Patents

Literature

3143 results about "Test board" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Definition of test board. : a paperboard for shipping containers that must test up to specific requirements (as for resistance to puncture)

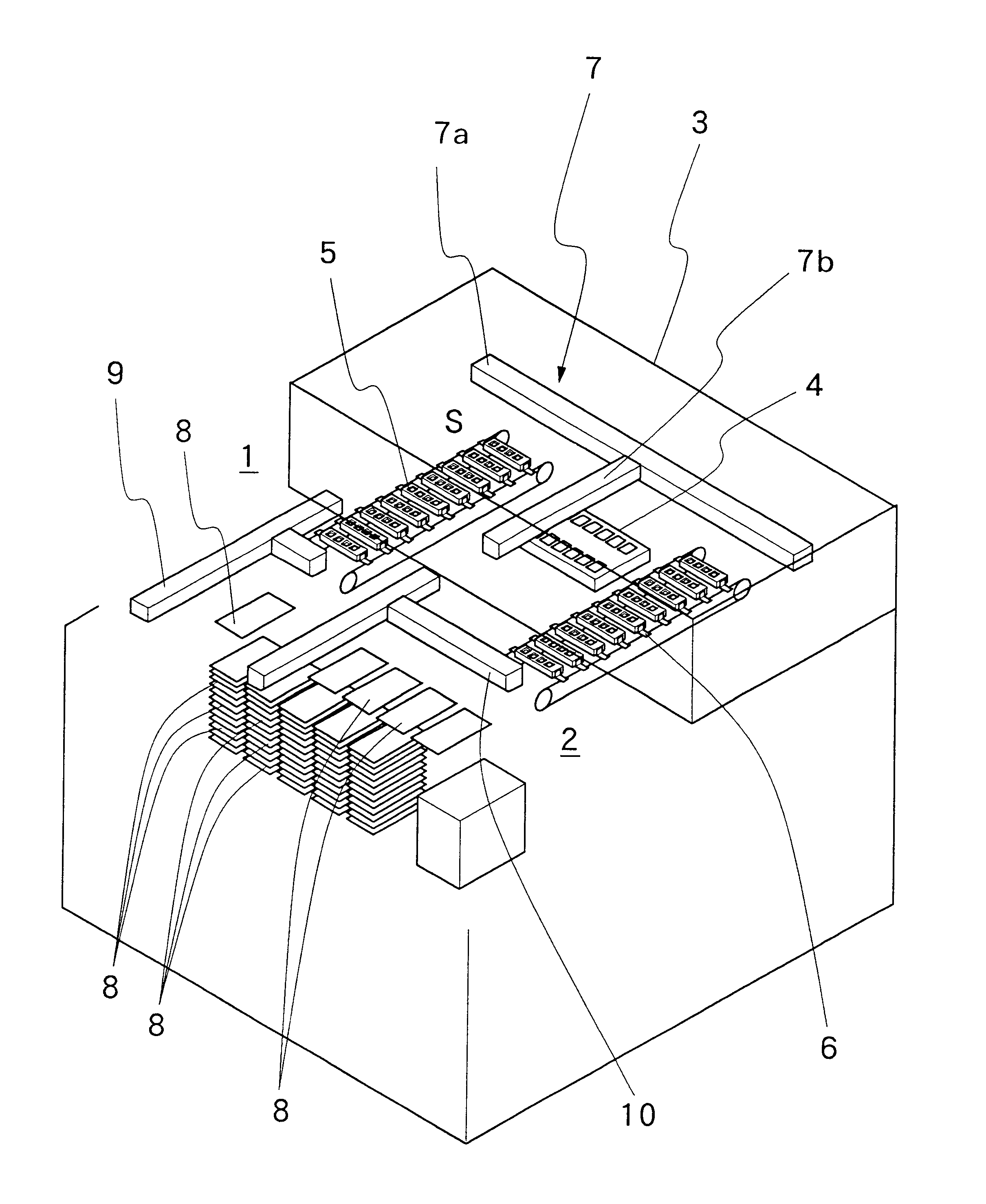

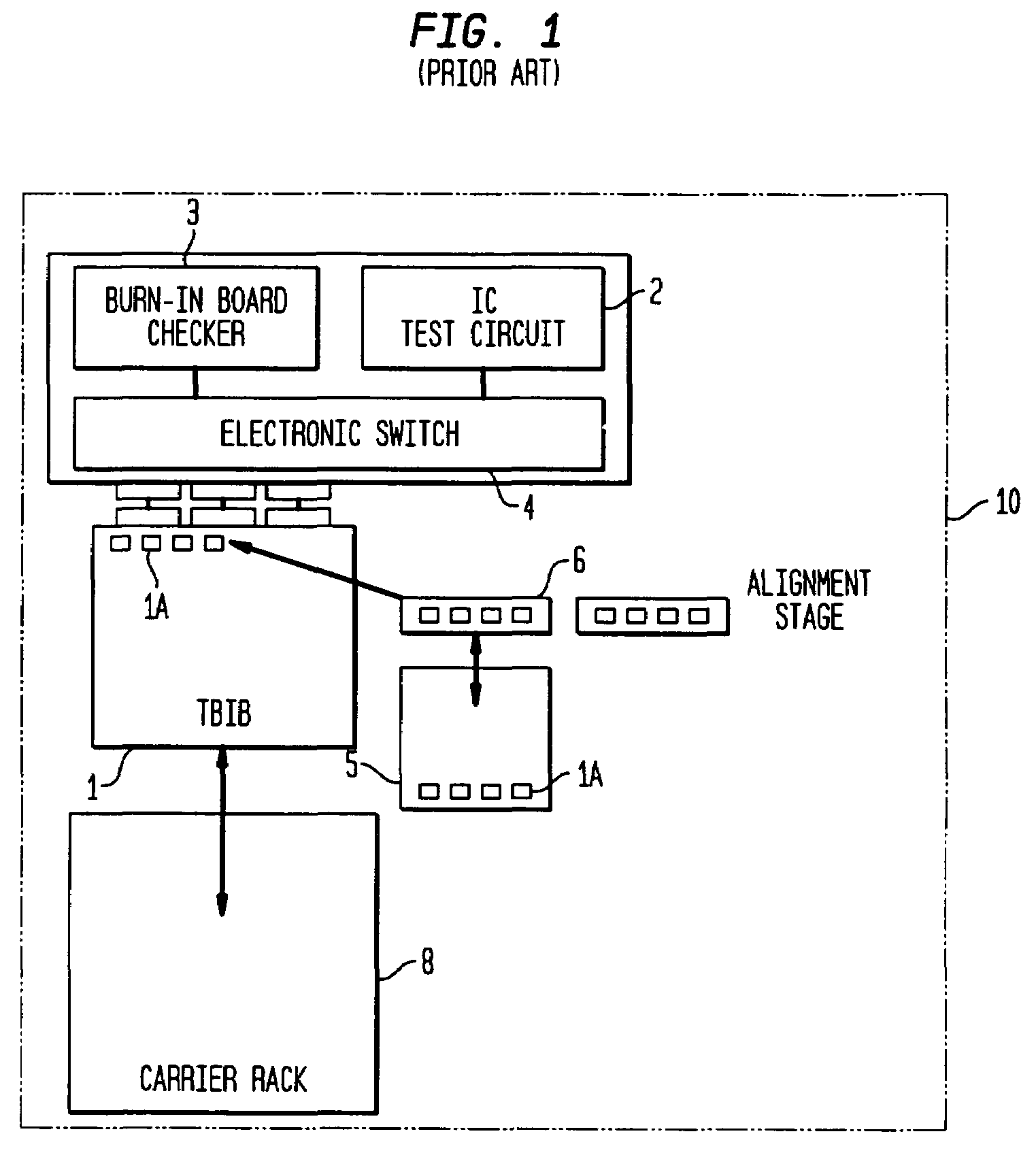

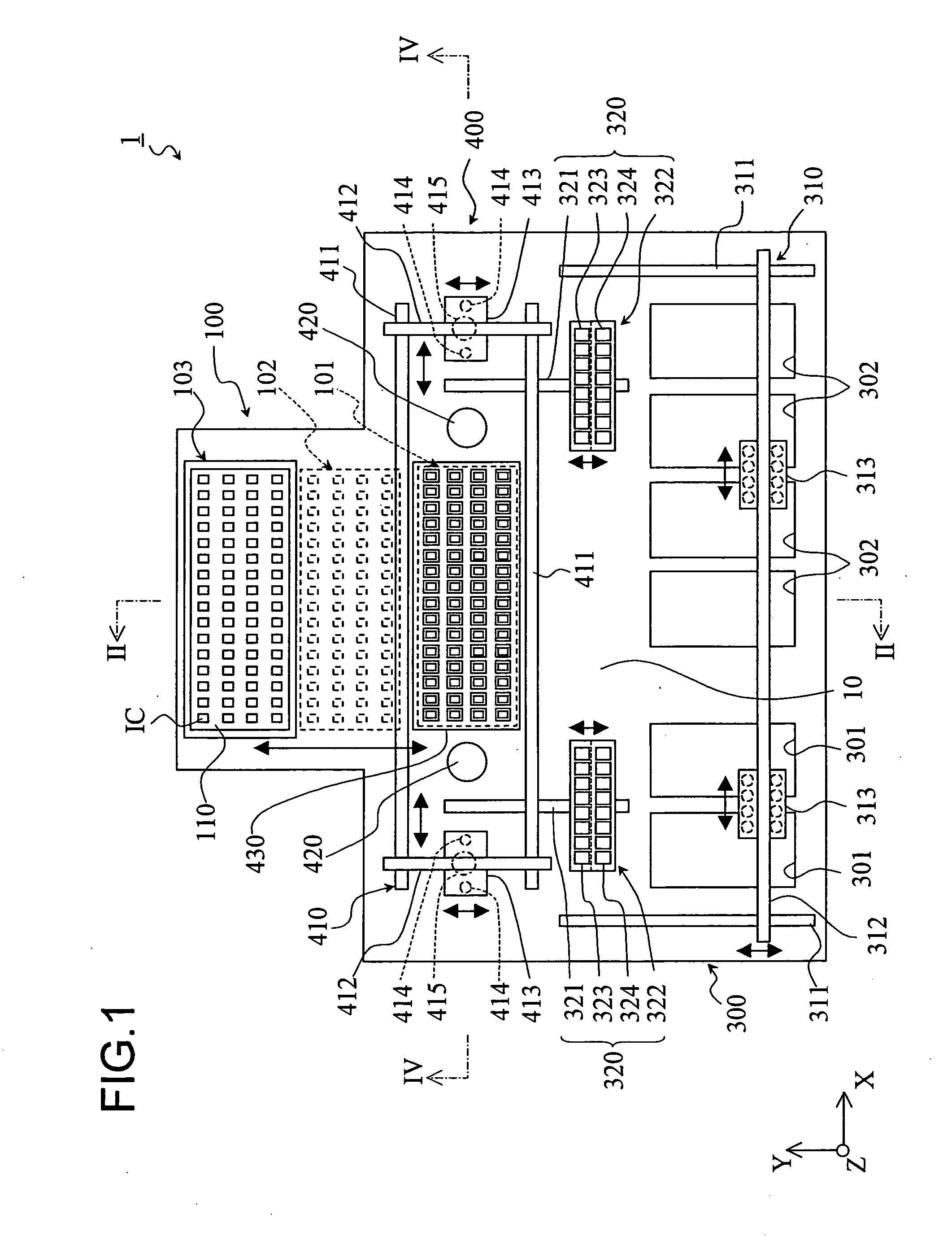

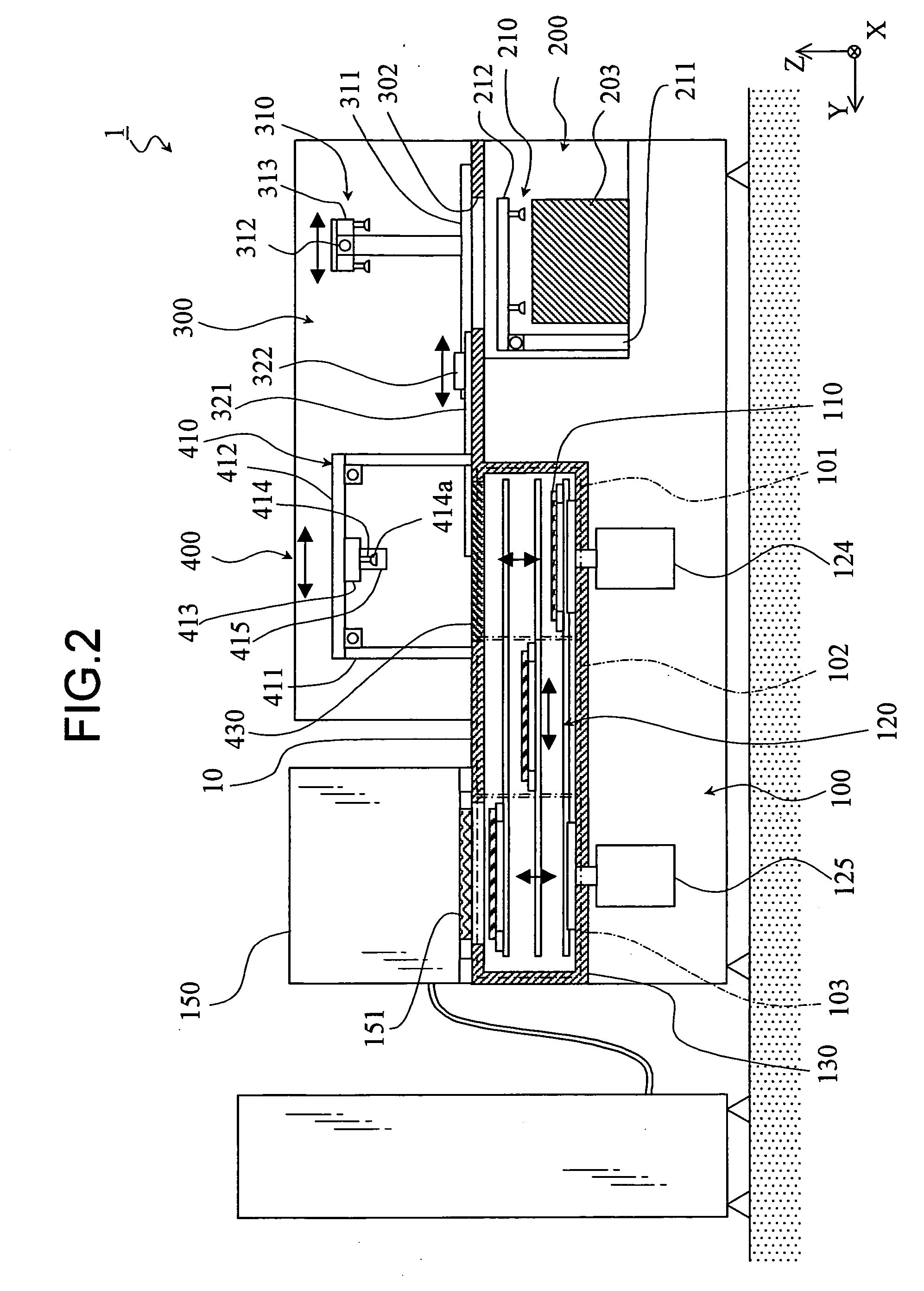

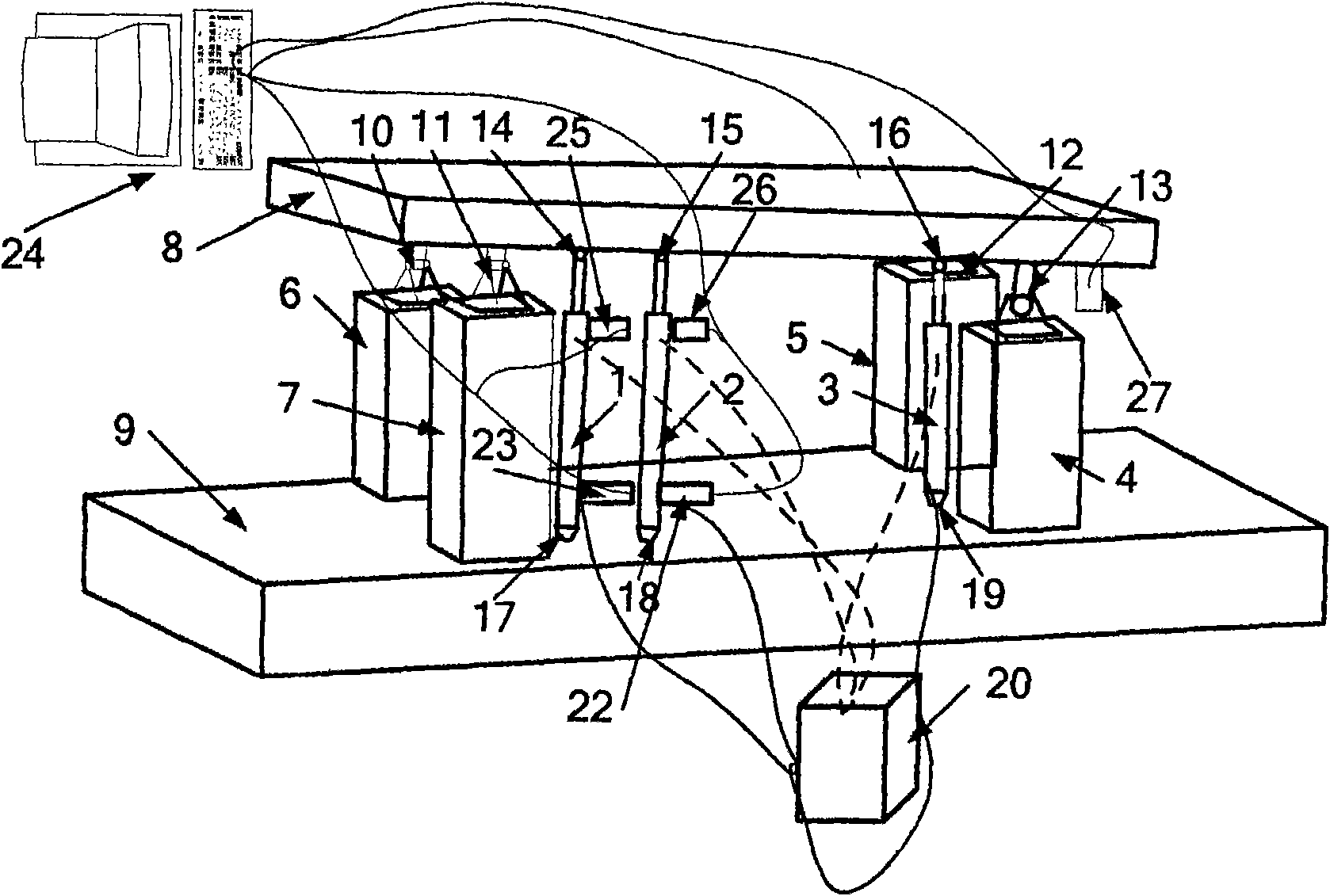

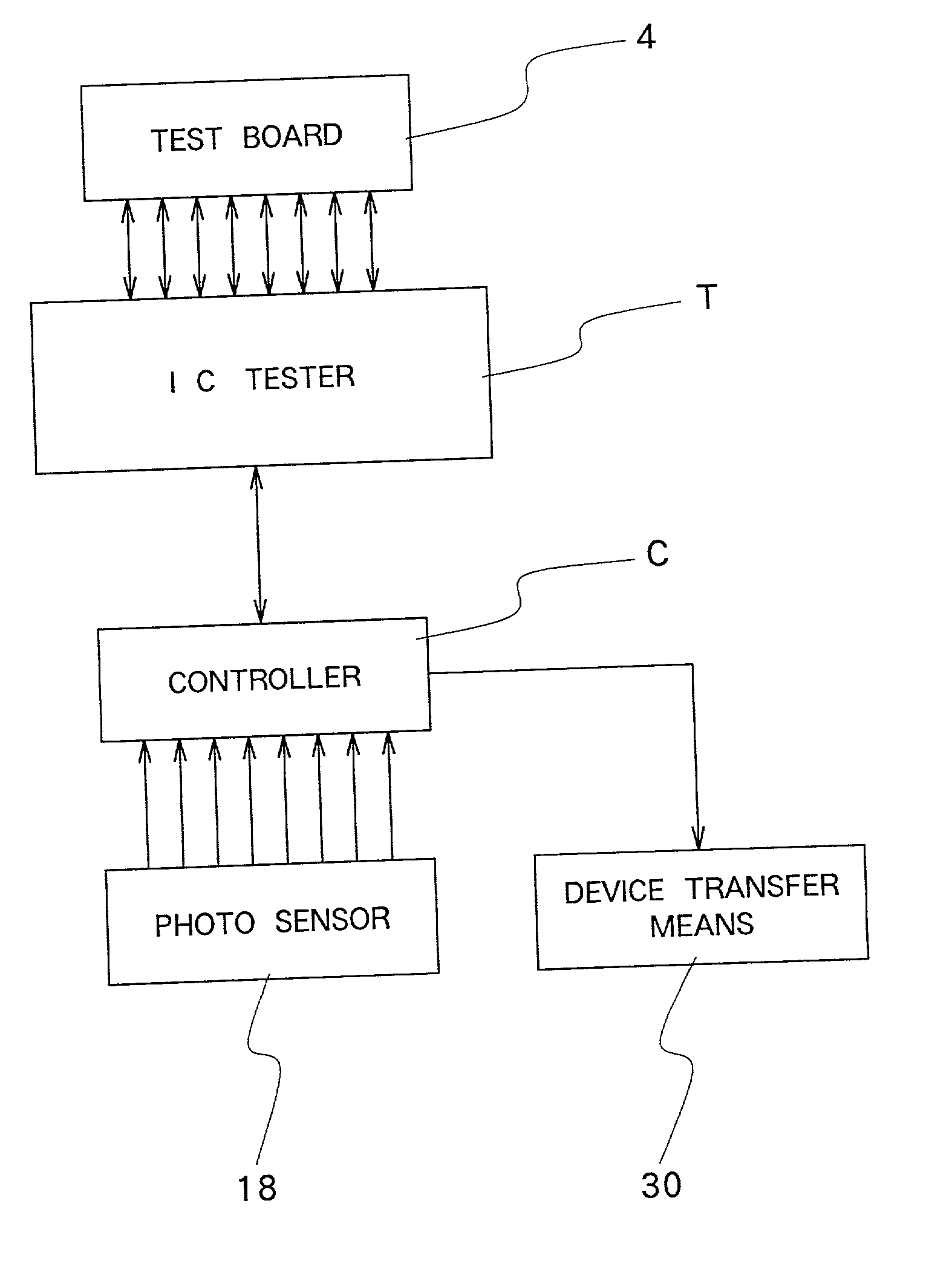

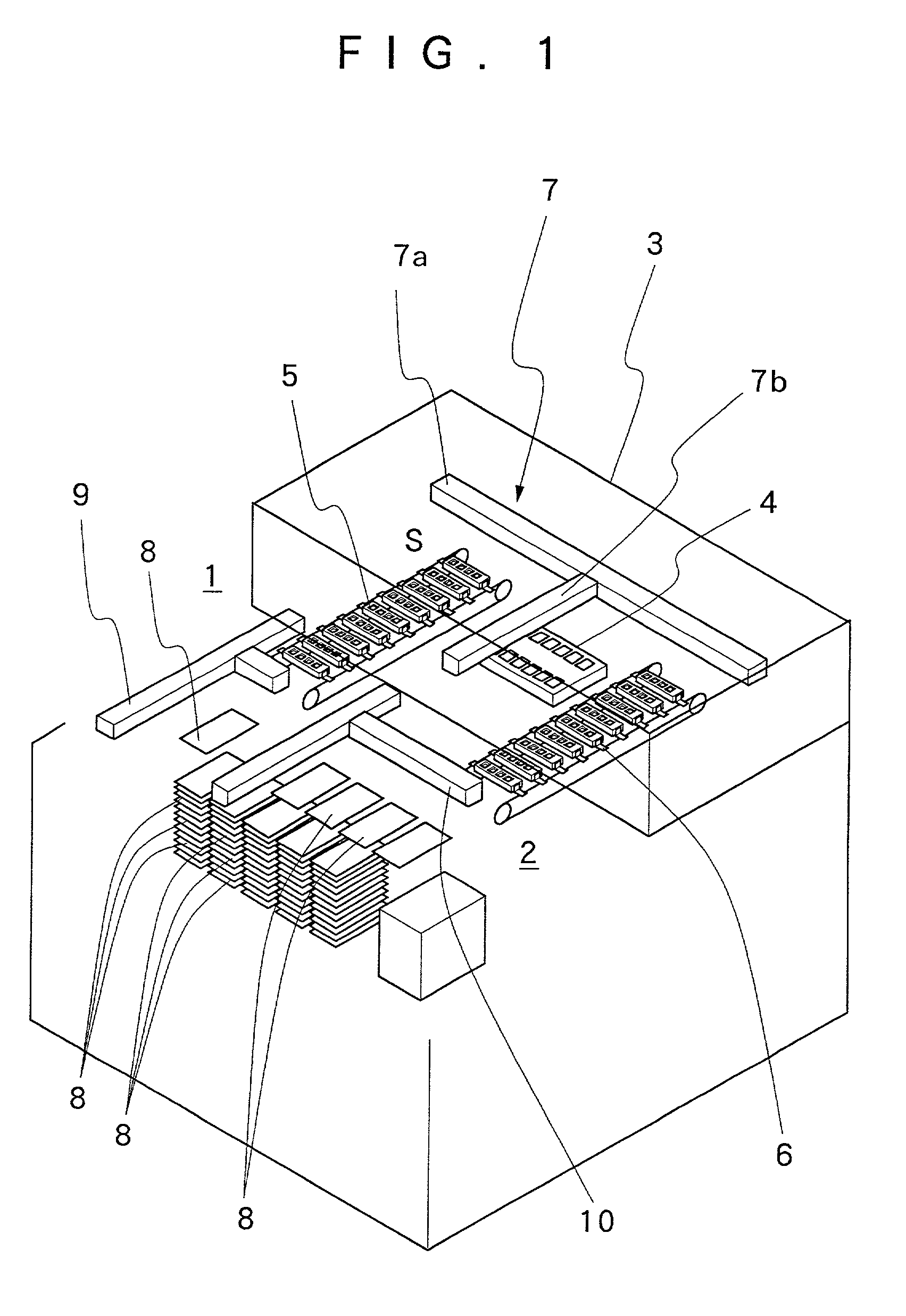

Method and apparatus for testing IC device

InactiveUS6515470B2Semiconductor/solid-state device testing/measurementDigital data processing detailsElectricityEngineering

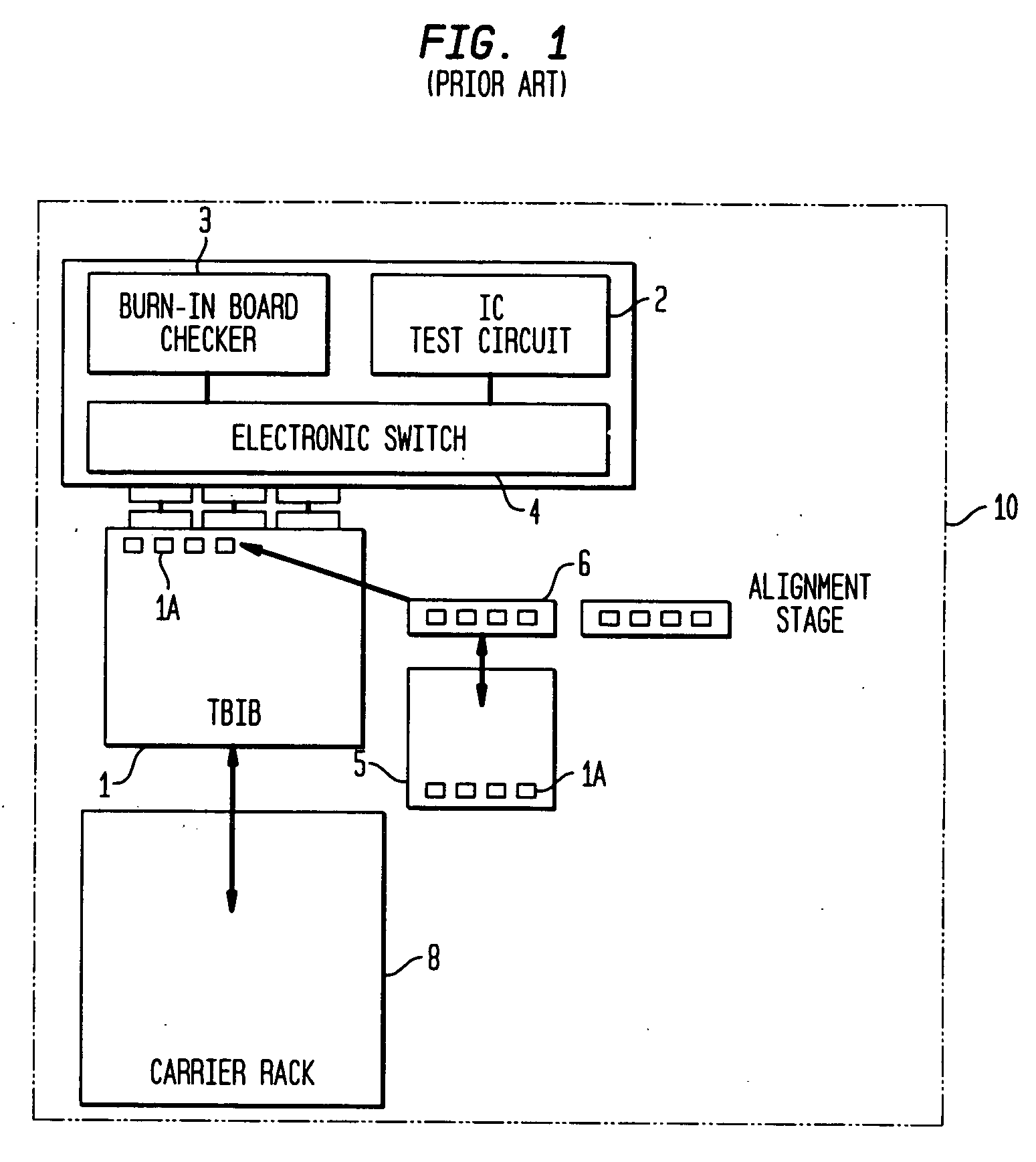

For testing electrical properties of packaged IC devices, there is provided an apparatus which includes a test board which is located at a testing station and provided with a plural number of contacting sockets for connecting individual IC devices to an IC tester separately and independently of each other, a loader which is located at a loading station and adapted to feed untested IC devices toward the test board, an unloader which is located at an unloading station and adapted to discharge tested IC devices from the test board at the testing station, and a device transfer mechanism which is movable across the testing station to transfer untested IC devices from the loader to the test board and also to transfer tested IC devices from the test board to the unloader. Upon detecting completion of a test on one of IC devices in one socket of the test board, a fresh untested IC device is transferred to the testing station to replace the tested IC device. As soon as the fresh IC device is set in position in that socket, execution of a test program is started with respect to that socket on the test board.

Owner:HITACHI ELECTRONICS ENG CO LTD

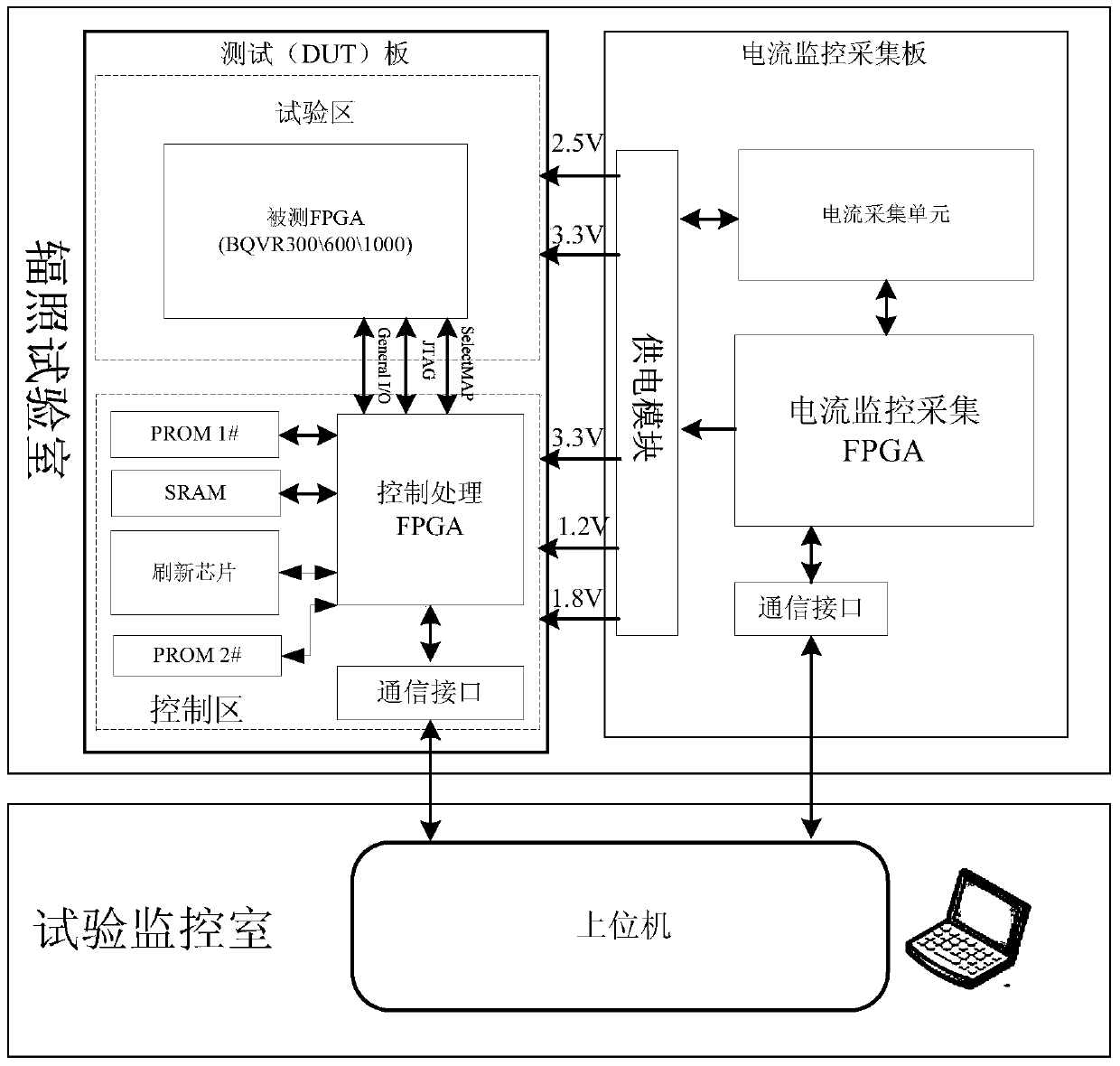

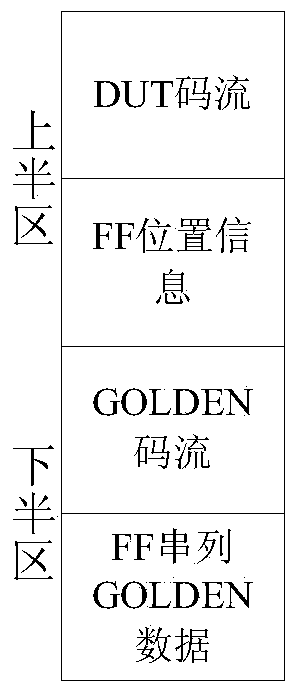

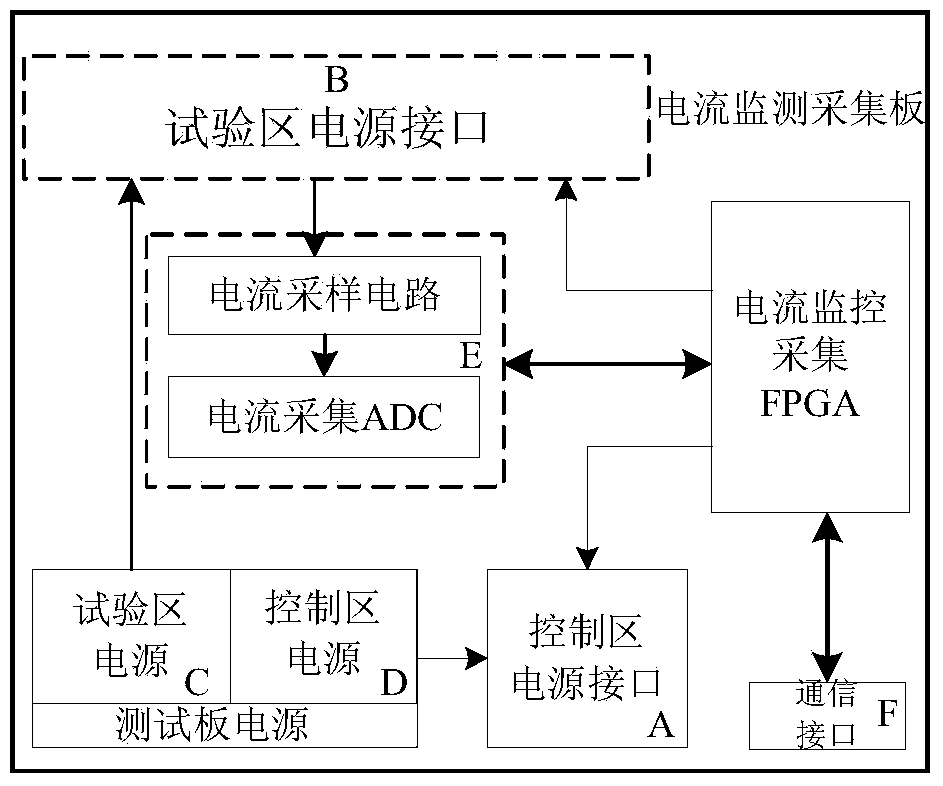

SRAM type FPGA single particle irradiation test system and method

ActiveCN103744014ARefresh is convenient and reliableReliably flip dataElectrical testingCommunication interfacePower flow

The invention provides an SRAM type FPGA single particle irradiation test system and method. The test system comprises a host computer, a current monitoring acquisition plate and a test plate. The current monitoring acquisition plate comprises a current monitoring acquisition FPGA, a current acquisition unit, a power supply module and a first communication interface; the test plate comprises a control processing FPGA, a refreshing chip, an SRAM, a configuration PROM, a storage PROM, a second communication interface and a detected FPGA; the host computer is in charge of flow control and data processing; the current monitoring acquisition plate is in charge of power-on and power-off of the test plate and monitoring and testing of FPGA currents; and the test plate is in charge of processing a command sent by the host computer and performing work such as single particle overturning, single particle function interruption detection and the like. According to the invention, the refreshing chip is utilized to replace some of the reconfiguration modules in a conventional irradiation test system so that a detected chip can be more conveniently and reliably refreshed; and the system and method provided by the invention can realize static and dynamic overturning testing on a trigger, and more reliable trigger overturning data can be obtained by combing the two methods.

