Patents

Literature

712 results about "SOCKS" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

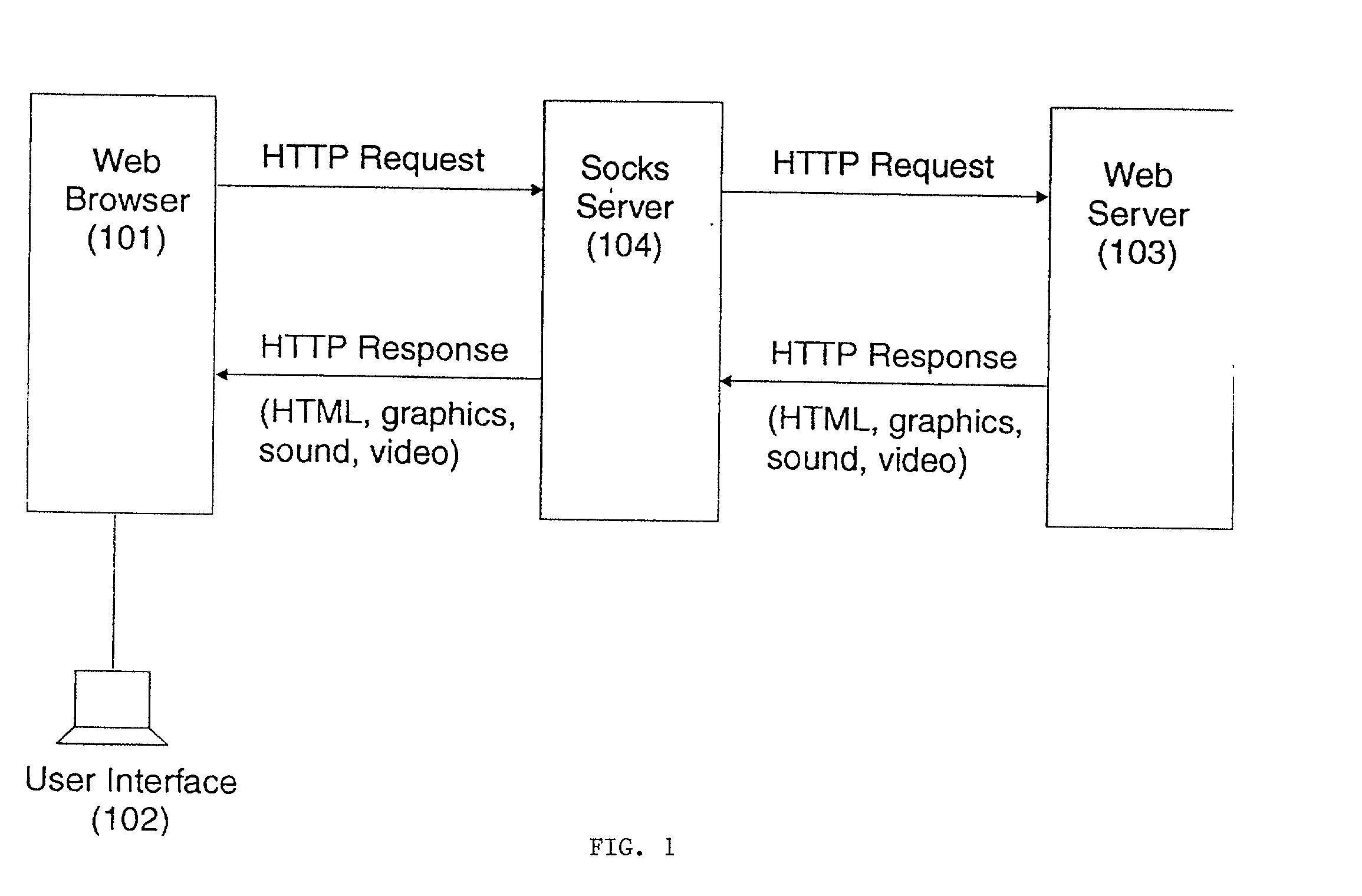

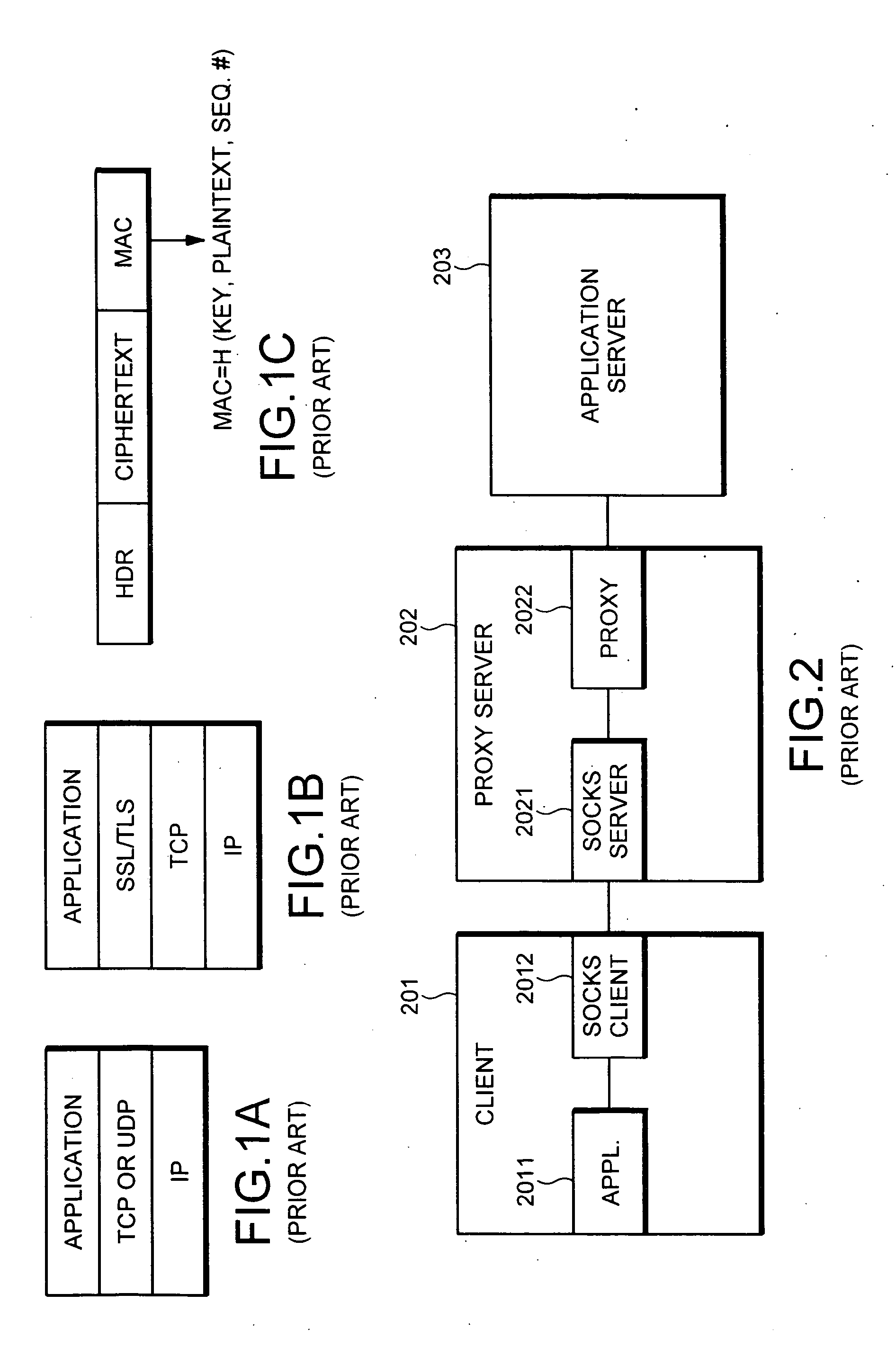

SOCKS is an Internet protocol that exchanges network packets between a client and server through a proxy server. SOCKS5 additionally provides authentication so only authorized users may access a server. Practically, a SOCKS server proxies TCP connections to an arbitrary IP address, and provides a means for UDP packets to be forwarded.

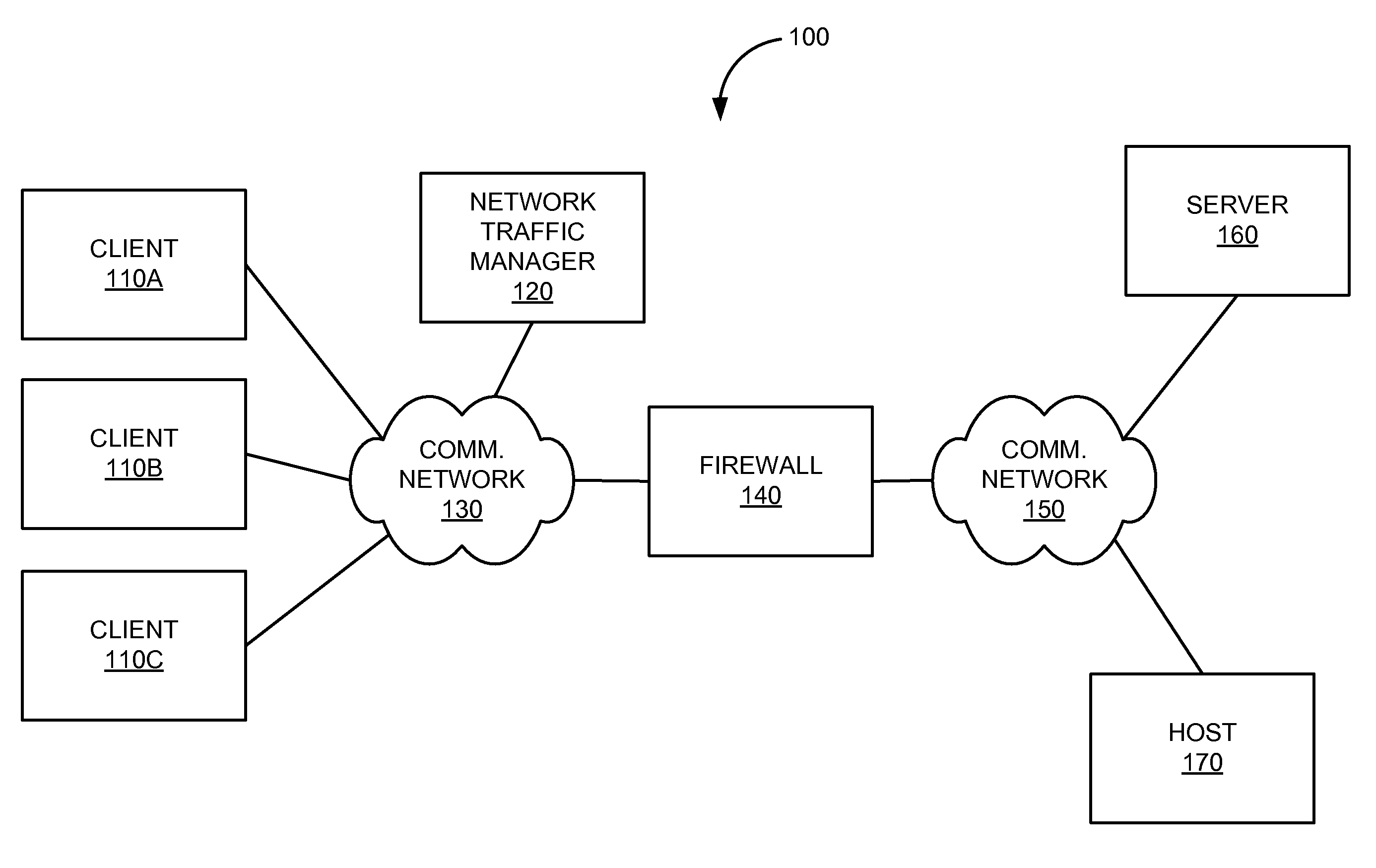

Method and apparatus for lightweight secure communication tunneling over the internet

InactiveUS6104716AData switching by path configurationMultiple digital computer combinationsSOCKSSecure communication

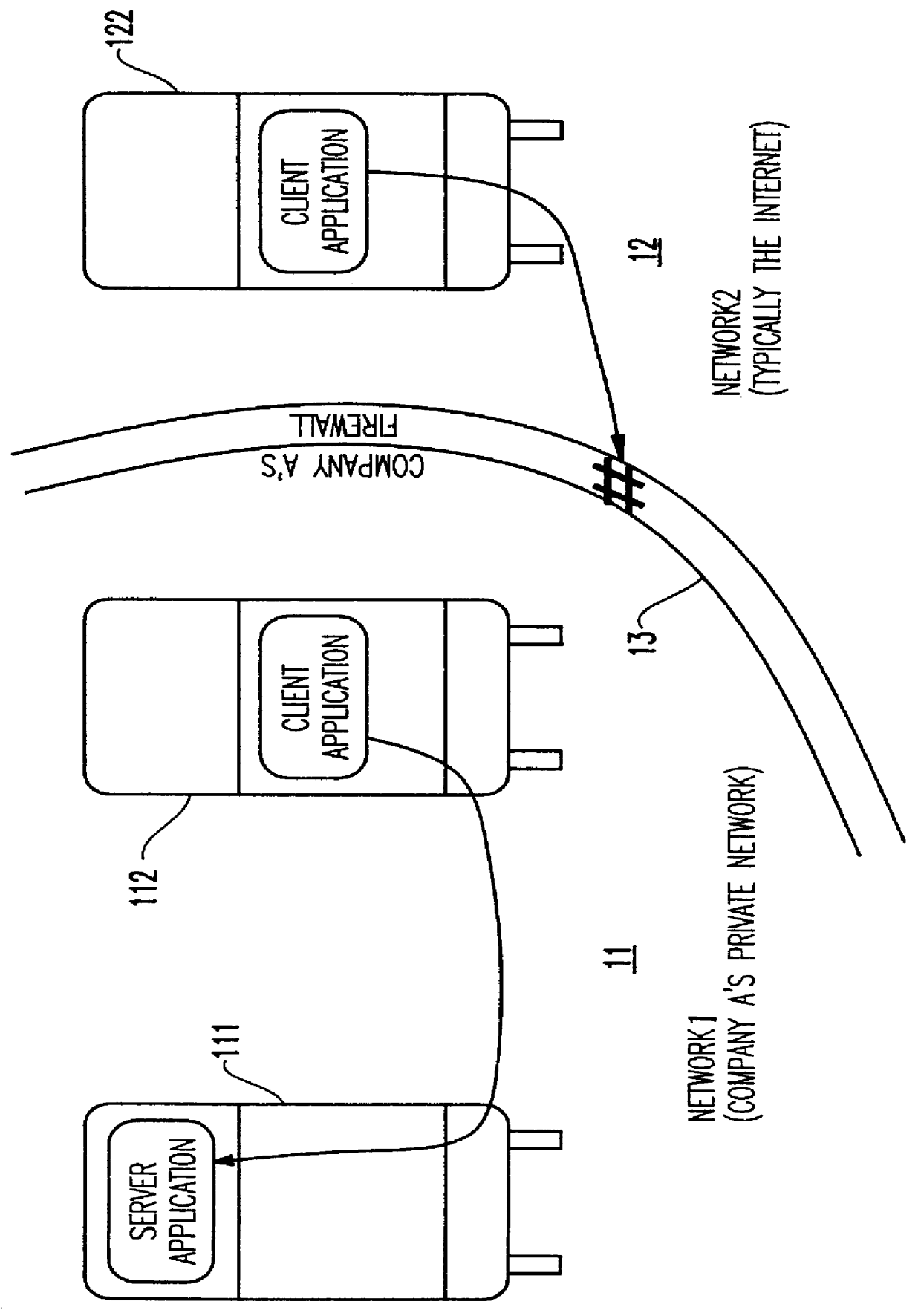

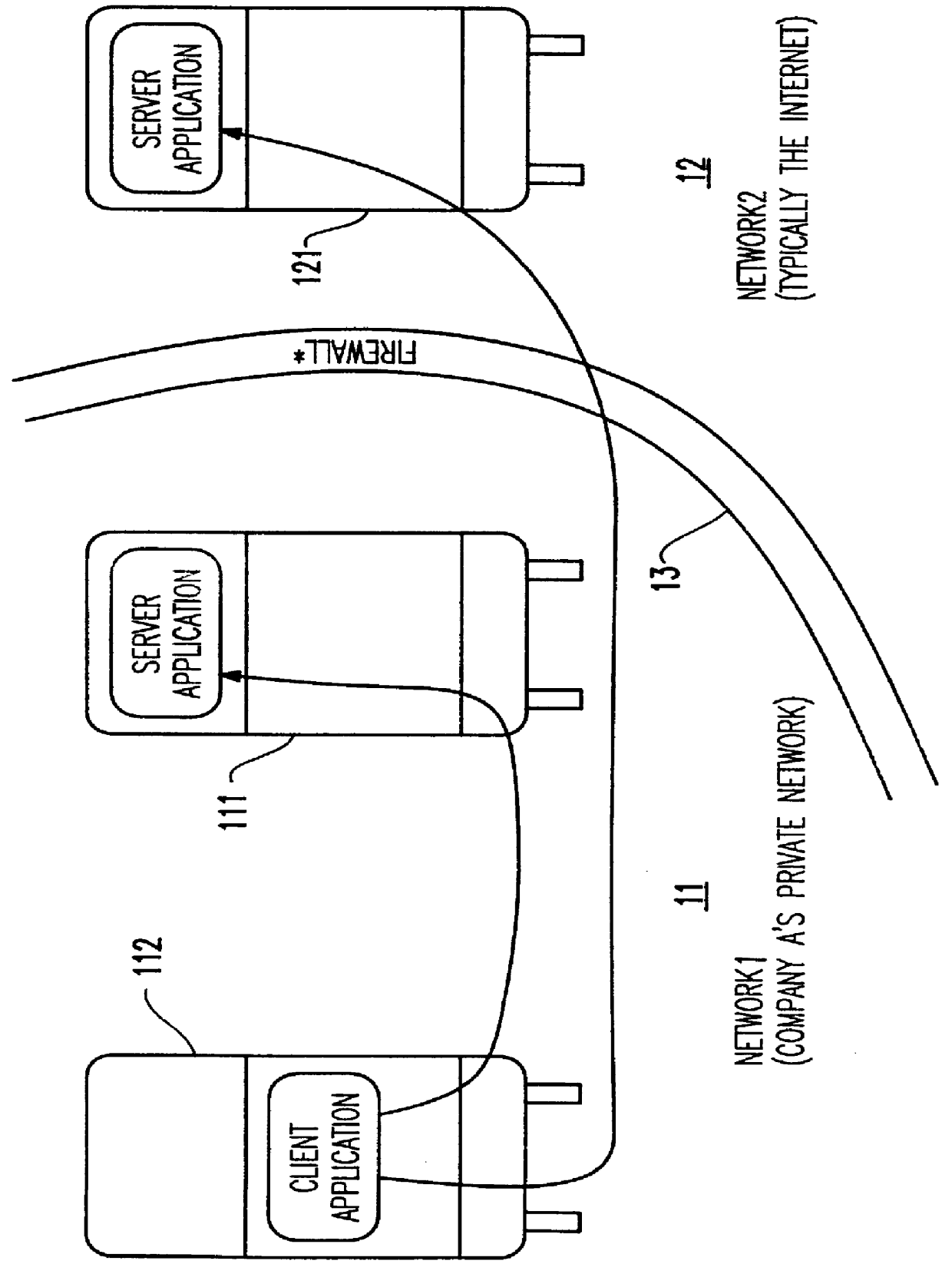

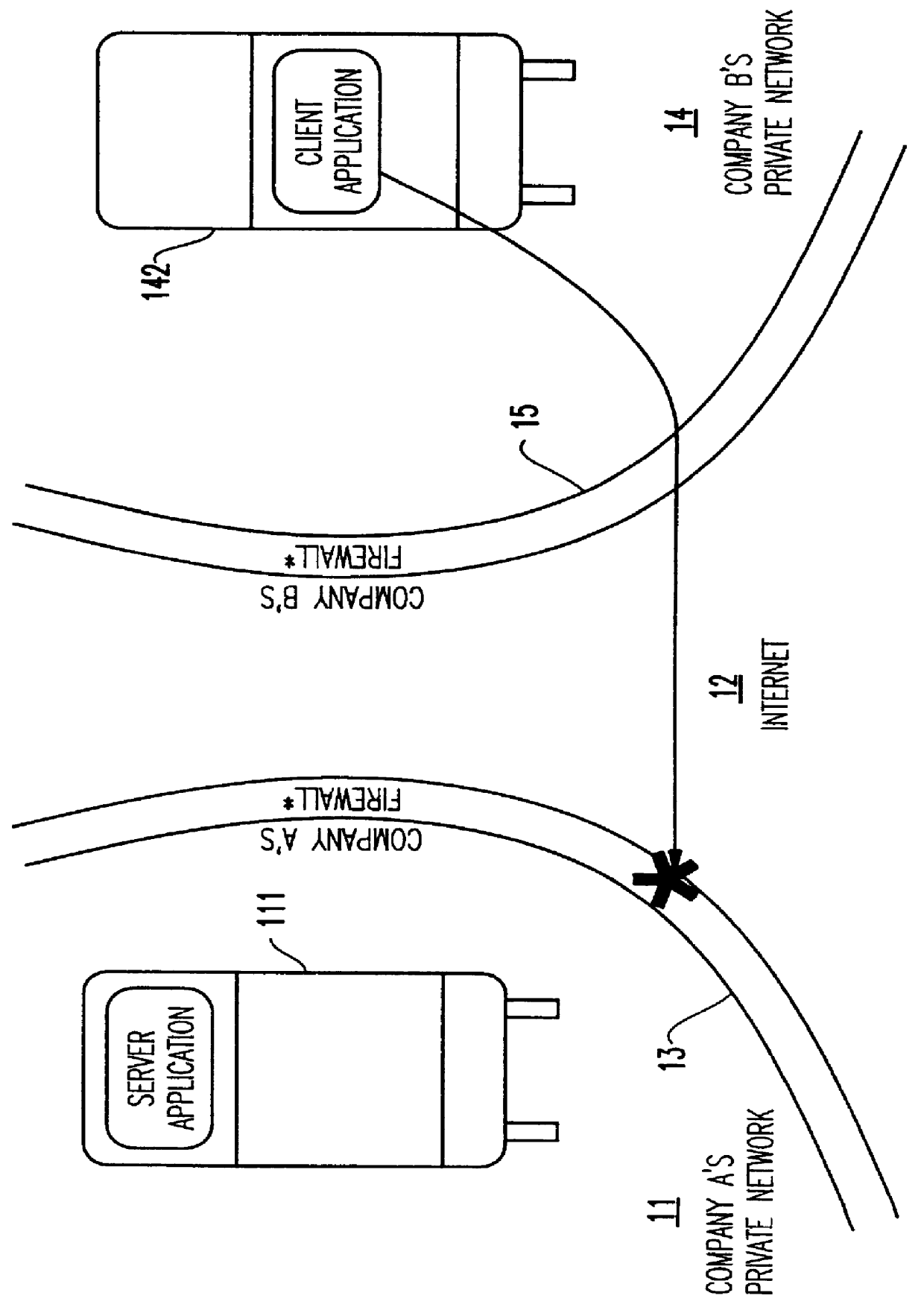

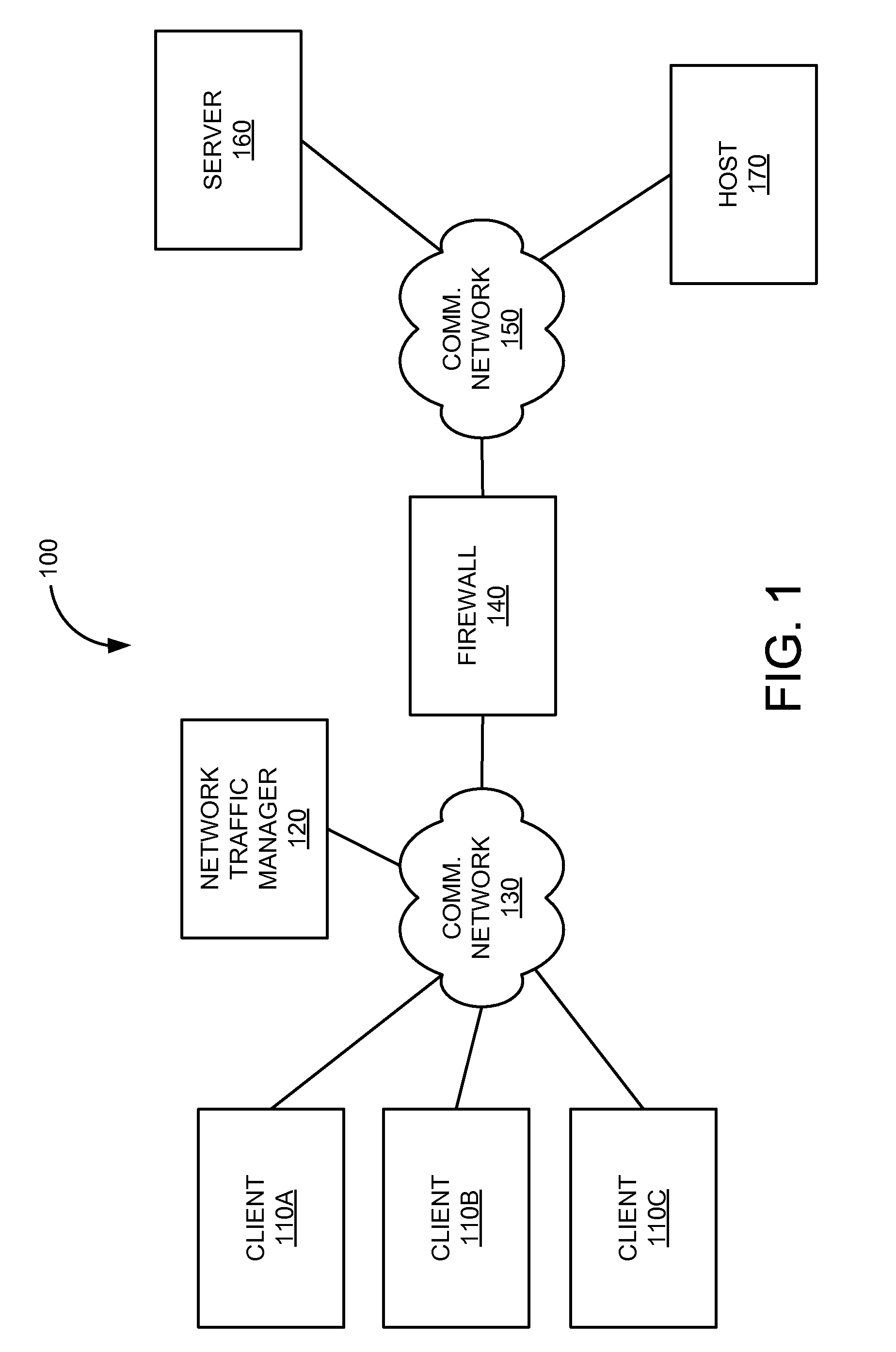

A lightweight secure tunneling protocol or LSTP permits communicating across one or more firewalls by using a middle server or proxy. Three proxies are used to establish an end-to-end connection that navigates through the firewalls. In a typical configuration, a server is behind a first firewall and a client behind a second firewall are interconnected by an untrusted network (e.g., the Internet) between the firewalls. A first inside firewall SOCKS-aware server-side end proxy connects to the server inside the first firewall. A second inside firewall SOCKS-aware client-side end proxy is connected to by the client inside the second firewall. Both server-side and client-side end proxies can address a third proxy (called a middle proxy) outside the two firewalls. The middle proxy is usually started first, as the other two end proxies (server and client) will initiate the connection to the middle proxy some time after they are started. Since the middle proxy is mutually addressable by both inside proxies, a complete end-to-end connection between the server and client is established. It is the use of one or more middle proxies together with the LSTP that establishes the secure communications link or tunnel across multiple firewalls.

Owner:IBM CORP

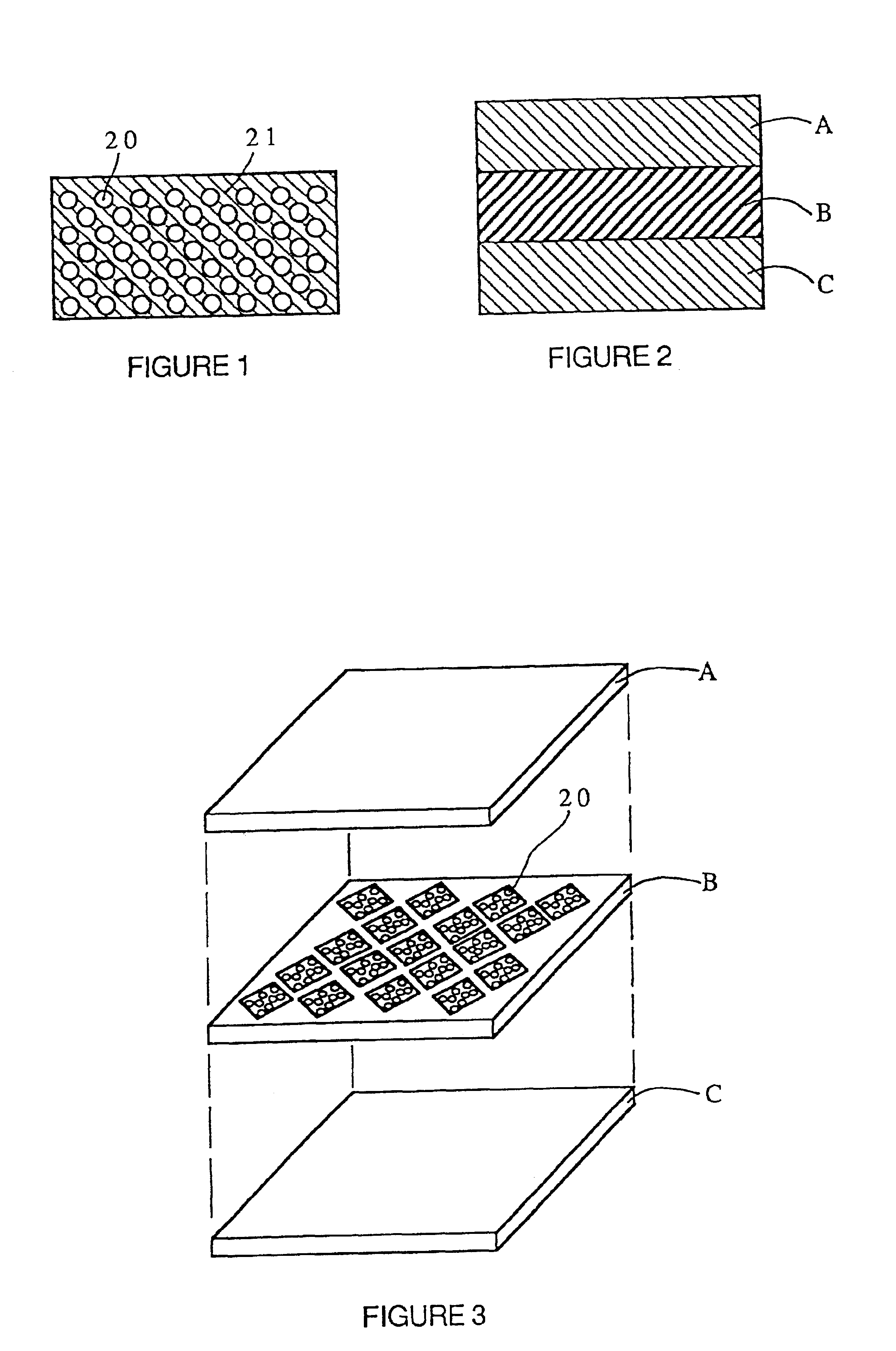

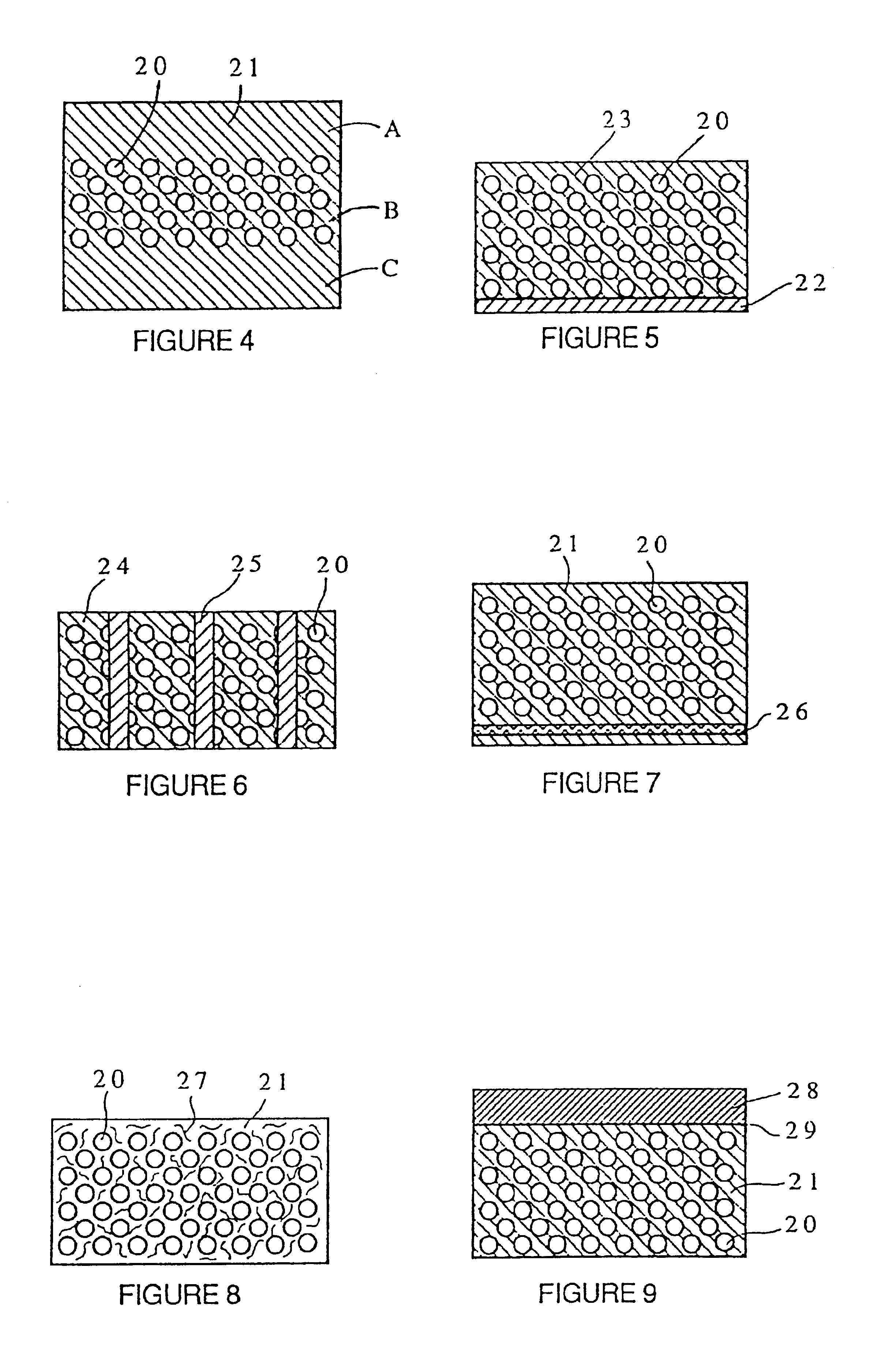

Phase change material thermal capacitor clothing

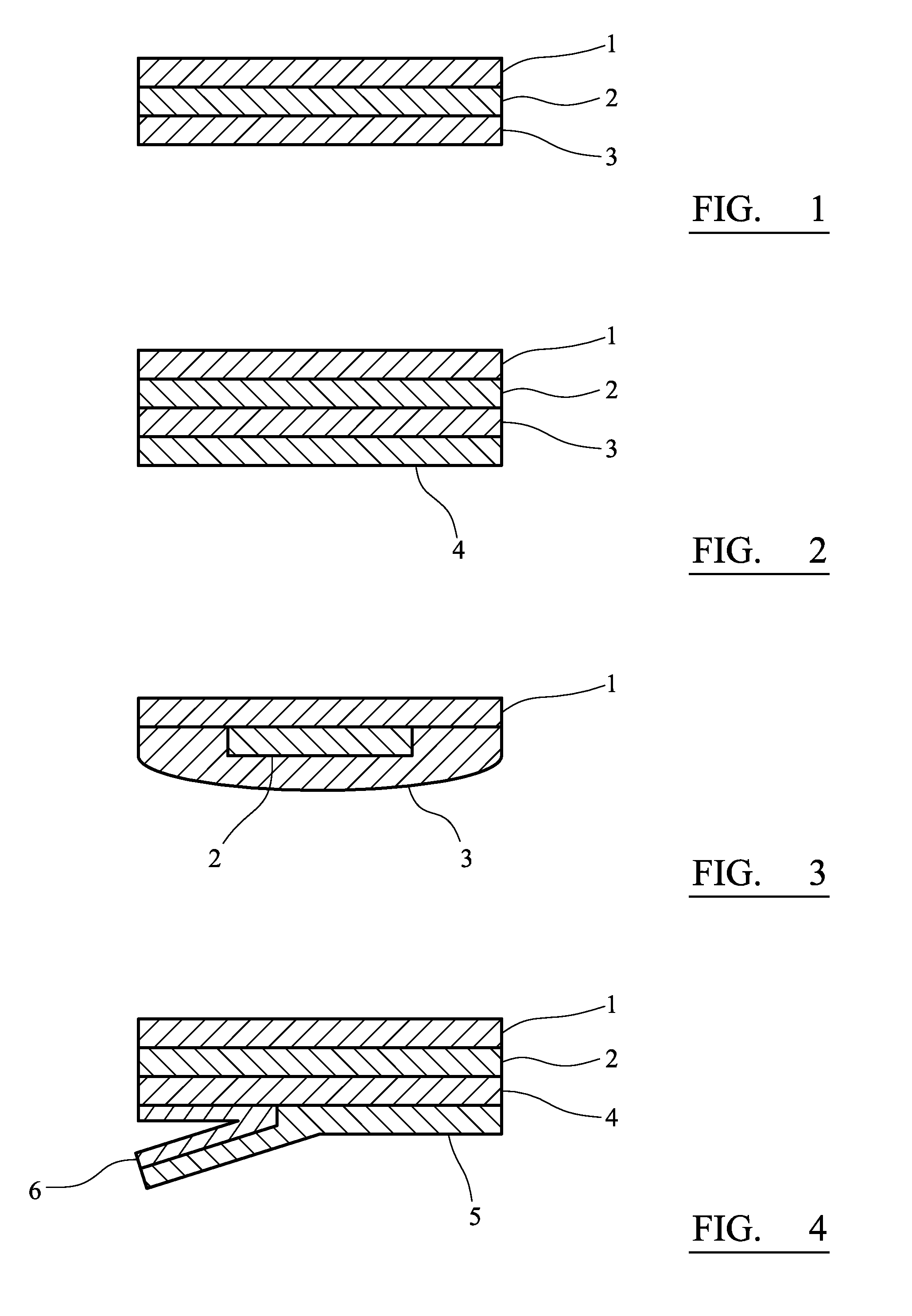

InactiveUS6855410B2Good thermal controlFast regenerationExothermal chemical reaction heat productionNatural cellulose pulp/paperSOCKSThermal insulation

