Patents

Literature

85results about How to "Realize automatic flipping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

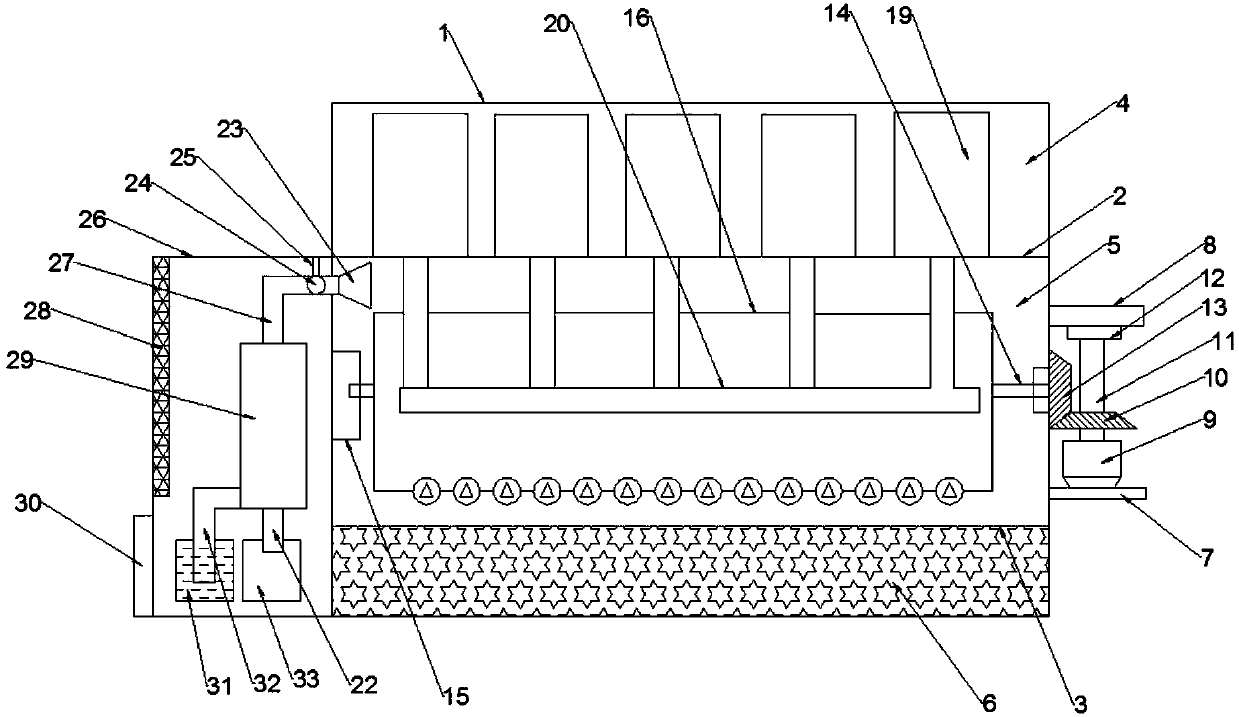

Sock production device

ActiveCN104233634ARealize automatic flippingBeautiful stitchesMechanical cleaningPressure cleaningSOCKSElectric machinery

The invention discloses a sock production device. The sock production device comprises a rack, a feeding device, a waste material recovery device, a sewing box, a discharging device and a sock turning device, wherein the feeding device comprises a guide rail, a guiding frame, a guiding box, a feeding box and a first electric motor component; the waste material recovery device comprises a negative air pressure pumping device and a pipeline, the negative air pressure pumping device is arranged on the rack, and one end of the pipeline is connected to the negative air pressure pumping device; the sewing box is fixedly arranged on the rack and is sequentially and fixedly provided with a first sewing head and a second sewing head from left to right; the right end of the rack is fixedly provided with the discharging device, the discharging device is provided with a discharging guide rail, the lower part of the discharging guide rail is provided with a sock guiding pipe, and the sock guiding pipe is provided with the sock turning device. According to the sock production device disclosed by the invention, socks can be automatically turned after the socks are sewed when a seam of a sock point is completely sewed, meanwhile, the situation that waster materials which are generated by the first sewing head, the second sewing head and a sock point cutting mechanism can be collected is realized, the automation degree is high, the working efficiency is increased, and the labor cost is reduced.

Owner:浙江圣邦化纤针织有限公司

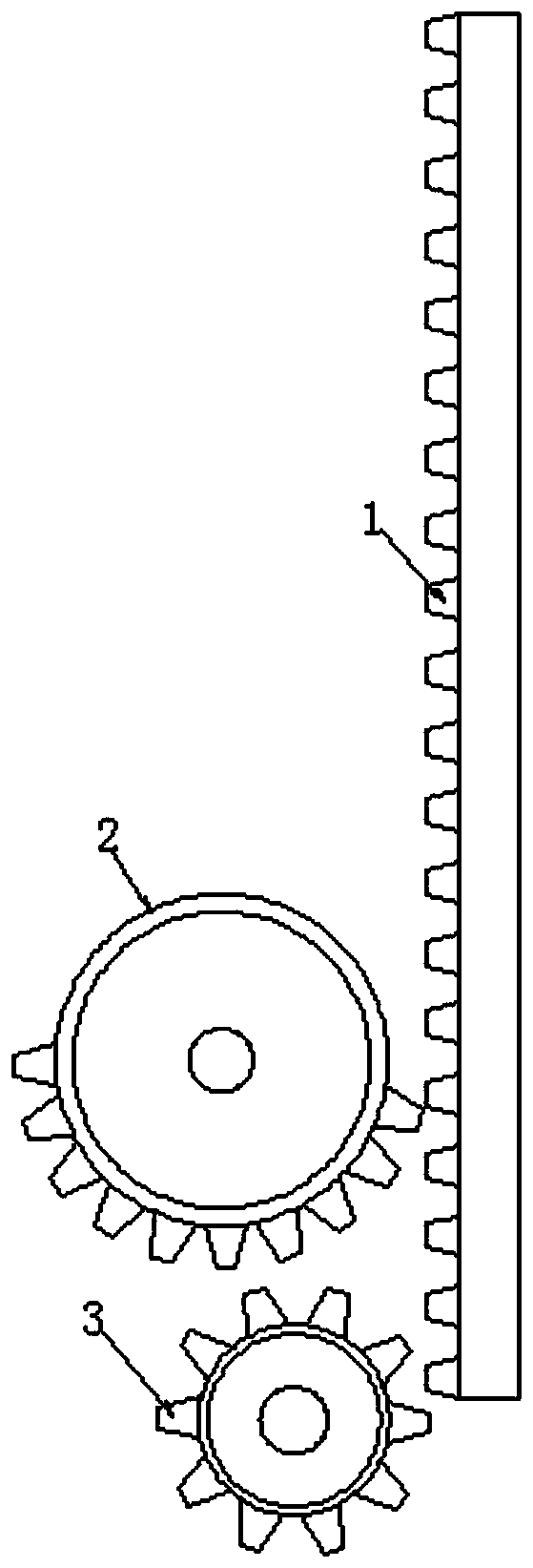

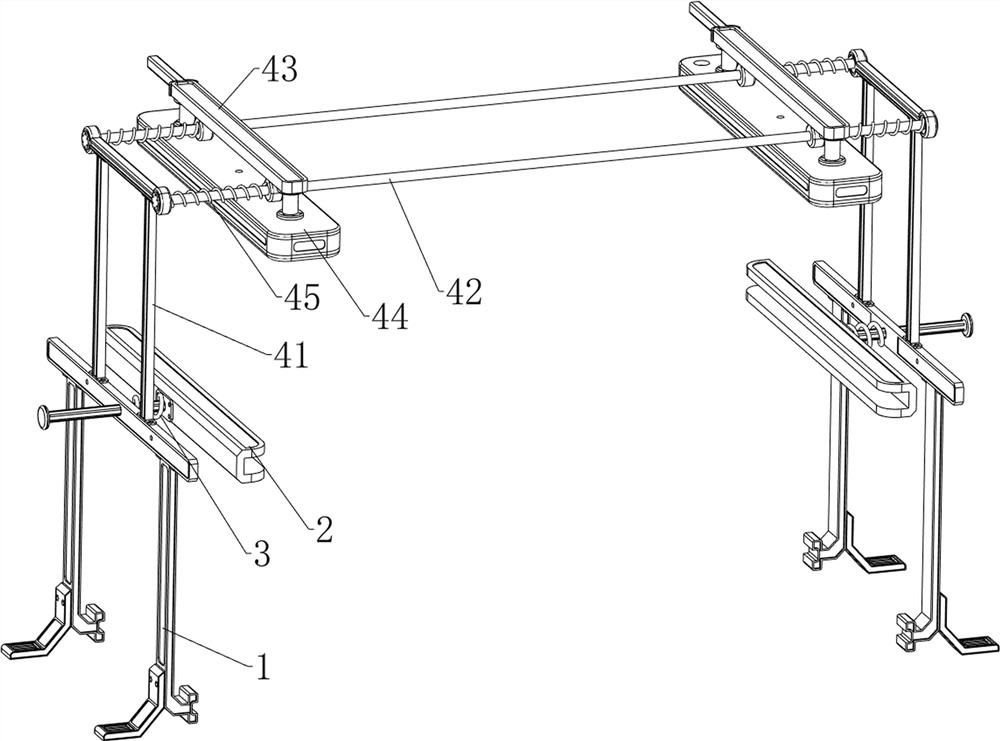

Plank slotting machine

PendingCN108705622ARealize automatic flippingReduce labor intensityWood mortising machinesWood slotting machinesSlide plateEngineering

The invention belongs to the technical field of plank processing and particularly discloses a plank slotting machine. The plank slotting machine comprises a workbench, the workbench is slidably provided with a sliding plate and a power mechanism for driving the sliding plate. The sliding plate is provided with two clamping plates. A slotting mechanism is arranged above the sliding plate. First racks are arranged at the positions, on the two sides of the sliding plate, of the workbench. The two sides of the sliding plate are provided with side plates, the side plates are provided with first gears and second gears, and the side plates are slidably connected with second racks meshed with the second gears. The ends of the second racks are hinged to the clamping plates. A movable rod is hingedbetween the middle of the clamping plates and the upper portions of the side plates. The middle of the sliding plate is slidably connected with a polishing block, and the second gears are connected with transmission mechanisms for driving the polishing block to perform reciprocating movement. In the work process of the plank slotting machine, automatic turning-over of a plank can be realized, thetwo sides of the plank are subjected to slotting, and slotting efficiency is high; and meanwhile, slots formed in the plank are subjected to polishing treatment through the polishing block, and the manual labor intensity is lowered.

Owner:重庆哲骁装饰工程有限公司

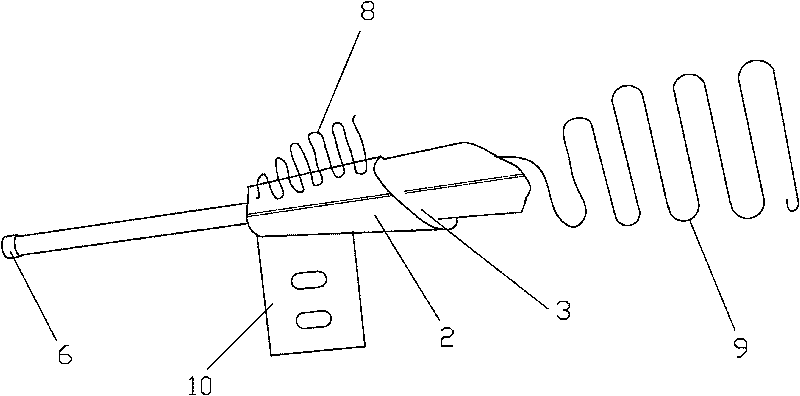

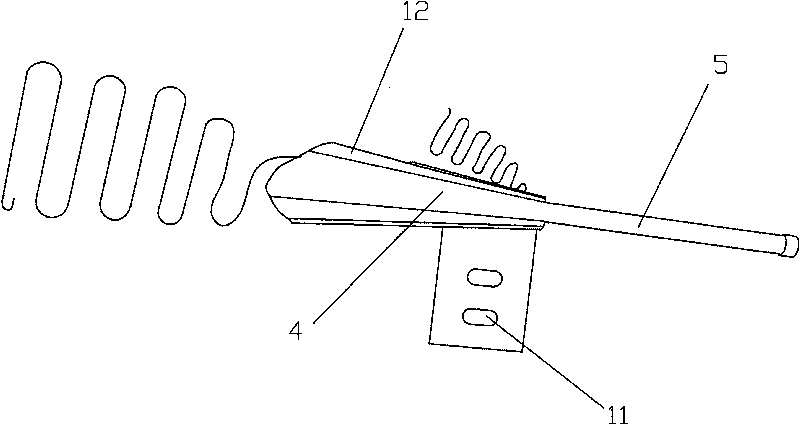

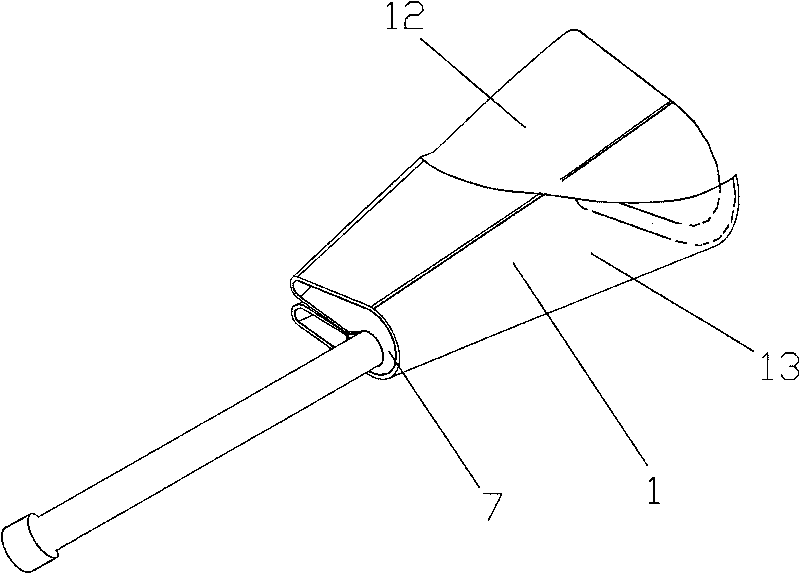

Belt-turning mechanism

InactiveCN101698969AIncrease productivitySimple structureMechanical cleaningPressure cleaningEngineeringSewing machine

The invention relates to a belt-turning mechanism for a sewing machine. The mechanism comprises a folding drum gradually furling from the back end to the front end; one side of the folding drum sinks inwards; a first channel convenient for an outer wrapping strip to bend to pass is formed between the inner edge of the one side and the other side of the folding drum, while a second channel for pulling back a turning belt is formed by the outer edge of the folding drum; the front end of the second channel is connected with a hollow liner tube communicated with the second channel; the front opening of the liner tube is formed into an inlet for stretching into and pulling back the front end of the turning belt; a gap for the outer wrapping strip to pass is reserved between the outer edge of the liner tube and the front outlet of the first channel; the upper end of the folding drum is connected with a first snakelike frame used to guide a liner elastic belt, while the back end is connected with a second snakelike frame used to guide the outer wrapping strip; and the folding drum is connected with an installing device connected with the sewing machine. The invention provides the belt-turning mechanism for the sewing machine which can complete belt turning and has the advantages of automatic manufacture, higher production efficiency and time and labor saving.

Owner:安泰(德清)时装有限公司

Film coating bracket and film-plating machine

InactiveCN101363117ARealize automatic flippingAccurate flip angle controlSpraying apparatusVacuum evaporation coatingMagnetic currentEngineering

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

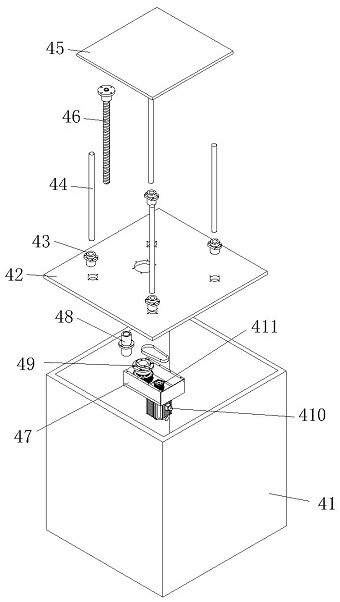

Automatic turning device for thrust ball bearing ferrule

The invention discloses an automatic turning device for a thrust ball bearing ferrule, and belongs to the technical field of bearing production equipment. The automatic turning mechanism comprises a motor, a positioning material channel and a circular check ring, wherein the top surface of the circular check ring is higher than the bottom surface of the positioning material channel; a workpiece inlet and a workpiece outlet of the circular check ring are respectively provided with an inlet stop block and an outlet stop block; the bottom surface of one end, connected with the workpiece inlet, of the positioning material channel is always higher than the end connected with the workpiece outlet; when the two stop blocks fall down, the top surfaces of the two stop blocks are not higher than the bottom surface of the positioning material channel; a positioning mechanism and a detection mechanism are respectively arranged on the two sides of the positioning material channel; through holes for realizing pressing of the positioning mechanism and detection of the detection mechanism are respectively formed in two side baffles of the positioning material channel; a quantification mechanism is arranged on the side of a material feeding channel; a control system controls a motor, a positioning pressing block driving mechanism, a probe driving mechanism and a quantification mechanism and drives cylinders of the inlet stop block and the outlet stop block to operate. The automatic turning device meets the demand that the end faces of the ferrule are needed to uniformly face to a direction during processing of the thrust ball bearing ferrule.

