Patents

Literature

1118results about How to "Improve melt strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High melt strength polypropylene

InactiveUS7365136B2Improve melt strengthHigh viscosityChemical/physical/physico-chemical stationary reactorsPolymer sciencePtru catalyst

The present invention concerns a high melt strength propylene polymer or copolymer suitable for manufacturing foams and thermoformed product exhibiting a melt strength of at least 3 g and comprising a high molar mass portion and a low or medium molar mass portion. The polymers are produced by subjecting propylene and optionally other olefins to polymerization in a plurality of polymerization reactors connected in series, employing different amounts of hydrogen as a molar mass modifier in at least two of the reactors, and carrying out the polymerization reaction in the presence of a catalyst system capable of catalyzing the formation of a high molar mass polymerization product having a MFR2 of less than 0.1 g / 10 min and a low or medium molar mass polymerization product having a MFR2 of more than 0.5 g / 10 min.

Owner:BOREALIS TECH OY

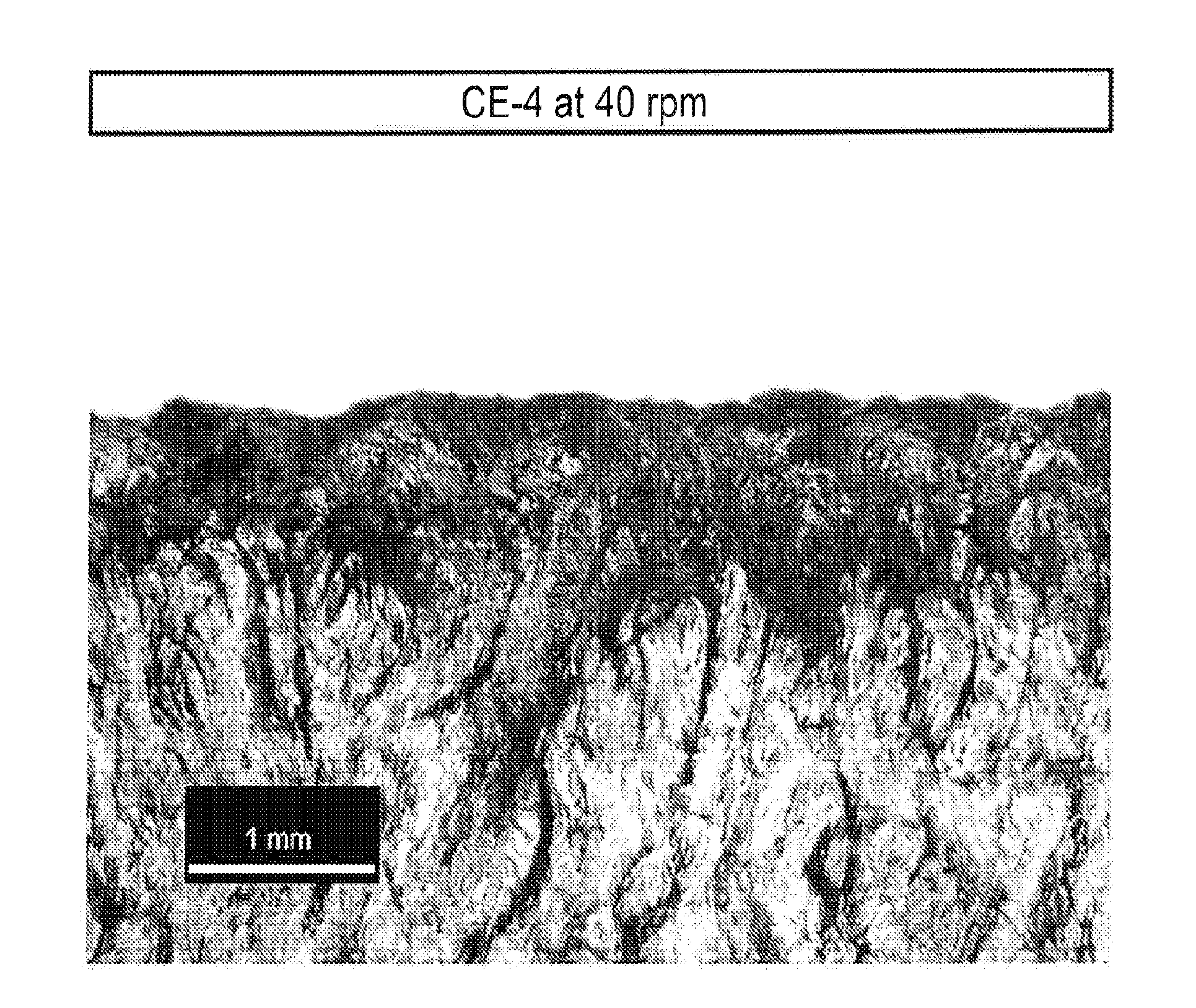

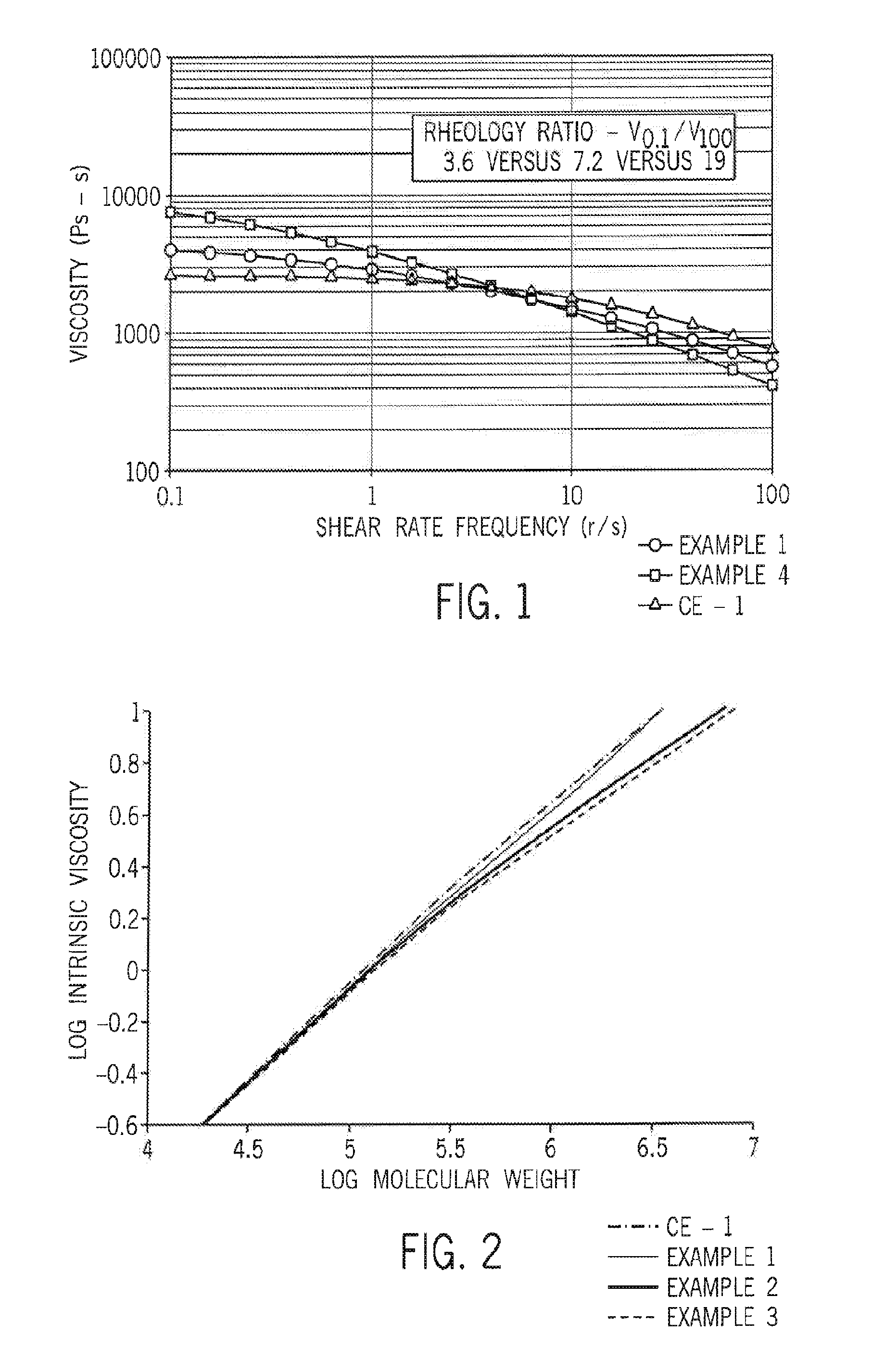

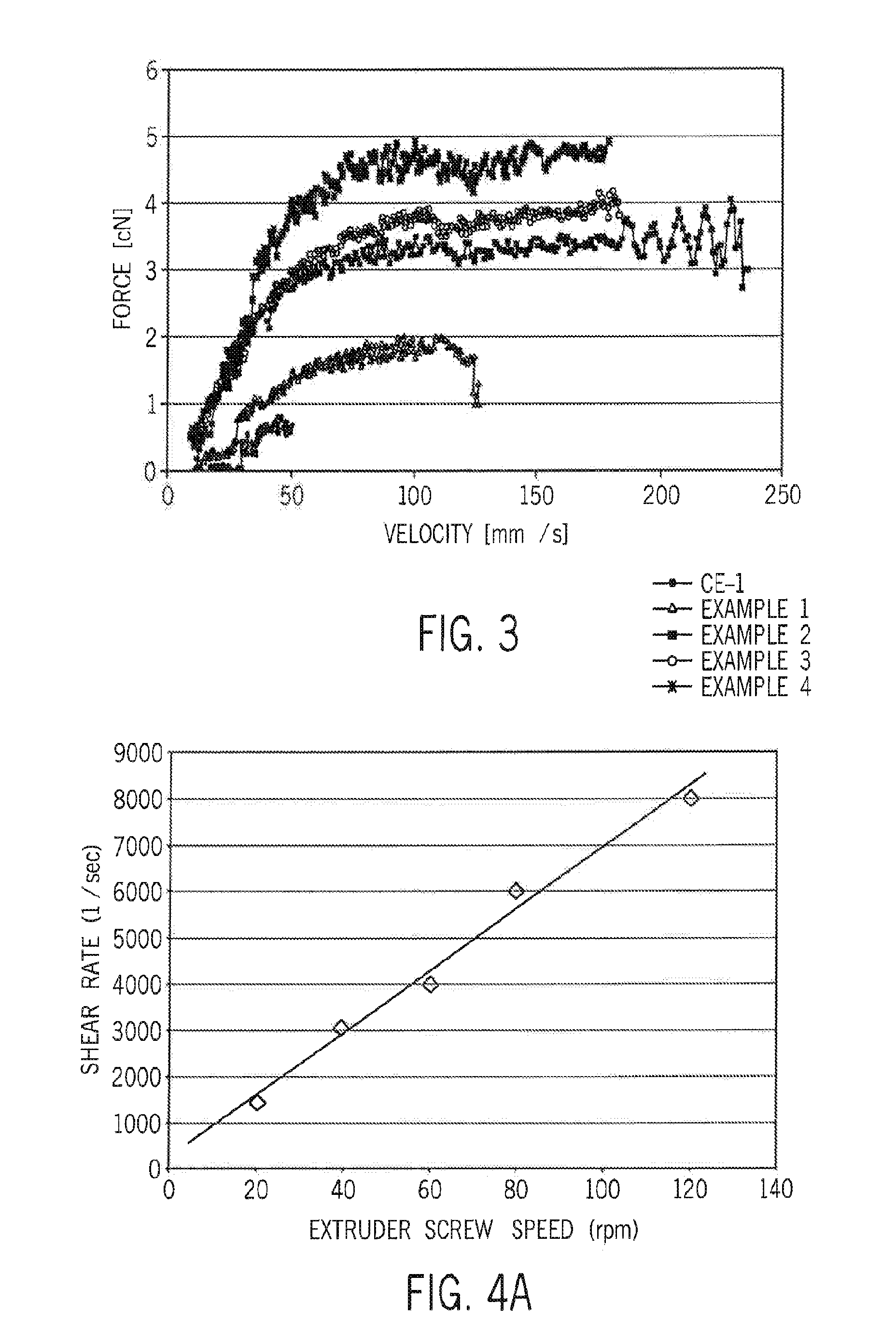

Polyester compositions for calendering

Polyester compositions that provide a higher throughput in calendering processes may be prepared from a polyester having crystallization half time of at least 5 minutes, an inherent viscosity of about 0.55 to about 0.75 dL / g, a branching monomer, and a release additive. The polyester compositions show a combination of excellent melt strength with good shear response that permits higher calendering line speeds before melt fracture occurs. Also disclosed are processes for film or sheet by calendering the above compositions and the film or sheet produced therefrom. The polyester compositions, film, or sheet also may include plasticizers and / or flame retardants to increase their flexibility and enable their use in commercial applications requiring flame resistance. The film and sheet have excellent appearance and can be used in a wide range of decorative and packaging applications.

