Patents

Literature

6561results about How to "Reduce accumulation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

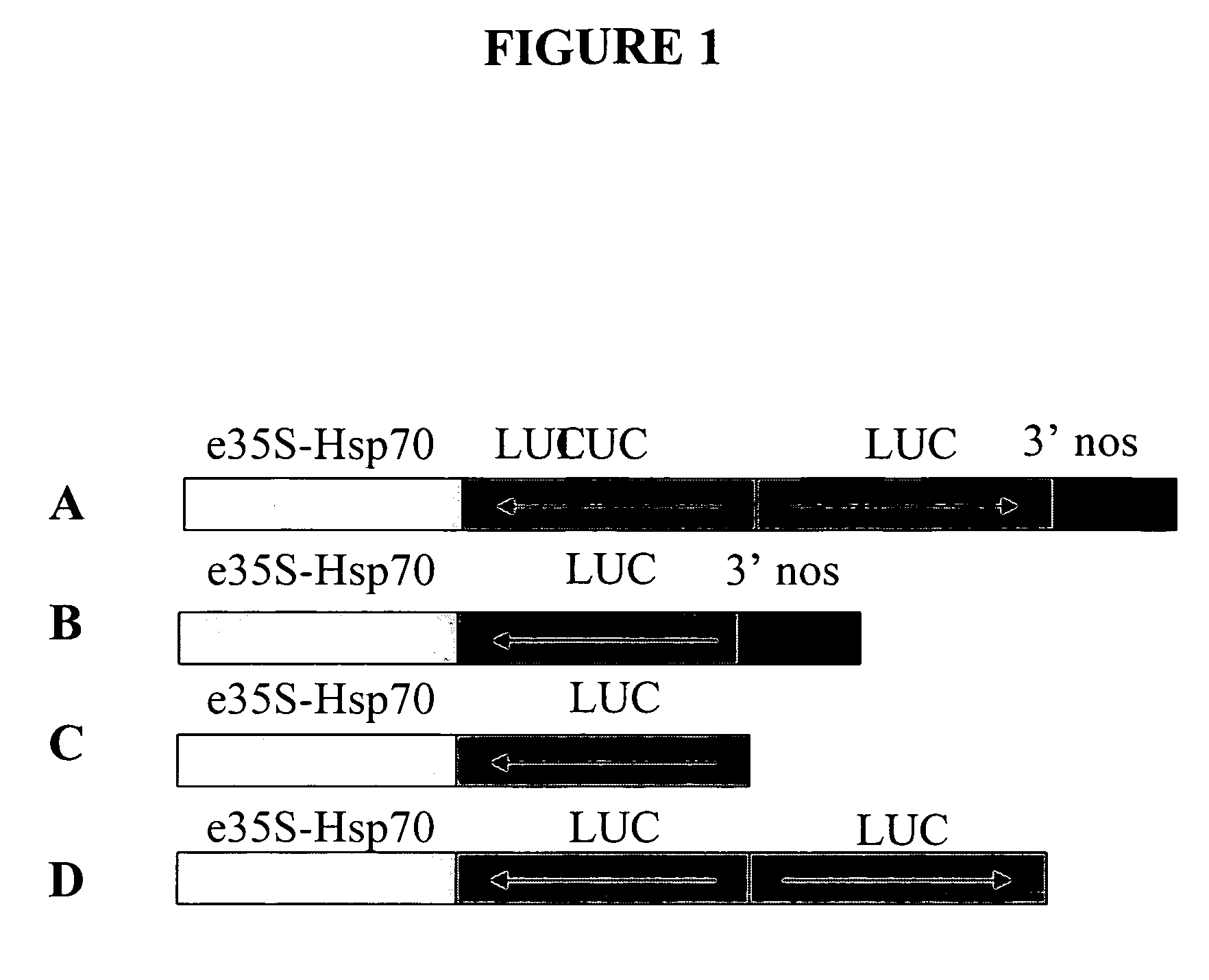

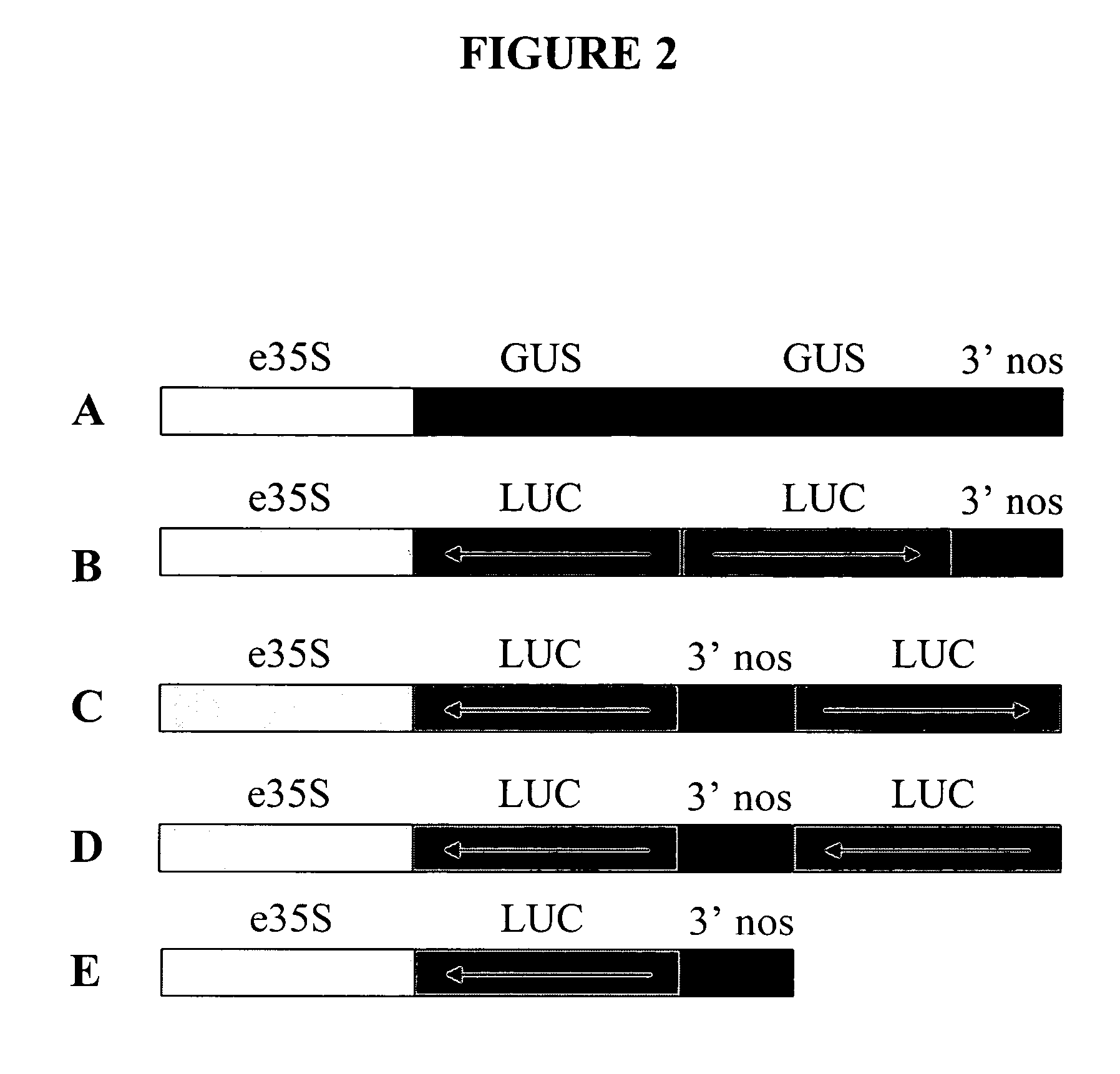

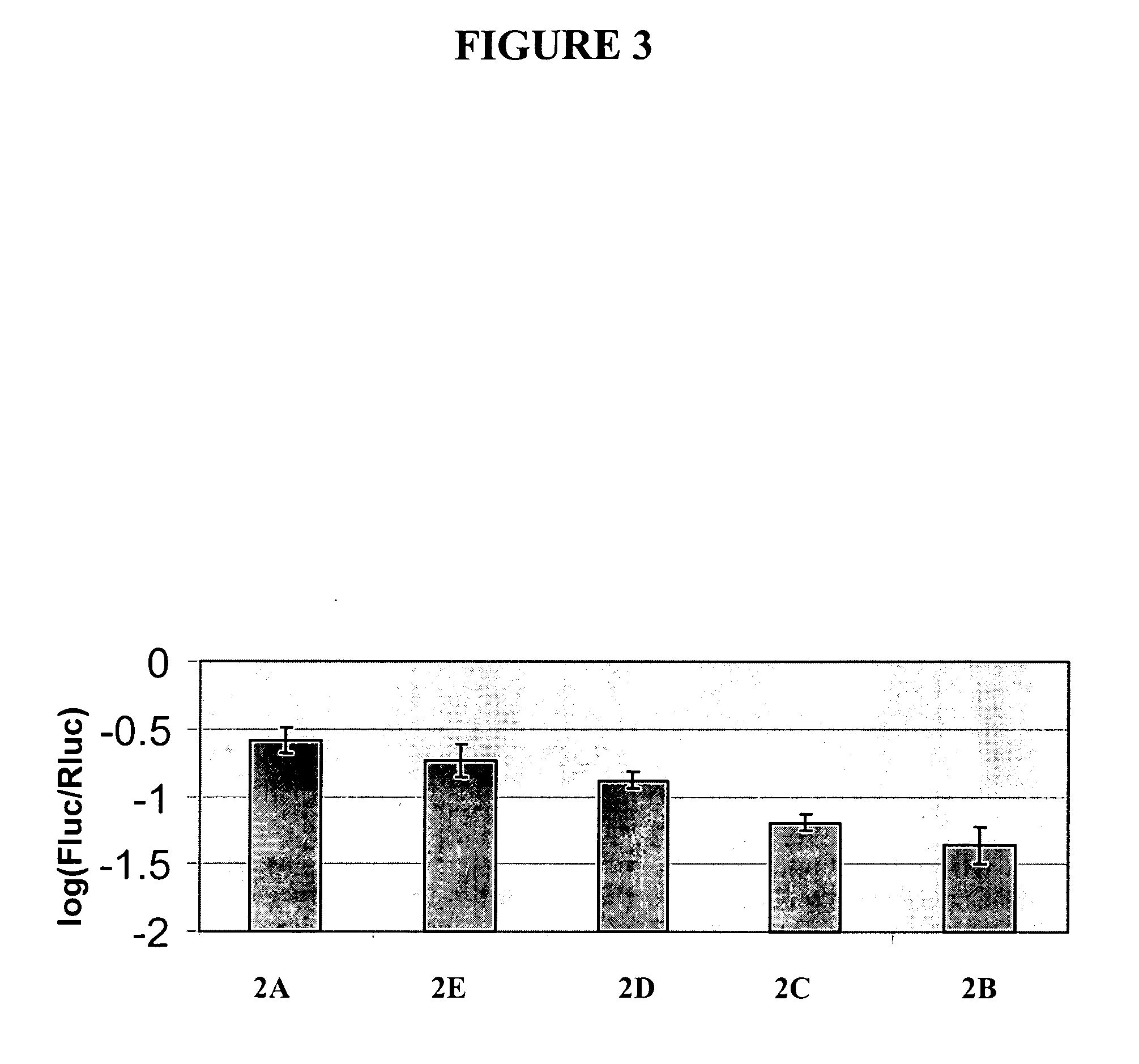

Recombinant DNA constructs and methods for controlling gene expression

InactiveUS20060200878A1Reduce accumulationClimate change adaptationOther foreign material introduction processesBiotechnologyHeterologous

The present invention provides molecular constructs and methods for use thereof, including constructs including heterologous miRNA recognition sites, constructs for gene suppression including a gene suppression element embedded within an intron flanked on one or on both sides by non-protein-coding sequence, constructs containing engineered miRNA or miRNA precursors, and constructs for suppression of production of mature microRNA in a cell. Also provided are transgenic plant cells, plants, and seeds containing such constructs, and methods for their use. The invention further provides transgenic plant cells, plants, and seeds containing recombinant DNA for the ligand-controlled expression of a target sequence, which may be endogenous or exogenous. Also disclosed are novel miRNAs and miRNA precursors from crop plants including maize and soy.

