Patents

Literature

670results about How to "Reduce smelting cost" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

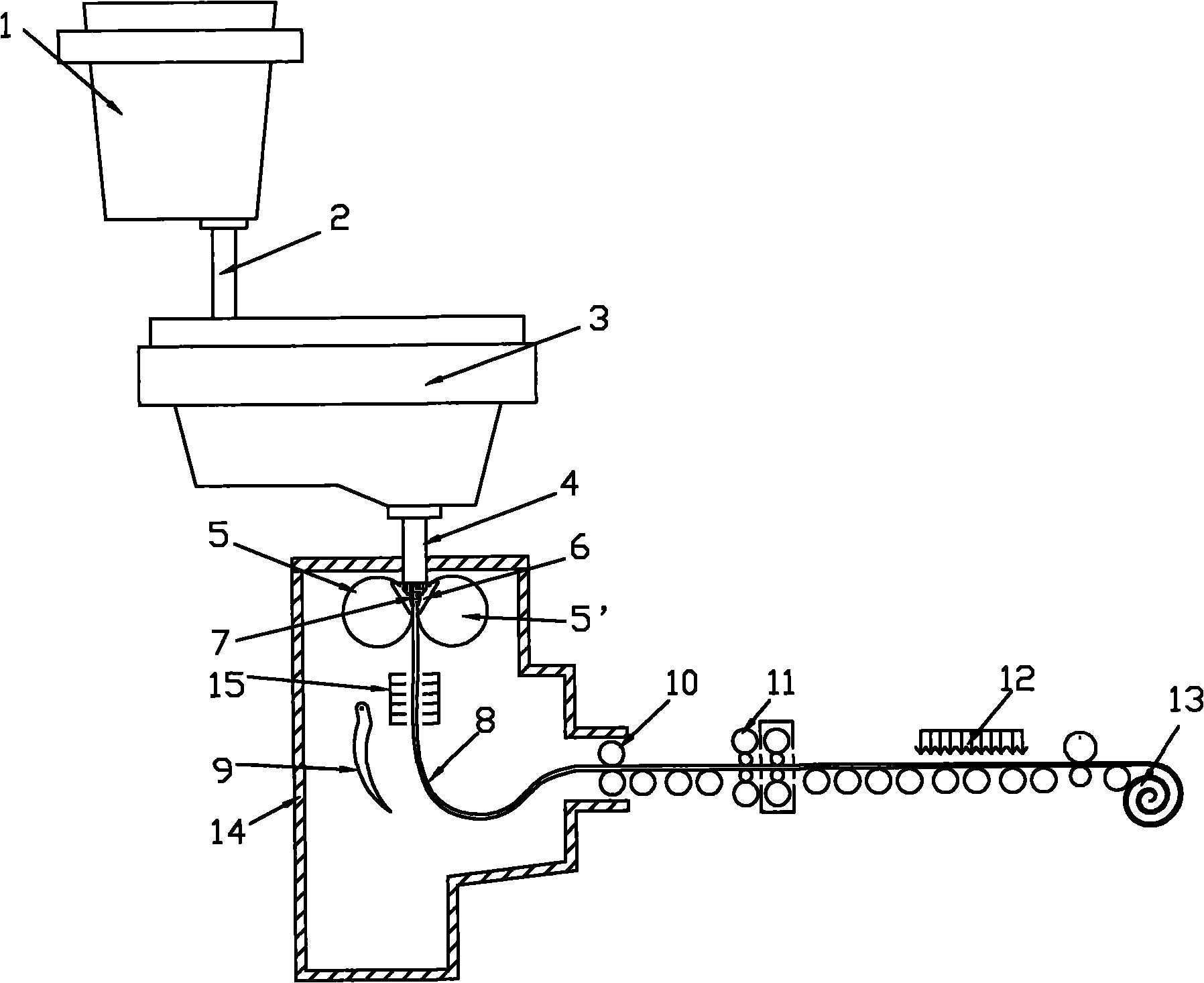

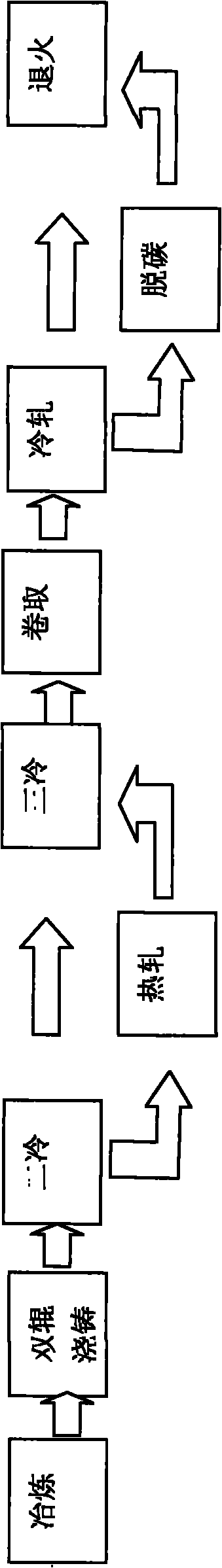

Manufacturing method of thin strip continuously cast and cold rolled non-oriented electrical steel

ActiveCN102041367AMeet needsReduce processHeat treatment process controlMelting tankElectrical steel

The invention relates to a manufacturing method of thin strip continuously cast and cold rolled non-oriented electrical steel, comprising the following steps: smelting molten steel the temperature and components of which meet the requirements, casting the molten steel into a molten bath formed by a pair of water-cooling crystallizing rolls rotating at high speed, then cooling for the second time, hot rolling, cooling for the third time, coiling, cooling to room temperature, pickling, cold rolling, and finally annealing to obtain the cold rolled non-oriented silicon steel sheet with high magnetic induction and low iron loss. In the invention, the thin strip continuous casting process can eliminate the hot rolling thinning procedure in the traditional process, thus avoiding quality defect caused by the improper hot rolling process, simultaneously reducing the equipment loss, and reducing the maintenance and overhaul costs of equipment; the solidification process is controlled to improve the medium axialite proportion of the casting strip, thus improving the corrugation defect of the product in the cold rolling process; and the range of components of the non-oriented silicon steel smelting is widened by the characteristic of quick solidification of the continuously cast thin strip, and the smelting cost is lowered. The invention has the advantages of short process flow, low energy consumption, high efficiency, low production cost, simple manufacturing method and obvious energy saving and consumption reducing effects.

Owner:BAOSHAN IRON & STEEL CO LTD

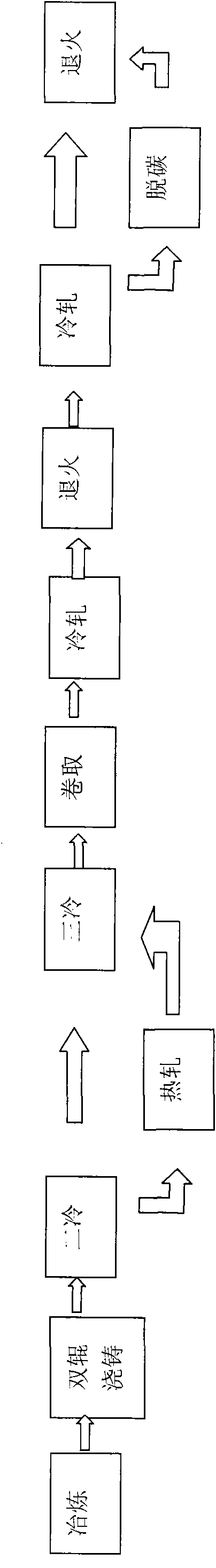

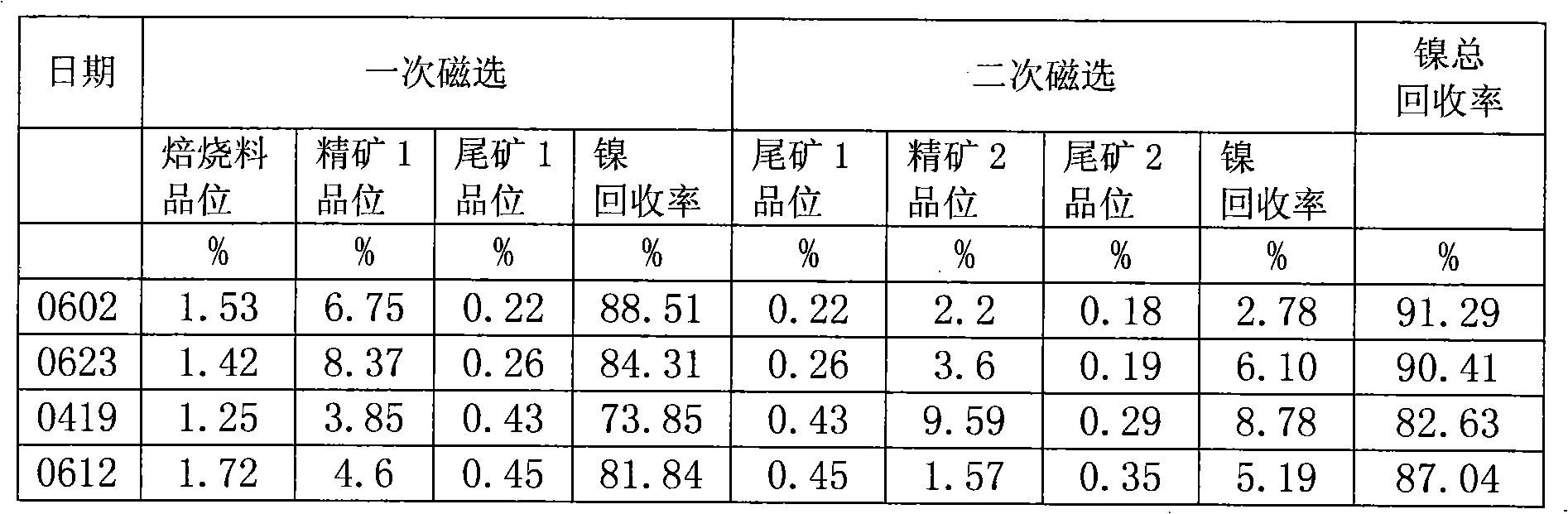

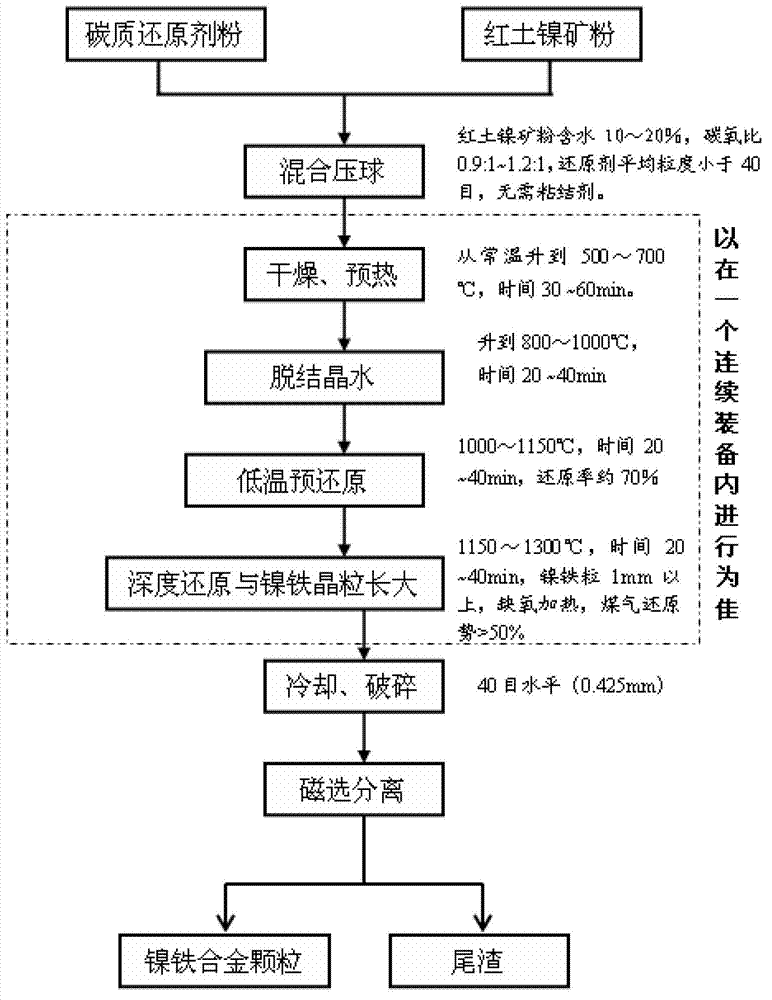

Method for enriching nickel iron ore concentrate from laterite type nickel ore by means of rotary kiln

InactiveCN101323904ANo pollution in the processSimple processRotary drum furnacesMagnetic separatorLaterite

The invention relates to a method for collecting ferronickel concentrate from lateritic nickel ores by a rotary kiln. The lateritic nickel ores are crushed, stirred and mixed with a carbonaceous reducing agent and a compound additive, made into pellets by a ball press or a marble machine and put into the rotary kiln for reducing and roasting; waste heat at the front part of the rotary kiln is used for carrying out the drying and preheating of the pellets; the high-temperature area of the rotary kiln is 9 to 10 meters away from a kiln outlet; the temperature of the high-temperature area is controlled to be 1000 to 1300 DEG C; roasting time is 0.5 to 2 hours; the dried pellets enter the high-temperature area of the rotary kiln for reducing and roasting; a magnetic separator with a magnetic field intensity of 3000 to 5000 gauss is adopted to sort roasted material obtained after water quenching and wet ball milling, thus obtaining high-content ferronickel concentrate; the method can realize the simultaneous recycling of nickel and iron and obtain the high-content ferronickel concentrate; the content of nickel is 5 to 13 percent and the recycling rate of nickel is 85 to 93 percent; the content of iron is 30 to 75 percent and the recycling rate of nickel is 60 to 85 percent; the reasonable utilization of the waste heat during process procedure achieves the purposes of saving energy and reducing discharge and greatly reduces pollution to the environment.

Owner:HONGHE HENGHAO MINING

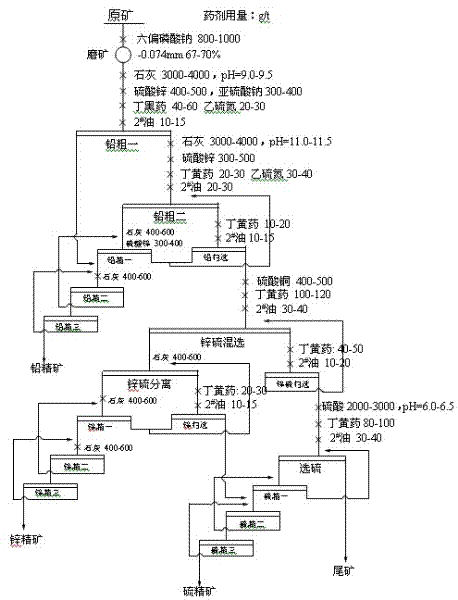

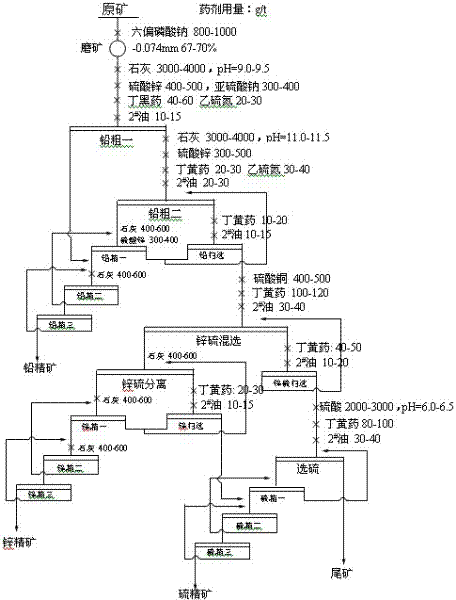

Technology of enhanced-dispersion partial selective and bulk flotation of lead and zinc sulfide ores under low and high alkalinity

The invention discloses a technology of enhanced-dispersion partial selective and bulk flotation of lead and zinc sulfide ores under low and high alkalinity. During grading of the lead and zinc sulfide ores, sodium hexametahposphate is taken as a dispersion agent and directly added into a ball mill, the ores are ground till the ores with the size of 0.074mm account for 67%-70%, lime is taken as an adjusting agent, zinc sulfate and sodium sulfite are taken as inhibitors, dithiophosphate BA and diethyldithiocarbamate are taken as collectors, and selective flotation of part of lead minerals with good floatability can be performed under low alkalinity; then xanthate and the diethyldithiocarbamate are taken as collectors, and the flotation of the lead minerals is further performed under high alkalinity; copper sulfate is added in lead flotation tailings for activation, butyl xanthate is further taken as the collector for flotation of zinc blende and part of pyrite, and zinc-sulfur separation flotation is further performed on zinc-sulfur mixed concentrate; and sulfuric acid is added in zinc flotation tailings for activation, and the xanthate is taken as the collector for flotation of the remaining pyrite. By adopting the technology, the lead-silver recovery rate can be improved, the using amount of lime and sulfuric acid can be reduced, the circulating amount of middlings can be reduced, the ore dressing cost can be reduced and the grade of the concentrate can be improved.

