Patents

Literature

154 results about "Labor burden" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Labor burden is the actual cost of a company to have an employee, aside from the salary the employee earns. Labor burden costs include benefits that a company must, or chooses to, pay for employees included on their payroll. These costs include but are not limited to payroll taxes, pension costs, health insurance, dental insurance, and any other benefits that a company provides an employee.

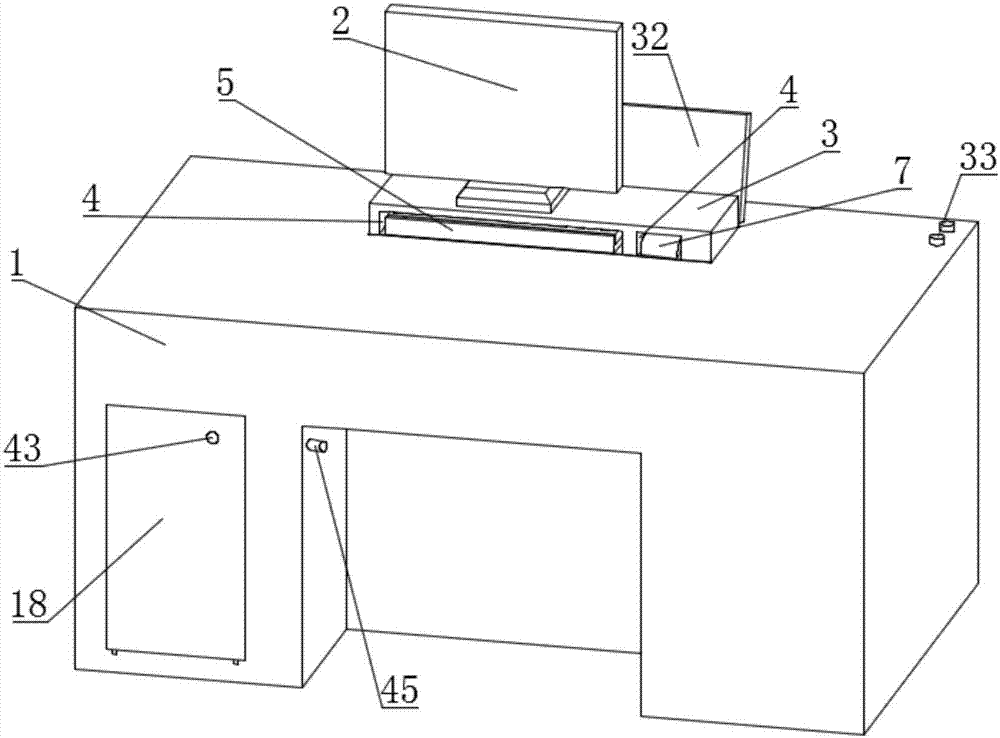

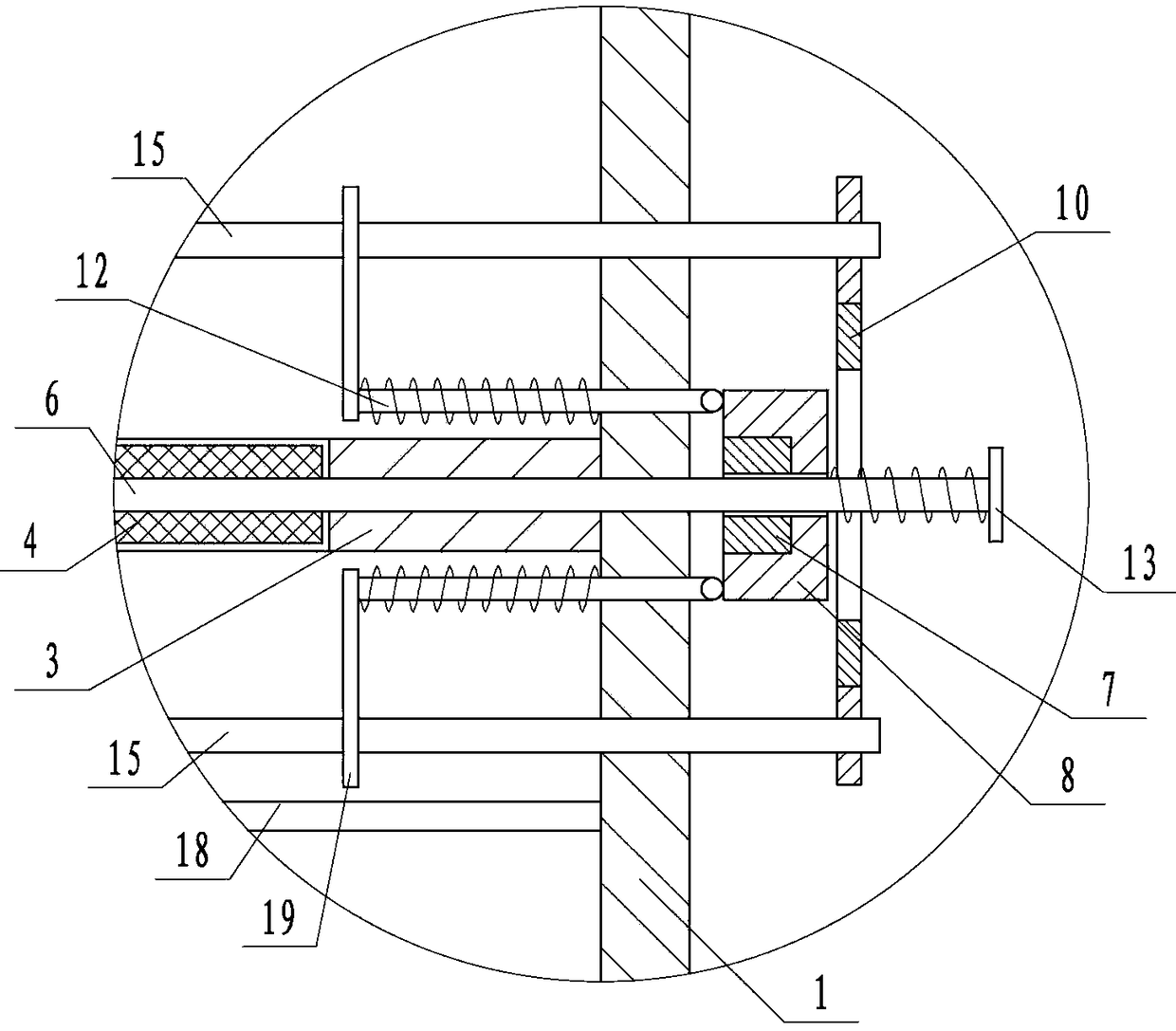

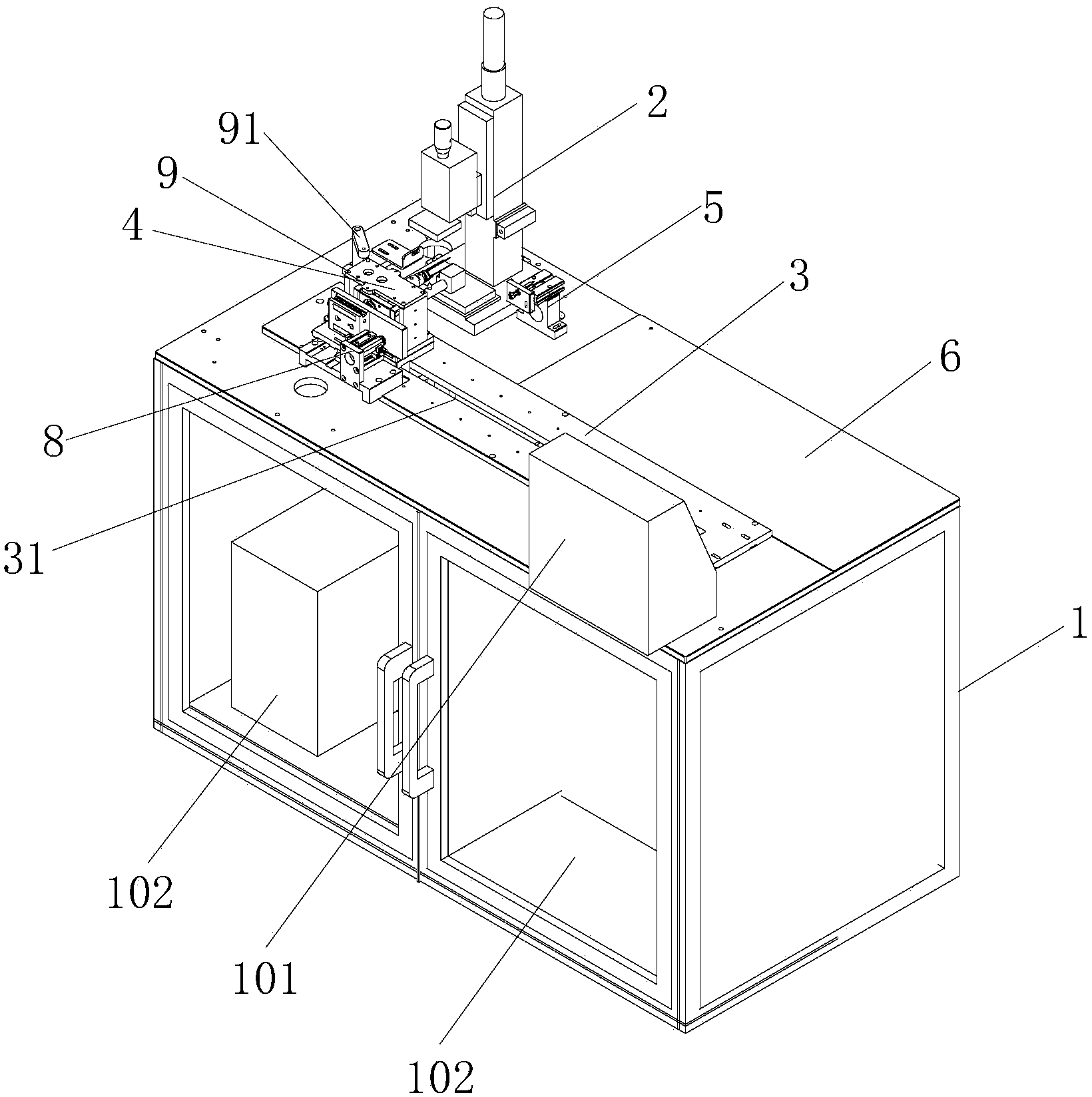

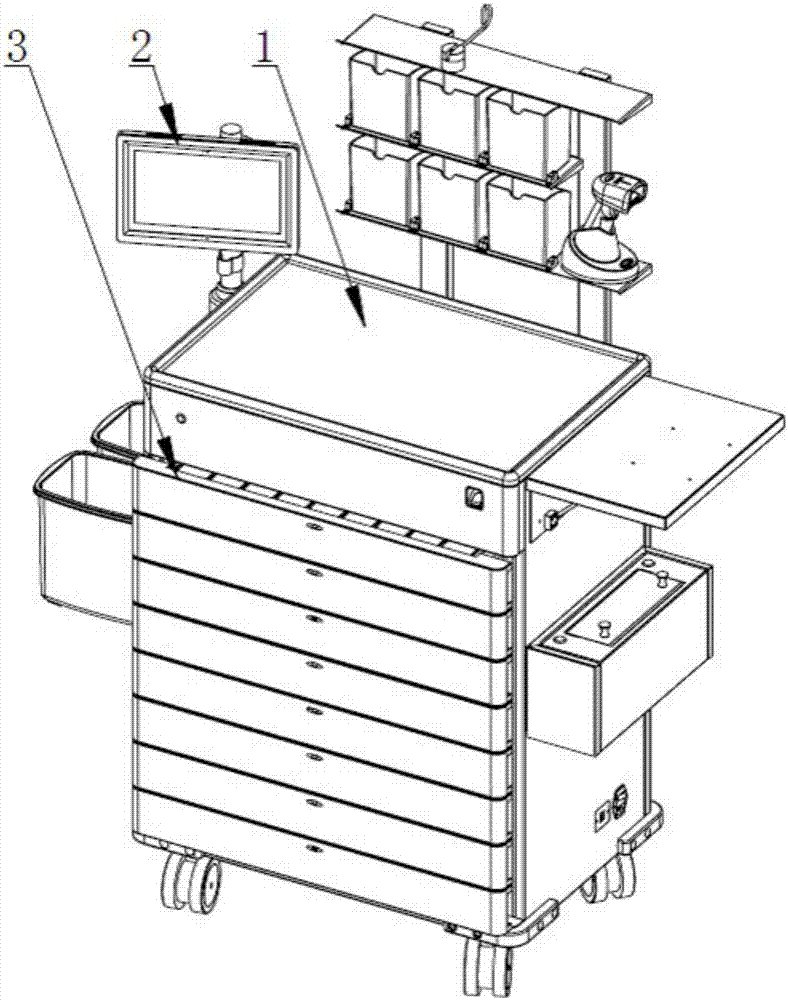

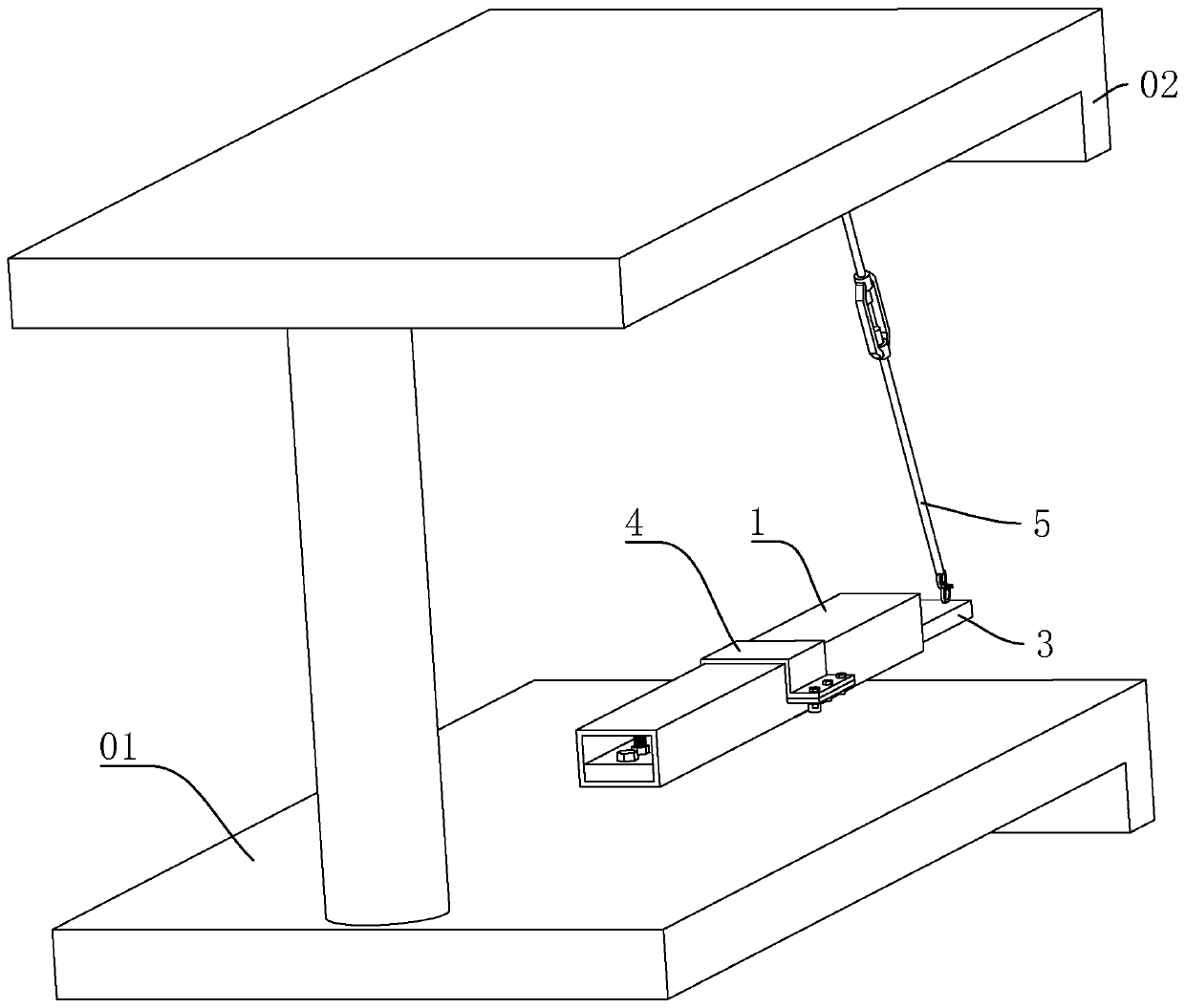

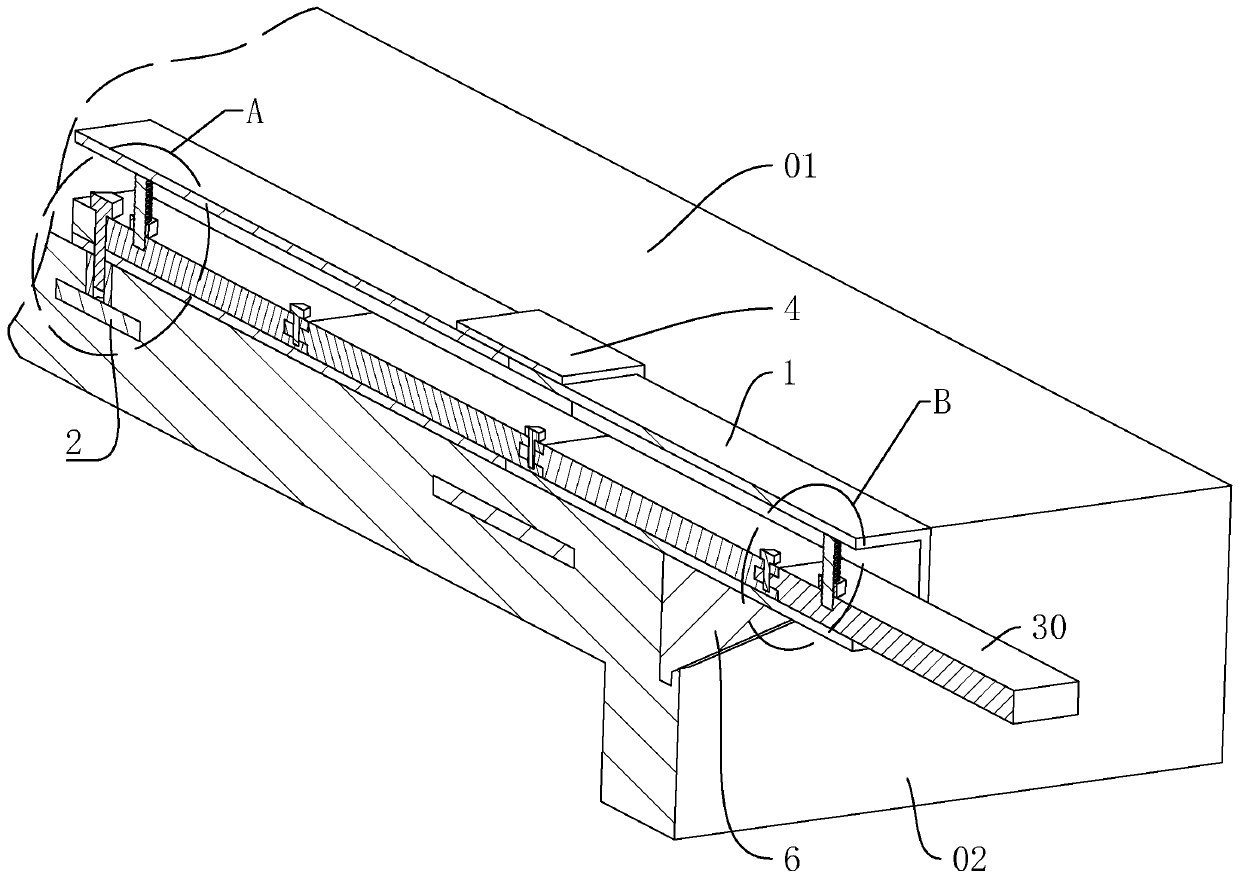

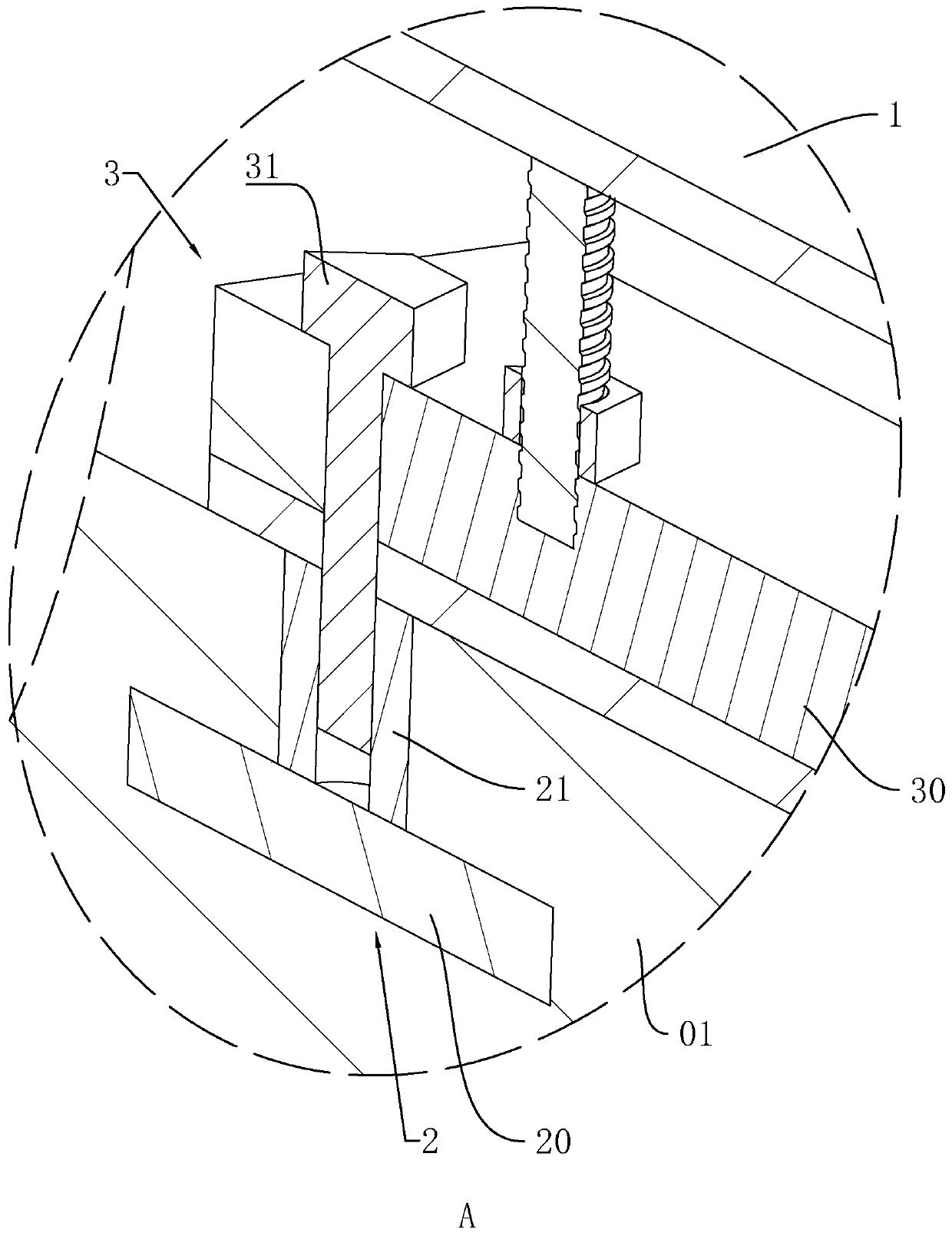

Hidden computer system for teaching machine room

InactiveCN107969801AReduce accumulationAvoid accumulationOffice tablesFurniture partsDisplay deviceComputerized system

The invention discloses a hidden computer system for a teaching machine room. The hidden computer system comprises a main body, a display and a fixing plate, two placing grooves are formed in the front end of the fixing plate, a keyboard is slidably connected to the placing groove on the left side, a mouse is arranged in the placing groove on the right side, the fixing plate is fixed to a supporting plate, a lifting groove is formed in the top of the main body, a first baffle is roatably connected to one side of groove opening of the lifting groove, thread rods are in threaded connection withthe four corners of the supporting plate, the upper ends of the thread rods are slidably connected to the top wall of the lifting groove, the other ends of the thread rods are connected to the bottomwall of the lifting groove, rotary shafts are connected to a position limiting plate, a first rotary shaft is connected to the thread rods respectively, and a first motor is fixedly connected to the bottom of the first rotary shaft. The hidden computer system can hide the computer display, a host, the mouse and the keyboard to reduce dust accumulation and labor burden, and can prevent students from randomly operating the computer when a teacher is teaching through an automatic storage function to improve teaching quality.

Owner:JIUZHOU VOCATION TECH COLLEGE

Sludge cleaning equipment for sewage treatment

ActiveCN108837562AChange the scope of dredgingImprove practicalitySettling tanks feed/dischargeGrain treatmentsSludgeDrive motor

The invention discloses sludge cleaning equipment for sewage treatment. The sludge cleaning equipment comprises a sedimentation basin, wherein sliding rail grooves are formed in two sides of the sedimentation basin; partition plates are fixedly arranged inside the sliding rail grooves; pulleys are arranged on two sides, close to the partition plates, of the interiors of the sliding rail grooves; mounting plates are fixedly arranged on the outer sides of the pulleys; side arms are fixedly arranged on the upper surfaces of the mounting plates; a beam is fixedly arranged on one side of the top end of the side arms; a hydraulic rod is fixedly arranged on the lower surface of the beam; a motor case is fixedly arranged at the bottom end of the hydraulic rod; a support frame is arranged on the lower surface of the motor case. According to the sludge cleaning equipment disclosed in the invention, sludge produced during sewage treatment can be cleaned, automation can be realized, and the working efficiency is improved. The pulleys are driven to move by a drive motor, so that the sludge cleaning range of the sludge cleaning equipment can be changed, the labor burdens of the staff can be alleviated, usage cost of large machinery can be reduced, and the operating cost can be reduced.