Owner:BEIJING MICROELECTRONICS TECH INST +1

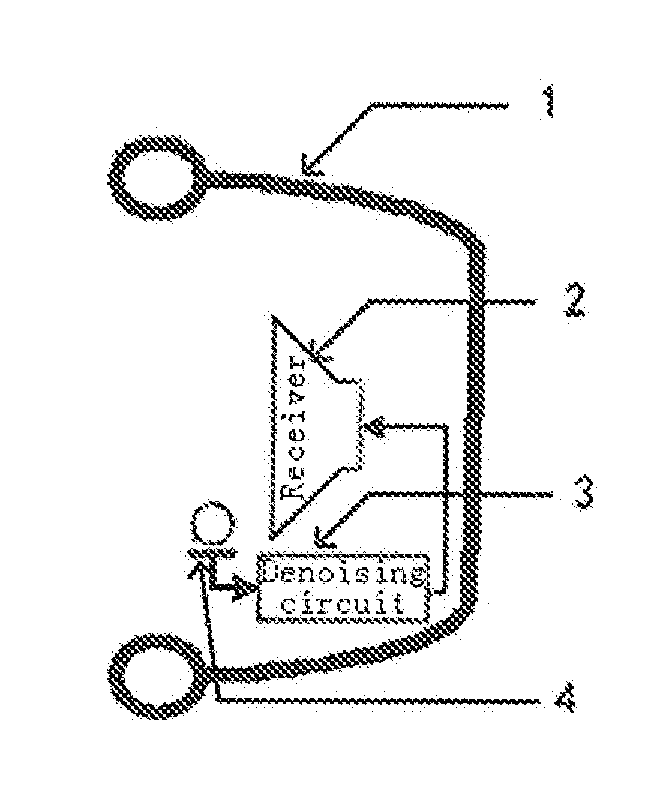

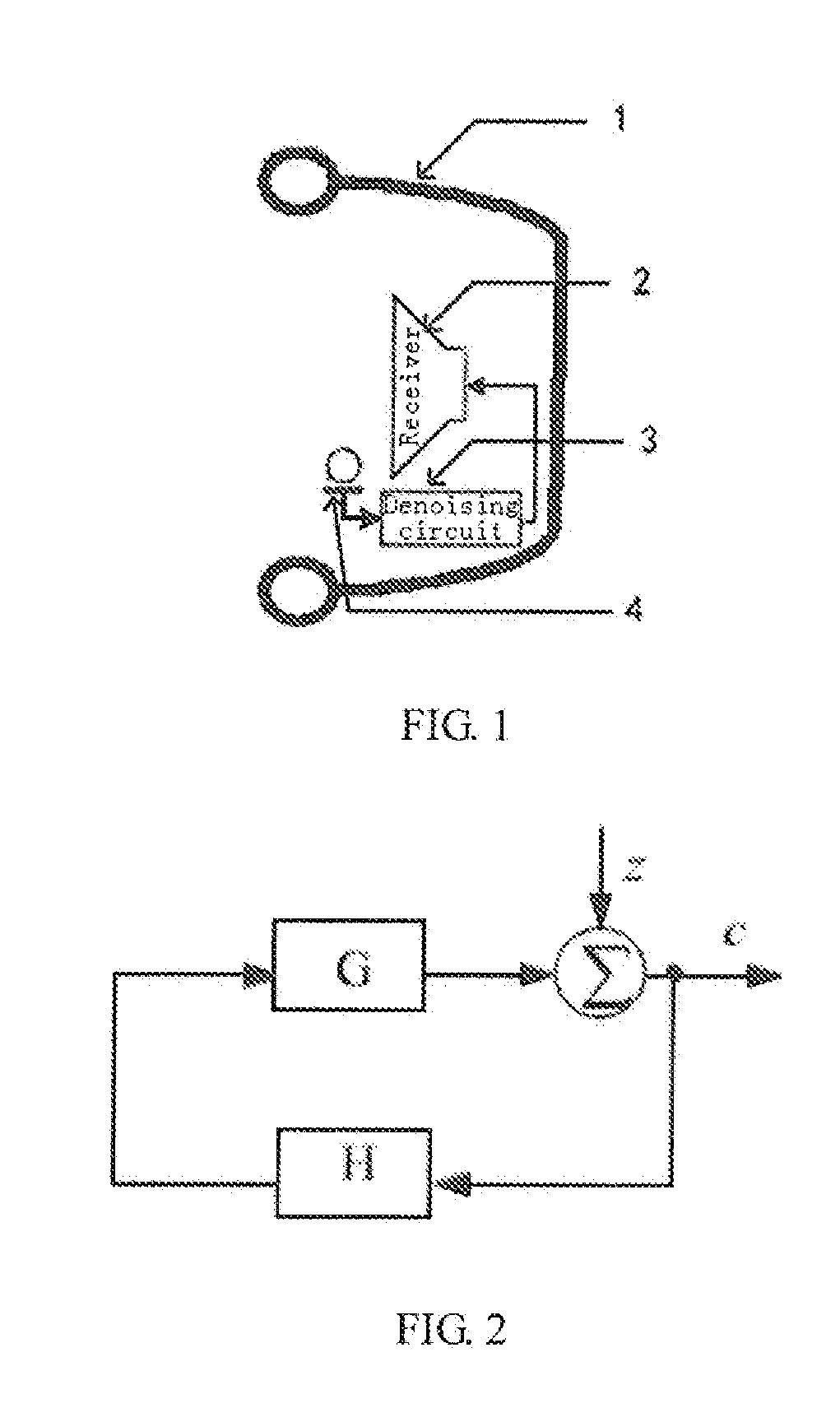

Test Device And Test Method For Active Noise Reduction Headphone

ActiveUS20140146973A1Reduce background noiseReduce test complexityEarpiece/earphone noise reductionAcoustic transmissionEngineering

The present invention discloses a test device and test method for the noise reduction headphone. The test device comprises: an enclosed cavity, a noise source, a test panel, a measuring microphone and a measure comparison module connected with the measuring microphone. The sound emitted from the noise source is sealed within the enclosed cavity. The test panel can cooperate with the noise reduction headphone to form a coupling cavity in the test. The test panel has a sound guiding hole in the common part with the enclosed cavity for transmitting the sound of the noise source into the interior of the coupling cavity. The test panel also has a mounting hole, and the measuring microphone is mounted on the mourning hole towards the direction of the coupling cavity. The measuring microphone records noise signals before and after the noise reduction function of the noise reduction headphone is activated. The measure comparison module receives the signals recorded these two times by the measuring microphone and performs comparison processing to obtain noise reduction amount of the noise reduction headphone. The technical solution of the present invention solves the problem of noise pollution caused by high-power external noise sources to the surrounding environment during the test process of noise reduction amount of the headphone, meanwhile, no special shielding room is required, and the requirement on test environment is relieved.