Owner:MONSANTO TECH LLC

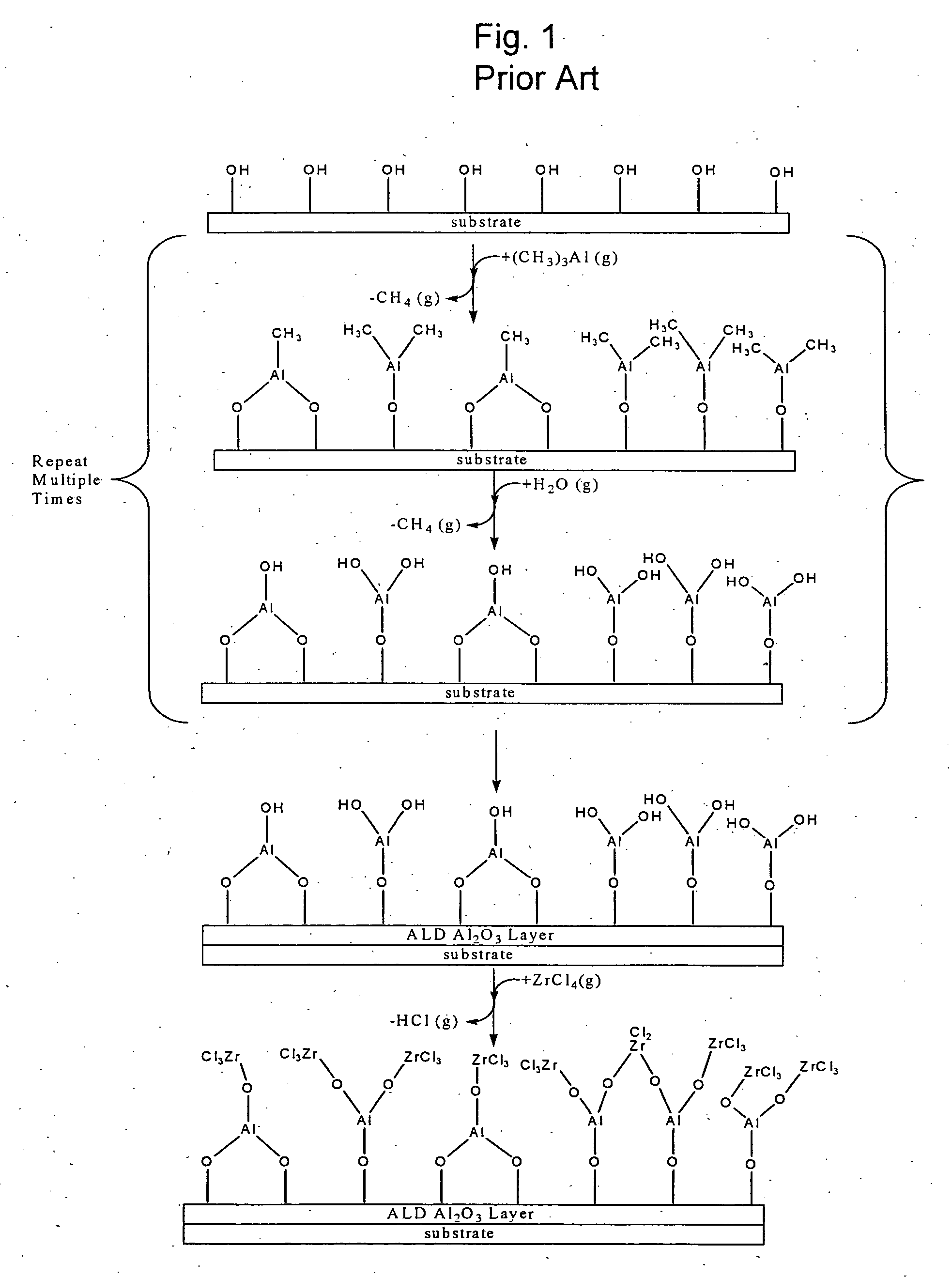

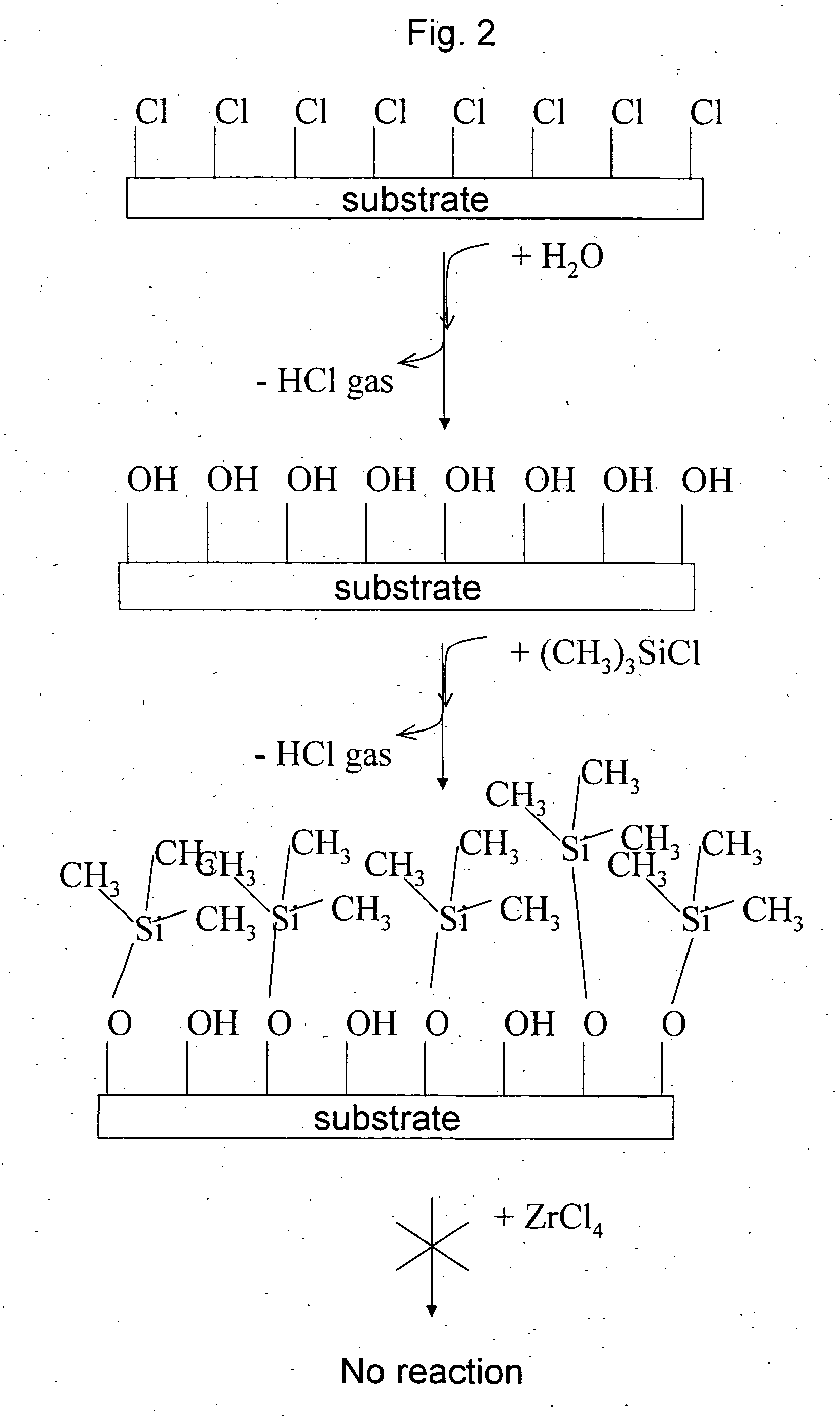

Passivating ALD reactor chamber internal surfaces to prevent residue buildup

InactiveUS20060040054A1Minimizing undesired chemisorptionReduce accumulationChemical vapor deposition coatingImproved methodDeposition process

This invention is directed to an improved method for preventing deposition residue buildup on the internal surfaces of an ALD reactor chamber. In an ALD deposition process, the surfaces of a substrate are treated with an initiating precursor generating a labile atom reactive with a deposition precursor. Excess initiating precursor is removed from the reactor and the substrate surface then is exposed to a deposition precursor reactive with the labile atom under conditions for generating a fugitive reaction product containing the labile atom and leaving a deposition product. The process is repeated generating alternate layers of initiation and deposition precursor reaction products. The improvement in the ALD process resides in passivating the internal surfaces of the reactor by removing labile atoms reactable with either the initiating or deposition precursors prior to effecting ALD deposition.

Owner:VERSUM MATERIALS US LLC

Contact structures for sliding switches

InactiveUS6979786B2Extended service lifeKeep the voltage stableContact driving mechanismsContact engagementsEngineeringContact position