Owner:海南诚和源水务工程质量检测有限公司

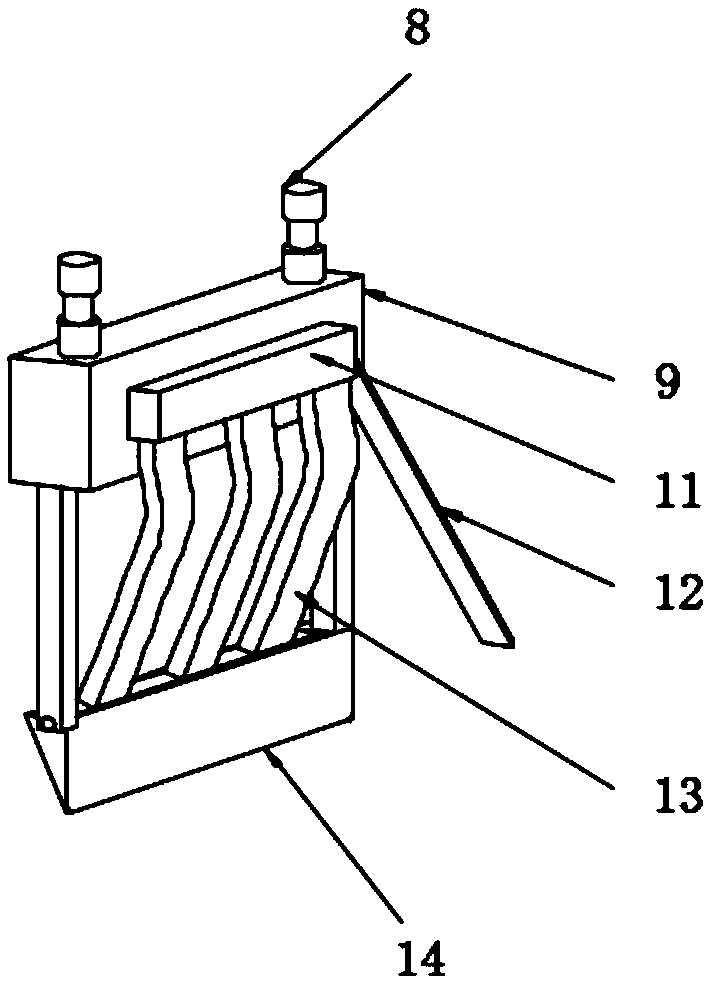

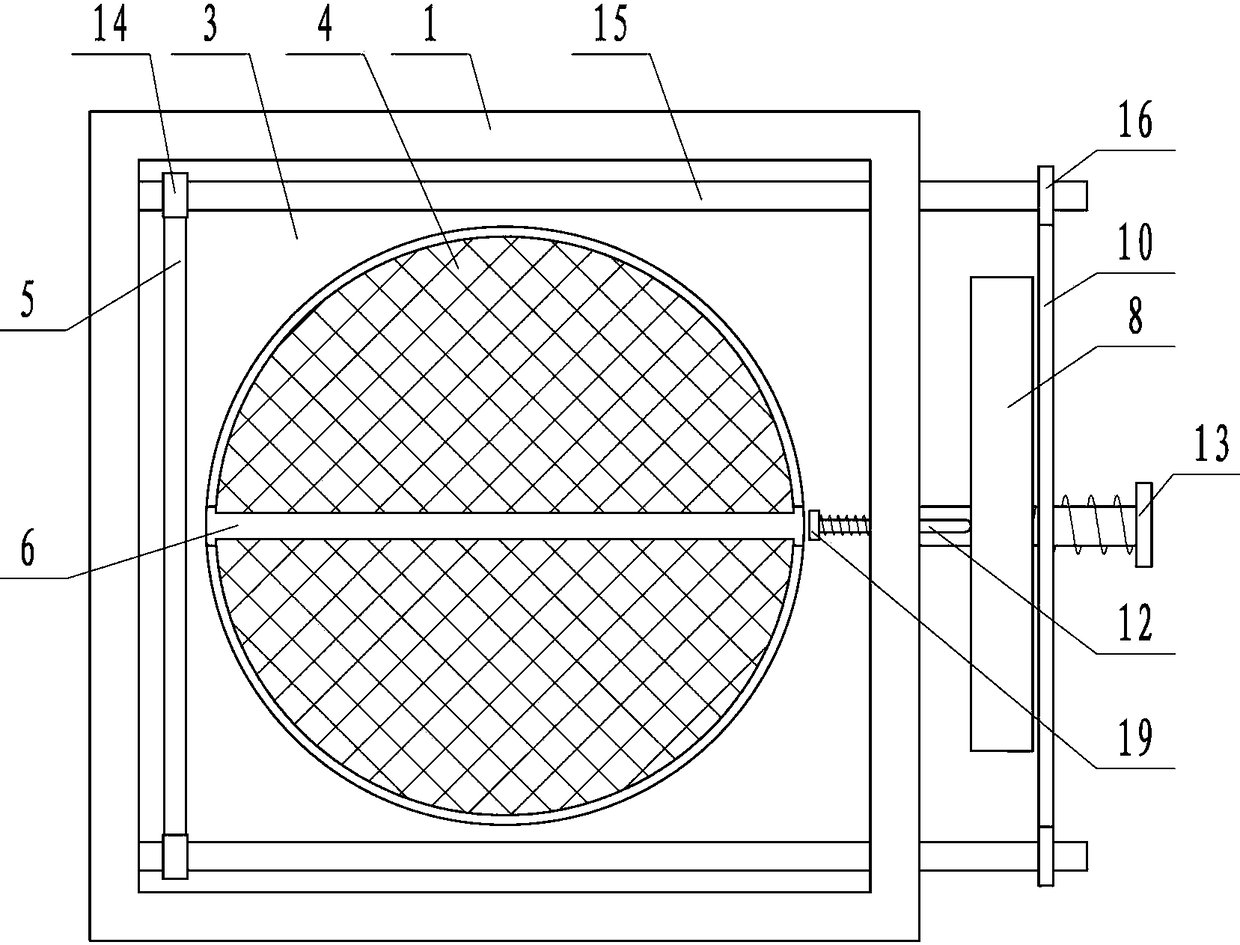

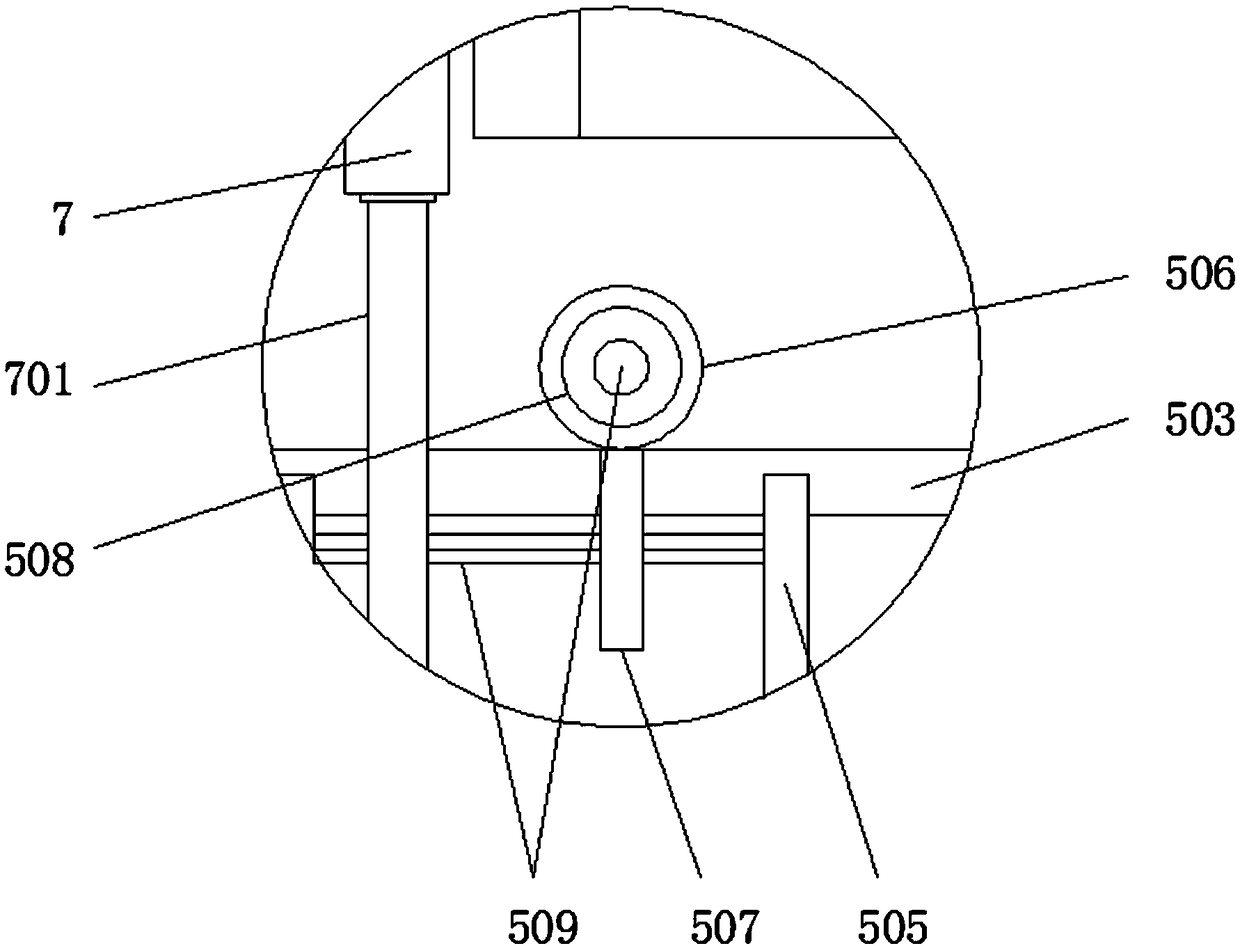

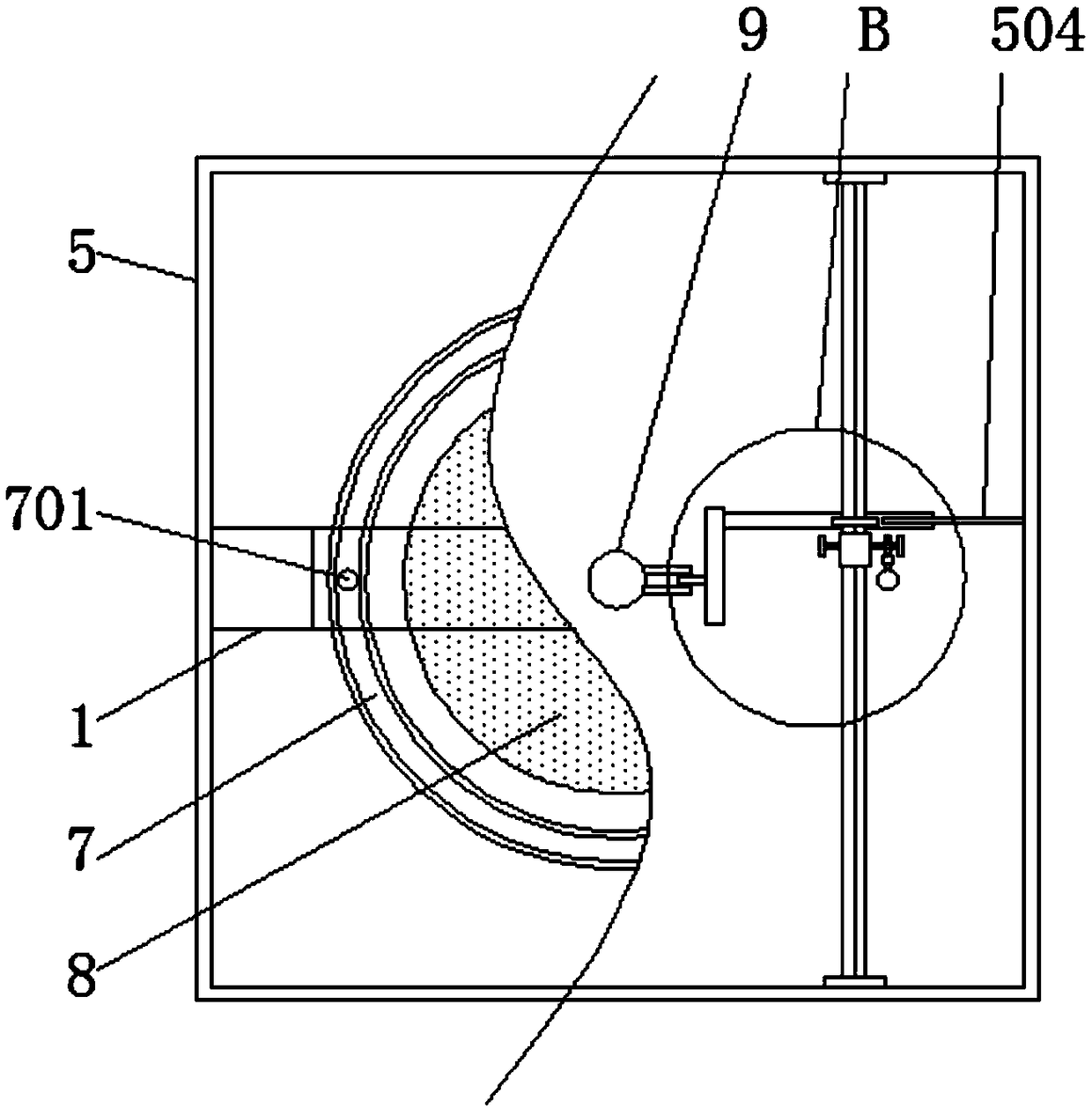

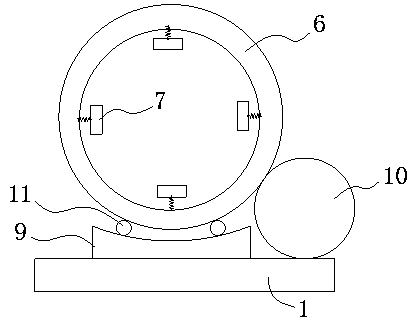

Dust collection device with filtering screen washing function

ActiveCN108854396AEfficient and clean treatmentIngenious structureCombination devicesTransportation and packagingEdge surfaceReciprocating motion

The invention relates to a dust collection device with a filtering screen washing function, aiming at effectively solving the problems that the dust filtering efficiency is low and a filtering screenis easy to block. According to the technical scheme, the dust collection device comprises a box body, wherein the box body is provided with two through holes; a horizontal baffle plate, which is located between the two through holes, is arranged in the box body; a supporting rod is arranged at the center of the baffle plate; a rotatable filtering screen is mounted on the supporting rod; two rotaryshafts, which are located at upper and lower sides of the filtering screen, are arranged in the box body; the two rotary shafts can do synchronous left-right reciprocating motion; the inner part of the rotary shaft located at the upper side is hollow and a spraying nozzle is arranged on an outer edge surface; a hairbrush is arranged on the outer edge surface of the rotary shaft located at the lower side; a unidirectional clutch sleeves the supporting rod at the outer side of the box body; a shell body sleeves the unidirectional clutch; an outer tooth ring sleeves the shell body; a push rod which can move leftward and rightward is arranged on a side wall of the box body; the outer end of the push rod can be in contact with the outer wall of the shell body. By adopting the dust collection device, labor burdens are alleviated and efficient and clean treatment of dust is realized.

Owner:上海进贤机电科技有限公司

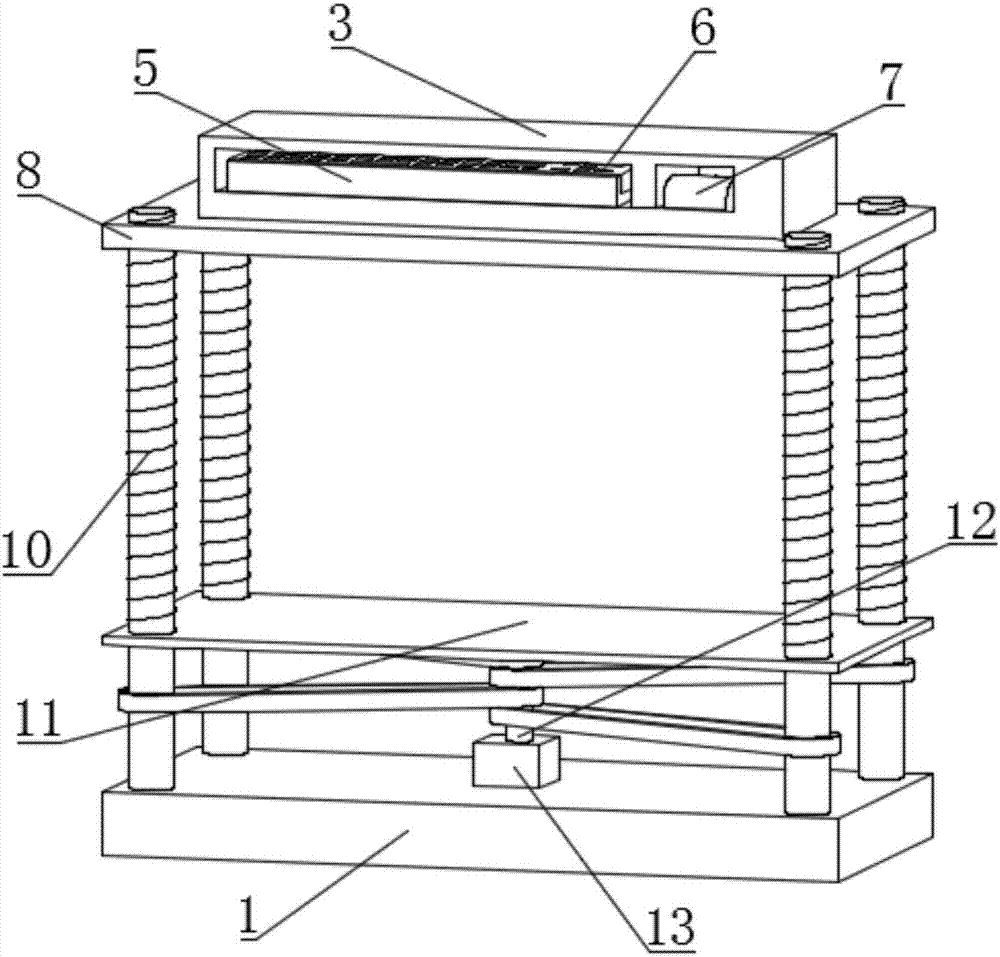

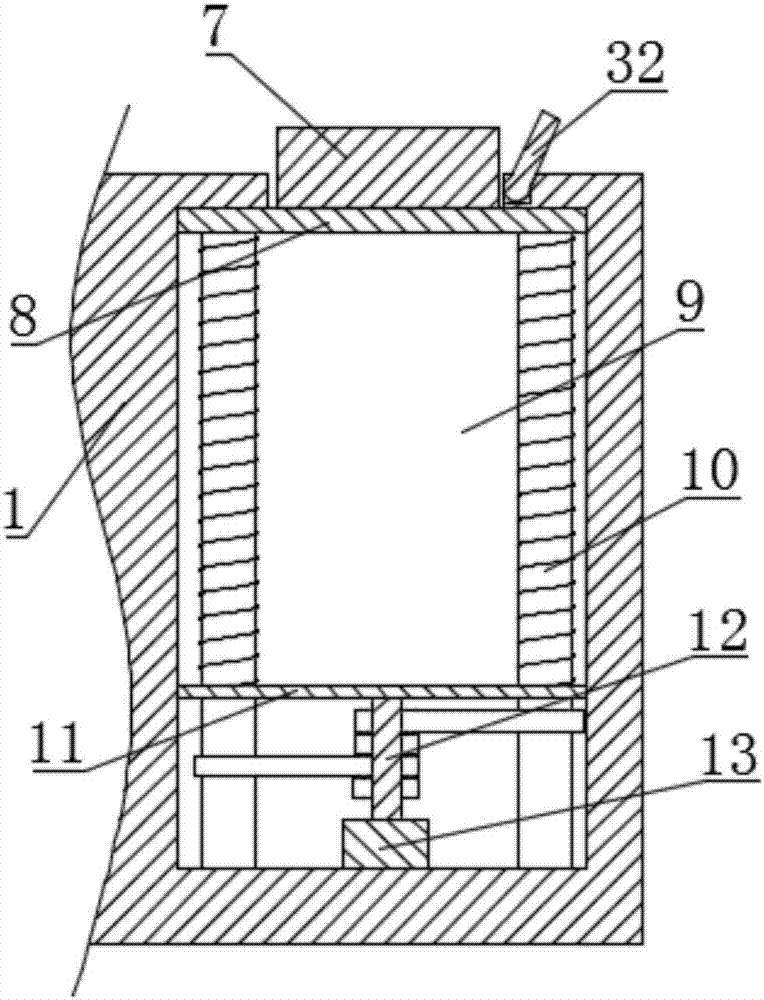

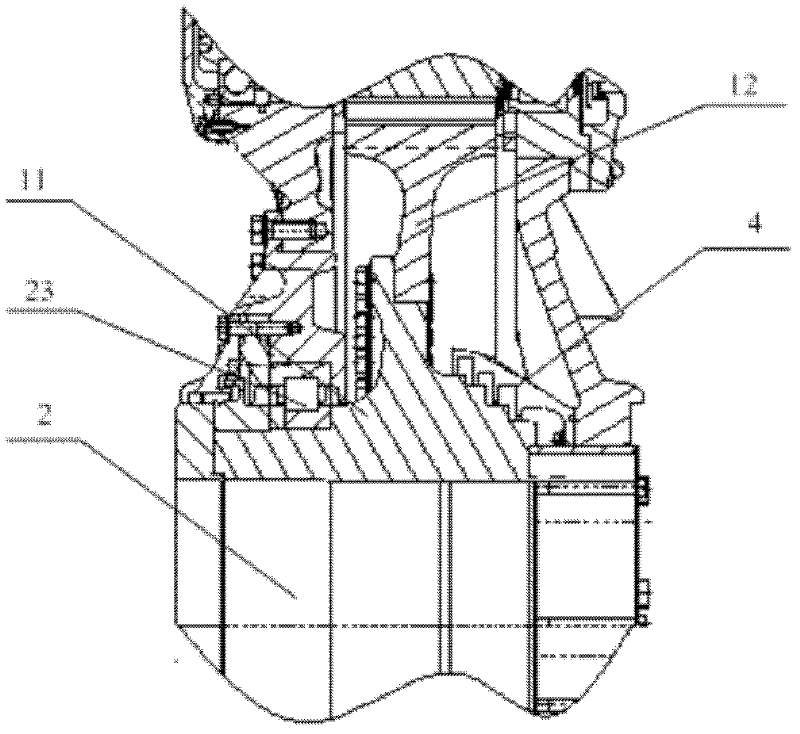

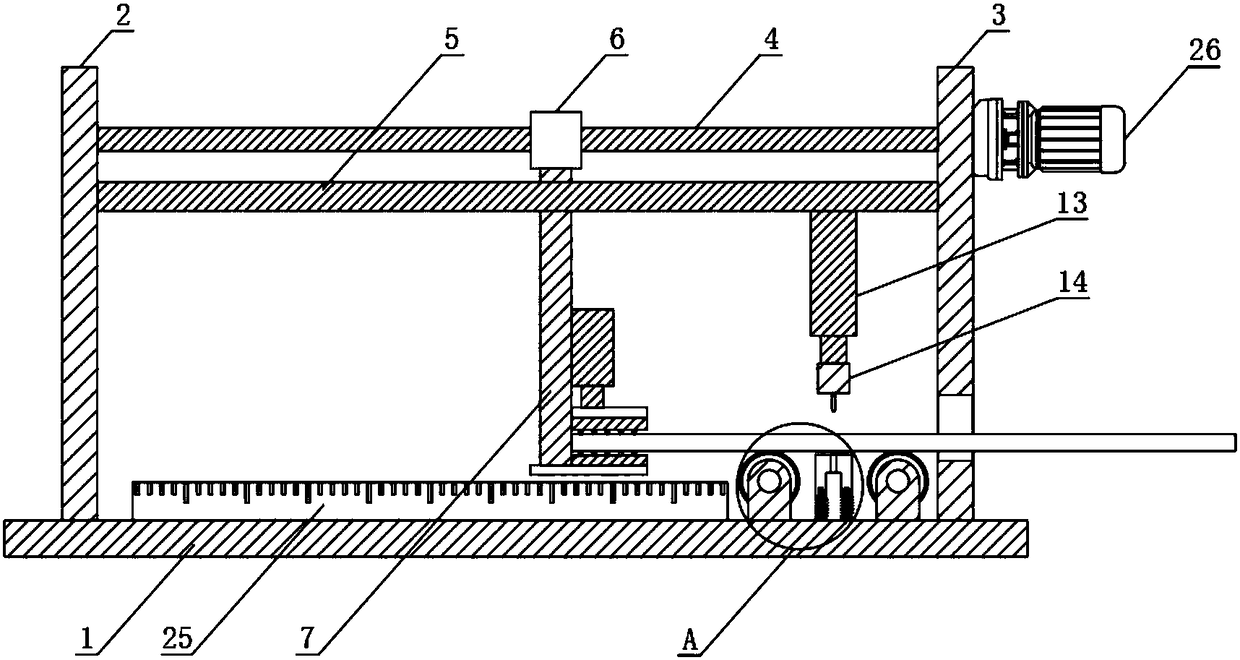

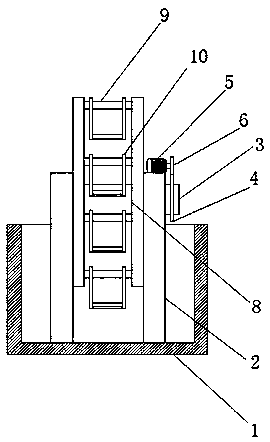

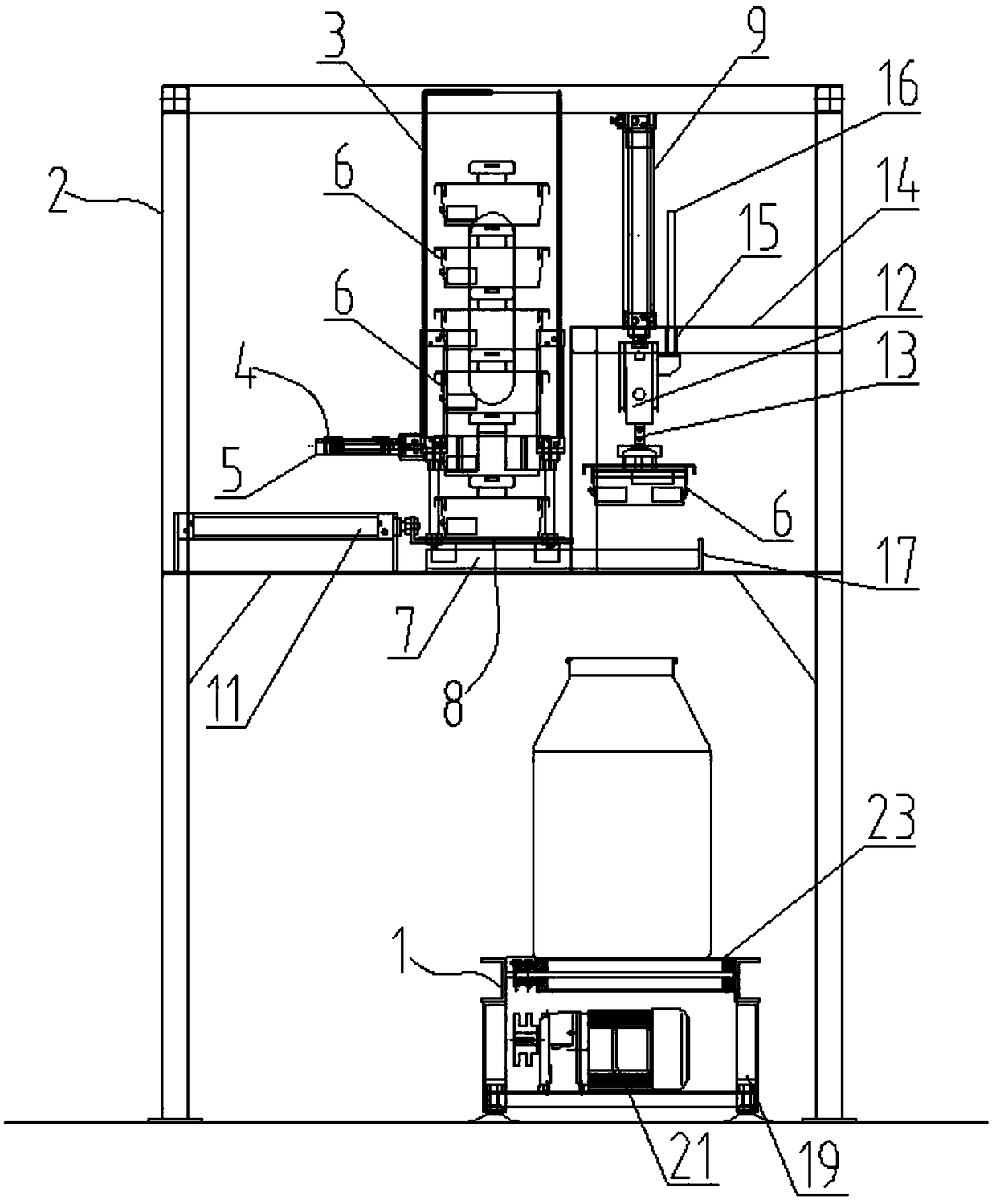

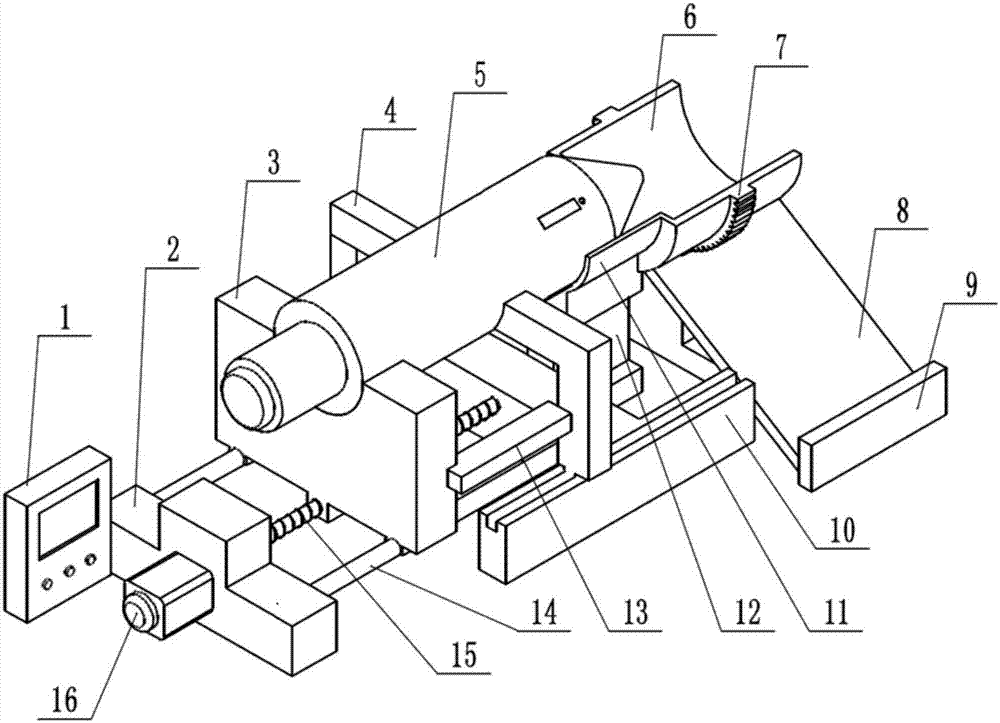

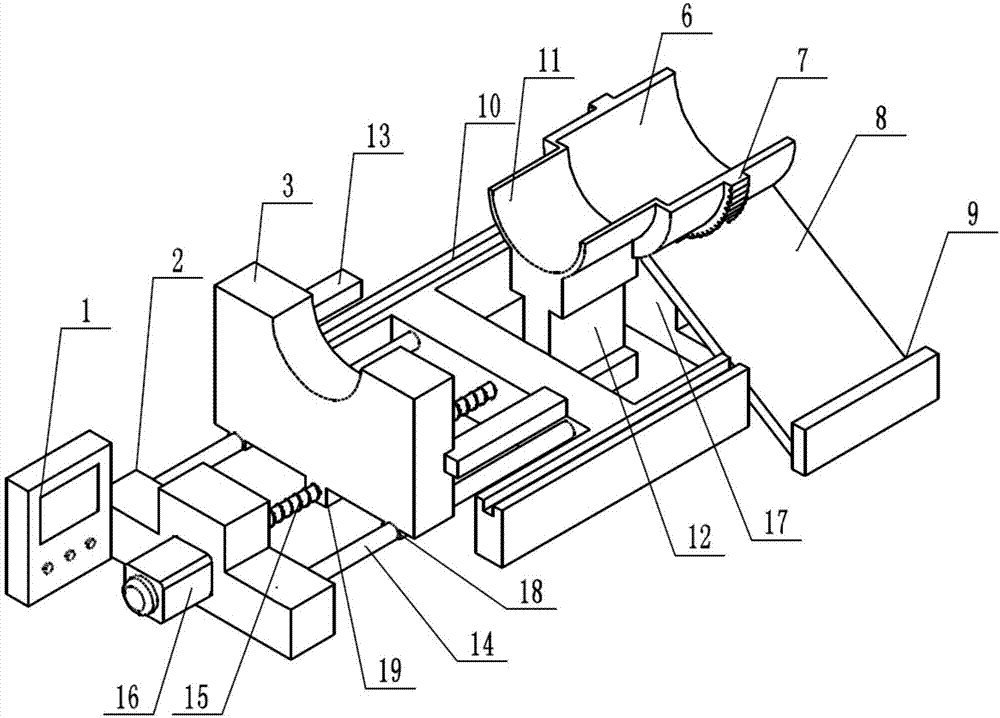

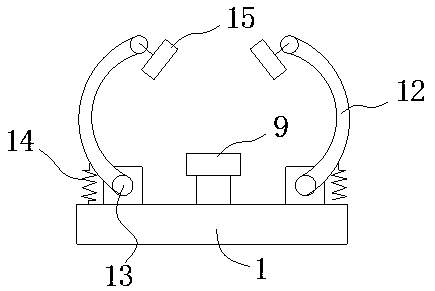

Assembly system of integrated gearbox

InactiveCN102350633AImprove assembly efficiencyPrecise positioningAssembly machinesLifting devicesDrive shaftAssembly systems

The invention provides an assembly system of an integrated gearbox, which comprises a box body overturning device and a swinging device, wherein the box body overturning device comprises a support; a first bearing pedestal and a second bearing pedestal are horizontally and oppositely arranged on the support; a driving shaft and a driven shaft are respectively arranged on the first bearing pedestal; executive parts used for clamping the box body and driving the box body to overturn are respectively and fixedly arranged at the end parts of the driving shaft and the driven shaft; the swinging device comprises an upper clamping plate and a lower clamping plate which are used for clamping a gear ring, and an adjusting and supporting device which is used for vertically positioning the upper andthe lower clamping plates and driving the upper and the lower clamping plates to move in opposite directions; and a hanging bracket used for being connected with an overhead traveling crane is also fixedly arranged at the top of the adjusting and supporting device. By adopting the assembly system of the integrated gearbox, which is provided by the invention, the gear ring can be accurately positioned while being mounted in the box body, so the assembly quality and the assembly efficiency are improved; and meanwhile, by adopting the box body overturning device, the assembly operation is also facilitated, the labor burdens of workers are lightened, and the assembly efficiency of the integrated gearbox is improved.

