivery via adaptive quality enhancement using error correction models

ActiveUS20180288440A1Attenuation bandwidthReduce duplicationCharacter and pattern recognitionImage codingComputer hardwareSelf adaptive

There is disclosed a technique for providing multimedia content comprising: compressing a multimedia stream; and generating an error correction model for providing an alternative version of the compressed multimedia stream by: decompressing the compressed multimedia stream; determining errors in the decompressed version by comparing to the input multimedia stream; and correcting the errors to minimise the difference between the decompressed version and the input multimedia stream.

Owner:PRJ HLDG CO LLC

Grease and scum removal in a filtration apparatus comprising a membrane bioreactor and a treatment vessel for digesting organic materials

InactiveUS20070084791A1Significant comprehensive benefitsLow costMembranesUltrafiltrationFiltrationMembrane bioreactor

The invention relates to a membrane bioreactor process combined with an advanced biological sludge digestion process that provides significant improvements in sludge digestion by reducing the costs and resources required for disposing of digested sludge. The offline treatment vessel is used to solubilize the organic material by operating in a very low oxygen environment. Digested process fluid is transferred back to the membrane bioreactor. The processes and apparatus substantially reduce the production of waste sludge. The device includes one or more weirs operable to remove grease and scum.

Owner:EVOQUA WATER TECH LLC

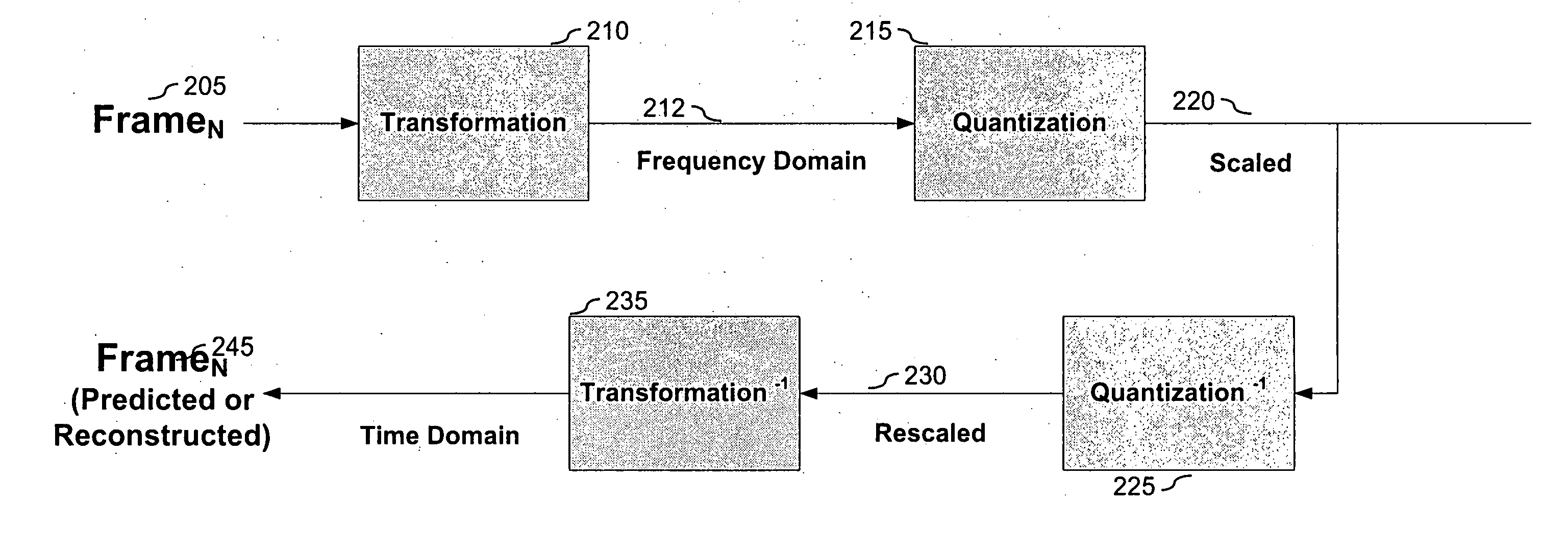

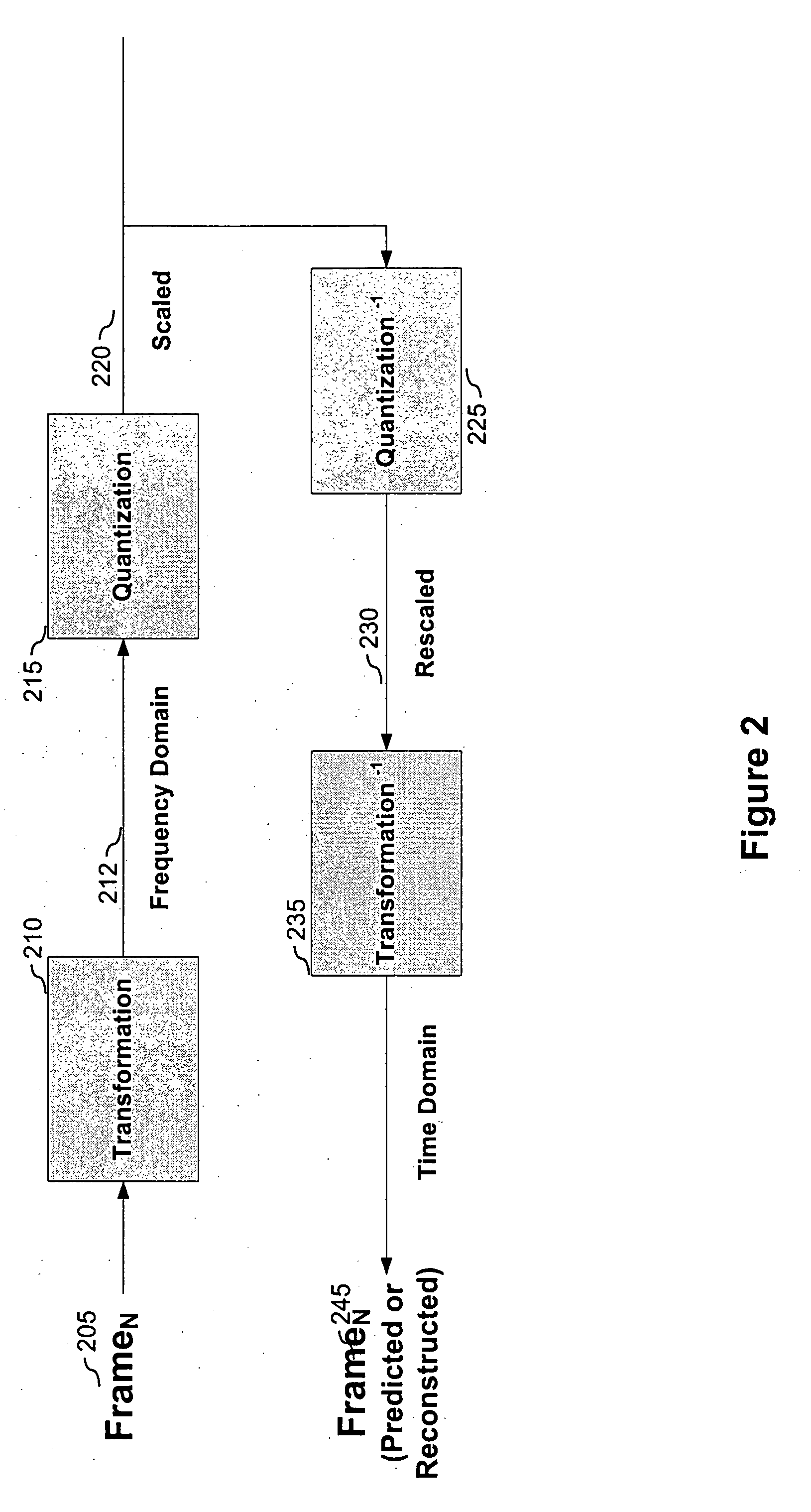

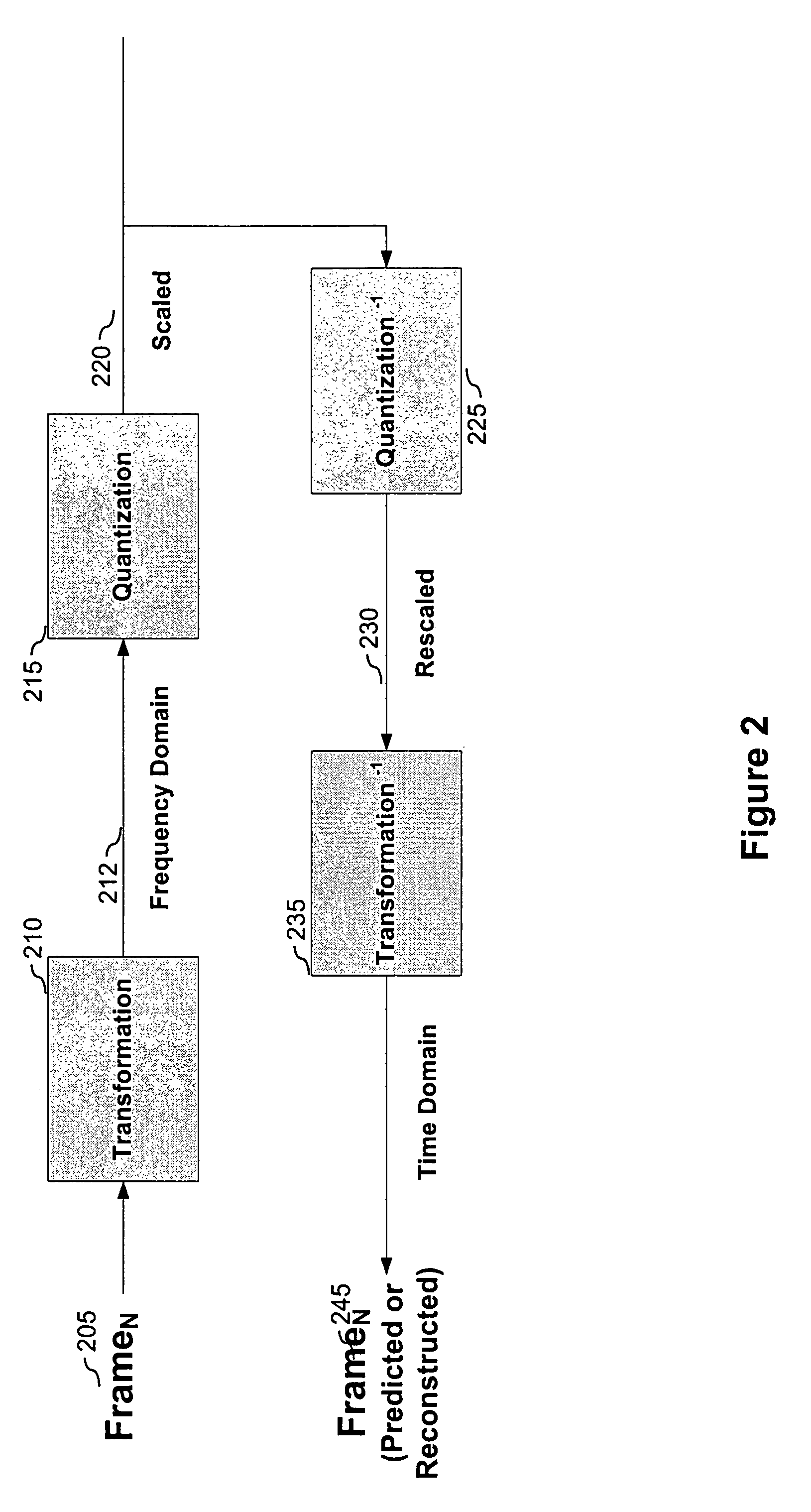

Prediction intra-mode selection in an encoder

InactiveUS20060165170A1Reducing resourceShorten the timeColor television with pulse code modulationColor television with bandwidth reductionAlgorithmTheoretical computer science

A prediction mode for encoding data is selected using a reduced number of rate-distortion cost computations. This reduction in rate-distortion cost computations is caused by filtering the number of potential intra prediction modes based on two criteria. First, the number of potential prediction modes is reduced based on at least one characteristic of a quantization procedure performed during the encoding procedure. Second, the number of potential prediction modes is reduced based on an error value calculated for each of the potential prediction modes.

Owner:SEIKO EPSON CORP

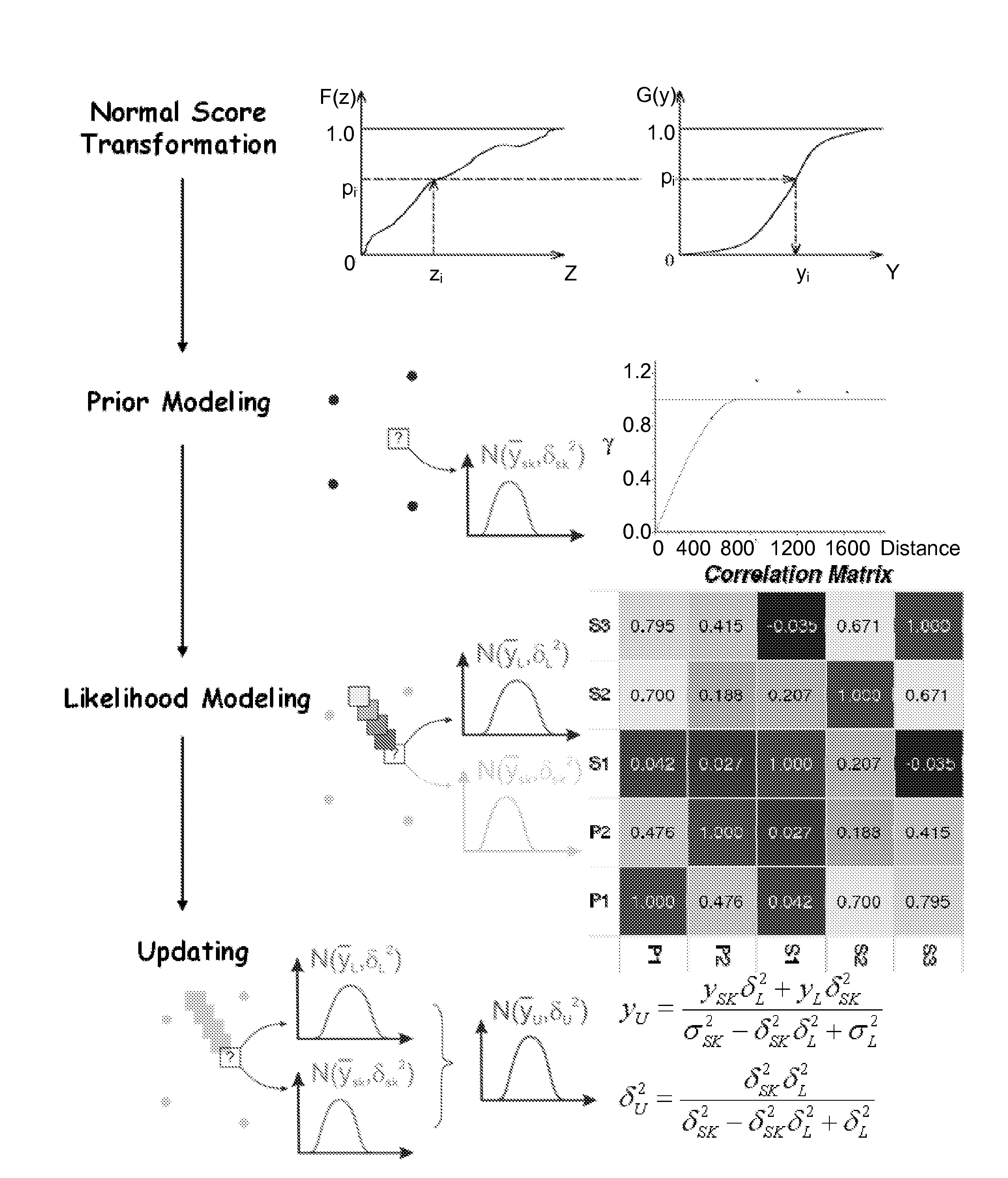

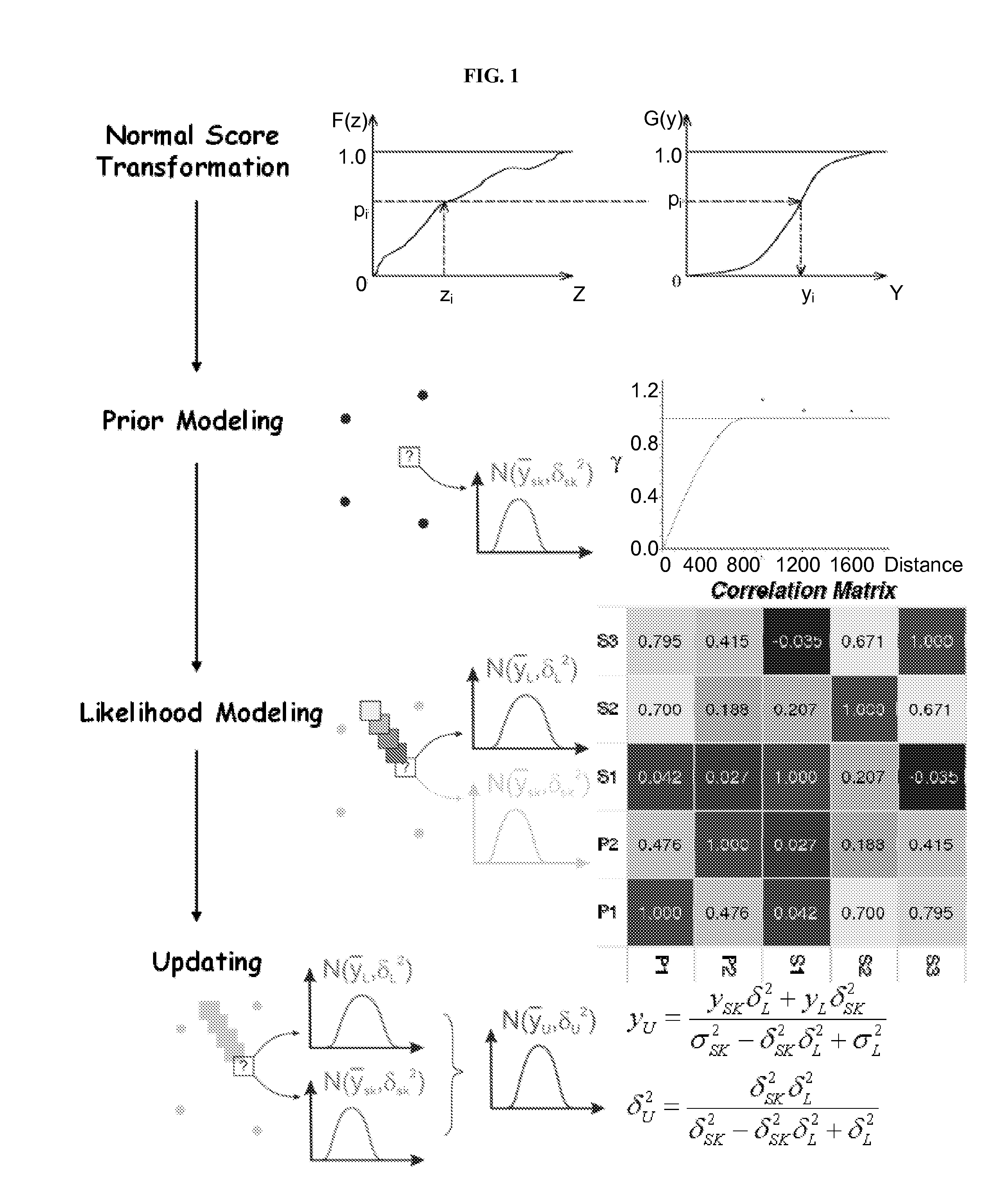

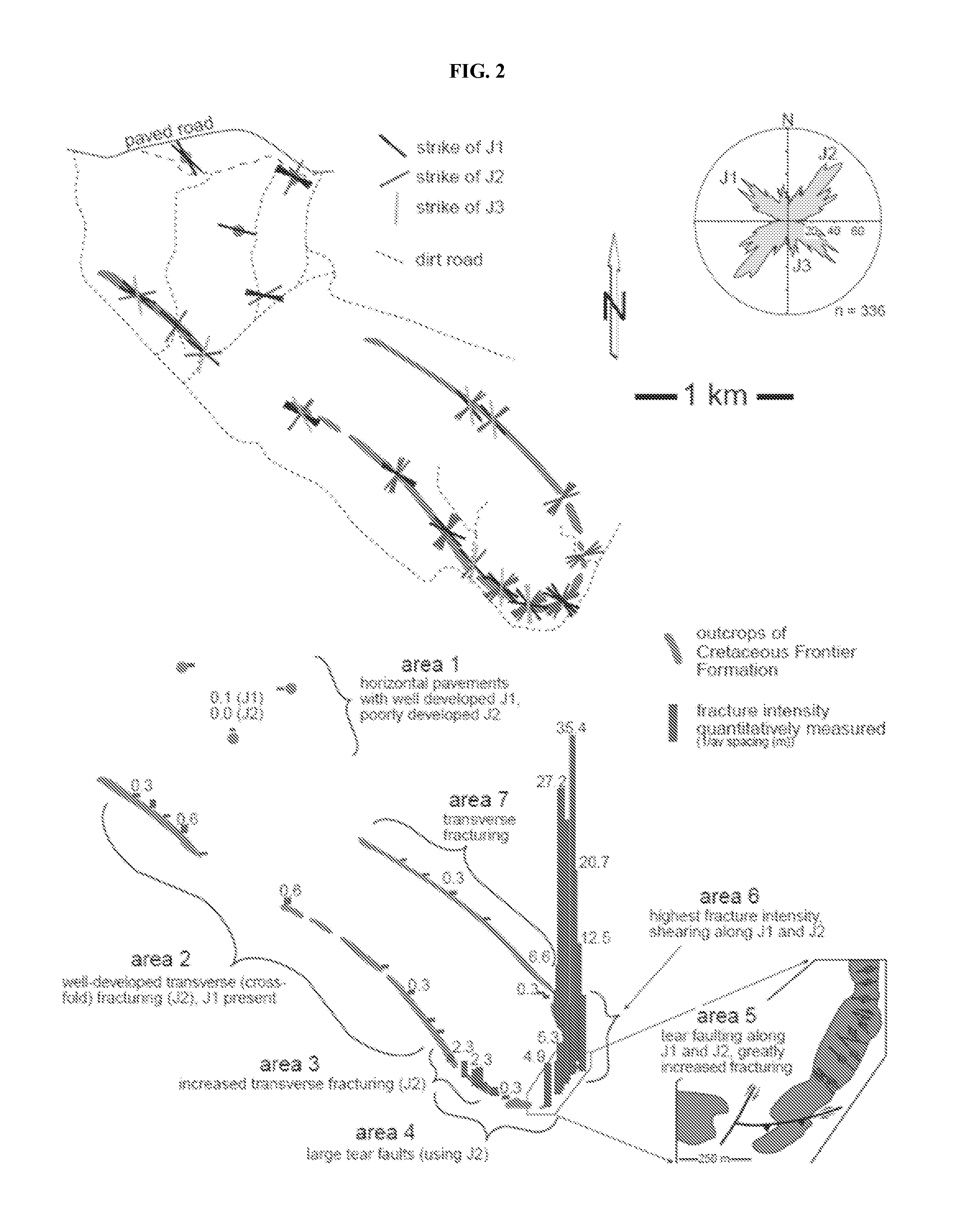

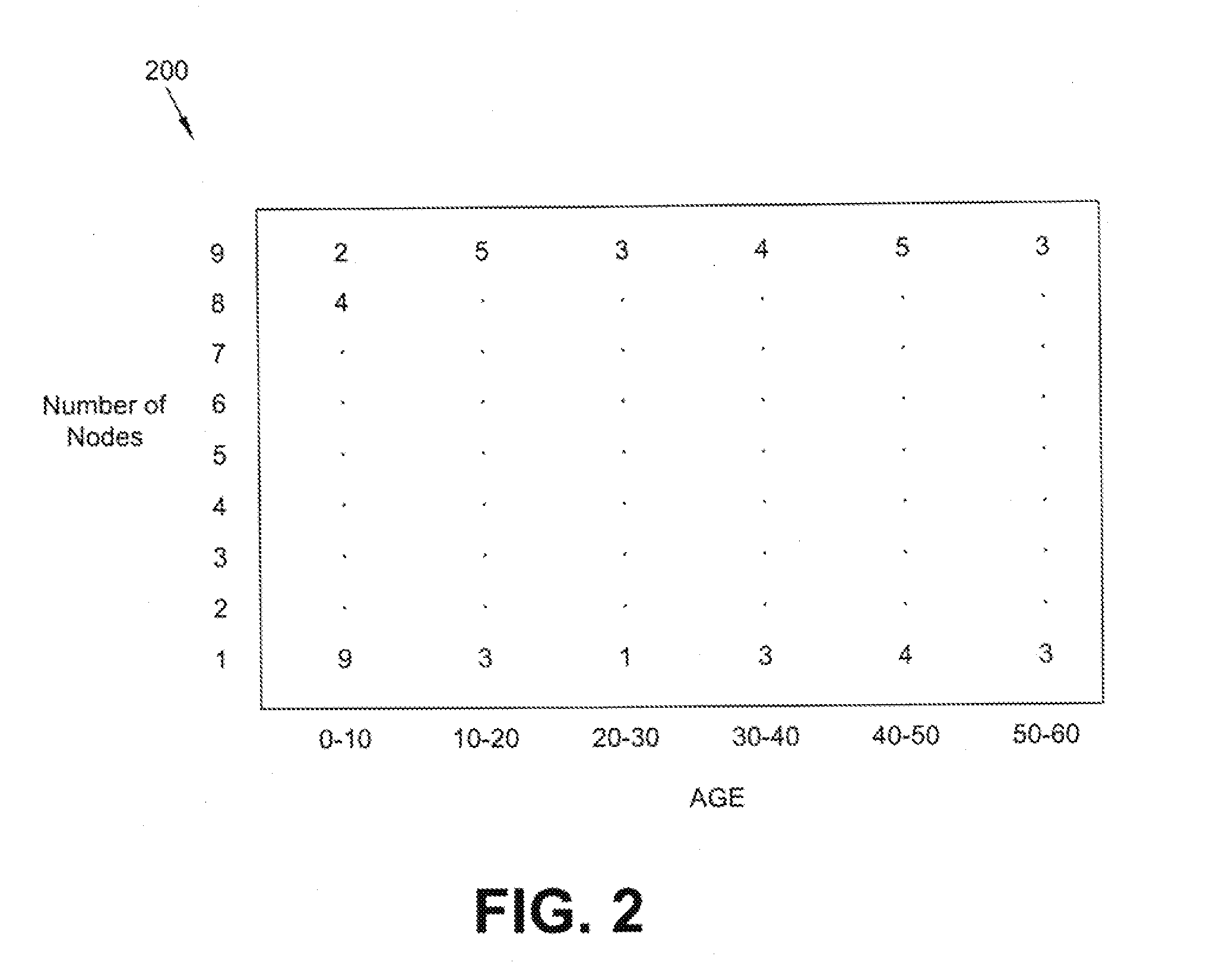

Attribute importance measure for parametric multivariate modeling

ActiveUS20110119040A1Reduce in quantityReduce uncertaintyComputation using non-denominational number representationComplex mathematical operationsRelative significanceObjective variables

Parametric Bayesian Updating method is described for attribute importance measures. AIM is a quantitative measure of the relative importance of multiple attributes used in a Bayesian Updating parametric multivariate modeling approach. The AIM is a function of the correlation coefficients between the attributes themselves and the attributes with collocated target variable. The importance calculation is straightforward, repeatable, and objective.