Owner:浙江盛达物联科技股份有限公司

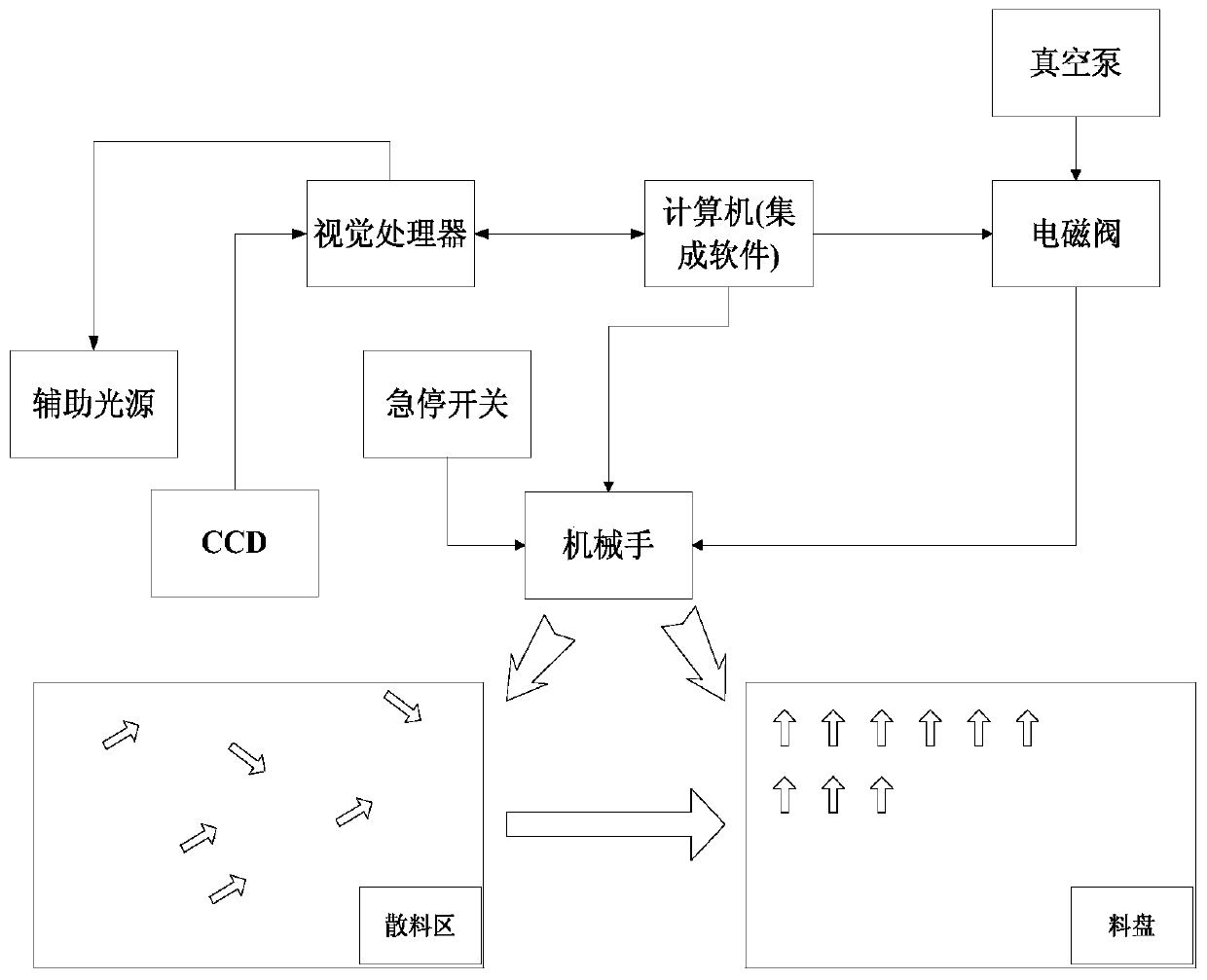

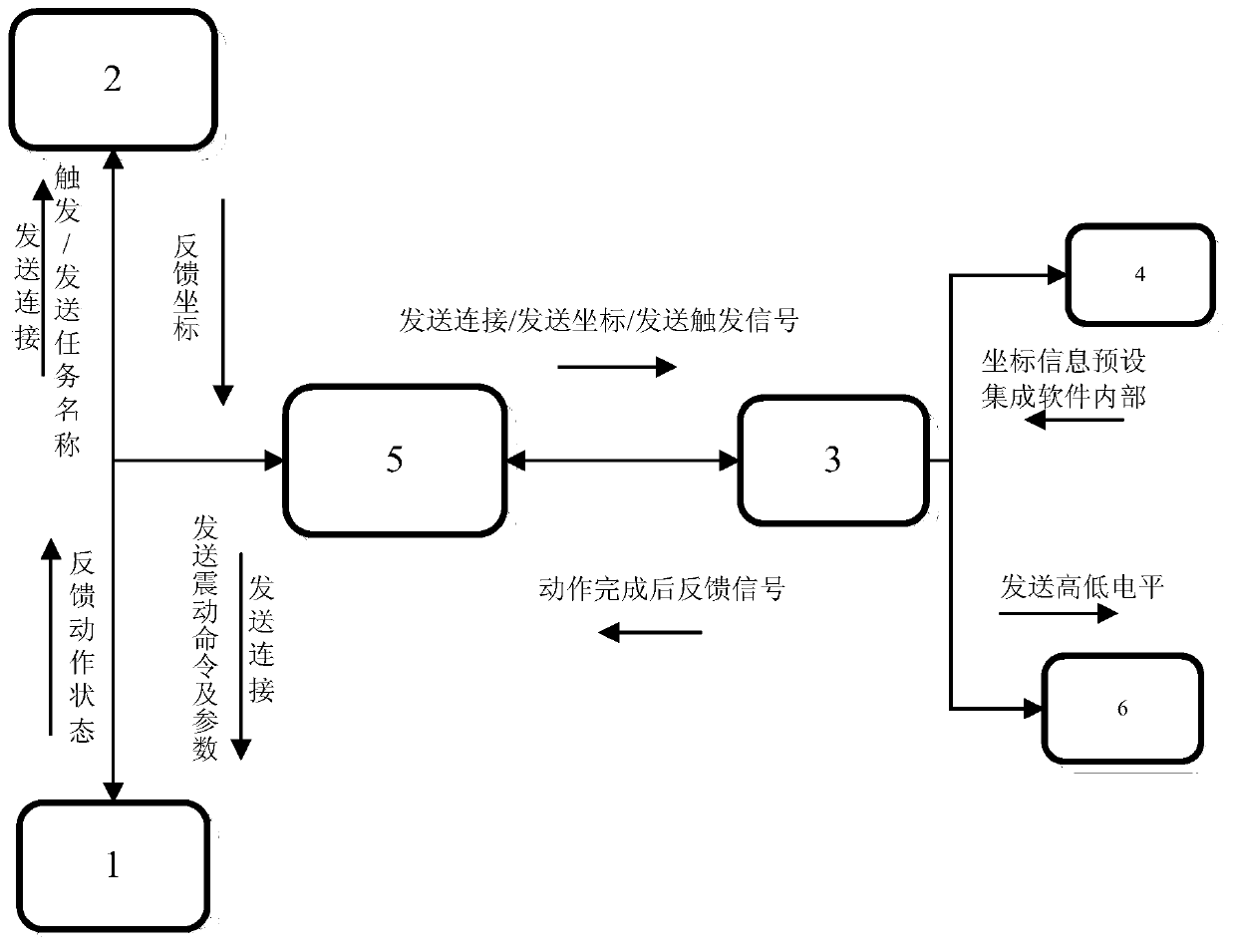

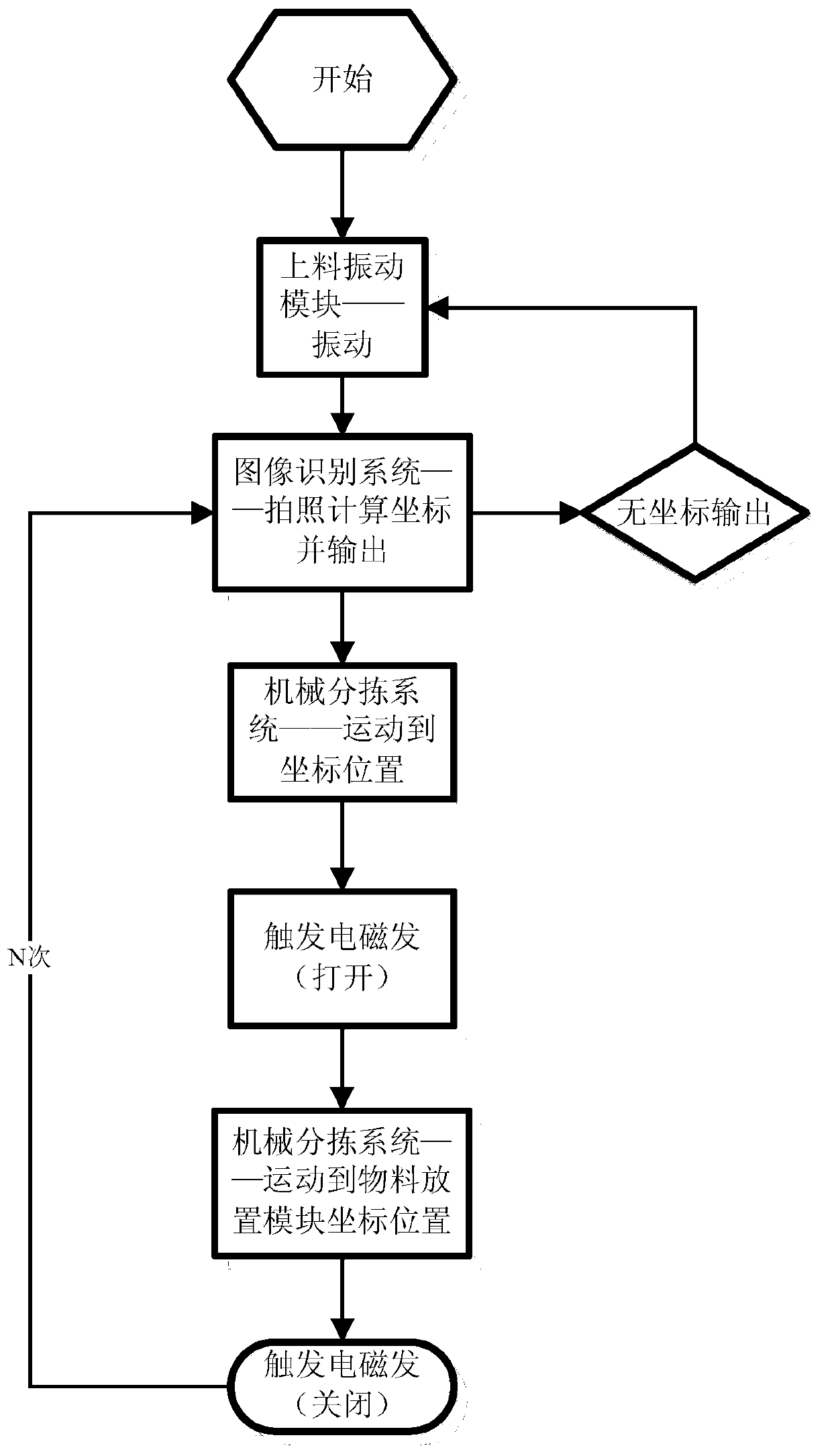

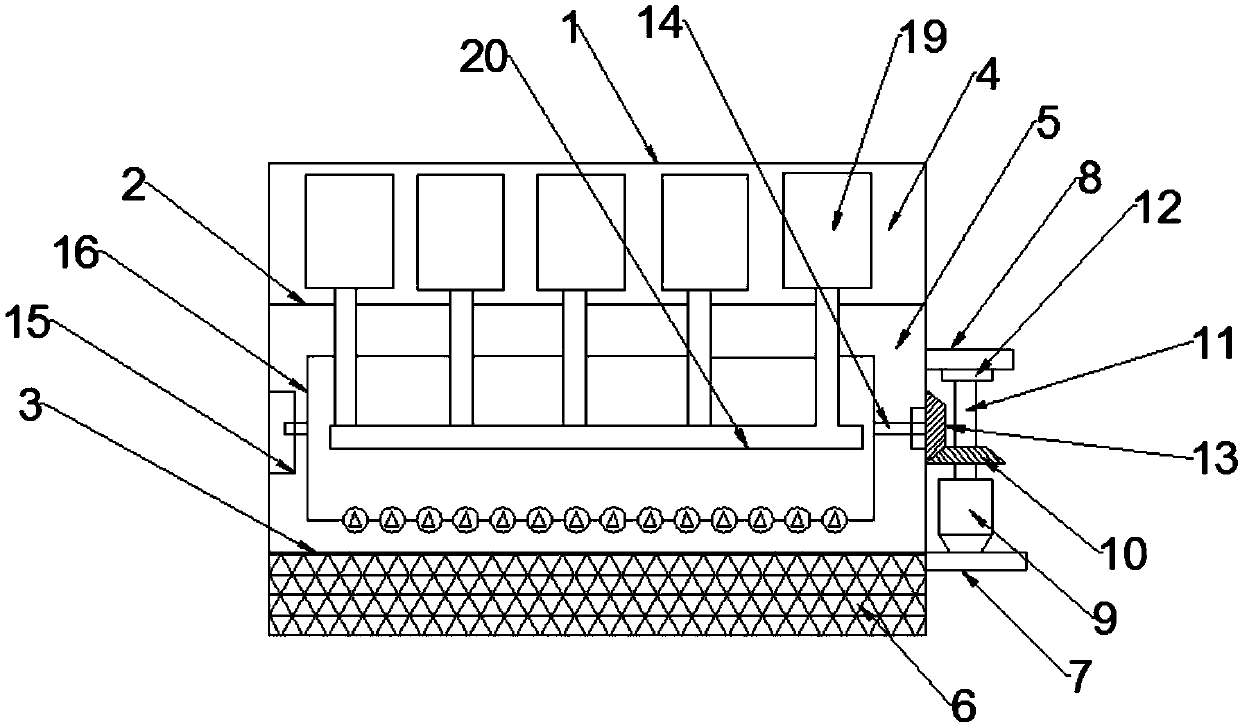

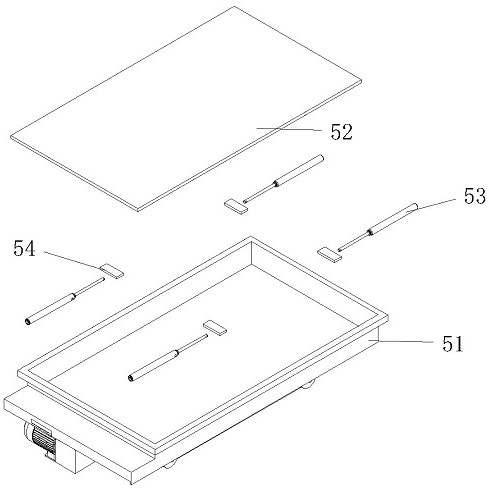

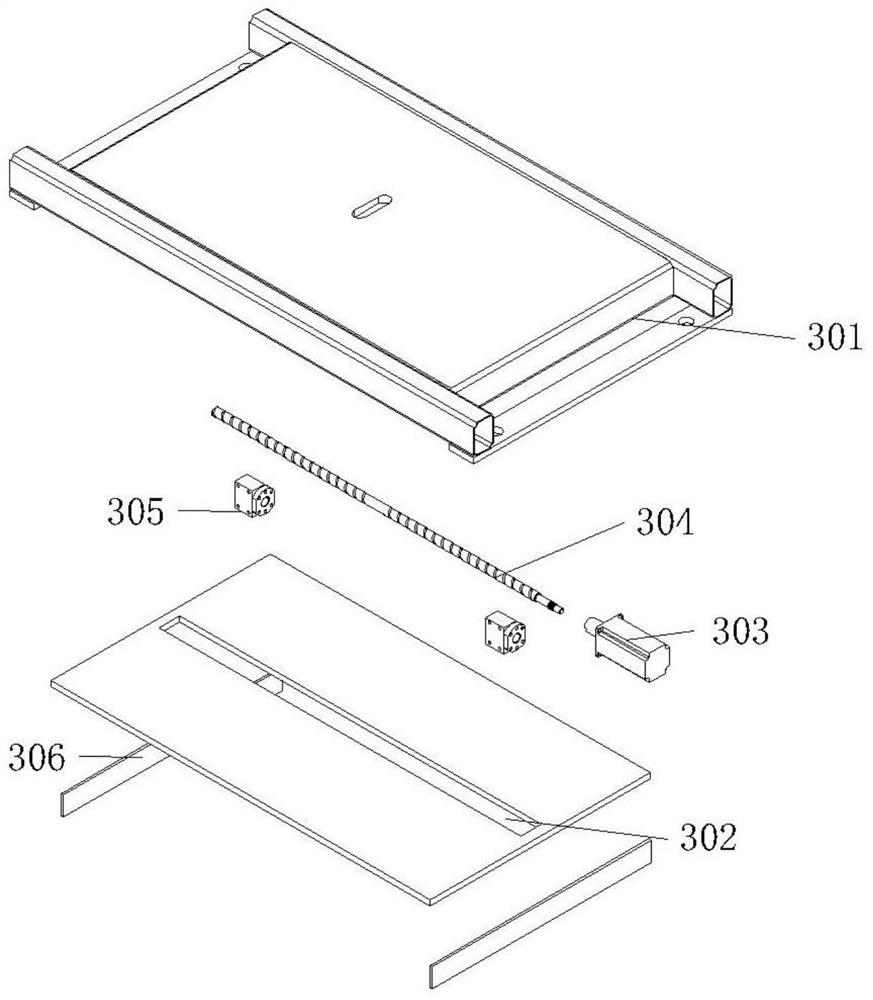

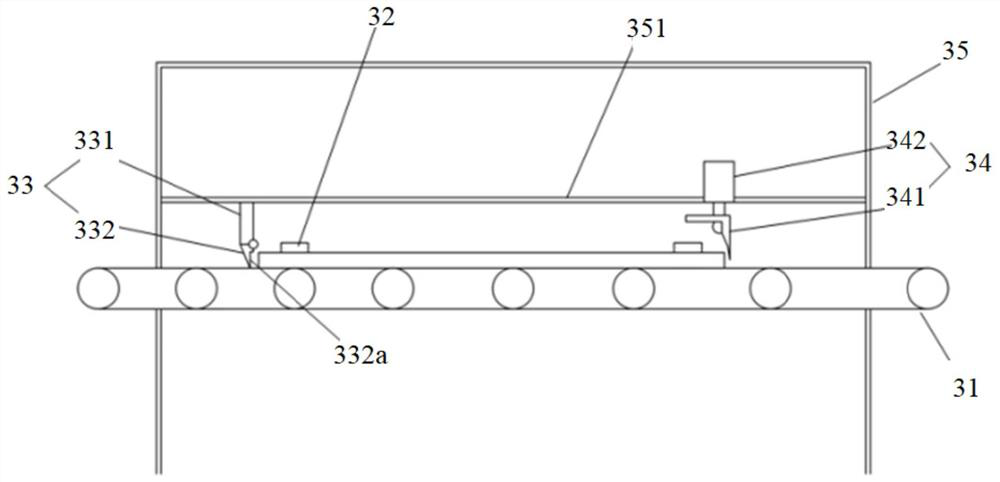

Intelligent sorting equipment for small-batch sheet type scattered devices

InactiveCN109731793ARealize automatic flippingEasy to operate and transferSortingNon destructiveOver treatment

The invention discloses intelligent sorting equipment for small-batch sheet type scattered devices. The equipment aims to solve the problem that small-batch bulk components after secondary screening of electronic components in the military industry cannot be produced by using automatic equipment. The accurate-positioning and non-destructive-picking intelligent sorting equipment for the small-batchsheet type scattered devices are designed through integrated research and development on a feeding vibration module, a mechanical sorting system, an image recognition system, a material placing module, software development and the like. According to the equipment, as a new breakthrough of intelligent manufacturing in the field of electronic assembly, under dragging by software, the feeding vibration module is driven to carry out turning-over treatment on the sheet type scattered devices, the software is switched to drive the image recognition system to realize automatic recognition and framejudgment of the sheet type components, the software commands and drives the mechanical sorting module to intelligently grab the sheet type scattered devices, accurate grabbing of 0402 packaging can beachieved, the software sets material placement to realize the high-precision array sorting and arranging of the sheet type scattered devices, and the sorting quantity and the operation period can further be clearly recorded.

Owner:SHANGHAI AEROSPACE ELECTRONICS CO LTD +1

Full-automatic barbecue machine with overturning and seasoning scattering functions

InactiveCN107713795ARealize automatic flippingReduce manual turning processRoasting apparatusRoasters/grillsScattering functionEngineering

The invention relates to a full-automatic barbecue machine with the function of turning over and spreading materials, which includes a box body, on which a fixed block a and a fixed block b are arranged, and the box body is sequentially provided with a partition a and a partition b from top to bottom , partition a and partition b divide the box from top to bottom into condiment box, barbecue box and heating box; the upper end of fixed block a is provided with a rotating motor, and the output shaft of the rotating motor is connected with a rotating rod a, which a is fixedly connected with a gear a, the end of the rotating rod a away from the rotating motor is movably connected with the bearing a at the lower end of the fixed block b; One end is connected with gear b, gear a meshes with gear b, and the left side of the barbecue frame is movably connected with bearing b through a roller; inside the condiment box, there are various lower ends running through the partition a and extending to the inner cavity of the barbecue box to connect with The condiment tank of the discharge plate; the invention has high grilling efficiency, uniform distribution of condiments, uniform heating of grilled skewers, good taste, and less oil fume inhaled by human body.

Owner:CHENGDU XINXIN HIGH STRENGTH FASTENER MFRCO

Garment ironing equipment capable of automatically turning garment to achieve double-side ironing

ActiveCN110820288AIncrease linkageImprove ironing effectIroning machinesTextiles and paperEngineeringMechanical engineering

The invention relates to the technical field of garments and discloses garment ironing equipment capable of automatically turning a garment to achieve double-side ironing. The garment ironing equipment comprises a moving plate, wherein a first gear is movably connected to the outer side of the moving plate. The garment ironing equipment has the advantages that a fourth gear rotates to drive a third gear to rotate so as to allow the first gear and a second gear to rotate sequentially, and accordingly the moving plate can stay still, move downwards and move upwards, an ironing mechanism moves synchronously to iron the garment in a reciprocating manner, a good ironing effect is achieved, the ironing mechanism stays still for a moment after each round of ironing to provided sufficient time forgarment turning, and structure co-movement is enhanced; the fourth gear rotates to drive a fifth gear to rotate intermittently so as to drive a slider to move leftwards and rightwards, the slider moves rightwards to drive an object placing plate to turn 180 degrees and then moves leftwards to approach the ironing mechanism so as to iron the side, which is not ironed, of the garment, two hands ofa user are freed, automatic garment turning is achieved, and operation convenience is achieved.

Owner:安徽优定服装科技有限公司

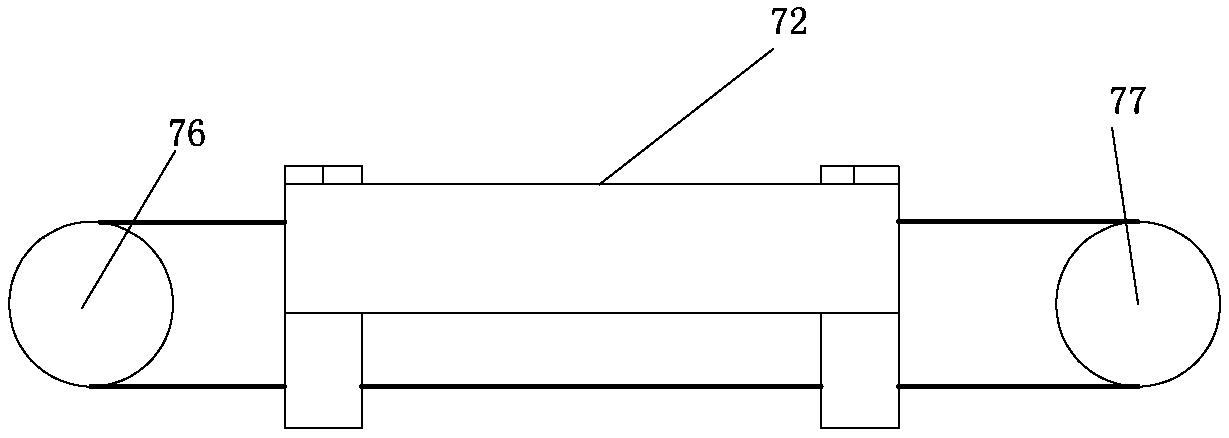

Turnover conveying device for production line

InactiveCN106115235ARealize automatic flippingAvoid damageConveyor partsProduction lineIndustrial engineering

The invention discloses a turnover conveying device for a production line, belongs to equipment for the production line, and aims to solve the technical problems about how to realize automatic turnover of a material on the production line and improve the degree of automation of the production line. The technical scheme is that the turnover conveying device structurally comprises a rack, a turnover device and two roller table conveying devices, wherein the turnover device and the roller table conveying devices are arranged on the rack, the two roller table conveying devices are arranged on two sides of the turnover device respectively, and a roller table drive device is arranged at one end of each roller table conveying device; the turnover device comprises an overturning frame, a turnover drive device, a turnover conveying drive device and a turnover conveying transmission device, an upper roller table and a lower roller table, the turnover drive device is arranged on one side of the overturning frame, the turnover conveying transmission device is arranged on the other side of the overturning frame, the upper roller table and lower roller table are arranged on the overturning frame, and the lower roller table is located below the upper roller table.

Owner:董来阳

Multi-angle grinding machine for surfaces of intelligent pantograph carbon contact strips and grinding method thereof

ActiveCN111360651AEasy sanding adjustmentReduce the burden of secondary flippingGrinding carriagesGrinding drivesElectric machineryGrinding

The invention discloses a multi-angle grinding machine for the surfaces of intelligent pantograph carbon contact strips. The multi-angle grinding machine for the surfaces of the intelligent pantographcarbon contact strips comprises a bottom plate, wherein fixing assemblies are mounted on the parts, located right below the two ends of a carbon contact strip, of the top surface of the bottom plate,and a second motor is movably connected with a rotary barrel on the same side through a driving mechanism; the outer end of a threaded rod is inserted into a third bearing; and a threaded barrel is spirally arranged at the middle of the threaded rod in a sleeving mode, a third extendable cylinder base is arranged on the bottom surface of the threaded barrel, a third extendable cylinder with the downward output end is arranged on the bottom surface of the third extendable cylinder base, and a rotary grinding piece is arranged at the end part of an extendable rod of the third extendable cylinder. The invention further discloses a grinding method of the multi-angle grinding machine for the surfaces of the intelligent pantograph carbon contact strips. The multi-angle grinding machine is simple in structure and convenient in operation, and can be suitable for the carbon contact strips with different distances between the two ends, and meanwhile, the multi-angle grinding machine can achieveautomatic overturning and grinding of the carbon contact strips, relieves the labor burden of workers, and improves the automatic grinding efficiency.

Owner:DATONG XINCHENG NEW MATERIAL CO LTD

Full-automatic quenching mechanism of quenching furnace

PendingCN112725600ARealize automatic integration of heating and coolingRealize automatic flippingFurnace typesHeat treatment furnacesEngineeringFully automated

The invention discloses a full-automatic quenching mechanism of a quenching furnace. The full-automatic quenching mechanism comprises a base, the quenching furnace, a guide rail, a cooling mechanism, a conveying mechanism, a moving mechanism, an overturning mechanism and a controller. The quenching furnace is arranged on the right side of the top end of the base, the guide rail is arranged at the top end of the base in the left-right direction, the cooling mechanism is embedded in the top end of the base and located on the left side of the quenching furnace, the conveying mechanism is arranged above the guide rail, the moving mechanism is mounted at the top end of the base and located on the upper left portion of the guide rail, the overturning mechanism is arranged at the bottom end of the moving mechanism, and the controller is mounted on the front side of the quenching furnace. The full-automatic quenching mechanism of the quenching furnace can realize automatic integration of heating and cooling of the quenching furnace, does not need to be matched with an external device for use, improves the processing efficiency, can realize automatic overturning of a quenching material to realize double-sided quenching, does not need to use an external hoisting device for overturning, and is simple to operate, and saves time and labor.

