Patents

Literature

1031results about How to "Maintain temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

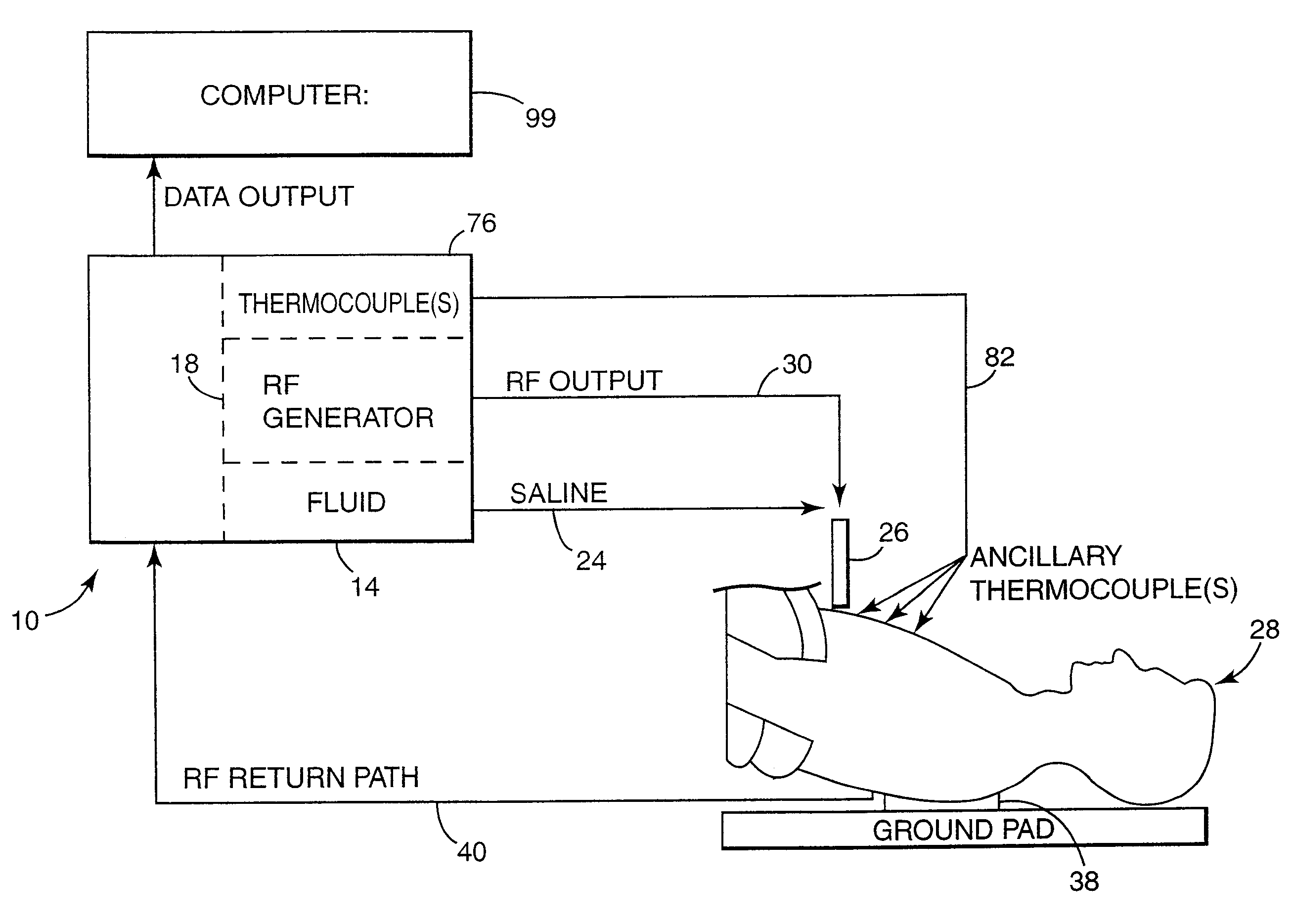

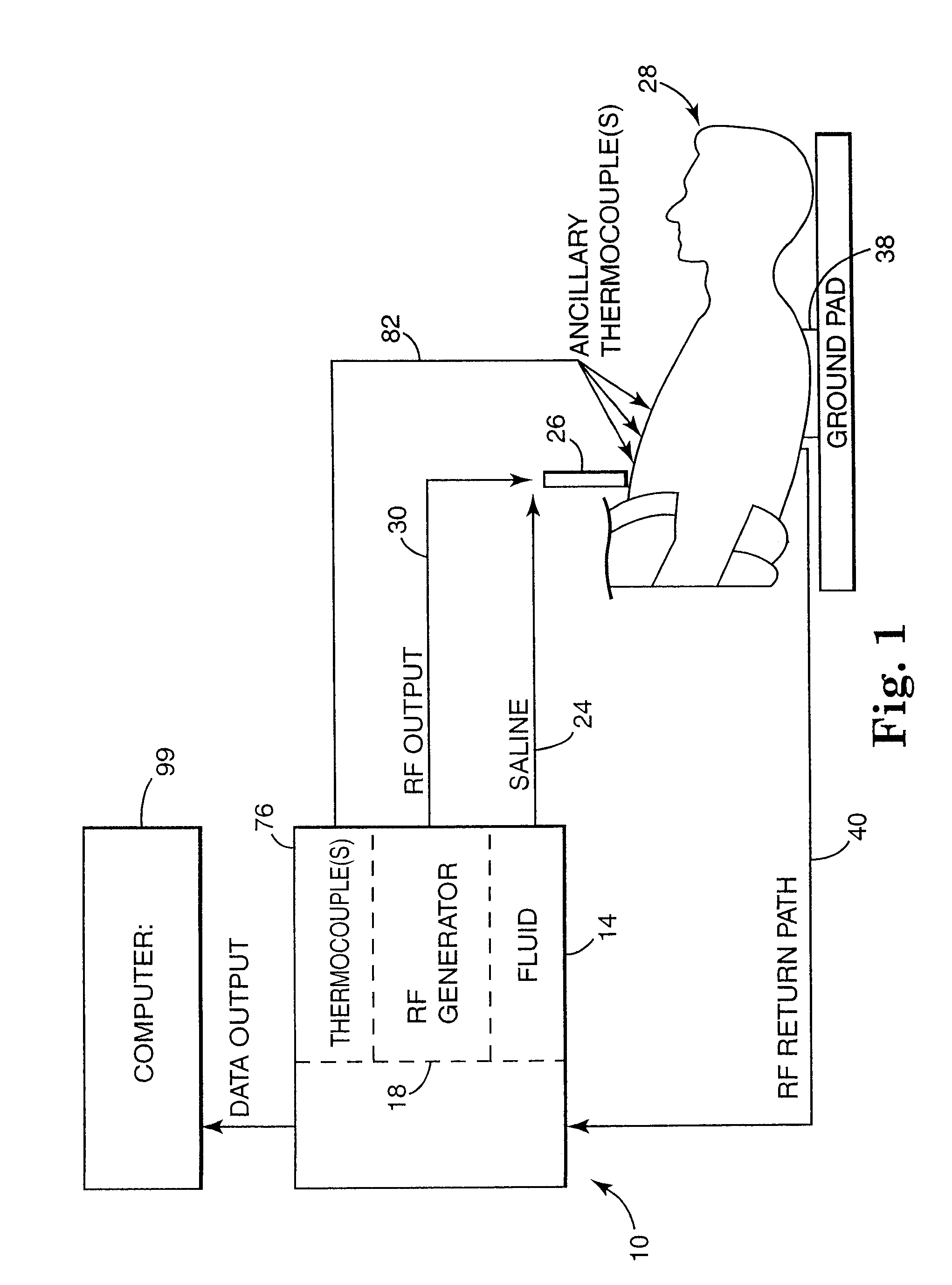

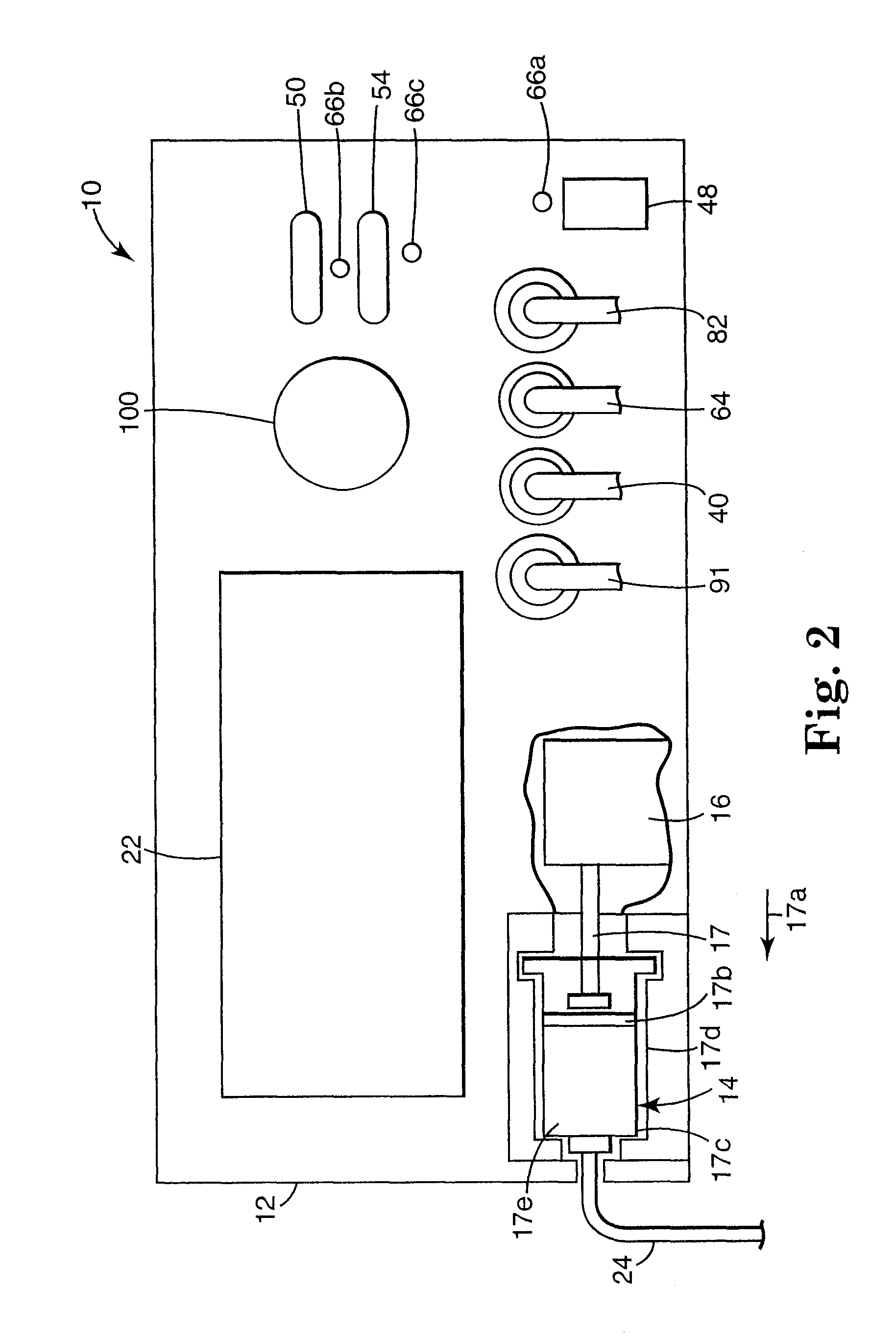

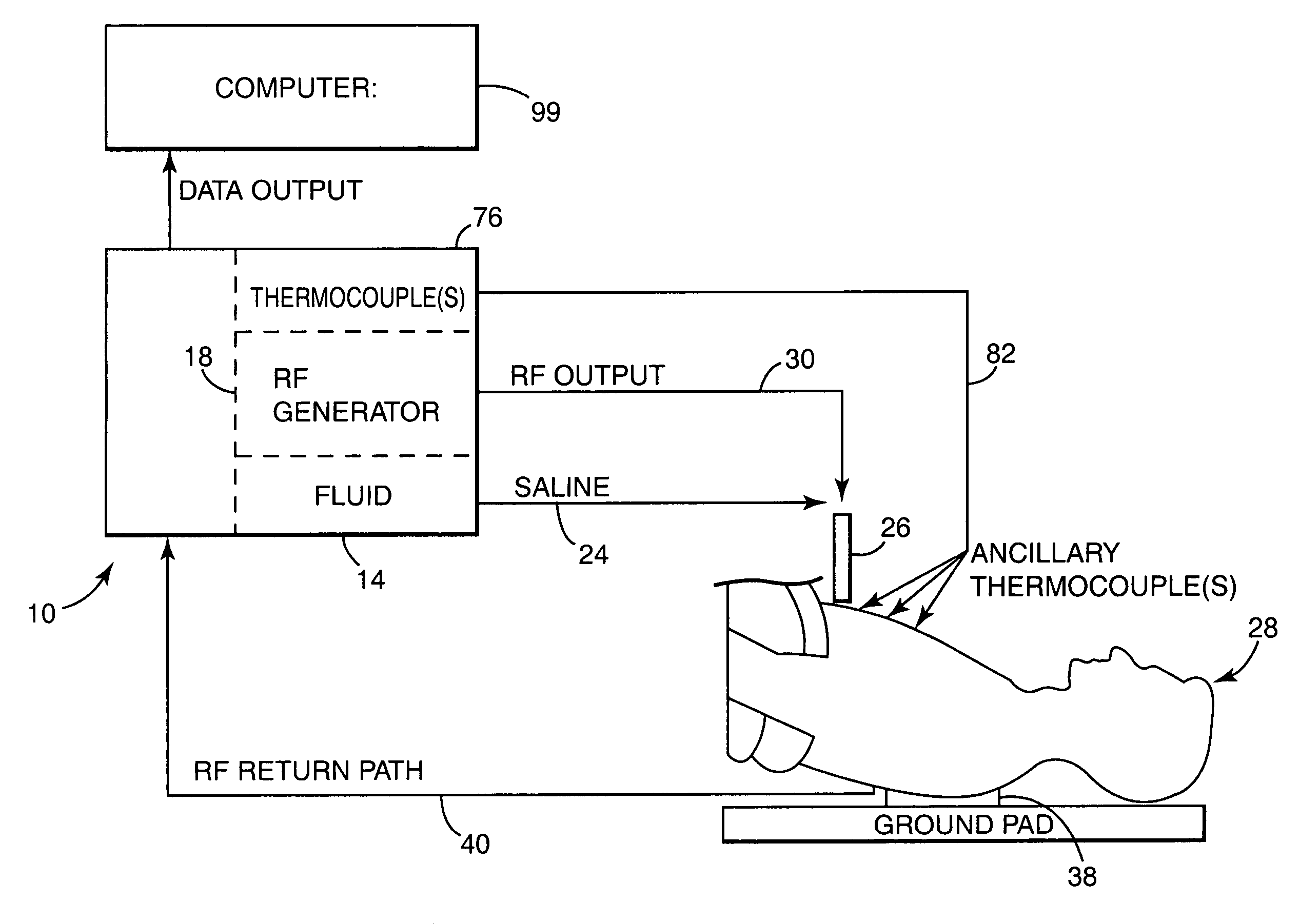

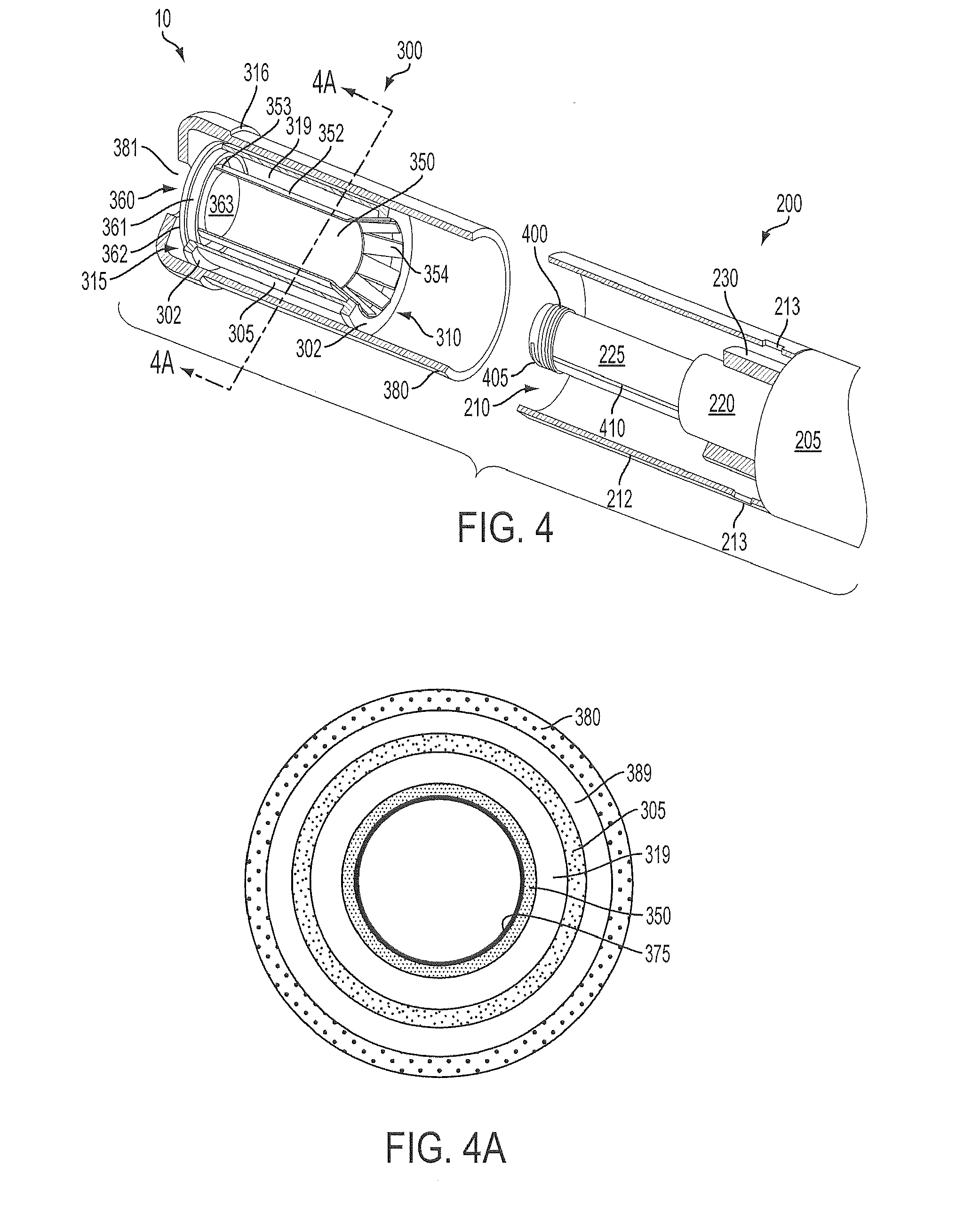

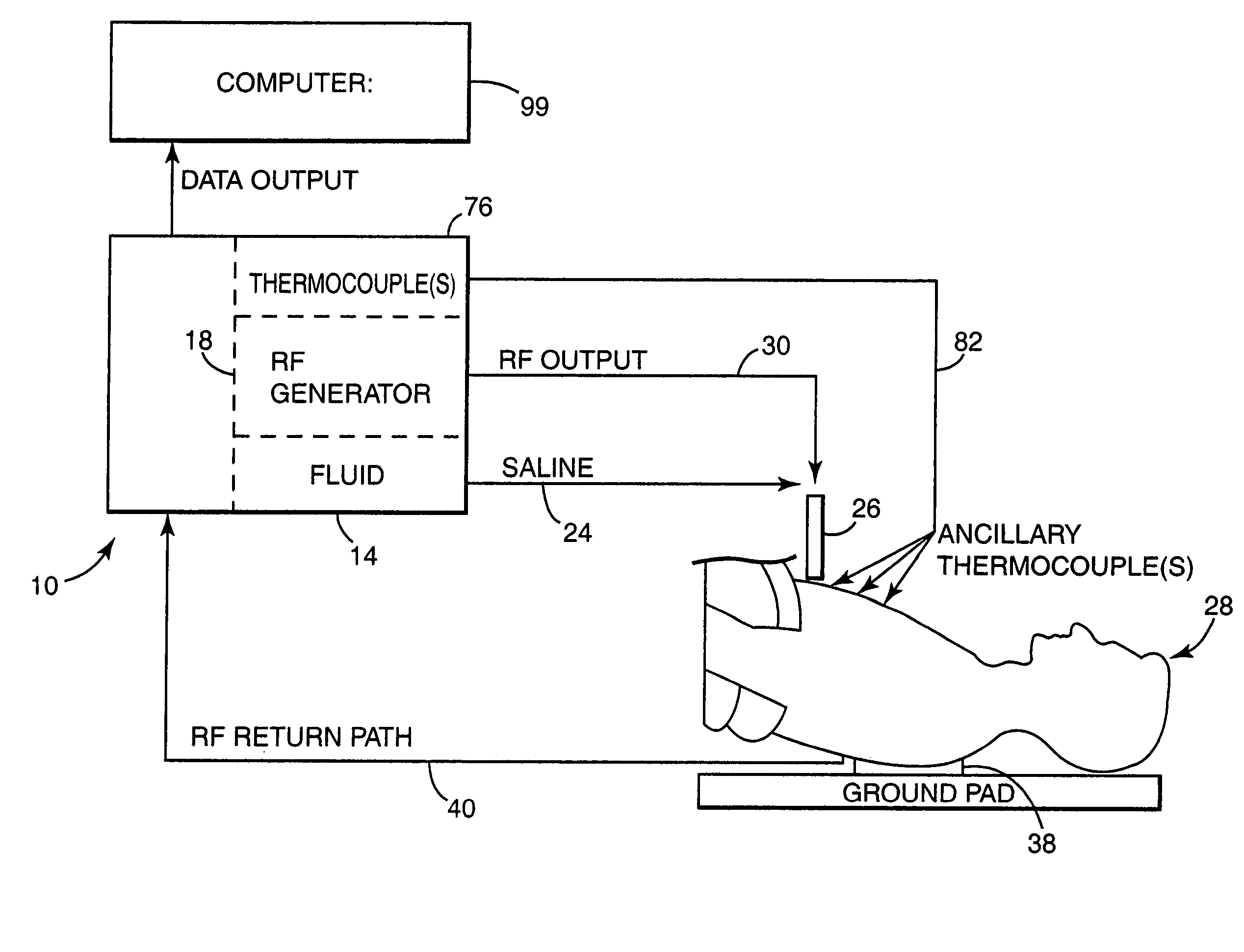

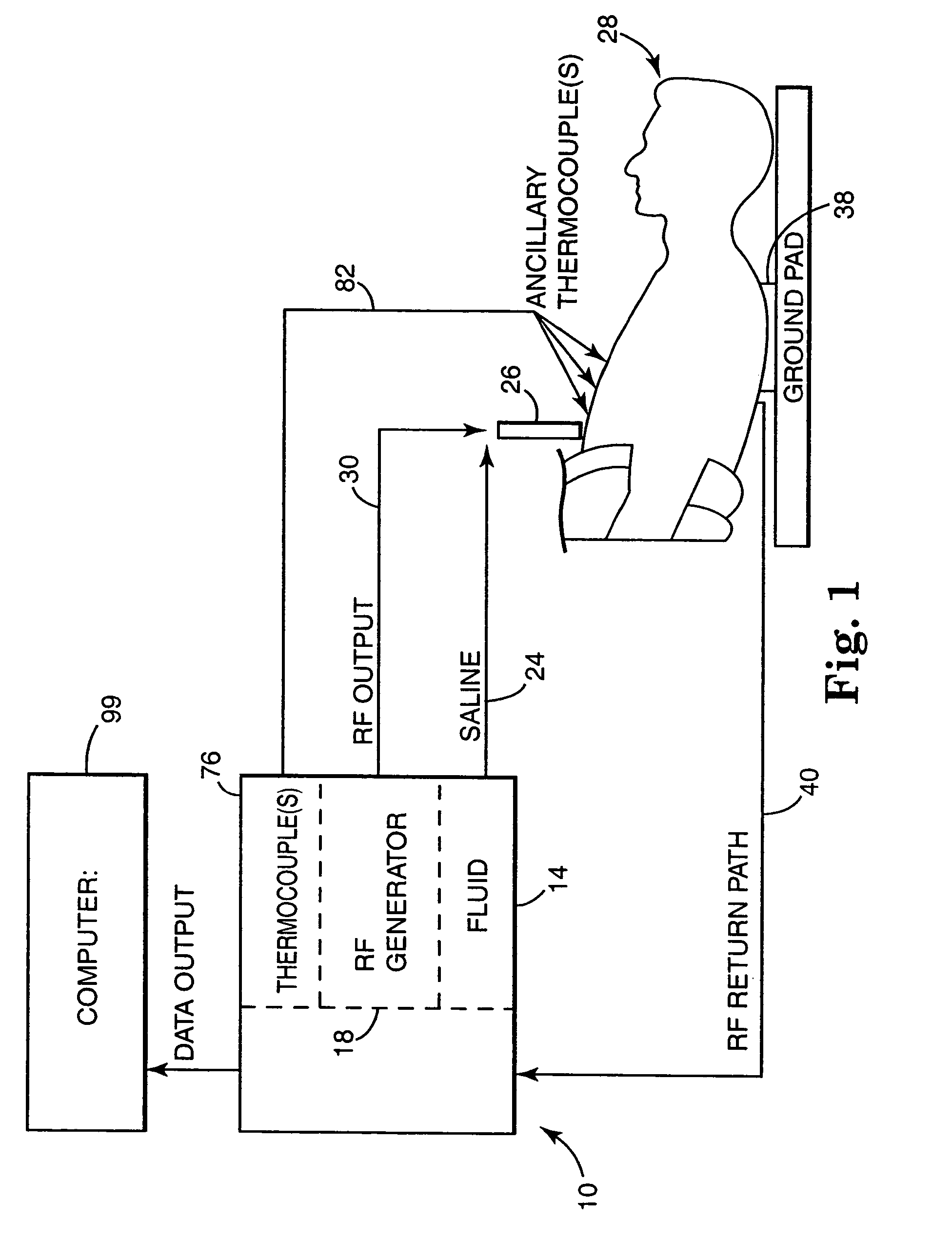

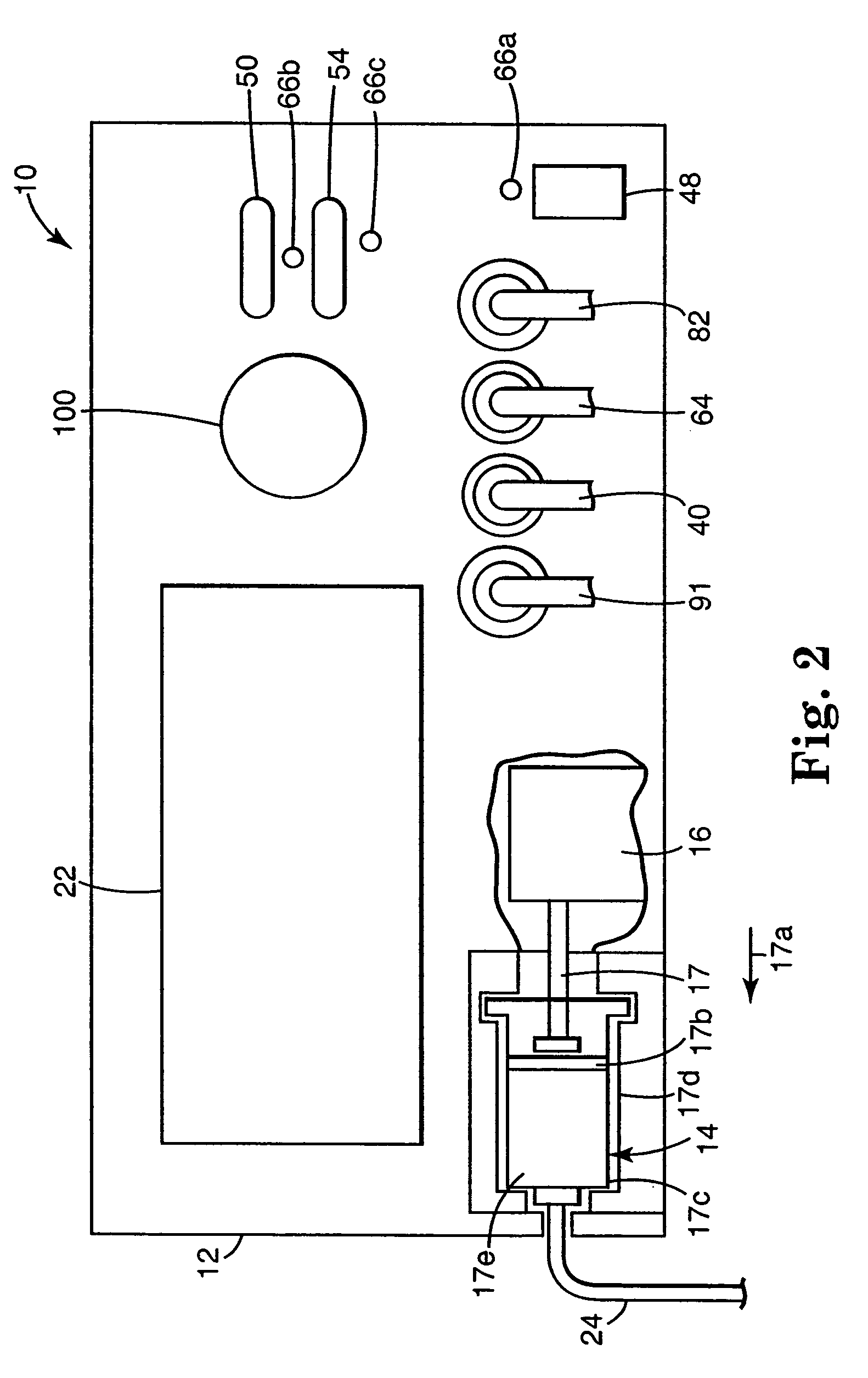

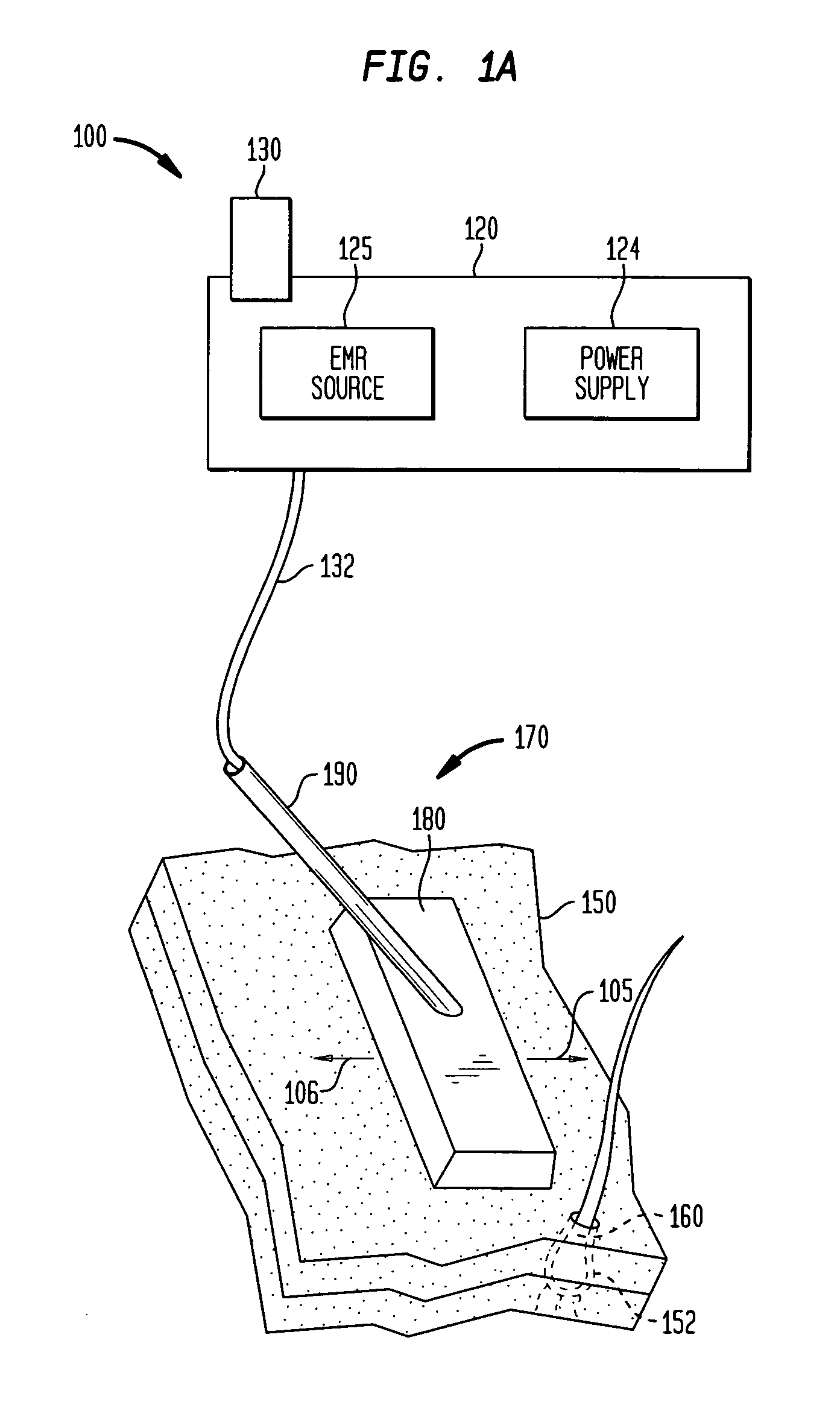

Apparatus and method for creating, maintaining, and controlling a virtual electrode used for the ablation of tissue

InactiveUS6849073B2Increase impedanceDiminish likelihoodSurgical instruments for heatingSurgical instruments using microwavesRadio frequencyElectric generator