Owner:GOERTEK INC

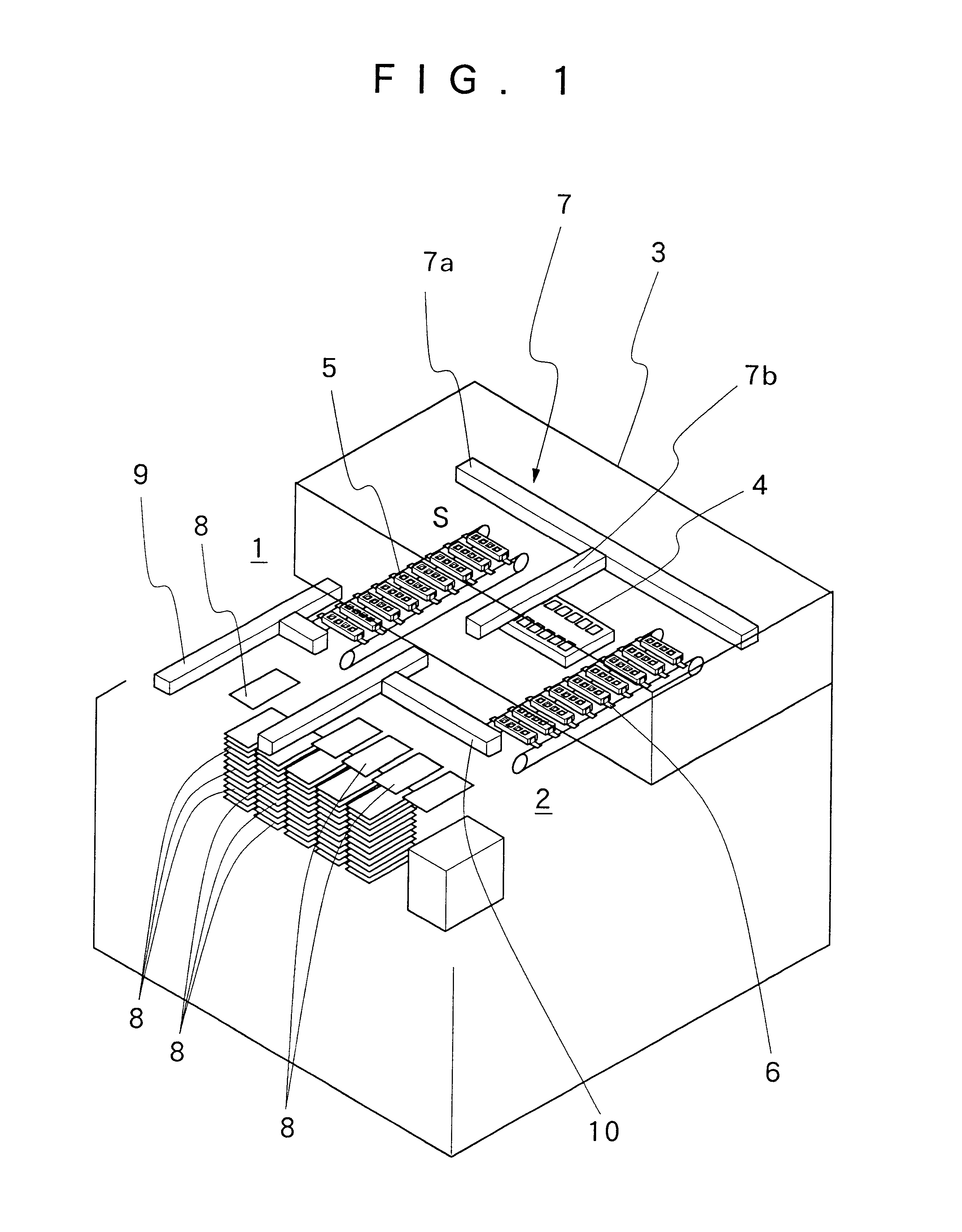

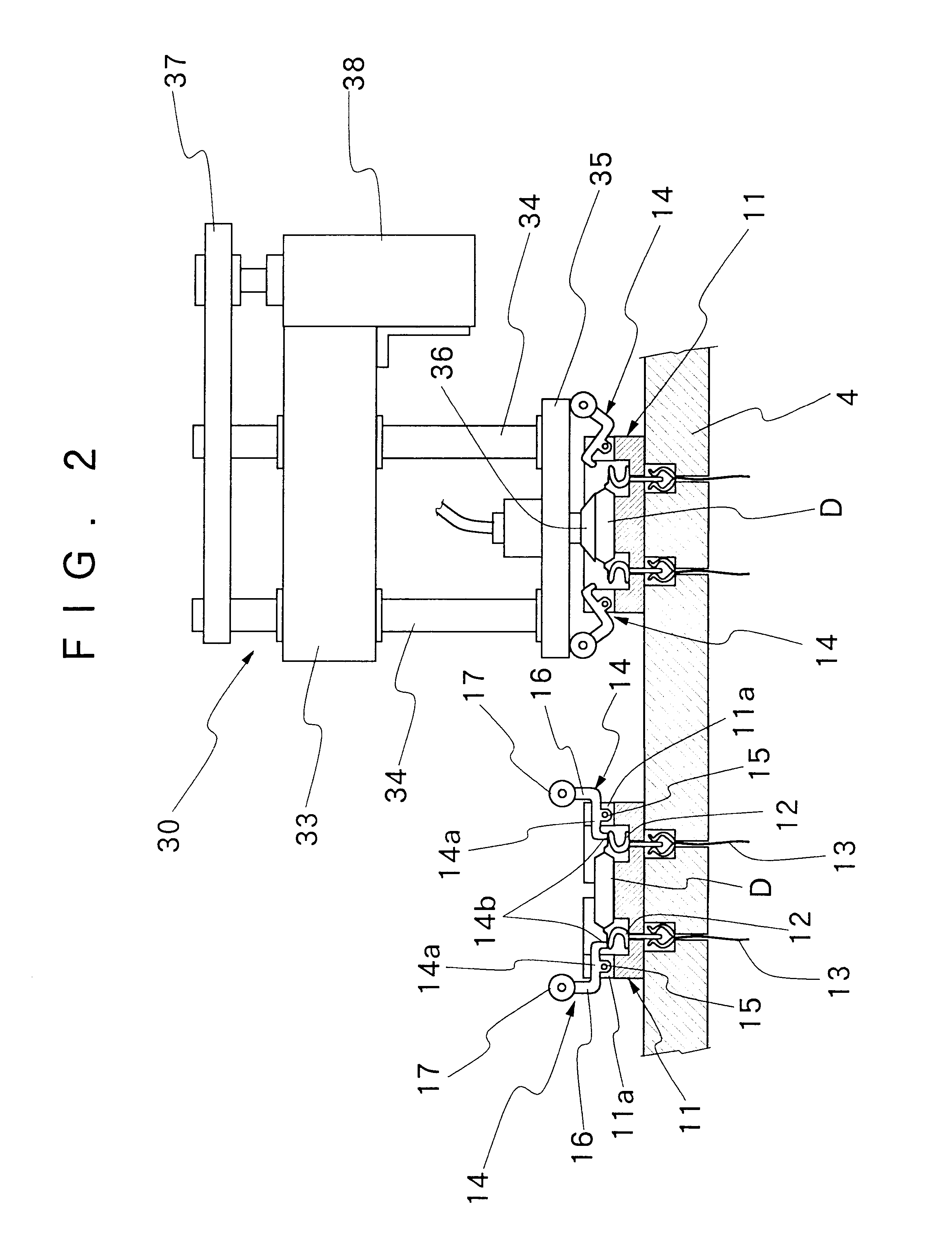

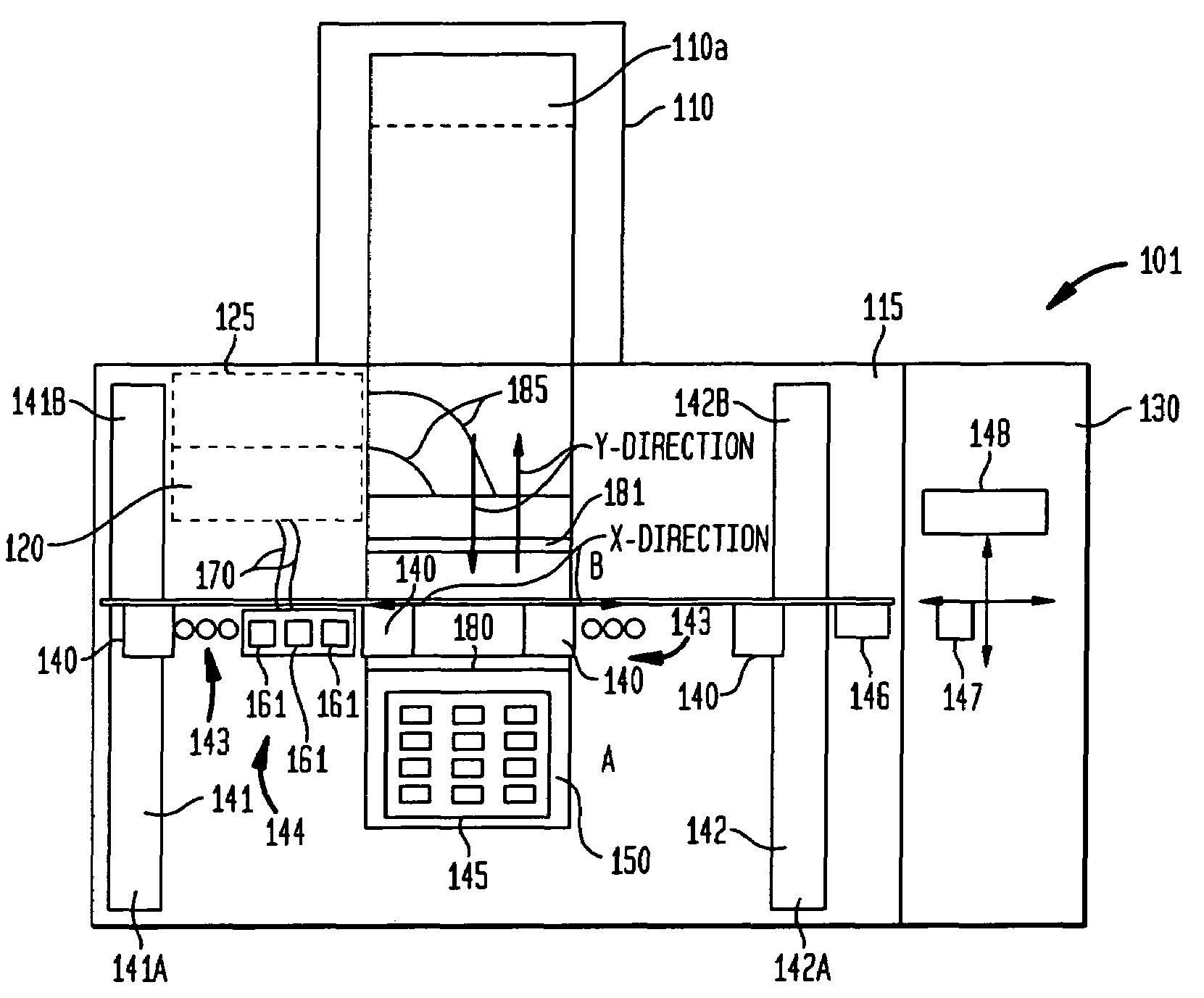

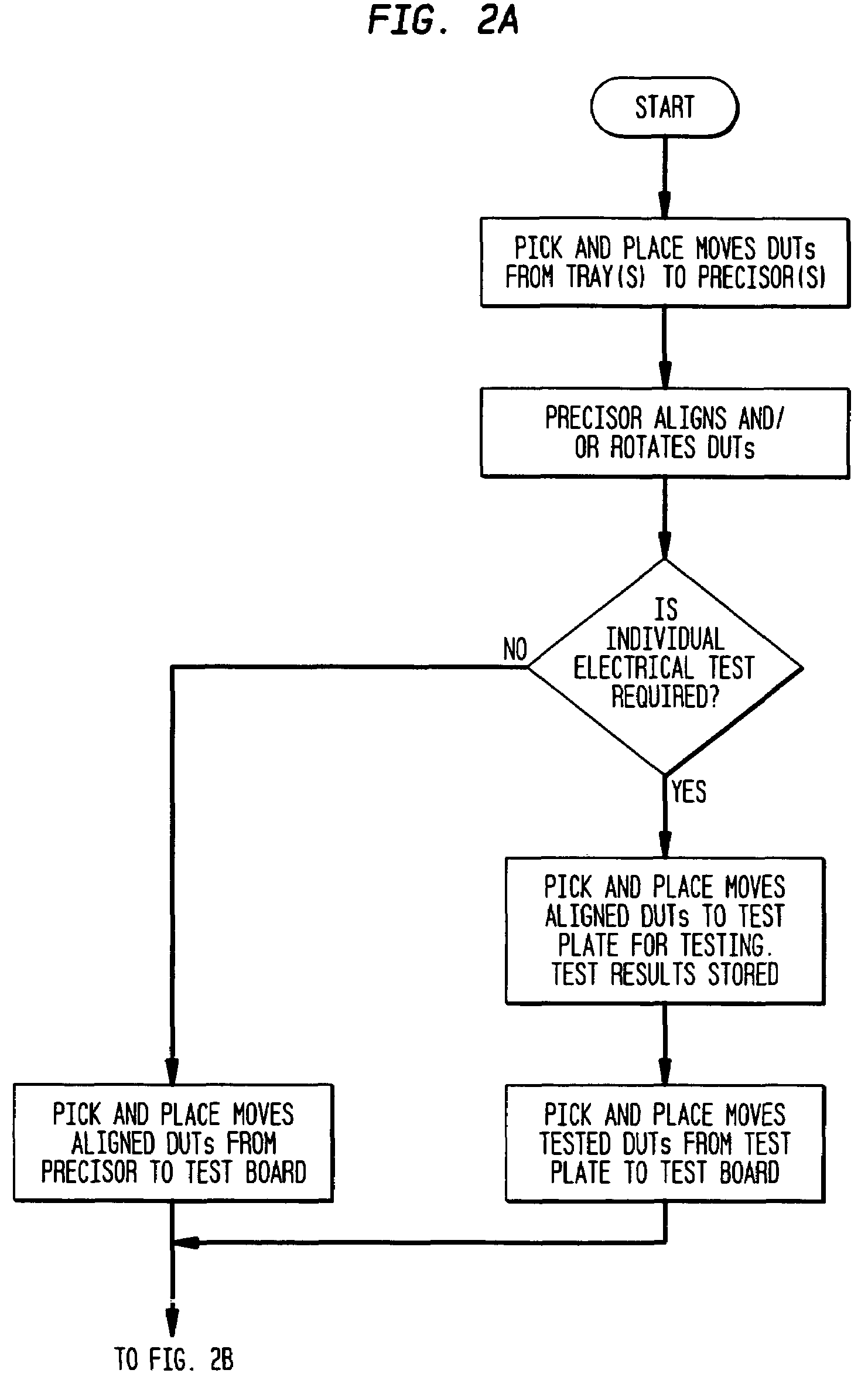

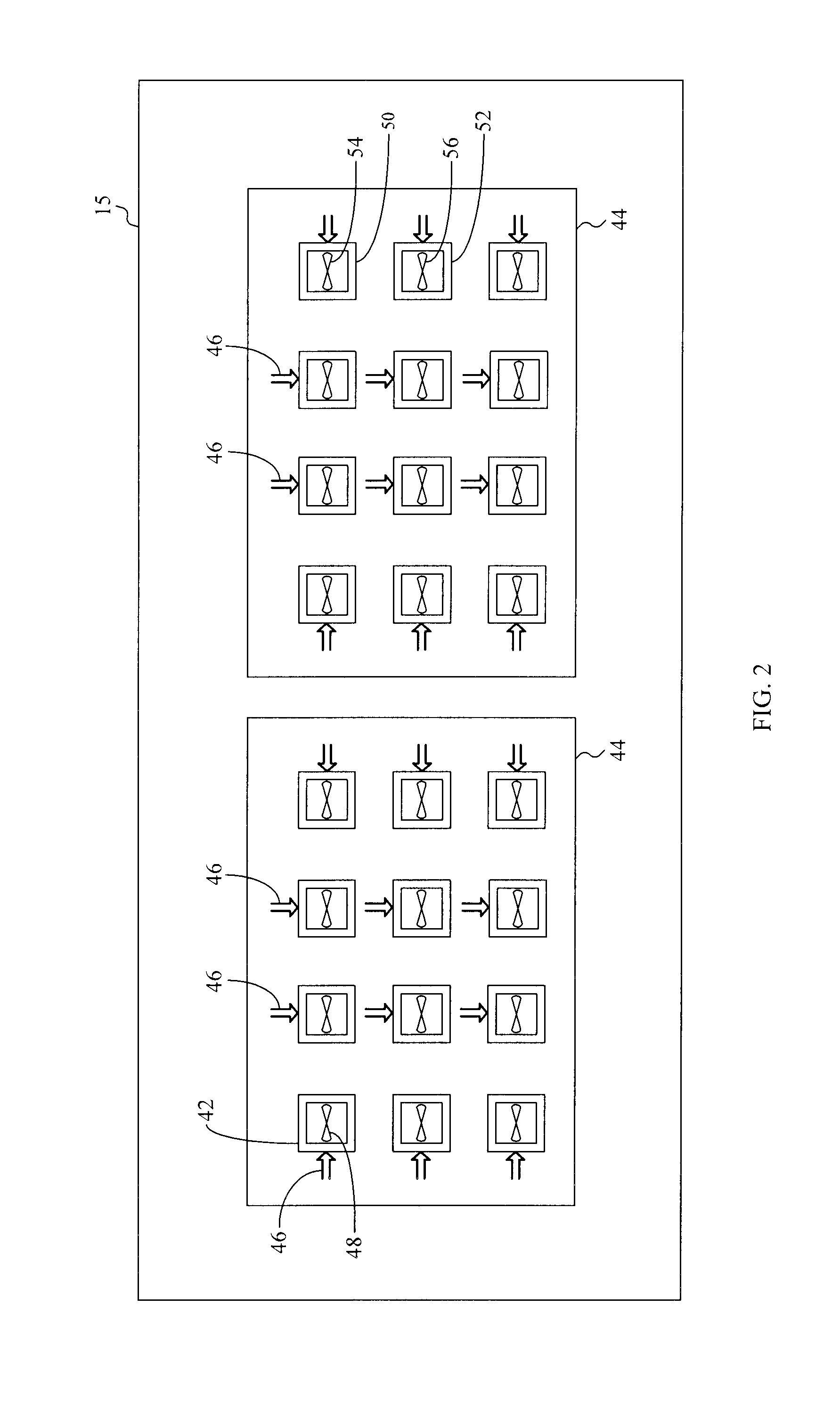

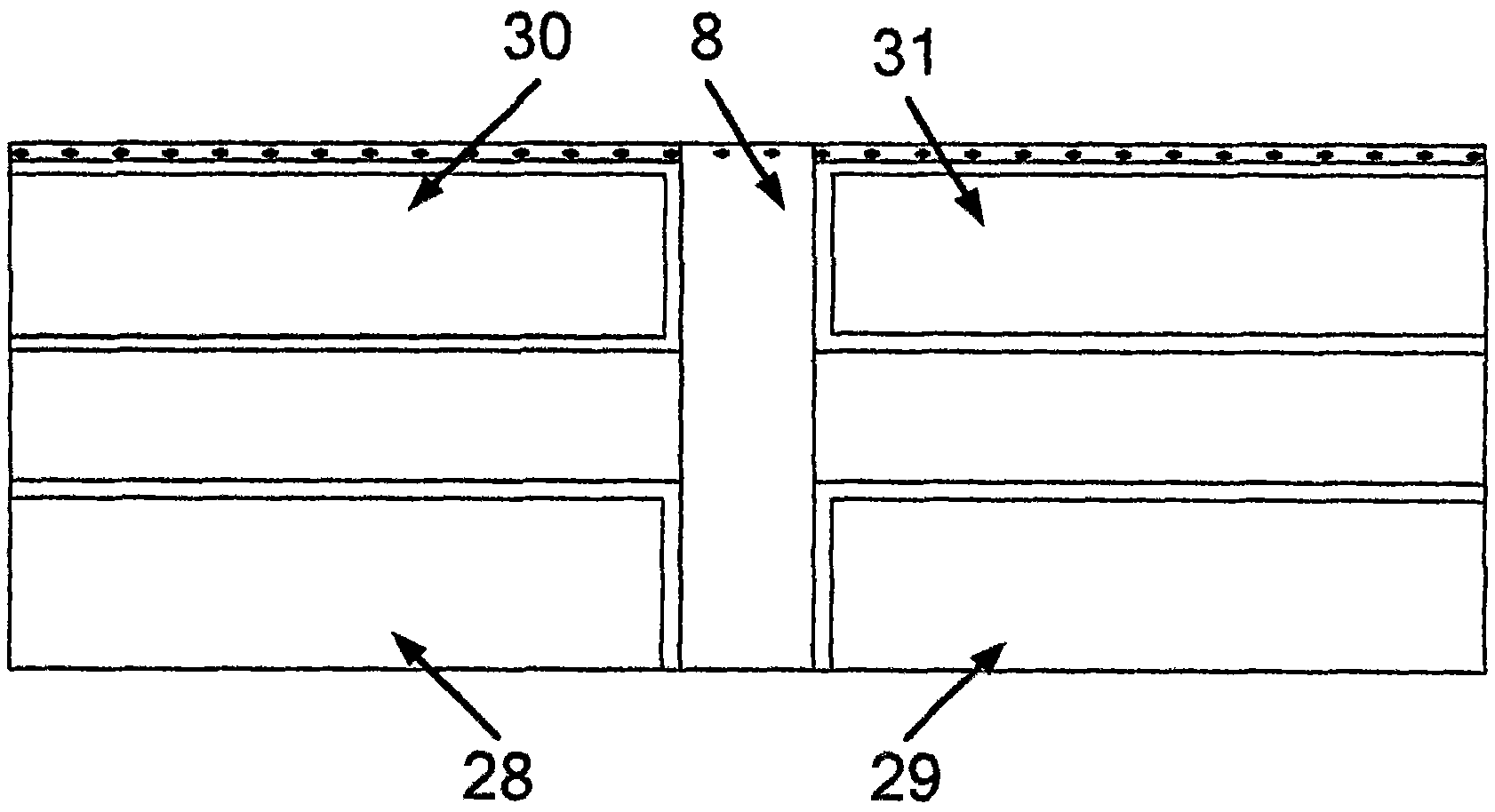

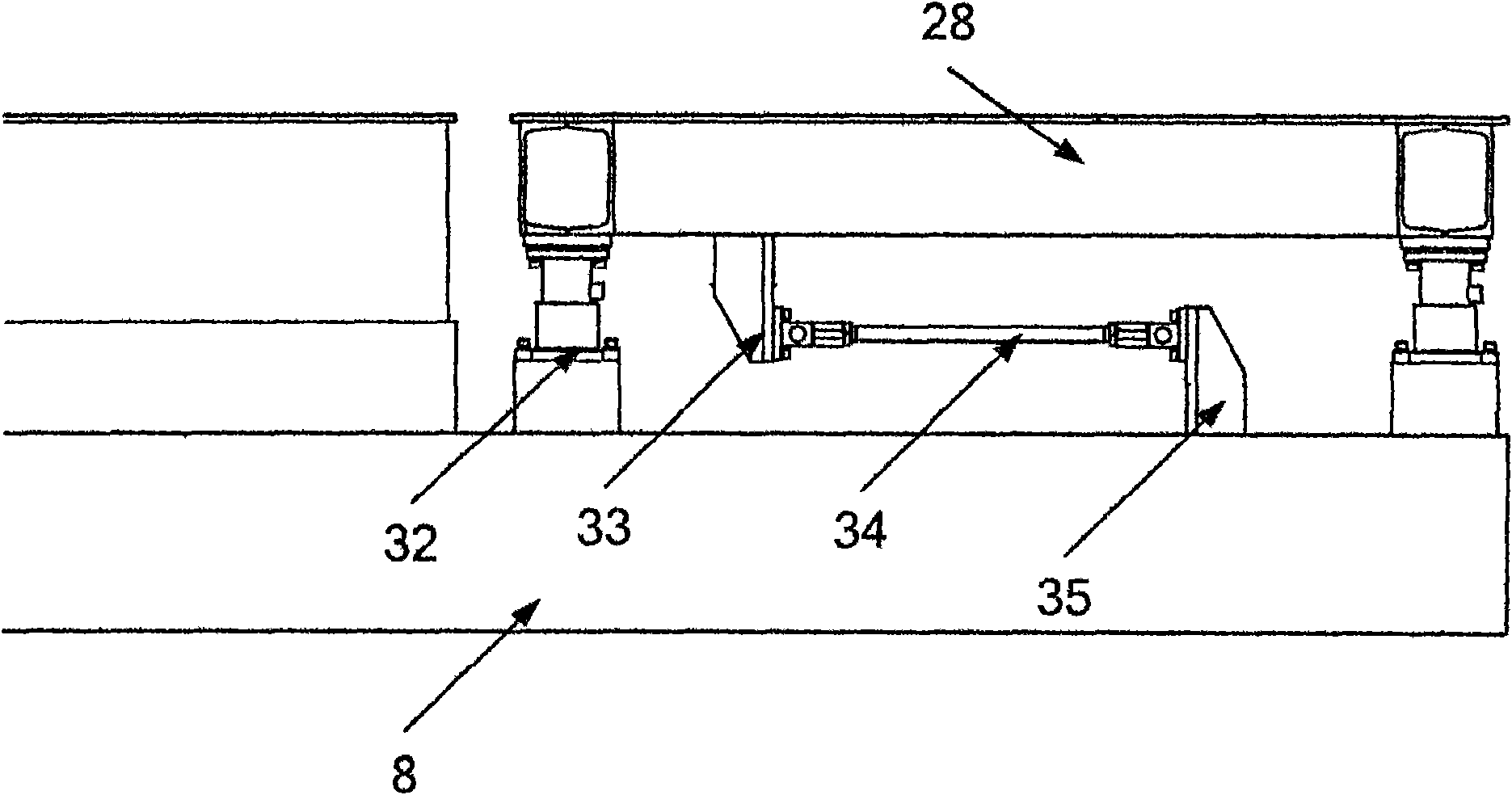

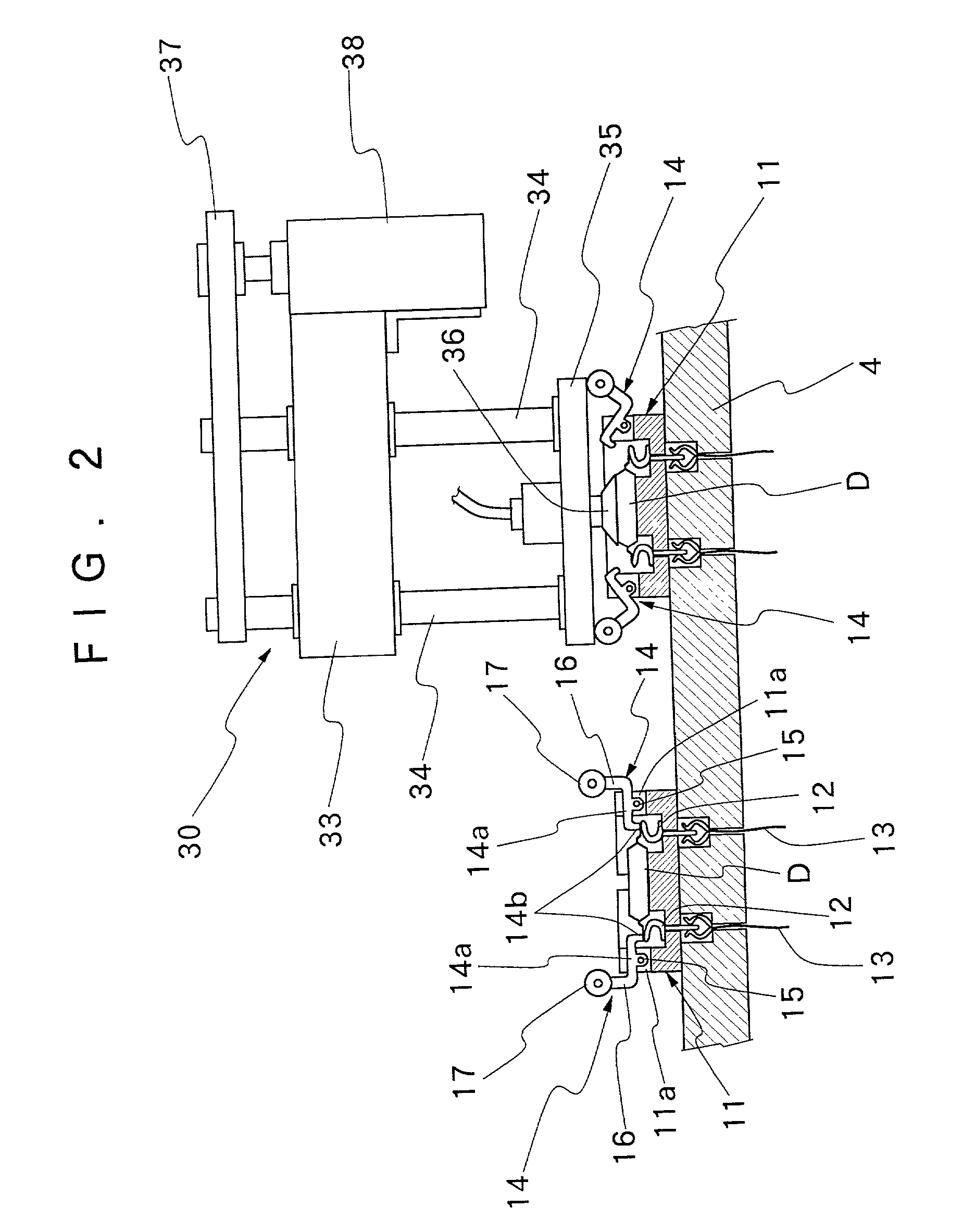

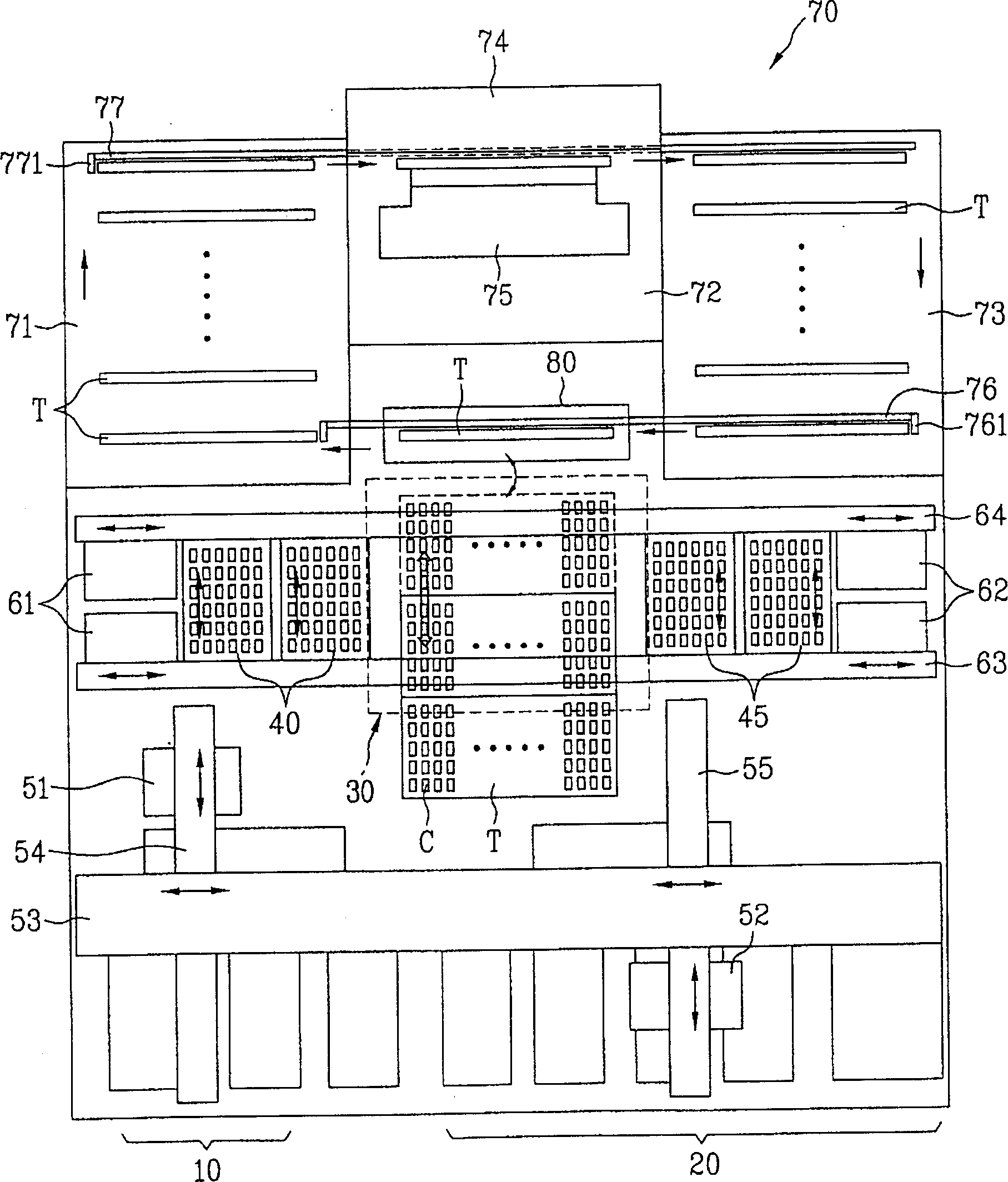

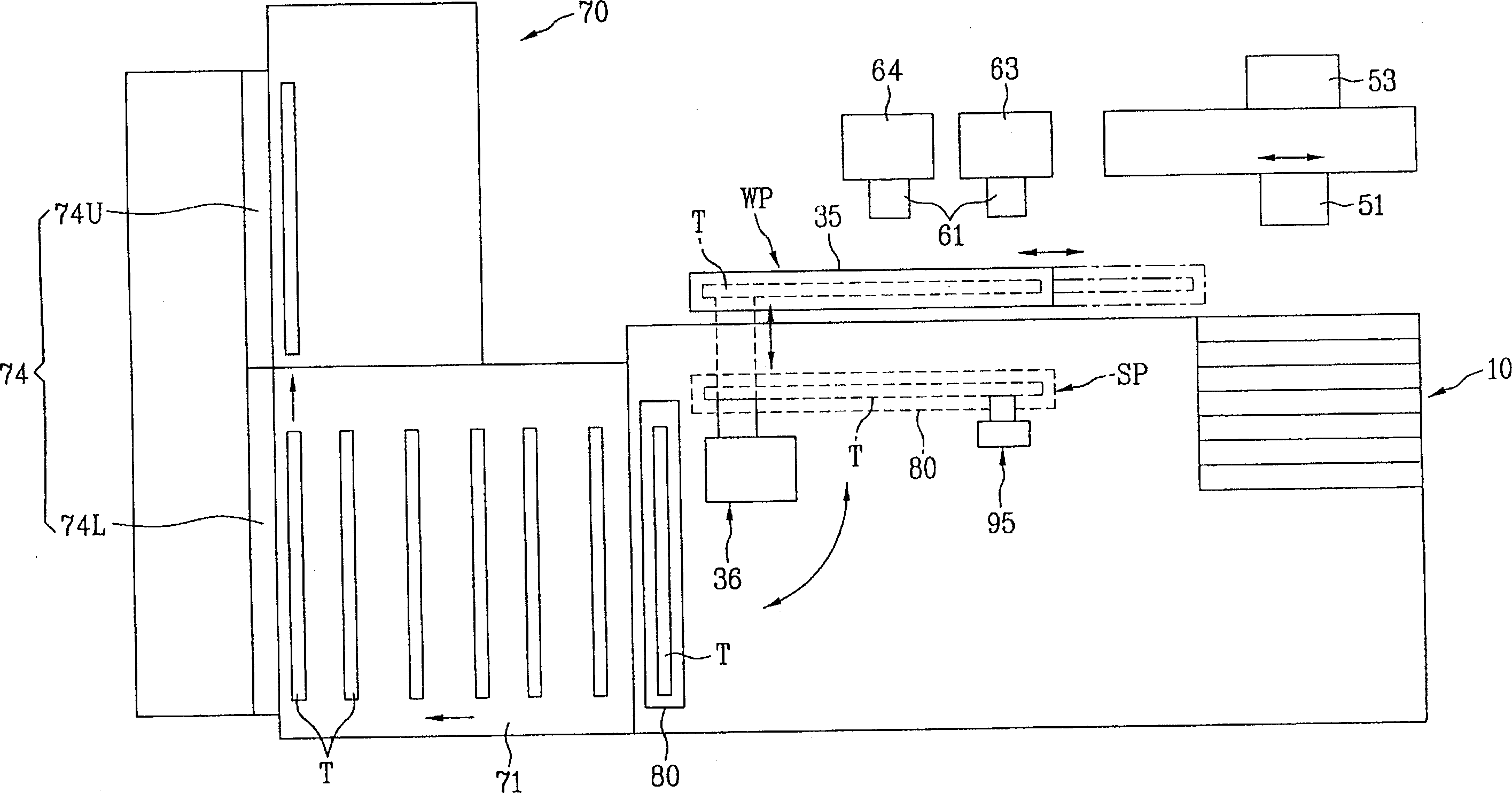

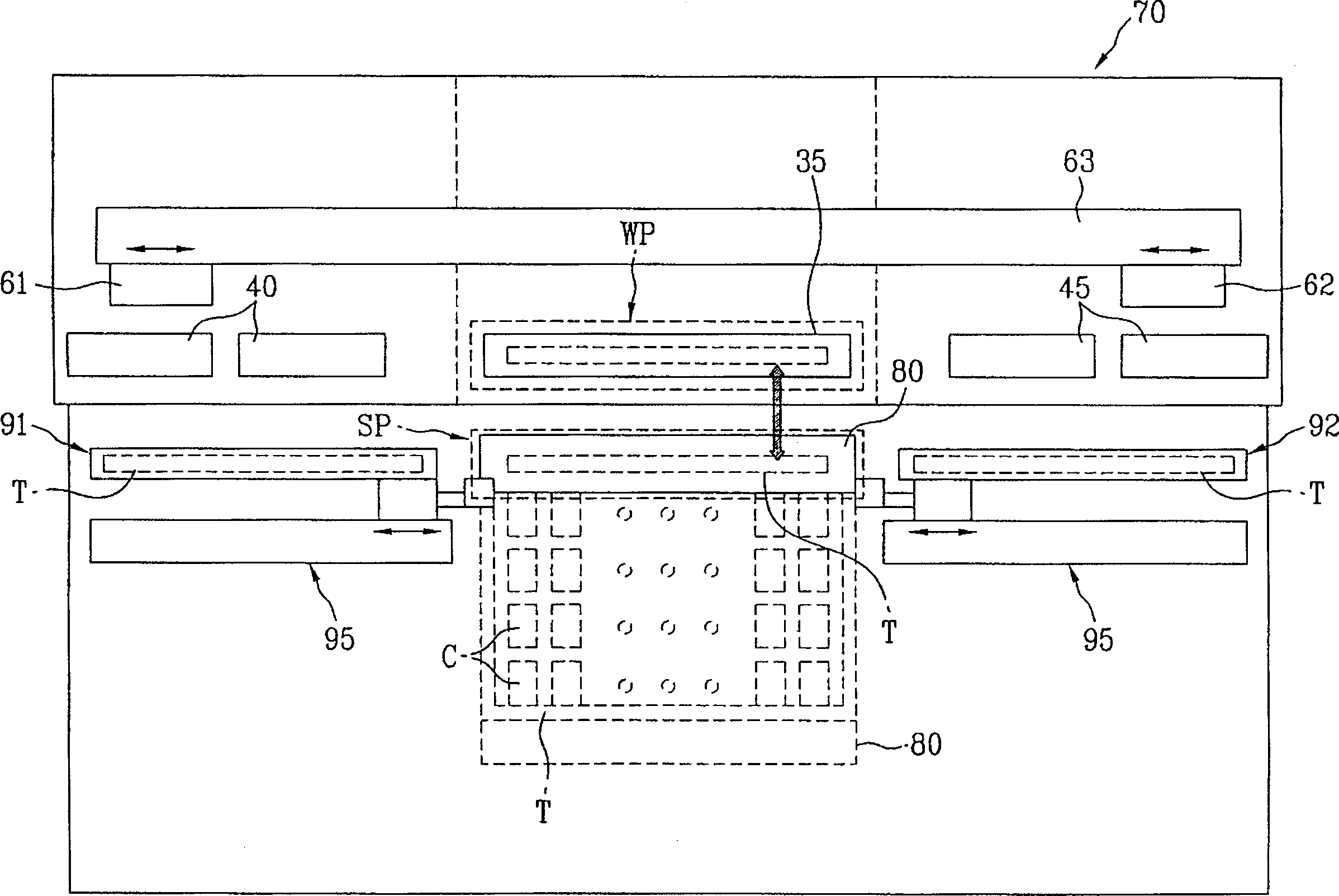

Method for testing semiconductor devices and an apparatus therefor

InactiveUS7151388B2Good flexibilityEfficient loadingSemiconductor/solid-state device testing/measurementElectrical measurement instrument detailsElectricityEngineering

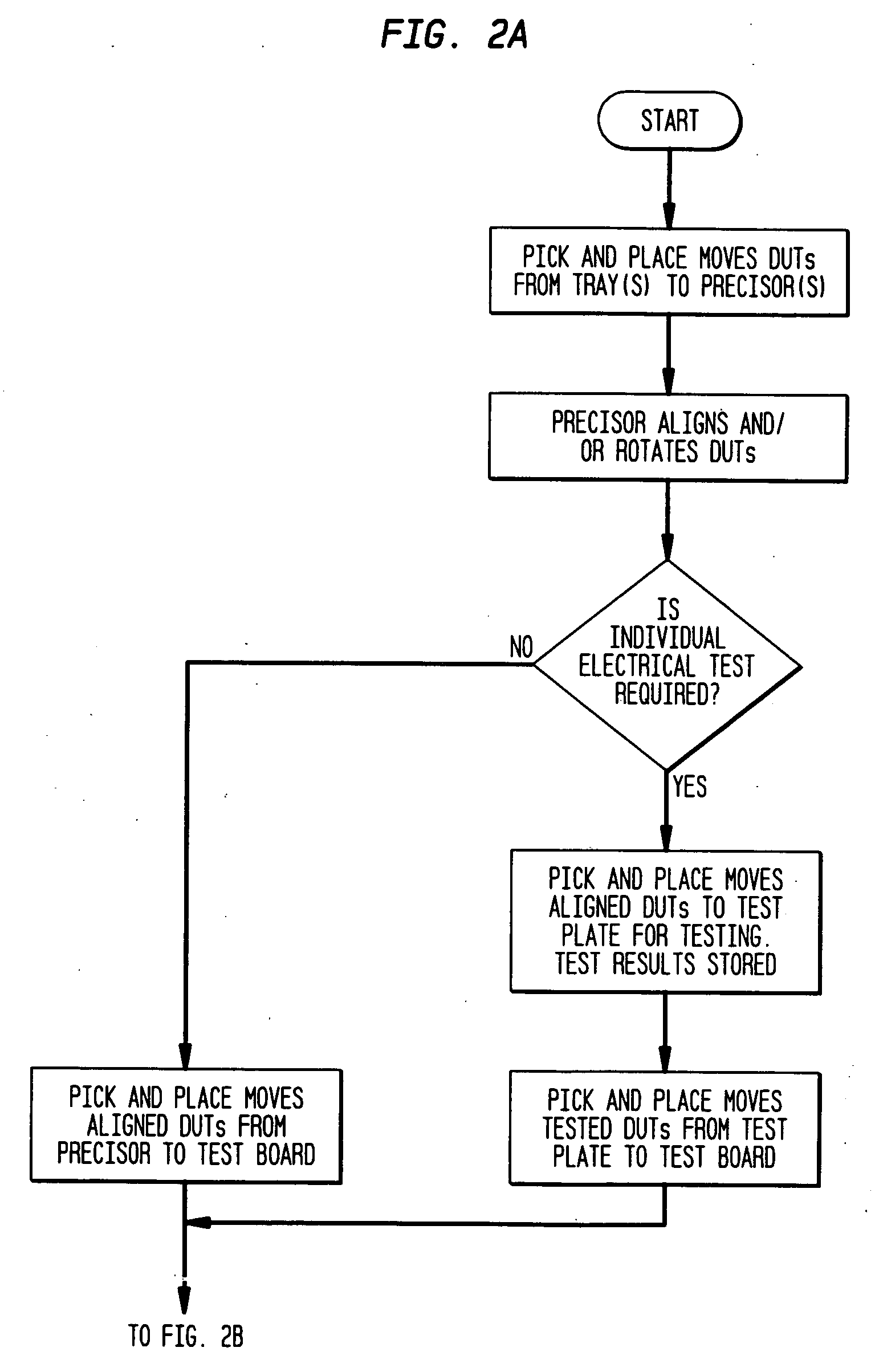

A method for testing integrated circuit devices and loading such devices into a test board for further testing and an apparatus therefor is disclosed. The method allows for selection between two modes of operation. In a first mode, the integrated circuit devices are subjected to an electrical test before being placed into the test board for further testing. In a second mode, the integrated circuit devices are tested after being placed in the test board. The apparatus allows for the selection between the first mode and the second mode. In either mode, information about the tested devices and the sockets in the test board is used to load the test boards intelligently. Intelligent loading means that devices under test (DUTs) are not placed in bad sockets and devices that do test bad are removed from the test board, with an option of replacing the failed DUT with another DUT before subsequent environmental testing of the DUTs in the test board is carried out.

Owner:KES SYST

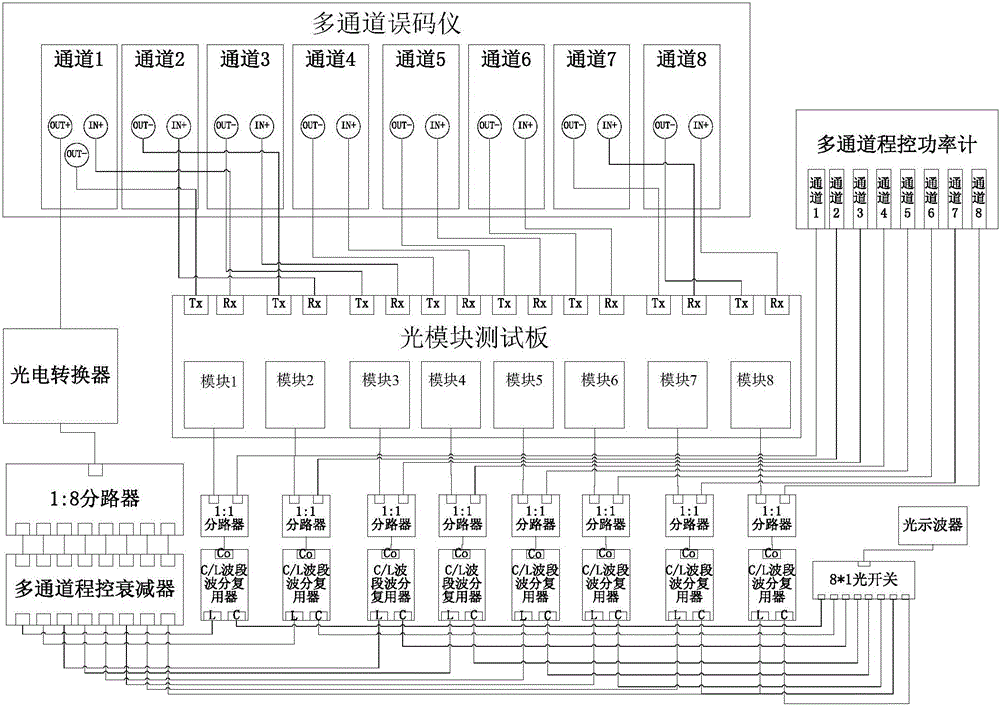

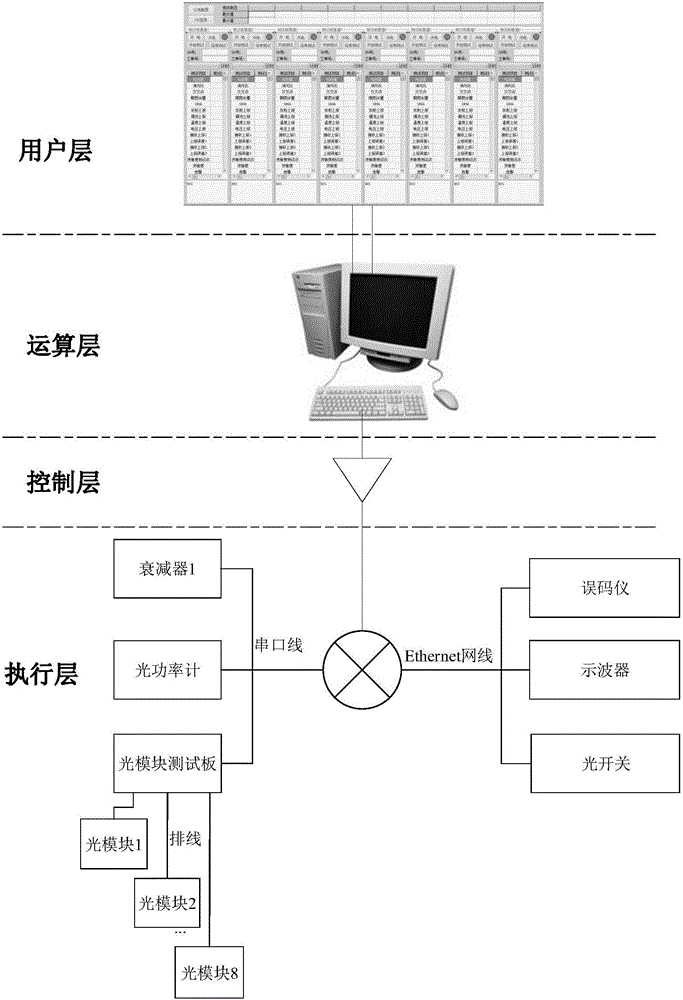

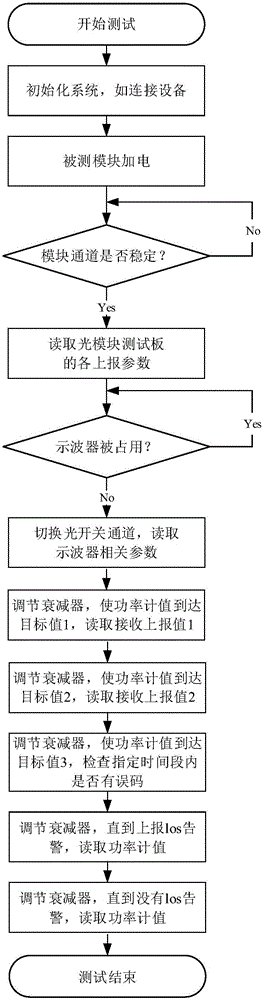

Active optical module multi-channel automatic test system and method

ActiveCN105049113AIncrease profitIncrease productivityTransmission monitoring/testing/fault-measurement systemsOptical power meterTime-sharing

The invention provides an active optical module multi-channel automatic test system and a method. optimal signals emitted by a tested optical module are monitored, and indexes of the incident light power, emission current, bias current, temperature, voltage, extinction ratio, eye diagram allowance, crossing point, OMA (optical modulation amplitude) etc. are measured and calculated; if the above indexes are all in accordance with the standard, the sensitivity of the optical module is tested, the emission optical power of the tested module is enabled to reach the sensitivity of the test standard via the adjustment of an attenuator, and error code tests are conducted; and if there is no error code, indexes of alarm value and alarm recovery etc. of the optical module are tested. According to the test system, an error detector, an optical module test board, an optical power meter, and the attenuator employed by the test system are all multi-channel devices, an optical switch and an optical splitter are combined for time-sharing multiplexing of one oscilloscope, at least 8 modules can be simultaneously tested, the utilization rate of the oscilloscope and the test efficiency of the optical module are greatly optimized, the equipment cost and the manual cost are reduced, and automatic and batch production of the optical modules is realized.

Owner:GUANGXUN SCI & TECH WUHAN

Cell analysis in multi-through-hole testing plate

InactiveUS20050059074A1Simplify the test procedureEasy constructionSequential/parallel process reactionsLibrary tagsGenetic diversityTonicity

A spatially fixed library of mutated cells and a method for creating such a library. The library is created by creating a set of cells having a genetic diversity, causing the cells to multiply and express phenotypes, preparing a solution containing the cells diluted in a medium, populating a plurality of through-holes of a testing plate with the solution such that surface tension holds the solution in respective through-holes, and analyzing the phenotypes of the cells in the solution on a hole-by-hole basis. Cells expressing specified phenotypes may then be retrieved.

Owner:LIFE TECH CORP

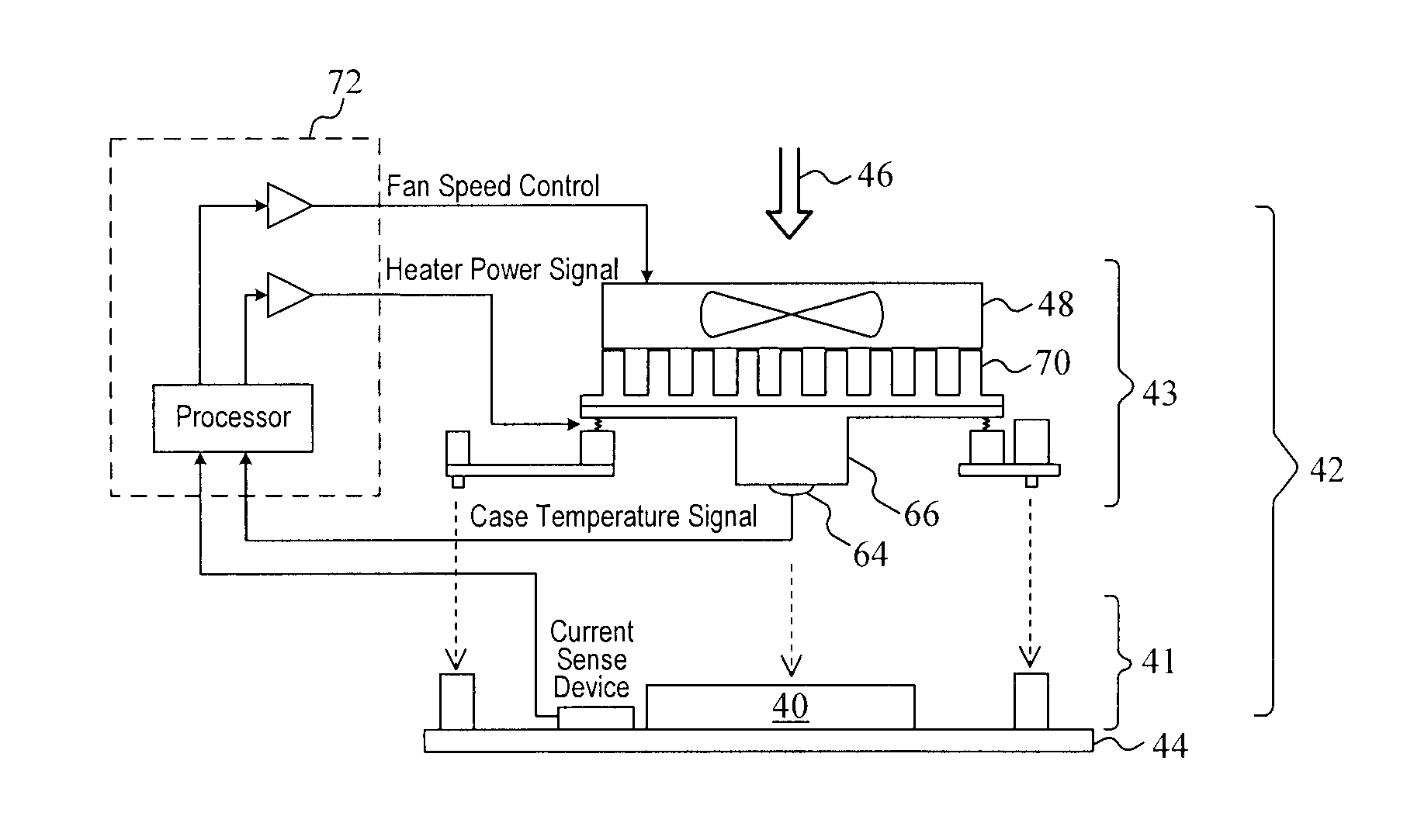

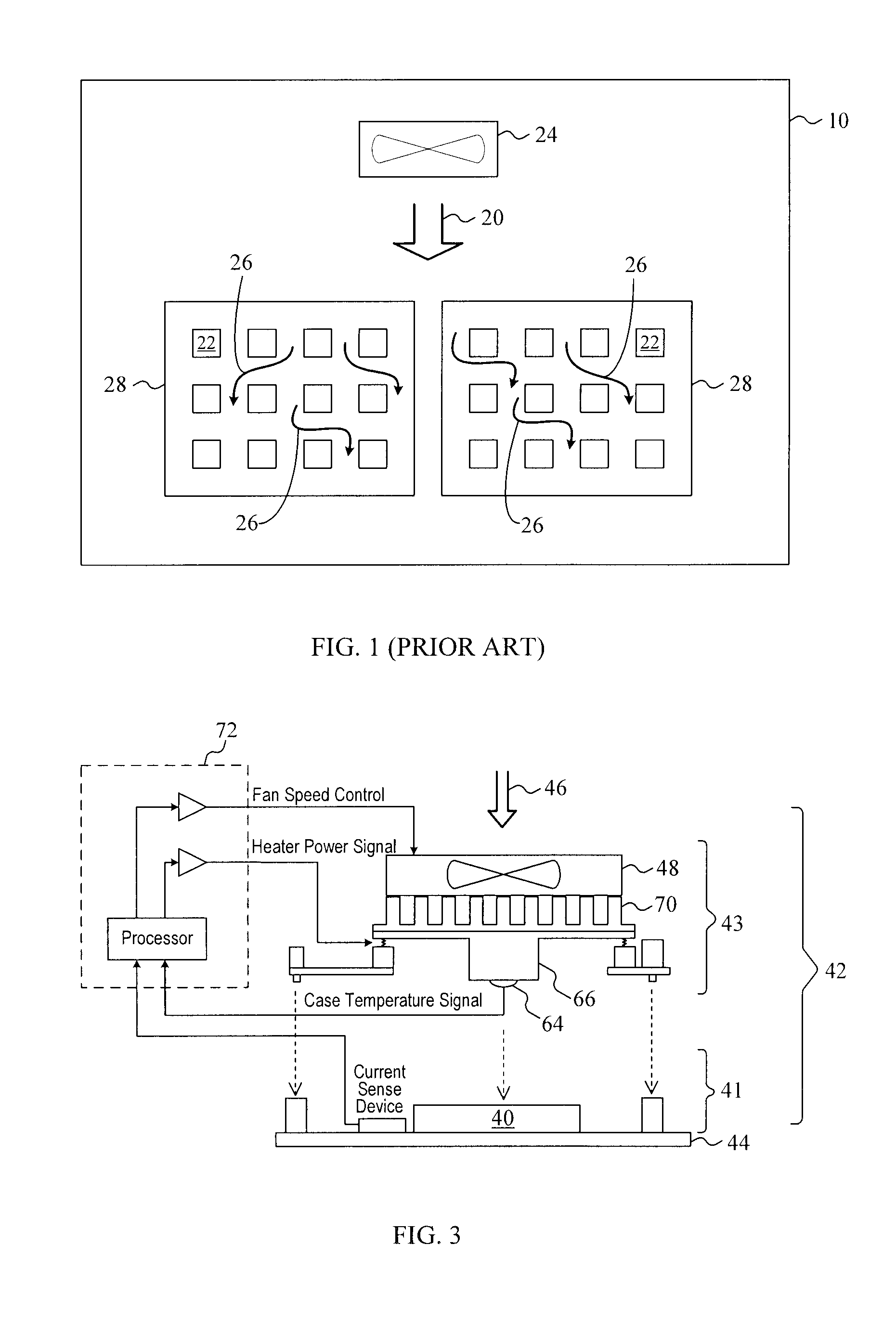

Temperature control in IC sockets

InactiveUS20060290370A1Maintain surface temperatureMaintain temperatureElectrical measurement instrument detailsFault location by increasing destruction at faultTemperature controlElectronic controller

A system and method are provided which provides more accurate temperature control of integrated circuits. A system for testing integrated circuit (IC) packages comprises a plurality of IC testing socket bases arranged on a testing board and configured to receive a plurality of IC packages. A plurality of IC testing socket lids are arranged to attach to the testing board. Each IC testing socket lid comprises a temperature sensor to thermally contact the IC package and measure a surface temperature of the IC package, a heater or cooler to directly contact the IC package, and an electronic controller to receive signals from the temperature sensor. The electronic controller is programmed to change the temperature of the heater or cooler responsive to the measured surface temperature of the IC package. A plurality of cooling devices individually removes heat generated by the plurality of IC packages. The electronic controller in each IC testing socket lid is further programmed to control a corresponding cooling device to maintain the surface temperature of the plurality of IC packages within a desired temperature range.

Owner:WELLS CTI LLC

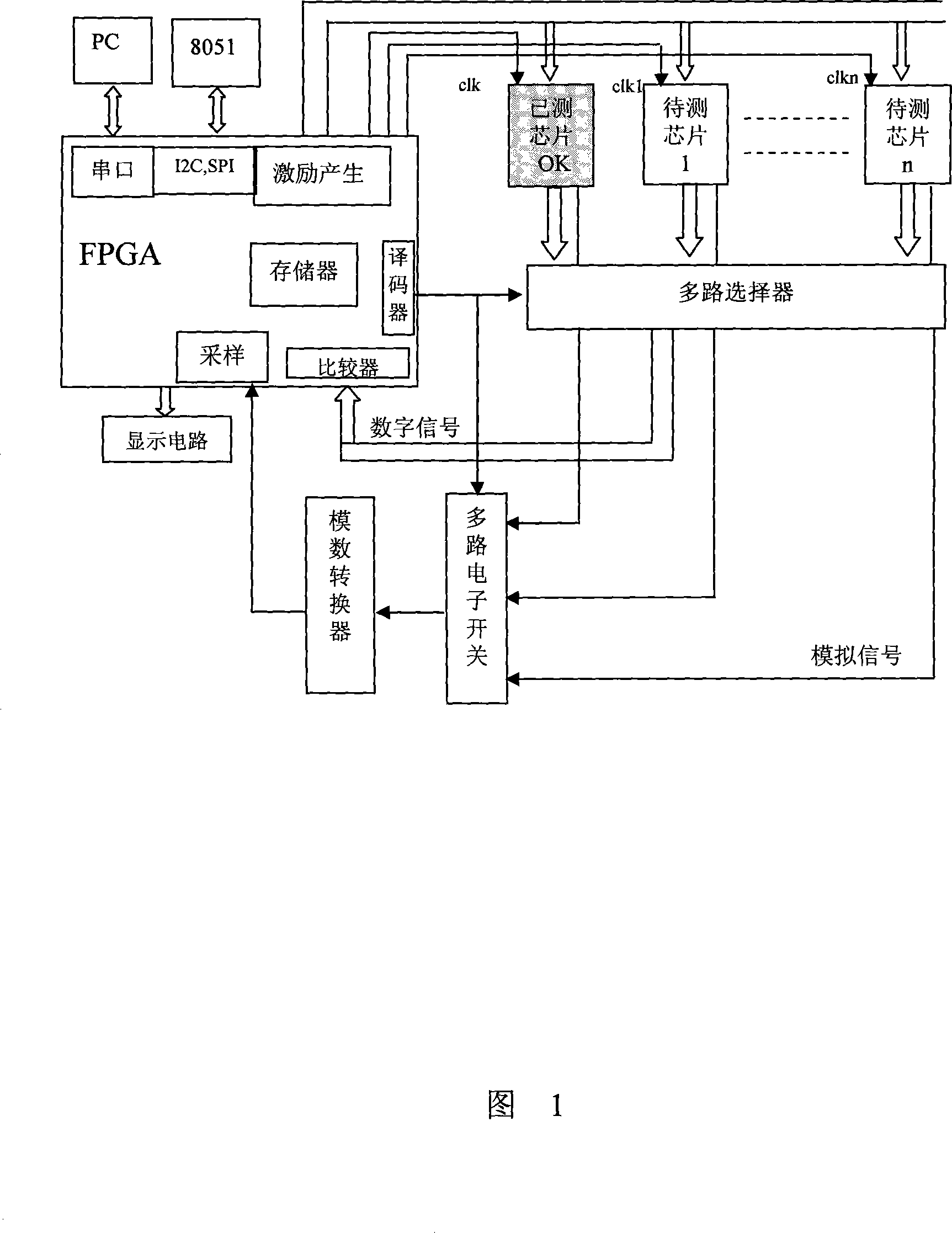

Multiple chips automatic test method based on programmable logic device

InactiveCN101158708AMeet the test requirementsImplement automated testingDigital circuit testingProgrammable logic deviceField-programmable object array

The invention relates to an automatic testing technology for molectron, in particular to an automatic testing method for multiple chips based on field programmable gate array (FPGA). According to the technical scheme provided by the invention, the field programmable gate array comprises the sample circuits that are connected to each other, a circuit of digital comparator, an encoder, and a pulse generating circuit. The technical scheme is characterized in that the input end of the circuit of digital comparator is connected with the output end of a multiplexer, the input end of the sample circuit is connected with a plurality of chips being tested; and the pulse generating circuit is connected with a plurality of chips being tested and a tested chip respectively; the output end of the encoder circuit is connected with the multiplexer. The invention uses the field programmable gate array (FPGA) to set up a simple automatic testing system, in which the automatic testing of a single or a plurality of chips can be implemented simultaneously on a testing board, The invention achieves automatic testing and has low input cost and rapid development, thus completely satisfying the requirement for the testing of small-lot products.

Owner:无锡汉柏信息技术有限公司

Method for testing semiconductor devices and an apparatus therefor

InactiveUS20060066293A1Good flexibilityEfficient loadingSemiconductor/solid-state device testing/measurementElectronic circuit testingElectricityEngineering

A method for testing integrated circuit devices and loading such devices into a test board for further testing and an apparatus therefor is disclosed. The method allows for selection between two modes of operation. In a first mode, the integrated circuit devices are subjected to an electrical test before being placed into the test board for further testing. In a second mode, the integrated circuit devices are tested after being placed in the test board. The apparatus allows for the selection between the first mode and the second mode. In either mode, information about the tested devices and the sockets in the test board is used to load the test boards intelligently. Intelligent loading means that devices under test (DUTs) are not placed in bad sockets and devices that do test bad are removed from the test board, with an option of replacing the failed DUT with another DUT before subsequent environmental testing of the DUTs in the test board is carried out.