Owner:KUNMING UNIV OF SCI & TECH

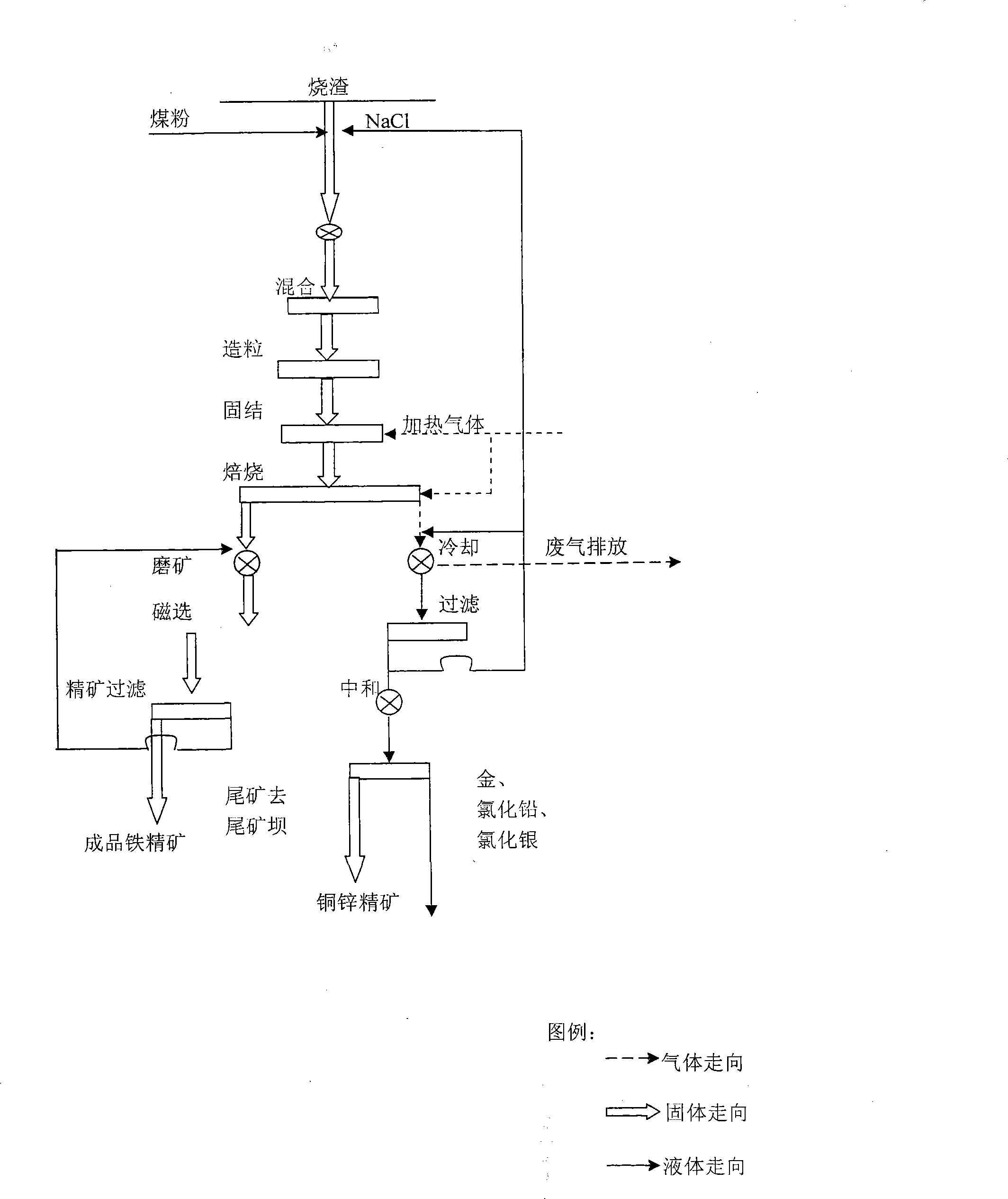

Method for recovering gold, silver, iron and lead from acid calcination slag by magnetization chlorination process

InactiveCN101225468AEliminate pollutionReduce wasteProcess efficiency improvementLimited resourcesSlag

The invention discloses a method to recover the gold, silver, iron and lead from the acidiation roasted cinder by a magnetic chlorination method, which is characterized in that the method comprises two sections, one is that the gold, silver, lead, and copper in the cinder are volatilized as a chloride gas through the high temperature chlorination roasting, and the gold, silver, copper and lead are recovered through the condensed gas; the other is that the iron is recovered by the process that the coal dust is filled during the granulation of the cinder, the magnetic reduction roasting is done with the chlorination roasting, the ferric oxide is reduced to the ferroferric oxide, and the processed cinder is ground and selected magnetically. Thanks to the recovering method, the recovery rate of the gold and silver is above 95%, the iron recovery rate is above 85%, and the lead recovery rate is above 90%, the production cost is about 300 RMB per ton, the profit is over 700 RMB per ton, so that a multiple billion RMB profit is harvested, and the waste of the limited resource is reduced. The method to recover the gold, silver, iron and lead from the acidiation roasted cinder by a magnetic chlorination method has the advantages of simple process, high efficiency, low smelting cost, comprehensive utilization of the ore resources, elimination of the environment pollution, and economic benefit growth of enterprise.

Owner:张伟晓

Double-slag converter process for producing high carbon low-phosphorus molten steel

InactiveCN1995403AReduce smelting costReduce consumption costManufacturing convertersMelting tankHigh carbon

The invention discloses a rotary furnace technique to manufacture high-carbon low-phosphor molten steel, which is characterized by the following: transmitting high-silicon high-phosphor molten iron into rotary furnace; blowing through gun-change and oxygen-change flow operation; removing phosphor first; pouring rich phosphoric slag at blowing time; adjusting terminal temperature and terminal carbon.

Owner:武钢集团有限公司

Utilization method for steel scoria

InactiveCN101403021ARealize hot recyclingReduce pollutionElectric furnaceElectric arc furnaceSmelting process

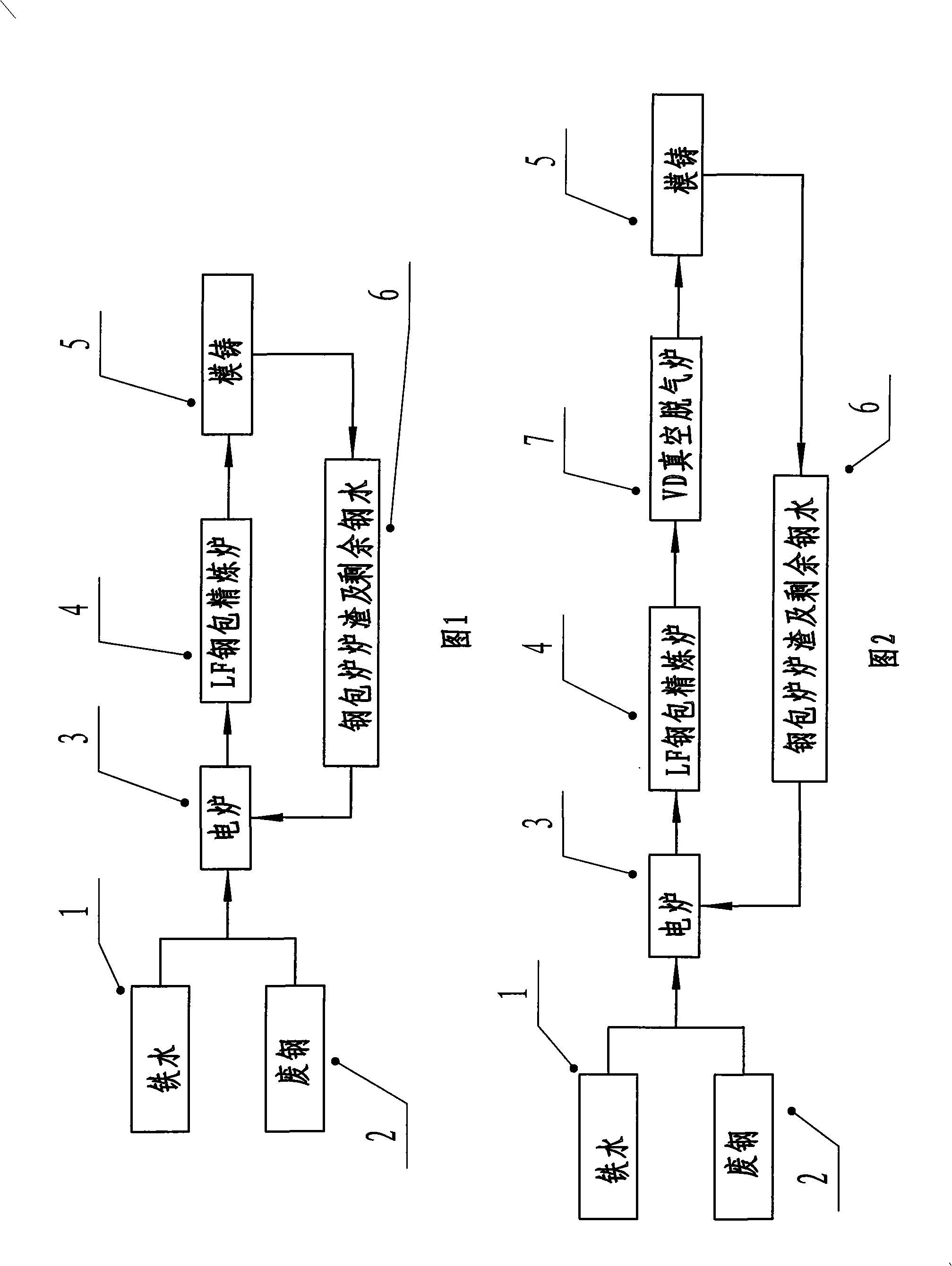

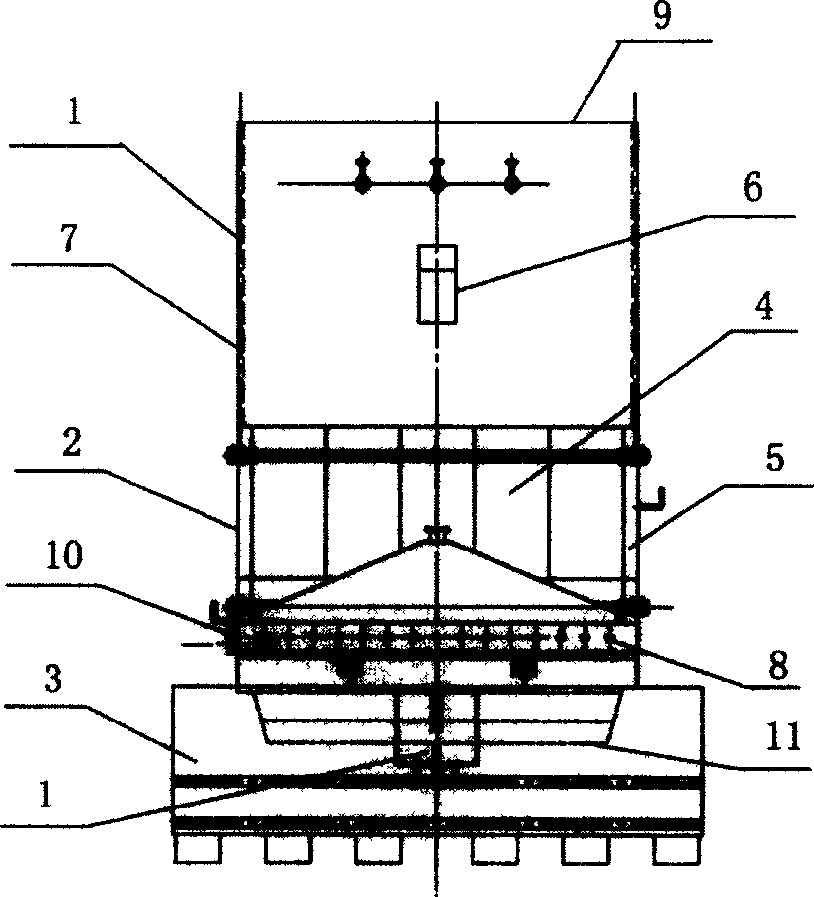

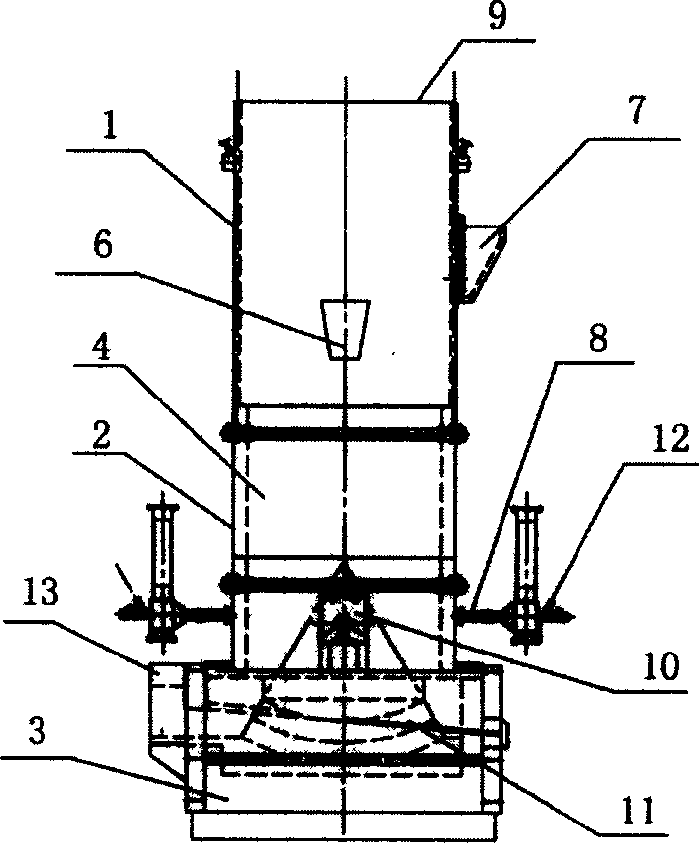

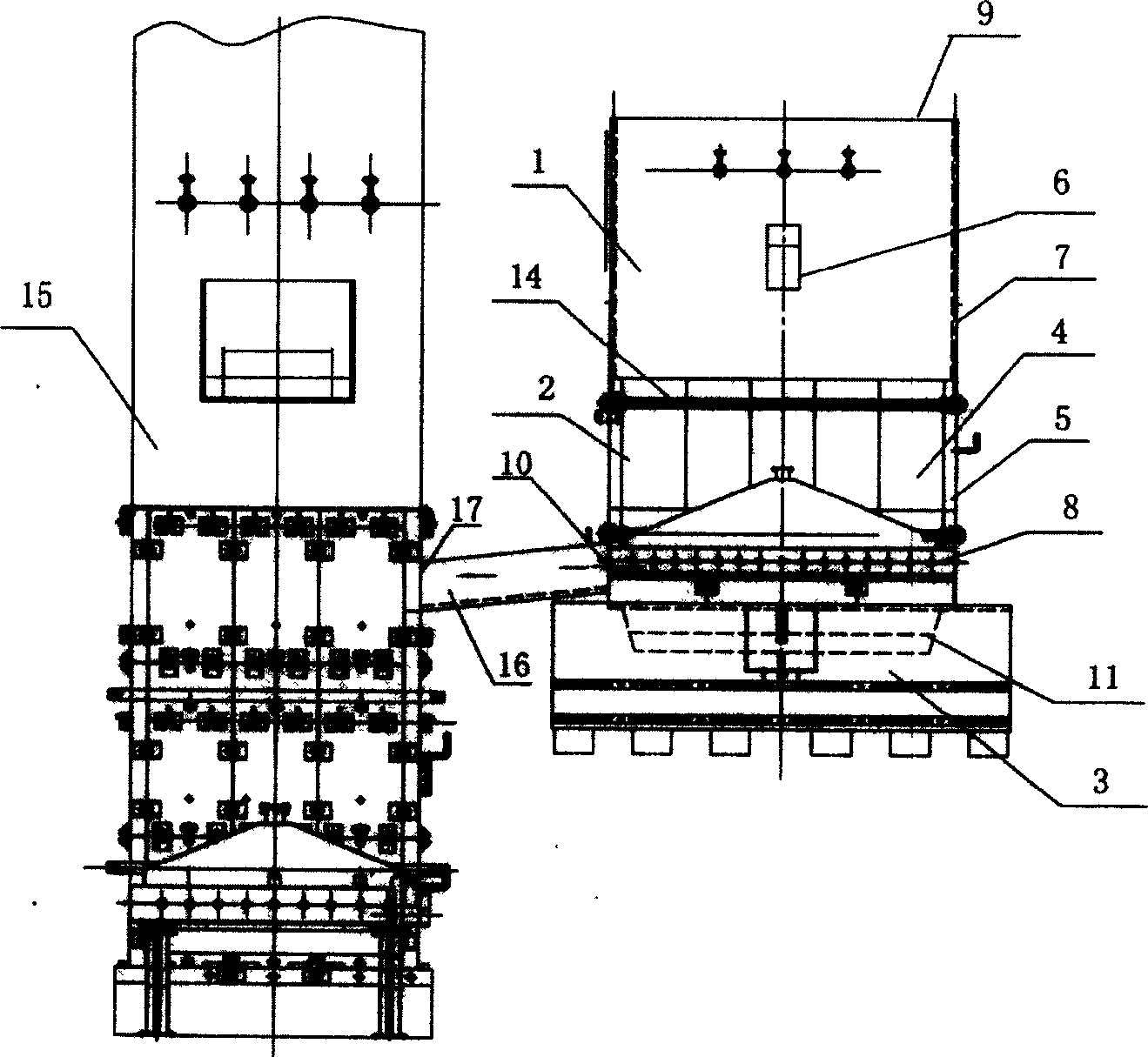

The invention relates to an utilization method of steel slag, which includes the following steps: slagging materials are added into an LF ladle refining furnace for slagging and refining and 20kg to 50kg / t of the slagging materials are added into each ton of molten steel; then in the moulding process, the slags of the ladle furnace and remanent molten steel after moulding are returned to an electric furnace for smelting; the slagging materials are added into the electric furnace and 50kg to 70kg / t of the slagging materials are added into one ton of the molten steel; in the smelting process of the electric furnace, the adding amount of the slagging material lime and the power supply volume of the electric furnace are decreased; as for steel grades which need to be deaerated, after the LF ladle refining furnace is refined and slags are made after the slagging materials are added, the molten steel is sent to a VD vacuum degassing furnace for deaeration; then moulding is carried out; and the slags of the ladle furnace and remanent molten steel after moulding are returned to the electric furnace for smelting. The utilization method of the steel slag is lower in cost and can avoid sulfur enrichment in the ladle refining process.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Smelting method and device of molten lead oxidation slag

An apparatus for smelting the oxide slags of molten lead is composed of the upper furnace body with water jacket-type or membrane-type side wall, smoke outlet, flux inlet and oxide slag inlet, the lower furnace body with water jacket-type wall, nozzle inlet and slag discharging outlet, and the furnace bottom with refractory liner and lead outlet. Its method includes reducing step and smoking step.