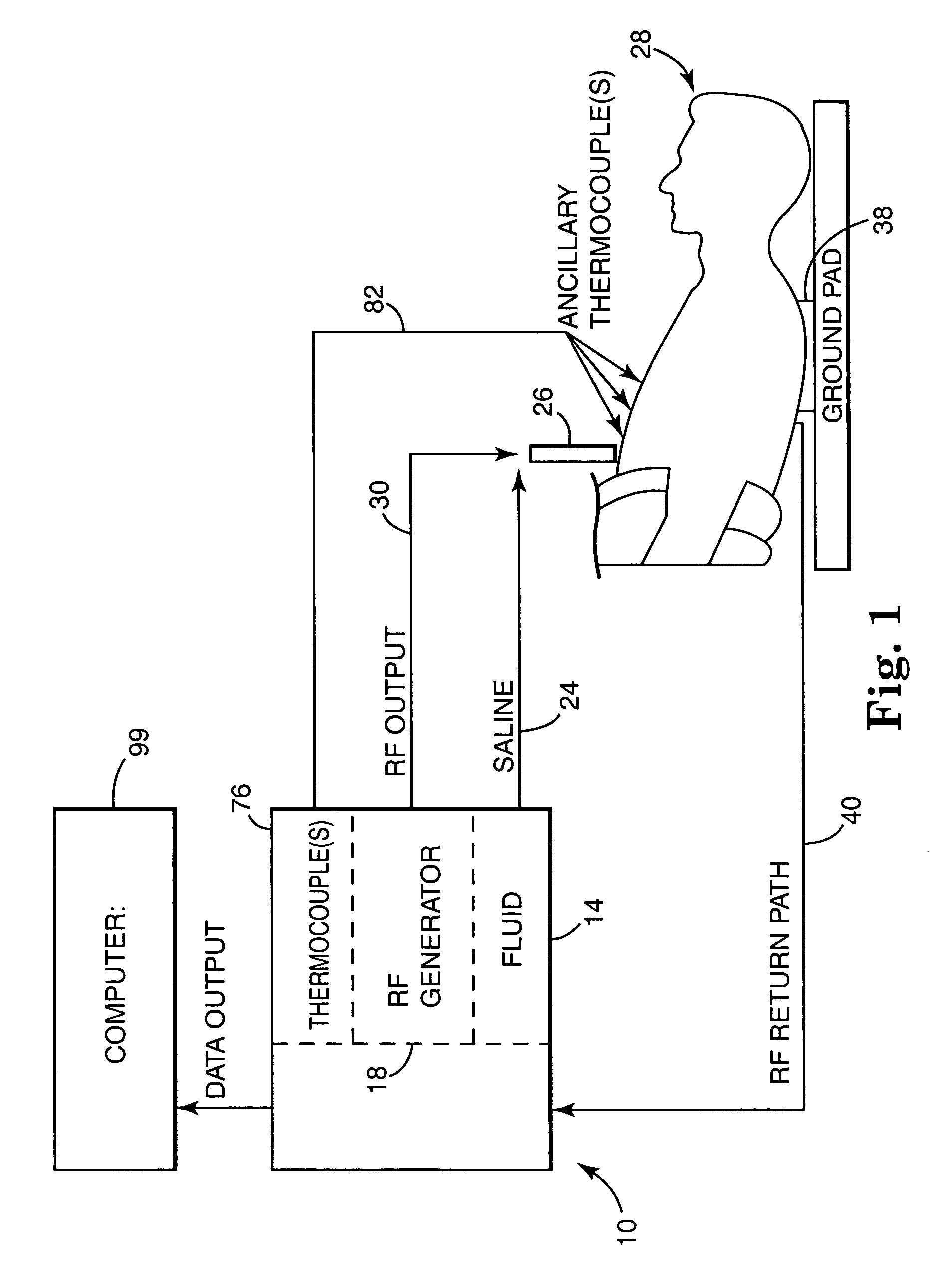

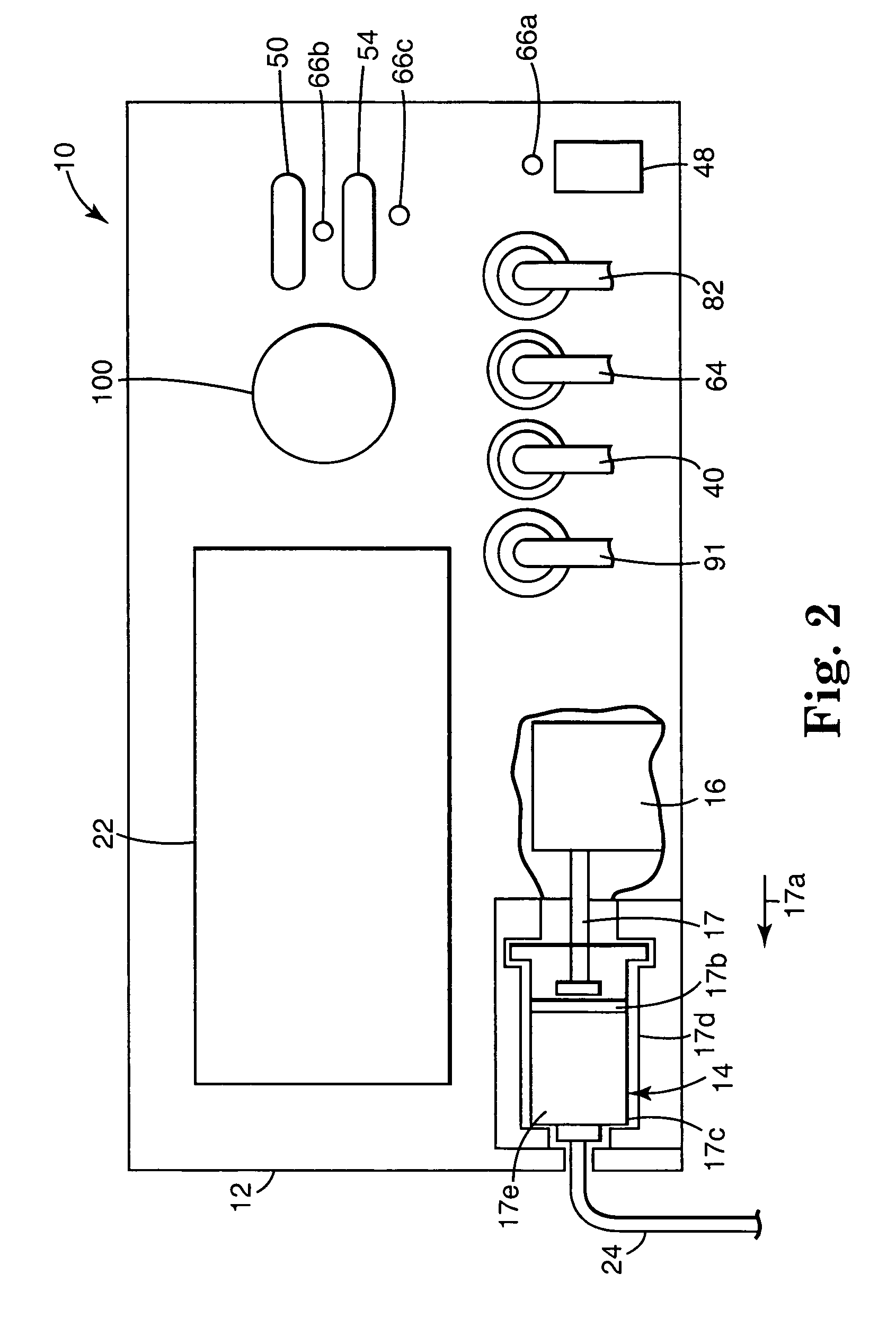

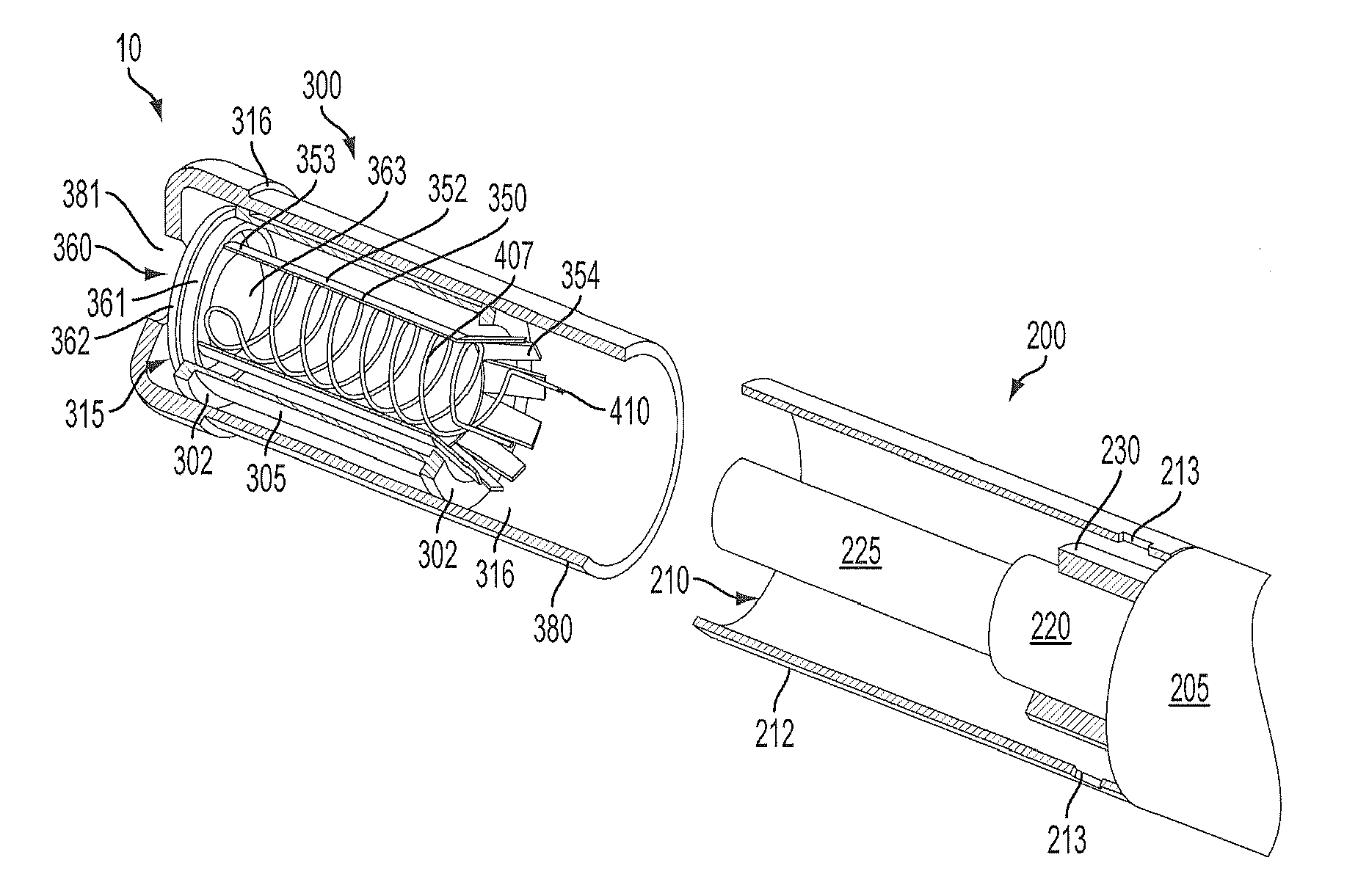

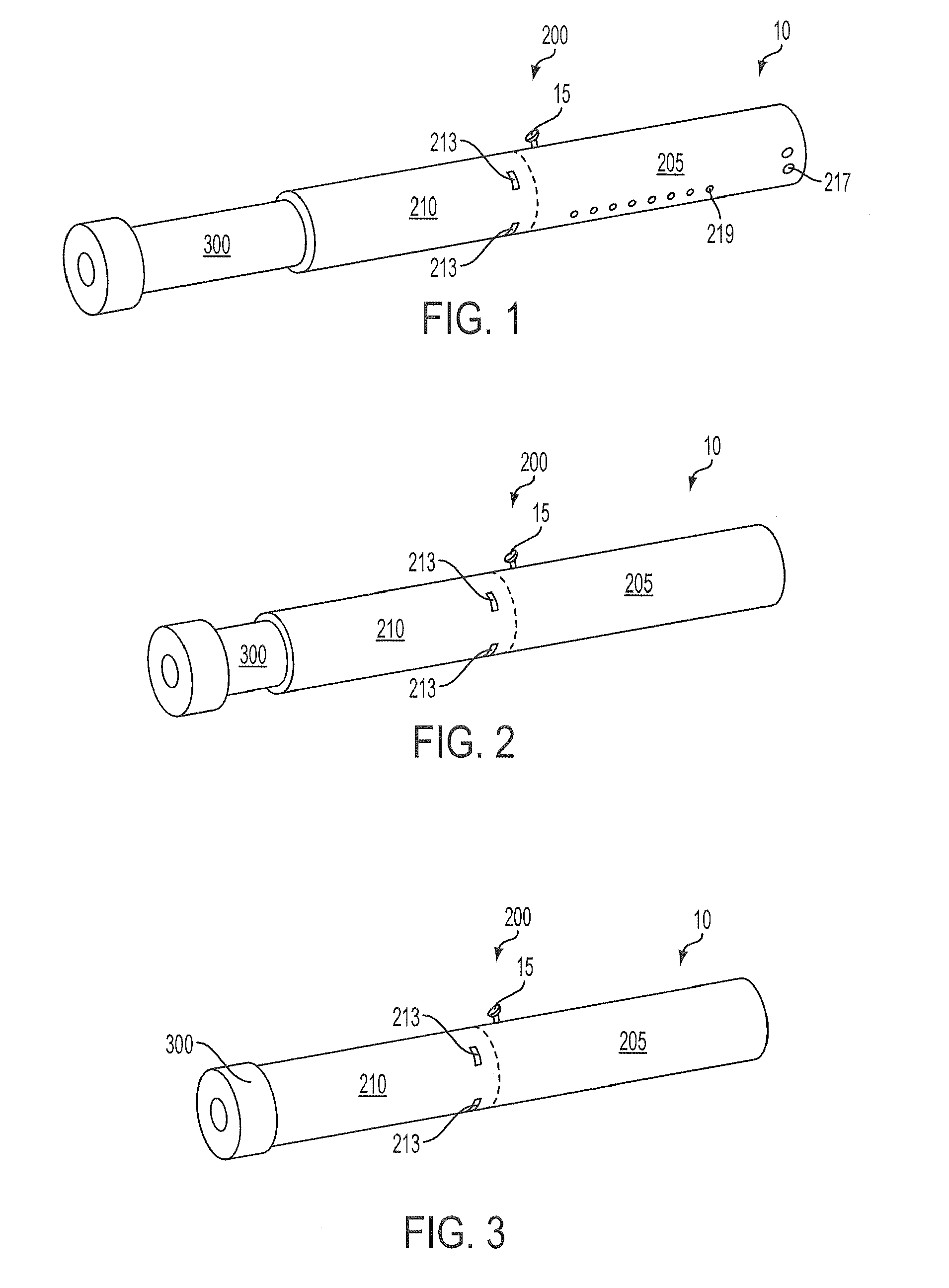

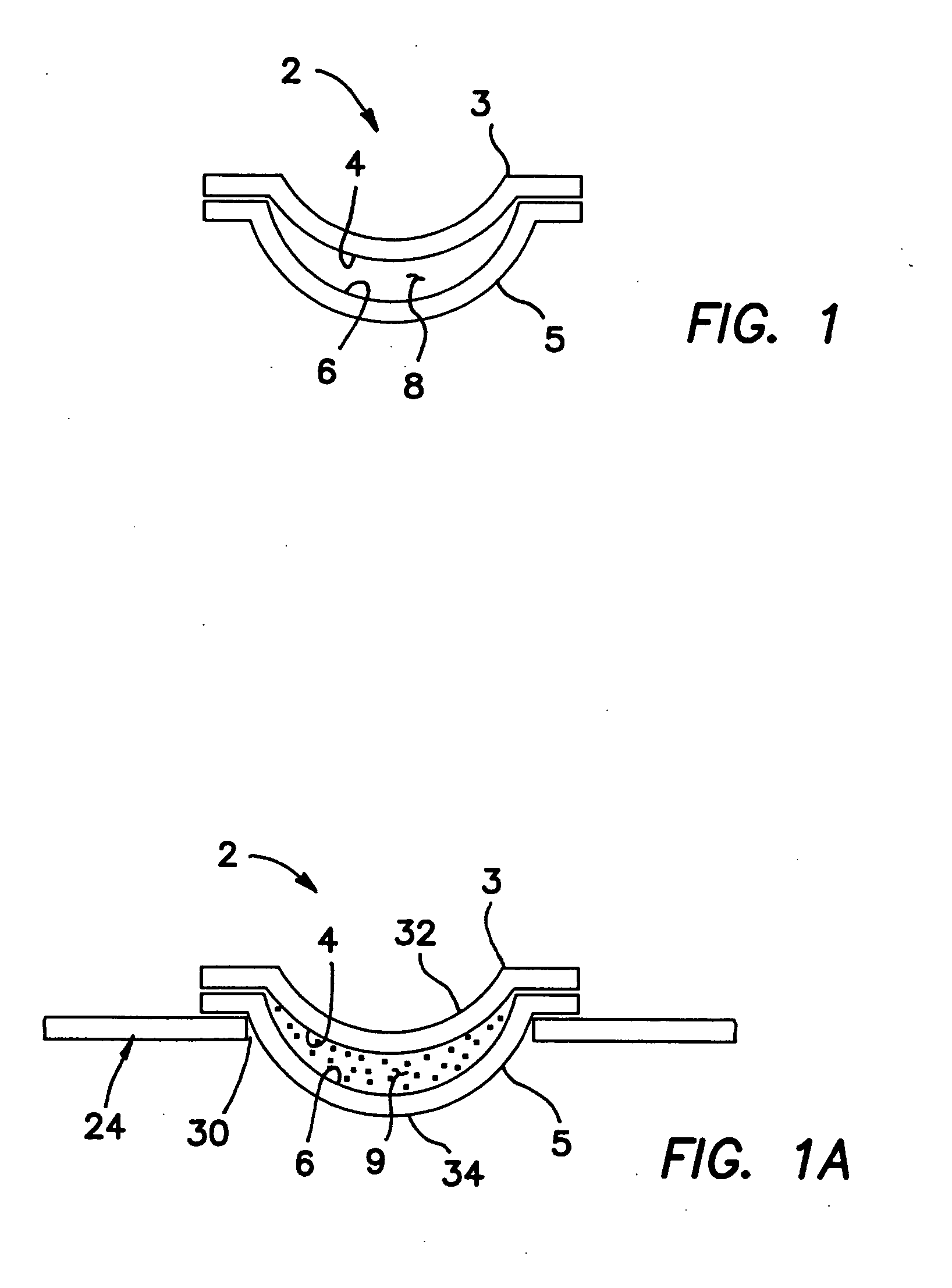

The present invention provides an apparatus and a method for producing a virtual electrode within or upon a tissue to be treated with radio frequency alternating electric current, such tissues including but not limited to liver, lung, cardiac, prostate, breast, and vascular tissues and neoplasms. An apparatus in accord with the present invention includes a supply of a conductive or electrolytic fluid to be provided to the patient, an alternating current generator, and a processor for creating, maintaining, and controlling the ablation process by the interstitial or surficial delivery of the fluid to a tissue and the delivery of electric power to the tissue via the virtual electrode. A method in accord with the present invention includes delivering a conductive fluid to a predetermined tissue ablation site for a predetermined time period, applying a predetermined power level of radio frequency current to the tissue, monitoring at least one of several parameters, and adjusting either the applied power and / or the fluid flow in response to the measured parameters.

Owner:MEDTRONIC INC

Apparatus and method for creating, maintaining, and controlling a virtual electrode used for the ablation of tissue

InactiveUS7169144B2Maintain temperatureImproving impedanceSurgical instruments for heatingSurgical instruments using microwavesBlood Vessel TissueVascular tissue

The present invention provides an apparatus and a method for producing a virtual electrode within or upon a tissue to be treated with radio frequency alternating electric current, such tissues including but not limited to liver, lung, cardiac, prostate, breast, and vascular tissues and neoplasms. An apparatus in accord with the present invention includes a supply of a conductive or electrolytic fluid to be provided to the patient, an alternating current generator, and a processor for creating, maintaining, and controlling the ablation process by the interstitial or surficial delivery of the fluid to a tissue and the delivery of electric power to the tissue via the virtual electrode. A method in accord with the present invention includes delivering a conductive fluid to a predetermined tissue ablation site for a predetermined time period, applying a predetermined power level of radio frequency current to the tissue, monitoring at least one of several parameters, and adjusting either the applied power and / or the fluid flow in response to the measured parameters.

Owner:MEDTRONIC INC

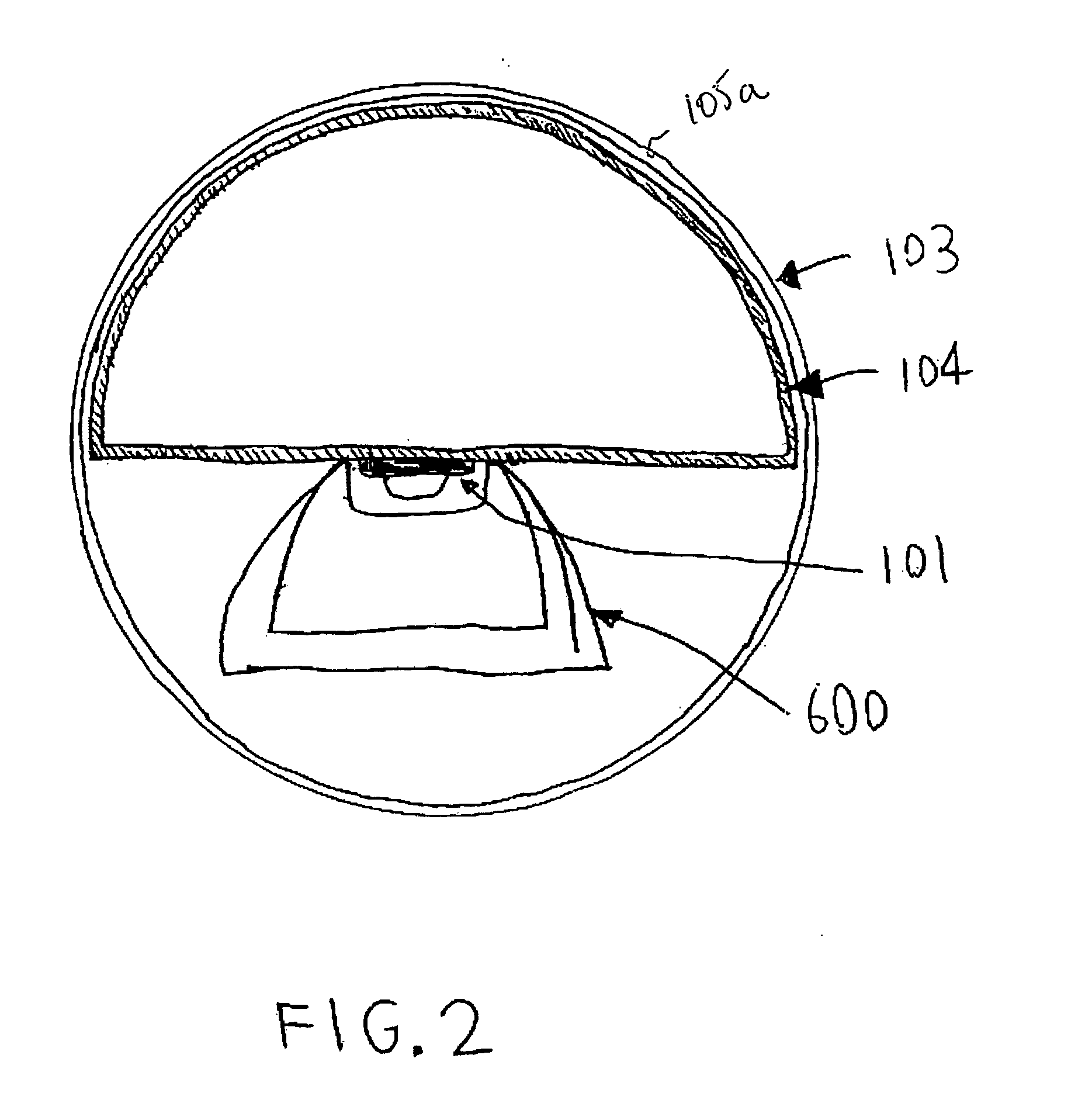

Smoking articles and use thereof for yielding inhalation materials

The present invention describes articles, such as smoking articles, that can provide an inhalable substance in a form suitable for inhalation by a consumer. The article comprises a cartridge with an inhalable substance medium therein, control housing that includes an electrical energy source and an electrical power source, and a heating member that may be located in either the cartridge or the control housing. The control housing further may include puff-actuated current actuation components and current regulation components.

Owner:RAI STRATEGIC HLDG INC

Apparatus and method for creating, maintaining, and controlling a virtual electrode used for the ablation of tissue

InactiveUS7247155B2Maintain temperatureImproving impedanceSurgical instruments for heatingSurgical instruments using microwavesVascular tissueBlood Vessel Tissue

The present invention provides an apparatus and a method for producing a virtual electrode within or upon a tissue to be treated with radio frequency alternating electric current, such tissues including but not limited to liver, lung, cardiac, prostate, breast, and vascular tissues and neoplasms. An apparatus in accord with the present invention includes a supply of a conductive or electrolytic fluid to be provided to the patient, an alternating current generator, and a processor for creating, maintaining, and controlling the ablation process by the interstitial or surficial delivery of the fluid to a tissue and the delivery of electric power to the tissue via the virtual electrode. A method in accord with the present invention includes delivering a conductive fluid to a predetermined tissue ablation site for a predetermined time period, applying a predetermined power level of radio frequency current to the tissue, monitoring at least one of several parameters, and adjusting either the applied power and / or the fluid flow in response to the measured parameters.

Owner:MEDTRONIC INC

Tissue Treatment Methods

ActiveUS20080077202A1Reduce and eliminate fat cellMinimize injuryChiropractic devicesSurgical instruments for heatingSubcutaneous adipose tissueReperfusion injury

Methods are provided herein for affecting a region of a subject's body, comprising exposing the region to a cooling element under conditions effective to cool subcutaneous adipose tissue in said region; and increasing the blood flow rate to the cooled tissue by exposing the tissue to an energy source. Methods are also provided for treating subcutaneous adipose tissue in a region of a subject's body, comprising exposing said region to a cooling element under conditions effective to cool said tissue; and exposing the tissue to an energy source to increase the blood flow rate to the cooled tissue, thereby stimulating reperfusion in, and / or causing an ischemia-reperfusion injury to, the cooled tissue.

Owner:ZELTIQ AESTHETICS INC

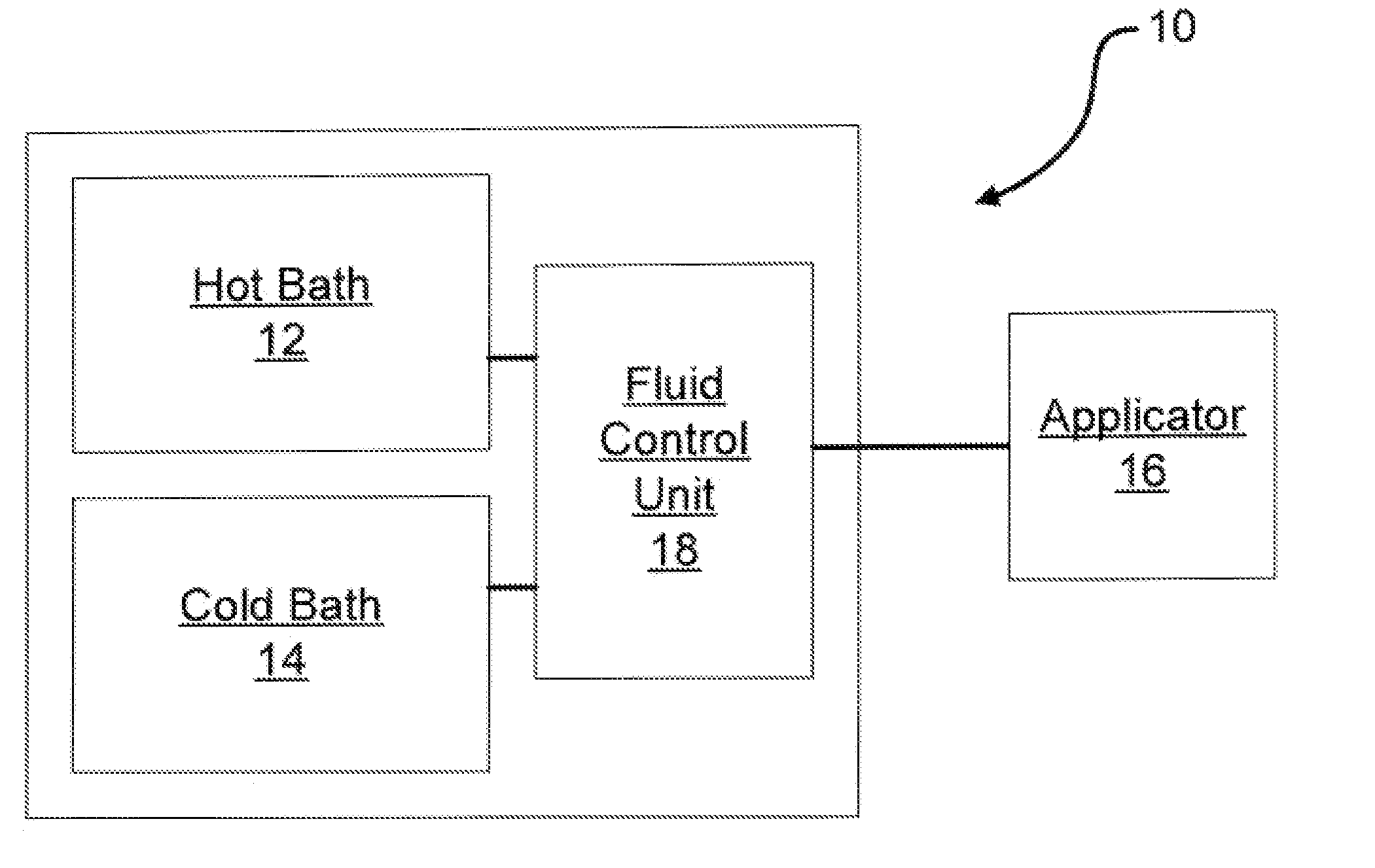

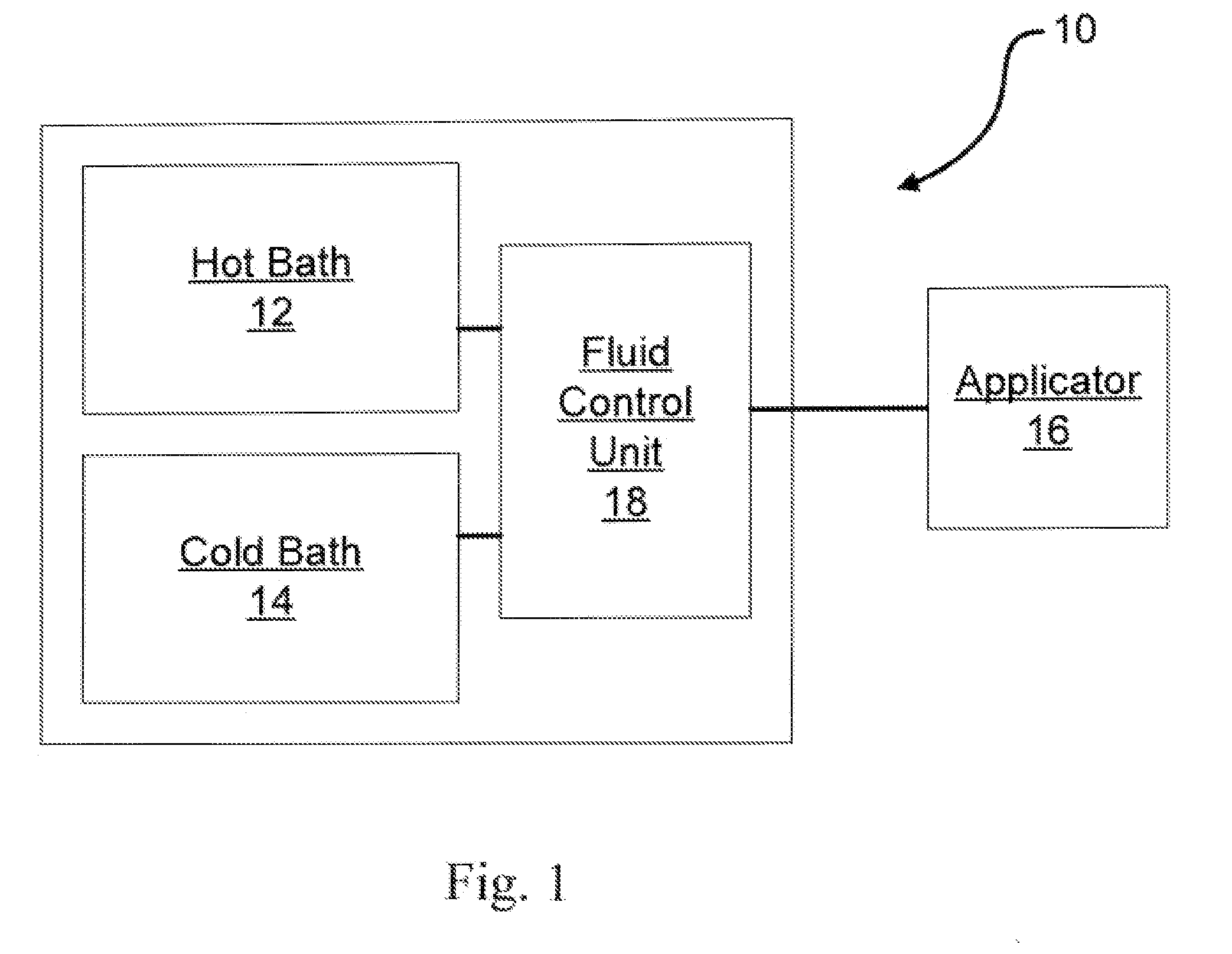

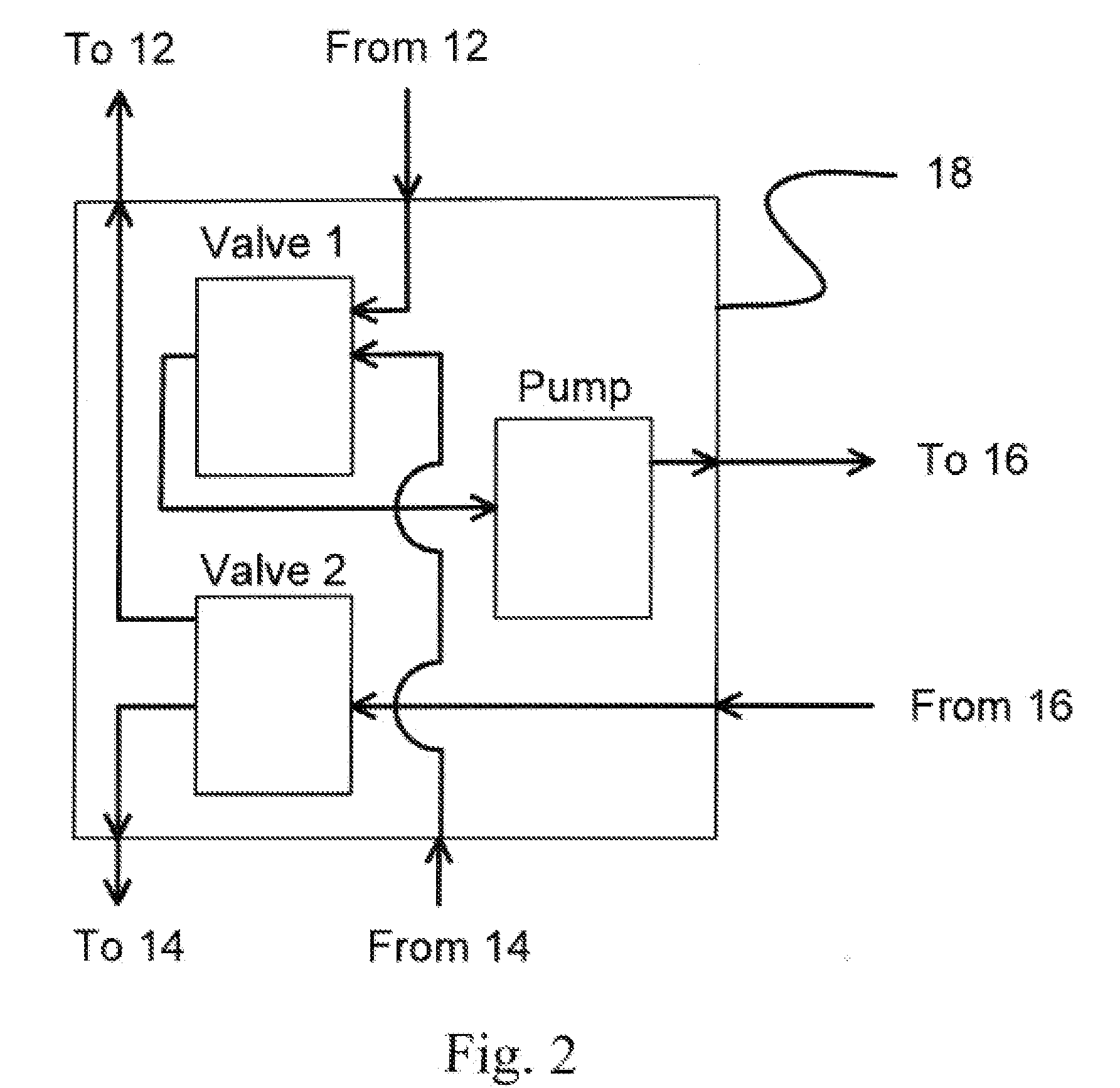

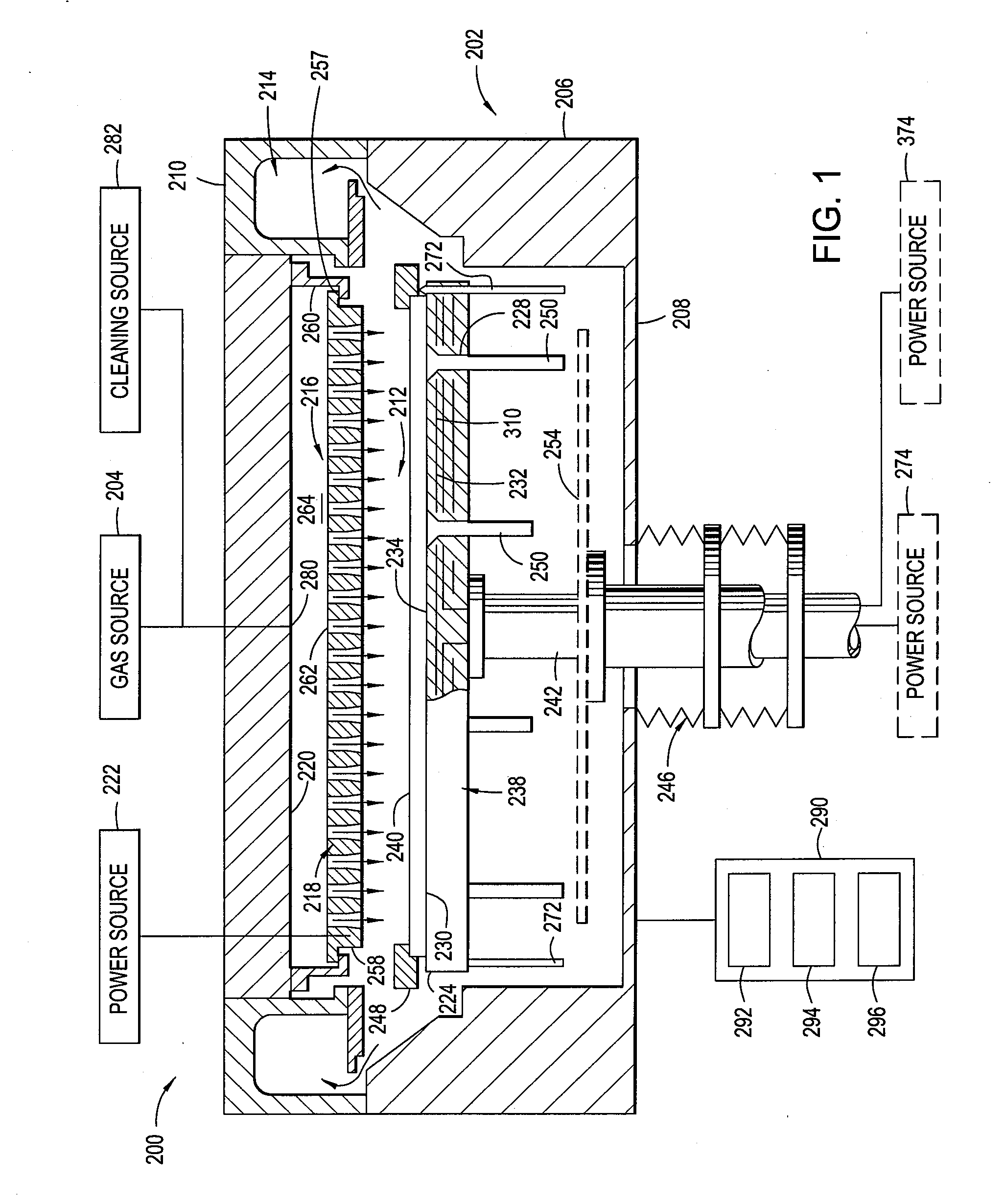

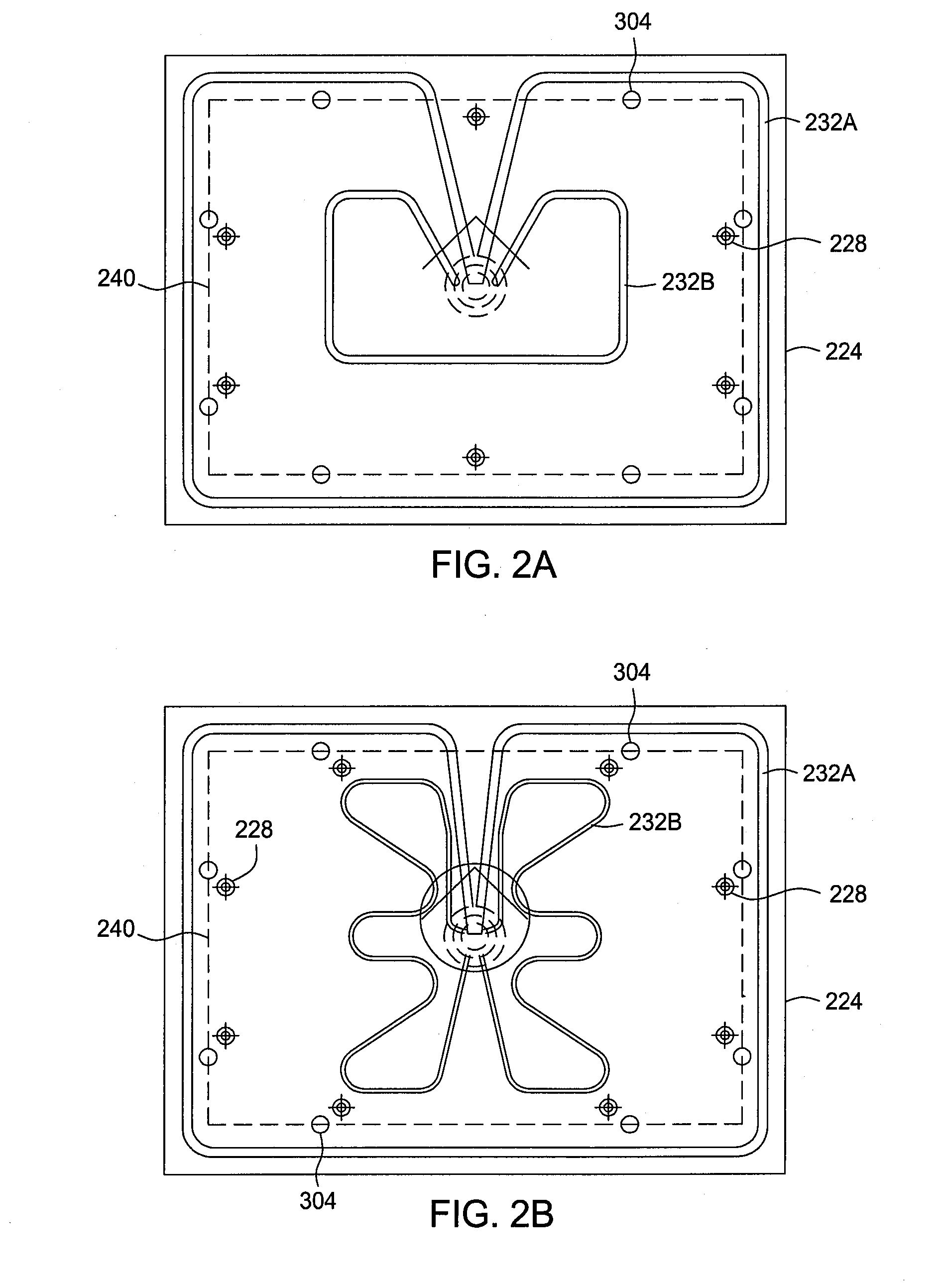

Heating and cooling of substrate support

InactiveUS20080035306A1Maintain temperatureLiquid surface applicatorsElectric discharge tubesEngineeringCooling channel

A process chamber and a method for controlling the temperature of a substrate positioned on a substrate support assembly within the process chamber are provided. The substrate support assembly includes a thermally conductive body, a substrate support surface on the surface of the thermally conductive body and adapted to support a large area substrate thereon, one or more heating elements embedded within the thermally conductive body, and two or more cooling channels embedded within the thermally conductive body to be coplanar with the one or more heating elements. The cooling channels may be branched into two or more equal-length cooling passages being extended from a single point inlet and into a single point outlet to provide equal resistance cooling.

