Patents

Literature

2682 results about "Well cementing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Well cementing is the process of introducing cement to the annular space between the well-bore and casing or to the annular space between two successive casing strings. Personnel who conduct this job are called "Cementers".

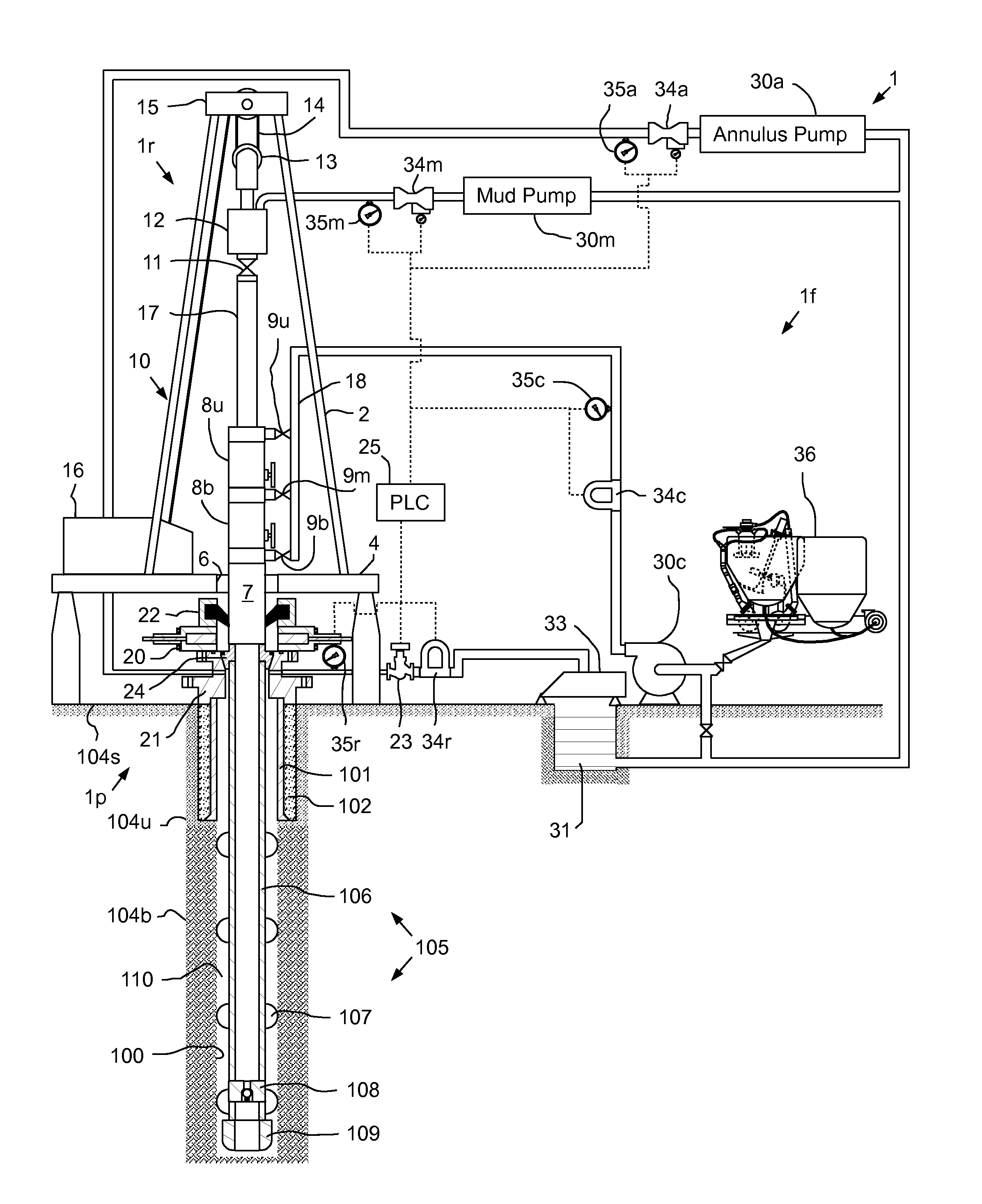

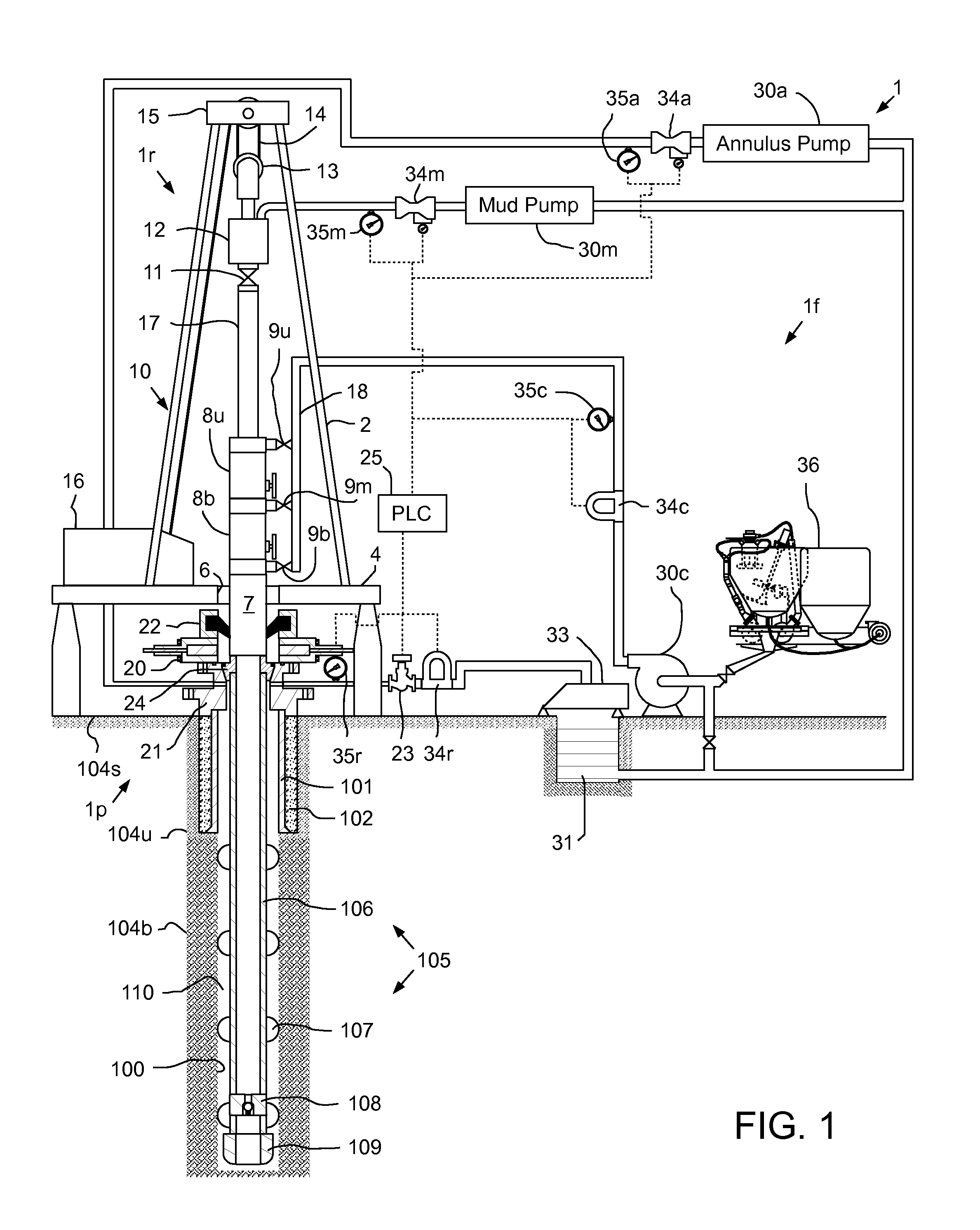

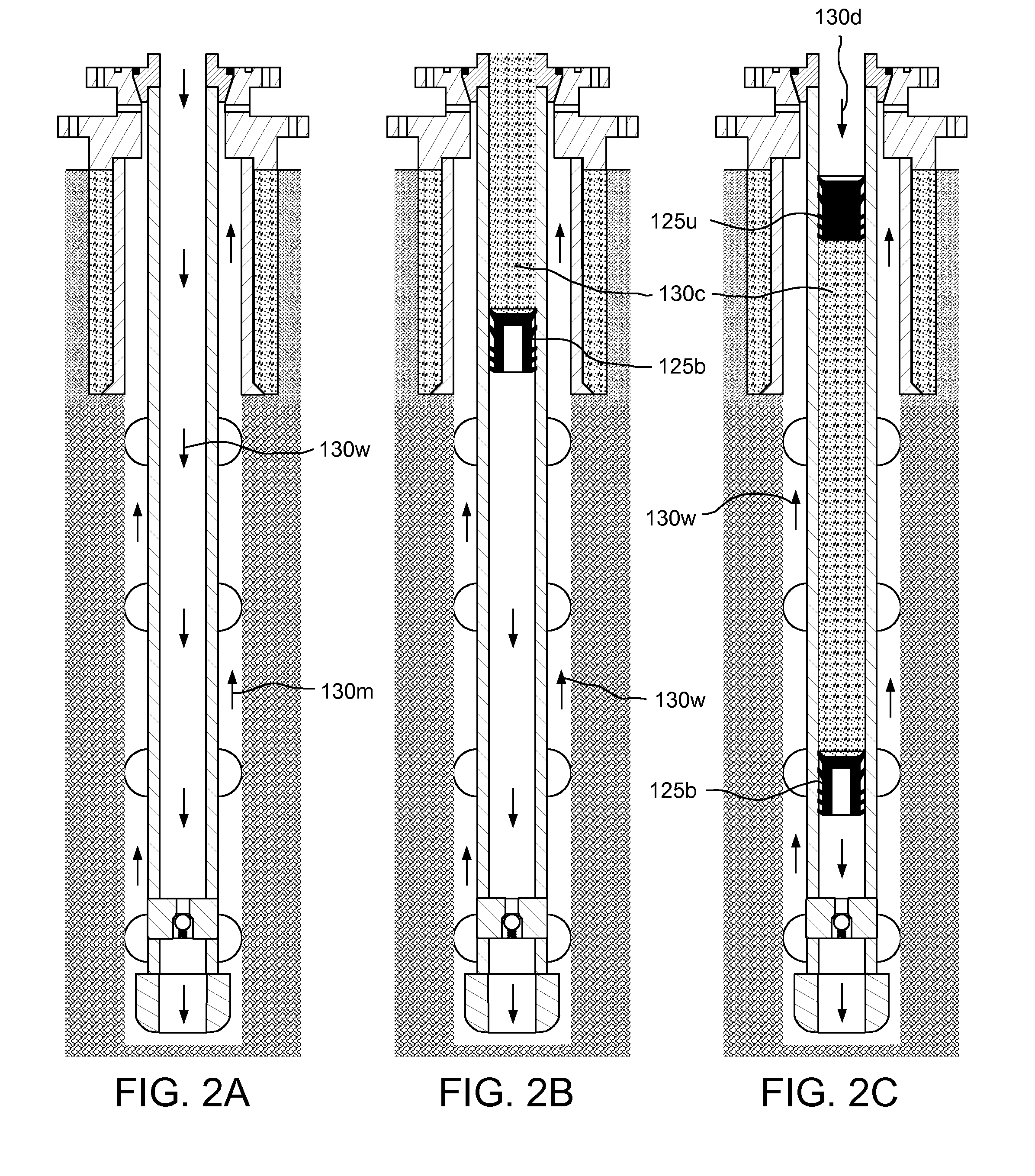

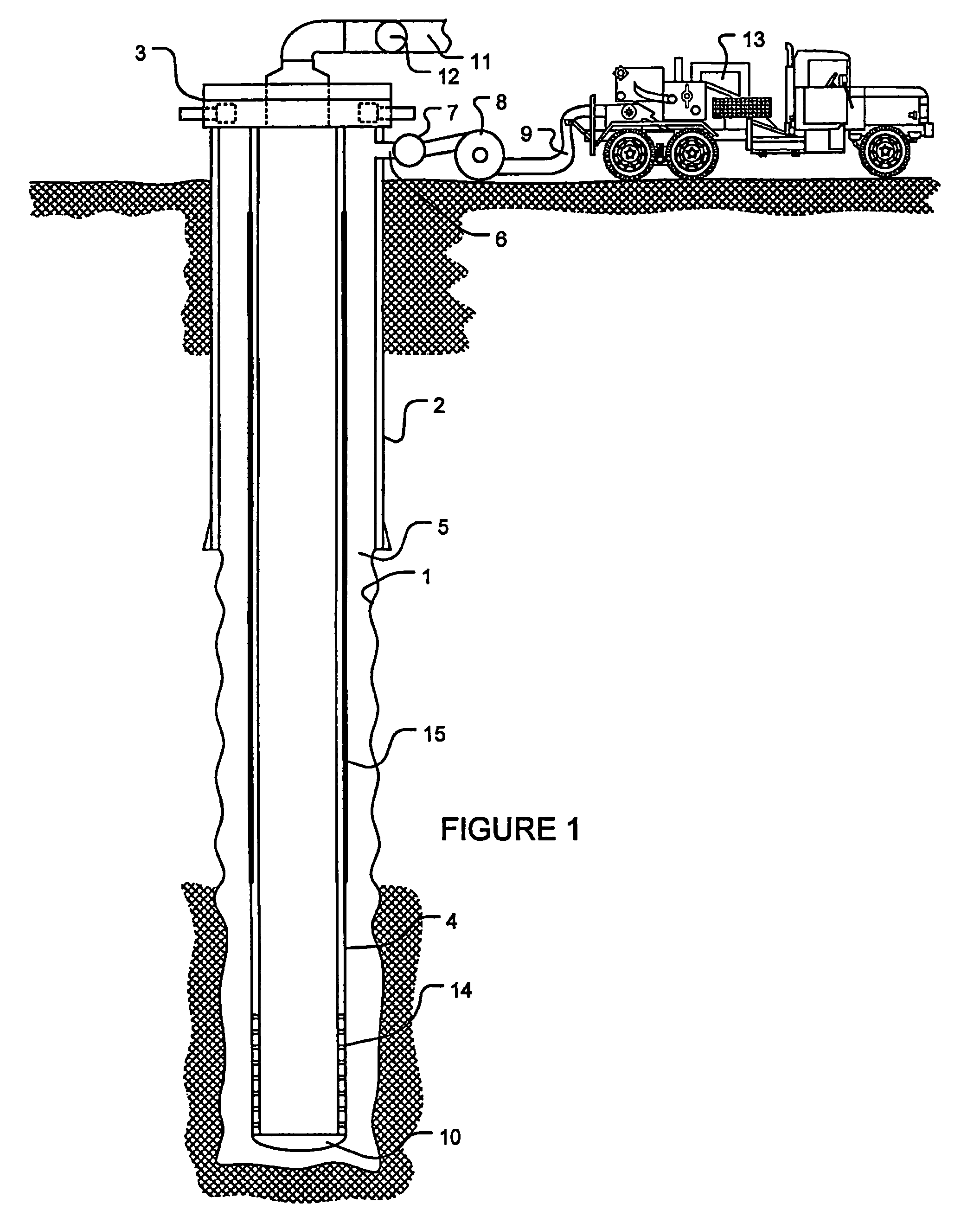

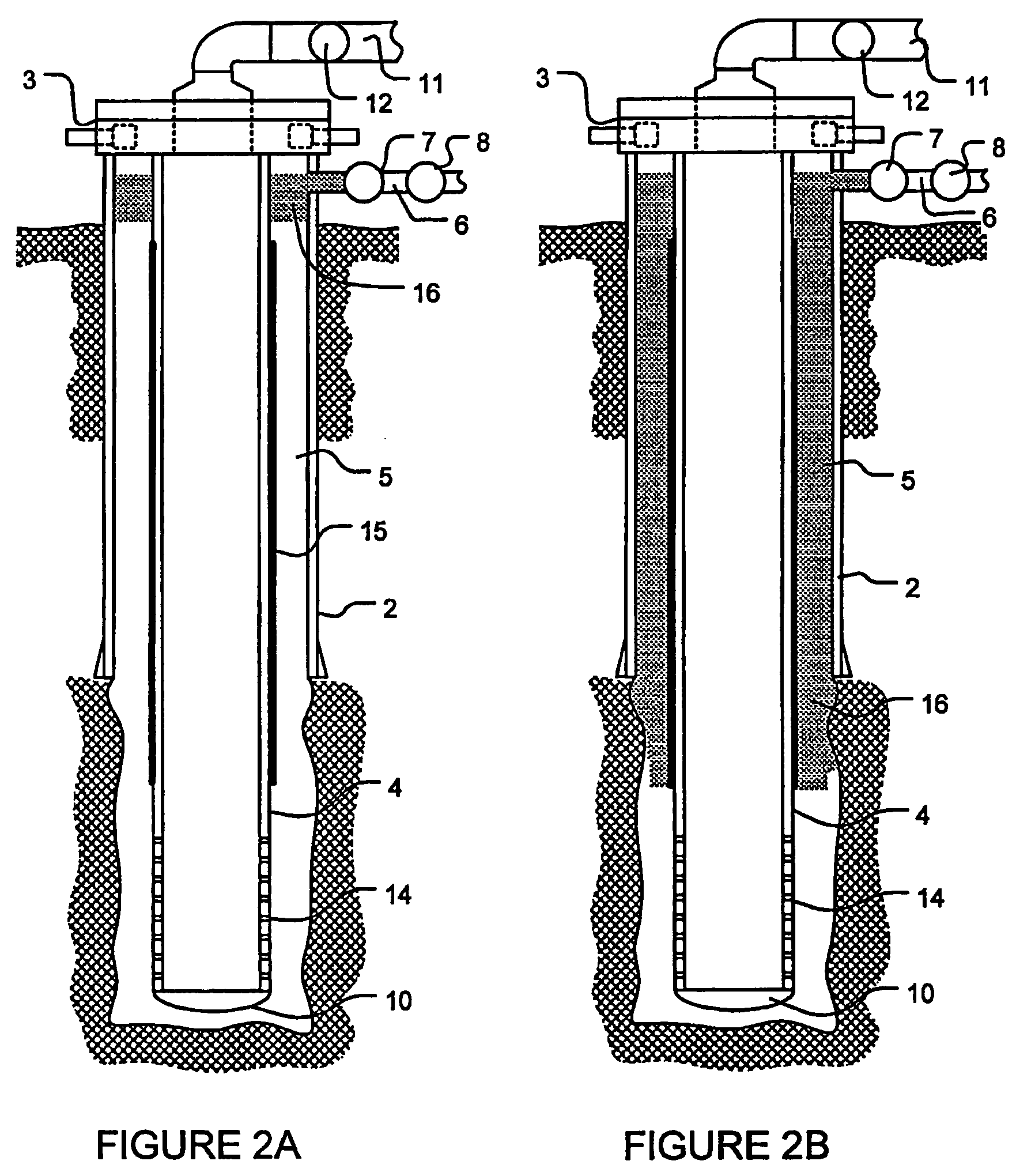

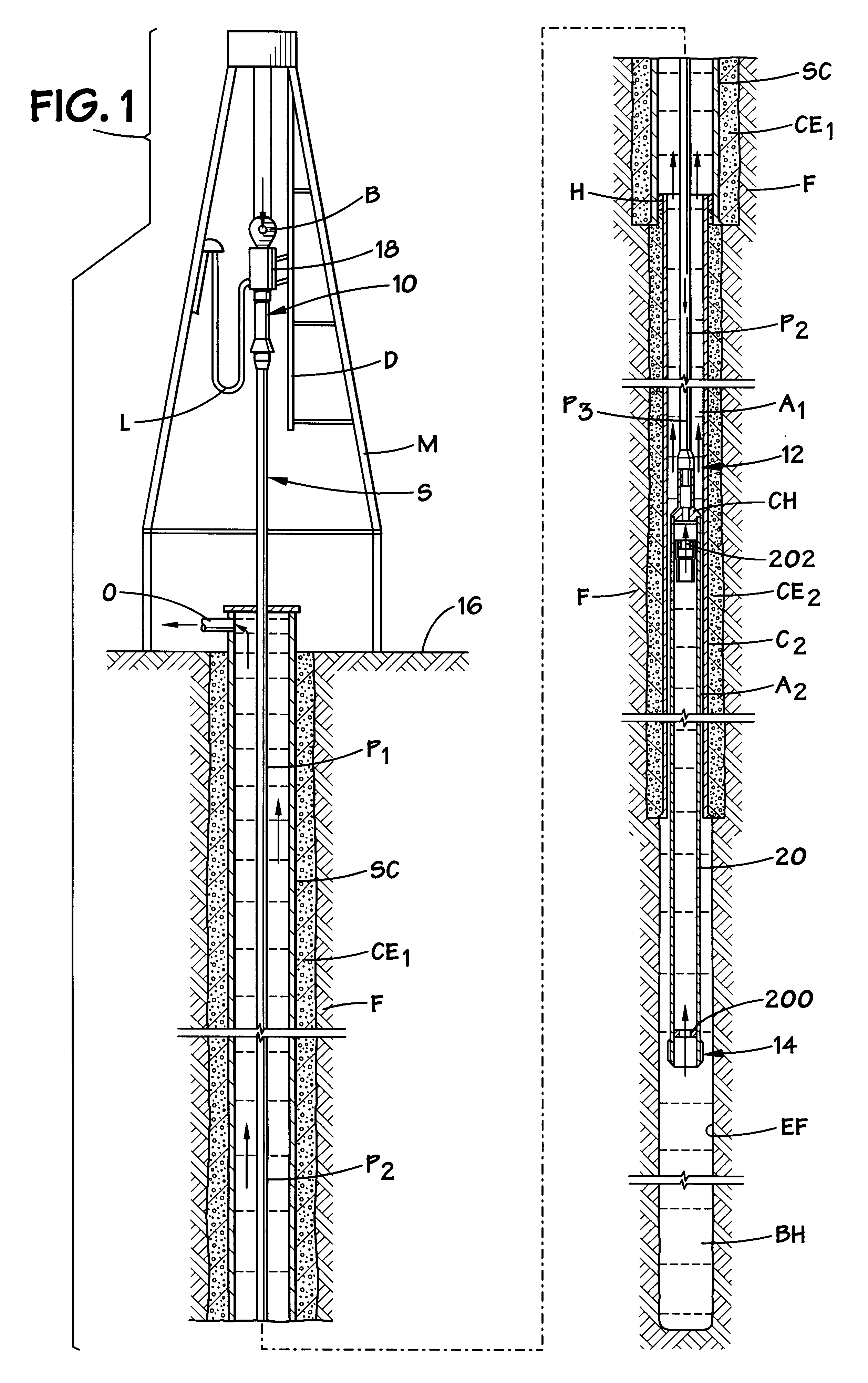

Managed pressure cementing

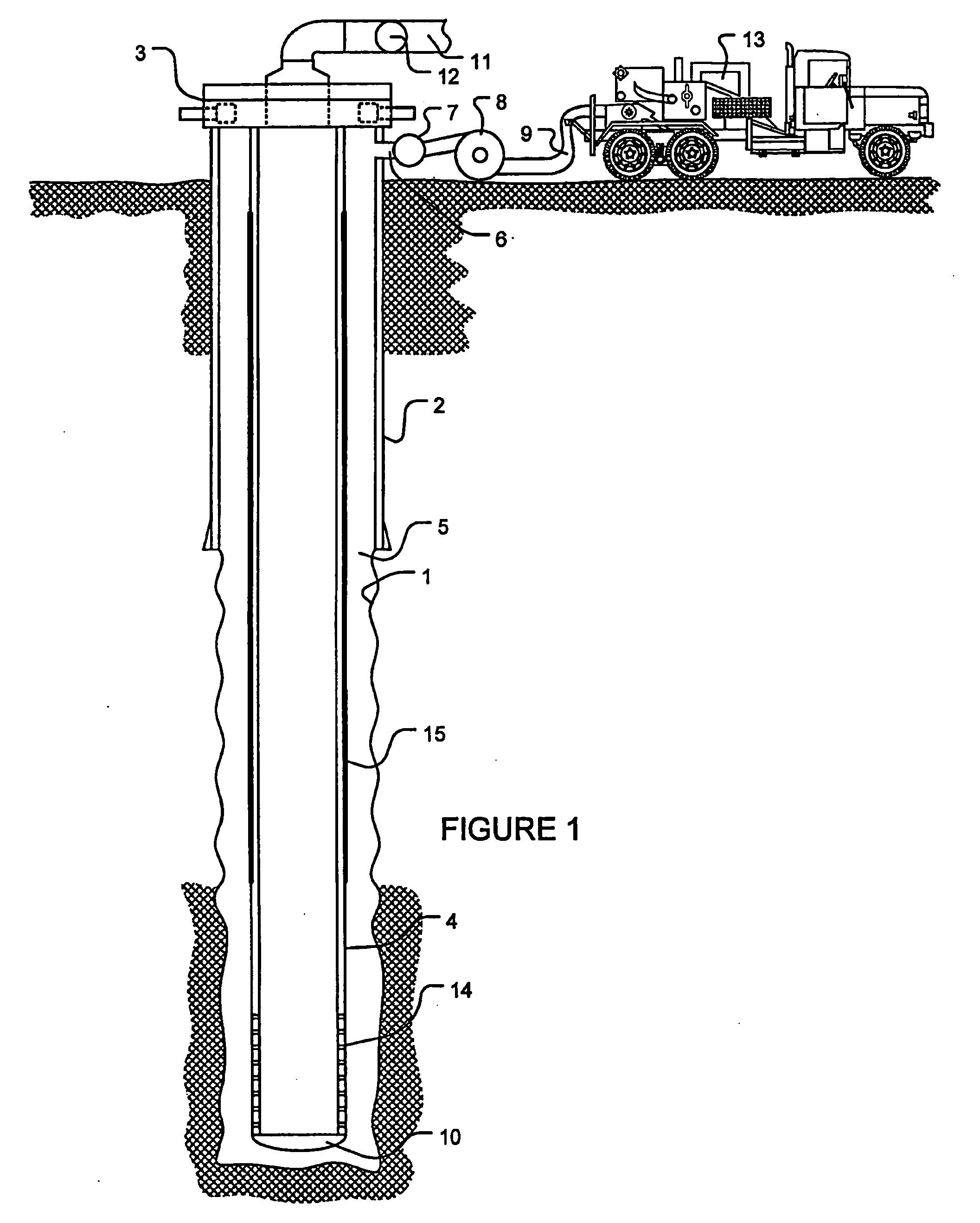

A method of cementing a tubular string in a wellbore includes: deploying the tubular string into the wellbore; pumping cement slurry into the tubular string; launching a cementing plug after pumping the cement slurry; propelling the cementing plug through the tubular string, thereby pumping the cement slurry through the tubular string and into an annulus formed between the tubular string and the wellbore; and controlling flow of fluid displaced from the wellbore by the cement slurry to control pressure of the annulus.