Owner:KES SYST

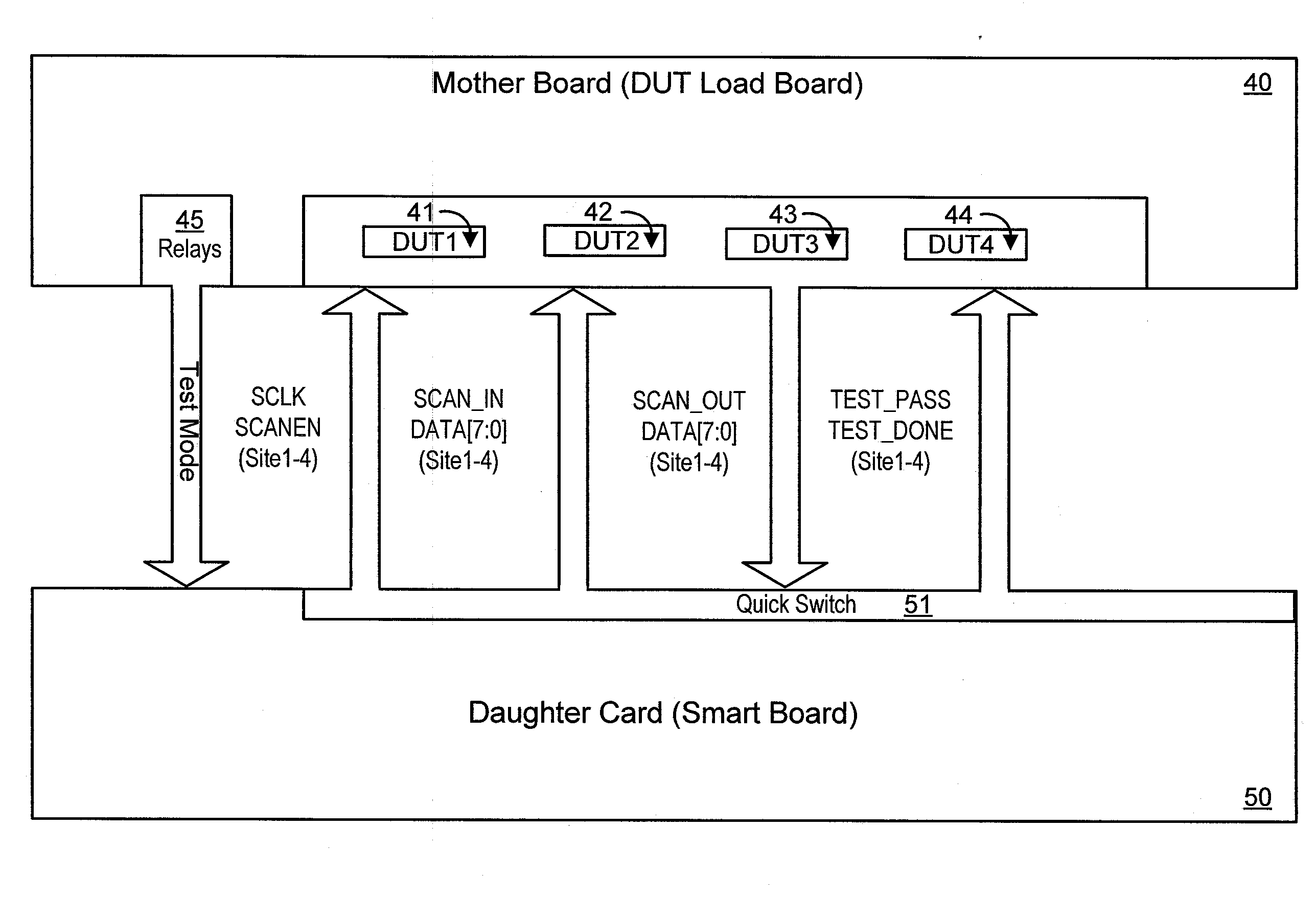

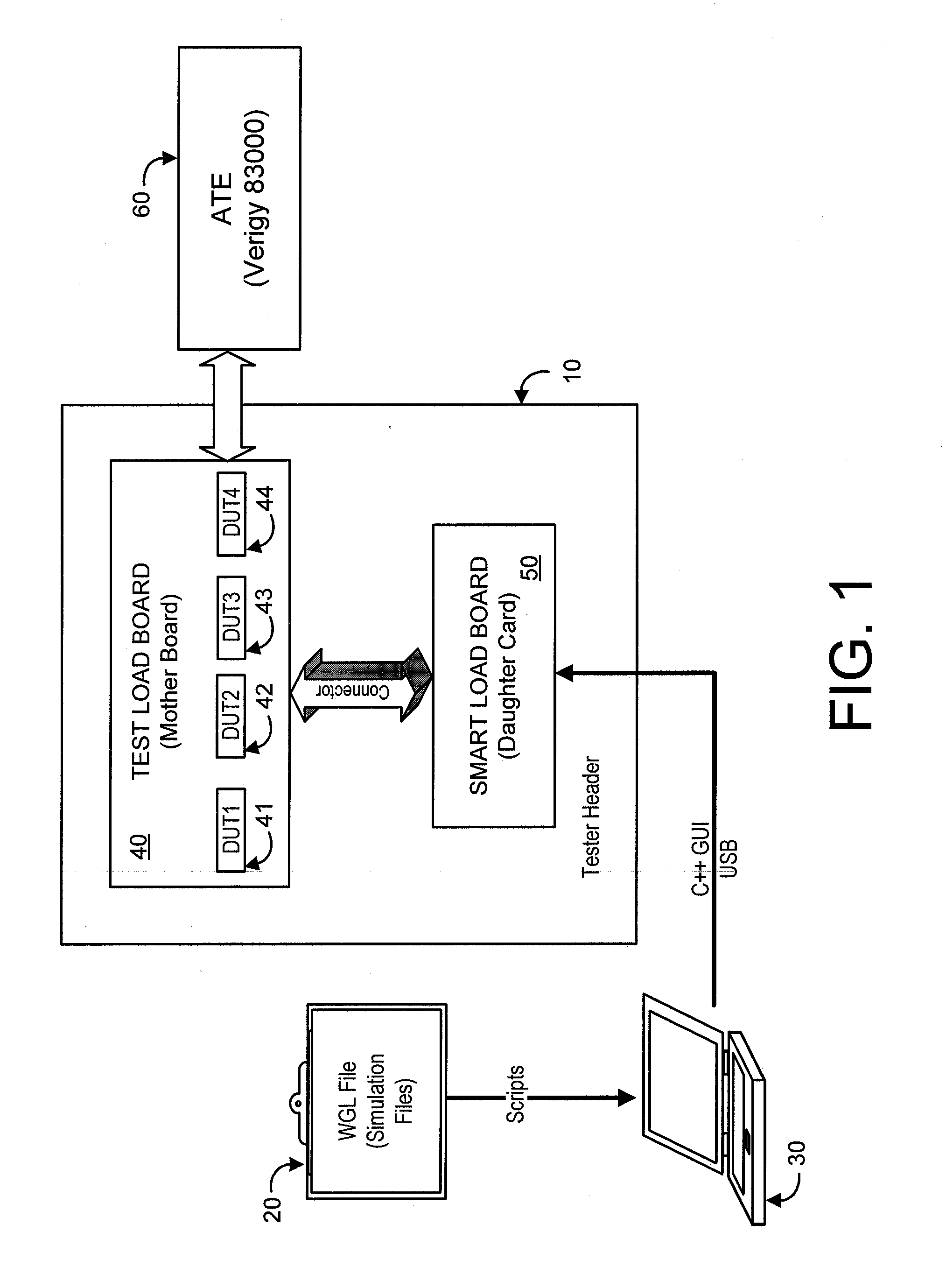

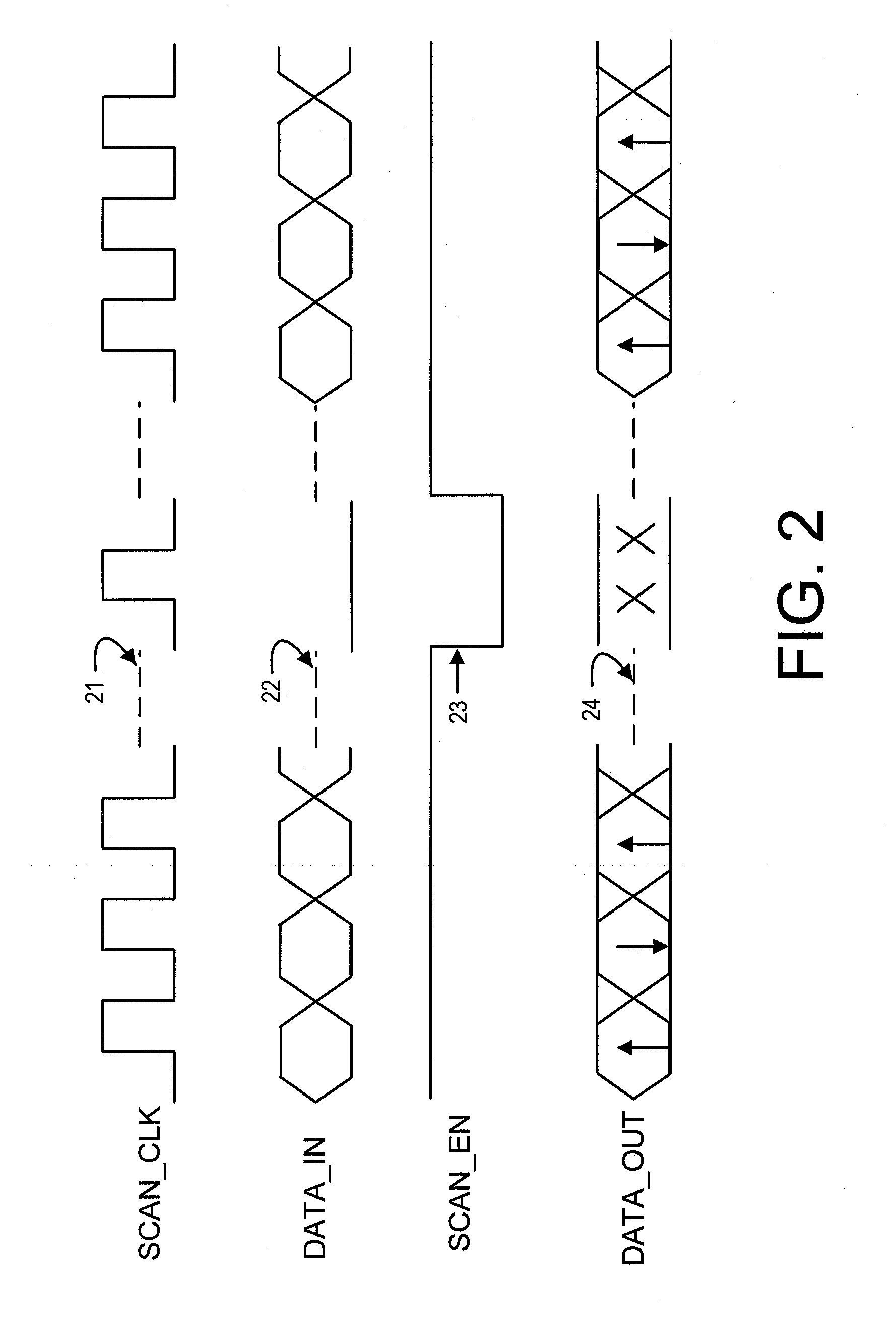

Method and Apparatus of ATE IC Scan Test Using FPGA-Based System

An apparatus and a method for enhancing the use of automated test equipment (ATE), are presented. The apparatus comprises a test load board that mounts a plurality of devices to be tested (DUTs), and a daughter card communicating with the test board and the ATE, testing each of the plurality of devices, and providing test results to the ATE. The method comprises mounting a plurality of devices to be tested on the test load board, using the daughter card to communicate with the test board and the ATE, and using the daughter card for testing each of the plurality of DUTs, providing test results to the ATE. Also provided is a system to perform automated tests of integrated chips, comprising an ATE scan test unit, an off-load tester resource coupled to the ATE scan test unit, a processor executing commands to control the ATE unit and the off-load tester resource.

Owner:INTEGRATED DEVICE TECH INC

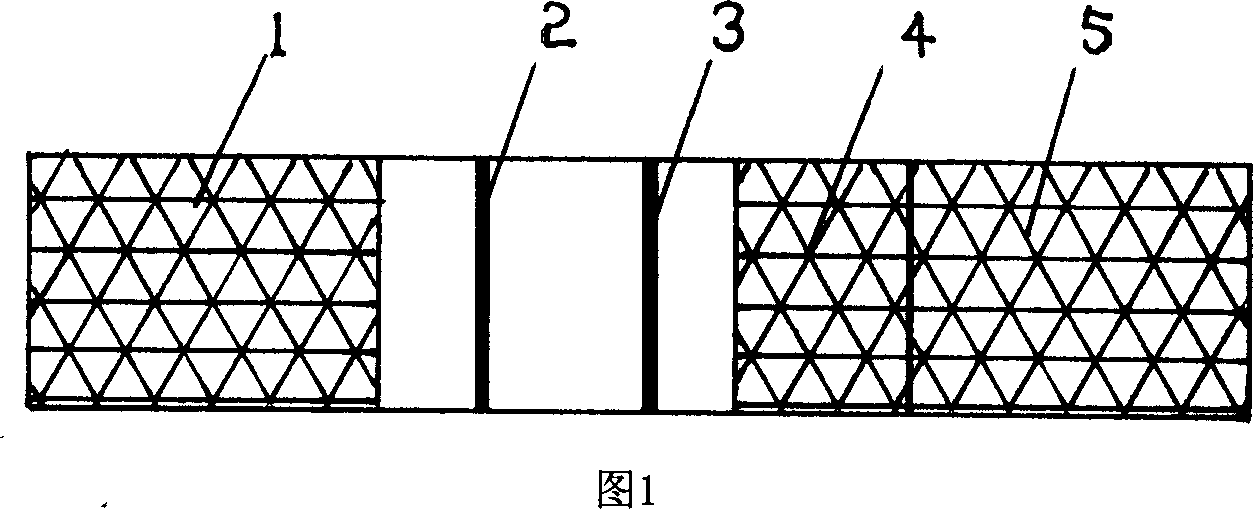

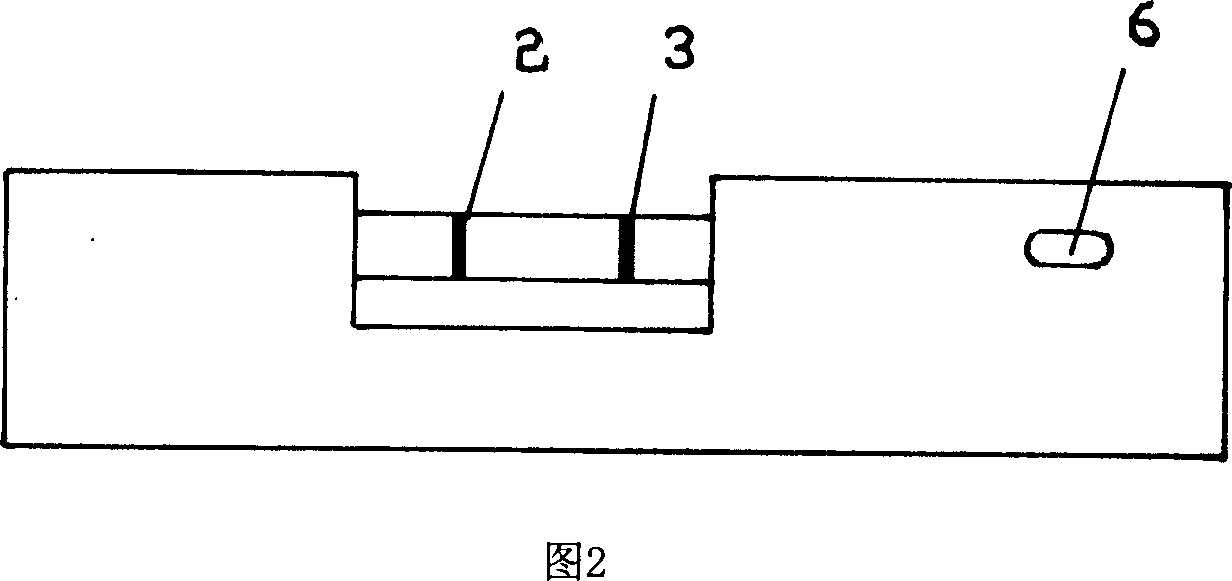

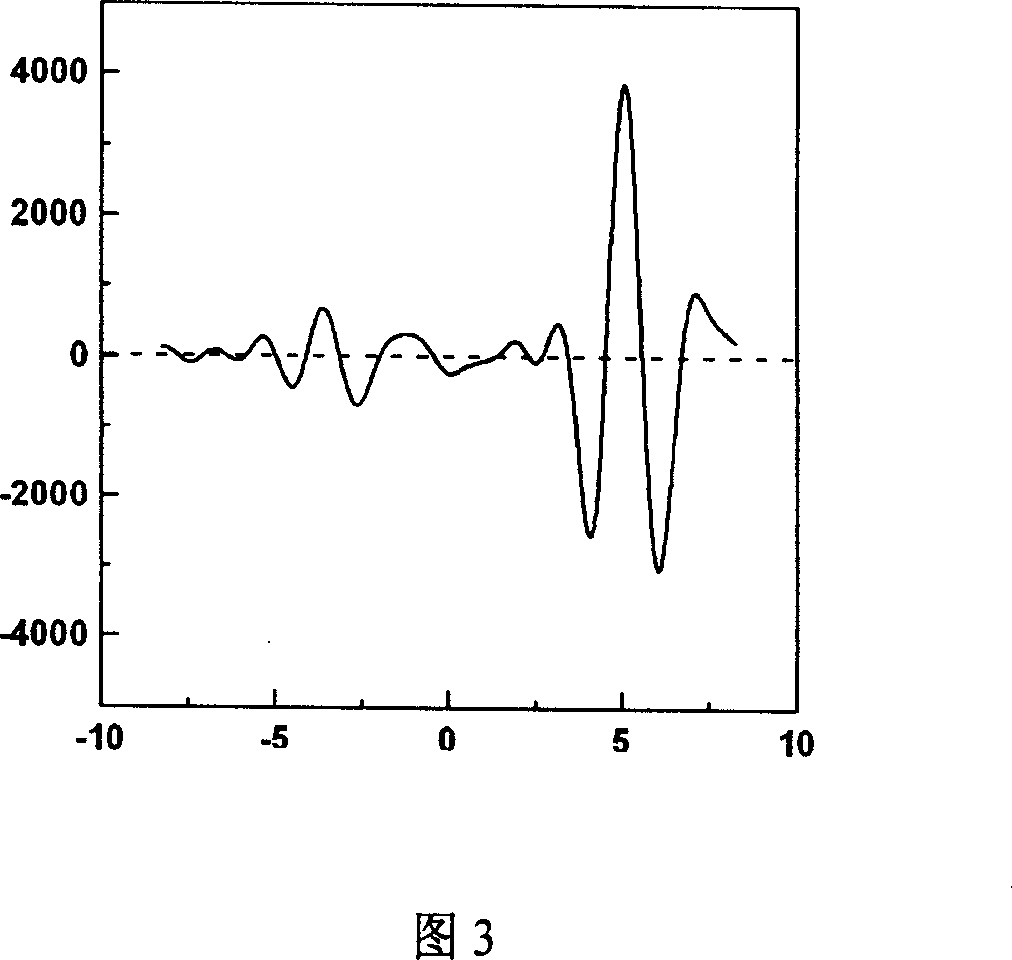

Immuno magnetic bead and producing method, and method and test plate for detection

An immune bead is made up of the magnetic carrier micro ball which combines at least one immune matching base. The micro ball is composed of the magnetic nm particle and the high molecular framework material which the core is the metal particle; the out of the core is high molecular framework, the out layer is the functional layer which can combines functional gene of different immune matching base. The manufacture method includes: the bead pretreatment, the bead activation, manufacture of the coupling antibody, closing the antibody with the confining liquid and purifying the immune bead. The detecting method is to detect the different things by the immunological response sandwich, the competition and the indirect method and set the control system on the testing board. The board is made up of the encrusting test paper, the coupling mat, the sample mat, the water suction mat, the coving film and the testing board outside calipers. It has the high sensitivity and accurate quantity; the regent is simple and cost low.

Owner:YANGTZE DELTA REGION INST OF TSINGHUA UNIV ZHEJIANG

Automobile pedal operating mechanism assembly performance test board

ActiveCN102353544AShorten the development and trial production cycleReduce test costsVehicle testingMachine gearing/transmission testingElectricityControl system

Owner:RES INST OF ZHEJIANG UNIV TAIZHOU

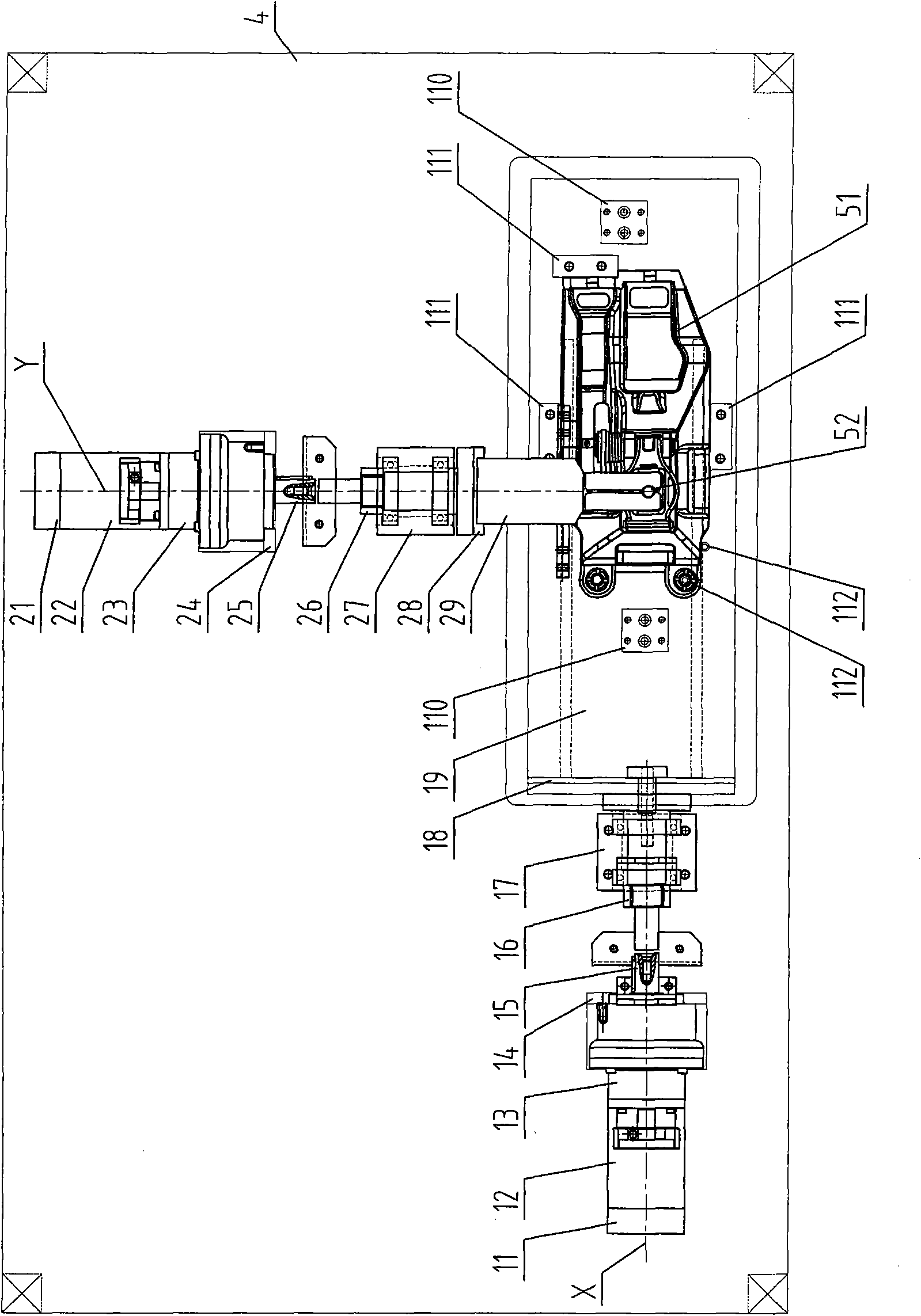

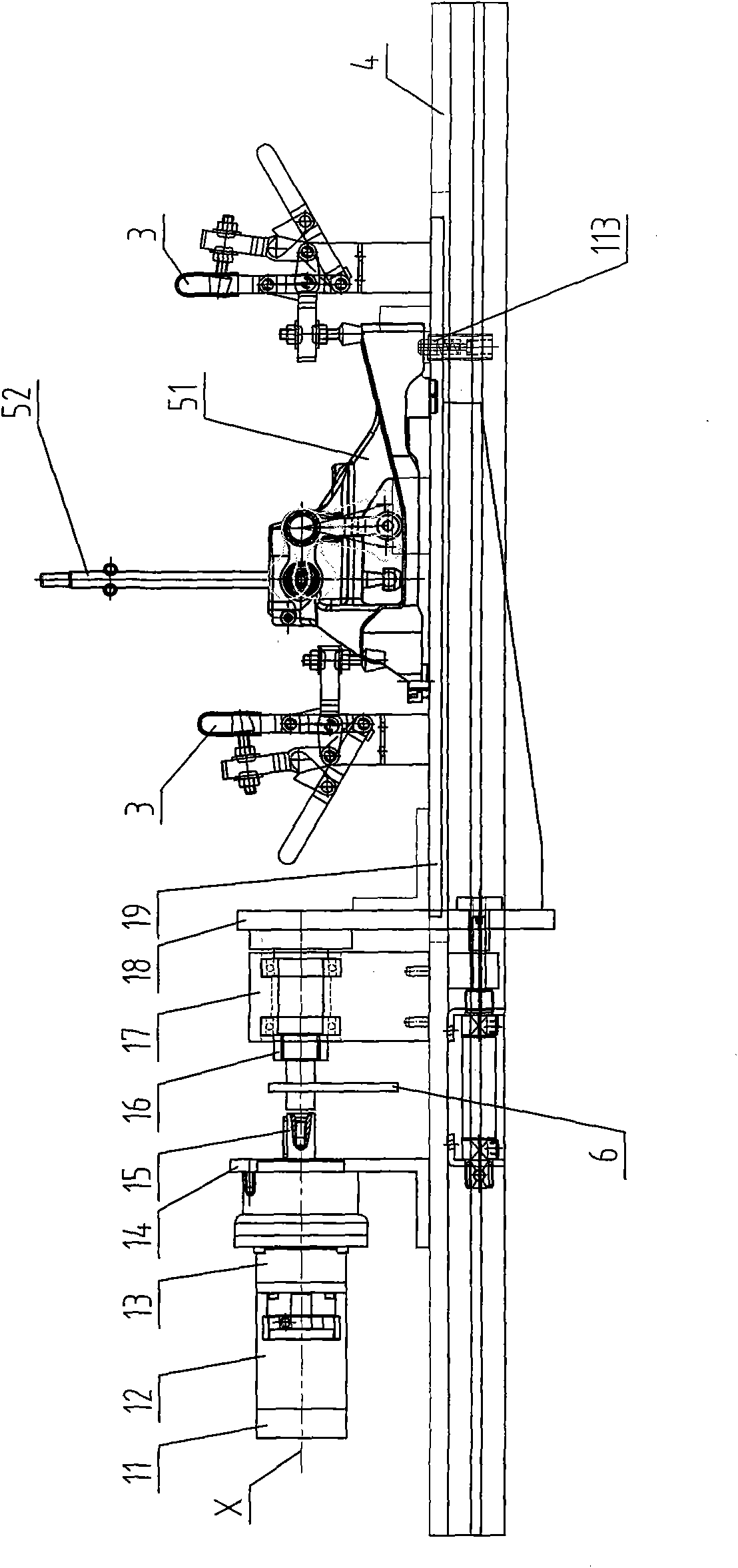

Performance detection workstation for automotive gear shifter assembly and detection method thereof

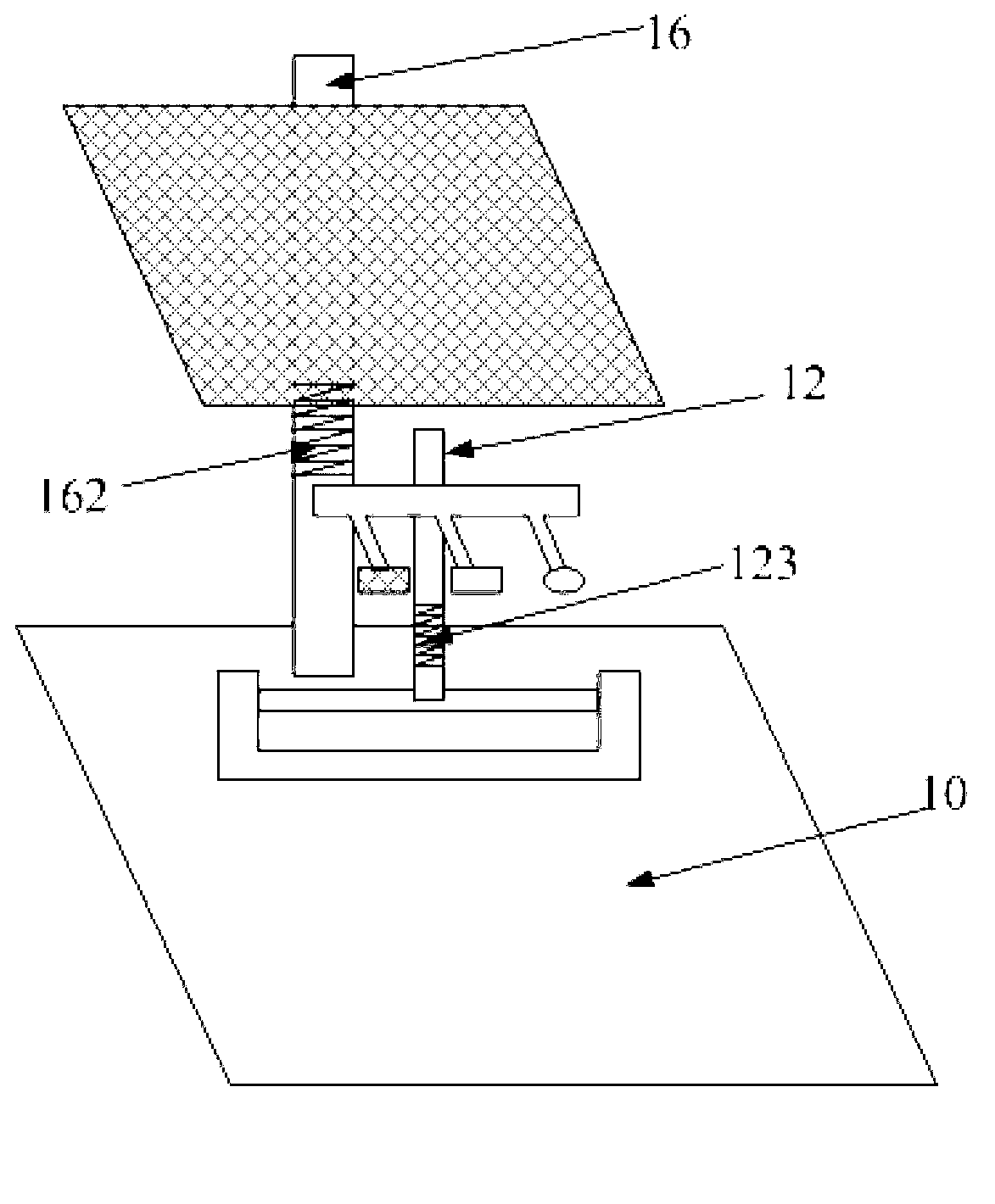

InactiveCN101566521ASimple structureEasy to assembleVehicle testingMachine gearing/transmission testingWorkstationTest board

The invention provides a performance detection workstation for an automotive gear shifter assembly. The automotive gear shifter assembly comprises a gear shifter body and a gear shifter handle; the performance detection workstation for the automotive gear shifter assembly comprises a first driving system, a second driving system, a test board used for fixing the gear shifter body, and a clamping jaw for clamping the gear shifter handle; the first driving system drives the test board and the gear shifter body to rotate around a first axis; the second driving system drives the clamping jaw and the gear shifter handle to rotate around a second axis; and the first axis and the second axis are mutually vertical. The performance detection workstation has the main advantages that: because the gear shifter body and the gear shifter handle are controlled by an individual mechanism to rotate, the structure is simple and the assembly is convenient; parts used by the workstation are standard pieces and do not need to be separately designed and manufactured, so the cost is greatly lowered; and the performance detection workstation is suitable for the performance detection of an automotive gear shifter of which all gear shifting rods have only one rotation center.

Owner:安徽格比智能科技有限公司

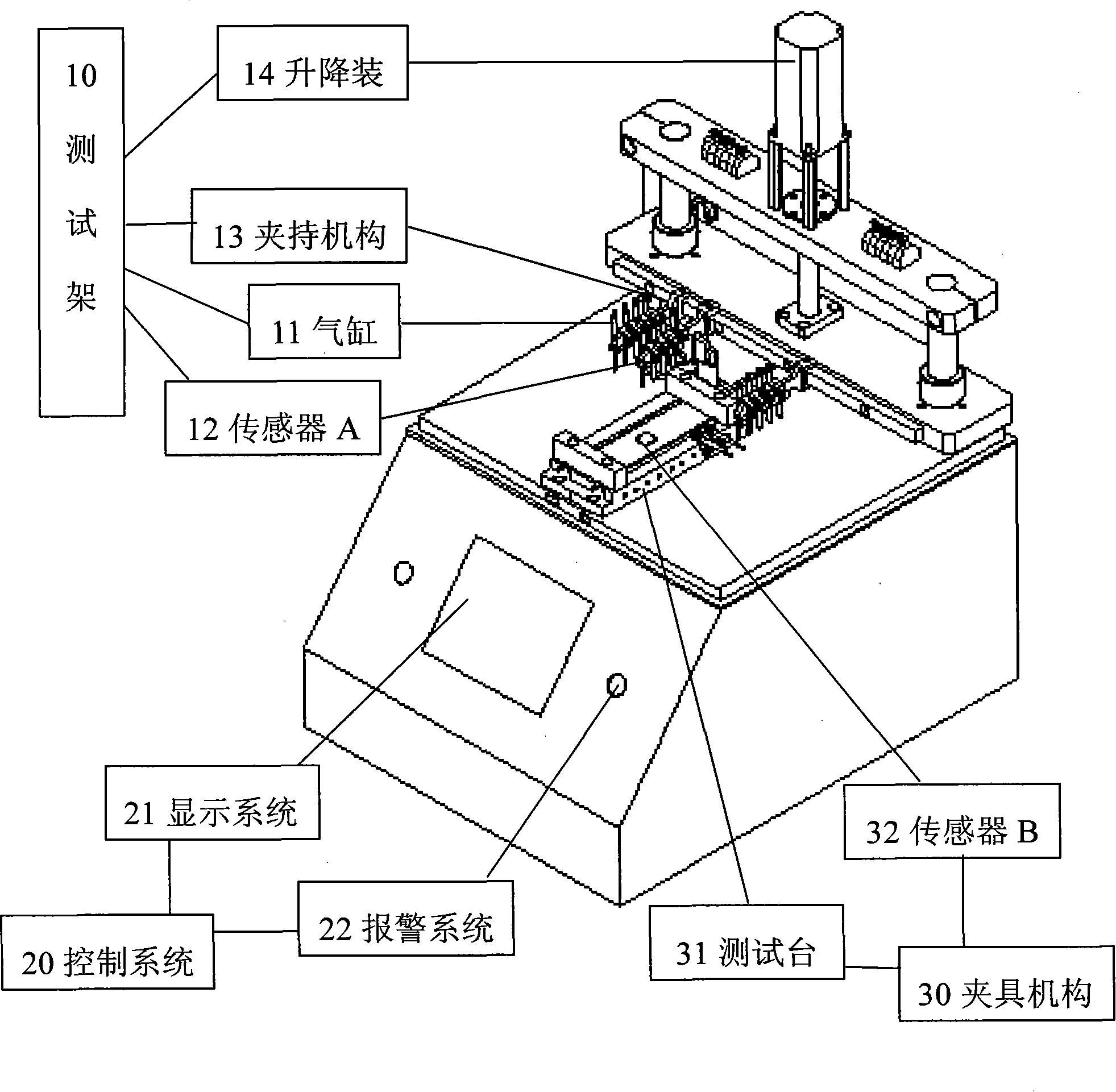

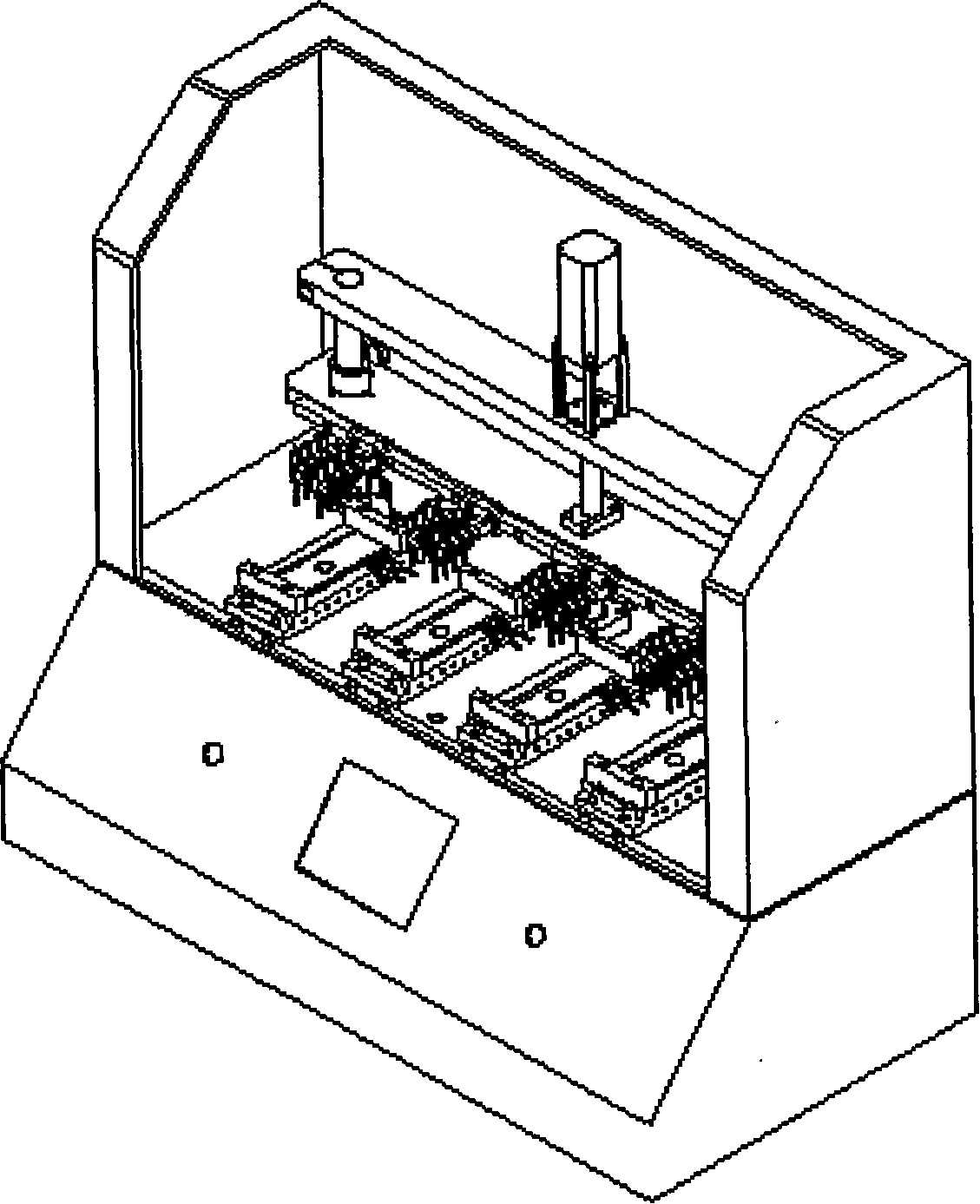

Press keys and touch screen testing device

InactiveCN101162248AImprove accuracyMeet the testing requirements of traceabilityStatic indicating devicesElectric programme controlKey pressingControl system

The invention relates to a test device for keys and touch screens and is used for testing keys and touch screens of an electronic produce, comprising: a test jig which comprises a pneumatic component to be pressed, a clamping device for holding the pneumatic component and elevating mechanism for adjusting the height of the pneumatic component, with the pneumatic component comprising an air cylinder, an adjusting valve for adjusting pressure and an air cylinder end component comprising a replaceable pressed head and a sensor A; a control system which comprises a programmable controller PLC, an alarming system, a display system and a circuit connecting device; a clamp device comprising a test board and a sensor B. The invention also discloses a method for displaying the test degree to achieve measurement traceability and for monitoring the testing state, comprising the following steps of: (1) displaying the pressing force in form of data and functional digraph; (2) testing validity of the keys and the screen and the firmness of the electronic produce for further continuous test or stopping to give an alarm; (3) recording all data during the test process.