Owner:CONOCOPHILLIPS CO

Filtration apparatus comprising a membrane bioreactor and a treatment vessel for digesting organic materials

InactiveUS7387723B2Significant comprehensive benefitsLow costWater/sewage treatment by centrifugal separationMembranesFiltrationMembrane bioreactor

The invention relates to a membrane bioreactor process combined with an advanced biological sludge digestion process that provides significant improvements in sludge digestion by reducing the costs and resources required for disposing of digested sludge. The offline treatment vessel is used to solubilize the organic material by operating in a very low oxygen environment. Digested process fluid is transferred back to the membrane bioreactor. The processes and apparatus substantially reduce the production of waste sludge.

Owner:EVOQUA WATER TECH LLC

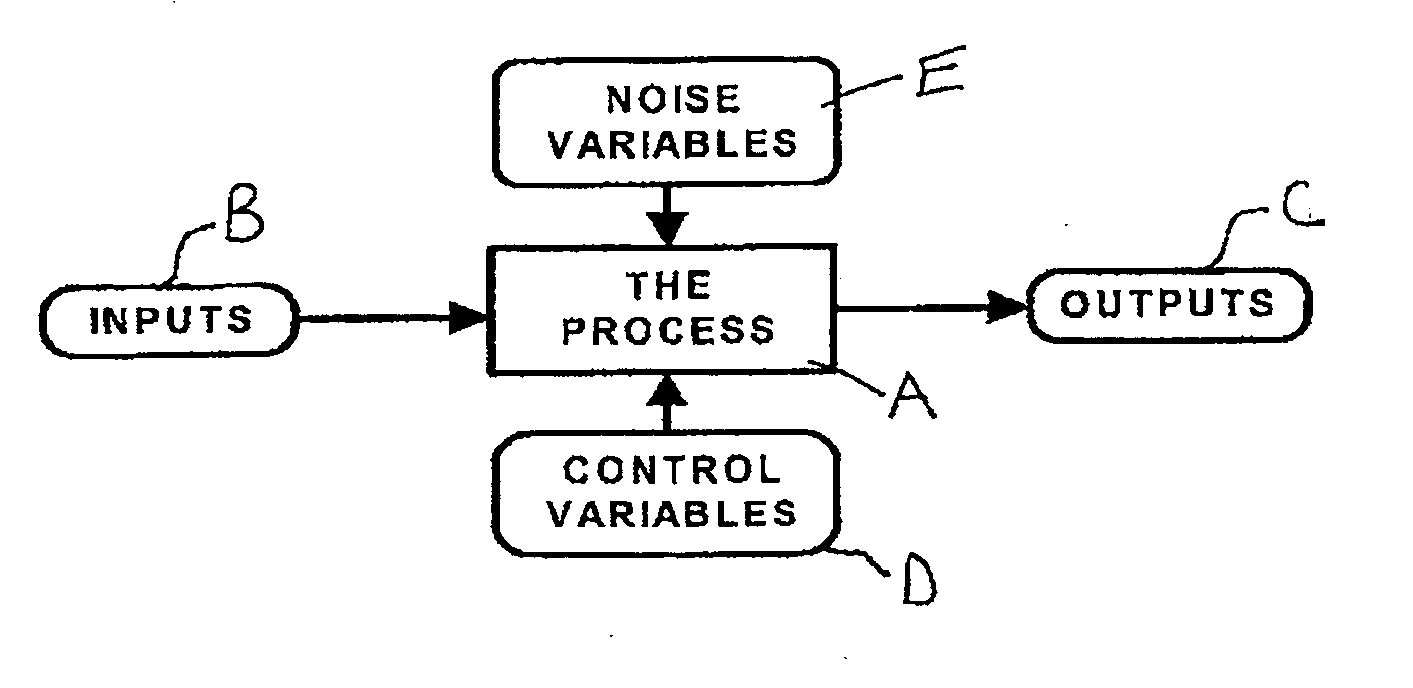

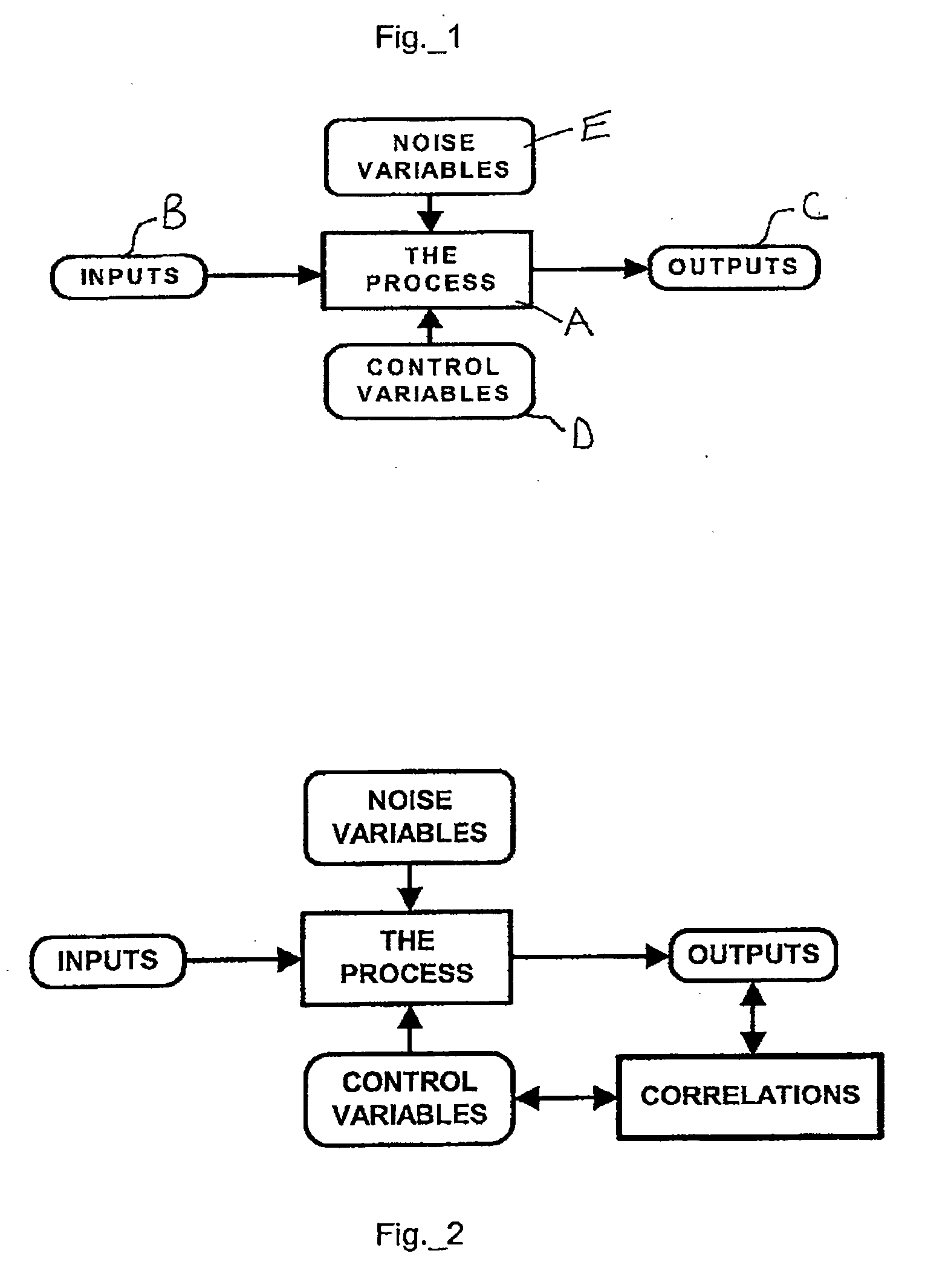

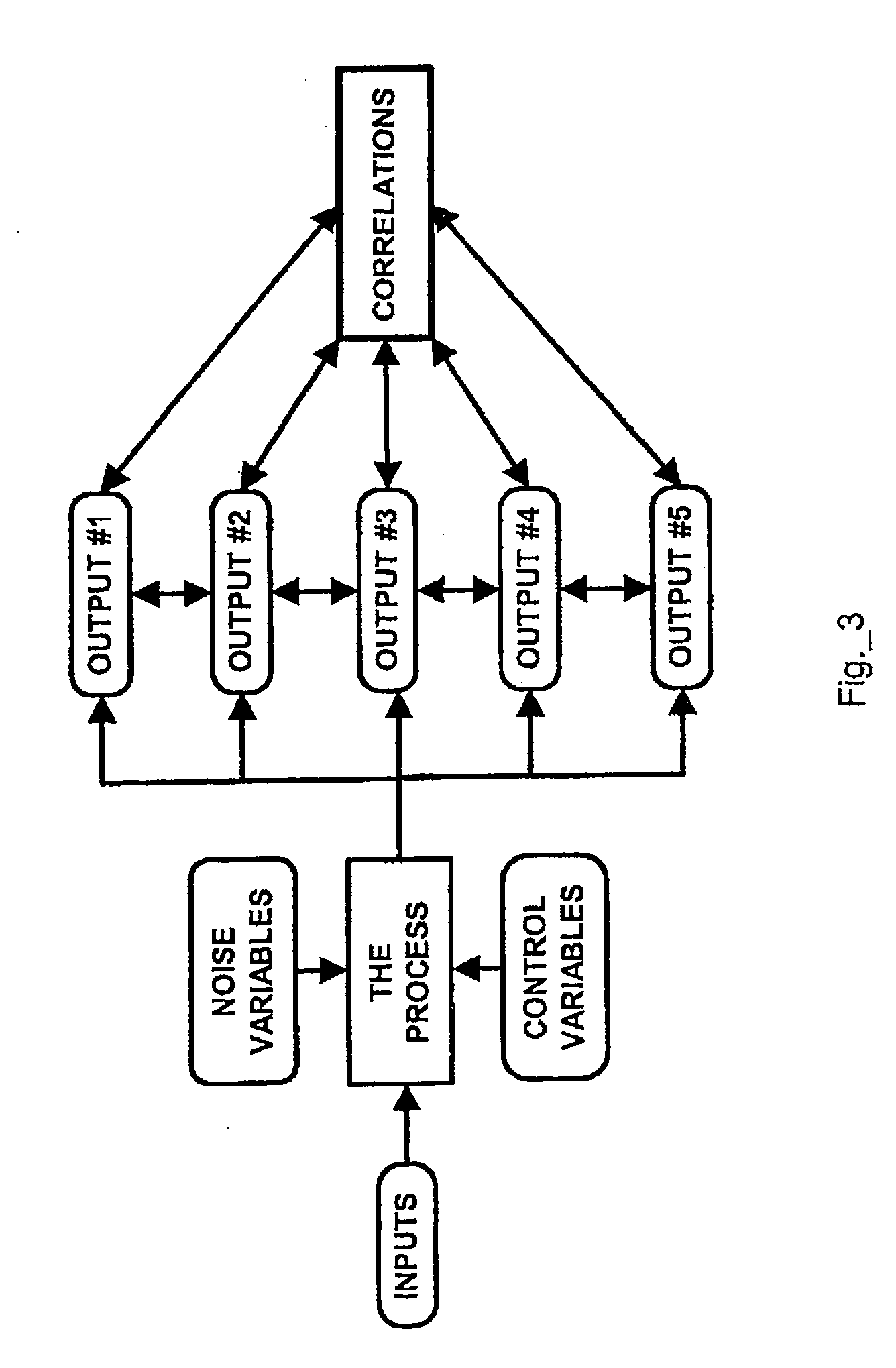

Manufacturing design and process analysis and simulation system

InactiveUS20050055110A1Simple designPromote productionSimulator controlElectric controllersProcess dimensionProcess simulation

A process simulation system that simulates the operation of the manufacturing and measurement systems used to produce and measure the articles being analyzed relative to engineering design targets, engineering design tolerances, producibility and / or quality. In one embodiment, the user is able to assess, without risk or production cost while accelerating speed-to-market, the effect of contemplated changes (i.) to engineering design targets, (ii.) to engineering design tolerances, (iii.) to tooling, (iv.) to part pre-process dimensions and (v.) to the measurement system—on manufactured part dimensions, producibility and quality (i.) without modifying tooling, (ii.) without changing part pre-process dimensions, (iii.) without producing new parts, (iv.) without measuring article characteristics on the new parts and (v.) without changing the measurement system. The simulation functionalities, according to embodiments of the present invention, enable the user to verify whether or not the contemplated changes will have the desired effect without incurring the time and expense involved in actually making the changes, producing parts, measuring part characteristics, changing the measurement system and then determining whether the changes accomplished the desired objectives.

Owner:TUSZYNSKI STEVE W

Coordinating workouts across remote exercise machines

ActiveUS10898760B2Reduce traffic problemsEmission reductionTeaching apparatusInput/output processes for data processingDisplay deviceEngineering

Owner:PELOTON INTERACTIVE INC

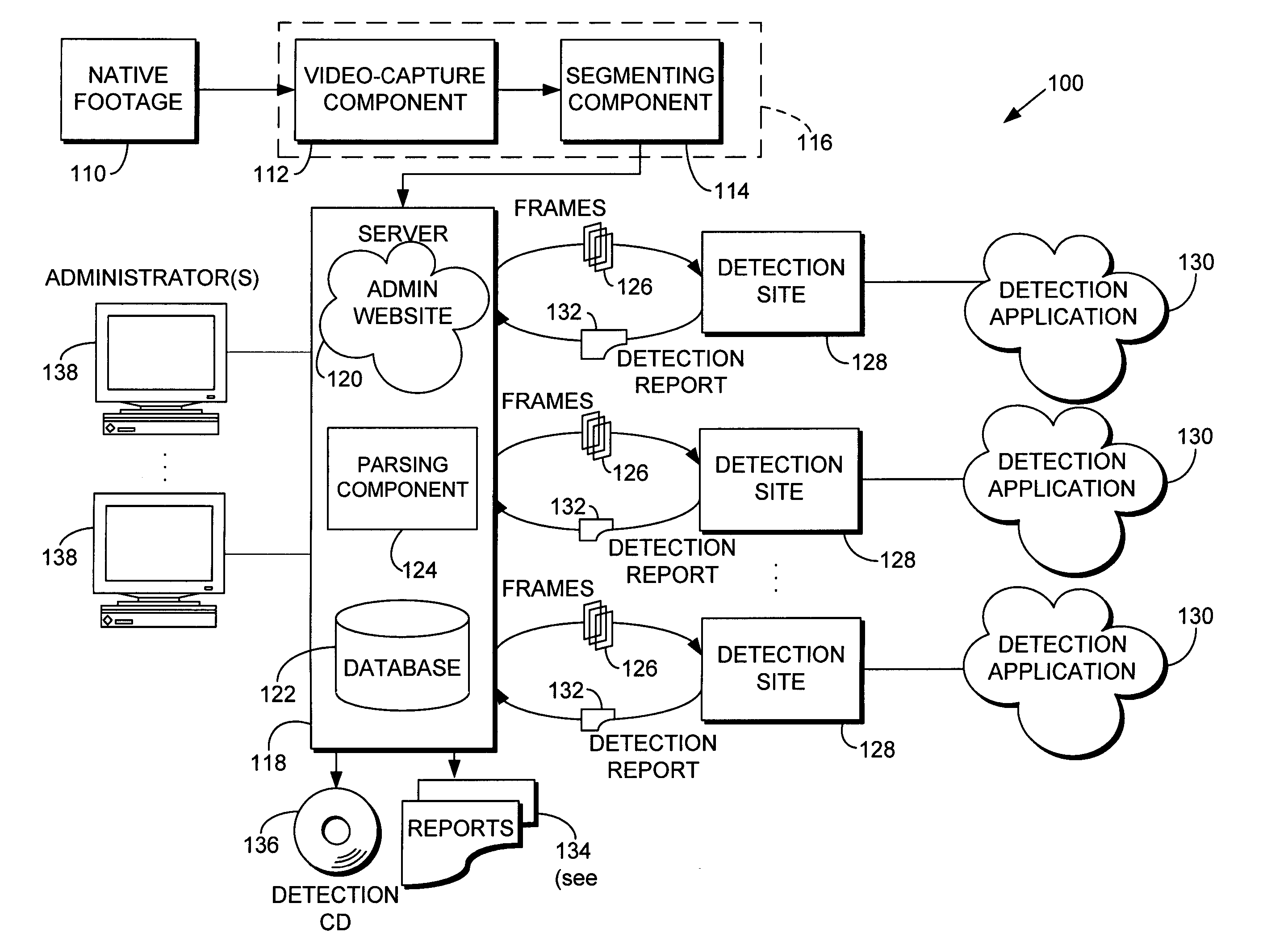

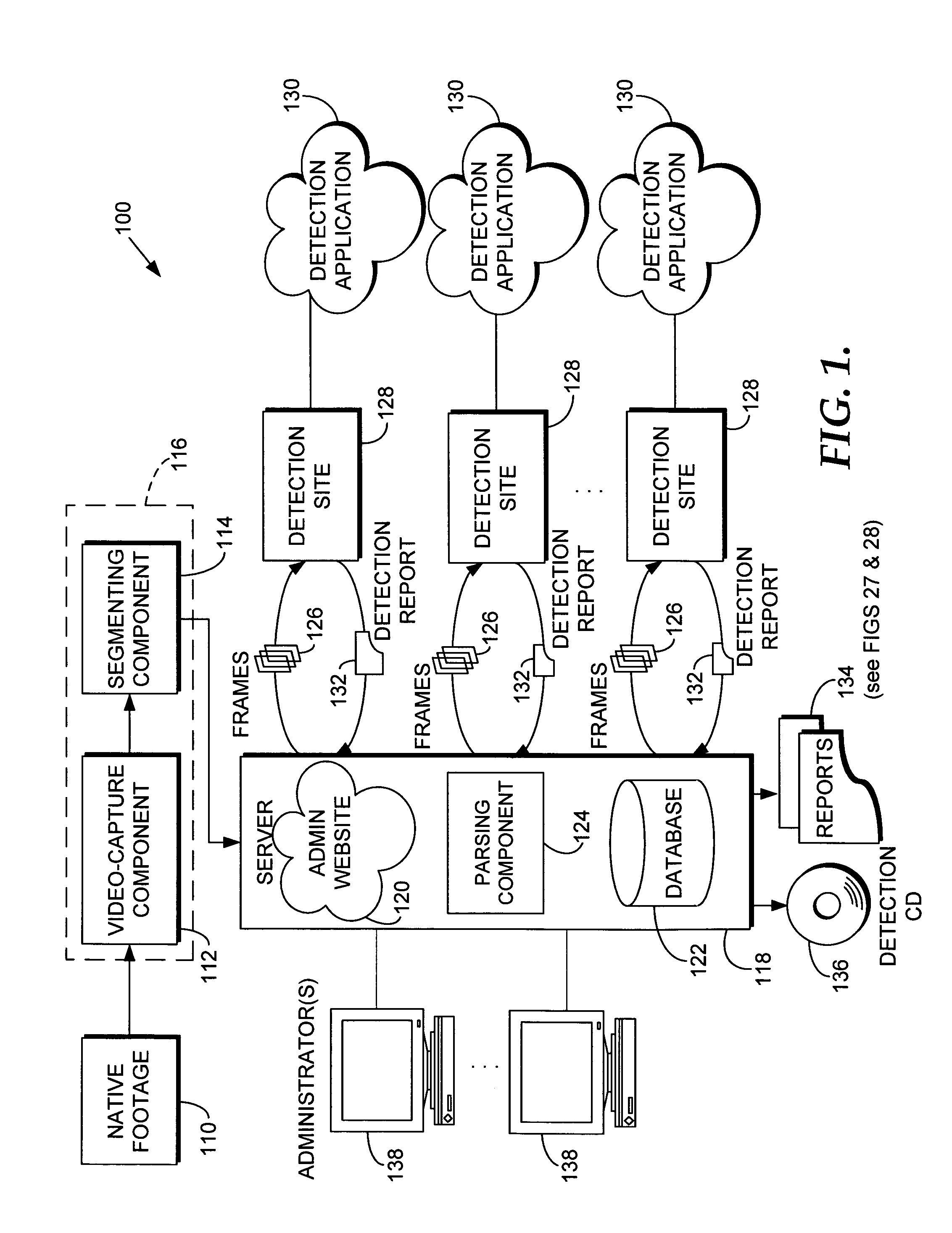

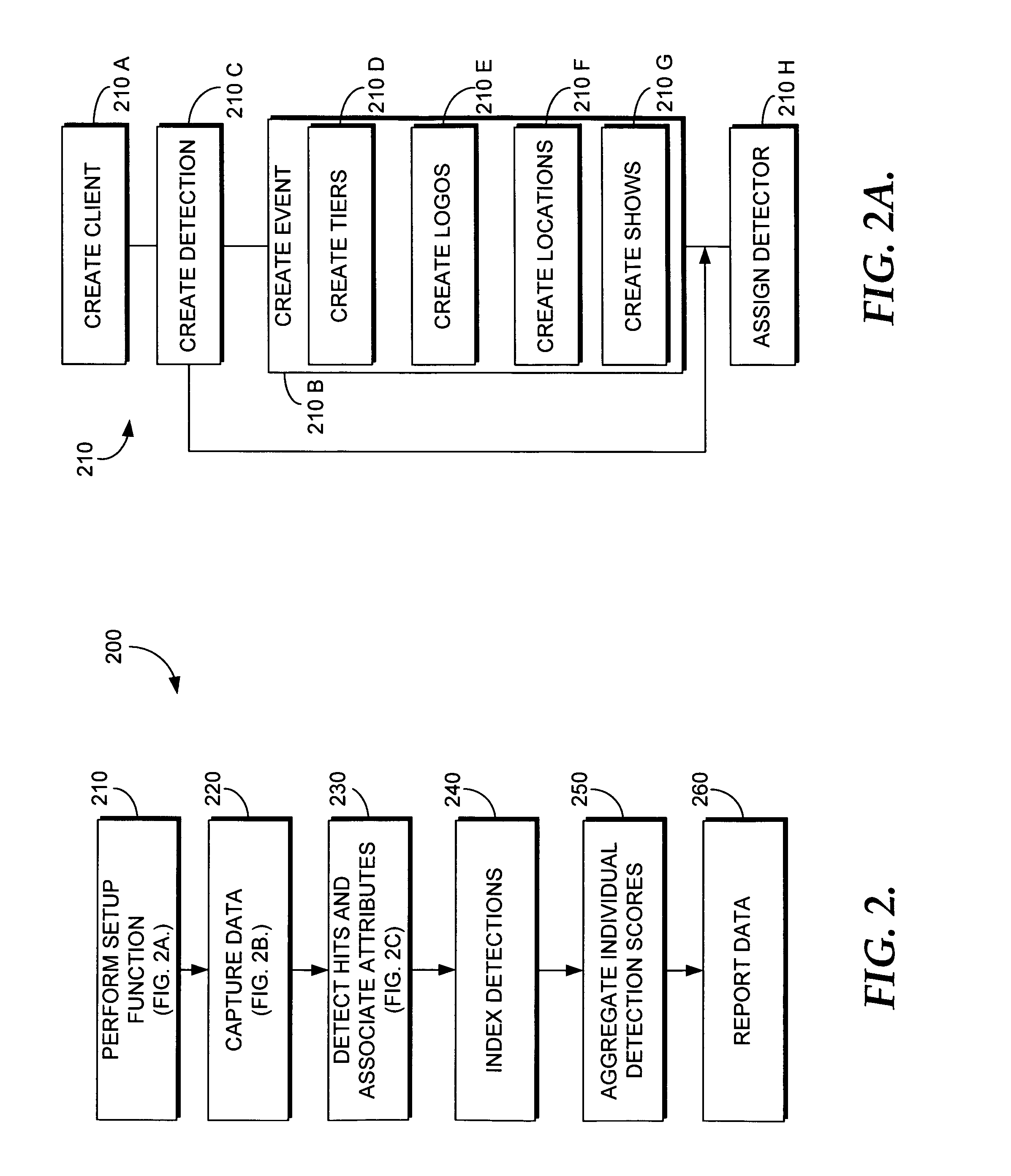

Method and system for quantifying viewer awareness of advertising images in a video source

