Patents

Literature

19796 results about "High polymer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

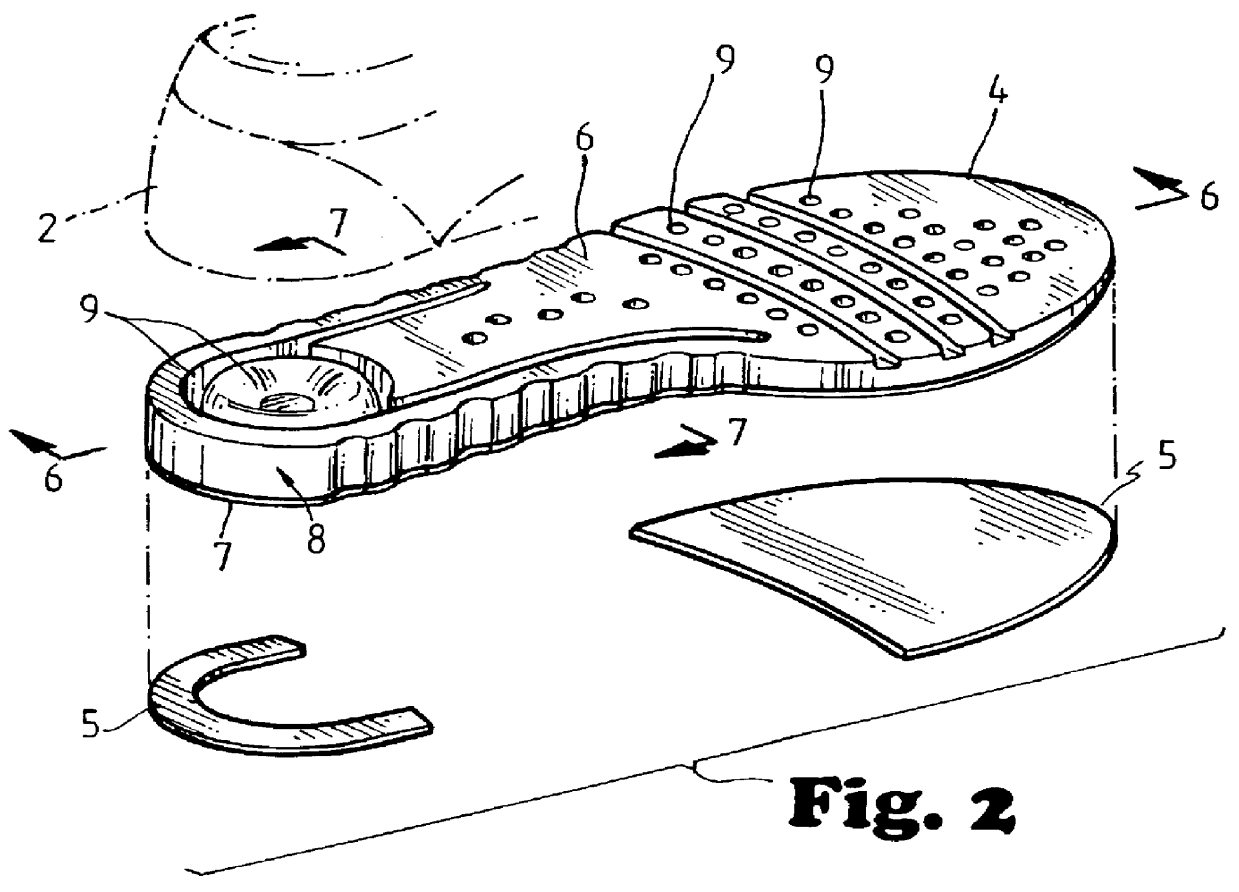

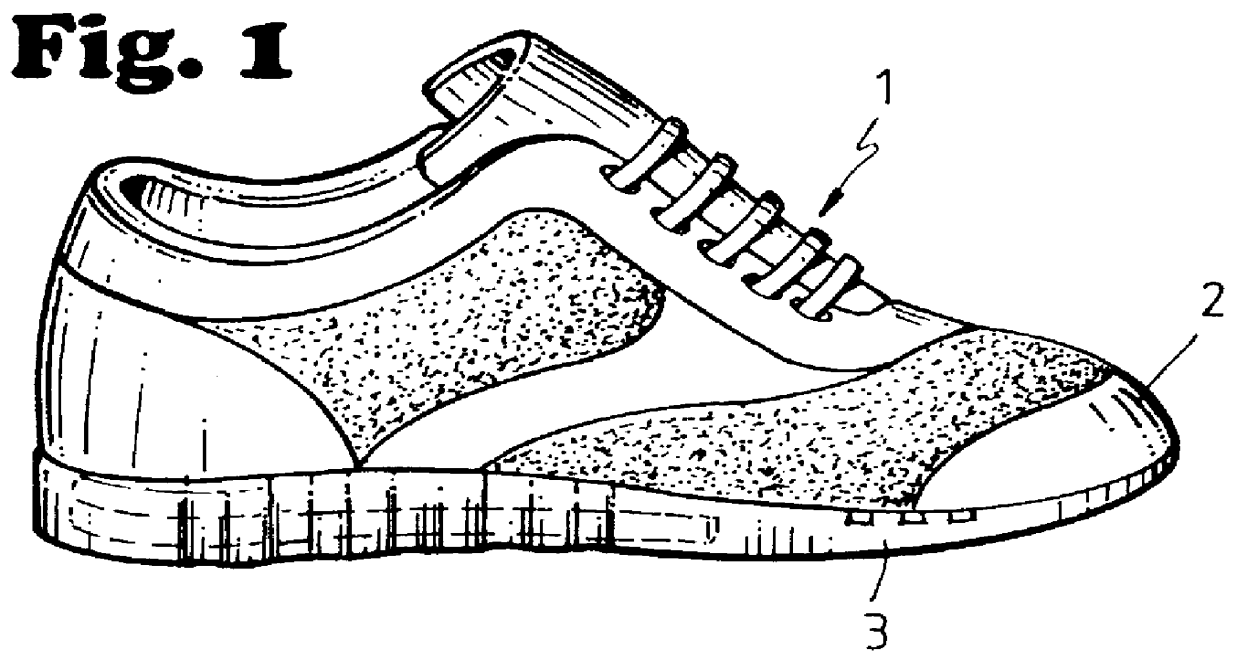

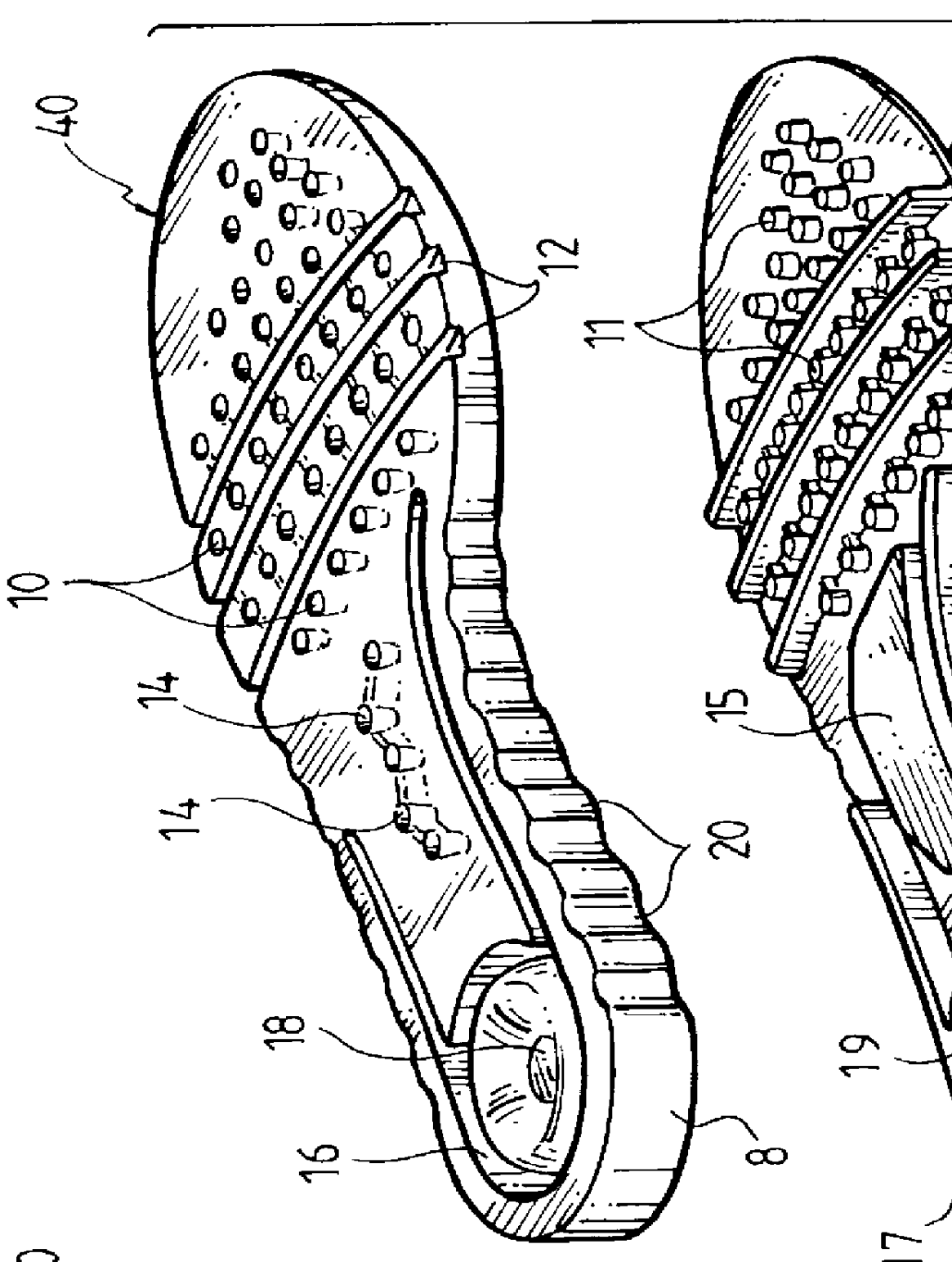

Shoe sole component and shoe sole component construction method

A high polymer resin material is configured into a shoe sole component having a plurality of inwardly extending indentations in one or both of the top and bottom members of the component. The indentations extend into the interval between the members and adjacent to the opposite member to provide support members for the sole component. The sole component can be constructed by molding upper and lower sole component halves wherein the molds are configured to provide indentations in the top and bottom members. The upper and lower sole component halves are then joined to complete the sole component.

Owner:LIESENFELD MARY C +1

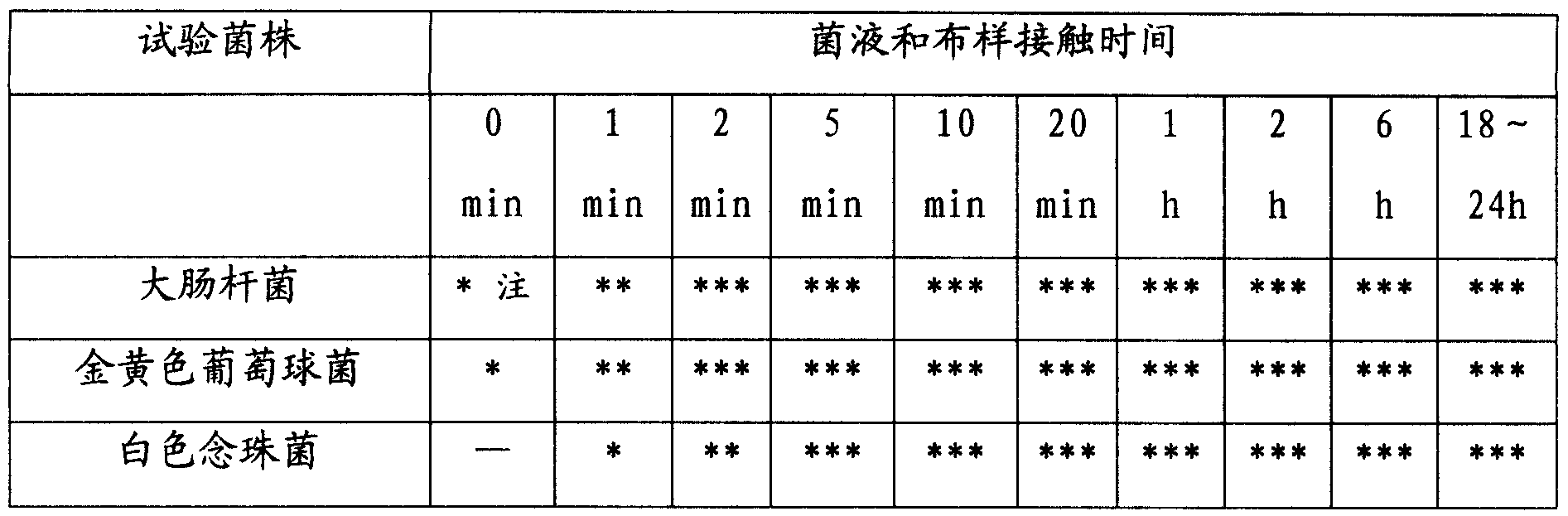

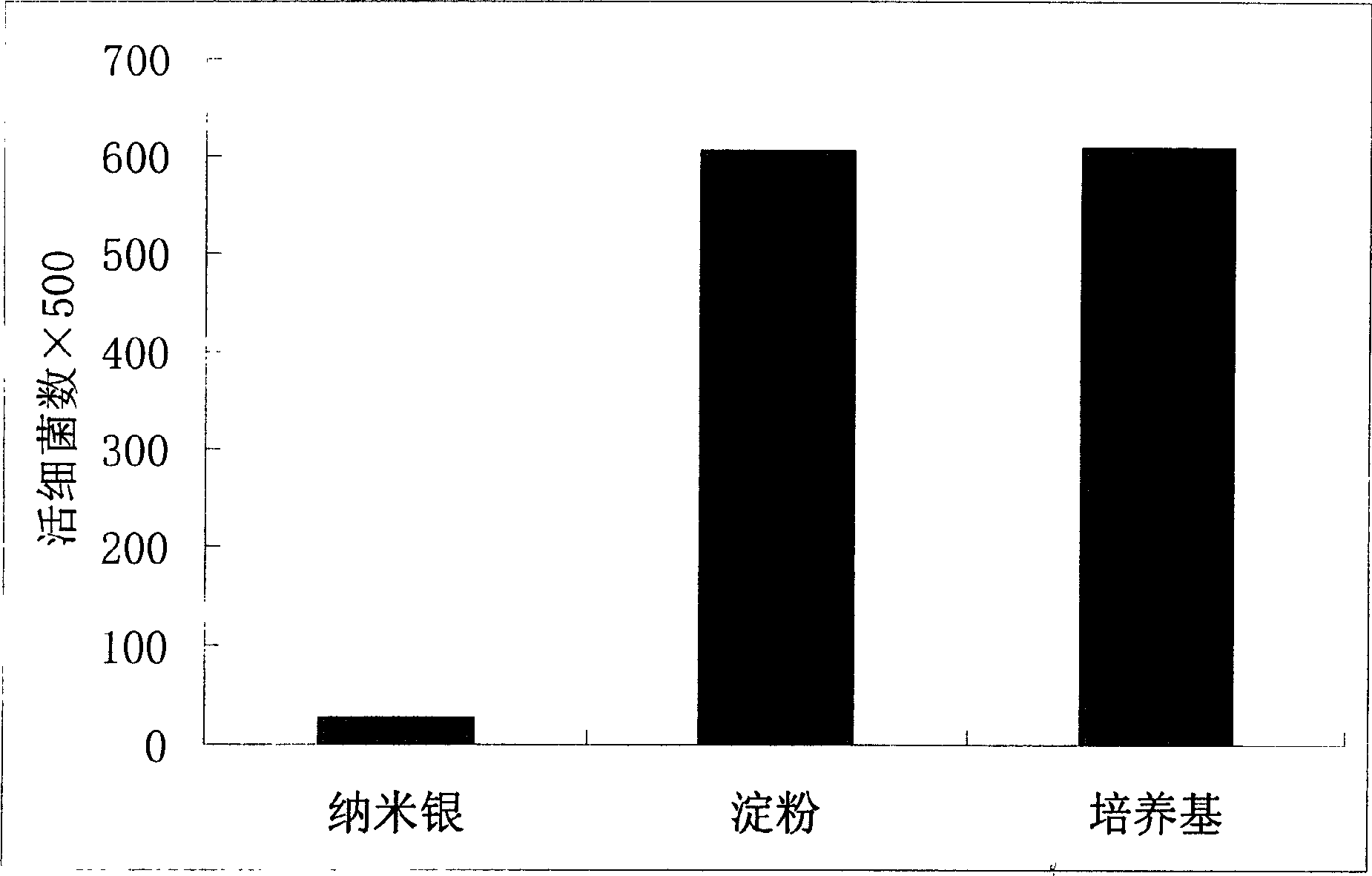

Inorganic/organic nano composite antibacterial agent and its fabric product application

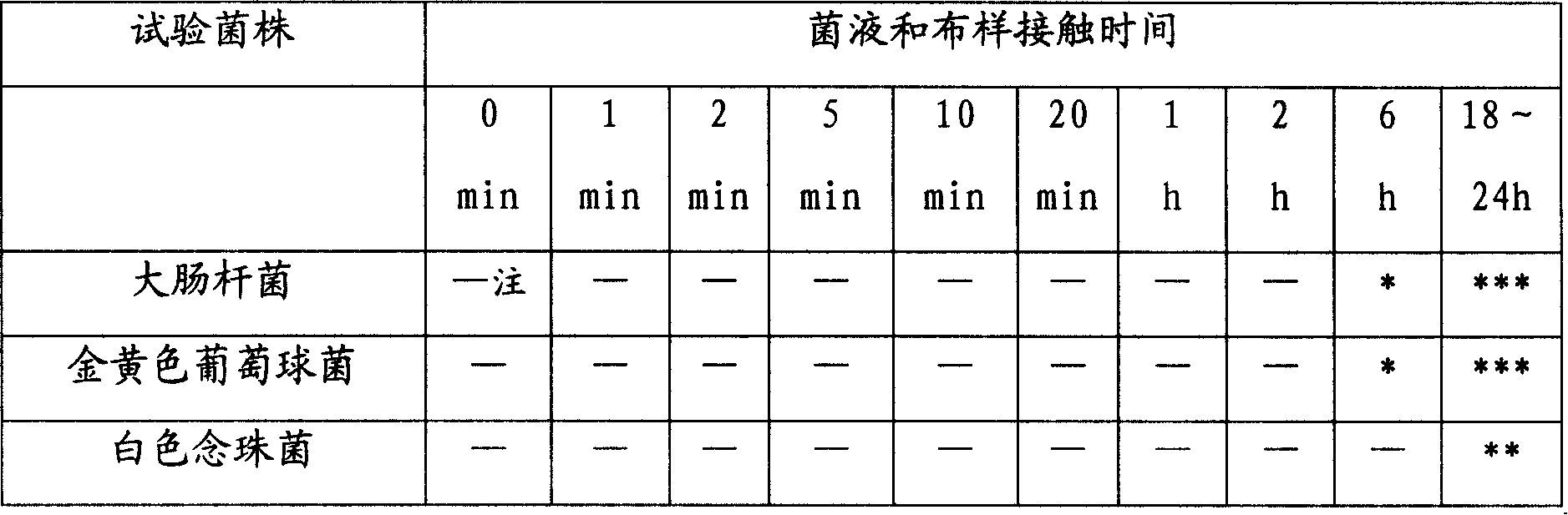

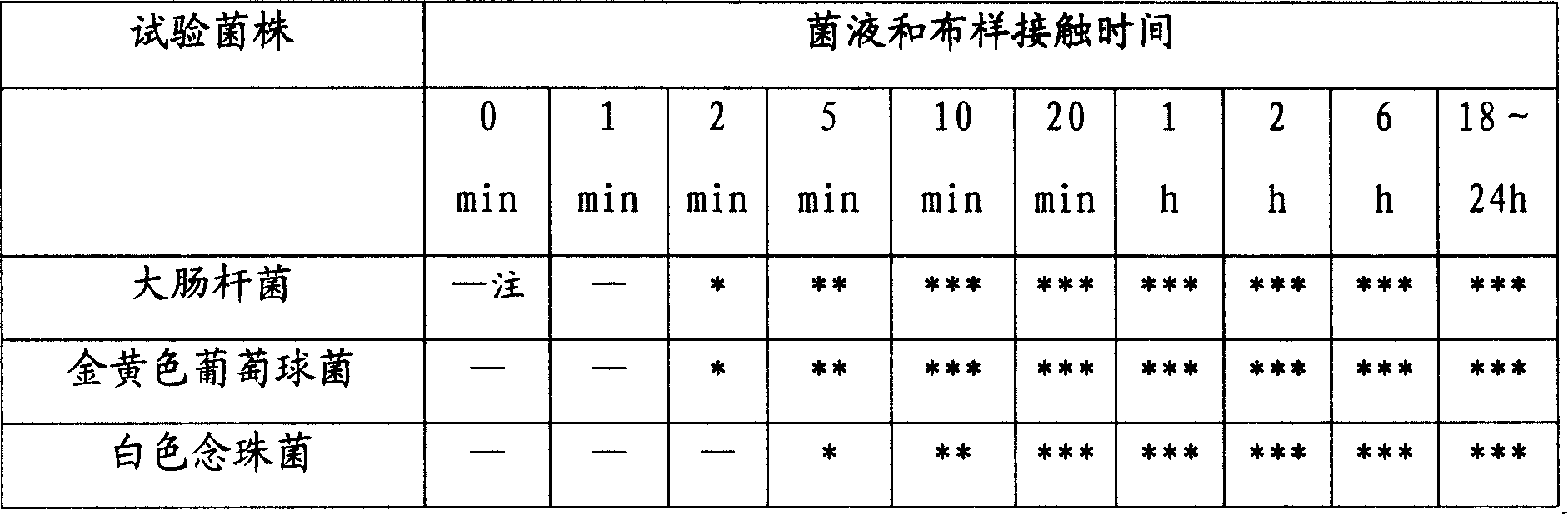

The invention relates to an inorganic / organic nano-composite antibacterial and application of fiber product thereof. 0.01-20 proportions of inorganic antibacterial, 0.01-35 proportions of organic antibacterial, 0.0001-0.4 proportion of inorganic / organic antibacterial compatibility finishing agent, 0.05-40 proportions of macromolecule bond, 0.0001-0.4 proportion of stabilizer that prevents color change of the inorganic antibacterial, 0.1-30 proportions of high efficiency emulsifying agent and 100 proportions of distilled water are added in sequence by weight proportion, wetted, dispersed, ground, dispersed at high-speed, stirred, etc., so as to acquire the nano-composite antibacterial. The antibacterial can process the fiber product by a dip-dye method, a roll-dye method, a spray method, etc. Dresses, socks and socks, blankets, beddings, gowns, patient wears, masks, medicinal gauzes, air filtering nettings, etc., made from the inorganic / organic nano-composite antibacterial of the invention are characterized by high antibacterial efficiency, rapid antibacterial function, long lasting antibacterial performance, laundering durability, etc., and the inorganic / organic nano-composite antibacterial of the invention is applicable to life, medical care, etc., and has the functions of preventing the occurrence and transmission of diseases, protecting the health of people and improving life quality.

