Patents

Literature

87 results about "Process dimension" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process Dimension. The Process Dimension action helps bring a cube to a fully processed state. This action helps prepare a test by ensuring it is only testing against an updated dimension. Once the editor has loaded, the user will need to input the following properties:

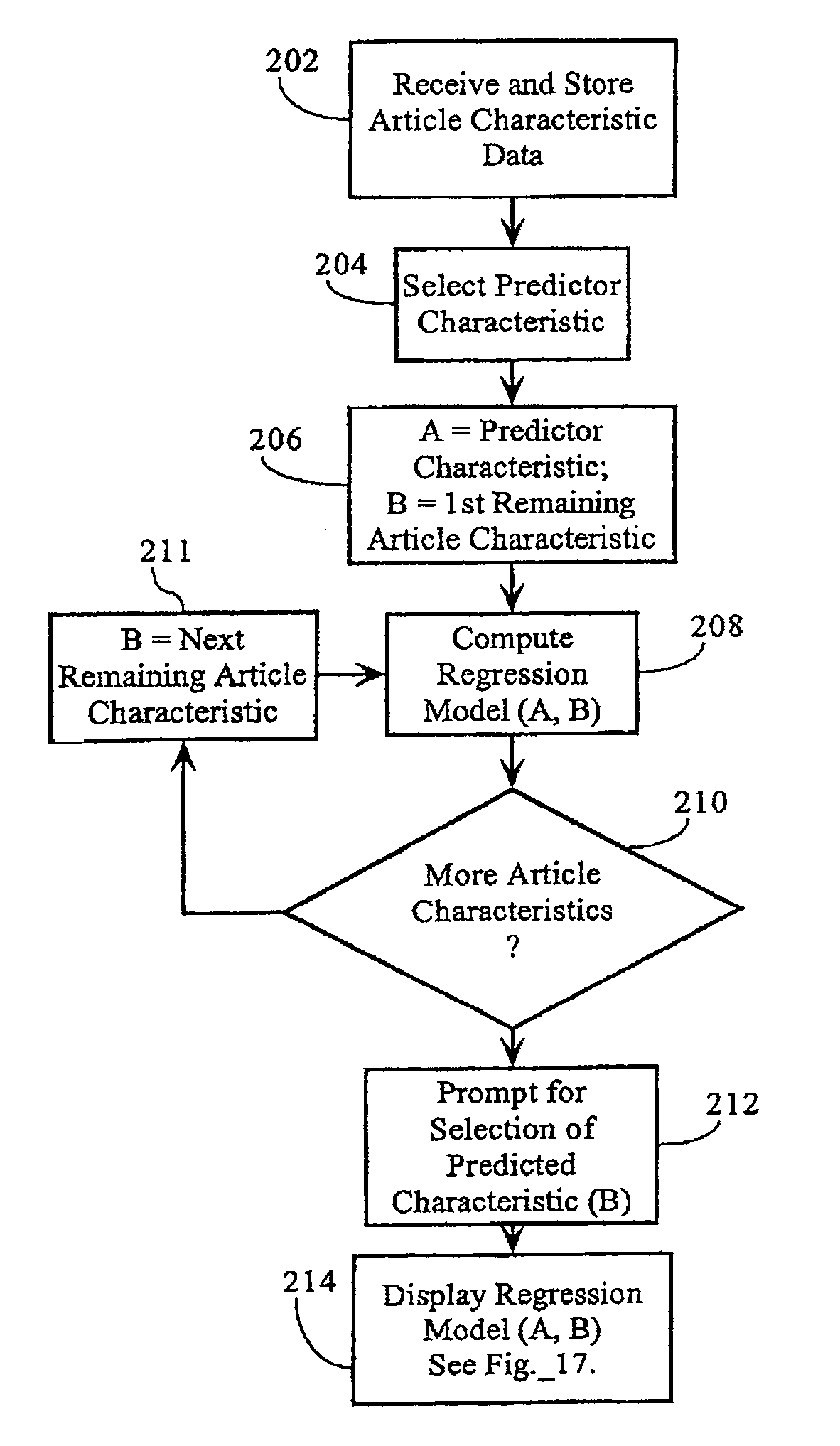

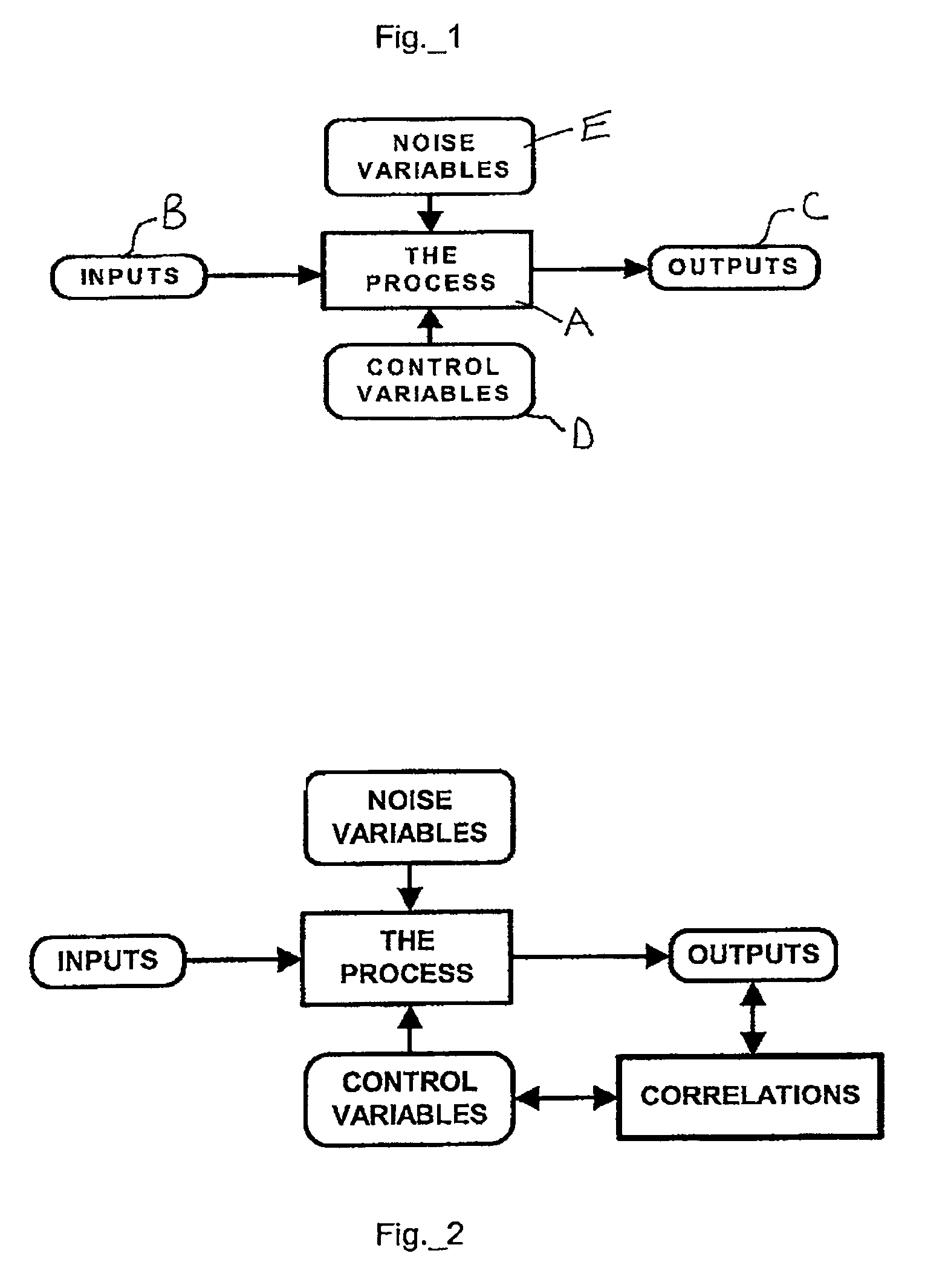

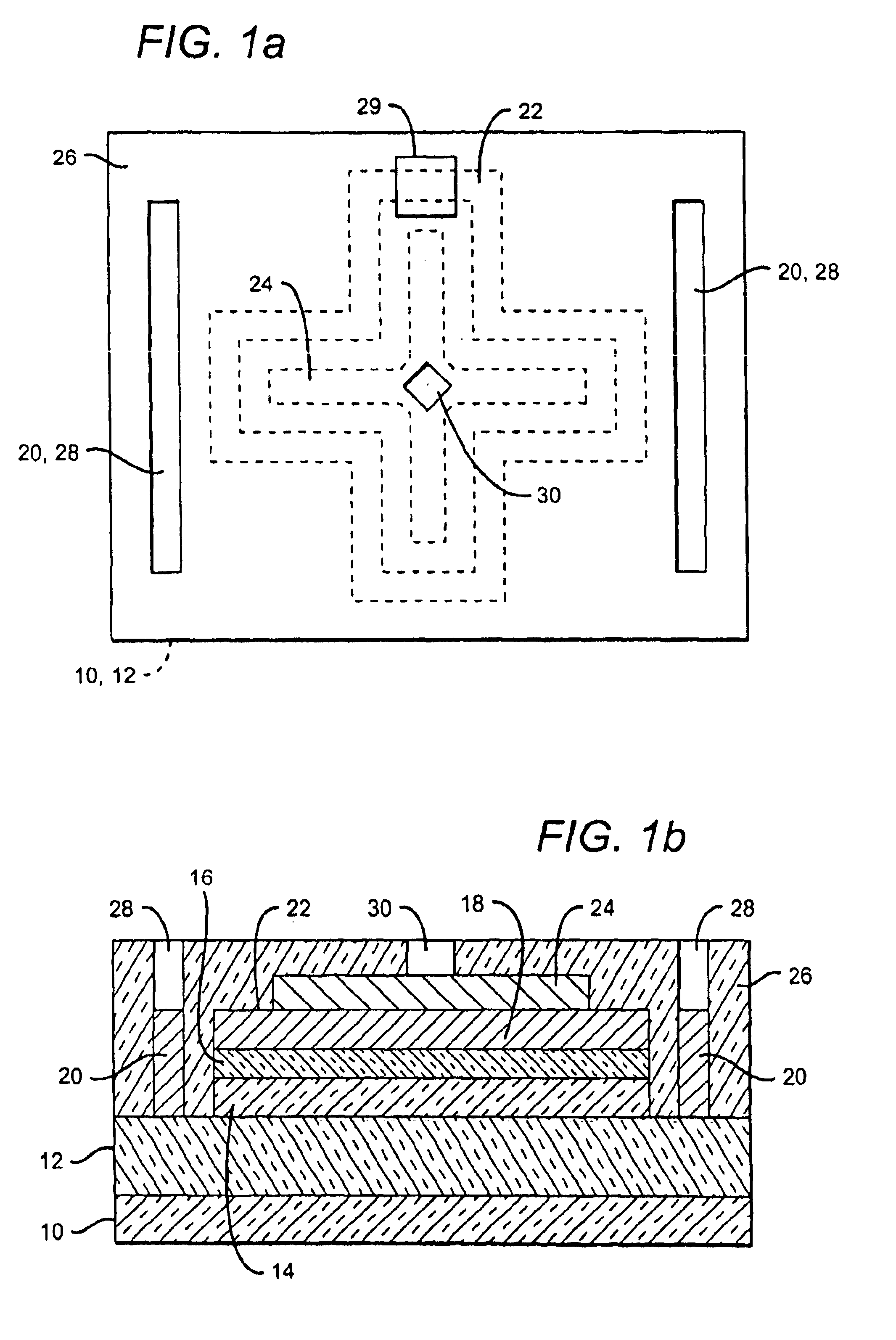

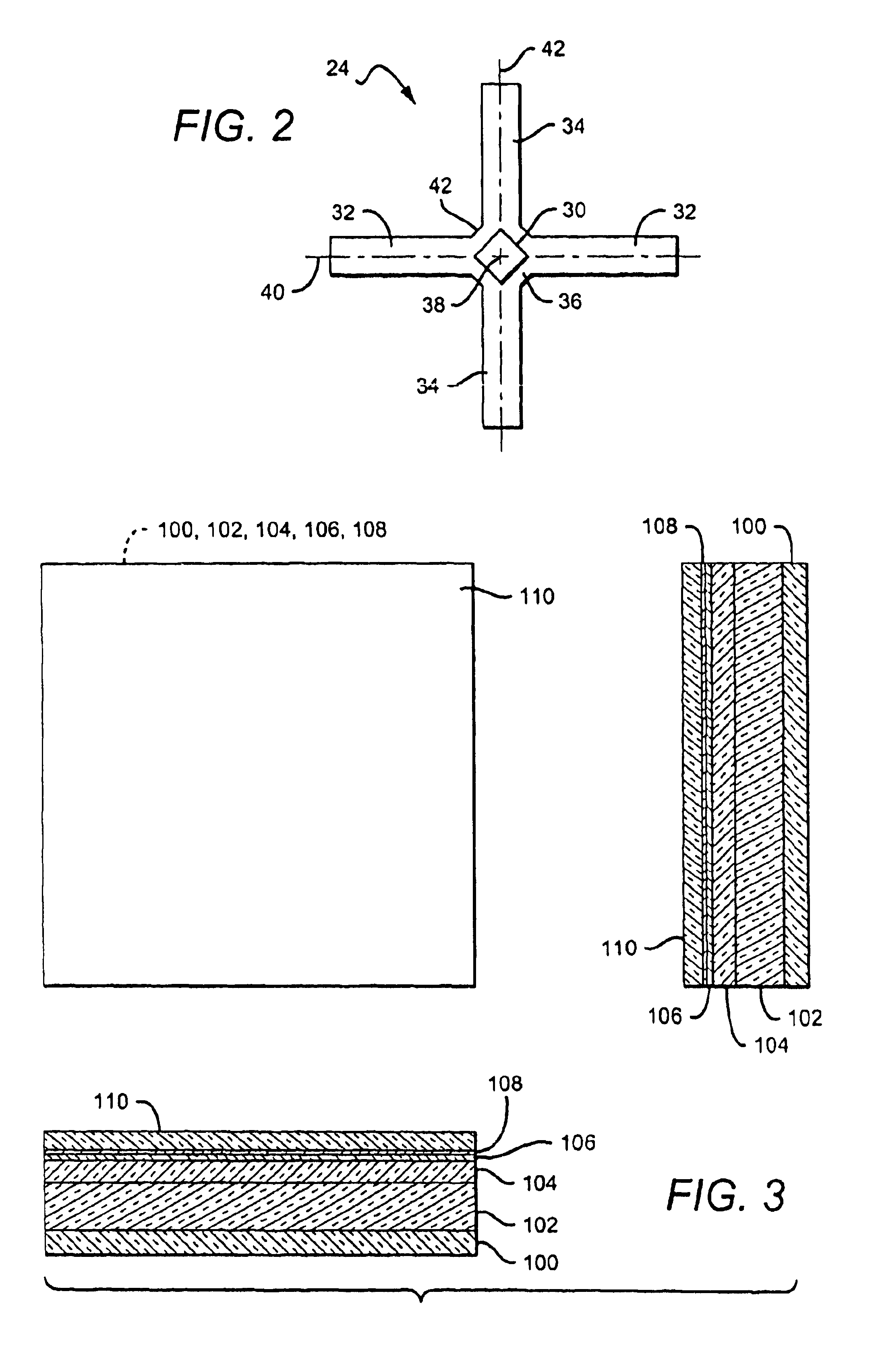

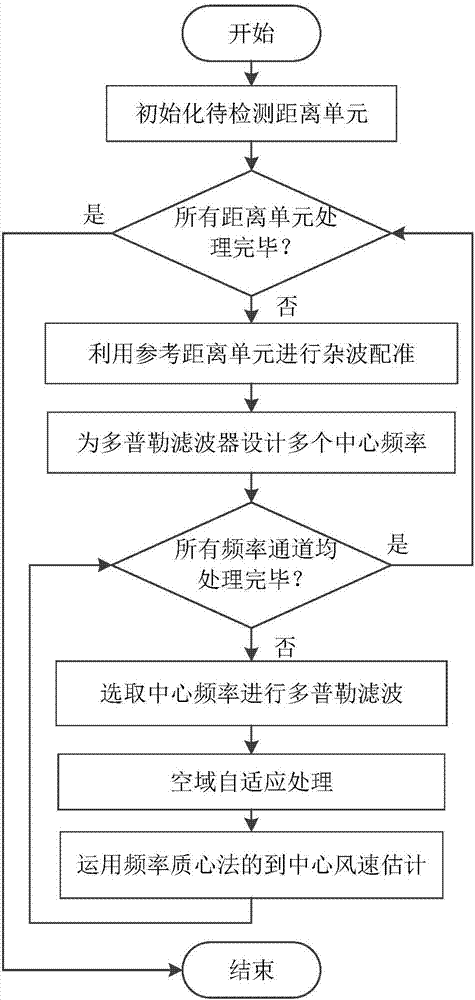

Manufacturing design and process analysis and simulation system

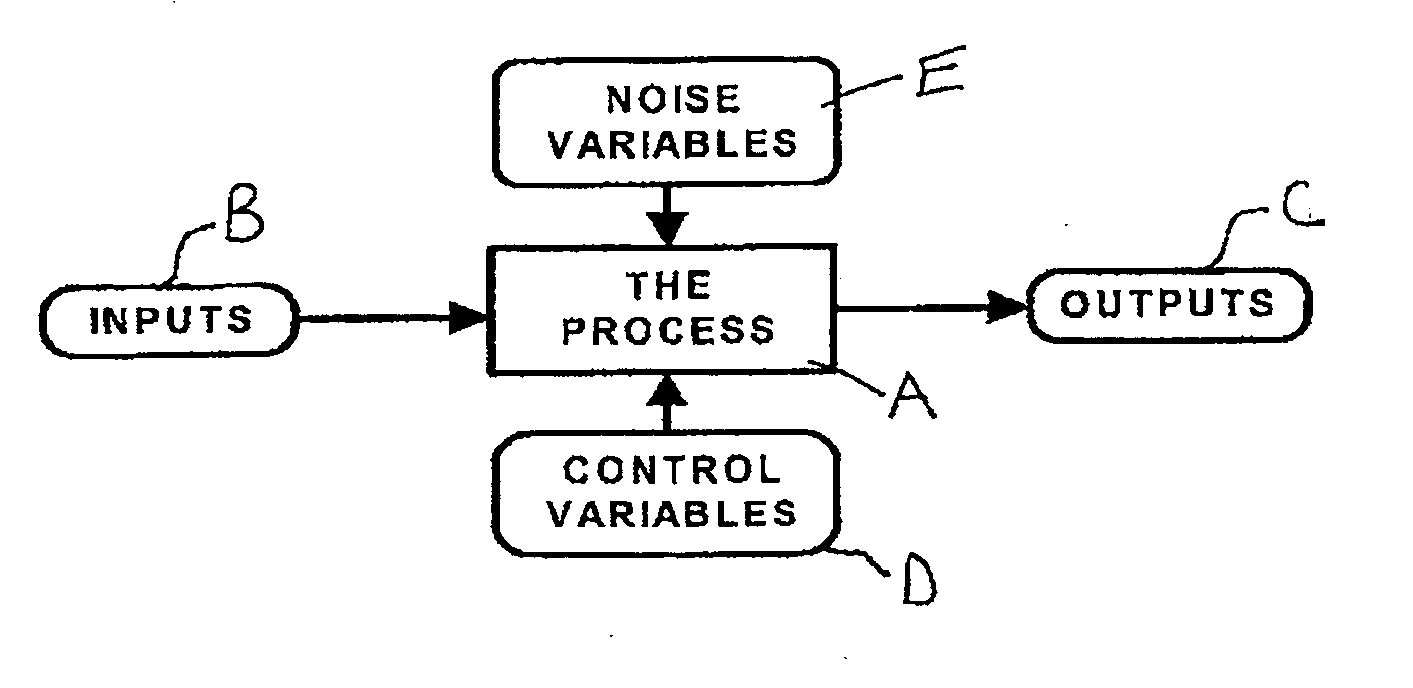

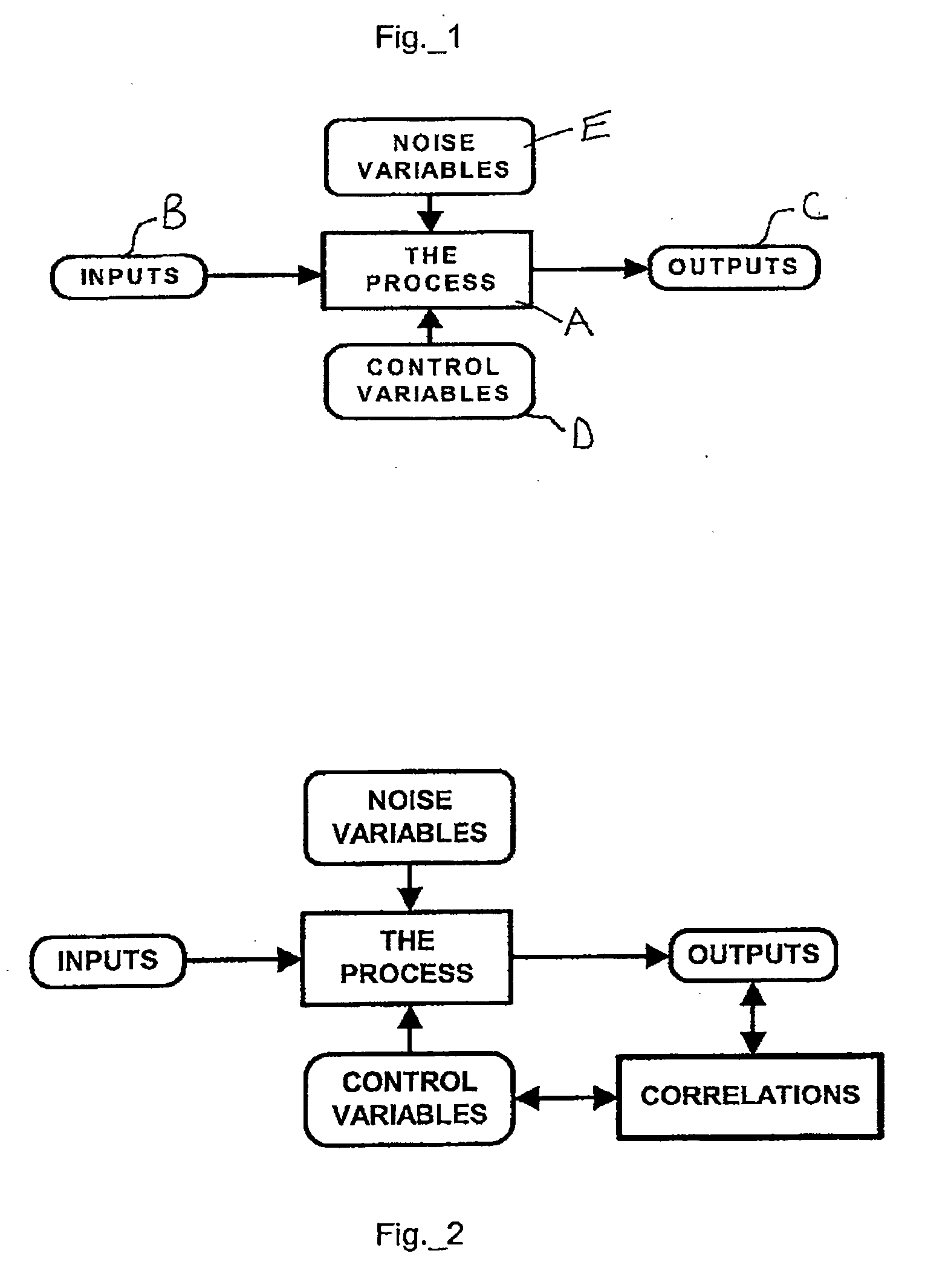

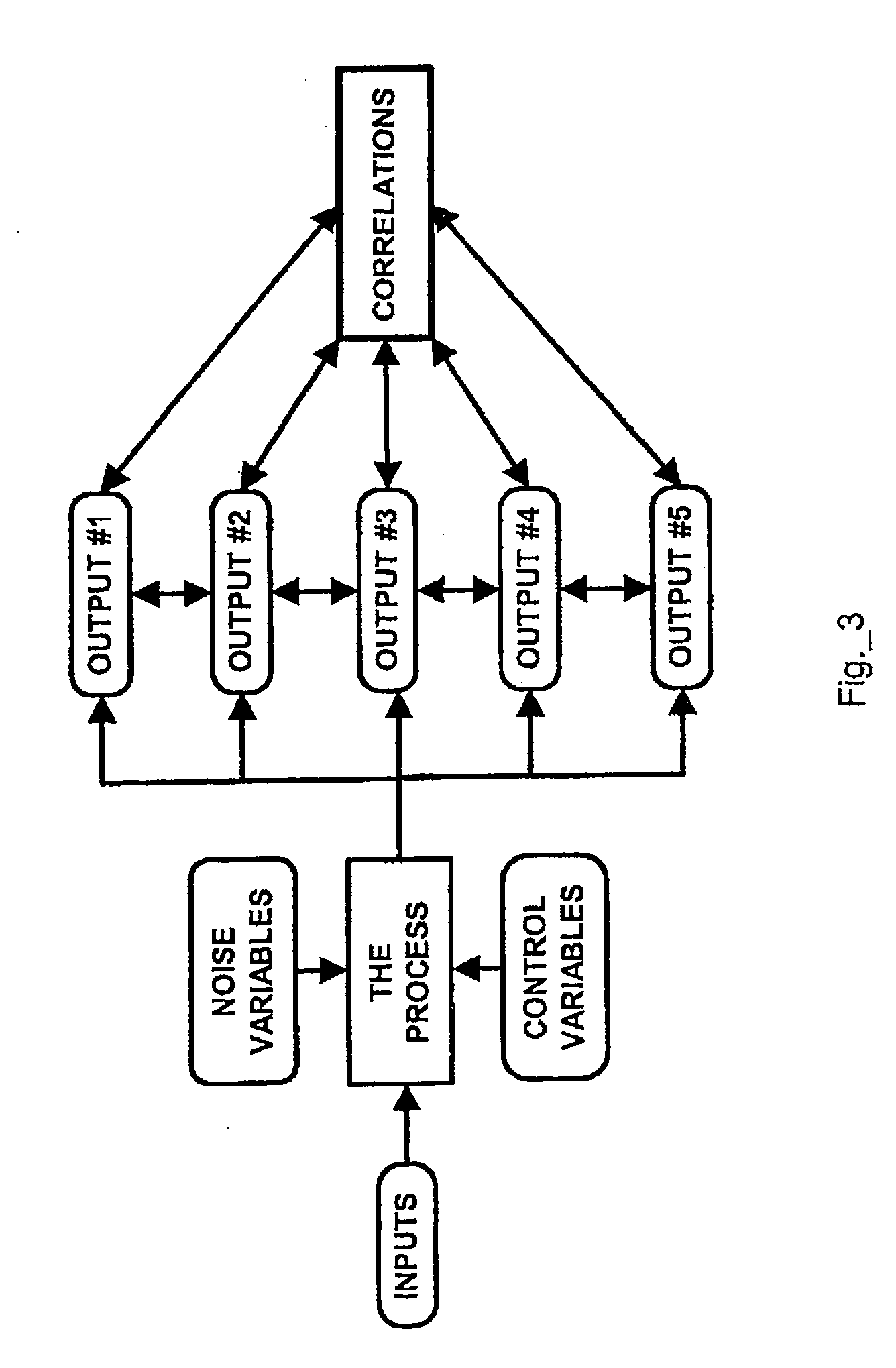

InactiveUS20050055110A1Simple designPromote productionSimulator controlElectric controllersProcess dimensionProcess simulation

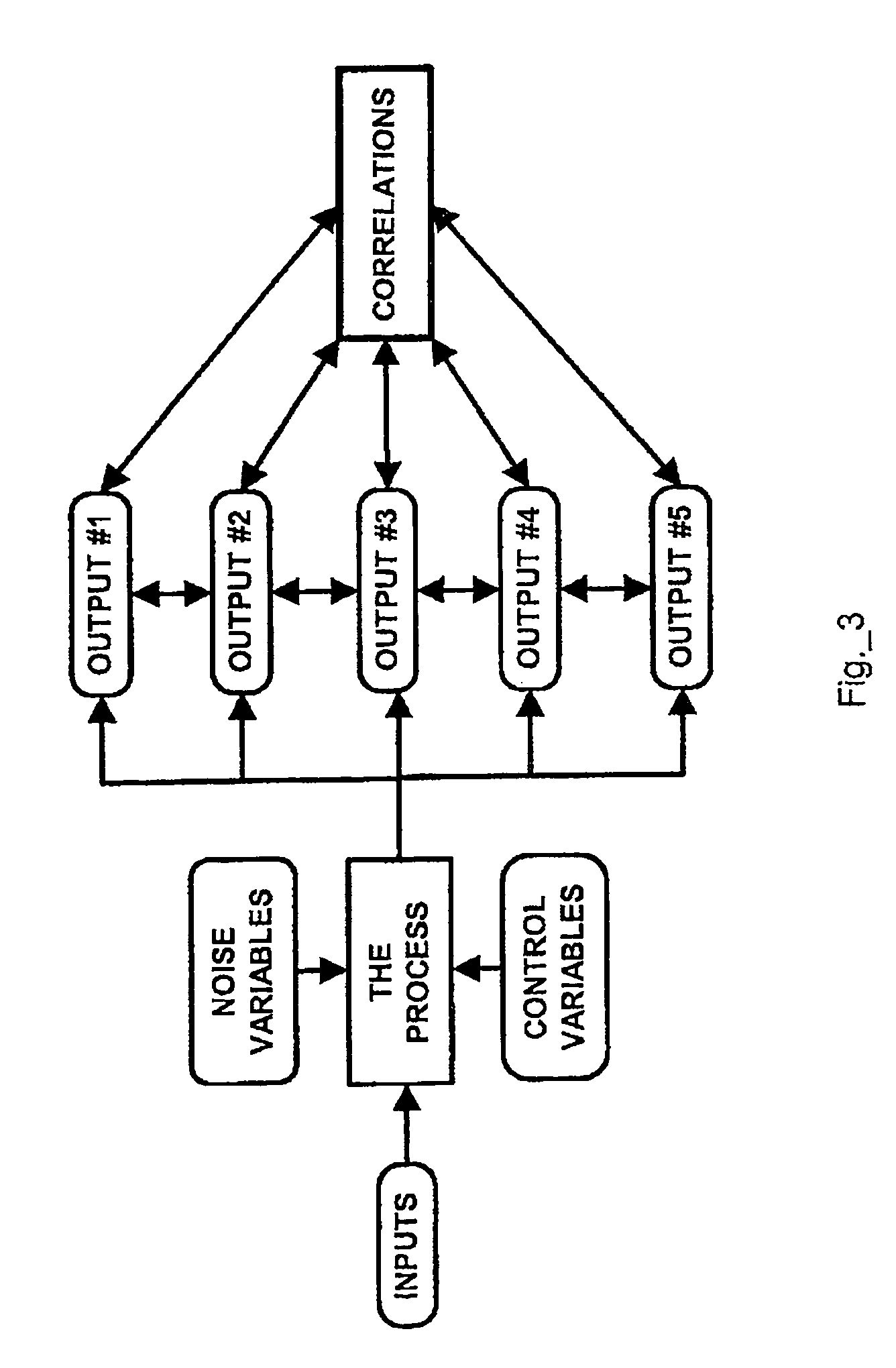

A process simulation system that simulates the operation of the manufacturing and measurement systems used to produce and measure the articles being analyzed relative to engineering design targets, engineering design tolerances, producibility and / or quality. In one embodiment, the user is able to assess, without risk or production cost while accelerating speed-to-market, the effect of contemplated changes (i.) to engineering design targets, (ii.) to engineering design tolerances, (iii.) to tooling, (iv.) to part pre-process dimensions and (v.) to the measurement system—on manufactured part dimensions, producibility and quality (i.) without modifying tooling, (ii.) without changing part pre-process dimensions, (iii.) without producing new parts, (iv.) without measuring article characteristics on the new parts and (v.) without changing the measurement system. The simulation functionalities, according to embodiments of the present invention, enable the user to verify whether or not the contemplated changes will have the desired effect without incurring the time and expense involved in actually making the changes, producing parts, measuring part characteristics, changing the measurement system and then determining whether the changes accomplished the desired objectives.

