Special resin with high melt strength for foaming of polylactic acid and preparation method thereof

A technology of polylactic acid foaming and high melt strength, which is applied in the field of polylactic acid foam sheets and polymers, can solve the problems of low melt strength of polylactic acid, achieve simple operation, easy control, and facilitate industrial implementation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

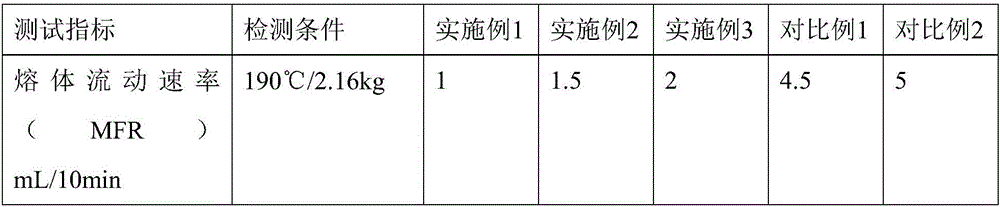

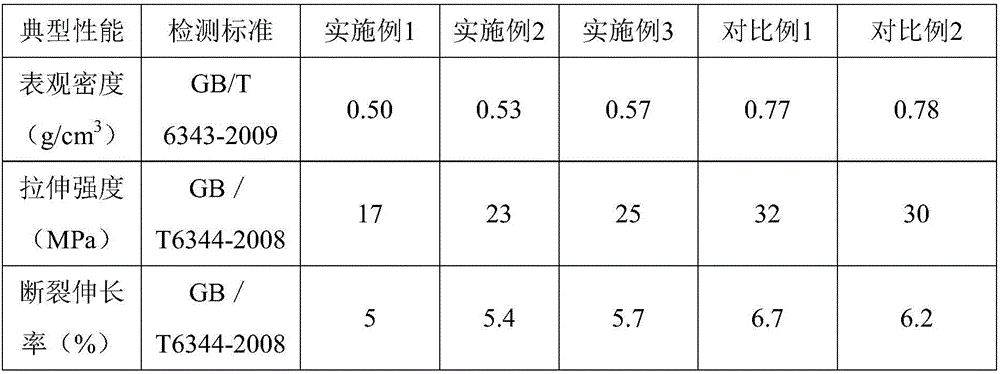

Embodiment 1

[0034] Made from the following raw materials in parts by weight:

[0035] Polylactic acid: 60 parts,

[0036] Biodegradable copolymer: 1 part of polyadipate-terephthalate-butylene glycol ester,

[0037] Chain extender: 0.1 part of 1-4 butanediol,

[0038] Melt Enhancer: PARALOID from The Dow Chemical Company TM BPMS-250, 1 part,

[0039] Nucleating agent: 0.1 part of talcum powder,

[0040] Lubricant: 0.5 parts of PE wax;

[0041] Include the following steps:

[0042] (1) Mix polylactic acid, biodegradable copolymer, chain extender, melt enhancer, nucleating agent, and lubricant evenly; among them, polylactic acid and biodegradable copolymer need to be crystallized and dried before use, and their moisture The weight percentage is within 250ppm;

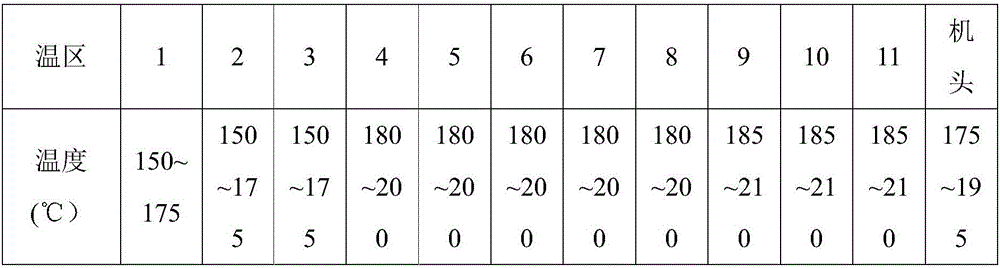

[0043] (2) The mixture prepared in step (1) is added to a twin-screw extruder, extruded and pelletized to obtain a polylactic acid modified resin, and after drying, a special resin for polylactic acid foaming is obtained;

[0...

Embodiment 2

[0048] Made from the following raw materials in parts by weight:

[0049] 80 parts of polylactic acid,

[0050] Biodegradable copolymer: 10 parts of polycaprolactone,

[0051] 0.5 part of chain extender 1-4 butane diisocyanate,

[0052] Melt Enhancer PARALOID from The Dow Chemical Company TM BPMS-255, 3 copies,

[0053] Nucleating agent: 2.5 parts of calcium carbonate,

[0054] Lubricant: 1.2 parts of calcium stearate.

[0055] The preparation method is the same as in Example 1.

Embodiment 3

[0057] Made from the following raw materials in parts by weight:

[0058] 95 parts of polylactic acid,

[0059] Biodegradable copolymer: polyethylene glycol 20 parts,

[0060] Chain extender: 1 part of toluene diisocyanate,

[0061] Melt Enhancer: PARALOID from The Dow Chemical Company TM BPMS-265, 5 copies,

[0062] Nucleating agent: 5 parts of titanium dioxide,

[0063] Lubricant: 2 parts of glyceryl monostearate stearic acid.

[0064] The preparation method is the same as in Example 1.

[0065] The effect of the present invention is further illustrated by the following experimental examples.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com