Owner:EASTMAN CHEM CO

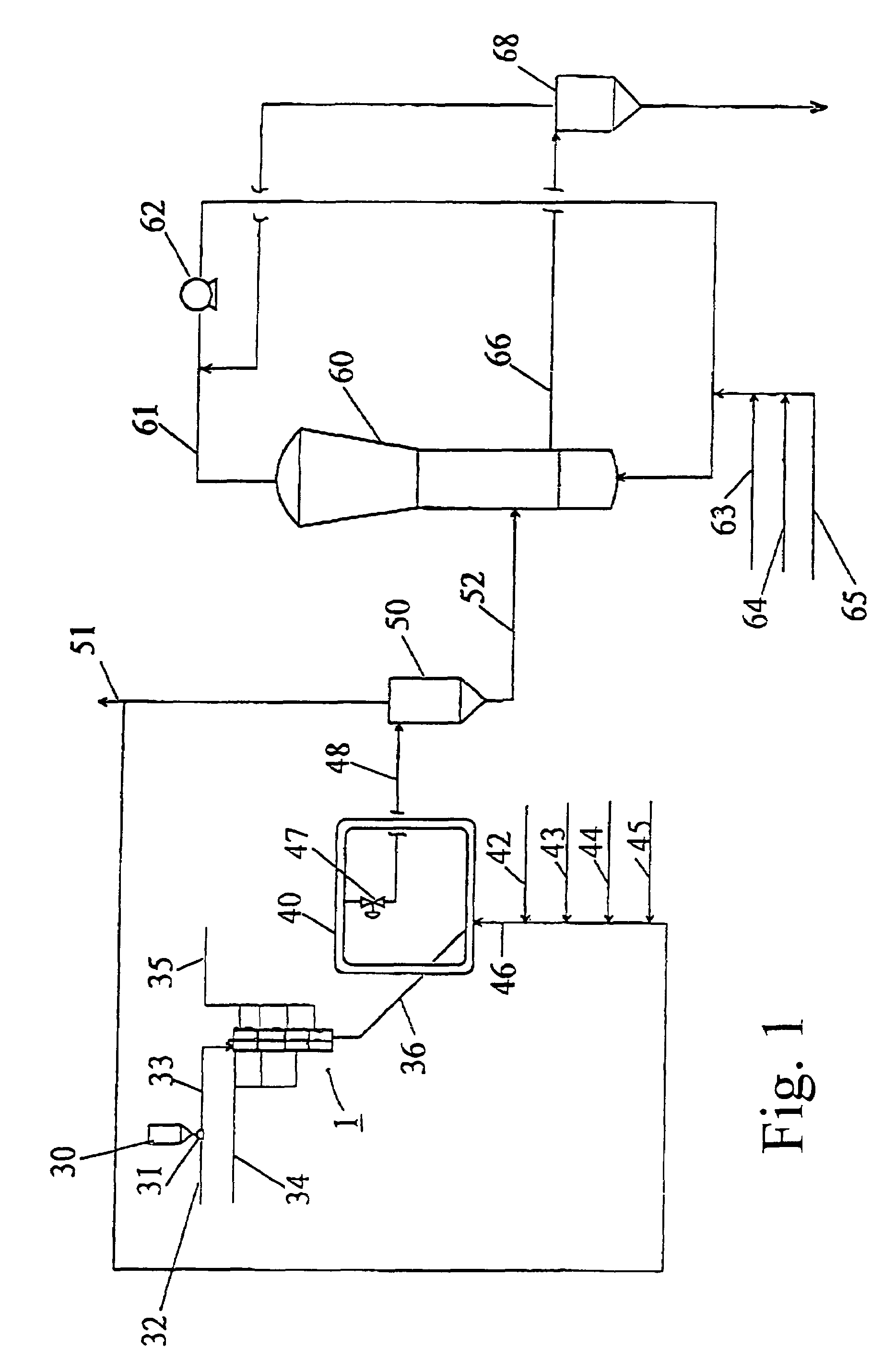

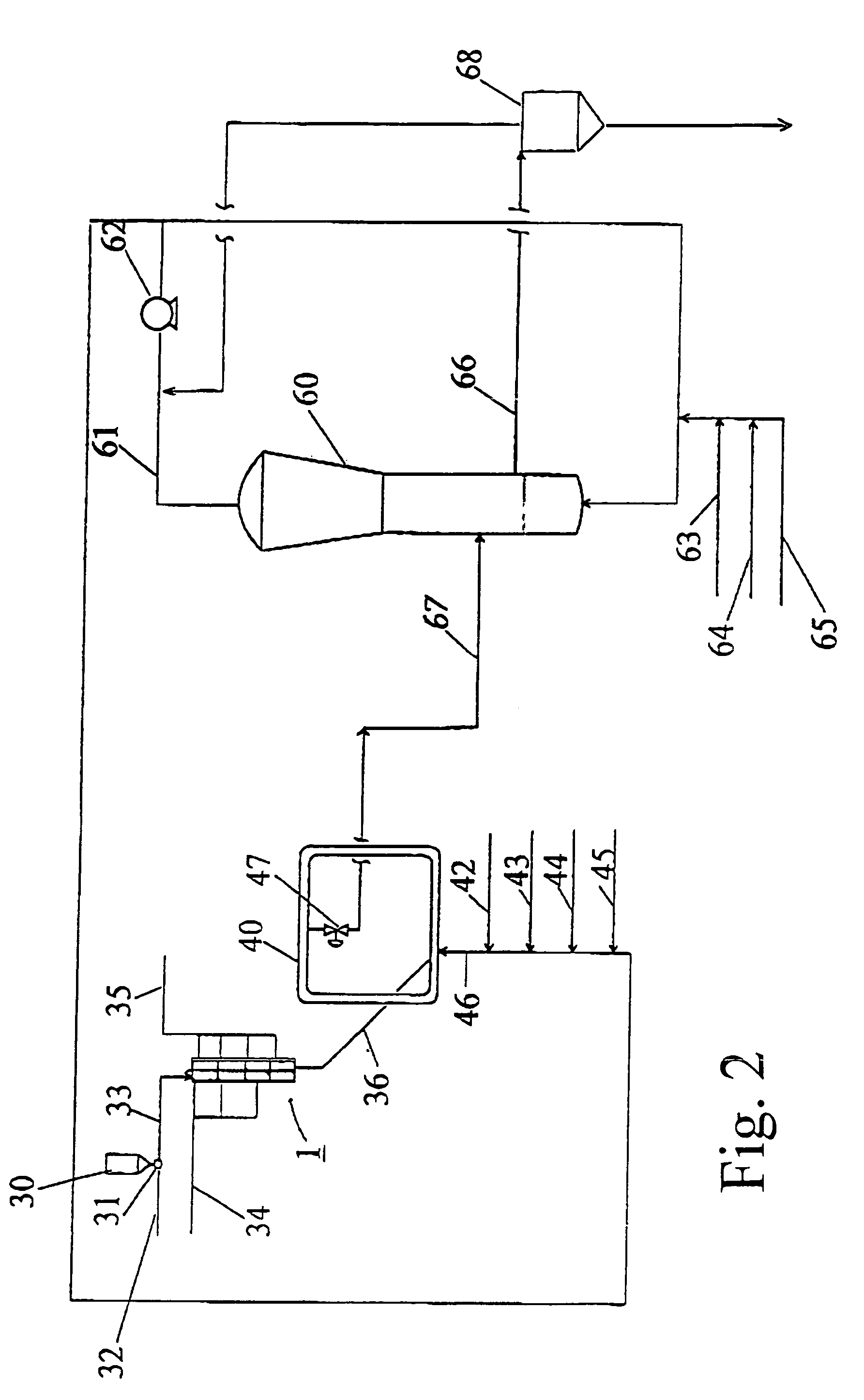

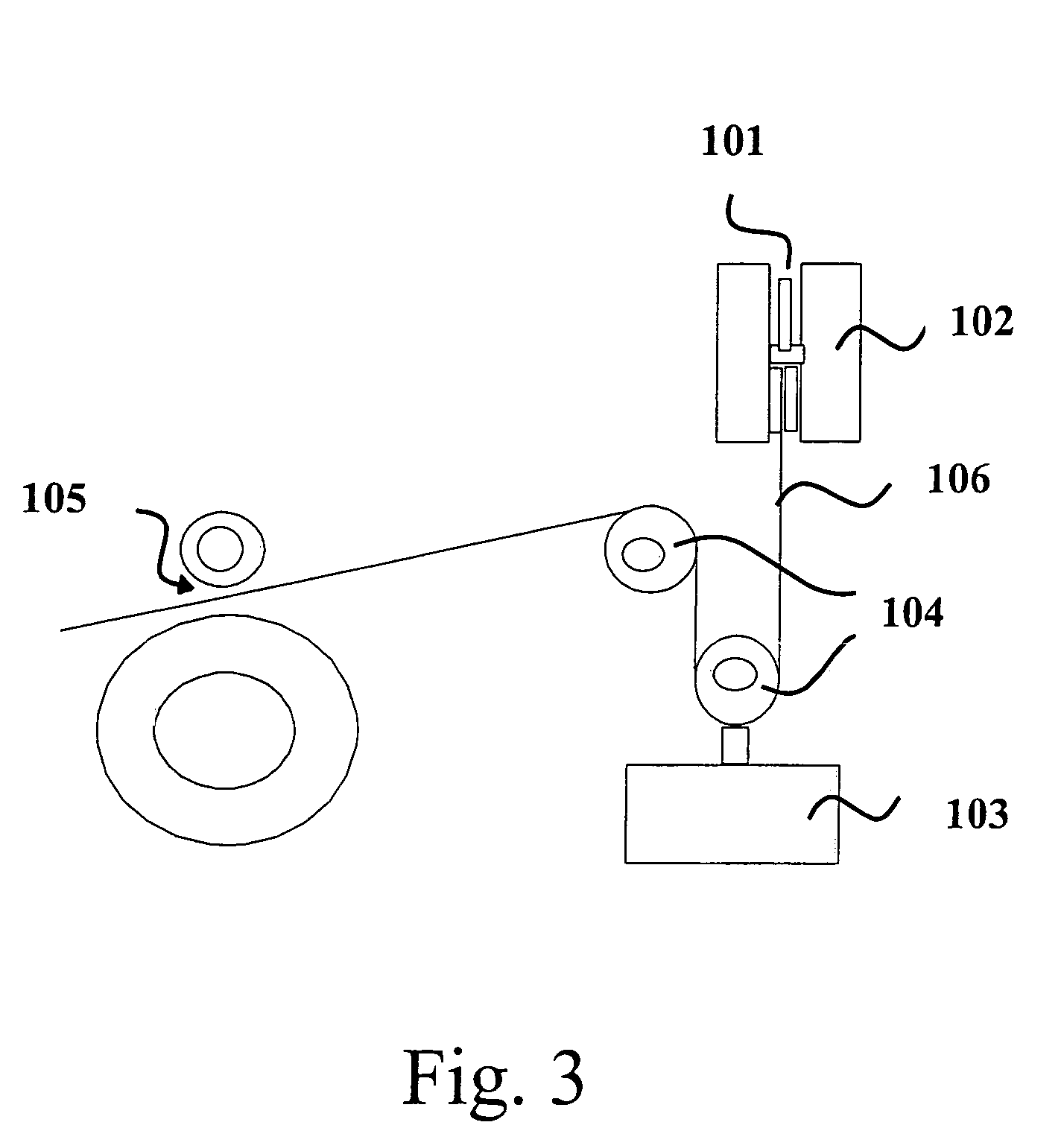

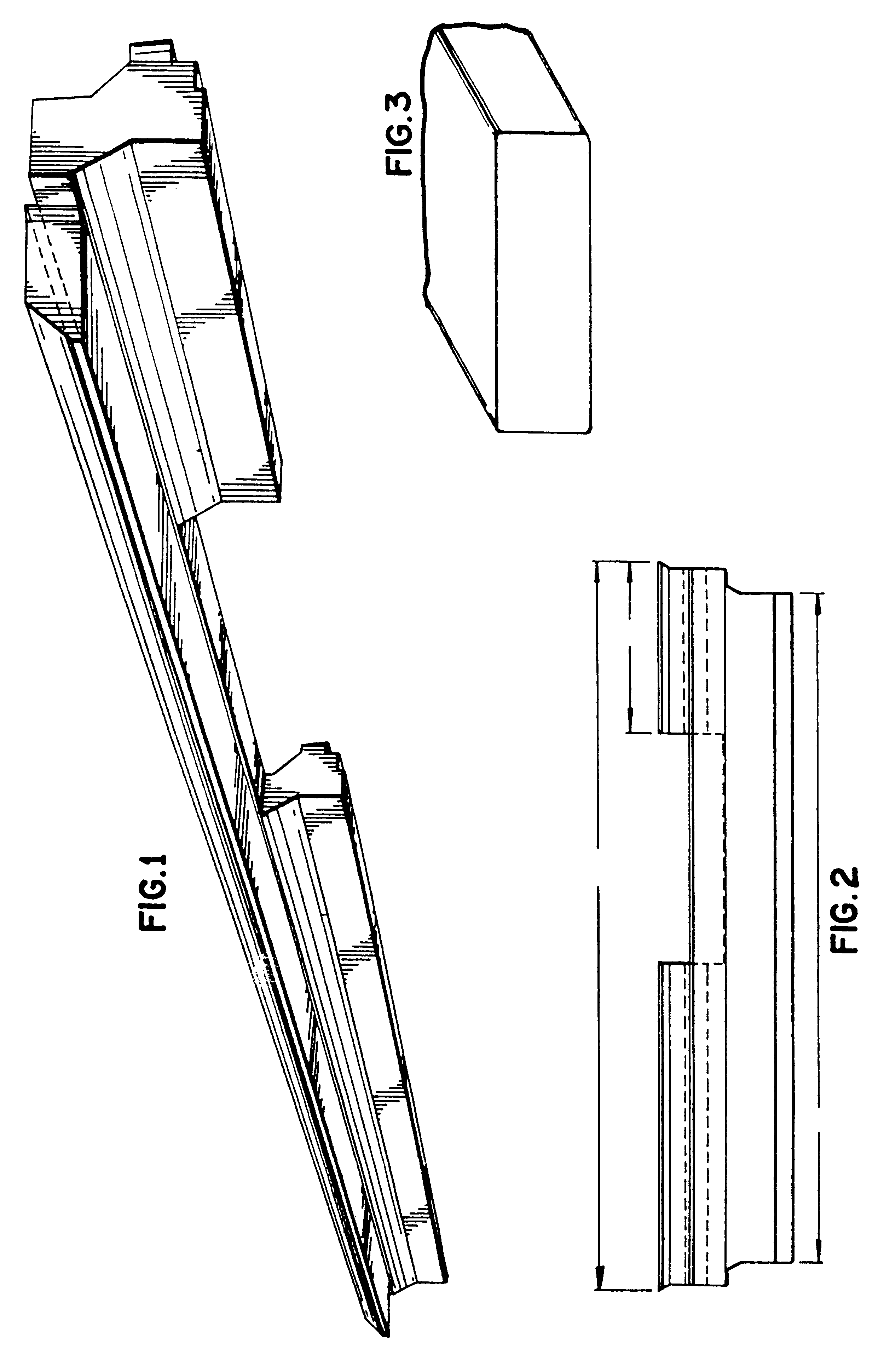

Method of forming a foamed thermoplastic polymer and wood fiber profile and member

InactiveUS6342172B1Improved thermal and physical propertyImprove performanceSemi-permeable membranesLaminationComposite constructionThermoplastic

Owner:ANDERSEN CORPORATION

Multimodal polyethylene pipe resins and process

ActiveUS20100092709A1Improve the immunitySolve low usageLayered productsThin material handlingCrack resistancePolymer science

Multimodal polyethylene resins having improved stress crack resistance and melt strength rendering them useful for the manufacture of thick-walled pipe are produced in a process wherein the second stage of the process is a copolymerization conducted at a high temperature with a low comonomer to ethylene ratio and a low hydrogen to ethylene ratio.