Owner:APPLIED MATERIALS INC

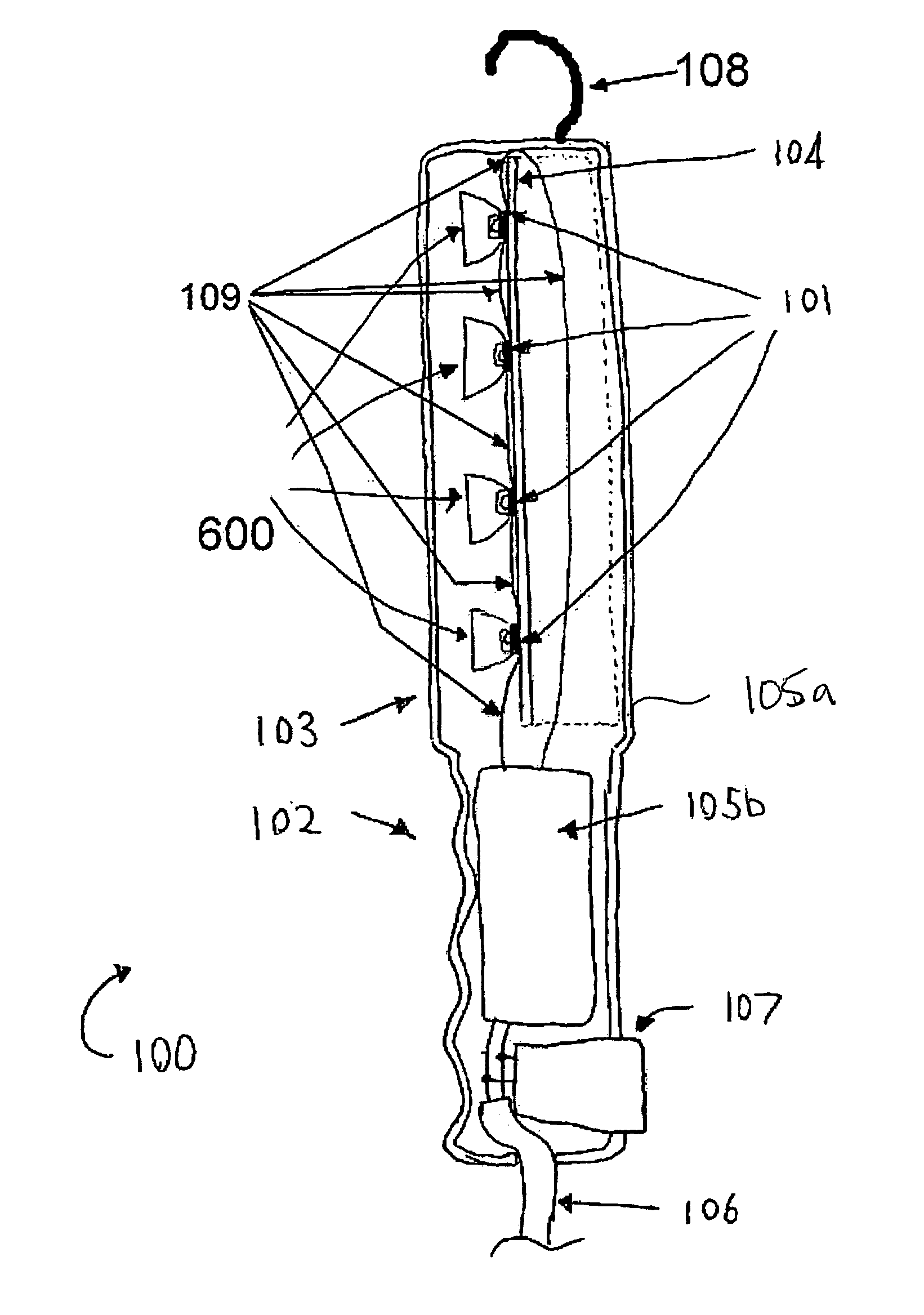

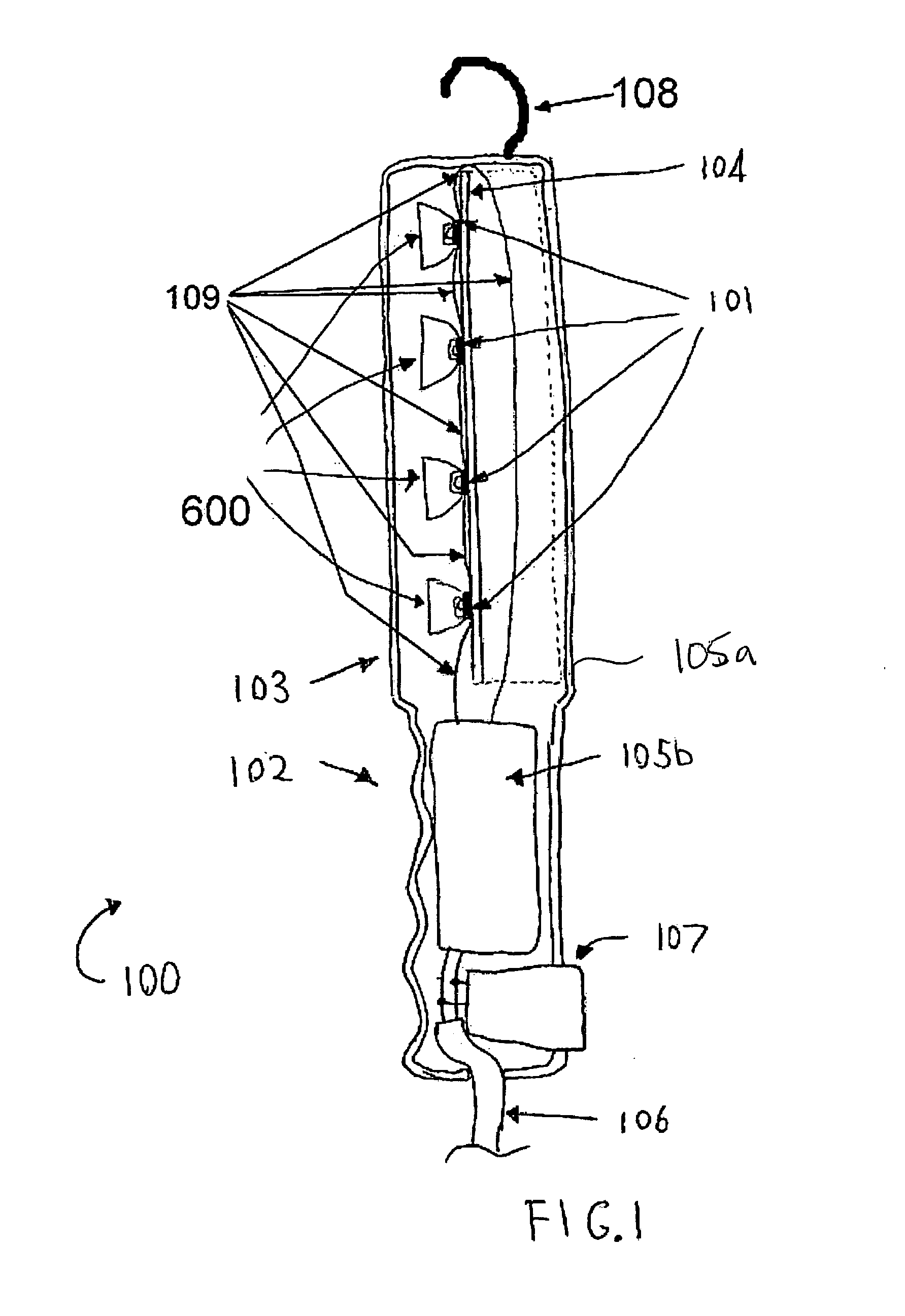

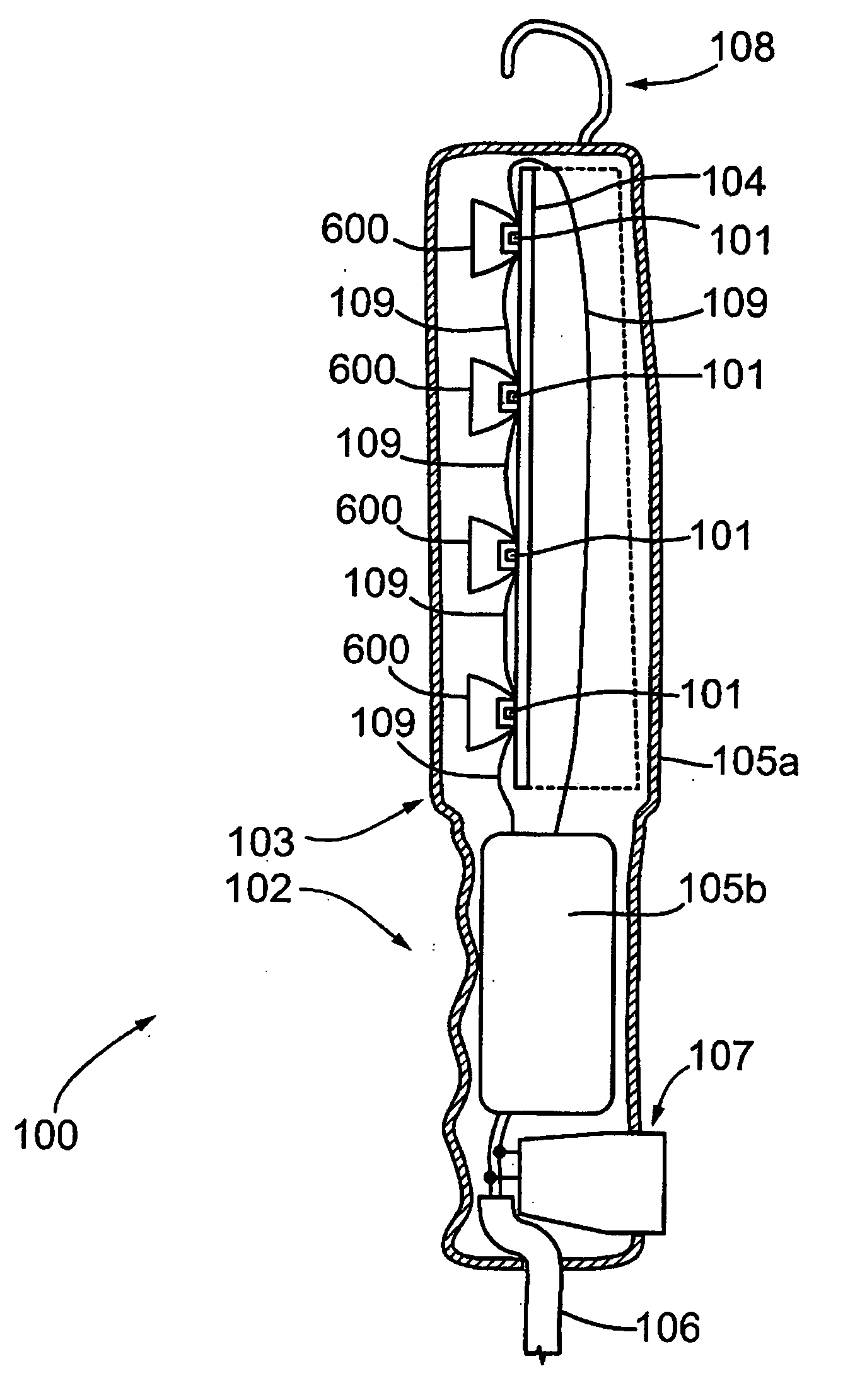

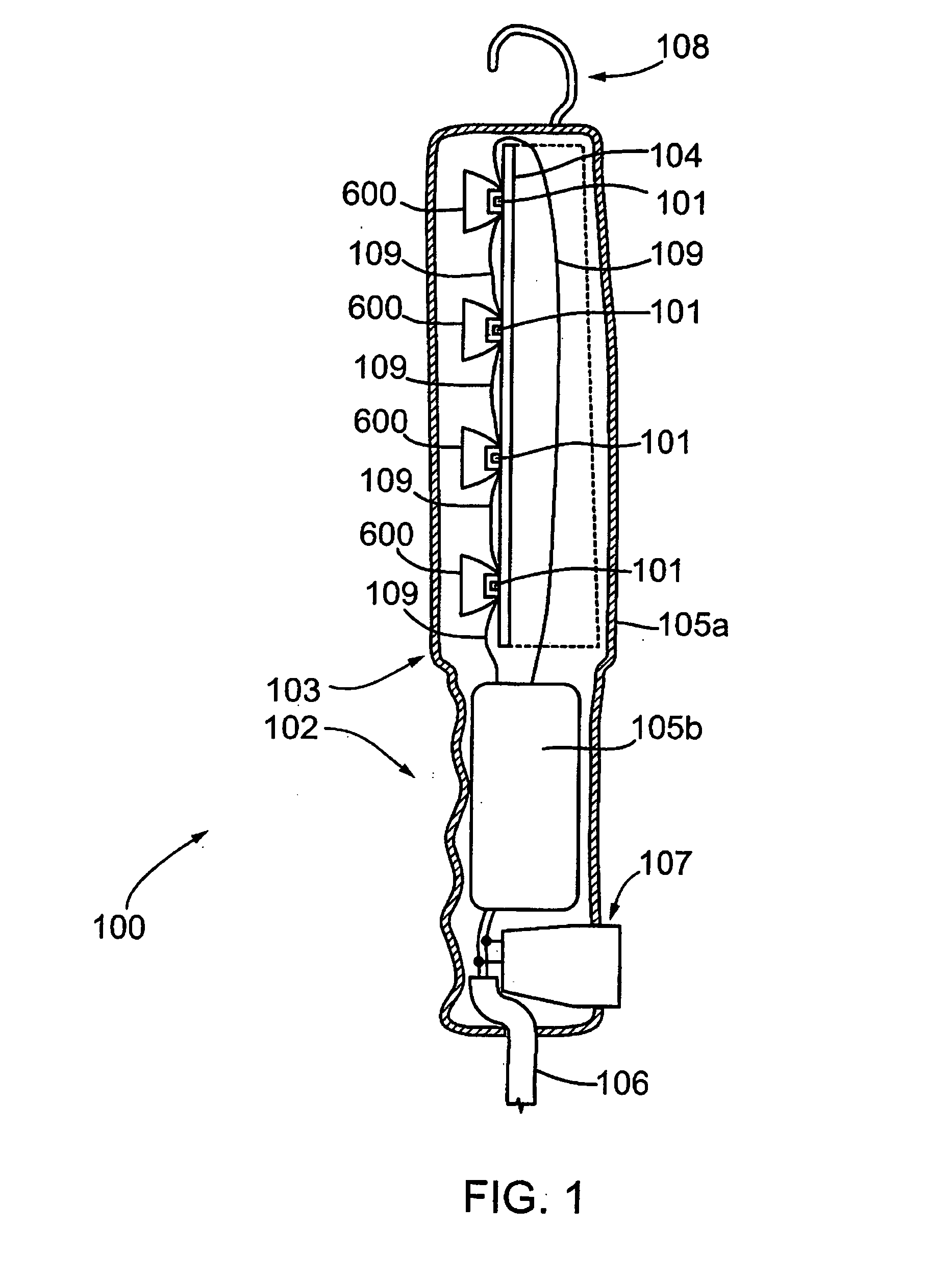

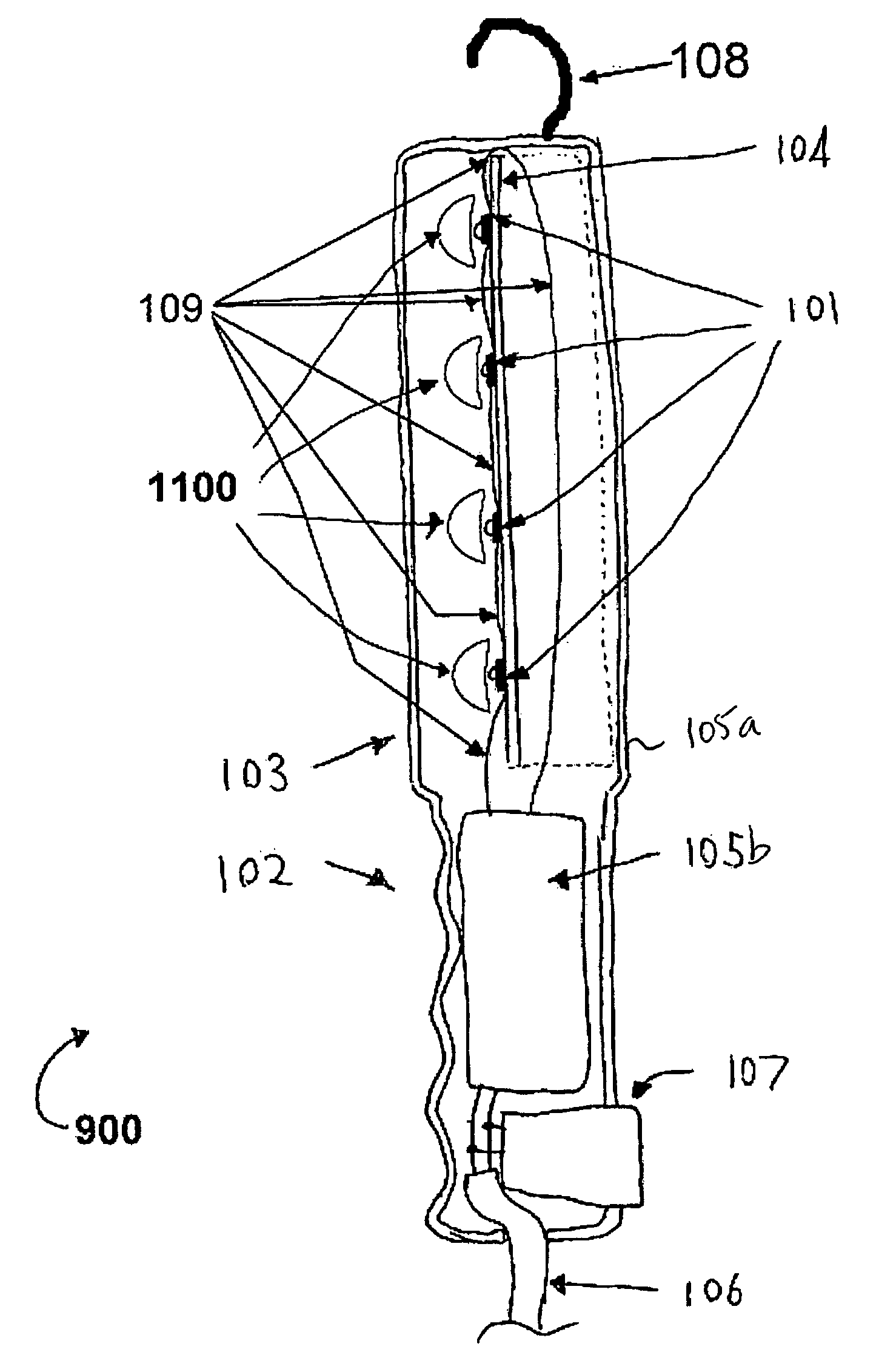

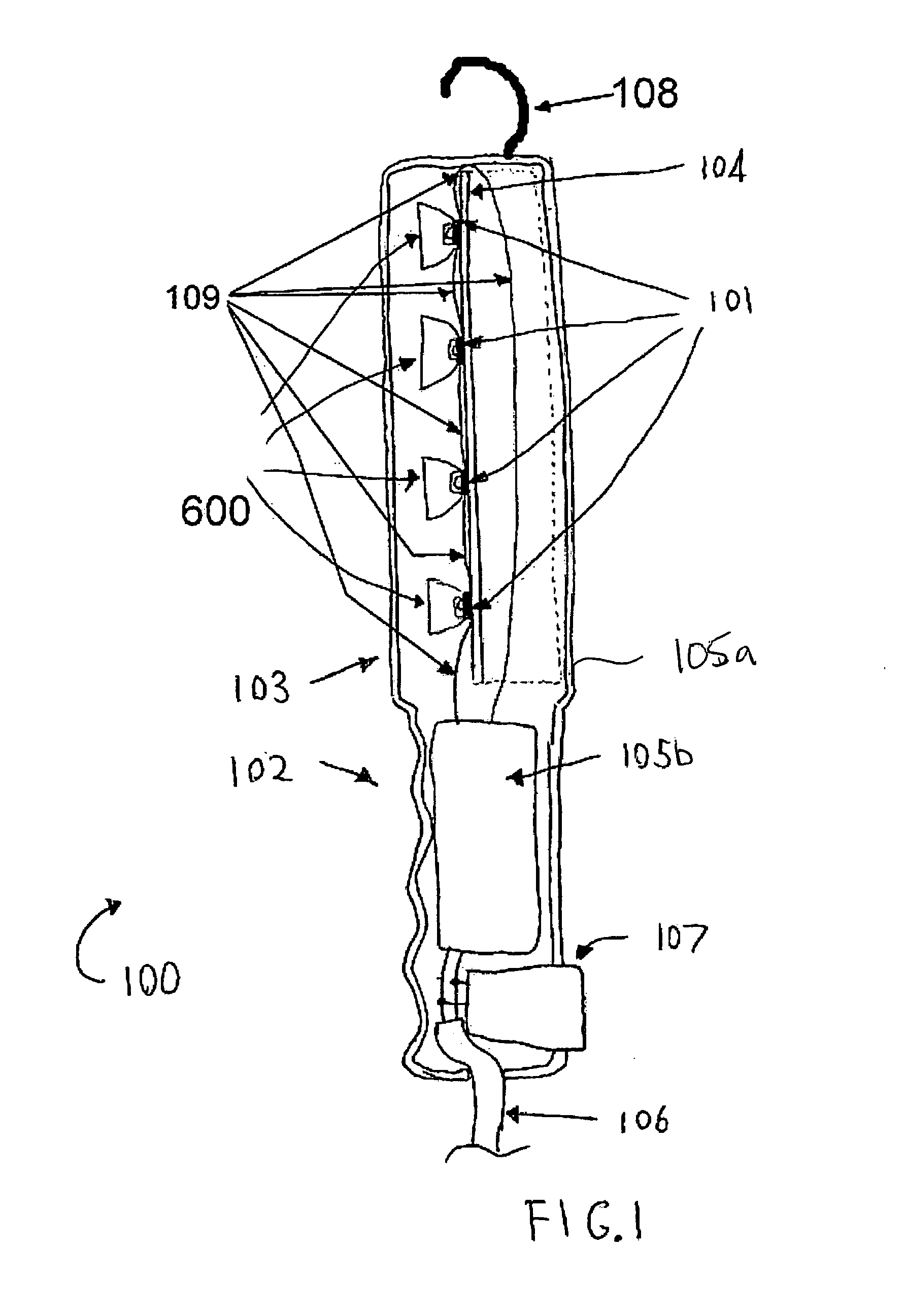

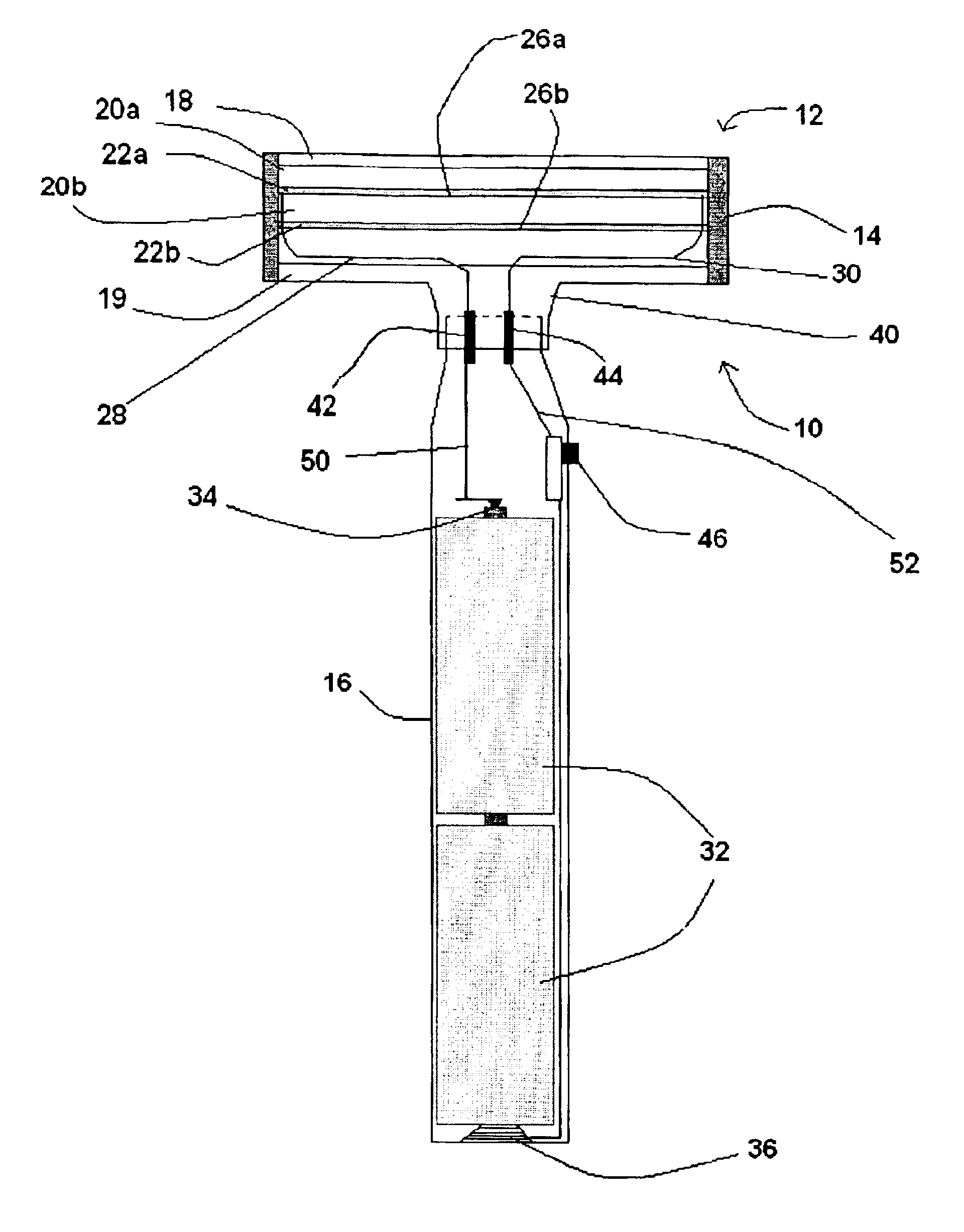

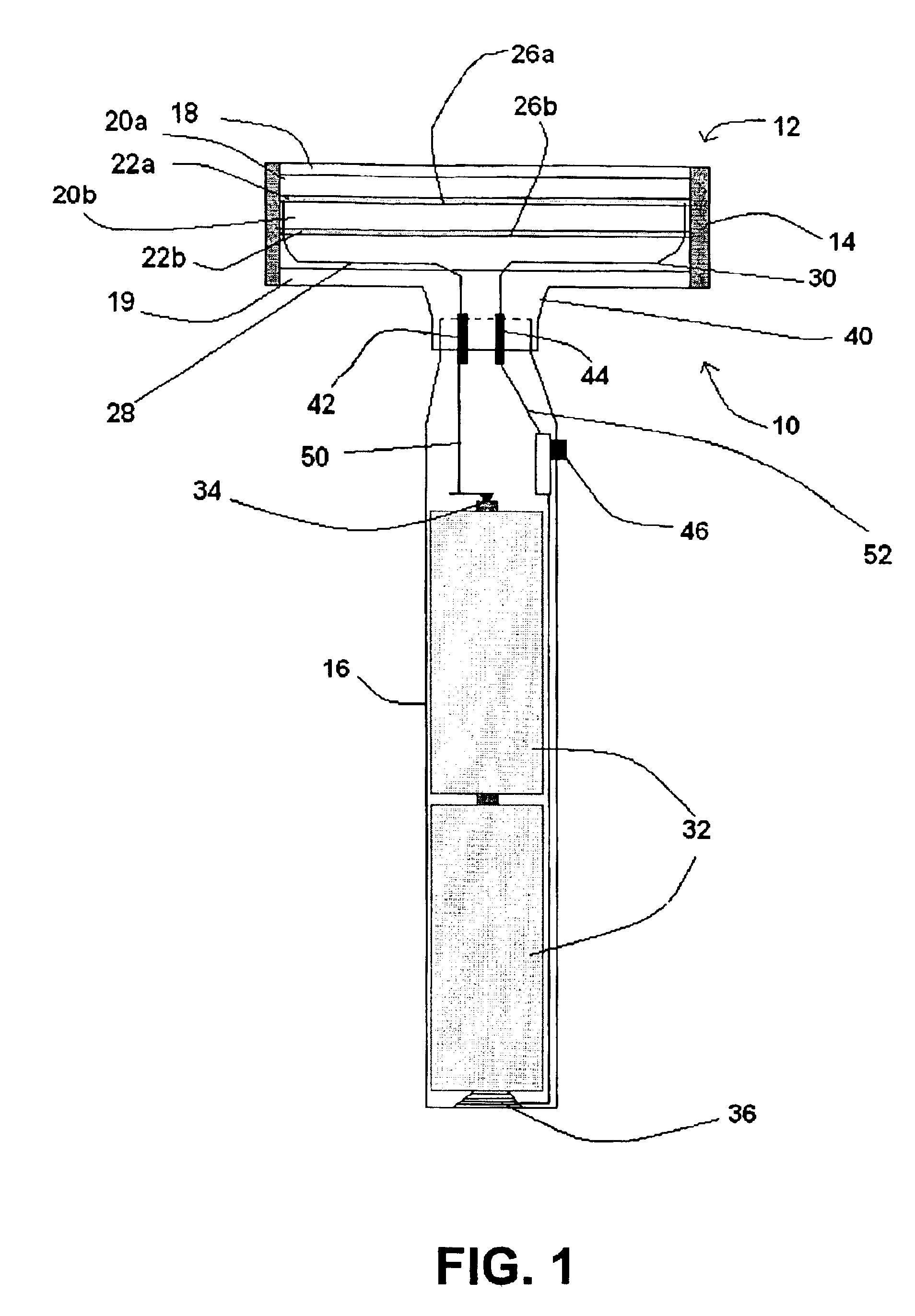

LED work light

ActiveUS20050265035A1Preserve useful working lifeIncrease powerElectric lighting for hand-held useLighting support devicesLow voltageLight beam

Work light has LEDs that require heatsink. Desired radiation pattern achieved by using optical components designed to produce beam or LEDs may have beams in different directions. Radiation pattern of LEDs may be changed by refractive-reflective optics or by convex lenses. Convex lenses may be hemispheres, other planoconvex shapes, concavo-convex shapes, or other shapes. Curved surfaces on any lenses may be spherical or aspheric. Ballast to operate the LEDs from line voltage AC or low voltage DC. Work light may contain batteries. The work light may be mounted on a stand. May have accessory mount. May have charging station. May have a paging transmitter to activate a paging receiver in work light. May have openings for heat transfer from heatsink to ambient air external to light.

Owner:ALLTEMP PROD CO LTD

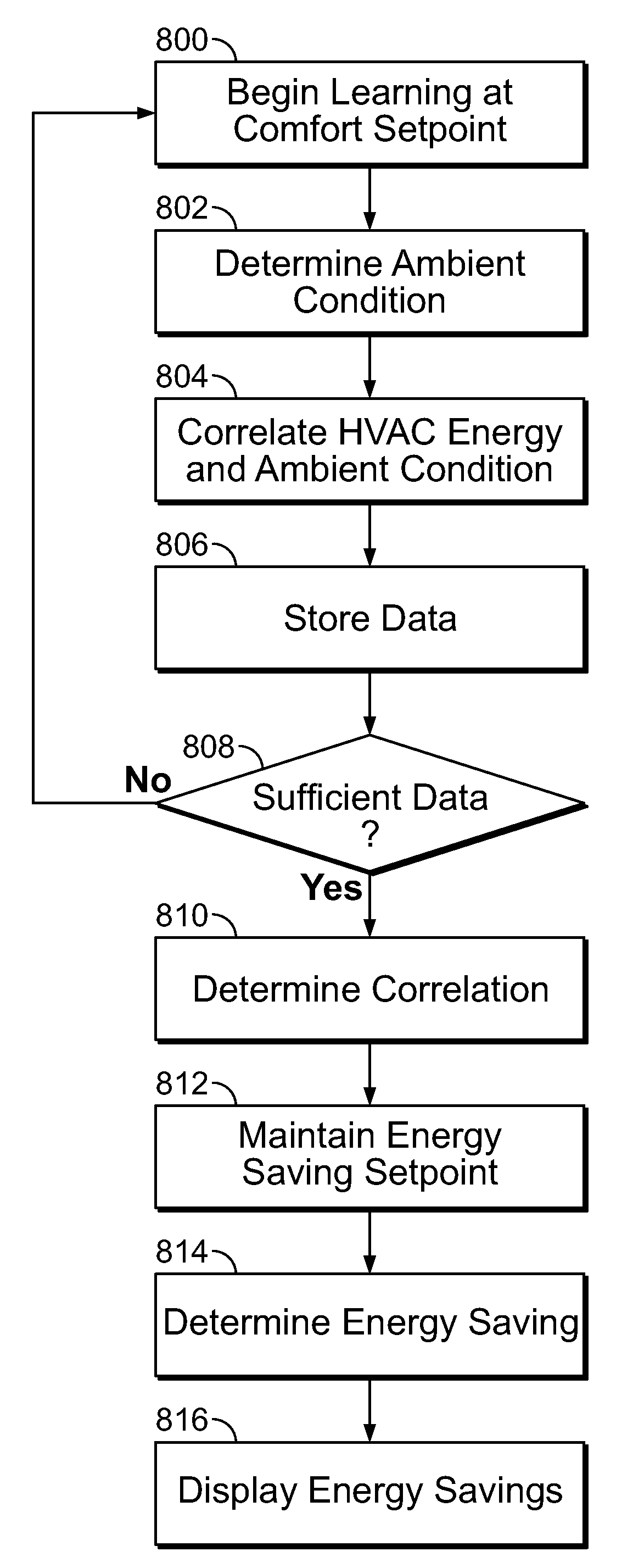

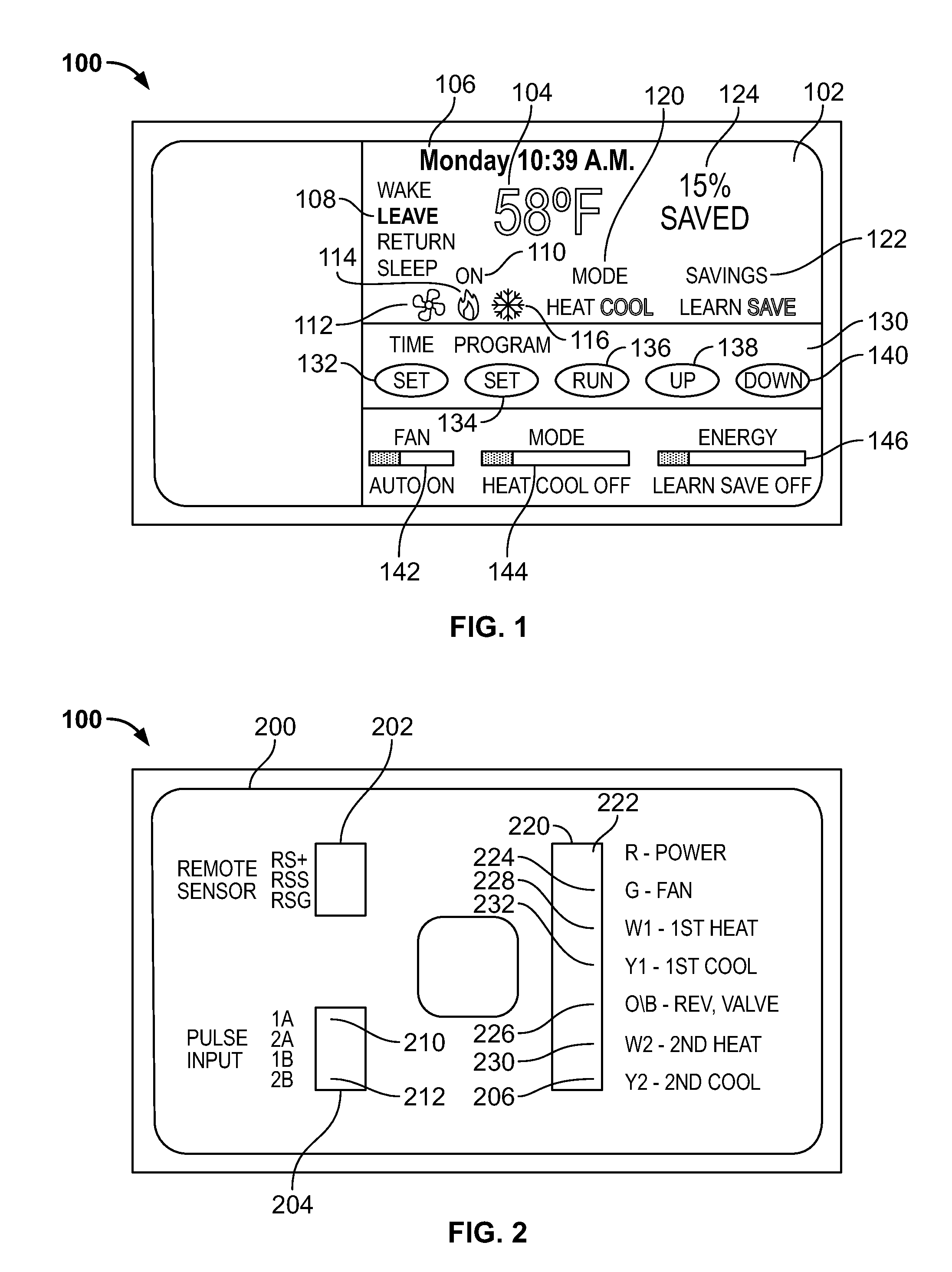

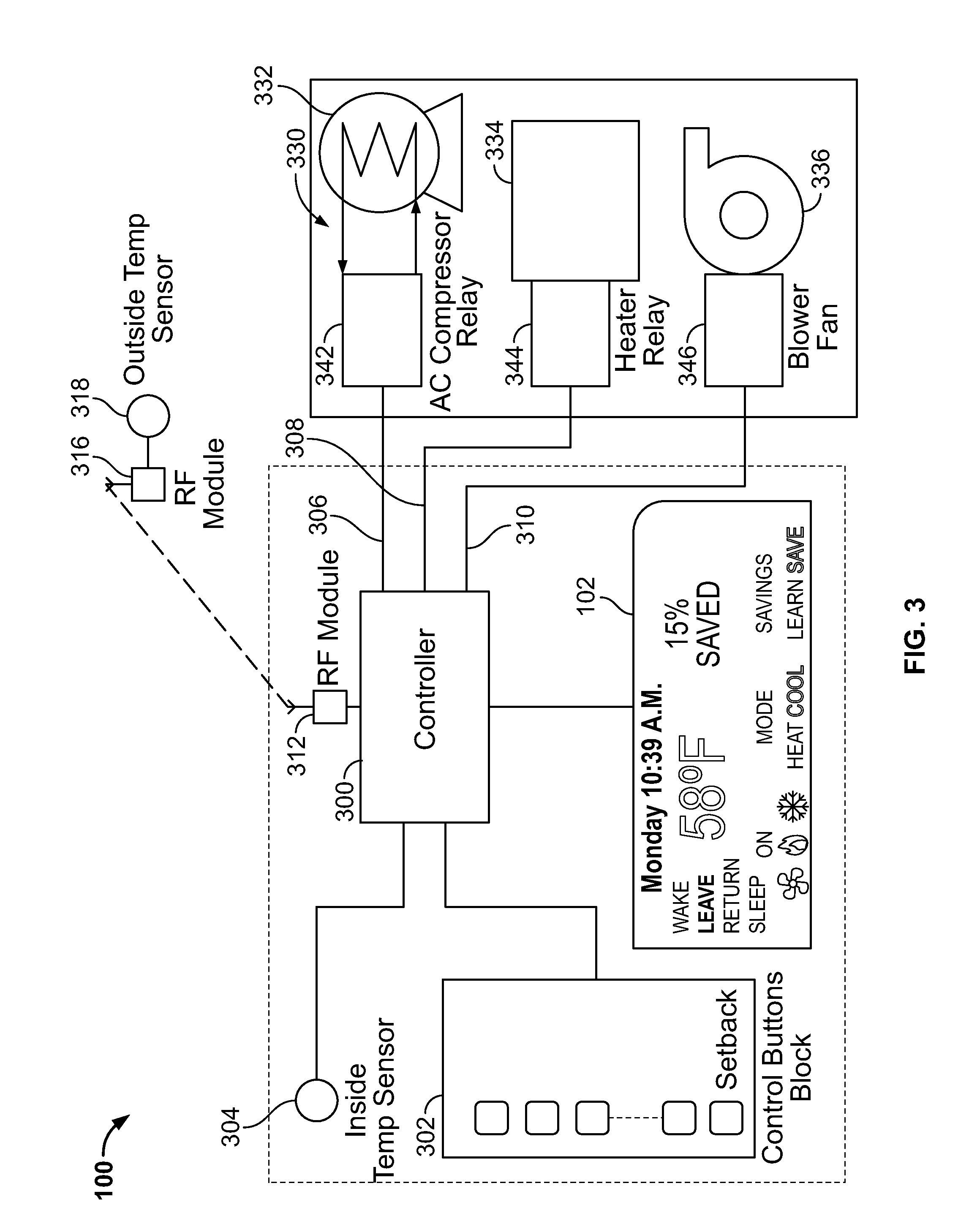

Methods and apparatuses for displaying energy savings from an HVAC system

ActiveUS20110160913A1Save energyMaintain temperatureMechanical apparatusLevel controlHVACProcess engineering

A method and system of determining and displaying energy savings from an HVAC system operating in an energy saving mode. The HVAC system is operated to maintain a comfort mode temperature during a learning period. The energy consumed by the HVAC system at multiple outside ambient conditions during the learning period is determined. The correlation between a specific ambient condition and energy consumed by the HVAC system is determined. The HVAC system is run to maintain an energy saving setpoint temperature. The energy consumed by the HVAC system is determined at an ambient condition while maintaining the energy saving setpoint temperature. The energy savings are calculated as a function of the difference between the energy that would have been consumed by the HVAC system at the ambient condition based on the determined correlation and the energy consumed by the HVAC system while maintaining the energy saving setpoint temperature at the ambient condition

Owner:SCHNEIDER ELECTRIC USA INC

LED lamps including LED work lights

ActiveUS20080212319A1Preserve useful working lifeIncrease powerPoint-like light sourceLighting support devicesLow voltageLight beam

Work light has LEDs that may require heatsink. Desired radiation pattern achieved by using optical components designed to produce beam or LEDs may have beams in different directions. Radiation pattern of LEDs may be changed by refractive-reflective optics or by convex lenses. Convex lenses may be hemispheres, other planoconvex shapes, concavo-convex shapes, or other shapes. Curved surfaces on any lenses may be spherical or aspheric. Ballast to operate the LEDs from line voltage AC or low voltage DC. Work light may contain batteries. The work light may be mounted on a stand. May have accessory mount. May have charging station. May have a paging transmitter to activate a paging receiver in work light. May have openings for heat transfer from heatsink to ambient air external to light.