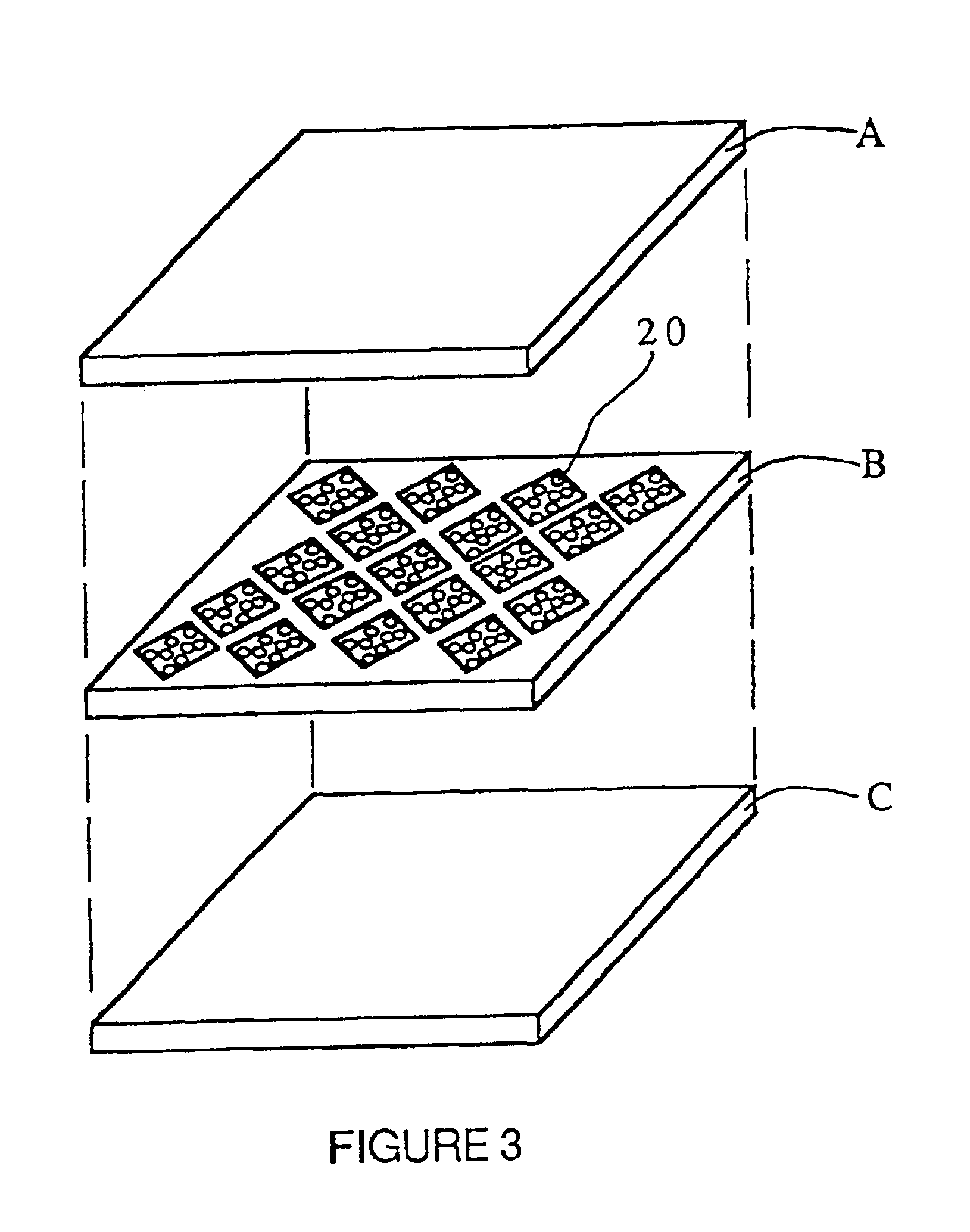

An apparatus and method for metabolic cooling and insulation of a user in a cold environment. In its preferred embodiment the apparatus is a highly flexible composite material having a flexible matrix containing a phase change thermal storage material. The apparatus can be made to heat or cool the body or to act as a thermal buffer to protect the wearer from changing environmental conditions. The apparatus may also include an external thermal insulation layer and / or an internal thermal control layer to regulate the rate of heat exchange between the composite and the skin of the wearer. Other embodiments of the apparatus also provide 1) a path for evaporation or direct absorption of perspiration from the skin of the wearer for improved comfort and thermal control, 2) heat conductive pathways within the material for thermal equalization, 3) surface treatments for improved absorption or rejection of heat by the material, and 4) means for quickly regenerating the thermal storage capacity for reuse of the material. Applications of the composite materials are also described which take advantage of the composite's thermal characteristics. The examples described include a diver's wet suit, ski boot liners, thermal socks, gloves and a face mask for cold weather activities, and a metabolic heating or cooling blanket useful for treating hypothermia or fever patients in a medical setting and therapeutic heating or cooling orthopedic joint supports.

Owner:BUCKLEY THERESA M

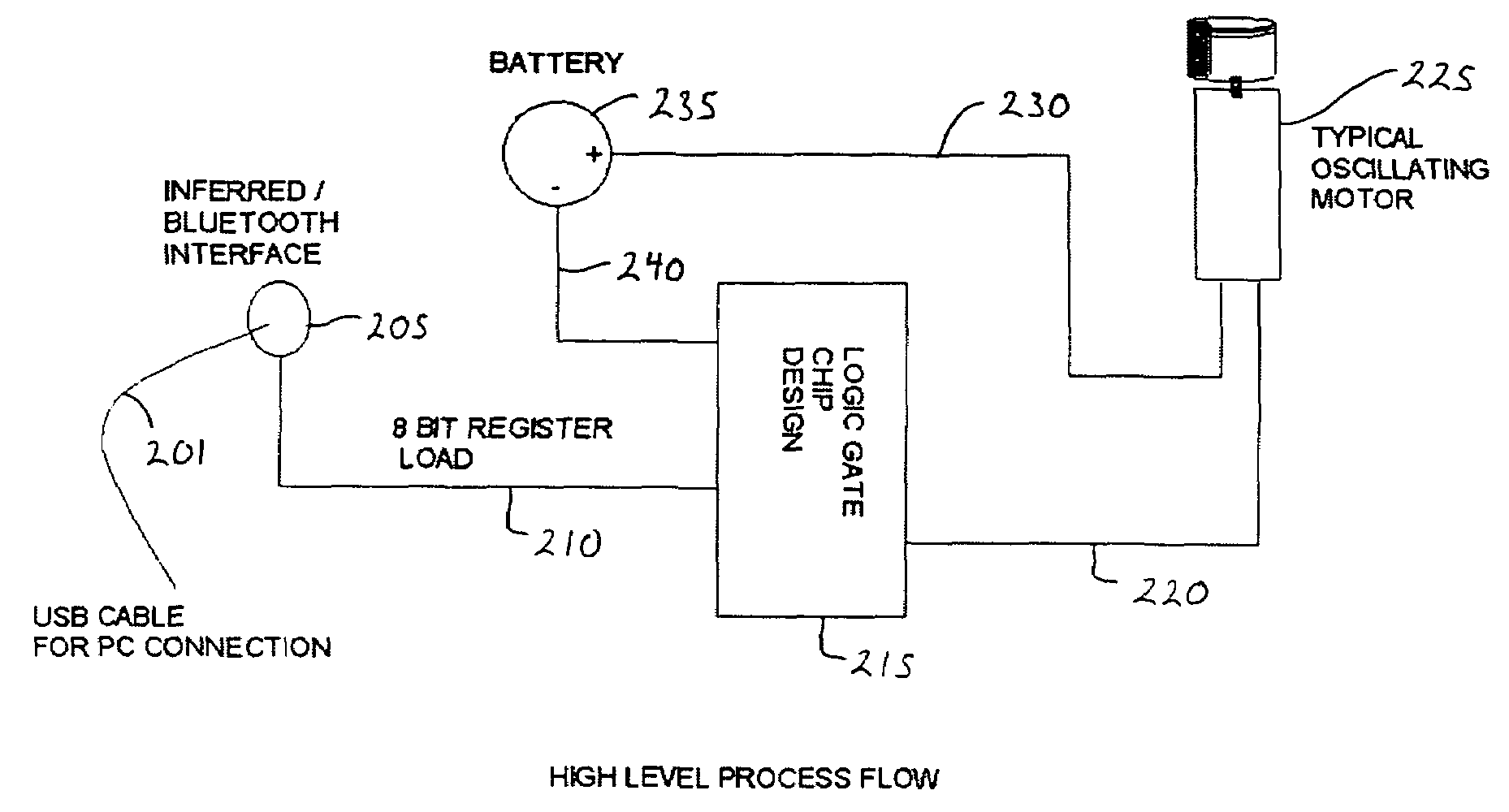

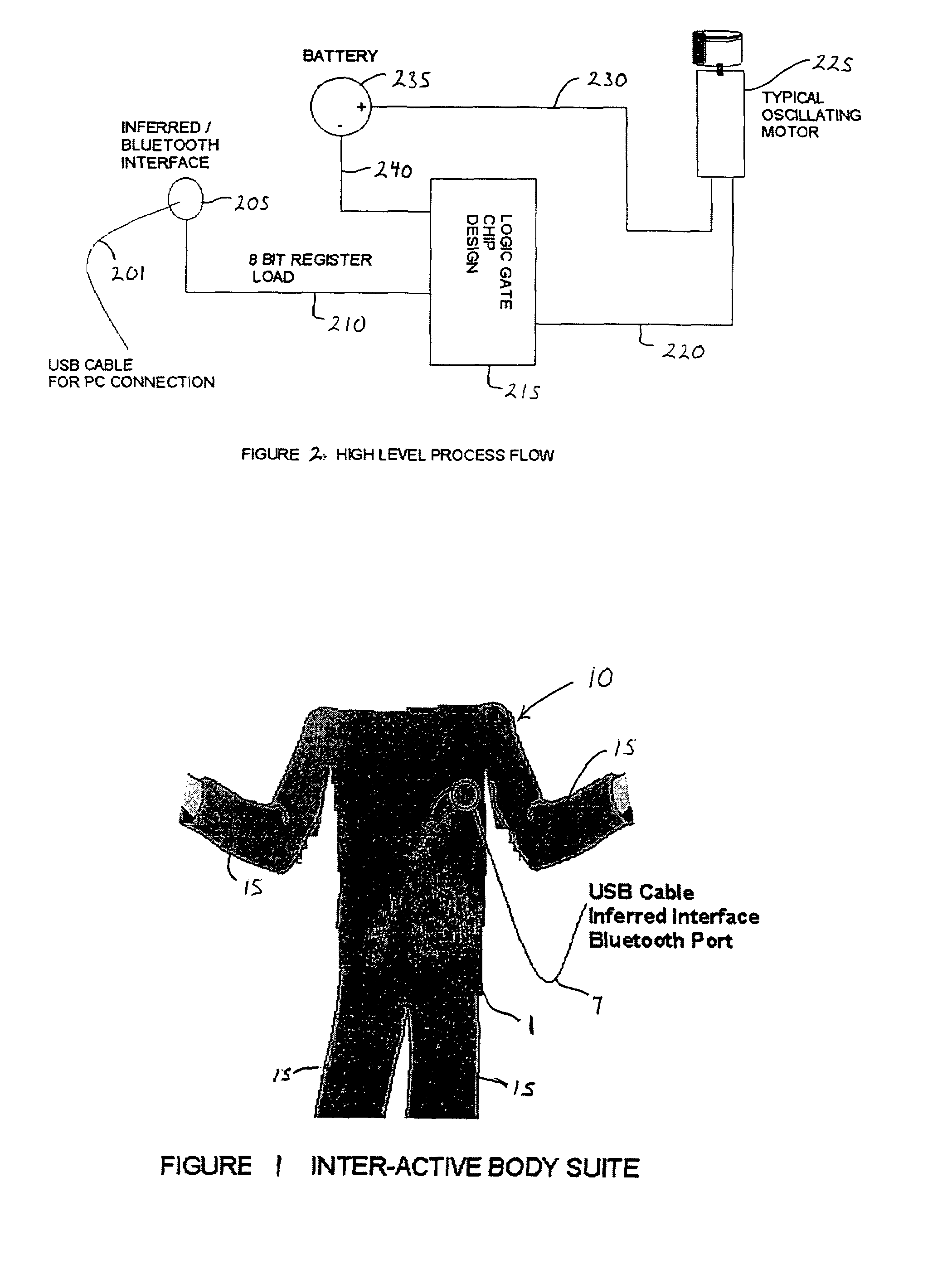

Interactive body suit and interactive limb covers

A system, apparatus and method, consisting of firmware, software, oscillating motors, a garment, and peripherals that permit users to interact over the Internet or wireless communications network with games or each other users whereby the sensation of touch is felt by the garment user. The invention consists of an interactive body suit that covers the torso. Peripheral gloves, socks, and adult entertainment attachments for men and women attach to the interactive body suit in appropriate locations.Small oscillating motors embedded in the garment and the peripherals produce a vibrating touch sensation when activated. Each motor has a logic address on the suit or peripheral device that correlates to a logical point on a computer graphic representing the user. Contact with the graphic will generate a command signal that activates a motor in the corresponding area on the suit. In one application, limb covers with embedded oscillating motors are used to provide medical treatment massage therapy.

Owner:DUNDON MICHAEL J

Method and system for optimally selecting a web firewall in a TCB/IP network

InactiveUS6892235B1Minimize Web service interruptionService availabilityError detection/correctionCode conversionSOCKSUniform resource locator

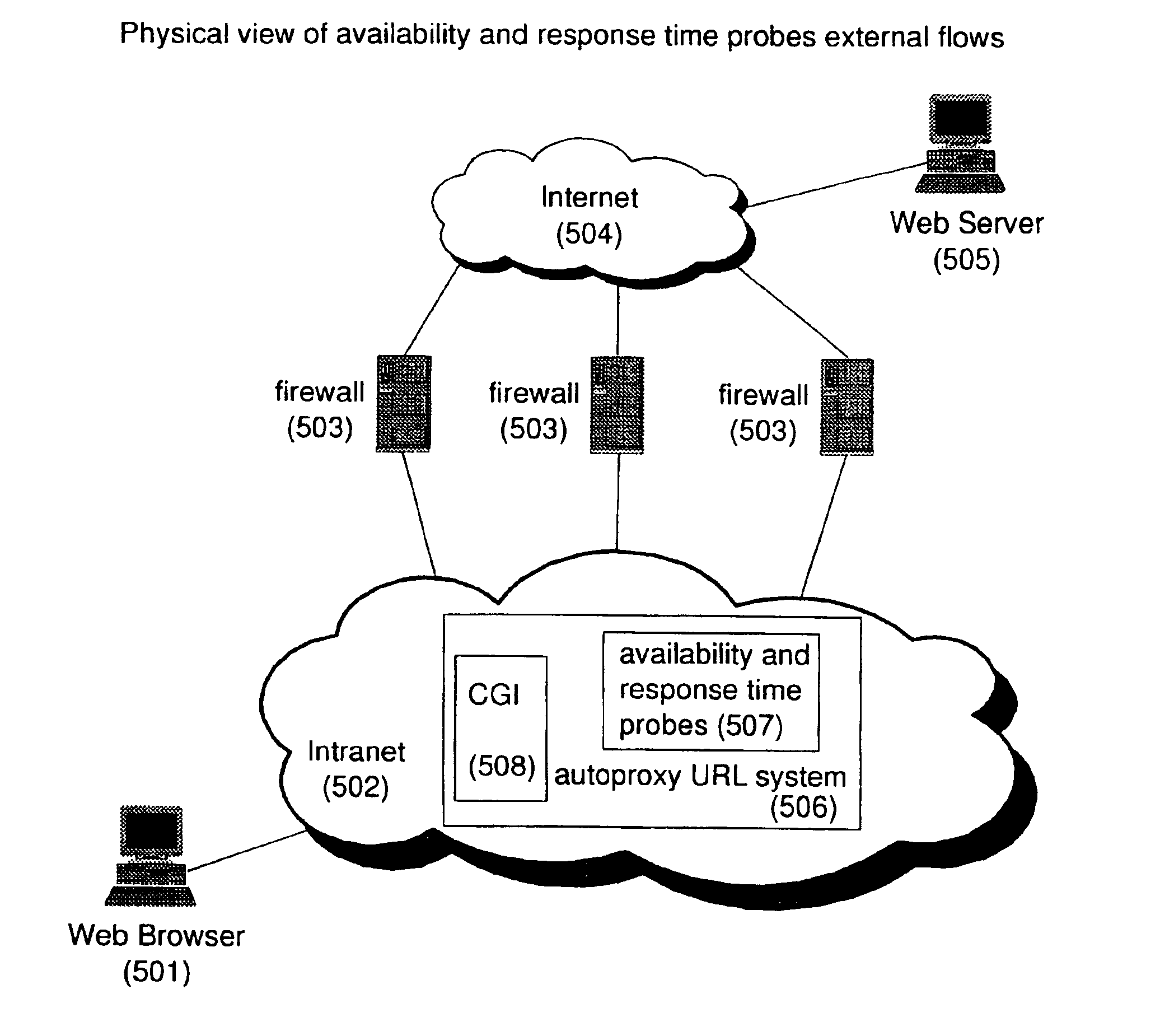

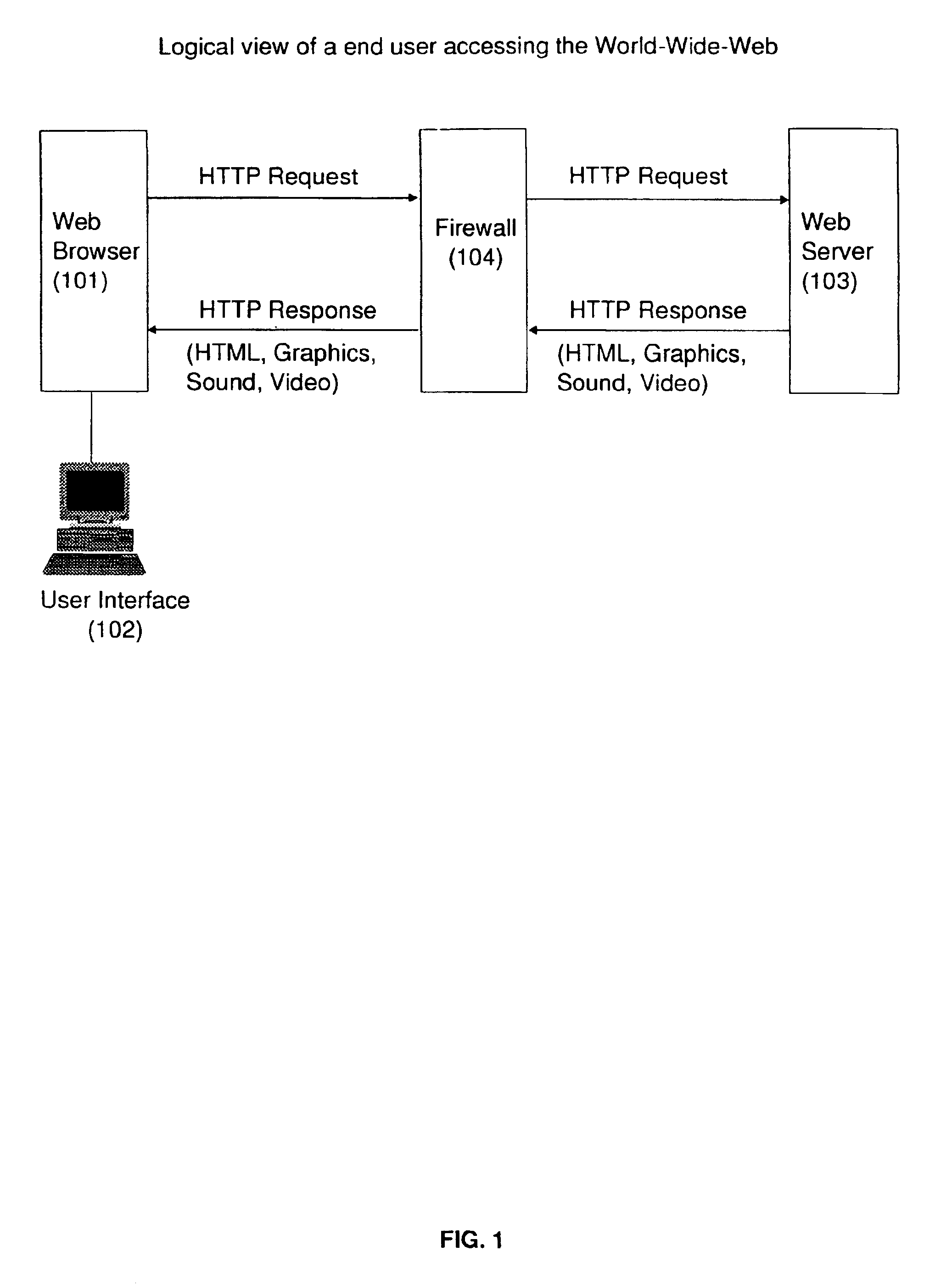

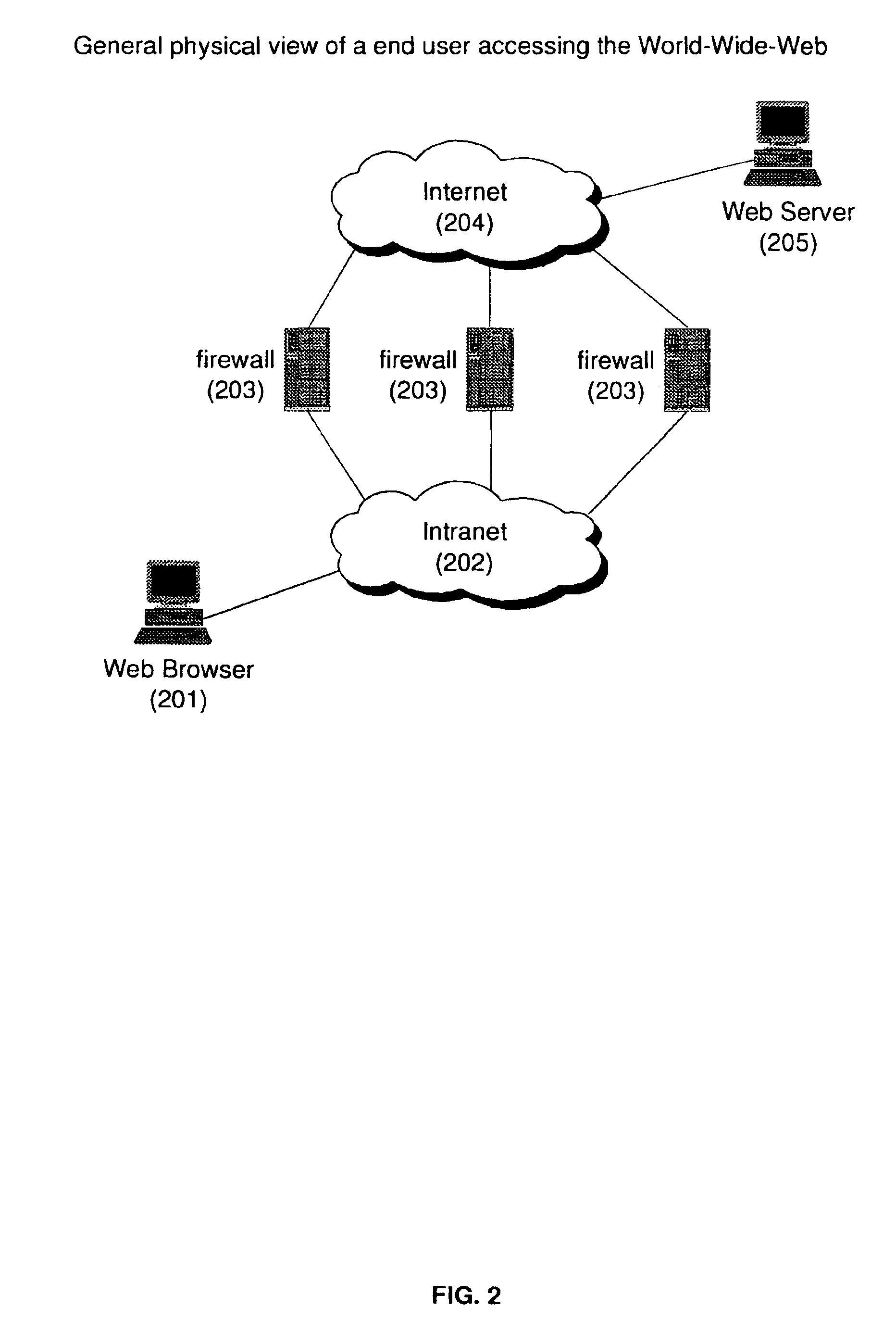

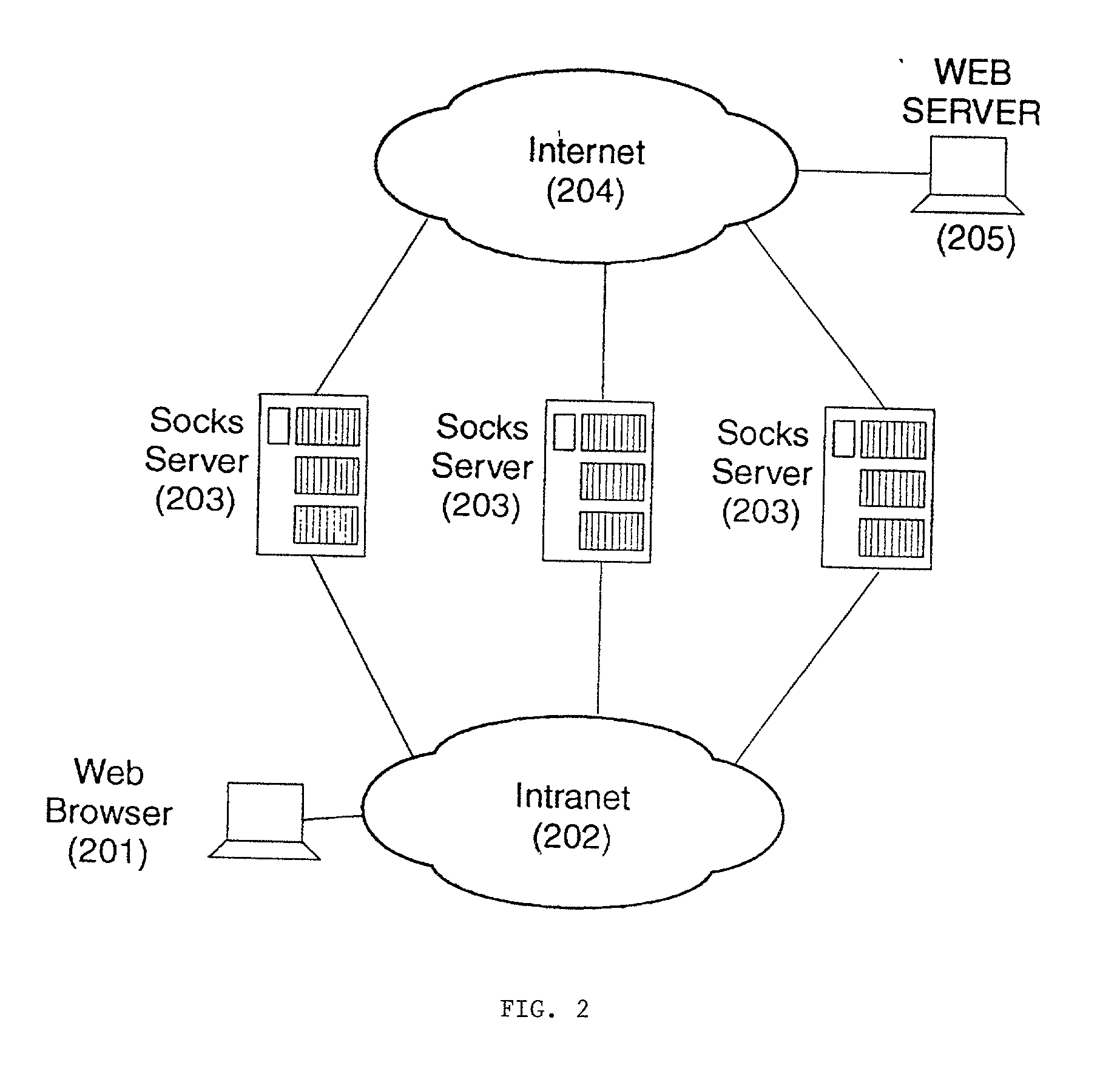

The present invention relies on dynamic autoproxy configuration and more particularly to a method and system for selecting a Proxy / Socks Server according to some response time and availability criteria. It rests on a dynamic autoproxy mechanism using availability and response time probes. It relies on probes retrieving well known HTML pages through each Proxy / Socks Server, measuring associated response time, detecting Proxy / Socks failures and degradation of response time. It also uses a CGI (Common Gateway Interface) program for dynamically creating autoproxy code (in a preferred embodiment Javascript code) on an autoproxy URL (Universal resource locator) system for selecting said Proxy / Socks Server.