ActiveUS20060174261A1Improve accuracyReducing resourceTelevision system detailsAnalogue secracy/subscription systemsComputer graphics (images)Computer vision

Owner:NIELSEN SPORTS AMERICA LLC

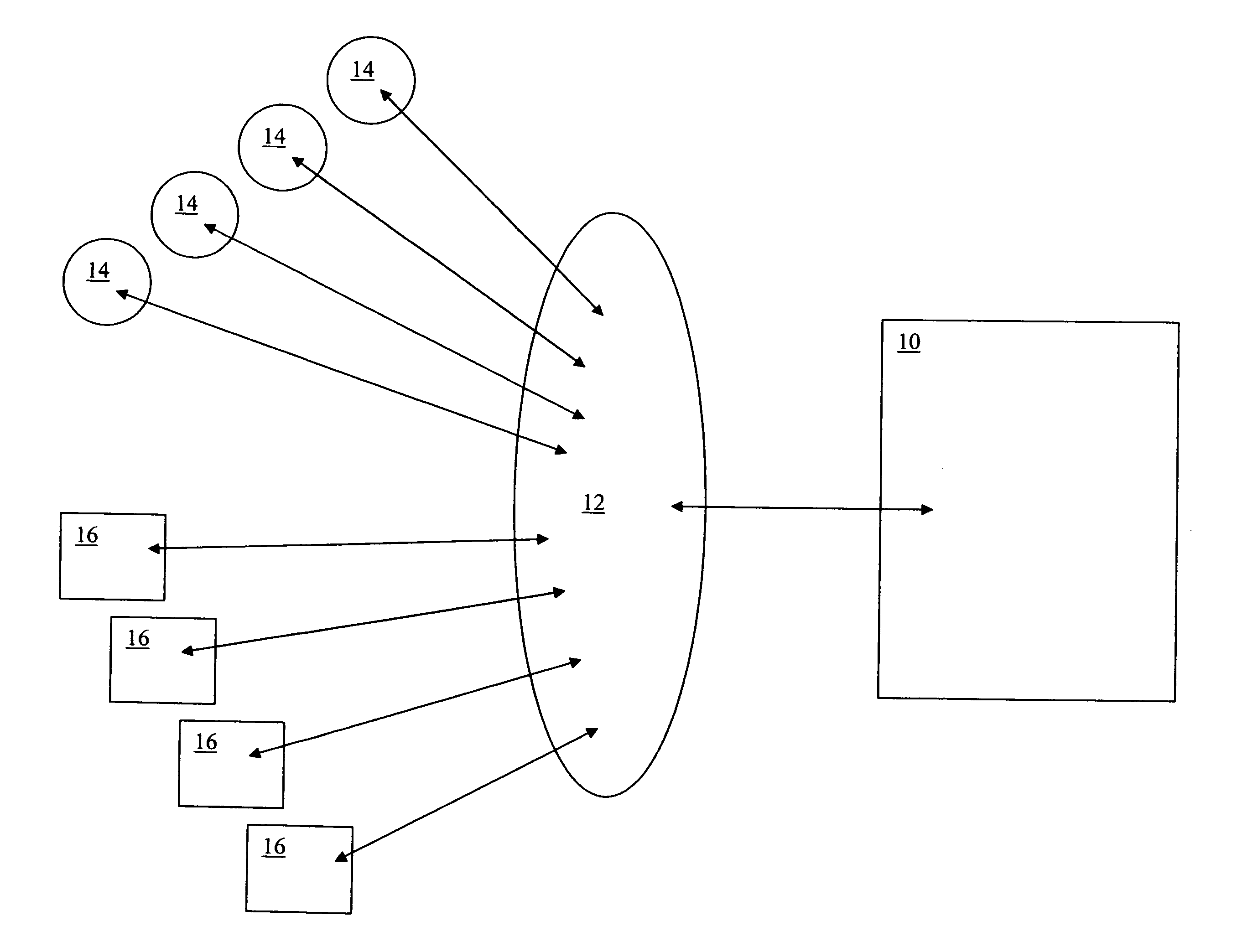

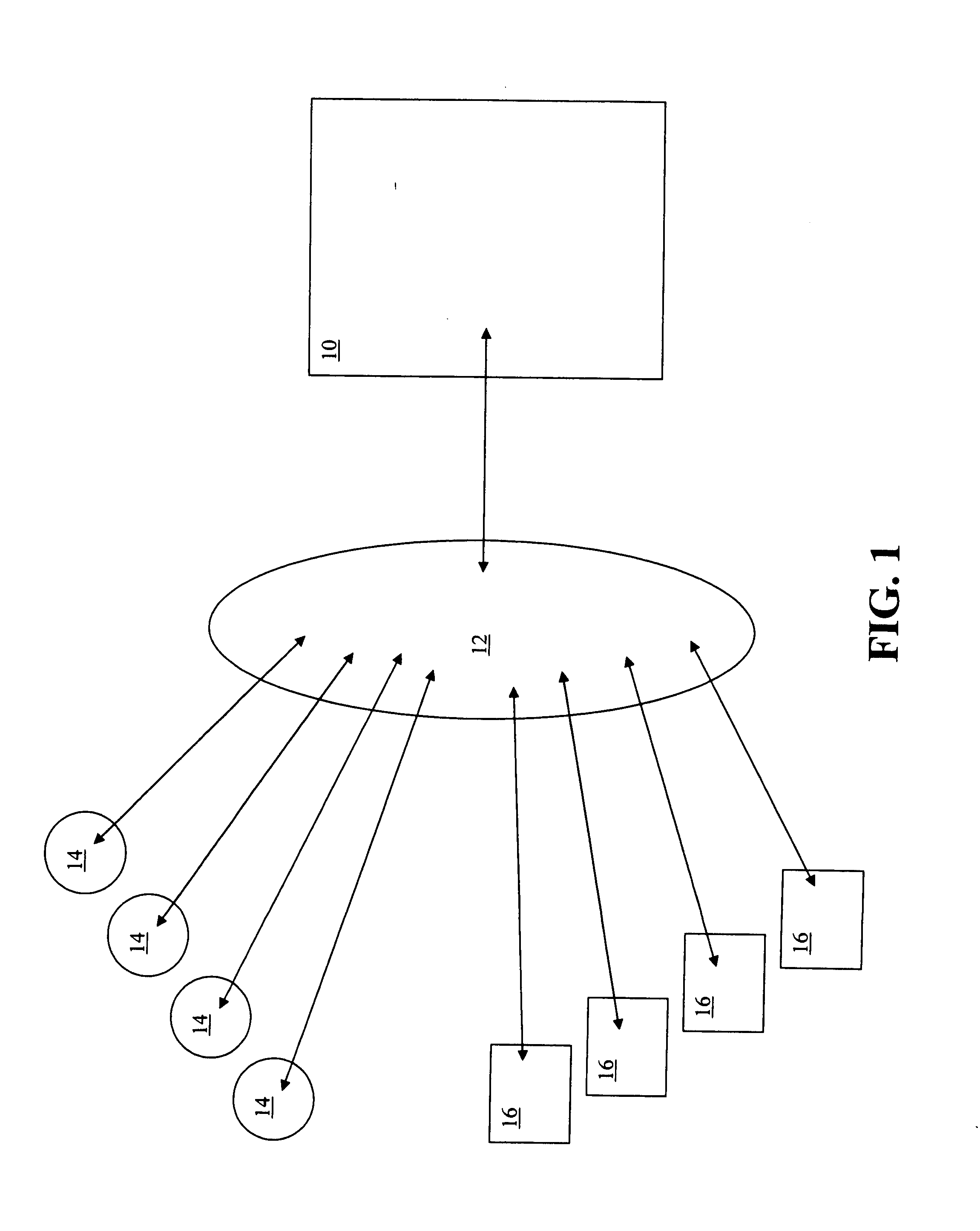

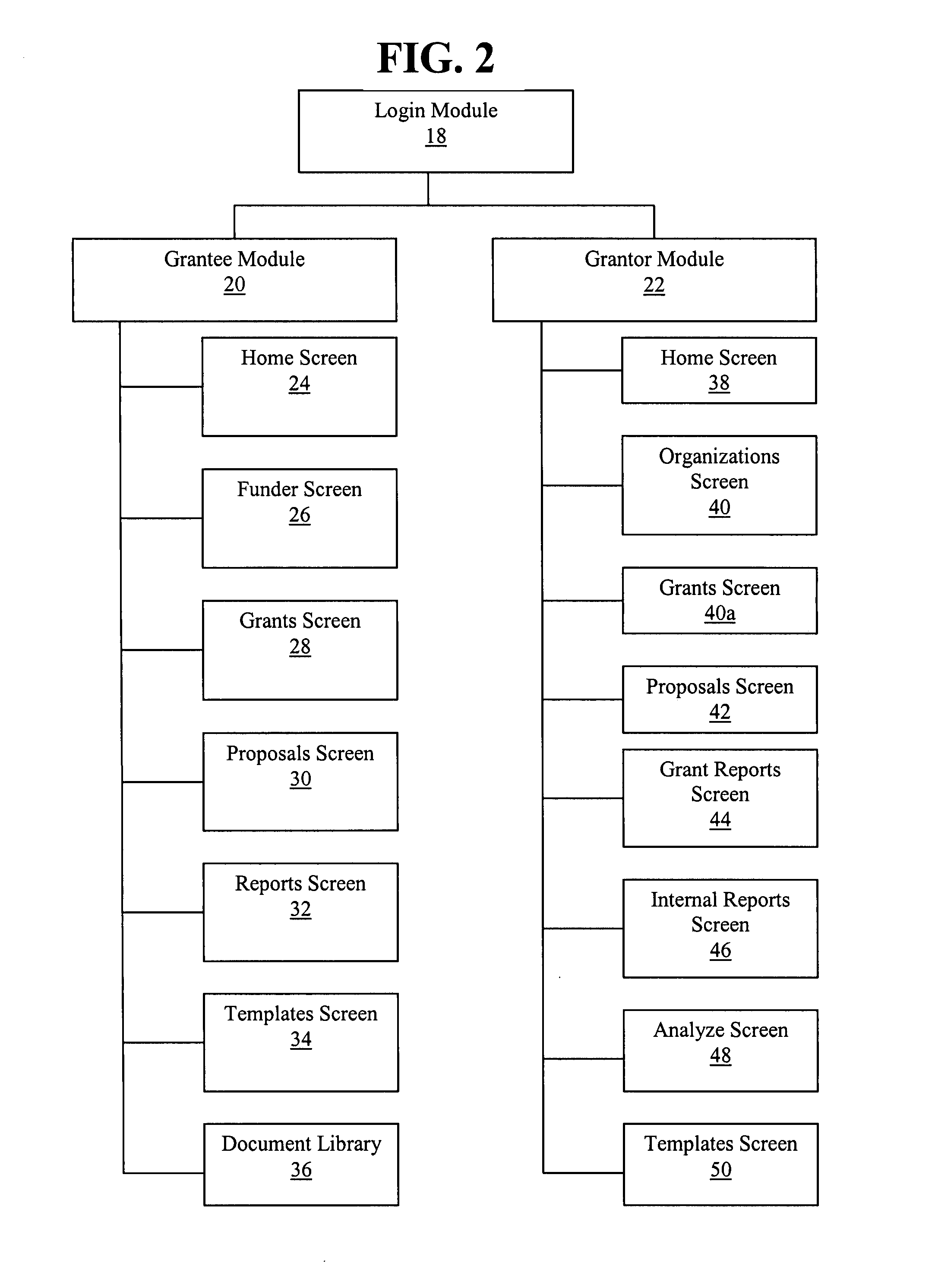

Grant administration system

ActiveUS20090117529A1Shorten the timeLow costMarketingMechanical appliancesQuestions and answersManagement system

A method and system are disclosed for facilitating the completion of a questionnaire. A storage medium stores a plurality of questions and associated answers. Similar questions are linked. An interface presents to a user through a computer network a presented question as part of a questionnaire to be completed. The interface also presents to the user answers associated with similar questions linked to the presented question. Upon user selection, an answer to a similar question is stored as an answer to the selected question. The user may modify the answer. The method and system may present additional questions and answers associated with similar questions linked to the additional question. A user may have access to stored questions, add questions, and link similar questions. Answers to questions may be stored before the user completes the questionnaire. The questionnaire may include fields populated with information previously supplied by the user without user selection. The storage medium may be a database.

Owner:ALTUM INC

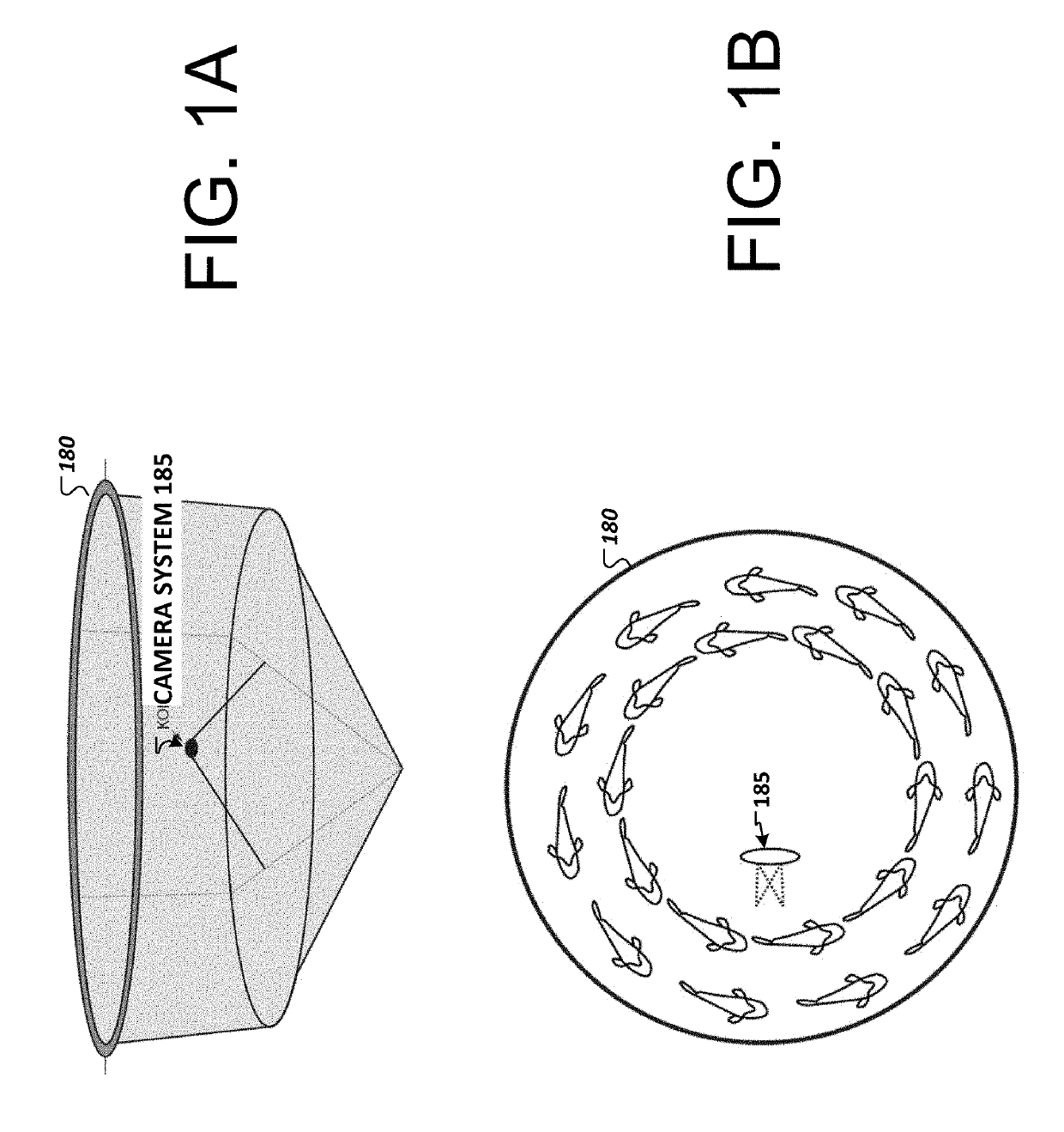

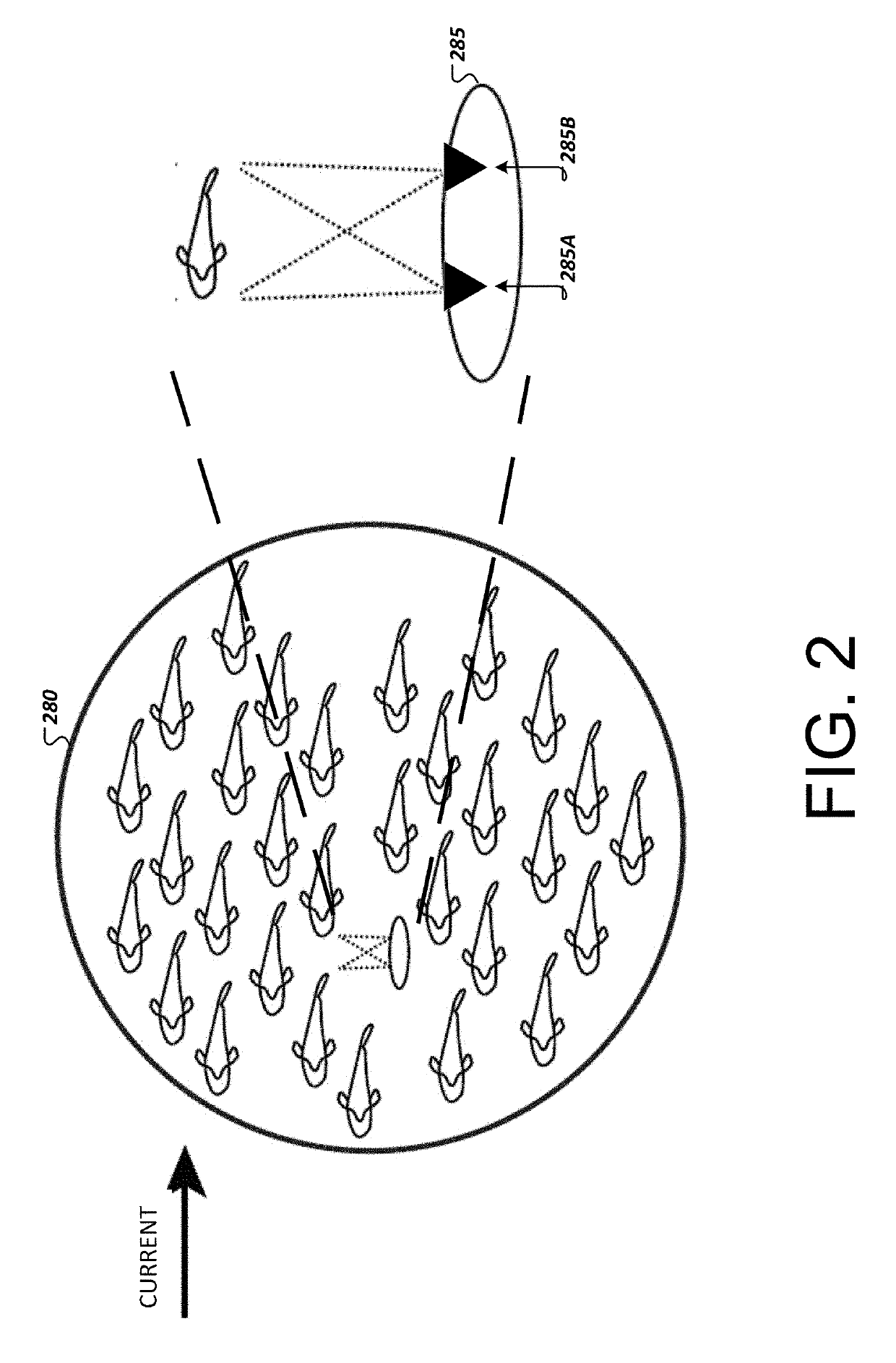

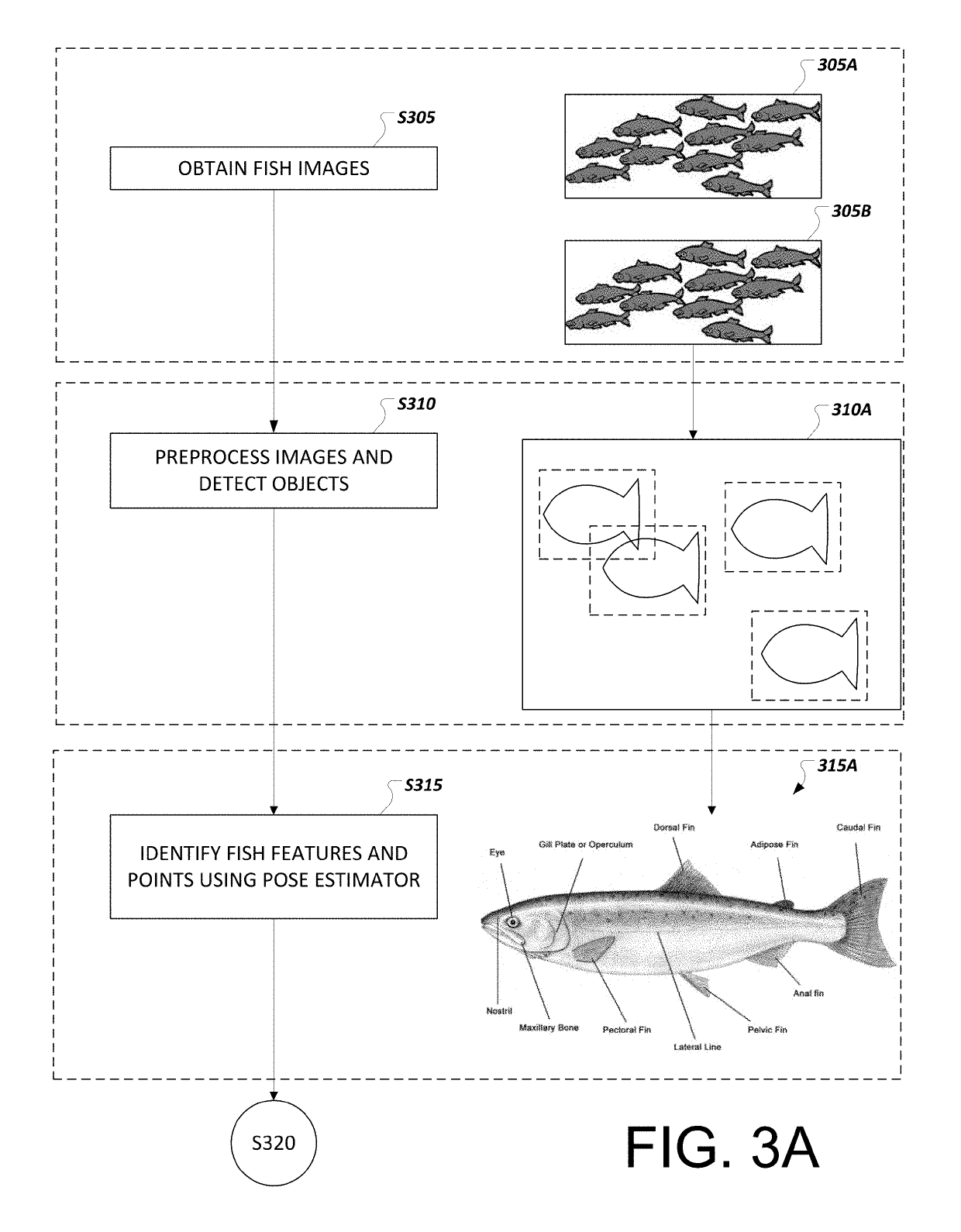

Fish biomass, shape, and size determination

ActiveUS20190228218A1Improve accuracyImprove consistencyImage enhancementImage analysisSize determinationStereo cameras

Methods, systems, and apparatuses, including computer programs encoded on a computer-readable storage medium for estimating the shape, size, and mass of fish are described. A pair of stereo cameras may be utilized to obtain right and left images of fish in a defined area. The right and left images may be processed, enhanced, and combined. Object detection may be used to detect and track a fish in images. A pose estimator may be used to determine key points and features of the detected fish. Based on the key points, a three-dimensional (3-D) model of the fish is generated that provides an estimate of the size and shape of the fish. A regression model or neural network model can be applied to the 3-D model to determine a likely weight of the fish.

