Patents

Literature

493 results about "Extensometer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An extensometer is a device that is used to measure changes in the length of an object. It is useful for stress-strain measurements and tensile tests. Its name comes from "extension-meter". It was invented by Charles Huston who described it in an article in the Journal of the Franklin Institute in 1879. Huston later gave the rights to Fairbanks & Ewing, a major manufacturer of testing machines and scales.

Thermo-mechanical-environmental coupling effect testing device and application from room temperature to ultrahigh temperature

ActiveCN104215521APrecise temperature controlTestable tensile strengthWeighing by removing componentMaterial strength using tensile/compressive forcesPower control systemTest fixture

The invention relates to the field of test of mechanical properties of materials and in particular relates to a thermo-mechanical-environmental coupling effect testing device and application from room temperature to ultrahigh temperature. The device comprises an electronic universal testing machine, a loading control system, a power supply control system, an induction heater, a strain measurement system, a sample clamp, a temperature measuring system, a pressure control system, a display and analysis system and a vacuum system, wherein a vacuum cavity in the electronic universal testing machine is in a fully water-cooled design, and various functional windows, such as a sensor connector of the clamp and the electronic universal testing machine, an infrared or thermocouple temperature measuring opening of the temperature measuring system, a pressure control opening of the pressure control system, an induction power supply introduction opening of the power supply control system, an extensometer introduction opening of the strain measurement system and a connector of the vacuum system and the vacuum cavity, are reserved in different parts of the vacuum cavity. The device disclosed by the invention can quantitatively research the thermo-mechanical-environmental coupling effect and has the advantages of diversified tested mechanical property parameters, high sample heating and cooling speed and the like.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

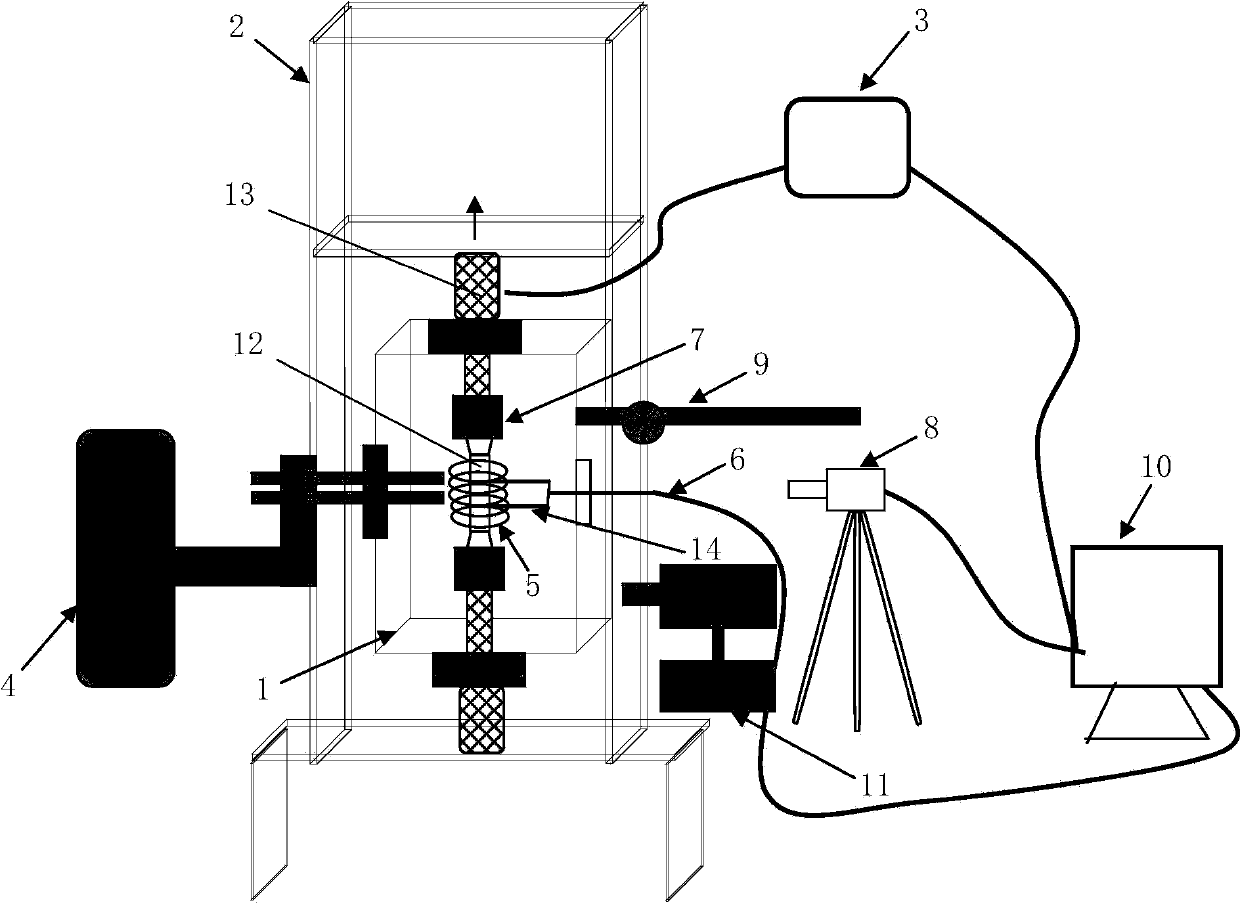

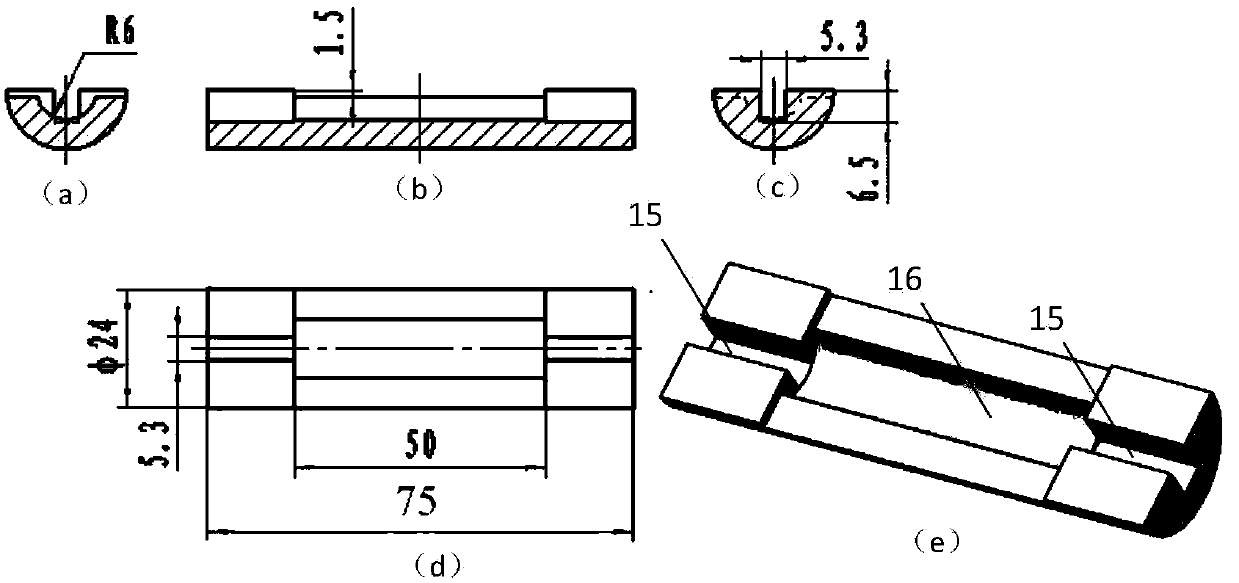

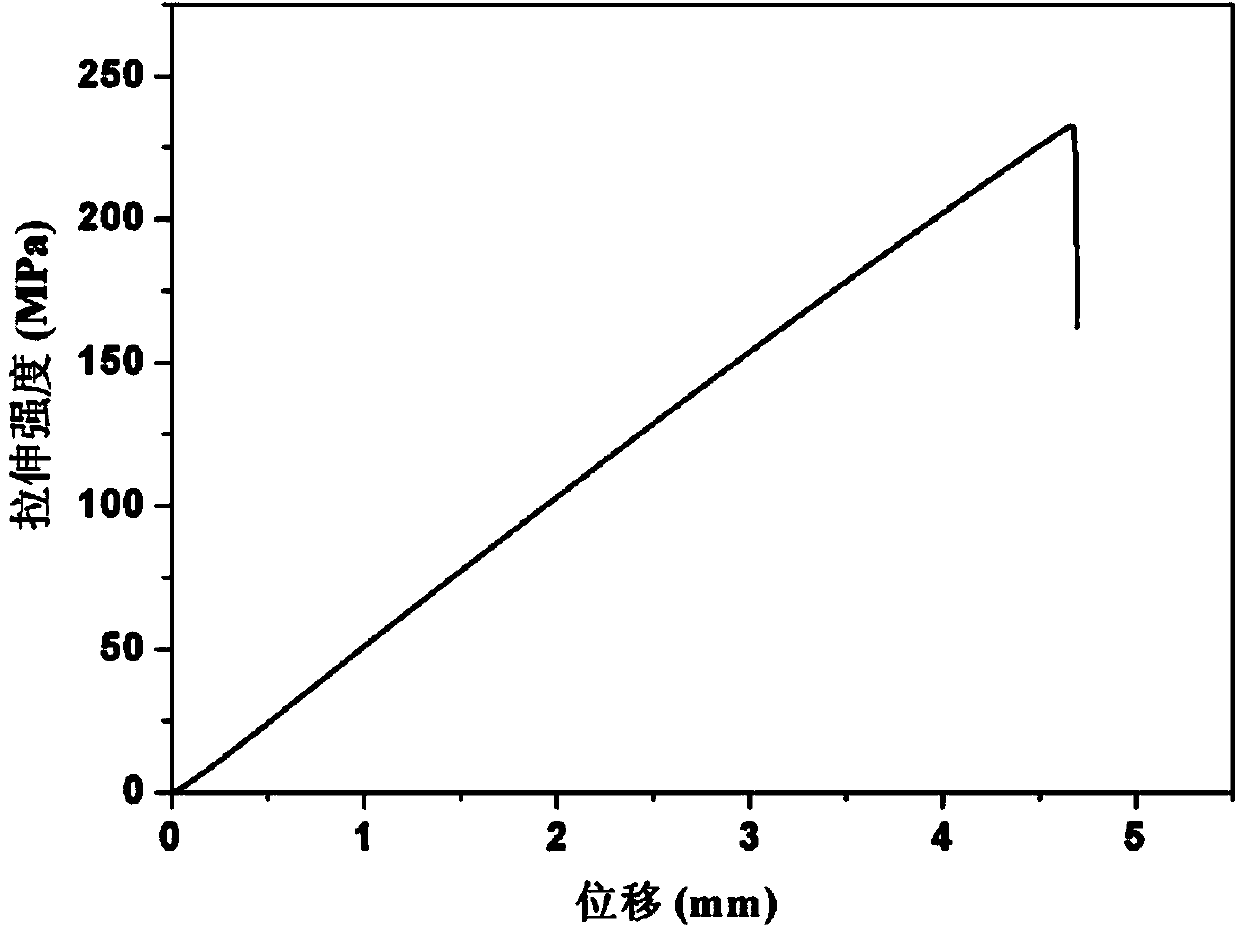

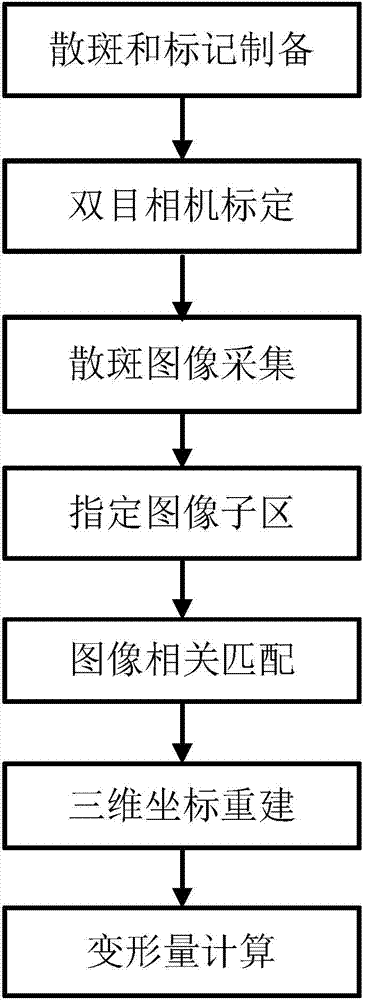

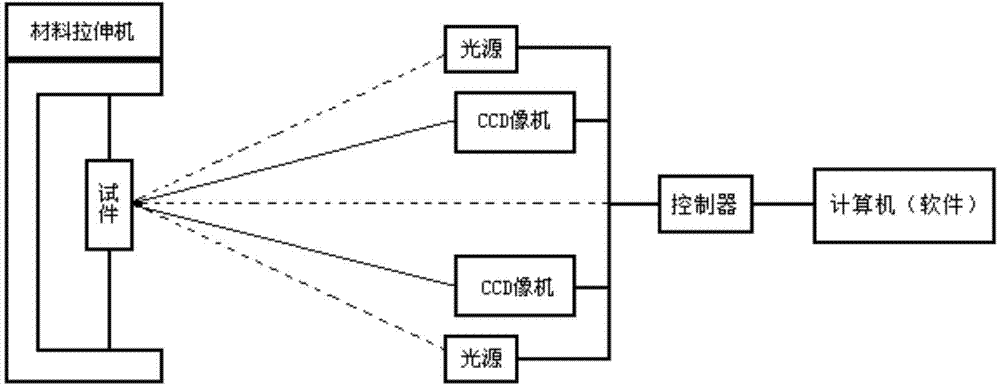

Vision extensometer implementation method based on digital speckles

ActiveCN103575227ASimple spraying workImprove measurement efficiencyUsing optical meansVisual perceptionImage acquisition

The invention discloses a vision extensometer implementation method based on digital speckles. The method includes the first step of speckle and mark making, the second step of binocular camera calibration, the third step of speckle image acquisition, the fourth step of image subarea specifying, the fifth step of image correlation matching, the sixth step of three-dimensional coordinate reconstruction and the seventh step of deformation calculation. Through the operating steps, the vision extensometer implementation method based on the digital speckles can be used for accurately measuring the deformation of materials in the tensile experiment process and has the advantages of being convenient to operate, capable of achieving non-contact measurement, accurate and reliable in measuring result and the like.

Owner:新拓三维技术(西安)有限公司

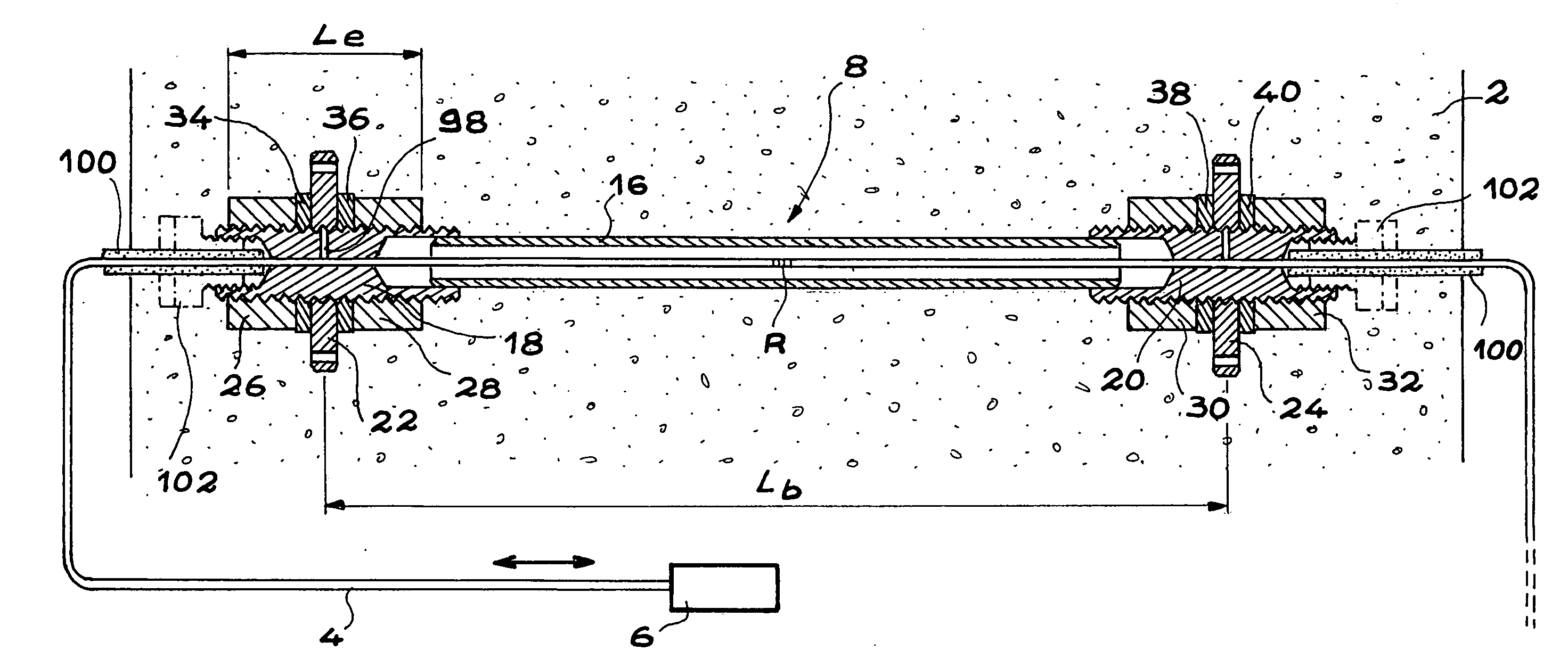

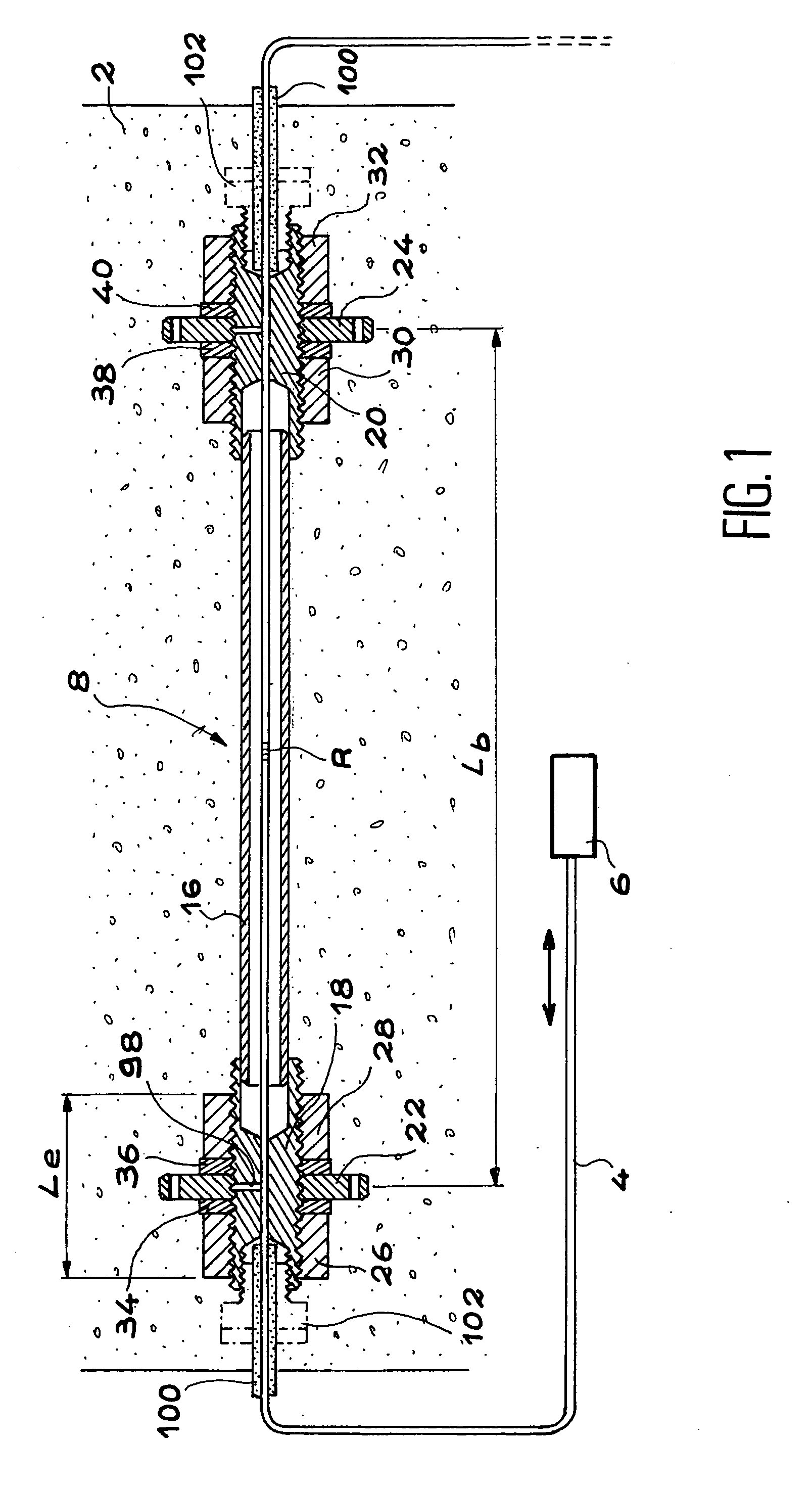

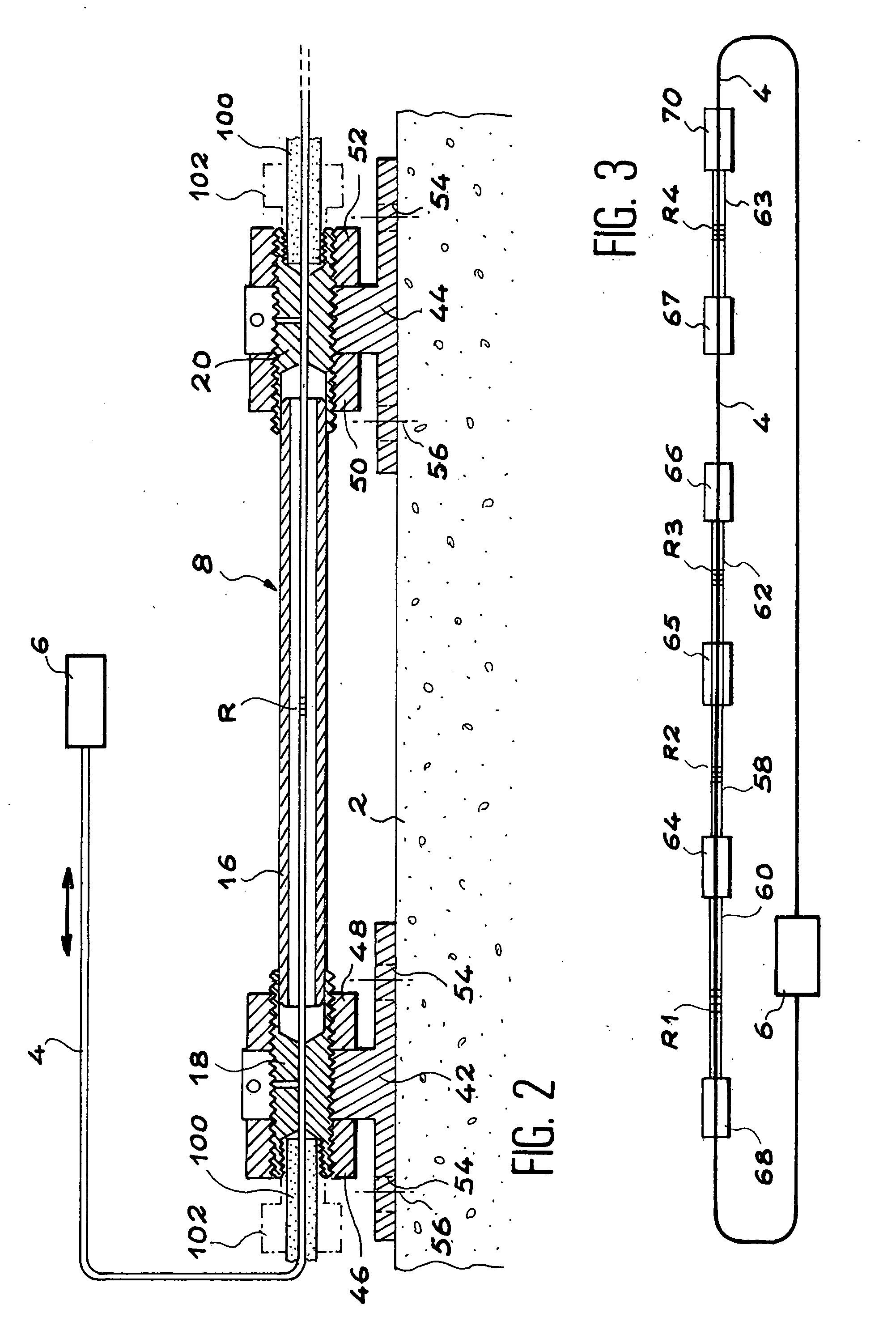

Extensometer with long base, tensioned optical fibre and bragg rating, and manufacturing process for this extensometer

InactiveUS20040114850A1Force measurement by measuring optical property variationUsing optical meansGratingBiochemical engineering

According to the invention, that relates particularly to monitoring of structures, part of the optical fiber (4) containing a Bragg grating (R) is arranged in a tube (16); this part is tensioned between the two ends of the tube; the ends of this part are fixed to the ends of the tube; this tube will be rigidly fixed to a host material (2).

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

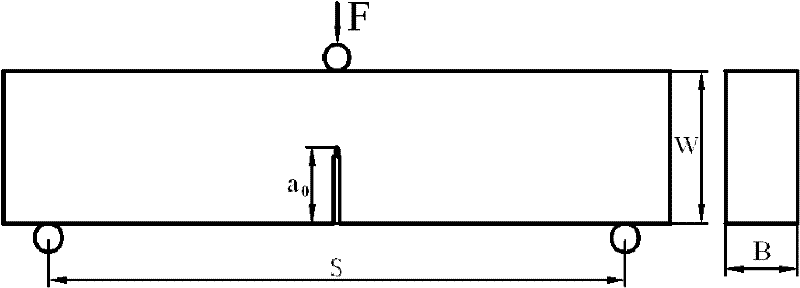

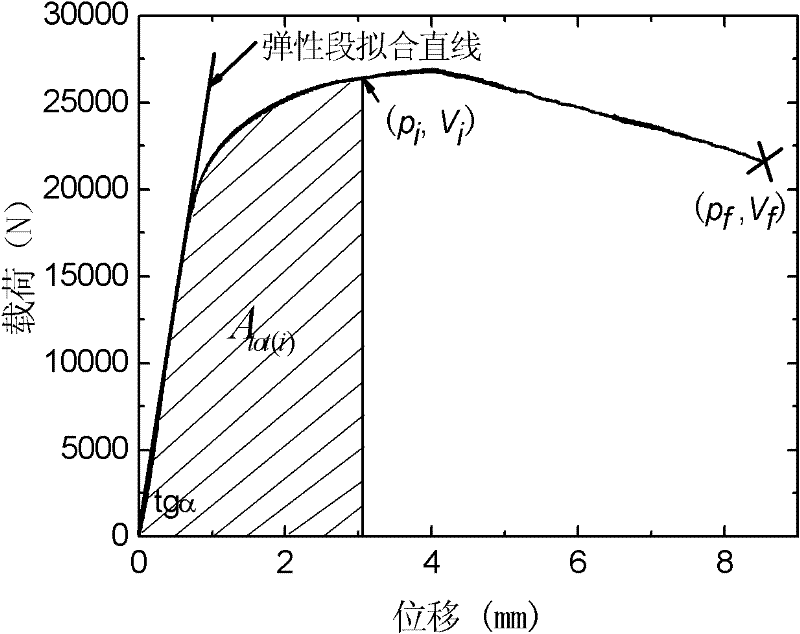

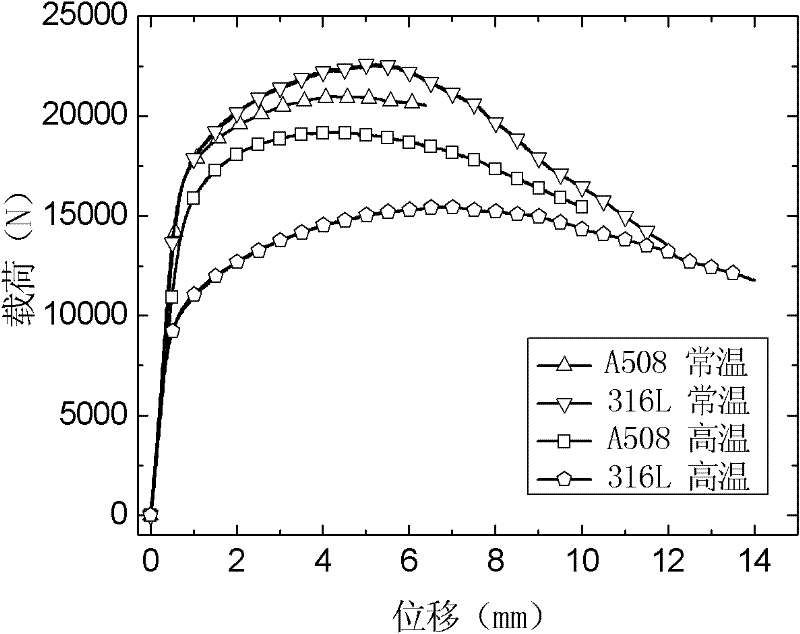

A method of measurement and determination on fracture toughness of structural materials at high temperature

ActiveUS20160299046A1Material strength using tensile/compressive forcesInvestigating material ductilityEquivalent weightFracture test

Disclosed is a method of measurement and determination on fracture toughness of structural materials at high temperature, comprising: preliminary assessing the ductility of a material based on a high-temperature uniaxial tensile test and the fracture characteristic; designing and manufacturing a CT specimen; conducting a monotonic loading fracture test on the CT specimen at high temperature; modifying a load-displacement curve output by a testing machine; determining a passivation coefficient M for the crack of the structural material; reversely recursing instant load-displacement data pairs corresponding to the instant crack length; calculating a J_R crack extension resistance curve of the tensile test; examining the validity of the J_R crack extension resistance curve and the fracture toughness JIC; calculating the fracture toughness per equivalent of the structural material KIC. The present invention overcomes the difficulty of placing an extensometer inside a high-temperature furnace.

