Ultrapure smelting process for nickel-base high-temperature alloy

A technology of nickel-based superalloy and smelting method, which is applied in the field of vacuum smelting, can solve problems such as inability to balance low-carbon and low gas content, unsatisfactory decarburization, degassing effect, and difficult control of volatile elements, so as to achieve easy alloy composition The effect of control and refining time is short and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention is described in detail below in conjunction with embodiment and accompanying drawing.

[0017] Taking a Ni75-Co5-W6-Cr6-A16-Ti2 experimental nickel-based superalloy as an example, at first nickel, cobalt, chromium and tungsten are subjected to the following degassing treatment:

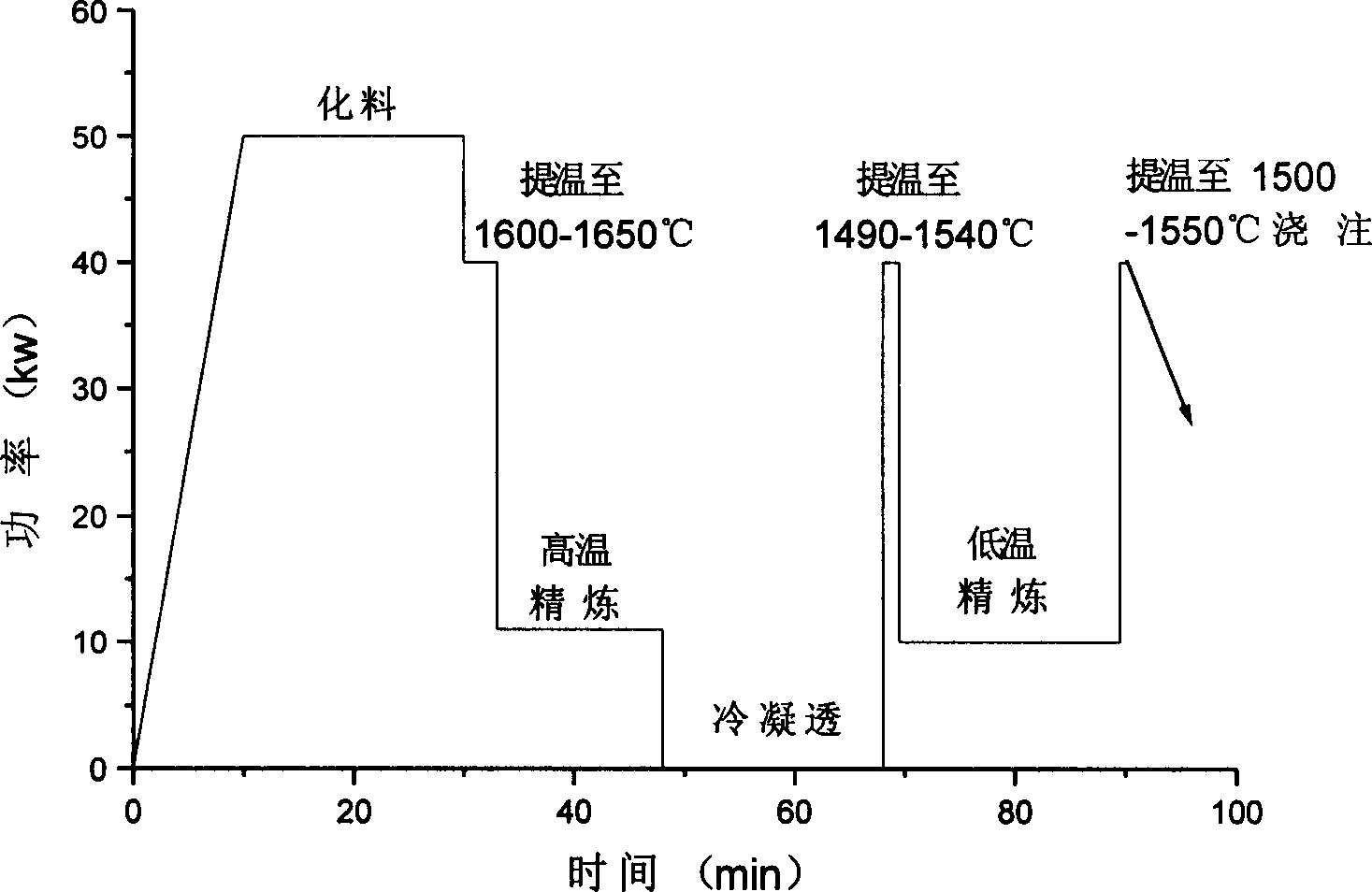

[0018] Take electrolytic nickel and electrolytic cobalt, respectively add 0.015% carbonization clear, then raise the temperature to 1600°C for high temperature refining for 15 minutes, turn off the power to condense thoroughly, then raise the temperature to 1490°C for low temperature refining for 20 minutes, after the low temperature refining, raise the temperature to 1500°C and pour into cast iron Ingots for spare. see figure 1 Process curve.