Owner:BEIJING CHAMGO NANO TECH

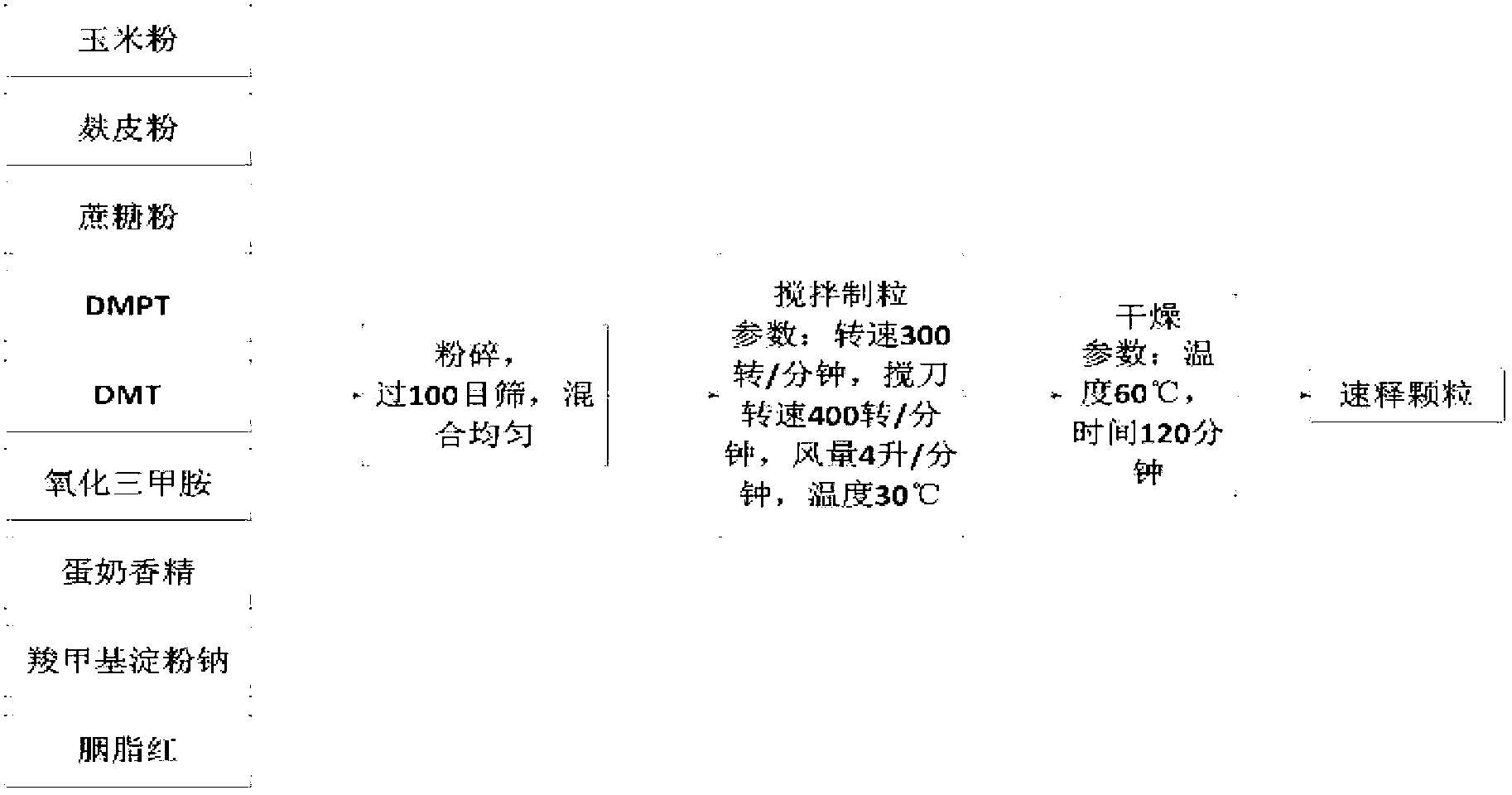

Controlled release bait material and preparation method thereof

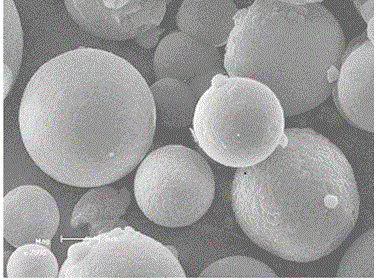

InactiveCN103004717AQuick and long-lasting releaseFast and long-lasting effectOther angling devicesWater insolubleMicrosphere

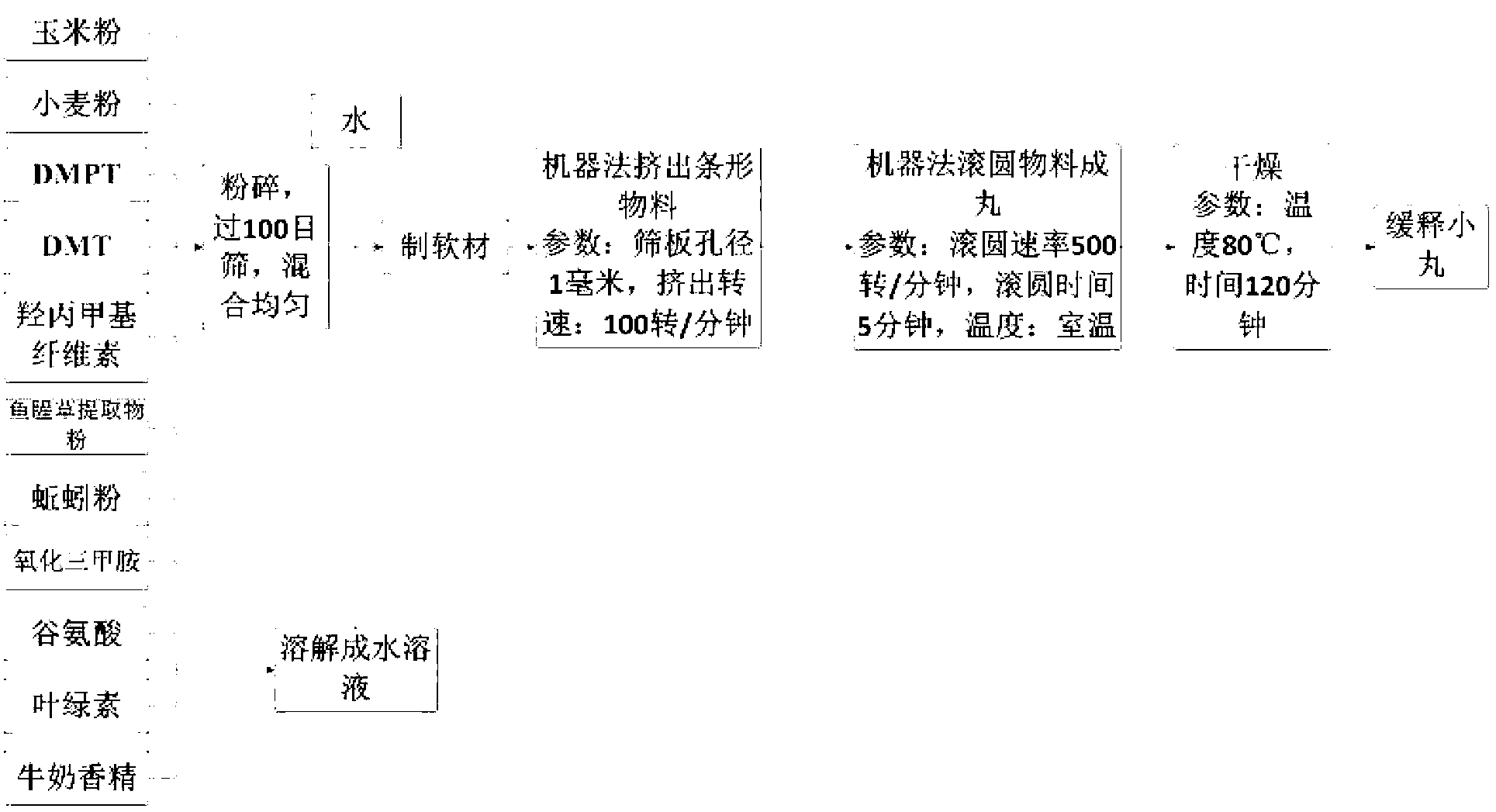

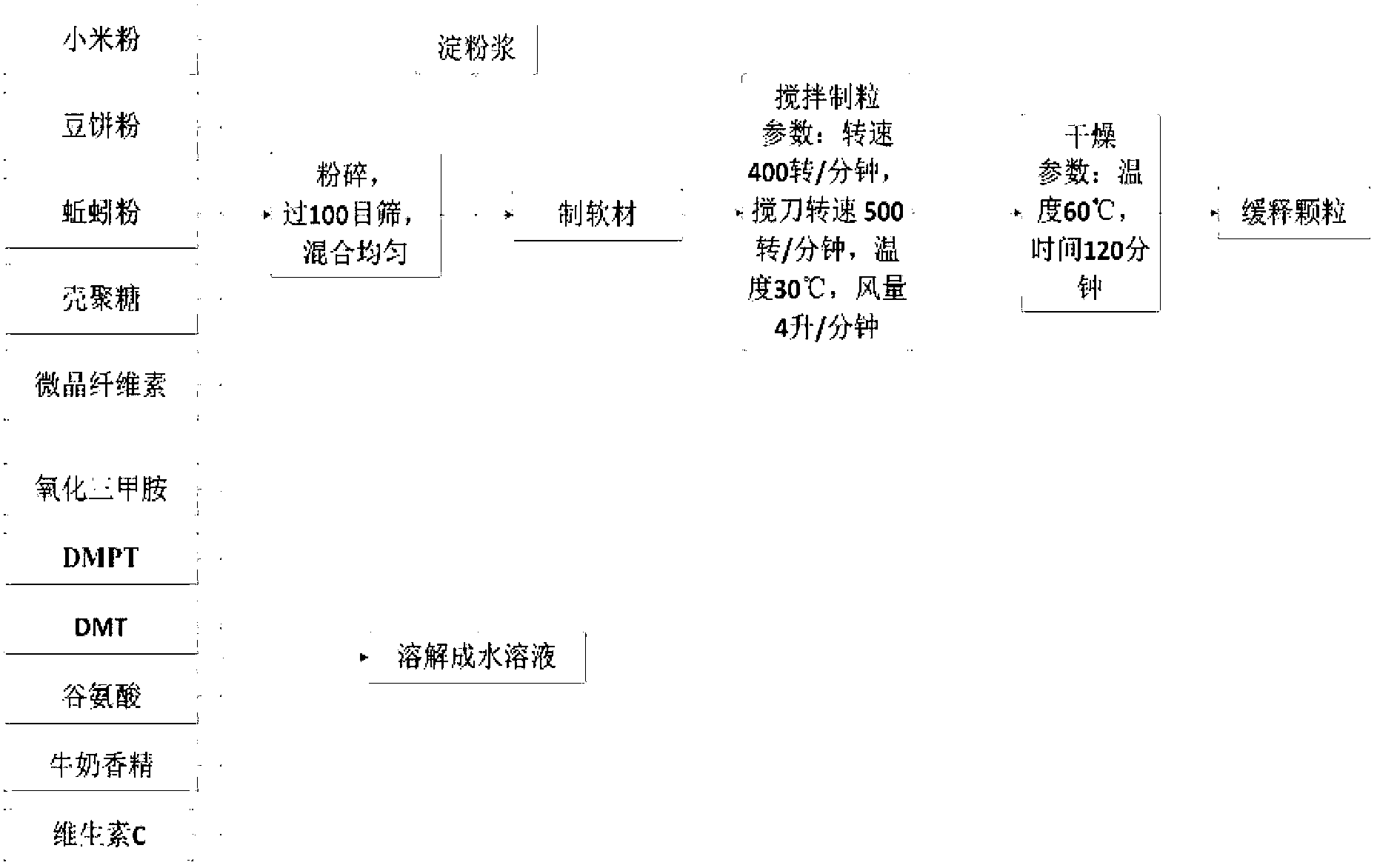

The invention relates to a controlled release bait material and a preparation method thereof. The controlled release bait material refers to small pills, micro-pills, microcapsules, microspheres, particles or sticks prepared from raw materials including a basic material, a feed attractant, a bonding agent, a hydrophilic high-polymer material, a water-insoluble high-polymer material, a quick-release material, a filler, a colorant, a flavoring agent and the like through a preparation means; and the controlled release bait material can be coated for improving the controlled release effect. The invention further discloses a preparation method of the bait material. The controlled release material has rapid and lasting attracting force on fishes, the fish attracting time can be adjusted according to the habit of a fisherman and the habits of fishes, the food ration and frequency of fishes are increased, the fishing success rate can be increased, the food intake of fishes in cultivation of fishes can be increased, the corrosion ratios of remnant feeds and feeds in water bodies are reduced, the utilization ratios of feeds is increased, and the water body environmental pollution is lowered. The preparation method provided by the invention is suitable for industrial production.