Owner:UNILAB SHANGHAI

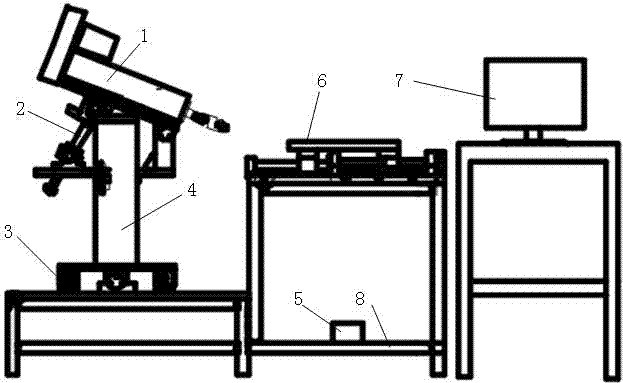

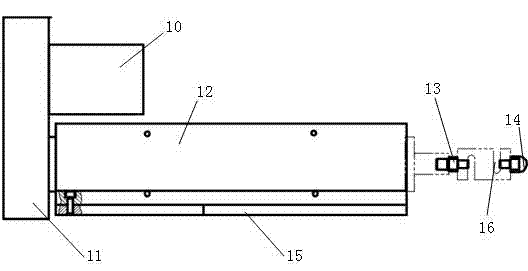

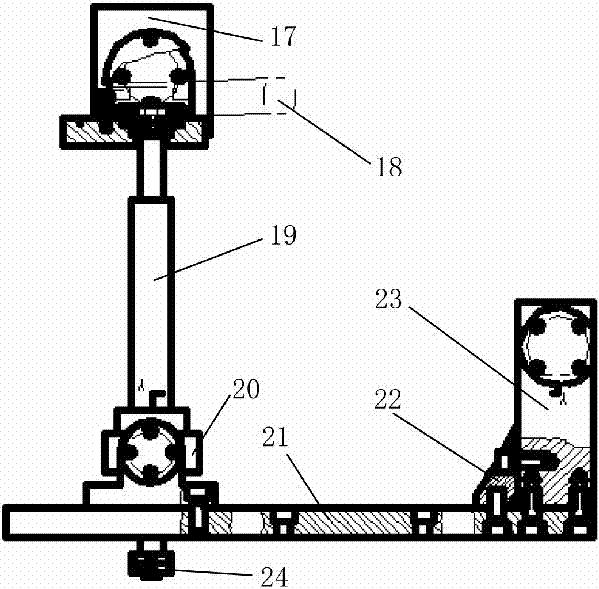

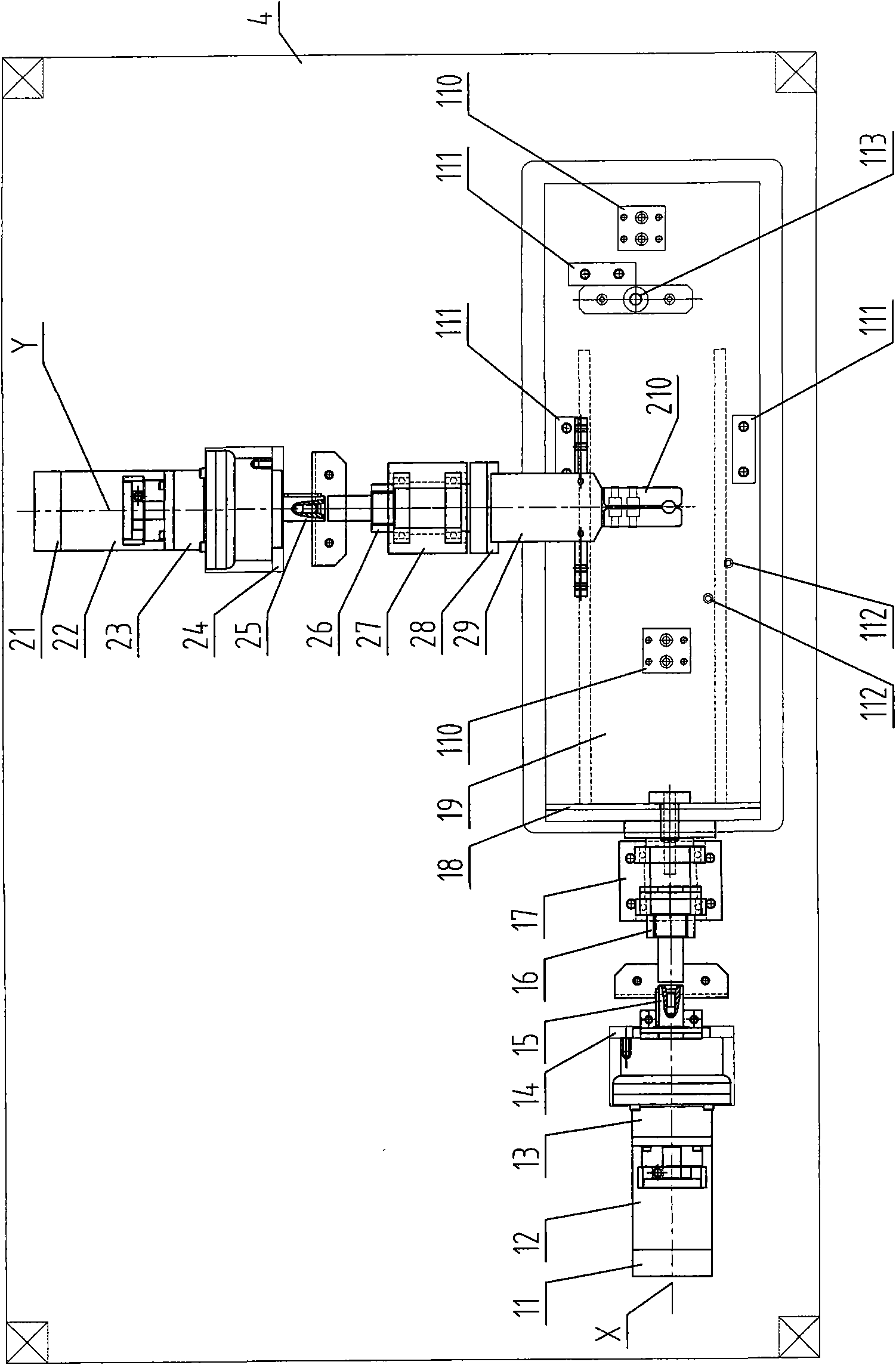

Full-automatic tension testing machine

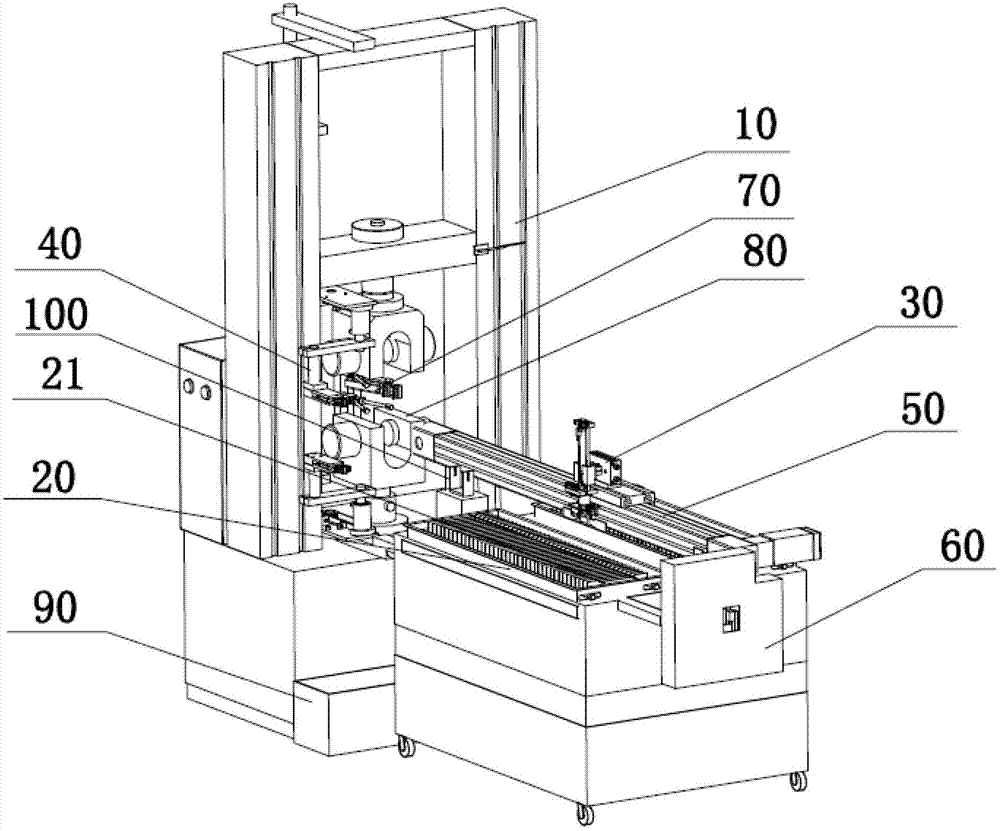

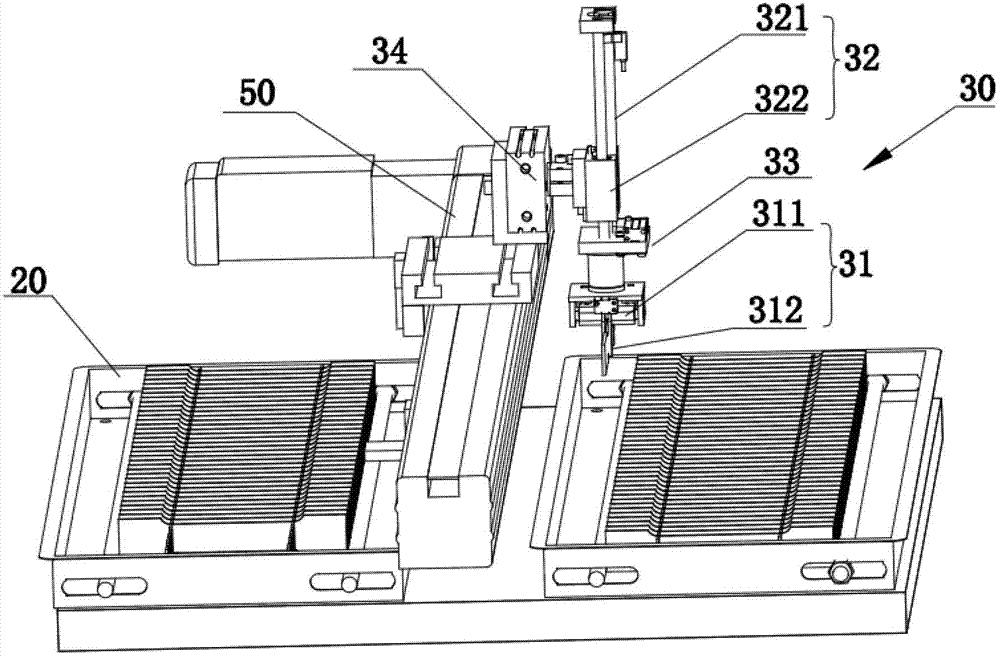

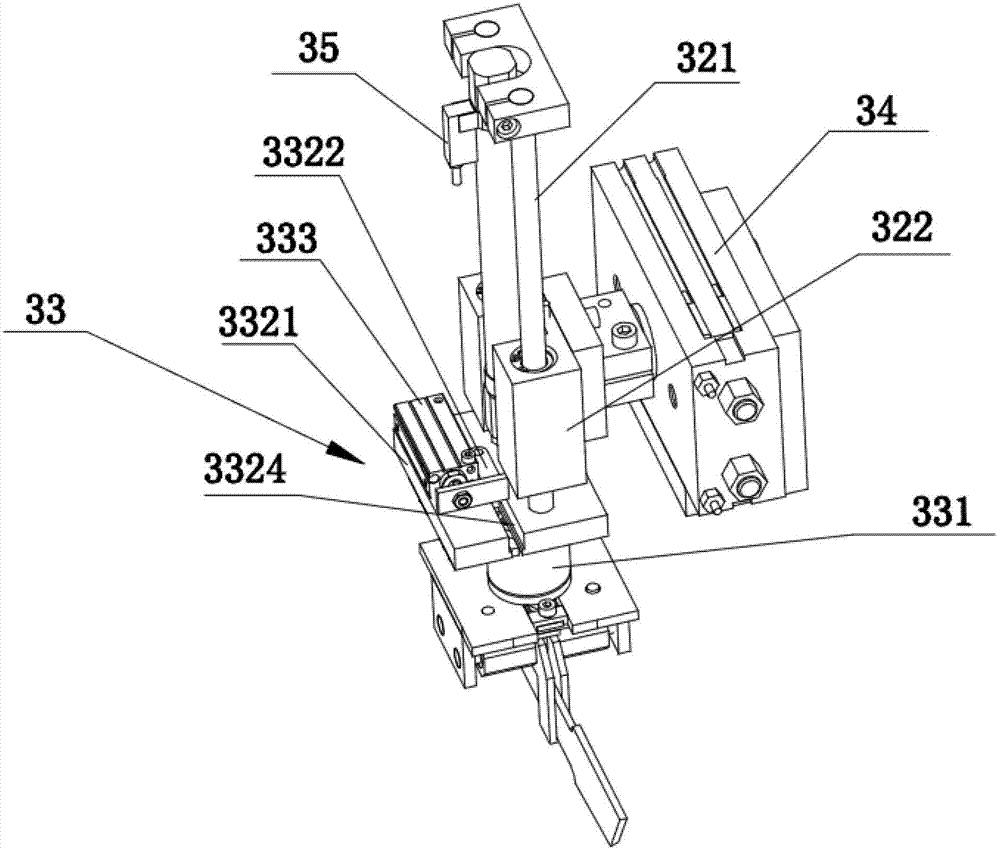

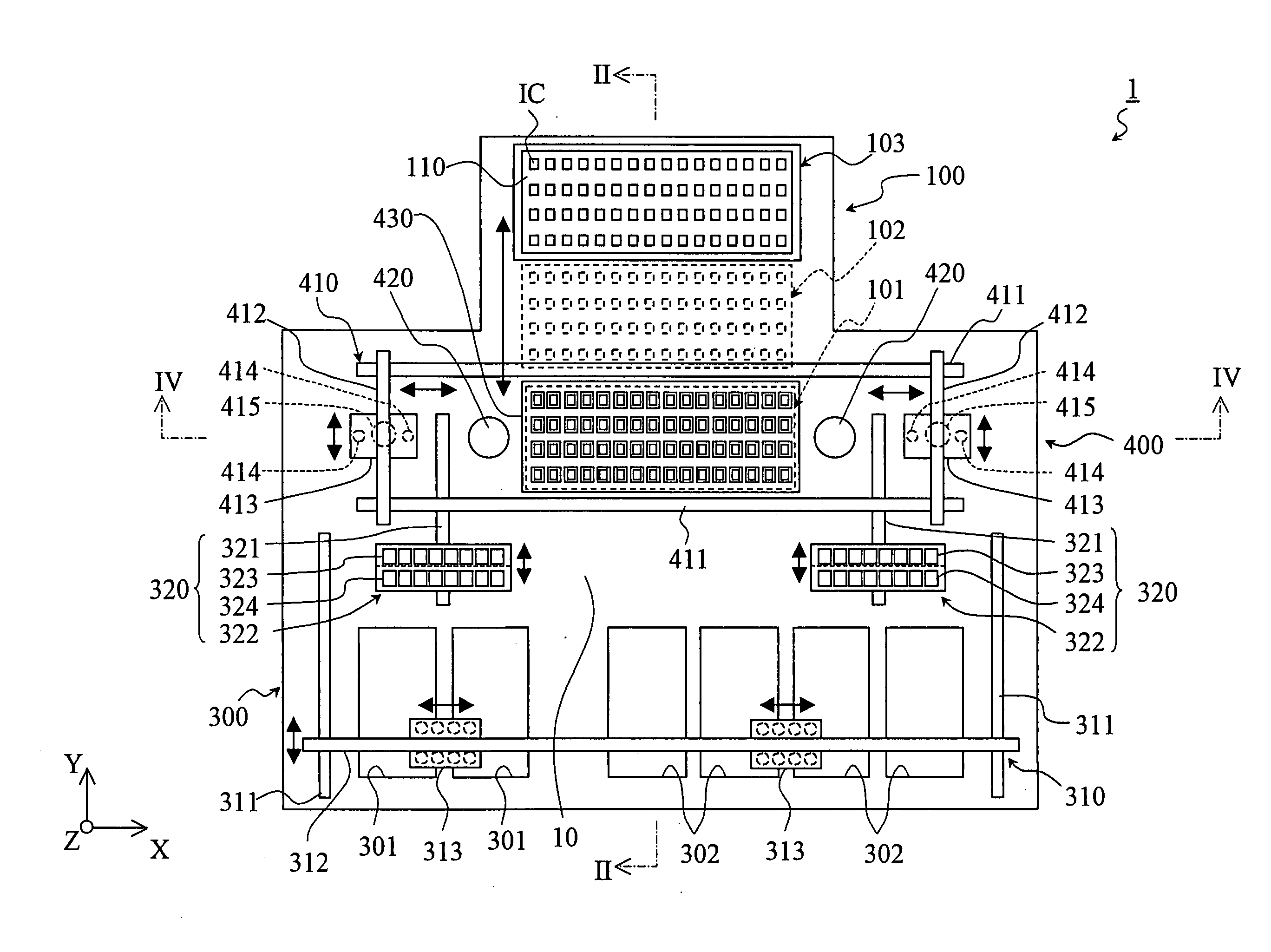

ActiveCN102778393AFully automatedImprove test efficiencyMaterial strength using tensile/compressive forcesTest efficiencyManipulator

The invention discloses a full-automatic tension testing machine. The full-automatic tension testing machine comprises a main machine, a lofting device, a material loading mechanical arm, a baiting mechanical arm, a propelling movement mechanism, a cross section test board, a full-automatic extensometer, a hydraumatic flat throw clamping apparatus and a recovery device, wherein the lofting device comprises a lofting tray used for placing samples; the material loading mechanical arm is used for clamping the samples from the lofting device so as to transfer the samples to the cross section test board through the propelling movement mechanism to measure or be transferred to the hydraumatic flat throw clamping apparatus; the main machine is used for stretching the samples clamped by the hydraumatic flat throw clamping apparatus; the full-automatic extensometer is used for measuring the deformation size of the samples; and the baiting mechanical arm is used for clamping the waste samples after testing so as to be transferred to the recovery device. The full-automatic tension testing machine provided by the invention can greatly promote test efficiency and can save labor cost.

Owner:MTS IND SYST CHINA

Electronic part test device

InactiveUS20060290369A1Improve test efficiencyMove quicklySemiconductor/solid-state device testing/measurementElectronic circuit testingEngineeringContact element

Owner:ADVANTEST CORP

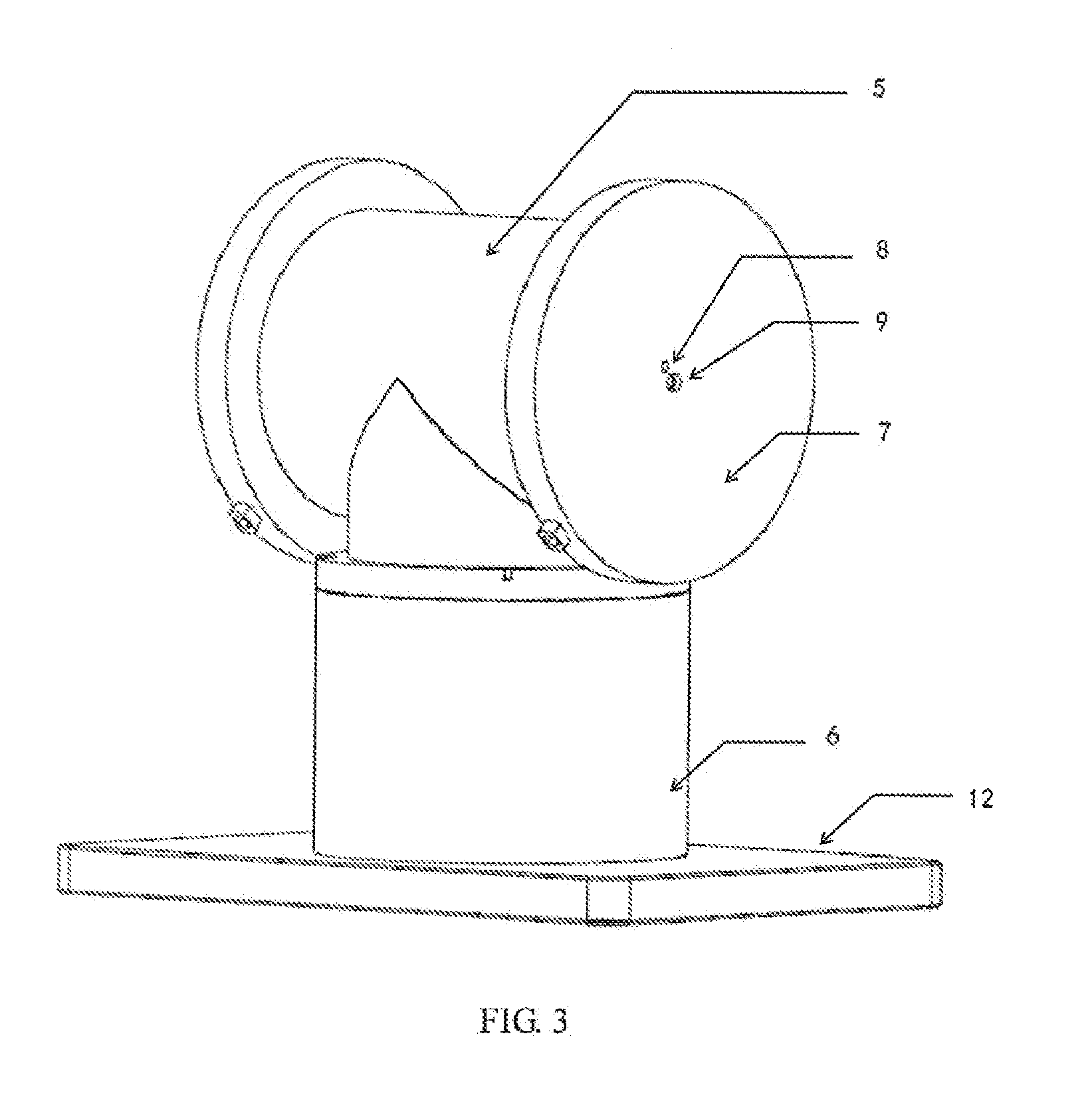

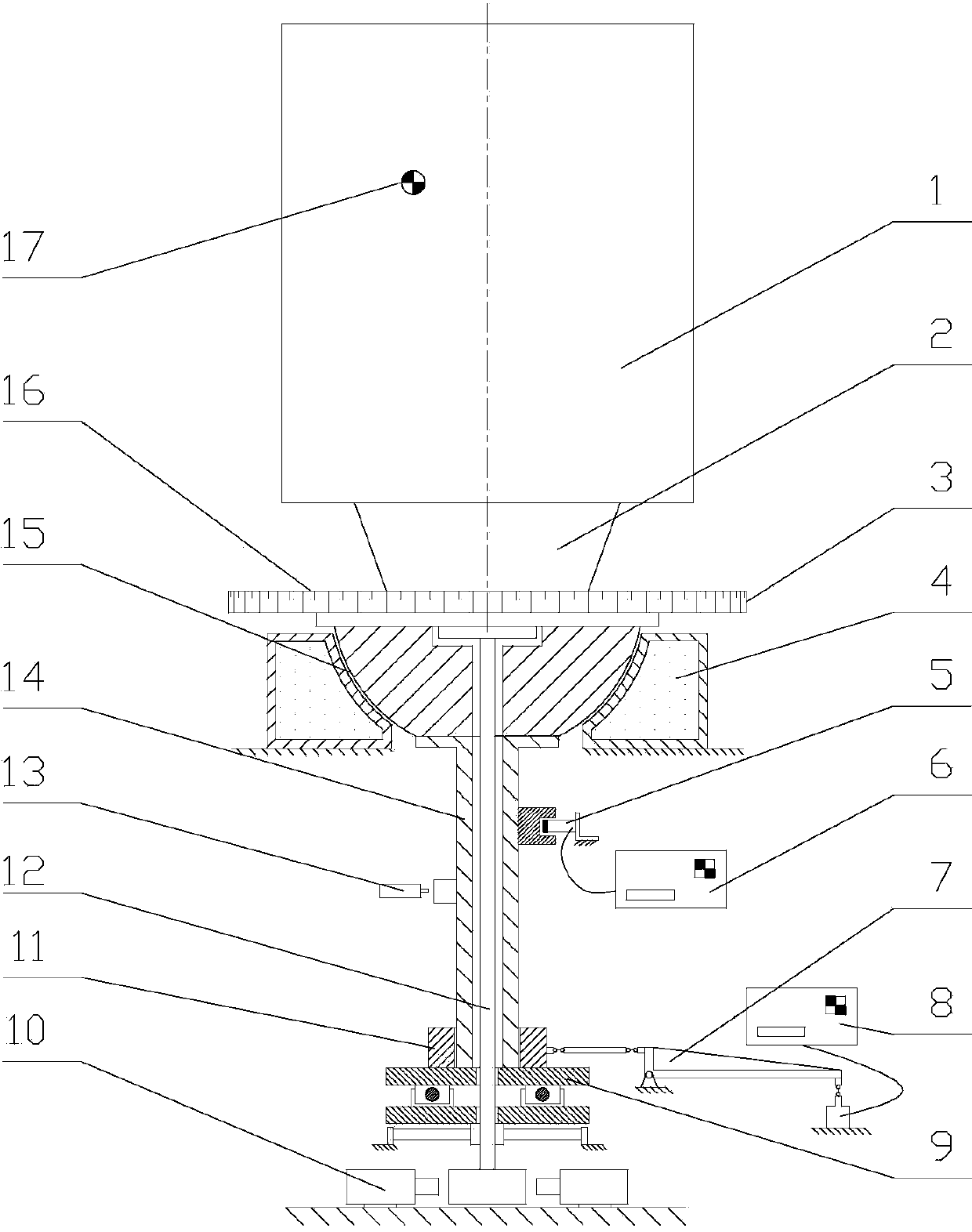

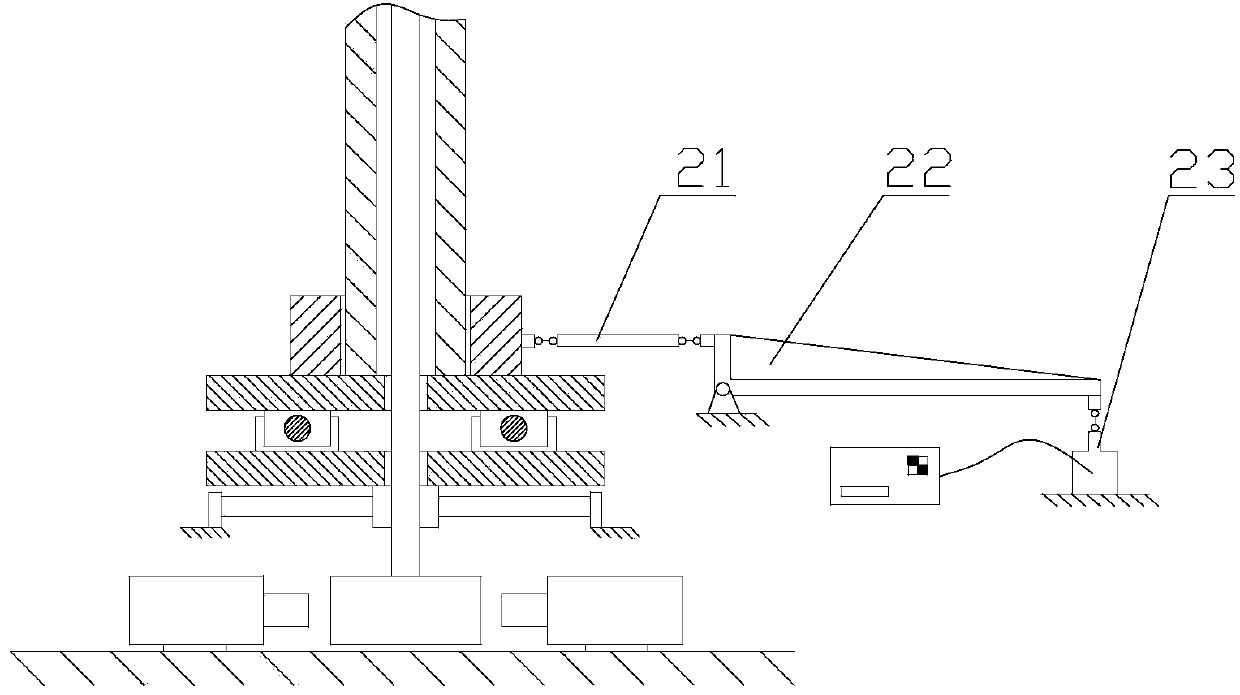

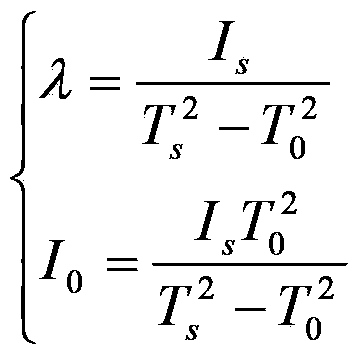

Spacecraft quality characteristic comprehensive test board based on spherical air bearing

InactiveCN103389183AImprove centroid measurement accuracyHigh measurement accuracyStatic/dynamic balance measurementAir bearingRotary inertia

The invention discloses a spacecraft quality characteristic comprehensive test board based on a spherical air bearing. The test board comprises devices such as the spherical air bearing, a torsional pendulum driving device, a torsion bar spring, a torque balancing device, a clamp position locking device, a cylindrical air bearing and the like. The centroid position of a spacecraft is measured with a torque balancing method, and the rotary inertia of the spacecraft is measured with an air floatation torsional pendulum method. The device can measure the transverse centroid and the vertical axis rotary inertia simultaneously, and the measuring accuracy is improved by one time compared with a prior device.

Owner:BEIJING INST OF SPACECRAFT ENVIRONMENT ENG

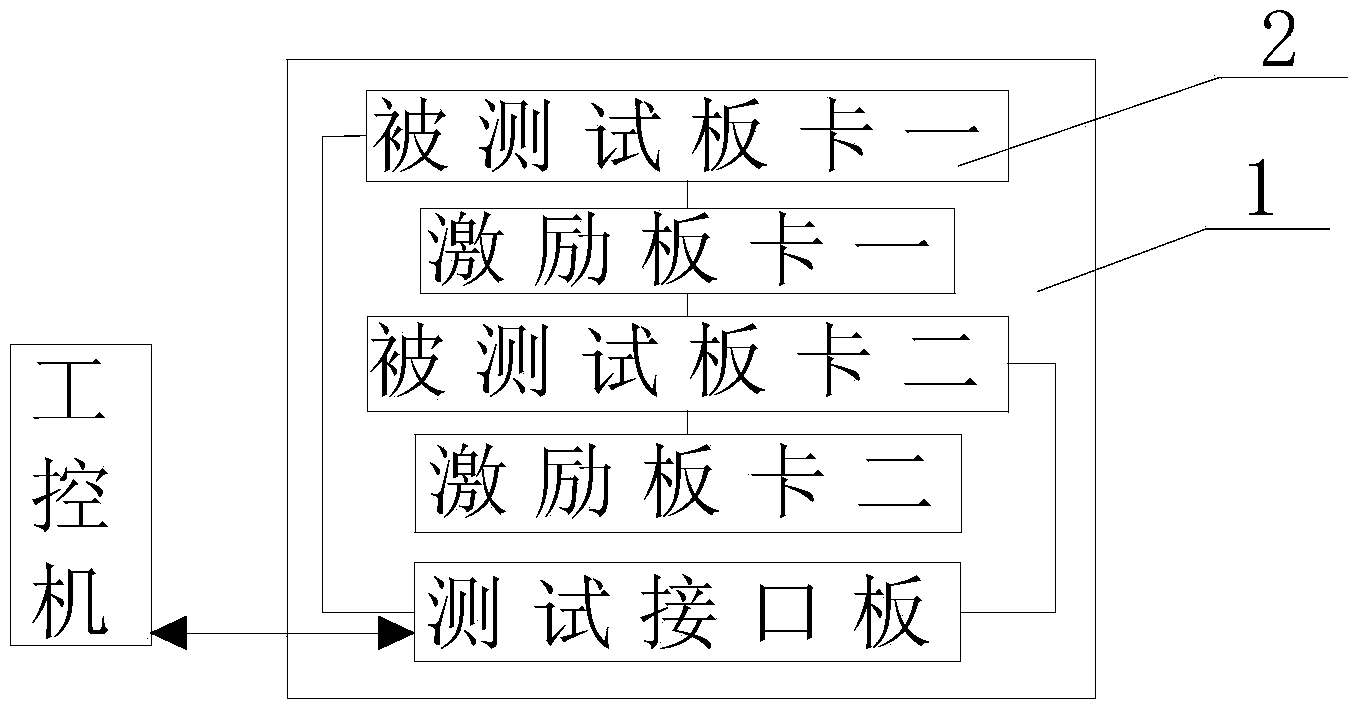

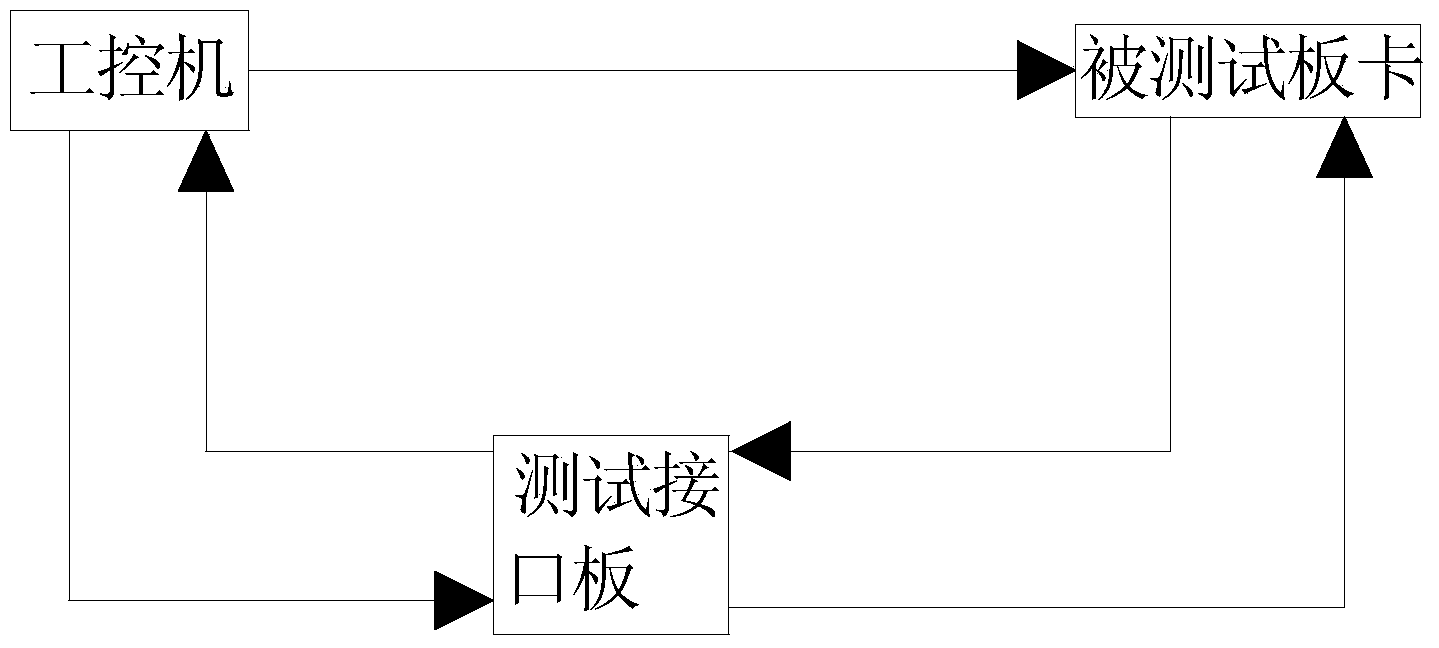

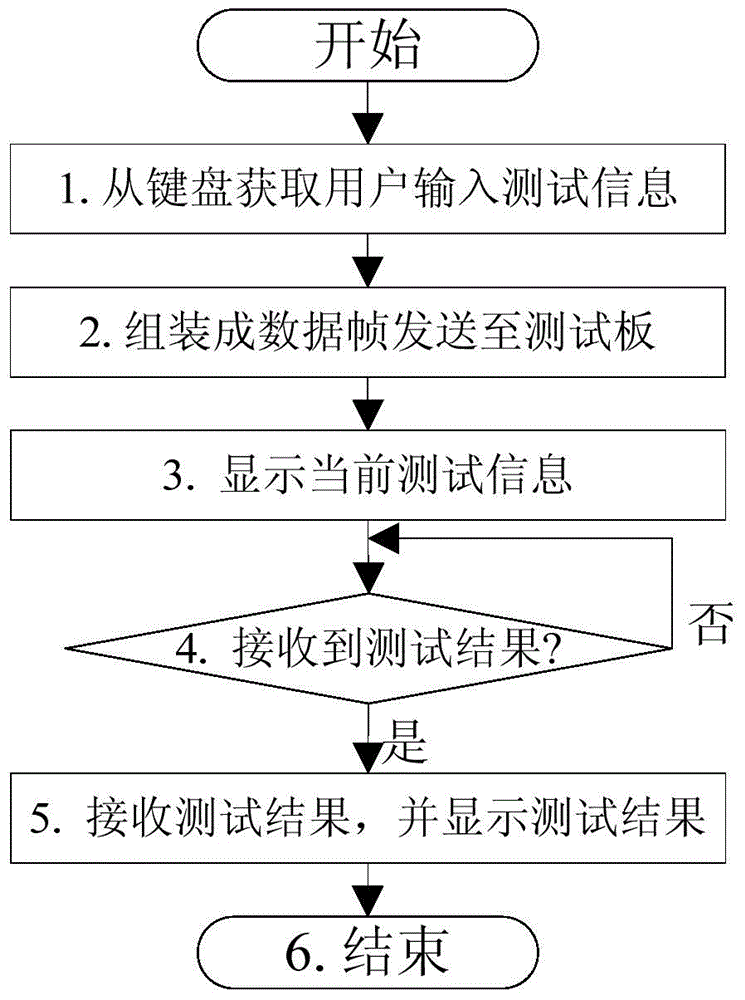

Board card automatic testing system and testing method thereof

InactiveCN103760443AShorten the production cycleReduce stepsElectronic circuit testingMeasurement instrument housingCommunication interfaceTest status

The invention discloses a board card automatic testing system and a testing method thereof. The automatic testing system comprises an industrial personal computer and a plurality of tested board cards, and further comprises a testing interface board. The testing interface board is provided with interfaces matched with the tested board cards, and the interfaces are used for being connected with the tested board cards with corresponding interfaces. The industrial personal computer is connected to the testing interface board through a communication interface. The industrial personal computer calls a detection program which is transmitted to the tested board cards through the testing interfaces. The automatic testing system of the board cards can be used for testing a plurality of board cards with different interfaces at the same time, the production cycle is shortened, and the board card production efficiency is improved. The testing method of the board card automatic testing system can monitor and store testing data of the tested board cards in real time, the testing data and testing states of the tested board cards are stored in the industrial personal computer, and errors can be conveniently tracked when errors of board card testing occur.

