Patents

Literature

375results about How to "Improve tissue performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

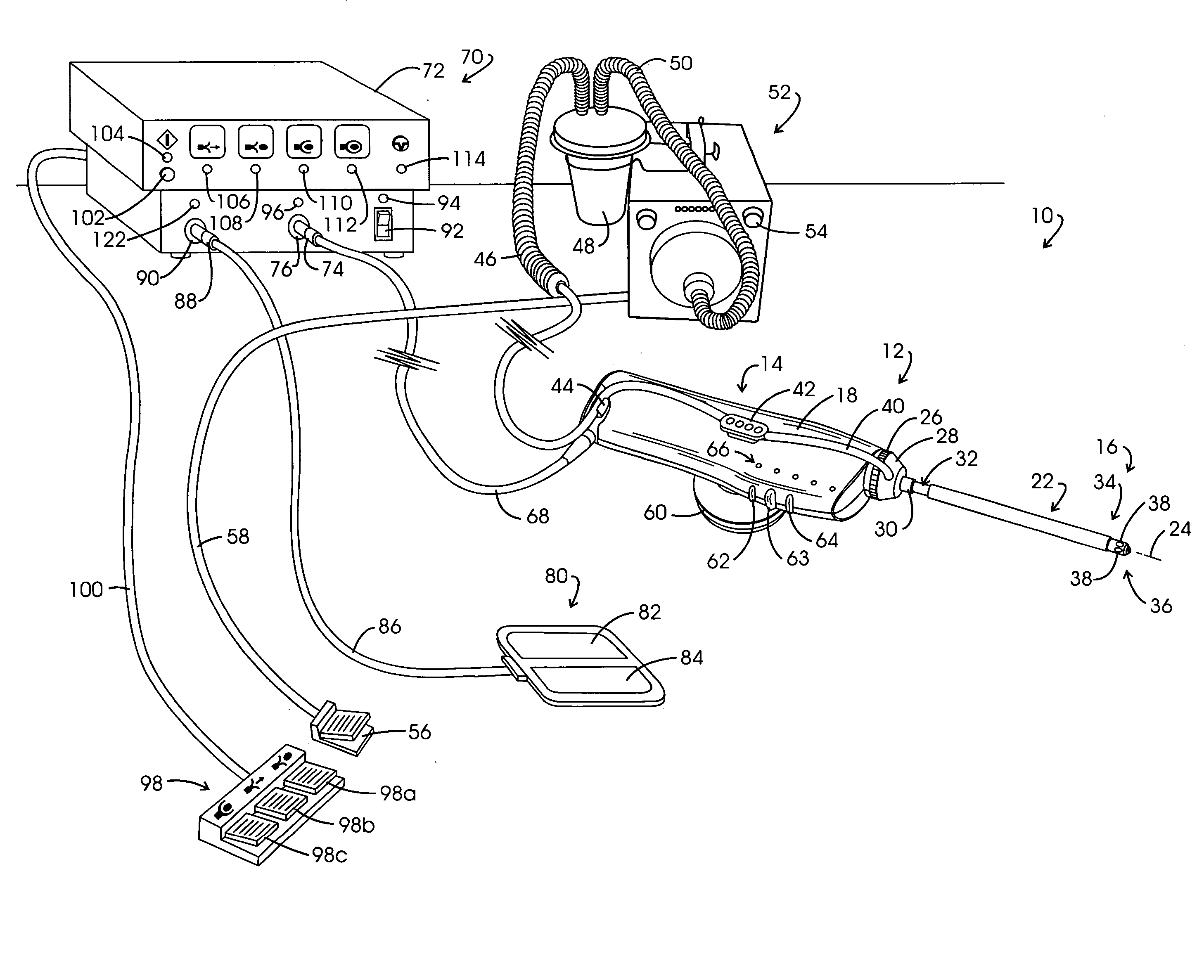

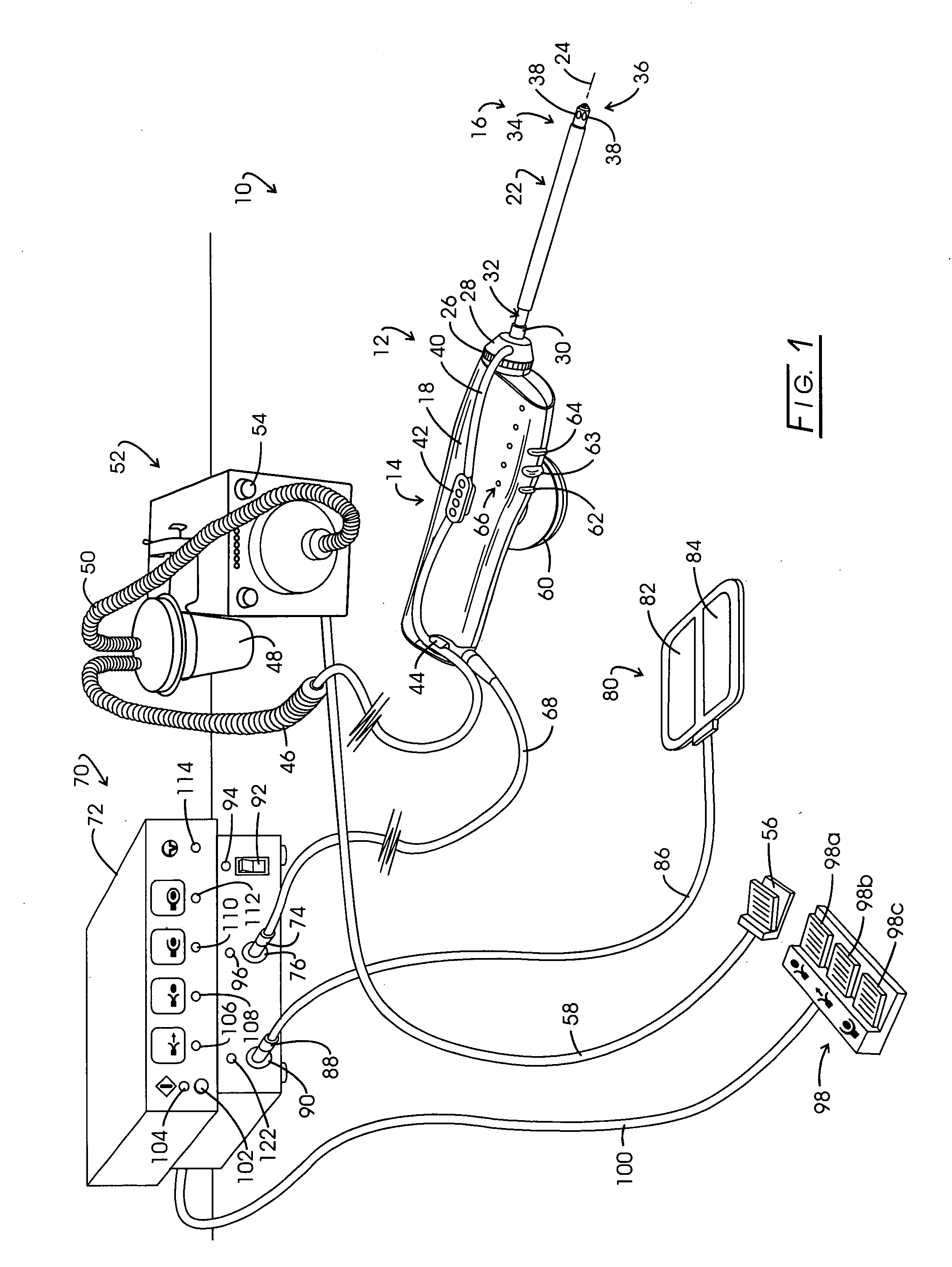

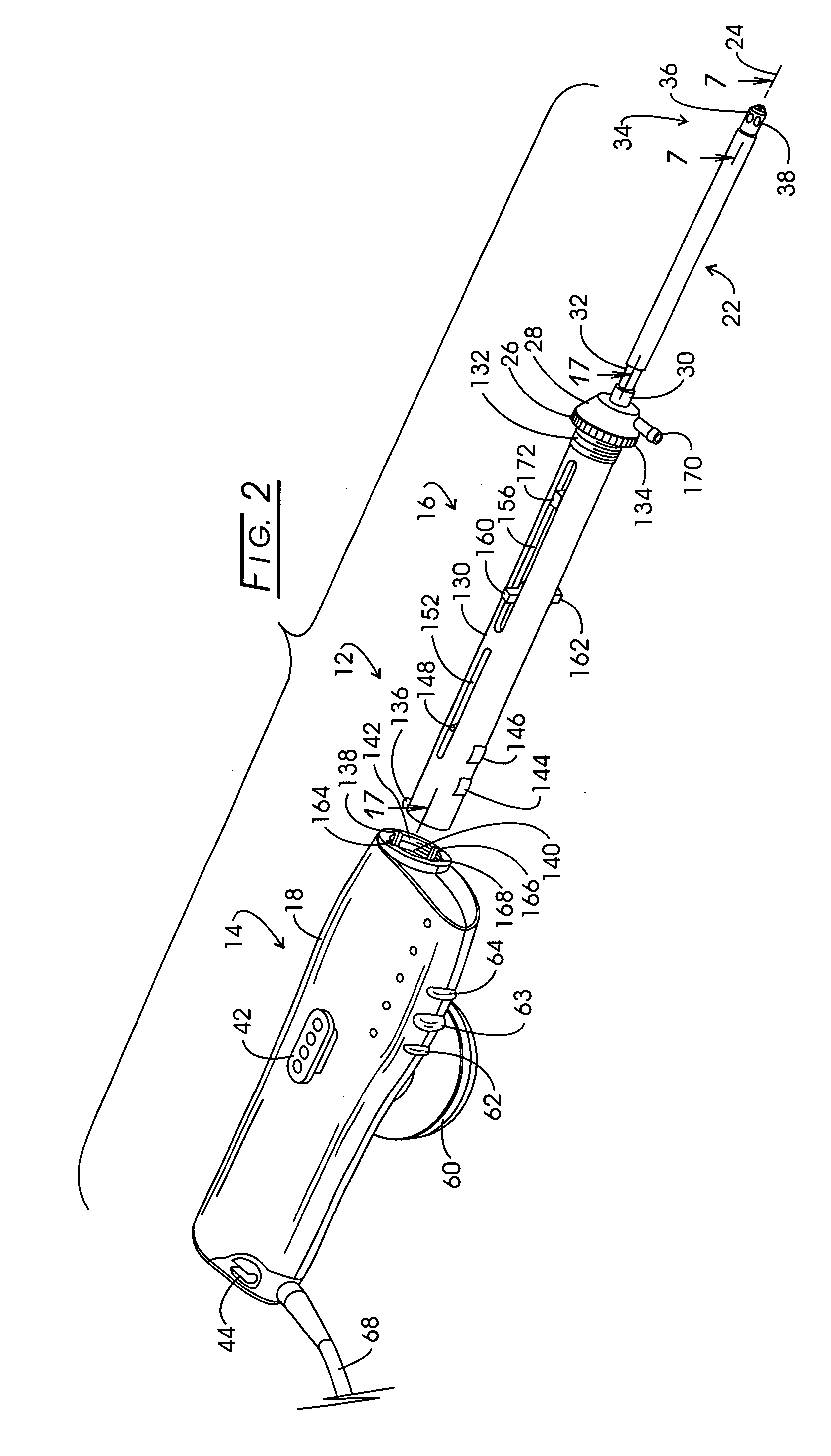

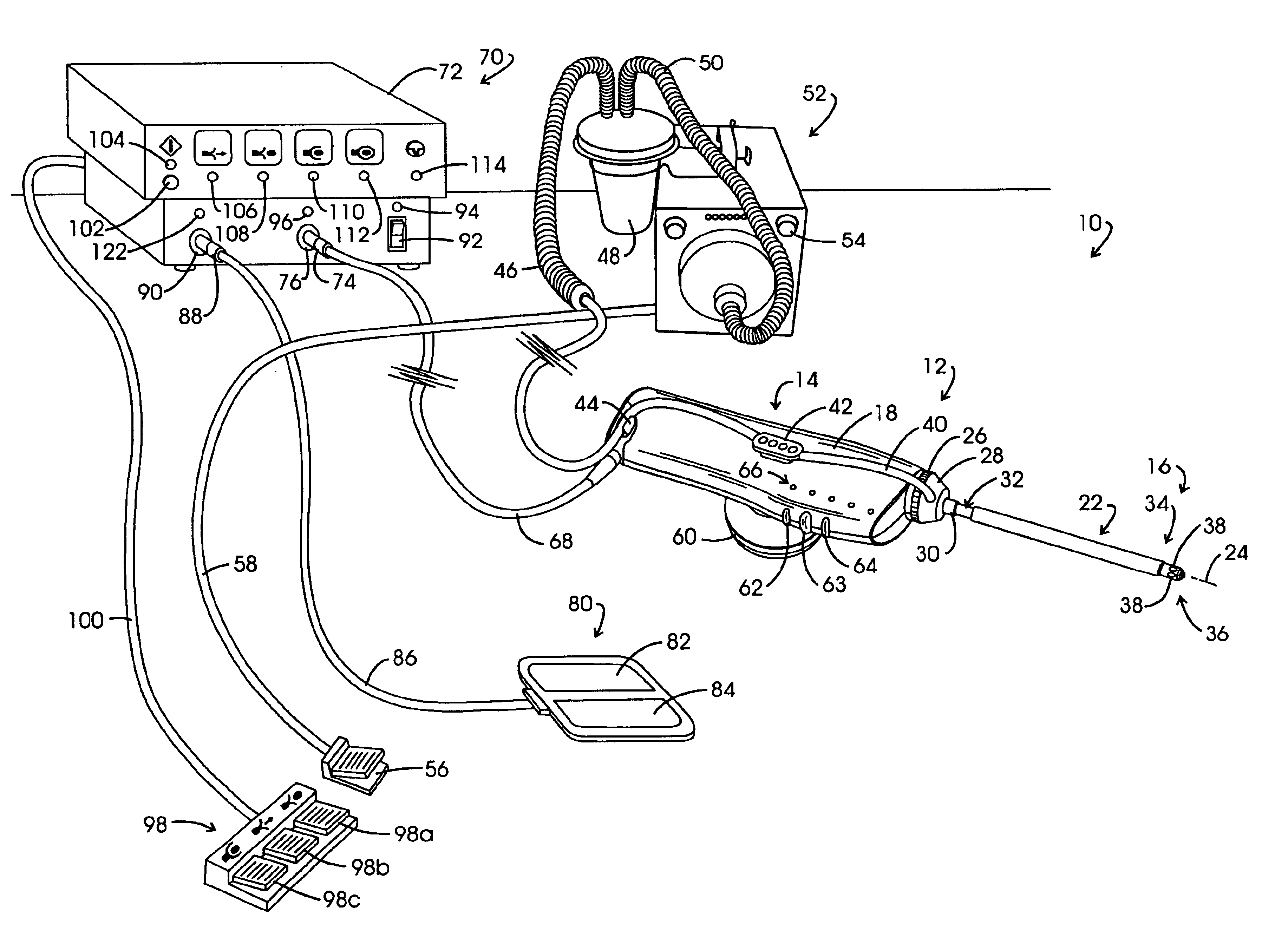

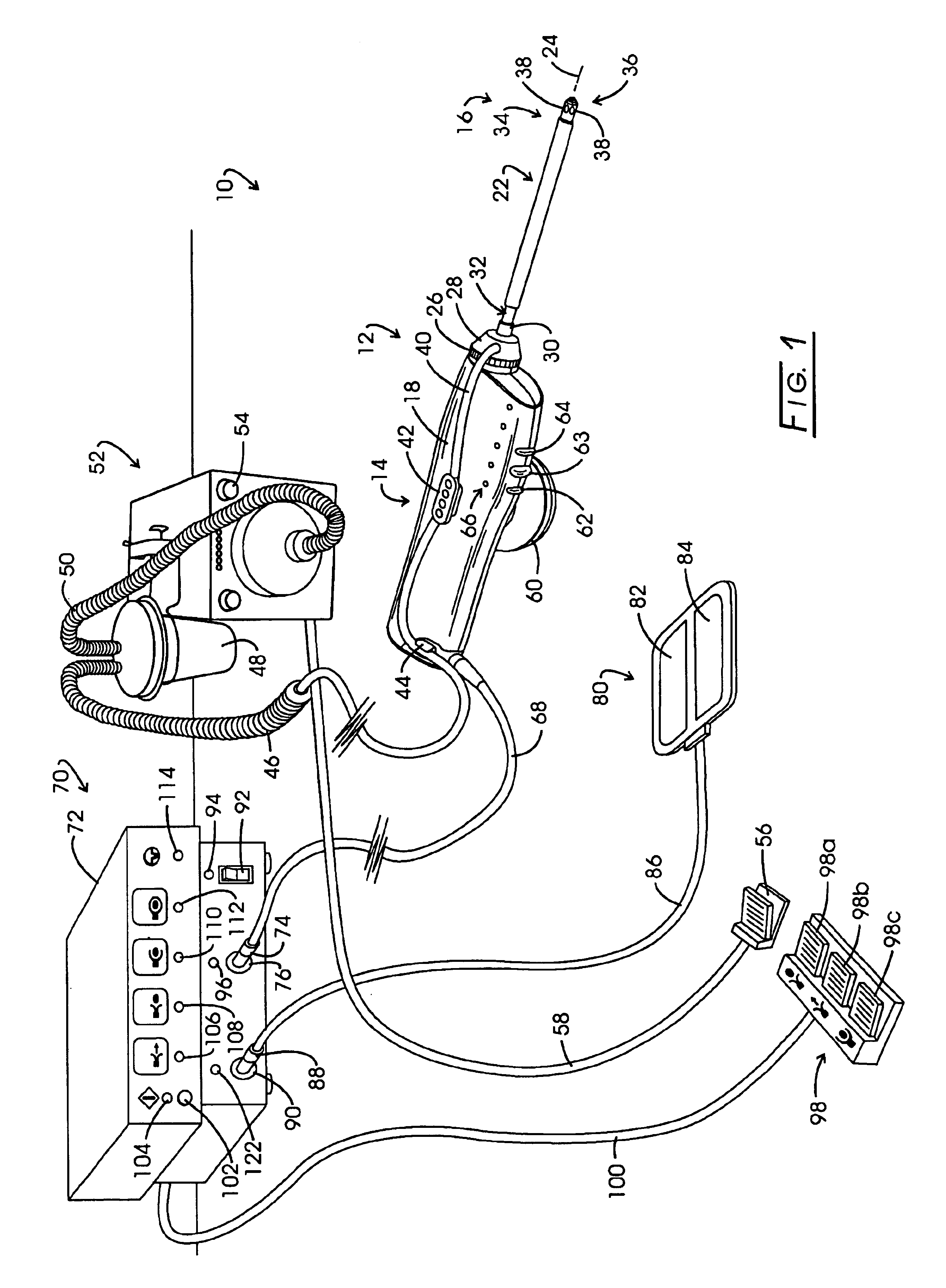

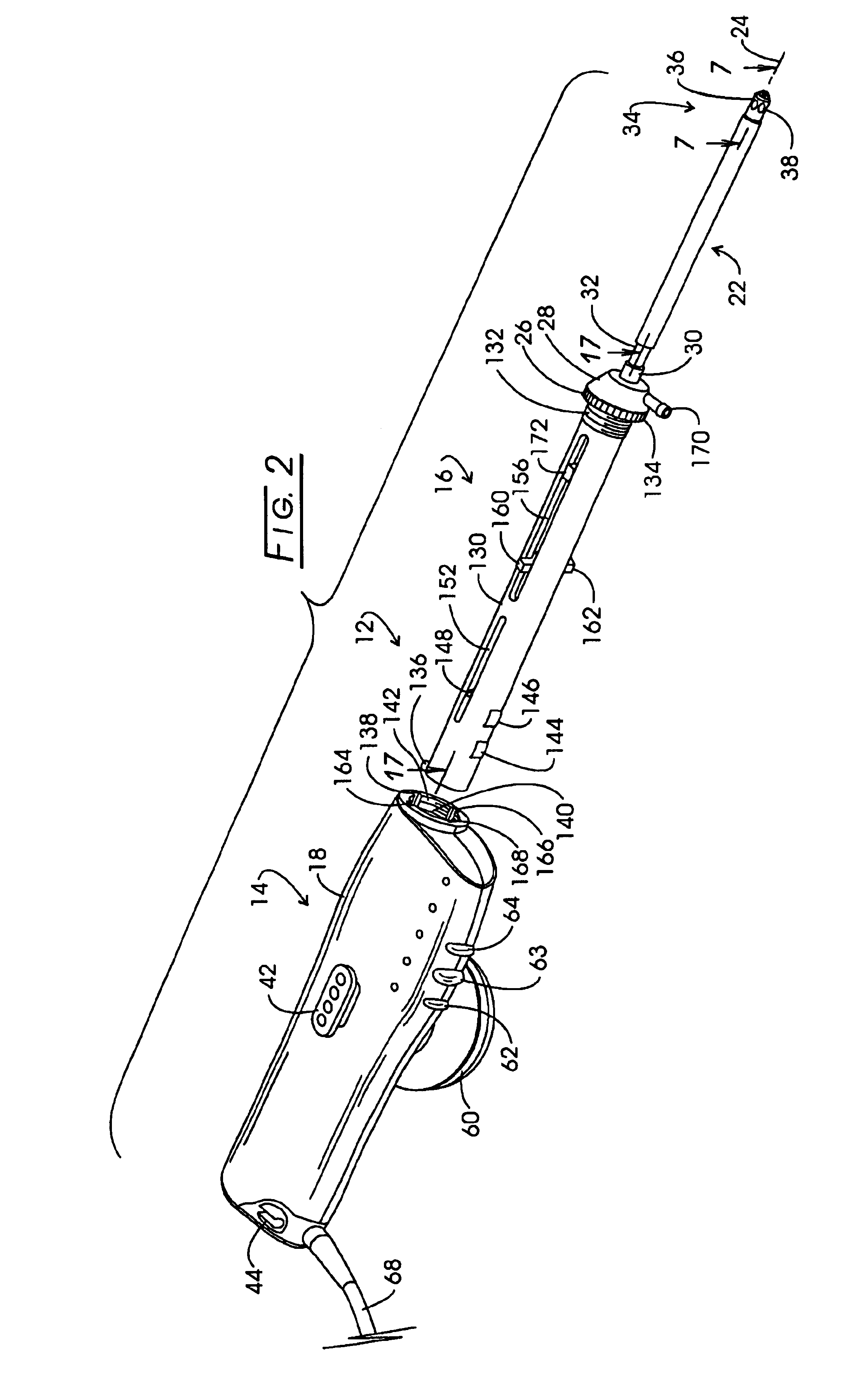

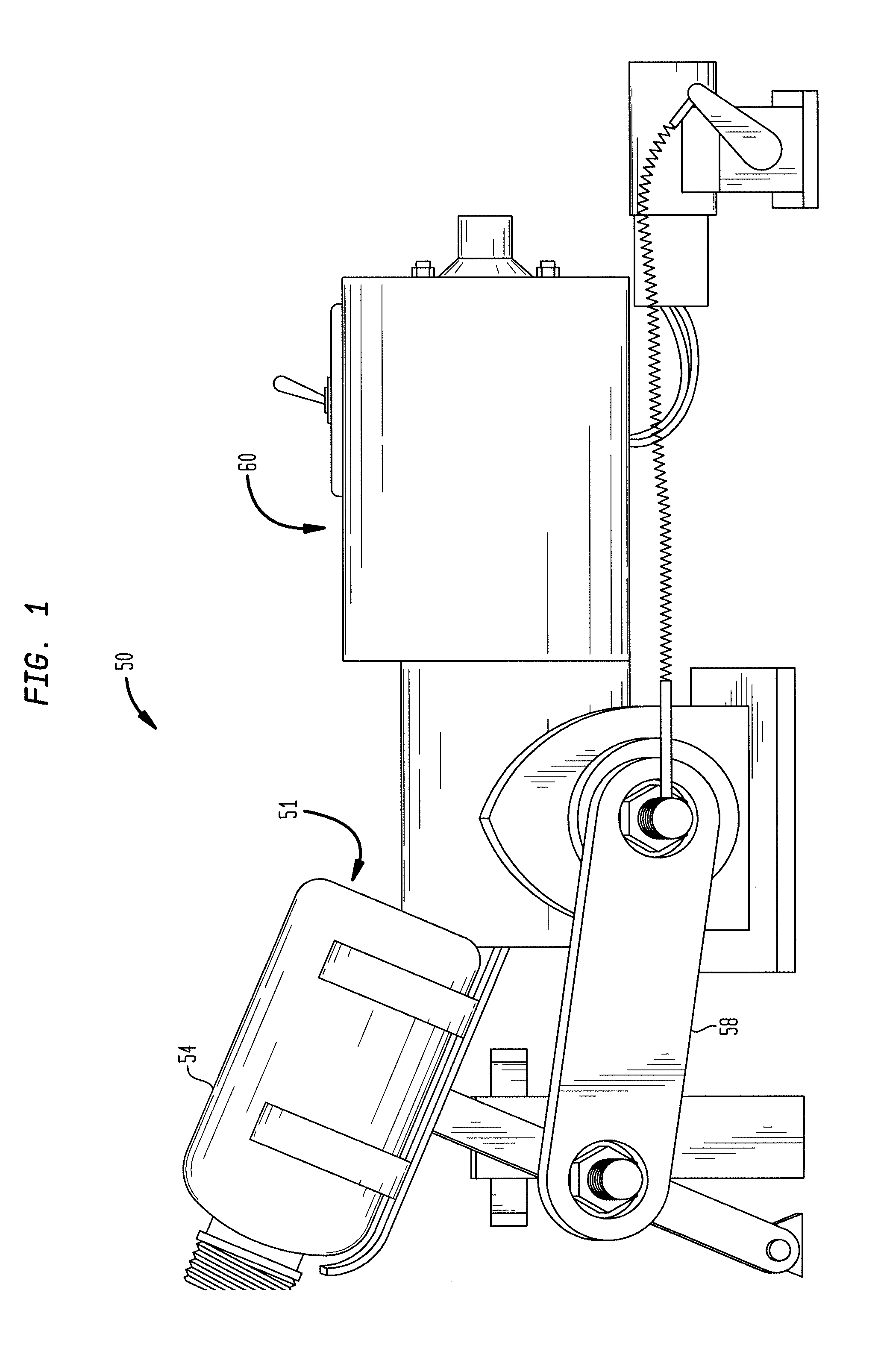

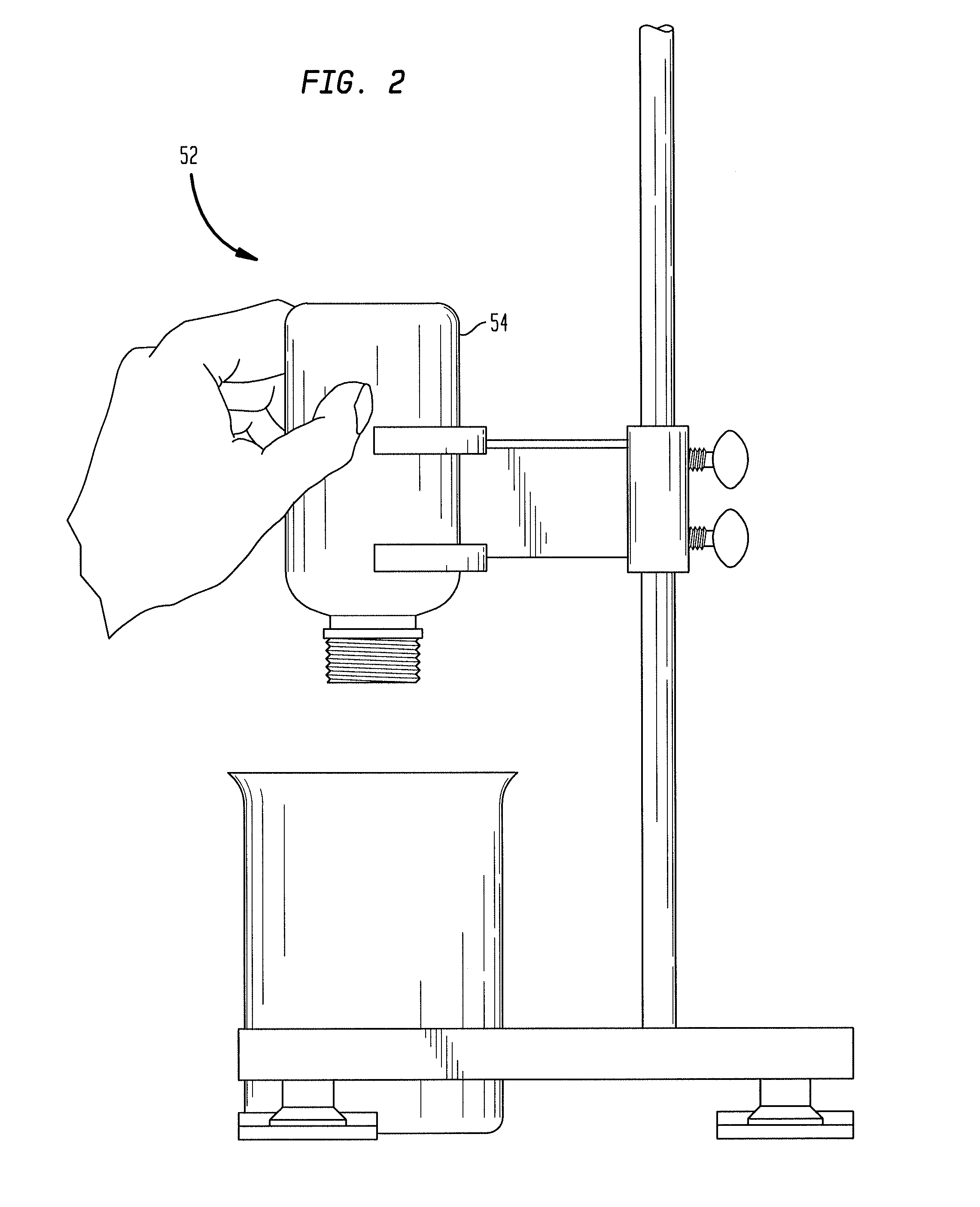

Minimally invasive instrumentation for recovering tissue

ActiveUS20050033286A1Improve tissue performanceHigh strengthSurgical needlesSurgical instruments for heatingUltimate tensile strengthBiomedical engineering

The capture component of tissue retrieval apparatus is strengthened to improve its structural integrity when utilized within very dense tissue. Eyelet structures carrying pursing cable are improved through the utilization of slightly expanded constant widths with diminished lengths to avoid fold back phenomena. The pursing cables employed with the capture component exhibit more than a 100% improvement in tensile strength at high electrosurgical cutting temperatures through the utilization of strands having about a 1.4 mil diameter formed with a type 316 stainless steel.

Owner:COVIDIEN AG

Minimally invasive instrumentation for recovering tissue

ActiveUS6923809B2Improve tissue performanceHigh strengthSurgical needlesSurgical instruments for heatingBiomedical engineeringStructural integrity

The capture component of tissue retrieval apparatus is strengthened to improve its structural integrity when utilized within very dense tissue. Eyelet structures carrying pursing cable are improved through the utilization of slightly expanded constant widths with diminished lengths to avoid fold back phenomena. The pursing cables employed with the capture component exhibit more than a 100% improvement in tensile strength at high electrosurgical cutting temperatures through the utilization of strands having about a 1.4 mil diameter formed with a type 316 stainless steel.