Owner:EQUSR CHEM LP

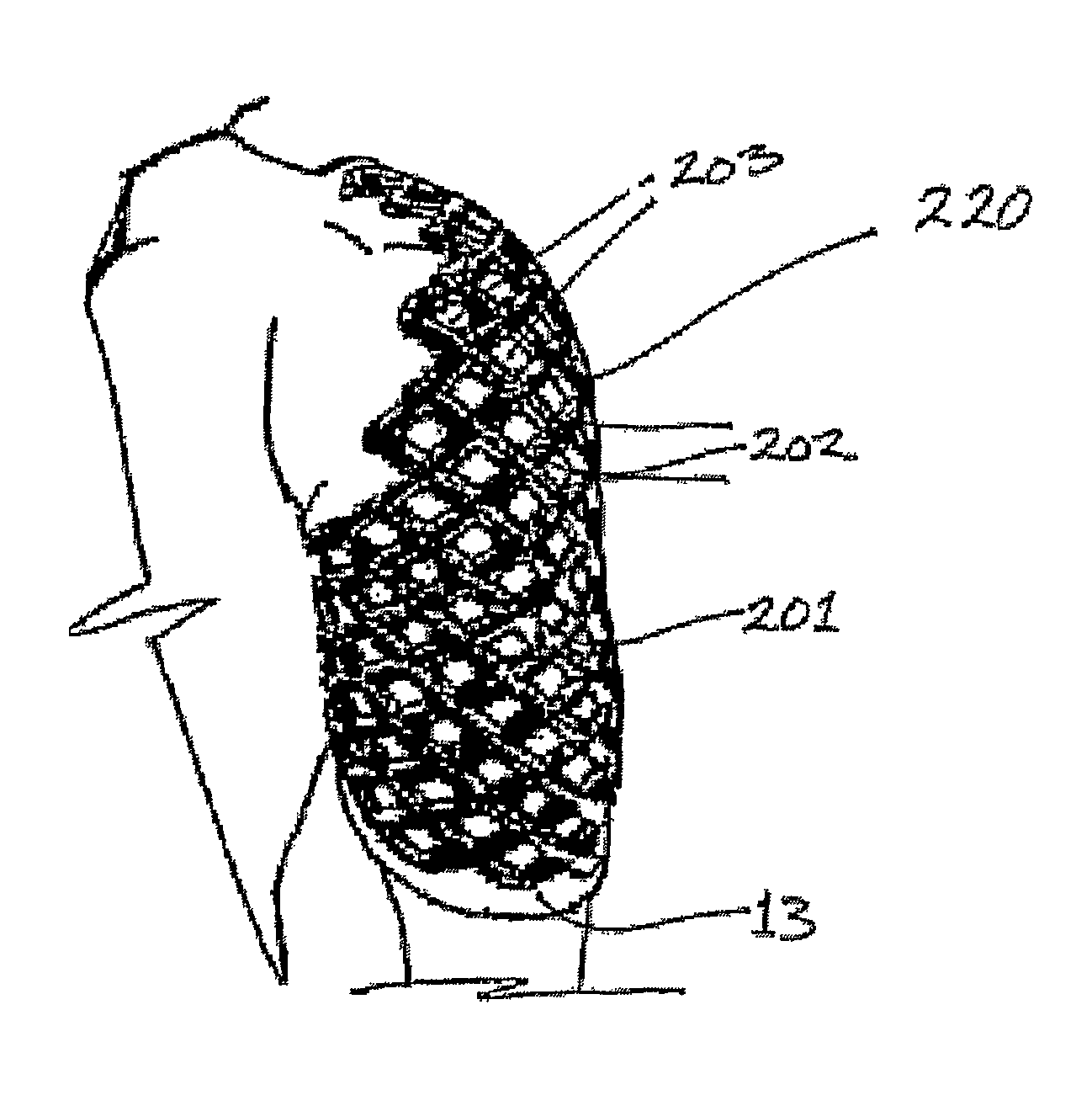

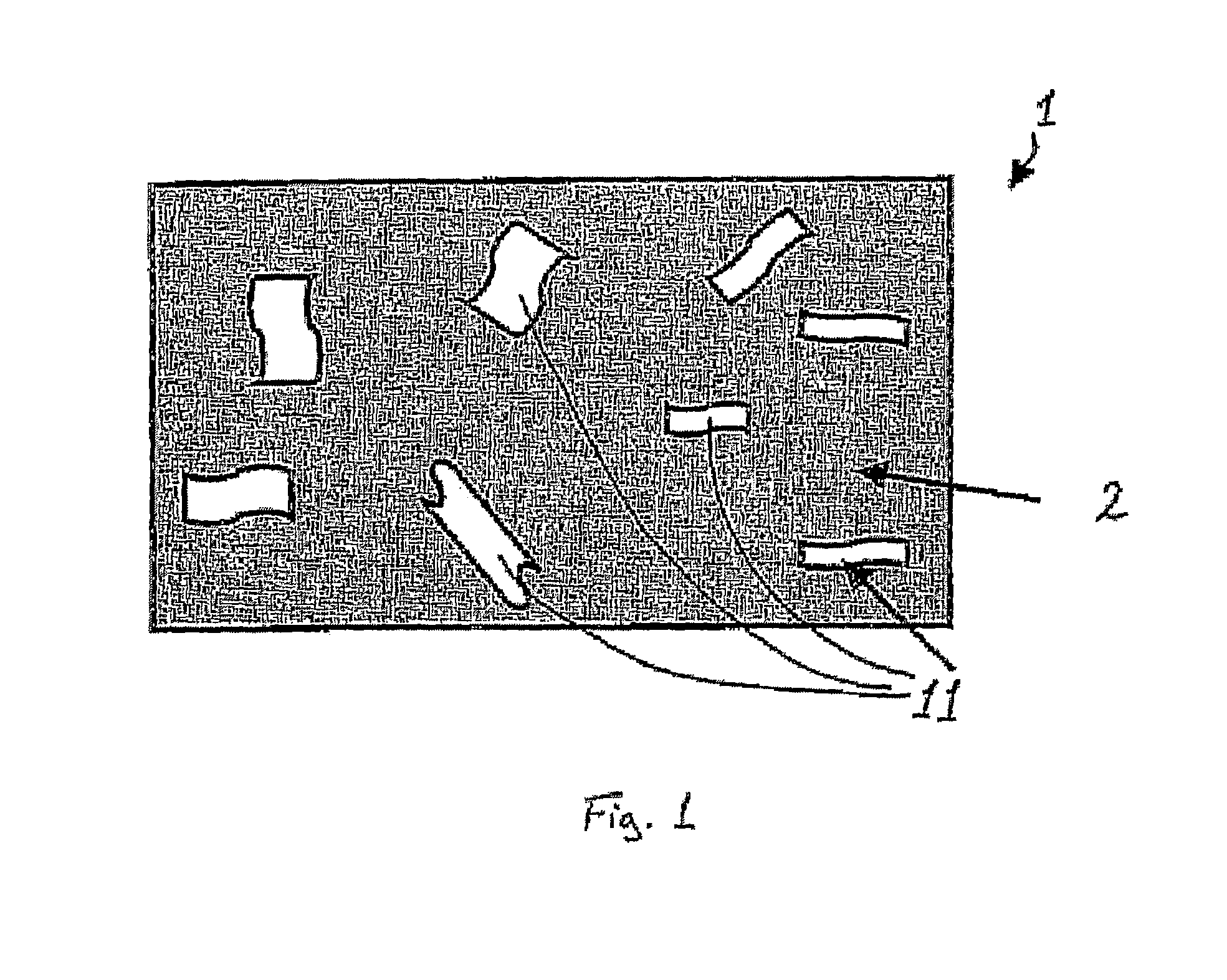

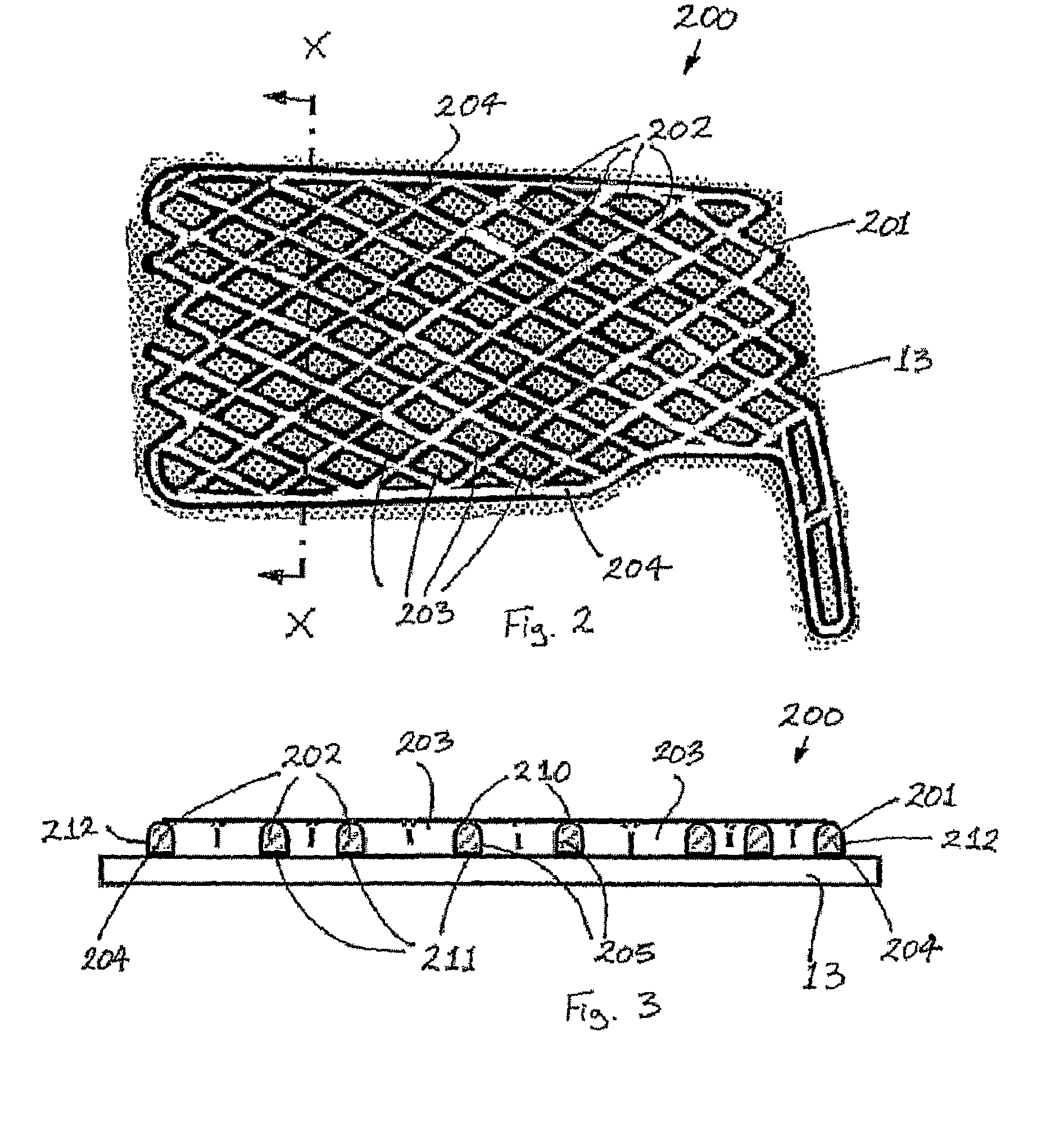

Geometrically apertured protective and/or splint device comprising a re-mouldable thermoplastic material

ActiveUS7985192B2Improve insulation performanceReduction in tackCosmetic preparationsImpression capsCelluloseMedicine

A protective and / or splint device, for example a distal radial splint device (200), comprises a protective and / or splint member (201) and a spacer member (13). The protective and / or splint member (201) comprises a composite protective and / or splint material and is formable at a forming temperature and is substantially rigid at ambient temperature. The material comprises a polycaprolactone and a ligno-cellulose additive material. The protective and / or splint member (201) comprises a mesh of elements (202), with a plurality of openings (203) through the protective and / or splint member (201). Away from the periphery of the splint member (201), the openings (203) are diamond-shaped. Two border elements (204) extend along the two sides of the periphery of the splint member (201). The three point bending strength to openness ratio of the member is greater than 0.1 and the unidirectional bending strength to openness ratio of the member is greater than 4. This results in a device (200) with sufficient strength, which is breathable with open surfaces, and the volume of material used is optimized. The strength of the member (201) parallel to the longitudinal direction of the arm is greater than the strength parallel too the circumferential direction. At the forming temperature the member (201) is stretchable. The member (201) is rounded between the outer surface of the member (201) and the edges around the openings (203).

Owner:FASTFORM RES

Thermoplastic olefin compositions, processes and articles

A thermoplastic olefin (TPO) composition comprises (1) a major amount by weight of (a) a substantially linear homopolymer or copolymer of a C2-C10 α-olefin in major proportion to (b) a long chain branched a linear homopolymer or copolymer of a C2-C10 α-olefin, (2) a minor amount by weight of a cross linkable elastomer, and (3) at least one thermally decomposing free radical generating agent present in an amount sufficient to promote an increase in melt strength of the composition over that of the melt strength of the linear homopolymer or copolymer of a C2-C10 α-olefin alone and insufficient to substantially degrade the α-olefinic polymers. The TPO composition is prepared by melt blending the components at a temperature sufficient to melt said homopolymers or copolymers of a C2-C10 α-olefin and thermally decompose said agent. Articles are thermoformed from the thermoplastic olefin.

Owner:EXOUSIA IP LLC

Foam security substrate

InactiveUS20050104365A1Deter counterfeitingImprove melt strengthOther printing matterDuplicating/marking methodsPolymer sciencePaper document

Owner:3M INNOVATIVE PROPERTIES CO

Blends of aliphatic-aromatic copolyesters with ethylene-vinyl acetate copolymers

ActiveUS7241838B2Excellent fragmentation and breakdownImprove melt strengthPaper coatingSpecial tyresPolymer scienceCopolyester

Disclosed are blends of aliphatic-aromatic copolyesters with poly(ethylene-co-vinyl acetate) copolymers and shaped articles prepared therefrom. These blends have higher melt strength than the aliphatic-aromatic copolyester alone and exhibit increased melt strength and better processability. In addition, the blends and shaped articles show bio-disintegration and / or biodegradability in a composting environment.