Owner:X DEV LLC

Prediction intra-mode selection in an encoder

InactiveUS7751478B2Reducing resourceShorten the timeColor television with pulse code modulationColor television with bandwidth reductionRate distortionAlgorithm

A prediction mode for encoding data is selected using a reduced number of rate-distortion cost computations. This reduction in rate-distortion cost computations is caused by filtering the number of potential intra prediction modes based on two criteria. First, the number of potential prediction modes is reduced based on at least one characteristic of a quantization procedure performed during the encoding procedure. Second, the number of potential prediction modes is reduced based on an error value calculated for each of the potential prediction modes.

Owner:SEIKO EPSON CORP

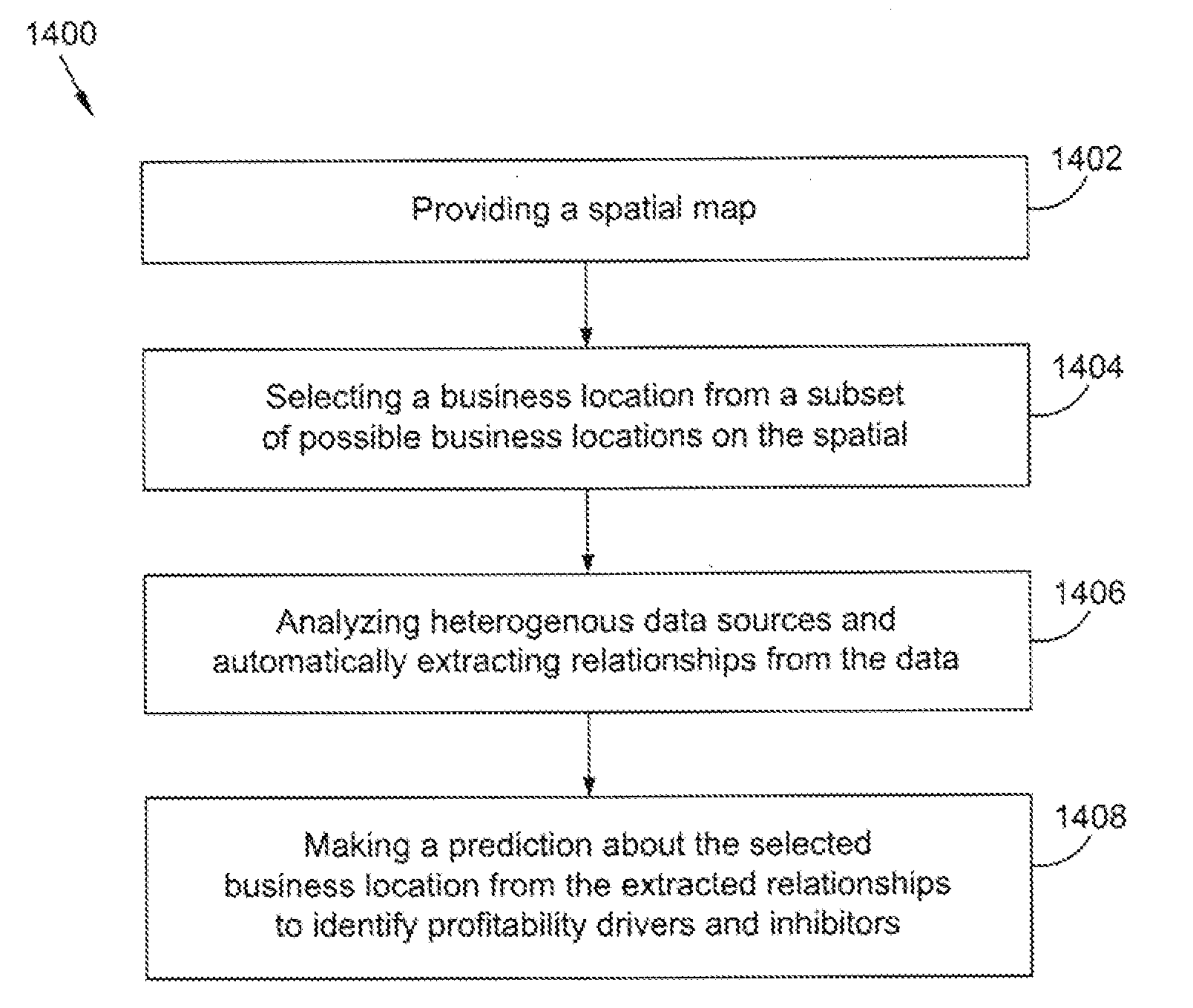

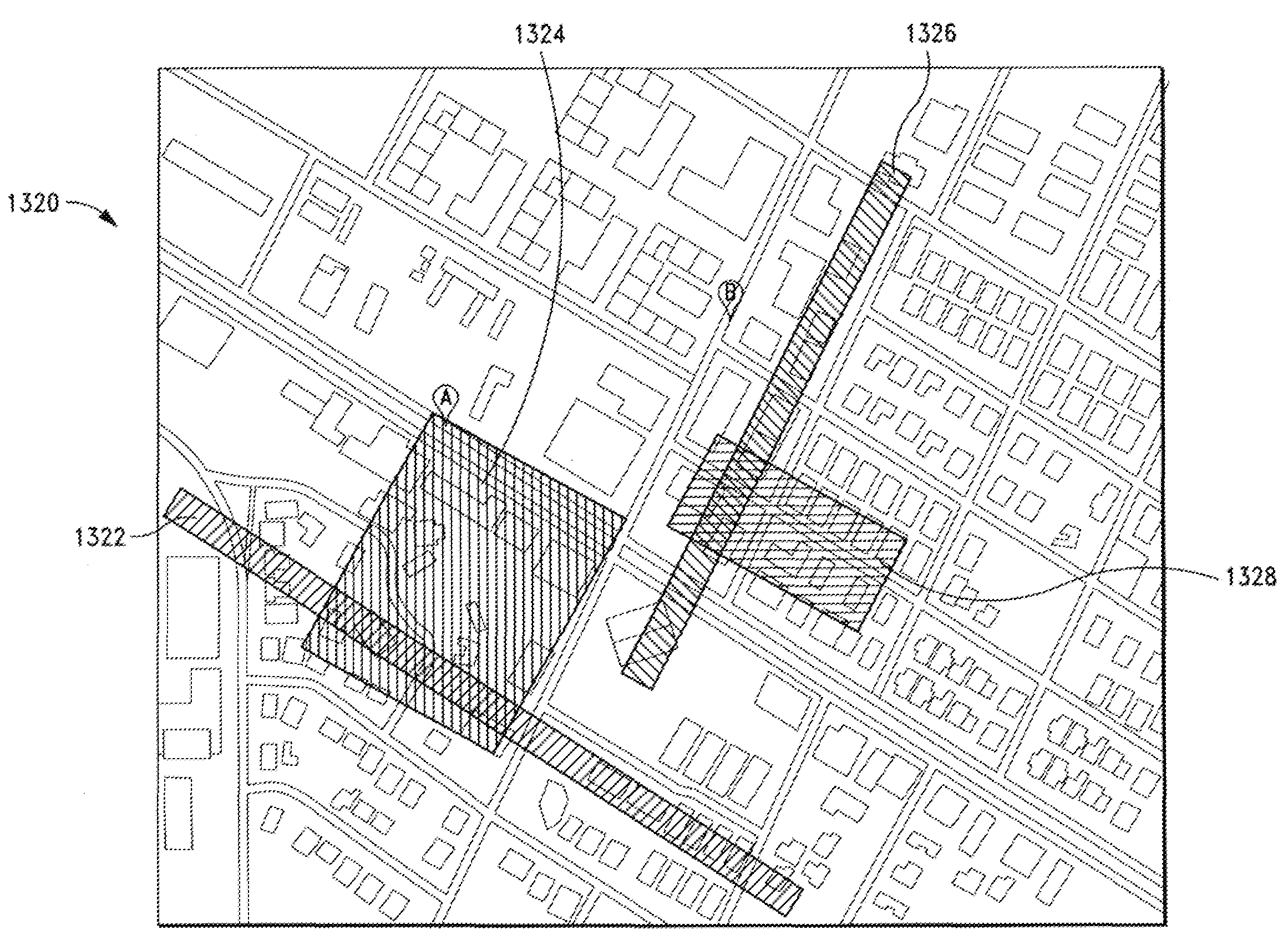

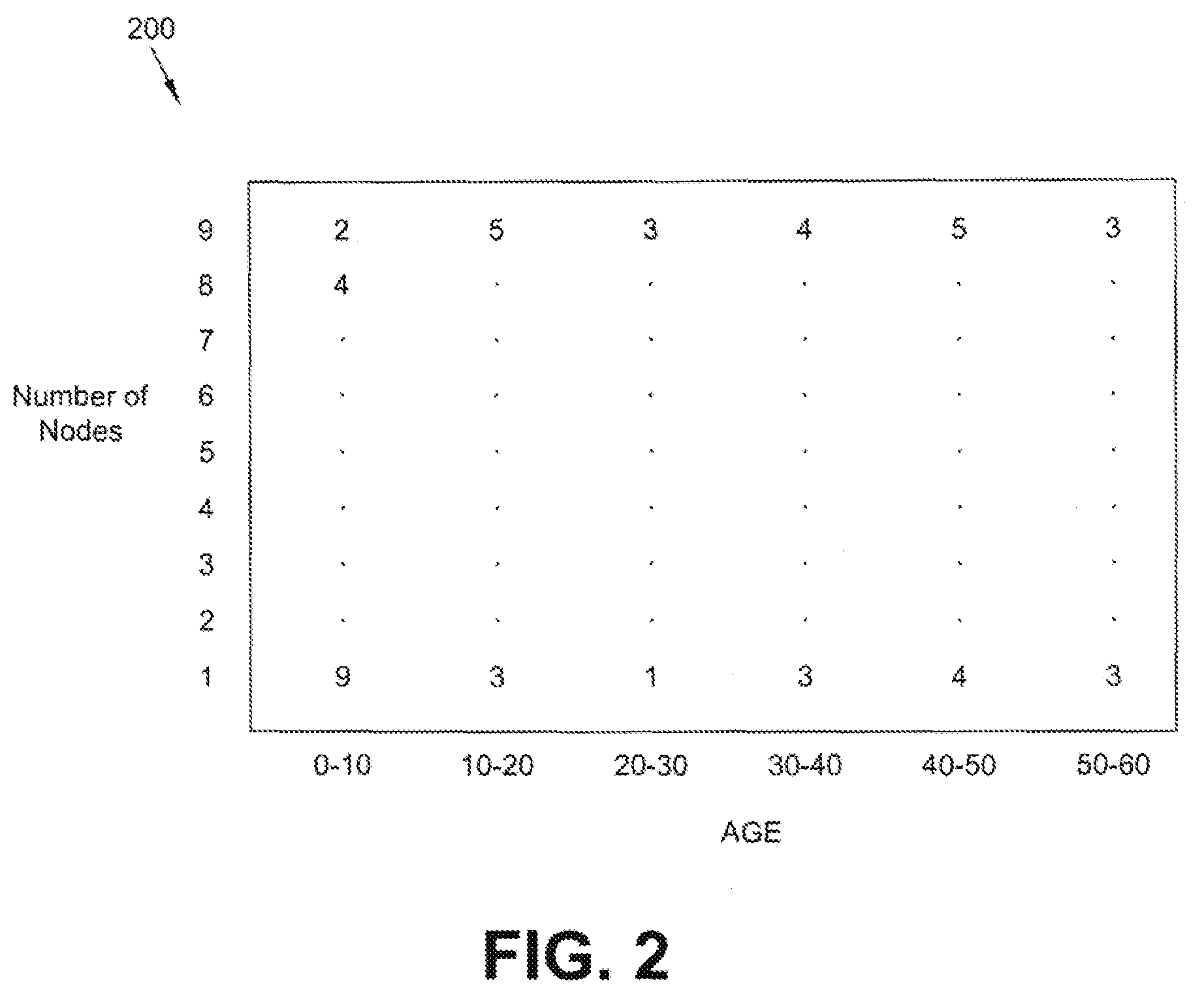

Method and system utilizing online analytical processing (OLAP) for making predictions about business locations

ActiveUS20080208652A1Reducing resourceShorten the timeForecastingCommerceSpatial mapsComposite indicator

A method and system that utilizes OLAP and supporting data structures for making predictions about business locations. The method includes providing a spatial map and analyzing heterogeneous data having a spatial component to find utilizable data. Relationships are automatically extracted from the utilizable data by employing machine learning. The step of automatically extracting relationships includes generating a composite indicator, which correlates spatial data with unstructured data. The extracted relationships are presented on a spatial map to make a prediction about at least one business location. Preferably, the predictions are presented as a rank-ordered list on the spatial map and a heat map overlays the spatial map to indicate predictions about particular regions.