Owner:COVIDIEN AG

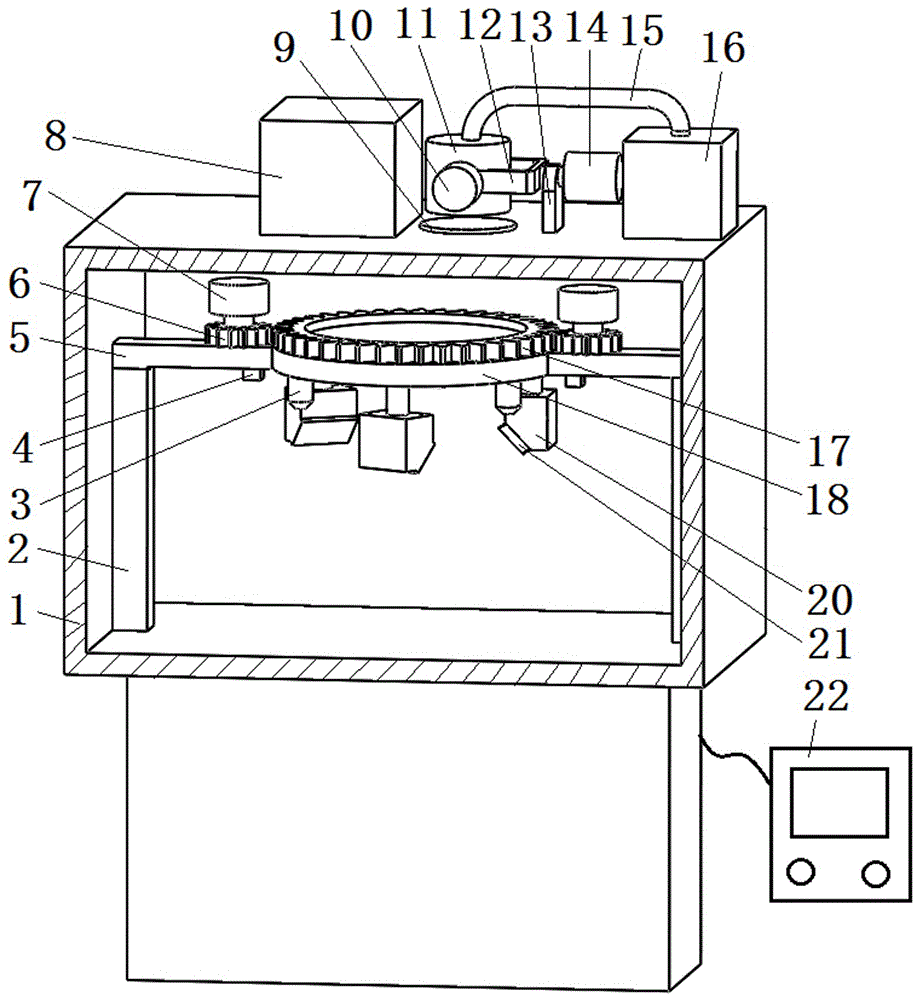

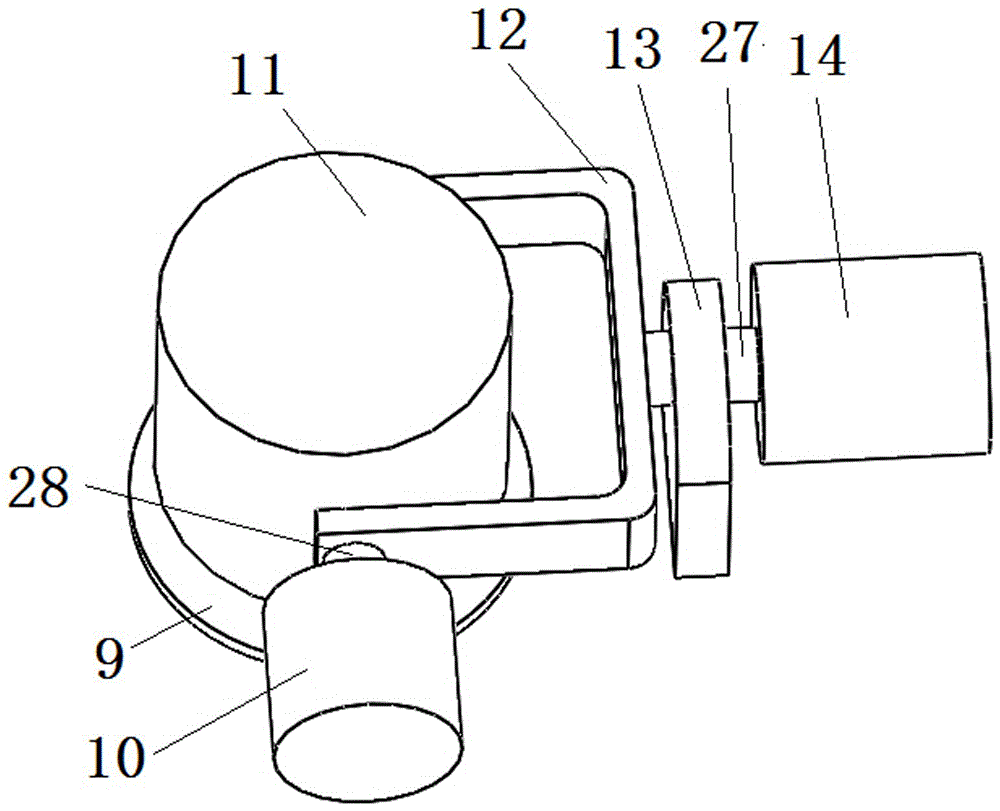

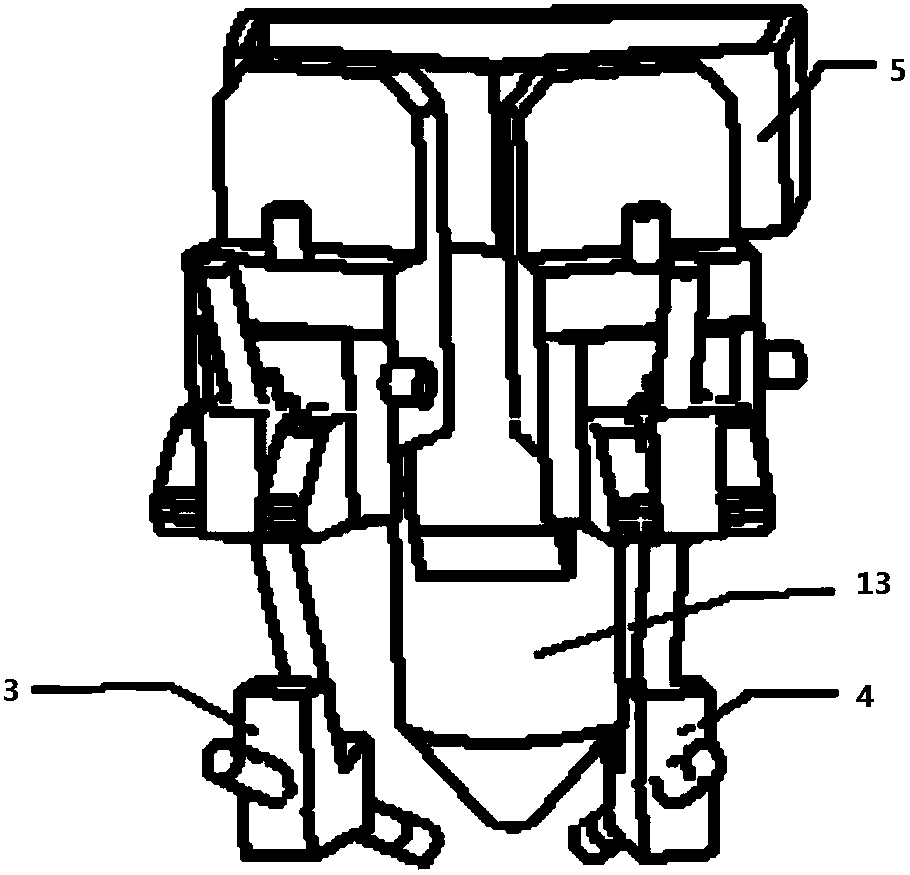

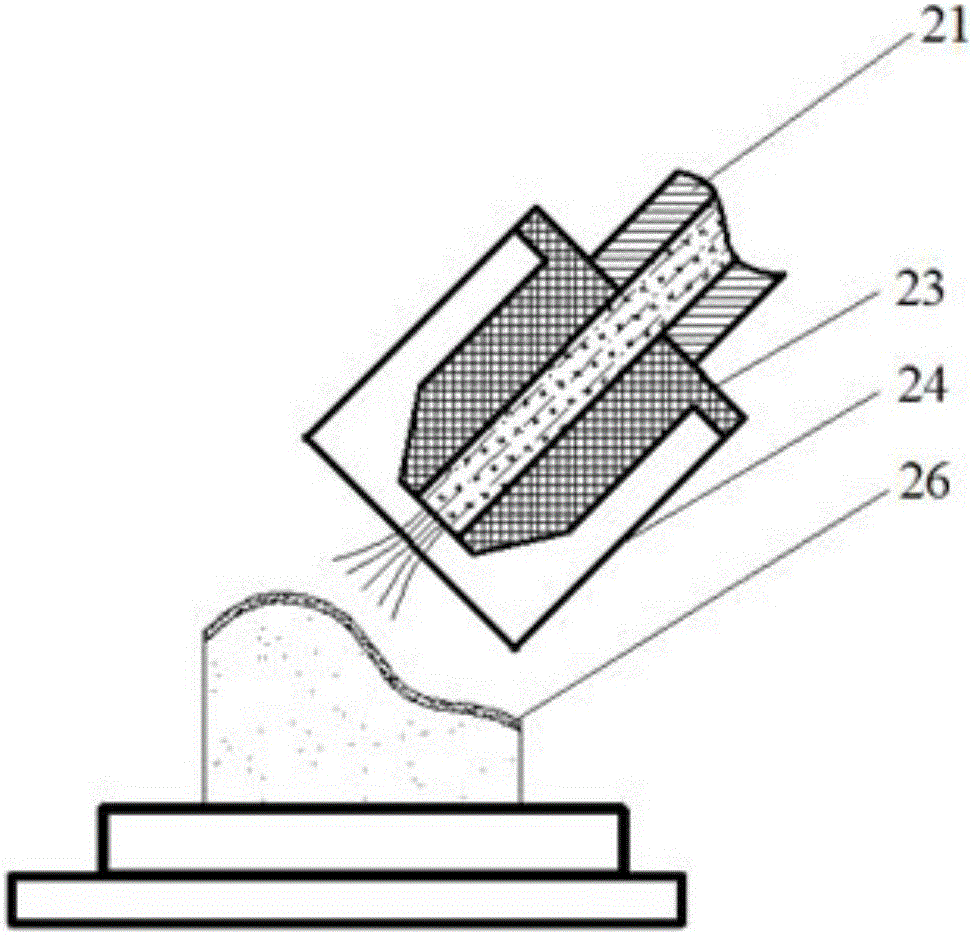

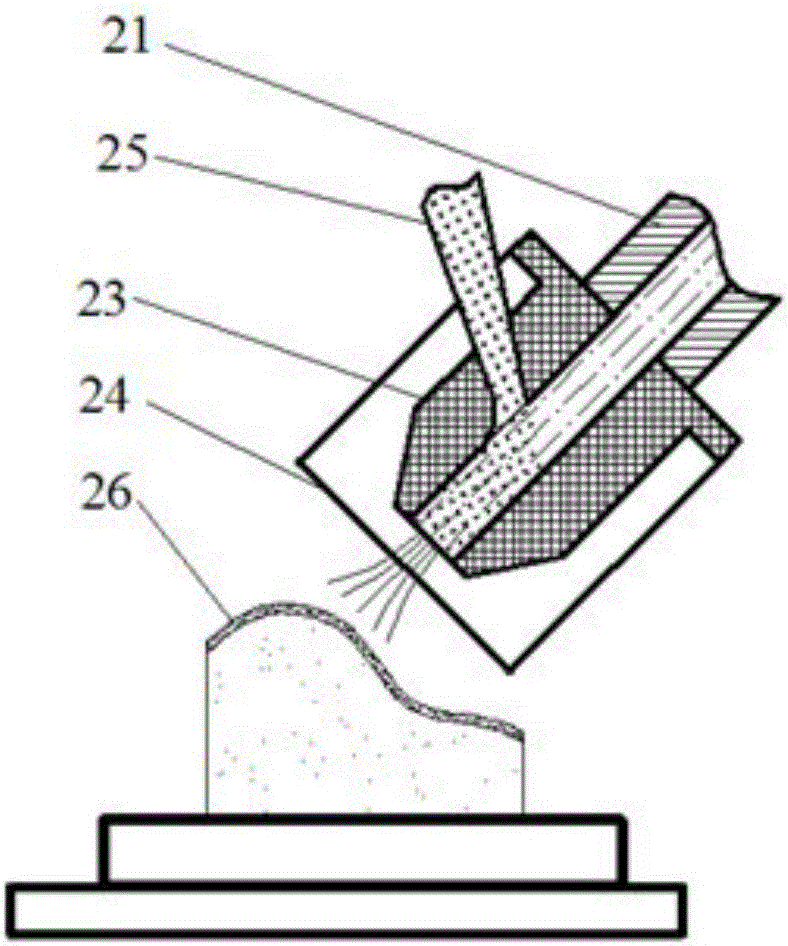

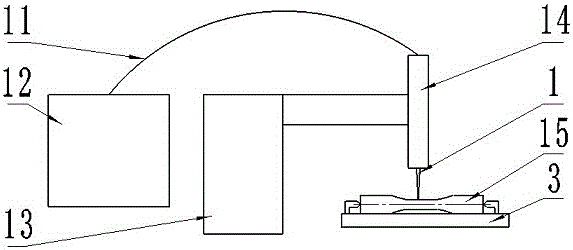

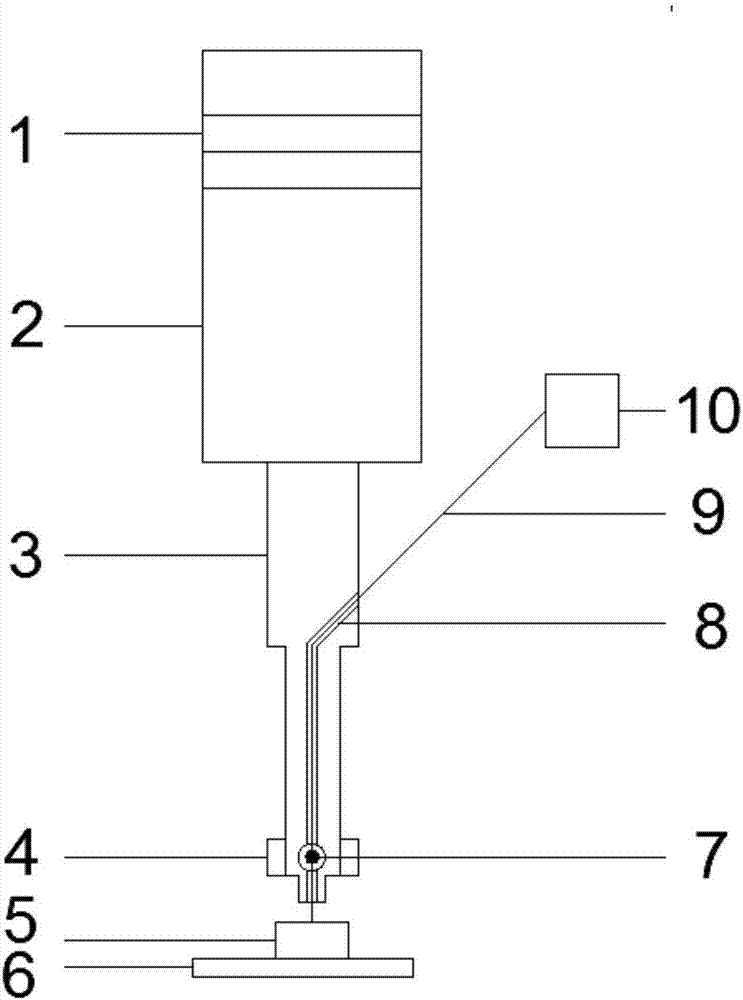

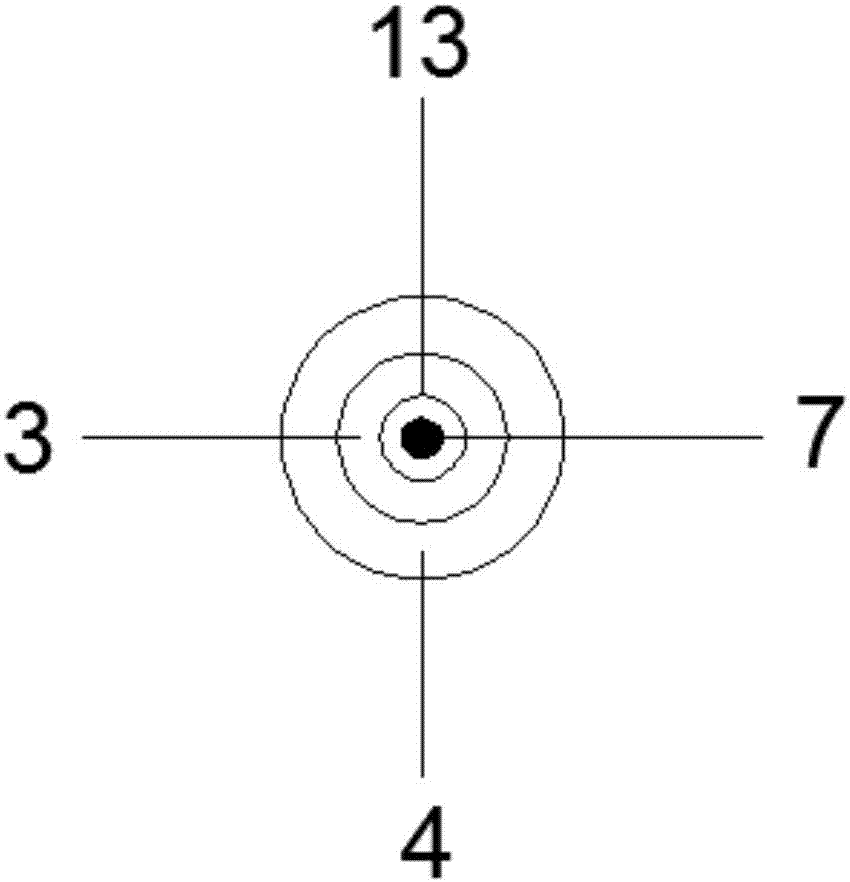

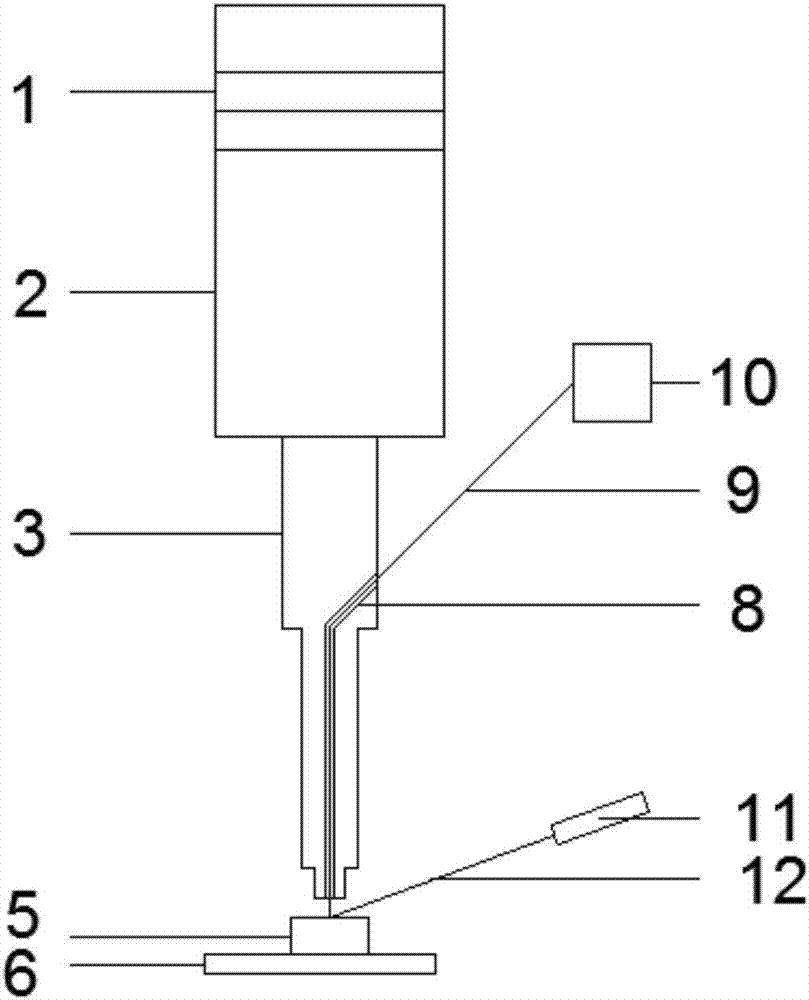

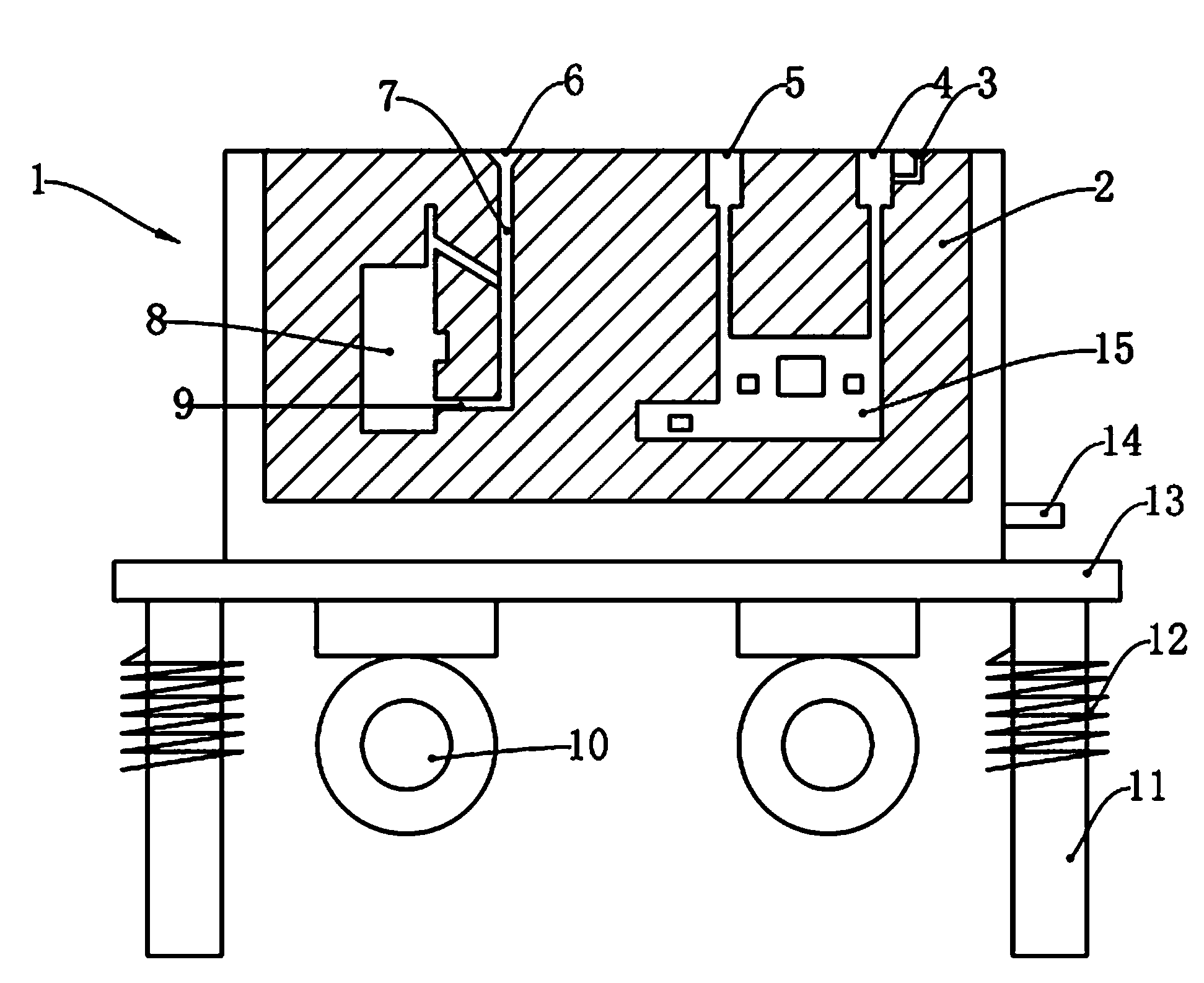

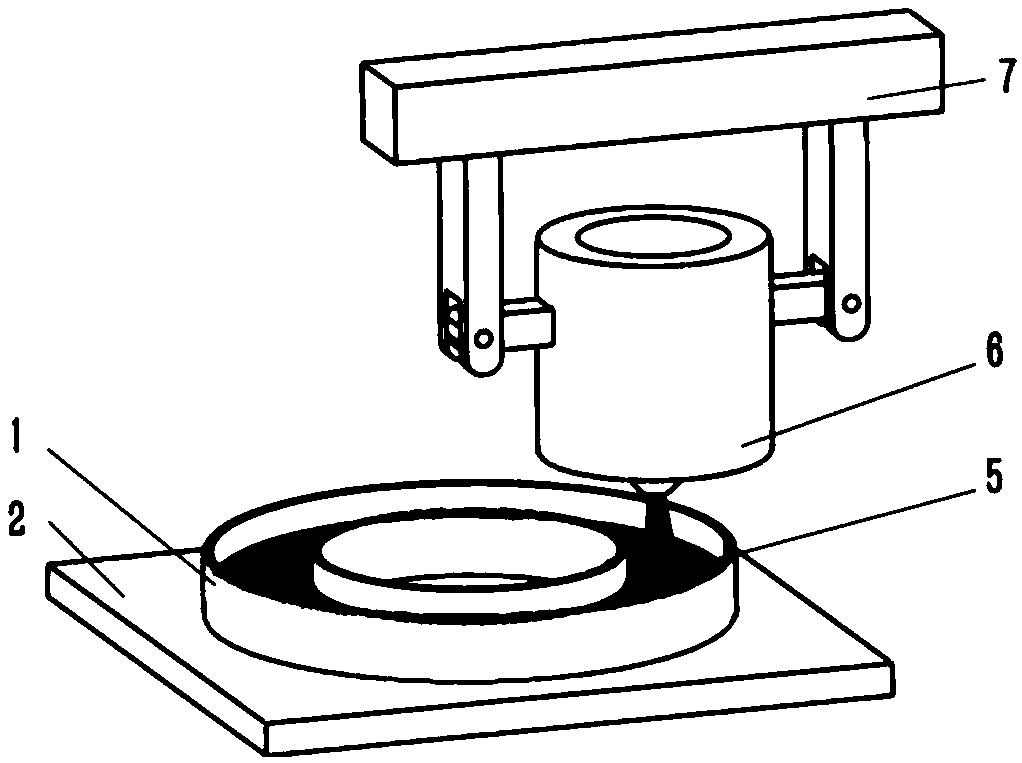

Selective laser melting forming molten bath real-time monitoring device and monitoring method

ActiveCN106363171AImprove yieldEasy to controlAdditive manufacturing apparatusIncreasing energy efficiencyForming processesPulsed laser

The invention relates to a selective laser melting forming molten bath real-time monitoring device and a monitoring method, and belongs to the technical field of 3D printing additive manufacturing. The selective laser melting forming molten bath real-time monitoring device and the monitoring method can monitor the molten bath temperature, the shape and the area in the SLM forming process in real time, conduct online assessment on the forming precision and the laser power and feed back the result. According to the adopted technical scheme, a melting forming laser system and a pulsed laser are arranged on the top of a forming cavity, a piece of transparent glass is arranged in the center of the top of the forming cavity, a laser lens tube is arranged above the transparent glass, and the pulsed laser is connected with the laser lens tube through an optical fiber. A lifting frame is arranged in the forming cavity, lifting mechanisms are arranged on the two sides of the lifting frame, and cameras are arranged at the bottom of the lifting frame in the mode of different angles. The melting forming laser system, the pulsed laser, the lifting mechanisms and the cameras are connected with a master control system. The selective laser melting forming molten bath real-time monitoring device and the monitoring method are widely used for real-time monitoring of a selective laser melting forming molten bath.

Owner:山西阳宸中北科技有限公司

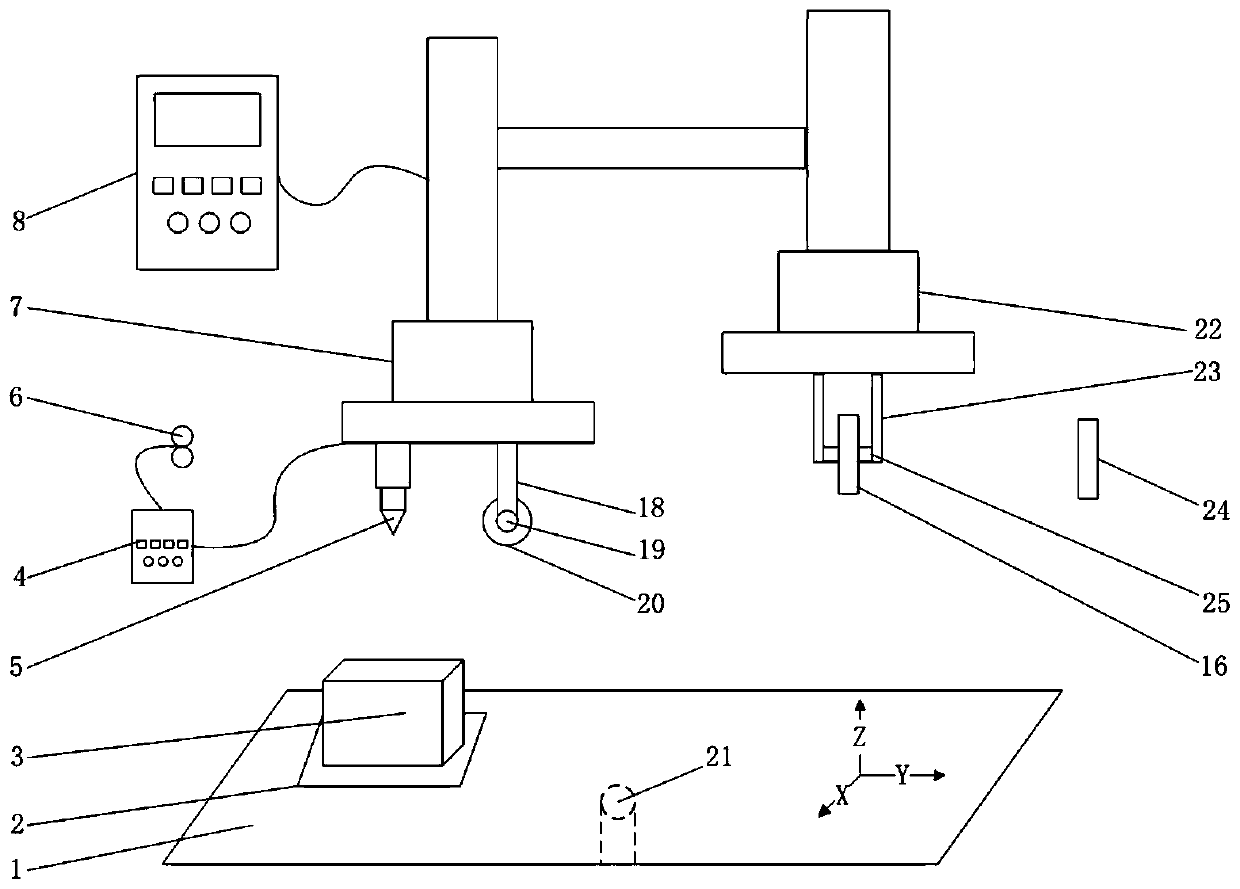

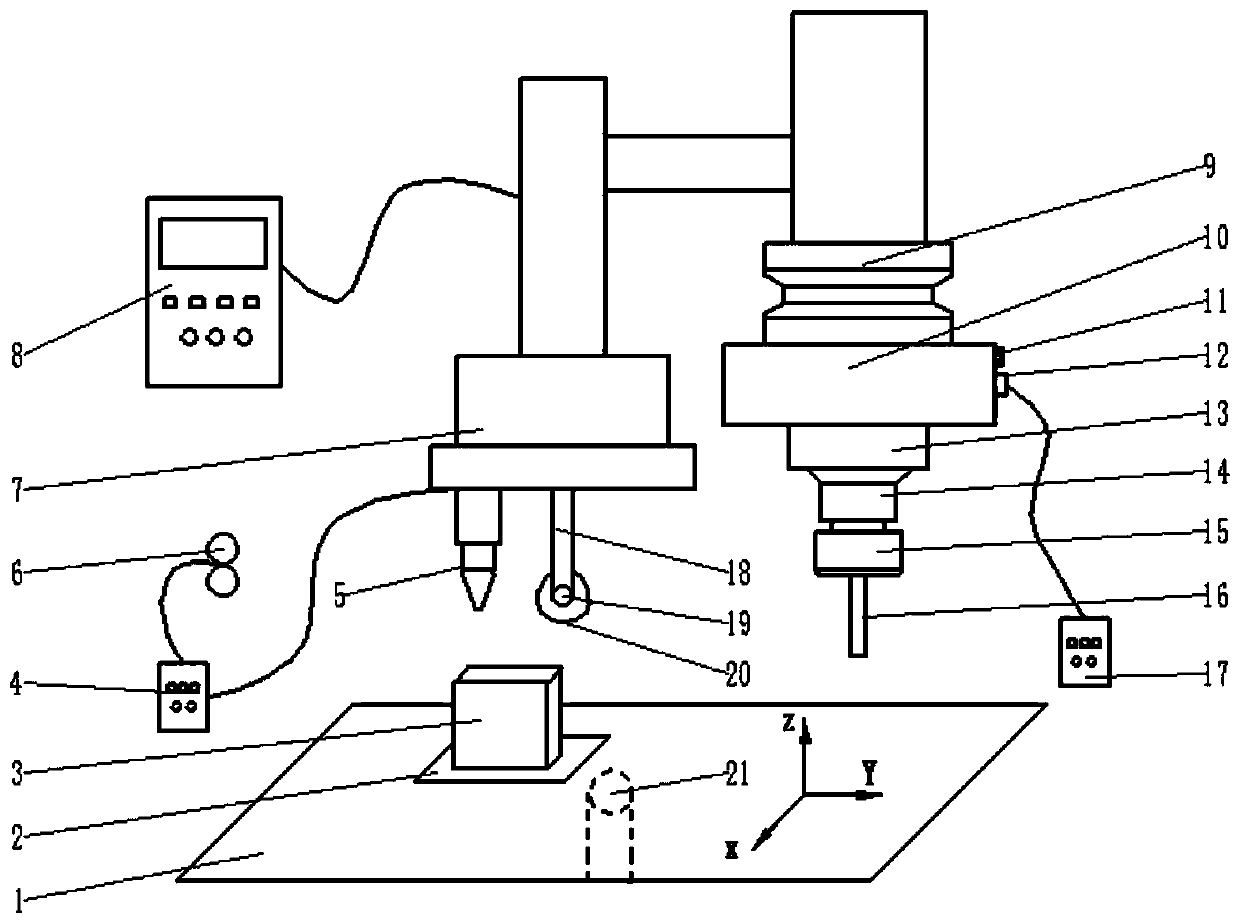

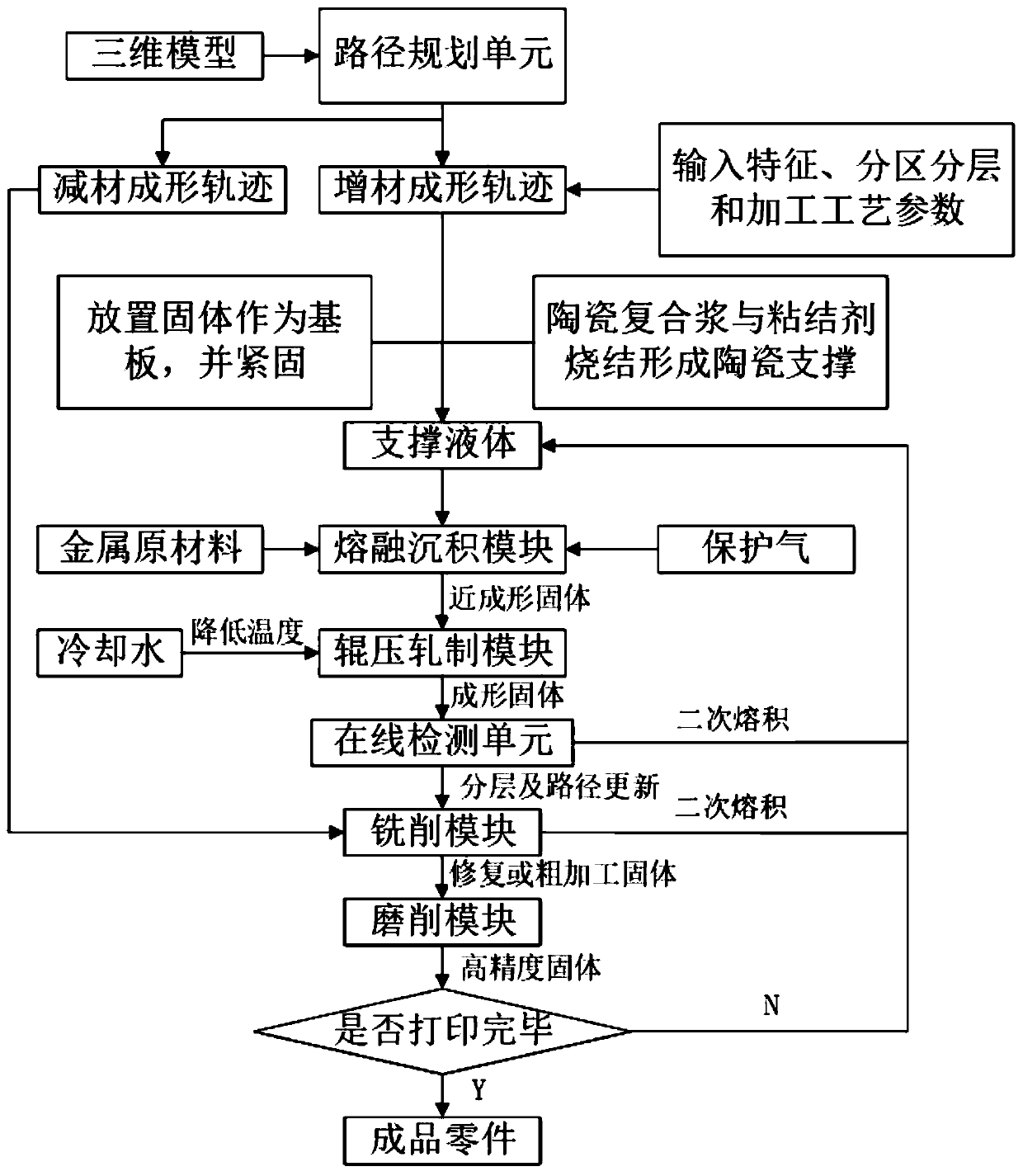

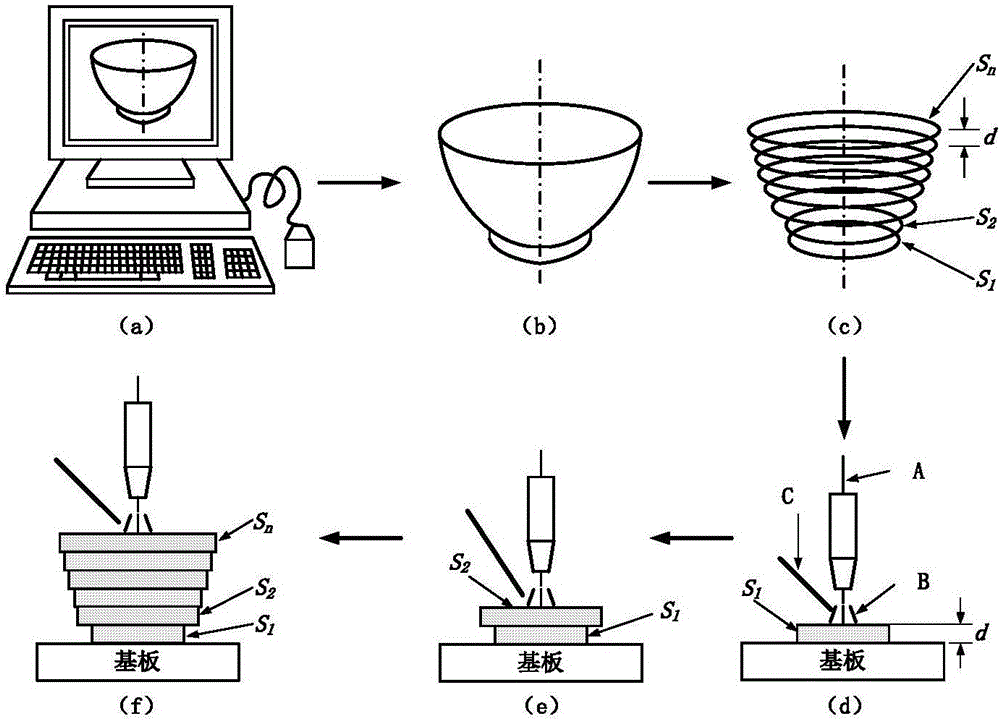

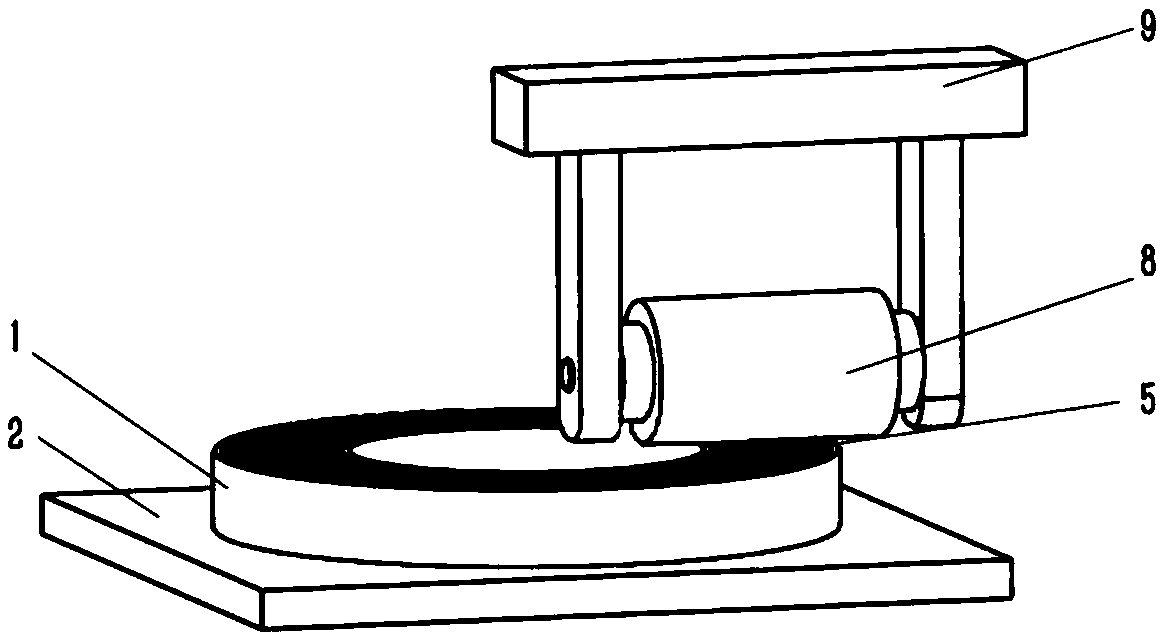

Metal part manufacturing system and method adopting micro-casting-forging and milling-grinding in-situ composite

InactiveCN110076566AImprove tissue mechanical propertiesImprove processing efficiencyAdditive manufacturing apparatusOther manufacturing equipments/toolsEngineeringManufacturing systems