Owner:WEATHERFORD TECH HLDG LLC

Methods of cementing high temperature wells and cement compositions therefor

Owner:HALLIBURTON ENERGY SERVICES INC

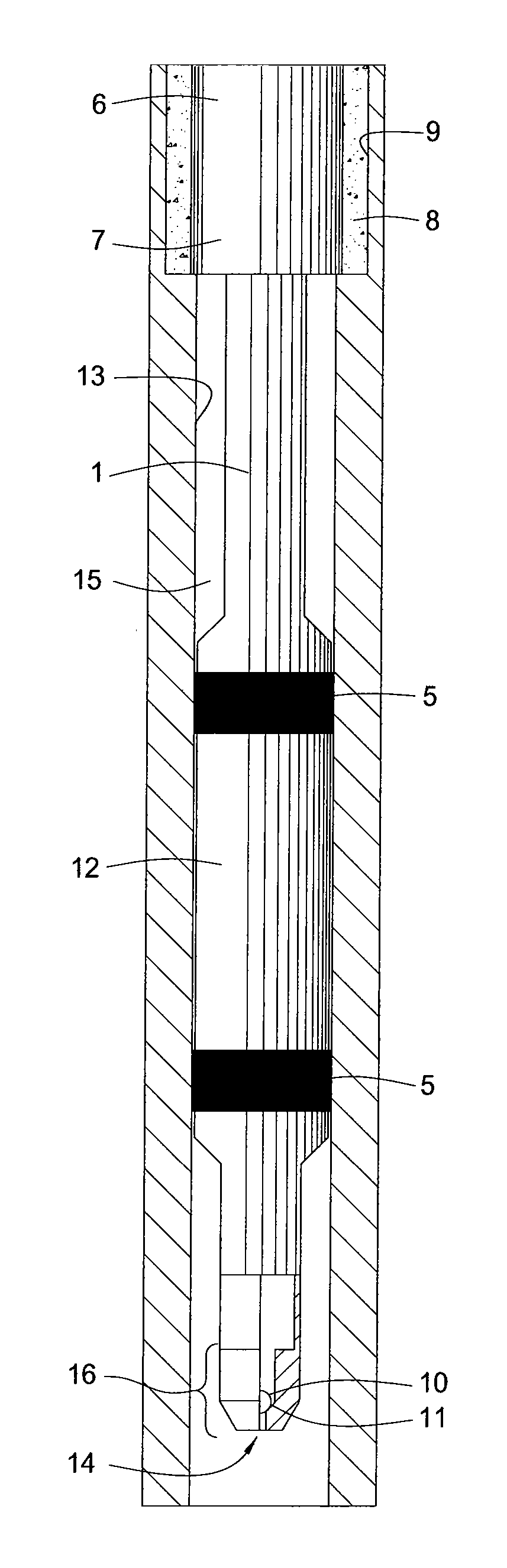

Casing strings and methods of using such strings in subterranean cementing operations

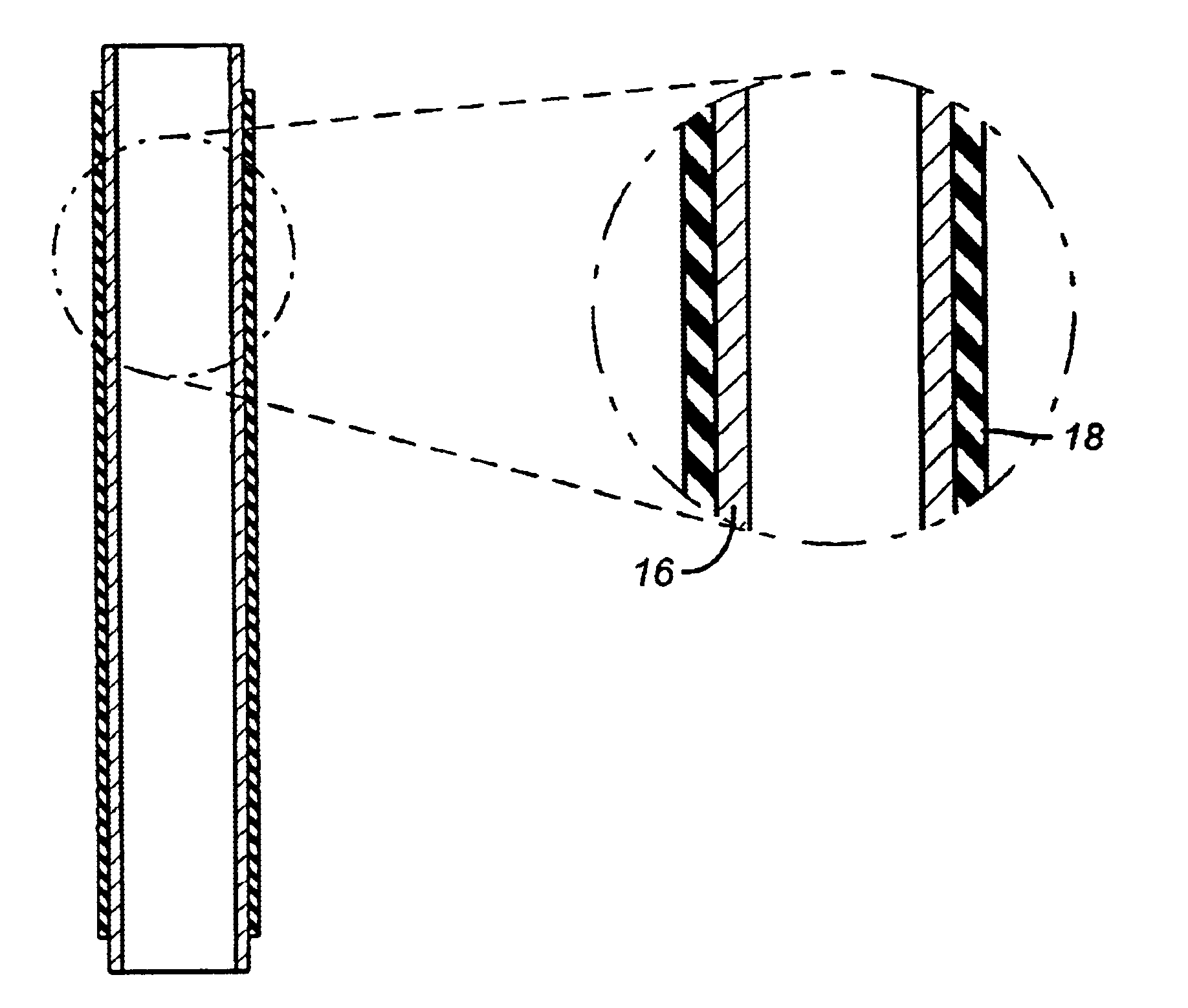

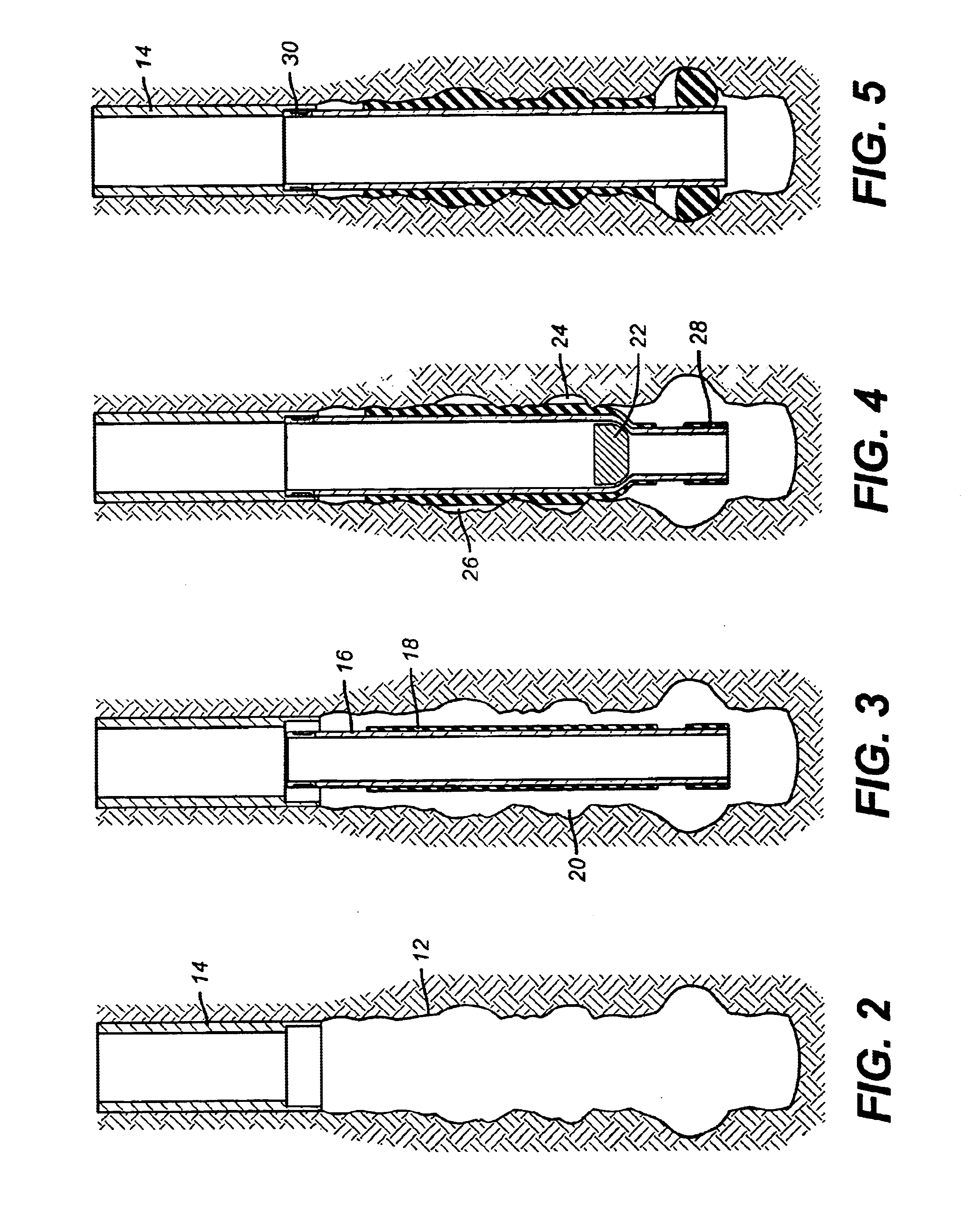

ActiveUS20060086503A1Extension of timeSolid waste managementFluid removalCasing stringWell cementing

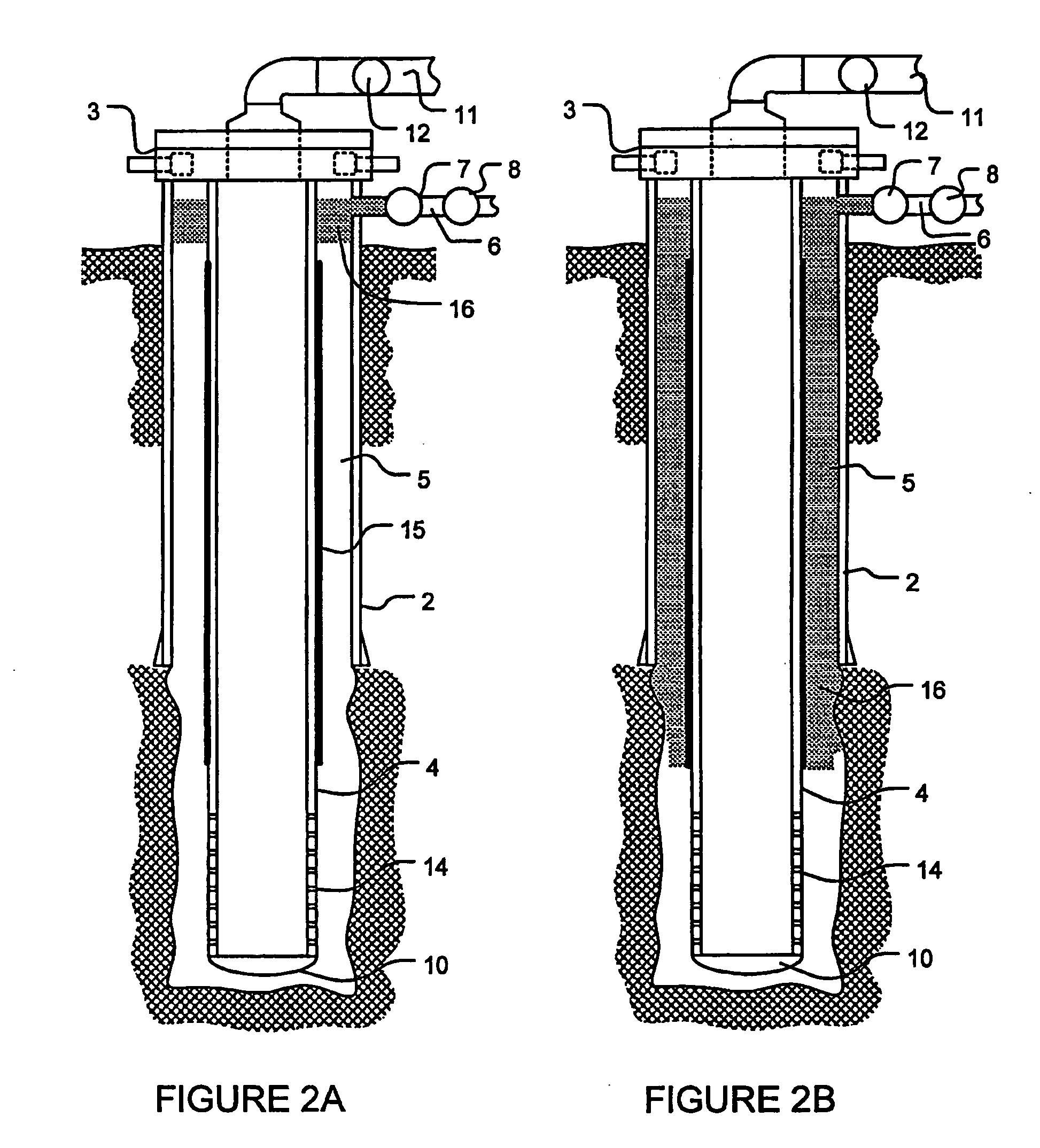

Improved casing strings, and methods of using improved casing strings in subterranean cementing operations, are provided. An example of an apparatus is a pipe string comprising at least one pipe section and a delivery system of an activator. Another example of an apparatus is a pipe string comprising at least one pipe section and a delivery system of a set retarder. An example of a method is a method of cementing in a subterranean formation. Other examples of methods are methods of cementing in a subterranean formation comprising a well bore.

Owner:HALLIBURTON ENERGY SERVICES INC

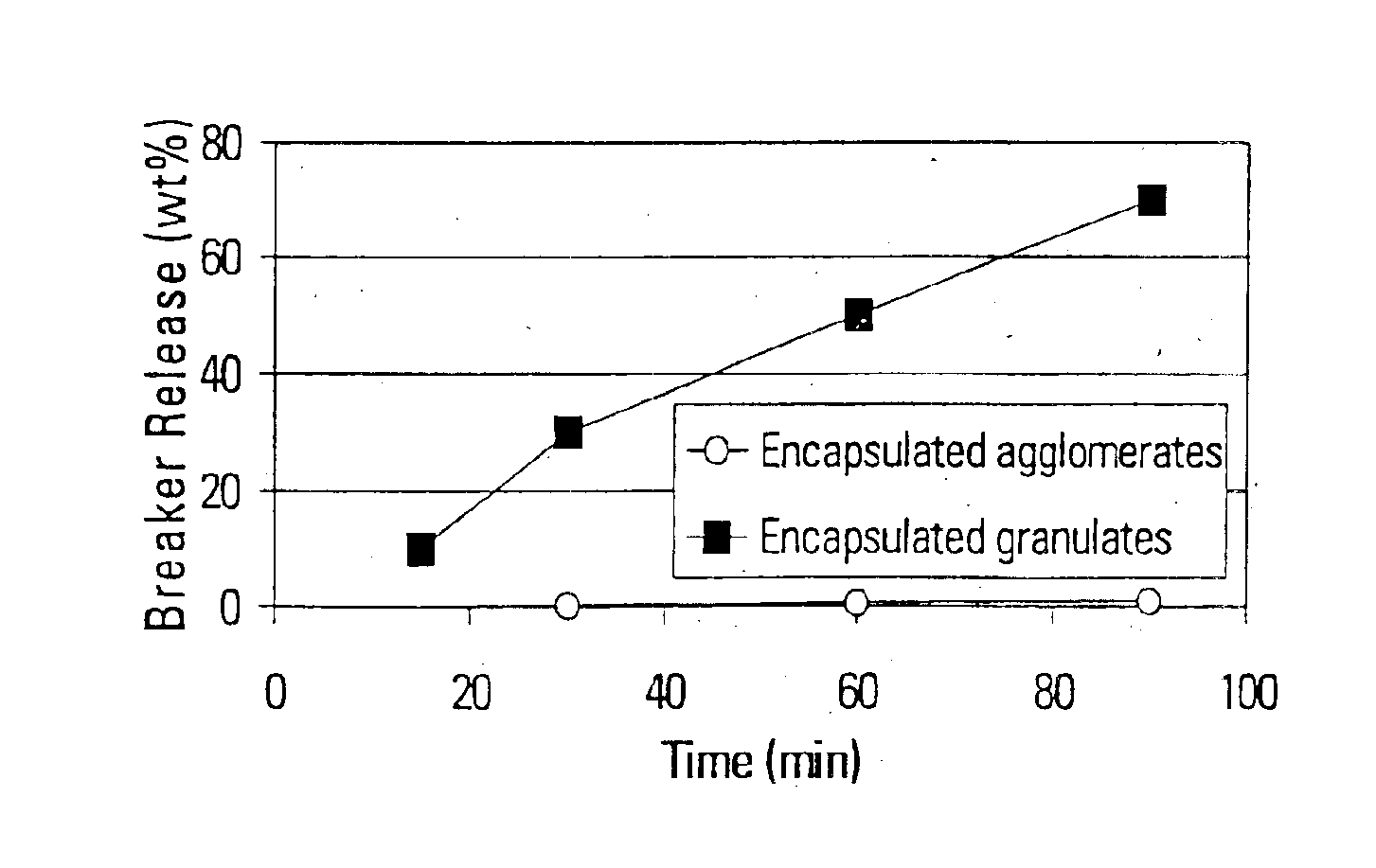

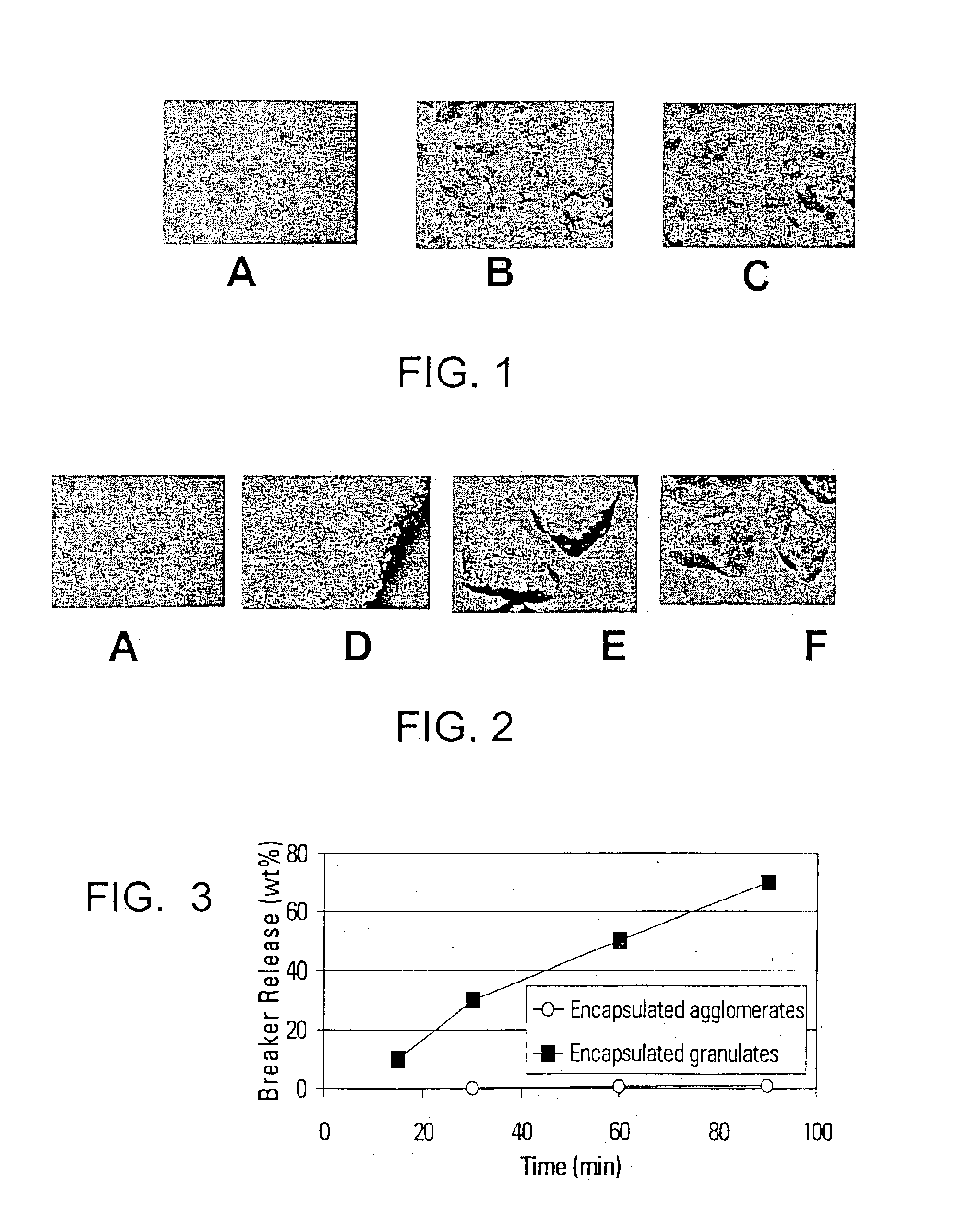

Method for treating subterranean formation

A method is given in which there is delayed release from the treatment fluid of solid chemicals that are obtained in bulk powder form. The method is used in situations in which it is difficult to encapsulate the chemical to achieve delayed release because the chemical is obtained in powdered form. The method involves delivering the powdered chemical in capsules consisting of encapsulated granulates obtained by aggregating the bulk powder under pressure to form a densified material and, optionally, then dry comminuting the densified material to produce granulates of the desired size. The treatment is hydraulic fracturing and the chemical is a breaker, or the treatment is well cementing and the chemical is a dispersing agent, fluid loss control additive, set accelerator, or extender.

Owner:SCHLUMBERGER TECH CORP

Cementing compositions and application of such compositions to cementing oil wells or the like

InactiveUS6874578B1Improve mechanical propertiesReduce penetrationFluid removalDrilling compositionPolymer sciencePortland cement

Method of well cementing with a foamed slurry having a very low water content. When based on ordinary cement, the solid fraction of the slurry includes (by volume) 20-35% Portland cement, 35-65% particles ranging from 200 μm to 600 μm, and 5% to 25% of fine particles in the range 0.5 μm to 5 μm and the water content is less than 50% by volume. When based on micro-cement, the solid fraction includes (by volume) 50-75% micro-cement, 15-40% fine particles in the range 0.5 μm to 5 μm, and 0-20% particles in the rang 3 nanometers to 60 nanometers and the water content is less than 72% by volume.

Owner:SCHLUMBERGER TECH CORP

Alternative method to cementing casing and liners

A method of sealing casing or liners in a wellbore is described. The stands of casing or liner receive a jacket bonded to the outer surface. Preferably, the jacket is a rubber compound bonded to the outer wall. The formulation responds to well fluids to swell at a predetermined rate. The casing or liner can also be expanded with a swage preferably prior to the onset of significant jacket swelling. Packers and sealing hangers can be optionally added at the extremes of the casing or liner string to further secure against channeling between adjacent formations.

Owner:BAKER HUGHES OILFIELD OPERATIONS LLC

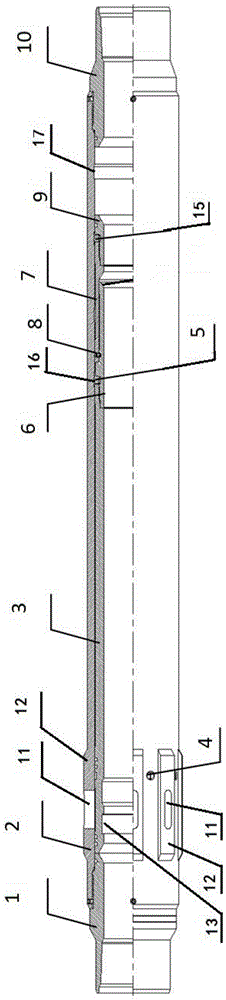

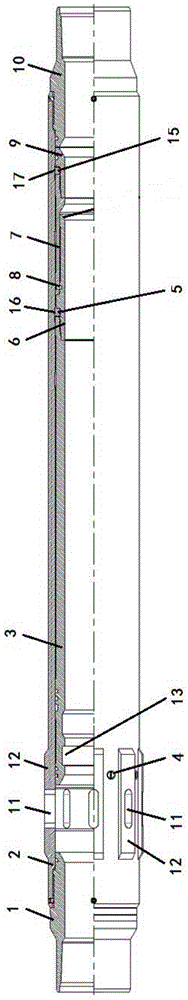

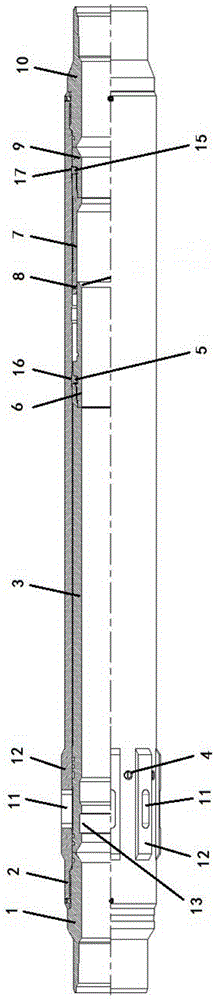

Switchable well cementation sliding sleeve based on fracturing of separate layers and construction method thereof

A switchable well cementation sliding sleeve based on fracturing of separate layers comprises an outer barrel, an upper joint and a lower joint are installed at the upper end and the lower end of the barrel respectively, a fracturing port is formed in the side wall of the upper portion of the outer barrel, and an upper center pipe, an upper connection sleeve, a lower center pipe and a lower connection sleeve are installed inside the outer barrel. The switchable well cementation sliding sleeve based on fracturing of the separate layers is not provided with a ball seat, so a full bore of the inner wall can be maintained, fracturing fluid can flow back in time, and the construction period is shortened. The well cementation sliding sleeve is set in the upper center pipe through a bottom packer, downward pushing force big enough can be generated in the process of annular or continuous tubing pressing, so the upper center pipe can overcome shearing force of corresponding shearing dowels and move downwards, and therefore the fracturing port of the well cementation sliding sleeve can be opened.