Owner:CHINA ENFI ENG CO LTD +1

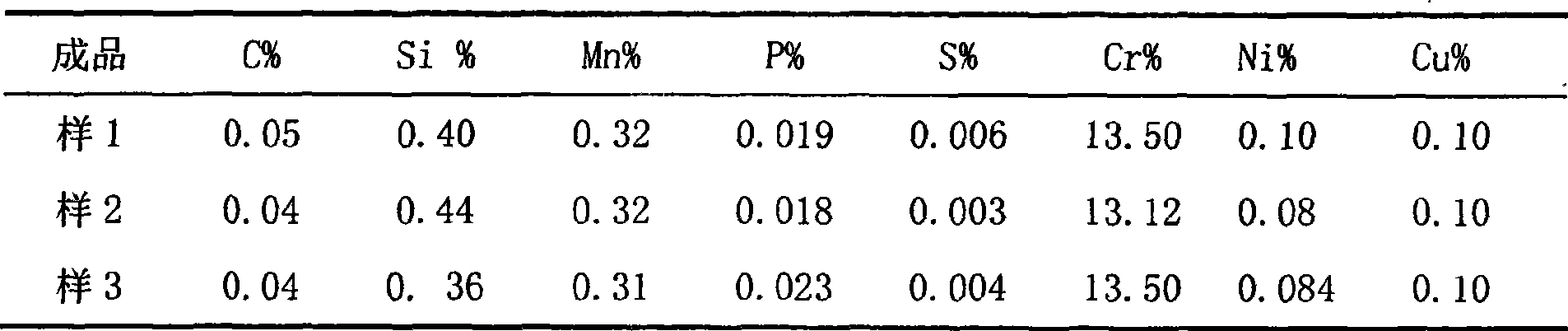

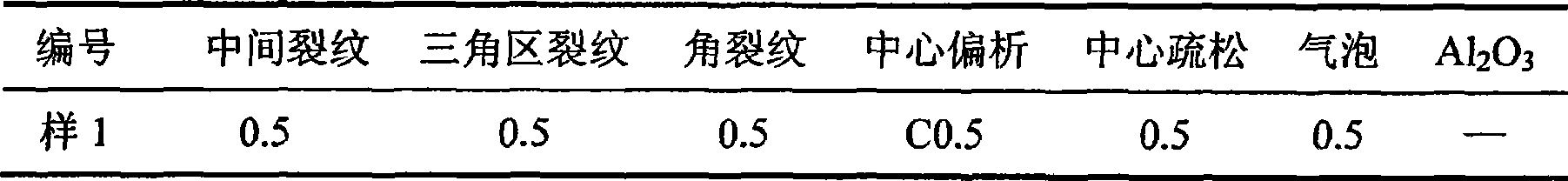

Two-step stainless steel smelting method

ActiveCN101457272AHigh recovery rateReduce consumptionProcess efficiency improvementElectric furnacePresent methodChromium nickel

The invention relates to a stainless steel smelting method by a two-step process. The method comprises the following steps: (1) smelting dephosphorized molten iron; (2) smelting semisteel; (3) lifting the semisteel to a deslagging station for deslagging treatment; (4) adding the semisteel to a GOR refining furnace for air refining; (5) refining; (6) continuous casting and (7) finishing, thinning and then rolling. Compared with the present method for producing the stainless steel by smelting, the method has the advantages of wide application scope of raw materials, low energy and resource consumption, strong variety development capacity, high recovery rate of chromium-nickel metal, high production efficiency and the like. Sulfide, oxide, silicate and punctiform non-metallic inclusion in the steel have low grade, the dephosphorized molten iron is provided by a top-bottom combined blowing converter and smelting is performed by the two-step process in an EAF+GOR refining furnace, thus the method has relatively low production cost and relatively large cost advantage, and the performance of a rolled finished product is consistent with a user quality standard.

Owner:SHANDONG TAISHAN STEEL GROUP

Method for producing nickel-iron alloy by smelting red earth nickel mineral at low temperature

The invention provides a method for producing nickel-iron alloy by smelting a red earth nickel mineral at a low temperature and belongs to the field of preparation of non-ferrous metallurgy. A process flow is as follows: after the red earth nickel mineral and a carbon reducing agent are molded, molding raw materials are subjected to drying, pre-heating and crystallization water removing; pre-reduction, deep reduction and growth of nickel-iron alloy grains are carried out; and after a cooling step, the separation of the nickel-iron alloy and furnace dregs is realized in a magnetic selection manner. Compared with the prior art, the method has the advantages of being low in reaction temperature, low in energy consumption, easy to obtain the high-quality nickel-iron alloy grains, simple in preparation process and low in production cost.

Owner:NEW METALLURGY HI TECH GRP

Zinc leaching slag treatment method

ActiveCN103421955AShort processShorten the smelting processProcess efficiency improvementLead smeltingMolten bath

A zinc leaching slag treatment method comprises the following steps: 1) The dried zinc leaching slag is evenly mixed with coke powder, and then the mixture is added to a volatilization kiln through a feeding scraper-trough conveyer at the tail of the kiln; 2) under the high-temperature condition of the volatilization kiln, the mixture generates kiln slag and smoke, valuable metals in the zinc leaching slag are deoxidize, as a result, lead and zinc steam is generated and gathered in the smoke, and gold, silver and copper enters to the kiln slag; 3) the kiln slag is delivered to a smelting furnace, furnace burden is added from the top of the smelting furnace, oxygen-enriched air is blown through an oxygen lance, the furnace hearth is stirred, the smelting temperature of the smelting furnace and the ratio of oxygen quantity to kiln slag dry measure are controlled, and slagging smelting is completed; 4) after the slagging smelting carried out in step 3), the valuable metals gold, silver and copper in the kiln slag are gathered in matte, the generated lead steam is gathered in smoke, and the kiln slag is cooled gradually. According to the zinc leaching slag treatment method, the technological process is short, the energy consumption is low, the cost is low, and the valuable metal recovery rate is high.

Owner:HUNAN SHUI KOU SHAN NONFERROUS METALS GRP

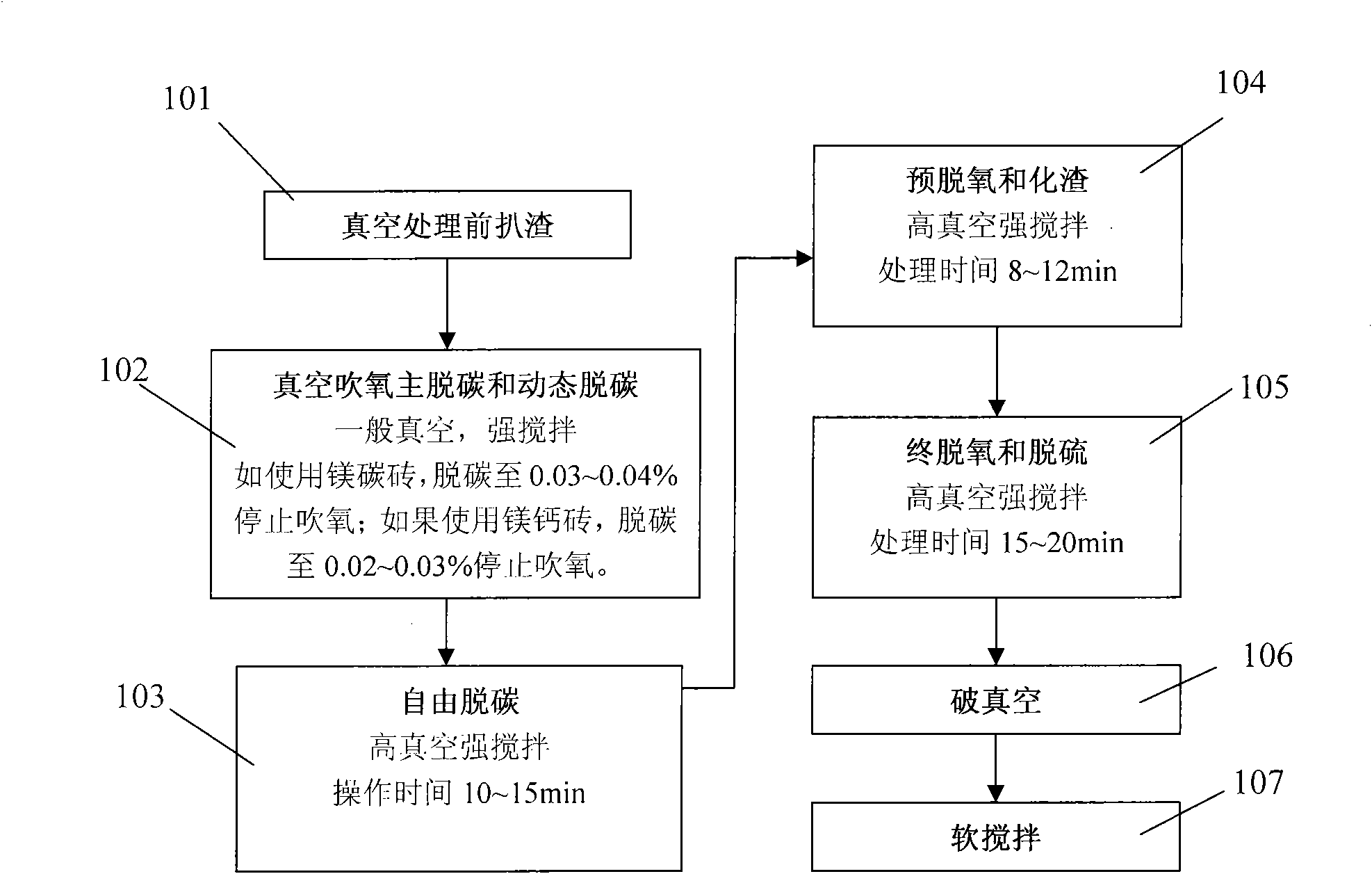

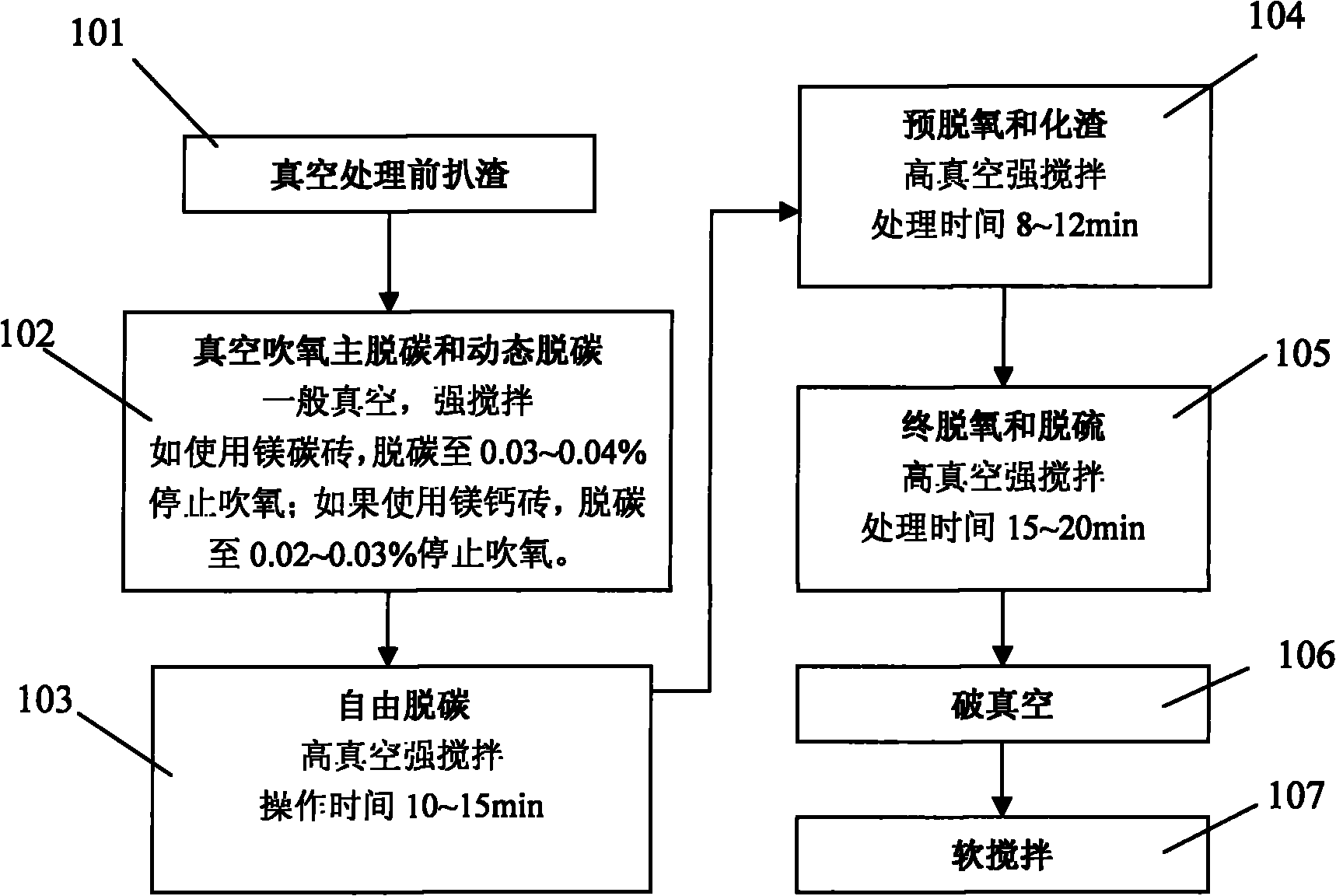

Method for refining ultra-low carbon ferritic stainless steel under vacuum

The invention discloses a method for refining ultra-low carbon ferritic stainless steel under vacuum, comprising the following steps: 1) steel ladle enters a vacuum oxygen-blowing decarburization furnace, the pressure in a vacuum is less than 100 Pa, initial chromium content of the molten steel is 10%-25%, the carbon content is 0.25%-0.60%, and the initial temperature of the molten steel is less than 1600 degrees C.; 2) oxygen-blowing decarburization processing, then main decarburization stage followed by dynamic decarburization stage; 3) free decarburization processing under high vacuum condition; 4) reducing, pre-deoxidizing, and adding active lime, ferrosilicon for pre-deoxidation and slag formation after free decarburization processing; deoxidizing, adding aluminum block, ferrosilicon, realizing final oxygen, silicon alloying, and desulphurizing strongly; 5) reducing argon-gas-blowing flow to small flow, conducting vacuum-breaking treatment, and then stirring to promote inclusion behavior to float up. The invention further reduces end-point carbon content during the ferritic stainless steel vacuum refining, meets requirements on strong desulphurization of molten steel, in order to increase the success rate of ultra-low carbon ferritic stainless steel smelting, thereby increasing the product quality and reducing the smelting cost.

Owner:BAOSHAN IRON & STEEL CO LTD

Converter vanadium extraction process adopting top blowing oxygen lance to blow cooling agents

The invention relates to a converter vanadium extraction process adopting a top blowing oxygen lance to blow cooling agents, belongs to the technical field of ferrous metallurgy, and is used for solving the problems that the temperature of a molten pool is difficult to control in the vanadium extraction course, the dynamic condition is poor and the like and increasing the oxidation conversion rate of vanadium and the quality of vanadium slag. The converter vanadium extraction process comprises a powder supply system and an oxygen supply system; and the cooling agents are blown through using a supersonic oxygen jet of the top blowing oxygen lance, and the aims of controlling the temperature of the molten pool in the vanadium extraction course and improving the stirring ability of the molten pool are achieved by utilizing a principle that powder rapidly reacts with hot iron to absorb heat, thereby achieving the technical effect of efficient vanadium extraction. The cooling agents enters the oxygen lance via a powder supply pipe in the powder blowing process; an outlet of the powder supply pipe can be positioned between the upper part of a lance body and an Raoult outlet of a blowing head; and the inner diameter of the powder supply pipeline is in the range of 15 to 180mm, the powder blowing flow rate is in the range of 20 to 800kg / min, the carrier gas flow rate is in the range of 100 to 4000Nm3 / h, and the carrier gas pressure is in the range of 0.5 to 1.6Mpa. The converter vanadium extraction process is suitable for vanadium extraction converters of 200 to 300t; and by adopting the converter vanadium extraction process, the semi-steel vanadium content can be reduced to below 0.03 percent, and the quality of vanadium slag (V2O5) is increased by more than 1 percent, so that the recovery rate of vanadium resources is increased.