Owner:EAST CHINA UNIV OF SCI & TECH +1

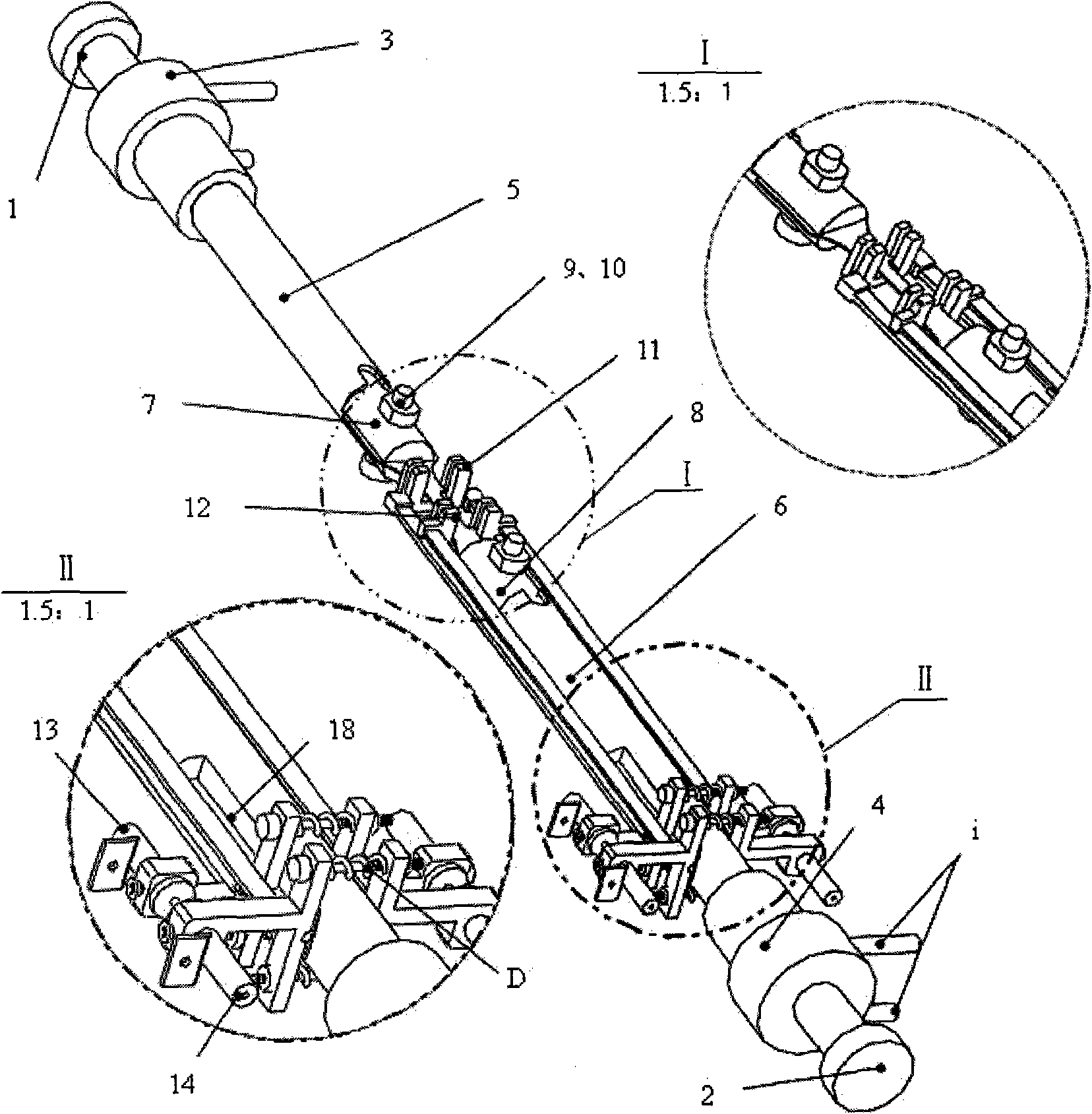

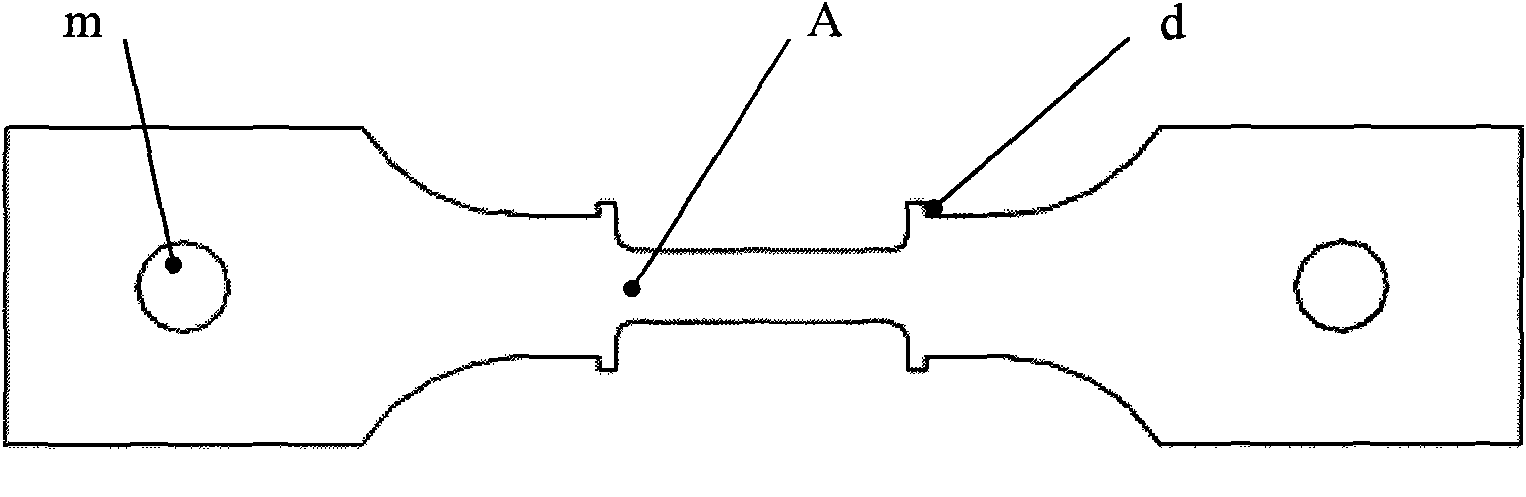

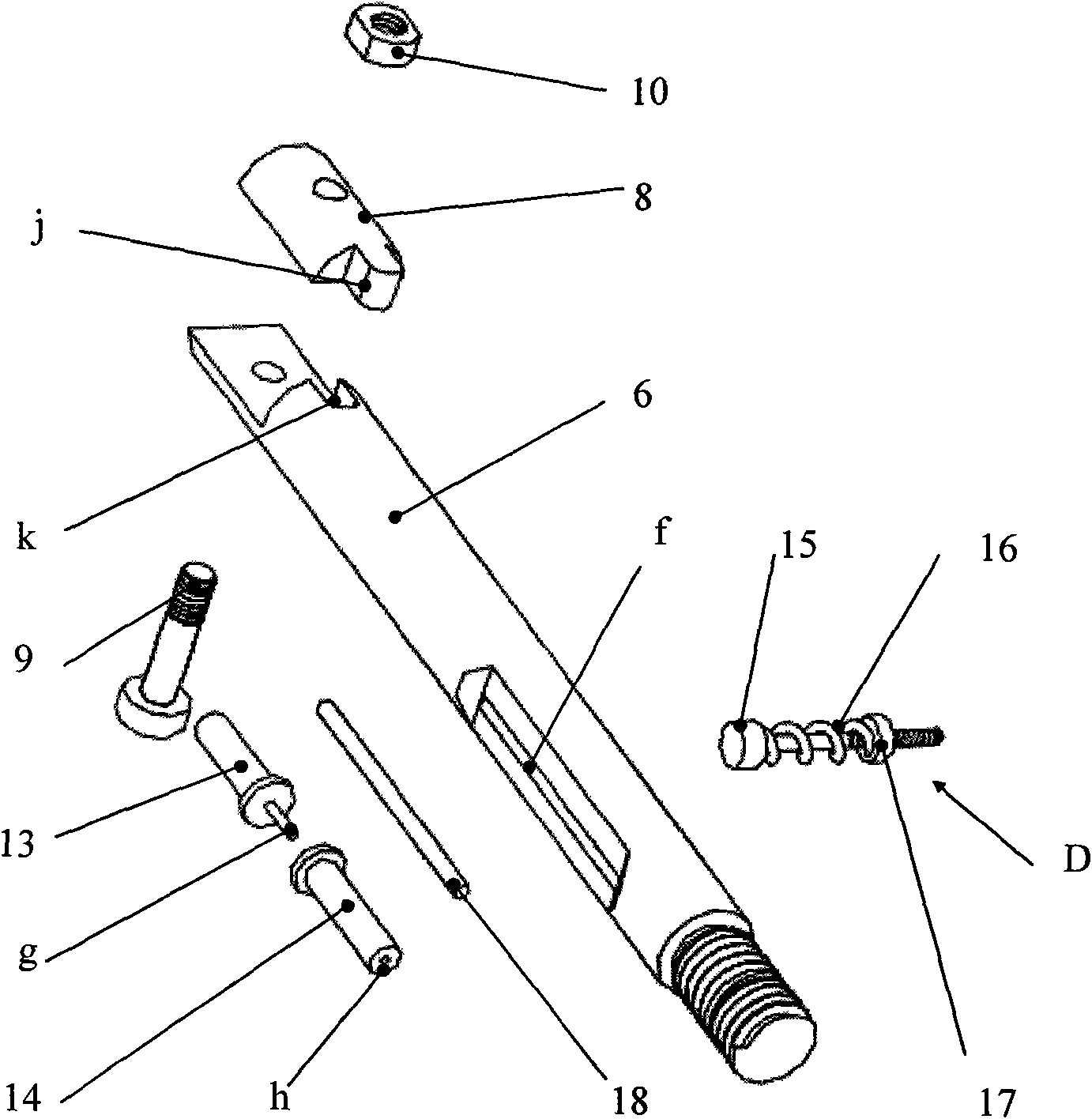

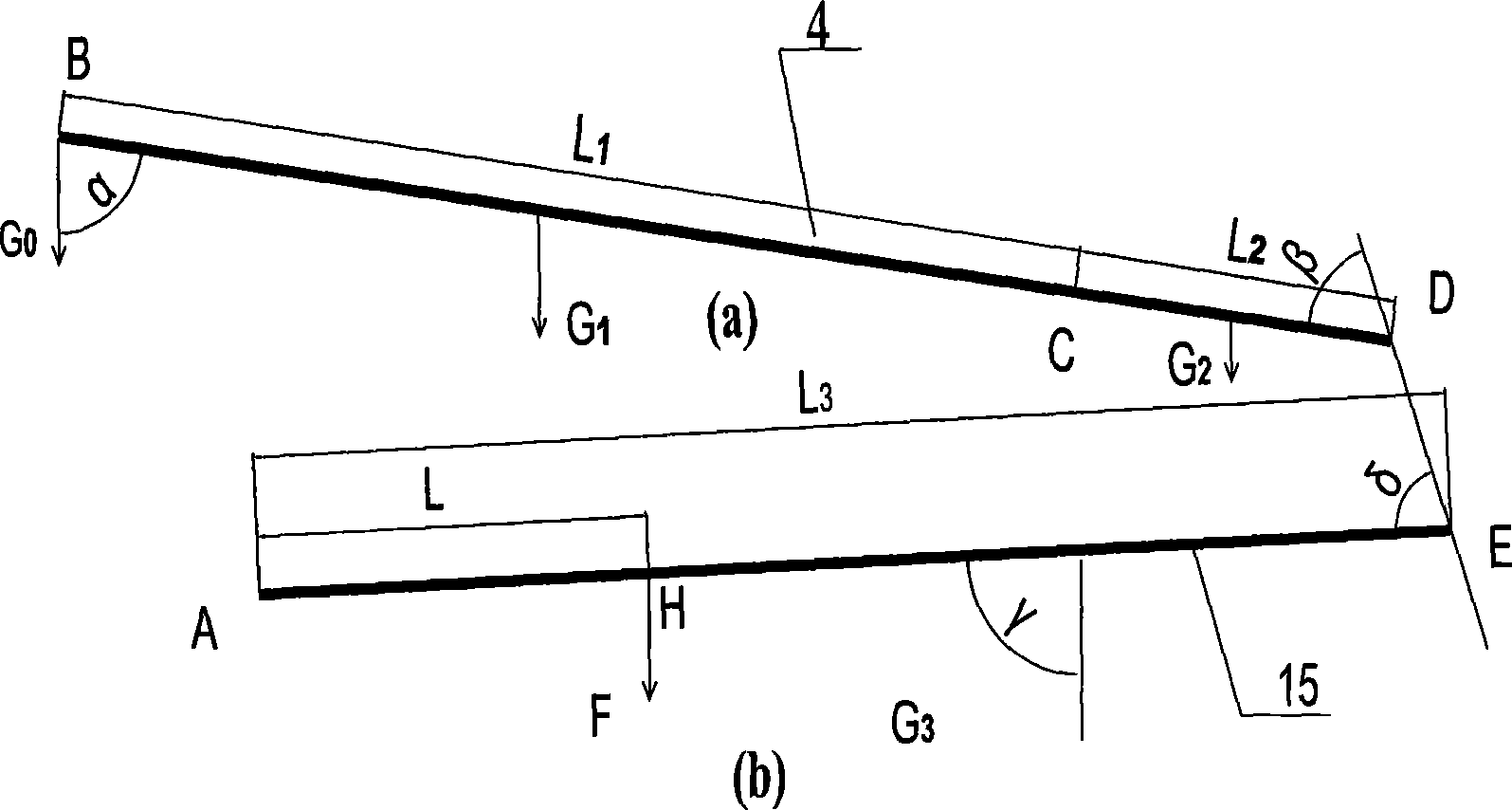

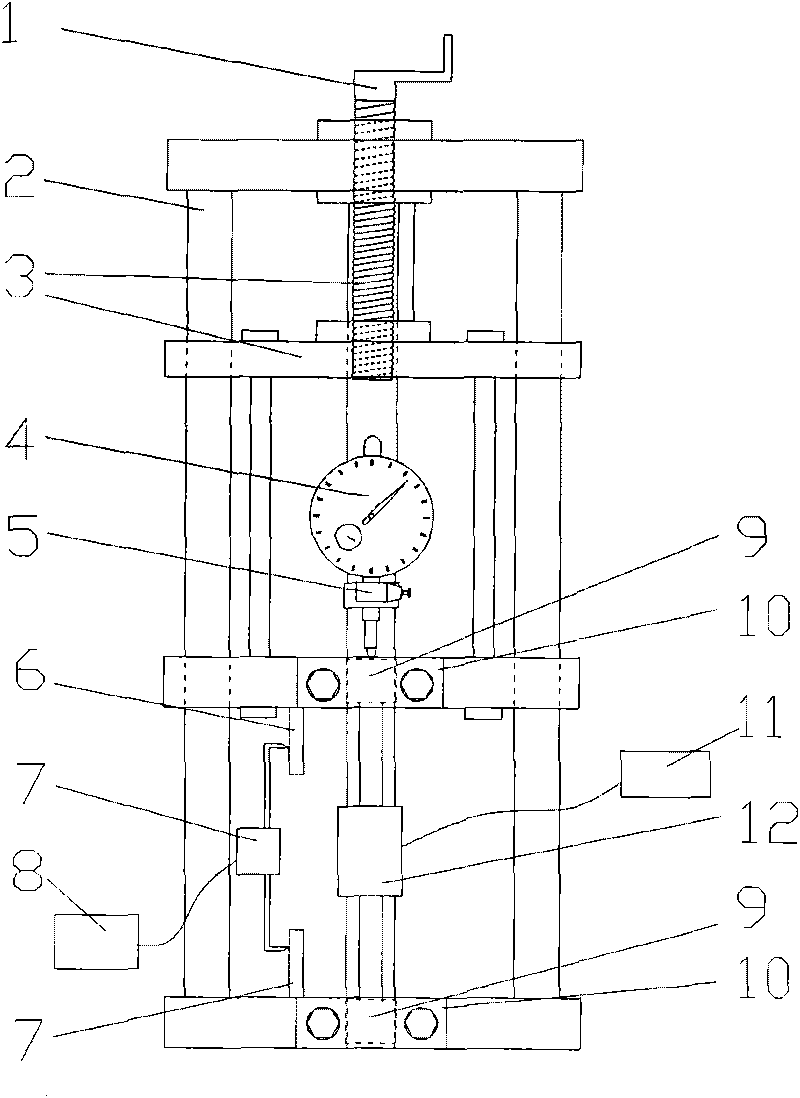

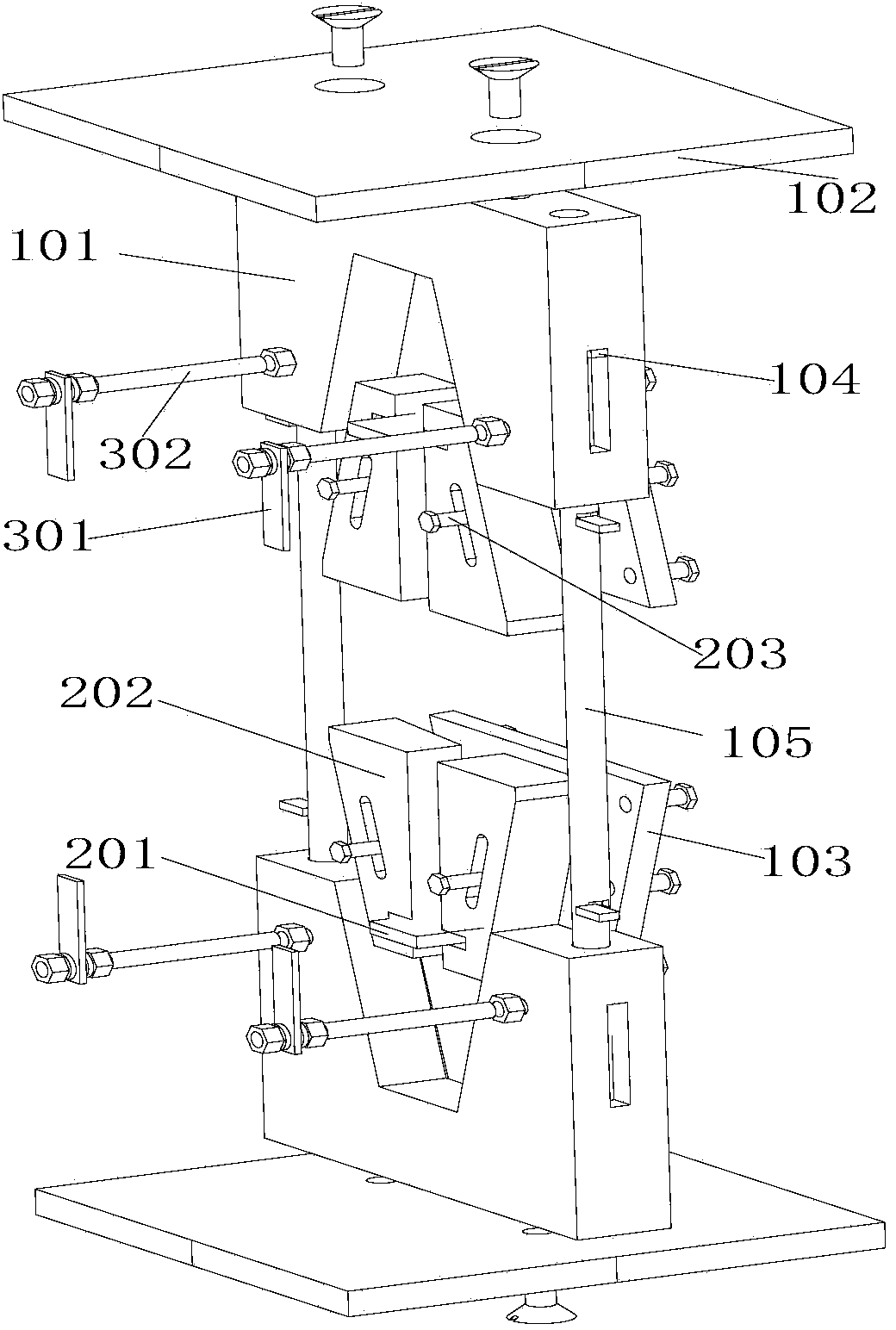

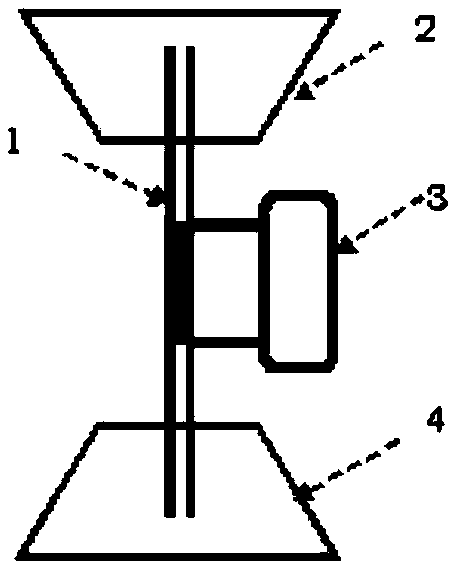

Uni-directional stretching test clamp for warm shaping of metal plate

InactiveCN101608988AReduce adverse effectsMaterial strength using tensile/compressive forcesEngineeringHeating furnace

A uni-directional stretching test clamp for warm shaping of a metal plate relates to the technology of testing warm shaping performance of metal plates. The clamp consists of a displacement magnitude leading-out part, a stretching test element positioning and clamping part and a test machine connecting part, and can lead the displacement magnitude of scale distance of a stretching test element with different softness degrees out of a heating furnace so as to provide convenience for accurately measuring the displacement by using an extensometer. After the stretching test element is provided with a clamp, the direction of a loading force and the direction of the length of the stretching test element can be ensured to be on the same line. A cooling device can effectively cool the connecting place between the clamp and a testing machine. The clamp can effectively improve the accuracy of a test result.

Owner:JIANGSU UNIV

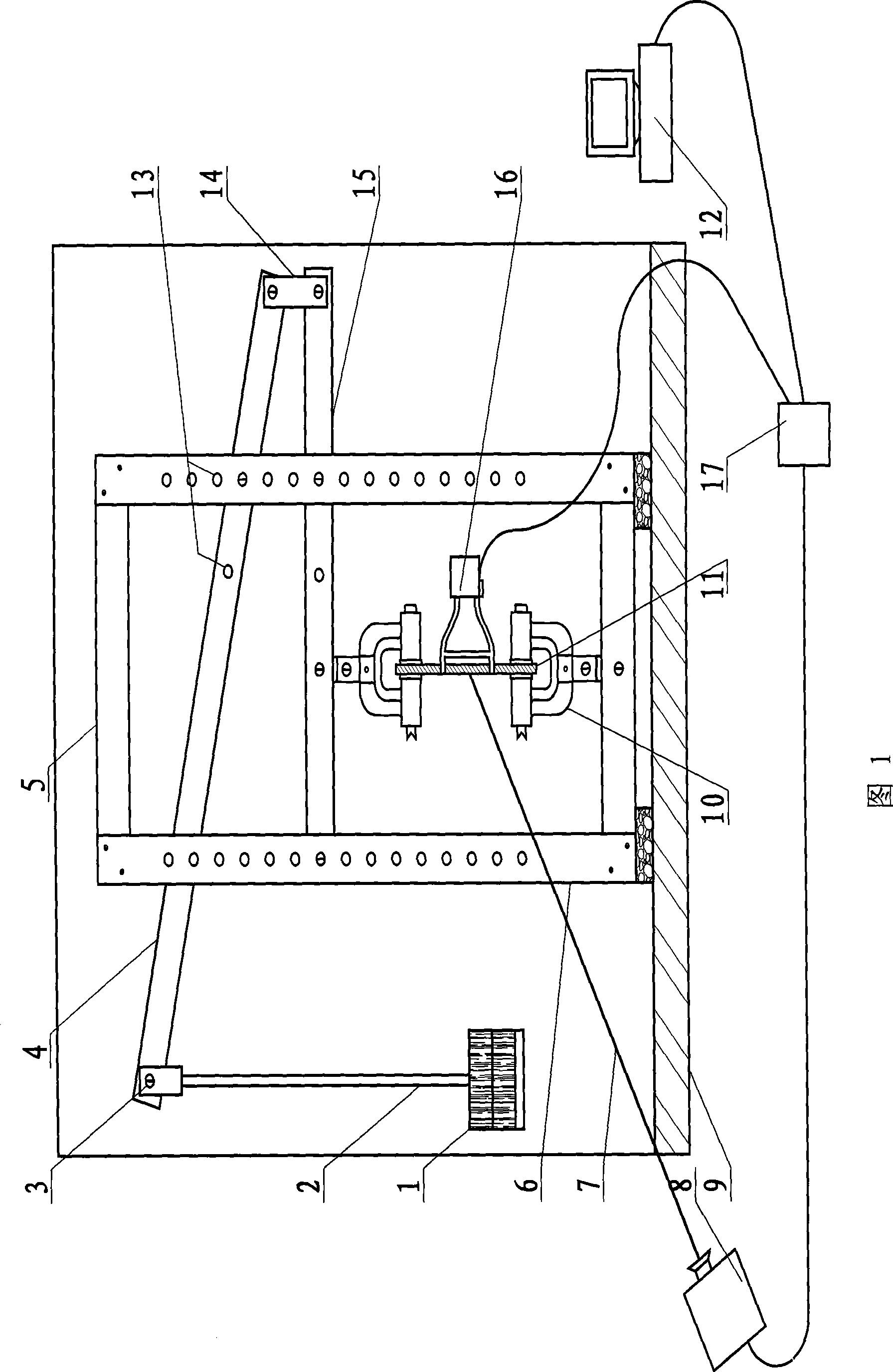

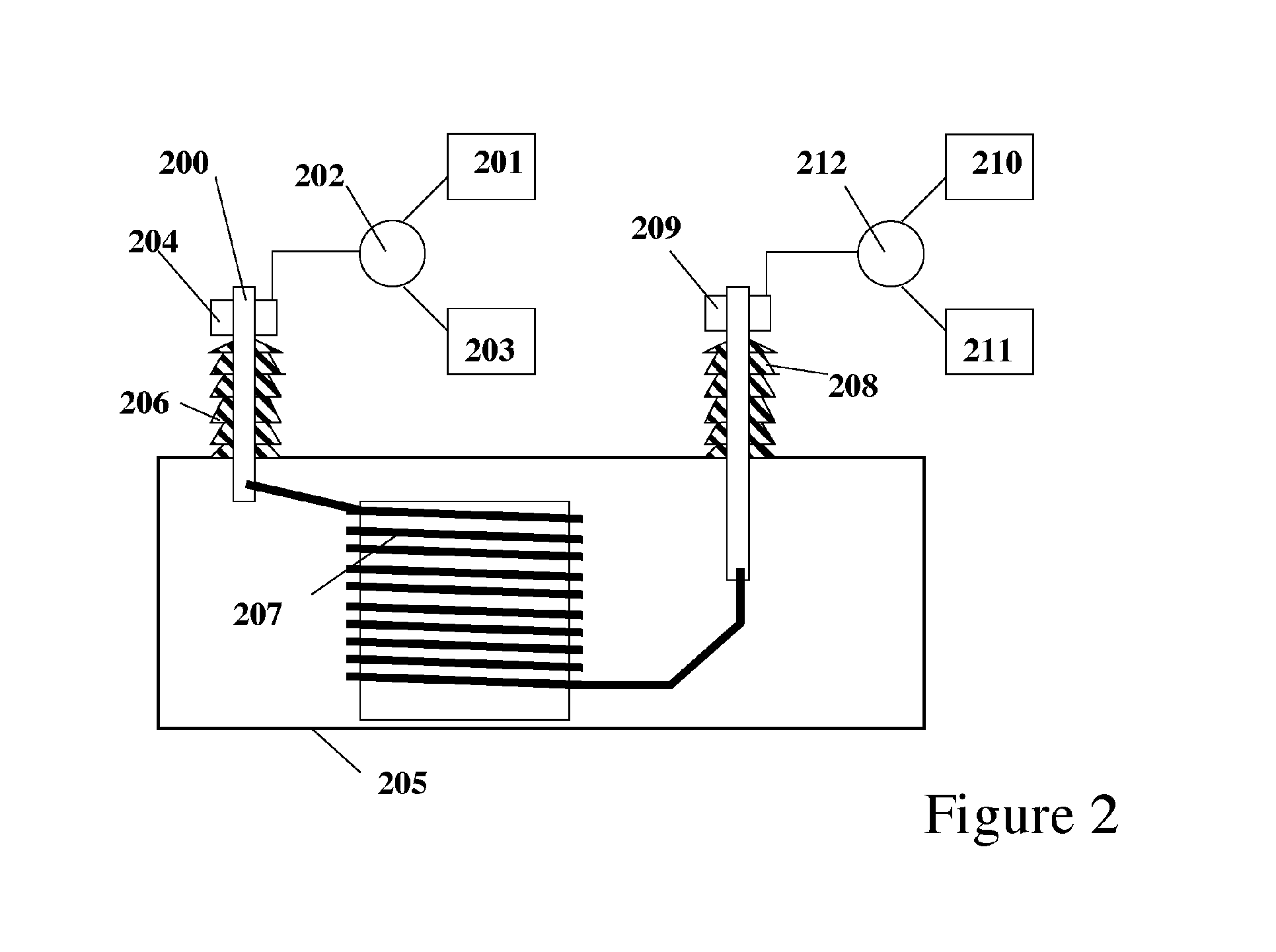

Aging test method and apparatus under wet, heat and power multiple-field coupling

InactiveCN101435811AImplement burn-in testingTest accurateWeather/light/corrosion resistanceMulti fieldData acquisition

The invention relates to an aging test method and an aging test device under the multi-field coupling of humidity, heat and force. The method is used for testing polymer materials and test specimens produced by composite materials of the polymer materials, and the test is based on the dynamic monitoring to the tensile creep compliance of the materials under the multi-field coupling of the humidity, the heat and the force. The device is based on a standard humid and hot environmental box controlled by a microcomputer, a test specimen clamping and loading mechanism is arranged in a box of the device, and an electronic extensometer and a laser extensometer are arranged to form a double displacement sensor and are connected to the microcomputer through an acquisition device after the data acquisition. The method and the device have the advantages of accurate and convenient test and low cost, and are suitable for the research of viscous-elastic mechanical properties and aging performances under the operation of polymers and composite materials of the polymers.