Owner:JEREH ENERGY SERVICES

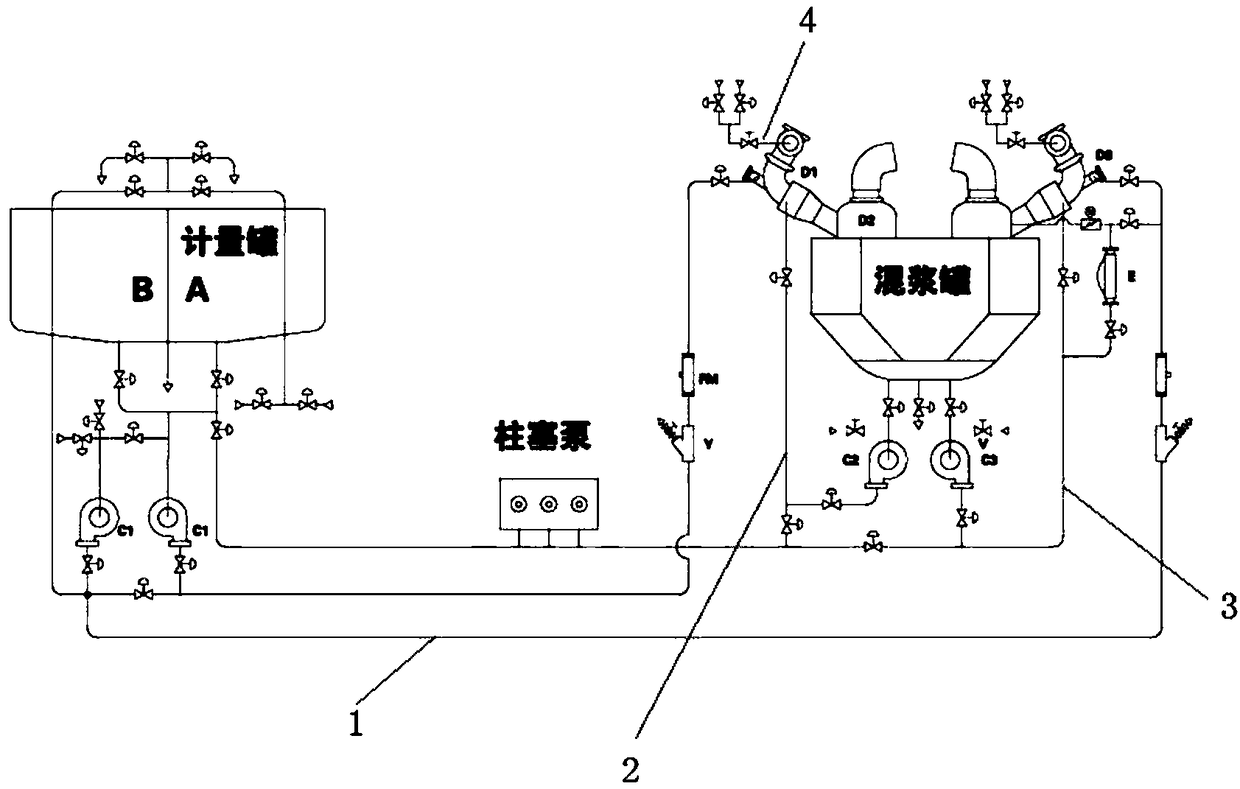

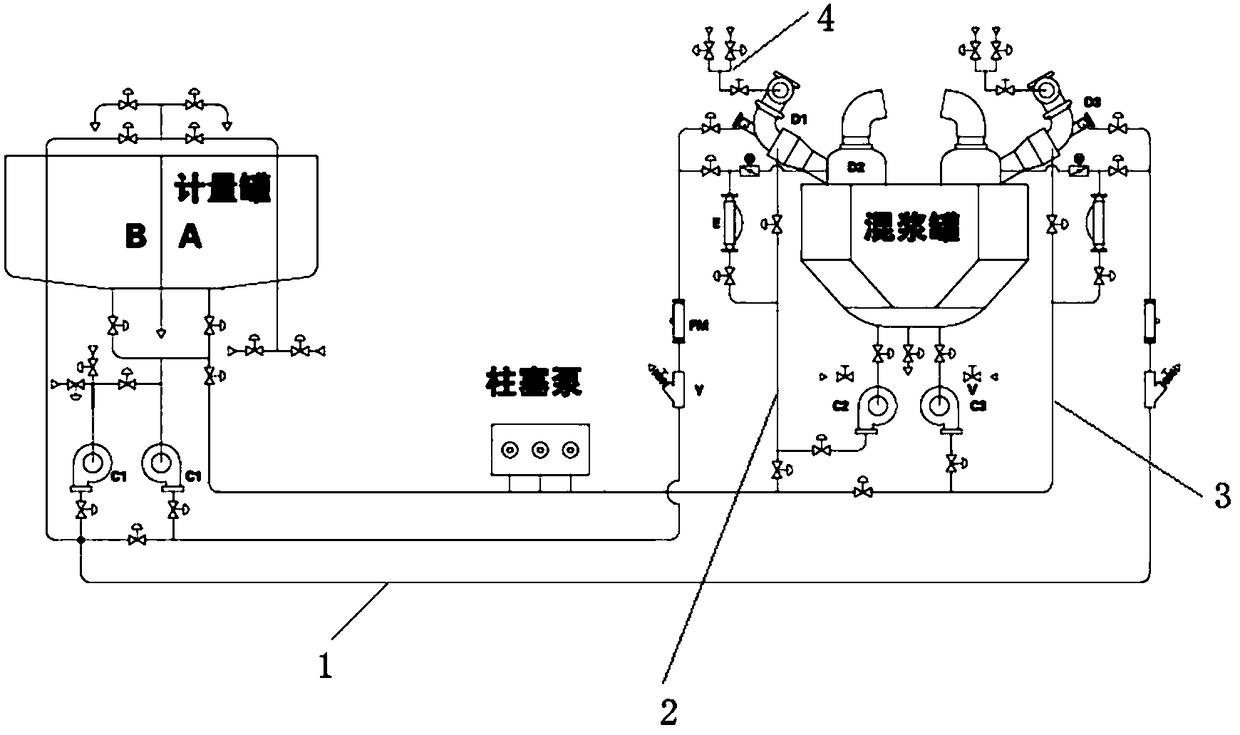

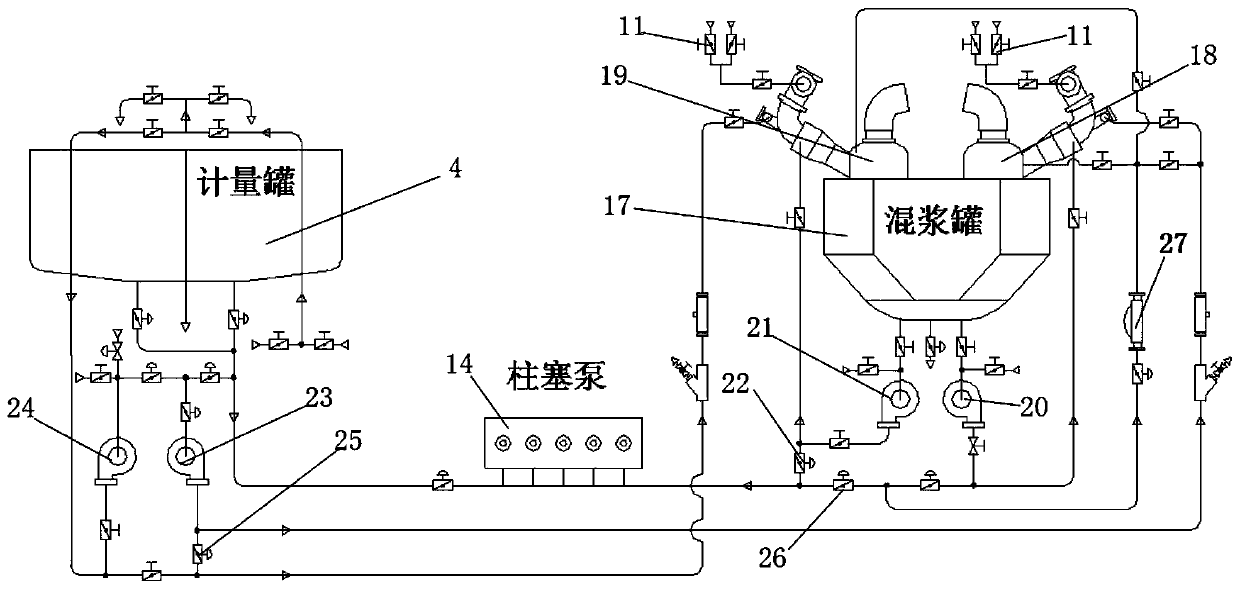

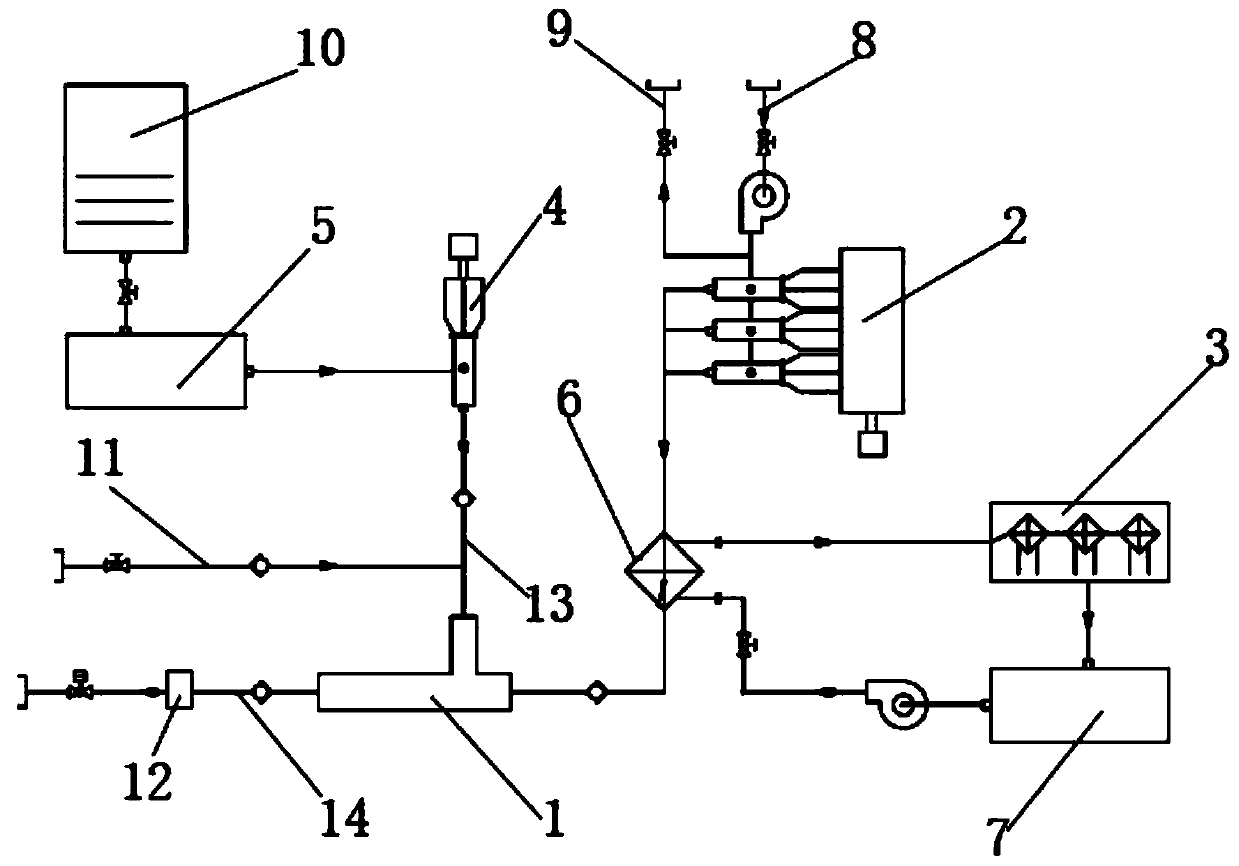

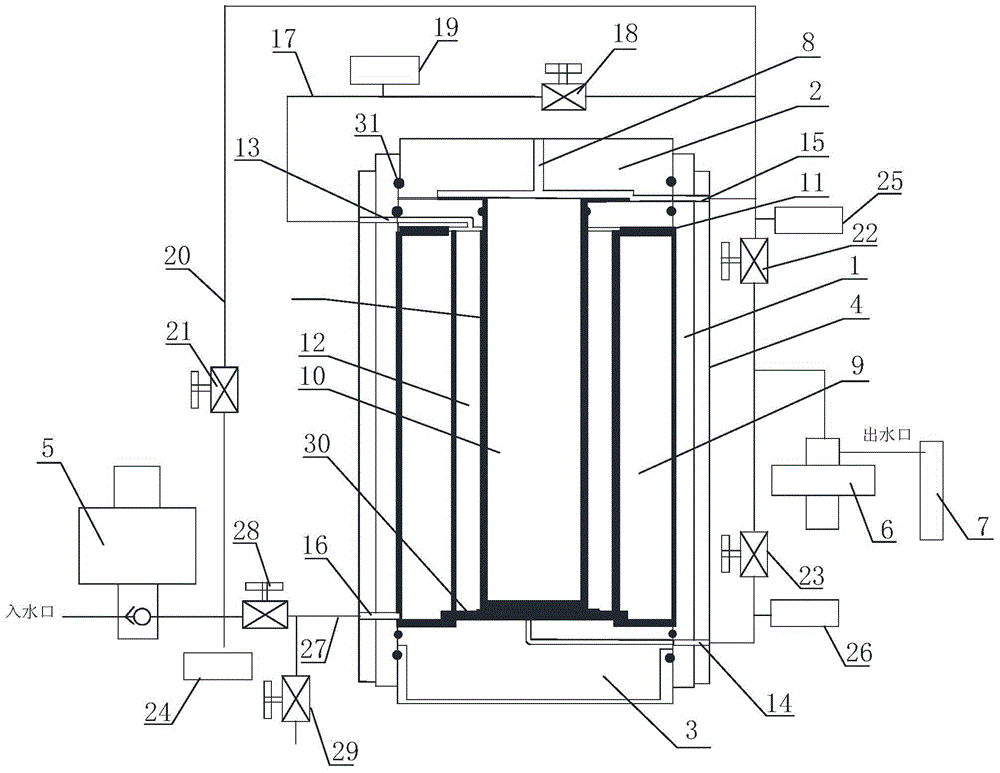

Efficient mixing system for well cementing operation

PendingCN108687954ARealize automatic controlEasy to operateCement mixing apparatusControl apparatusHybrid systemControl system

The invention relates to the technical field of petroleum equipment, in particular to an efficient mixing system for well cementing operation. The efficient mixing system comprises a measuring tank, aclear water manifold assembly, a cement grey feeding manifold assembly, high-energy mixers, a mud mixing tank and a mud manifold assembly. The mud mixing tank is at least connected with two high-energy mixers, and an inlet of the mud mixing tank is connected with diffusion boxes which are connected with the high-energy mixers. Discharged materials of the high-energy mixers are guided into the mudmixing tank through the diffusion boxes, and the at least one diffusion box is connected with a density control system. The multiple sets of mixers are integrated, and the large-discharge-capacity and efficient mixing effect can be achieved with existing operation conditions.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

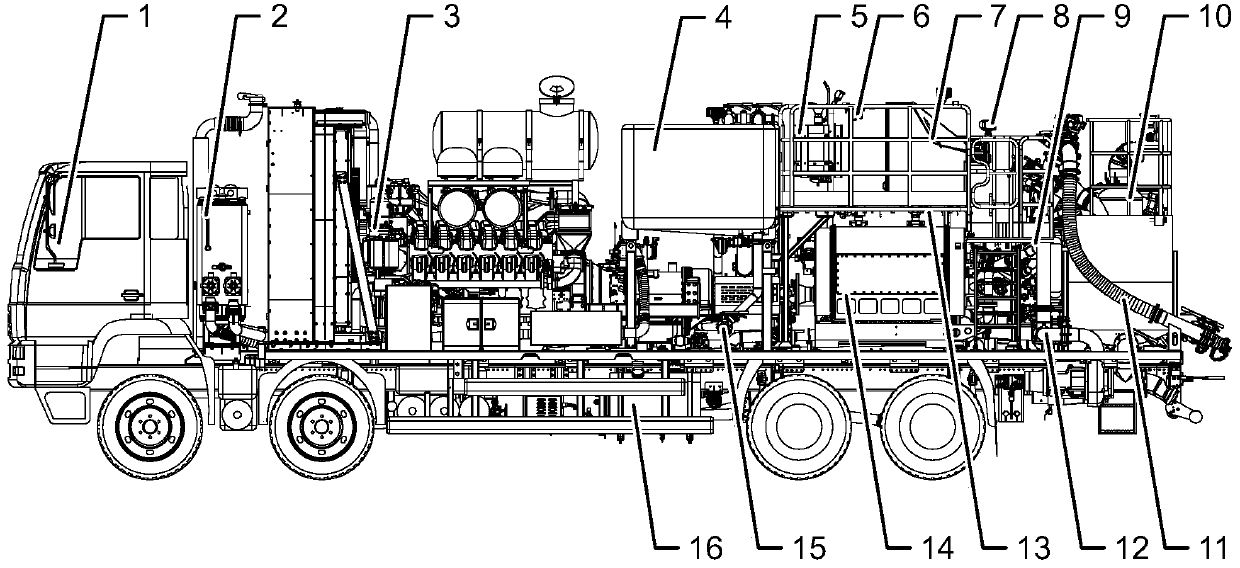

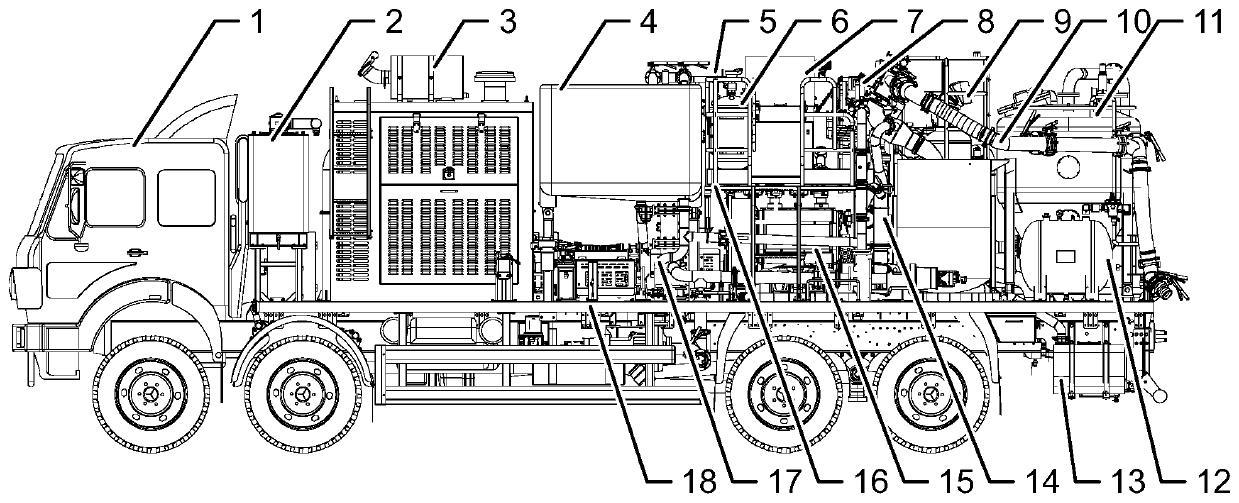

Novel ultra-large-displacement ultrahigh-pressure well cementing equipment

PendingCN111173476AIncrease pressureIncrease displacementItem transportation vehiclesSealing/packingUltra high pressureDrivetrain

The invention discloses novel ultra-large-displacement ultrahigh-pressure well cementing equipment. The novel ultra-large-displacement ultrahigh-pressure well cementing equipment comprises a loading carrier. A hydraulic system, a power transmission system, a metering tank, an electrical system, an air path system, a control system, an operating platform, a plunger pump, a clean water manifold, a mud manifold, a high-pressure manifold, a mixing system and an ash feeding manifold are mounted on the loading carrier, wherein the plunger pump is a five-cylinder plunger pump. The five-cylinder plunger pump is adopted to increase the pressure and displacement of the well cementing equipment, and the requirements of high pressure and large displacement are met; slurry mixing is carried out by double mixing devices, the mixing efficiency is improved, the stability of the slurry mixing density is improved, and the requirement of long-time uninterrupted operation is guaranteed; a mixing system pipeline is optimized, multiple sets of mixing systems are integrated on one slurry mixing tank, and the stability of the equipment is improved; and the clean water manifold is optimized, so that watersupply requirements of the multiple mixing devices can also be met at the same time by using one injection pump, and the requirement of large displacement is met.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

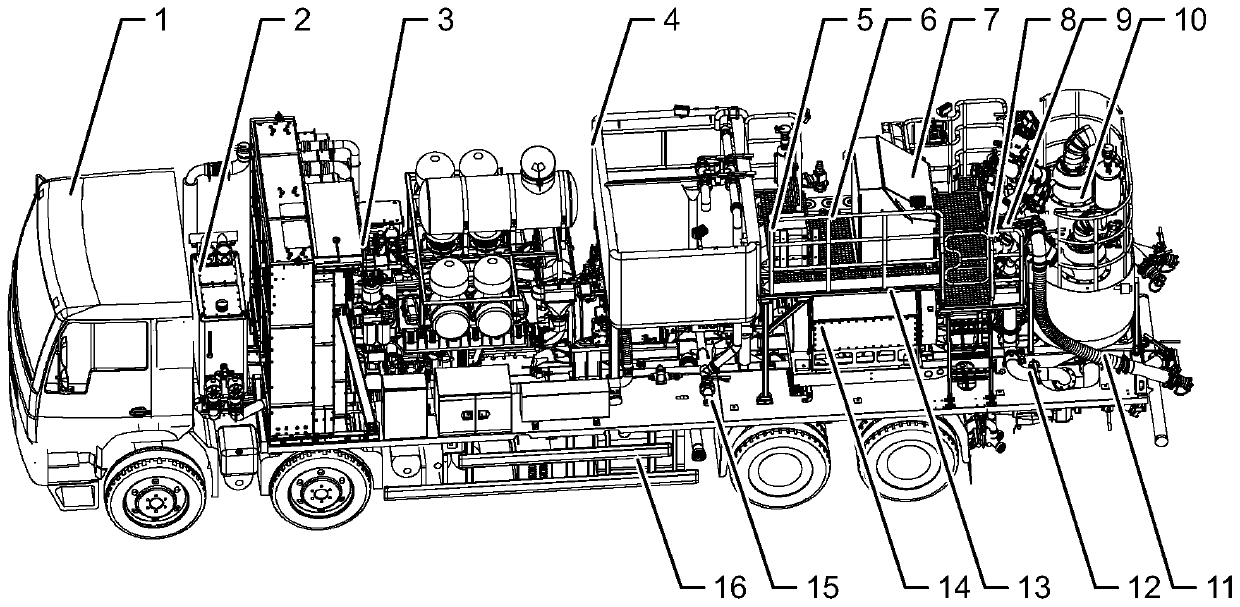

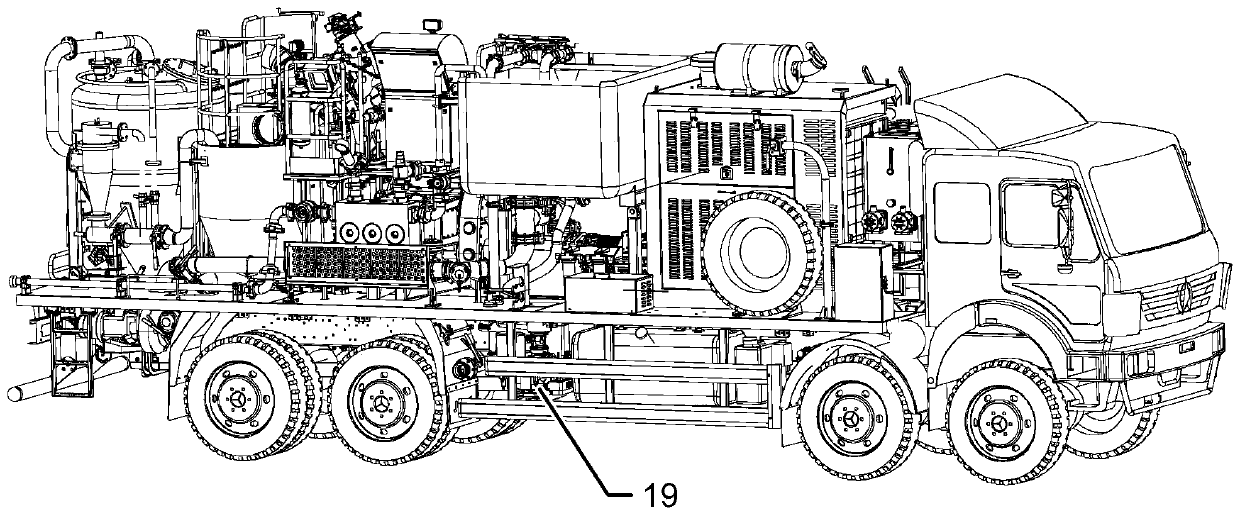

Novel well cementation truck

PendingCN111075391AEasy to operateFlexible and Efficient MobileItem transportation vehiclesSealing/packingDrivetrainWell cementing

The invention discloses a novel well cementation truck, which comprises a loading body, an electrical system, a plunger pump, a clear water manifold, a mud manifold and a high-pressure manifold, wherein the loading body is provided with a cross beam; the cross beam is provided with a hydraulic system, a power transmission system, a metering tank, an operating platform and a mixing system in sequence; the operating platform is provided with a gas path system and an operating system in sequence; the electrical system supplies power to the well cementation truck; the plunger pump, the clear watermanifold, the mud manifold and the high-pressure manifold are all arranged below the operating platform; the clear water manifold supplies water to the plunger pump and the mixing system; the mud manifold provides mud for the plunger pump; the plunger pump injects the mud into a well through the high-pressure manifold; and the well cementation truck also integrates with a steady pressure ash can,an air compressor and an air bottle. The novel well cementation truck has the beneficial effects that a spatial layout is optimized, and the steady pressure ash can, the air compressor and the air bottle are integrated in one well cementation truck. An ash feeding manifold is optimized, so that the steady pressure ash can supplies ashes, and ash supply equipment can be externally connected for supplying ashes. The large-volume air bottle is adopted, and therefore, air can be supplied to other equipment while the requirements of the well cementation truck are met.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

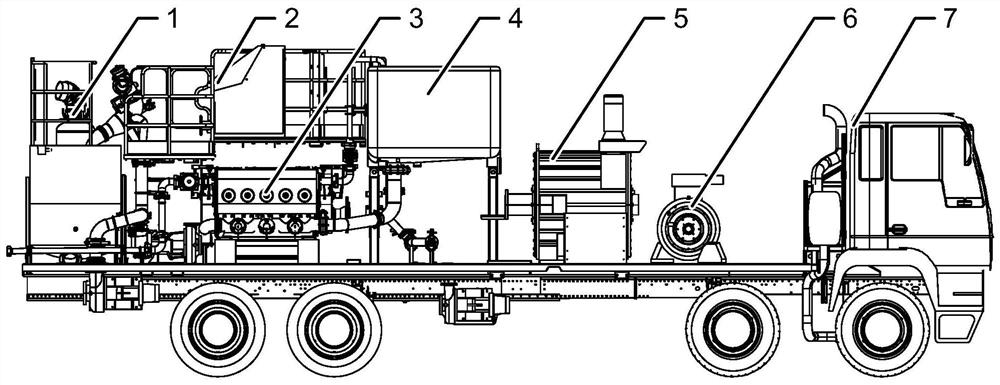

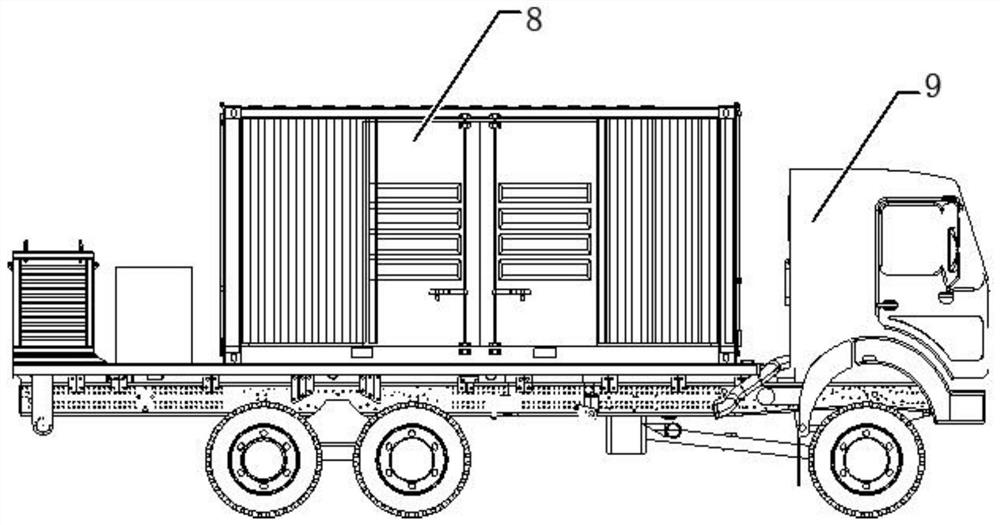

Electrically-driven ultra-large-displacement well cementation equipment

PendingCN111677476AIncrease layout spaceReduce dependenceDischarging apparatusPumpsConvertersFrequency changer

The invention discloses electrically-driven ultra-large-displacement well cementation equipment. The electrically-driven ultra-large-displacement well cementation equipment comprises a first loading body and a second loading body; an auxiliary motor, a main motor, a clear water module, a pumping module, a control module, a hydraulic module and a mixing module are fixedly loaded on the first loading body; and a frequency converter module is fixedly loaded on the second loading body. The electrically-driven ultra-large-displacement well cementation equipment has the beneficial effects that the main motor is adopted to drive a plunger pump, torque converters are reduced, the layout space of the whole vehicle is increased, the auxiliary motor is adopted to drive a whole vehicle hydraulic system, and the number of driving motors is reduced; the frequency converter module and the well cementation equipment are loaded separately, the loading requirement is lowered, the structure is simpler, the occupied space is reduced, one frequency converter module can supply power to all the modules on the multiple first loading bodies at the same time, and use is flexible; and the main motor, the auxiliary motor and the hydraulic heat dissipation device are intensively distributed on the front portion of the first loading body, wiring is simple, connection is convenient, heat dissipation of equipment is intensively achieved, scalding accidents of workers in the operation process are avoided, and operation safety is improved.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