Owner:EASTMAN CHEM CO

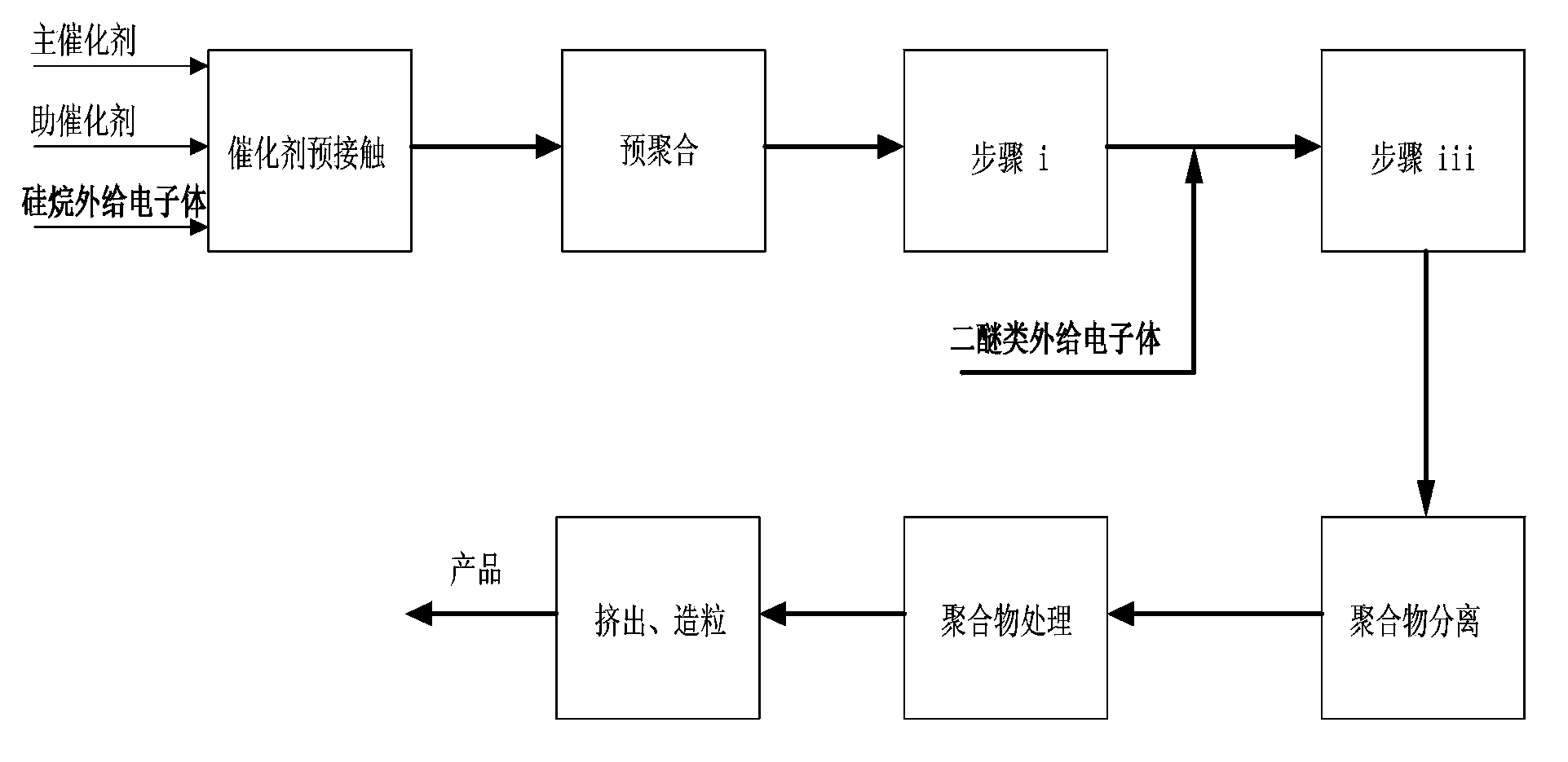

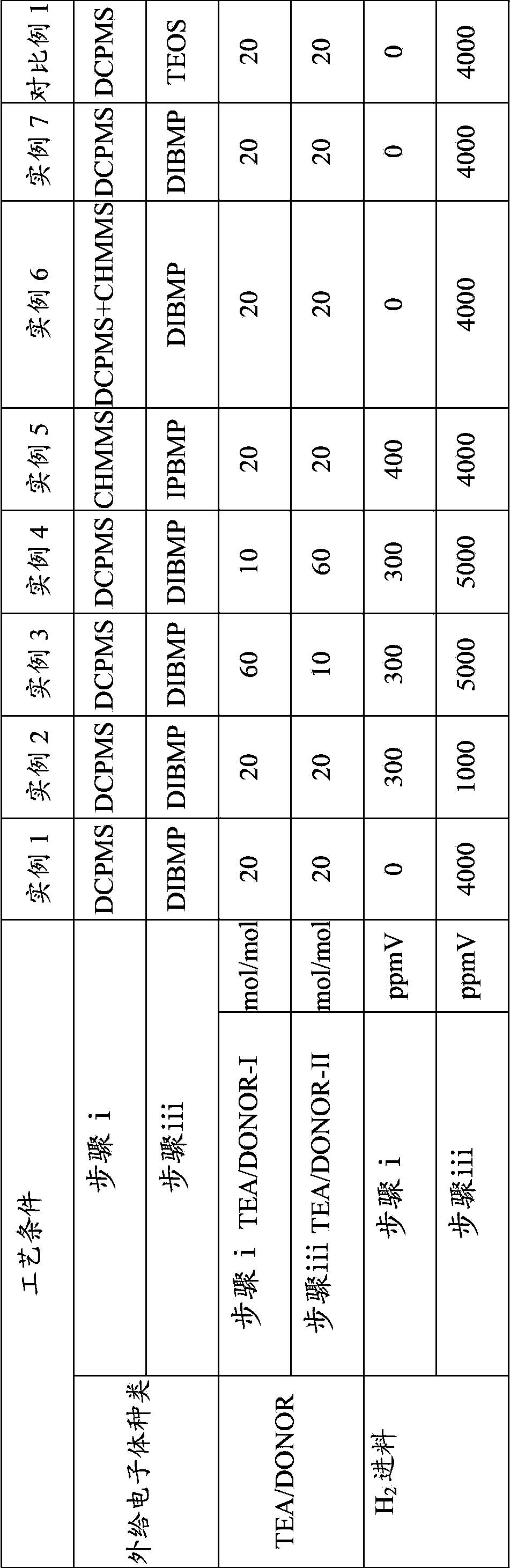

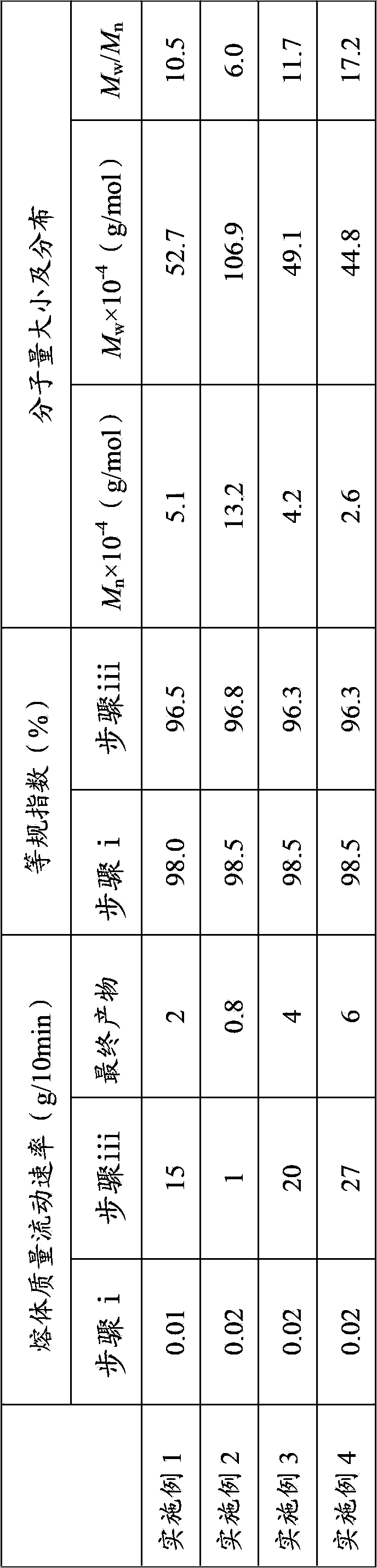

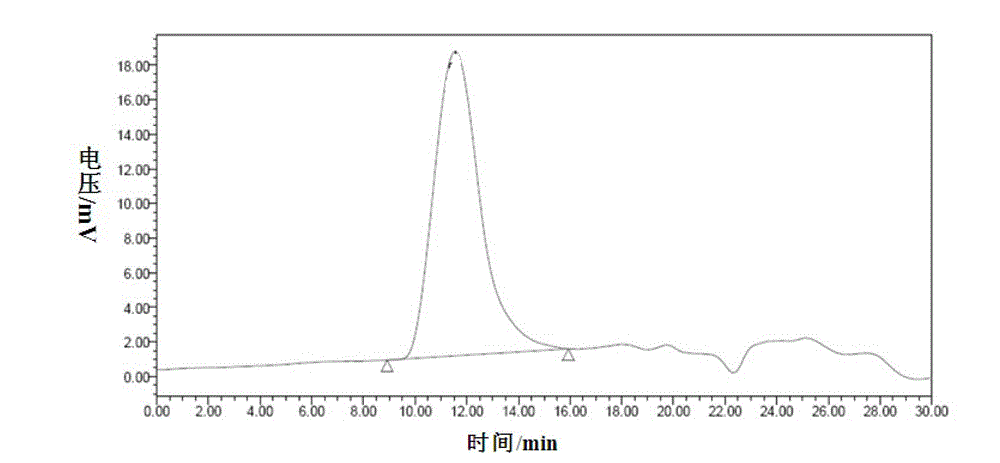

Preparation method of polypropylene with high melt strength

ActiveCN103788265AHigh hydrogen tone sensitivityImprove melt strengthPolypropyleneHydrogen concentration

The invention discloses a preparation method of polypropylene with high melt strength. The method includes i) a step of, under the action of a Ziegler-Natta catalyst containing a silane type external electron donor, subjecting propylene or propylene with other alpha-olefin to polymerization to obtain a polymer A having a melt mass flow rate of 0.01-0.4 g / min, with a hydrogen concentration being not more than 400 ppmV; ii) a step of adding a 1,3-diether type external electron donor and premixing the 1,3-diether type external electron donor and the polymer A; iii) a step of, under the existence of hydrogen and the premixed materials in the step ii), subjecting the propylene or the propylene with other alpha-olefin to polymerization to obtain a polymer B having a melt mass flow rate of 1.0-60 g / 10min; and a step of preparing polypropylene C with high melt strength comprising the polymer A and the polymer B. The melt mass flow rate of the polypropylene C is 0.8-15 g / 10min. The preparation method is simple and feasible and is convenient to operate and prone to industrial production. High-performance products with high melt strength and wide molecular weight distribution can be prepared by the method. The method has wide application prospect.

Owner:CHINA PETROLEUM & CHEM CORP +1

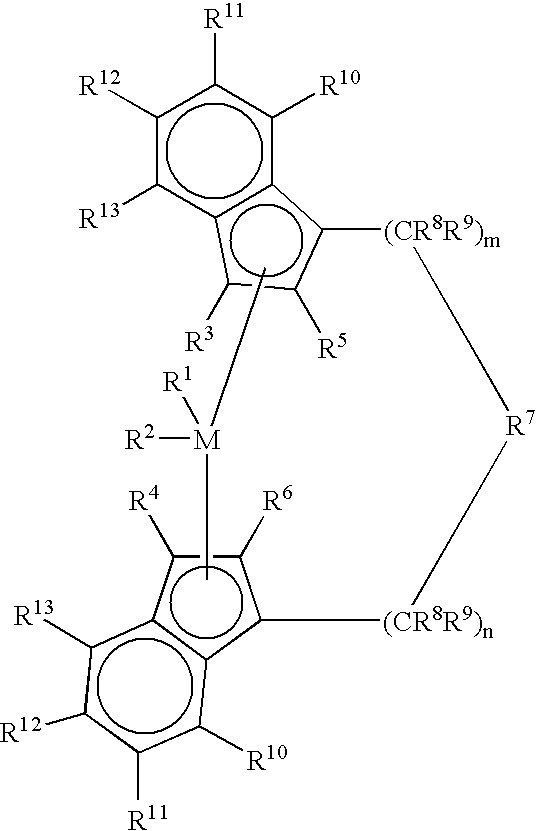

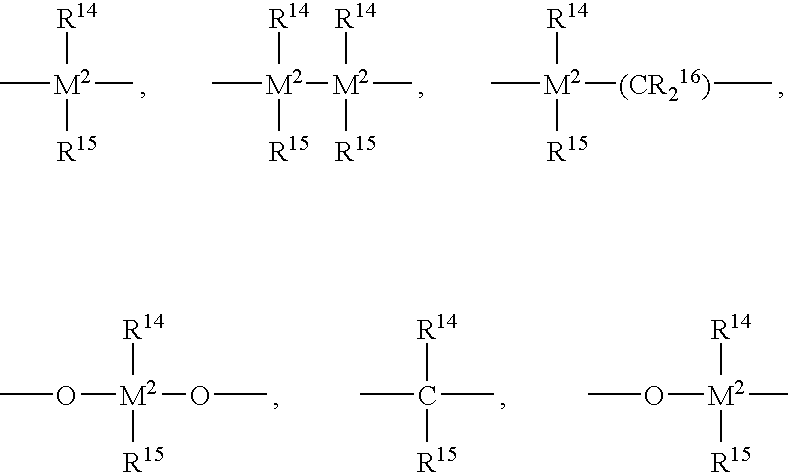

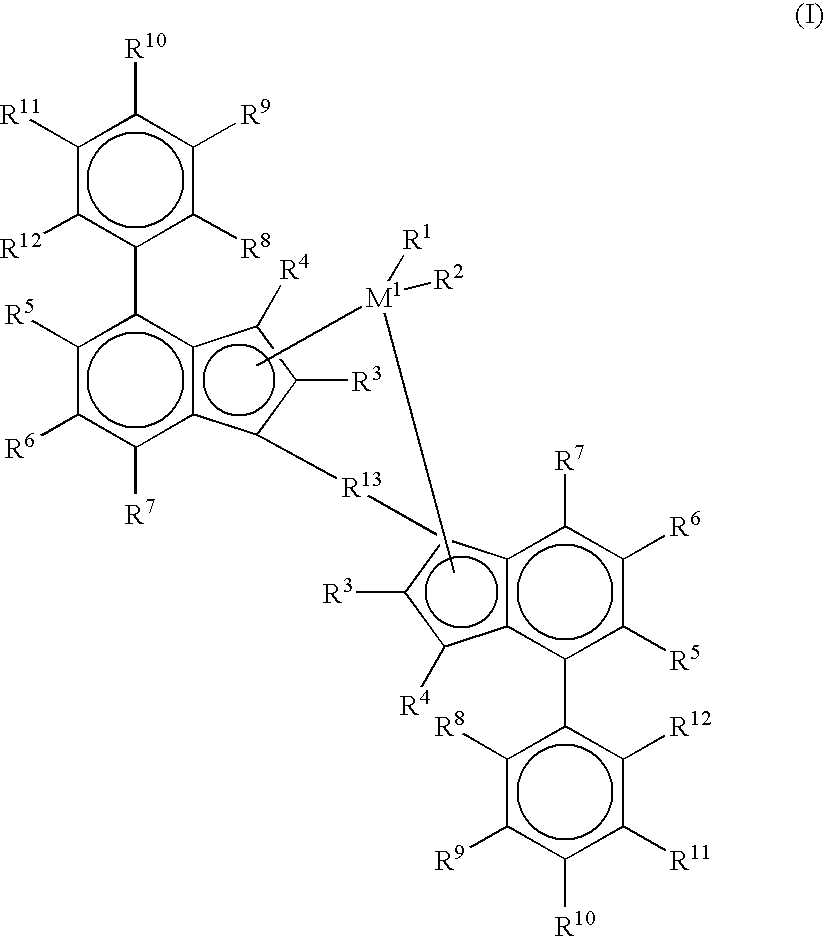

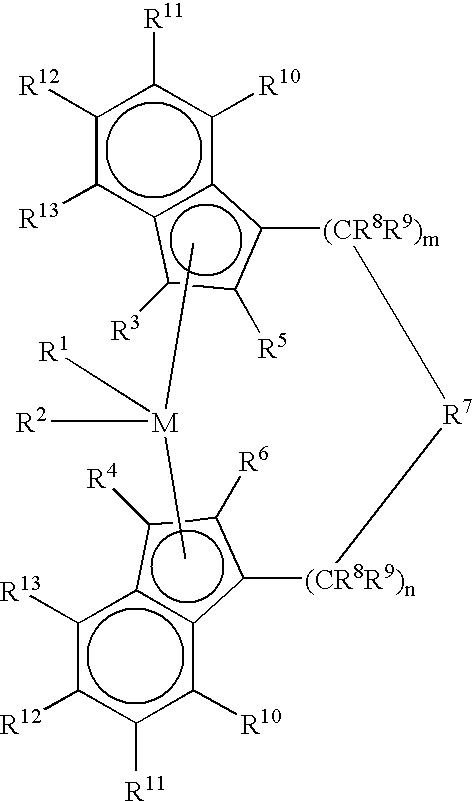

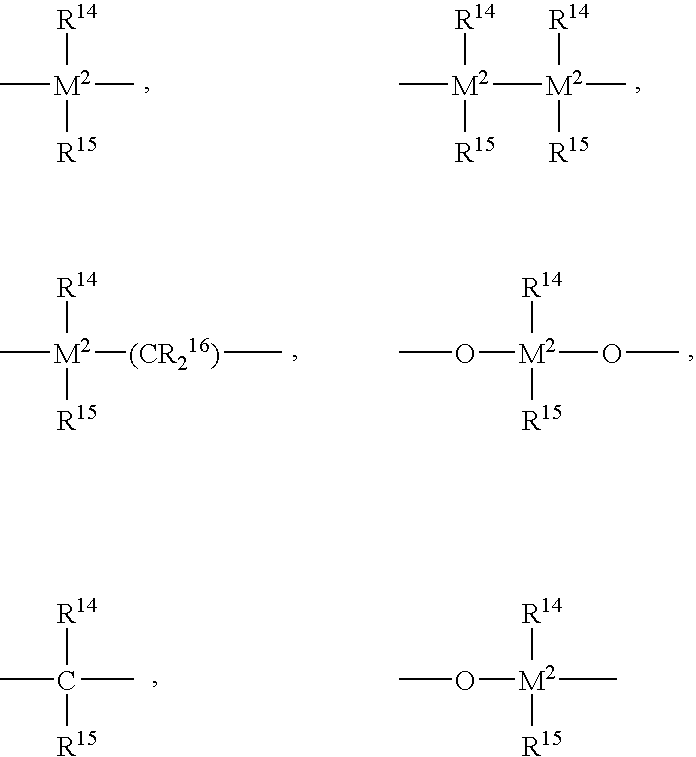

Branched crystalline polypropylene

Branched crystalline polypropylene compositions and methods for the preparation of branched crystalline polypropylene compositions are provided. For example, described herein is a process of preparing a branched crystalline polypropylene composition that includes combining two or more different metallocene catalyst compounds with a polymerization medium that includes propylene, for a time sufficient to provide branched crystalline polypropylene that has from 0.0 wt % to 2.0 wt % ethylene and a heat of fusion of 70 J / g or more.