Owner:李群益 +2

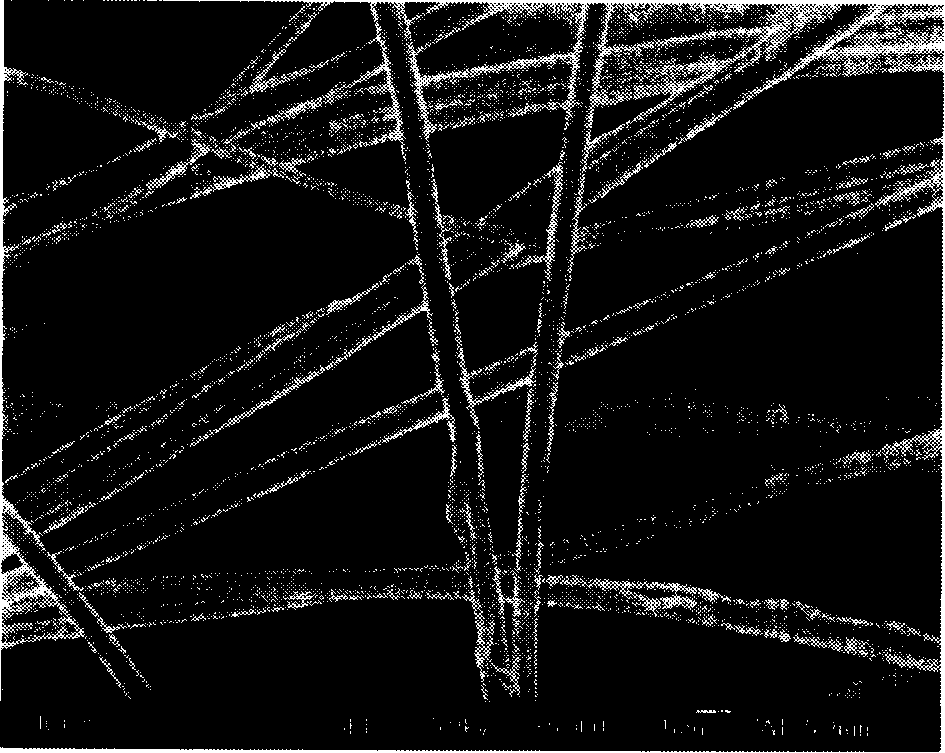

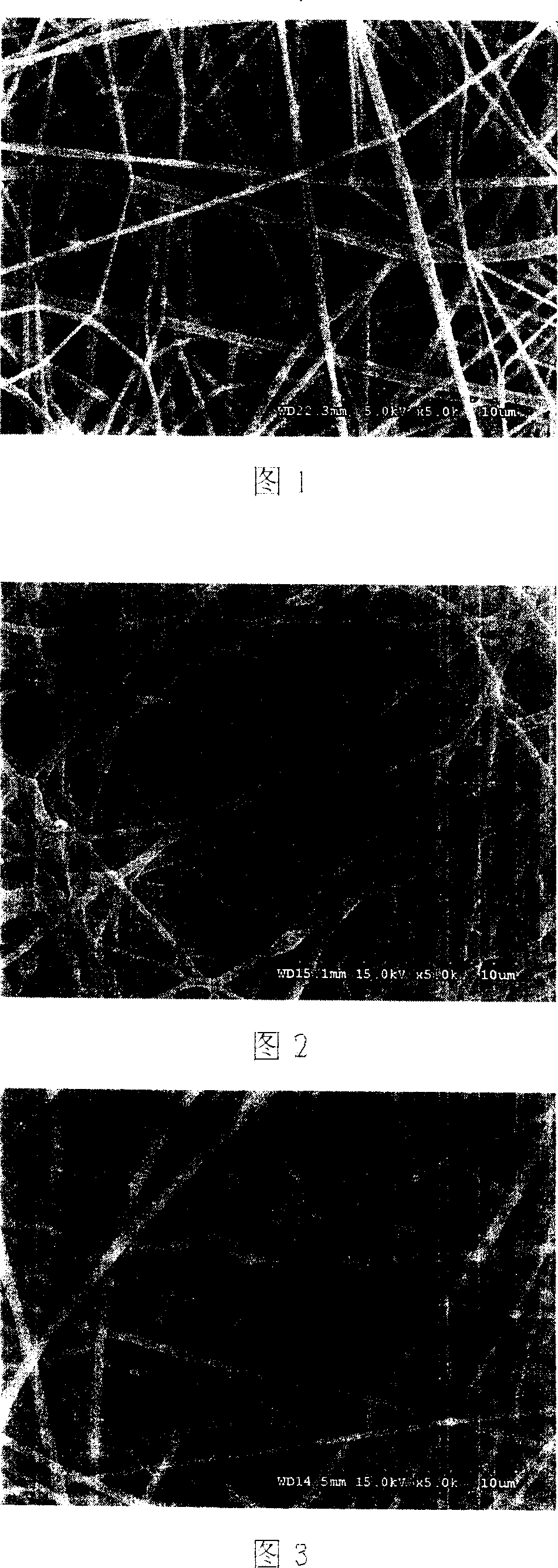

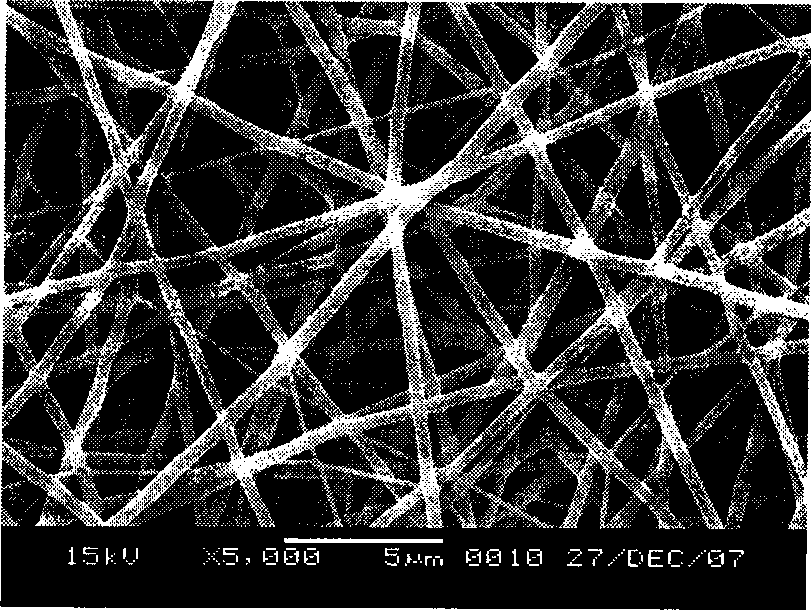

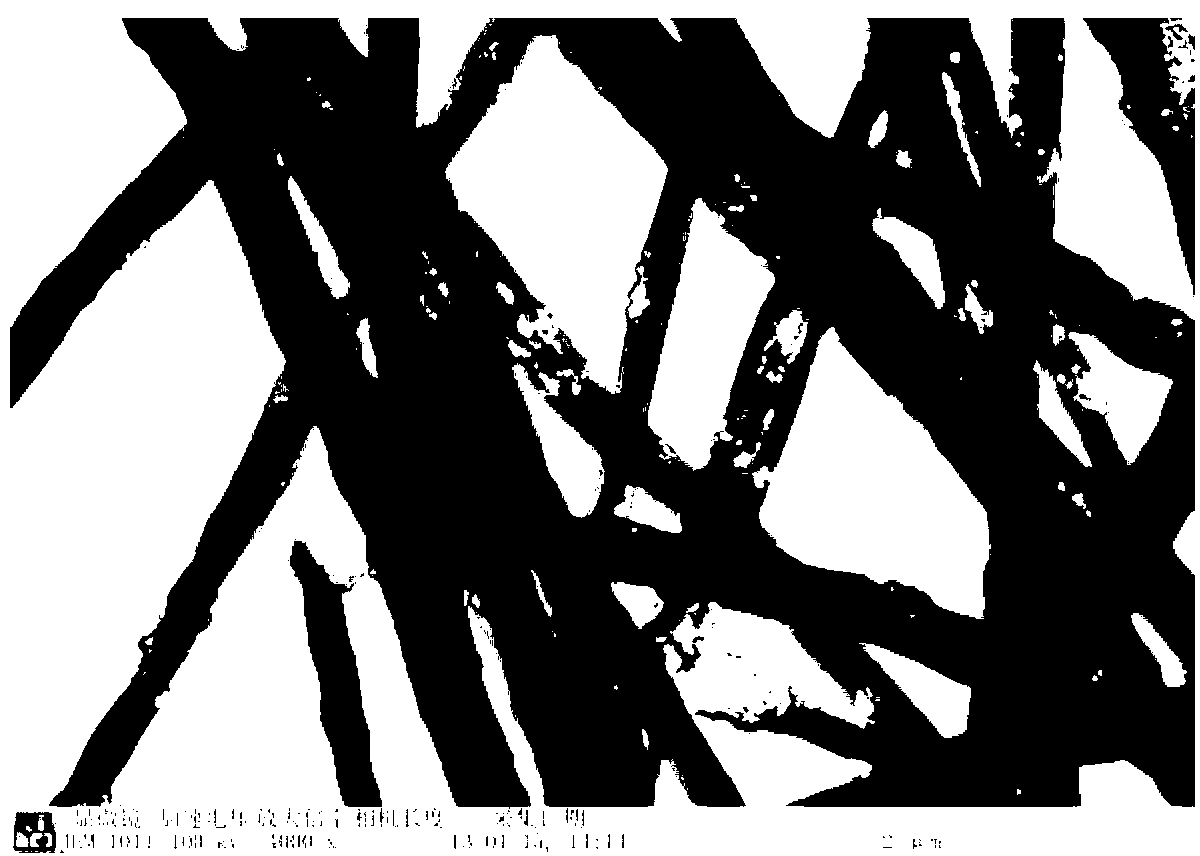

Biopolymer nano tunica fibrosa material capable of being biological degraded and absorbed, preparing method and uses of the same

InactiveCN101172164AGood biocompatibilityPromote degradationSurgeryFilament/thread formingFiberCellulose

The invention relates to compound millimicron fibrous membrane material of cellulose and cellulose matrix which can perform the biological degradation and the biological absorption and a preparation method thereof and an industry and medical purpose, and belongs to the biological macro-molecule non woven fabric material field which can perform the biological degradation and the biological absorption. Electrostatic spinning equipment is used to obtain the fibrous membrane material which can perform the biological degradation and the biological absorption, the weight of the cellulose is taken as basic reference, the component of the material comprises cellulose more than 0 and less than or equal to 100 weight parts, other biomacromolecule more than and equal to 0 and less than 100 weight parts, 0 to 10 weight parts of curative drug or 0 to 50 weight parts of inorganic catalyzer and / or 0 to 50 weight parts of inorganic strengthening agent. The material of the invention has good biological compatibility, biological degradation property and degradation absorptivity, and can be used for haemostasia material, wound cladding material, organization engineering supporting rack material, the transportation and release of medicine, artificial skin and blood vessel, and postoperation anti blocking material, beauty material and catalyzer carrier, filtering membrane and radiation protection material and so on.

Owner:INST OF CHEM CHINESE ACAD OF SCI

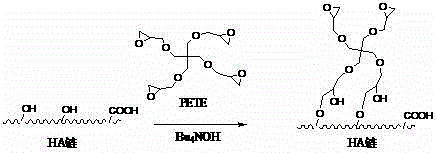

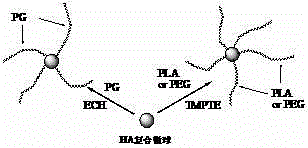

Hyaluronan and biodegradable high polymer modified material and preparation method

The invention relates to a hyaluronan and biodegradable high polymer modified material and a preparation method, in particular to a method for complex crosslinking and grafting of the hyaluronan and a derivative thereof with a biodegradable high polymer with active functional groups through a crosslinking agent. The method comprises the steps of taking the hyaluronan and the biodegradable high polymer as raw materials, conducting complex crosslinking or grafting reaction of a hyaluronan aqueous solution and at least one biodegradable high polymer solution with the presence of the crosslinking agent, and removing a solvent. According to the method, plural gel, an amphiphilic polymer, a graft polymer, a star polymer and a microsphere can be prepared. The method has the advantages that the reaction condition is simple, the utilization ratio of the crosslinking agent is high, the residual quantity of the crosslinking agent is small, and the gel is higher in thermostability and good in biological compatibility. The method is applicable to the fields of cosmetics, tissue filling and repair, biological stents, ophthalmonogy, sustained-release delivery and targeted drug delivery and the like, and has a wider application prospect.

Owner:IMEIK TECH DEV CO LTD

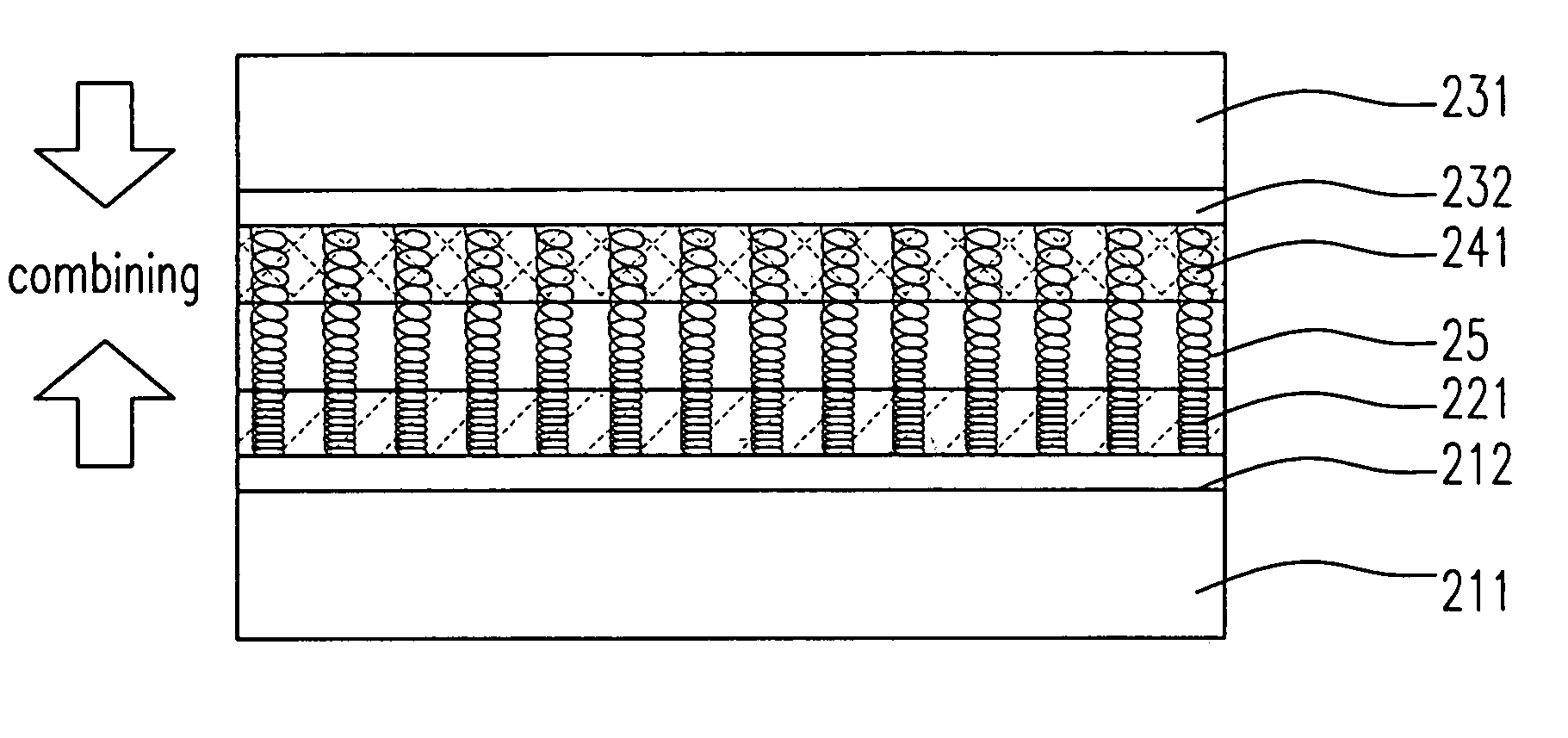

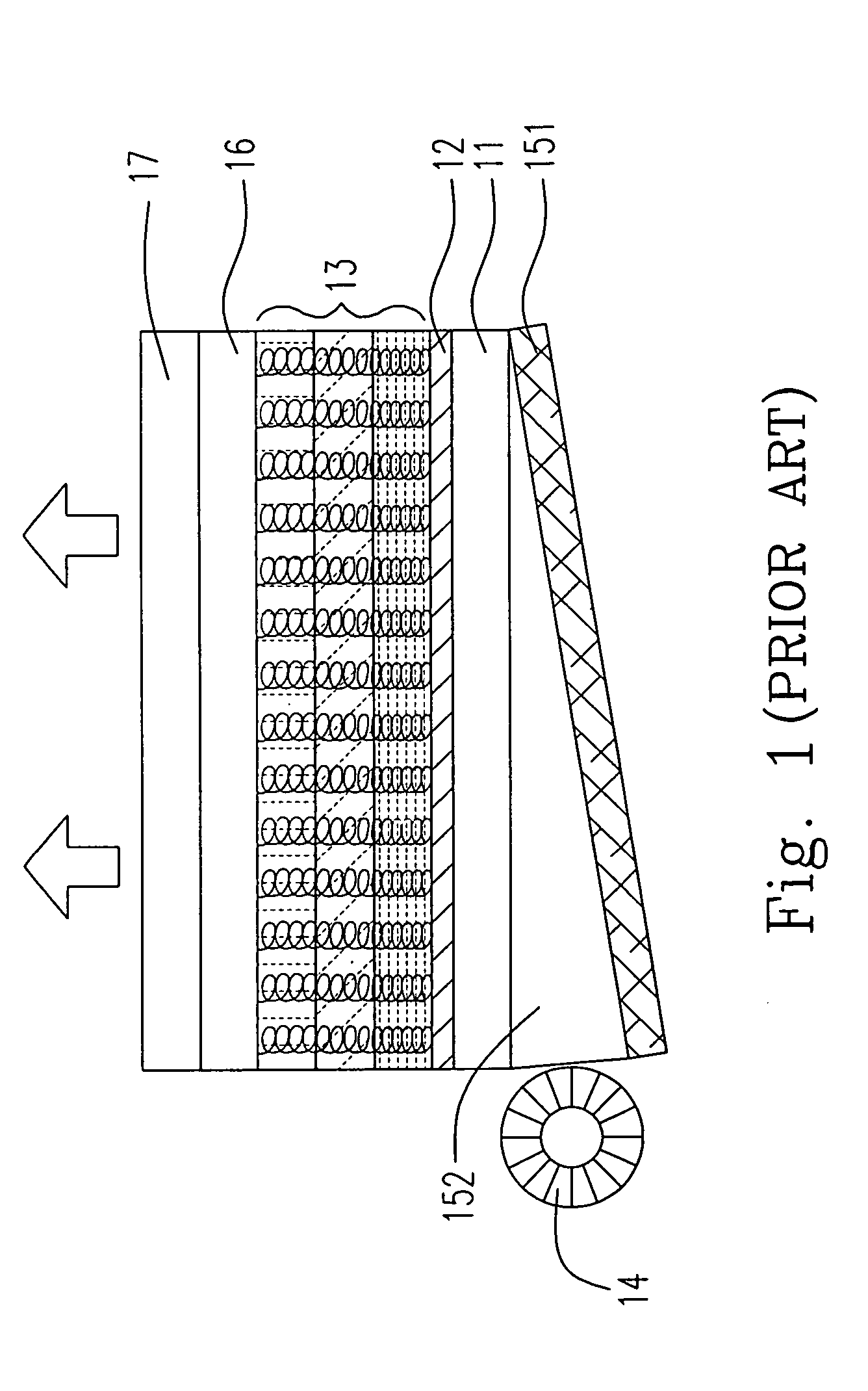

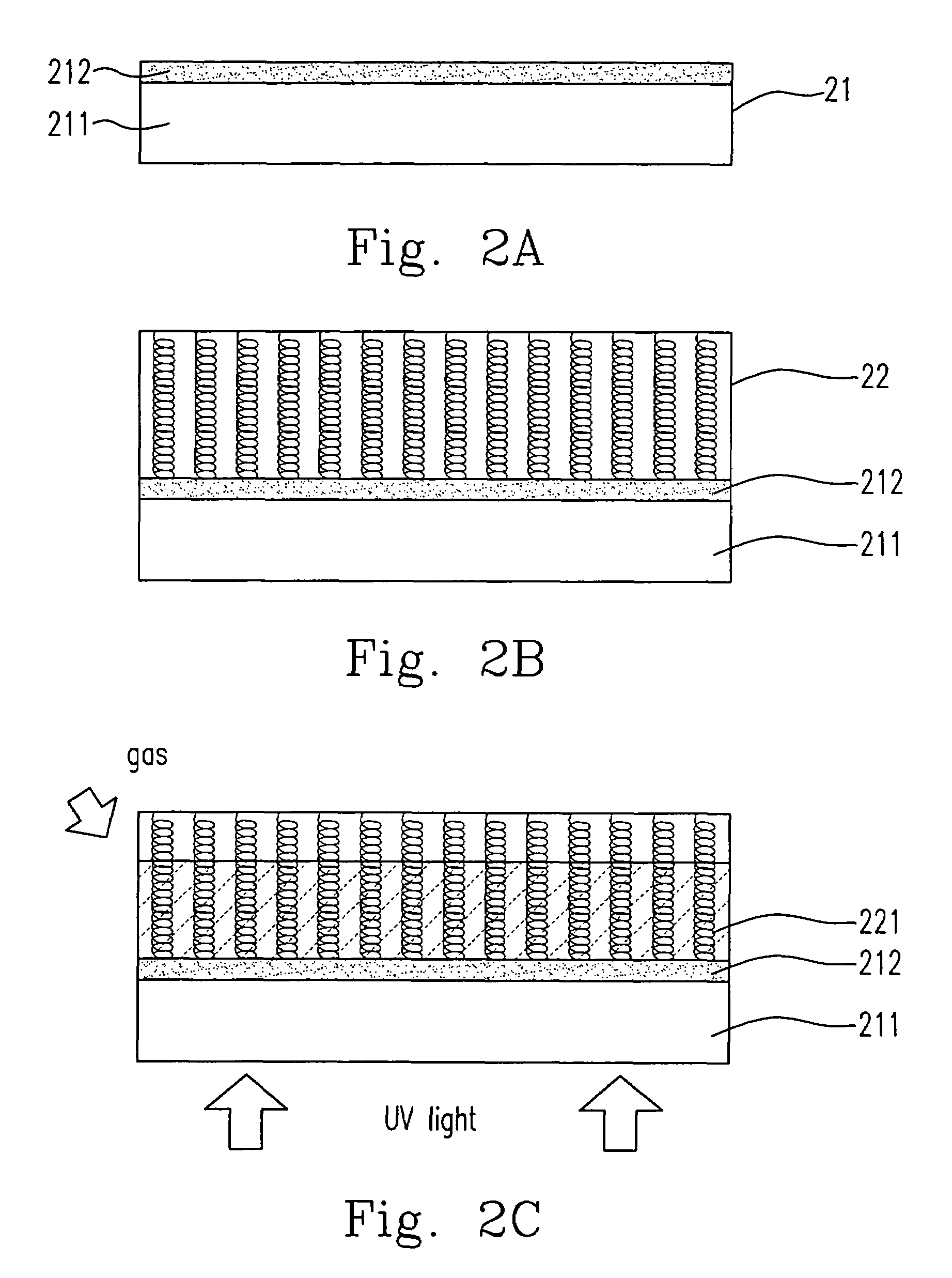

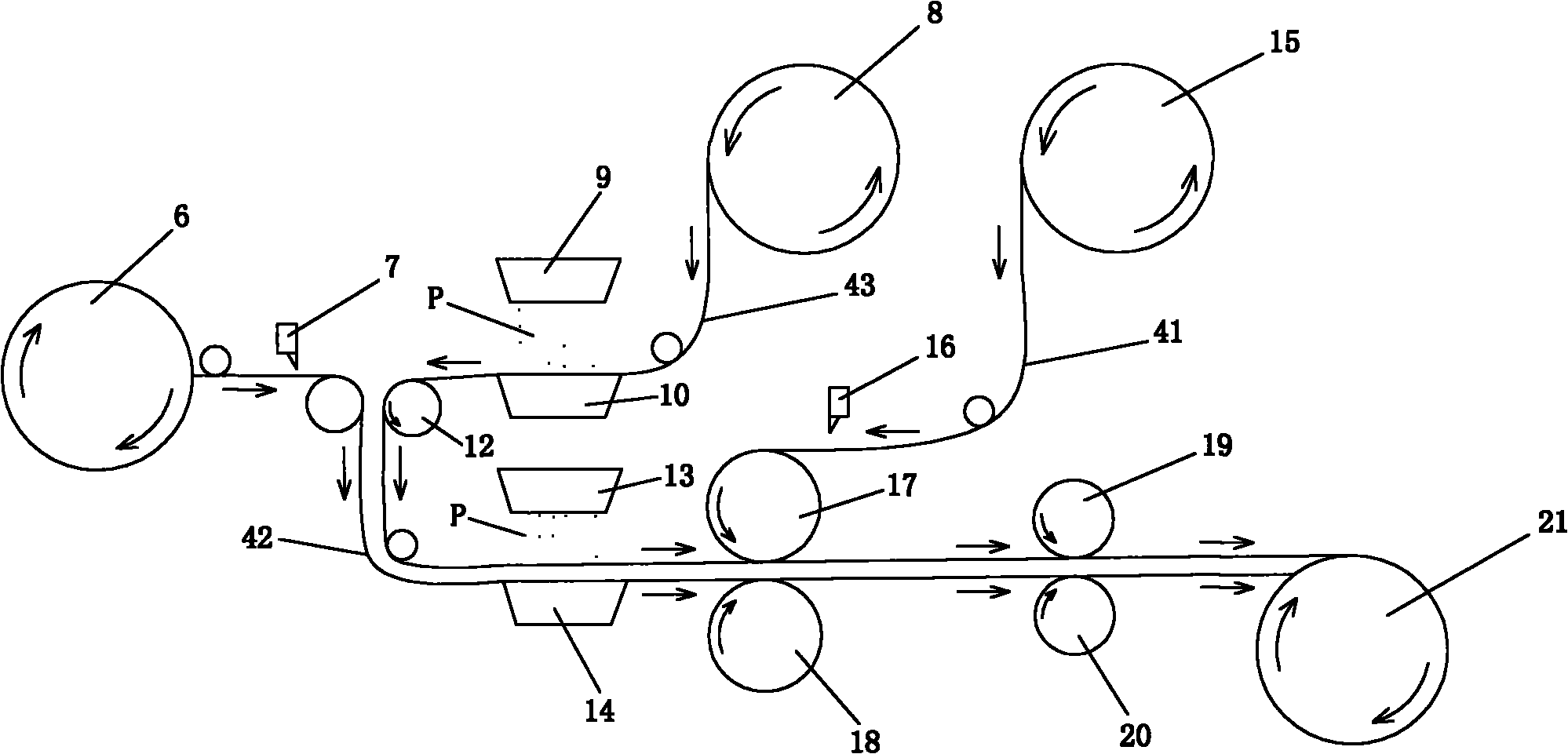

Method for manufacturing brightness enhancement film of liquid crystal display and structure thereof

InactiveUS7132064B2Manufacturing a plurality of CLC films fast and simplyImprove lighting efficiencyOptical articlesPolarising elementsLiquid-crystal displayBrightness perception

A method for manufacturing a brightness enhancement film of a liquid crystal display and a structure thereof are provided. The method includes: (a) providing a first substrate, (b) forming a first macromolecule liquid crystal on said first substrate, (c) curing a part of said first macromolecule liquid crystal on said first substrate for forming a first light transmitting layer, (d) providing a second substrate, (e) forming a second macromolecule liquid crystal on said second substrate, (f) curing a part of said second macromolecule liquid crystal on said second substrate for forming a second light transmitting layer, (g) combining a non-curing part of said first macromolecule liquid crystal and said second macromolecule liquid crystal for forming a third macromolecule liquid crystal between said first light transmitting layer and said second light transmitting layer, and (h) curing said third macromolecule liquid crystal for forming a third light transmitting layer.

