Patents

Literature

3322 results about "Pressure pipe" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pressure Pipe. PVC Pressure pipe is primarily used in water service systems. It can be used in residential, commercial, and industrial applications as a water main, to convey water from main to house, or to convey water from well to the house. In addition it can be used in the well to hang the pump or foot valve and for irrigation systems.

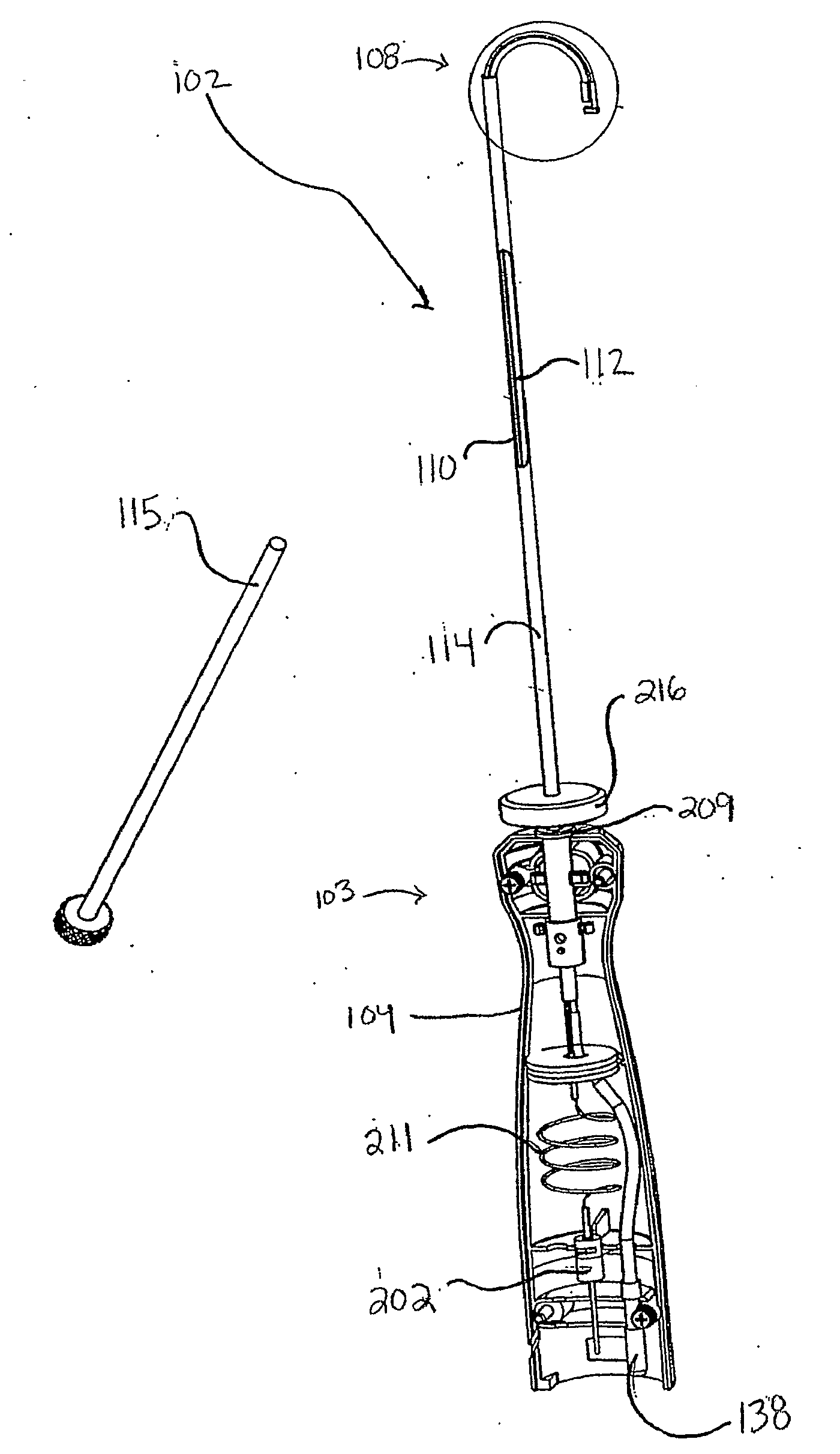

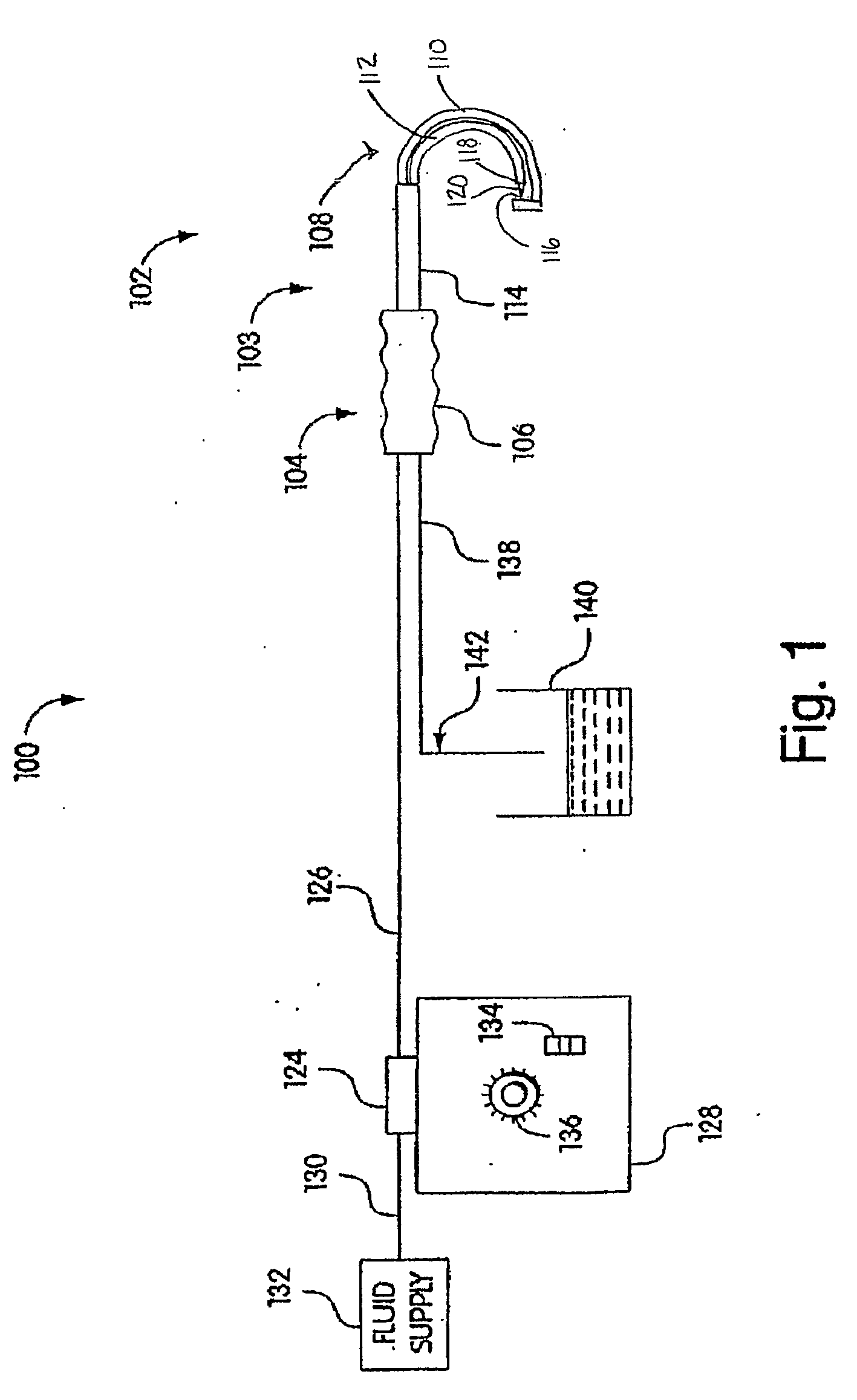

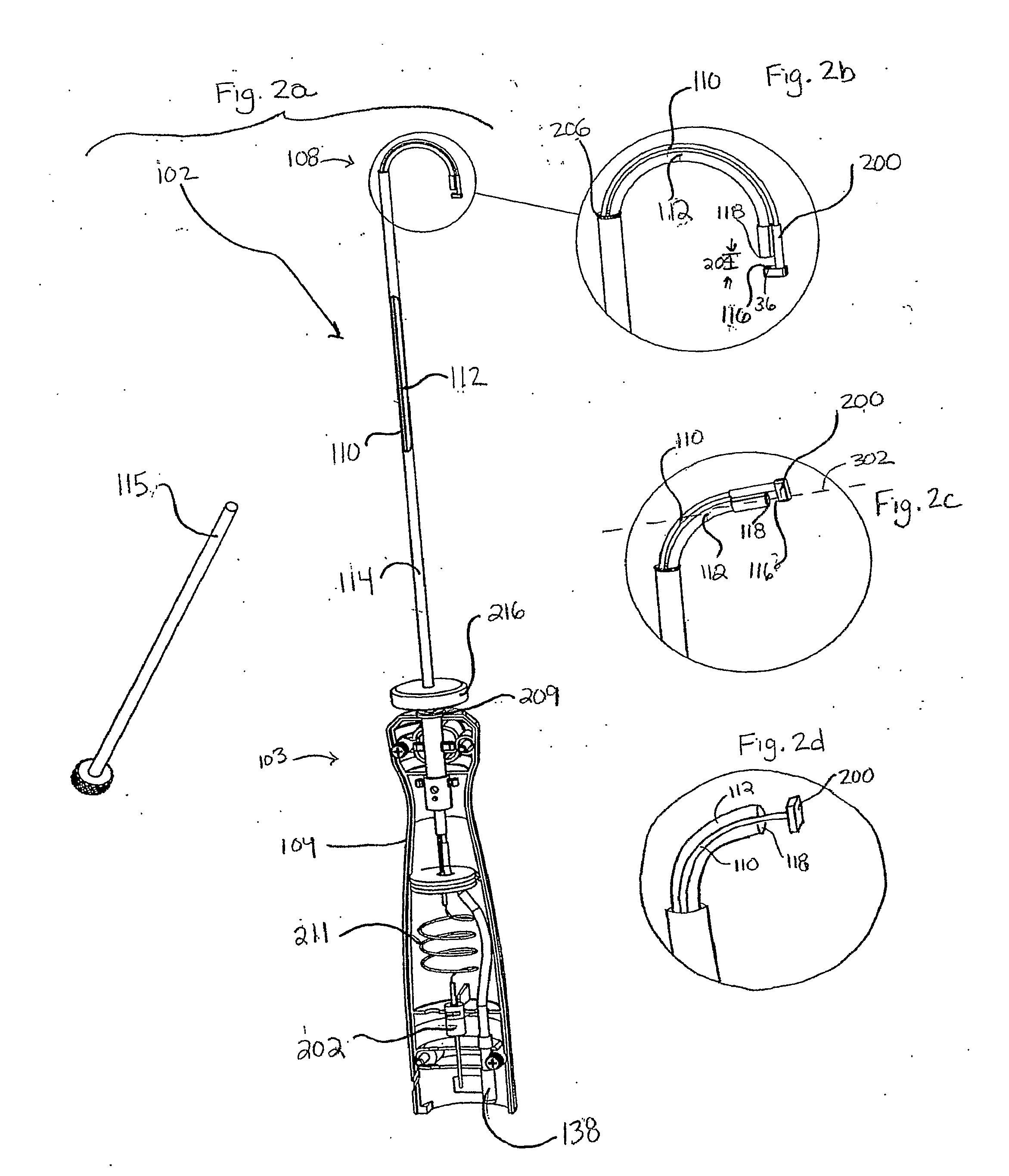

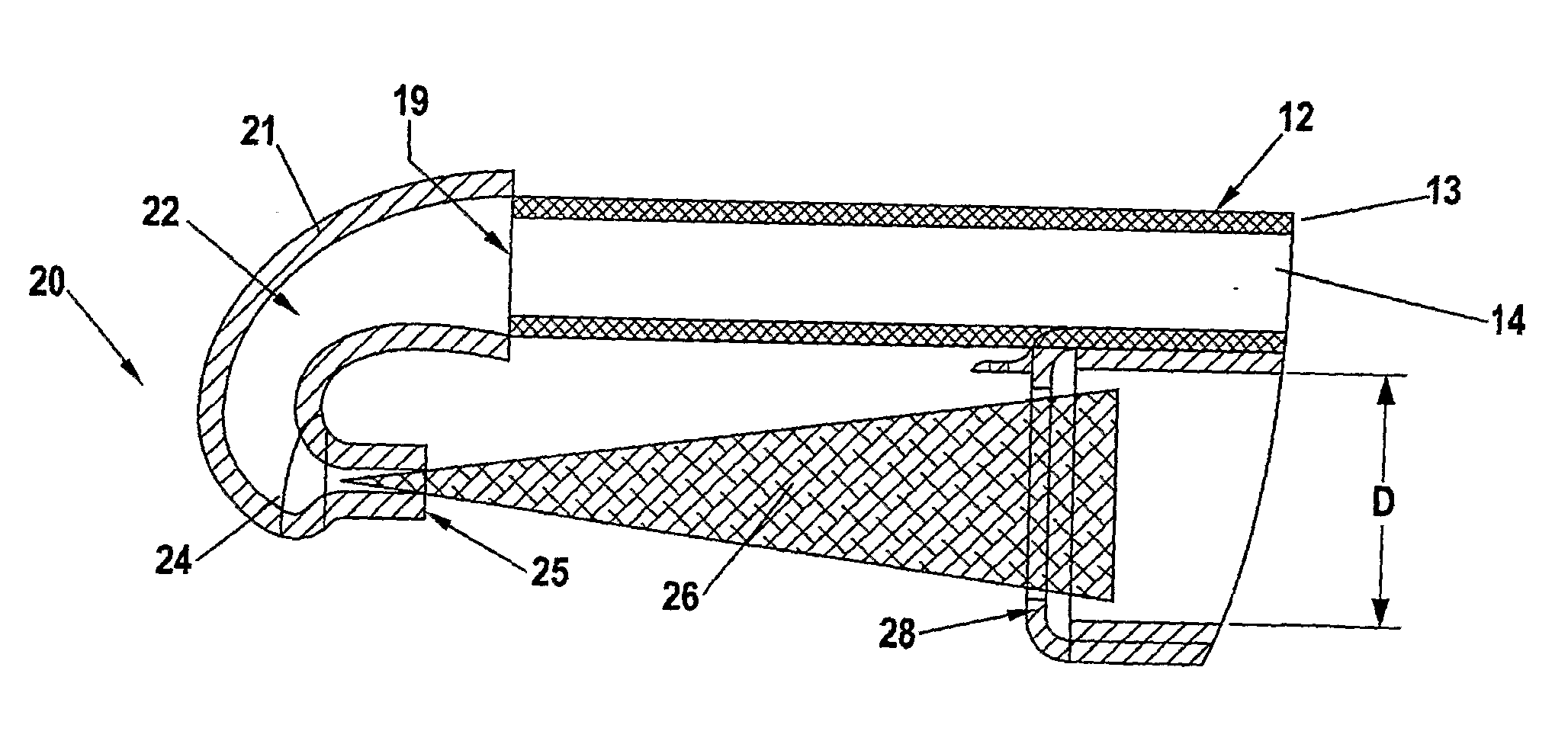

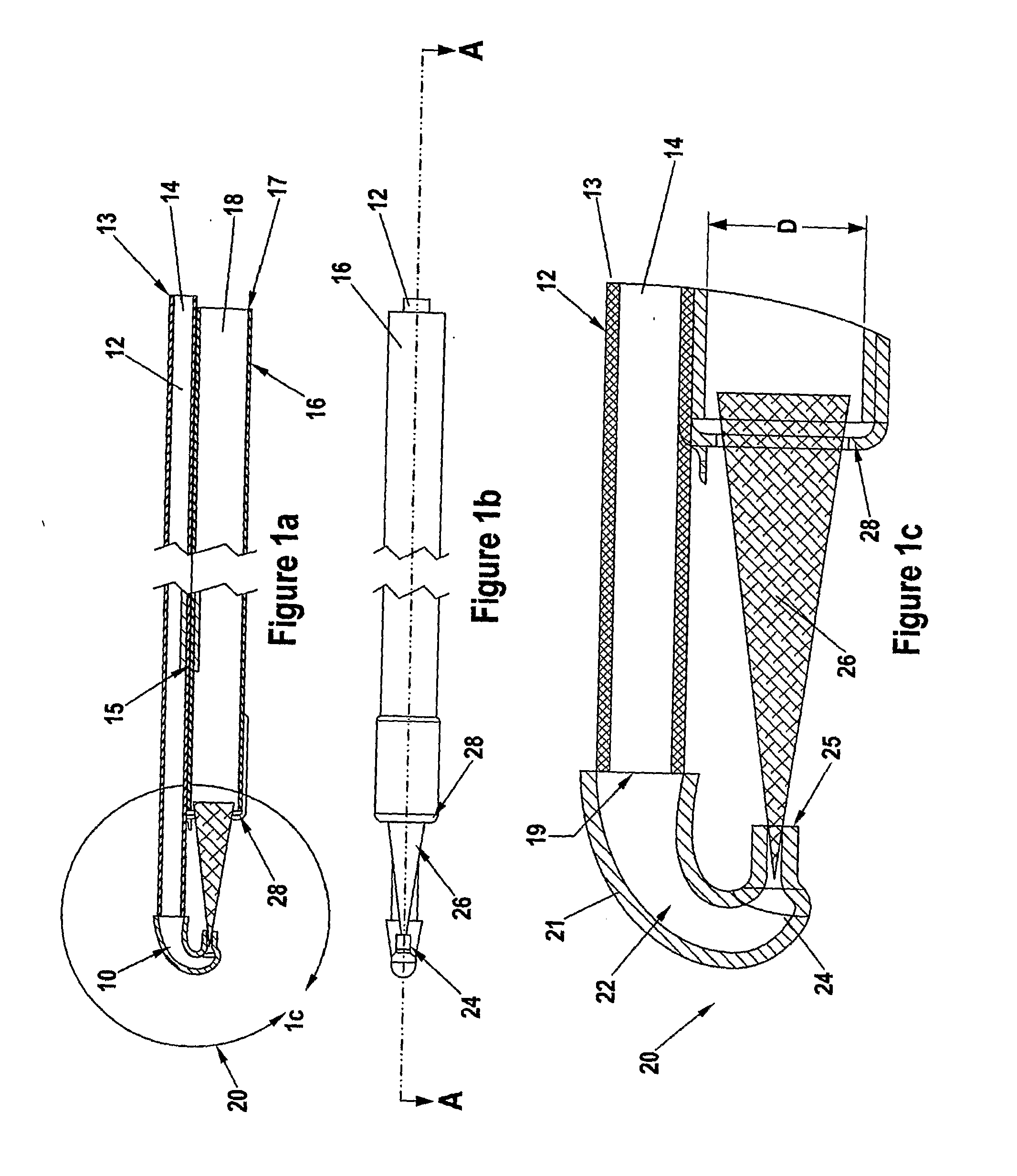

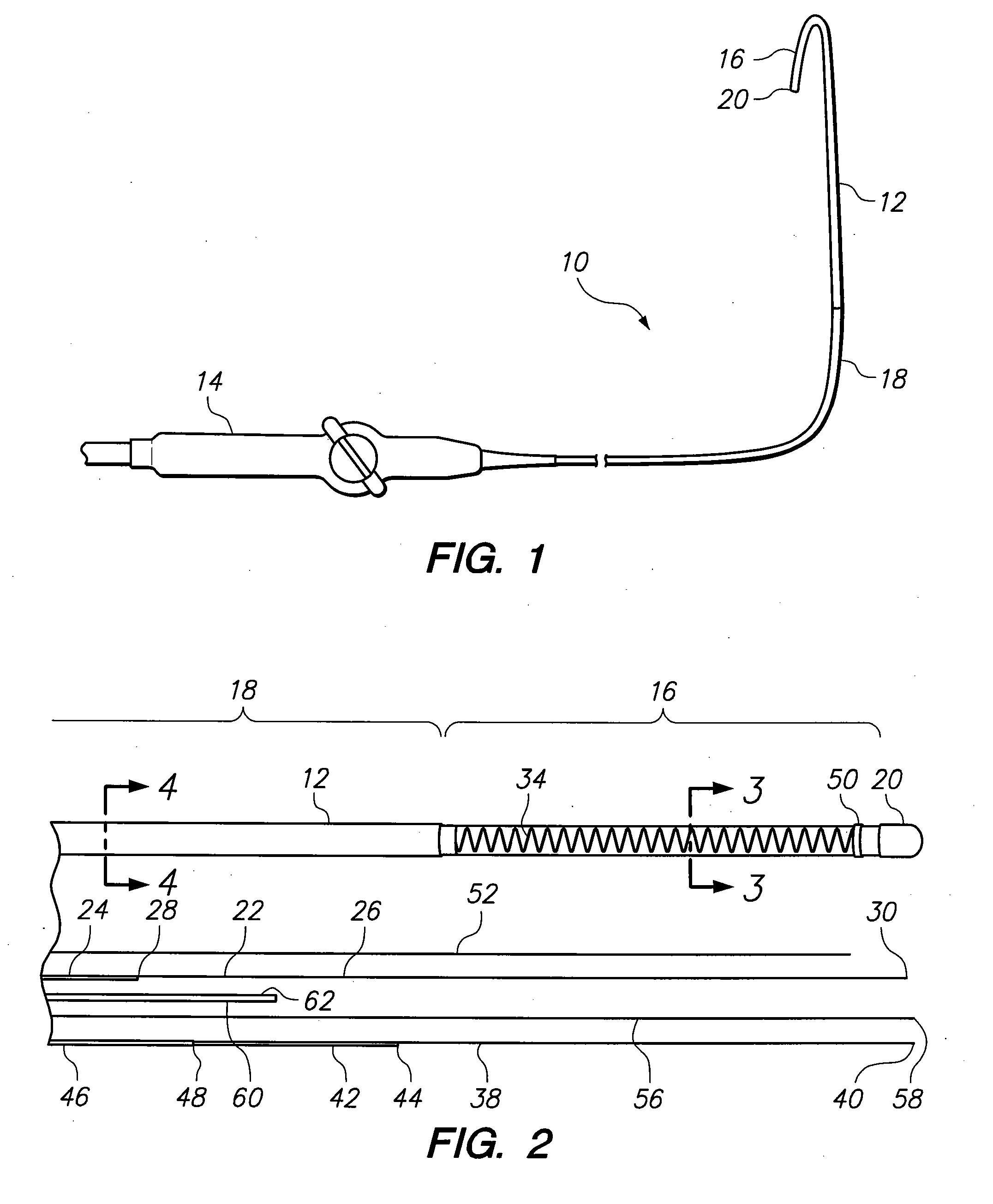

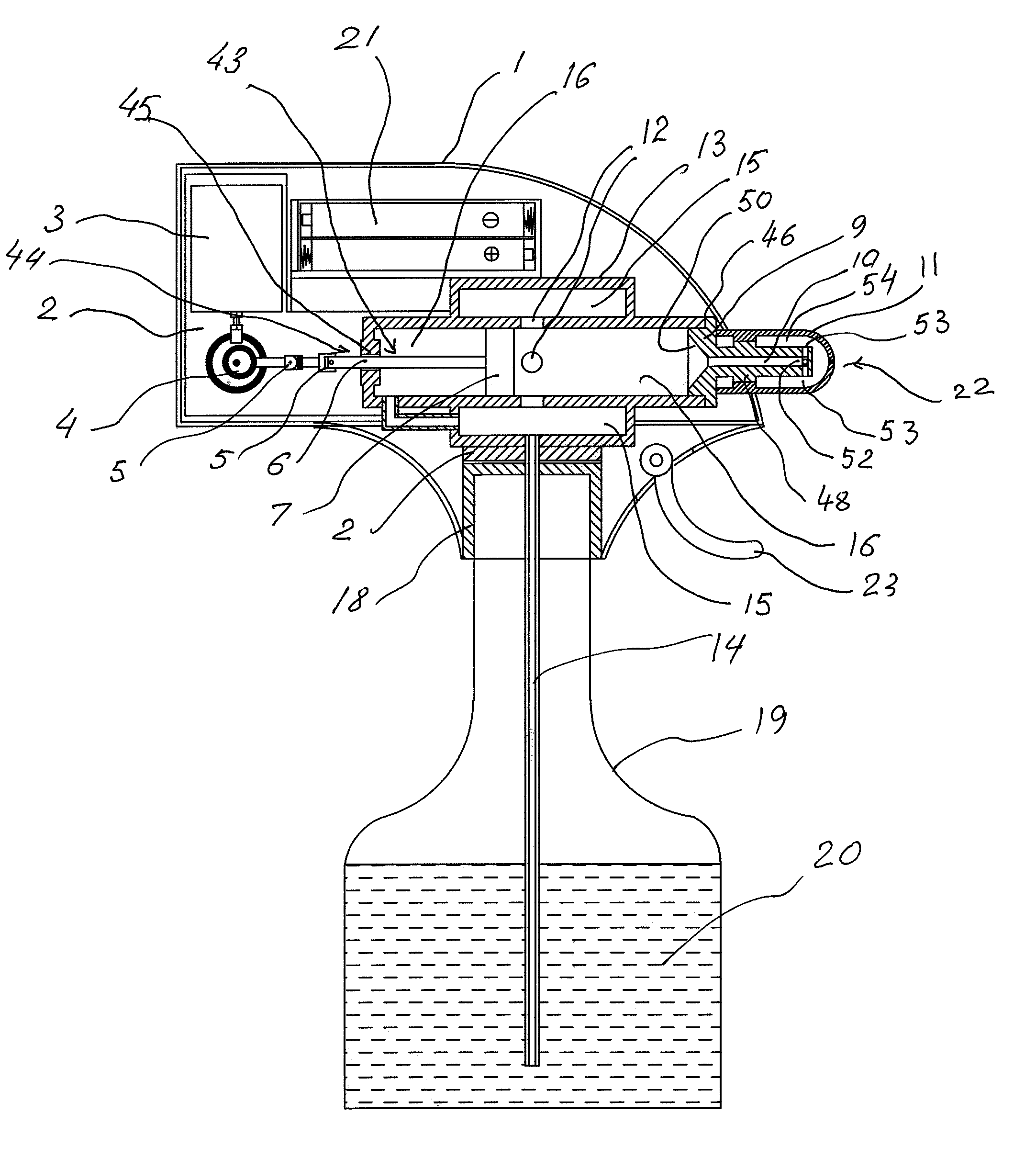

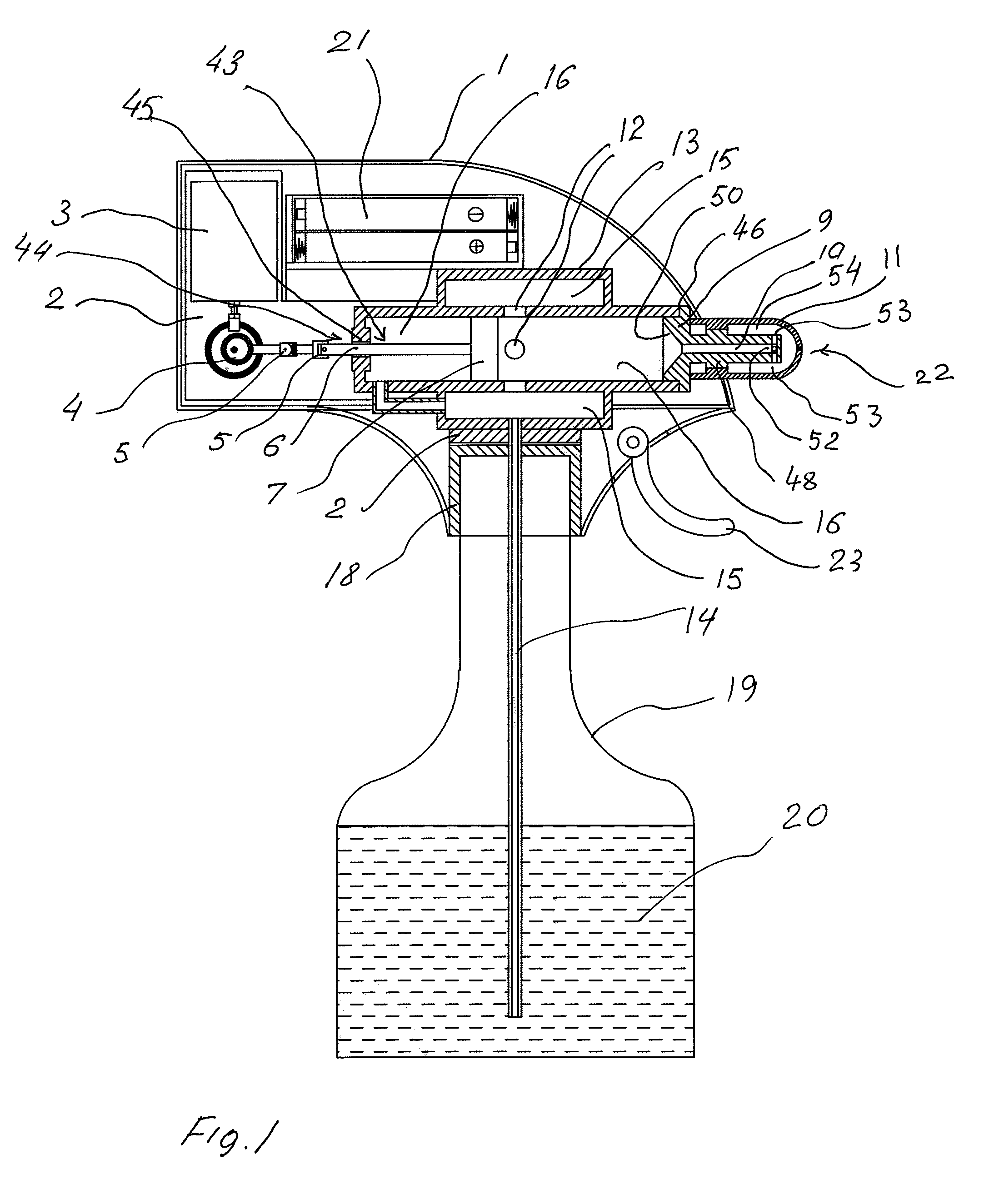

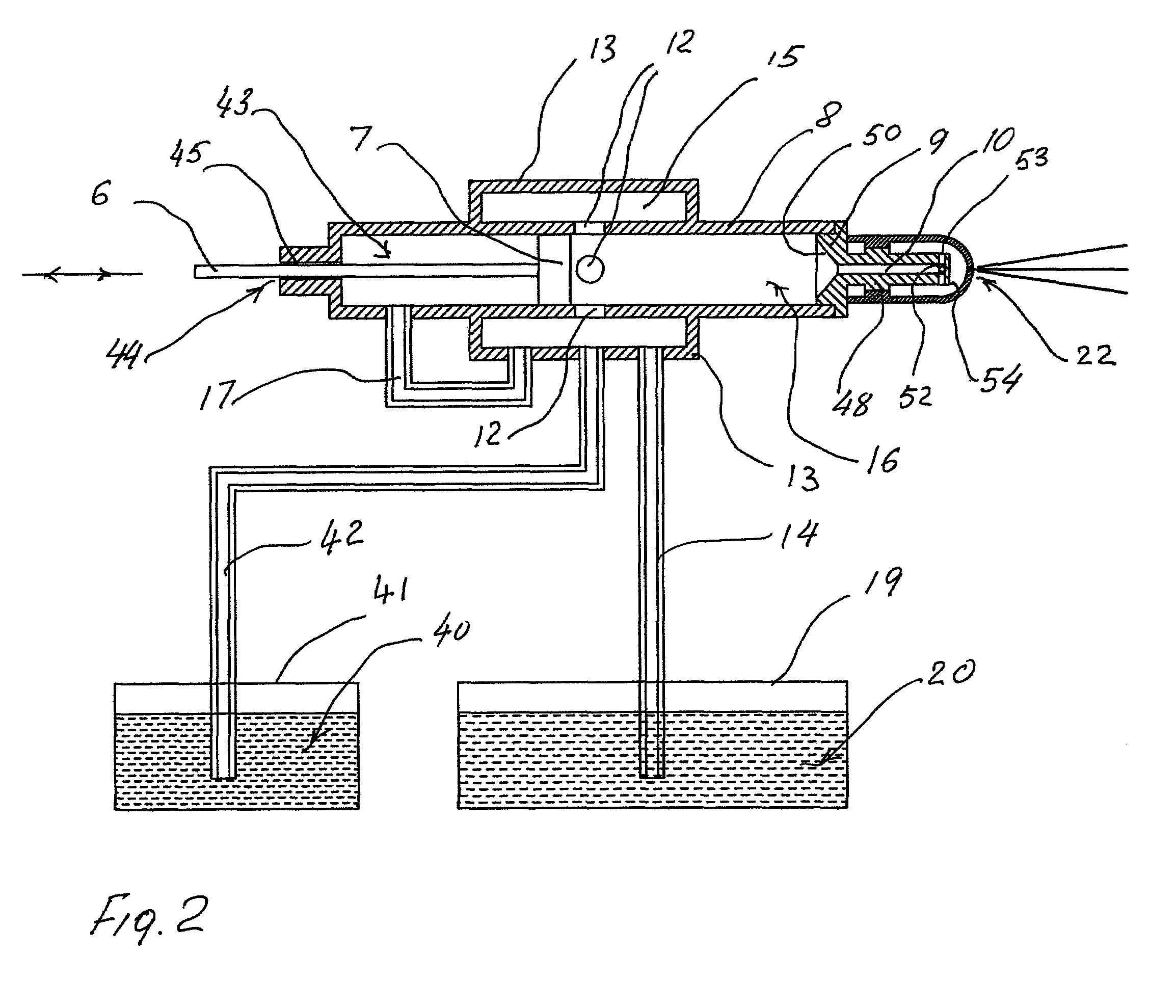

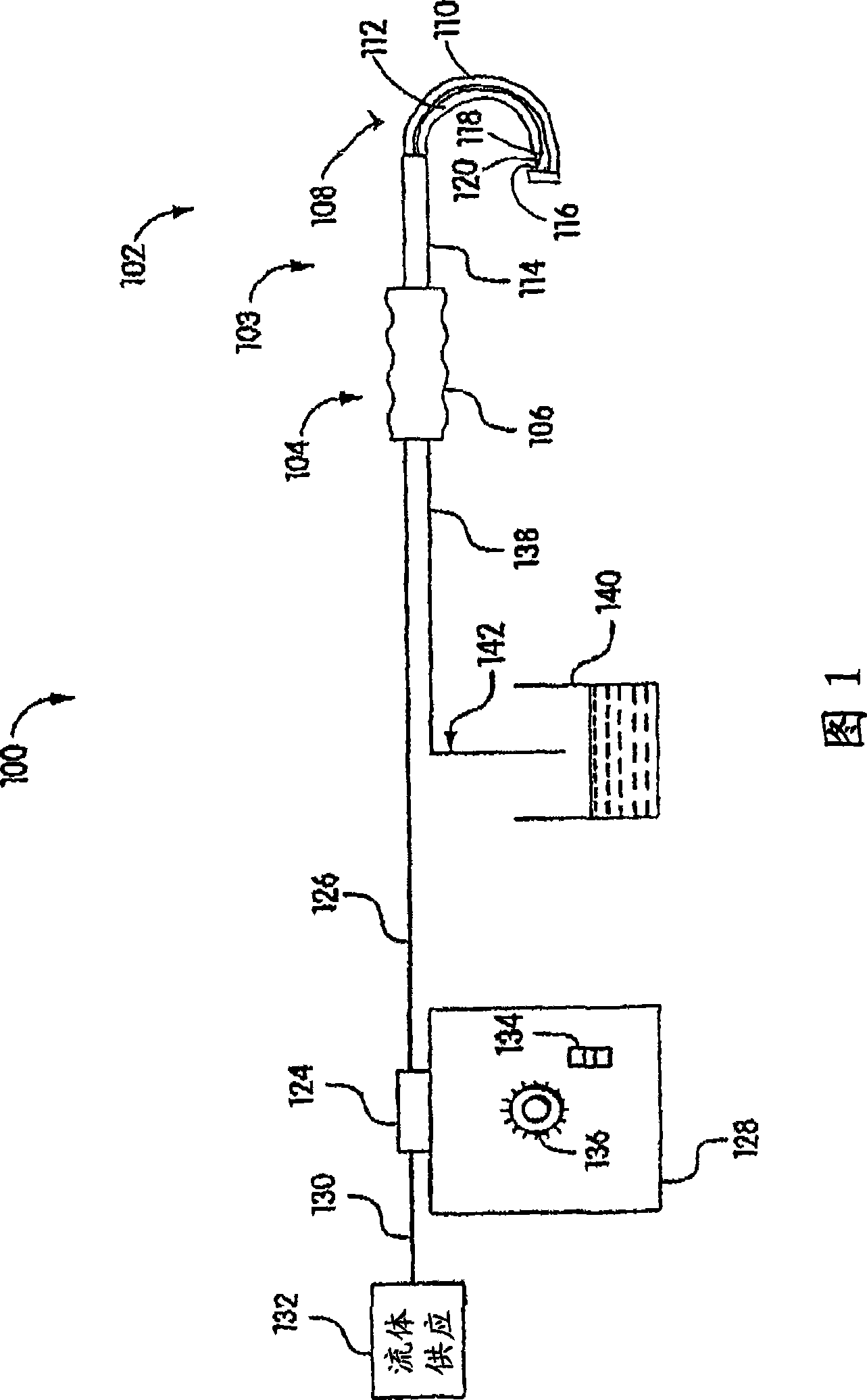

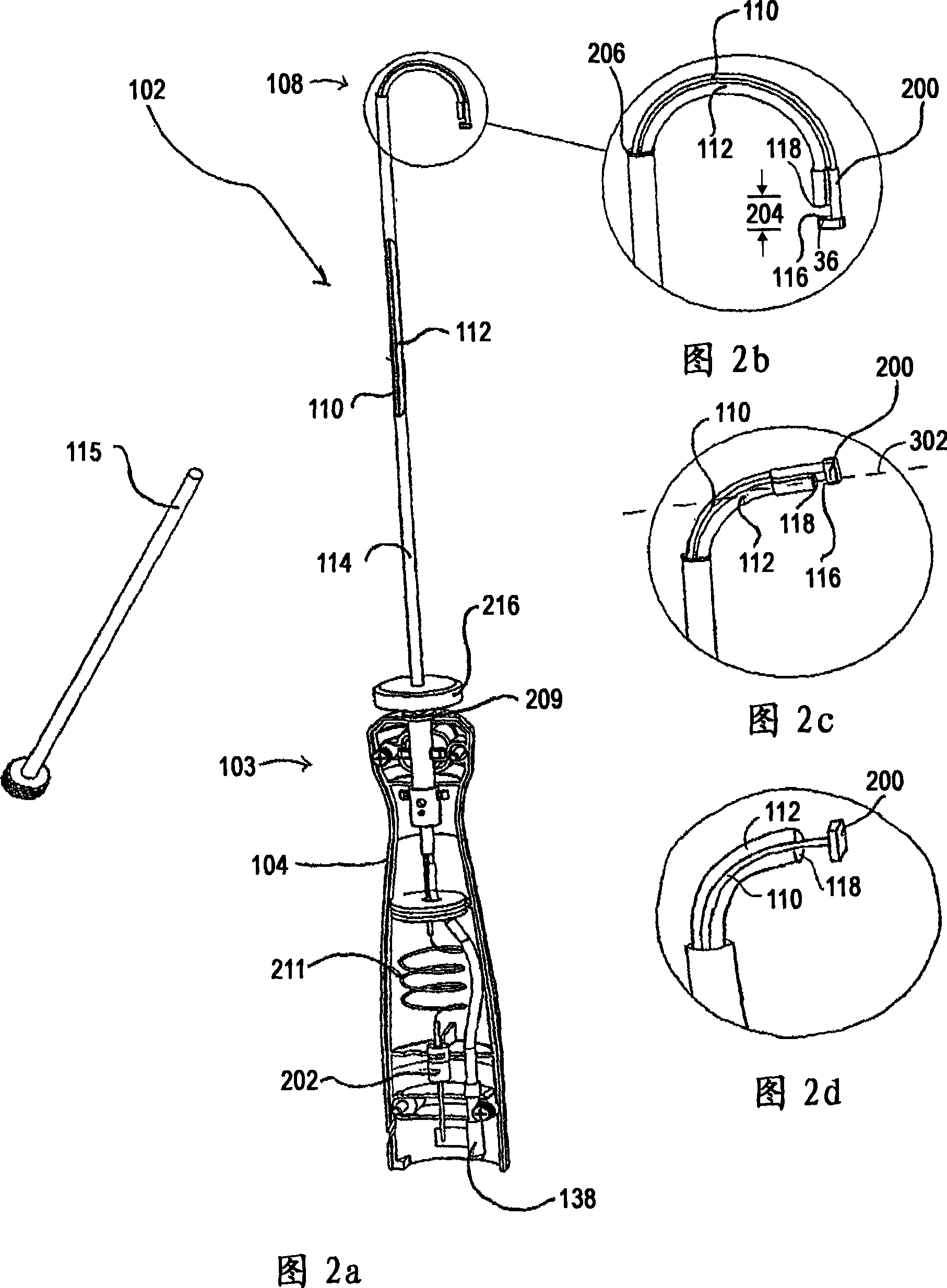

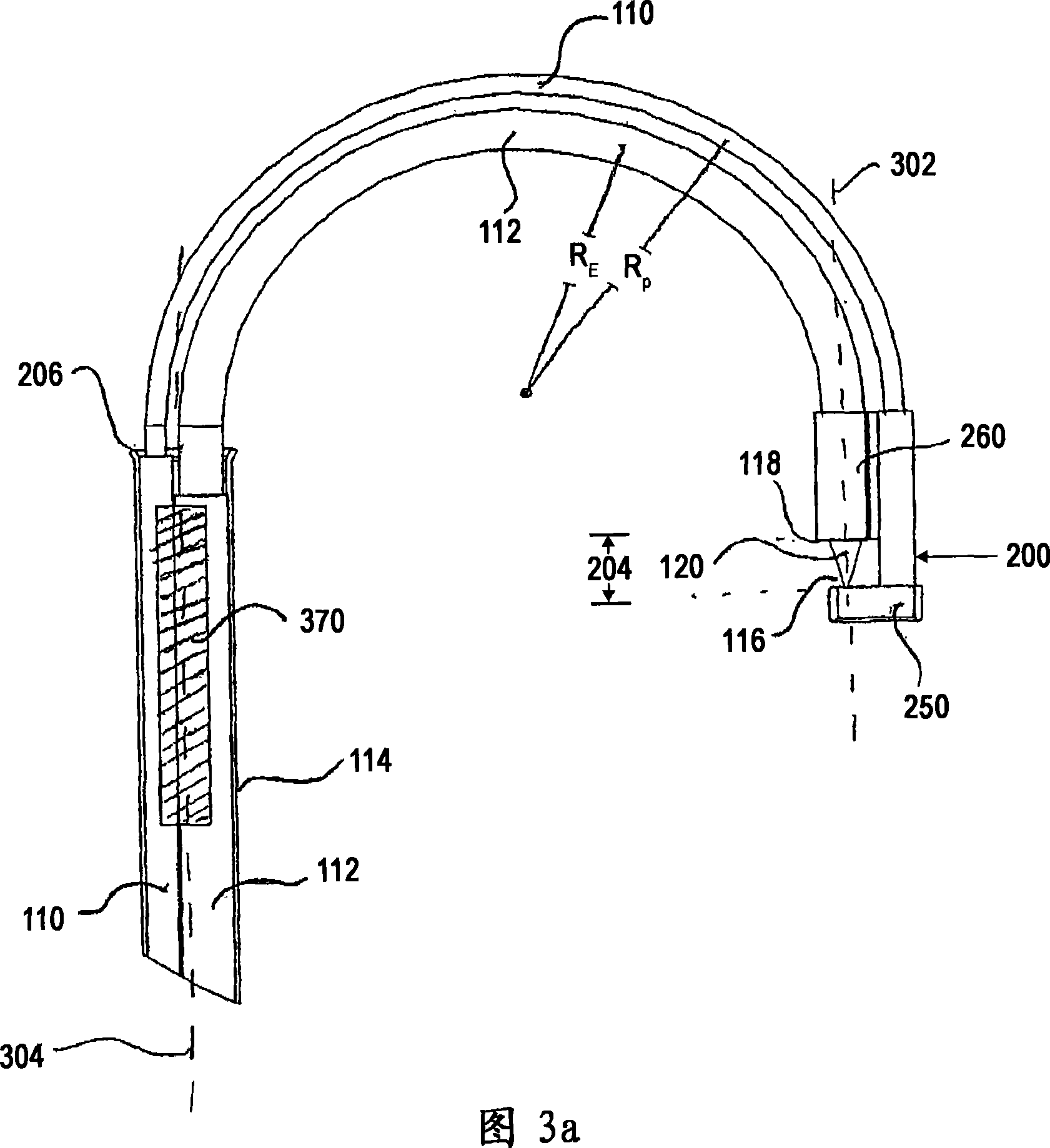

Liquid jet surgical instrument having a distal end with a selectively controllable shape

InactiveUS20100010524A1High burst resistanceFluid jet surgical cuttersMedical atomisersLiquid jetIntervertebral disc

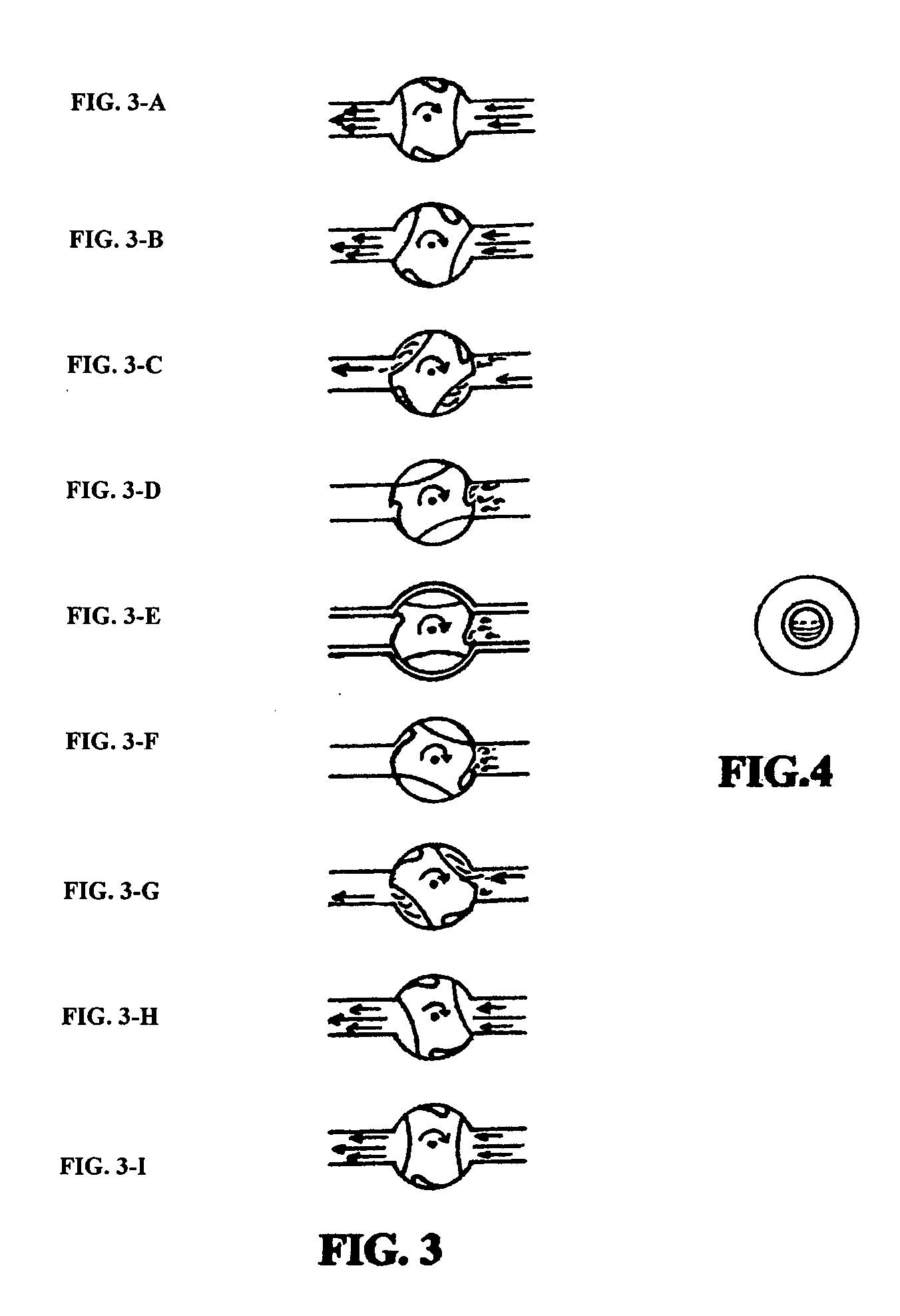