Owner:NANJING CHANGJIANG IND FURNACE TECH GRP CO LTD

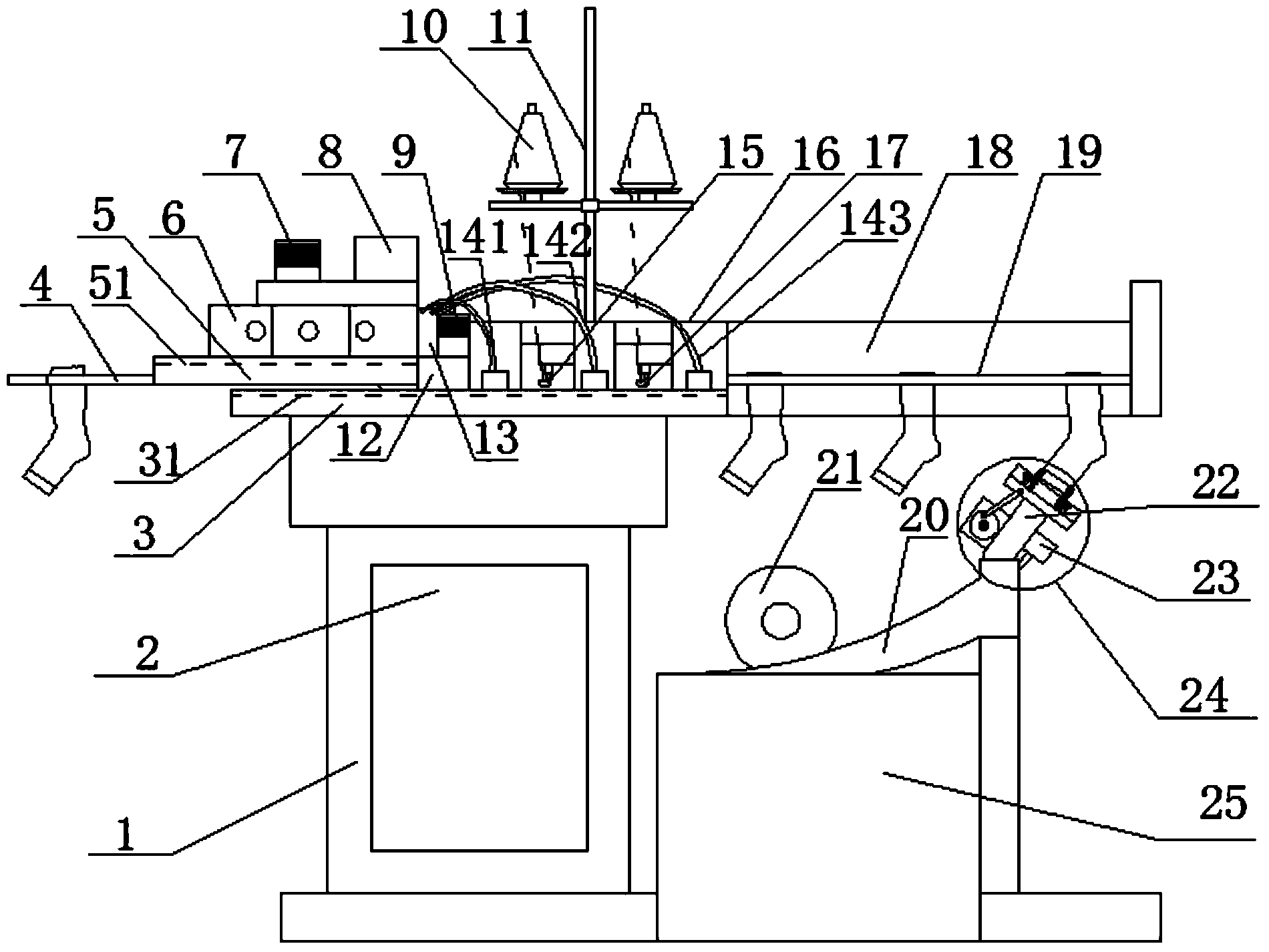

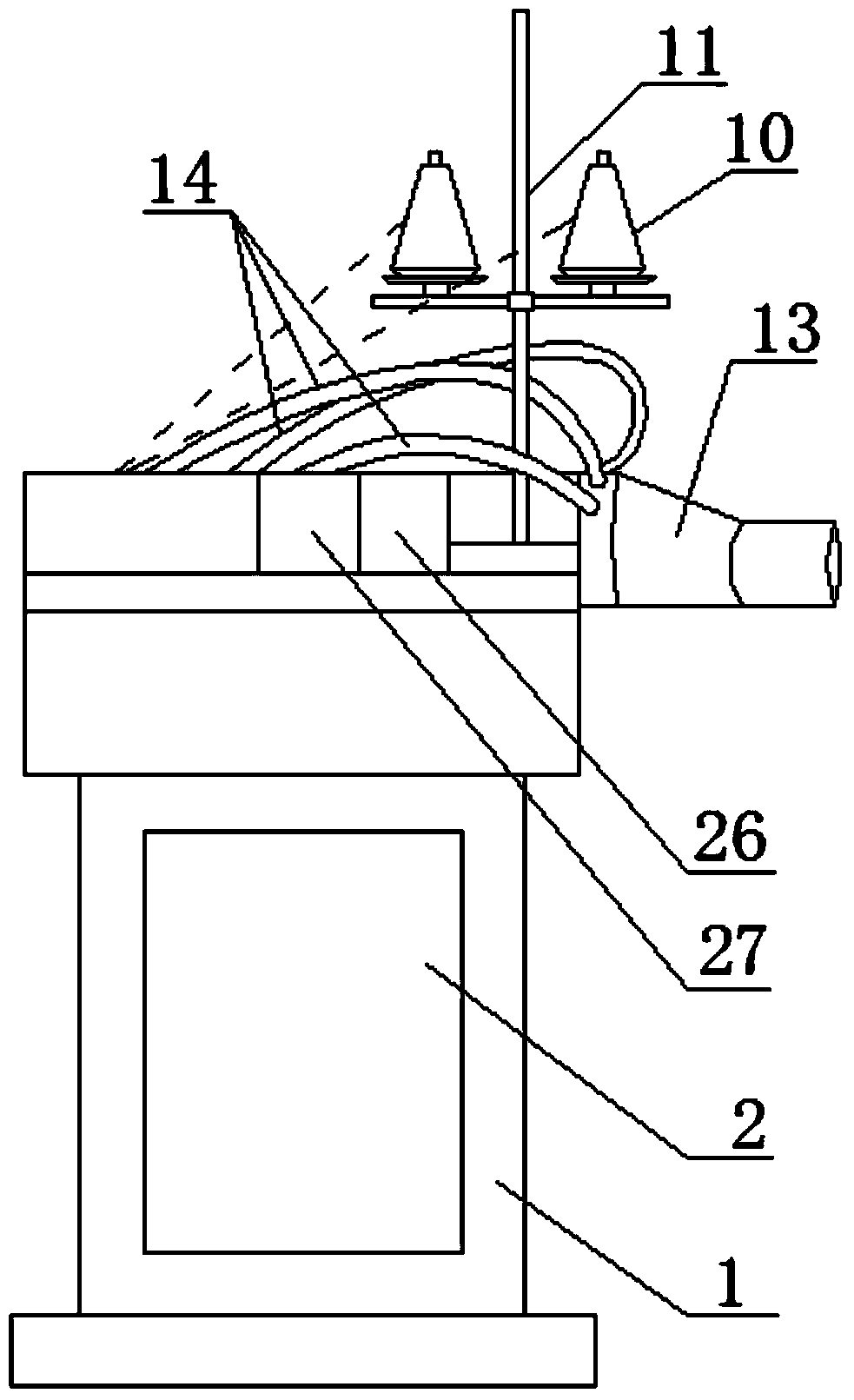

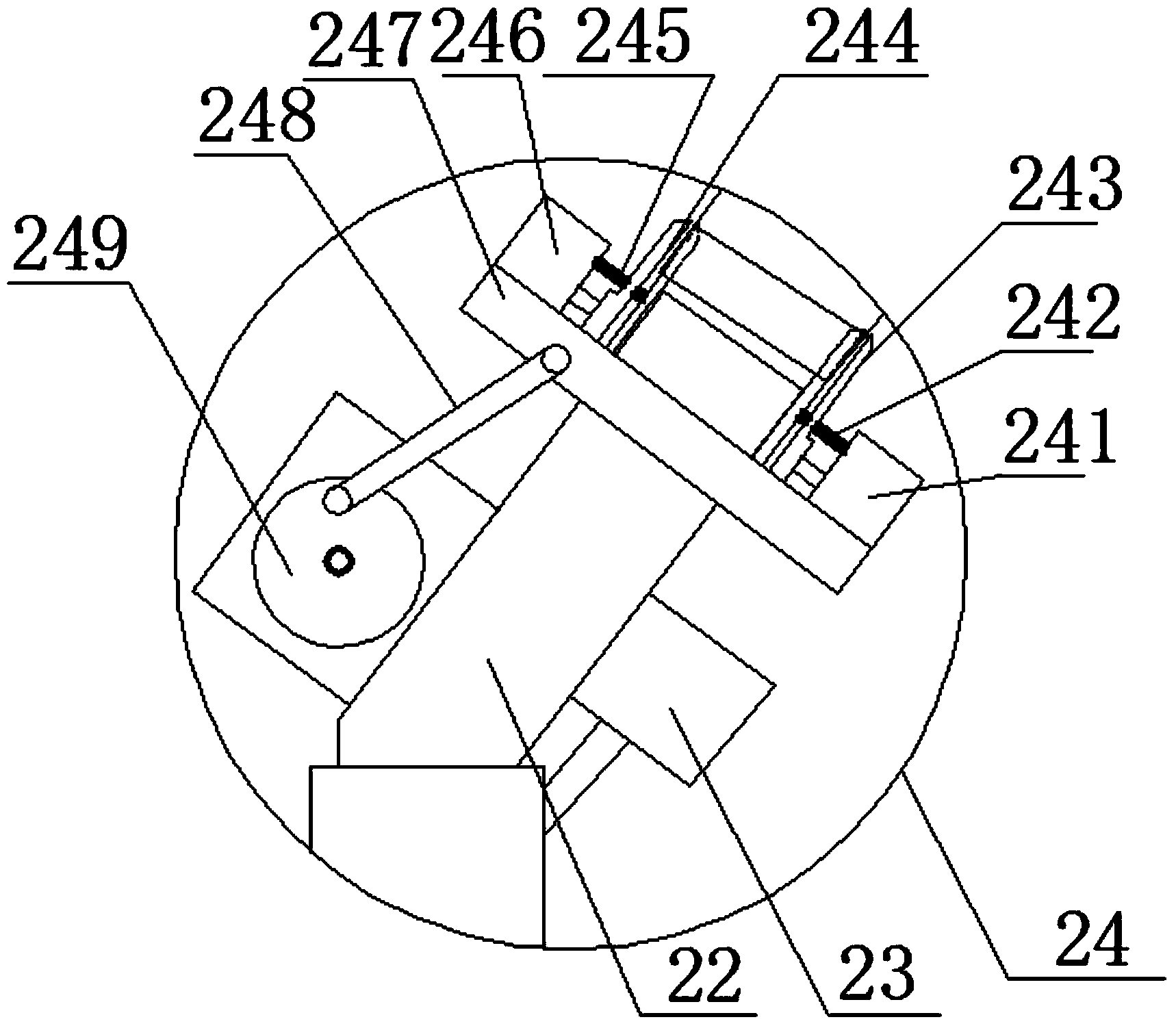

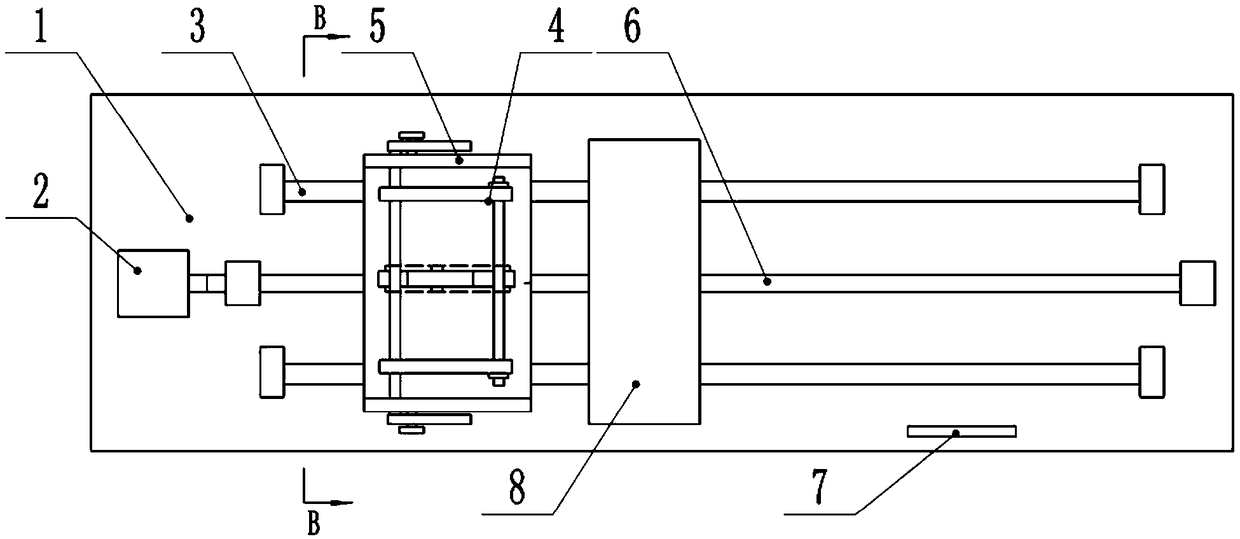

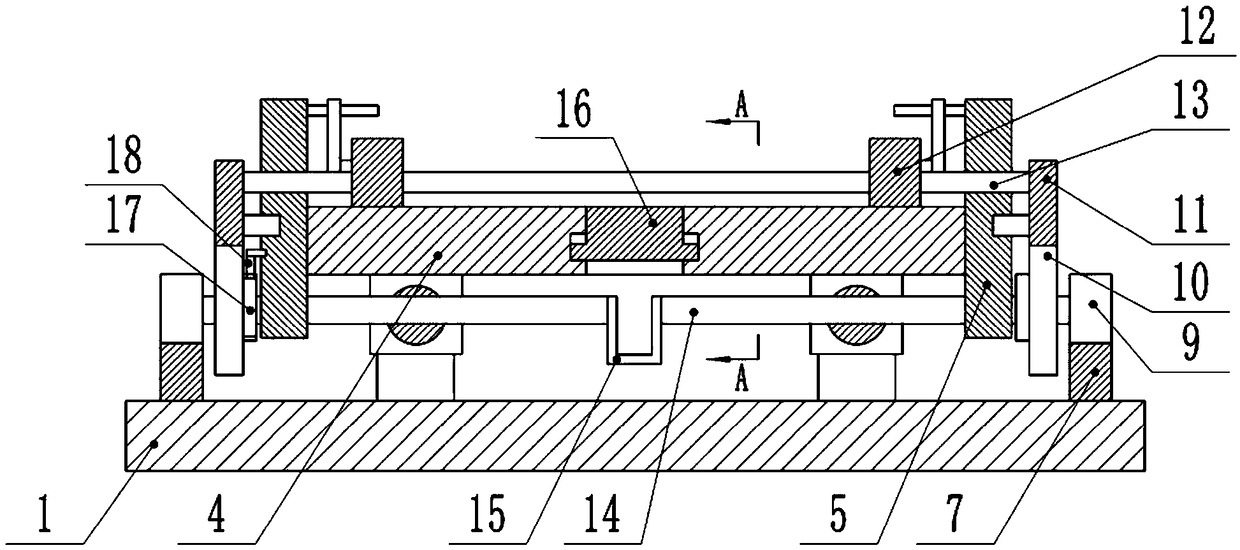

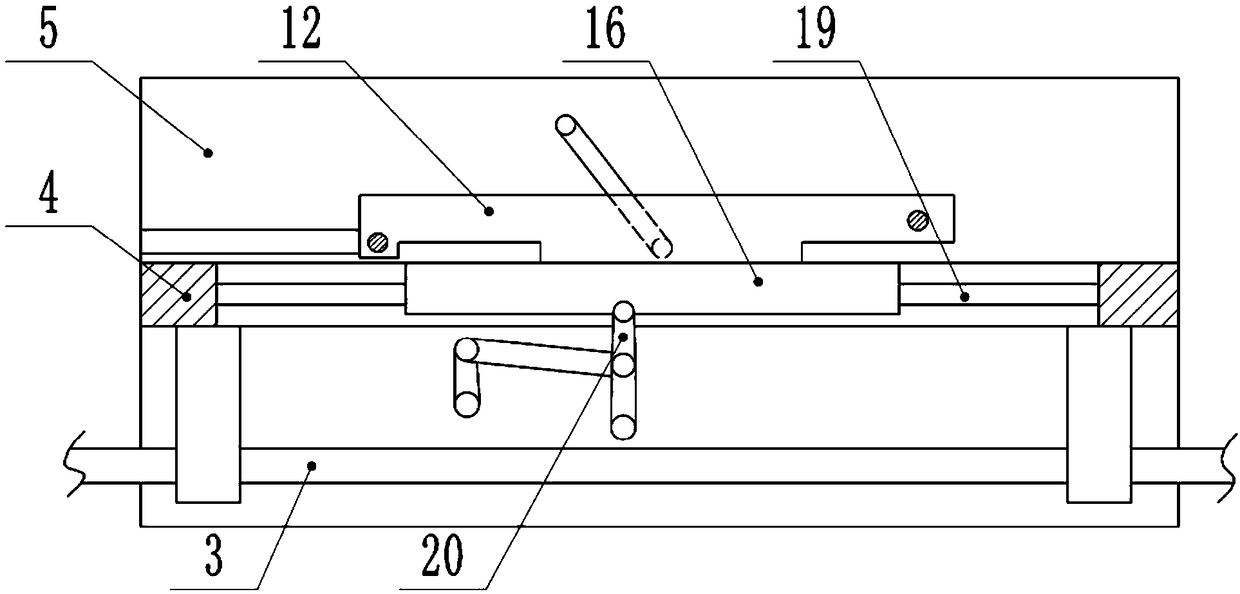

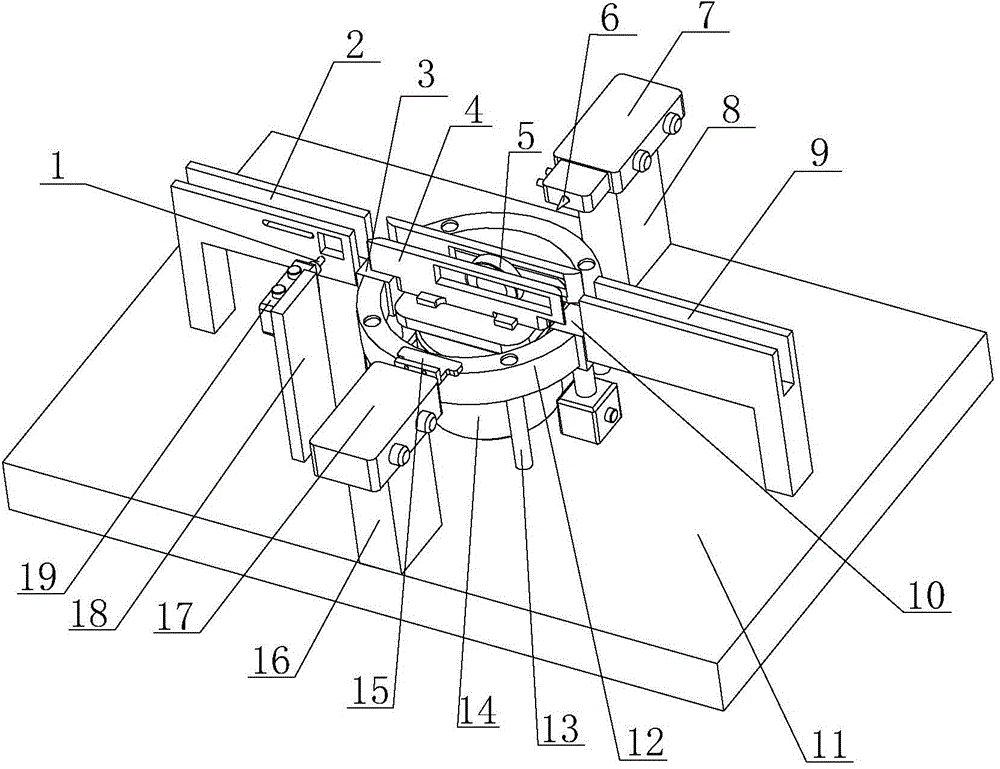

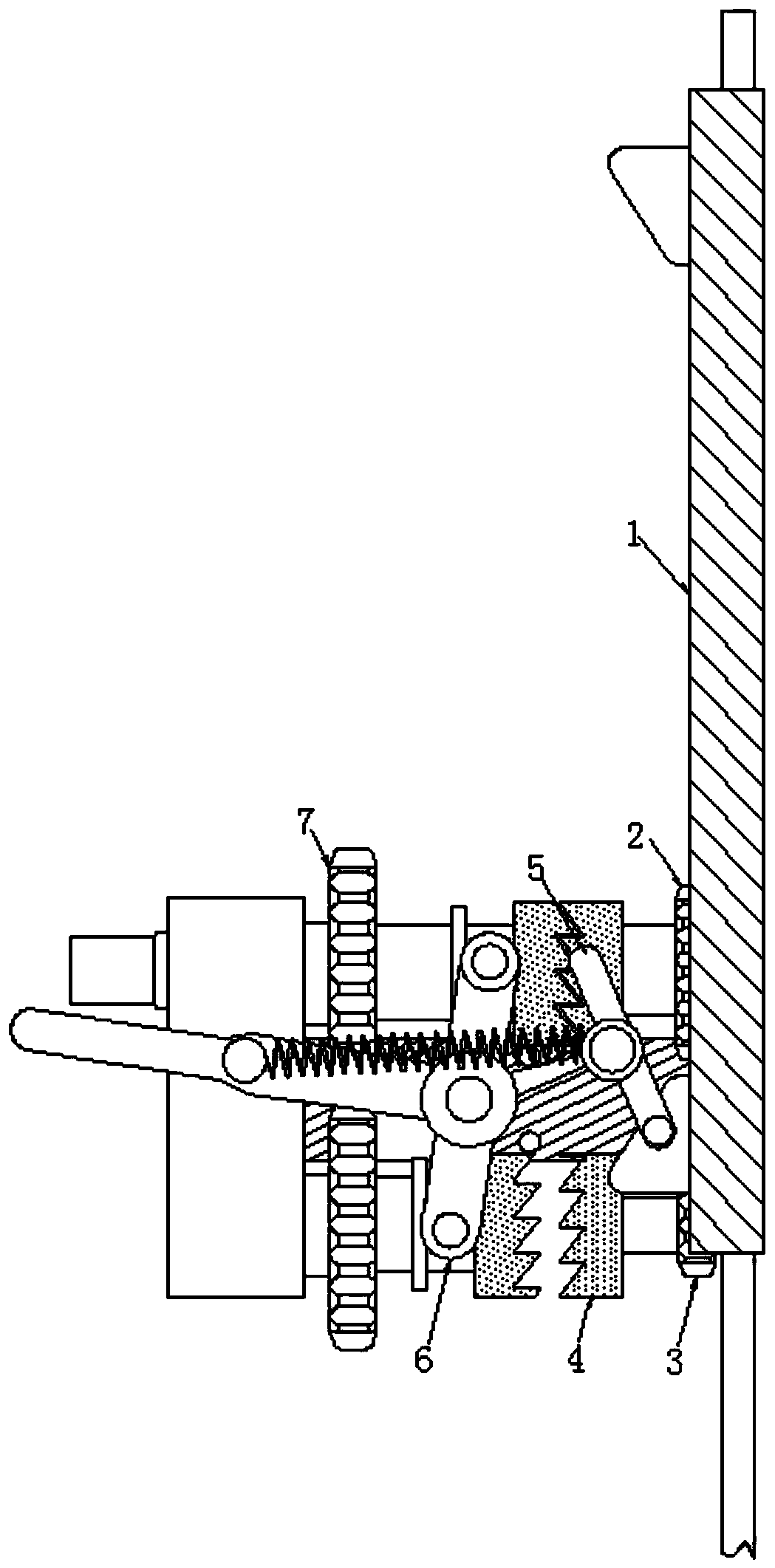

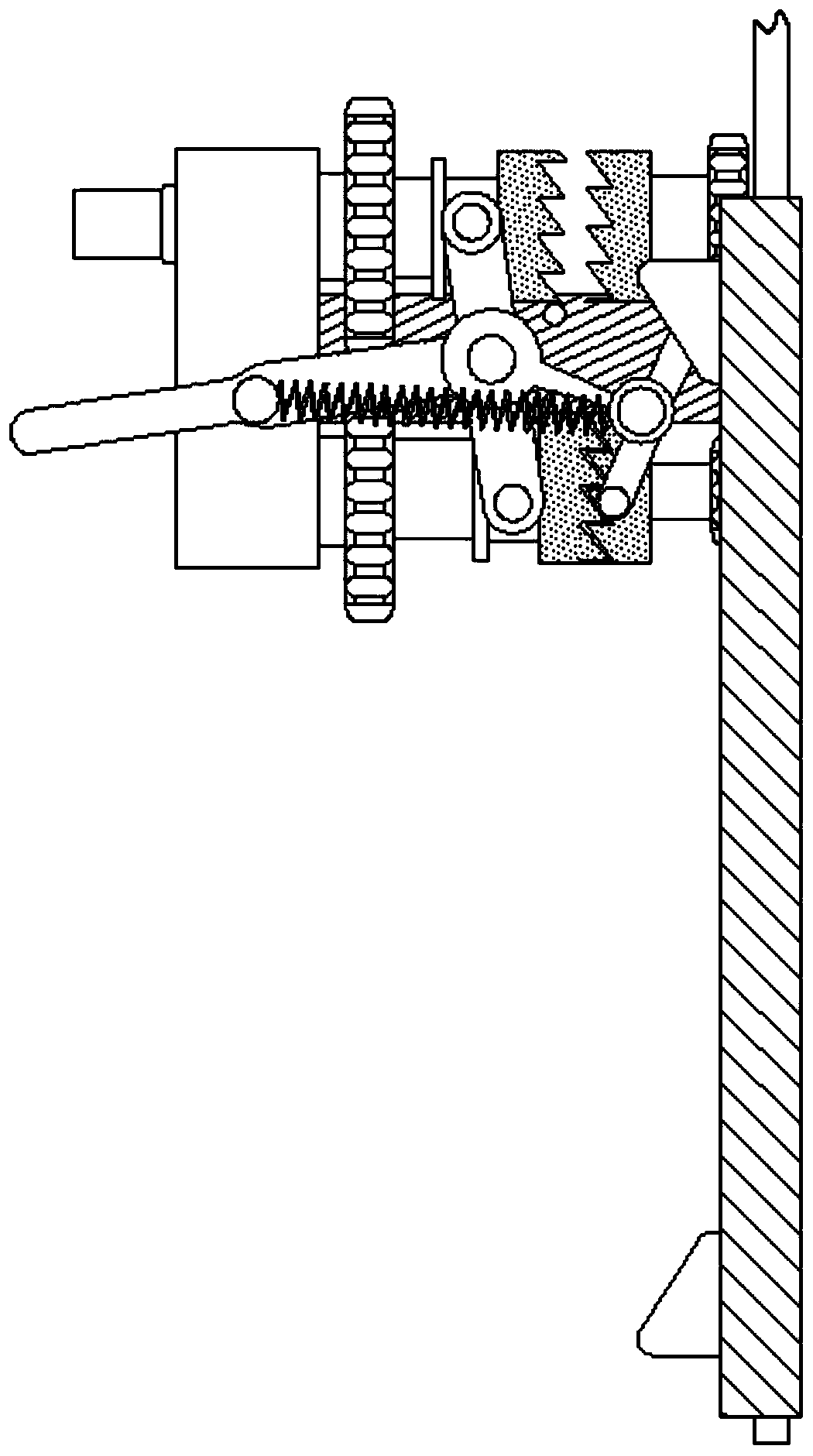

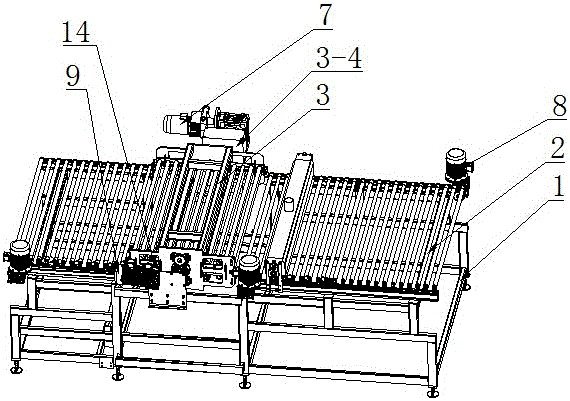

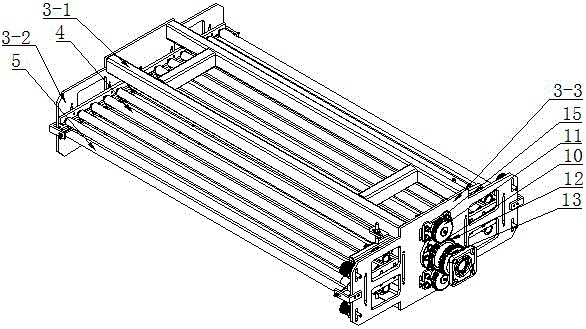

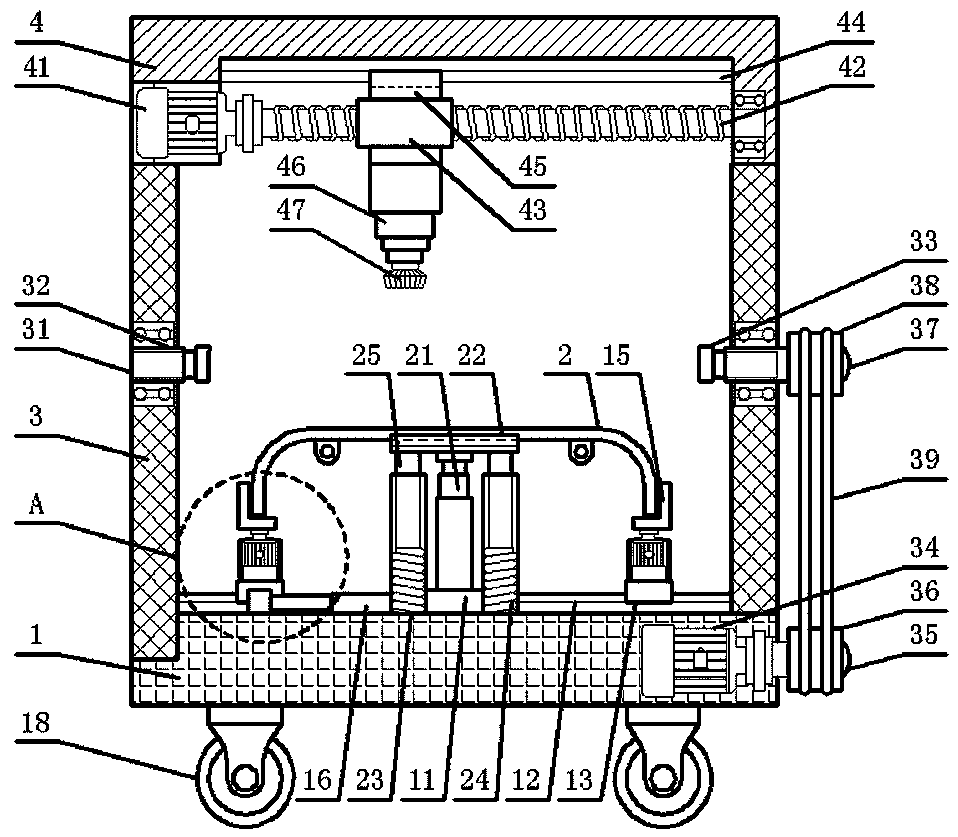

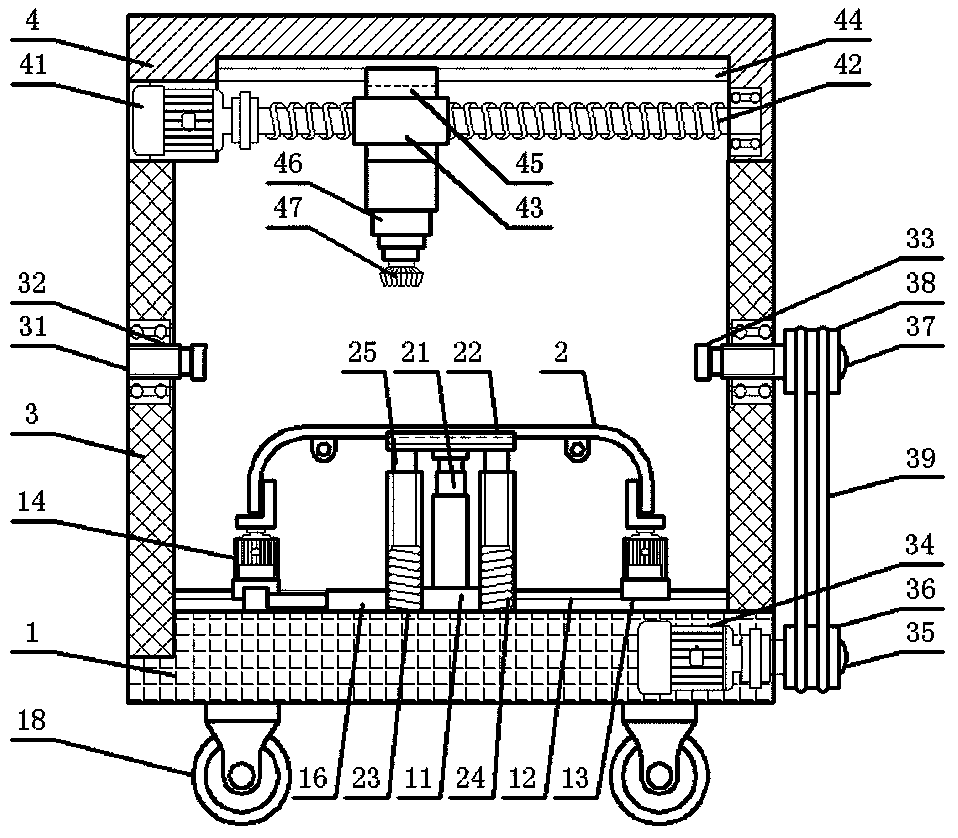

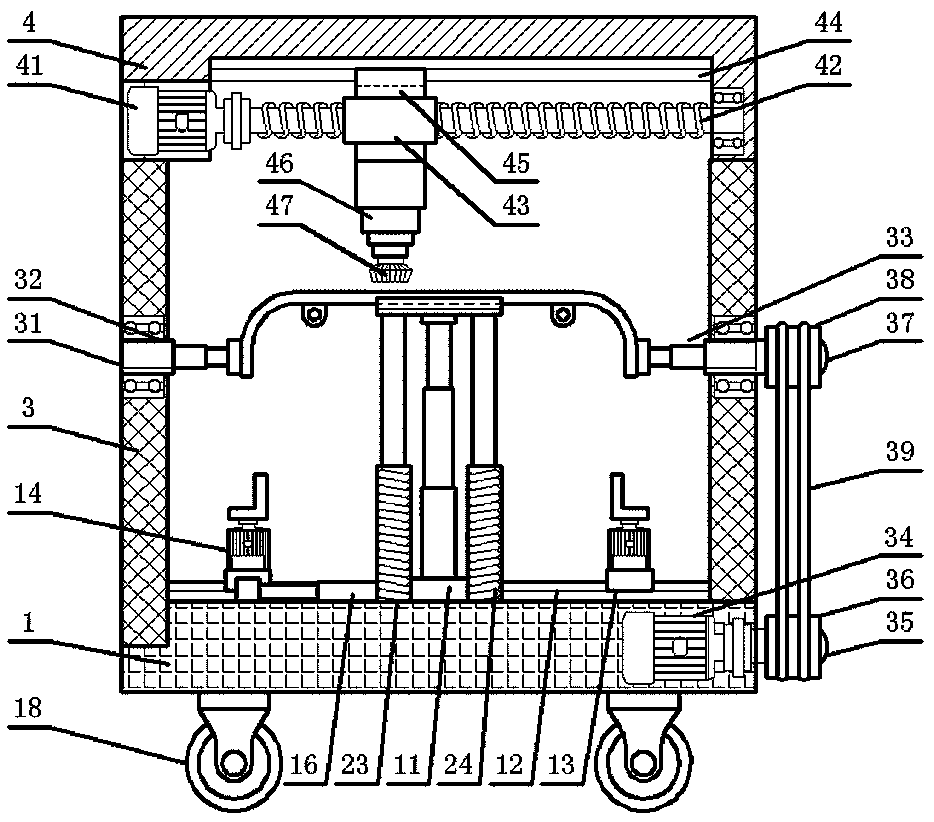

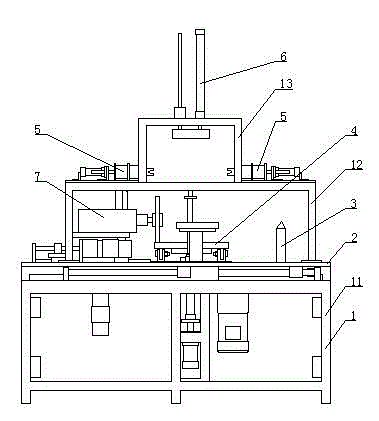

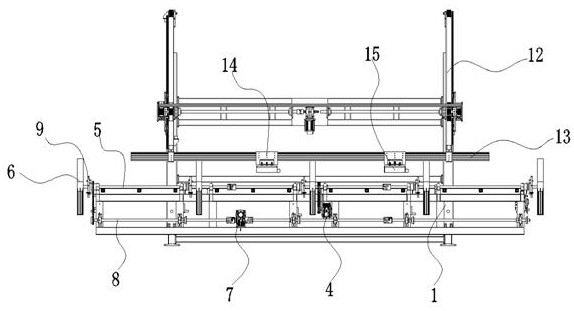

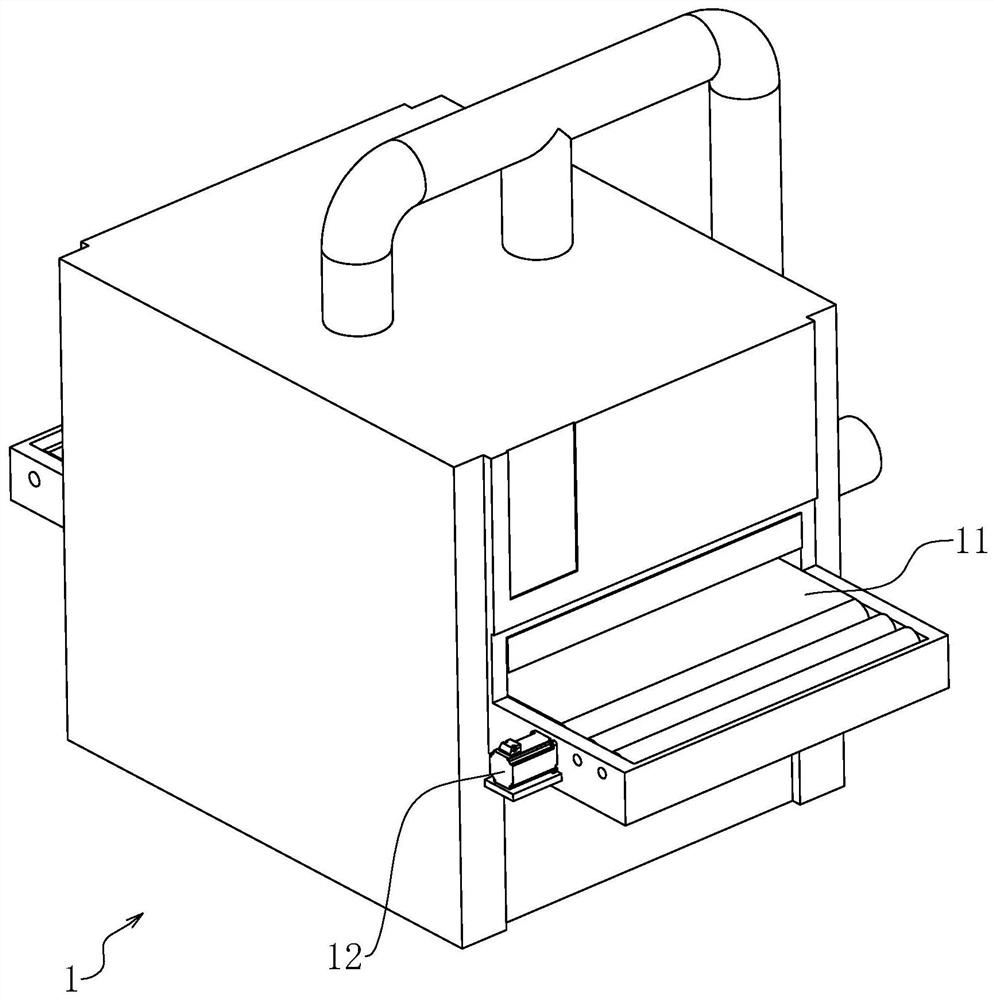

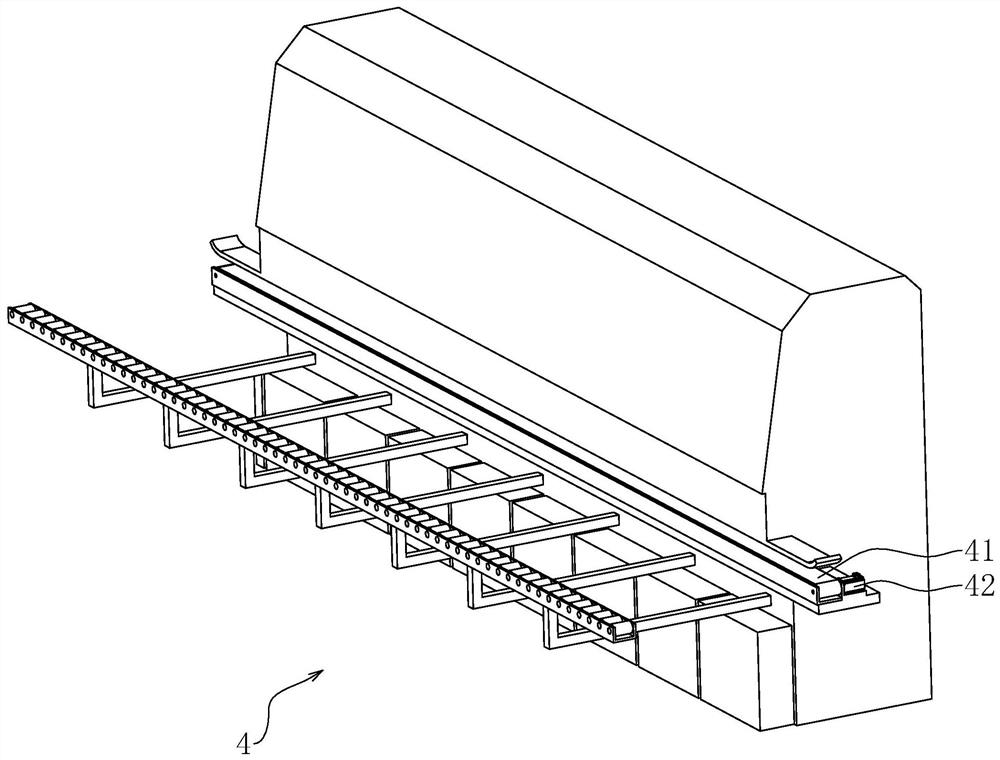

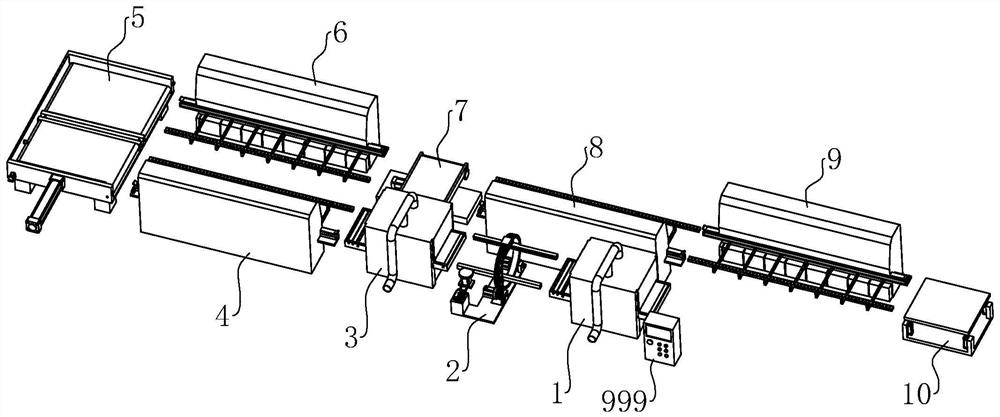

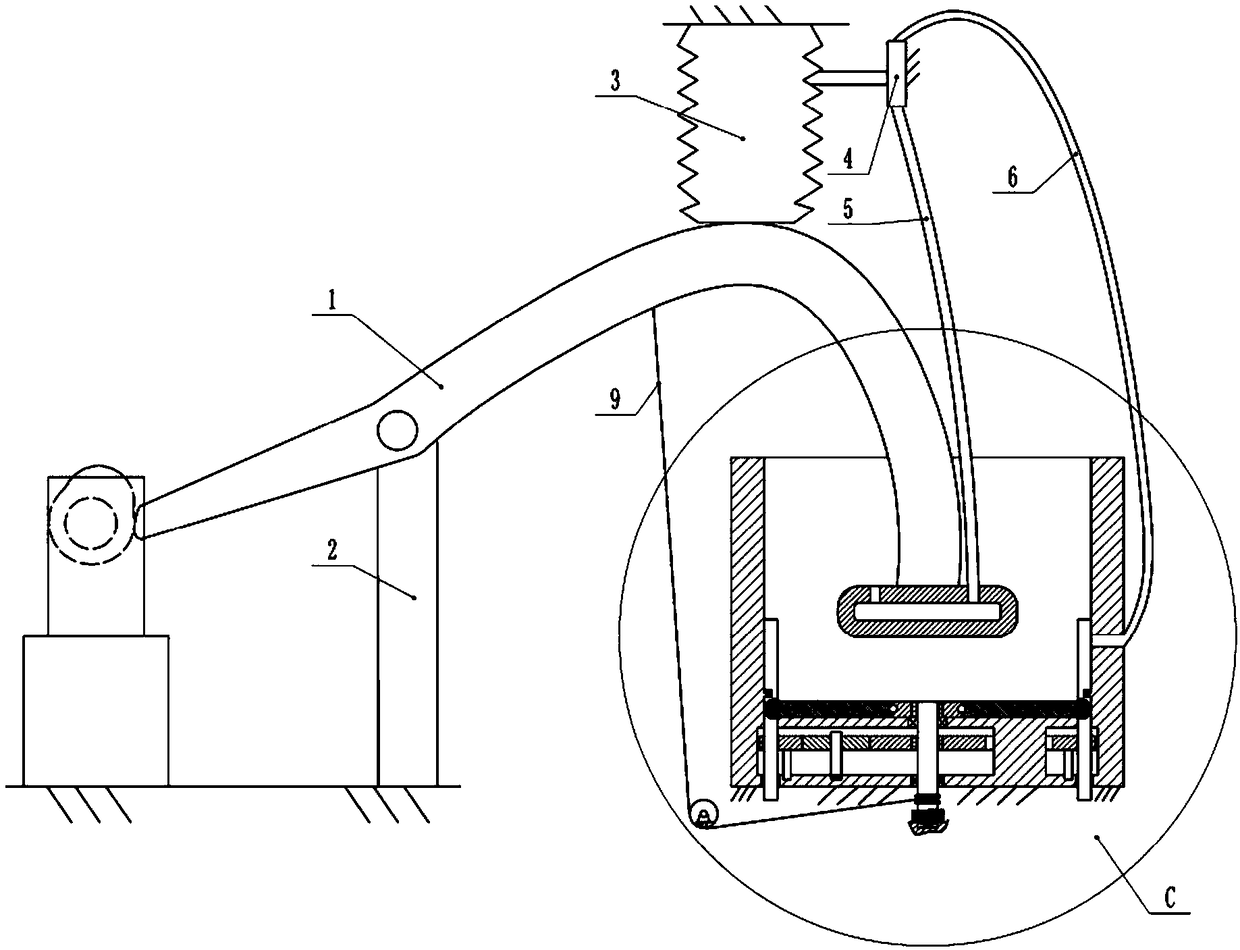

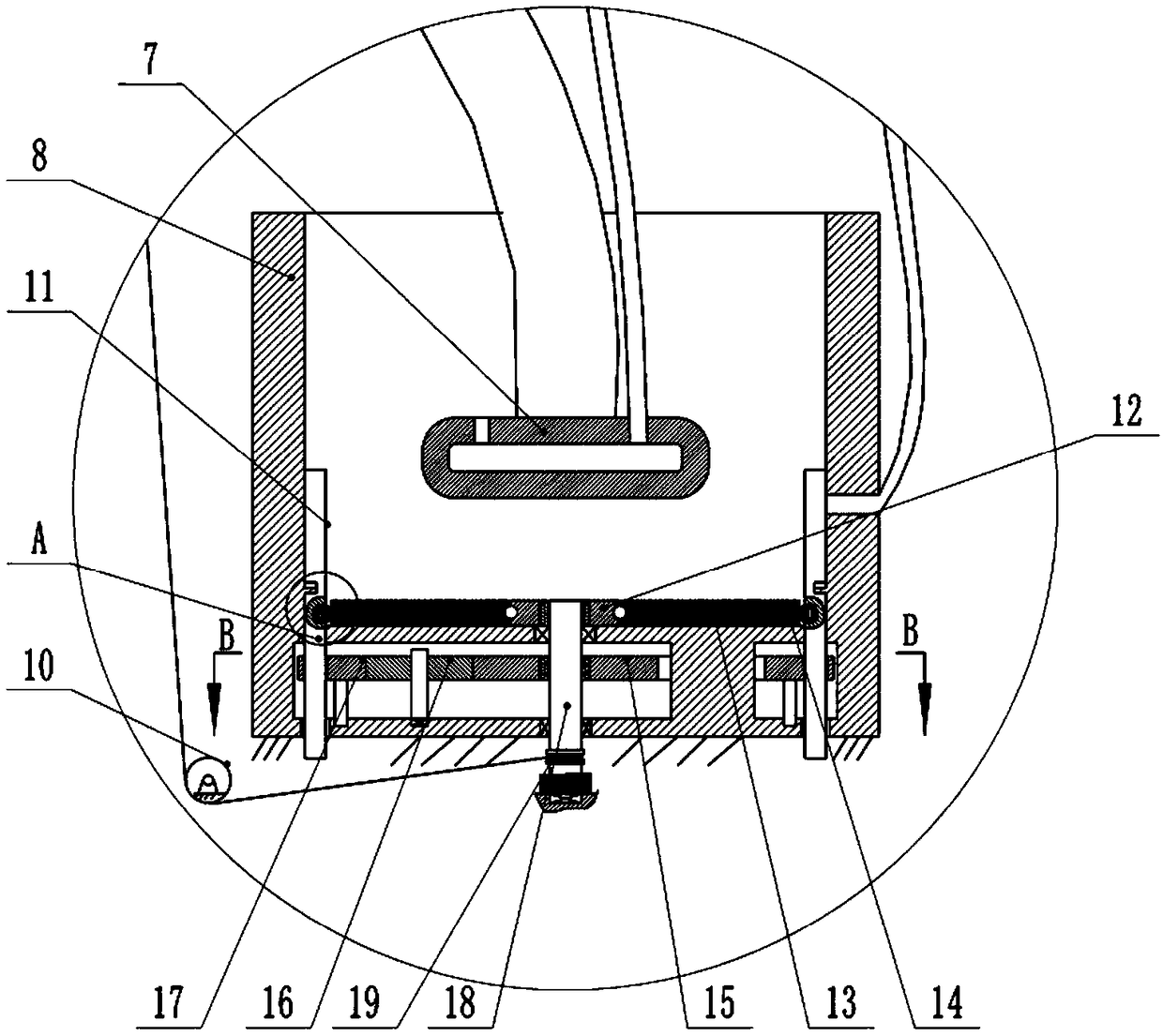

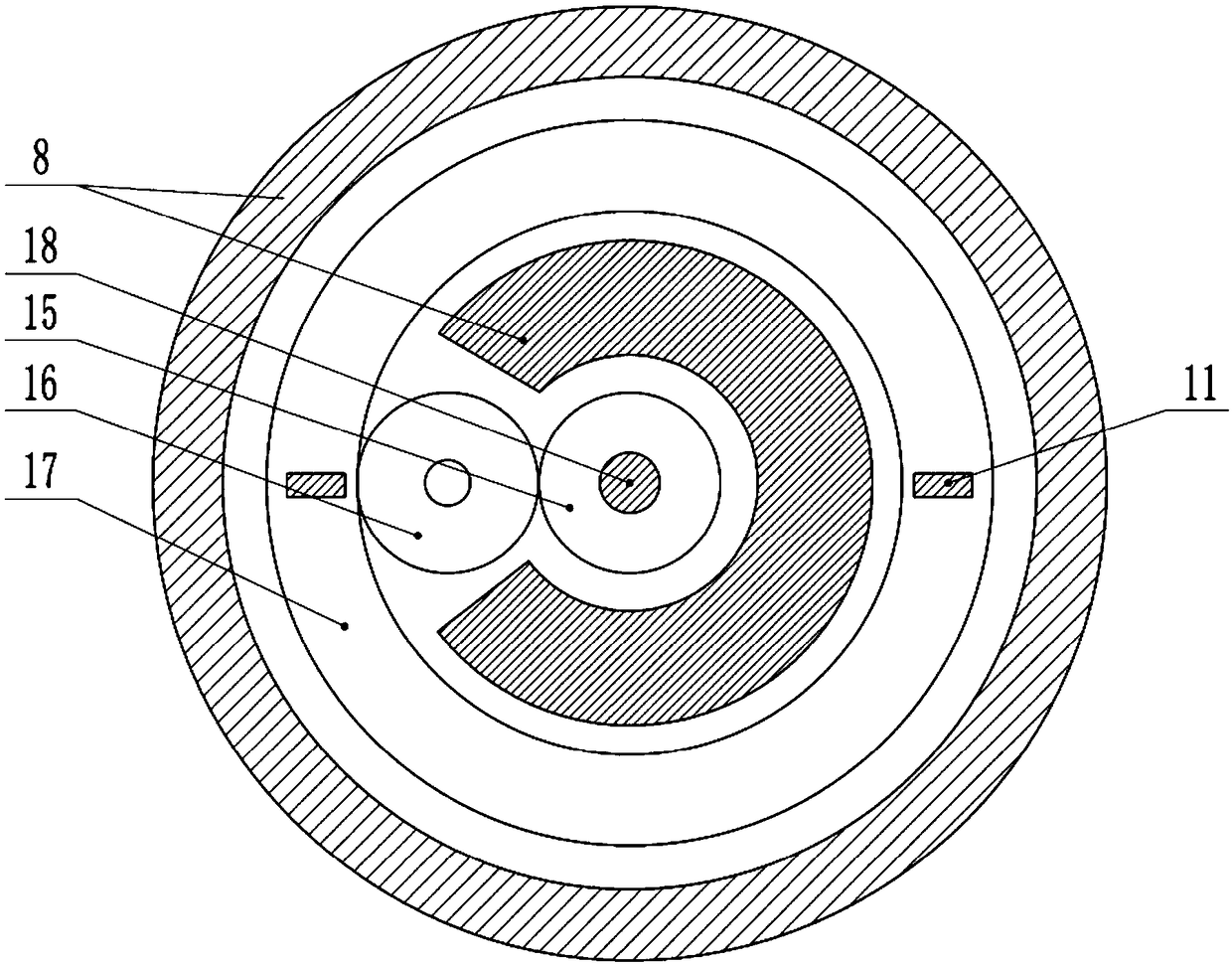

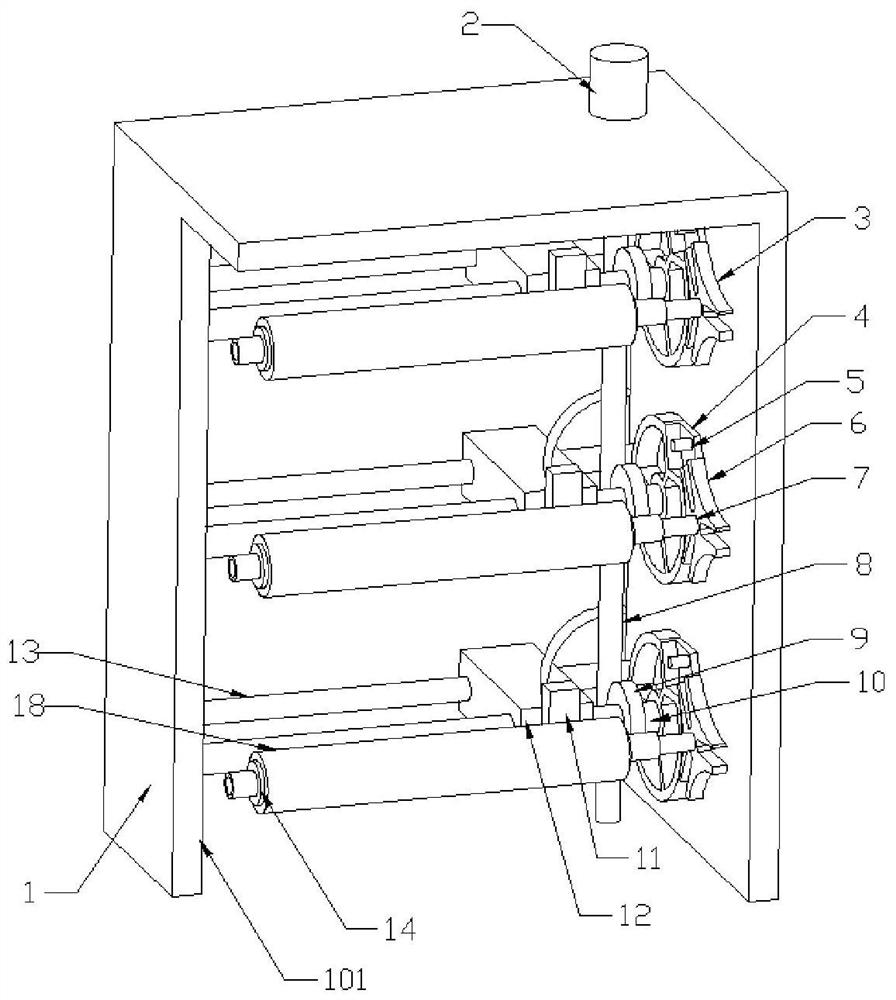

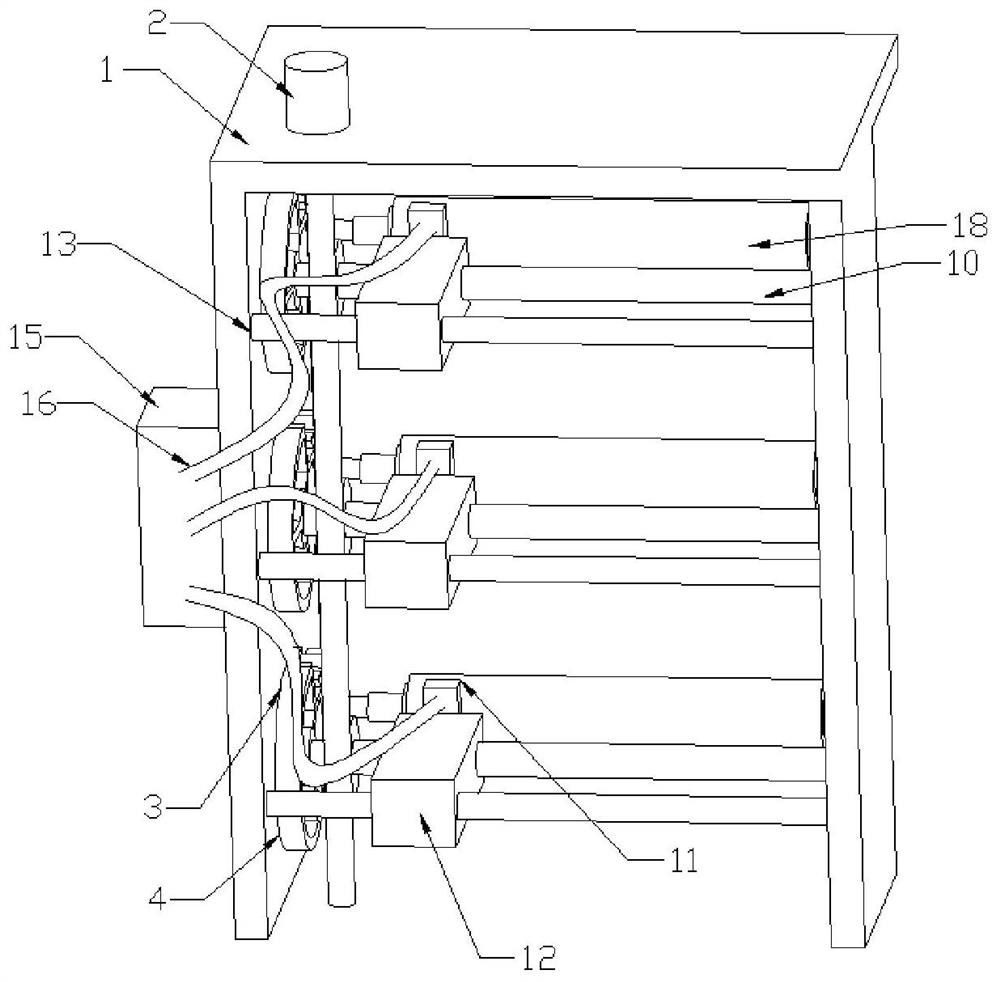

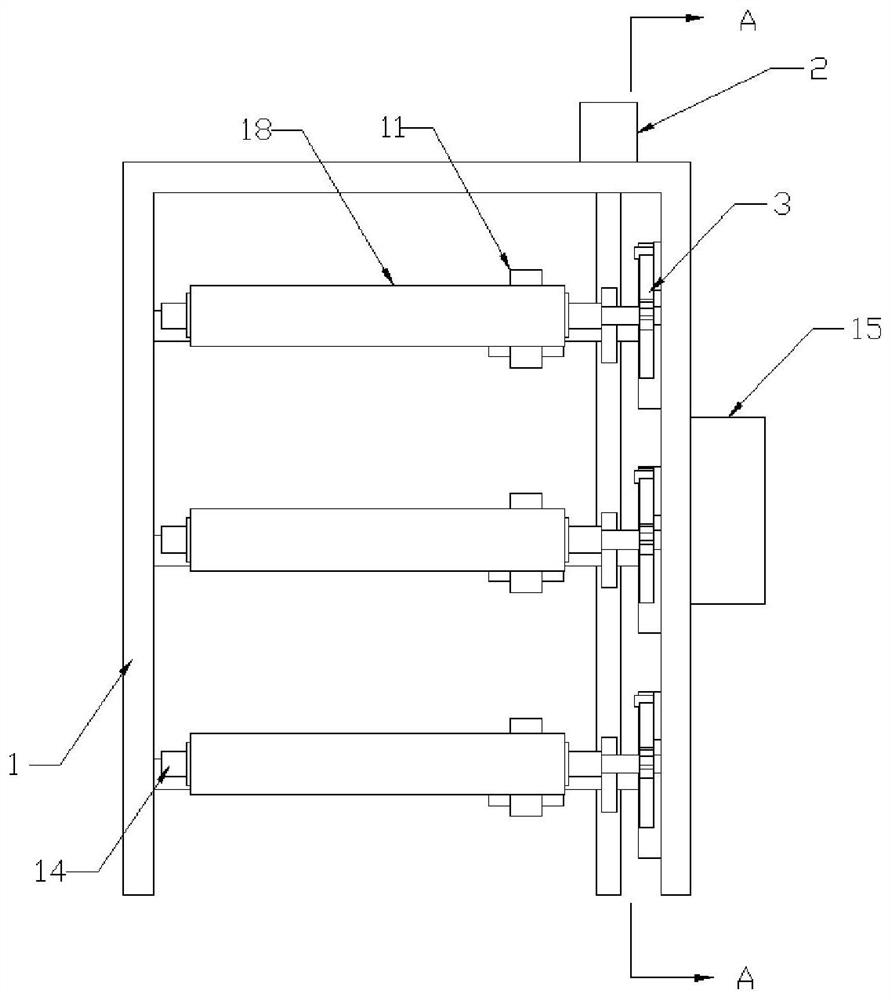

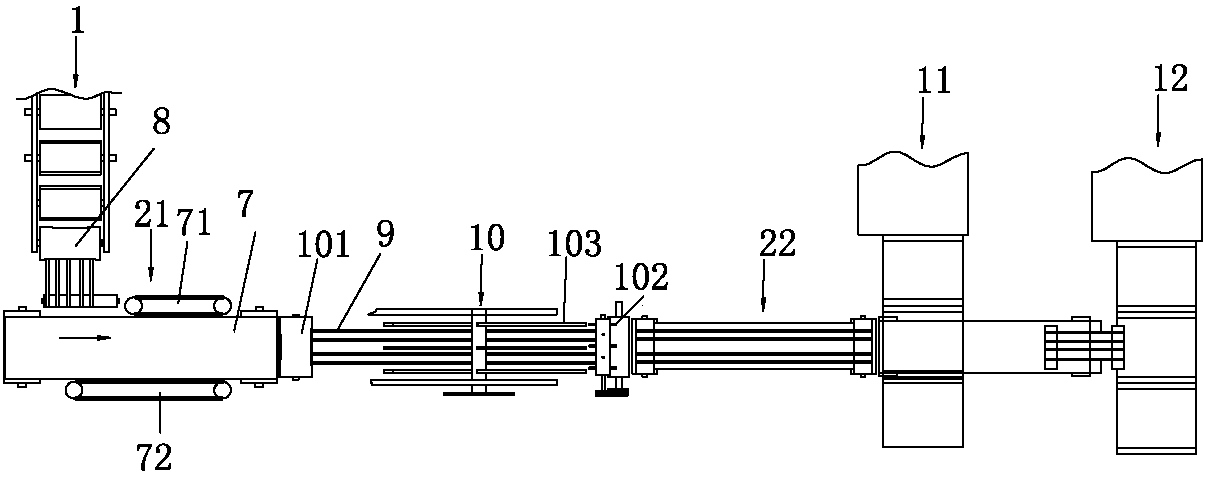

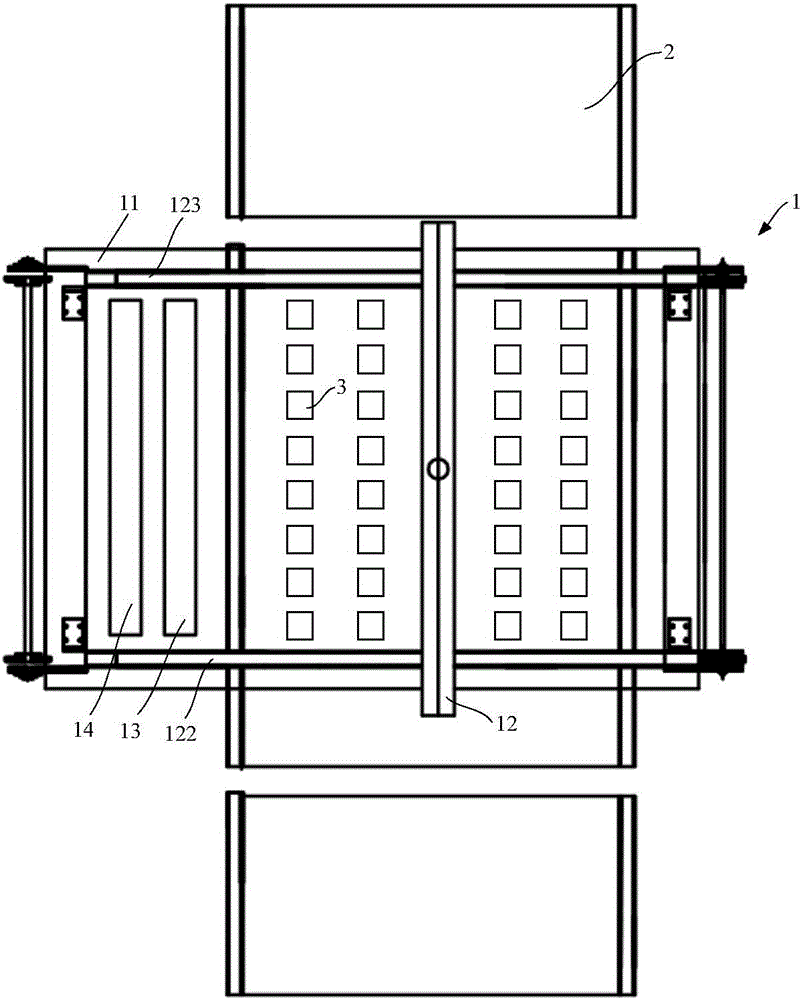

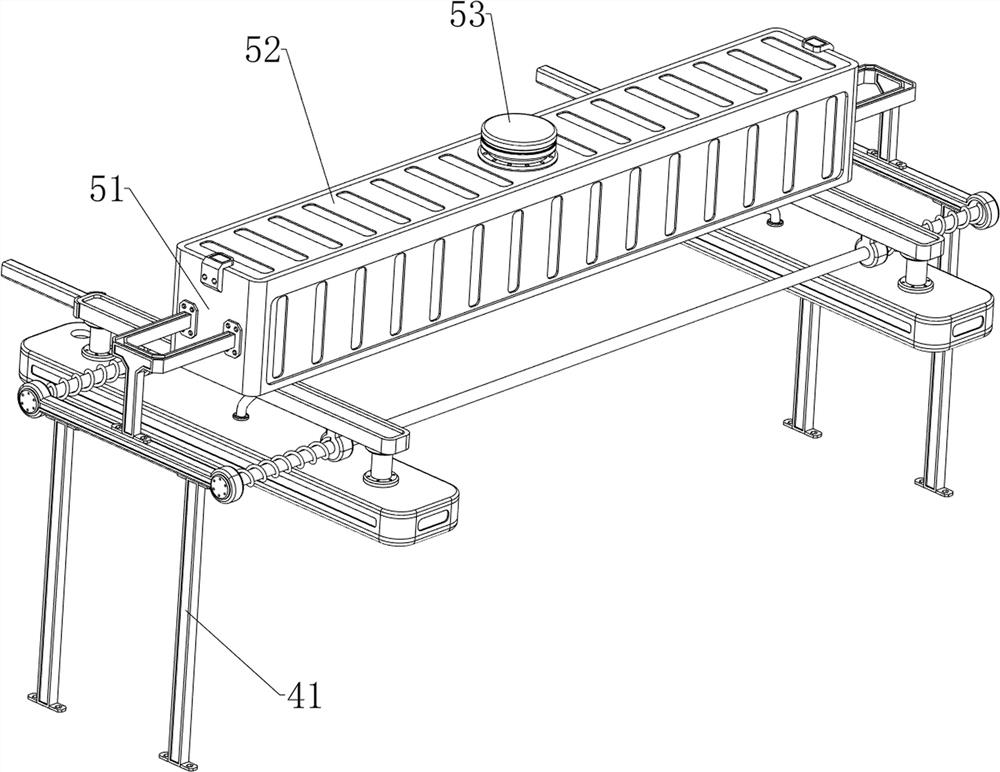

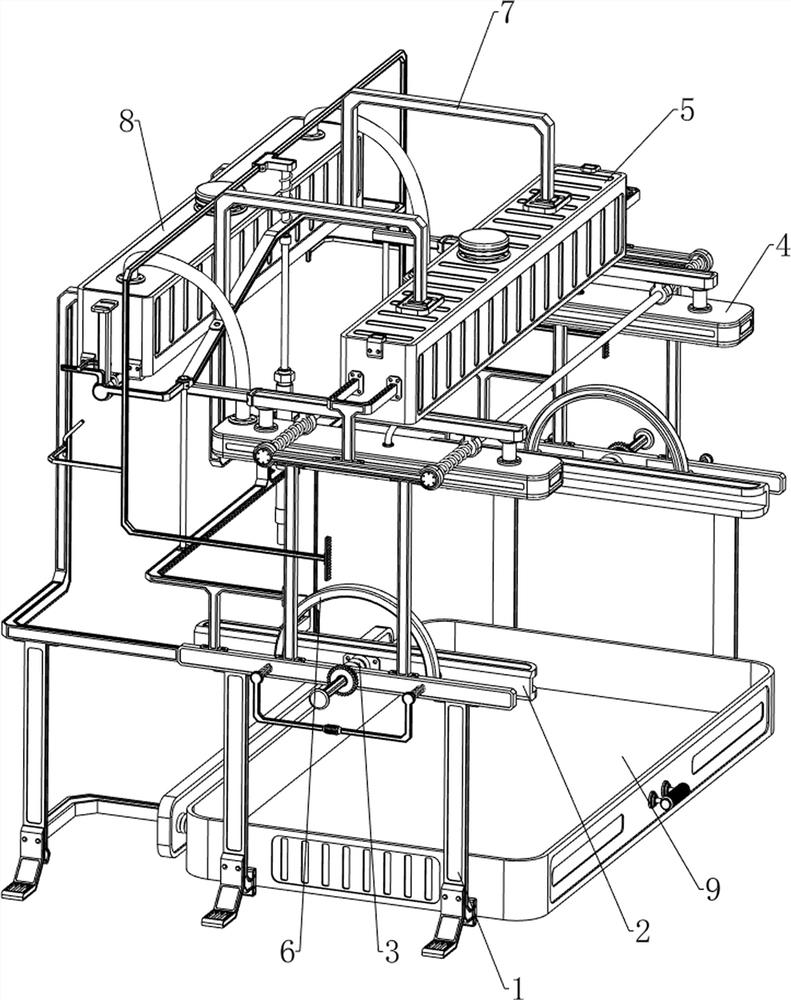

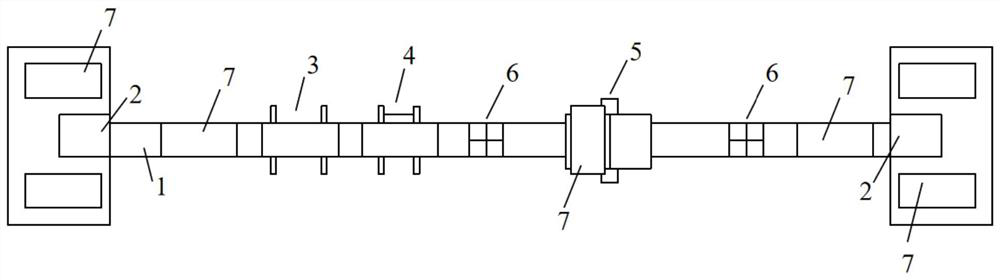

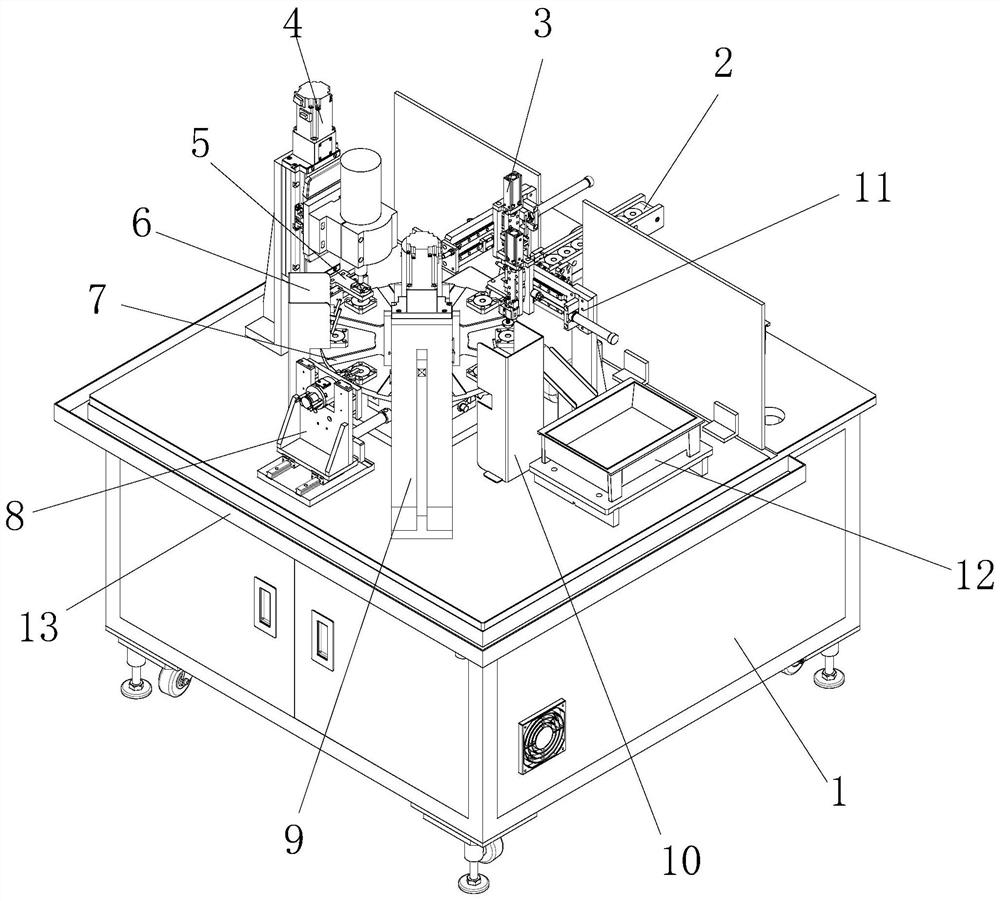

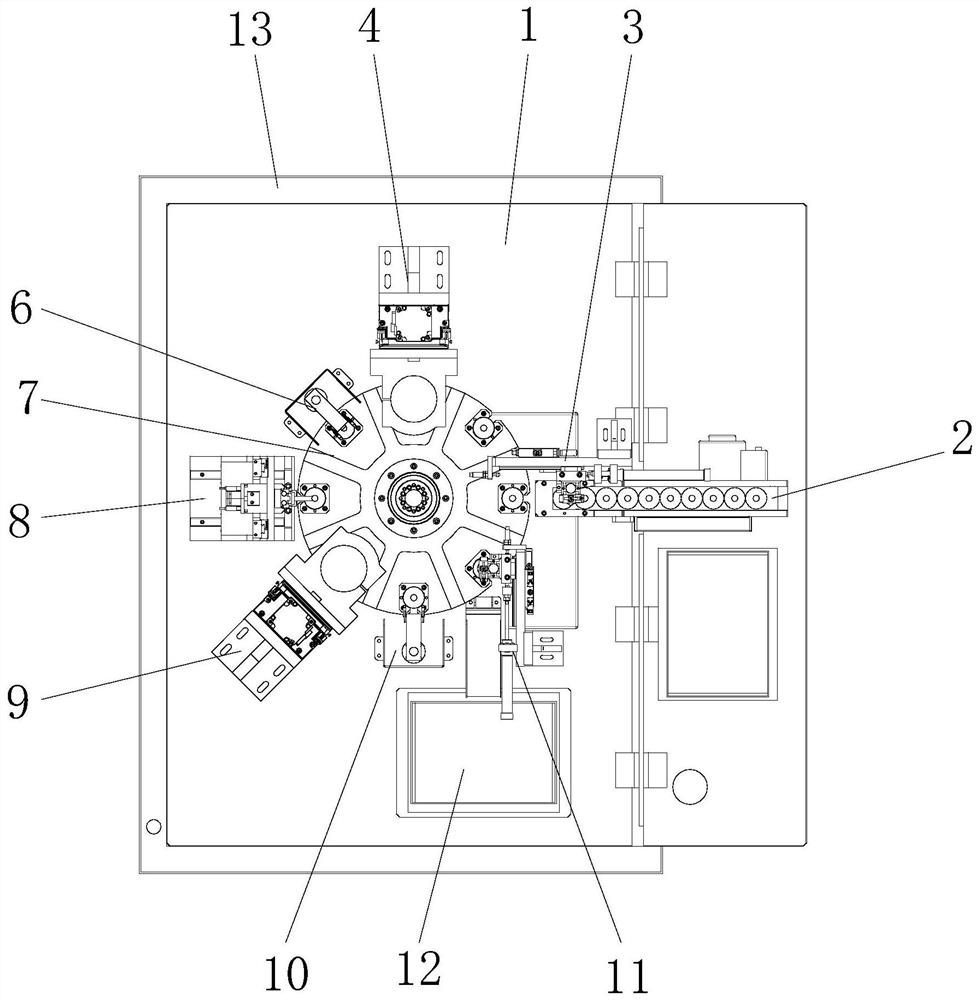

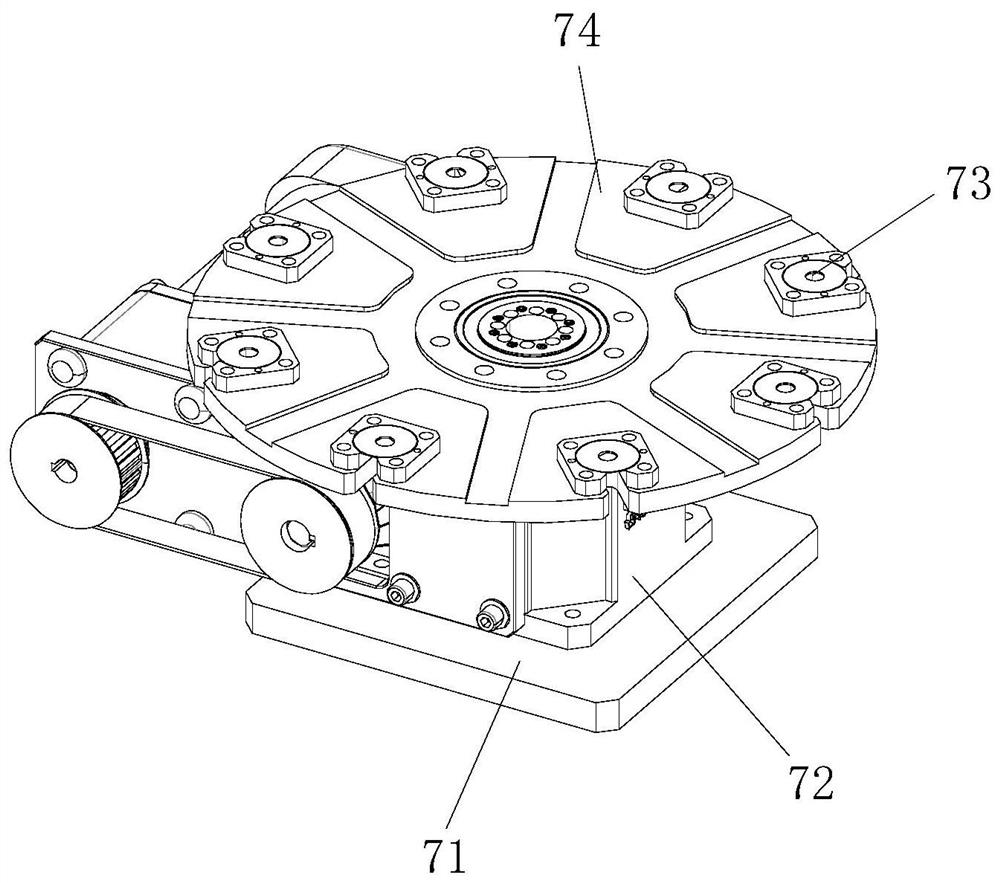

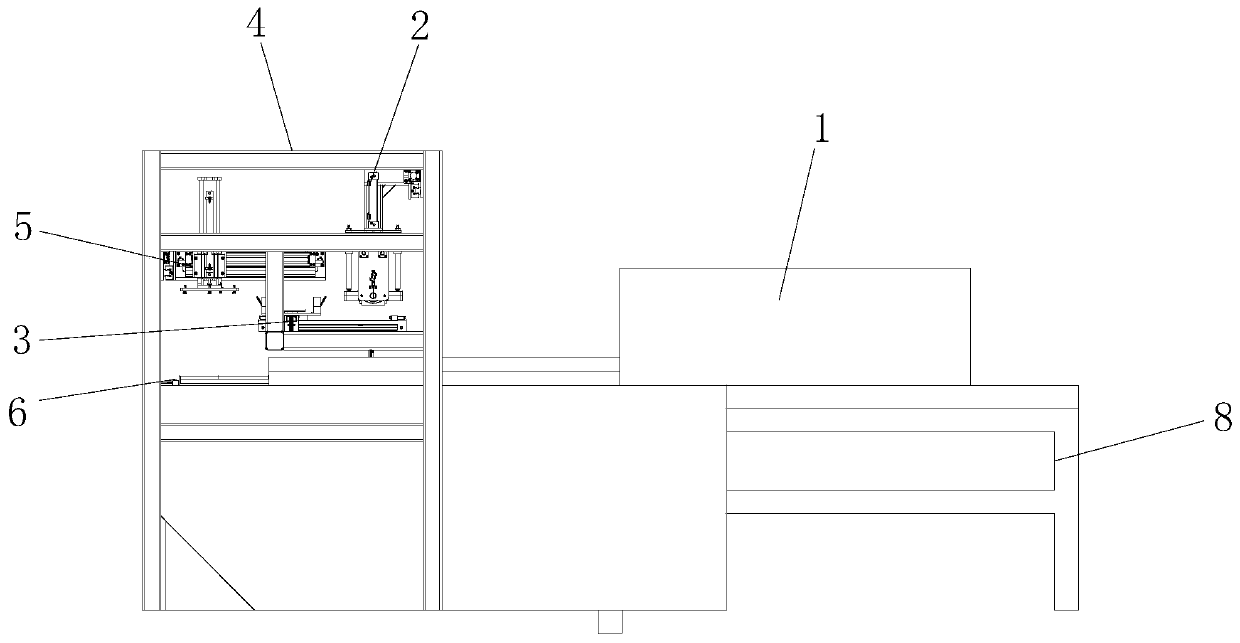

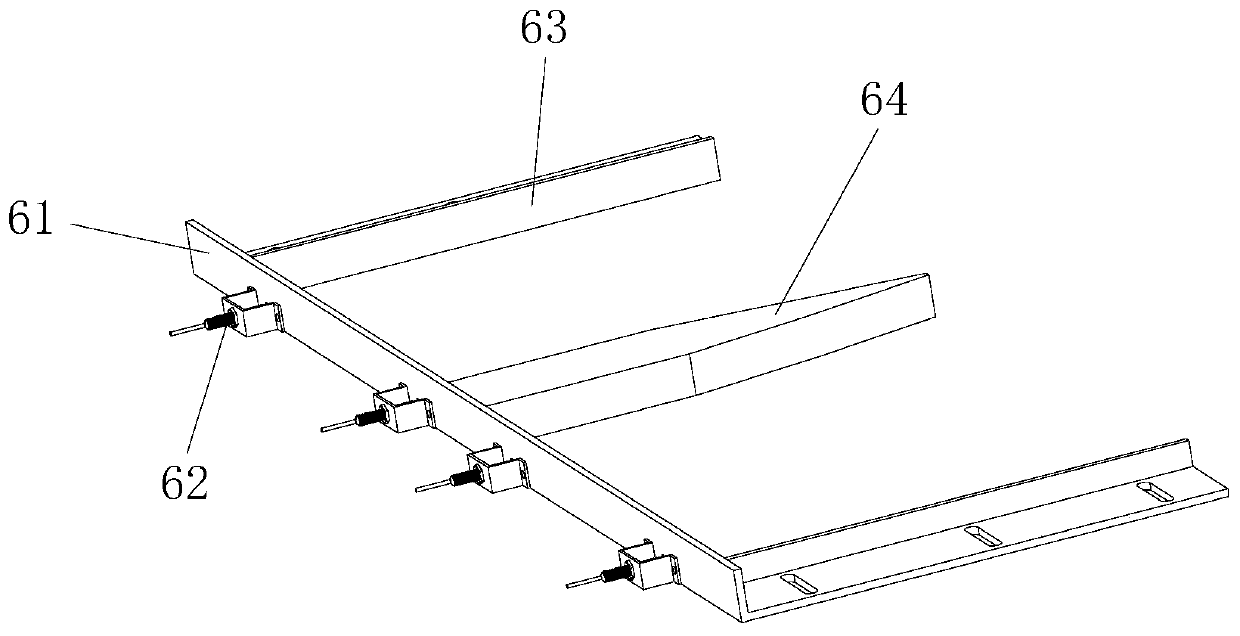

Full-automatic big diamond saw blade double-surface edging machine

InactiveCN104551239ARealize automatic flippingRealize the grinding operationGrinding machine componentsSawing tools dressing arrangementsEngineeringAutomation

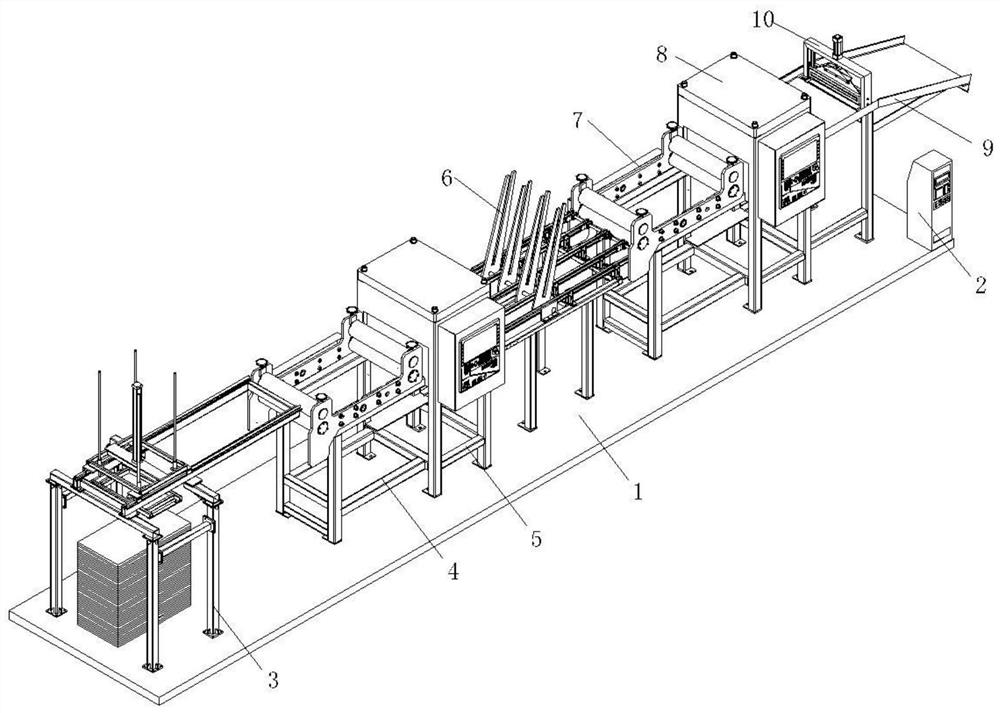

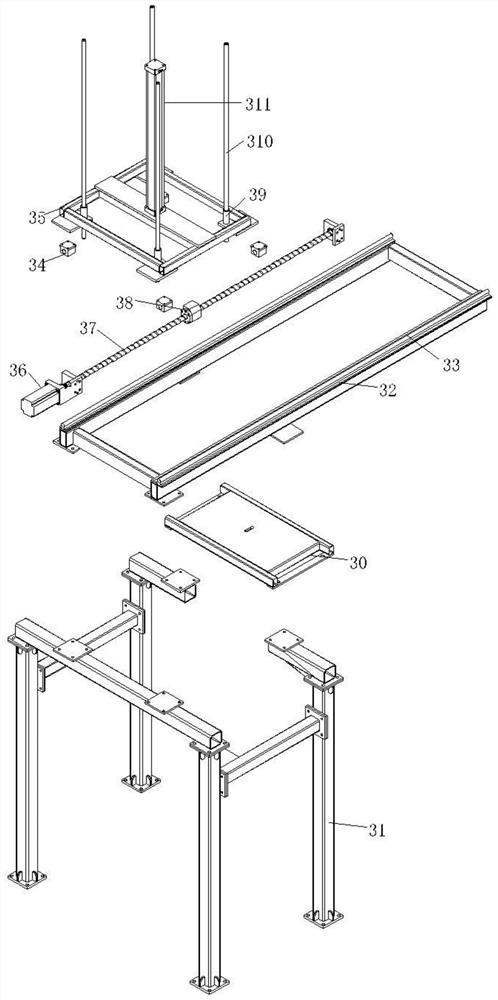

The invention discloses a full-automatic big diamond saw blade double-surface edging machine. The full-automatic big diamond saw blade double-surface edging machine is characterized by comprising a rack (1), a big panel (2), a feeding and discharging device (3), a working platform rotating mechanism (4), material clamping and overturning mechanisms (5), a lifting mechanism (6) and a grinding head assembly (7), wherein the