Owner:TREND MICRO INC

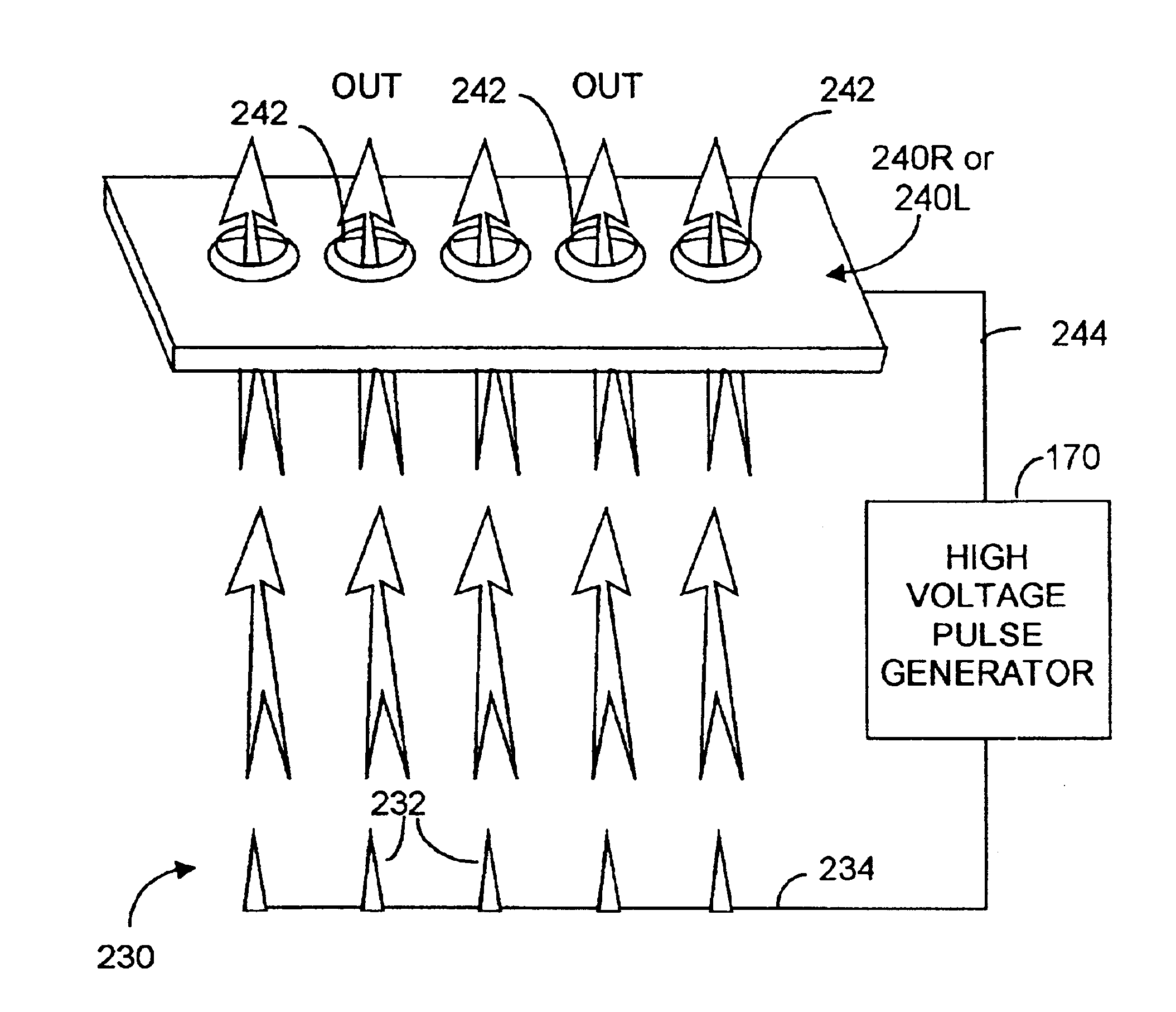

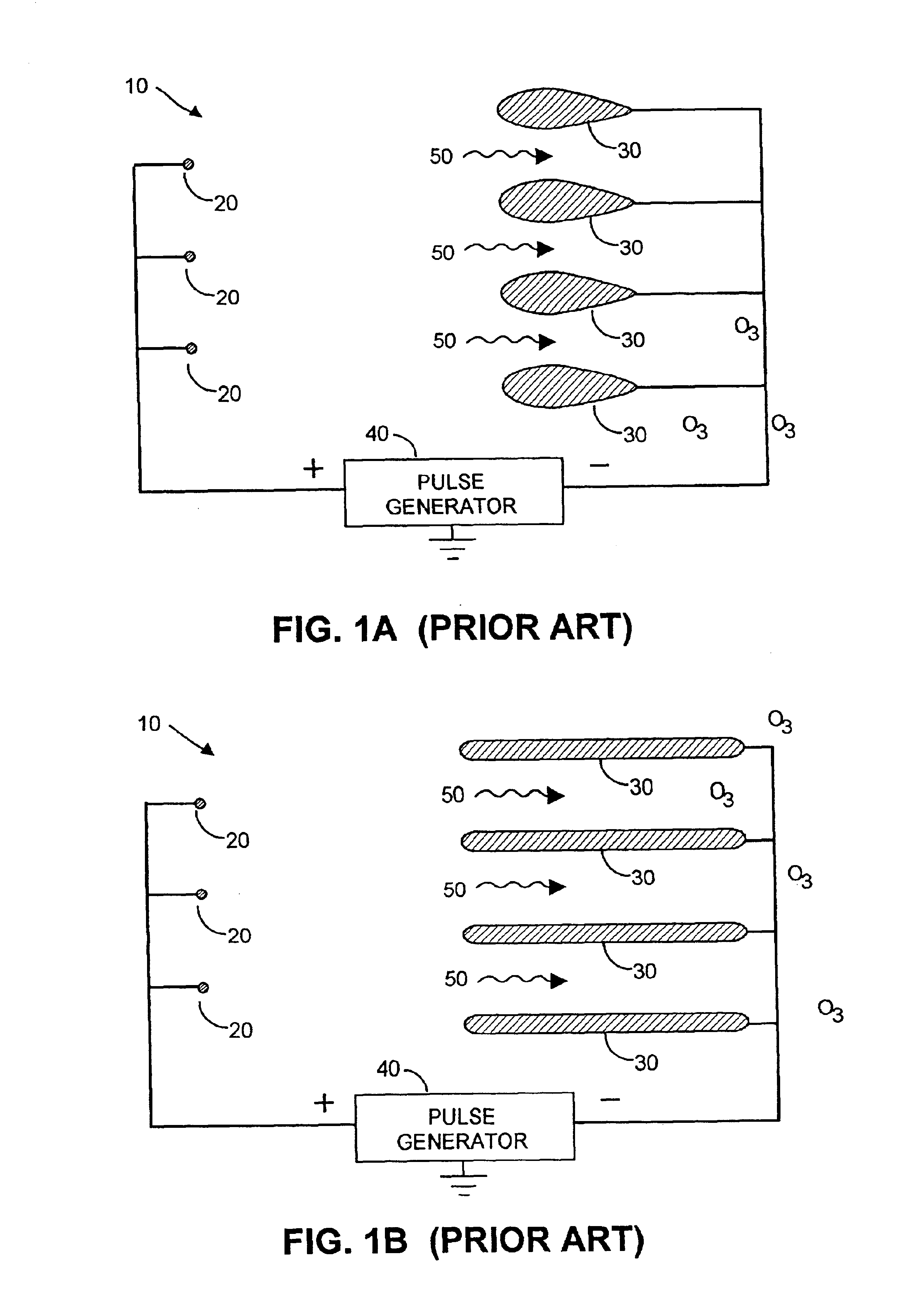

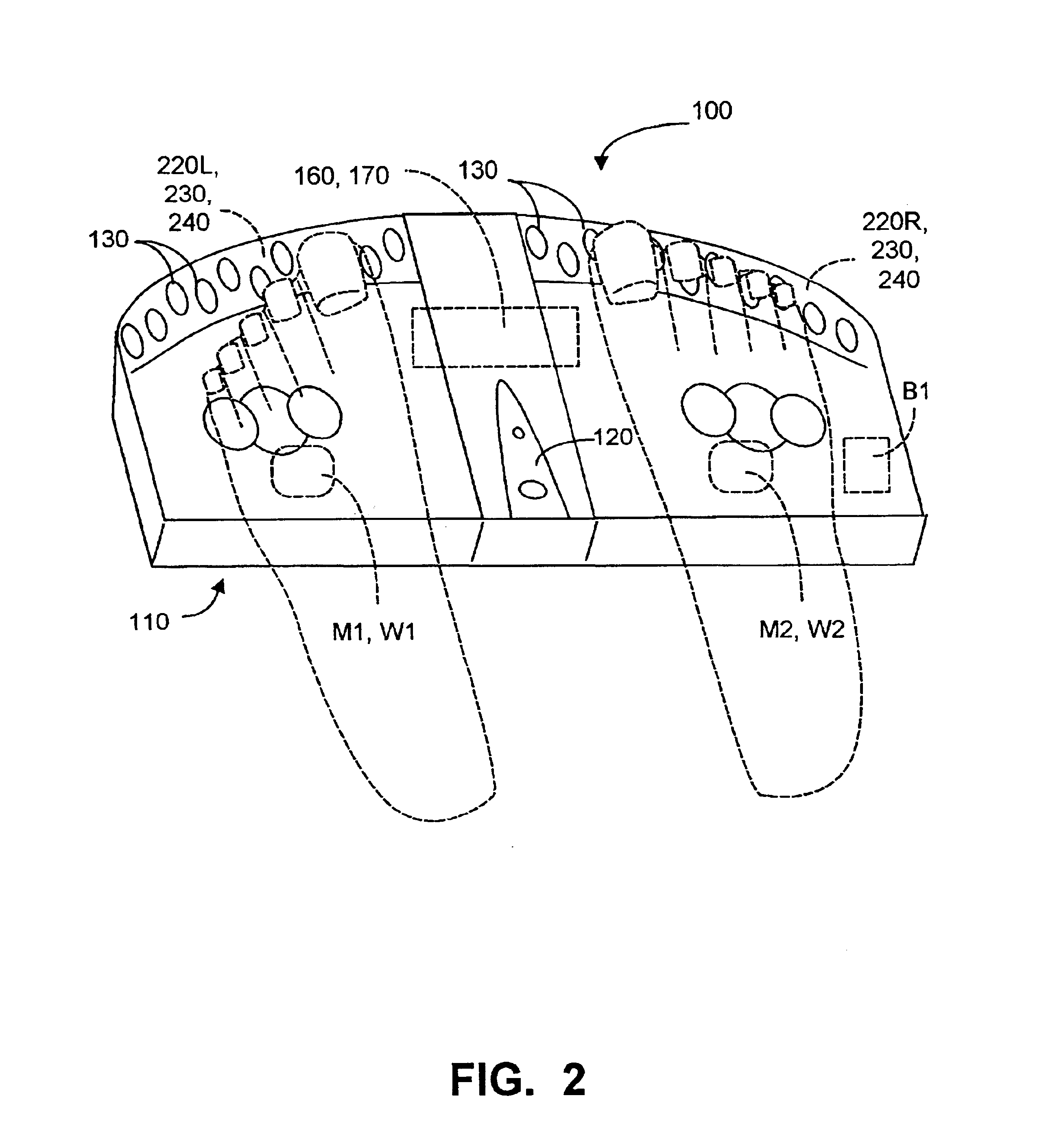

Electro-kinetic air transporter-conditioner with a multiple pin-ring configuration

InactiveUS6863869B2Increase humidityEliminate odorMechanical apparatusLighting and heating apparatusSOCKSPunching

A system massages a user's feet and generates an electro-kinetic airflow that contains safe amounts of ozone that can deodorize the user's feet or socks. The system includes an ion generator comprising a high voltage pulse generator whose output pulses are coupled between left and right first and second electrode arrays. Preferably the first electrode array includes first and second pointed electrodes, and the second electrode array includes annular-like electrodes having a central opening coaxial with the associated pointed electrode. Preferably the annular-like electrodes are formed from a single sheet of metal by extrusion or punching such that the surface of the annular-like electrodes is smooth and continuous through the opening and into a collar region through which the air flows. Particulate matter in the ambient air electrostatically adheres to the smooth continuous surface of the annular-like electrodes.

Owner:TESSERA INC

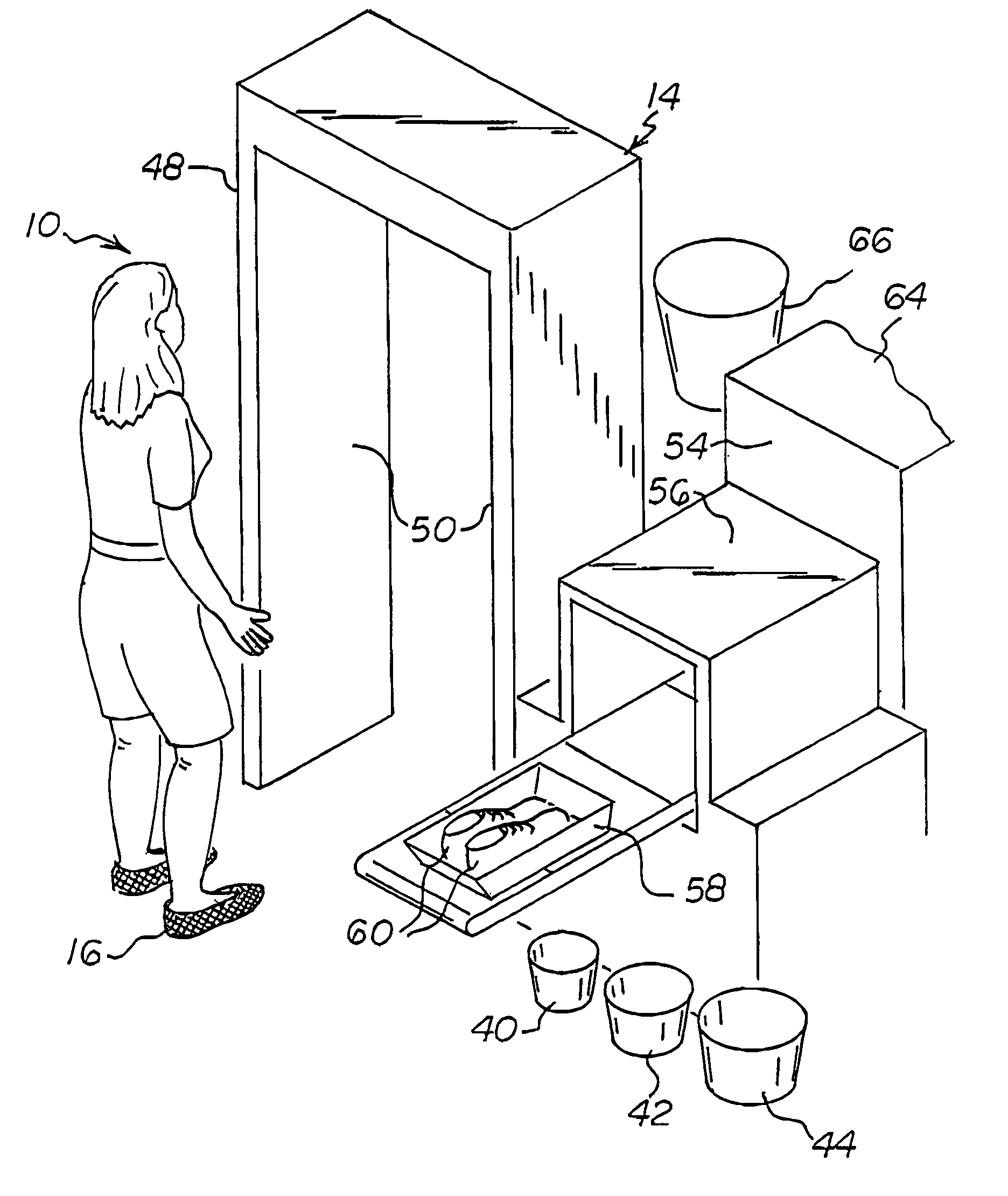

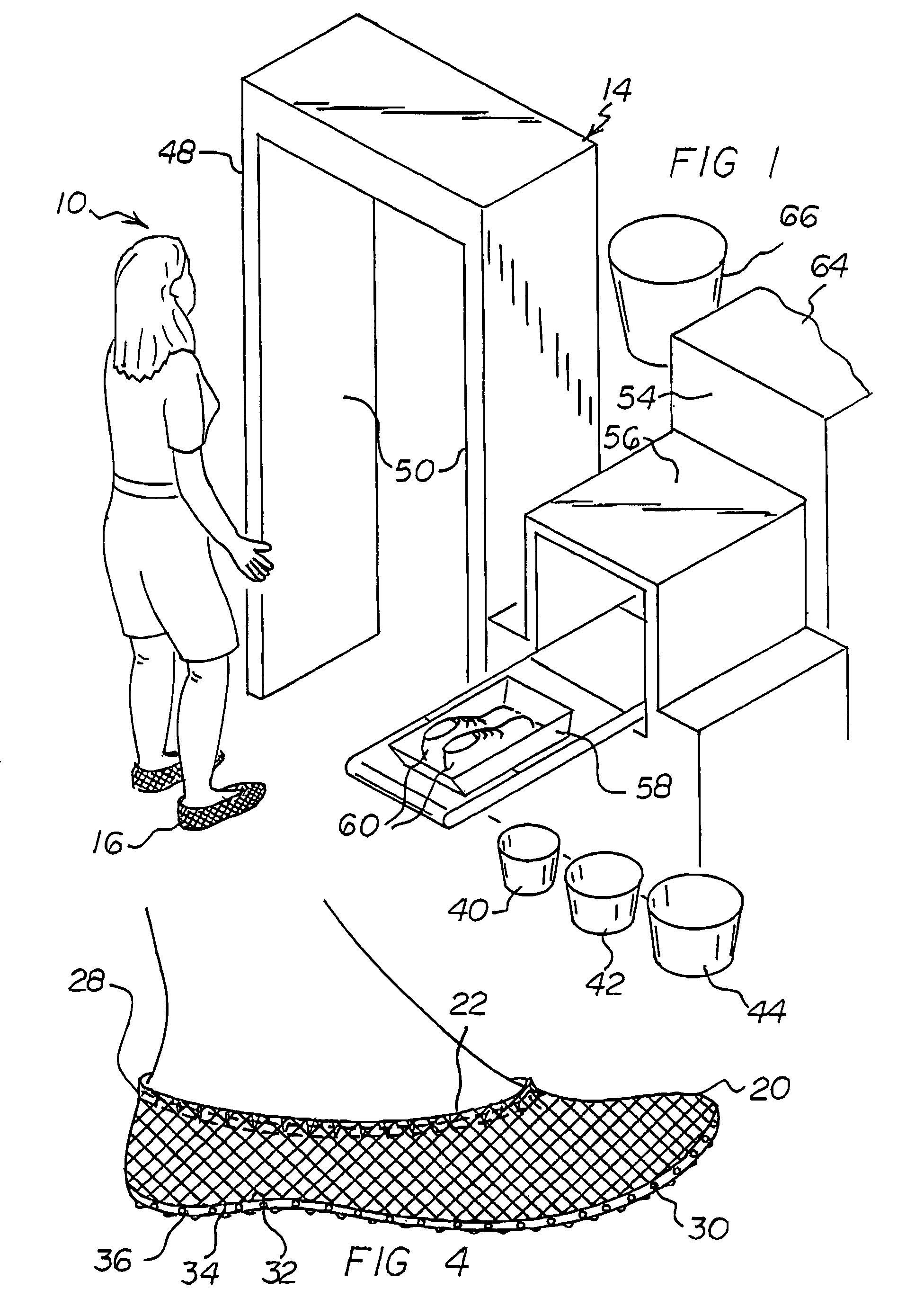

Sanitary security sock system

InactiveUS7012525B1Easy and efficient to manufactureDurable and reliable constructionInsolesPanty-hoseSOCKSEngineering

A plurality of socks each has a closed end, an open end and an intermediate extent there between. Each sock has an elastomeric pad. The pads each have an upper face in secure contact to the intermediate extent. The pads each have a lower face with projections in rows and columns integrally formed with the pad for traction purposes. The socks are designated “one size fits all” and are arranged in pairs. A plurality of containers containing pairs of socks of a common size are to be selected by a passenger to be screened for security purposes.

Owner:GHIOTO DIANE

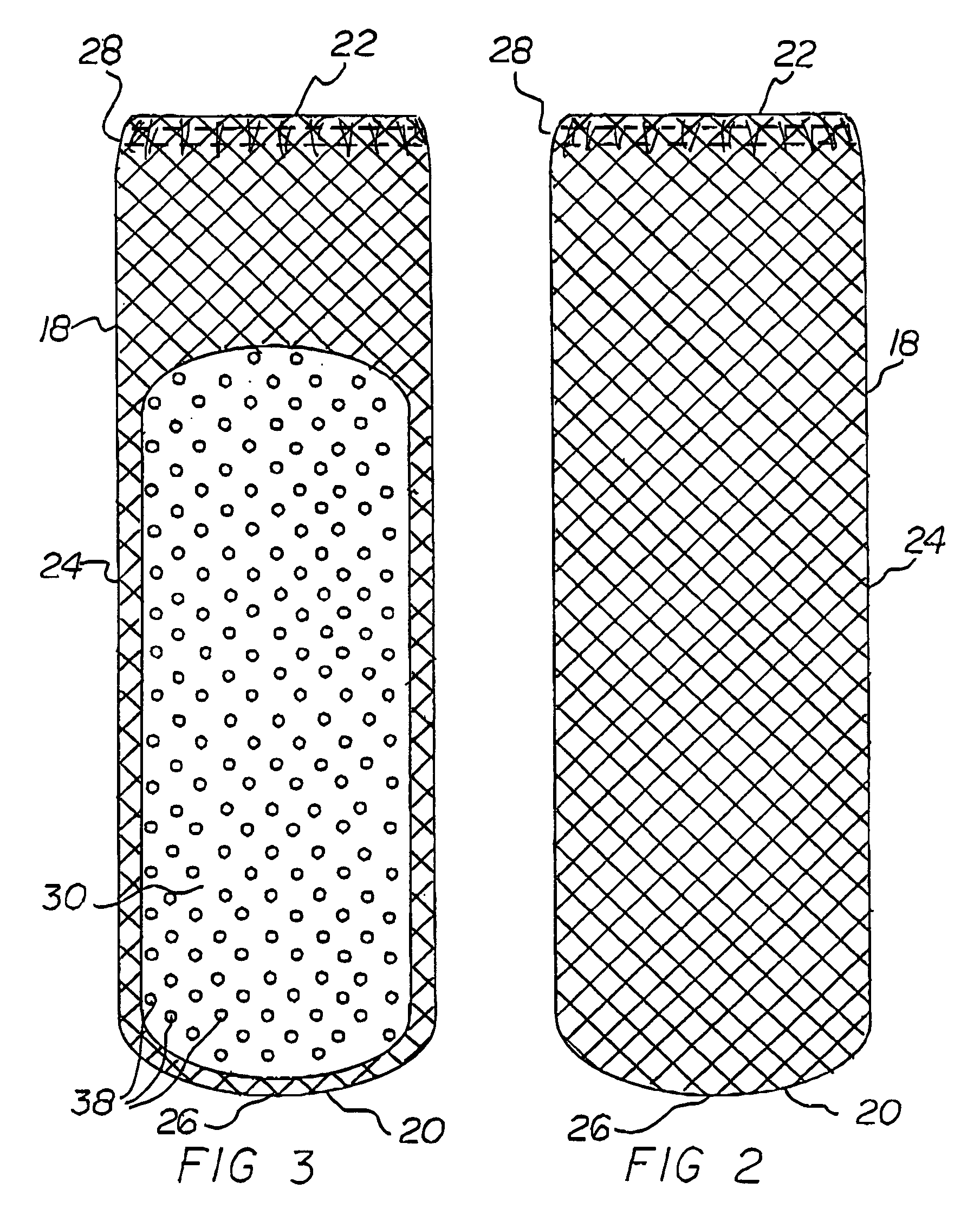

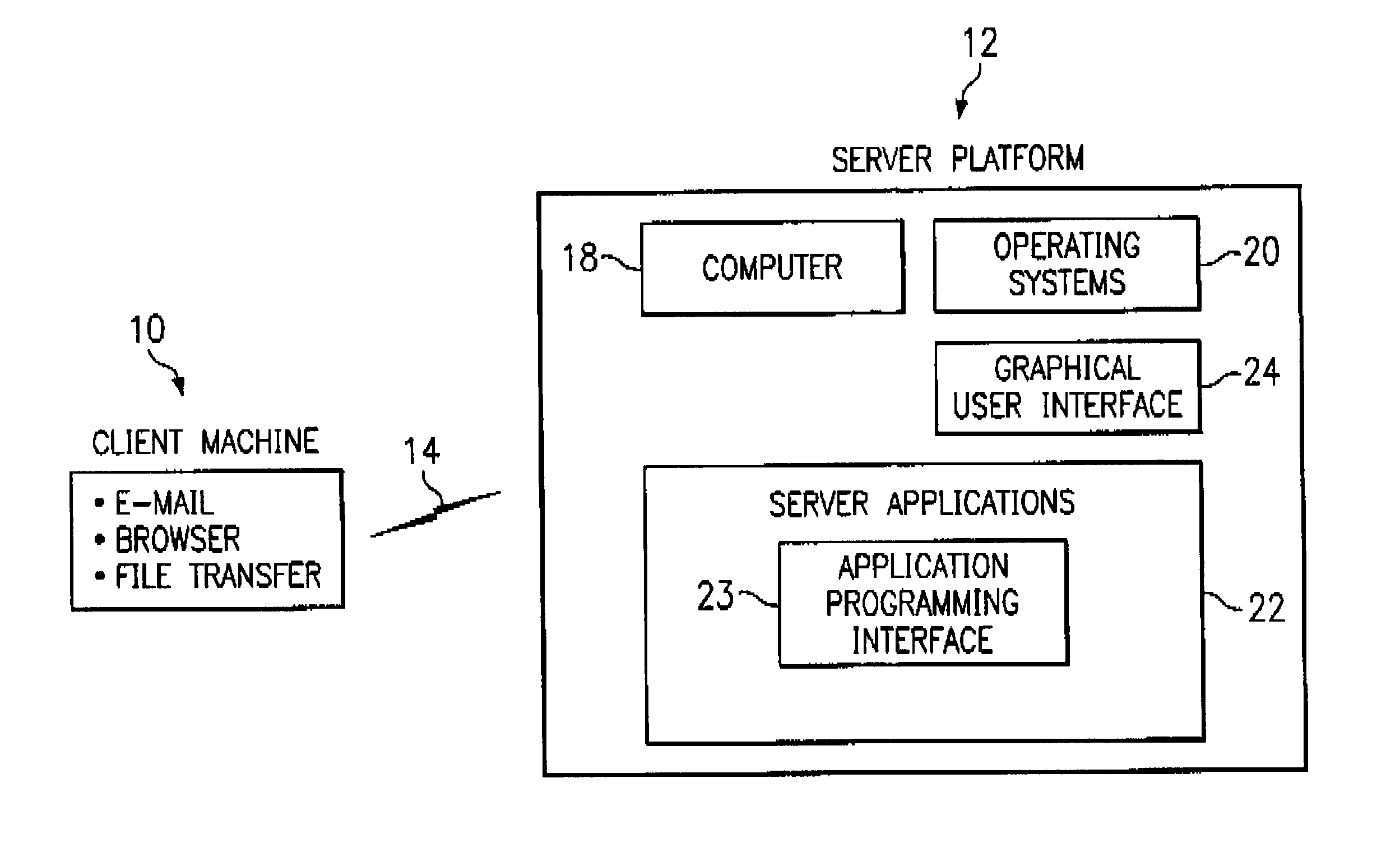

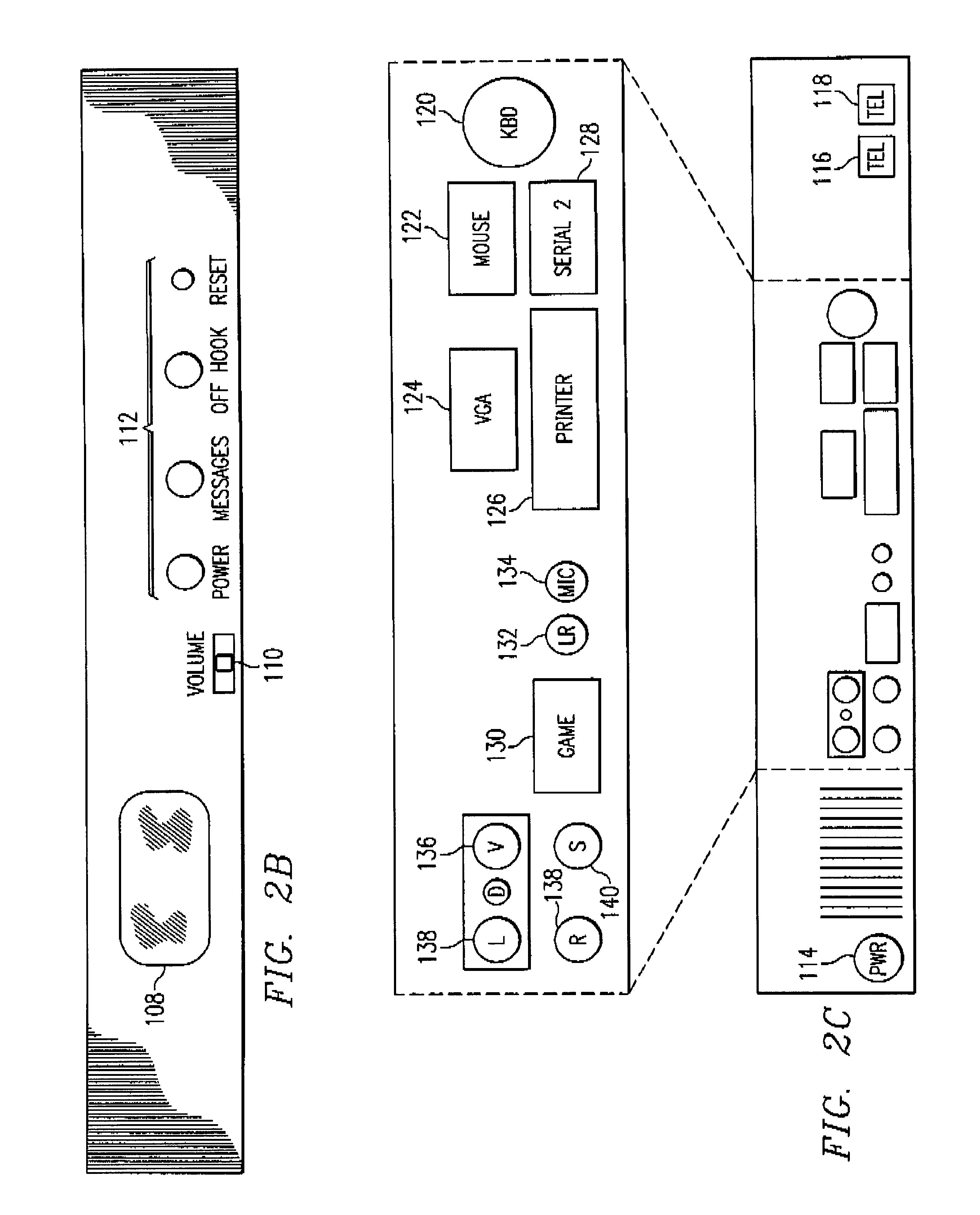

Client side socks server for an internet client

InactiveUS7020700B1Efficient managementTo offer comfortDigital computer detailsTransmissionSOCKSOperational system

An Internet client is provided with a SOCKS server. The client comprises a processor having an operating system, and a suite of one or more Internet tools. The SOCKS proxy server includes means for intercepting and servicing connection requests from the Internet tools. Preferably, the proxy server has a predetermined Internet Protocol address, preferably the loopback address. If the loopback address is not available on the protocol stack, a redirecting mechanism is used to redirect connection requests associated with stale IP addresses to a current IP address. The SOCKS server includes a filtering mechanism for filtering connection requests to particular servers, and a monitoring mechanism for monitoring network IP activity.

Owner:IBM CORP

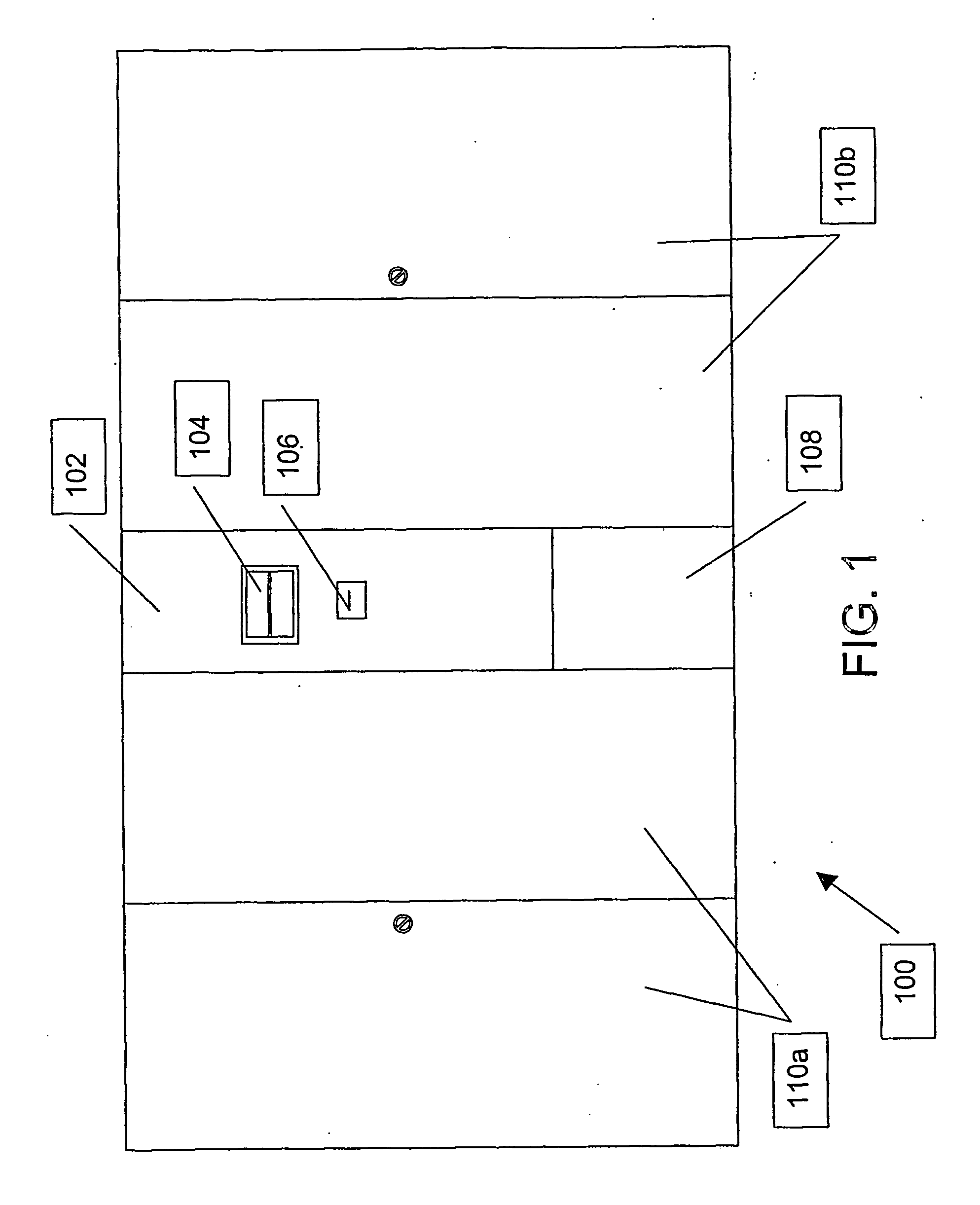

Window multifunction guard rail and manufacturing method and application thereof

InactiveCN101270631AWill not affect daylightingNice appearanceFixed grillesBurglar alarm mechanical actuationSOCKSElectronic switch

The invention relates to a multi-function window guardrail and a manufacturing method and application, which belongs to the anti-creep, burglary-prevention and protecting device of the wall, the balcony and the window of a building. The invention comprises a fender bracket that is characterized in that the fender bracket is provided with a setting spring and an electronic switch. The electronic switch is connected with an alarm. The fender bracket is a mobile part. When external force acts, the fender bracket rotates to an angle and the electronic switch is turned on. Meanwhile, the alarm gives warning and the external force is lost. With the aid of the spring, the fender bracket is reset and the alarm stops giving warning. The multi-function window guardrail is installed outside the balcony and the window to be used for guarding against being climbed and theft, giving shoes and socks an airing and actively giving the warning. In addition, the multi-function window guardrail is also used for guarding against the creeper and the theft and protection for the pipes of the building and wall.