Owner:SAAMA TECH

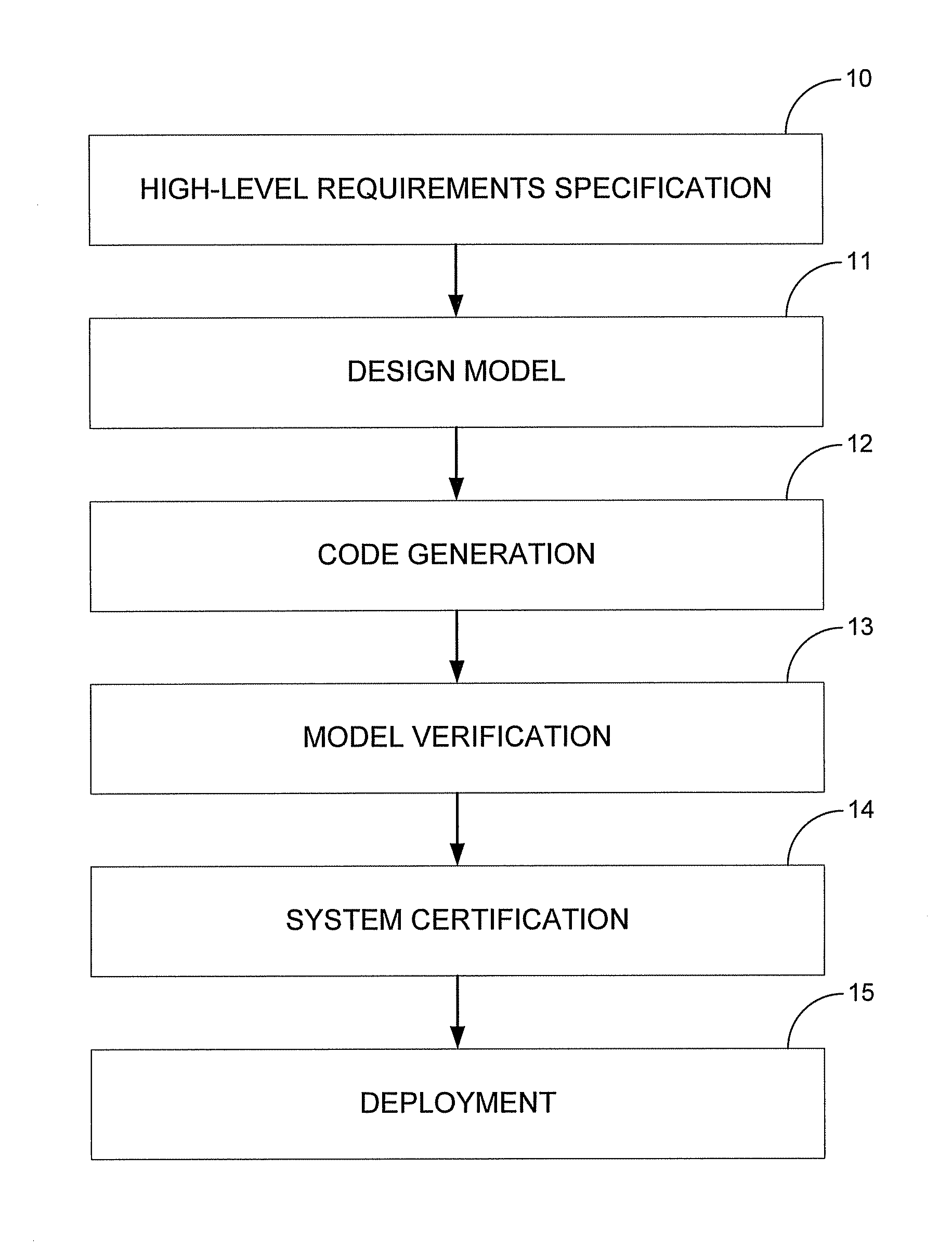

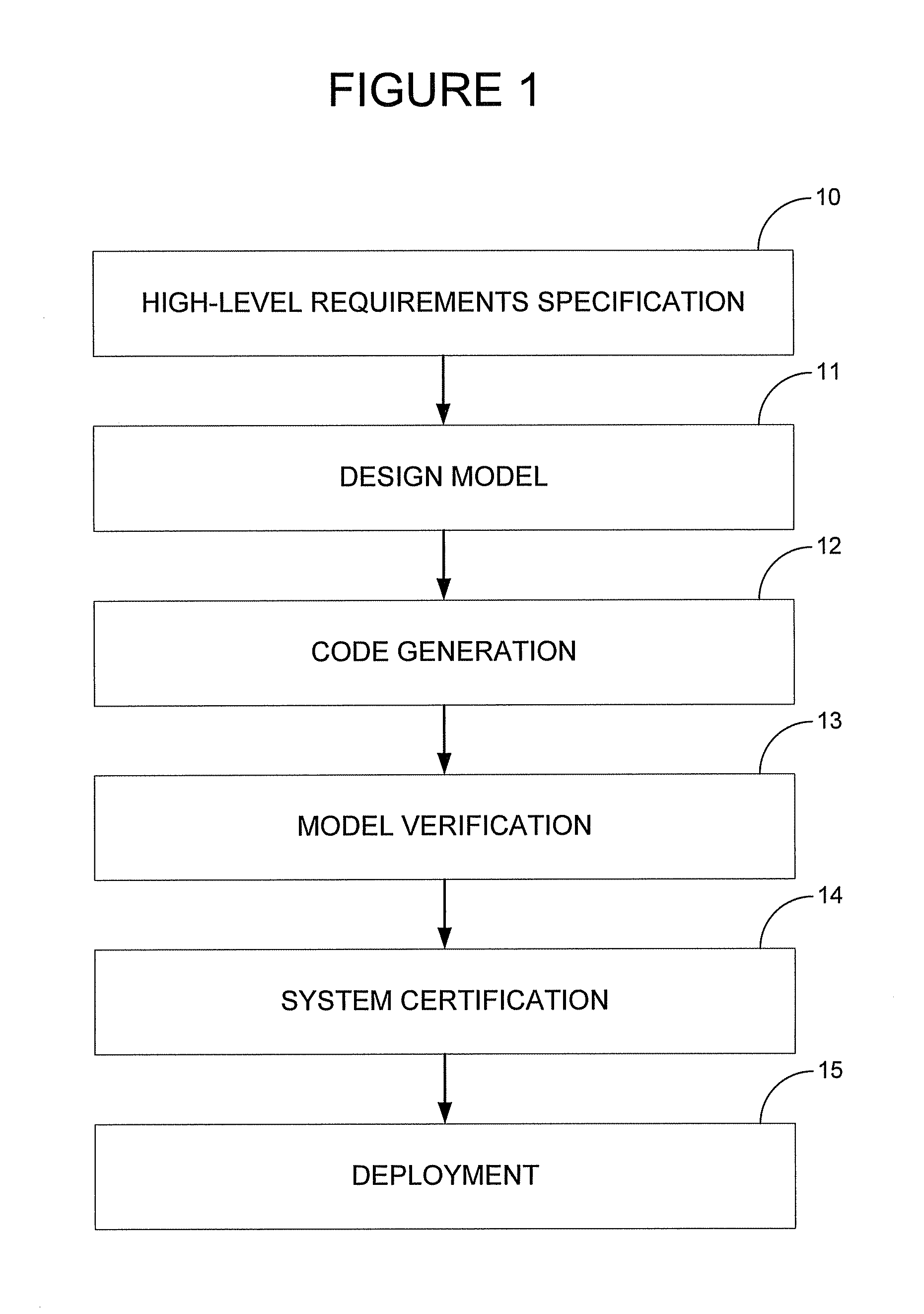

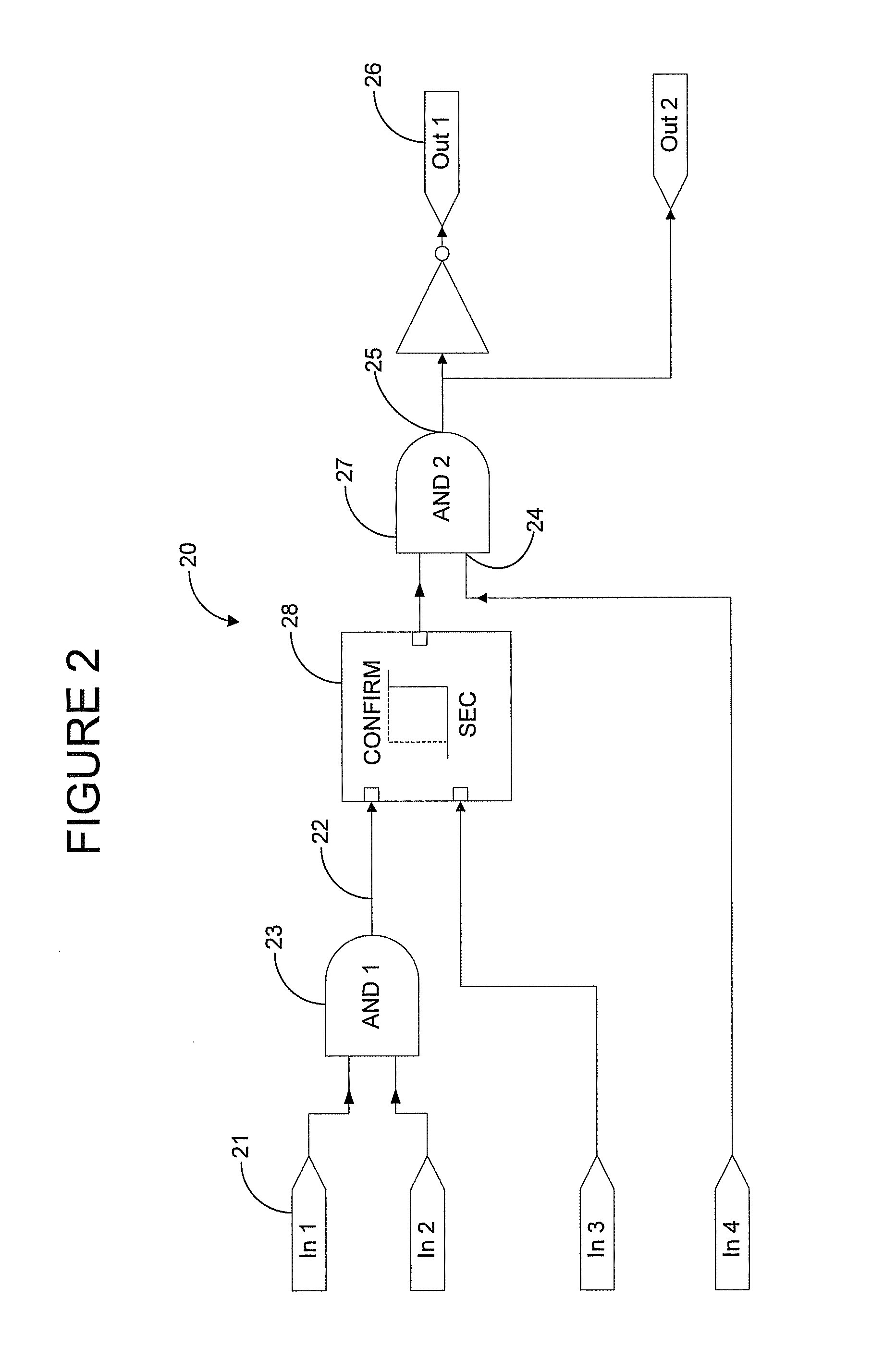

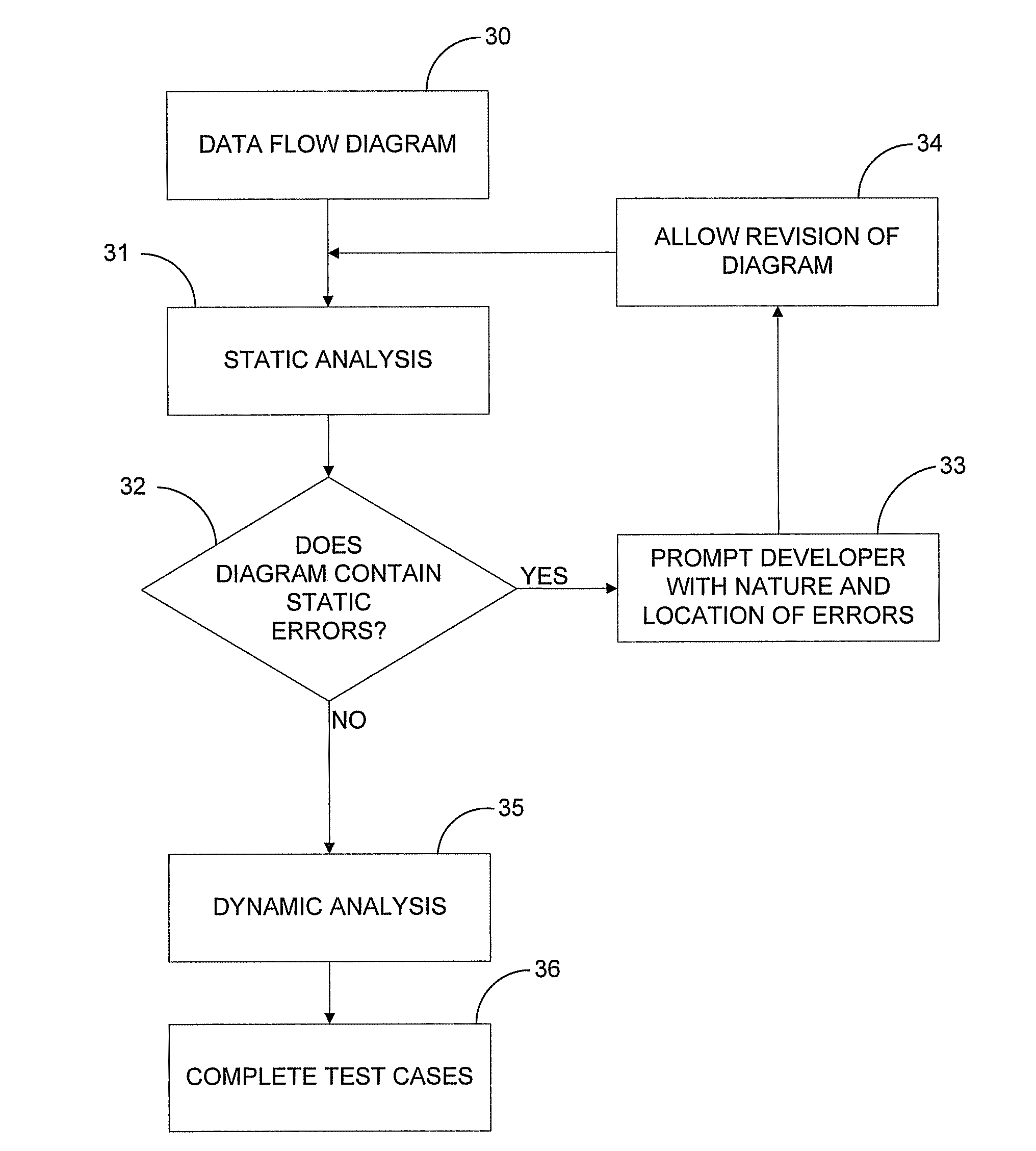

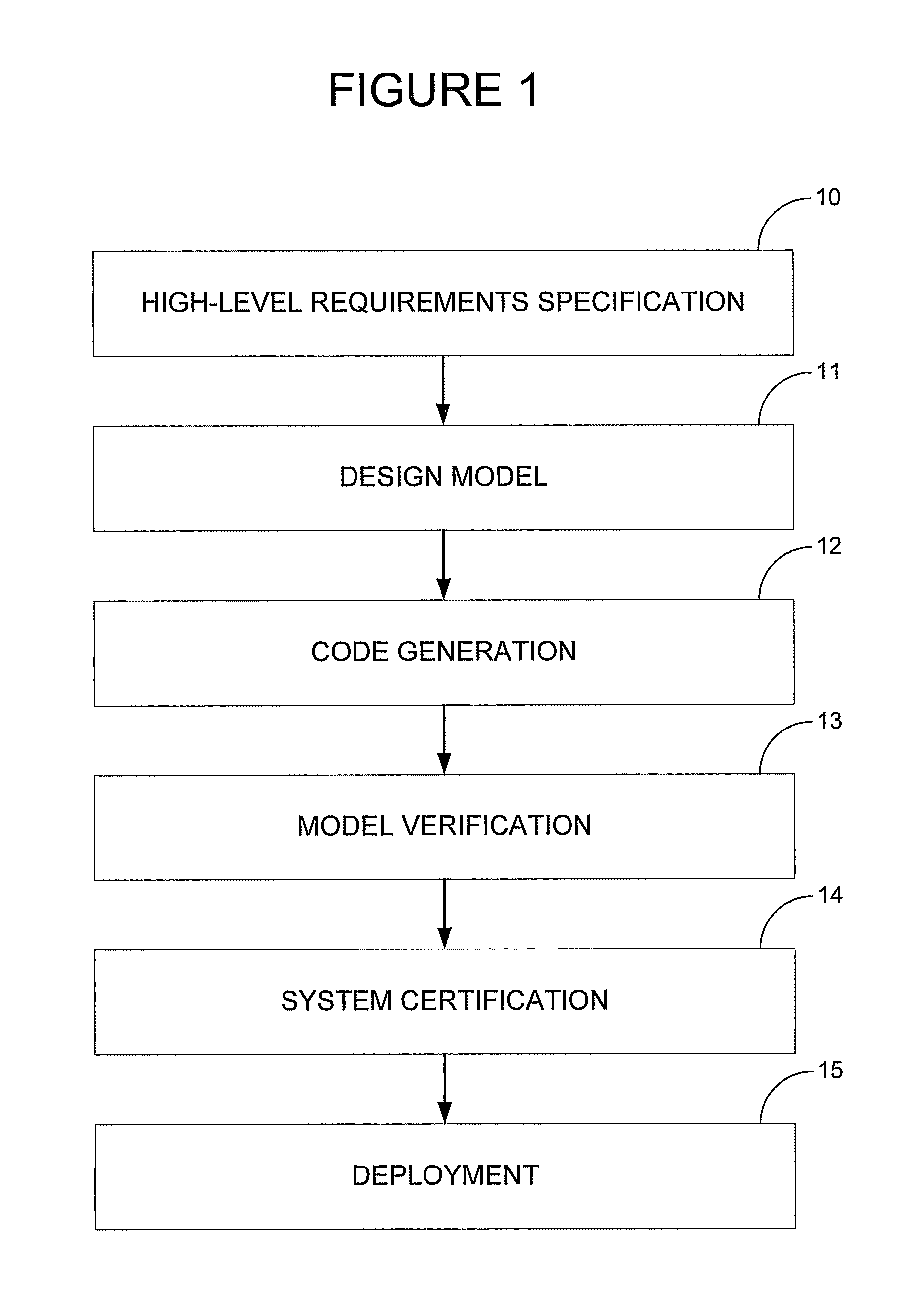

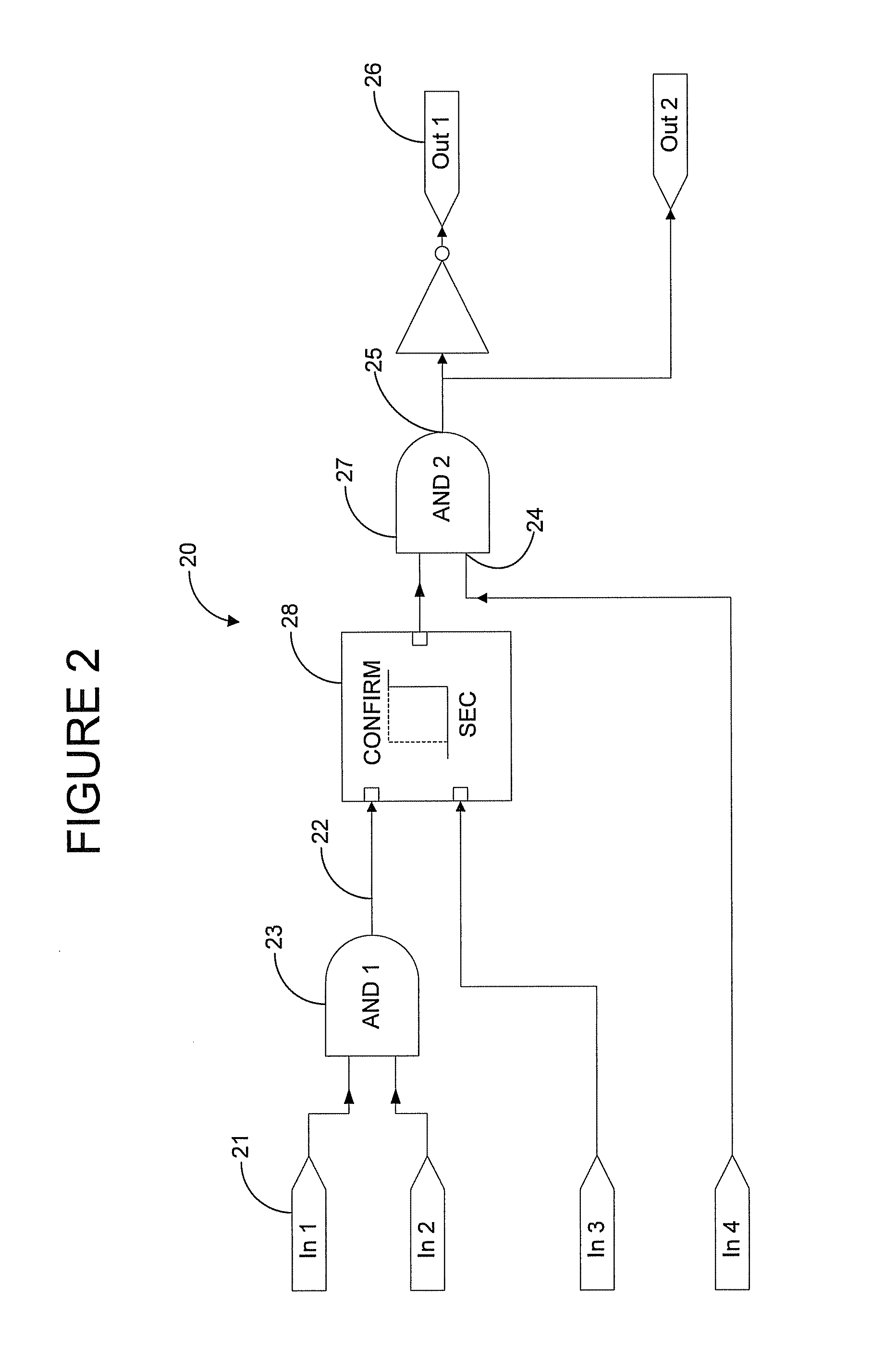

Requirements-Based Test Generation

ActiveUS20080126902A1Reduce time and resourceFacilitates meeting DO-178B objectivesElectronic circuit testingError detection/correctionTest generatorBlock diagram

This test generator takes data flow block diagrams and uses requirements-based templates, selective signal propagation, and range comparison and intersection to generate test cases containing test vectors for those diagrams. The templates are based on the functionality and characteristics of a block type, and each block type has associated templates. These templates provide maps for the creation of test values that verify the functionality of particular instances of that block type. Signal propagation allows the generation of diagram-level test cases that verify particular characteristics of a single embedded block. The methods disclosed for signal propagation utilize range intersection, equivalence classes, and block type formulae to create efficient and complete test cases. This test generation method would preferably be repeated until all blocks in a data flow block diagram were verified in their respective contexts, and it creates test cases that cover multiple time steps.

Owner:HONEYWELL INT INC

Method and system utilizing online analytical processing (OLAP) for making predictions about business locations

A method and system that utilizes OLAP and supporting data structures for making predictions about business locations. The method includes providing a spatial map and analyzing heterogeneous data having a spatial component to find utilizable data. Relationships are automatically extracted from the utilizable data by employing machine learning. The step of automatically extracting relationships includes generating a composite indicator, which correlates spatial data with unstructured data. The extracted relationships are presented on a spatial map to make a prediction about at least one business location. Preferably, the predictions are presented as a rank-ordered list on the spatial map and a heat map overlays the spatial map to indicate predictions about particular regions.

Owner:SAAMA TECH LLC

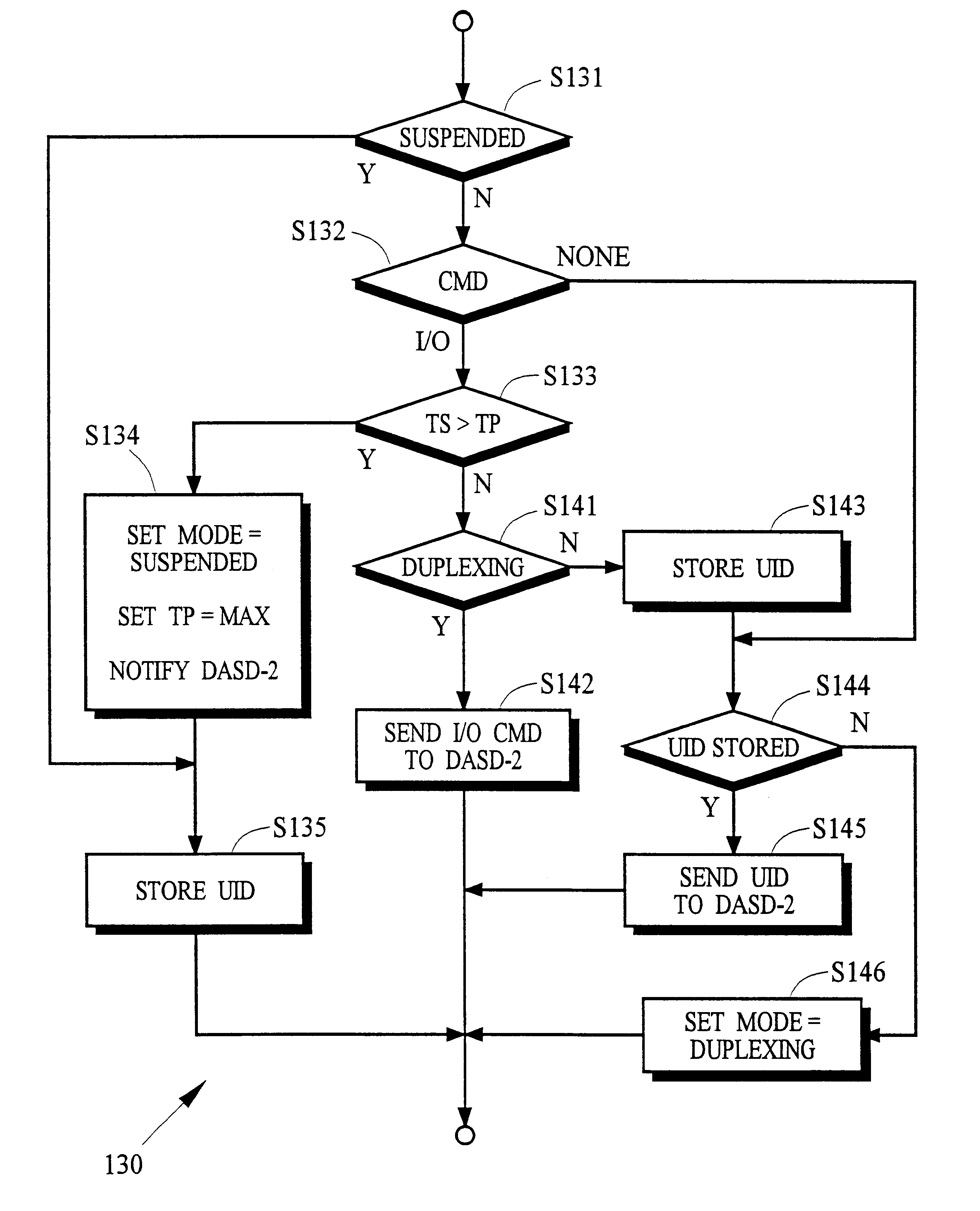

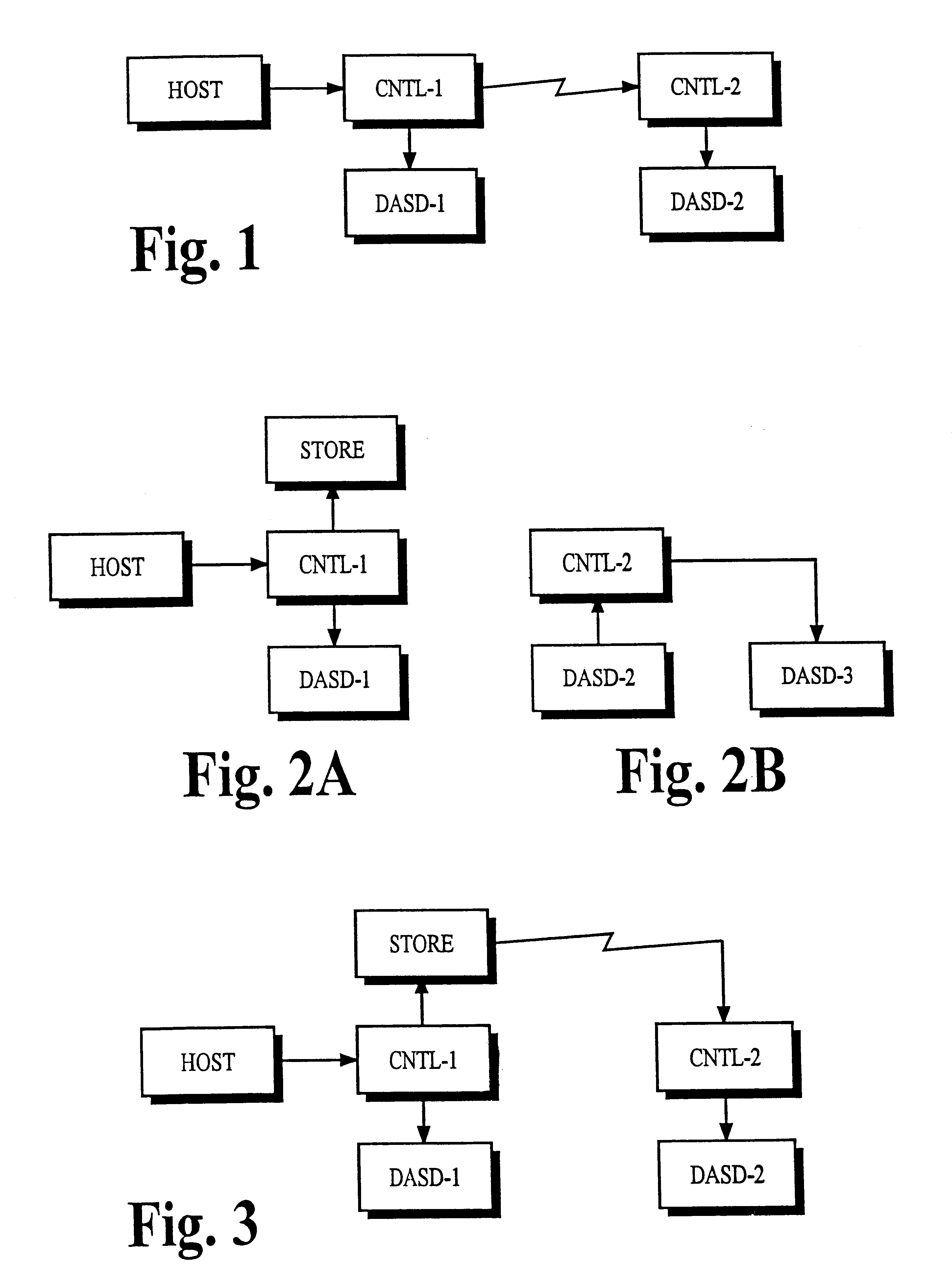

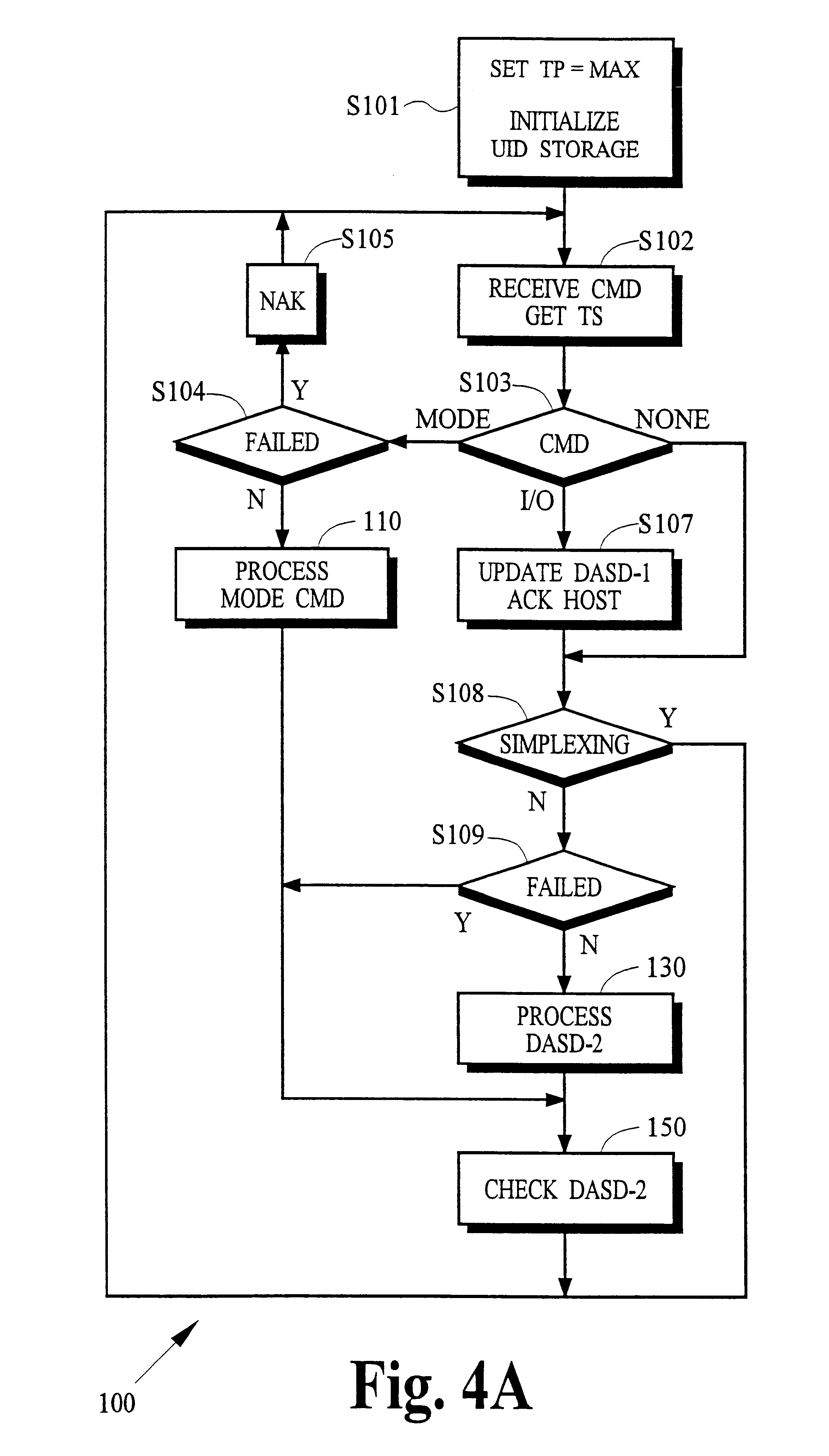

Remote data copy using a prospective suspend command

InactiveUS6789178B2Improve usabilityReducing resourceInput/output to record carriersData processing applicationsComputerized systemOperation mode

In a computer system, the controller of one or more primary data recording devices sends update information to the controller of one or more secondary data recording devices to maintain a remote copy of data stored on the primary data recording devices. The primary controller receives a command from a computer that specifies a prospective suspend time after which remote copy operation is to be suspended. After the suspend time passes, the primary controller stops sending the update information to the secondary controller and begins storing indicators of the updated information in cache memory. The primary controller may resume remote copy operation in response to a command received from the computer by first entering into a pending mode of operation in which cached indicators are used to identify update information that must be sent to the secondary controller to resynchronize the remote copy. When the information for all cached indicators has been sent, normal remote copy operation may be resumed.