Owner:CRRC DALIAN CO LTD

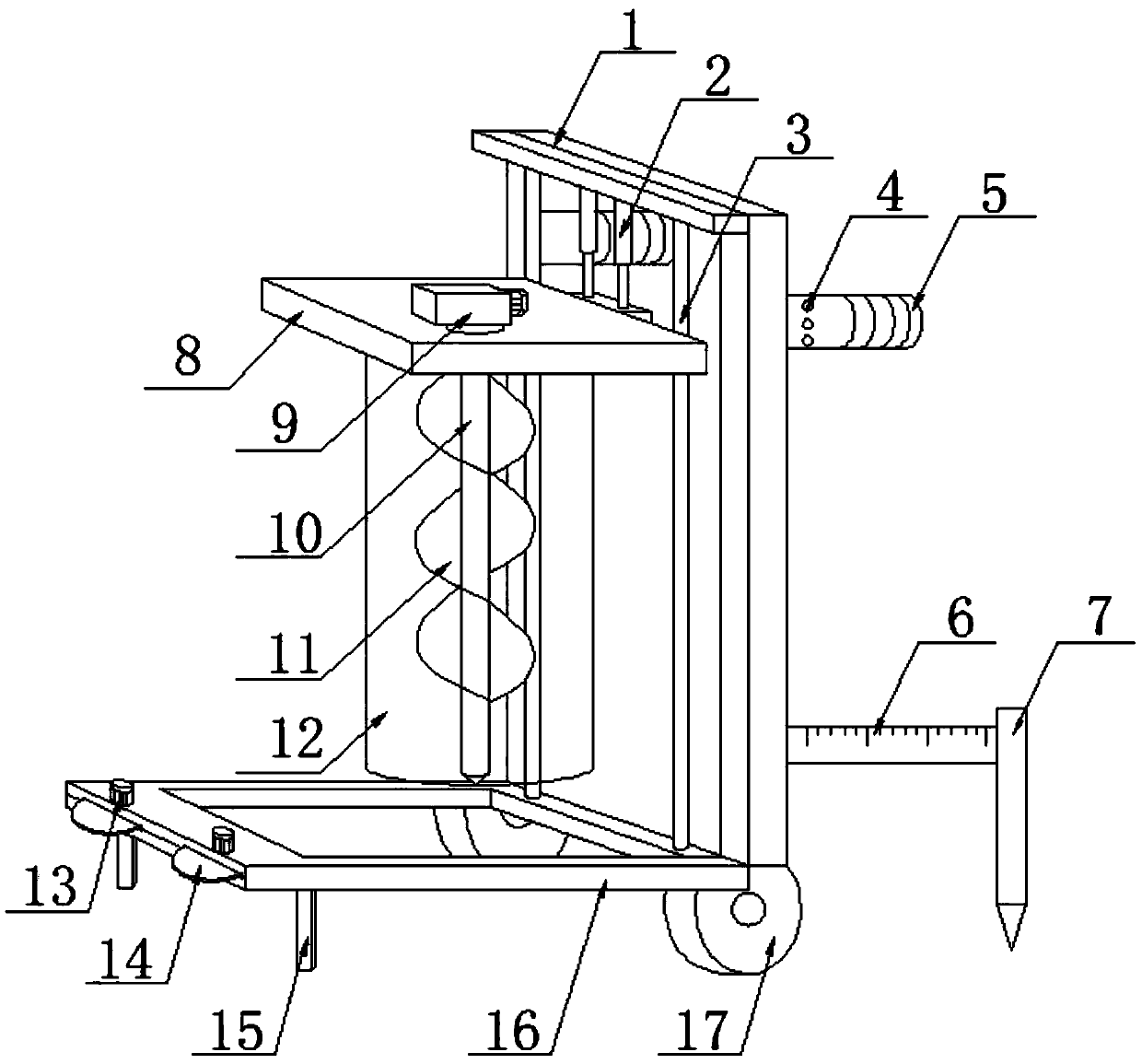

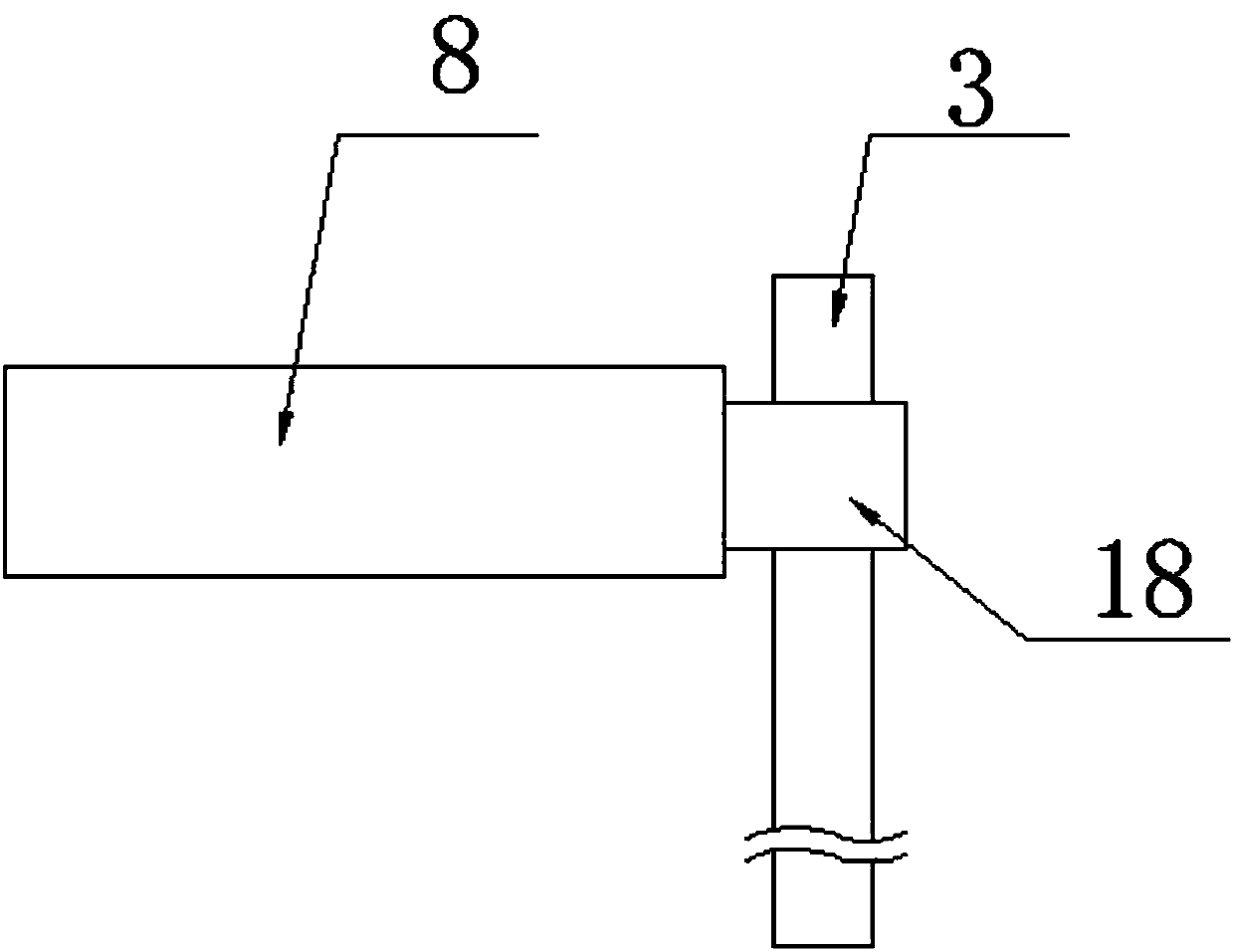

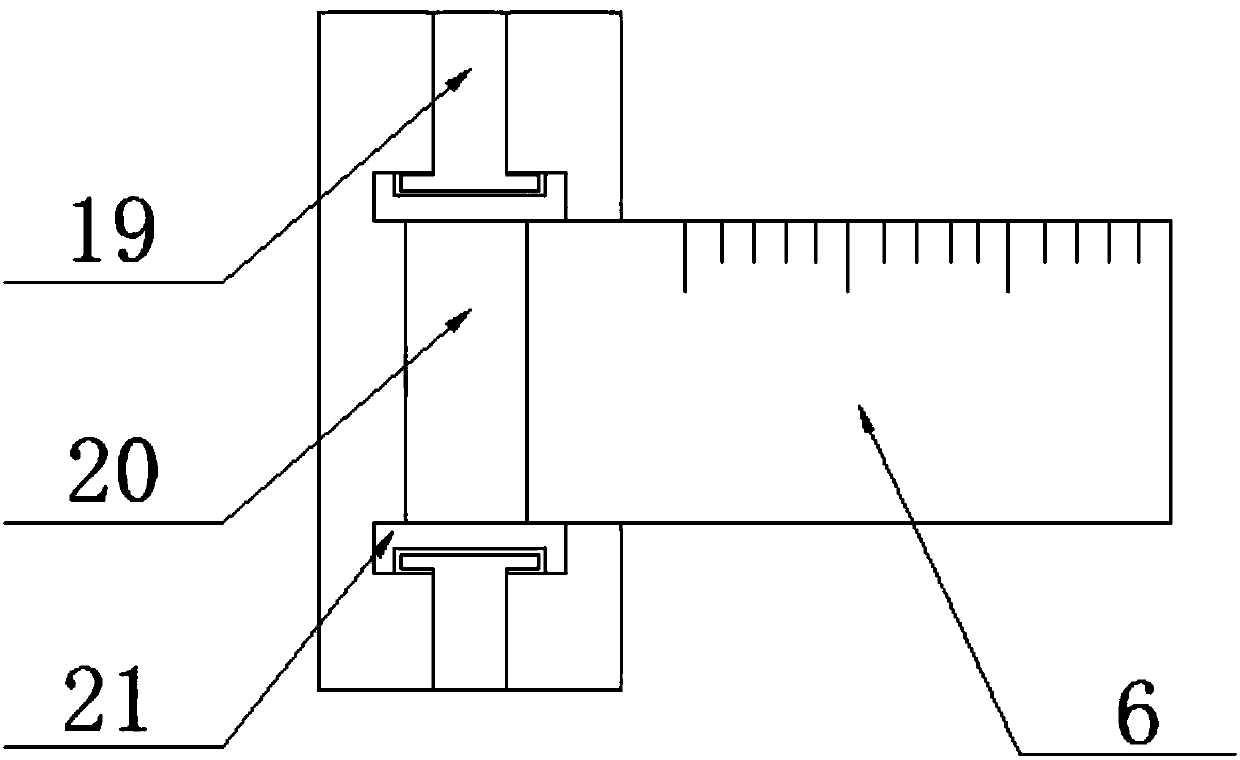

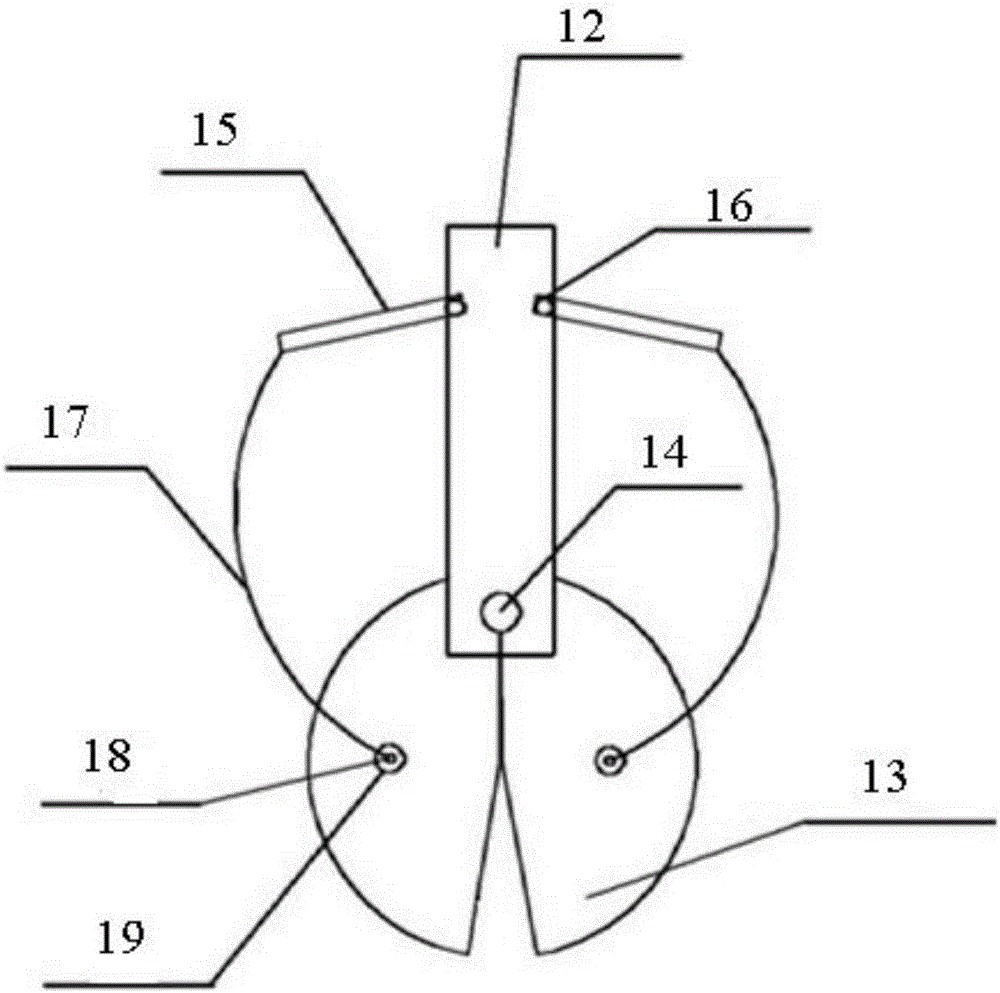

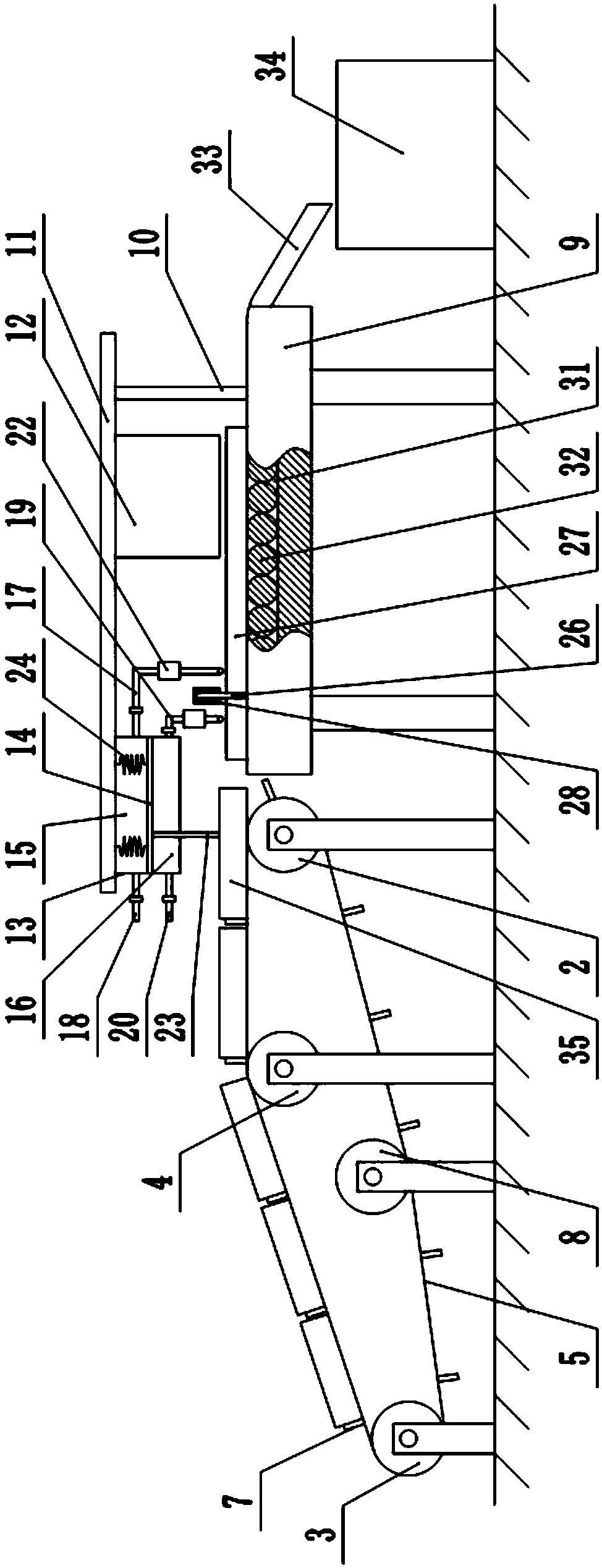

Fixed-point pit digging device for planting peach trees

PendingCN107710977AReduce labor burdenPromote growthPlantingFurrow making/coveringEngineeringPointing device

The invention discloses a fixed-point pit digging device for planting peach trees. The fixed-point pit digging device comprises an outer frame, pneumatic rods, limiting rods, press buttons, handles, aflexible rule, an inserting rod, a top plate, a first motor, a rotary shaft, spiral blades, a protection cover, counterweight rings, a net surface, second motors, round blades, supporting rods, a bottom frame, universal wheels, a sleeve, a connecting rod, a power spring and a rotary barrel. The fixed-point pit digging device disclosed by the invention has the beneficial effects that movement is carried out in a hand pushing manner, so that labor saving and rapidness are realized, and the labor burden of growing staff is alleviated; meanwhile, the pit digging efficiency is accelerated; the blades with a double-spiral structure are used for digging pits, and the pit digging efficiency is high; an external protection net is matched, so that a phenomenon that soil flies out can be effectivelyavoided, and the safety performance is high; meanwhile, the flexible rule can be used for determining the distance of the peach trees which are planted in rows, so that the planted peach trees are ordered and attractive; meanwhile, the growth of the peach trees is accelerated by adopting the reasonable distance; furthermore, the round blades are additionally arranged, and can be used for cuttingweeds and the like in planting fields, so that a condition that a rotary shaft is wound by disordered grass is avoided.

Owner:ANHUI UNIV OF SCI & TECH

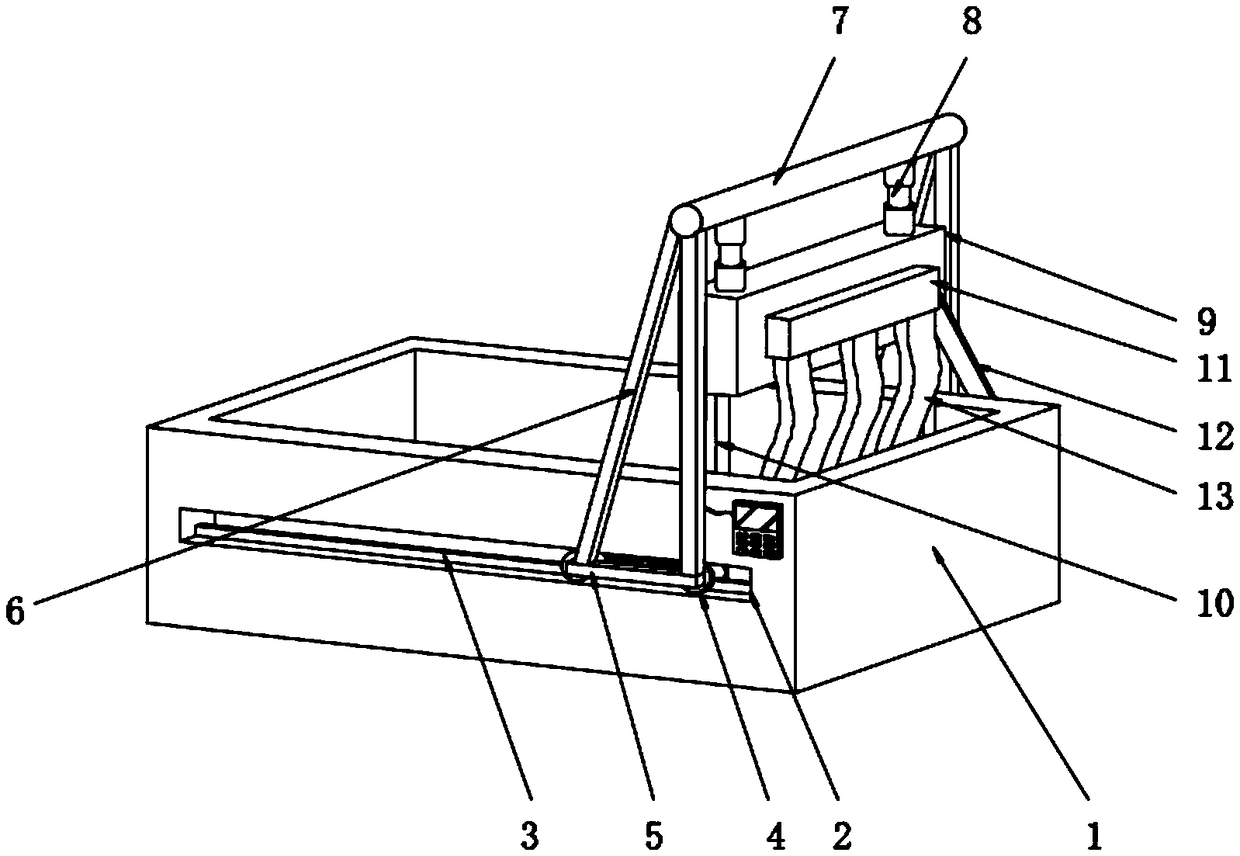

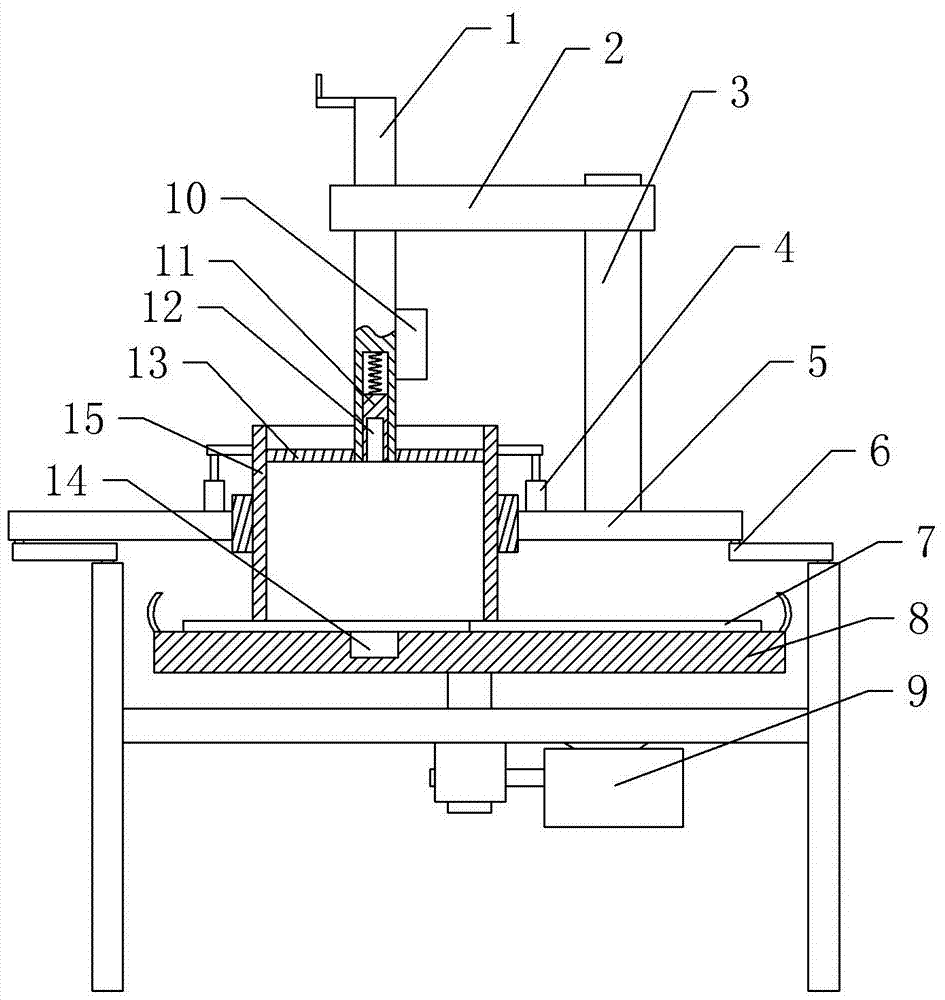

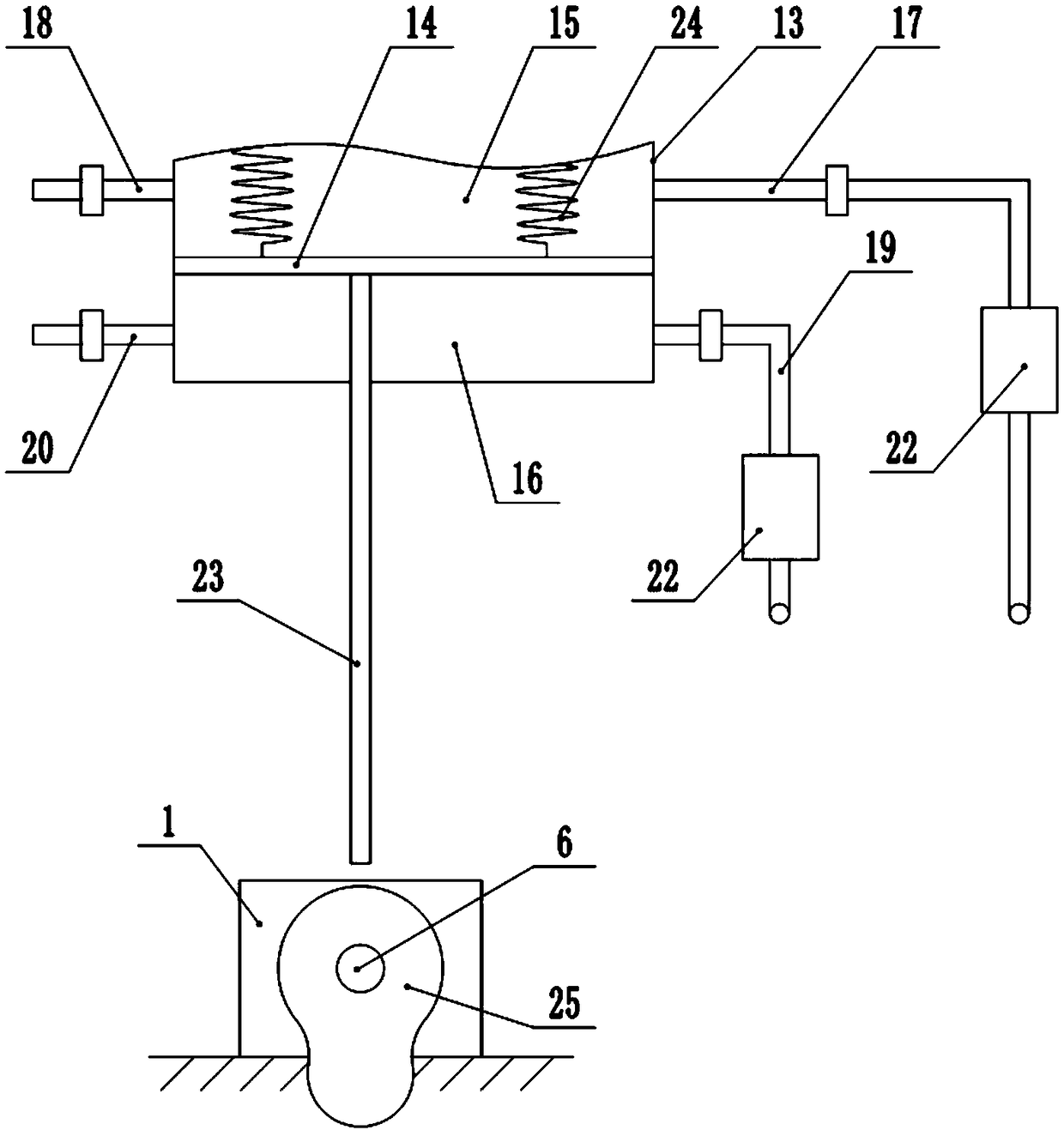

Black tea twisting method

InactiveCN107183239AScattered in timeSpread out in timePre-extraction tea treatmentHydraulic cylinderBlack tea

The invention discloses a black tea twisting method. In the method, a twisting device is adopted, the twisting device comprises a support, a twisting plate is rotationally connected with the support, and multiple radially distributed ribs are fixedly connected with the upper surface of the twisting plate; a twisting barrel and a moving frame are arranged above the twisting plate, wherein the moving frame drives the twisting barrel to do horizontal circular motion, the twisting barrel is vertically connected with the moving frame in a sliding mode, the moving frame is provided with a hydraulic cylinder used for driving the twisting barrel to vertically move, a pressing plate is arranged in the twisting barrel, and an ejector pin is arranged on the pressing plate; a blind hole is formed in the bottom of the ejector pin, a push rod is arranged in the blind hole, a tension spring is arranged at the upper end of the push rod, an electromagnet is embedded into the lower end of the push rod, and a permanent magnet is embedded into the twisting plate, wherein the permanent magnet can be opposite to the electromagnet in a heteropolar mode. A transverse supporting plate is arranged above the twisting barrel, the upper end of the enjector pin penetrates through the supporting plate, the upper end of the enjector pin is in threaded connection with the supporting plate, and an upright rod is arranged between the supporting plate and the moving frame. By means of the method, the problem that the labor burden of workers is large when the workers twist black tea leaves is solved.

