Patents

Literature

3683 results about "Cement slurry" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The cement slurry used in the drilling industry is a cement suspension with a high water content and a relatively low viscosity. A cement slurry is forced into the annulus between the outside of the casing that has been run in the well and the walls of the borehole. Cement slurry is a mixture of Portland cement, water, and additives.

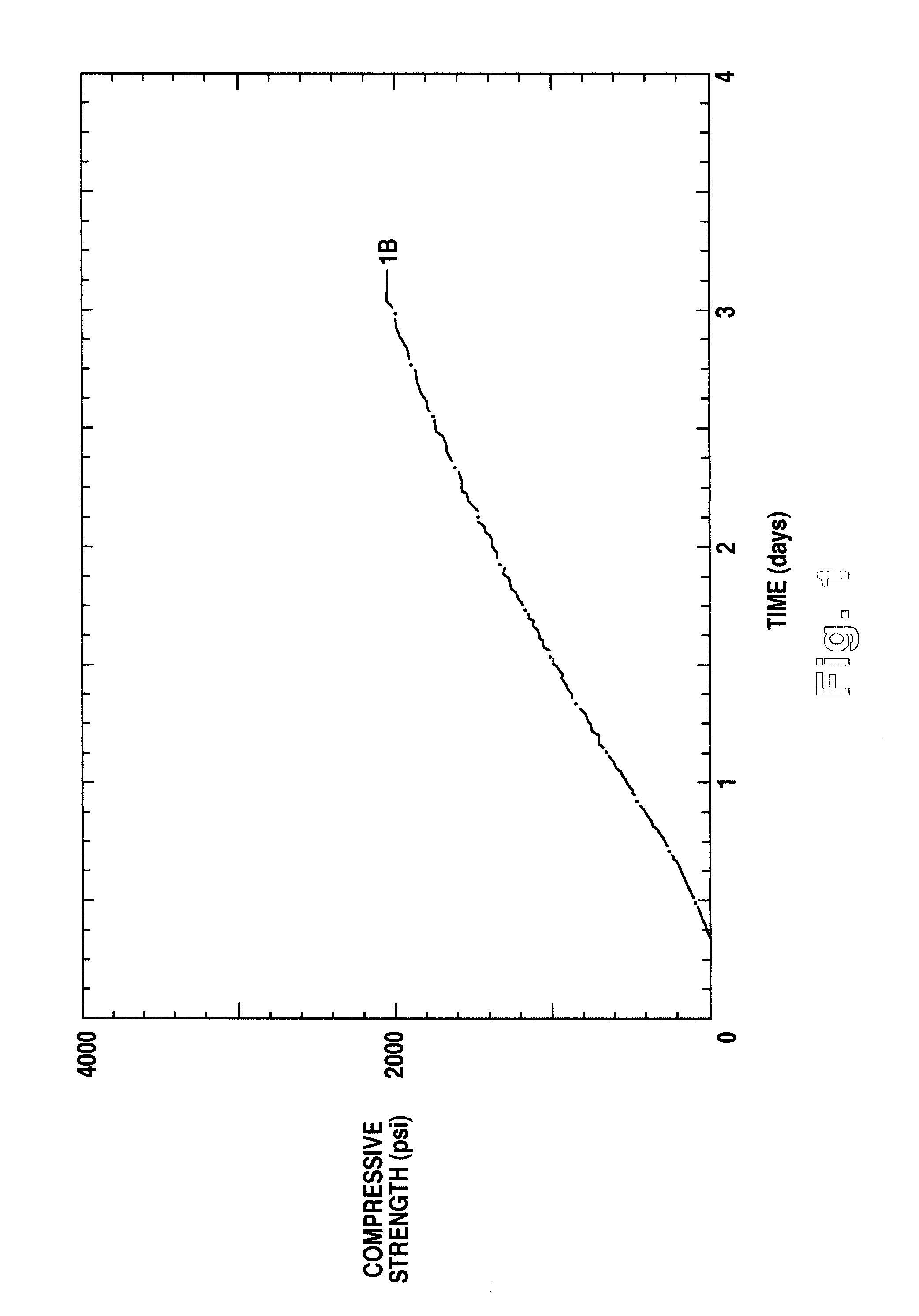

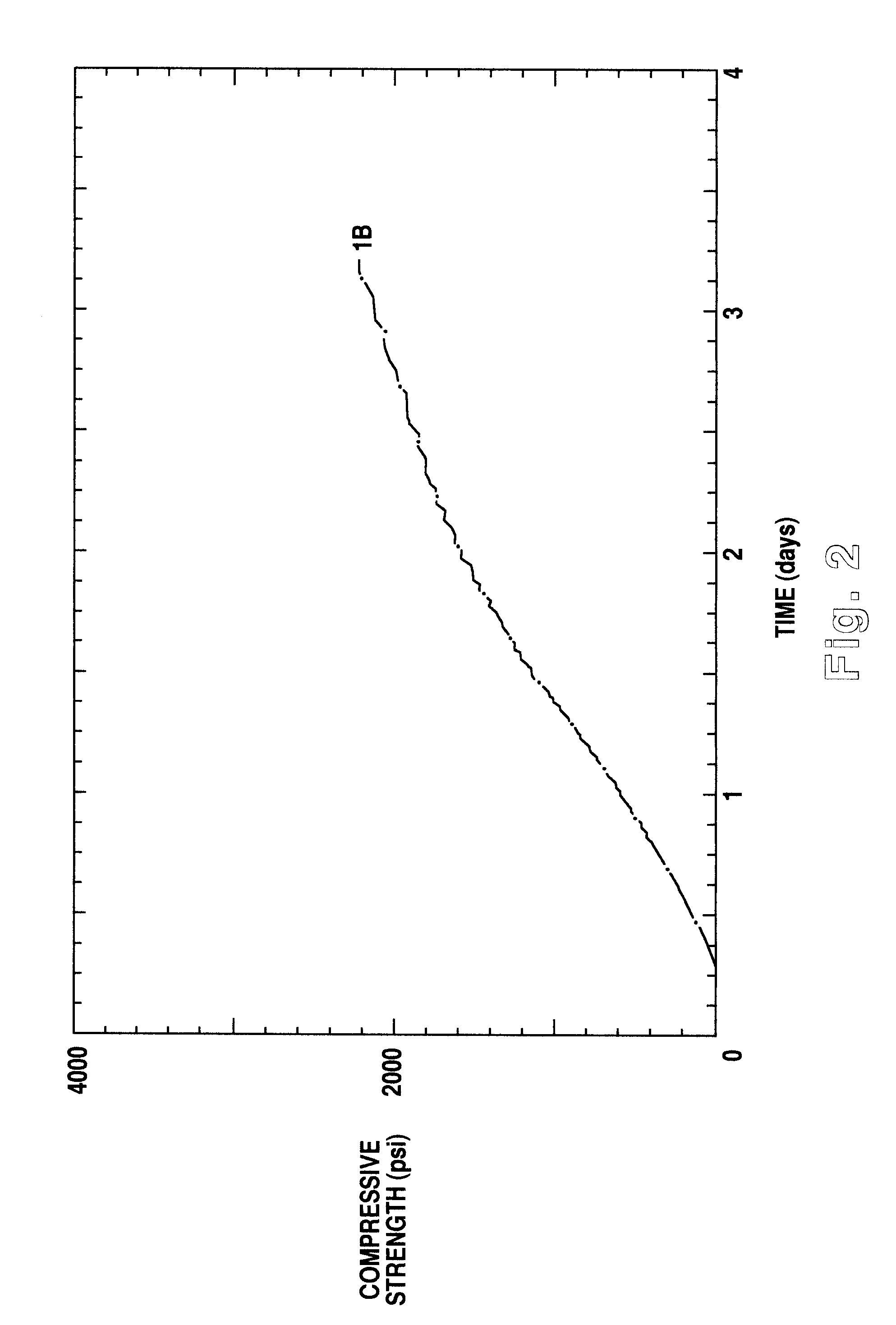

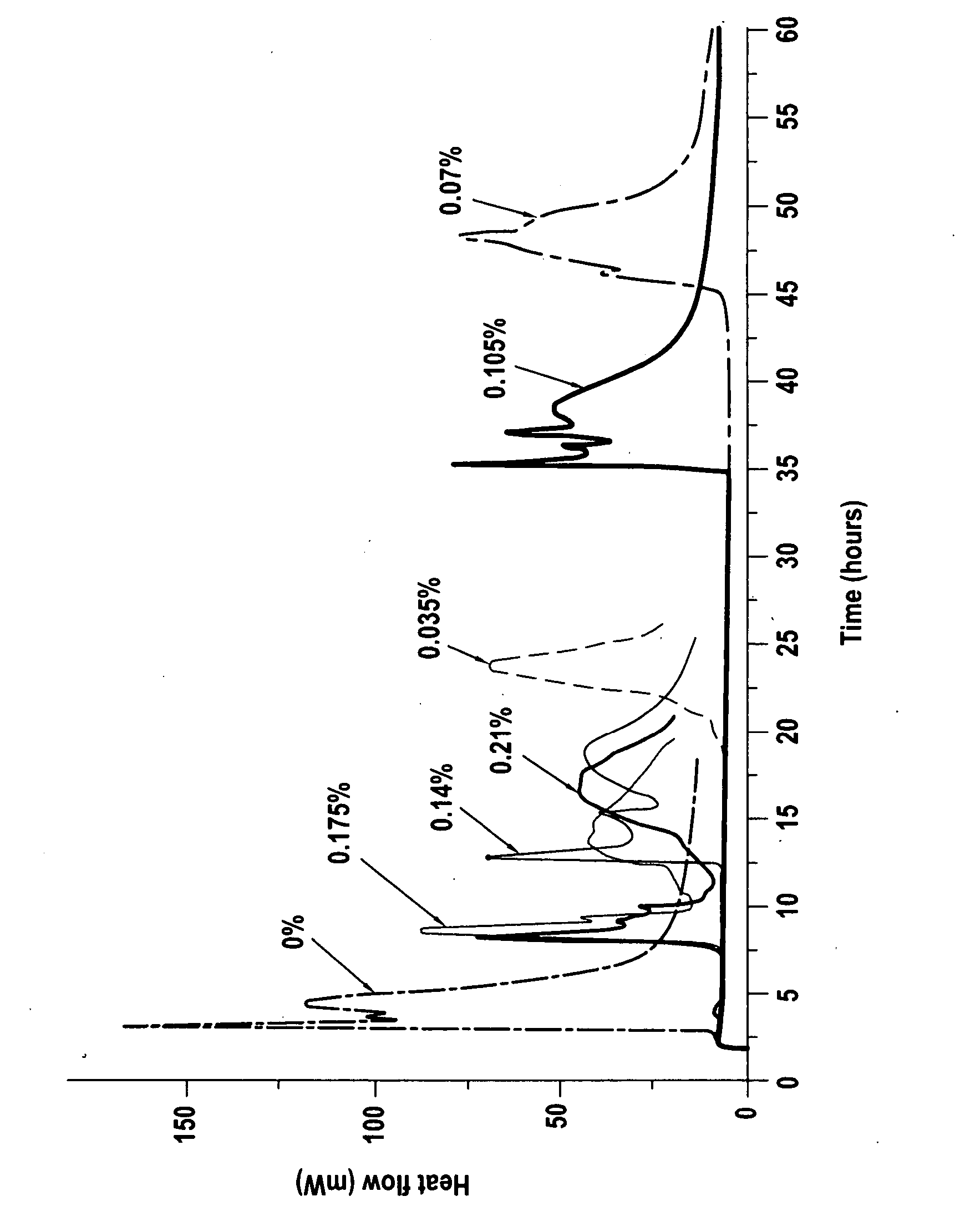

Methods and compositions for use in cementing in cold environments

Cement compositions for cementing wellbores in cold environments. The cement compositions may include a mixture of a reactive aluminum silicate, aluminum sulfate and hydraulic cement, and may include one or more other additives. The cement compositions may be formulated to have reduced heat of hydration as compared to conventional cements, making them suited for cementing in permafrost environments. The cement slurries may optionally be foamed using a foaming agent and energizing phase.