Owner:SHANGHAI UNIV

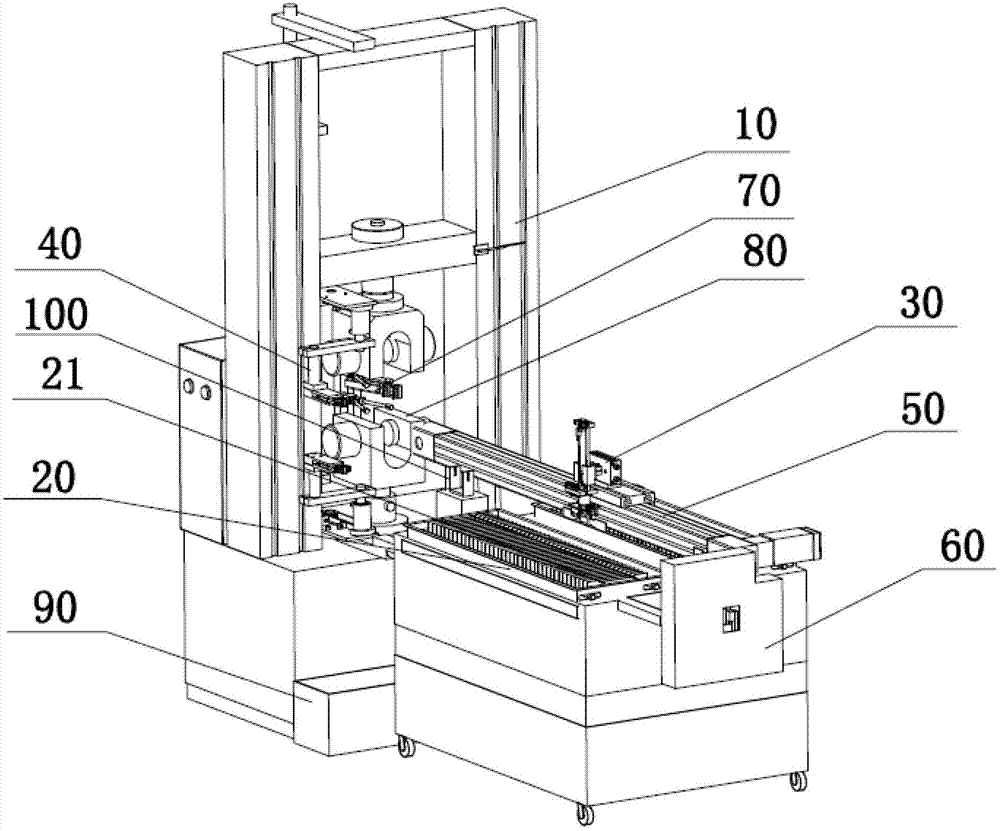

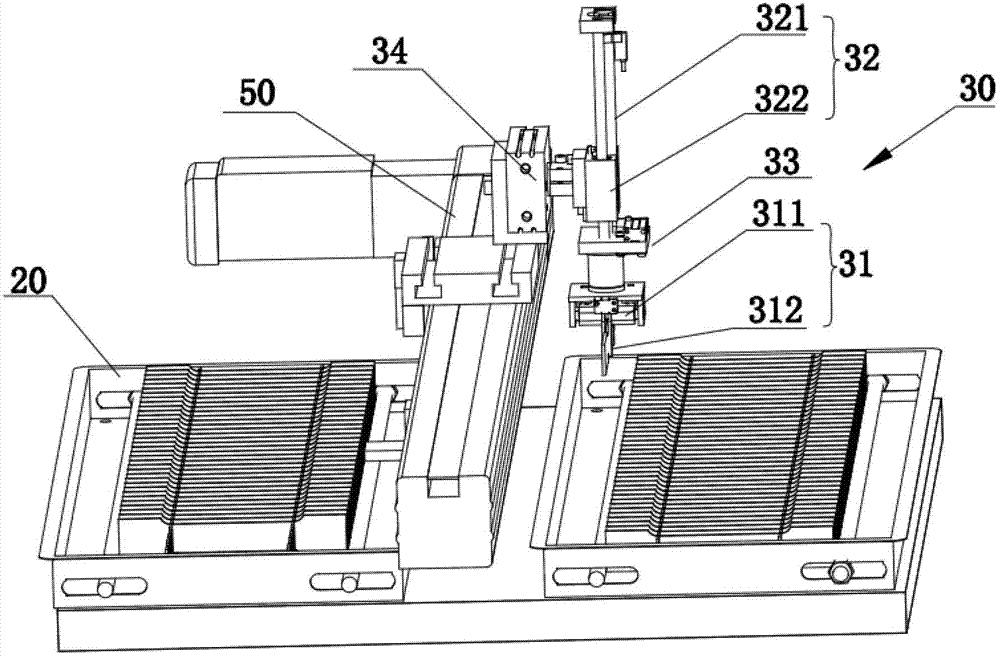

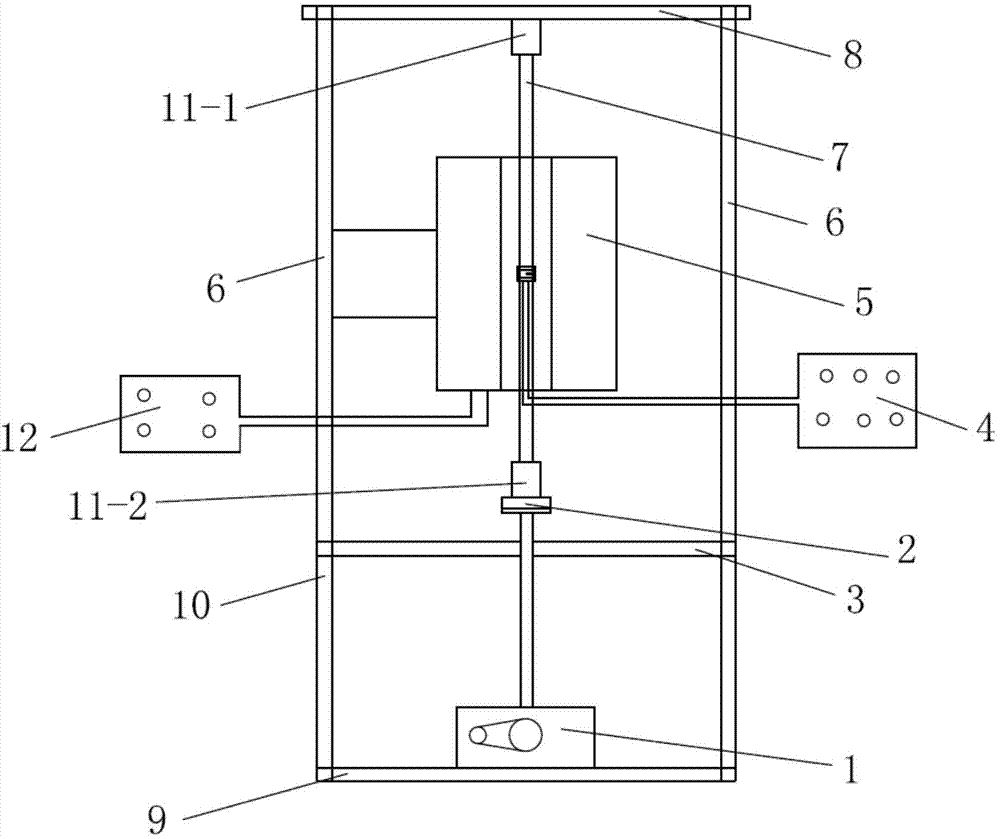

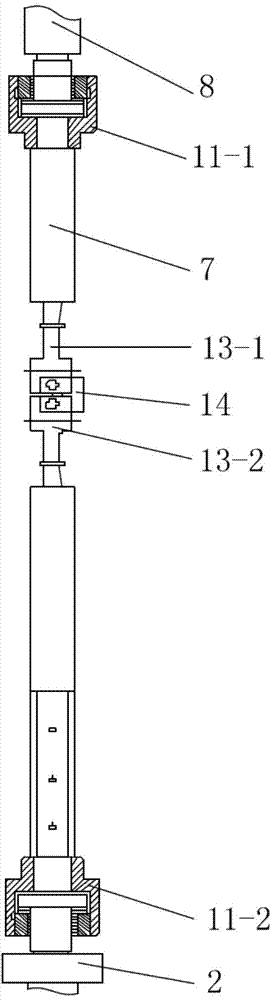

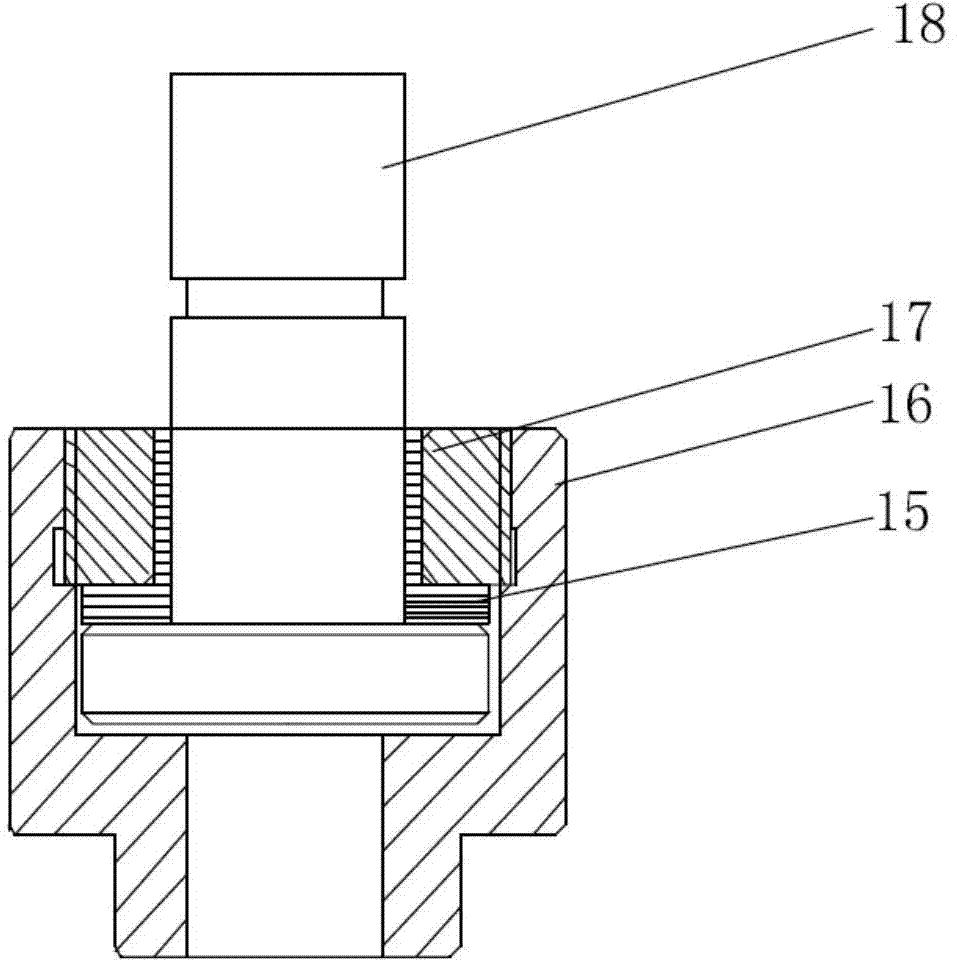

Full-automatic tension testing machine

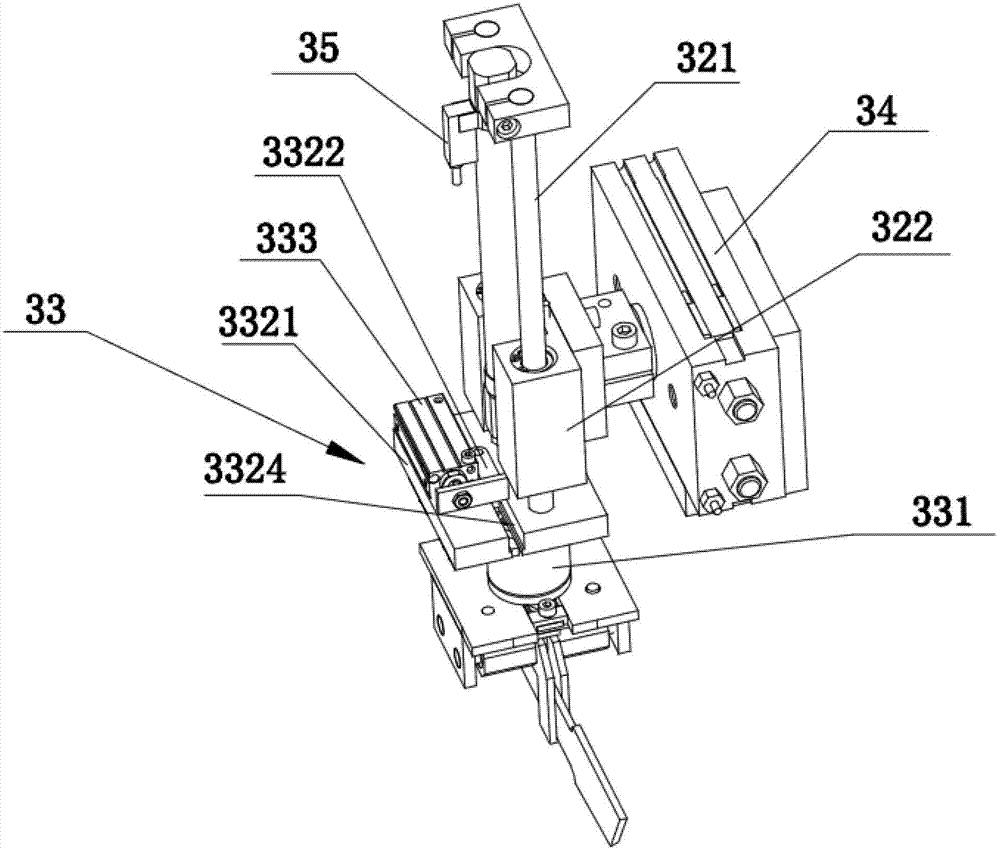

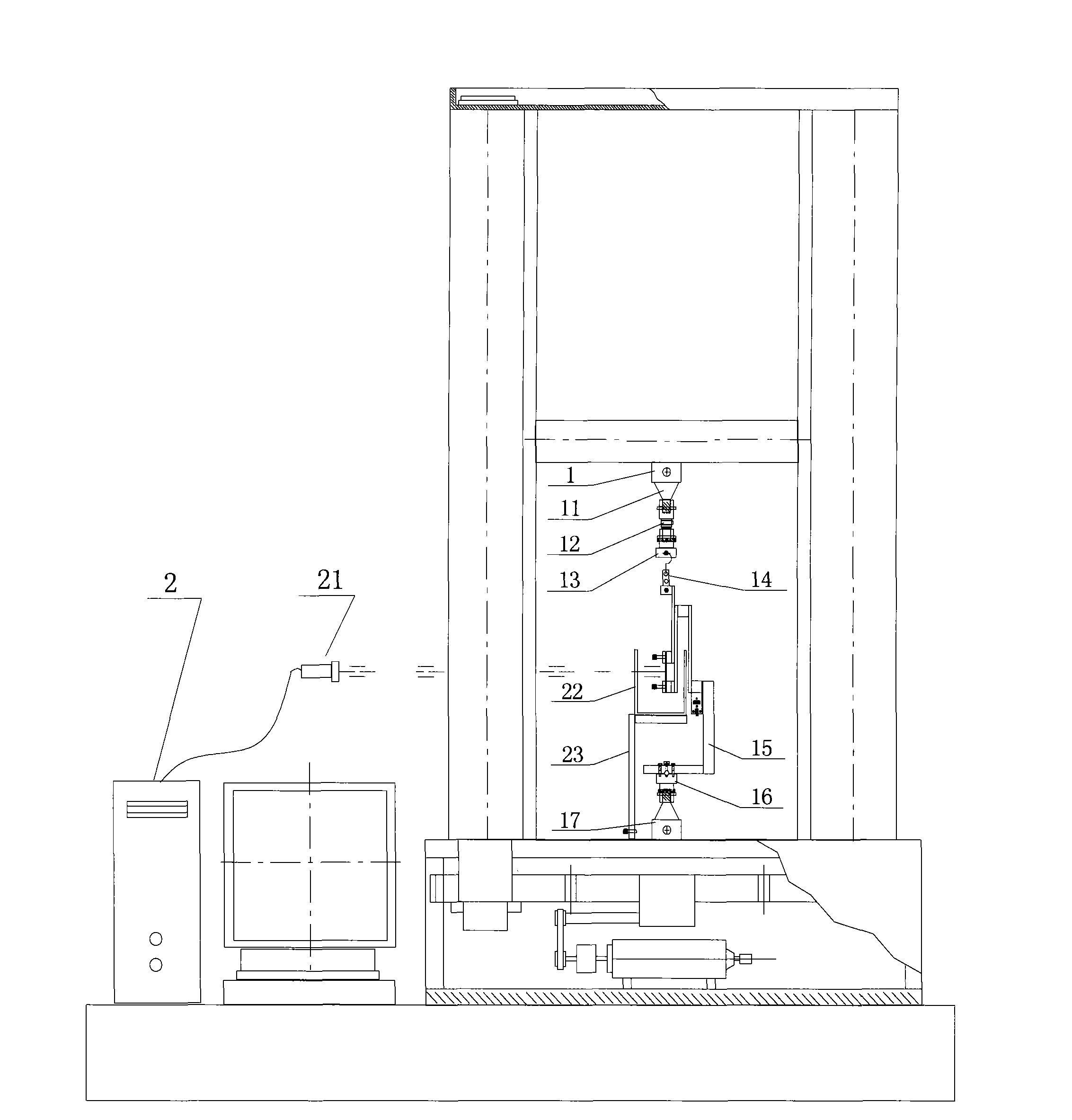

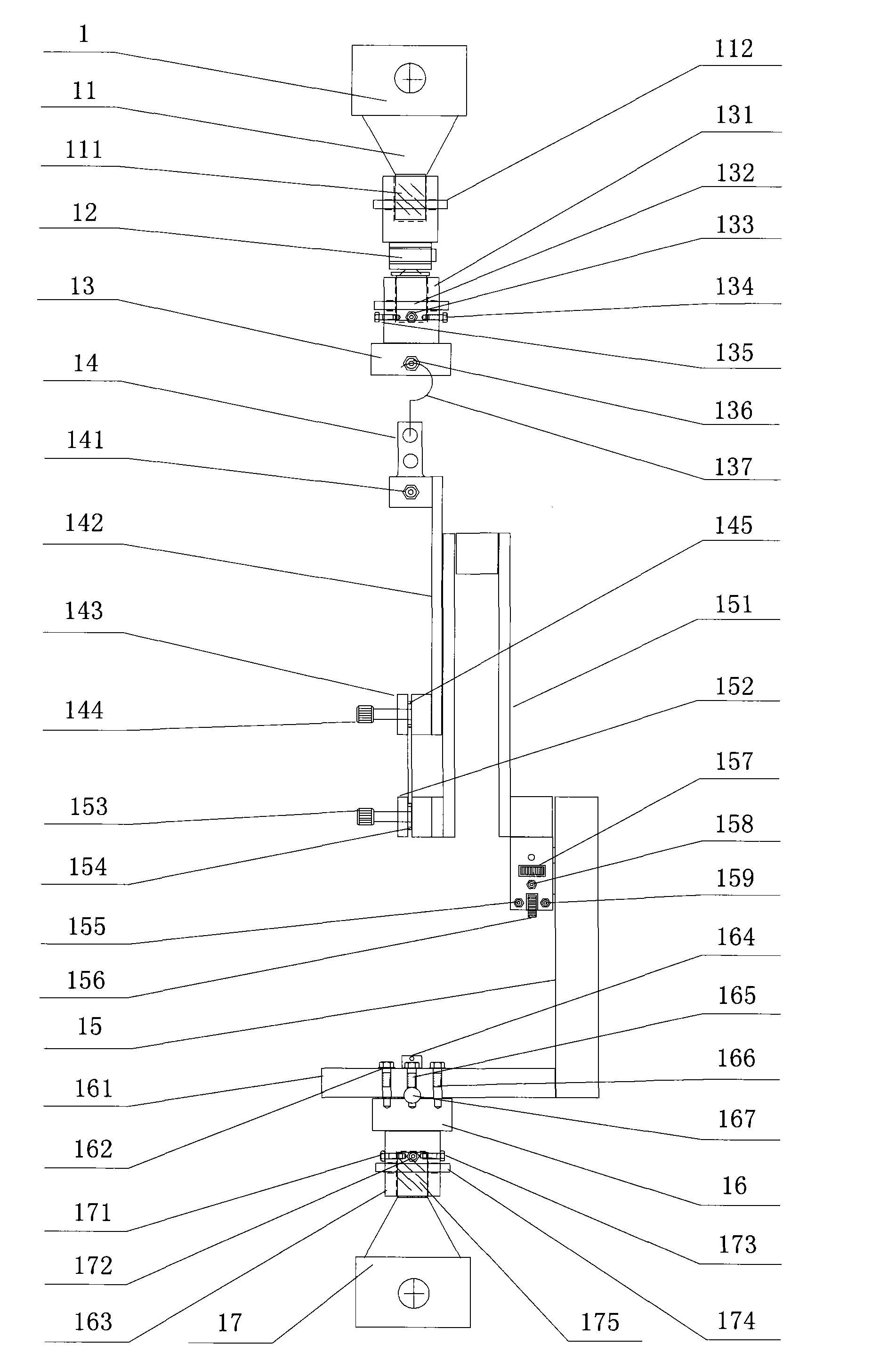

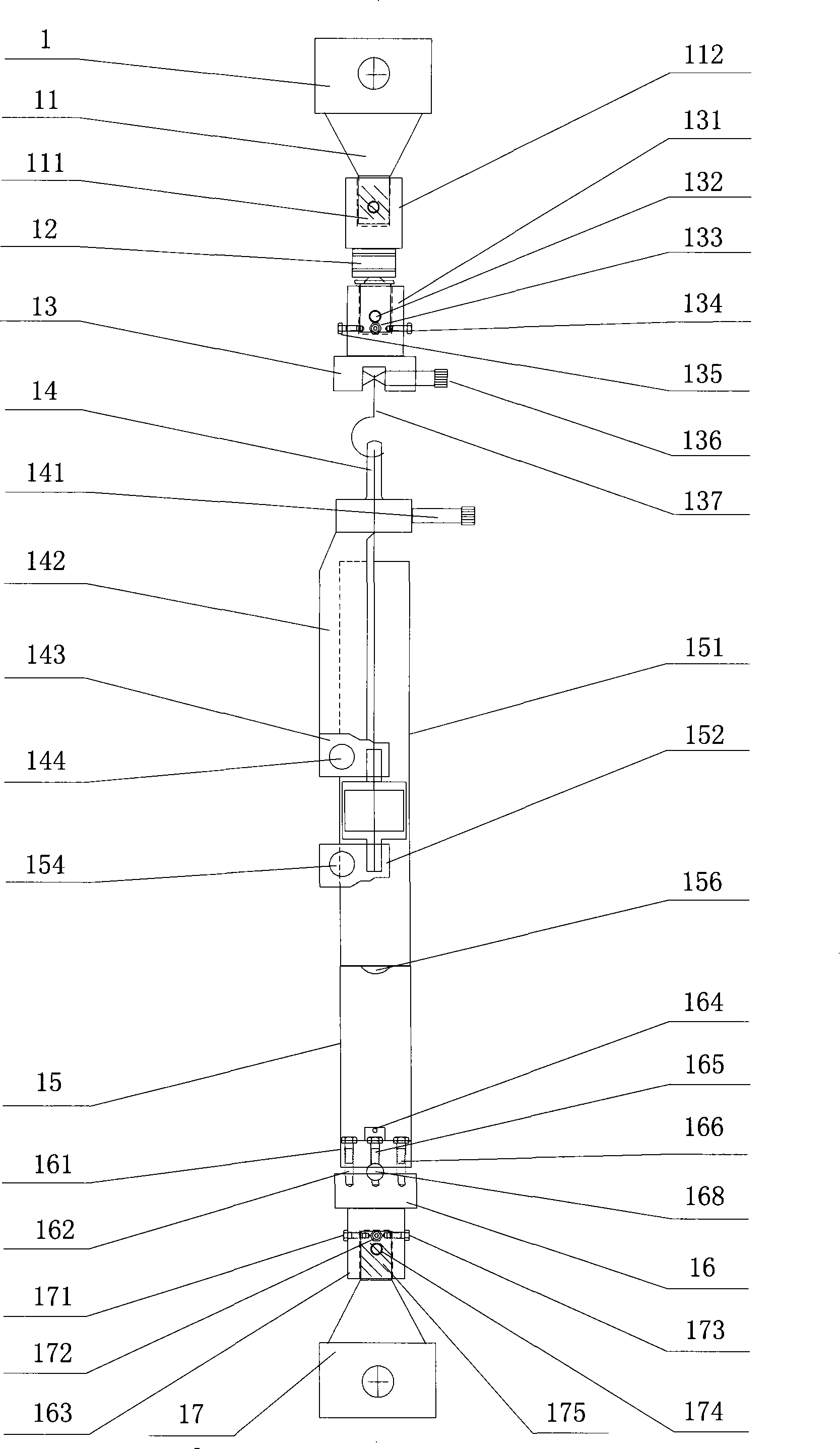

ActiveCN102778393AFully automatedImprove test efficiencyMaterial strength using tensile/compressive forcesTest efficiencyManipulator

The invention discloses a full-automatic tension testing machine. The full-automatic tension testing machine comprises a main machine, a lofting device, a material loading mechanical arm, a baiting mechanical arm, a propelling movement mechanism, a cross section test board, a full-automatic extensometer, a hydraumatic flat throw clamping apparatus and a recovery device, wherein the lofting device comprises a lofting tray used for placing samples; the material loading mechanical arm is used for clamping the samples from the lofting device so as to transfer the samples to the cross section test board through the propelling movement mechanism to measure or be transferred to the hydraumatic flat throw clamping apparatus; the main machine is used for stretching the samples clamped by the hydraumatic flat throw clamping apparatus; the full-automatic extensometer is used for measuring the deformation size of the samples; and the baiting mechanical arm is used for clamping the waste samples after testing so as to be transferred to the recovery device. The full-automatic tension testing machine provided by the invention can greatly promote test efficiency and can save labor cost.