Owner:TUSZYNSKI STEVE W

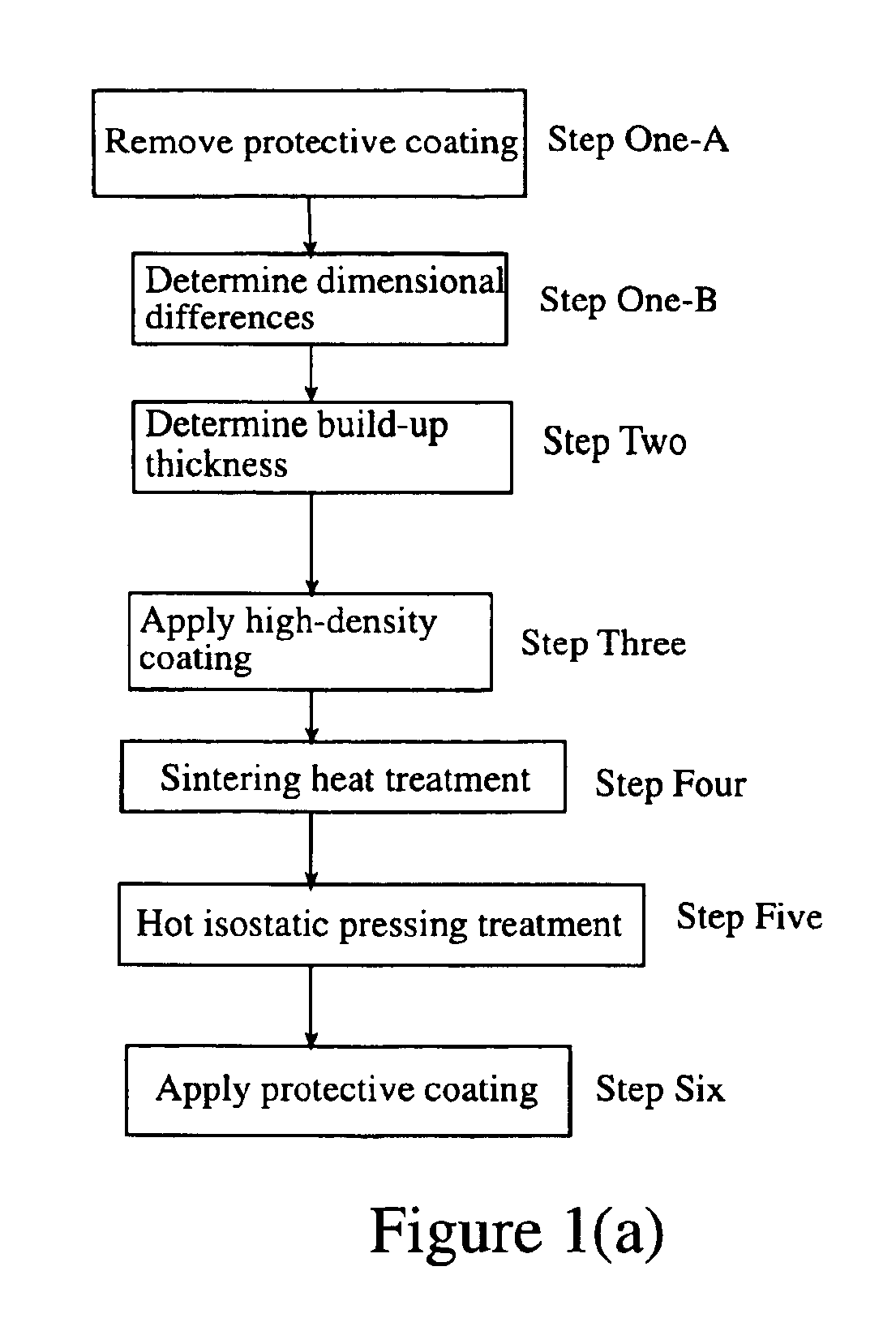

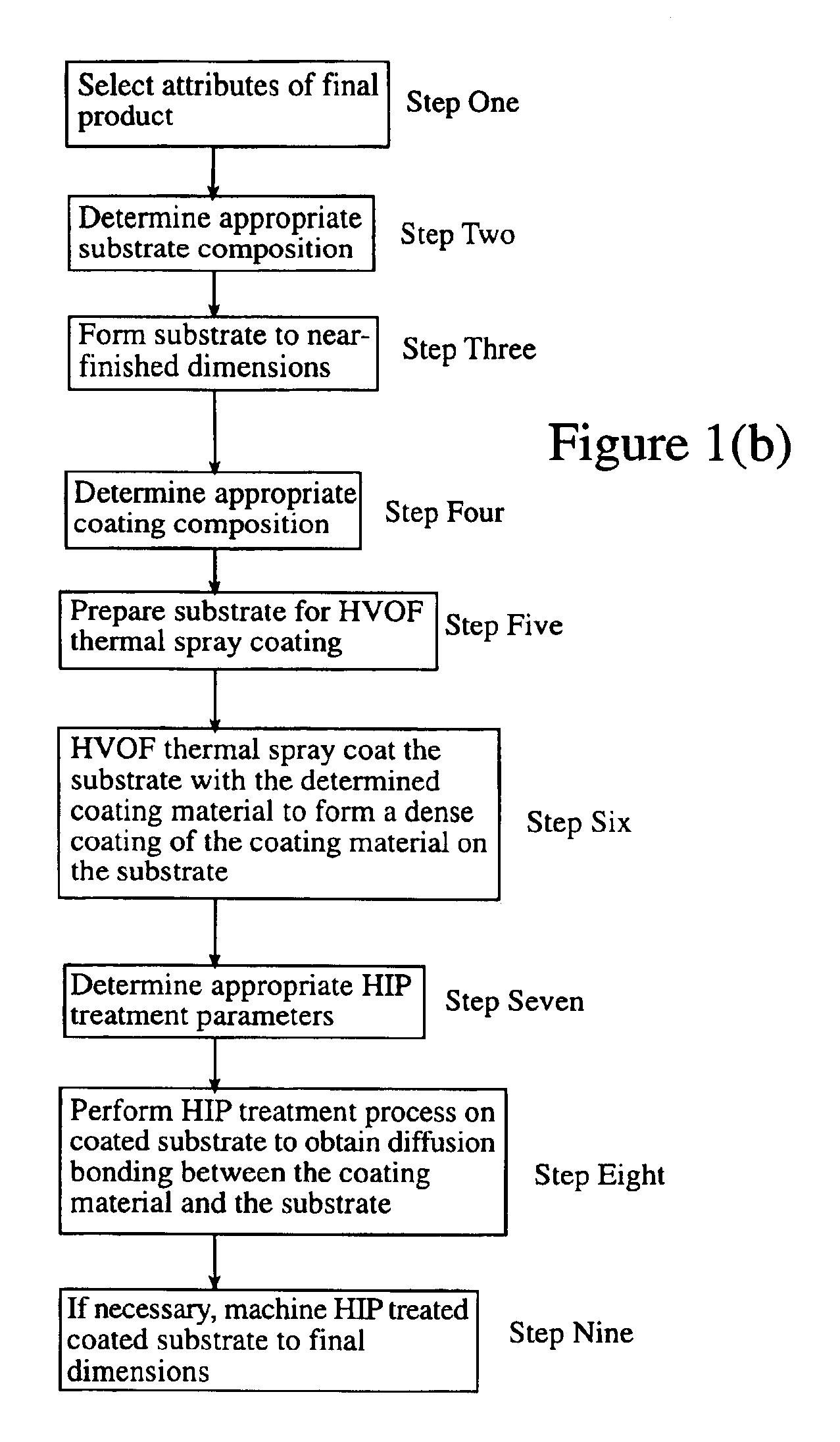

Methods for forming metal parts having superior surface characteristics

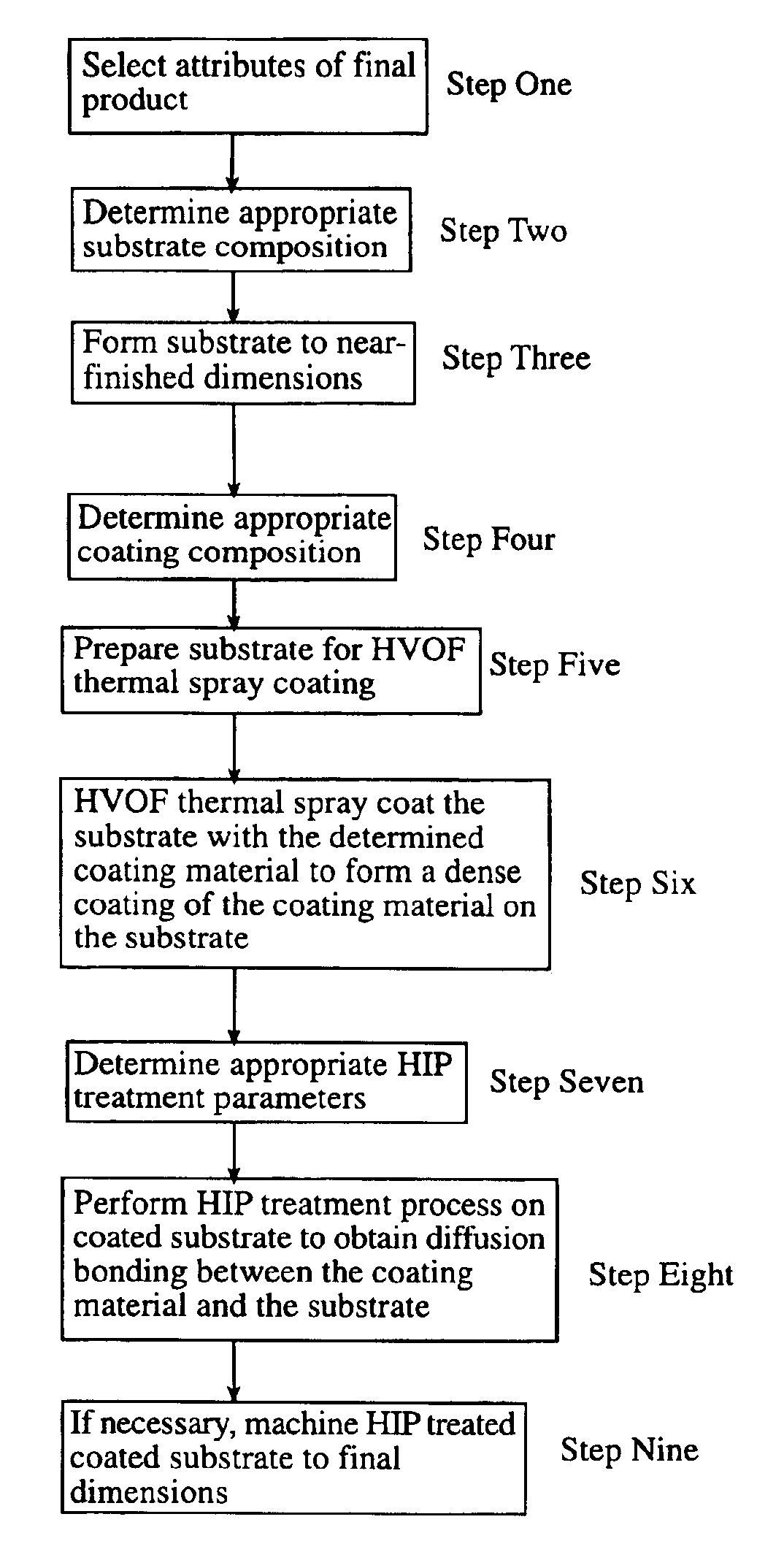

InactiveUS7043819B1Improve surface propertiesOvercomes drawbackMolten spray coatingMetal rolling stand detailsHigh densityMetal alloy

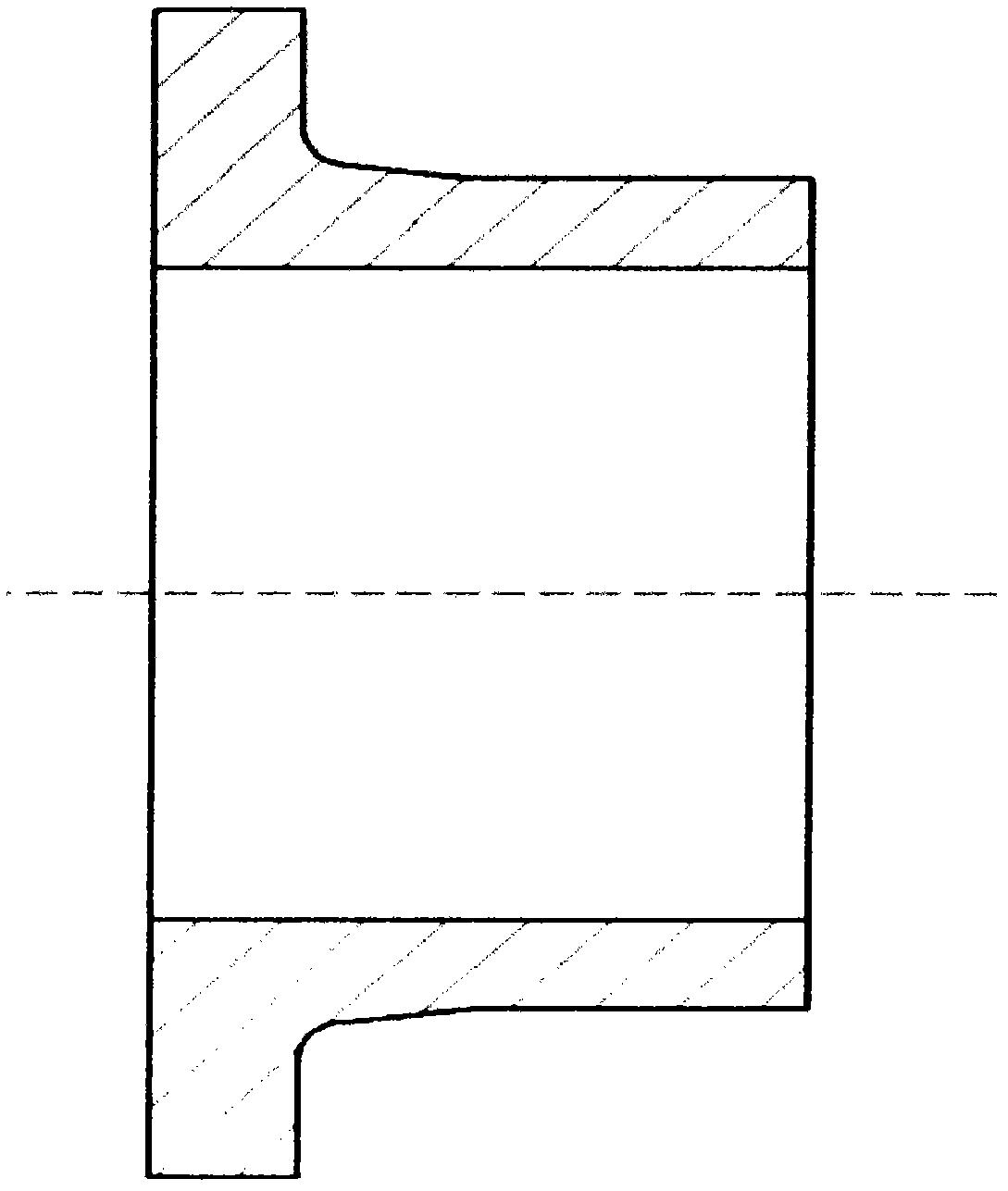

A method of forming a metal product. A metal alloy workpiece substrate is provided have pre-process dimensions. The dimensional differences are determined between the pre-process dimensions of the workpiece substrate and desired post-process dimensions of a post-process metal product formed from the workpiece substrate. A build-up thickness is determined of coating material required to obtain the desired post-process dimensions of the post-process metal product. A high-density coating process is performed to coat the workpiece substrate with a coating material to build-up a thickness of coating material effective to obtain desired finished dimensions after performing a sintering heat treatment process and / or a hot isostatic pressing treatment. The sintering heat treatment is performed on the coated workpiece substrate to densify the coating material. Then, the hot isostatic pressing treatment is performed to obtain the post-process metal product having the desired post-process dimensions and having diffusion bonding between the coating material and the workpiece substrate.

Owner:RECAST AIRFOIL GROUP

Manufacturing design and process analysis and simulation system

InactiveUS7239991B2Facilitate design and production and measurement taskReduce analysisSimulator controlElectric controllersProcess dimensionProcess simulation

A process simulation system that simulates the operation of the manufacturing and measurement systems used to produce and measure the articles being analyzed relative to engineering design targets, engineering design tolerances, producibility and / or quality. In one embodiment, the user is able to assess, without risk or production cost while accelerating speed-to-market, the effect of contemplated changes (i.) to engineering design targets, (ii.) to engineering design tolerances, (iii.) to tooling, (iv.) to part pre-process dimensions and (v.) to the measurement system—on manufactured part dimensions, producibility and quality (i.) without modifying tooling, (ii.) without changing part pre-process dimensions, (iii.) without producing new parts, (iv.) without measuring article characteristics on the new parts and (v.) without changing the measurement system. The simulation functionalities, according to embodiments of the present invention, enable the user to verify whether or not the contemplated changes will have the desired effect without incurring the time and expense involved in actually making the changes, producing parts, measuring part characteristics, changing the measurement system and then determining whether the changes accomplished the desired objectives.

Owner:TUSZYNSKI STEVE W

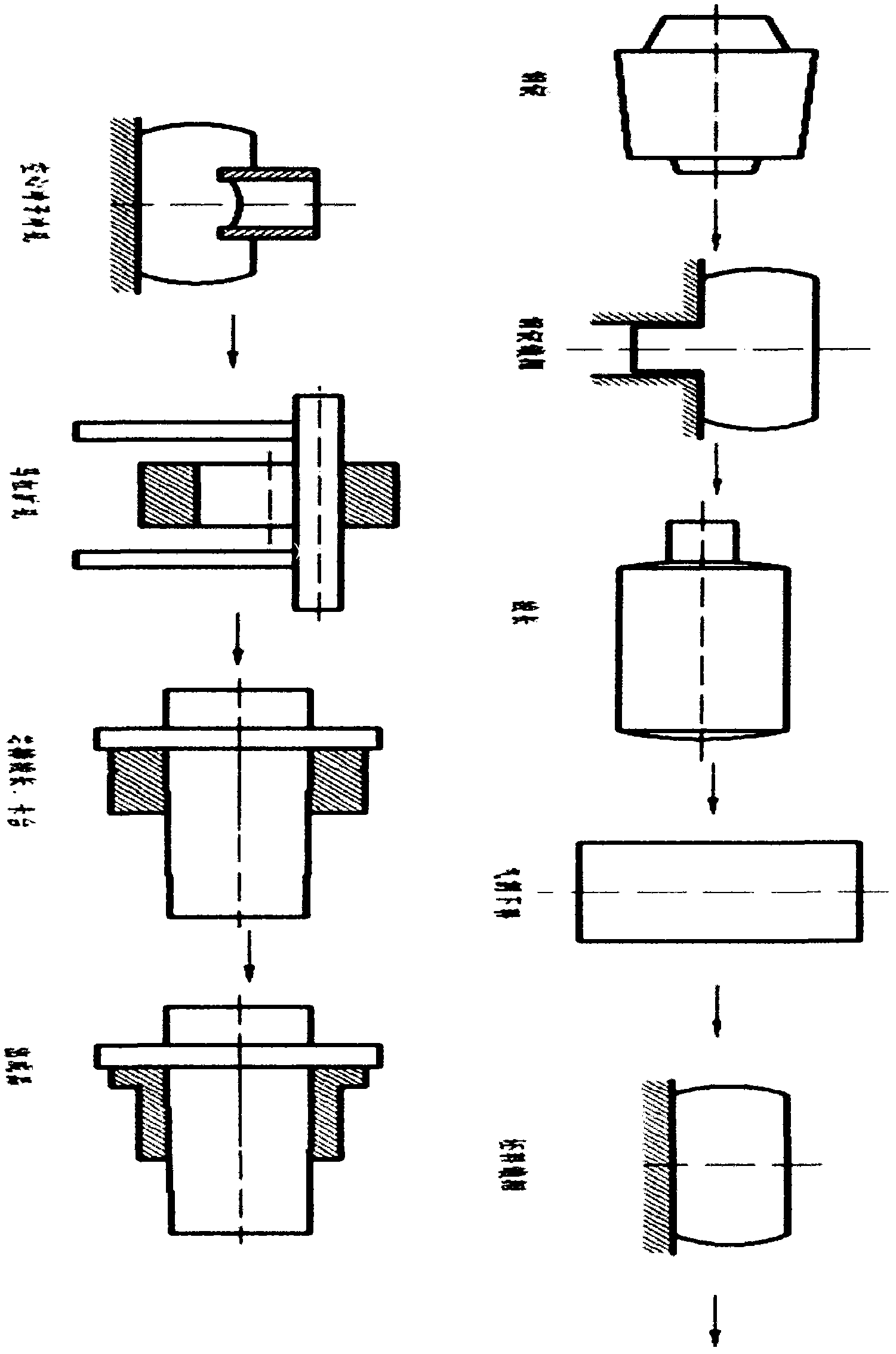

Forging method for thin-walled step short sleeve type main shaft flange of water turbine

ActiveCN102527897AUniform deformationStreamline continuousMetal-working apparatusWater turbineProcess dimension

A forging method for a thin-walled step short sleeve type main shaft flange of a water turbine is characterized in that both the physical dimension and internal quality of a forge piece can be allowed for in an overall free-shaped forging way of combining upsetting and stretching. The forging method comprises the technological processes of upsetting, stretching, baiting, upsetting, punching, broaching, stretching with a core bar, pressing out a step, and finishing until the dimension of the forge piece conforms to the process dimension. By adoption of the method, the integrity of metal streamline of the forge piece in the following processing procedures is ensured, and finally the mechanical properties of parts are greatly improved. Compared with the prior well-known method, the forging method provided by the invention has the advantages that the utilization ratio of material is greatly improved, the amount of following mechanical processing is reduced, the production cost is reduced, and the production efficiency is increased.