Owner:HITACHI DATA SYST CORP

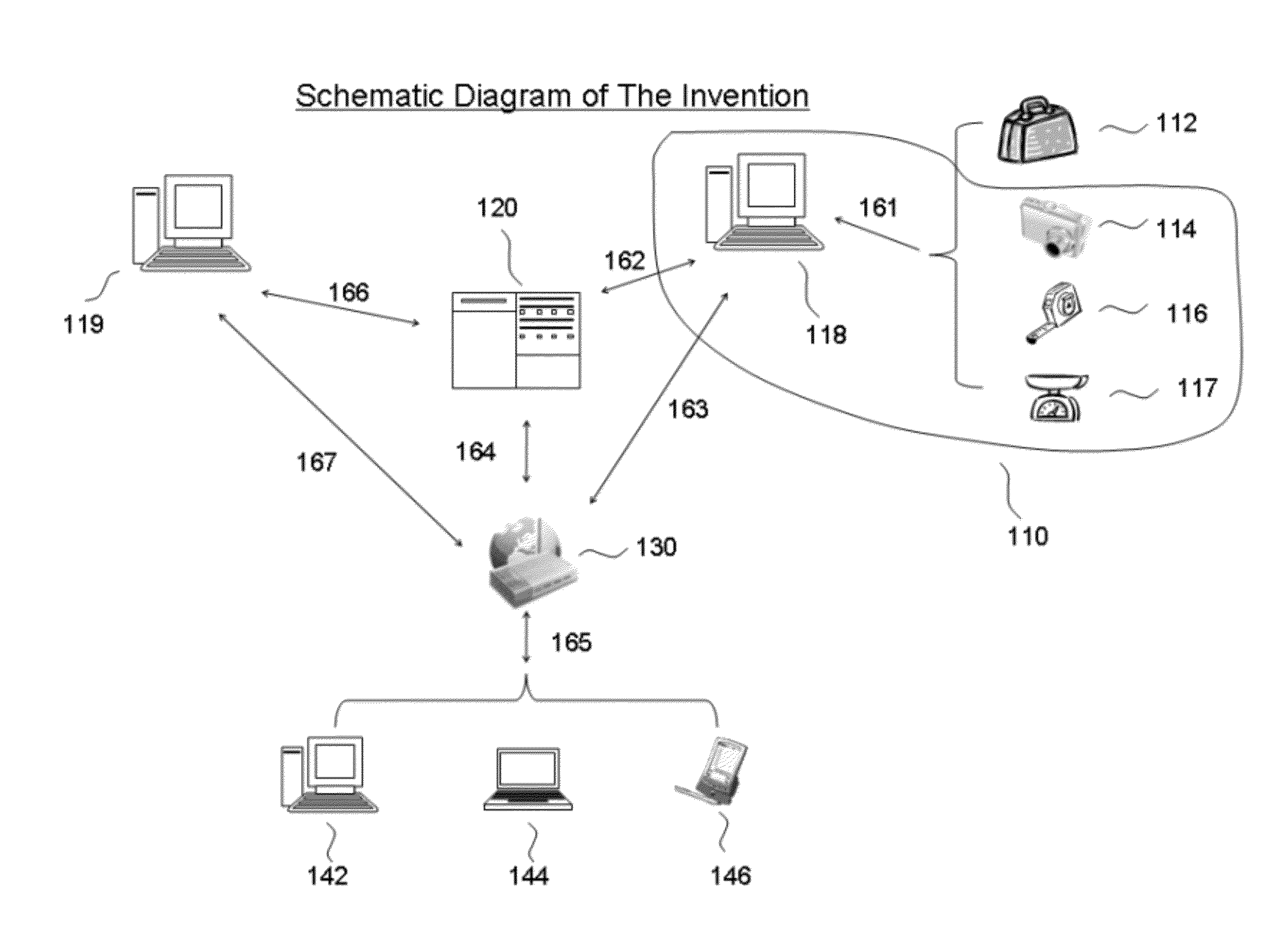

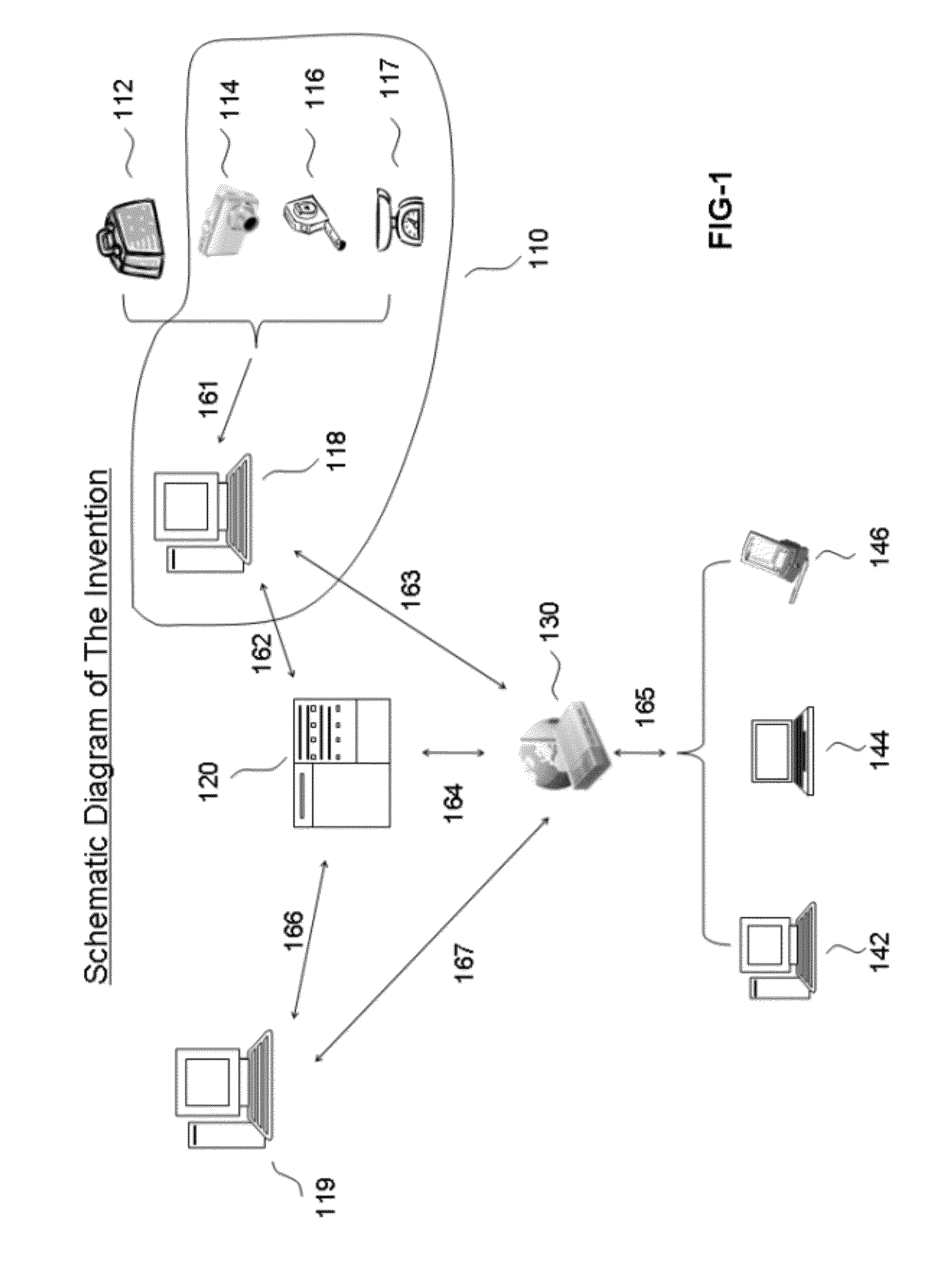

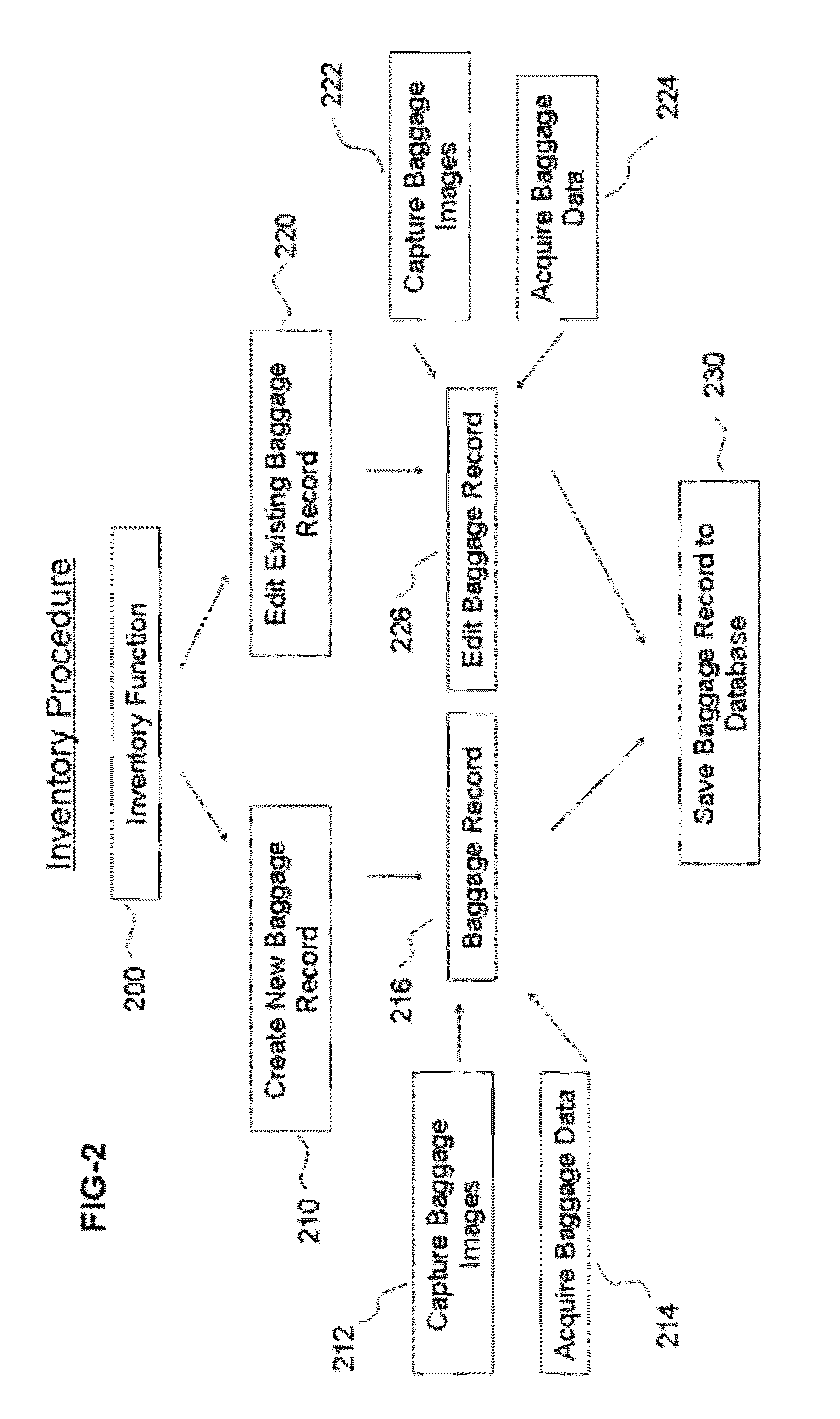

System and method for retrieving lost baggage in travel industry

InactiveUS20120089639A1Increase success rateLess compensationDigital data processing detailsOffice automationData managementCentral database

A system and method for retrieving a lost baggage by its owner is provided. This method provides the baggage owner a system to actively participate in searching the lost baggage using the provided World Wide Web portal site, which is connected to the central database server. This system includes baggage warehouse; baggage inventory terminals; baggage data management software; central database server which will hold the textual information and images on the baggage and its content; a user browsing and searching interface through the said portal site. The baggage owner can actively join the search process for the lost baggage by searching the database, browsing the search results, viewing the baggage images. This system increases the success rate of returning the lost baggage to its owner by utilizing the owner's knowledge on the lost baggage.

Owner:WANG DAPENG

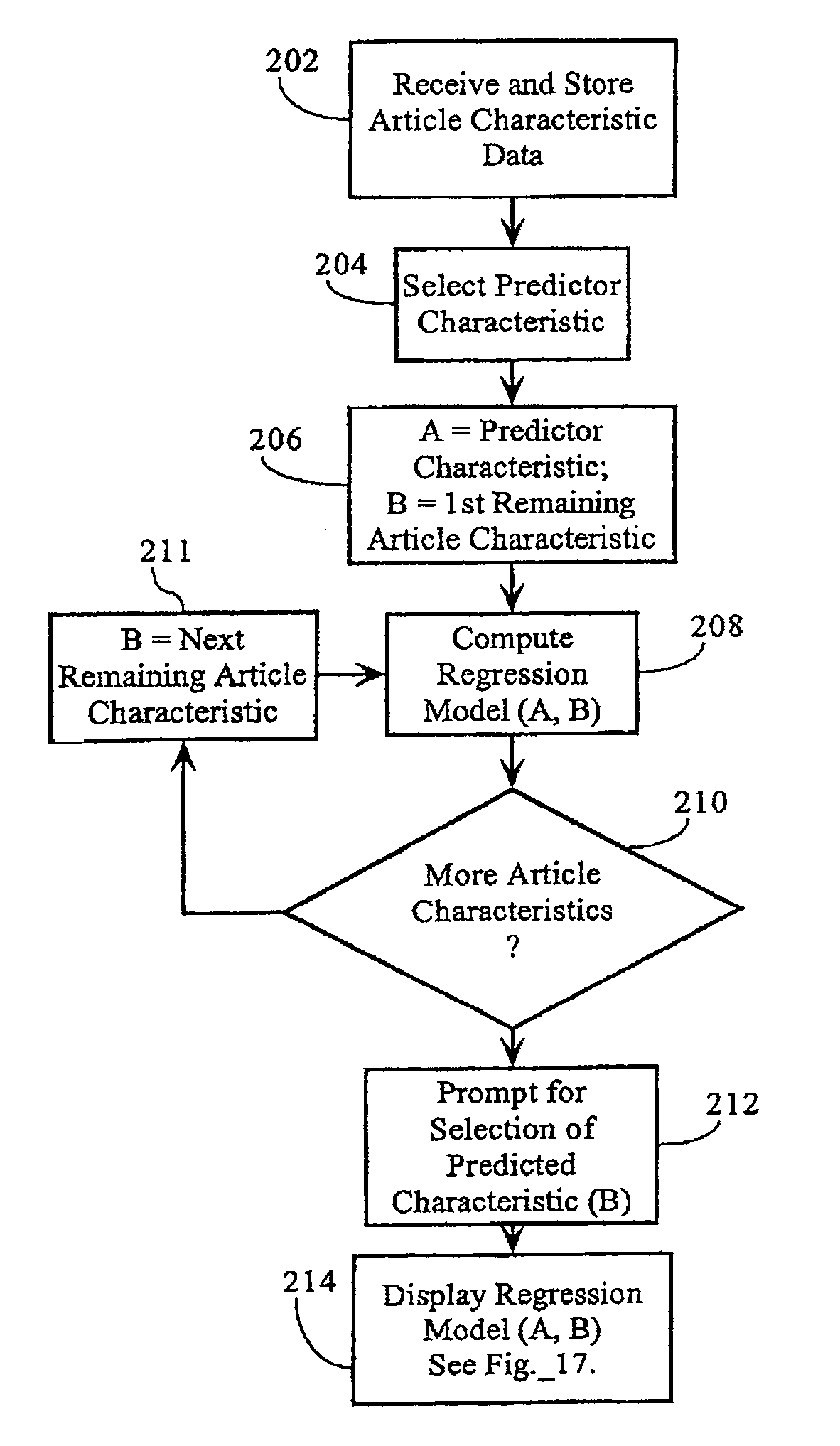

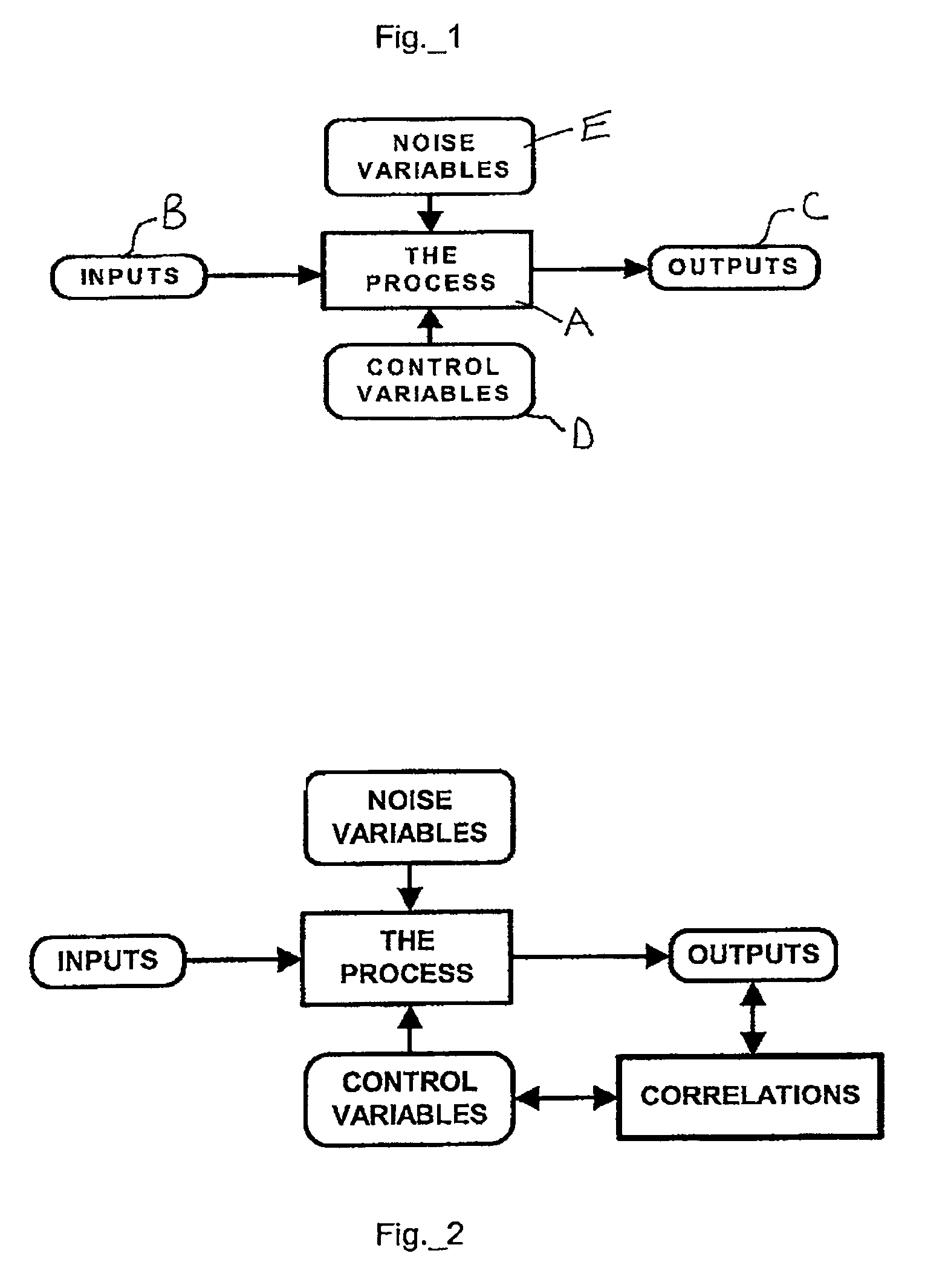

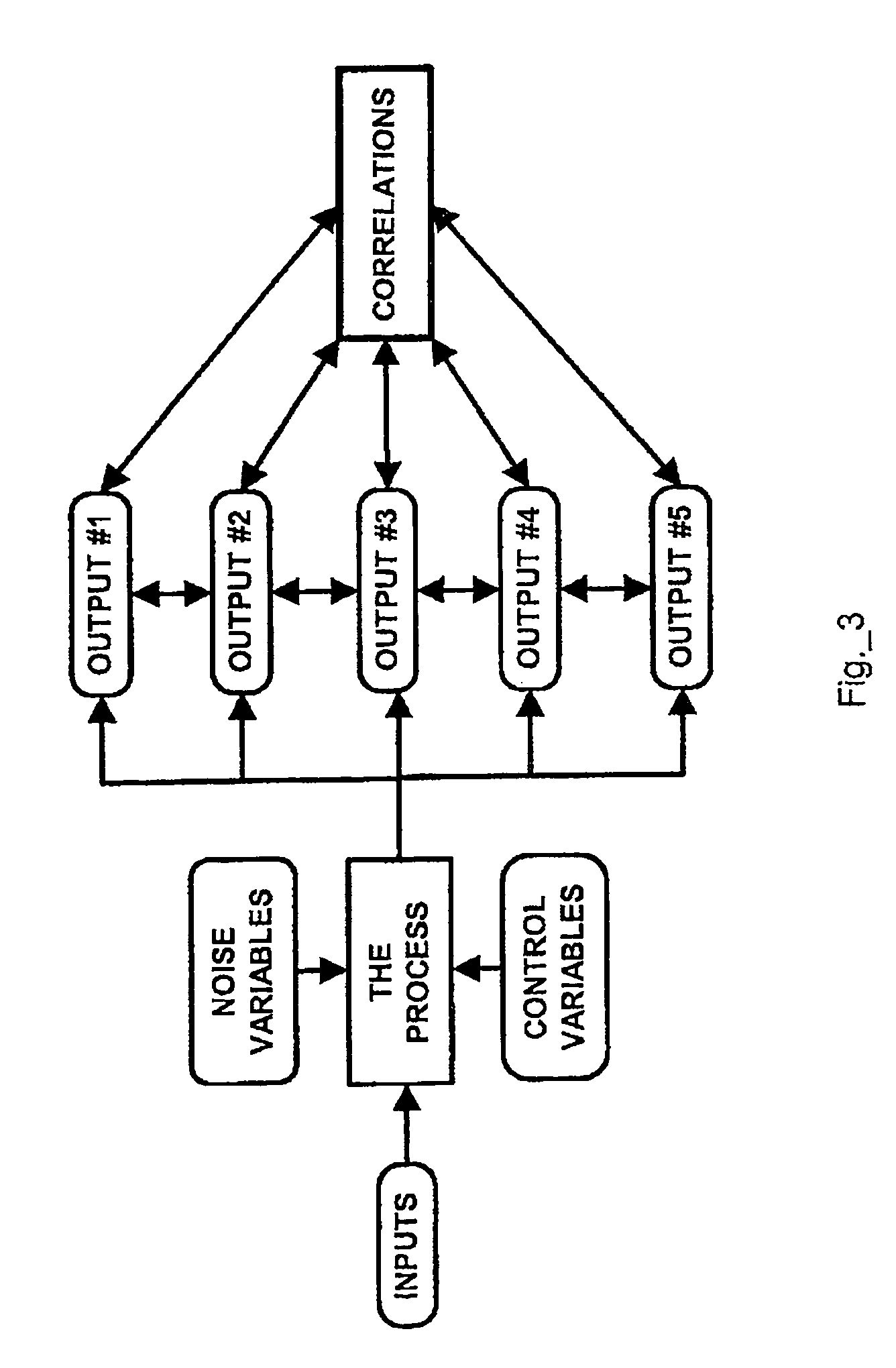

Manufacturing design and process analysis and simulation system

InactiveUS7239991B2Facilitate design and production and measurement taskReduce analysisSimulator controlElectric controllersProcess dimensionProcess simulation

A process simulation system that simulates the operation of the manufacturing and measurement systems used to produce and measure the articles being analyzed relative to engineering design targets, engineering design tolerances, producibility and / or quality. In one embodiment, the user is able to assess, without risk or production cost while accelerating speed-to-market, the effect of contemplated changes (i.) to engineering design targets, (ii.) to engineering design tolerances, (iii.) to tooling, (iv.) to part pre-process dimensions and (v.) to the measurement system—on manufactured part dimensions, producibility and quality (i.) without modifying tooling, (ii.) without changing part pre-process dimensions, (iii.) without producing new parts, (iv.) without measuring article characteristics on the new parts and (v.) without changing the measurement system. The simulation functionalities, according to embodiments of the present invention, enable the user to verify whether or not the contemplated changes will have the desired effect without incurring the time and expense involved in actually making the changes, producing parts, measuring part characteristics, changing the measurement system and then determining whether the changes accomplished the desired objectives.