Owner:UNIV OF SCI & TECH BEIJING

Method for smelting titanium slag with electric stove

The invention provides a method for smelting titanium slag by an electric stove. The method comprises the following steps: titanic iron and a reducing agent are mixed to prepare charging materials which are added into the electric stove; the titanium slag is smelted, the power of the electric stove is between 12MV.A and 30MV.A in the smelting process; and the slag is discharged, and the iron is discharged.

Owner:PANGANG GROUP TITANIUM INDAL +1

Steel-making method for prolonging service life of bottom-blowing oxygen converter through CO2

ActiveCN105907914ALower furnace bottom temperatureExtended service lifeManufacturing convertersThermodynamicsHydrocotyle bowlesioides

The invention belongs to the field of the metallurgy technology, and relates to a steel-making method for prolonging the service life of a bottom-blowing oxygen converter through CO2. According to the method, mixed gas of O2 and CO2 serves as bottom main blowing gas, mixed gas of hydrocarbon and CO2 serves as protective gas, and the CO2 mixing proportion in the bottom-blowing mixed gas of O2 and CO2 and the mixed gas of hydrocarbon and CO2 is controlled according to different smelting stages of the bottom-blowing oxygen converter; and by means of the characteristics that CO2 reacts with iron and carbon to absorb heat, and CO2 does not contaminate molten steel, the outlet temperature of a bottom-blowing nozzle is reduced, consumption of hydrocarbon is reduced, the quality of molten steel is improved, and therefore the service life of the bottom-blowing oxygen converter is prolonged, and the smelting cost is reduced. The steel-making method is suitable for the bottom-blowing oxygen converter of 30-350 tons; and by means of the steel-making method, the bottom service life of the bottom-blowing oxygen converter can be prolonged by 300-600, the smelting cost of steel per ton can be reduced by 2-3 yuan, and the end-point molten steel carbon-oxygen equilibrium can be reduced by 0.0002-0.0004.

Owner:UNIV OF SCI & TECH BEIJING

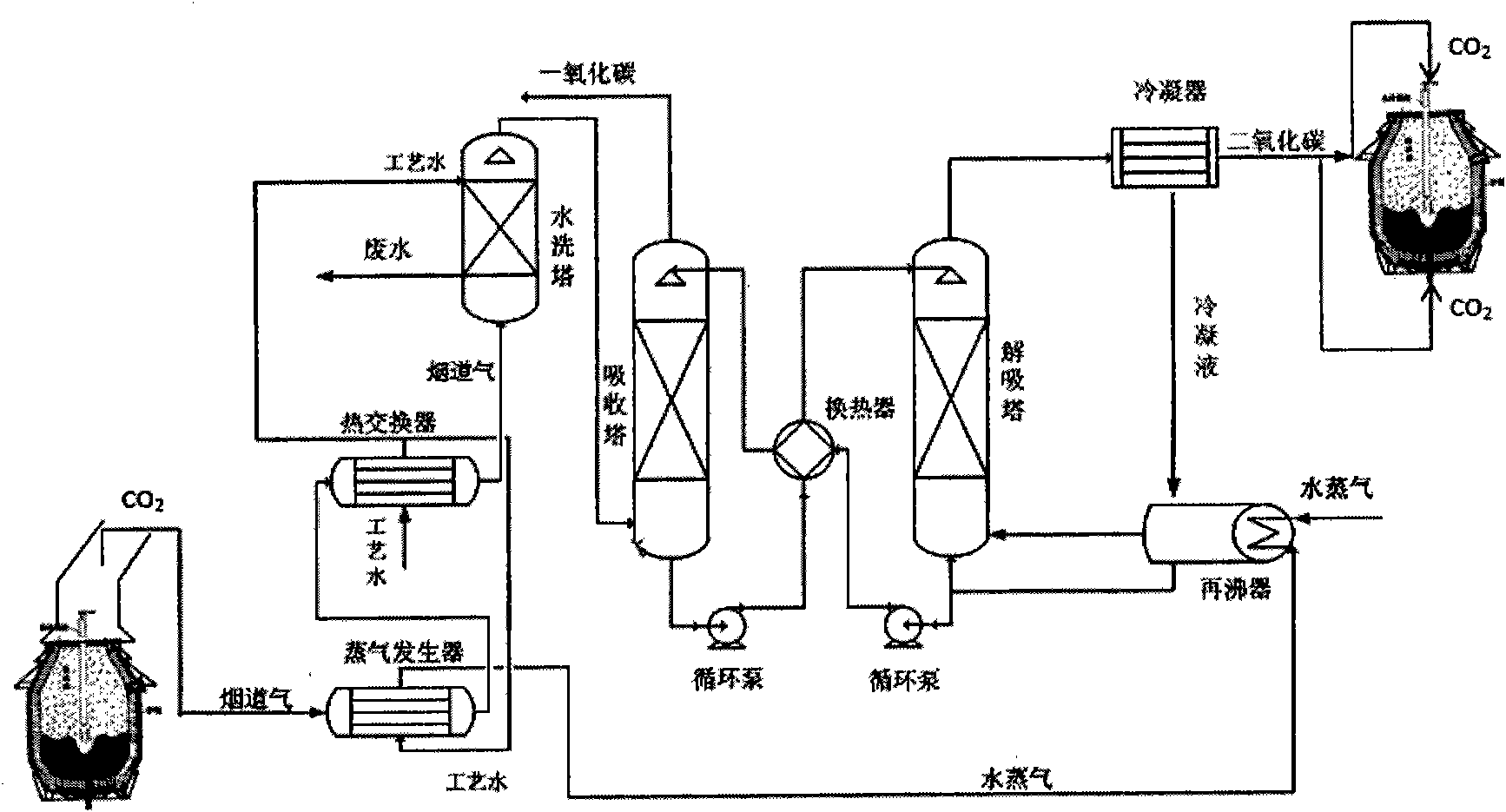

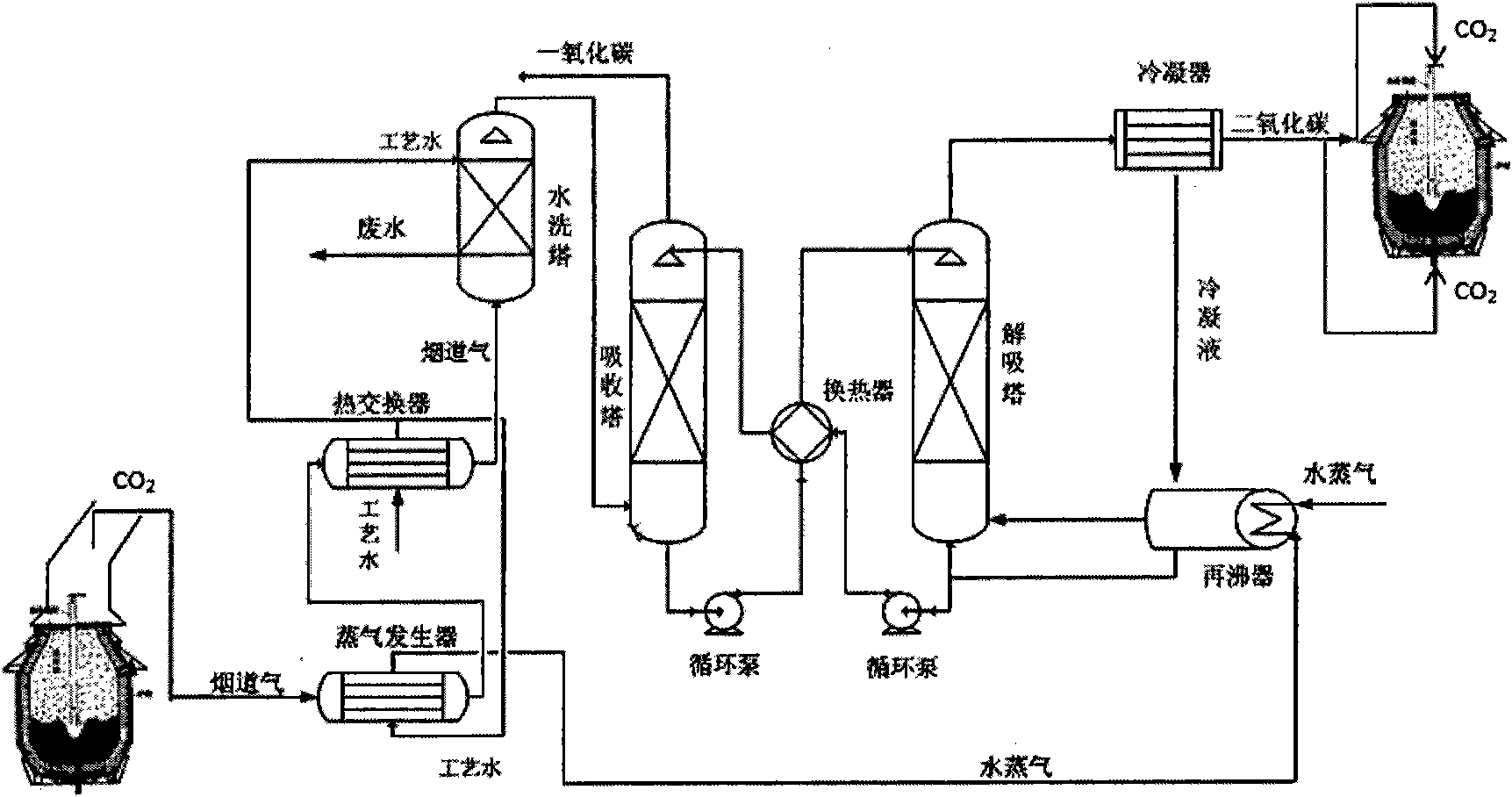

Method for recycling CO2 separated from converter steel-making gas for top blowing and bottom blowing

InactiveCN101818227AHigh carbon contentControl heating rateManufacturing convertersGas emission reductionProduct gasProcess engineering

The invention discloses a method for recycling CO2 separated from converter steel-making gas for top blowing and bottom blowing and belongs to the fields of ferrous metallurgy, energy conservation and environment protection. In the invention, the CO2 in the converter steel-making gas is separated and recycled after being cooled and dedusted; the recovery is 100 to 15,000Nm<3> / h; and the concentration of CO in the converter gas is improved by 5 to 20 percent at the same time. The CO2 serves as a gas source for the top blowing and the bottom blowing of a top and bottom combined blown converter. A chemical absorption separation method is adopted to separate the CO2; steam added with rich liquid is generated by using the residual heat of the converter gas; and almost no additional energy is consumed in the process for separating the carbon dioxide. 1 to 30 percent of the CO2 and 99 to 70 percent of O2 are blown from the top part; pure CO2 or a mixture of the CO2 and N2 or Ar or O2 or gas and the like is adopted in the whole process of the bottom blowing; and the amount of the CO2 is 100 to 3,000Nm<3> / h. The method is applicable to a steel-making process for a 30 to 350 ton converter. By adopting the method, for each ton of steel, 1 to 20 m3 of CO2 emission is reduced synthetically; the soot amount is reduced by 1 to 30 percent; and the content of the CO in the gas is improved to more than 2 to 15 percent.

Owner:UNIV OF SCI & TECH BEIJING

Mono-slag converter process for producing high carbon low-phosphorus molten steel

InactiveCN1995404AReduce smelting costReduce consumption costManufacturing convertersHigh carbonSlag

The invention discloses a manufacturing method of high-carbon low-phosphor molten steel of rotary furnace in the metallurgical technical domain, which comprises the following steps: transmitting high-silicon high-phosphoric molten steel in the rotary furnace; blowing through gun-changing oxygen-changing flow operation; removing phosphor first; pouring rich phosphoric slag at blowing time; adjusting terminal temperature and terminal carbon.