Owner:CITIC HEAVY INDUSTRIES CO LTD

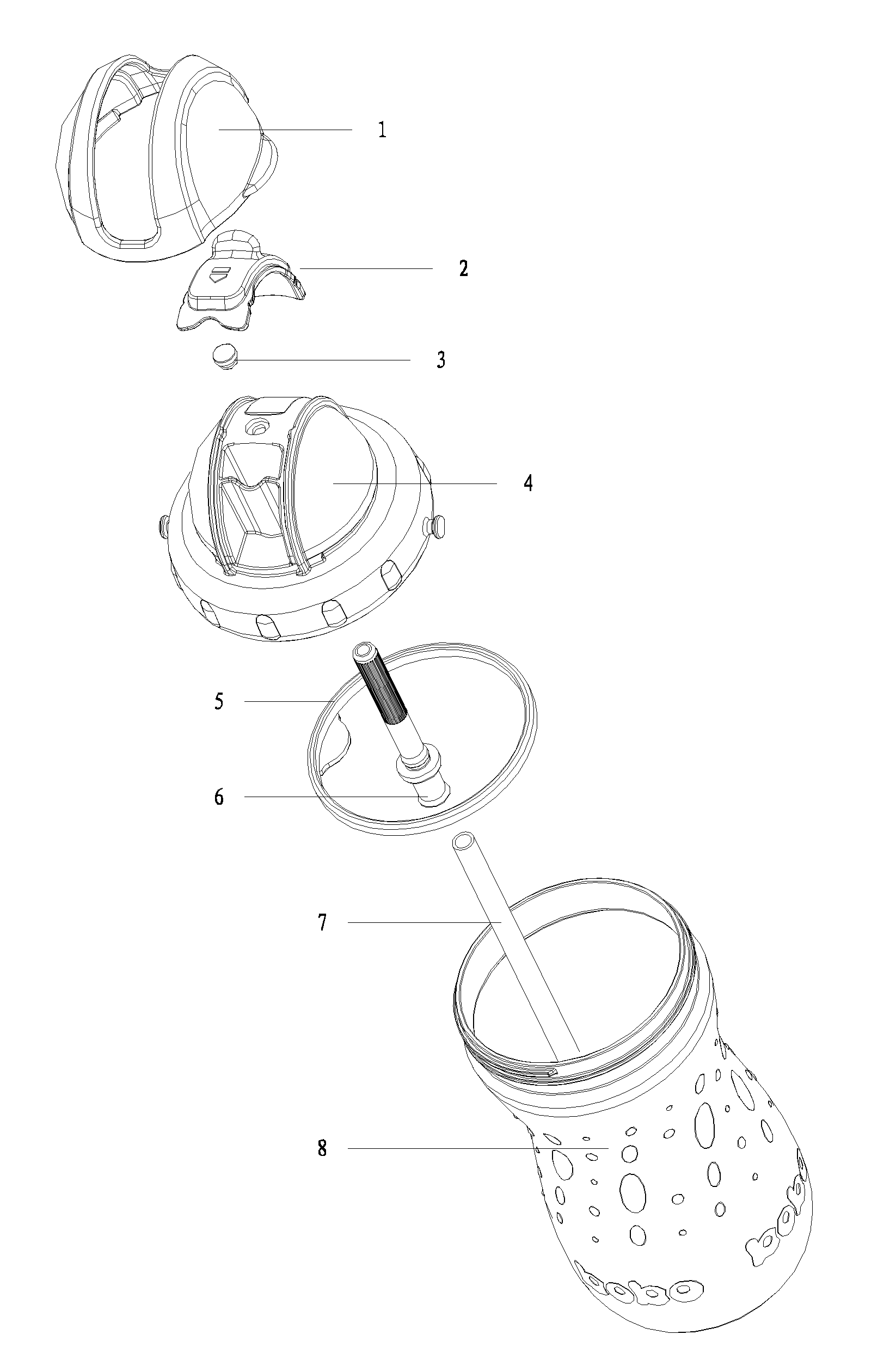

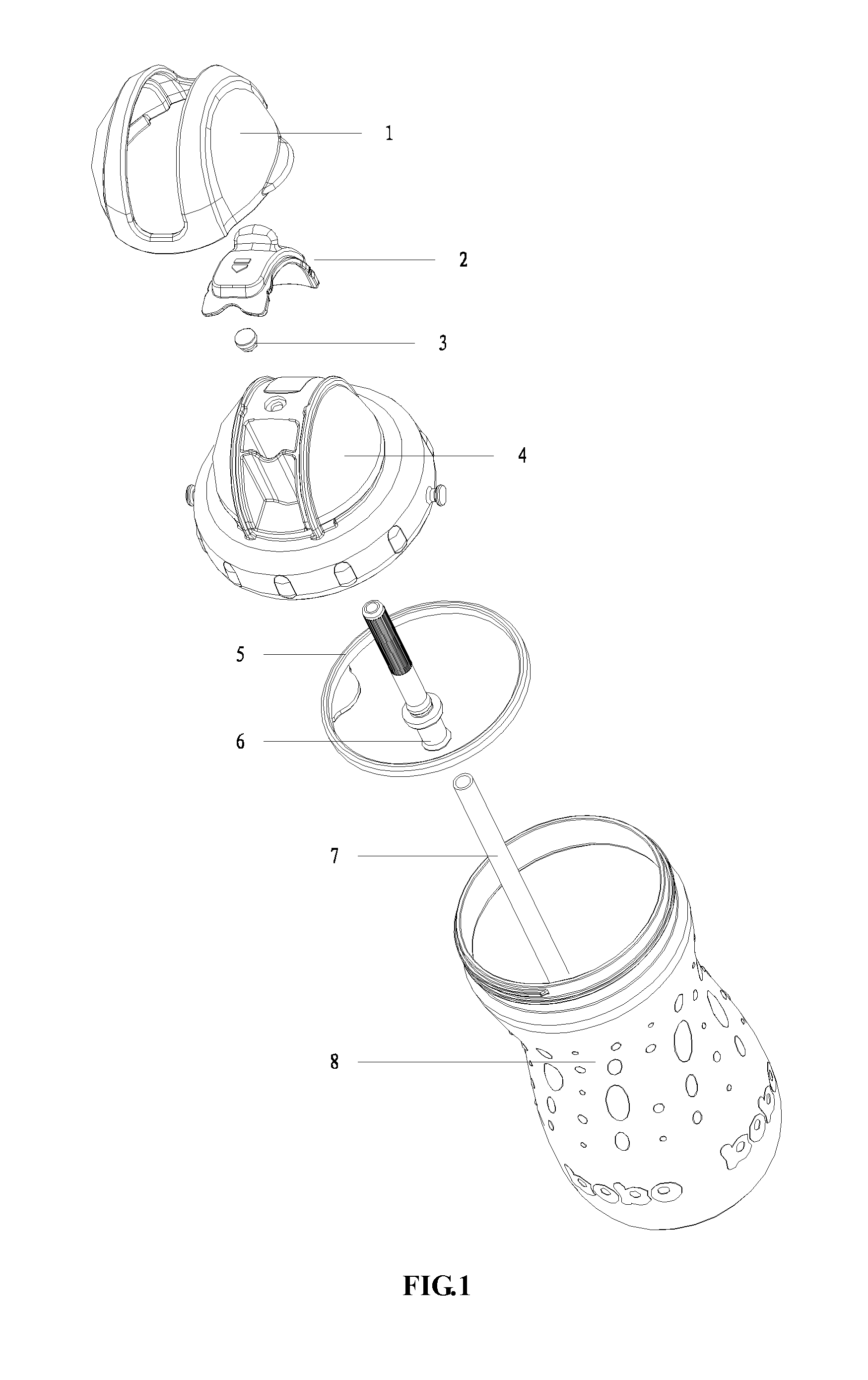

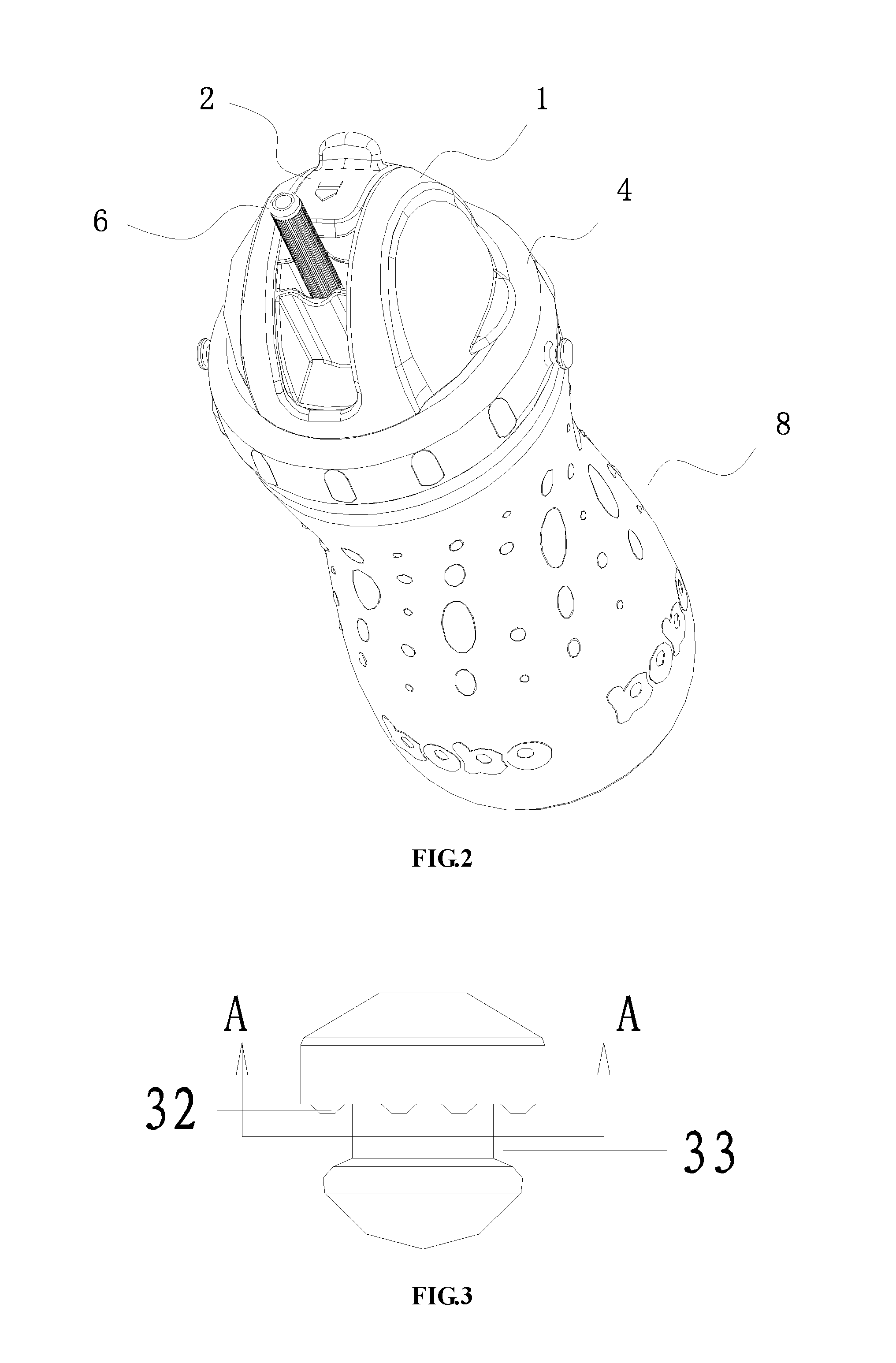

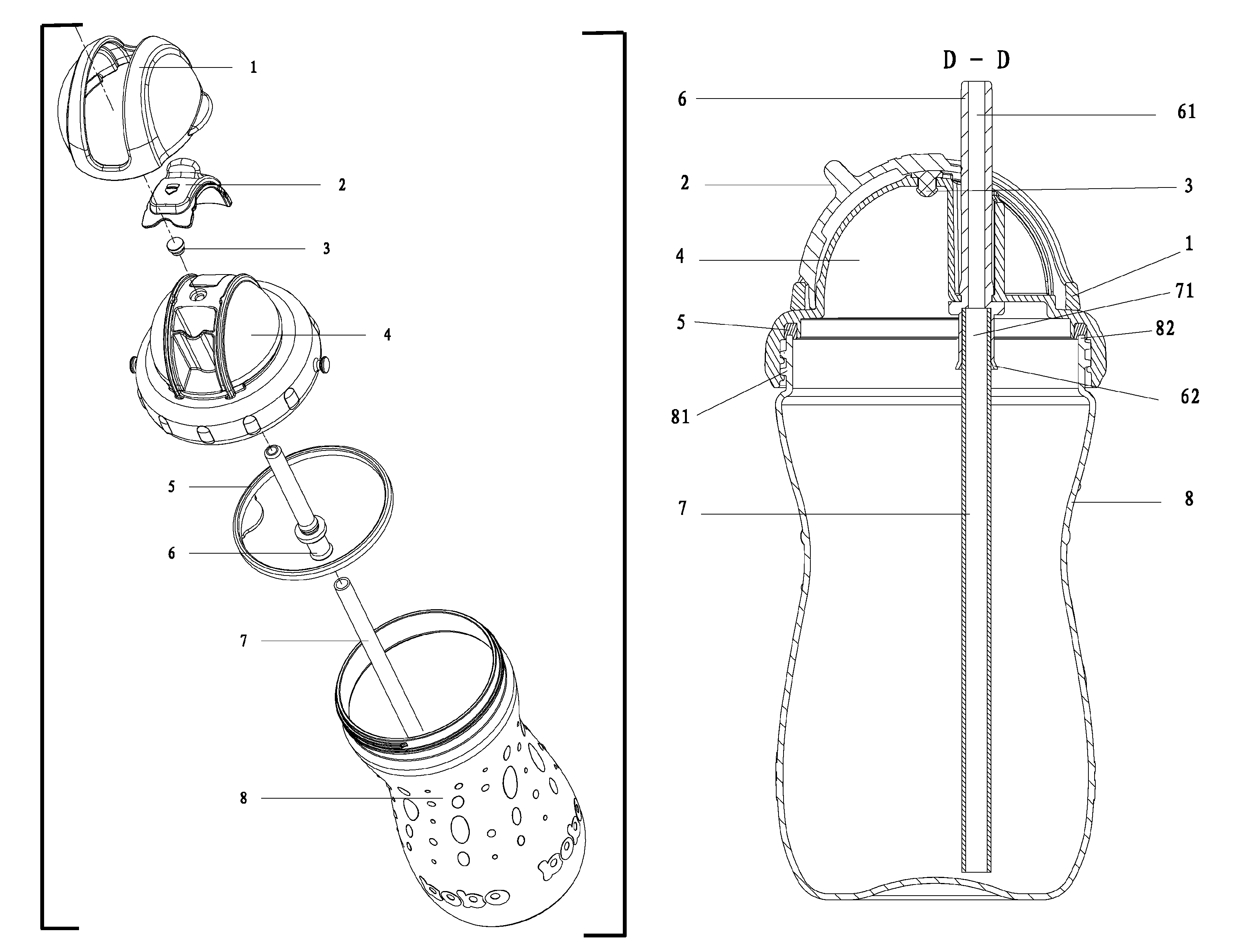

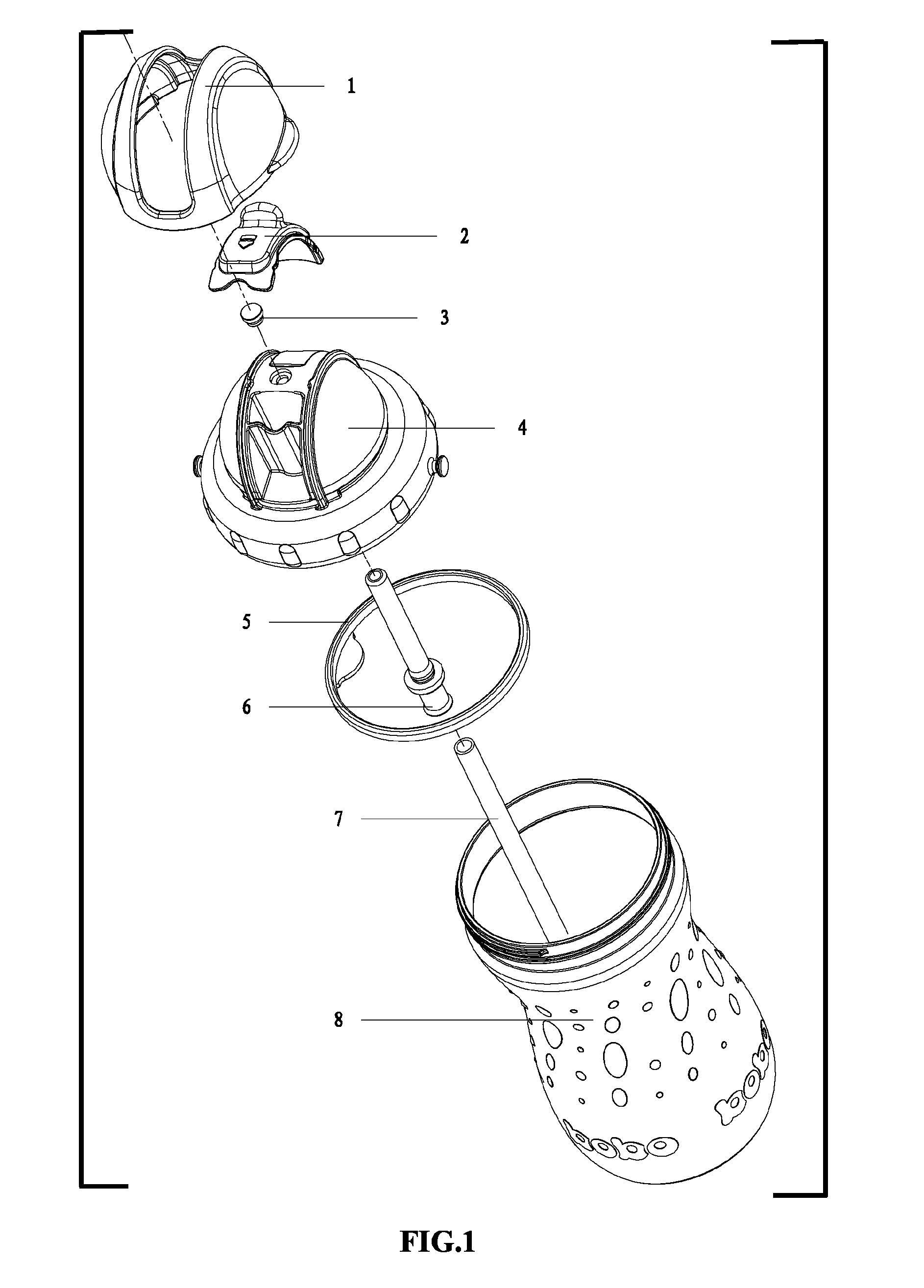

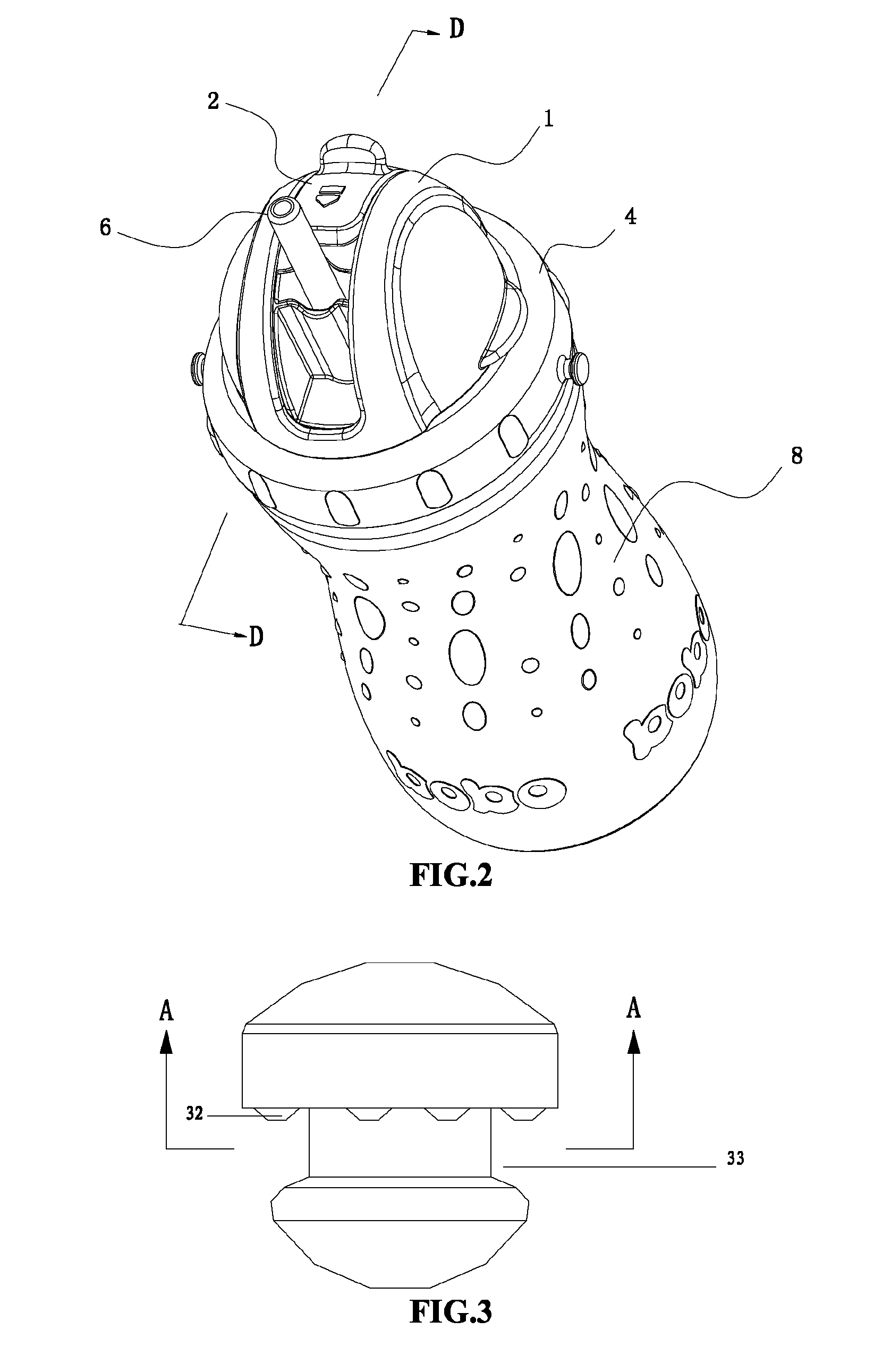

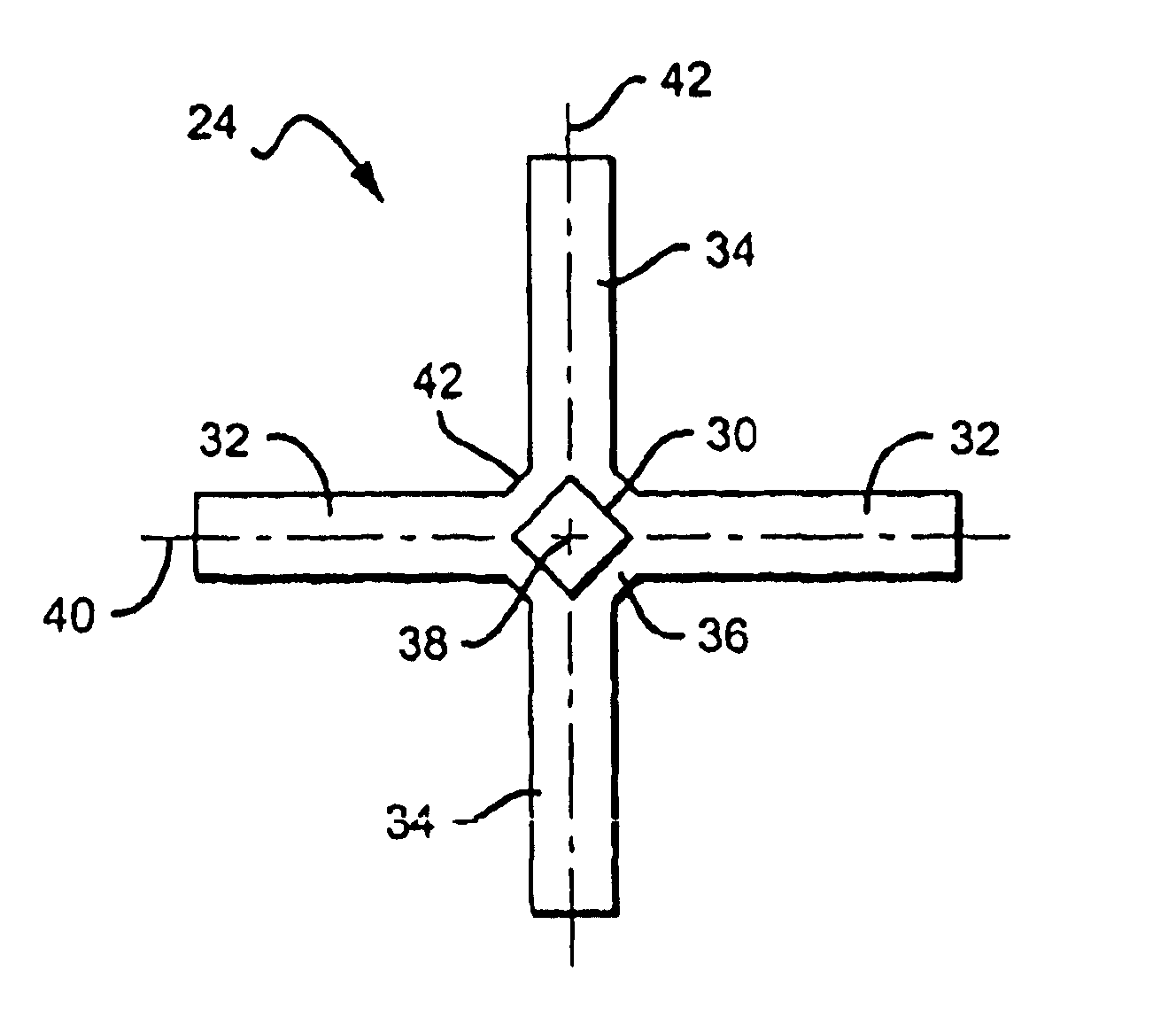

Drinking container with suction pipe

InactiveUS20120160851A1Easy to cleanEasy to useCapsClosure using stoppersProcess dimensionDrinking straw

A drink container with suction pipe is provided. The container comprises a container body, a cap assembly and a flexible straw; the cap assembly comprises an inner cap and a valve assembly which can open and close the passage between inside and outside of the container body by respectively extending and bending the flexible straw; and the cap assembly also comprises a venting switch assembly which comprises a venting valve hole mounted on the inner cap, a float venting valve, protrusions mounted respectively on both ends of the inner side of the slide sheet, and hollow portion mounted between two the protrusions. The float venting valve is movably mounted to the venting valve hole and comprises one or a plurality of elastic protrusions on its contact surface. When the slide sheet is in its completely open or closed position, one of the protrusions mounted on both ends of the inner side of the slide sheet is pressed against the float venting valve to press the elastic protrusion of the float venting valve to cling to the surface of the venting valve hole for waterproof sealing. Therefore, the requirement to the process dimension of assembling of the venting switch assembly in accordance with this invention is lower, and the float venting valve is easy to be replaced.

Owner:CHIANG YAT SAN

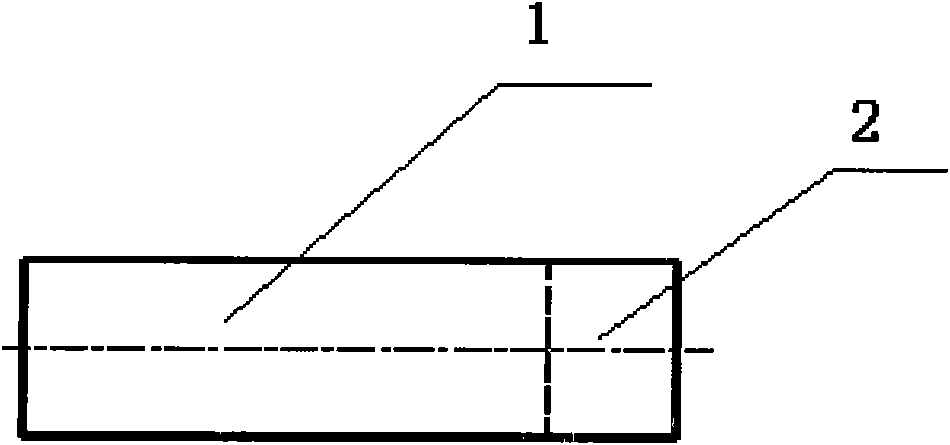

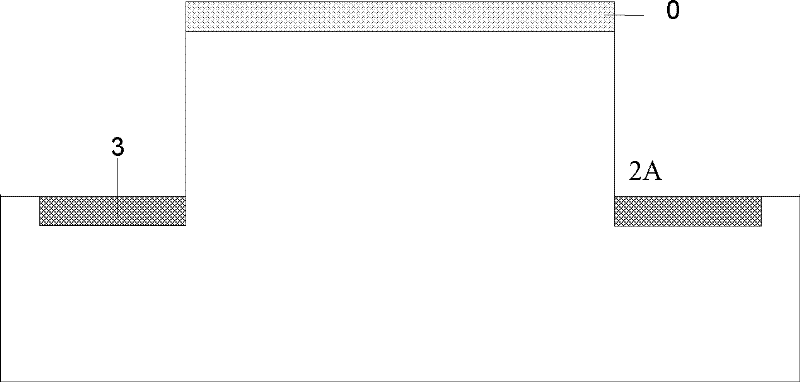

Method for forging thin and short shaft section at end of large-scale step shaft

InactiveCN101979179ASolve the problem of not enough ingredientsSolve unformable problemsForging/hammering/pressing machinesEngine componentsProcess dimensionMaterial distribution

The invention discloses a method for forging a thin and short shaft section at the end of a large-scale step shaft. The method comprises the following steps of: (A) forging a pre-forging part and separating a material for the thin and short shaft section (3) of the pre-forging part; (B), drawing a small step section (2) out to obtain the thin and short section (3) of the pre-forging part; (C) upsetting a large step section (1) in a molding bed; and (D) stripping a mold, and drawing the thin and short shaft section (3) of the pre-forging part and the large step section (1) out to process dimensions so as to forge the thin and short shaft section at the end of the large-scale step shaft. The forging method of the invention is different from a conventional forging method from a large diameter to a small diameter, and solves the problem that the thin and short shaft section at the end of the large-scale step shaft cannot be formed because of the insufficiency of material distribution. A step shaft product produced by the method has continuous forging streamlines, reasonable distribution, stable quality and great reduction of blanking weight of a forge piece. The forging method of the invention is simple and easy to implement, the quality is reliable and the raw material utilization ratio is high.