Owner:AMERICAN CEMENTING LLC

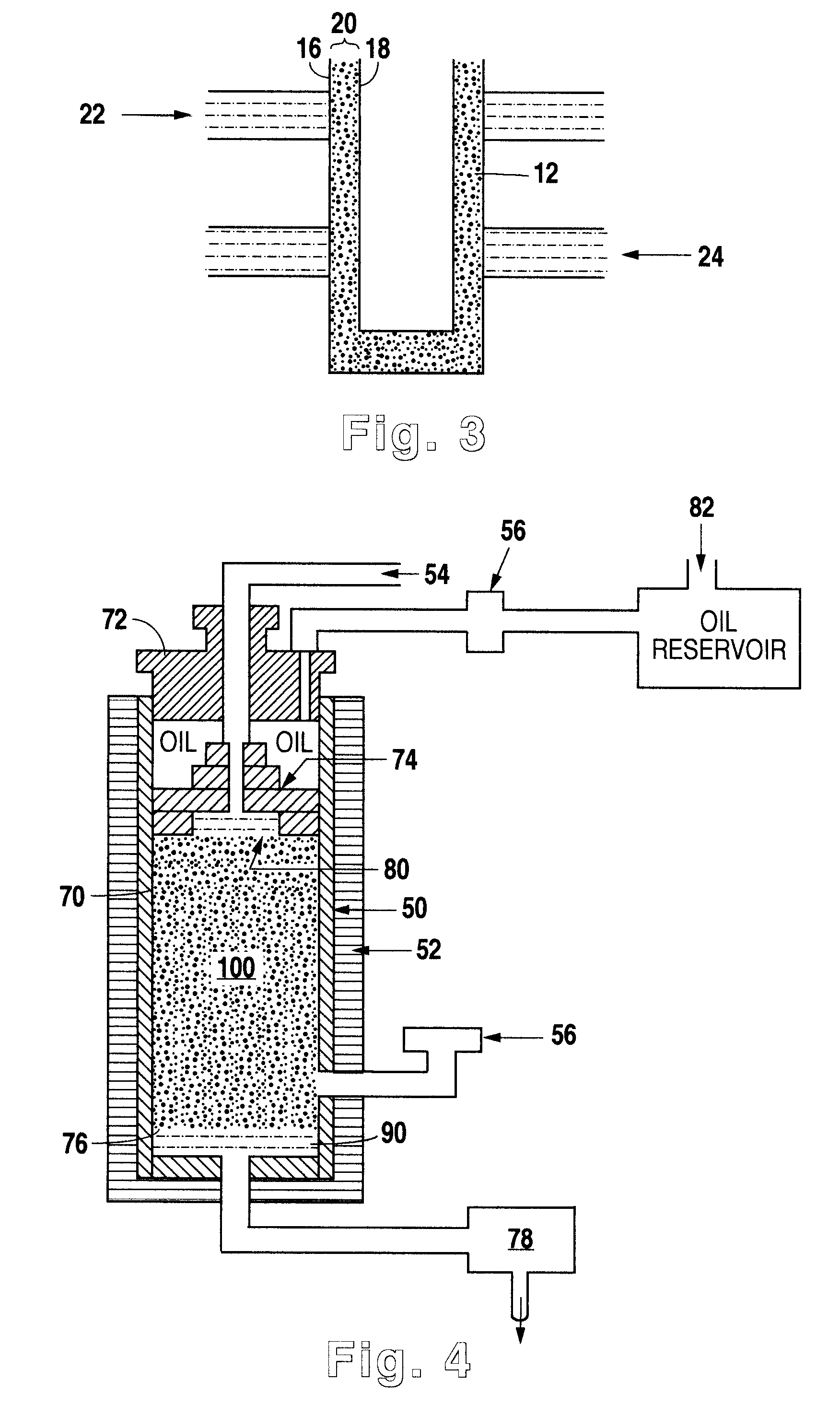

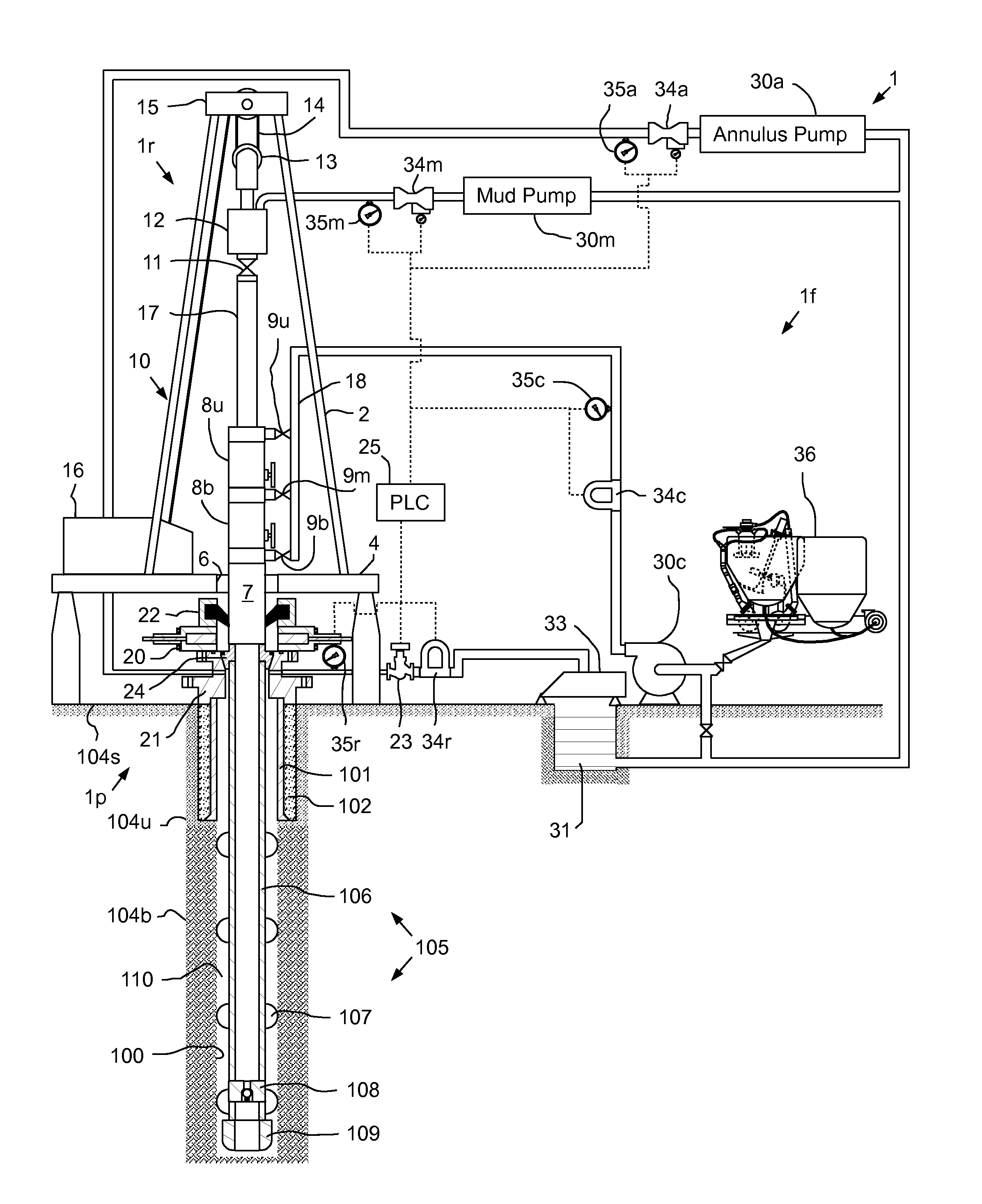

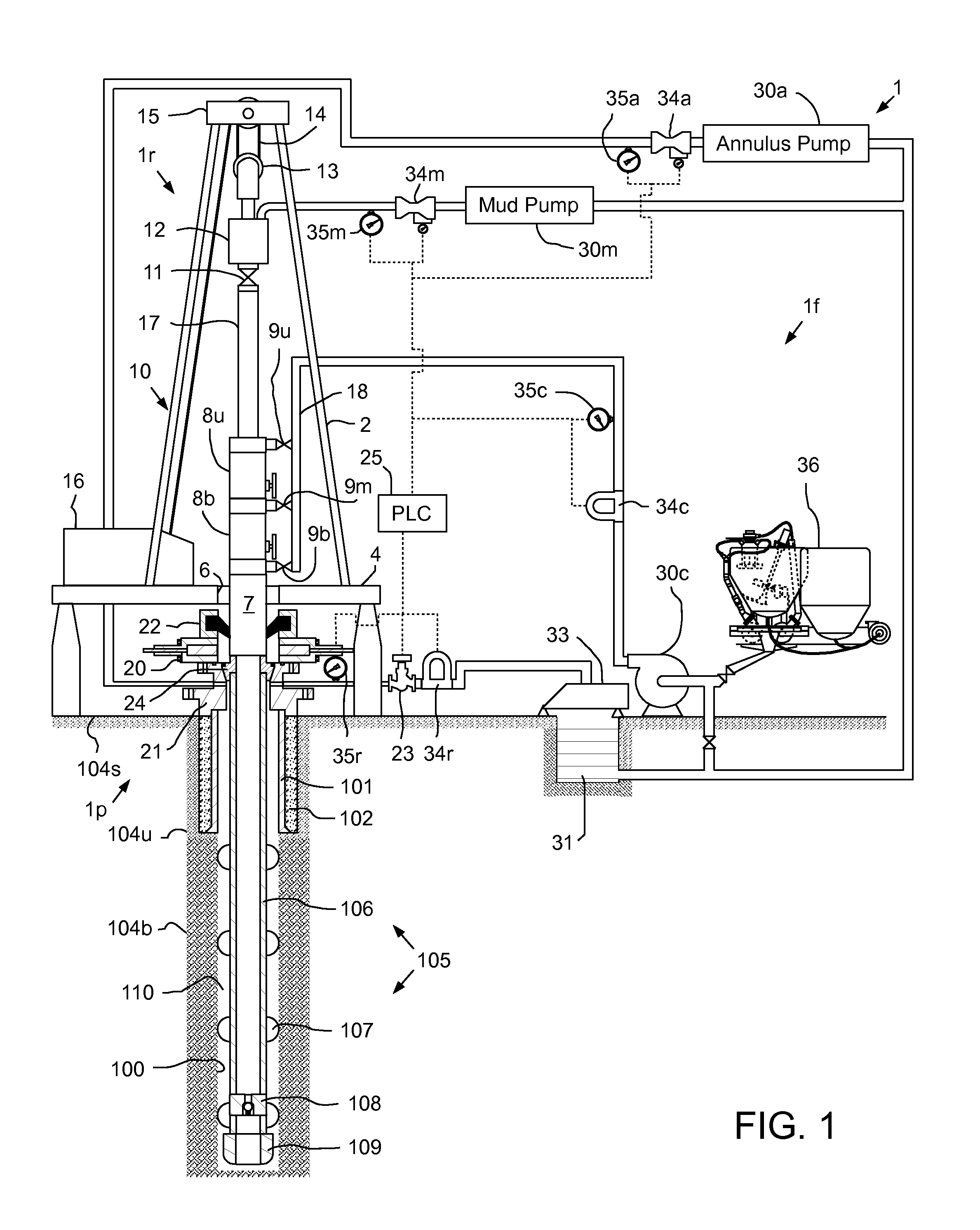

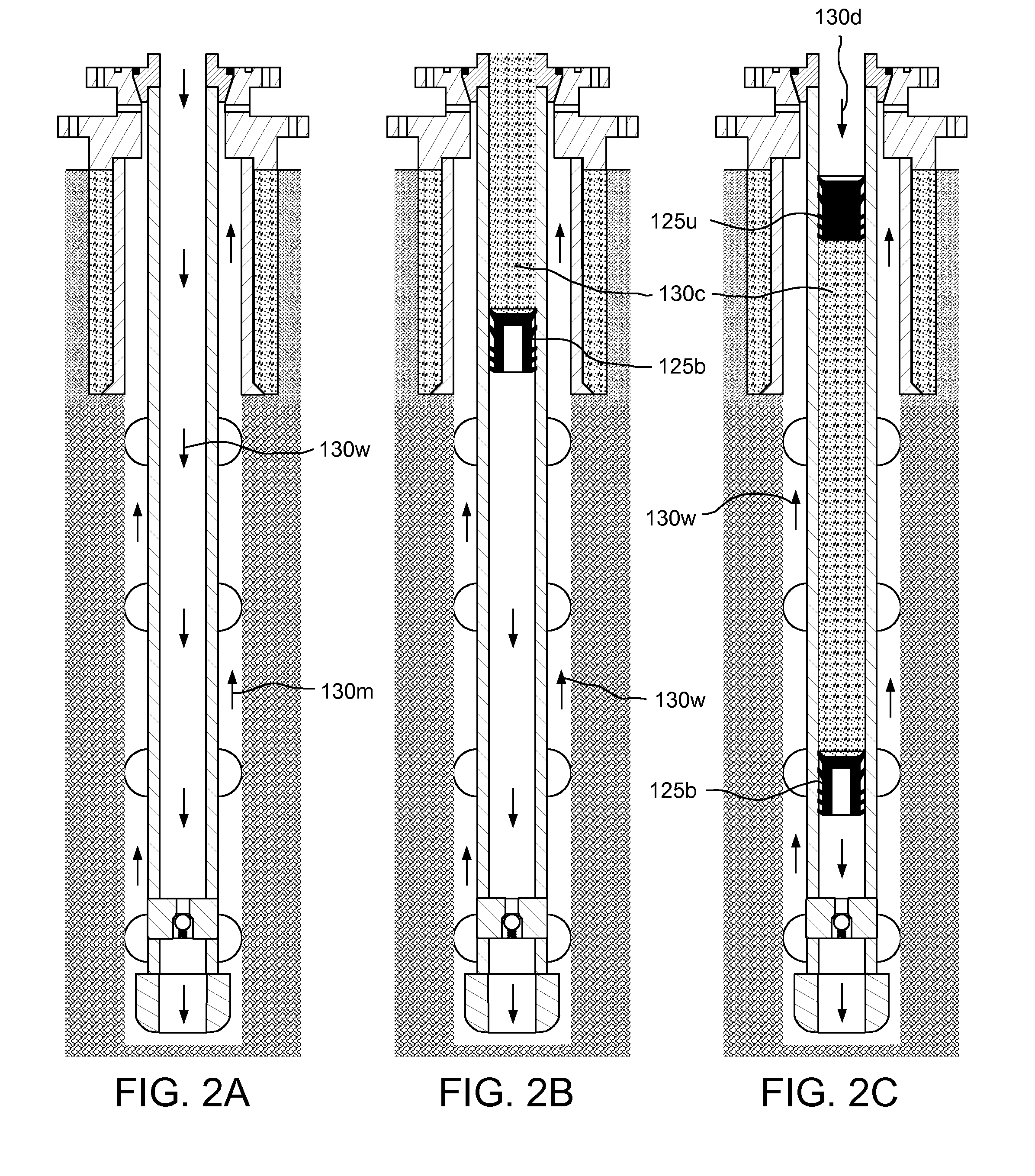

Managed pressure cementing

A method of cementing a tubular string in a wellbore includes: deploying the tubular string into the wellbore; pumping cement slurry into the tubular string; launching a cementing plug after pumping the cement slurry; propelling the cementing plug through the tubular string, thereby pumping the cement slurry through the tubular string and into an annulus formed between the tubular string and the wellbore; and controlling flow of fluid displaced from the wellbore by the cement slurry to control pressure of the annulus.

Owner:WEATHERFORD TECH HLDG LLC

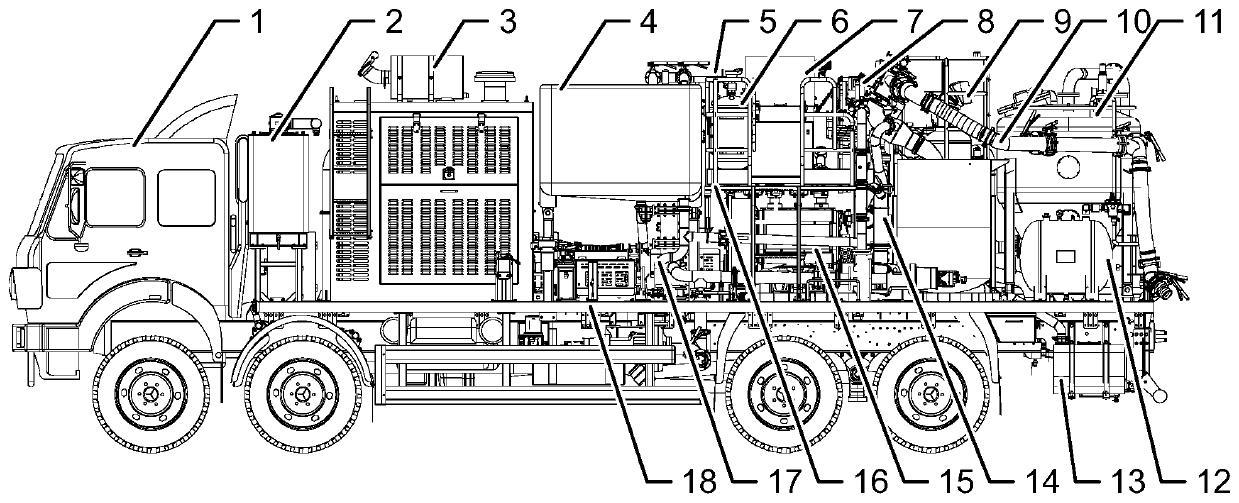

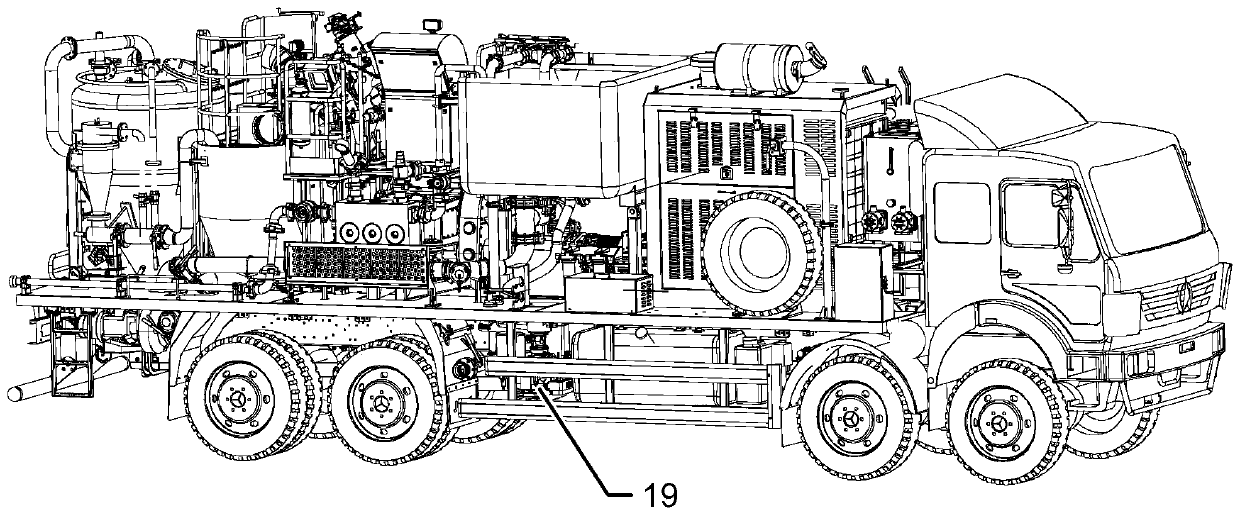

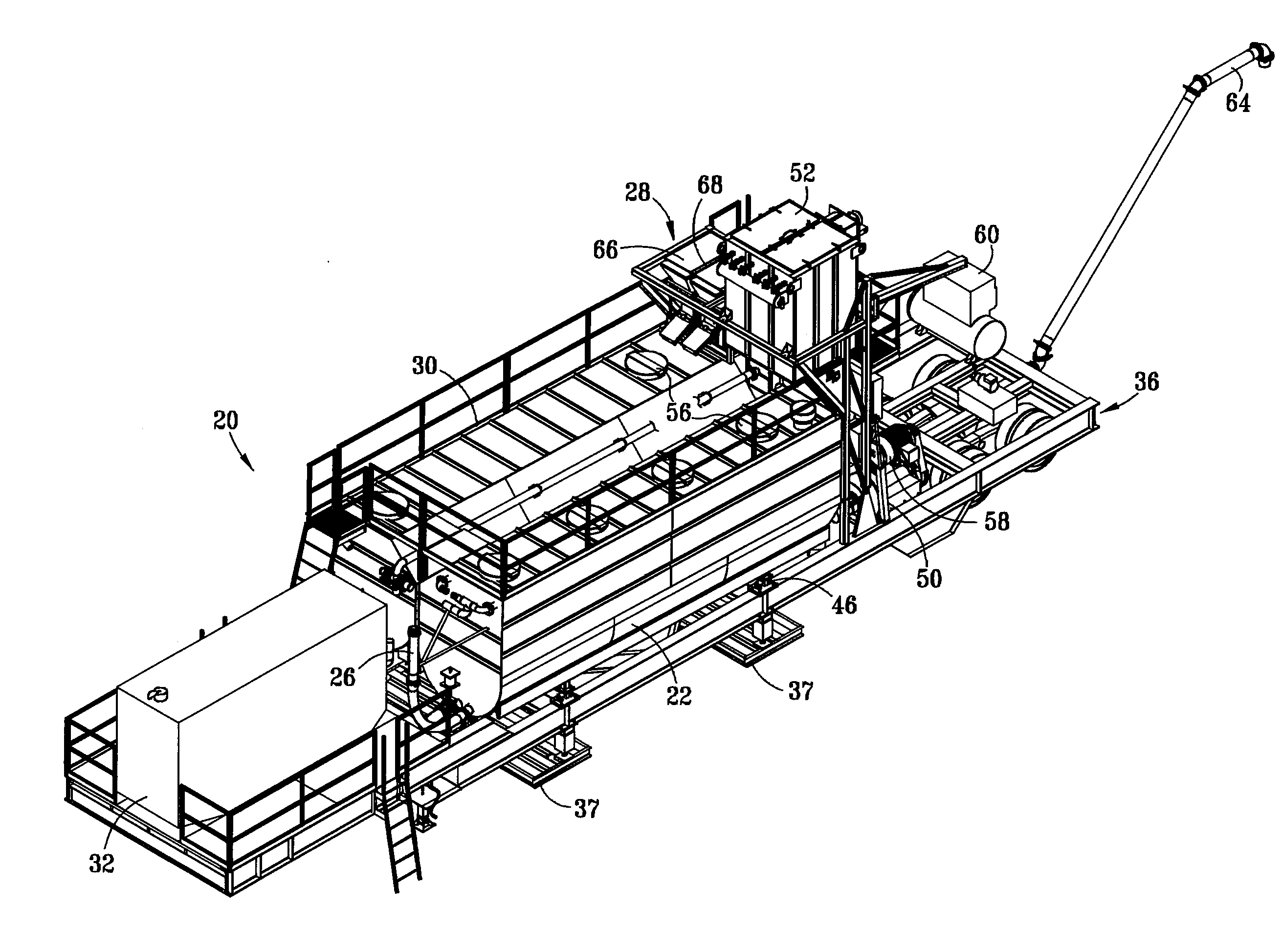

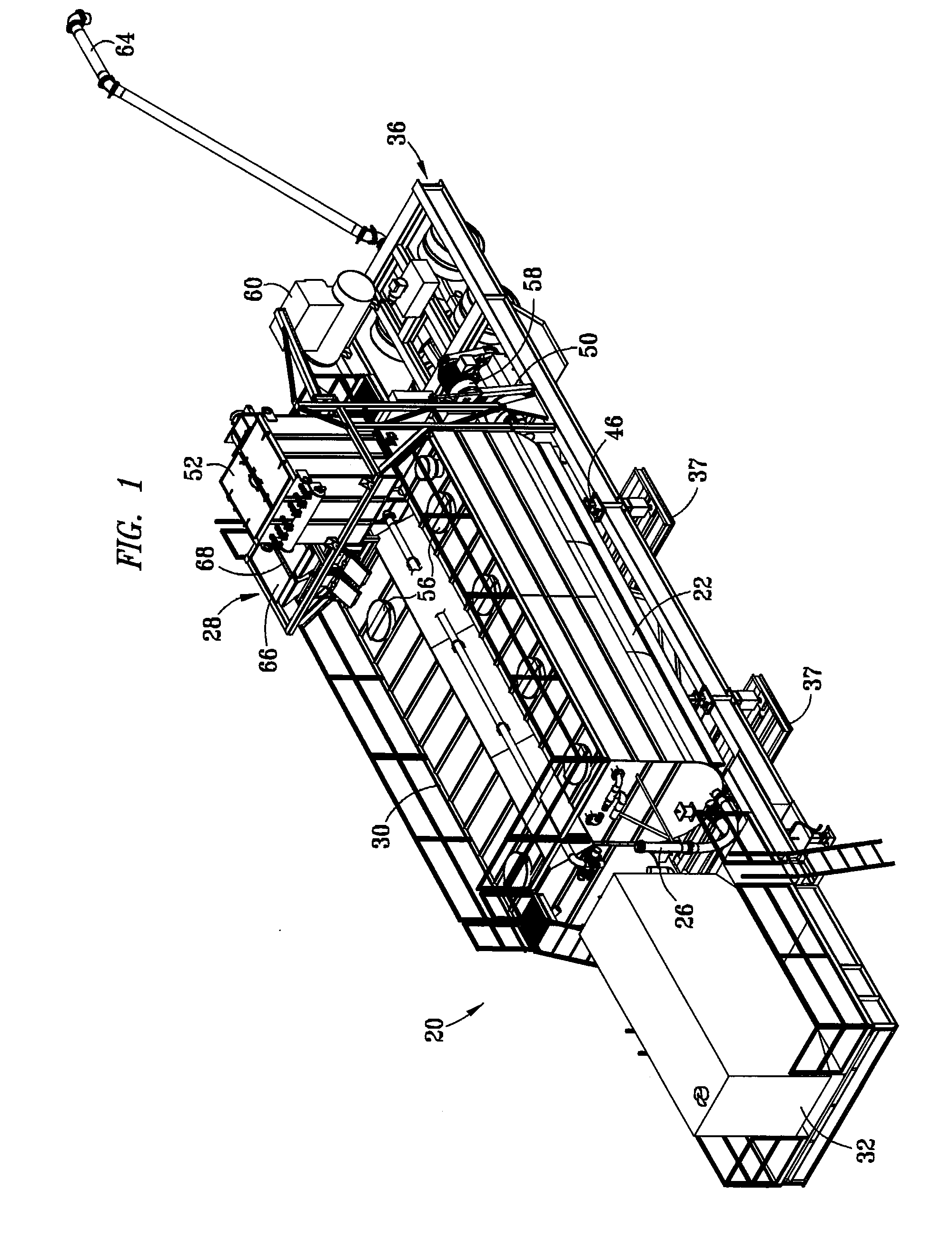

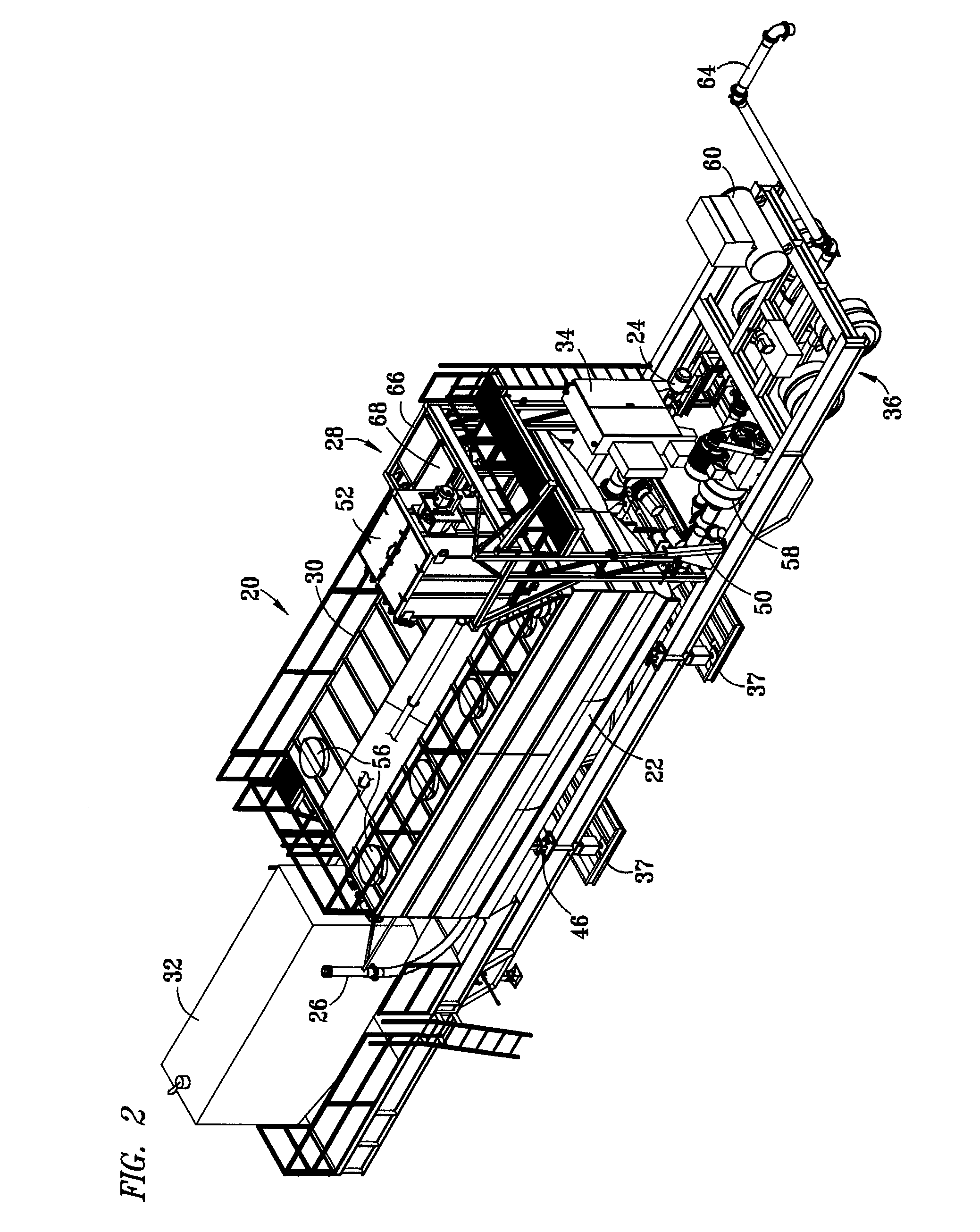

Novel well cementation truck

PendingCN111075391AEasy to operateFlexible and Efficient MobileItem transportation vehiclesSealing/packingDrivetrainWell cementing

The invention discloses a novel well cementation truck, which comprises a loading body, an electrical system, a plunger pump, a clear water manifold, a mud manifold and a high-pressure manifold, wherein the loading body is provided with a cross beam; the cross beam is provided with a hydraulic system, a power transmission system, a metering tank, an operating platform and a mixing system in sequence; the operating platform is provided with a gas path system and an operating system in sequence; the electrical system supplies power to the well cementation truck; the plunger pump, the clear watermanifold, the mud manifold and the high-pressure manifold are all arranged below the operating platform; the clear water manifold supplies water to the plunger pump and the mixing system; the mud manifold provides mud for the plunger pump; the plunger pump injects the mud into a well through the high-pressure manifold; and the well cementation truck also integrates with a steady pressure ash can,an air compressor and an air bottle. The novel well cementation truck has the beneficial effects that a spatial layout is optimized, and the steady pressure ash can, the air compressor and the air bottle are integrated in one well cementation truck. An ash feeding manifold is optimized, so that the steady pressure ash can supplies ashes, and ash supply equipment can be externally connected for supplying ashes. The large-volume air bottle is adopted, and therefore, air can be supplied to other equipment while the requirements of the well cementation truck are met.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

Cement Stabilization of Soils Using a Proportional Cement Slurry

ActiveUS20090044726A1Composition is stableAvoid settingSolid waste managementCement mixing apparatusChemical treatmentCellulose

A novel cement slurry composed of cement and water that can be used in cement stabilization applications. The cement slurry compound itself is chemically treated, by means of a cellulosic or other thixotropic thickening agent(s) to create a thixotropic system wherein the wetted cement remains in suspension and does not settle out prior to use even without further mixing. A chemical retarder / stabilizer is also used to prevent the slurry from prematurely setting during shipping. A novel apparatus and method for mixing the novel cement slurry is disclosed to insure the exact proportioning of all ingredients and the proper wetting of the cement.