Owner:ALLTEMP PROD CO LTD

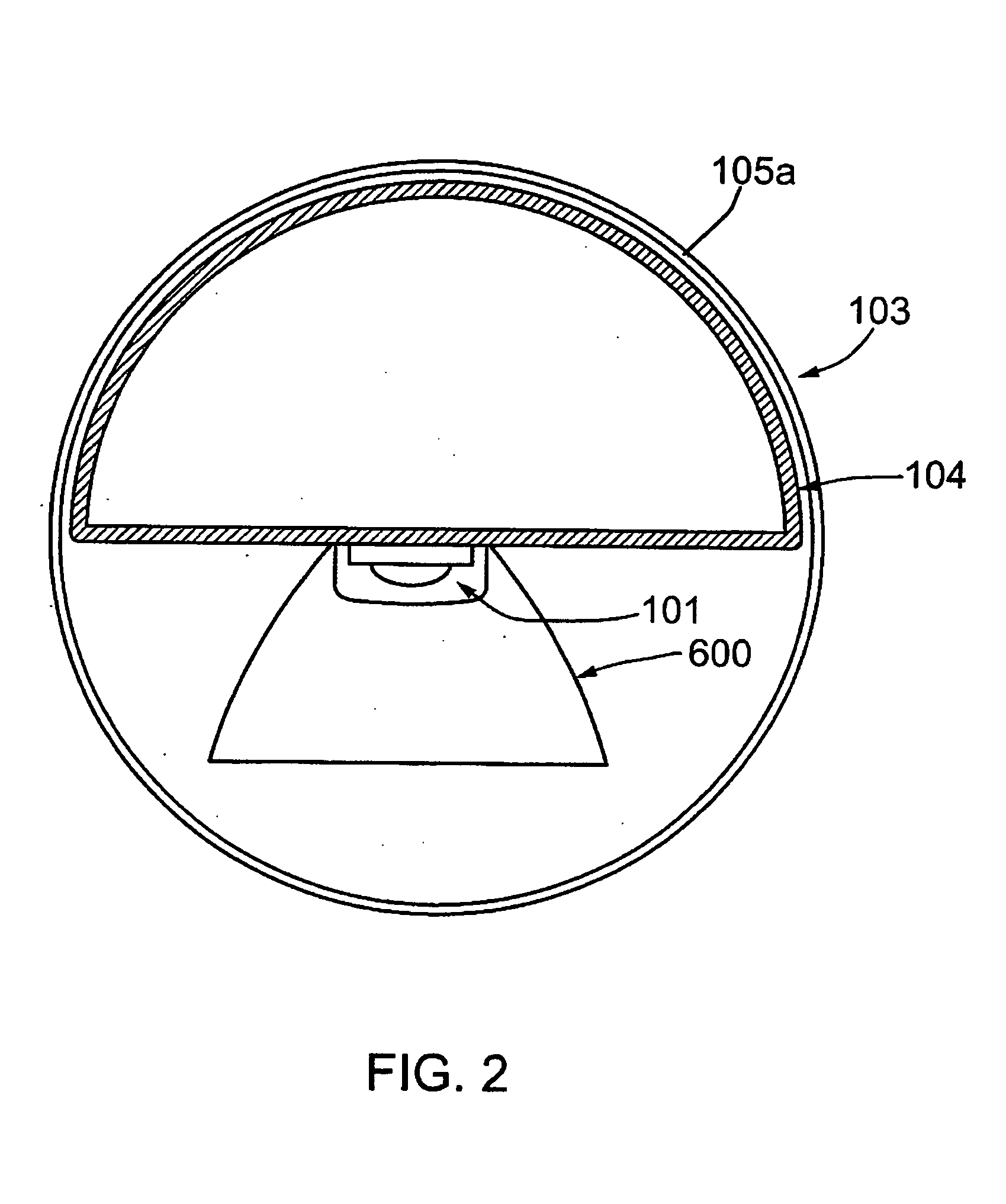

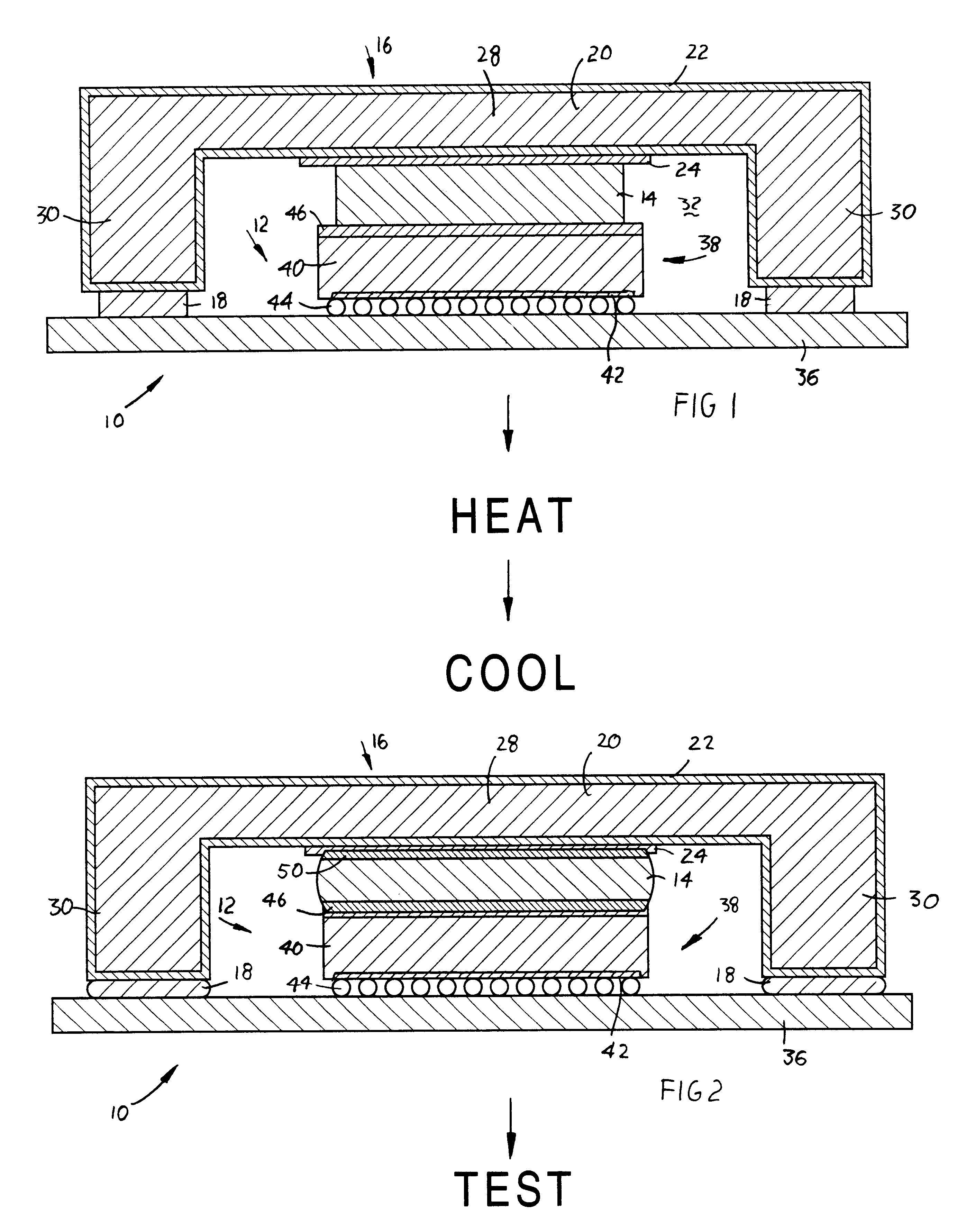

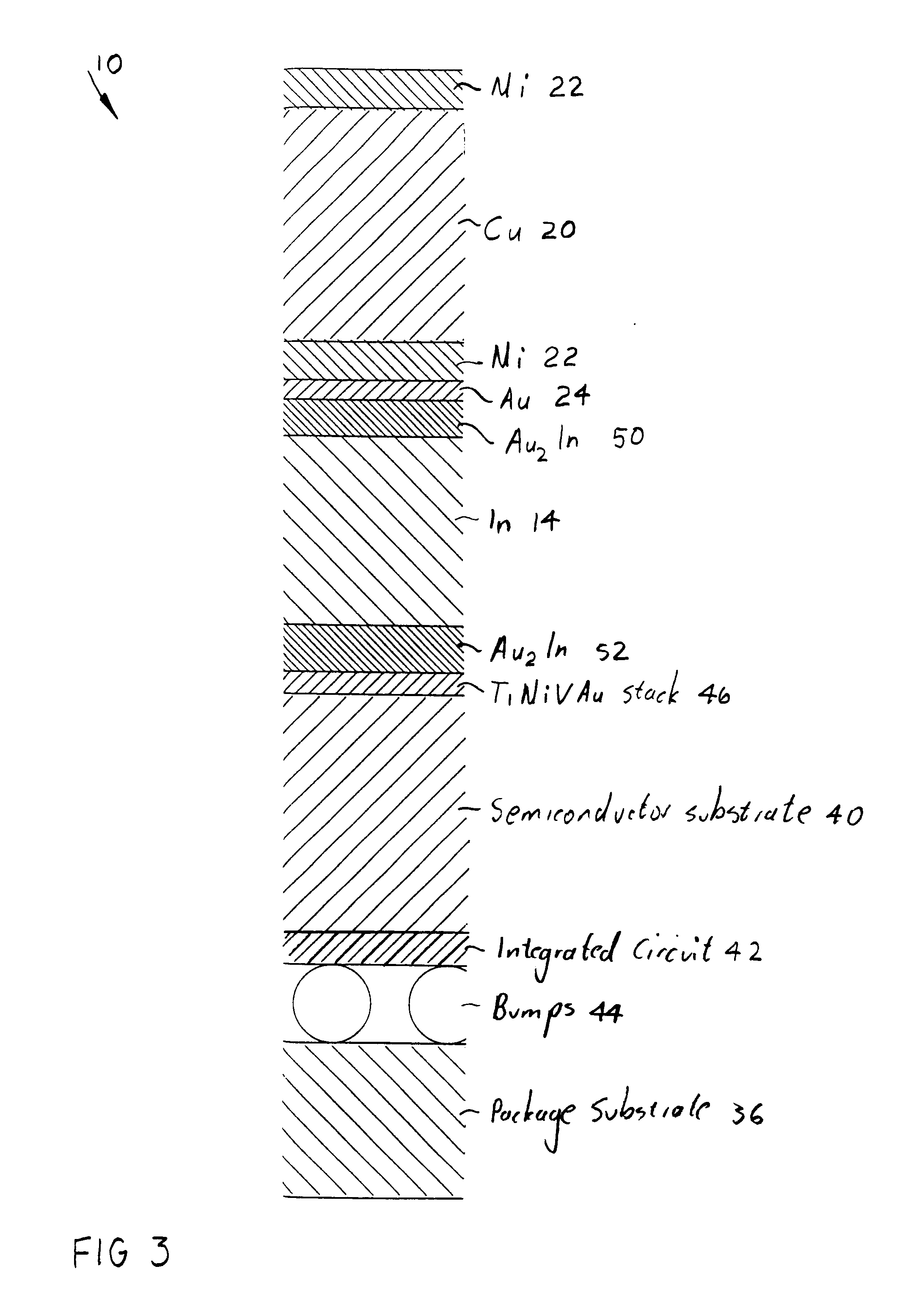

Electronic assembly having a wetting layer on a thermally conductive heat spreader

InactiveUS6504242B1Maintain temperatureSemiconductor/solid-state device detailsSolid-state devicesIndiumHeat cycling

An electronic assembly including a die, having an integrated circuit formed therein, a thermally conductive heat spreader, and indium located between the die and the heat spreader, is described. The heat spreader has a layer of nickel. A gold layer is formed on the nickel layer, and provides better wetting of indium than nickel. A better structural connection between the indium and the heat spreader is provided, especially during thermal cycling.

Owner:INTEL CORP

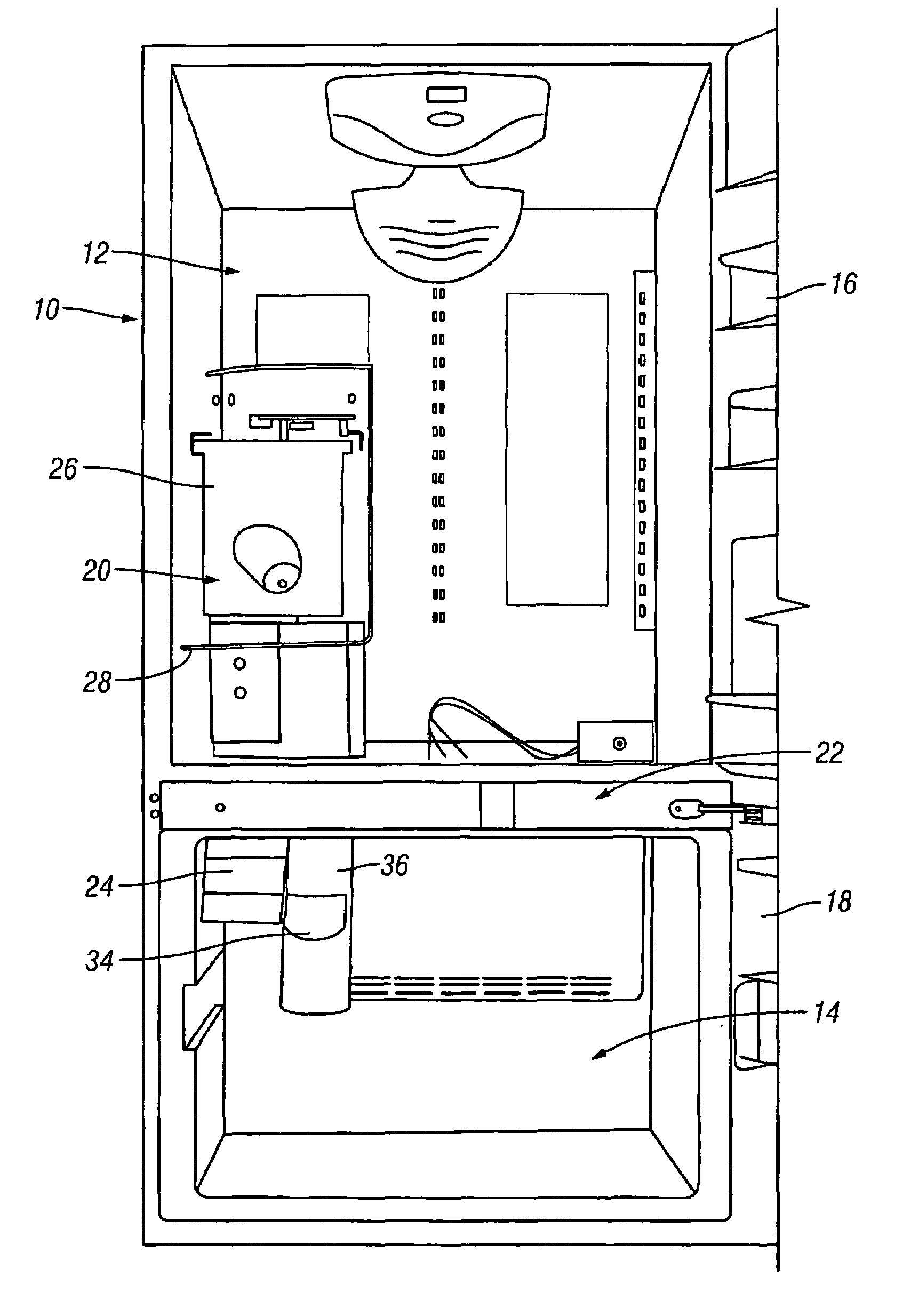

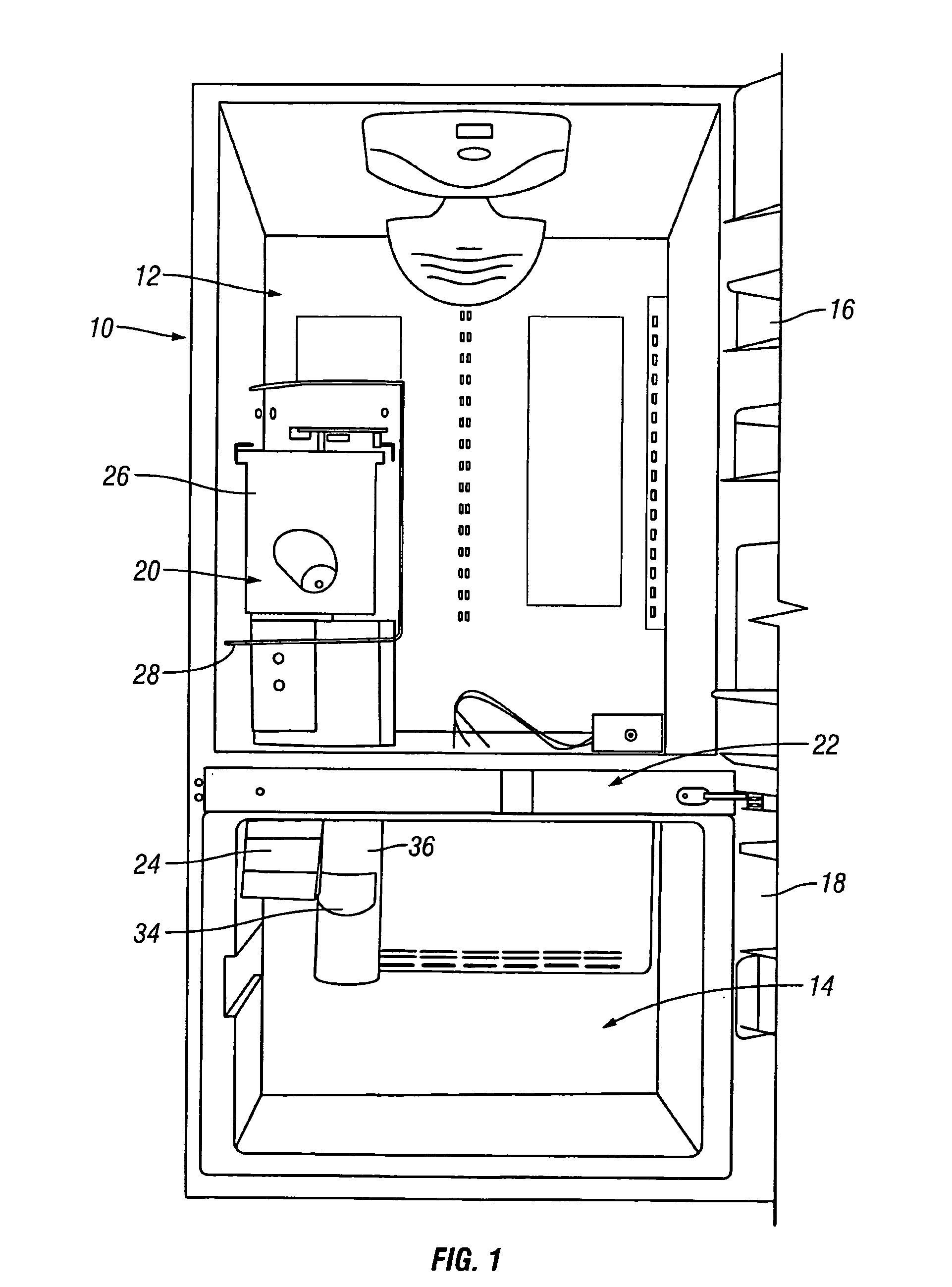

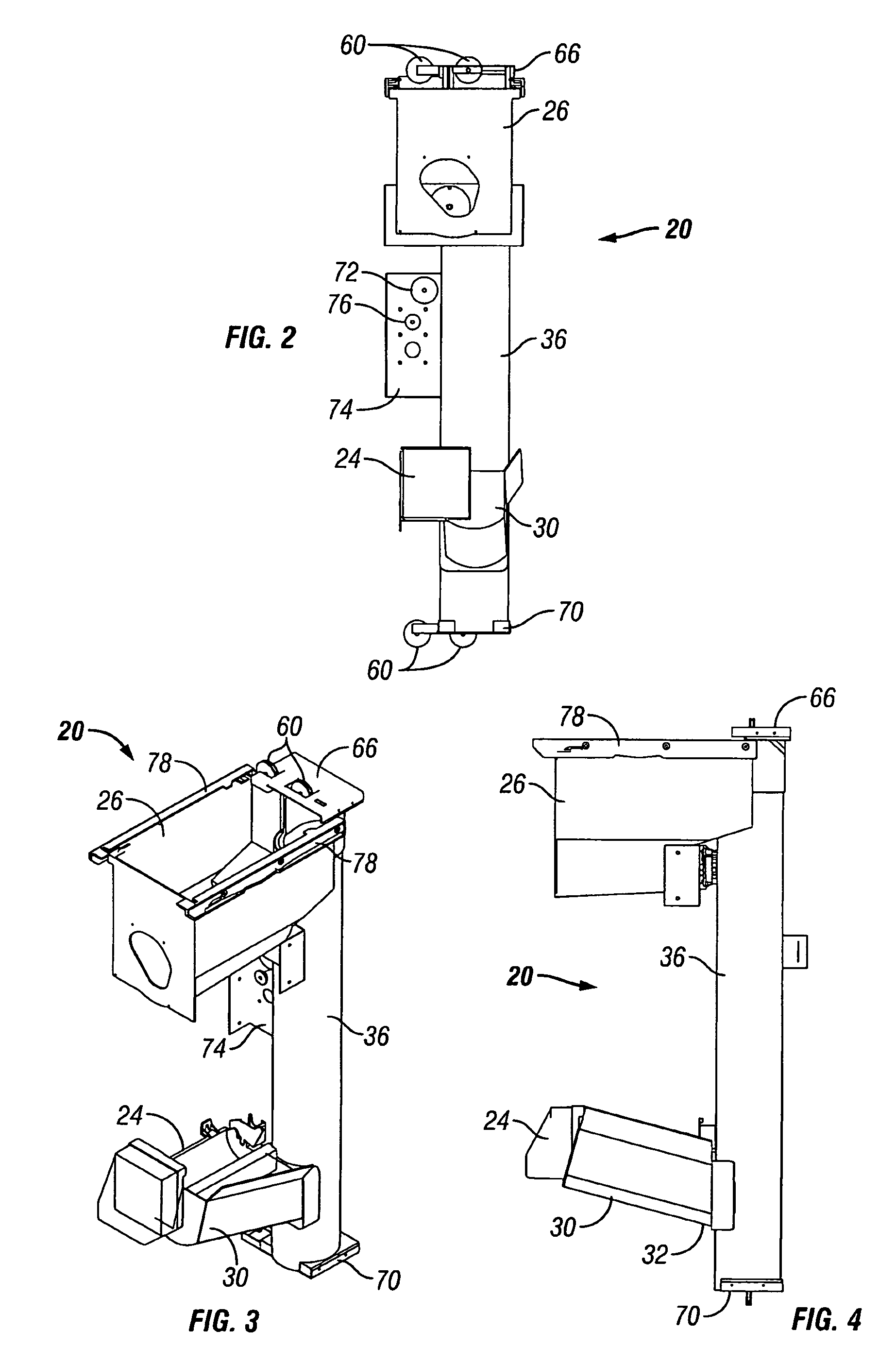

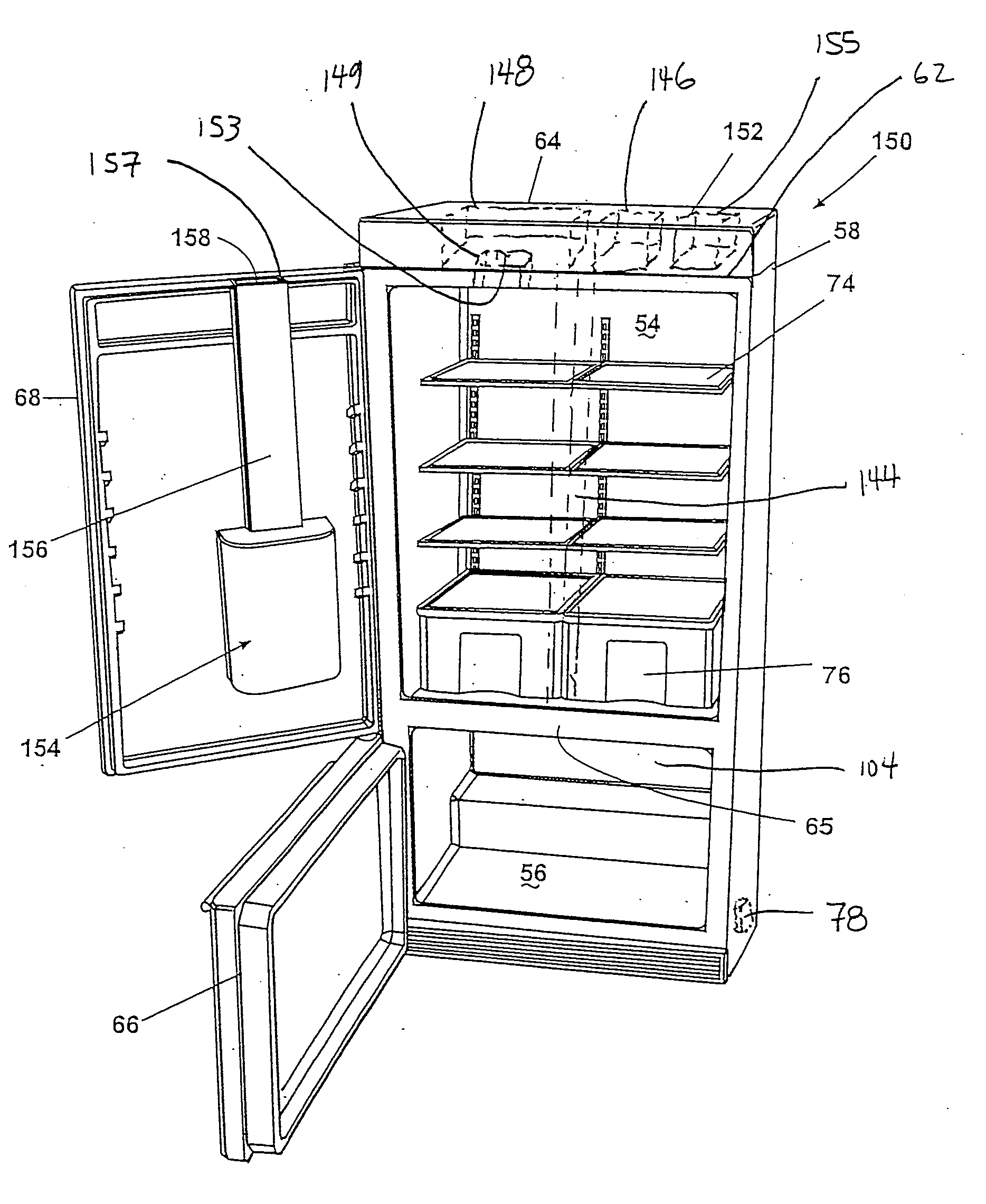

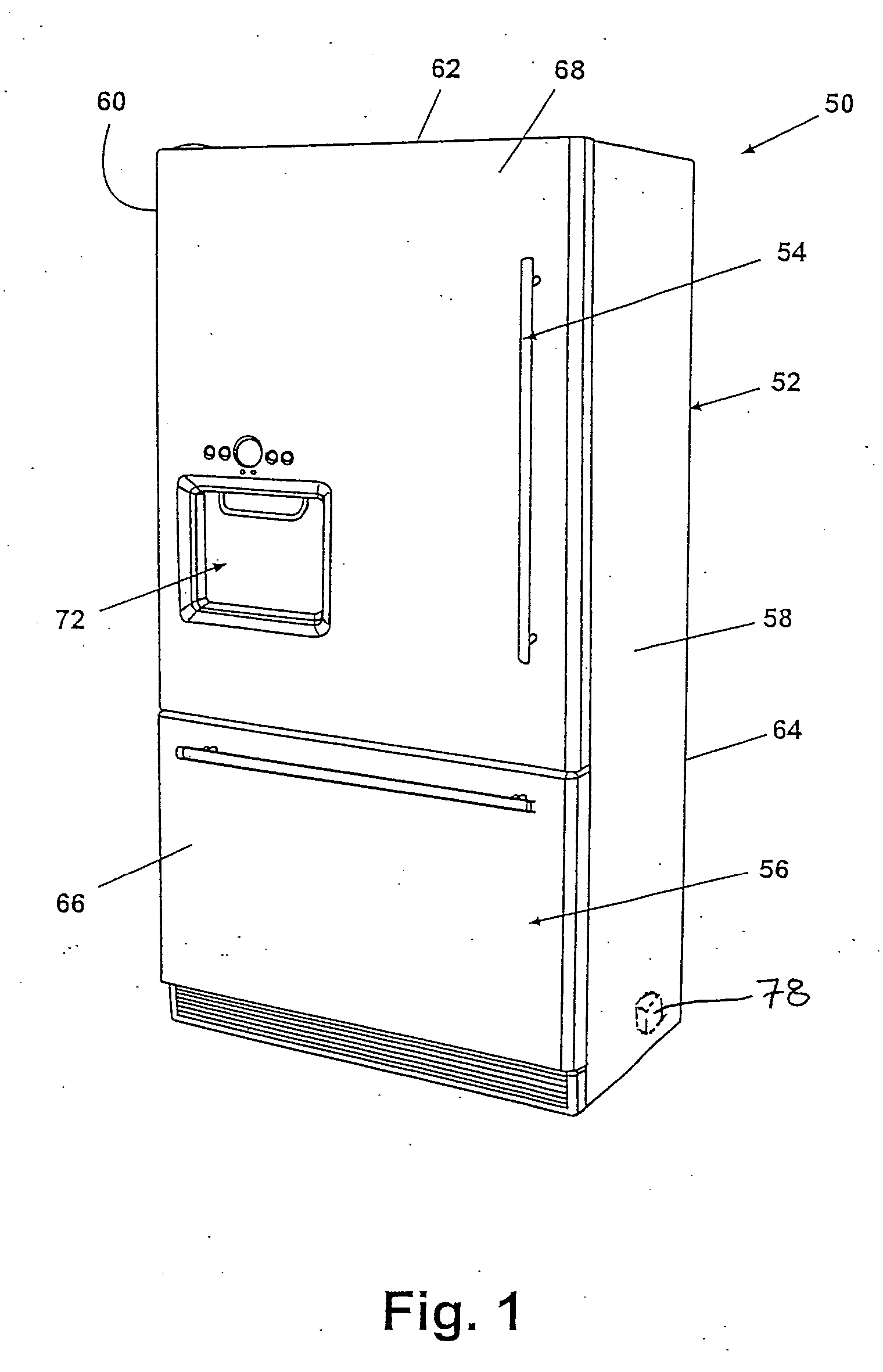

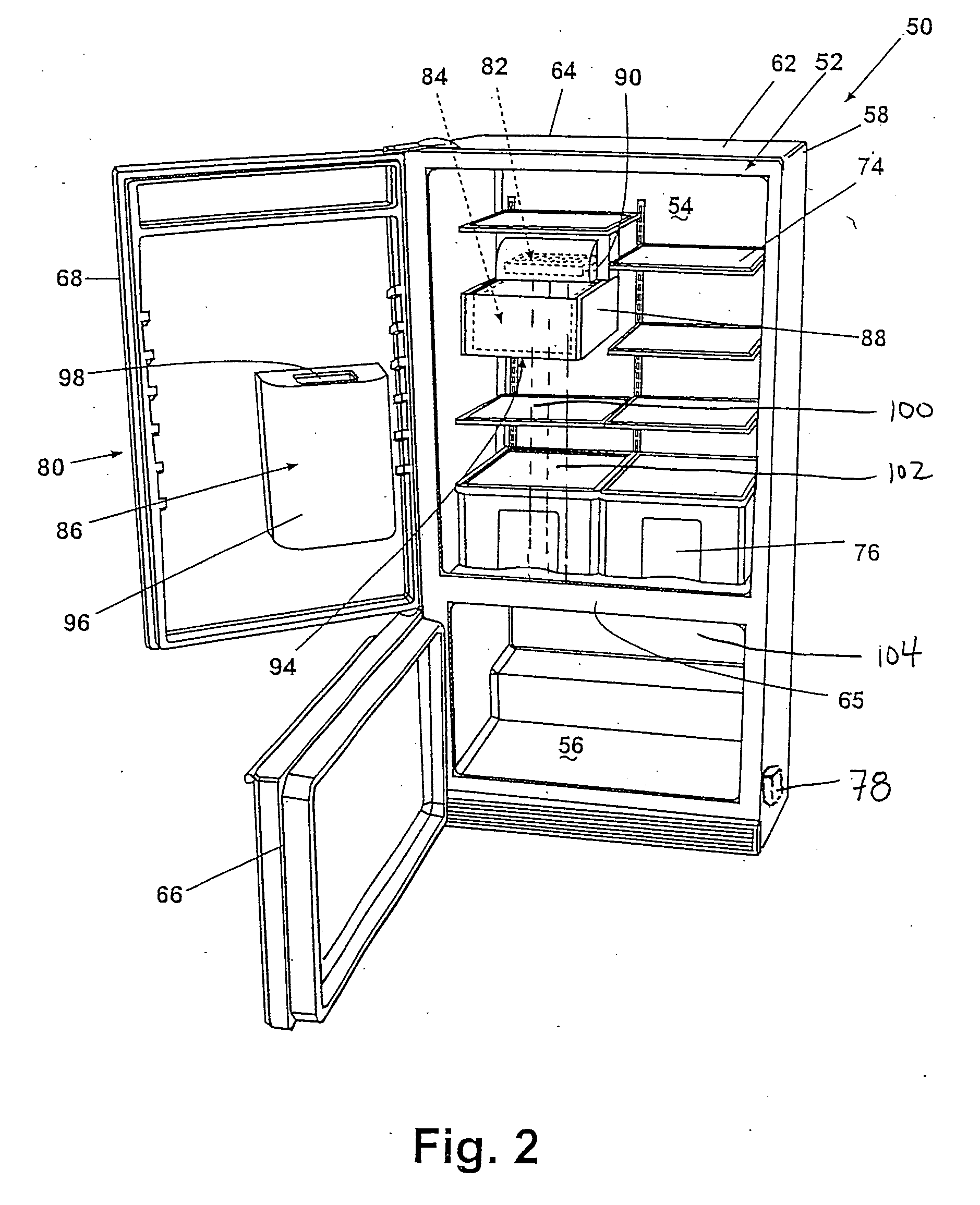

Ice dispenser for refrigerator with bottom mount freezer

ActiveUS7065975B1Maintain temperatureLighting and heating apparatusIce productionMotor driveEngineering

An ice dispensing system is provided for a refrigerator having a bottom freezer. The system includes an ice maker in the freezer compartment and an ice bucket in the refrigerator compartment. A shuttle carries ice from the ice maker to the bucket through a tube extending upwardly through the dividing wall between the freezer and refrigerator compartments. The bucket includes an auger in communication with an ice dispensing opening in the refrigerator door for ice on demand by a user. The shuttle is raised and lowered by a motor-driven cable.

Owner:IOWA STATE UNIV RES FOUND +1

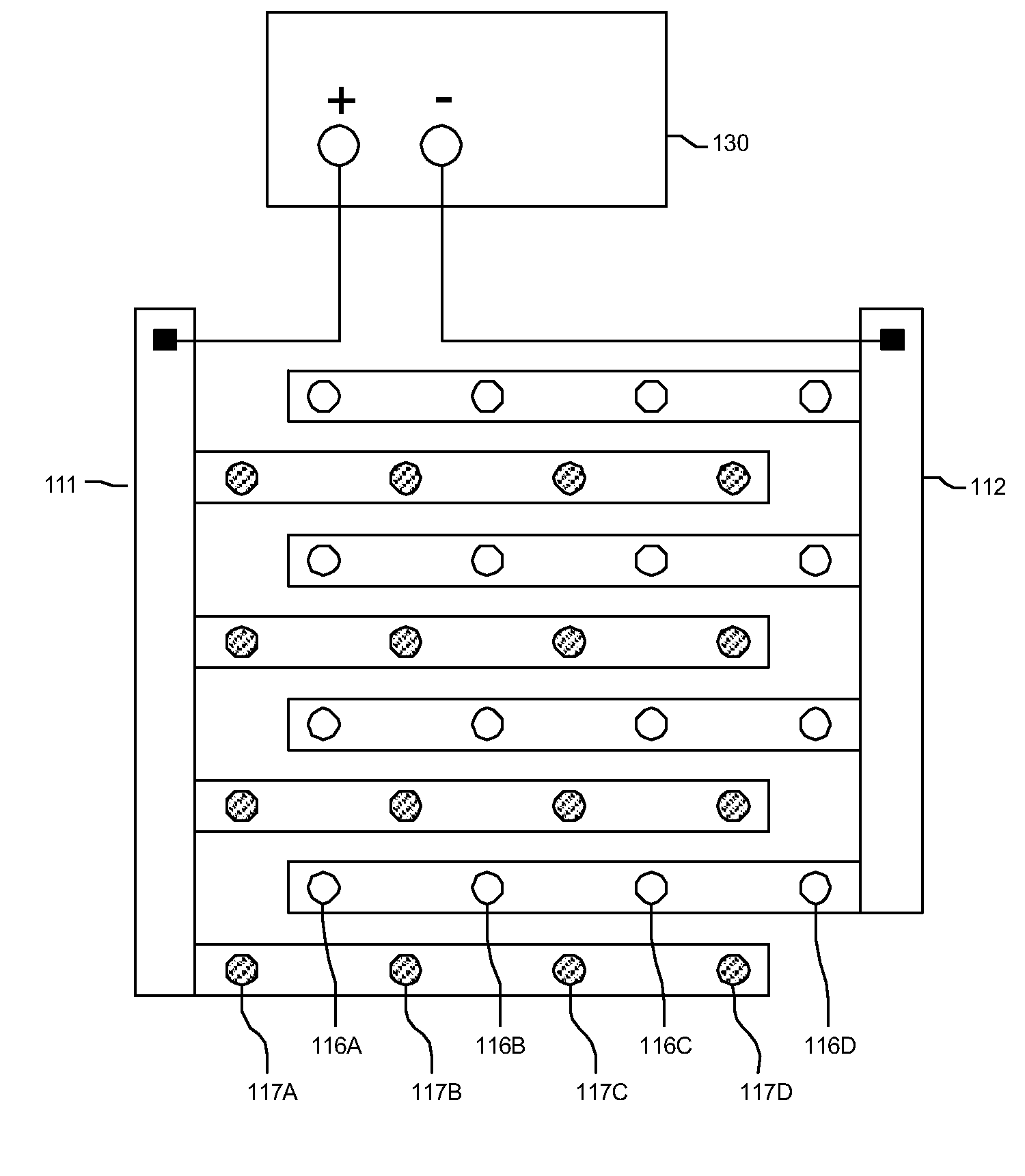

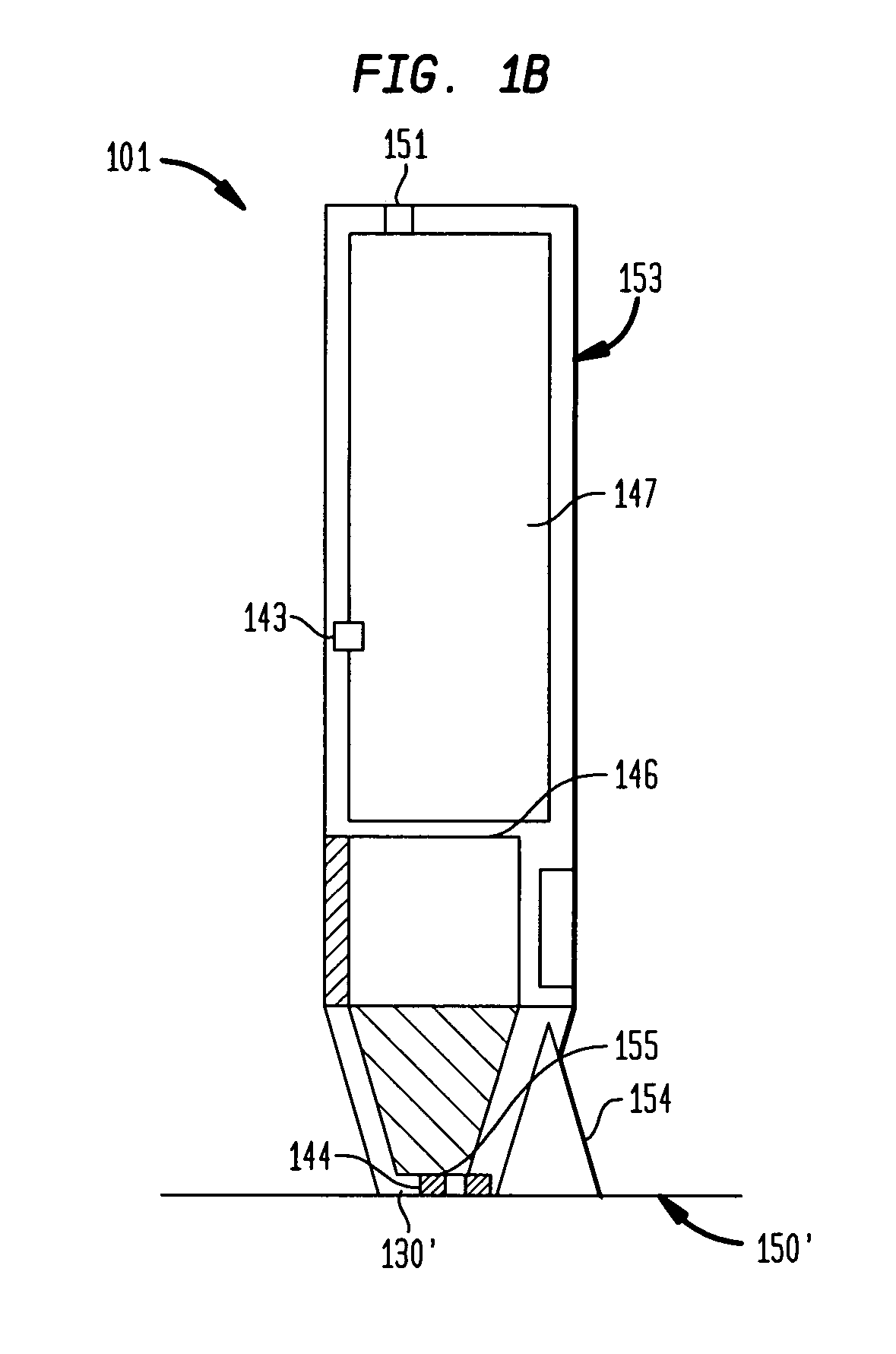

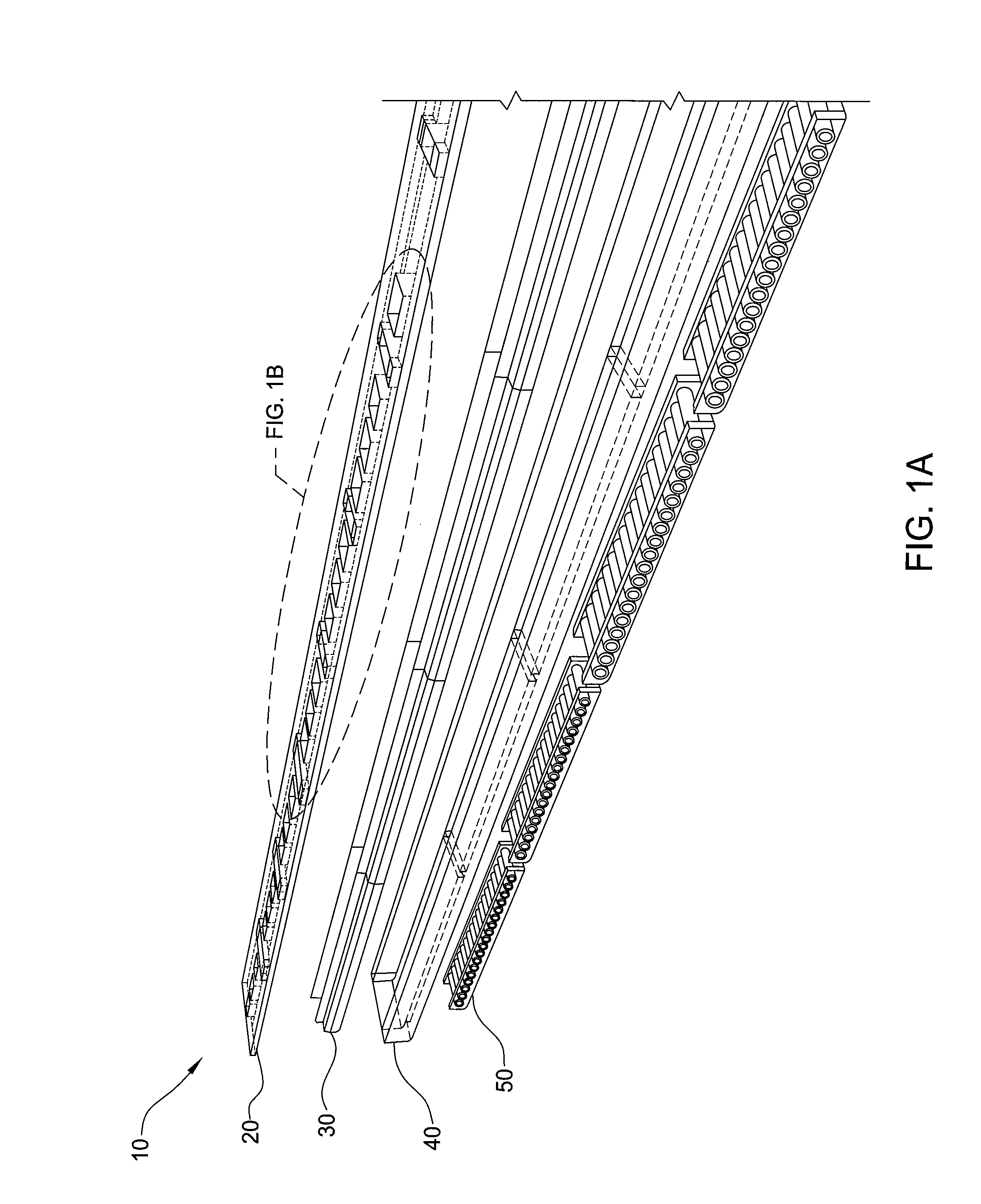

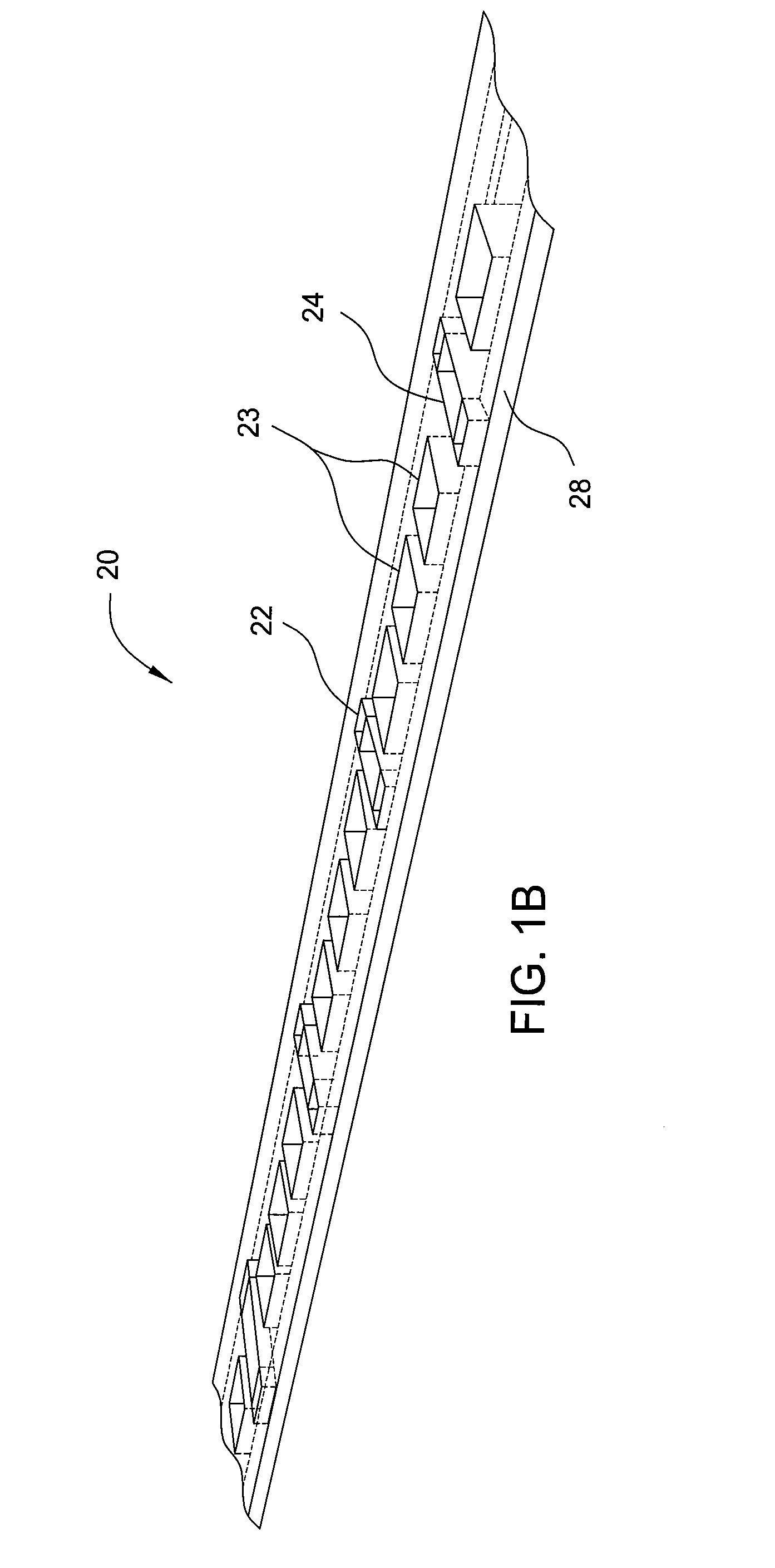

Method and Apparatus for Micro-Needle Array Electrode Treatment of Tissue

InactiveUS20070142885A1Avoid overall overheatingMaintain temperatureSurgical needlesMicroneedlesAging skinsMicro-needle

The invention describes a system and method for revitalizing aging skin using electromagnetic energy that is delivered using a plurality of needles that are capable of penetrating the skin to desired depths. A particular aspect of the invention is the capability to spare zones of tissue from thermal exposure. This sparing of tissue allows new tissue to be regenerated while the heat treatment can shrink the collagen and tighten the underlying structures. Additionally, the system is capable of delivering therapeutically beneficial substances either through the penetrating needles or through channels that have been created by the penetration of the needles.