rack (1) comprises a lower rack (11), a middle rack (12) and an upper rack (13), the middle rack (12) is arranged on the lower rack (11), and the upper rack (13) is arranged on the middle rack (12); the big panel (2), the feeding and discharging device (3) and the working platform rotating mechanism (4) are arranged on the lower rack (11); the material clamping and overturning mechanisms (5) are arranged on the middle rack (12); the lifting mechanism (6) is arranged on the upper rack (13); the grinding head assembly (7) is arranged on the big panel (2). According to the full-automatic big diamond saw blade double-surface edging machine disclosed by the invention, automatic overturning on a big diamond saw blade can be realized, double-surface edging is realized, feeding and discharging are automatic, the feed amount can be accurately controlled, the automation degree is high, and the edging quality is good.

Owner:HUANGSHI QIBANG AUTOMATION EQUIP

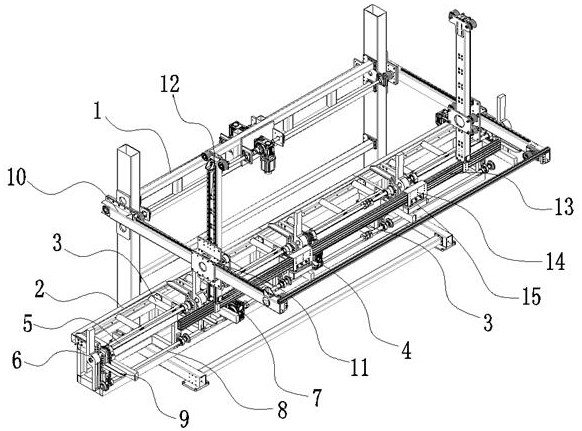

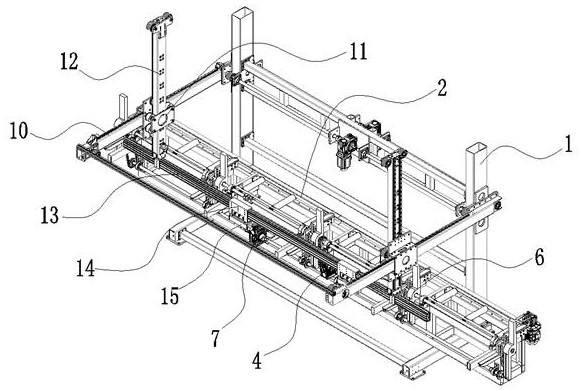

Automatic stacking machine for C-shaped steel and Z-shaped steel

PendingCN113148672AIncrease the scope of applicationImprove work efficiencyStacking articlesDe-stacking articlesPhysicsElectric machinery

The invention discloses an automatic stacking machine for C-shaped steel, Z-shaped steel and steel bar truss plates, and relates to the technical field of C-shaped steel stacks, Z-shaped steel stacks and steel bar truss plate stacks. The automatic stacking machine specifically comprises a main frame and a conveying frame. The main frame is formed by welding rectangular pipes. The conveying frame is fixedly installed at the bottom of the main frame, and conveying carrier rollers are arranged on the surface of the conveying frame. The conveying frame further comprises a first turnover arm, a second turnover shaft and a second turnover arm, wherein the first turnover arm is mounted on the surface of a first turnover shaft in a sleeving connection manner; the second turnover shaft is connected to the side face of a second turnover motor; and the second turnover arm is connected to the outer wall of the first turnover shaft in a sleeving manner. According to the automatic stacking machine for the C-shaped