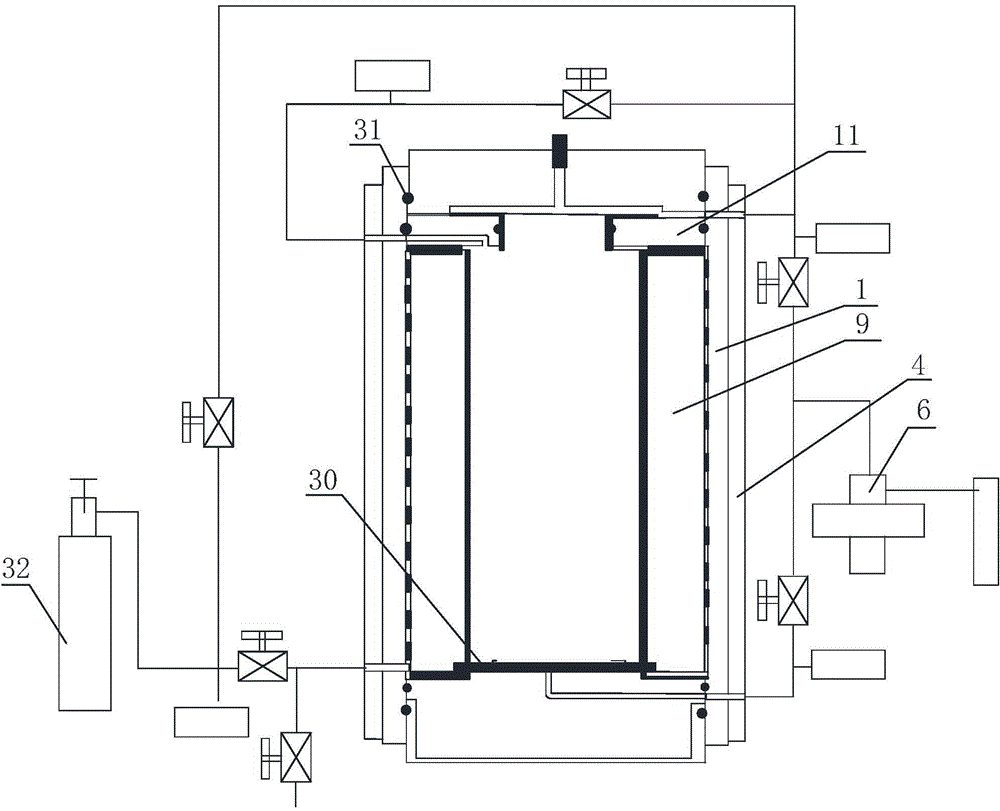

Device and method for preparing nitrogen foam cement

InactiveCN111206901ALow densityReduce energy consumptionSealing/packingHigh pressure waterNitrogen gas

The invention discloses a device and method for preparing nitrogen foam cement. The preparing device comprises a foam cement producer, a liquid nitrogen evaporator, a liquid nitrogen plunger pump, a foam liquid plunger pump, a foam liquid tank, a heat exchange system, a liquid nitrogen pipeline, a high-pressure cement paste pipeline, a first pipeline, a foam cement discharge pipeline and a densitydetecting device. The heat generated by a power unit, a hydraulic system and other devices in a nitrogen foam well fixing device is recovered through the heat exchange system, the recovered heat is used as a heat source of the liquid nitrogen evaporator, energy conservation and environment protection are realized, the energy utilization rate is high, and equipment input is low. Liquid nitrogen and foam liquid are pressurized through a high-pressure liquid nitrogen plunger pump and a high-pressure foam liquid plunger pump, the mixing uniformity is increased, and the density of foam cement is reduced. The density of the foam cement is detected in real time through the density detecting device, the flow of the liquid nitrogen and / or foam liquid is adjusted according to the density, and the density is simply controlled. By arranging a clear water tank, after operation ends, the equipment and pipelines are flushed, and the service life is polonged.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

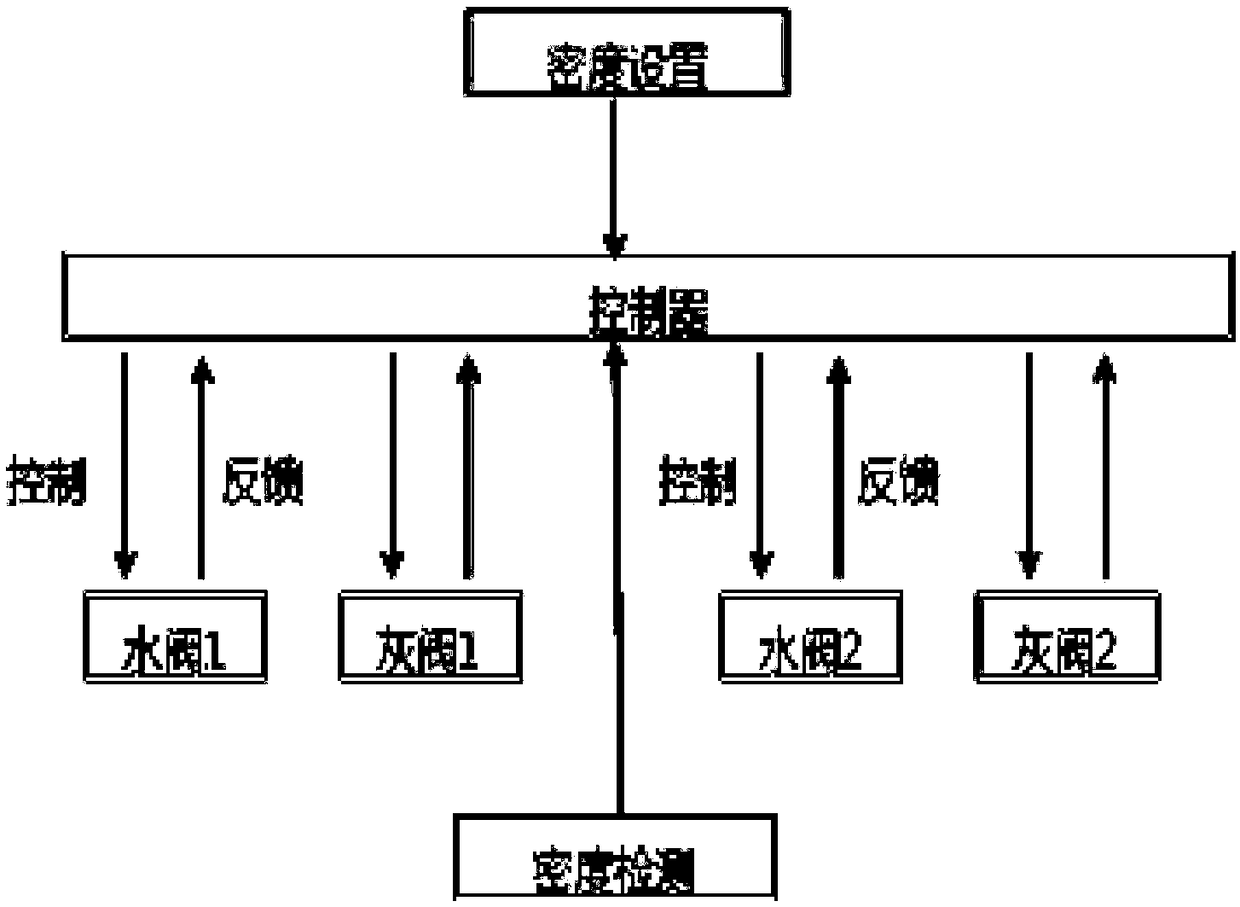

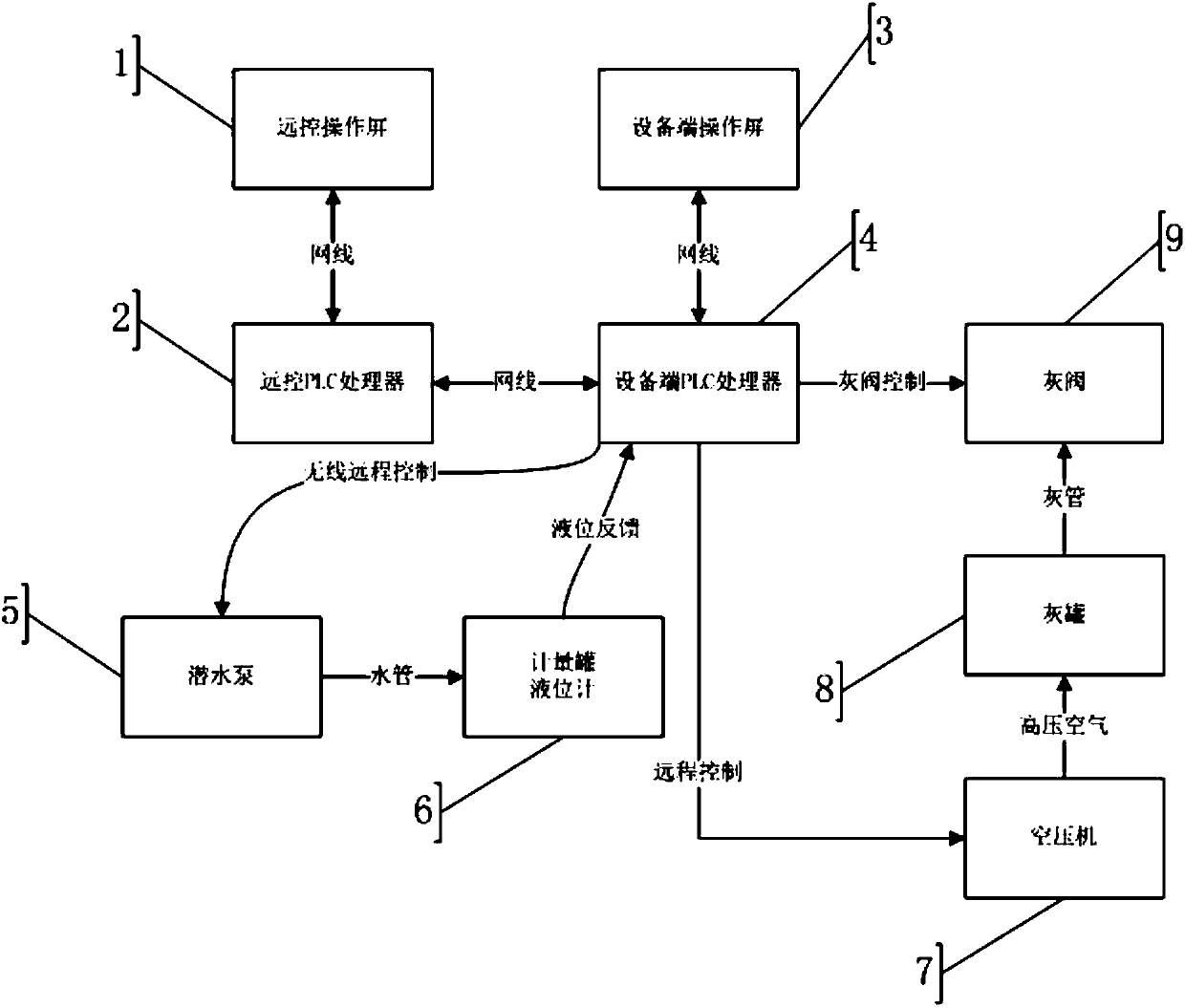

Remote automatic cement supplying control system

PendingCN107656499ARealize remote automatic centralized controlRealize the centralized control of the whole processProgramme control in sequence/logic controllersProportional controlRemote control

The invention belongs to the field of petroleum equipment, and particularly relates to full-automatic intelligent remote controlled well solidifying equipment, and to a remote automatic cement supplying control system for well solidifying equipment. The remote automatic cement supplying control system comprises a control unit, an air compressor, a cement tank and a cement valve. The remote automatic cement supplying control system is characterized in that the control unit comprises an equipment end operating screen, an equipment end PLC processor, a remote control operating screen and a remotecontrol PLC processor; the equipment end operating screen, the equipment end PLC processor, the remote control operating screen and the remote control PLC processor are connected through netting twines; the equipment end PLC processor can remotely control a remote control module for starting and stopping the air compressor, thereby controlling the air compressor through the remote control module;after the air compressor is started, high-pressure air is discharged to the cement tank; the equipment end PLC processor automatically calculates a required cement supplying amount through a preset density of the well solidifying equipment; through comparing the calculated cement supplying amount with a current acquired cement supplying amount, proportion controlling and adjustment of the cementvalve are performed; and furthermore the cement supplying amount of the equipment is controlled.

Owner:CNPC DRILLING RES INST +2

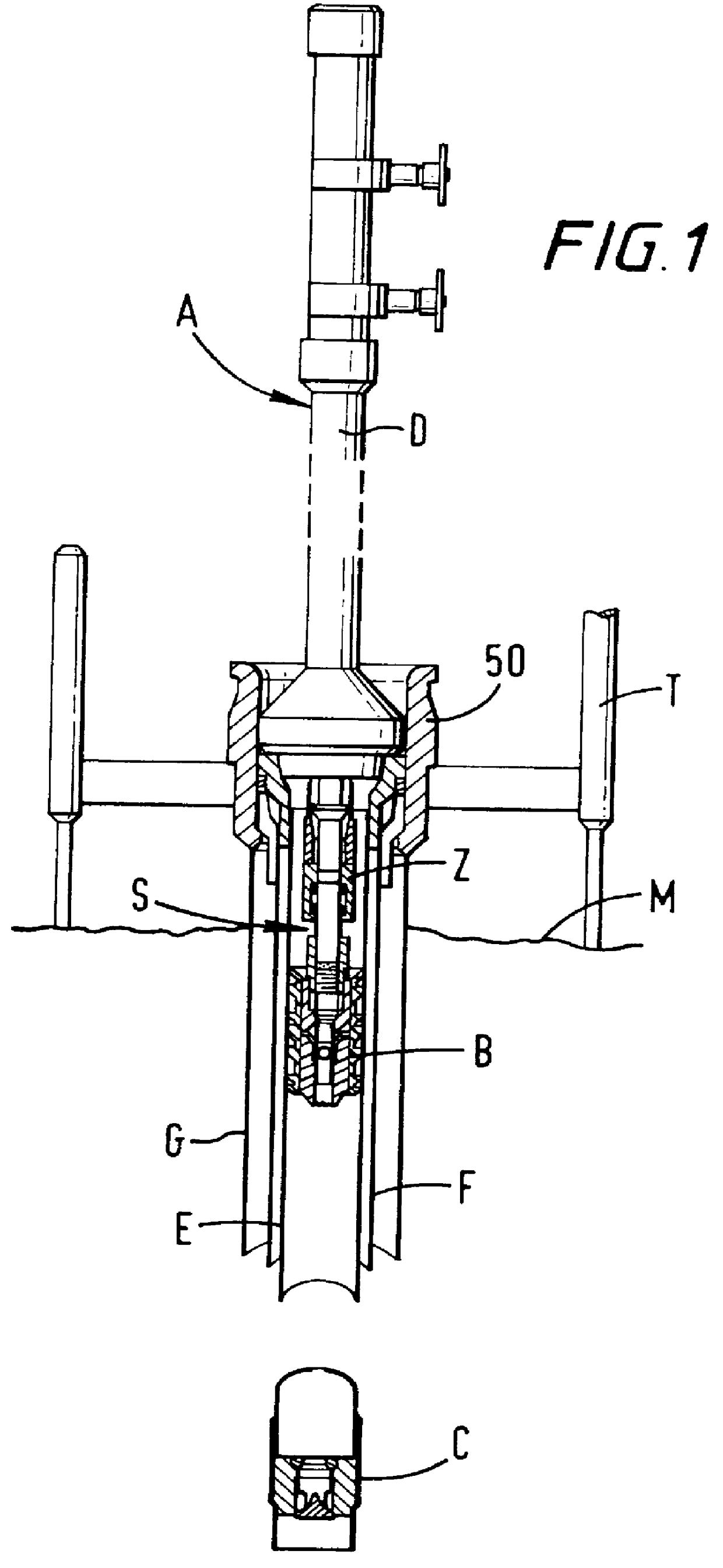

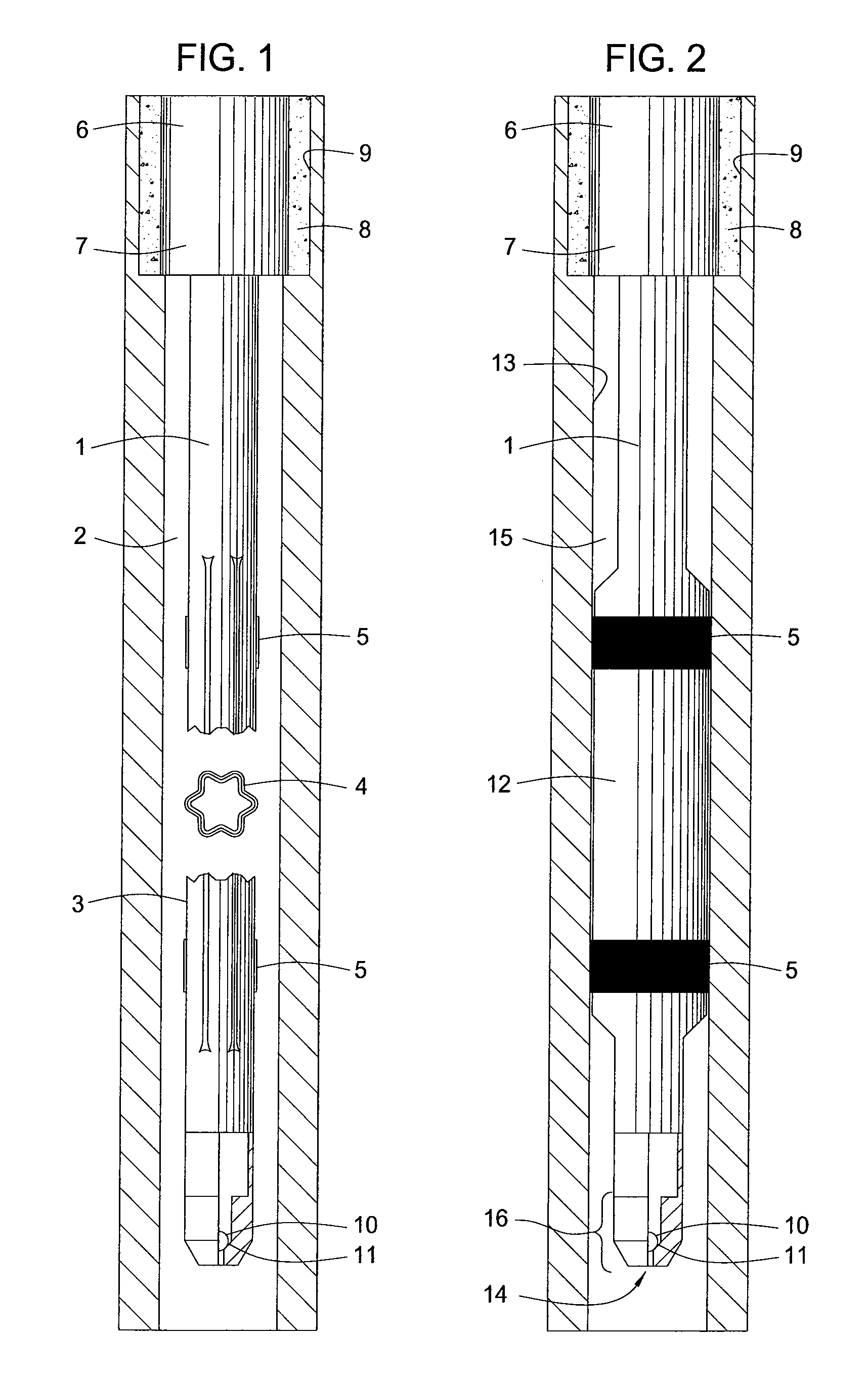

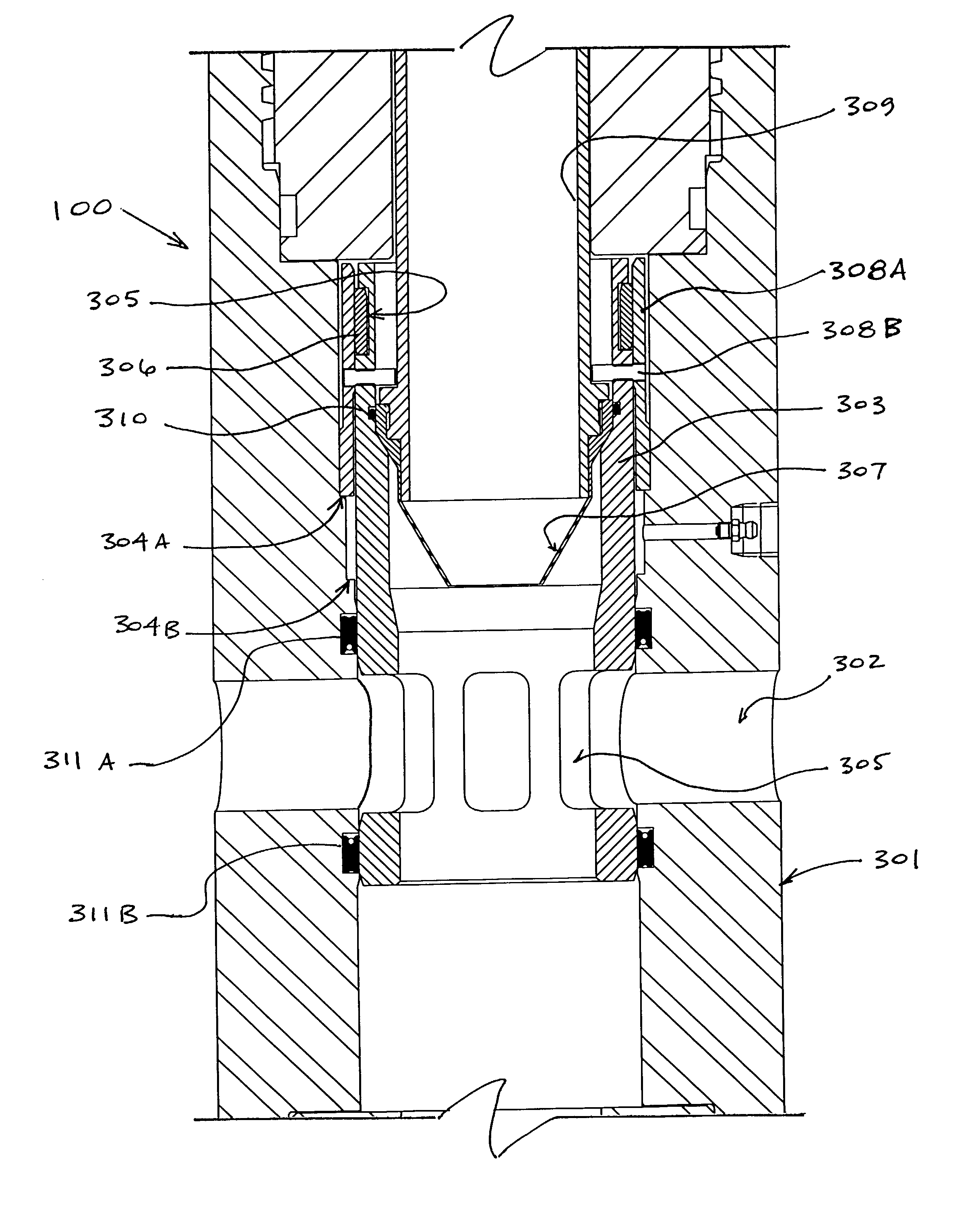

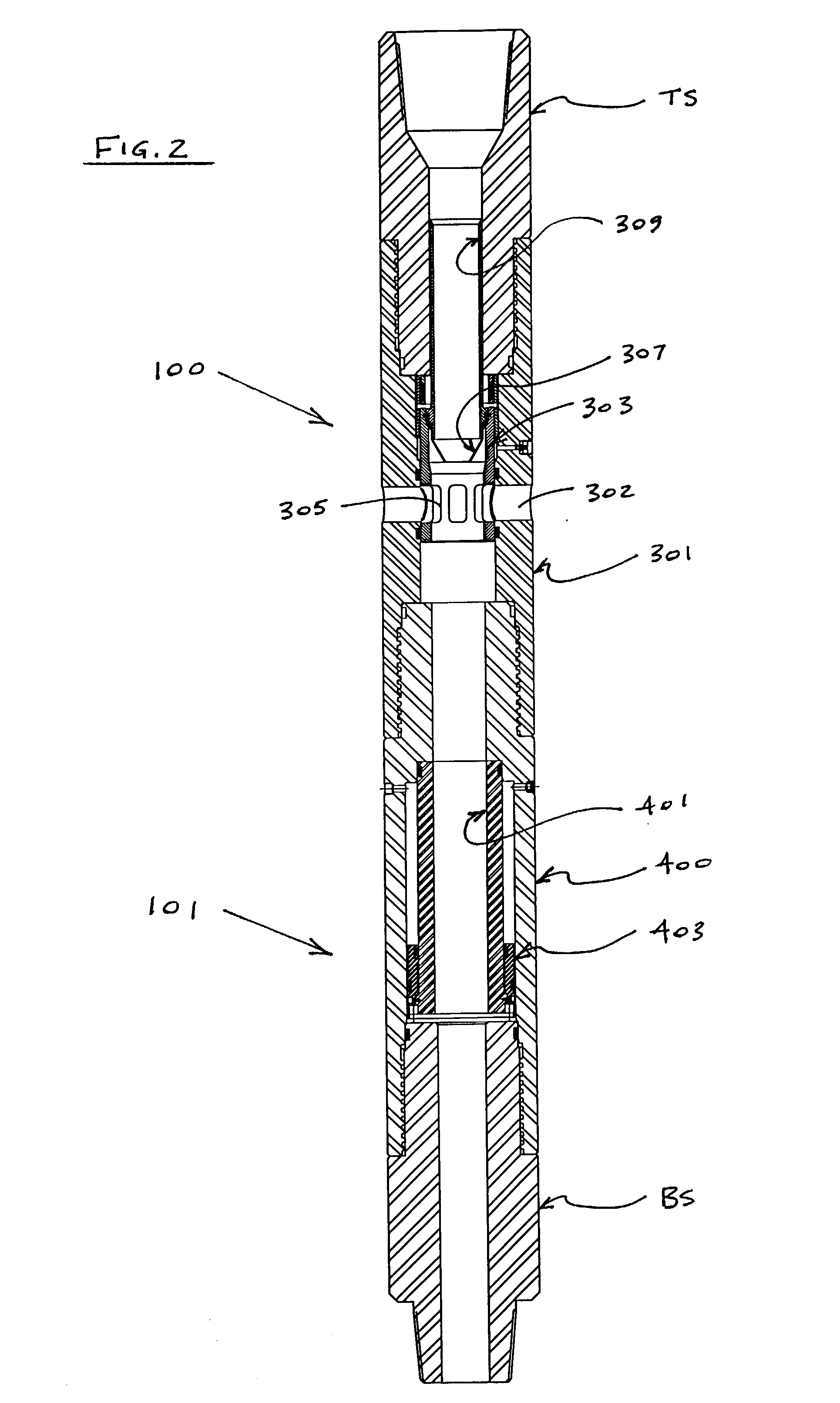

Cementing systems for wellbores

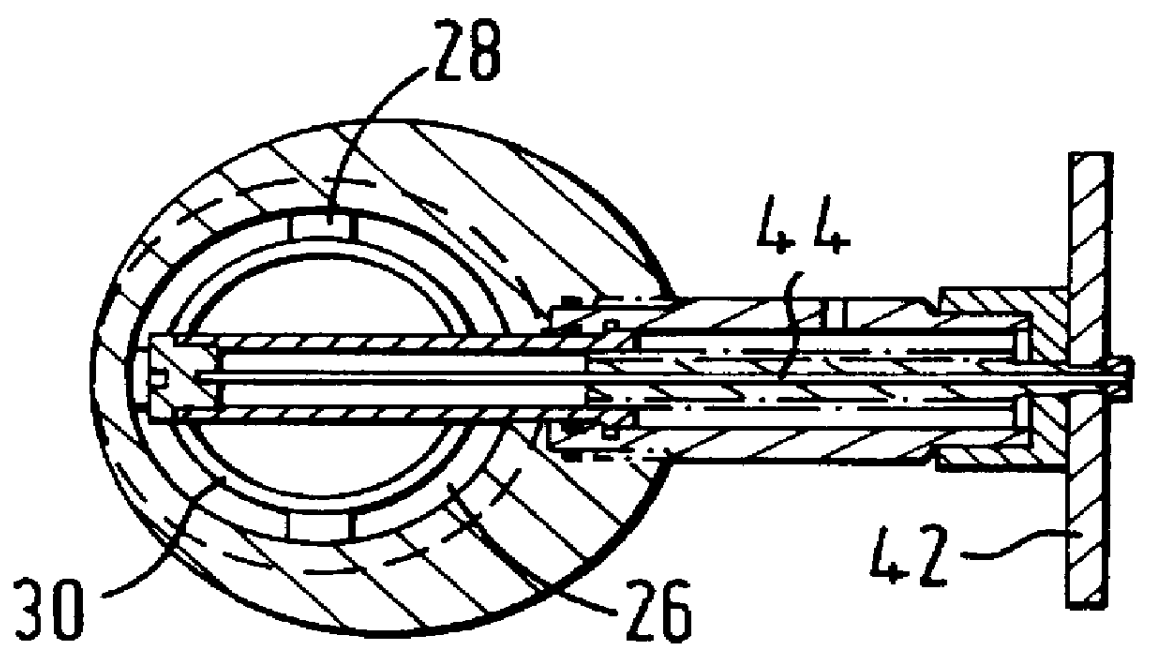

InactiveUS6056053AReduced inner body thicknessEasy to bendCleaning apparatusFluid removalWell cementingMetallic materials

A new wellbore cementing system has been developed which includes, in certain embodiments, a plug container with a flow diverter for diverting a portion of flowing fluid away from plugs in the plug container; a plug set system with internal sleeves or dart receivers with shearable parts for shearing to selectively release plugs-all in certain embodiments made of non-metal material and / or plastic; a swivel equalizer with internal valving to isolate a plug set (or any other item) from torque and to relieve pressure below the swivel equalizer; and unique burst tube systems for selectively controlling fluid flow and plug system operation. In one aspect a plug nose is tapered to correspond to a taper of a landing ring so that wedge-locking of the nose and ring effects desired non-rotation of the plug during drilling. In one aspect plug fin bending is facilitated by reducing plug body thickness so that an alternate fluid flow path is provided for cementing. In one aspect a new float valve system is provided with a top baffle that prevents debris etc. from shutting off fluid flow to a float valve.

