Preparation of high melt strength polypropylene

A high-melt-strength, polypropylene technology is applied in the field of high-melt-strength polypropylene preparation, which can solve the problems of large equipment investment, high technical requirements, and high odor, and achieves low equipment investment, simple process and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Example 1 50 g of polypropylene (homopolypropylene powder, melt index: 7.2 g / 10 min) and 0.1 g of antioxidant B215 were pre-mixed. 2,5-dimethyl-2,5-bis(tert-butylperoxy)hexane was dissolved in acetone according to the amount of 3.8mmol / kg polypropylene, and trimethylolpropane triacrylate was dissolved according to 44mmol / kg polypropylene The amount of propylene is dissolved in acetone, after the dissolution is complete, the acetone solution is evenly sprayed on the pre-mixed polypropylene powder, put in a vacuum oven at 40°C for 12 hours, and the vacuum degree is 10 -6 MPa, and then put it into the material chamber of the internal mixer, the temperature is set as: 175 °C in the first zone, 180 °C in the second zone, 180 °C in the third zone, the speed is 60 rpm, and the material is discharged after 7 minutes of reaction when the torque is stable. Some samples were taken for performance testing and melt strength determination. The results are shown in Table 1.

Embodiment 2

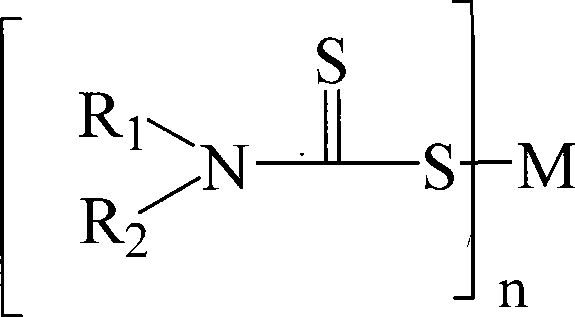

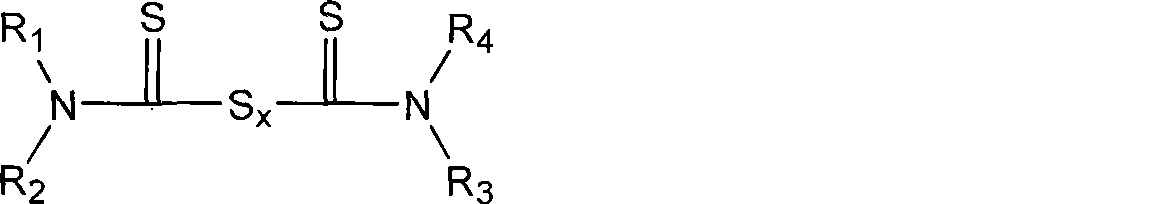

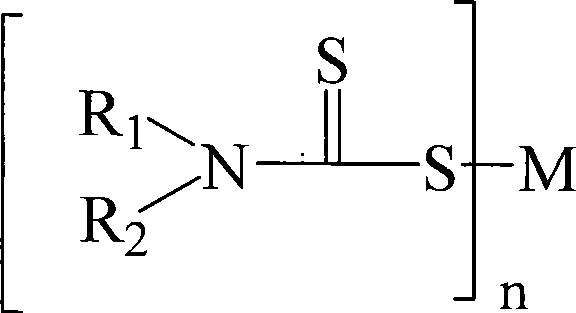

[0044] Example 2 50g polypropylene (homopolypropylene powder, melt index is 7.2g / 10min), 0.1g antioxidant B215 and copper dimethyl dithiocarbamate are premixed, dimethyl dithiocarbamate The amount of copper formate is 1.84mmol / kg polypropylene. 2,5-dimethyl-2,5-bis(tert-butylperoxy)hexane was dissolved in acetone according to the amount of 3.8mmol / kg polypropylene, and trimethylolpropane triacrylate was dissolved according to 44mmol / kg polypropylene The amount of propylene is dissolved in acetone, after the dissolution is complete, the acetone solution is evenly sprayed on the pre-mixed polypropylene powder, put in a vacuum oven at 40°C for 12 hours, and the vacuum degree is 10 -6 MPa, and then put it into the material chamber of the internal mixer, the temperature is set as: 175 °C in the first zone, 180 °C in the second zone, 180 °C in the third zone, the speed is 60 rpm, and the material is discharged after 7 minutes of reaction when the torque is stable. Some samples were...

Embodiment 3

[0045] Example 3 500 g of polypropylene (homopolypropylene powder, with a melt index of 7.2 g / 10 min) and 1 g of antioxidant B215 were premixed. 2,5-dimethyl-2,5-bis(tert-butylperoxy)hexane was dissolved in acetone according to the dosage of 3.4mmol / kg polypropylene, and trimethylolpropane triacrylate was dissolved according to 20mmol / kg polypropylene The amount of propylene is dissolved in acetone, after the dissolution is complete, the acetone solution is evenly sprayed on the pre-mixed polypropylene powder, put in a vacuum oven at 40°C for 12 hours, and the vacuum degree is 10 -6 MPa, and then put it into a twin-screw extruder with L / D=40 and Φ of 24mm. The speed of the extruder is set at 100 rpm. The extruder is divided into eight heating zones, respectively: 185°C , 210°C, 220°C, 220°C, 220°C, 220°C, 220°C, 230°C, extrusion granulation. Some samples were taken for performance testing and melt strength determination. The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com