Owner:TUSZYNSKI STEVE W

Requirements-based test generation

ActiveUS7644334B2Facilitates meeting DO-178B objectivesReducing resourceElectronic circuit testingError detection/correctionBlock typeTest vector

This test generator takes data flow block diagrams and uses requirements-based templates, selective signal propagation, and range comparison and intersection to generate test cases containing test vectors for those diagrams. The templates are based on the functionality and characteristics of a block type, and each block type has associated templates. These templates provide maps for the creation of test values that verify the functionality of particular instances of that block type. Signal propagation allows the generation of diagram-level test cases that verify particular characteristics of a single embedded block. The methods disclosed for signal propagation utilize range intersection, equivalence classes, and block type formulae to create efficient and complete test cases. This test generation method would preferably be repeated until all blocks in a data flow block diagram were verified in their respective contexts, and it creates test cases that cover multiple time steps.

Owner:HONEYWELL INT INC

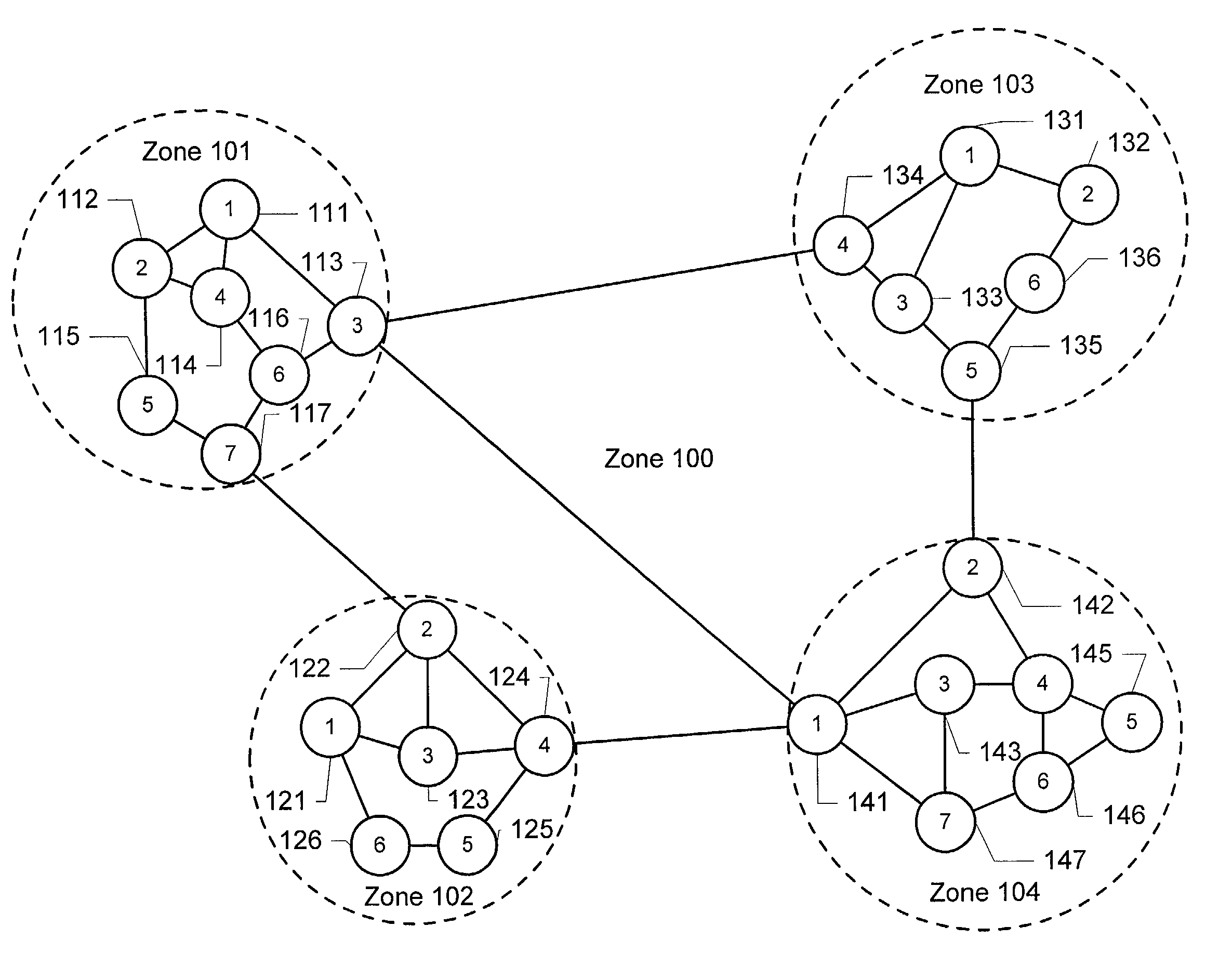

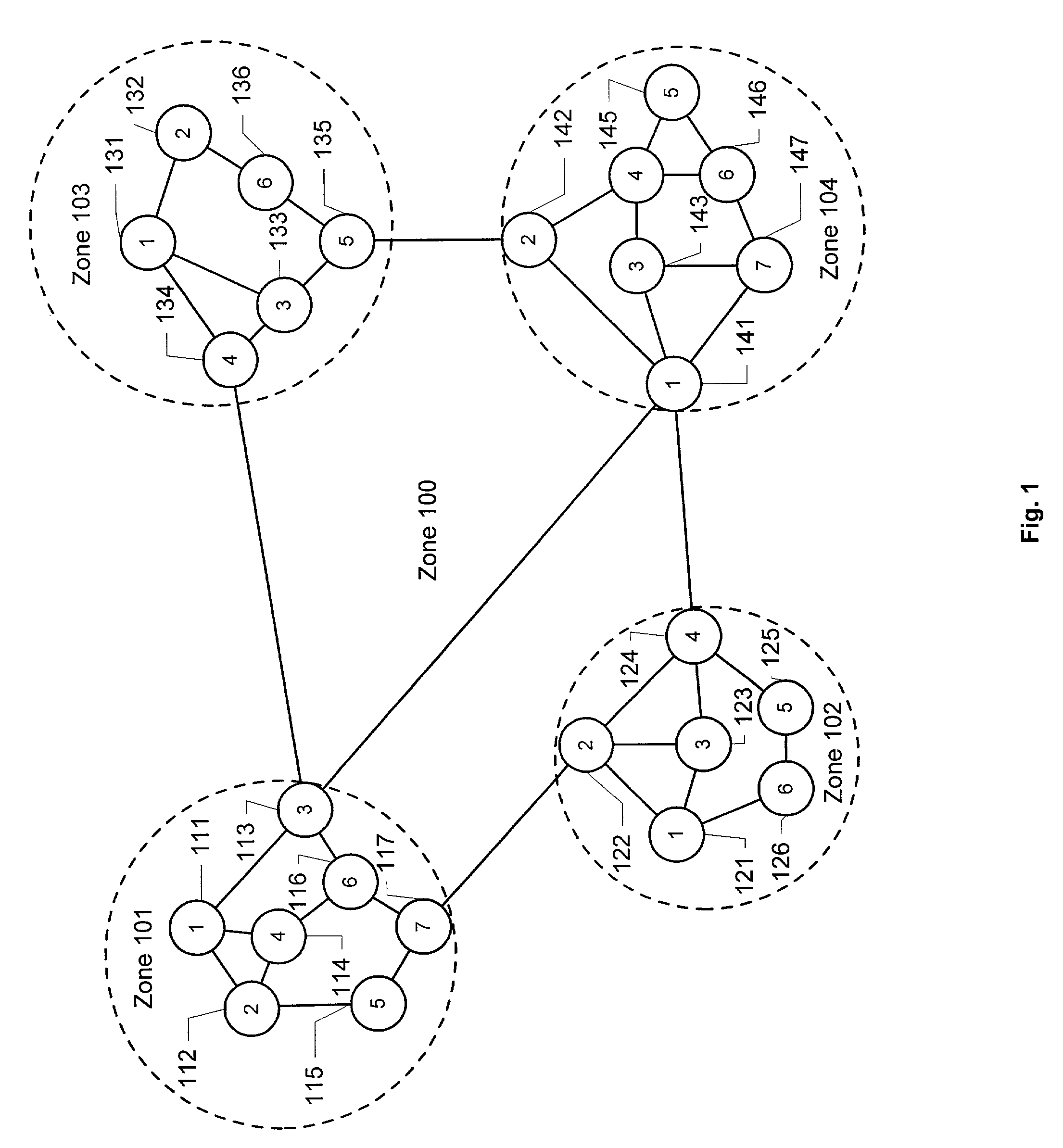

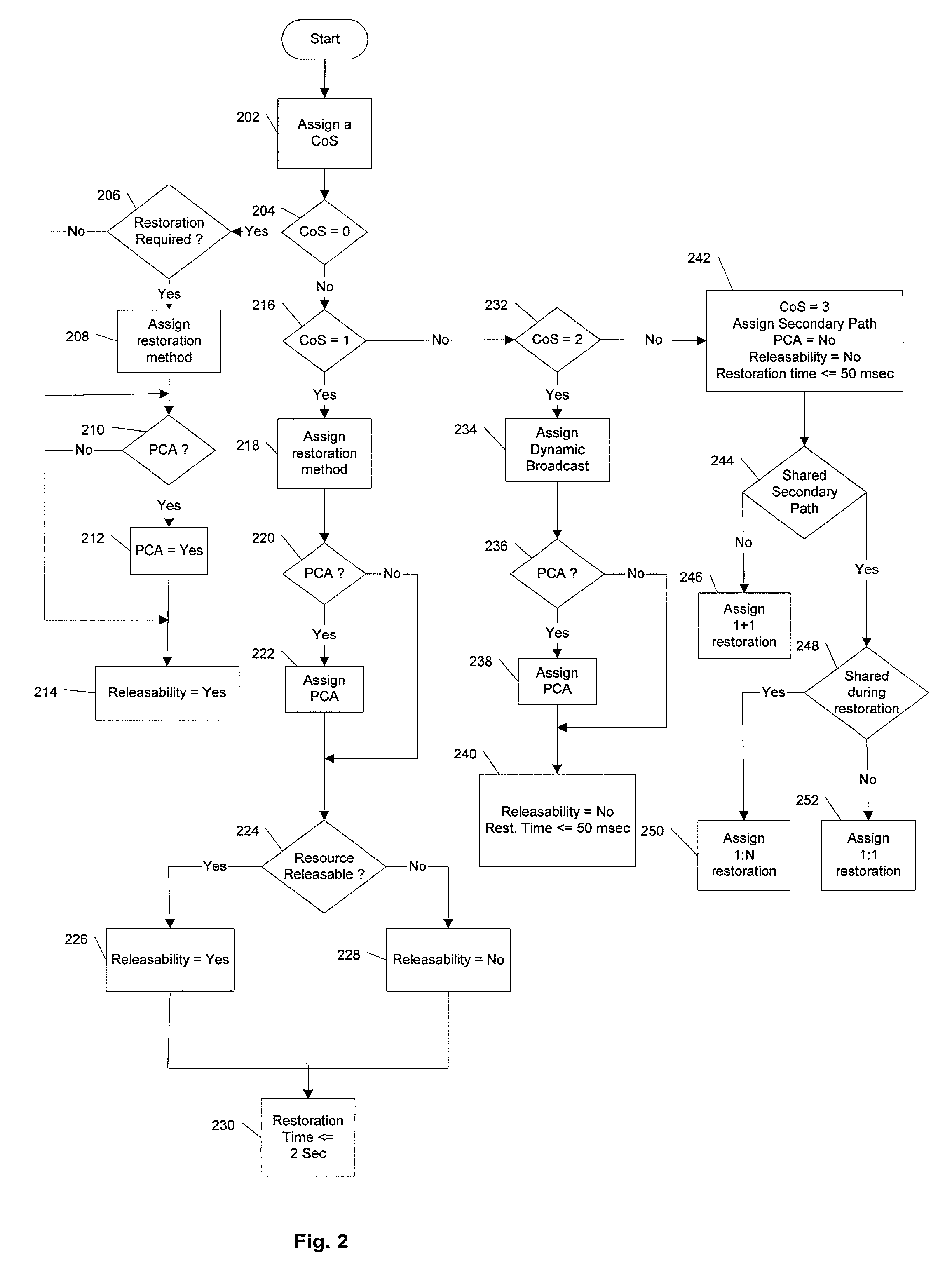

Resource reservation scheme for path restoration in an optical network

InactiveUS7352692B1Shorten the timeReduces resourceMultiplex system selection arrangementsError preventionClass of serviceDistributed computing

A method for reserving resources for restoration of a failed virtual path in a mesh optical network is defined. The method in one embodiment, defines multiple classes of service for the virtual path by allocating certain path performance, path implementation and path restoration related attributes to the virtual path. Each class of service defines the relative restoration priority of the virtual path. In a case of a path failure, the class of service is used by each node, to determine how the virtual path will be restored. The higher class of service guarantees a maximum acceptable restoration time during a path failure.

Owner:CISCO TECH INC

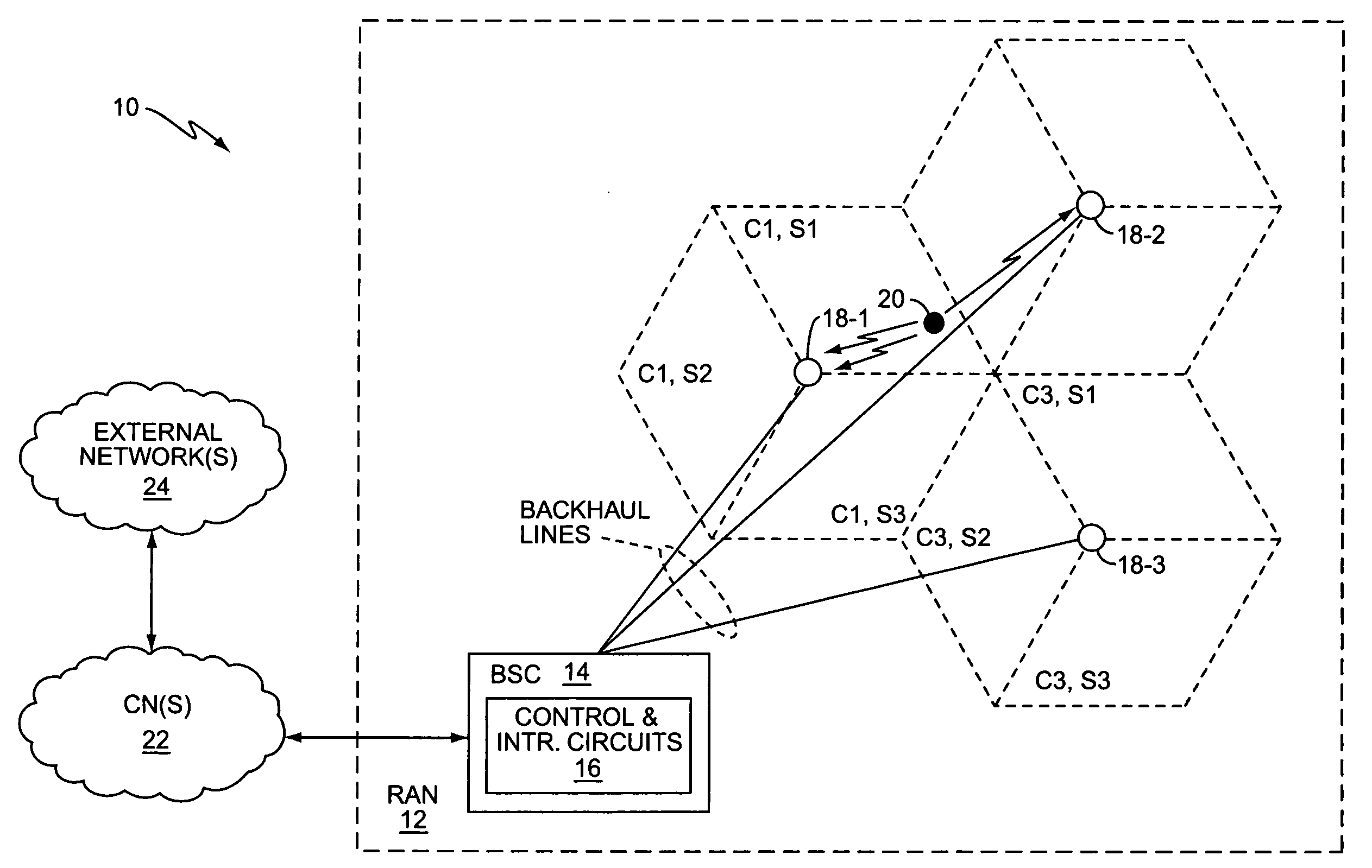

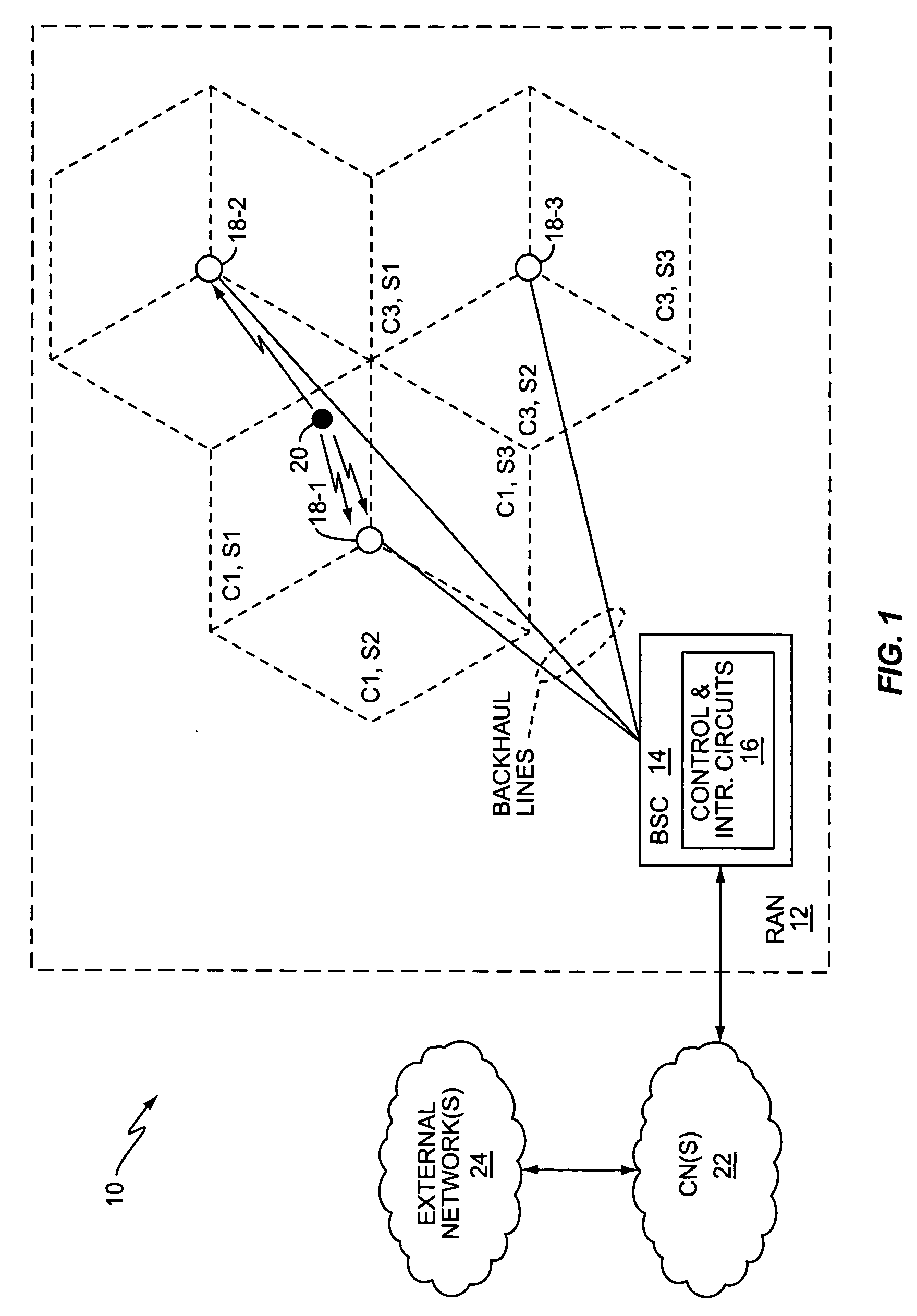

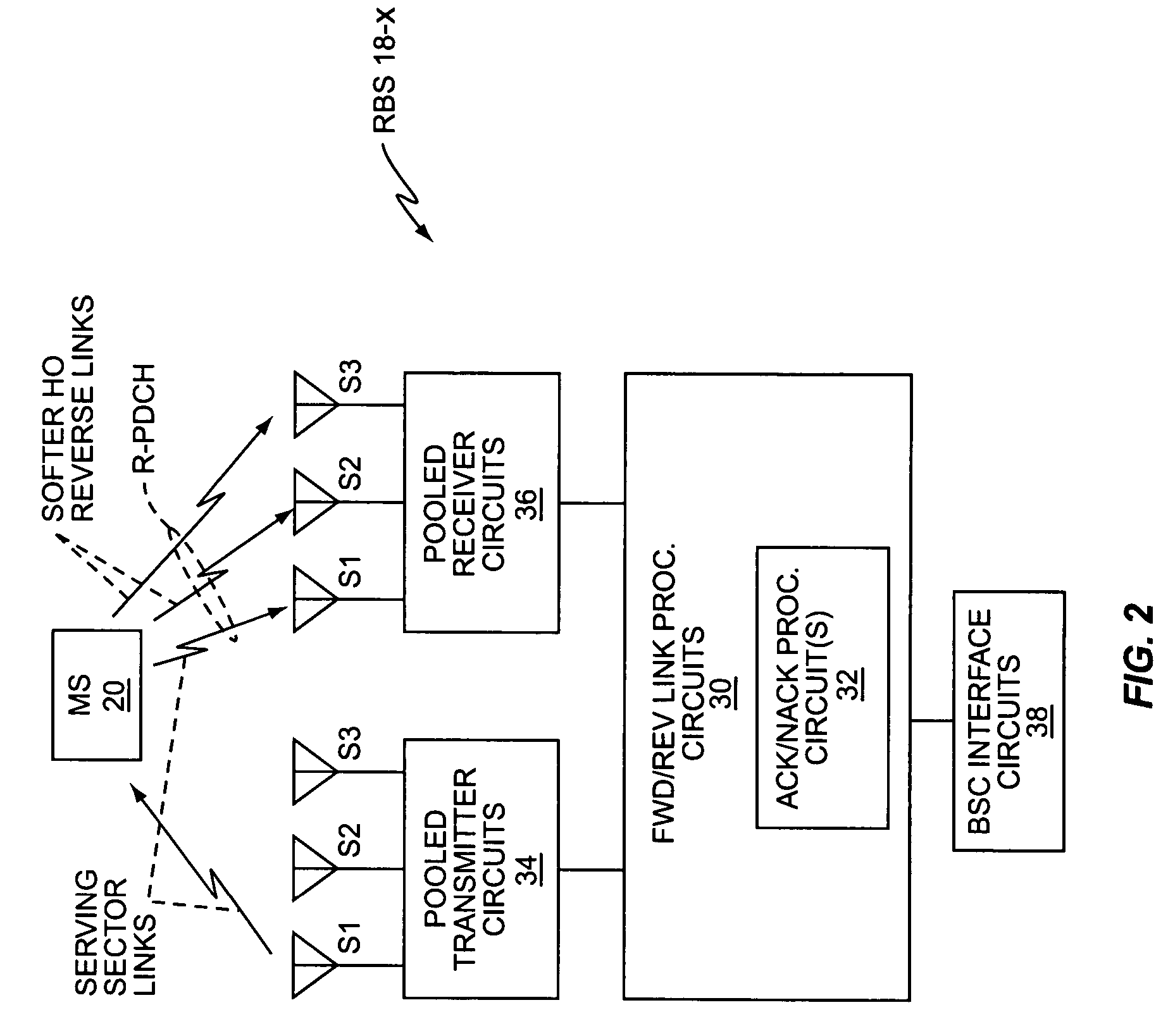

Method and apparatus for cell-site ARQ generation under softer handoff conditions

InactiveUS20050181834A1Improve reliabilityReduce power levelError prevention/detection by using return channelSubstation equipmentCell siteMobile station

A base station generates per-cell ACK / NACK responses rather than per-sector ACK / NACK responses. For a given mobile station signal received in softer handoff at two of the base station's sectors, the base station generates an ACK response if at least one of the soft handoff sectors correctly receives the signal, and otherwise generates a NACK response. Alternatively, the base station can combine the softer handoff signals and generate ACK / NACK responses based on whether the combined signal is correctly received. Since only one set of ACK / NACK responses are generated for all of the softer handoff sectors, the base station can use the forward link in just one softer handoff sector to send the ACK / NACK responses to the mobile station, consuming fewer forward link transmit resources at the base station. Or, the base station can send the same ACK / NACK responses from two or more softer handoff sectors, thus allowing diversity combining of the ACK / NACK responses at the mobile station.