Owner:WEATHERFORD TECH HLDG LLC

Pumice containing compositions for cementing a well

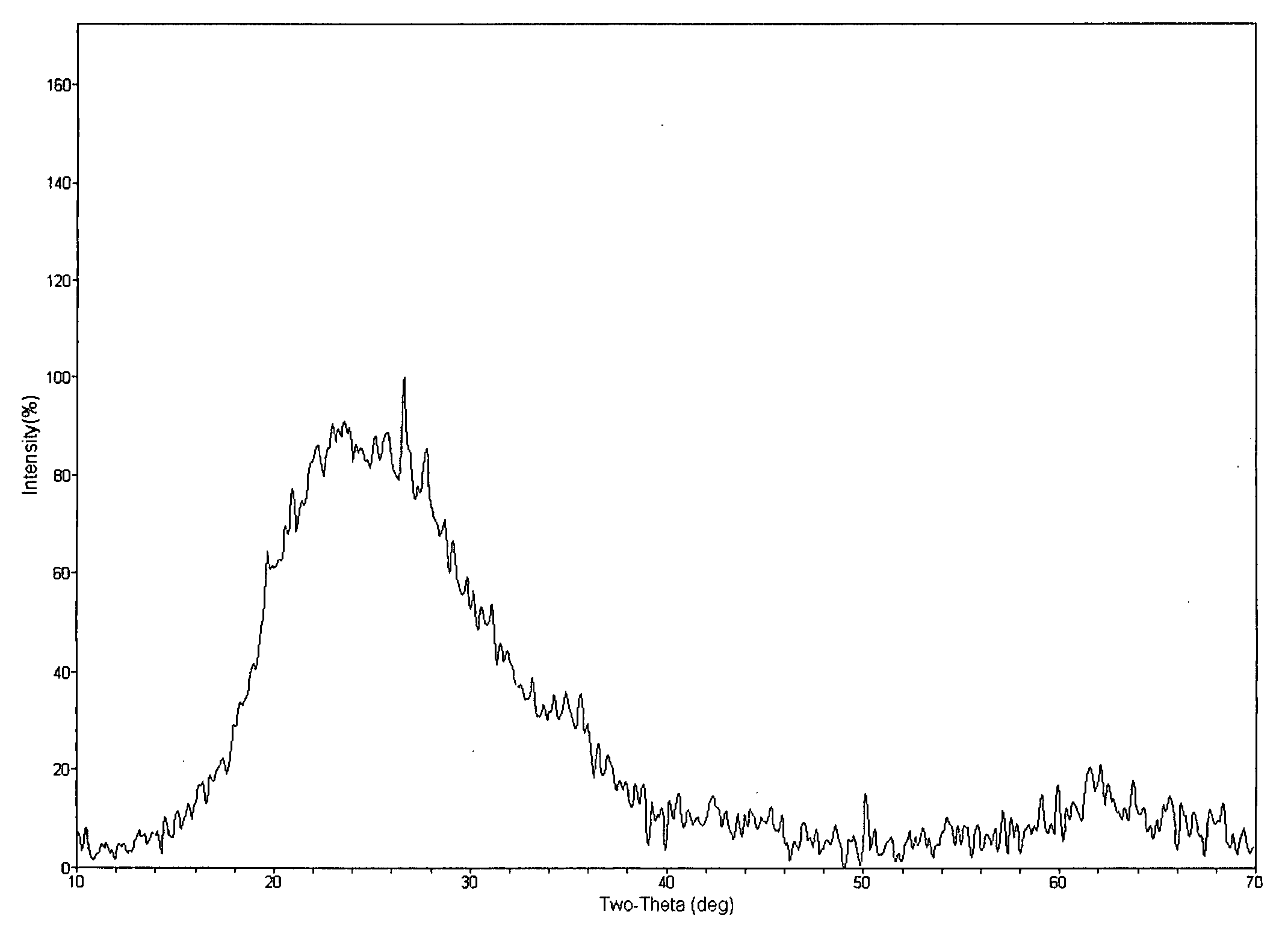

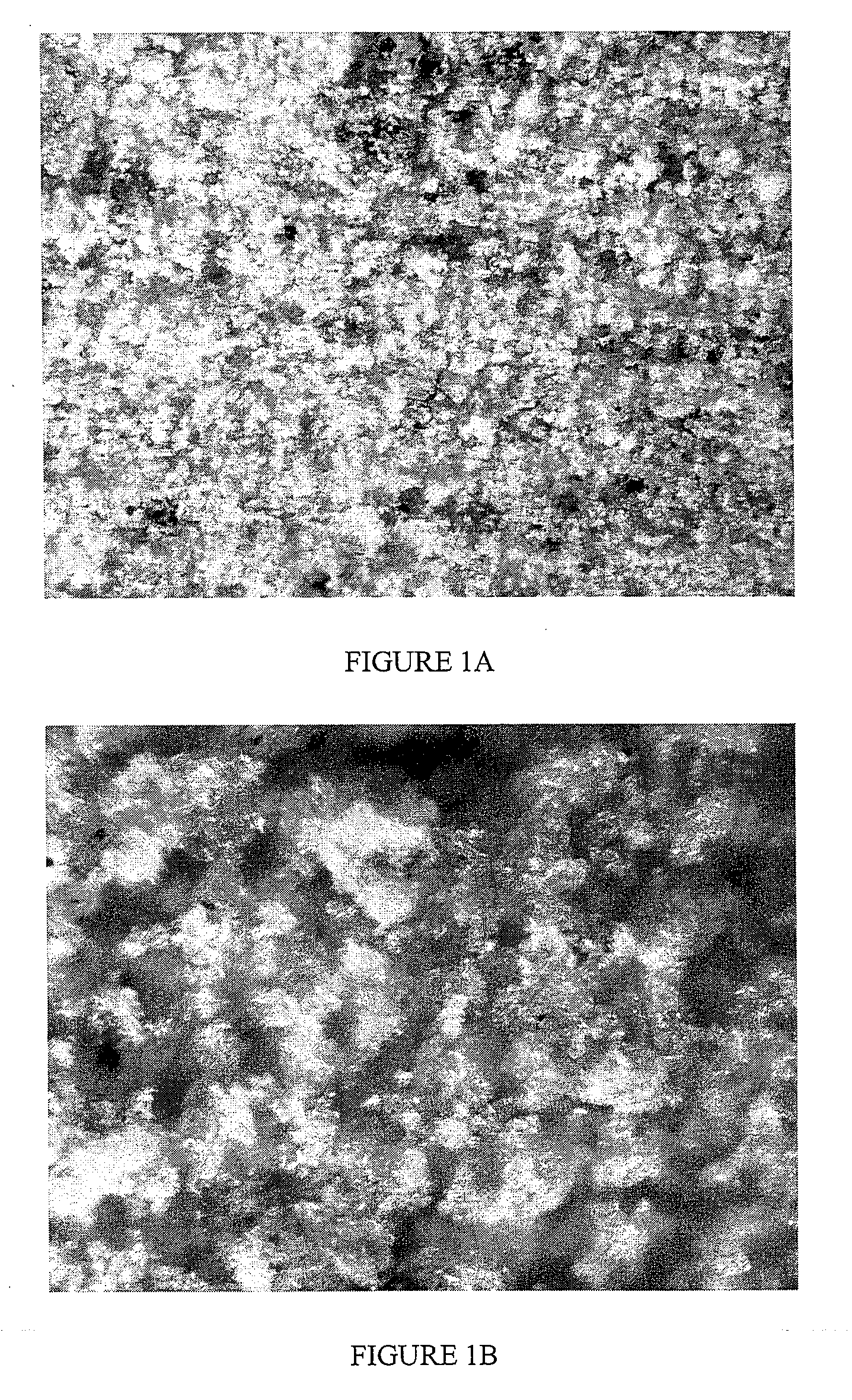

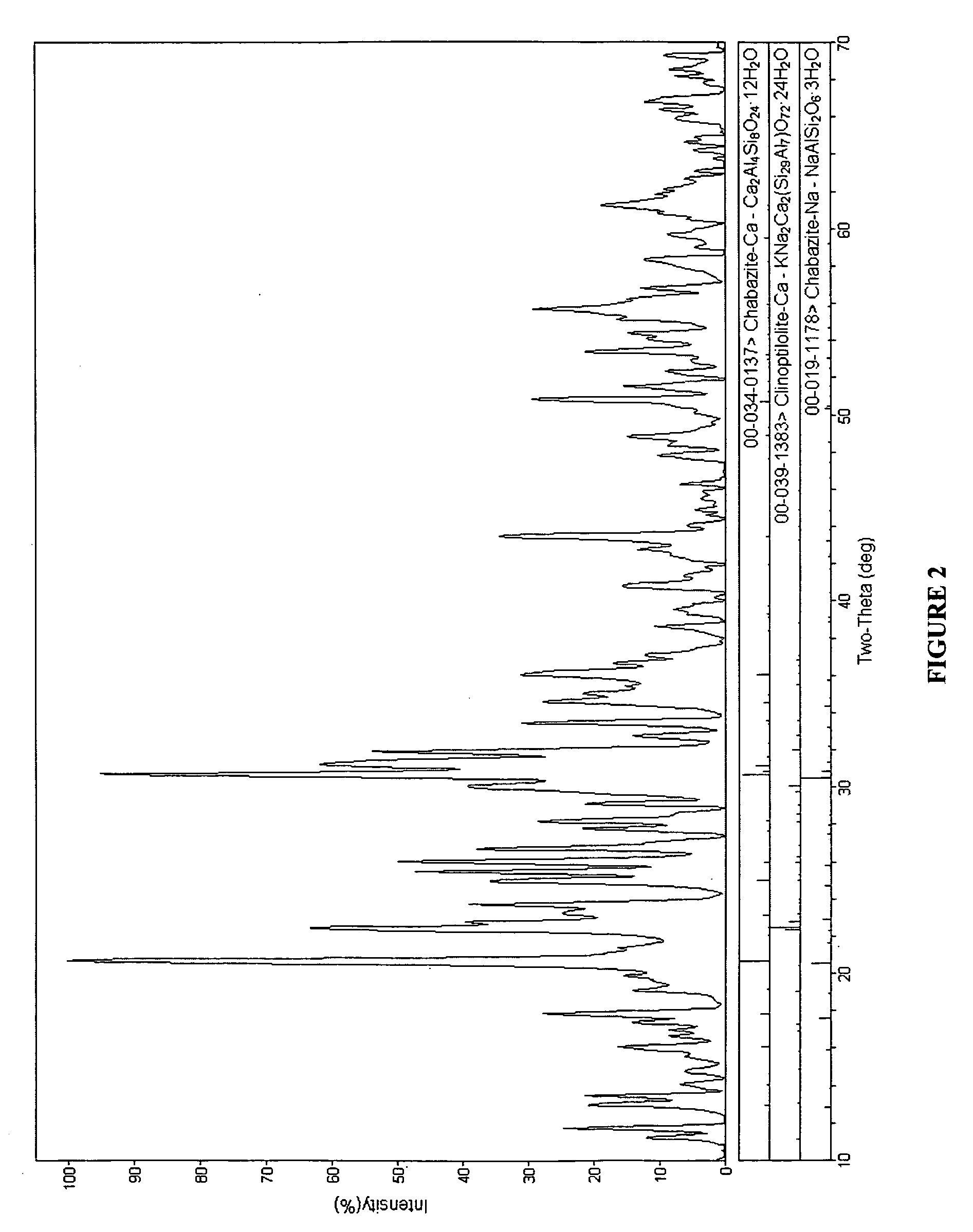

ActiveUS20090105099A1Reduce carbon dioxide emissionsReduce CO<subSolid waste managementFlushingWell cementingOil well

A cement composition comprises fine pumice particles, for use in cementing subterranean wells, and oil and gas wells in particular. The pumice containing cement blends feature enhanced compressive strength, and favourable compressive strength to Young's Modulus ratios. Lightweight cement blends containing pumice, and their use in cementing oil and gas wells are also described.

Owner:SANJEL ENERGY SERVICES INC

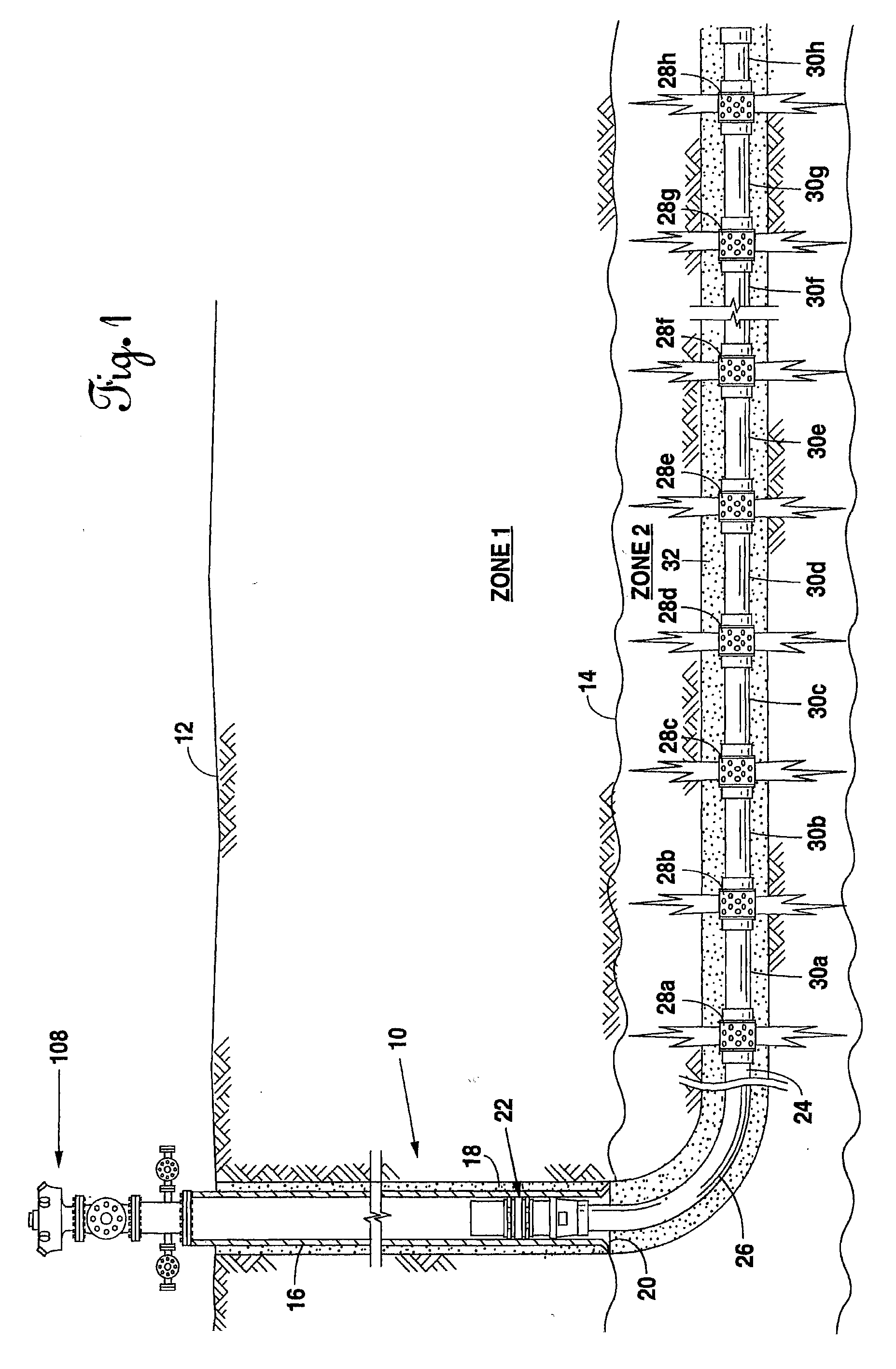

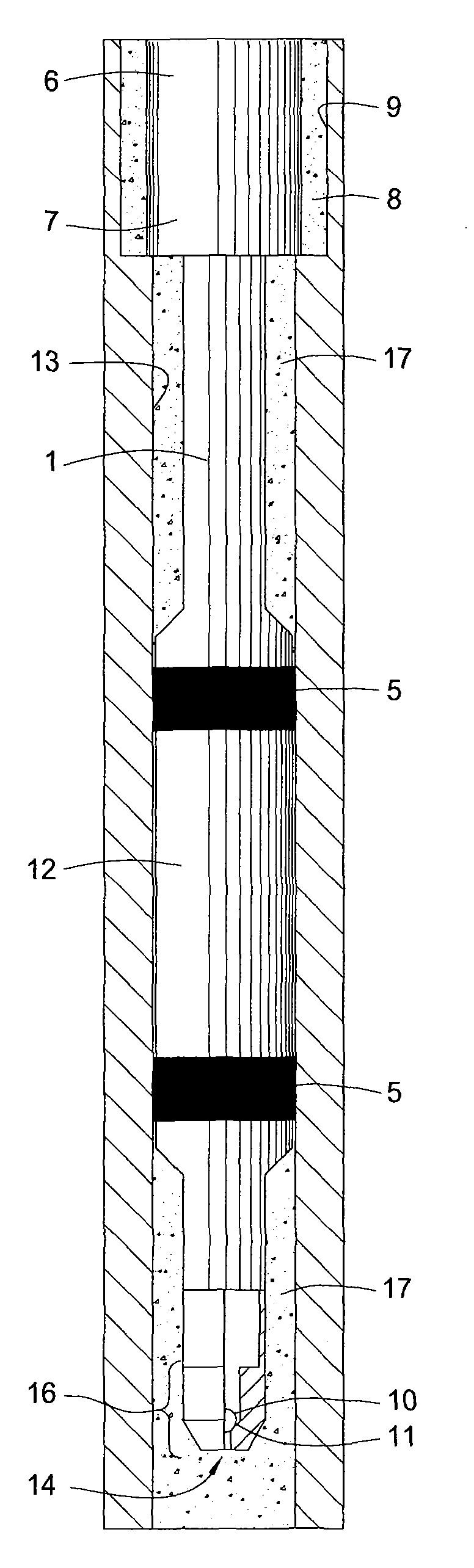

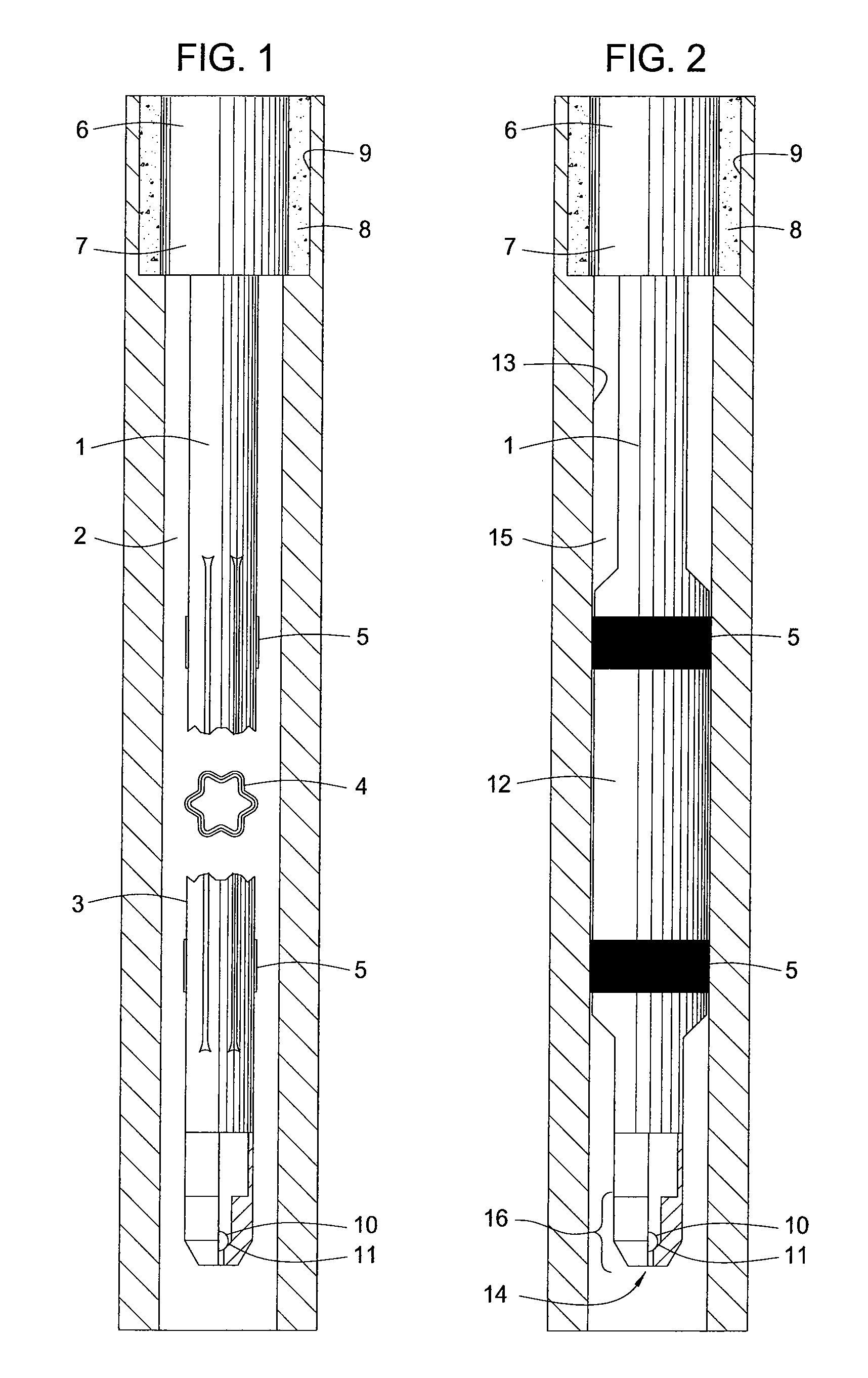

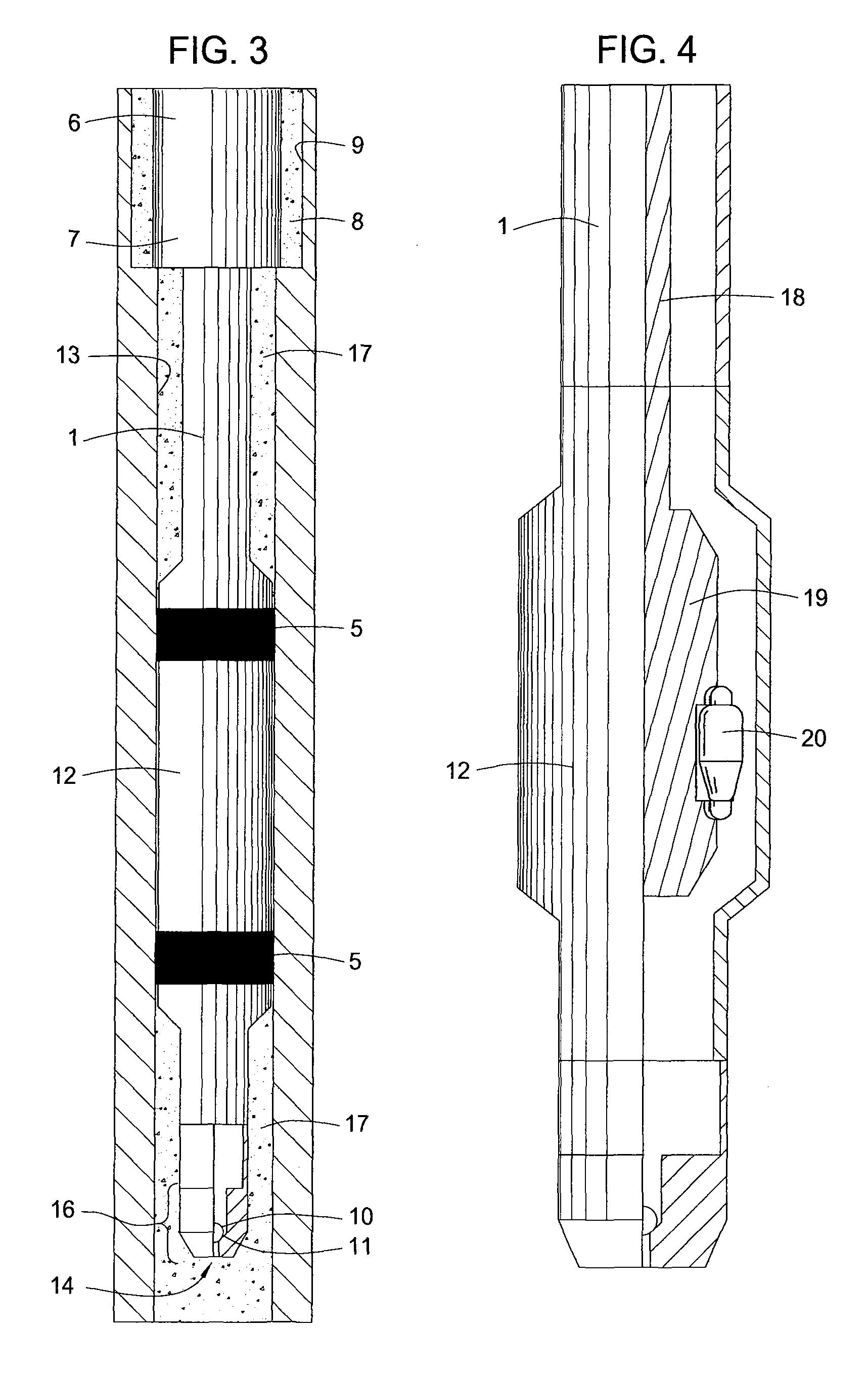

Cemented Open Hole Selective Fracing System

A cemented open hole selective fracing system and method are shown. In the producing zone, an open hole is drilled therein and a production tubing is cemented in place. At preselected locations along the production tubing, the production tubing will have sliding valves located there along. The sliding valves may be selectively opened, and the cement around the sliding valve dissolved. Thereafter, the formation may be fraced immediately adjacent the opened sliding valve. By selectively opening different combinations of sliding valves, fracing can occur in stages with more fracing pressure and more fracing fluid being delivered deeper into the formation. Just as the sliding valves can be selectively opened, the sliding valves can also be selectively closed to protect the production of the well.