Owner:张朝峰

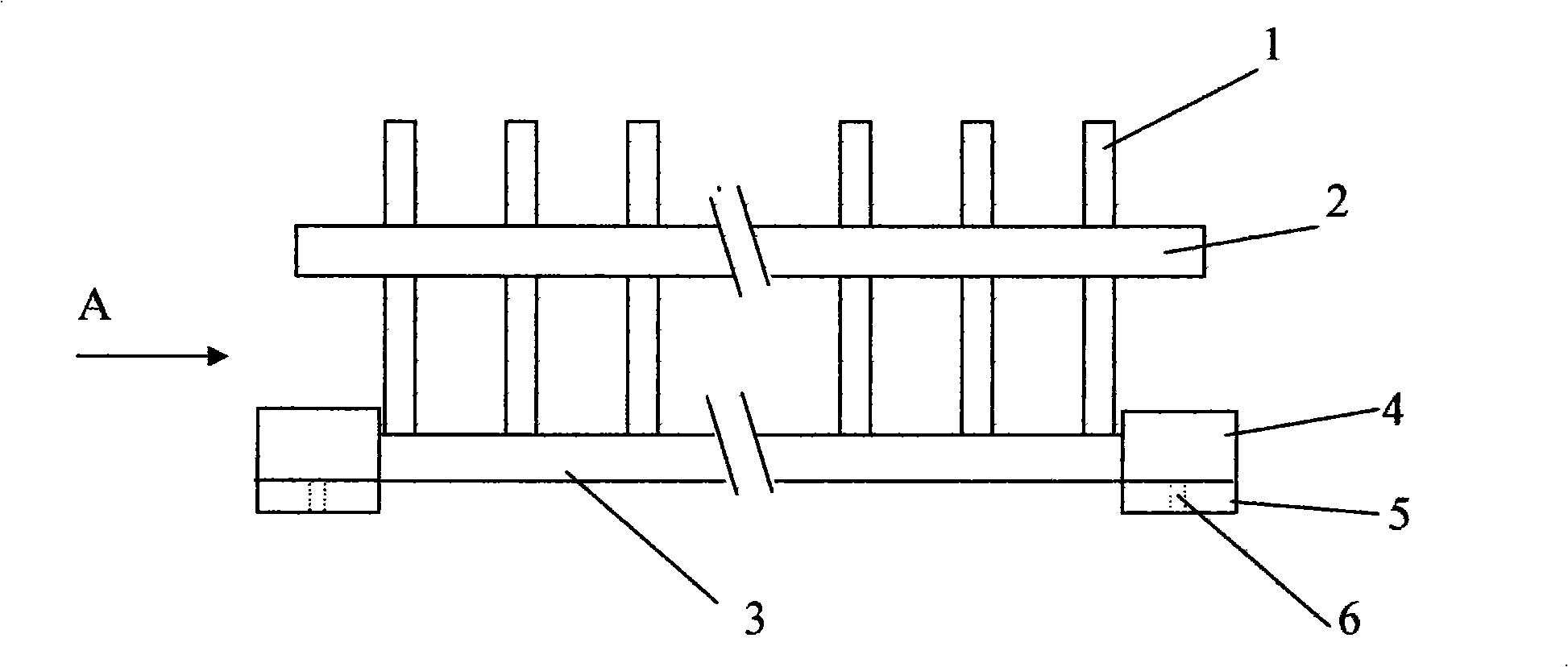

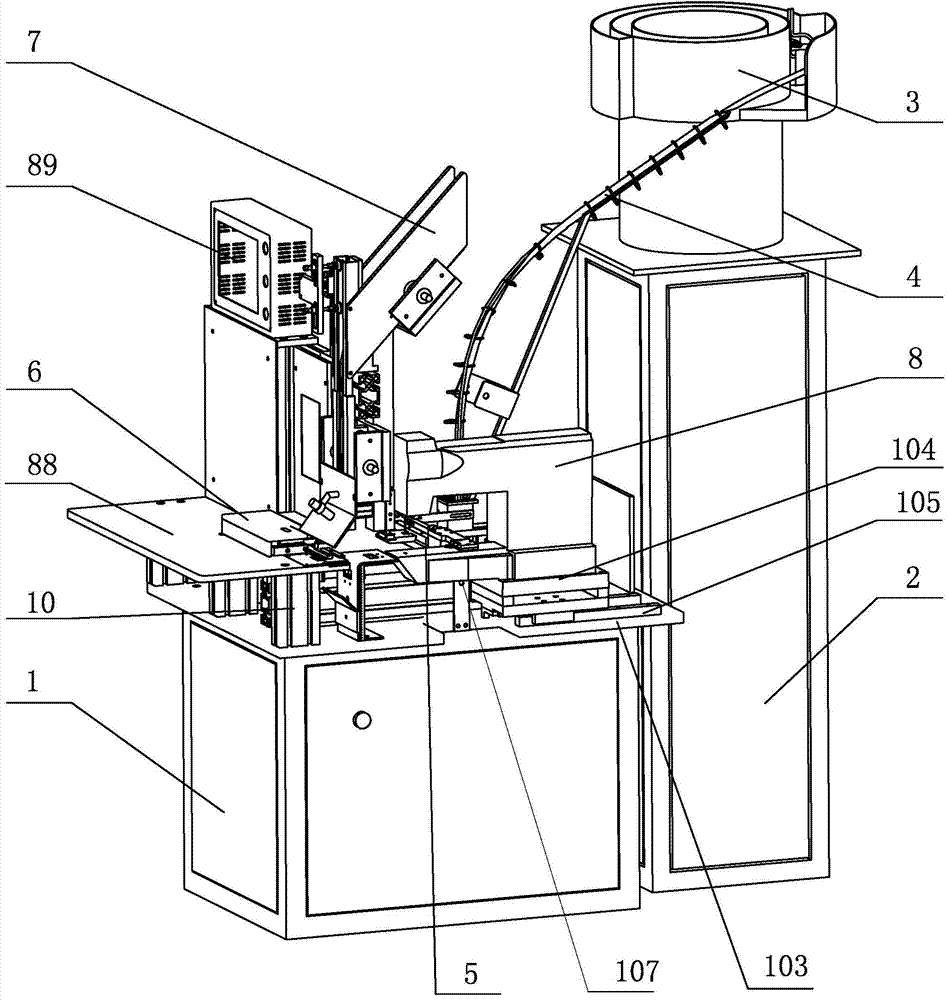

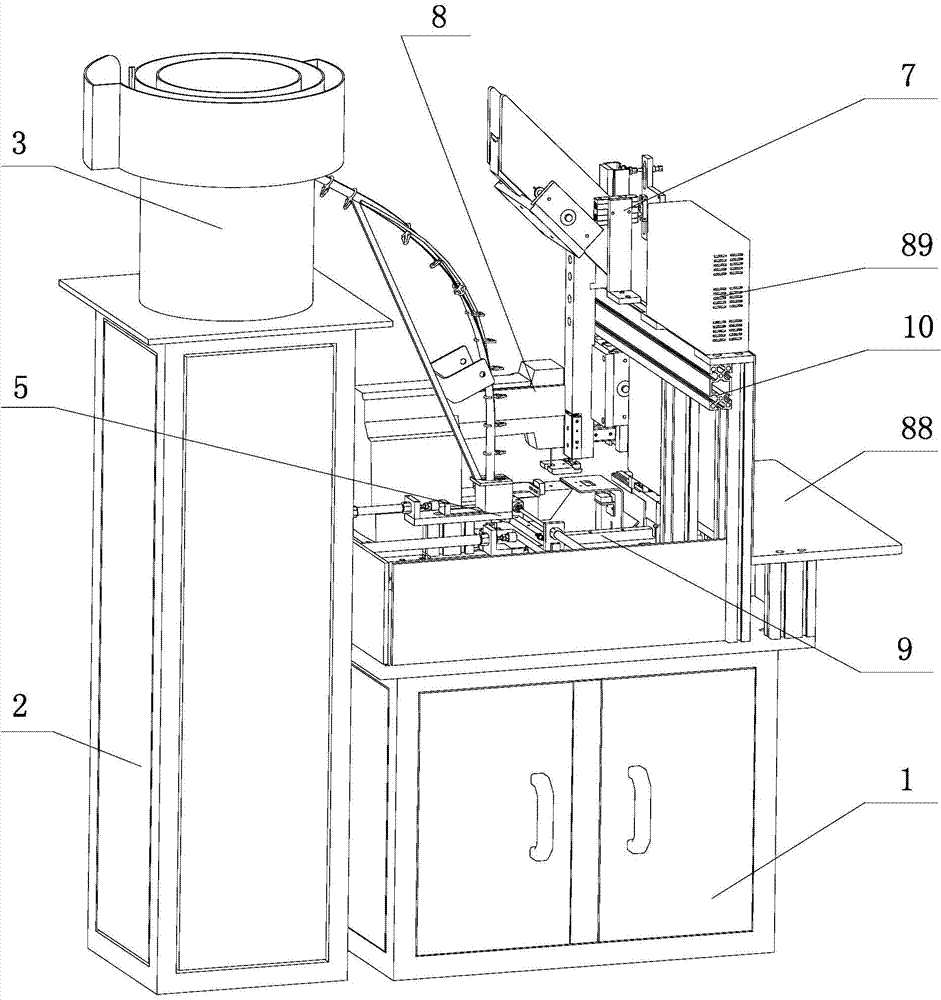

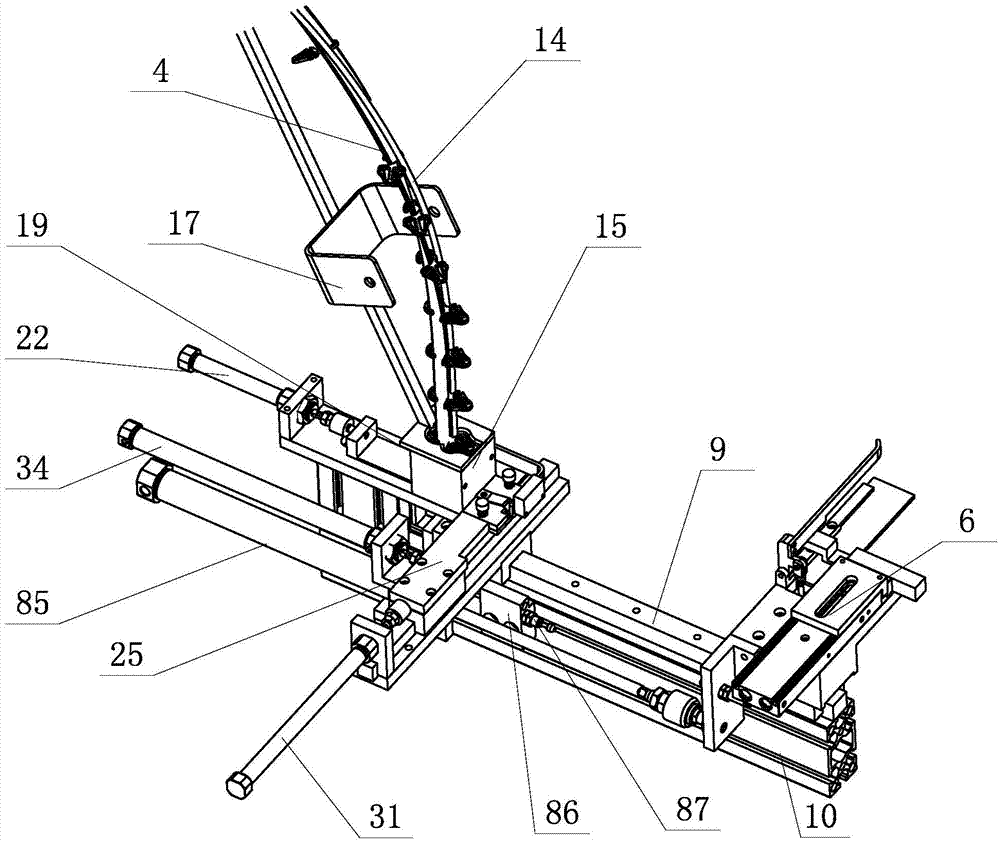

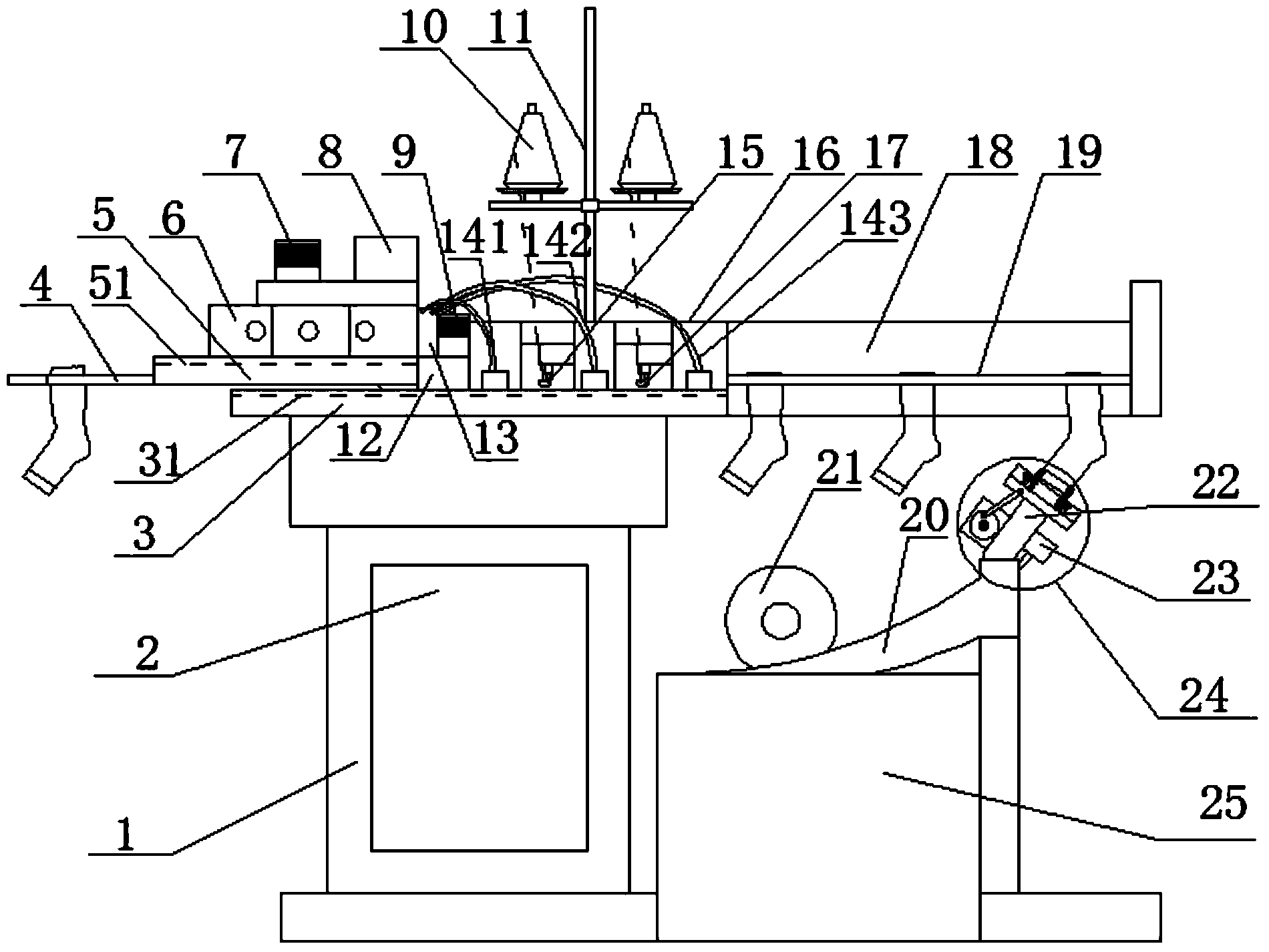

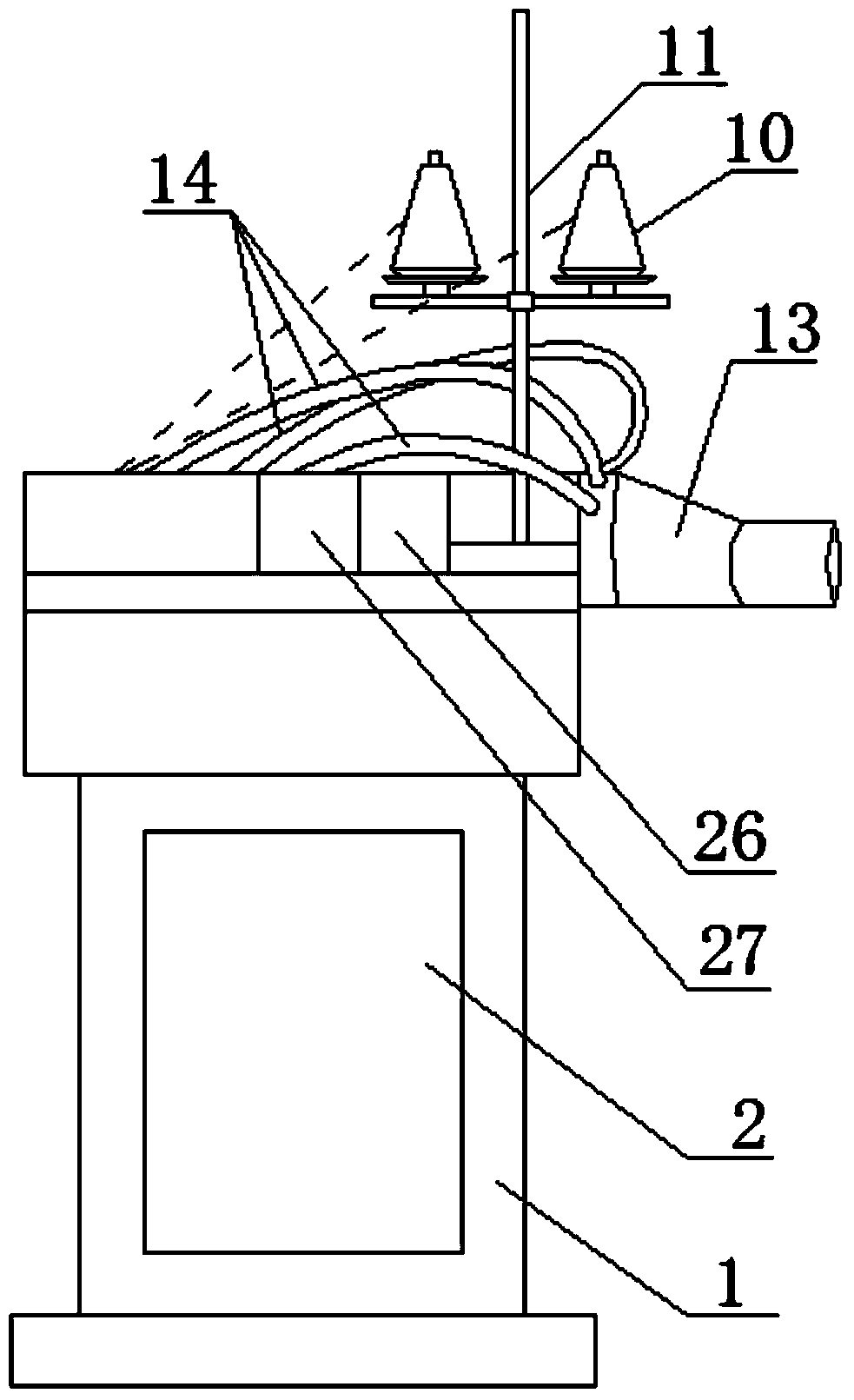

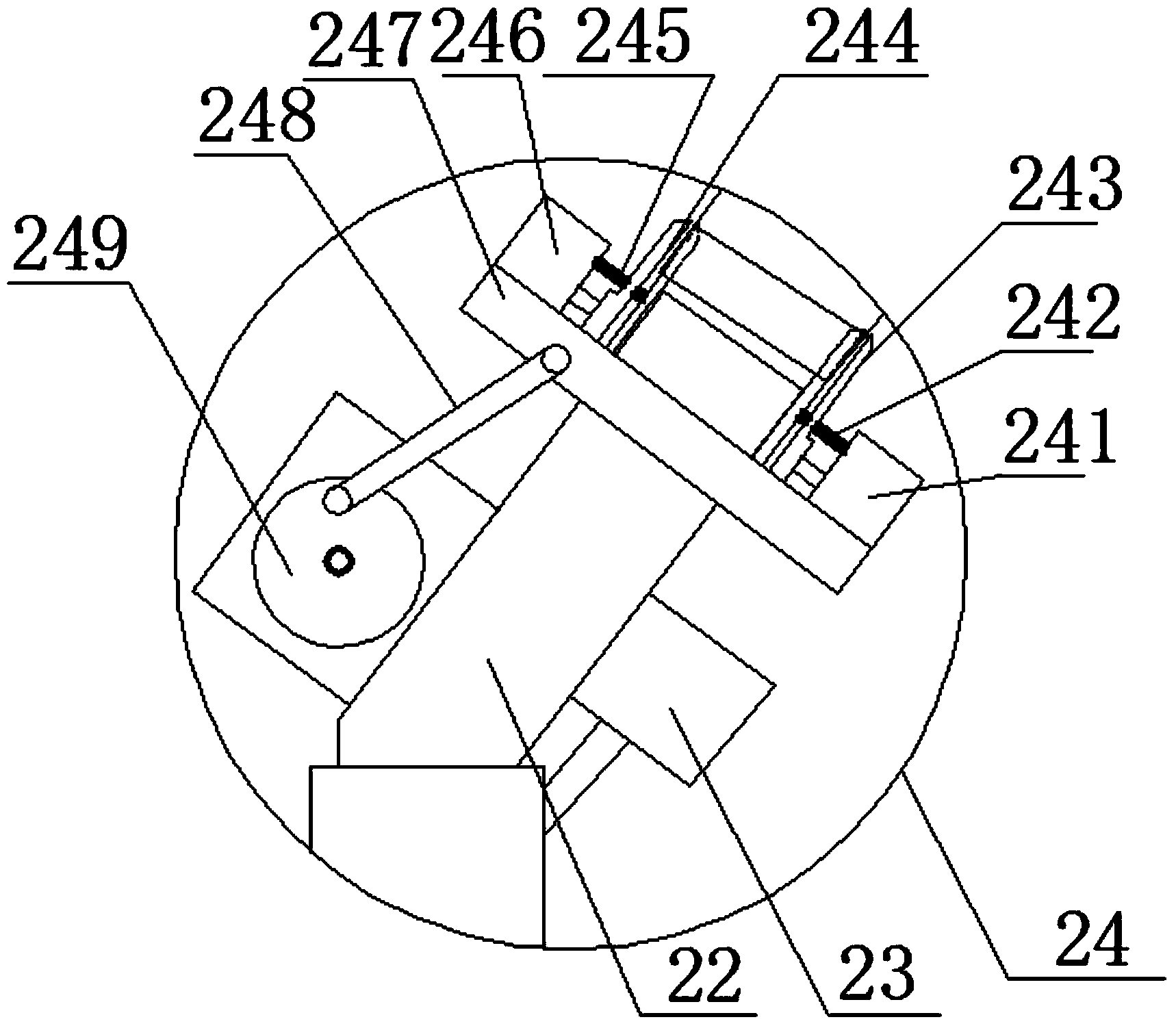

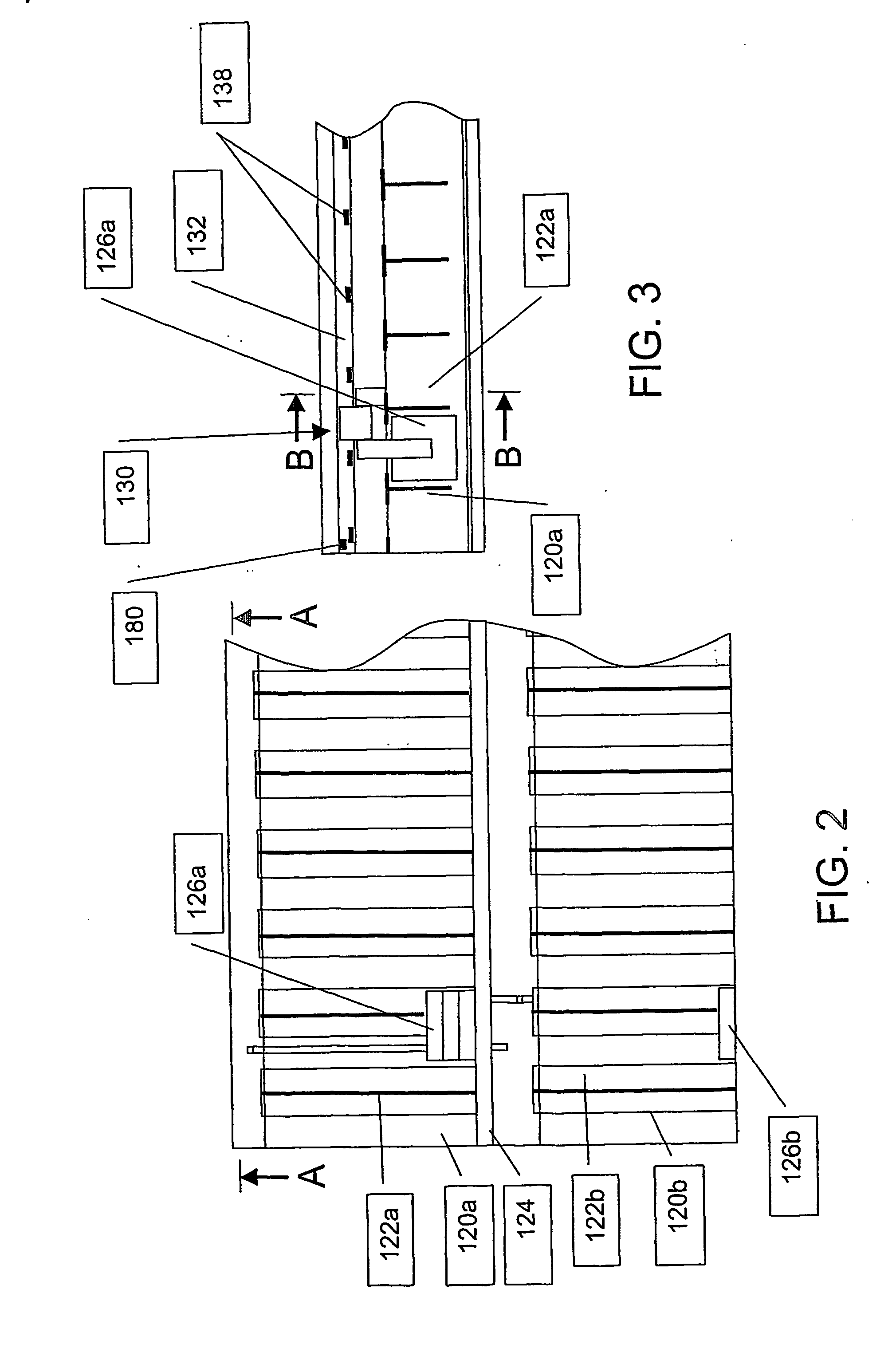

Label sewing fully automatic socks packaging machine

ActiveCN103482108ARealize automatic delivery hookRealize automatic sewingPackagingArticle feedersSOCKSEngineering

The invention discloses a label sewing fully automatic socks packaging machine. The label sewing fully automatic socks packaging machine comprises a vibrating disk bracket, wherein the vibrating disk bracket is provided with a vibrating disk; a spiral material passage is arranged on the outer side of the vibrating disk; the lower end of the spiral material passage is connected with a hook mounting component; a socks feeding component is arranged in front of the hook mounting component; a vertical paper card bin component is arranged between the hook mounting component and the socks feeding component; a label sewing machine is arranged behind the socks feeding component; the hook mounting component and the socks feeding component are arranged on a same longitudinally arranged linear guide rail. The label sewing fully automatic socks packaging machine has the advantages that (1) the vibrating disk is arranged, so that automatic hook feeding can be realized, (2) the hook mounting component is arranged, so that automatic hook mounting can be realized, (3) the paper card bin component is arranged, so that automatic paper card feeding can be realized, (4) the socks feeding component is arranged, so that automatic socks feeding can be realized, and (5) the label sewing machine is arranged, so that automatic sewing can be realized.

Owner:佛山市南海大欣针织业有限公司

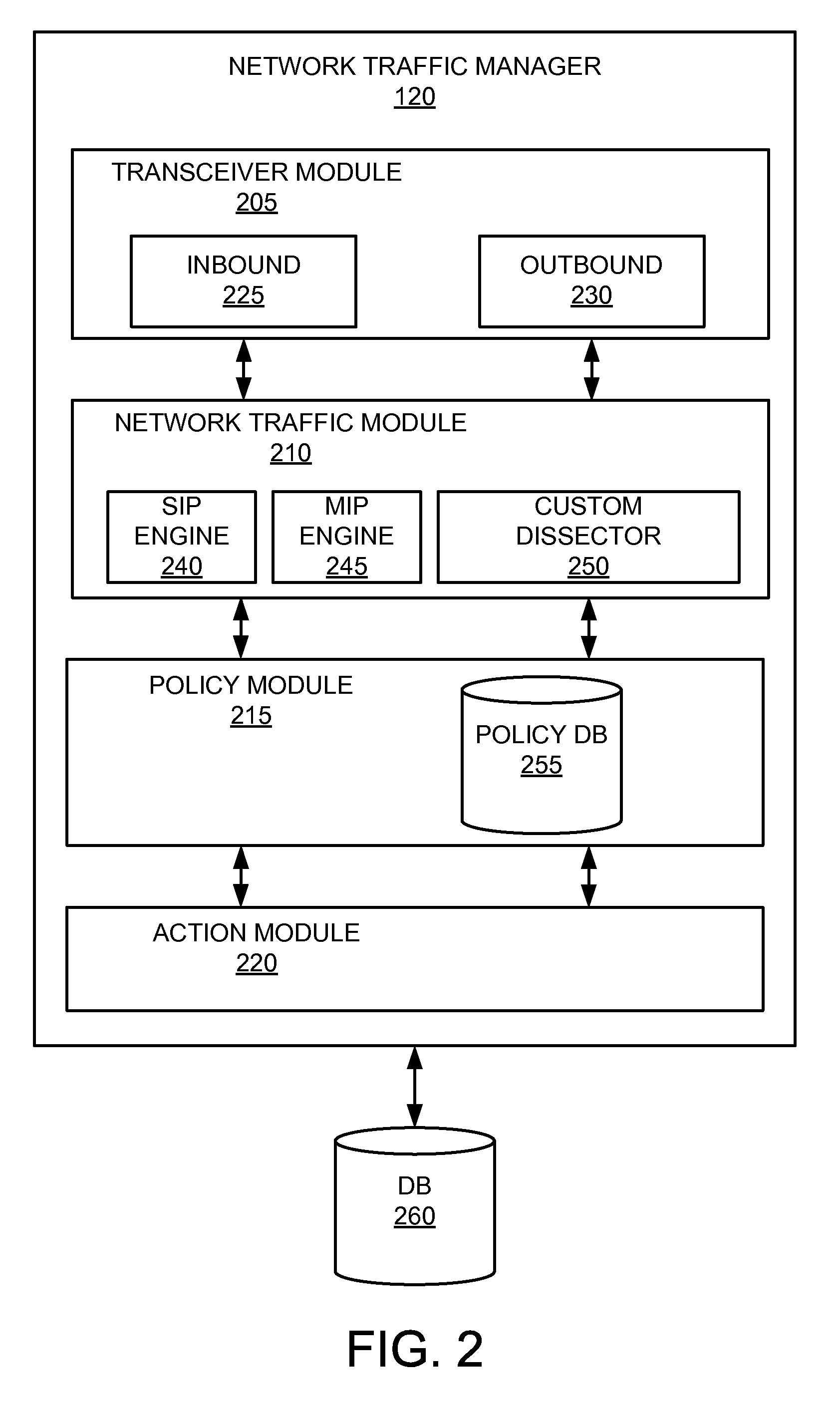

Techniques for dynamic updating and loading of custom application detectors

In various embodiments, a data-driven model is provided for an application detection engine for the detection and identification of network-based applications. In one embodiment, information can be input into an application detection database. The information may include a hostname, ports, transport protocol (TCP / UDP), higher layer protocol (SOCKS, HTTP, SMTP, FTP, etc), or the like. The information may be associated with a given application. The information may be used to create rule sets or custom program logic used by one or more various application detection engines for determining whether network traffic has been initiated by a given application. The information may be dynamically loaded and updated at the application detection engine.

Owner:ACTIANCE

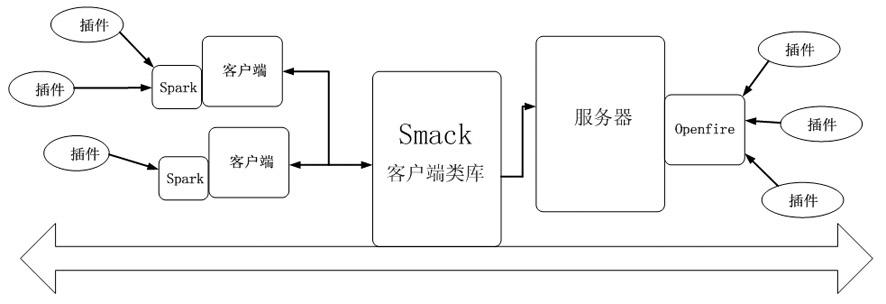

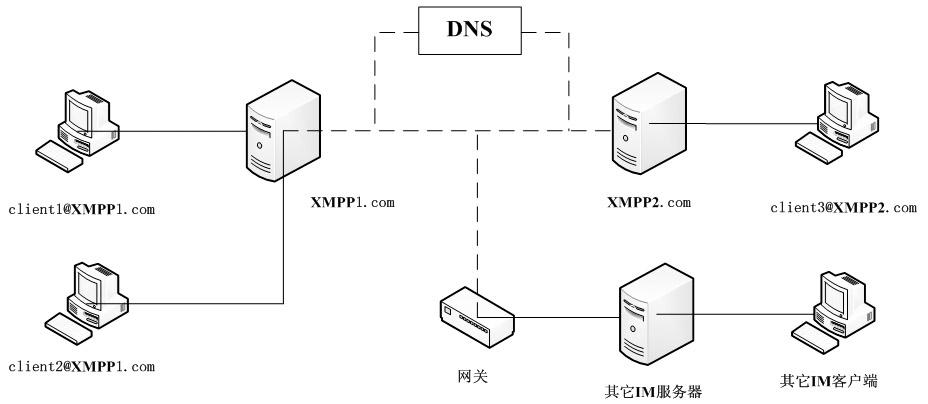

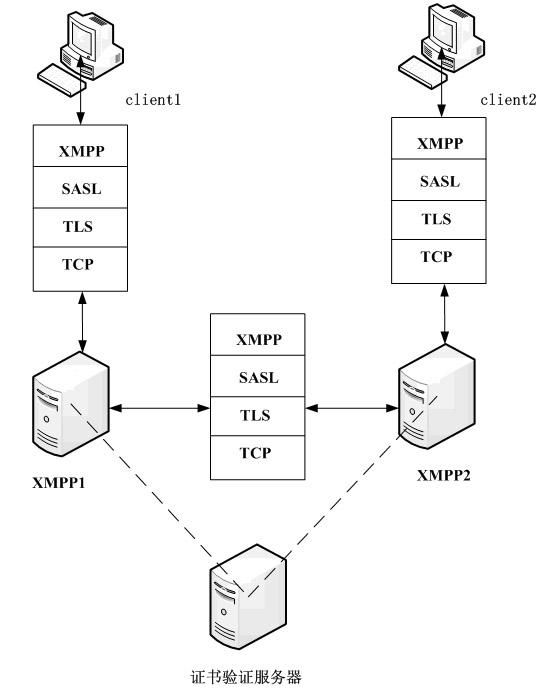

Instant message transmission method based on XMPP

The invention discloses an instant message transmission method based on an XMPP (Xmlbased Messaging And Presence Protocol). Open source Openfire is taken as a server; a Spark client is taken as a main client framework; a client based on the XMPP is edited with the Java language at a Smack client; MySQL in Xampp software is taken as a database; and data transmission of instant messages inside and outside an enterprise is successful achieved by adopting XMPP technology, SOCKS technology, database technology and socket technology. The method provided by the invention can well meet users' basic demand, management demand and functional demand, and besides, high safety and expansibility can be achieved, and connection and communication between the instant message and other instant communication system can be realized.