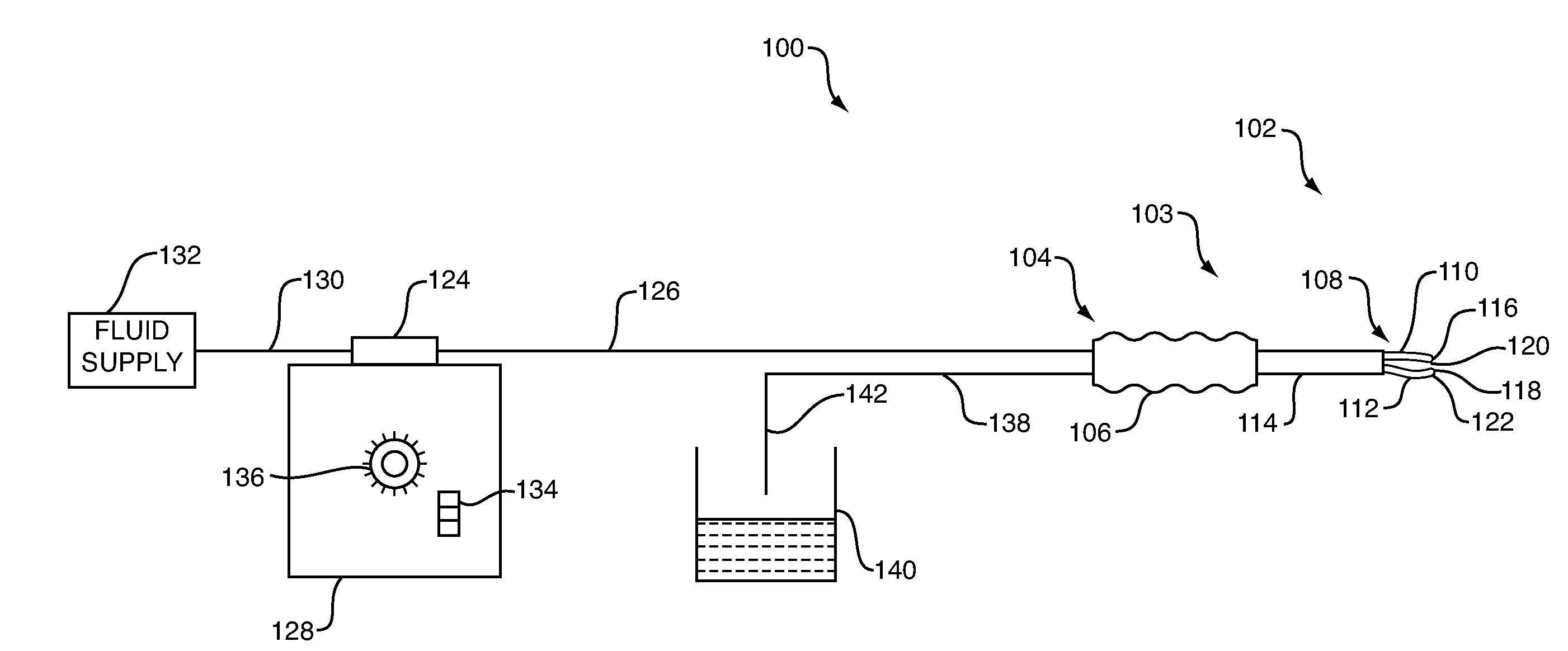

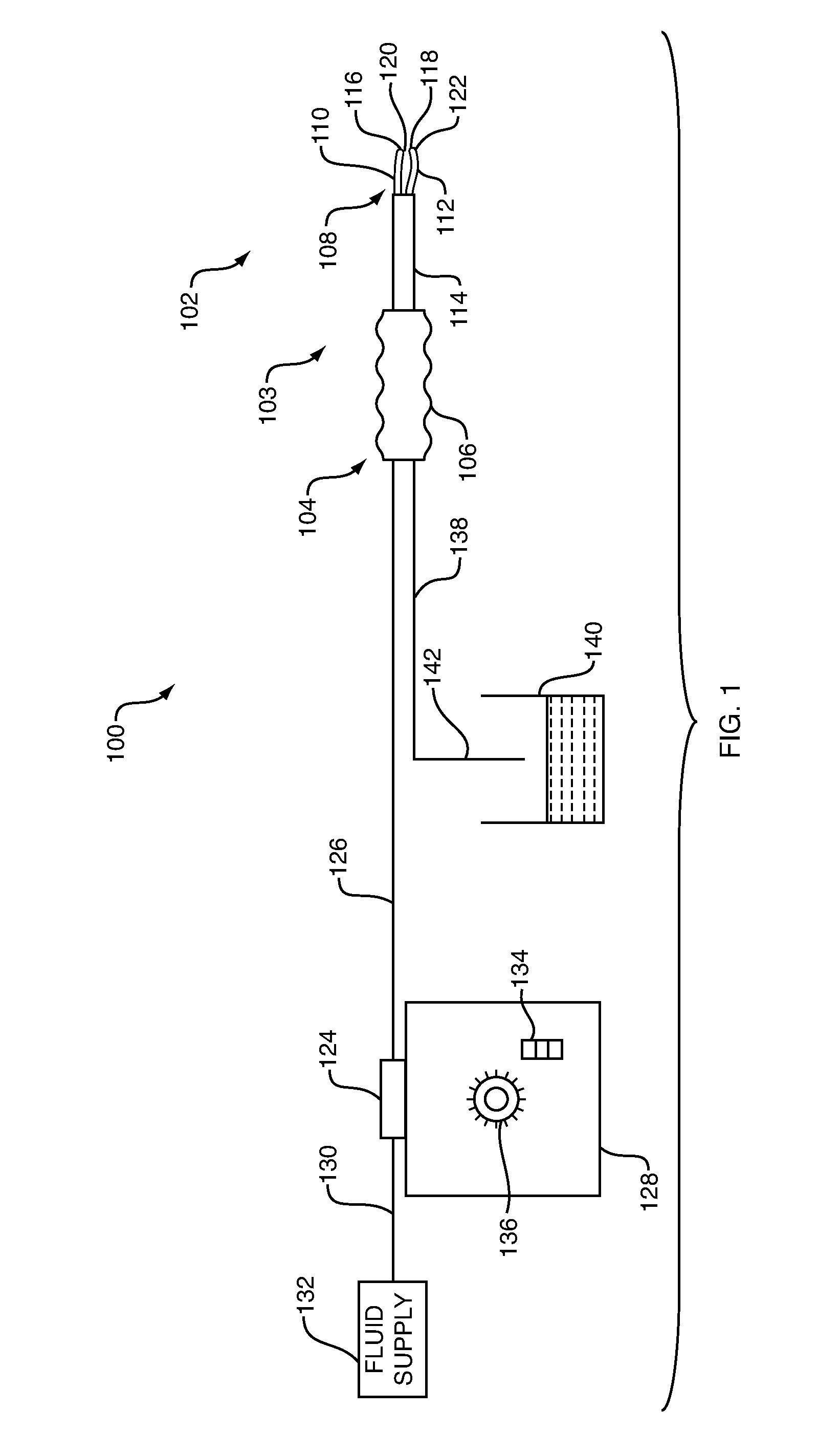

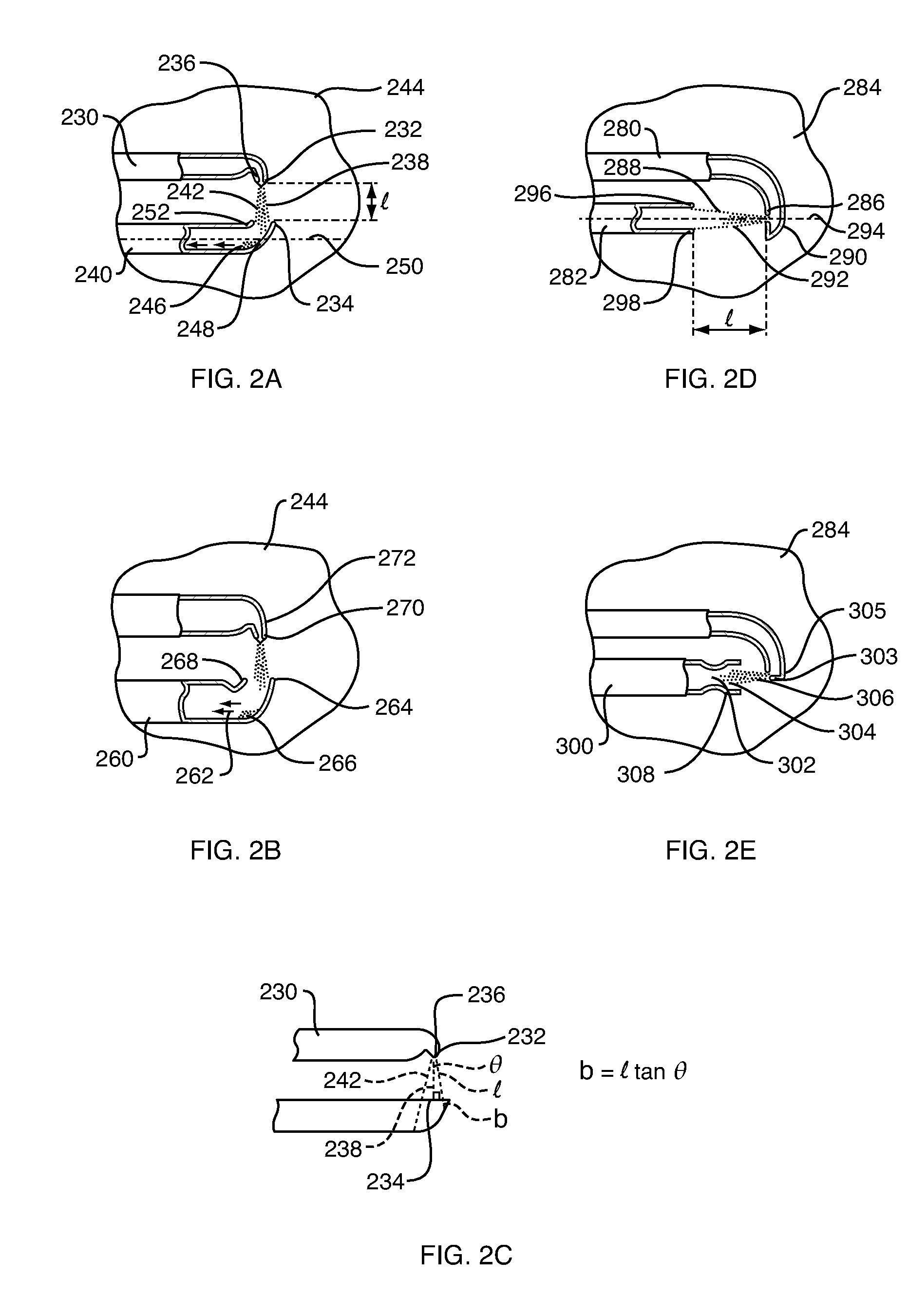

The invention provides a variety of surgical instruments for forming a liquid jet, which are useful for performing a wide variety of surgical procedures. In some embodiments, the invention provides surgical liquid jet instruments having a pressure tube and an evacuation tube, where the pressure tube includes at least one nozzle for forming a liquid jet and where the evacuation tube includes a jet-receiving opening for receiving the liquid jet when the instrument is in operation. In some embodiments, the distal ends of both the pressure and evacuation tubes have a first configuration in a non-relaxed state and a second configuration in a more relaxed state. In some embodiments, a straightener is constructed to selectively control the configuration of the distal ends of both the pressure and evacuation tubes. The invention also provides surgical methods utilizing the inventive surgical liquid jet instruments for cutting or ablating a selected tissue within portions of a patient's spine, such as within the intervertebral disc.