Owner:EXXONMOBIL CHEM PAT INC

High melt strength polypropylene material and preparation

InactiveCN101486817AOther physical and mechanical properties remain unchangedPhysical and mechanical properties unchangedPolymer sciencePolypropylene

The invention relates to a high melt strength polypropylene material and a preparation method. The high melt strength polypropylene material consists of 100 parts of polypropylene, 5-60 parts of high-melting point crystalline polymer, 2-50 parts of compatilizer, 0-40 parts of polyethylene and other additives according to parts by weight. The preparation method includes the following steps of: measuring the polypropylene, the high-melting point crystalline polymer, the compatilizer, the polyethylene and a processing agent according to formula amount, premixing the materials uniformly and then melting and blending the materials by a screw extruder at controlled temperature and rotating speed, thus obtaining the high melt strength polypropylene material which is applicable to extrusion foaming and other hot forming technologies.

Owner:SOUTH CHINA UNIV OF TECH

Pre-irradiation polypropylene graft copolymer and preparation method thereof

The application relates to a pre-irradiation polypropylene graft copolymer and a preparation method thereof. At present, the exploration of methods for improving surface property remains a research hotspot in the field of modification of polypropylene always. The method comprises the following steps: performing pre-irradiation on polypropylene resin after having constant weight at the temperature of 60 DEG C by using a 60 Co radiation source or a DD-1.2 / 1.0-800 type high-frequency high-pressure electron accelerator in air, keeping the dosage rate at 300Gy / min, keeping the dose at 3-50kGy, adding the pre-radiated polypropylene resin into solution containing N, N'-methylenebis acrylamide, auxiliary monomers and additives, keeping the using amount of the N, N'-methylenebis acrylamide to be 0.5-5% by weight of the weight of polypropylene, performing nitrogen filling and oxygen removal on mixed solution for 30 minutes, then heating to 50-75 DEG C for performing reaction for 6 hours under magnetic stirring, nitrogen production and reflux conditions, washing the polypropylene resin which is filtered out with ethanol-water twice, further extracting with ethanol-water solution for 24 hours, drying at the temperature of 60 DEG C and enabling the weight to be constant. The method is used for preparing the polypropylene graft copolymer.

Owner:TECHN PHYSICS INST HEILONGJIANG ACADOF SCI

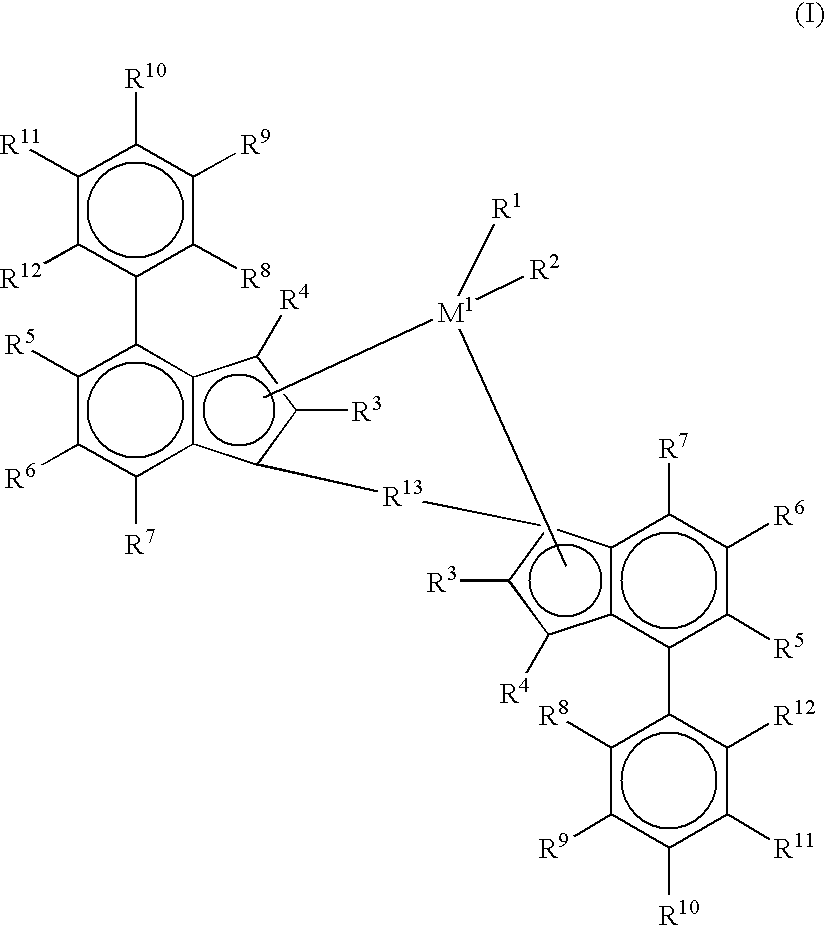

Long Chain Branched Propylene-Alpha-Olefin Copolymers

ActiveUS20100285253A1Higher shear thinning behaviorSpeed up the processSynthetic resin layered productsMonocomponent polypropylene artificial filamentAlpha-olefinAlkene

Substantially isotaclic propylene interpolyraets comprise (A) at least 60 weight percent (wt %) units derived from propylene, and (B) between greater than zero and 40 wt % units derived from ethylene, the propylene interpolyrner further characterized by at least one of the following properties: (1) a ratio of less than 1 measured at interpolyraer number average molecular weight (Mn), (2) a relative compositional drift of less than 50%, arid (3) propylene chain segments having a chain isotacticity triad index of at least 70 mole percent.