Owner:OPTIMAX TECHNOLOGY CORPORATION

Nano copolymer fibrous membrane material capable of being biodegraded and absorbed and preparation process and use thereof

InactiveCN1961974AOvercome the technical problem of difficult spinningSurgical adhesivesPharmaceutical containersFiberAqueous solution

The invention relates to a gelatin nanometer fiber film which can biologically degrade and absorb, and relative preparation, wherein it via the control on static spin realizes the static spin on gelatin water solution and gelatin / macromolecule mixture water, to obtain the nanometer fiber, which comprises: 0 A61L 27 / 14 A61K 45 / 00 D01D 5 / 00 D01F 1 / 00 A61L 27 / 60 A61L 33 / 06 A61L 24 / 04 A61L 15 / 22 A61F 2 / 02 2 14 3 2005 / 11 / 9 1961974 2007 / 5 / 16 000000000 Institute of Chemistry Chinese Academy of Science Beijing 100080 Han Zhichao He Aihua Li Junxing libai 31002 Shanghai Patent Agency of the Chinese Academy of Sciences No.319 Yueyang Road, Shanghai 200031

Owner:INST OF CHEM CHINESE ACAD OF SCI

Water gel containing natural high molecule and its radiation preparing method

InactiveCN1944495AImprove water absorptionGood flexibilityOrganic active ingredientsAntipyreticCross-linkWound dressing

The present invention provides one kind of water gel containing natural high molecular material and its preparation process. The water gel has cross-linking degree of 70-95 % and water absorption of 500-80000 %, and contains natural high molecular material or its derivative selected from chitin, chitin derivative, chitosan, chitosan derivative, carrageenin, etc. The water gel may have synthetic high molecular material, inorganic filler, cross-linking sensitizer, medicine and other assistant added. It is prepared through radiation cross-linking, with the radiation dosage being 10-40 kGy. The water gel of the present invention has high water absorption, high flexibility, good medicine slow releasing performance, and may be used in wound dressing, etc.

Owner:厦门凝赋生物科技有限公司

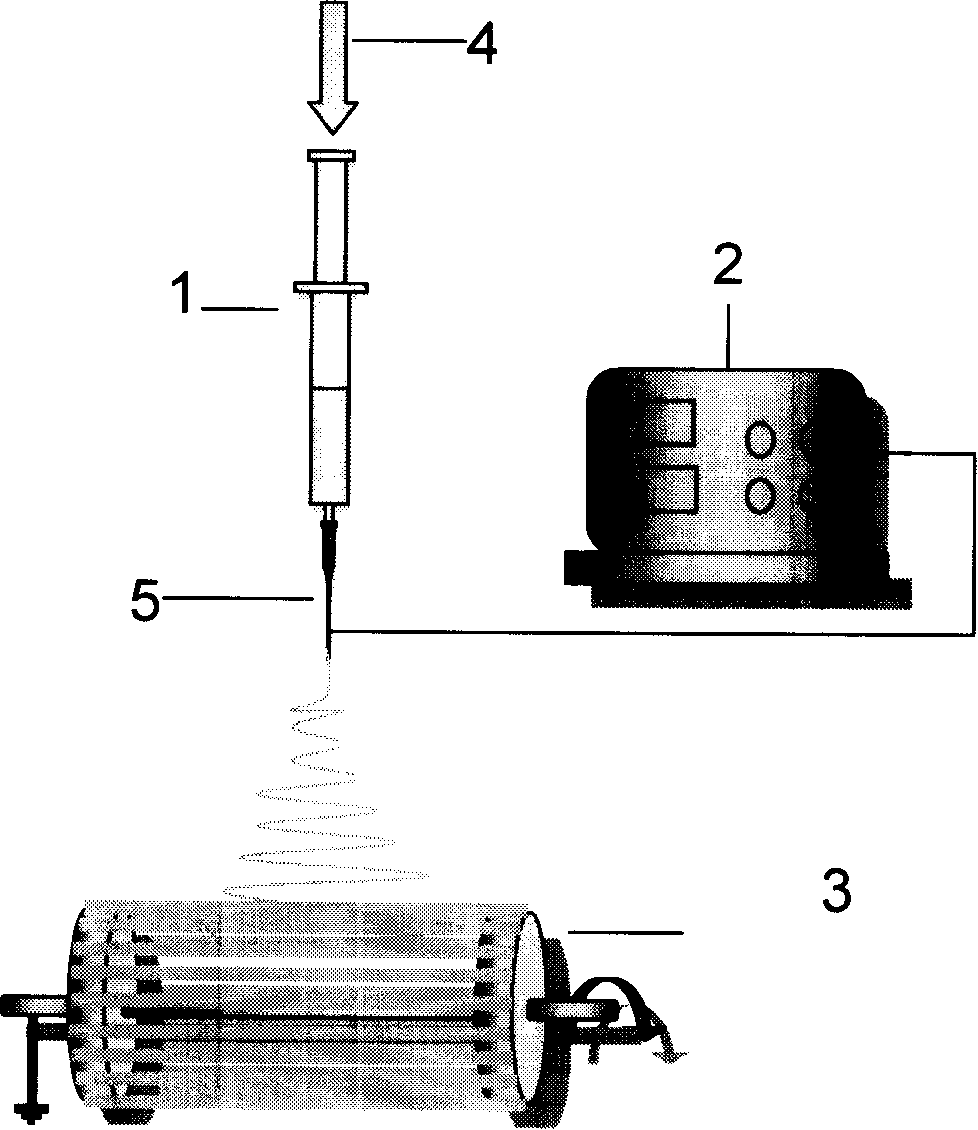

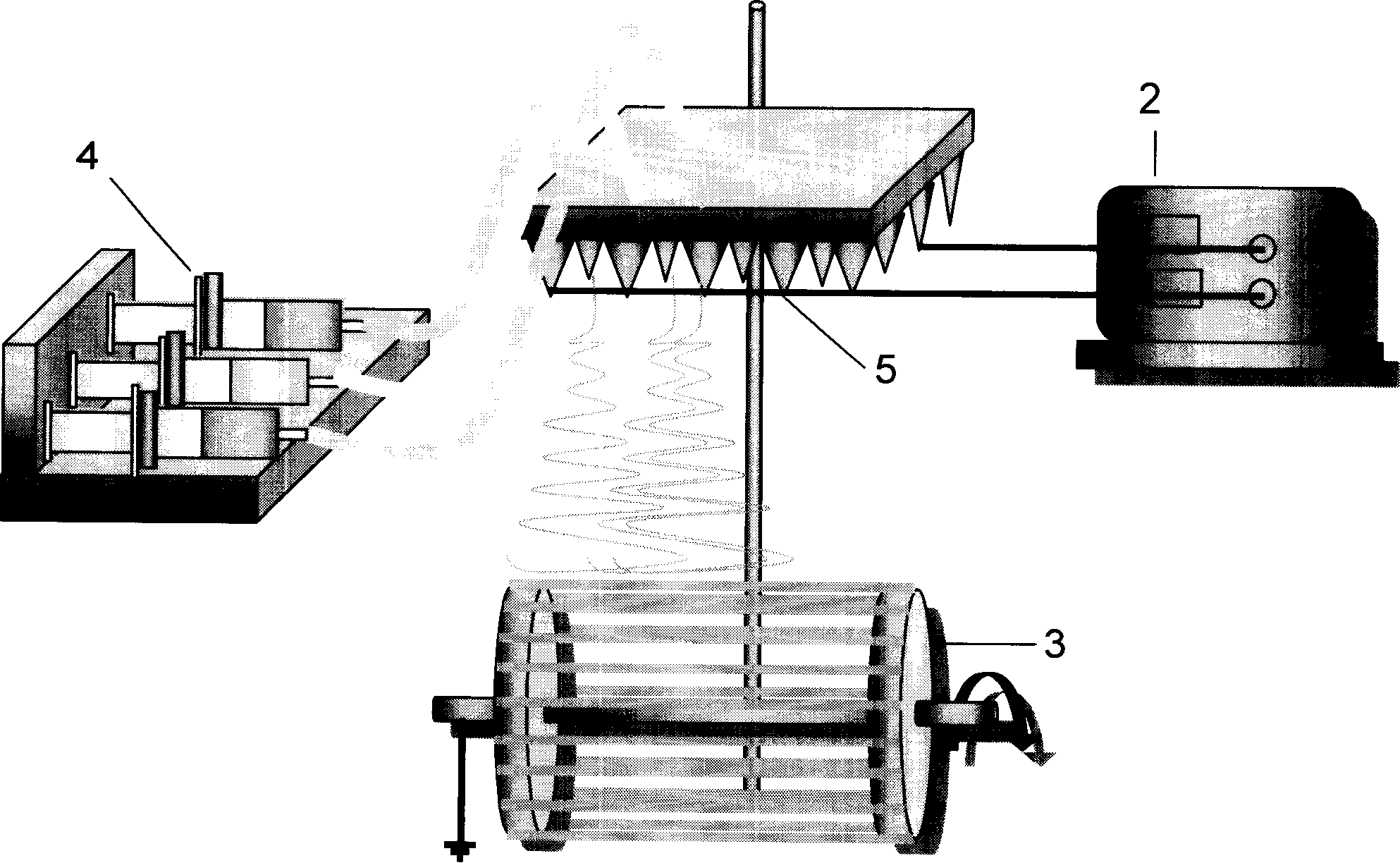

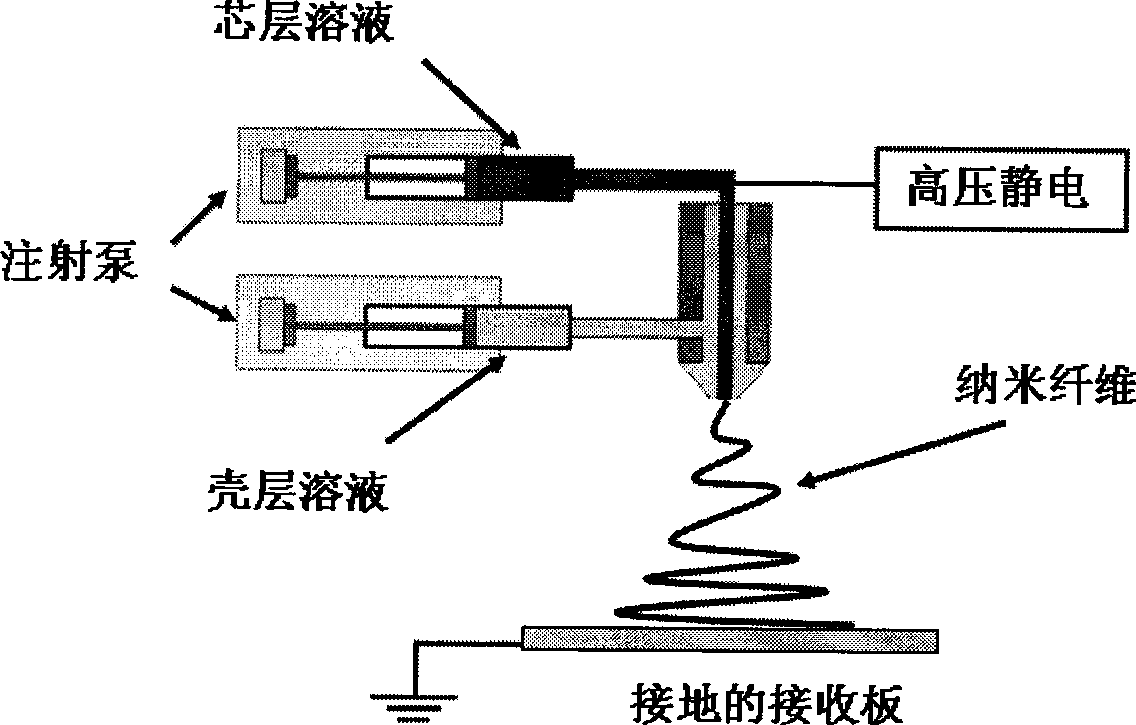

Method for producing shell-core structure medicament nano-fibre with coaxial electrostatic spinning technology

InactiveCN101509153AFix monotonic release behaviorMeet needsPharmaceutical delivery mechanismFilament/thread formingFiberDissolution

The invention relates to a method for preparing shell-core structured medicament nano fiber by coaxial electrostatic spinning technology, comprising: (1) dissolving high molecular polymer and medicament in mass proportion of 60-99.9:0.1-40 in organic solvent with high volatility, and stirring until complete dissolution to obtain shell solution; (2) dissolving one or more than one of natural polymer, medicament, and bioactive factor in the solvent, or dissolving the same in super pure water under aseptic condition to obtain core solution; and (3) carrying out coaxial electrostatic spinning, setting the spinning voltage at 15-25kv, the reception distance at 8-20cm, the spinning pushing speed at 0.1-1.5mL / h, and the spinning nozzle as 0.9mm, to obtain the shell-core structured medicament nano fiber. The preparation method is simple in operation, mild in reaction condition, low in cost and favorable for economic benefit; in preparing the shell-core structured medicament nano fiber, two or more than two medicaments can be simultaneously loaded and released, thus meeting requirements of tissue regeneration or patients.

Owner:DONGHUA UNIV

Plastic profiled bar decorative layer combination material with metal-like natural texture, preparation method and application thereof

The invention provides a plastic profiled bar decorative layer combination material with natural texture for co-extrusion molding, formed by mixing 15-80wt% of plastic substrate, 15-80wt% of composite pigment and 0-50wt% of inorganic powder, wherein the composite pigment comprises pigment or dye with natural color texture effect; inorganic pigment and inorganic powder in the composite pigment need to be respectively and actively processed by a surface conditioning agent or a coupling agent; the combination material provides the surface of the plastic profiled bar with a high-polymer material co-extrusion composite layer with stronger adhesion and endows the surface of the plastic profiled bar with the metal-like texture effects, such as the colors of gold, silver, copper or other natural metal materials. The decorative layer has a certain thickness, high hardness, strong scratch resistance and longer product service life and can be used for industries, such as electronic appliance shells, plastic color windows and doors, plastic profiled bars, furniture sheets, and the like.

Owner:GUANGDONG SHENGHENGCHANG CHEM IND

High strength and high toughness modified poly-propylene material

The present invention belongs to the field of polymer material technology, and is especially one kind of modified polypropylene material comprising at least polymer base, strengthening agent and toughening agent. The polymer base may be polypropylene or polypropylene composition; the strengthening agent is inorganic or organic matter with great aspect ratio, such as inorganic or organic crystal whisker, fiber, mica, etc; and the toughening agent may be polypropylene beta-nucleater, rubber elastomer, etc. The modified polypropylene material has high strength, high toughness, etc and may be applied widely in automobile, pipeline, electric appliance and other fields.

Owner:FUDAN UNIV

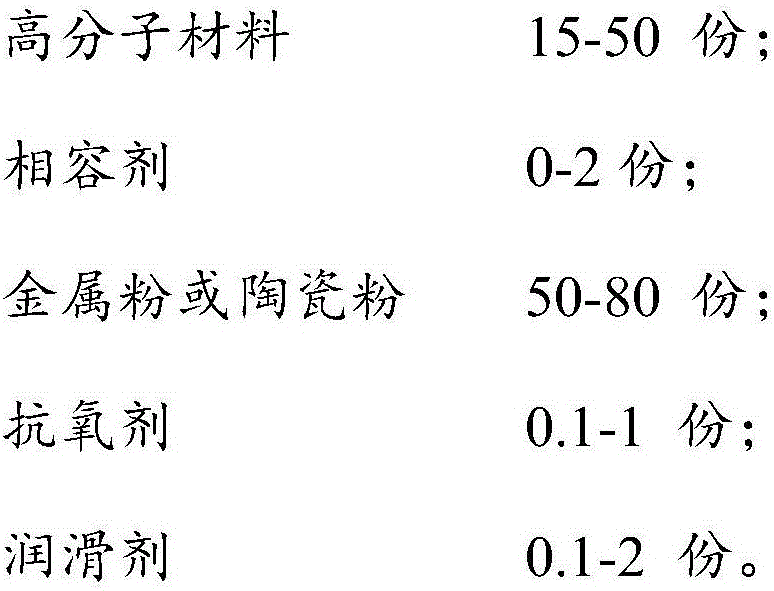

Metal or ceramic consumable item for FDM 3D printing, preparation method for metal or ceramic consumable item and finished product printing method

InactiveCN105665697AEasy to handleUnlimited structureAdditive manufacturing apparatusTransportation and packagingMiniaturizationVolumetric Mass Density

The invention discloses a metal or ceramic consumable item for FDM 3D printing, a preparation method for the metal or ceramic consumable item and a finished product printing method. The metal or ceramic consumable item comprises, by weight, 15-50 parts of a high polymer material, 0-2 parts of a compatilizer, 50-80 parts of metal powder or ceramic powder, 0.1-1 part of an antioxygen and 0.1-2 parts of a lubricating agent. The cost for equipment, the materials and machining is low; a printing structure is free of limitation, collapsing conditions do not exist in the printing process, supports can be removed before fusion sintering of the product, and treatment is easier compared with a manner that the supports are removed after SLS or EBAM fusion sintering; the requirements for the sphericity degree, the size distribution, the mobility and the like are relatively low; the types of metal and ceramic capable of being printed are wider; and the density of the finished products is higher, the strength is high, the degree of finish is higher, the miniaturization capacity is high, the thin-wall capacity is high, the complexity is high, the design tolerance level is high, and the material adaption scope is wide.

Owner:HUIZHOU RES INST OF SUN YAT SEN UNIV

Flame retardant microcapsule and application thereof

ActiveCN101885859AImprove flame retardant performanceHigh mechanical strengthThin material handlingMicroballoon preparationCellulosePolymer science

Owner:INST OF CHEM CHINESE ACAD OF SCI

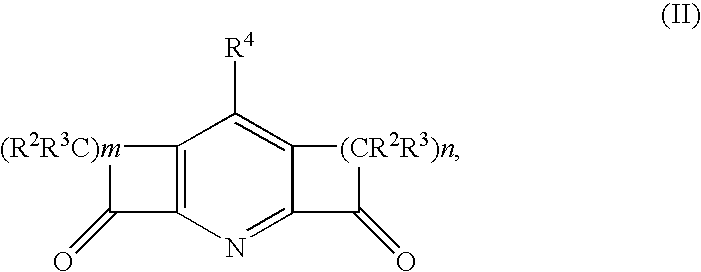

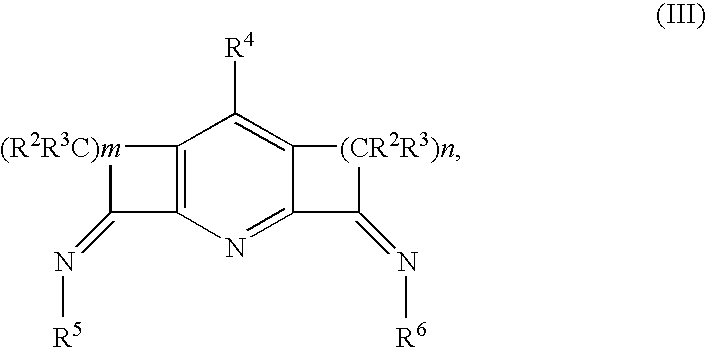

Catalysts for olefin polymerization or oligomerization

ActiveUS7442819B2Organic-compounds/hydrides/coordination-complexes catalystsIron group organic compounds without C-metal linkagesAlpha-olefinPyridine

Novel iron and cobalt complexes of certain novel tricyclic ligands containing a “pyridine” ring and substituted with two imino groups are polymerization and / or oligomerization catalysts for olefins, especially ethylene. Depending on the exact structure of the ligand, and polymerization process conditions, products ranging from α-olefins to high polymers may be produced. The polymers, especially polyethylenes, are useful for films and as molding resins.