Owner:PEAK COMPLETION TECH

Casing strings and methods of using such strings in subterranean cementing operations

Improved casing strings, and methods of using improved casing strings in subterranean cementing operations, are provided. An example of an apparatus is a pipe string comprising at least one pipe section and a delivery system of an activator. Another example of an apparatus is a pipe string comprising at least one pipe section and a delivery system of a set retarder. An example of a method is a method of cementing in a subterranean formation. Other examples of methods are methods of cementing in a subterranean formation comprising a well bore.

Owner:HALLIBURTON ENERGY SERVICES INC

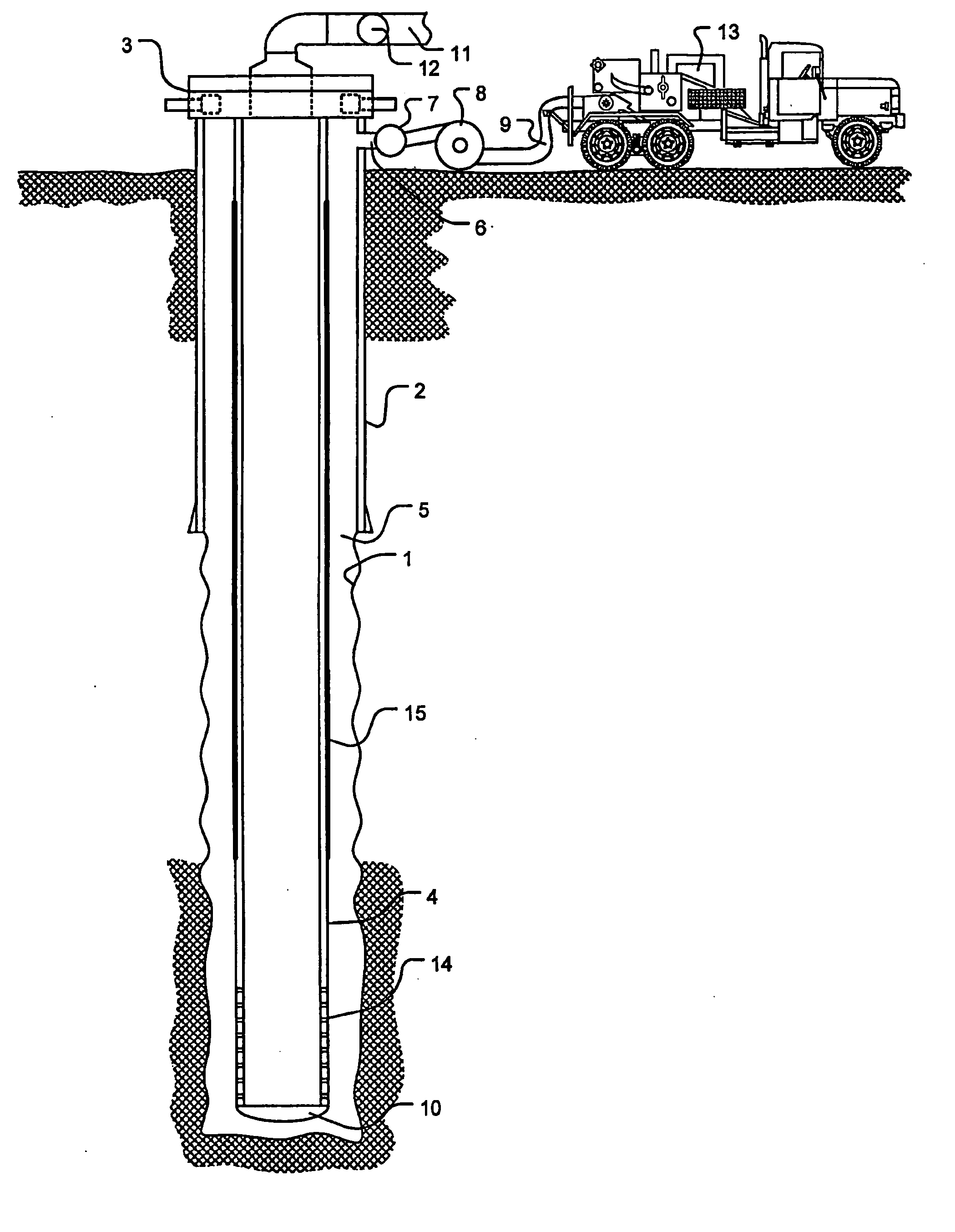

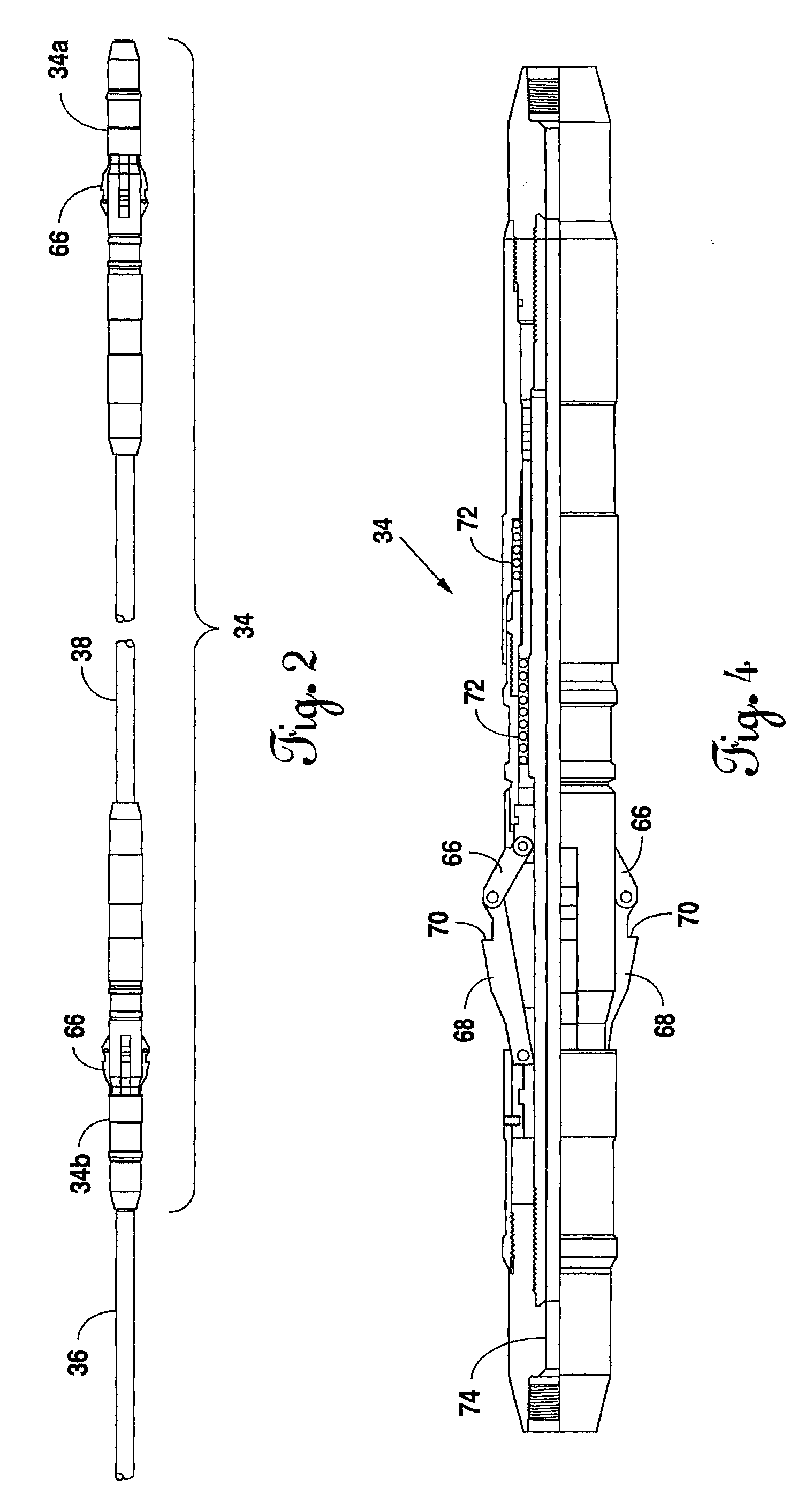

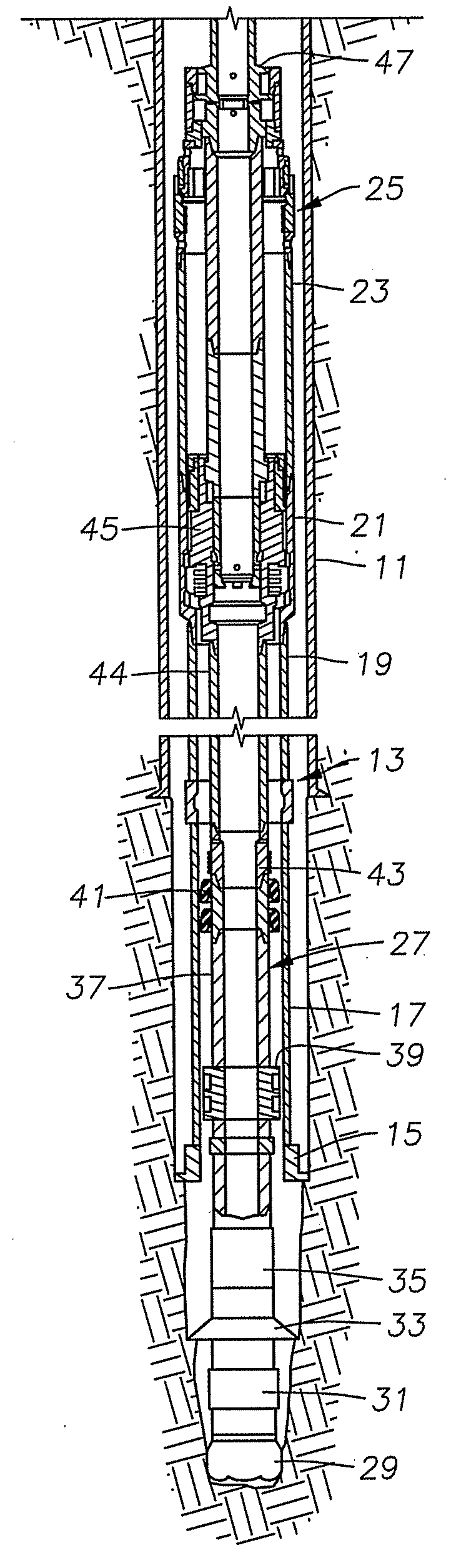

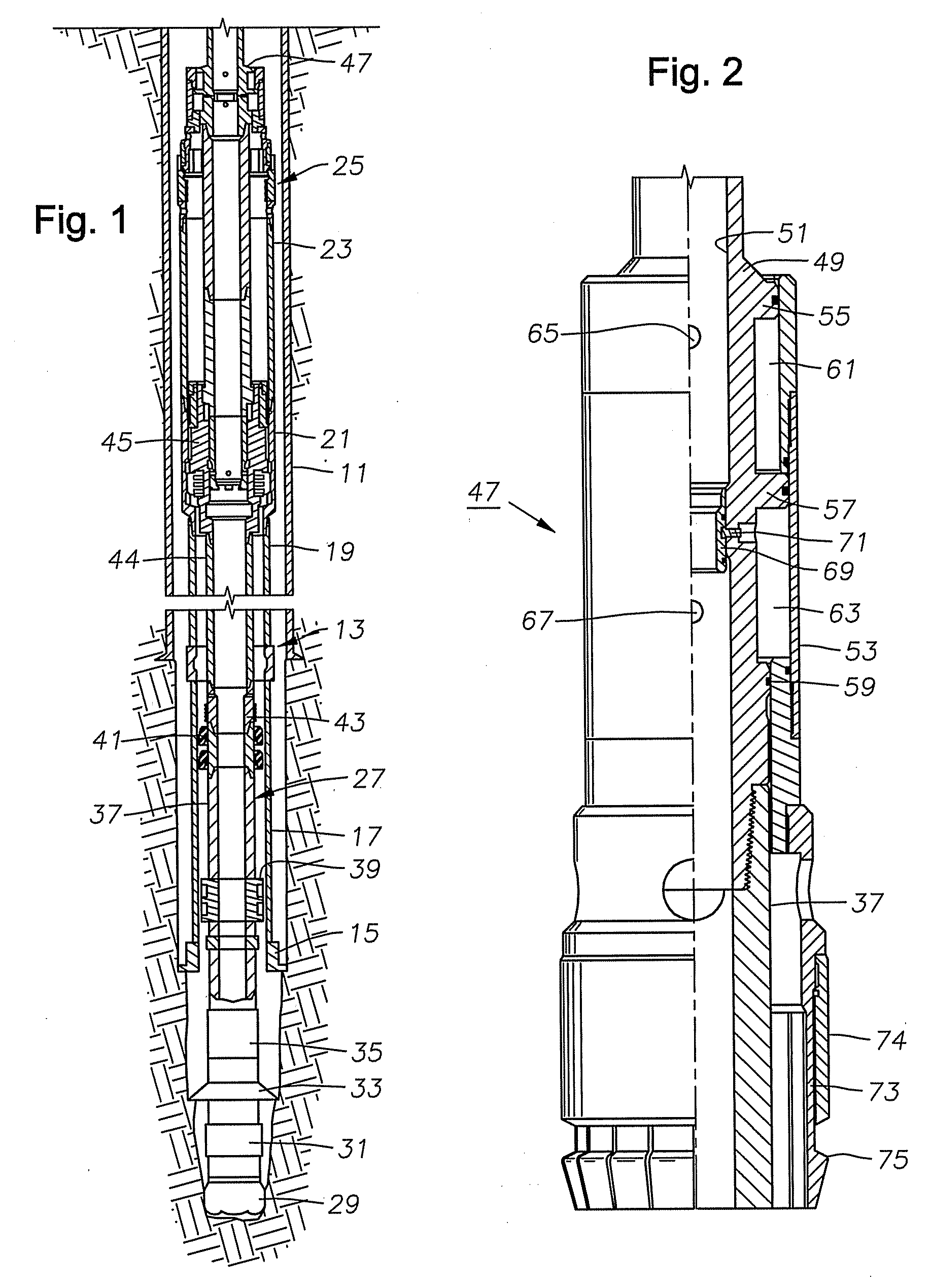

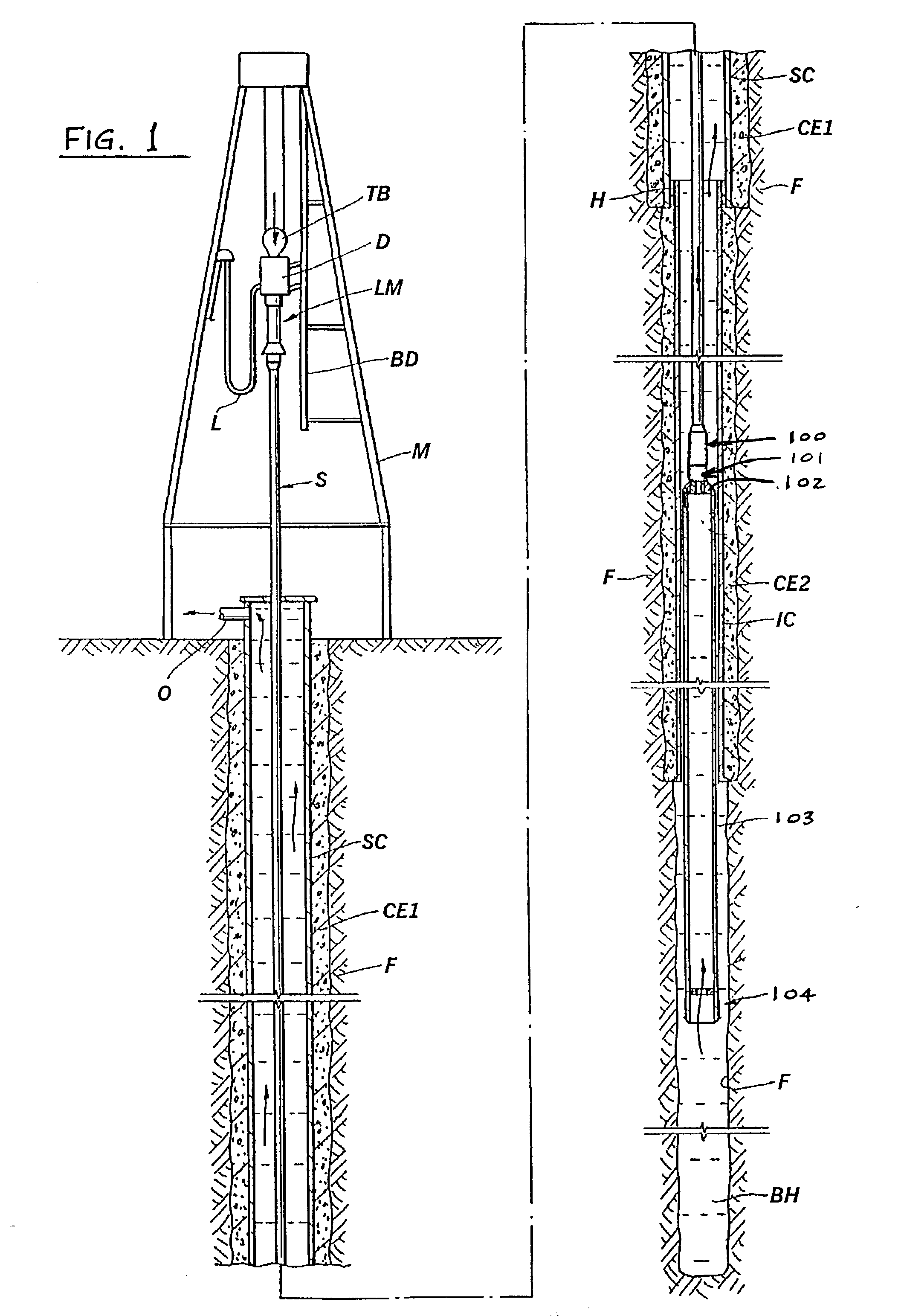

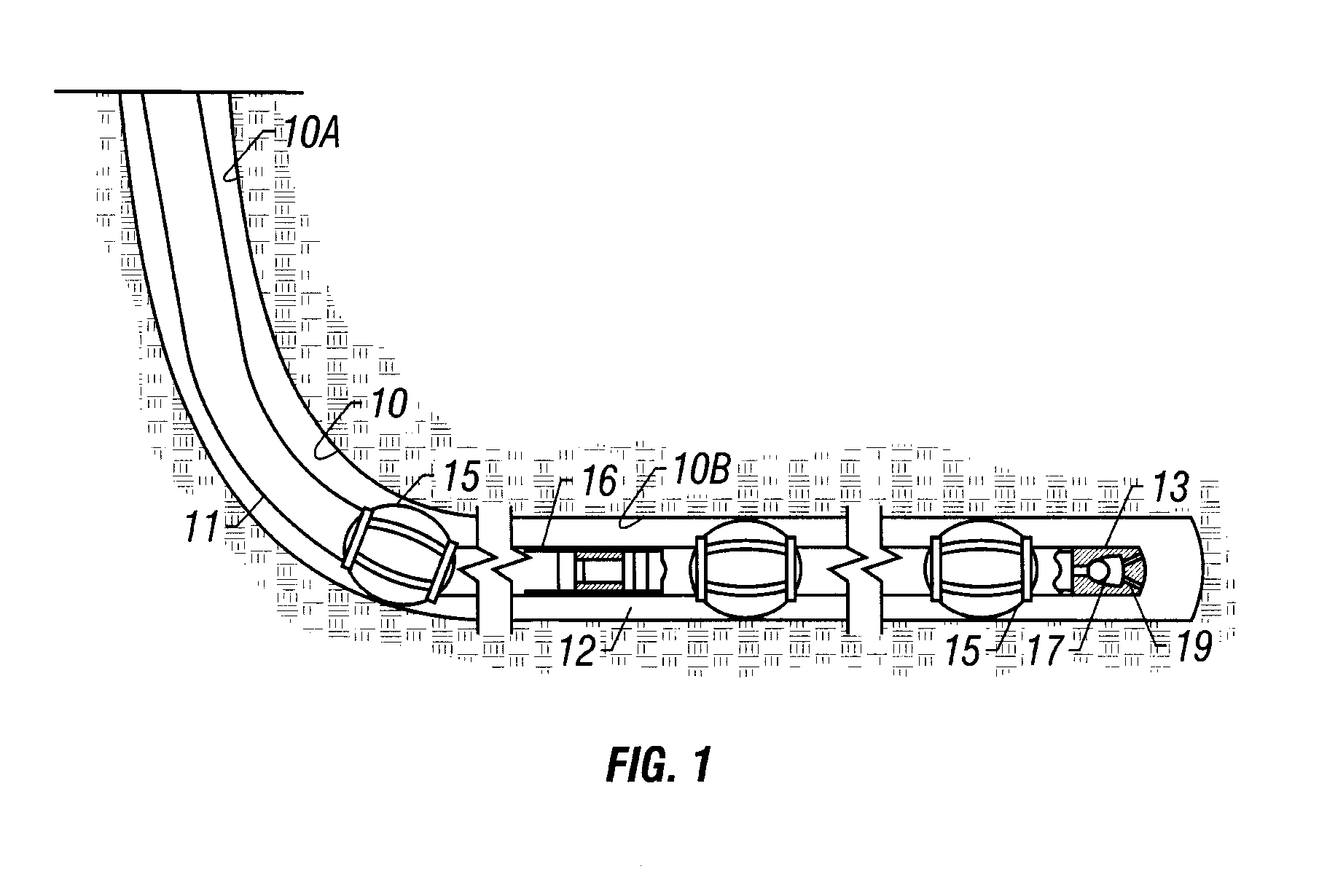

Liner Drilling and Cementing System Utilizing a Concentric Inner String

A method of drilling a well and installing a liner includes assembling concentric inner and outer strings of tubulars. A drill bit is located at the lower end of the inner string and a liner with a liner hanger makes up part of the outer string. The inner and outer strings may be rotated in unison to drill the well. At a selected depth, the operator sets the liner hanger and retrieves the inner string. The operator lowers a packer and a cement retainer on a string of conduit. The packer engages the liner hanger and the cement retainer is conveyed to the lower end of the liner. The cement retainer prevents cement in the outer annulus from flowing back up the string of conduit. The operator manipulates the conduit to set the packer.

Owner:SCHLUMBERGER TECH CORP

Apparatus and methods for creation of down hole annular barrier

InactiveUS20070029082A1Facilitate flow velocityReducing tendency of gasSurveyConstructionsWell cementingEngineering

Methods and apparatus are provided for performing an expedited shoe test using an expandable casing portion as an annular fluid barrier. Further provided are methods and apparatus for successfully recovering from a failed expansion so that a shoe test can be completed without replacement of the expandable casing portion. In one recovery method, a selectively actuatable fluid circulation tool is provided to further expand the expandable portion or perform a cementing operation. Additionally, methods and apparatus are provided to drill a wellbore and form an annular fluid barrier in a single trip.