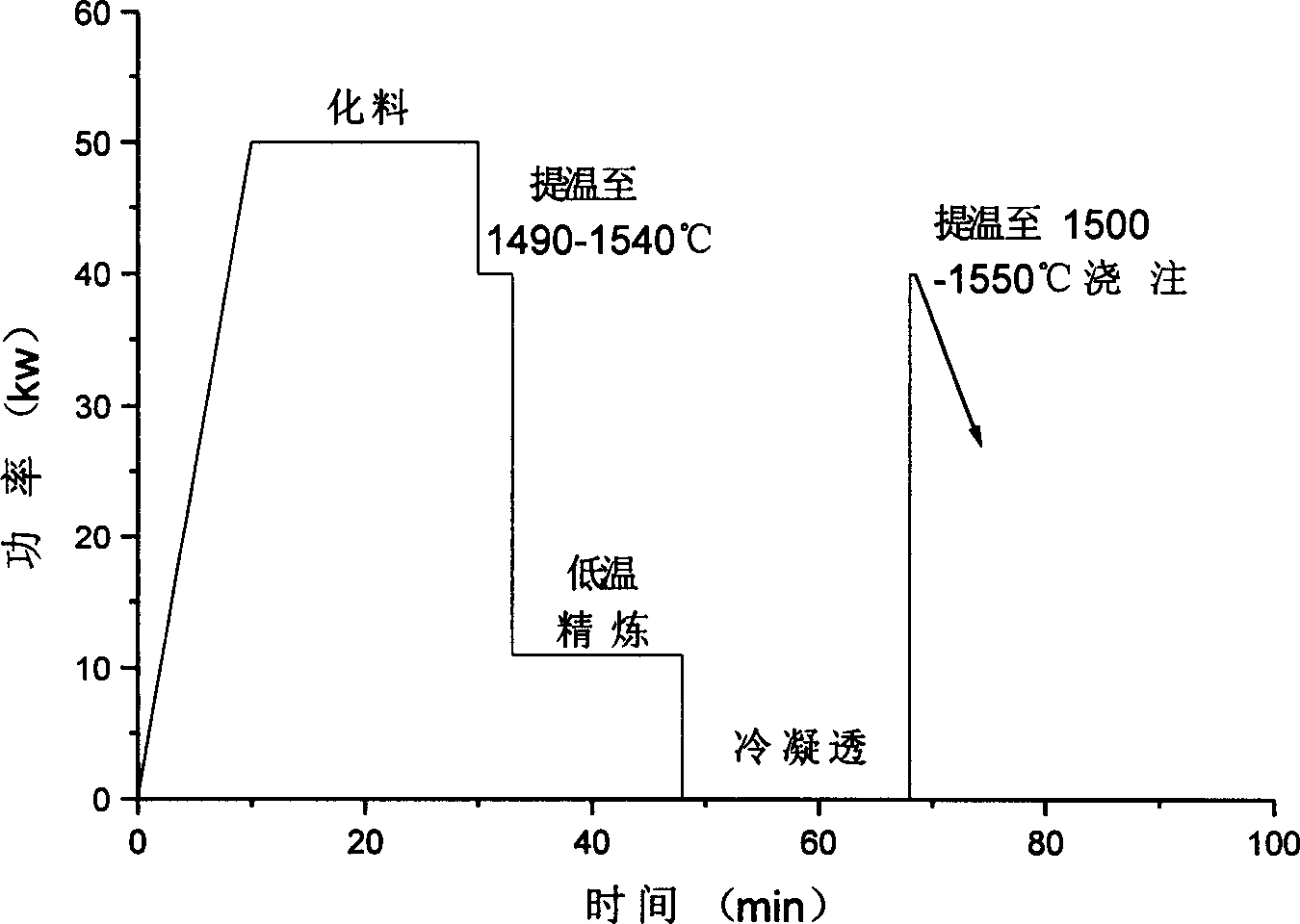

[0019] Take electrolytic chromium and tungsten strips and add 50% electrolytic nickel solution respectively, then raise the temperature to 1650°C for high-temperature refining for 20 minutes, power off to condense thoroughly, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com