The invention belongs to the field of metal part manufacturing, and particularly discloses a metal part manufacturing system and method adopting the micro-casting-forging and milling-grinding in-situcomposite. The system involves a micro-casting-forging module, a milling module, a five-axis linkage workbench and a control device, wherein the micro-casting-forging module is connected with the milling module and comprises a fusion deposition sub-module and a roller-pressing rolling sub-module, the five-axis linkage workbench is positioned below the micro-casting-forging module and the milling module, and is used for containing metal parts to be formed, and the control device is connected with the fusion deposition sub-module, the roller-pressing rolling sub-module, the milling module and the five-axis linkage workbench. According to the system and method, micro-casting-forging and a milling process are composited to process and manufacture the metal parts, so that the problems that whenthe metal parts are made through the additive manufacturing, the structure is not uniform, the deformation is serious, the residual stress is large, the structure performance is poor, and the surfacequality is poor are solved, and the system and method is especially suitable for processing a high-performance complicated special-shaped element.

Owner:HUAZHONG UNIV OF SCI & TECH

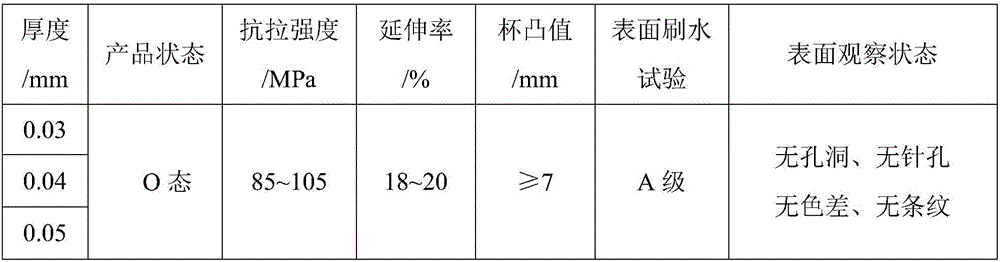

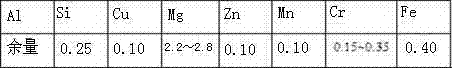

Lithium-battery 8021 soft packaging aluminum foil and production method thereof

ActiveCN106191544AReduce hydrogen contentImprove sealingJackets/cases materialsMetallurgyIngot casting

The invention discloses lithium-battery 8021 soft packaging aluminum foil and a production method thereof. Aluminum alloy containing Si, Fe, Cu, Mn, Mg, Cr, Zn, Ti and the balance Al is smelted and subjected to ingot casting, then an ingot is subjected to surface milling and soaking treatment; and the lithium-battery 8021 soft packaging aluminum foil is obtained after the steps of hot rolling, cold rolling, annealing, foil rolling, roll combining, combined roll annealing and roll dividing. The lithium-battery 8021 soft packaging aluminum foil prepared through the good technological process is a finished product in the O state, the ductility reaches 18-20%, the cupping value is larger than or equal to 7 mm, and the fracture resistance, stamping resistance and the like of the soft packaging aluminum foil are effectively improved. The aluminum foil has no holes or pinholes completely, so that a lithium battery soft package prepared from the aluminum foil has good airtightness and is free of liquid leakage and safe to use. The lithium-battery 8021 soft packaging aluminum foil has good social and economical benefits and broad application prospects.