Owner:RELIANT TECH INC

Tissue treatment methods

ActiveUS8192474B2Reduce and eliminate fat cellMinimize injuryChiropractic devicesSurgical instruments for heatingSubcutaneous adipose tissueReperfusion injury

Methods are provided herein for affecting a region of a subject's body, comprising exposing the region to a cooling element under conditions effective to cool subcutaneous adipose tissue in said region; and increasing the blood flow rate to the cooled tissue by exposing the tissue to an energy source. Methods are also provided for treating subcutaneous adipose tissue in a region of a subject's body, comprising exposing said region to a cooling element under conditions effective to cool said tissue; and exposing the tissue to an energy source to increase the blood flow rate to the cooled tissue, thereby stimulating reperfusion in, and / or causing an ischemia-reperfusion injury to, the cooled tissue.

Owner:ZELTIQ AESTHETICS INC

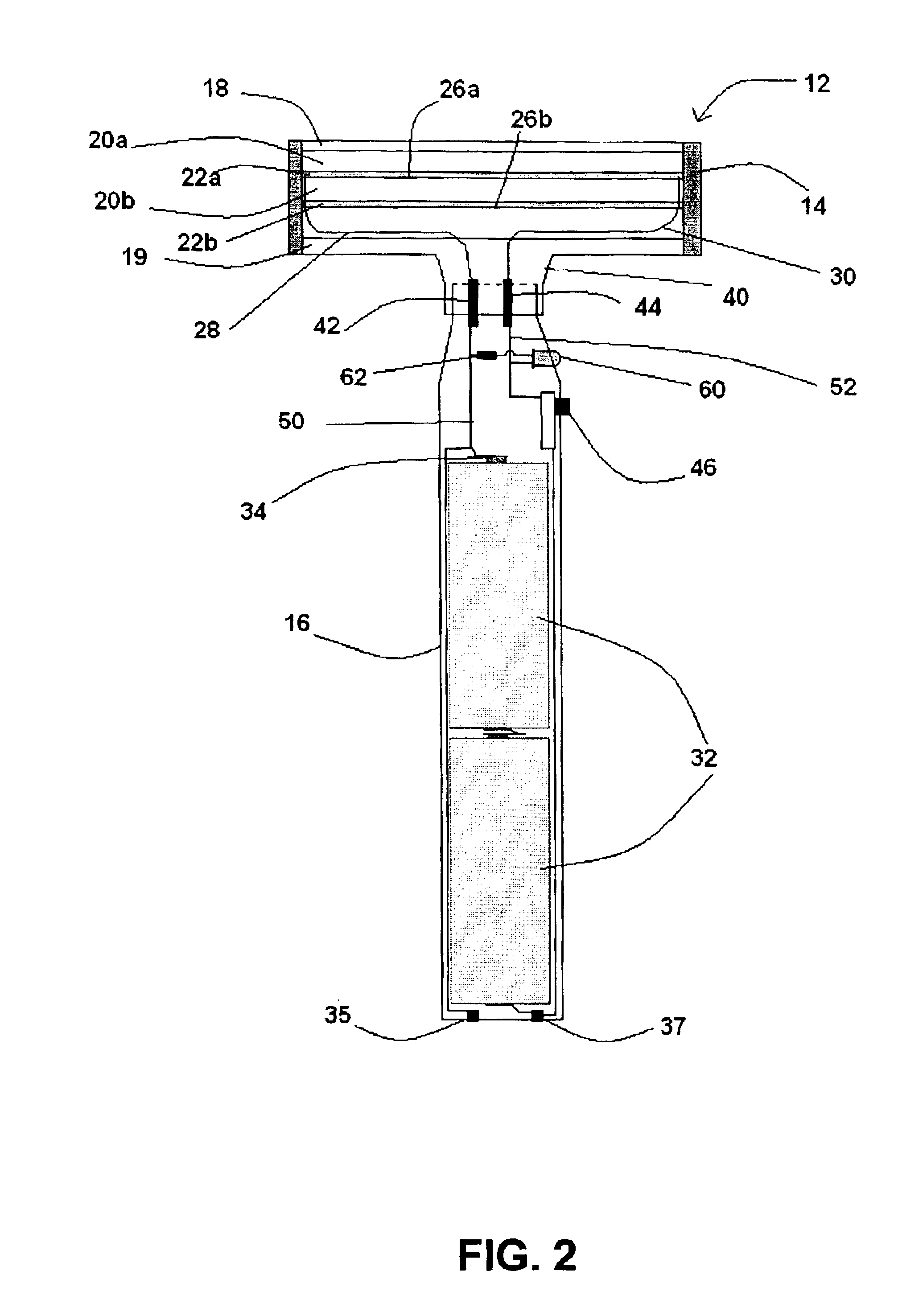

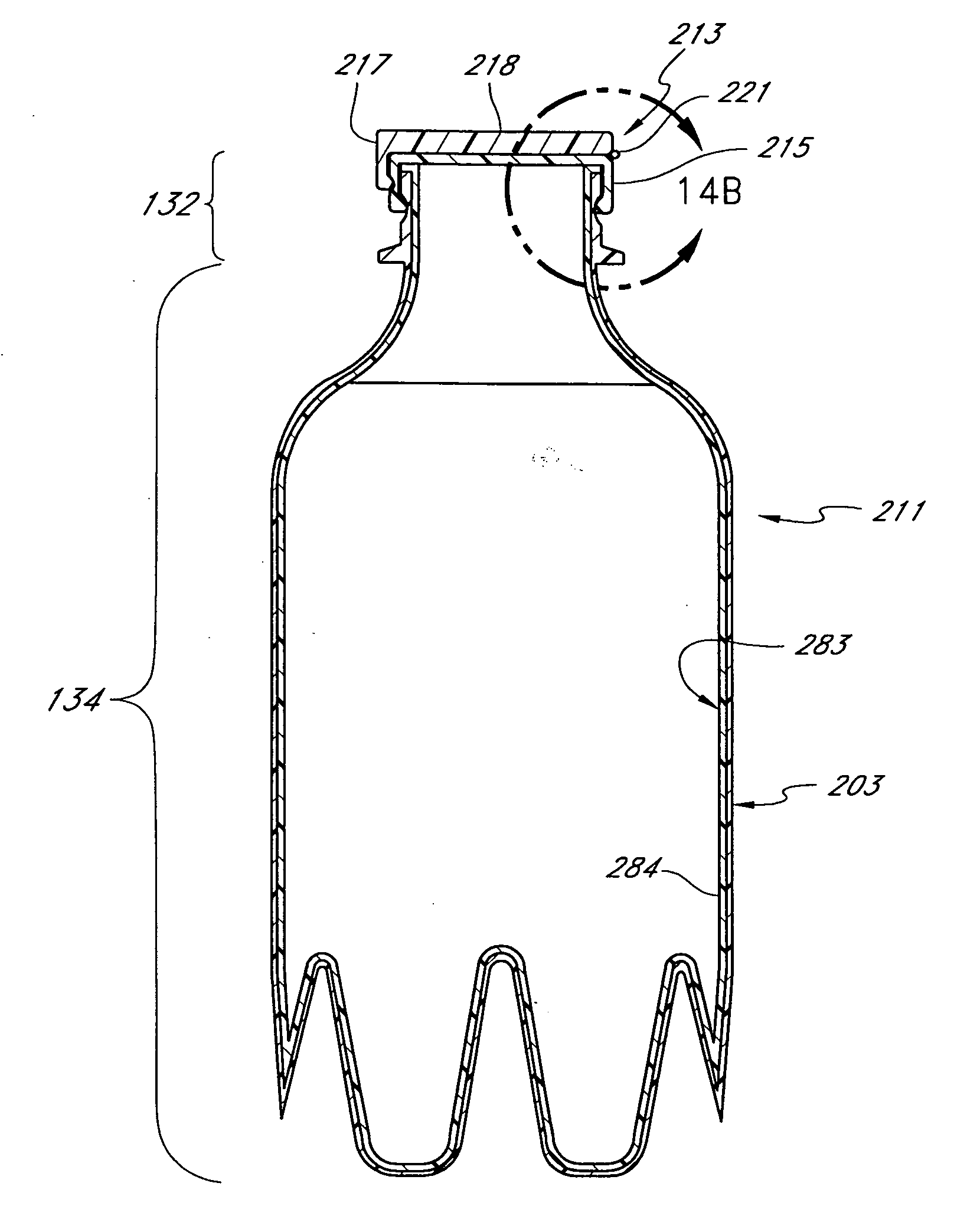

Phototreatment device for use with coolants and topical substances

InactiveUS7135033B2Reduce the temperatureMaintain temperaturePhotodynamic therapyControlling energy of instrumentAdjuvantMedicine

Methods and systems are disclosed for phototreatment in which replaceable containers comprising one or more adjuvant (consumable or re-useable) substances are employed. The adjuvant substance can be, for example, a topical substance or a coolant. Systems are disclosed for using a topical substance to detect contact of a phototreatment device with a tissue, detect speed of a phototreatment device over the tissue, detect regions of tissue that have been treated by a phototreatment device and / or to provide other benefits to the tissue such as improved skin tone and texture, tanning, etc. Safety systems are also disclosed that ensure that a proper consumable substance and / or container is connected to a phototreatment device and / or directed to a proper target. Additionally, cooling systems and methods that utilize phase change materials for extracting heat from a light generating device are disclosed.

Owner:PALOMAR MEDICAL TECH

LED work light

ActiveUS7553051B2Preserve useful working lifeUseful working lifeElectric lighting for hand-held useLighting support devicesElectrical ballastElectrical battery

Work light has LEDs that require heatsink. Desired radiation pattern achieved by using optical components designed to produce beam or LEDs may have beams in different directions. Radiation pattern of LEDs may be changed by refractive-reflective optics or by convex lenses. Convex lenses may be hemispheres, other planoconvex shapes, concavo-convex shapes, or other shapes. Curved surfaces on any lenses may be spherical or aspheric. Ballast to operate the LEDs from line voltage AC or low voltage DC. Work light may contain batteries. The work light may be mounted on a stand. May have accessory mount. May have charging station. May have a paging transmitter to activate a paging receiver in work light. May have openings for heat transfer from heatsink to ambient air external to light.

Owner:ALLTEMP PROD CO LTD

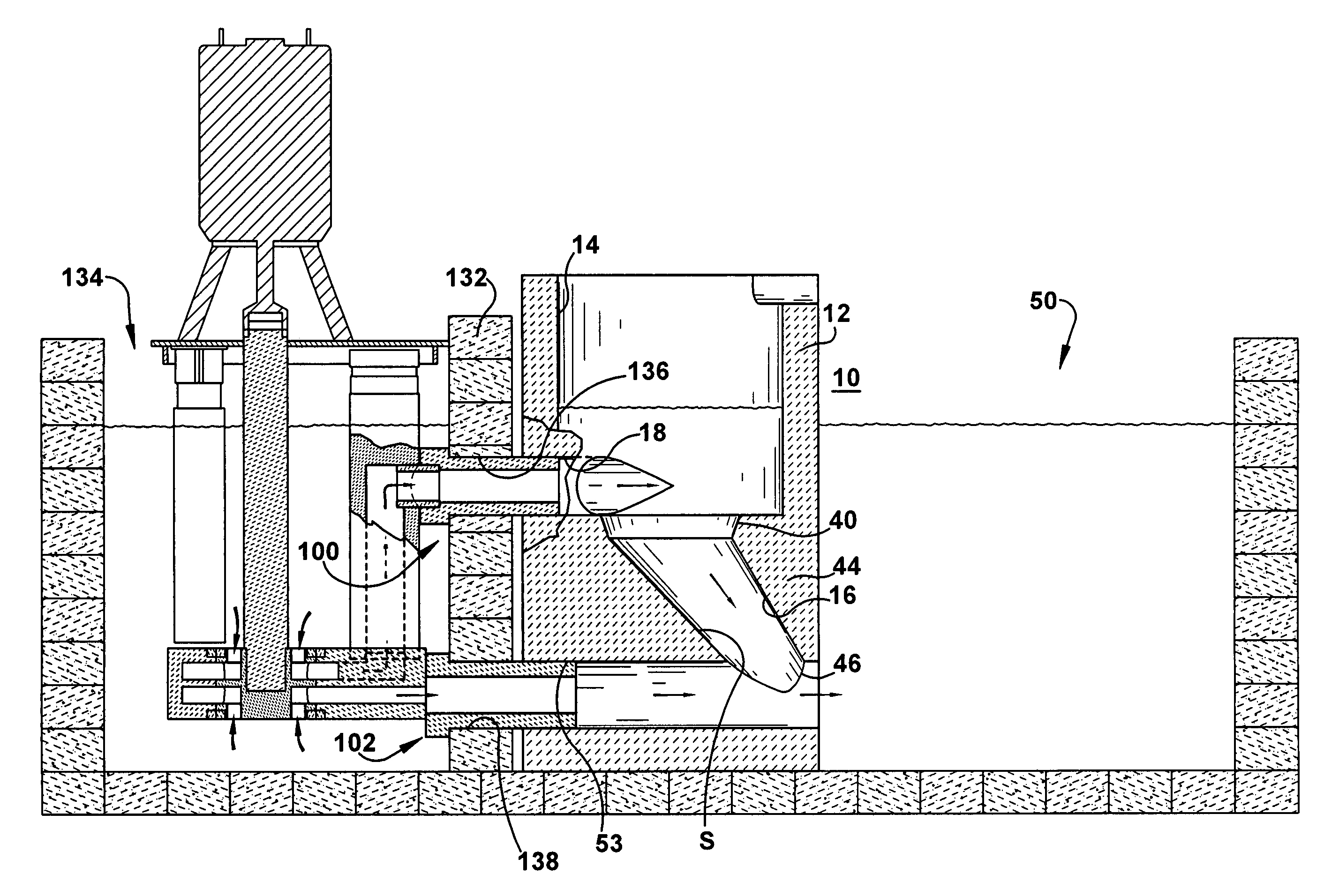

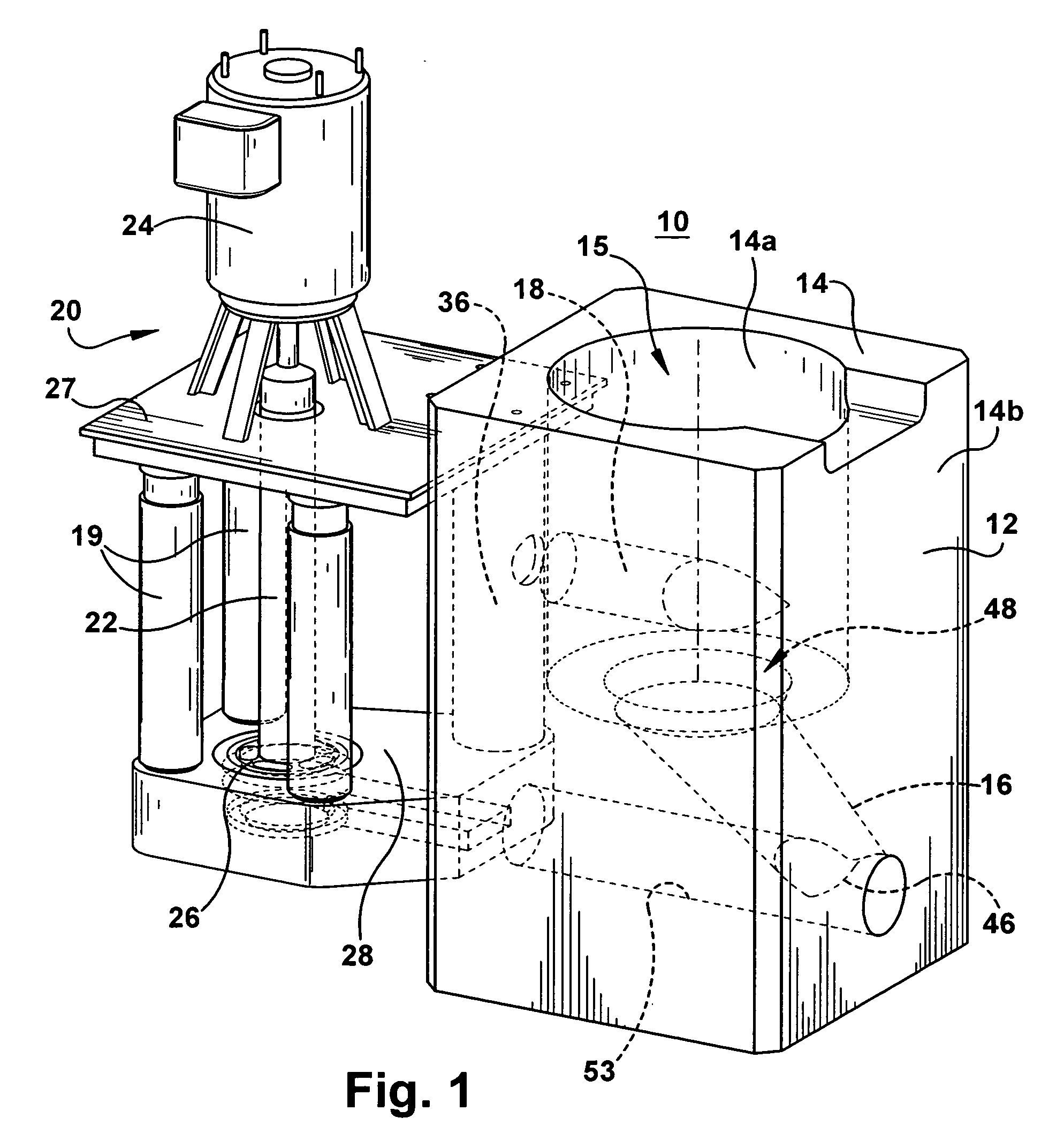

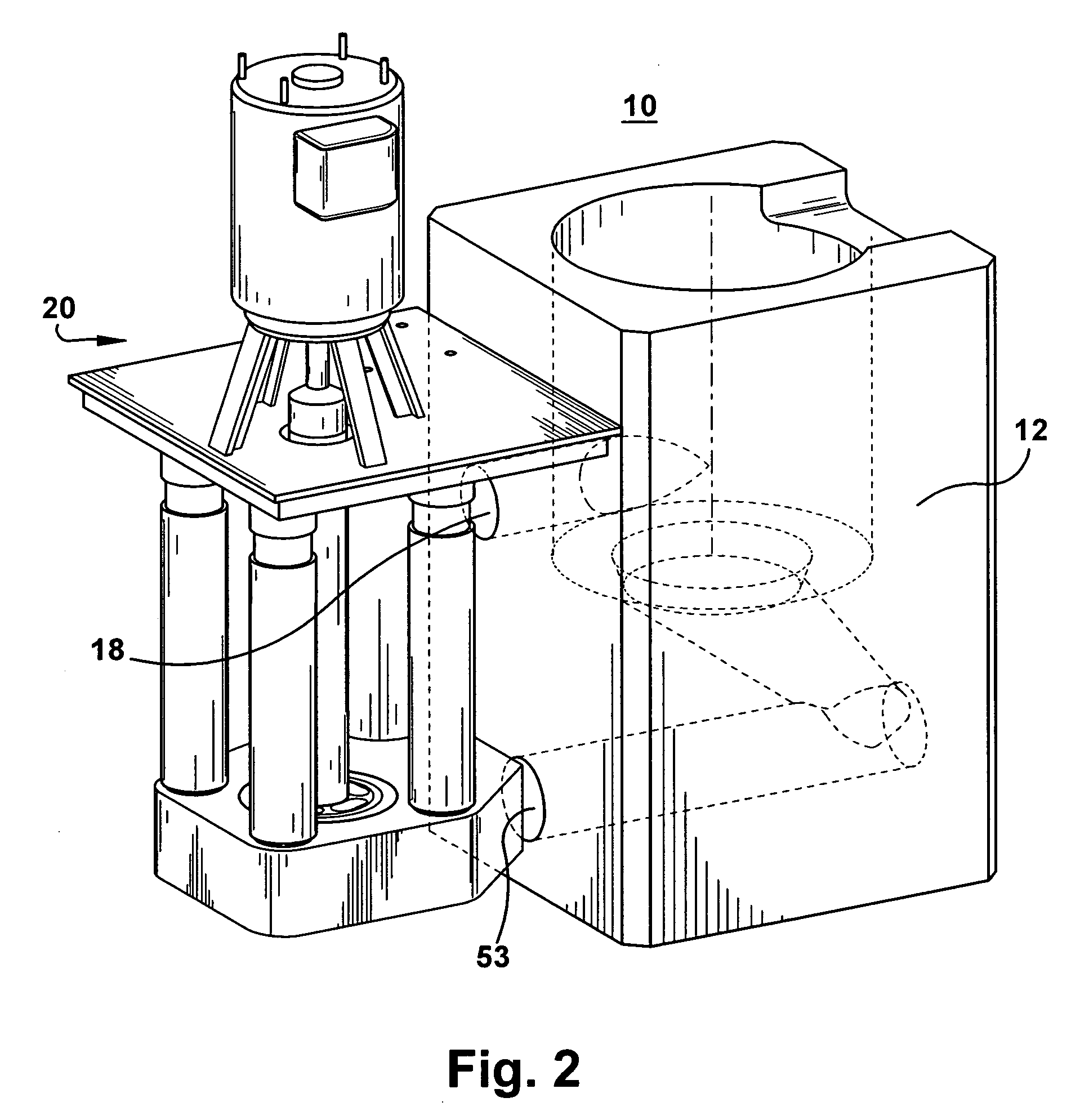

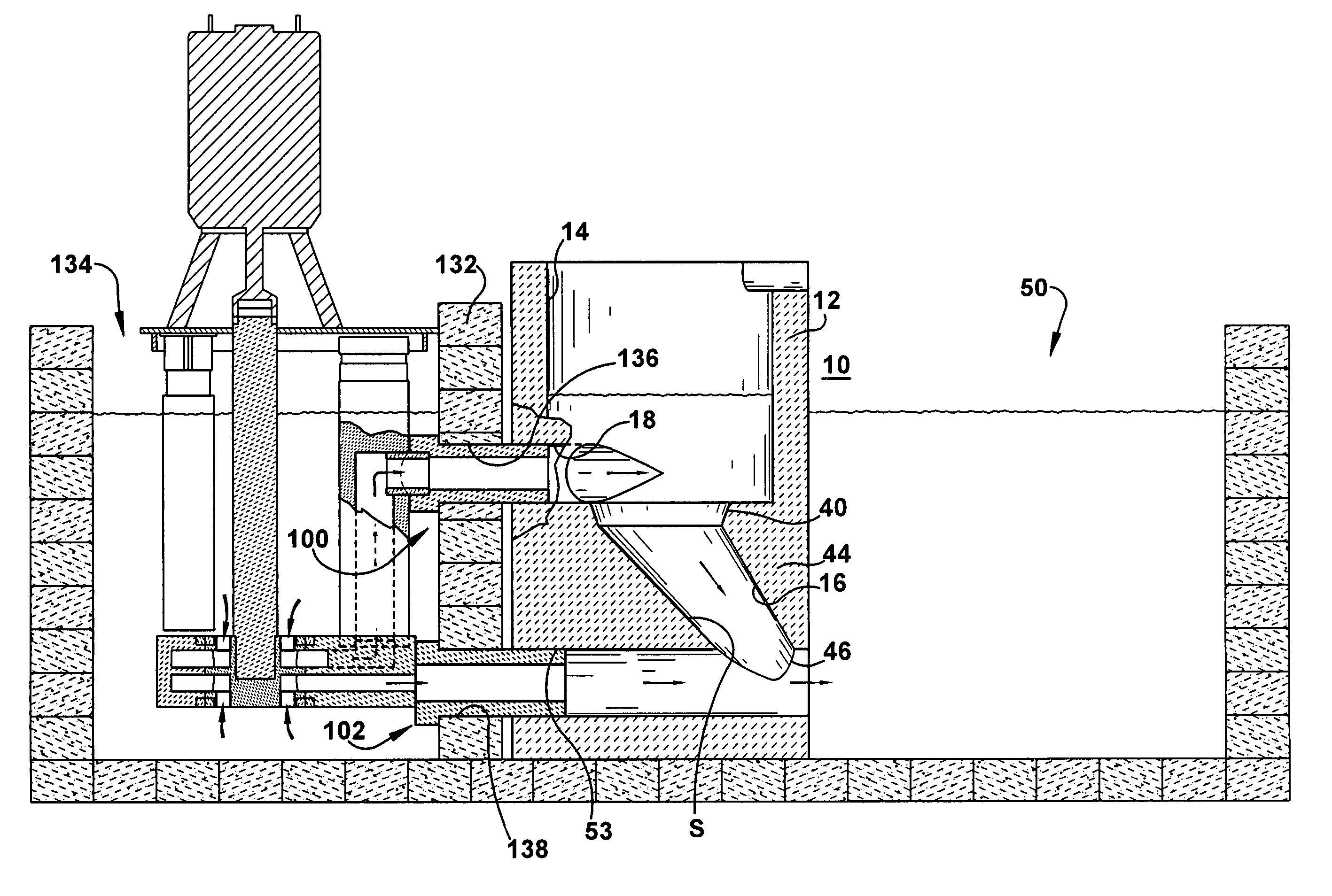

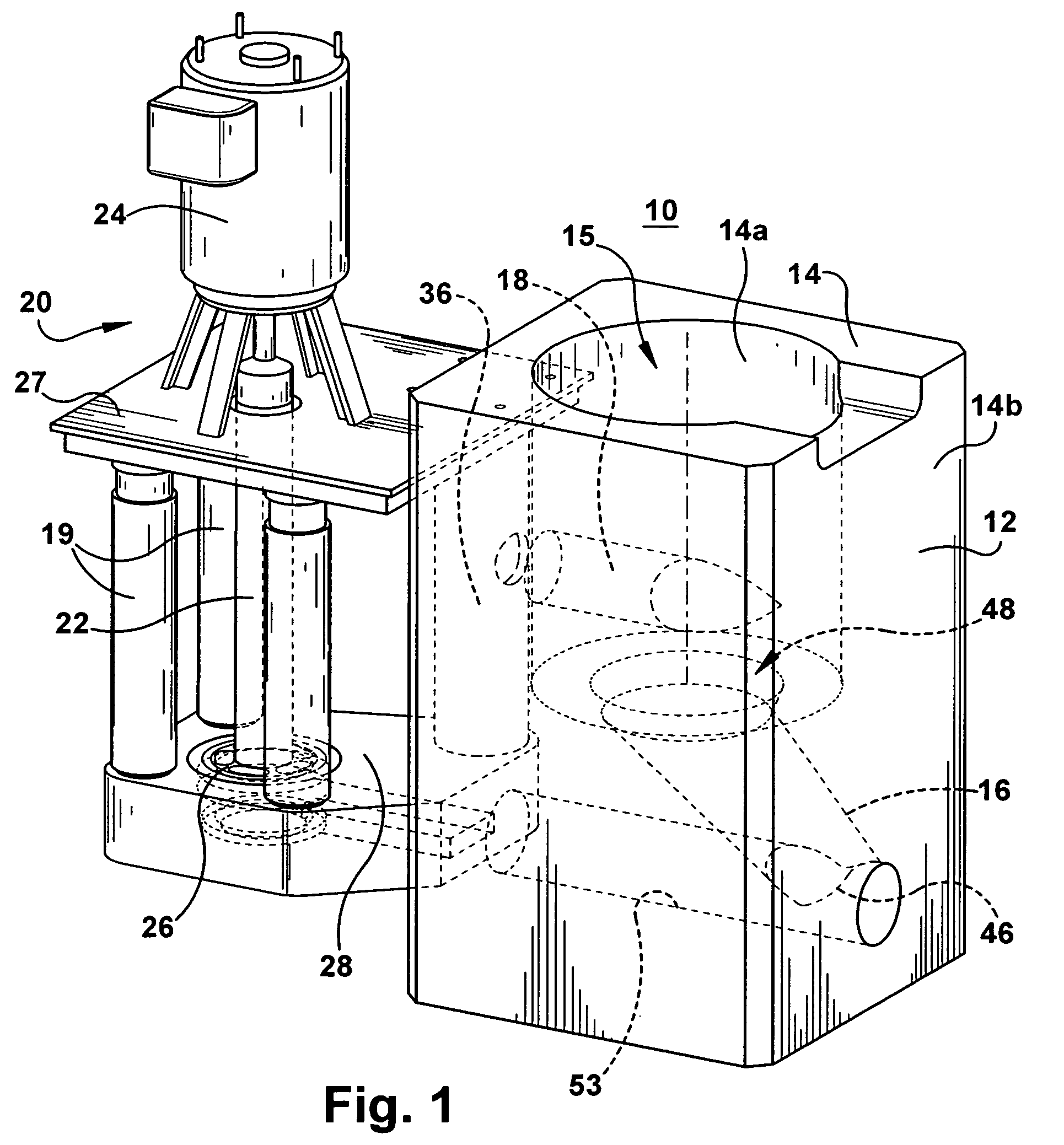

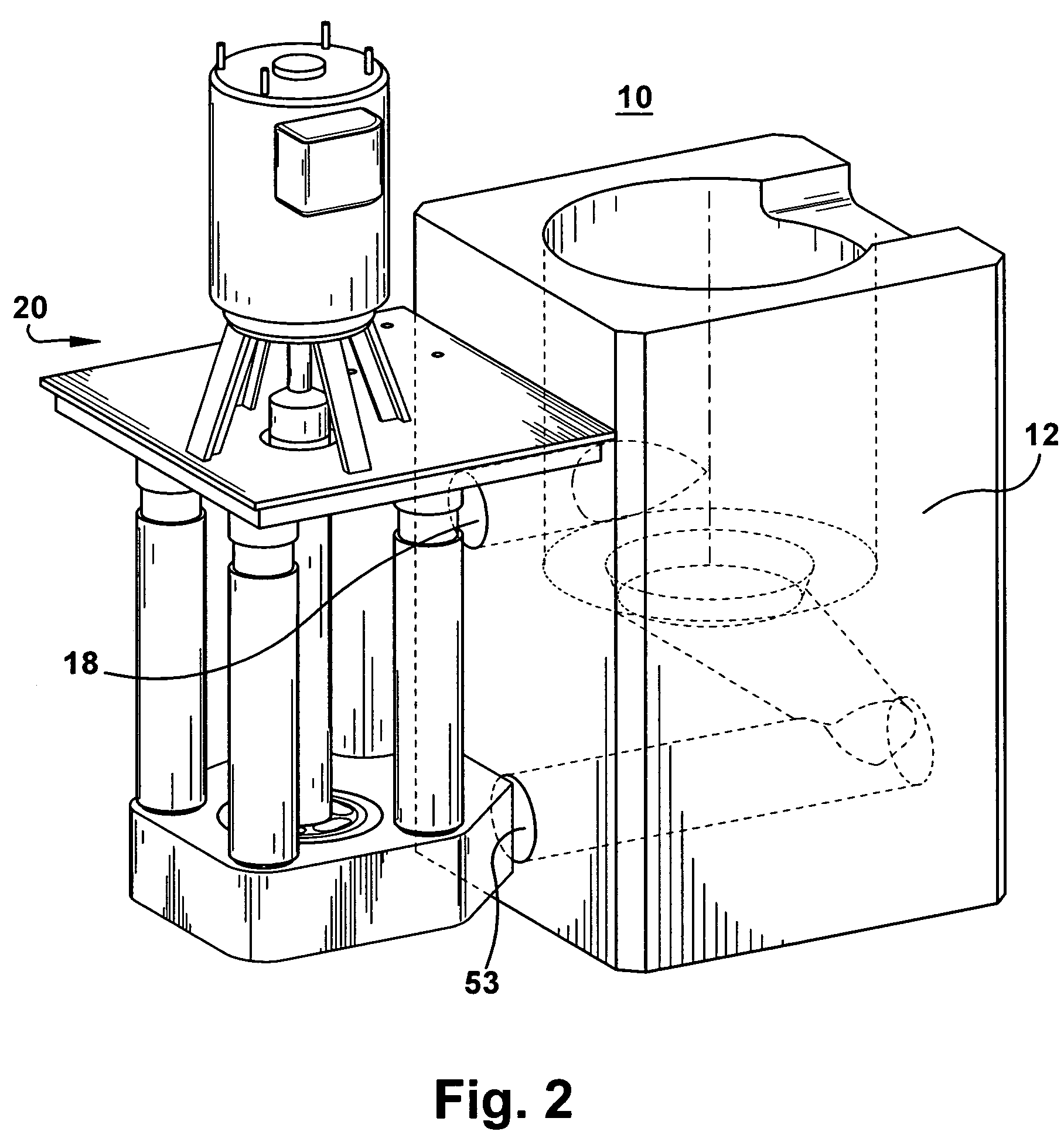

Vortexer apparatus

ActiveUS20060180963A1Facilitates submergence and meltingMaintain temperatureStirring devicesCharge manipulationImpellerPositive pressure

The present invention features a vortexer apparatus including a vessel comprising an exterior surface, an interior surface containing fluid and a mouth for receiving material at an upper end portion of the interior surface. In one application the material is metal scrap that is melted in molten metal as the fluid. All components that contact the molten metal are formed of refractory material. An outlet passageway extends downwardly from the interior surface. A vessel inlet opening is located between the exterior and interior surfaces above the outlet passageway. A center line passes through a center of the interior surface and the vessel inlet opening is disposed at a location offset from the center line. A pump is adapted to pump fluid into the vessel effective to form a vortex of fluid in the vessel. The base and impeller are configured and arranged effective to provide molten metal leaving the base outlet with a positive pressure. An outlet conduit extends from the base outlet to near the vessel inlet opening and can be maintained at a temperature above which molten metal solidifies, along its entire length. Instead of the vortexer vessel, the inventive vortexer apparatus may integrate a chamber of a furnace (e.g., a charge well). The chamber may be rectangularor include arcuate portions. Corner inserts may be used to provide the chamber with an oval or generally circular shape that may facilitate the vortex. One feature of the invention is a vortex vessel that includes an offset inlet opening and lower circulation opening. Also featured is a baffle impeller that may be vaned or barrel type. In addition, the invention features a pump having upper and lower impeller chambers separated by a web in the base, and impeller outlets that are isolated from fluid communication with each other.