Owner:HYDROCISION

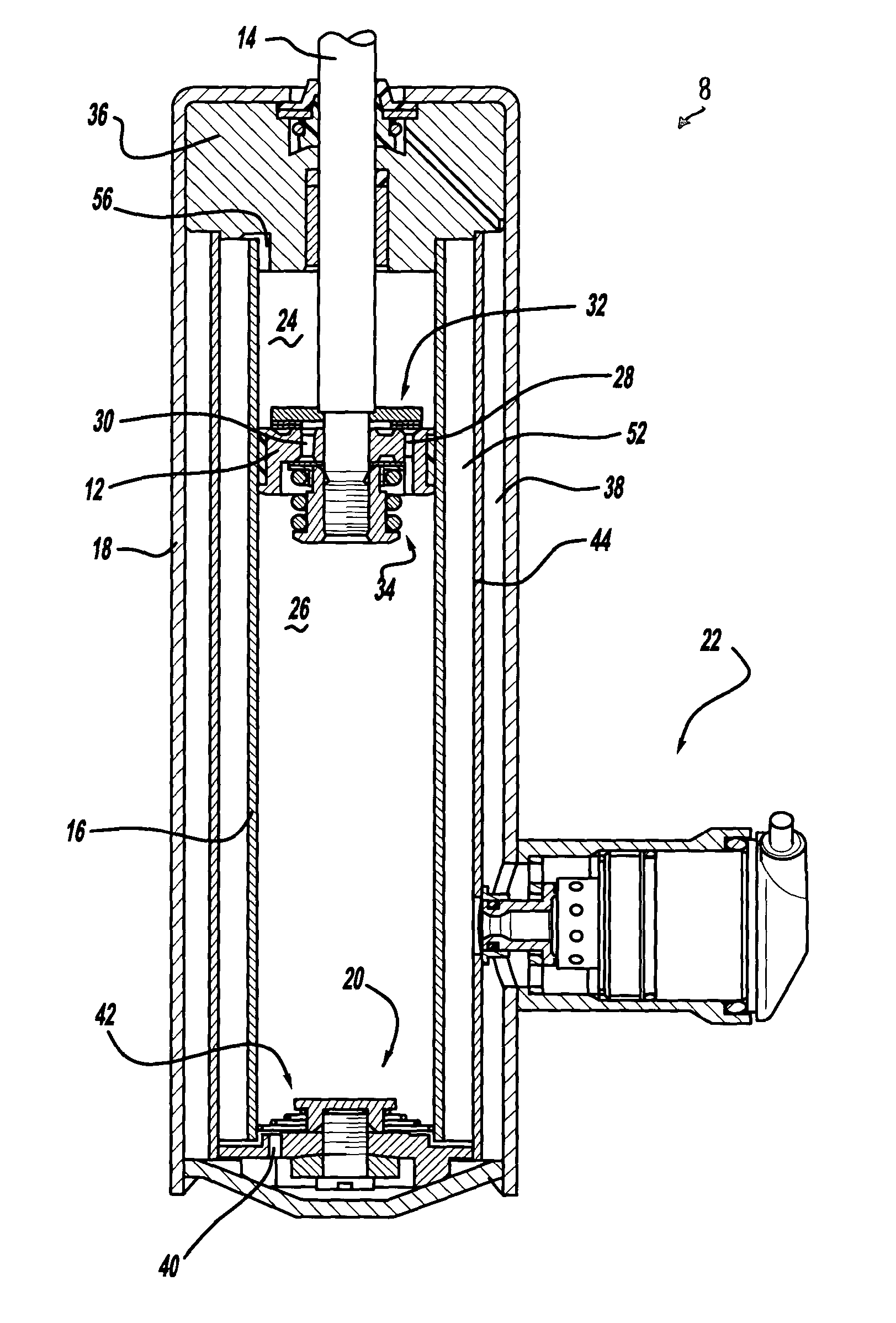

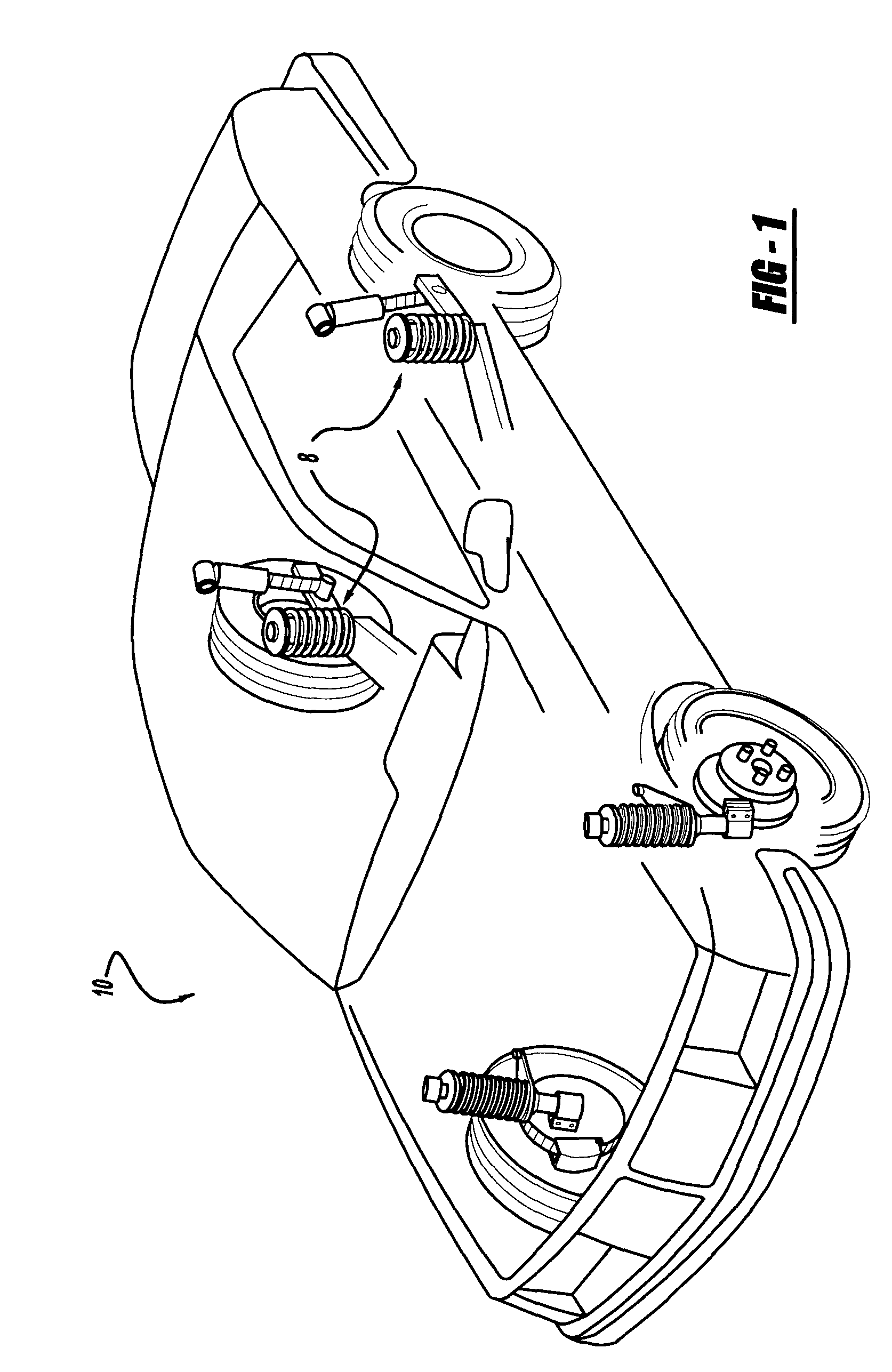

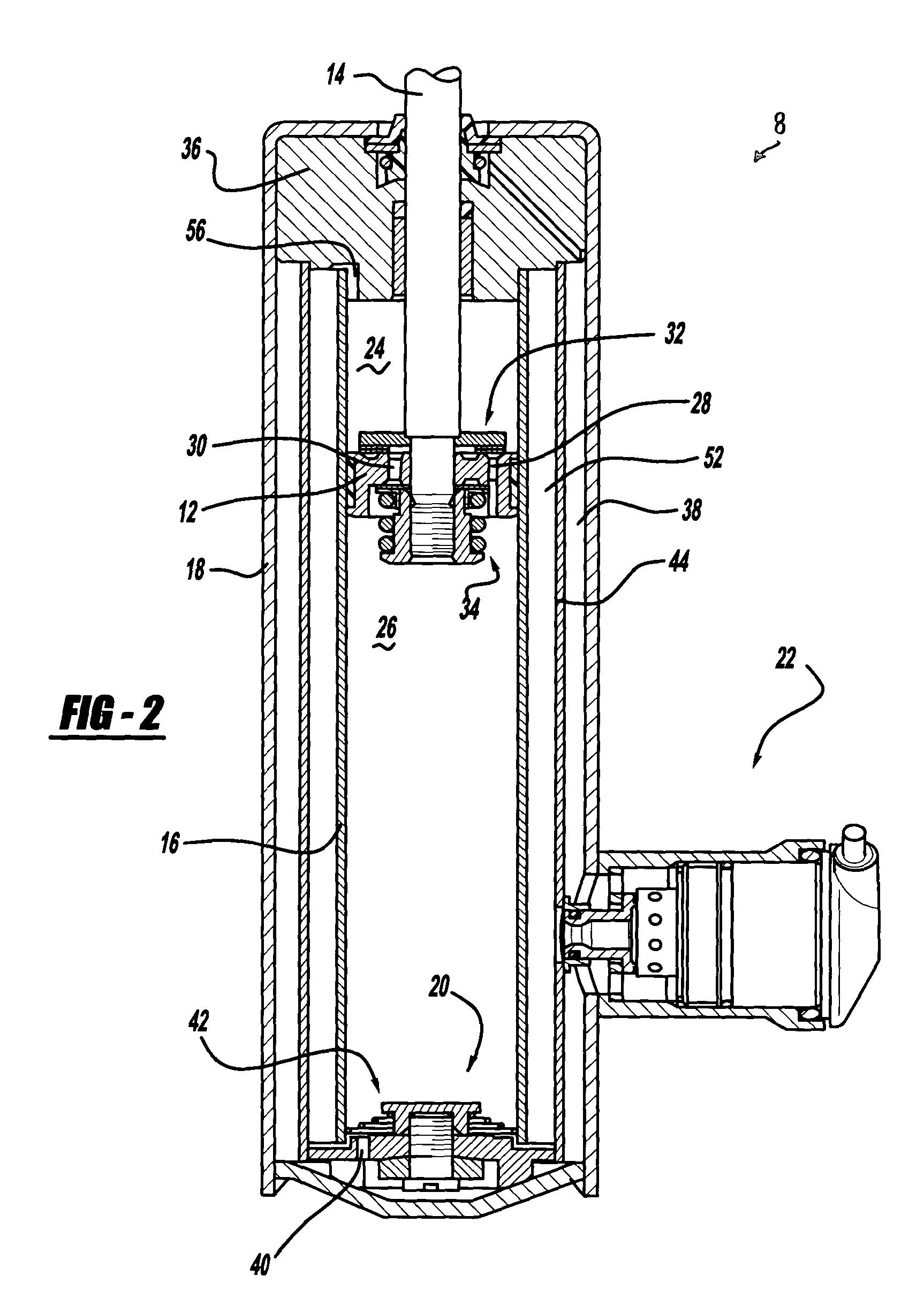

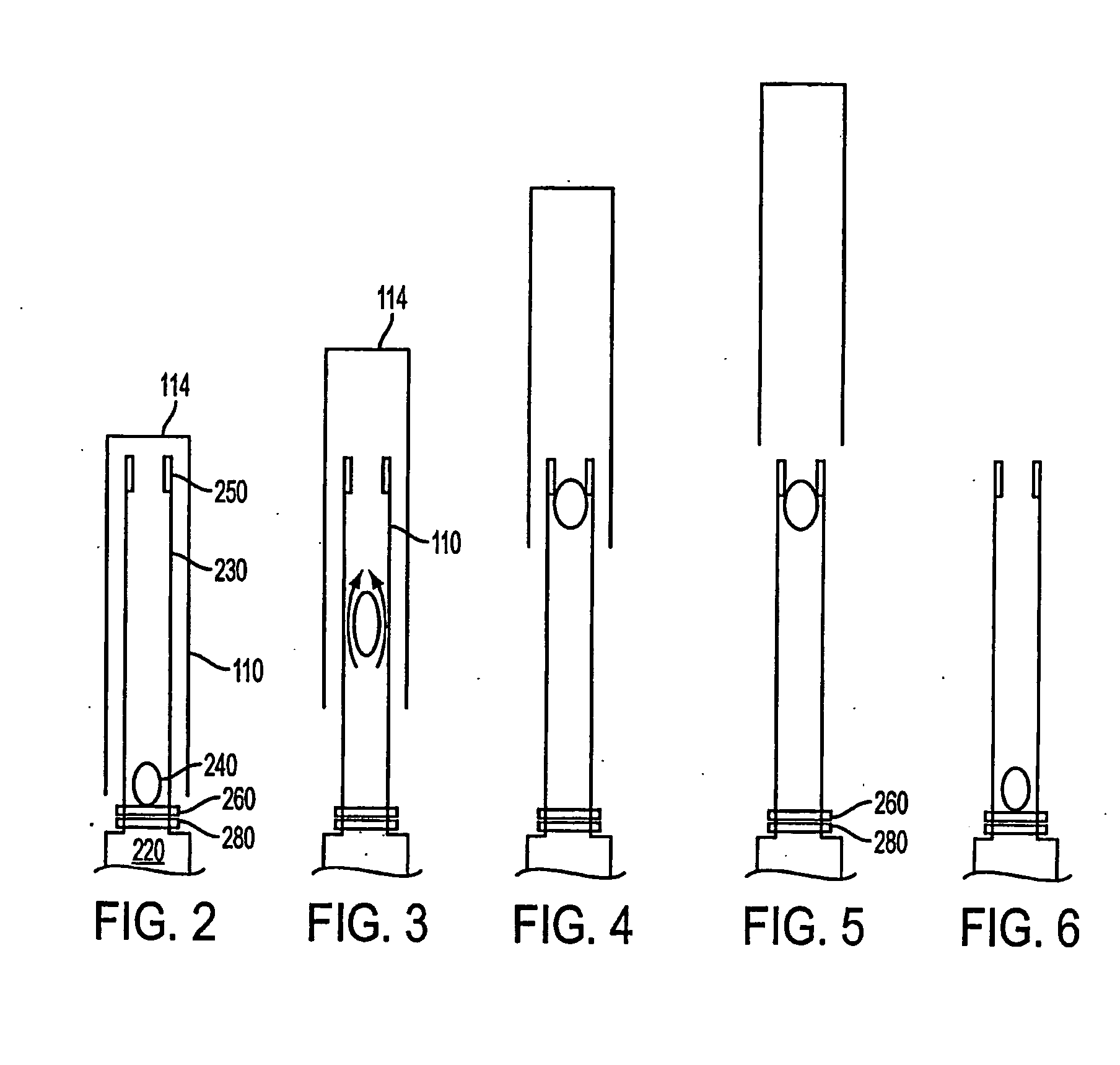

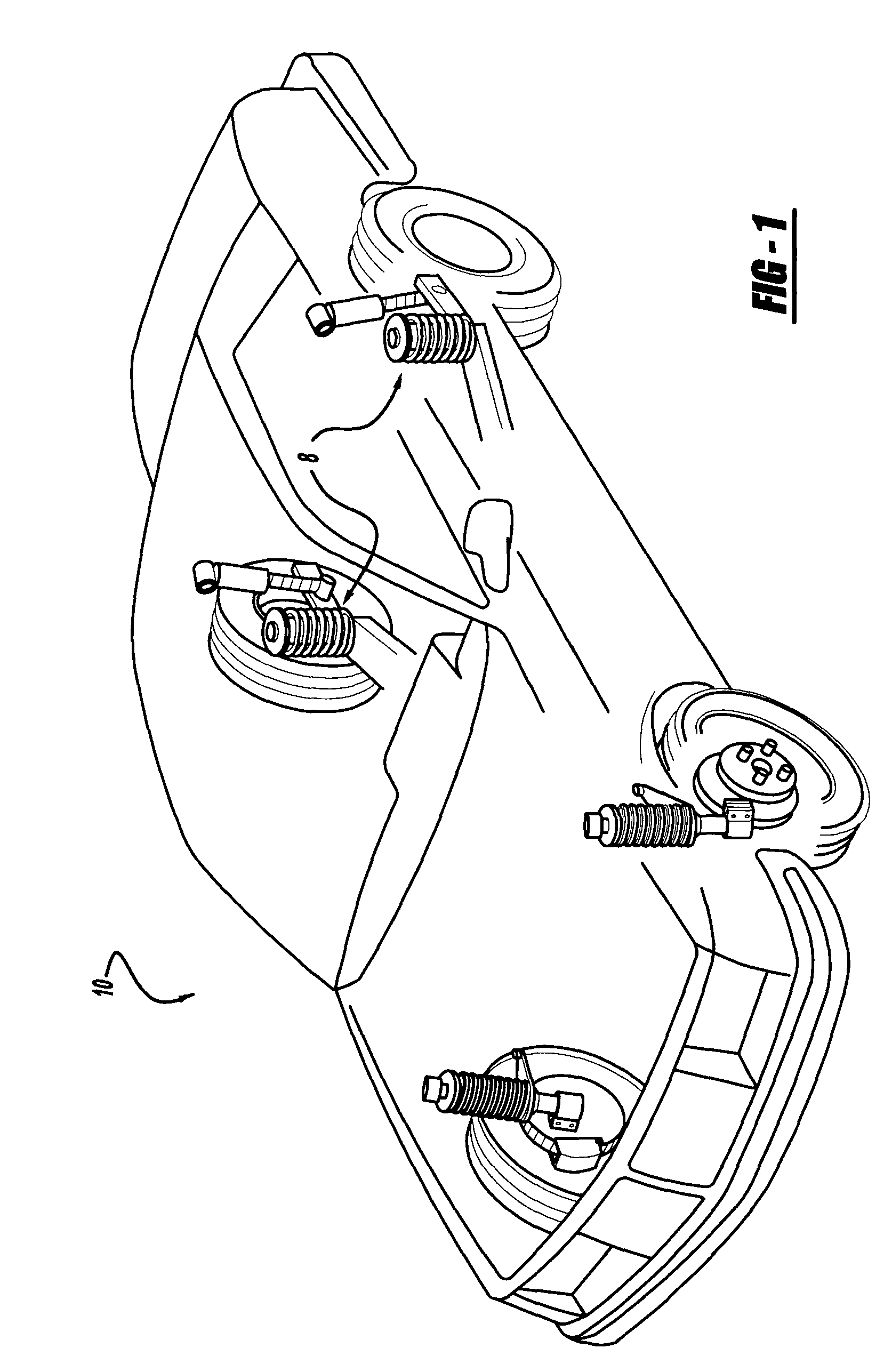

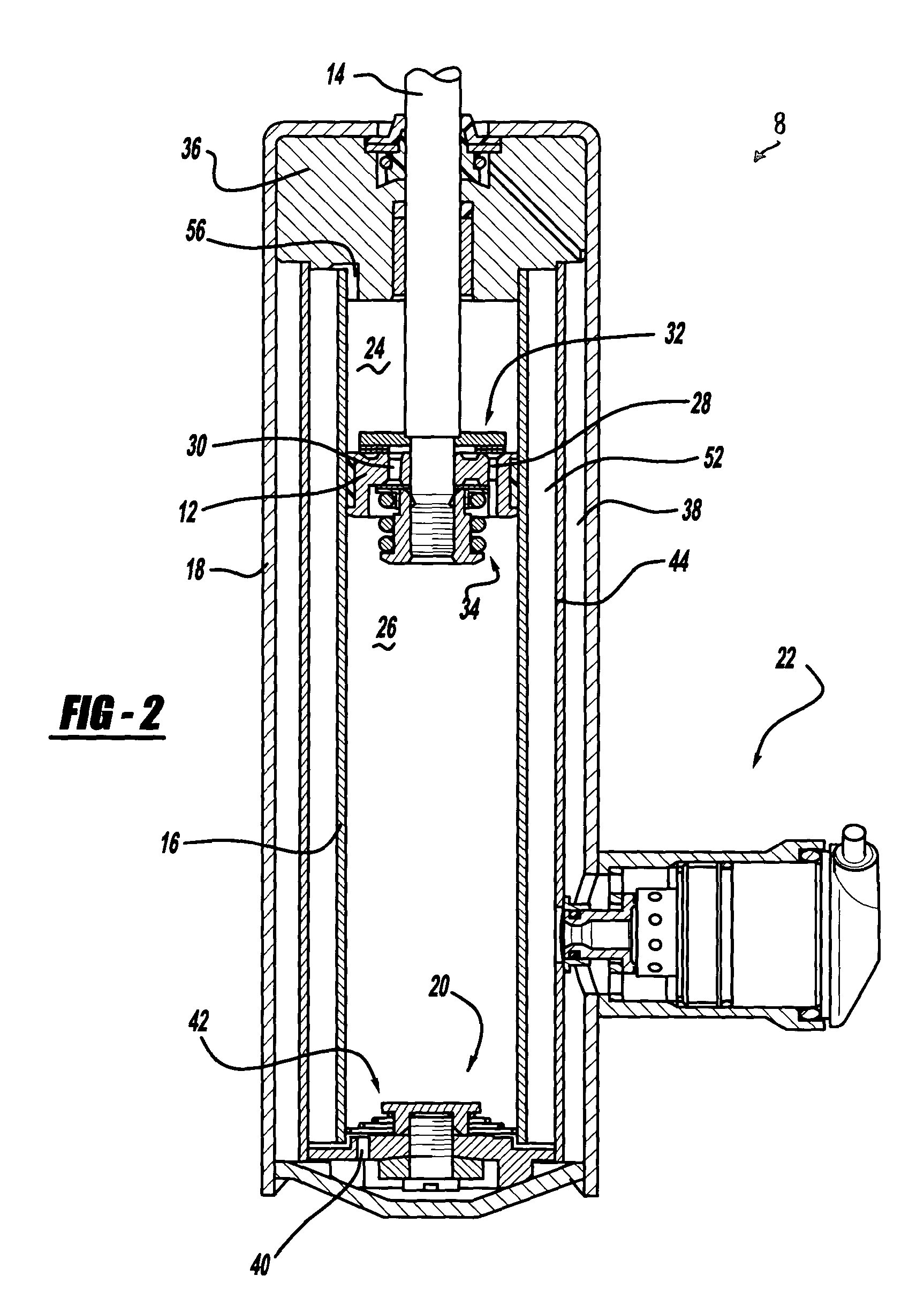

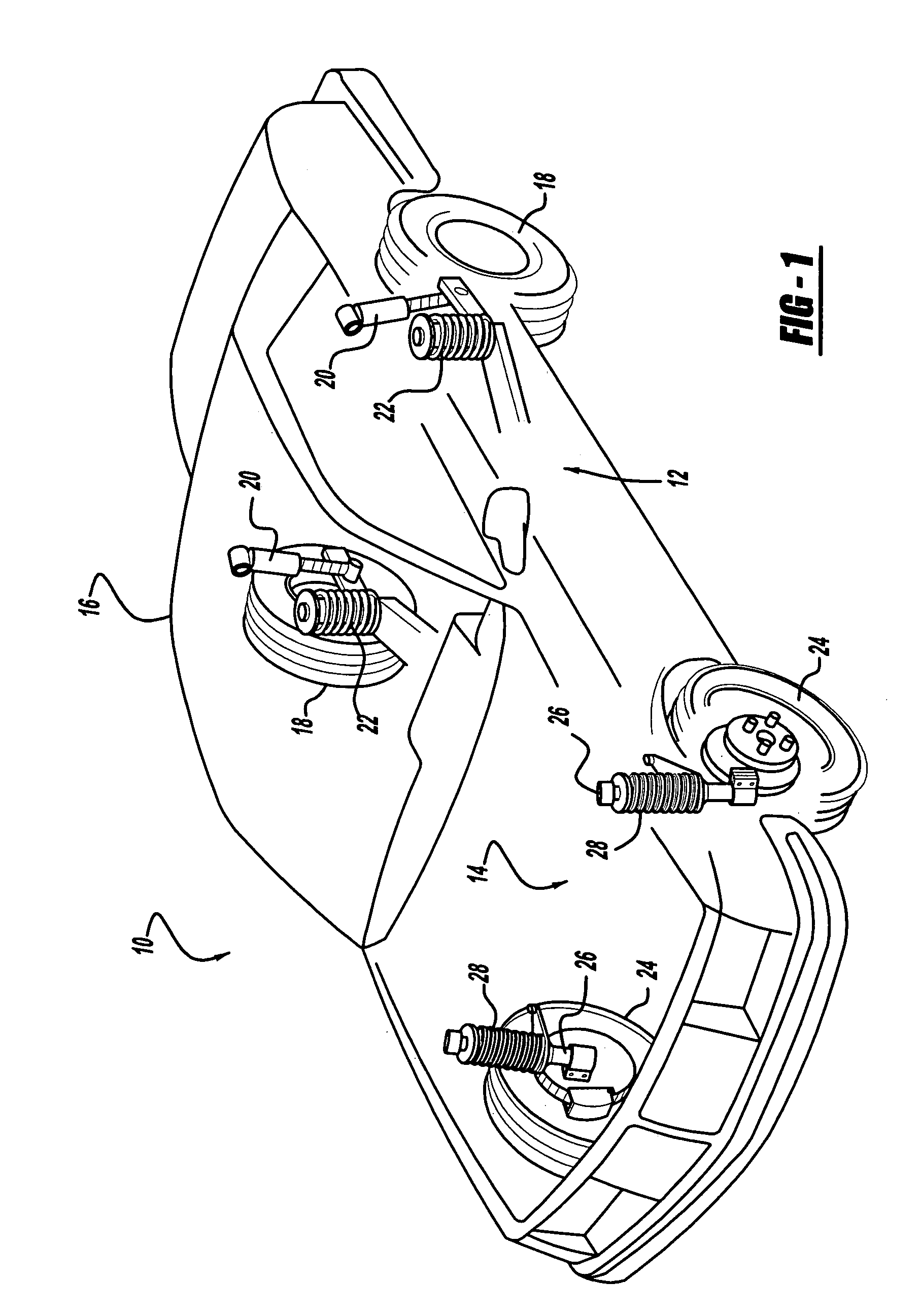

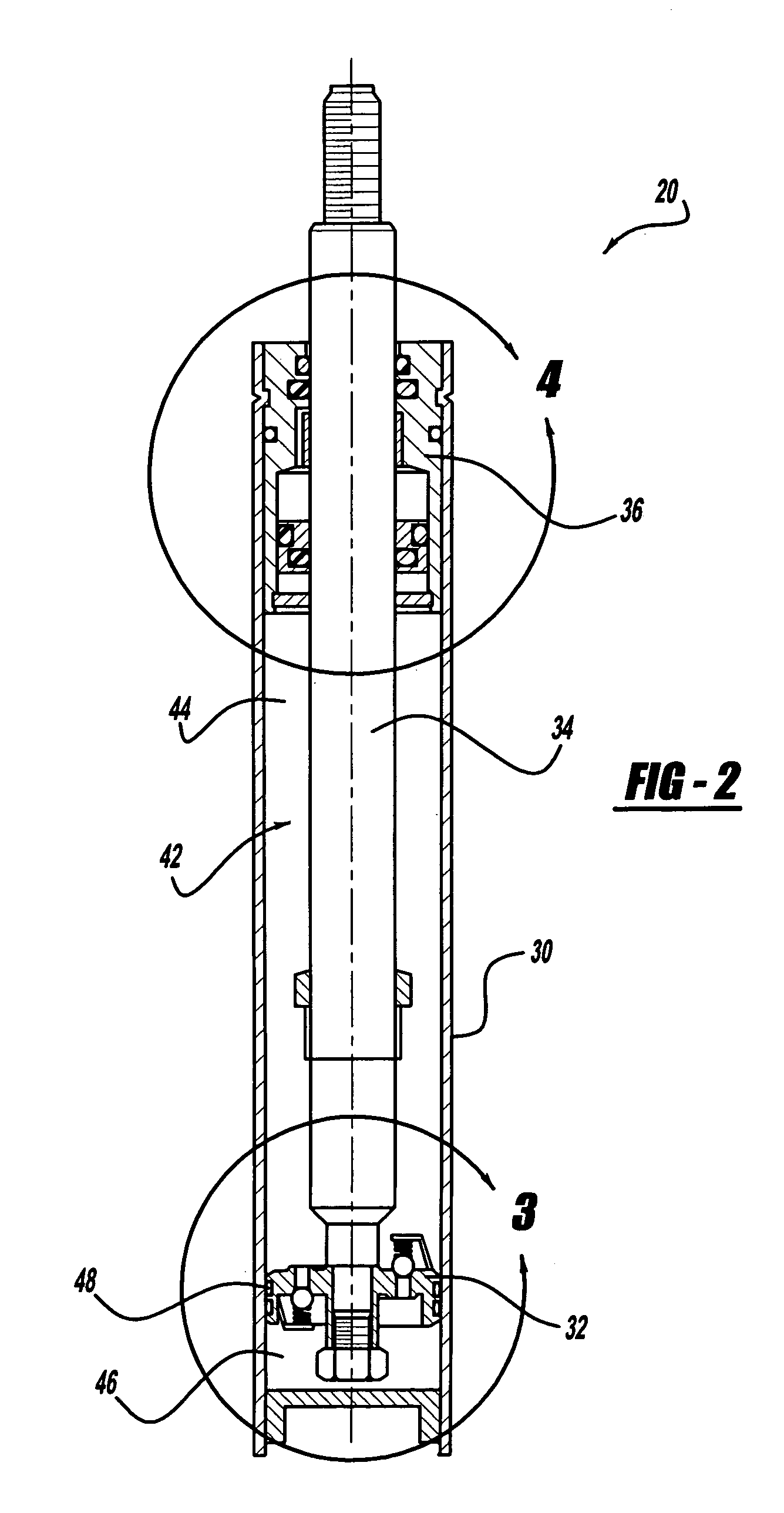

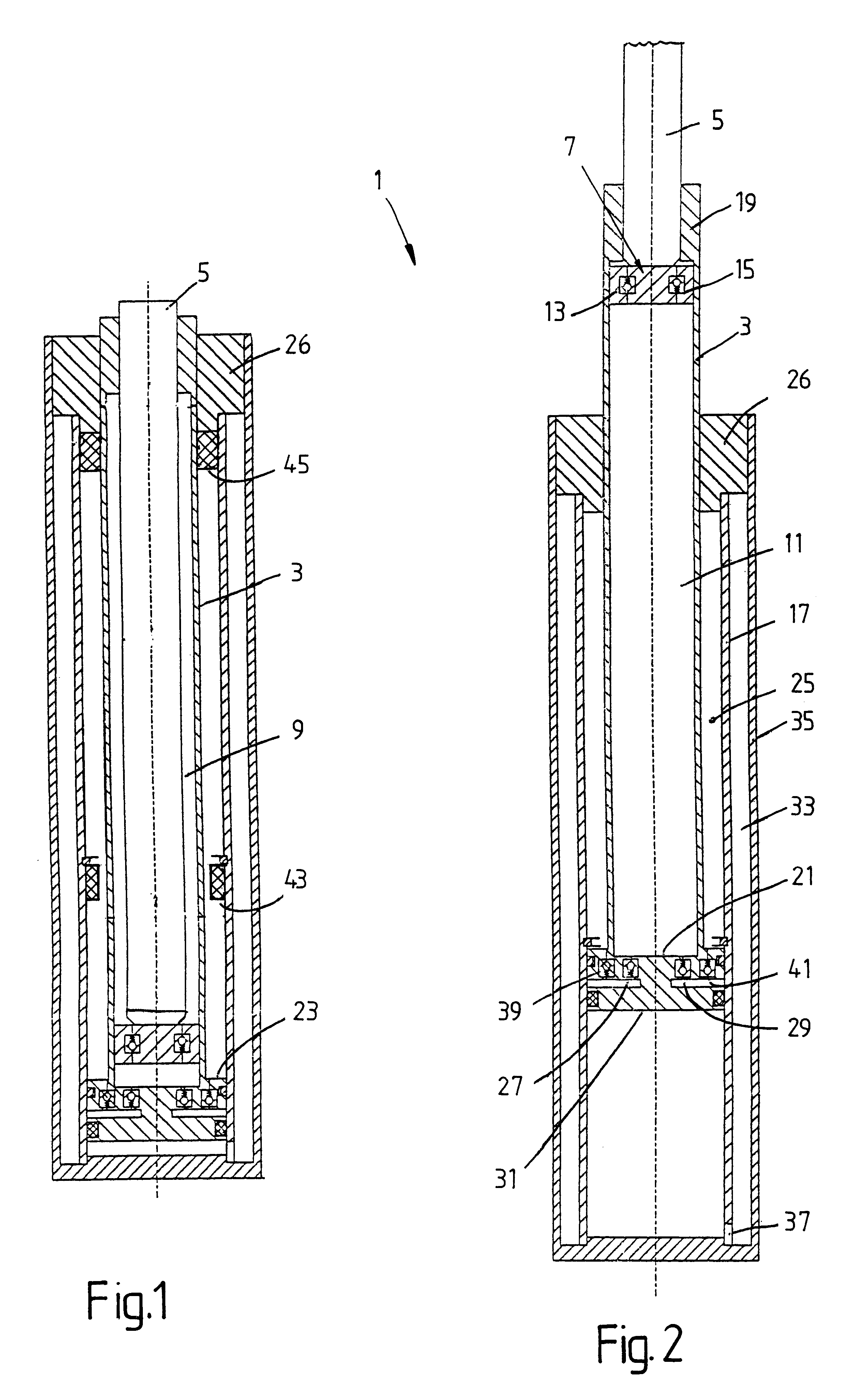

Adjustable damper with control valve, mounted in an external collar

A shock absorber according to the present invention includes a pressure tube having a working chamber disposed therewithin. A piston is slidably disposed within the working chamber and divides the working chamber into an upper working chamber and a lower working chamber. An intermediate tube is disposed around the pressure tube and the working chamber to define an intermediate chamber. A reserve tube is disposed around the intermediate tube. A collar is attached to the intermediate tube. The collar is defined by a shoulder portion extending generally lateral to the intermediate tube and a radial neck portion extending generally perpendicularly to the intermediate tube. An external control valve includes a valve seat received within the collar in an installed position. The external control valve is attached to the reserve tube.