Owner:桐梓县清馨茶果业有限公司

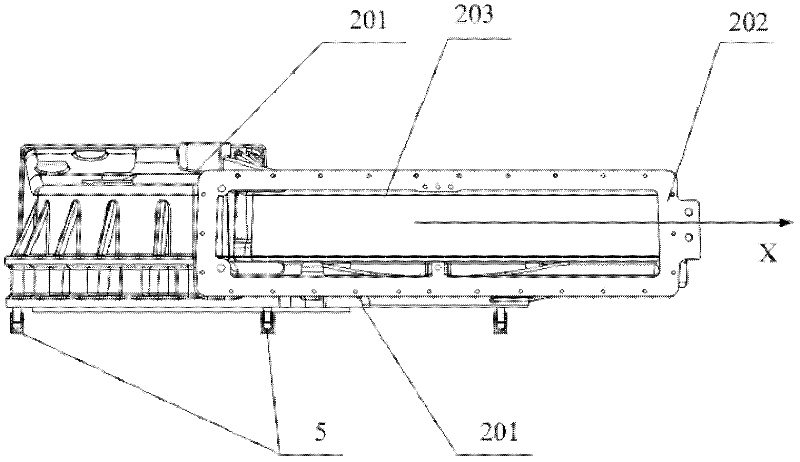

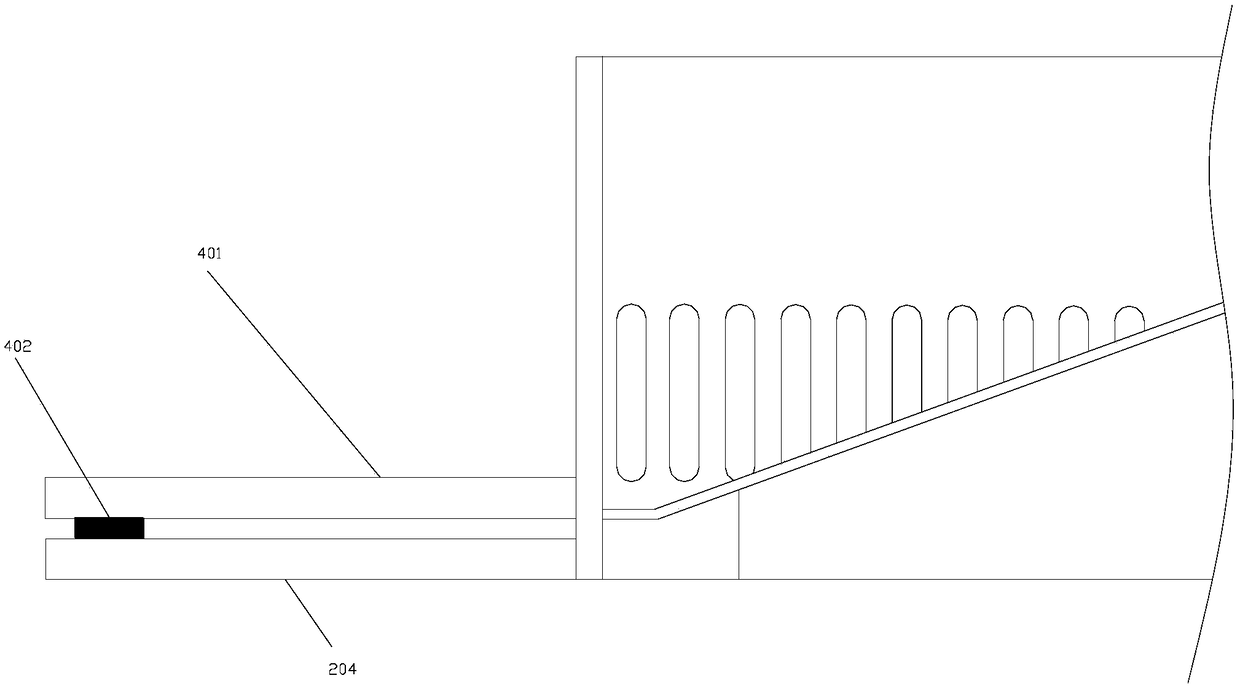

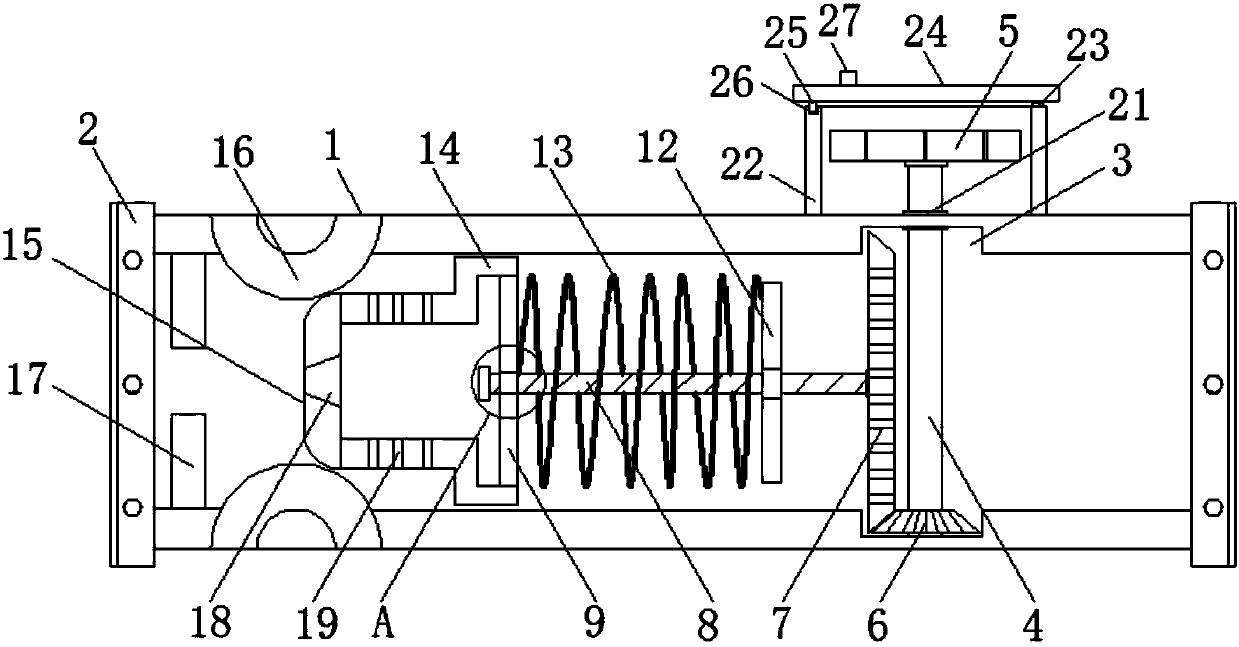

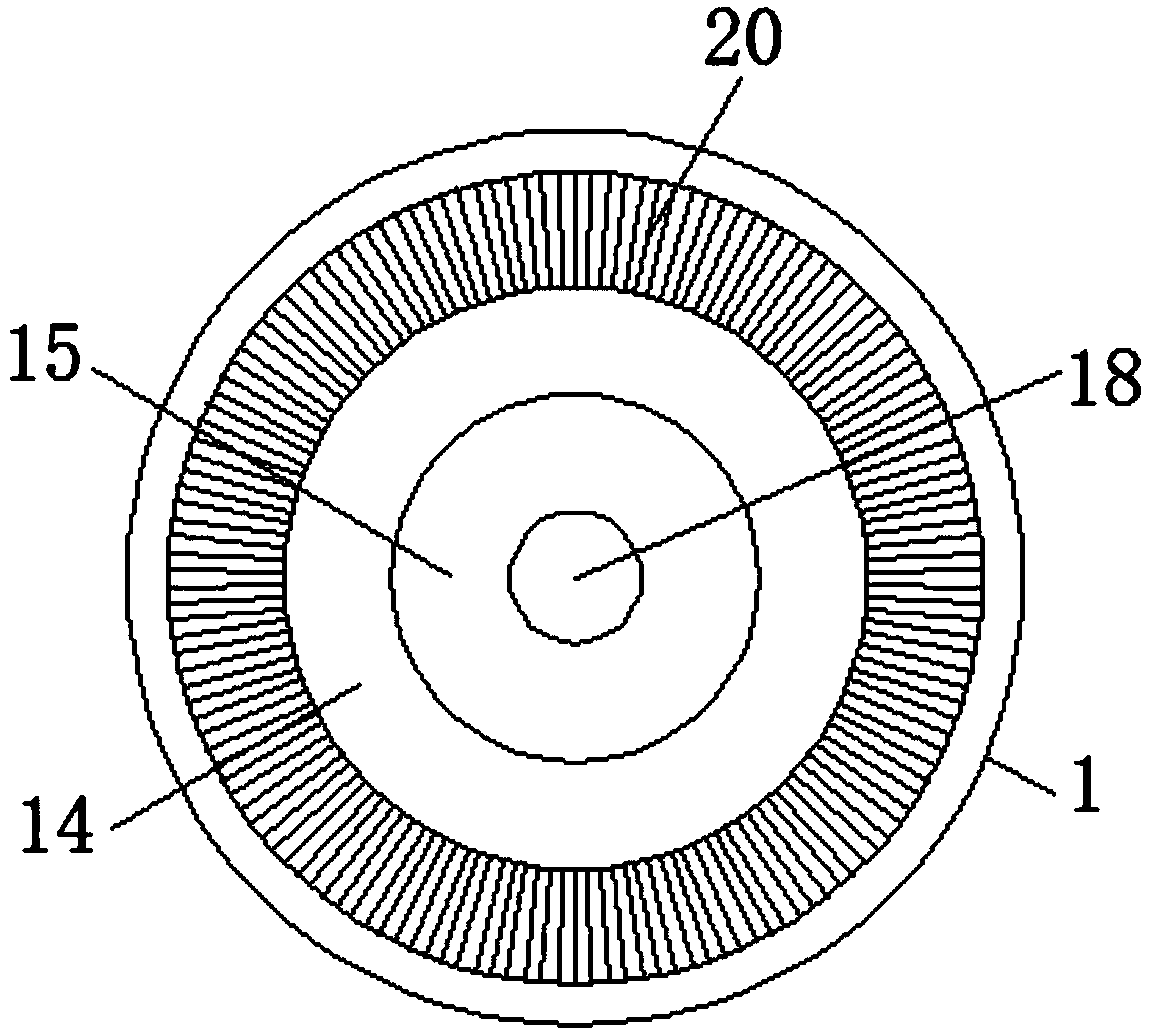

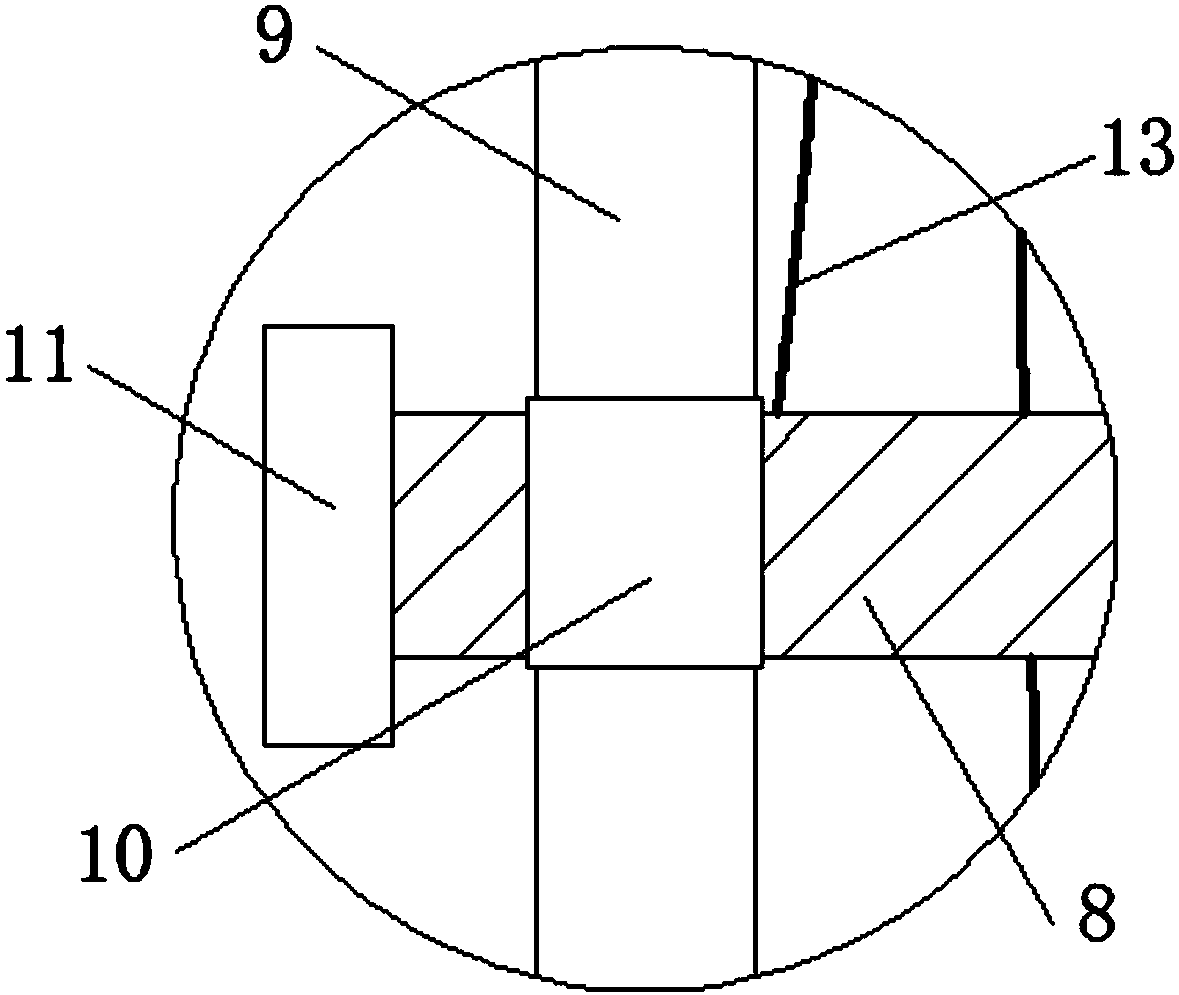

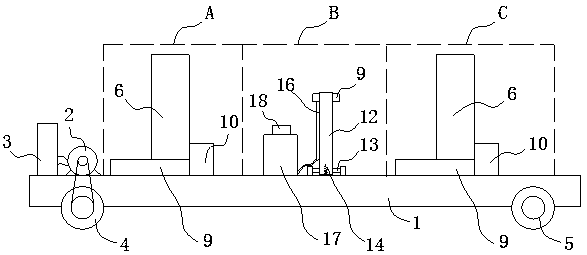

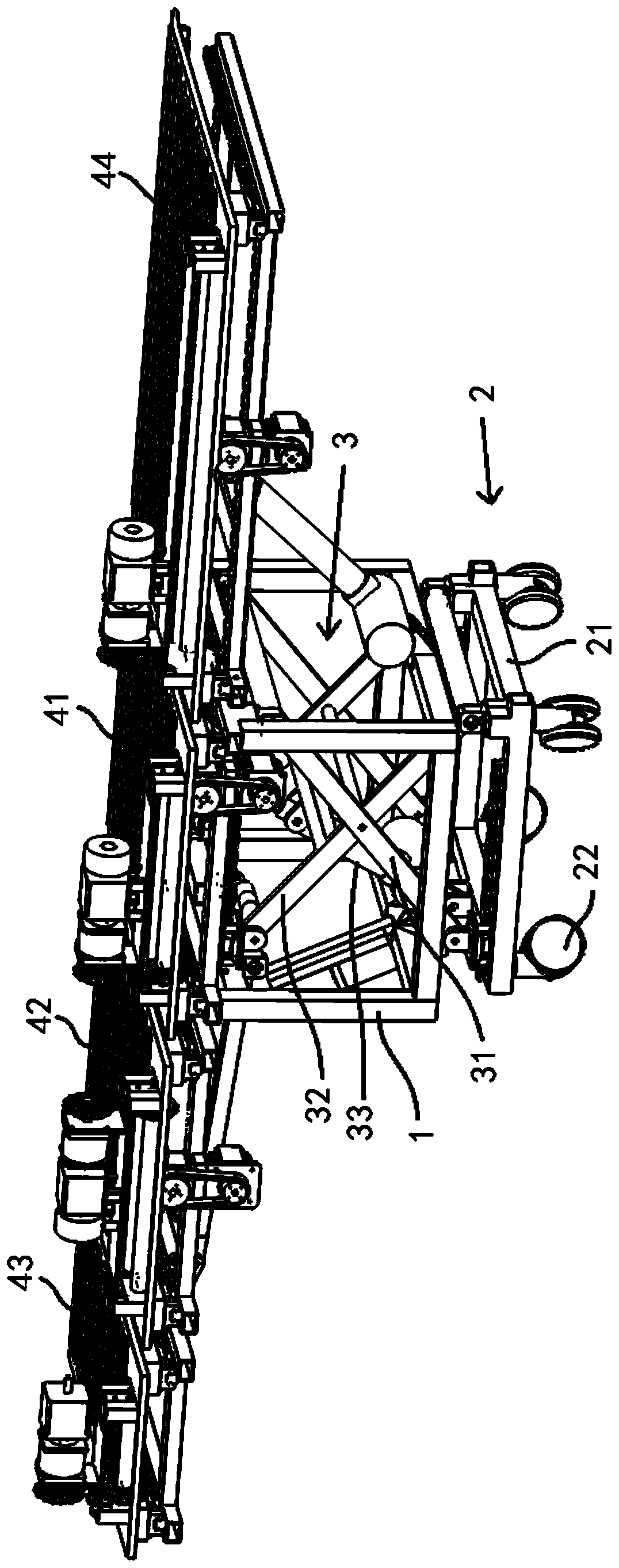

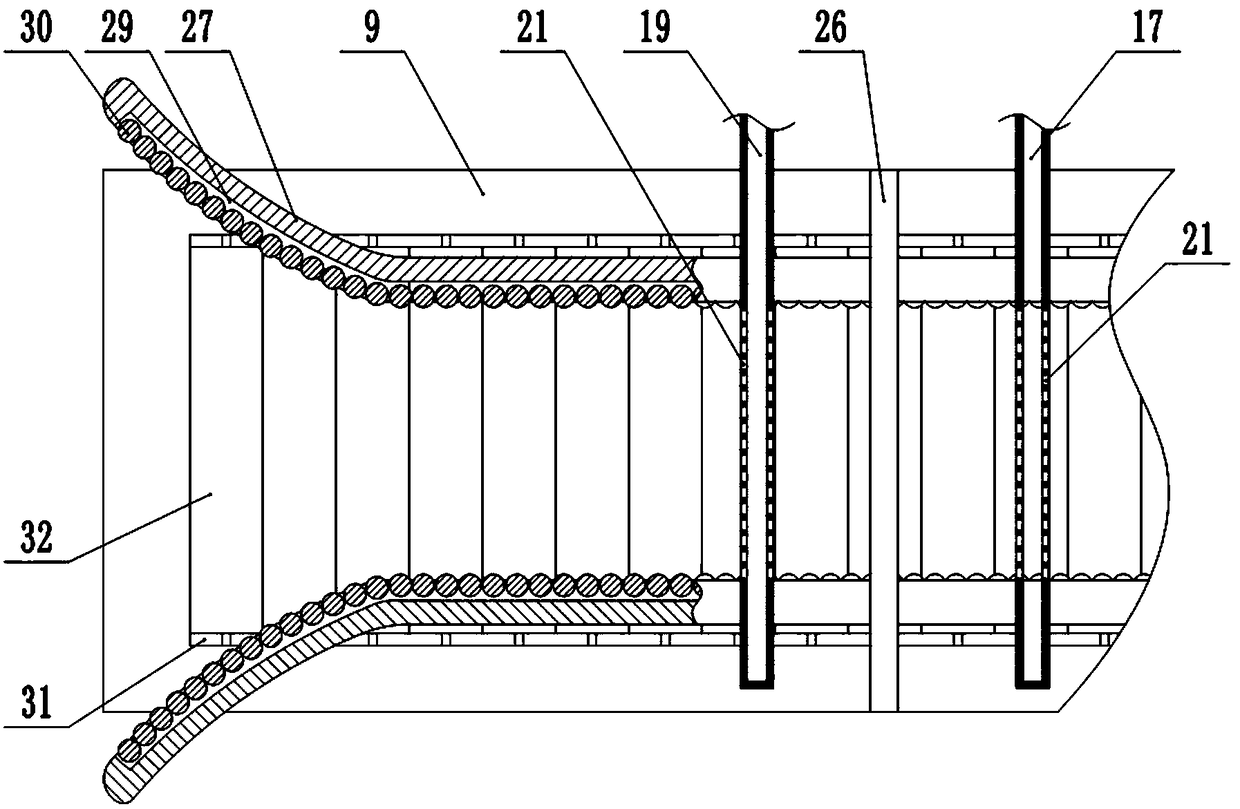

Full-automatic wheel set surface laser paint removing device

PendingCN110586581AEasy to handleRealize processingRailsMetal working apparatusForeign matterSurface cleaning

The invention discloses a full-automatic wheel set surface laser paint removing device. The device comprises a rack, a working track, a feeding mechanism, a discharging mechanism, a rotating mechanismand a laser cleaning mechanism; the working track is buried in the bottom surface of the rack and used for wheel set roll passing; the feeding mechanism is arranged at one end of the working track and used for pushing a wheel set to a cleaning station above the feeding mechanism; the discharging mechanism is arranged at the other end of the working track and used for pushing the wheel set to be separated from the cleaning station; the rotating mechanism is arranged at the cleaning station and used for driving the wheel set to rotate in the circumferential direction; and the laser cleaning mechanism is movably arranged on the rack and used for removing impurities on the surface the wheel set at the the cleaning station. According to the full-automatic wheel set surface laser paint removingdevice, foreign matters such as paint, oil stain and rust on the surface of the wheel set can be conveniently and efficiently removed, the labor burden of manpower is reduced, and the wheel set surface cleaning efficiency and the environmental protection performance are improved.