Owner:THUT BRUNO H

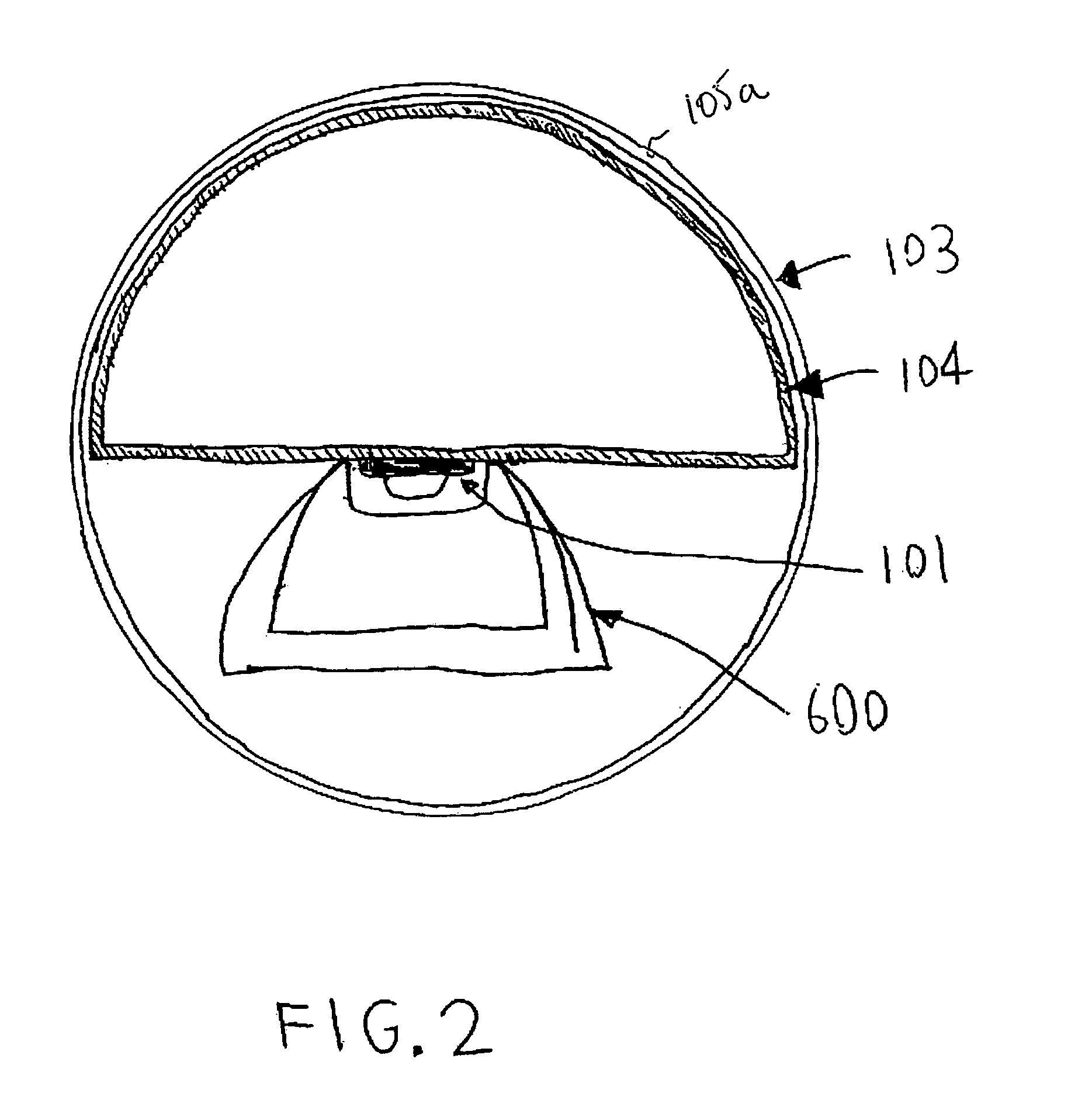

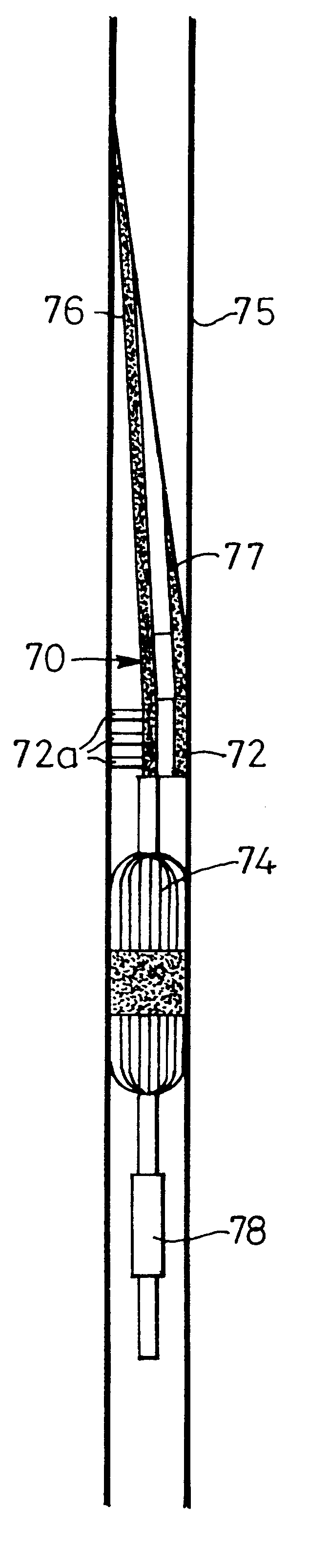

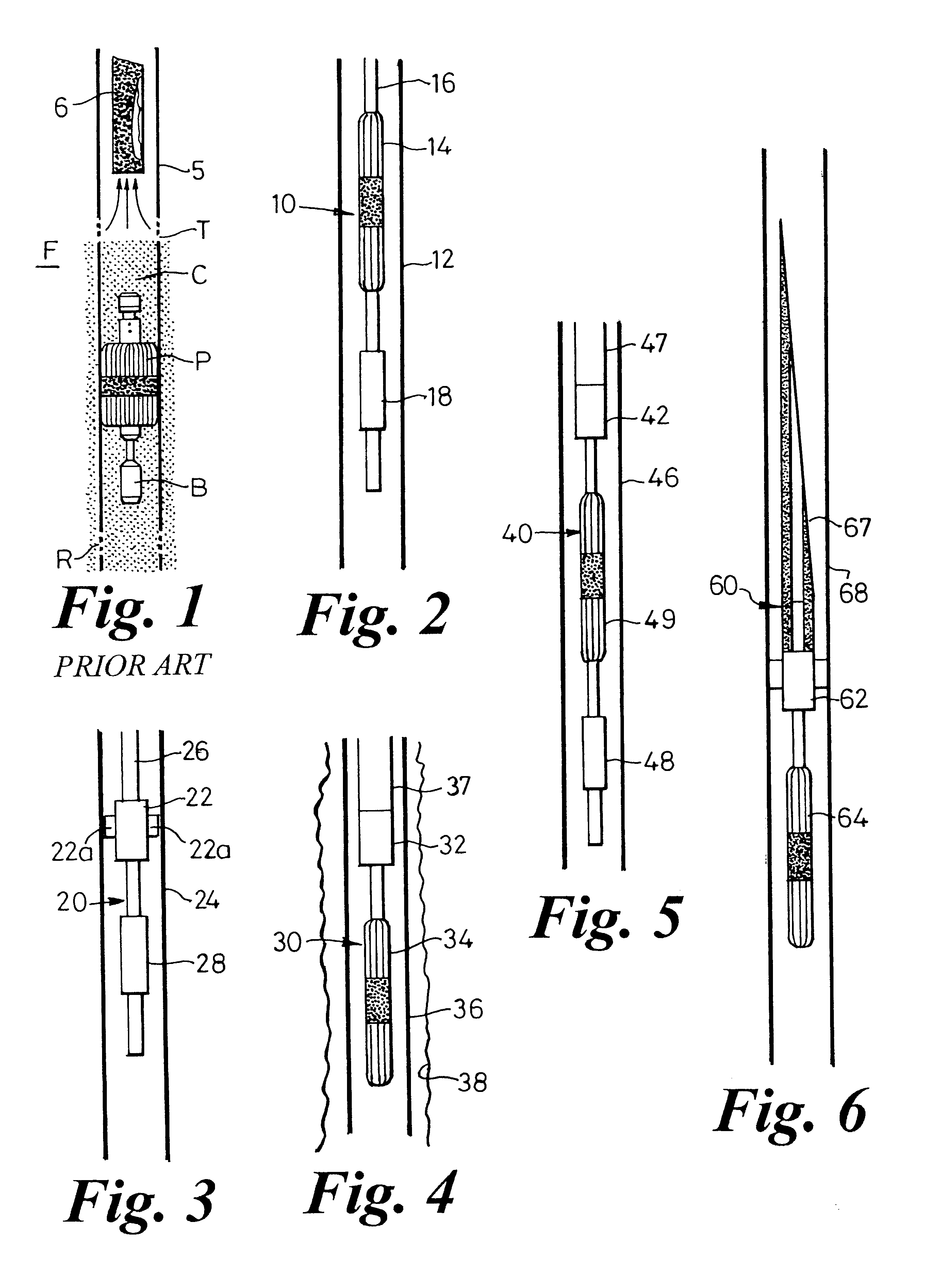

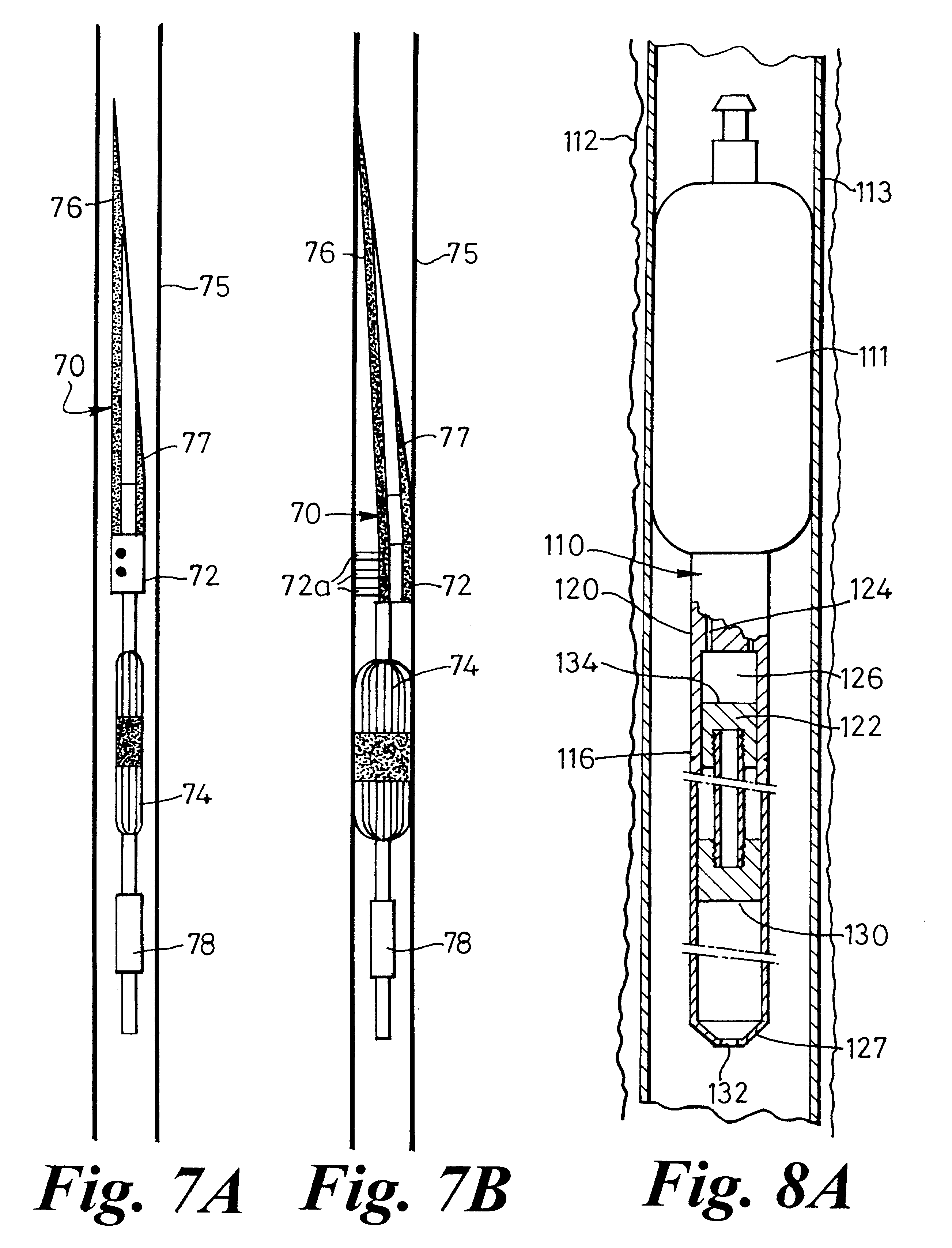

Wellbore primary barrier and related systems

InactiveUS6209636B1Facilitate packer inflationMaintain temperatureEarth drilling toolsDrill bitsEngineeringWellbore

A new wellbore apparatus has been invented which, in certain aspects, has anchor apparatus for anchoring the wellbore apparatus in a bore, the anchor apparatus actuated by fluid under pressure supplied thereto, and sealing apparatus selectively inflatable to close off the bore to fluid flow therethrough, and temperature compensating apparatus for maintaining a desired fluid pressure in the sealing apparatus to prevent it from bursting or deflating. A method for closing off a bore in a well has been invented which, in certain aspects, includes installing wellbore apparatus in the bore, the wellbore apparatus comprising anchor apparatus for anchoring the wellbore apparatus in a bore, the anchor apparatus actuated by fluid under pressure supplied thereto, and sealing apparatus interconnected with the anchor apparatus and selectively inflatable with fluid under pressure to close off the bore to fluid flow therethrough, and the wellbore apparatus upon anchoring in the bore and inflation of the sealing apparatus including a primary barrier in the bore.

Owner:WEATHERFORD TECH HLDG LLC

Vortexer apparatus

ActiveUS7497988B2Facilitates submergence and meltingMaintain temperatureStirring devicesCharge manipulationImpellerPositive pressure

Owner:THUT BRUNO H

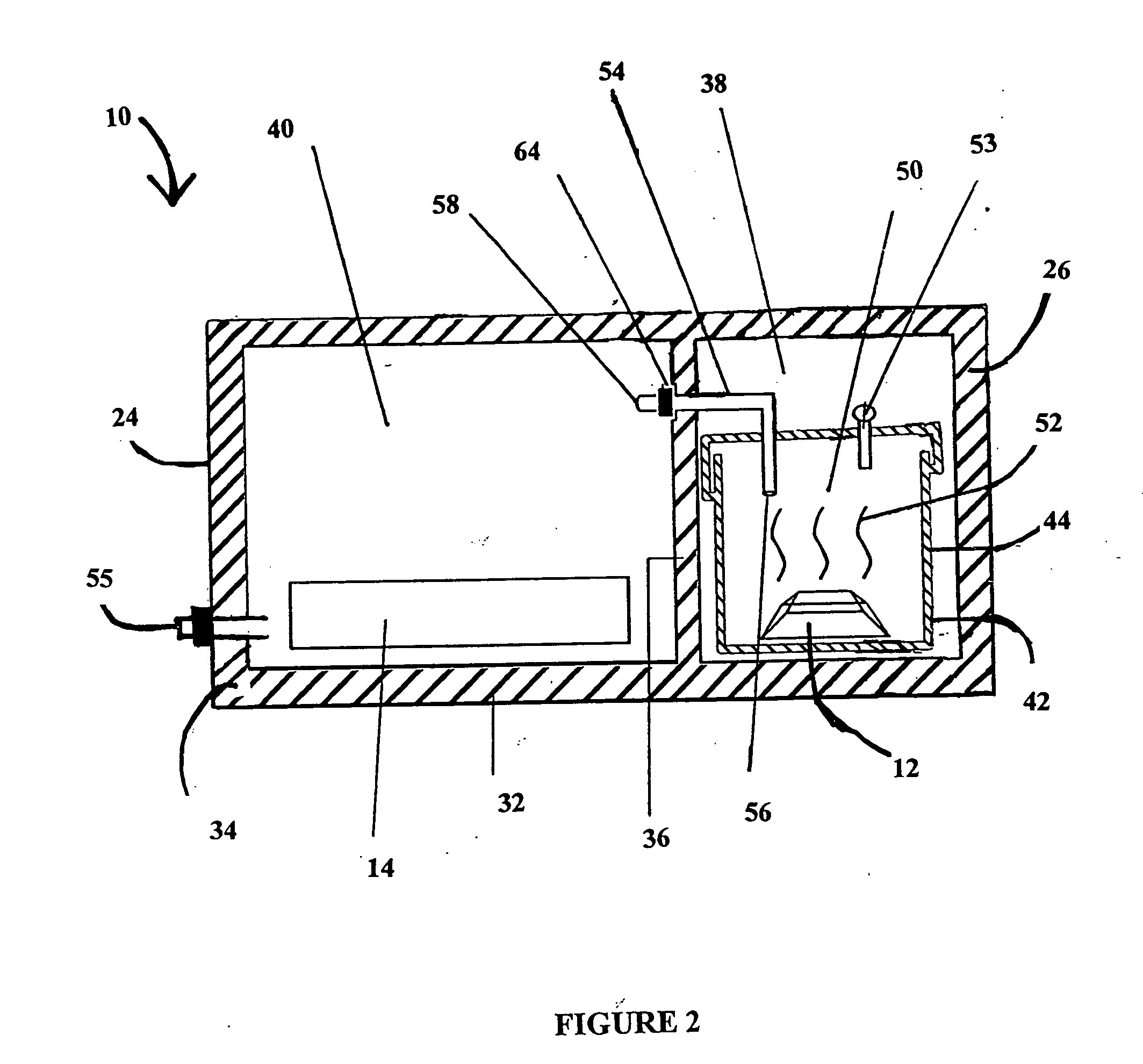

Low temperature cooler

InactiveUS20060053828A1Economically constructMaintain temperatureDomestic cooling apparatusIce productionDry iceChiller

The invention is directed to a low-temperature cooler using dry ice as a cooling agent. The cooler has two compartments, one for the dry ice and one for chilled storage. The cooler self-regulates via an aqueous filled temperature-regulating valve to maintain a desired temperature in the storage compartment such that the products stored therein are stored at an optimum temperature. Upon achieving a predetermined temperature in the storage compartment, the valve closes, thereby maintaining the predetermined temperature in the storage compartment.

Owner:SHALLMAN RICHARD W +1

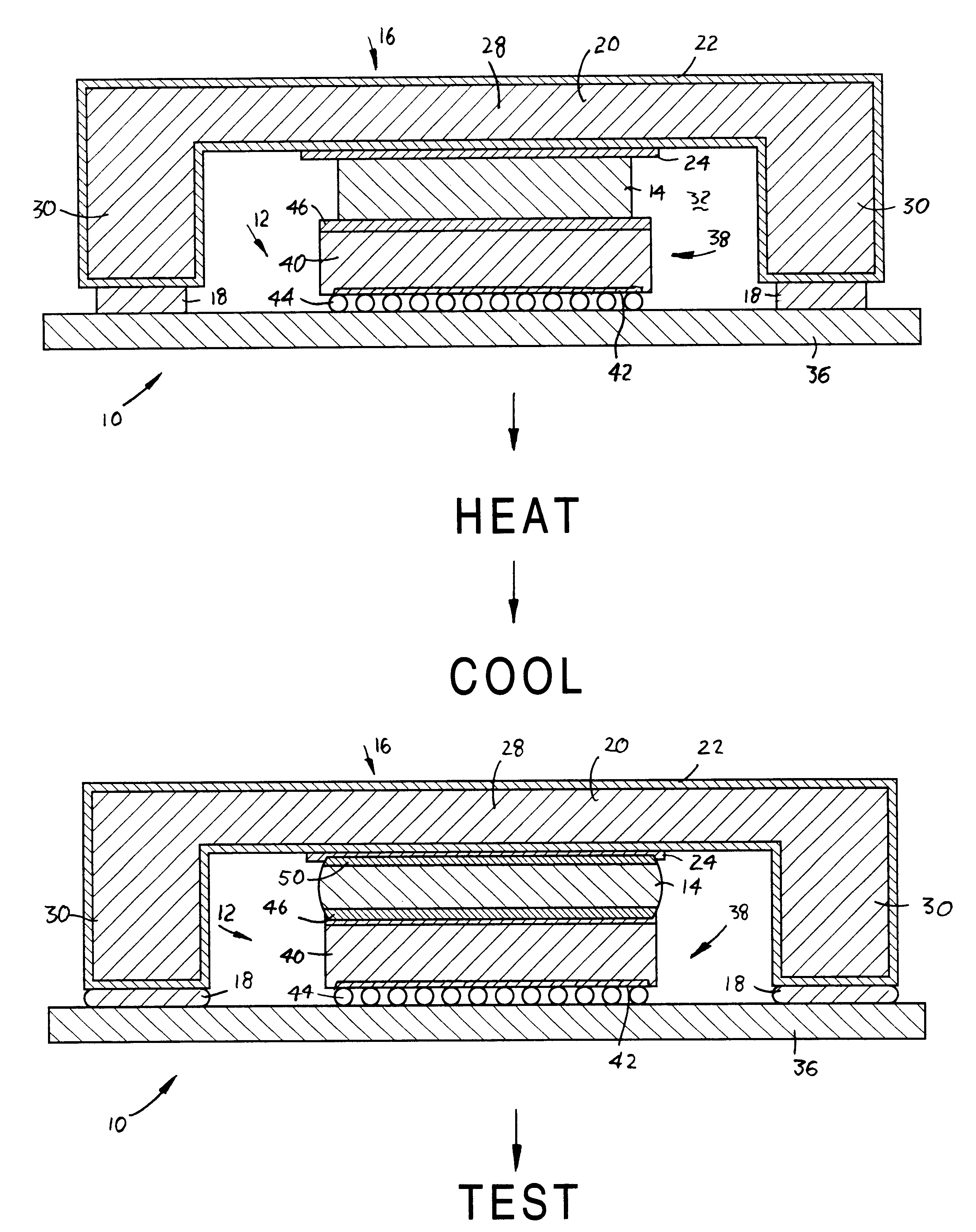

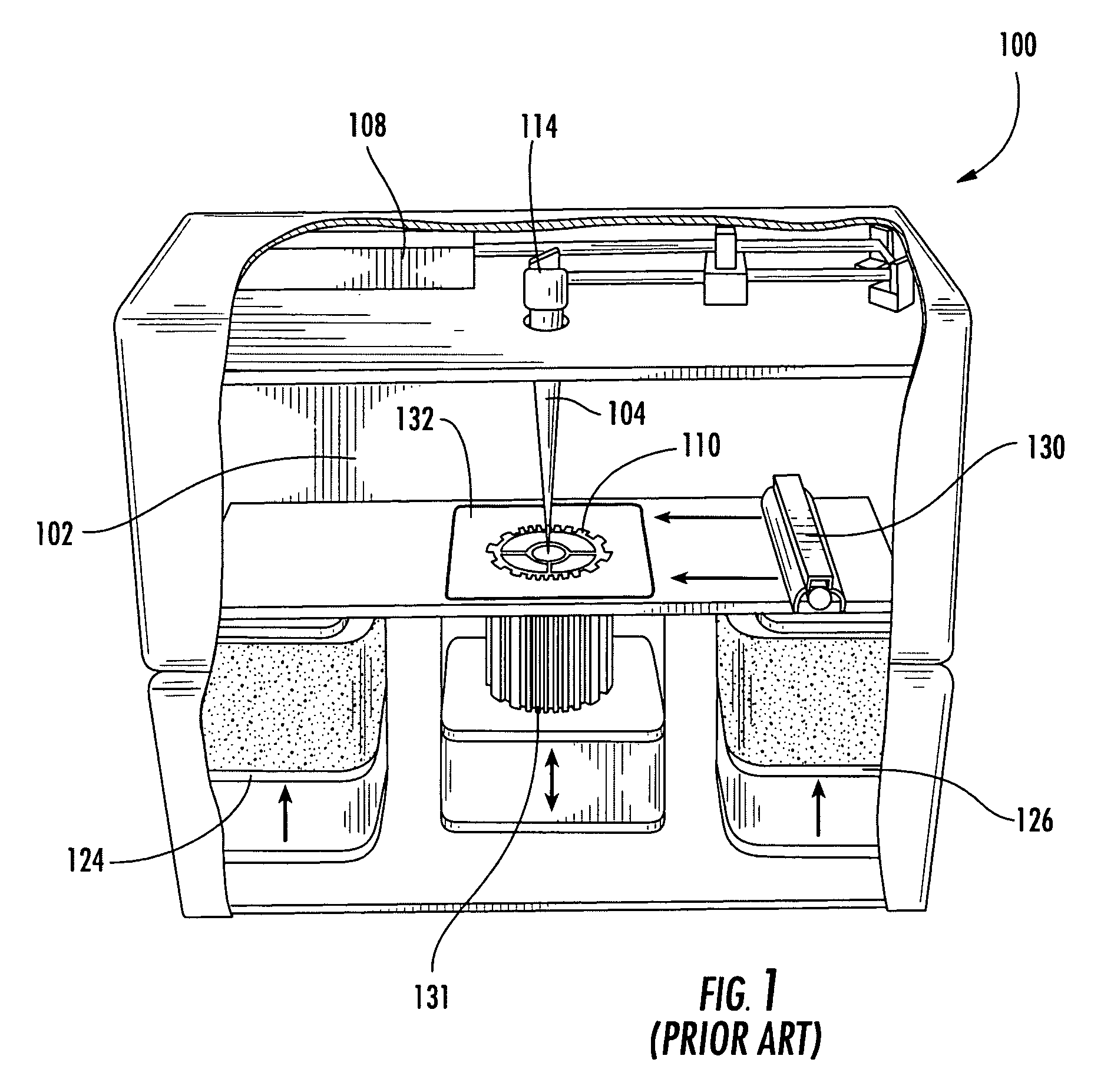

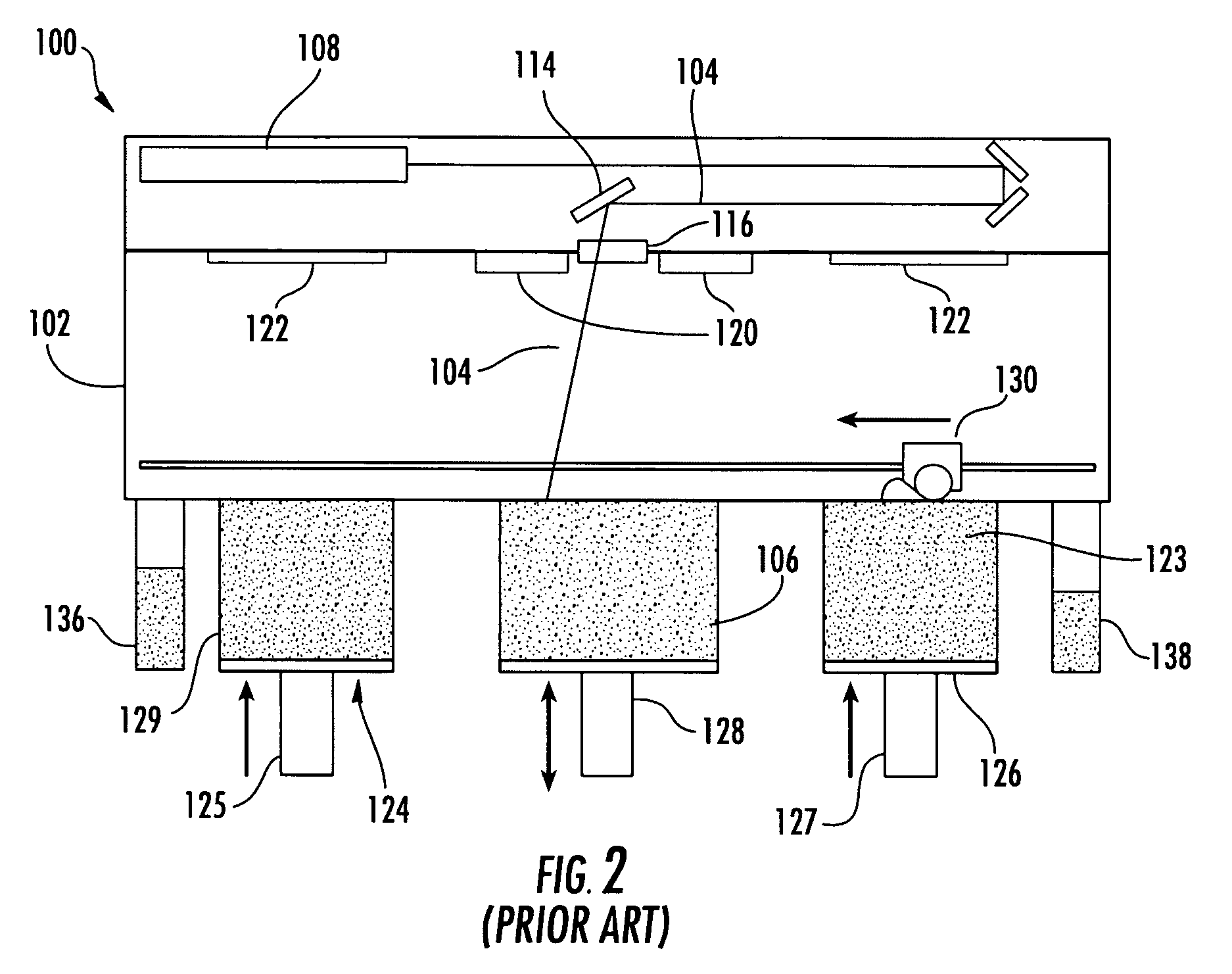

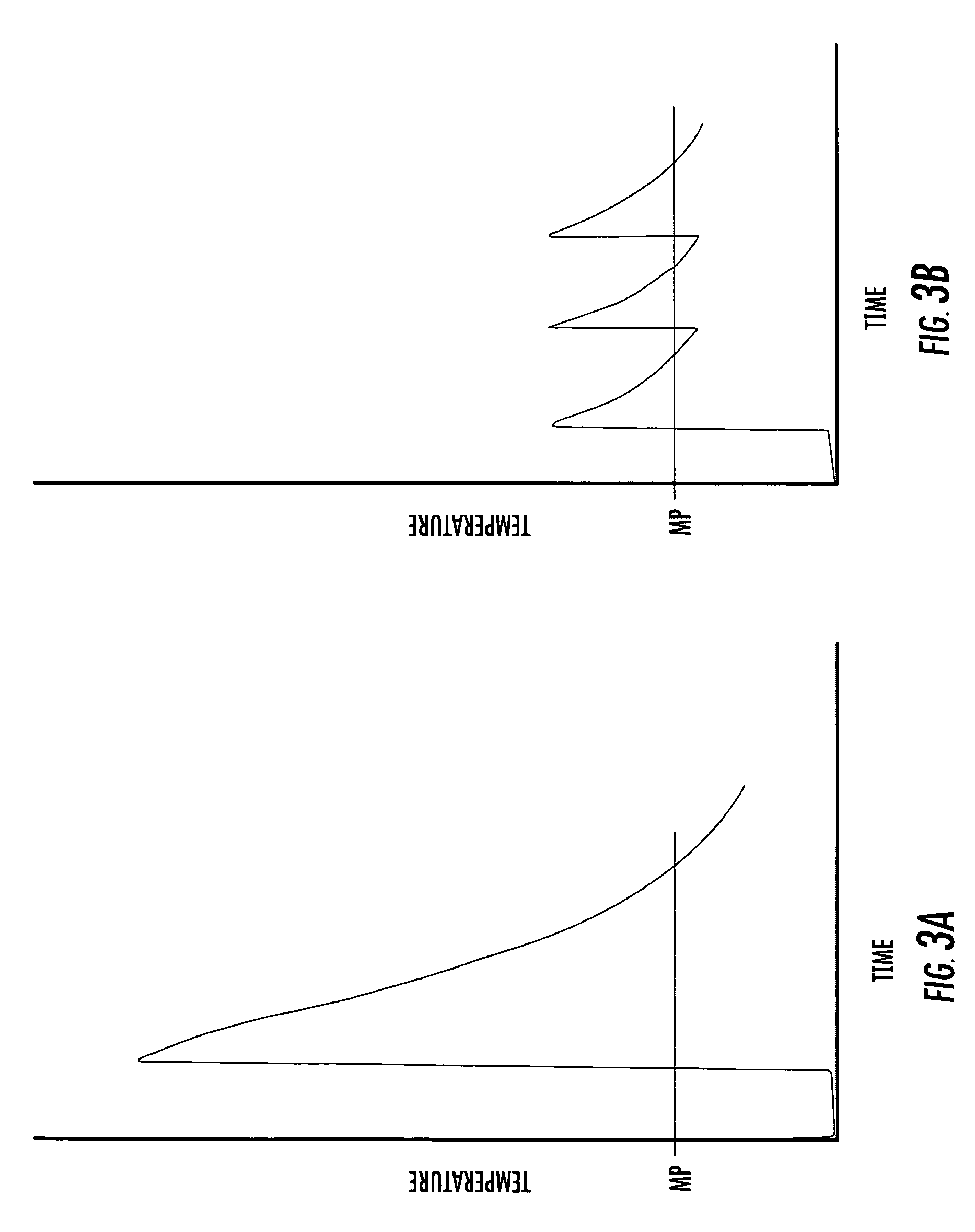

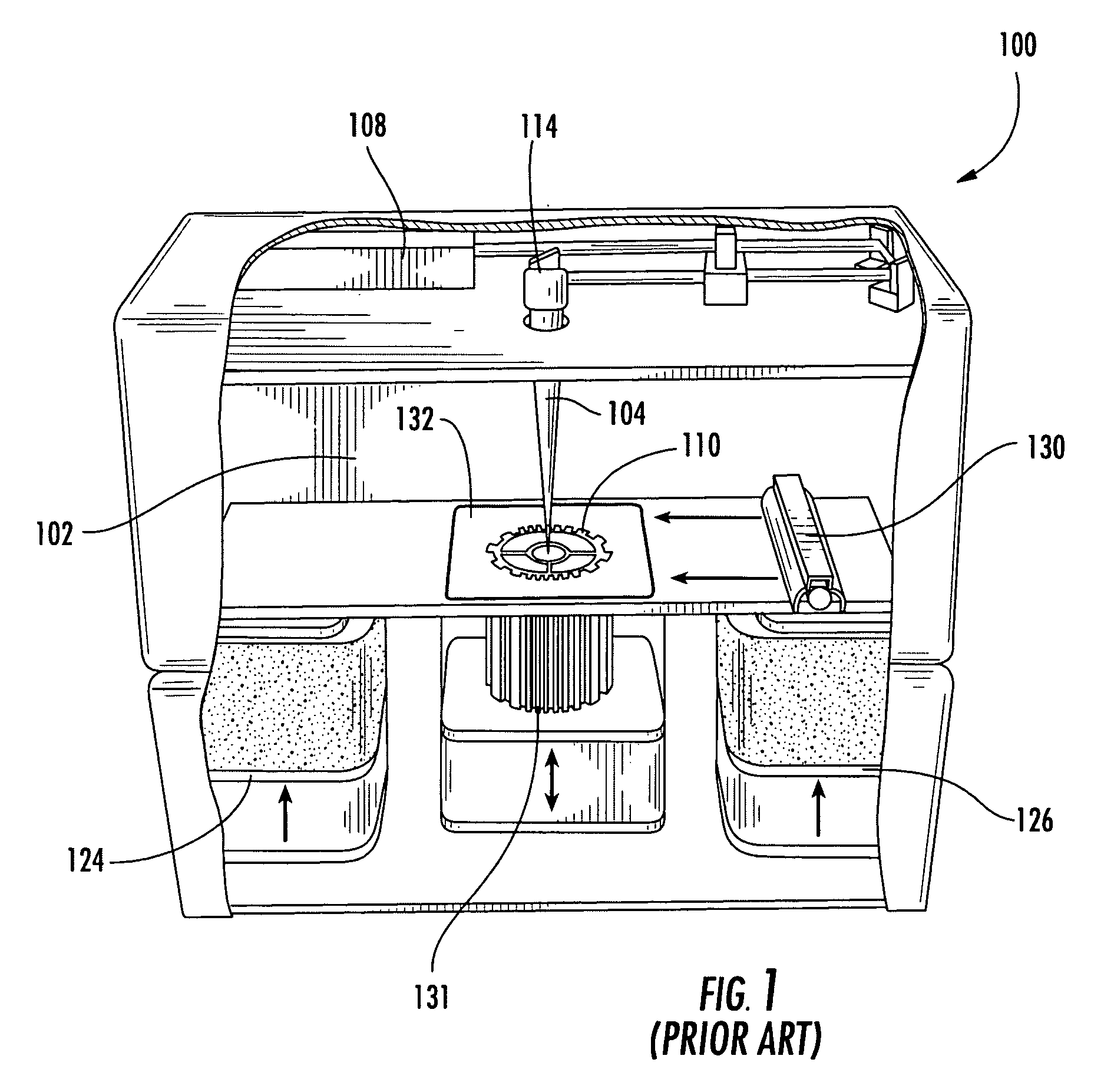

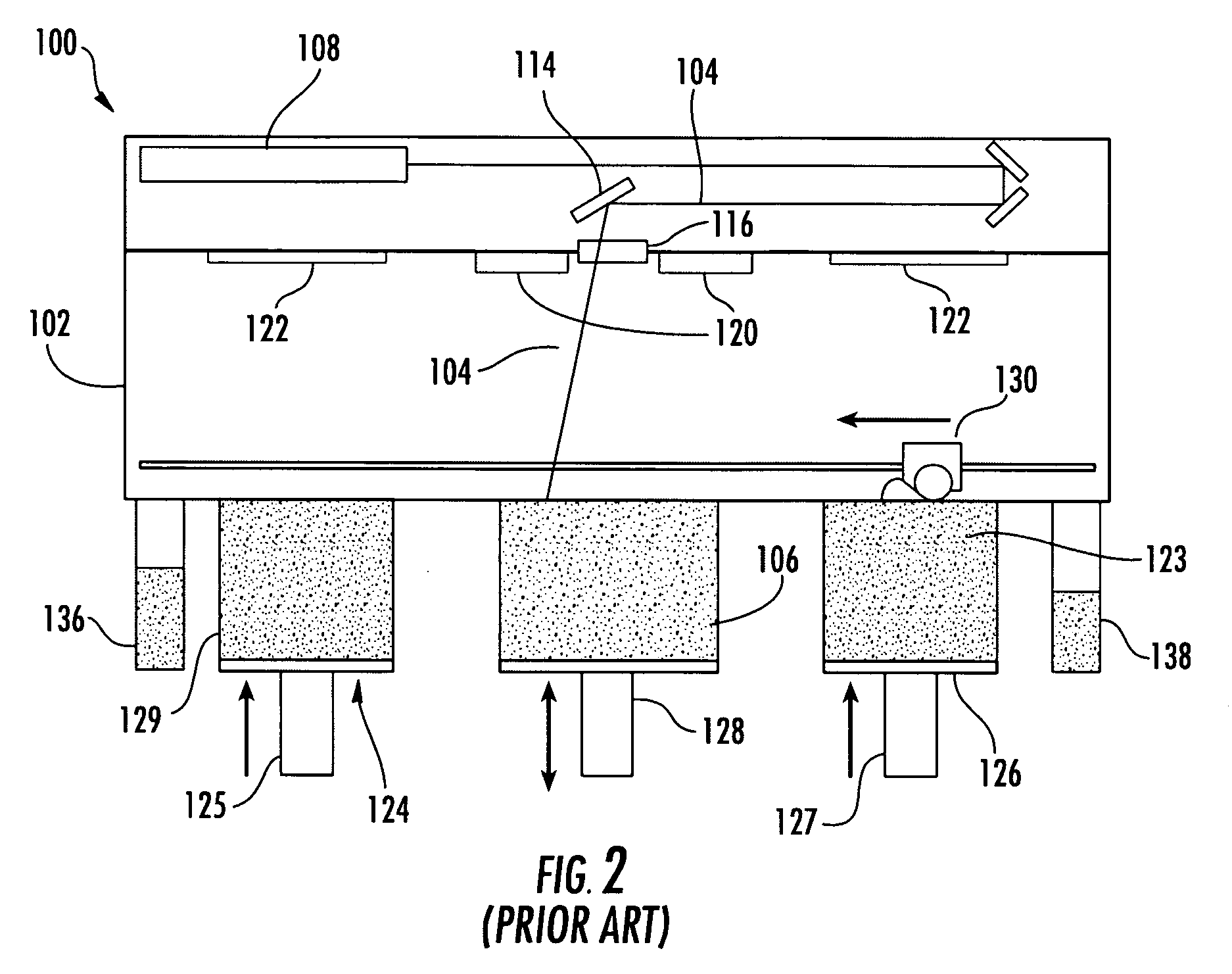

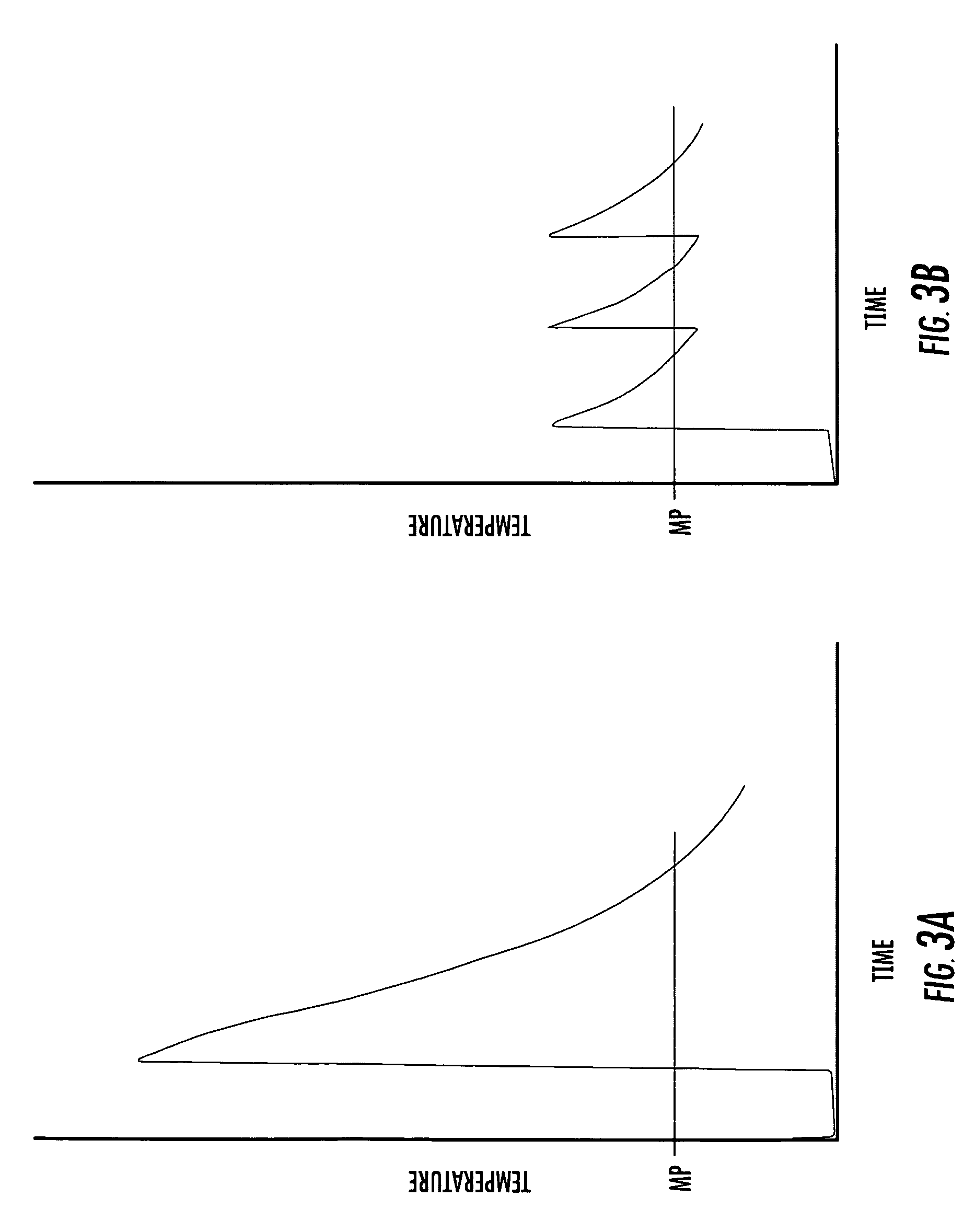

Controlled densification of fusible powders in laser sintering

ActiveUS7569174B2Heat dissipationSimple methodAdditive manufacturing apparatusAuxillary shaping apparatusHigh energyTime segment

The invention relates to a method producing parts using laser sintering wherein a fusible powder is exposed to a plurality of laser scans at controlled energy levels and for time periods to melt and densify the powder and in the substantial absence of particle bonding outside the fusion boundary. Strength is improved up to 100% compared to previous methods. An example includes a relatively high energy initial scan to melt the powder followed by lower energy scans controlled to densify the melt and separated in time to dissipate heat to the surrounding part cake. The rate and extent to which the powder particles are fused together can be controlled so that each successive scan can be used to fuse the particles together in discreet incremental steps. As a result, the final dimensions of the part and its density and mechanical properties can be improved compared to conventional methods and part growth avoided.

