Camera module test platform

A camera module and test platform technology, applied in photography, optics, instruments, etc., can solve problems such as unreliable test results of camera modules, and achieve smooth test process, high test efficiency, and good consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] This embodiment discloses a camera module testing platform, comprising:

[0033] A base, the base is provided with a sliding shaft parallel to the surface of the base. The surface of the base is flat and preferably rectangular, and is used to carry the camera module and other components of the camera module test platform. The sliding axis is parallel to the surface of the base.

[0034] The first bracket is slidably arranged along the axial direction of the sliding shaft, that is, the first bracket can slide freely in the axial direction of the sliding shaft. The first bracket includes at least one first support column.

[0035] A close-range target, a stain test board, and a relay mirror are arranged on the first bracket.

[0036] A second bracket, the second bracket is arranged on the base, and a long-range target is set on the second bracket, and the distance between the long-range target and the surface of the base is greater than the distance between the relay m...

Embodiment 2

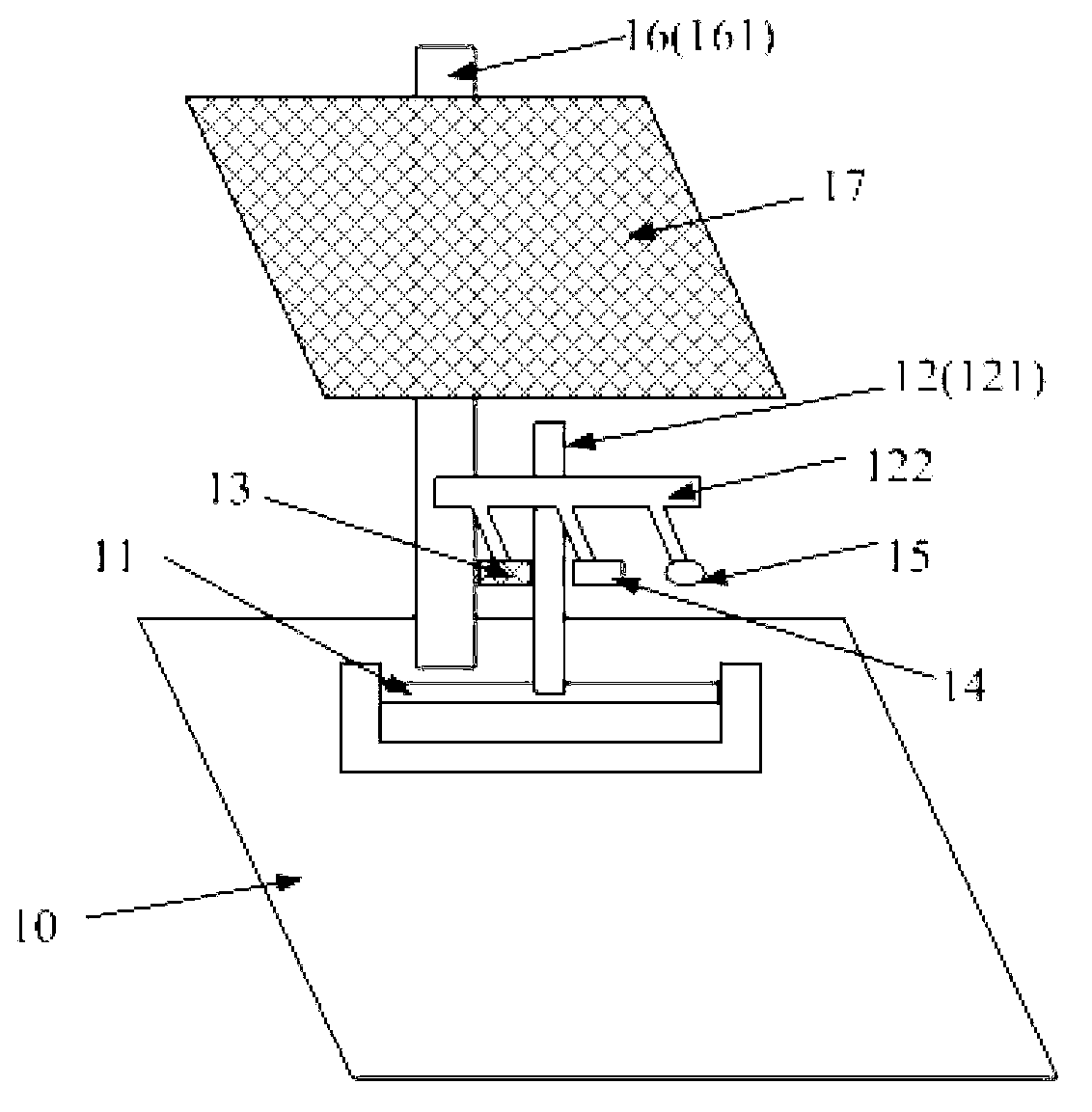

[0040] This embodiment discloses another camera module test platform, such as figure 1 shown, including:

[0041] The base 10 is provided with a sliding shaft 11 parallel to the surface of the base 10 . The surface of the base 10 is flat and preferably rectangular, and is used to carry the camera module and other components of the camera module test platform. The sliding shaft 11 is fixed on the surface of the base 10 through a shaft bracket 12 , and the axial direction of the sliding shaft 11 is parallel to the surface of the base 10 . Wherein, the length of the sliding shaft 11 depends on specific conditions, and is not limited here.

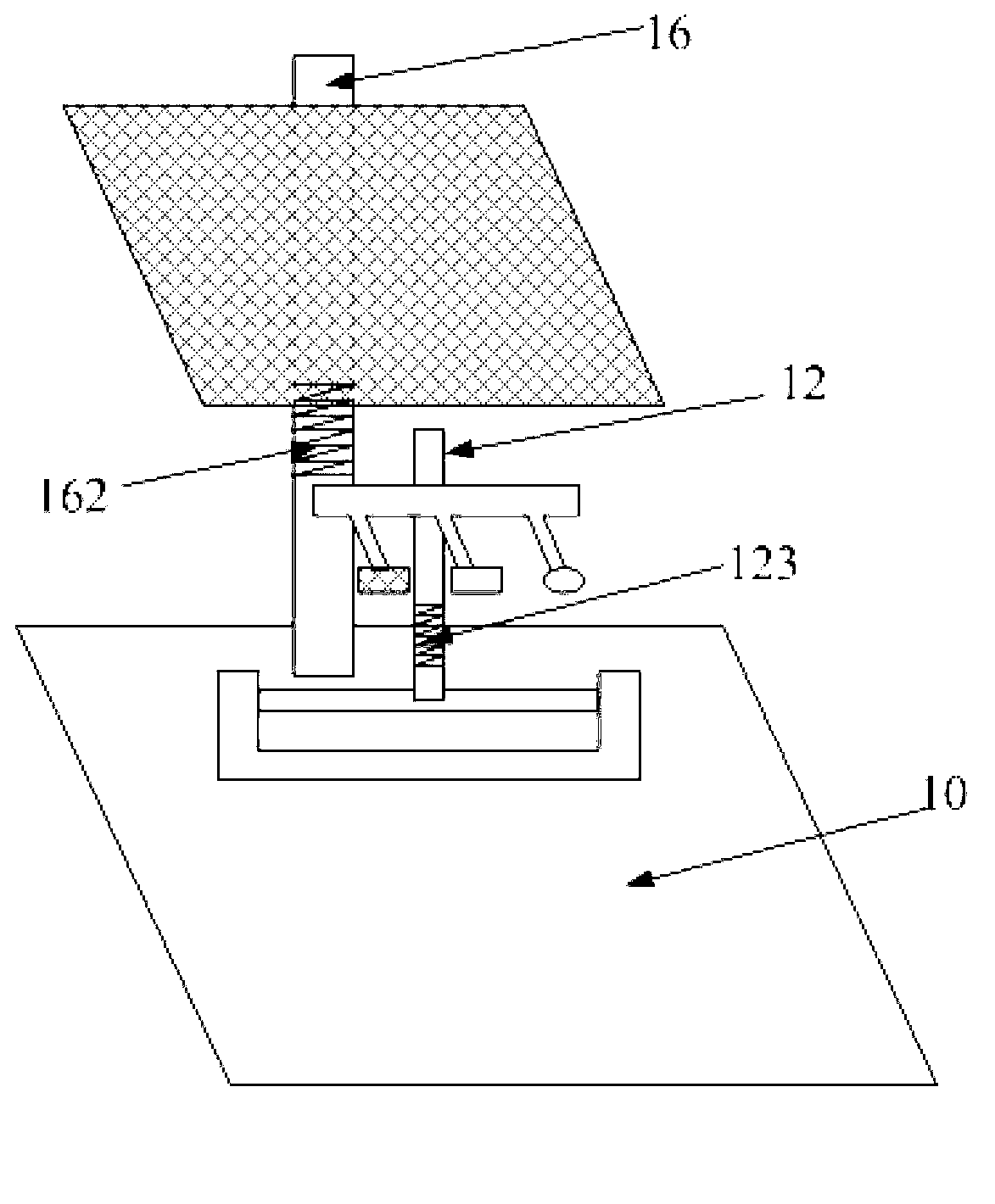

[0042] The first bracket 12 is slidably arranged along the axial direction of the sliding shaft 11 . The first bracket 12 includes a first support column 121, and a transverse support rod 122 parallel to the axial direction of the sliding shaft 11 is arranged on the first support column 121, and the transverse support rod 122 is connected t...

