Drilling and sealing method and sealing device for ultra-high pressure fracturing holes in underground coal mines

A sealing device and fracturing hole technology, which are applied in the directions of sealing/isolation, earthwork drilling, wellbore/well components, etc., can solve the problems of blocking the water outlet hole of the fracturing pipe, unable to fracturing, and affecting the fracturing effect. , to achieve the effect of increasing perfusion pressure, high blocking success rate and reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Example 1 see figure 1 A drilling and sealing method for ultra-high pressure fracturing holes in underground coal mines, comprising the following steps:

[0033] a Drill a plugging hole 1 with a depth of 15m~50m on the coal rock mass;

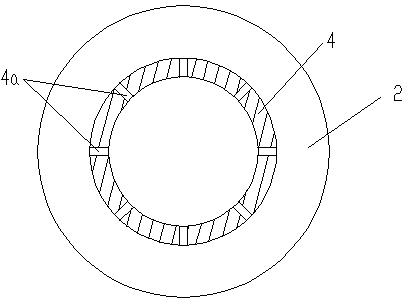

[0034] b Continue to drill a fracturing hole 2 whose diameter is smaller than the plugged hole 1 in the plugged hole 1;

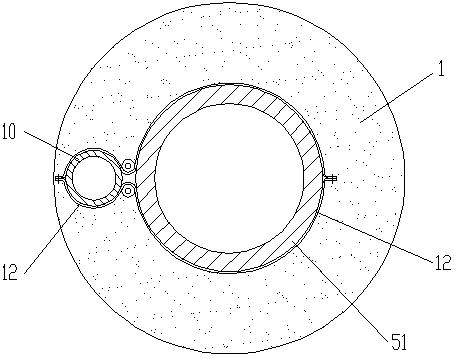

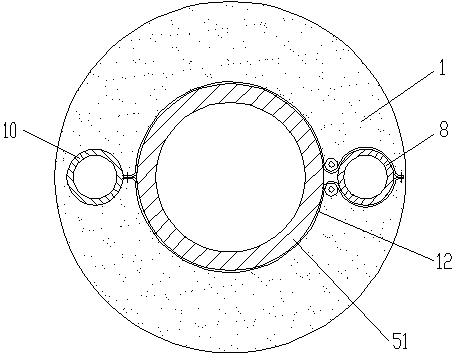

[0035] c Send the underground ultra-high pressure fracturing sealing device into the plugging hole 1, so that the grouting pipe 8, the grout return pipe 10 and the nozzle of the fracturing pipe provided with the underground ultra-high pressure fracturing sealing device in the coal mine are exposed to the sealing hole. Plugging hole 1 orifice outside; grouting pipe 8 is provided with the bottom end of grouting hole 81 to be apart from plugging hole 1 orifice proper distance, and the bottom end of grouting hole 10a that return grouting pipe 10 is provided with is 1 hole away from plugging hole The water outlet hole 4a...

Embodiment 2

[0043] Example 2 see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , a kind of hole sealing device for the drilling and sealing method of the ultra-high pressure fracturing hole in the coal mine underground for the ultra-high pressure fracturing hole in the coal mine of embodiment 1, comprising the grouting pipe 8 and the return The grout pipe 10, the fracturing pipe extending from the plugging hole 1 to the fracturing hole 2, the grouting pipe 8, the grout returning pipe 10 and the fracturing pipe are connected into one body, the grouting pipe 8, the grout returning pipe 10 and the fracturing pipe One end of the plugging hole 1 orifice is exposed, and a stop valve 3 is provided at the end of the grouting pipe 8 and the grouting pipe 10 that exposes the plugging hole 1 orifice. The front end of the grouting pipe 8 is provided with a plurality of grouting holes 81, The bottom end of the slurry return pipe 10 is provided with a plurality of slurry return holes 10a,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com