Owner:中数智科(杭州)科技有限公司

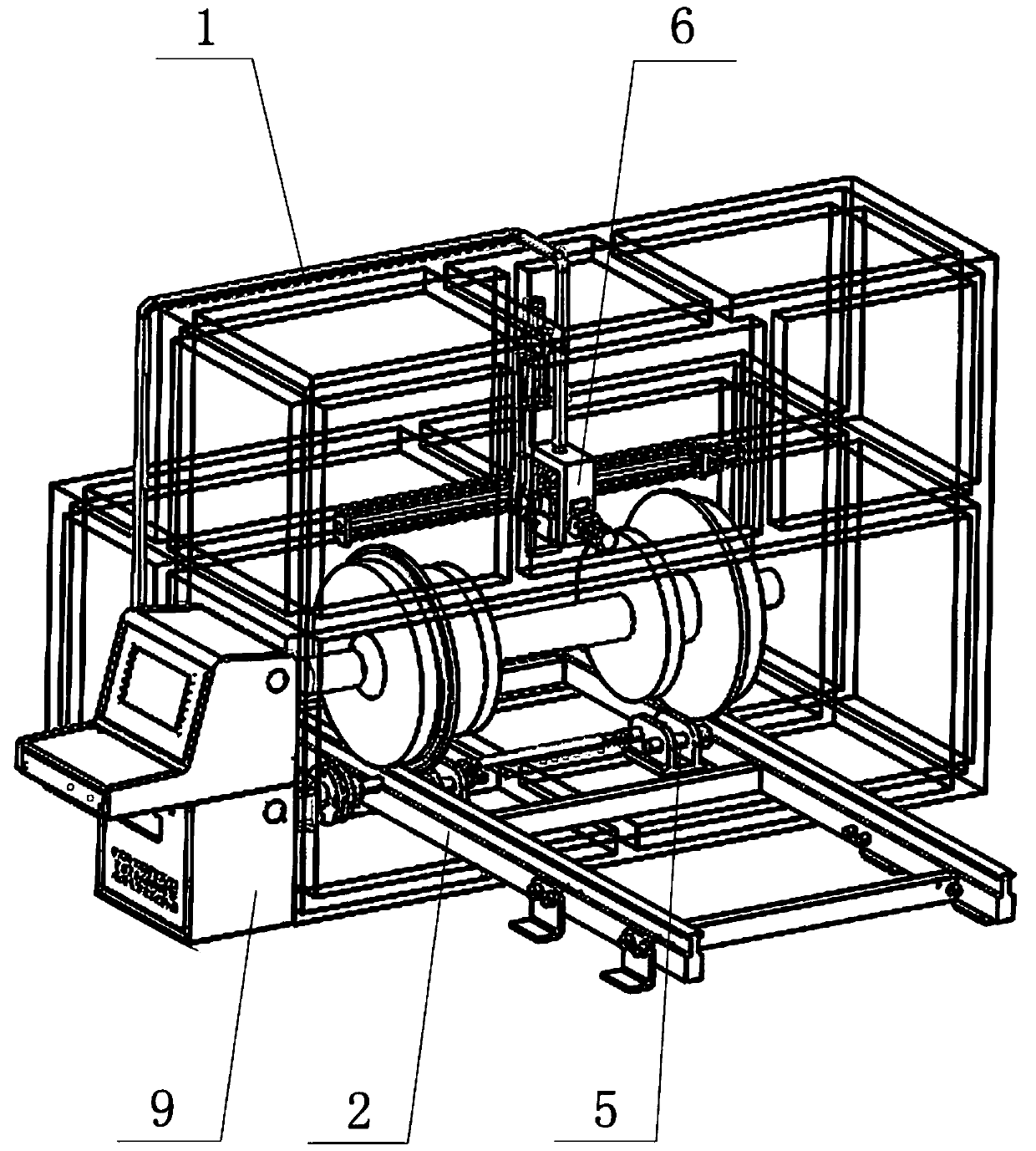

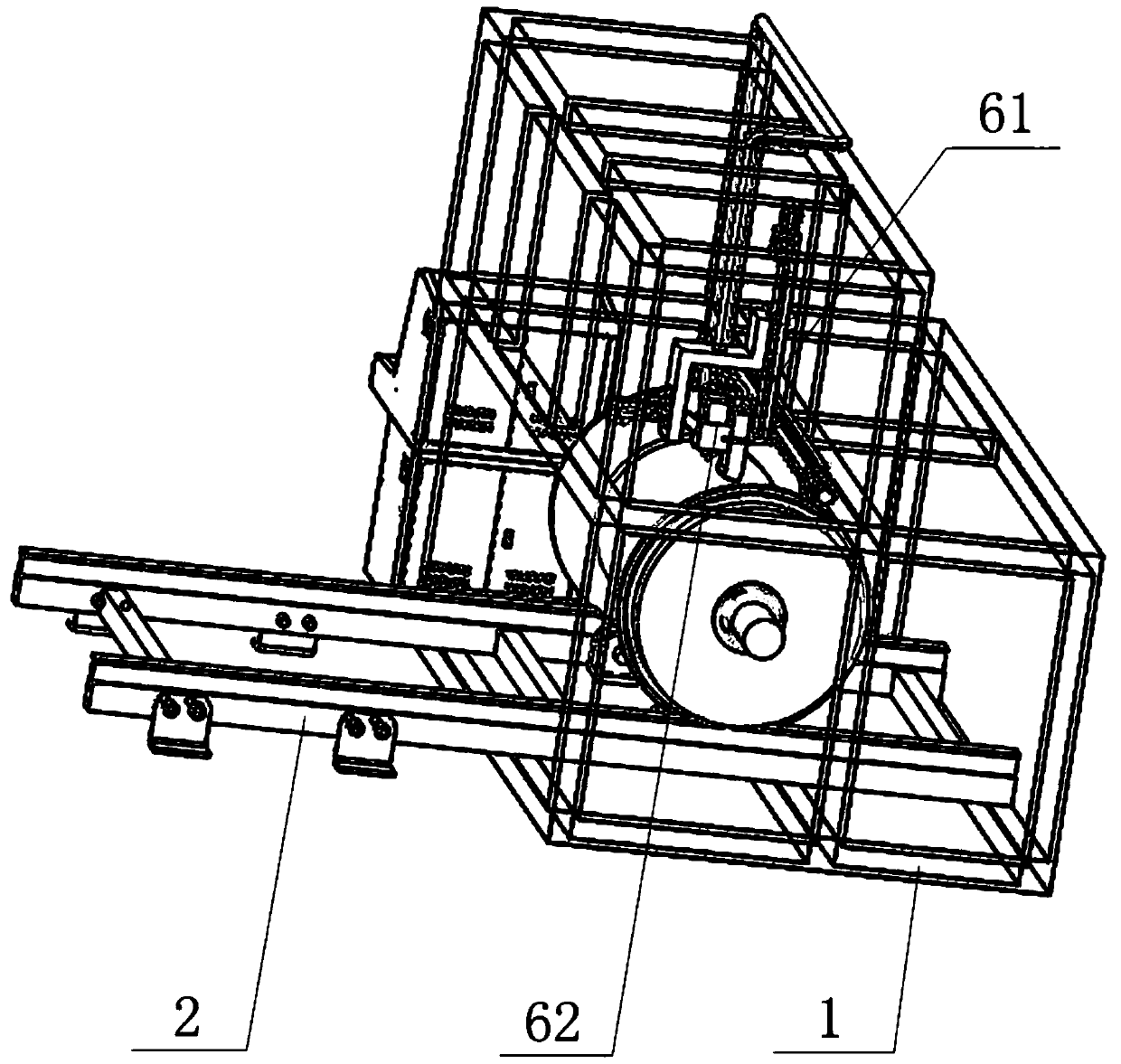

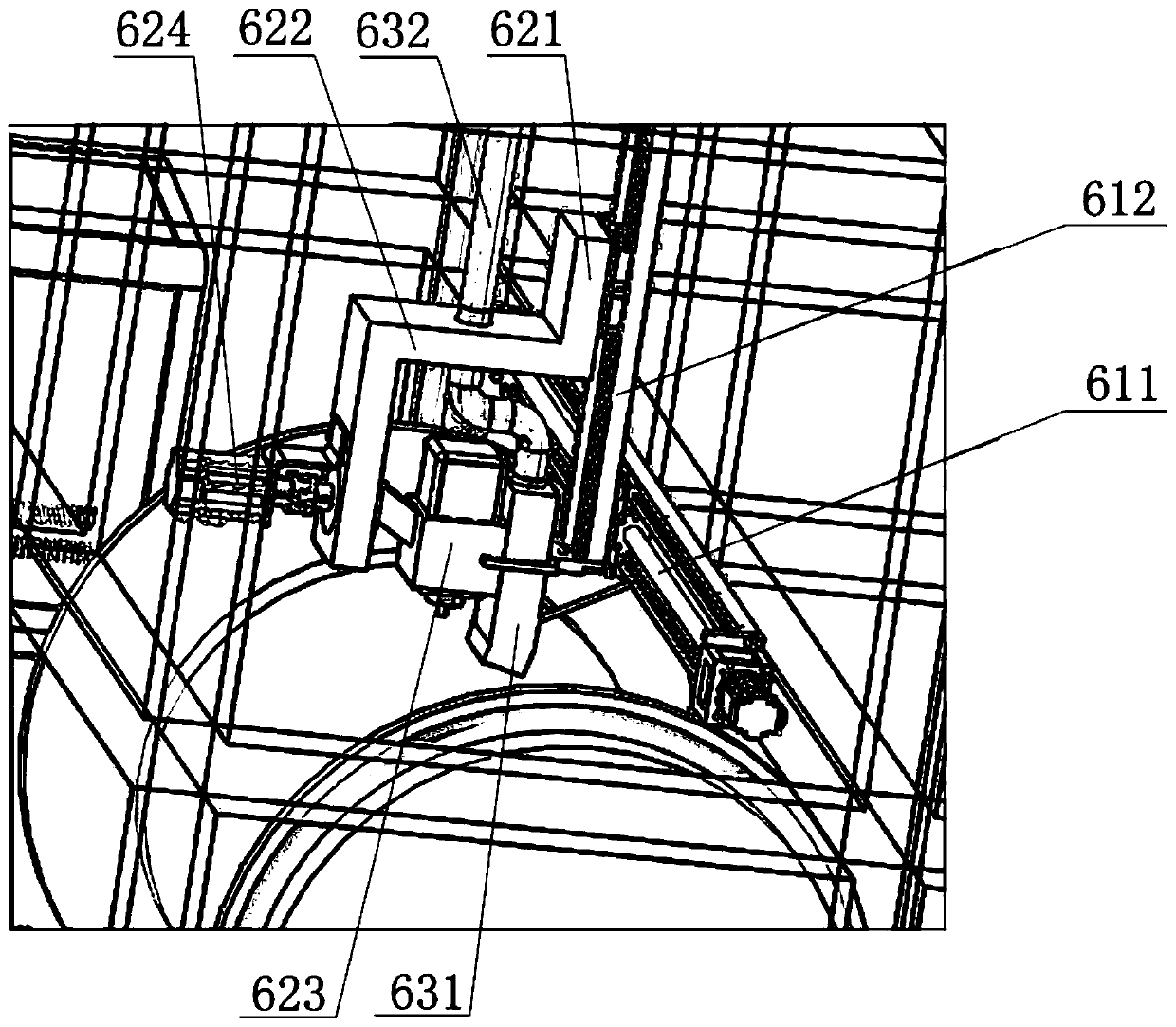

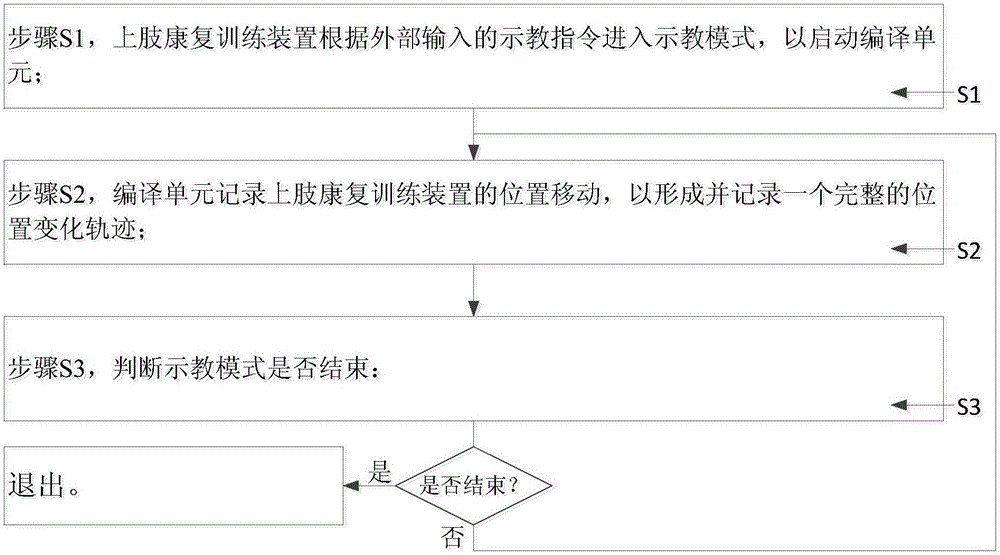

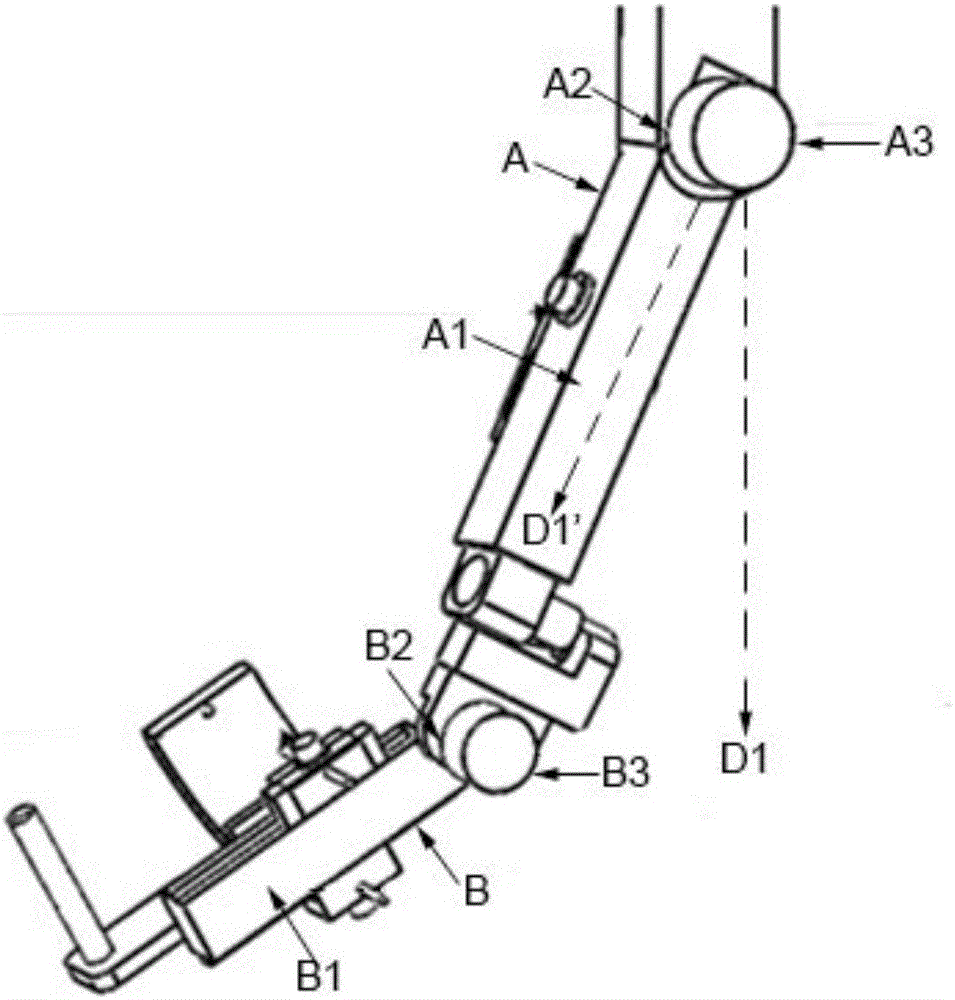

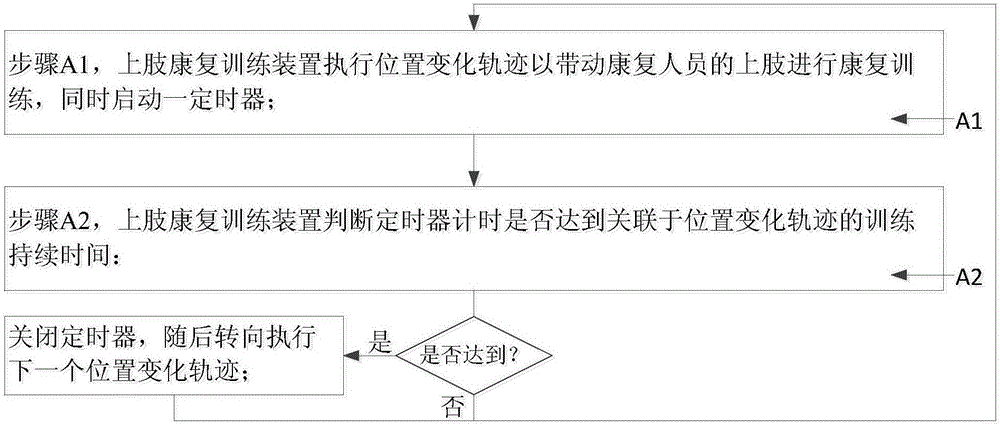

Rehabilitation training demonstration method and upper limb rehabilitation training device

InactiveCN105853150AReduce the burden onReduce labor costsChiropractic devicesPhysical therapistUpper limb rehabilitation

The invention discloses a rehabilitation training demonstration method and an upper limb rehabilitation training device, and belongs to the technical field of rehabilitation training. The method comprises the steps that 1, the upper limb rehabilitation training device enters a demonstration mode according to an externally-input demonstration instruction to start a coding unit; 2, the coding unit records location moving of the upper limb rehabilitation training device to form and record a complete location changing track; 3, whether the demonstration mode is finished or not is judged, if yes, the demonstration mode exits, if not, the step returns to the step 2, and the upper limb rehabilitation training device executes all the recorded location changing tracks according to the time sequence of recording the location changing tracks to drive the upper limbs of rehabilitation personnel to perform rehabilitation training. The rehabilitation training demonstration method and the upper limb rehabilitation training device have the advantages that the repeated labor burden of physical therapists is relieved, the labor cost is reduced, and the rehabilitation training effect is improved.

Owner:SHANGHAI ELECTRICGROUP CORP

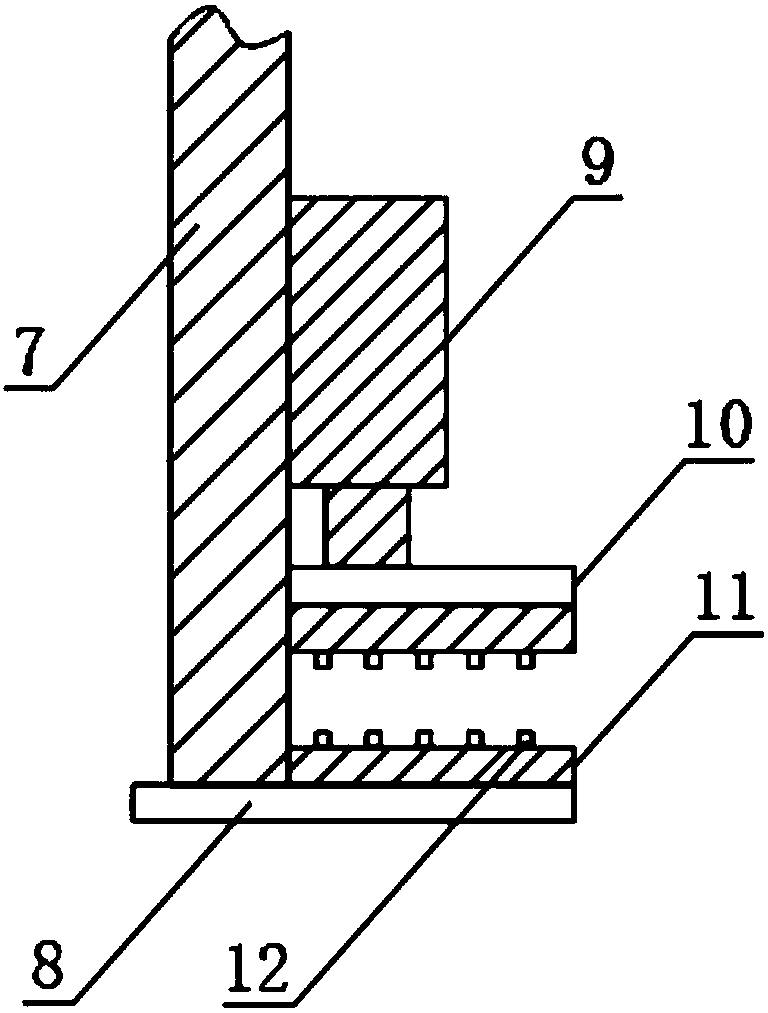

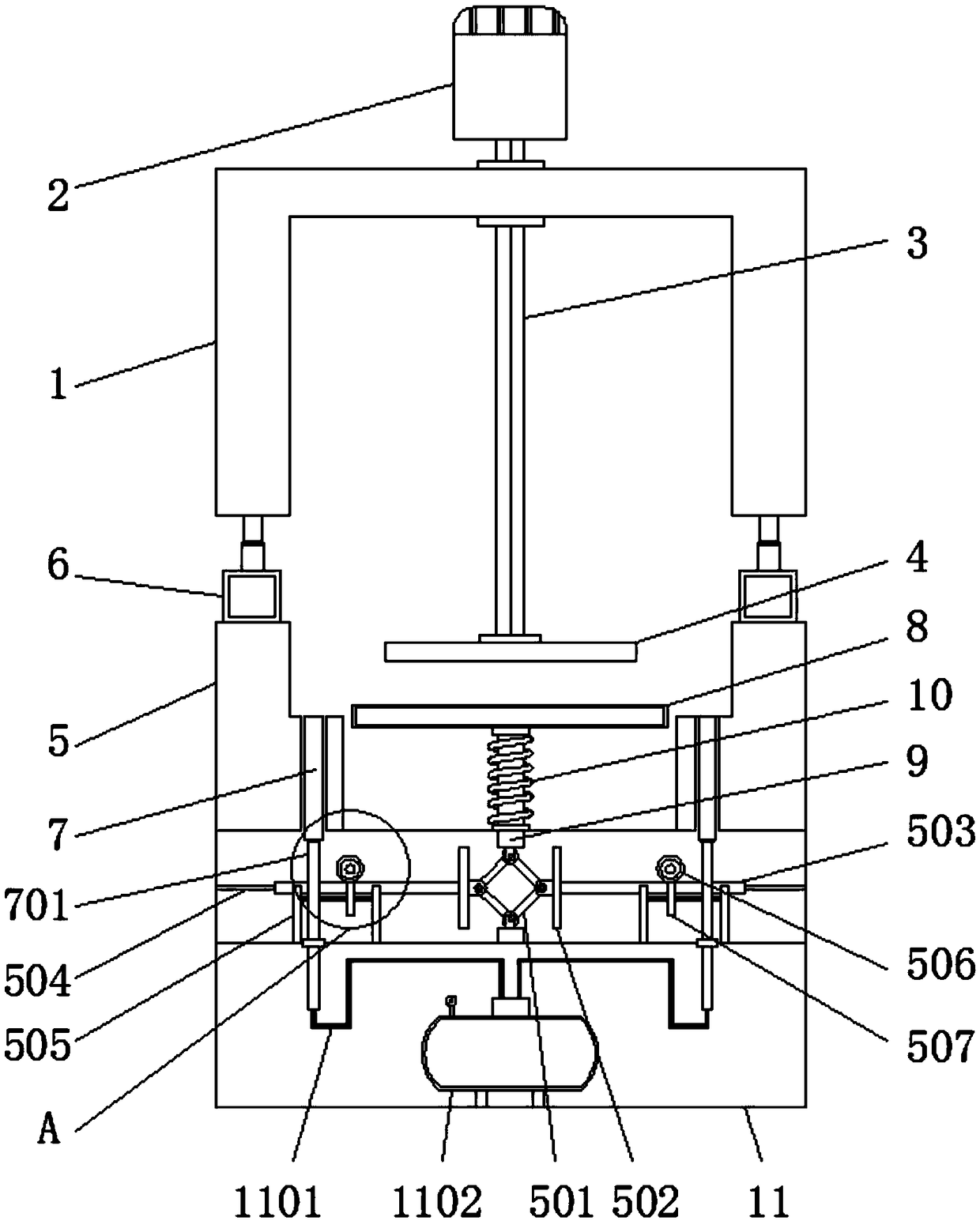

Punching device

InactiveCN108543859AReduce manpower burdenControl the moving distanceMetal-working feeding devicesMetal working apparatusPunchingEngineering

Owner:ANHUI ANLAN MOLD

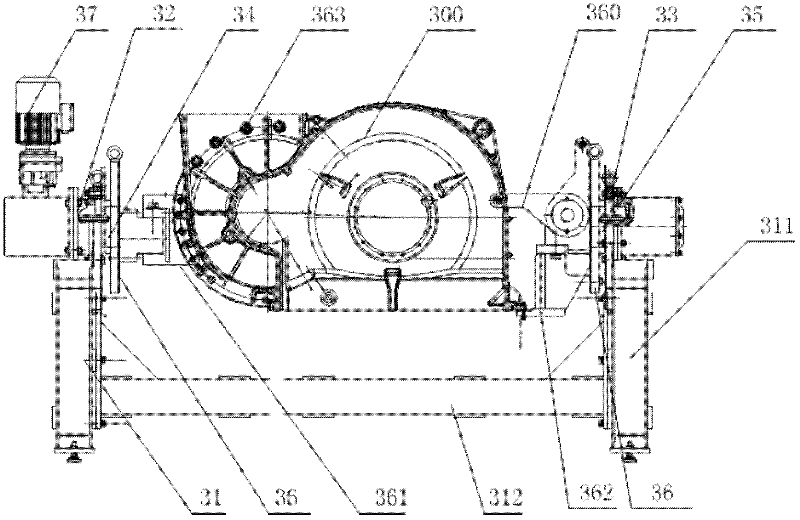

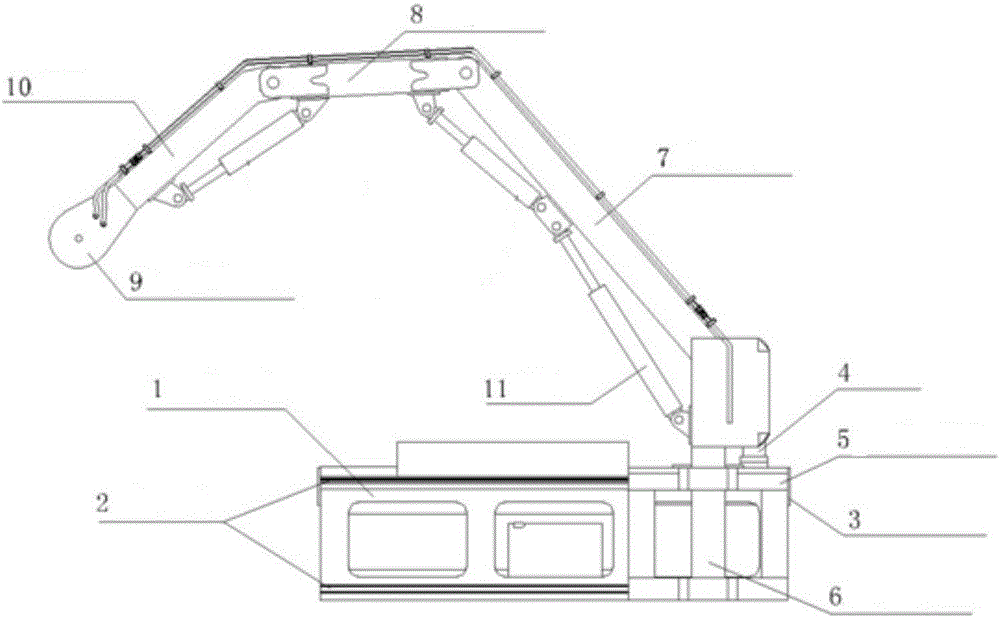

Greening and pruning multifunctional robot

InactiveCN105103982AReduce labor burdenImprove work efficiencyCuttersCutting implementsWalking around obstaclesGreening

The invention discloses a greening and pruning multifunctional robot which comprises a workbench frame and an accessory head. Linear guide rails are arranged above and below the workbench frame respectively. A movable workbench capable of sliding on the linear guide rails is installed on the linear guide rails. A guide rail baffle is arranged on the side wall at one end of the workbench frame. A movable arm frame is fixed to the movable workbench and composed of four movable arms of four different lengths. An oil cylinder is arranged between every two adjacent movable arms, and the number of the oil cylinders is three. A rotary connector is arranged in the middle of the end of one movable arm, and the accessory head is detachably installed on the corresponding movable arm through the rotary connector. The robot is provided with a detachable and replaceable machine head, the machine head can be used in cooperation with a mowing head having the mowing function, a pile-bypassing cutting head capable of bypassing an obstacle to achieve mowing, a mow sweeping head having the sweeping function and a branch pruning head having the branch pruning function and has the multiple functions of mowing, pile bypassing, sweeping, branch pruning and the like, the labor burden of workers is lowered, and working efficiency is improved.