Owner:MTS IND SYST CHINA

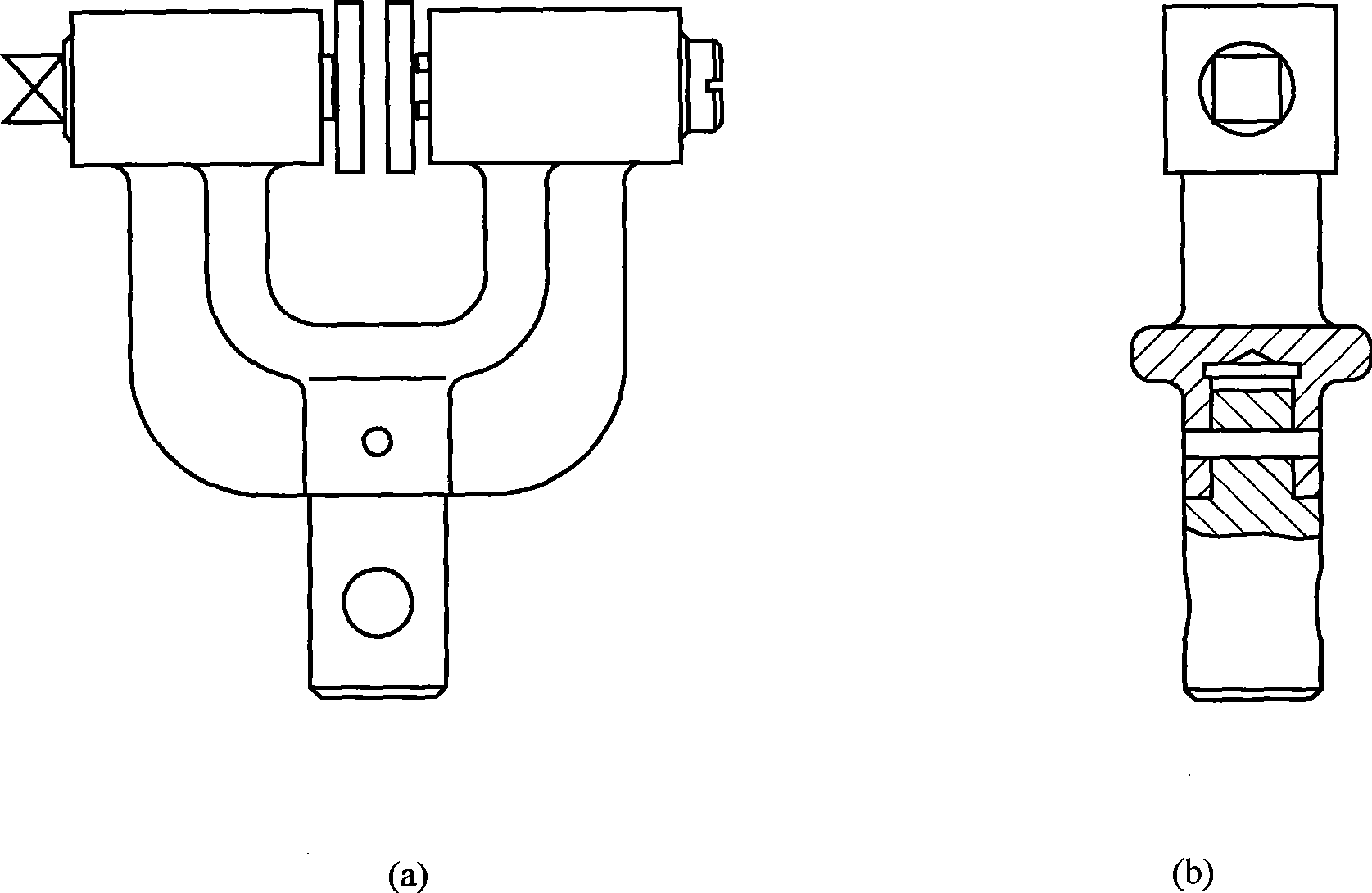

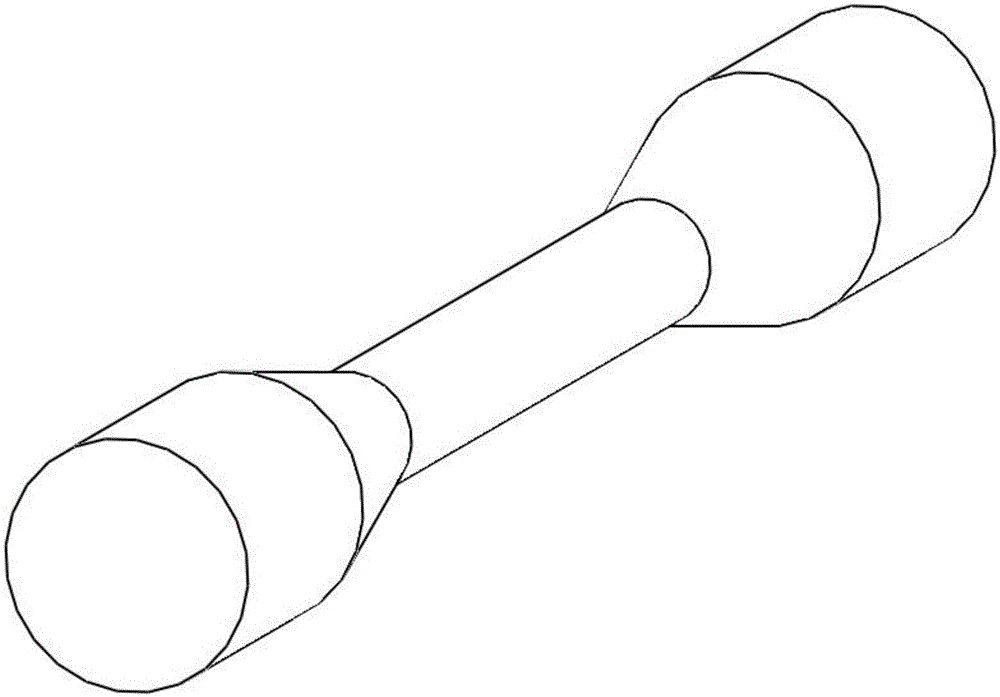

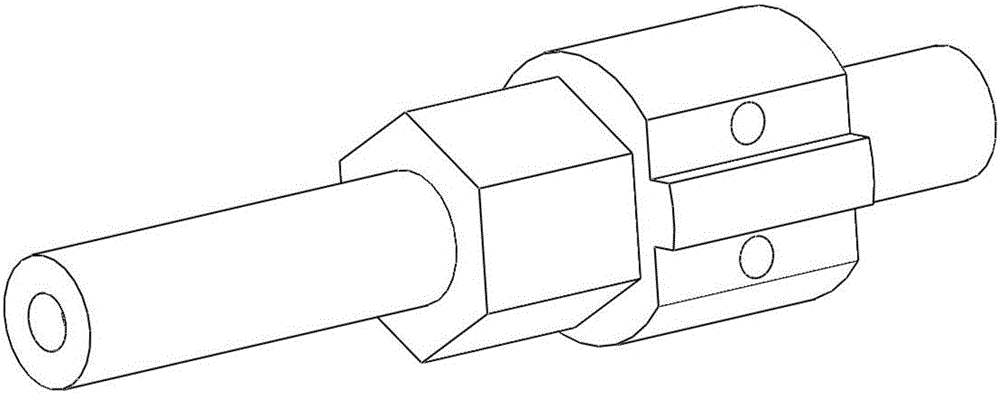

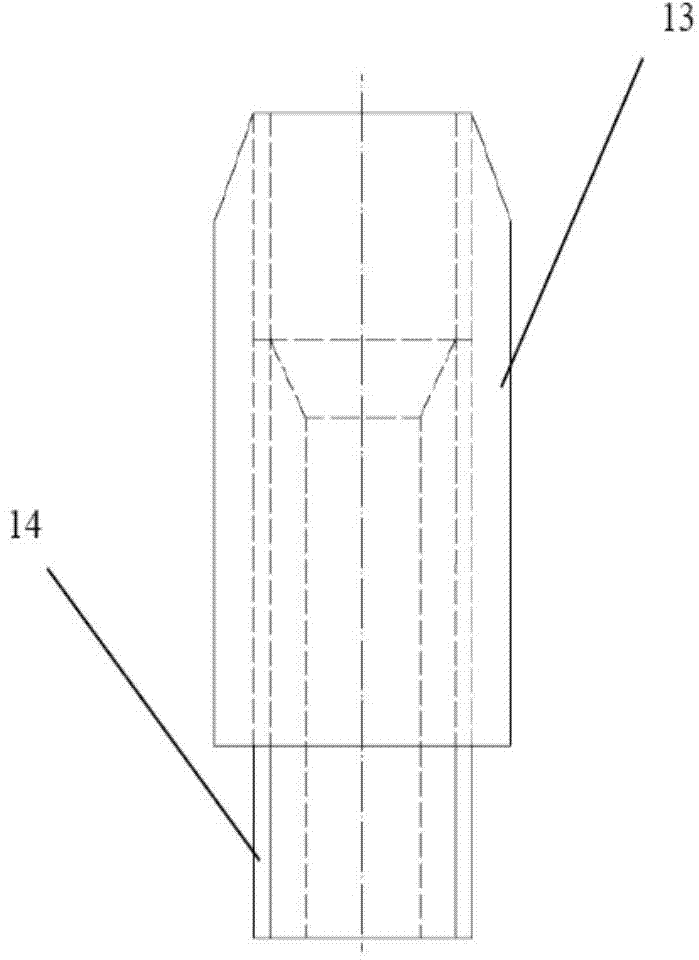

Testing machinery cellfiber clamper and method for measuring tensile strength

InactiveCN101251455AGuaranteed verticalityThe strain value is scientific and accurateMaterial strength using tensile/compressive forcesSingle fibreEngineering

The invention provides a tester single fibre clamp and a tensile strength measuring method relating to a clamp and tensile strength measurement. The invention provides a tester single fibre clamp and a method for measuring the tensile strength of ceramic single fibre. The clamp is provided with an upper collet device of a tester, a load sensor, a tenaculum device, an upper and lower clamping device, a horizontal adjusting device and a lower collet device of the tester. The adjusting clamp in proper alignment measures the load linearity in vertical direction and rectifies the focus of a photoelectric extensometer; the parameters of an measuring program are set; single fibre is put on the centerline of a hole of a square paper frame, then placed in the middle of the upper and lower clamping device; the vertical direction of the single-fibre is adjusted; the edge of the square paper frame is burned off; a strain collecting device is started to trace the edge distance between the upper and the lower paper frames; a tensile program is started up to begin the measurement; the relation between the load and the strain is recorded to obtain a fibre fracture load value and deformation data, thereby measuring a fibre strain value; a diameter value of a fracture is observed and input to the tester in order to acquire the fracture strength of the single fiber.

Owner:XIAMEN UNIV

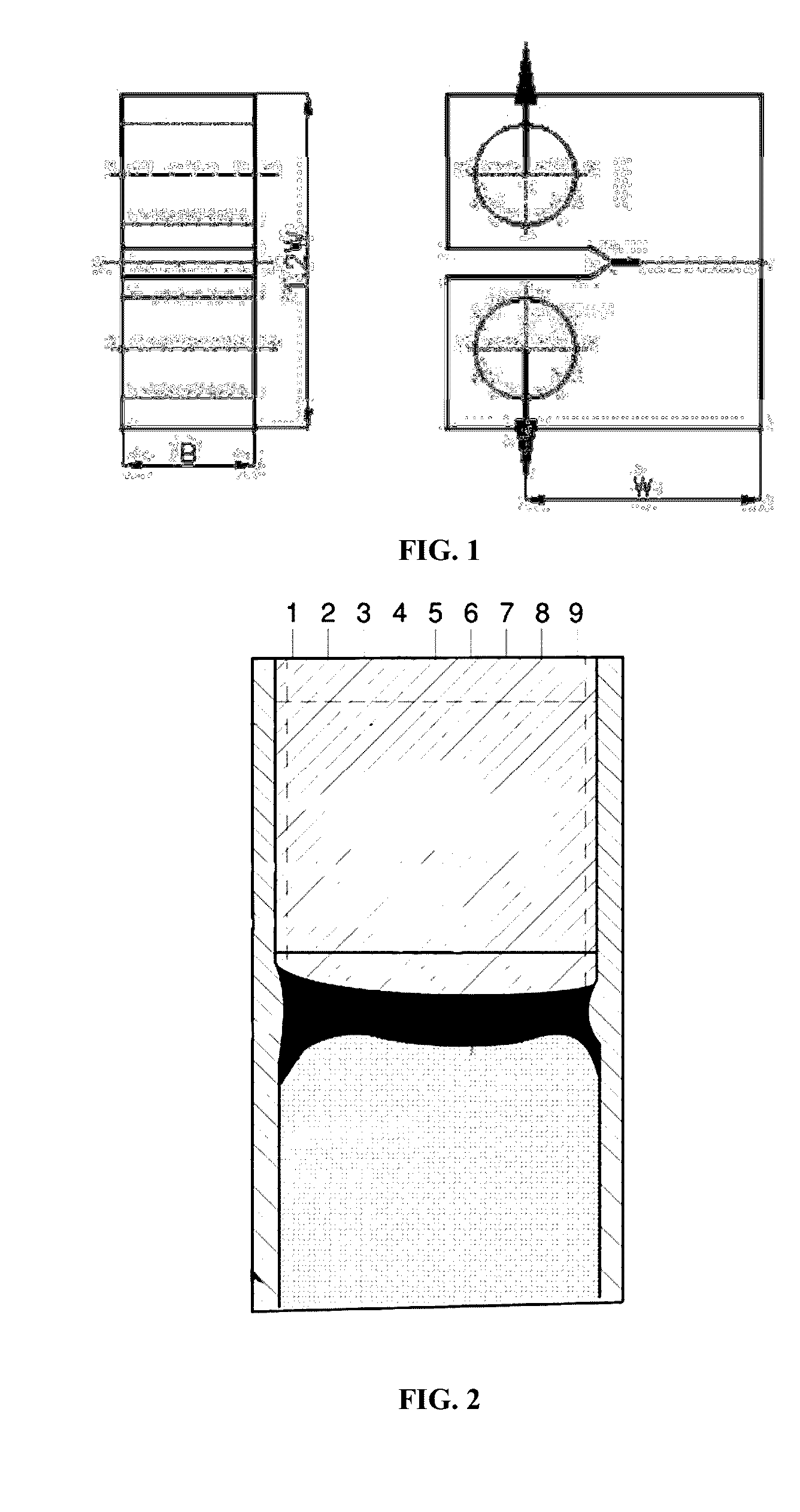

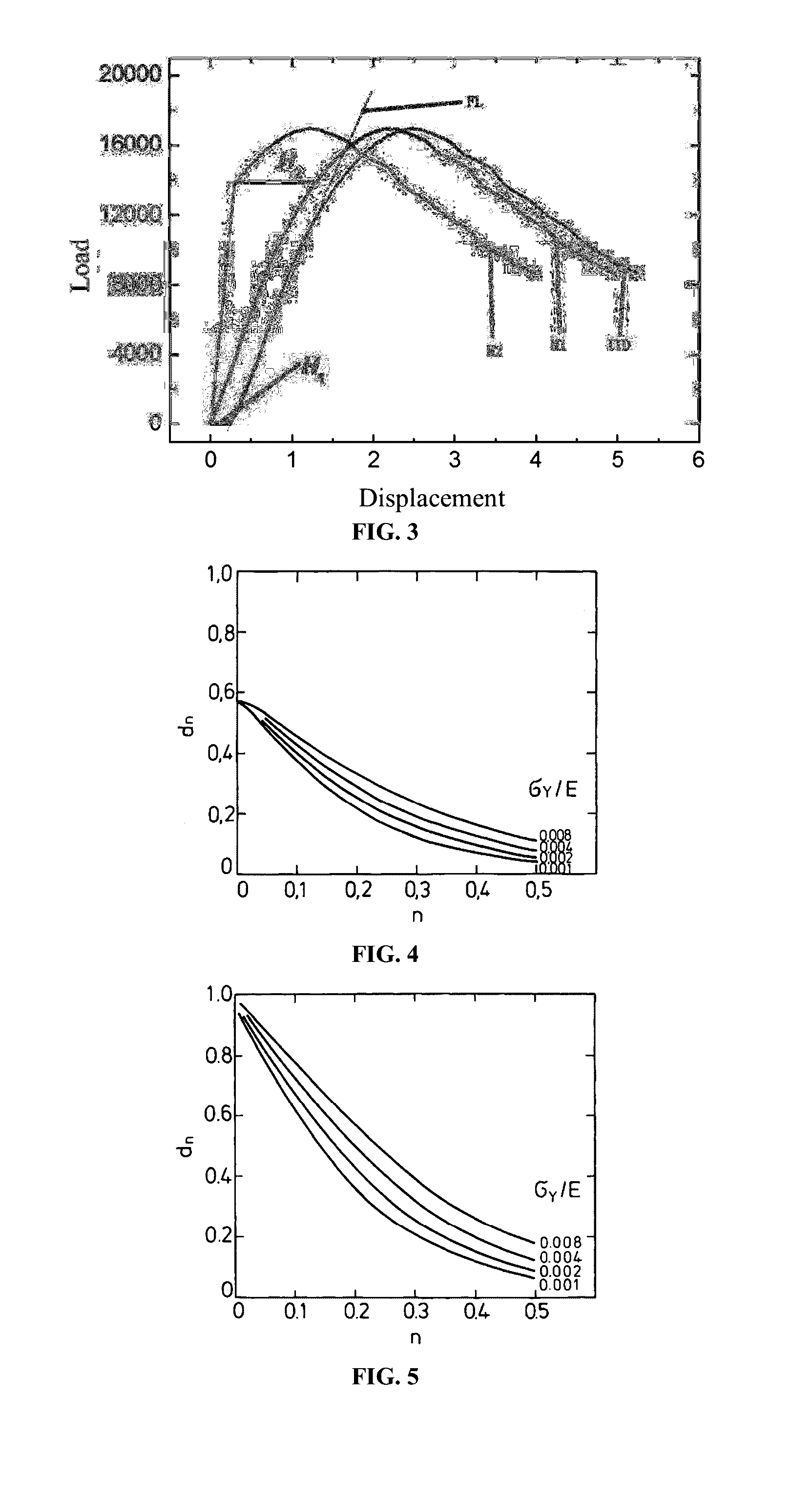

Test method for J-R resistance curve of high-toughness material

ActiveCN102353595AAvoid restrictionsMaterial strength using steady bending forcesMaterials testingLarge deformation

The invention relates to a test method for a J-R resistance curve of a high-toughness material. The method comprises the steps of sample processing, three point bending test, determination of crack length, calculation of J-integration at every load, establishment of a difference function, recursive calculation of crack length and p-V data pairs and construction of the J-R resistance curve. According to the invention, an extensometer is not employed for testing opening displacement and unloading flexibility of a crack mouth; instead, a testing machine is used for direct acquisition of deformation of a three point bending sample and a load-displacement curve in the whole process of fracture; then, the J-R resistance curve of the material is obtained through a series of calculation; therefore, the problem of restriction of testing apparatuses caused by large deformation of a sample in the testing of high-toughness materials is overcome, a J-R resistance curve in the situation of expandedlong size crack is measured, and the test method is applicable to measuring of J-R resistance curves of samples at different temperature and with different dimension.

Owner:EAST CHINA UNIV OF SCI & TECH

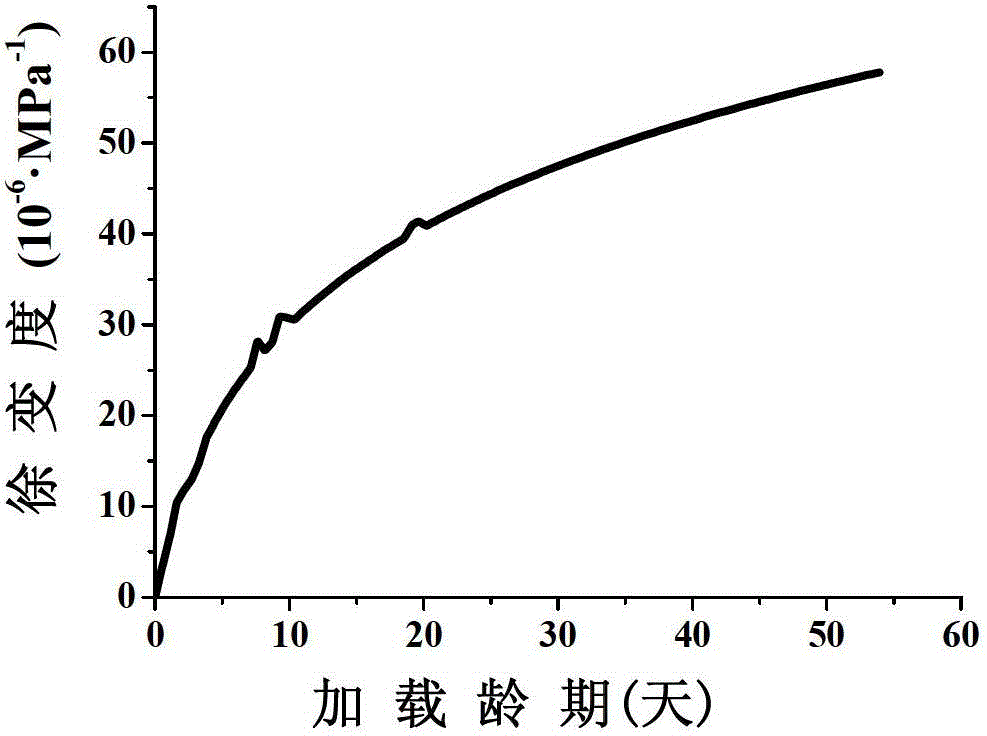

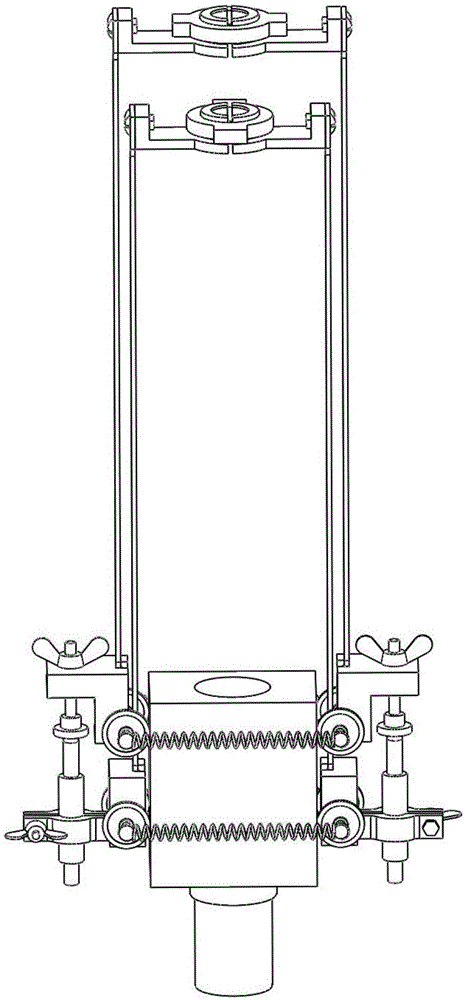

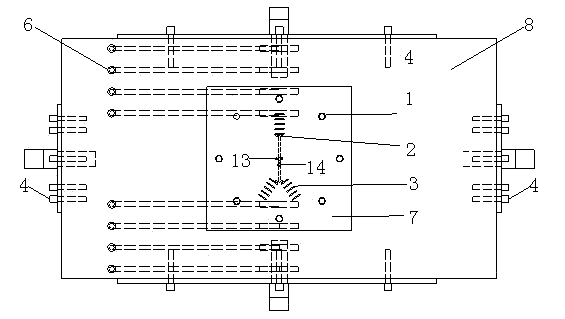

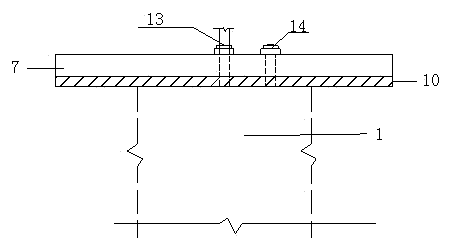

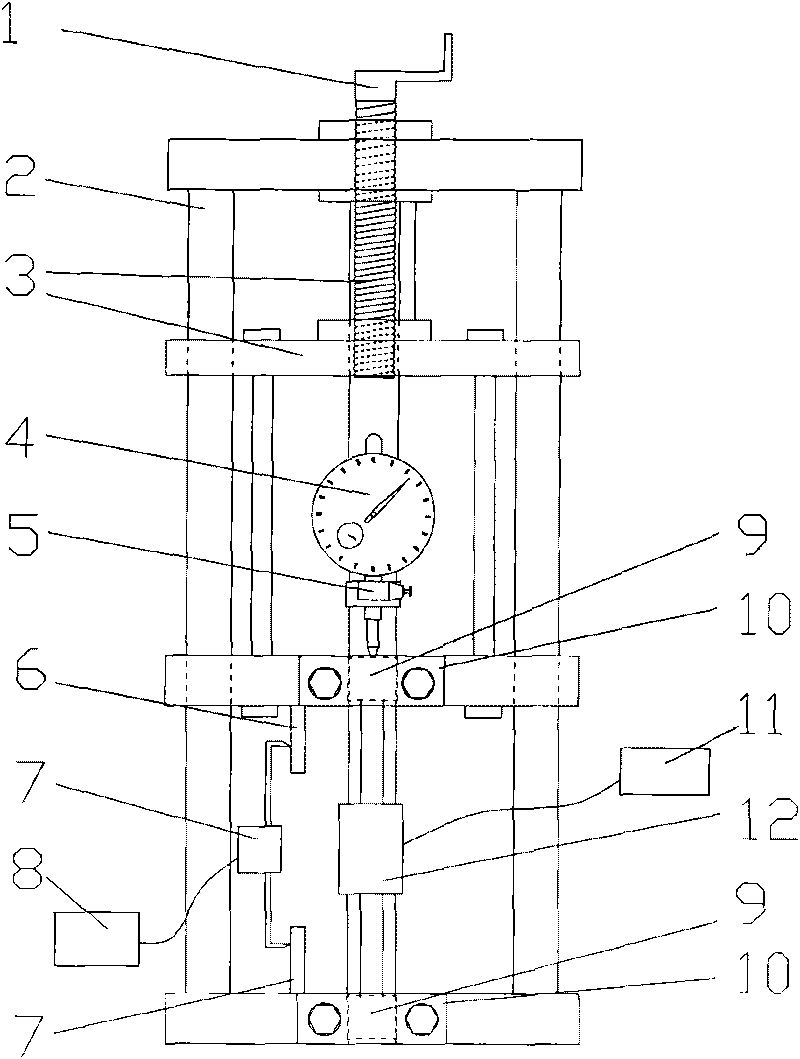

Concrete axis stretching creep tester and test method thereof

InactiveCN103149100AImprove continuityRealize acquisitionInvestigating material ductilityStress concentrationConstant stress

The invention discloses a concrete axis stretching creep tester and a test method thereof. The tester comprises an upper pulling plate, a lower pulling plate, pulling bars, screws, a spring, a stress sensor and vibrating string extensometers, the pulling bars are fixed on the lower pulling plate, and the upper ends of the pulling bars are provided with thread ends; the upper pulling plate traverses the upper ends of the pulling bars and is sleeved on the thread ends, and the thread ends at the upper and lower sides of the upper pulling plate are provided with nuts to fix the upper pulling plate; the upper and lower pulling plates are provided with the screws respectively and are used for the fixed connection of the upper and lower end of a concrete test piece, and the vibrating string extensometers are arranged at two sides of the concrete test piece; and the screw on the upper pulling plate stretches out of the upper pulling plate, the spring is sleeved on the stretching end of the screw, the stretching screw is also sequentially sleeved with a pad and a nut, and the stress sensor is arranged between the pad and the nut. The tester and the method realize the continuous automatic detection and acquisition of deformation; and no eccentricity, concentrated stress and constant stress are realized in the stretching process, so the test accuracy is improved.