Owner:3D SYST INC

Heated razor and electric shaver

InactiveUS6836966B2Efficient heatingMaintain temperaturePortable power-driven toolsMetal working apparatusElectrical conductorEngineering

Owner:SLE

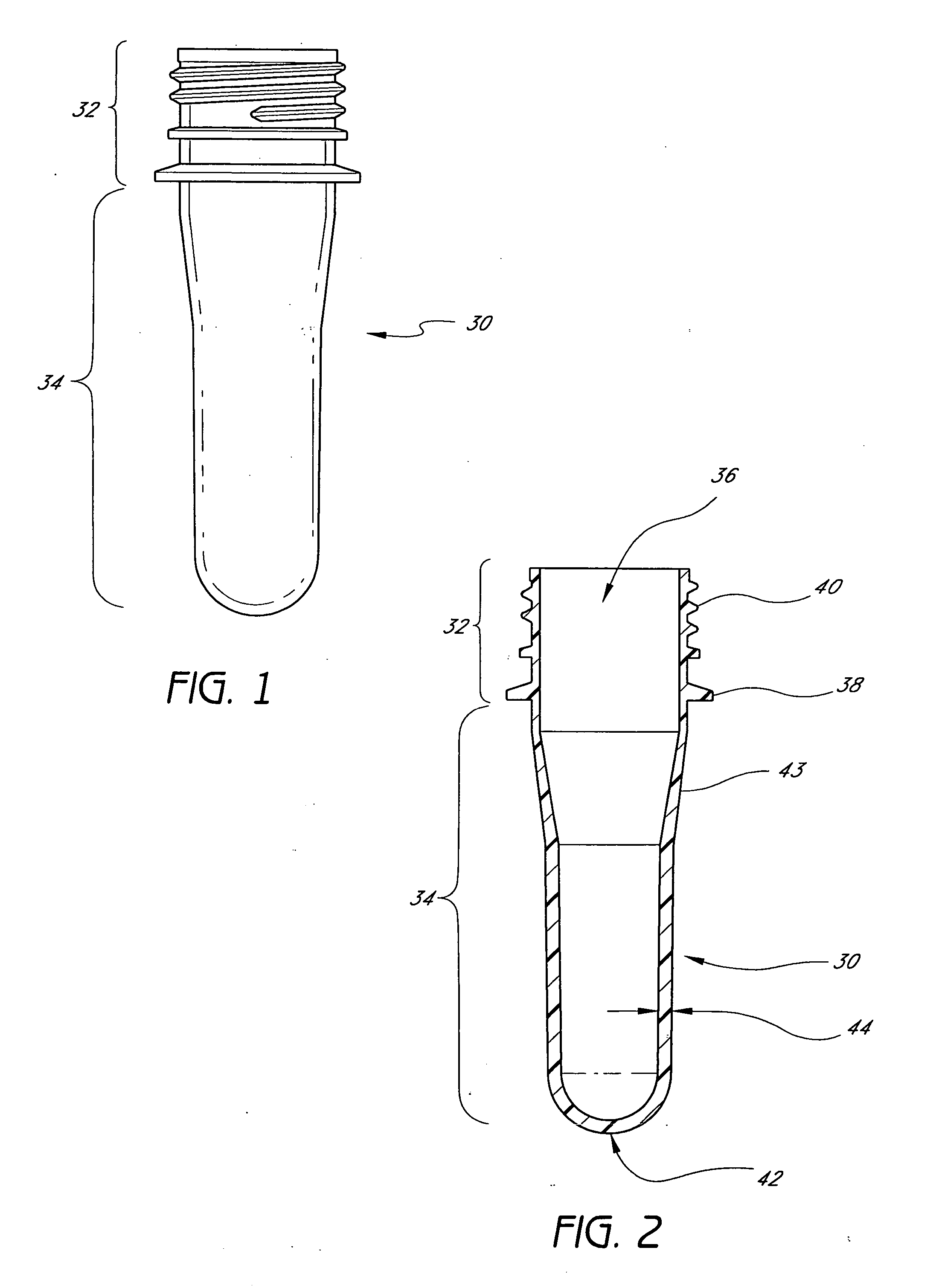

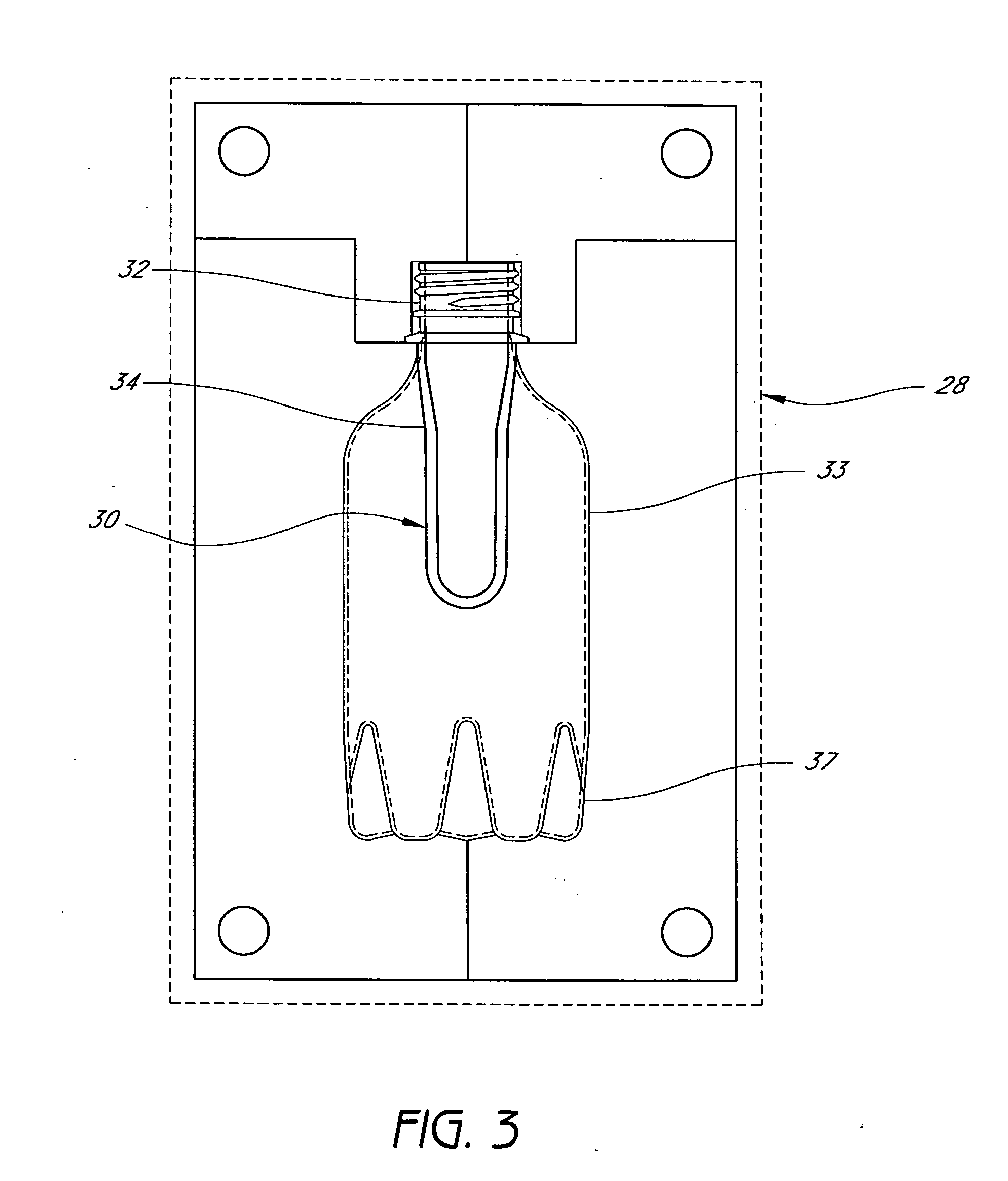

Mono and multi-layer articles and extrusion methods of making the same

InactiveUS20060073298A1Easy to processImprove melt strengthBottlesSynthetic resin layered productsThermoplasticPolyester

An extruded blow molded bottle comprises a neck portion and a body portion. The body portion comprises a first inner layer and a second layer. The first inner layer comprises a first material selected from a group consisting of polyester, phenoxy type thermoplastics, phenoxy-polyolefin thermoplastic blends, and combinations thereof. The second layer comprises a second material selected from a group consisting of virgin PET, recycled PET, PETG, foam, polypropylene, polyester, polyolefins, phenoxy type thermoplastic, phenoxy-polyolefin thermoplastic blends, regrind scrap materials, and combinations thereof. The second material is different from the first material.

Owner:PEPSICO INC +1

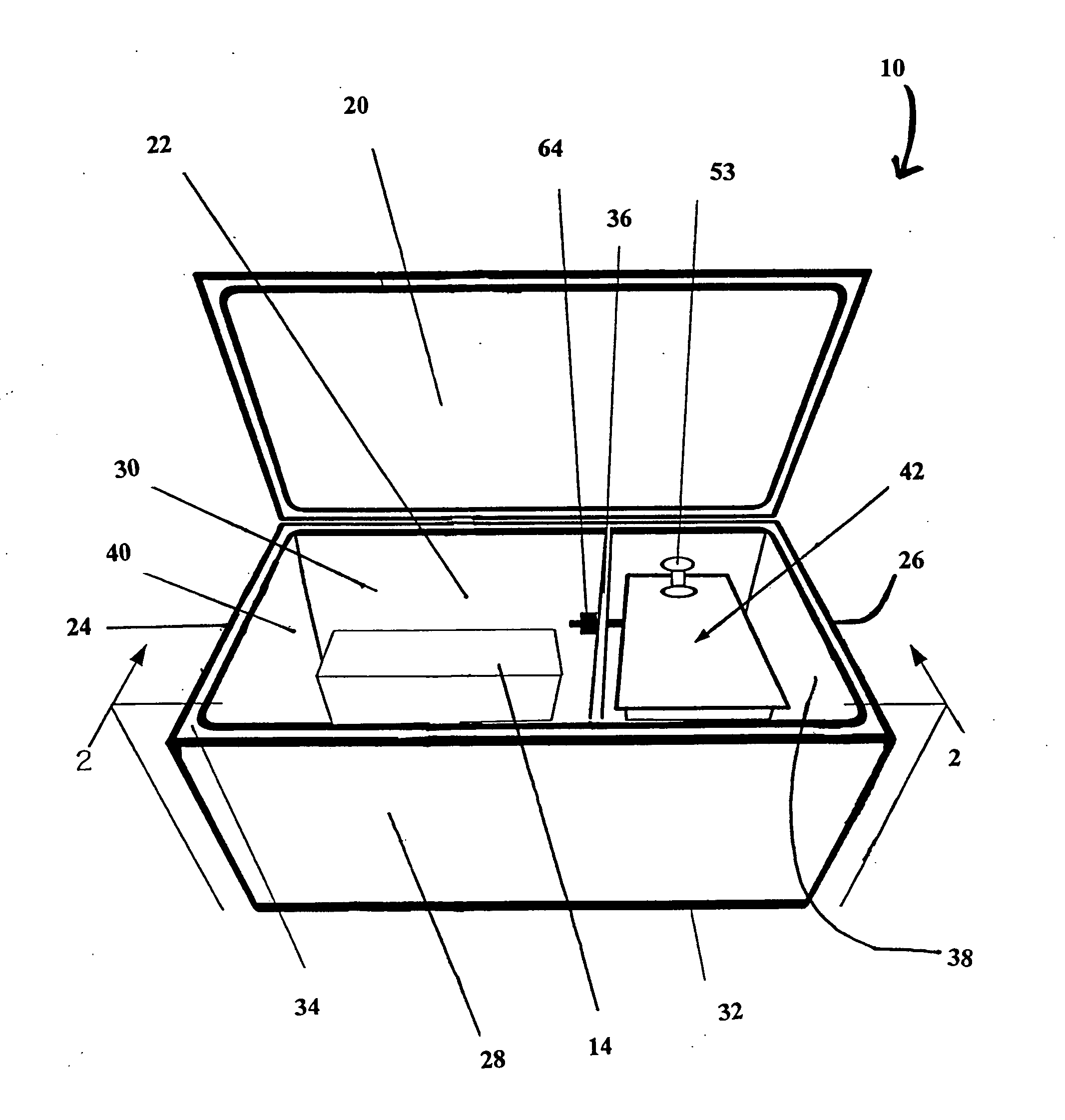

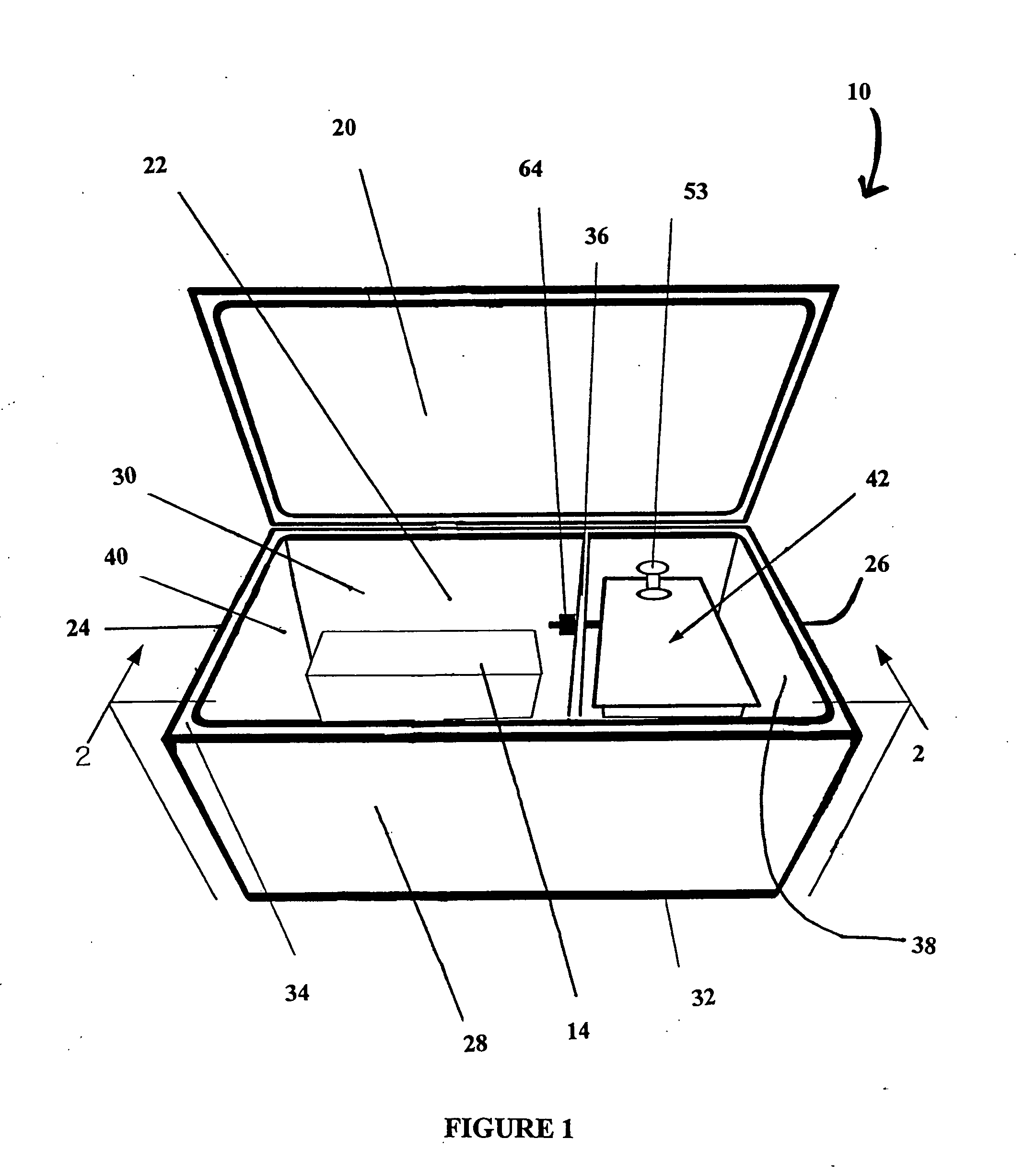

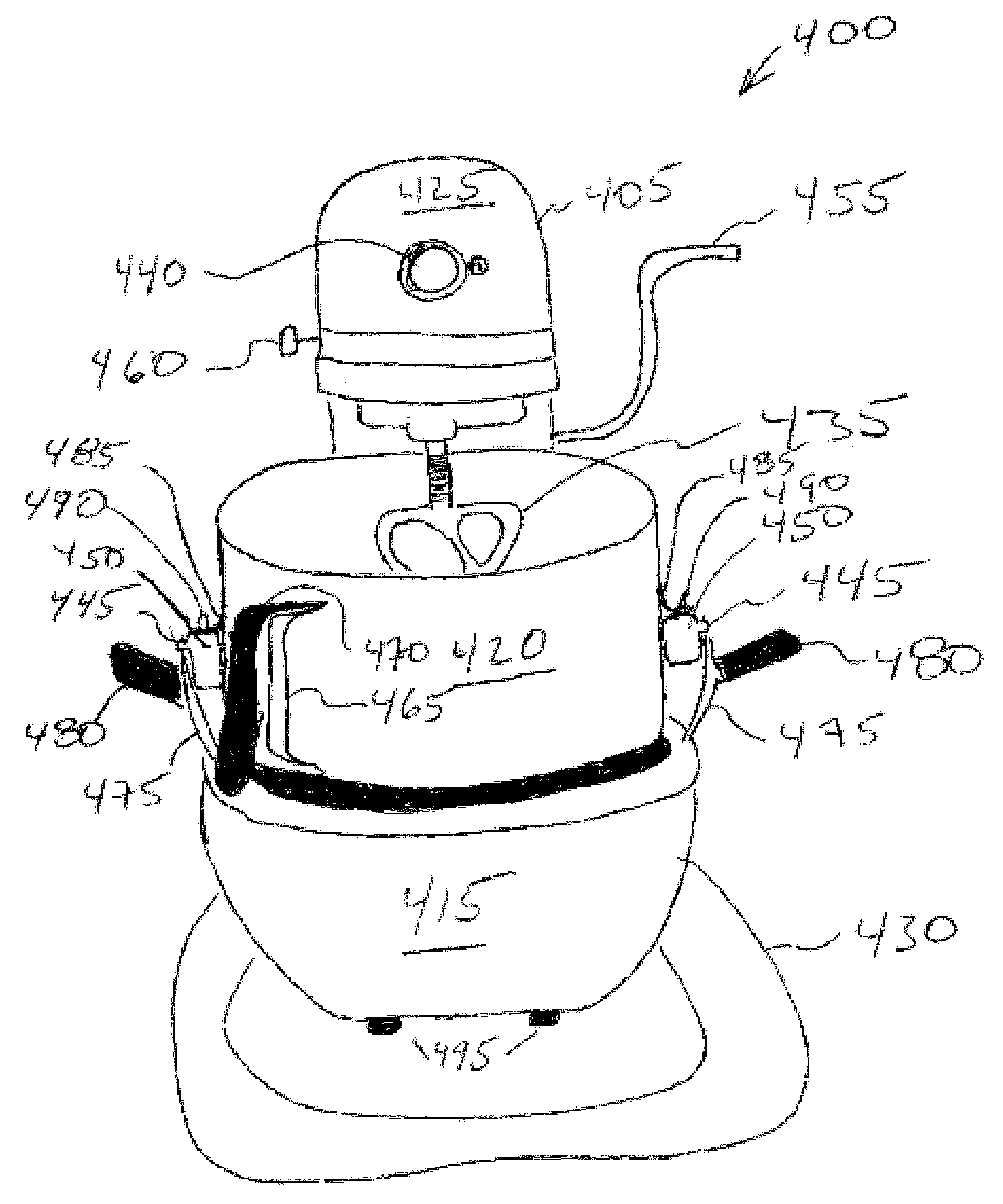

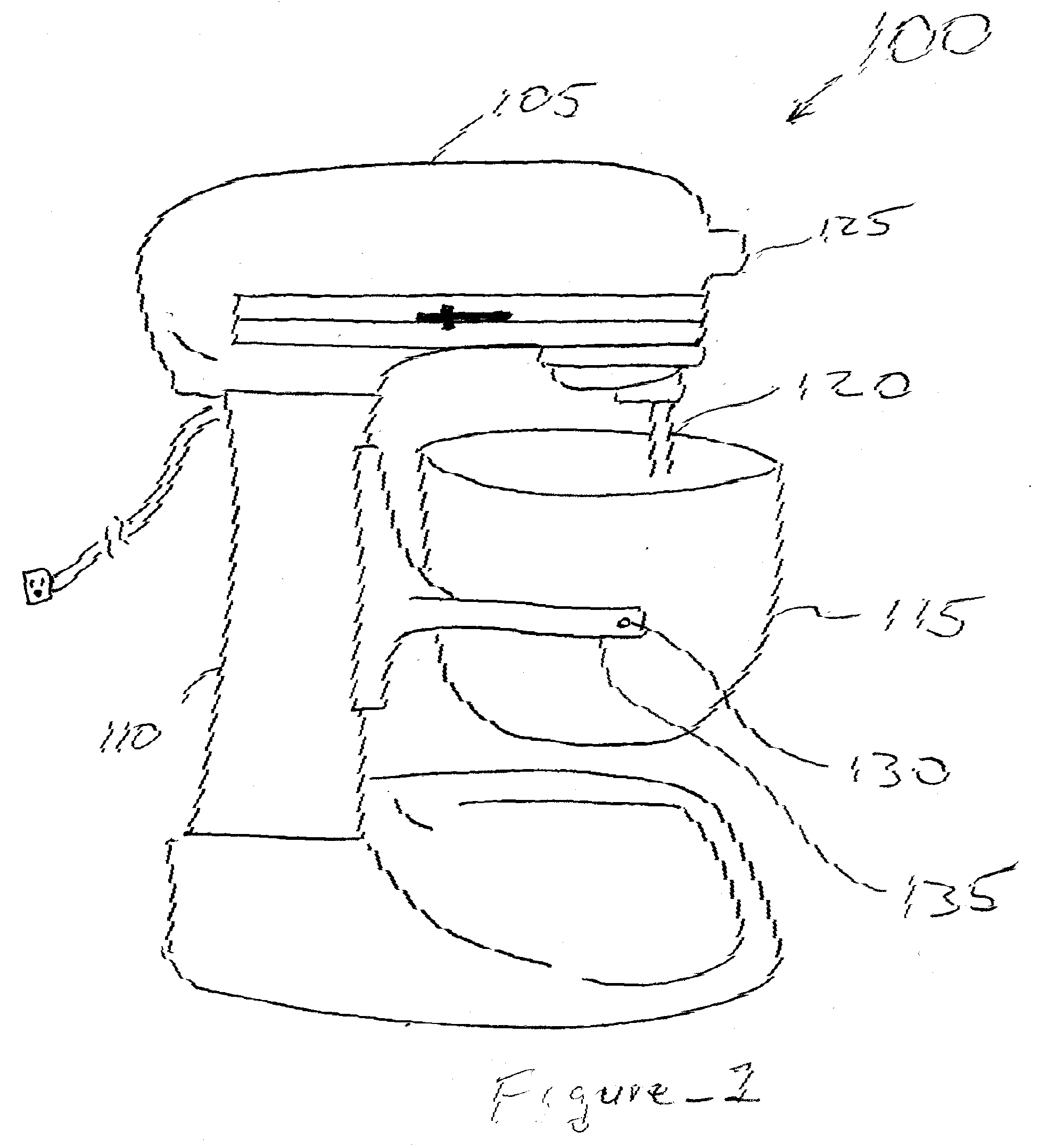

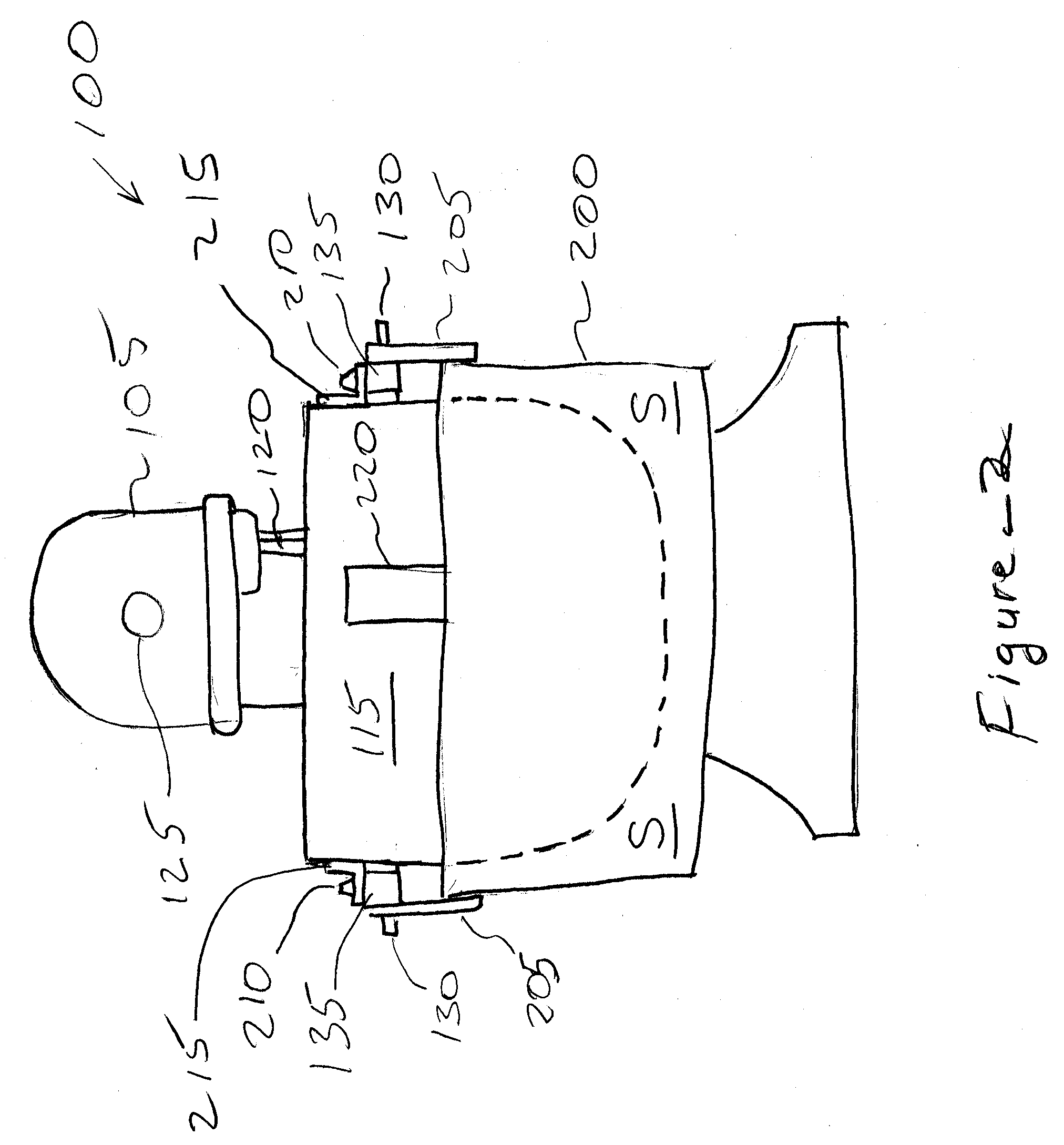

Method and system for producing a temperature profile in a food preparation container

InactiveUS20060044935A1Improve versatilityMaximize productionBoiling over preventionRotary stirring mixersEngineeringFood preparation

A temperature-controlled container includes a container having a temperature source incorporated into at least a portion of a sidewall of the container or into a retrofit influencer mounted proximate the container; and a power coupler, coupled to the temperature source, for receiving a power line coupled to a power source for operating the temperature source. In a preferred embodiment, the container is adapted to operate in conjunction with a power mixer. The method for processing one or more ingredients of a food recipe includes the steps of regulating a temperature source disposed in a wall of a container adapted for use with a mixing machine system, the container holding the one or more ingredients with the temperature source regulated to establish a desired temperature profile for the container appropriate for the recipe and / or the ingredients, the temperature source coupled to a power source through a power line coupled to an exterior port of the wall; and engaging the container with the mixing machine system; and thereafter operating the mixing machine system while the temperature source is being regulated.

Owner:BENELLI BRANDON P +3

Controlled densification of fusible powders in laser sintering

ActiveUS20060119012A1Heat dissipationSimple methodAdditive manufacturing apparatusAuxillary shaping apparatusHigh energyLaser scanning

The invention relates to a method producing parts using laser sintering wherein a fusible powder is exposed to a plurality of laser scans at controlled energy levels and for time periods to melt and densify the powder and in the substantial absence of particle bonding outside the fusion boundary. Strength is improved up to 100% compared to previous methods. An example includes a relatively high energy initial scan to melt the powder followed by lower energy scans controlled to densify the melt and separated in time to dissipate heat to the surrounding part cake. The rate and extent to which the powder particles are fused together can be controlled so that each successive scan can be used to fuse the particles together in discreet incremental steps. As a result, the final dimensions of the part and its density and mechanical properties can be improved compared to conventional methods and part growth avoided.

Owner:3D SYST INC

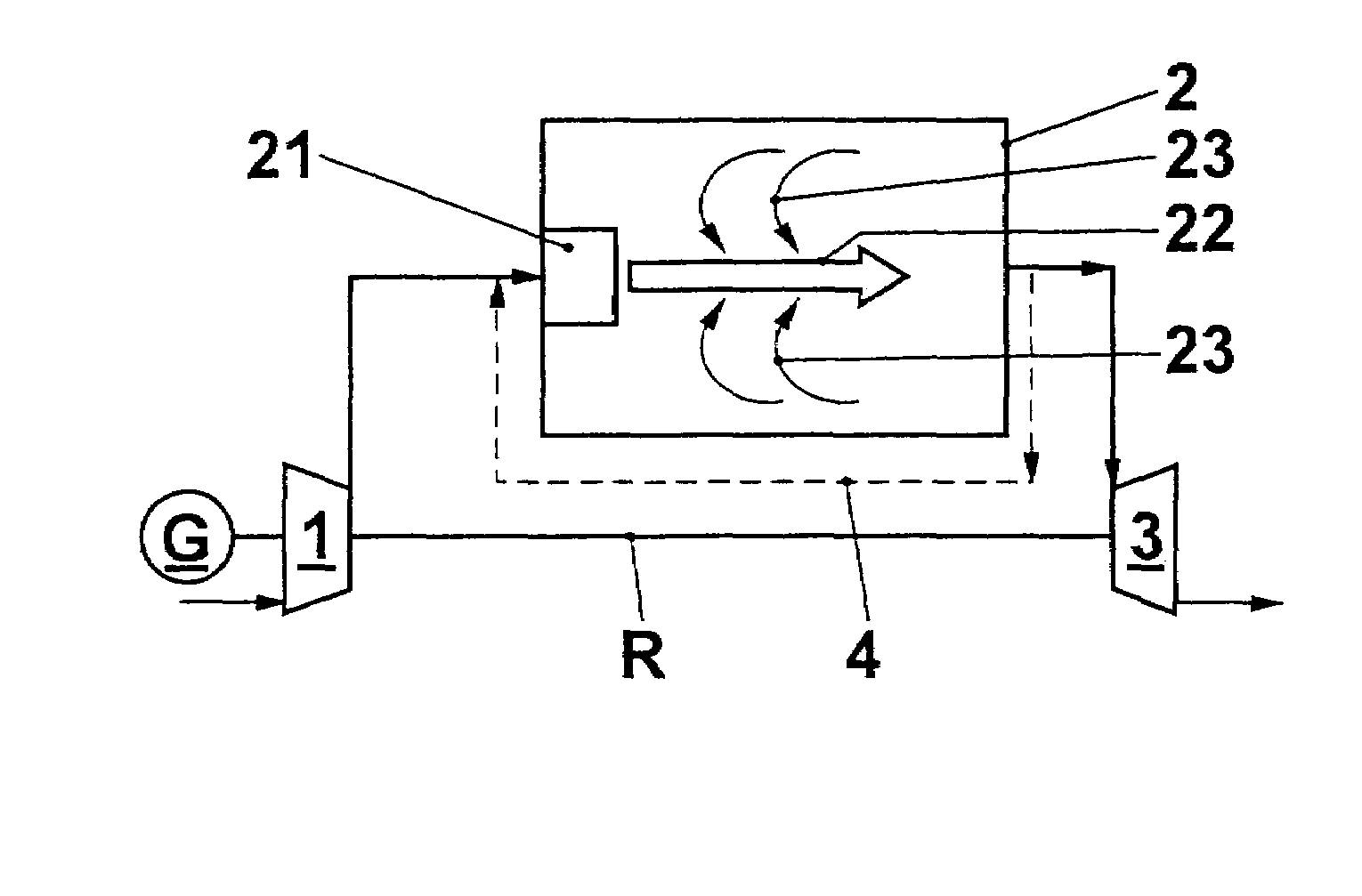

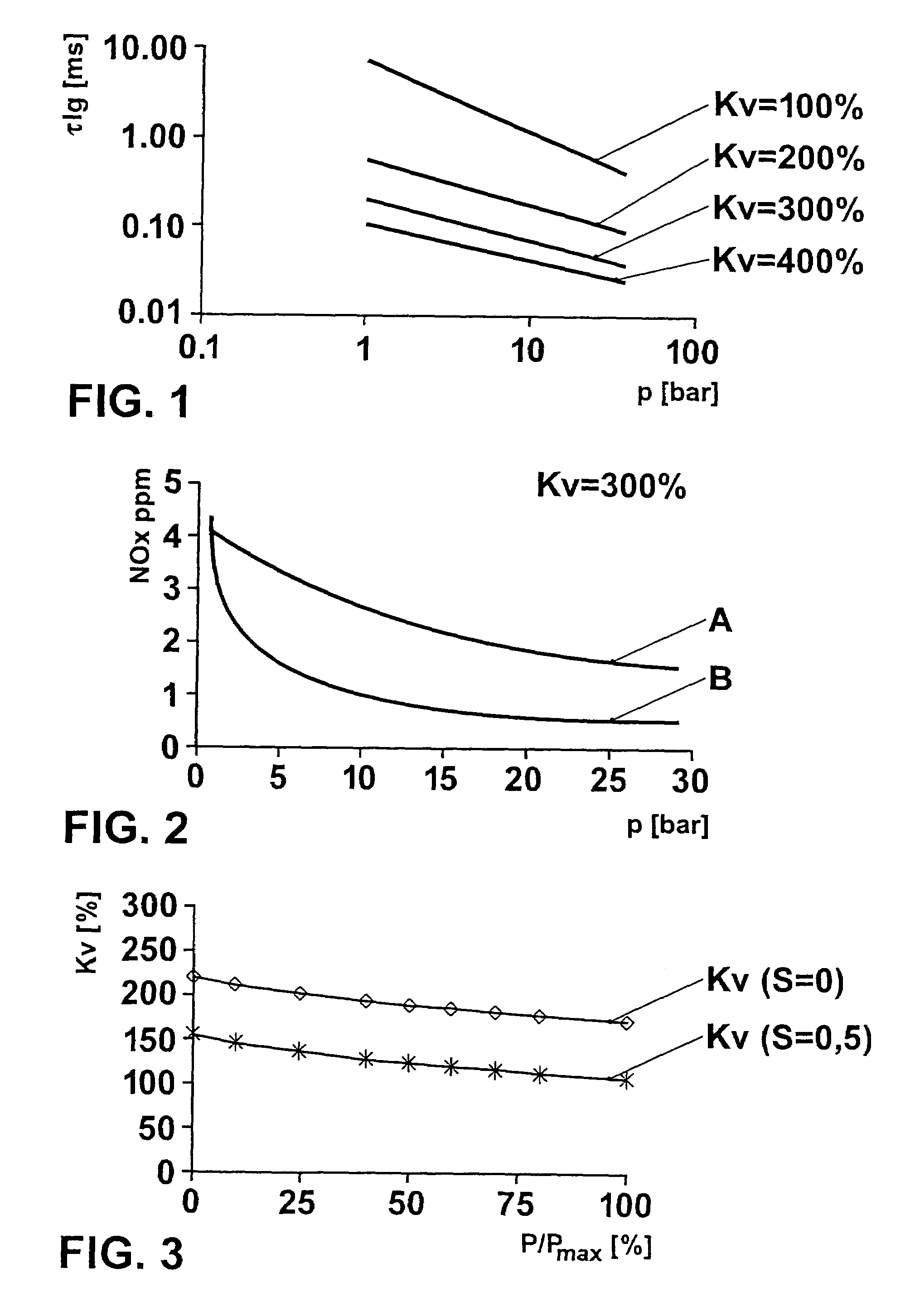

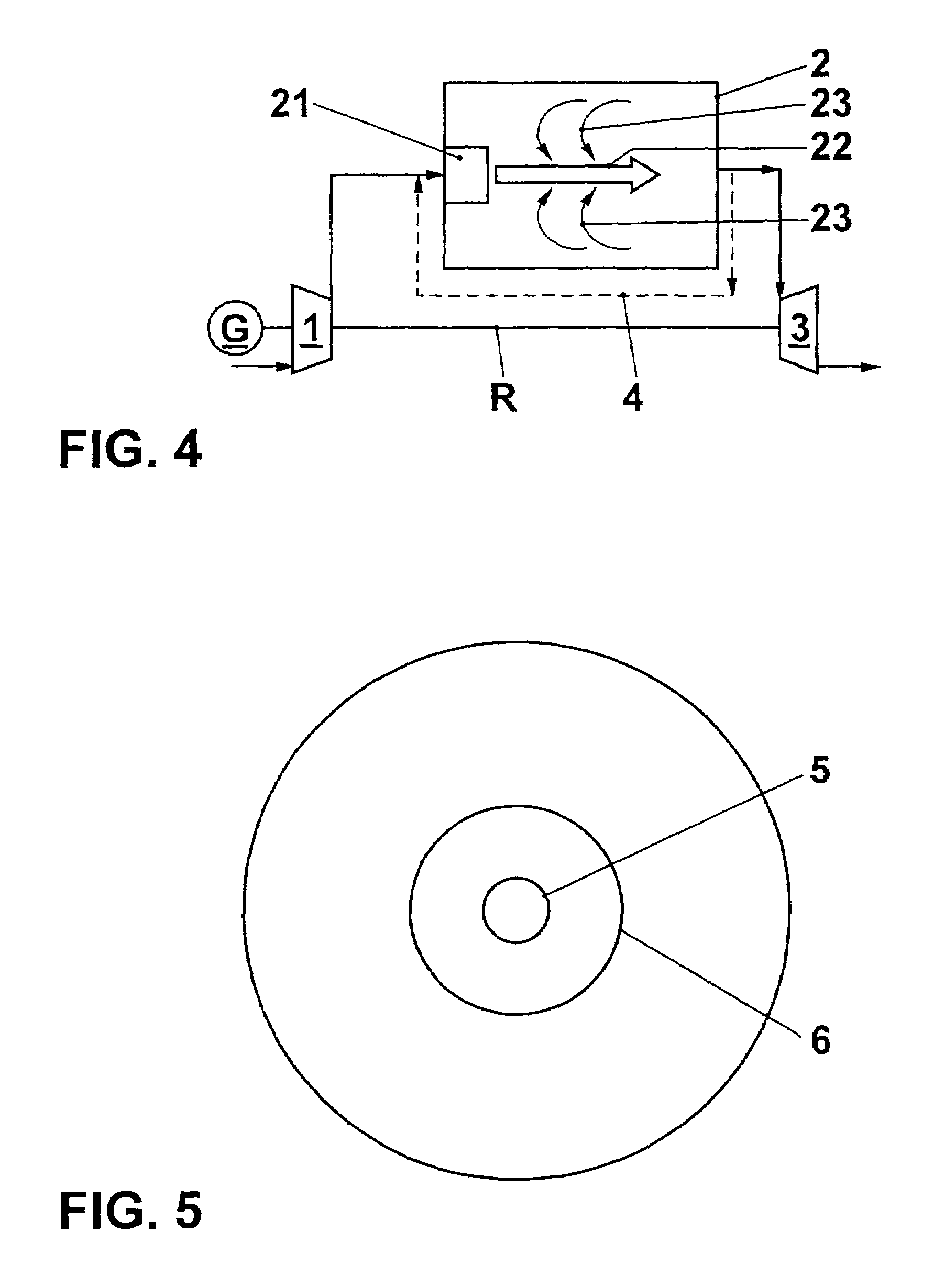

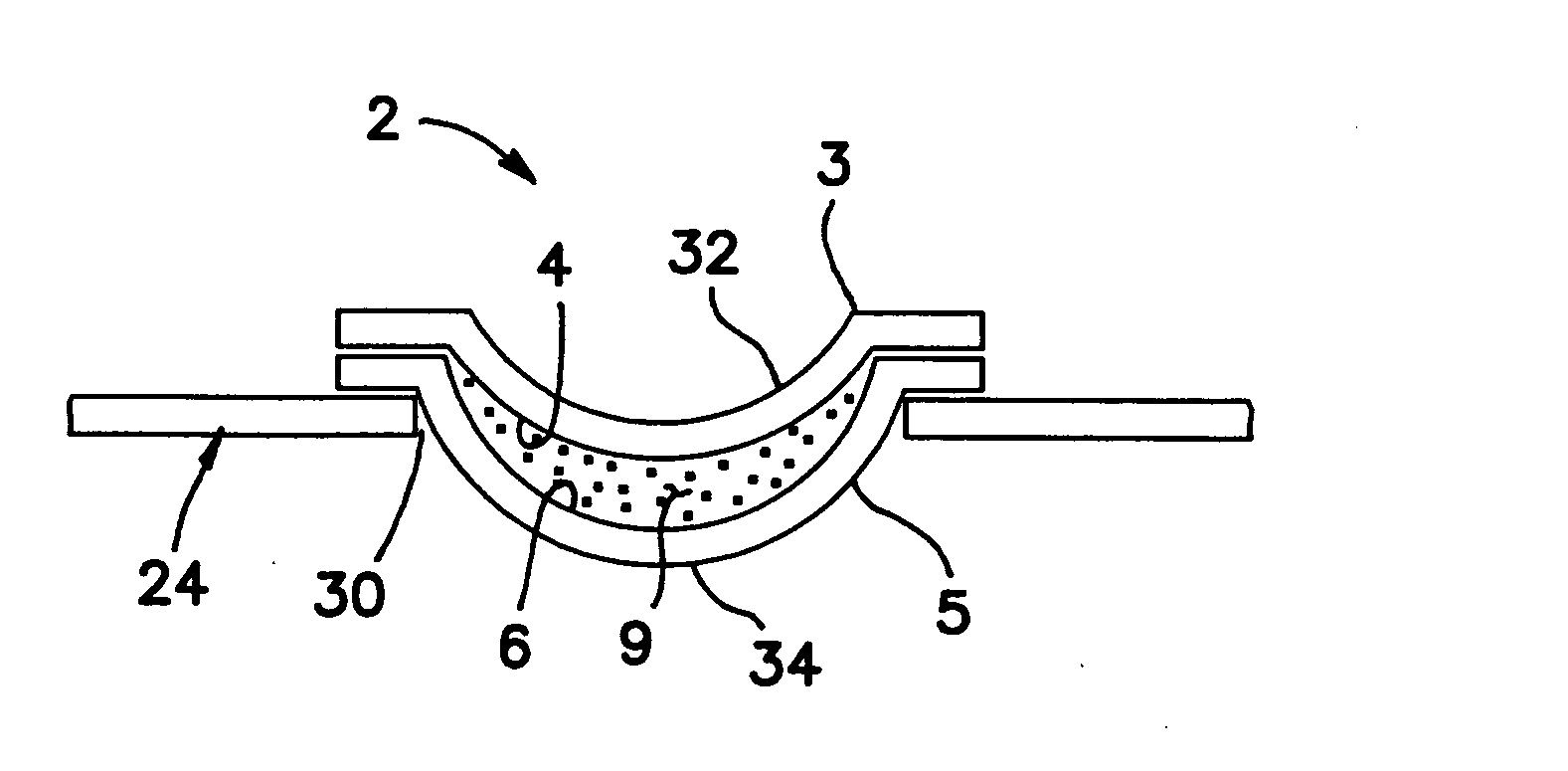

Method for combustion of a fuel

InactiveUS7363756B2Increase speedAccelerated dilutionContinuous combustion chamberGas turbine plantsCombustion chamberFront velocity

In a method for the combustion of a fuel, a fuel or a premixed combustible mixture is introduced into a combustion space as a combustible fluid open jet. The velocity of the open jet is selected in such a way that it is impossible for a stable flame front to form, i.e. is in any event greater than the flame front velocity, and that, on account of a jet pump effect, flue gas is mixed into the combustible fluid jet from the combustion chamber in a jet-induced recirculation internally within the combustion chamber. The admixed flue gas dilutes and heats the combustible fluid. The heating causes the spontaneous ignition temperature to be exceeded, and a low-pollutant volumetric flame is formed in a highly dilute atmosphere.