Owner:DOW GLOBAL TECH LLC

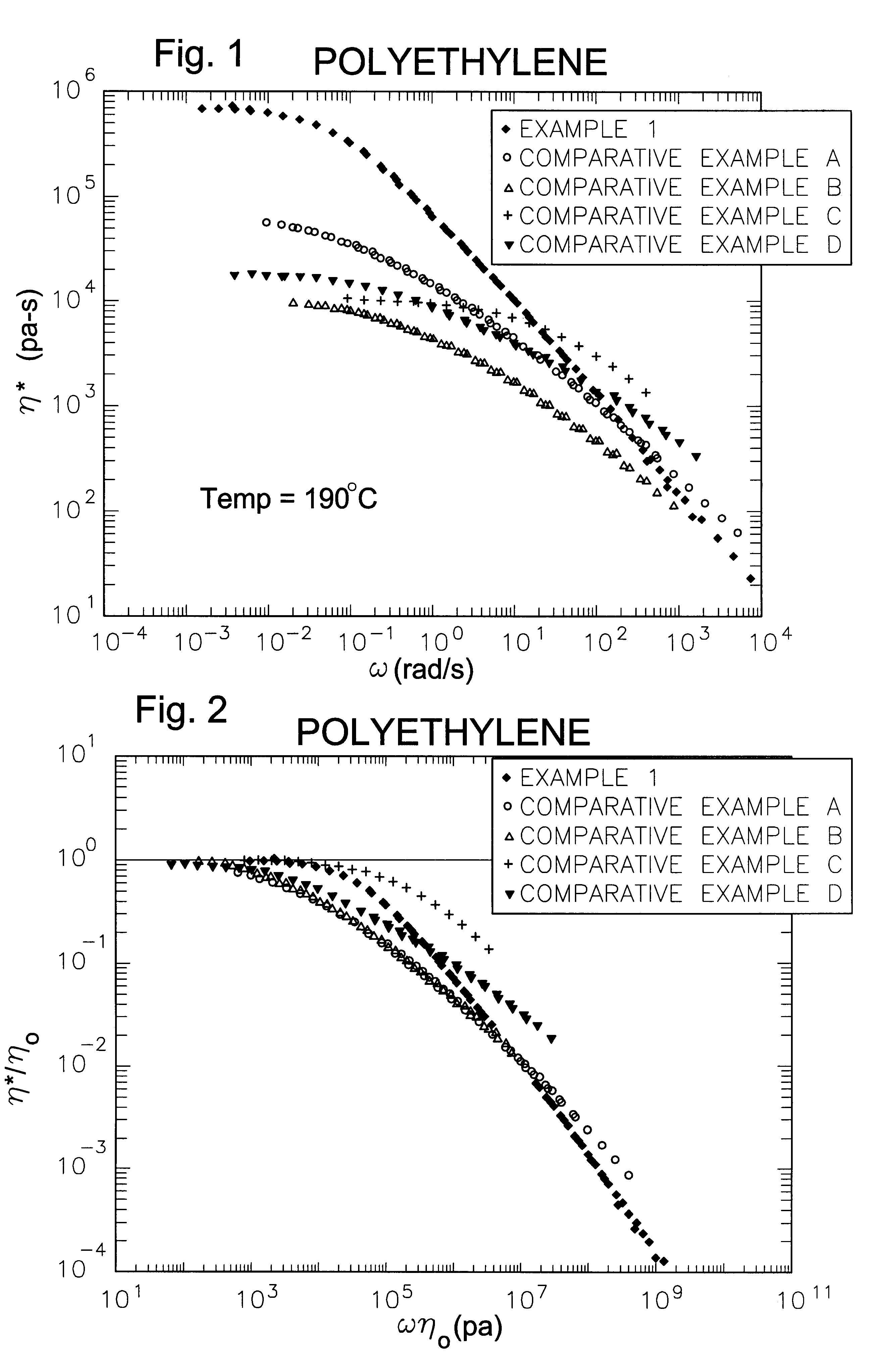

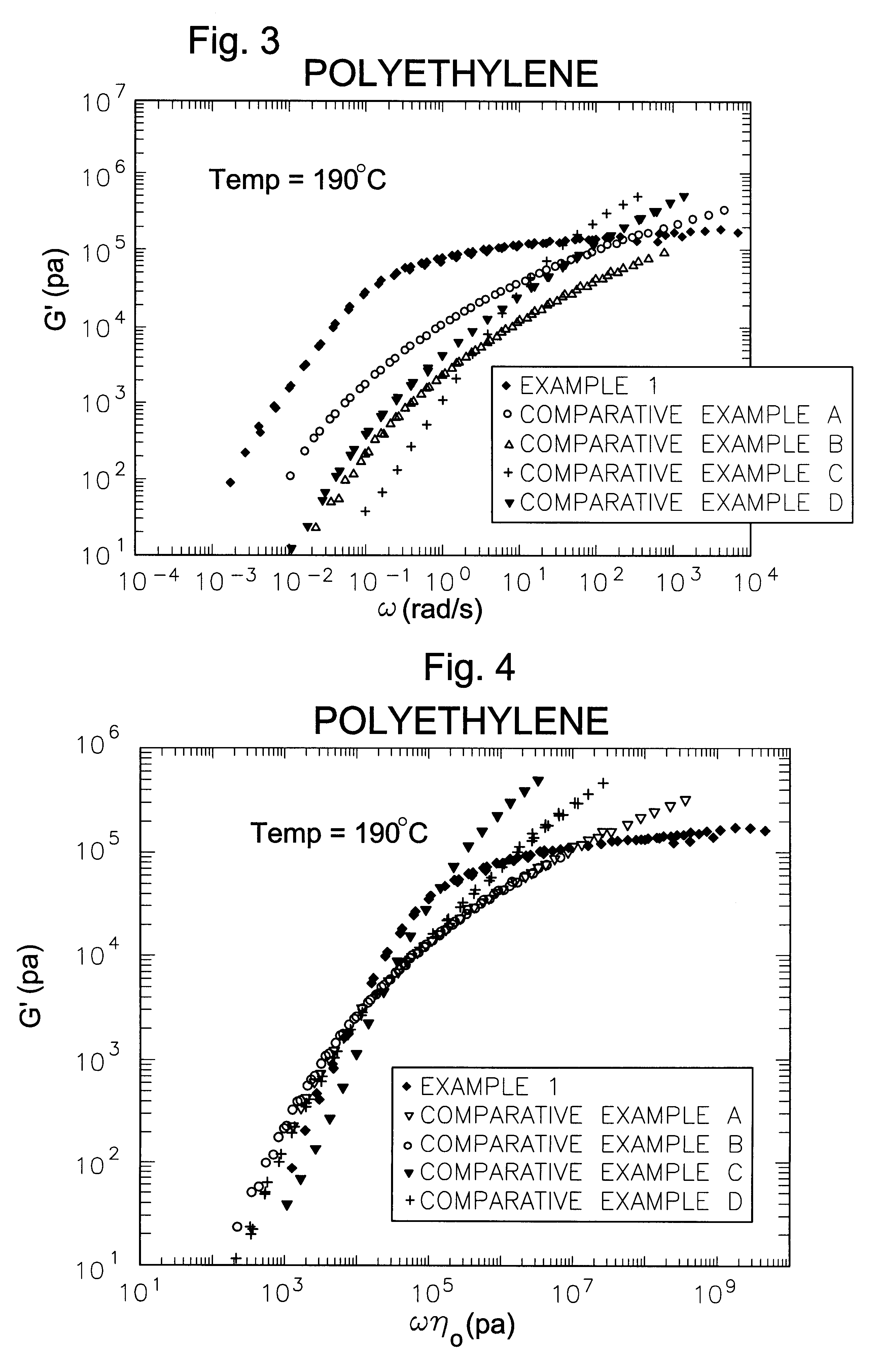

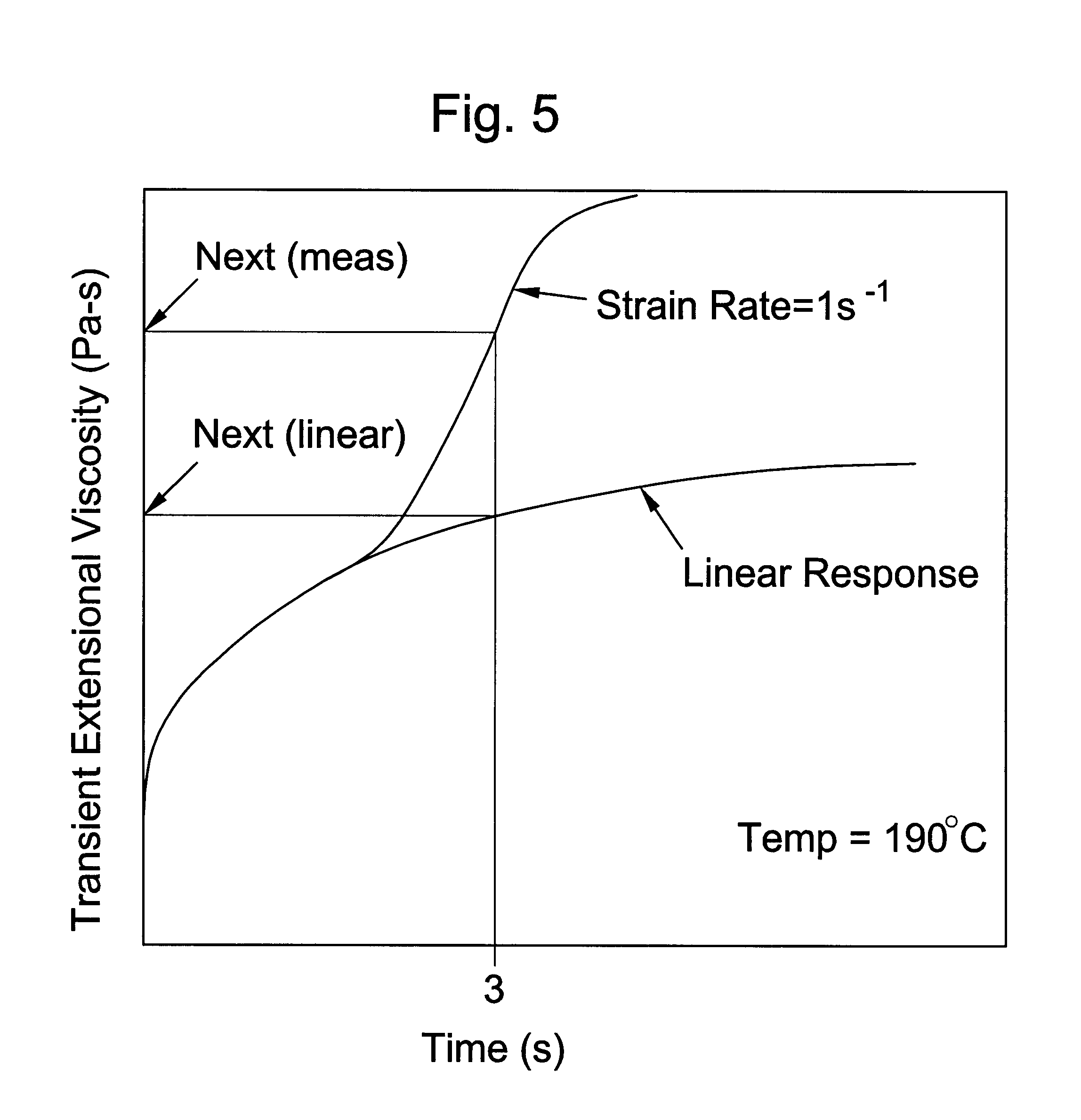

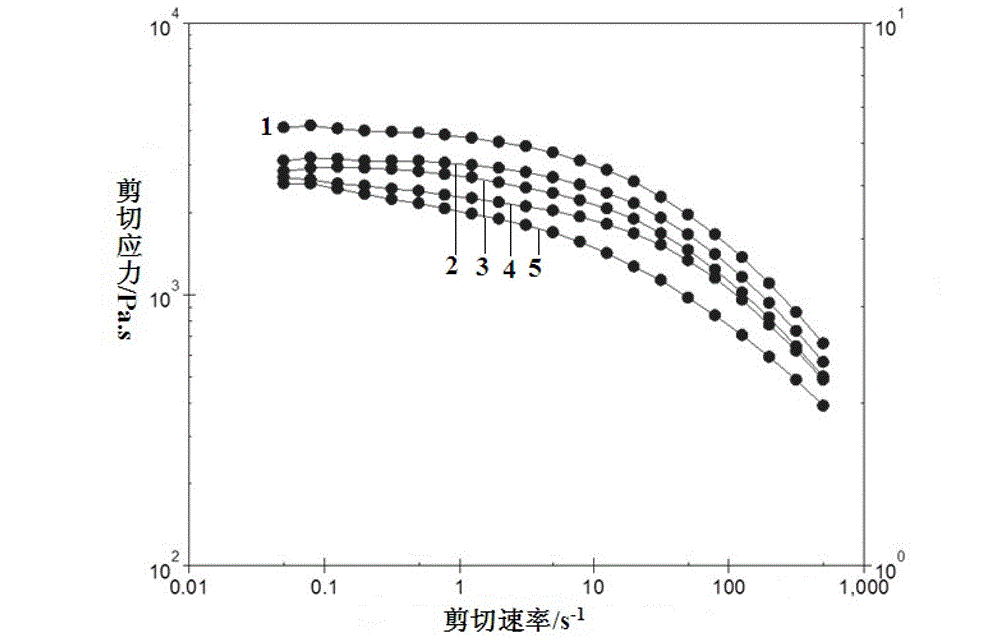

Processing olefin copolymers

The invention is directed to essentially saturated hydrocarbon polymer composition comprising essentially saturated hydrocarbon polymers having A) a backbone chain, B) a plurality of essentially hydrocarbyl sidechains connected to A), said sidechains each having a number-average molecular weight of from 2500 Daltons to 125,000 Daltons and a MWD by SEC of 1.0-3.5; and having A) a Newtonian limiting viscosity (eta0) at 190° C. at least 50% greater than that of a linear olefinic polymer of the same chemical composition and weight average molecular weight, preferably at least twice as great as that of said linear polymer, B) a ratio of the rubbery plateau modulus at 190° C. to that of a linear polymer of the same chemical composition less than 0.5, preferably <0.3, C) a ratio of the Newtonian limiting viscosity (eta0) to the absolute value of the complex viscosity in oscillatory shear (eta*)at 100 rad / sec at 190° C. of at least 5, and D) a ratio of the extensional viscosity measured at a strain rate of 1 sec-1, 190° C., and time=3 sec (i.e., a strain of 3) to that predicted by linear viscoelasticity at the same temperature and time of 2 or greater. Ethylene-butene prepared by anionic polymerization and hydrogenation illustrate and ethylene-hexene copolymers prepared by coordination polymerization illustrate the invention. The invention polymers exhibit improved processing characteristics in that the shear thinning behavior closely approaches that of ideal polymers and exhibit improved strain thickening.

Owner:EXXONMOBIL CHEM PAT INC

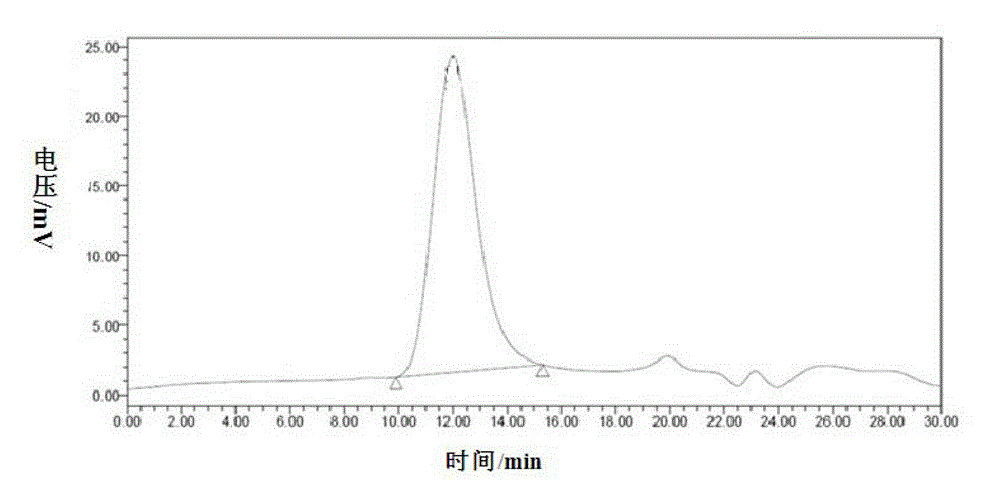

Propylene homopolymer having high melt strength and preparation method thereof

The present invention provides a process for preparing high melt strength propylene polymer by direct polymerization, comprising that a propylene polymer with wide molecular weight distribution and containing “very high molecular weight fraction” can be prepared by controlling the species and ratios of the external electron donors in the Ziegler-Natta catalyst system at different reaction stages according to the requirment for different molecular weight fractions in the different propylene polymerization stage of the series operation, and said polymer has excellent mechnical properties, especially with very high melt strength. The present invention also provides a propylene homopolymer with high melt strength, comprising the following features: (1) the MFR is 0.2-10 g / 10 min at 230° C. with a load of 2.16 kg; (2) the molecular weight distribution Mw / Mn is 6-20; (3) the content of the fraction with a molecular weight higher than 5,000,000 is higher than or equal to 0.8 wt %; (4) Mz+1 / Mn is higher than or equal to 70. Said homopolymer can be used in the preparation of foam products, thermoforming products, biaxial stretching films, blown films and blow-molded products.

Owner:CHINA PETROCHEMICAL CORP +1

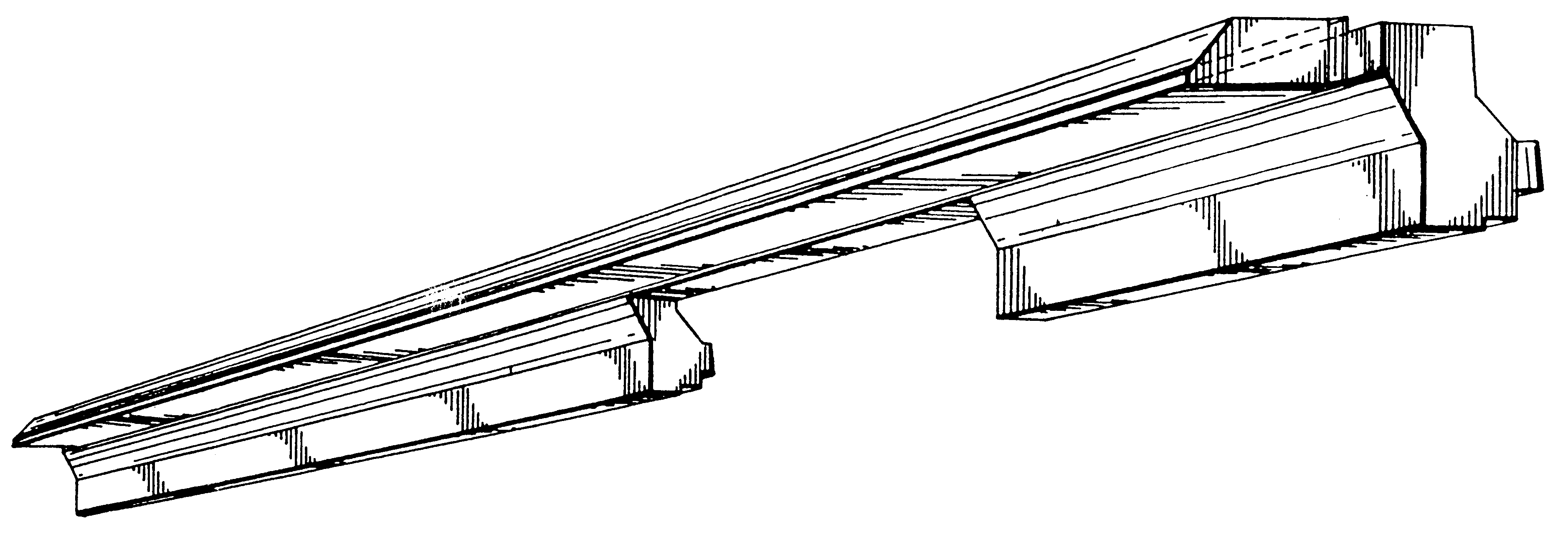

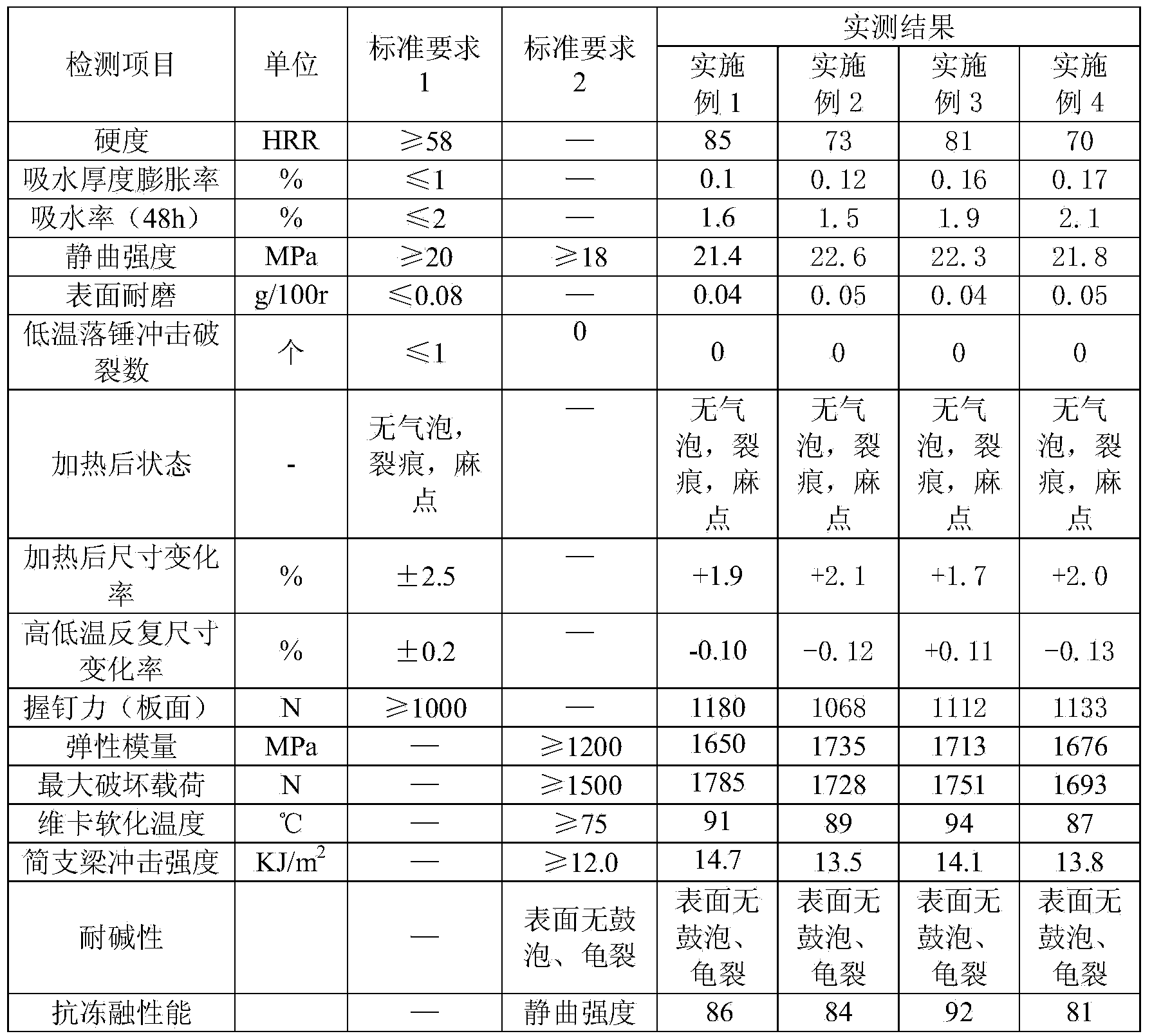

Environment-friendly single-layer microcellular foam PVC (polyvinyl chloride) wood-plastic composite board and preparation method thereof

The invention discloses an environment-friendly single-layer microcellular foamPVC (polyvinyl chloride) wood-plastic composite board and a preparation method thereof. According to an adopted raw material formula,the board comprises the components in percentage by mass as follows: 20%-60% of a PVC reclaimed material, 15%-45% of PVC resin, 5.6%-10% of wood fiber powder, 5%-8.9% of filler, 4%-4.4% of a foaming conditioning agent, 1%-1.5% of a compound stabilizer, 0.7%-0.9% of a foaming agent, 2%-2.5% of a reinforcing agent, 2.2%-2.4% of an impact modifier, 0.3%-0.45% of a lubricating agent, 0.1%-0.15% of a coupling agent and 3%-5% of a functional additive, and the functional additive is an anti-aging agent, a fire retardant or a coloring agent. The composite board has the processability similar to that of wood, can substitute for a wood board and also has thecharacteristics of fireproof property, moistureproof property, smooth and attractive appearance and the like, and the wood does not have the characteristics; according to the preparation method of the composite board, waste PVC can be used for performing cycle production, waste materials can be changed into things of value, waste of wood resources can be reduced, and the pollution caused by plastic products to the environment can also be avoided.