Owner:武钢集团有限公司

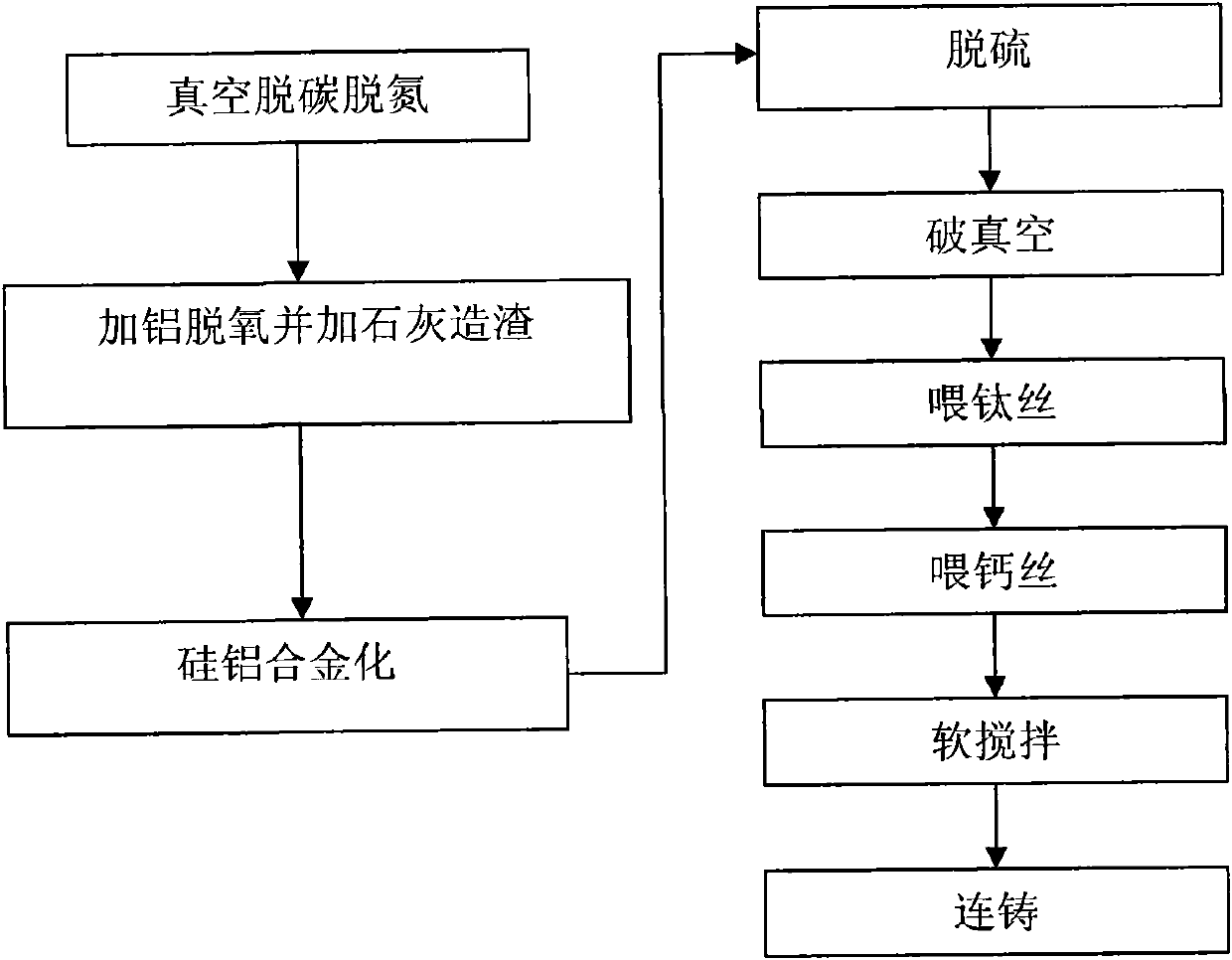

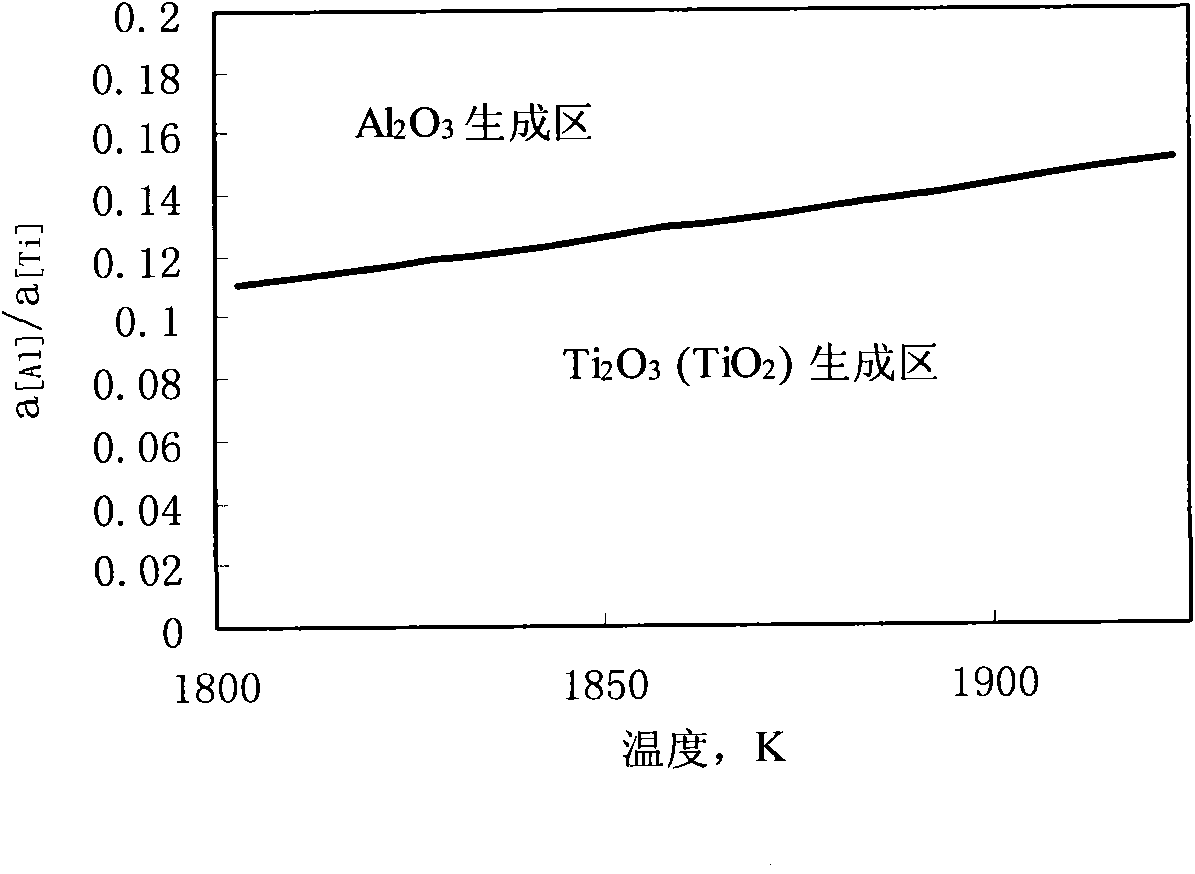

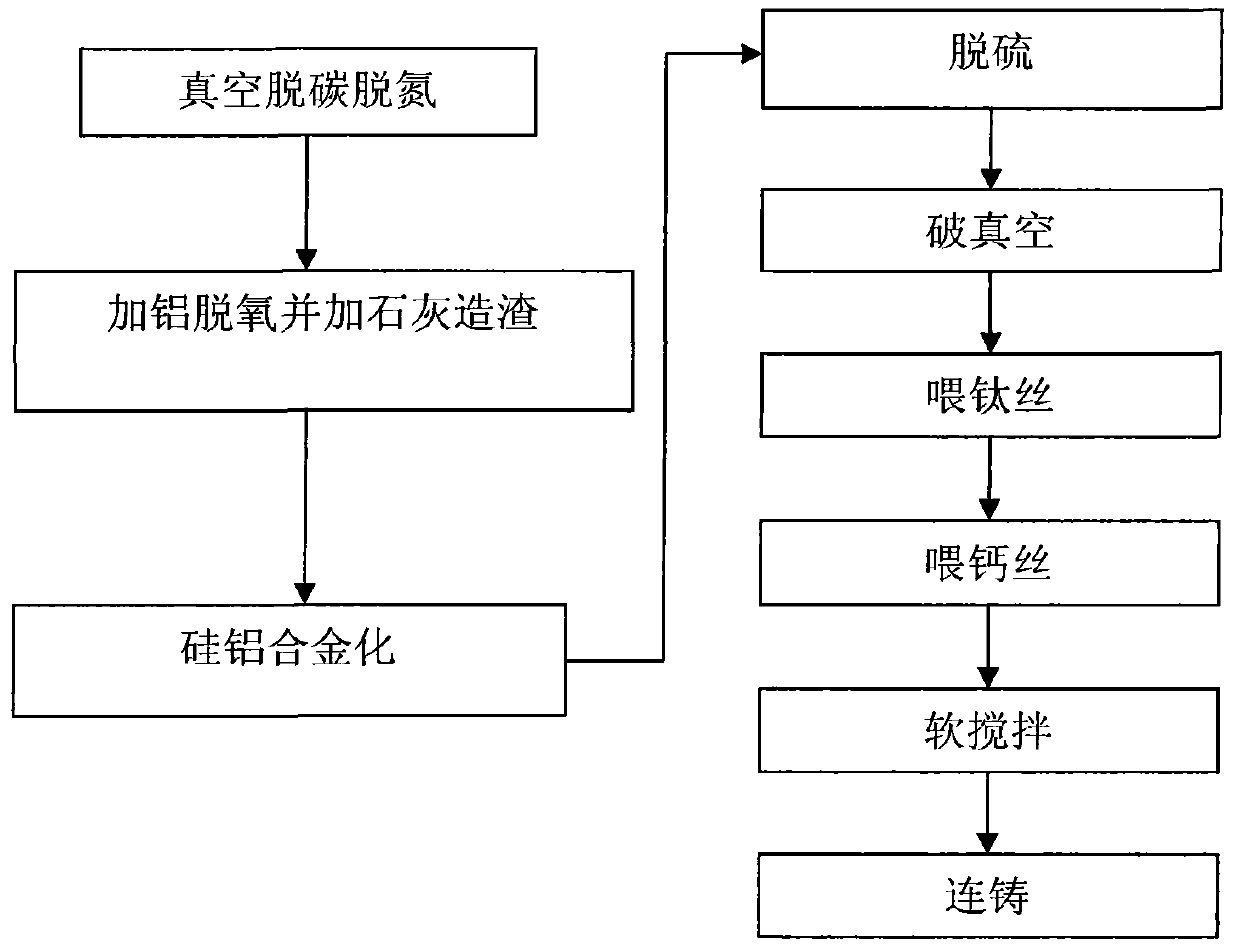

Production method of ultralow-oxygen titanium-containing ferrite stainless steel

The invention discloses a production method of ultralow-oxygen titanium-containing ferrite stainless steel, which comprises the following steps: 1) preparing molten ferrite stainless steel under a vacuum condition in a vacuum oxygen blowing decarburization furnace, wherein the carbon mass percentage content and nitrogen mass percentage content in the molten ferrite stainless steel are both less than 0.01 percent; 2) performing deoxidization, namely adding 6 to 12 kilograms of aluminum block or grains into each ton of steel and adding 10 to 28 kilograms of active lime into each ton of steel; 3) alloying silicon and aluminum, namely adding 2 to 9 kilograms of silicoferrite which contains 70 to 80 percent of silicon into each ton of steel and adding 0 to 1 kilogram of aluminum blocks or grains into each ton of steel, wherein the aluminum content is 0.02 to 0.1 percent; 4) performing desulphurization; (5) breaking vacuum; 6) softly stirring; 7) feeding titanium wires; 8) feeding silicon and calcium wires, wherein the calcium content is 5 to 30ppm; 9) softly stirring; and 10) continuously casting. The method can be used for producing ultralow-oxygen titanium-containing ferrite stainless steel, prevent or inhibit forming magnesia alumina spinel which are harmful impurities in a production process, improve product quality, prevent the water gap of tundish from being blocked in a continuous casting process and guarantee smooth production.

Owner:BAOSHAN IRON & STEEL CO LTD

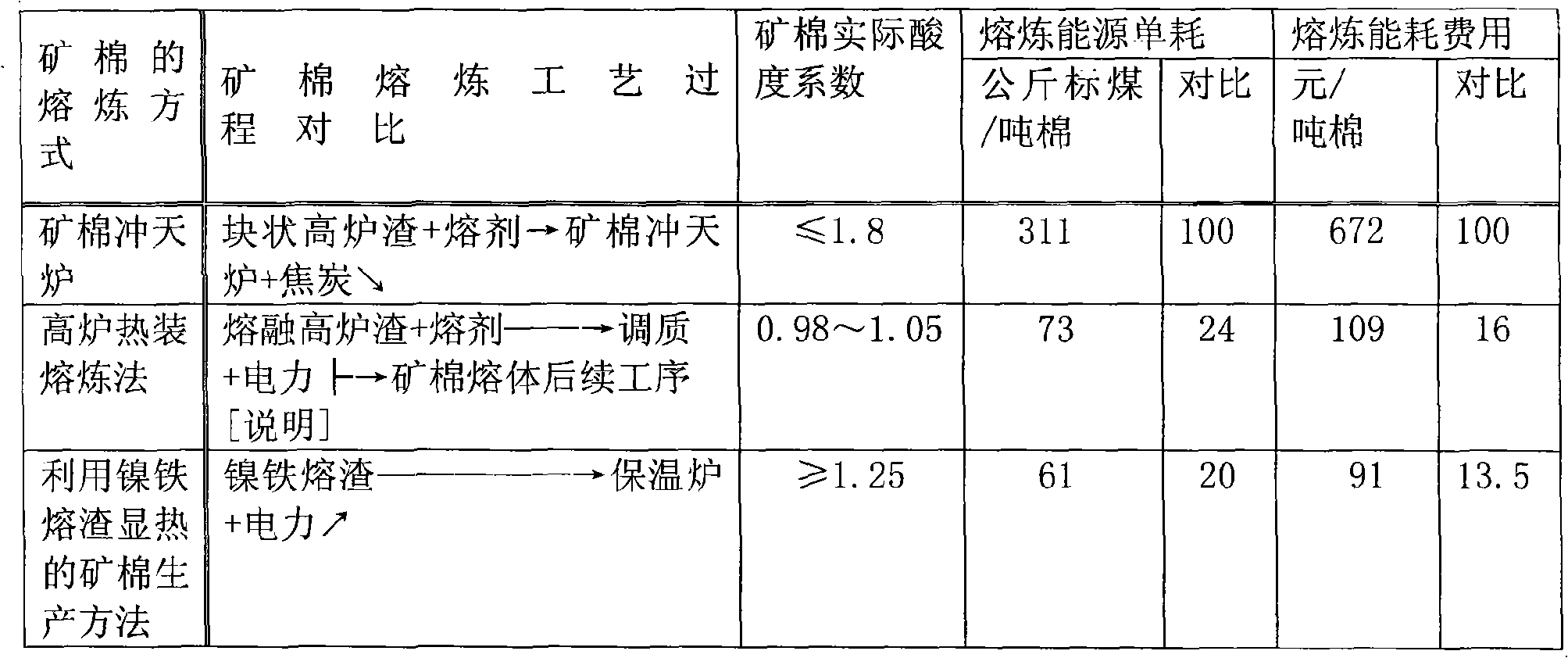

Method for preparing mineral wool by using ferronickel dross sensible heat

InactiveCN101293731AReduced service lifeMeet quality requirementsGlass making apparatusThermal insulationCotton fibre

The invention relates to the technical filed of mineral cotton production, which is a method for producing mineral cotton by using the sensible heat of ferronickel slag. The method includes the following steps: laterite-nickel ore is adopted as basic material, and the ferronickel slag with the temperature of 1450 to 1500 DEG C and acidity coefficient being equal to or more than 1.25 is poured into a power thermal insulation furnace with the capacity being 15 tons without adding any fusing agent; the temperature of melts is adjusted and kept within the range of 1350 to 1400 DEG C; then the melts with adjusted temperature are correctly led to a four-roller centrifugal machine by a water-cooling controllable head piece and a diversion trench so as to lead the ferronickel slag to be directly transformed into the mineral cotton fiber with high quality. Electrode materials in the power thermal insulation furnace are metal or carbon.