Owner:JIANGSU JINYUAN FORGE

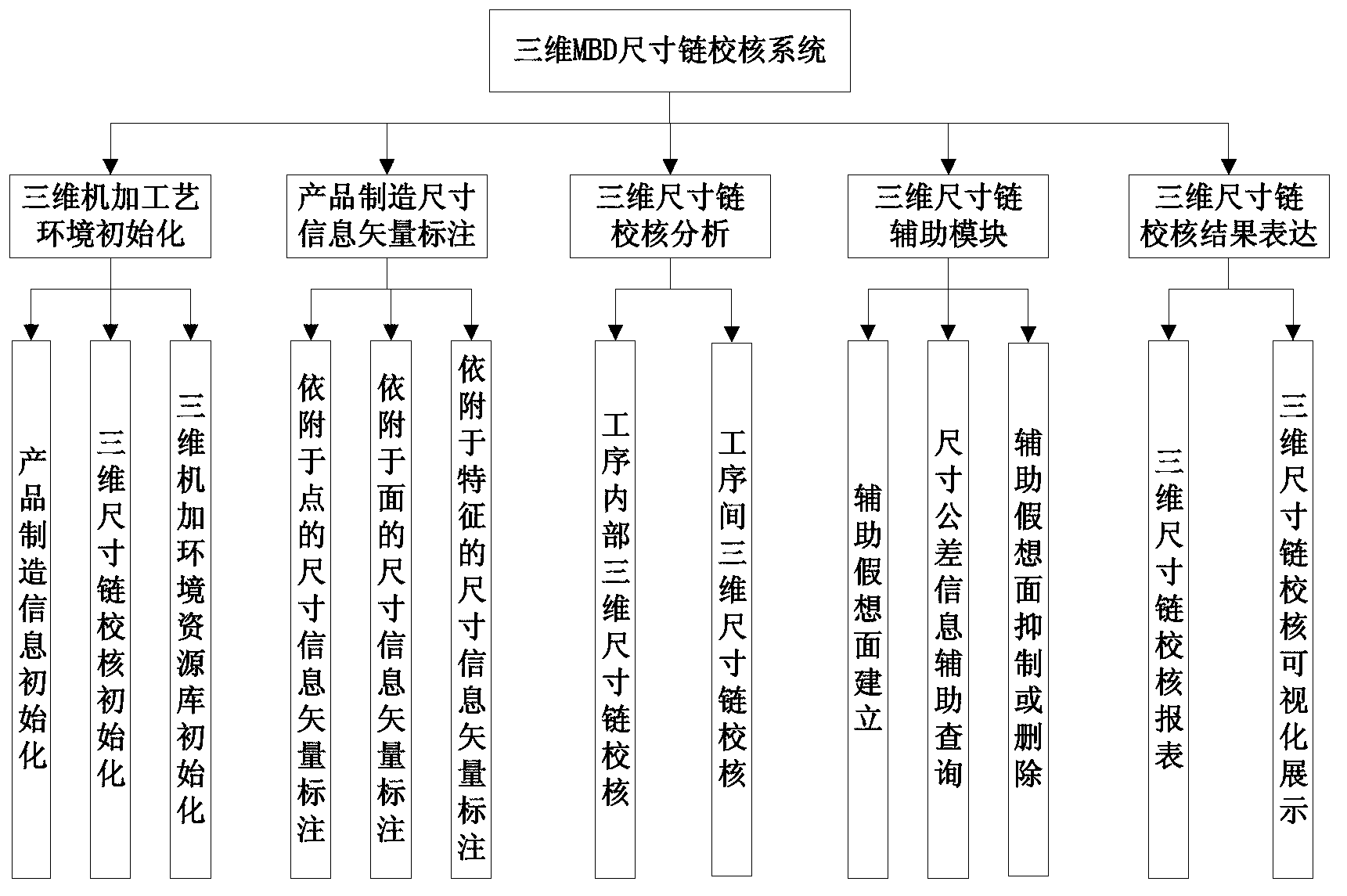

Dimension chain checking method based on three-dimensional model

InactiveCN103310058APrecisely solve analytical calculation problemsSolving Analytical Computational ProblemsSpecial data processing applicationsModeling softwareSimulation

The invention discloses a dimension chain checking method based on three-dimensional model and aims to solve the technical problem that a conventional dimension chain checking method is low in efficiency. The technical scheme is that a vector dimension system based on a fixed datum is established by using a space nature of the three-dimensional model. Vector annotation is performed on a three-dimensional dimension, so that the dimension required to be checked under a three-dimensional environment has a vector characteristic, and further automatic checking of a dimension chain is realized according to the principle that the vector sum is zero; and function modules such as automatic judgment of increase and decrease of rings, tolerance modification real-time update, dimension chain check record queries, check record report generation, inter-process dimension chain visual display and the like are provided, so that a dimension chain analysis calculation problem can be solved conveniently, rapidly and accurately. The dimension chain checking efficiency is improved, and an effect for facilitating rapid generation and optimization of a product process is realized. The method can be completed across platforms, and dimension chain checking can be performed through resume vector annotation systems in different modeling software.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Drinking container having slidable cover and drinking straw

InactiveUS8376165B2Simple structureEasy to disassembleCapsClosure using stoppersProcess dimensionDrinking straw

A drink container with suction pipe is provided. The container comprises a container body, a cap assembly and a flexible straw; the cap assembly comprises an inner cap and a valve assembly which can open and close the passage between inside and outside of the container body by respectively extending and bending the flexible straw; and the cap assembly also comprises a venting switch assembly which comprises a venting valve hole mounted on the inner cap, a float venting valve, protrusions mounted respectively on both ends of the inner side of the slide sheet, and hollow portion mounted between two the protrusions. The float venting valve is movably mounted to the venting valve hole and comprises one or a plurality of elastic protrusions on its contact surface. When the slide sheet is in its completely open or closed position, one of the protrusions mounted on both ends of the inner side of the slide sheet is pressed against the float venting valve to press the elastic protrusion of the float venting valve to cling to the surface of the venting valve hole for waterproof sealing. Therefore, the requirement to the process dimension of assembling of the venting switch assembly in accordance with this invention is lower, and the float venting valve is easy to be replaced.

Owner:CHIANG YAT SAN

BJT device configuration and fabrication method with reduced emitter width

InactiveUS6858887B1Reduce widthSuitable for use with compound semiconductor-based devicesSemiconductor/solid-state device manufacturingSemiconductor devicesEngineeringProcess dimension

Owner:TELEDYNE SCI & IMAGING

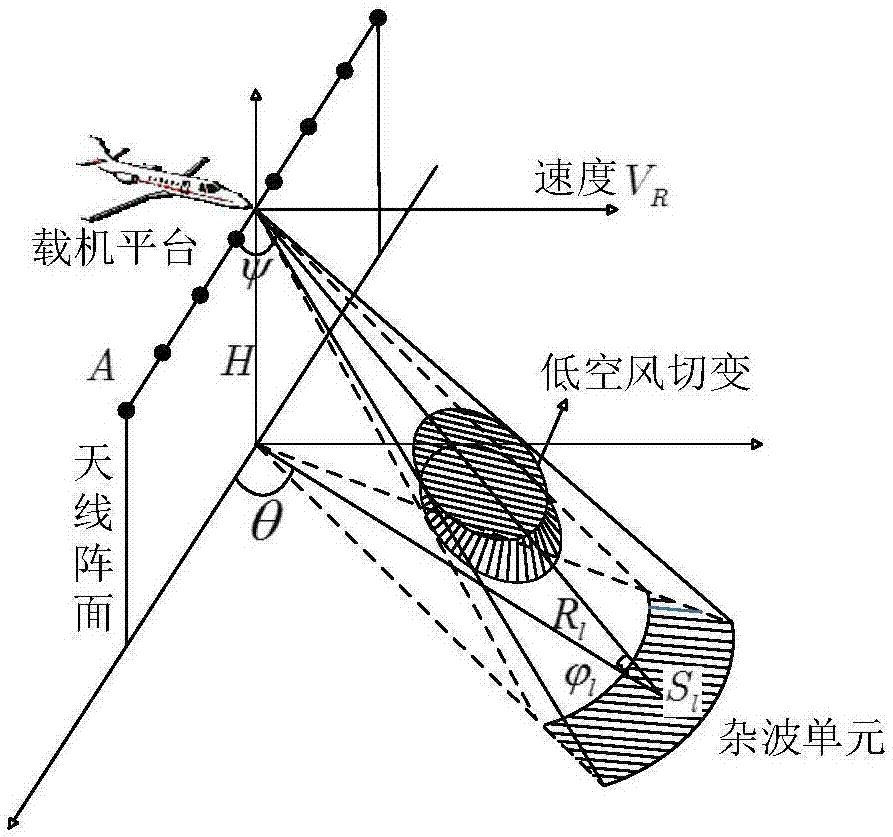

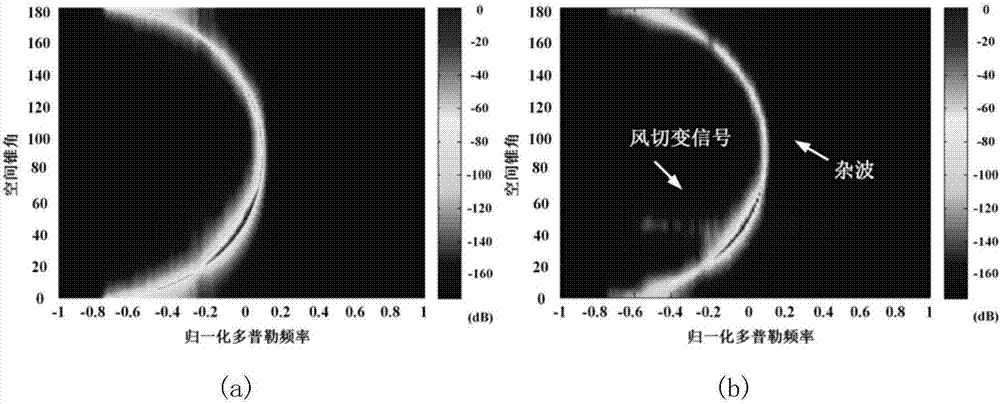

Doppler pre-filtering based dimension-reduced STAP (Space-Time Adaptive Processing) microburst center wind speed estimation method

InactiveCN106872982AEffective estimateVerify validityRadio wave reradiation/reflectionICT adaptationAlgorithmCovariance matrix

The invention relates to a Doppler pre-filtering based dimension-reduced STAP (Space-Time Adaptive Processing) microburst center wind speed estimation method, which comprises the steps of 1) processing radar receiving data by using a clutter spectrum registration method one distance unit by one distance unit, and solving an IID sample required by clutter covariance matrix estimation of a distance unit to be detected; 2) selecting a certain Doppler frequency to be a central Doppler frequency, building a time domain dimension-reduced matrix at the frequency, and processing data in the IID sample; 3) solving a dimension-reduced optimal weight vector by using a space domain secondary covariance matrix at the central Doppler frequency estimated by dimension-reduced data estimation; and 4) processing dimension-reduced data by using the dimension-reduced optimal weight vector to acquire a center wind speed estimated value and a distribution condition. It is proved by a simulation result that an accurate wind field speed estimation result can be acquired according to the method under the background of strong clutters, and the method is obviously reduced in computation amount compared with an optimal processor due to adoption of the dimension-reduced structure.

Owner:CIVIL AVIATION UNIV OF CHINA

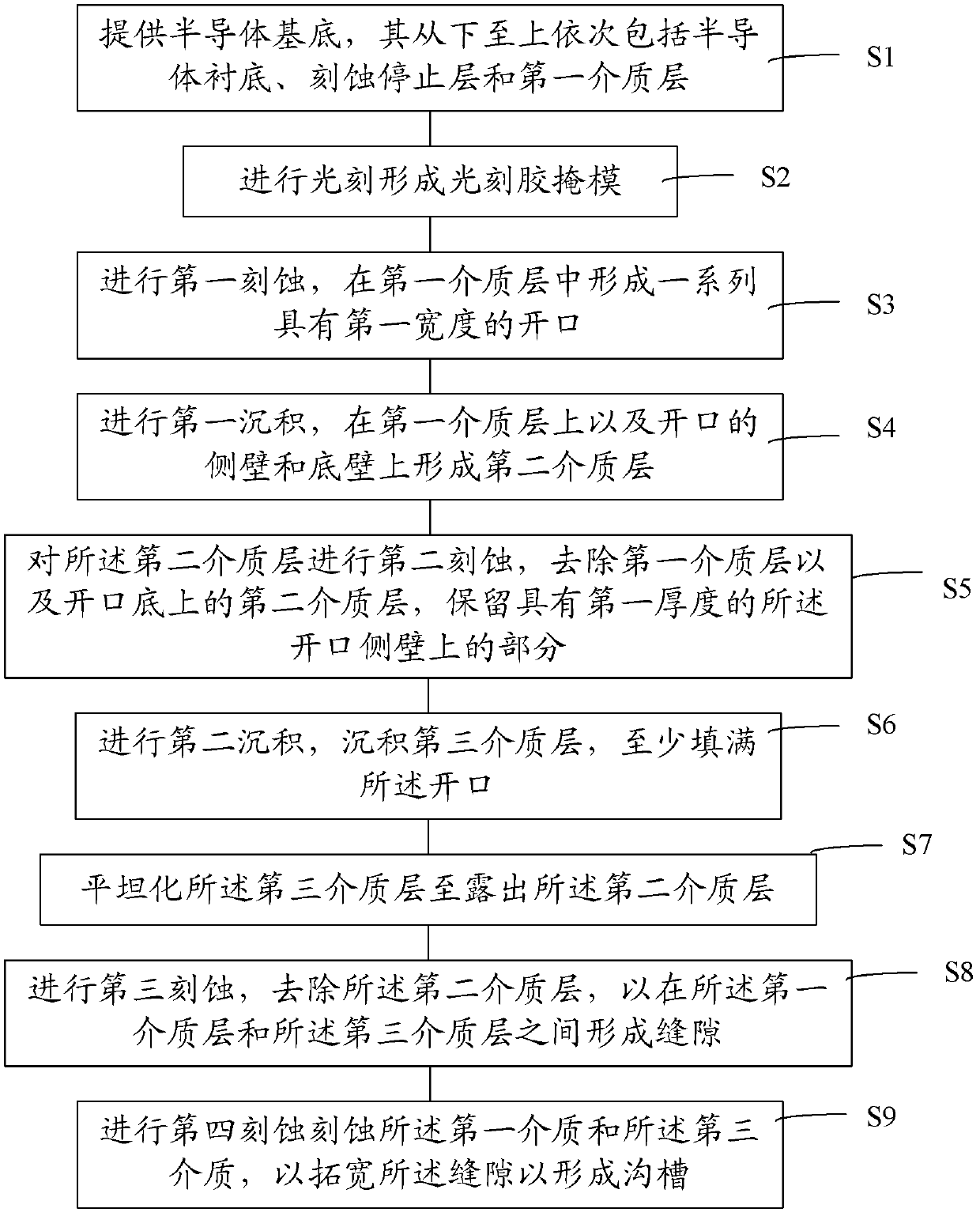

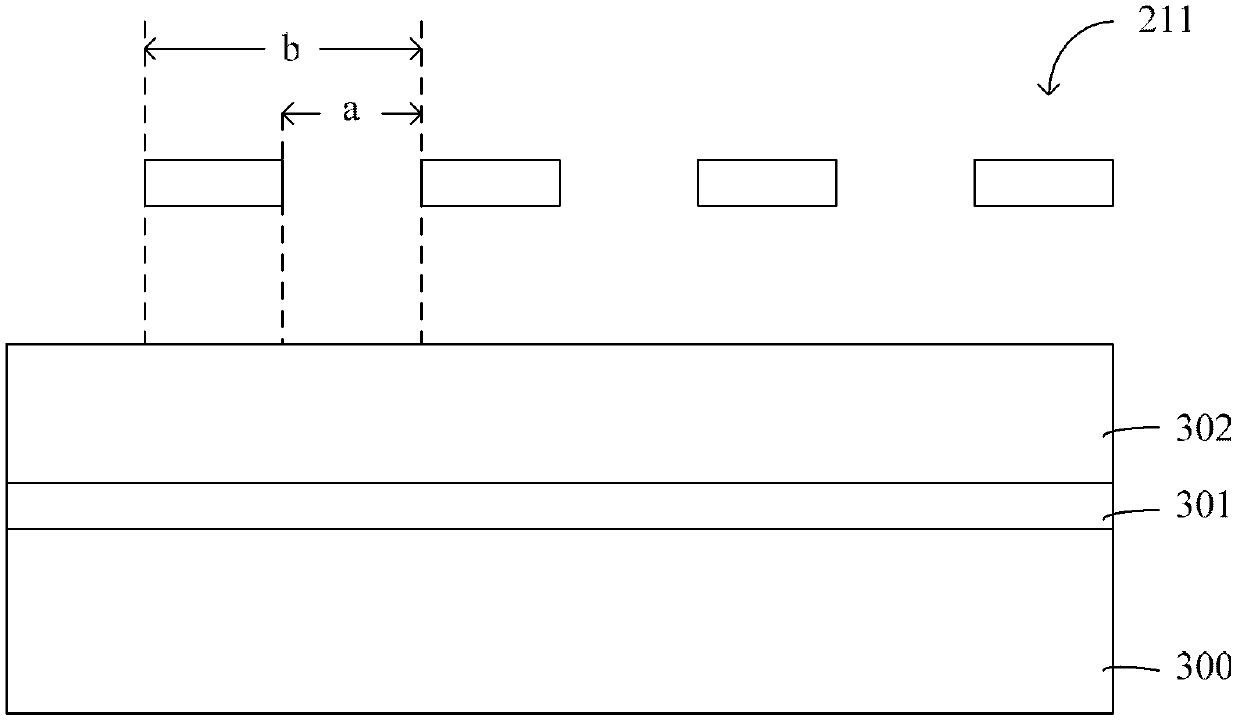

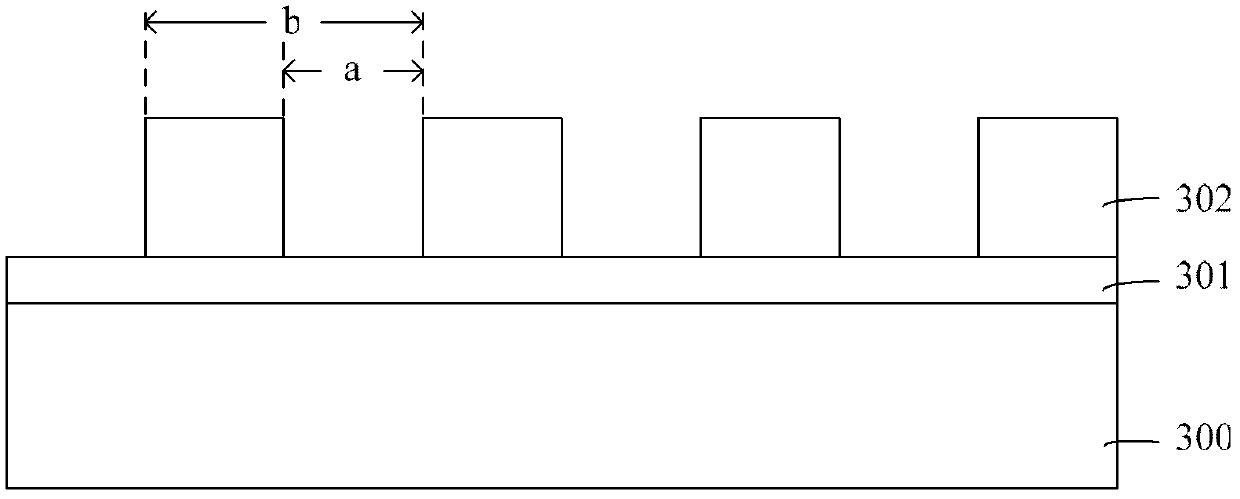

Method for etching grooves

ActiveCN103311092AFit line widthReduce the size of the etchSemiconductor/solid-state device manufacturingEtchingProcess dimension

A method for etching grooves comprises: providing a semiconductor substrate on which an etching stop layer and a first dielectric layer are formed in sequence; forming a photoresist mask; performing a first etching so that openings, each of which is with a first width, are formed on the first dielectric layer; performing a first depositing and thus a second dielectric layer is formed; performing a second etching on the second dielectric layer and removing the second dielectric layer that is on the first dielectric layer and the bottom walls of the openings so that the second dielectric layer that is on the side walls of the openings, each of which is with the first width, is remained; performing a second depositing and depositing a third dielectric layer so that the third dielectric layer at least fills up the openings; flattening the third dielectric layer until the second dielectric layer is exposed; performing a third etching to remove the second dielectric layer so that gaps are formed between the first dielectric layer and the third dielectric layer; and performing a fourth etching to etch the first dielectric layer and the third dielectric layer so that the gas are widened to form grooves. According to the method, a more advanced process dimension requirement can be realized with current exposure equipment.