Owner:SOUTHEAST UNIV

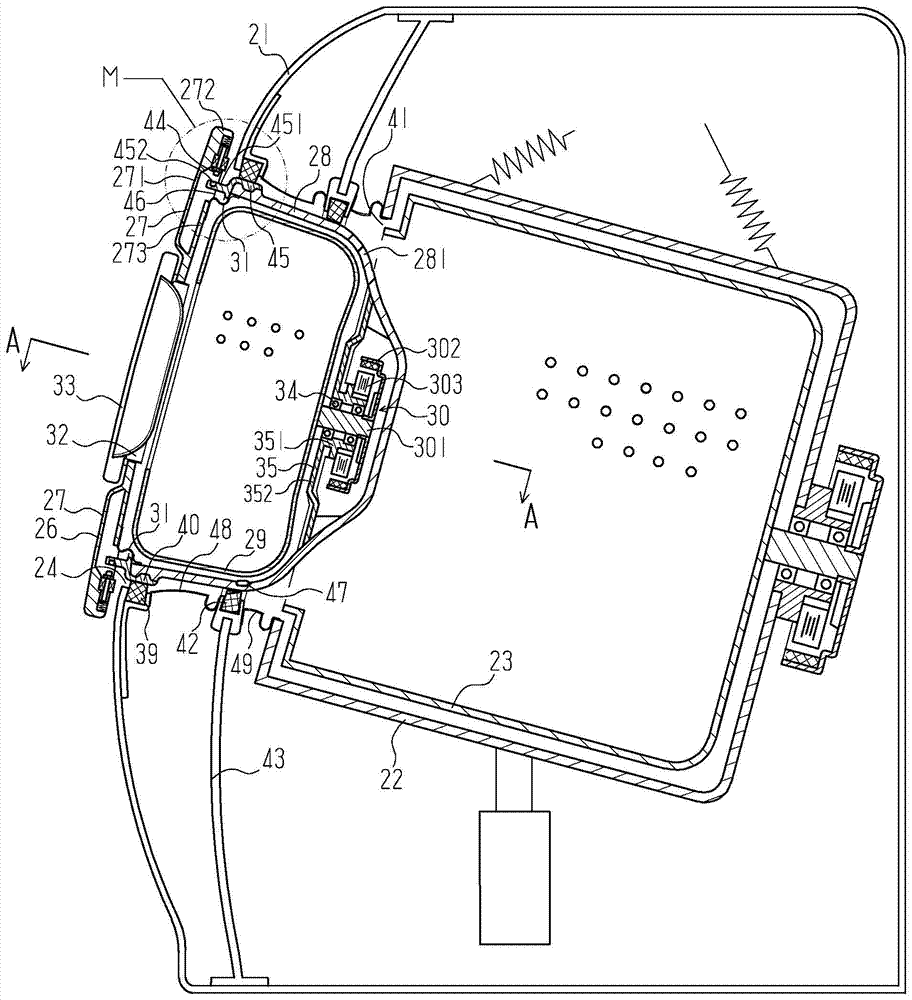

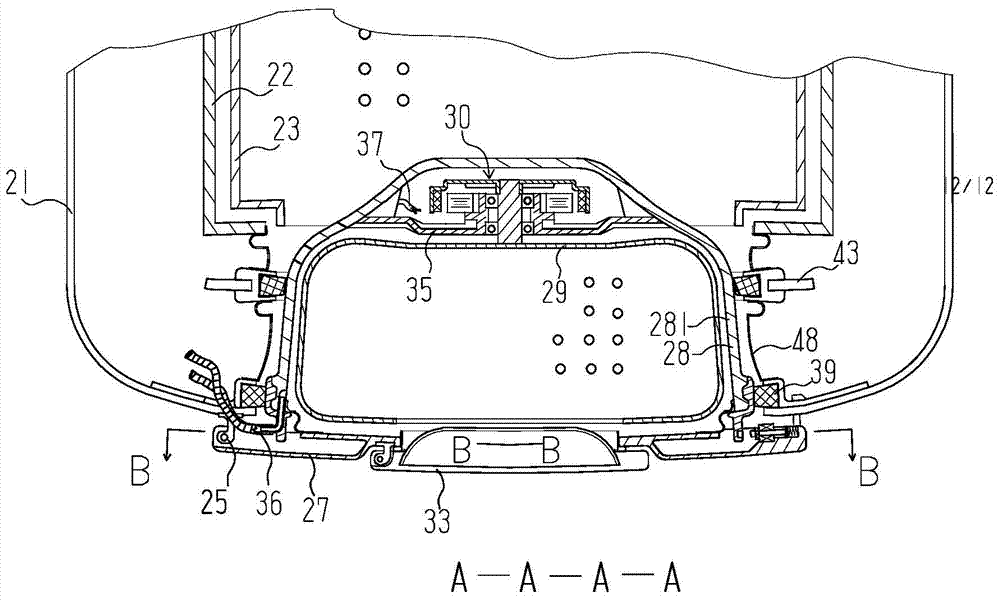

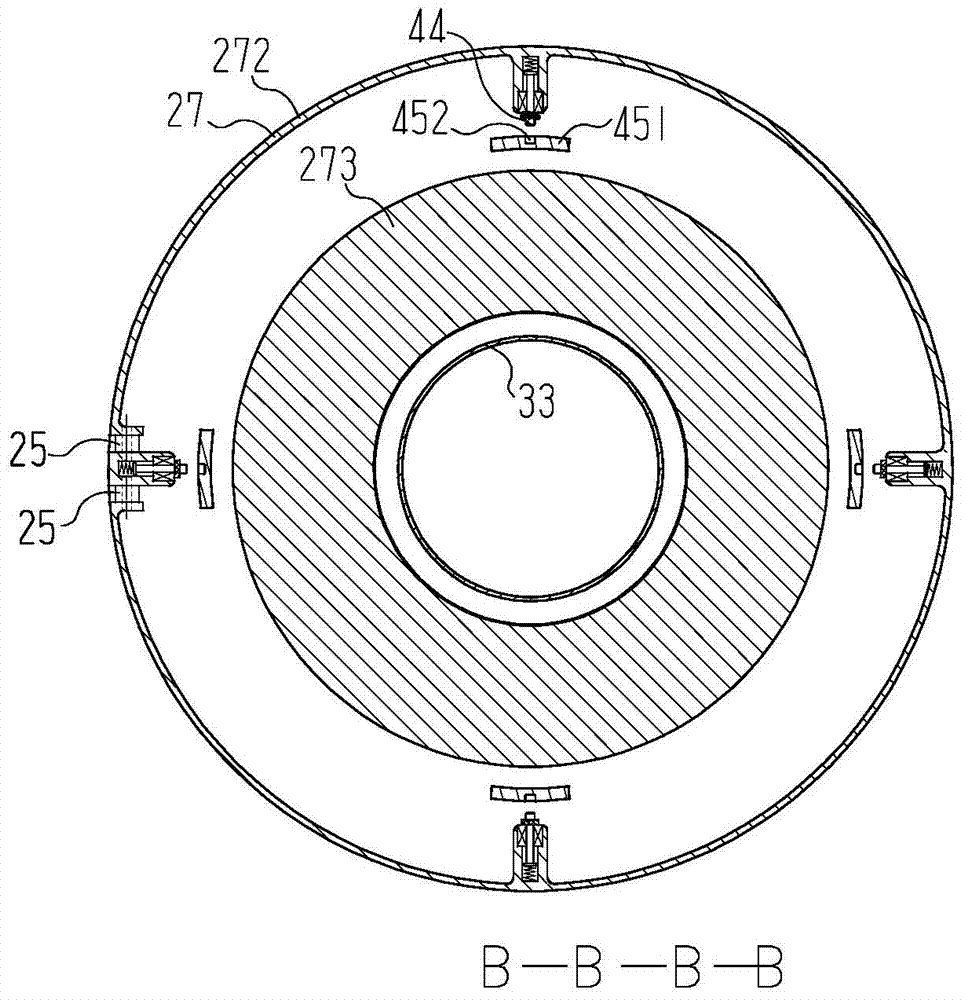

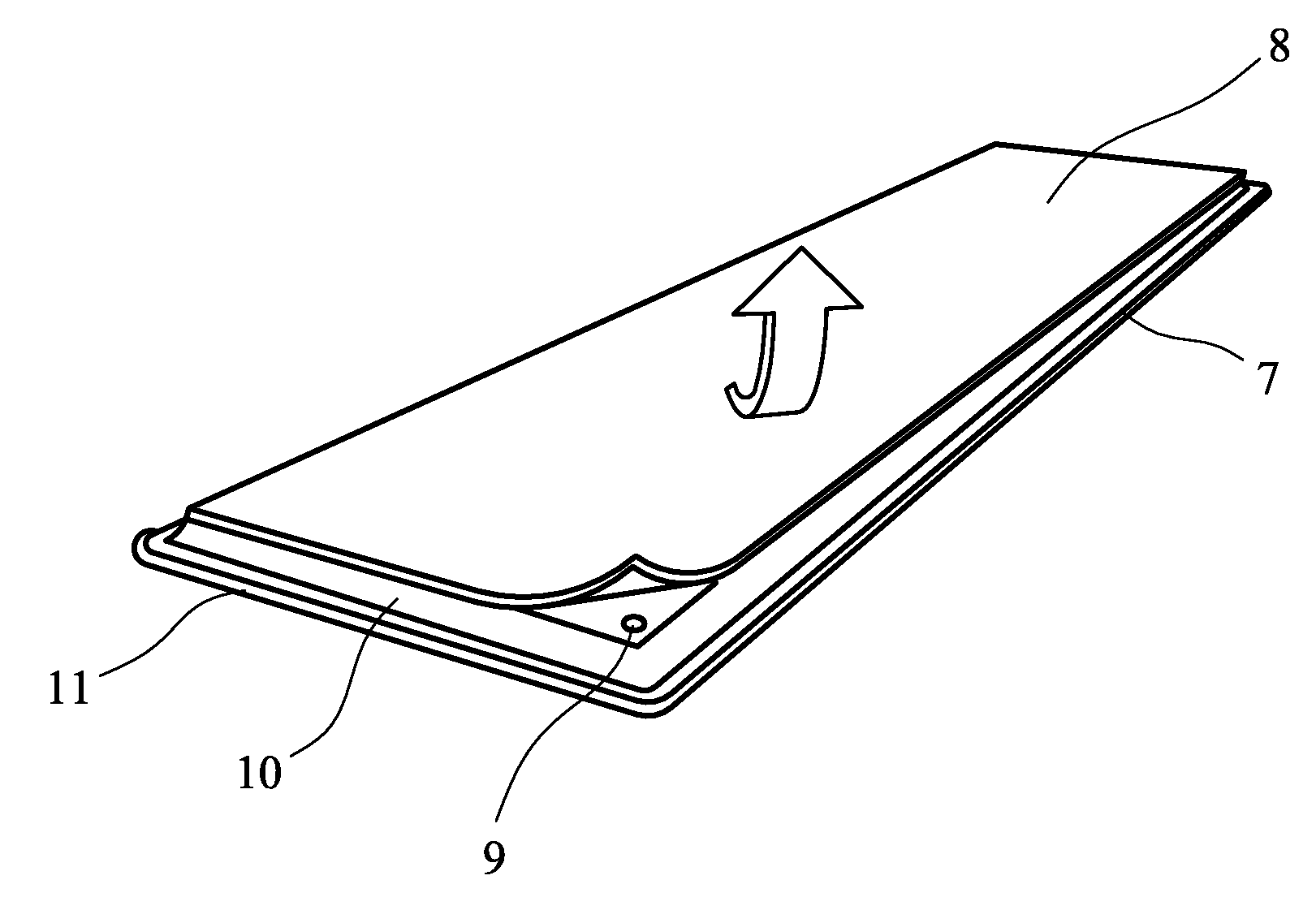

Horizontal type or obliquely horizontal type roller washing machine

ActiveCN103572547ASave spaceEasy to useOther washing machinesWashing machine with receptaclesSOCKSMotor drive

The invention provides a horizontal type or obliquely horizontal type roller washing machine, which comprises a door cover for closing or opening an orifice of an outer box, wherein the door cover comprises a front cover part and a rear cover part which are separated and are connected by a flexible connecting ring, adjacent rigid parts of the front cover part and the rear cover part are provided with contact gaps, an electromagnet actuated or motor driven movable connecting piece is arranged between the front cover part and the rear cover part for enabling the front cover part and the rear cover part to be controlled in the manner that the rear cover part is fixedly supported by the front cover part or the front cover part and the rear cover part are only flexibly connected by the flexible connecting ring, an elastic supporting device used for supporting the rear cover part is arranged in the outer box, a rotating roller driven by a driving motor at the rear part of the rear cover part is arranged in a cavity formed by the front cover part and the rear cover part, a water inlet pipe, a water outlet pipe and a power line and a control line entering the door cover are arranged in the cavity, and the front cover part is provided with an opening and a small door cover allowing small clothes to enter or exit. The roller washing machine is particularly suitable for placing small clothes or only a few clothes, such as underwear, socks or infant clothes requiring classified washing into the rotating roller of the door cover for washing, so that the space is saved, and the use is convenient.