Owner:SOUTHEAST UNIV

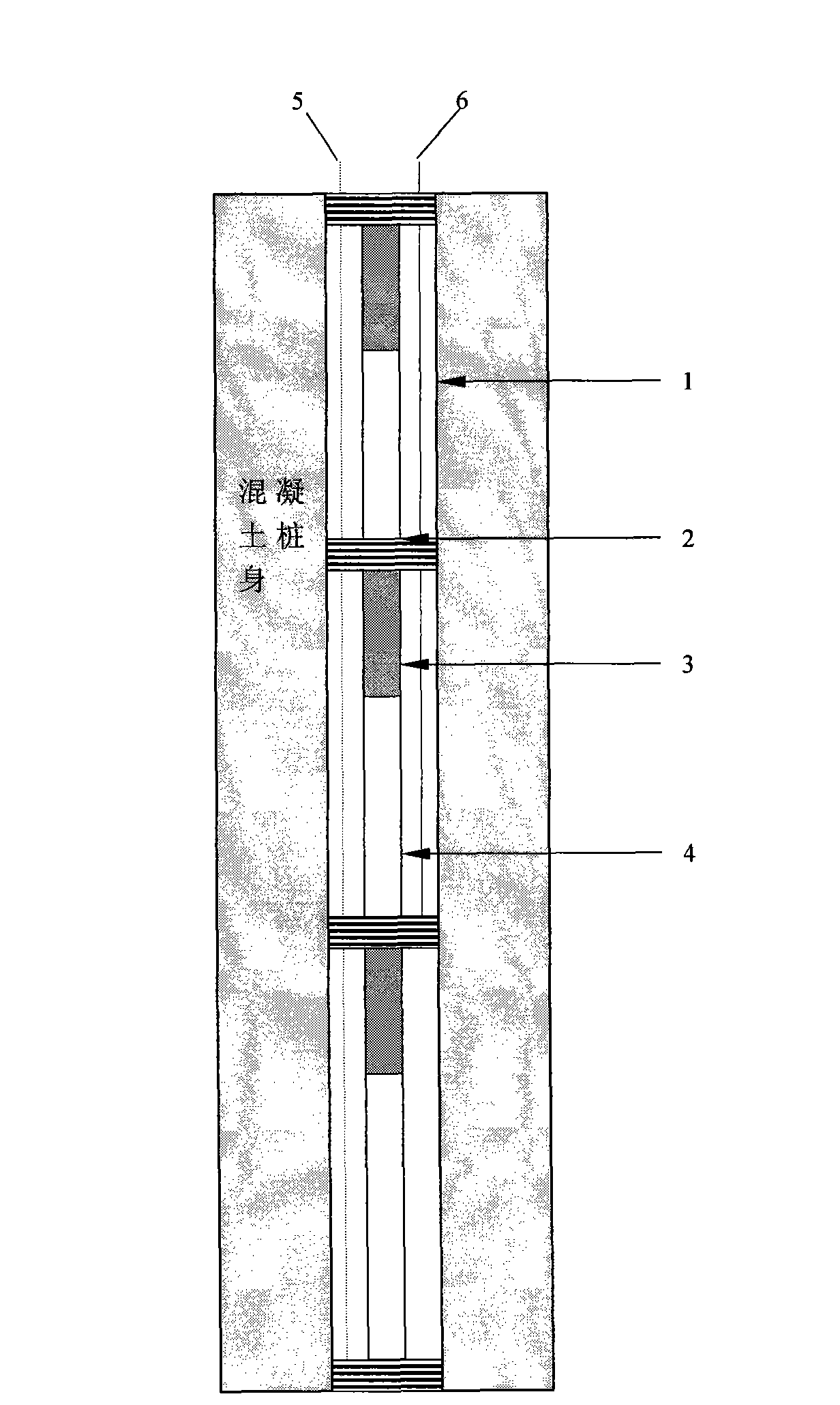

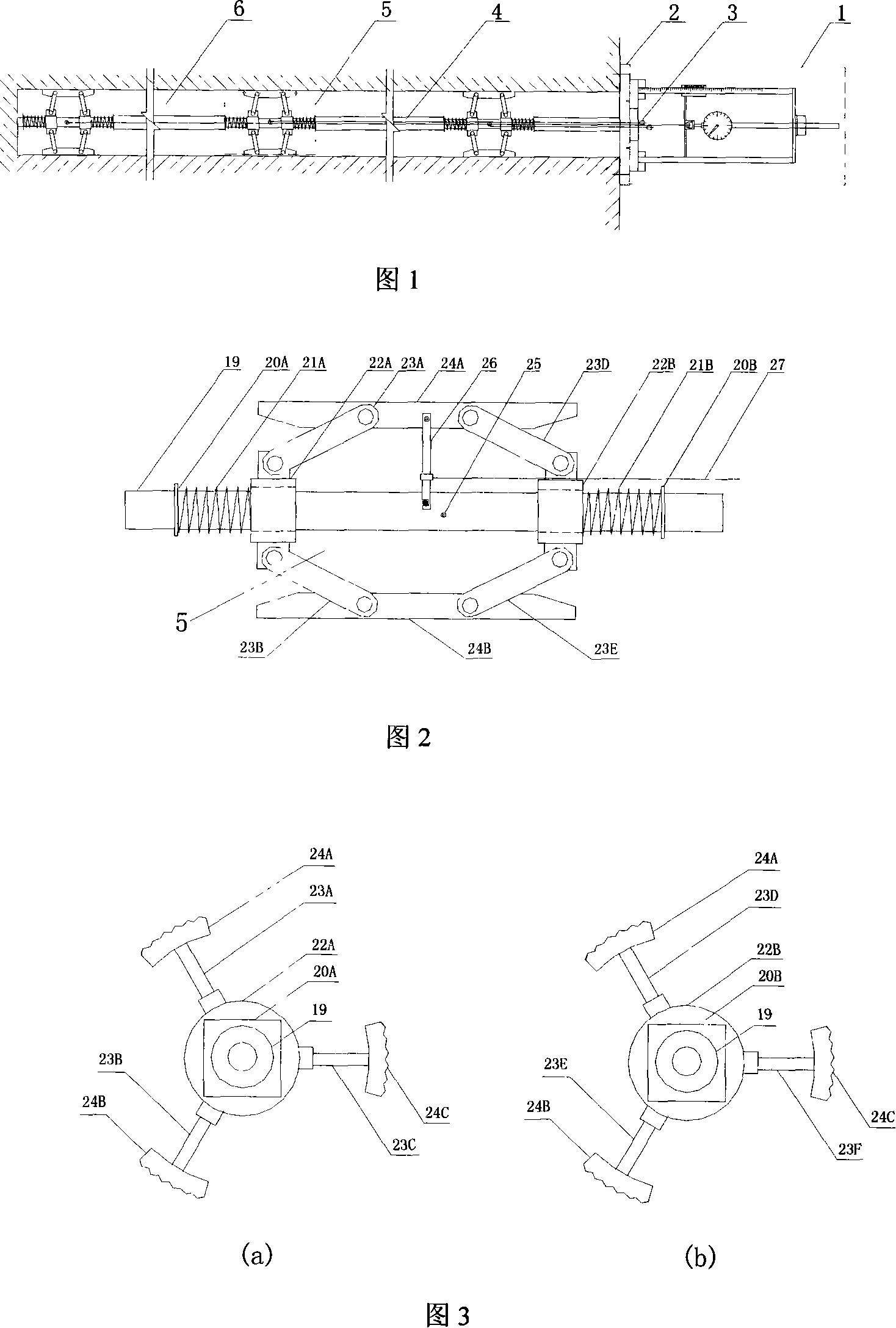

Method for measuring pile shaft internal force and cross section displacement in vertical dead-load test of foundation pile

InactiveCN101638902AResolve accuracyAddress reliabilityFoundation testingForce measurementRelative displacementVertical displacement

The invention belongs to the technical field of pile foundation quality detection in civil engineering, in particular to a method for measuring pile shaft internal force and cross section displacementin vertical dead-load test of a foundation pile. In the method, firstly, a casing is embedded on a pile shaft lengthways or holes are directly drilled on the pile shaft lengthways; a measuring systemis arranged in the casing or the drilling hole and is composed of an anchor head, a multiple position extensometer, an extension bar and a pressure pipe, wherein, the pressure pipe pressurizes to expand the anchor head so as to ensure that the anchor head is fixed in the casing or the drilling hole; after the anchor head is fixed, the multiple position extensometer measures vertical deformation between two adjacent anchor heads by the extension bar; according to a vertical displacement observation result and vertical deformation between two adjacent anchor heads, the layering frictional resistance of each soil layer, pile end supporting force and the vertical displacement of anchor head embedding cross section are calculated, and the relation of pile soil relative displacement and pile side frictional resistance is built so as to realize pile shaft internal force and cross section vertical displacement measurement. The invention has high test accuracy and favorable reliability, can replace traditional method using strain or string-wire sensors and displacement rods to measure pile shaft internal force and cross section vertical displacement.

Owner:高飞

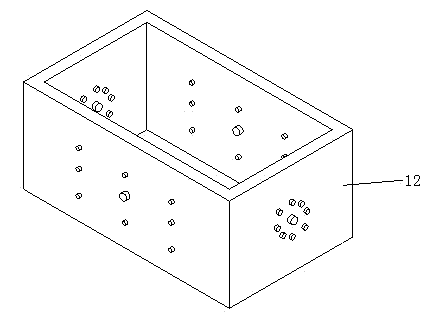

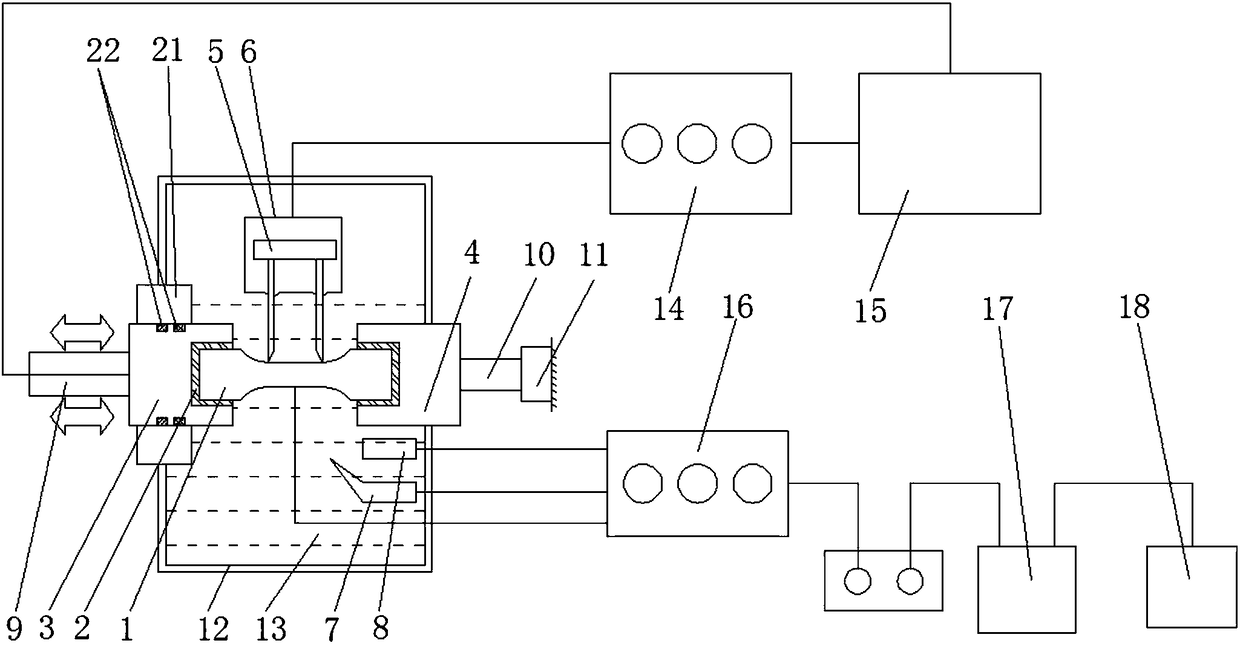

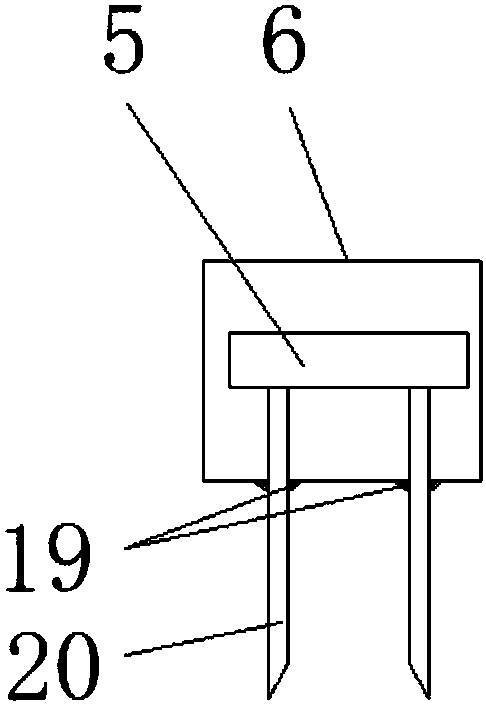

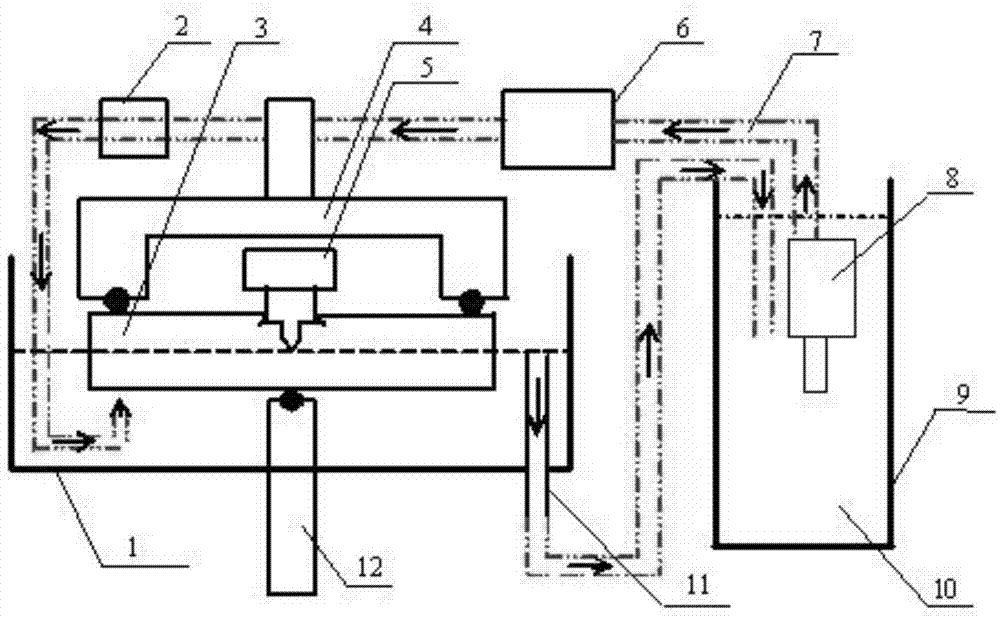

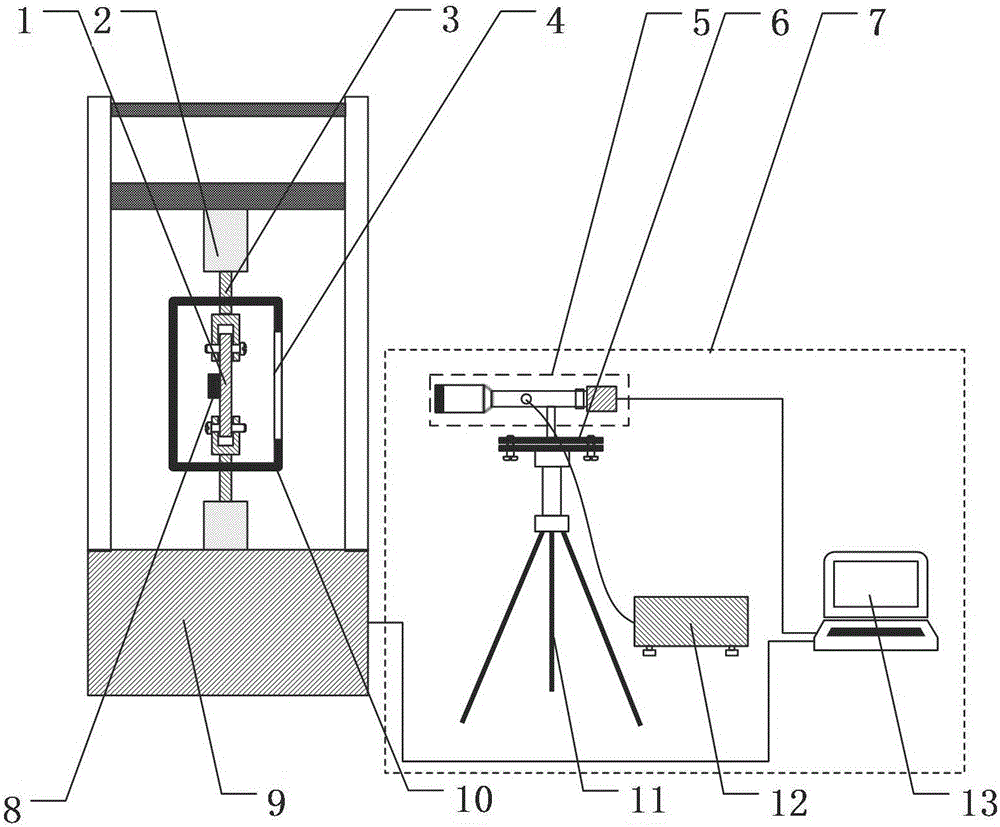

High-temperature creep fatigue test system

InactiveCN105021468AHigh measurement accuracyEasy to operateMaterial strength using tensile/compressive forcesEngineeringFatigue testing

A high-temperature creep fatigue test system, which consists of a fatigue testing machine, specimen holders, a high temperature furnace, a sample, a high temperature extensometer, a cooler and host computer. Upper and lower specimen holders are in threaded connection to ensure the uniform axial loading of the specimen; the specimen holders are connected to the fatigue testing machine; the high-temperature extensometer is connected with the specimen through a jaw; a high temperature furnace mounted on the fatigue testing machine moves to a corresponding position, and wraps the specimen inside; the cooler through inlet and outlet pipes is respectively connected to the upper and lower specimen holders; the fatigue testing machine and the high-temperature extensometer are connected to the host computer; the host computer by reading real-time measurement strain of the high-temperature extensometer controls the fatigue testing machine, so as to conduct strain-controlled high-temperature creep fatigue test. The present invention has the beneficial effects that deformation of the material in high-temperature creep fatigue test can be measured, and has the characteristics of easy operation and high measurement accuracy.

Owner:BEIHANG UNIV

Mechanical type multiple-point displacement gage

InactiveCN101105387AClose contactMeet measurement needsMechanical solid deformation measurementsIndiumMultiple point

The invention discloses a mechanical type multipoint extensometer, which comprises an orifice reading machine, an orifice reference plate, an indium wire, and an anchoring head for point measurement inside a pore. The orifice reference plate is fixed on the pore wall with an expansion bolt, a pilot pin at the bottom plate of the orifice reading machine is inserted into the locating hole in the orifice reference plate, the orifice reading machine is fixed in the orifice reference plate, one end of the indium wire is fixed on a fastening bolt of anchoring head for point measurement inside a pore, the other end of the indium wire is fixed passed through a center hole of the orifice reference plate and fixed on a conical clip with point measurement marks, and the conical clip with point measurement marks is connected with a conical hanger of the orifice reading machine. The invention has the advantages of simple structure, large measurement range, easy operation, rapid anchoring, and reliable performance; and is suitable for point measurement in a pore with different bore sizes.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

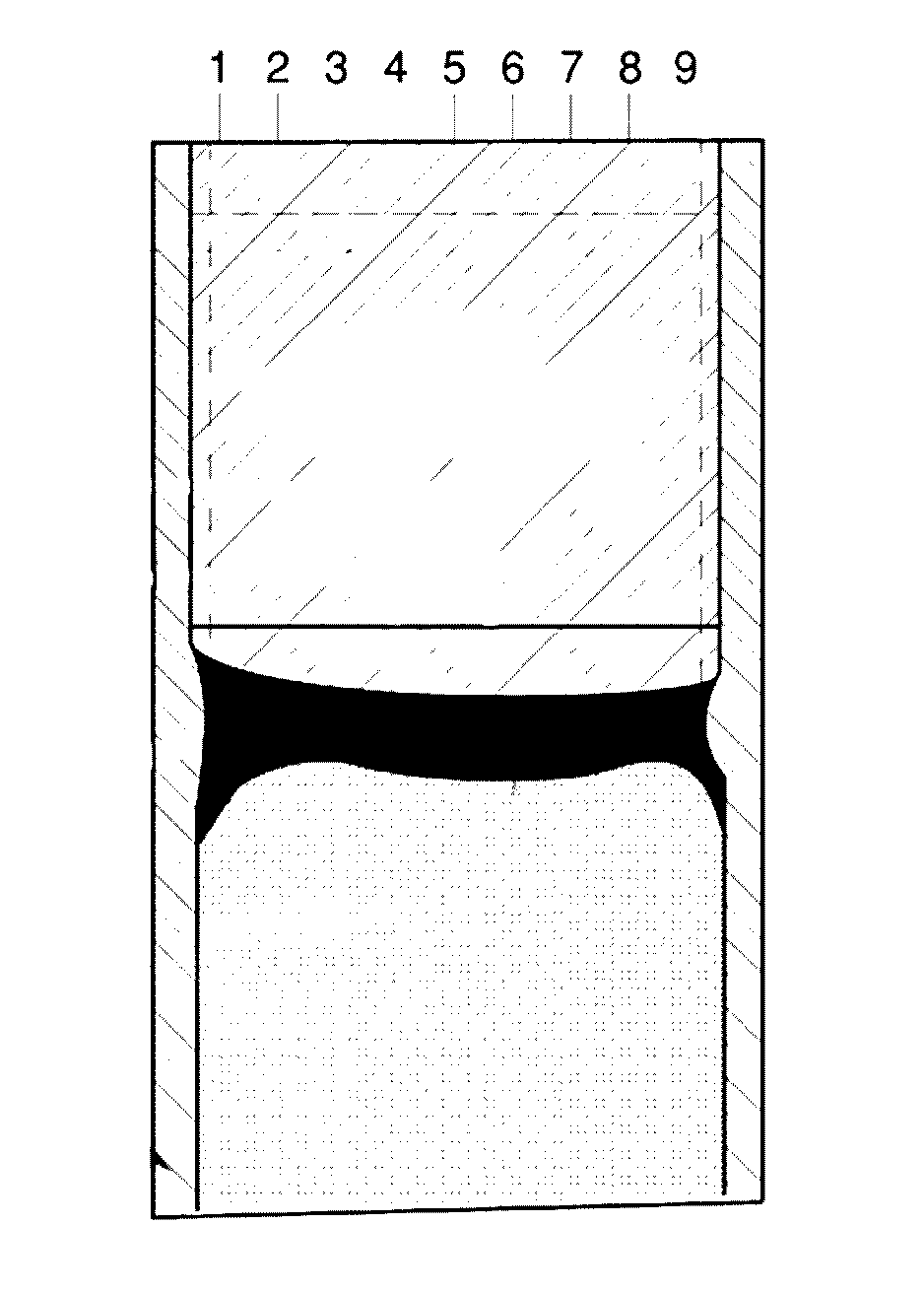

Simulated testing device for hydraulic fracture of concrete member under different stress conditions

ActiveCN103698218AConvenient pre-embeddedReal-time acquisitionPreparing sample for investigationMaterial strength using tensile/compressive forcesStructural waterHigh pressure water

The invention discloses a simulated testing device for the hydraulic fracture of a concrete member under different stress conditions, relating to the technical field of testing devices for the hydraulic fractures of concrete members. The simulated testing device comprises a cuboid die with an opening on one surface, wherein the die is filled with concrete to obtain the concrete member, the concrete member is internally provided with eight high-pressure-resistant water elbows in advance, and the tail end of each high-pressure-resistant water elbow is provided with a water pressure sensor connector; a steel sheet is pulled out of the concrete member to prefabricate an initial crack, a groove defined within a certain range is polished at the periphery of the crack, a strain gauge and a clip extensometer are arranged, and the groove is filled with waterproof insulating cement and ground to be flush; and the member is provided with a water seal steel sheet on which a water inlet and an exhaust port with a sealing cap are arranged. Based on the simulated testing device, the testing research for the hydraulic fracture of the concrete member can be realized under a different stress condition and different initial crack inclination angle condition combined condition.

Owner:HOHAI UNIV

Rock double linkage three axis rheogeniometer

InactiveCN101135622AImprove versatilityImprove reliabilityFlow propertiesUsing mechanical meansEngineeringTunnel wall

The invention comprises a pressure sensor, a displacement sensor servo system, an axial output oil cylinder piston, an axial servo loading system, a computer and a loading frame. The loading frame is connected to the pressure sensor; the pressure sensor is connected to the triaxial pressure chamber; the triaxial pressure chamber is connected to the metal piece; the triaxial pressure chamber is respectively connected to the loading frame and base; there is an axial spacer located in the triaxial pressure chamber; a lateral extensometer chain and a lateral extensometer clamp are mounted on the sample tunnel wall of the triaxial pressure chamber.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

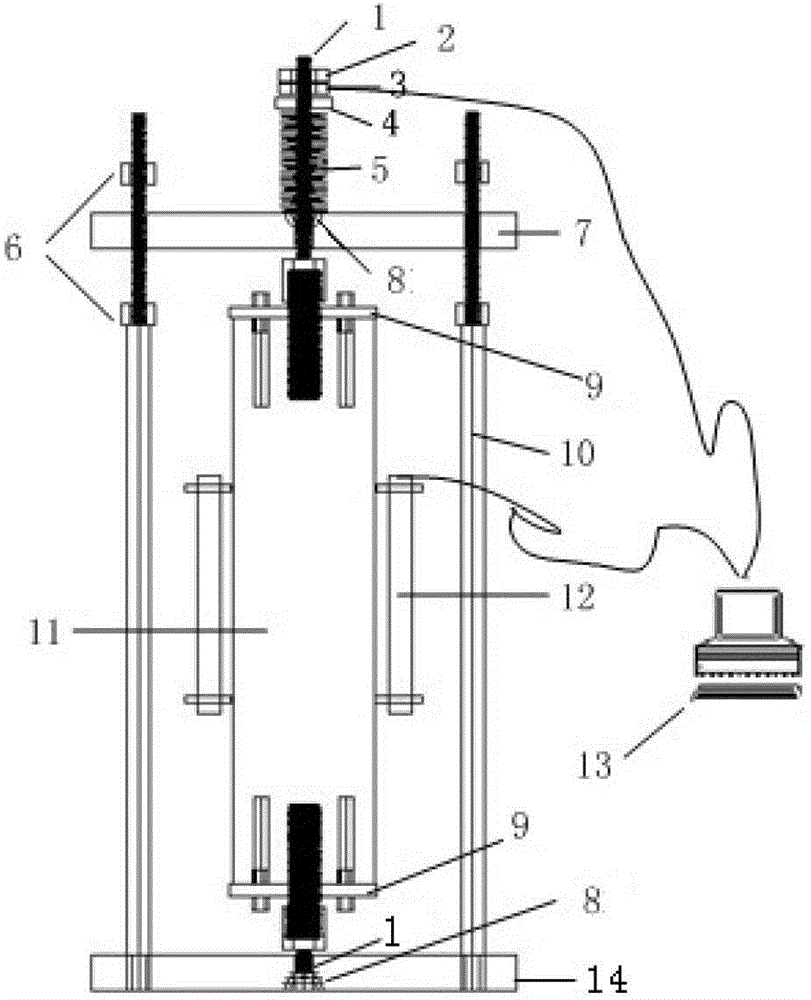

Creep deformation-fatigue crack growth testing device and corresponding testing method

InactiveCN103884603ACompact structureEasy to operateMaterial strength using tensile/compressive forcesCollection systemLength measurement

The invention relates to a creep deformation-fatigue crack growth testing device and a corresponding testing method. The device comprises a loading system, a temperature control system and a measurement and collection system, wherein the measurement and collection system comprises a load linear displacement measurement system and a crack length measurement system; the upper and lower ends of a test sample are fixedly connected with an upper clamp and a lower clamp respectively; a high temperature furnace is connected with the temperature control system and the measurement and collection system; the test sample is loaded by an alternating current servo motor and a controller. The invention further relates to the corresponding testing method. The testing device provided by the invention is compact in structure and convenient to operate; the testing device adopts an insulating chuck and the insulating chuck ensures that constant-current current passing through the test sample is stable; aiming at the test sample of a creep deformation-fatigue crack growth test, the clamps are designed and machined; the temperature in the furnace is high so that a high-temperature clamping type extensometer is used for introducing load linear displacement out of a heating furnace to be measured. The testing method is simple and convenient to operate; the crack length is measured by using an electric potential method and the continuous test can be carried out for long time.