Owner:DUPONT POLYMERS INC

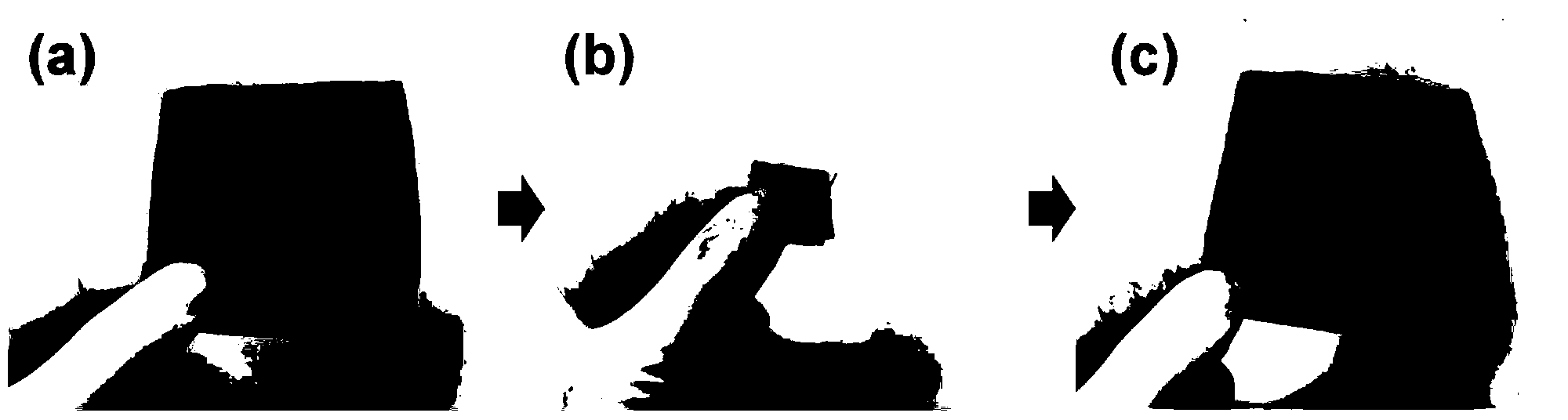

Composite natural polymer gel material

ActiveCN105837861ALarge specific surface areaImprove mechanical propertiesAerogel preparationColloidal chemistry detailsNon solventWater based

The invention discloses a composite natural polymer gel material with a cross-linking agent. The material comprises hydrogel, organogel, aerogel and bioplastics and mainly overcomes the problem of low mechanical strength of conventional natural polymer gel materials. According to the invention, a certain amount of the cross-linking agent is added into a natural polymer water-based solution or dispersion liquid, then stirring is carried out, the obtained mixture is placed in a non-solvent for physical cross-linking, and then washing is carried out so as to obtain composite natural polymer hydrogel; water in the composite natural polymer hydrogel is replaced with an organic solution so as to prepare composite natural polymer organogel; the composite natural polymer hydrogel or organogel is dried so as to prepare composite natural polymer aerogel; the composite natural polymer aerogel is subjected to hydrophobic treatment so as to obtain hydrophobic aerogel; the composite natural polymer aerogel is subjected to heat treatment so as to obtain carbon aerogel; and one or more selected from the above-mentioned gel materials are subjected to high-temperature pressing so as to prepare composite natural polymer bioplastics. The composite natural polymer gel material prepared in the invention has the advantages of excellent mechanical properties, a high specific surface area, high elongation at break, etc., and can be easily processed into molded products of a plurality of forms.

Owner:浙江绍兴万德福生物技术有限公司 +1

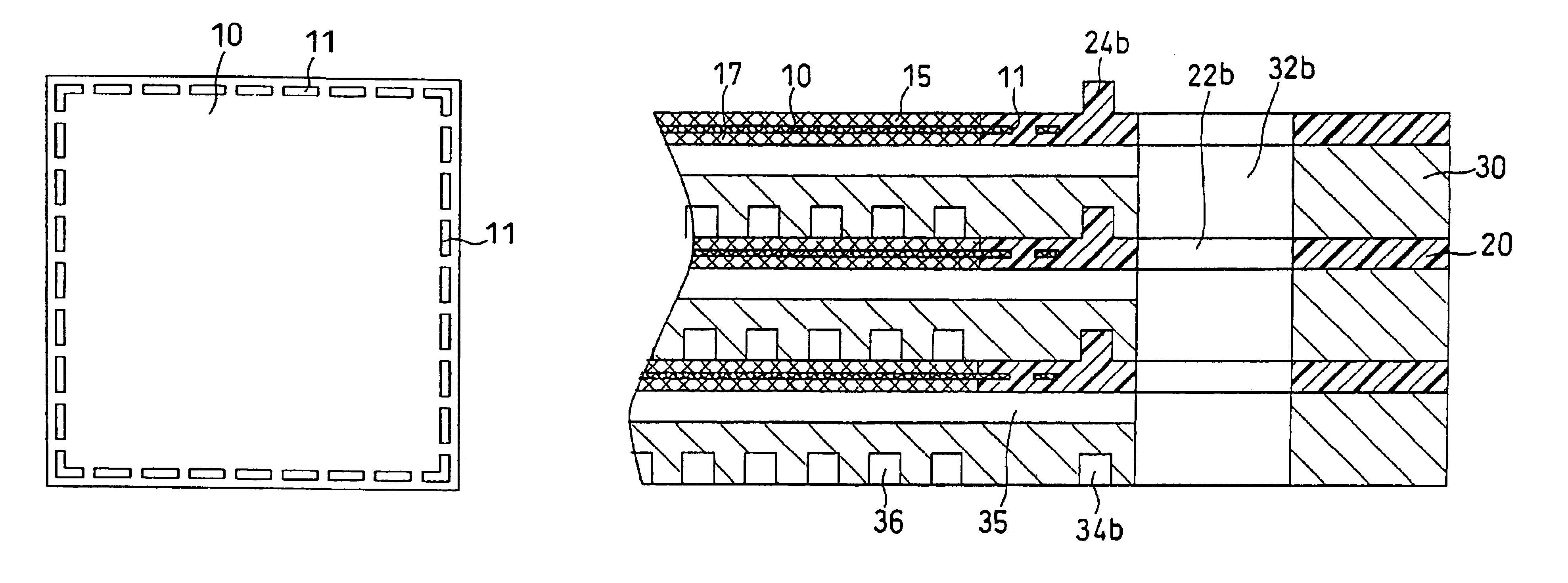

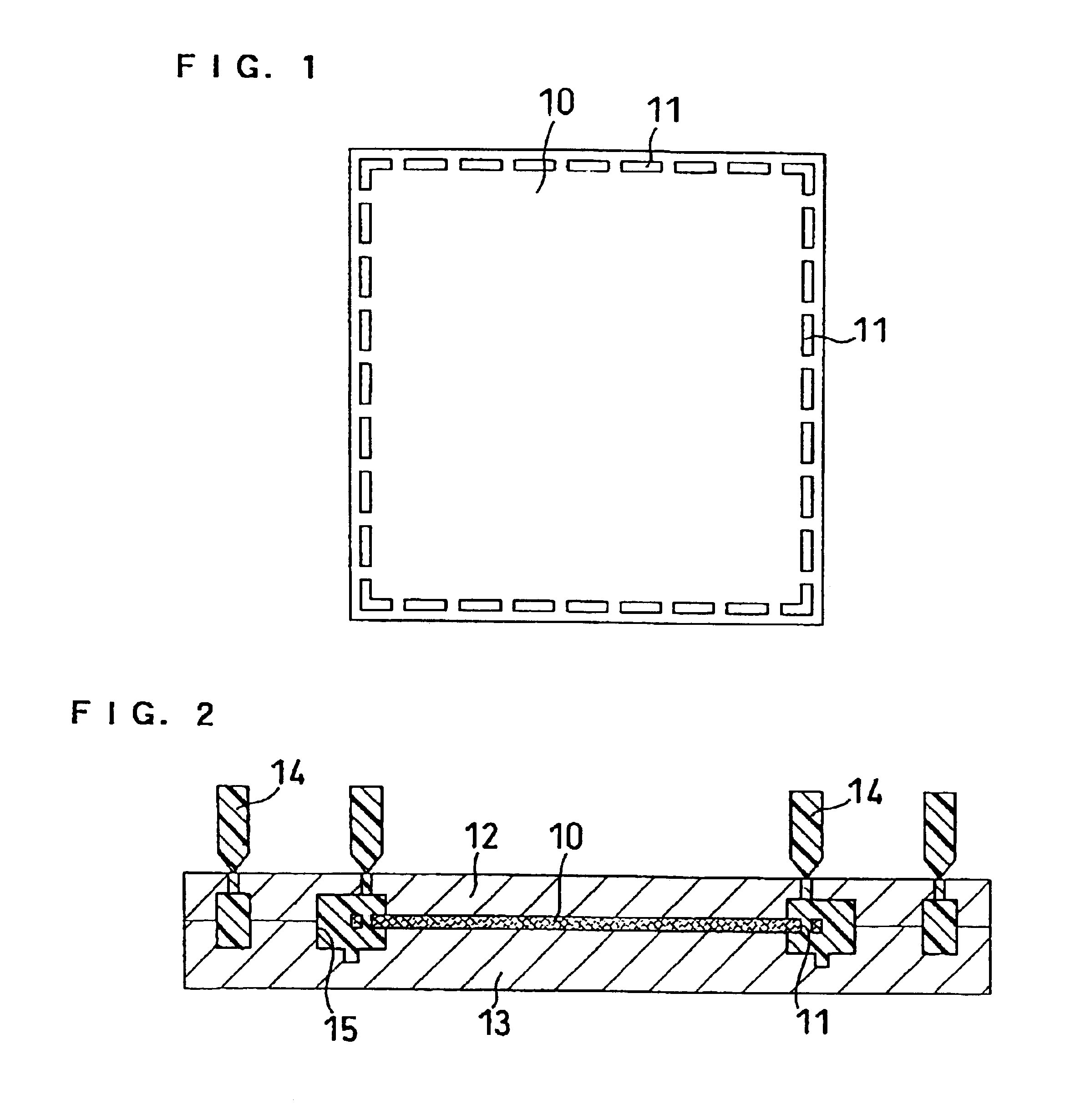

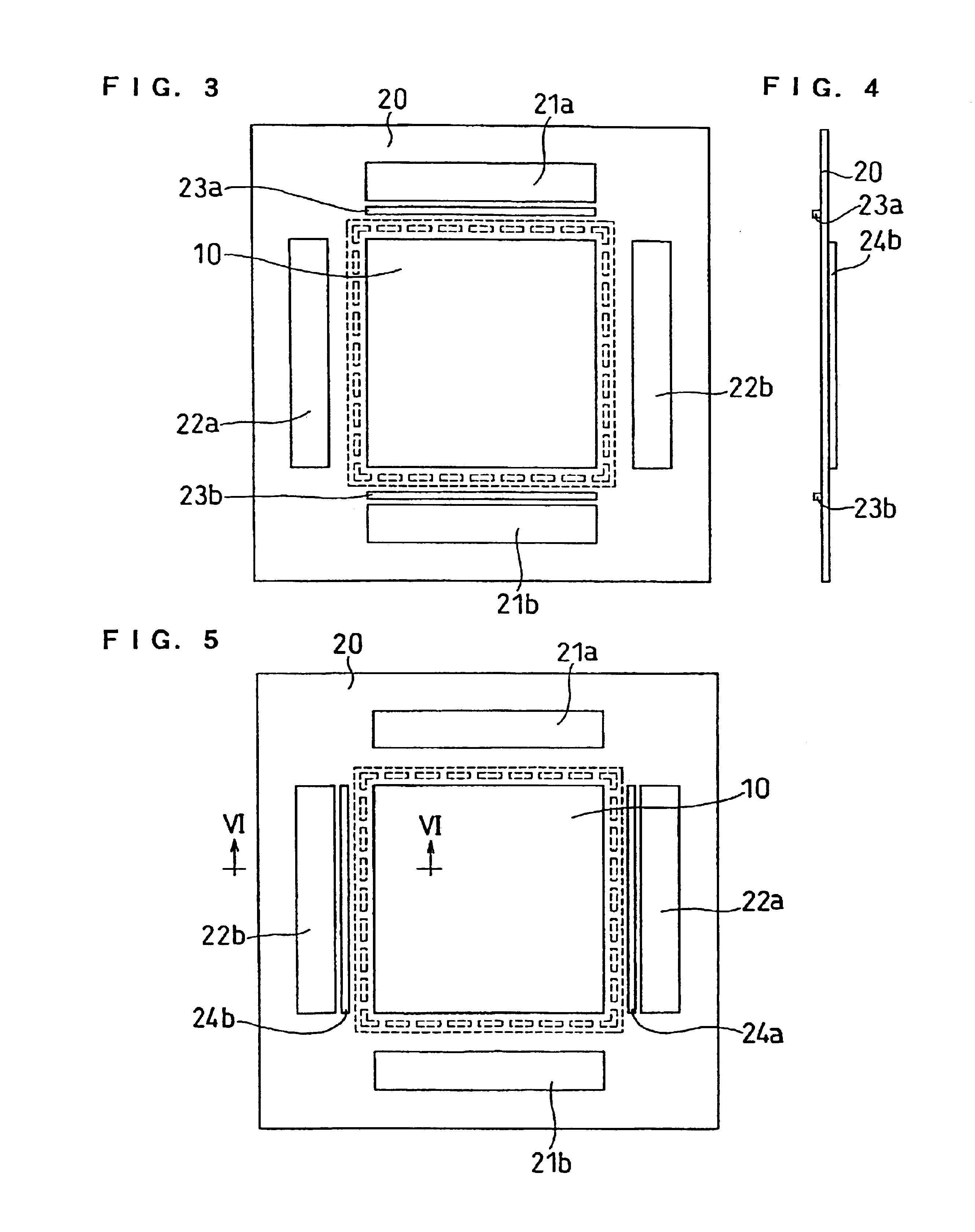

High polymer electrolyte fuel cell and electrolyte film-gasket assembly for the fuel cell

InactiveUS6840969B2Prevent gas leakageImprove sealingFuel cells groupingPrimary cellsPolymer electrolytesFuel cells

An electrolyte membrane-gasket assembly for a fuel cell, including a polymer electrolyte membrane and a gasket, made of a seal material, covering the peripheral portion of the electrolyte membrane, in which the electrolyte membrane has a sequence of a plurality of through-holes in the peripheral portion, and a portion of the gasket covering one surface of the electrolyte membrane and a portion covering the other surface are connected to each other through the through-holes of the electrolyte membrane. This assembly provides a polymer electrolyte fuel cell free from gas cross leakage caused by a detachment of the gasket from the polymer electrolyte membrane. It is preferable to further include catalyst layers carried on both surfaces of the polymer electrolyte membrane, respectively, and protective films covering, respectively, sections spanning from the peripheral portion of each of the catalyst layers to the peripheral portion of the polymer electrolyte membrane.

Owner:PANASONIC CORP

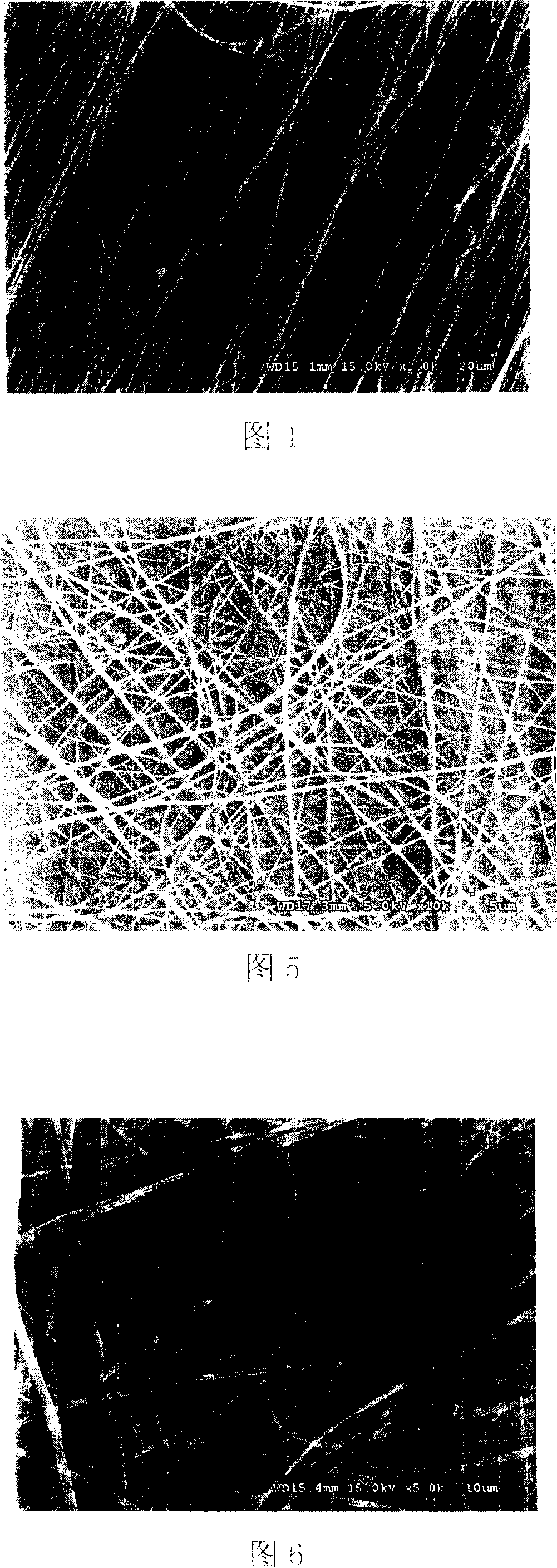

Preparation method of core-shell structured synthetic polymer-natural polymer composite fiber

InactiveCN102817105ASimple and fast operationMild reaction conditionsConjugated cellulose/protein artificial filamentsFilament/thread formingFiberPolymer science

The invention discloses a preparation method of a core-shell structured synthetic polymer-natural polymer composite fiber, and the method comprises the steps of: (1) selecting one or several of synthetic polymers to dissolve in a solvent, and conducting stirring until complete dissolution; (2) selecting a natural polymer to dissolve in a solvent, or adding a spinning assistant, and carrying out stirring until complete dissolution; and (3) taking the solution prepared in step (1) as an outer tube spinning solution, adopting the solution prepared in step (2) as an inner tube spinning solution, injecting them into the inner tube and the outer tube of a coaxial spinneret, and performing coaxial electrospinning at room temperature. The core-shell structured nano-fiber prepared by the invention selects the synthetic polymer as the shell layer, and can inhibit water molecules from penetrating the natural polymer as the core layer. The natural polymer as the core layer can more effectively encapsulate active substances to avoid inactivation of the active substances in the presence of an organic solvent, so that the core-shell structured composite fiber can play a good drug sustained release role in the drug carrier field, and an integral activity can be maintained.

Owner:SHANGHAI JIAO TONG UNIV +1

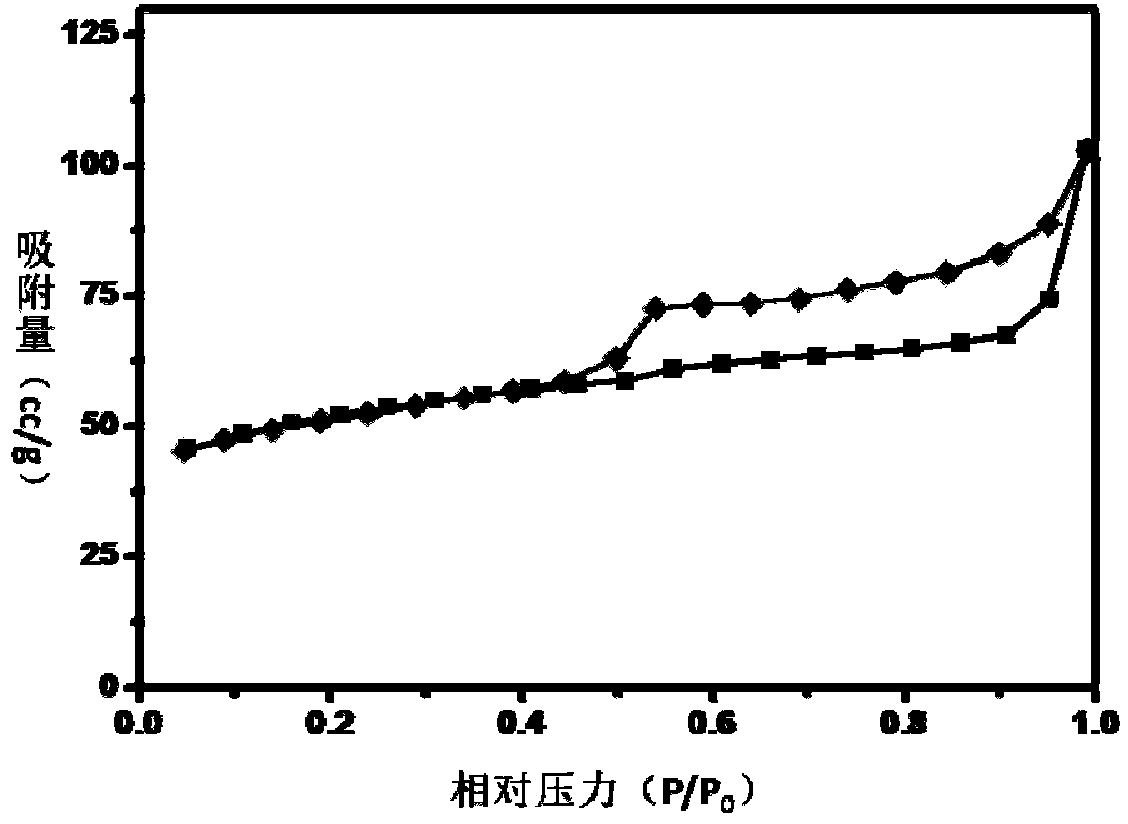

Porous carbon fiber, and preparation method and application thereof

ActiveCN103225135AEasy to makeLow costFilament/thread formingArtificial filament chemical after-treatmentFiberCarbon fibers

The invention discloses a porous carbon fiber and a preparation method thereof. The method comprises the following steps: spinning a spinning liquid composed of a pore forming agent, a high polymer and an organic solvent, carbonizing, and pickling to obtain the porous carbon fiber. The method has the advantages of simple preparation, high output and low cost, and allows the porous carbon fiber simultaneously having micro-pores, meso-pores and macro-pores to be prepared; and the carbon fiber prepared in the invention is more flexible than that of carbon fibers prepared through other methods.