Owner:TEXAS INDUSTRIES

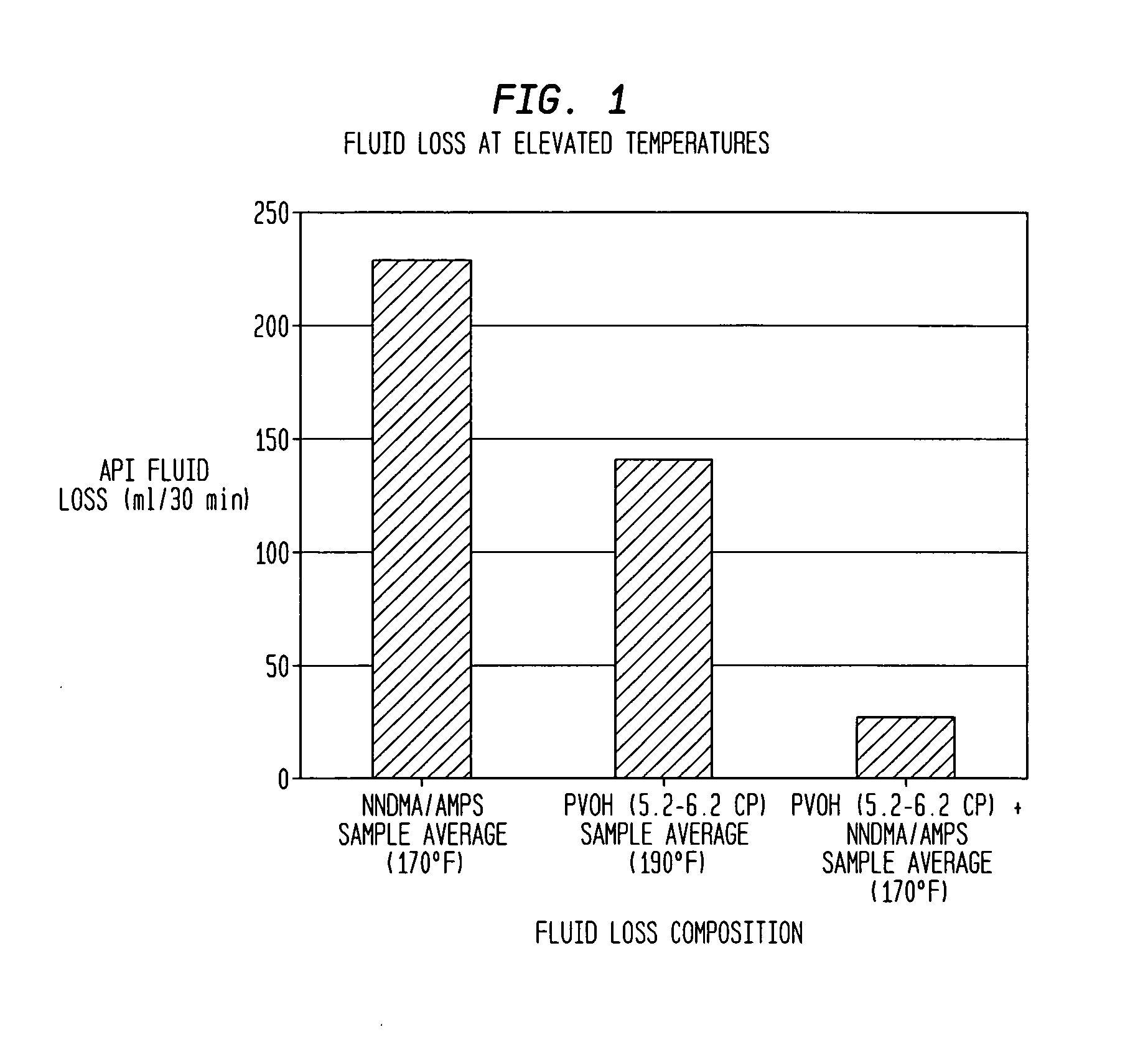

Fluid loss concentrate for hydraulic cement

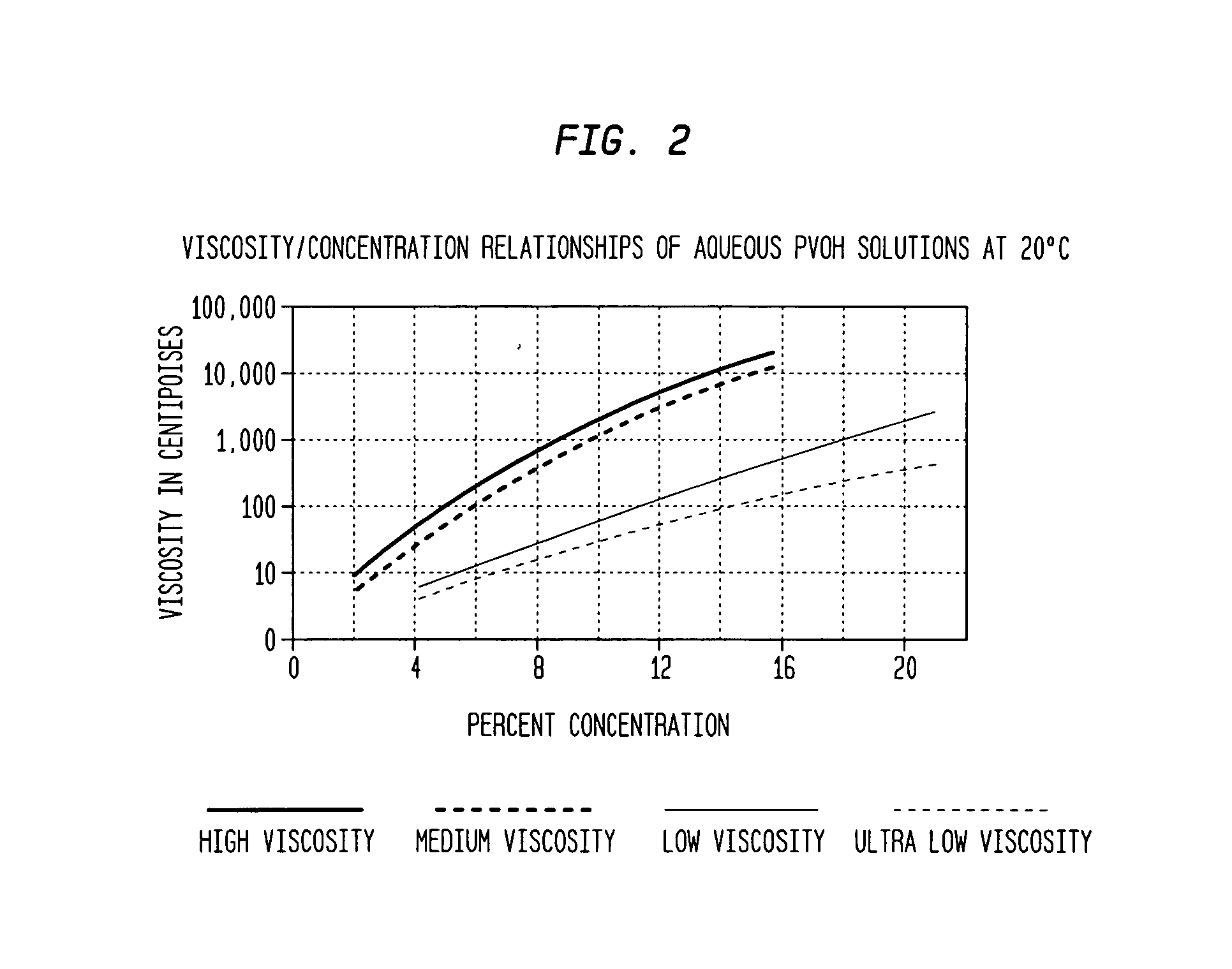

InactiveUS20060041060A1Reduced fluid lossImprove rheologyTransportation and packagingMixingPolyvinyl alcoholCement slurry

A fluid loss additive for hydraulic cement, comprising a polyvinyl alcohol resin and a fluid loss ameliorating sulfonic acid-functionalized co-resin, where the polyvinyl alcohol has a characteristic viscosity in the range of about 1 to about 25 cps. The invention includes, in some embodiments, an aqueous concentrate of the PVOH resin and the sulfonic acid-functionalized co-resin, where the total resin content is in the range of about 10% to about 40% and the viscosity is less than 15,000 cps. By way of the invention it is possible to adjust hydraulic cement slurry characteristics in real time upon demand and reduce inventory by providing a concentrated aqueous fluid loss additive.

Owner:SEKISUI SPECIALTY CHEM AMERICA

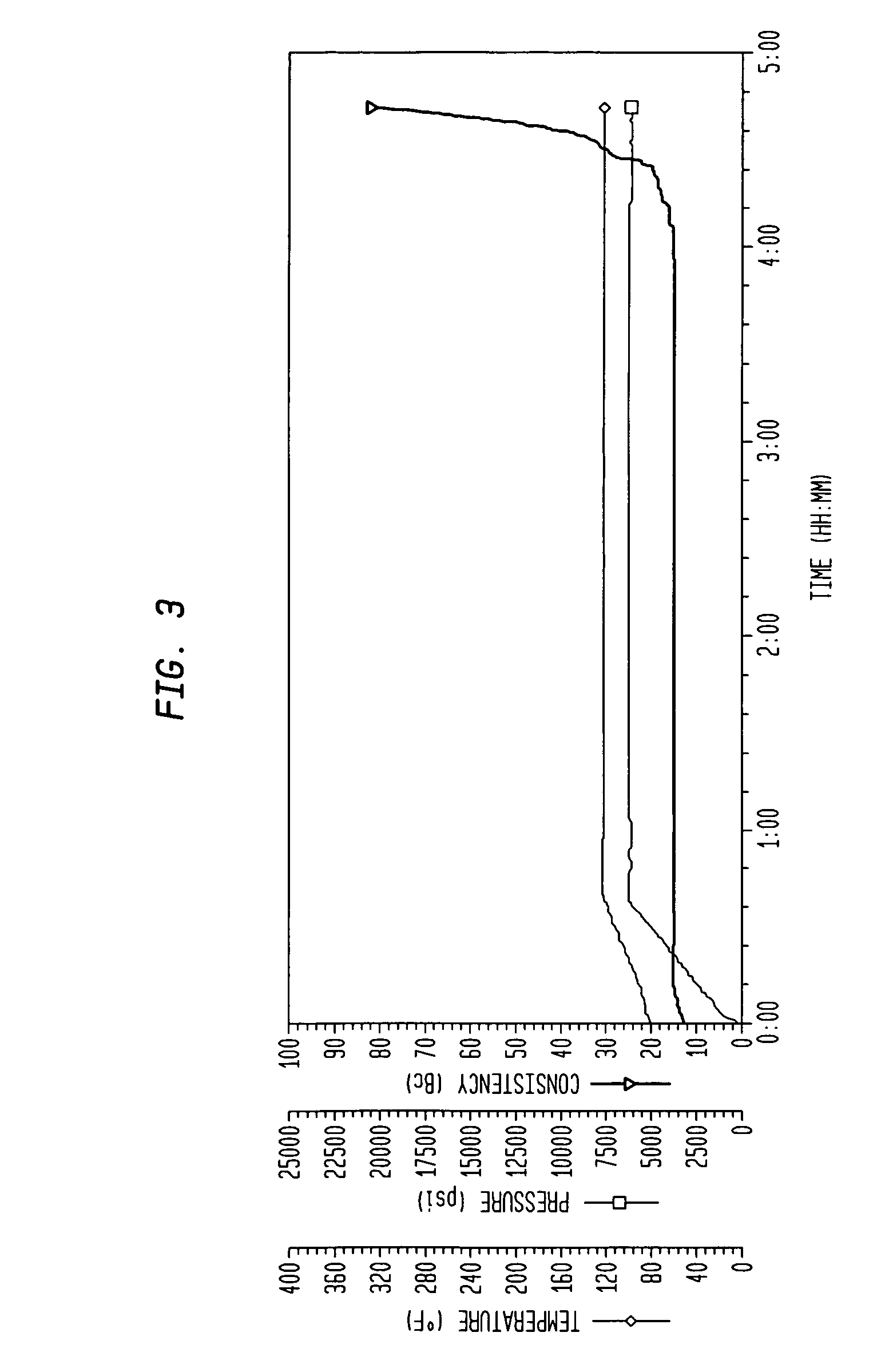

Methods of using colloidal silica based gels

Methods of controlling flow through a subterranean formation may include providing a cement slurry, a colloidal silica, and an activator. The methods may include introducing the cement slurry, the colloidal silica, and the activator into a portion of a well bore that penetrates a subterranean formation The methods may include allowing the cement slurry, colloidal silica, and activator to remain static.

Owner:HALLIBURTON ENERGY SERVICES INC

Deep-water low-temperature low-density early-strength cementing slurry for well cementation

ActiveCN101747880ARapid development of strengthImprove early strengthDrilling compositionVolumetric Mass DensityCement slurry

The invention relates to deep-water low-temperature low-density early-strength cementing slurry for well cementation in petroleum drilling engineering, which contains 100 parts of low-temperature early-strength cement, 10 to 30 parts of low-temperature reinforcing material, 10 to 80 parts of low-density light-weight material, 0.5 to 4 parts of drag reducer, 2.5 to 8 parts of fluid loss additive, 0.1 to 5 parts of retarder, 0.15 to 1.2 parts of defoamer, 2.5 to 8 parts of early strength agent and 57 to 95 parts of water, and slurry with the density of 1.2g / cm3 to 1.7g / cm3 can be prepared. The slurry system at least has the following advantages that: the maximum early strength (24 hours) can reach 14.7MPa, the long-term strength stability is good, the static gelling transition time is short, and the system is stable. The invention provides technical support for the quality of deep-water well cementation.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

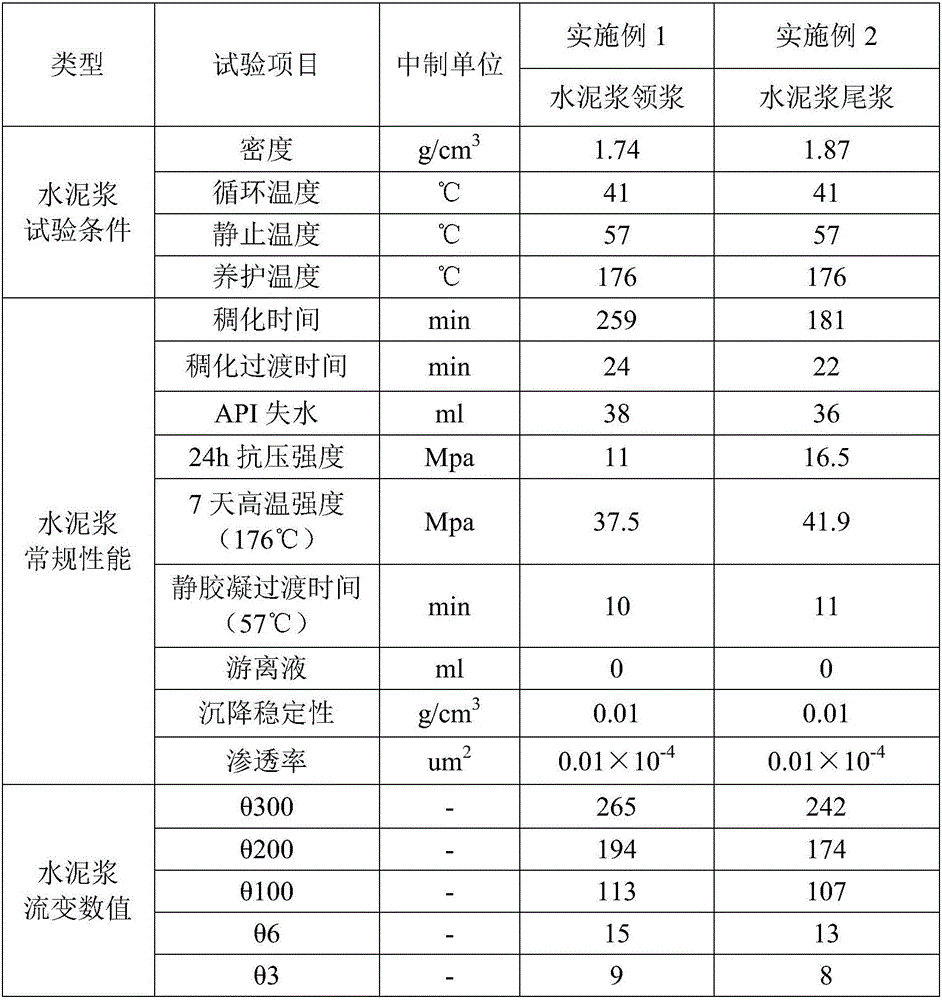

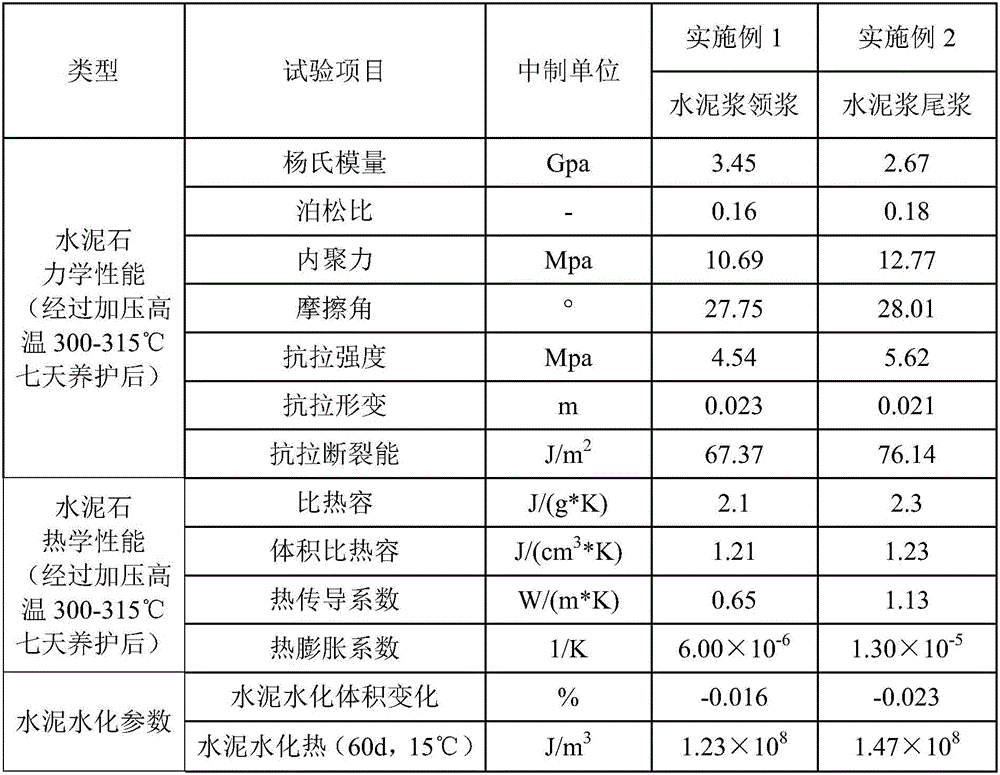

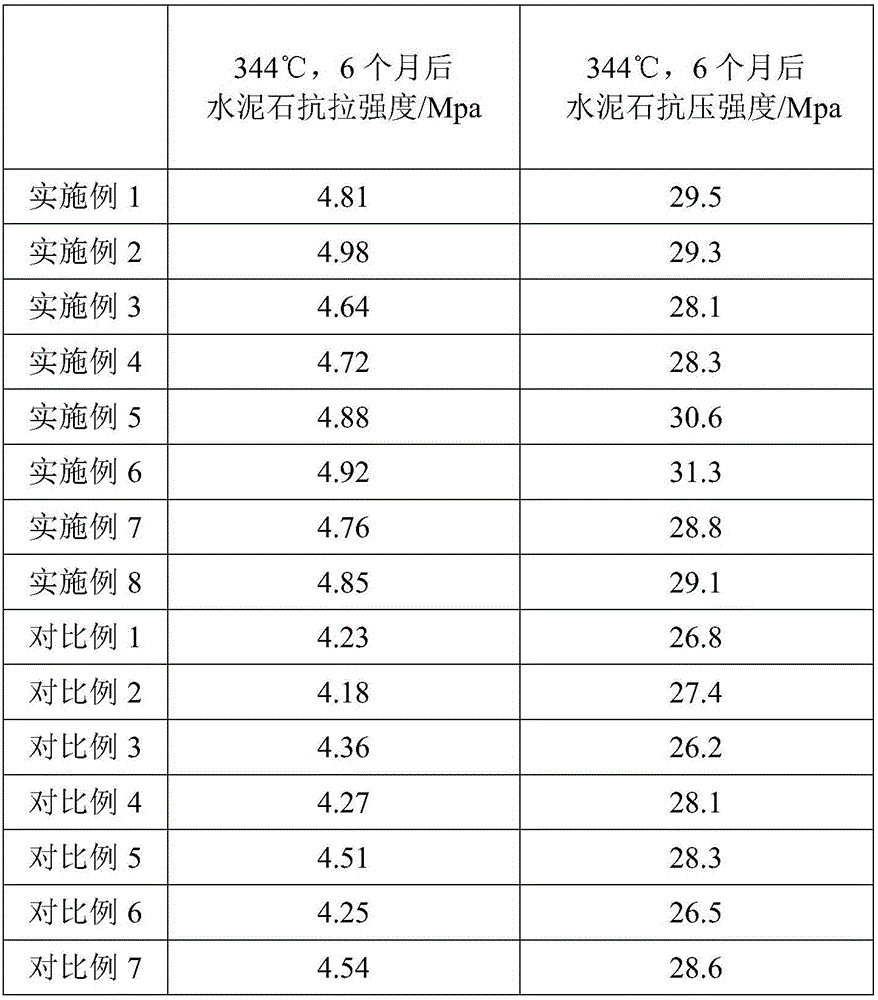

Cement slurry with long-term-integrity cement sheath for heavy-oil thermal-recovery well and preparation method thereof

ActiveCN106007545AGuaranteed general performanceEnsure that the cement slurry system has conventional comprehensive performanceDrilling compositionFiberClay minerals

The invention provides a cement slurry with long-term-integrity cement sheath for a heavy-oil thermal-recovery well. The cement slurry comprises, by weight, 100 parts of thermally responsive cement, 25 to 65 parts of water and 0.2 to 8 parts of a cement slurry aid. The thermally responsive cement comprises 30 to 60 parts of oil well cement, 10 to 20 parts of active silicon powder, 0 to 10 parts of hollow glass beads and 10 to 50 parts of a thermally responsive composite material. The thermally responsive composite material comprises 20 to 30 parts of clay mineral, 10 to 20 parts of fly ash and / or vulcanic ash, 5 to 20 parts of rubber powder and / or latex powder, 3 to 10 parts of carbon fiber, 10 to 15 parts of nanometer silicon dioxide, 5 to 10 parts of calcined magnesia, 10 to 20 parts of ultrafine superfine slag powder and 5 to 10 parts of inorganic whiskers. The cement slurry provided by the invention can solidify at normal temperature; and set cement can resist long-term high temperature, and the mechanical properties and thermal properties of the set cement in a high temperature environment are integrally adaptive to strata and casing pipes.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Storable nonaqueous cement slurries and methods of using same

A method of servicing a wellbore comprising preparing a nonaqueous storable cementitious composition, mixing said composition with an aqueous fluid and, placing said composition into a wellbore. A method of cementing comprising preparing a mixture of cement, a suspension fluid, a dehydrating agent, a first surfactant, and a suspension aid, adding an aqueous solution and a second surfactant to said mixture and, placing the mixture downhole, and allowing the cement to set. A method of producing a lightweight cement slurry comprising the addition of a nonaqueous fluid to cement and water wherein the water content is less than about 40% by total weight of the composition. A method of servicing a wellbore comprising preparing a cement composition comprising from about 80% by weight cement suspended in a nonaqucous fluid, and stabilizing said cement composition through the addition of a suspension aid.