steel and the Z-shaped steel, the C-shaped steel, the Z-shaped steel, columnar profiles and steel bar truss plates can be clamped and turned over, the application range of the automatic stacking machine is widened, meanwhile, the profiles can be stacked in order, and therefore the manual turnover and stacking mode is replaced, the working efficiency is improved easily, the stacking uniformity is improved, and the automatic stacking machine solves the problems about industrial automation and recruitment difficulty for production enterprises, and achieves the aim of people substitution with machines.

Owner:辽宁鑫硕智能机械有限公司

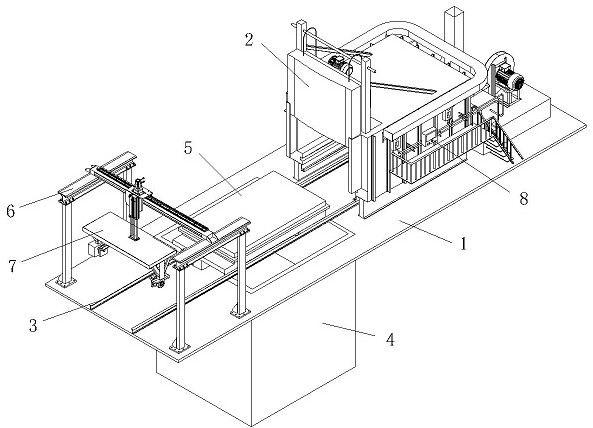

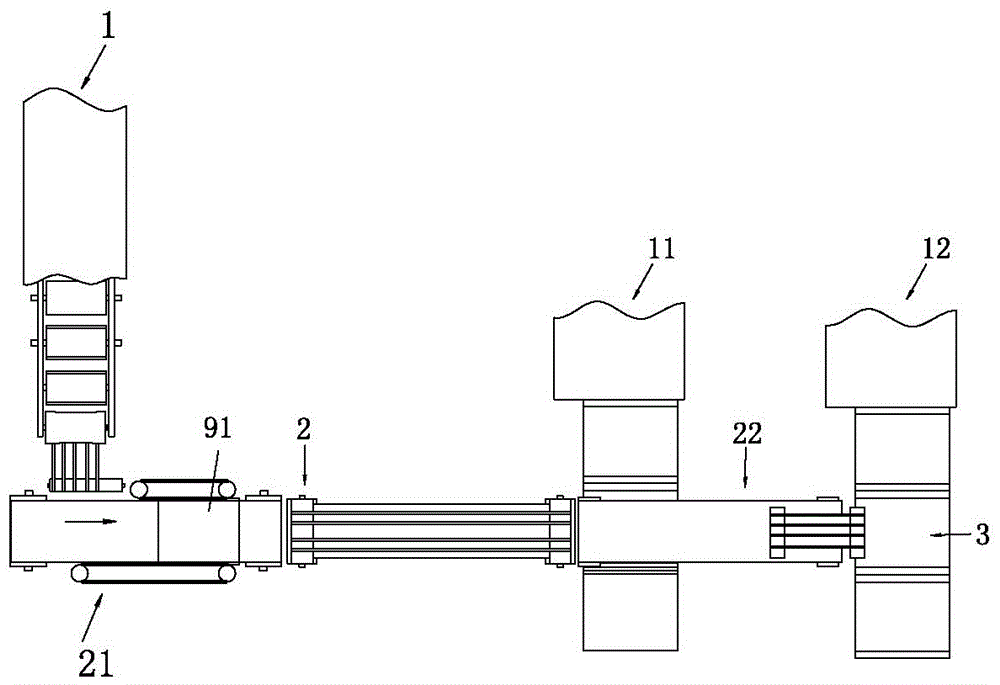

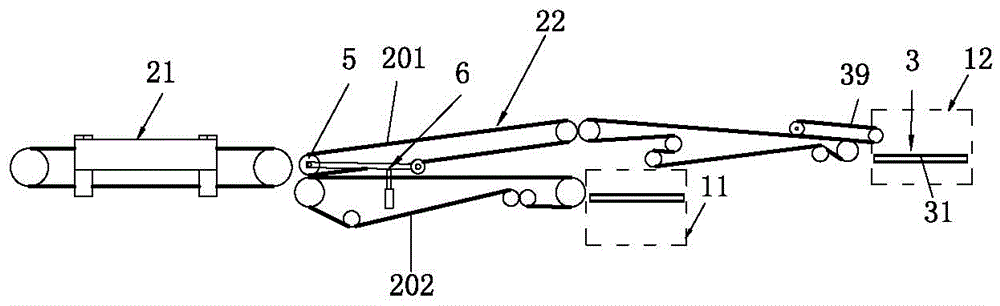

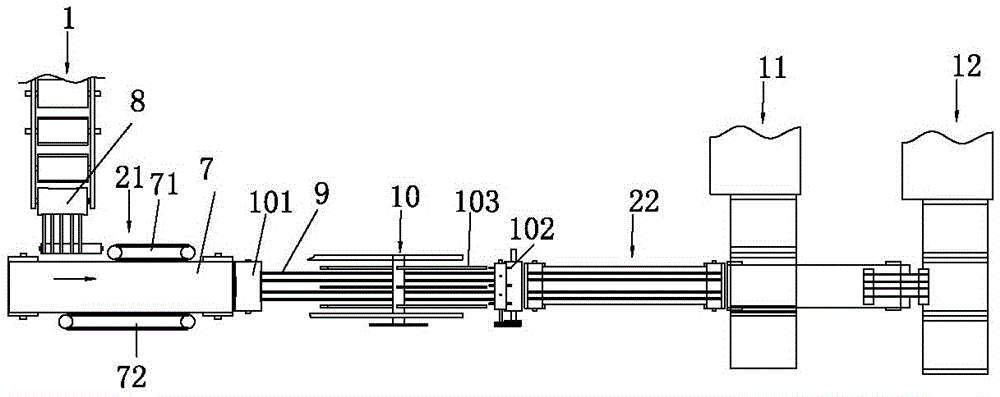

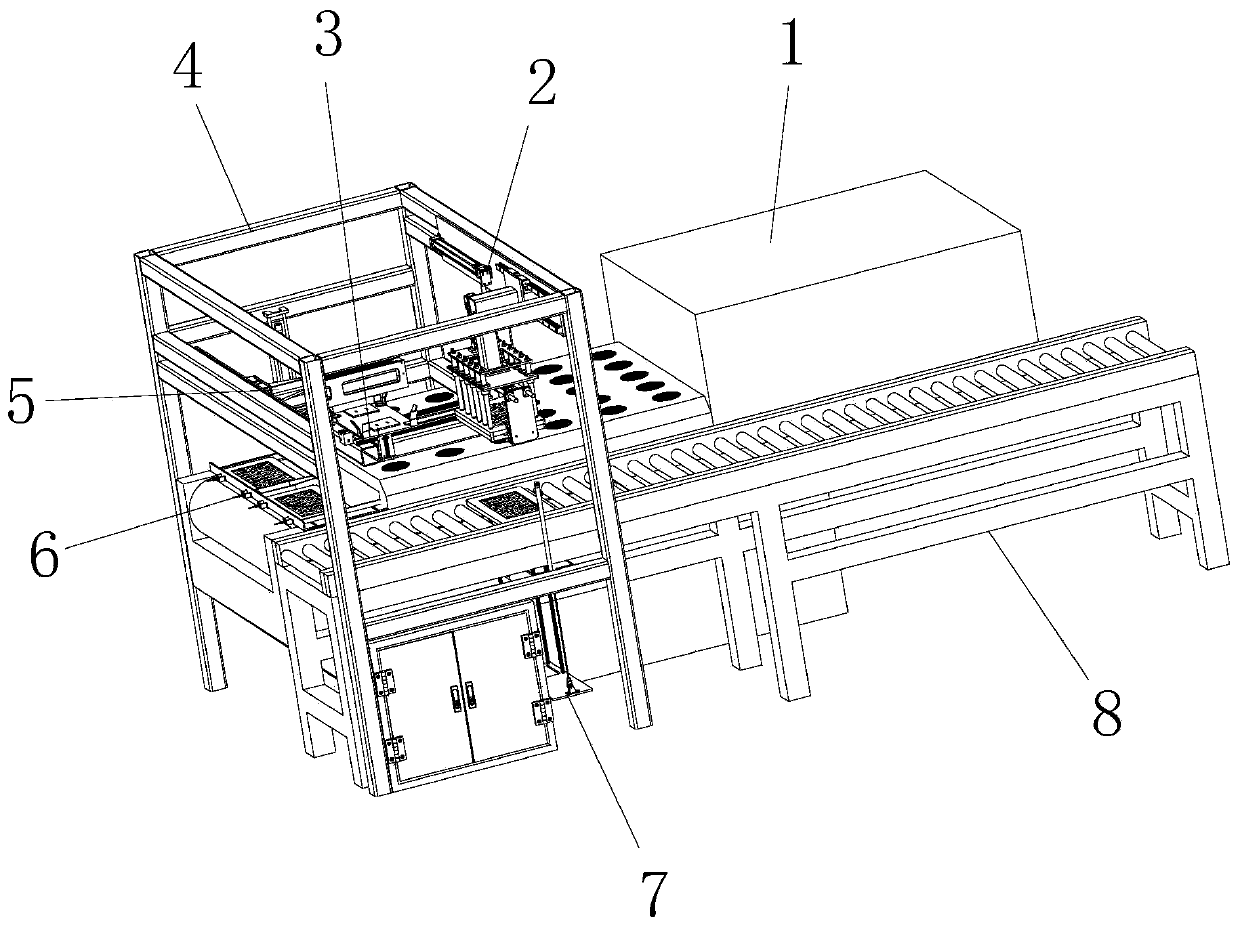

Automatic production line and production process of solid wood cabinet plate

InactiveCN111993190ARealize automatic flippingHigh degree of automationWood working apparatusGrinding feedersSolid woodProduction line

The invention relates to the field of plate processing, in particular to an automatic production line and production process of a solid wood cabinet plate. The production line comprises a first sanding machine, a turnover mechanism, a second sanding machine, a first edge sealing machine, a second edge sealing machine, an edge changing mechanism, a third edge sealing machine, a fourth edge sealingmachine and a controller, wherein the first sanding machine, the turnover mechanism, the second sanding machine, the first edge sealing machine, the second edge sealing machine, the edge changing mechanism, the third edge sealing machine and the fourth edge sealing machine are sequentially arranged, and the controller is used for controlling the action of various electrical equipment in the production line; the turnover mechanism is used for driving the plate to turn over in the vertical direction and driving the plate in the direction close to the second sanding machine; and the edge changingmechanism is used for driving the plate to rotate in the horizontal direction and driving the plate in the direction close to the third edge sealing machine. The turnover mechanism drives the plate to rotate