Owner:天津奥克森重型机床有限公司

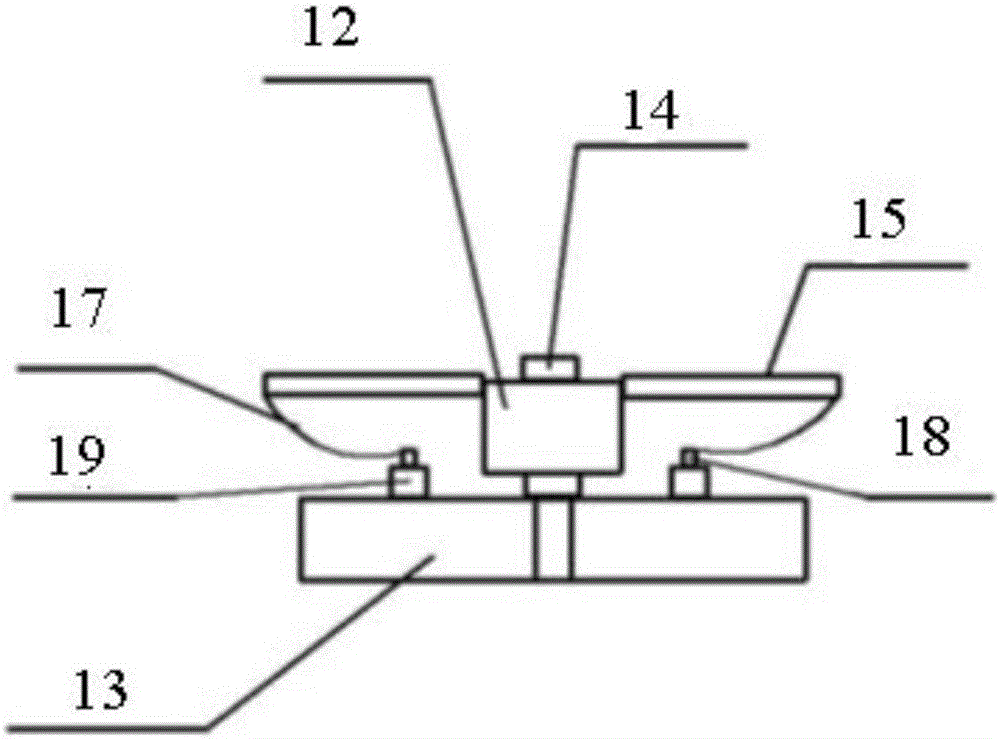

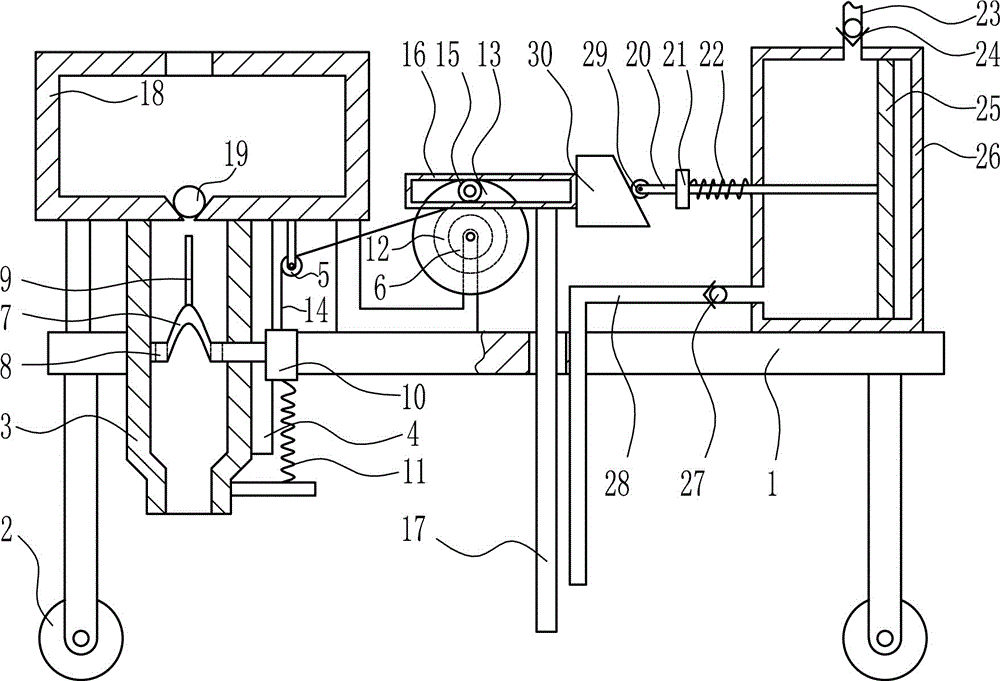

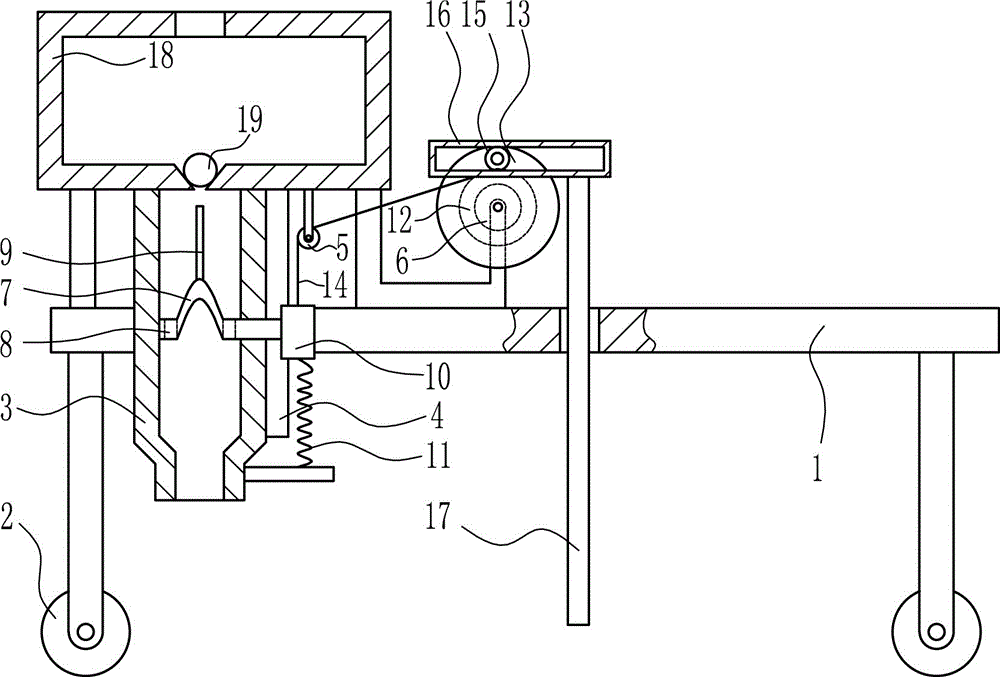

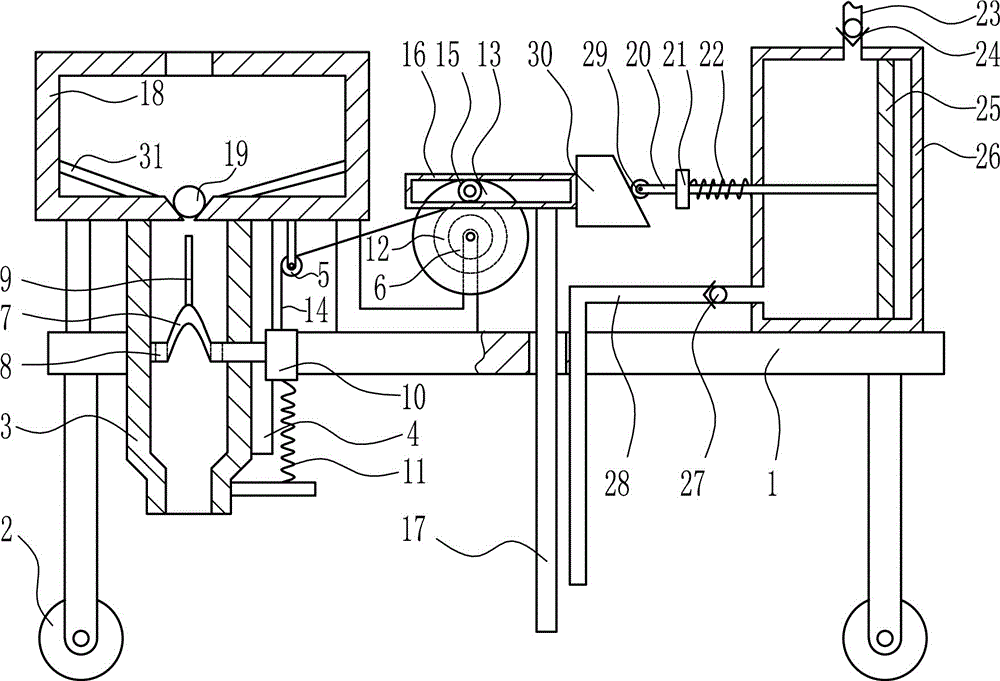

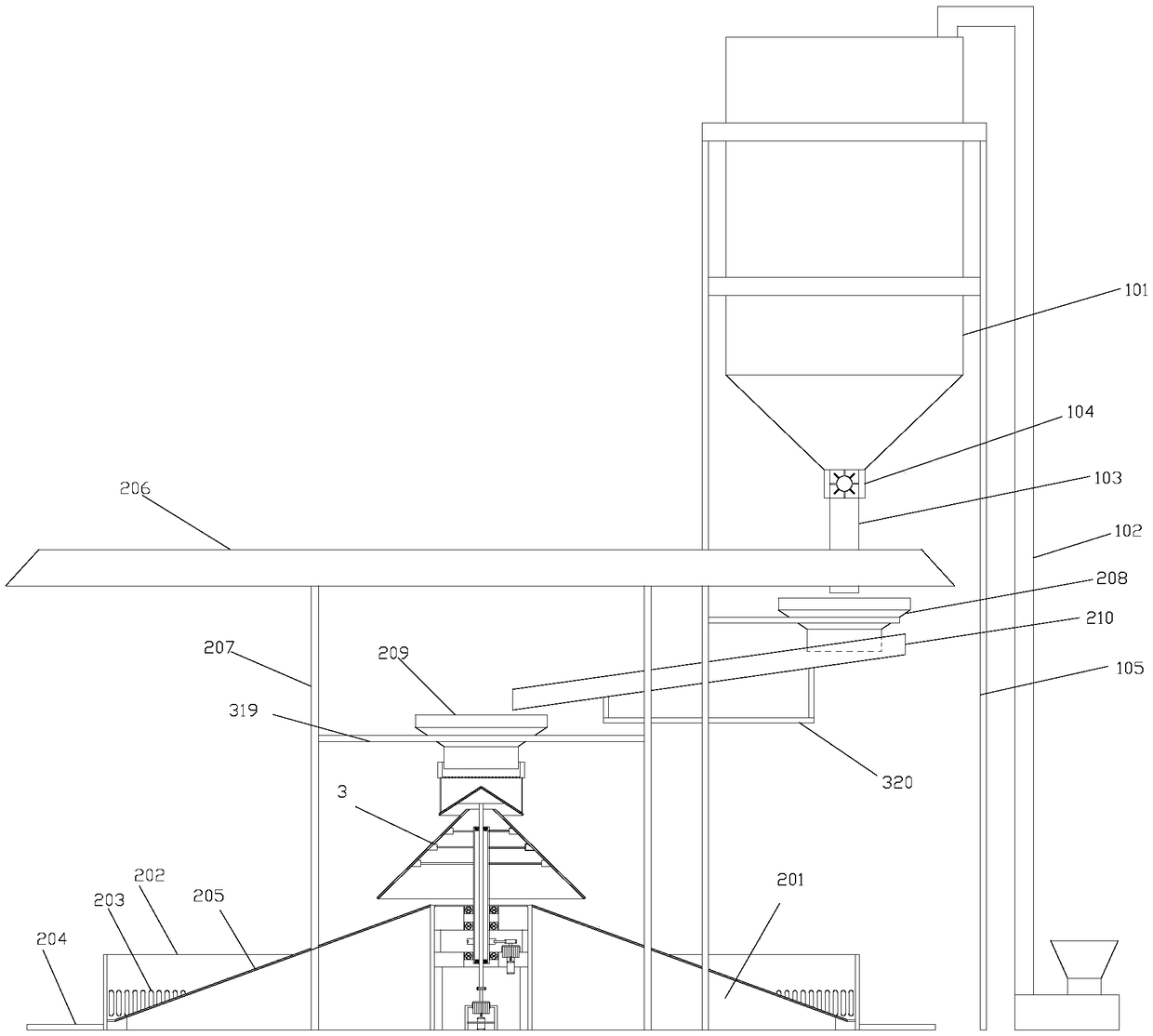

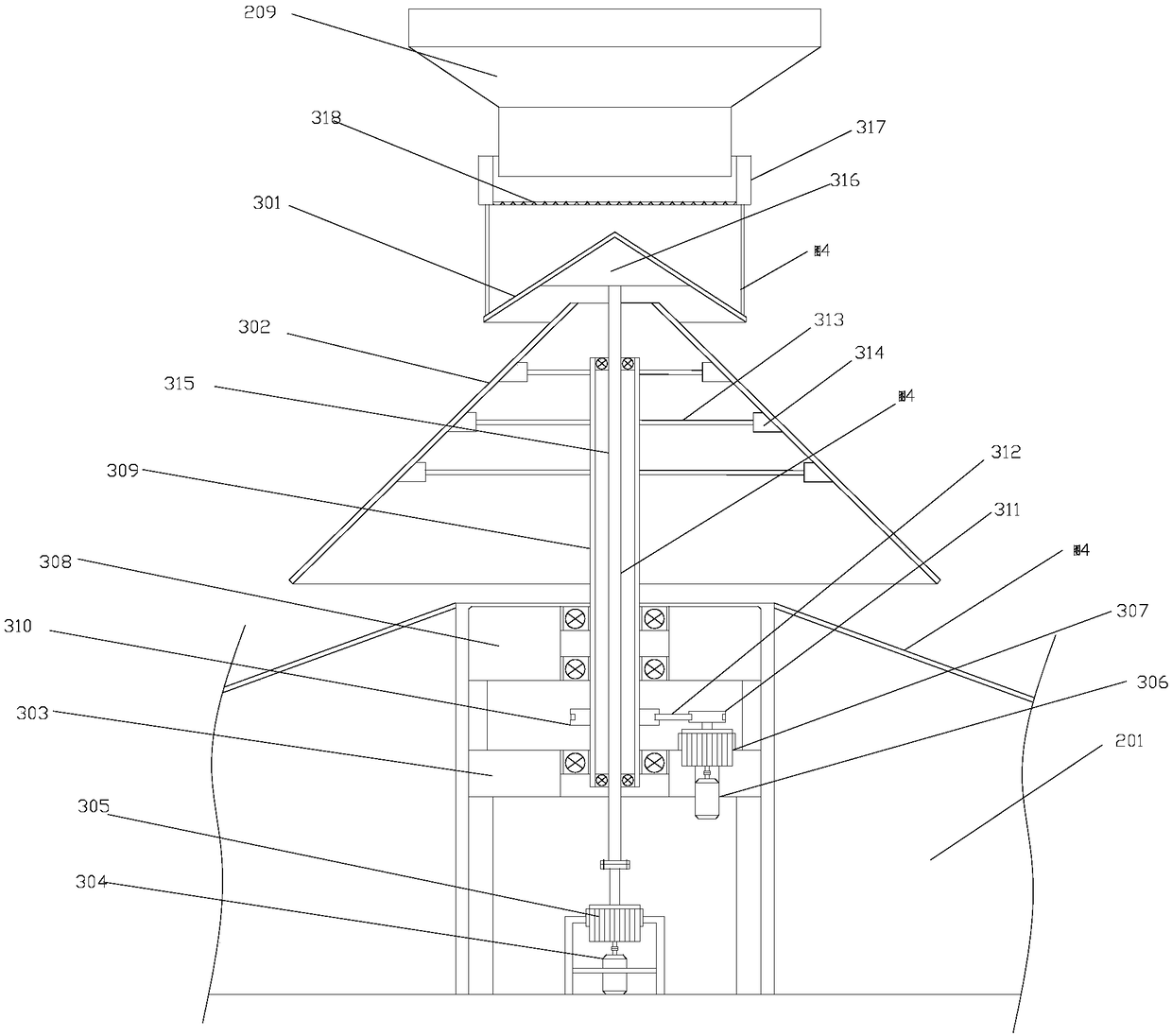

Burrowing and fertilizing integrated equipment for garden

ActiveCN106797739ASmall environmental restrictionsEasy to usePlantingFertiliser distributersEngineeringPiston

The invention relates to burrowing and fertilizing equipment, particularly relates to burrowing and fertilizing integrated equipment for a garden, and aims at providing the burrowing and fertilizing integrated equipment for the garden, which is good in burrowing effect, high in work efficiency and diverse in function. In order to achieve the aim, the invention provides the burrowing and fertilizing integrated equipment for the garden, which comprises a vehicle plate, wheels, a guide channel, a sliding rail, a guide wheel, a motor, an arc-shaped piston, a support rod, a first spring, a reel, a disk, a stay wire and a roller, wherein the wheels are rotationally arranged at the bottom of the vehicle plate; the top of the vehicle plate is sequentially provided with a fertilizer tank body and the motor from left to right; the bottom of the fertilizer tank body is sequentially provided with the guide channel, the sliding rail and the guide wheel from left to right. The effects that the burrowing and fertilizing integrated equipment for the garden is good in burrowing effect, high in work efficiency and diverse in function are achieved, and the labor burden can be reduced when large-area garden planting burrowing and fertilizing are carried out.

Owner:天津创世生态景观建设股份有限公司

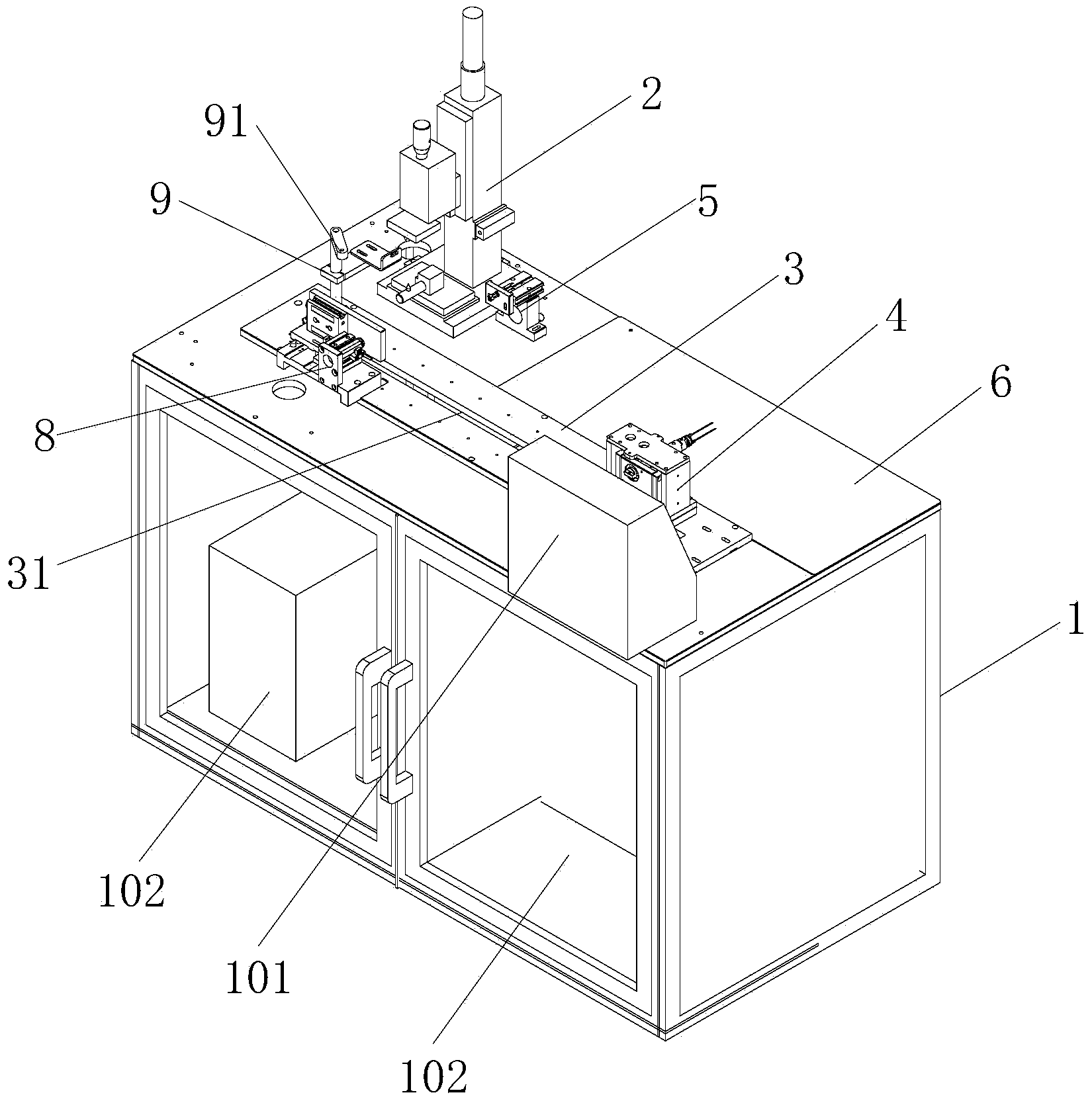

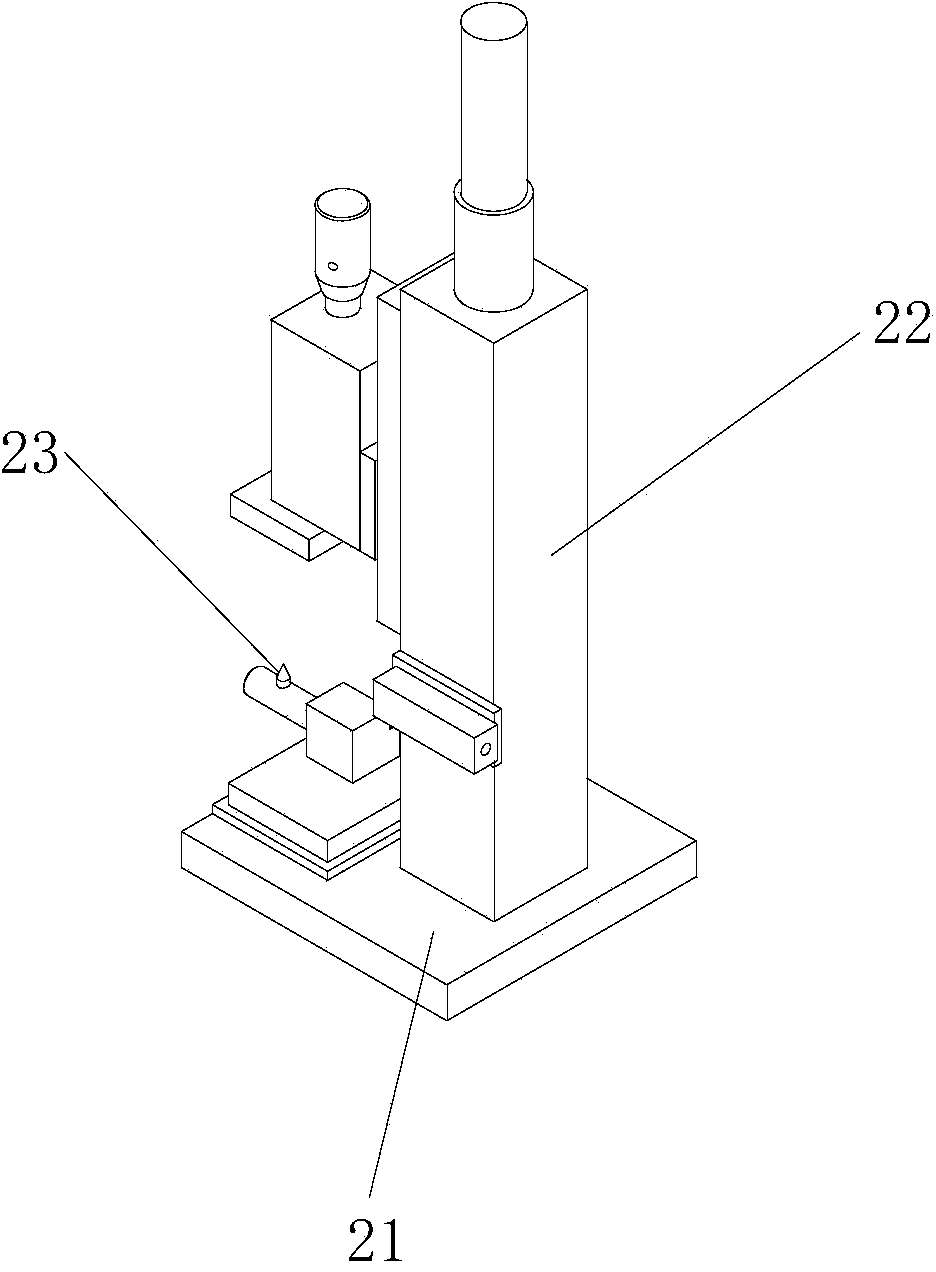

Novel electric resistance welding integral machine

ActiveCN103846536AOvercoming the disadvantages of manual welding workIncrease productivityWelding electric supplyElectricityEngineering

The invention discloses a novel electric resistance welding integral machine, which comprises a machine table, electric resistance welding equipment, a delivery mechanism, a detection mechanism and a control device, wherein the electric resistance welding equipment is arranged on the machine table, and is used for welding a product, the delivery mechanism is arranged on the machine table, and comprises a transverse assembly and a carrying device, the carrying device is movably connected with the transverse assembly, the transverse assembly comprises a delivery end and a welding end, the electric resistance welding equipment is positioned at one side of the welding end of the transverse assembly, the carrying device is used for conveying a to-be-welded product to the welding end along the transverse assembly to be welded by the electric resistance welding equipment, the detection mechanism is arranged on the machine table, and is used for detecting the qualified rate of the welded product, and the control device is connected with a power source, and is electrically connected with the electric resistance welding equipment, the delivery mechanism and the detection mechanism. The novel electric resistance welding integral machine has the advantages that the functions of delivery, carrying, welding, detection and the like are integrated, the automation level is improved, the labor burden of workers is reduced, and the production efficiency is greatly improved.

Owner:昆荣机械(昆山)有限公司

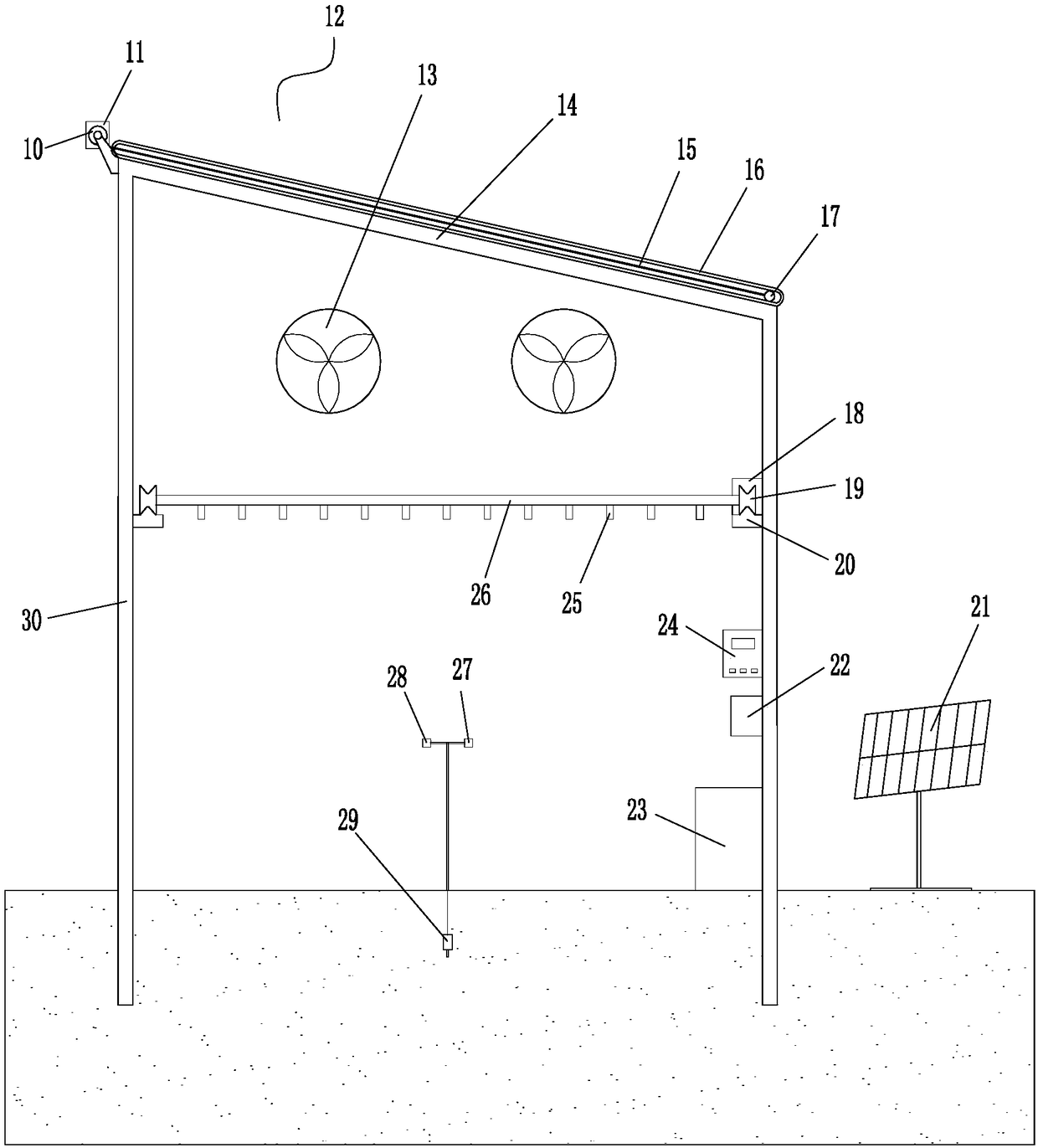

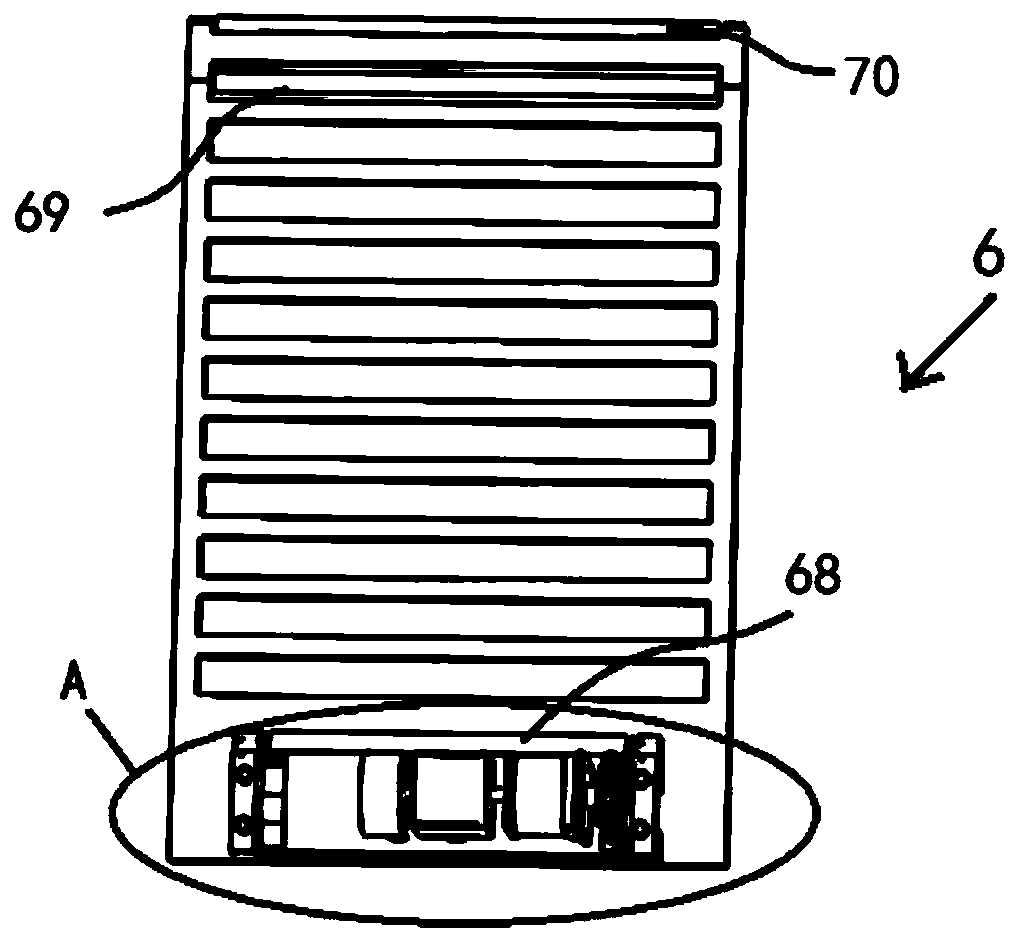

Seedling nursery for seedling cultivation

InactiveCN108142159AAffect growthRealize automated cultivationBatteries circuit arrangementsClimate change adaptationAutomatic controlGreenhouse

A seedling nursery for seedling cultivation comprises a greenhouse body, a roller shutter motor, a winding shaft, a sunshade net, a controller, a light sensor, a temperature sensor, an exhaust fan, asoil humidity sensor, a water pump, a transverse rod and a plurality of spraying nozzles uniformly distributed along the length direction of the transverse rod. The top of the greenhouse body is provided with a slope inclined towards one side, the sunshade net covers the slope, one end of the sunshade net is connected with the winding shaft while the other end is connected with a gravity shaft, two ends of the gravity shaft are positioned in a guide ring, and the winding shaft is mounted at a highest position of the top of the greenhouse body. The light sensor and the temperature sensor are mounted on the ground in the middle of the greenhouse body and positioned away from the ground by 90cm, exhaust fans are arranged on the side wall of the greenhouse body, the soil humidity sensor is buried in depth of 15cm, and the transverse rod is mounted on the side wall of the greenhouse body and positioned away from the ground by 200cm. Environmental conditions including seedling growth soil moisture, illumination, temperature and the like can be automatically controlled, and accordingly manual participation quantity is reduced, and labor burden of planting personnel is sharply relieved.

Owner:铜陵县黑你养殖专业合作社

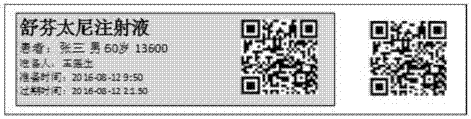

Medicine closed loop control system

InactiveCN107978351AReduce lossReduce the possibility of recording errorsChestsDrug and medicationsUse medicationLoop control

The invention provides a medicine closed loop control system, which can automatically record the time when the medicine package is opened and can monitor the expiry date of the medicine. The automaticrecording of medicine doses can be realized, the left doses of medicine can be automatically calculated, and a doctor can be reminded to conduct left liquid discarding after the medicine is expired.The invention is advantageous in that the automatic management including medicine fetching, packaging opening, medicine taking, medicine reserving and discarding can be realized; medicine informationof each link can be recorded, and labor burden on medical affairs can be reduced; possibility of medicine loss or information record error can be decreased.