Owner:ANSALDO ENERGIA SWITZERLAND AG

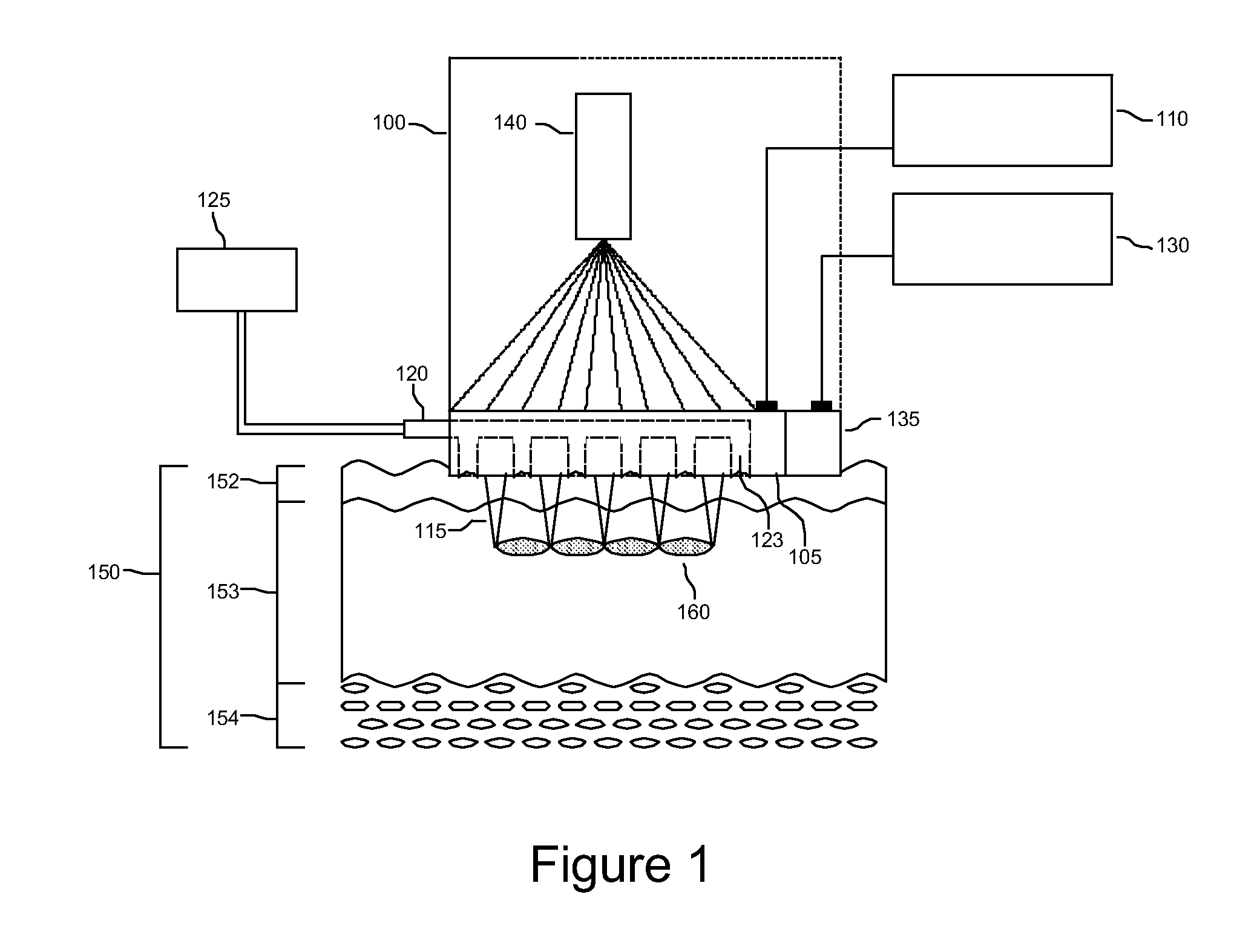

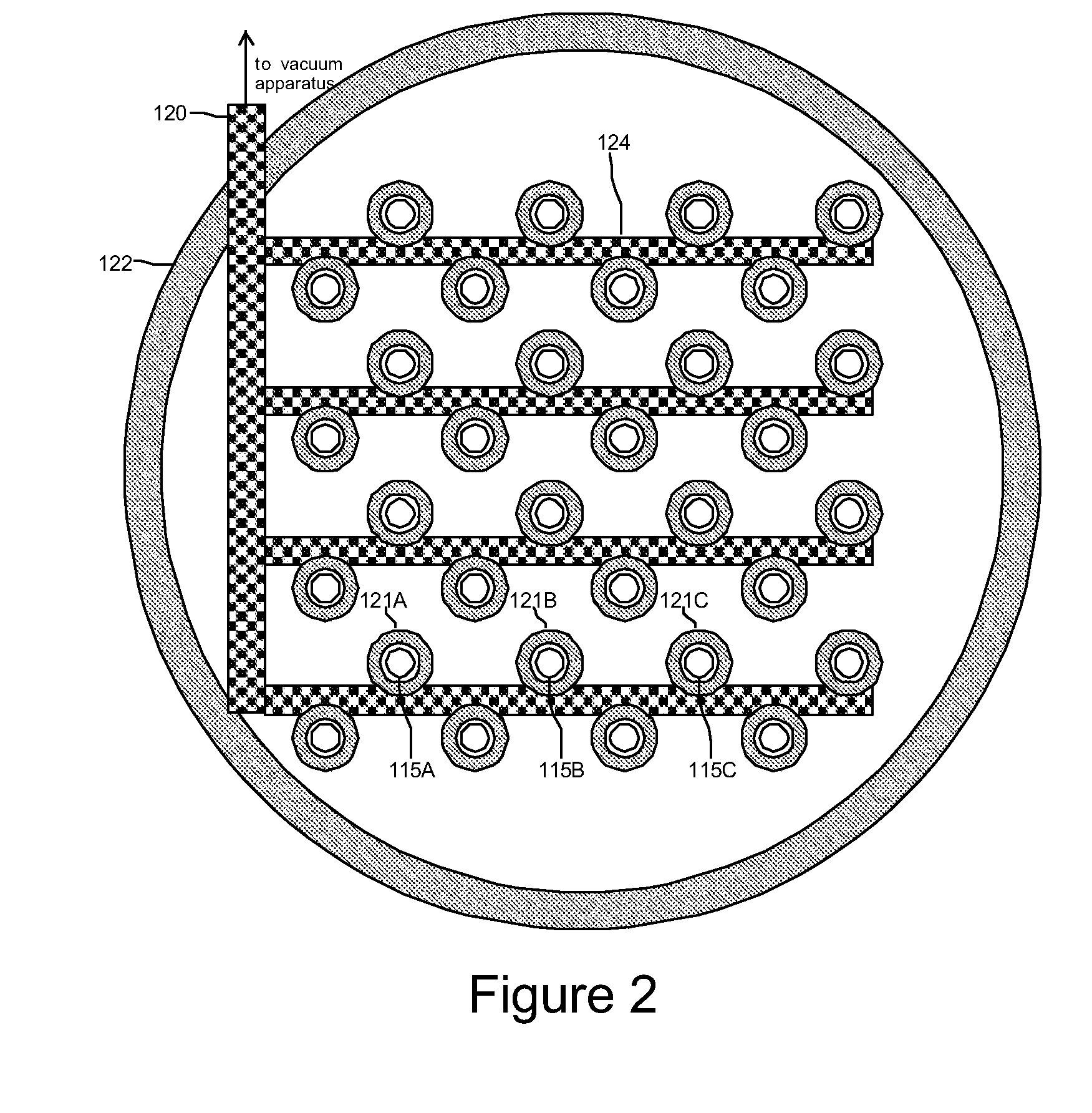

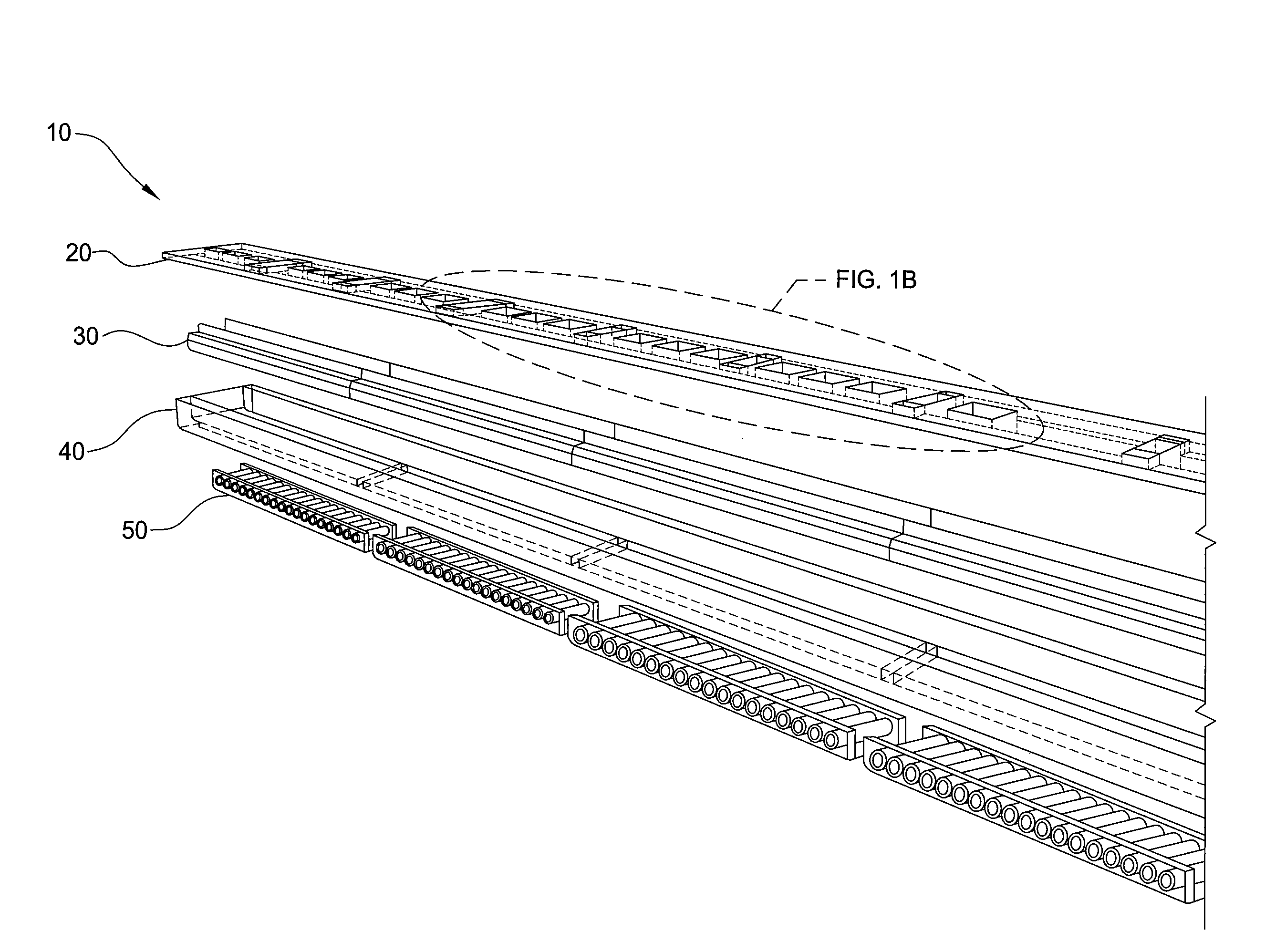

Systems and methods for producing contact lenses from a polymerizable composition

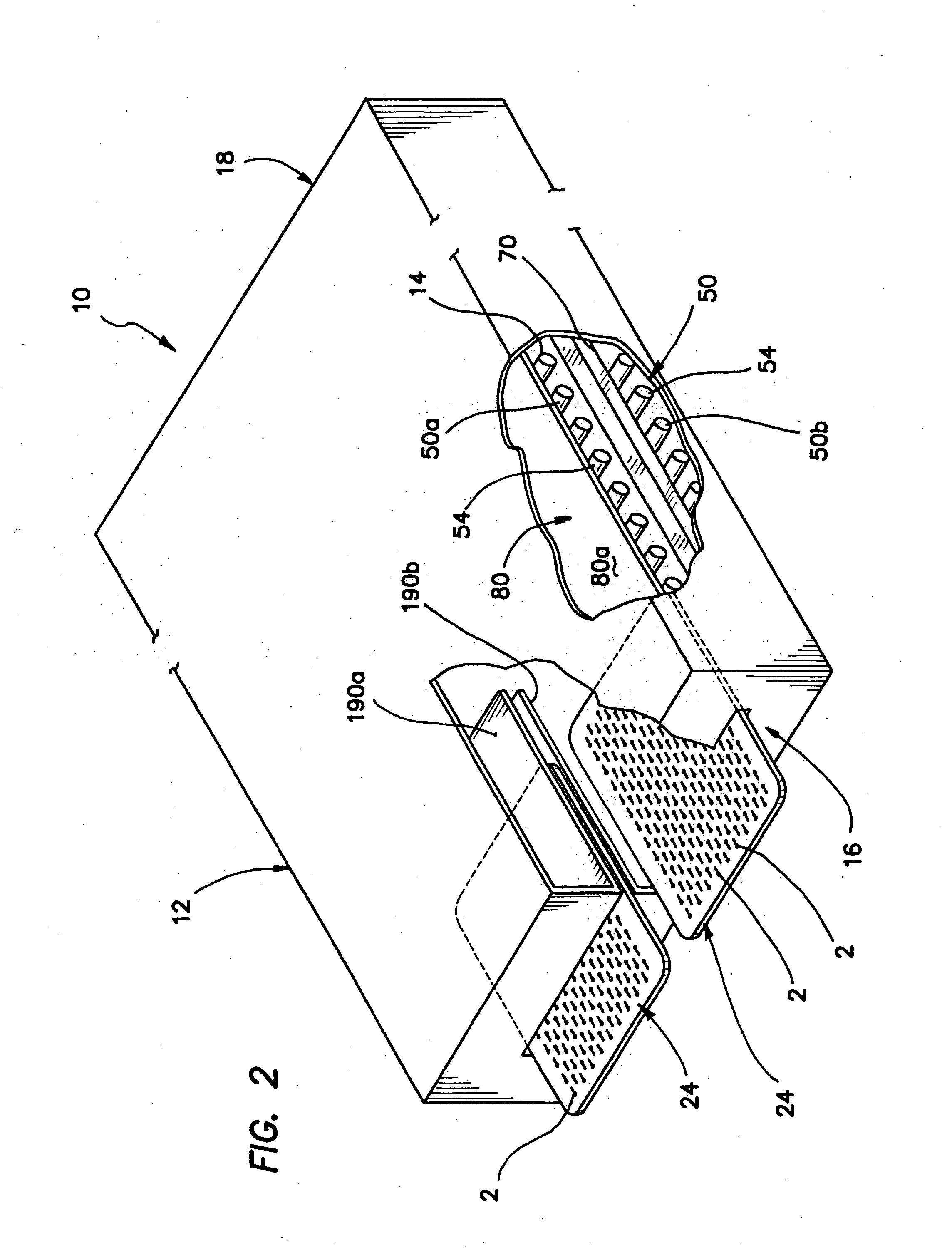

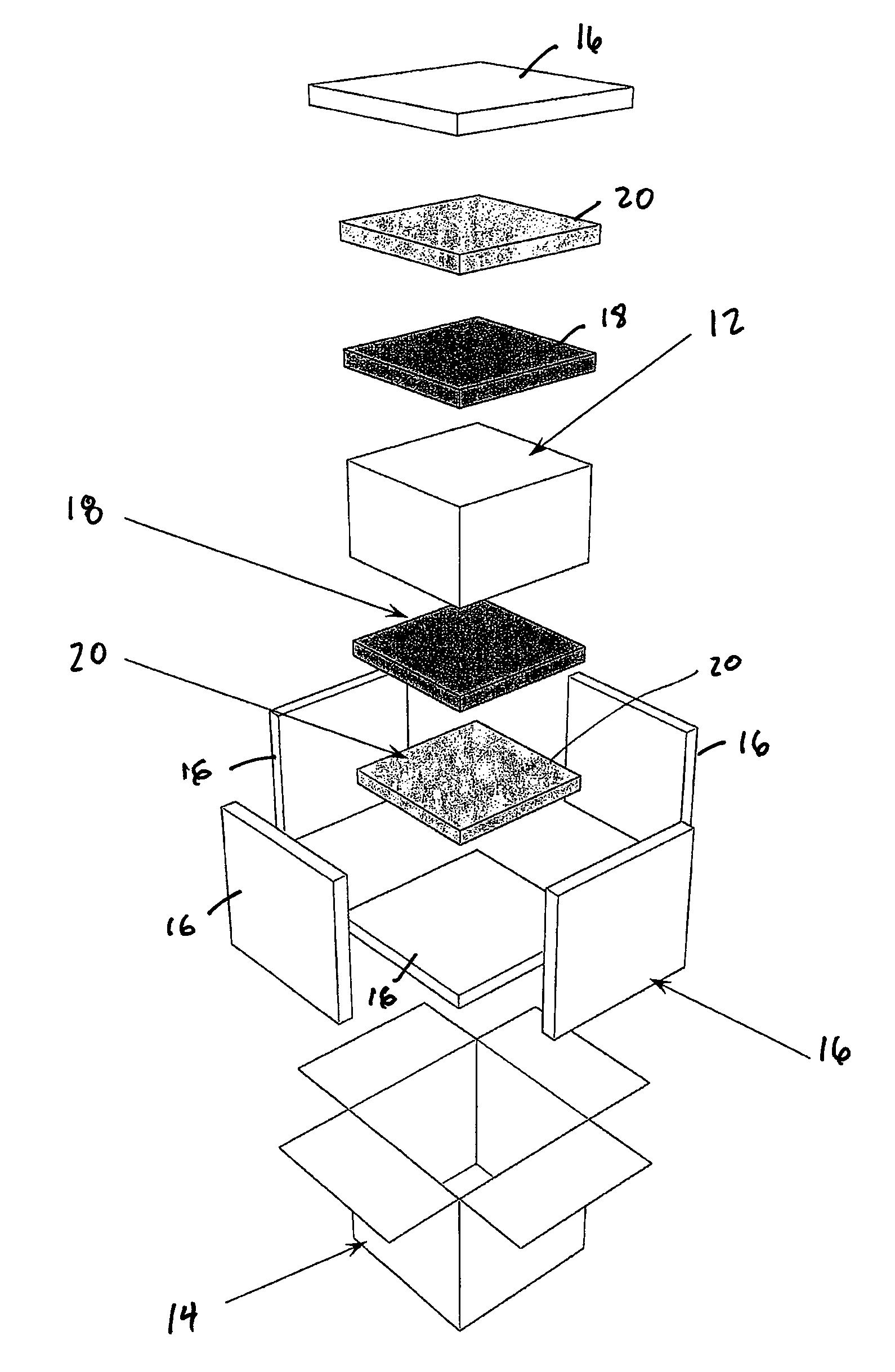

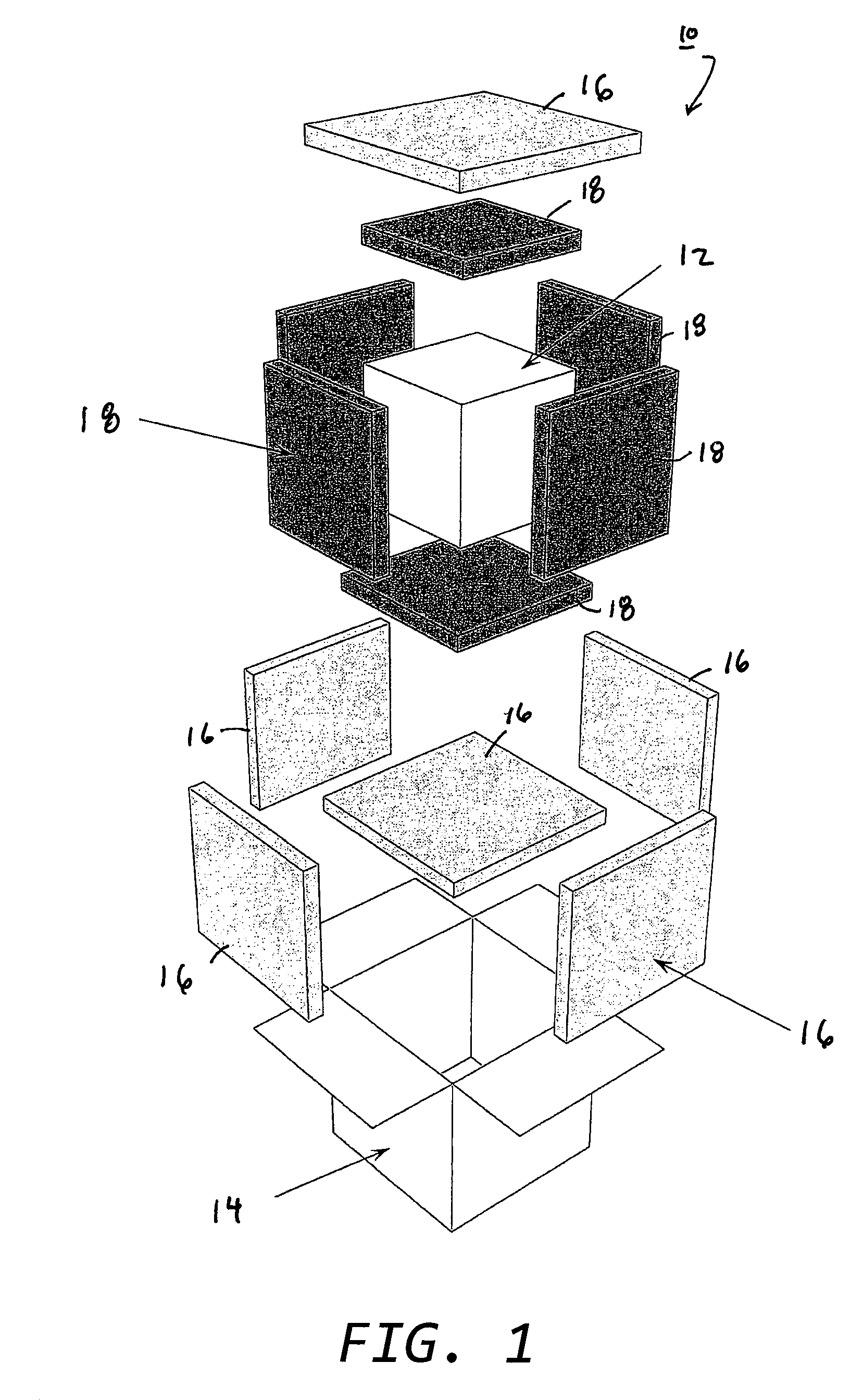

ActiveUS20070035050A1Minimizing lens distortionImproving edge shapeConfectioneryOptical articlesMonomer compositionLight energy

Systems and methods of manufacturing ophthalmic lenses, for example, soft, extended wear silicone hydrogel contact lenses, are provided. The systems generally include a housing having an illuminated chamber, a carrier, for example a tray, movable in the illuminated chamber from an inlet portion to an outlet portion of the housing, and the tray configured to carry a plurality of contact lens molds. Polymerizing light energy is provided, for example, by multiple fluorescent lamps, to the molds at an intensity effective to at least initiate polymerization of a monomer composition located in each of the molds. The light may be illuminated onto two opposing sides of each mold. In some cases, the intensity of the light provided to one side of the mold may be different to the light intensity provided to the opposing side of the mold. In addition, the system may include features that are effective to provide for an instantaneous start and an instantaneous end to the light induced cure of the monomer in the molds. The system may include DALI protocol based technology for controlling the fluorescent lamps.

Owner:COOPERVISION INT LTD +1

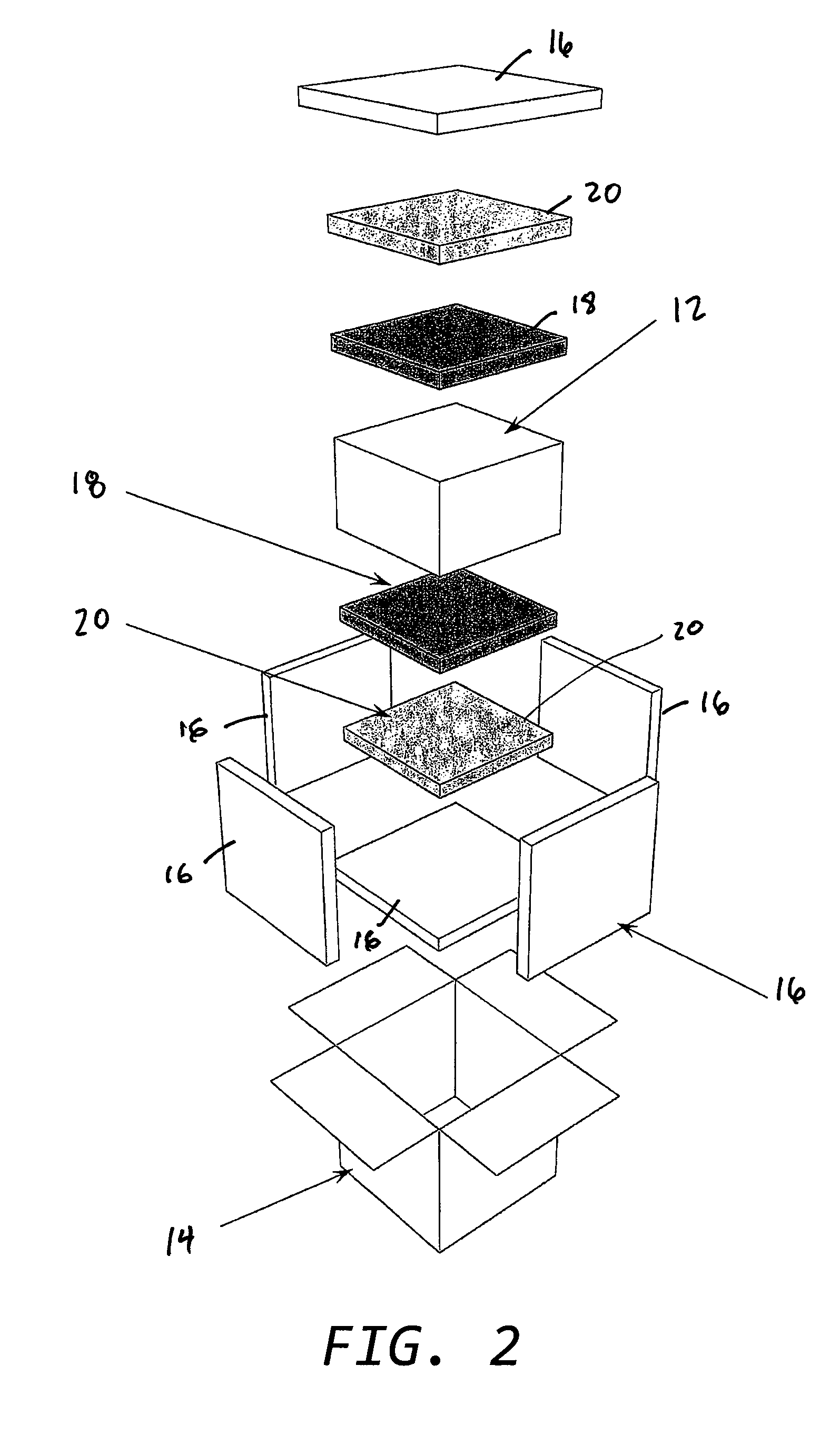

Package having phase change materials and method of use in transport of temperature sensitive payload

ActiveUS7908870B2Maintain temperatureLighting and heating apparatusContainer/bottle contructionThermal insulationEngineering

Owner:ENTROPY SOLUTIONS

Ice making and dispensing system

ActiveUS20060086132A1Maintain temperatureDomestic refrigeratorsRefrigeration componentsCold storeRefrigerated temperature

An ice making and dispensing system suitable for making and dispensing ice through the refrigerator compartment door of a bottom freezer refrigerator. The ice maker is positioned in an insulated sub-compartment in the refrigerator compartment maintained at a temperature below 0° C. An insulated ice cube storage bin and ice dispenser are positioned on the refrigerator compartment door for dispensing ice cubes through the face of the refrigerator compartment door.

Owner:WHIRLPOOL CORP

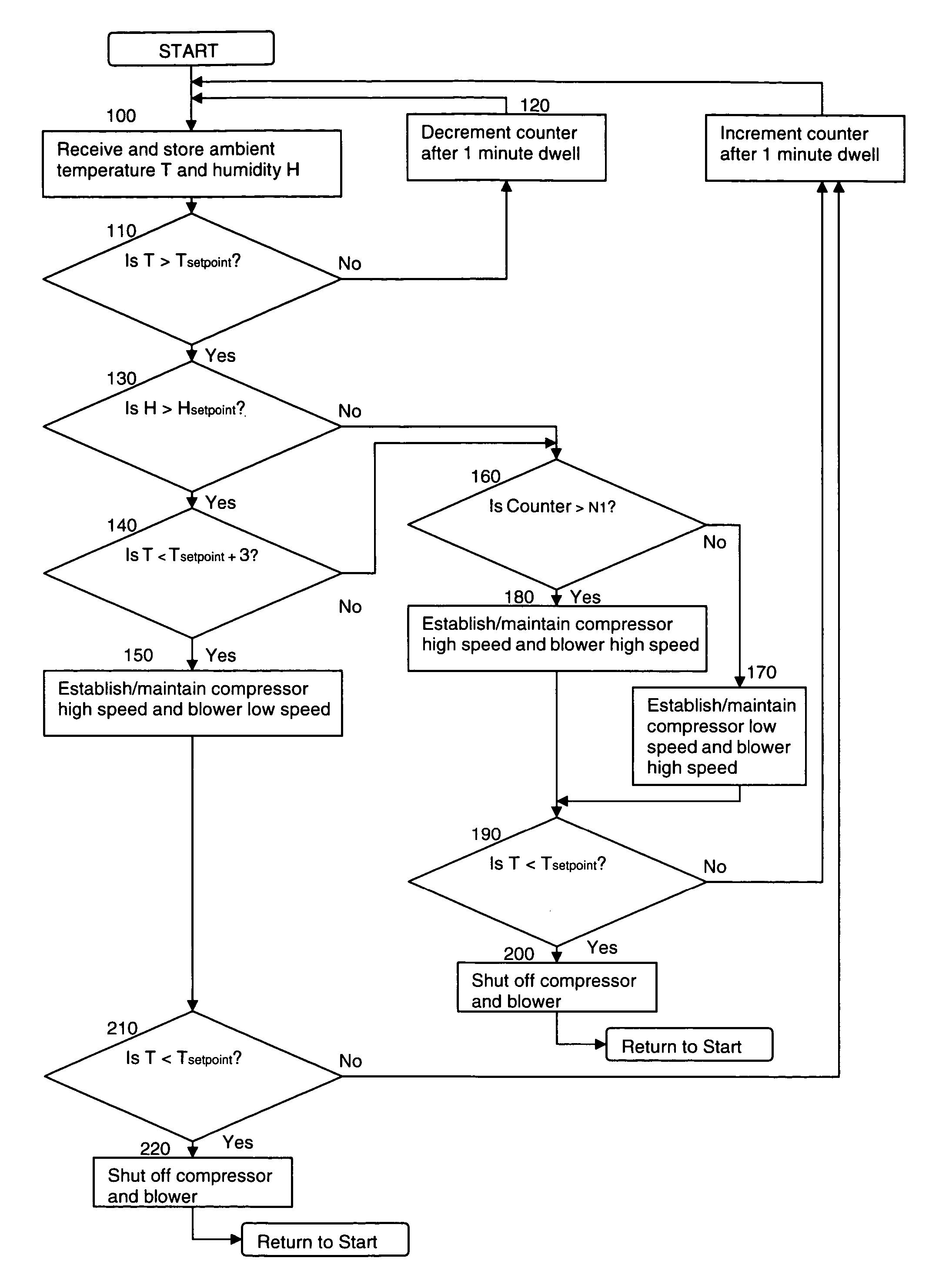

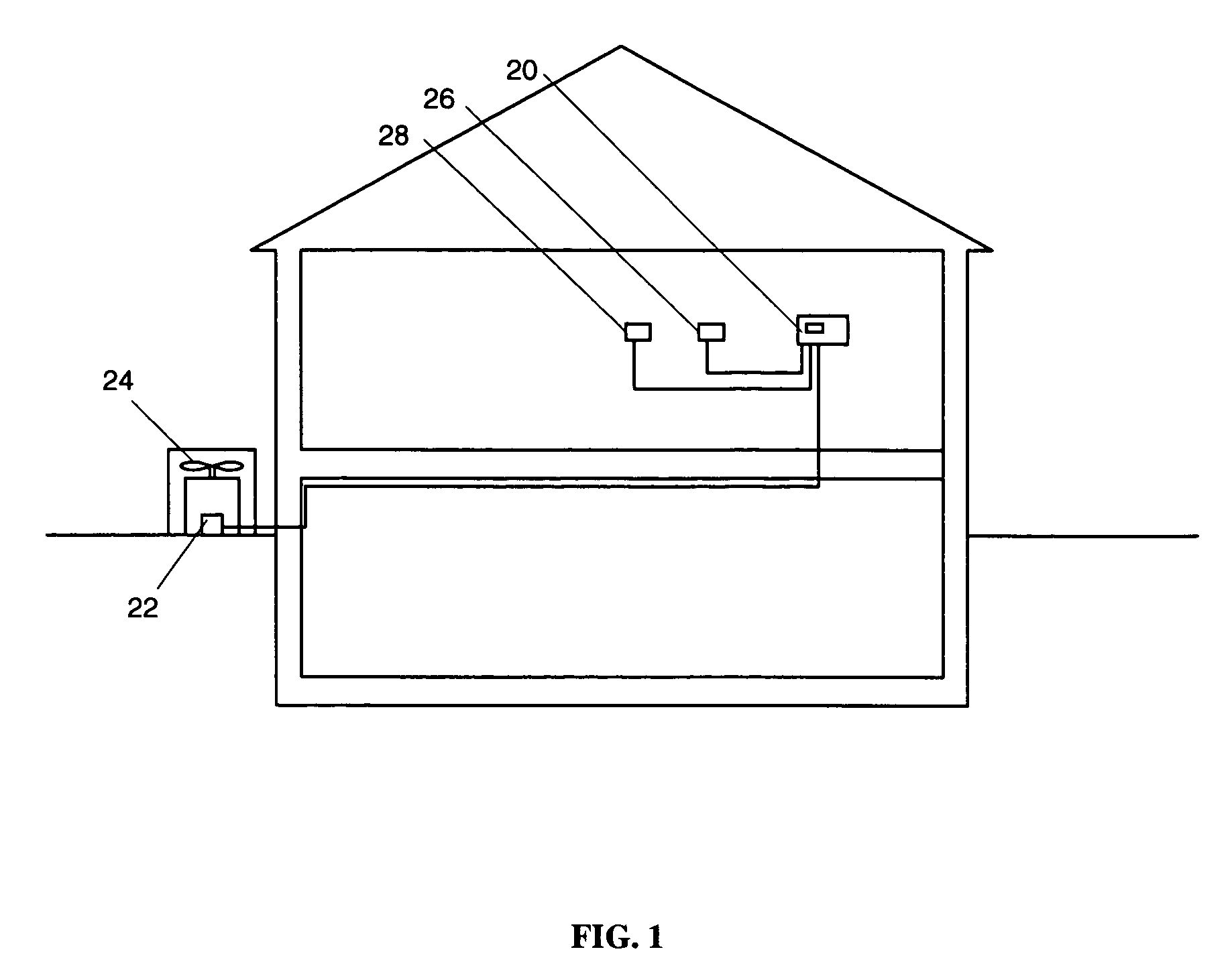

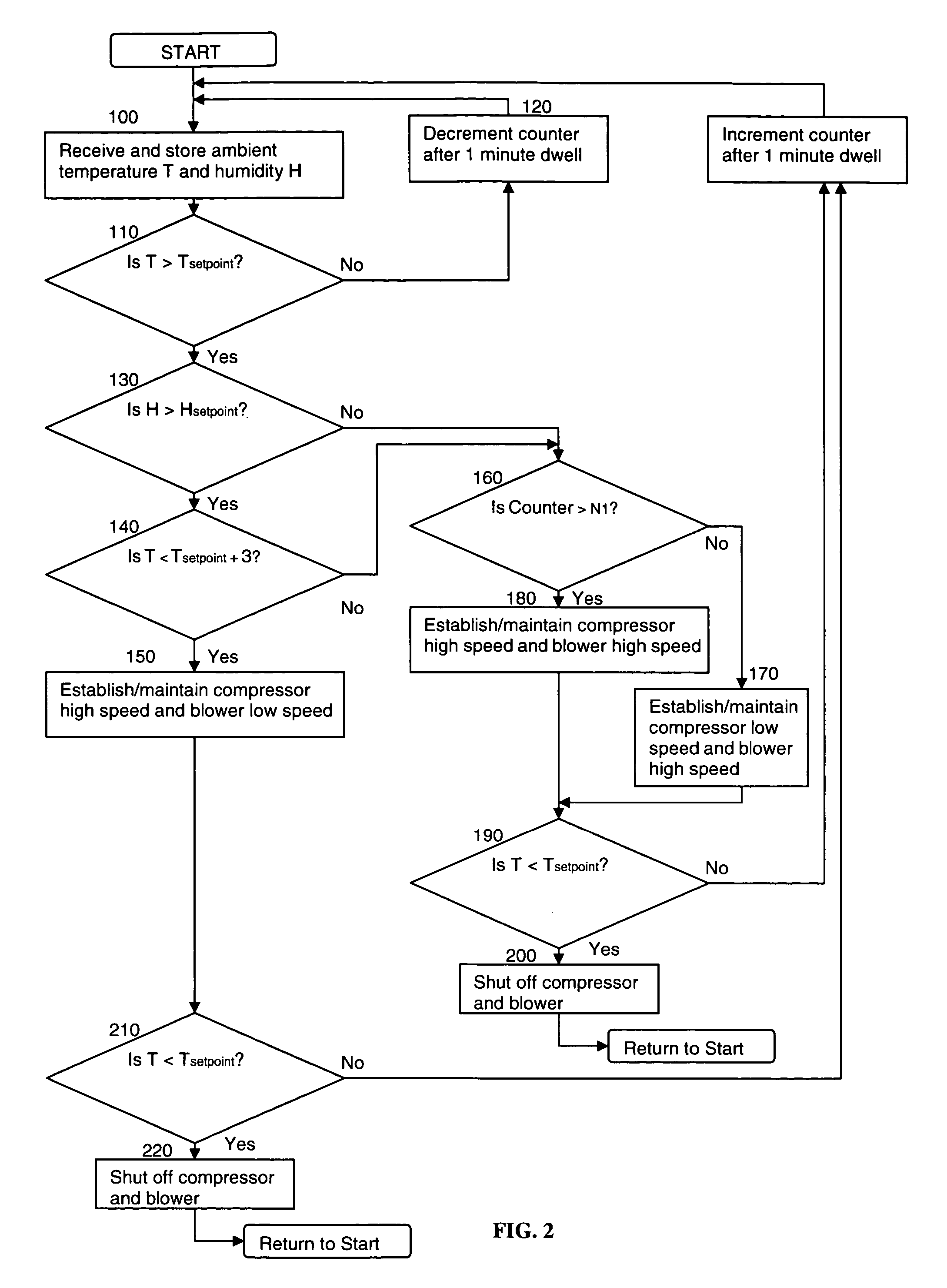

Thermostat and method for operating in either a normal or dehumidification mode

InactiveUS20060260334A1Speed up dehumidificationMaintain temperatureMechanical apparatusSpace heating and ventilation safety systemsMarine engineeringThermostat

The inventive thermostat provides for sensing the temperature and humidity within the space, and responsively controlling the operation of an air conditioning compressor and blower to maintain the desired temperature and humidity. In a first mode, the thermostat operates the compressor at maximum capacity and the blower at less than maximum capacity to provide dehumidification when the humidity level is above a set point. In a second mode, the thermostat operates the compressor and blower at maximum capacity to provide full cooling capacity when the sensed temperature is more than a predetermined amount above the desired temperature setting. The thermostat is also configured to automatically switch from the first mode of operation to the second mode of operation.

Owner:EMERSON ELECTRIC CO

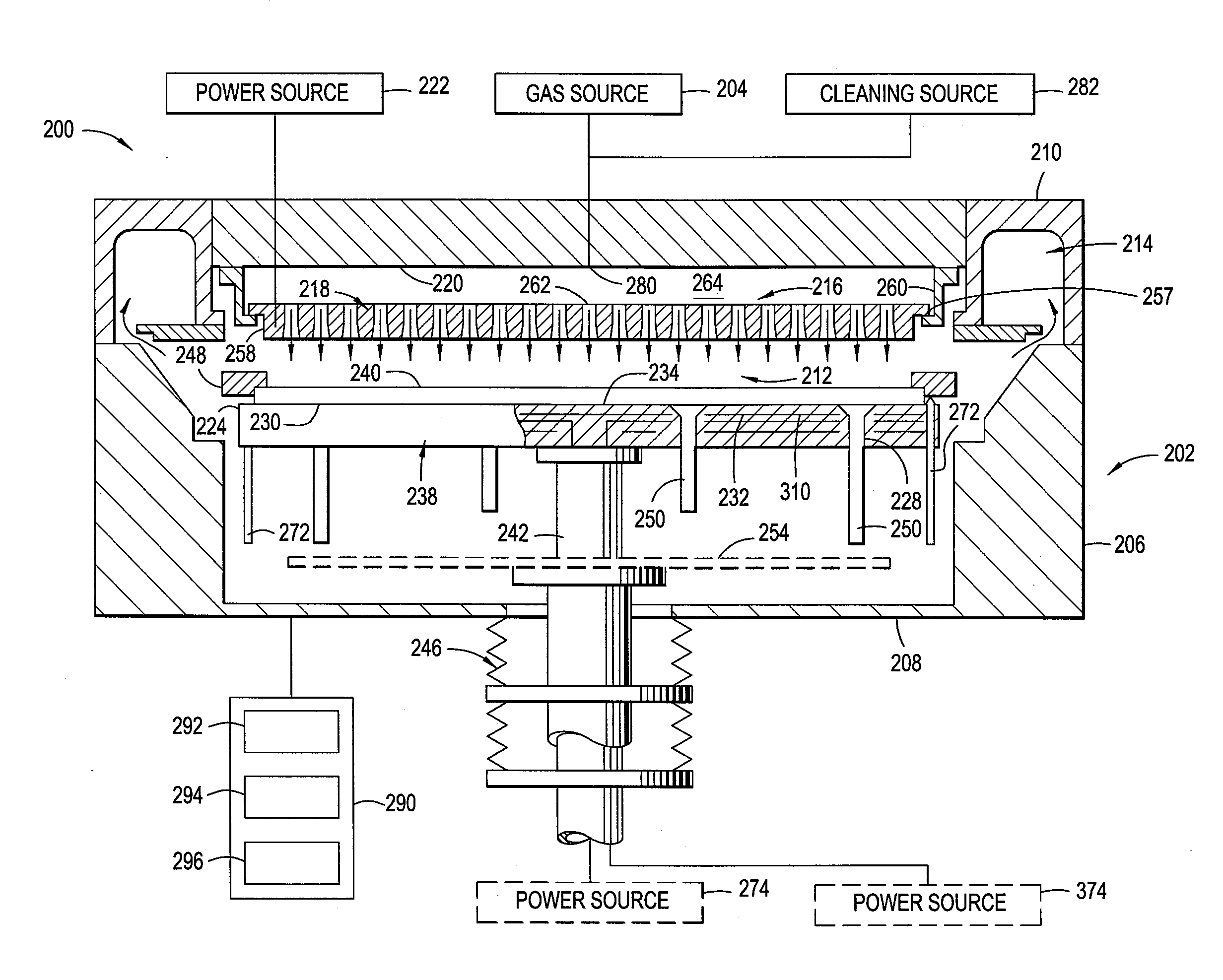

Methods and apparatus for a chemical vapor deposition reactor

ActiveUS20090324379A1Avoid enteringAvoid mixingPolycrystalline material growthLiquid surface applicatorsEngineeringChemical vapor deposition

Embodiments of the invention generally relate to a levitating substrate carrier or support. In one embodiment, a substrate carrier for supporting and carrying at least one substrate or wafer is provided which includes a substrate carrier body containing an upper surface and a lower surface, and at least one indentation pocket disposed within the lower surface. In another embodiment, the substrate carrier includes at least open indentation area within the upper surface, and at least two indentation pockets disposed within the lower surface. Each indentation pocket may be rectangular and have four side walls extending substantially perpendicular to the lower surface. In another embodiment, a method for levitating substrates disposed on a substrate carrier is provided which includes exposing the lower surface of a substrate carrier to a gas stream, forming a gas cushion under the substrate carrier, levitating the substrate carrier within a processing chamber, and moving the substrate carrier along a path within the processing chamber.

Owner:ALTA DEVICES INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com