Owner:浙江众合科技股份有限公司

Stability parameter test board for automobile

ActiveCN101788385AAchieving rollover resistanceReduce testing workloadVehicle testingStatic/dynamic balance measurementRolloverStability parameter

The invention discloses a stability parameter test board for an automobile and belongs to the technical field of measurement. The test board is used for integrally testing a quality parameter, a mass center position parameter and an anti-rollover angle parameter of the automobile. The stability parameter test board consists of a measuring table board, four platform scales, a table board pillar, a foundation, three hydraulic cylinders, an inclination angle measuring device, hydraulic sensors, a pumping station and a computer, wherein the platform scales are arranged on the measuring table board and supported by a weighing sensor; supporting points of the table board pillar are distributed in a form of rectangular top points; the foundation is used for supporting the pillar and the table board; the three hydraulic cylinders are arranged between the table board and the foundation and can make the table board incline longitudinally or laterally; the inclination angle measuring device is fixed on the table board; the hydraulic sensors are arranged at upper and lower cavity positions of two hydraulic cylinders which make the table board incline longitudinally; the pumping station is connected with the hydraulic cylinders; and the computer is used for acquiring data of the weighing sensor, oil pressures of the hydraulic cylinders and the inclination angle of the table board and performing an operation. The table board has the advantage that: compared with a conventional test device, the device can complete tests on the total mass, the axle load, the wheel load, the mass center position, the anti-overturn angle and the like of the automobile, so the test workload and the test cost of the parameter test are lowered.

Owner:武汉元丰汽车电控系统股份有限公司

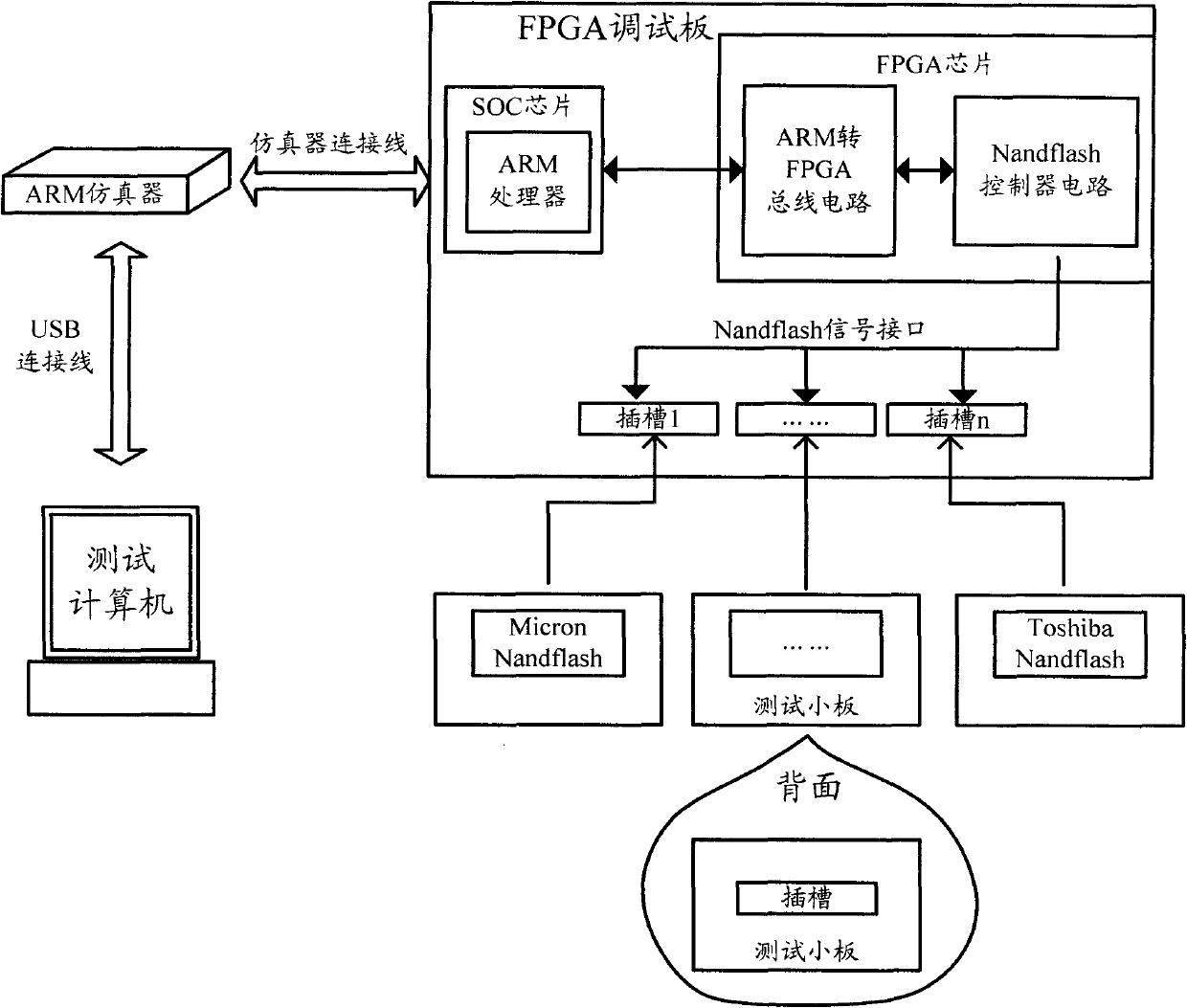

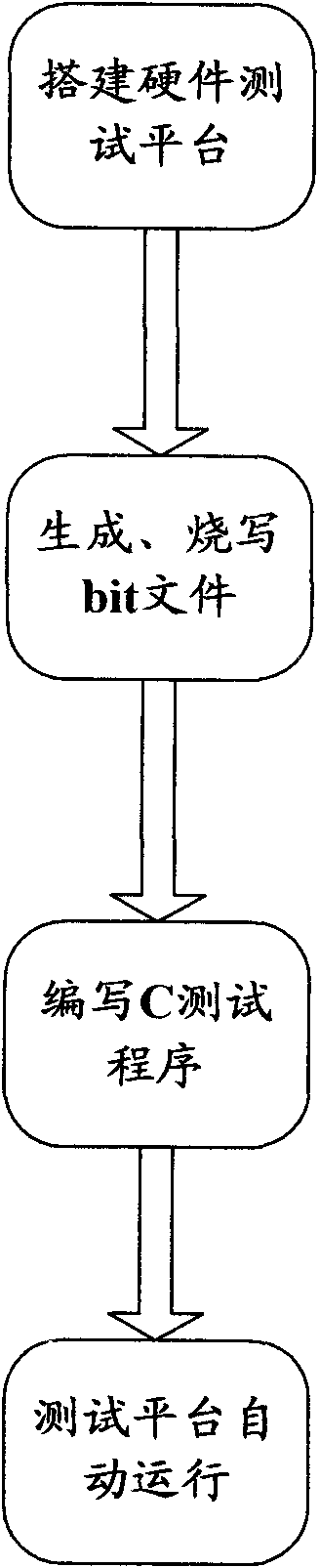

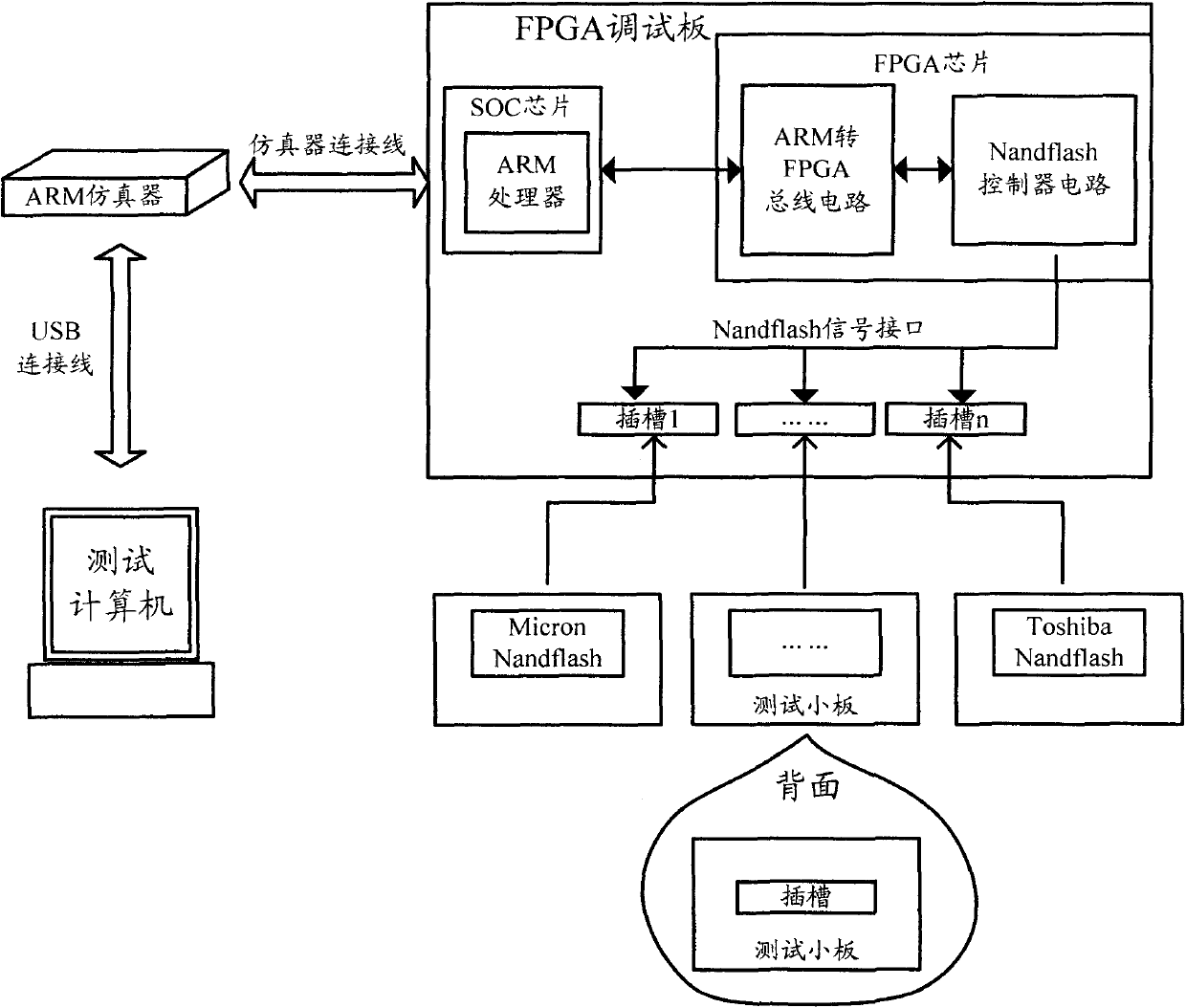

Platform system for realizing circuit verification of Nandflash flash memory controller based on FPGA (Field Programmable Gate Array) and method thereof

InactiveCN102201267AHigh degree of automationImprove test efficiencyStatic storageTest efficiencyWork performance

The invention relates to a platform system for realizing circuit verification of a Nandflash flash memory controller based on an FPGA (Field Programmable Gate Array). An FPGA debugging plate is provided with an SOC (System on Chip) chip, an FPGA chip and a plurality of Nandflash signal interface modules, the FPGA chip is provided with a bus switching circuit module and an Nandflash controller circuit module, a computer to be tested is connected with each Nandflash signal interface module through a test simulator, the SOC chip, the bus switching circuit module and the Nandflash controller circuit module, and each Nandflash signal interface module is connected with a corresponding test board. The invention further relates to a method for realizing the circuit verification of the Nandflash flash memory controller through the platform system. By adopting the platform system for realizing the circuit verification of the Nandflash flash memory controller based on the FPGA (Field Programmable Gate Array) and the method thereof, disclosed by the invention, the degree of automation is extremely high, the period of research and development is shortened, the cost of research and development is reduced, the test efficiency is high, the use is convenient and fast, the working performance is stable and reliable and the application range is wider.

Owner:SHANGHAI MOBILEPEAK SEMICON

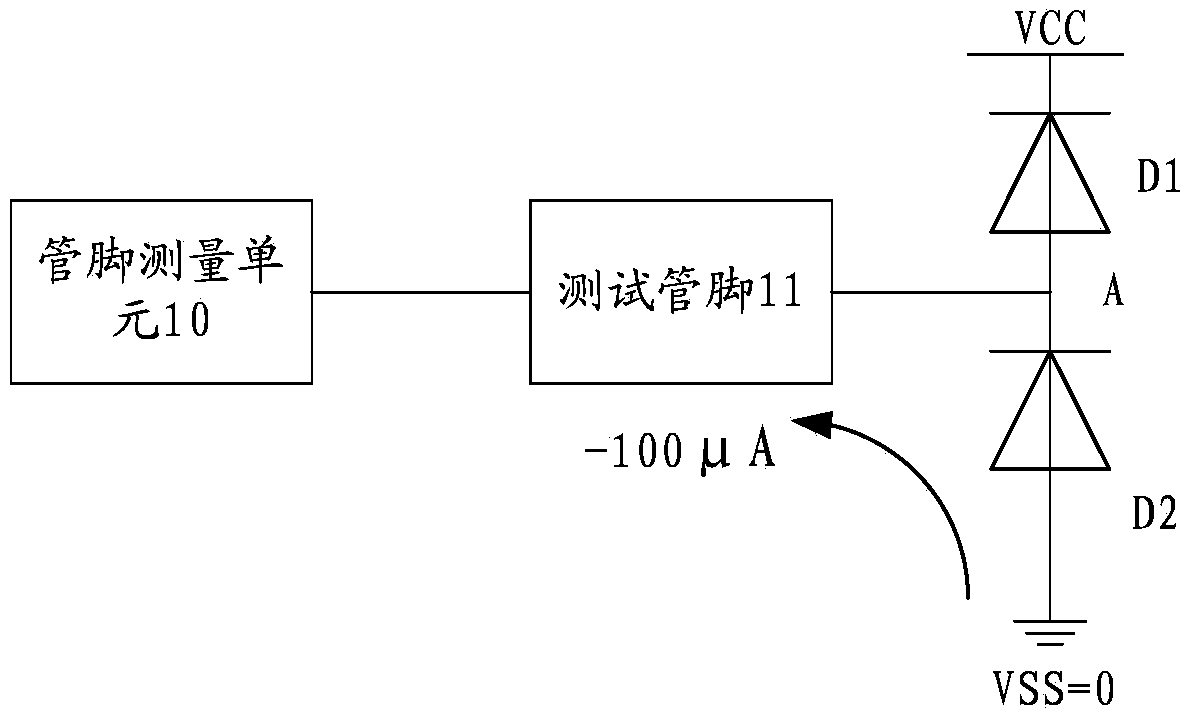

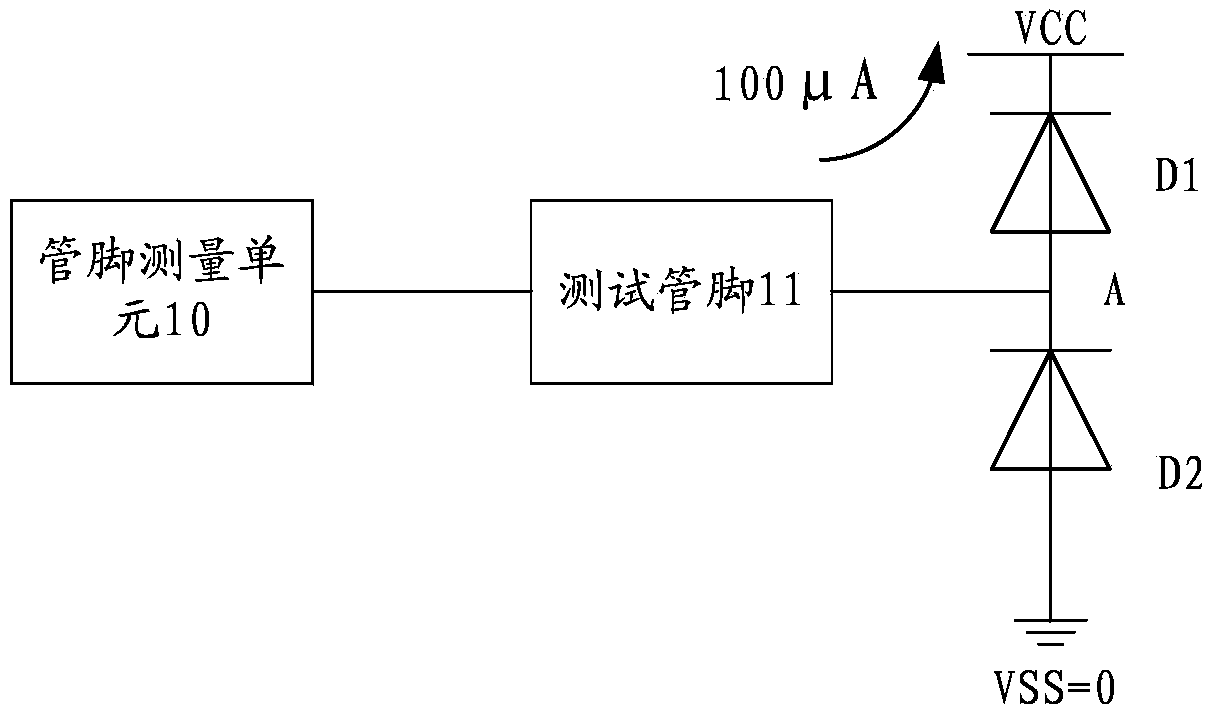

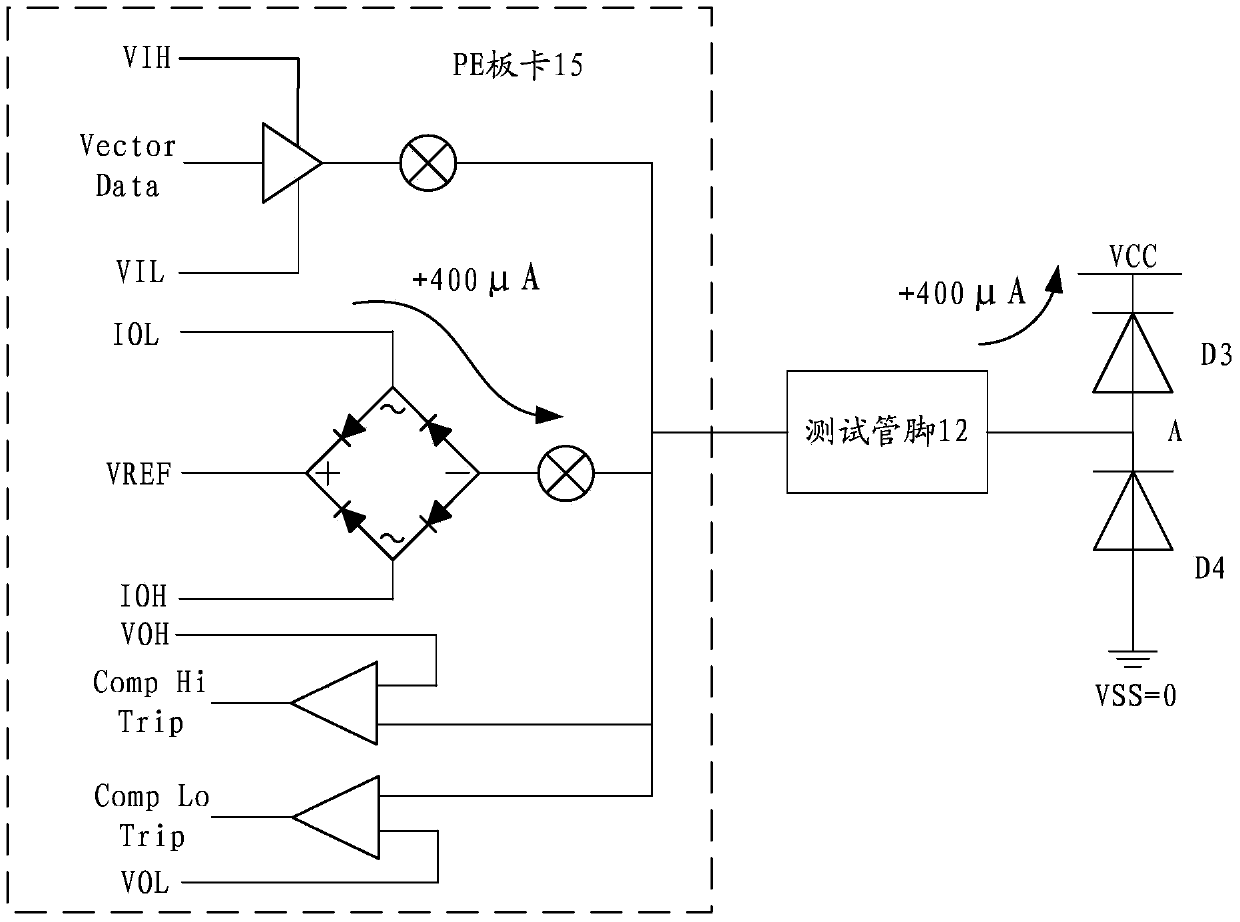

Open circuit short circuit test device and test method of chip base pin

ActiveCN103698654AReduce in quantityReduce testing costsElectrical testingShort-circuit testControl signal

The invention provides an open circuit short circuit test device and an open circuit short circuit test method of a chip base pin. The test device comprises at least one test board card, wherein a main control chip group and a base pin measuring unit array are arranged on each test board card, the base pin measuring unit array receives control signals output by the main control chip group and comprises a plurality of base pin measuring units, a channel switching switch array is also arranged on the test board card, the channel switching switch array comprises a plurality of channel switching switch units, a channel interface is also formed in the test board card, the channel interface comprises a plurality of test passages, each channel switching switch unit can be used for switching more than two test passages for testing, and the test passages of one base pin measuring unit are switched by each channel switching switch unit. The test method belongs to a method for testing the base pin of a chip by adopting the method. The device and the method provided by the invention have the advantages that the base pin of the chip can be fast tested, in addition, the size of the test device is small, and the test cost is low.

Owner:ALLWINNER TECH CO LTD

Method and apparatus for testing IC device

InactiveUS20020026258A1Semiconductor/solid-state device testing/measurementDigital data processing detailsTransfer mechanismIc devices

For testing electrical properties of packaged IC devices, there is provided an apparatus which includes a test board which is located at a testing station and provided with a plural number of contacting sockets for connecting individual IC devices to an IC tester separately and independently of each other, a loader which is located at a loading station and adapted to feed untested IC devices toward the test board, an unloader which is located at an unloading station and adapted to discharge tested IC devices from the test board at the testing station, and a device transfer mechanism which is movable across the testing station to transfer untested IC devices from the loader to the test board and also to transfer tested IC devices from the test board to the unloader. Upon detecting completion of a test on one of IC devices in one socket of the test board, a fresh untested IC device is transferred to the testing station to replace the tested IC device. As soon as the fresh IC device is set in position in that socket, execution of a test program is started with respect to that socket on the test board.

Owner:HITACHI ELECTRONICS ENG CO LTD

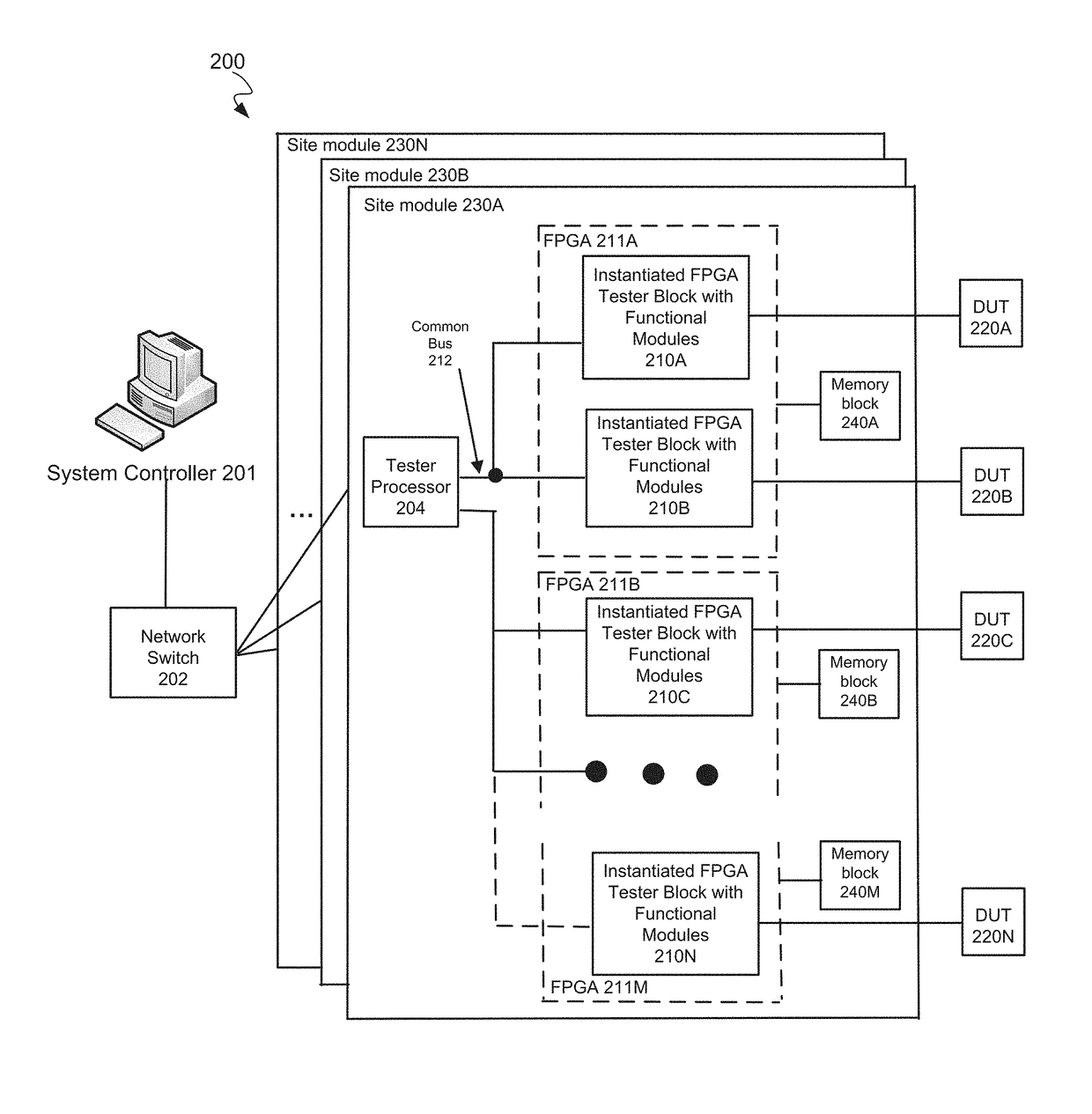

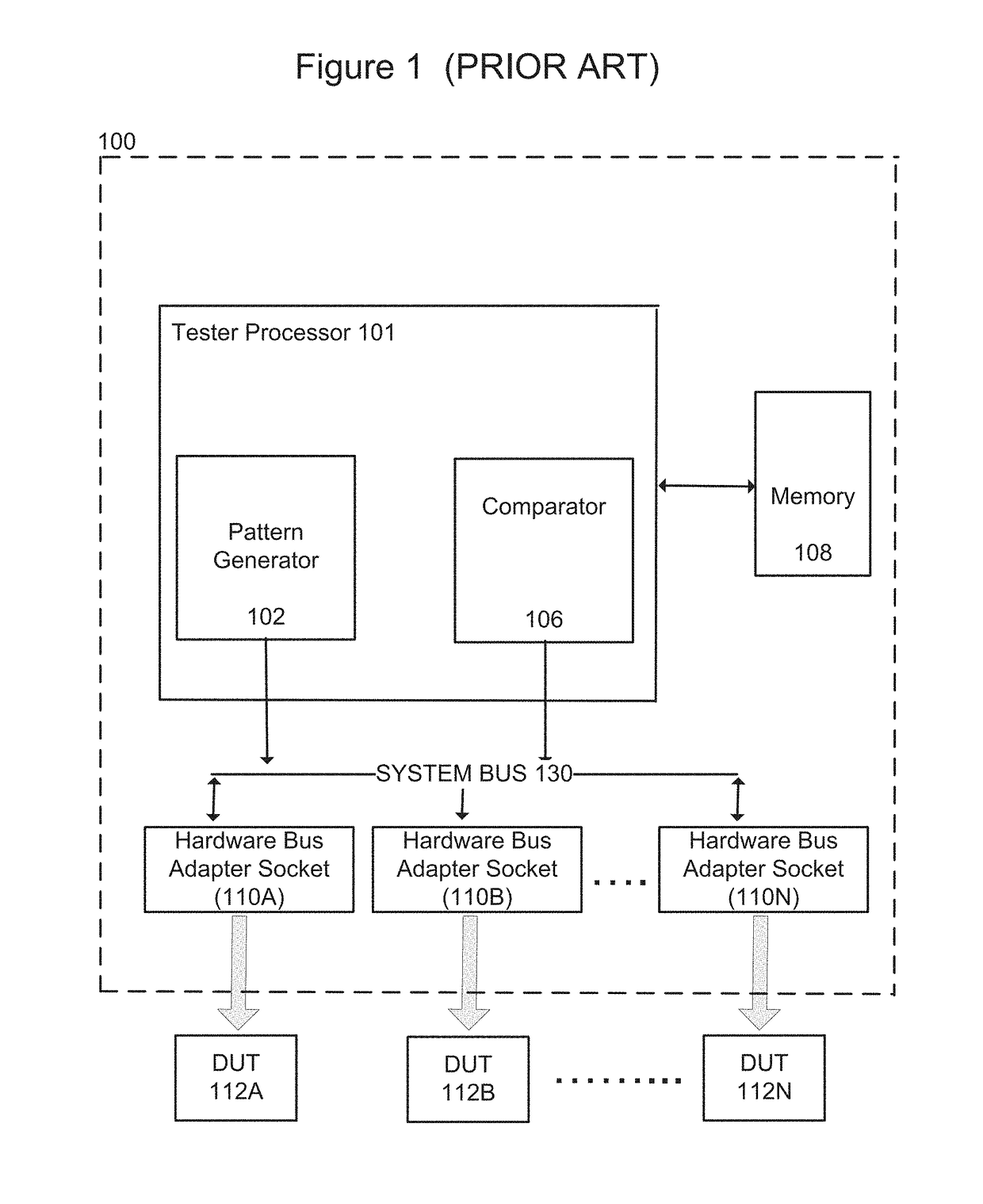

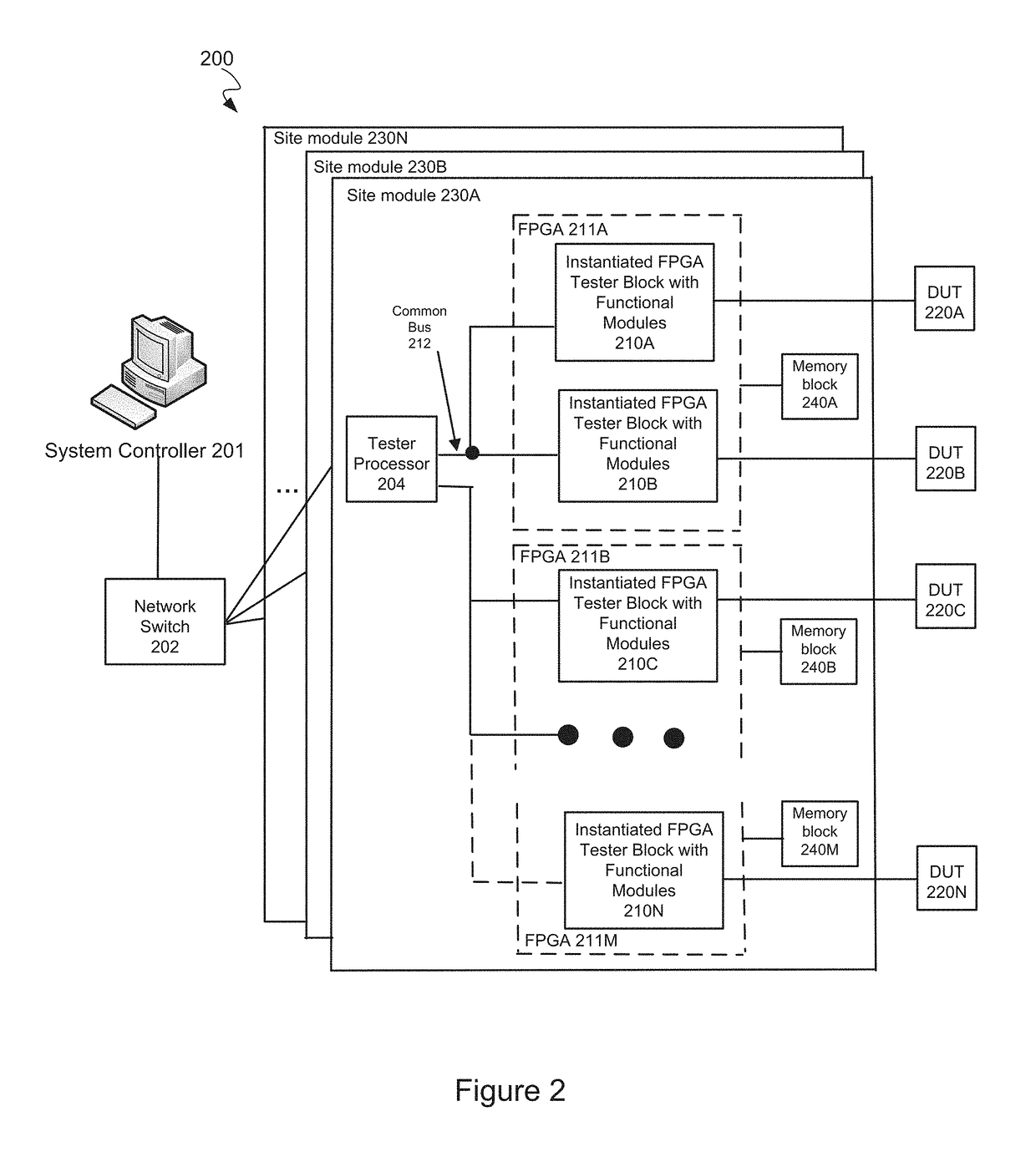

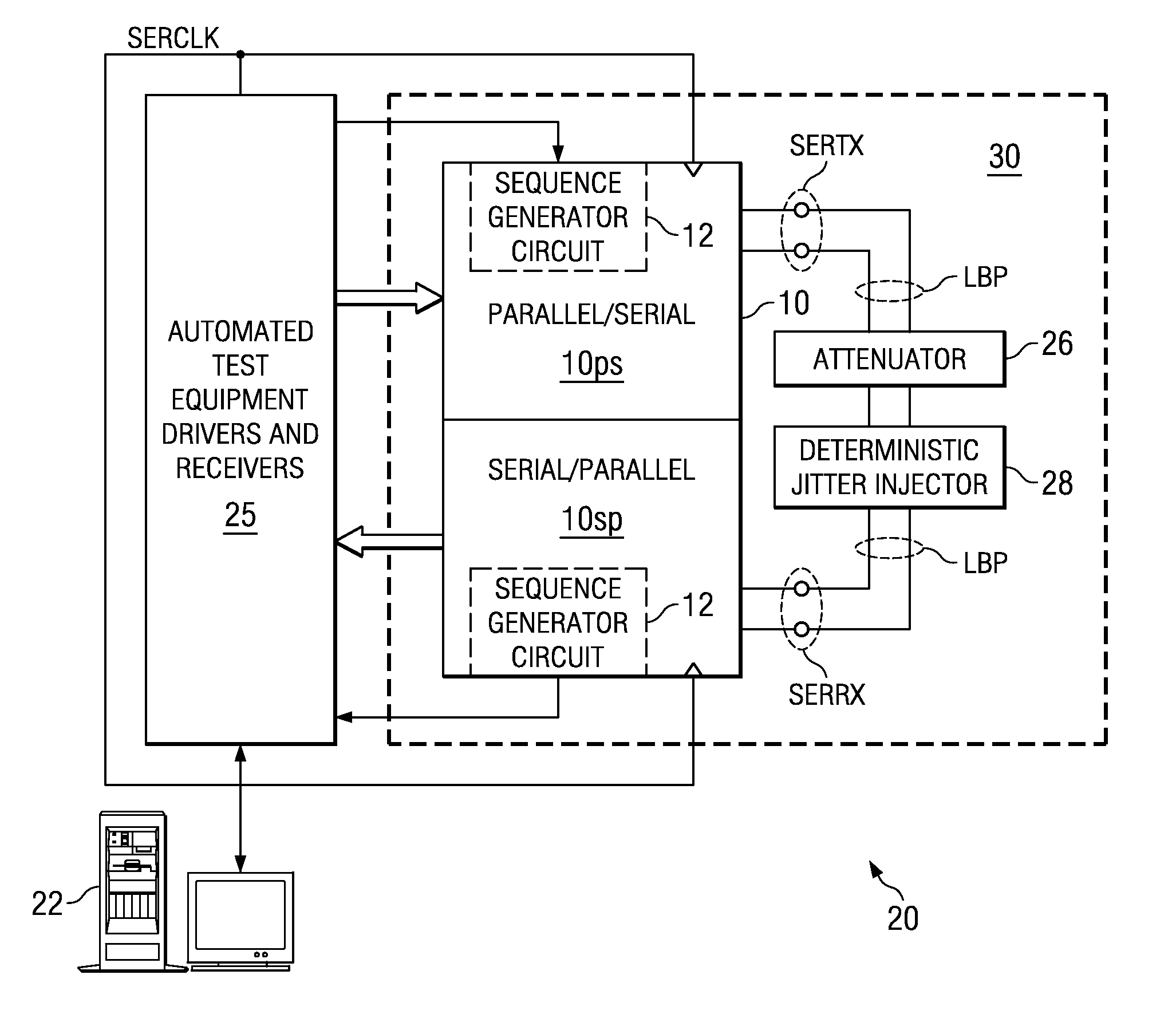

Test architecture with an FPGA based test board to simulate a dut or end-point

ActiveUS20180196103A1Bandwidth requirement can be keptMinimal processing loadDigital circuit testingError detection/correctionComputer hardwareTelecommunications link

An automated test equipment (ATE) system capable of performing a test of semiconductor devices is presented. The system comprises a first test board including a first FPGA communicatively coupled to a controller via an interface board, wherein the first FPGA comprises a first core programmed to implement a communication protocol, and further wherein the FPGA is programmed with at least one hardware accelerator circuit operable to internally generate commands and data for testing a DUT. The system also includes a second test board comprising a second FPGA communicatively coupled to the first test board, wherein the second FPGA comprises a second core programmed to implement a communication protocol for a device under test, wherein the second FPGA is further programmed to simulate a DUT, and wherein the first FPGA is operable to communicate with the second FPGA in order to test a communication link between the first test board and the second test board.