Owner:TENNECO AUTOMOTIVE OPERATING CO INC

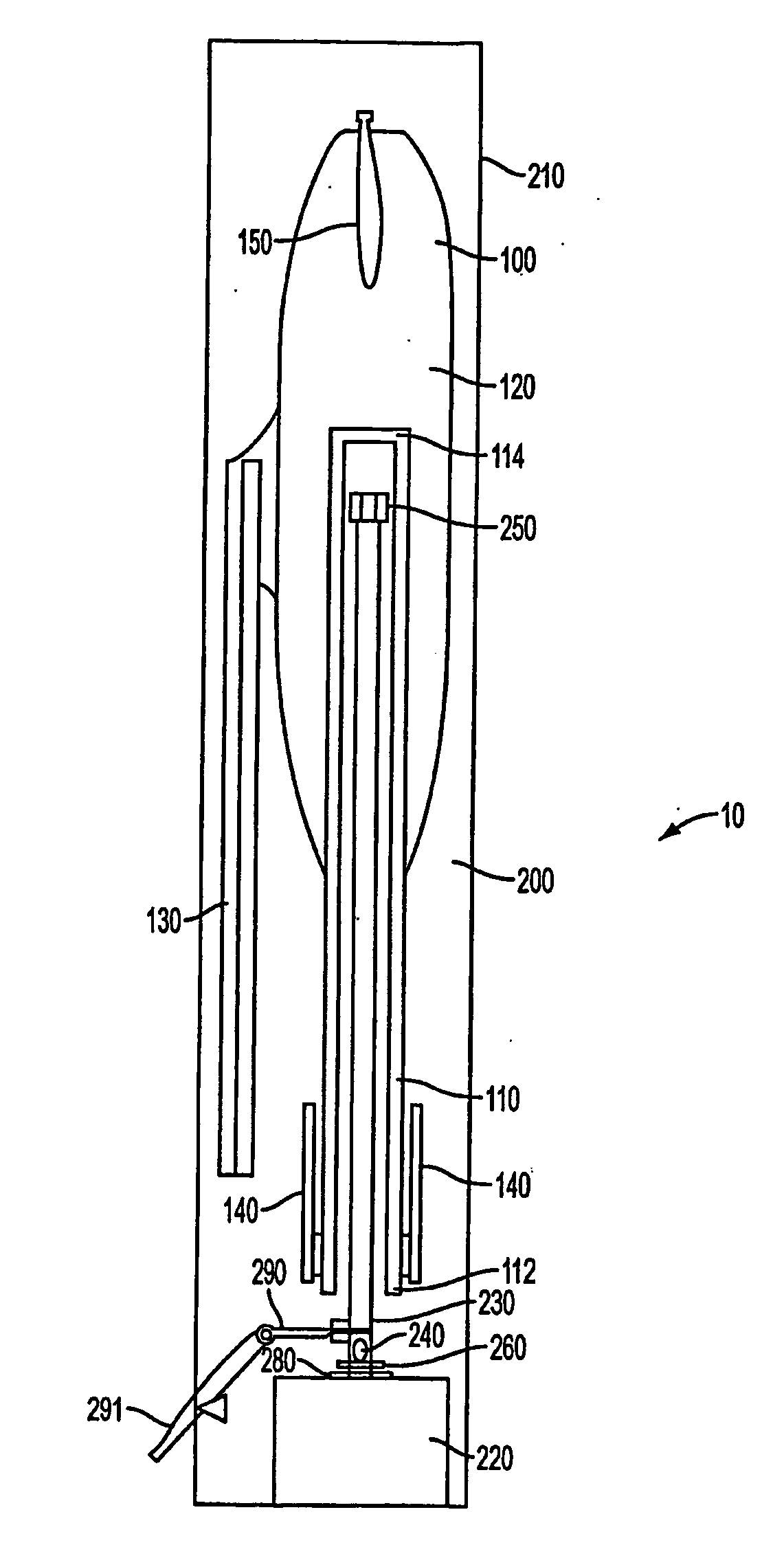

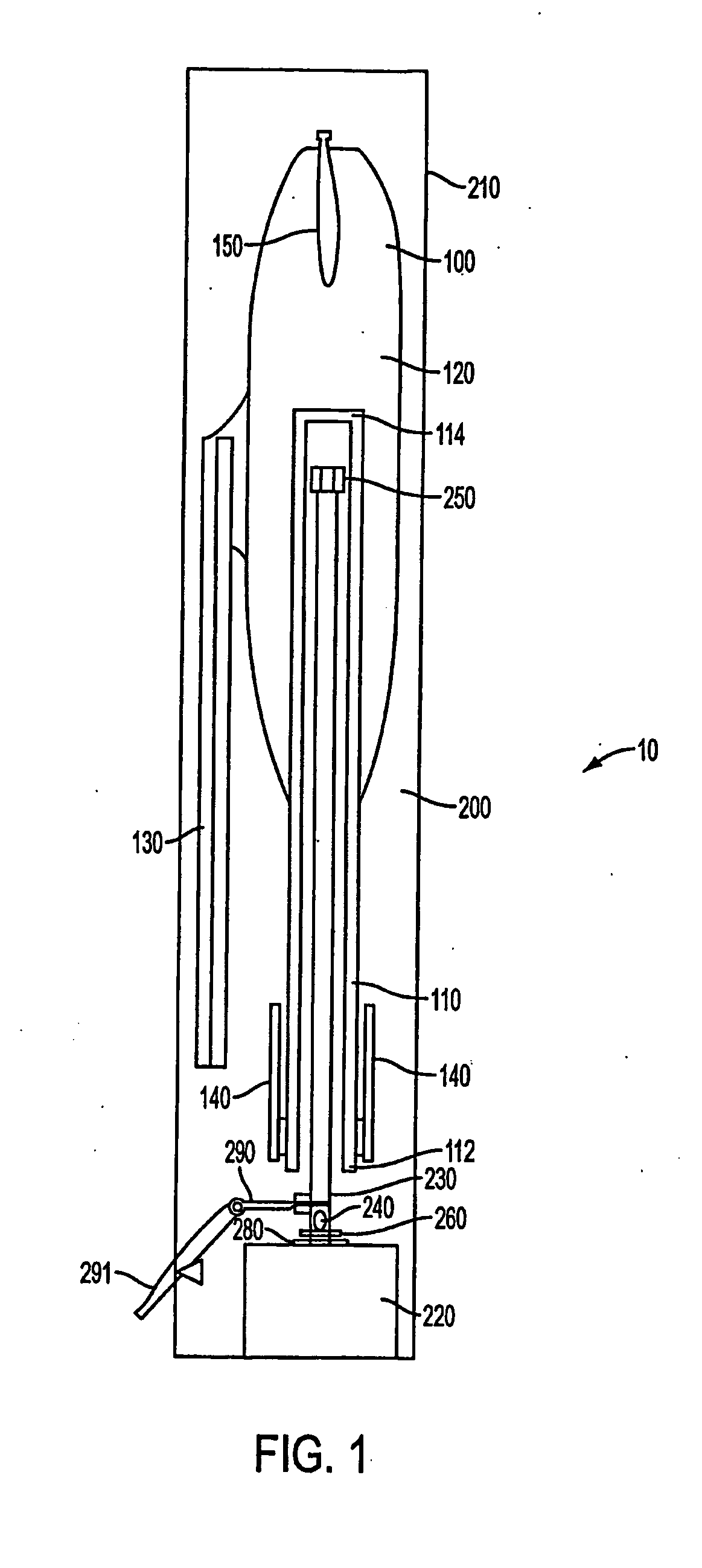

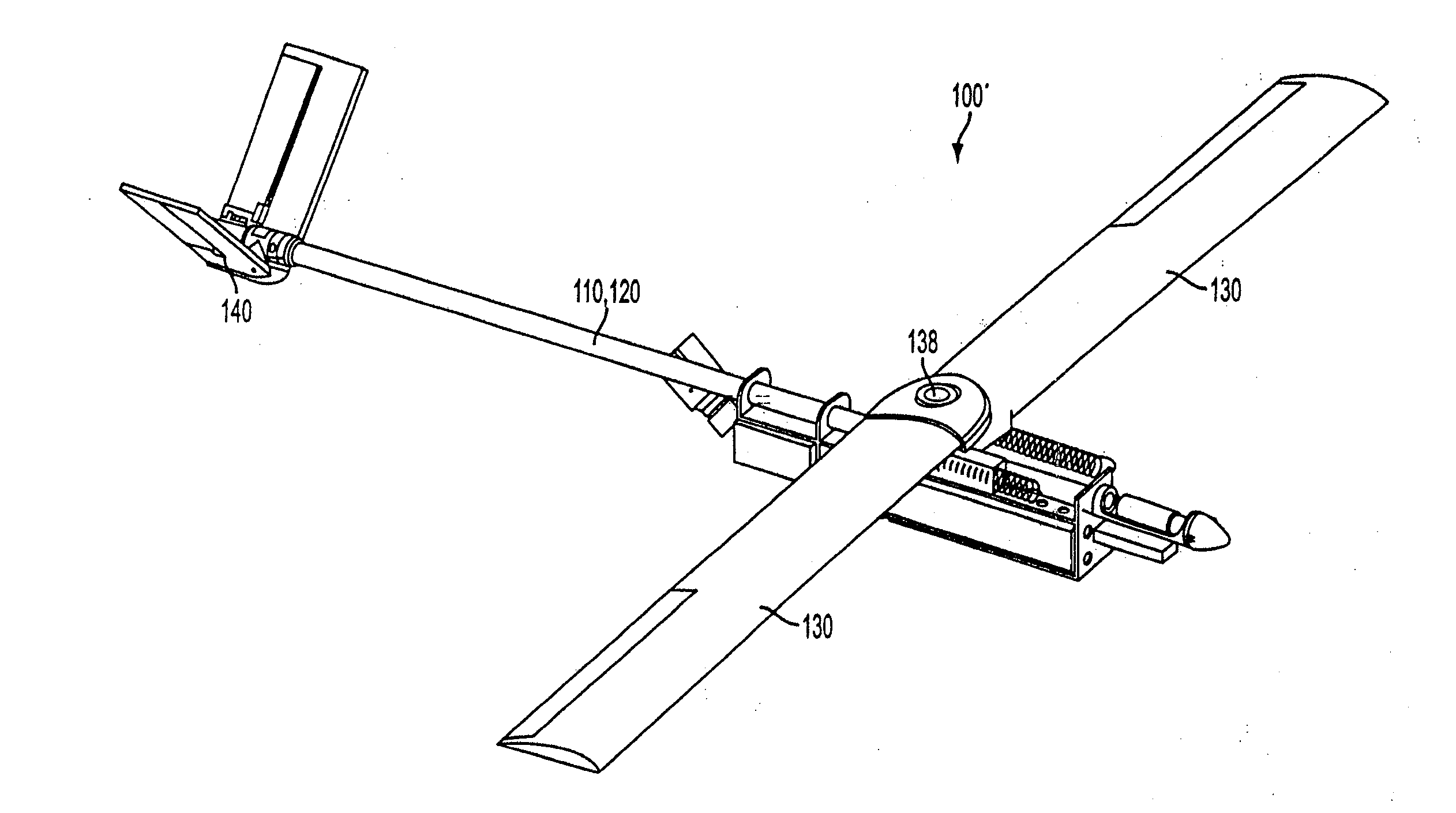

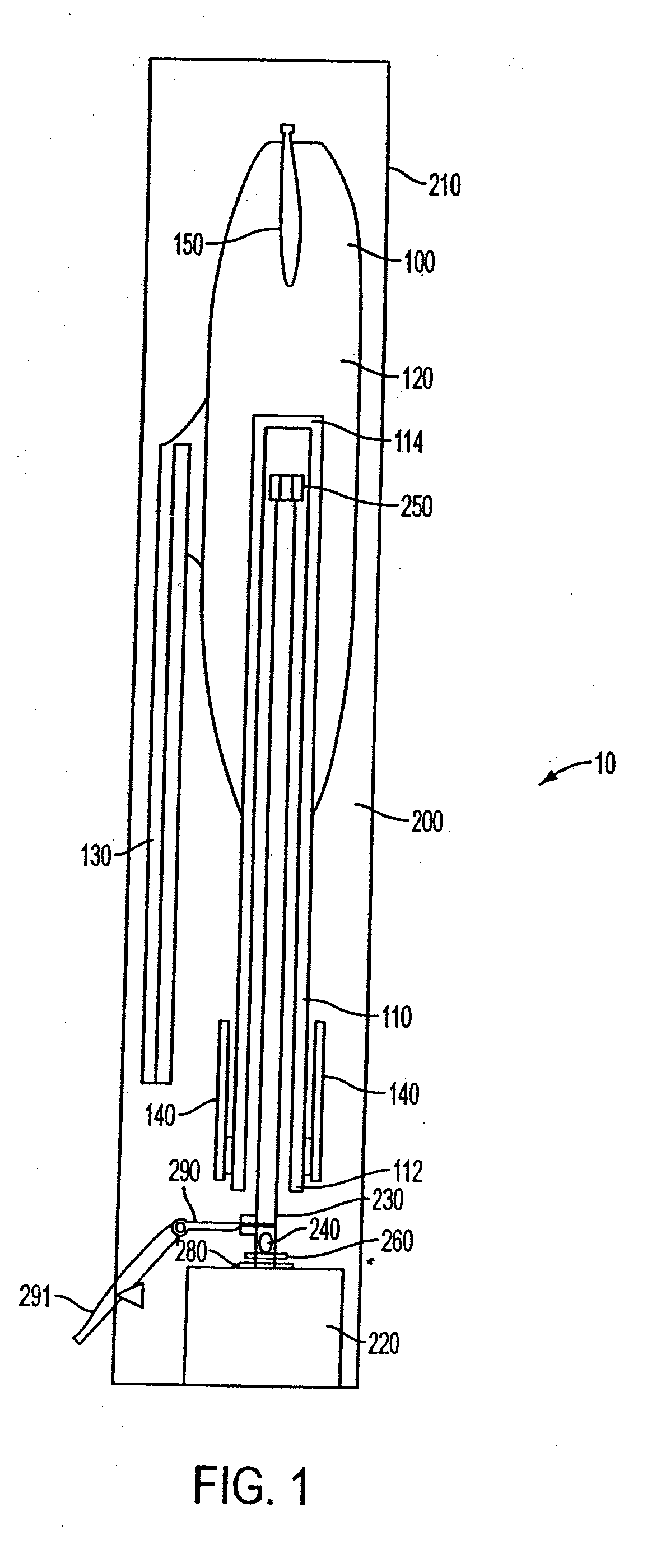

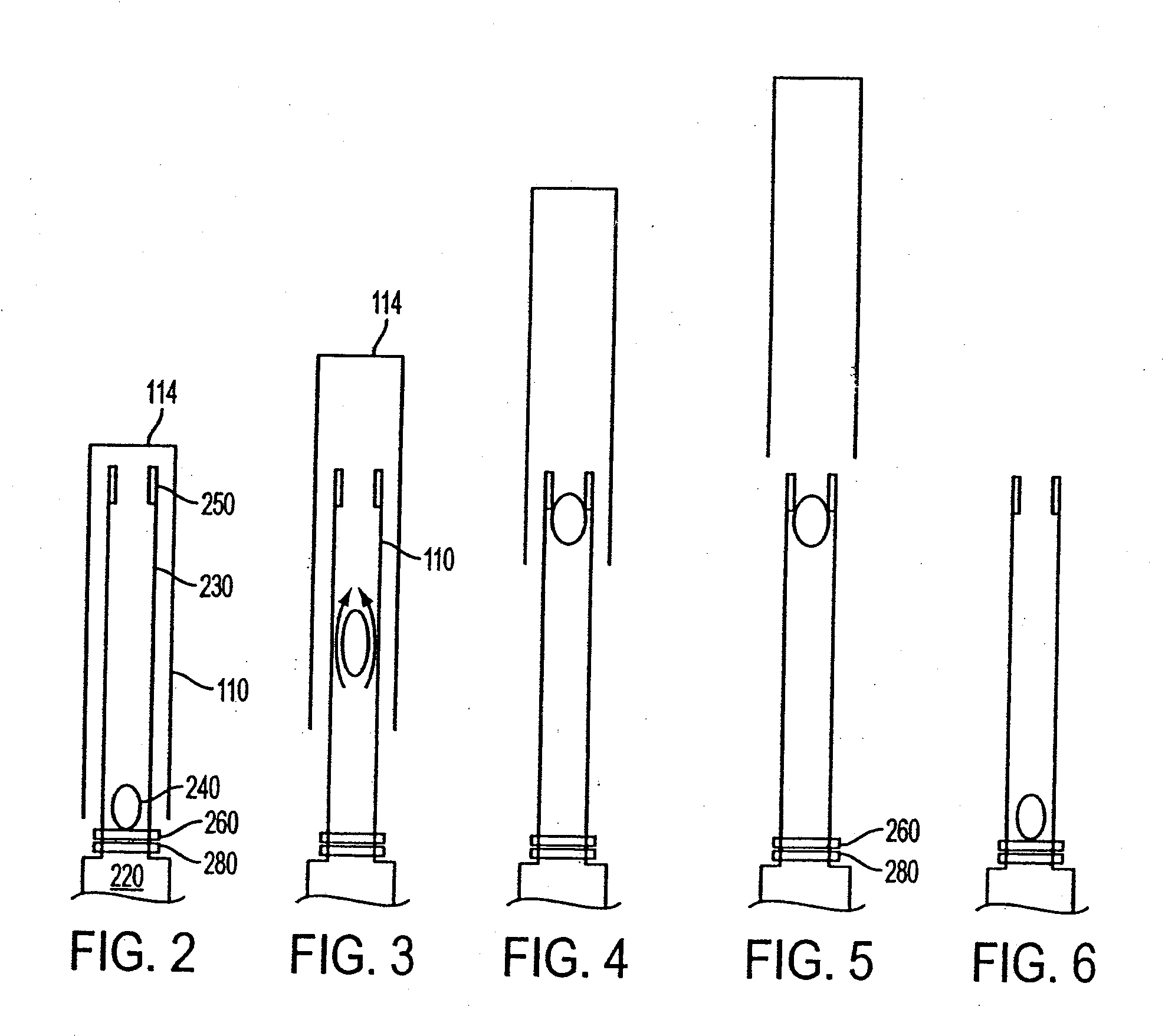

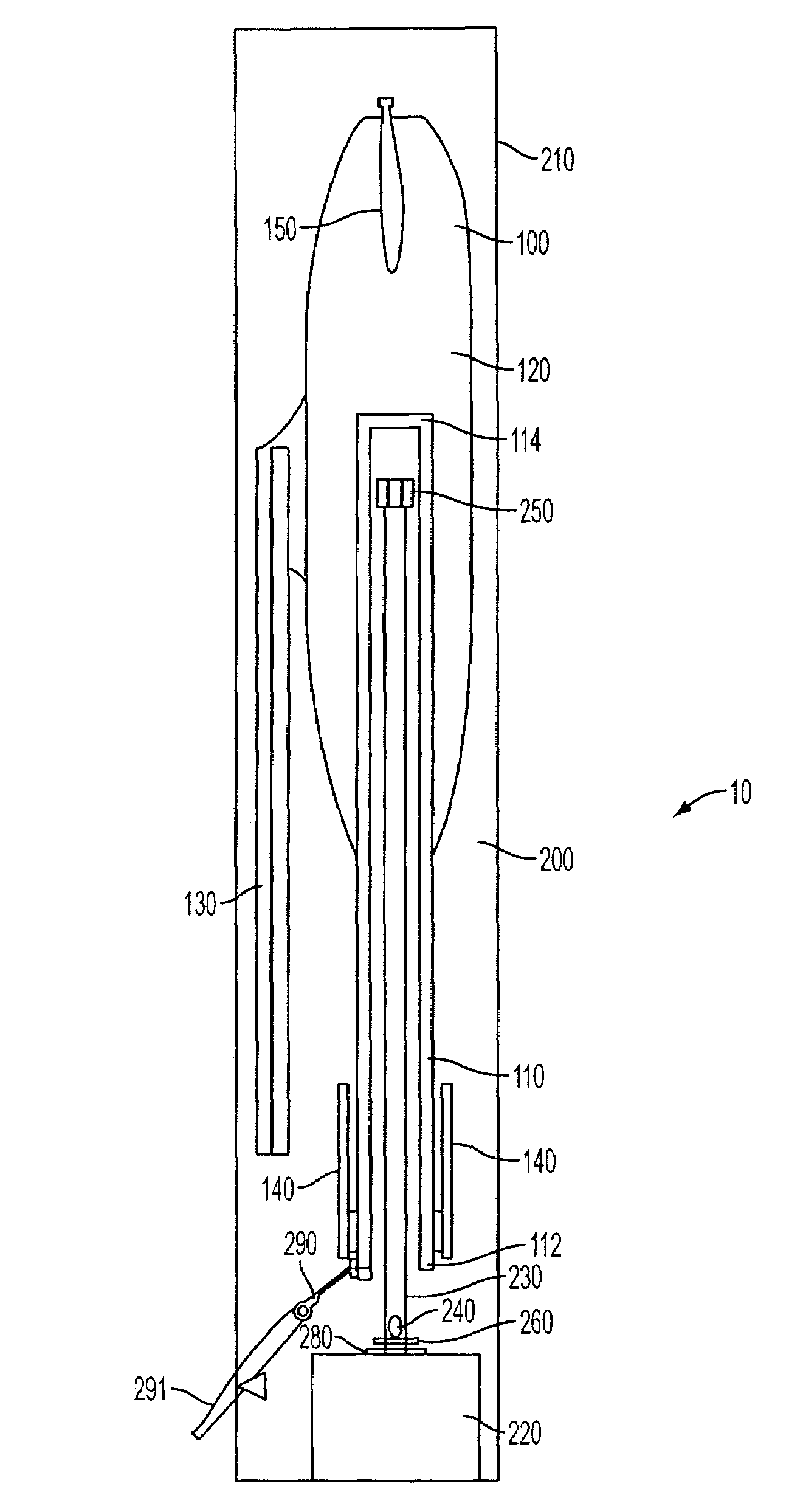

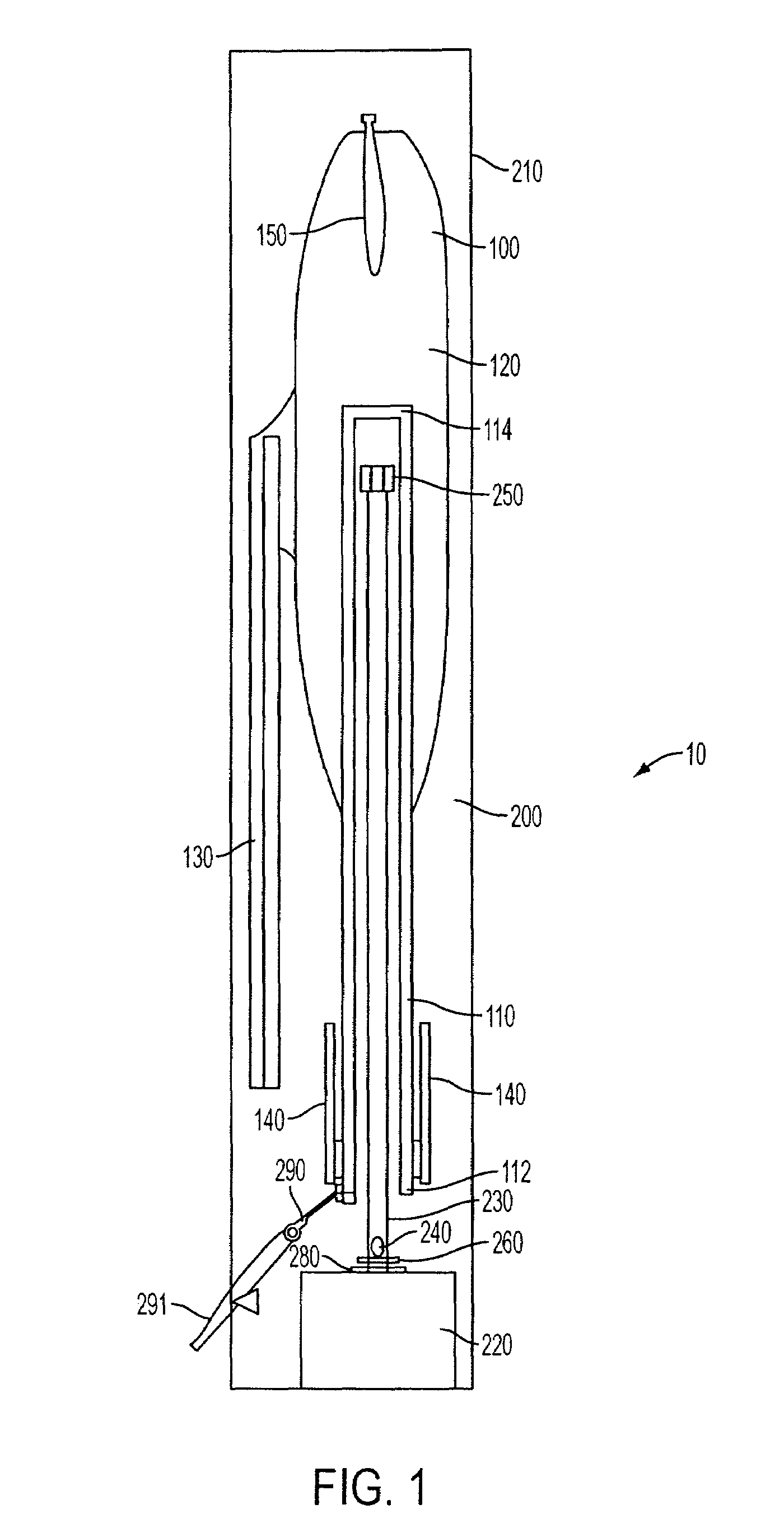

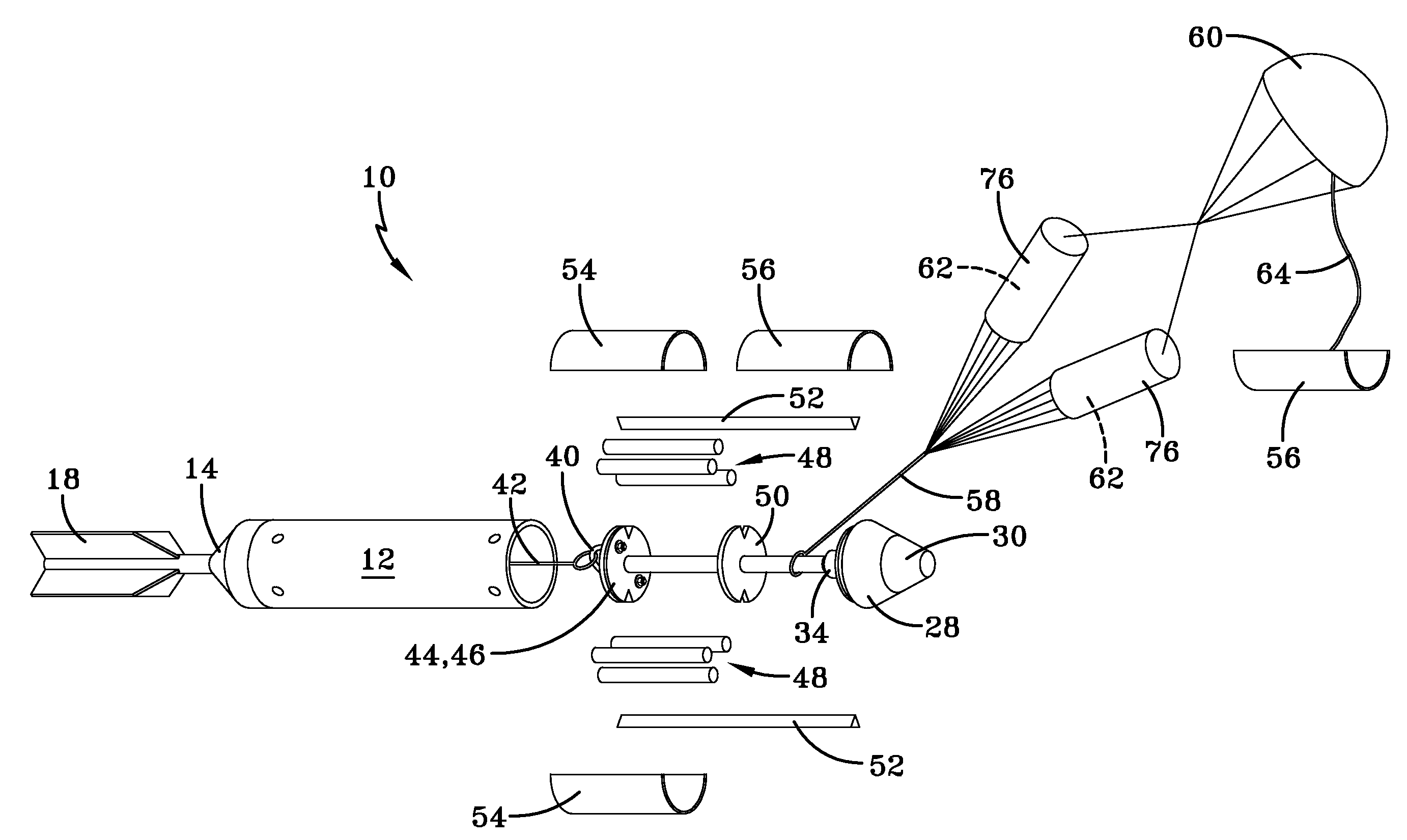

Lightweight air vehicle and pneumatic launcher

ActiveUS20050274845A1Easy to carryAvoid damageLaunching/towing gearUnmanned aerial vehiclesFlight vehicleUnmanned air vehicle

A portable unmanned air vehicle and launcher system is provided that includes a foldable unmanned air vehicle having a pressure tube; a launch gas reservoir for holding launch gas; a launch tube operatively connected to the launch gas reservoir and having a free end that is positioned in the pressure tube of the air vehicle; a free piston positioned within the launch tube; and a free piston stop to prevent the free piston from leaving the launch tube. A first portion of the launch gas in the launch gas reservoir is released into the launch tube and forces the free piston from an initial position to an end position at which the free piston is stopped by the free piston stop.

Owner:AIRPORTS AUTHORITY OF INDIA

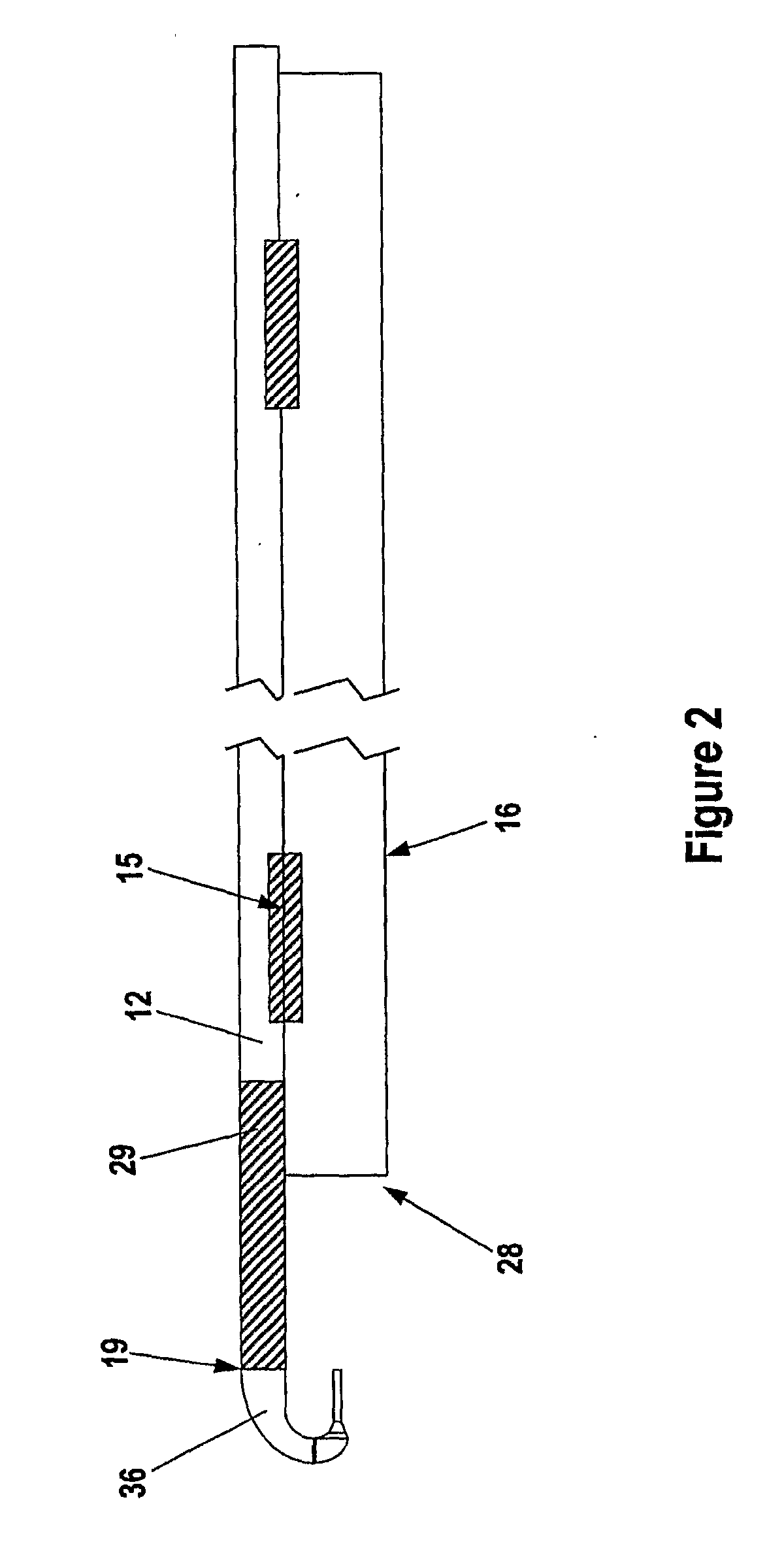

Electroformed liquid jet surgical instrument

InactiveUS20090306692A1Minimize the numberMinimize complexityMedical devicesSurgical instrument detailsLiquid jetEngineering

Certain embodiments of the invention provide a variety of methods of manufacturing a liquid jet-forming surgical instrument. According to these methods, a nozzle assembly of the instrument is electroformed on a mandrel. The nozzle assembly includes a nozzle providing a jet-opening, wherein the nozzle is shaped to form a liquid jet. In some embodiments, the mandrel includes a first mandrel portion and a second mandrel portion. Once the nozzle assembly is formed, the mandrel may be removed from the nozzle assembly. The nozzle assembly may in certain embodiments be coupled to an outlet of the pressure tube. In certain embodiments, an inlet of an evacuation tube is positioned such that a jet-receiving opening of the evacuation tube is positioned opposite the jet-opening of the nozzle.

Owner:HYDROCISION

Lightweight air vehicle and pneumatic launcher

ActiveUS20080093501A1Easy to carryAvoid damageLaunching/towing gearUnmanned aerial vehiclesFlight vehicleUnmanned air vehicle

Owner:AIRPORTS AUTHORITY OF INDIA

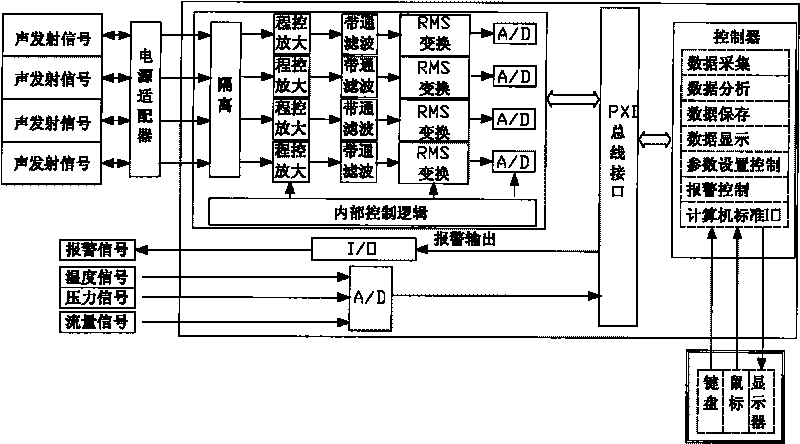

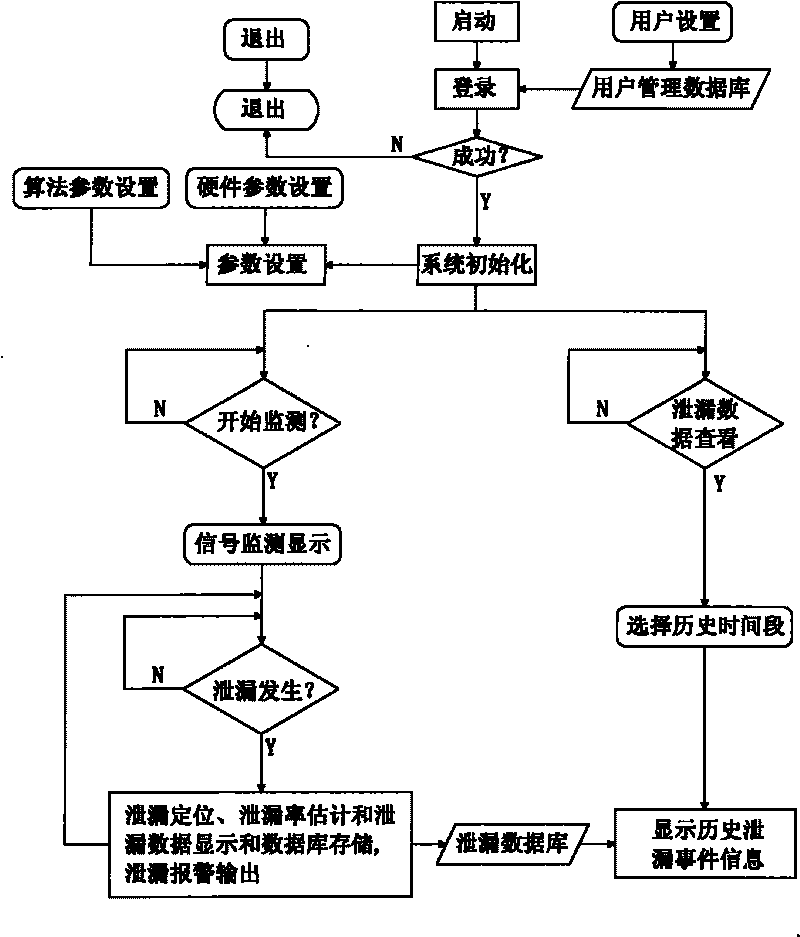

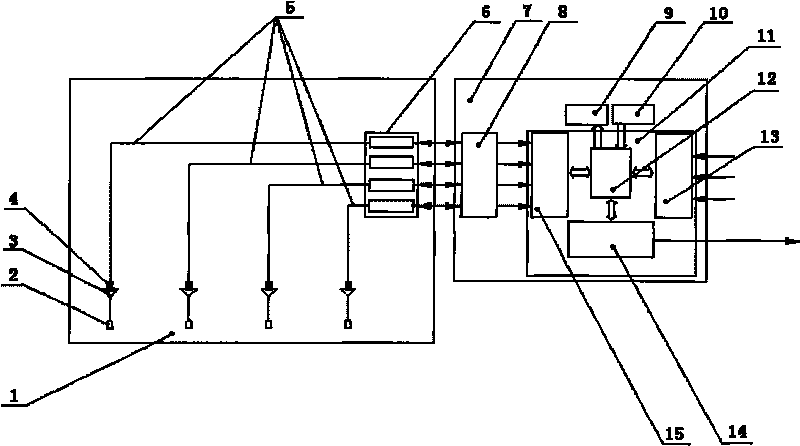

Method for monitoring pressure pipeline leakage acoustic emission in nuclear power plant and monitoring system thereof

ActiveCN101706039AImprove real-time performanceHigh sensitivityPipeline systemsNuclear engineeringNuclear power

The invention relates to a method for monitoring pressure pipe leakage acoustic emission in a nuclear power plant and a monitoring system thereof. The monitoring method adopts the technical scheme that a pressure pipe leakage test piece is prepared; the initiation, crack, expansion and through leakage of the pipeline of the nuclear power plant are imitated, a leakage acoustic emission calibration test is performed, and the through crack leakage of the pipeline under high temperature and high pressure environment in nuclear power plant is imitated. The monitoring system adopts a standardized and modularized design which is based on PXI bus and convenient for system maintenance and part replacement. Through adopting the monitoring method and the monitoring system, the data record of leakage event and the database management of monitoring result can be achieved; moreover, the leak position and the dynamic change of leak rate are completely reflected.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