Owner:杨铧 +1

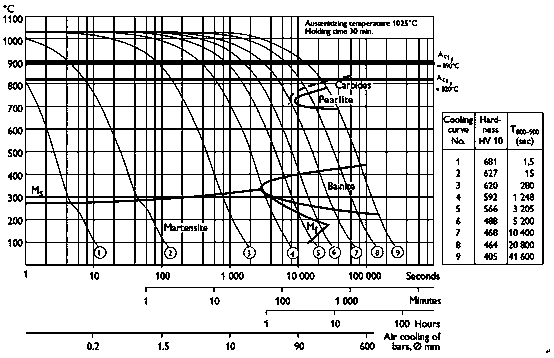

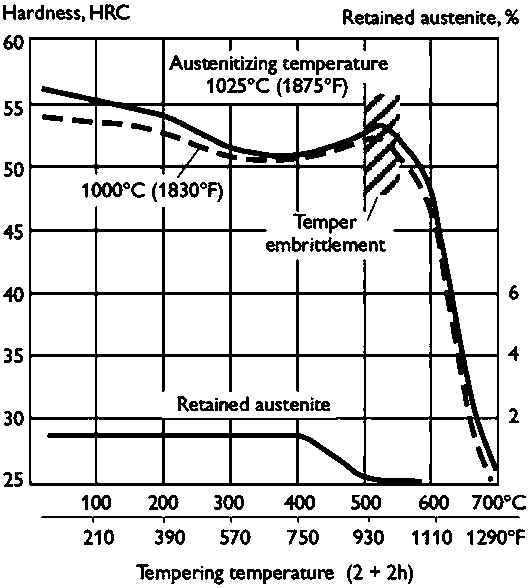

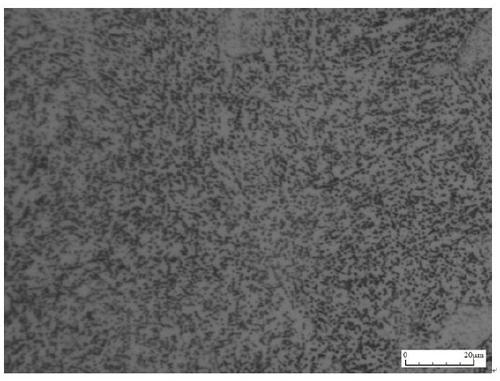

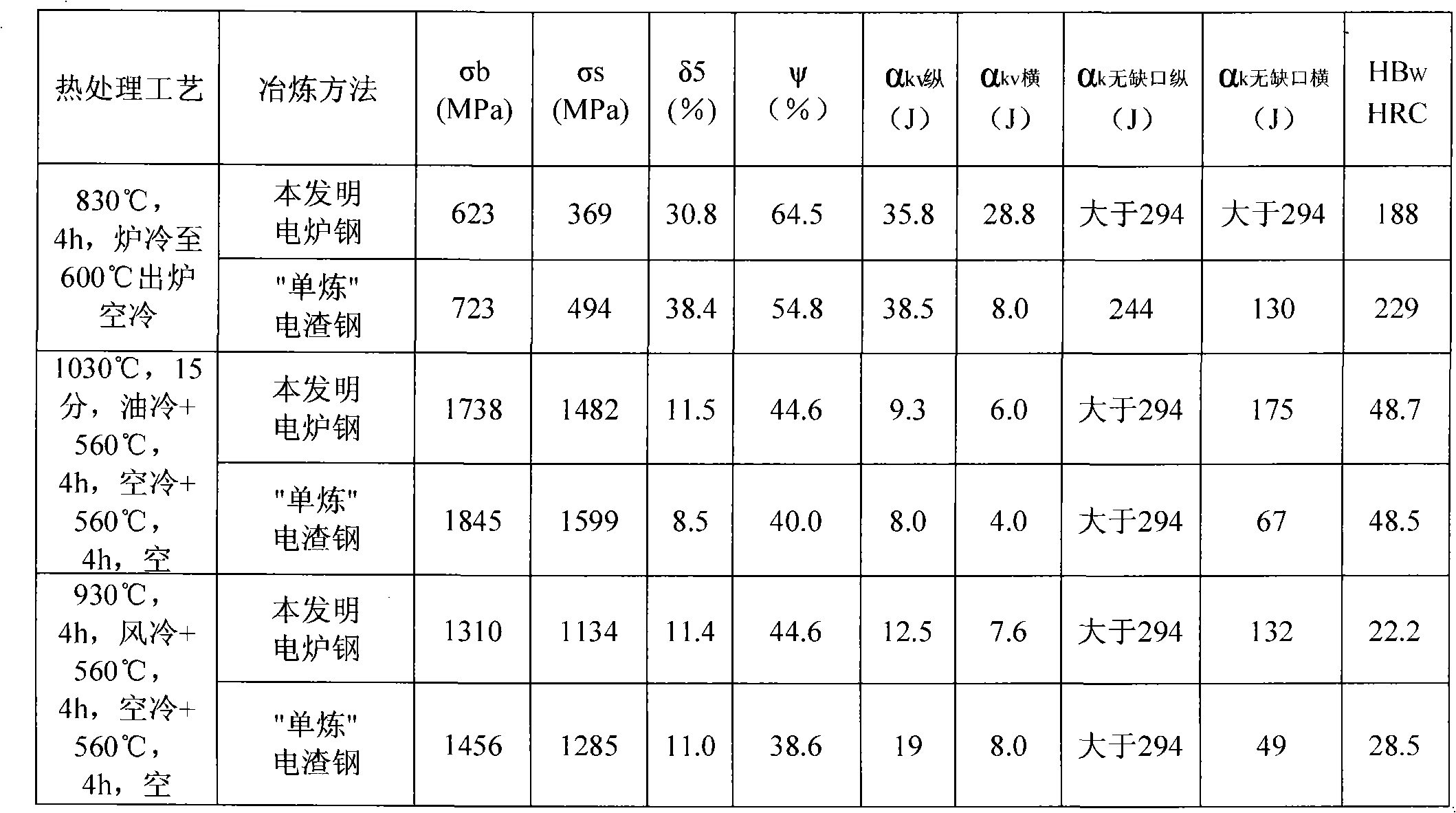

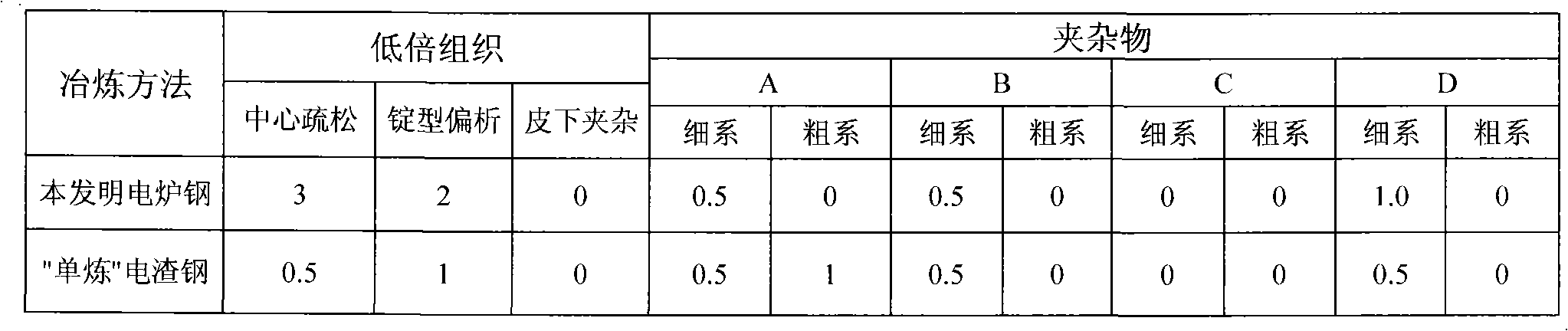

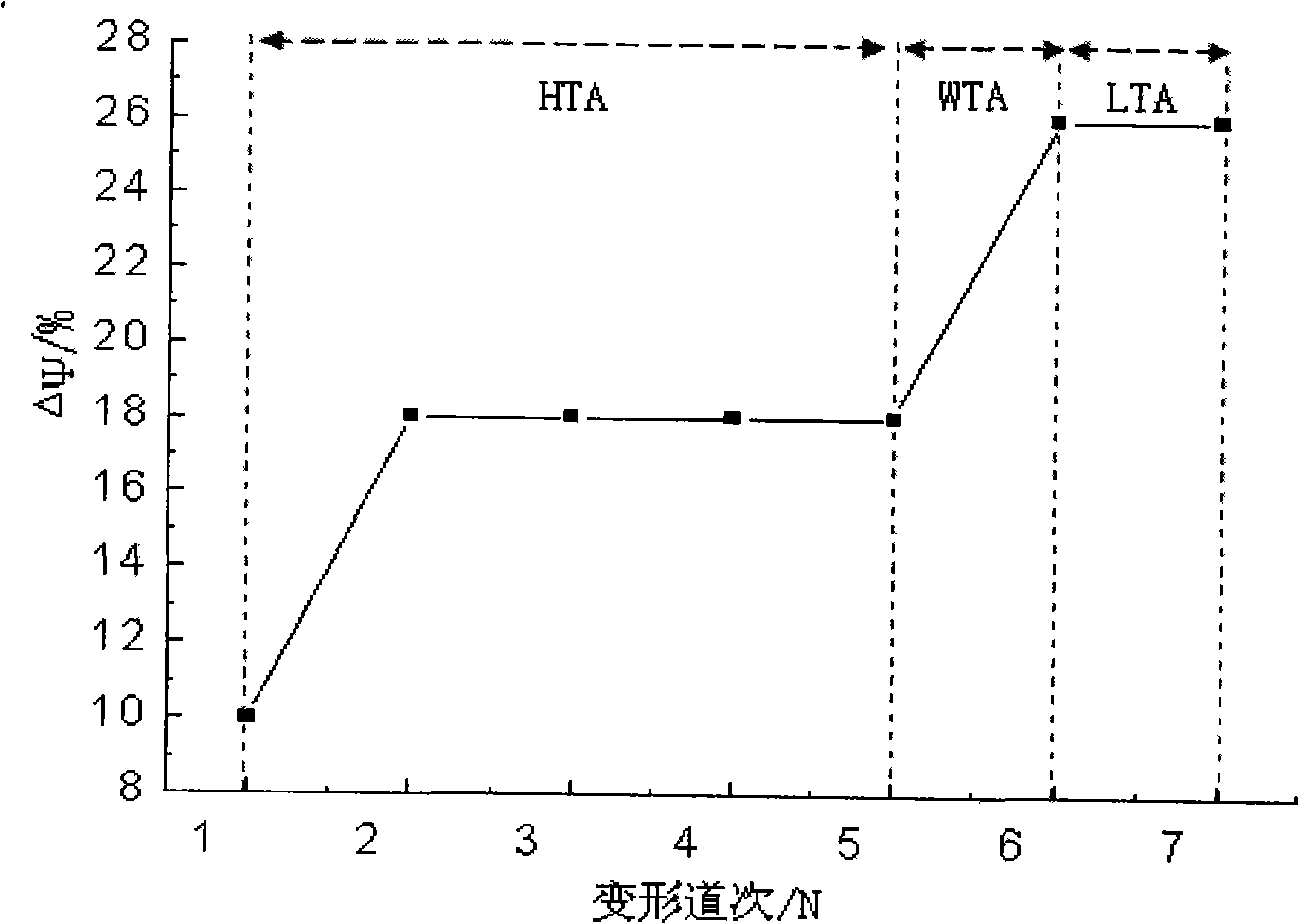

High-performance hot work die steel and manufacturing technology thereof

InactiveCN109280849AImprove thermal stabilityReduce carbon contentManufacturing technologyHeat stability

The invention relates to high-performance hot work die steel and manufacturing technology thereof. The high-performance hot work die steel comprises, by mass percent, 0.20%-0.30% of C, 0.40%-0.80% ofSi, 0.40%-0.80% of Mn, 3.10%-4.00% of Cr, 1.60%-2.00% of Mo, 0.5%-1.00% of W, 0.10%-0.30% of V, smaller than 0.010% of P, smaller than 0.005% of S and the balance Fe. The manufacturing process of thedie steel includes the following steps that burdening, smelting and pouring are conducted; then electroslag remelting is conducted; high-temperature diffusion heat treatment is conducted, then multidirectional forging hot working is conducted, and controlled cooling is conducted after forging; then secondary carbide refining heat treatment and isothermal annealing treatment are conducted; and finally, quenching and tempering heat treatment are conducted. The high-performance hot work die steel and manufacturing technology thereof have the beneficial effect that the quenching degree, the heat stability, the impact toughness and the thermal fatigue performance of the hot work die steel are superior to H13 steel, the hot work die steel can be machined into large die casting dies with the weight of the single piece reaching 5 tons or higher, and the good use performance is achieved; and in addition, the steel ingot smelting cost can be reduced, and the service life of dies is prolonged.

Owner:RUGAO HONGMAO HEAVY FORGING

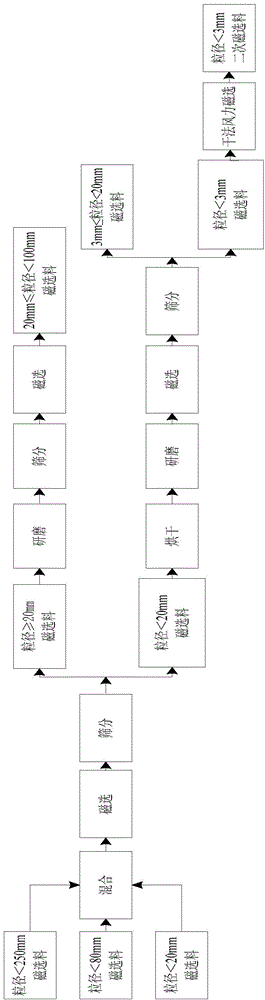

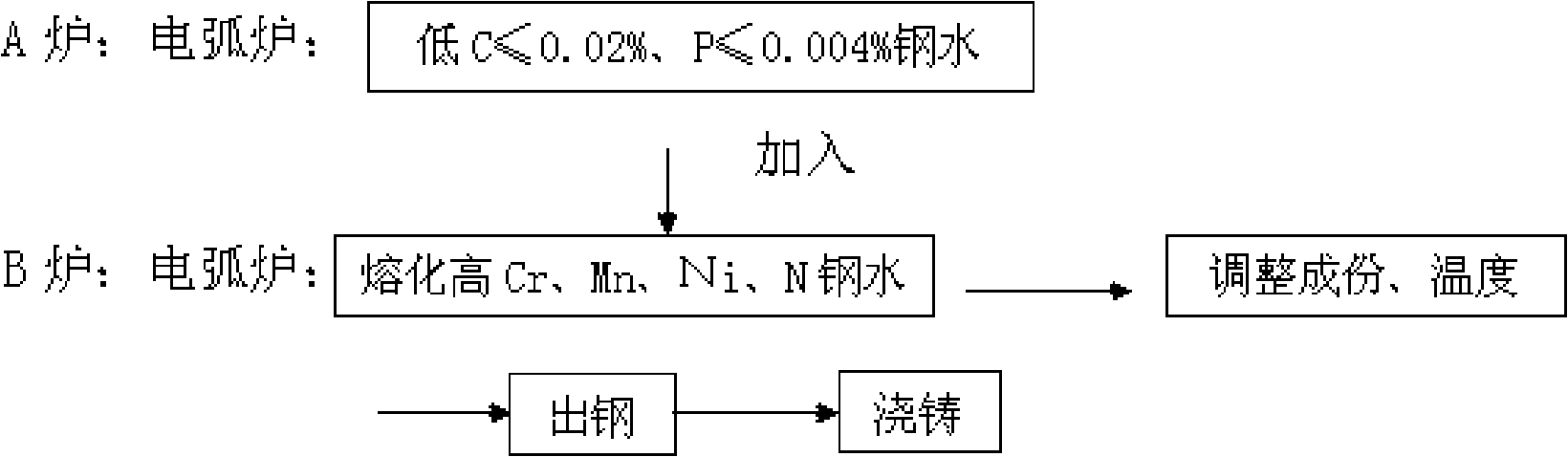

Mixing method of high quality low phosphor and sulfur high-alloy steel

The invention provides a mixing mix method for high alloy steel with high quality and low phosphorus and sulfur. In the invention, iron water or pig iron smelted from a blast furnace is put in an electric furnace or a revolving furnace for smelting by the continuous oxidation method; in particular, at the same time, an iron alloy or return materials are put in another induction furnace or electric furnace for smelting by the continuous loading method; and the iron water smelted by the electric furnace or the revolving furnace and the iron alloy smelted by the induction furnace or the electric furnace are mixed in a molten steel container for external furnace refining and ingot mold casting. The mixing method of the invention has the advantages of simpleness, standard, low cost, and capability of continuous refining the high alloy steel with high quality and the alloy ratio of more than 5 percent, completely solves the problems of uncontrollable phosphorus, five-harmful elements and harmful microelements in steel in the production of the high alloy steel by the prior smelting method; therefore, the mixing method is particularly suitable for the smelting of mould steel, nonrust heat resisting steel, rotor steel, valve steel, high-speed tool steel, high temperature alloy, etc.

Owner:DAYE SPECIAL STEEL CO LTD

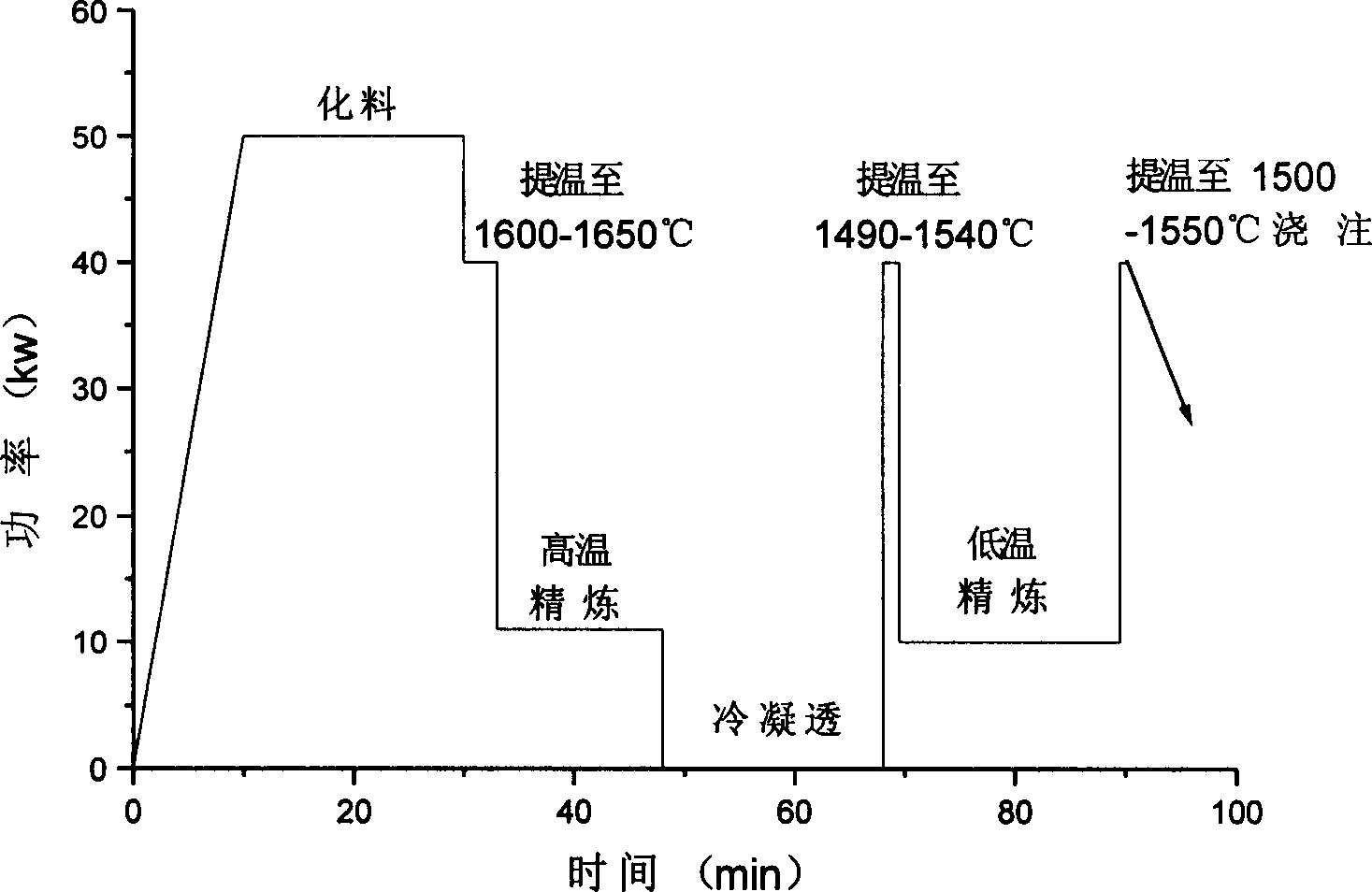

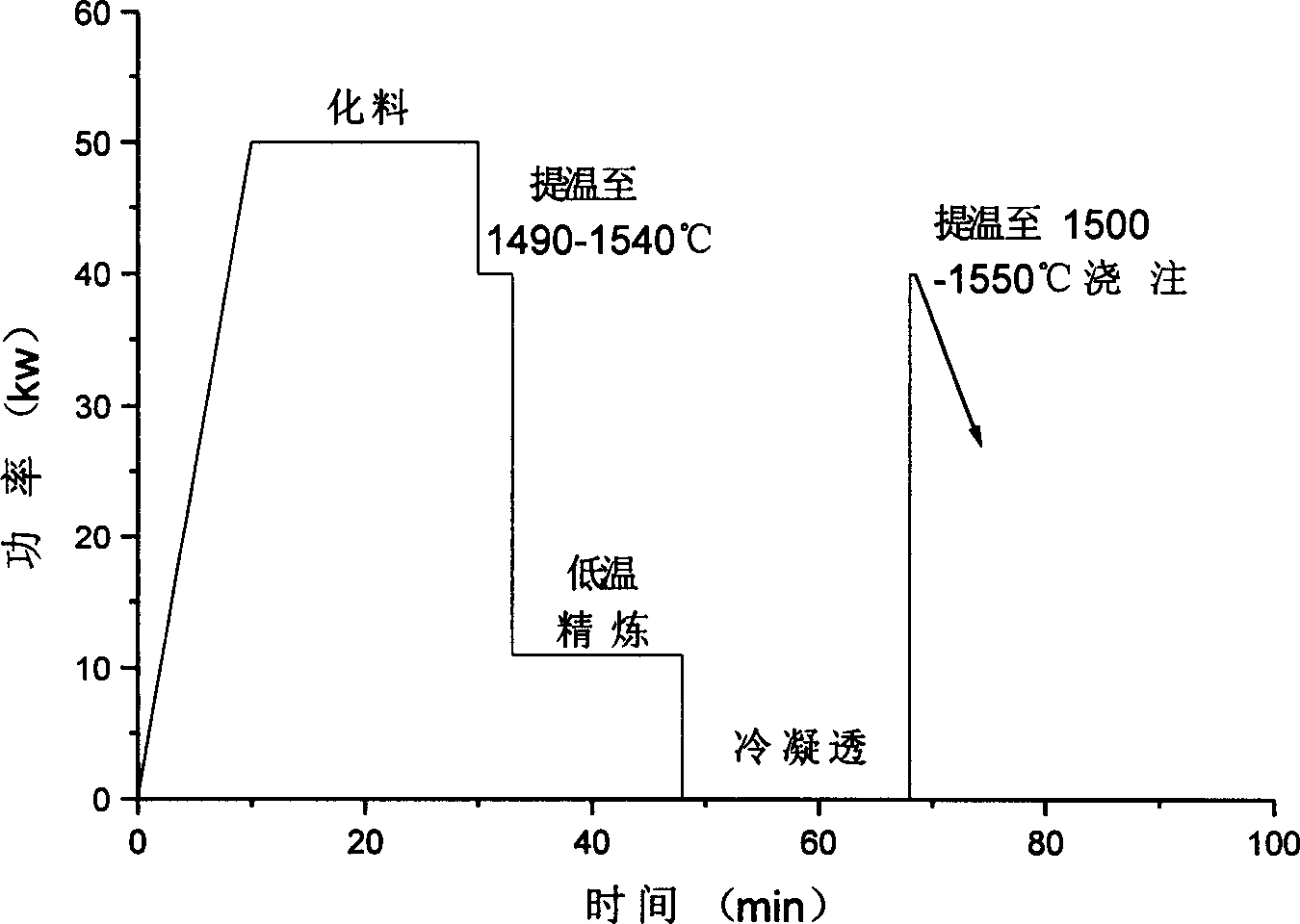

Ultrapure smelting process for nickel-base high-temperature alloy

Process for melting Ni based high temperature alloy with super purity is carried out by degassing at first, purifying alloy elements and heating-up to 1600 - 1650 deg.C for 15 - 20 minutes, cooling to condense, next, heating-up to 1490 - 1540 deg.C for 20 - 30 minutes again, casting into ingots at 1500 - 1550 deg.C, then, melting degassed elements as raw materials to produce Ni based alloy with low carbon and gas contents. Because the raw material is degassed, no carbon is added, and melting time is not long, The Ni based alloy with low carbon and gas contents is obtained.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Steel slag recycling method