Owner:HALLIBURTON ENERGY SERVICES INC

Drifting sand layer and gravel stratum water-moving double-liquid high pressure slip-casting water-blocking construction method

InactiveCN101255698AHigh strengthImprove water stabilitySolid waste managementUnderground chambersWater blockCement slurry

The present invention discloses a running sand layer and sandy gravel layer dynamic-water double-liquid high-pressure slurry-injecting water-shutoff construction method which comprises the following construction steps: drilling a hole, flushing the hole, executing double-liquid high-pressure slurry-injecting operation and sealing the hole. The running sand layer and sandy gravel layer slurry-injecting liquid adopts an ordinary portland cement (P.O.42.5) and 40''Be sodium silicate as material for preparing the slurry, according to the weight proportion of water: cement, namely the cement slurry is prepared with the water cement ratio for 0.5-1.2:1. Then the slurry-injecting liquid is prepared with the volume ratio of cement slurry: sodium silicate for 1:0.08-0.15. The sodium silicate is taken as additive for regulating the initial setting time of the slurry-injecting liquid. The cement slurry can also be doped with fly-ash with cement consumption (weight proportion) for 10%-15%. The invention executes water-insulating construction aiming at the characteristics of large pressure of the underground dynamic water and high flowing velocity in the running sand layer and sandy gravel layer, and can obtain the maximal application sphere and optimum water-shutoff effect.

Owner:HUNAN CONSTR ENG GRP COR

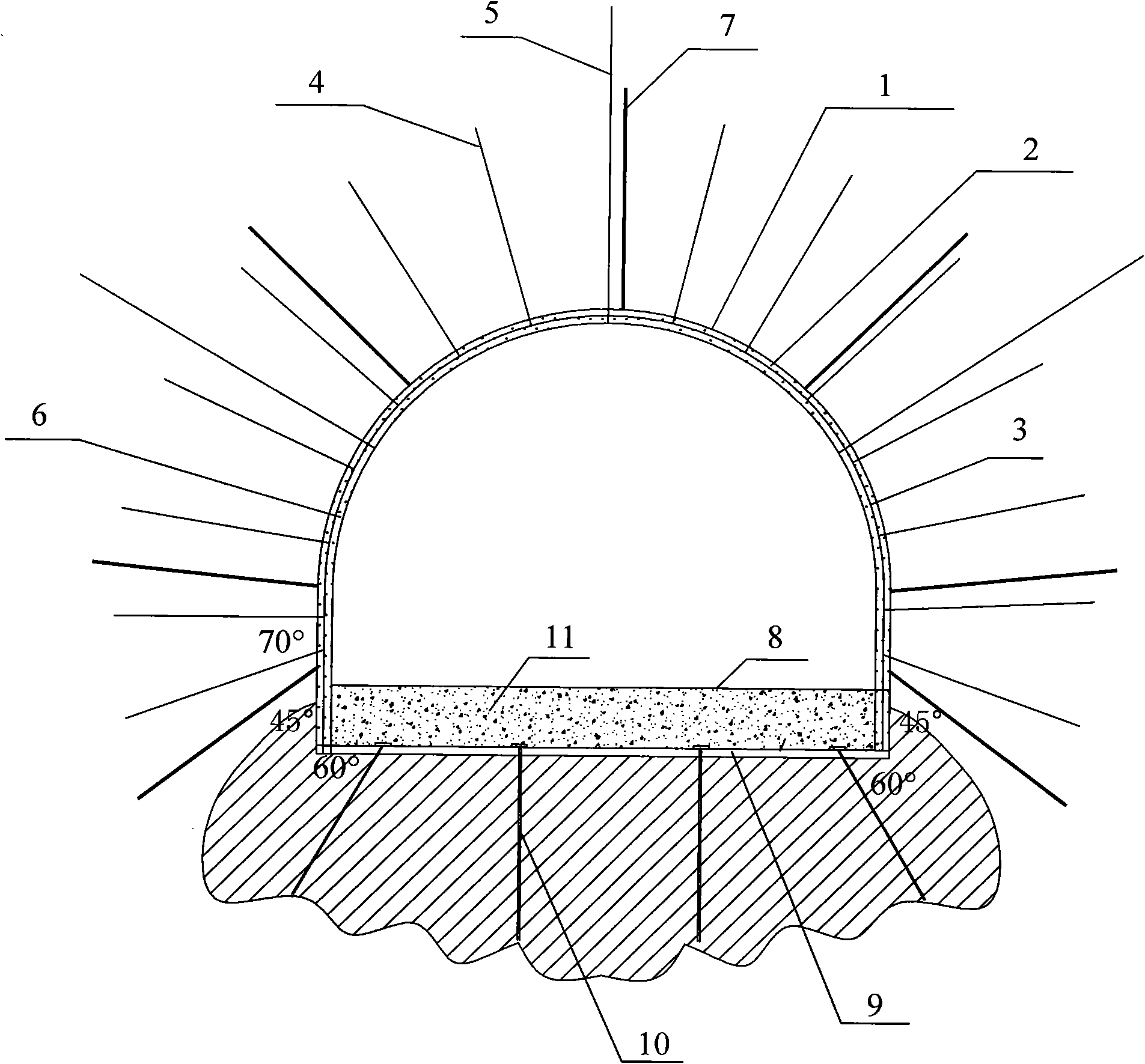

Deep well tunnel cable anchor rigid-flexible coupling support and surrounding rock overall reinforced support method

InactiveCN101967984AImprove carrying capacityPrevent shear deformationUnderground chambersTunnel liningPre stressCoupling

Owner:ANHUI UNIV OF SCI & TECH

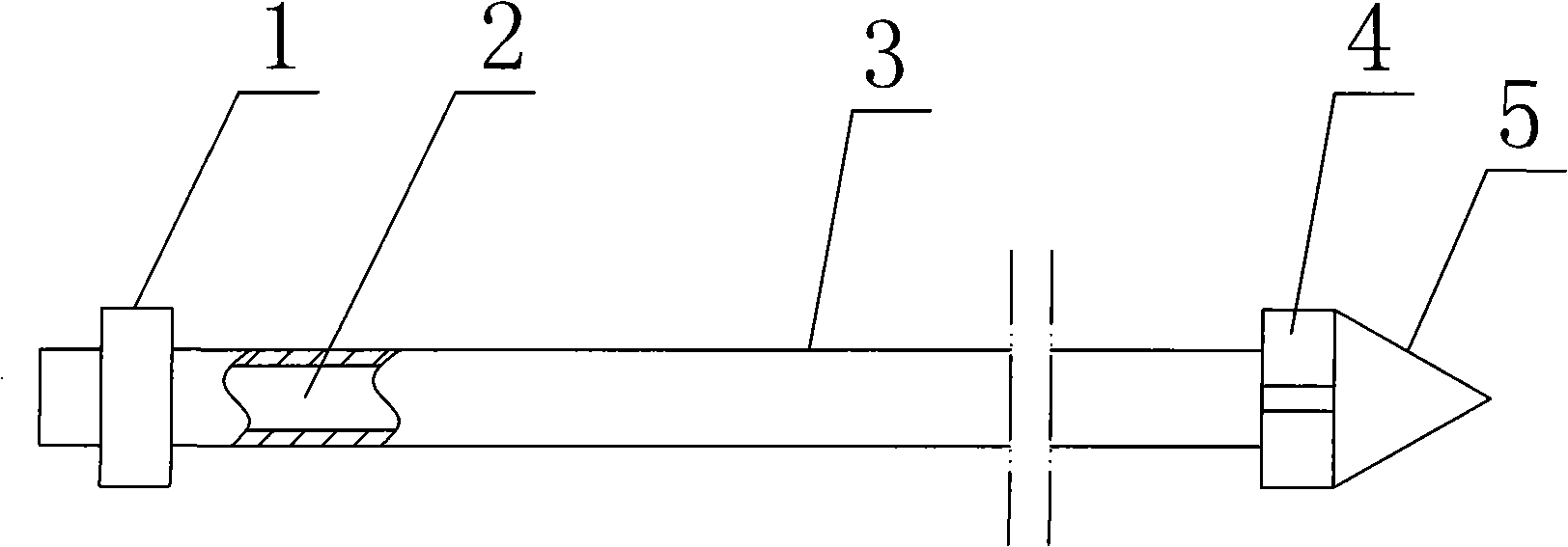

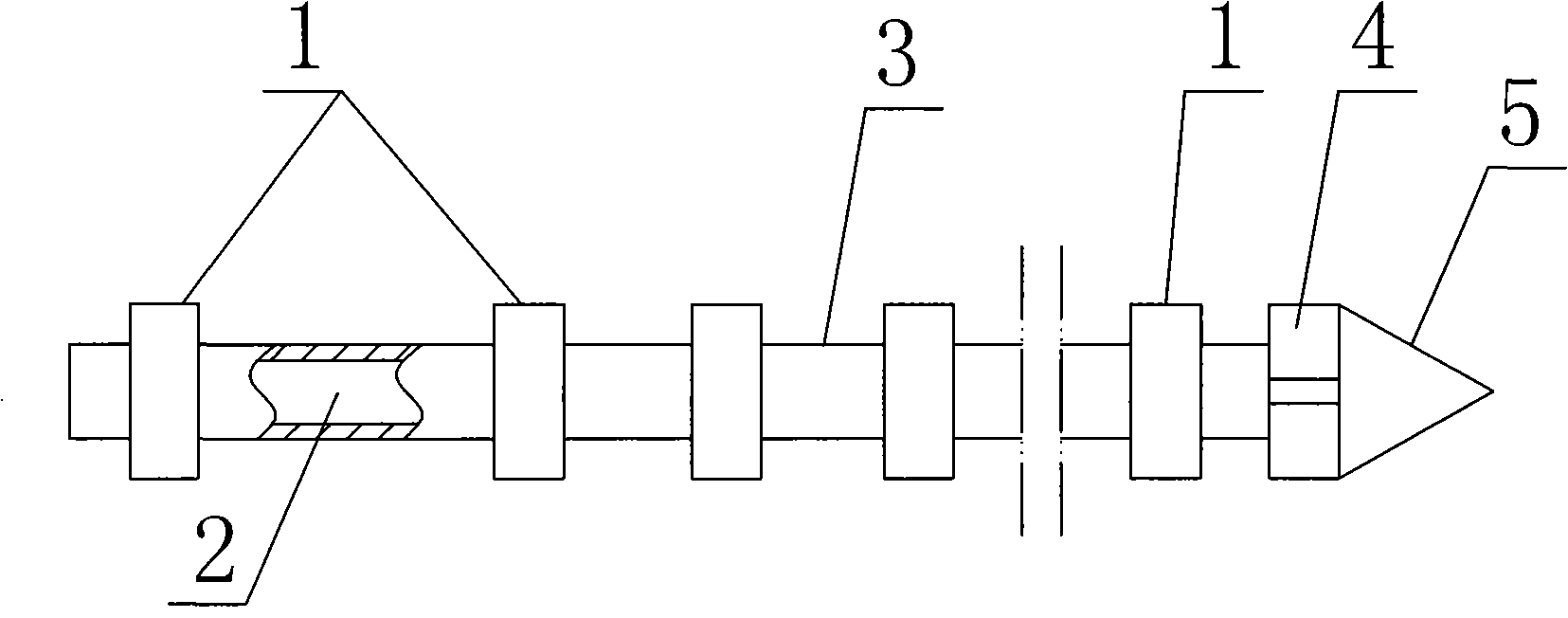

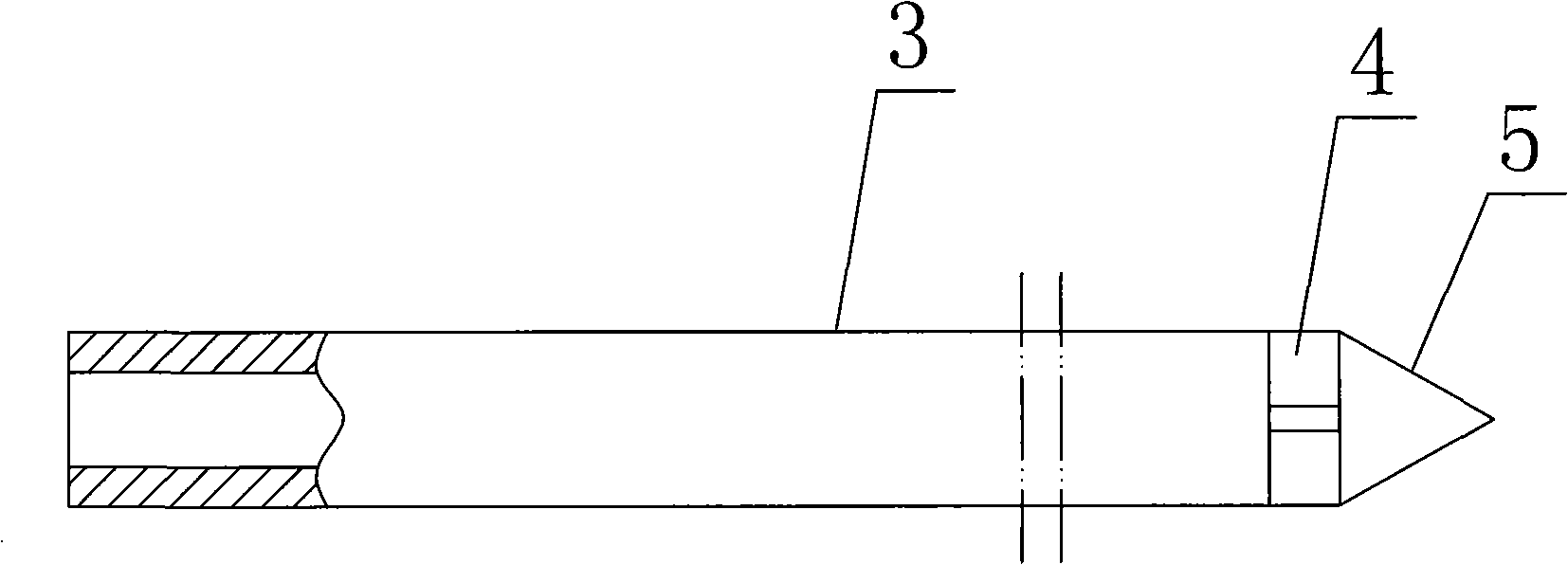

Drilling and sealing method and sealing device for ultra-high pressure fracturing holes in underground coal mines

The invention discloses a drilling-sealing method and a sealing device of a coal mine underground ultrahigh pressure fracturing hole. The drilling-sealing method comprises the following steps: drilling a plugging hole on coal rock body; going on drilling a fracturing hole forward in the plugging hole; transmitting the sealing device into the plugging hole, enabling a water outlet hole of a fracturing pipe to stretch into the fracturing hole and enabling a taper sleeve sleeved on the fracturing pipe and made of soft material to plug on a hole opening of the fracturing hole; sealing by using polyurethane and solidifying for 30 minutes for 1 m length section at the hole opening of the plugging hole; and grouting cement slurry greater than 425 into the plugging hole with pressure by a grouting pipe, and solidifying for 48 hours after finishing grouting. The device comprises a grouting pipe and a slurry returning pipe and a fracturing pipe. The grouting pipe and the slurry returning pipe are arranged in the plugging hole. The grouting pipe, the slurry returning pipe and the fracturing pipe are connected integrally. A soft taper sleeve is arranged on the fracturing pipe. The soft taper sleeve is plugged at the hole opening of the fracturing hole. The invention has the advantages that the sealing method has high sealing success rate, good effect and wide application range; and the sealing device has simple structure and convenient operation.

Owner:重庆市能源投资集团科技有限责任公司 +1

Preparation method for inorganic foaming fireproof insulation plate

InactiveCN102503525AIncrease late strengthImprove crack resistanceCeramicwareCement slurryMaterials science

The invention discloses a preparation method for an inorganic foaming fireproof insulation plate. The preparation method comprises the steps of selecting materials, preparing a superfine cement slurry, preparing a foaming liquid material and forming. As the above technical scheme is adopted, the preparation method disclosed by the invention has the characteristics of simple construction and easy industrial production; and the inorganic foaming fireproof insulation plate prepared by the method has the characteristics of lightness, good strength, high closed cell rate, low water absorptivity, small dry shrinkage value, good freezing resistance, excellent insulation performance and simple and convenient construction.

Owner:SHANDONG ZHONGYUAN HUILI ENERGY SAVING BUILDING MATERIAL CO LTD

Solvent free fluidized polymer suspensions for oilfield servicing fluids

This invention relates to a composition and use application of aqueous fluidized polymer suspensions of water soluble polysaccharides and / or polyvinyl alcohol (PVA) for use in oil field applications such completion fluids, drilling fluids, fracturing fluids and oil well cement slurries as rheology / viscosity modifier and fluid loss reducer for use where the affect on the marine environment is to be minimized.