Owner:SEMICON MFG INT (SHANGHAI) CORP

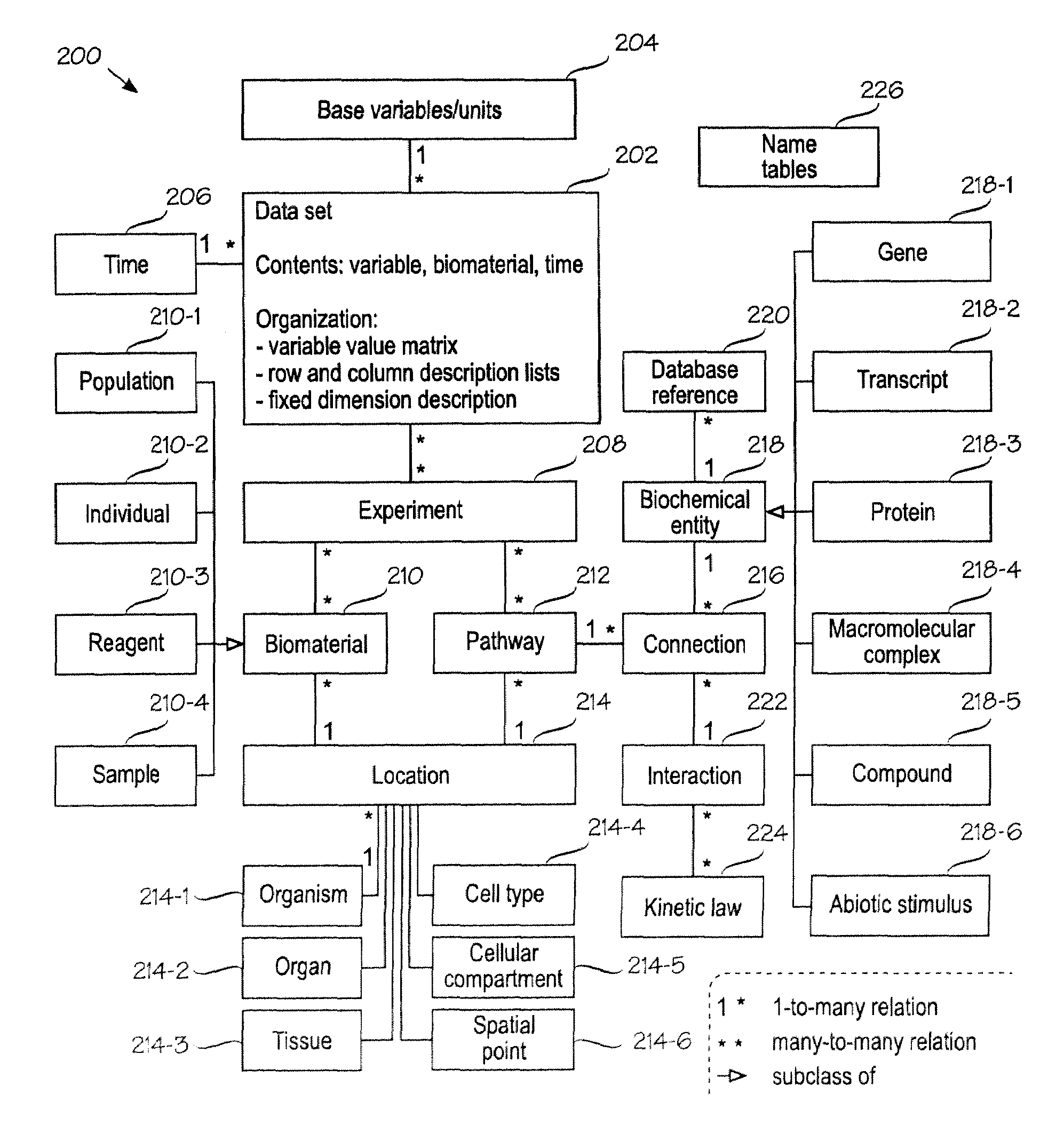

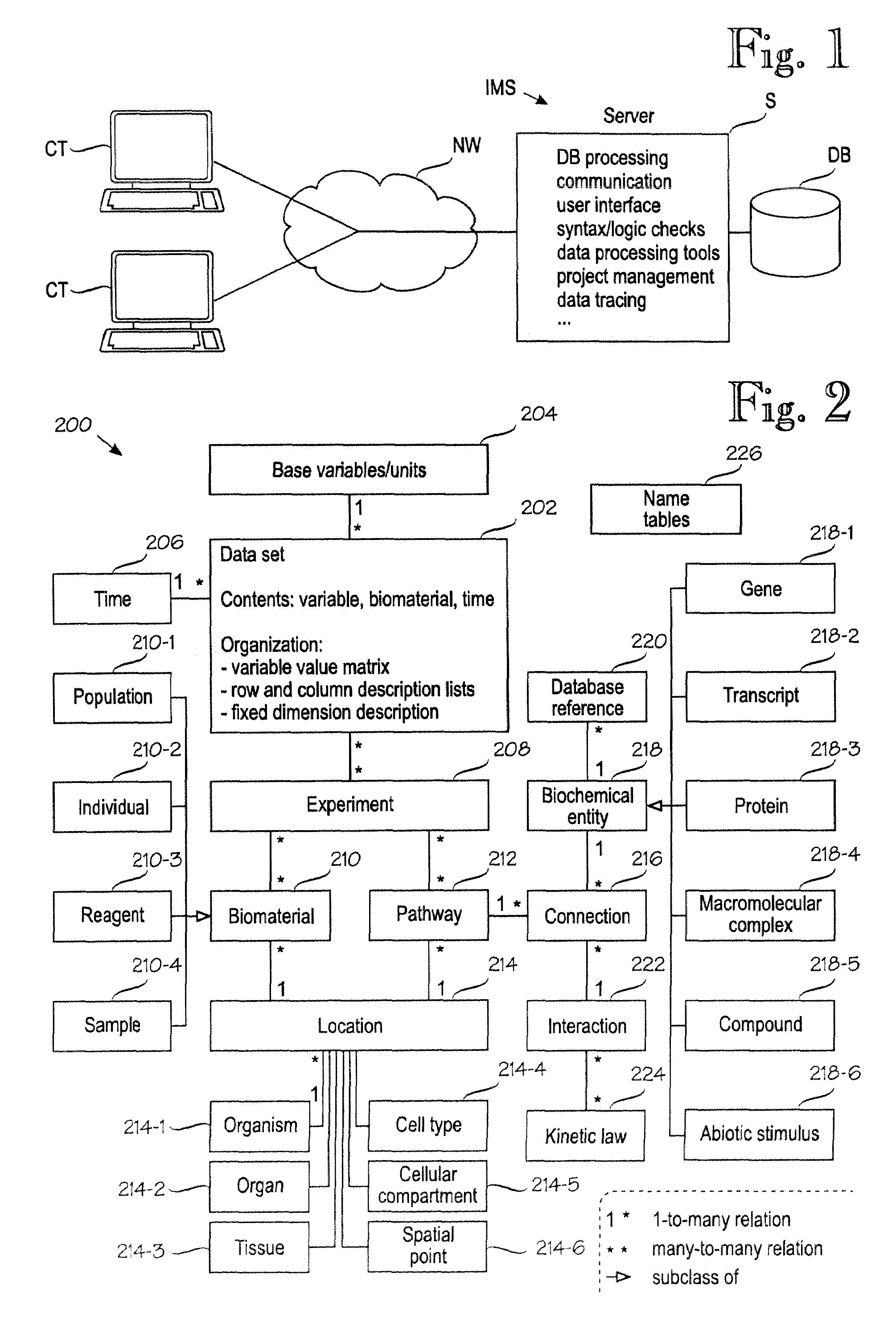

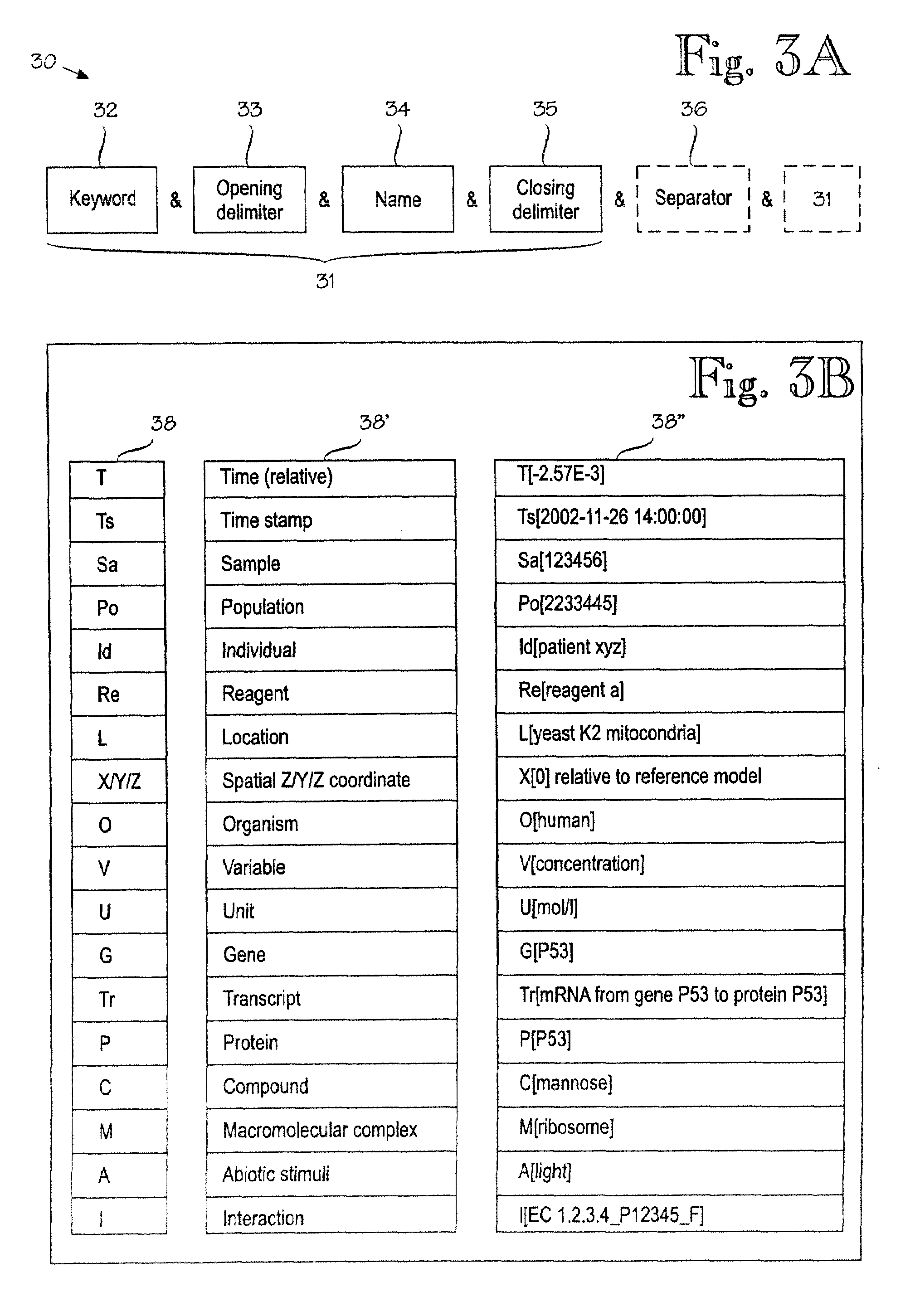

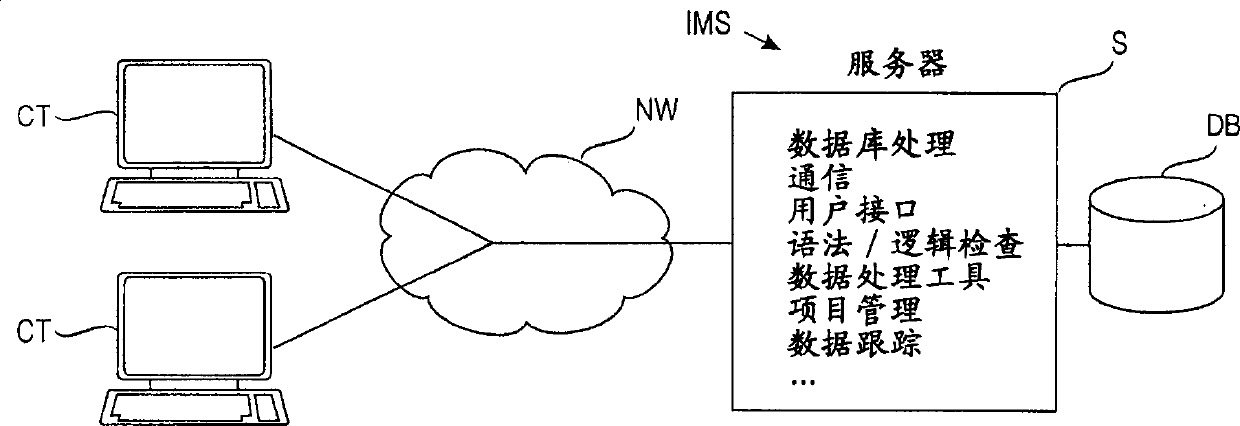

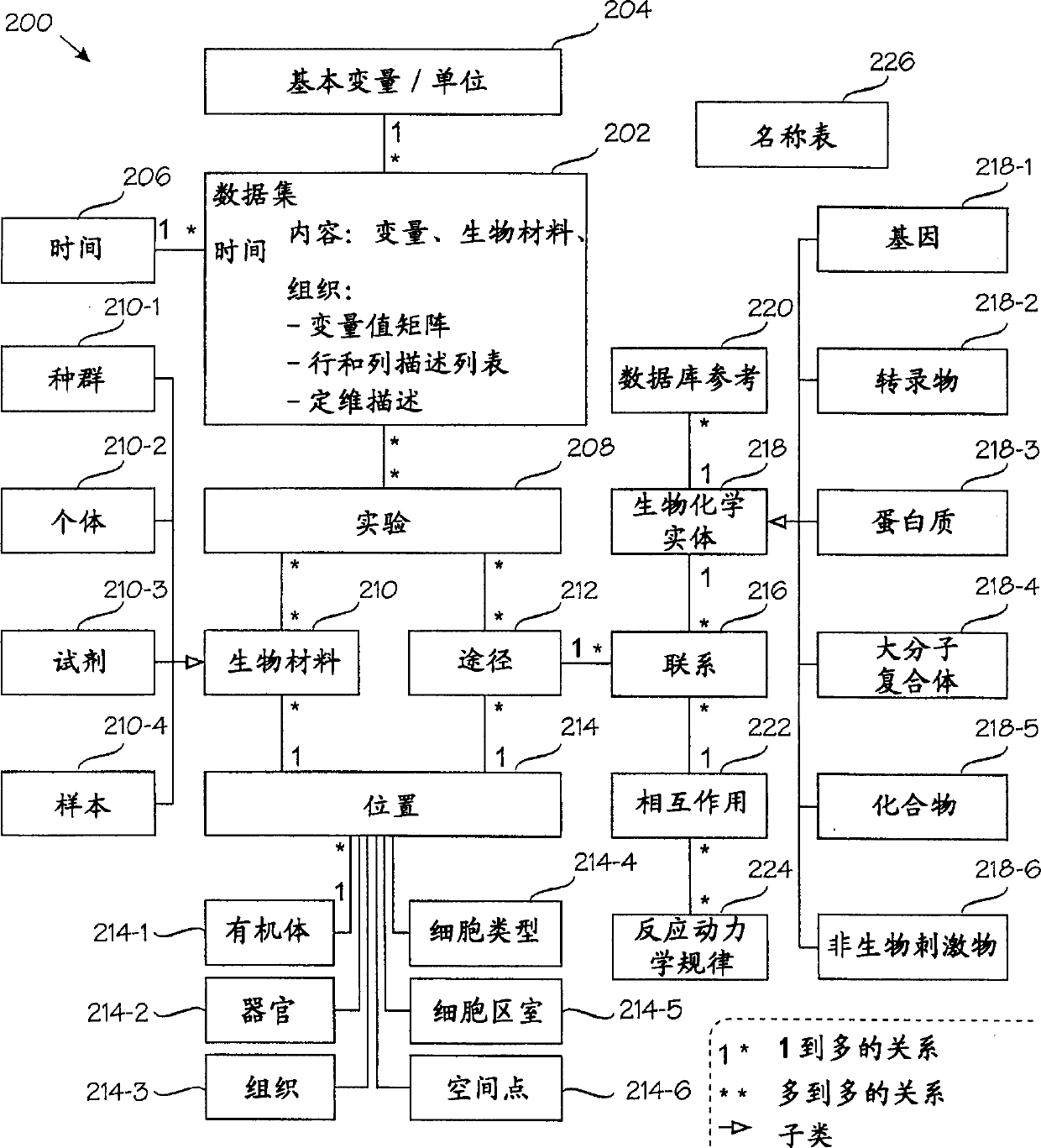

Information management system for biochemical information

InactiveUS7340485B2Reduce in quantityImprove processing speedDigital data processing detailsOffice automationCluster algorithmData set

An information management system for managing biochemical information (200). The biochemical information (200) comprises data sets (202) and each data set comprises a variable value matrix containing variable values organized as rows and columns; a row description list, in a variable description language, of the rows in the variable value matrix; a column description list, in a variable description language, of the columns in the variable value matrix; and a fixed dimension description, in a variable description language, of one or more fixed dimensions that are common to all values in the variable value matrix. A benefit achieved by storing the numerical values as a scalar matrix is that the matrix can be analyzed with many commercially available data-mining tools, such as self-organizing maps or other clustering algorithms, that do not readily process dimensioned values.

Owner:MEDICEL

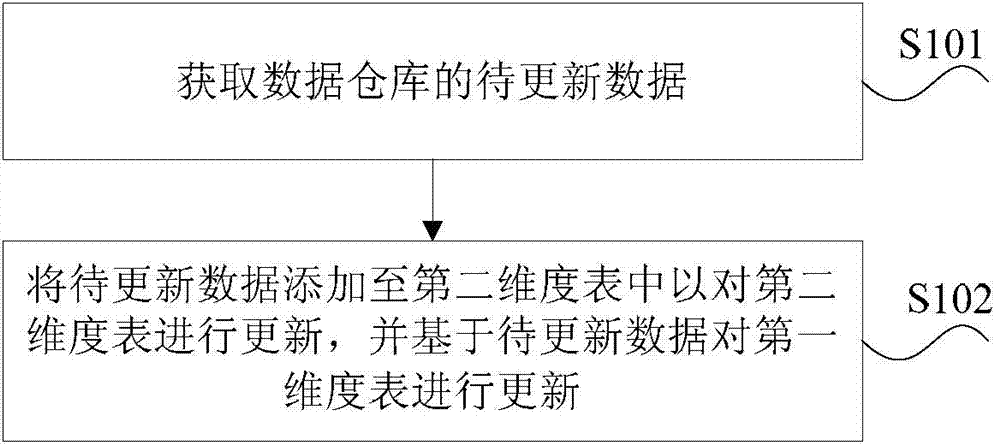

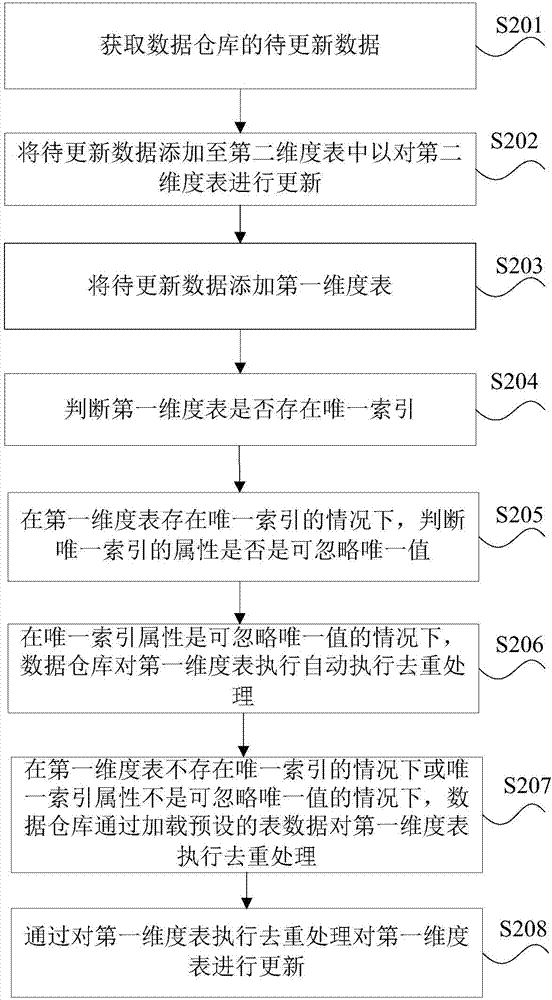

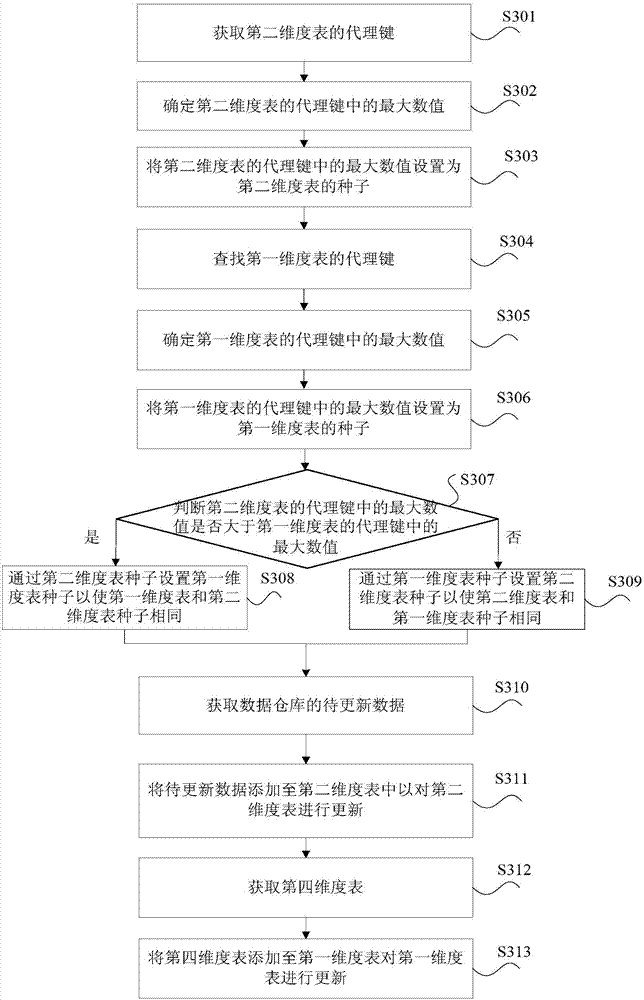

Method and device for processing dimension in data warehouse

ActiveCN104239567AImprove update speedFast updateDatabase updatingMulti-dimensional databasesData warehouseProcess dimension

The invention discloses a method and a device for processing the dimension in a data warehouse. A first dimension table and a second dimension table which are created in advance are stored in the data warehouse, wherein the first dimension table is used for storing all historical data in the data warehouse; the second dimension table is used for updating according to the first dimension table for storing data of one lately dimension processing time period in the first dimension table. The method comprises the following steps of acquiring data to be updated in the data warehouse; adding the data to be updated in the second dimension table for updating the second dimension table, and updating the first dimension table based on the data to be updated. According to the method and the device, the problem that the update speed of a snapshot dimension table is low when a historical dimension table is updated is solved, and the effect of increasing the update speed of the snapshot dimension table is realized.

Owner:BEIJING GRIDSUM TECH CO LTD

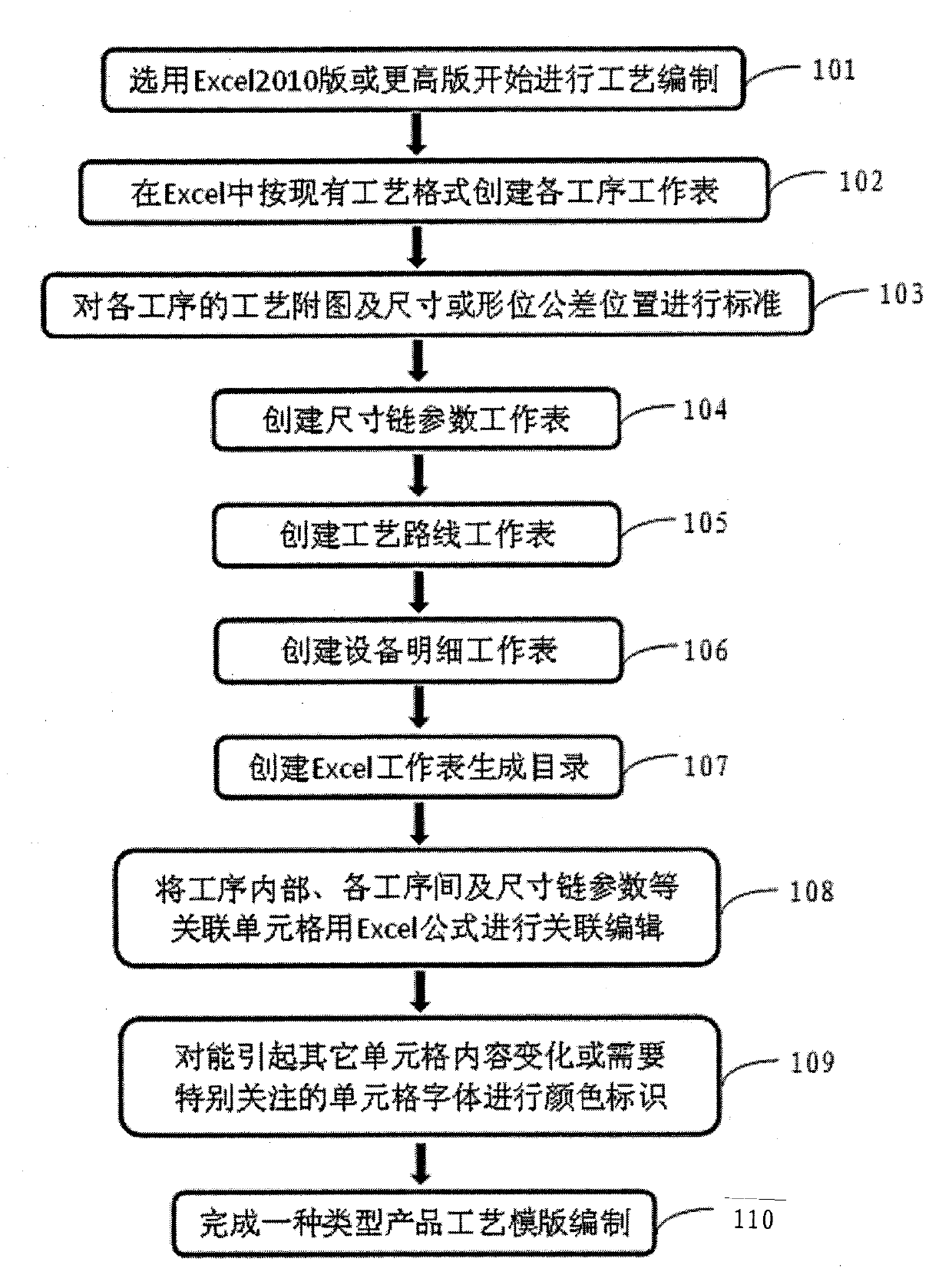

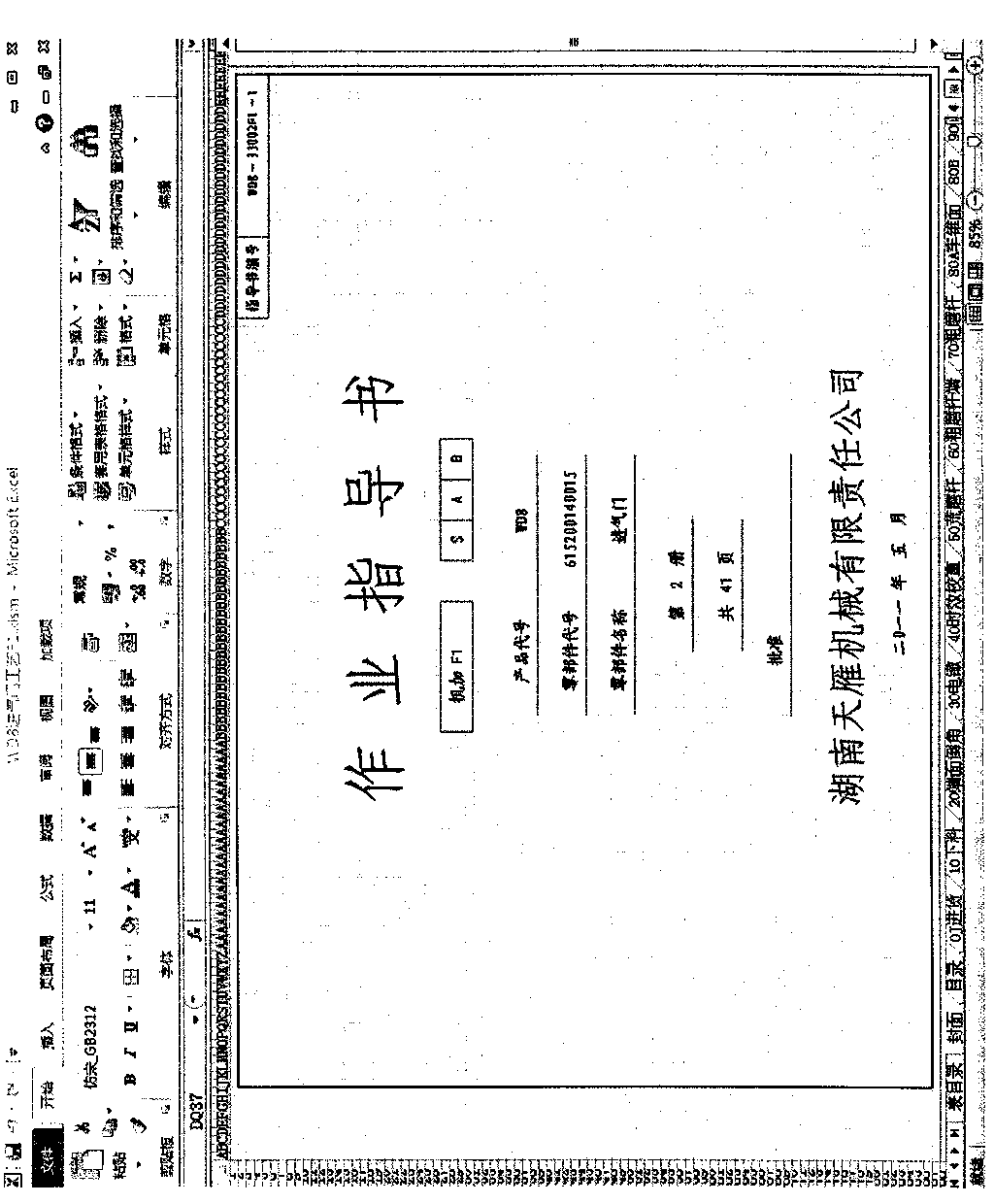

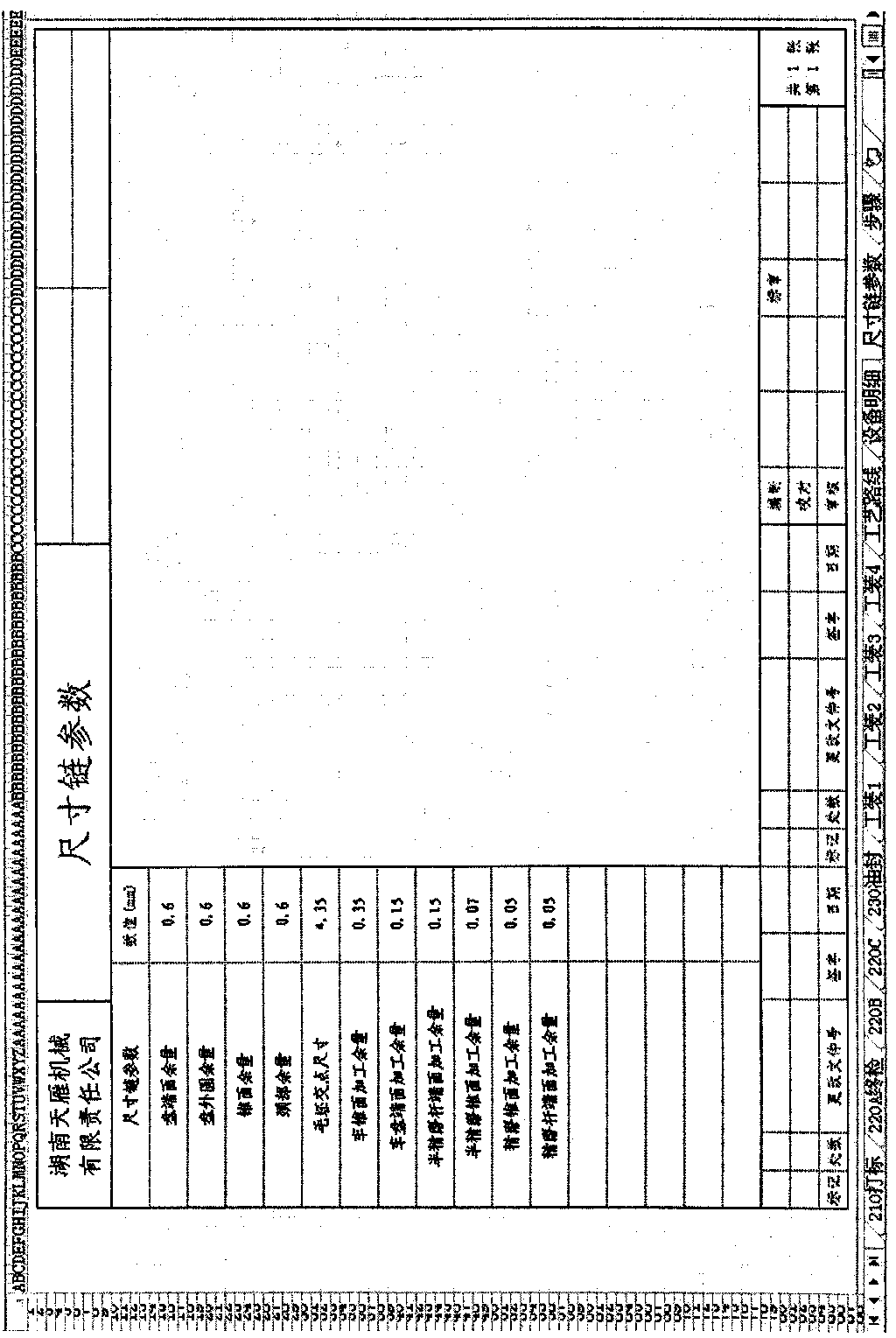

Excel-based product process planning method

InactiveCN103473216AEnsure consistencyImprove work efficiencyResourcesSpecial data processing applicationsProcess dimensionPlanning method

The invention discloses an excel-based product process planning method, which comprises the following steps of creating a worksheet of each procedure in an Excel according to a conventional process format, and standardizing a process attached drawing, a dimension and a geometric tolerance position in each procedure; creating a dimension chain parameter worksheet template, thereby automatically calculating a process dimension chain of a related procedure; creating process route worksheet templates and equipment detail worksheet templates, thereby realizing the linked association of a product process procedure directory and related contents of each procedure; performing associated edition on all required item contents by utilizing an Excel formula tool to change only contents at one position for the same contents of a product process without changing procedure contents automatically calculated through a dimension chain, and performing color identification on cell fonts which may cause changes in contents of other cells or require special attentions. Therefore, errors can be effectively avoided, and the working efficiency can be improved.

Owner:HUNAN TYEN MACHINERY

New process for shaping large disk-shaped forging

The invention relates to a new process for shaping a large disk-shaped forging, which comprises the following steps of: upsetting a steel ingot, drawing out and blanking by using a WHF forging method, pre-upsetting the blank, spinning to deform, roll forging the outer circle, spinning for the second time, heating in a furnace, cooling in the air, spinning and shaping on a rolling anvil and the like. The new process decreases the heating number, raises the production efficiency, eliminates the residual micro holes in the inclusion crack repaired by the high temperature diffusion, improves the performance of the internal structure of the forging, ensures the process dimension, avoids the unbalanced loading phenomenon of the device as a result of controlling the anvil feeding in the shaping process of the disk-shaped forging, and eliminates the damage to the device.

Owner:CITIC HEAVY INDUSTRIES CO LTD

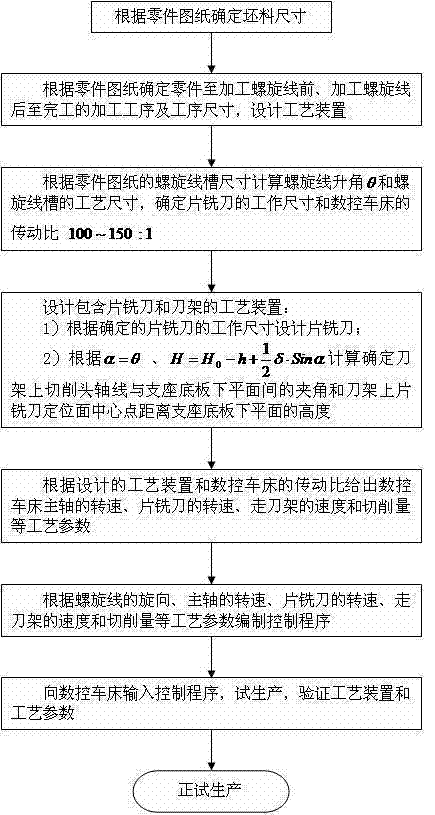

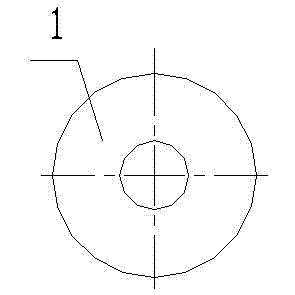

Method for processing external spiral slot with large screw pitch by numerically controlled lathe and process device

InactiveCN103203491AReduce speedReduce wearAttachable milling devicesMilling equipment detailsMilling cutterProcess dimension

The invention relates to a method for processing an external spiral slot with large screw pitch by a numerically controlled lathe and a process device. The method is characterized by comprising the following steps: determining a blank size according to a part drawing; determining process procedures and process dimensions of the blank before spiral slot processing, after spiral slot processing to the end of the process, and designing a process device; calculating a spiral line lift angle theta and process size of the spiral slot, determining working dimensions of a sheet milling cutter and transmission ratio of the numerically controlled lathe; and designing the process device comprising a sheet milling cutter and a knife rest used in the method: providing process parameters required by the method; and programming a control program. For usage, the control program is input to the numerically controlled lathe; the numerically controlled lathe is started, and the spindle and the sheet milling cutter respectively rotate in opposite directions at the same time, and a walking knife rest drives the knife rest and the sheet milling cutter to move forward; and the cutter is retracted after the processing.