Owner:HENAN MINGTAI AL INDUSTRIAL CO LTD

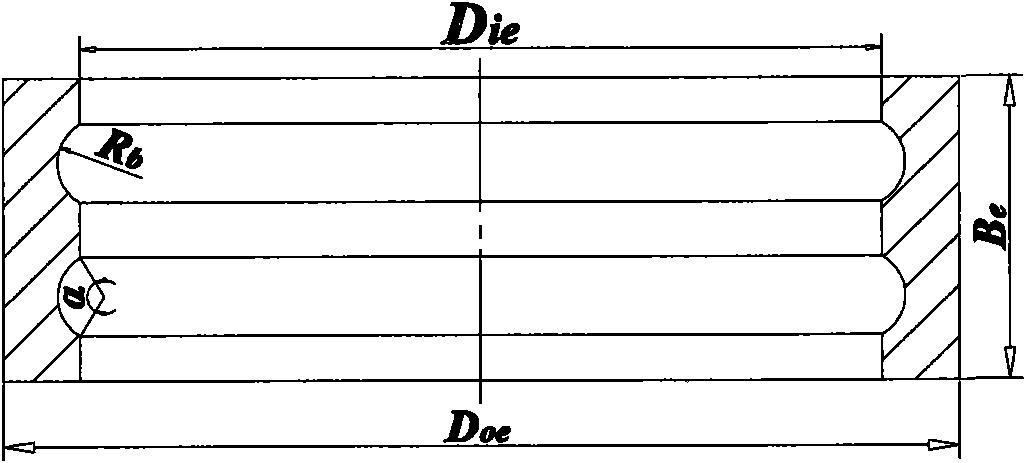

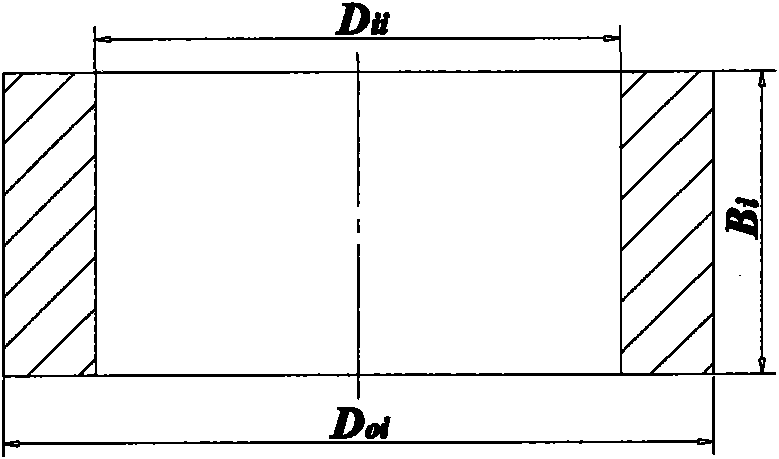

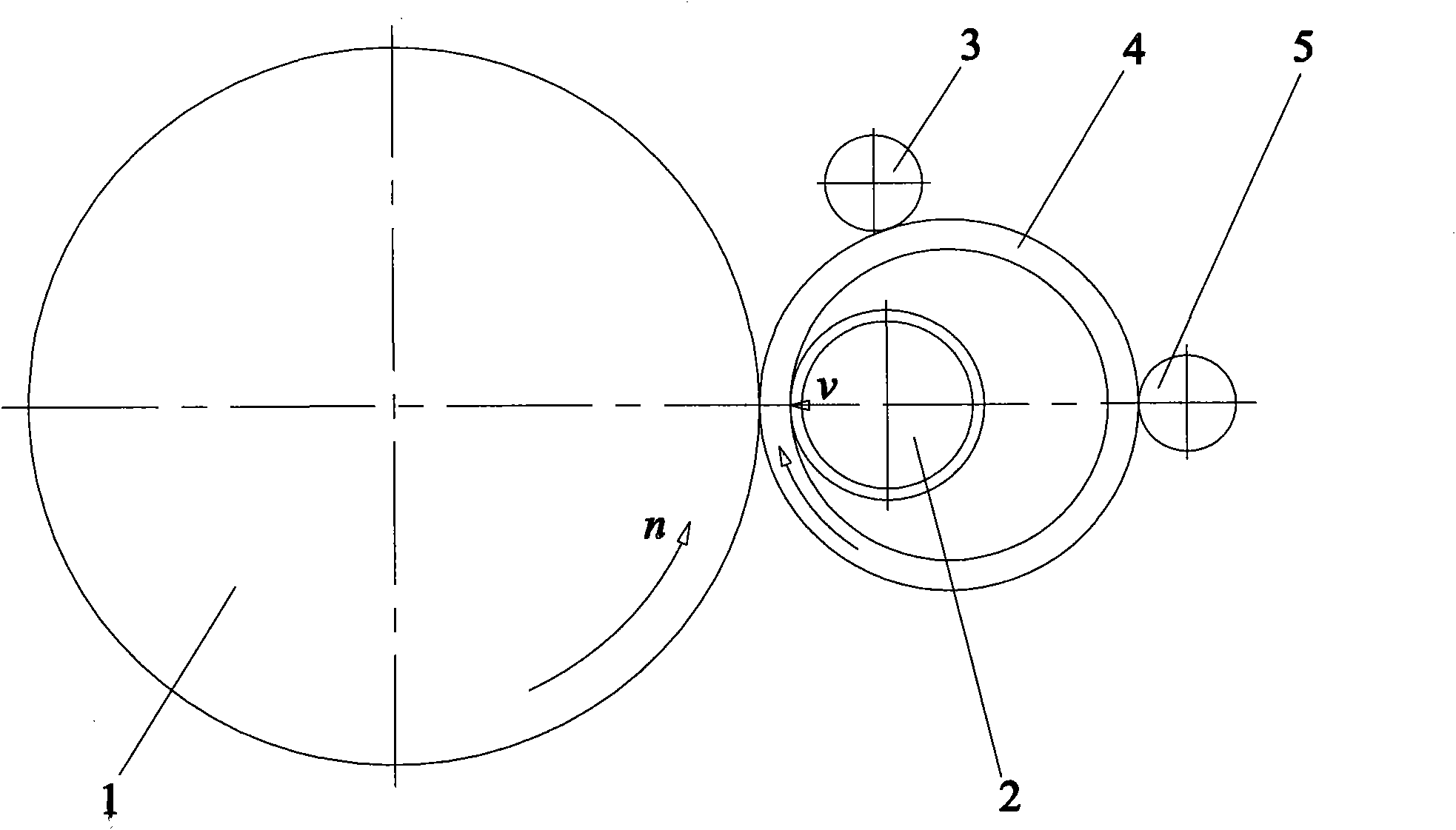

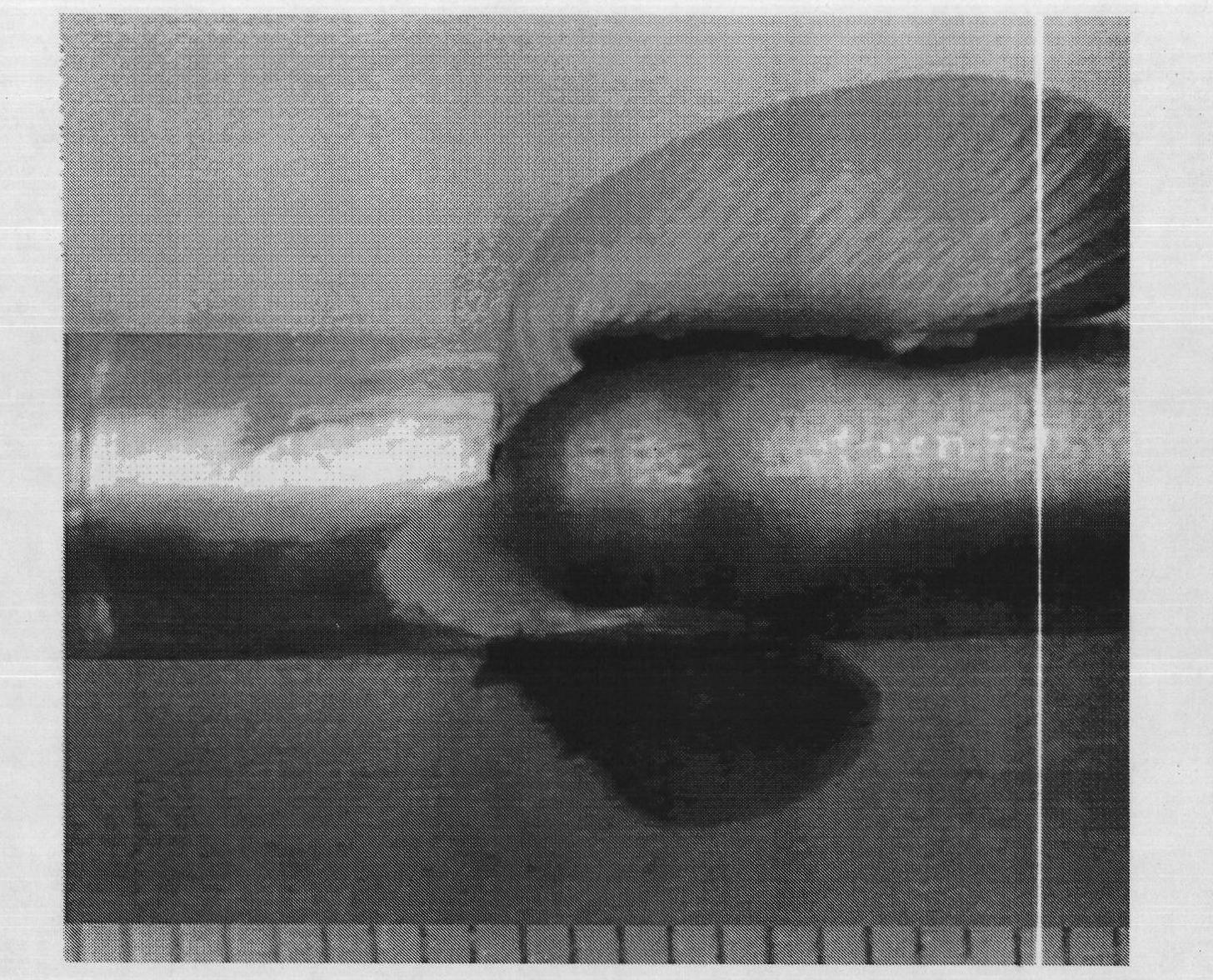

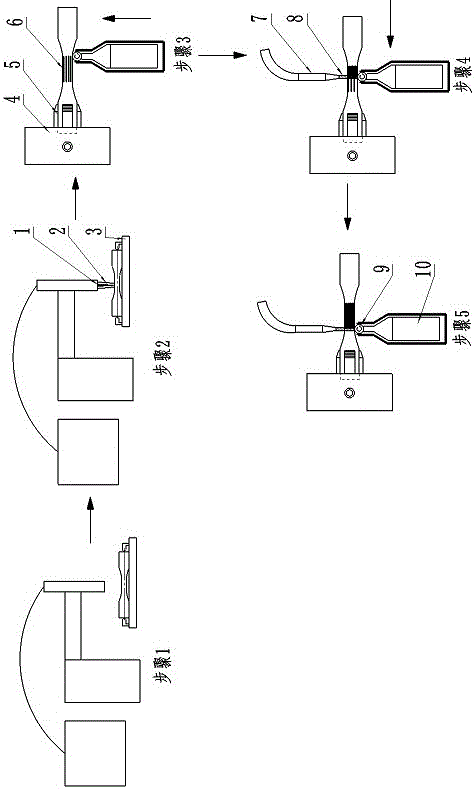

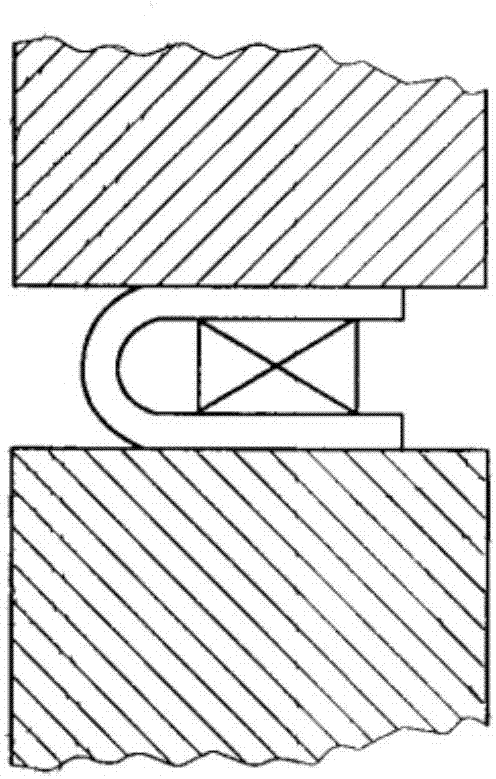

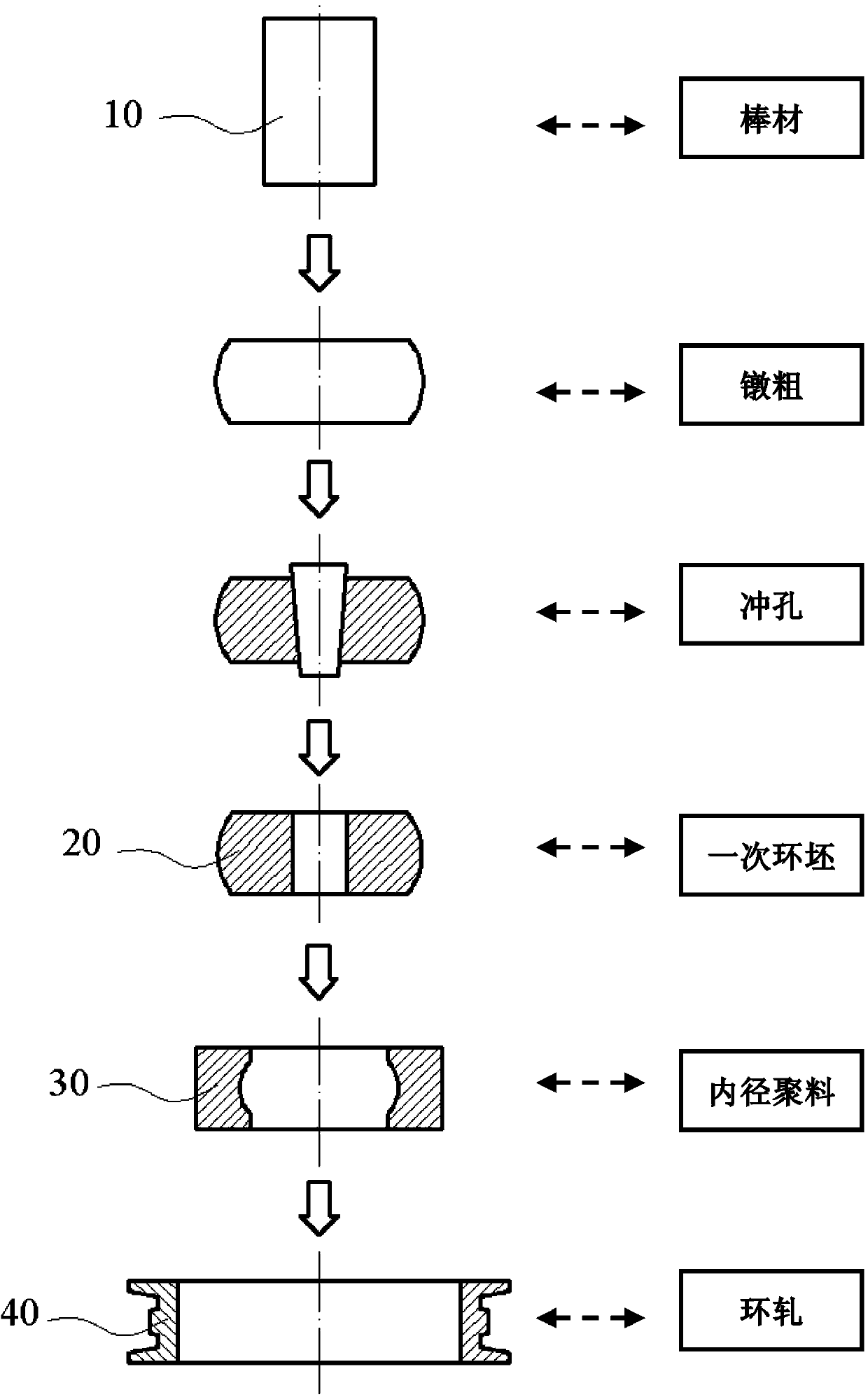

Cold ring rolling forming method for double-flute section ring

ActiveCN101829745AImprove distributionImprove tissue performanceRollsMetal rolling arrangementsFlutePunching

The invention relates to a cold ring rolling forming method for a double-flute section ring. The method comprises the following implementation steps of: (1) preforming, namely uniformly heating a bar section to the forging temperature from room temperature; upsetting, punching and punching wad to form a ring roughcast used for ring rolling; and designing the size of the ring roughcast; (2) roll pass design; and (3) ring rolling forming by using a ring rolling machine, wherein a core roll stops feeding and a ring rolling process is finished when the outside diameter of an obtained double-flute section ring is measured to reach a predetermined value; and the ring roughcast finally forms the double-flute section ring in a predetermined size. In the method, the double-flute section ring is produced by adopting a cold ring rolling process; the double-flute section ring is formed through continuous local plastic deformation of a rectangular section ring by reasonably designing the ring roughcast, ring rolling pass and forming parameters; and therefore, the consumption of raw materials and processing time are reduced, metal streamline distribution and organization properties of the ring are improved, work efficiency and product quality are improved, and production cost is reduced.

Owner:WUHAN UNIV OF TECH +1

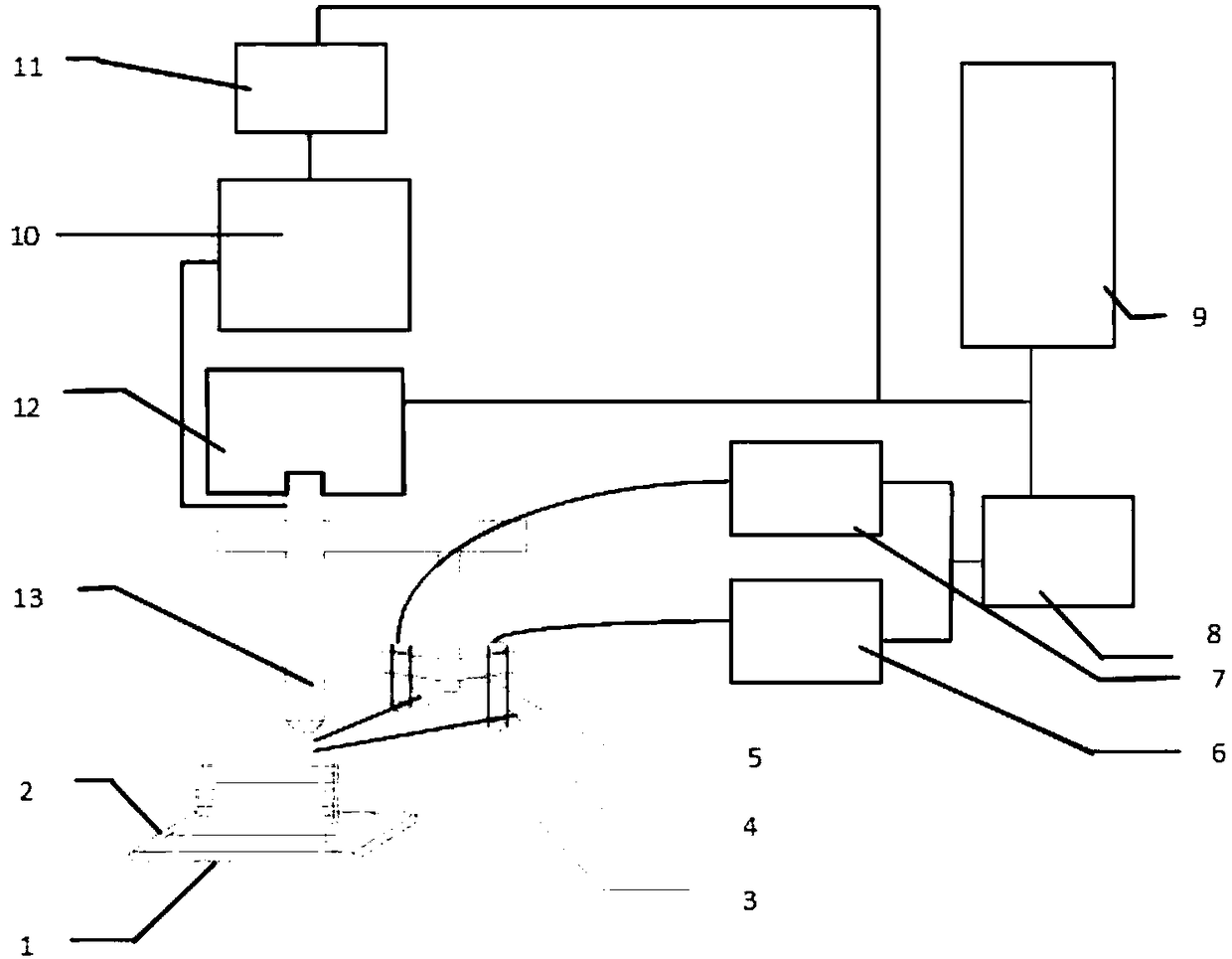

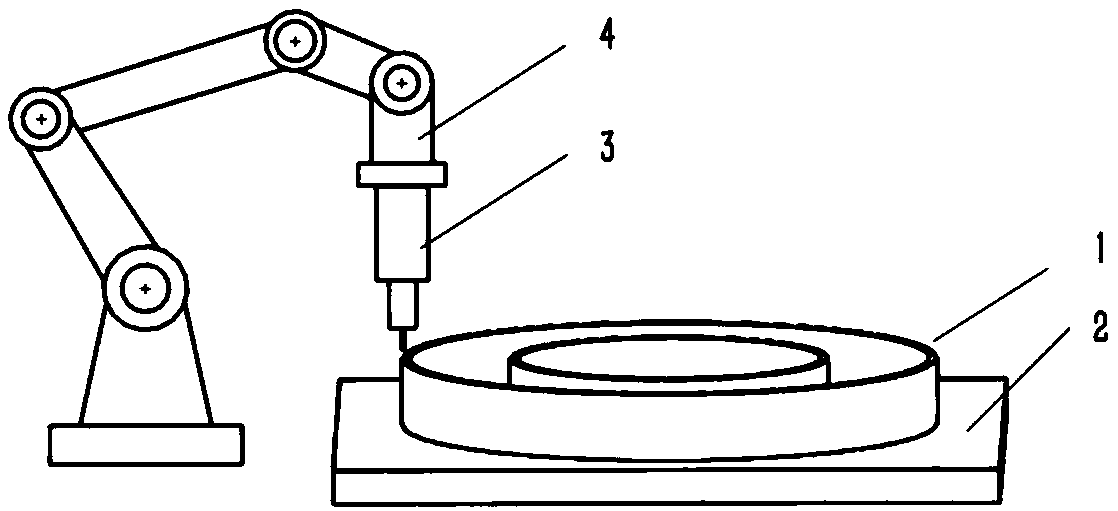

Automatic additive manufacturing method and device for robot plasma arc double-cooled filler rod

ActiveCN108067715ALow dilution rateImprove tissue performancePlasma welding apparatusEngineeringRobot control

The invention discloses an automatic additive manufacturing method and device for a robot plasma arc double-cooled filler rod. The device comprises a working platform, a base plate, a plasma welding gun, two wire feeding nozzles, clamps of the wire feeding nozzles, two wire feeders, a twin-wire coordination controller, a robot control cabinet and the like. The method mainly includes the steps thatthe two wire feeders are adopted to feed cold wire materials, and the robot control cabinet and the twin-wire coordination controller are in communication so as to control the two wire feeders to achieve synchronous or alternate feeding; and meanwhile the control cabinet controls a welding machine to achieve synchronization of wire feeding and arc ignition. By adoption of the device, plasma arc additive manufacturing of the double-cooled filler rod made of the same wire material and different types of the wire materials can be achieved by controlling different wire feeding signals by a robotand further changing the varieties and textures of the wire materials. By means of the method and device, plasma arc additive manufacturing of the same type of the double-cooled filler rod made of carbon steel, stainless steel and the like is realized, and the additive manufacturing efficiency is doubled compared with a single-wire mode. Plasma arc additive manufacturing of the double-cooled filler rod different from welding wires can further be realized, and a novel composite material structural member which is low in cost and high in efficiency can be manufactured.