at an angle of 180 degrees in the vertical direction, so that automatic turnover of the plate is realized; and the edge changing mechanism drives the plate to rotate at an angle of 90 degreesin the horizontal direction, so that automatic rotation of the plate is realized, and manual intervention is not needed. The automatic production line and production process have the effects of beinghigh in automation degree of a production line, low in labor consumption, low in working labor intensity of workers and capable of saving cost.

Owner:太仓顾奇实业有限公司

Meat hammering device

ActiveCN108713580ARealize automatic flippingGuaranteed uniformityBeating-based meat tenderisingEngineeringMechanical engineering

The invention belongs to the technical field of edible meat processing equipment and particularly discloses a meat hammering device. The device comprises a hammering barrel, a hammering head, a powersource, a transmission mechanism and a stirring mechanism. The power source drives the hammering head to perform repeated hammering in the hammering barrel through the transmission mechanism; the stirring mechanism comprises a rotating disk at the bottom of the hammering barrel; the rotating disk comprises a middle fixed plate and two movable plates articulated with the two sides of the fixed plate; a rotating shaft is fixedly arranged at the lower end of the fixed plate; a central gear is arranged on the rotating shaft; a transmission gear and a gear ring are rotationally connected below therotating disk; scrapers are connected with the left side and the right side of the gear ring in a sliding manner; first sliding cavities and second sliding cavities are arranged on the two sides of the two scrapers; two arc sliding rails are arranged on an inner wall of the hammering barrel; the second sliding cavities of the two scrapers are connected onto the two sliding rails in a sliding manner; one side, close to the inner wall of the hammering barrel, of each scraper is adhered to the inner wall of the hammering barrel; and the two movable plates are connected into the two first slidingcavities in a sliding manner. The device automatically hammers meat, achieves automatic stirring of the meat at the same time and improves working efficiency.