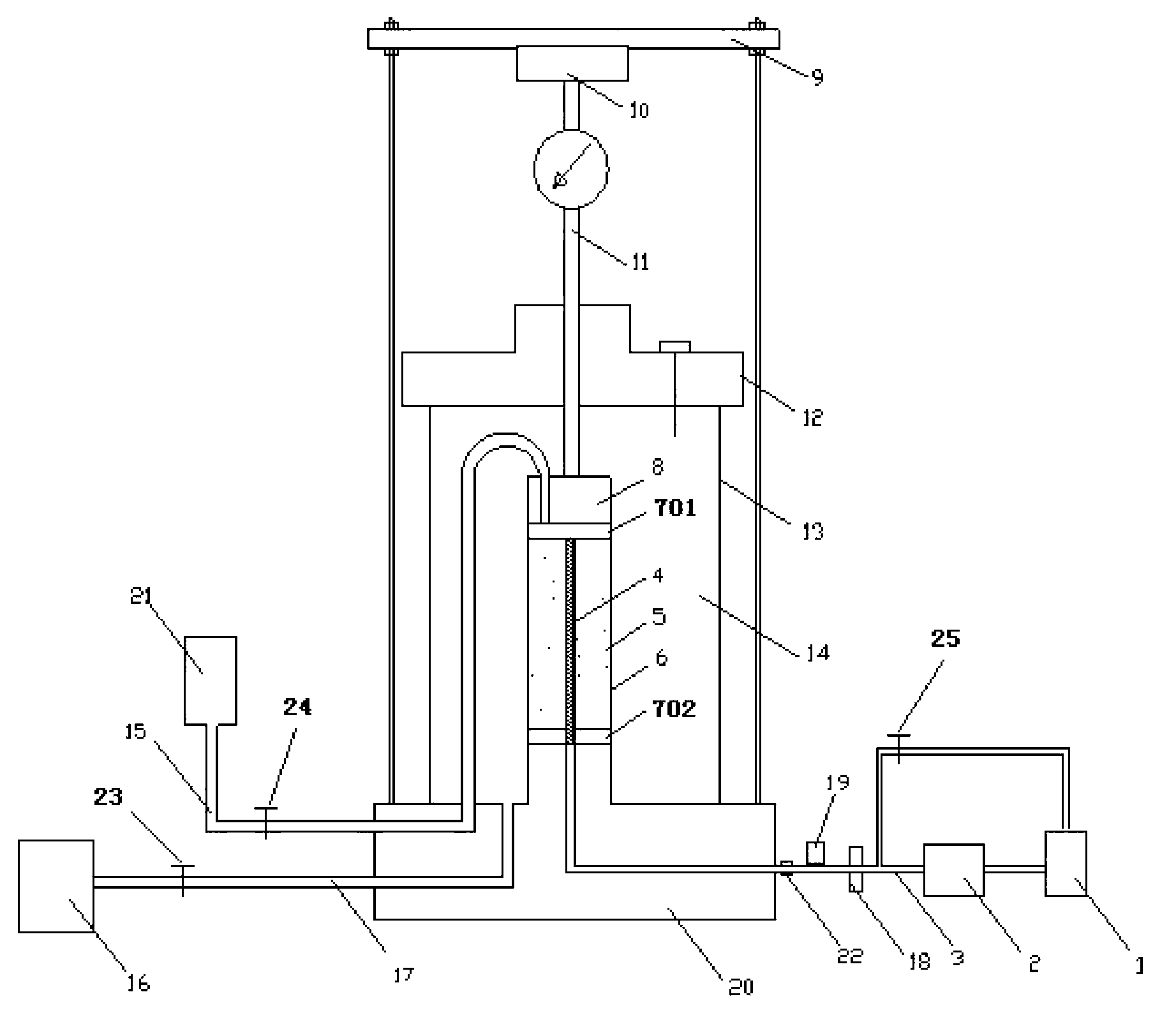

Indoor grouting testing device under simulation of complex stress effect and testing method thereof

InactiveCN103018152ASolve drainage problemsDoes not affect the drainage effectPermeability/surface area analysisRubber membranePressure system

Owner:HUNAN UNIV OF SCI & TECH

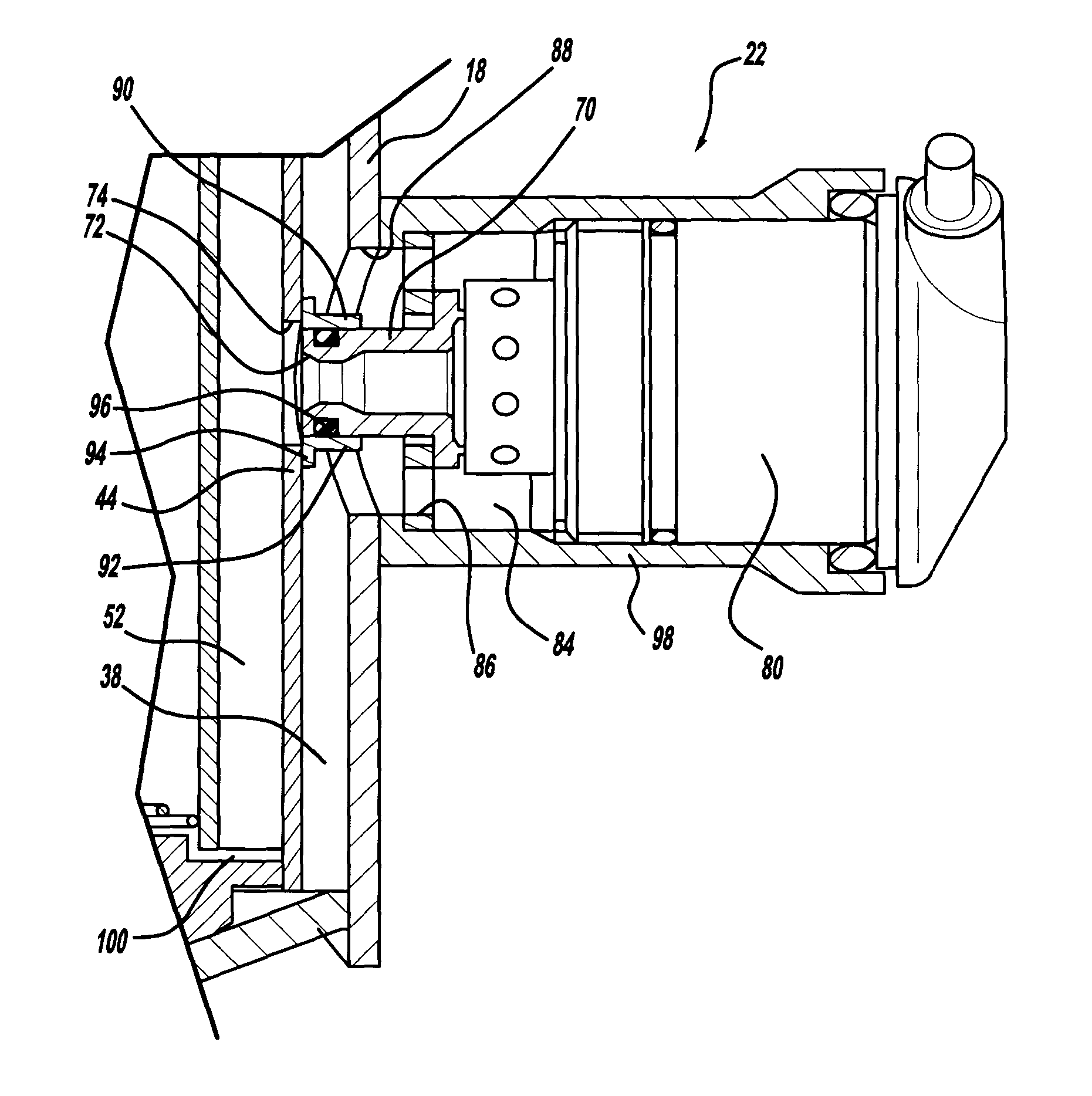

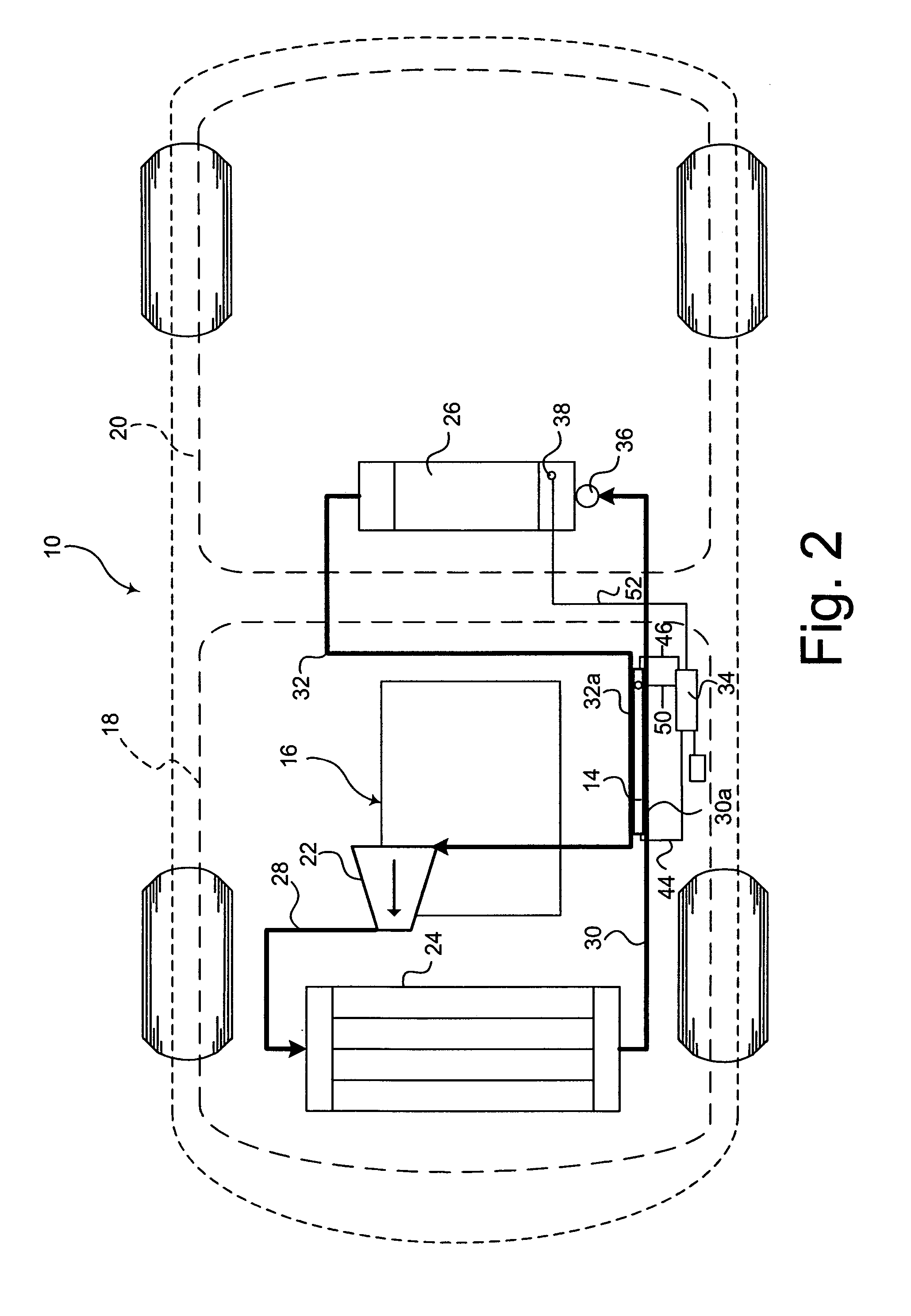

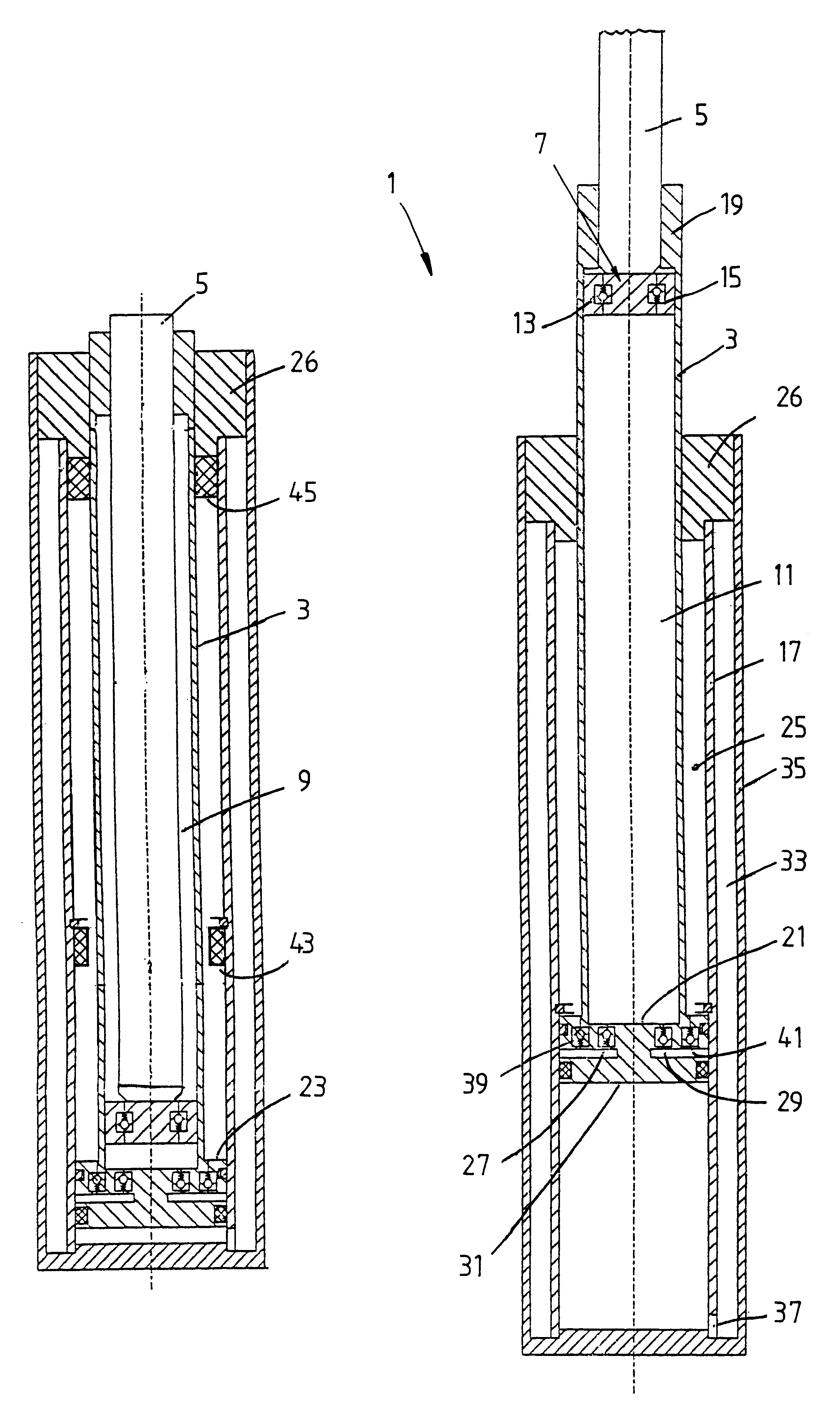

Adjustable damper with control valve, mounted in an external collar

A shock absorber according to the present invention includes a pressure tube having a working chamber disposed therewithin. A piston is slidably disposed within the working chamber and divides the working chamber into an upper working chamber and a lower working chamber. An intermediate tube is disposed around the pressure tube and the working chamber to define an intermediate chamber. A reserve tube is disposed around the intermediate tube. A collar is attached to the intermediate tube. The collar is defined by a shoulder portion extending generally lateral to the intermediate tube and a radial neck portion extending generally perpendicularly to the intermediate tube. An external control valve includes a valve seat received within the collar in an installed position. The external control valve is attached to the reserve tube.

Owner:TENNECO AUTOMOTIVE OPERATING CO INC

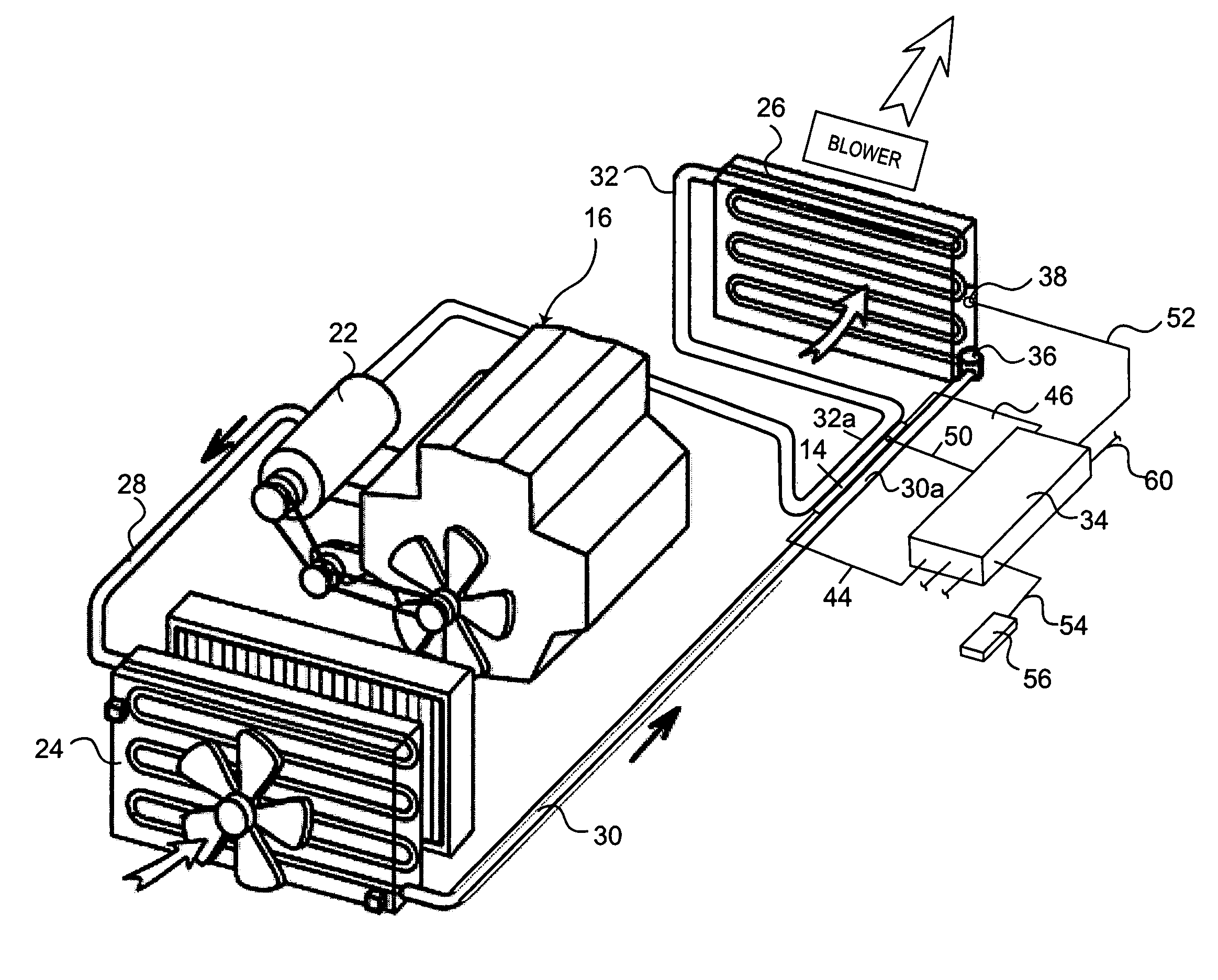

Vehicle air conditioning system

InactiveUS7363766B2Improve cooling effectImprove efficiencyCompression machines with non-reversible cycleVehicle heating/cooling devicesEngineeringAir conditioning

A vehicle air conditioning system includes a compressor, a condenser, an evaporator and a thermoelectric device. The compressor is configured to receive a refrigerant and compress the refrigerant to a compressed state. The condenser is in fluid communication with the compressor to receive the refrigerant in the compressed state via a high pressure tube. The evaporator is in fluid communication between the condenser and the compressor to receive the refrigerant from the condenser and convey the refrigerant to the compressor via a low pressure tube. The thermoelectric device is operatively arranged relative to at least a portion of the high pressure tube to remove heat from the high pressure tube.

Owner:NISSAN MOTOR CO LTD

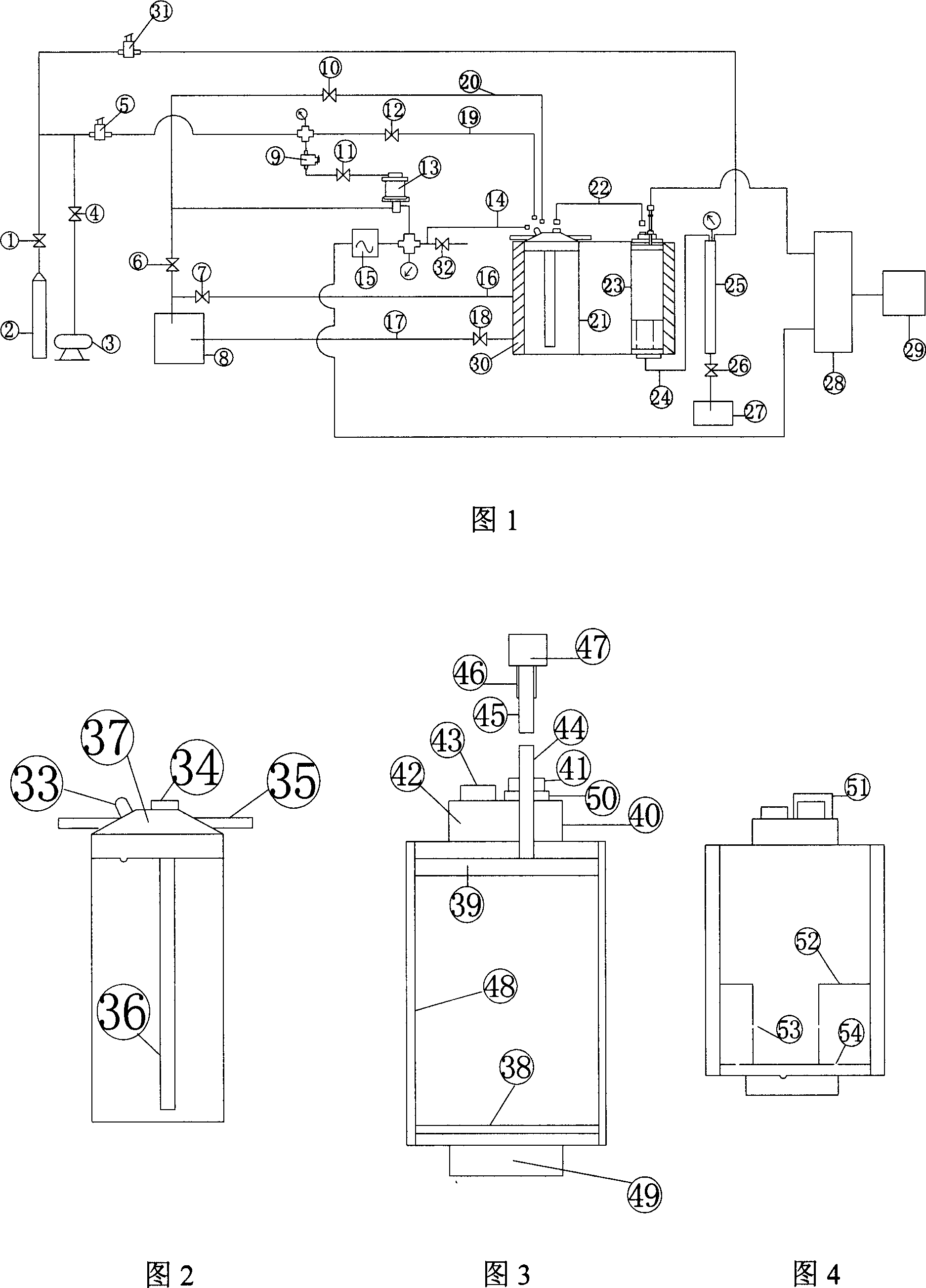

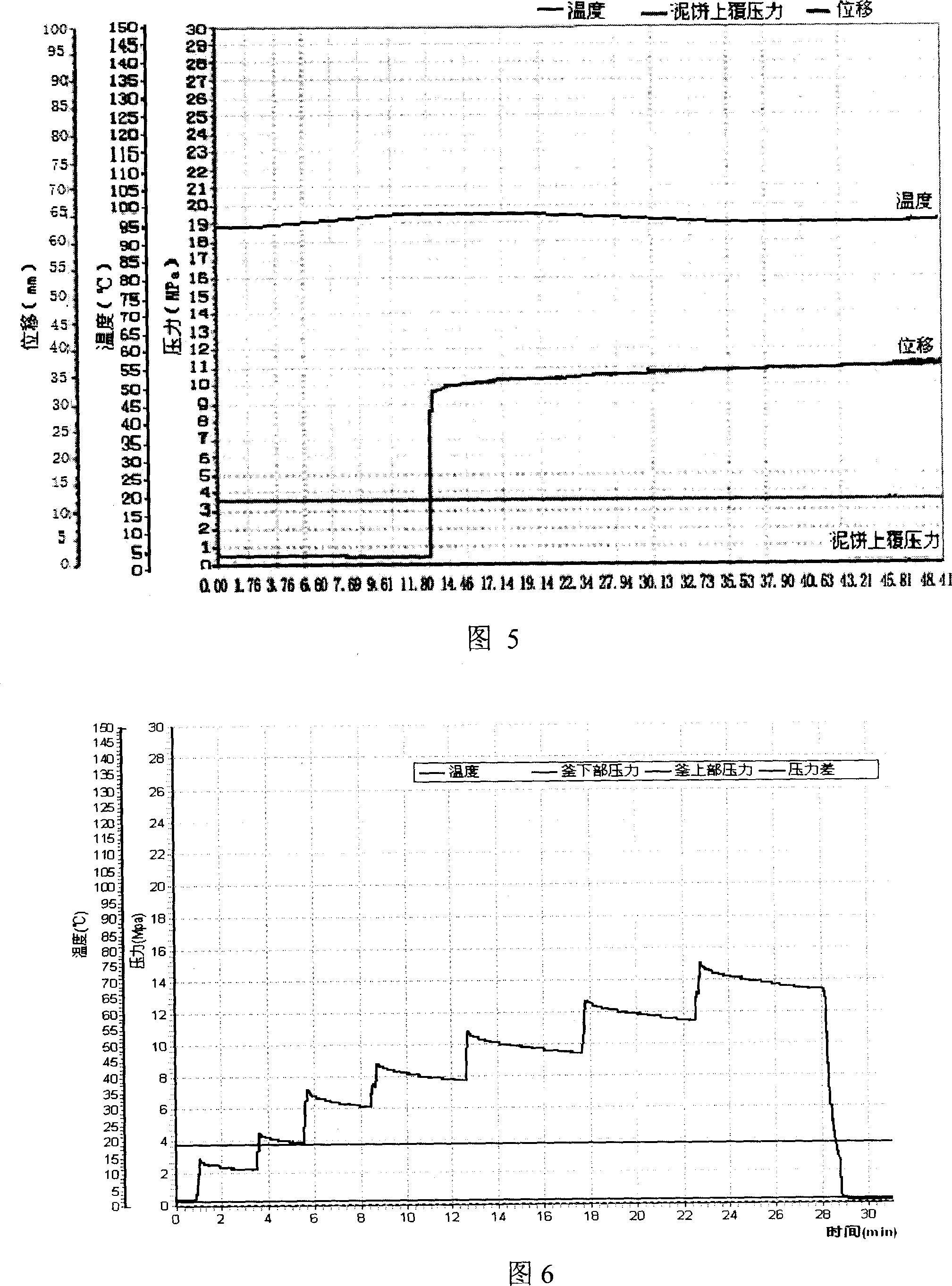

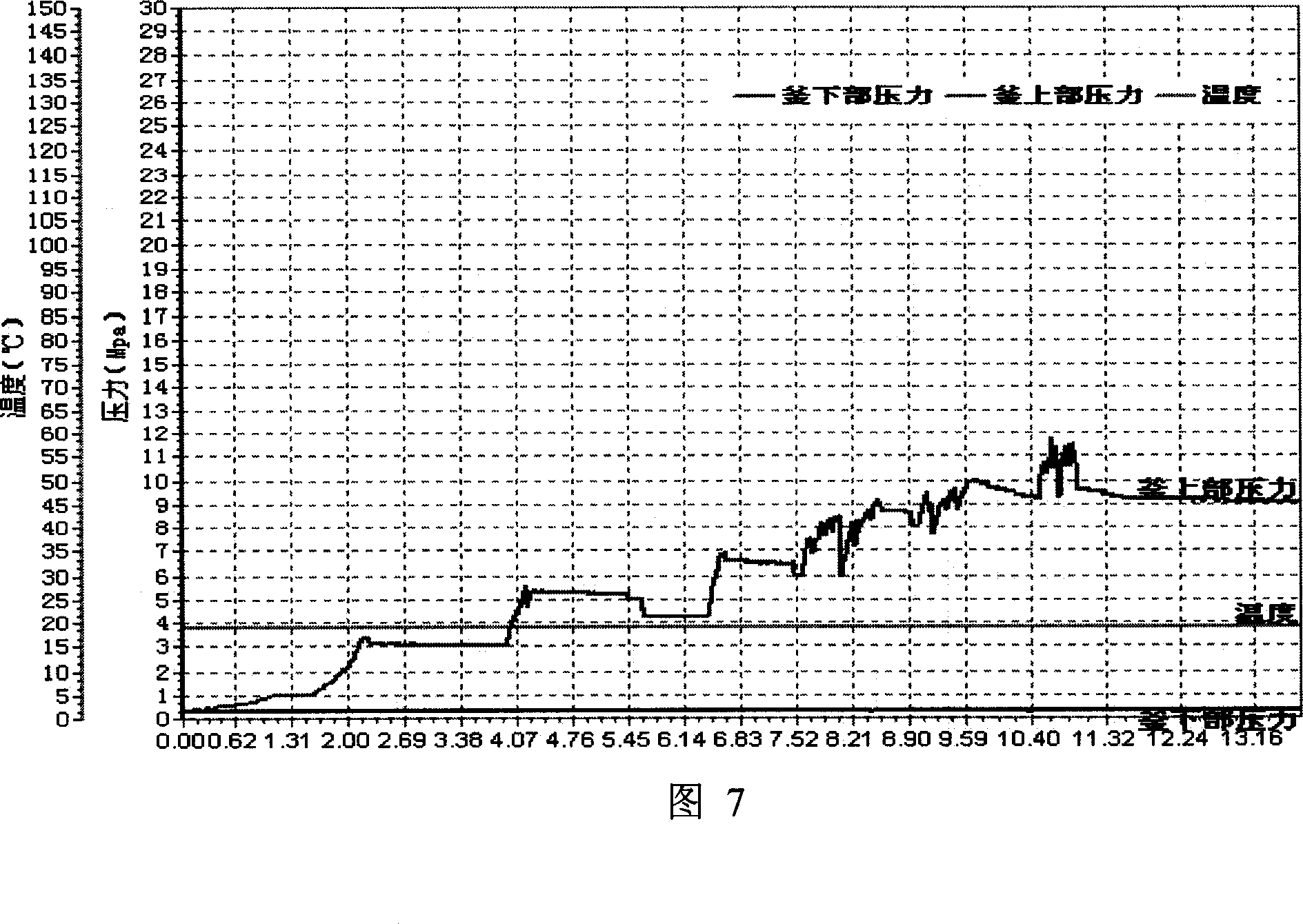

Bearing strength experiment instrument of high-temperature high-pressure mud cake plugging

ActiveCN101109739AEvaluation of closureThe experimental effect is intuitiveBorehole/well accessoriesMaterial analysisSlurryData treatment

The invention provides a tester for the bearing and plugging strength of a mud cake under high temperature and high pressure, which can simulate the static conditions in a well and test the invasion depth of slurry filter liquid, bearing strength of mud cake, plugging and bearing strength against cracks in drilling for oil (gas) wells. The tester essentially comprises a mud-cake performance evaluation and test vessel assembly, a pressure pipe system, a temperature control system, a displacement record system, an automatic cleaning system and a computer data processing system. The tester allows all-sided simulation of the temperature, pressure and stratum features (seepage) under a well, determination the plugging and bearing strength of mud cakes, optimization of drilling fluid, rapid and safe drilling, therefore the tester is of a very wide application prospect.