Owner:ADVANTEST CORP

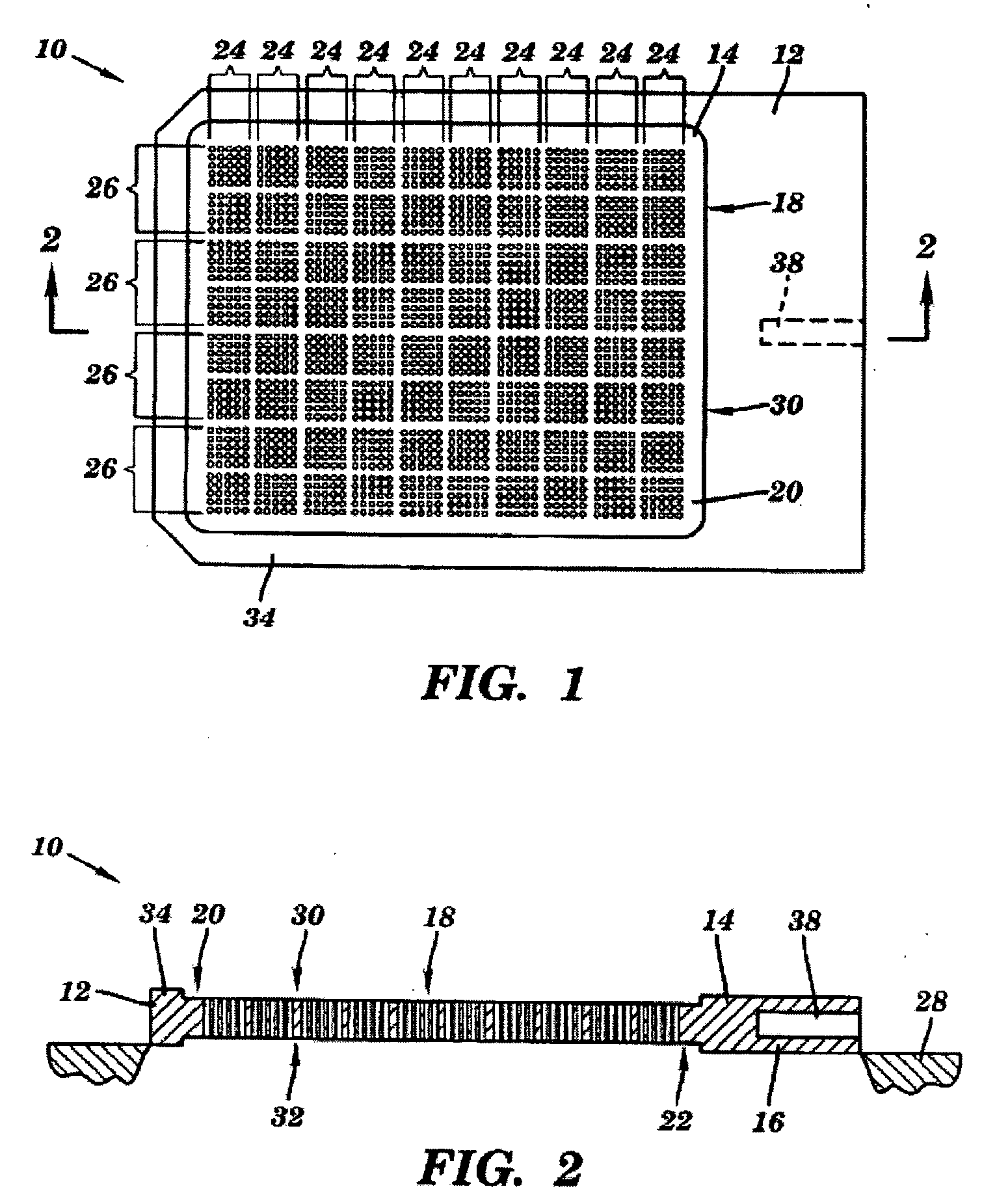

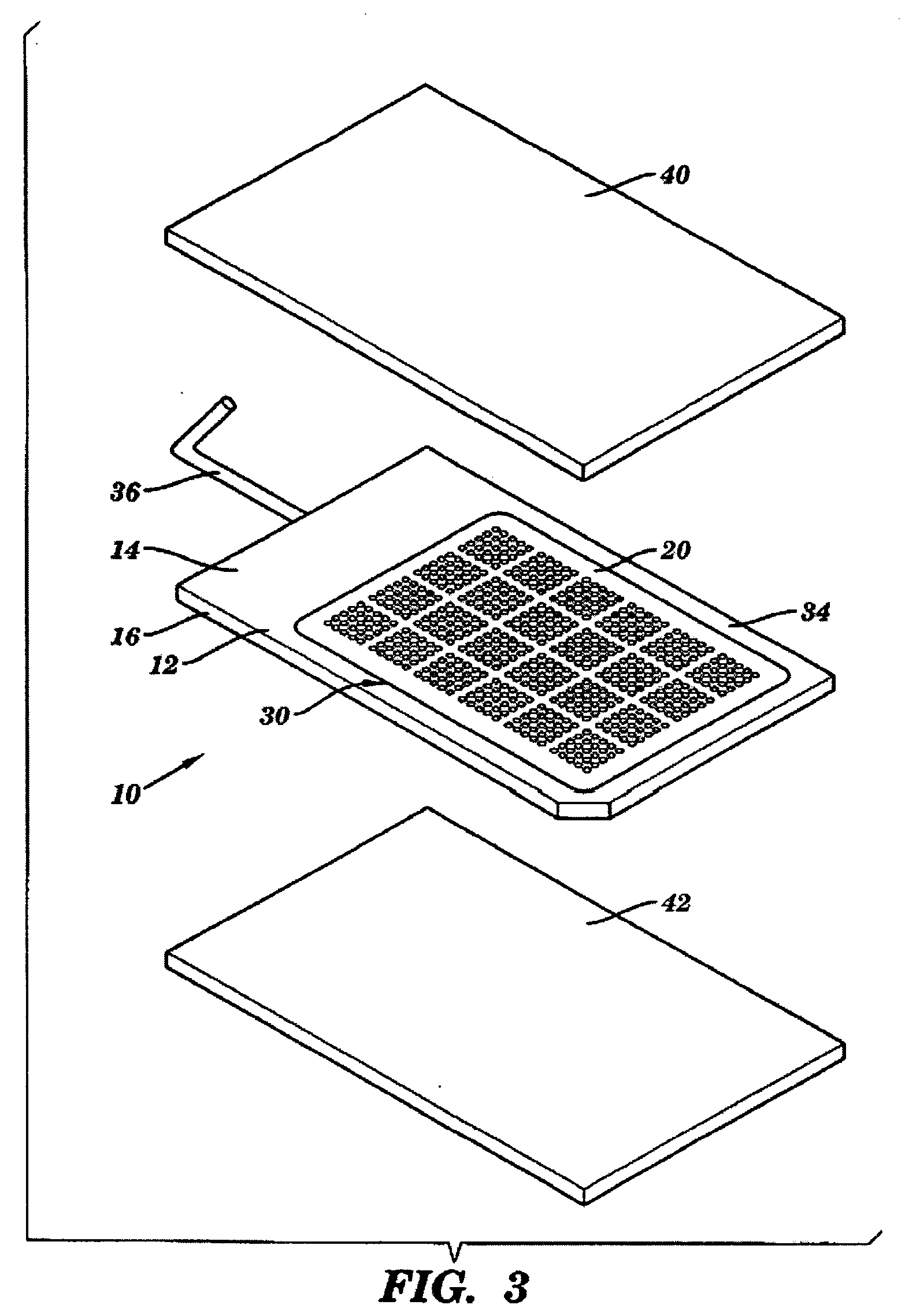

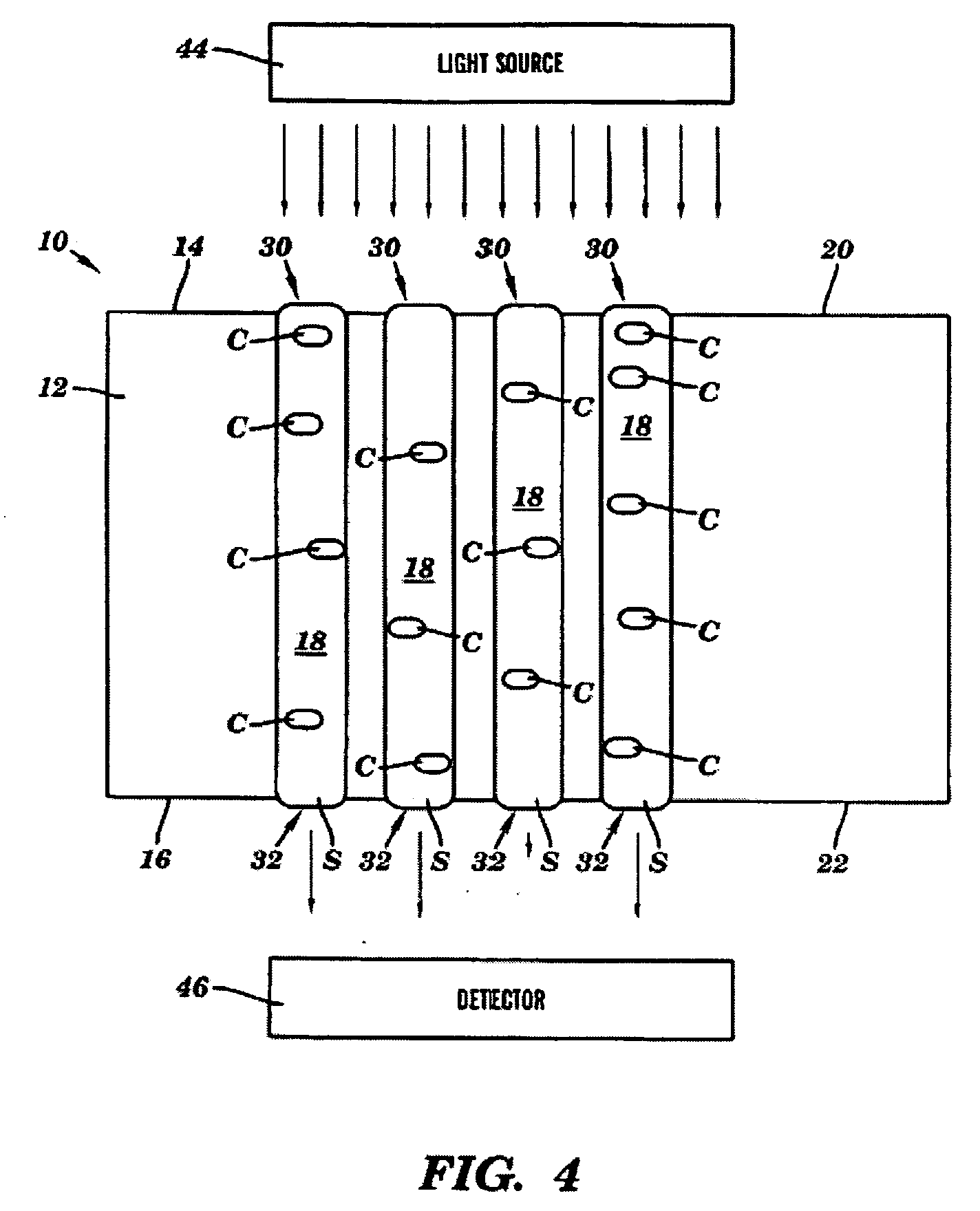

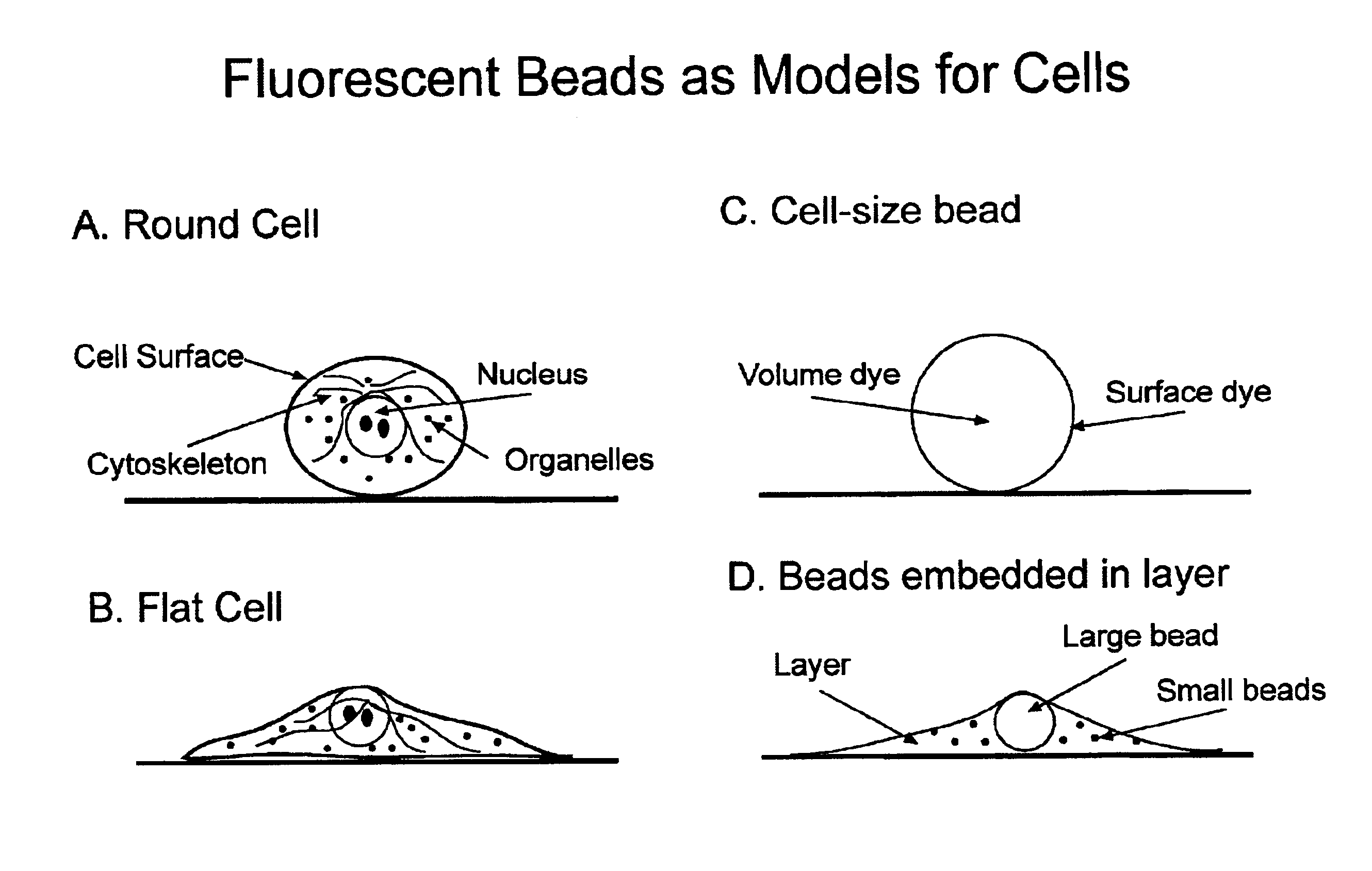

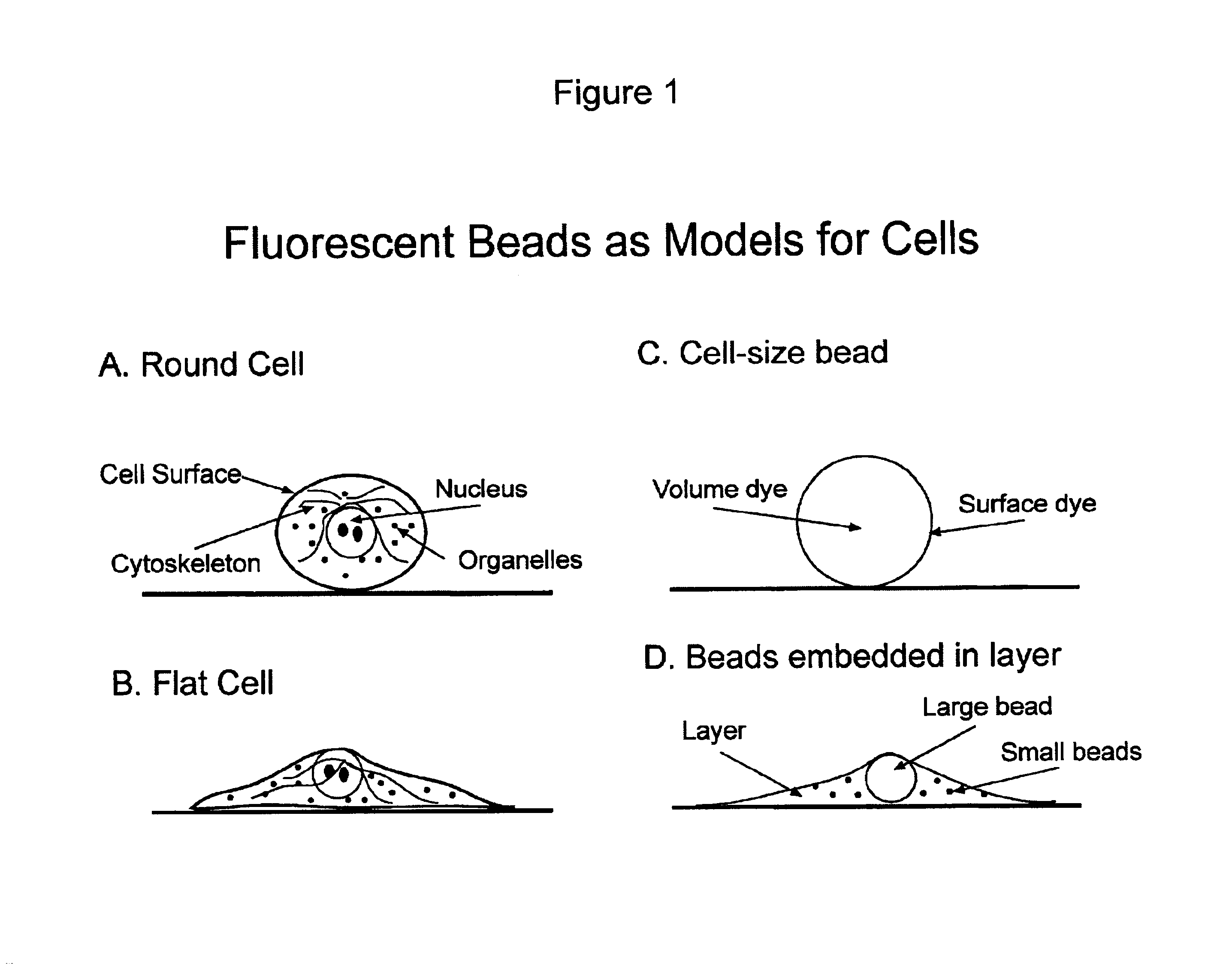

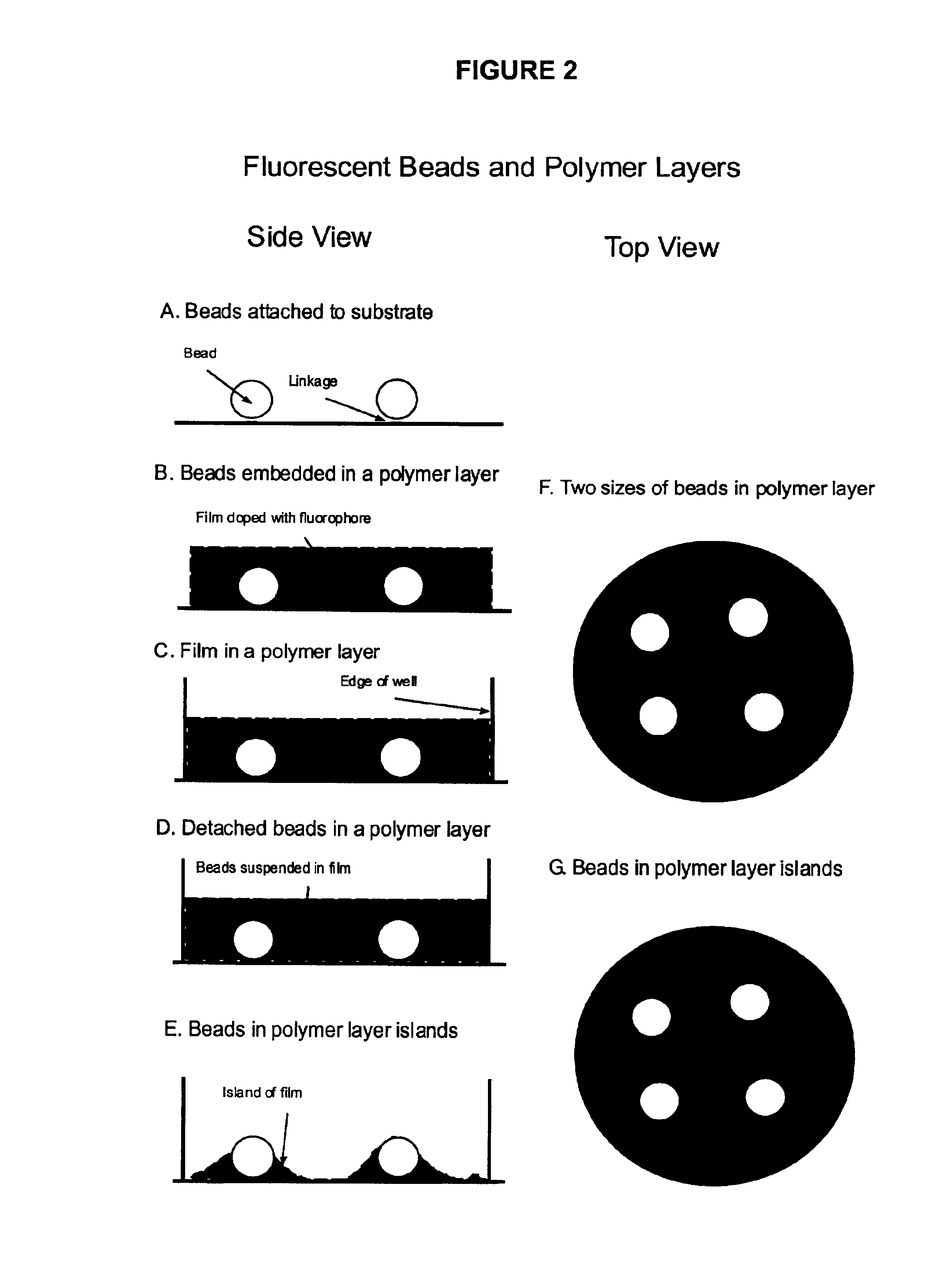

Microbead-based test plates and test methods for fluorescence imaging systems

InactiveUS6905881B2Analysis using chemical indicatorsSugar derivativesEngineeringFluorescent imaging

The present invention provides a test plate and methods for adjusting fluorescence imaging systems involving using a plate with fluorescent microbeads bound to a surface.

Owner:CELLOMICS

Camera module test platform

The invention discloses a camera module test platform which comprises a base, a first bracket, a close shot target, a stain test board, a relay lens and a second bracket, wherein the base is provided with a sliding shaft parallel to the surface of the base; the first bracket is arranged in a sliding manner along the axial direction of the sliding shaft; the close shot target, the stain test board and the relay lens are arranged on the first bracket; the second bracket is arranged on the base, and a long shot target is arranged on the second bracket; and the distance between the long shot target and the surface of the base is greater than the distance between the relay lens and the surface of the base. In a process of testing a camera module by use of the camera module test platform, the long shot focusing test, close shot focusing test and stain and vignetting test on the camera module can be finished simply by horizontally switching the close shot target, the stain test board and the relay lens. The camera module test environment has good consistency, and the reliability of the camera module test result is improved.

Owner:TRULY OPTO ELECTRONICS

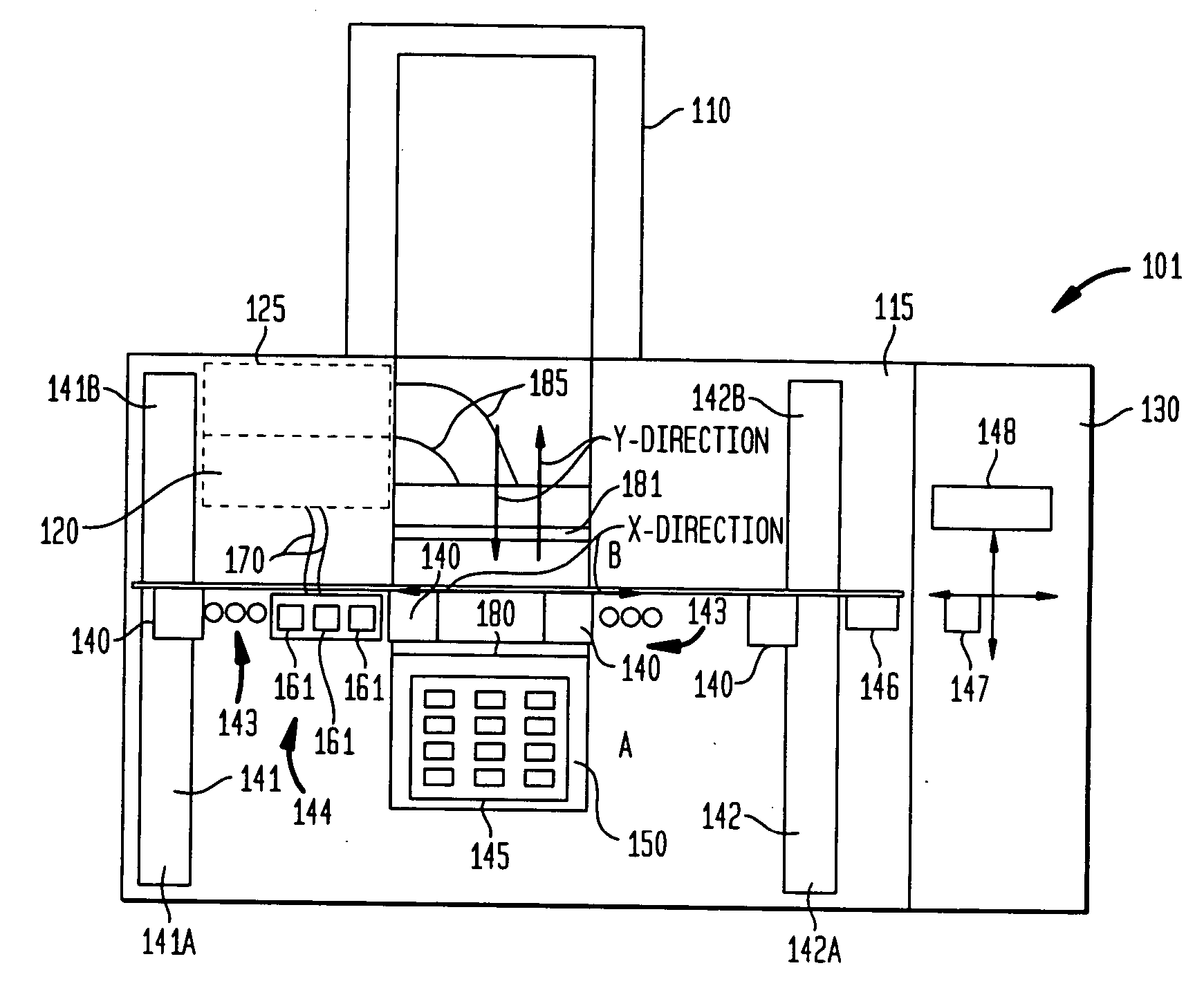

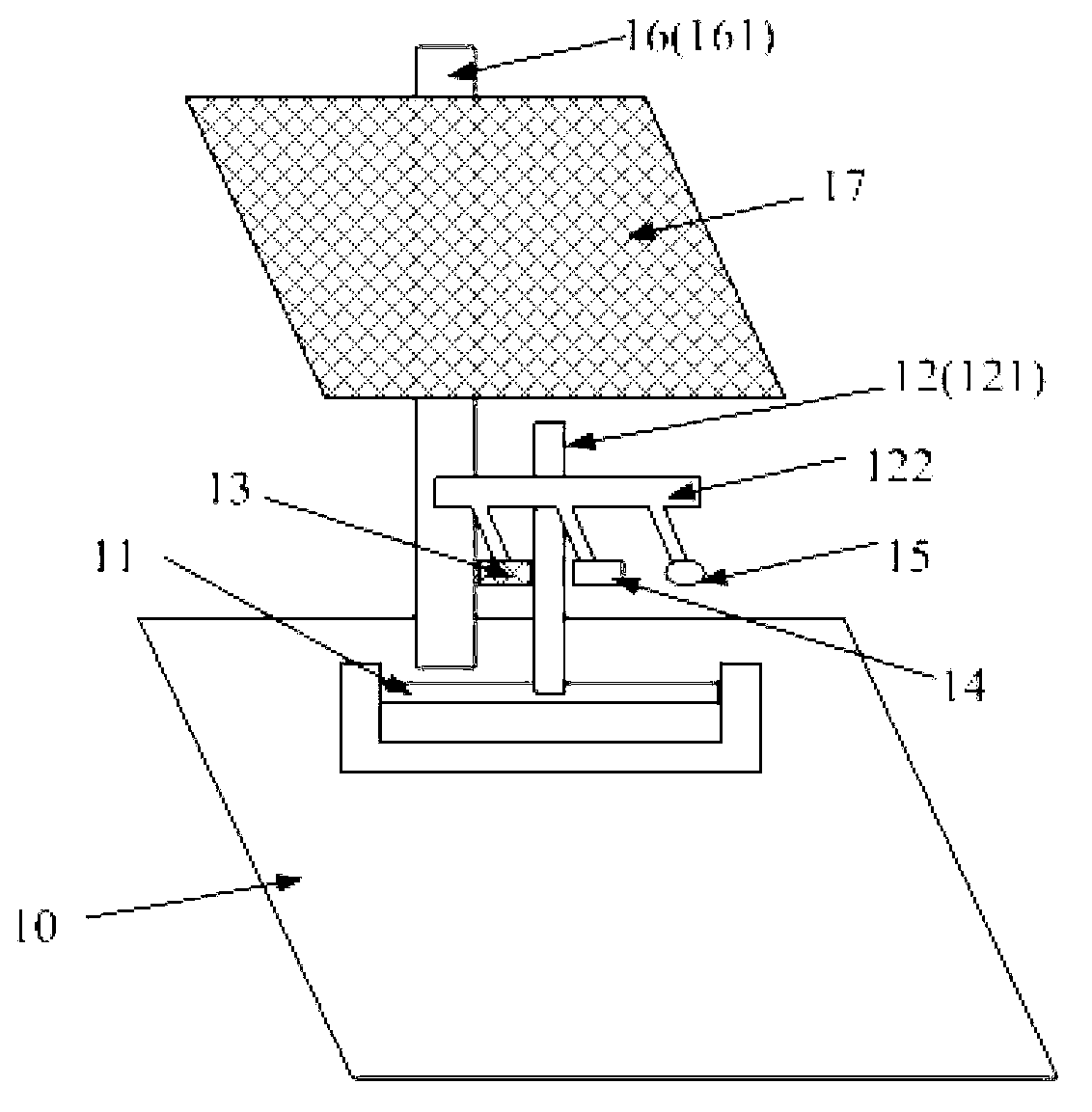

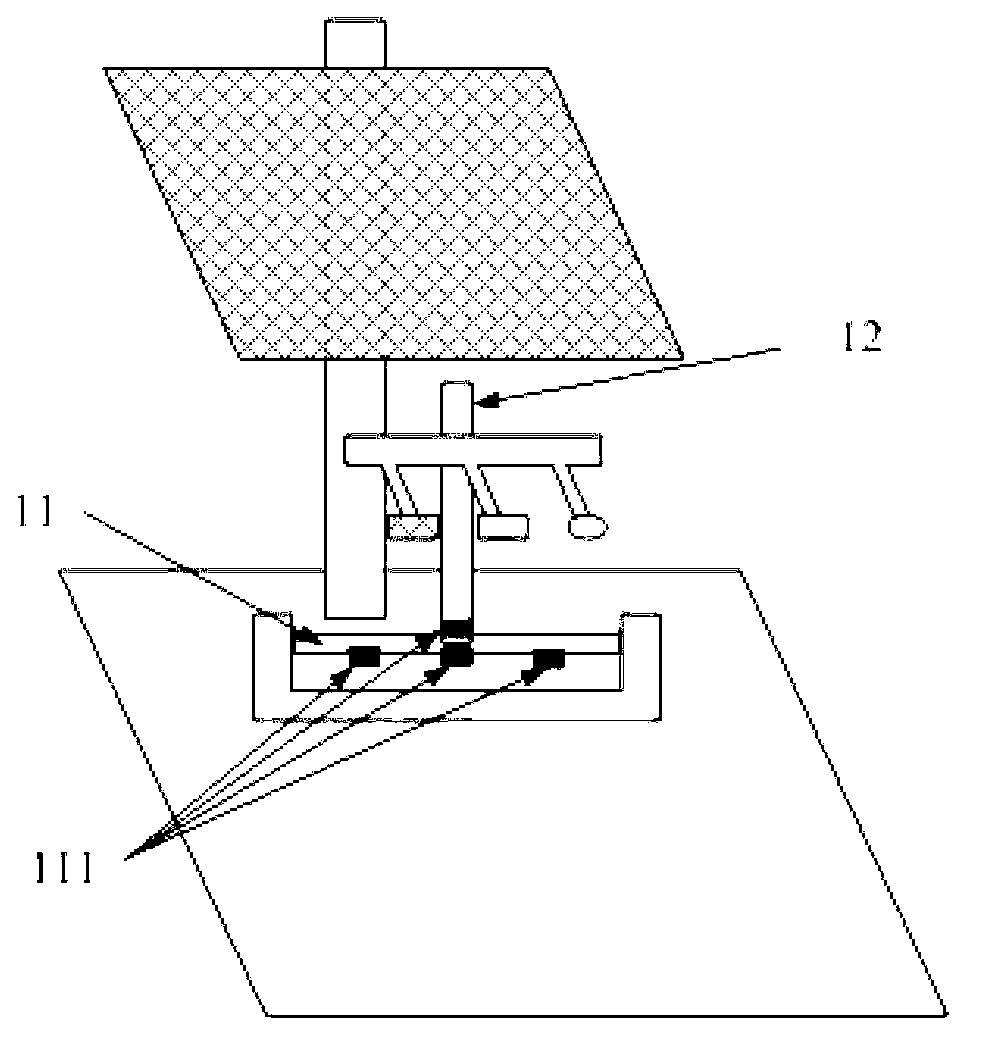

Handler for testing semiconductor devices

InactiveCN1837841ASimple structureSimplified loading/unloading procedureSemiconductor/solid-state device testing/measurementElectronic circuit testingElectricityEngineering

A handler for testing semiconductor devices is disclosed which is capable of simplifying the process carried out in an exchanging station, namely, the process of loading / unloading semiconductor devices in / from test trays, and greatly increasing the number of simultaneously testable semiconductor devices. The handler includes a loading station, an unloading station, test trays, an exchanging station comprising a horizontal moving unit for horizontally moving a selected one of the test trays by a predetermined pitch at a working place, a test station in which at least one test board having a plurality of test sockets to be electrically connected with semiconductor devices is mounted, the test station performing a test while connecting the semiconductor devices in one of the test trays, which is fed from the exchanging station to the test station, to the test sockets, device transfer units for transfer the semiconductor devices between the loading station and the exchanging station and between the exchanging station and the unloading station, respectively, and a tray transfer unit for transfer the test trays between the exchanging station and the test station.