Owner:北京华兴长泰物联网技术研究院有限责任公司

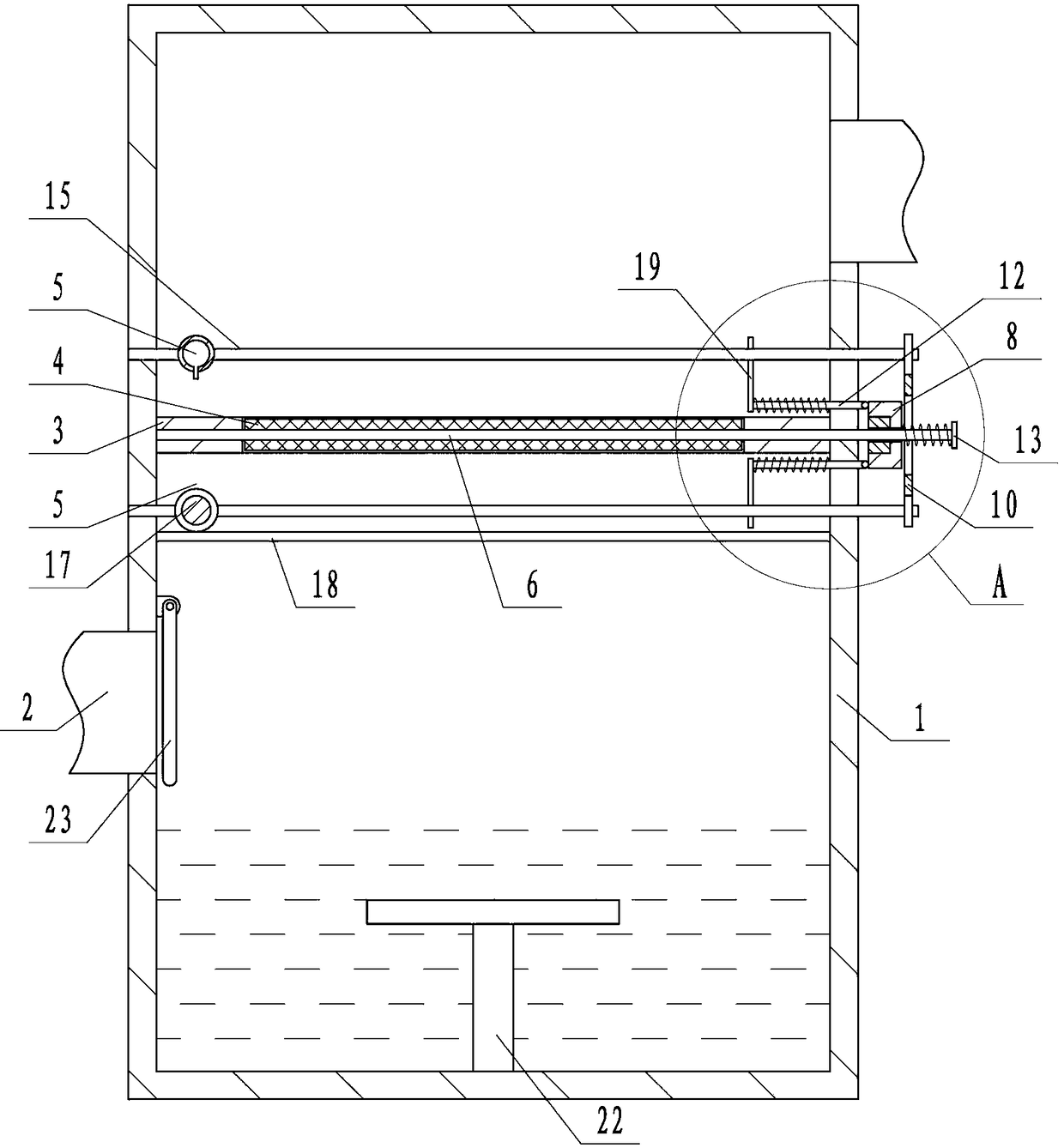

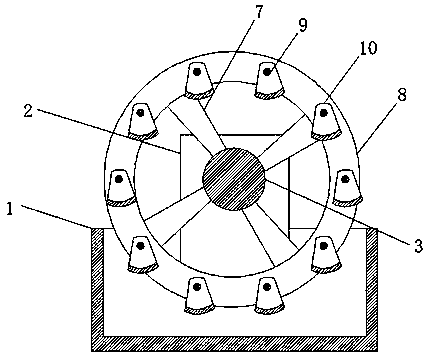

Quenching device for casting machining

PendingCN109338056AImprove work efficiencyReduce labor burdenFurnace typesHeat treatment furnacesEngineeringQuenching

The invention relates to the technical field of quenching, and particularly discloses a quenching device for casting machining. The quenching device comprises a cooling water pool. Two supporting plates are fixed to the bottom and the top of the cooling water pool. A rotating shaft is rotationally connected between the supporting plates. The right end of the rotating shaft extends to the other sides of the supporting plate. A gear ring is fixed to the right end of the rotating shaft. A motor is fixed to the top of the supporting plate on the right side. A straight gear is fixed to the output shaft end of the motor and is engaged with the gear ring. Four connecting rods are circumferentially fixed to the surfaces of the two ends of the part, located between the supporting plates, of the rotating shaft at equal distances. In the quenching device, through the motor and a circular ring, multiple castings can be quenched at the same time; when the castings are placed, the treated castings are taken down at the same time, and the work efficiency is improved; and through automatic design, casting quenching is automatic, manual placement and taking out are replaced, and the labor burdens of workers are relieved.

Owner:阜宁隆德机械制造有限责任公司

Grinding device for hardware machining

ActiveCN108714831APrevent proliferationKeep healthyGrinding machinesGrinding/polishing safety devicesHydraulic cylinderEngineering

The invention discloses a grinding device for hardware machining. The device comprises an upper rack, a lower rack, a supporting rod and a dust collection chamber; an electric motor is fixed to the upper rack, the electric motor is connected with a grinding disc through a rotating shaft, the lower rack is connected with the upper rack through a hydraulic cylinder, a dust suction cylinder is arranged in the lower rack, a worktable is welded to the upper end of the supporting rod, the bottom end of the supporting rod extends into the lower rack, the position, between worktable and the lower rack, of the supporting rod is sleeved with an elastic spring, and the dust collection chamber and the lower rack are of an integrated structure. The grinding device for hardware machining is provided with the dust suction cylinder and the dust collection chamber, dust in the grinding process is collected, dust is prevented from being diffused out, dust obtained after grinding does not need to be cleaned, body health of a person is ensured, labor burdens of the person are reduced, and practicability is high.

Owner:佛山市汇伟智科技有限公司

New synthesis process of maleic anhydride monomethyl and dimethyl maleate concrete polycarboxylic acid slump retaining agent

InactiveCN106977660AReduce the labor burden of configuration operationsSimple processMonoethyl maleateVitamin C

The invention provides a new synthesis process of a maleic anhydride monomethyl and dimethyl maleate concrete polycarboxylic acid slump retaining agent, the new synthesis process is characterized in that the process is polymerization of maleic anhydride monomethyl and dimethyl maleate and polyoxyethylene ether under effect of an initiator and a redox agent, the initiator is hydrogen peroxide; and the process is simple and easy to operate. The polymerization process is short, and production efficiency is high. The maleic anhydride monomethyl and dimethyl maleate concrete polycarboxylic acid slump retaining agent can be synthesized at normal temperature, and can also be heated and synthesized. The polymerization process has the advantages of flexible selection of temperature and low production cost. A polymerization drop solution is prepared only by use of deionized water to dissolve vitamin C, only needing dropwise addition, preparation operating labor burden of an operator can be reduced, the preparation is single, and has small error probability, and a basis for stable product quality is provided from operational aspects.

Owner:四川金江建材科技有限公司

Feeding device for chicken breeding and control method thereof

The invention discloses a feeding device for chicken breeding. The feeding device is characterized by comprising a feed drum positioned on a support, wherein one side of the feed drum is provided witha feed lifter; the feeding device also comprises a cement-casted hollow circular truncated cone; a barrier wall is arranged around the outer periphery of the circular truncated cone; through groovesare arranged on the barrier wall at intervals; a rainproof roof is fixedly arranged above the circular truncated cone; an upper discharge hopper and a lower discharge hopper are fixedly arranged belowthe rainproof roof; and the feeding device also comprises a feed distribution unit. The feeding device provided by the invention can uniformly feed chicken, minimizes individual differences, can prevent a feed from being contaminated due to behaviors like shitting and trampling of the chicken in the feed intake process, thereby preventing the health of the chicken from being affected; and a plurality of the feeding devices provided by the invention can be arranged at fixed positions in a free-ranging farm, and the feeding devices are utilized for timed and automatic feeding, so labor burden can be reduced, and feeding is more uniform. The invention also discloses a control method for the feeding device for chicken breeding.

Owner:NINGXIA SHUNBAO MODERN AGRI CO LTD

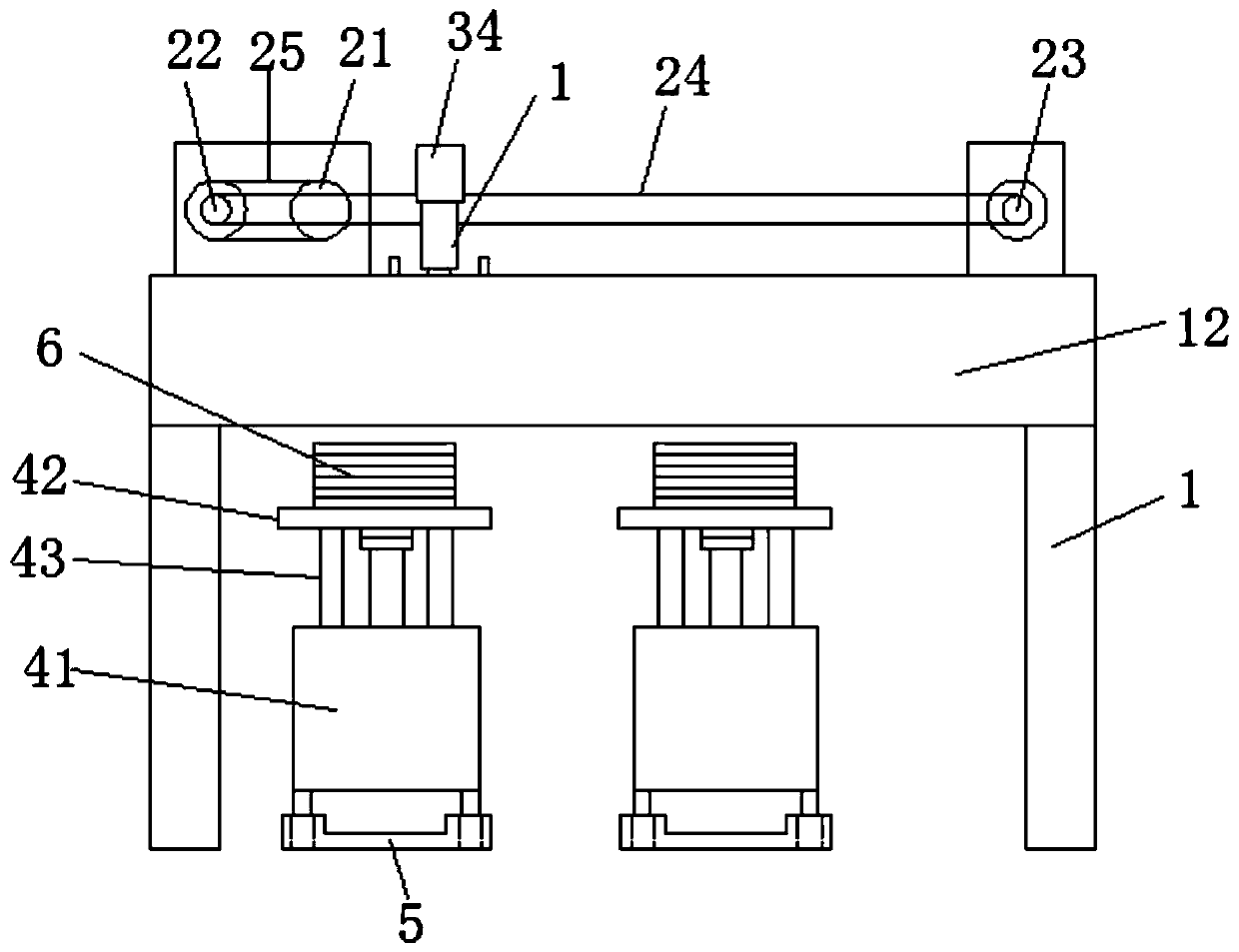

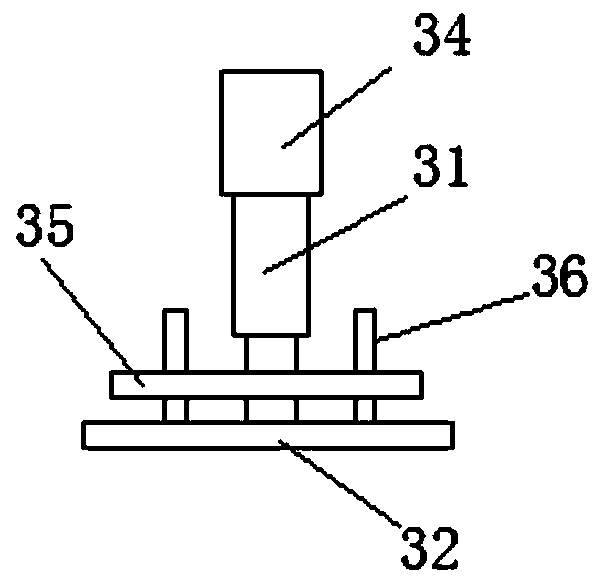

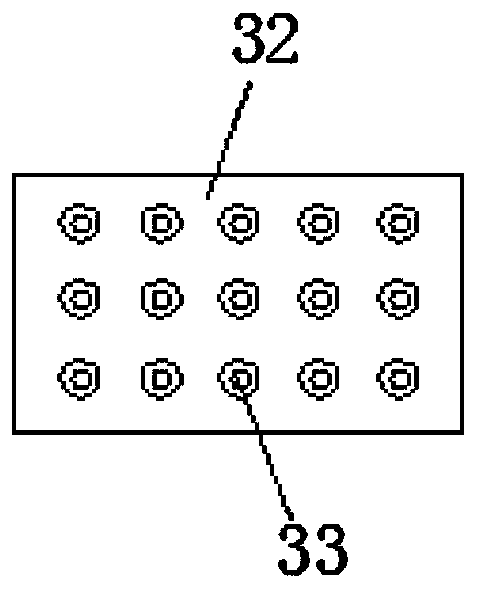

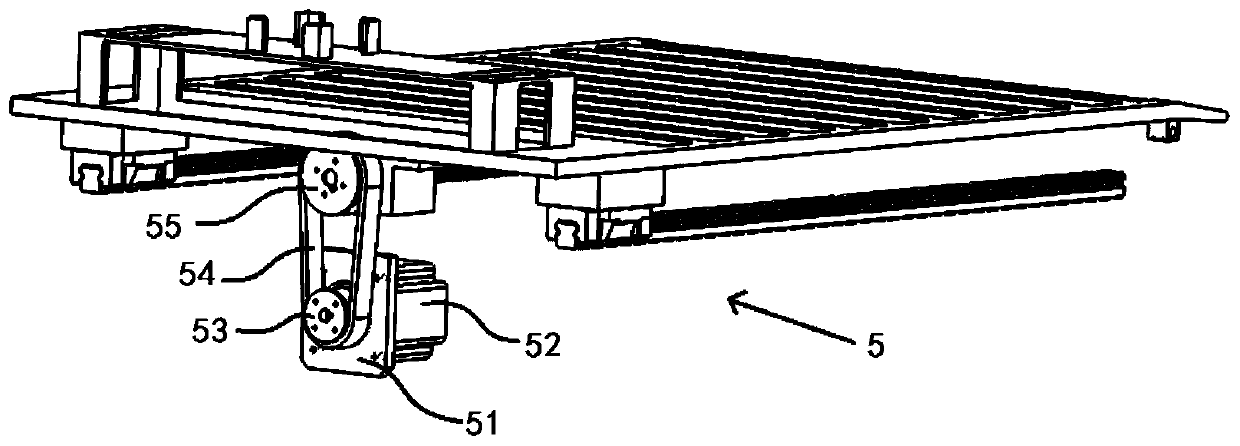

Automatic feeding mechanical hand mechanism for punching machine

InactiveCN109773070AQuality improvementReduce labor burdenMetal-working feeding devicesPositioning devicesPunchingDrive motor

The invention provides an automatic feeding mechanical hand mechanism for a punching machine. The automatic feeding mechanical hand mechanism comprises a feeding frame, feeding tables and a feeding mechanical hand movably connected with the feeding frame; the feeding mechanical hand comprises a linear translation assembly and a vertical lifting assembly; the linear translation assembly comprises adriving motor, a driving wheel, a driving gear, a transmission gear and a chain, the driving motor is in transmission connection with the driving wheel, the driving wheel is in transmission connection with the driving gear through a belt, and the driving gear is in transmission connection with a driven gear through a chain; the vertical lifting assembly comprises a lifting air cylinder and a mechanical hand connected with the lifting air cylinder, the mechanical hand is a suction plate, and the bottom of the suction plate is provided with a plurality of uniformly-distributed suction cups; andthe lifting air cylinder is connected with the chain through an installation seat, and the chain is arranged in the horizontal direction of the feeding frame. The automatic feeding mechanical hand mechanism for the punching machine can replace manpower to automatically complete feeding work, the quality of aluminum sheets is ensured, meanwhile, the labor burden of workers is lowered, and the working efficiency is improved.

Owner:苏州冬宝光电科技有限公司

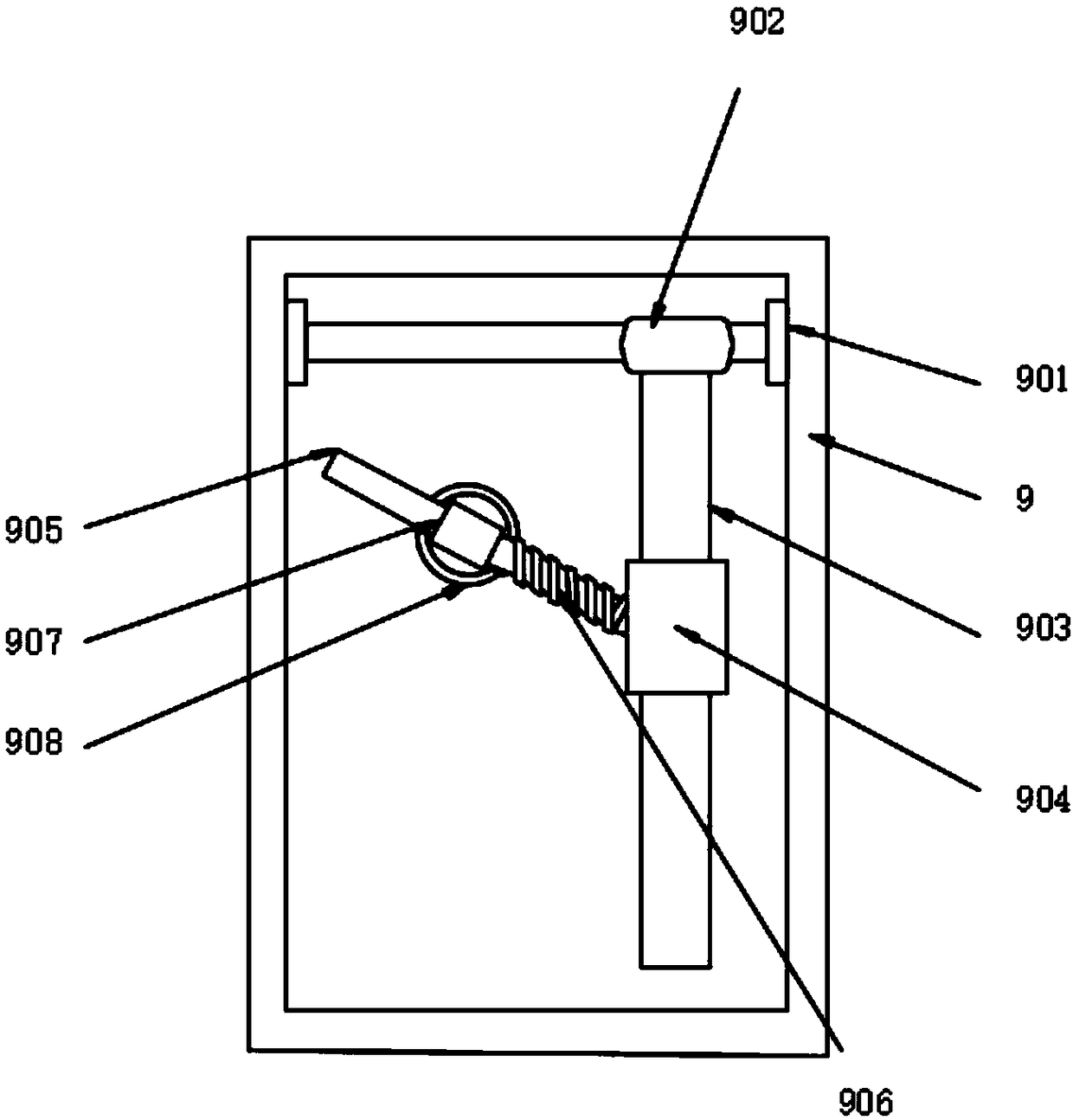

Throttle valve with cleaning structure and flow-slowing structure and capable of adjusting flow rate

InactiveCN108050261AAdjust the elasticityAvoid damageOperating means/releasing devices for valvesHollow article cleaningWater qualityWater flow

The invention relates to the technical field of one-way valves, and discloses a throttle valve with a cleaning structure and a flow-slowing structure and capable of adjusting the flow rate. Accordingto the throttle valve, a screw rod (8), a supporting plate (9), a threaded joint (10), a clamping plate (14), a brush (20) and the like are arranged, water flow pushes the clamping plate (14) so thatthe supporting plate (9) can move and rotate on the screw rod (8) through the threaded joint (10), and therefore the brush (20) on the clamping plate (14) is driven to clean the interior of a valve body; and meanwhile, a buffer spring (13) is matched to drive the supporting plate (9) to move and rotate back and forth, and therefore the brush (20) can clean the interior of the valve body all the time, sundries such as moss which can destroy water quality can be prevented from growing in the valve body, periodical cleaning is not needed, and the labor burden of workers can be greatly reduced.

Owner:丁锋燕

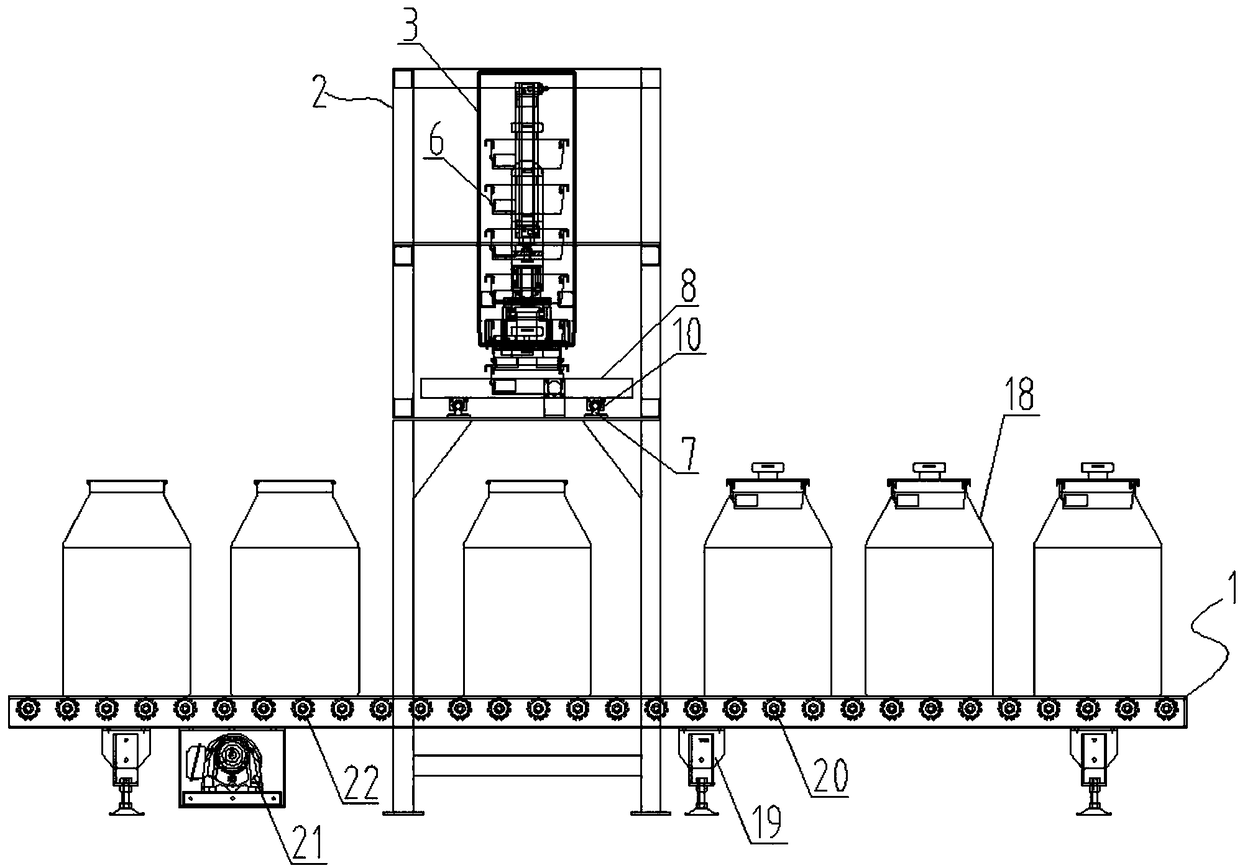

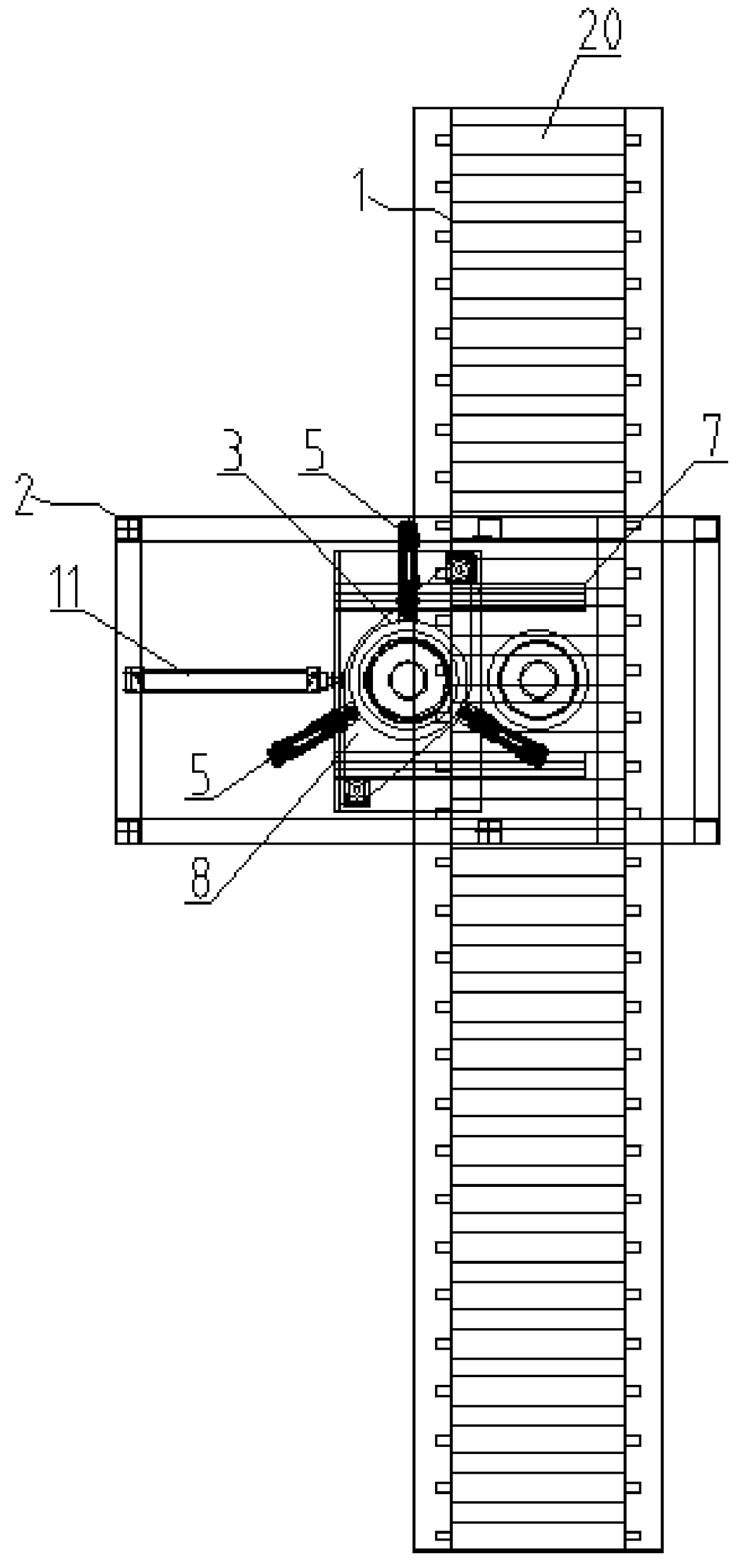

System used for packaging sample barrel

The invention discloses a system used for packaging a sample barrel. A vertical telescopic device is fixedly connected to the position, corresponding to the middle segment of a conveyor, of the upperportion of the rack, the left side of the upper portion of the rack is fixedly connected to a discharging cylinder vertically arranged, a pair of sliding rails extending in the left and right direction is fixedly connected to the position, below the lower end of the discharging cylinder, of the middle of the rack, and a horizontal telescopic device B is fixedly connected to the position, on the left side of the discharging cylinder, of the middle of the rack; a limiting mechanism composed of multiple horizontal telescopic devices A is arranged at the lower end of the discharging cylinder, thetelescopic parts of the horizontal telescopic devices A extend into the discharging cylinder in a sliding manner through through holes in the discharging cylinder, a sliding frame is arranged on the sliding rails in a matched manner, a telescopic part of the horizontal telescopic device B is connected with the left end of the sliding frame, a telescopic part of the vertical telescopic device is fixedly connected with a barrel pressing rod, and the lower end of the barrel pressing rod is connected with an electromagnetic suction cups matched with a barrel cover. The system can effectively improve the packaging efficiency, labor burdens of an operator can be reduced, and manpower cost can be effectively reduced.