Owner:DELPHI TECH INC

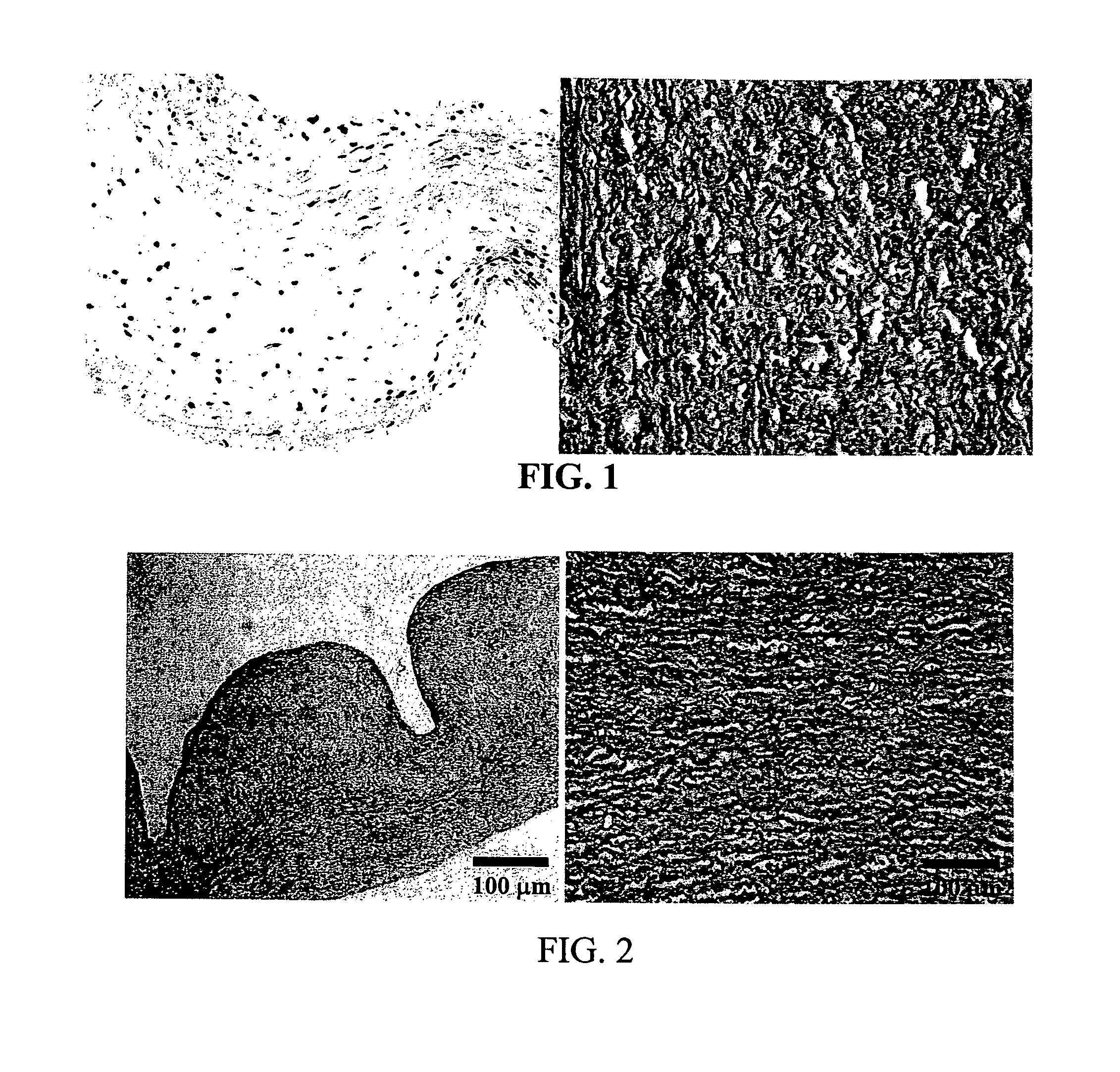

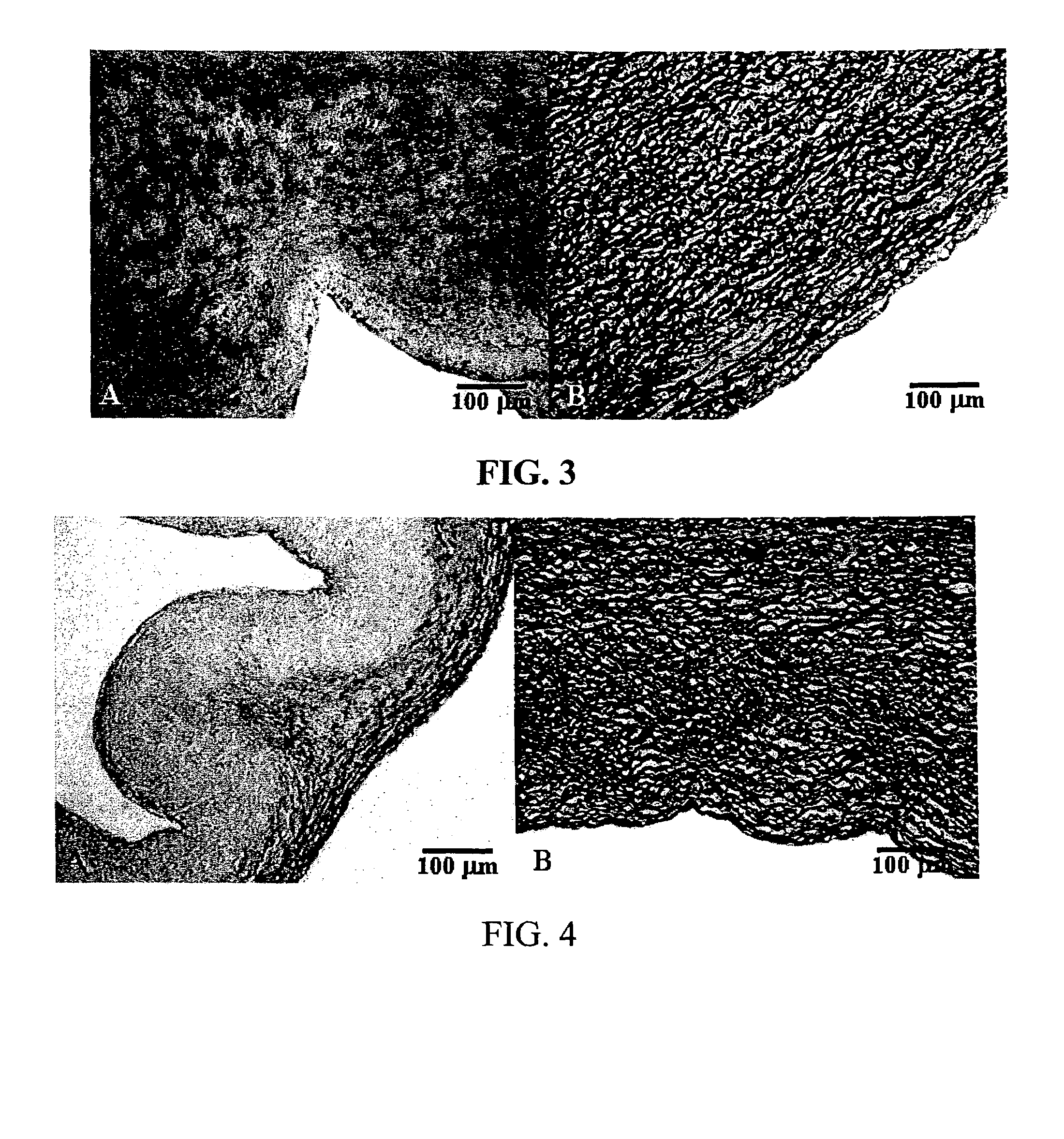

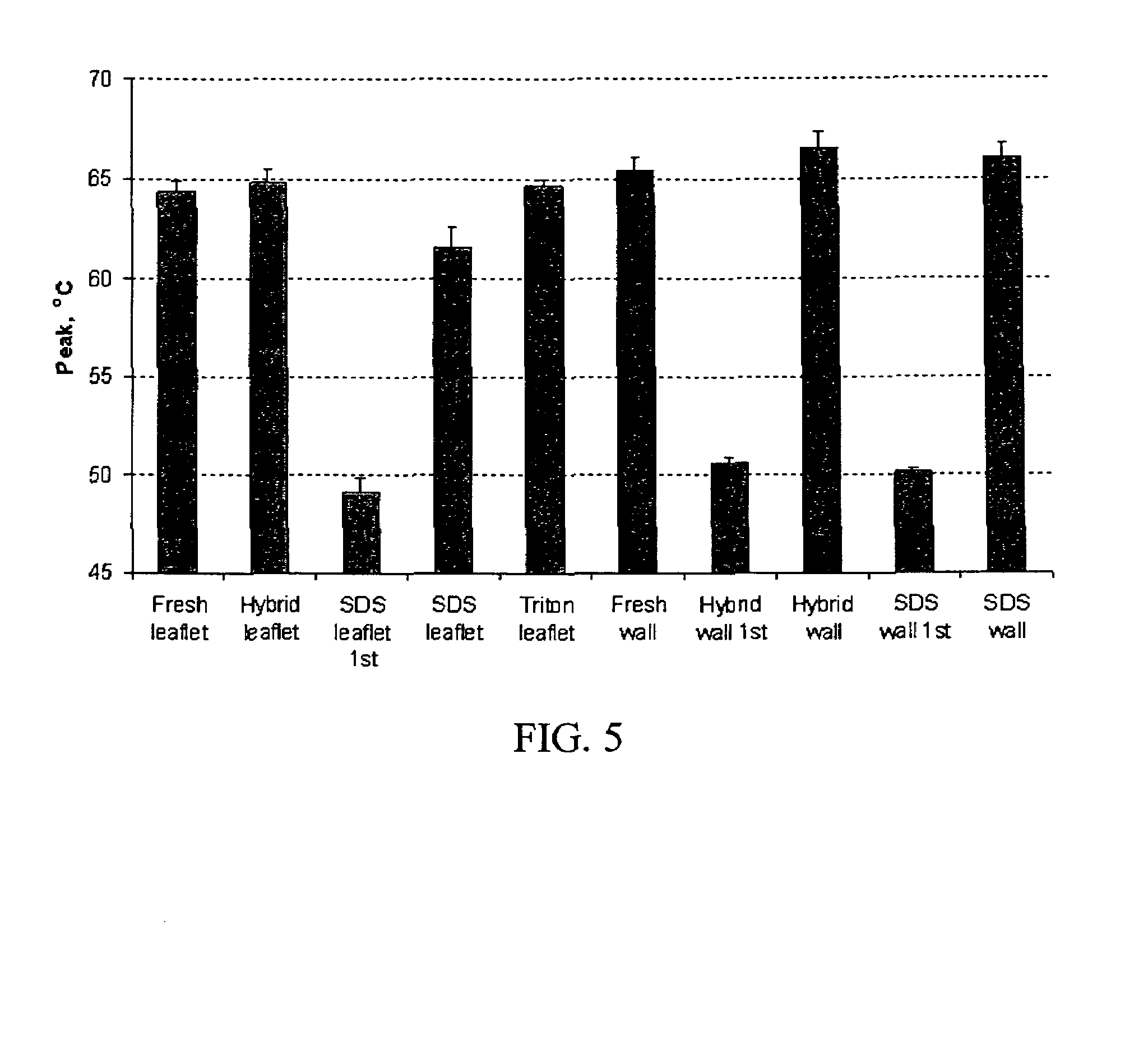

Process for reducing mineralization of tissue used in transplantation

InactiveUS7078163B2Reducing level of mineralizationLower Level RequirementsDead animal preservationProsthesisMedical deviceOxidizing agent

A method of making a tissue-derived implantable medical device that includes contacting the tissue with a composition comprising at least one oxidizing agent prior to implantation of the medical device.

Owner:MEDTRONIC INC

Process for the removal of nitrogen compounds from a fluid stream

ActiveUS7205448B2Increase capacityReduce accumulationMolecular sieve catalystsHydrocarbonsMolecular sieveNitrite

At lower temperatures an acidic molecular sieve adsorbent preferentially adsorbs water and basic organic nitrogen compounds over weakly basic organic nitrogen compounds such as nitrites. Elevated temperatures improve the capacity of acidic molecular sieve adsorbents to adsorb nitrites in the presence of water.