Embodiment 3

[0049] This embodiment discloses another camera module testing platform, which includes: a base, and a sliding shaft parallel to the surface of the base is arranged on the base. The sliding axis is parallel to the surface of the base.

[0050] The first bracket is slidably arranged along the axial direction of the sliding shaft, that is, the first bracket can slide freely in the axial direction of the sliding shaft. The first bracket includes at least one first support column.

[0051] A close-range target, a stain test board, and a relay mirror are arranged on the first bracket.

[0052]A second bracket, the second bracket is arranged on the base, and a long-range target is set on the second bracket, and the distance between the long-range target and the surface of the base is greater than the distance between the relay mirror and the surface of the base.

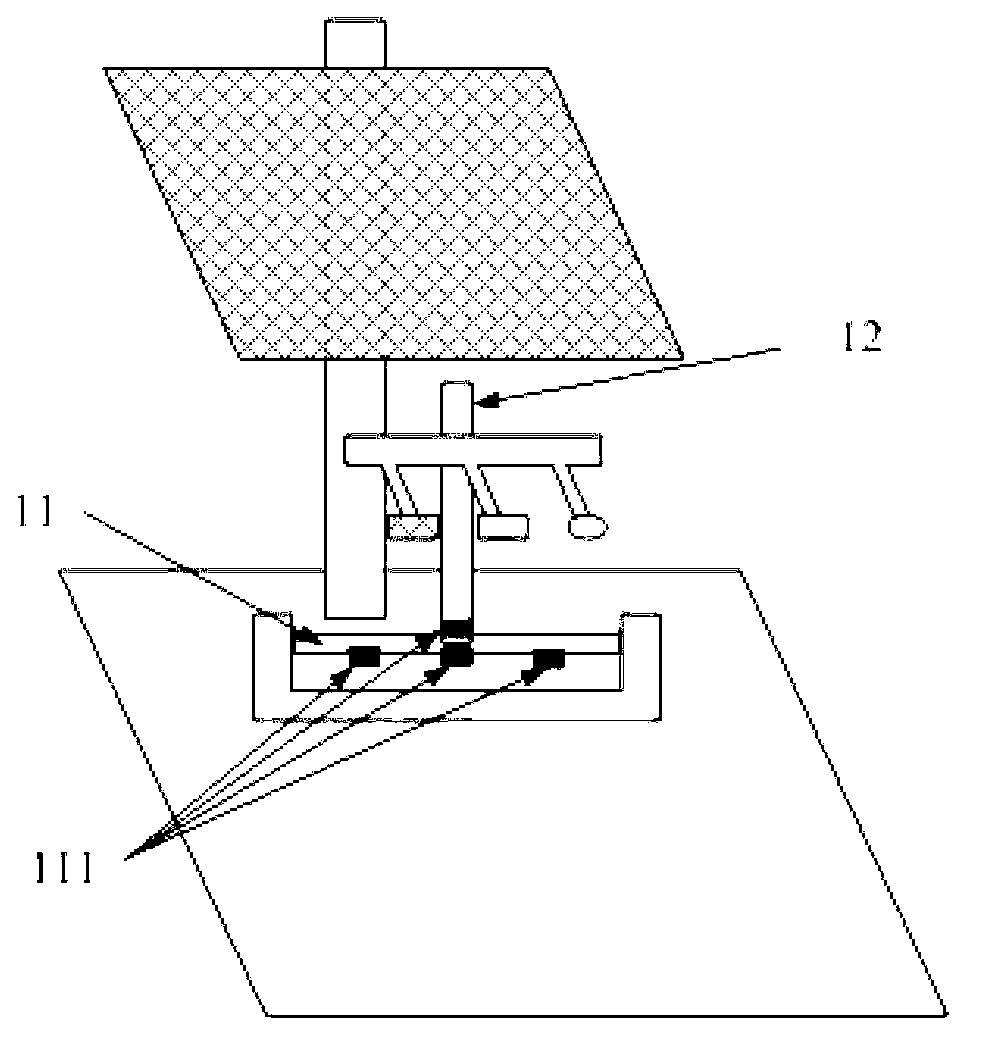

[0053] The difference from the above-mentioned embodiment is that, if figure 2 As shown, a positioning magnet 111 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com