Owner:NANJING UNIV OF SCI & TECH

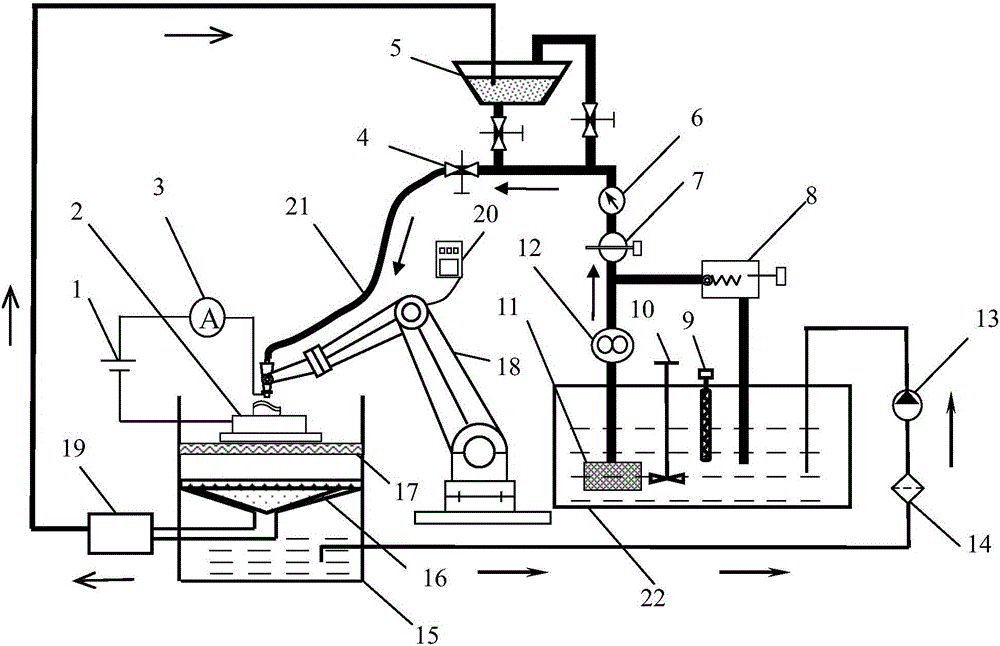

Three-dimensional surface shot peening jet electrodeposition manufacturing method and device

InactiveCN105951141ARemove in timeInhibit nodulationElectrolysis componentsElectrolytic coatingsNumerical controlImpurity

The invention provides a three-dimensional surface shot peening jet electrodeposition manufacturing method and device. According to the manufacturing method and device, a deposition solution and hard particles are mixed and deposit on a conductive substrate in a spraying manner, so that the rapid manufacturing technology of electrodeposition is realized, the growth rate of grains in the electrodeposition process is slowed down, the purpose of refining the grains is reached, and the quality of a deposition layer is dramatically improved; with combination of the shot peening strengthening technology and the electrodeposition technology, the defects of loose texture, pockmarks, pits and the like of the deposition layer caused by single electrodeposited cathode hydrogen evolution and impurity adhesion can be effectively overcome, and the hardness and the compactness of the deposition layer are improved; meanwhile, by introducing a five-axis linkage numerical control machining system, processing formation of a three-dimensional space can be realized, and the uniformity and the shape accuracy of the deposition layer are improved; and the technology can be widely applied to production of noble metal devices and parts in complex shapes and can also be used for surface rapid coat-plating, a strengthening technology and the like.

Owner:JIANGSU UNIV

Production and heat treatment method of aluminum alloy continuous-casting continuous-rolling billet

The present invention belongs to the technical field of non-ferrous metal processing, and particularly relates to a production and heat treatment method of a 5052 aluminum alloy continuous-casting continuous-rolling billet. The production and heat treatment method comprises steps such as smelting, continuous casting, continuous rolling, coiling and heat treatment, and is characterized in that the Hazelett continuous-casting continuous-rolling process is used after the smelting, and the smelting step comprises three refining and concretely comprises material preparing, aluminum alloy liquid smelting, first refining, slag skimming, alloy element adding, second refining, alloy component adjusting, third refining, degassing filtration, and standing. With the production and heat treatment method of the present invention, the key technology that the Hazelett process is adopted to produce the 5052 aluminum alloy plate material and perform the heat treatment is solved, the blank of the production process is filled up, and the high economic benefits and the high practical values are provided.

Owner:JIANGSU UNIV

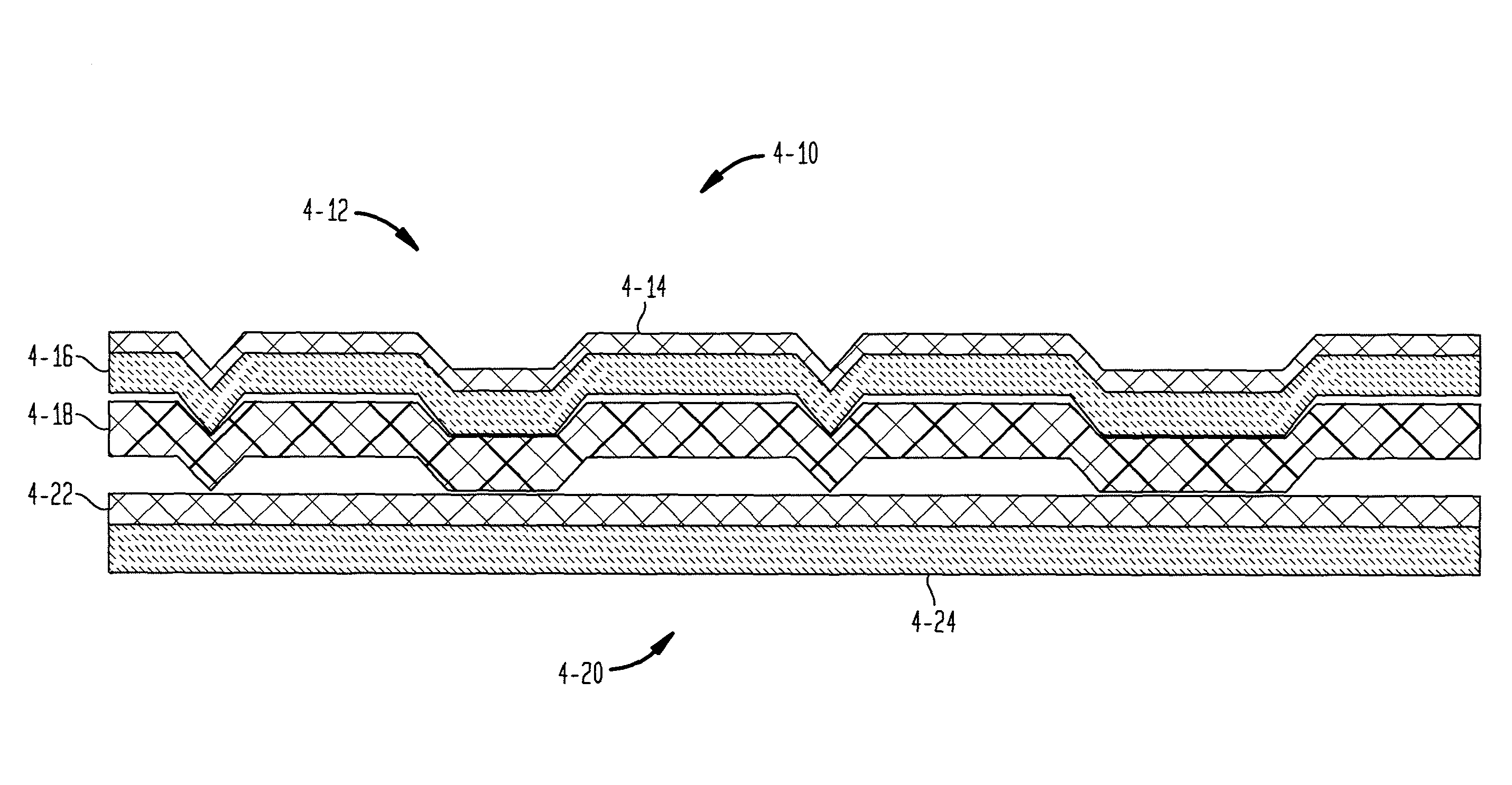

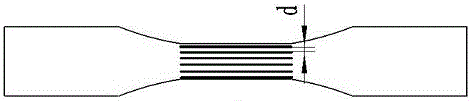

High softness, high durability bath tissues with temporary wet strength

ActiveUS9309627B2Improve tissue performanceGood flexibilityPersonal careReinforcing agents additionWet strengthCalipers

A multi-ply bath tissue having no more than three plies and no fewer than two plies. The multi-ply tissue has a basis weight of from about 20 to about 35 lbs per 3000 sq foot ream and includes from about 3% to about 50% cellulosic microfiber, from about 50% to about 97% wood pulp fibers, has a geometric mean (GM) dry tensile of from about 17 to 80 g / 3 in. per pound of basis weight, a cross-machine direction (CD) dry tensile of between about 30 to about 60 g / 3 in. per pound of basis weight, and sufficient temporary wet strength resin to provide an initial Finch Cup CD wet tensile of from about 2.5 to about 20 g / 3 in. per pound of basis weight. The initial Finch Cup CD wet tensile decays to less than 65% of the initial value in less than fifteen minutes after immersion in water. The product has a caliper of at least 5 mils per 8 sheets per pound of basis weight.

Owner:GPCP IP HLDG LLC

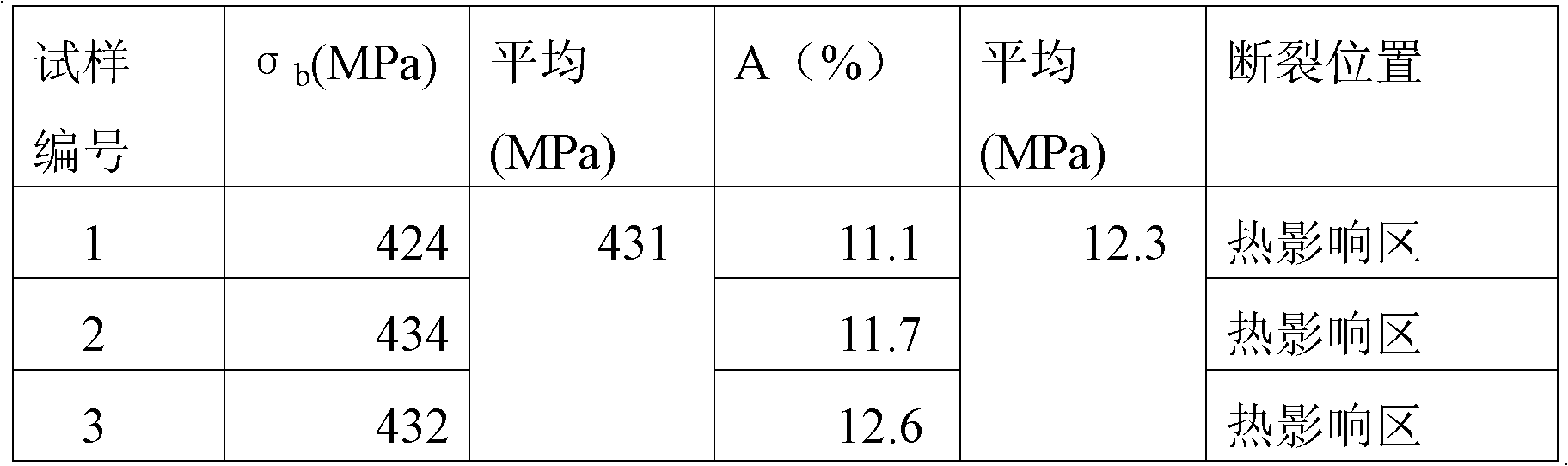

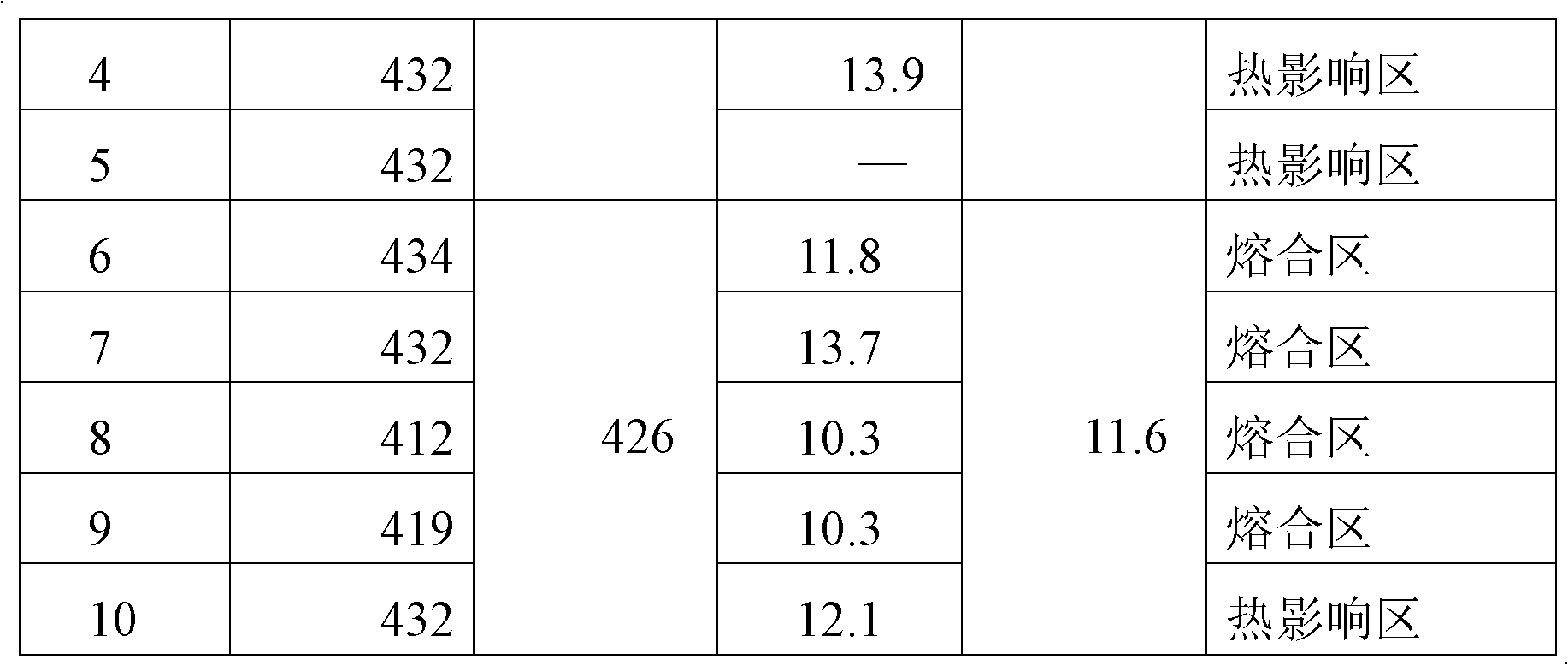

Welding wire matched with corrosion-resistant aluminum-magnesium-scandium alloy and preparation method thereof

ActiveCN101941122AImprove toughnessChemical composition equivalentWelding/cutting media/materialsSoldering mediaIngot castingFuel tank

The invention provides a welding wire matched with a corrosion-resistant aluminum-magnesium-scandium alloy and a preparation method thereof. The welding wire comprises the following components: 3.0-5.0wt% of Mg, 0.1-0.2wt% of Zr, 0.1-0.2wt% of Sc, 0.2-0.3wt% of Mn, 0.05-0.15wt% of Ti, 0.05-0.25wt% of Cr, 0.01-0.05wt% of Ce, 0.01-0.05wt% of Y and the balance of Al. The preparation method of the welding wire matched with the corrosion-resistant aluminum-magnesium-scandium alloy comprises the following steps: (1) preparing an aluminum-based master alloy; (2) preparing alloy raw materials; (3) refining the alloy; (4) measuring hydrogen content; (5) ingot casting; and (6) extruding and drawing for molding. The invention meets the need for welding production of an aircraft fuel tank and a rocket tank, and welding seams can obtain higher comprehensive mechanical property of joints.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH

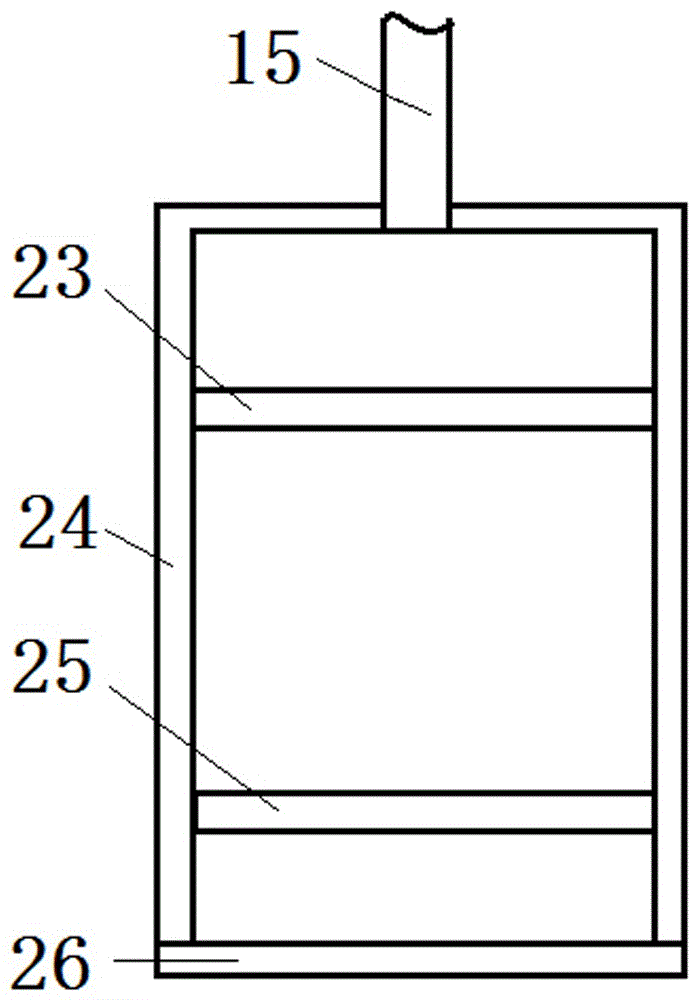

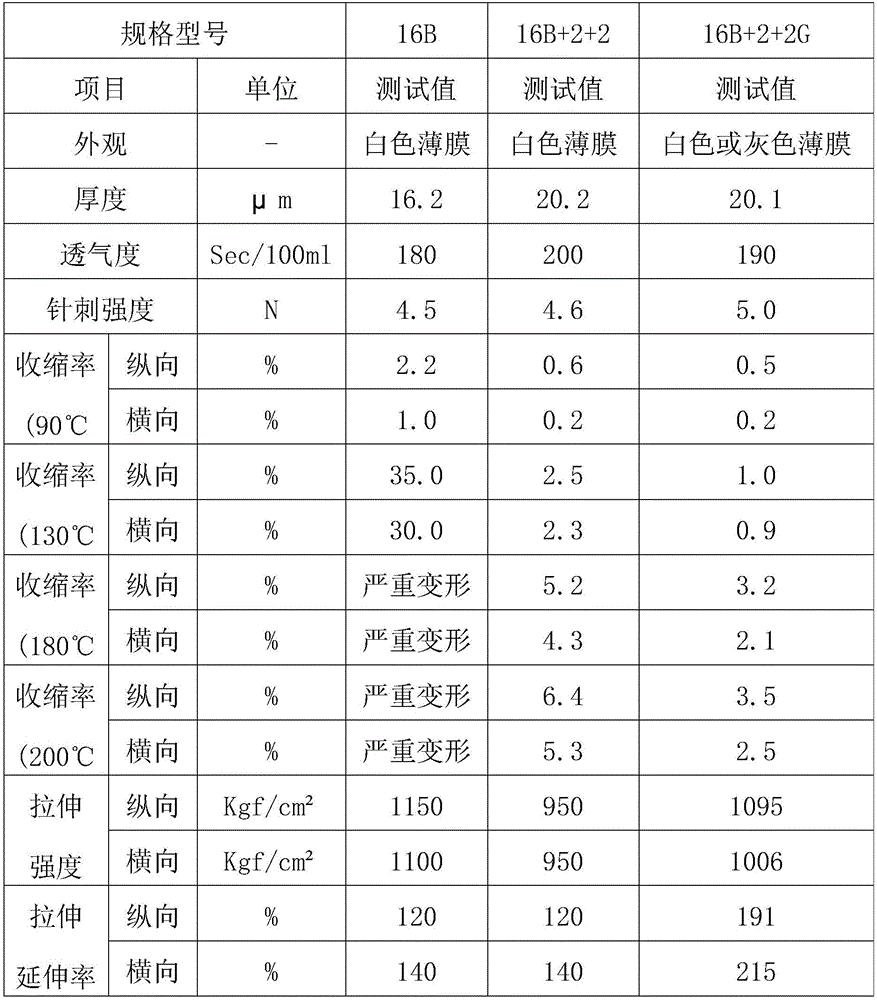

Preparation method of high-temperature-resistant low-resistivity lithium ion battery diaphragm

ActiveCN106299208AImprove securityFast chargingSecondary cellsCell component detailsSlurryLithium-ion battery

The invention relates to a preparation method of a high-temperature-resistant low-resistivity lithium ion battery diaphragm and belongs to the technical field of battery diaphragms. The high-temperature-resistant low-resistivity lithium ion battery diaphragm comprises a base film and a coating slurry layer applied to one lateral end surface or two lateral end surfaces of the base film, the coating slurry layer is made of ceramic slurry or graphene-modified ceramic slurry, and the coating slurry layer on at least one of the two lateral end surfaces of the base film is made from graphene-modified ceramic slurry; the preparation of the diaphragm comprises the steps of preparing graphene-modified ceramic slurry, pretreating a base film and coating and drying; sodium polyacrylate, ammonia water, alcohol, graphene and waterborne acrylic emulsion as well as sodium carboxymethyl cellulose solution are added in sequence during preparation of the graphene-modified ceramic slurry, the slurry that is obtained has stable properties and is as advantageous as the ceramic slurry and graphene material, a battery diaphragm with the base film coated with the slurry has low shrinkage and high safety, battery charging speed is high, and the diaphragm is suitable the industries requiring high-temperature operation and quick-charge batteries, such as electric vehicles.

Owner:HEBEI GELLEC NEW ENERGY MATERIAL SCI&TECHNOLOY CO LTD

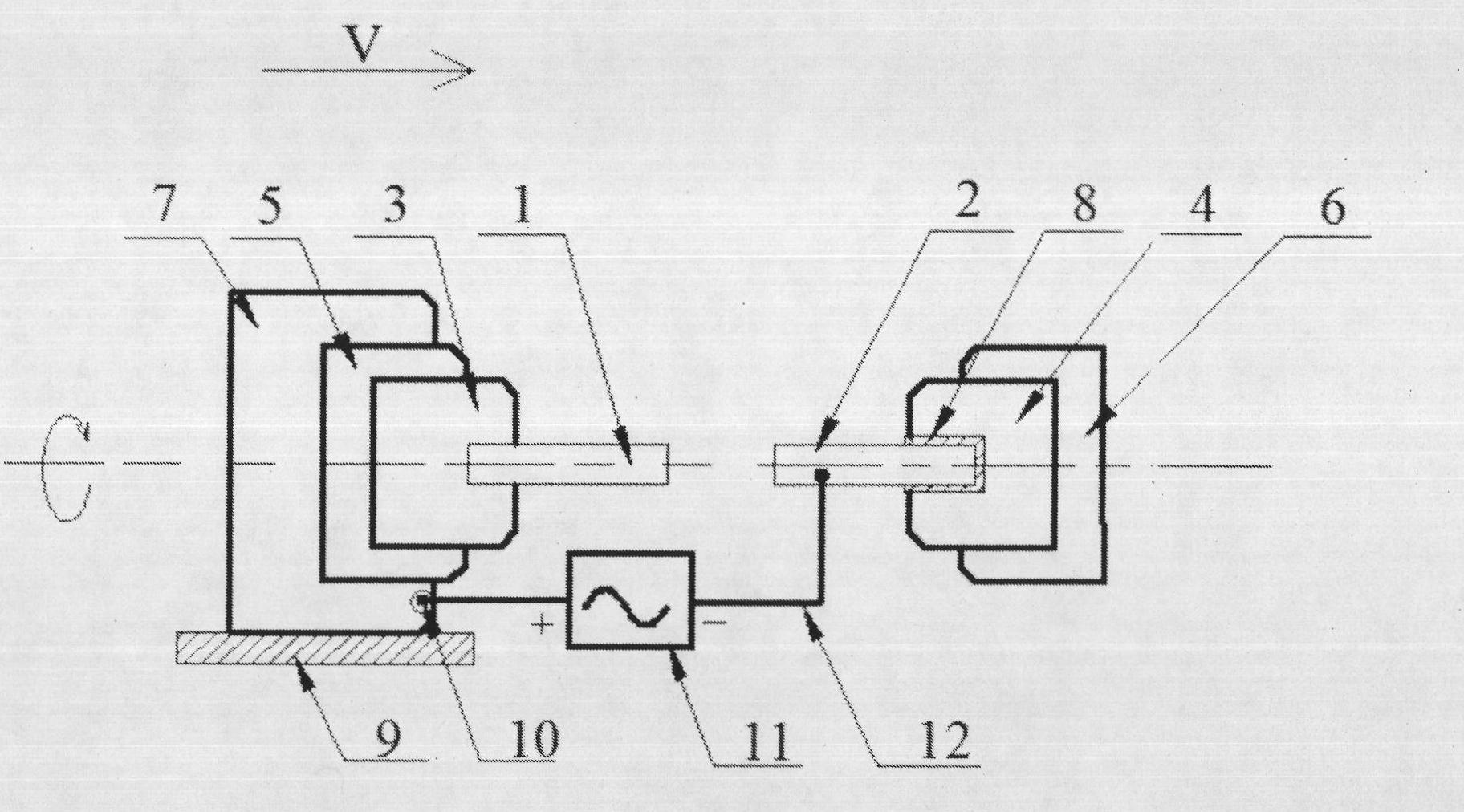

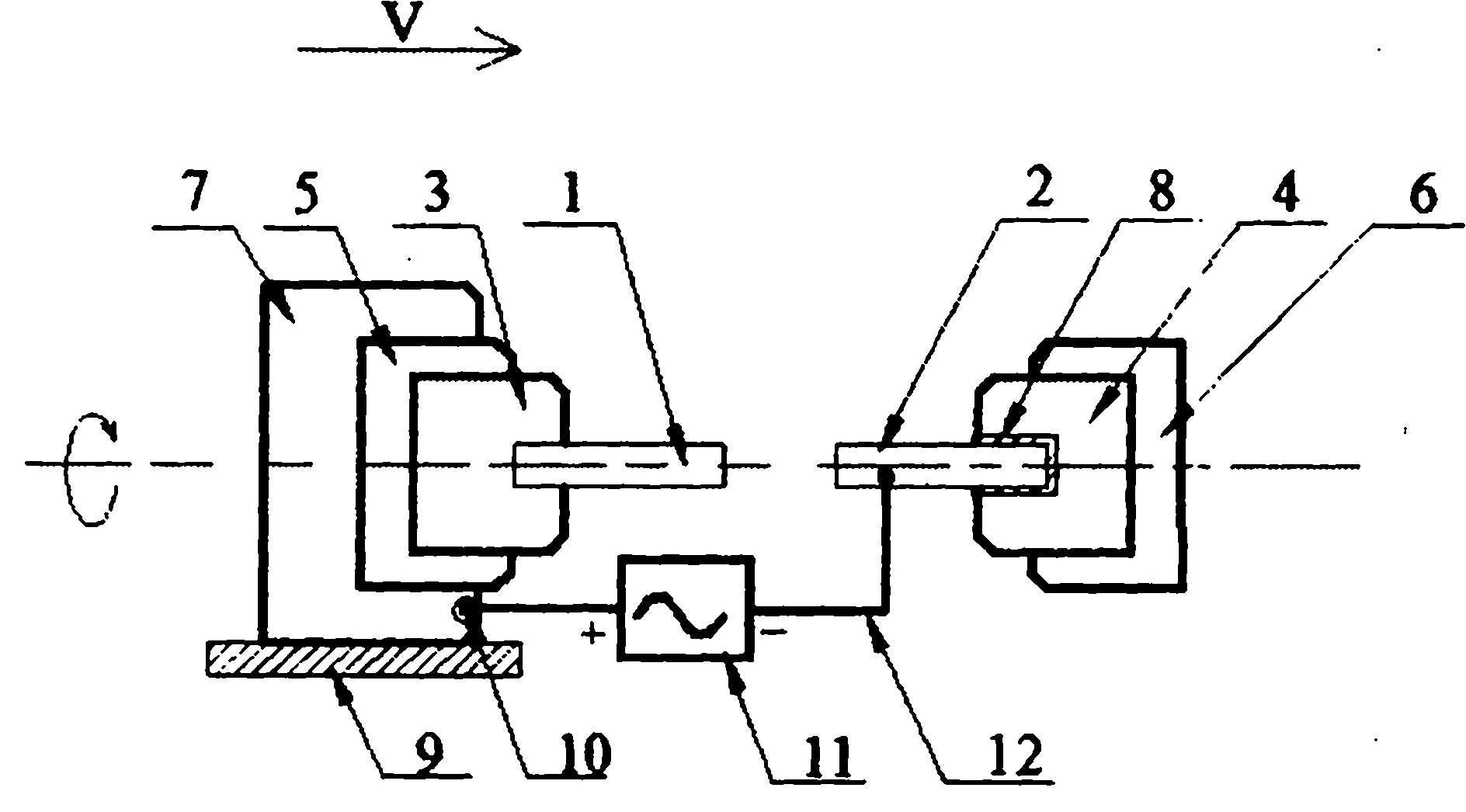

Current-carrying inertial axial friction composite welding method and equipment thereof

InactiveCN101829853AGuaranteed normal rotationGuaranteed electrical conductivityResistance welding apparatusNon-electric welding apparatusFriction weldingElectrical resistance and conductance

The invention relates to a current-carrying inertial axial friction composite welding method and equipment thereof. In the inertial axial friction welding process, a unique current loading method without an electric brush is adopted, current is introduced into a friction welding head to enable a friction interface to generate resistance heat, and the resistance heat and friction heat form a friction composite heat source for together heating joints and carrying out friction and plastic deformation to realize the purpose of welding through the method and the equipment. The method and the equipment can shorten the heating time of friction welding, improve the production efficiency of welding, the friction pressure, the power of a main shaft and the special requirements for the capacity of a friction welding machine, can adopt resistance heat to carry out heat treatment after welding and preheating before welding on welding seams and improve the structure property of joints, and are especially suitable for friction welding of rotator joints of high-melting point and high-hardness dissimilar materials, small-size pipes or bars and the like.