Owner:CHINA PETROLEUM & CHEM CORP +1

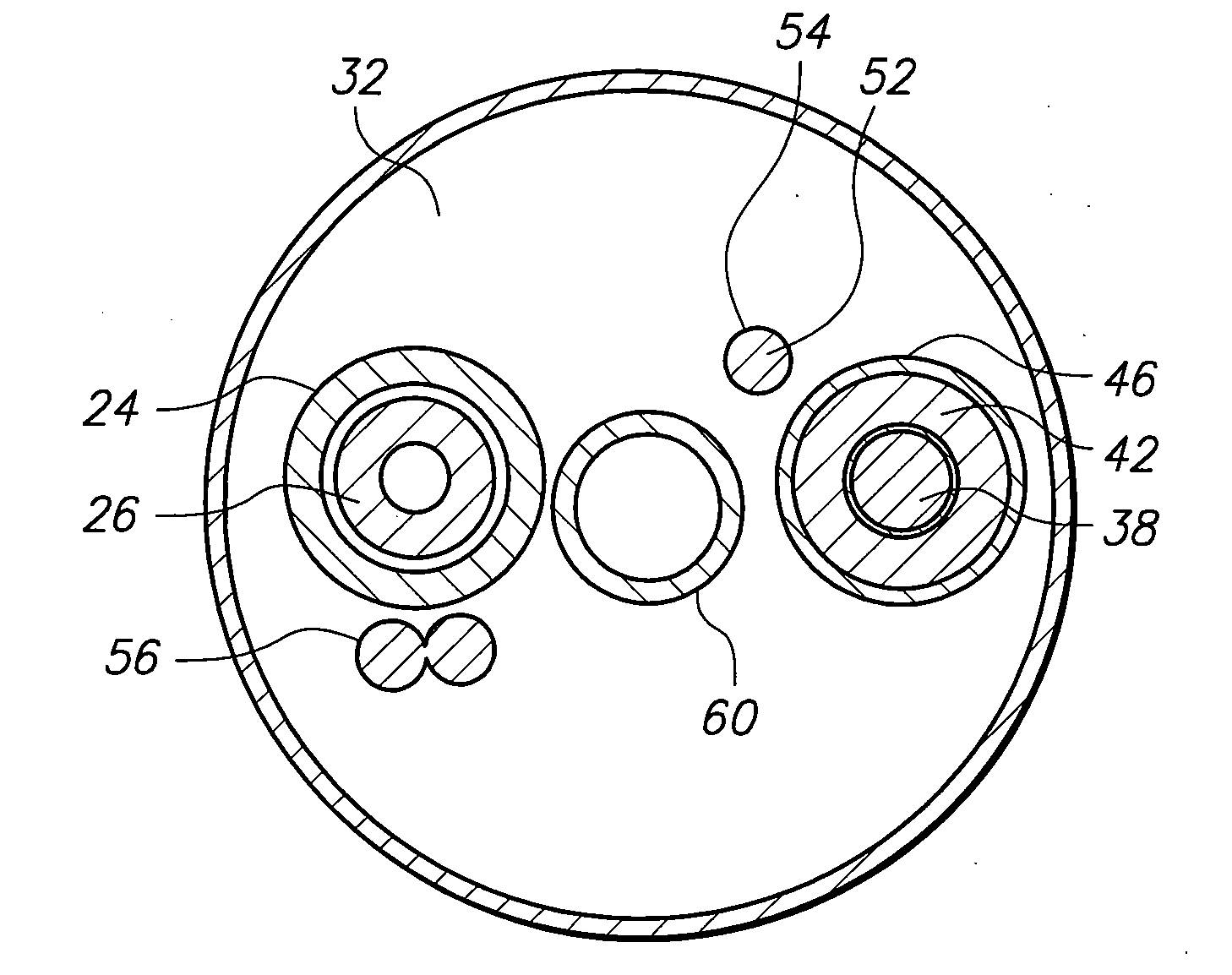

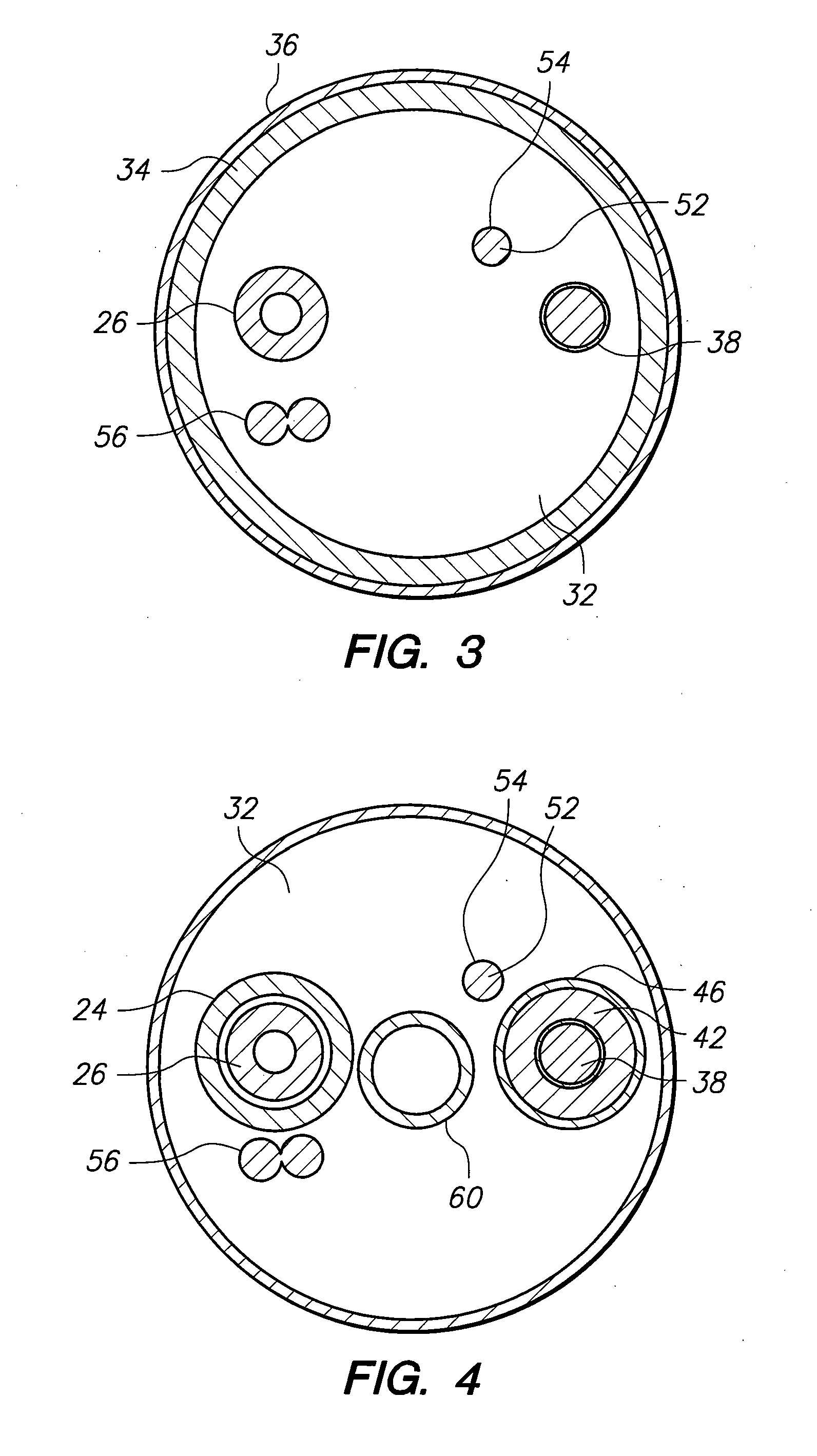

Cryo-applicator cross-section configuration

ActiveUS20080306475A1Sufficient pressureReduce pressureCatheterSurgical instruments for coolingCatheter accessoriesLine tubing

A configuration for a cryo-catheter which optimizes both the catheter's outer diameter and the size of the catheter's internal refrigerant flow path is described. Specifically, the inner dimensions of the cryo-catheter are configured to accommodate a pre-selected flow of refrigerant into the catheter's distal tip, and a return flow of refrigerant from the distal tip. The return flow is established in the void spaces between a refrigerant supply line and the inner wall of the catheter body. The available void space varies along the catheter length and depends on the presence / absence of various catheter accessories (i.e. pull wires, pressure tubes, etc.) which typically only extend through a portion of the catheter length. The disclosed configuration ensures that the cryo-catheter does not operate in a refrigerant limited condition, maintains the refrigerant as a liquid in the supply tube, and maintains the return line pressure at about 1 atmosphere.

Owner:CRYOCOR

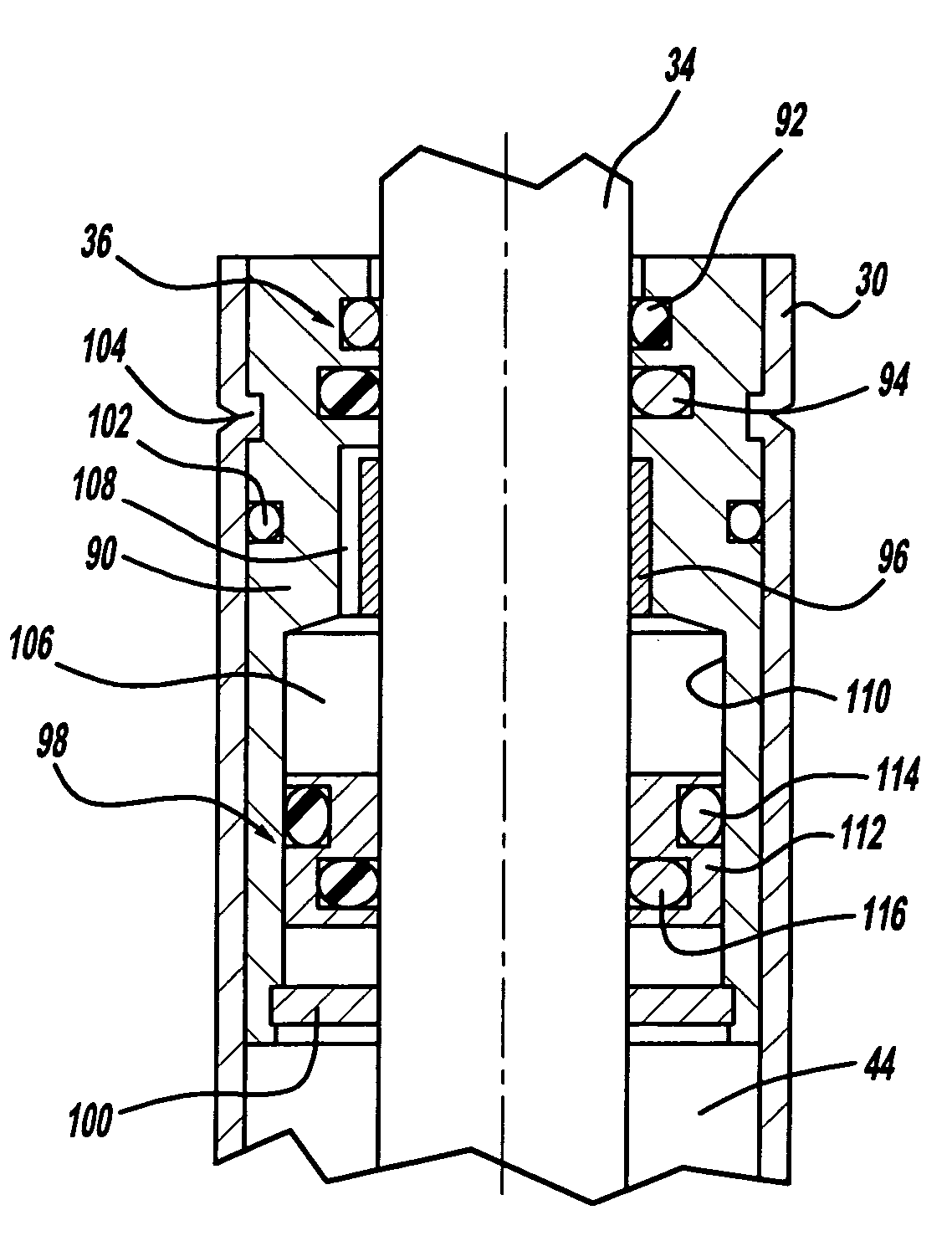

Rod guide and seal system for gas filled shock absorbers

A gas shock absorber has a pressure tube which defines a working chamber. A piston assembly divides the working chamber into an upper working chamber and a lower working chamber. A plurality of extension passages extend through the piston assembly and are opened and closed by an extension valve assembly. A plurality of compression passages extend through the piston assembly and are opened and closed by a compression valve assembly. A rod guide assembly is located between the pressure tube and the piston rod. The rod guide assembly includes an oil chamber for sealing and lubricating the piston rod. An axially movable piston maintains the pressure within the oil chamber equal to the pressure in the upper working chamber.

Owner:TENNECO AUTOMOTIVE OPERATING CO INC

Lightweight air vehicle and pneumatic launcher

ActiveUS7410124B2Easy to carryMore transportableUnmanned aerial vehiclesLaunching/towing gearUnmanned air vehiclePiston

A portable unmanned air vehicle and launcher system including a foldable unmanned air vehicle with a pressure tube; a launch gas reservoir for holding launch gas; a launch tube operatively connected to the launch gas reservoir and having a free end that is positioned in the pressure tube of the air vehicle; a free piston positioned within the launch tube; and a free piston stop to prevent the free piston from leaving the launch tube. A first portion of the launch gas in the launch gas reservoir is released into the launch tube and forces the free piston from an initial position to an end position at which the free piston is stopped by the free piston stop.

Owner:AIRPORTS AUTHORITY OF INDIA

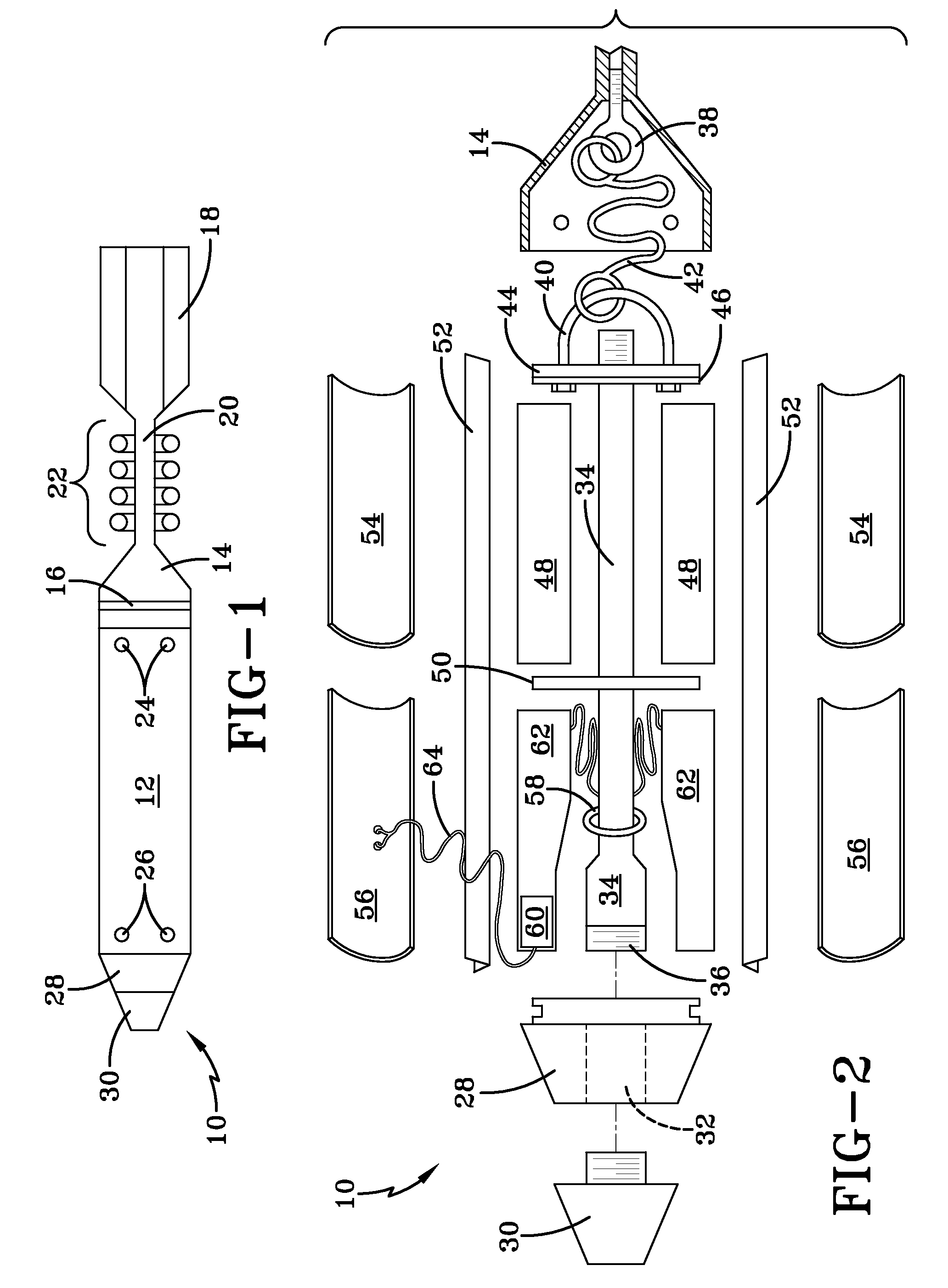

Non-lethal cargo projectile

InactiveUS7360489B1Minimizes ejection forceAmmunition projectilesTraining ammunitionEngineeringStern

A non-lethal cargo projectile comprises a projectile body; a fuze adapter attached to a front of the projectile body; a fuze attached to the fuze adapter; a boattail attached to a rear of the projectile body; a pressure tube extending from the fuze adapter to the boattail; a decelerator and drogue chute disposed aft of the fuze adapter; a flexible line that connects the pressure tube to the decelerator; a center disc disposed aft of the decelerator and drogue chute; a rear disc disposed aft of the center disc, the center disc and the rear disc defining a payload volume therebetween; a second flexible line that connects the rear disc to the boattail; at least one shearable fastener that fastens the projectile body to the fuze adapter; and at least one vent extending from the boattail to the fuze adapter.

Owner:UNITED STATES OF AMERICA THE AS REPRESENTED BY THE SEC OF THE ARMY

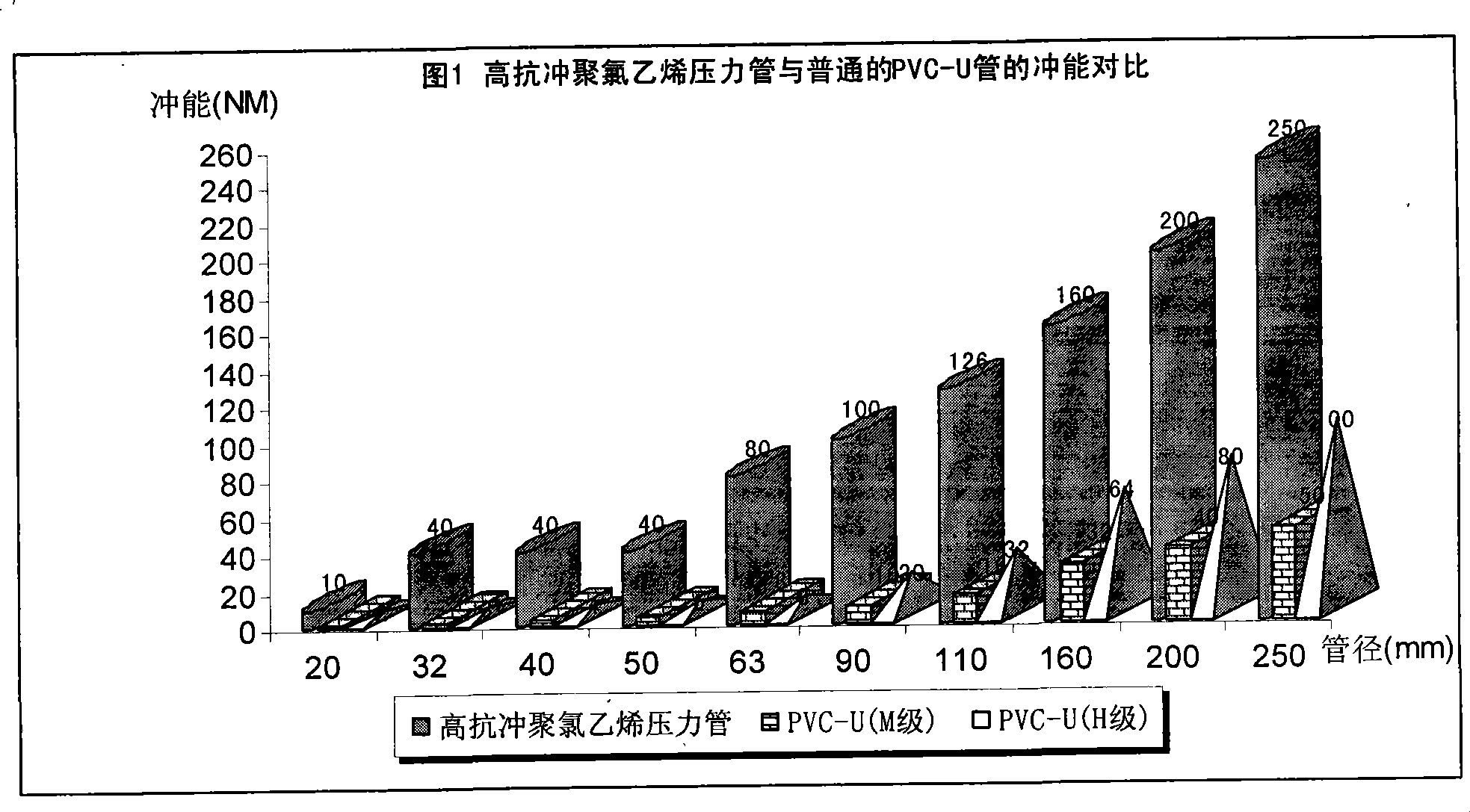

High impact polychloroethylene pressure tube

The invention relates to a polyvinyl chloride pressure tube with high impact resistance. The pressure tube comprises 100 portions of PVC resin, 1.5 to 4.0 portions of thermal stabilizing agent, 0.4 to 1.2 portions of lubricant, 6 to 12 portions of impact modifier, 0 to 5 portions of filler and 2 to 3 portions of colorant according to weight unit. Compared with a common PVC-U tube material, the polyvinyl chloride pressure tube keeps high strength of the PVC-U tube material and greatly improves toughness and impact resistance of the tube material.

Owner:福建亚通新材料科技股份有限公司

Piston vibratory pump

InactiveUS7354255B1Improve efficiencyOptimization mechanismPositive displacement pump componentsLarge containersPistonPressure pipe

Owner:LISHANSKI GRIGORI +1

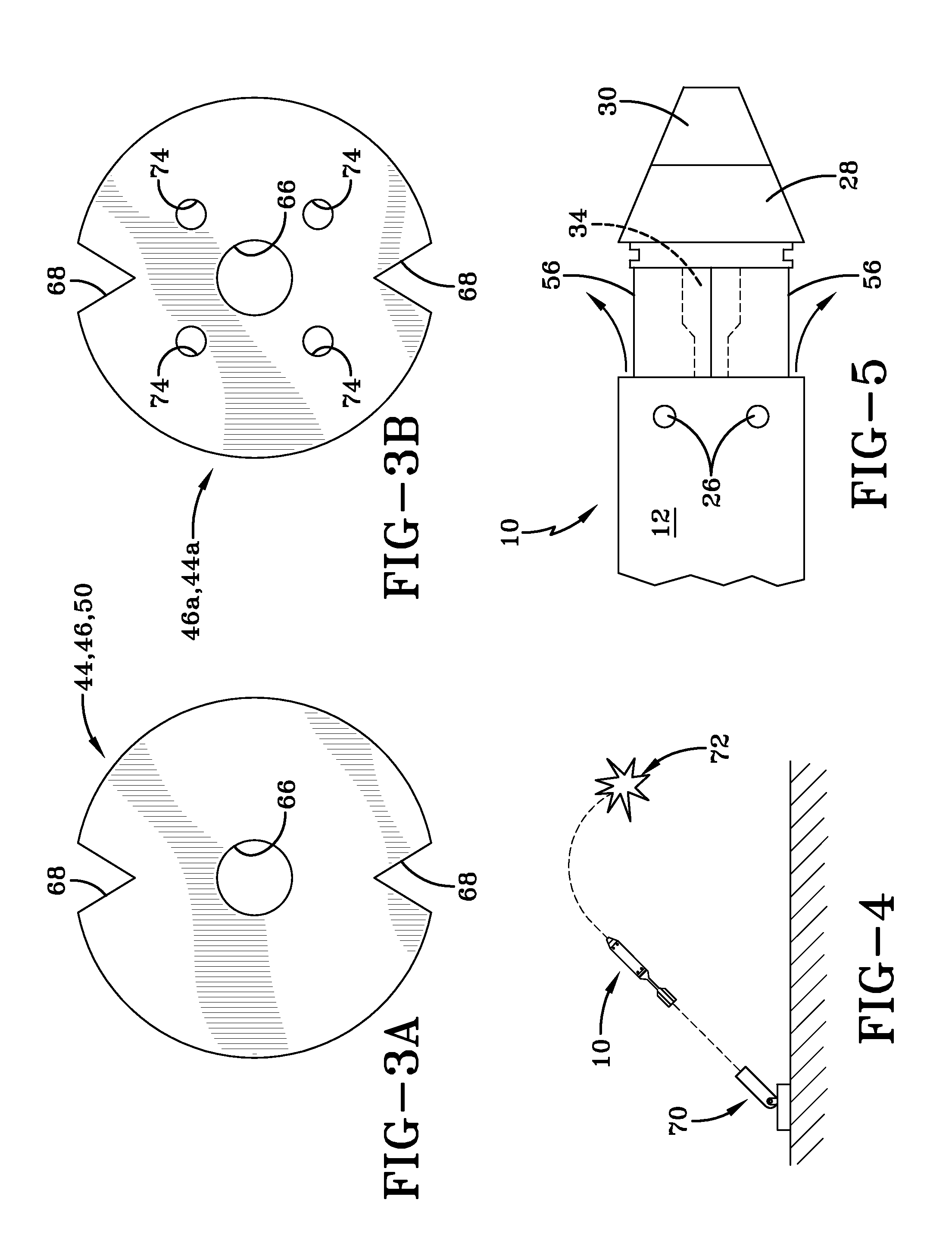

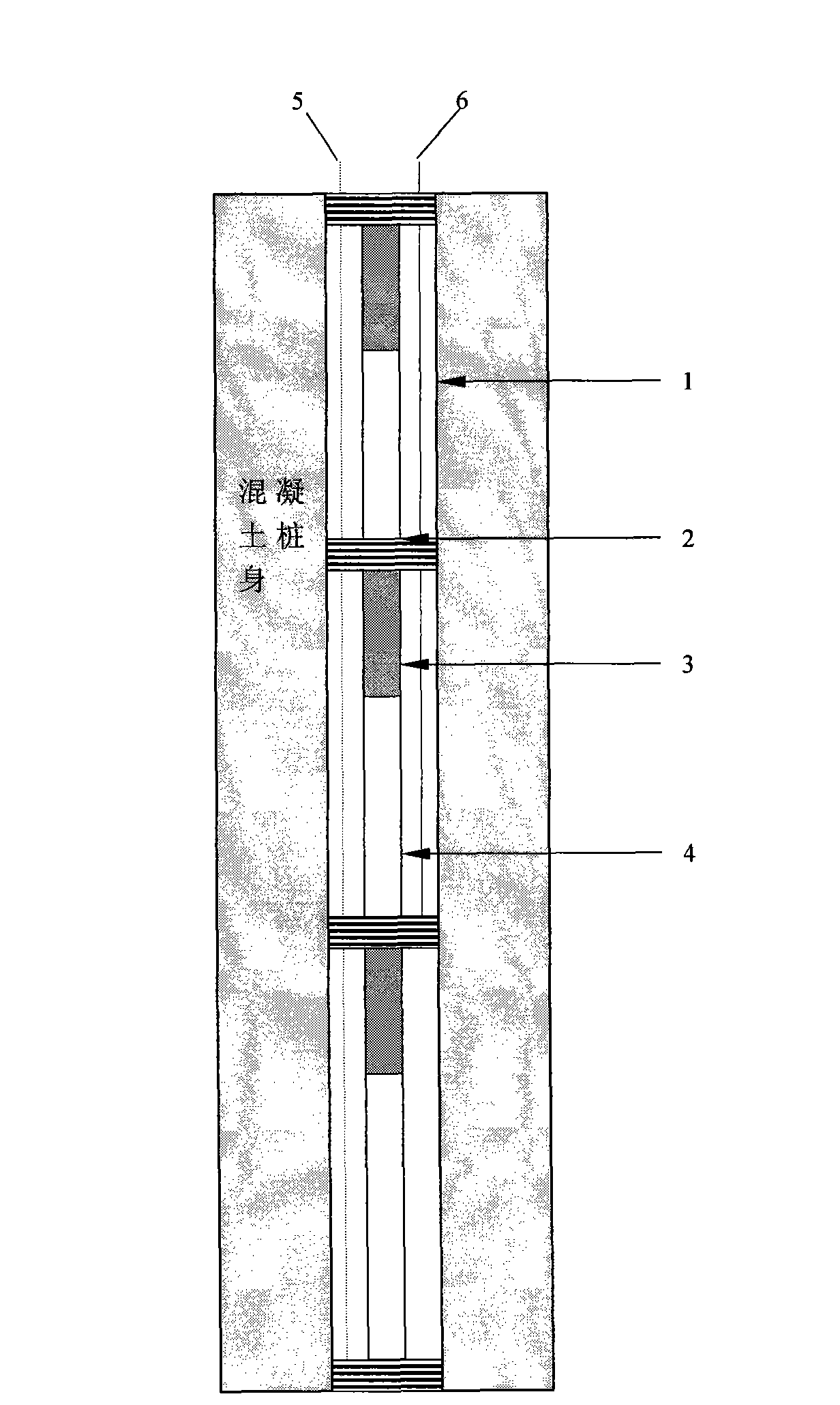

Method for measuring pile shaft internal force and cross section displacement in vertical dead-load test of foundation pile

InactiveCN101638902AResolve accuracyAddress reliabilityFoundation testingForce measurementRelative displacementVertical displacement

The invention belongs to the technical field of pile foundation quality detection in civil engineering, in particular to a method for measuring pile shaft internal force and cross section displacementin vertical dead-load test of a foundation pile. In the method, firstly, a casing is embedded on a pile shaft lengthways or holes are directly drilled on the pile shaft lengthways; a measuring systemis arranged in the casing or the drilling hole and is composed of an anchor head, a multiple position extensometer, an extension bar and a pressure pipe, wherein, the pressure pipe pressurizes to expand the anchor head so as to ensure that the anchor head is fixed in the casing or the drilling hole; after the anchor head is fixed, the multiple position extensometer measures vertical deformation between two adjacent anchor heads by the extension bar; according to a vertical displacement observation result and vertical deformation between two adjacent anchor heads, the layering frictional resistance of each soil layer, pile end supporting force and the vertical displacement of anchor head embedding cross section are calculated, and the relation of pile soil relative displacement and pile side frictional resistance is built so as to realize pile shaft internal force and cross section vertical displacement measurement. The invention has high test accuracy and favorable reliability, can replace traditional method using strain or string-wire sensors and displacement rods to measure pile shaft internal force and cross section vertical displacement.

Owner:高飞

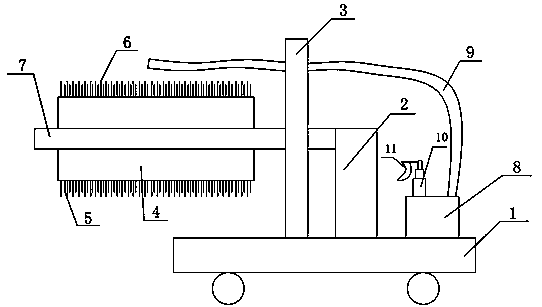

Petroleum pipeline cleaning machine

InactiveCN104001701AQuick clean upExpand the scope of cleaningHollow article cleaningElectric machineryPetroleum engineering

The invention discloses a petroleum pipeline cleaning machine. The petroleum pipeline cleaning machine comprises a base, a cleaning brush, a rotating shaft, a motor, a vertical plate and an air pressure container; the vertical plate, the motor and the air pressure container are fixed on the base, a round hole is formed in the middle part of the vertical plate, a bearing is mounted in the round hole, the cleaning brush is mounted on the rotating shaft, the rotating shaft is connected with an output shaft of the motor by virtue of the bearing, soft hair and hard hair are arranged alternately on the cleaning brush and the hard hair is shorter than the soft hair, a water outlet pipe and an air pressure pipe are connected to a port of the air pressure container, the water outlet pipe penetrates through the vertical plate and extends to be above the cleaning brush, and one end of the air pressure pipe is connected to an air pressure handle. The petroleum pipeline cleaning machine is capable of quickly clearing a petroleum pipeline; the soft hair and the hard hair are used simultaneously to clear away oil contamination to the utmost extent; due to the telescopic structure of the rotating shaft, the cleaning range of the cleaning brush is expanded; the air pressure container is capable of jetting out a cleaning liquid or water to help to clear away the oil contamination; in short, because of the use of the petroleum pipeline cleaning machine, the efficiency is improved, and time and labor are saved.