Owner:HERCULES INC

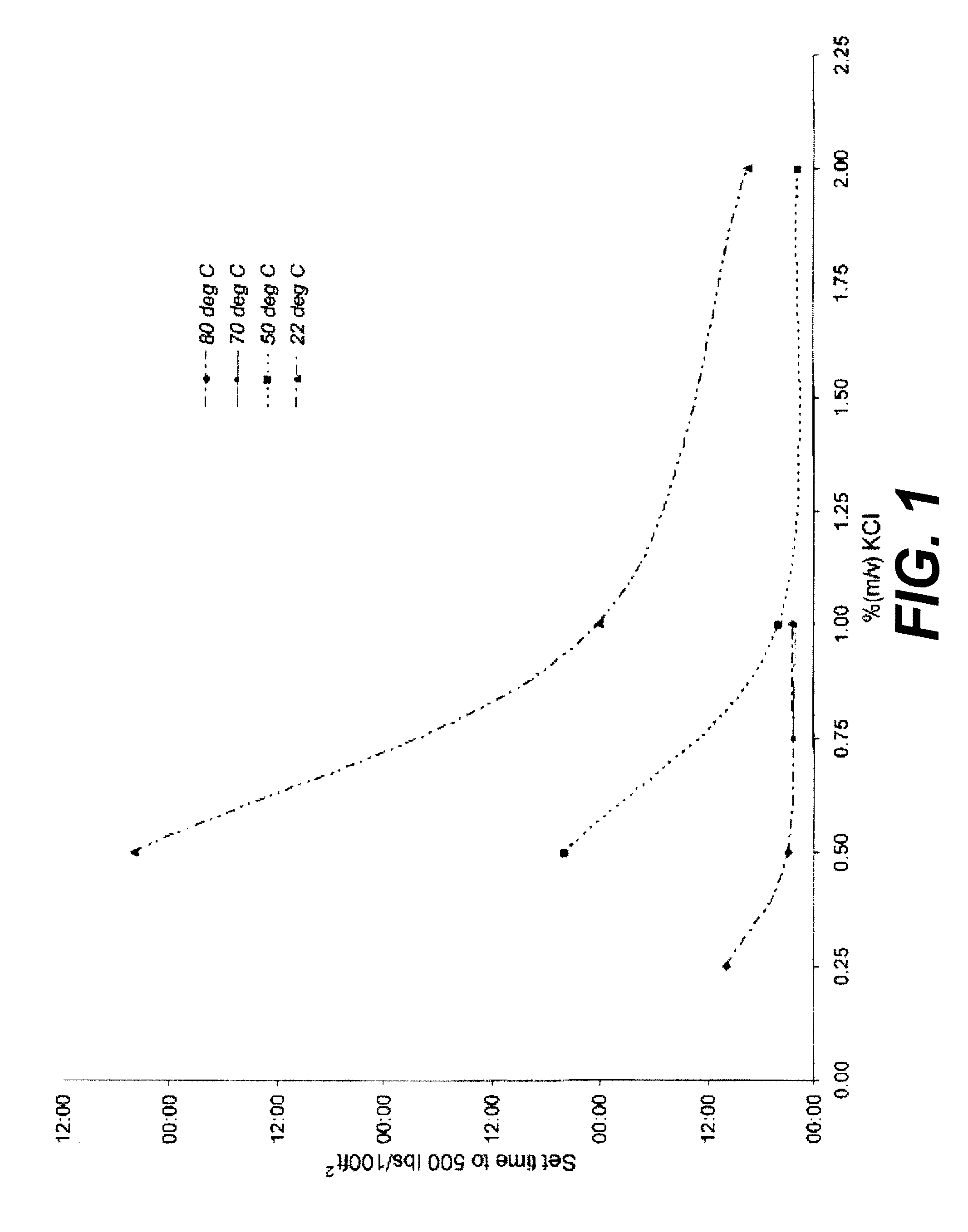

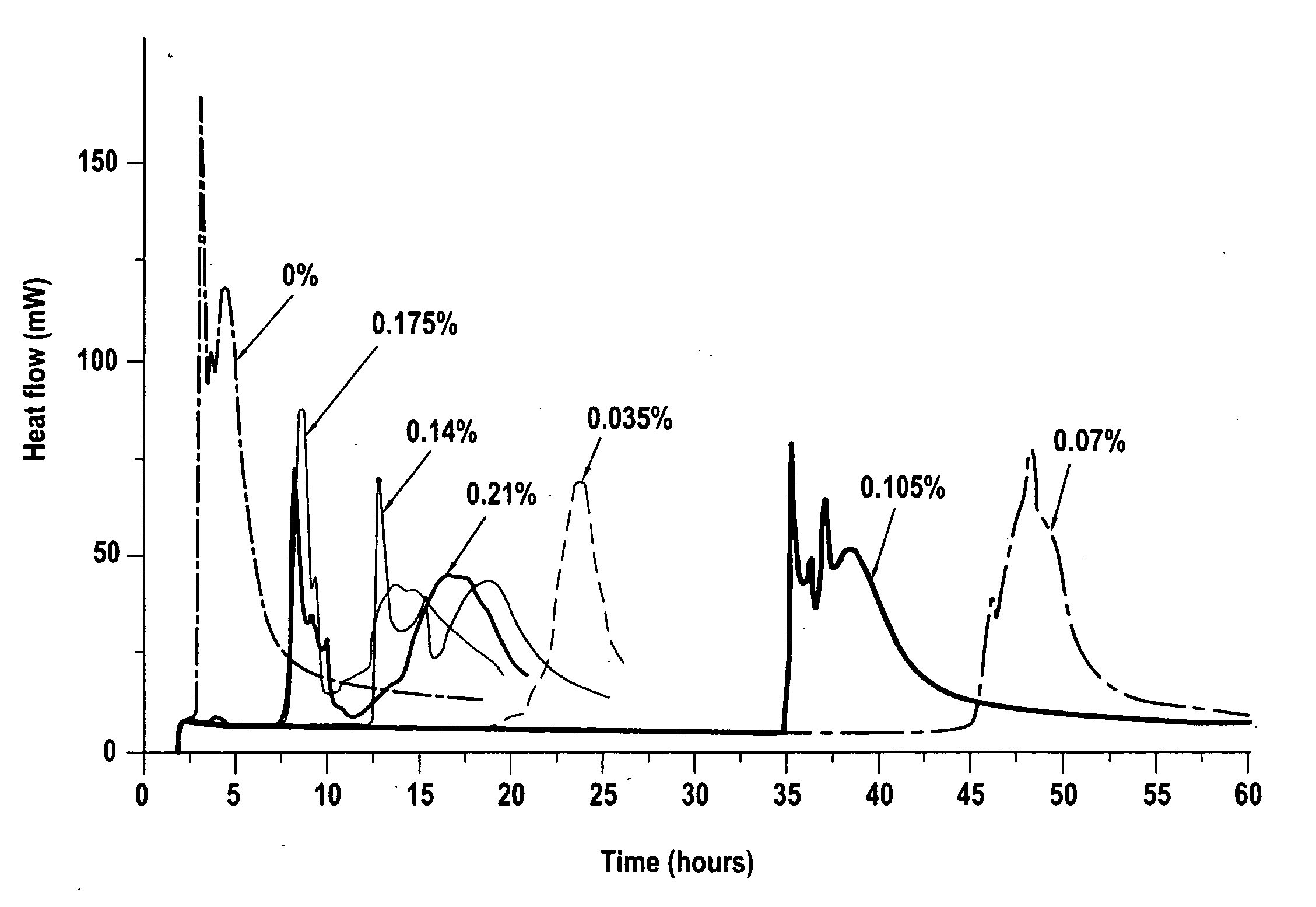

Cement Retarder Systems, and Retarded Cement Compositions

A cement retarder system for use in underground wells included a borate compound, an organophosphonate salt, and a copolymer formed from AMPS and a monomer selected from the group consisting of acrylic acid, acrylamide and mixtures thereof. A method of using the retarder system in an underground well having a borehole drilled therein with a borehole wall, and further including a casing disposed in said borehole, such that an annulus exists between said casing and said borehole wall, comprising the steps of providing a cement composition and a liquid carrier, providing a retarder system for said cement composition comprising a borate compound, an organophosphonate salt, and a copolymer formed from AMPS and a monomer selected from the group consisting of acrylic acid, acrylamide, and mixtures thereof, mixing a sufficient amount of said retarder system to create a desired induction period with said cement composition and said liquid carrier to form a cement slurry, pumping the cement slurry from the surface down the casing, and causing said slurry to return to the surface in the annulus between the casing and the borehole wall.

Owner:SCHLUMBERGER TECH CORP

Low-density composite foaming cement and preparation method thereof

The invention discloses low-density composite foaming cement and a preparation method thereof, relating to a light building material. The foaming cement is prepared by adopting a normal-temperature foaming technology, and comprises the following components in parts by weight: 100 parts of cement, 10-50 parts of active admixture, 1-5 parts of redispersible emulsion powder, 1-4 parts of water repellent, 0.5-1.5 parts of cellulose ether, 0.3-0.7 parts of reinforced fiber, 0.2-0.5 parts of foam stabilizer, 3-8 parts of foaming agent and 50-80 parts of water. The method comprises the following preparation steps of: proportionally mixing and stirring the cement, active admixture, redispersible emulsion powder, water repellent, cellulose ether, reinforced fiber, foam stabilizer, and water into cement slurry; adding the foaming agent; and stirring, molding by casting and naturally curing. The foaming cement disclosed by the invention has the advantages of low volume weight, small heat conducting coefficient, small shrinkage ratio, high intensity, integration of heat preservation, sound insulation, fire prevention and low carbon, simple and convenient production preparation process and easiness in controlling.

Owner:JIANGSU JINMAO TECH DEV

Fluid loss control agents and compositions for cementing oil wells comprising said fluid loss control agent

The present invention concerns a fluid loss control agent for a petroleum industry (or analogous) cement slurry, comprising a surfactant and a micro-gel obtained by chemical cross-linking of a polyvinyl alcohol. The micro-gel and the surfactant are advantageously compatible with a wide range of petroleum industry cement additives and can also produce compositions which are gas tight.

Owner:SCHLUMBERGER TECH CORP

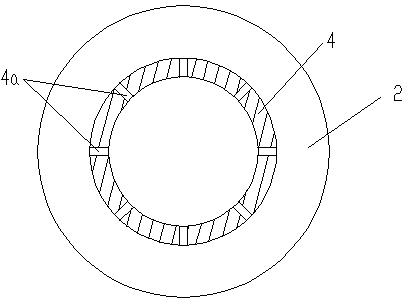

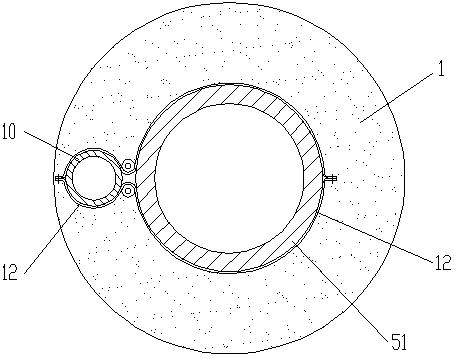

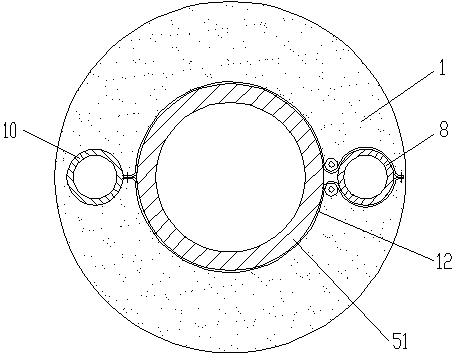

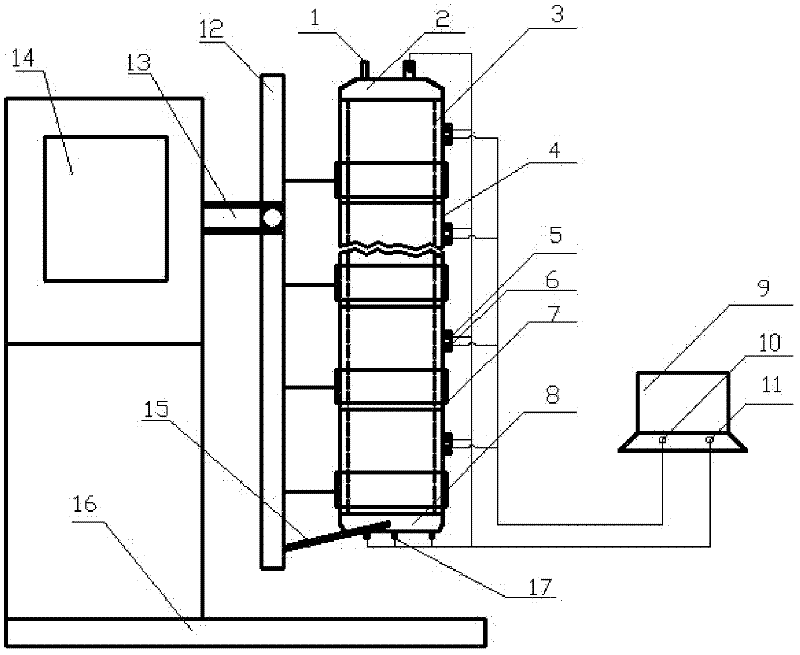

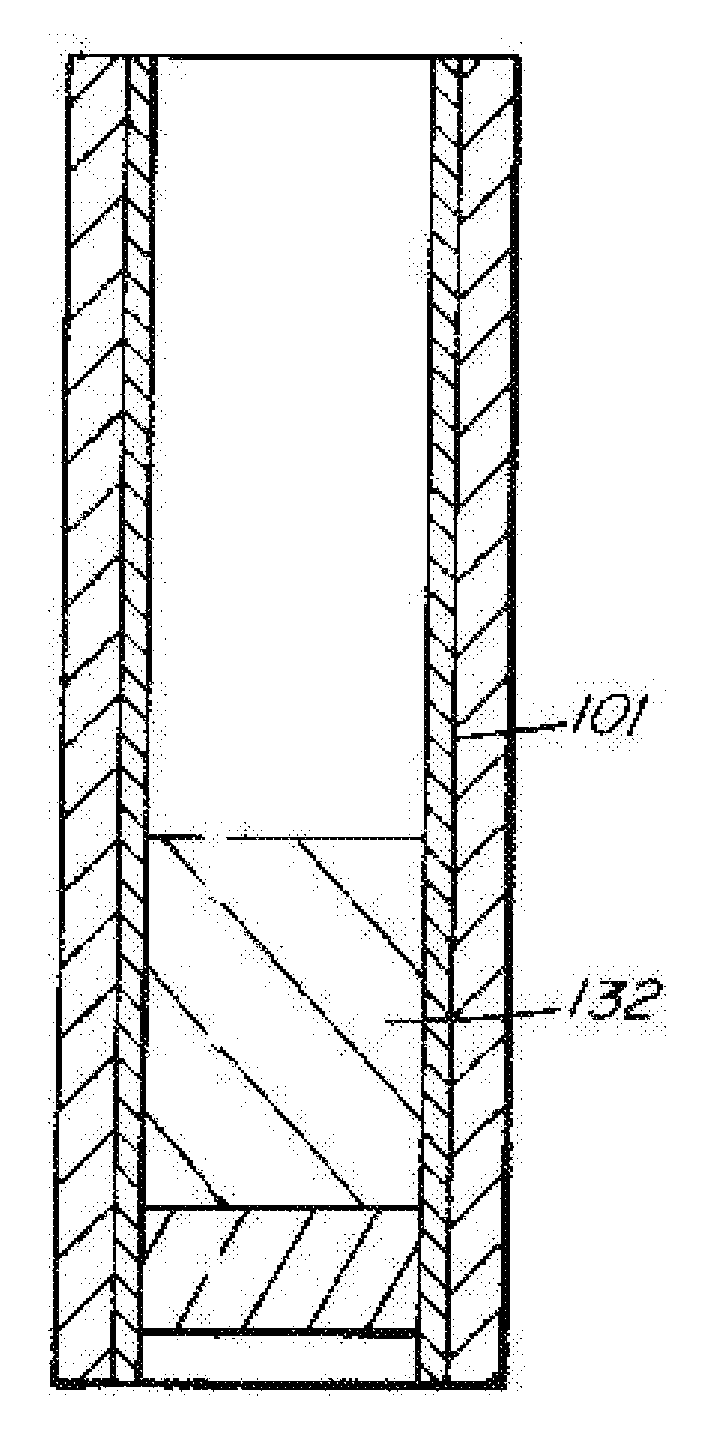

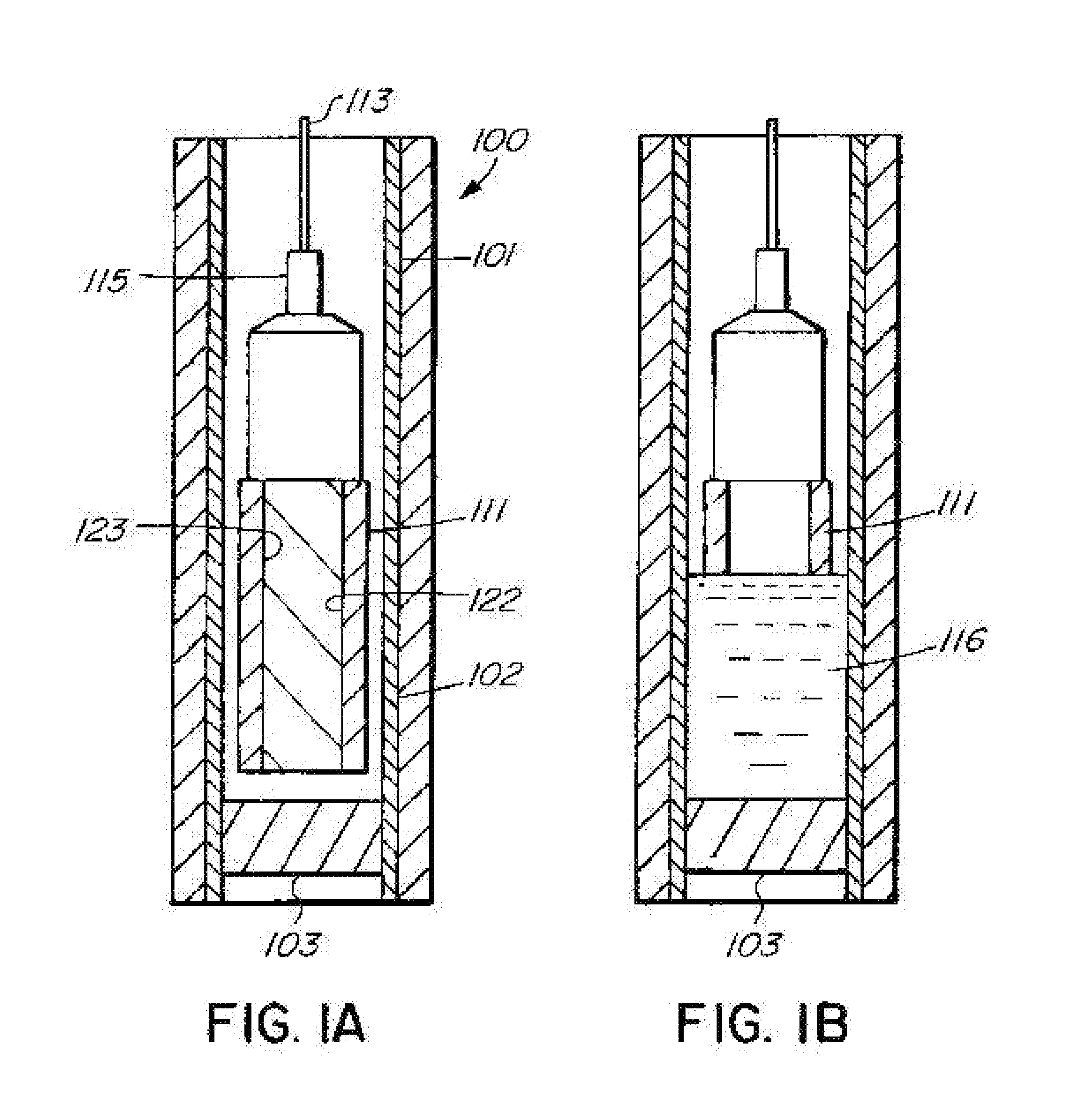

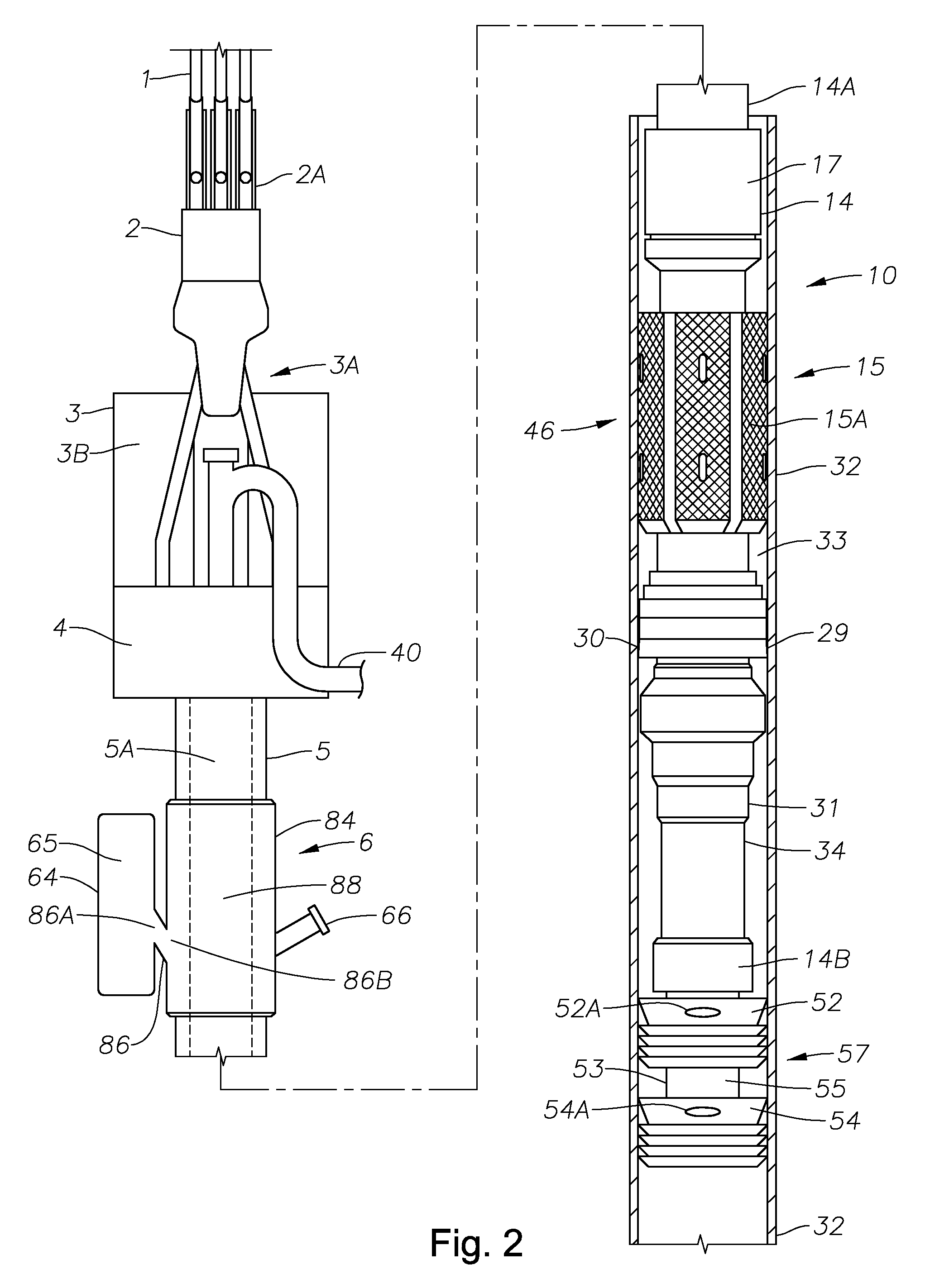

Measuring device and measuring method for well-cementing annular weight loss of cement slurry

ActiveCN102392634AEasy to operateSolve the problem of downhole temperature changeSurveyConstructionsMeasurement deviceWell cementing

The invention relates to a measuring device and measuring method for well-cementing annular weight loss of cement slurry. The device is mainly composed of a base, a control panel, an upright strut, a slurry cylinder and a computer, wherein the upright strut is connected with the slurry cylinder through a support shaft and with the control panel through a rotating shaft; the slurry cylinder is provided with a pressurizing hole, an inner cylinder, an outer cylinder and an annular space between the inner and outer cylinders; the slurry cylinder is a segmented combination with each segment provided with a temperature sensor, a pressure sensor and a heating cooling jacket; the slurry cylinder controls the eccentricity of the inner cylinder through an eccentric cover, three pressure sensors arearranged at the lower part of the slurry cylinder; and the temperature sensors and the pressure sensors respectively transmit data to the computer. The invention can simulate different temperature differences of downhole temperature changing along with hole depth, and acquisition and regulation are controlled by the computer, so that the operation is simple and convenient; the eccentricity of thesleeve is controlled by the eccentric cover, so that the safety, stability and reliability are ensured; and the measuring device and the measuring method are suitable for operations such as petroleumand natural gas well cementation, cement extrusion, cement injection and the like.