Owner:EAST CHINA UNIV OF SCI & TECH

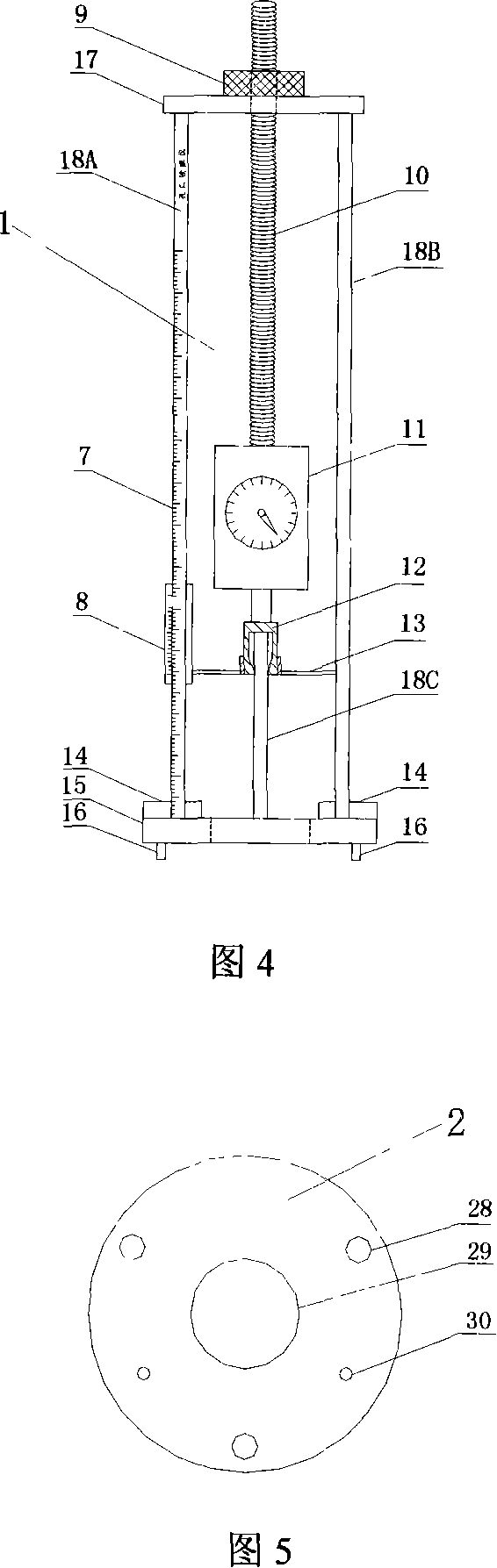

Calibrating device for vibrating string type strain transducer

InactiveCN101738157AImprove measurement accuracyHigh calibration measurement accuracyMechanical solid deformation measurementsTransducerFrequency meter

The invention discloses a calibrating device for a vibrating string type strain transducer. Mounting blocks at two ends of the vibrating string type strain transducer are sleeved on a fixed lantern ring, the lantern ring is arranged on a bracket through a locking piece, a spinodal handle is connected with a dial gauge through a threaded differential fine tuning mechanism, the dial gauge is arranged on a gauge stand, and two ends of the gauge stand are connected with the threaded differential fine tuning mechanism and the vibrating string type strain transducer respectively; the number of measuring bars is two, the two measuring bars are fixed at the upper and lower ends of a bracket respectively, two ends of an extensometer are connected with the two measuring bars respectively, the extensometer is connected with a measuring indicator, and the extensometer is positioned on one side of the vibrating string type strain transducer; and a frequency meter is connected with the vibrating string type strain transducer. Based on the differential thread transmission principle, the calibrating device realizes the function of rotary fine tuning movement, has high measurement accuracy, realizes wide-range measurement, is simple to operate, calibrates the vibrating string type strain transducer through simulation, and is applicable to the metering calibration for various graded places.

Owner:SOUTH CHINA UNIV OF TECH

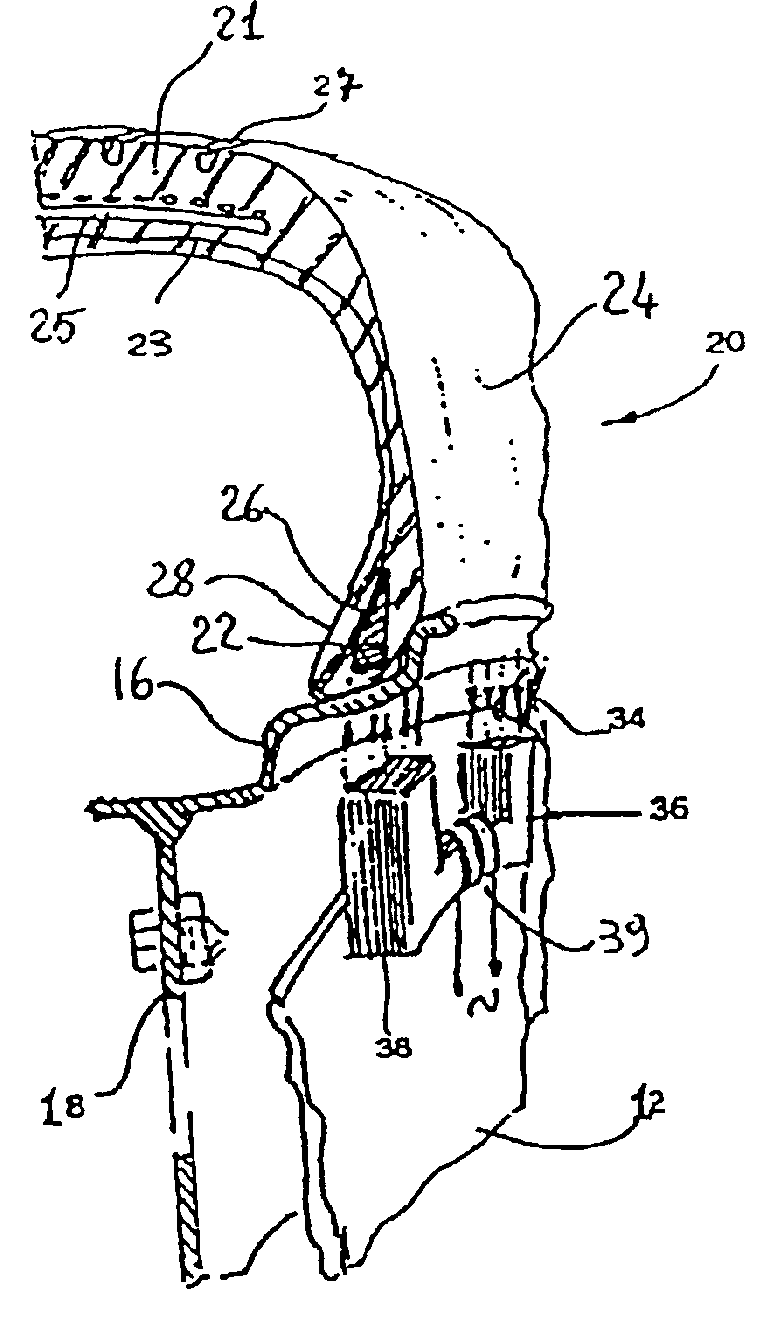

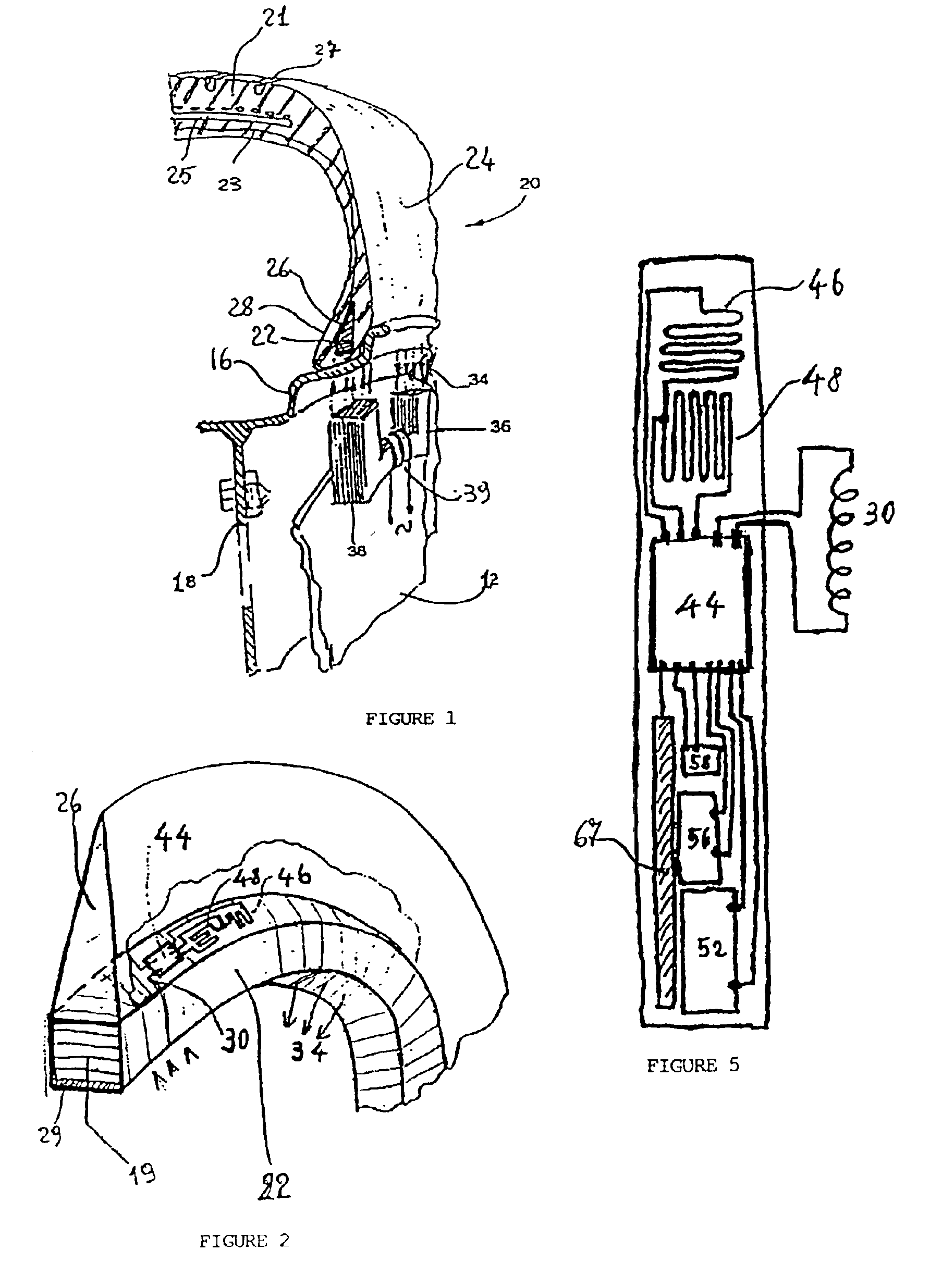

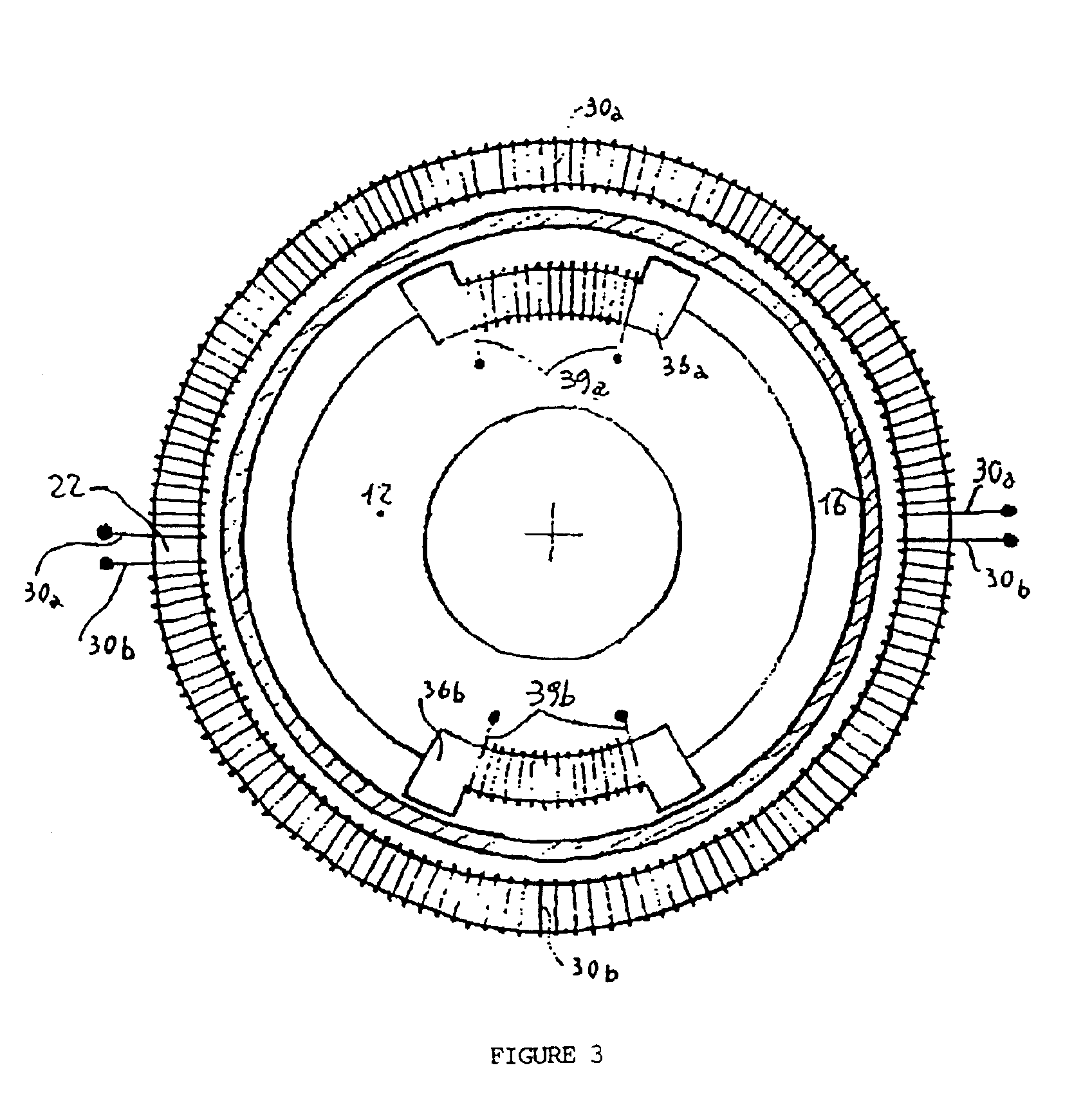

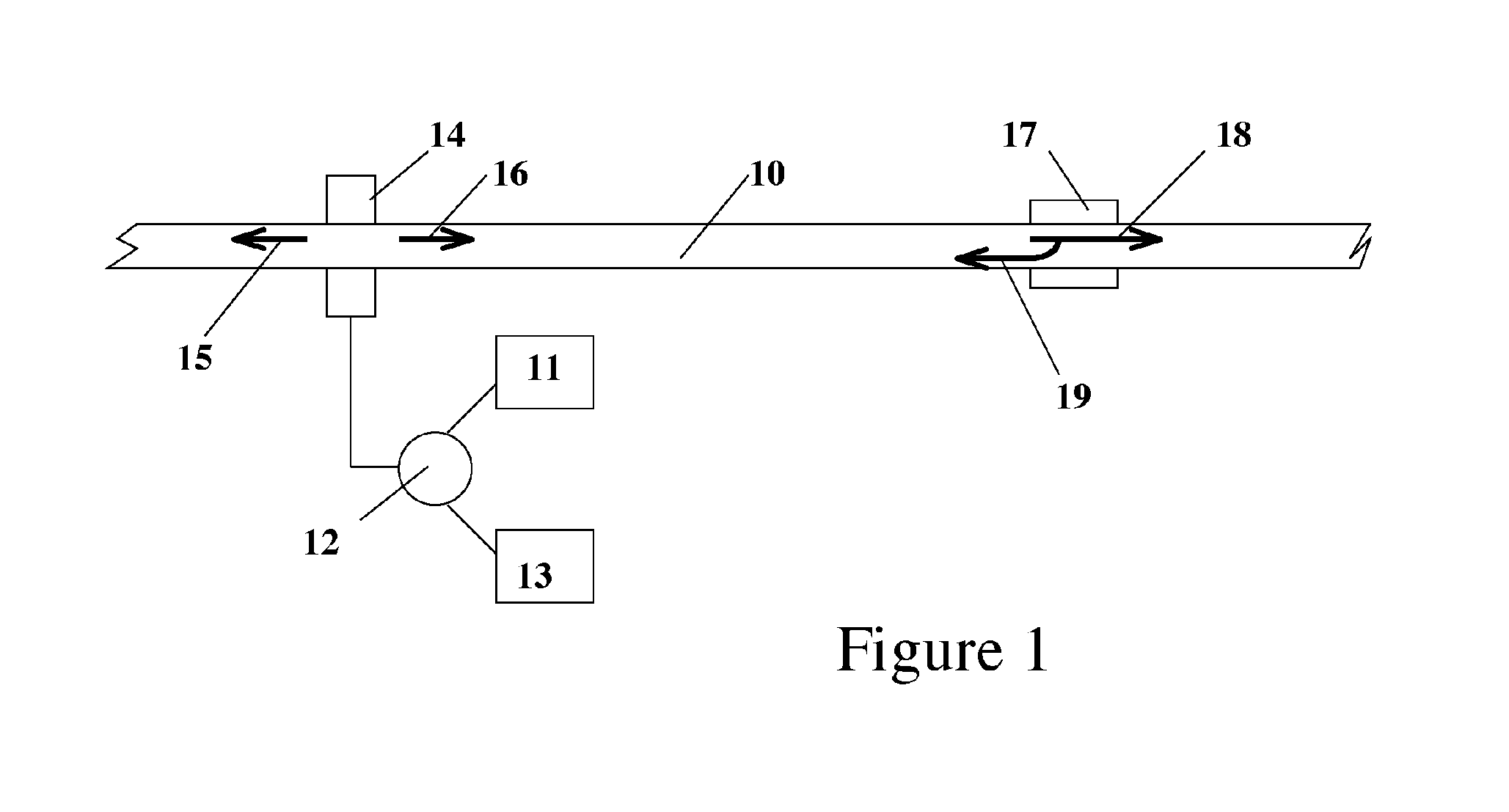

Method for generating an electric current within a tire

A method for generating an electric current within a tyre includes the step of including a variable magnetic field in at least one winding. The tire includes at least one bead core and the at least one winding. The at least one winding includes at least one turn wound around the at least one bead core. The electric current may power one or more electronic devices. The one or more electronic devices may include means for sensing one or more parameters associated with the tire, such as temperature sensors, pressure sensors, or a pair of extensometers orientated perpendicularly to each other to sense deformations of the at least one bead core. The at least one winding may form at least part of a first inductive element associated with and movable with respect to at least one second inductive element to form an electrical generator.

Owner:PIRELLI TYRE SPA

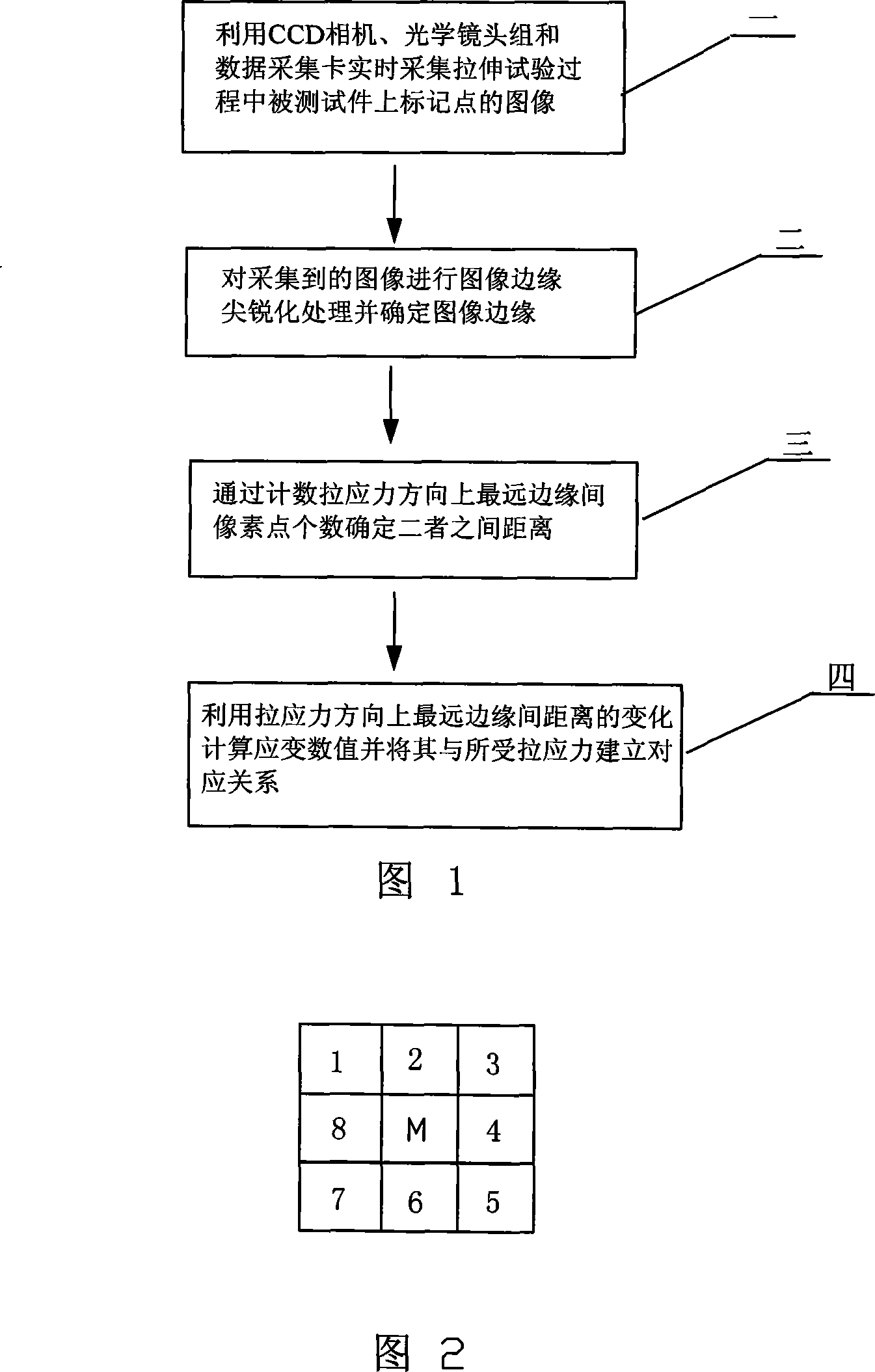

Non-contact type strain measurement method based on visual discrimination

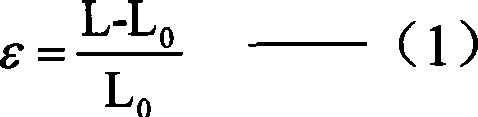

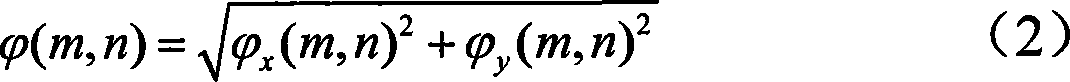

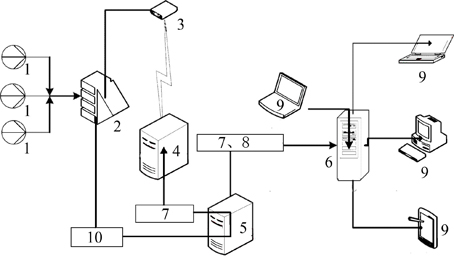

InactiveCN101196390AHigh resolutionHigh sensitivityImage enhancementUsing optical meansVision basedContact type

A non-contact strain measuring method based on visual discrimination is provided, which relates to the strain measuring method of miniature device. The invention overcomes the defect that using the traditional contact extensometer or strain foil is unable to measure the tensile property of miniature device and is easy to damage the test piece. Firstly, use CCD camera, optical lens set and data collecting card to collect the image of the mark on the tested piece during tension test process; secondly, conduct quickness processing to the edge of the collected image; thirdly, fix the distance between two points according to the quantity of pixels in the furthest edge in the direction of tension force; fourthly, utilize the change of the distance in the furthest edge in the direction of tension force to count the strain value and build corresponding relationship with the received tension. The invention can precisely measure the strain in the single-direction tension test of miniature device or micro-forming material, which has the advantages of no abrasion, strong anti-interference performance and high precision.

Owner:HARBIN INST OF TECH

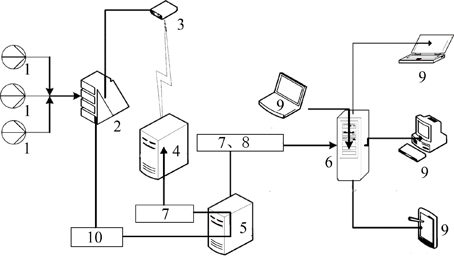

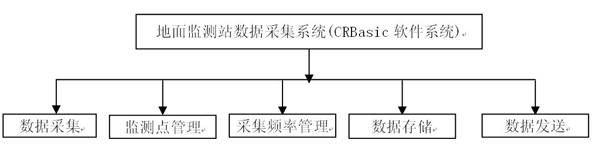

Ground sedimentation monitoring system

ActiveCN101813478AAccurate land subsidence monitoring dataMake up cycleNetwork topologiesSurveying instrumentsData acquisitionSedimentation

The invention relates to the technical field of geological condition monitoring, in particular to a ground sedimentation monitoring system which comprises a plurality of sensors, a programmed data acquisition unit and a data acquisition processing server. The sensors are arranged in a borehole extensometer and a water level well. A star topology structure consists of the sensors and the data acquisition unit, and the data acquisition processing server establishes connection with the data acquisition unit. The ground sedimentation monitoring system is characterized in that the data acquisition unit is connected with a CDMA (Code Division Multiple Access)module which is connected with a fixed IP server by a CDMA network, the fixed IP server is connected with a communication port of the data acquisition processing server by an LAN (Local Area Network), unique code corresponding to a placing area is stored in each sensor, and the data acquisition processing server is internally provided with an item table for recording and setting the code information corresponding to sensor codes. The invention has the advantages of acquiring ground sedimentation monitoring data in real time with high efficiency and overcoming the defects of long period and less data of manual monitoring.

Owner:上海市地质调查研究院 +1

Device and method for testing dynamic hydrogen brittleness of metal material under constant strain amplitude

InactiveCN108548736AAccurate detectionAvoid corrosionMaterial strength using repeated/pulsating forcesElectricityHydrogen

Owner:武汉钢铁有限公司

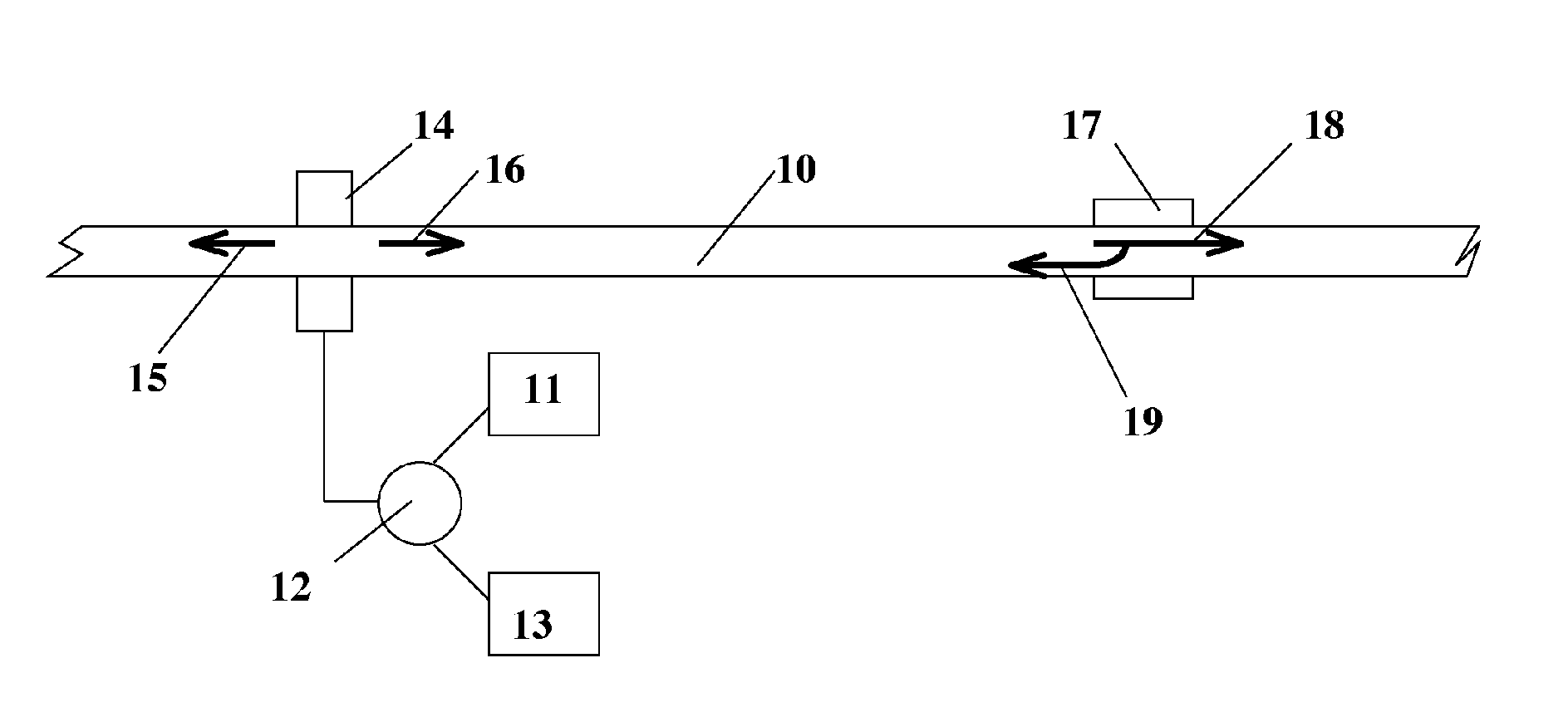

Device for testing fatigue crack growth rate of metal material in aqueous corrosive medium

InactiveCN103487339ASolve corrosionRealize automatic measurementMaterial strength using repeated/pulsating forcesMetallic materialsEngineering

The invention aims to provide a device for testing a fatigue crack growth rate of a metal material in an aqueous corrosive medium. The device comprises a liquid storage container, a test container and a fatigue testing machine, wherein the liquid storage container is filled with a corrosive solution for testing, the corrosive solution sequentially flows through a rust filtering device and a temperature controller through a water supply hose to be communicated with the test container, an upper pressure head and a lower pressure head are mounted on the fatigue testing machine respectively, a test piece is clamped between the upper pressure head and the lower pressure head and placed in the test container, the upper pressure head has two loading points matched with the upper surface of the test piece, the lower pressure head has one loading point matched with the lower surface of the test piece, an extensometer is mounted in a crack opening of the test piece and connected with the fatigue testing machine, an overflow pipe is arranged in the test container and communicated with the corrosive solution in the liquid storage container through the water returning hose. The device can completely protect the extensometer and the fatigue testing machine from being corroded by the corrosive solution, the labor intensity can be reduced, and the testing accuracy of a fatigue crack length can be improved.