Owner:蒋新东

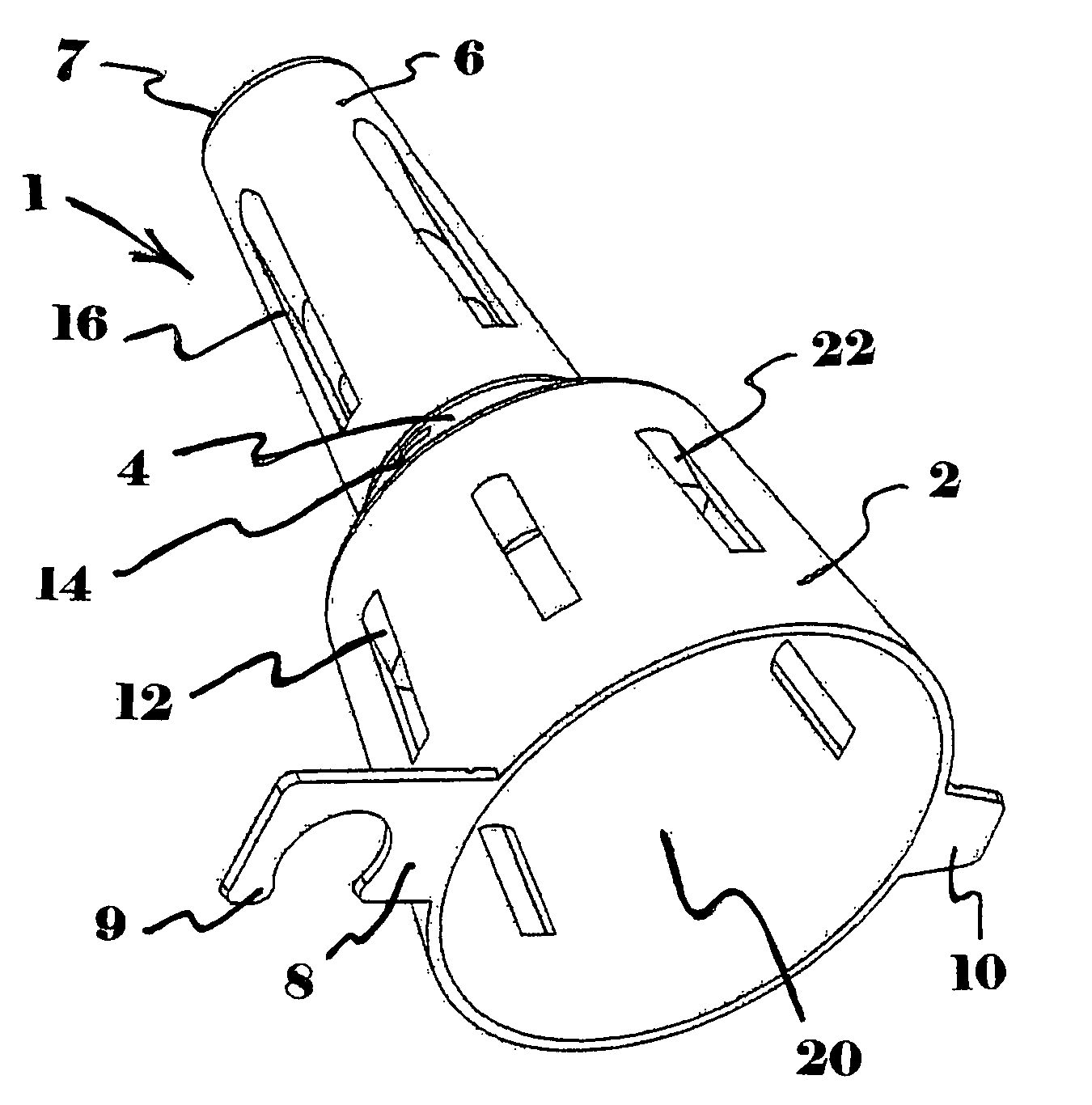

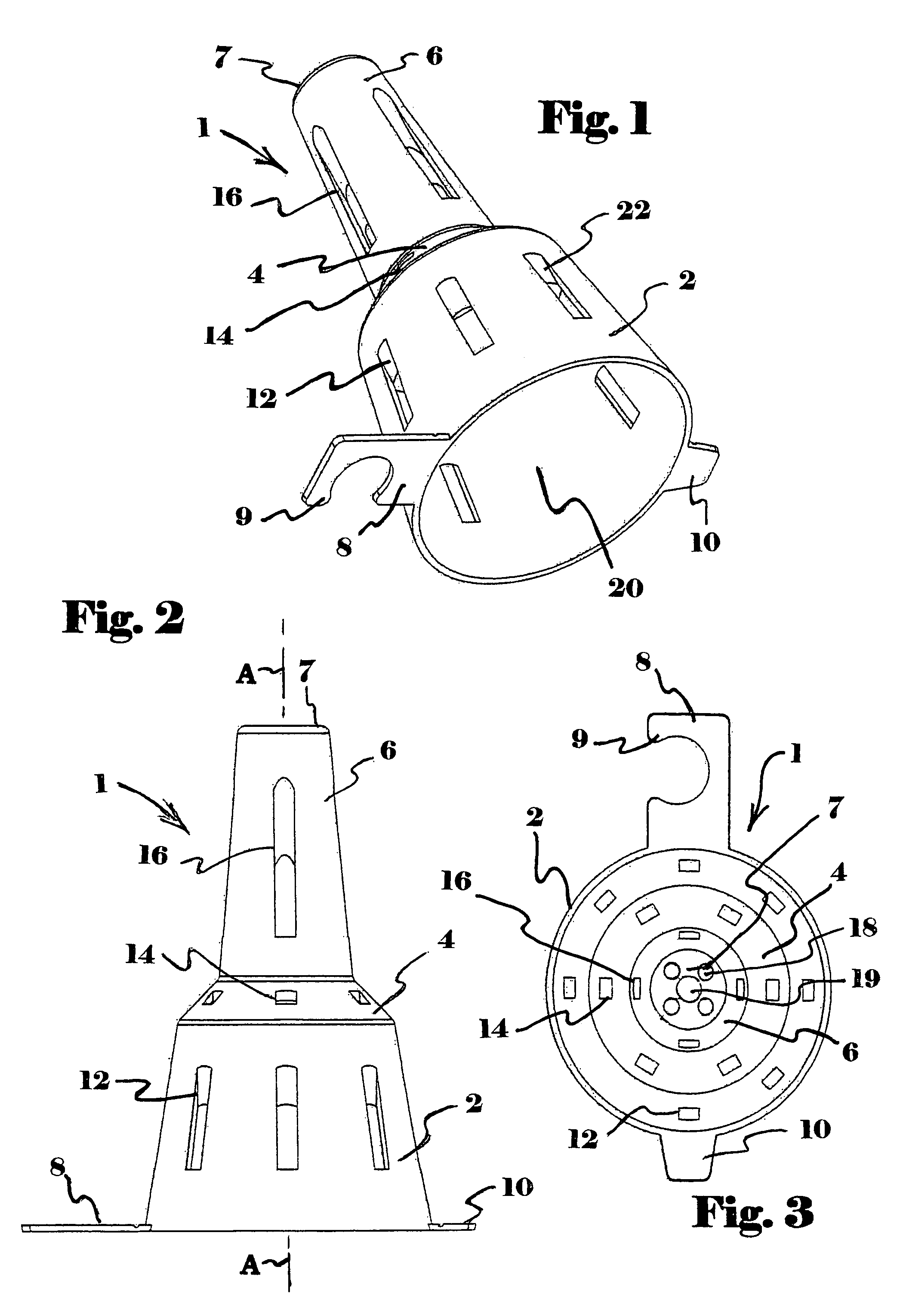

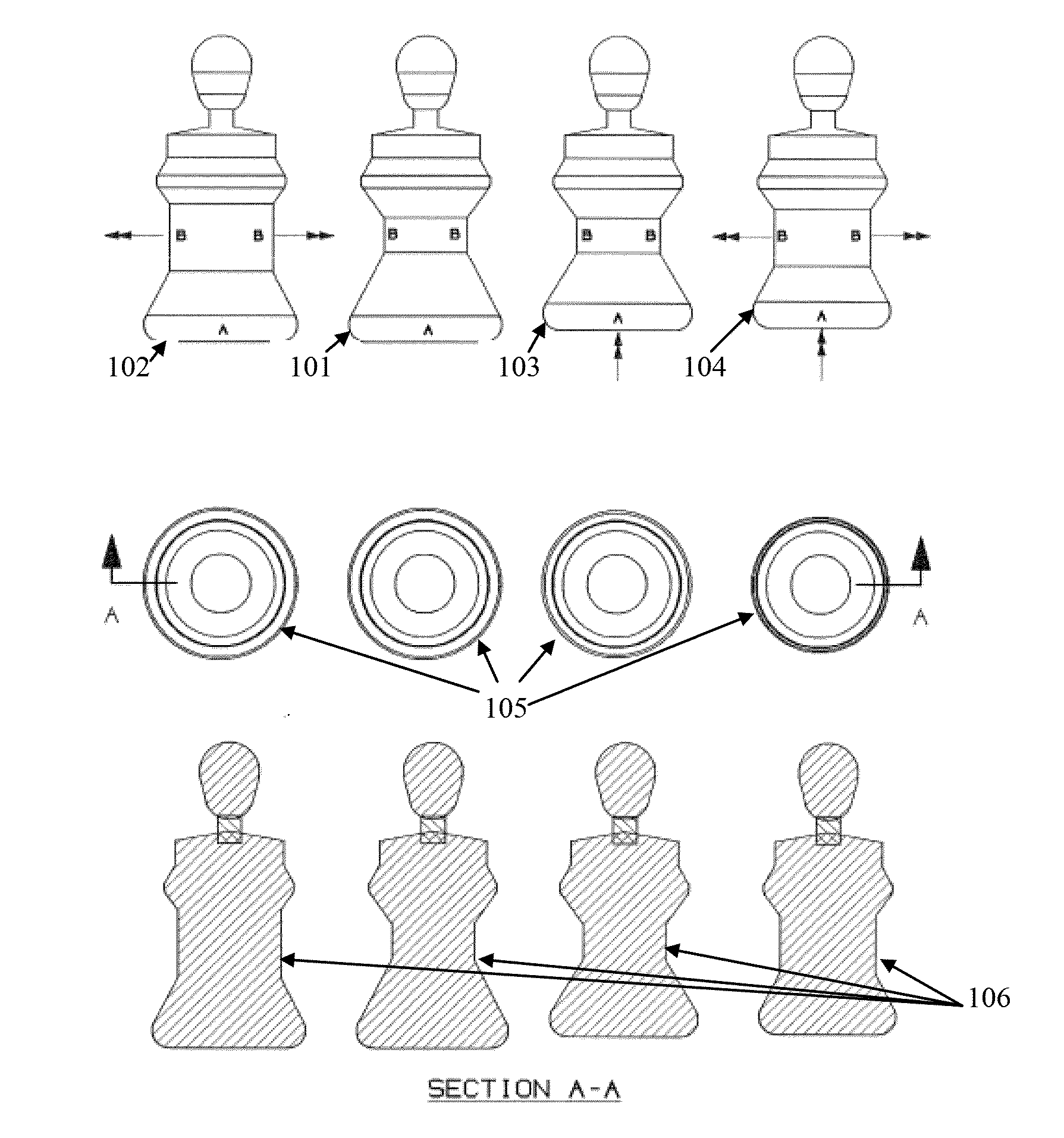

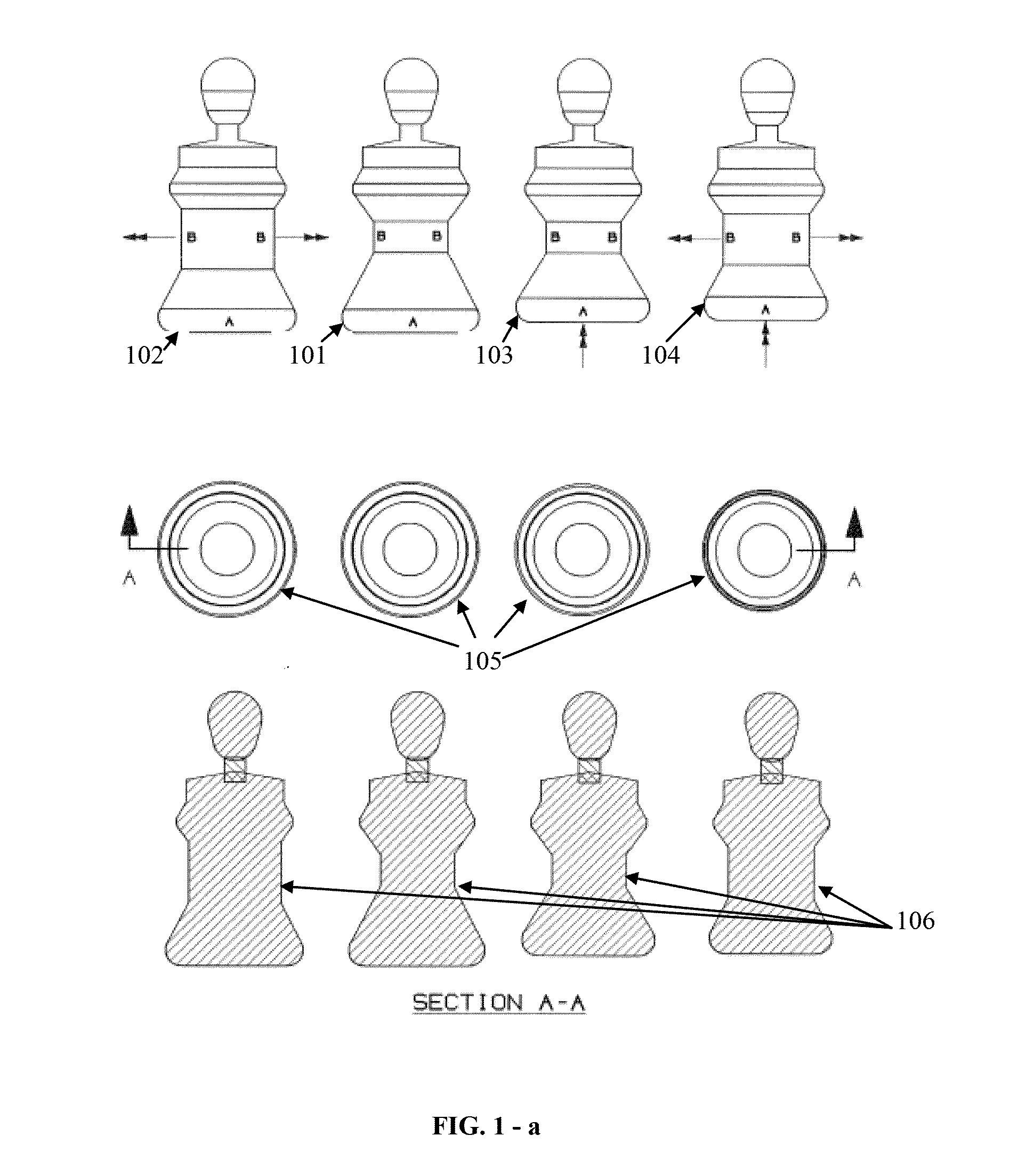

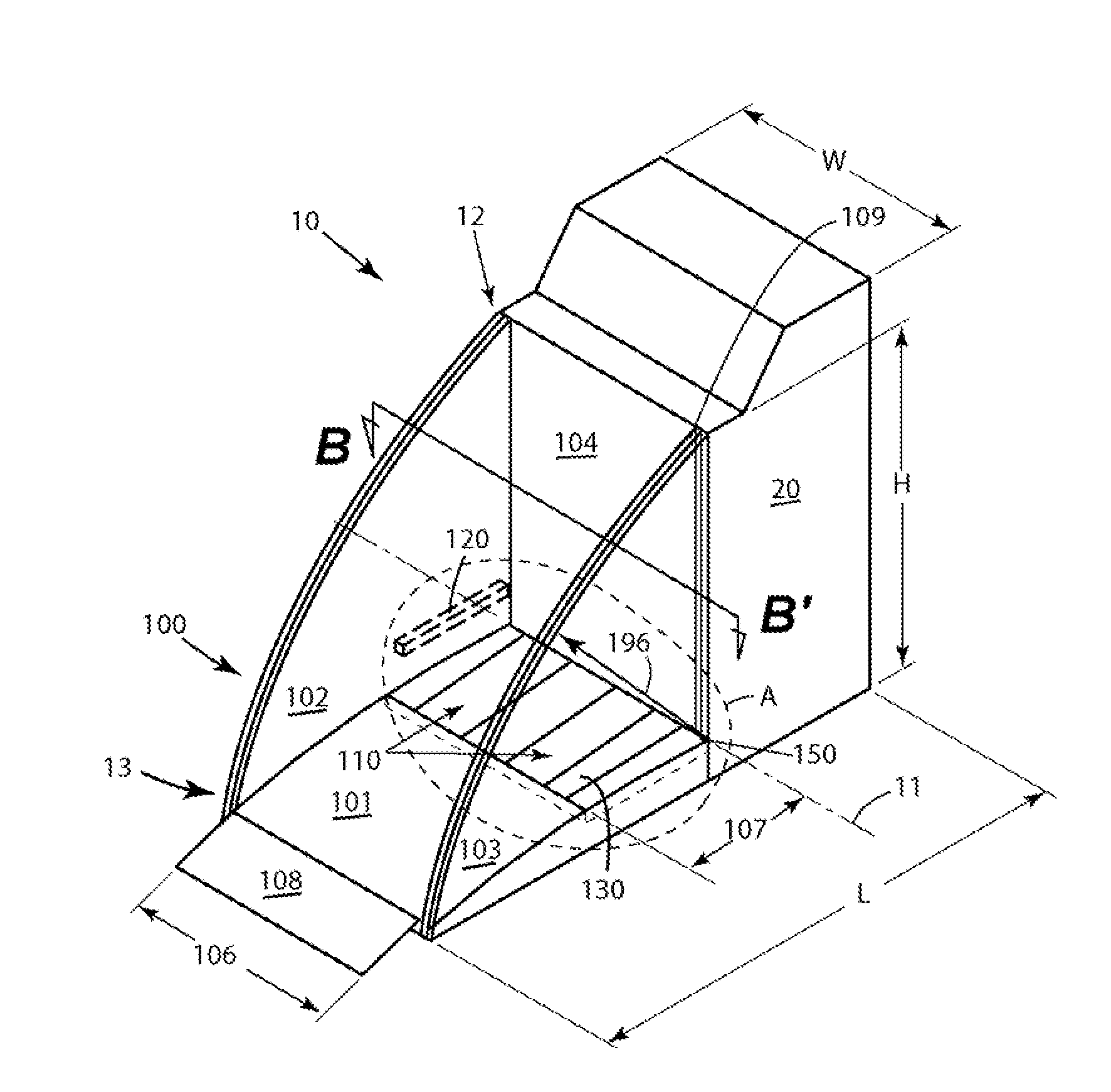

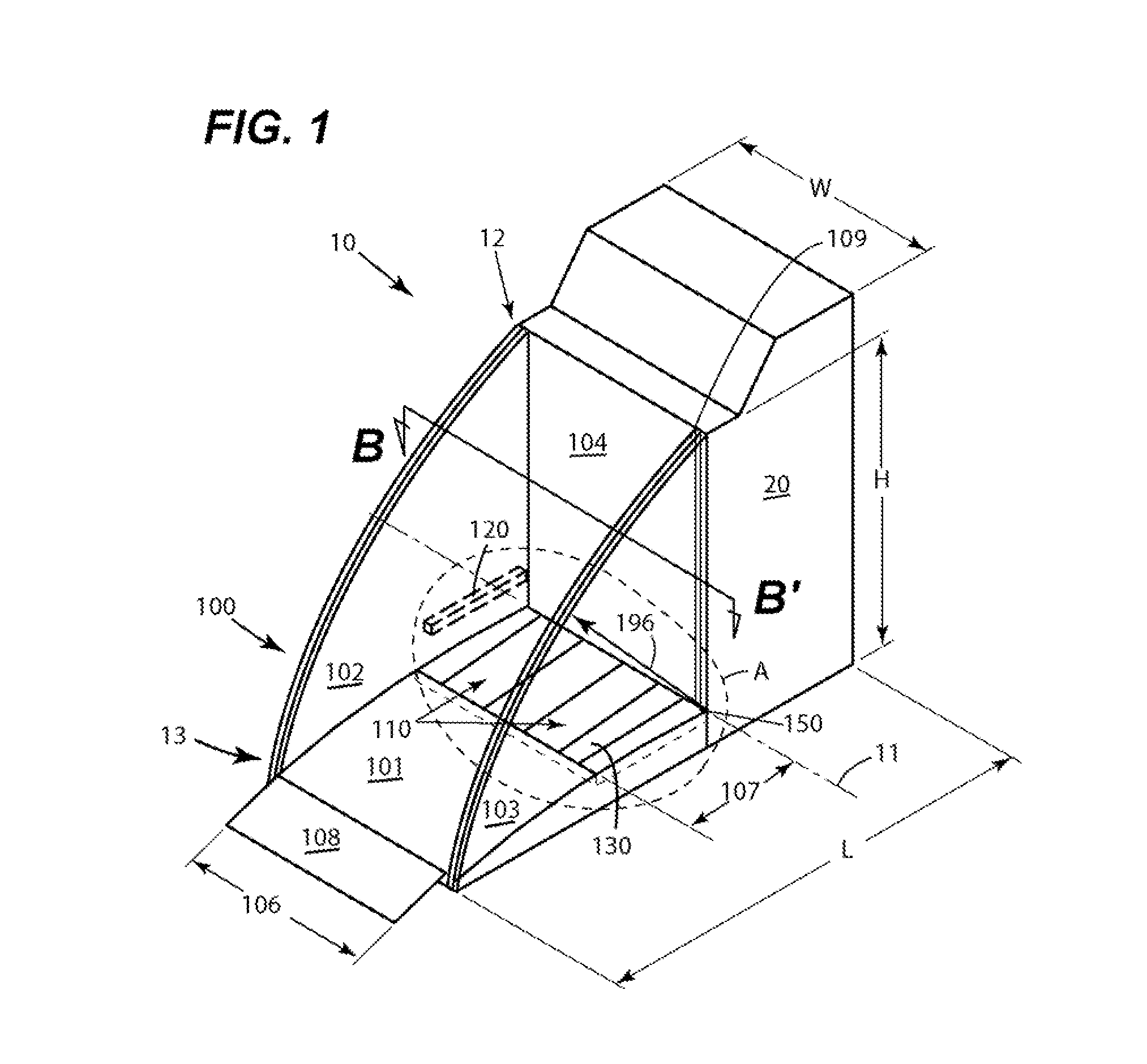

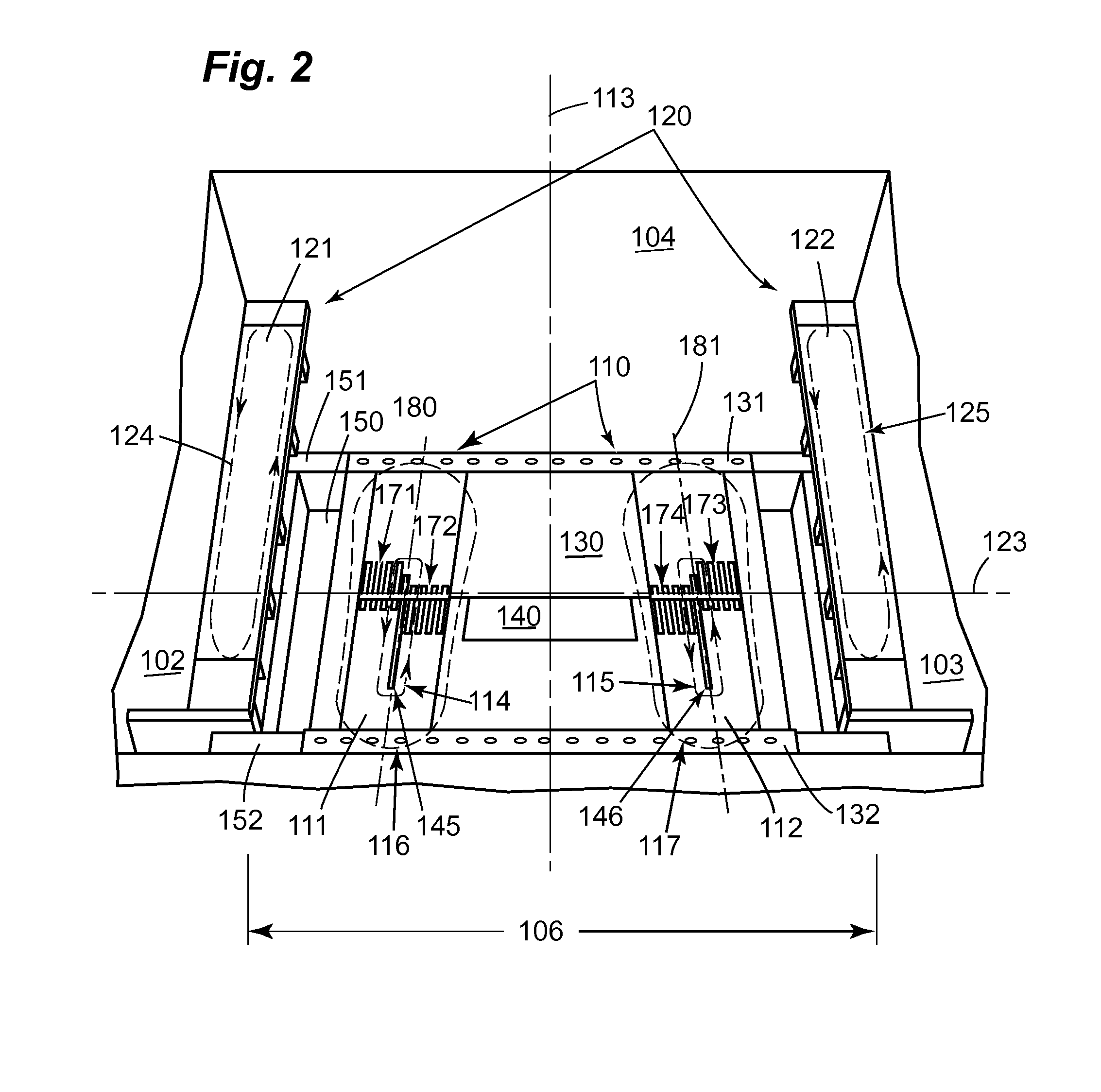

Glove dryer

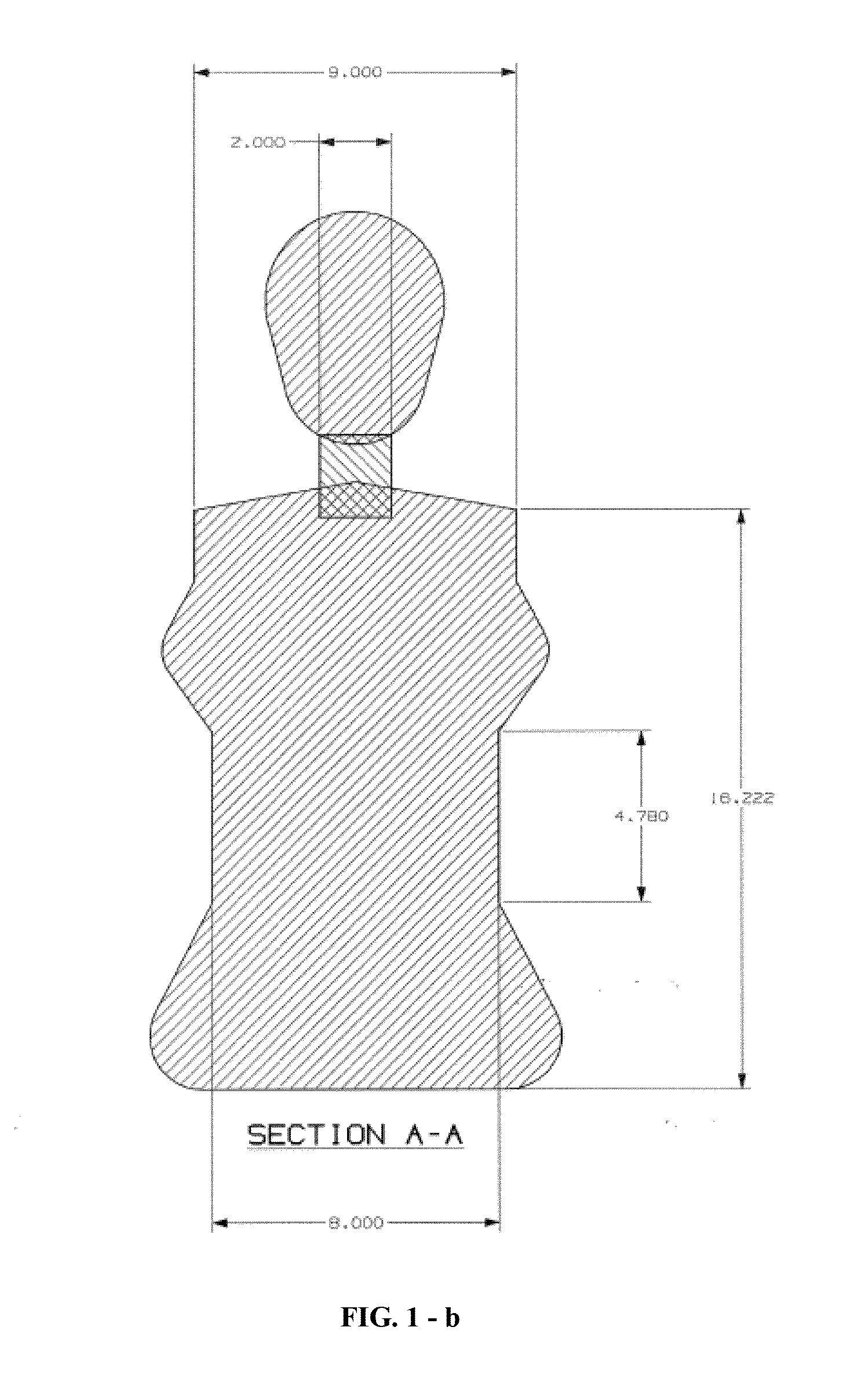

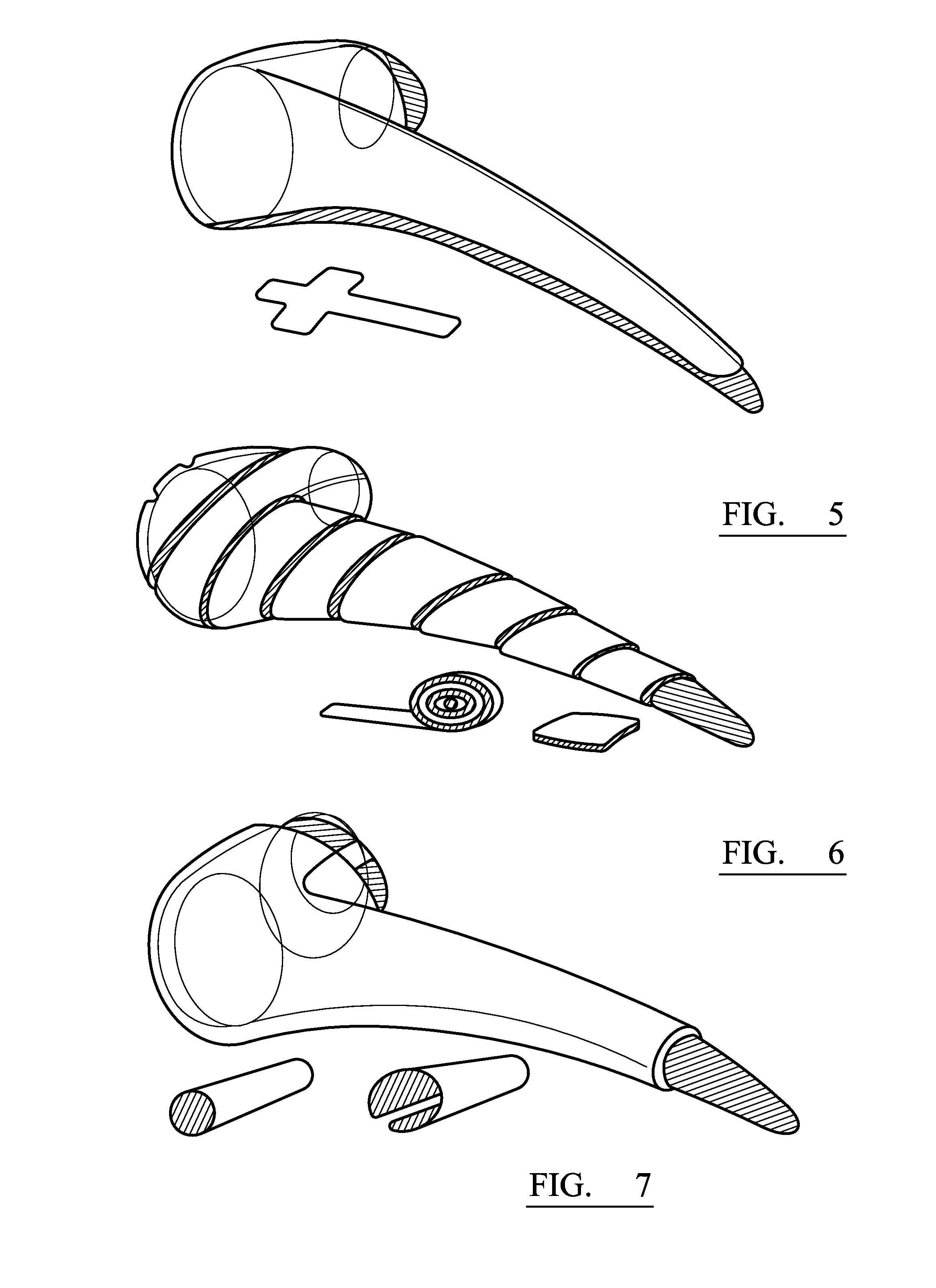

A portable, free-standing dryer device with generally tapered portions formed about a generally central axis facilitating insertion into clothing items to be dried from inside, for example gloves, mittens, socks and other substantially tubular items. The device has a connector temporarily fastening it to a forced air vent. The dryer device comprises at least first and second drier portions joined by an intermediate shoulder portion, each of which defines multiple air passages widening from inner to outer surfaces of the portions to define an expansion volume fostering air flow. A larger substantially open end in the first portion receives air from the vent. The air flows from within the drier outwardly through the passages. An angular relationship of outer surfaces of the first, second and intermediate portions relative to the device central axis ensures that the second drier portion has an extended, narrowing configuration facilitating its insertion into clothing items.

Owner:HICKS NEIL

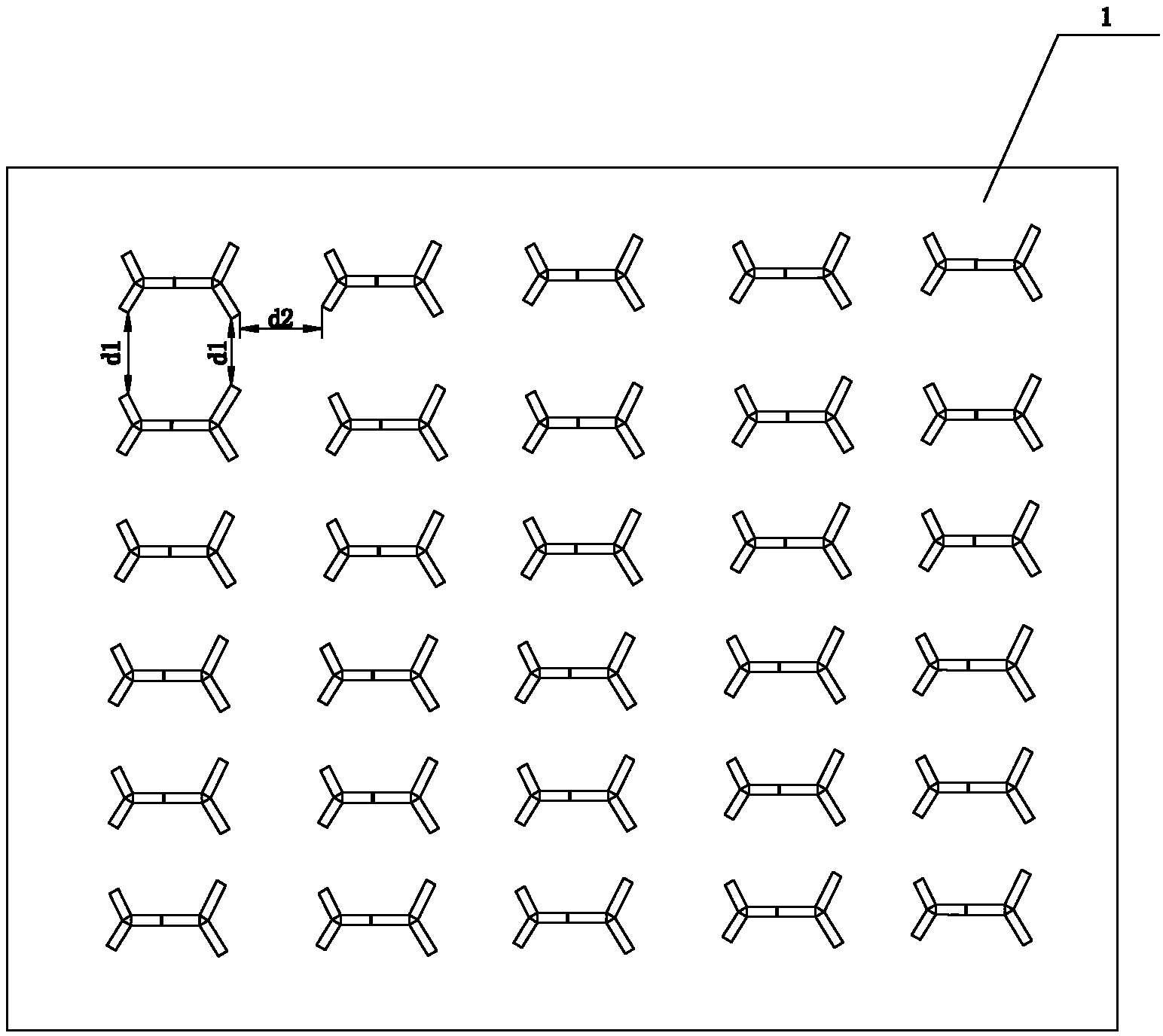

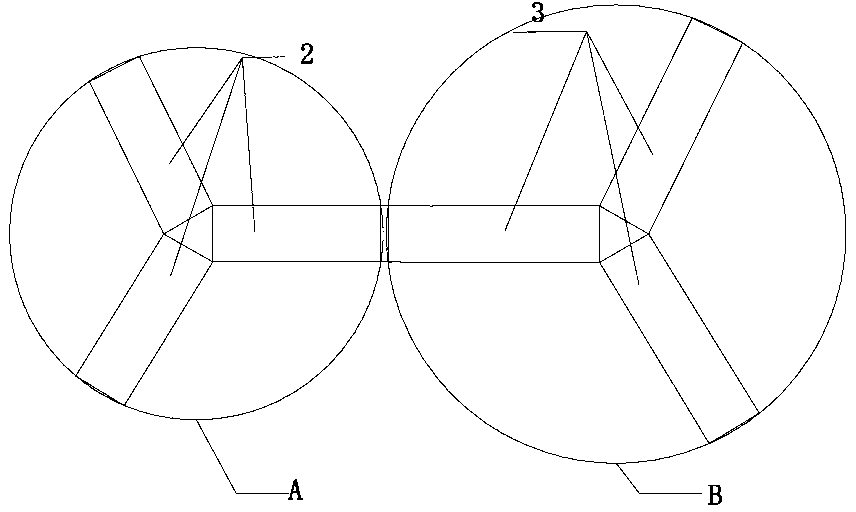

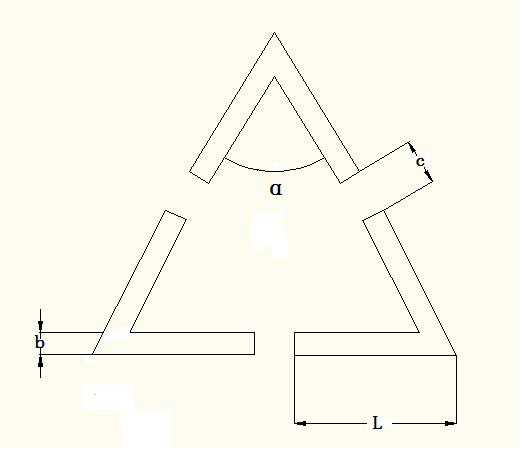

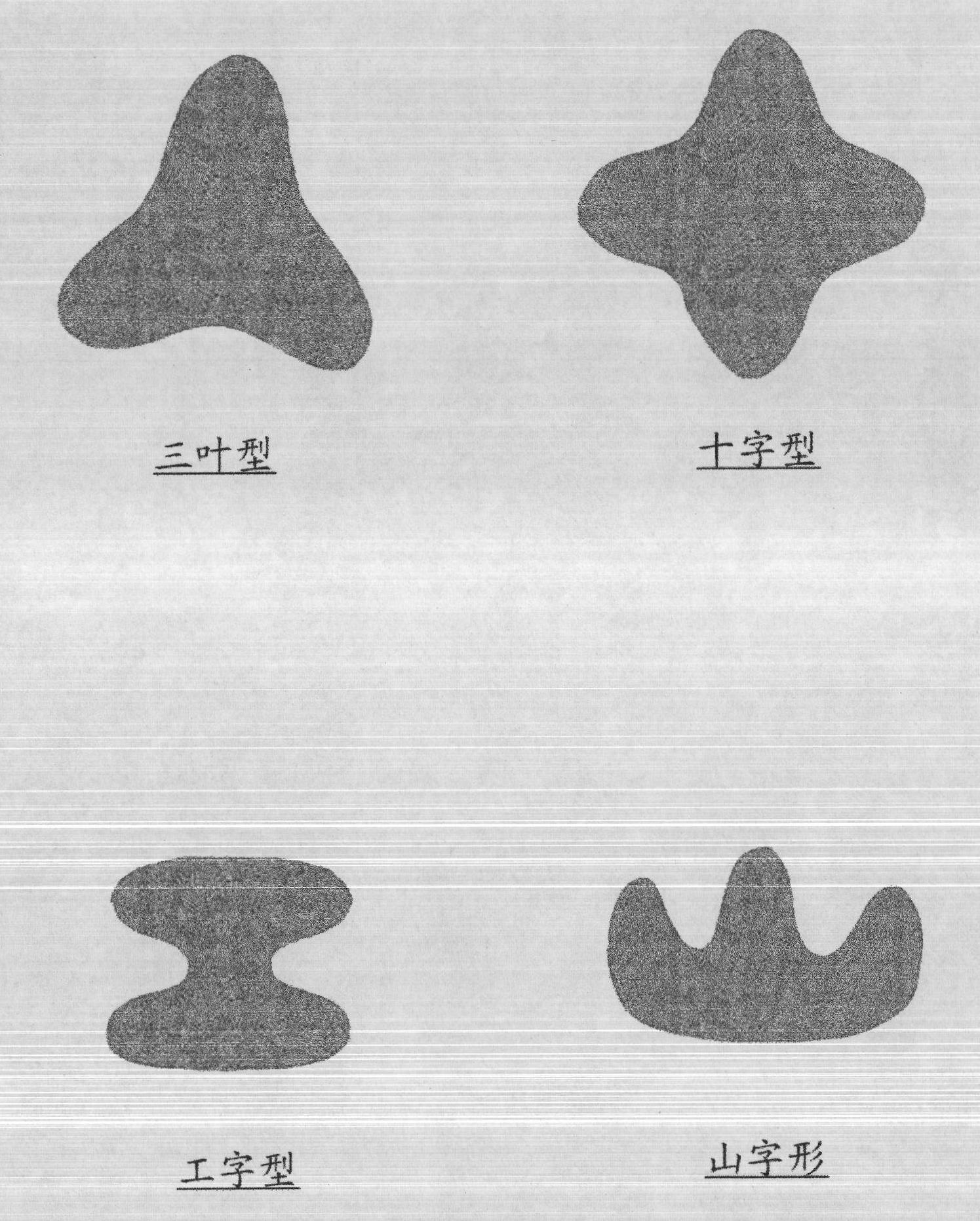

Side by side composite fiber spinneret plate, method of preparing three-dimensional crimp antibacterial fiber with spinneret plate and application of three-dimensional crimp antibacterial fiber

ActiveCN103225118AImprove breathabilityImprove perspirationFilament/thread formingConjugated synthetic polymer artificial filamentsSOCKSMelt extrusion

The invention relates to a side by side composite fiber spinneret plate, a method of preparing a three-dimensional crimp antibacterial fiber filament, and an application of the three-dimensional crimp antibacterial fiber filament. The method comprises the steps that the side by side composite fiber spinneret plate is used; every two groups of rectangular spinneret orifices in unequal dimensions at 120 degrees form every equilateral three-blade A and B; an ingredient A and an ingredient B with different thermal shrinkage rates are selected; an antimicrobial agent ingredient C is added into the ingredient A; the ingredient A and the ingredient C are subjected to melt extrusion by two twin screws, enter a parallel composite component and the spinneret plate after metered, and are subjected to parallel composite distribution, cross air blow, low-temperature shock cooling, oiling and winding to form a winding yarn; and the winding yarn is subjected to drawing, false twisting and thermoforming to form a DTY (Draw Textured Yarn) or subjected to the drawing and thermoforming to form the DTY. A three-dimensional crimp antibacterial fiber prepared by the method is soft and elastic, has the characteristics of good breathability, wicking, quick drying, antibacterium and the like since various grooves are formed in the cross section, and is applied to the development of shell fabrics of undergarments, sports suits, socks, bedclothes and the like and medical dressings.

Owner:JIAXING UNIV

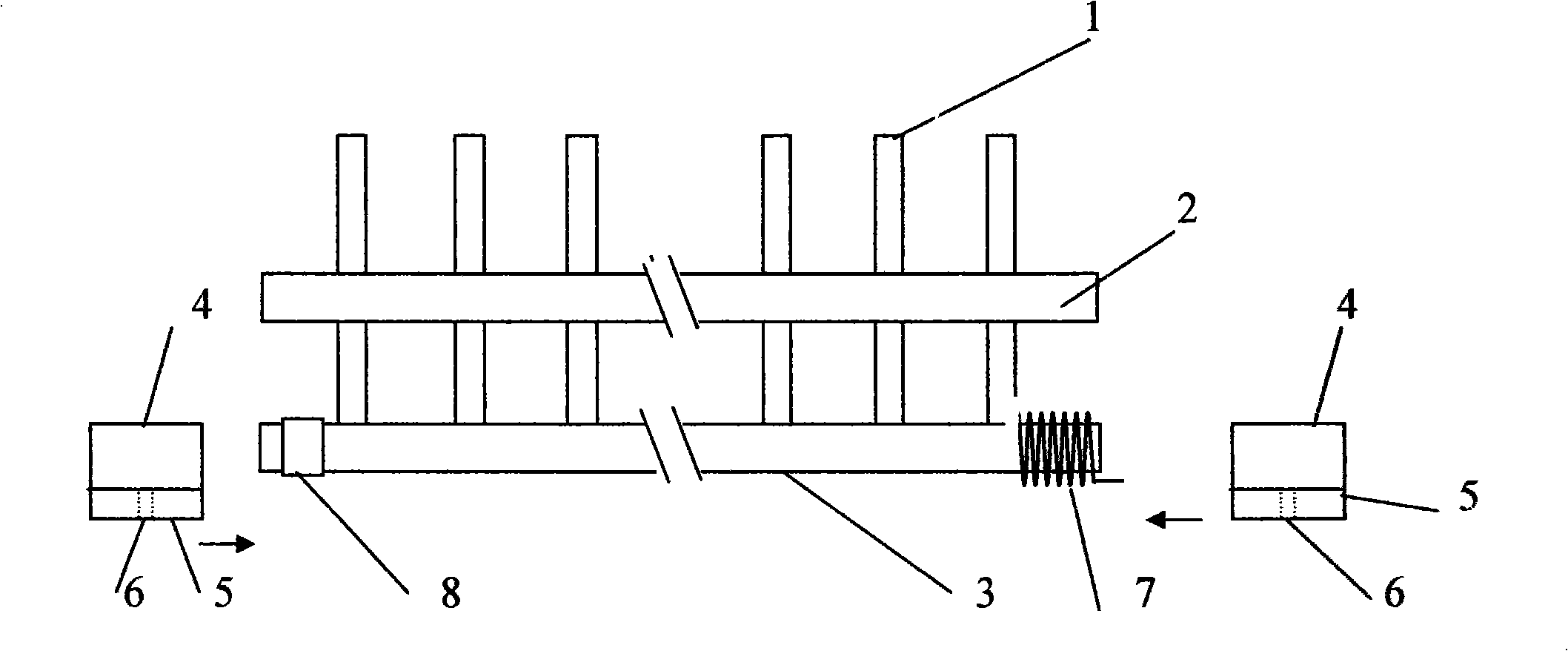

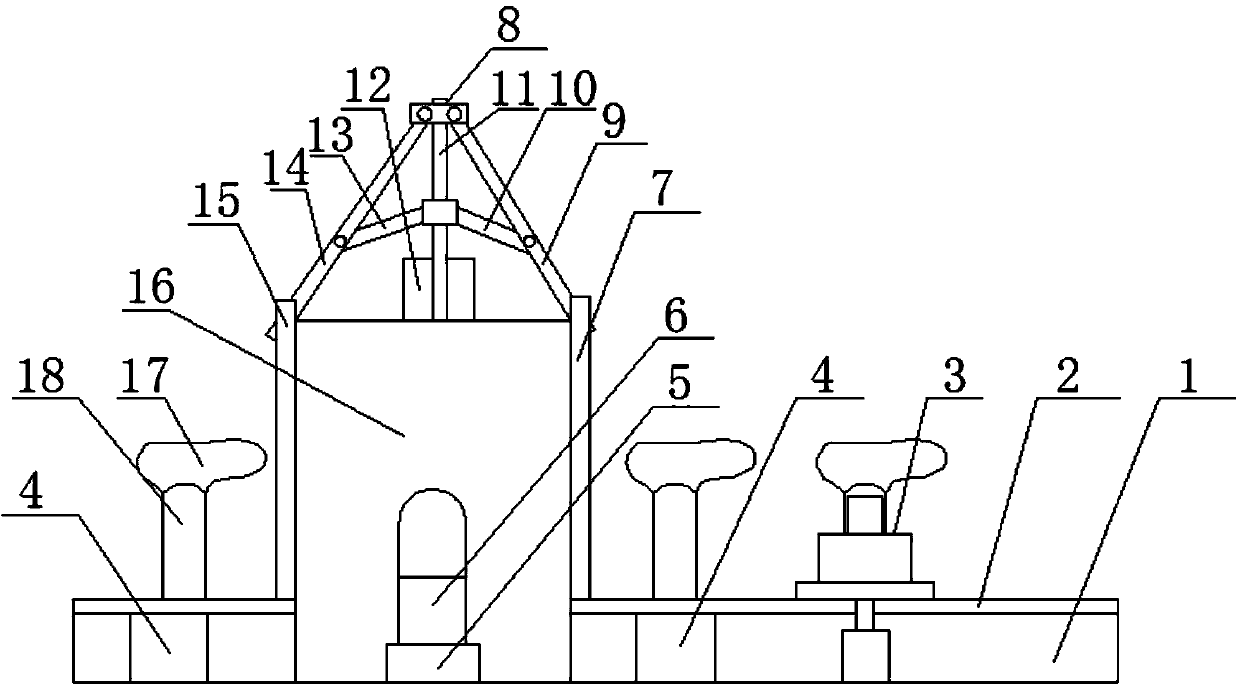

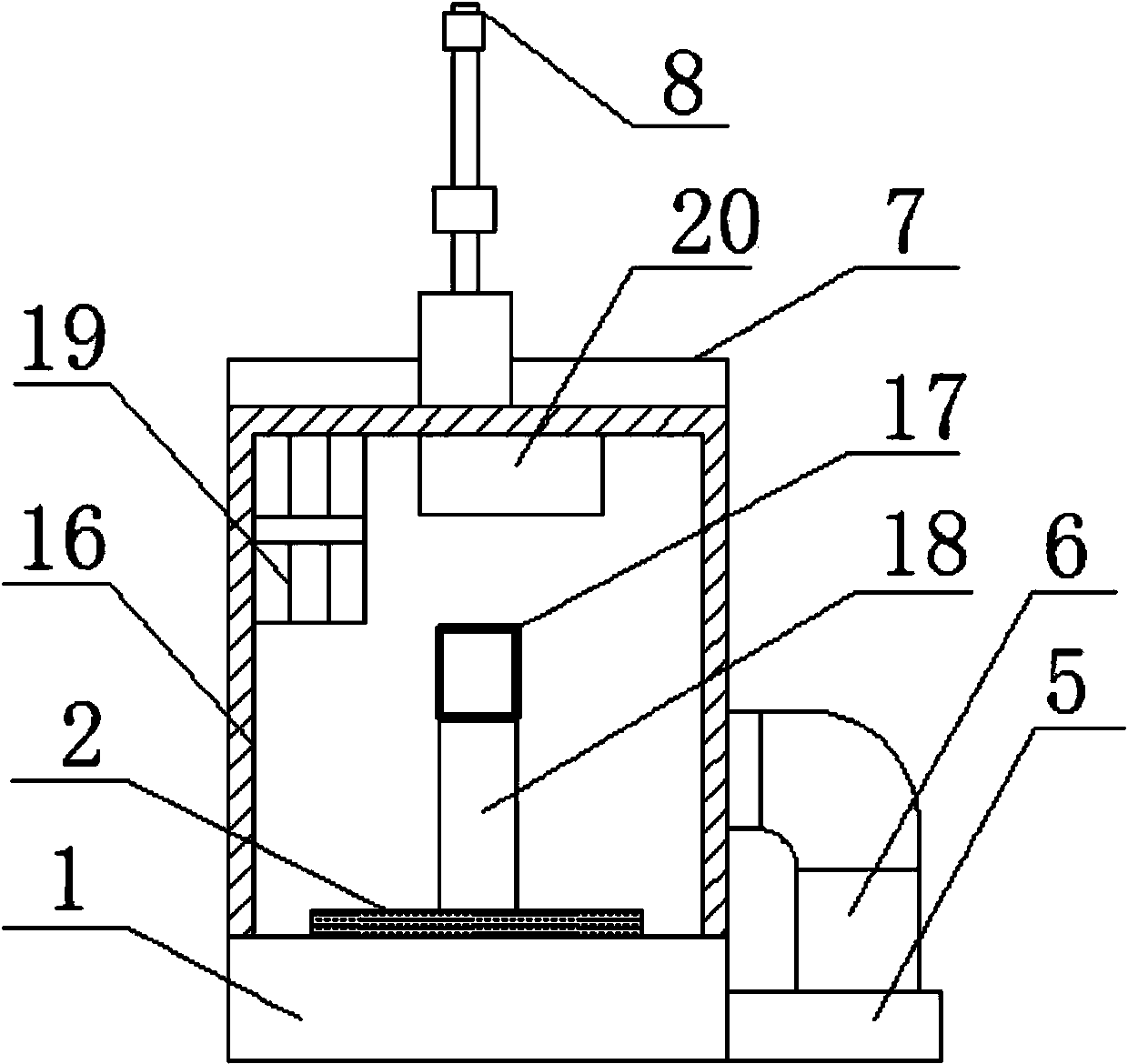

Sock production device

ActiveCN104233634ARealize automatic flippingBeautiful stitchesMechanical cleaningPressure cleaningSOCKSElectric machinery

The invention discloses a sock production device. The sock production device comprises a rack, a feeding device, a waste material recovery device, a sewing box, a discharging device and a sock turning device, wherein the feeding device comprises a guide rail, a guiding frame, a guiding box, a feeding box and a first electric motor component; the waste material recovery device comprises a negative air pressure pumping device and a pipeline, the negative air pressure pumping device is arranged on the rack, and one end of the pipeline is connected to the negative air pressure pumping device; the sewing box is fixedly arranged on the rack and is sequentially and fixedly provided with a first sewing head and a second sewing head from left to right; the right end of the rack is fixedly provided with the discharging device, the discharging device is provided with a discharging guide rail, the lower part of the discharging guide rail is provided with a sock guiding pipe, and the sock guiding pipe is provided with the sock turning device. According to the sock production device disclosed by the invention, socks can be automatically turned after the socks are sewed when a seam of a sock point is completely sewed, meanwhile, the situation that waster materials which are generated by the first sewing head, the second sewing head and a sock point cutting mechanism can be collected is realized, the automation degree is high, the working efficiency is increased, and the labor cost is reduced.

Owner:浙江圣邦化纤针织有限公司

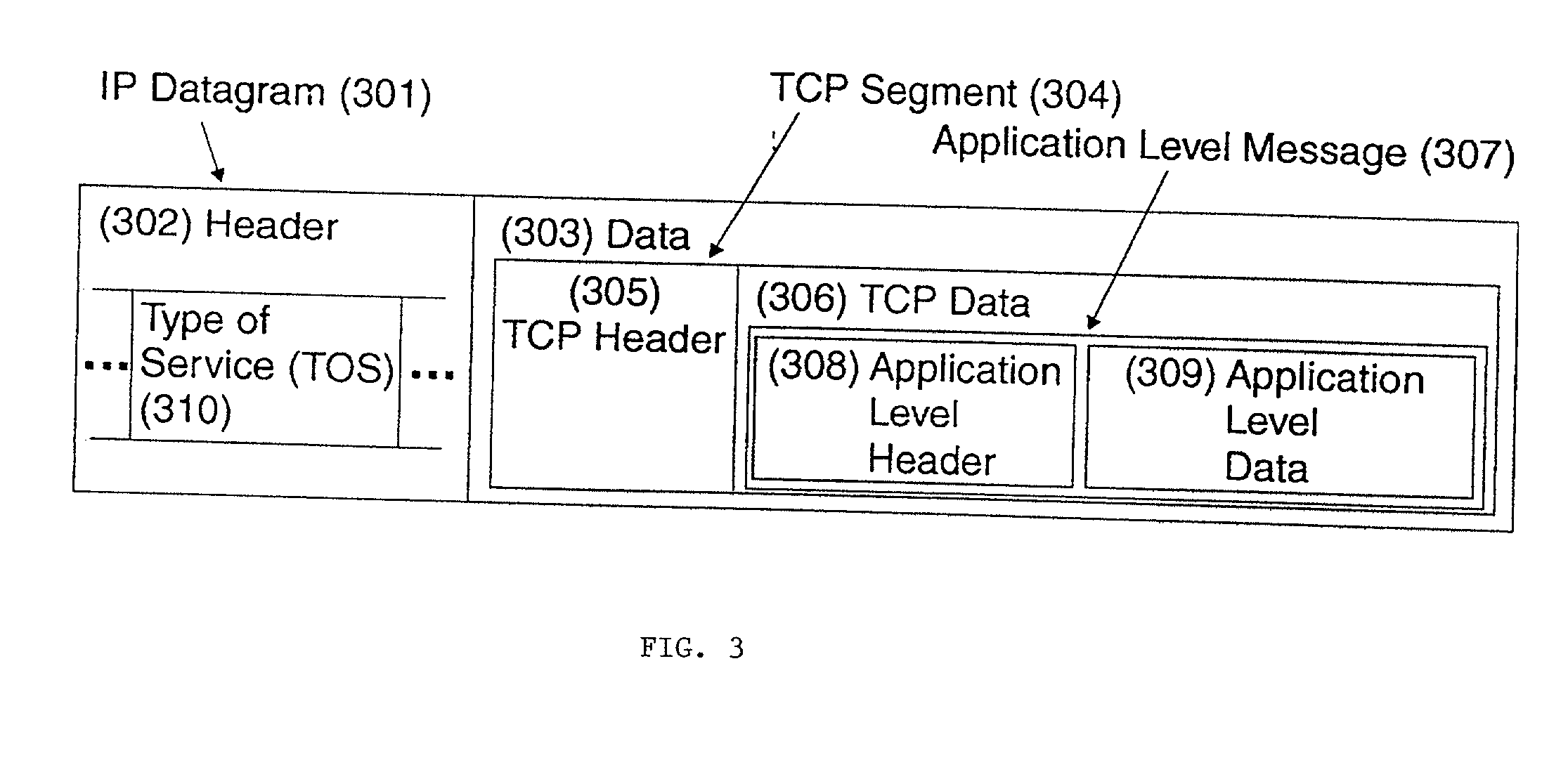

Method and system of dispatching socks traffic using type of service (TOS) field of IP datagrams

InactiveUS20010023451A1Minimizing interruptionWEB access availabilityError preventionTransmission systemsTraffic capacitySOCKS

The present invention relates to a system and method of dispatching an IP datagram comprising socks traffic on a socks server, in an Internet Protocol (IP) network comprising a plurality of socks servers, the IP datagram comprising an IP header comprising a Type Of Service (TOS) field. The method comprises in a socks dispatcher the steps of retrieving the value of the Type Of Service (TOS) field from the IP header of the IP datagram and selecting a socks server referring to a first table, said first table defining for each value of the TOS field one or a plurality of socks servers. The IP datagram is sent by an IP network device with a given priority. The step of retrieving the value of the Type Of Service (TOS) field is followed by the further step of determining the priority of the IP datagram by referring to a second table, the second table defining a priority for each value of the Type Of Service (TOS) field. The IP datagram comprising data according to a given application level protocol, the step of determining the priority of the IP datagram comprises the further step of determining the application level protocol of data transported in the IP datagram by referring to the second table, the second table defining a priority and an application level protocol for each value of the Type Of Service (TOS) field. In case of congestion in one or a plurality of output queues, the step of determining the priority of the IP datagram is followed by the further steps of discarding in the one or plurality of output queues IP datagrams having the lowest priority until there is no more congestion, and discarding the IP datagram when said IP datagram compared with IP datagrams in said one or plurality of output queues, has the lowest priority.

Owner:LINKEDIN

Fashion design method, system and apparatus

The present invention relates to methods, systems and apparatuses for computerized design and / or selection of clothes, fashion accessories, and / or similar items. More particularly, the present invention relates to methods, systems and apparatuses that can be used for clothes and fashion design and / or selection at one's home or office by individual designer who may be a professional or non-professional. In an embodiment, the present invention creates personalized 3D virtual human models of the users, or other persons, and converts the data into 2D design drawings or transfers the data to a machine capable of building a 3D physical model, which can then be used for fit and esthetic analysis. A push and pull technique is used to create a personalized 3D virtual model from a library model, which can then be used for an analysis as to how a certain clothing, for example, will look on a particular person. The push and pull technique may also be used to personalize 2D design templates and / or drawings which may be preloaded into the computer library or added by the user by drawing them directly on the computer using a CAD software for example, or added by other ways as for example drawing on paper and scanning the drawing into the computer. In addition, final verifications are achieved by a inputting into a special purpose computer a combination of person's actual measurements, fit tolerance, and / or fit preference. One of the goals of the present invention is to bridge the gap between designers, who may be professionals, or not, and manufacturers. The present invention makes clothing design and / or selection look so realistic that everyone that sees it can easily picture how the clothing will look like on a particular person when it is made. A user can use the teachings of the present invention to design and / or select clothing like, for example, dresses, skirts, shirts, bras, pants, coats, lingerie, T-shirt, sweater, pullover, suit, socks, hat, cap or gloves, to design and / or select shoes, or, to design and / or select fashion accessories like, for example, jewelry, eyeglasses, purses or hand bags.

Owner:ZENG BELINDA LUNA

Apparatus and method for detecting metallic objects in shoes

InactiveUS7595638B2Interference minimizationMagnetic property measurementsElectric/magnetic detectionSOCKSResonance

An inspection system positions a balancing shim to asymmetrically balance a magnetic field generated by an inductive sensor, which forms part of the inspection system. Additionally, relays and capacitors used to tune the inductive sensor to a desired resonance frequency are geometrically arranged to minimize electrical interference generated by operation of the relays and capacitors. A shielding device, which may be formed on a printed circuit board, protects a magnetic field generated by the inductive sensor from external electromagnetic interference. A slot positioned in the inductive sensor may be used to tune a resonant mode of the inductive sensor to accurately and particularly detect metallic shanks and / or other metallic objects in shoes, socks, and / or clothing.