Owner:SOUTHWEST PETROLEUM UNIV

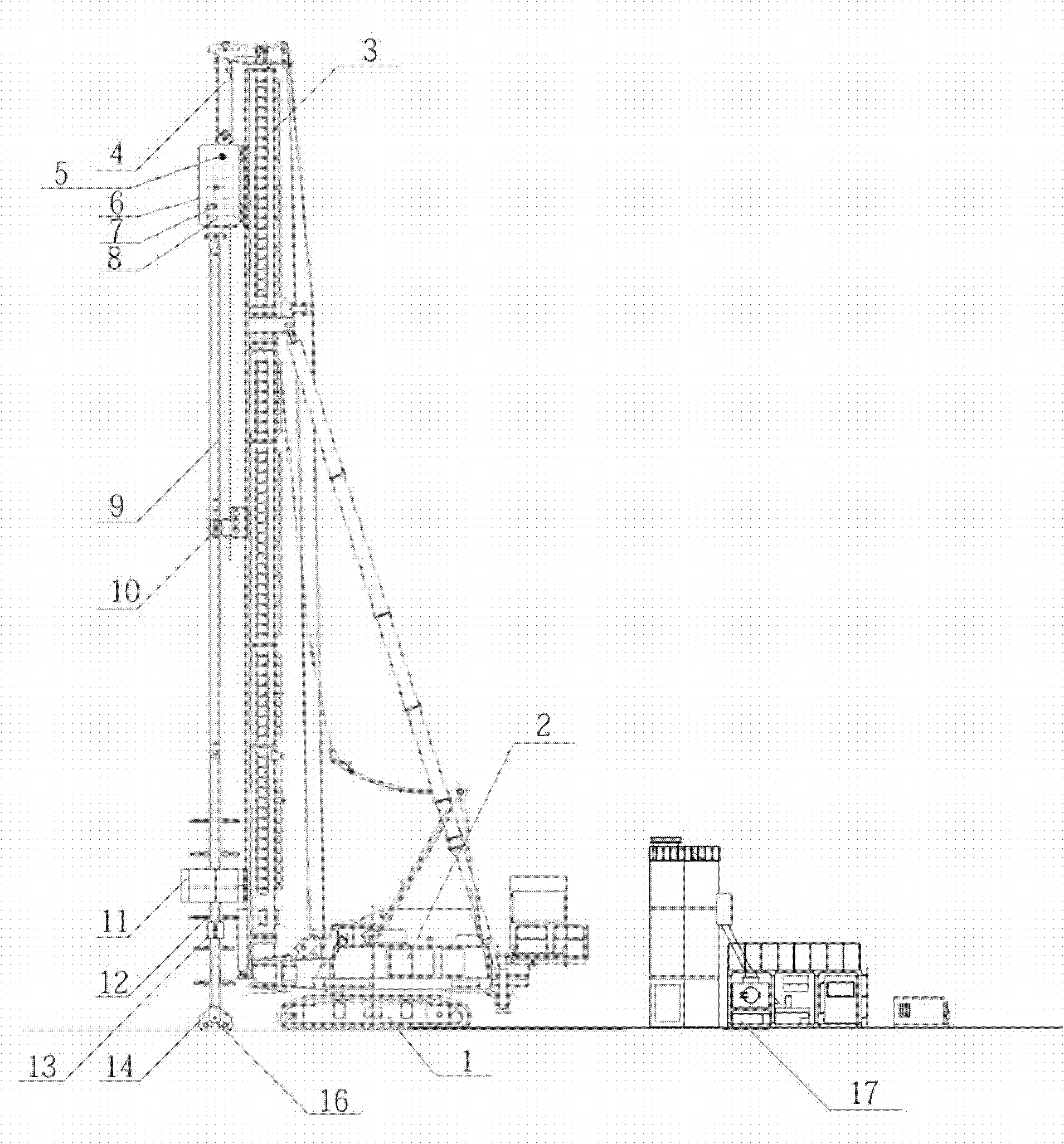

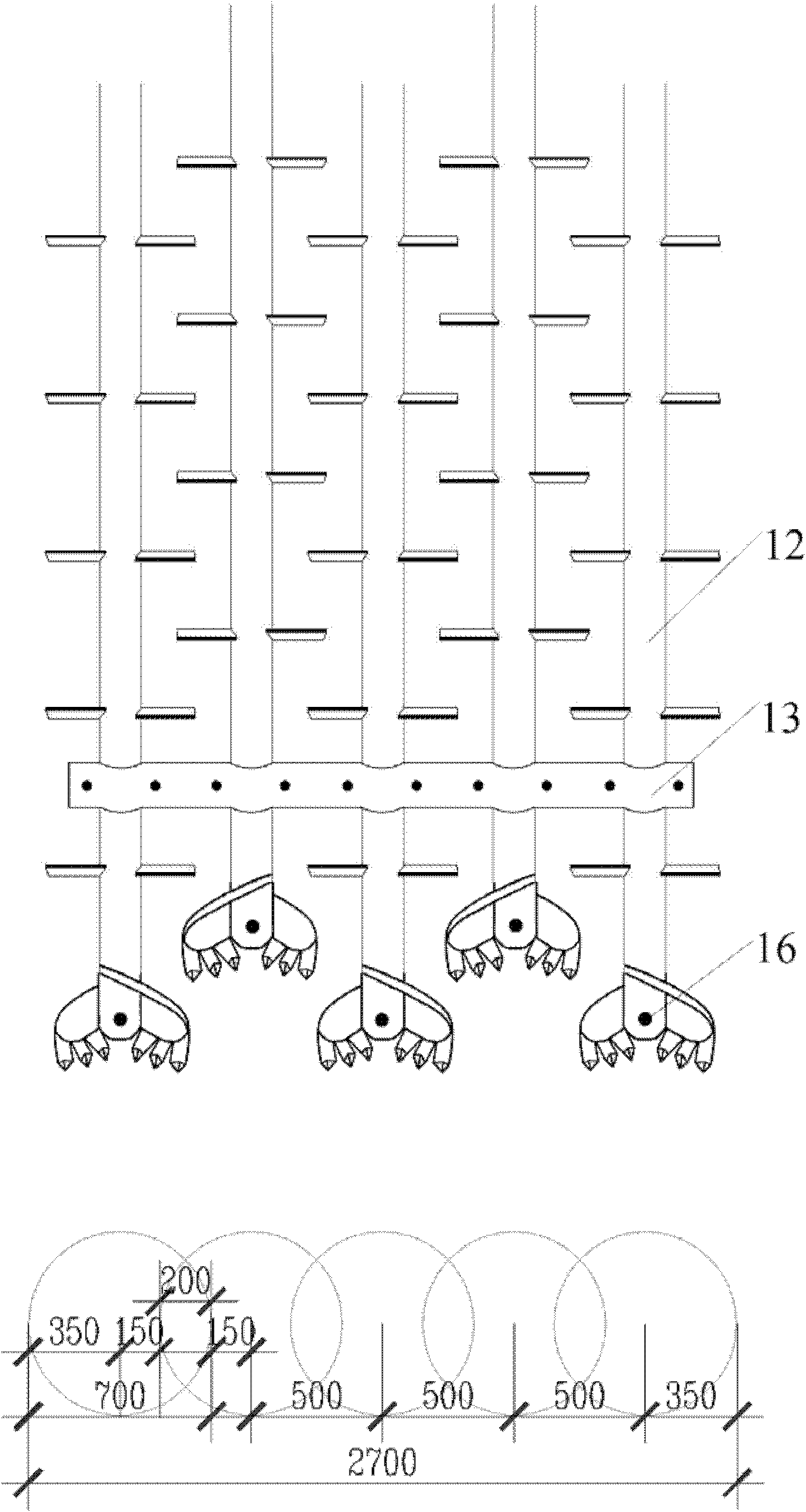

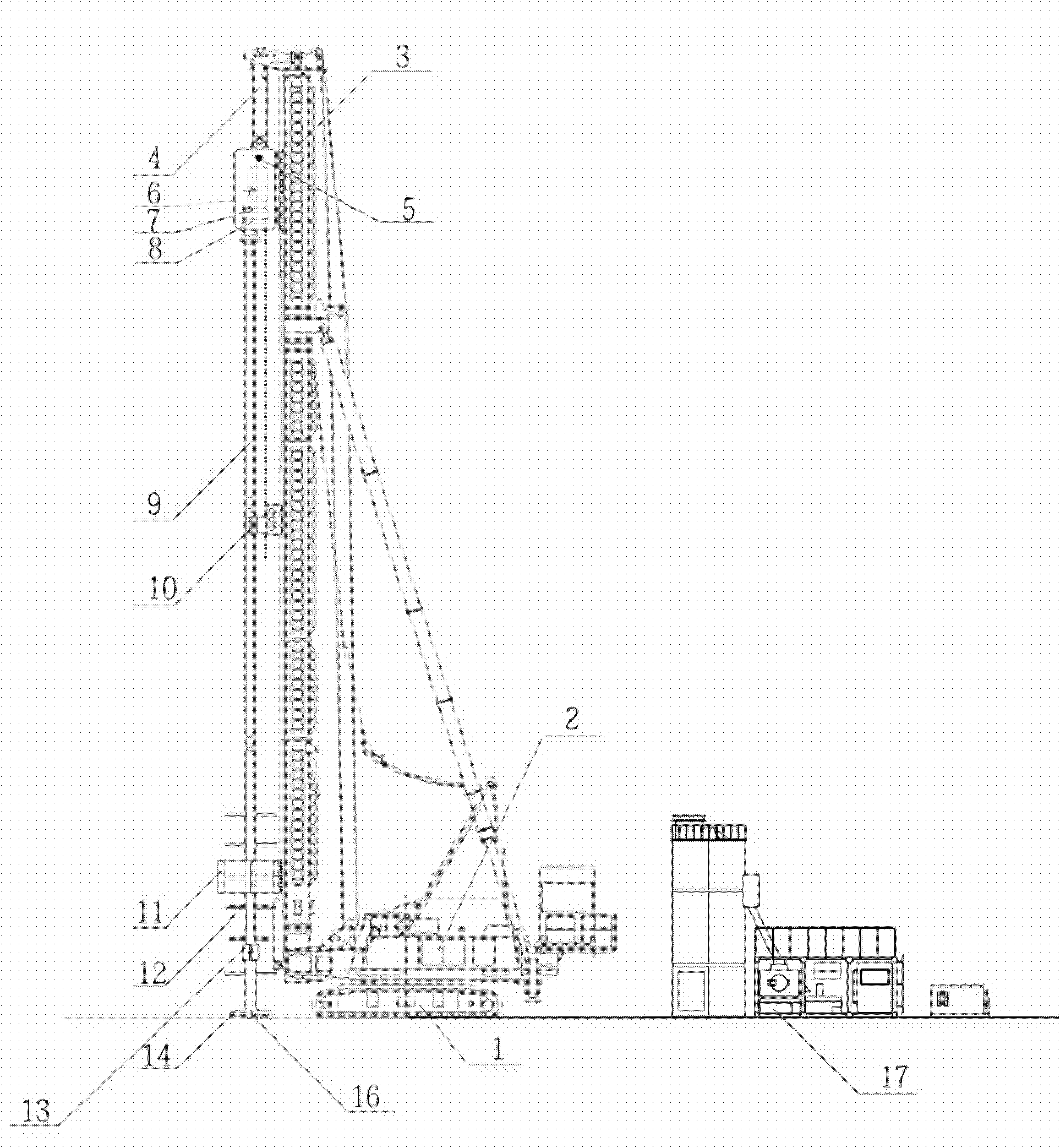

Five-axis cement-soil mixing pile device and construction method

The invention relates to a five-axis cement-soil mixing pile device and a construction method. The device comprises a walking-type and crawler-type host machine, a winding machine, a guide rod, a steel wire rope, a slurry inlet, a power head, a speed change box, a speed reducer, drill stems, a middle support frame, a lower support frame, drill stems with wings, hoops, a multifunctional drill head, a slurry spraying opening and a background cement slurry mixing system, wherein the winding machine and the guide rod are fixed on the host machine; the power head is connected with a pulley on the top of the guide rod through the steel wire rope; the steel wire rope drives the power head to rise and fall in a vertical direction; the power head is connected with five drill stems sequentially through the speed change box and the speed reducer; the middle support frame is arranged on the middle parts of the five drill stems, and the lower support frame is arranged on the lower parts of the five drill stems; the drill stems with wings are connected to the lower ends of the drill stems; the hoops are arranged on the drill stems with the wings; the lower ends of the drill stems with the wings are connected with the multifunctional drill head; and the slurry spraying opening is formed in the multifunctional drill head. Compared with the prior art, the five-axis cement-soil mixing pile device has the advantages of guaranteeing the safety and the quality, reducing the cost, shortening the work period and the like along with no noise, no vibration and high efficiency.

Owner:SHANGHAI CHENGDI CONSTR

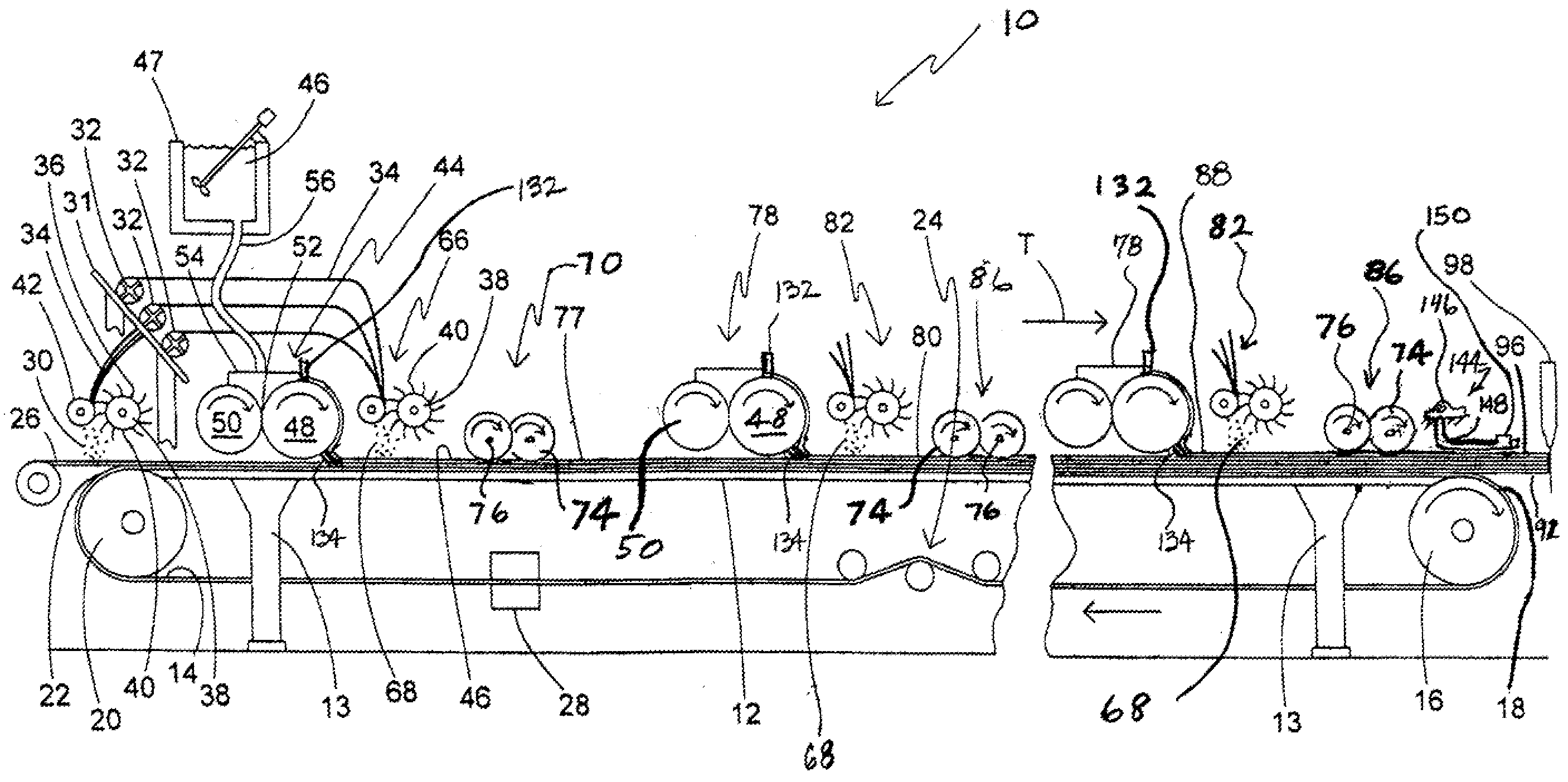

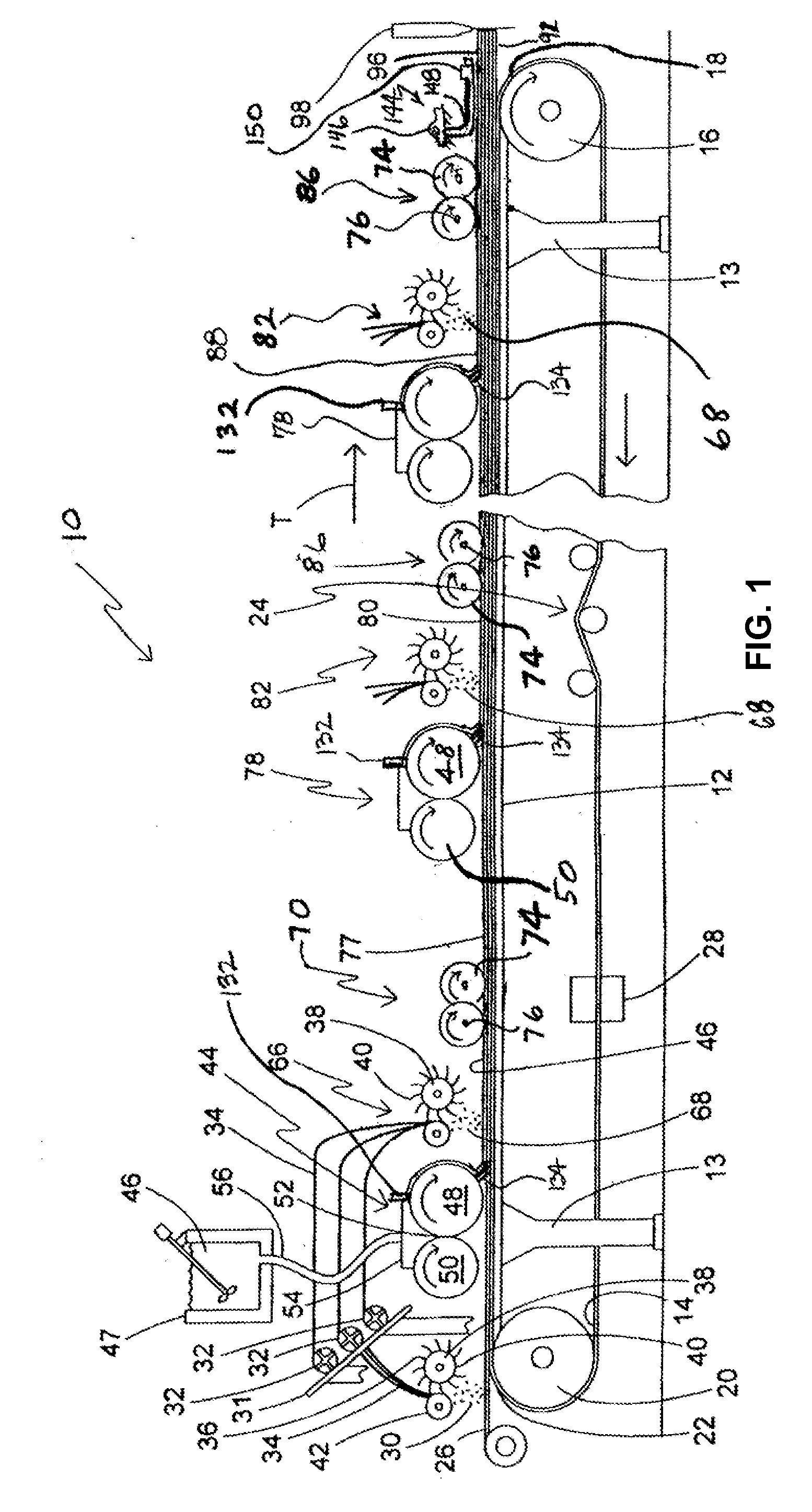

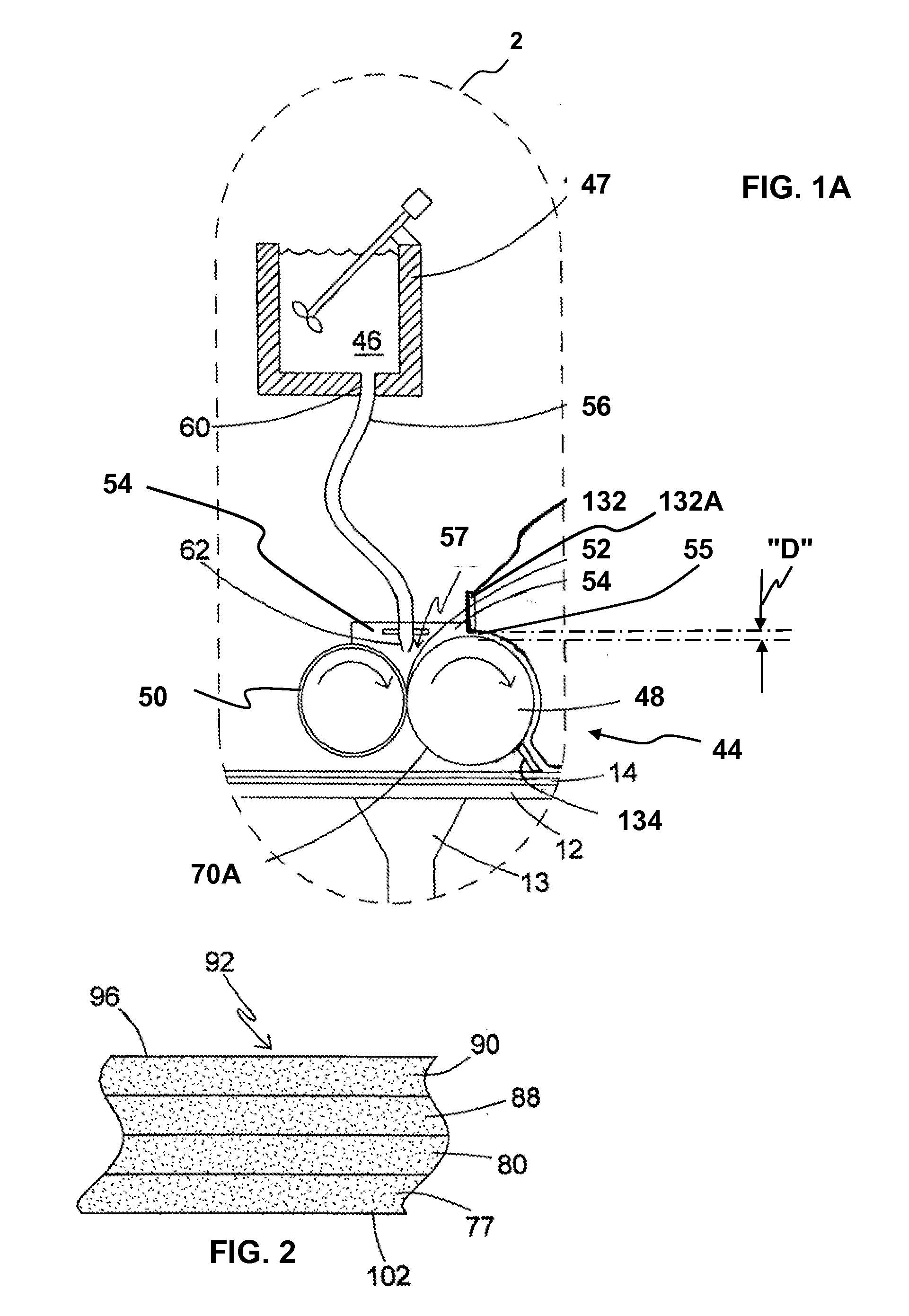

Process and apparatus for feeding cementitious slurry for fiber-reinforced structural cement panels

ActiveUS20080099171A1Good strength propertiesA large amountNon-fibrous pulp additionNatural cellulose pulp/paperEngineeringFibre reinforcement

A head-box for depositing slurry upon a moving web including a main metering roll, a companion roll disposed in closely spaced relation to the metering roll and a vibrating gate which forms a nip between the metering roller and the gate. The nip is arranged to retain a supply of the slurry, and the rolls are driven so slurry retained in the nip progresses over an upper outer peripheral surface of the metering roll to be deposited upon the web. Also, preferably included is a doctor blade disposed in operational relationship to the metering roll for directing the slurry downwardly from the outer metering roll surface to a point above the surface of a carrier for a fiberglass layer upon which the slurry layer is deposited. The vibrating gate and doctor blade may be pivotally mounted to either side of the surfaces of the head-box.