Owner:WEATHERFORD TECH HLDG LLC

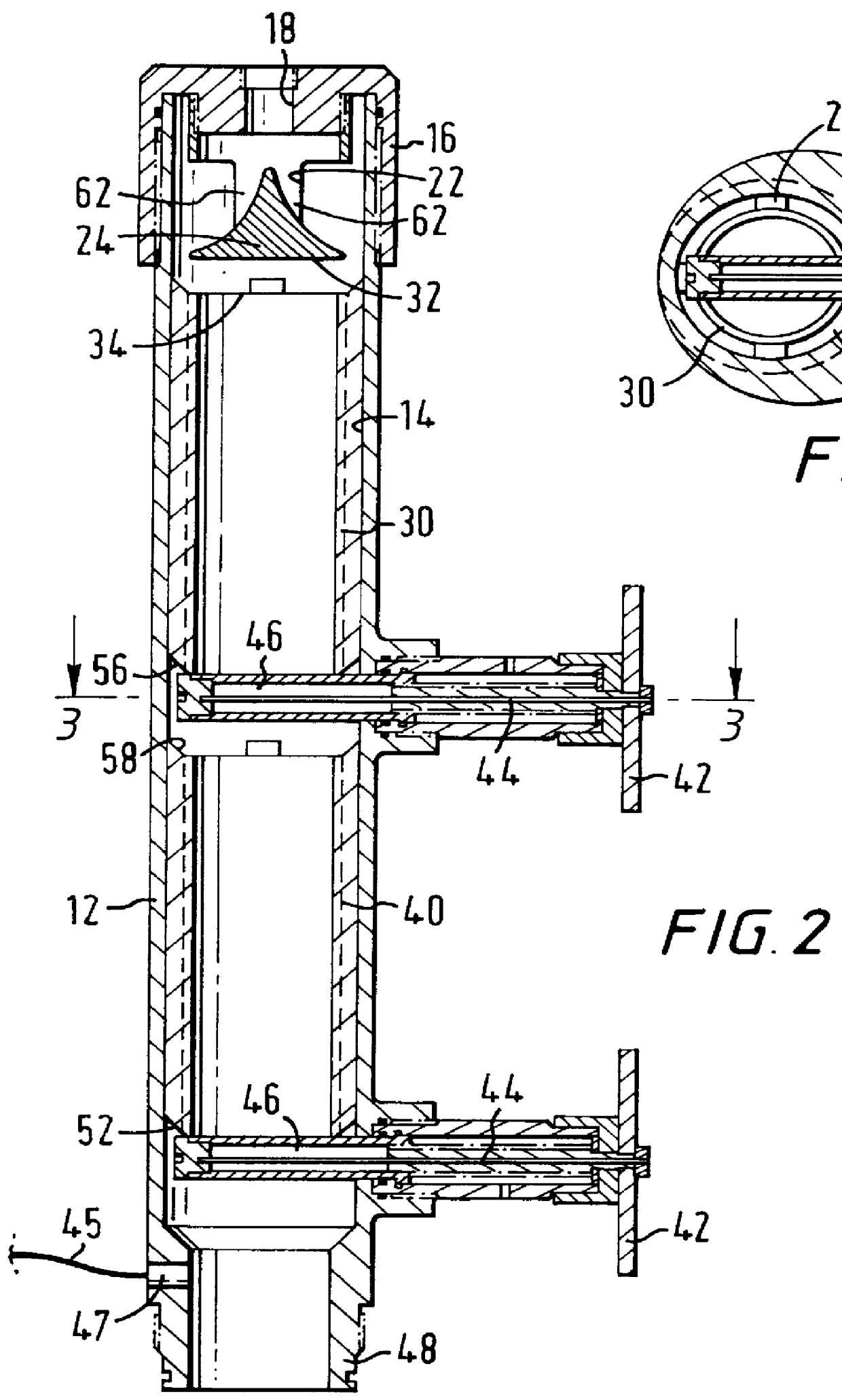

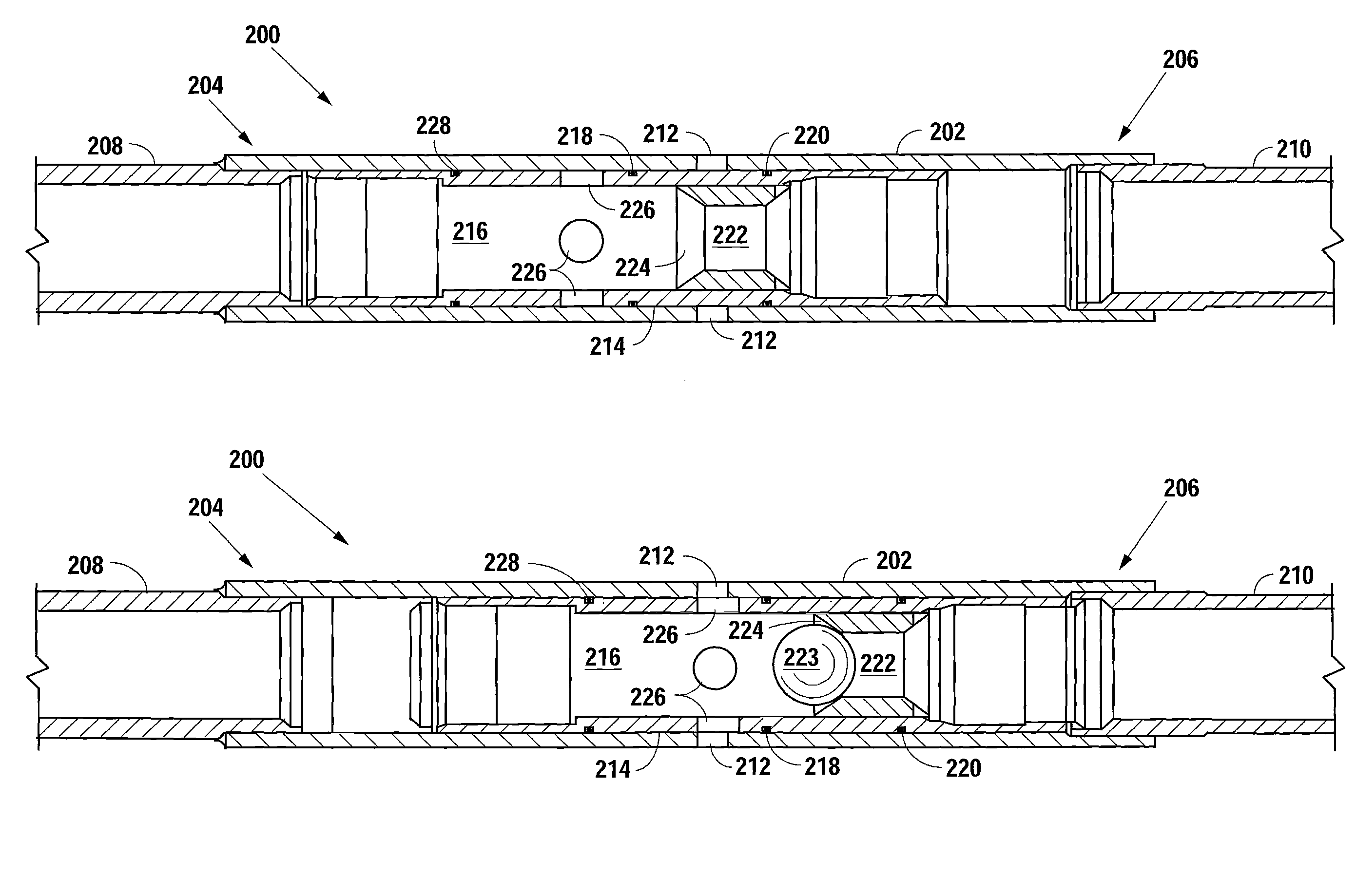

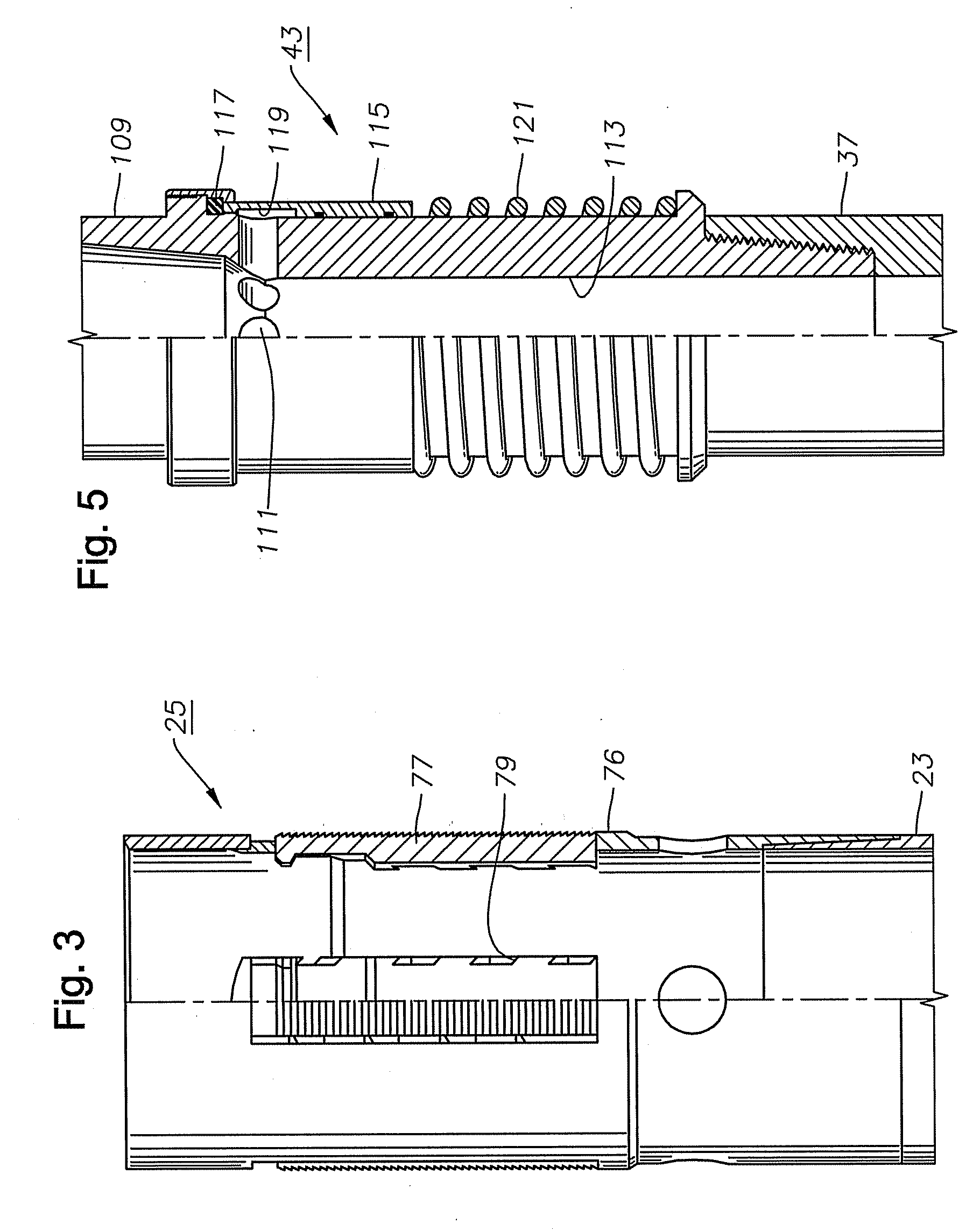

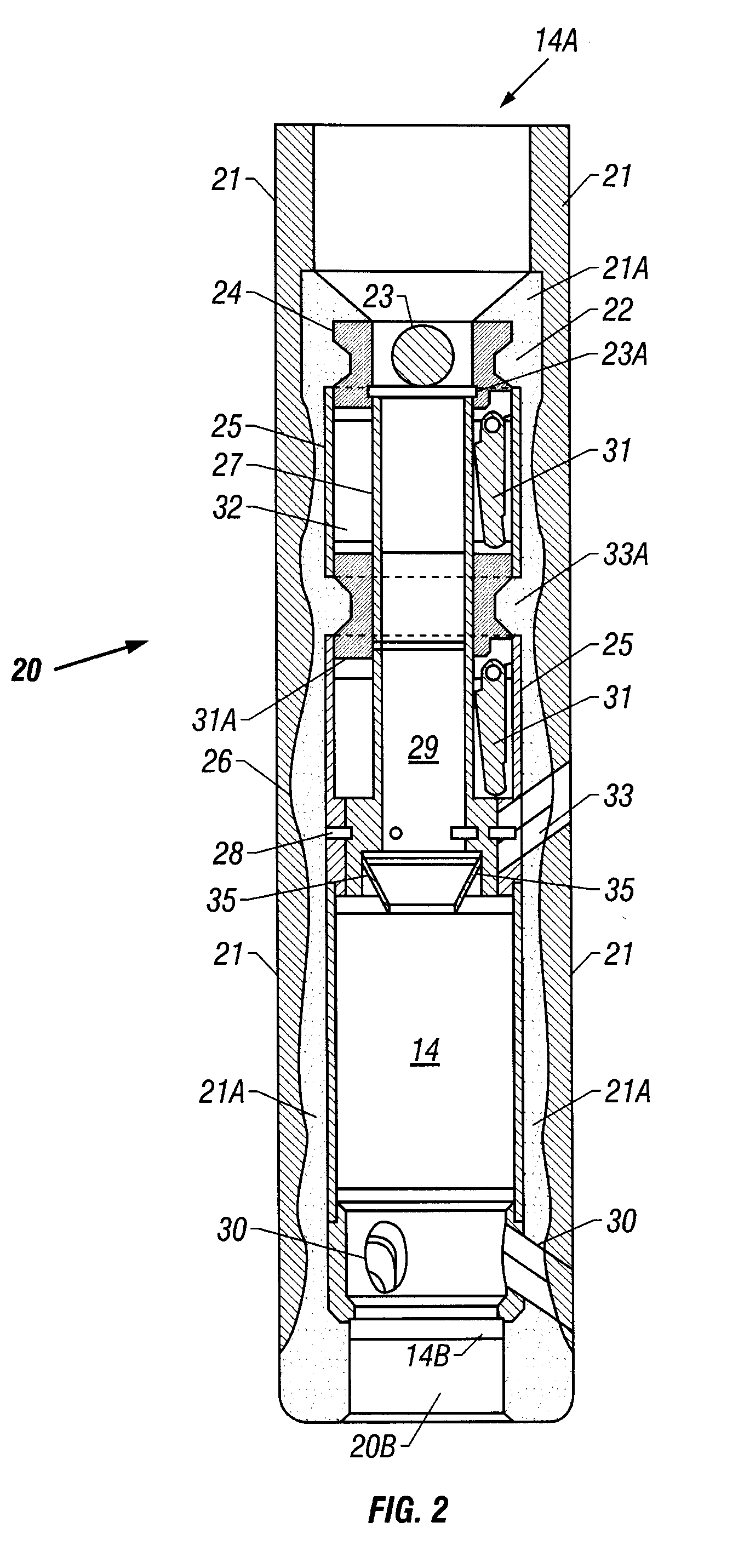

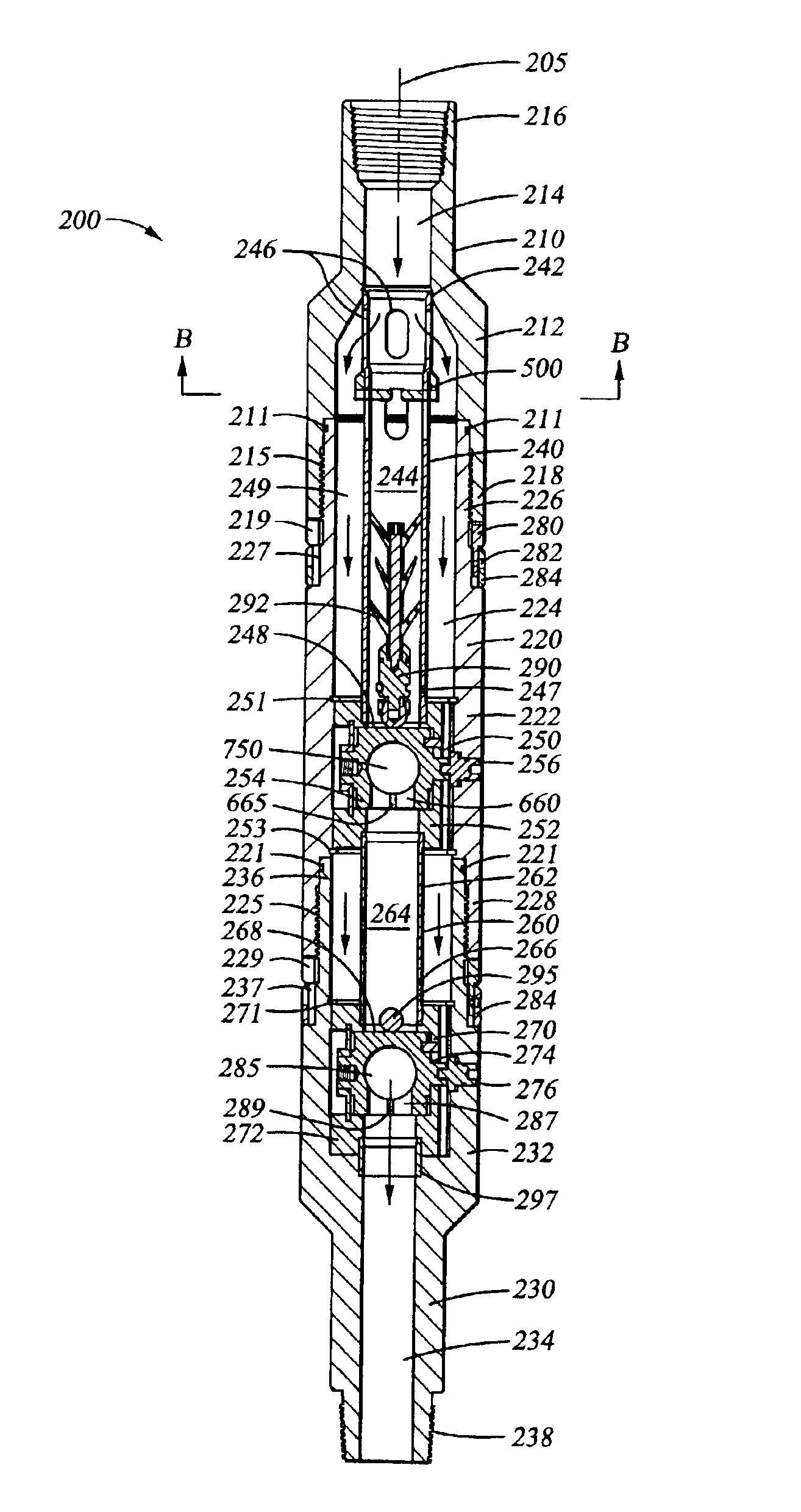

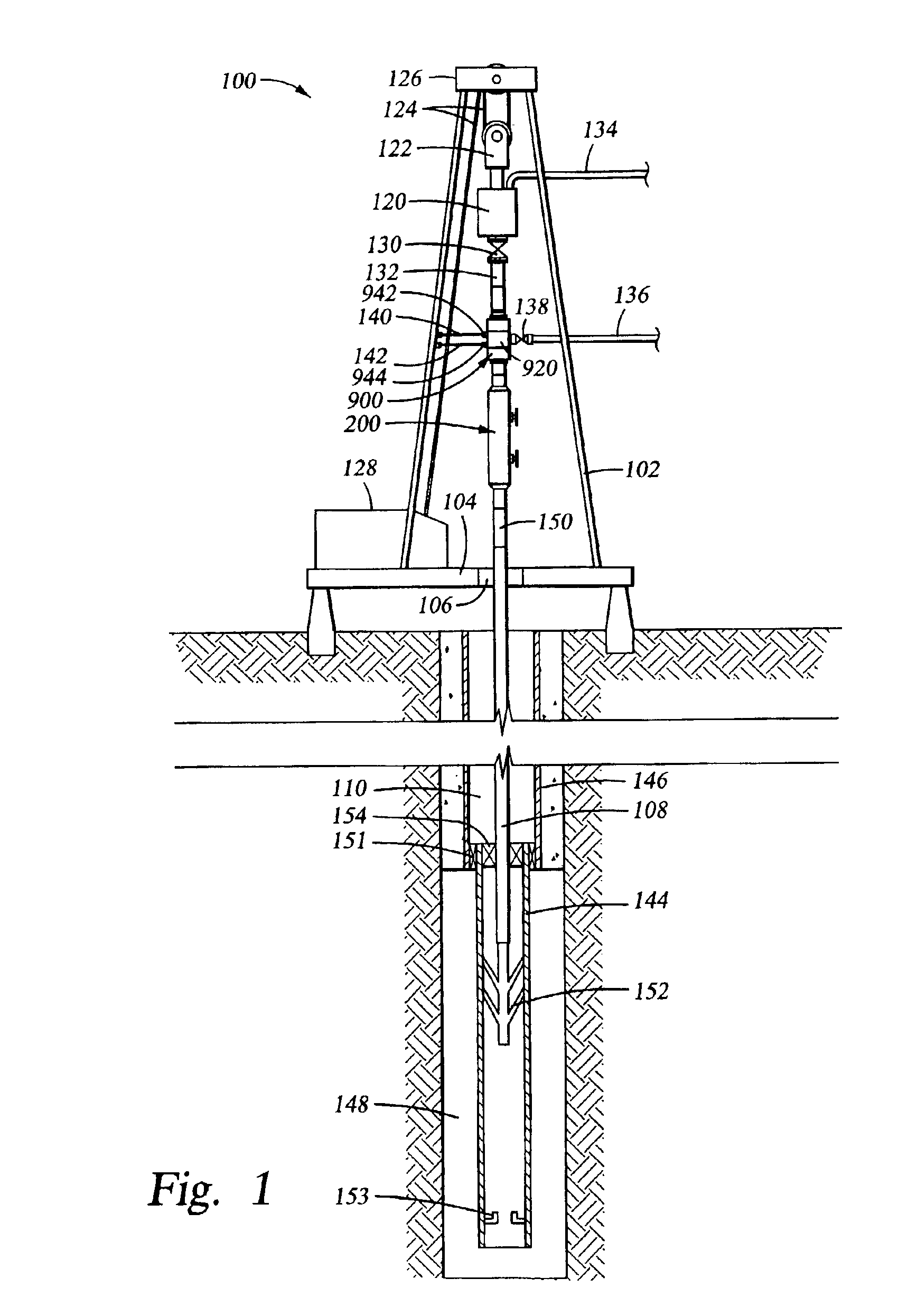

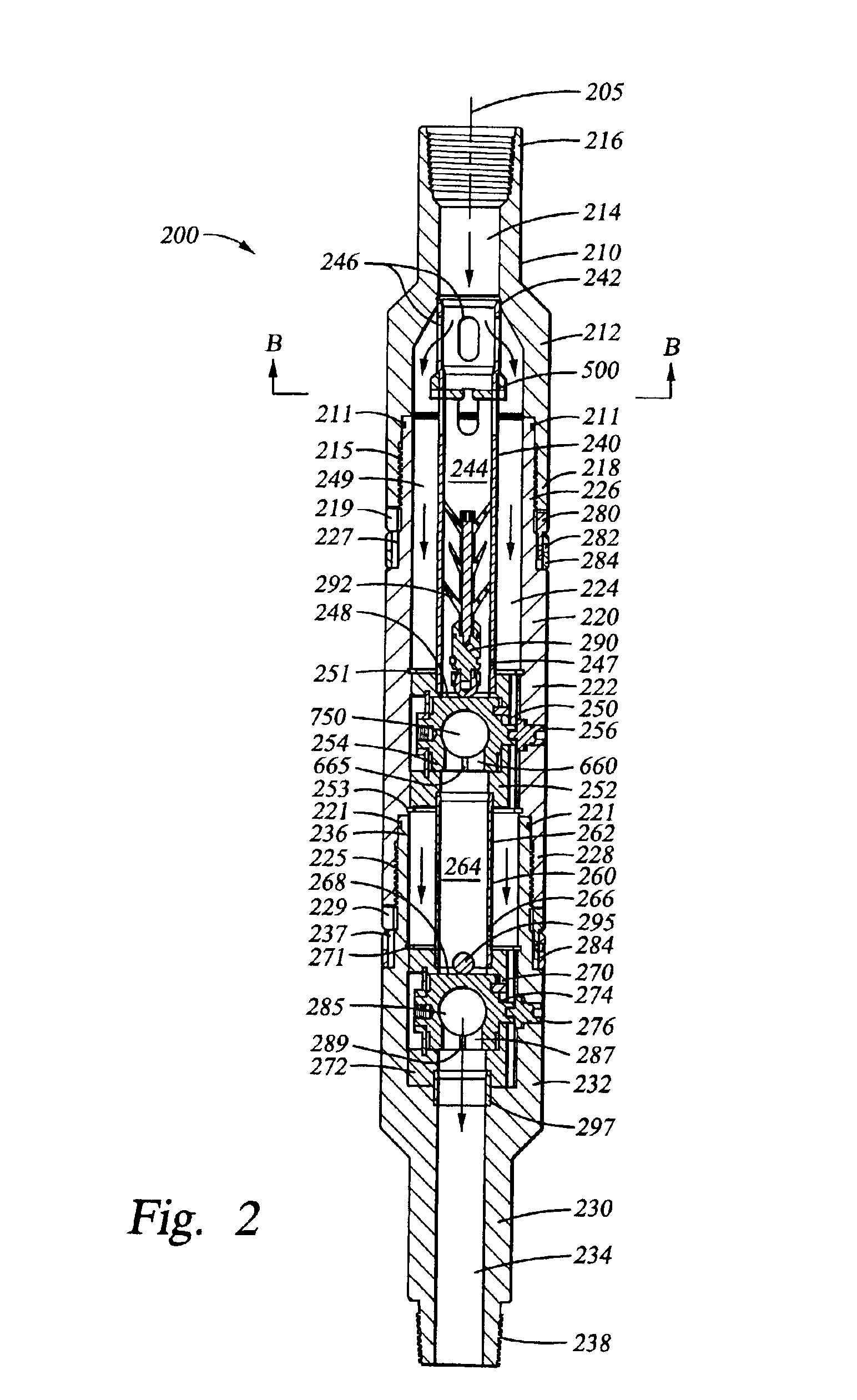

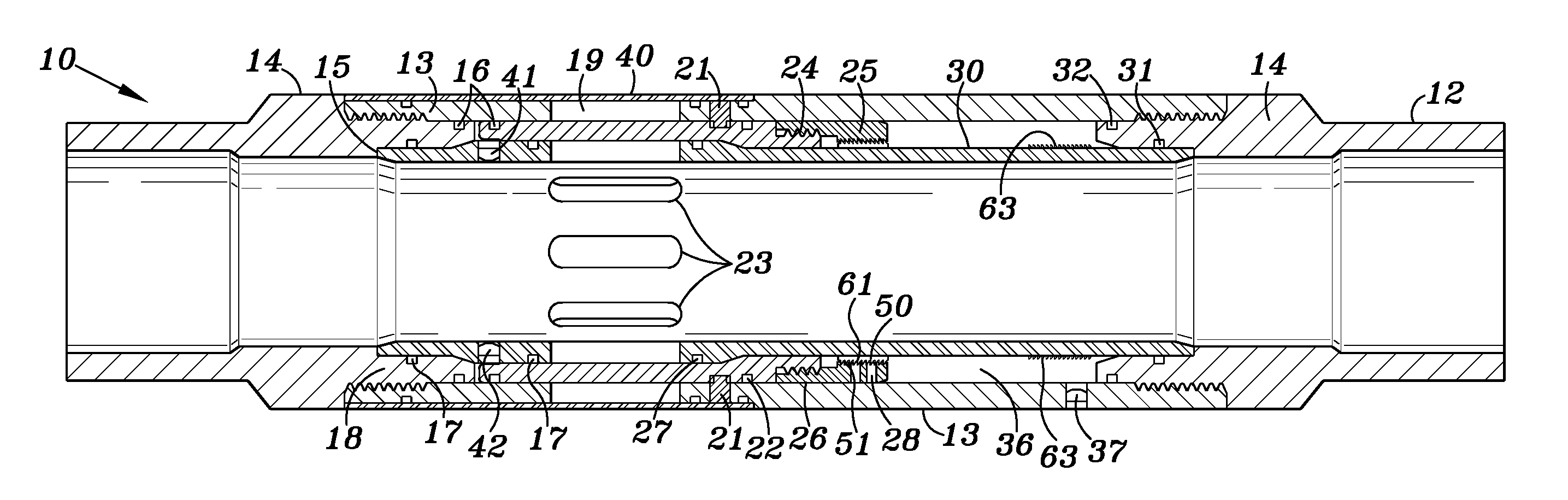

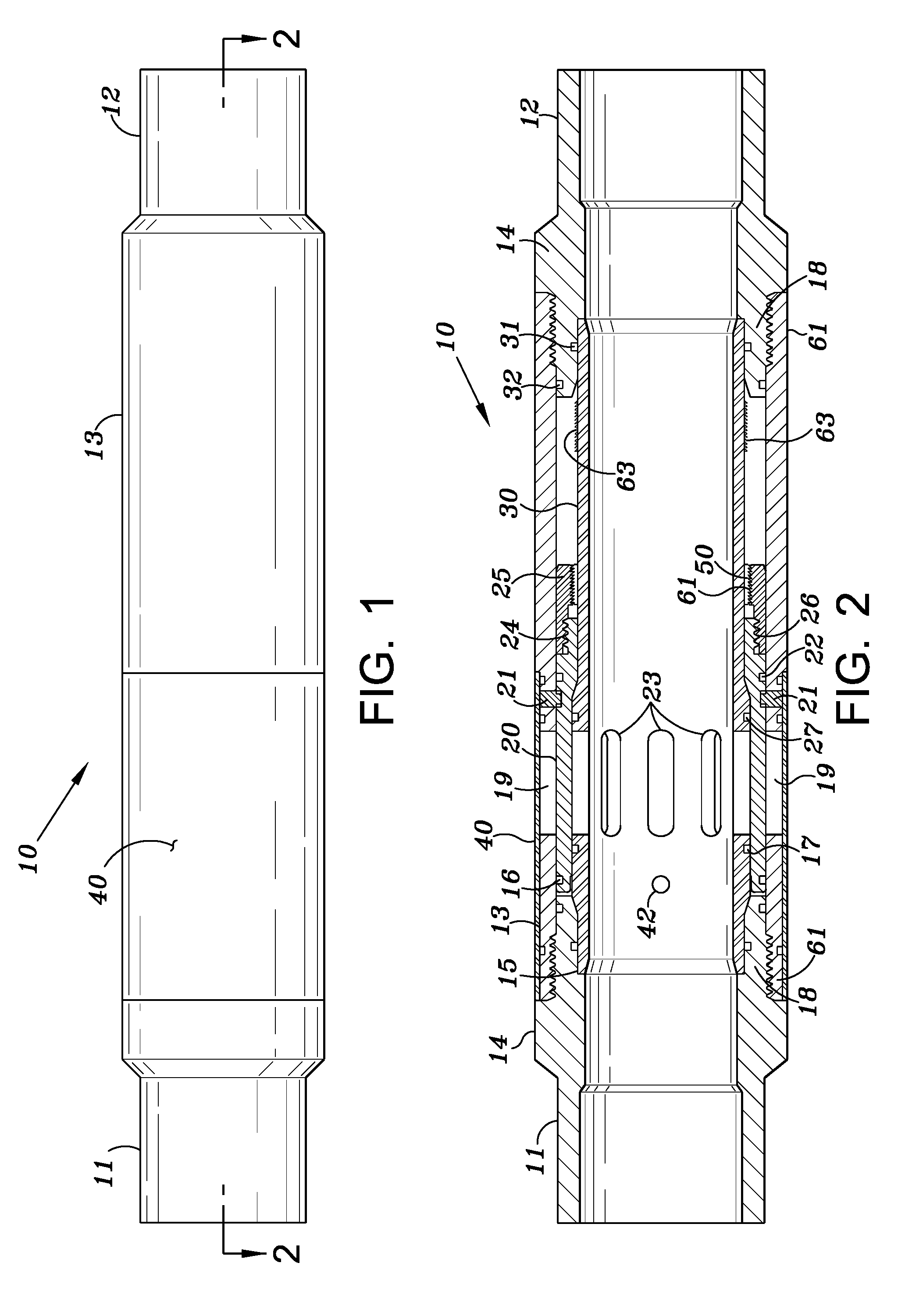

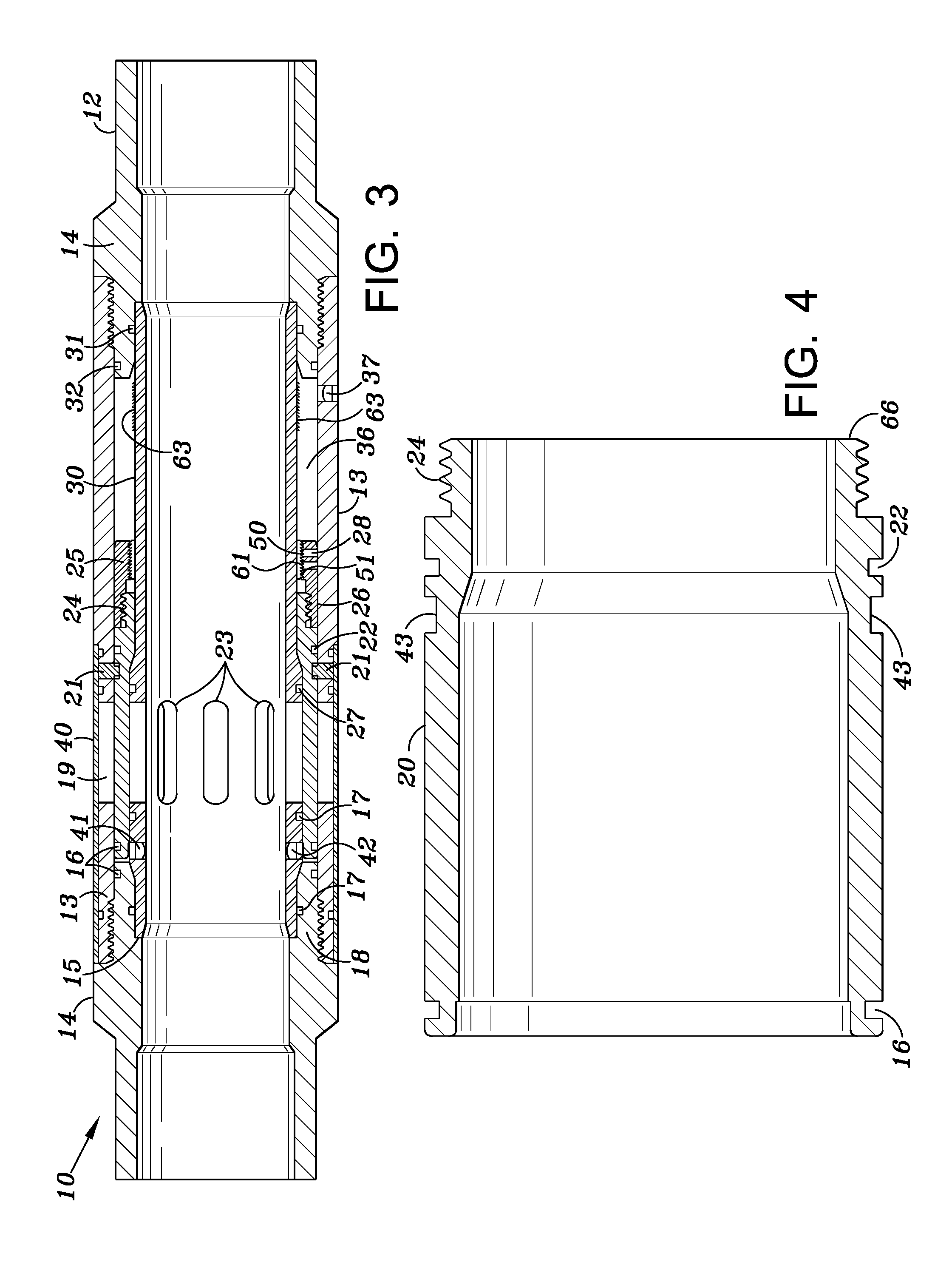

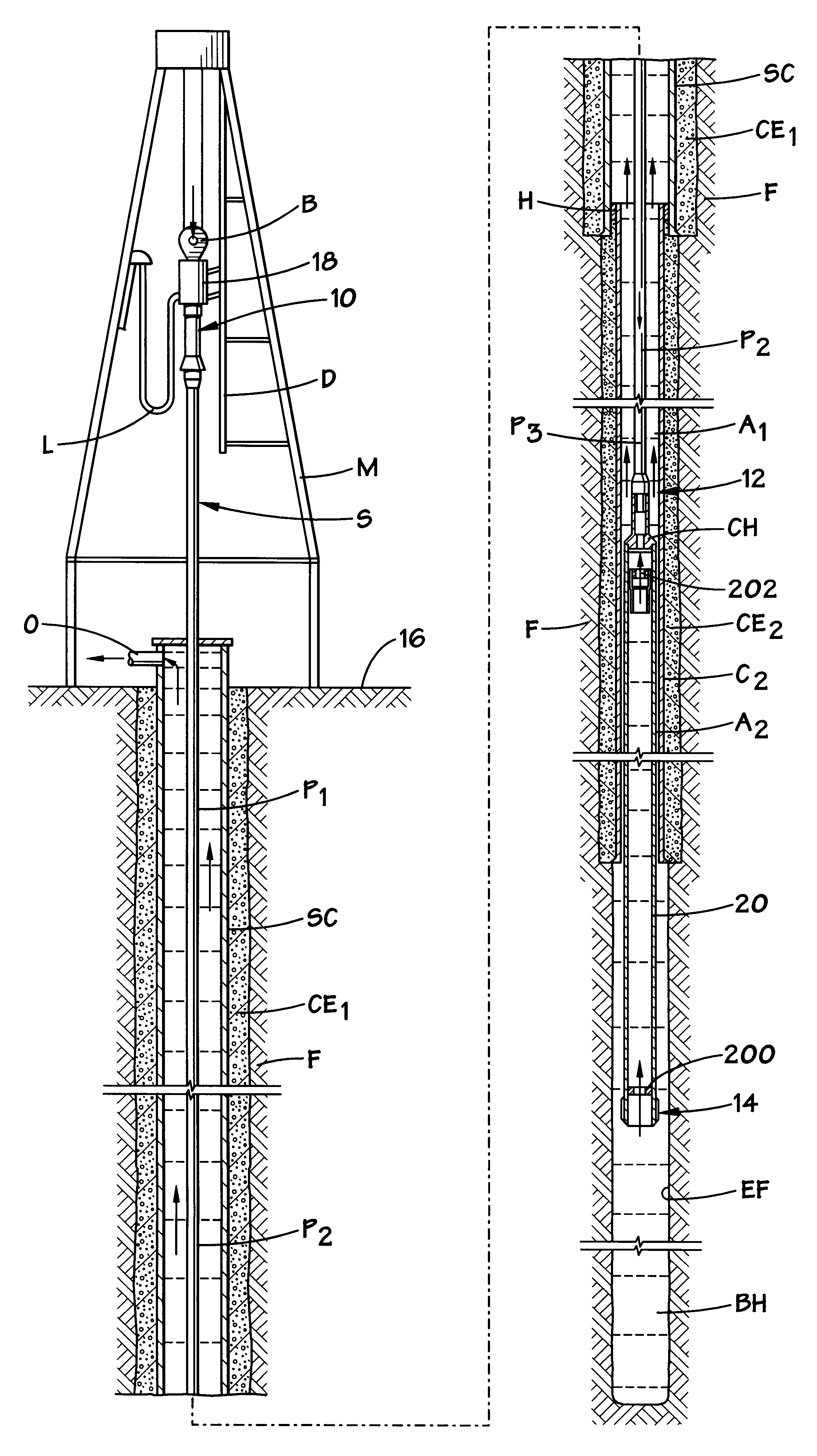

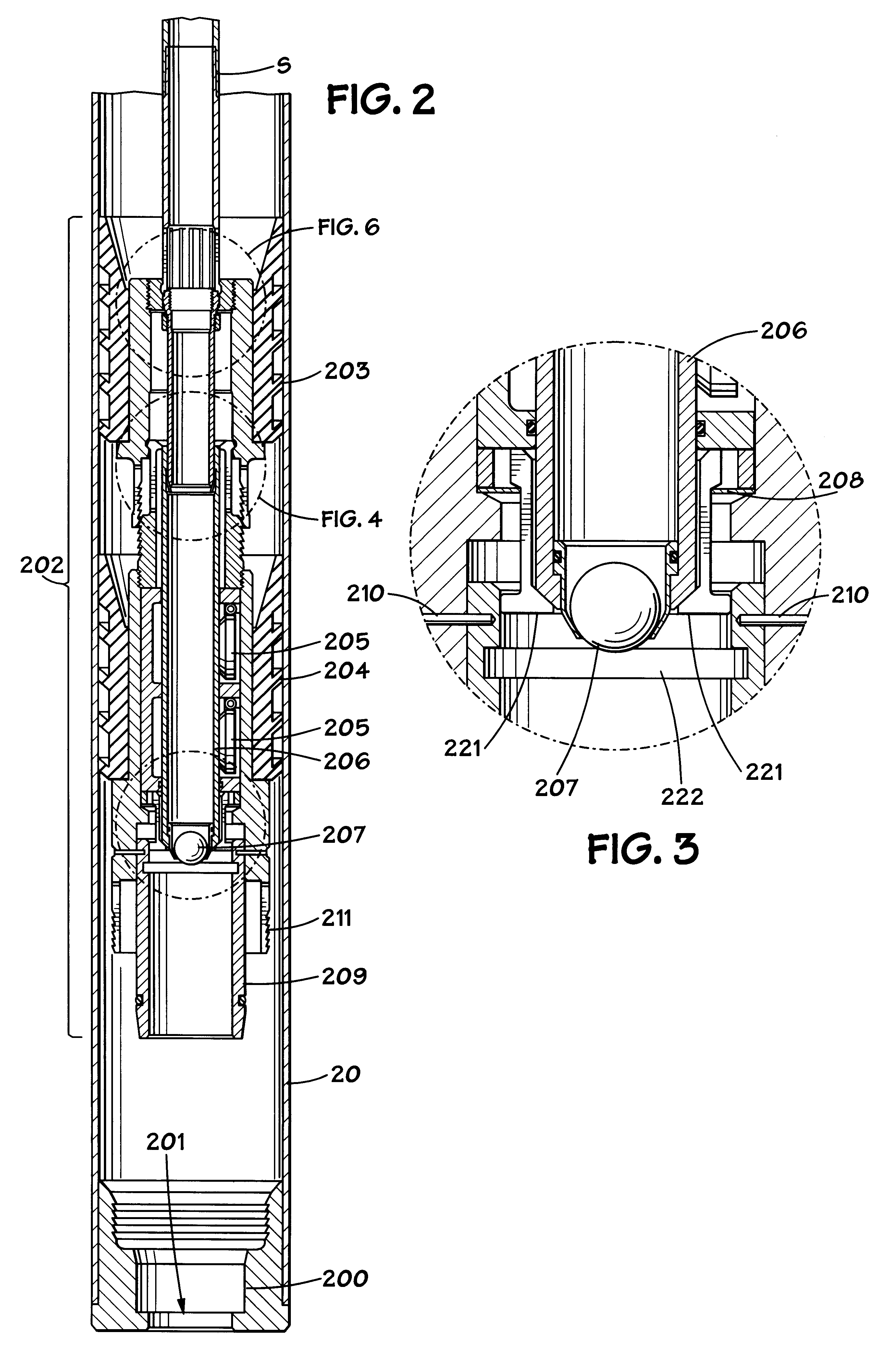

Downhole surge reduction method and apparatus

InactiveUS20040000406A1Facilitate surge pressureEasy to operateDrilling rodsFluid removalPressure reductionMechanical engineering

A method and apparatus for use in the oil well industry for running in drilling / production liners and sub-sea casings down a borehole through drilling fluid on a drill pipe using a running tool with the benefits of surge pressure reduction are disclosed. In accordance with the present invention, a surge pressure reduction tool includes a diverter device having a housing with a set of flow holes formed therein and a sliding sleeve residing within the housing having a set of flow ports formed therein. By aligning the set of flow holes of the housing with the set of flow ports of the sleeve, the tool is set in a "surge pressure reduction" mode. By shifting, or axially indexing, the sleeve downward, the set of flow holes is blocked by the sleeve thus setting the tool in a "cementing" or "circulation" mode. This shifting or indexing is accomplished using an indexing mechanism. The indexing mechanism of the present invention includes a spring ring which is initially compressed and set in a circumferential groove formed around the top of the sleeve. As the sleeve is shifted downward from surge reduction mode to cementing / circulation mode, the spring ring decompresses radially outward to engage a circumferential groove formed in the housing. This effectively locks the sliding sleeve in the cementing / circulation mode. In accordance with the present invention, a surge pressure reduction tool further includes a volume compensation device which enables the diverter device to be shifted axially downward into the cementing / circulation mode even where the drilling / production liner or sub-sea casing is plugged with drill cuttings or downhole debris. In the cementing / circulation mode, a flow path is established for cement or drilling fluid to flow downward from the drill pipe, through the diverter device, volume compensation device, and running tool, and out into the borehole via the drilling / production liner or sub-sea casing. In the surge pressure reduction mode, an alternative flow path is established for drilling fluid to flow upward from the borehole into the drilling / production liner or sub-sea casing, through the running tool and volume compensation device, and into an annular space between the drill pipe and the borehole via the set of flow holes of the diverter device.

Owner:ALLAMON INTEREST +1

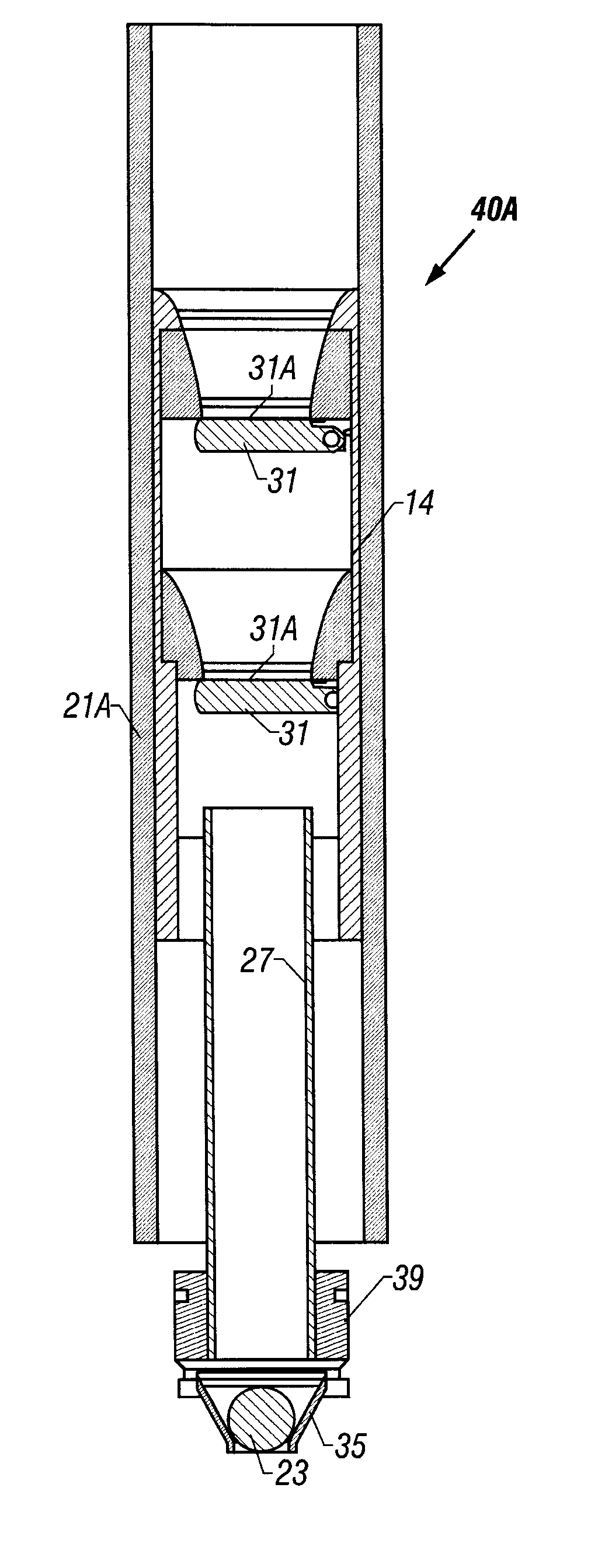

Multi-purpose float equipment and method

A float shoe / collar apparatus and method for multi-purpose use in running a tubular string such as a casing string or liner into a wellbore and for optimizing cementing operations. In one presently preferred embodiment, the apparatus permits auto filling of the tubular string as the string is lowered into the wellbore. Circulation can be effected through down jets for washing the wellbore as necessary. After the tubular string is positioned, the down jets can be blocked off and up jets opened to thereby direct cement upwardly to optimize cement placement. Check valves can also be activated to prevent flow from the wellbore into the tubular string. In one embodiment, the apparatus comprises an inner member and tubular member. The inner member is movable upon release of shear pins to cause longitudinal movement relative to the outer member. The movement of the inner member may close a plurality of downward jets and may also open a plurality of upward jets, if desired. The apparatus may also be equipped with a set of check valves which can be held open on run in, and subsequently activated to thereby automatically close upon cementing to prevent "u-tubing" of fluid back into the casing. In another embodiment a float collar comprises the same valve / valves as the float shoe, without jets. This float collar may be run in conjunction with a guide shoe, with or without jets.

Owner:FORUM US

Storable water-microsphere suspensions for use in well cements and methods