Owner:INST OF CHEM CHINESE ACAD OF SCI

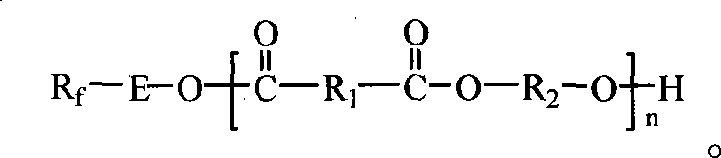

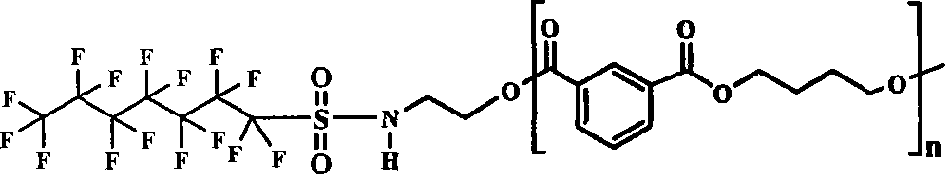

Fluorinated polyesters with low surface energy and preparation method thereof

The present invention belongs to the field of mnacromolecule, relating to the fluorine-containing polyester of low surface energy and the preparation method of the fluorine-containing polyester. The polyester has the following chemical structure (1): wherein R f C is the straight chain of 2 - 21 C or the branch-chain pseudo-perfluoroalkyl; R1, R2 is the alkyl, aryl, or naphthenic base of the C1-C8; E is -(CH2) m-; formula (3) or formula (4); R' is H or the straight chain or the branch-chain alkyl under C4; m is an integer between 0 or 10. The polyester preparation method is that dibasic acid or the correspondent diester, dihydric alcohol and perfluoroalkane, which are 0.05 percent to 10 percent of the total material weight, are fused and polymerized under vacuum condition. The polyester preparation method at the pseudo-perfluoroalkyl sealed end is simple, and is of good drainage and oil dredging properties. The present invention can be widely used in antifouling coatings, and is of important development and application value.

Owner:DALIAN UNIV OF TECH

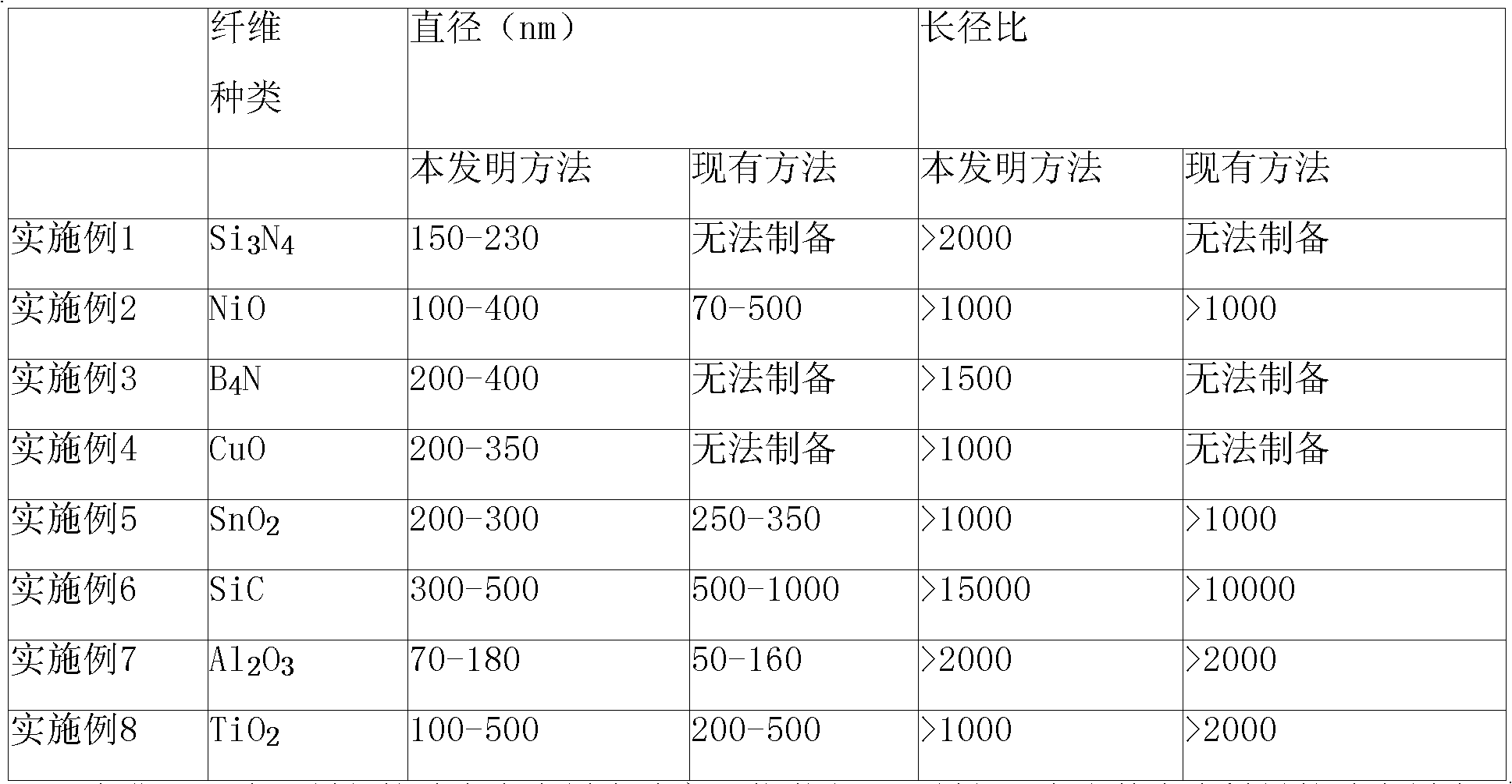

Method for preparing nano ceramic fibers

InactiveCN101880917AAverage diameter distributionHigh aspect ratioInorganic material artificial filamentsFilament/thread formingFiberWater baths

The invention discloses a method for preparing nano ceramic fibers, which is implemented by the following steps: 1, preparing 3 to 15 volume percent of 10 to 30 nanometer ceramic nanoparticles, 5 to 30 volume percent of spinnable high polymer, 0.5 to 5 volume percent of dispersant and the balance of solvent, wherein the total volume of the raw materials is 100 volume percent; 2, adding the spinnable high polymer into the solvent, heating the mixture in a water bath with magnetic stirring to obtain solution of spinnable high polymer; 3, adding the ceramic nanoparticles and the dispersant into the solution of spinnable high polymer obtained by the step 2, keeping the temperature of the mixture constant in a water bath, performing dispersion and ultrasonic dispersion, and performing swelling at a constant temperature to obtain ceramic nanoparticle / spinnable high polymer / solvent spinning solution; 4, controlling the electrostatic spinning process parameters of the spinning solution obtained by the step 3 to obtain nano fibers; and 5, sintering the nano fibers at 400 to 1,200 DEG C to obtain nano ceramic fibers.

Owner:XIAN UNIV OF TECH

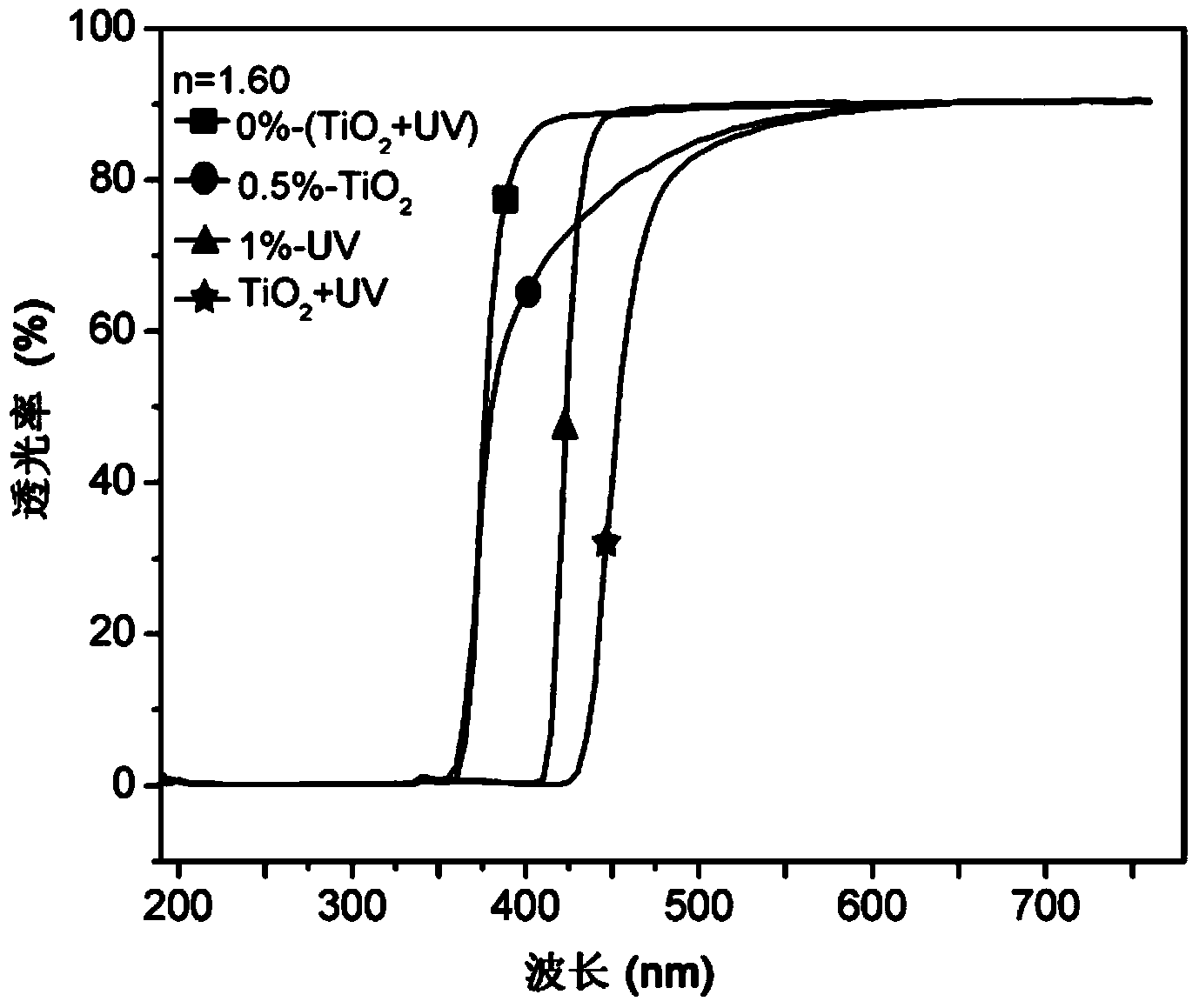

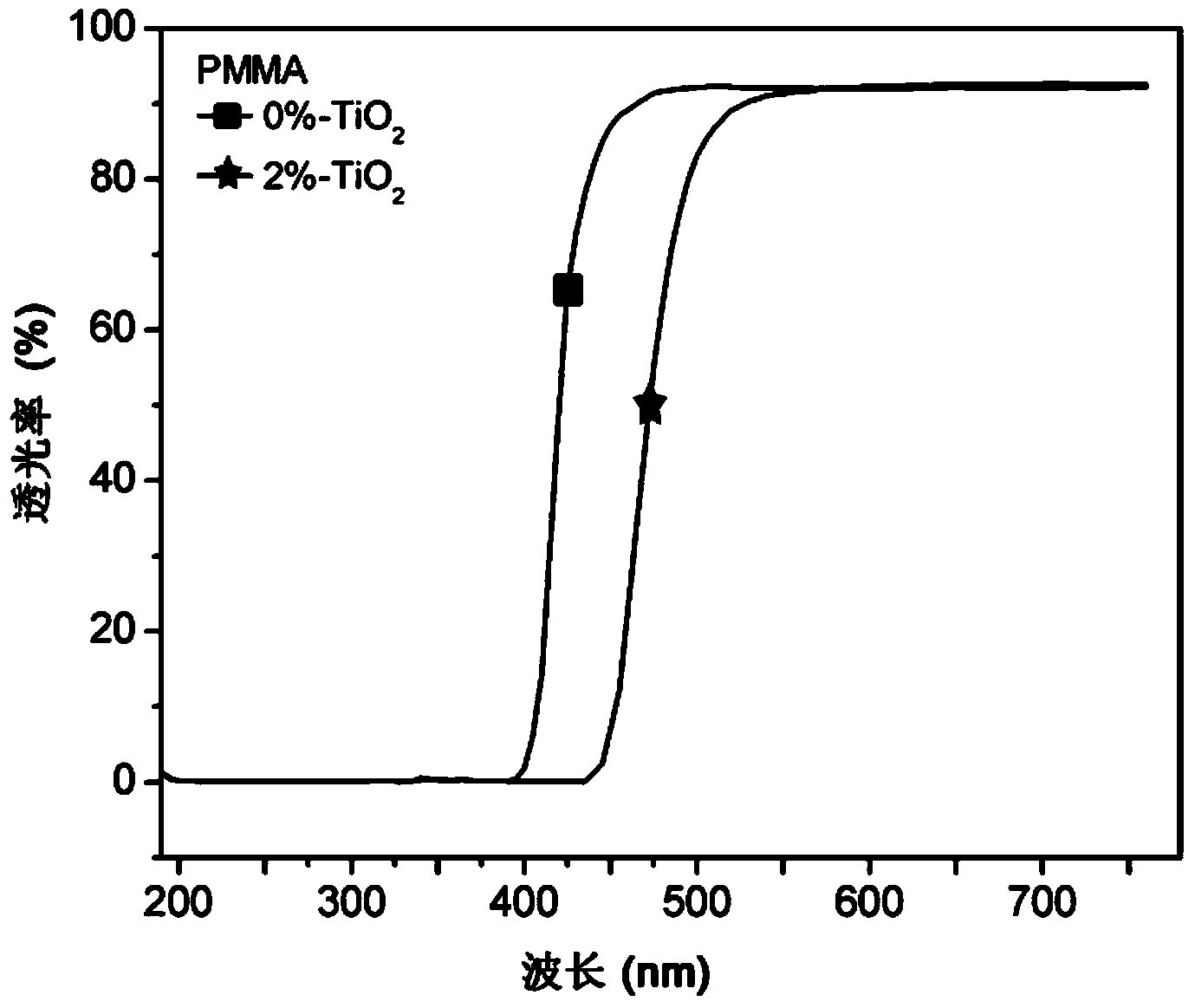

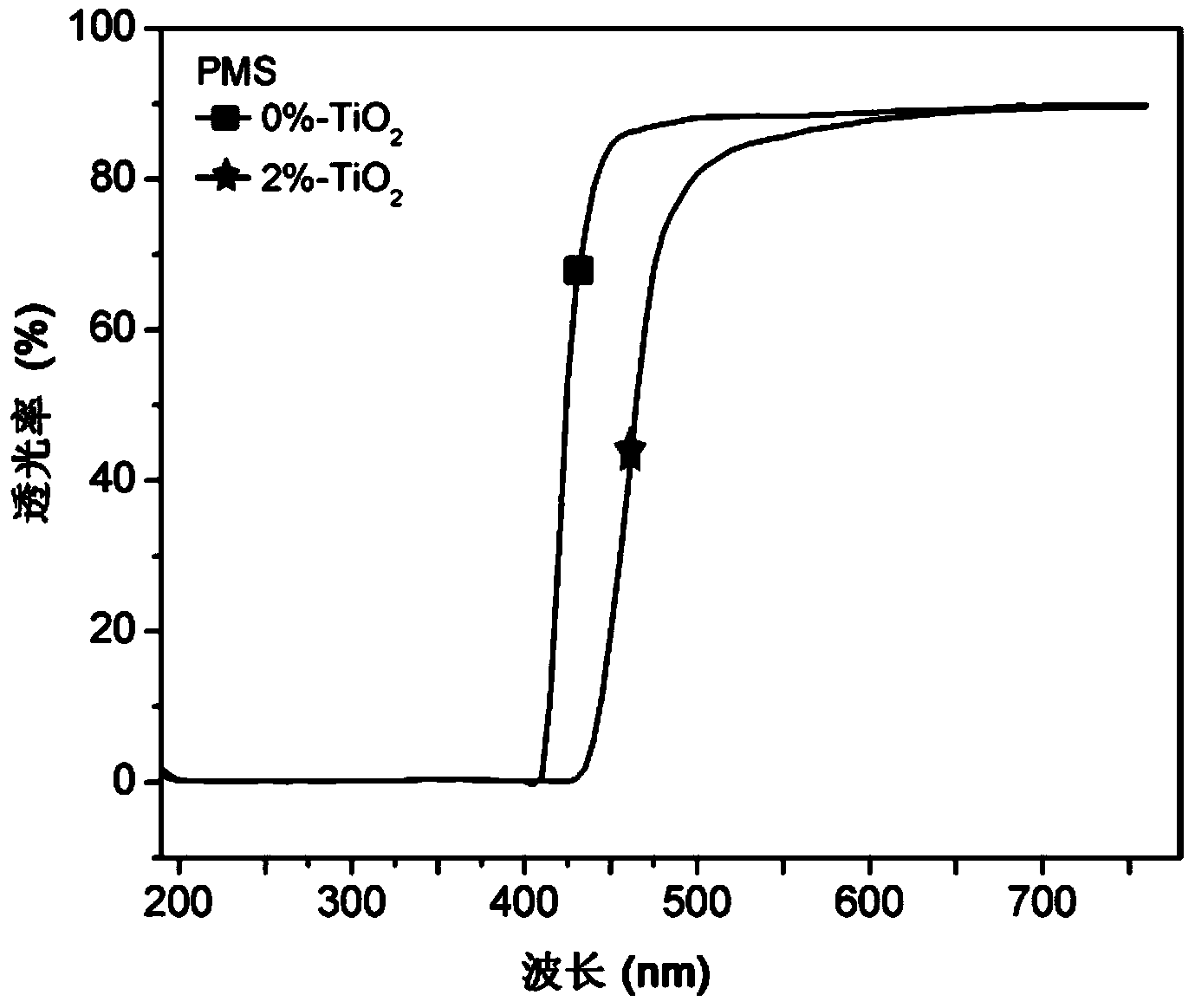

Blue light cut nano compound resin material, lens and preparation method thereof

ActiveCN103980643AEvenly dispersedComprehensive and excellent comprehensive performanceOptical partsHigh energyUltraviolet lights

The invention relates to a blue light cut nano compound resin material and lens and a manufacturing method thereof. The blue light cut nano compound resin material comprises macromolecule resin as well as core-shell type transition metal oxide nano particles and an ultraviolet light absorber which are dispersed in the macromolecule resin, wherein the core-shell type transition metal oxide nano particles account for 0.2-2% of the total weight of the resin, and the ultraviolet light absorber accounts for 0.5-5% of the total weight of the resin; particle size of nano particles is 20-50nm; the shell is a surface active agent, and thickness is 3-10nm; the nano particles and the ultraviolet light absorber are fully dispersed in a macromolecule monomer, and a prepolymerization and secondary polymerization technological process is carried out, so that the blue light cut compound resin material is obtained. The manufacturing method of the blue light cut compound resin material is simple in technology and good in reproducibility, the manufactured resin material and lens can efficiently and permanently shield high energy harmful blue light and ultraviolet light with wavelength within the range of 380-450nm, vision is clear and colour vision is soft under strong and weak light environments respectively, and the blue light cut compound resin material has excellent overall performance.