Owner:JIANGSU RUNJU ENVIRONMENTAL TECH CO LTD +1

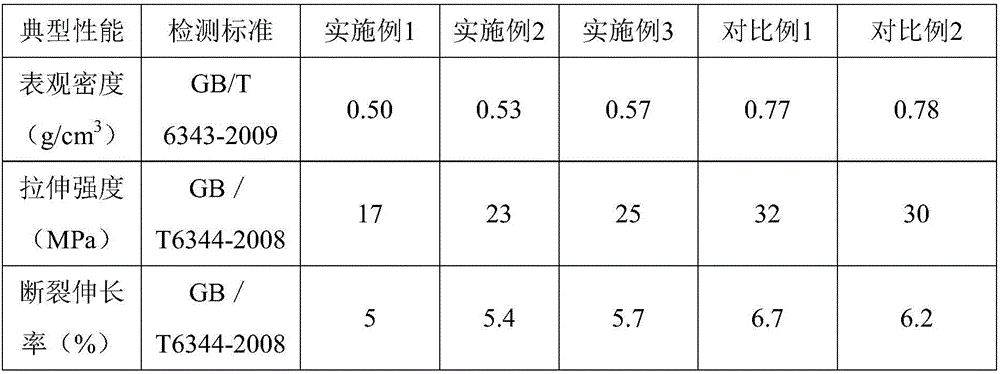

High-melt strength polypropylene foam material and preparation method thereof

The invention discloses a high-melt strength polypropylene foam material and a preparation method thereof. The matrix resin of the foam material is high-melt strength polypropylene. The high-melt strength polypropylene foam material has the following characteristics: (1) the melt index (190 DEGC / 2.16kg) is 1.0-10g / min; (2) the molecular weight distribution Mw / Mn is 6-20; (3) the content of the molecules with molecular weight over 5 million is greater than or equal to 0.8% by weight; and (4) (Mz+1) / Mn is greater than or equal to 70. The foam material is prepared by premix melting, blending and foaming of the following components in parts by weight: 100 parts of high-melt strength polypropylene and 1-15 parts of foaming agent. The obtained foam material meets the environmental protection requirements of degradability, uniform cell, high physical heat resistance, low production cost and smooth surface, and is suitable for continuous large-scale production.

Owner:CHINA PETROLEUM & CHEM CORP +1

Branched crystalline polypropylene

Branched crystalline polypropylene compositions and methods for the preparation of branched crystalline polypropylene compositions are provided. For example, described herein is a process of preparing a branched crystalline polypropylene composition that includes combining two or more different metallocene catalyst compounds with a polymerization medium that includes propylene, for a time sufficient to provide branched crystalline polypropylene that has from 0.0 wt % to 2.0 wt % ethylene and a heat of fusion of 70 J / g or more.

Owner:EXXONMOBIL CHEM PAT INC

Modified polylactic acid composite material suitable for 3D printing and preparation method of composite material

The invention relates to a modified polylactic acid composite material suitable for 3D printing and a preparation method of the composite material. The modified polylactic acid composite material suitable for 3D printing is prepared from the following raw materials in percentage by weight: 80-90% of polylactic acid, 6-10% of a flexibilizer, 1-2% of a nucleating agent, 1-3% of a dispersing agent, 1-2% of a chain extender and 1-3% of a compatilizer. The preparation method of the modified polylactic acid composite material suitable for 3D printing comprises the following steps: mixing the raw materials by virtue of a high-speed mixer, and extruding and drawing by using a single-screw extruder. Compared with the prior art, the composite material prepared by the method is good in flexibility; meanwhile, the impact strength, the heat resistance and the breakage elongation can be greatly improved; the printing is smooth when the composite material is used for 3D printing; the finished product has the advantages of smooth surface, beautiful and shapely appearance and stable size.

Owner:SHANGHAI RES INST OF MATERIALS CO LTD

Plant fiber-reinforced polylactic acid foam material and preparation method thereof

The invention discloses a plant fiber-reinforced polylactic acid foam material, which is prepared from the following components: 20 to 95 percent of polylactic acid, 1 to 60 percent of plant fiber powder, 1 to 5 percent of foaming agent, 1 to 5 percent of nucleating agent, 1 to 5 percent of antioxidant and 1 to 5 percent of bulking agent. The invention also discloses a preparation method for the material. The foam material has the advantages of low apparent density, biodegradability, no environmental pollution, capacity of replacing polyolefin foam materials, wide application in the fields of heat insulation, buffer and packaging, simple preparation process and high production efficiency.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

Preparation of PC/ABS alloy

This invention refers to a kind of preparation method of PC / ABS alloy, adopts ABS / PP-g-MAH as the compatiblizing agent of PC / ABS and is composed of polycarbonate, acrylonitrile-styrene- butadiene copolymer (ABS), ABS / PP grafts, antioxidant, lubricant and other auxiliary agents. We mix them in double-screwed extruder, discharges, extrudes, cools, dries, granulates and gets the turnoff. The invention is characterized with good mechanical properties, processing propertyies and high thermal endurance and is adaptable to injection molding.

Owner:上海普利特伴泰材料科技有限公司 +5

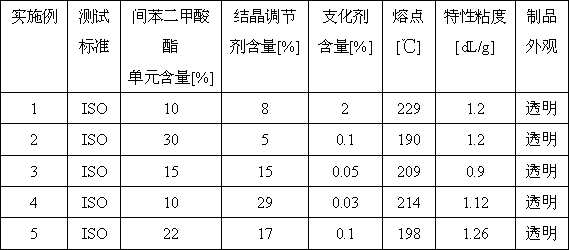

Low-melting point and transparent PET copolyester, its preparation method and application

ActiveCN103102473ASolve problems such as whiteningHigh transparencyMolten statePolyethylene terephthalate glycol

The invention discloses a low-melting point and transparent PET (polyethylene terephthalate) copolyester, its preparation method and application. The PET copolyester comprises, by mass: 60-84% of PET, 10%-30% of a unit derived from isophthalic acid, 5%-29% of a crystallization adjusting agent, and 0.03-2% of a branching agent. According to the preparation method, in a synthesis process of PET, based on p-phthalic acid (PTA) and ethylene glycol (EG), the unit derived from isophthalic acid, the crystallization adjusting agent and the branching agent are added to undergo a chemical reaction together, thus obtaining the low-melting point and transparent PET copolyester. The PET copolyester provided by the invention has an intrinsic viscosity greater than 0.9dL / g and a melting point lower than 230DEG C, can be solidified into an amorphous state from a molten state during injection molding, and has good transparency as well as further improved processing performance.

Owner:KINGFA SCI & TECH CO LTD +2

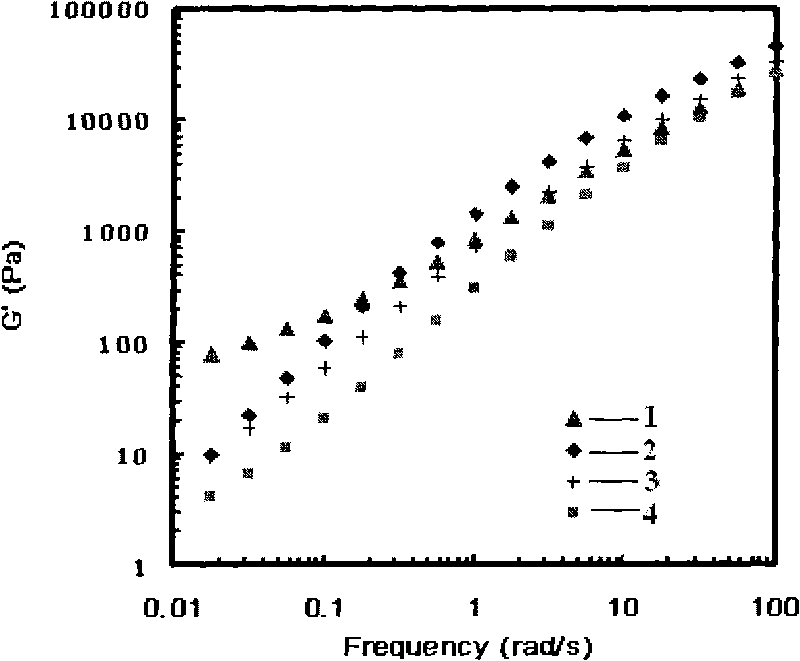

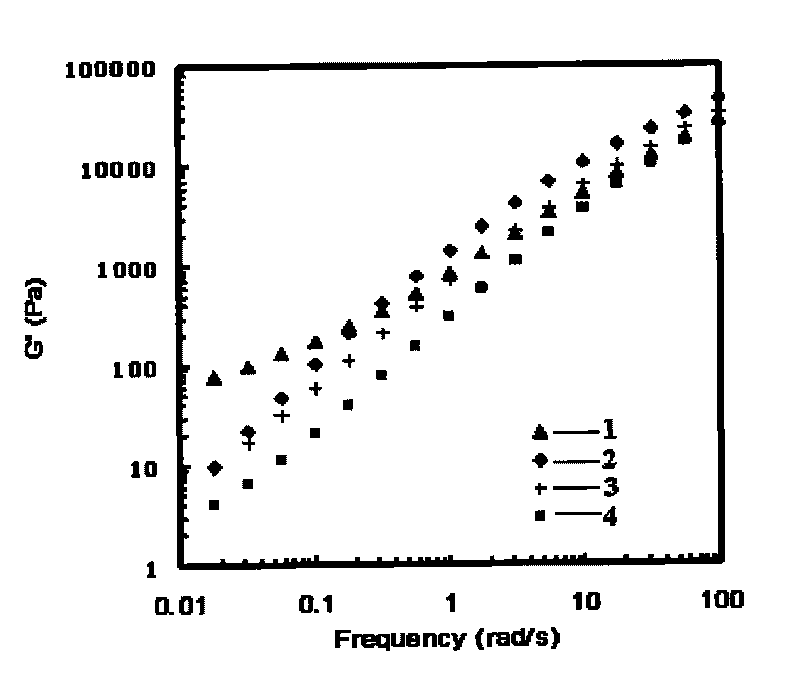

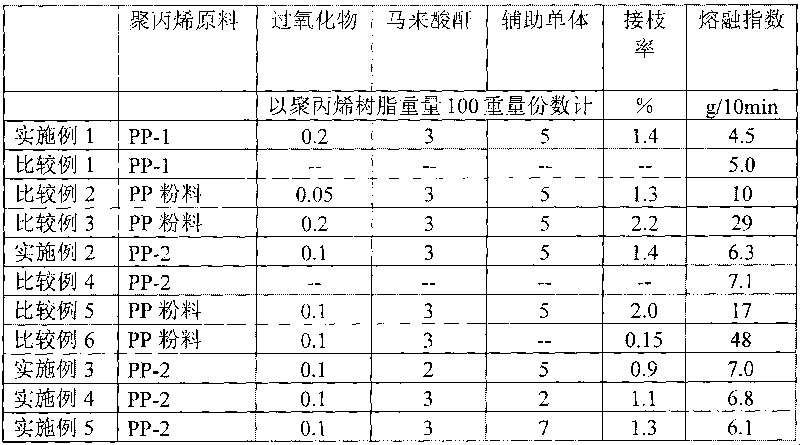

Preparation method of maleic anhydride drafted polypropylene resin graft polymer

ActiveCN101724128AMitigation of thermo-oxidative degradationImproved melt elasticityMaleic anhydrideDouble bond

The invention provides a preparation method of a maleic anhydride drafted polypropylene resin graft polymer, relating to a maleic anhydride melt-drafted polypropylene resin technology. The polypropylene resin is an antioxidant-free polypropylene powder. The preparation method comprises the following steps of: melting and blending 0.1 to 1 part of antioxidant and the polypropylene powder in 100 parts by weight of the polypropylene, and then carrying out the melting free radical grafting reaction on the polypropylene resin melted and blended with the antioxidant; initiating the melting free radical grating reaction by a peroxide initiator, and introducing an auxiliary monomer except for adding grafting monomer maleic anhydride, wherein the auxiliary monomer is an organic monomer containing two or more carbon-carbon double bonds, the using amount of the auxiliary monomer is 2 to 8 parts in 100 parts by weight of the polypropylene resin, and the using amount of the maleic anhydride is 1 to 8 parts in 100 parts by weight of the polypropylene resin. The preparation method of the maleic anhydride drafted polypropylene resin can obtain the polypropylene resin graft polymer with higher molecular weight and melt strength.

Owner:CHINA PETROLEUM & CHEM CORP +1

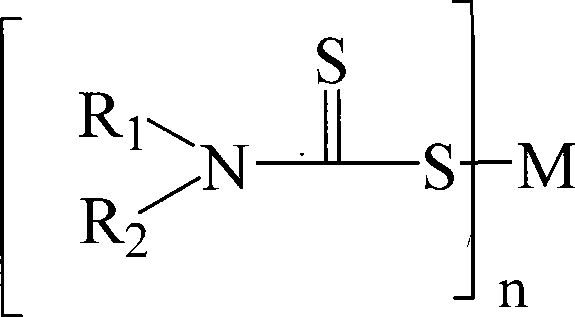

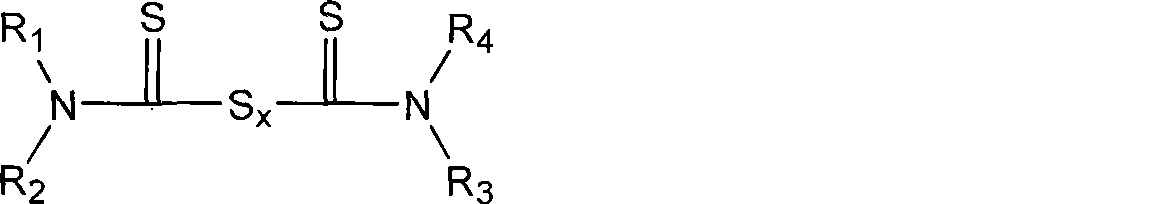

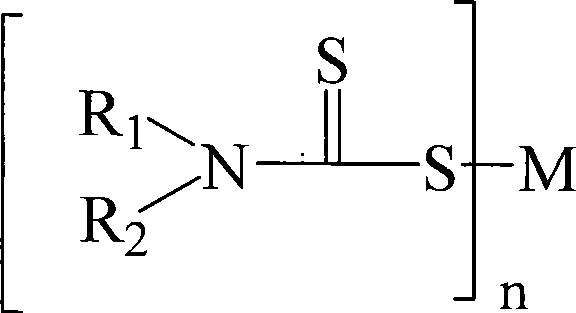

Preparation of high melt strength polypropylene

The invention discloses a method for preparing polypropylene with high melt strength, which comprises melt-blending polypropylene, monomer containing double bond, peroxide, dithiocarbamate series substance and antioxidant. The dithiocarbamate is added as adjuvant to inhibit the propylene degradation of the peroxide, improve the graft ratio, reduce monomer amount containing double bond, and save the cost. The obtained polypropylene with high melt strength has melt strength more than 2-15 times of that of raw material, and gel content smaller than 10%.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Blends of aliphatic-aromatic copolyesters with ethylene-vinyl acetate copolymers

ActiveUS20050137303A1Excellent fragmentation and breakdownImprove melt strengthPaper coatingSpecial tyresPolymer scienceCopolyester

Disclosed are blends of aliphatic-aromatic copolyesters with poly(ethylene-co-vinyl acetate) copolymers and shaped articles prepared therefrom. These blends have higher melt strength than the aliphatic-aromatic copolyester alone and exhibit increased melt strength and better processability. In addition, the blends and shaped articles show bio-disintegration and / or biodegradability in a composting environment.