Owner:王立波

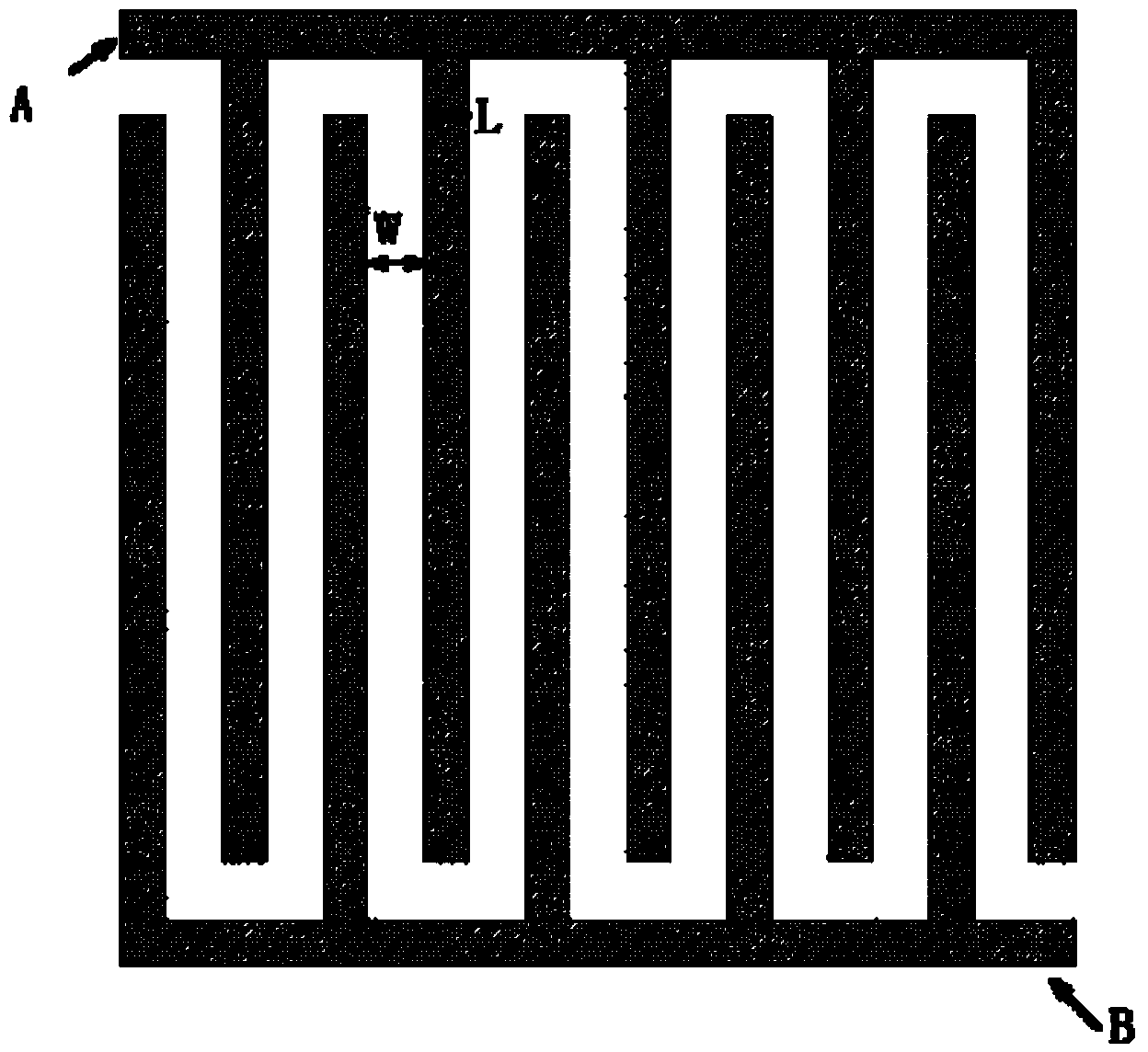

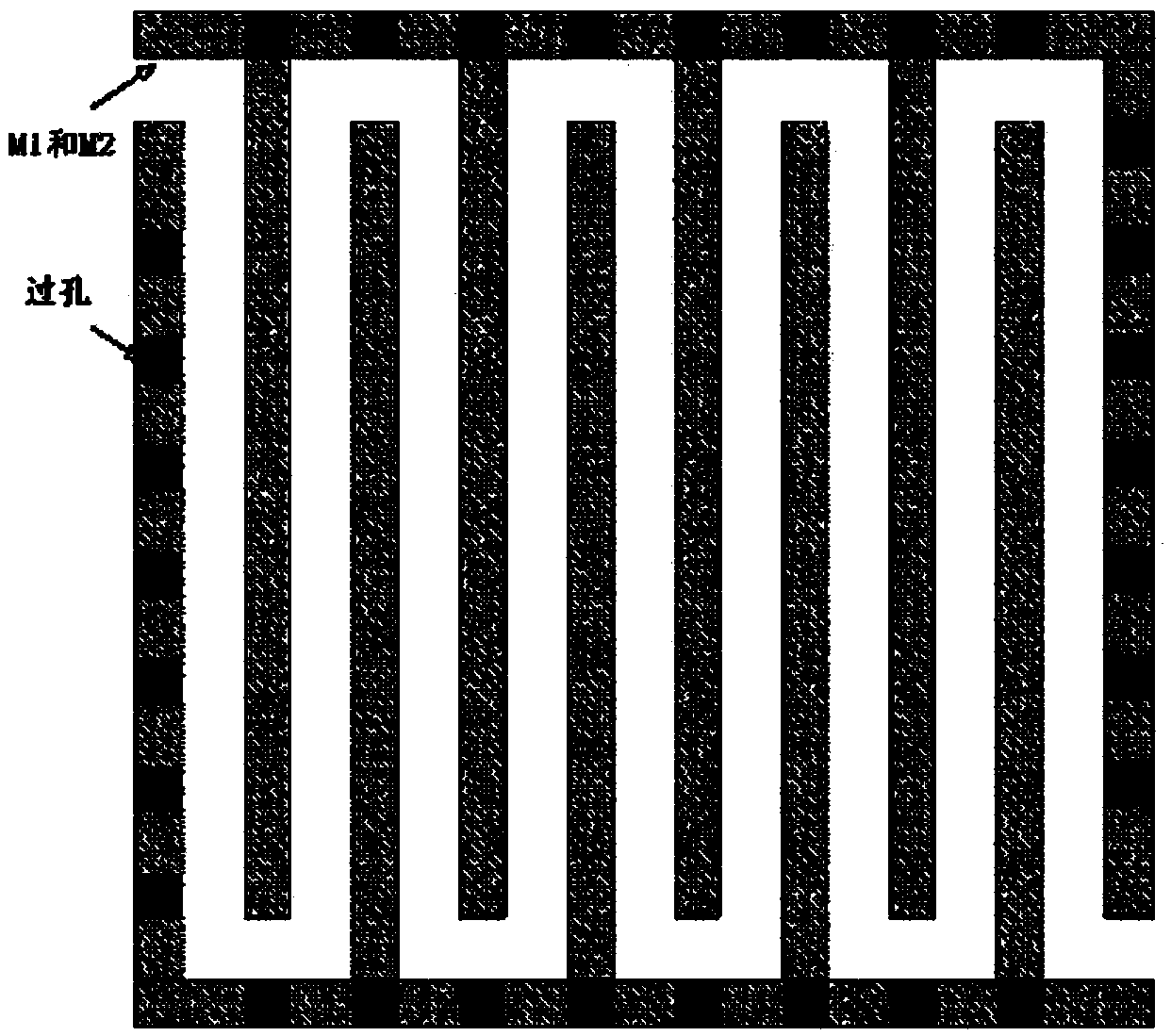

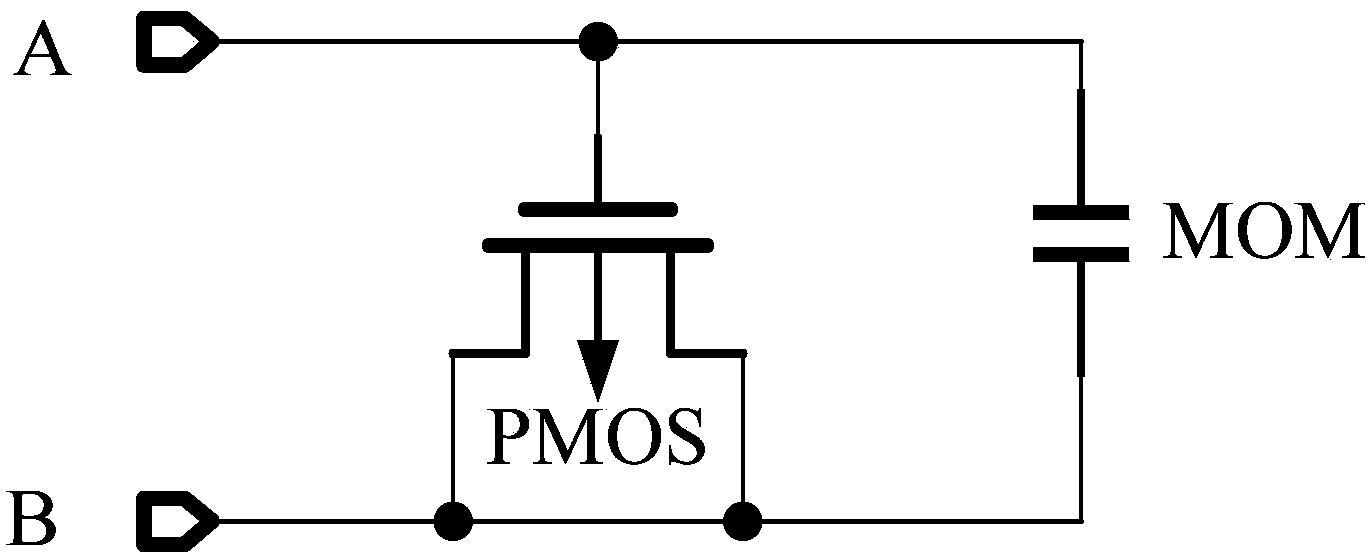

Method for manufacturing capacitors with large unit capacitance in ordinary LOGIC process

InactiveCN103762157AGuaranteed functionReduce manufacturing costSemiconductor/solid-state device manufacturingCapacitorsCapacitanceProcess dimension

The invention discloses a method for manufacturing capacitors with large unit capacitance in an ordinary LOGIC process. On the basis of MOM capacitors, capacitors of MOS transistors are added. A metal insertion finger is designed for the MOM capacitors according to a minimum process dimension, multiple metal layers are arranged according to the structure of the insertion finger, and the arrangement of the MOM capacitors formed by the different metal layers is completely the same. The MOM capacitors and the capacitors of the MOS transistors are of a perpendicular structure, and the capacitors of the MOS transistors are located below the MOM capacitors. The source electrode and the drain electrode of each MOS transistor are connected to form one end of the corresponding capacitor, and the grid electrode of each MOS transistor forms the other end of the corresponding capacitor. The two ends of each MOM capacitor are connected with the two ends of the capacitor of the corresponding MOS transistor, and therefore a parallel connection frame is formed. According to the method, in the specific process, under the condition that the MASK is not increased, the capacitors with the largest unit capacitance are manufactured. When the method is used, production cost of chips can be obviously reduced under the condition that functions of the chips are ensured.

Owner:常州新超电子科技有限公司

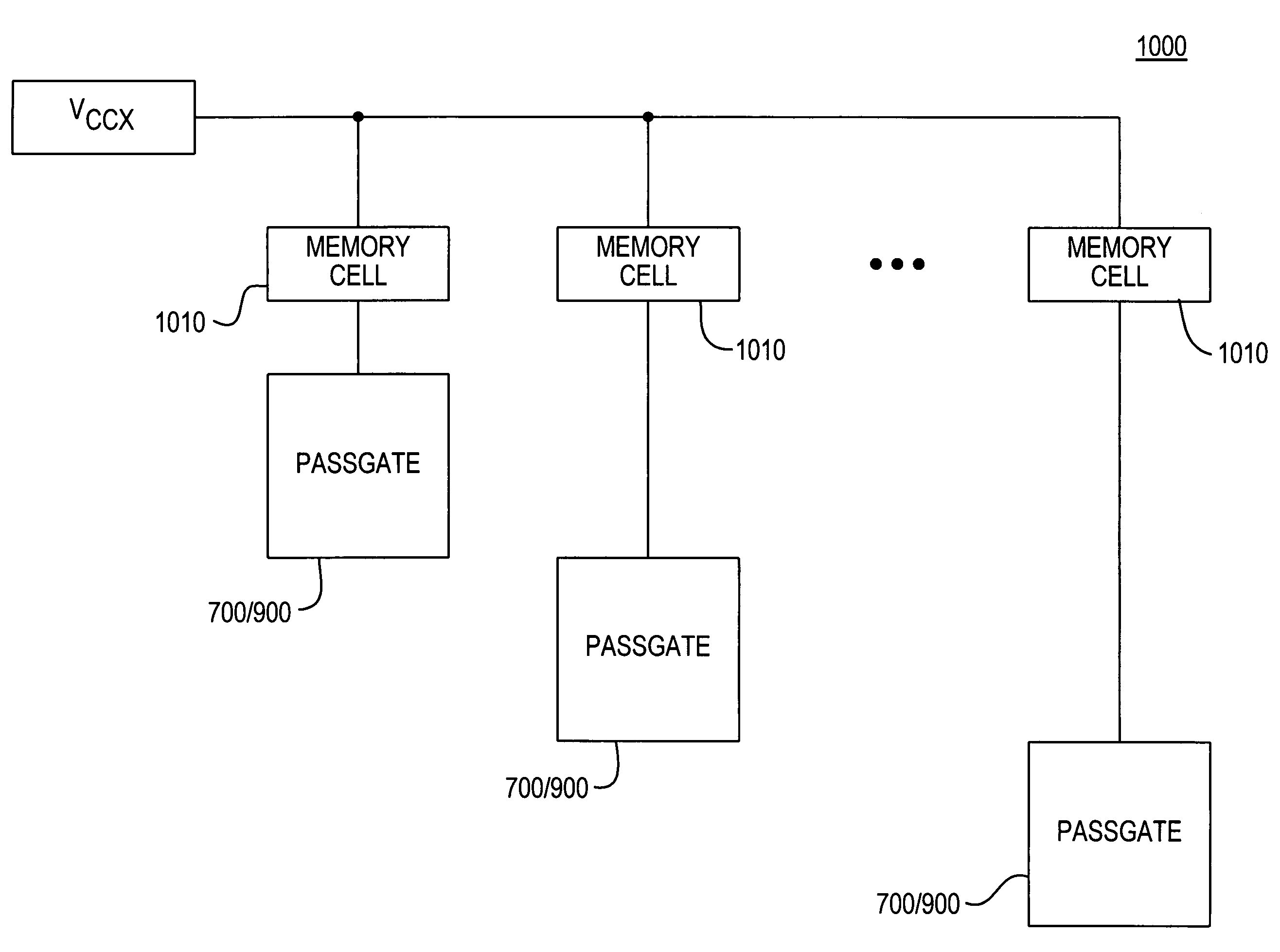

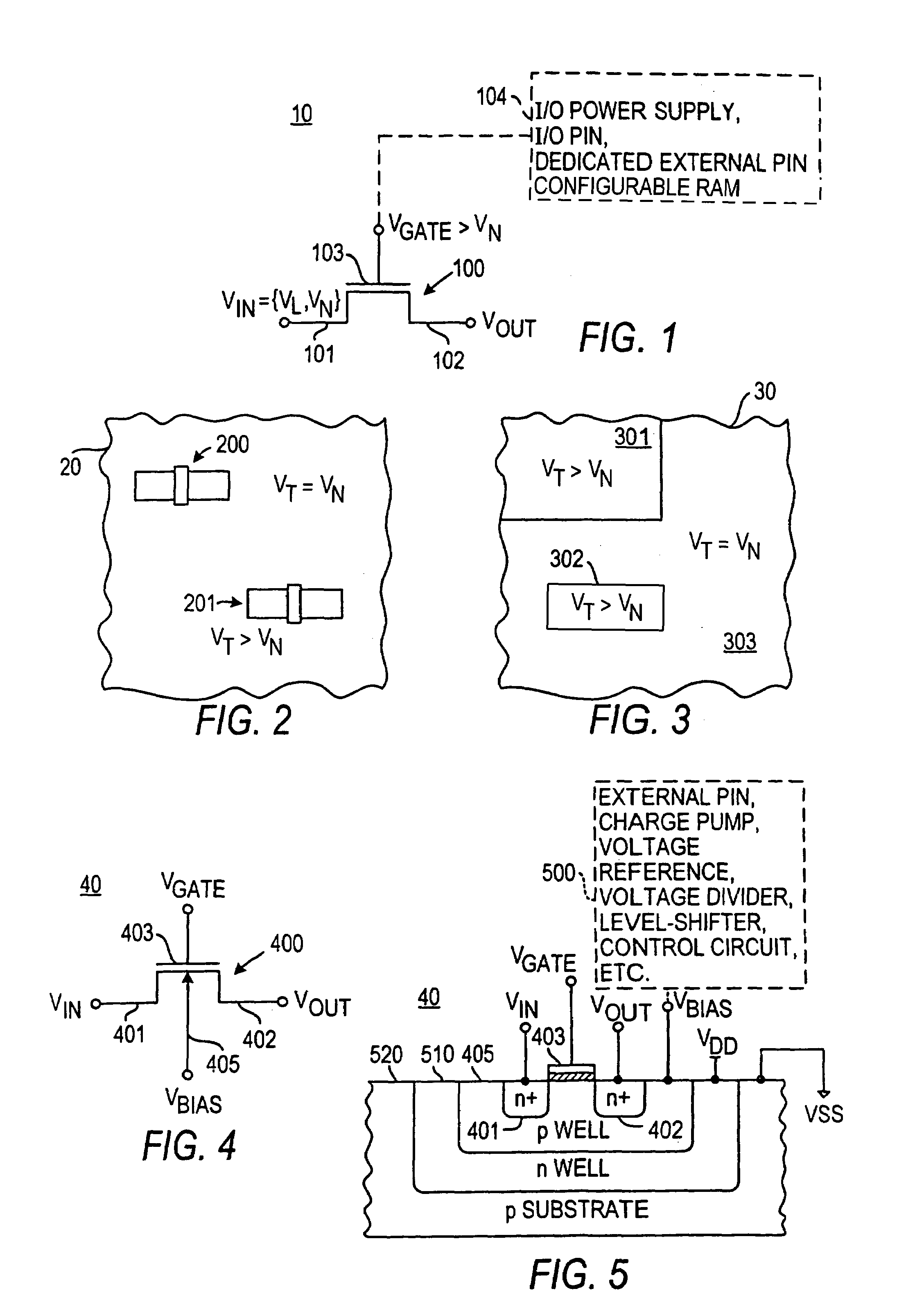

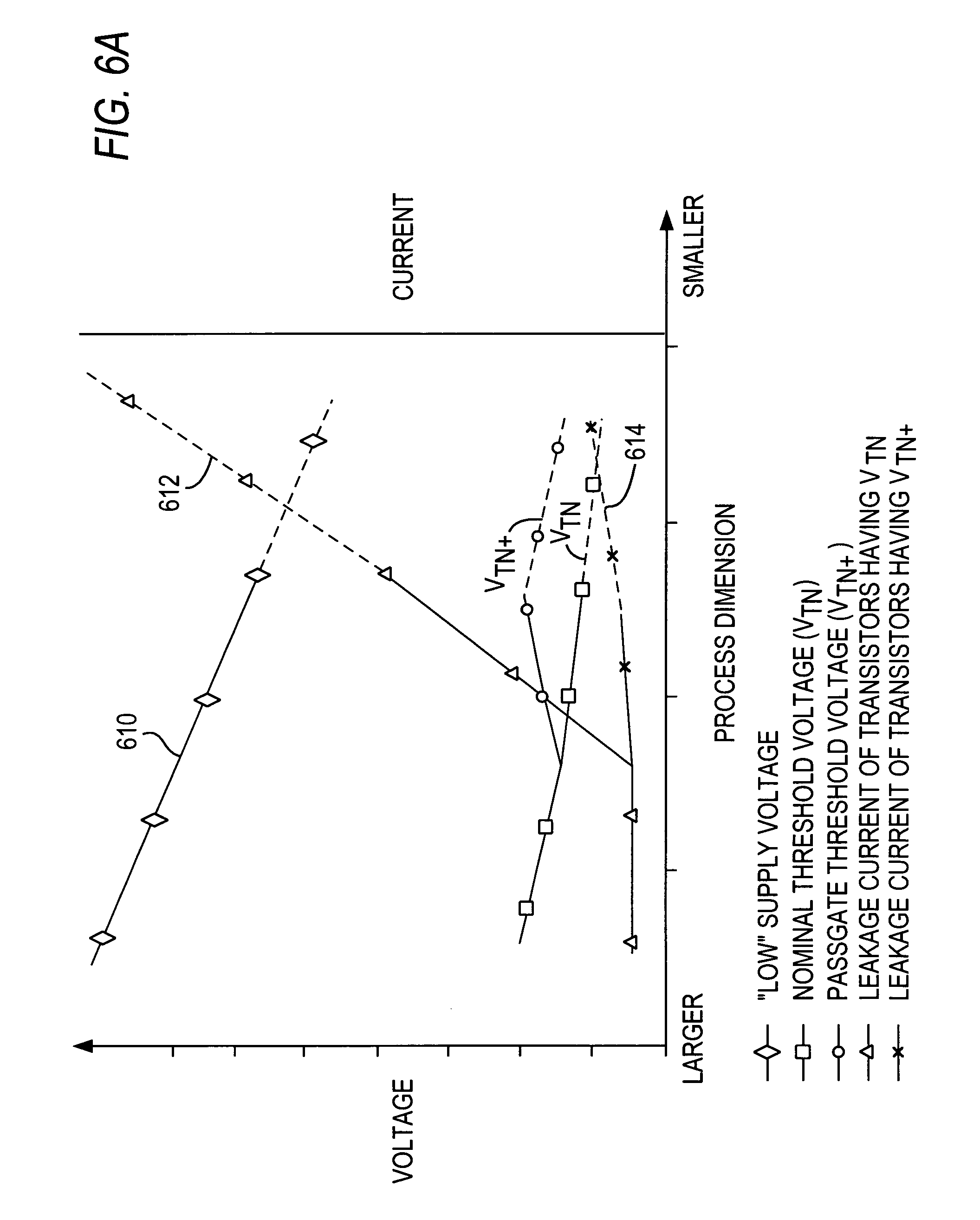

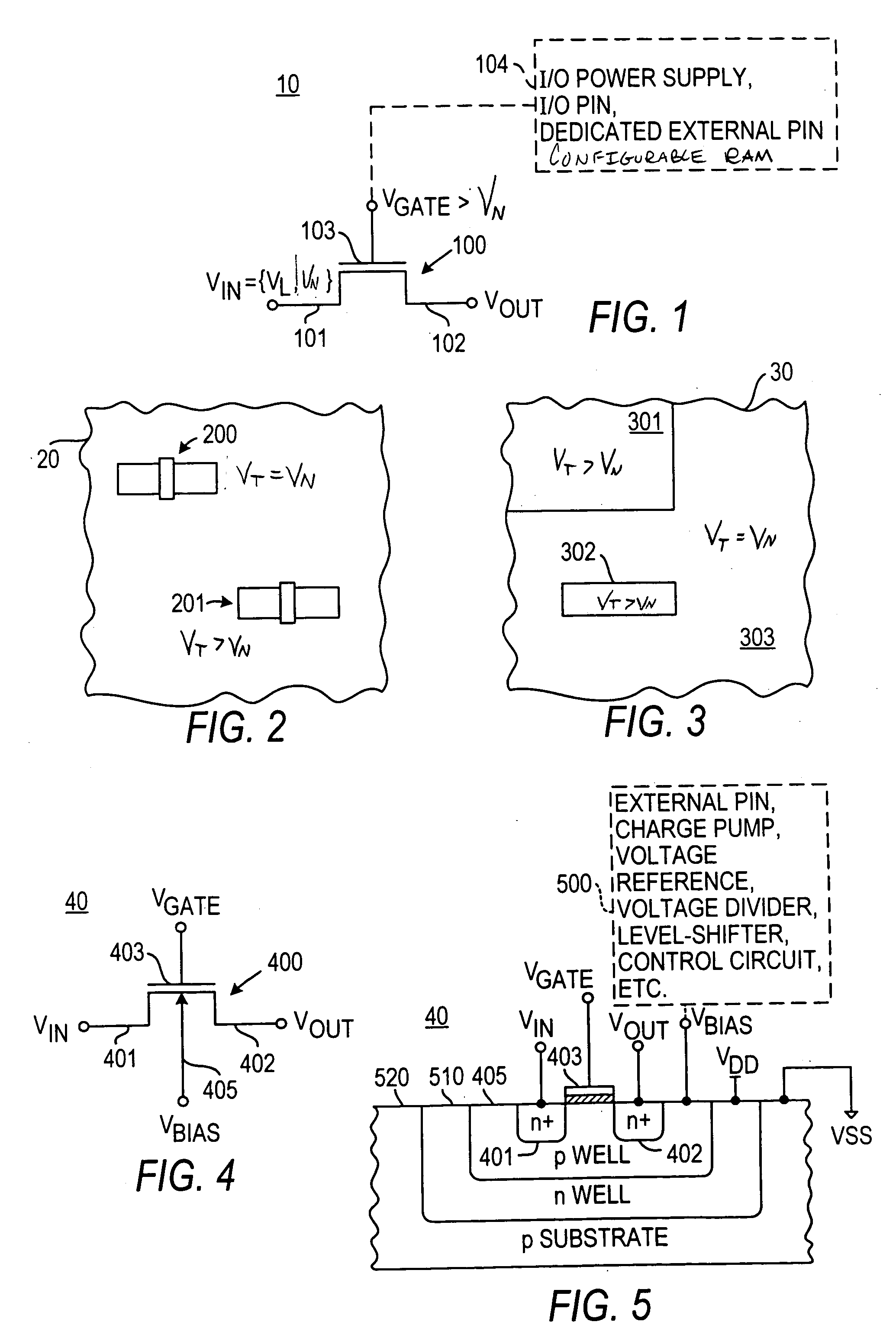

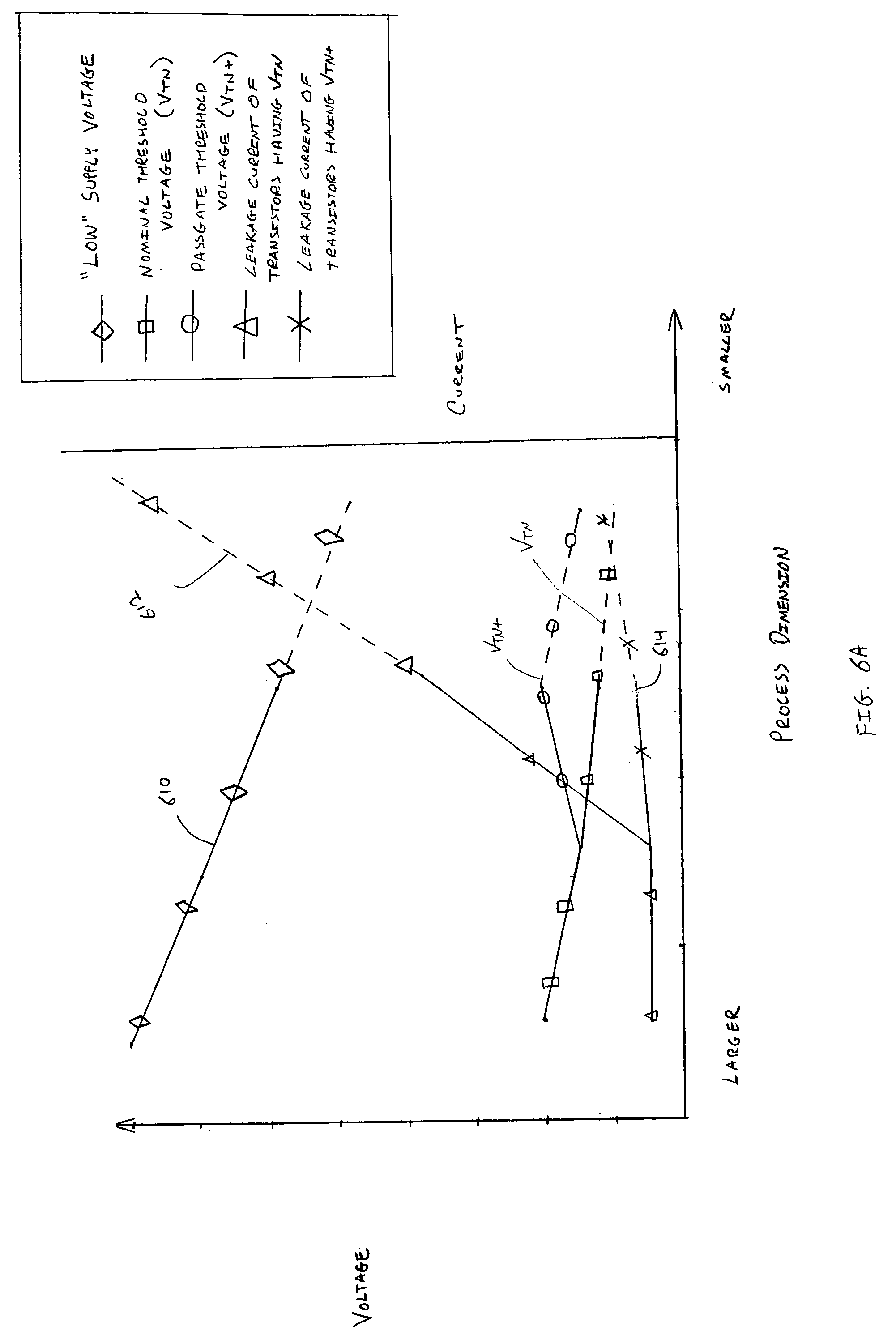

Enhanced passgate structures for reducing leakage current

InactiveUS7292065B2Reduce leakage currentGuaranteed high speed operationSolid-state devicesLogic circuits using elementary logic circuit componentsLow voltageProcess dimension

Enhanced passgate structures for use in low-voltage systems are presented in which the operational speed of the passgate structures is maximized, while minimizing leakage current when the structure is turned “OFF.” In one arrangement, the VT of the pass-gate structures is increased relative to the VT of other transistors fabricated according to a particular process dimension. In addition, a passgate activation voltage is applied to the passgate structures such that the passgate activation voltage is higher in voltage than a nominal voltage being supplied to circuitry other than the passgate structures.