Owner:HARBIN ENG UNIV

Temperature sensor and extensometer

InactiveUS7575371B1Low powerStatic/dynamic balance measurementMagnetic property measurementsPower cableElectrical conductor

A thermometer and extensometer for cables and conductors is described. The travel time of one or more acoustic signals along a conductor is used to determine the temperature along the conductor and the length of the conductor. The acoustic frequency is selected to minimize temporal dispersion of the propagating acoustic energy. The technique can be used to measure the temperature and sag of an overhead power line, the temperature of the windings in a transformer, or the temperature of the central conductor in a coaxial power cable.

Owner:FIELDMETRICS

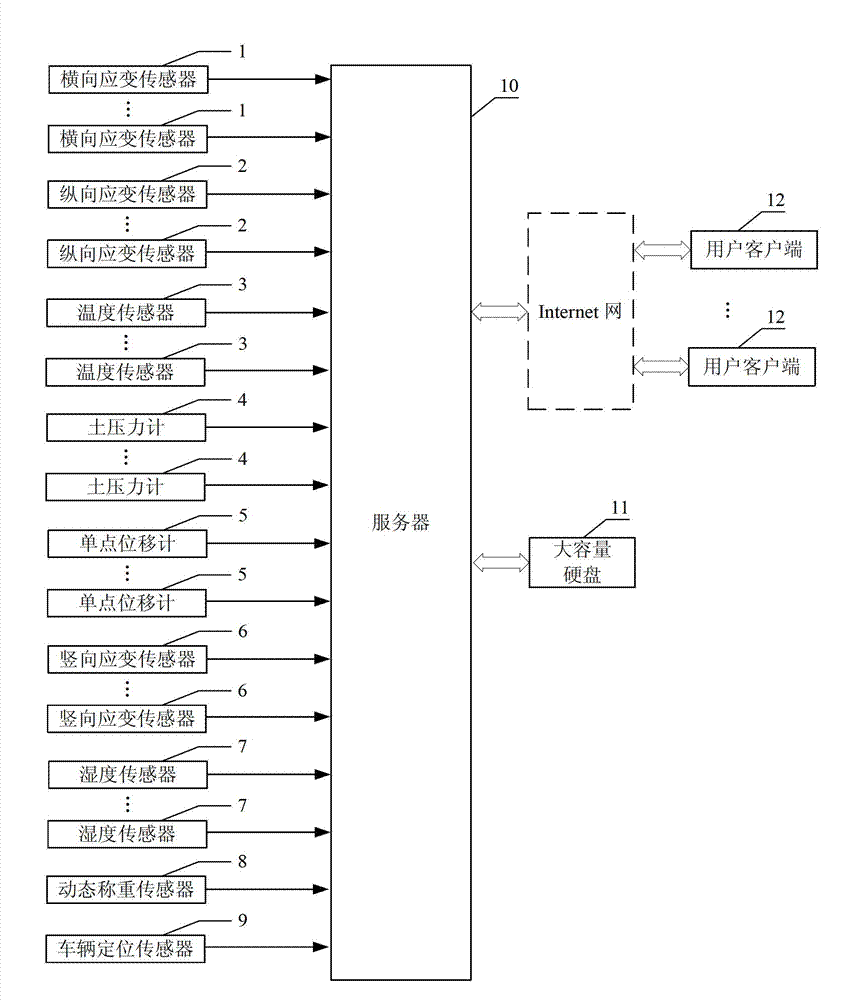

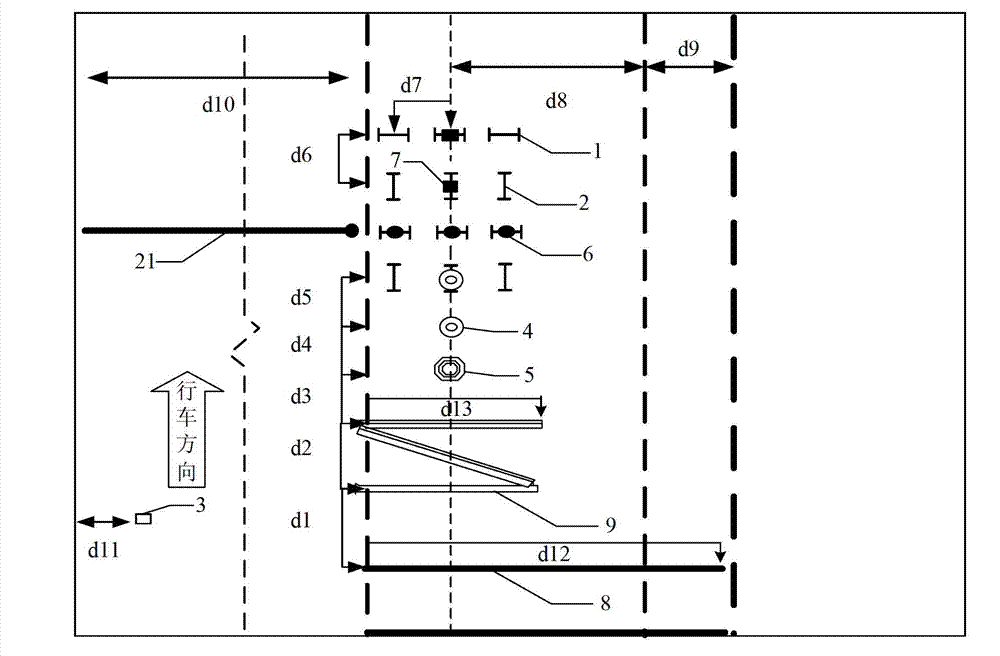

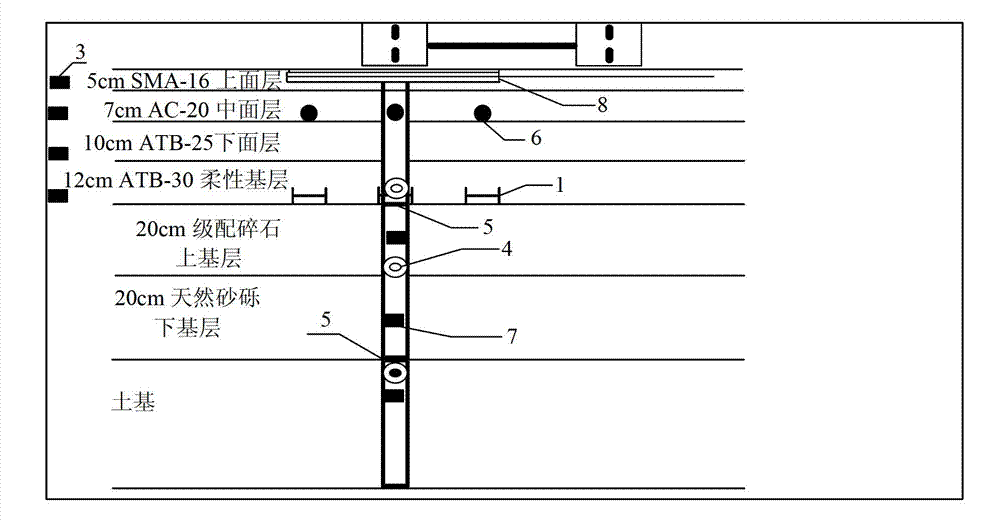

Long-term real-time monitoring system for asphalt pavement structure information based on optical fiber Bragg grating sensor

InactiveCN102900011ARealize evaluationRealize the estimateEmbedding padsRoads maintainenceGratingRoad surface

The invention discloses a long-term real-time monitoring system for asphalt pavement structure information based on an optical fiber Bragg grating sensor and relates to a long-term real-time monitoring system for the asphalt pavement structure information. The long-term real-time monitoring system meets the requirement of long-term real-time monitoring of the asphalt pavement structure information. Various data of the asphalt pavement are acquired by adopting A transverse strain sensors, B longitudinal strain sensors, C temperature sensors, D earth pressure gauges, E single point extensometers, F vertical strain sensors, G humidity sensors, a dynamic weighing sensor and a shaft position sensor and are processed by a server, and thus the long-term real-time monitoring on the asphalt pavement structure information is realized. The long-term real-time monitoring system disclosed by the invention is suitable for long-term real-time monitoring of the asphalt pavement structure information.

Owner:HARBIN INST OF TECH

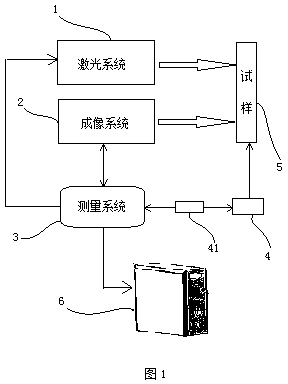

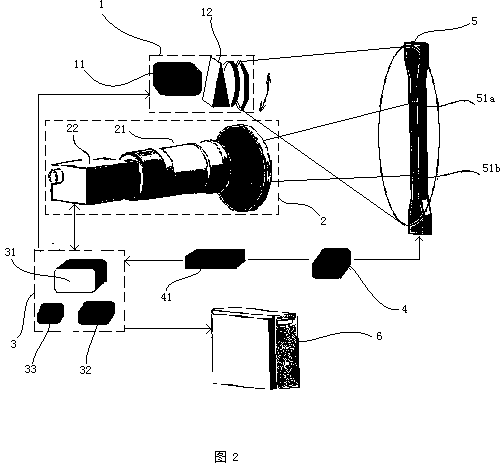

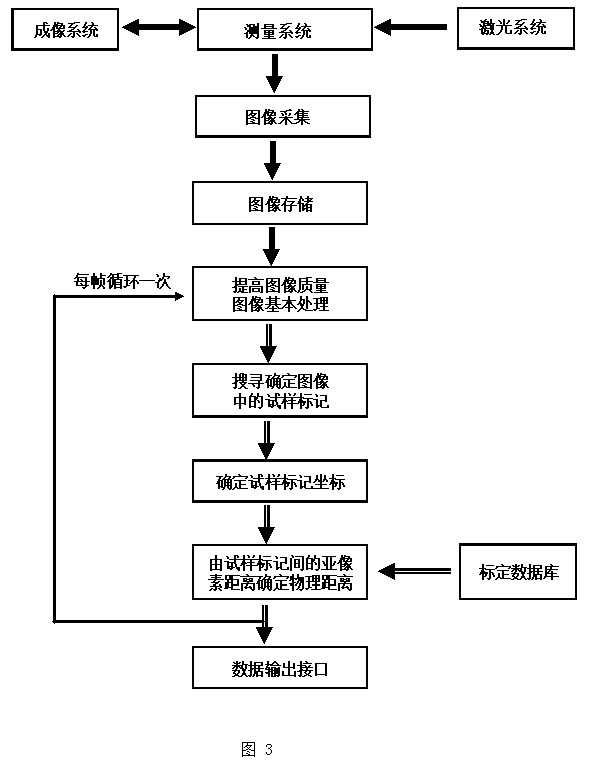

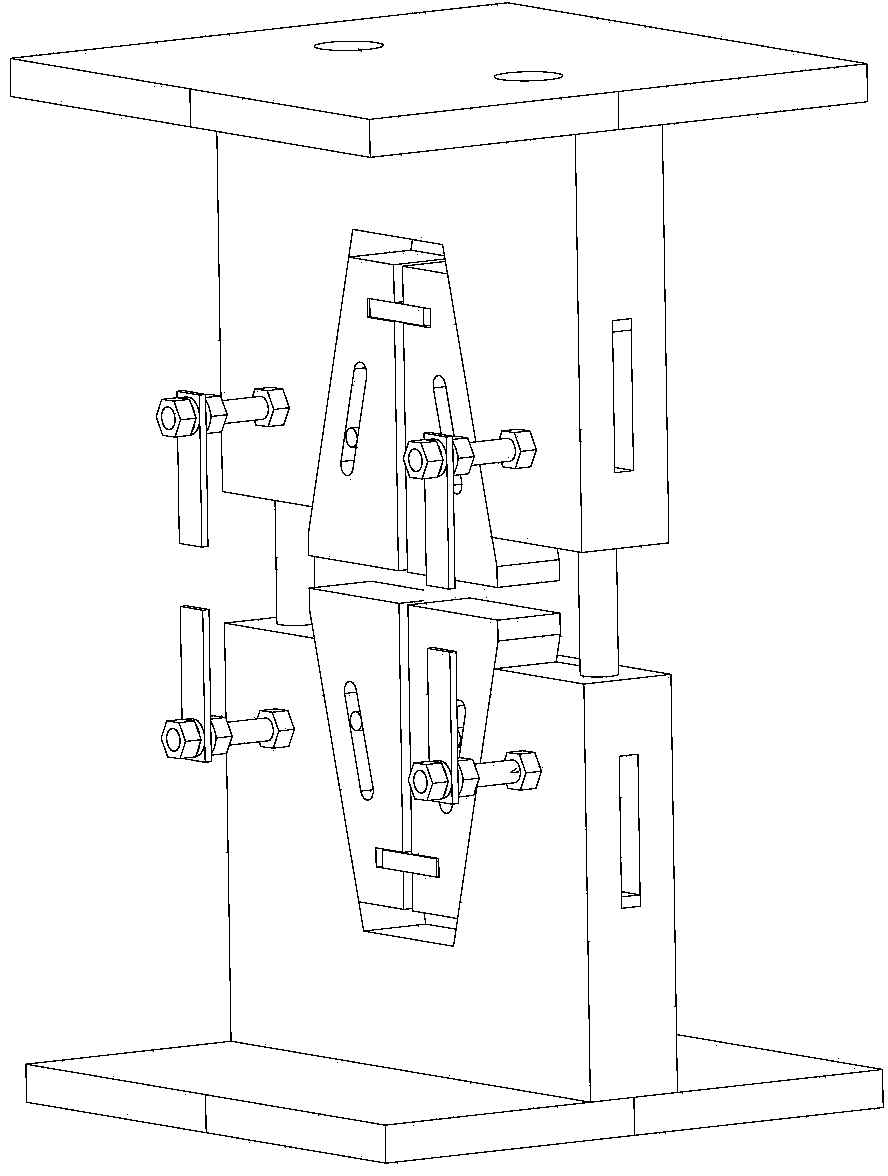

Extensometer and measuring method thereof

ActiveCN103760025AAdd test functionThe force measurement process is convenientMaterial strength using tensile/compressive forcesUsing optical meansTest sampleEngineering

The invention relates to an extensometer and a measuring method thereof. The extensometer structurally comprises a laser system, an imaging system and a measuring system, wherein the laser system is used for generating laser to irradiate on a test sample on a testing machine bench; the imaging system is used for collecting an image of the test sample; the measuring system is used for testing image collecting control and image signal processing to obtain measurement data and outputs the data; the measuring system is connected with the laser system and the imaging system. The invention further provides a measuring method of the extensometer, which comprises the following steps: setting the sample; adjusting the laser system; adjusting the imaging system; testing; measuring. The extensometer adopts the integrated design of the laser system and the imaging system, and has the advantages of compact structure, multifunction, high precision and good environmental adaptability; the measuring method disclosed by the invention has the advantages of simplicity in method, precise measurement and multifunction, can easily measure dynamic and static parameters of the to-be-tested sample, and greatly improves the testing efficiency.

Owner:深圳三思纵横科技股份有限公司

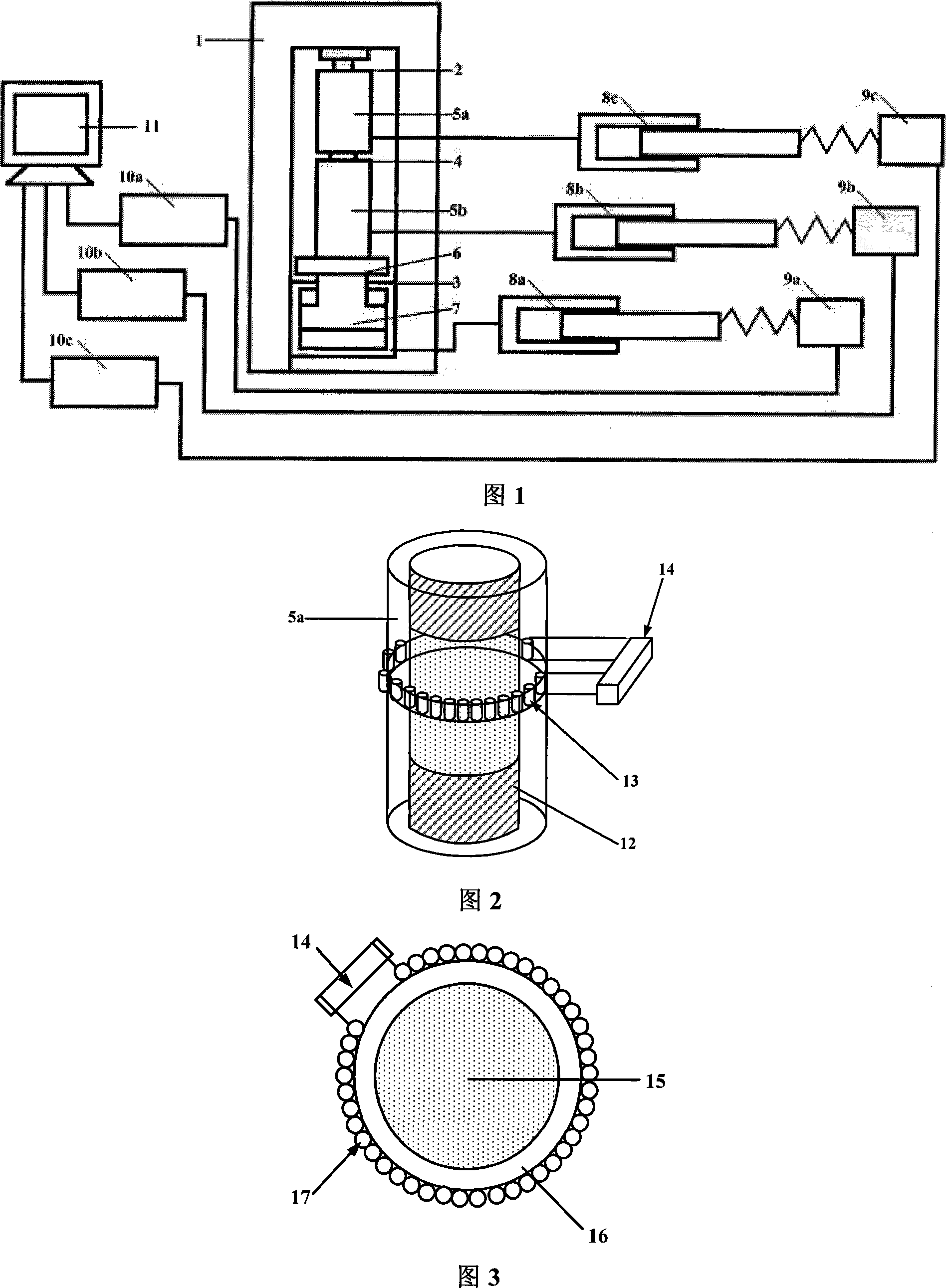

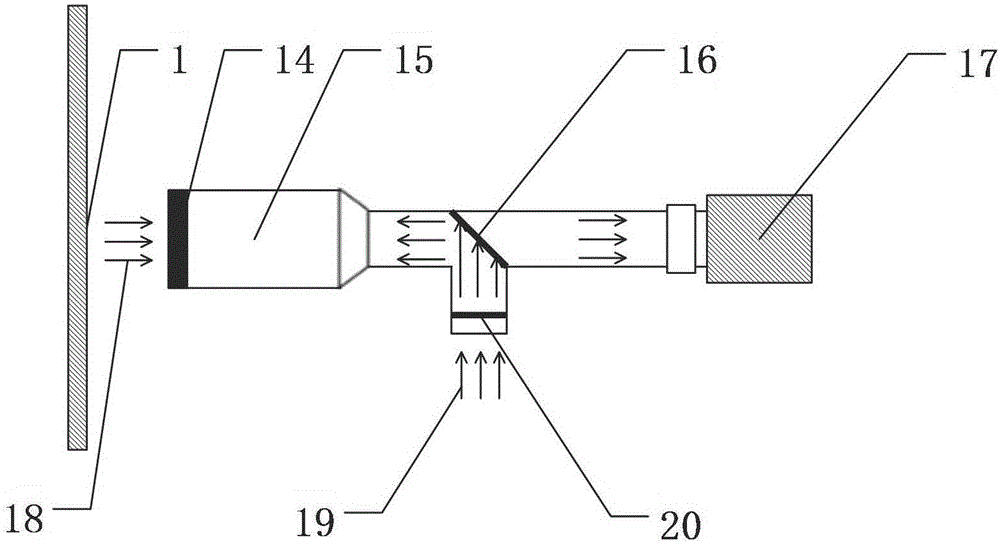

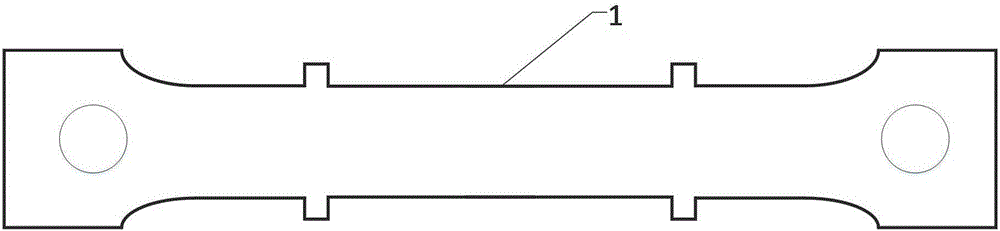

High-precision ultrahigh temperature video extensometer and measurement method thereof

The invention relates to a high-precision ultrahigh temperature video extensometer and a measurement method thereof. The high-precision ultrahigh temperature video extensometer comprises an ultraviolet camera (17), a coaxial telecentric imaging system (5), a monochromatic light source (12), a narrow band-pass filter (14) which is corresponding to the wavelength of the monochromatic light source, a mechanical support adjusting platform (6) and a computer (13). High-temperature-resistant speckles are manufactured on the surface of a test piece or a special test member of which the edge has four bosses is adopted. A high temperature testing machine having an observation window is utilized to apply force and thermal load to a measured rectangular section or circular section test piece. The test piece is actively lighted by coaxial ultraviolet light, and surface video images of the test piece are acquired by the high temperature video extensometer. High-precision real-time measurement is performed on the strain of the surface of the test piece by utilizing a digital image correlation method. The video extensometer is simple in principle and compact in structure and can be cooperated with the high temperature testing machine to perform real-time and high-precision measurement on deformation and mechanical properties of the surface of the test piece under the environment from room temperature to ultrahigh temperature of 2000 DEG C.

Owner:深圳市海塞姆科技有限公司

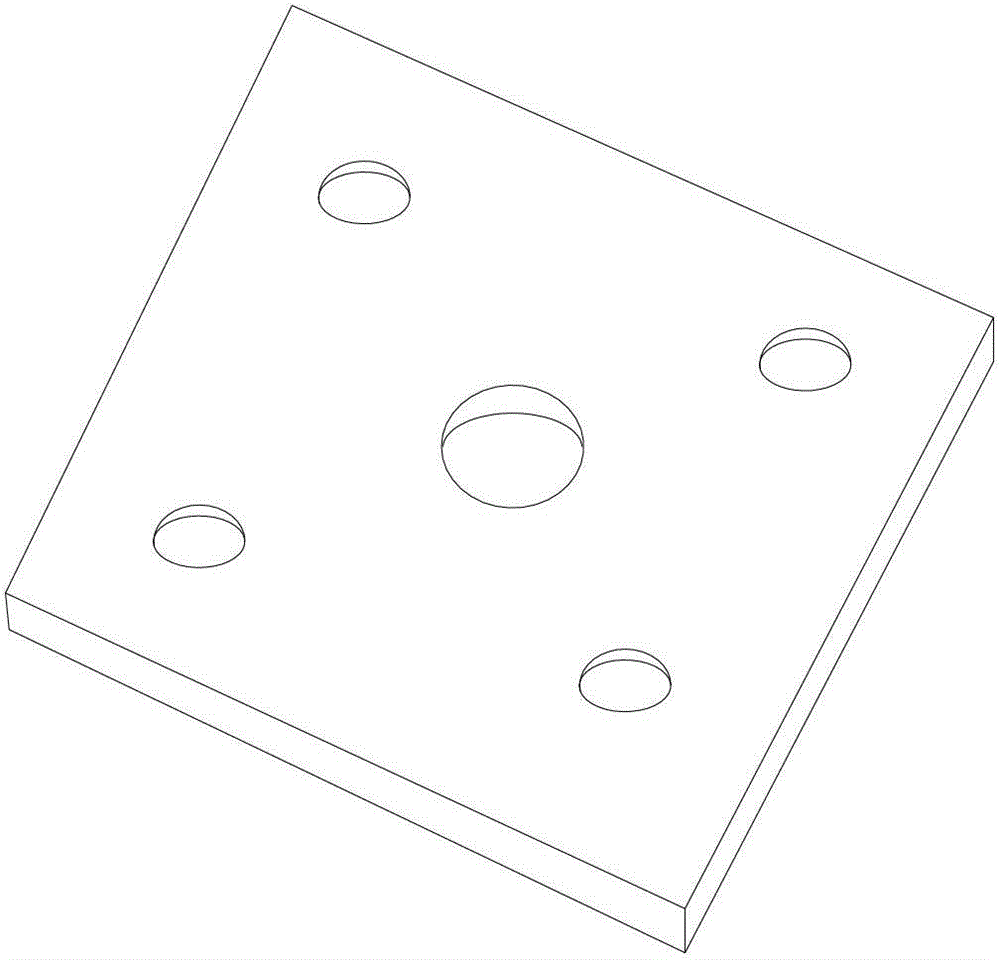

Novel composite material unnotched compression test fixture

InactiveCN103969118AEasy to install and replaceImprove test efficiencyMaterial strength using tensile/compressive forcesSemi openComputer module

The invention discloses a novel composite material unnotched compression test fixture which comprises a test loading module, a test clamping module and a strain measurement module, wherein the test loading module comprises a base, an end press plate, a clamp block cover plate, a guide shaft and a stroke control key; the test clamping module comprises a press piece, a clamp block and a clamp block guide pillar; the strain measurement module comprises an extensometer clamping piece and an extensometer support pillar. According to the novel composite material unnotched compression test fixture, the clamp block is driven to unclamp or clamp by the up and down movement of the base, and a test piece can be automatically aligned when being clamped by the clamp block; the alignment accuracy can be adjusted by introducing an extensometer and adjusting the screw pitches of threads in the strain measurement module; a series of strain measurement data with different accuracies are acquired, so that a strain measurement part capable of meeting the requirements of the different accuracies can be formed; the clamp block cover plate is assembled with the base by a bolt, so that a semi-open type structure can be formed in the clamping space of the test fixture, the test piece can be conveniently clamped, and the whole efficiency of the test is improved.