Owner:重庆登娃食品开发有限公司

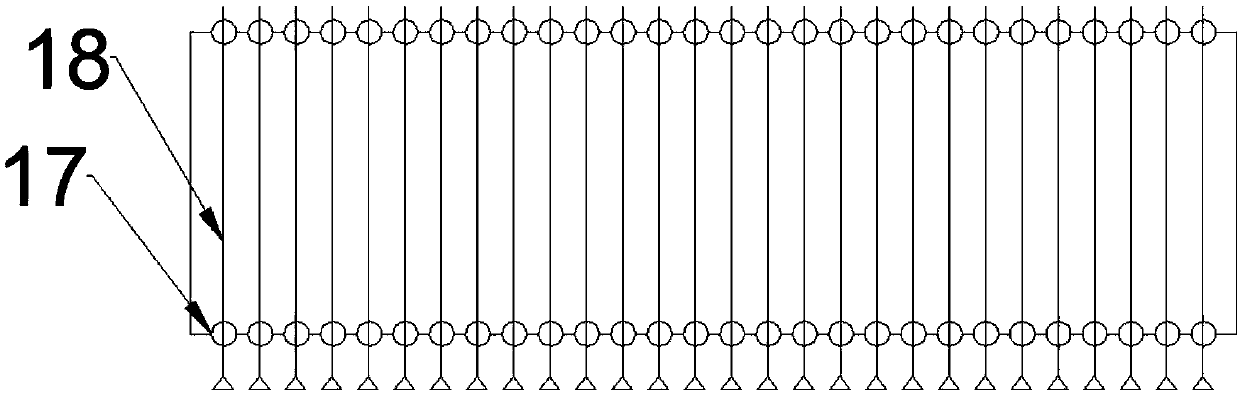

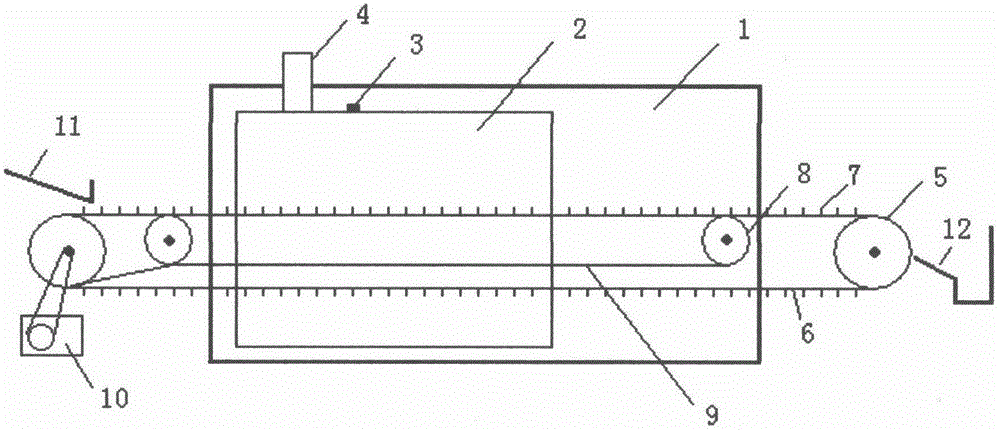

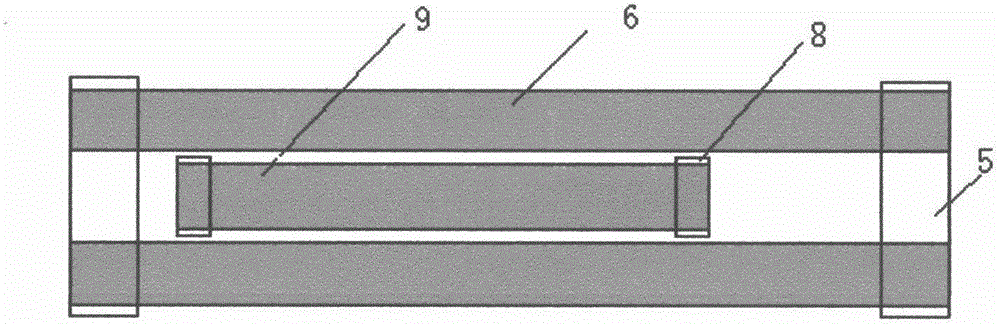

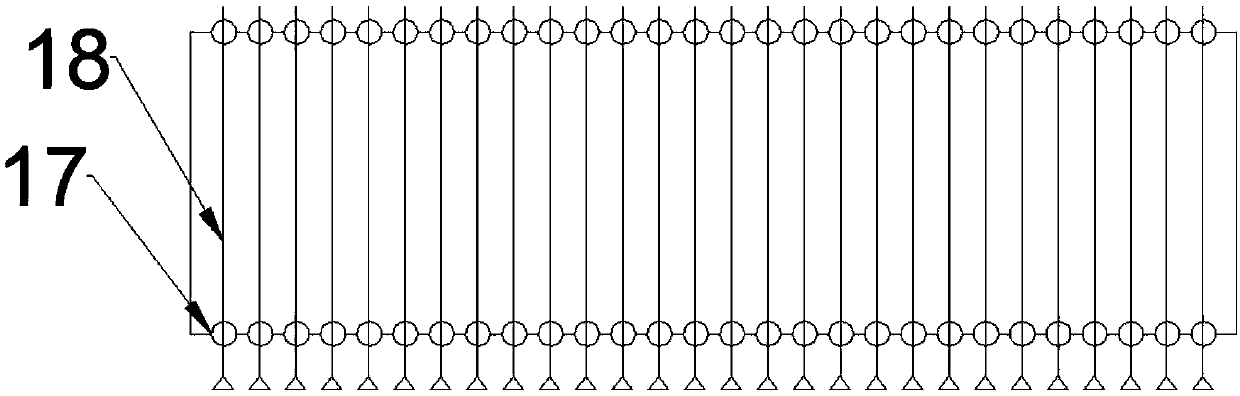

Differential mesh belt type tempering furnace

The invention discloses a differential mesh belt type tempering furnace which comprises a tempering furnace body, a heating section, a feeding table, primary chain mesh belts, primary chain wheels, baffles, a secondary chain mesh belt, secondary chain wheels and a transmission system. The primary chain mesh belts, the primary chain wheels and the baffles form an operating loop. The secondary chain mesh belt and the secondary chain wheels form operating loop. The middle of a bar-shaped tempering part is placed on the secondary chain mesh belt. The two ends of the bar-shaped tempering part are separated by the baffles on the primary chain mesh belts. The diameters of the main chain wheels are larger than those of the secondary chain wheels. The operating speeds of the primary chain mesh belts are lower than that of the secondary chain mesh belt. The speed difference realizes the automatic turning of the tempering part in the tempering furnace, the heat treatment quality of the tempering part can be improved greatly, and the special design of the feeding table can realize the feeding automation.

Owner:四川行健车轴科技有限公司

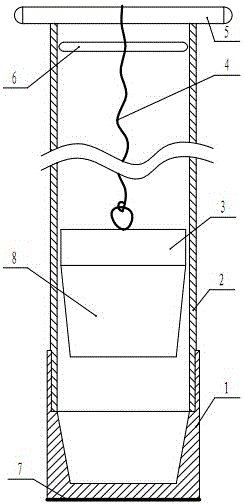

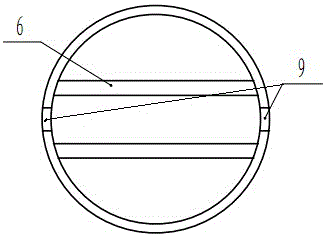

Simple sample crushing device and operation method thereof

InactiveCN105728093AImprove operational safetyOperation saves time and effortPreparing sample for investigationGrain treatmentsProblem of timeSimple sample

The invention discloses a simple sample crushing device and an operation method thereof. The simple sample crushing device comprises a crushing barrel, a guiding barrel and a crushing hammer. The guiding barrel is disposed on the crushing barrel; the crushing hammer is disposed in the guiding barrel and can move to the bottom of the crushing barrel; the upper end of the crushing hammer is connected with a steel wire; and the steel wire can penetrate through the upper end of the guiding barrel, and the length of the steel wire is larger than that of the guiding barrel. According to the simple sample crushing device and the operation method thereof, by means of the crushing barrel, the guiding barrel and the crushing hammer, the crushing hammer is lifted through the steel wire and freely falls along the guiding barrel, so that crushing of a coal and rock sample is achieved; the crushing hammer freely falls, so that time and effort are saved during operation; crushing is performed in the relatively enclosed environment, so that crushed particles do not fly around disorderly, the operation safety is high, and the operation environment is good; the structure is simple, and the cost is low; the crushing hammer only needs to be lifted, and the operation is simple; the crushing hammer freely falls along the guiding barrel and directly faces and crushes the sample, so that the crushing effect is good; and the problems of time and effort wasting, poor safety, operation environment and crushing effect, high cost and complicated operation in the prior art are effectively solved.

Owner:GUIZHOU UNIV

Paint spraying device for resistor machining

InactiveCN113318886AEvenly paintedImprove paint qualitySpraying apparatusReciprocating motionStructural engineering

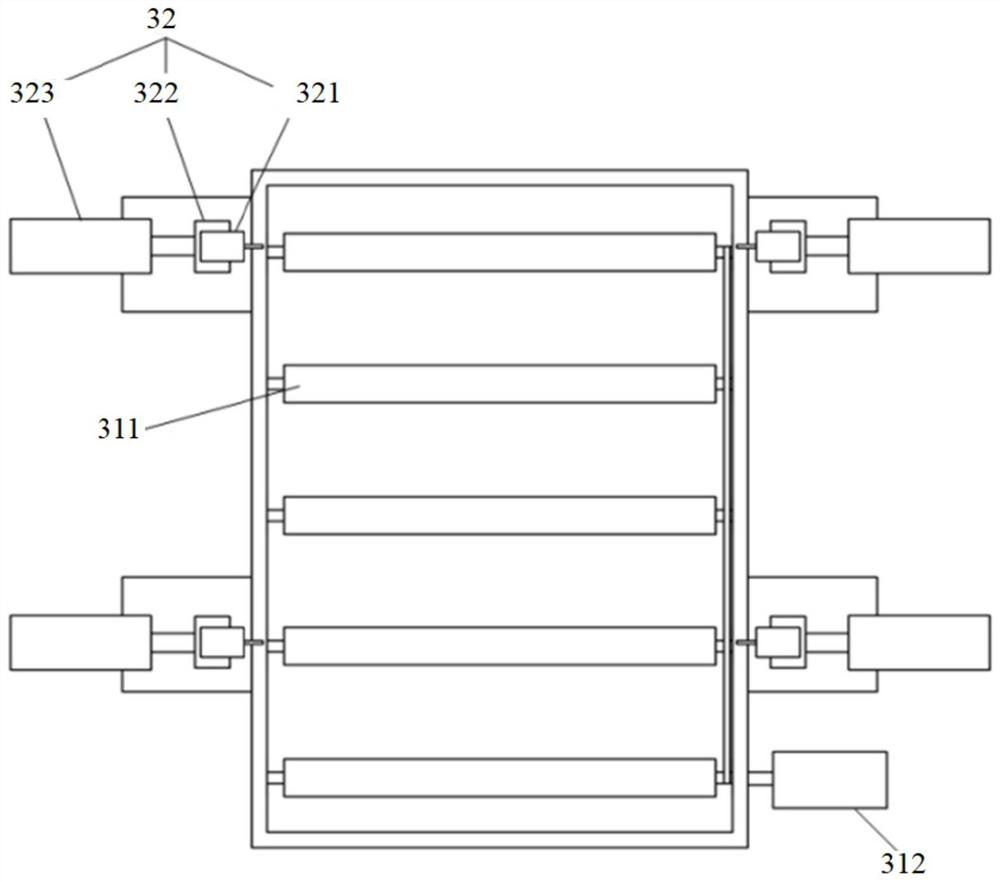

The invention discloses a paint spraying device for resistor machining. The paint spraying device comprises a support, a driving mechanism, a plurality of paint spraying assemblies and a plurality of connecting shafts. The connecting shafts are sequentially and horizontally arranged in the height direction and are rotationally arranged on the inner side wall of one side of the support under driving of the driving mechanism. Each connecting shaft is provided with a clamp for clamping a resistor. Each paint spraying assembly can do horizontal reciprocating motion along the corresponding connecting shaft under the driving of the driving mechanism. According to the paint spraying device, automatic overturning and uniform paint spraying of the resistor are realized.

Owner:安徽功率电气有限公司

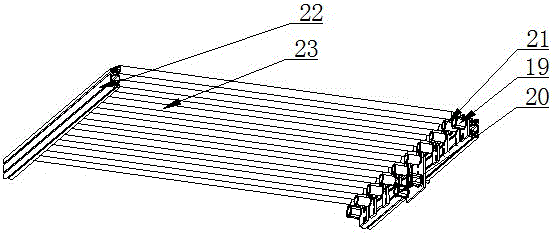

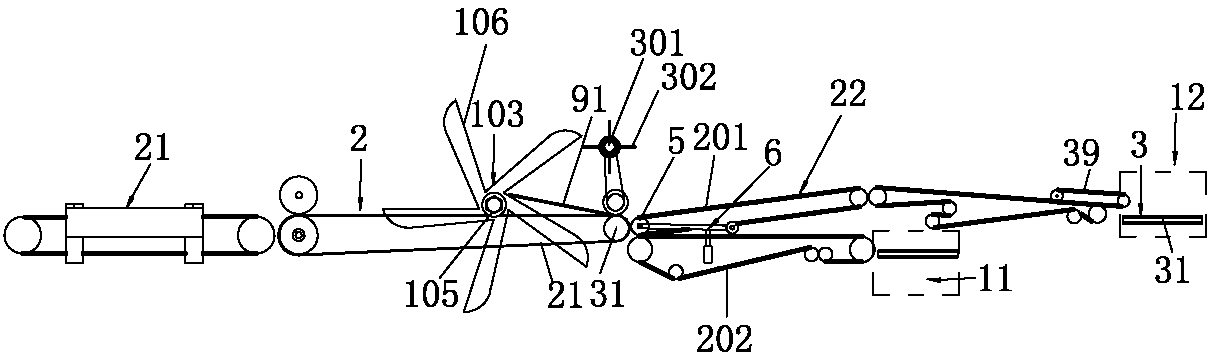

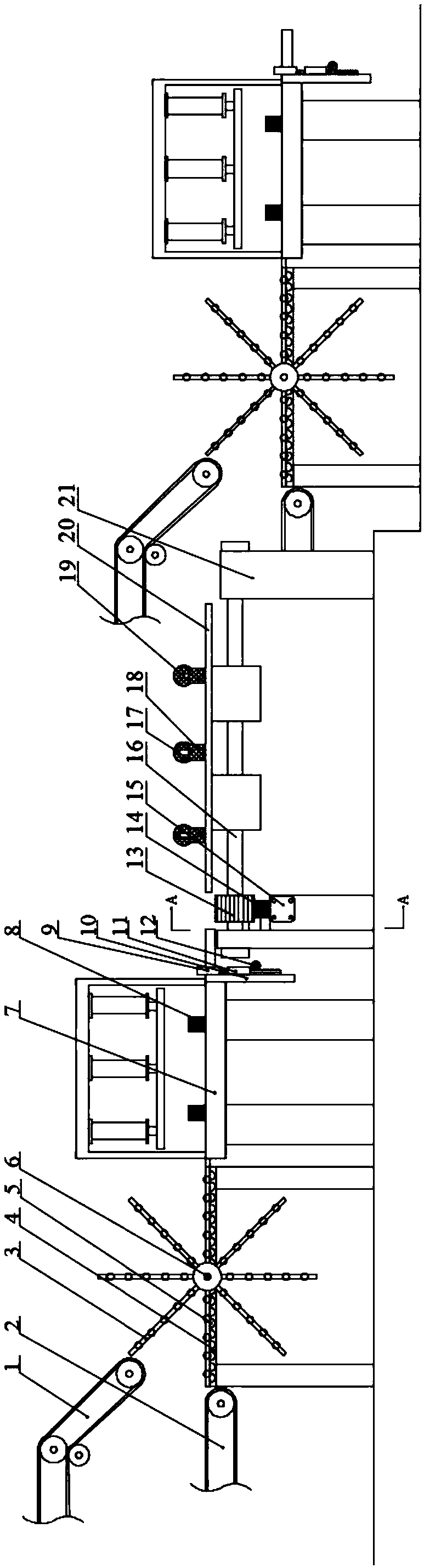

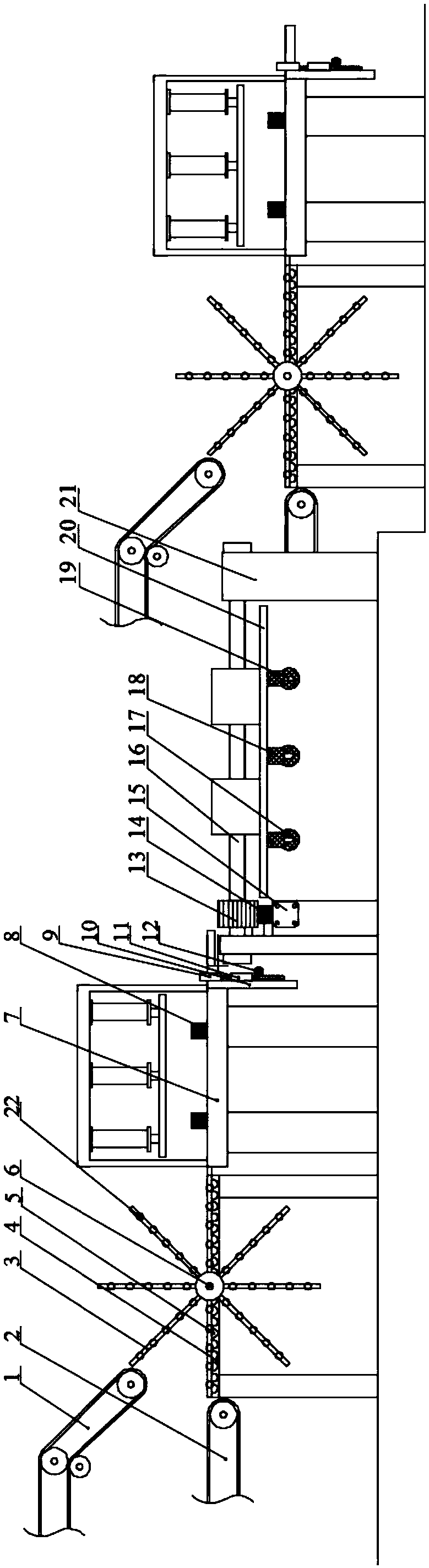

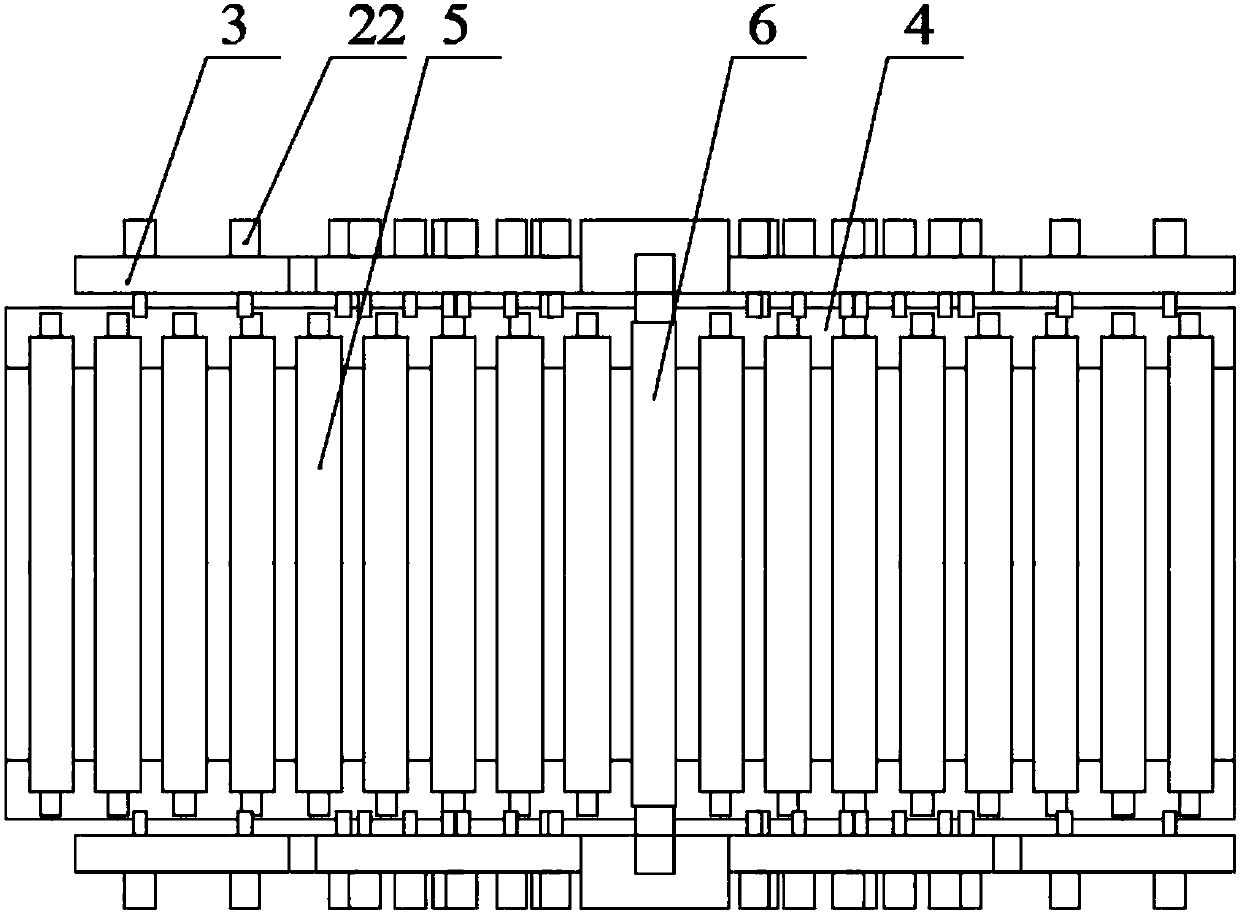

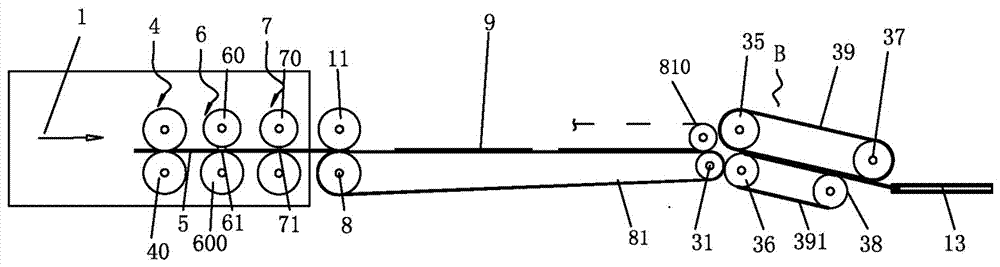

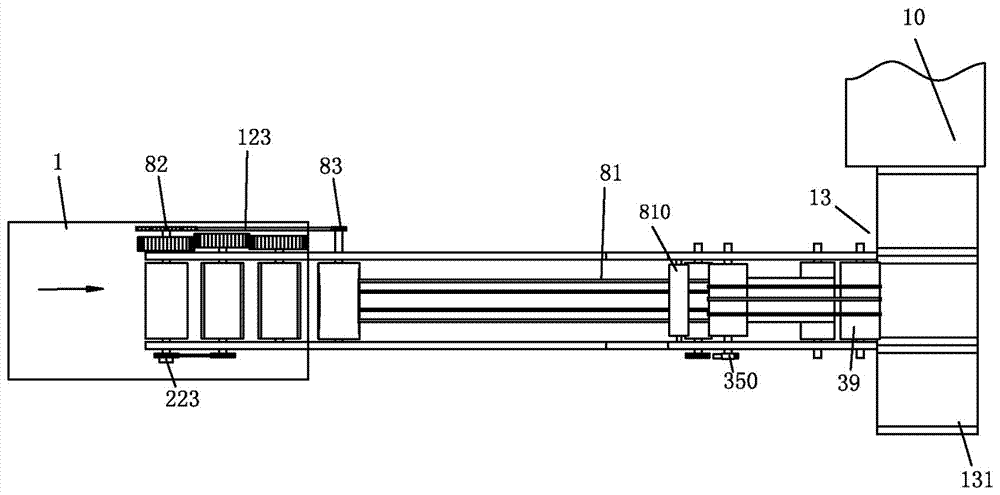

Two-driven-by-one overturning and conveying device for mask blank making machine

ActiveCN107792695ACommutation is accurateAccurate conformal positioningOverturning articlesArticle feedersRespiratorEngineering

A two-driven-by-one overturning and conveying device for a mask blank making machine is characterized in that the conveying device comprises a feeding conveying mechanism connected with the mask blankmaking machine and a double-channel conveying mechanism connected with mask ear ribbon welding machines; and an overturning and conveying mechanism is arranged between the feeding conveying mechanismand the double-channel conveying mechanism. According to the two-driven-by-one overturning and conveying device for the mask blank making machine, the mask blank making machine and the two mask ear ribbon welding machines can be organically combined through the feeding conveying mechanism, the overturning and conveying device and the double-channel conveying mechanism, and finally mask blanks arestably conveyed to the mask ear ribbon welding machines at a constant speed; and conveying belts are arranged on the feeding conveying mechanism in a 3D manner, precise reversing and conformal positioning of the mask blanks produced by the blank making machine are guaranteed, finally the machining efficiency of mask ribbon welding is improved, and the machining cost is saved.