Owner:ALTERA CORP

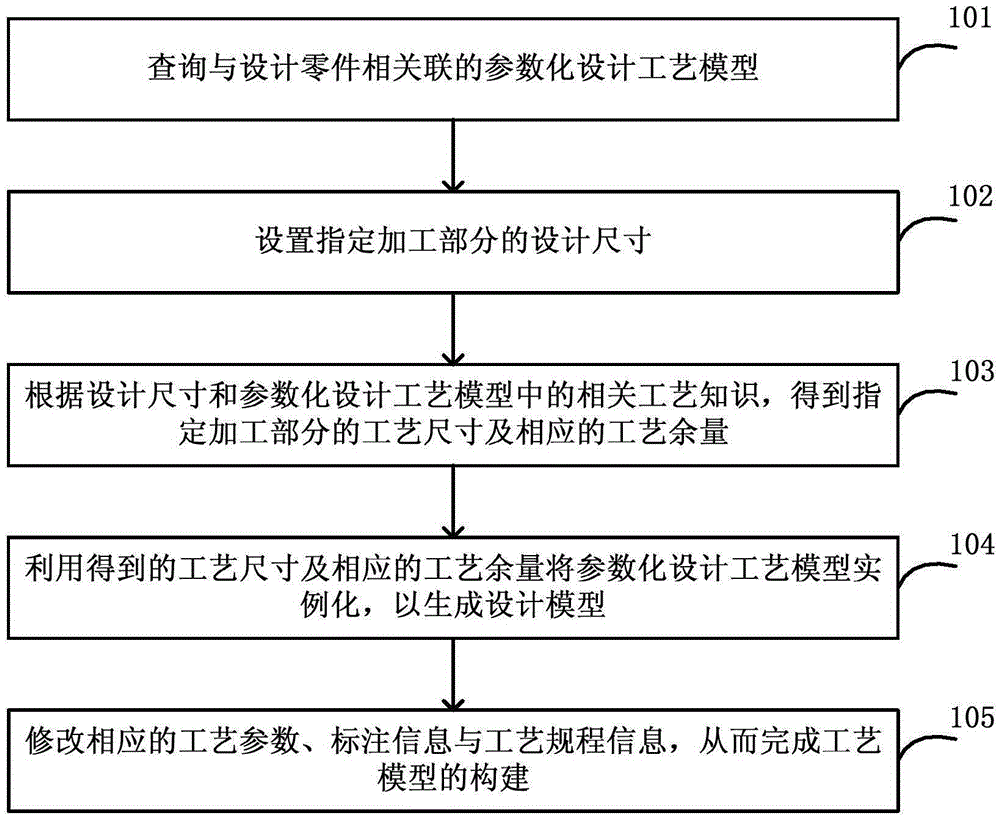

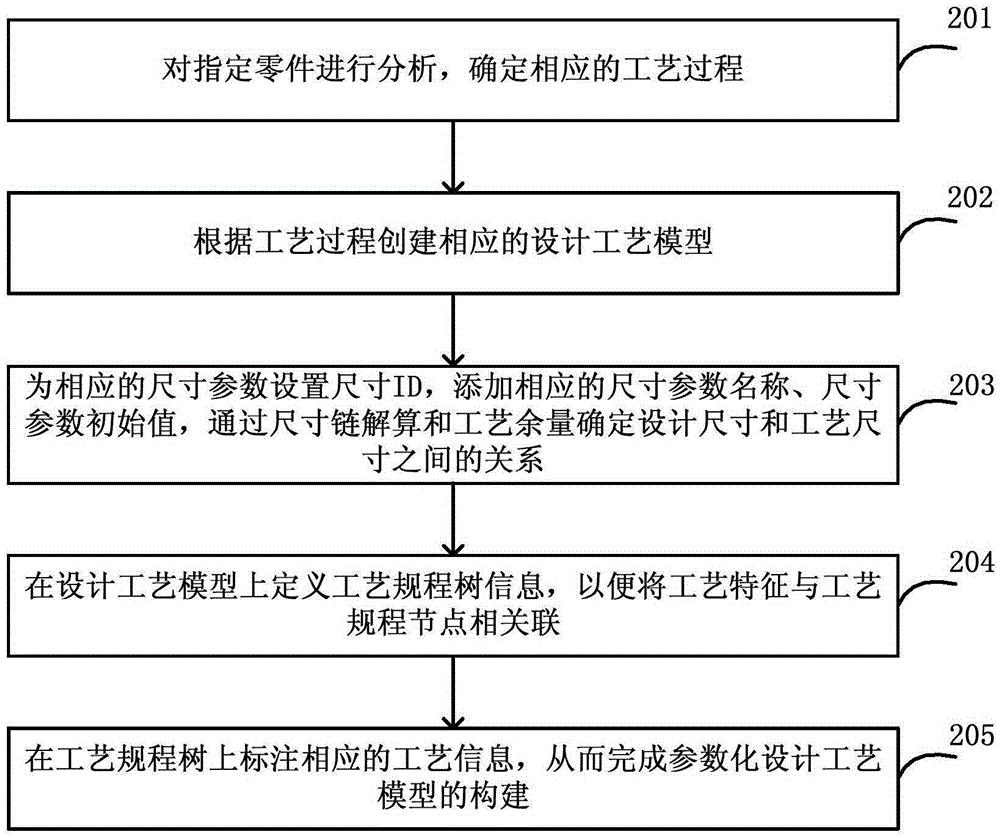

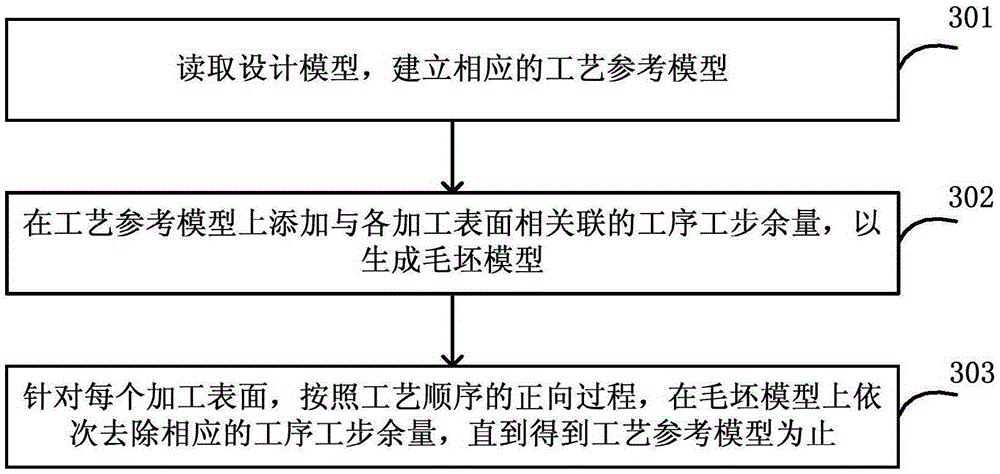

Method and system for constructing process model on the basis of parameterization

InactiveCN105550387AQuick buildBeneficial precipitationSpecial data processing applicationsGenerative DesignProduct modeling

The invention discloses a method and a system for constructing a process model on the basis of parameterization. A parameterization design process model is constructed in advance; when a specific part is designed, the parameterization design process model associated with part design is inquired; the design dimension of an appointed processing part is set; according to the design dimension and relevant process knowledge in the parameterization design process model, the process dimension of the appointed processing part and corresponding process margin are obtained; and the obtained process dimension and the obtained corresponding process margin are used for carrying out instantiation on the parameterization design process model to generate a design model and revise corresponding process parameters, label information and process procedure information so as to finish the construction of the process model. The parameterization DPM (Design Process Model) which is generated in advance is called to construct an instancing model, the quick definition of a product and the quick generation of the process are realized, and product design efficiency is improved. Meanwhile, the process knowledge is combined into a product modeling process so as to be beneficial for the precipitation and the inheritance of enterprise knowledge.

Owner:XCMG CONSTR MACHINERY

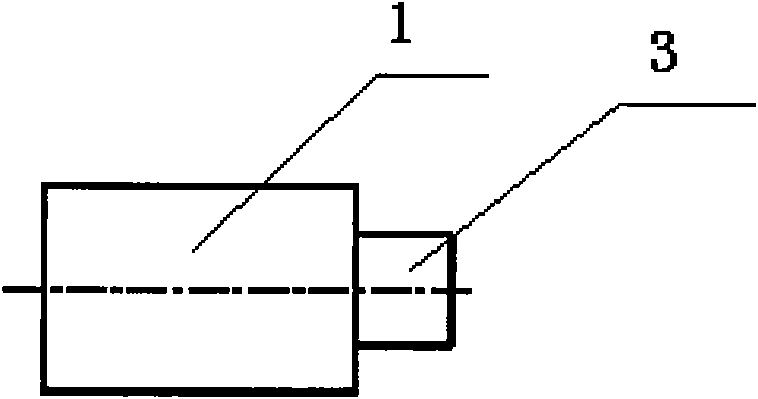

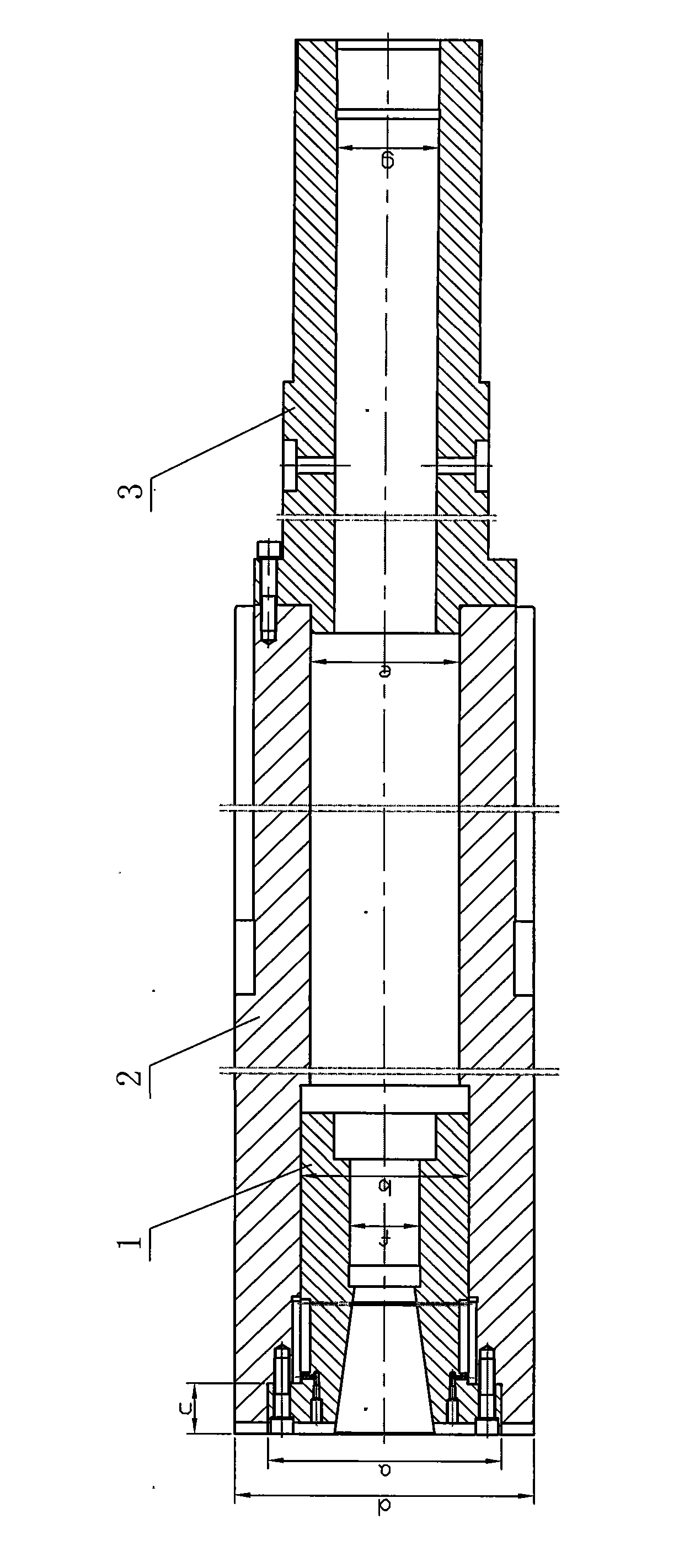

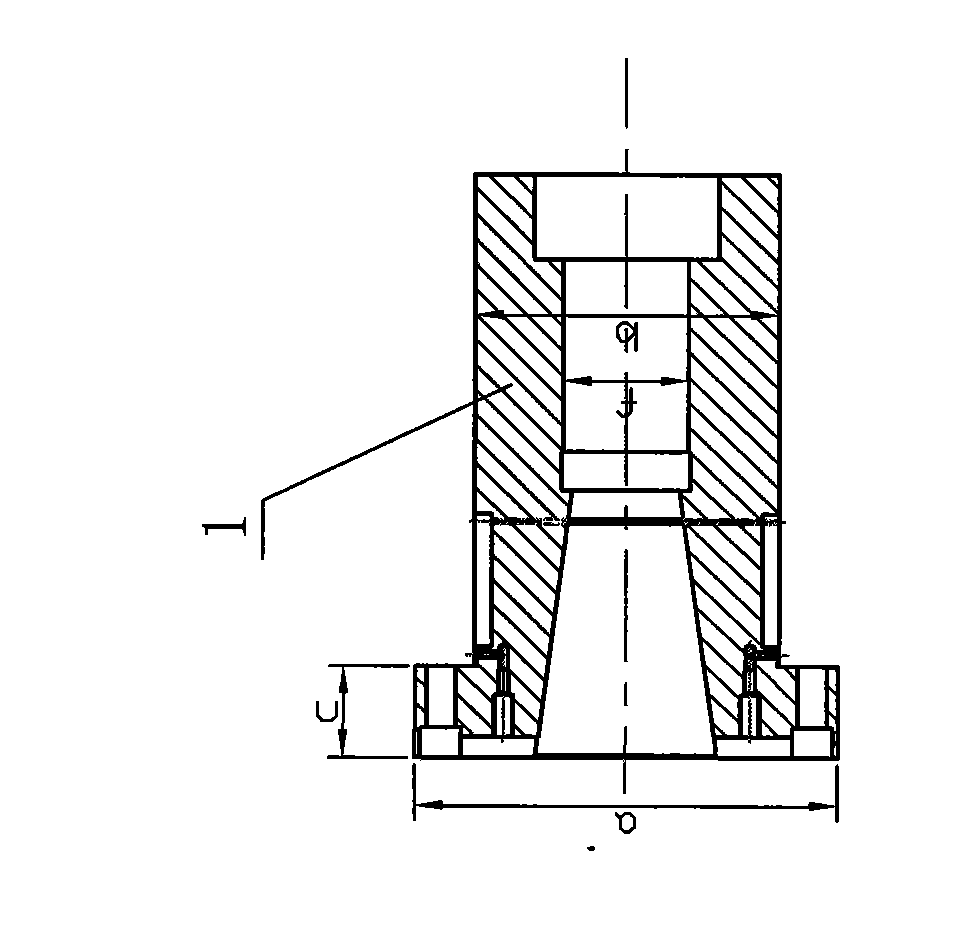

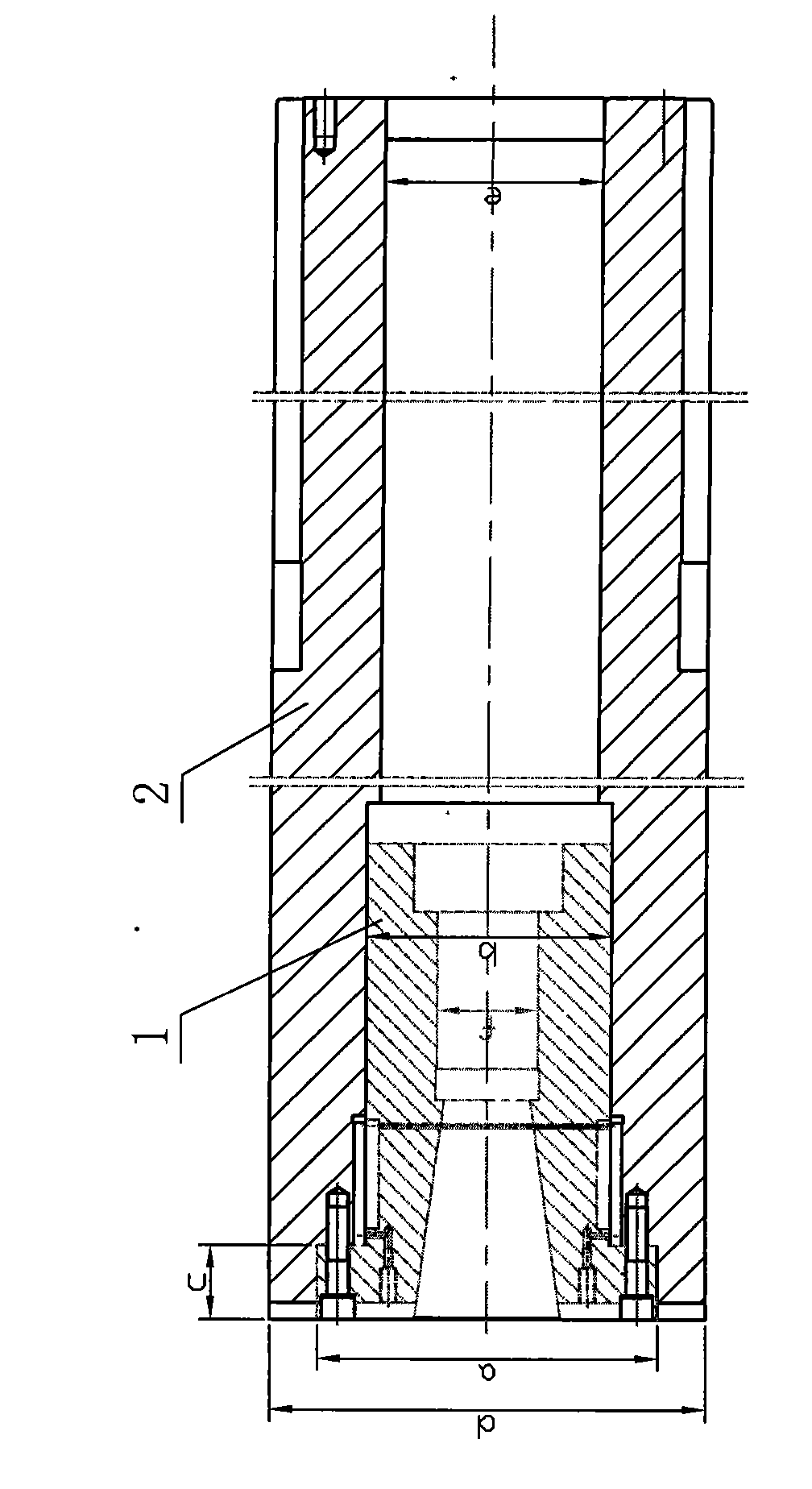

Machining process of combined boring spindle

ActiveCN101637825AAvoid machining the long axis at one timeReduce processing difficultyMetal-working apparatusEngineeringProcess dimension

The invention relates to a machining process of a combined boring spindle, mainly solving the problem that the coaxiality of a front end hole, a tail hole and an outer ring can not reach 0.01 requiredin the prior boring spindle machining. The method comprises the following steps: blanking and respectively normalizing, rough machining and ageing; match grinding the outer circles a, b of a front section (1) and a middle section (2), processing dimension c to reach the requirement of a graph paper, grinding an inner circle f in the front section (1) and an inner circle g in a back section (3) toreach the requirement of the graph paper, processing an outer circle d and an inner circle e of the middle section (2), match grinding the outer circle e of the back section (3) and the middle section (2); combining the front section (1) with the middle section (2), processing the left end surface of an overall length, and then nitriding the combined front section (1) and the combined middle section (2), injecting glue by glue injection holes; combining the back section (3) with the front section (1) and the middle section (2), and after fastening, machining all dimensions to reach the requirement of the graph paper. The method for processing the combined boring spindle has low processing difficulty and high precision and reduces the labor intensity.

Owner:通用技术齐齐哈尔二机床有限责任公司

Preparation method for high temperature battery positive electrode

InactiveCN103236516AImprove high temperature performanceUniform particle sizePrimary cell electrodesLithiumFiber

The invention relates to a preparation method for a high temperature battery positive electrode, especially to a preparation method for a lithium thionyl chloride battery positive electrode. The preparation method for the high temperature battery positive electrode is characterized by comprising the following steps: 1) mixing; 2) shot blasting; 3) extrusion of a carbon bag; 4) drying and fiber making; 5) crushing and infiltration; 6) laying of a screen; 7) rolling; 8) fiber making; and 9) molding, wherein precision pressing is carried out on a carbon sheet according to batteries with different models so as to obtain appropriate process dimensions of the carbon sheet. The preparation method provided by the invention enables high temperature performance of a lithium thionyl chloride battery to be substantially improved.

Owner:河南直通电子能源科技有限公司

Silicon germanium heterojunction NPN (negative-positive-negative) transistor and manufacture method

ActiveCN102544079ASimple processRealize exportSemiconductor/solid-state device manufacturingSemiconductor devicesHeterojunctionImpurity doping

The invention discloses a silicon germanium heterojunction NPN (negative-positive-negative) transistor. A collector region is formed in an active region, is connected with N-type pseudo buried layers at the bottoms of shallow trench field oxides on two sides of the active region and is led out through deep-hole contacts, an emitter window is formed through outer spacers, a P-type silicon germanium epitaxial layer at the bottom of the emitter window is an intrinsic base region, outer base regions are formed on the P-type silicon germanium epitaxial layer outside the emitter window through further impurity doping by means of ion implantation, the outer spacers can prevent ions of the outer base regions from influencing the intrinsic base region, an emitter region consists of N-type polycrystalline silicon which is completely filled into the emitter window and extends out of the emitter window from the top of the emitter window. The invention further discloses a manufacture method for the silicon germanium heterojunction NPN transistor. The silicon germanium heterojunction NPN transistor has the advantages that the dimension of the transistor can be reduced, parasitic resistance can be reduced, characteristic frequency can be improved, the process flow can be simplified, use of photomasks is decreased, cost is reduced, and the process dimension is accurately controlled.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

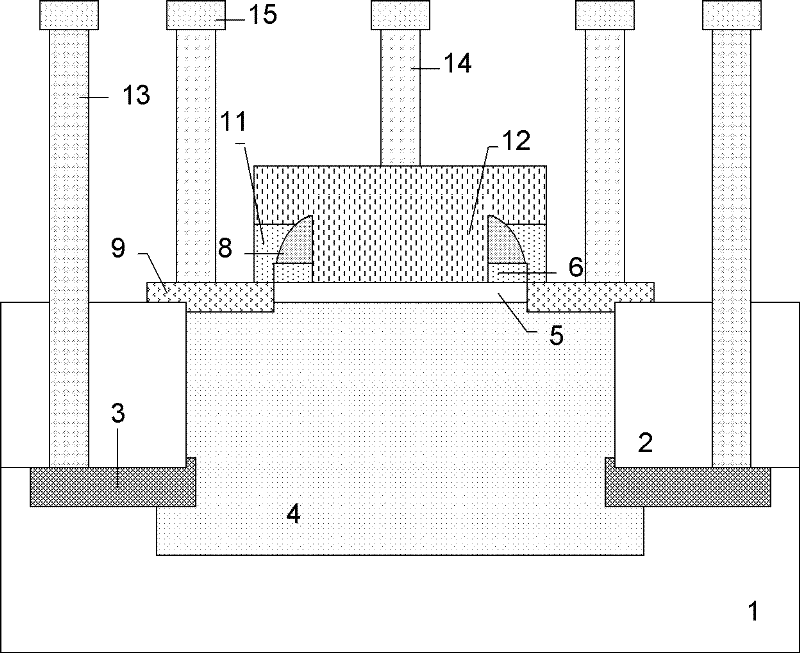

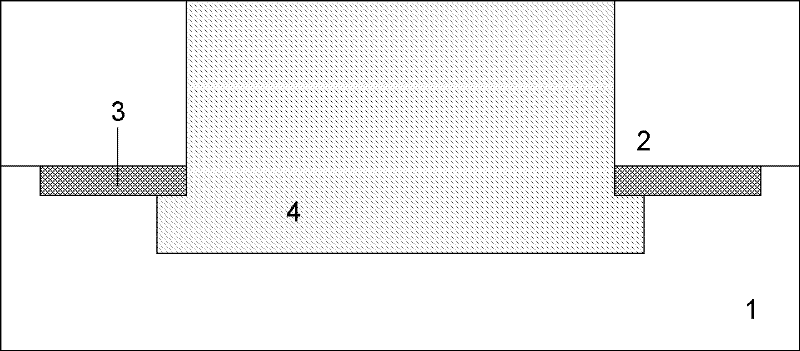

Double-end-face over-locating fixture

ActiveCN103962597AEnsure tight fitGuarantee the problem of unstable process sizeExpansion mandrelsHydraulic cylinderPull force

The invention provides a double-end-face over-locating fixture. The double-end-face over-locating fixture comprises a pull rod, a connecting disk and a mandrel, wherein the pull rod is connected with a hydraulic cylinder of a machine tool, the connecting disk is connected with the pull rod in a matched mode for transmitting the pull force of the pull rod, and the mandrel is mounted on the connecting disk in a sleeved mode and fixedly connected with a machine tool workbench. An over-locating pad used for axially locating and limiting a workpiece is fixedly mounted on the mandrel. The connecting disk is also connected with an expansion sleeve, and the mandrel is sleeved with the expansion sleeve. The expansion sleeve is pulled through the pull rod, the expansion sleeve expands in an inner hole of the workpiece and tightens the workpiece, and the workpiece is pulled backwards to generate certain controllable axial deformation; before the workpiece is turned, the expansion sleeve is pulled backwards to make a part be tightened in the radial direction and the end face be located in the axial direction; meanwhile, since the over-locating pad is adopted to locate and limit the workpiece, the problem that process dimensions are unstable because the thin-walled part generates uncontrollable elastic deformation and molding deformation in the turning process under the influence of back pull force generated by pulling the expansion sleeve backwards and the extrusion force generated in the cutting process of a blade is avoided, a process dimensional tolerance and a related form and location tolerance are guaranteed, and the stability of machining dimensions is also guaranteed.