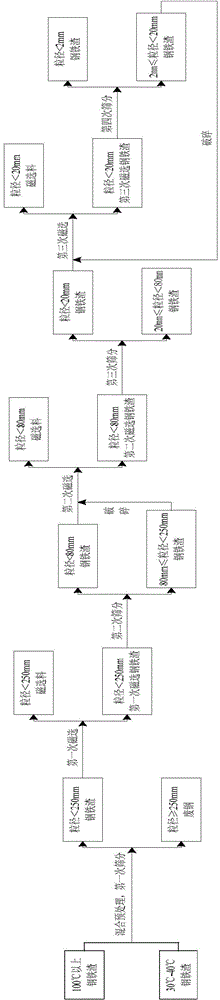

ActiveCN104789718AShort processHigh recycling purposeRecycling and recovery technologiesProcess efficiency improvementSlagPre treatment

The invention relates to a steel slag recycling method. The method comprises the following steps: carrying out mixing pretreatment on 100DEG C or above steel slag and 30-40DEG C steel slag, and carrying out multi-time magnetic separation, multi-time screening and multi-time fragmentation for recovery in order to obtain a low-iron metallurgy production auxiliary material substitute; and carrying out magnetic separation on a magnetic separation material in the steel slag, grinding, screening, and carrying out dry wind magnetic separation for recovery in order to obtain a high-iron metallurgy production auxiliary material substitute. The method reduces the smelting cost of a steel plant, reduces the exploitation and calcination of natural ore, reduces the discharge of greenhouse gas, has very good environmental protection benefit, and realizes short flow and high recovery utilization of the steel slag.

Owner:MCC BAOSTEEL TECH SERVICE

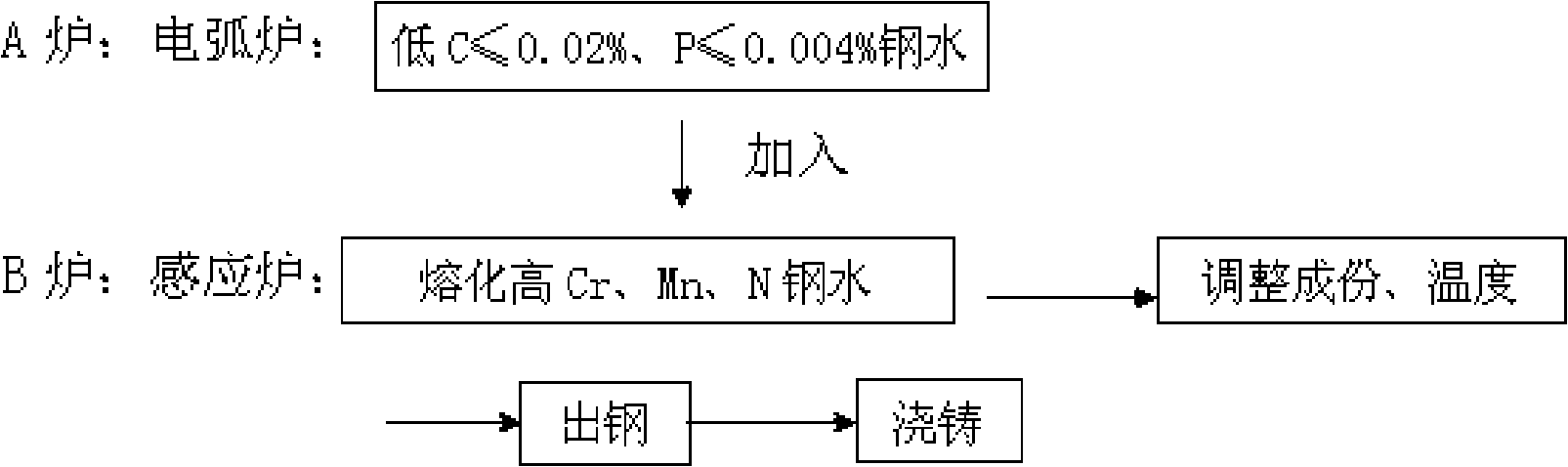

Method for smelting high-nitrogen steel

The invention discloses a method for smelting high nitrogen steel, which comprises a smelting method of a high nitrogen steel which can effectively improve and guarantee the content of N in alloy, the technical proposal which is adopted comprises the following steps: firstly, smelting molten steel with an electric arc furnace or an induction furnace, secondly, simultaneously adopting another electric arc furnace or an induction furnace to smelt nitrogen containing alloy, adapting the sum of molten steel components in the step one and the step two with steel grade, thirdly, adding molten steel which is smelted in nitrogen containing alloy solution, and refining under the protection of nitrogen, and getting high nitrogen steel. The technical proposal of the invention which is adopted by the invention to smelt high nitrogen steel without needing complex pressurization and remelting equipment, the total smelting time is greatly shortened, which is only one half of the time for smelting high nitrogen steel in the prior art, the operation is simple, and chemical components in steel are stable, fluctuation of steel components among furnaces is small, which is beneficial for processing follow-up process. And meanwhile, the number of deoxidation reducing agent is greatly reduced, and smelting cost is lowered.

Owner:CHINA ERZHONG GRP DEYANG HEAVY IND

Method for producing pipeline steel plate by continuous casting billet under condition of small reduction ratio

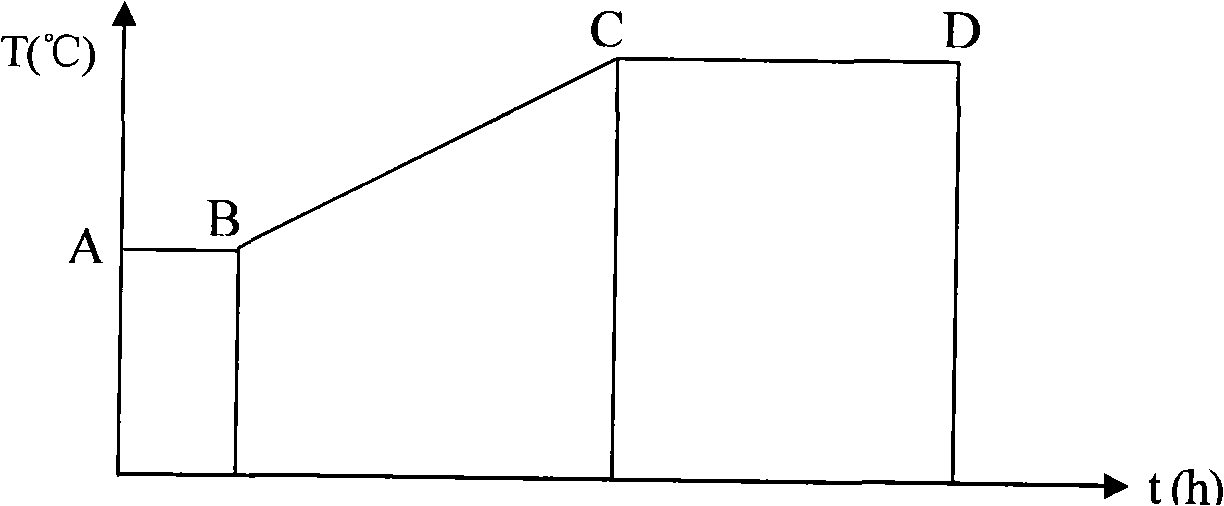

ActiveCN103639198AIncrease pass reduction rateReduce smelting costWork treatment devicesMetal rolling arrangementsReduction ratioAustenite

The invention provides a method for producing a pipeline steel plate by a continuous casting billet under the condition of a small reduction ratio. The method includes the steps: heating the continuous casting billet with 300mm thickness and 1800-2000mm width to reach the temperature of 1150-1250 DEG C and keeping the temperature for more than 400 minutes; rolling an austenite recrystallization zone and an austenite non-recrystallization zone for the heated continuous casting billet; cooling the rolled steel plate at the speed of 5-20 DEG C / s to obtain the pipeline steel plate with 40-50mm thickness and 3200-4000mm width. In rolling of the austenite recrystallization zone, the start rolling temperature is 1150-1200 DEG C, the width expansion ratio is at least 1.6, and the holding thickness is 2-4 times of the thickness of a finished product. In rolling of the austenite non-recrystallization zone, the start rolling temperature is 830-900 DEG C. The start cooling temperature is 700-800 DEG C, and the final cooling temperature is 550-600 DEG C. P and S contents do not need to be controlled and are quite low, and smelting cost is reduced.

Owner:LAIWU STEEL YINSHAN SECTION CO LTD

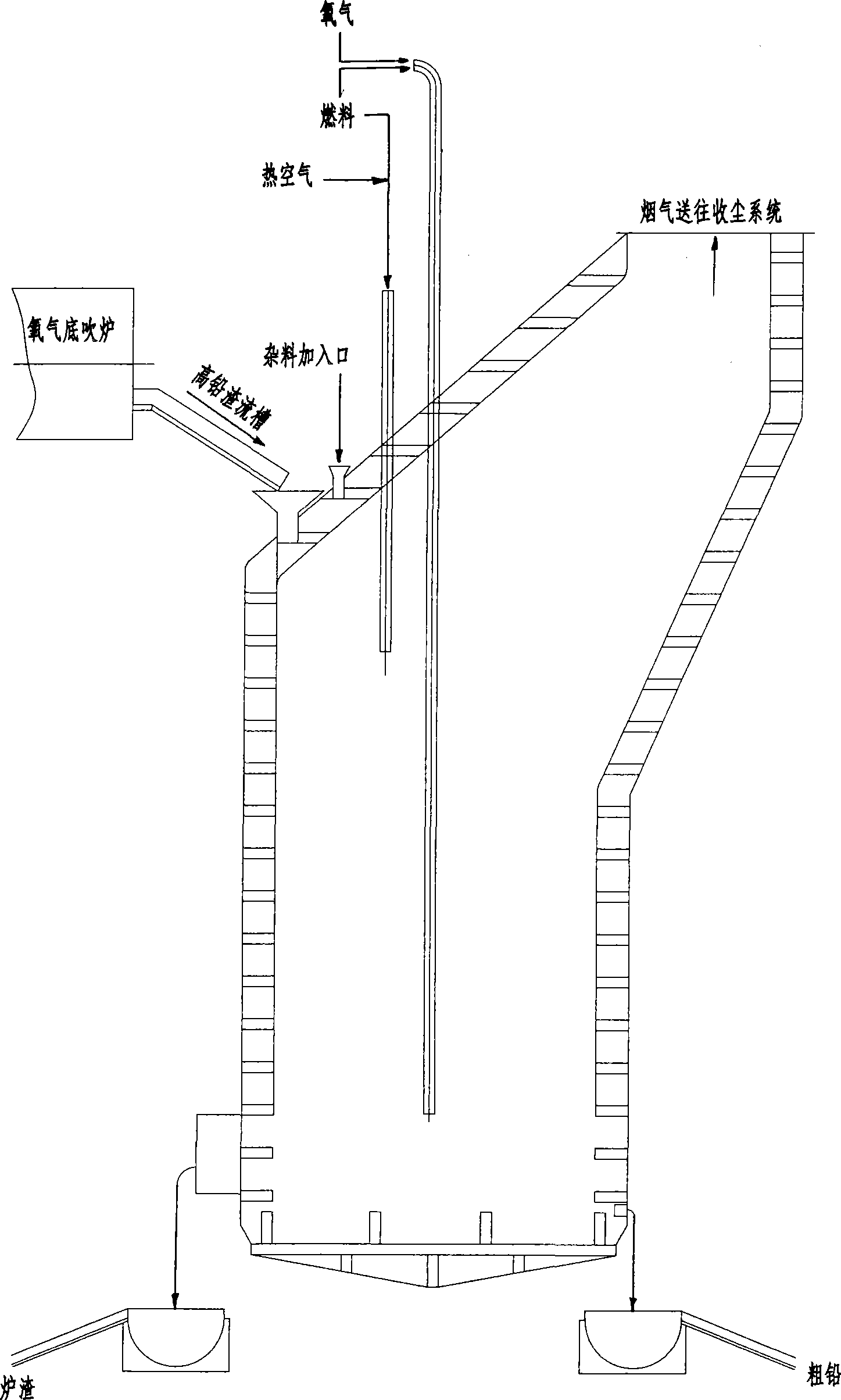

Process for direct reduction of liquid high-lead skim with reduction furnace

The invention discloses a process of directly reducing liquid high lead slag in reducing furnace, secondary lead-containing materials such as the liquid high lead slag, lead concentrate, scrap leads, waste accumulators and the like generated from the oxygen bottom blowing smelting furnace or zinc leaching residues are used as raw materials and are added from the top end of the reducing furnace; coal powder and natural gas used as fuel and oxygen-enriched air used as combustion improver are continuously led in from the top of the reducing furnace to carry out combustion reaction; the temperature in the reducing furnace is kept at 1000-1500 DEG C; the coal powder and natural gas can be simultaneously used as reducing agents and fall into the reaction tank at the bottom of the reducing furnace after being fully mixed with the raw materials; the lead oxides in the raw materials are reduced to crude lead and the addition of the reducing agents is subject to full reduction of the lead oxides in the raw materials. The process of the invention directly reduces the liquid high lead slag, fully utilizes the thermal energy of the high lead slag and further reduces the coke consumption and flue gas volume, thereby dramatically reducing the smoke dust rate and the smelting cost.