Owner:CHONGQING UNIV

Ultrasonic rolling recombination laser remelting method for improving fatigue property of welded joint

InactiveCN106283038AReduce frictionReduce roughnessMetallic material coating processesSurface layerMaterials processing

The invention relates to an ultrasonic rolling recombination laser remelting method for improving the fatigue property of a welded joint, and belongs to the field of material processing and surface strengthening. The method comprises the following steps: first, the surface modification of the welded joint is performed according to the laser remelting technology, and then ultrasonic surface rolling treatment is performed. Compared with a pure ultrasonic surface rolling processing method, the ultrasonic rolling recombination laser remelting method has the advantages that not only can surface nanocrystallization and ultra-low roughness of the welded joint be realized, but also the welded joint structure can be improved, welding defects can be eliminated, and the depth of a modified surface layer can be deepened, so that the fatigue strength of the welded joint is greatly improved.

Owner:JILIN UNIV

Metal diaphragm storage box made of carbon-fiber composite materials and manufacturing method thereof

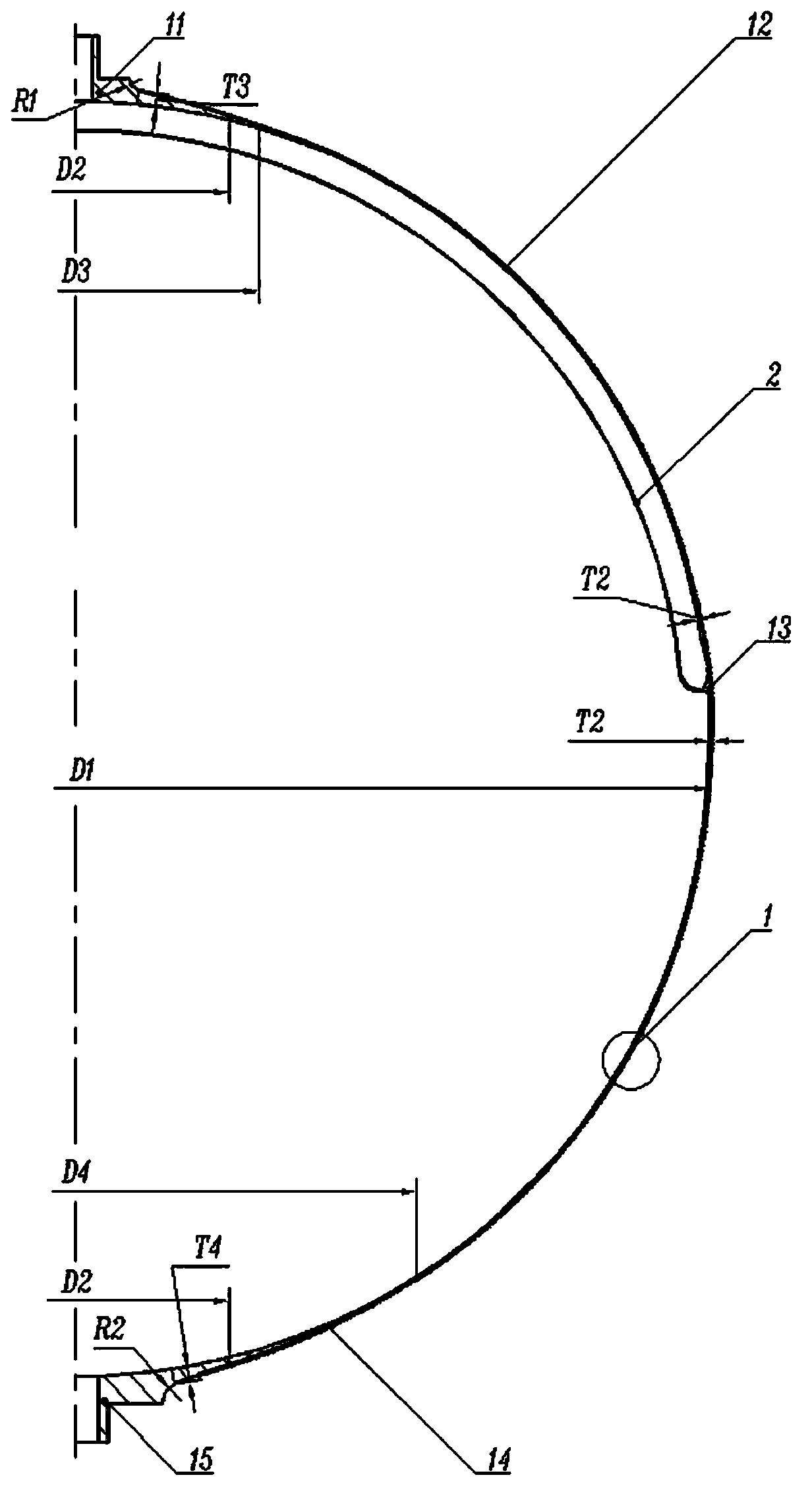

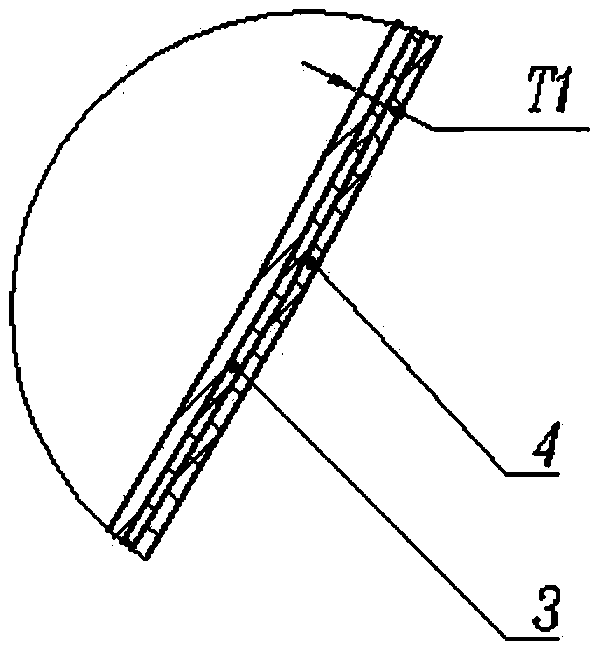

ActiveCN103437913ASimple structureGood manufacturing processRocket engine plantsCarbon fiber compositeFlange

The invention provides a metal diaphragm storage box made of carbon-fiber composite materials and a manufacturing method thereof. The metal diaphragm storage box comprises a liner 1 and a metal diaphragm 2 and also comprises an insulating layer 3 and a carbon-fiber composite material layer 4, wherein the liner 1 comprises an upper flange 11, an upper hemisphere 12, a connecting ring 13, a lower hemisphere 14 and a lower flange 15; the upper hemisphere 12 and the lower hemisphere 14 are connected by the connecting ring 13; the upper flange 11 is connected with the upper hemisphere 12; the lower flange 15 is connected with the lower hemisphere 14; the metal diaphragm 2 is butted with the connecting ring 13; the outer surface of the liner 1 is coated with the insulating layer 3; the outer surface of the insulating layer 3 is wound with the carbon-fiber composite material layer 4, and is connected with the carbon-fiber composite material layer 4 in a bonding manner. The metal diaphragm storage box provided by the invention has the advantages that the problems of large weight and low structure efficiency of the metal diaphragm storage box are solved, the light-weight design of the metal diaphragm storage box is realized, the cost is reduced and the performance of a product is improved.

Owner:SHANGHAI INST OF SPACE PROPULSION

3D print head

InactiveCN107199338AGrain refinementHigh bonding strengthAdditive manufacturing apparatusManufacturing material handling3d printMolten state

The invention discloses a 3D print head. The 3D print head is characterized by comprising an ultrasonic transducer, an ultrasonic amplitude transformer and an ultrasonic welding rod. The ultrasonic transducer is connected with the ultrasonic amplitude transformer, the ultrasonic welding rod is connected with the ultrasonic amplitude transformer, the ultrasonic welding rod is provided with a through hole which is used for conveying a printing material, the through hole extends to the end portion of the ultrasonic welding rod, and a fusing device which is used for heating the printing material into a molten state is also arranged. According to the 3D print head, the ultrasonic transducer and the ultrasonic amplitude transformer generate and amplify ultrasonic vibration, the bottom of the ultrasonic welding rod makes direct contact with the molten material, the ultrasonic vibration is transmitted into the molten material, when the metal printing material is printed in a vacuum or protective atmosphere, the molten metal makes contact with a printed workpiece, an upper metal layer is connected with a lower metal layer, under the ultrasonic vibration environment, structure grains are refined, pores, cracks, incomplete fusion and other defects are reduced, the structure performance is improved, the combination strength between the layers is improved, and the printing quality is further improved.

Owner:WUHAN UNIV OF TECH

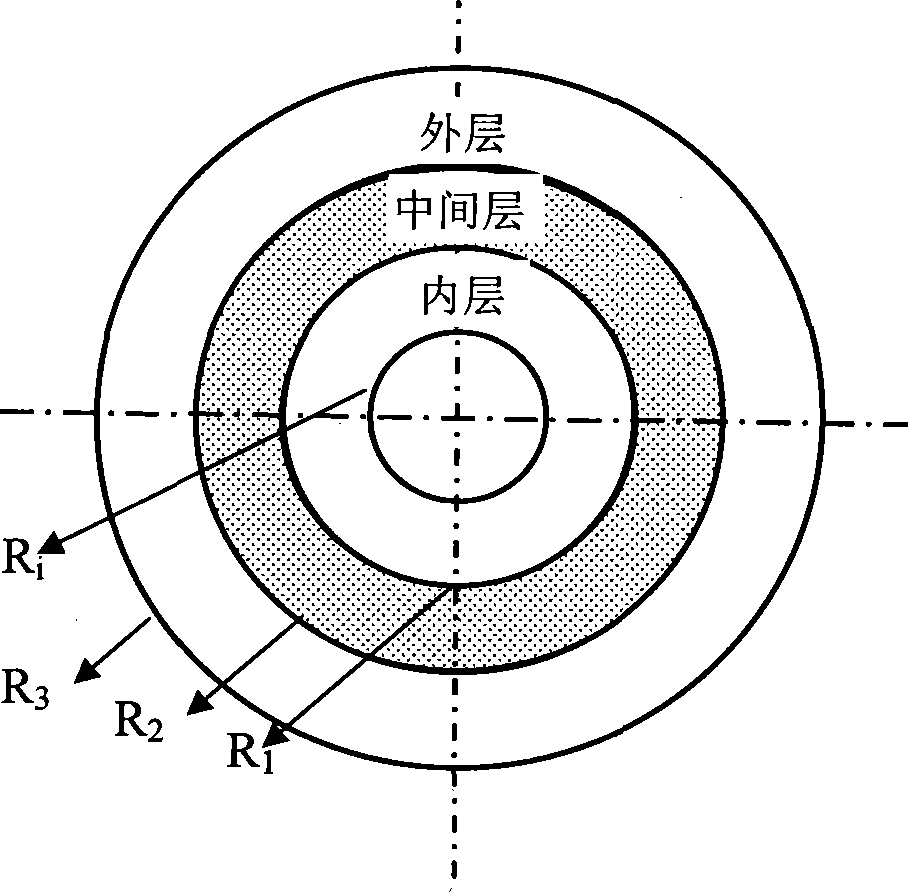

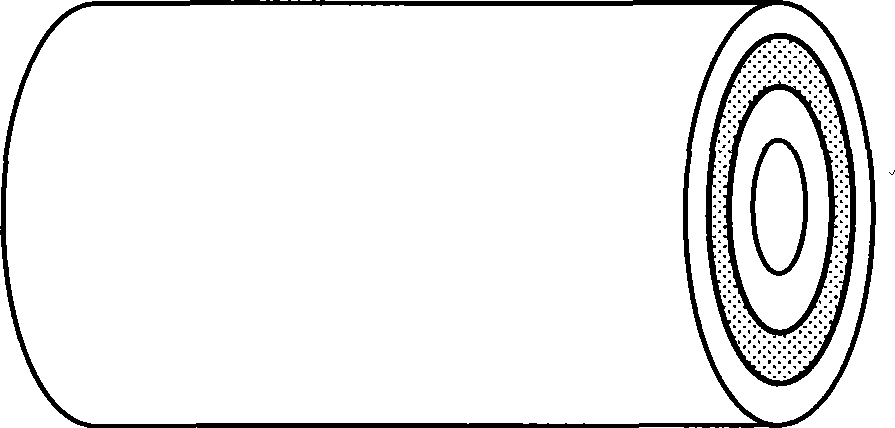

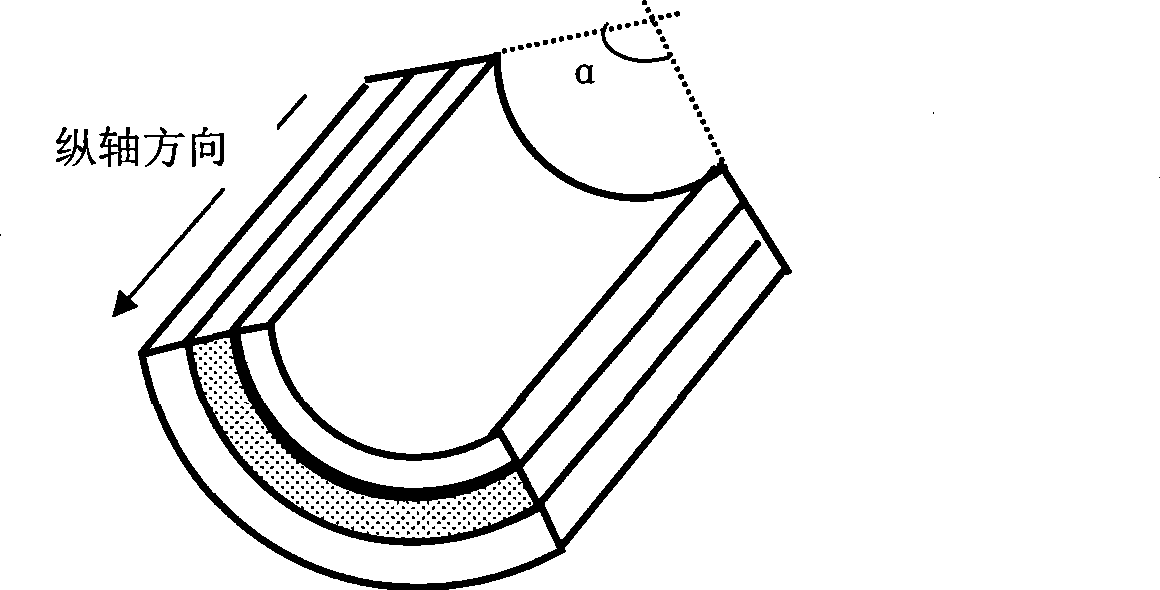

Short stage preparation method of multi-layer metal composite plate

ActiveCN101417387AAvoid cleaningAvoid surface treatmentMetal rolling arrangementsComposite plateHeating furnace

The invention relates to a short-process preparation method of a multi-layer metal composite plate and belongs to the technical field of short-process preparation of metal composite plates. The technology is characterized in that a corresponding centrifugal casting composite tube blank is chosen through calculation according to the innerlayer and outerlayer components and dimensional requirement of a finished product; the composite tube blank is dissected into 2 to 10 tile shapes along the direction of a vertical axis, with a fan-shaped cross section, and the central angle Alpha is 40 to 120 degrees; the blank cut is put into a heating furnace to be heated with the heating temperature of 1050 to 1280 DEG C and the time at maximum temperature of 0.5 to 5 hours; composite plates with various specifications are manufactured through hot rolling transformation; and a sheet metal is continued to be cold-rolled and transformed to produce the sheet metal with the thickness of 0.1 to 3mm. The technology is short in process, simple in operation, and high in bonding strength of layers of the composite plate produced and eliminates the nonuniform phenomenon of interface organization through the technologies of heating and transformation.

Owner:SICHUAN XINDING NEW MATERIALS

Lost foam casting production low-carbon steel upper core disc and impact seat processing method

InactiveCN104162633AAvoid crackingImprove compromiseFoundry mouldsFoundry coresManufacturing technologyHigh volume manufacturing

The invention discloses a lost foam casting production low-carbon steel upper core disc and impact seat processing method. The method comprises the following steps: making foam polystyrene EPS into a foaming member, which has the same shape as a cast and is a little bigger than the cast; painting a plurality of fireproof coatings on the surface of the foaming member, placing the foaming member in non-adhesive moulding sands, carrying out casting on the foaming member, wherein during the casting process, the foam polystyrene EPS foaming member is burnt and gasified under the assistance of vacummizing and vibration during the casting process, and finally the molten liquid replaces the foaming member as the cast. The lost foam technology is used to manufacture upper core disc and impact seat, is capable of reducing the metal tissue defects and improving the compactness and anti-fatigue strength of metals, moreover has the advantages of high precision in size, reducing on cleanness, reduced processing time, compact tissue of products, suitability for massive production, and high automation, can greatly improve the operation environment, and has greater advantages and a vaster prospect, compared to the conventional manufacture technology of upper core disc and impact seat.