Owner:西安双特智能传动有限公司

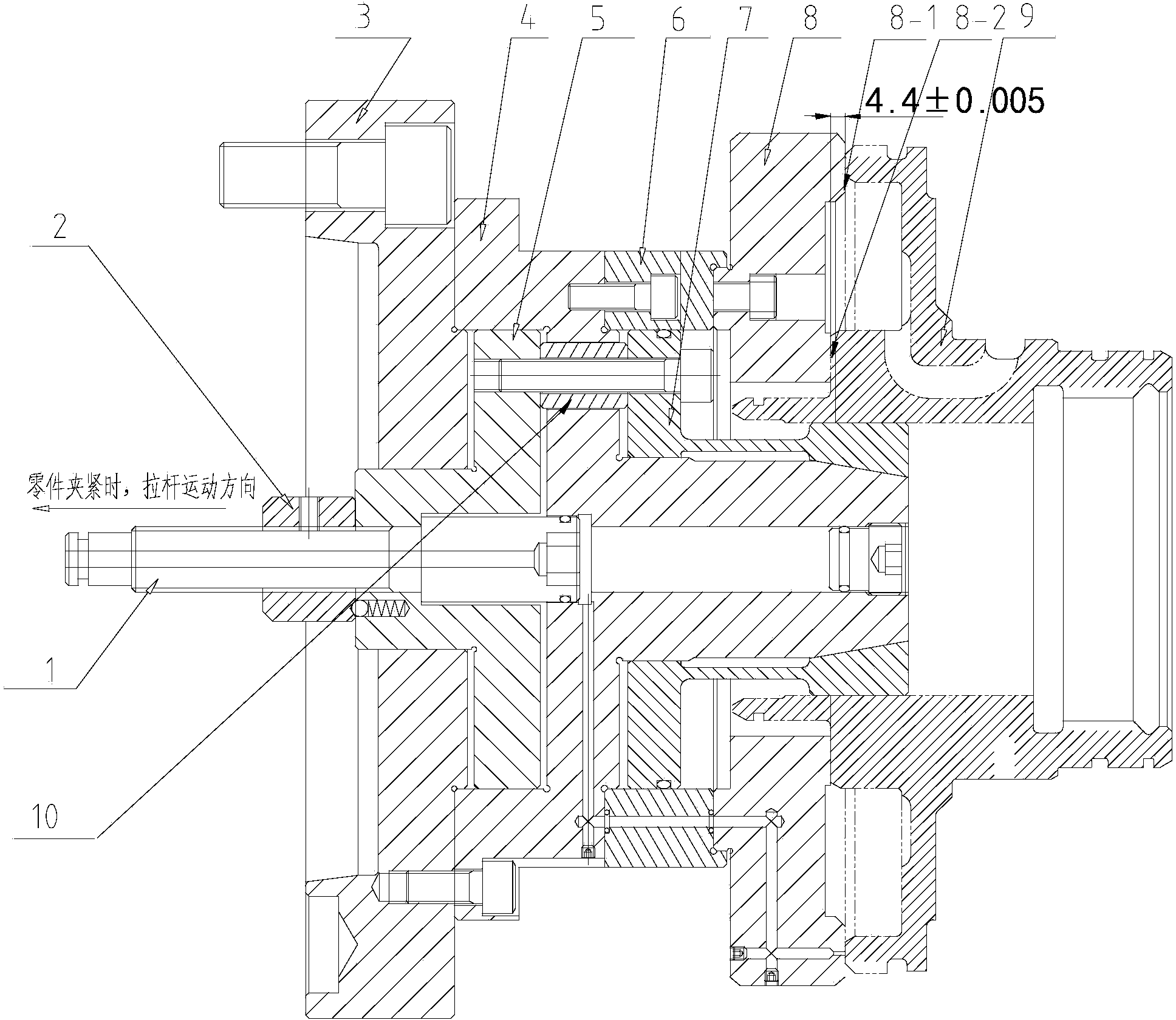

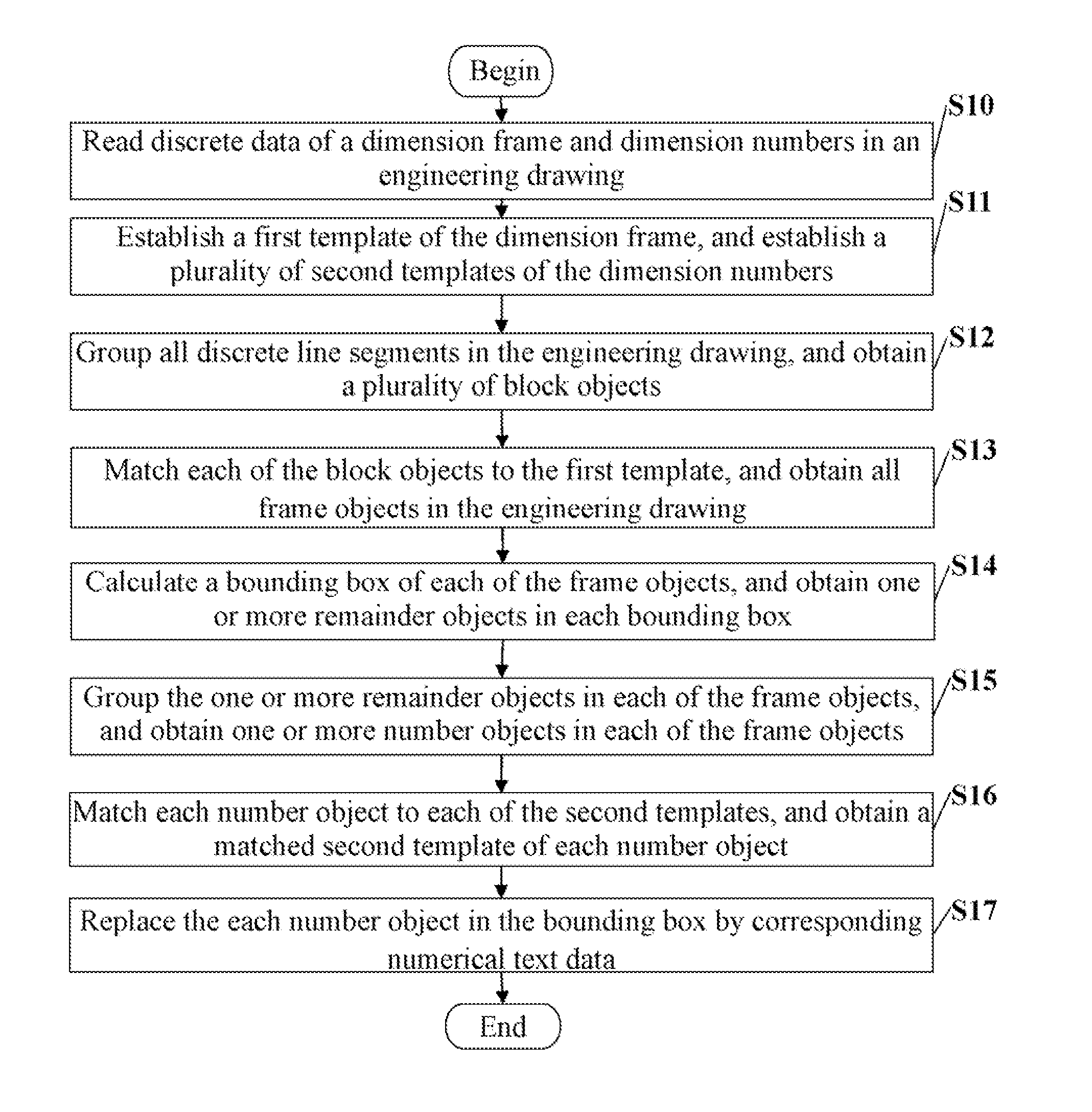

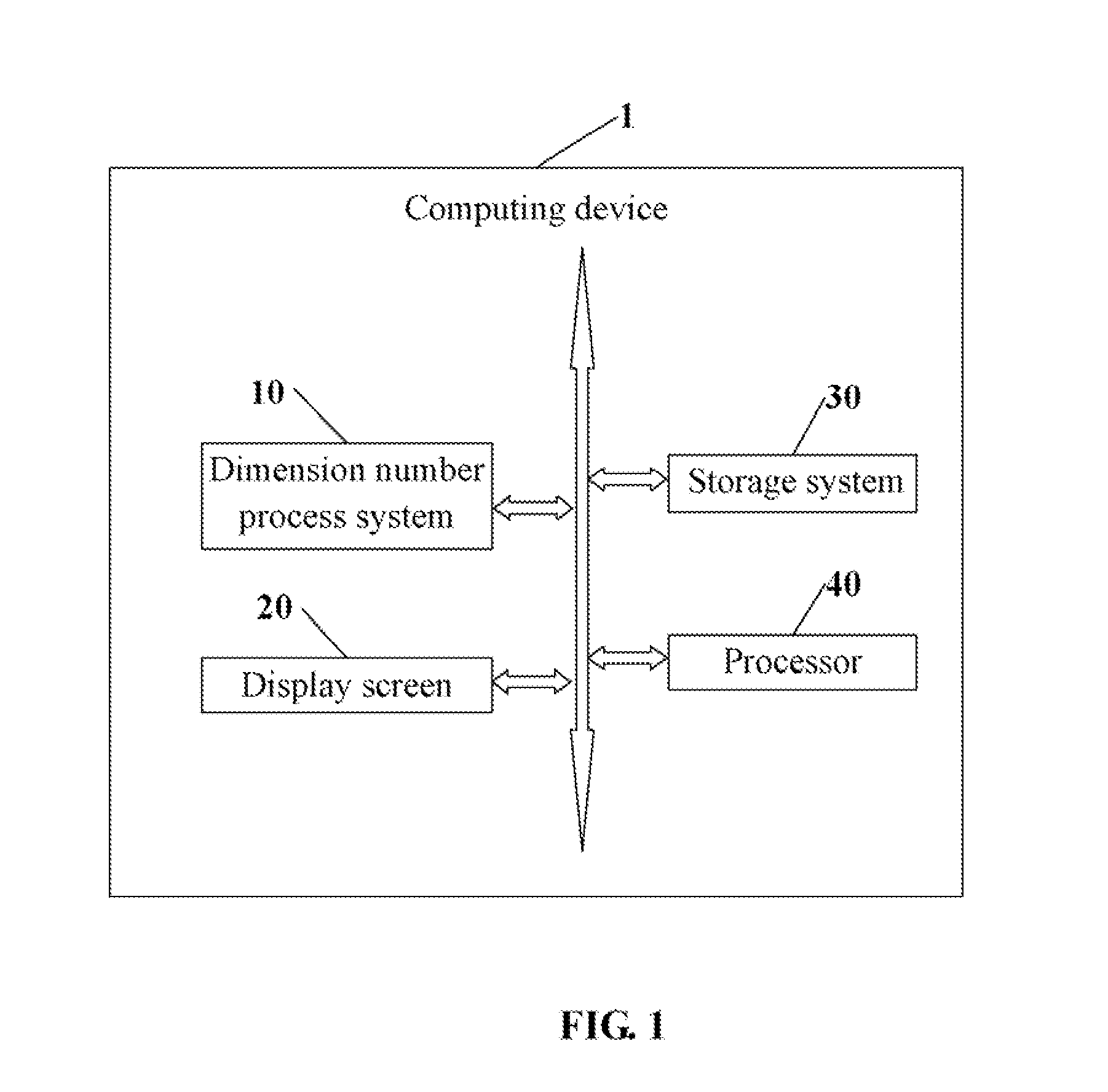

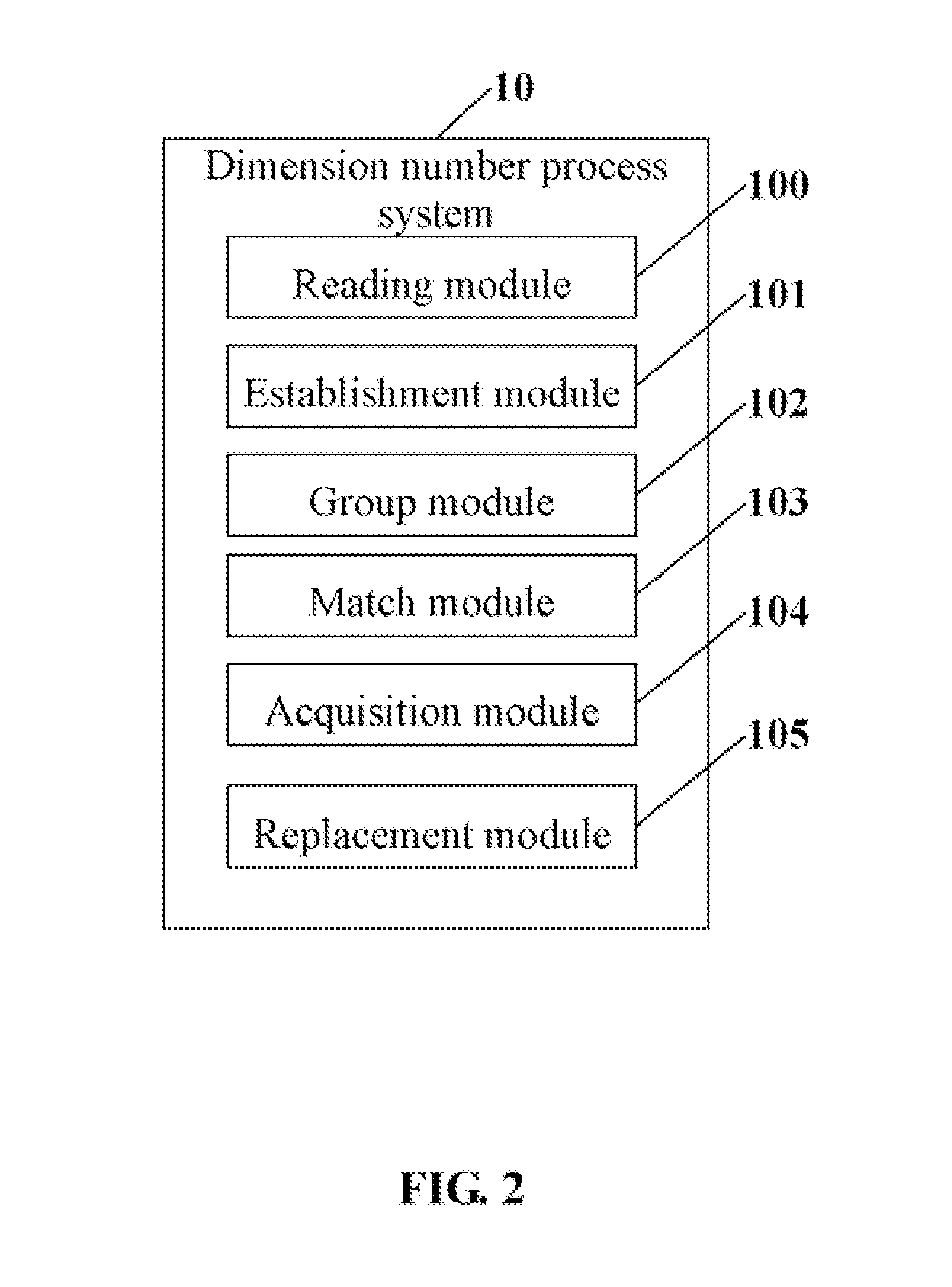

Computing device, storage medium and method for processing dimension numbers using the computing device

InactiveUS20130103361A1Character and pattern recognitionComputer aided designTemplate matchingProcess dimension

A method for processing dimension numbers using a computing device, a first template of a dimension frame and a plurality of second templates of dimension numbers 0-9, and a numerical text data of each second template are established. A plurality of block objects are obtained by grouping all discontinuous line segments in the engineering drawing. All frame objects in the engineering drawing are obtained by matching each of the block objects with the first template. One or more remainder objects in each bounding box are obtained, and grouped to obtain one or more number objects in each of the frame objects. A matched second template of each of the number objects is obtained by matching each of the number objects with each of the second templates. The number objects in each of the frame objects are replaced by corresponding numerical text data.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

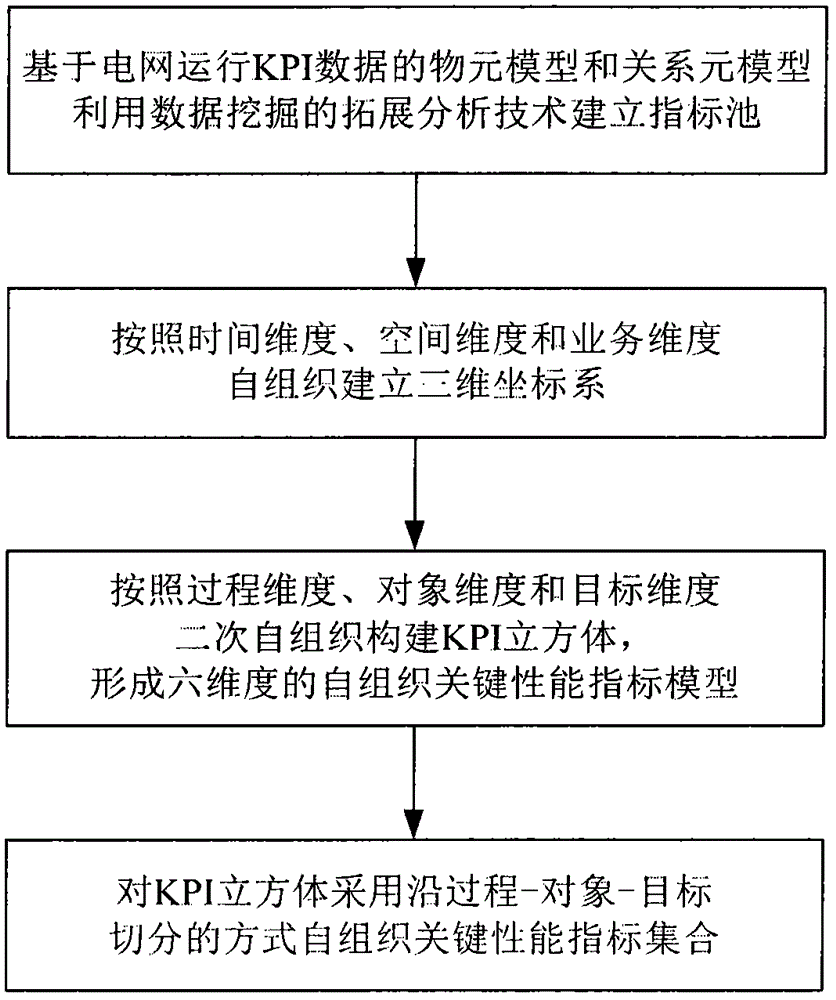

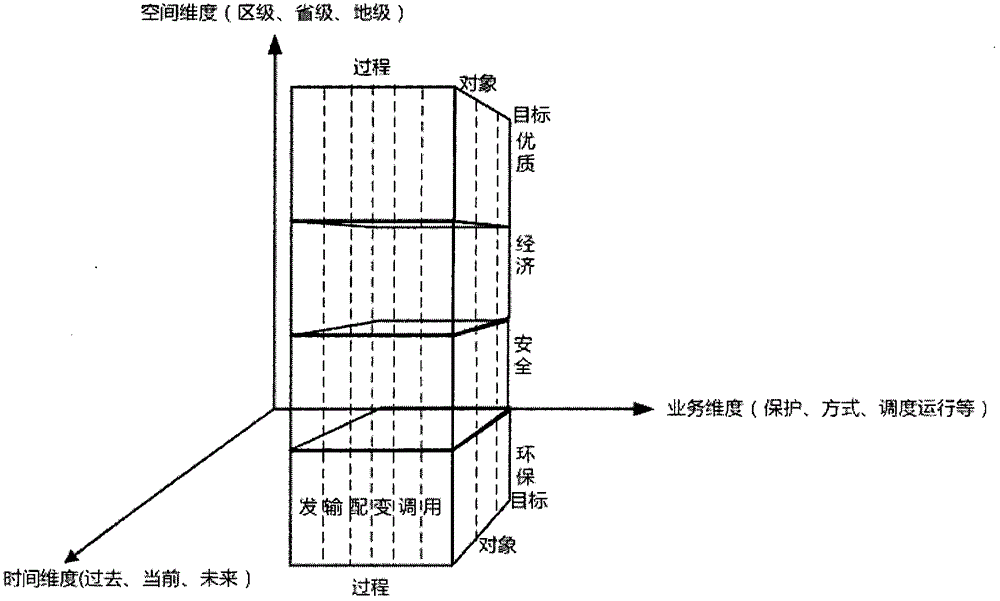

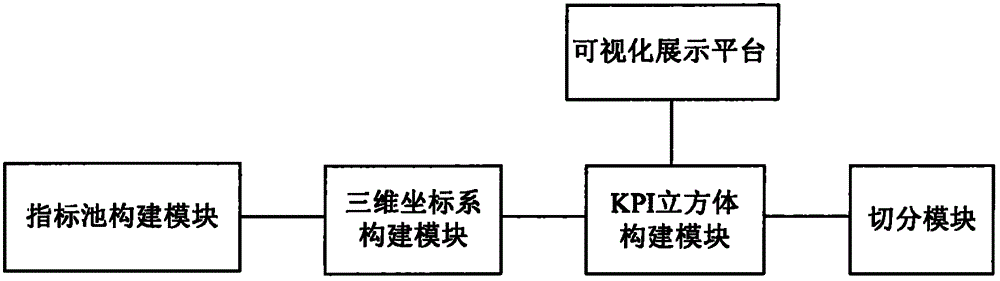

Modeling method and device for automatically organizing key performance indicators

InactiveCN104574218AWith refinementImprove scalabilityData processing applicationsInformation technology support systemModel methodElement model

The invention relates to a modeling method and device for automatically organizing key performance indicators. According to the method, based on an object element model and a relation meta model of power grid running KPI data, the expansion analysis technology for data mining is utilized for setting up an indicator pool, then the KPI data in the indicator pool are automatically organized according to the time dimension, the space dimension and the service dimension to set up a three-dimensional coordinate system, on the basis of the three-dimensional coordinate system, the KPI data are automatically organized secondarily according to the process dimension, the object dimension and the target dimension to construct a KPI cube to form a six-dimensional automatic key performance indicator organizing model, and then according to a decision-making objectives of power grid service, the KPI cube is segmented along the process dimension, the object dimension and the target dimension for automatically organizing a key performance indicator set. According to the method, according to different kinds of service and the decision-making objectives, the key performance indicators and correlation control strategies can be organized automatically and efficiently, and by setting up the automatic key performance indicator organizing model, the actual running state of a power grid can be mastered fast, accurately and comprehensively.

Owner:YUNNAN ELECTRIC POWER DISPATCH CONTROL CENT +1

6000-series high-performance aluminum alloy plate for automobile panel and manufacturing method thereof

The invention relates to a 6000-series high-performance aluminum alloy plate for an automobile panel and a manufacturing method thereof. The 6000-series high-performance aluminum alloy plate contains Si, Fe, Cu, Mn and Mg and comprises a 6016 high-performance aluminum alloy plate, a 6022 high-performance aluminum alloy plate and a 6111 high-performance aluminum alloy plate. The manufacturing method comprises the following steps: adding an alloy, determining a metallographical refinement level, casting an aluminum plate ingot of a certain thickness, carrying out mechanical cold working to a certain process dimension, determining gate arrangements, rolling reductions and front and back tensile forces for hot rolling and cold rolling, carrying out recrystallization annealing at 370-390 DEG C for 10-20 minutes, thereby manufacturing the 6000-series high-performance aluminum alloy plate for an automobile panel. Thus, the invention achieves the purposes of automobile weight reduction, energy conservation and emission reduction.

Owner:JIANGSU CAIFA ALUMINUM

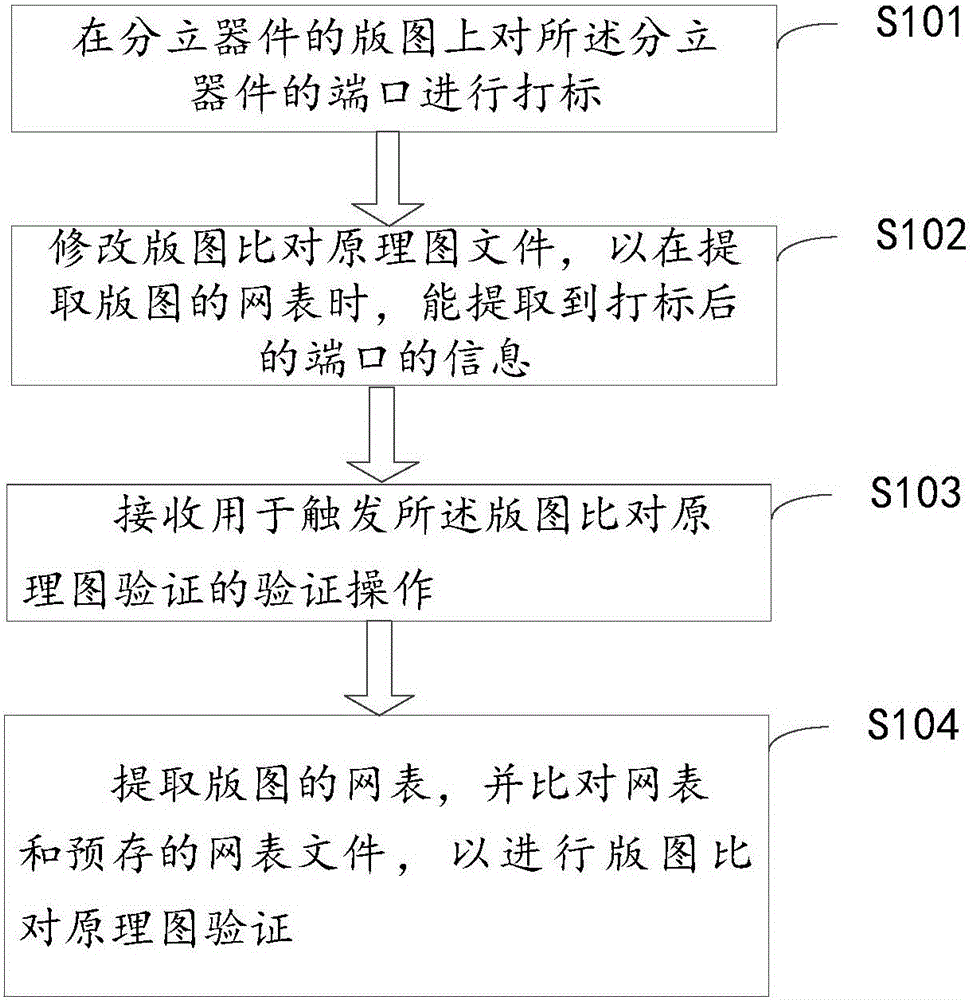

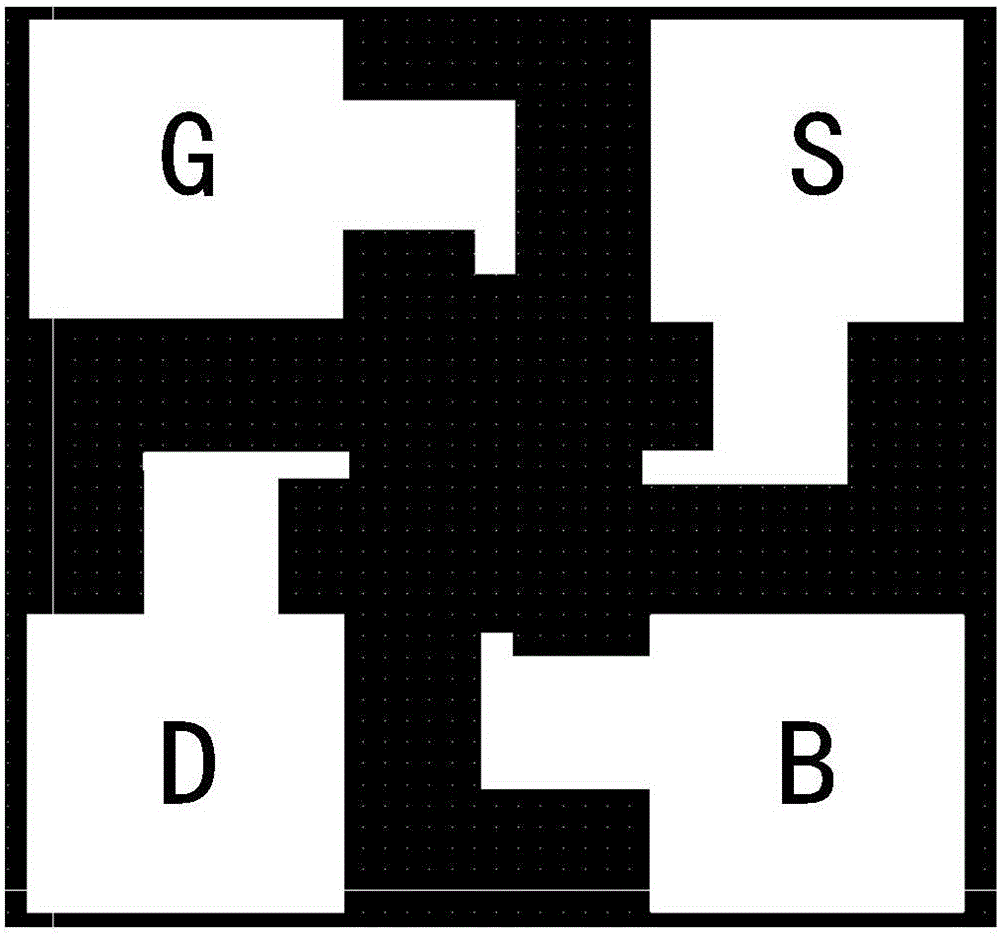

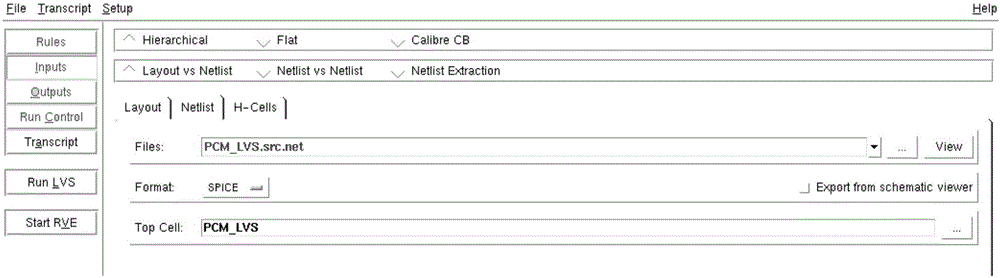

Layout comparing schematic verifying method and device of discrete device

ActiveCN105844012AImprove the efficiency of LVS verificationImprove accuracySpecial data processing applicationsProcess dimensionLayout Versus Schematic

The invention discloses a layout comparing schematic verifying method and device of a discrete device. The method comprises the following steps: marking ports of the device on a layout of the discrete device; modifying a layout comparing schematic file to ensure that the information of the marked ports can be extracted when a netlist of the layout of the discrete device is extracted; receiving a verifying operation for triggering the layout comparing schematic verifying; and extracting the netlist of the layout and comparing the netlist with a prestored netlist file to carry out the layout comparing schematic verifying, wherein the netlist file comprises port information and process dimension information of the verified device. The method and the device which are provided by the invention have the advantages that the technical problems that in the prior art, circuit drawing is needed for the LVS (Layout Versus Schematics) verification of the discrete device, the efficiency is low and the error rate is high without the LVS verification are solved; and the technical effects of increasing the efficiency of carrying out the LVS verification on the discrete device and increasing the layout accuracy are realized.

Owner:SOI MICRO CO LTD

Enhanced passgate structures for reducing leakage current

InactiveUS20060028240A1Reduce leakage currentGuaranteed high speed operationSolid-state devicesLogic circuits using elementary logic circuit componentsLow voltageProcess dimension

Enhanced passgate structures for use in low-voltage systems are presented in which the operational speed of the passgate structures is maximized, while minimizing leakage current when the structure is turned “OFF.” In one arrangement, the VT of the pass-gate structures is increased relative to the VT of other transistors fabricated according to a particular process dimension. In addition, a passgate activation voltage is applied to the passgate structures such that the passgate activation voltage is higher in voltage than a nominal voltage being supplied to circuitry other than the passgate structures.

Owner:ALTERA CORP

Hot-working process capable of improving cogging for titanium alloy cast ingot

The invention discloses a hot-working process capable of improving the cogging for a titanium alloy cast ingot. The process comprises the following steps of: 1, scalping the titanium alloy cast ingot and then cutting off a dead head, and then removing the surface defects of the titanium alloy cast ingot by means of grinding; 2, placing the titanium alloy cast ingot in a heating furnace to preheat, and then heating up to 150-200 DEG C above the phase transformation point of a cast ingot beta and preserving heat; 3, placing the heat-preserved titanium alloy cast ingot on a press of greater than 2000 T, and then performing cogging forging, so as to obtain a titanium alloy blank with one end which is forged to process dimensions; and step 4, placing the titanium alloy blank with one end which is forged to process dimensions in the heating furnace, heating, and forging the other end to the process dimensions in the same manner. The hot-working process disclosed by the invention is easy to realize standardized work, and reduce the instability phenomenon of head shrinkage cavity caused by human factors, thus increasing the yield of products; and with the adoption of the process method, the blanks which are less in end-surface shrinkage cavity removal amount and good in surface quality can be produced, thus increasing the yield of products.

Owner:WESTERN TITANIUM TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com