Storable water-microsphere suspensions for use in well cements and methods of cementing well bores are provided. The storable water-microsphere suspensions are basically comprised of water, microspheres and an effective amount of a suspending agent selected from the group consisting of microfine or colloidal materials and gel forming polymers.

Owner:HALLIBURTON ENERGY SERVICES INC

Apparatus and methods for creation of down hole annular barrier

InactiveUS7798225B2Velocity increasesReduced form requirementsSurveyConstructionsRecovery methodBarrier method

Owner:WEATHERFORD TECH HLDG LLC

Cementing manifold assembly

InactiveUS6904970B2Erosion minimizationFluid removalVibration devicesWell cementingMechanical engineering

A cementing manifold is disclosed that preferably includes: modular housings that can be stacked together and interconnected to add multi-dart or multi-sphere capability; identical, interchangeable valves; internal bypass capability; a minimum number of protrusions into the pressure containing components; and no externally mounted welded or threaded components.A cementing swivel is also disclosed that preferably includes connections that are formed integrally to the housing, redundant cement connections, angled cement ports, and seal assemblies that do not require individual placement of each seal.

Owner:SMITH INT INC

Valve for hydraulic fracturing through cement outside casing

A valve for use in fracing through cement casing in a well allows for flow of cement down the well during the cementing process and in the open position allows for fracing fluid to be directed through the cement casing for fracturing the formation adjacent the valve. The valve is constructed so as to reduce the likelihood of the valve to jam as a result of cement or other foreign material.

Owner:INNOVEX DOWNHOLE SOLUTIONS INC

Contained micro-particles for use in well bore operations

Owner:HALLIBURTON ENERGY SERVICES INC

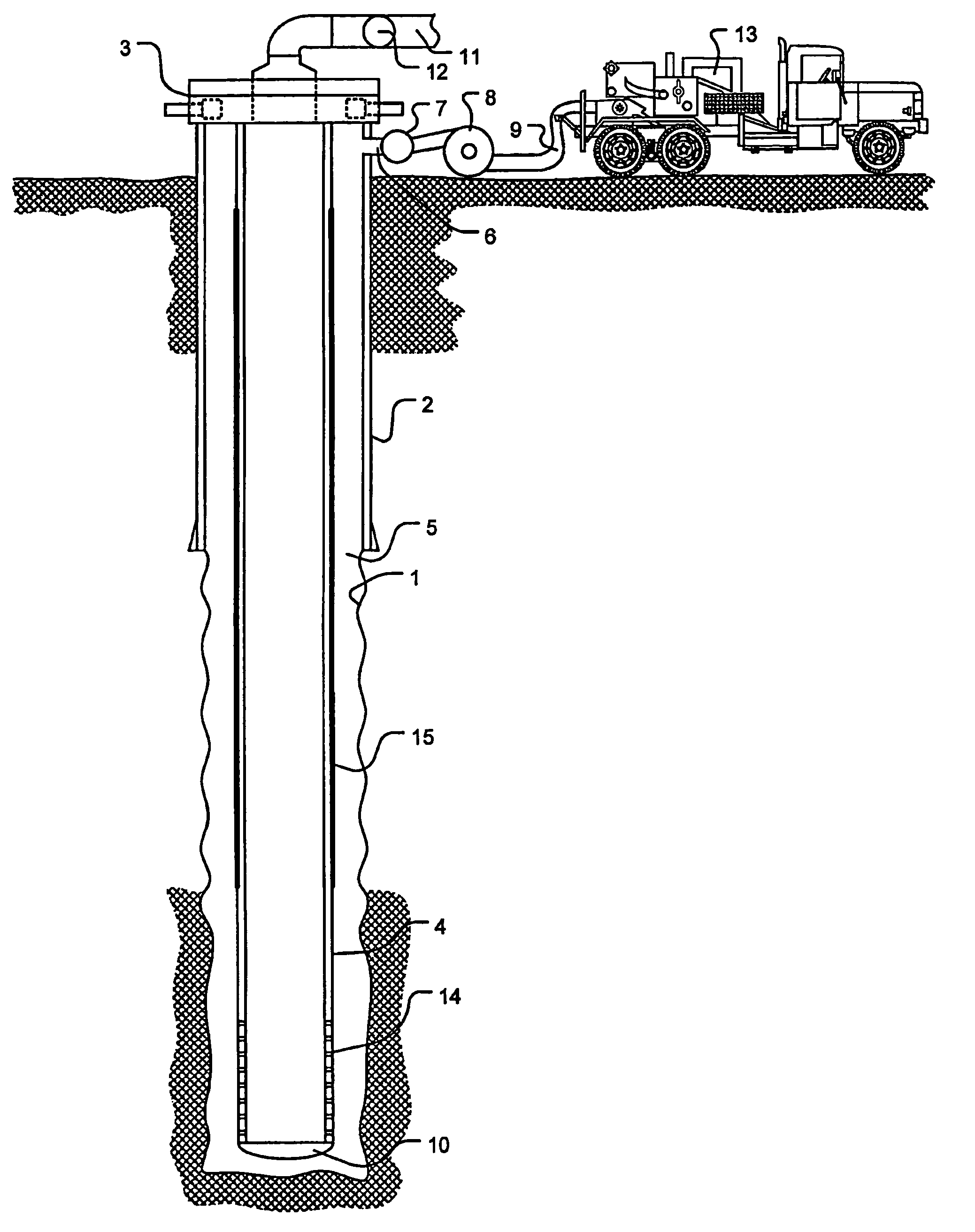

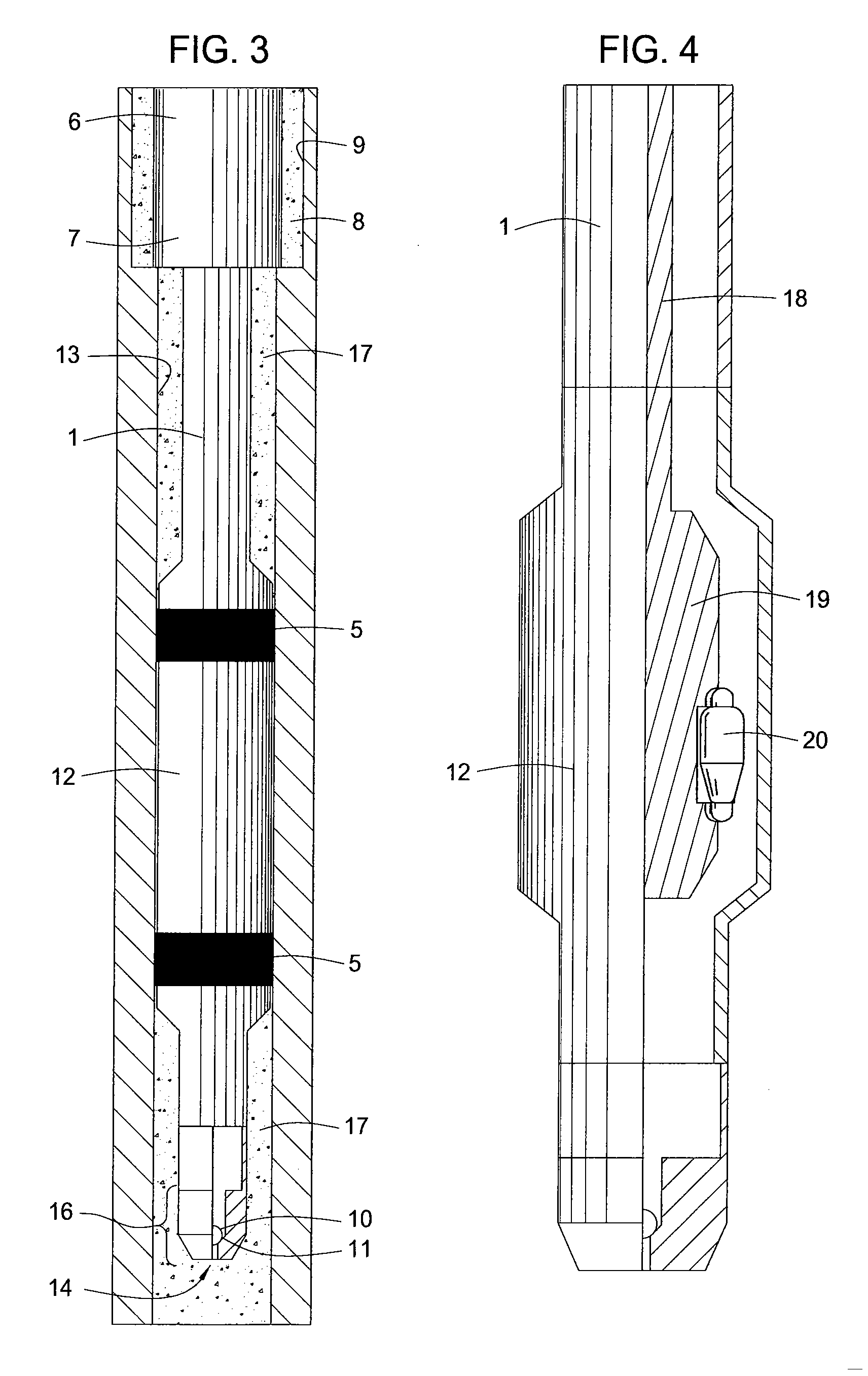

Pumpdown valve plug assembly for liner cementing system

Method and apparatus are disclosed for use in cementing a tubular member which is run into a borehole using a drill string. A landing collar is attached to the tubular member near the bottom of the tubular member, and the landing collar has an opening at least five inches in diameter. A liner wiper assembly is releasably suspended from the drill string. The liner wiper assembly comprises a lower liner wiper plug comprising float valves and an upper liner wiper plug. With the method and apparatus of the present invention, plugging problems are minimized.

Owner:BLACKHAWK SPECIALTY TOOLS

Oil-gas well cement sheath seal characteristic simulation test device and test method

ActiveCN104153760AQuantitative evaluation of the degree of hydraulic cementationRealize quantitative evaluationConstructionsWell cementingEngineering

The invention discloses an oil-gas well cement sheath seal characteristic simulation test device and a test method. The device comprises a kettle, an upper kettle cover, a lower kettle cover, a heating jacket, a booster pump, a pressure relief pump and a liquid level and air flow recorder. A simulated stratum core can be placed in the kettle, a mud cake is formed on the inner wall of the core, and insertion of a casing pipe and grouting of cement paste can be realized. A solidification process of the cement paste under underground operating conditions is simulated, clean water, oil or a gaseous medium can be applied to two ends of an annular cylindrical cement sheath to form differential pressure, seal characteristics of the cement sheath in corresponding size can be evaluated by measuring leakage or variation of the differential pressure at two ends, and factors such as the casing pipe size, cement paste performance, mud cake thickness, curing pressure, temperature and the like can be changed to evaluate influences of the factors on the seal characteristic of the cement sheath.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Methods of generating gas in and foaming well cement compositions

The present invention relates to methods of generating gas in and forming cement compositions that may be introduced into a subterranean zone. A method of the present invention provides a method of generating gas in a cement composition that comprises providing the cement composition comprising a hydraulic cement and water; providing an oxidizing agent; providing at least one gas generating chemical; and contacting the cement composition with the oxidizing agent and / or the gas generating chemical downstream of at least one cement pump so that a gas is generated in the cement composition downstream of at least one cement pump. Methods of foaming cement compositions are also provided.

Owner:HALLIBURTON ENERGY SERVICES INC

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com