Owner:XIANGTAN SANTAI MACHINERY MFG

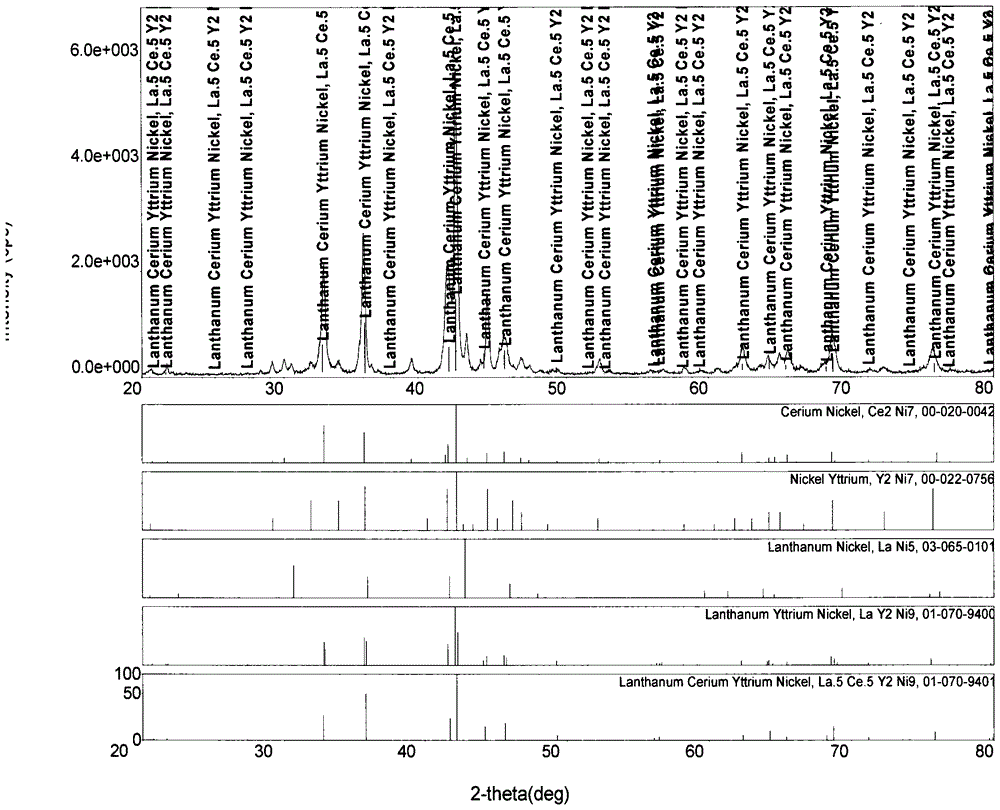

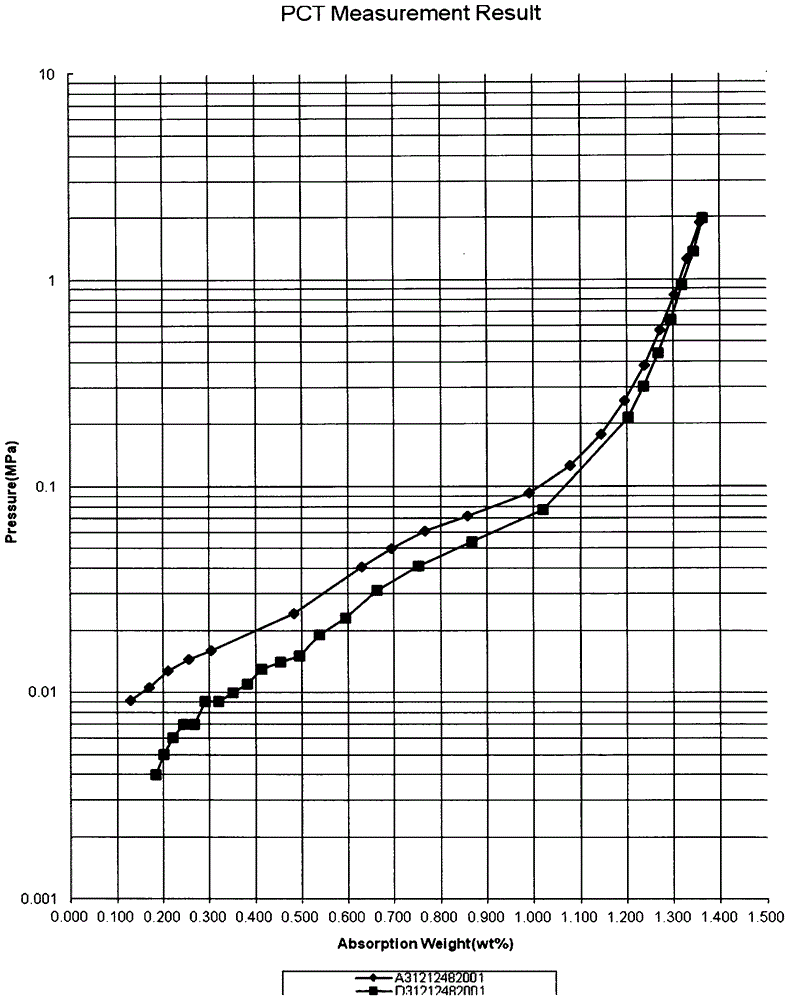

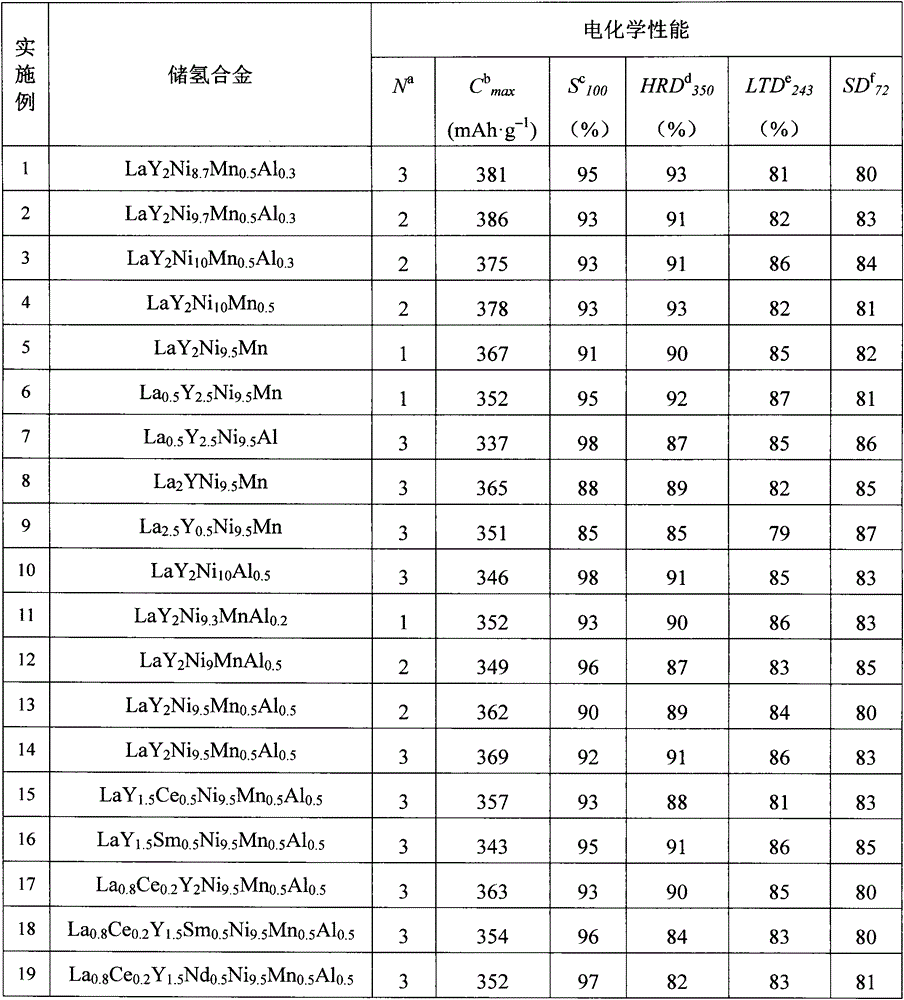

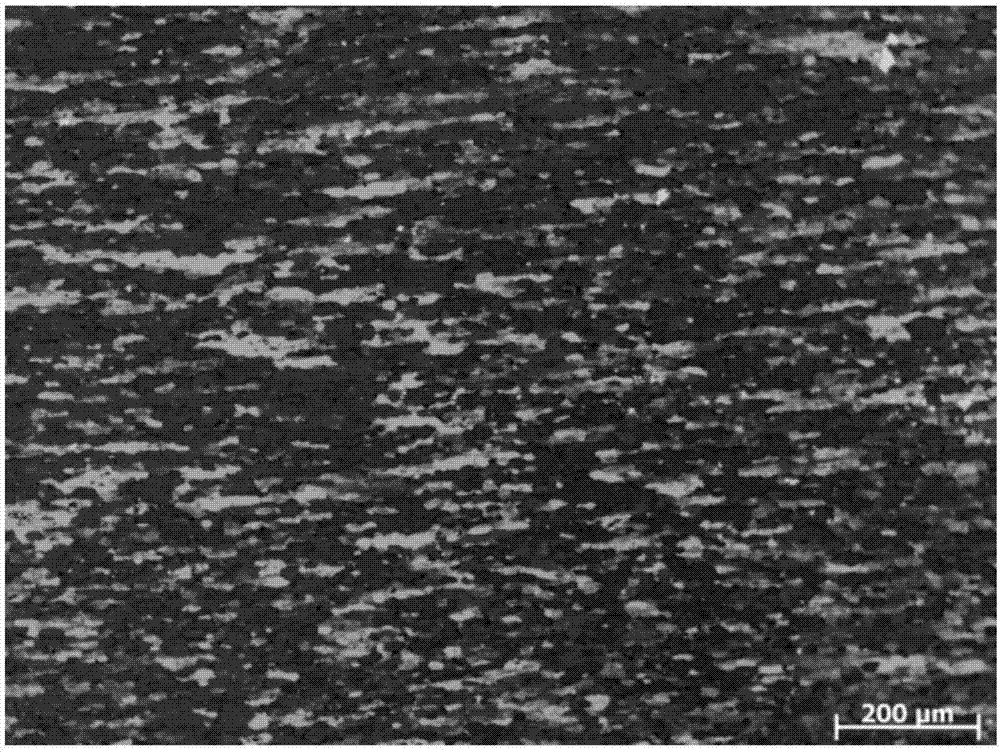

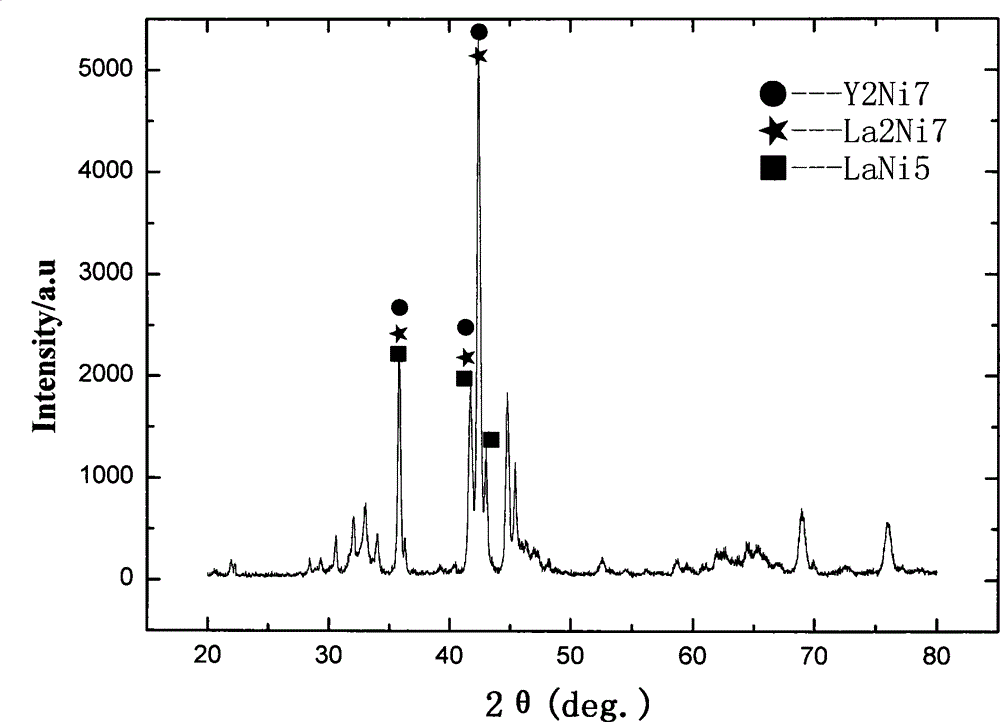

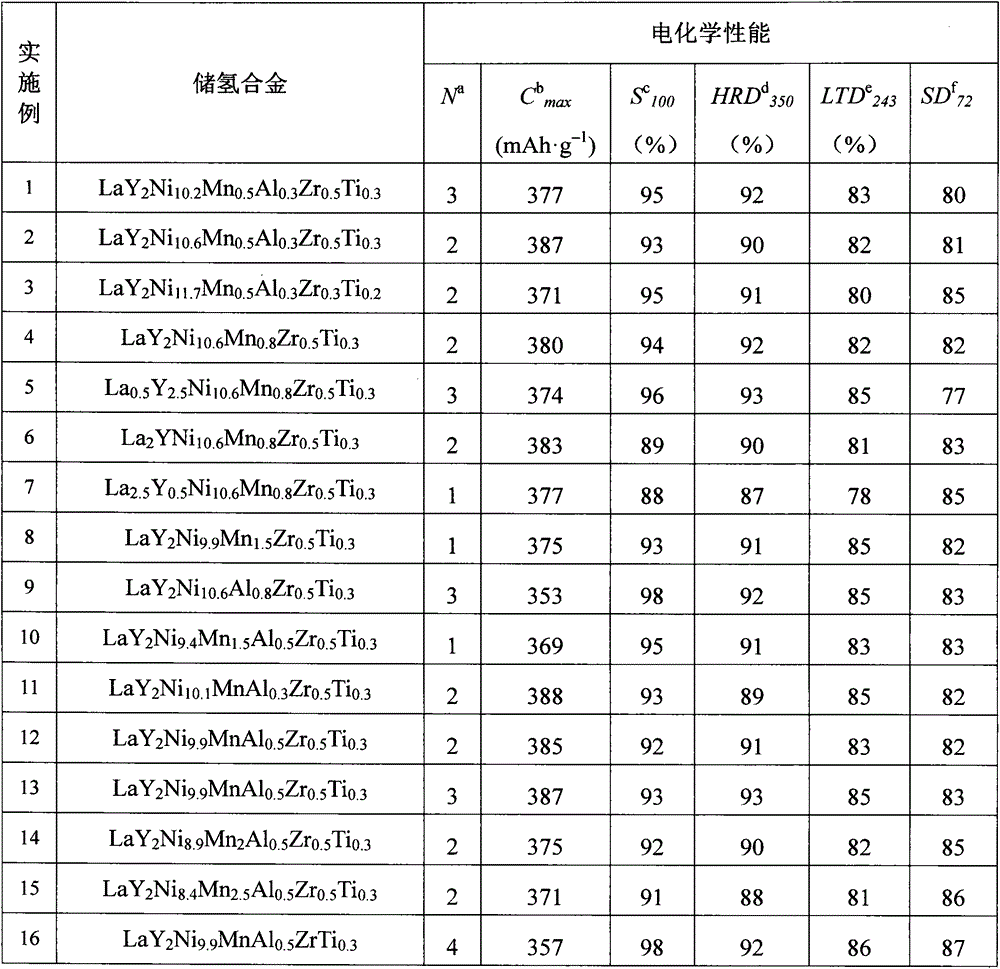

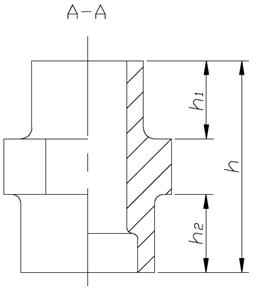

Yttrium-nickel rare earth-based hydrogen storage alloy

ActiveCN104532095AStructural stress reliefEliminate component segregationAlkaline accumulator electrodesGas phaseRare earth

The invention relates to A2B7 type RExYnNiz-a-bMnaAlb hydrogen storage alloy. The alloy is good in pressure-composition-isothermality, and has a maximum hydrogen storage amount of up to more than 1.36 wt.% under usual conditions. The alloy of the invention has better electrochemical performance as a hydrogen storage electrode and better gas-phase hydrogen absorption and desorption performance as a hydrogen storage material than traditional LaNi5 type hydrogen storage alloy; the alloy contains no magnesium element in the composition, so the preparation method of the alloy is simple and safe when compared with that of traditional rare earth-magnesium-nickel-based A2B7 type hydrogen storage alloy.

Owner:BAOTOU RES INST OF RARE EARTHS +2

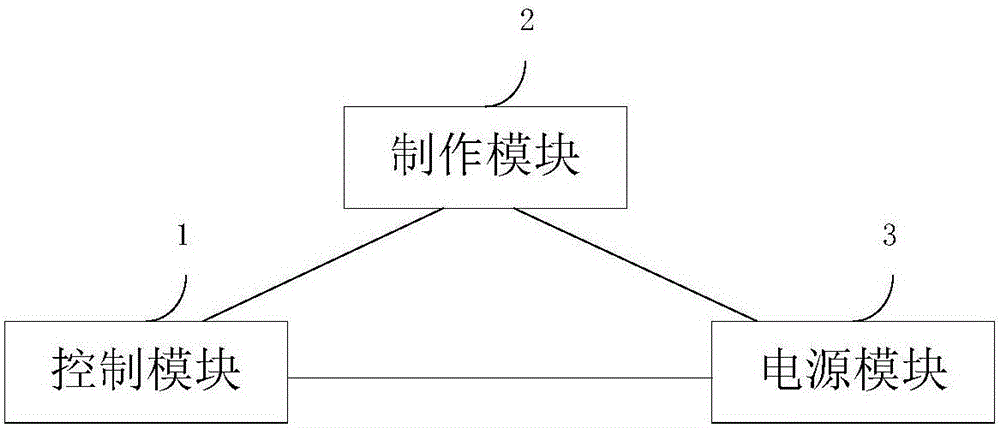

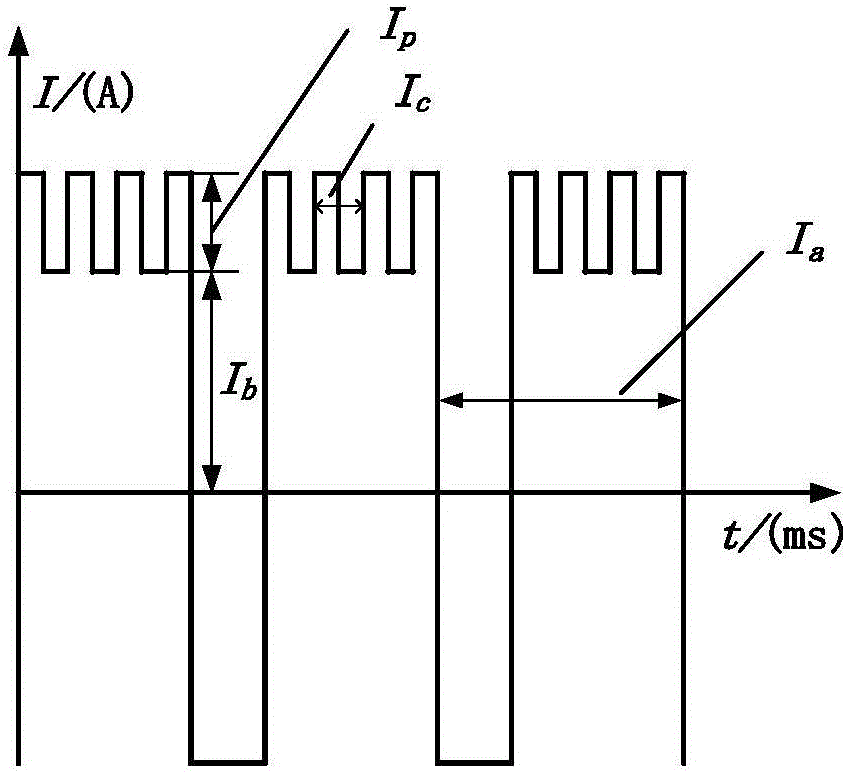

Additive manufacturing method for electric arc filler wire and device

InactiveCN106735730AHigh penetration rateImprove tissue performanceArc welding apparatusElectric arc furnaceSurface roughness

The invention provides an additive manufacturing method for an electric arc filler wire and a device. The device comprises a control module, a manufacturing module and a power module which are connected mutually. The control module is used for controlling the manufacturing module to be operated to manufacture a product, and controlling the power module to supply the power. The power module is used for, under the control of the control module, outputting compound superaudio frequency pulse current to the manufacturing module so as to provide a heat source to the manufacturing module. The added compound superaudio frequency pulse has the remarkable modulating action to GTAW electric arc, the electric arc shrinkage is remarkable, the electric arc force is greatly improved, the fusion penetration rate of the settled layer is improved, the side surface roughness of the settled layer is reduced, and the forced vibration of the liquid metal in a weld pool can be caused by the electric arc ultrasound effect, so the liquid metal flow is a double-circle flow mode, the air hole defect is reduced, the gain structure is refined, and the component performance is improved.

Owner:BEIHANG UNIV

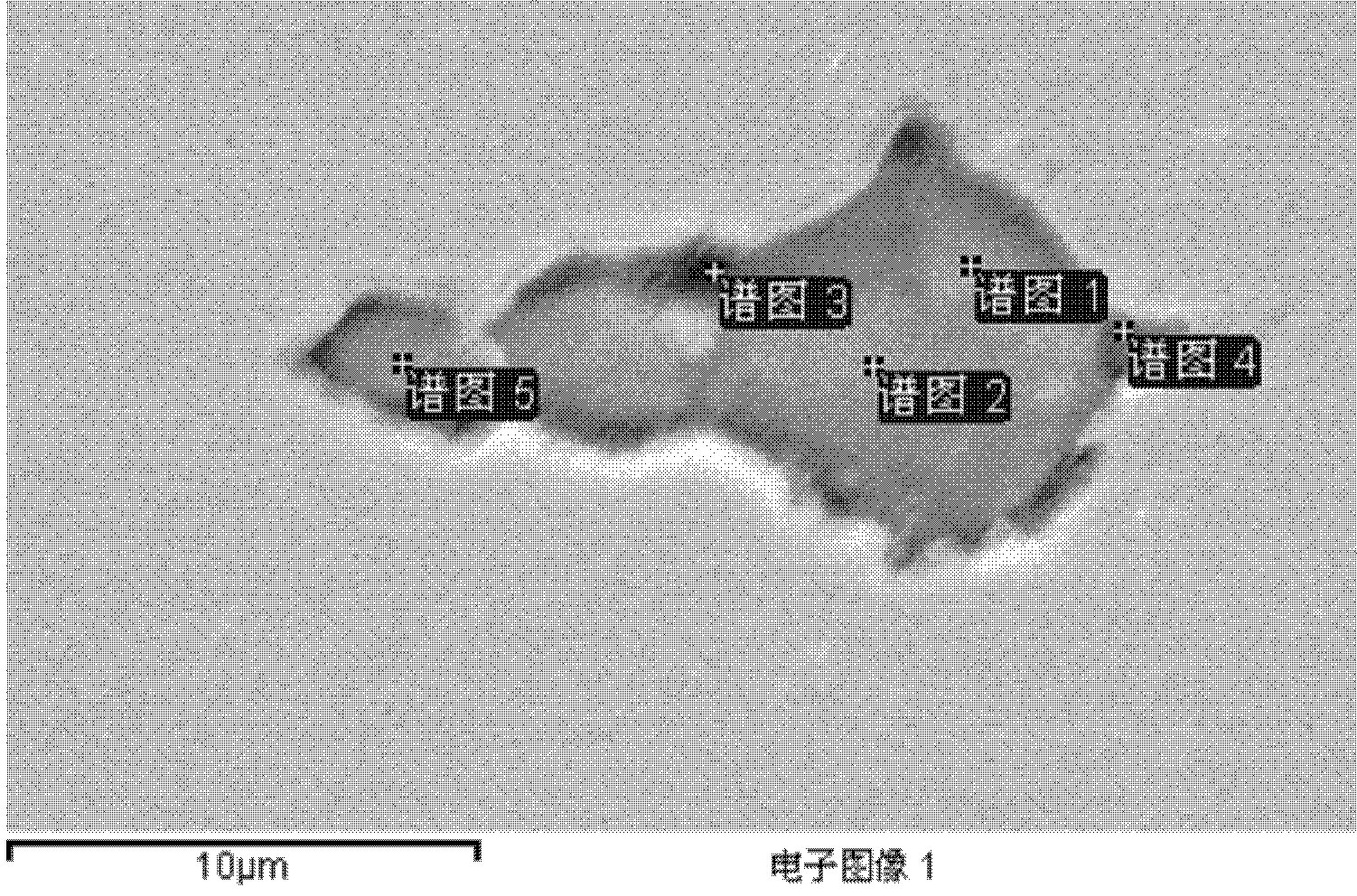

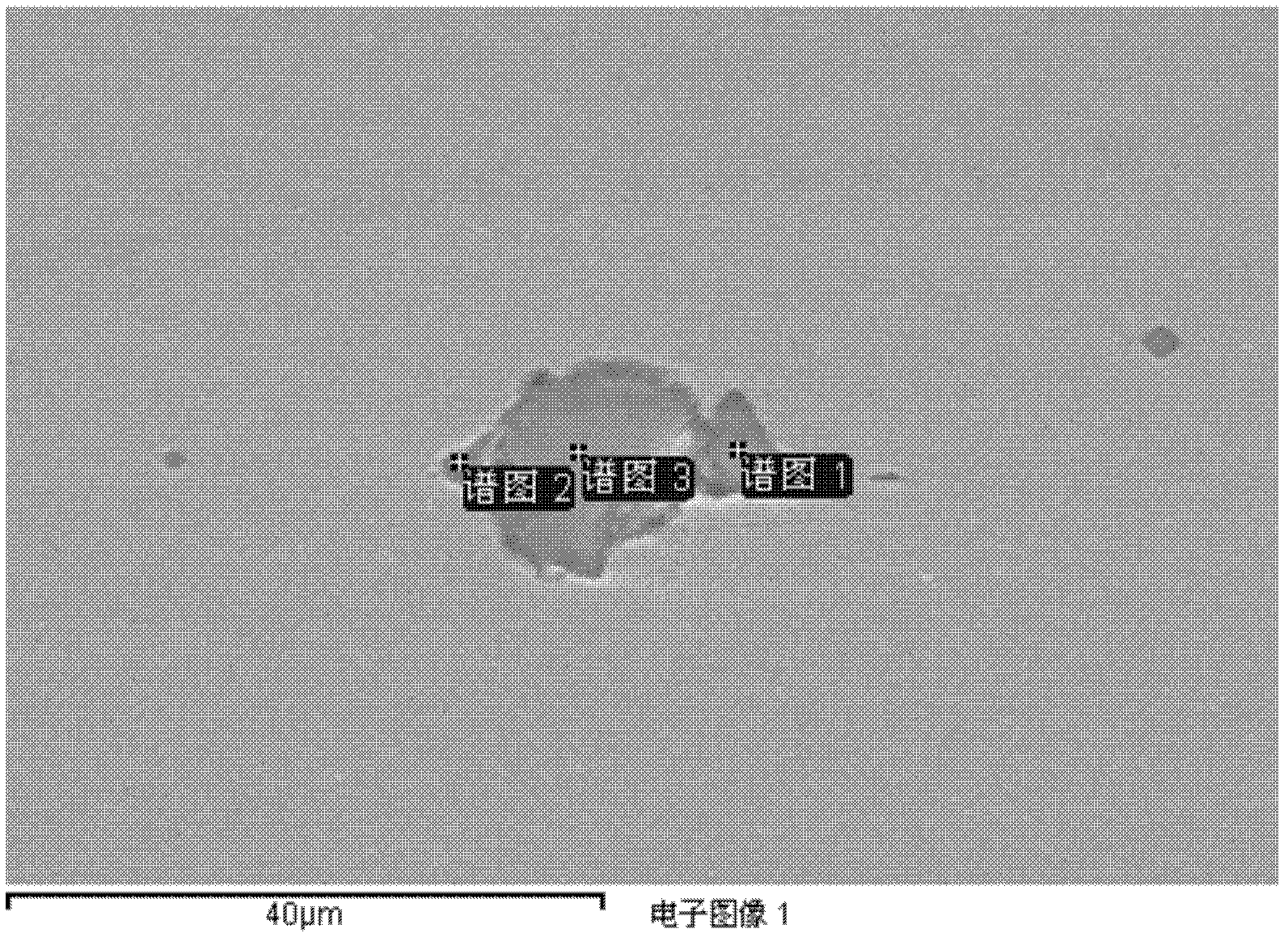

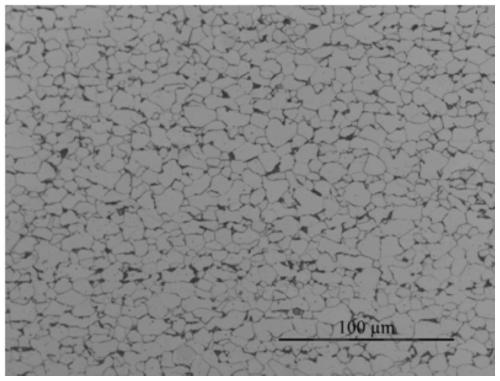

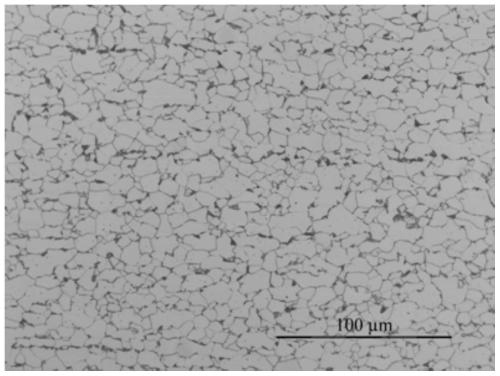

Control method for bearing steel network carbides and banded carbides and bearing steel

ActiveCN105648170AReduce formation effectReduce the formation effect of bearing steel network carbides and banded carbides Significant formation effectTemperature controlCarbide

The invention discloses a control method for bearing steel network carbides and banded carbides and bearing steel. The temperature of a finishing pass during hot rolling of the bearing steel is controlled to be within the range of 830 to 870 DEG C, and a large number of carbides are prevented from being separated out; then cooling equipment is utilized for performing water cooling on eventually rolled bar materials, the temperature of the bar materials is made to rapidly pass through the temperature range being 700 to 850 DEG C, the carbides are forcefully inhibited from being separated out, and the proportion of cementite in pearlite is increased; and meanwhile, the temperature of the bar materials after water cooling is controlled to be 600 DEG C to 650 DEG C, and a bainite or martensite structure is prevented from being generated. Production proves that the effect on reducing formation of the bearing steel network carbides and banded carbides is remarkable through the method, the grade of the network carbides in the bearing steel is decreased to the second grade or third grade from above third grade in GB / T18254 and the metallographic phase form of the carbides is a semi-net shape or a mass point shape, and the grade of the banded carbides in the bearing steel reaches the first grade in GB / T18254.