Owner:TELEFON AB LM ERICSSON (PUBL)

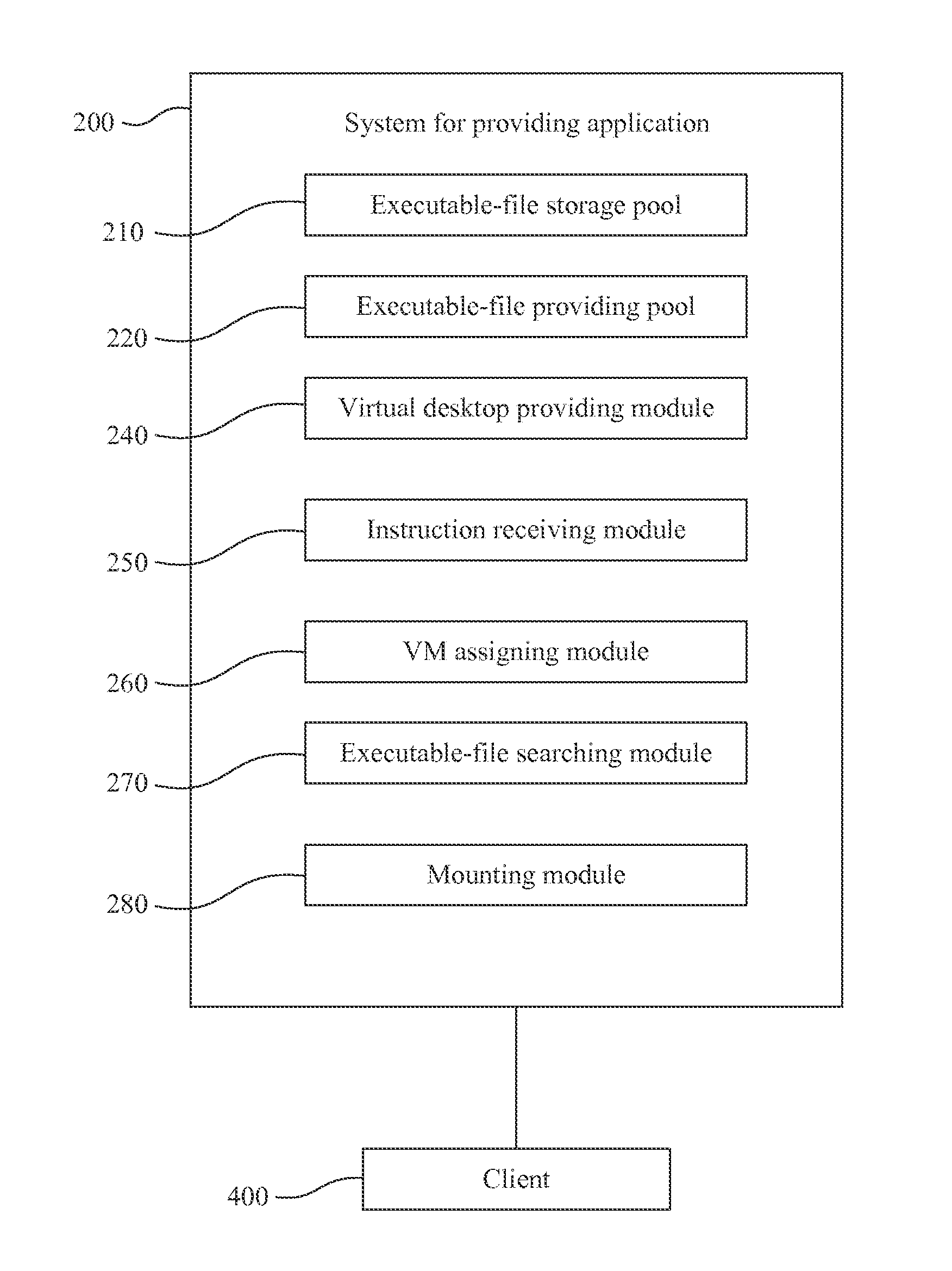

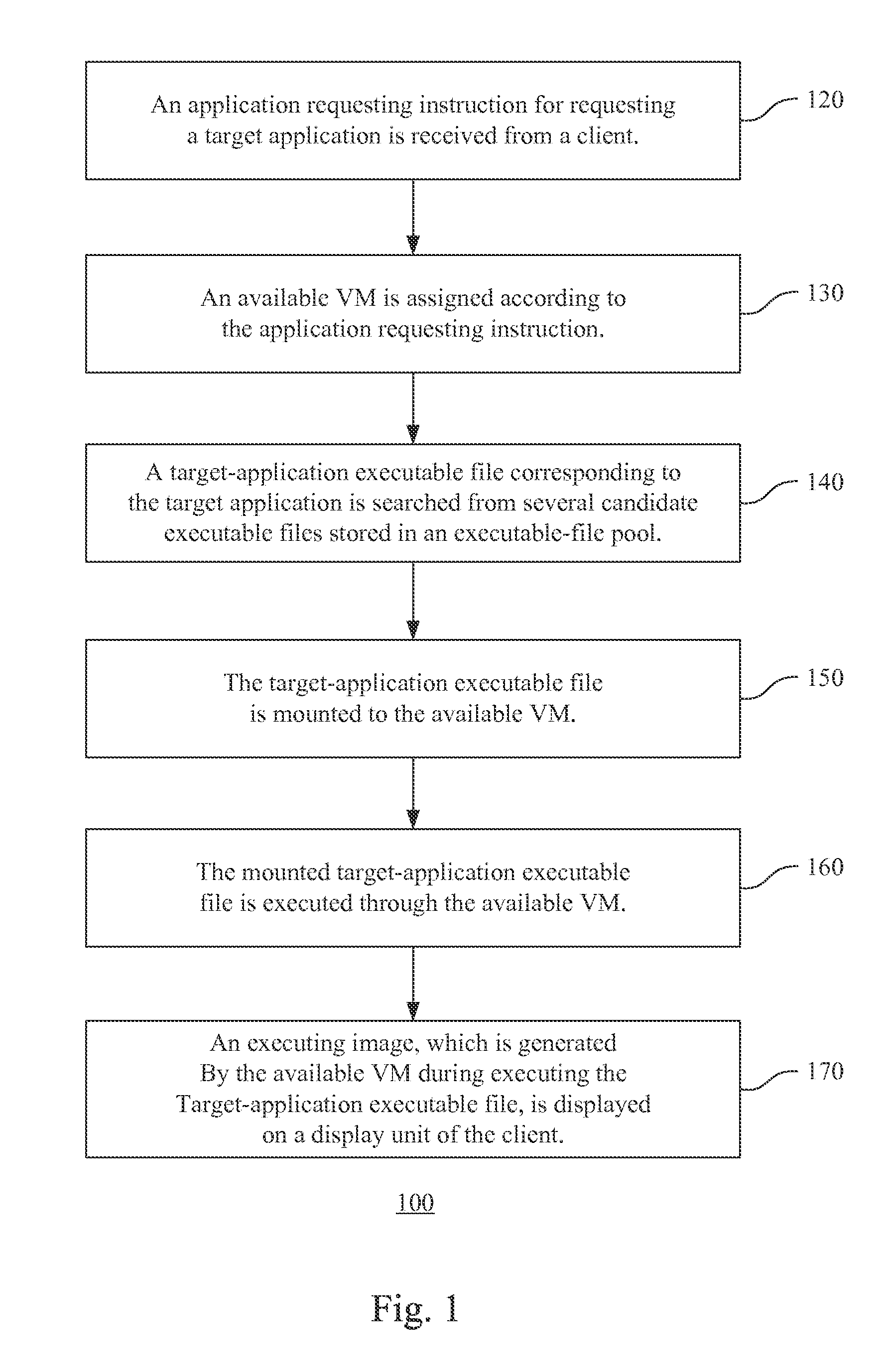

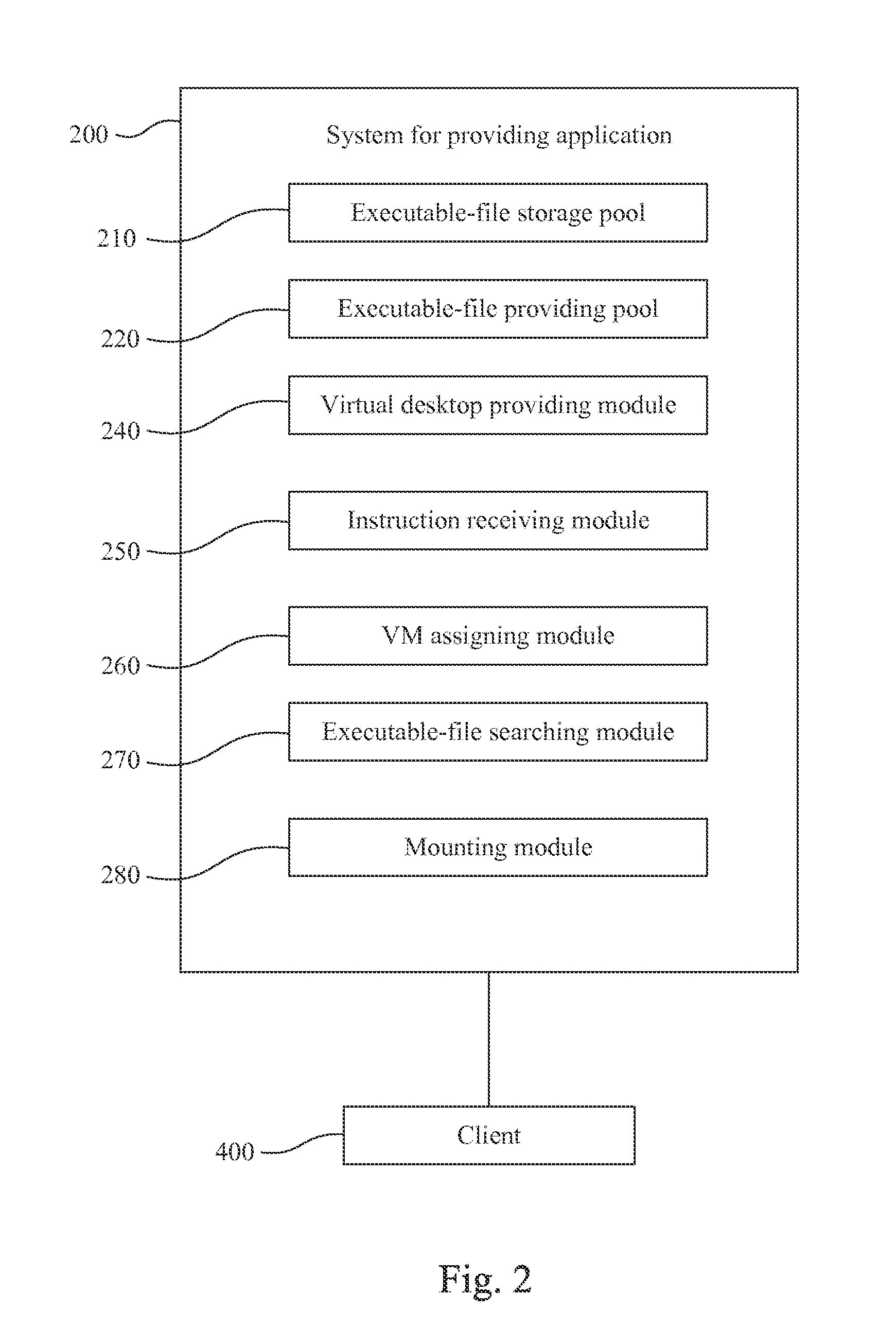

Method and System for Providing Application by Virtual Machine and Computer-Readable Storage Medium to Execute the Method

InactiveUS20130132953A1Reducing resourceShorten the timeSoftware simulation/interpretation/emulationMemory systemsClient-sideApplication software

In a method for providing an application by a virtual machine (VM), an application requesting instruction for requesting a target application is received from a client. An available VM is assigned according to the application requesting instruction. A target-application executable file corresponding to the target application is searched from several candidate executable files stored in an executable-file storage pool. The target-application executable file is mounted to the available VM. The mounted target-application executable file is executed through the available VM.

Owner:INSTITUTE FOR INFORMATION INDUSTRY

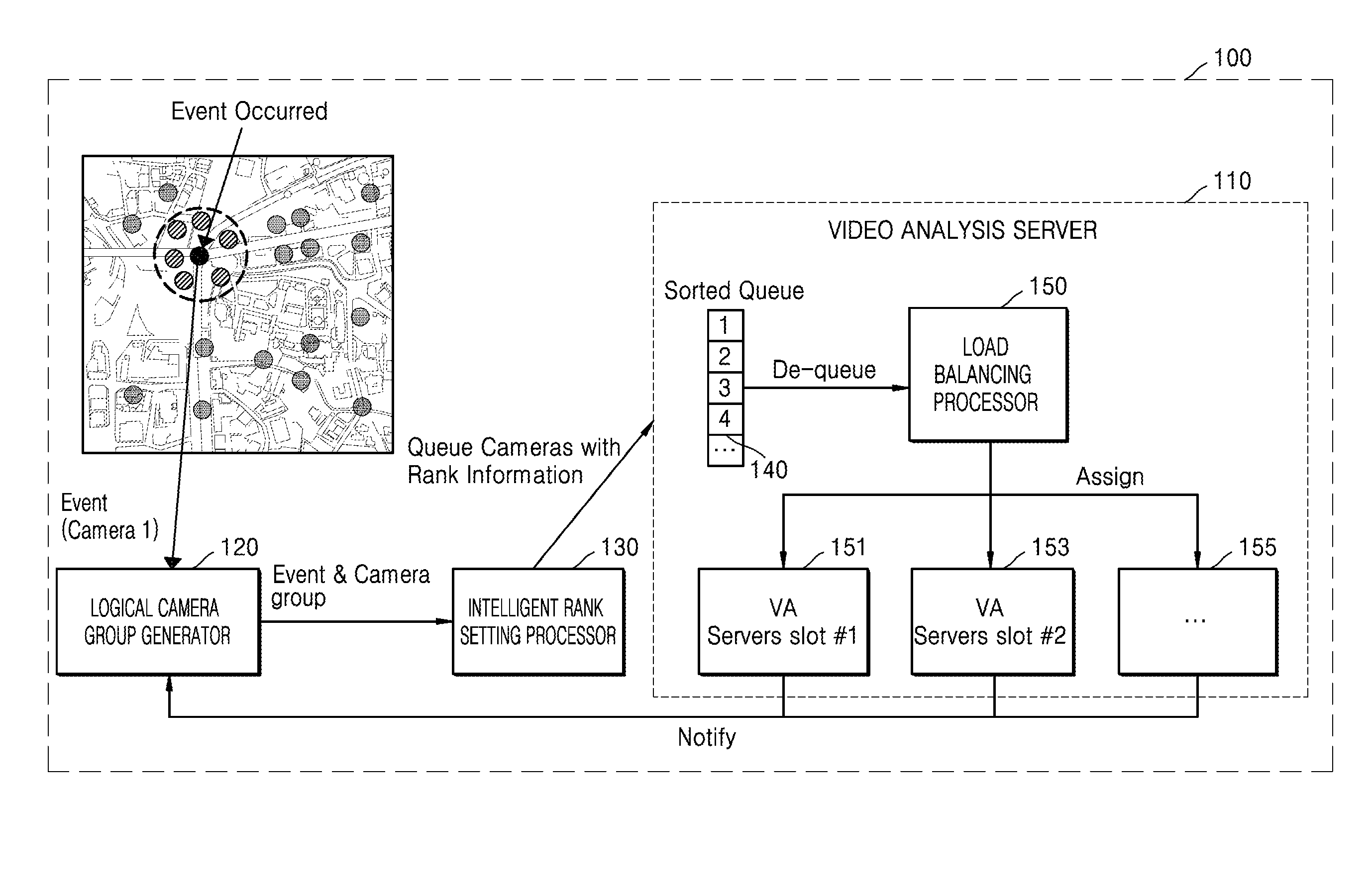

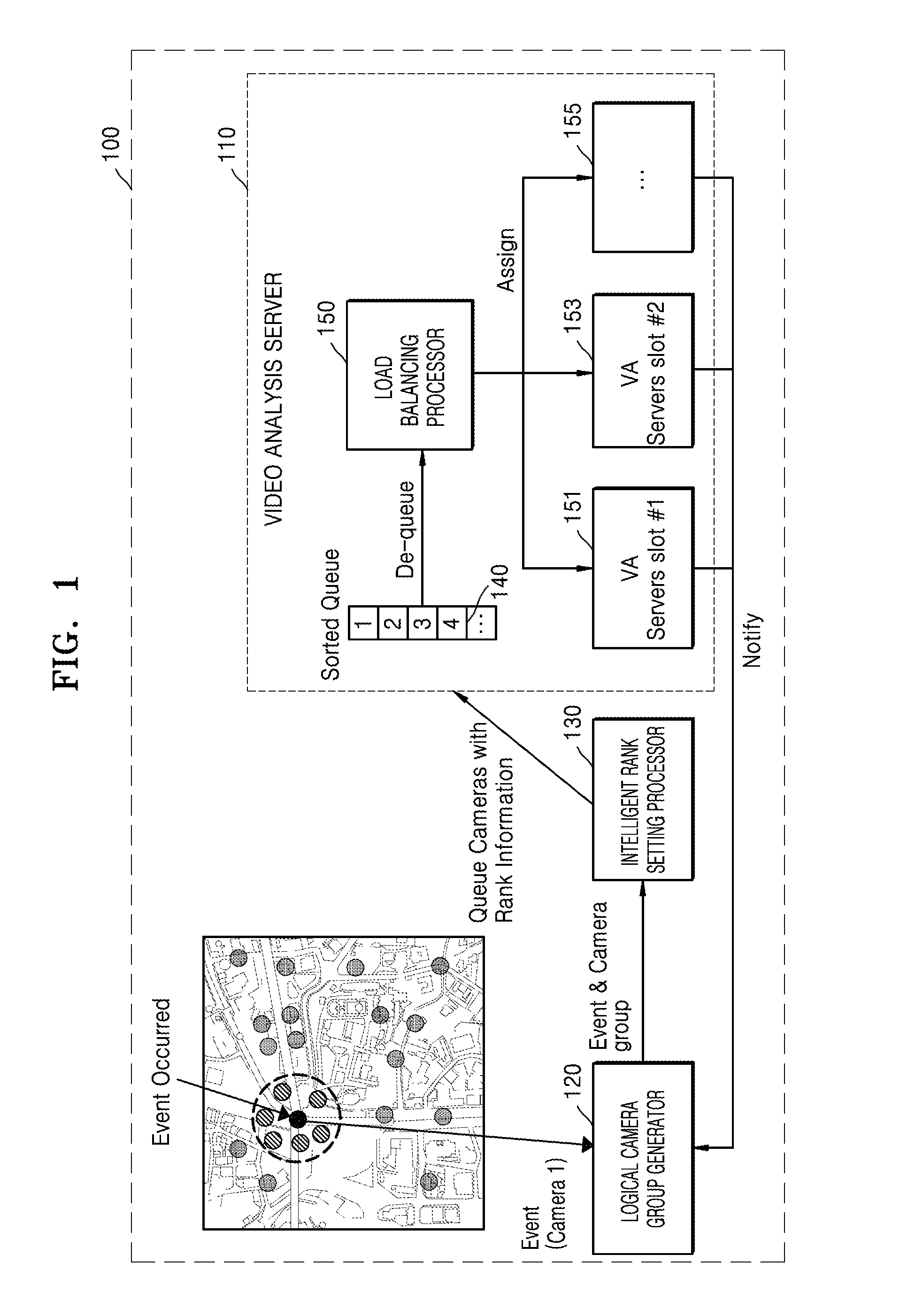

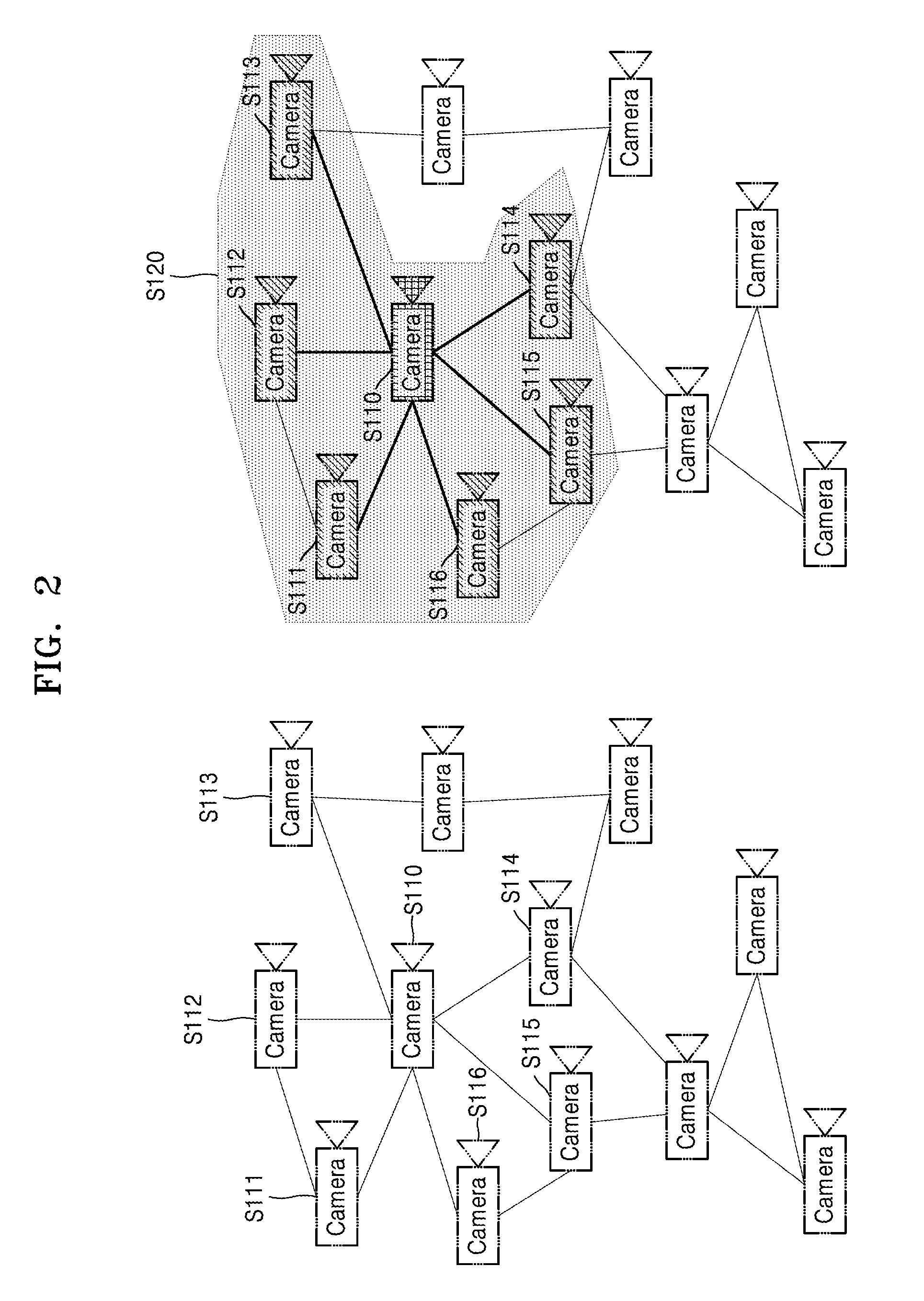

Intelligent video analysis system and method

ActiveUS20160050396A1Reducing resourceShorten the timeClosed circuit television systemsBurglar alarmSurveillance cameraAnalysis method

An intelligent video analysis method and system logically selects only surveillance cameras associated with an event and assigns different ranks to the selected surveillance cameras according to the importance thereof. Thereafter, more video analysis resources are assigned to a surveillance camera of high importance, thereby rapidly and efficiently performing video analysis.

Owner:HANWHA VISION CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com