Owner:UNITED STATES GYPSUM CO

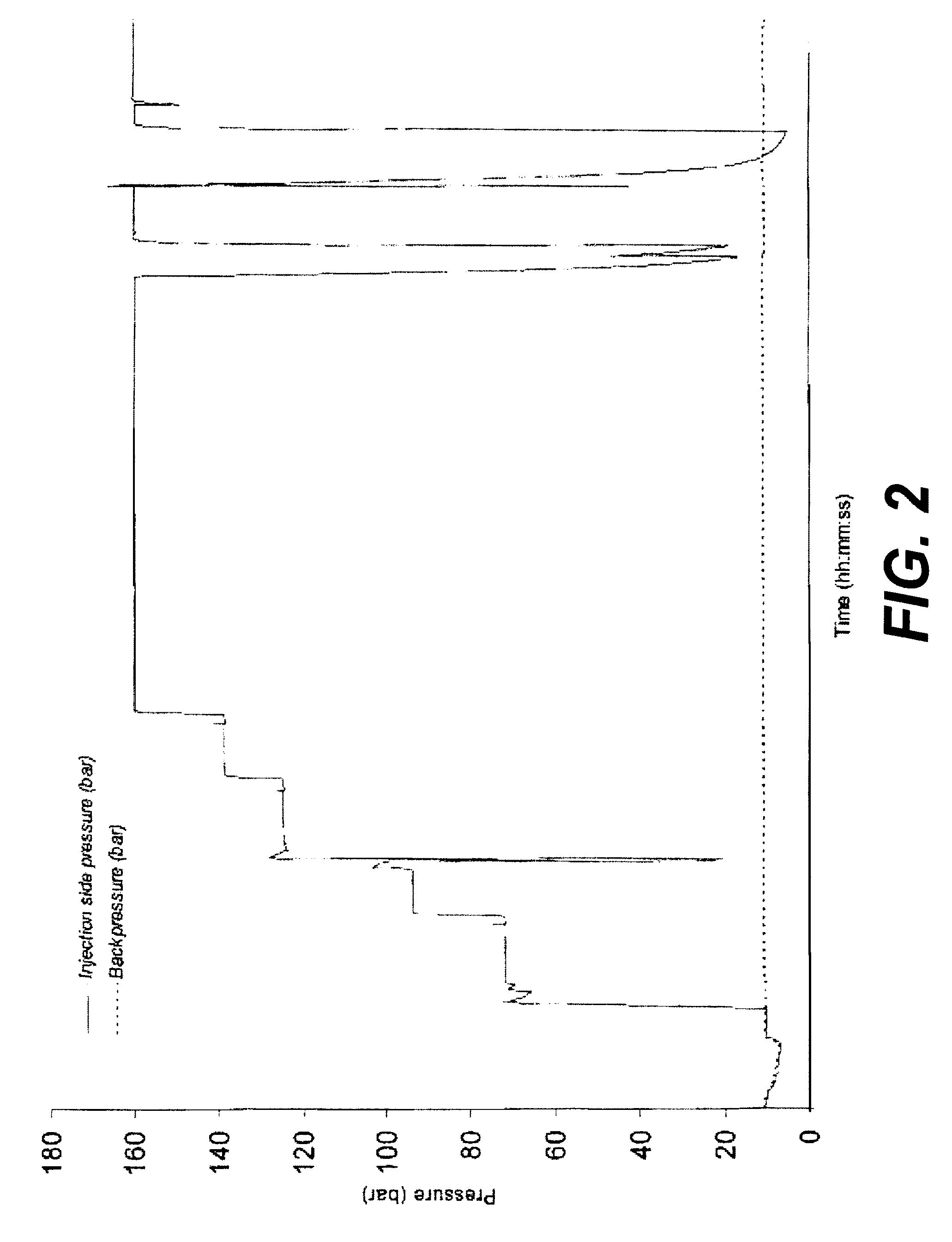

Method of using a swelling agent to prevent a cement slurry from being lost to a subterranean formation

InactiveUS20040168804A1Simple compositionLiquid/gas jet drillingFluid removalGeomorphologyCement slurry

Methods of cementing in a subterranean formation include passing a swelling agent to a permeable zone in a subterranean formation. The swelling agent is combined with a carrier fluid before being passed to the permeable zone. Upon contacting an aqueous fluid, the swelling agent swells in the permeable zone. The aqueous fluid may already be present in the subterranean formation, or alternatively, it may be introduced to the subterranean formation after passing the swelling agent into the subterranean formation. The swelling agent substantially inhibits a cement slurry subsequently pumped into the subterranean formation from passing through the permeable zone. The cement slurry therefore continues flowing down through the casing and up through the annulus where it sets and forms a strong cement column.

Owner:HALLIBURTON ENERGY SERVICES INC

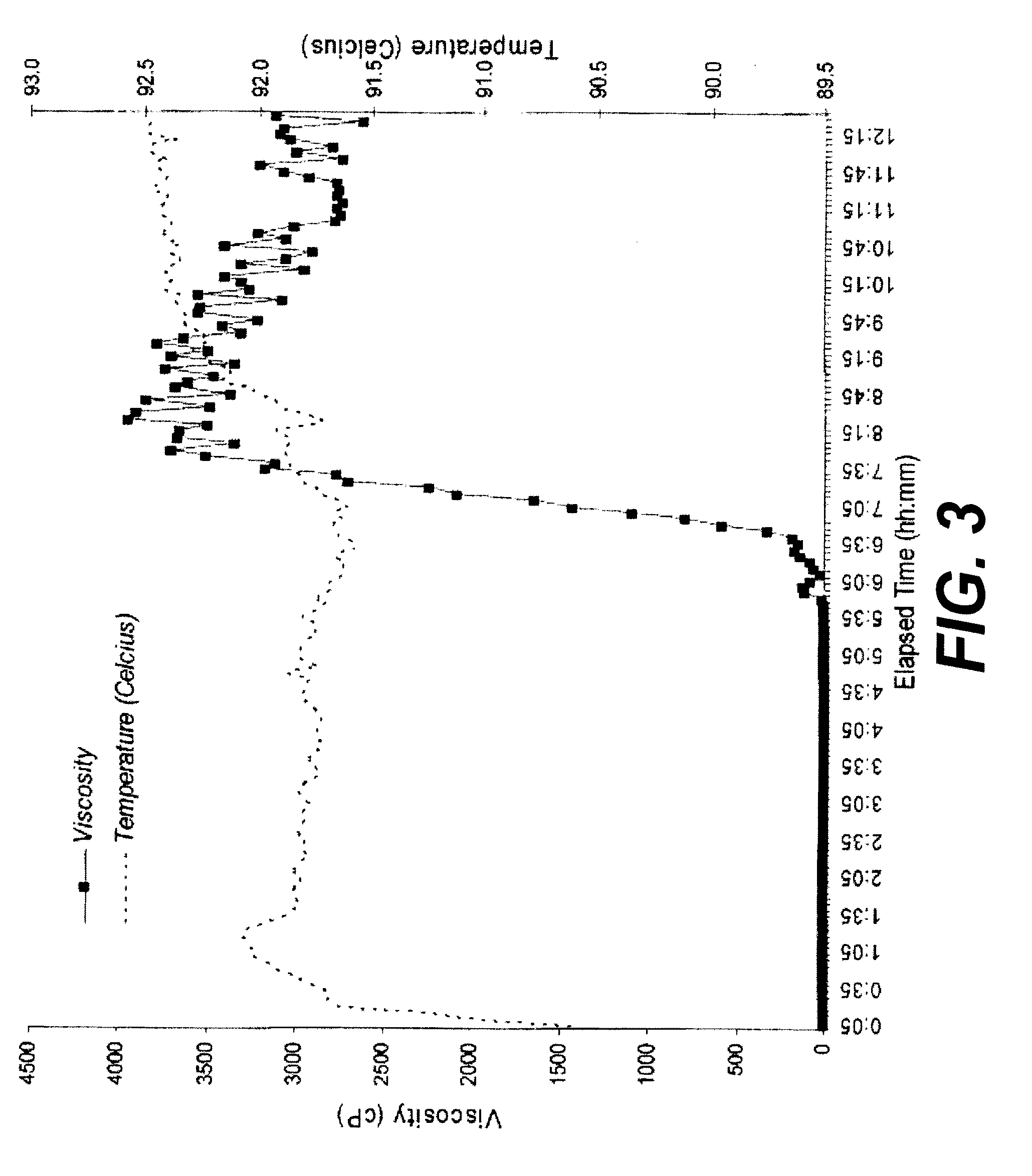

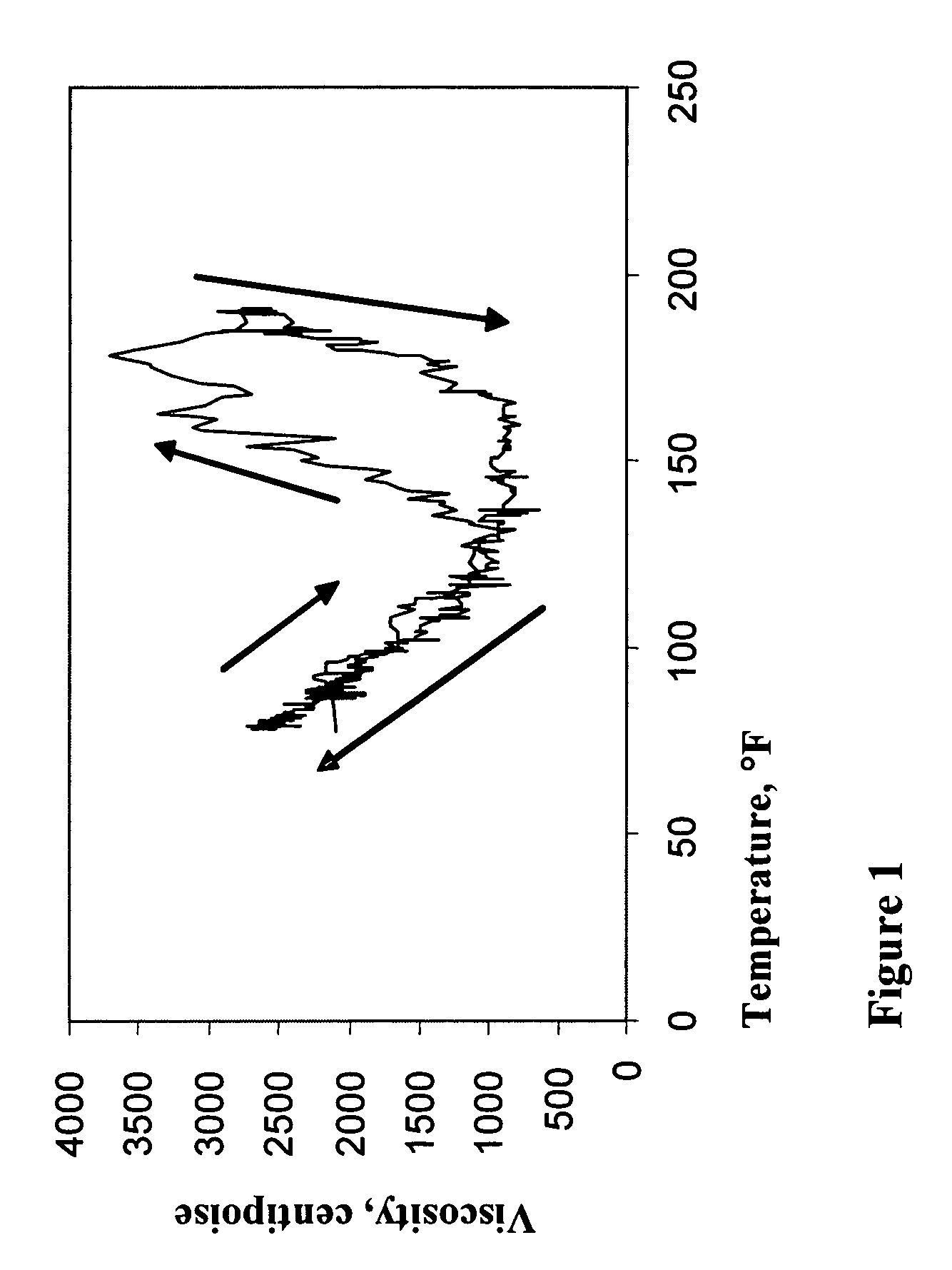

Well bore servicing fluids comprising thermally activated viscosification compounds and methods of using the same

Well bore servicing fluids are provided that include a thermally activated viscosification compound. Further, methods of servicing a well bore are provided that include displacing such a servicing fluid into the well bore, wherein a viscosity of the servicing fluid increases as it passes down the well bore due to its temperature increasing. Thus, the viscosity of the servicing fluid is effective to suspend solids therein when the servicing fluid is in the well bore. The servicing fluid may be, for example, a cement slurry, a drilling fluid, a gravel packing fluid, a fracturing fluid, a completion fluid, or a work-over fluid. In an embodiment, the thermally activated viscosification compound includes at least one water-soluble hydrophobically modified polymer comprising a hydrophobic substituent having from about 1 to about 22 carbon atoms.

Owner:HALLIBURTON ENERGY SERVICES INC

Methods of using cement compositions having long-term slurry-state stability

InactiveUS20050109507A1Improved long-term slurry-state stabilitySolid waste managementDrilling compositionCement slurryCalcium

The present invention relates to cementing operations, and more particularly, to cement slurry compositions demonstrating improved long-term slurry-state stability, and methods of using such compositions in subterranean applications. In one embodiment, the present invention provides a method of cementing in a subterranean formation, comprising the steps of: providing a cement composition comprising water, a cement, a set retarder, and a gelation prevention agent, the gelation prevention agent comprising a salt and a calcium sequestering agent; permitting the cement composition to remain in a slurry state for at least twenty-four hours; activating the cement composition at a desired time; placing the cement composition in a subterranean formation; and permitting the cement composition to set therein.

Owner:HALLIBURTON ENERGY SERVICES INC

Cement oil-based mud spacer formulation

A spacer fluid made of a viscosity thinner, a weighting agent, an antifoaming agent, and a non-ionic surfactant in a base aqueous fluid. In some instances, the viscosity thinner is a sulfomethylated tannin, the weighting agent is barium sulfate, the antifoaming agent is a silicone, and the non-ionic surfactant is an ethoxylated alcohol. A method of treating a well bore annulus in preparation of introducing water-based cement slurry into a well bore using the spacer fluid. A method of using the spacer fluid to position a first fluid into a well bore annulus of a well bore containing a second fluid. A method for fluidly isolating at least a portion of a well bore annulus in a well bore containing an oil-based drilling fluid using water-based cement slurry and the spacer fluid.

Owner:SAUDI ARABIAN OIL CO

Method and apparatus for sealing abandoned oil and gas wells

Apparatus and method for forming a solid sealing plug of bismuth-tin alloy material within a well casing for sealing oil or gas wells. Solid alloy material is positioned within a heating tool and lowered to a position within the well casing where the seal is to be formed. The heating tool is heated to liquefy the alloy material and the alloy material then runs out of the heating tool and solidifies on top of a cement plug previously formed within the well casing. A cement slurry or other fluid material may subsequently be deposited on top of the liquefied alloy material to enhance the sealing of the alloy plug, to form a barrier to subsequent creep of the alloy plug when the alloy solidifies and to counteract any pressure acting vertically on the bottom of the plug.

Owner:SPENCER HOMER L

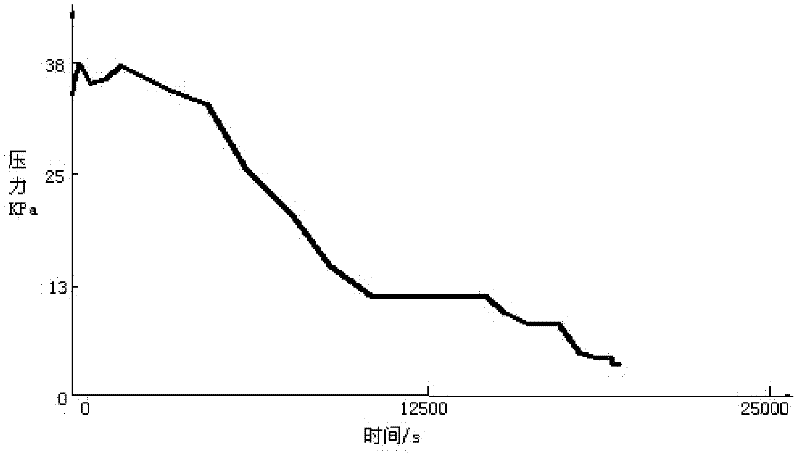

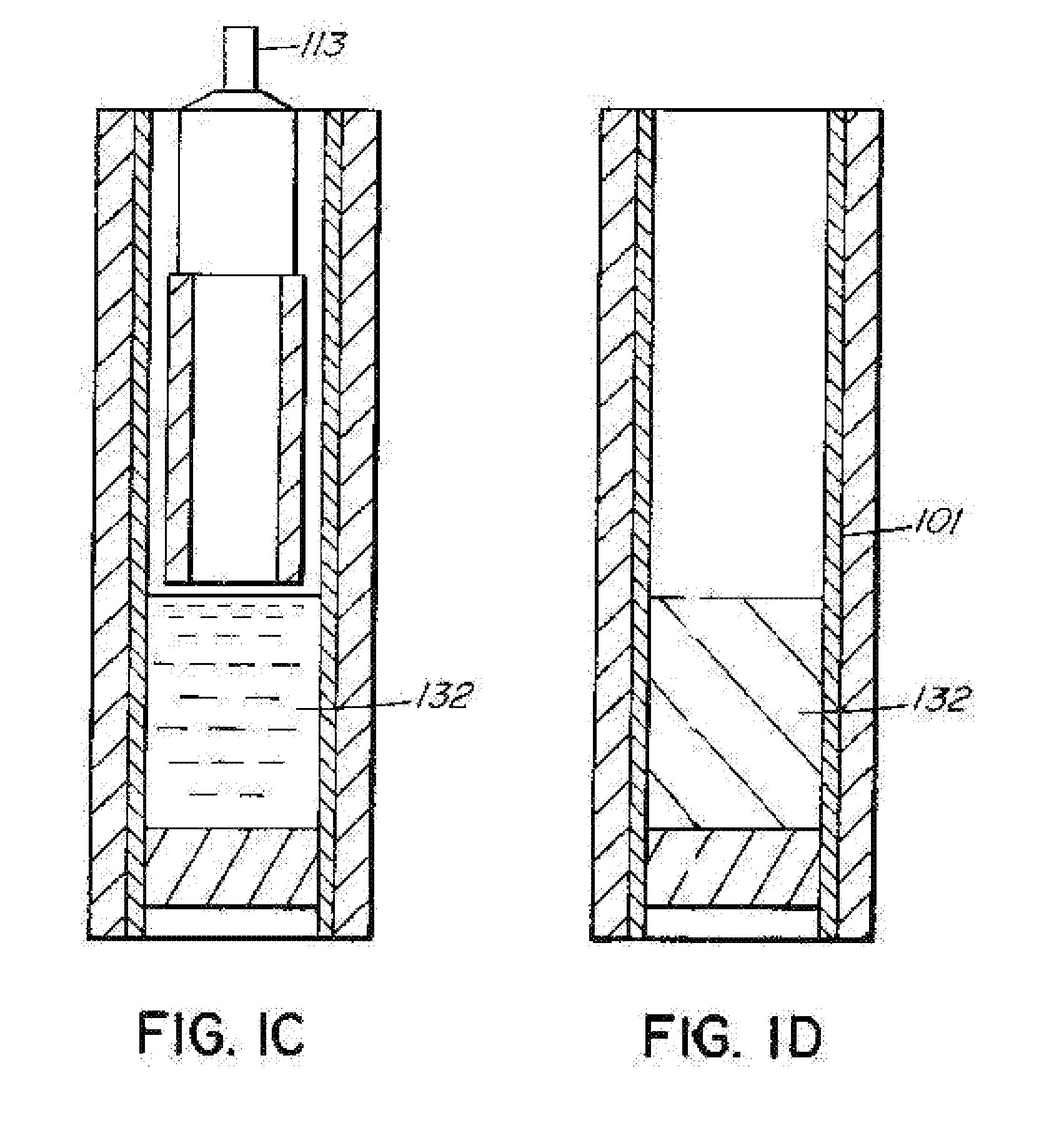

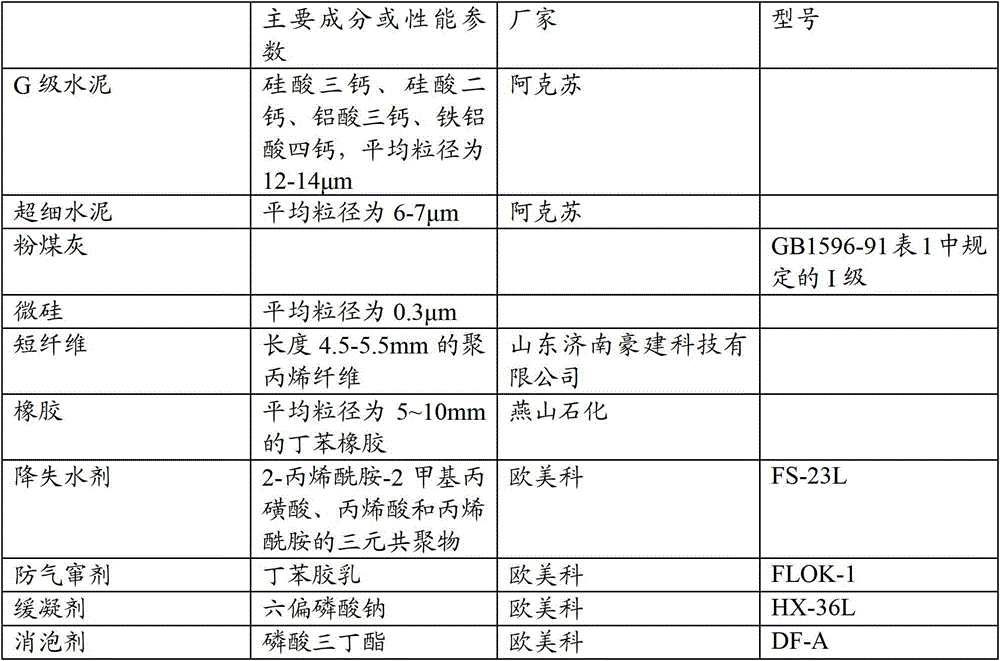

Apparatus and method for testing cementation capability of well cementation first and second interfaces under high-temperature high-pressure conditions

ActiveCN104406910AReflect the state of stressAccurate evaluation of sealing capacityUsing mechanical meansMaterial analysisEngineeringHigh pressure

The invention discloses an apparatus and a method for testing cementation capability of well cementation first and second interfaces under high-temperature high-pressure conditions. The apparatus is mainly composed of a kettle body, an outer pressure pump, an inner pressure pump, a heating belt, a surrounding pressure sleeve, an inner pressure pipe, a nitrogen source, a rotor flow meter, an observation conical flask, an outer pressure sensor, an outer galvanic couple, an inner pressure sensor, an inner galvanic couple, a gas-liquid discharge valve and a computer. The method comprises: (1) sleeving an imitated rock core with the surrounding pressure sleeve, putting in the kettle body and pouring a drilling fluid; (2) heating the kettle body, injecting a pressure P1 into the drilling fluid, and maintaining for 3 d to form an artificial mud cake; (3) pouring a cement slurry into an annular space formed by the inner pressure pipe and the imitated rock core, setting the temperature as a downhole temperature T1, pressurizing to a surrounding pressure P2 needed by an experiment, and maintaining for 3 d to form a cement sheath; and (4) pressurizing the interior of the inner pressure pipe to a pressure P3 needed by the experiment, and testing the cementation capability of the first and the second interfaces. The principle is reliable, the apparatus and the method are capable of accurately testing the cementation capability of the well cementation first and second interfaces under the high-temperature high-pressure conditions, and the evaluation result is relatively precise.