Owner:MORPHO DETECTION INC

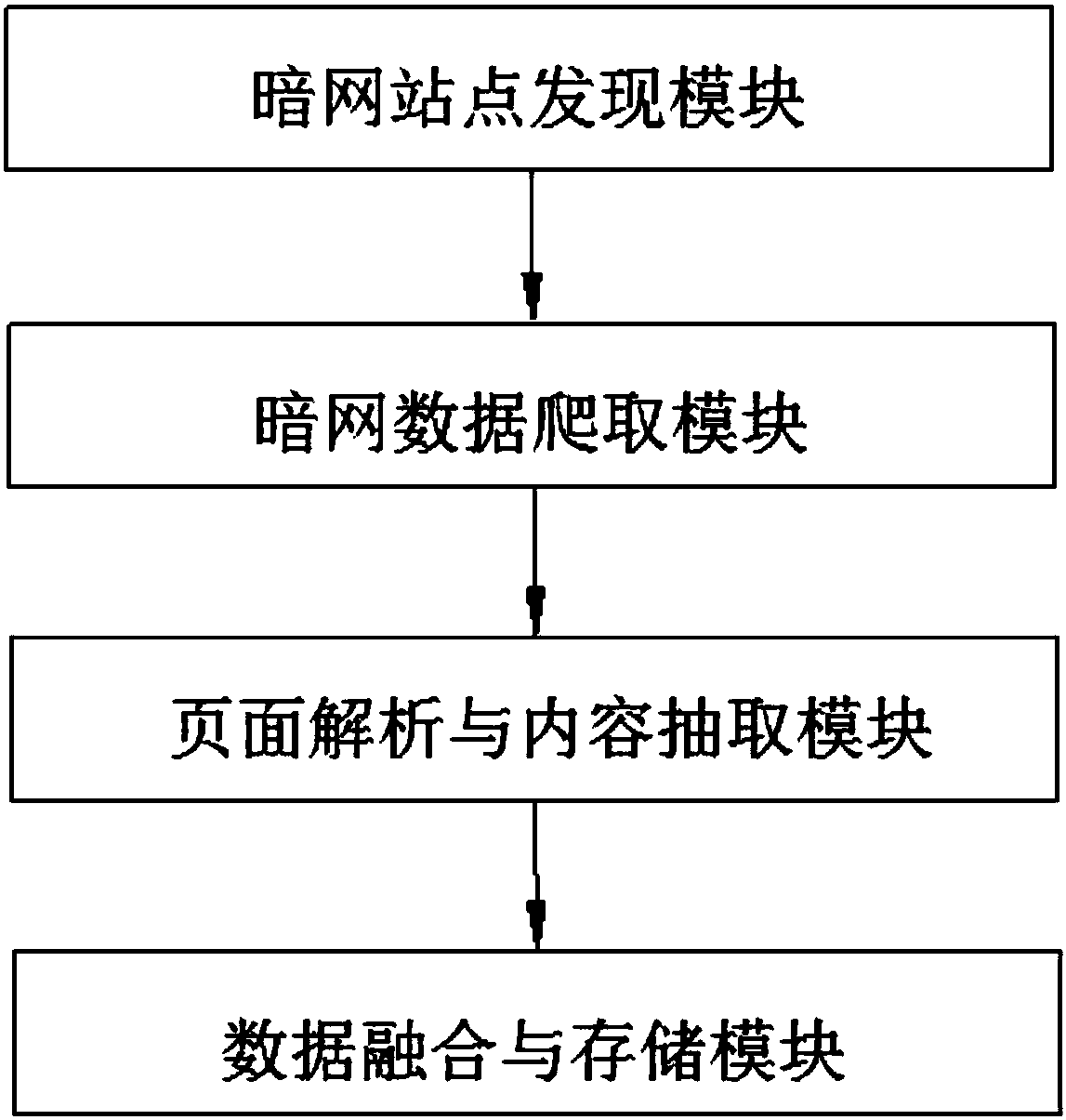

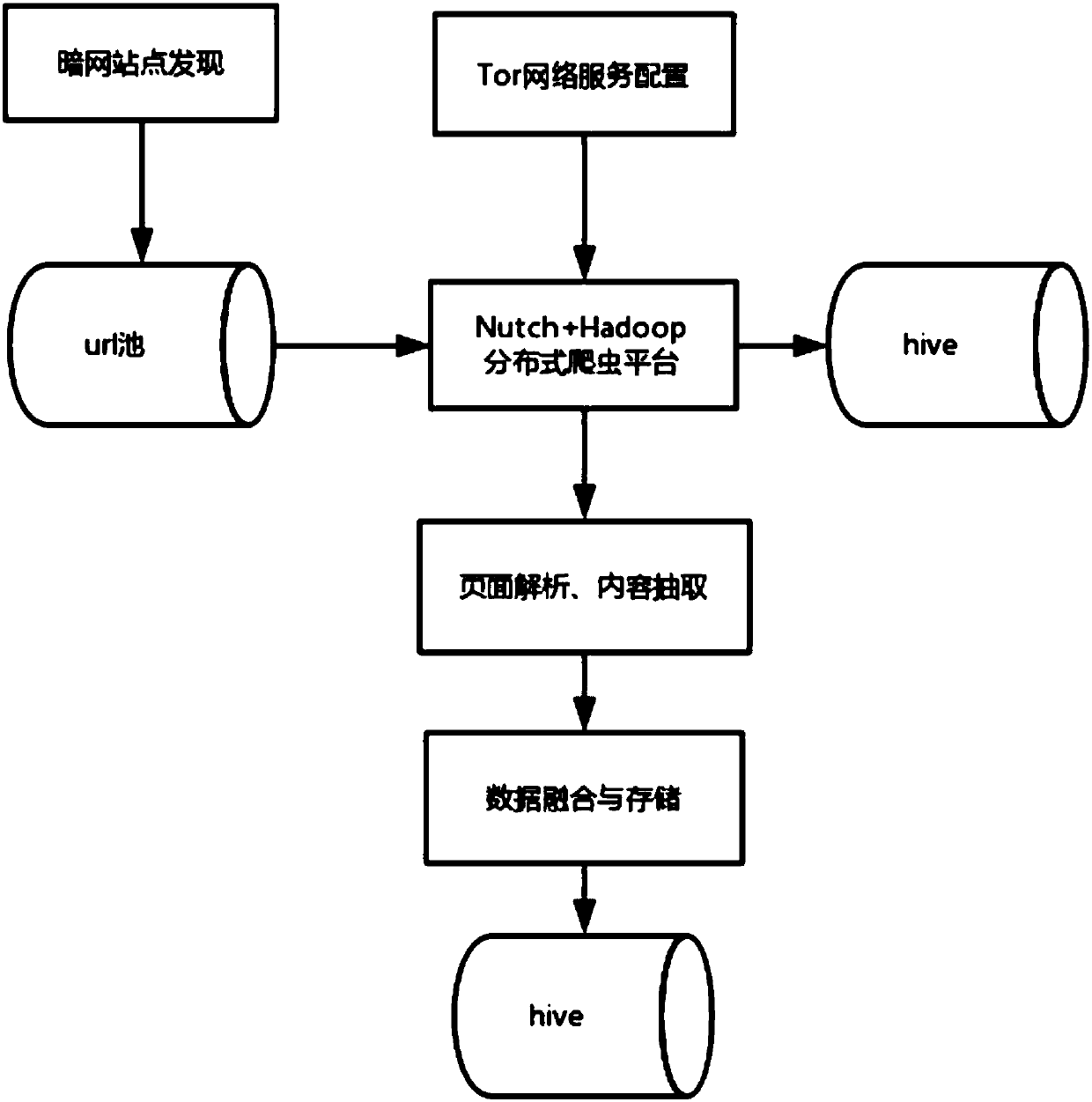

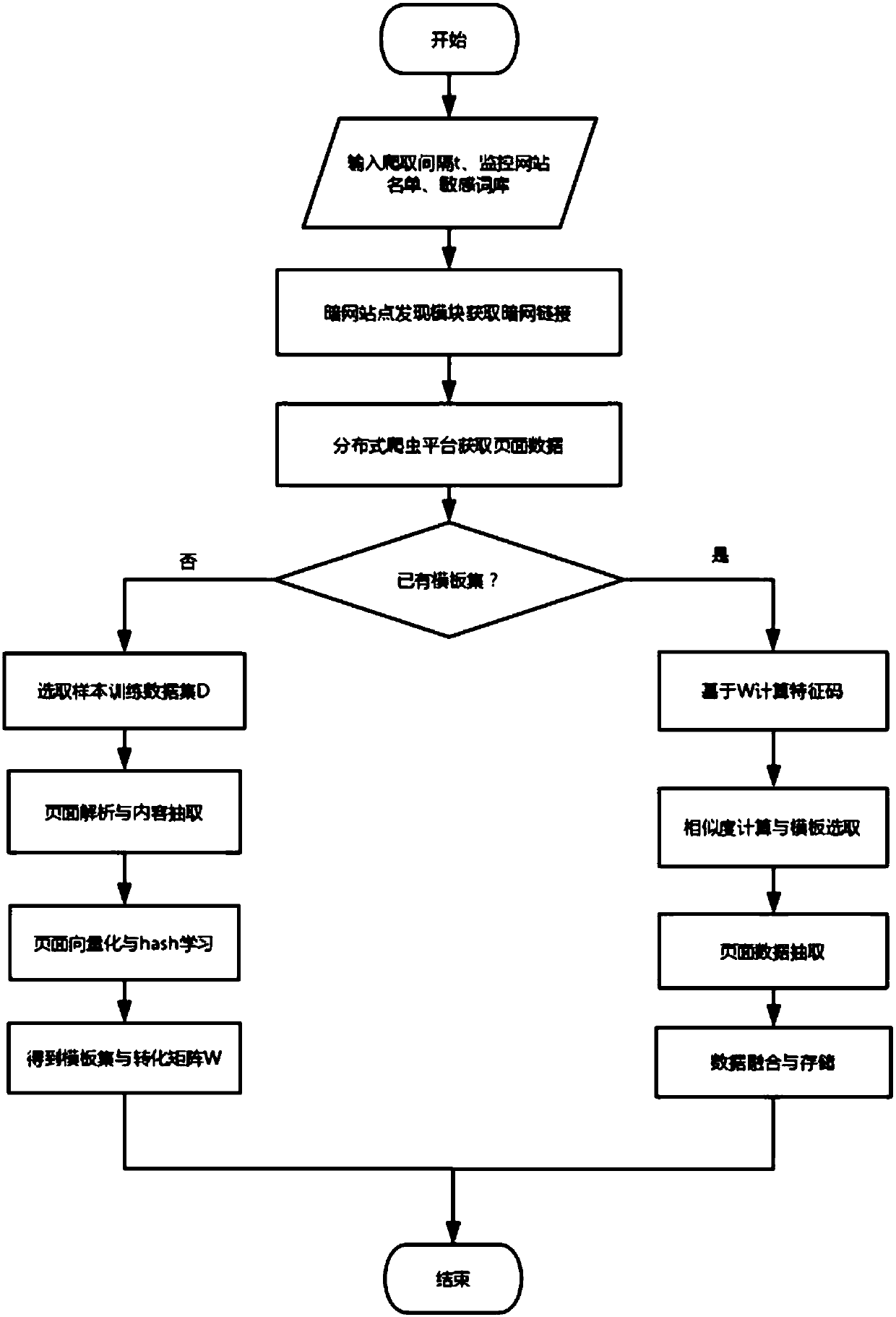

Dark network data collection and extraction system and method

ActiveCN107808000AGet multi-nodeGet multi-node distributionWeb data indexingMulti-dimensional databasesSOCKSSystems design

The present invention relates to a dark network data collection and extraction system and method. The system comprises a dark network point discovery module, a dark network data crawling module, a page parsing and content extraction module, and a data fusion and storage module that are connected in sequence; the dark network point discovery module obtains dark web urls in multi-source data; the dark network data crawling module is configured with the Tor service, modifies Nutch configuration to make the Nutch interact with a socks protocol, and crawls data; the page parsing and content extraction module carries out page parsing, page vectoring, signature generation, similarity calculation, template set updating, and page content extraction; and the data fusion and storage module reorganizes the extracted content by using a data alignment strategy, and fuses similarly-closed data records into a database. According to the system and method disclosed by the present invention, a complete system design flow from page saving to content extraction is realized, and data support is provided for the discovery of illegal transaction activities in the dark network and the establishment of thedark network knowledge map.

Owner:HARBIN INST OF TECH AT WEIHAI +1

Surface mountable delivery device

InactiveUS20110111000A1Increased internal surface areaSettlement inhibitionBiocideHydroxy compound active ingredientsSOCKSEngineering

There is described a surface mountable delivery device which has a multi layer construction comprising a liquid permeable support layer adjacent to a porous reservoir layer, the porous reservoir layer being provided with a backing layer. The surface mountable delivery device may comprise of stickers, tapes, pads, tubes, socks, etc.

Owner:SURFACESKINS

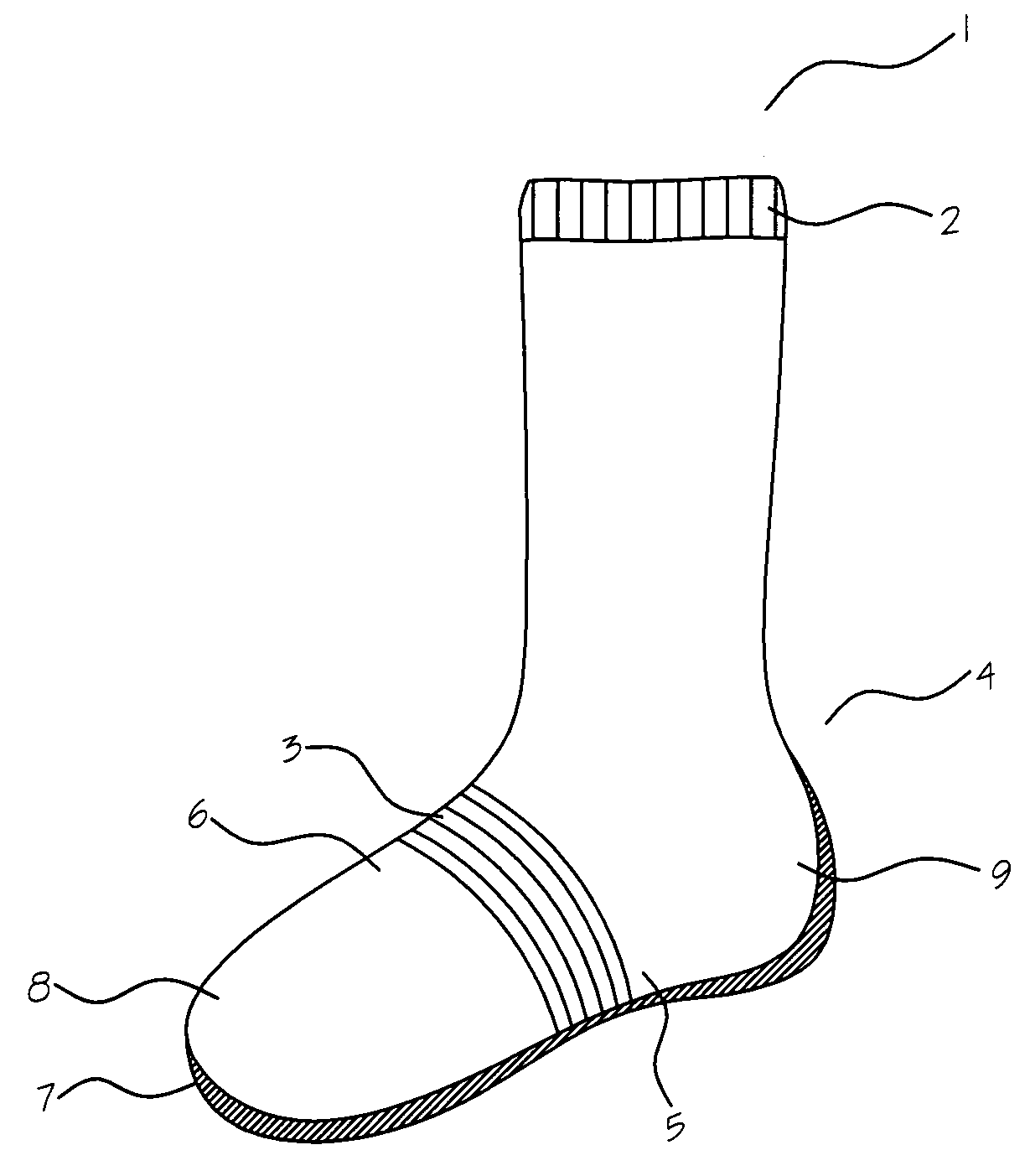

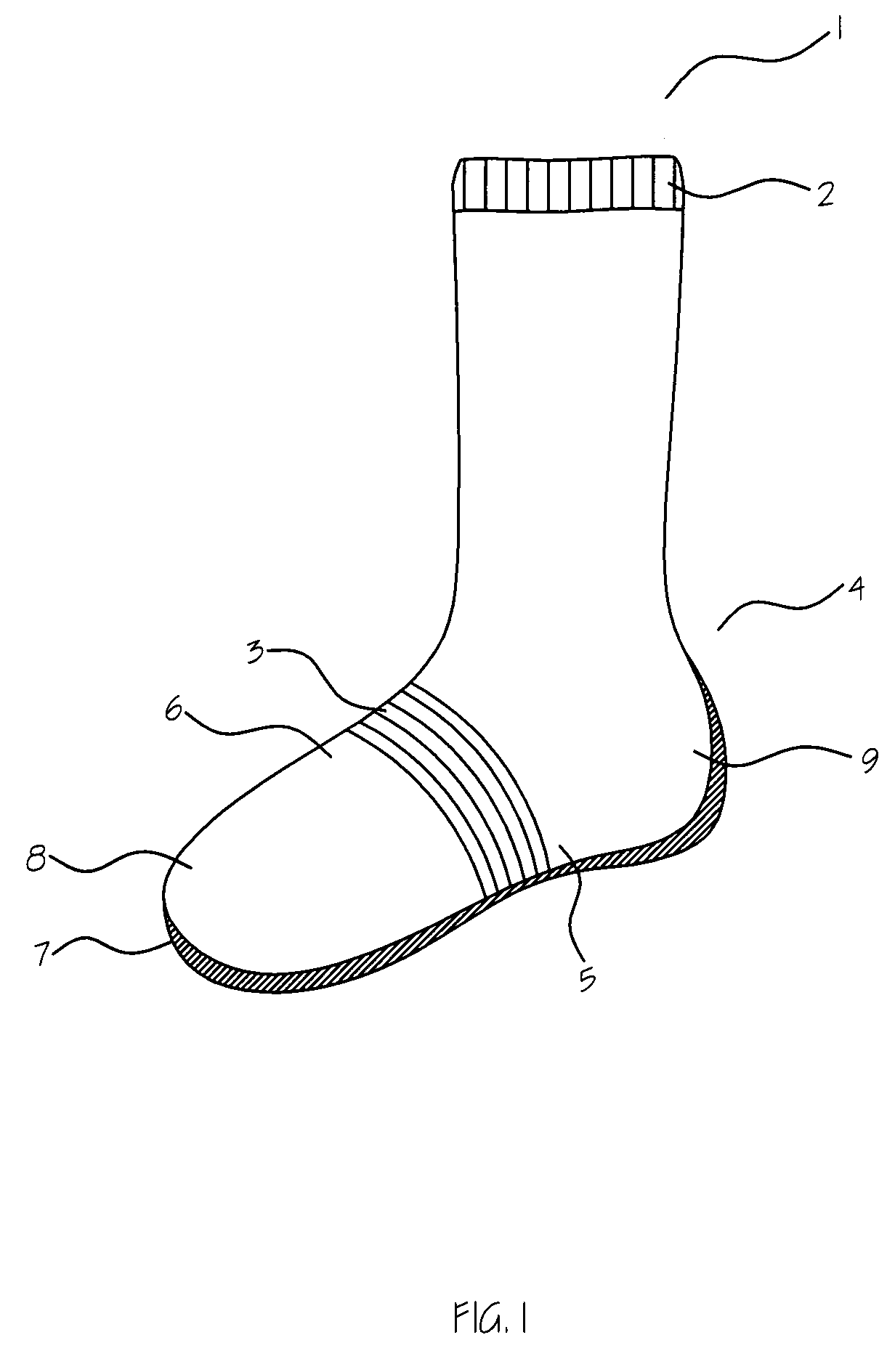

Method of producing porous nitrile rubber coated indoor athletic socks

A method of producing a porous, rubbery polymer coated sock comprising: 1) preparing a double layered sock; 2) wearing the sock on mold hanging on a continuous line; 3) pre-treating the sole portion of the sock a with calcium nitrate solution; 4) preparing a first nitrile rubber solution by stirring a solution comprising foaming agents and acrylo-nitrile butadiene rubber (NBR) at 1,200 r.p.m. for 30 minutes; 5) dipping the sock worn on the mold in a first, deep bath containing the first, foamed nitrile rubber solution; 6) air-drying the solvent in the polymer solution and developing foam in the rubber layer; 7) preparing a second, foamed nitrile rubber solution by stirring a solution comprising foaming agents and nitrile rubber at 1,200 r.p.m. for 30 minutes; 8) dipping sock worn on the mold in a second, shallow bath containing the second, foamed nitrile rubber solution; 9) air-drying the solvent in the second polymer solution and developing foam in the rubber layer; and 10) washing the sock from step 9) in a cleaning solution to eliminate the calcium nitrate and organic solvents and drying the washed sock 110° C. for 40 minutes. The sock thus produced has a bottom face covered with nitrile rubber foams having 0.5 μm voids therein. The portion of the sock from toe to ball is coated with nitrile rubber foam of 1 mm to 3 mm thickness, while the heel portion of the sock is coated with nitrile foam of 0.5 mm thickness. The nitrile rubber foam coating provides a friction surface as well as a cushion for shock absorption.

Owner:WHANG BRIAN +1

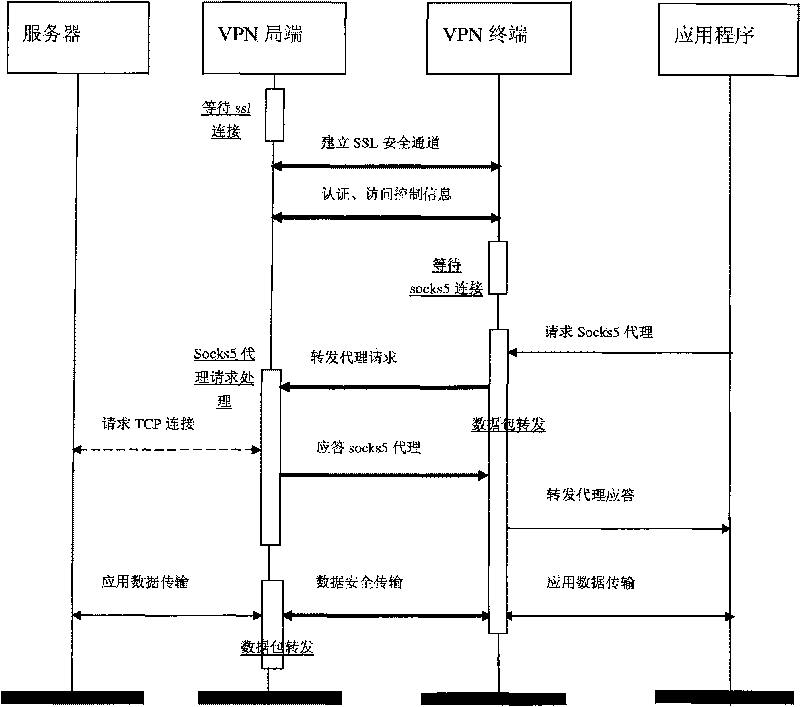

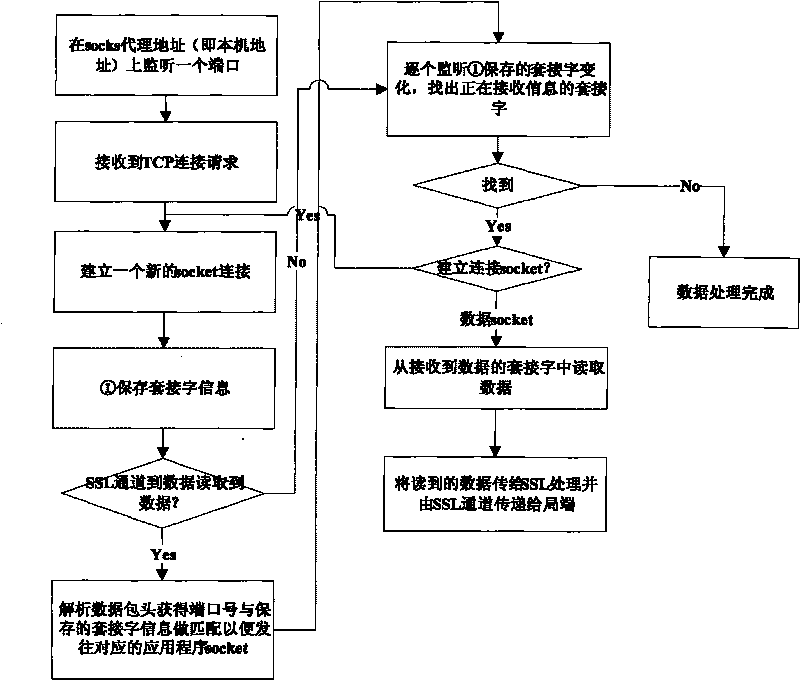

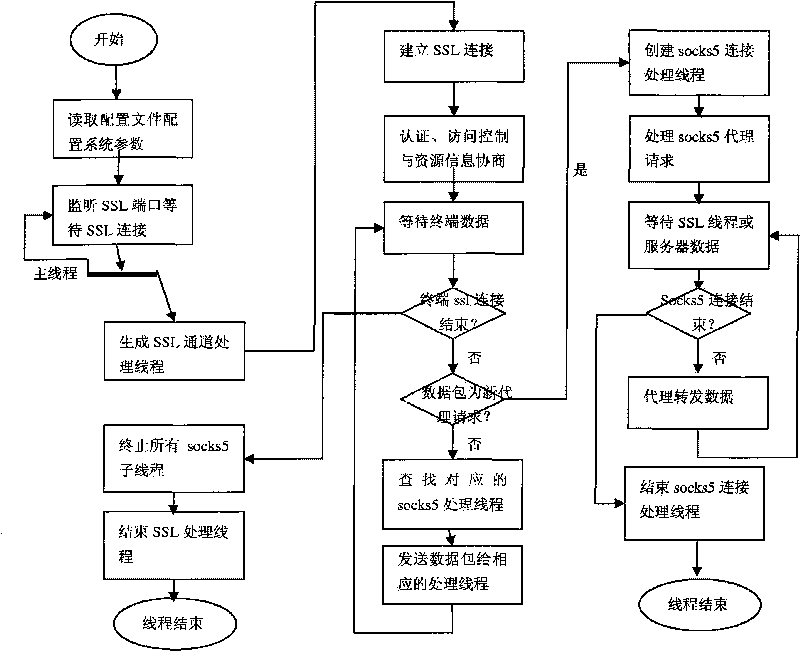

Method for improving performance of mobile SSL VPN by utilizing remote Socks5 technology

InactiveCN101729543AEnable secure accessUninterrupted secure transmissionNetworks interconnectionSOCKSClient-side

Owner:TONGJI UNIV

Dryer-added fabric care articles

Dryer-added fabric conditioning articles that comprise friable microcapsules, wherein the microcapsules comprise a blooming perfume composition, provide consumers an impactful freshness experience while wearing clothing that is treated by the article. The microcapsules that are deposited on treated clothing rupture upon the mechanical stresses imposed upon the microcapsules through daily activities of wearing clothing such as putting on socks or putting on a coat. Furthermore, perfume microcapsules also allows the consumer to have a delightful scent experience on fabrics which have been stored even for long durations of time due to their ability to protect perfume from volatilization to the surrounding air space.

Owner:THE PROCTER & GAMBLE COMPANY

Flexible and heterogeneous nylon-6 fiber and preparation method thereof

ActiveCN102409419AStable structureLow apparent densityHollow filament manufactureFilament/thread formingSOCKSNylon 6

The invention relates to the technical field of functional and differentiated fiber production, and aims to provide flexible and heterogeneous nylon-6 fiber and a preparation method thereof. The flexible and heterogeneous nylon-6 fiber is formed by V-shaped jet micropore spinning and a melting spinning method by using fiber-level nylon-6 chips as substrates; the internal part of the section of the flexible and heterogeneous nylon-6 fiber is hollow, and the periphery of the section is triangular; and the relative radial profile degree of the cross section of the flexible and heterogeneous nylon-6 fiber is 20 to 30 percent, and the relative section profile degree is 35 to 55 percent, and hollowness of the flexible and heterogeneous nylon-6 fiber is 10 to 30 percent. The fiber has good mechanical properties, and high elasticity, hygroscopicity and heat retention, and can be widely used for the fields of underwear, socks, clothing and the like.