Owner:仙桃市犇牛机械制造有限公司

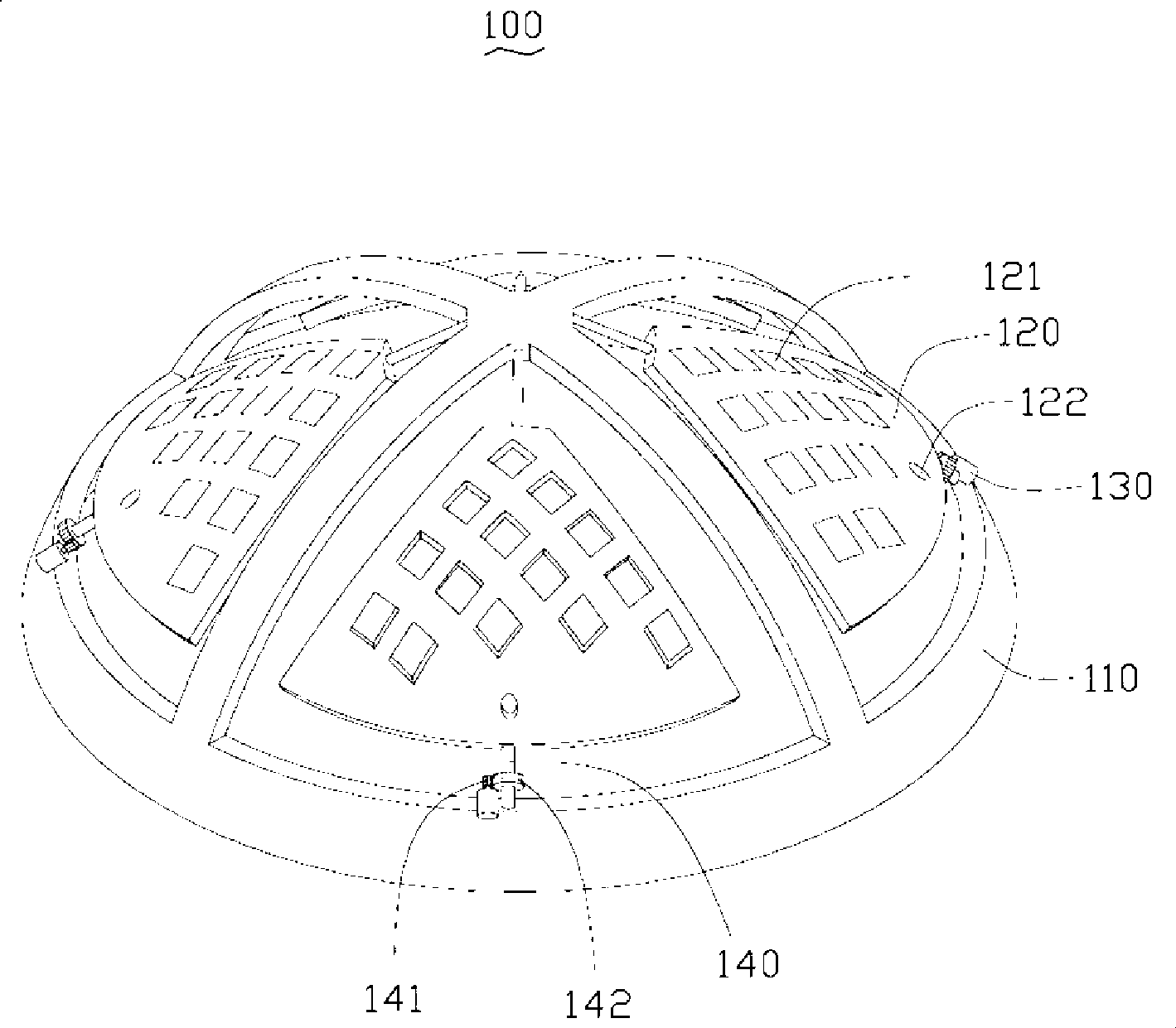

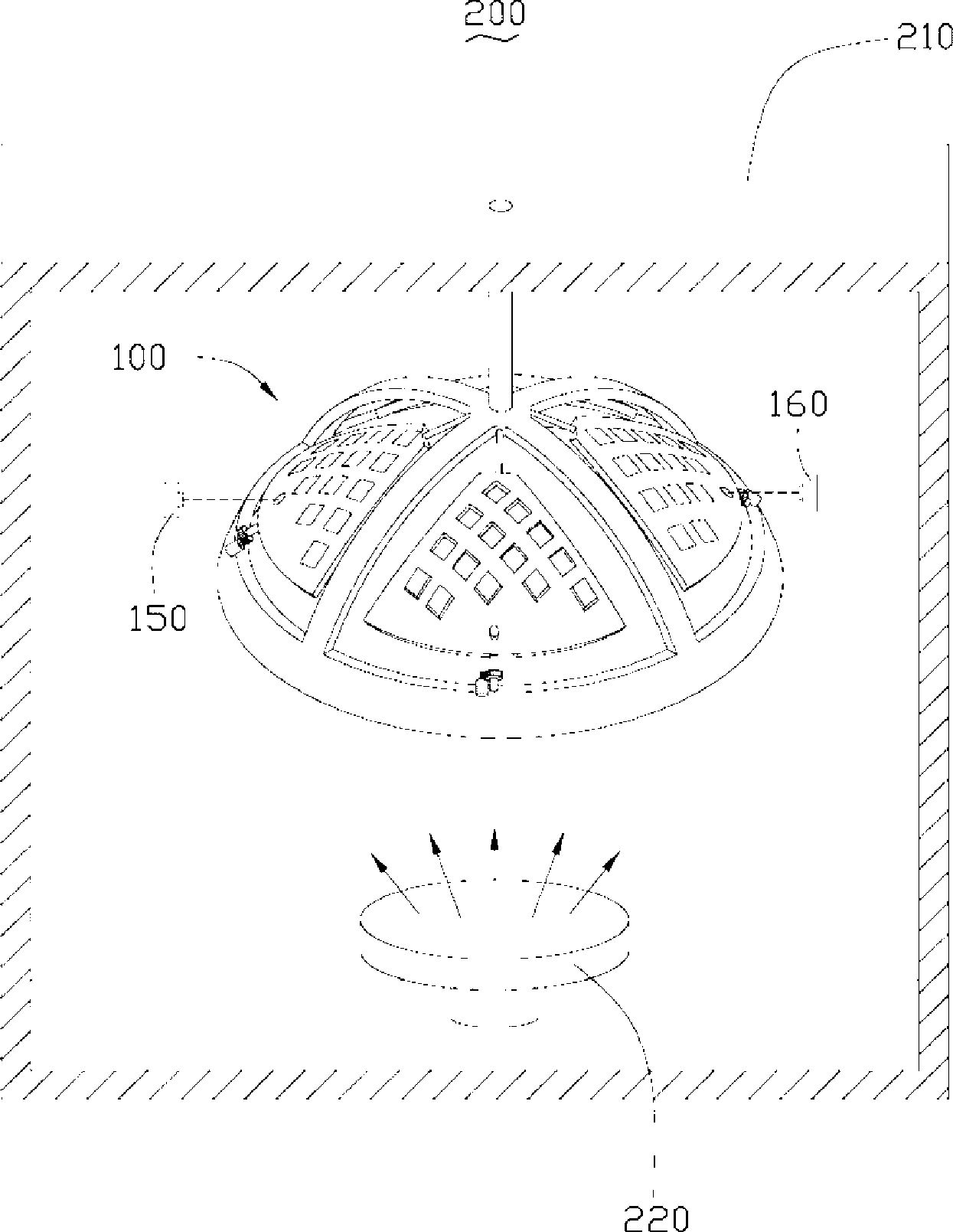

Automatic cell material overturning device and method and solar cell production line

ActiveCN106611729ARealize automatic flippingLittle impact on photoelectric conversion efficiencyFinal product manufactureSemiconductor/solid-state device manufacturingProduction lineContact type

The invention relates to an automatic cell material overturning device and method and a solar cell production line, and belongs to the technical field of solar cells. The automatic cell material overturning device comprises a frame assembly, a cell material pickup mechanism, a cell material overturning mechanism and a control mechanism, the cell material pickup mechanism picks up a cell material, conveys the picked up cell material to a predetermined position, and comprises at least one non-contact type sucker for picking up the cell material in a non-contact manner; the cell material overturning mechanism overturns the cell material conveyed to the predetermined position by the cell material pickup mechanism for 180 degree; and the control mechanism is in signal connection with the cell material pickup mechanism and the cell material overturning mechanism to control motions of the cell material pickup mechanism and the cell material overturning mechanism, so that the cell material can be turned over automatically. The an automatic cell material overturning device can reduce contact with the cell material, reduces the probability of cell material pollution, and has less influence on the photoelectric conversion efficiency of solar cells.

Owner:ENN SOLAR ENERGY

Blockboard appearance flatness detection device for wood processing

InactiveCN112525112ARealize automatic flippingReduce manual operationsUsing optical meansAgricultural engineeringWood processing

The invention discloses a blockboard appearance flatness detection device for wood processing. The blockboard appearance flatness detection device comprises a base, a controller, a feeding mechanism,a first electric conveying roller, a first CCD detection device, a turnover mechanism, a second electric conveying roller, a second CCD detection device, a discharging groove and an electric gate plate; the controller is mounted at the right rear part of the top end of the base; the feeding mechanism is arranged on the front side of the top end of the base; the first electric conveying roller is arranged at the top end of the base and located on the rear side of the feeding mechanism; the turnover mechanism is arranged at the top end of the base and located at the position corresponding to a discharging port in the rear side of the first CCD detection device. According to the blockboard appearance flatness detection device for wood processing, automatic feeding detection of the blockboardappearance flatness can be achieved, manual operation items of workers are reduced, the production period is shortened, automatic turnover of blockboards can be achieved, double-face detection is achieved, manual turnover of the workers is not needed, and time and labor are saved.

Owner:阿依努尔哈帕实

Aluminum alloy plate paint spraying equipment for industrial production

PendingCN114669418ASpray evenlyRealize all-round paintingLiquid spraying apparatusMetallurgyIndustrial engineering

The invention relates to paint spraying equipment, in particular to aluminum alloy plate paint spraying equipment for industrial production. According to the aluminum alloy plate paint spraying equipment for industrial production, all-directional paint spraying can be conducted, and the paint spraying speed is high. According to the technical scheme, the aluminum alloy plate paint spraying equipment for industrial production comprises first supports, clamping blocks, compression springs, a spraying mechanism and a discharging mechanism, the clamping blocks are movably arranged on the upper portions of the two first supports, the compression springs are arranged on the inner sides of the first supports and correspondingly matched with the clamping blocks, the spraying mechanism is arranged between the tops of the first supports, and the discharging mechanism is arranged between the tops of the first supports. And a discharging mechanism is arranged on the spraying mechanism part. Through cooperation of the spraying mechanism, the rotating mechanism and the power mechanism, when the equipment is used for paint spraying, paint can be uniformly sprayed on an aluminum alloy plate, and automatic turning can be achieved.

Owner:黄转

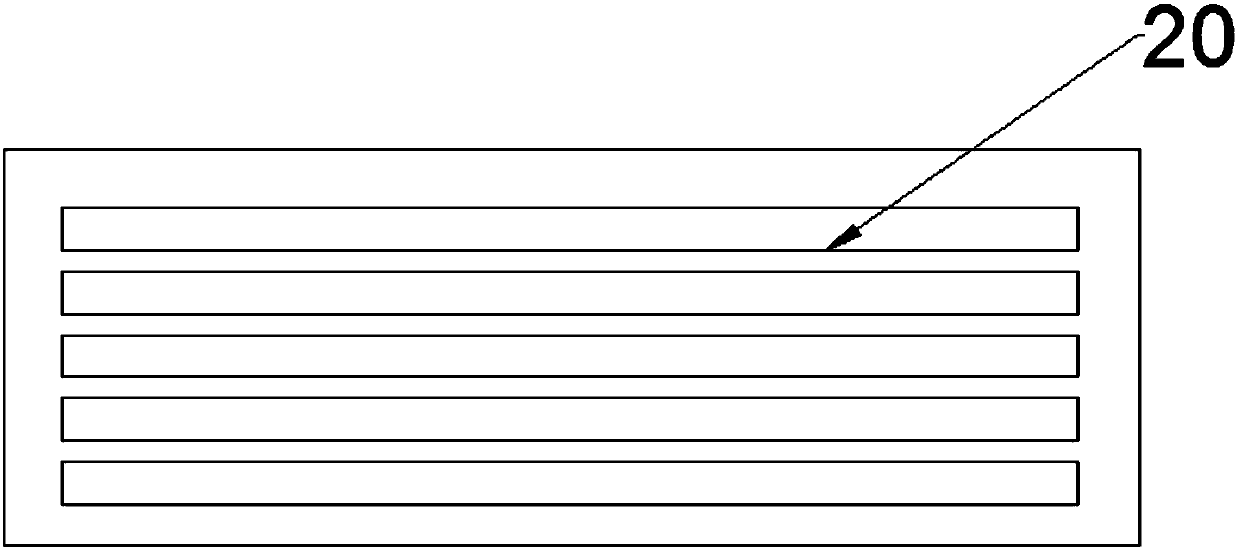

Wood board double-sided hot press-fit processing device

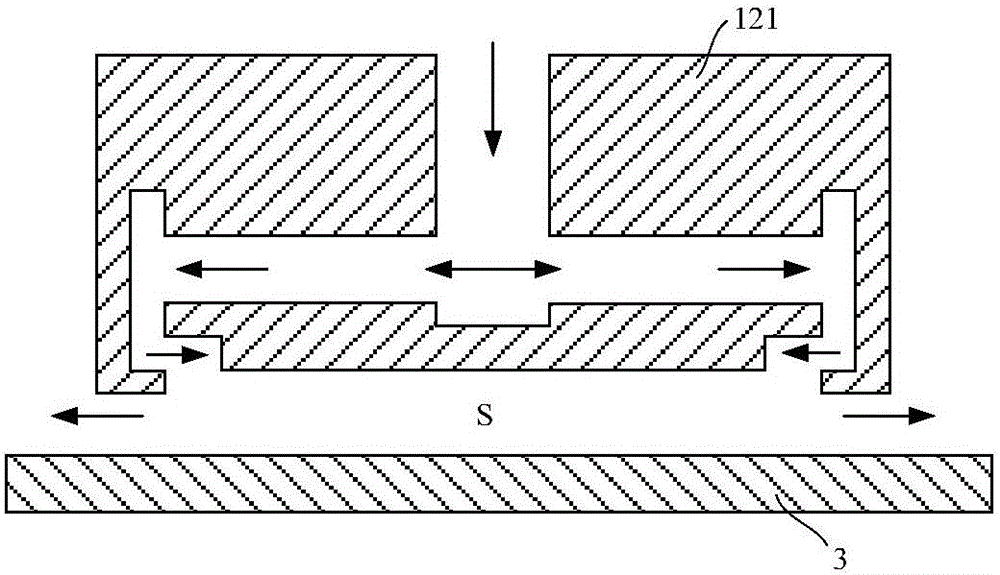

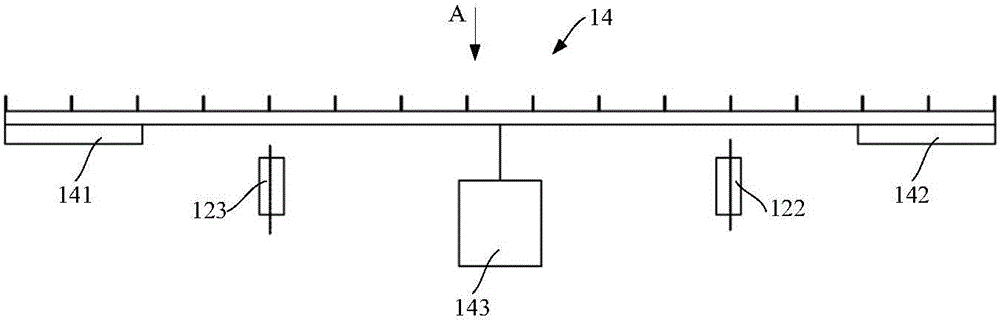

InactiveCN109940729ARealize automatic flippingAutomatic turning over fully automaticWood veneer joiningRotational axisPulp and paper industry

The invention discloses a wood board double-sided hot press-fit processing device. The wood board double-sided hot press-fit processing device comprises a positioning hot-pressing unit and a turnovertable, wherein the positioning hot-pressing unit is arranged at the feeding end and the discharging end of the turnover table; the positioning hot-pressing unit comprises a double-layer feeding belt,a feeding table and a hot-pressing machine which are connected in sequence, wherein rotating shafts are arranged on the two sides of the feeding table in a penetrating manner, and a plurality of rotating supports are arranged at the two ends of the rotating shafts in the radial direction; the turnover table comprises a turnover support, a turnover unit and a power unit, wherein the turnover support is rotationally connected with the turnover unit, the power unit is arranged on the turnover support, and the power unit provides power to drive the turnover unit to turn over. The wood board double-sided hot press-fit processing device can perform multi-layer positioning and hot-pressing bonding processing on the wood board, the board turning operation can be carried out on the wood board in afull-automatic mode, the problems that the production efficiency is low due to the fact that the wood board hot pressing cooperation industry needs to be manually stacked and positioned and the wood board is turned over and the like are solved.

Owner:QIANMUYE FURNITURE TIANJIN

Rotary drying type vegetable dehydration system

InactiveCN105768142AAvoid inconsistent dehydrationPrevent drynessFood treatmentMechanical engineeringDehydration

The invention discloses a rotary drying type vegetable dehydration system, which comprises a drying box and a heat exchange box, the side of the drying box is provided with a feed inlet and a discharge outlet, the feed inlet and the discharge outlet are located on the same side of the drying box, the bottom of the feed inlet is inclined, a first conveyer belt, a second conveyer belt and a third conveyer belt are arrange sequentially from the top down along a vertical direction in the drying box, the first conveyer belt and the third conveyer belt are located at one side close to the feed inlet in the drying box, the second conveyer belt is located at the other side in the drying box, the first conveyer belt, the second conveyer belt and the third conveyer belt have the same structure, which comprises a driving roller, a driven roller and a belt body, and the sidewall of the drying box is provided with a power chamber which is raised outward. By arranging the three conveyer belts in the drying box, the rotary drying type vegetable dehydration system can automatically turn vegetables during dehydration, thus preventing the ununiformity of vegetable dehydration effect caused by piling.

Owner:施婷婷

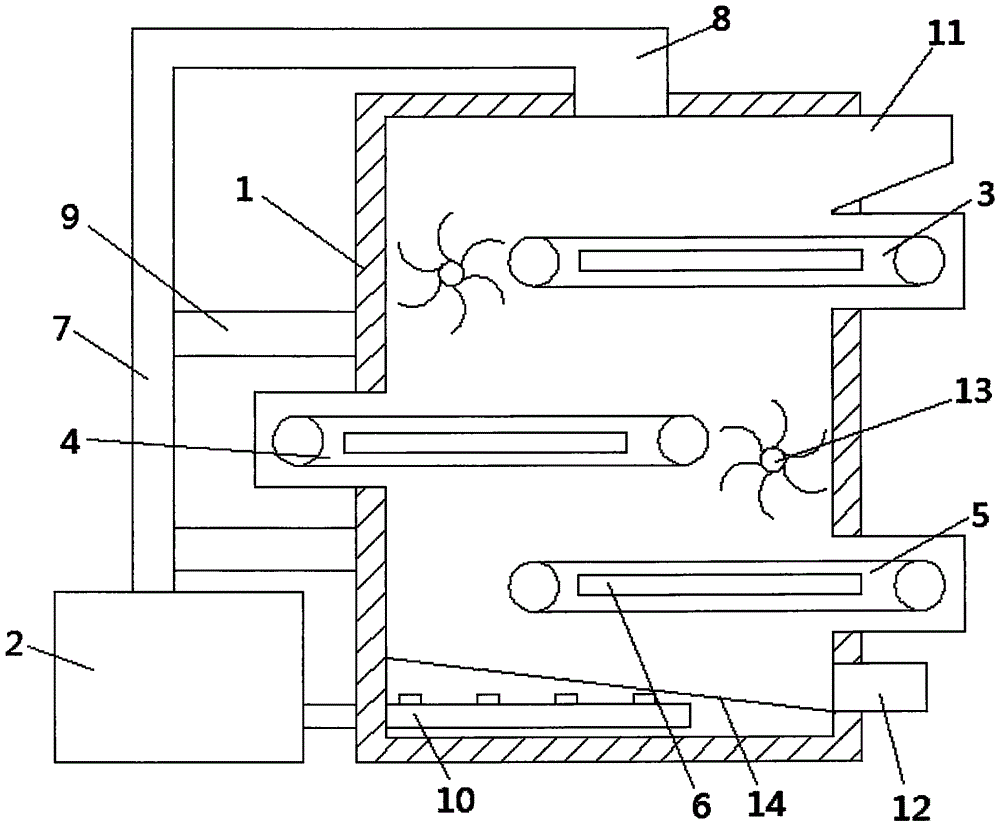

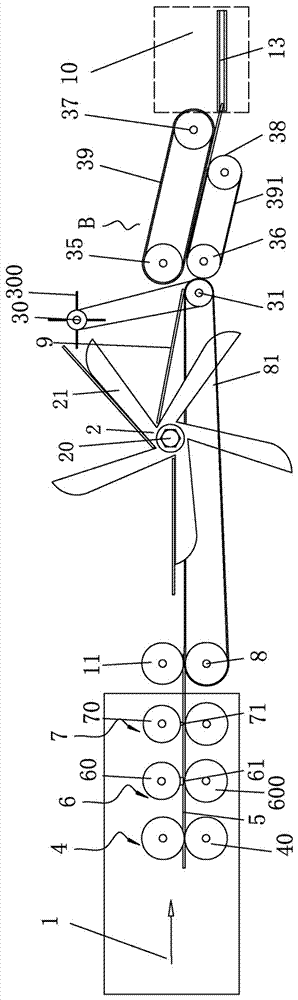

Automatic linking device between mask cutting process and belt welding process

PendingCN107455821AAccurately "fork"Improve patencyThrowing machinesConveyorsEngineeringMechanical engineering

Provided is an automatic linking device between the mask cutting process and the belt welding process. A mask cutting machine is adopted in the mask cutting process. A mask ear belt welding machine is adopted in the mask belt welding process. A material collecting conveying belt is arranged on the mask ear belt welding machine. The linking device is characterized by being composed of a material inlet conveying mechanism connected with the mask cutting machine and a material throwing conveying belt connected with the mask ear belt welding machine, the material inlet conveying mechanism comprises a main conveying roller and an auxiliary conveying roller, a plurality of main conveying belts are wound on a transmission roller system composed of the main conveying roller and the auxiliary conveying roller, the left end of the material throwing conveying belt is in butt joint with the auxiliary conveying roller, the right end of the material throwing conveying belt is in butt joint with the inlet of the material collecting conveying belt of the mask ear belt welding machine. The automatic conveying device is located between the mask cutting process and the belt welding process so that seamless linkage of mask processing processes can be realized, and mask pieces are conveyed in through the material inlet conveying mechanism, are automatically positioned and are stably conveyed onto the material throwing conveying belt at uniform speed.

Owner:仙桃市犇牛机械制造有限公司

Automatic barbecue machine capable of carrying out oil fume absorption treatment in barbecue process

InactiveCN107692856AReduce manual turning processReduce artificial inhalation of oil fumeCombination devicesDomestic stoves or rangesAbsorption rateAutomatic processing

The invention relates to an automatic barbecue machine capable of oil fume absorption treatment during the barbecue process, comprising a box body, on which a fixed block a and a fixed block b are arranged, and the box body is sequentially divided into a condiment box, a barbecue box, and a grill box from top to bottom. box and heating box; the grill box is connected with a grill frame, and there are various seasoning tanks arranged side by side in the seasoning box, and the lower end of the seasoning tank runs through the partition a and extends to the inner cavity of the grill box to connect with a discharge plate; the box body The oil fume absorption box is provided on the left side. The oil fume absorption box includes an absorption pipe. One end of the absorption pipe is connected to an absorption cover. The absorption pipe is provided with a suction fan. There is a filter adsorption plate; the invention has high grilling efficiency, uniform heating of grilled skewers, high oil fume absorption rate, low environmental pollution, and small harm to human health.

Owner:CHENGDU XINXIN HIGH STRENGTH FASTENER MFRCO

Door sheet production system

PendingCN112091616ARealize automatic flippingDetermine where to stopWork clamping meansFeeding apparatusPalletizerEngineering

The invention discloses a door sheet production system. The system comprises a conveyor, stacking robots arranged at a feeding position and a discharging position, a drilling machine used for drillingholes in the side faces of door sheets, an automatic door sheet hole milling device used for milling holes in the surfaces of the door sheets, a door sheet overturning mechanism used for overturningthe door sheets and rotary conveyors used for changing the directions of the door sheets. The stacking robots, the drilling machine, the automatic door sheet hole milling device, the door sheet overturning mechanism and the rotary conveyors are connected through the conveyor. The door sheet production system is simple in structure, stable in work and wide in application occasion and capable of achieving automatic production of the door sheets.

Owner:鹤山天山金属材料制品有限公司

Two-in-one automatic production machine for masks

PendingCN106671435AImprove patencyImprove processing efficiencyDomestic articlesMachining processEngineering

The invention discloses a two-in-one automatic production machine for masks. The two-in-one automatic production machine comprises a mask slicing machine and mask ear belt welding machines. The two-in-one automatic production machine is characterized in that the mask production machine further comprises a conveying and transferring device; the discharging end of the mask slicing machine is in butt joint with the feeding end of the conveying and transferring device; and the discharging end of the conveying and transferring device is in butt joint with the two mask ear belt welding machines. According to the two-in-one automatic production machine for the masks, seamless connection in the mask machining process can be achieved, mask slices can be provided for the two mask ear belt welding machines through one mask slicing machine, the problems that a traditional mask slicing machine and mask ear belt welding machines are not consistent in production takt, low in efficiency and inaccurate in slice conveying are solved, a feeding conveying mechanism of the two-in-one automatic production machine is used for achieving mask slice automatic positioning, and the conveying and transferring device can be used for stably conveying the mask slices to the mask ear belt welding machines at a constant speed.

Owner:仙桃市犇牛机械制造有限公司

Chamfering equipment for inner circles on two sides and implementation method thereof

PendingCN112388482AReduce labor intensityImprove work efficiencyEdge grinding machinesGrinding carriagesManufacturing engineeringMechanical engineering

Owner:东阳东磁自动化科技有限公司

Magnetic material tray switch and implementation method thereof

PendingCN111439584AReduce labor intensityHigh degree of automationConveyorsControl devices for conveyorsStructural engineeringTransfer line

The invention discloses a magnetic material tray switch. The magnetic material tray switch comprises a dryer and a conveying line arranged on one side of the dryer, wherein a mounting machine frame isarranged above the discharging end of the dryer, a tray guiding mechanism is connected with the upper portion of the discharging end of the dryer, a first carrying mechanism, corresponding to the upper portion of the tray guiding mechanism is connected with the mounting machine frame, a first transplanting mechanism, located on one side of the first carrying mechanism is connected with the mounting machine frame, and a second carrying mechanism, located on one side, away from one side of the first carrying mechanism of the first transplanting mechanism is connected with the mounting machine frame. The invention further discloses an implementation method of the magnetic material tray switch. According to the magnetic material tray switch, manpower can be completely replaced, a product canbe overturned completely, the automation degree is high, the working efficiency of the product overturning is greatly improved, and the labor intensity of workers is reduced. The magnetic material tray switch can completely eradicate the operation of manual overturning and tray-arranging operation on the product, and greatly improves the yield of the product.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com