Owner:SOUTHWEST PETROLEUM UNIV

High temperature viscosifying and fluid loss controlling additives for well cements, well cement compositions and methods

InactiveUS6770604B2Improved high-temperature viscosifying and fluid loss controllingOther chemical processesMixingWell cementingCement slurry

Owner:HALLIBURTON ENERGY SERVICES INC

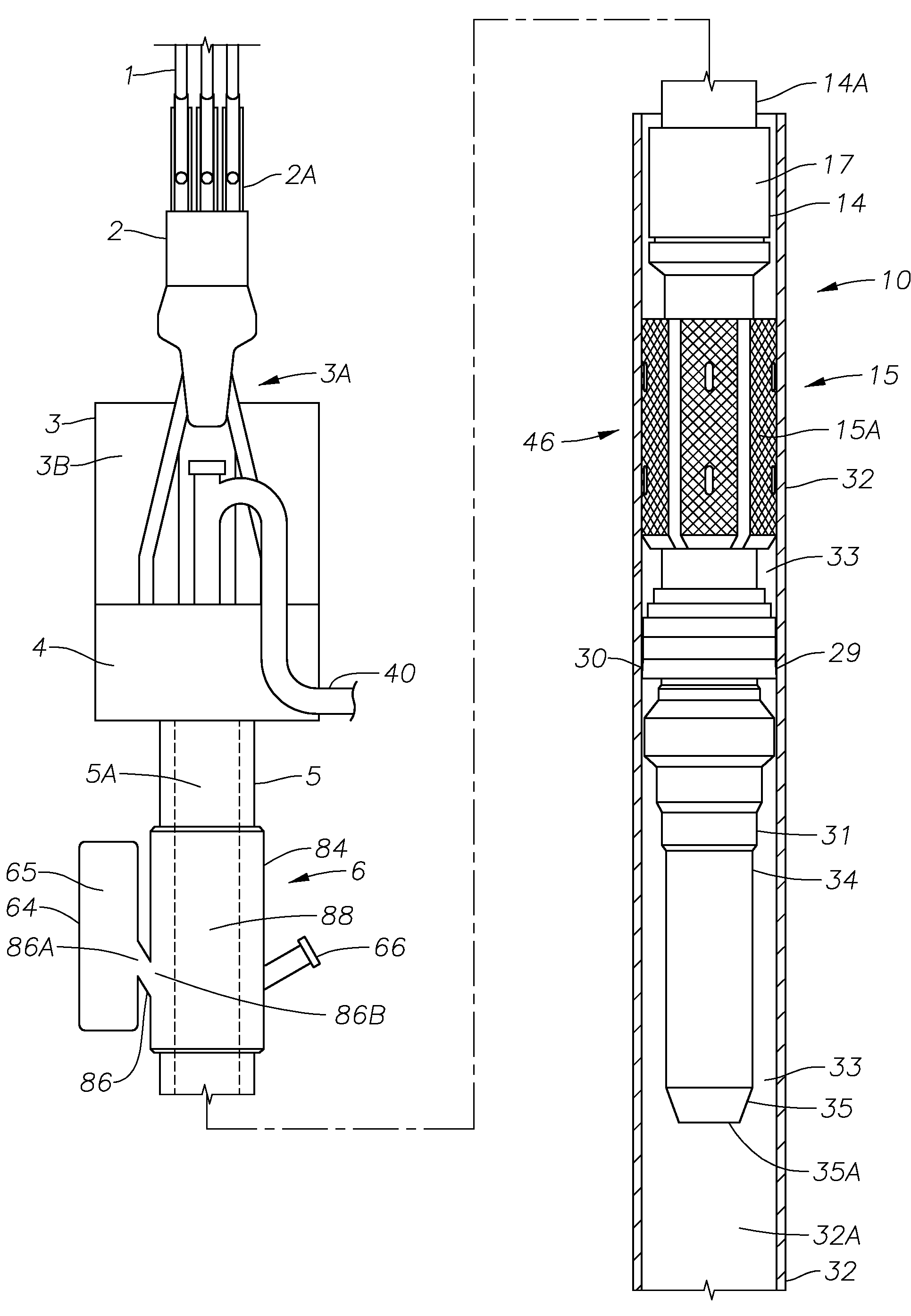

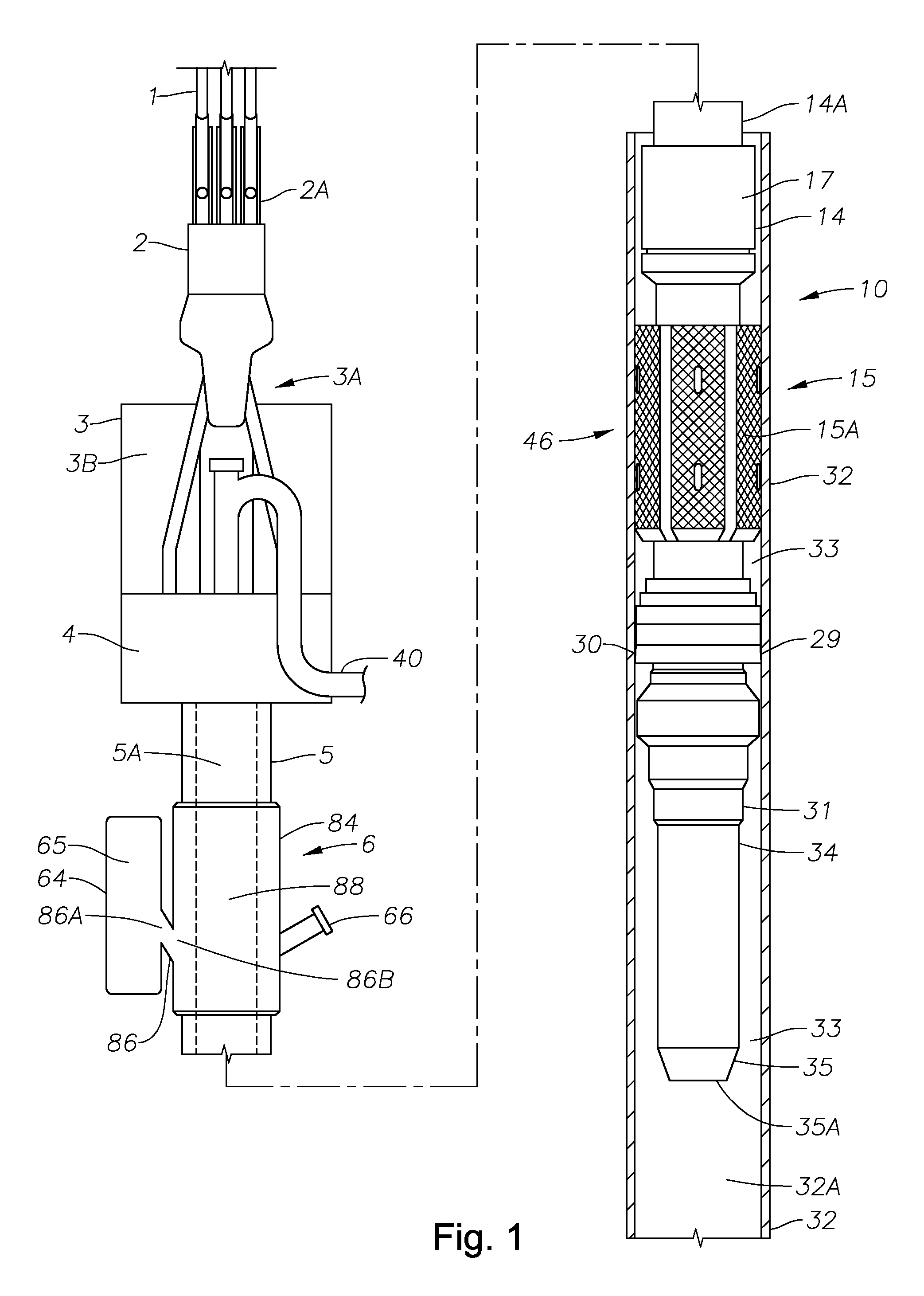

Casing make-up and running tool adapted for fluid and cement control

The apparatus of the present invention provides a top drive supported tool for making up and running casing strings into a borehole. The tool comprises a fill-up and circulation assembly and a launcher assembly that is adapted to cooperate with a connectable cement wiper plug assembly for launching wiper plugs that control cement placement in the annulus between a casing string and a borehole containing the casing string. The tool of the present invention shortens or eliminates delays in well operations, thereby improving integrity of cement liners formed by placing cement slurry in a targeted interval.

Owner:FRANKS INT

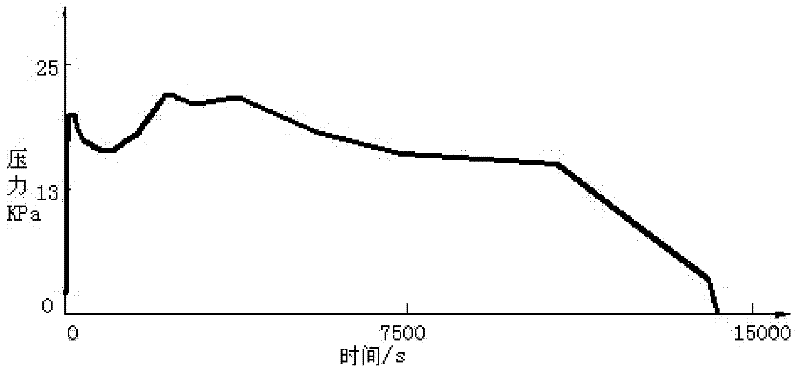

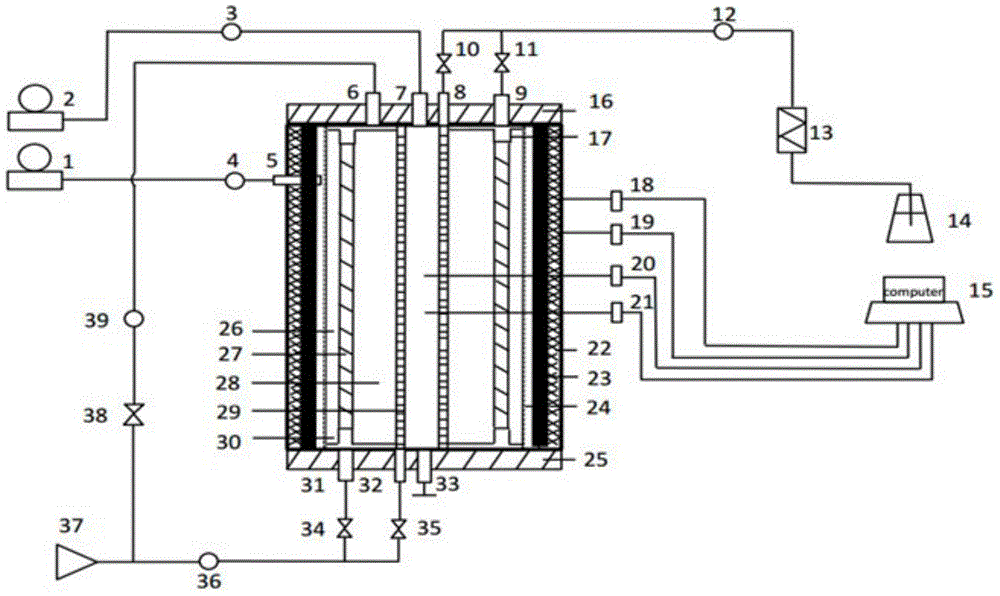

Device and method for evaluating influence of pressure change on completeness of cement sheath

The invention provides a device and a method for real simulation of underground environments, completeness maintaining of experiment equipment, and accurate and omnibearing evaluation of completeness of a cement sheath. The device mainly comprises an upper end cap, a lower end cap, an outer pipe, a middle pipe, the cement sheath, a sleeve pipe, a long source distance sector cement bond logging instrument (SBT (segmented bond tool)) and a high-temperature and high-pressure kettle. The method comprises the following steps of utilizing the high-temperature and high-pressure kettle to simulate the stratum temperature pressure of the curing and forming of the cement sheath; loading and unloading an inner annulus and an outer annulus, so as to simulate the actions of change of well shaft pressure and stratum pressure on the cement sheath under the actual working condition; utilizing a transmitting probe and a receiving probe of the SBT to continuously transmit and receive acoustic wave signals, and performing the omnibearing and high-resolution compensation type attenuation rate measurement, so as to obtain the bonding qualities of a first interface and a second interface of the cement sheath of the well cementing cement sheath under the actual stratum environment, and the amounts, sizes and bearings of cracks and channeling in the cement sheath. The device and the method have the advantage that the underground environment can be really simulated in the omnibearing way, so as to accurately and efficiently evaluate the completeness of the well cementing cement sheath, provide the new method and basis for indoor cement slurry evaluation systems and sites to take the targeted measures, and improve the well cementing quality.

Owner:SOUTHWEST PETROLEUM UNIV

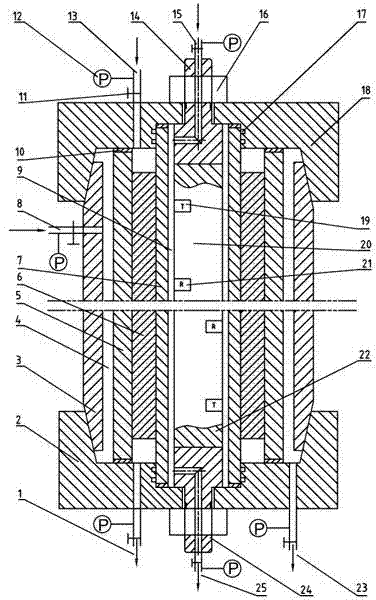

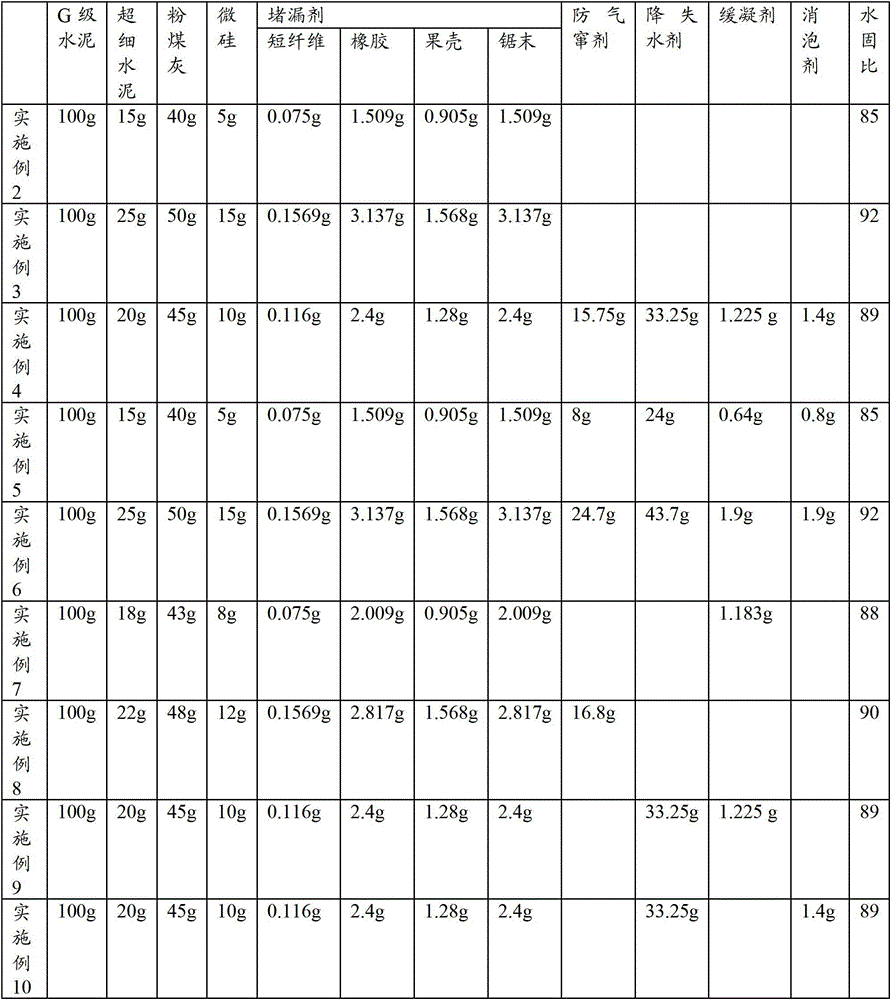

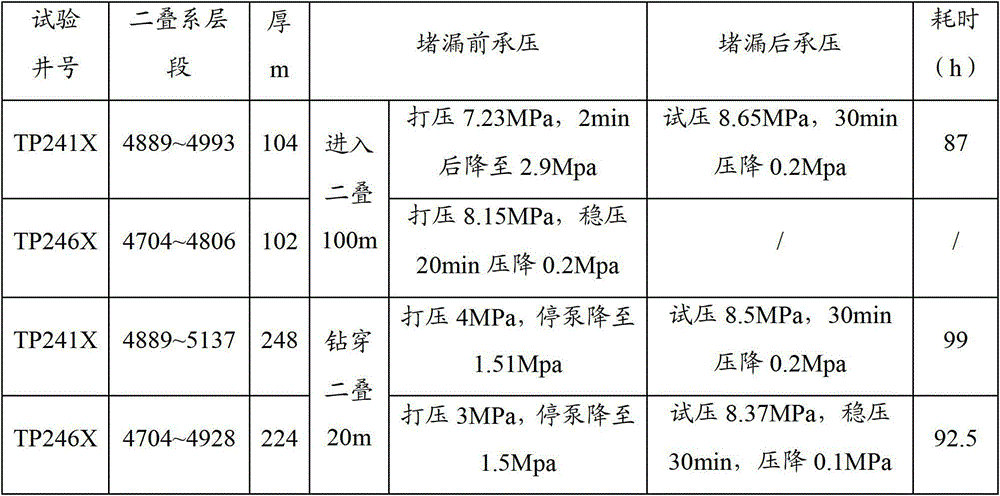

Plugging cement slurry and igneous rock fracture developing well plugging method

InactiveCN102977870AMeet drillingFulfil requirementsDrilling compositionSealing/packingSolid componentFiber

The invention provides plugging cement slurry and an igneous rock fracture developing well plugging method. The water-solid ratio of the cement slurry is (85-92):100. The cement slurry comprises the following solid components in parts by weight: 115-125 parts of cement, 40-50 parts of weight-reducing agent flyash and 5-15 parts of stabilizing agent microsilica, wherein the cement comprises 100 parts of first cement components with average particle sizes being 12-14mu m and 12-18 parts of second cement components with average particle sizes being 6-7mu m; each liter of cement slurry further comprises 4-8g of plugging agent by volume; and the plugging agent comprises 0.1-0.2 part of staple fiber, 2-4 parts of rubbers and 3.2-6 parts of packing particles by weight. The cement slurry and the method have the beneficial effects that the bridging fiber materials, elastic rubber powder materials and shell and / or saw dust packing materials are combined for use, the cement slurry is suitable for igneous rock fracture developing wells and can meet the requirements of well drilling and well cementation constructions; and the construction time is greatly shortened by adopting the plugging technology idea of integrating packing, bridging and coagulation.

Owner:CHINA PETROLEUM & CHEM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com