Owner:EASTMAN CHEM CO

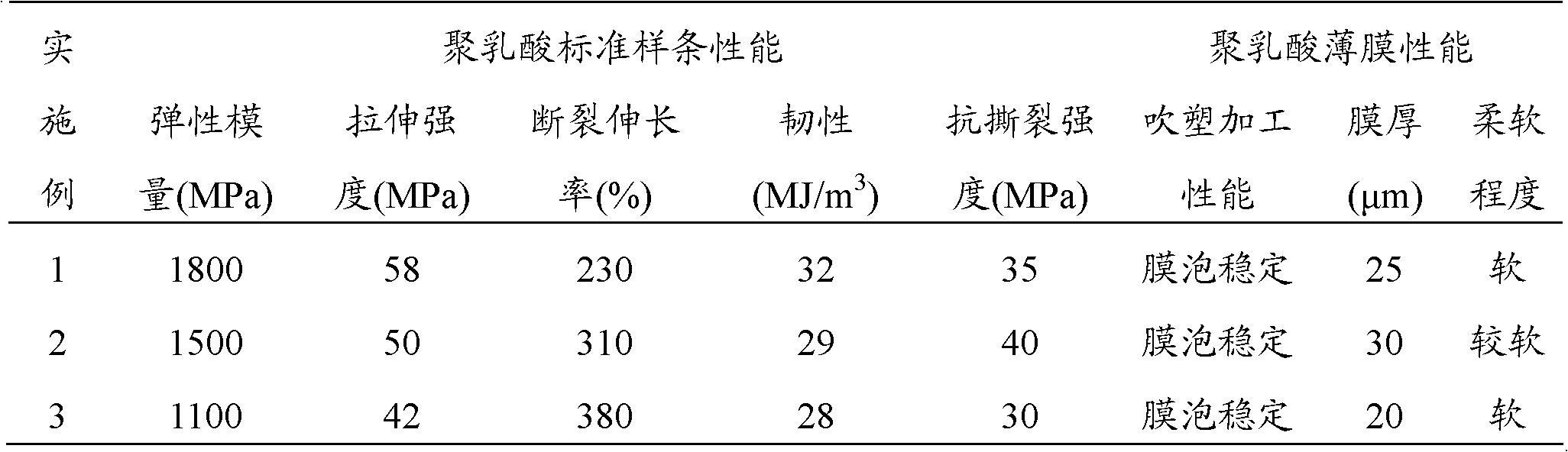

Polylactic acid composition and polylactic acid product

InactiveCN102618003AGood comprehensive mechanical propertiesImprove blow molding processabilityPlasticizerPolylactic acid

The invention provides a polylactic acid composition and a polylactic acid product. The polylactic acid composition comprises the following components by weight percent: 50 to 80 percent of polylactic acid, 0 to 35 percent of adipic acid-polybutylene terephthalate, 0 to 35 percent of poly(butylene succinate), 0.05 to 0.5 percent of peroxide, 0.05 to 0.5 percent of chain extendor and 3 to 15 percent of plasticizer, wherein the content of the adipic acid-polybutylene terephthalate and the content of the poly(butylene succinate) are not 0 percent. The mechanical properties such as melt strength, elongation at break, tenacity and anti-tear strength of the polylactic acid composition provided by the invention are improved, so that the polylactic acid composition with better comprehensive mechanical properties can be obtained, and the polylactic acid composition has more stable processability and better film forming stability.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

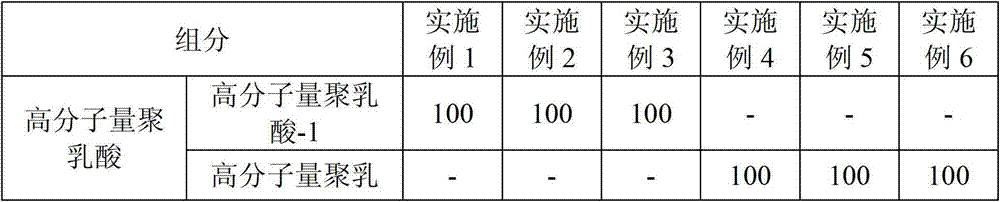

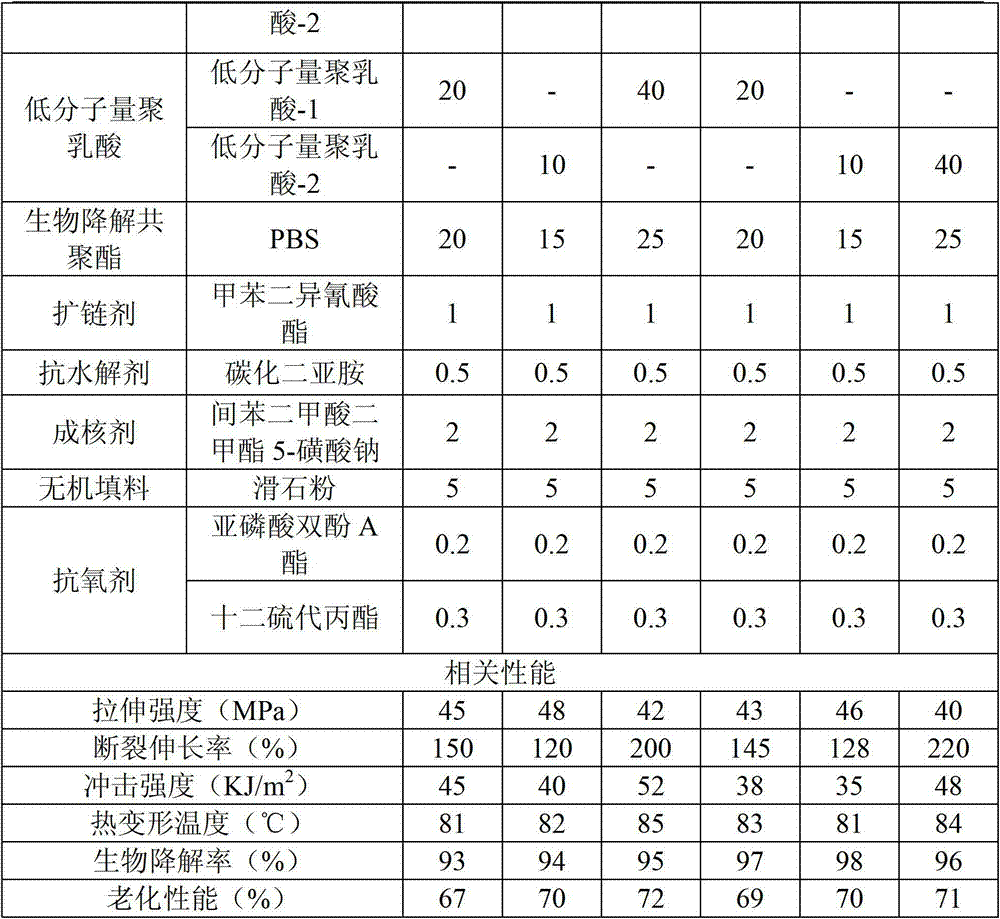

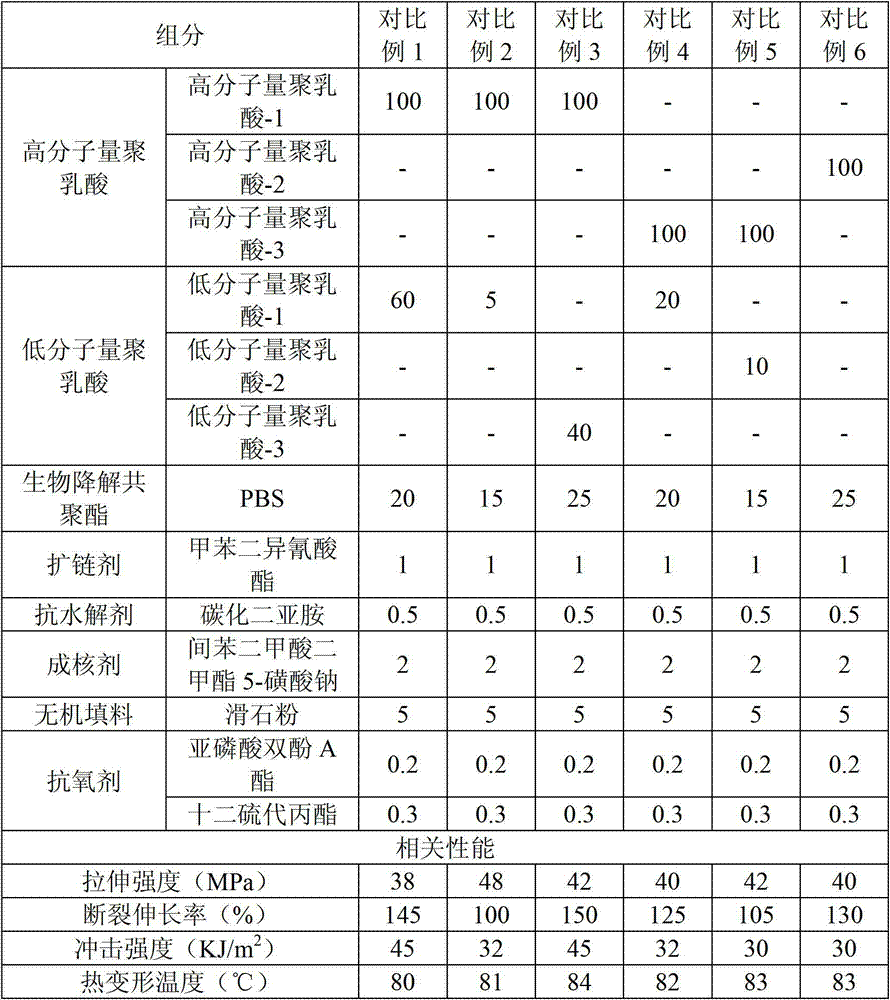

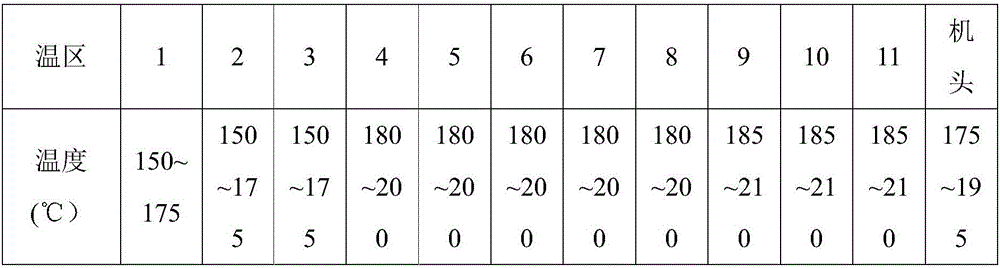

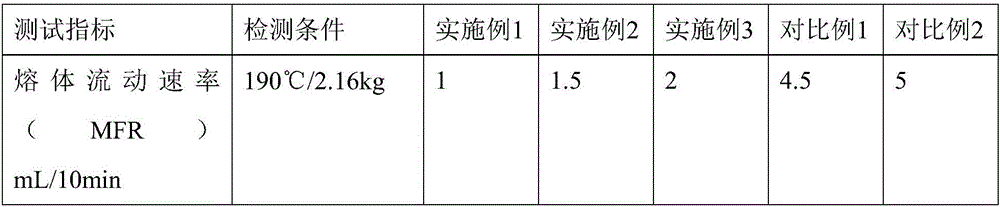

Biodegradable polylactic acid composite material, and preparation method and application thereof

ActiveCN103087488AHigh impact strengthIncreased tensile elongation at breakPolymer scienceAntioxidant

The invention discloses a biodegradable polylactic acid composite material, and a preparation method and an application thereof. The biodegradable polylactic acid composite material comprises the components of, by weight, 100 parts of high-molecular-weight polylactic acid, 10-40 parts of low-molecular-weight polylactic acid, 10-30 parts of biodegradable copolyester, 0.1-3 parts of a chain extender, 0.1-3 parts of an anti-hydrolysis agent, 0.1-5 parts of a nucleating agent, 5-20 parts of an inorganic filler, and 0.1-0.8 parts of an antioxidant. The weight average molecular weight Mw of the high-molecular-weight polylactic acid is greater than 100000 and no greater than 200000, and the weight average molecular weight Mw of the low-molecular-weight polylactic acid is no lower than 60000 and no greater than 100000. The polylactic acid composite material provided by the invention has high melt strength, high toughness, high heat resistance, high water resistance and good processing properties. The material can be widely applied in the fields such as toys, offices, cars and electronic appliances.

Owner:KINGFA SCI & TECH CO LTD +2

Preparation method of biodegradable polyester with low carboxyl end group content

The invention relates to a preparation method of biodegradable polyester, and specifically relates to a preparation method of biodegradable polyester with a low carboxyl end group content. The method comprises esterification reactions and condensation and polymerization reactions: after the esterification reaction, polycyclic oxy-compounds are directly added into the reaction products to carry out reactions, and the reaction products are subjected to carry out condensation and polymerization reactions so as to obtain the biodegradable polyester with a low carboxyl end group content, wherein the carboxyl end group content is 5 to 20 mmol / kg. The invention aims to solve the problem of high carboxyl end group content in biodegradable polyesters, namely aliphatic polyester / copolymer and aliphatic-aromatic copolyester materials. The method provided by the invention reduces the carboxyl end group content in the materials, improves the flux strength, shortens the reaction time, obtains a polyester material with a good color (low b value), improves the anti-aging ability of the biodegradable polyester material, and prolongs the service life of the biodegradable polyester material. The preparation method has the advantages of controllable reaction conditions, low cost, and suitability for industrial production.

Owner:山东悦泰生物新材料有限公司

Special resin with high melt strength for foaming of polylactic acid and preparation method thereof

The invention relates to special resin with high melt strength for foaming of polylactic acid and a preparation method thereof, and belongs to the technical field of macromolecules. The special resin is prepared from the following raw materials in parts by weight: 60 to 95 parts of polylactic acid, 1 to 20 parts of biodegradable copolymer, 0.1 to 1 part of chain expander, 1 to 5 parts of melt enhancer, 0.1 to 5 parts of nucleating agent, and 0.5 to 2 parts of lubricant. The special resin has the advantages and beneficial effects that by improving the melt strength of the polylactic acid and enhancing the adsorbing ability of polylactic acid on CO2 (carbon dioxide), the foaming property of the polylactic acid is enhanced. The used devices are universal devices in the technical field of macromolecules, such as a double-screw extruder, a crystallizing drier and a plastic extrusion foaming machine. The special resin has the advantages that the operation is simple and convenient, the control is easy, the industrialized implementing is easy, and the economic benefit is high.

Owner:JILIN COFCO BIOCHEM

Degradable polylactic acid diblock copolymer, preparation method and application to modified polylactic acid

The invention discloses a degradable polylactic acid diblock copolymer, a preparation method and application to modified polylactic acid, solving the problems of instable performance, high preparation cost and unsuitability for industrialized continuous production of modified polylactic resin in the prior art. The preparation method of the degradable polylactic acid diblock copolymer comprises the following steps of: adding dried and dewatered polylactic acid A with an end group being hydroxy into a reaction device under the protection of an inert atmosphere, adding diisocyanate B, heating to 185-190 DEG C, reacting with stirring for 5-8h, adding degradable high polymer C containing hydroxy, reacting with stirring for 1-2h at the temperature of 185-190 DEG C, adding the diisocyanate B, and reacting at the temperature of 185-190 DEG C until the stirring is difficult to obtain the degradable polylactic acid diblock copolymer. The degradable polylactic acid diblock copolymer disclosed by the invention is good in compatibility with the polylactic resin, is used for modifying the polylactic resin, is capable of remarkably improving processing property and mechanical property of the polylactic resin, and has the elongation at break reaching 60 percent.

Owner:CHANGZHOU INST OF ENERGY STORAGE MATERIALS &DEVICES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com