Owner:BEIHANG UNIV

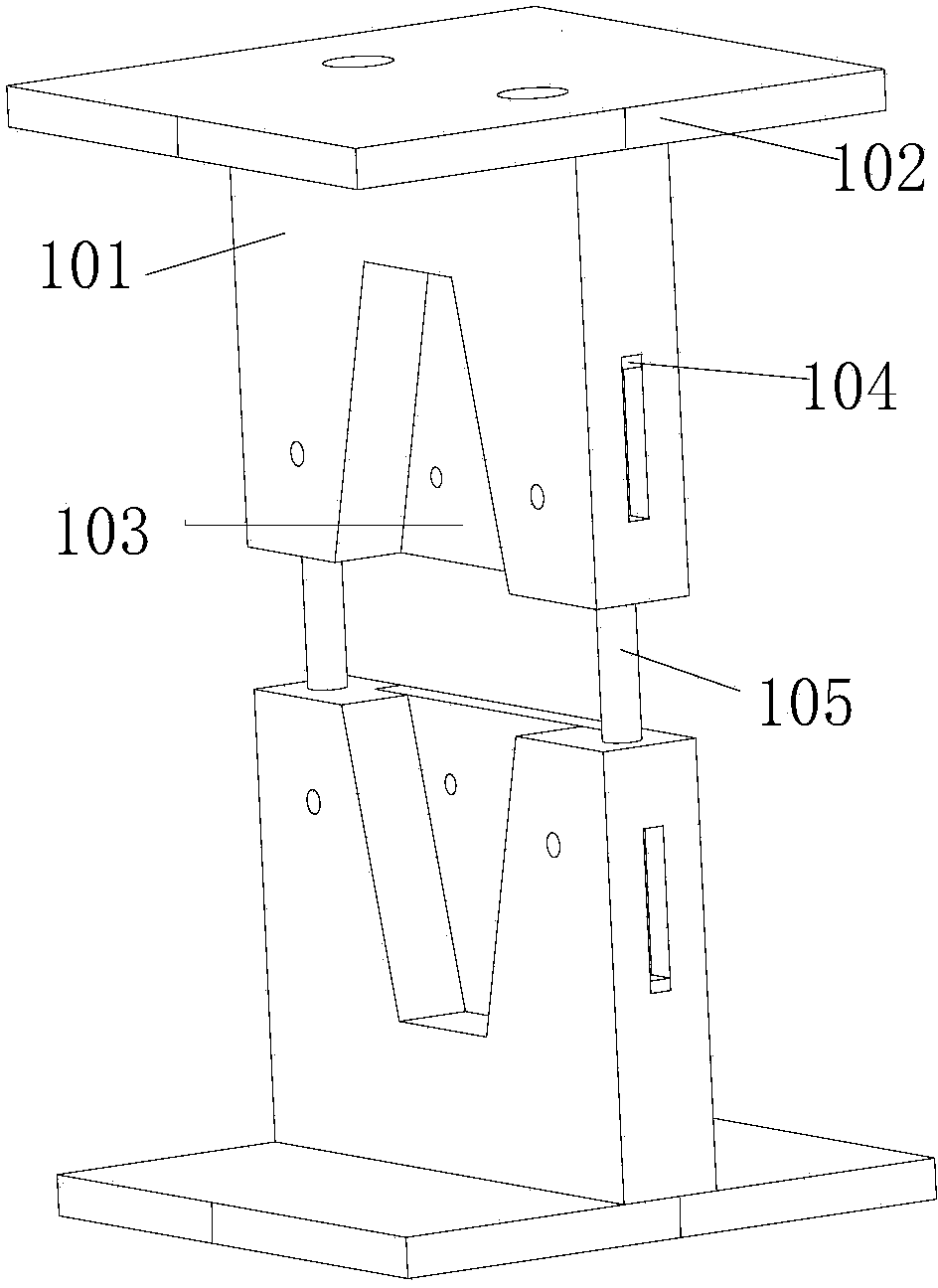

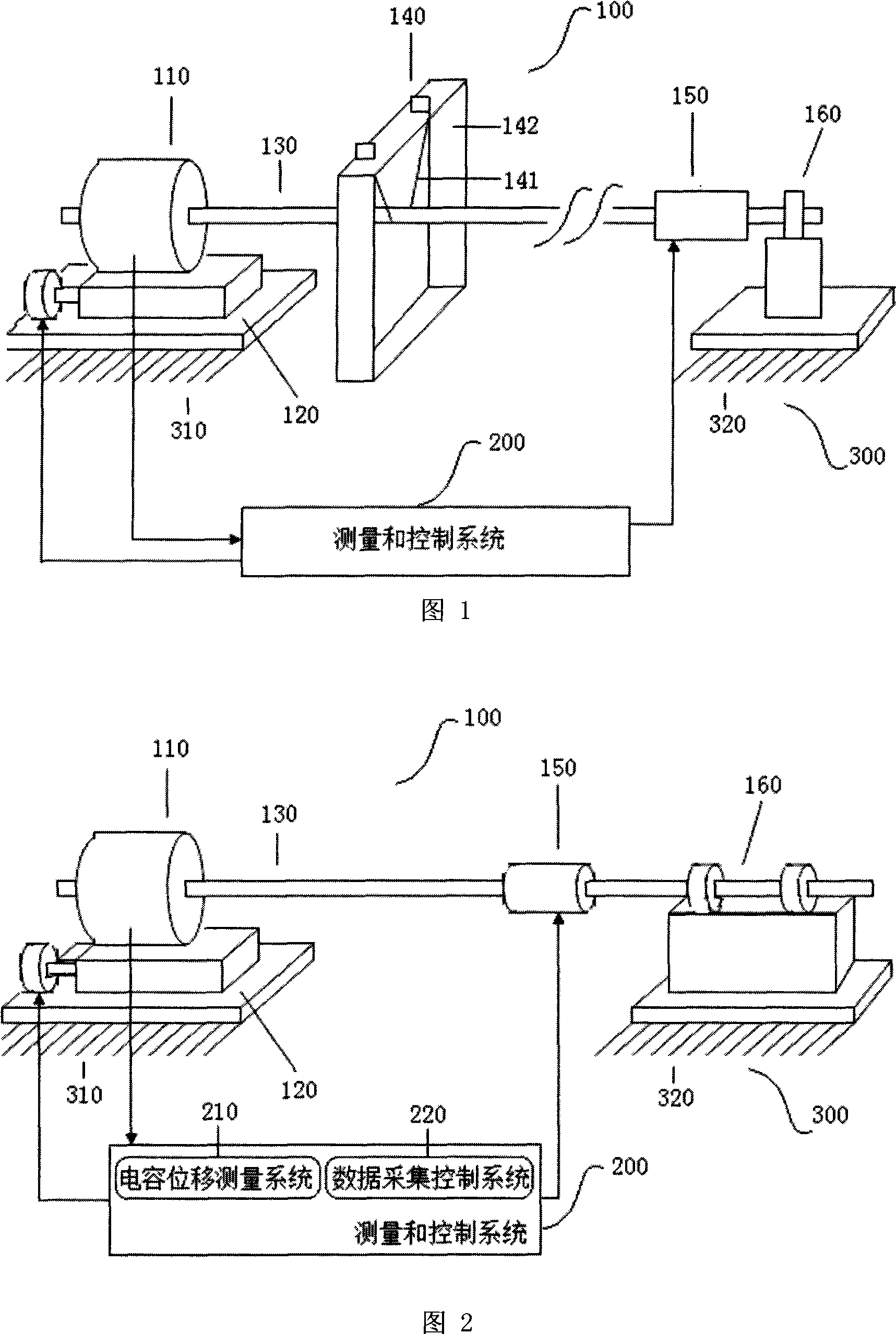

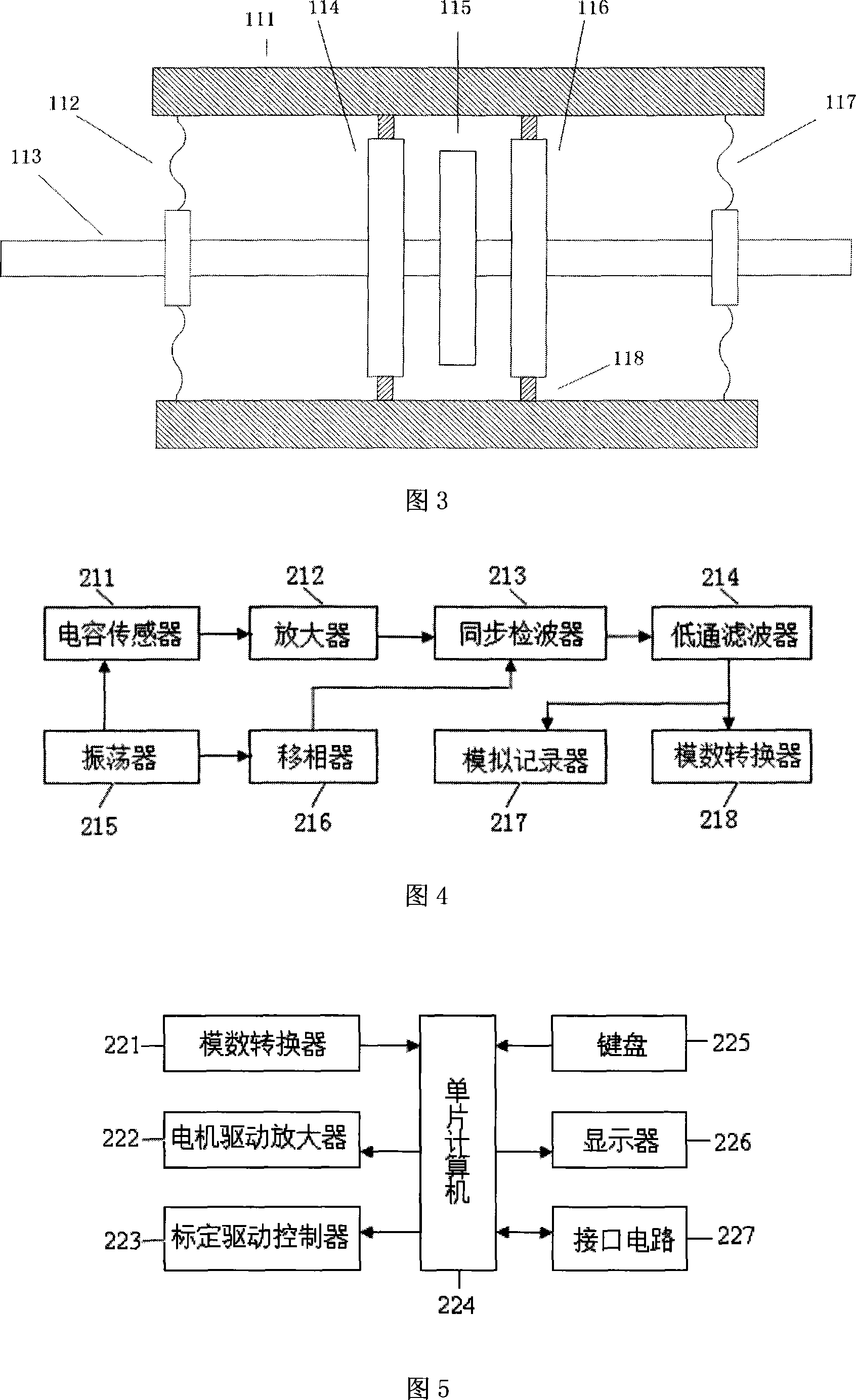

Ultrashort baseline extensometer

ActiveCN101118150AImprove observation accuracyImprove stabilityInput/output for user-computer interactionSeismologyControl systemEngineering

The present invention discloses an ultra short baseline extensometer, which relates to an extensometer. The present invention has the structure that one end of a baseline bar (130) is connected with a displacement sensor (110), which is connected with a first base rock (310) through a nulling device (120); the other end of the baseline bar (130) is connected with a calibrater (150) and then connected with a second base rock (320) through a fixed end (160); the displacement sensor (110) is respectively connected with a measurement and control system (200) through the calibrater (150); the displacement sensor (110) is a differential capacitance sensor (211) with an entire seal structure. The baseline of the present invention is not more than 100 cm, the resolving ability is superior to 1 is multiplied by 10 and then minus 10, the mechanical drive does not exist, the calibration is reliable; the extensometer can be arranged vertically; the volume is small, thus the extensometer is suitable for carrying, and adaptable to the flow of the forerunning effect of earthquake and the emergency monitoring; and the extensometer can be generalized to be used on a long baseline extensometer and other micro-displacement measuring devices.

Owner:INST OF EARTHQUAKE CHINA EARTHQUAKE ADMINISTRATION

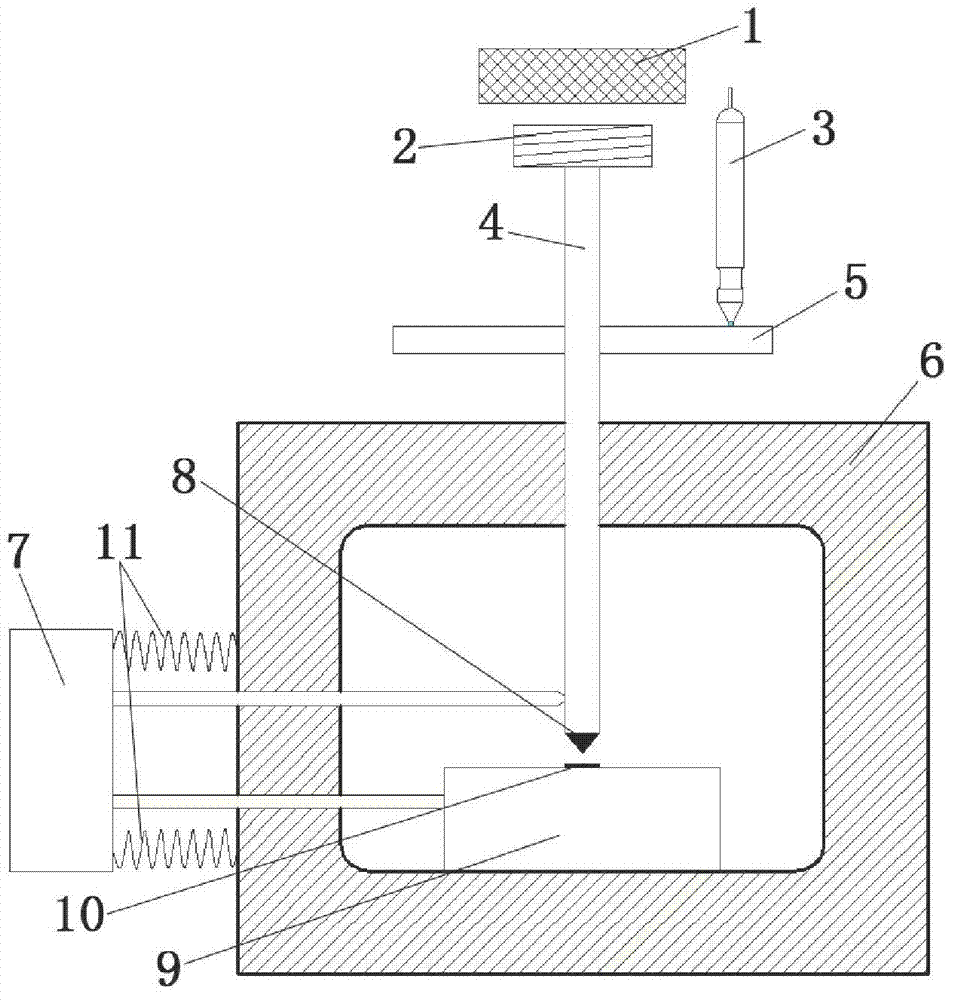

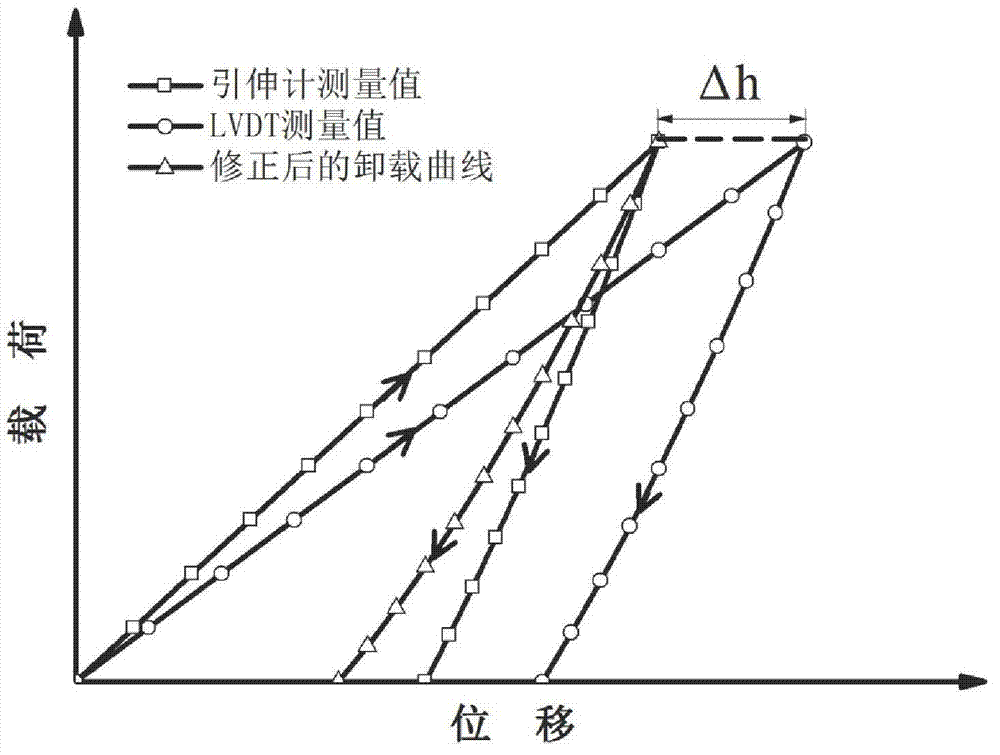

Device and method for testing ultrahigh-temperature indentation load-displacement curve

ActiveCN102967508AAchieve mechanical propertiesRealize researchMaterial strength using tensile/compressive forcesObservational errorEngineering

The invention discloses a device and a method for testing an ultrahigh-temperature indentation load-displacement curve. A to-be-tested ultrahigh-temperature material test piece is placed on a test piece loading platform in a high temperature furnace; one end of a loading rod is connected with a loading device located outside the high temperature furnace, a press head is arranged at the other end of the loading rod, and the other end of the loading rod stretches into the high temperature furnace and contacts the test piece; an ultrahigh-temperature extensometer for measuring displacement of the loading rod in the furnace is arranged on the high temperature furnace; a precise displacement sensor is used for measuring the displacement of the loading rod outside the high temperature furnace; and the test piece and the press head are heated to an experiment temperature by the high temperature furnace, after the temperature is stable, the test piece is loaded and unloaded by adopting the loading device, meanwhile, the ultrahigh-temperature extensometer close to the test piece and the precise displacement sensor away from the test piece are adopted to measure indentation displacement, and the ultrahigh-temperature extensometer and the precise displacement sensor are cooperated to measure the ultrahigh-temperature indentation load-displacement curve with high precision. According to the device and the method for testing the ultrahigh-temperature indentation load-displacement curve, measuring error of the extensometer caused by reverse motion idle running in the transforming process from loading to unloading is eliminated by two displacement sensors, and the measurement precision is improved.

Owner:PEKING UNIV

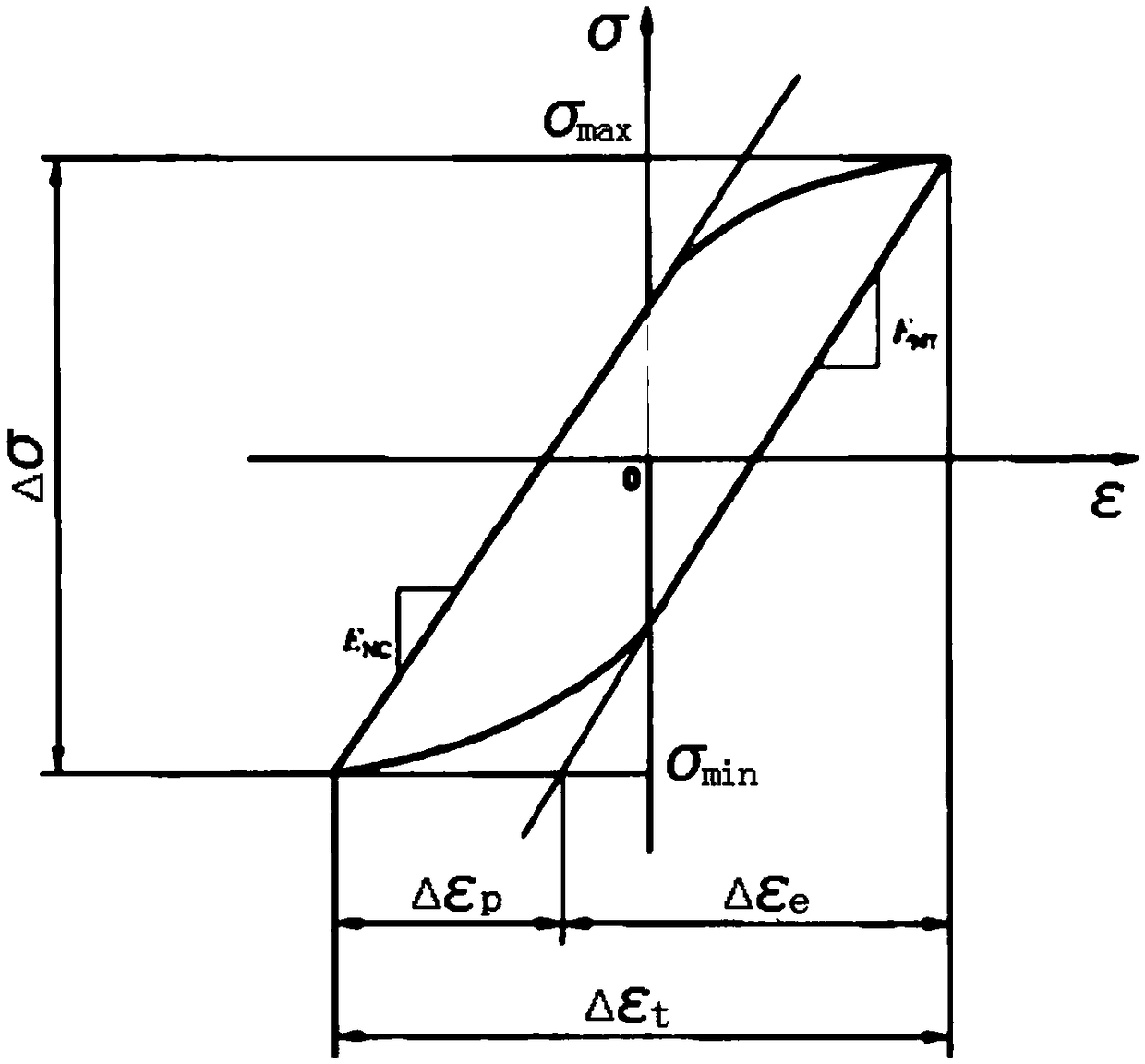

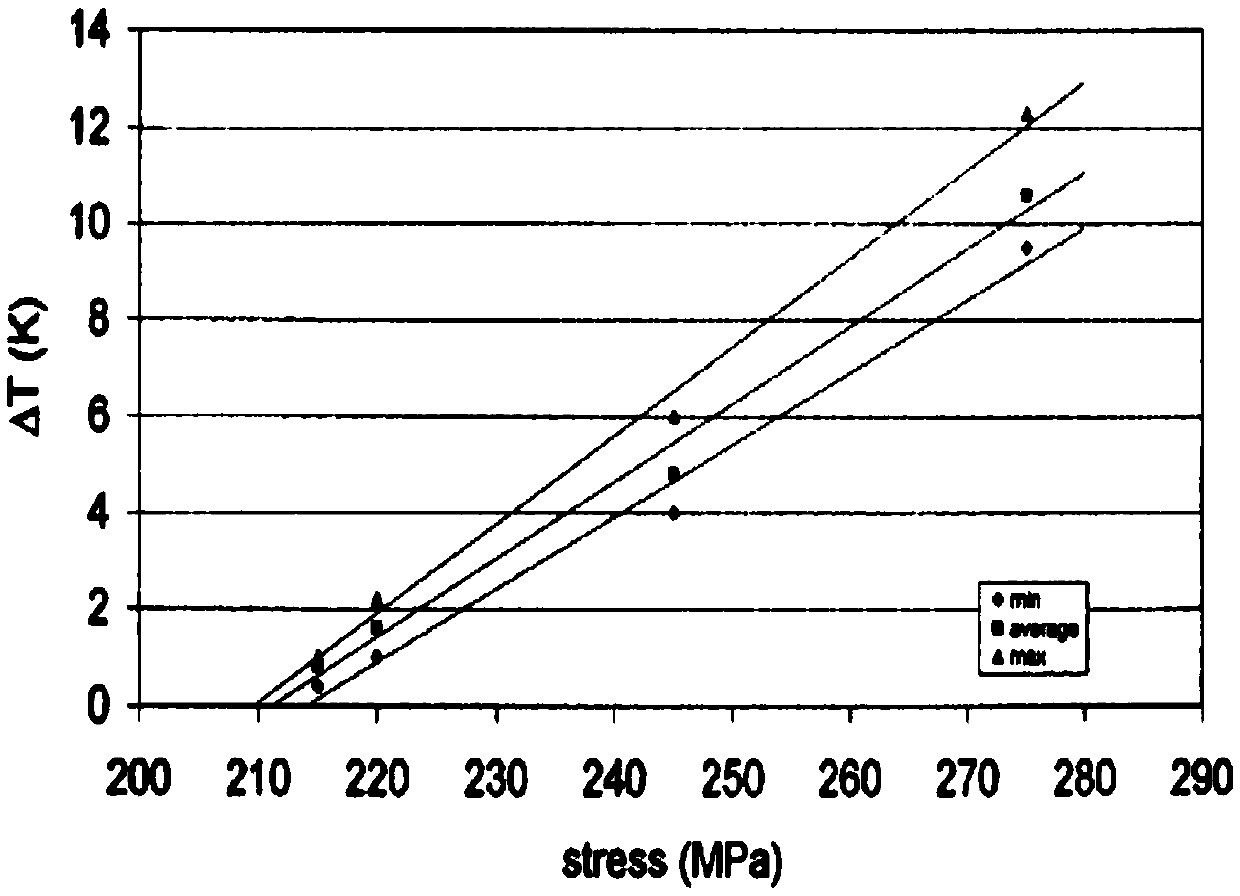

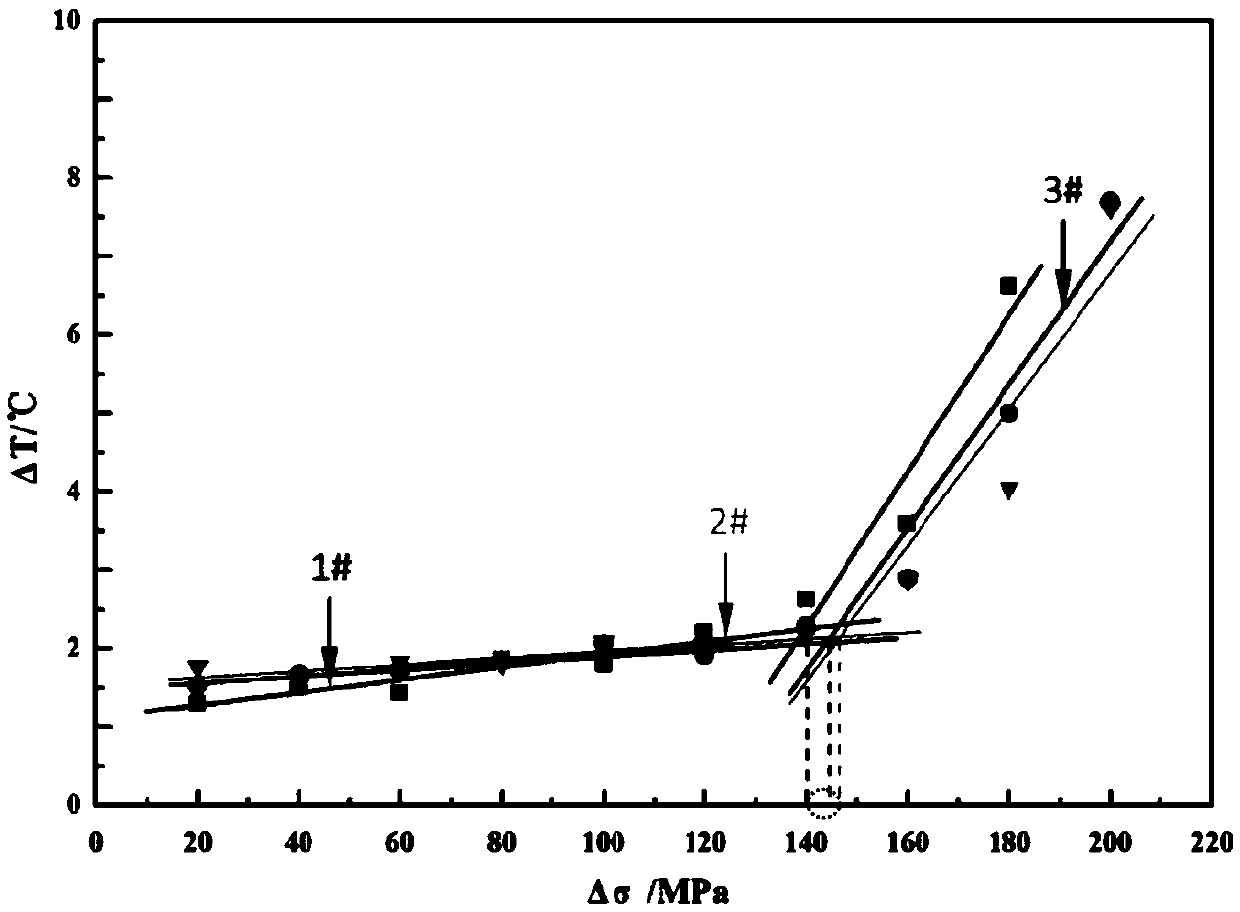

Fatigue limit rapid prediction method based on strain increment

ActiveCN105372136AMaterial strength using repeated/pulsating forcesPredictive methodsEconomic benefits

A fatigue limit rapid prediction method based on strain increment belongs to the field of rapid prediction of material fatigue limit. The invention discovers that under gradient stress load, the variation rule of strain capacity is very similar to the variation rule of temperature. Since the Luong method can use corresponding stable temperature rise value under gradient load to predict the fatigue limit, the strain capacity under gradient load can theoretically be used for rapid prediction of fatigue limit. The method utilizes a fatigue testing machine and an extensometer thereof (no dependence on expensive high-precision thermal infrared imager), and theoretically only uses one specimen to rapidly and economically predict a reliable fatigue limit of the material or a simple member in a day time according to variation rule of strain capacity under gradient load. The traditional lifting method and grouping method spend a few months and consume a large amount of human and financial resources, therefore the present invention has high engineering practical value and significant economic benefits.

Owner:ACADEMY OF ARMORED FORCES ENG PLA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com