Owner:MIRAE CORPORATION

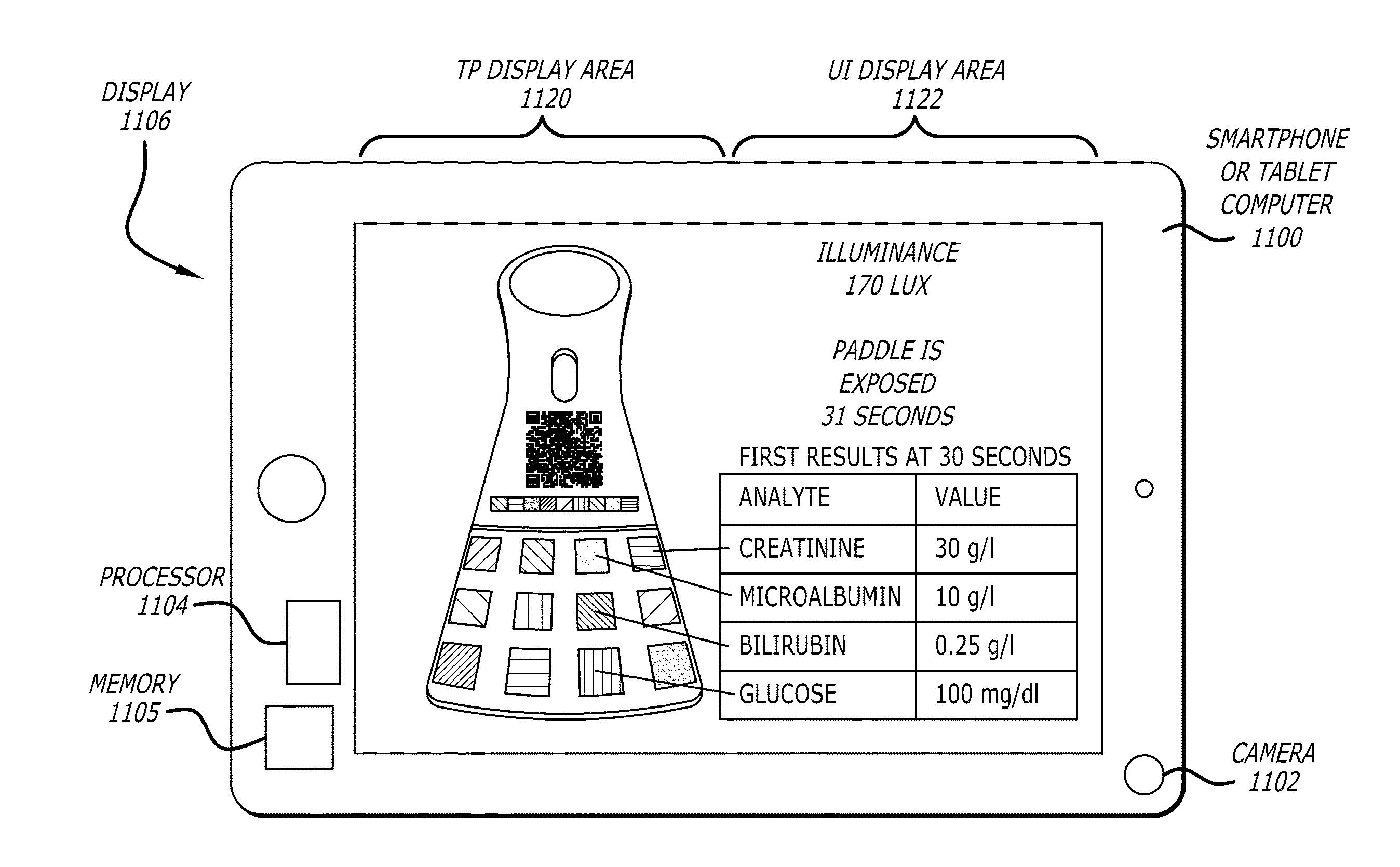

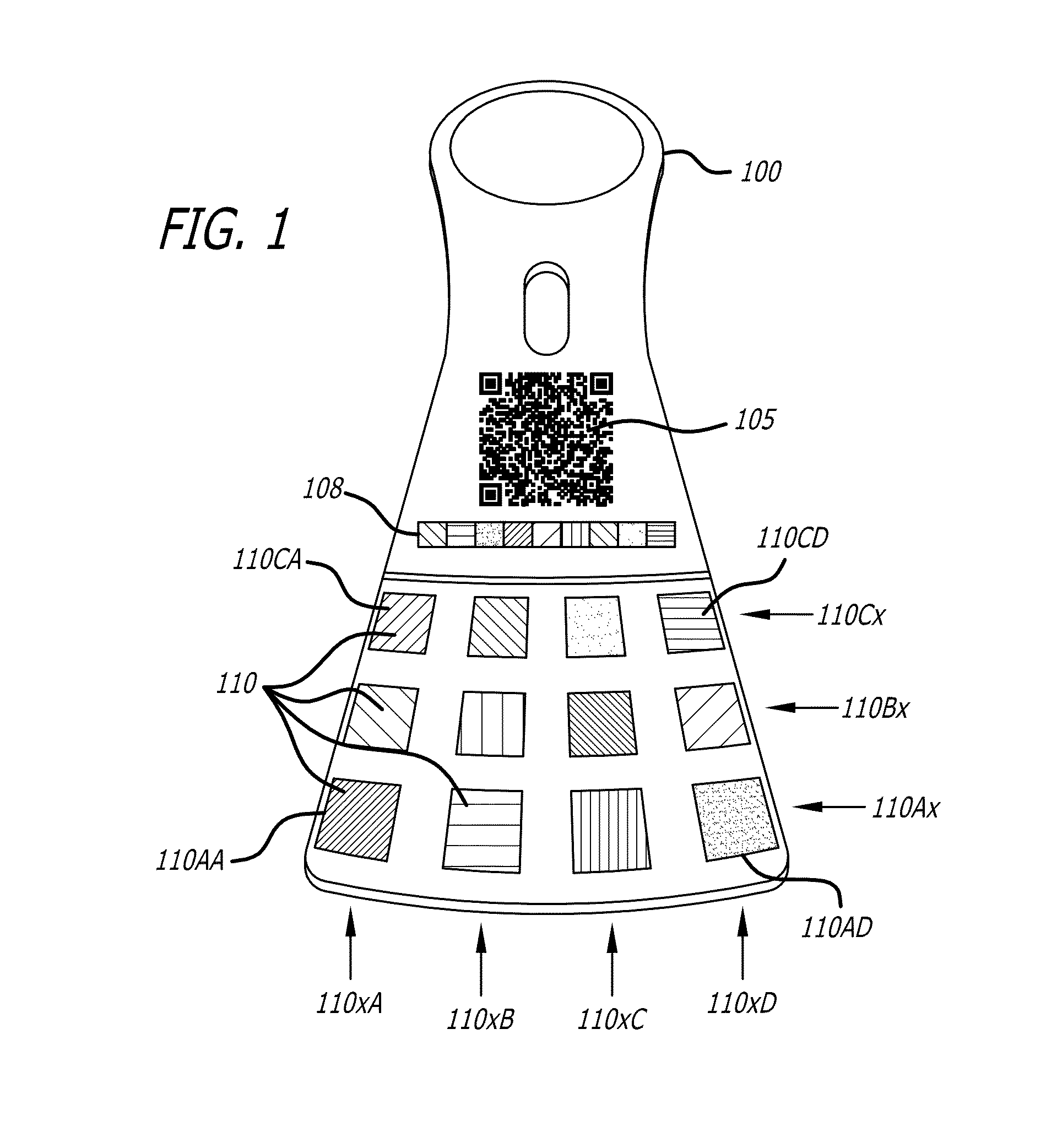

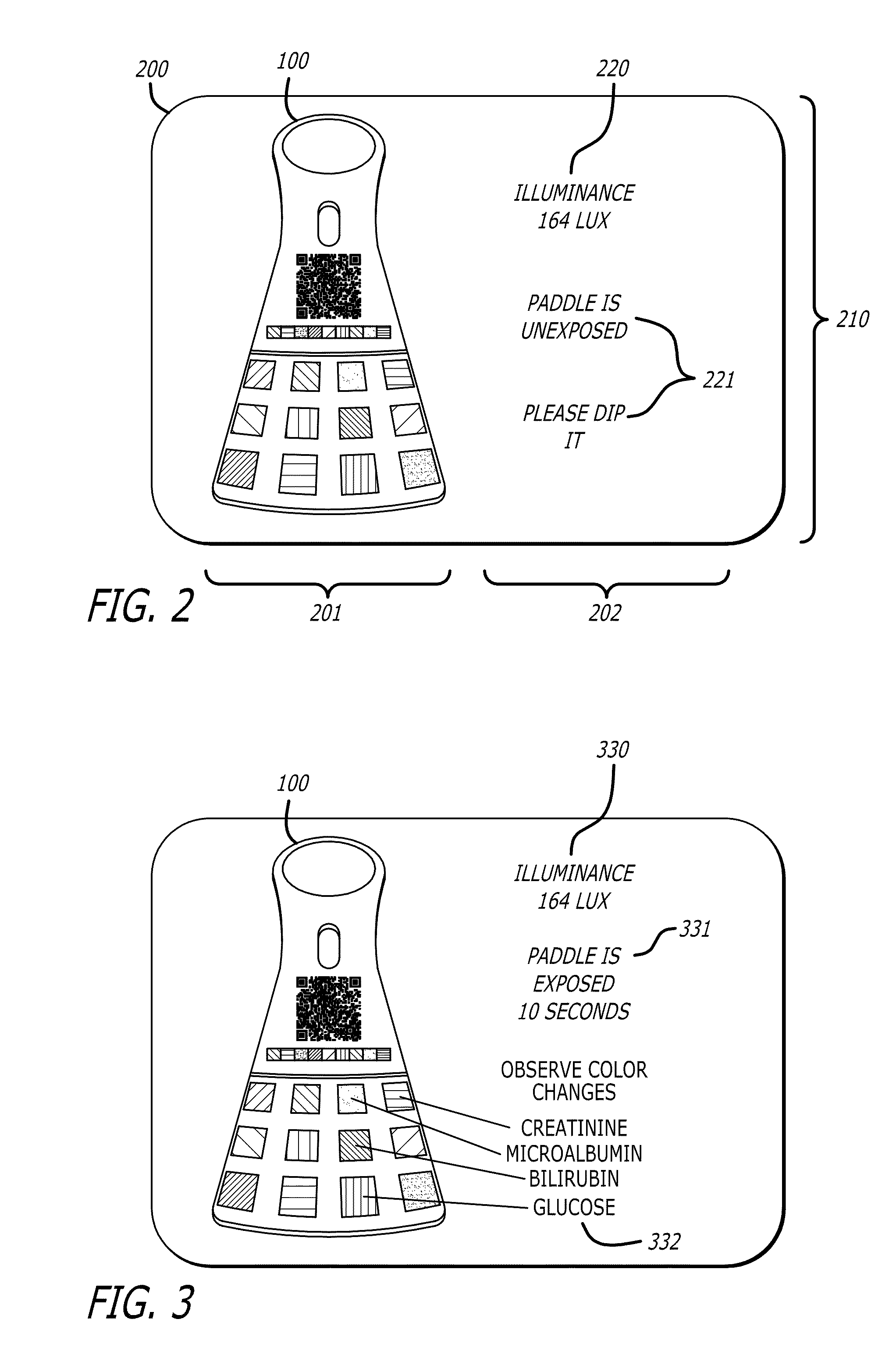

Method and apparatus for determining analyte concentration by quantifying and interpreting color information captured in a continuous or periodic manner

ActiveUS20150241358A1Eliminate errorsTelevision system detailsAnalysis using chemical indicatorsAnalyteDisplay device

In one embodiment, an apparatus for automatic test diagnosis of a test paddle is disclosed. The apparatus comprises a personal computing device including: a camera to capture images over time of test pads of a test paddle, a processor coupled to the camera, and a display device coupled to the processor. The processor analyzes the color changes over time of each test pad to determine a color trajectory over time for each test pad. The processor compares the color evolution trajectory for each test pad with color calibration curves for each test pad to determine an analyte concentration of a test biological sample, such as urine. During the analysis by the processor, the display device displays a user interface with results of the analyte concentration in response to the analysis over time.

Owner:HEALTHY IO LTD

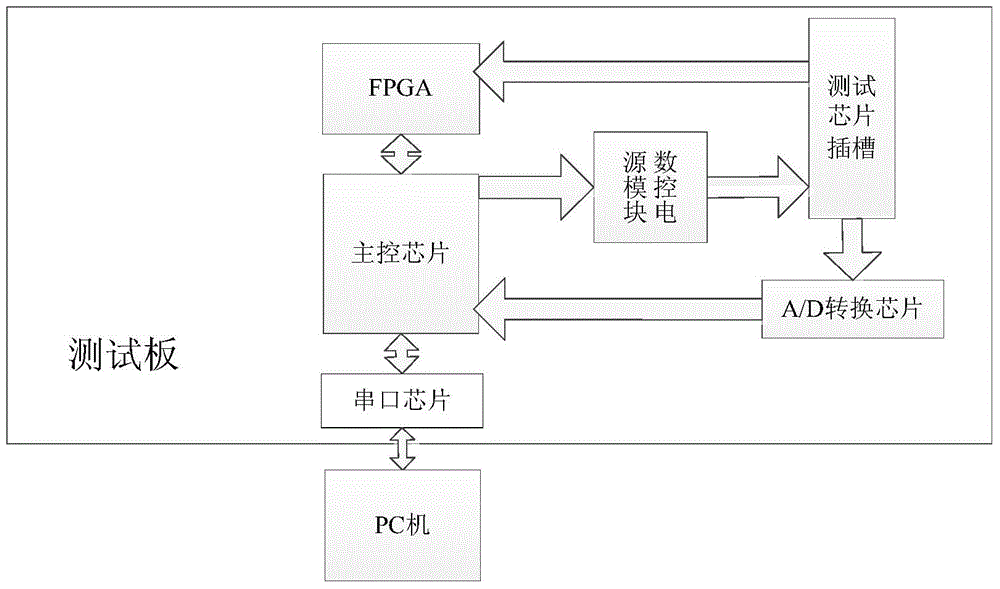

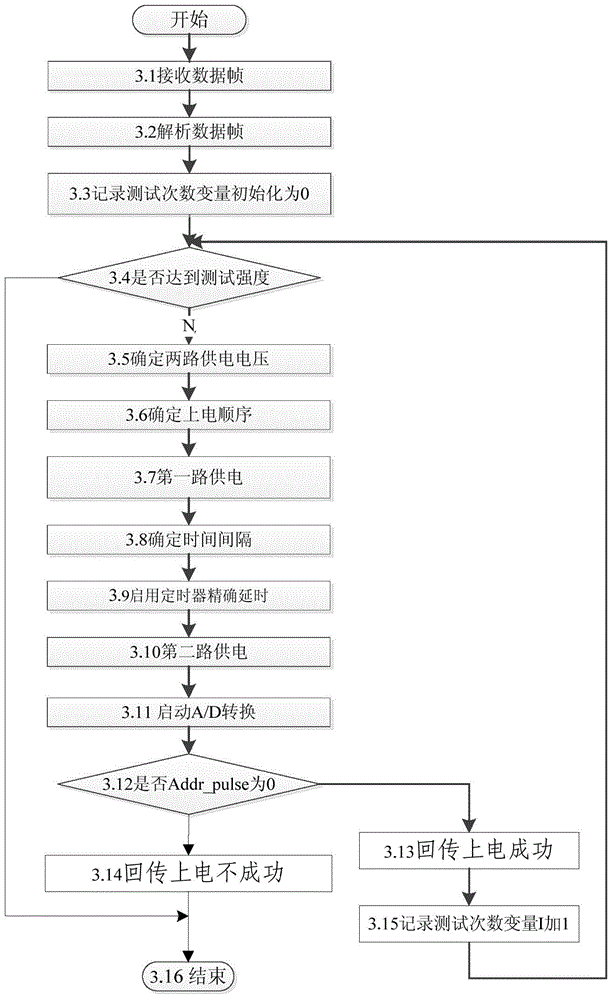

Automatic chip power-on reliability detection device and detection method

ActiveCN105093094AImprove accuracyIncrease flexibilityElectronic circuit testingNumerical controlElectricity

The invention discloses an automatic chip power-on reliability detection device and a detection method and aims to solve technical problems in the prior art that hand-operated operation easily causes errors, measurement is inaccurate, and long-time and large-intensity power-on detection is not suitable. The device comprises a PC used for operating display and control software and a test board for chip tests, wherein the PC is equipped with the display and control software, and the test board comprises a serial port chip, an FPGA, a main control chip, a numerical control power supply module, an A / D conversion chip, a slot of a test chip and a card in matching with the slot of the test chip. The automatic chip power-on detection method comprises steps that, the PC receives test information, the display and control software assembles the test information into data frames and sends the data frames to the serial port chip, a tested chip is tested through the test board, and the data frames transferred from the FPGA are parsed by the automatic power-on reliability detection software of the main control chip. According to the device and the method, test result accuracy is improved, the test process is simple, and operation is simple and convenient.

Owner:NAT UNIV OF DEFENSE TECH

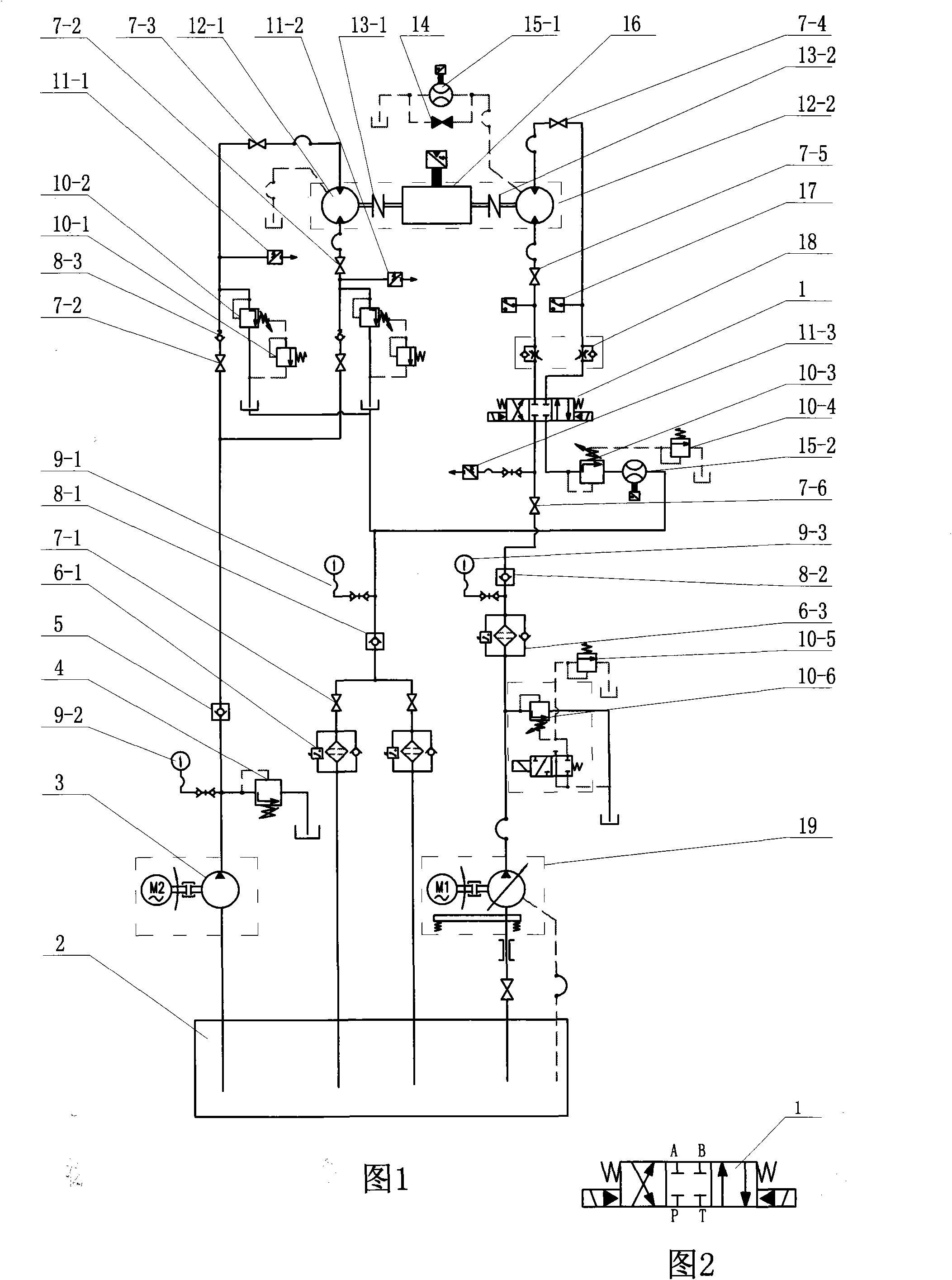

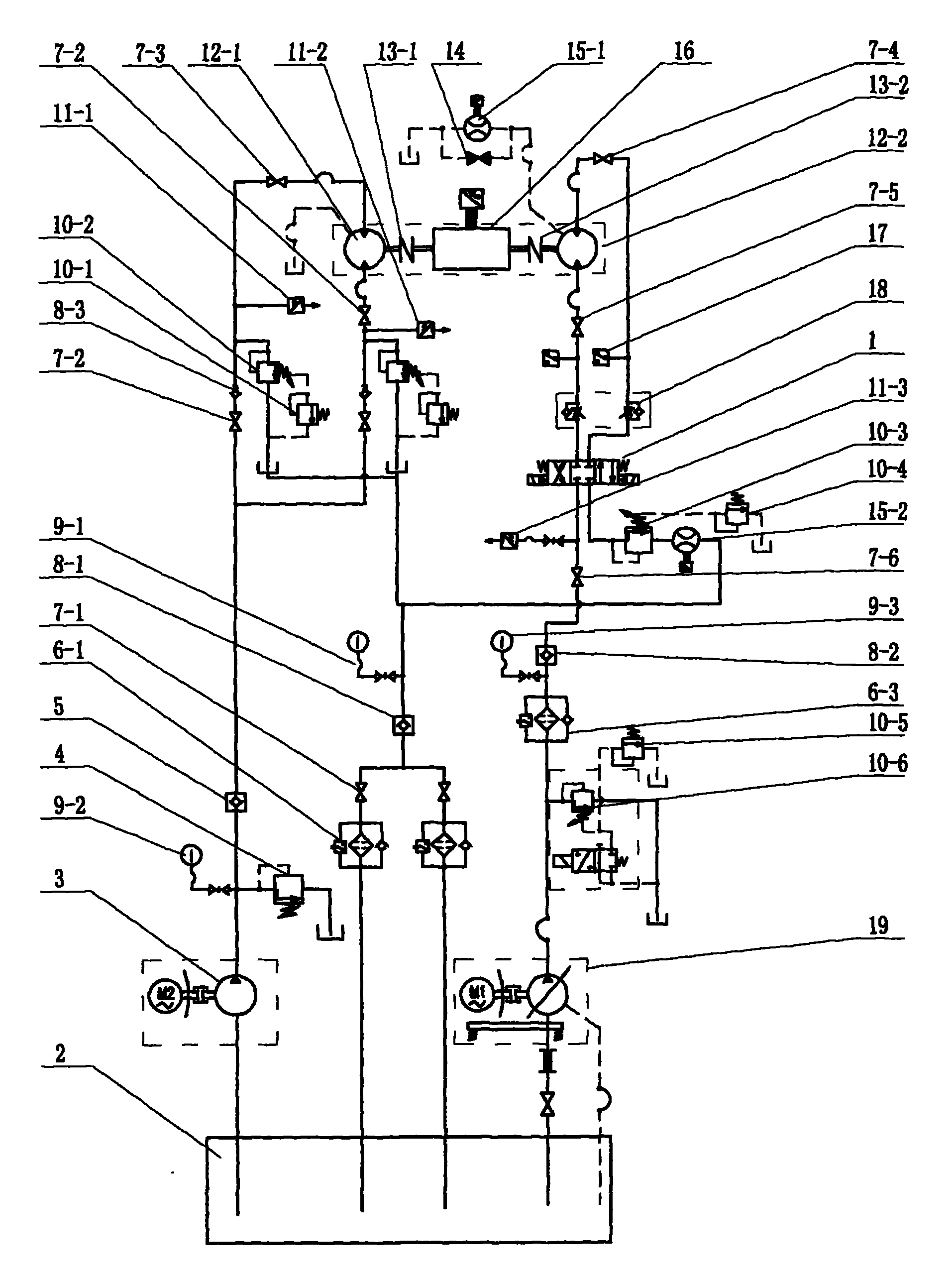

Loading device of hydraulic motor test board

ActiveCN101871478AConvenience to workReduce labor intensityFluid-pressure actuator testingHydraulic motorRemote control

The invention relates to a loading device of a hydraulic motor test board, which is characterized in that a high-pressure oil pump which is connected with an oil tank is connected with an electro-hydraulic reversing valve, a bi-direction retaining throttling valve and a test motor oil inlet through a high-pressure filter and an oil inlet retaining valve, a test motor oil outlet forms a test loop with an oil return retaining valve and an oil return filter oil return box after being connected with a remote counterbalance overflow valve, a flow-rate sensor, through the bi-direction retaining throttling valve and an electro-hydraulic reversing valve oil outlet. A loader is formed by joining a loading motor and a testing motor respectively with a rotation speed torque instrument through a coupling joint, at the same time, a low-pressure pump which is connected with the oil tank enters two ends of the loading motor through two retaining valves, the testing motor rotates to drive the loading motor to rotate, the oil outlet retaining valve is automatically closed, and the outlet oil forms a loading circuit through the counterbalance overflow valve, the remote overflow valve, the oil return retaining valve and the oil return filter oil return box. The loading motor is used for substituting an original magnetic powder loader, so the size is greatly reduced, the energy consumption is reduced, the remote control adjustment is convenient for test personnel to work, the loading force is large, torque of 60000 N.m can be tested, the testing range is wide, and the practicability is strong.

Owner:宁波恒通诺达液压股份有限公司

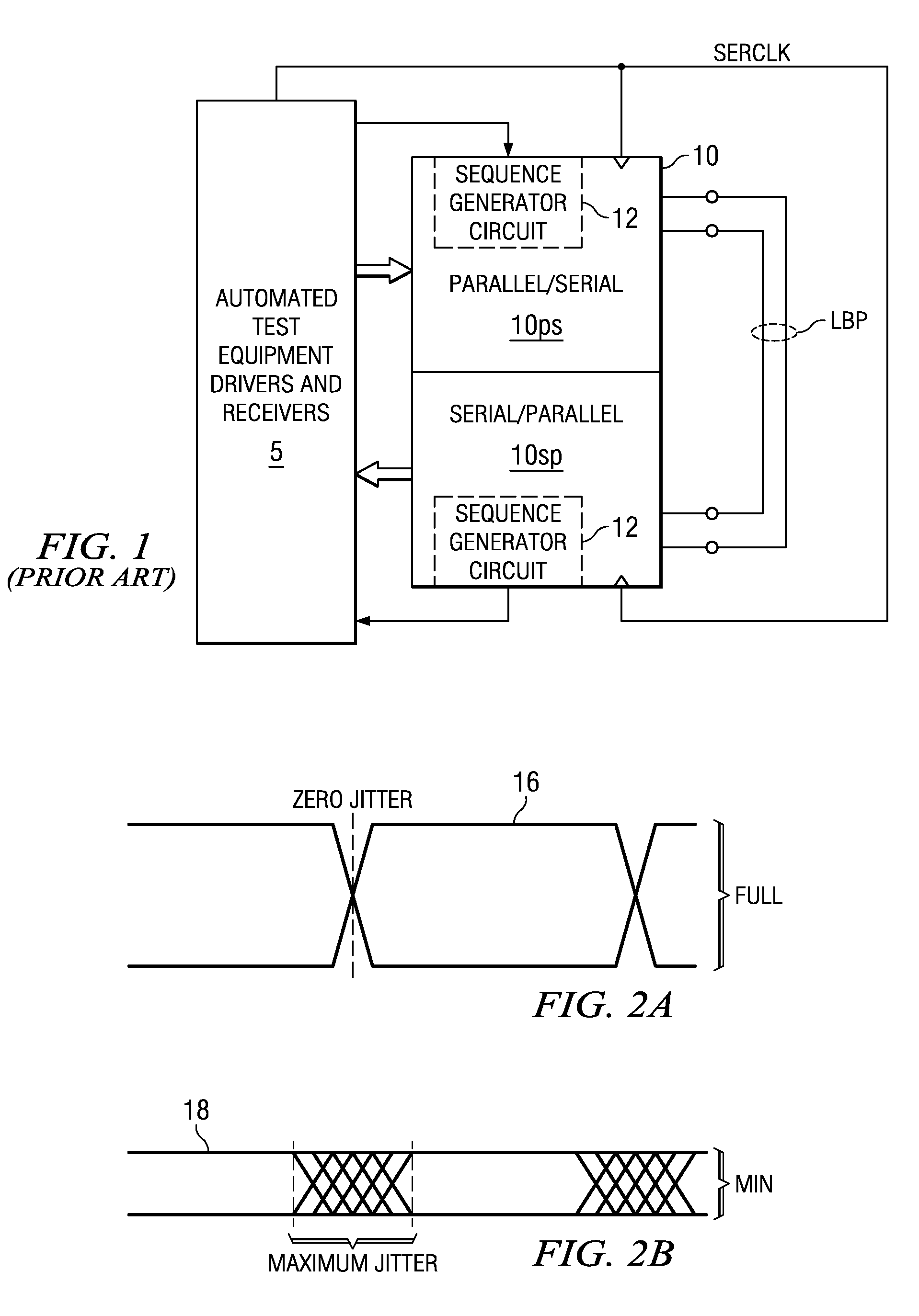

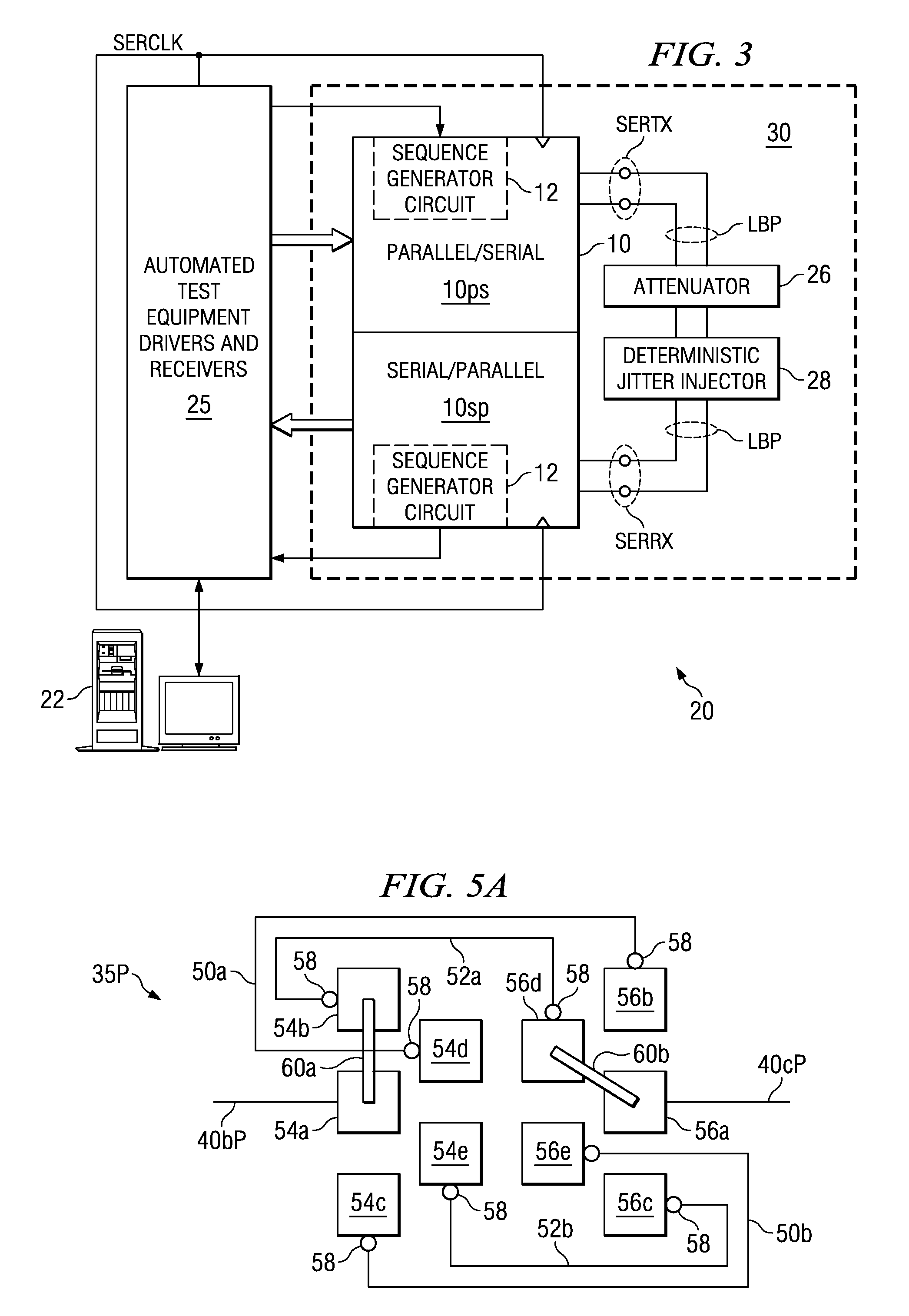

Automated test of receiver sensitivity and receiver jitter tolerance of an integrated circuit

ActiveUS7203460B2Accurate settingDigital circuit testingNoise figure or signal-to-noise ratio measurementEngineeringVariable length

An automated test system (20) for testing a high-speed communications integrated circuit (10), such as a serializer / deserializer, is disclosed. The system (20) is able to test the parameters of receiver jitter tolerance and receiver sensitivity in a loopback connection arrangement, in which serial output terminals (SERTX) of the integrated circuit (10) are connected to serial input terminals (SERRX) of the integrated circuit (10). An attenuator (26), which in the disclosed embodiment includes programmable attenuators (30P, 30N) and a fixed attenuator (32), one of which is selected, is disposed in the loopback path. A deterministic jitter injector (28) is also in the loopback path, and may be implemented by way of variable length trace blocks (35P, 35N) on the test board (30). In this way, the serial output signals generated by the integrated circuit (10) are modified by the attenuator (26) and deterministic jitter injector (28) so that the signal as received at the serial input terminals (SERRX) can be at the specification limits of the circuit (10).

Owner:TEXAS INSTR INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com