Owner:WUXI JINDING OIL PIPE FITTINGS

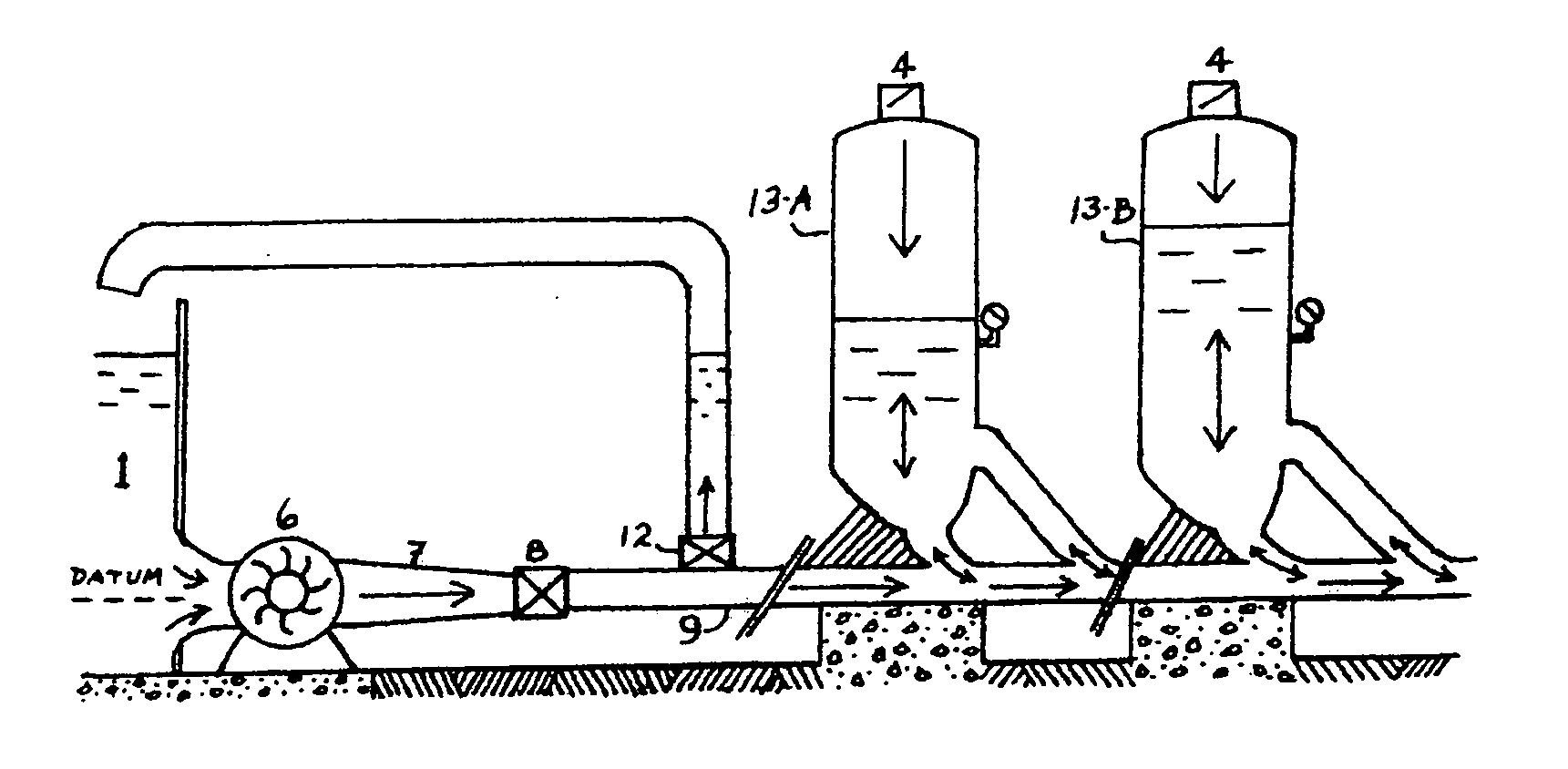

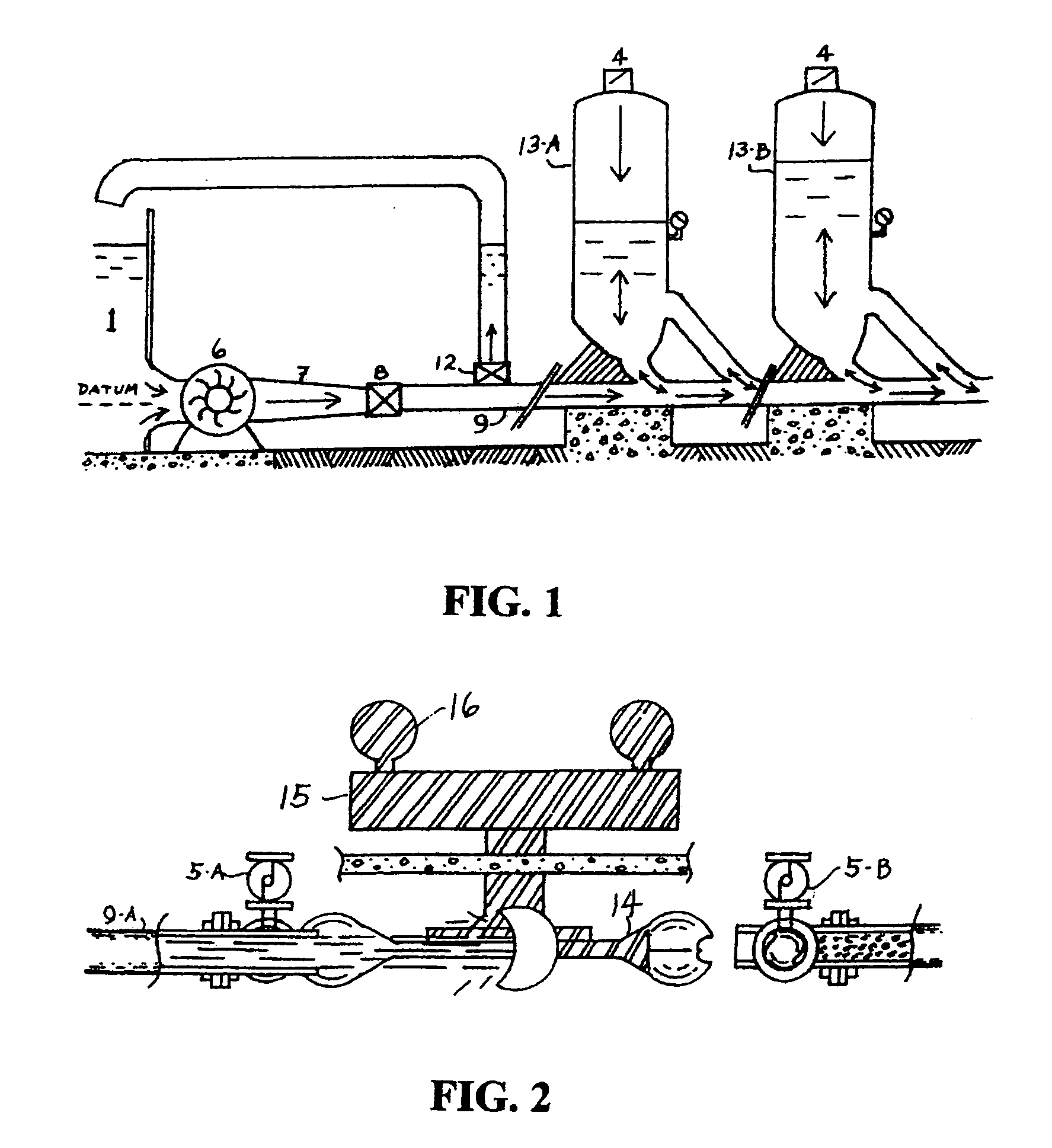

Multiple energy inputs hydropower system

InactiveUS20090152871A1Short construction timeKeep levelEngine componentsMechanical power devicesSaline waterDesalination

The present invention has incorporated a re-boosting pump to re-boost and to supply additional pressure energy input to a system periodically. The re-boosting pump gets its energy from a starting / re-boosting generator. This works to keep the level of the energy output sustainable.Another feature of the present invention is that it has incorporated a convergence recoil nozzle that utilizes a recoil force of the water jet. This recoil force which is equal in magnitude and opposite in direction, will push a piston that is inside a pressure chamber. This force is capable of doing different kinds of works, such as a pressurized liquid to add energy input to the system through a pressure pipe into the main penstock or it can be used as a pressure energy for the desalination of saline water.

Owner:CHING JOSE ONG

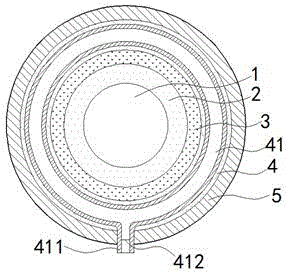

Moisture-proof cable

ActiveCN105575523AGuaranteed drynessWater vapor penetrationClimate change adaptationInsulated cablesWater resistantProtection layer

The invention relates to a moisture-proof cable. The moisture-proof cable comprises a conductive wire core which is externally wrapped by an insulating protection layer. The insulating protection layer is externally wrapped by a blocking layer which is made of elastic material. The blocking layer is externally wrapped by a moisture-proof tube which is externally wrapped by an external protection layer with a water-resistant function. The moisture-proof tube is made of porous water swelling material. Negative pressure tubes are equidistantly arranged along the axial direction of the moisture-proof tube in the tube wall of the moisture-proof tube. Capillary holes are arranged on the tube wall of the negative pressure tubes. Air extraction valves are also adjacently connected on the negative pressure tubes. The air extraction valves stretch out of the external protection layer. The moisture-proof cable is relatively low in mass, exquisite in structure, great in the moisture-proof effect and convenient for later maintenance.

Owner:湖南湘江电缆有限公司

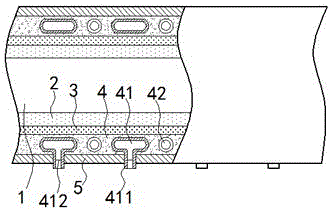

Telescopic vibration damper

InactiveUS6619445B2Reduce differential pressureReduce loadLiquid springsGas and liquid based dampersEngineeringPiston rod

A telescopic vibration damper, comprising a pressure tube filled with a damping medium, in which a piston rod is arranged such that it can move axially, the pressure tube being axially displaceably guided in an intermediate tube. An annular chamber between the pressure tube and the intermediate tube is likewise filled with the damping medium, there being a flow connection between the pressure tube and the annular chamber, and a compensating chamber accommodates the displaced volume of the components that can be telescoped toward one another. The annular chamber formed by the intermediate tube and the pressure tube, and the pressure tube, are hydraulically separated from the compensating chamber.

Owner:ZF SACHS AG

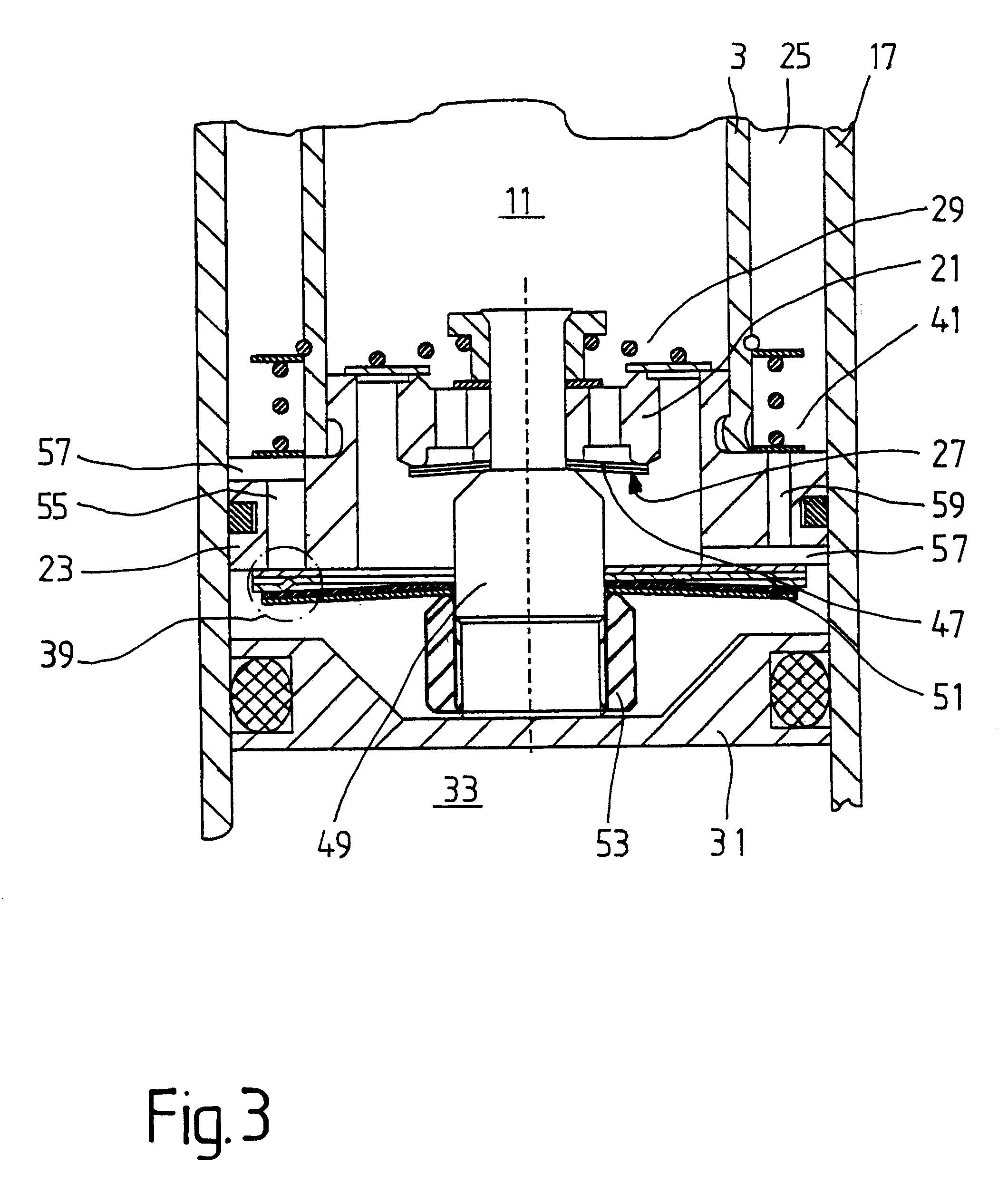

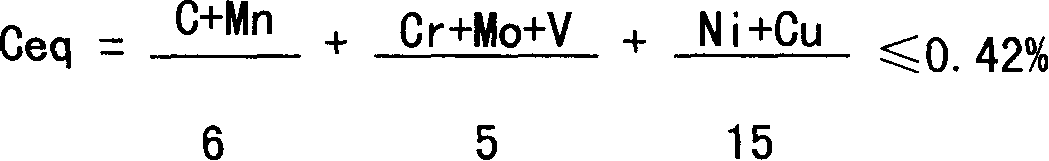

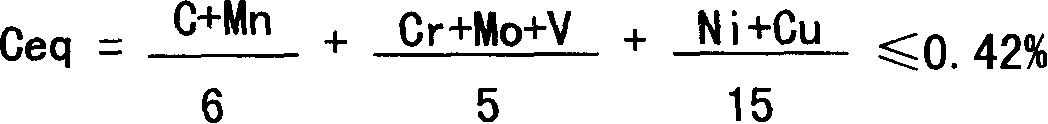

Oil-gas transportation large-scale high-pressure pipe fittings steel as well as pipes, pipe fittings and welding materials produced thereby

The invention relates to steel used for oil and gas transportation large high pressure pipe fittings and steel pipes, pipe fittings and welding materials made of the steel. The invention is developed for solving the problems of the low grade, high carbon content, poor welding property, etc., of the present fitting used steel. The compositions of the steel are less than or equal to 0.12 percent of C, less than or equal to 0.35 percent of Si, less than or equal to 1.60 percent of Mn, less than or equal to 0.030 percent of P, less than or equal to 0.015 percent of S, less than or equal to 0.50 percent of Ni, less than or equal to 0.30 percent of Cr, less than or equal to 0.30 percent of Cu, less than or equal to 0.25 percent of Mo, less than or equal to 0.05 percent of Nb, less than or equal to 0.09 percent of V, less than or equal to 0.05 percent of Ti and less than or equal to 0.060 percent of Al, and the rest is Fe. When using the steel of the invention for producing the oil and gas transportation high pressure steel pipes and the welding materials, the fitting heat treatment quenching heating temperature is 900-980 DEG C. The quenching heating time is the wall thickness of the fittings in millimeter multiplied by 2-3m / mm; the tempering heating temperature is 600-700 DEG C; the tempering heating time is the wall thickness of the pipes in millimeter multiplied by 3-6m / mm. the oil and gas transportation high pressure pipe fittings of the invention can satisfy the production demands of high pressure steel pipes and fittings for X80 grade pipeline.

Owner:辽阳石化机械设计制造有限公司

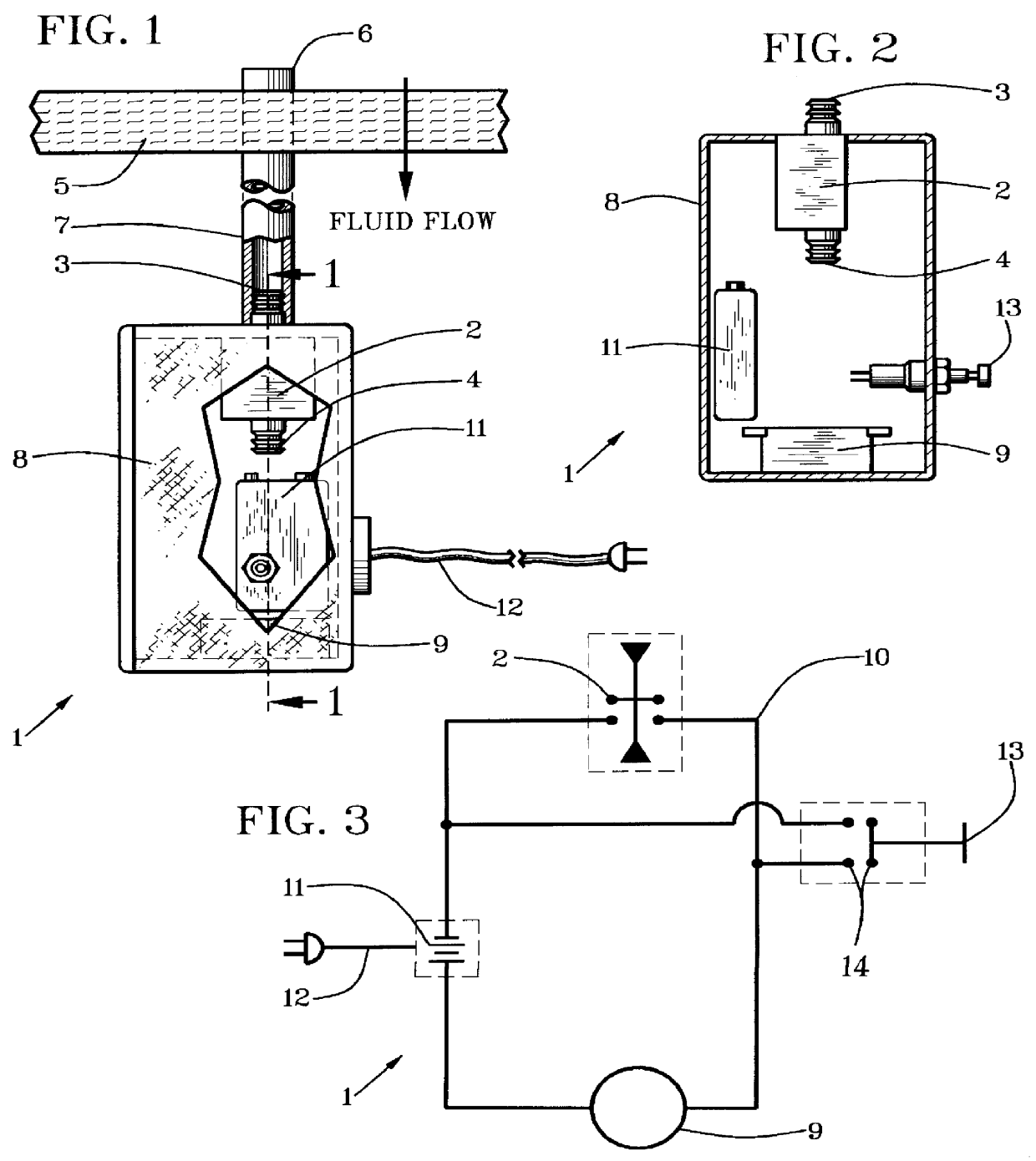

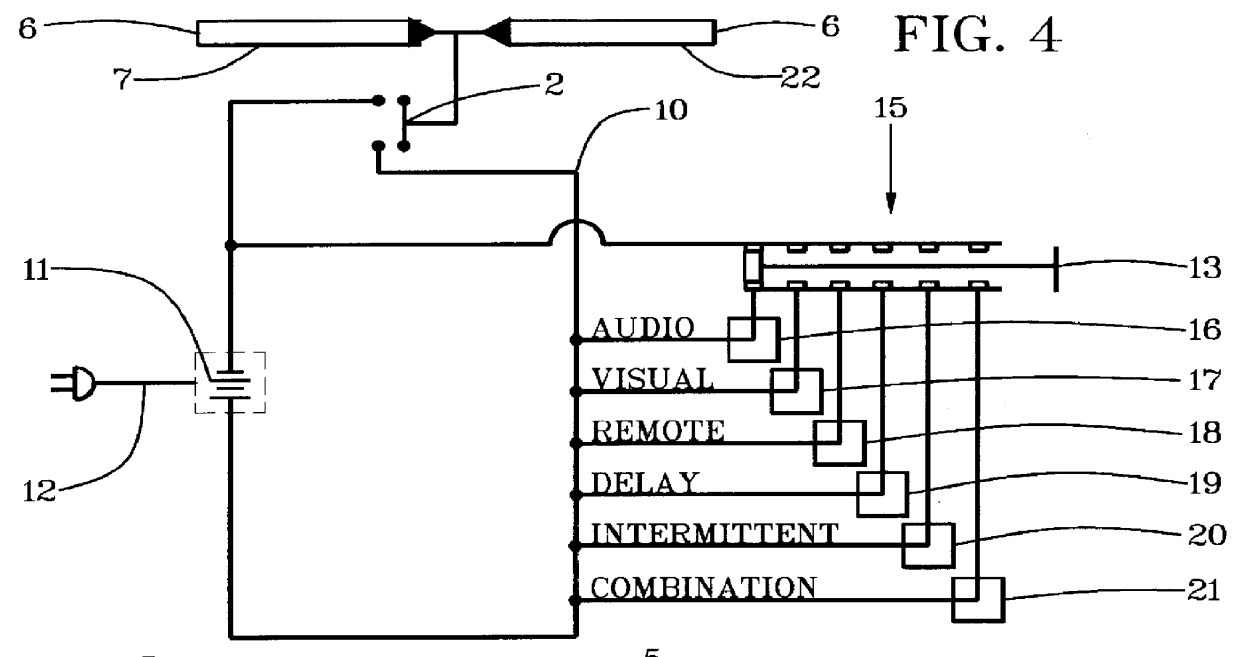

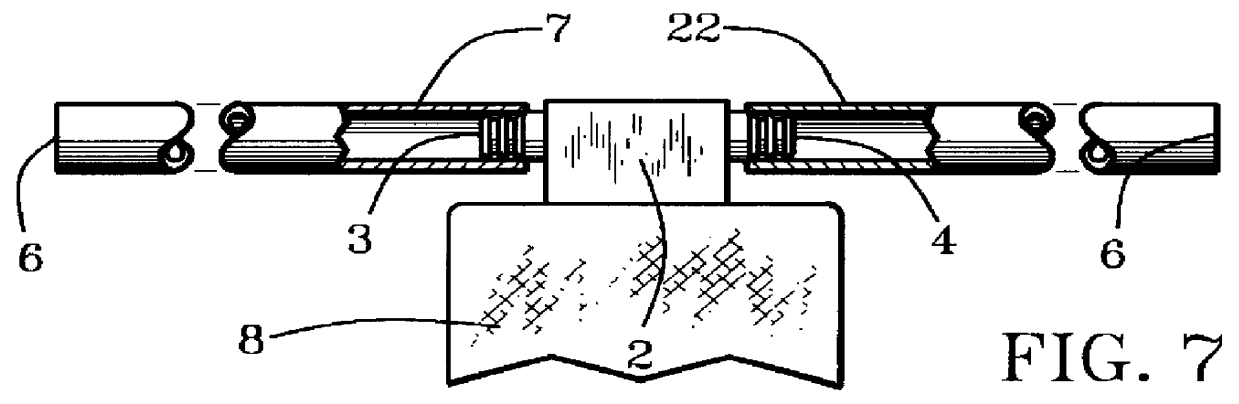

Filter alert

A filter alert has a pressure differential switch that is responsive to positive and / or negative pressure through a pressure tube. The pressure tube is in fluid communication intermediate a positive-pressure or high-pressure side of an intended filter and a positive-pressure inlet aperture of a pressure-differential switch for indication of positive pressure across the intended filter. Optionally, the pressure tube is in fluid communication intermediate a negative-pressure or low-pressure side of a filter and a low-pressure inlet aperture of the pressure-differential switch for indication of low pressure across the filter. The pressure-differential switch actuates an actuator for alarm signals for desired action. The filter alert also includes a switch condition communication component, a filter condition alert and an alert container on which the pressure-differential switch is positioned.

Owner:CHAMPIE MAX C

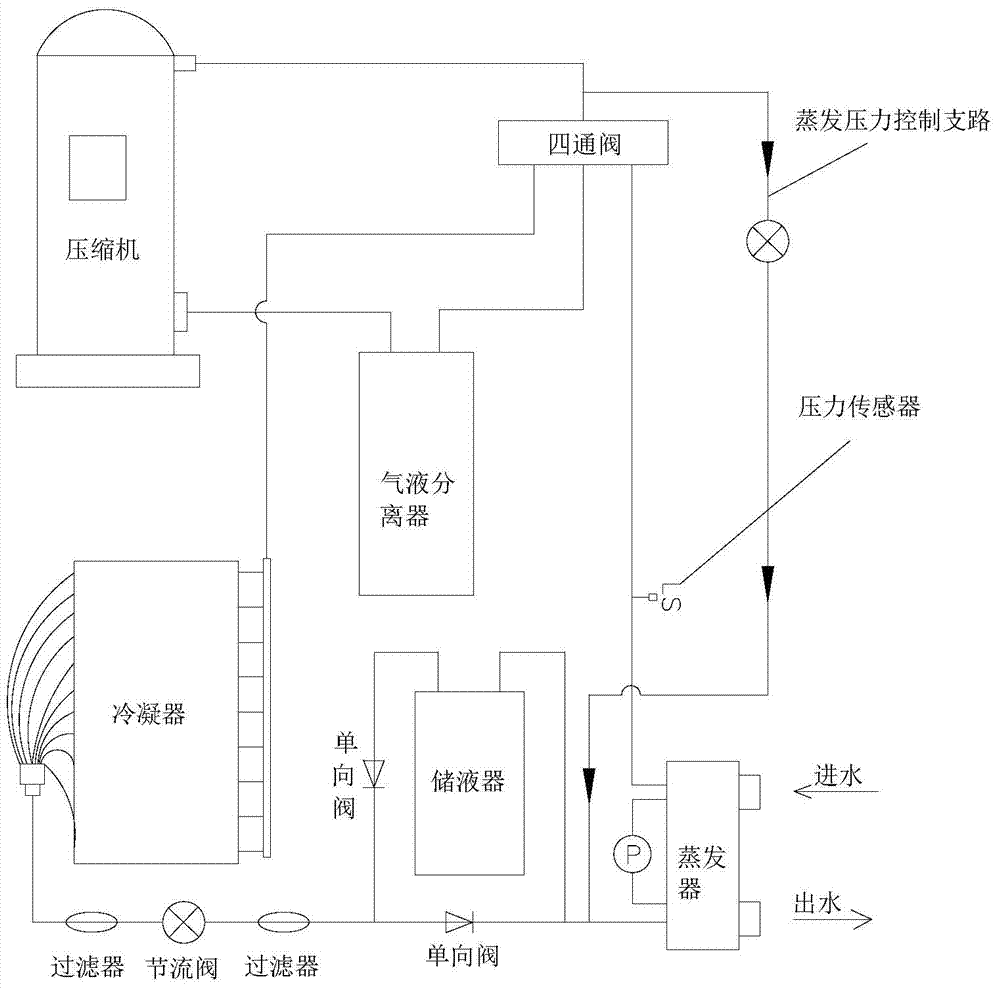

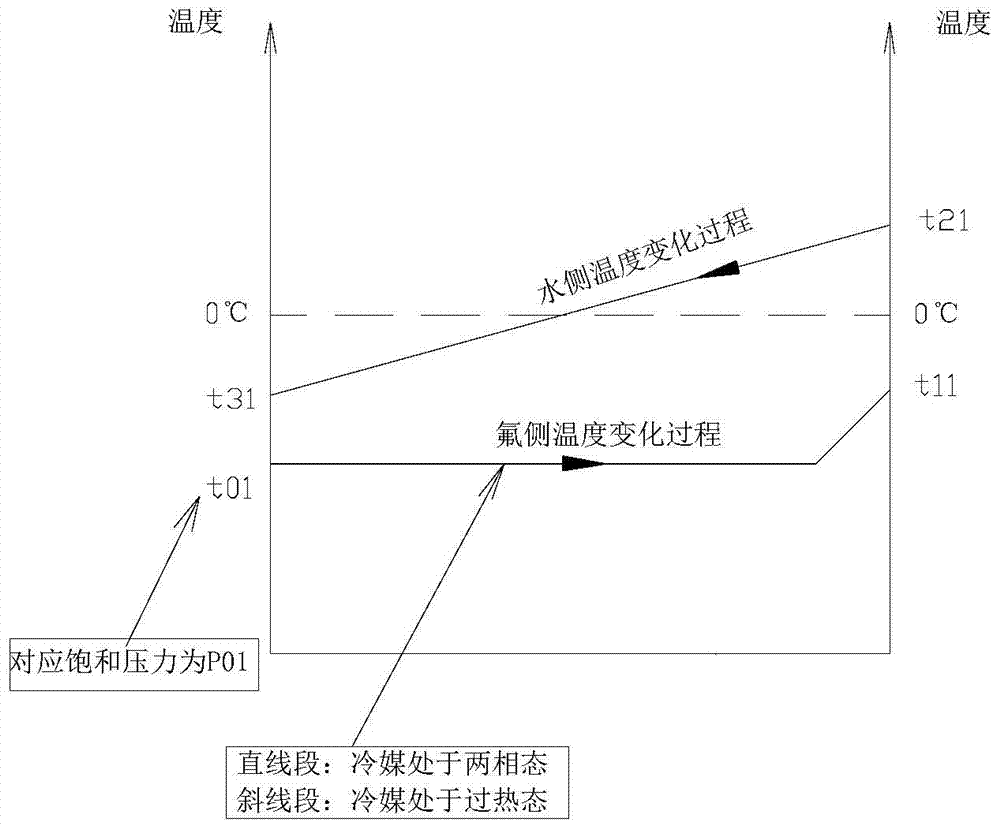

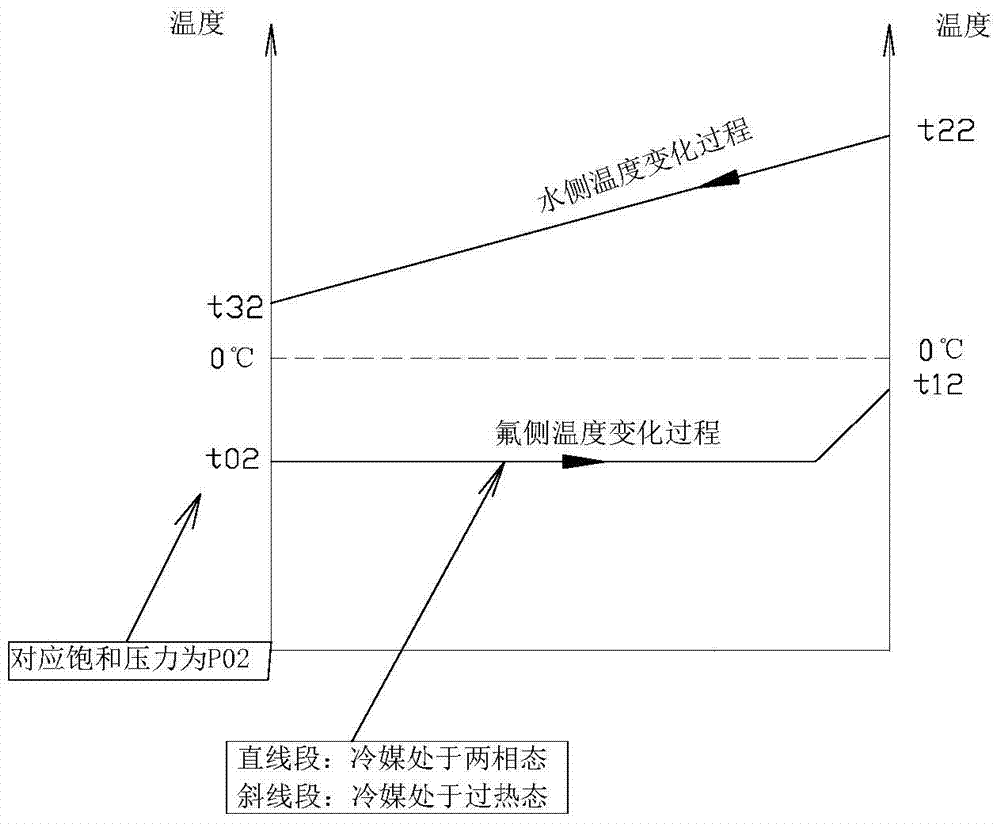

Anti-freezing method and device for water chilling unit of air conditioning unit

ActiveCN104729033APrevent from being damaged by freezingMechanical apparatusSpace heating and ventilation safety systemsVapor liquidEvaporation

The invention discloses an anti-freezing method and device for a water chilling unit of an air conditioning unit. The method and the device aim at preventing frost cracking of an evaporator. According to the method, vapor-liquid two-phase-state pressure of a refrigerant of an inlet of the evaporator is controlled, and evaporation pressure in the evaporator is not lower than a certain value, so that the lowest temperature of the side, loading the refrigerant, in the evaporator is not lower than 0 DEG C. According to the device, a flow control device is connected between a compressor exhaust pressure pipe and an evaporator inlet pipeline, a pressure sensor is connected between an outlet of the evaporator and an air suction port of the compressor, and a control unit instructs to adjust the opening degree of the flow control device according to the difference between pressure after evaporation and target evaporation pressure. In comparison with the prior art, by controlling the vapor-liquid two-phase-state pressure of the refrigerant of the inlet of the evaporator, the evaporation pressure of the evaporator is not lower than the target evaporation pressure, the temperature t32 of the side, loading the refrigerant, in the evaporator is larger than 0 DEG C, and frost damage to the evaporator is prevented.