Owner:江苏德博利恩工业科技有限公司

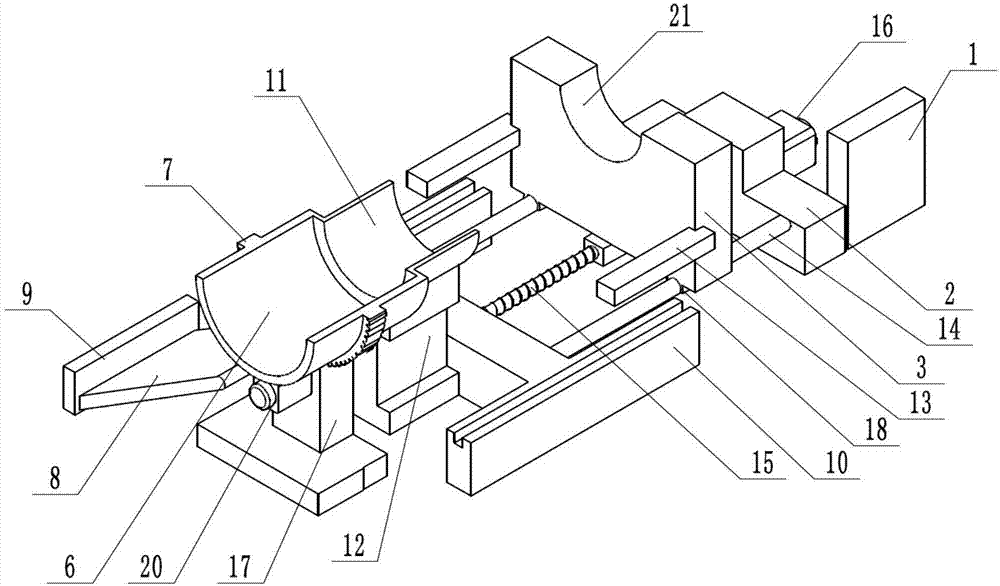

Device for taking bearing ring casting part out

The invention relates to a device for taking a bearing ring casting part out, and belongs to the field of casting processing equipment. The device is composed of a control cabinet, a base, a bracket, a first supporting frame, a supporting mechanism, a first arc plate bracket, a rack, a slide plate, a baffle, a first sliding rail, a second arc plate bracket, a second supporting frame, a connecting rod, a feed rod, a first screw rod, a displacement motor, a third supporting frame, a sliding cooperation block and a discharging motor, height difference between the first arc plate bracket and the second arc plate bracket is used for taking the bearing ring casting part out, no manual intervention is needed, at the same time, the supporting mechanism adopts the design of a conical guide head, the supporting mechanism thus conveniently enters an inner ring of the bearing ring casting part, at the same time, through the ingenious cooperation of a circular platform and a tightly holding block, dynamic supporting of the supporting mechanism is achieved, the supporting mechanism is close to closed design, and the influence of high temperature on the service life of the device can be effectively reduced. According to the device, the mechanism is ingenious, people's labor burden can be effectively reduced, and the production cost is reduced.

Owner:山东之华管业有限公司

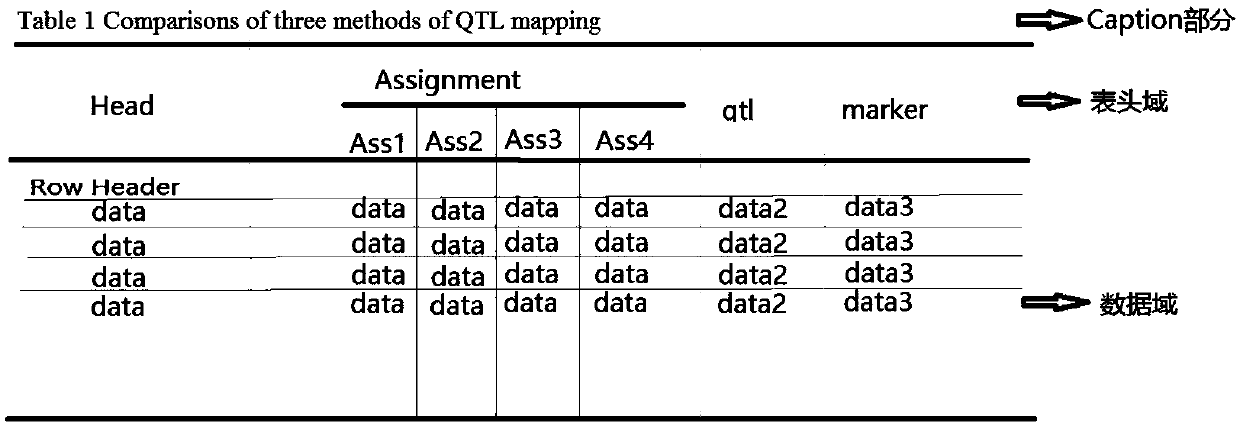

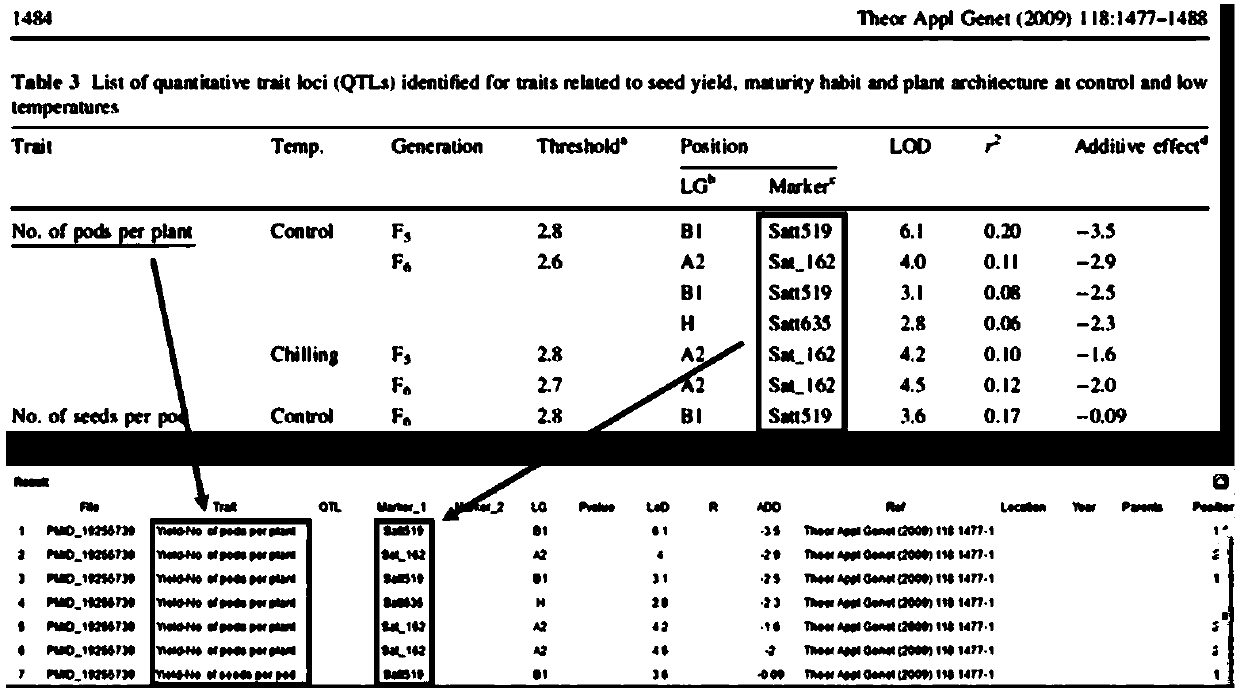

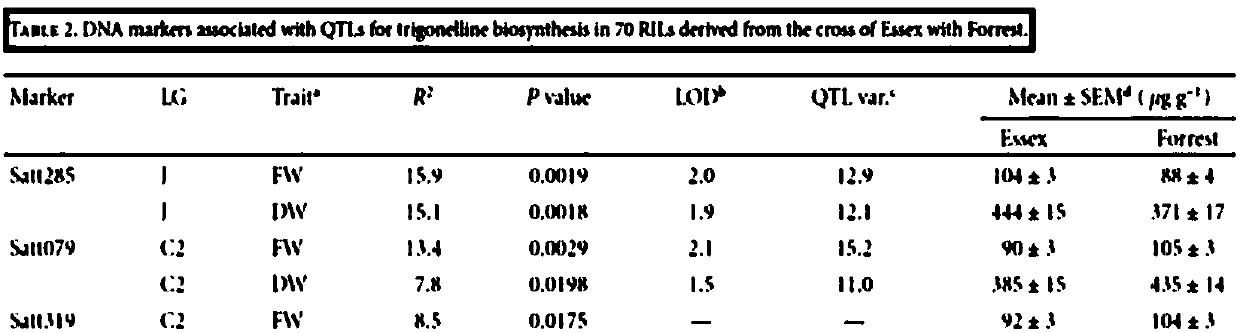

Method of automatically acquiring QTL data from literature

InactiveCN107590448AReduce labor burdenCharacter and pattern recognitionSpecial data processing applicationsData dredgingText mining

The invention belongs to the bioinformation field, and especially relates to a method of automatically acquiring QTL (quantitative trait locus) data from literature. The method of automatically acquiring QTL data from literature automatically excavates the information from the related literature, such as QTL and gene functions through a text excavation method, automatically acquires the QTL information from the literature in the PDF format through a computer data excavation technology so as to solve the problem that the current literature artificial reading method is large in the workload, isslow and cannot timely processing newly published number. And at same time, the method of automatically acquiring QTL data from literature can greatly reduce the labor burden for database construction.

Owner:武汉古奥基因科技有限公司

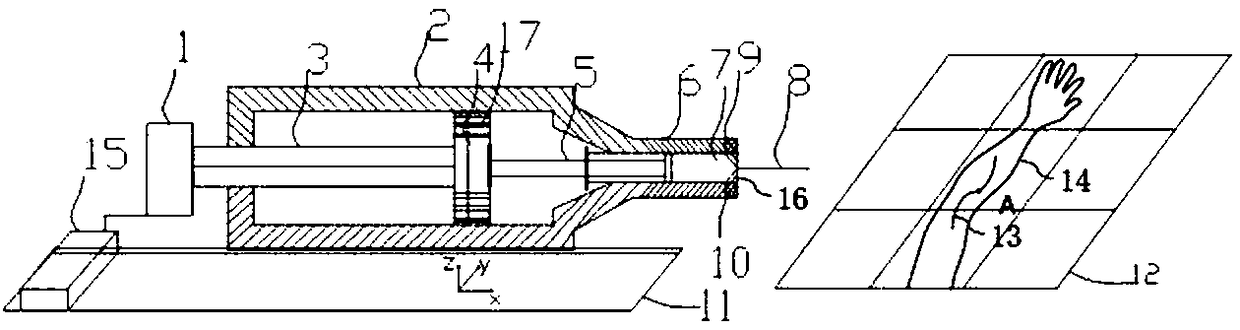

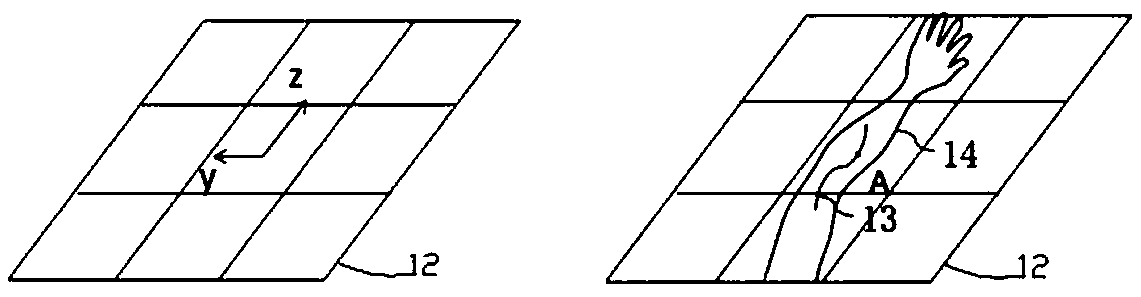

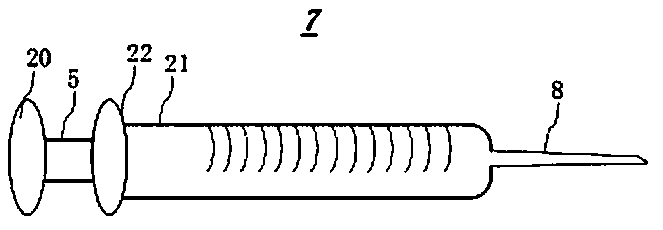

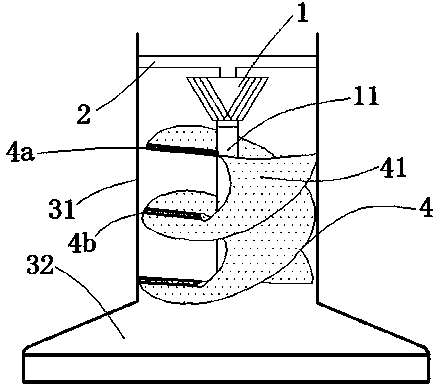

Injection device and injection method for automatic intravenous injection

ActiveCN108355203ASteady injectionInjection uniform speedAutomatic syringesIntravenous devicesEngineeringCylinder block

The invention discloses an injection device and injection method for automatic intravenous injection. The device includes a syringe for injection, a front cylinder, a piston, a piston rod, a motor system and a rear cylinder. The front cylinder is used for fixing the syringe, the internal diameter of the front cylinder is the same as the external diameter of the syringe and smaller than that of therear cylinder; a piston handle of the syringe is mounted on the piston, the piston rod is used for pushing the piston to move through the control of the motor system; the motor system is used for controlling the syringe to inject or absorb medicines according to a control instruction; the internal diameter of the rear cylinder is the same as the diameter of the piston, and the rear cylinder is used for movement of the piston. The injection device is of a double-layer piston structure to reduce the sensitivity of the piston and keep the piston in a stable and uniform injection; through an automatic intravenous injection method, a nurse does not need to participate, the operation saves time and labor, and the labor burden of medical workers is reduced.

Owner:青岛市中医医院

Range hood easy to clean

InactiveCN108506987AAvoid the hassle of cleaning the filterDomestic stoves or rangesLighting and heating apparatusAgricultural engineeringDrive motor

The invention provides a range hood easy to clean. The range hood easy to clean comprises a smoke collecting cover and an air pipe connected to the upper portion of the smoke collecting cover; a driving motor with a downward vertical shaft is fixed in the air pipe through an air pipe support; the driving motor rotationally drives one base rod extending downwards and coaxial with the axis of the air pipe; a spiral fan blade is arranged on the periphery of the base rod; the outer edge line of the spiral fan blade is a vertical spiral line coaxial with the air pipe, and the radial interval between the outer edge line and the interior of the air pipe is 2 mm to 4 mm; the inner edge line is a vertical spiral line on the surface of the base rod; oil absorbing paper is laid on each of the upper surface and the lower surface of the spiral fan blade; the base rod can be pulled out of the vertical shaft of the driving motor; and the oil dirt filtering effect of the range hood easy to clean is remarkably improved, cleaning is convenient after using, and the labor burden of people is relieved.

Owner:丁向峰

Cantilever force-bearing frame and mounting method thereof

The invention discloses a cantilever force-bearing frame and a mounting method thereof, and relates to a force-bearing frame. The cantilever force-bearing frame aims to solve the technical problem that a force-bearing frame in the prior art needs to be mounted by welding, and time and effort are consumed. According to the key points of the technical scheme, the cantilever force-bearing frame comprises a square tube, a pre-embedded part disposed in a floor slab, a fixing part inserted into a cavity of the square tube and connected with the pre-embedded part and a limiting part disposed at the edge of the floor slab and used for fixing the square tube, a hanging part is arranged on the side wall of a wall body, and the hanging part is used for connecting the end, away from the fixing part, of the square tube; when the force-bearing frame is mounted, the fixing part is first inserted into the cavity of the square tube, one end of the fixing part is installed on the floor slab by using thepre-embedded part, and the other end of the fixing part is lifted by the hanging part, so that the square tube is conveniently and quickly mounted on the floor slab, finally the mounting stability ofthe square tube is strengthened by the limiting part, the force-bearing frame can be conveniently and quickly built, and the labor burden of workers is conveniently reduced.

Owner:江苏溧阳建设集团有限公司

Circular tube polishing and painting device

InactiveCN109277935ASimple structureEasy to operateGrinding carriagesPolishing machinesMechanical engineeringLabor burden

The invention aims to provide a circular tube polishing and painting device capable of improving the polishing and painting efficiency and lowering the labor burden of workers. The circular tube polishing and painting device is composed of a travelling frame, a polishing mechanism, a paint spraying mechanism and a painting mechanism, wherein the polishing mechanism, the paint spraying mechanism and the painting mechanism are arranged on the travelling frame; the polishing mechanism is composed of a rotating frame of a tubular structure and a driving mechanism for driving the rotating frame torotate, and grindstones are mounted on the inner wall of the rotating frame through elastic mechanisms; the paint spraying mechanism comprises three or more clasping arms, one ends of the clasping arms are connected with the travelling frame through elastic mechanisms so that the free ends of the clasping arms tend to be in a clasping state, and the free ends of the clasping arms are provided withidler wheels; the clasping arms are provided with paint tubes, the ends of the paint tubes are provided with paint spraying holes, the paint tubes are connected with a paint storage cylinder on the travelling frame, and the paint storage cylinder is provided with a pressurizing device; and the painting mechanism is composed of a rotating frame of a tubular structure and a driving mechanism for driving the rotating frame to rotate, and brushes are mounted on the inner wall of the rotating frame through elastic mechanisms.

Owner:广东家加美不锈钢管制造有限公司

Transporting device with nursing function

PendingCN110200758AReduce the burden of transshipmentWide applicabilityStretcherNursing bedsButtocksEngineering

The invention discloses a transporting device with nursing function, wherein the transporting device comprises a mounting frame; the lower end of the mounting frame is equipped with a transferring andloading mechanism for moving the device; the transferring and loading mechanism is equipped with a height regulating mechanism; the height regulating mechanism is equipped with a nursing function executing mechanism, and the height regulating mechanism is used for regulating the height of the nursing function executing mechanism; the nursing function executing mechanism comprises a buttock support assembly located on the mounting frame, the left side of the buttock support assembly is hinged with a thigh support assembly and a crus support assembly in turn, and the right side of the buttock support assembly is hinged with a back support assembly. The transporting device can realize transporting of wounded personnel in different height beds and operating tables under a condition without changing of wounded personnel position and posture; people can bend their legs up and down and sit up according to the needs of nursing and patients, the living conditions of the wounded personnel are improved and the labor burden of nursing and medical staff is reduced.

Owner:SHANGHAI UNIV OF ENG SCI

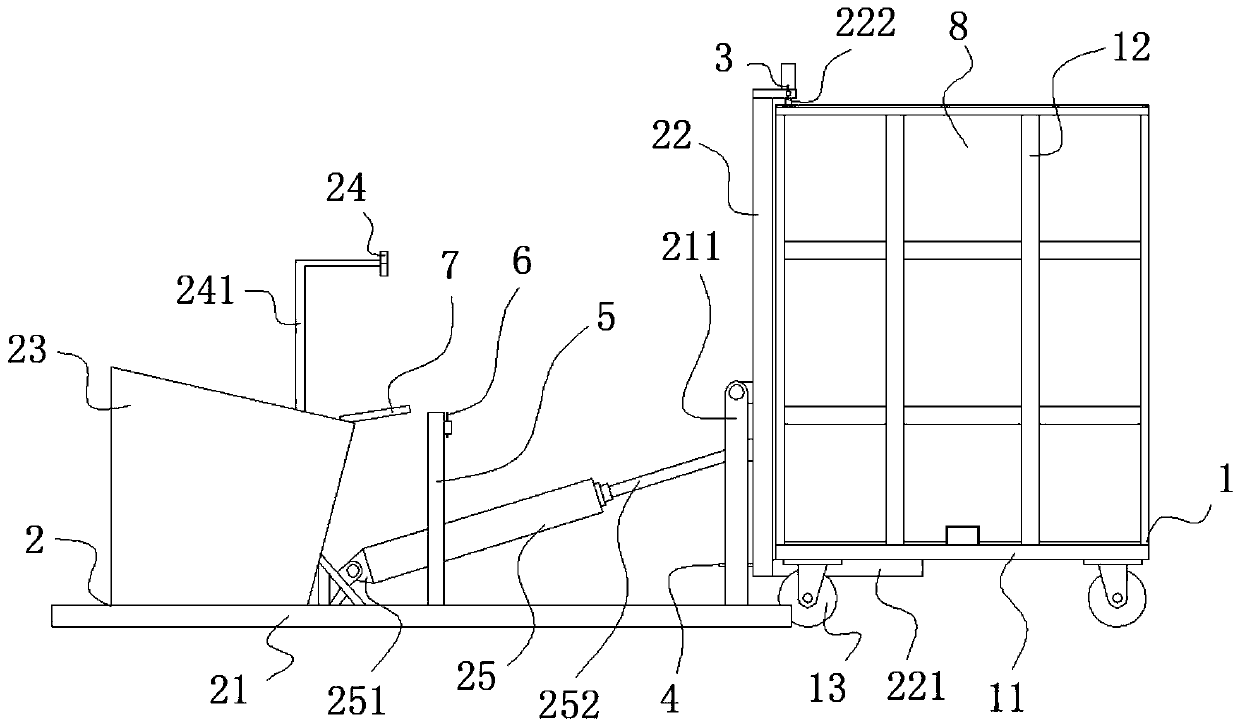

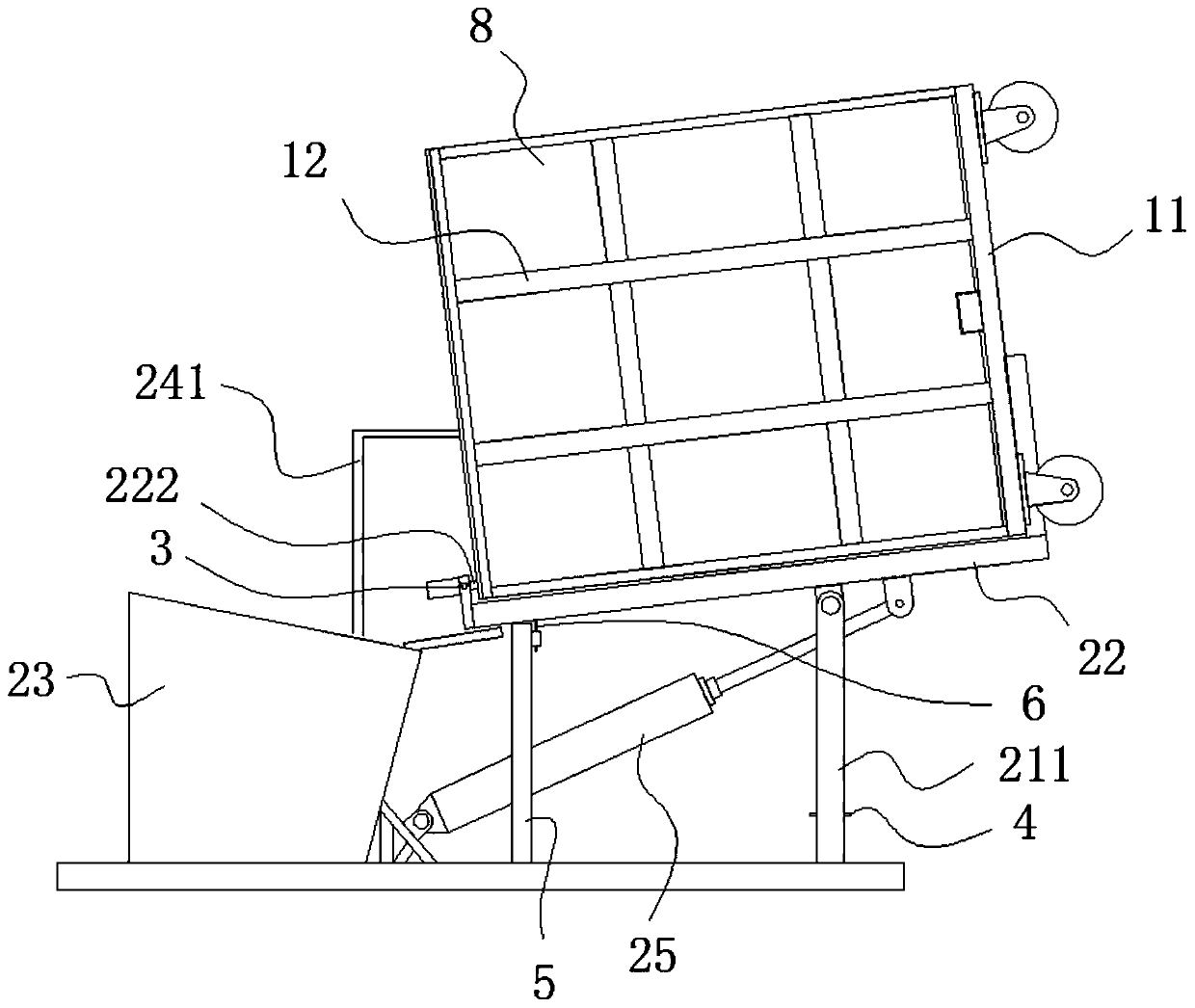

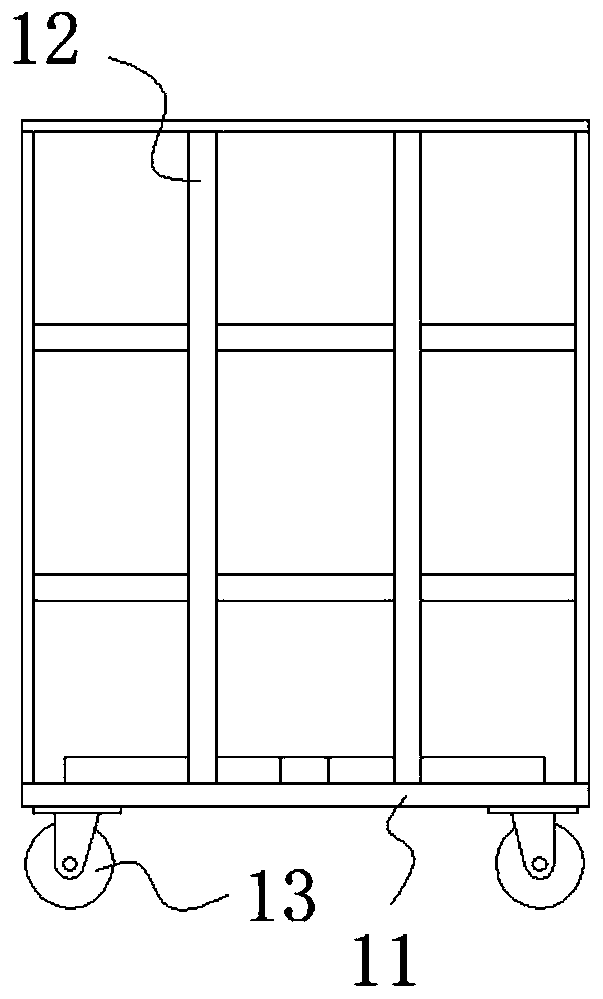

Automatic tilting overturning type barrel washing device

PendingCN110238141AReduce labor burdenEasy to operateHollow article cleaningPhysical healthEngineering

The invention provides an automatic tilting overturning type barrel washing device, and belongs to the technical field of garment printing and dyeing. The automatic tilting overturning type barrel washing device comprises a movable supporting seat and an overturning assembly. According to the device, a containing barrel to be tilted and cleaned is fixed on the movable supporting seat, the two ends of an overturning base of the overturning assembly are provided with a material receiving hopper and a vertical support correspondingly, a cleaning spray head is arranged in the material receiving hopper in an upward-extending-out mode, the middle area of a overturning frame is hinged to the top end of the vertical support, a bracket and a telescopic clamping block are arranged at the bottom end and the top end of the overturning frame respectively, so that the movable supporting seat is fixed on the overturning frame, meanwhile, a driver connected to the overturning base is hinged to the lower part of the overturning frame, the overturning frame is driven by the driver to drive the movable supporting seat to overturn, so that automatic tilting of the containing barrel is realized; and the cleaning spray head is started to spray water to automatically flush the containing barrel, operation is convenient, the labor burden is reduced, the risks of influence on physical health and smashing injury caused by manual operation are avoided, and the safety guarantee is higher.

Owner:NINGBO DAQIAN TEXTILE

Film laminator feeding mechanism

PendingCN108819208AEasy to placeImprove the efficiency of lamination workFlat articlesEngineeringCam

The invention relates to the technical field of furniture processing, and particularly discloses a film laminator feeding mechanism. The film laminator feeding mechanism comprises a motor, a driving roller, a driven roller, a guiding roller, a conveyor belt and a motor for driving the driving roller, and the guiding roller is flush with the driving roller, the guiding roller is located between thedriving roller and the driven roller, the driven roller is lower than the guiding roller, and the conveyor belt is fixedly connected with a plurality of baffle plates; a film laminating platform is arranged beside the driving roller, a film laminator and a cylinder body are mounted above the film laminating platform, a piston is slidably connected in the cylinder body, the piston is connected with a piston rod, and a cam for pushing the piston rod is fixedly connected to the output end of the motor; and the cylinder body is communicated with an air inlet tube and an air outlet tube, each of the air inlet tube and the air outlet tube is provided with a one-way valve, one segment, positioned above the film laminating platform, of the air inlet tube is provided with a plurality of vent holes, the air inlet tube is provided with a buffer chamber, and a sponge body is arranged in the buffer chamber. The film laminator feeding mechanism can convey furniture plates by the conveyor belt to realize loading, so the labor burden of the staff is reduced, and the film laminating efficiency of the furniture plates is improved.

Owner:重庆银木莊美装家具有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com