Owner:SUZHOU SUXIN SPECIAL STEEL +2

Additive manufacturing method and device for large metal part

ActiveCN109014200AImprove performanceSmall grain sizeAdditive manufacturing apparatusManufacturing technologyAdditive layer manufacturing

The invention belongs to the field of additive manufacturing, and specifically discloses an additive manufacturing method and device for a large metal part. Firstly, the additive manufacturing technology is used, slice processing is performed according to a data model of the part, then contour data of all layers are extracted, a deposition path of a contour is generated, a metal cavity having a certain thickness and depth is manufactured on a substrate, smelted metal is injected into the metal cavity, after the smelted metal is in the solidification or semi-solidification state, the part is rolled and processed, deposition of a new metal cavity in the part is continuously carried out, and the above steps are continuously executed until the overall part is completed. The additive manufacturing method and device solve the defects that a current large-scale metal part wholly adopts the additive manufacturing process so that the efficiency can be insufficient and cracking can be easy, thecasting process is adopted so that defects such as contraction and shrinkage can exist, the shortcoming that the process is complicated and the cycle is too long and the shortcoming that the forging process is adopted so that a forging press can have the tonnage limit and the cycle can be too long, and the high-performance metal parts can be quickly manufactured with low cost.

Owner:HUAZHONG UNIV OF SCI & TECH

Al-Mg-Si system aluminum alloy extrusion profile and production process thereof

The invention provides an Al-Mg-Si system aluminum alloy extrusion profile and a production process thereof, and relates to the technical field of non-ferrous metal material processing engineering. The Al-Mg-Si system aluminum alloy extrusion profile comprises the alloy element components, by weight: 0.65%-0.85% of Si, 0.2%-0.3% of Fe, 0.45%-0.65% of Mg, 0.15%-0.25% of Cu, 0.25%-0.45% of Mn, 0.15%-0.25% of Cr, 0.05%-0.07% of Ti, 0-0.1% of Zn and the balance Al. When the Al-Mg-Si system aluminum alloy extrusion profile is produced, the raw material is prepared according to the composition of the alloy element components and subjected to homogenization treatment, then hot extrusion is conducted, quenching is conducted on line, and aging treatment is conducted finally. According to the production process of the Al-Mg-Si system aluminum alloy extrusion profile, the structure property and the alloy plasticity of the material can be significantly improved, so that the obtained profile has the excellent bending property, the follow-up bending forming requirements are met, and the product yield is increased.

Owner:SHANDONG NANSHAN ALUMINUM +1

A5B19 type rare earth-yttrium-nickel system hydrogen storage alloy added with zirconium and titanium elements

ActiveCN104152749AIncrease capacityThe manufacturing method is simple and safeCell electrodesRare earthTitanium

The invention relates to rare earth system hydrogen storage alloy with the general formula of RExYyNiz-a-b-cMnaAlbMcZrATiB. The peak capacity of an alloy electrode is higher than that of LaNi5 type hydrogen storage alloy, and the manufacturing method is simple and safe. The hydrogen storage alloy has the good activation property, the rate discharge capability, and charging and discharging or hydrogen absorption and desorption circular stability, can be used in the wider temperature range, and is small in self discharging. The method can be used for manufacturing a cathode of an alkaline rechargeable battery and a rechargeable battery with the hydrogen storage alloy.

Owner:BAOTOU RES INST OF RARE EARTHS +2

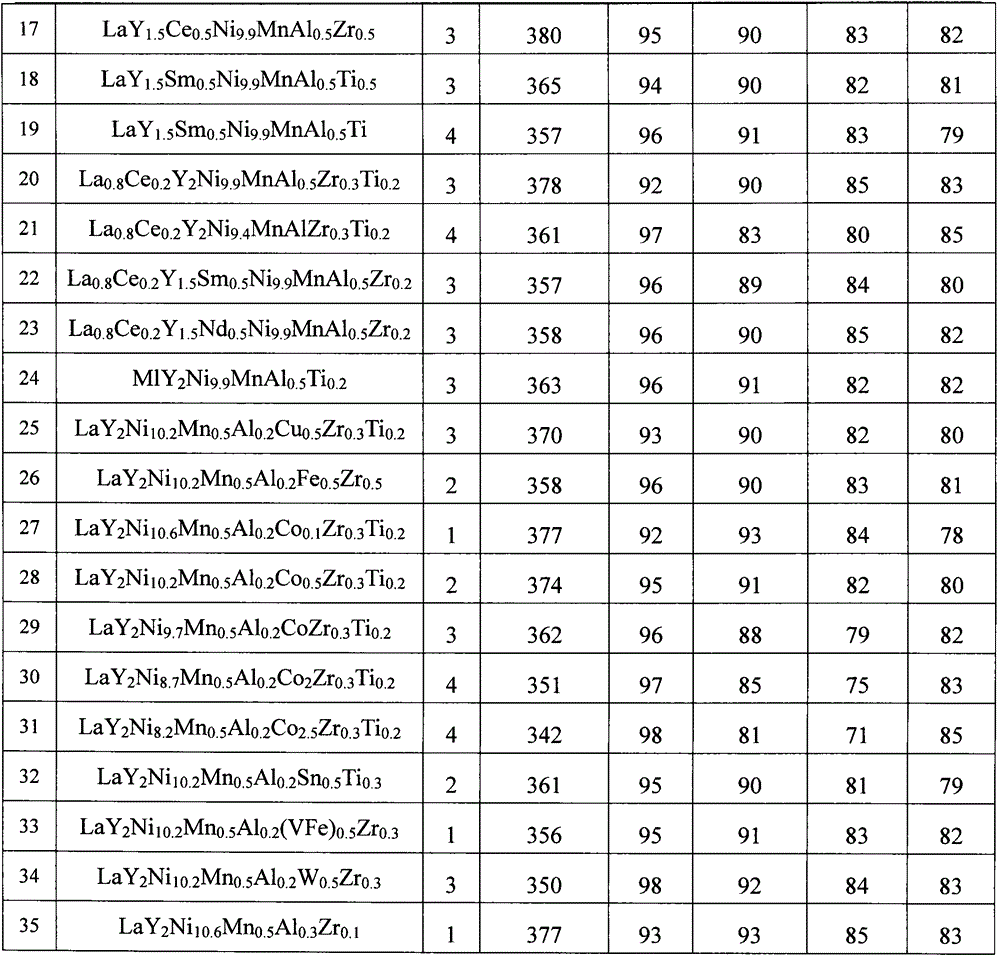

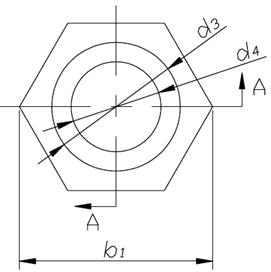

Device and method for compounding and forming central flange pipe joint from pipe blank in single-step and multi-directional way

ActiveCN102303090AReduce forming loadGood metal fluidityExtrusion diesExtrusion mandrelsExtrusion mouldingForming force

The invention discloses a device and a method for compounding and forming a central flange pipe joint from a pipe blank in a single-step and multi-directional way. The method comprises the following steps of: applying enough pressure on an appropriate pipe billet serving as a blank to make the whole pipe billet plastically deformed; forming a central flange of the pipe joint by upsetting; and inversely extruding to form a small head end part of the pipe joint and positively extruding to form a large head end part of the pipe joint, so metal upwards, downwards and radially flows, the forming force is small, and the number of stations is small. Compared with a cutting pipe joint, the invention has the advantages of high material utilization ratio and production efficiency and good metal flow structure, and is particularly applicable for production of high-pressure pipe joints.

Owner:JIANGSU UNIV

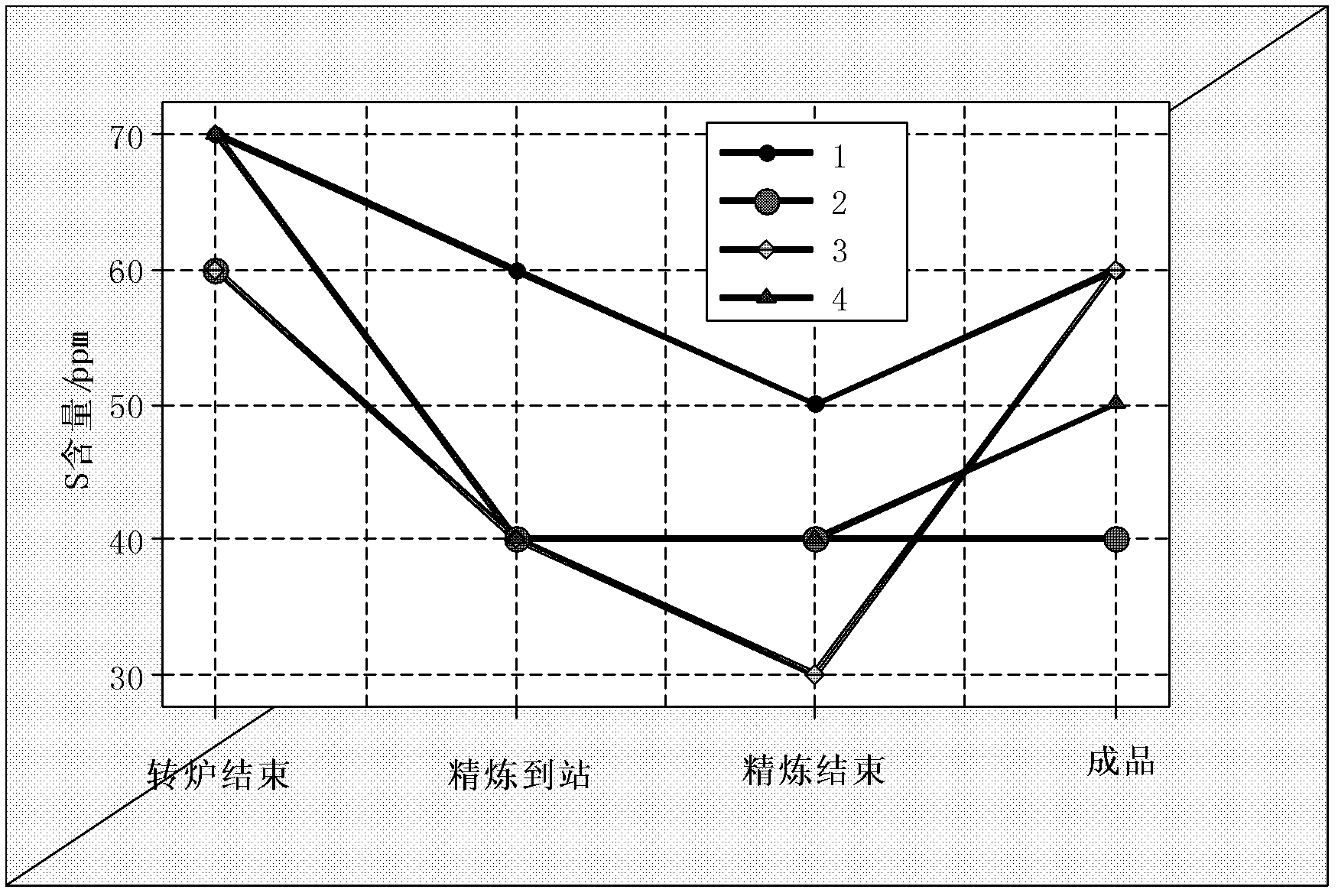

Low-cost steel for automobile beam and manufacturing method thereof

InactiveCN102212747AHigh strengthGuaranteed toughnessRoll mill control devicesManufacturing convertersProcess systemsNiobium

The invention relates to low-cost steel for an automobile beam and a manufacturing method thereof. The steel comprises the following chemical components in percentage by weight: 0.06-0.12% of carbon, 0.08-0.20% of silicon, 1.00-1.40% of manganese, 0.015-0.03% of niobium, less than or equal to 0.015% of phosphorus, less than or equal to 0.008% of sulphur, 0.02-0.06% of aluminium, less than or equal to 0.003% of [O], less than or equal to 0.005% of [N], and the balance of iron and unavoidable micro impurities. In the invention, by optimizing a process route, the problems of long smelting cycle of an LF (Ladle Furnace) and high power consumption for refining can be solved; the alloy production cost is reduced; by means of the process, the electricity consumption per ton of steel is reduced; the total refining cycle is shortened; and the beam steel production with low alloy cost is realized by using an optimized controlled rolling and controlled cooling process system.

Owner:SHOUGANG CORPORATION

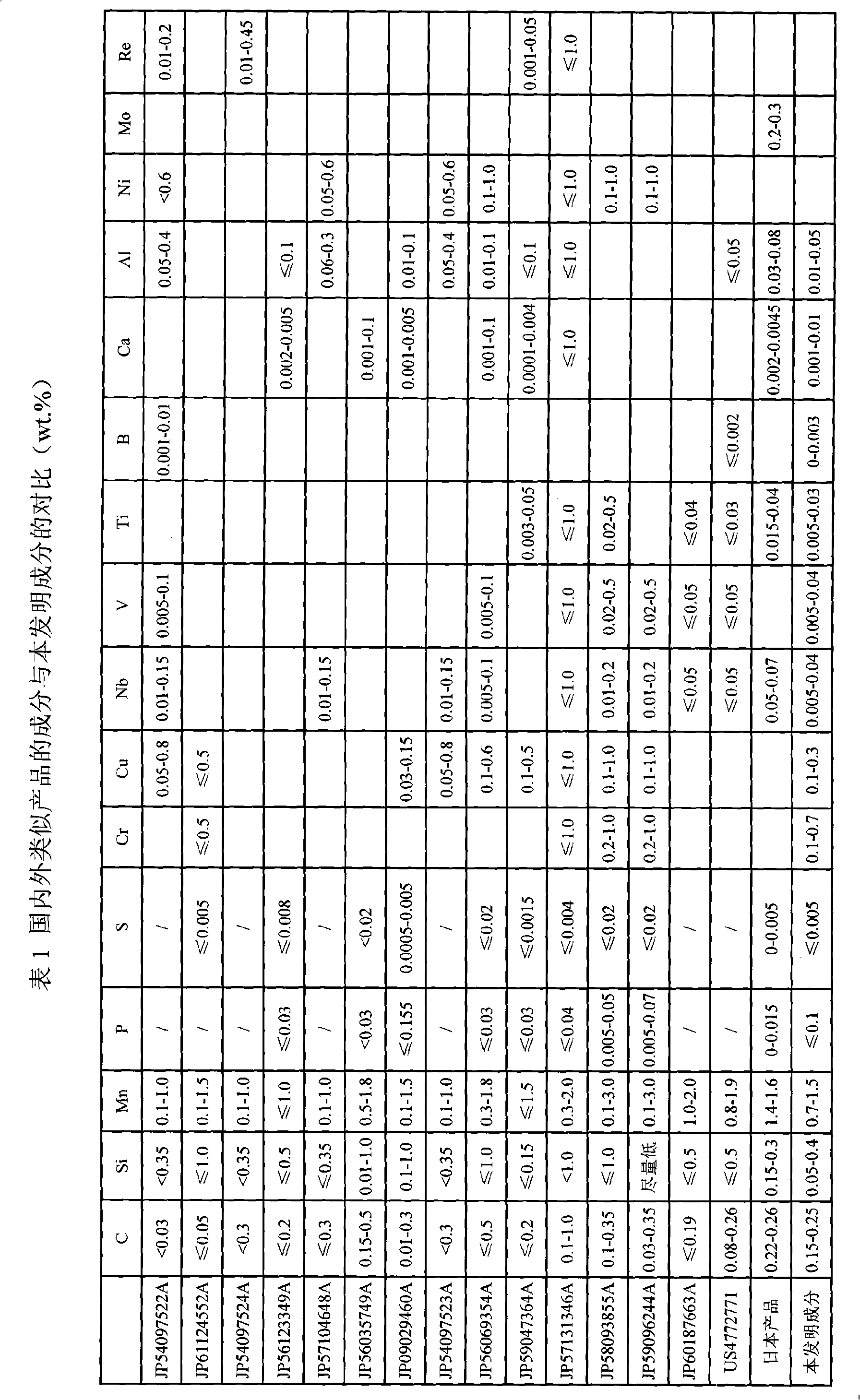

Grooving corrosion resistant high strength steel for ERW soldering sleeve, sleeve and production method

ActiveCN101353766AExcellent resistance to trench corrosionImprove tissue performanceTemperature control deviceChemical compositionHigh intensity

The invention provides a steel used for a guttering corrosion resistant high-strength ERW welding socket, and the chemical compositions of which by weight percentage are as follows: 0.15 percent to 0.25 percent of C, 0.05 percent to 0.4 percent of Si, 0.7 percent to 1.5 percent of Mn, less than or equal to 0.1 percent of P, less than 0.005 percent of S, 0.005 percent to 0.03 percent of Ti, 0.005 percent to 0.04 percent of Nb, 0.005 percent to 0.04 percent of V, 0.1 percent to 0.7 percent of Cr, 0.1 percent to 0.30 percent of Cu, 0 percent to 0.003 percent of B, 0.002 percent to 0.04 percent of Al and 0.001 to 0.01 percent of Ca, and the rest are Fe and other unavoidable impurities. The invention also provides a cannula prepared by adopting the steel and a manufacturing method thereof. The steel of the invention has excellent performance of guttering corrosion resistance and does not contain expensive alloying elements such as Mo and Ni and the like, therefore, the cost of the cannula is low.

Owner:BAOSHAN IRON & STEEL CO LTD

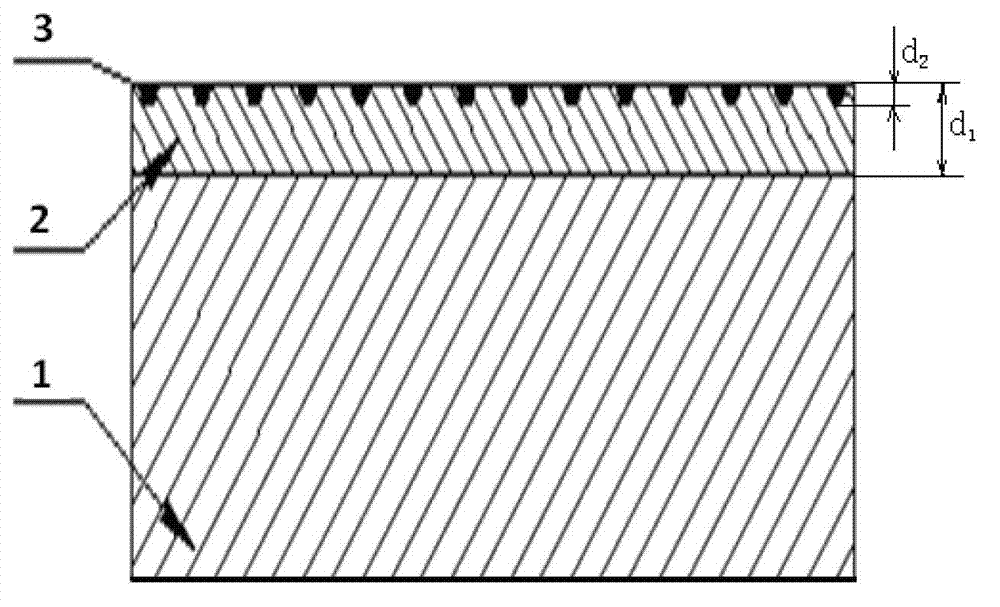

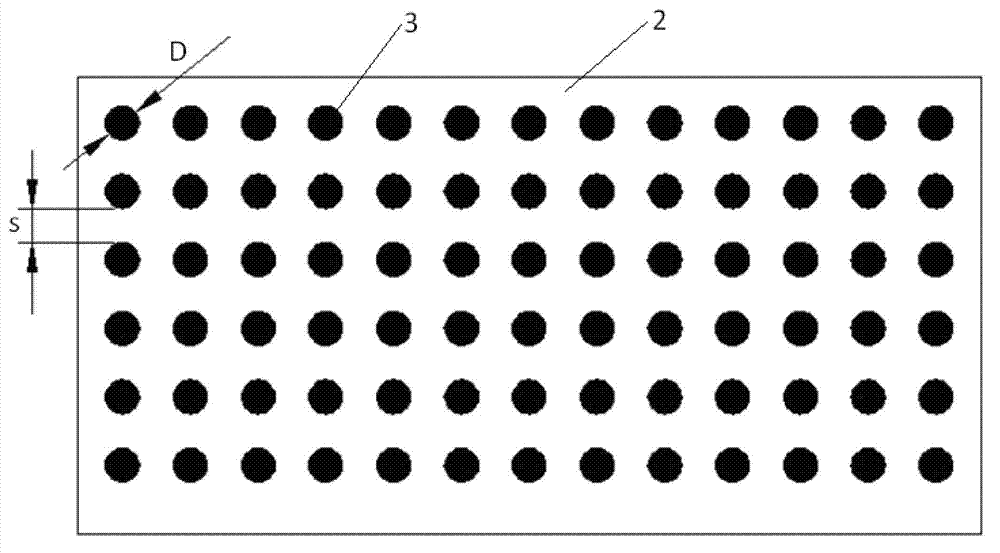

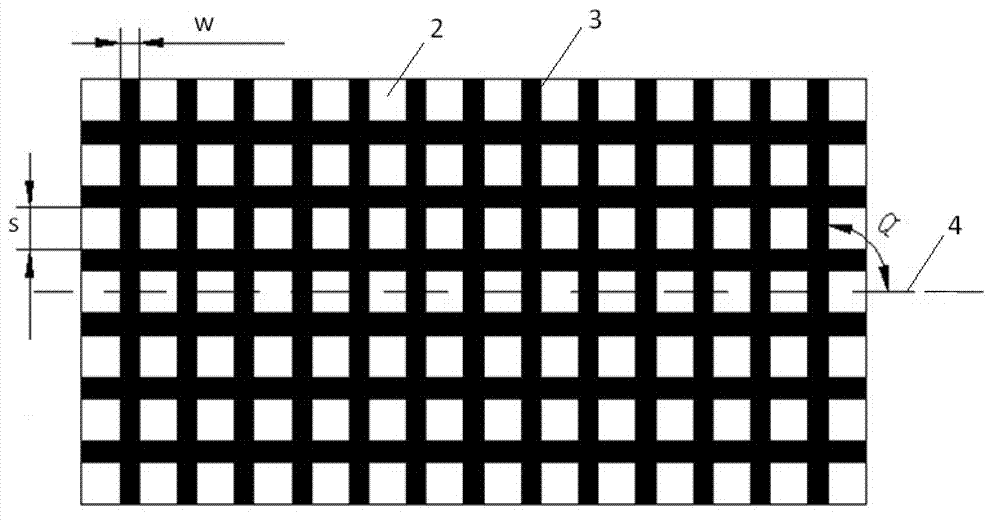

Bionic coupling cast iron guide rail and manufacturing method thereof and regeneration method of waste machine tool guide rail

InactiveCN103111850ASmall sizeImprove performanceLarge fixed membersLaser beam welding apparatusEngineeringLiving body

The invention relates to a bionic cast iron guide rail and a manufacturing method of the bionic cast iron guide rail and a regeneration method of a waste machine tool guide rail. The cast iron guide rail is composed of a guide rail main body and a surface structure refining layer of the guide rail main body. Nanoscale martensite units are distributed on the surface structure refining layer. The manufacturing method of the cast iron guide rail and the regeneration method of the waste machine tool guide rail mainly comprise the following steps of obtaining the surface structure refining layer by using high-frequency electric pulses to process the guide rail, and manufacturing the nanoscale martensite units on the surface structure refining layer by the adoption of laser fusing method. The units and a guide rail parent together form a bionic coupling area which is soft and hard and resembles a living body structure, the units function as firm pile screws or reinforcing ribs which are additionally arranged on the surface layer of the guide rail, and parent materials surround the units and enable the unit to be connected into a whole so as to enable local peak values of the surface of the guide rail to be dispersed and stress of the guide rail to be even. The bionic cast iron guide rail has superior mechanic property and fatigue and abrasion resistant performance.

Owner:JILIN UNIV

Roll forming method of 4340 H steel E-shaped ring forging

ActiveCN103350167AImprove tissue performanceMeet the requirementsMetal rollingStrip millThermal insulation

The invention discloses a roll forming method of a 4340 H steel E-shaped ring forging, which is provided for guaranteeing a forming size of the E-shaped ring forging and preventing the defects of folding, offset, insufficient filling and the like. The method comprises processing steps as follows: a 4340 H steel bar material which is subjected to blanking according to specification is heated to a forging temperature ranging from 1,100 DEG C to 1,140 DEG C and is upset and punched to obtain a primary ring blank on a press machine; then, the primary ring blank is heated to a forging temperature ranging from 1,120 DEG C to 1,160 DEG C and is subjected to inner-bore material gathering to obtain a secondary ring blank on a ring rolling machine; and the secondary ring blank is placed in the ring rolling machine equipped with a main roller die for roll forming after the secondary ring blank is heated to a forging temperature ranging from 1,140 DEG C to 1,200 DEG C, the deformation is larger than or equal to 45%, and the E-shaped ring forging is obtained. The E-shaped ring forging is subjected to quenching and high-temperature tempering thermal treatment after forged, the quenching is that the E-shaped ring forging is heated to 860 DEG C and is subjected to oil cooling after thermal insulation, and the high-temperature tempering is that the E-shaped ring forging is heated to 590 DEG C and is subjected to air cooling after thermal insulation. The forging is mainly used for the field of wind power and mining machinery and the like.

Owner:GUIZHOU ANDA AVIATION FORGING

Cold-rolled weathering resistant steel and preparation method thereof

The invention discloses cold-rolled weathering resistant steel and a preparation method thereof. The cold-rolled weathering resistant steel comprises the following chemical components of, by weight, 0.05%-0.08% of C, 0.25%-0.40% of Si, 0.25%-0.40% of Mn, 0.060%-0.100% of P, less than or equal to 0.020% of S, 0.008%-0.030% of Als, 0.12%-0.20% of Ni, 0.25%-0.40% of Cu, 0.30%-0.50% of Cr, less than or equal to 0.0080% of N, and the balance Fe and inevitable impurities. Reasonable chemical component design is achieved, noble metal alloys such as Ti, Nb and B are not added, a hot rolling process, acold rolling process, a continuous annealing process and a flattening process are controlled, so that the cold-rolled weathering resistant steel with good surface quality is obtained, in the case ofthe cold-rolled weathering resistant steel, the yield strength is larger than or equal to 350 MPa, the tensile strength is larger than or equal to 500 MPa, the A50 elongation percentage is larger thanor equal to 30%, and the good atmospheric corrosion resistance and welding performance are achieved.

Owner:MAANSHAN IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com