Owner:SHENZHEN MCQUAY AIR CONDITIONING

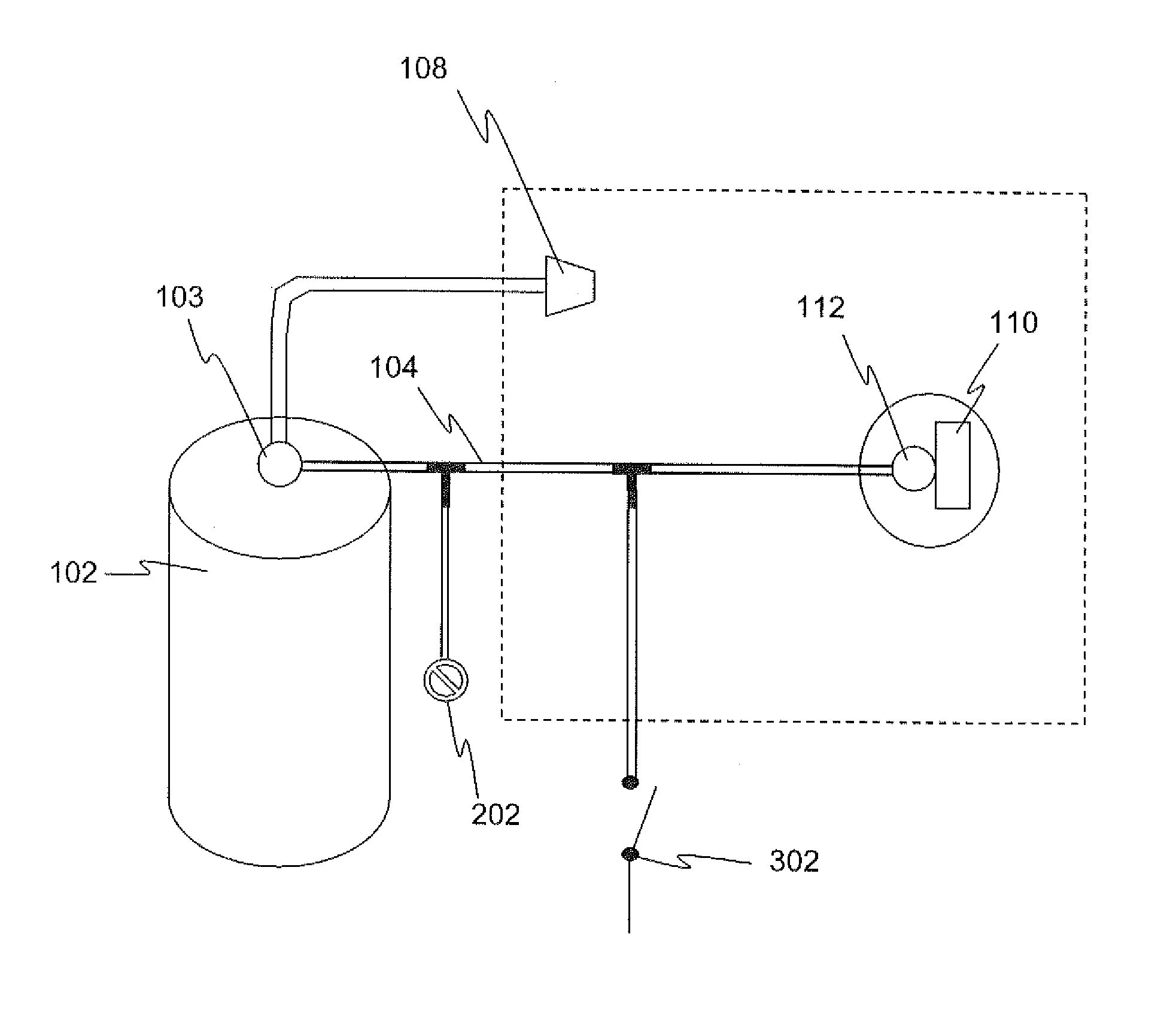

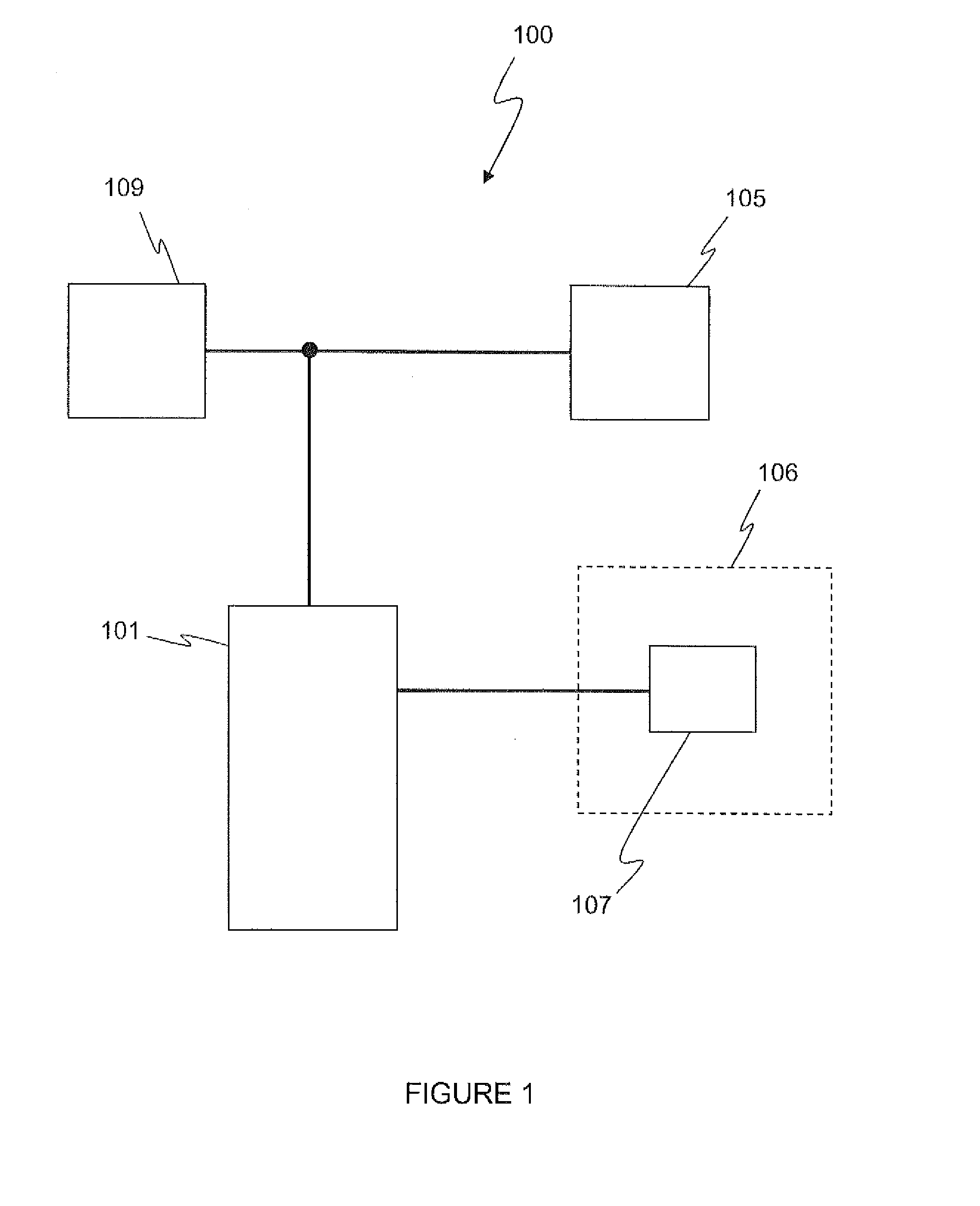

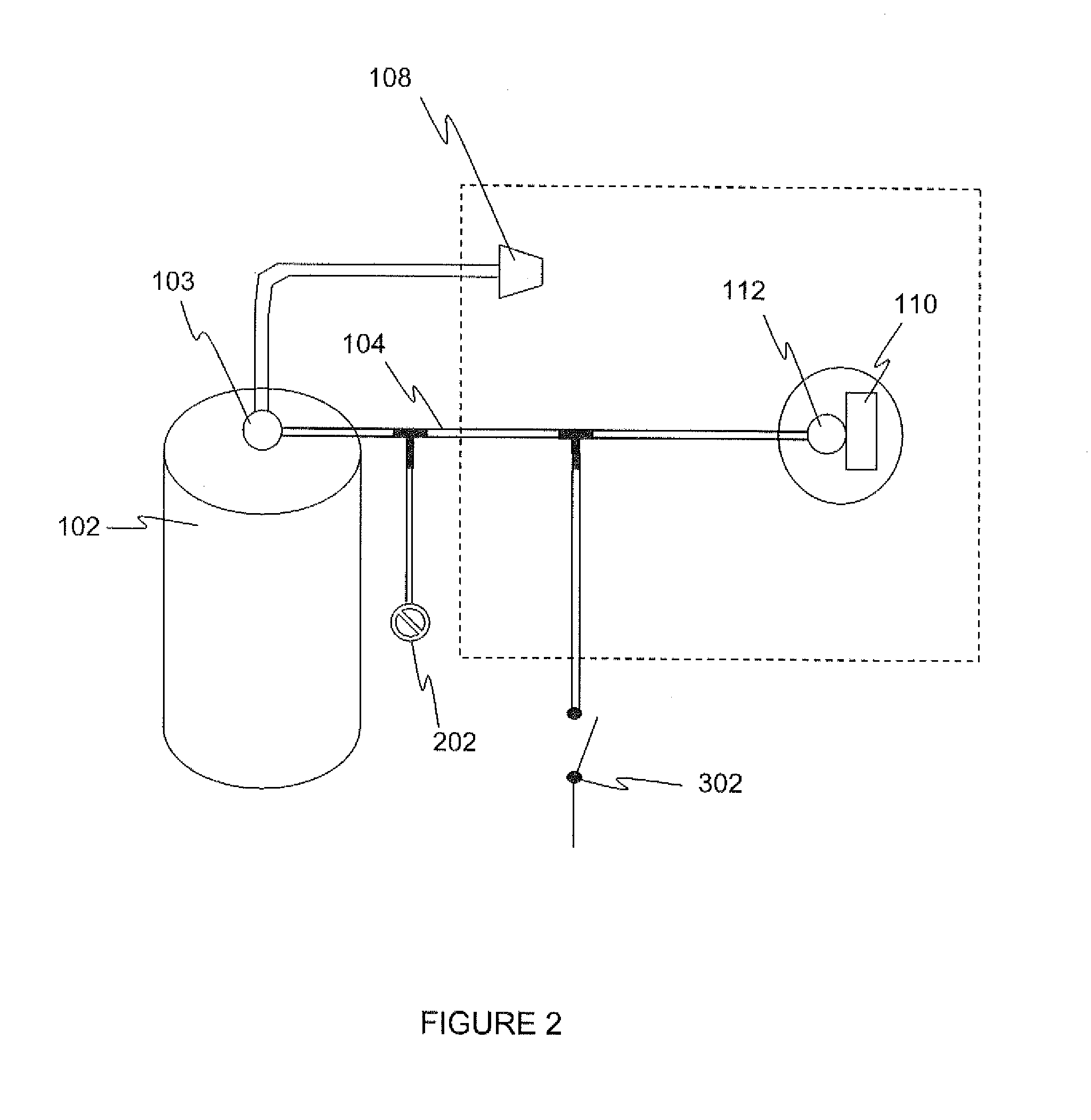

Methods and apparatus for hazard control

Owner:FIRETRACE USA LLC

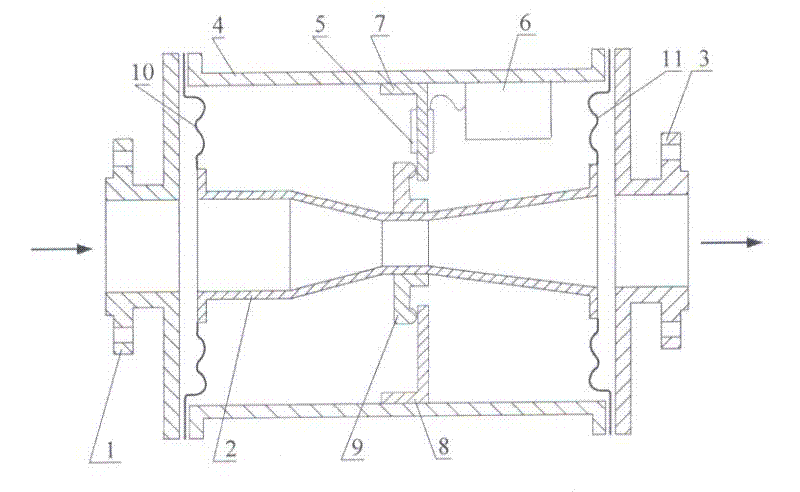

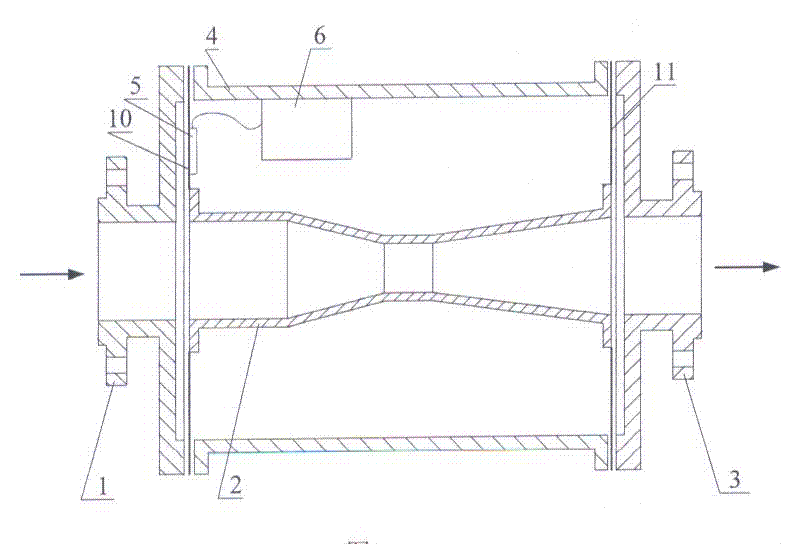

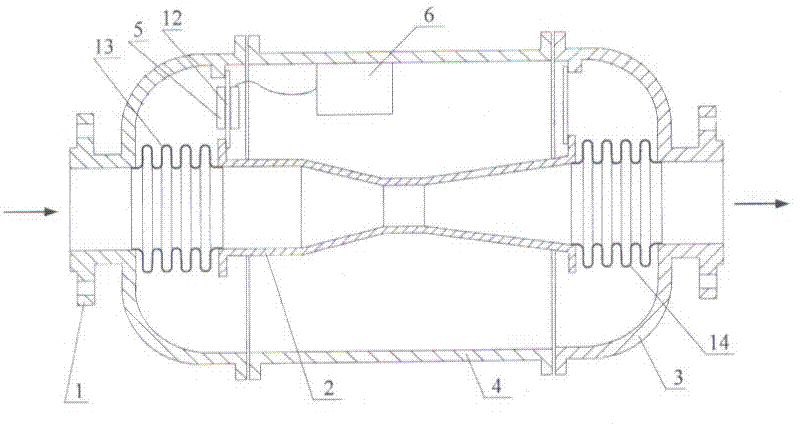

Flowmeter with middle through-hole movable throttling element connected with elastic membranes or bellows

InactiveCN102353406ALittle flow resistance lossEasy to useVolume/mass flow by differential pressureDifferential pressureEngineering

The invention discloses a flowmeter with a middle through-hole movable throttling element connected with elastic membranes or a bellows, which belongs to the throttling flowmeter in the automatic detection technical field; the patent 'a middle through-hole movable throttling element flowmeter' depends on the thrust of the movable throttling element, and does not like a fixed throttling element which measures the flow according to the flow differential pressure, so a pressure pipe can be dispensed, the flowmeter is applicable to measuring small calibers and dirty liquids, the isolation, the pressure-bearing, the support and other functions of the flowmeter are all respectively realized through different components, and the integral structure is more complicated. The flowmeter adopts the elastic membranes or the bellows to be connected with the middle through-hole movable throttling element, the isolation, the pressure-bearing, the support and other functions are realized independently by the elastic membranes or the bellows, the integral structure of the flowmeter is greatly simplified, not only are all the advantages of the through-hole movable throttling element obtained, but also a plurality of performances are improved, and the invention makes the through-hole movable throttling element flowmeter which is a novel meter be more easily popularized and used.

Owner:王可崇

Liquid jet surgical instrument

InactiveUS20100228273A1Avoid heat damageIncrease differentiationDiagnosticsFluid jet surgical cuttersLiquid jetIntervertebral disc

The invention provides a variety of surgical instruments for forming a liquid jet, which are useful for performing a wide variety of surgical procedures. In some embodiments, the invention provides surgical liquid jet instruments having a pressure tube and an evacuation tube, where the pressure tube includes at least one nozzle for forming a liquid jet and where the evacuation tube includes a jet-receiving opening for receiving the liquid jet when the instrument is in operation. In some embodiments, the surgical liquid jet instrument is constructed to minimize damage to the tissue surrounding the tissue that is desired to be removed. In some embodiments, the outer surface of the distal tip of the evacuation tube wall and / or the pressure tube wall is blunted to minimize tissue damage. The invention also provides surgical methods utilizing the inventive surgical liquid jet instruments for cutting or ablating a selected tissue within portions of a patient's spine, such as within the intervertebral disc.

Owner:HYDROCISION

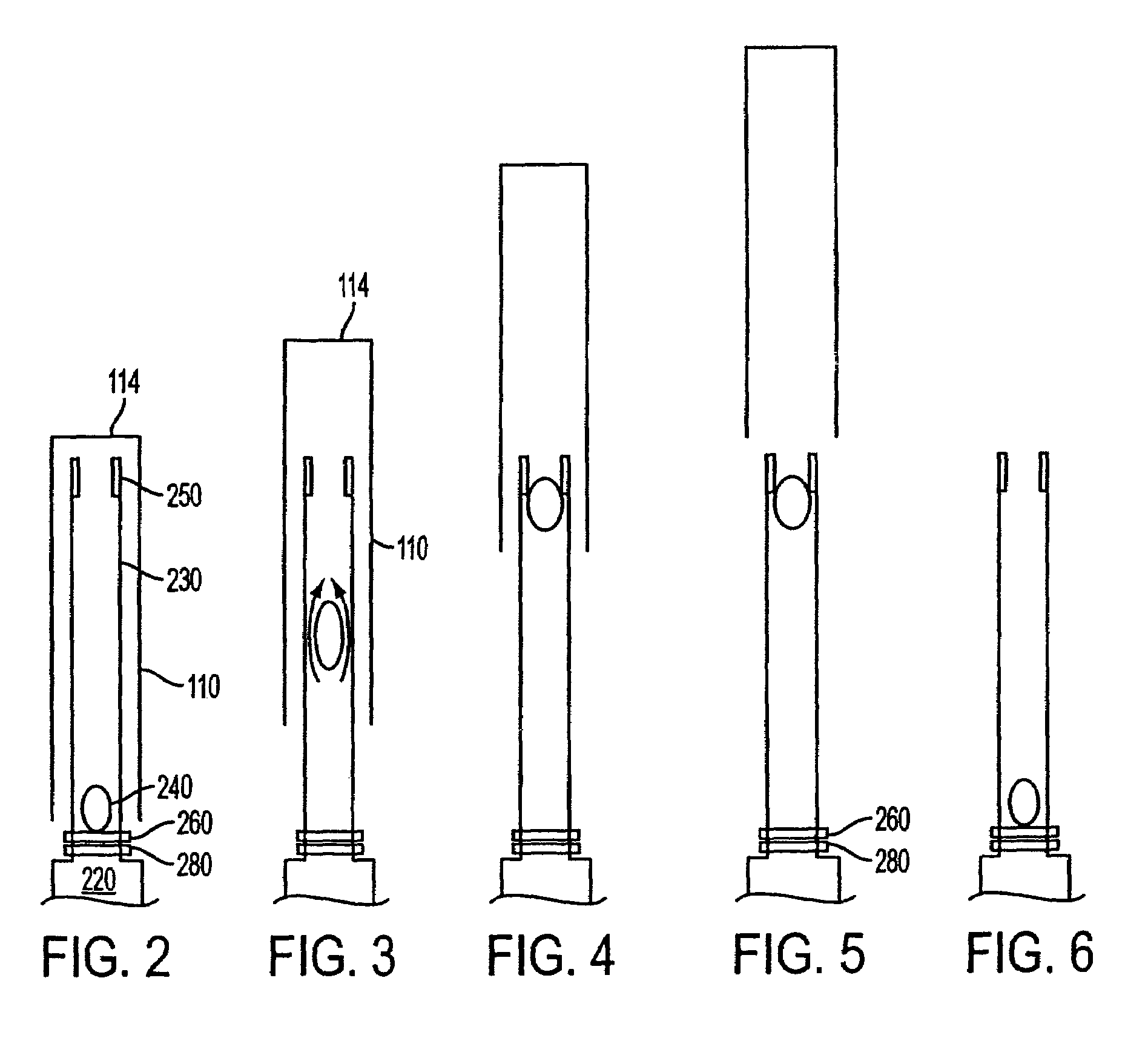

Liquid jet surgical instrument having a distal end with a selectively controllable shape

The invention provides a variety of surgical instruments for forming a liquid jet, which are useful for performing a wide variety of surgical procedures. In some embodiments, the invention provides surgical liquid jet instruments having a pressure tube and an evacuation tube, where the pressure tube includes at least one nozzle for forming a liquid jet and where the evacuation tube includes a jet-receiving opening for receiving the liquid jet when the instrument is in operation. In some embodiments, the distal ends of both the pressure and evacuation tubes have a first configuration in a non- relaxed state and a second configuration in a more relaxed state. In some embodiments, a straightener is constructed to selectively control the configuration of the distal ends of both the pressure and evacuation tubes. The invention also provides surgical methods utilizing the inventive surgical liquid jet instruments for cutting or ablating a selected tissue within portions of a patient's spine, such as within the intervertebral disc.

Owner:HYDROCISION

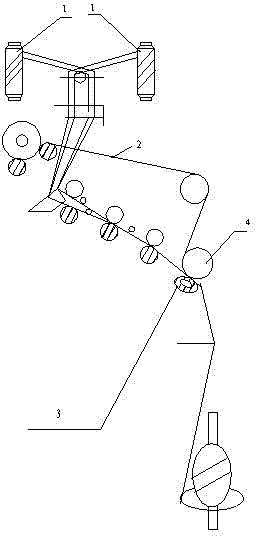

Production technology of siro compact spinning covering yarn

The invention relates to the production technology of a siro compact spinning covering yarn. A traditional compact spinning negative pressure pipe negative pressure groove is designed in an I-shaped straight groove mode, a cotton net is too narrow and the yarn-leakage phenomenon exists, meanwhile, the yarn hairiness is serious, evenness is poor, strength is low, fluctuation is large, and wool particles / neps are prone to being formed during a post processing process. The production technology of the siro compact spinning covering yarn enables the negative pressure pipe negative pressure groove to be designed into a V-shaped groove; meanwhile, the siro spinning technology is used, two coarse yarns are fed at the same time at one spindle position at a certain interval, the two coarse yarns are dragged respectively, an elastic filament is arranged between the two coarse filament, two fiber beams are formed in a negative pressure zone formed by the V-shaped groove after the two coarse yarns are dragged, the filament is guided to be arranged between the two fiber beams from the position behind a clustering front leather roller, and therefore the filament can be effectively wrapped, and a good covering yarn product can be manufactured.

Owner:重庆三峡技术纺织有限公司

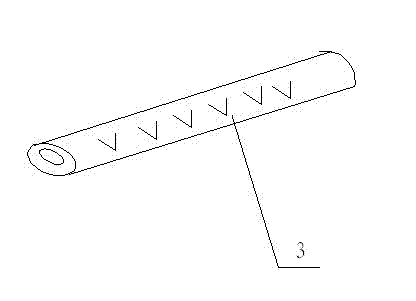

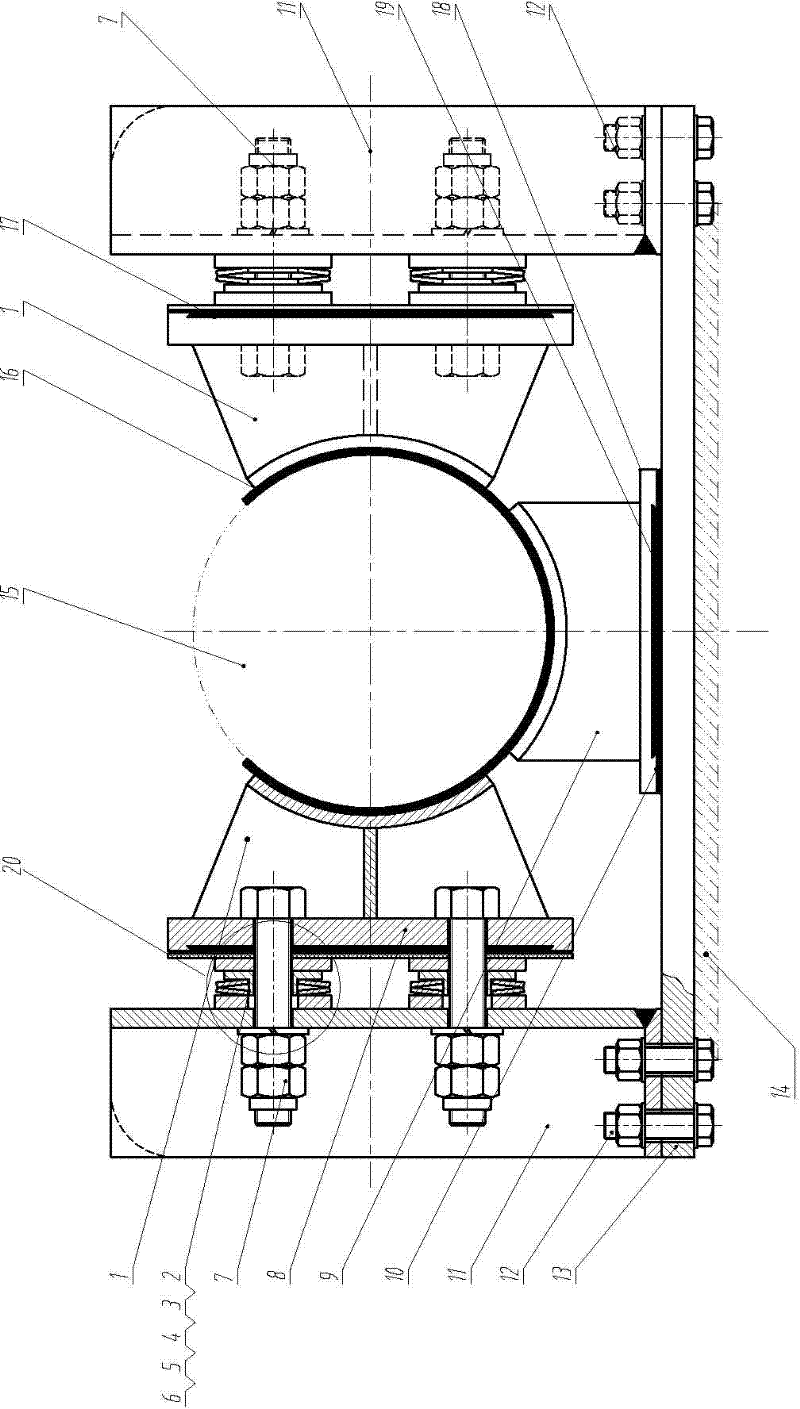

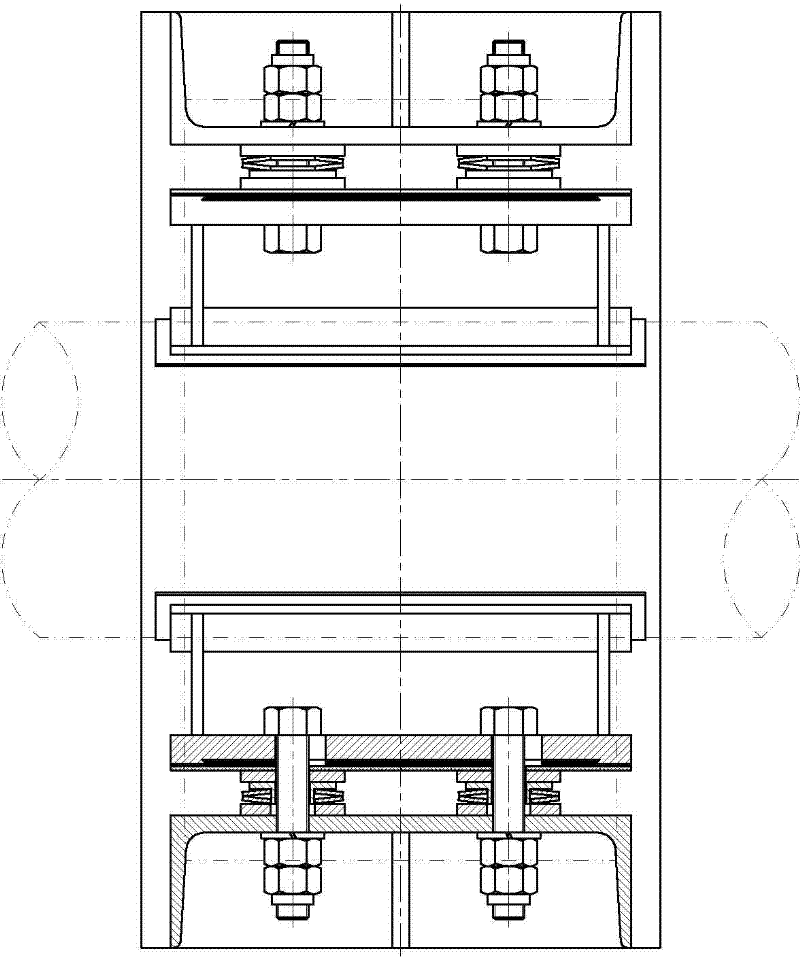

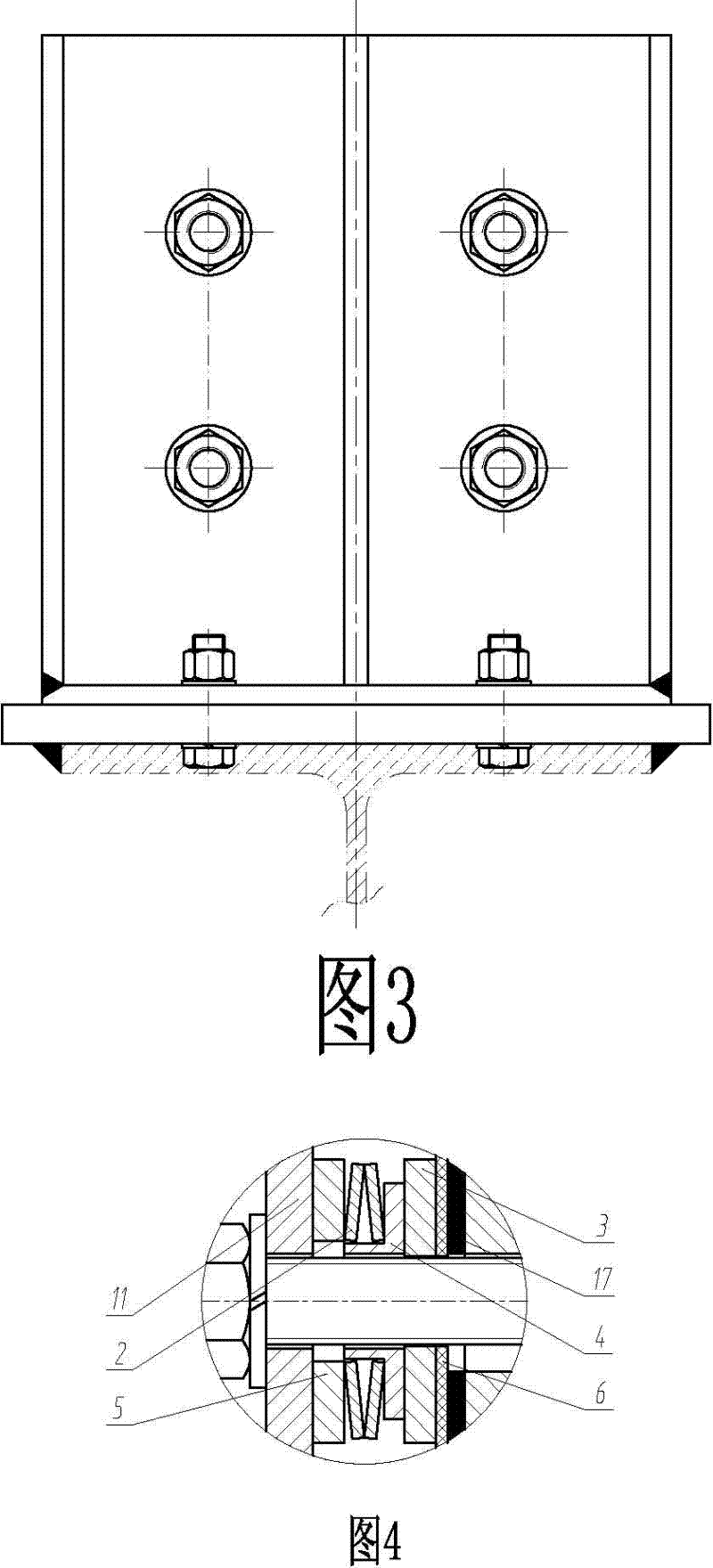

Pressure pipe radial vibration damping force stilling support

ActiveCN102297291AVibration stress reliefGuaranteed rigidityPipe supportsRadial vibrationPressure pipe

The invention relates to a radial vibration-reducing stress-dissipating bracket for a pressure pipeline. The radial vibration-reducing stress-dissipating bracket for the pressure pipeline comprises a lower supporting block (9) and a lower bottom plate (13); the pressure pipeline (15) is supported on the lower supporting block (9); and the lower supporting block (9) is supported on the lower bottom plate (13). The radial vibration-reducing stress-dissipating bracket for the pressure pipe is characterized in that vertical type fixing brackets (11) are symmetrically arranged at two sides of the lower bottom plate (13); two radial clamping blocks (1) which are matched with the two sides of the pressure pipeline (15) are respectively connected with corresponding supporting plates (8); the supporting plates (8) are connected with corresponding vertical type fixing brackets (11) through respective fastening connecting pieces (7); and elastic supporting assemblies (20) are mounted on the fastening connecting pieces (7) and between the vertical type fixing brackets (11) and the supporting plates (8). With the adoption of the radial vibration-reducing stress-dissipating bracket for the pressure pipe, the rigidity of a piping system can be maintained and a vibrating stress generated in the radial direction of the piping system can be eliminated, thus the requirement of vibration-reducingsupport for the pressure pipeline can be satisfied.

Owner:JINAGSU SUNPOWER PIPELINE ENG TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com