Owner:YIWU HUADING NYLON

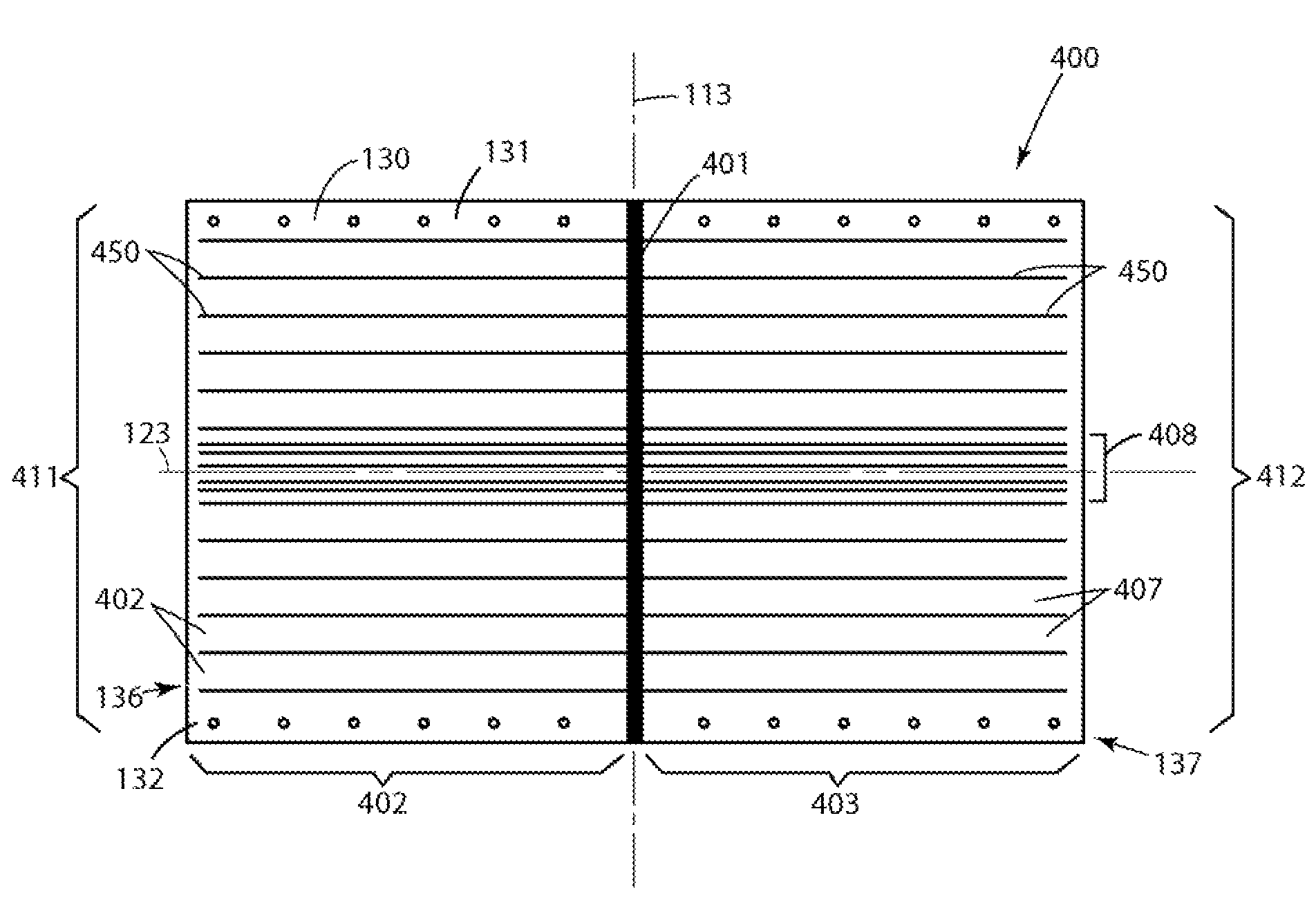

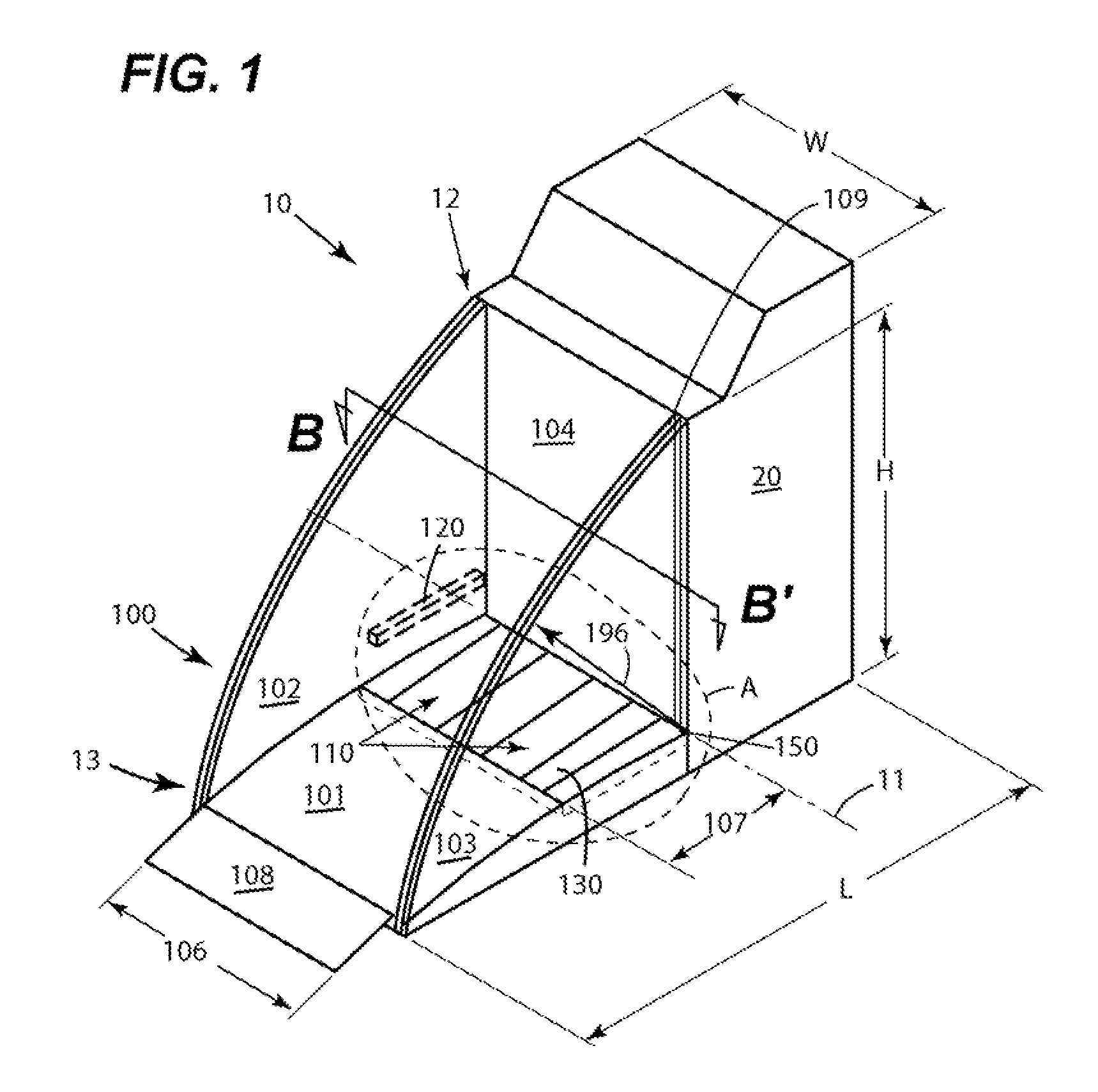

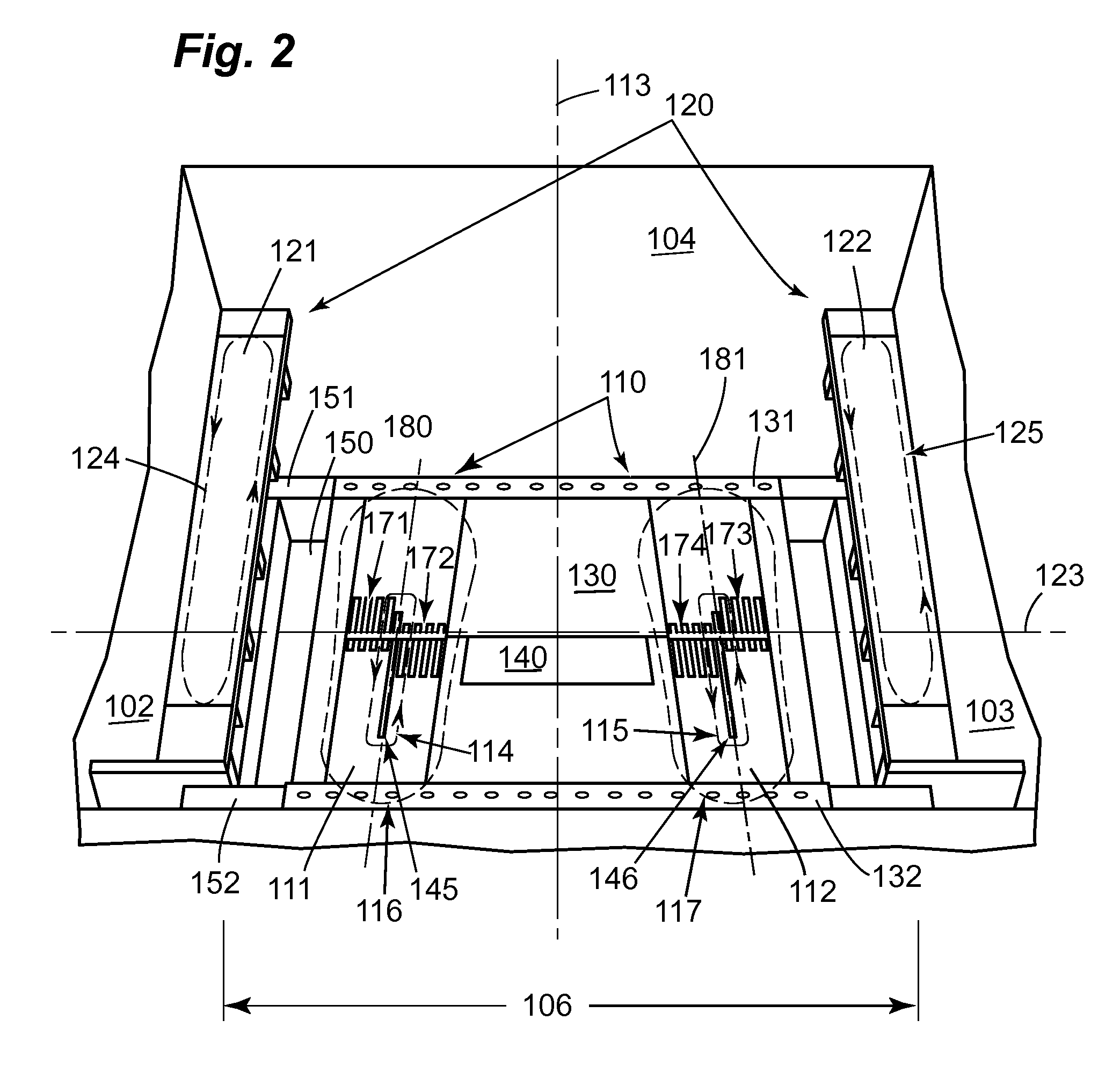

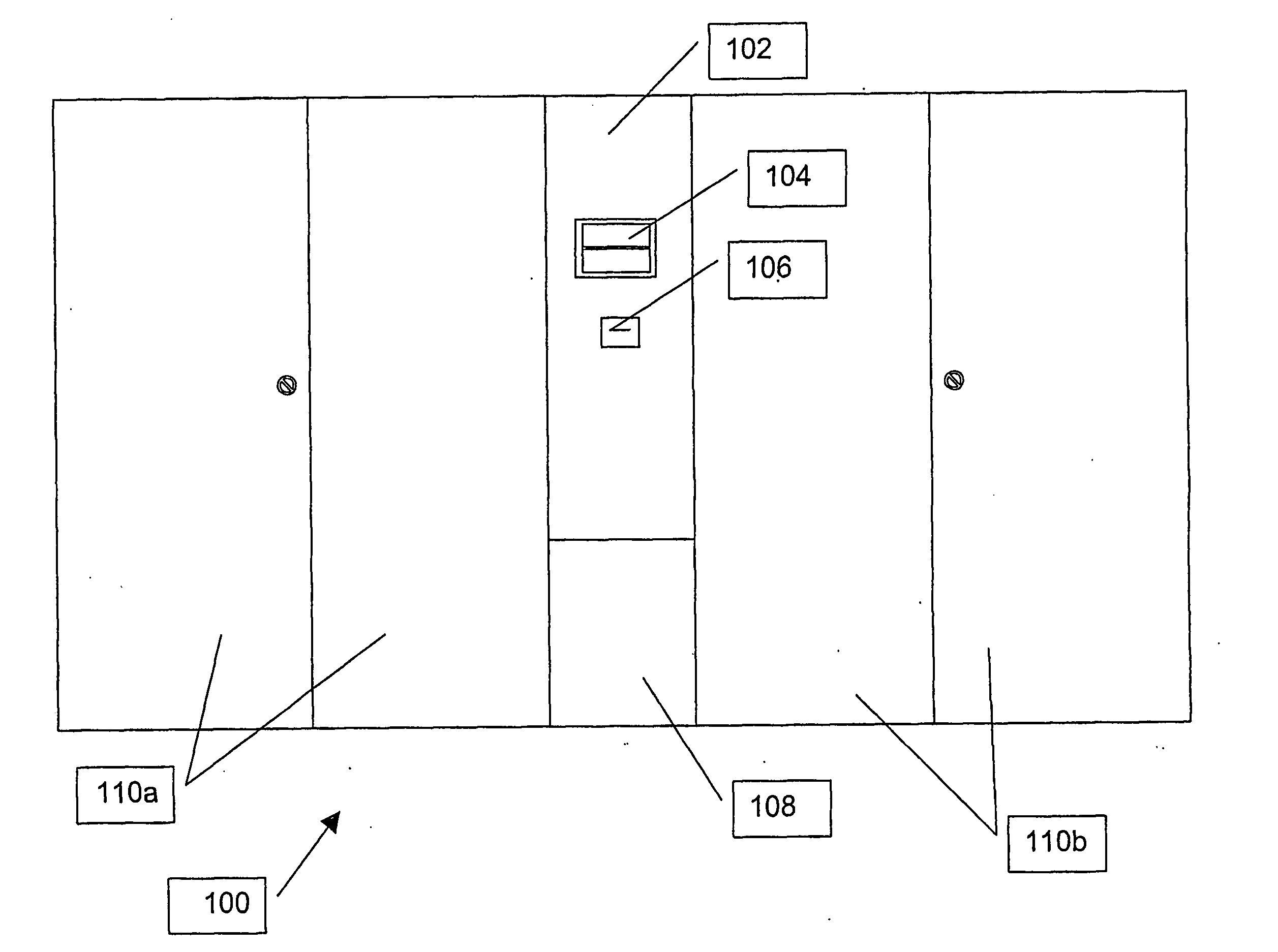

Interactive automated article dispensing system

Disclosed is an interactive automated system for dispensing cloth articles, the principles of which may be readily adapted for use in systems for dispensing a wide variety of articles suitable for distribution by use of a vending style device, such as, but not limited to hospital scrub outfits, clean rooms suits, towels, blankets, sweat suits, t-shirts, socks, underwear, under shirts, ties, scarves, hats, and rain suits. Further, systems of the present invention will be of benefit to a variety of institutions and outlets, such as, but not limited to, hospitals, hotels, motels, resorts, health clubs, country clubs, swimming pools, college and university dormitories, shopping malls, tourist attractions, sport stadiums and arena, fair ground, sport shops, factories, laboratories and the like. The general principles of the present invention include: providing an article dispensing device; receiving a user order; ascertaining if the order may be fulfilled by the dispensing device at which such order was placed; if “yes”, then fulfilling the order; and if “no” providing an alternative ordering solution based on the user's requested order and information from a system wide database. The alternative ordering solutions may include an alternate article from the dispensing device at which the order is received, the location of an alternate dispensing device at which the desired article may be obtained, or a request that the user return a used article to an associated return device. The system may be configured for loaning articles with the intention that the articles be returned. Alternatively, the system may be configured for vending articles.

Owner:POLYTEX TECH

Antibacterial, hydroscopic and perspiratory polyester fiber with self-hydrophilicity

InactiveCN102433603AGood antibacterial effectHas antibacterial functionMonocomponent polyesters artificial filamentArtifical filament manufactureSOCKSAfter treatment

Owner:SHANGHAI VITA SCI & TECH

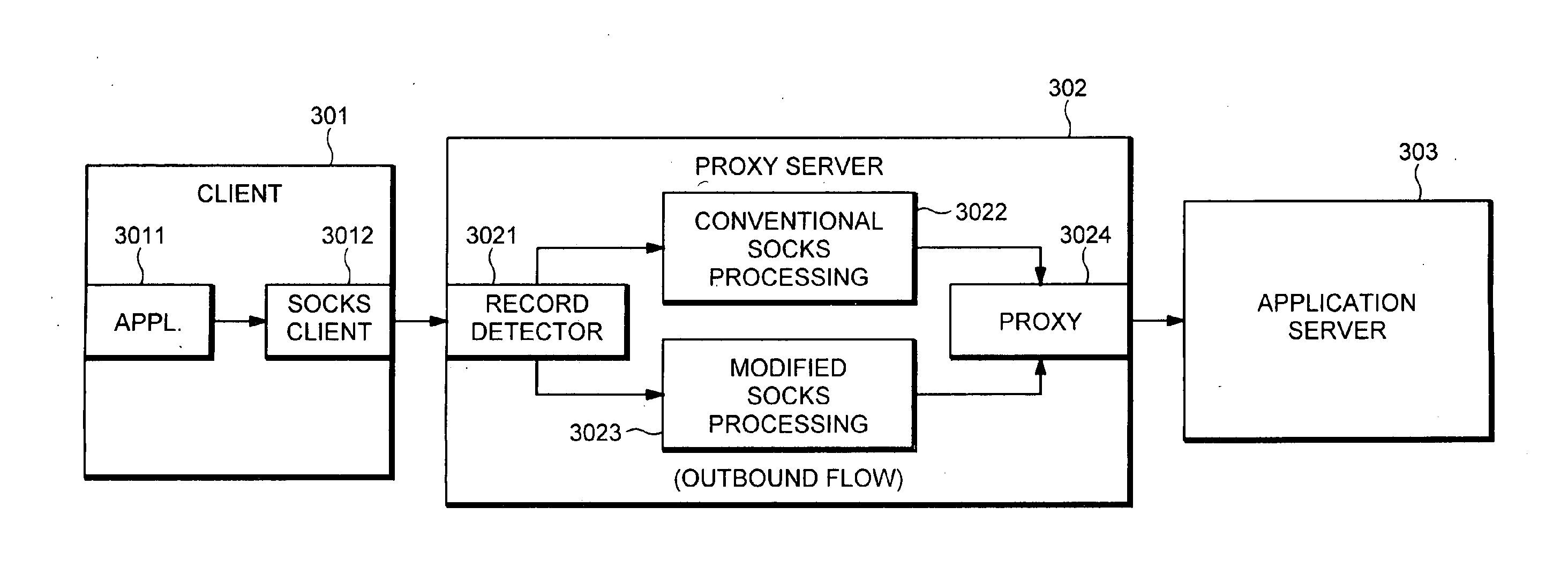

Method and apparatus for providing secure streaming data transmission facilities using unreliable protocols

InactiveUS20130346739A1Overcome problemsKey distribution for secure communicationSynchronising transmission/receiving encryption devicesStreaming dataSOCKS

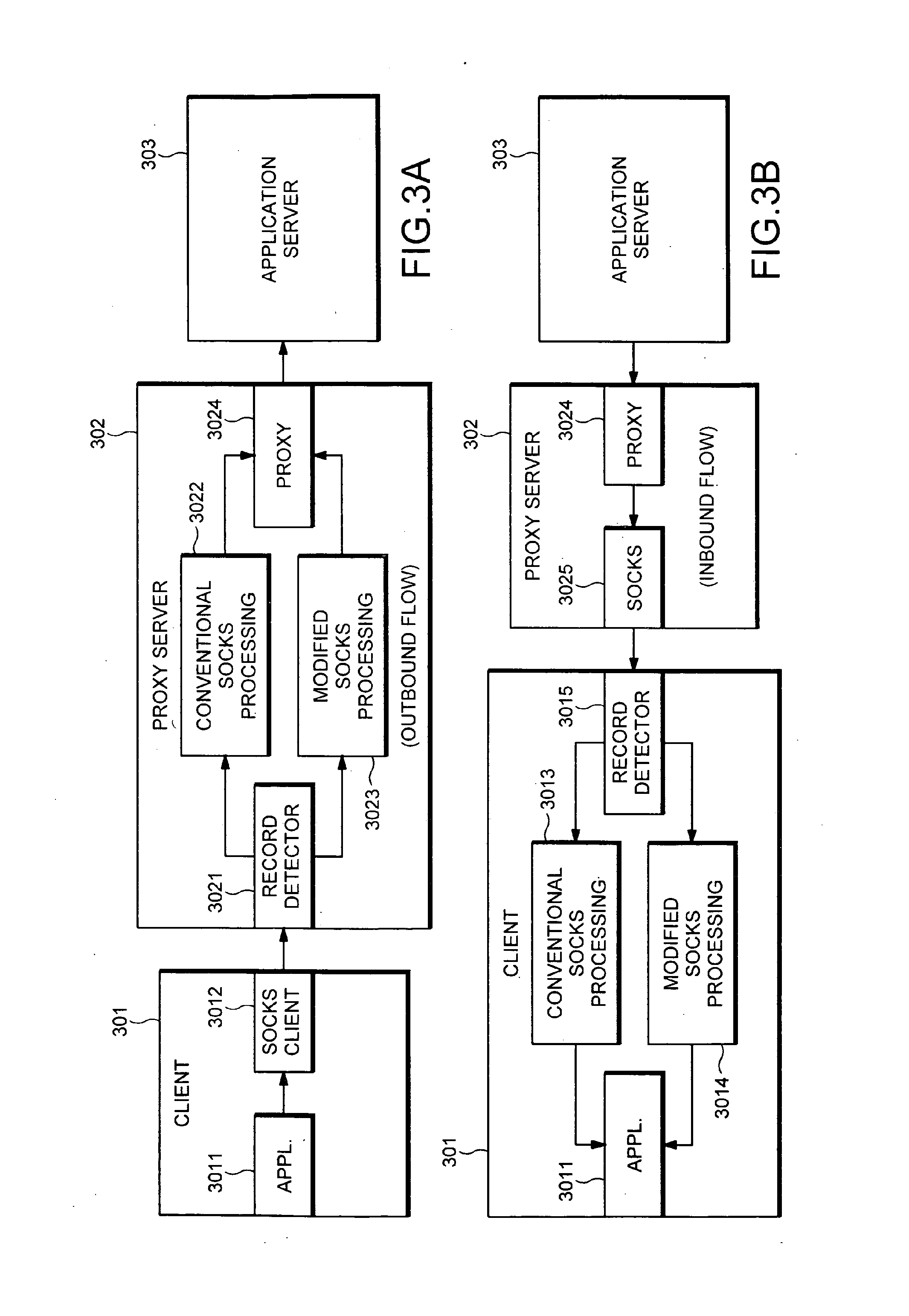

The disclosure provides a method and apparatus for transmitting data securely using an unreliable communication protocol, such as User Datagram Protocol. In one variation, the disclosure describes retaining compatibility with conventional Secure Sockets Layer (SSL) and SOCKS protocols, such that secure UDP datagrams can be transmitted between a proxy server and a client computer in a manner analogous to conventional SOCKS processing. Further, the disclosure describes a network arrangement that employs a cache having copies distributed among a plurality of different locations. SSL / TLS session information for a session with each of the proxy servers is stored in the cache so that it is accessible to at least one other proxy server. Using this arrangement, cached SSL / TLS communication session information may be retrieved and used by a second proxy server to accept a session with the client device when the client device switches proxy servers.

Owner:SONICWALL US HLDG INC

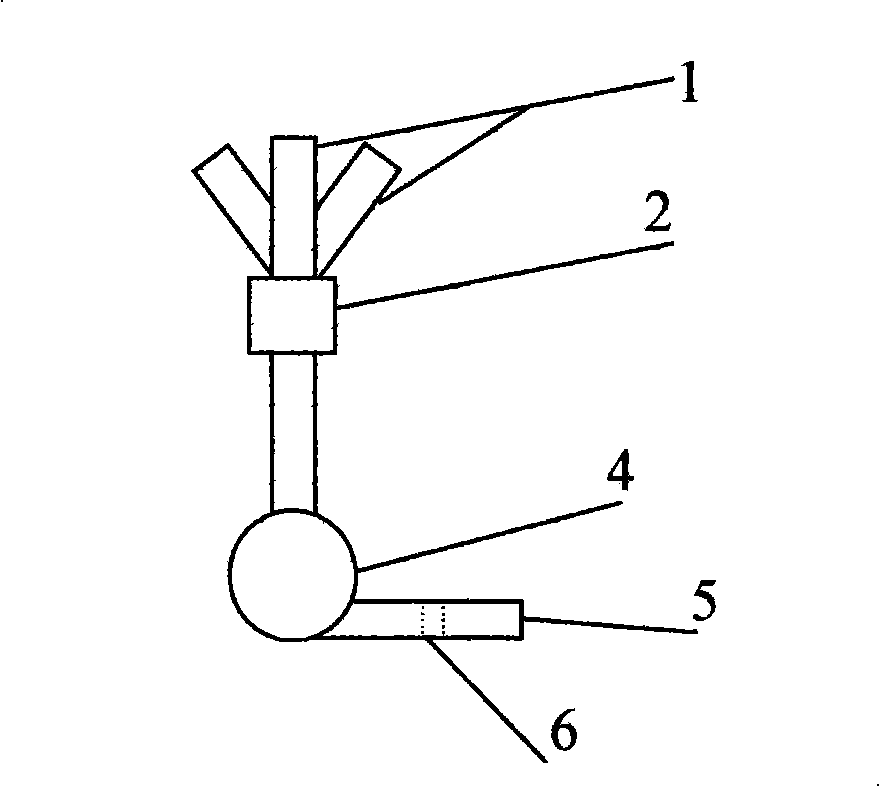

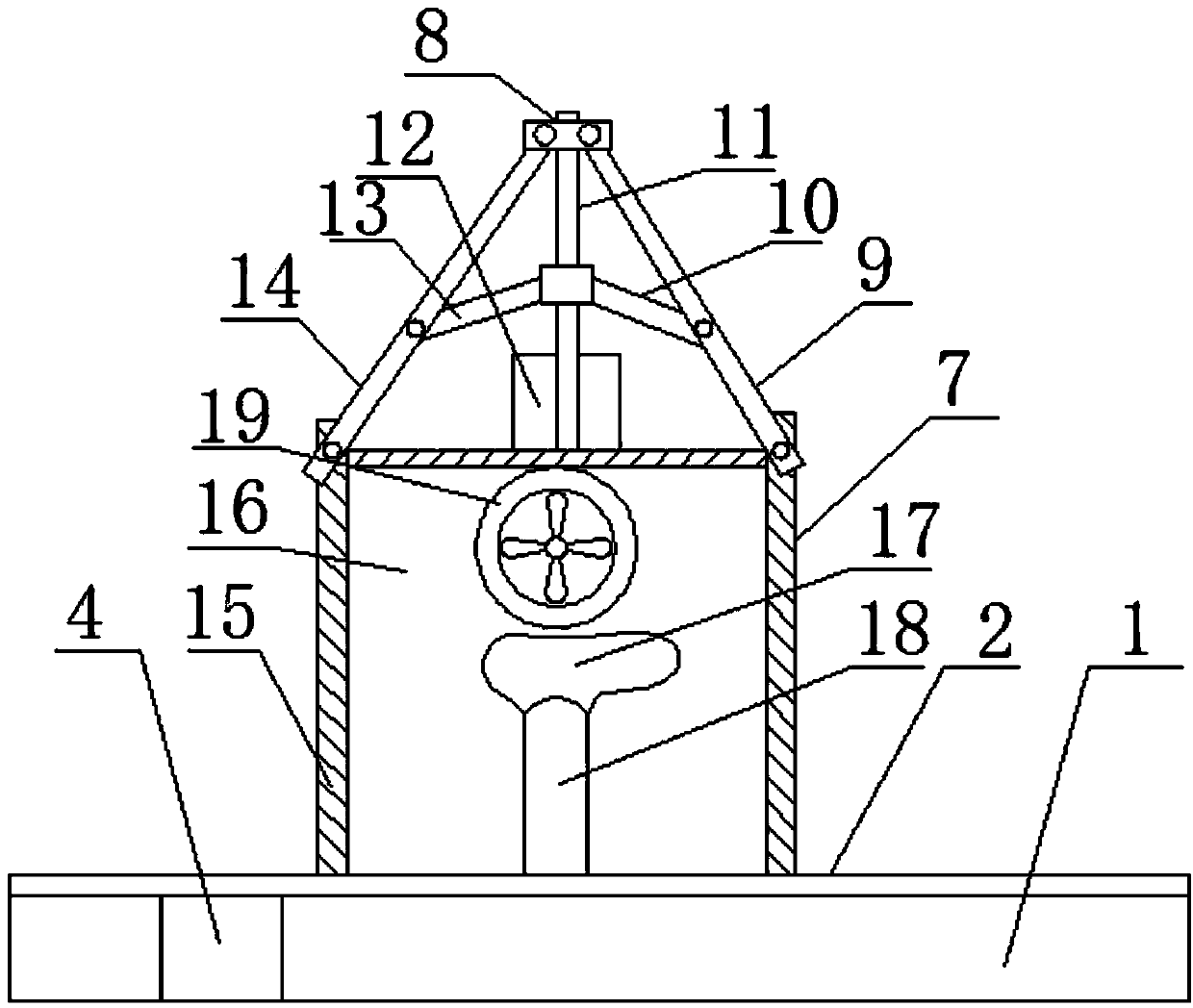

Integrated device for shaping and demoulding socks

ActiveCN104195781AEasy to useReduce energy consumptionShaping/stretching tubular fabricsConveyor partsSOCKSEngineering

The invention discloses an integrated device for shaping and demoulding socks. The integrated device comprises a base, a transmission belt, a driver, a lifting device, a shaping box, a magnetron and a sock demoulding device, wherein the transmission belt is mounted on the base; a plurality of sock dies are mounted on the transmission belt and are sleeved by the socks; the driver is mounted on the base and connected with the transmission belt; the shaping box is mounted on the base; the side wall of the shaping box is communicated with the magnetron by virtue of a waveguide tube; a front box door and a rear box door are mounted on the front side and the rear side of the shaping box, respectively; the lifting device is mounted on the shaping box in a manner of being hinged with the front box door and the rear box door; the sock demoulding device is mounted on the base. The integrated device is simple in structure, has an energy-saving effect, is safe, has the functions of simultaneously shaping and automatically demoulding the socks, and is high in automation degree; the working efficiency is improved and the labor cost is reduced.

Owner:诸暨振光针纺有限公司

Apparatus and method for detecting metallic objects in shoes

InactiveUS20080111545A1Minimize electrical interferenceInterference minimizationMagnetic property measurementsElectric/magnetic detectionSOCKSResonance

An inspection system positions a balancing shim to asymmetrically balance a magnetic field generated by an inductive sensor, which forms part of the inspection system. Additionally, relays and capacitors used to tune the inductive sensor to a desired resonance frequency are geometrically arranged to minimize electrical interference generated by operation of the relays and capacitors. A shielding device, which may be formed on a printed circuit board, protects a magnetic field generated by the inductive sensor from external electromagnetic interference. A slot positioned in the inductive sensor may be used to tune a resonant mode of the inductive sensor to accurately and particularly detect metallic shanks and / or other metallic objects in shoes, socks, and / or clothing.

Owner:MORPHO DETECTION INC

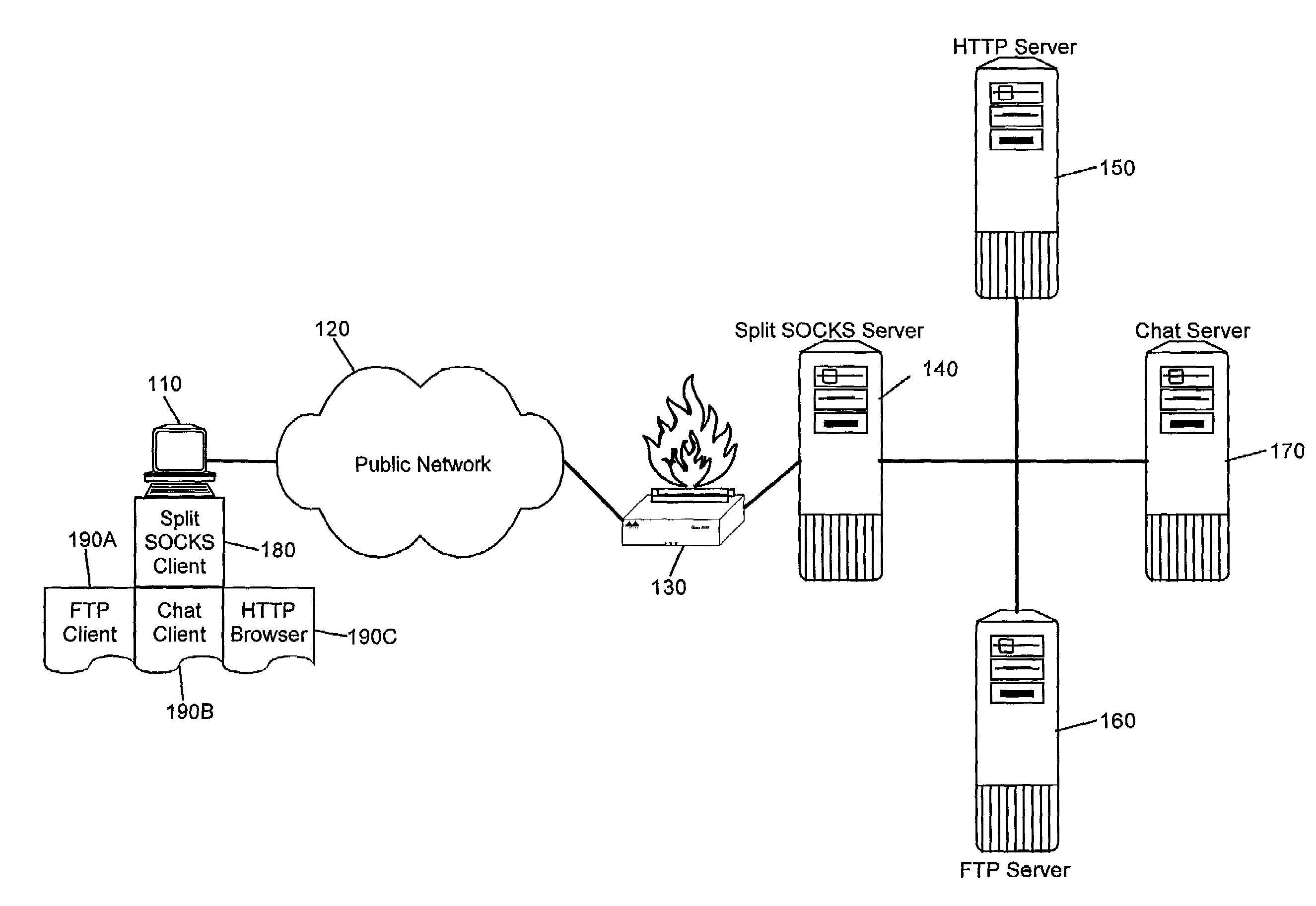

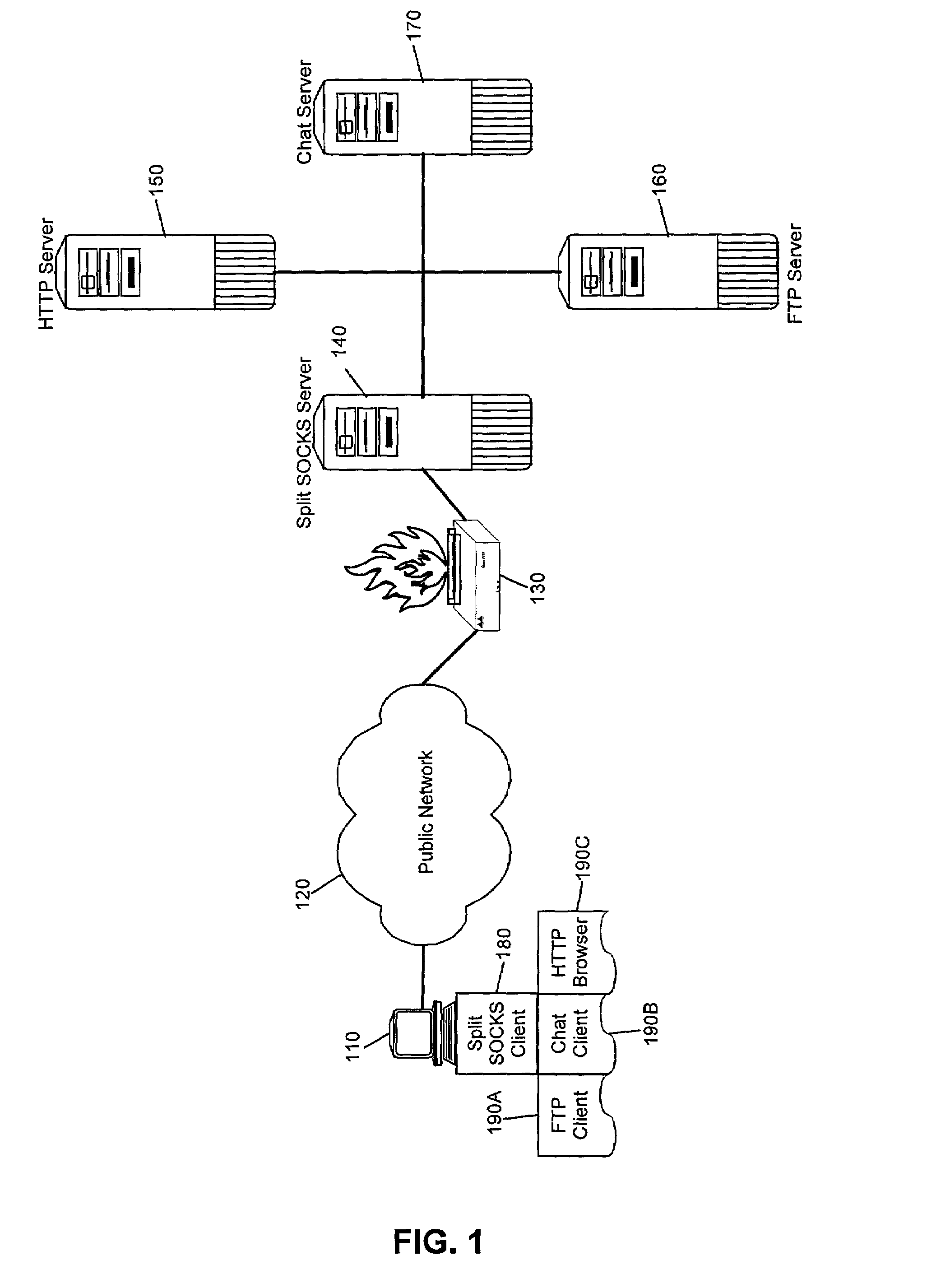

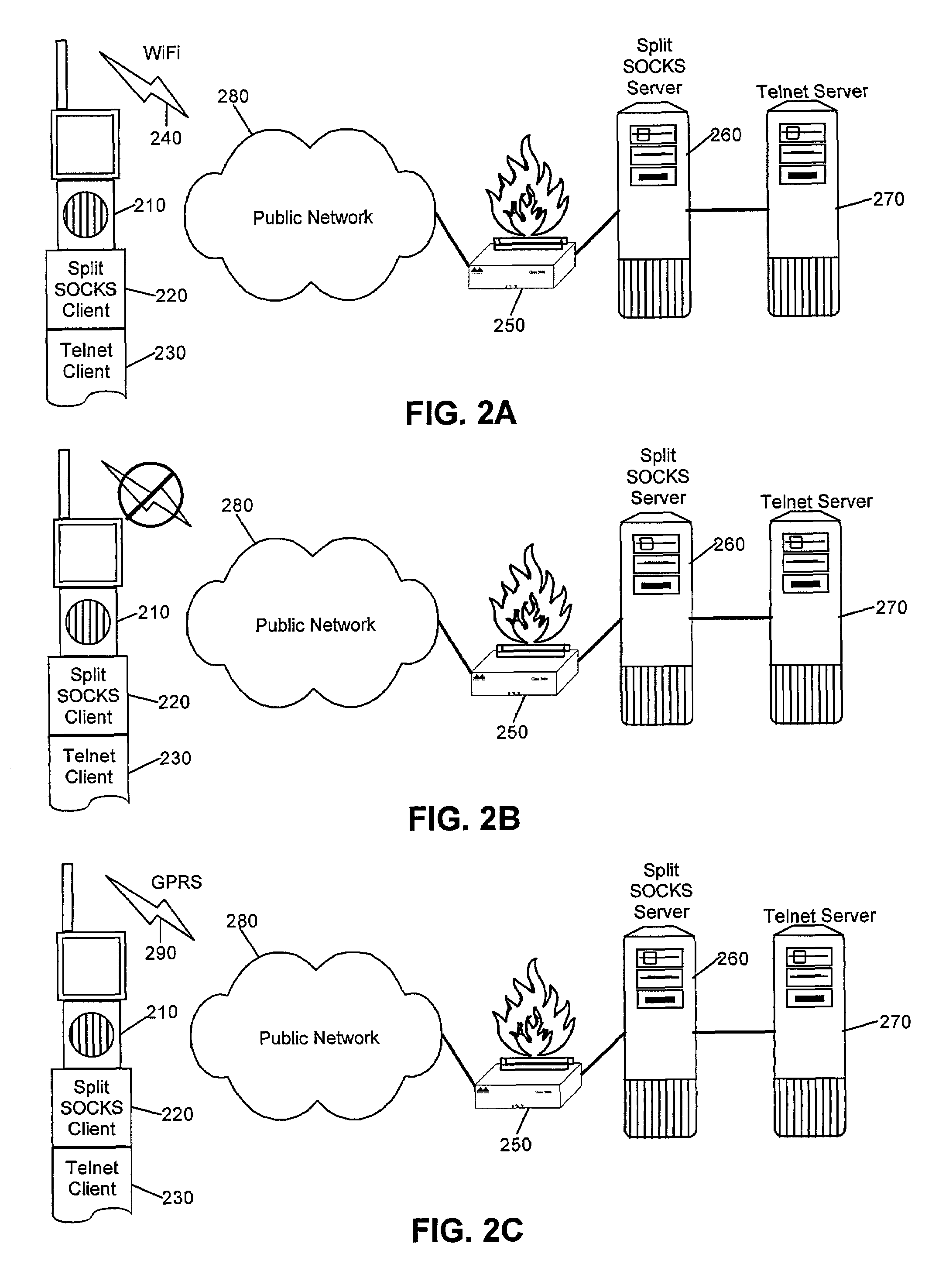

Efficient transmission of IP data using multichannel SOCKS server proxy

ActiveUS7278157B2StabilizationReducing flow of trafficDigital data processing detailsMultiple digital computer combinationsSOCKSTraffic capacity

In a data communications network, a split proxy can include a split proxy server disposed behind a firewall in a private portion of the data communications network; a split proxy client disposed in a client computing device positioned externally to the private portion of the data communications network; a split proxy client interface to at least one client application in the client computing device, and a split proxy server interface to at least one server application corresponding to the at least one client application in the private portion of the data communications network. A tunnel can be established between the split proxy client and split proxy server. The tunnel can host all Internet Protocol (IP) data traffic between the client application and the corresponding server application in the private portion of the data communications network.

Owner:GOOGLE LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com