Owner:JIANGSU SHIKEXINCAI CO LTD

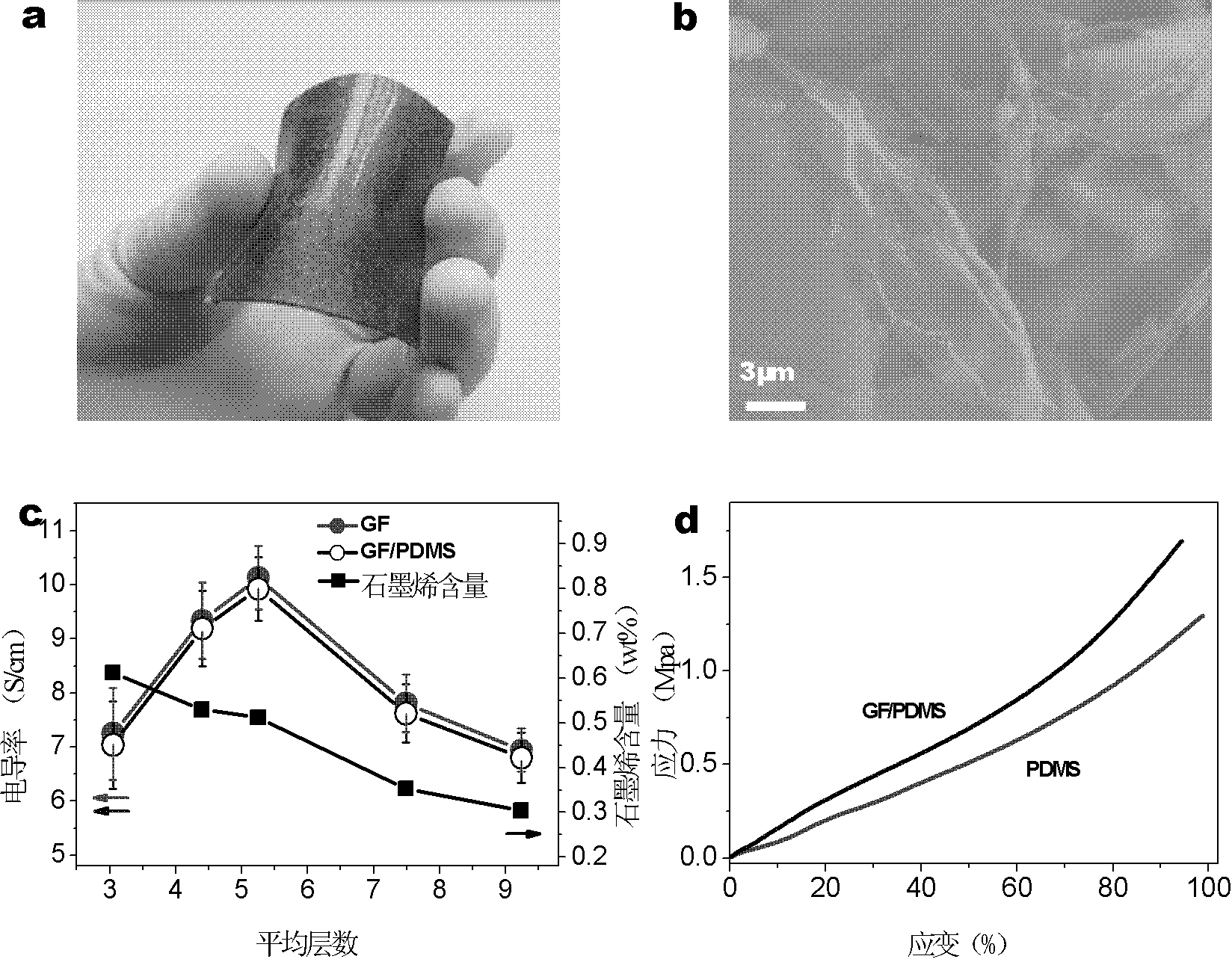

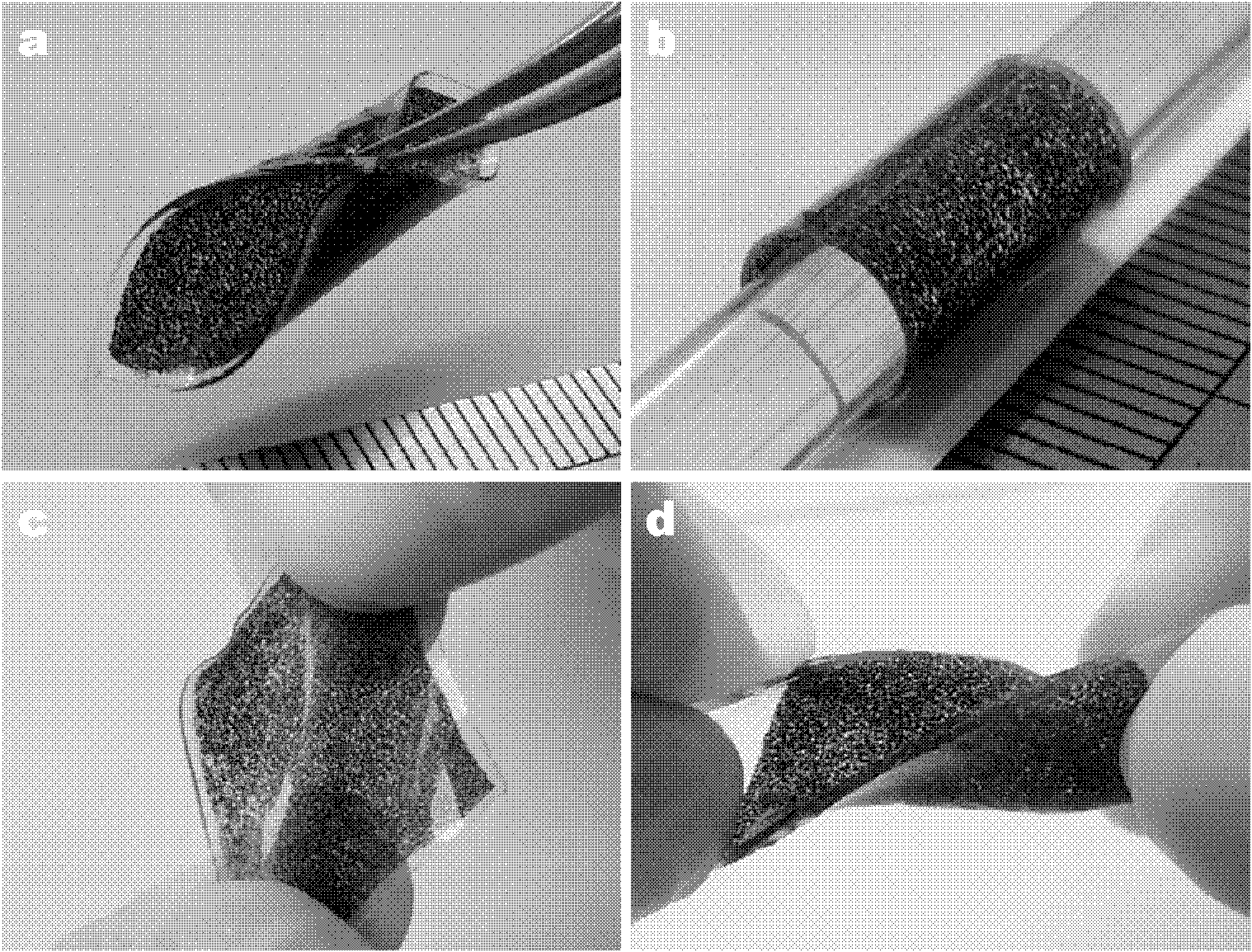

Graphene foam/polymer high-conductivity composite material preparation method and application thereof

ActiveCN102732037AImprove conductivityEasy to manufactureChemical vapor deposition coatingMaterials preparationGraphite

The invention relates to the graphene composite material field, and particularly to a graphene foam / polymer high-conductivity composite material, a preparation method and applications thereof. Steps of the method comprises as follows: providing a fully communicated three-dimension grapheme foam network and a precursor solution of a high-molecular polymer; mixing the graphene foam with the precursor solution of the high-molecular polymer to form a graphene foam / high-molecule polymer precursor mixture; and solidifying the precursor of the high-molecular polymer in the mixture to form a high-conductivity graphene foam composite material. The invention adopts the three-dimension graphene foam to form a fully- communicated graphite rapid transmission network by a seamless connection, which enables the graphene foam composite material to possess great conductivity and mechanical property and can be widely applied to the conductive composite materials and elasticity conductor field.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

A thermoplastic polymer-based thermally conductive composite material and its preparation method

InactiveCN102286207AImprove thermal conductivityHeat-exchange elementsPolymer scienceVolumetric Mass Density

The invention discloses a thermoplastic polymer-based heat-conducting composite material, which belongs to the technical field of polymer materials. The thermoplastic polymer-based thermally conductive composite material provided by the present invention has a higher thermal conductivity when adding less thermally conductive filler; the thermally conductive composite material includes a thermoplastic polymer matrix and a thermally conductive filler, and also includes compatible polymers. The present invention introduces a polymer that is incompatible with the polymer matrix into the composite system, so that the thermally conductive filler is selectively distributed in one of the phases, thereby significantly increasing the packing density of the thermally conductive filler in the polymer component of this phase, thereby improving the The overall thermal conductivity of the material; when the ratio of the two is 50 / 50, the thermal conductivity of the material can reach the thermal conductivity when the amount of thermal conductive filler is doubled.

Owner:SICHUAN UNIV

Thin film produced by using starch fiber waste plastic

The invention discloses a thin film produced by using starch fiber waste plastic. The new breakthrough and technical innovative points are applied to an environment-friendly plastic synthesized thin film or sheet. The produced environment-friendly plastic synthesized thin film or sheet comprises the following raw materials of 10-60 percent of high polymer waste plastic (regenerated plastic), 10-60 percent of modified starch, 10-50 percent of natural plant fiber, 5-30 percent of inorganic material and 2-15 percent of modifier, compatilizer and processing aid. In the plastic-synthesized thin film or sheet, the thickness of the membrane is 0.01-0.6mm and the thickness of the sheet is 0.6-3mm. The preparation of the thin film has the advantages that the environment-friendly practical thin film or sheet with degradation time with different efficiencies, transmissivity, stress degrees and the like can be obtained by adjusting the mixture ratio of various materials.

Owner:陈天云

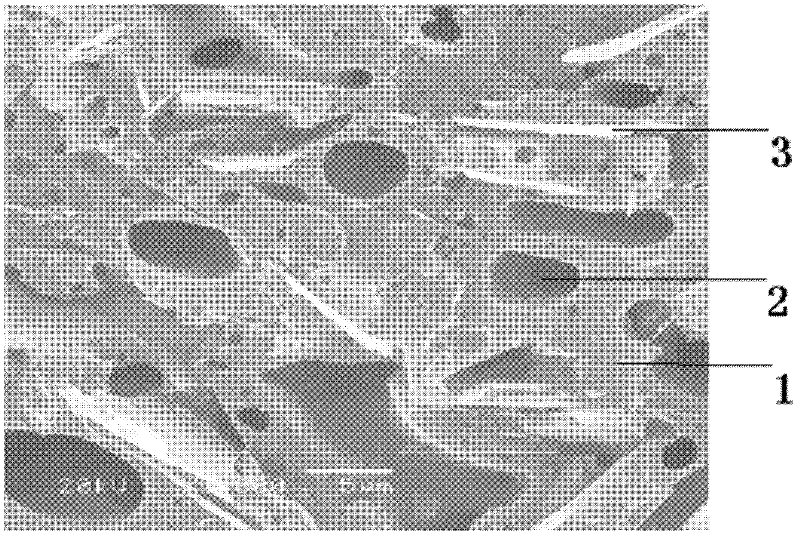

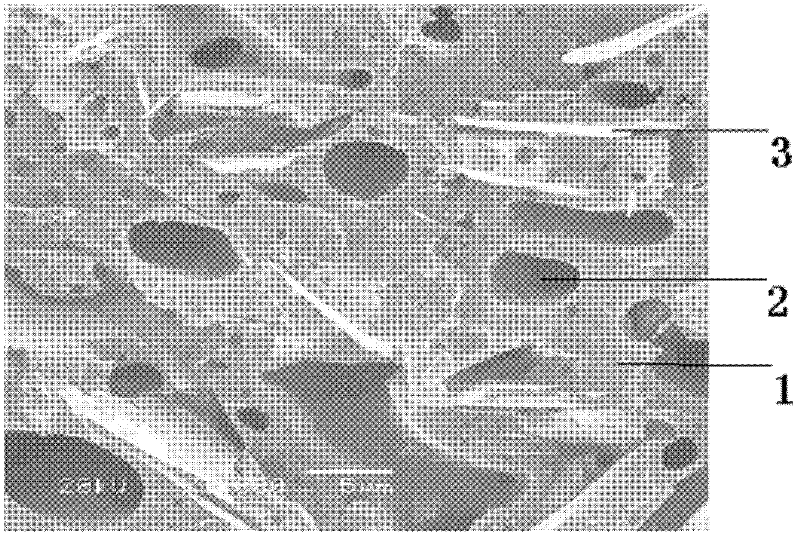

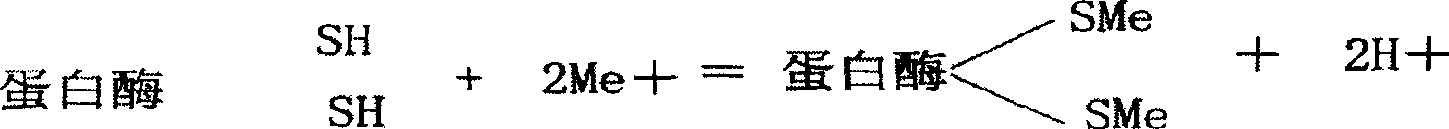

Method for preparing nanometer silver solution and nanometer silver powder by using high polymer as stabilizer

InactiveCN1653907AImprove antibacterial propertiesNo side effectsBiocideAnimal repellantsOrganic solventWater soluble

The present invention discloses the preparation process of nanometer silver solution and nanometer silver powder with polymer as stabilizer. Water soluble polymer as stabilizer in solution of 0.001-0.05 g / ml solution and silver nitrate in solution of 0.001-0.1 mol / L are compounded and reduced with water soluble reductant in solution of 0.001-0.2 mol / L to obtain nanometer silver particle of 5-100 nm size. The nanometer silver particle in solution may be further deposited and washed with sodium hydroxide solution, dried and crushed to obtain nanometer silver particle of 5-100 nm size. The prepared solution may be used in medical article, and prepared nanometer silver powder may be used widely in household appliance, plastic product, paint, etc. The present invention is environment friendly, low in cost and simple in operation, and the prepared nanometer silver particle has extremely powerful antibiotic capacity and wide antibiotic spectrum.

Owner:ZHEJIANG UNIV

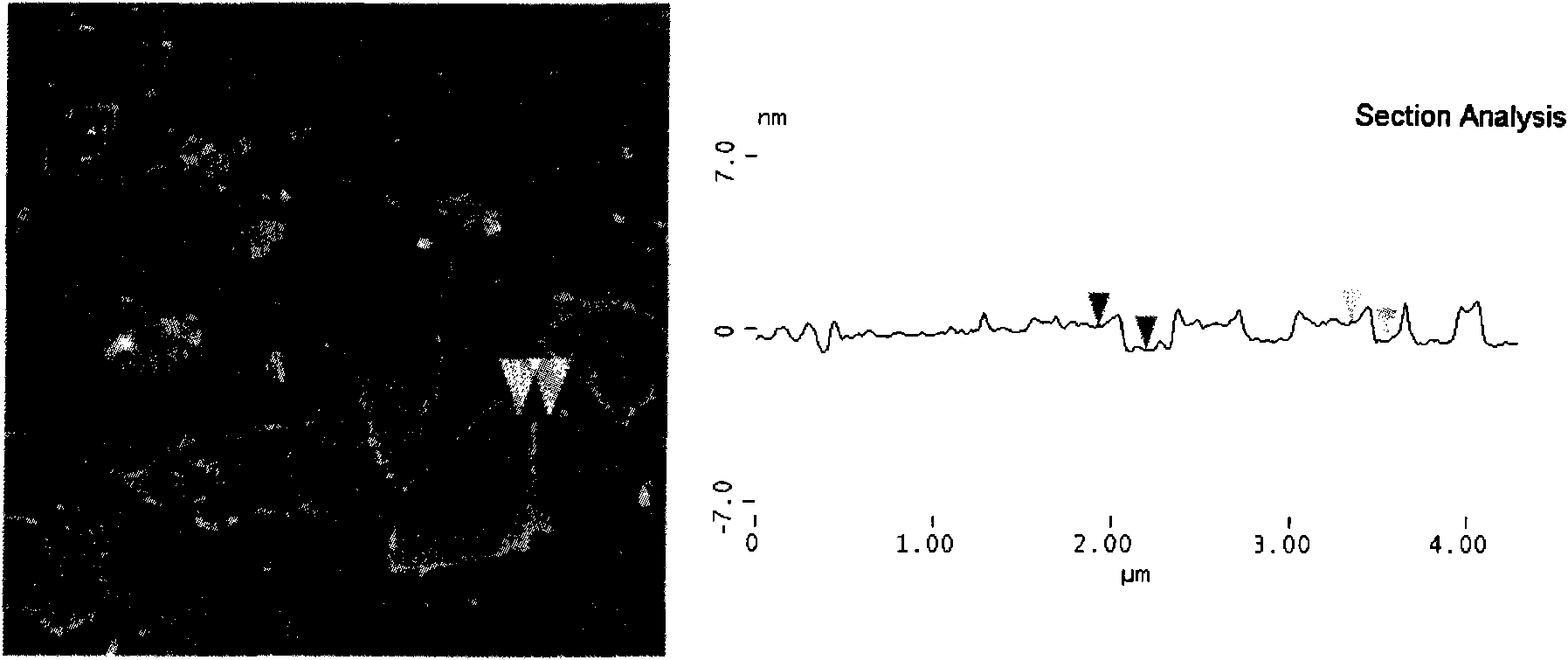

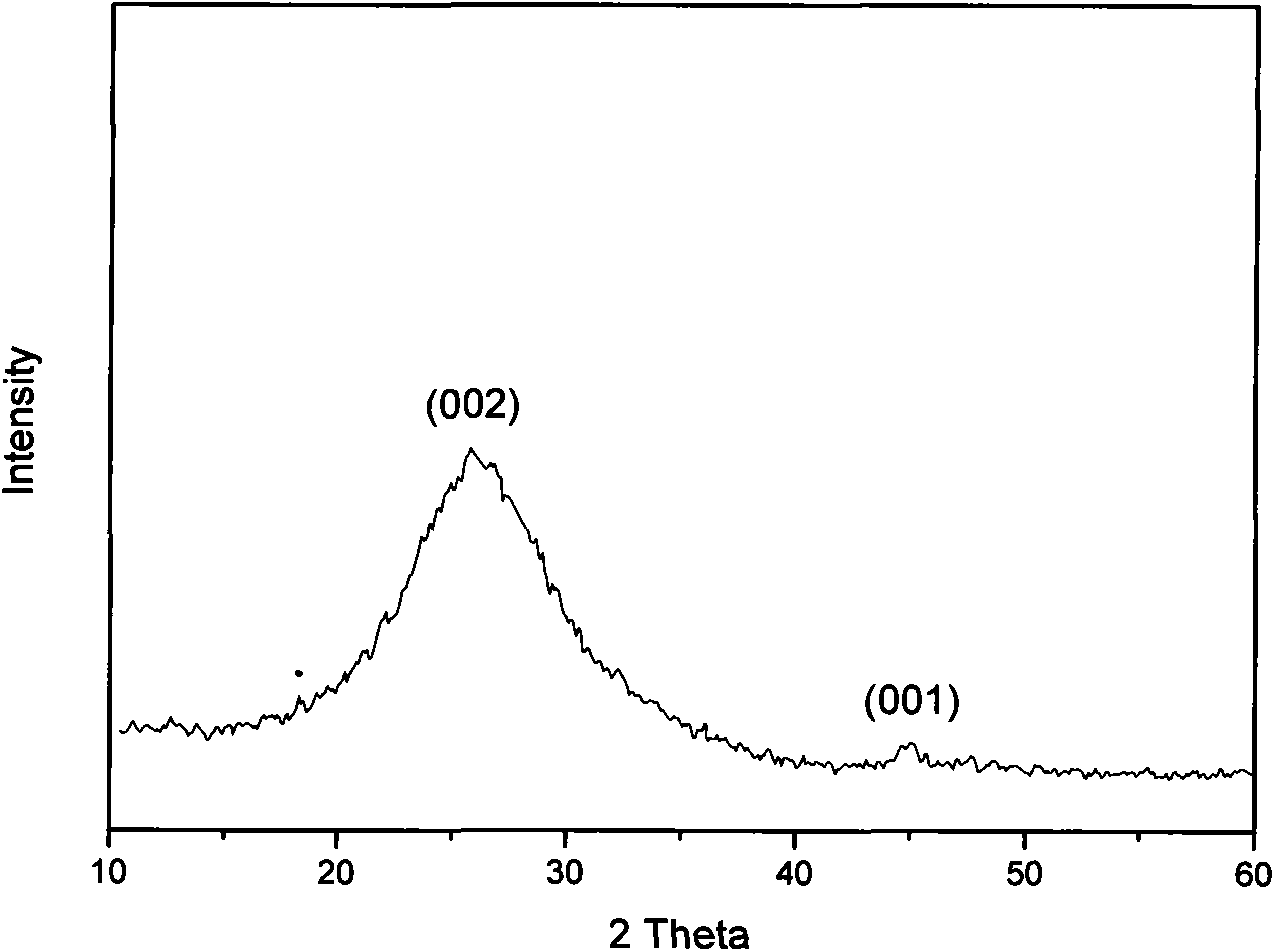

Preparation method of high-dispersivity graphene

The invention discloses a green preparation method of high-dispersivity graphene, which comprises the following steps: preparing graphite oxide, performing ultrasonic-stripping to obtain graphene oxide, adding water-soluble high polymer as a dispersant, and reducing under the irradiation of ultraviolet light to obtain high polymer surface-modified high-dispersivity graphene. The method has the advantages of simple technical process and low cost, and does not need any reducing chemical reagent; the prepared graphene has high dispersivity and stability; and the obtained high polymer surface-modified graphene is beneficial to further application.