Owner:安徽铜冠有色金属(池州)有限责任公司

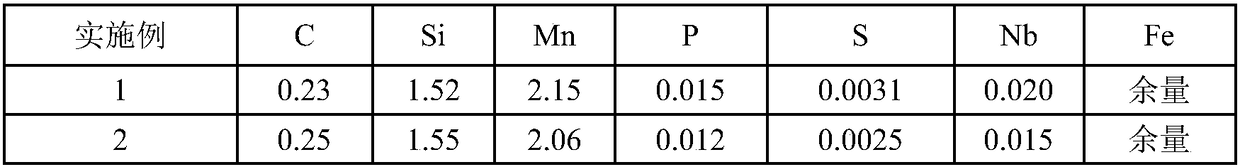

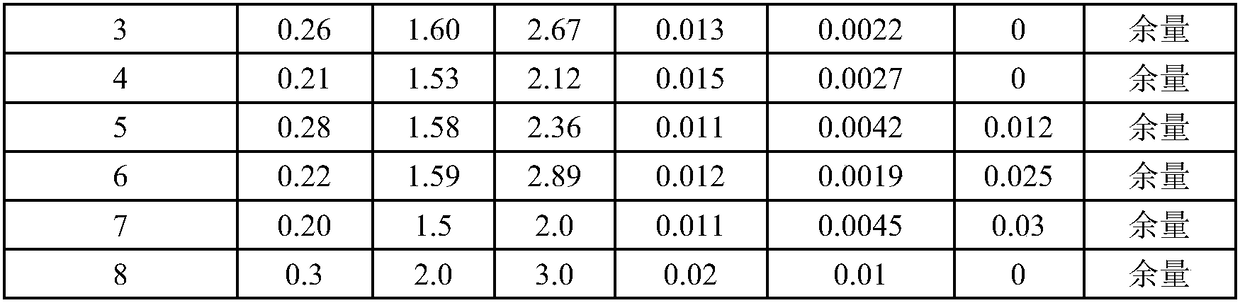

Quenched partitioned cold-rolled steel sheet with tensile strength of greater than 1180 MPa, and production method thereof

The invention relates to a quenched partitioned cold-rolled steel sheet with tensile strength of greater than 1180 MPa, and a production method thereof. During annealing heating, a steel plate is partially austenitized, so the enrichment of carbon in an austenite structure is realized; the two-phase-region slow cooling is employed for adjusting the volume fractions of an austenite phase and a ferrite phase, carbon is further enriched in the austenite; then rapid cooling at a cooling rate of 30-40 DEG C / s is carried out to partially convert the austenite into martensite; then heating and heat preservation are carried out; and finally, air-cooling to room temperature is carried out to obtain a multi-phase structure of ferrite, martensite and metastable austenite. The invention has the advantages that the production method is used for batch production of the quenched partitioned cold-rolled steel sheet with the tensile strength of greater than 1180 MPa; the quenched partitioned cold-rolled steel sheet has simple chemical components, no elemental Nb or only a small amount of elemental Nb is added except C, Si and Mn, so smelting cost is low, and process control is simple; two-phase-region heating is employed for continuous annealing; rapid cooling requires a low cooling speed and has low requirements on the equipment capacity of a continuous-annealing unit is low; and the production method is simple.

Owner:ANGANG STEEL CO LTD

Method for smelting medium ferrovanadium

The invention belongs to the metallurgy field and in particular relates to a method for smelting medium ferrovanadium. The invention aims to solve the technical problem of an electro-aluminothermic process with high vanadium recovery from smelting and is specifically characterized by adopting the mixed materials of V2O5 and V2O3 as the raw materials and using the electro-aluminothermic process to smelt the medium ferrovanadium. The method comprises the following steps: A. preparing bottom materials and main materials; B firstly adding the bottom materials for smelting at the initial stage of smelting; C. then adding the main materials after the bottom materials react steadily; and D. refining. The bottom materials include aluminium, V2O5, iron and lime. The main materials include V2O3, aluminium, V2O5, iron, lime and fluorite. The method not only fully utilizes the reaction heat, but also simplifies the technological process, reduces the viscosity of the slag and ensures the ferrovanadium recovery from smelting to be steadily increased by over 96%.

Owner:SICHUAN CHUANWEI GRP CO LTD +1

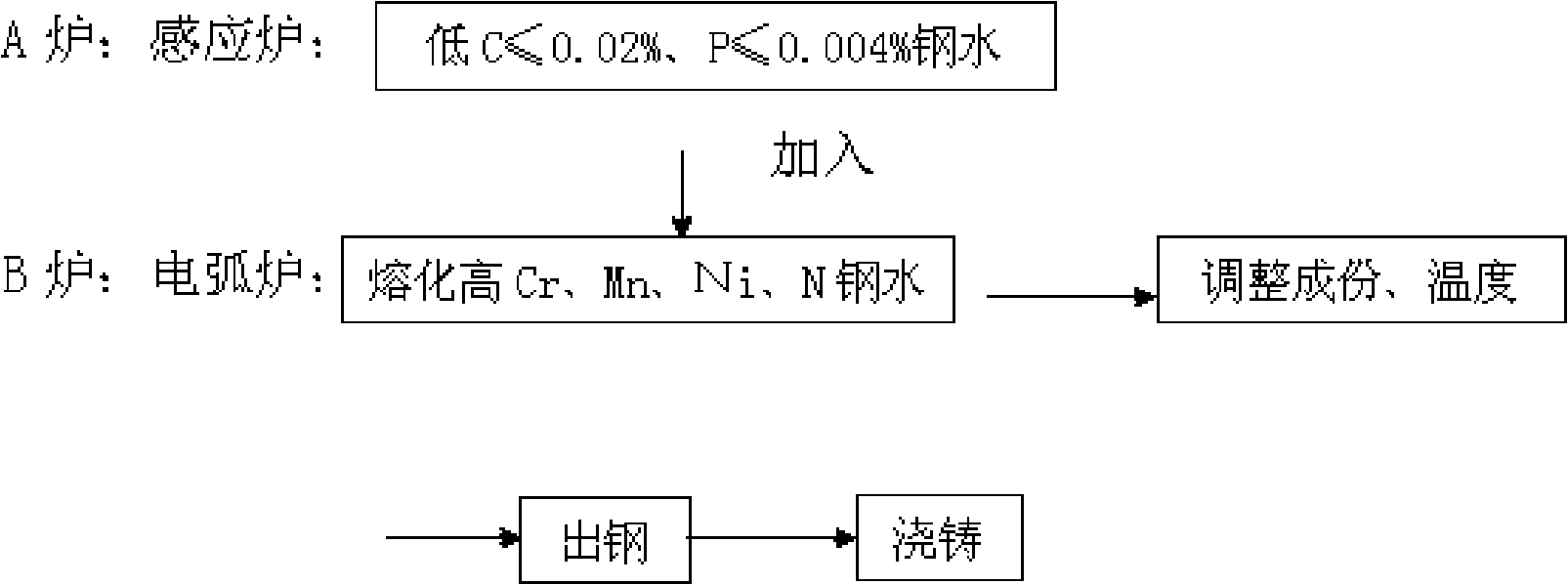

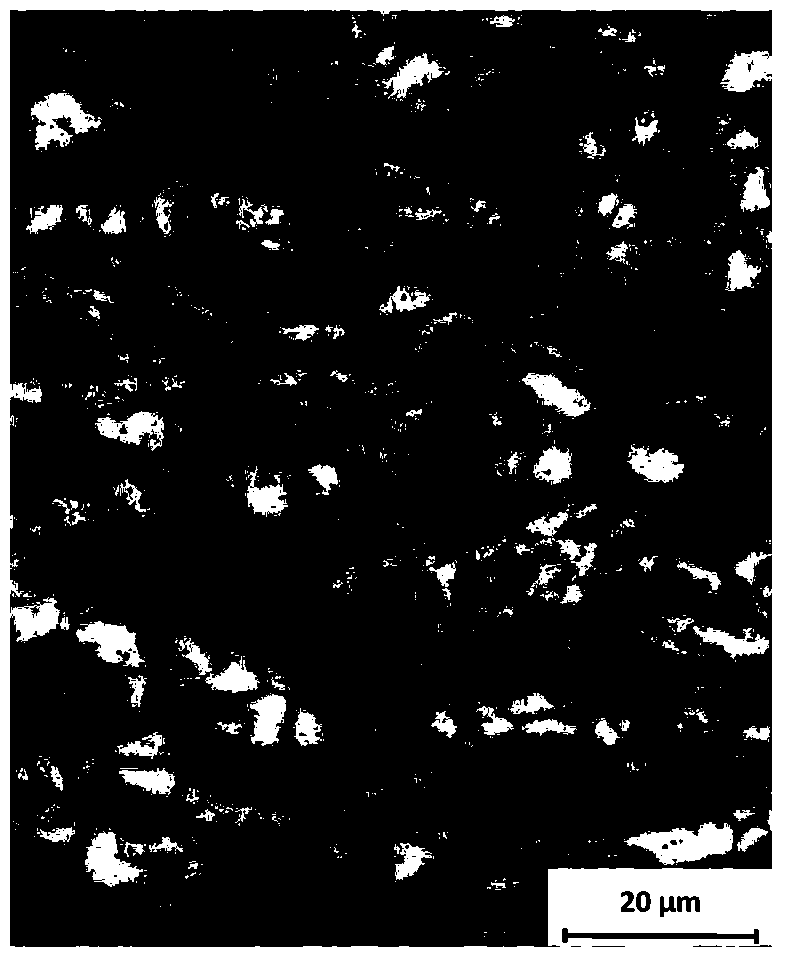

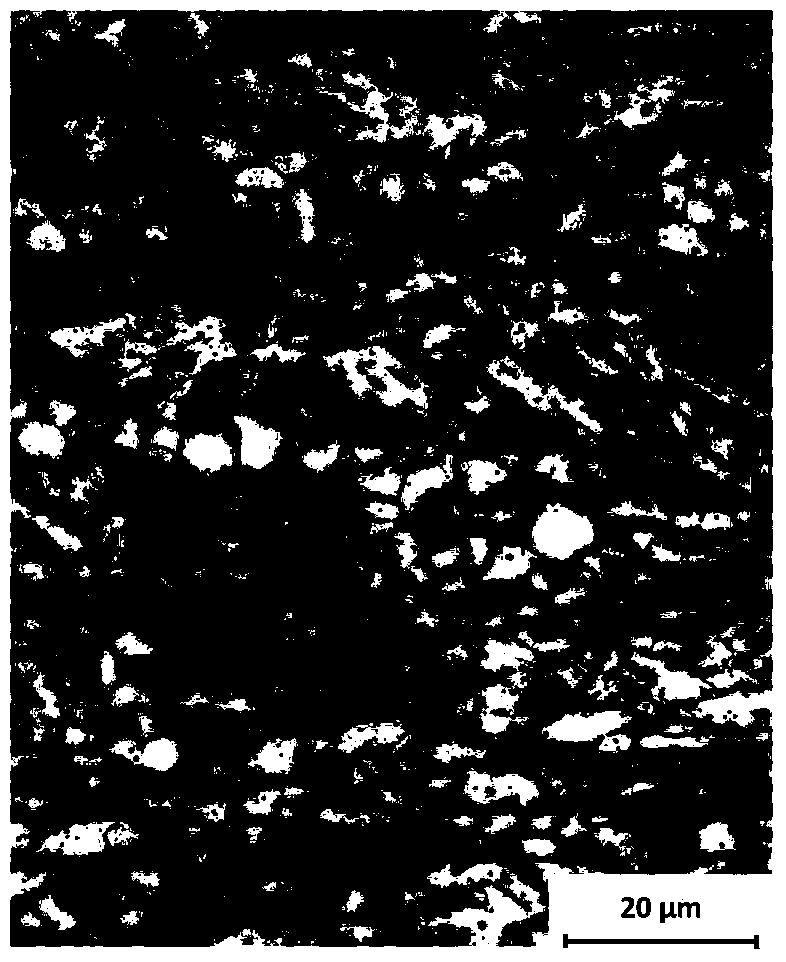

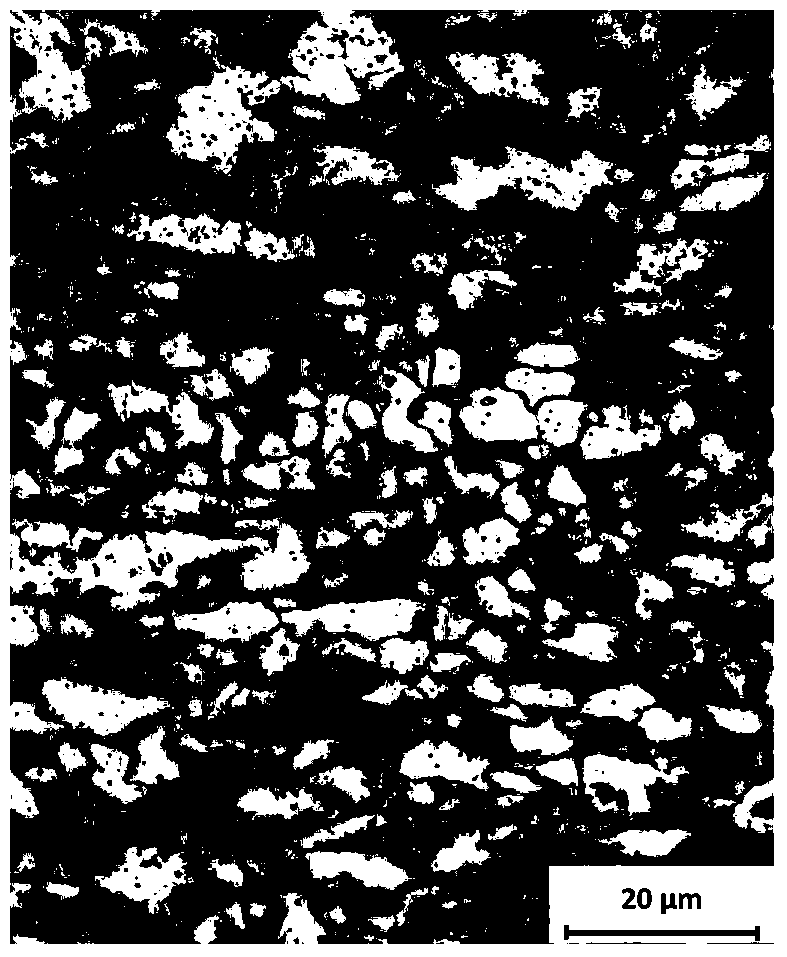

Non-magnetic stainless steel with high strength and toughness, manufacturing method and application thereof

The invention provides non-magnetic stainless steel with high strength and toughness, a manufacturing method and application thereof. The stainless steel comprises the following chemical components in percentage by weight: less than or equal to 0.04 percent of C, 0.35 to 0.65 percent of Si, 17.00 to 22.00 percent of Mn, 13.00 to 17.00 percent of Cr, 0.30 to 0.50 percent of Mo, 0.15 to 0.45 percent of Ni, 0.30 to 0.80 percent of N, less than or equal to 0.03 percent of P, less than or equal to 0.005 percent of S, and the balance being Fe and inevitable impurities. The steel improves the rust resistance and corrosion resistance of the stainless steel by adopting a low-carbon and high-chromium content design, reduces the nickel content by replacing the nickel with manganese and nitrogen at the same time, and reduces production cost. The steel is smelted by adopting an EAF, AOD and LF method, the forging process is divided into two temperature stages, the steel is treated by adopting different deformation amounts, and the method is simple and convenient to apply and has good effect. The invention also provides application of the stainless steel in a petroleum drill.

Owner:宝武特种冶金有限公司

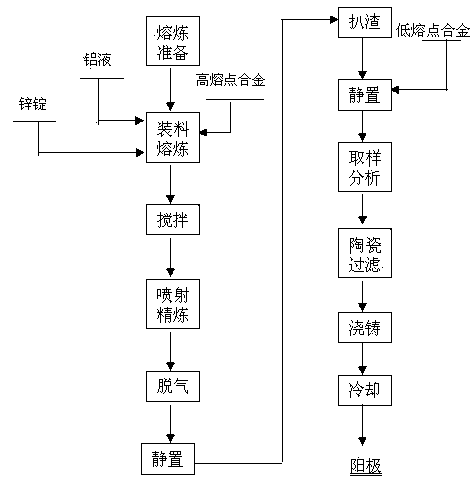

Casting method of aluminum alloy sacrificial anode

The invention belongs to the technical field of corrosion and prevention, and in particular relates to a casting method of an aluminum alloy sacrificial anode. The casting method comprises the following steps: adding basic electrolytic molten aluminum to a resistance furnace; then adding a zinc ingot to obtain molten aluminum alloy; performing jet refining on the molten aluminum alloy by adopting an argon located refining agent; charging argon to refined aluminum alloy melt to degas; drossing oxidizing scum on the surface of the aluminum alloy melt through a drossing tool; adding a low melting point metallic element to drossed aluminum alloy melt; electromagnetically agitating the melt after pressing the low melting point metal; carrying out ceramic filtering; pouring and casting the aluminum alloy melt to a preheated iron anode mould at an even casting speed under the temperature of 700 to 740 DEG C until the mould is full of the aluminum alloy melt; and moving the aluminum alloy melt out of the mould after cooling, solidifying and molding, so as to obtain the aluminum alloy sacrificial anode. The casting method has the characteristics of being short in smelting time, small in loss of iron scale, high in degassing and purifying performances, and low in smelting cost.

Owner:NORTHEASTERN UNIV +1

Technique for manufacturing ultra-low phosphoretic steel with outside-stove refining dephosphorization of liquid steel

The invention relates to a method for controlling phosphorus in the production of ultra-low phosphorous steel by microalloy steel, high carbon steel and special steel, in particular to a process method for producing the ultra-low phosphorous steel by external refining dephosphorization of molten steel, which comprises the following steps of: 1) converter tapping: the temperature is between 1,550 and 1,660 DEG C, the content of the phosphorus is less than 0.02 percent, and the nondeoxidation and the slag-stopping treatment are adopted for tapping; 2) initial dephosphorization: dephosphorizing flux is added into a ladle with steel stream during the converter tapping, and the adding amount is between 5 and 20kg / t; 3) deep dephosphorization: the positions of a blanking tube and a descending tube are adjusted to ensure that the descending tube is positioned at the opposite side of the blanking tube, a ladle is transported to a RH station and is pumped into vacuum, compound spheres are added from a RH high-level bin with a circulation for 0.1 to 15min; 4) slag skimming: the vacuum breaking and the slag skimming are performed , and ladle covering flux is added; 5) heating and stirring: the heating and stirring are performed in a refining furnace, and the heating temperature is controlled to between 1,580 and 1,620 DEG C; 6) the deoxidation and the alloying refining treatment are performed; and 7) continuous casting: the continuous casting adopts the whole-process protection.

Owner:ANGANG STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com