Owner:XIANGTAN UNIV

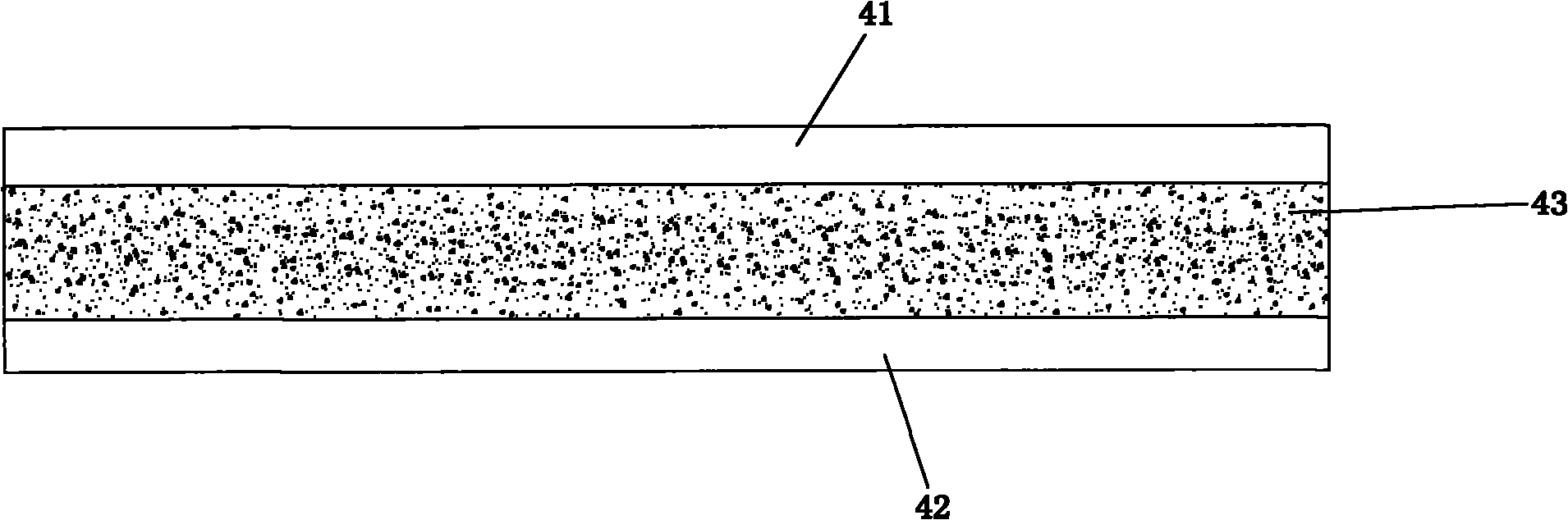

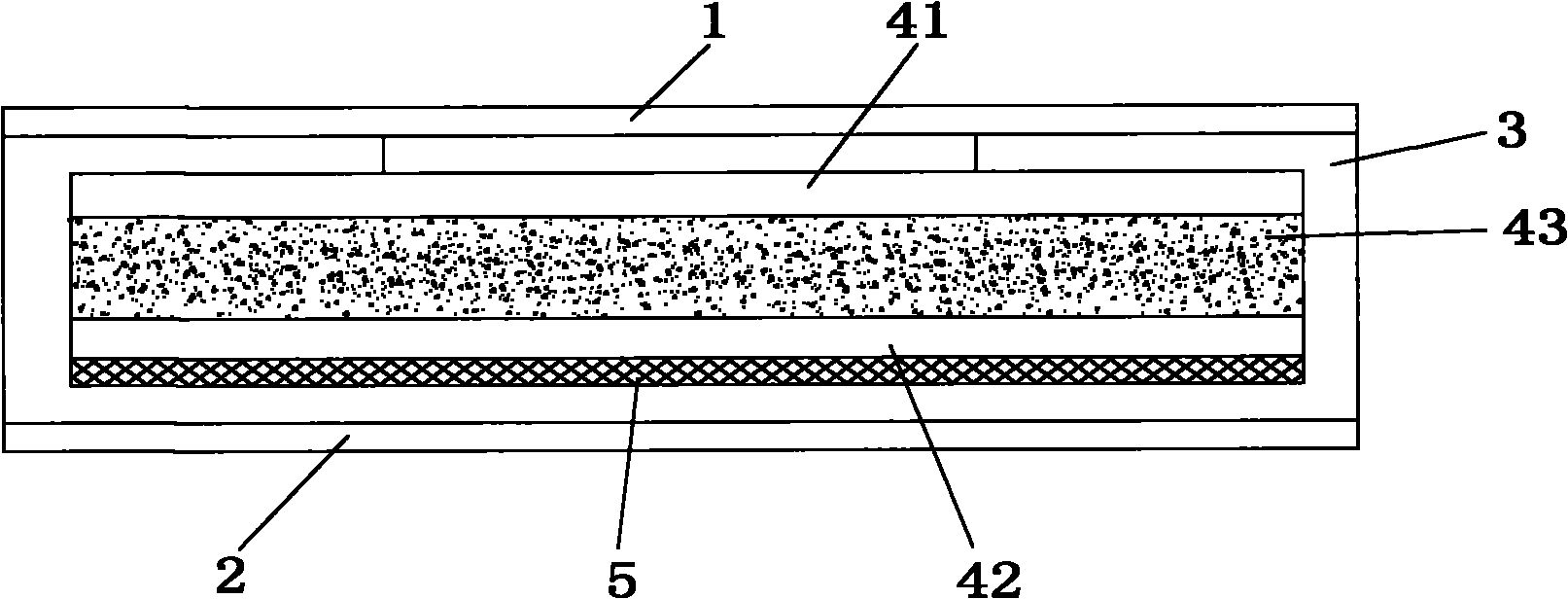

Polymer compound core body and preparation method thereof

InactiveCN101797201AImprove adhesionEffective inhalationSynthetic resin layered productsPaper/cardboard layered productsPolymer scienceSurface layer

The invention discloses a polymer compound core body and a preparation method thereof and relates to a polymer compound core body. The invention provides a polymer compound core body which is mainly used for paper diapers and panty diapers, the polymer compound core body which cam not form lump and can not be broken or delaminated and a preparation method thereof. The compound core body is provided with an airlaid paper surface layer, an airlaid paper bottom layer and a bulking non-woven fabric layer, wherein the bulking non-woven fabric layer is arranged between the airlaid paper surface layer and the airlaid paper bottom layer and is adhered to the airlaid paper surface layer and the airlaid paper bottom layer by an adhesive; and water absorbent resin is uniformly penetrated in the bulking non-woven fabric layer. Urine can be rapidly and completely penetrated to the polymer compound core body; the airlaid paper surface layer of the compound core body can effectively absorb the urine; a polymer water absorbent resin of the polymer compound core body can effectively absorb and store the urine; and the bulking non-woven fabric layer can ensure that the urine rapidly penetrates towards the direction of the bottom layer, thus the water-absorbing quantity is large, the surface layer is kept in a drier state and a human feels comfortable.

Owner:厦门造福堂文化传媒有限公司

Multiple network compound aquogel material with high mechanical intensity and electrochemical activity and preparation method thereof

InactiveCN101602876AImprove mechanical propertiesElectrochemically activeElectricityNetwork structure

The invention relates to a multiple network compound aquogel material with high mechanical intensity and electrochemical activity and a preparation method thereof; artificially-synthesized aquogel material and natural aquogel material are used as a first network or a second network, electric-conducting macromolecule aquogel material is used as a second and a third network, so as to prepare the compound aquogel material with a multiple network structure. The networks at different levels are provided with different mechanical performances which are mutually acted on, so as to lead the compound aquogel material to have high mechanical intensity; the electric-conducting macromolecule aquogel material is used as a constituent of the compound aquogel, so as to lead the compound aquogel material to have electrochemical activity. The multiple network compound aquogel material with high mechanical intensity and electrochemical activity can be applied to the field of electrochemical sensors, supercapacitors, electrochemical exciters, artificial muscles and the like. The invention also discloses a preparation method thereof.

Owner:NANJING UNIV

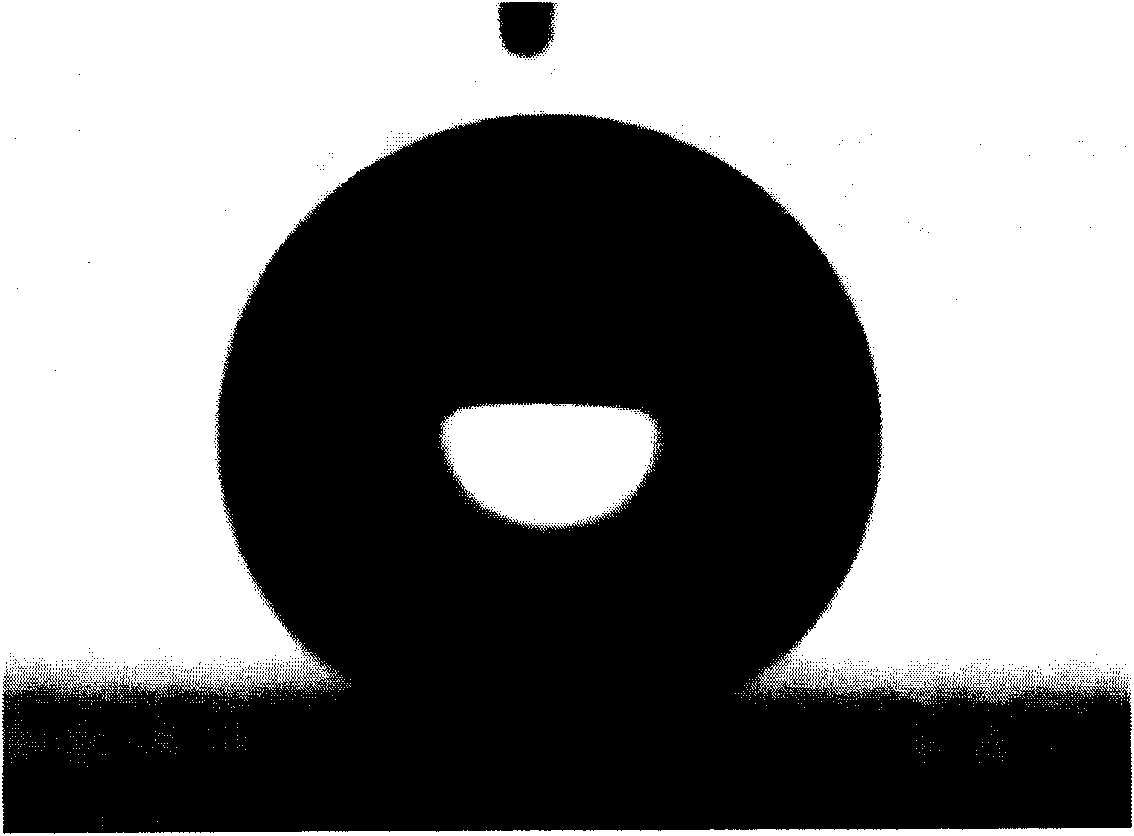

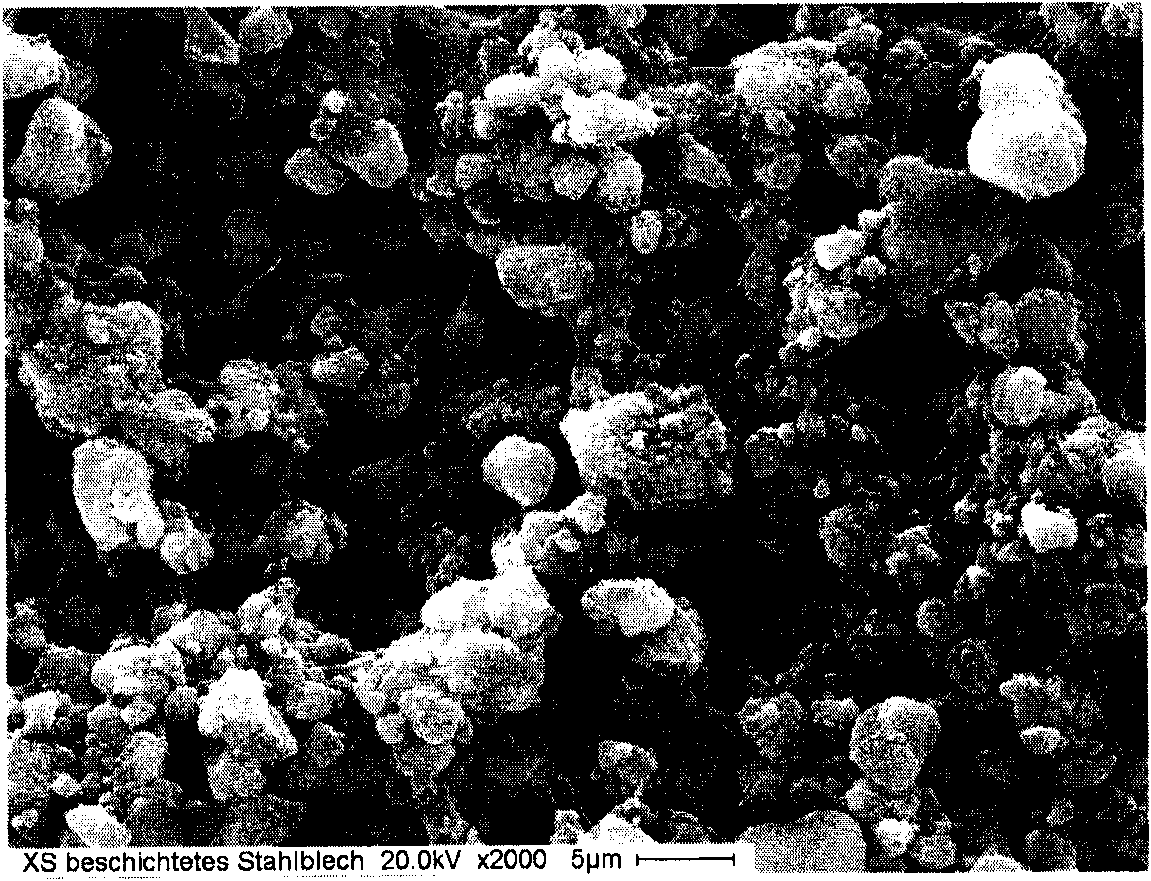

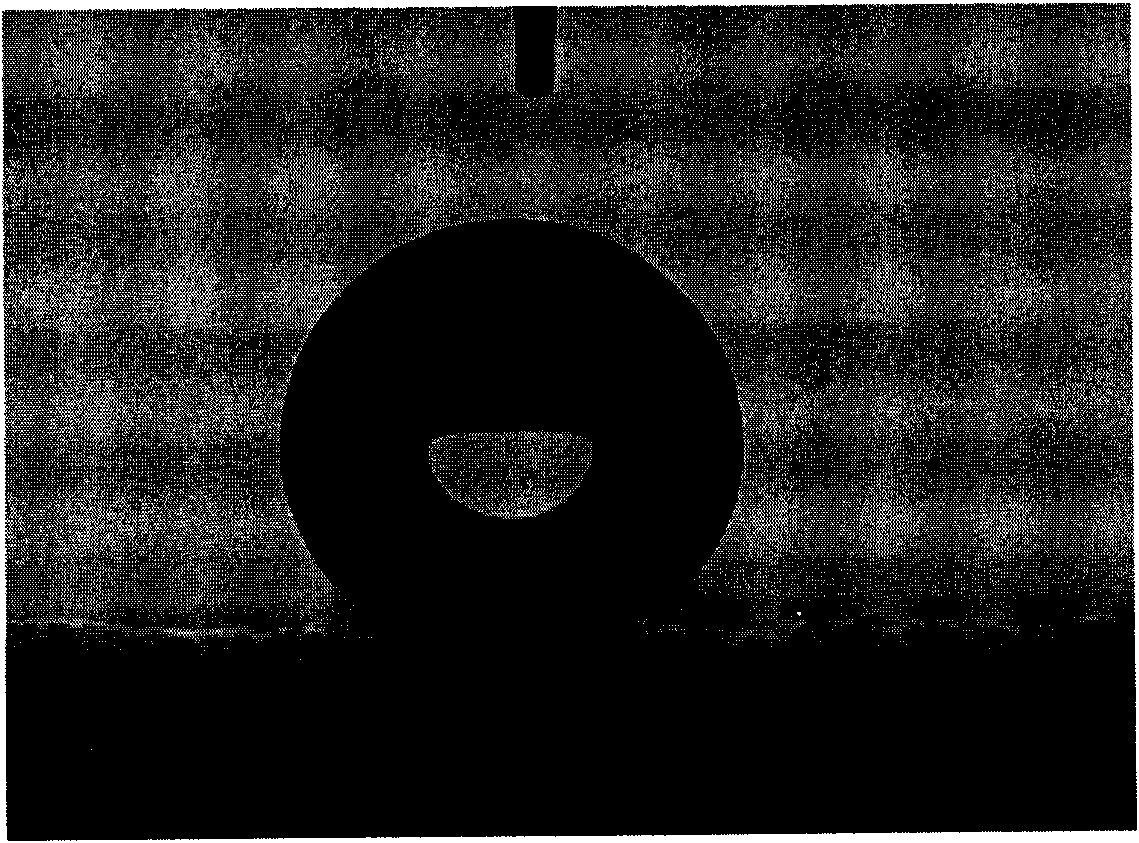

Super-hydrophobic coating material, preparation method thereof and super-hydrophobic coating

InactiveCN102051120AThe preparation method is simple and easy to obtainEasy to realize industrial applicationCoatingsOrganic solventHydrogen

The invention provides a super-hydrophobic coating material, which comprises water or emulsifier or organic solvent, a polysiloxane compound having more than three silicon-hydrogen bonds and solid particles. The invention also provides the preparation method of the super-hydrophobic coating material and the preparation method of a super-hydrophobic coating. The invention provides the super-hydrophobic coating material which is prepared by a simple method, has high mechanical strength, is durable, practical and capable of self-cleaning and the preparation method of the super-hydrophobic coating material. The super-hydrophobic coating material provided by the invention can solidify in a wider temperature range and is applicable to substrates made of various materials such as metal, glass and high polymer materials.

Owner:HENKEL KGAA

Nanometer cellulose/polyvinyl alcohol gel composite material

ActiveCN102786642ALarge specific surface areaHigh porosityChemical industryChemical industryPolyvinyl alcohol

The invention relates to a nanometer cellulose / polyvinyl alcohol gel composite material, which is characterized by comprising hydrogel and aerogel. A preparation method of the nanometer cellulose / polyvinyl alcohol gel composite material comprises the following process steps of 1, nanometer cellulose preparation by a chemical combination mechanical treatment method; 2, composite hydrogel preparation; and 3, composite aerogel preparation. The nanometer cellulose / polyvinyl alcohol gel composite material has the advantages that the composite aerogel belongs to a porous amorphous solid material consisting of nanometer level colloid particles or high-polymer molecules, and a unique open nanometer level porous structure and a continuous three-dimensional reticular structure are adopted, so the density is extremely low, the specific surface area is high, and the porosity is high, wherein the solid phase of the aerogel accounts for 0.2 percent to 20 percent of the total volume percentage, the characteristics of high adsorption catalytic capability, low thermal conductivity, low sound resistance, low refractive index and the like are shown, and wide application prospects are realized in the fields of aviation, spaceflight, chemical industry, metallurgy, energy-saving building and the like.

Owner:SHANDONG LVSEN WOOD PLASTIC COMPOSITE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com