Owner:UOP LLC

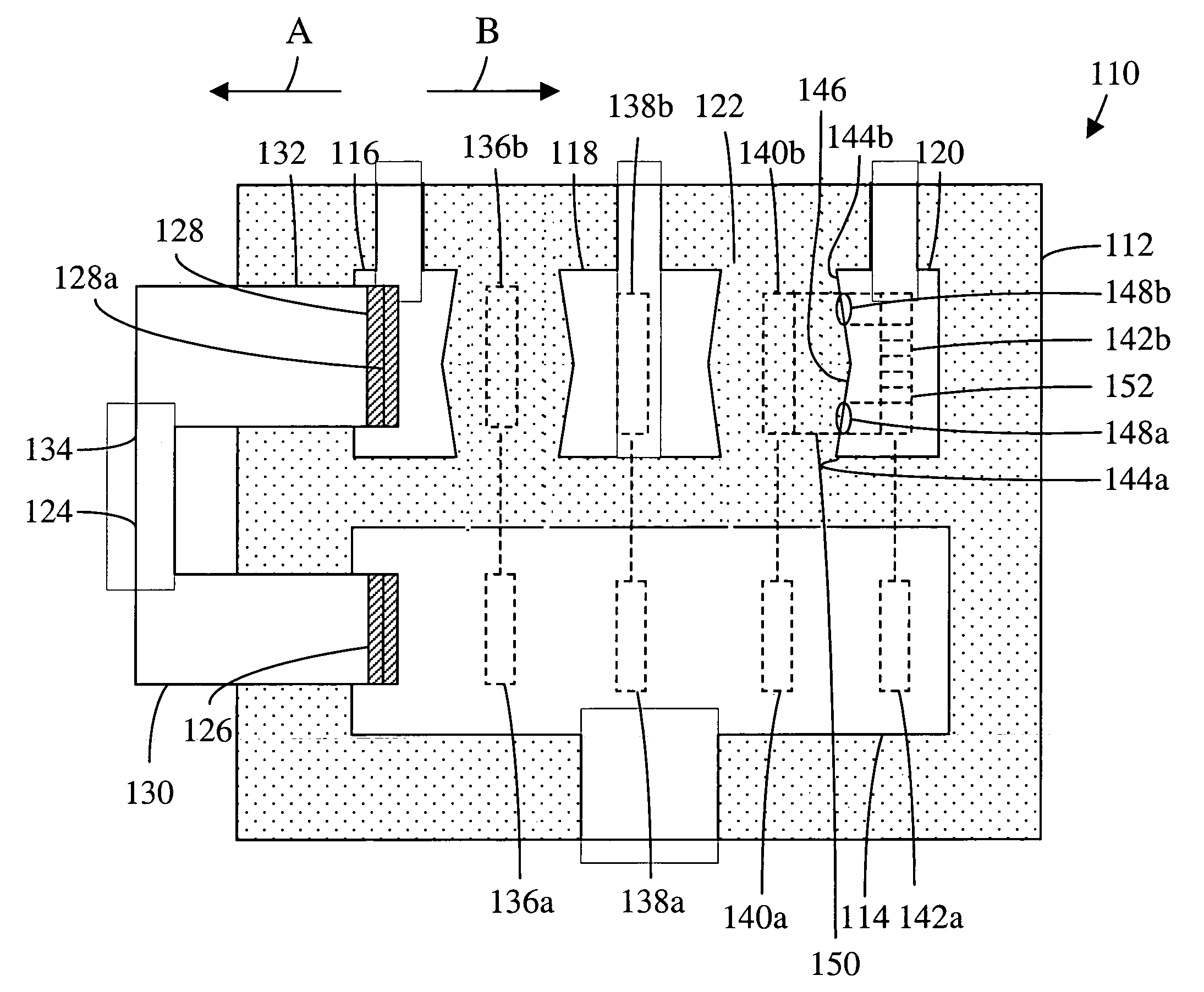

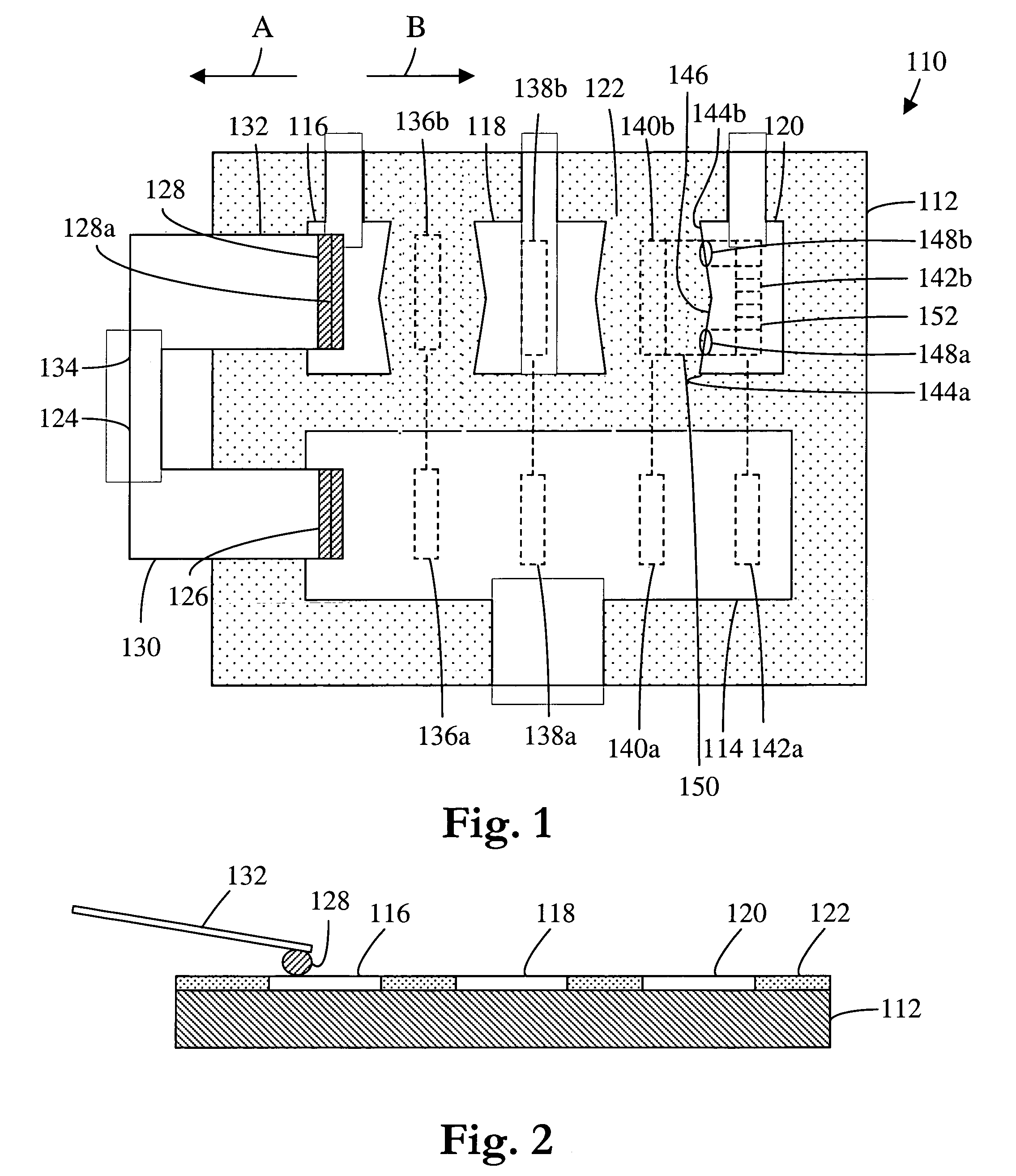

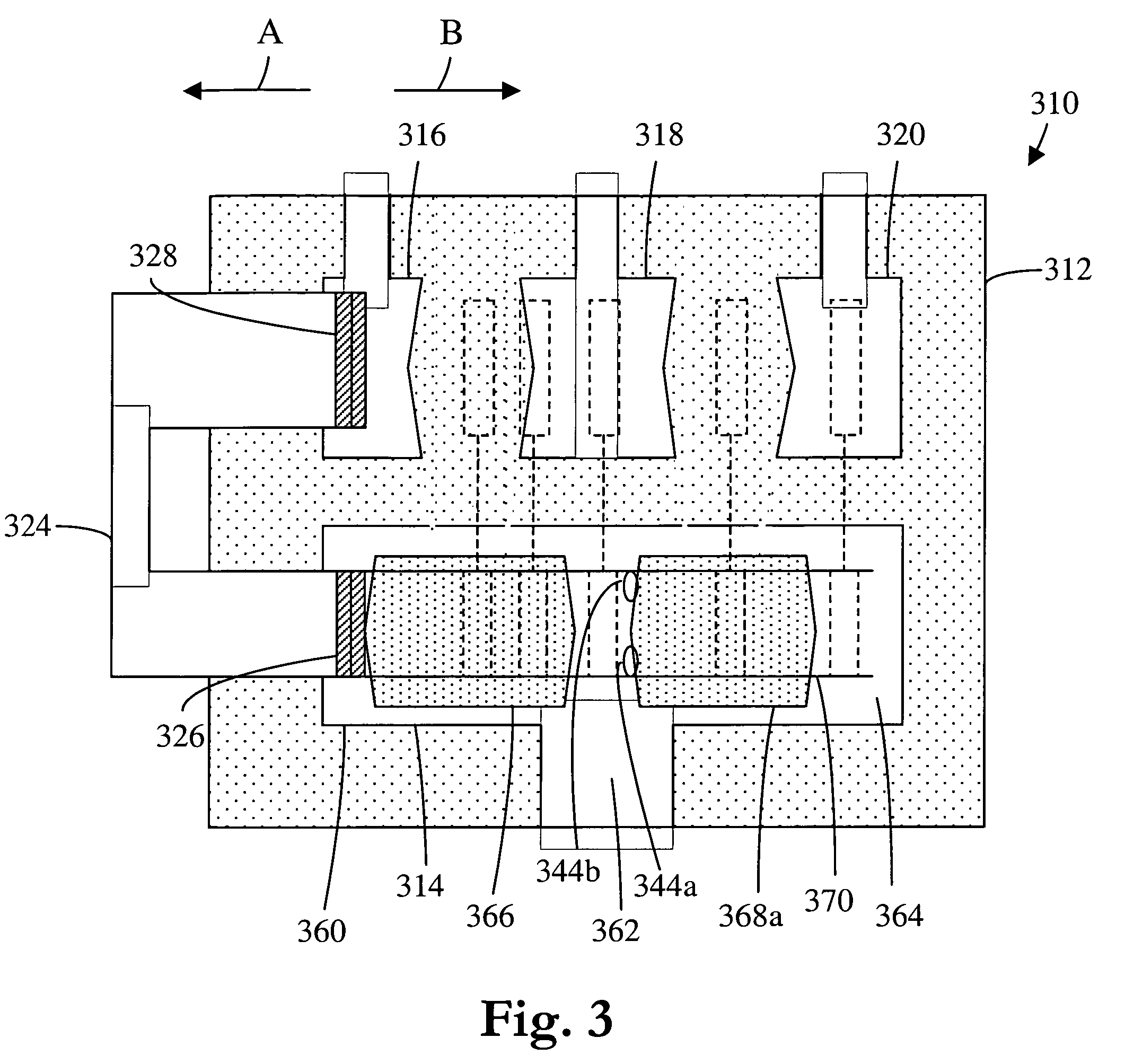

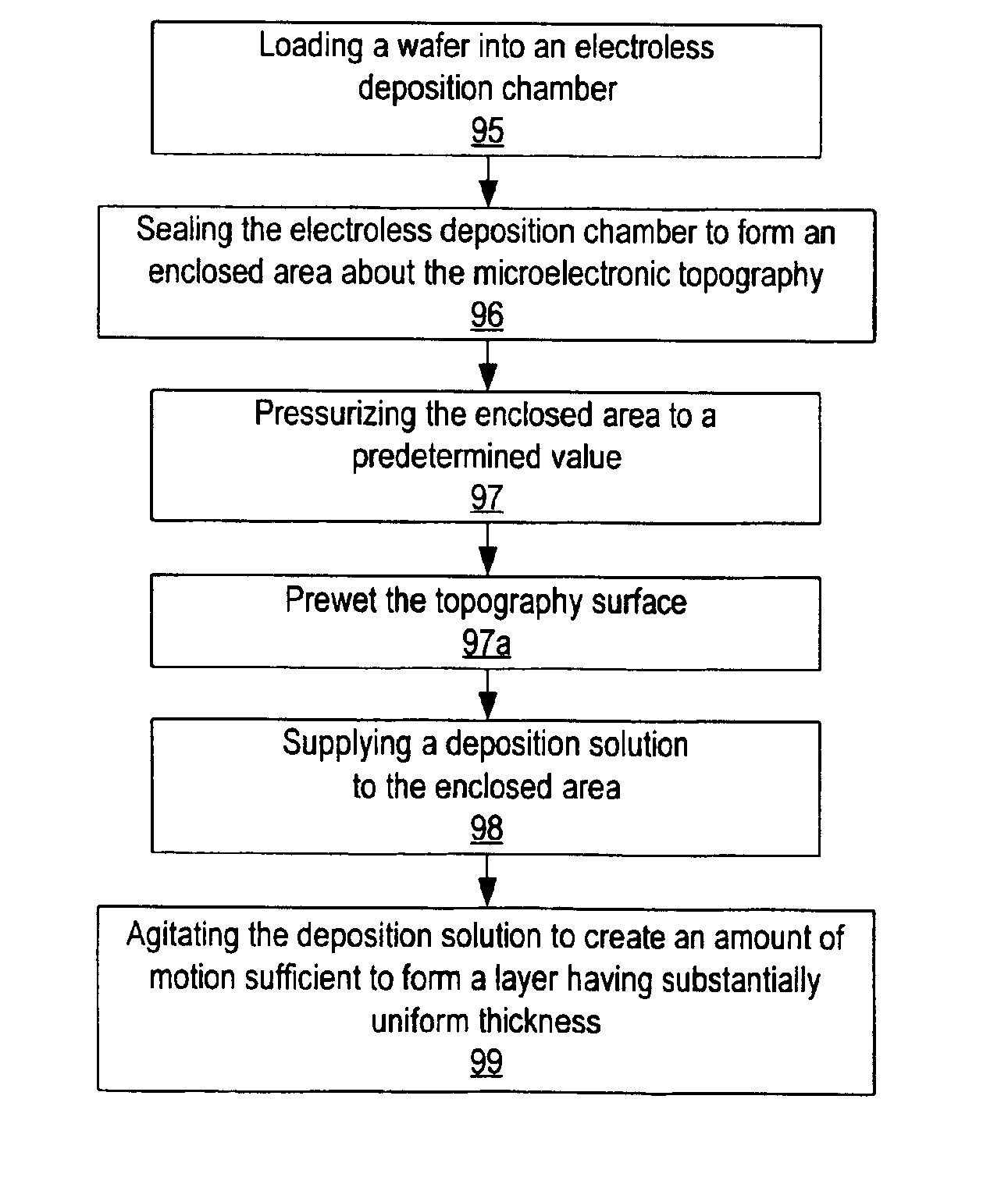

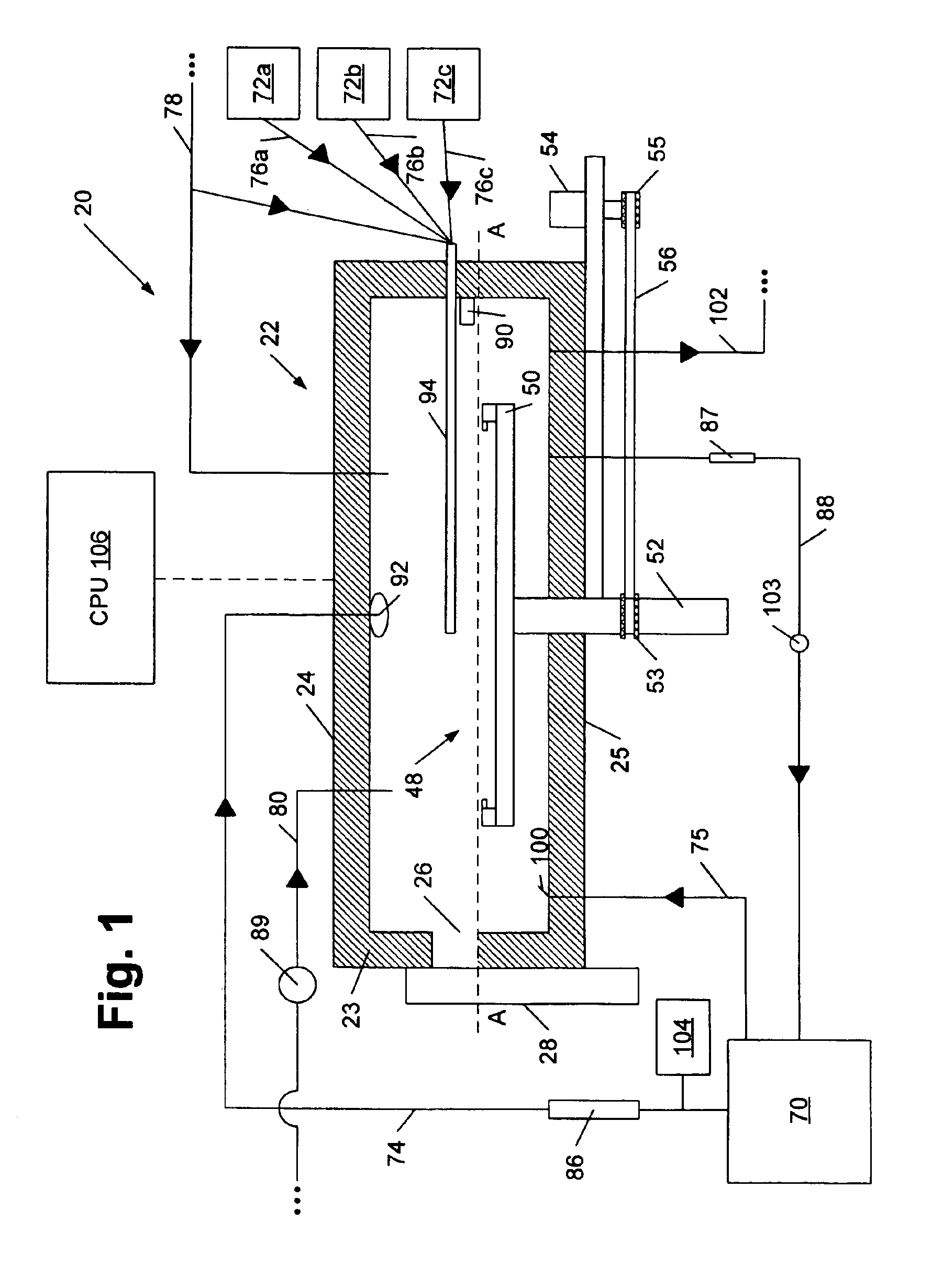

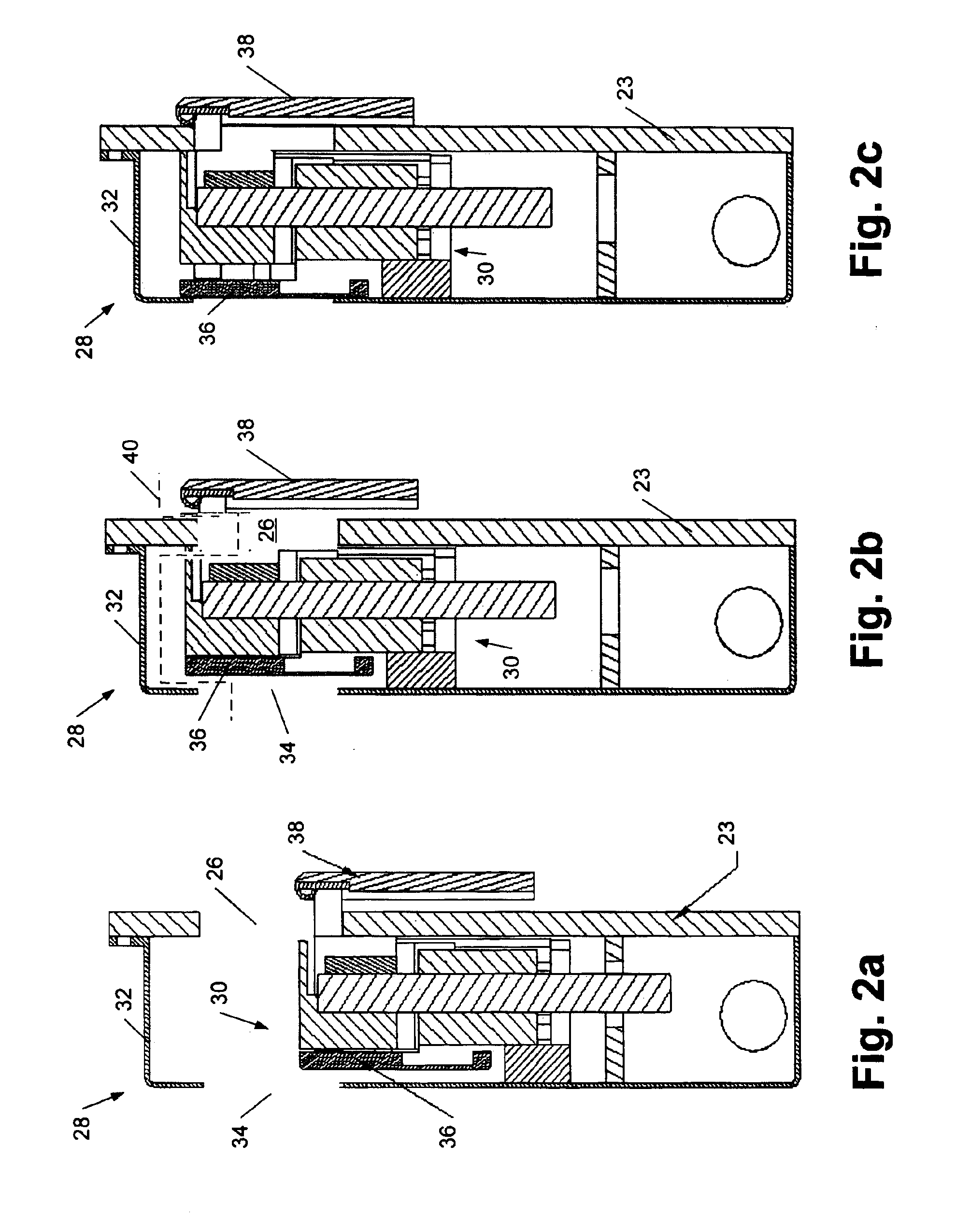

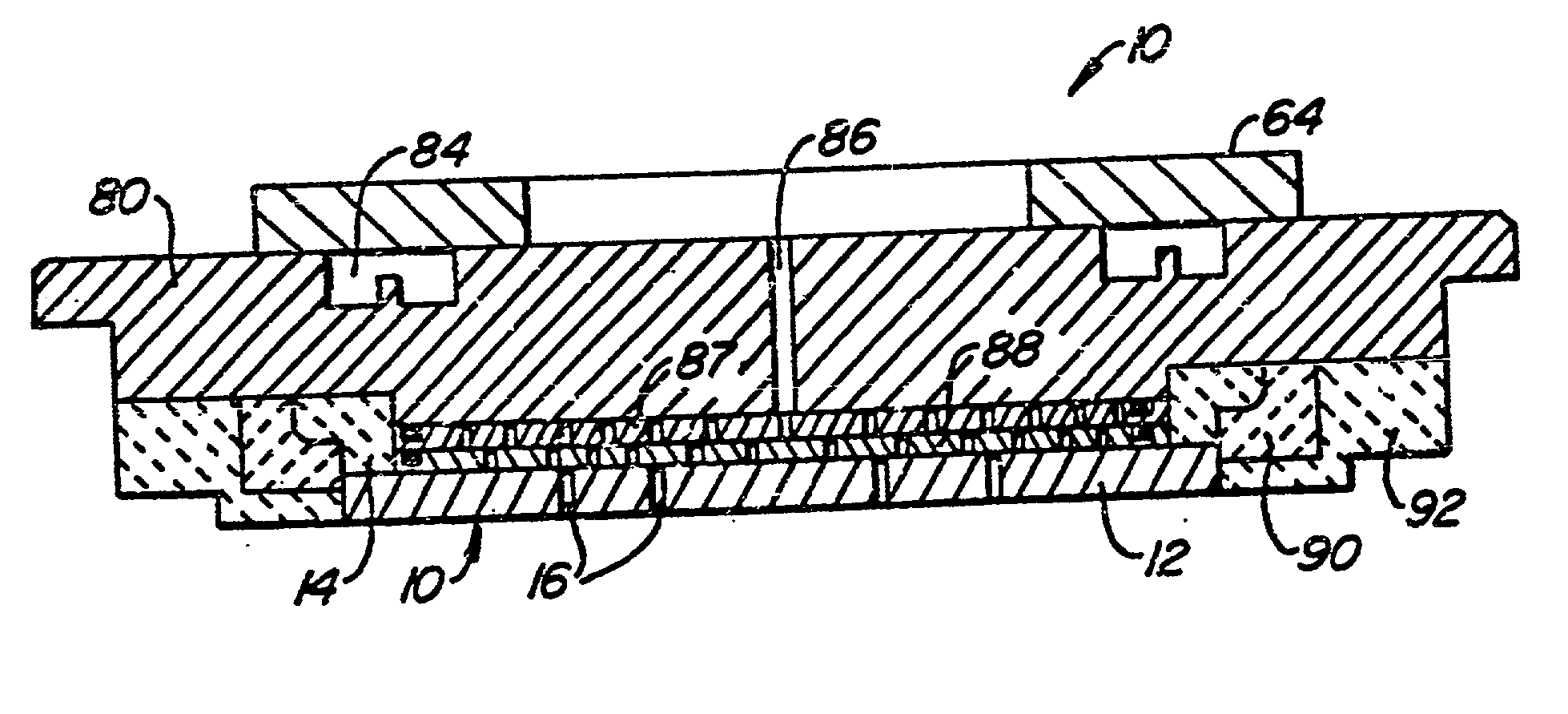

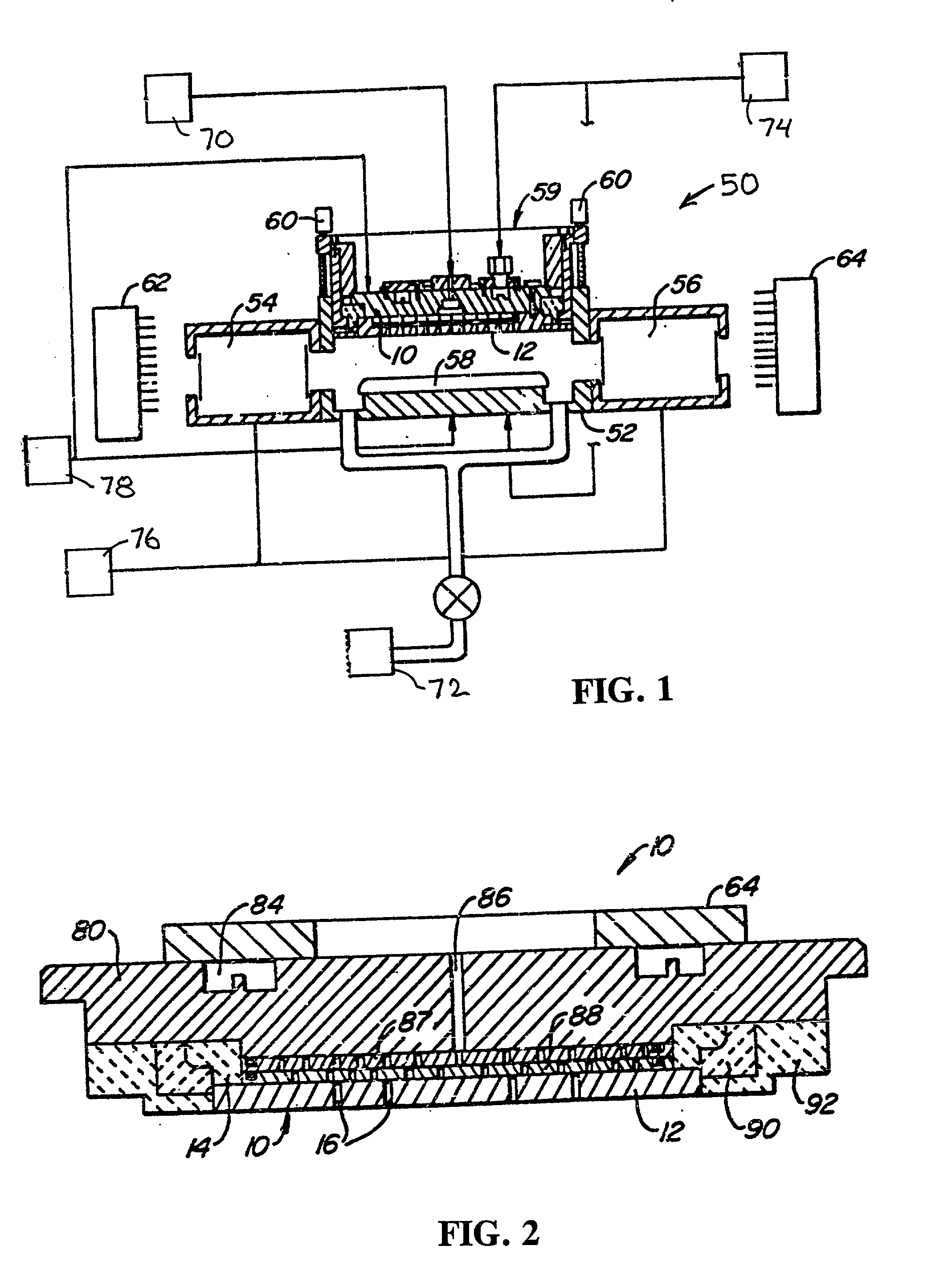

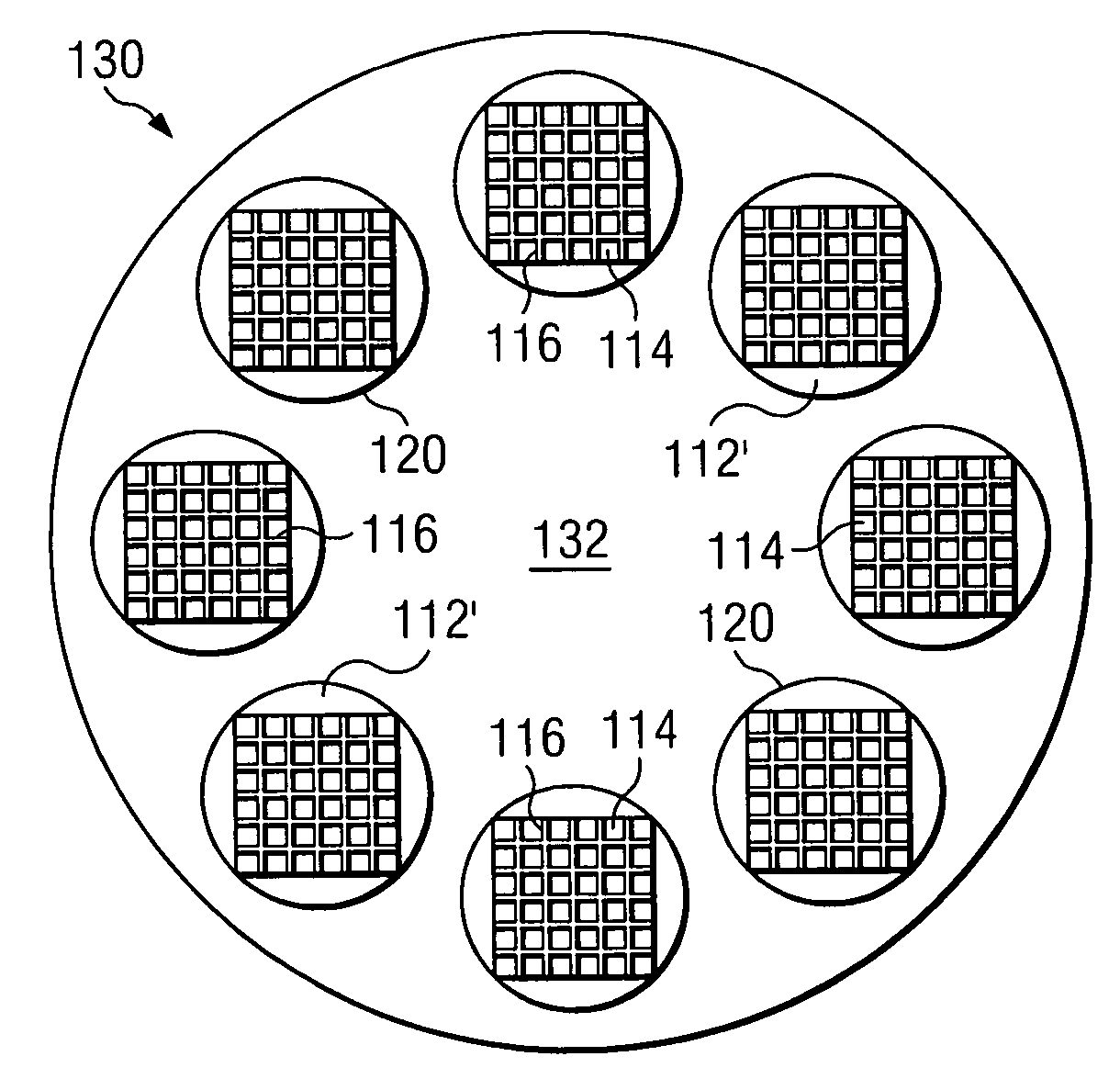

Methods and system for processing a microelectronic topography

InactiveUS6881437B2Avoid flowHigh boiling pointSemiconductor/solid-state device manufacturingPretreated surfacesElectroless depositionTopography

Methods and systems are provided which are adapted to process a microelectronic topography, particularly in association with an electroless deposition process. In general, the methods may include loading the topography into a chamber, closing the chamber to form an enclosed area, and supplying fluids to the enclosed area. In some embodiments, the fluids may fill the enclosed area. In addition or alternatively, a second enclosed area may be formed about the topography. As such, the provided system may be adapted to form different enclosed areas about a substrate holder. In some cases, the method may include agitating a solution to minimize the accumulation of bubbles upon a wafer during an electroless deposition process. As such, the system provided herein may include a means for agitating a solution in some embodiments. Such a means for agitation may be distinct from the inlet / s used to supply the solution to the chamber.

Owner:LAM RES CORP

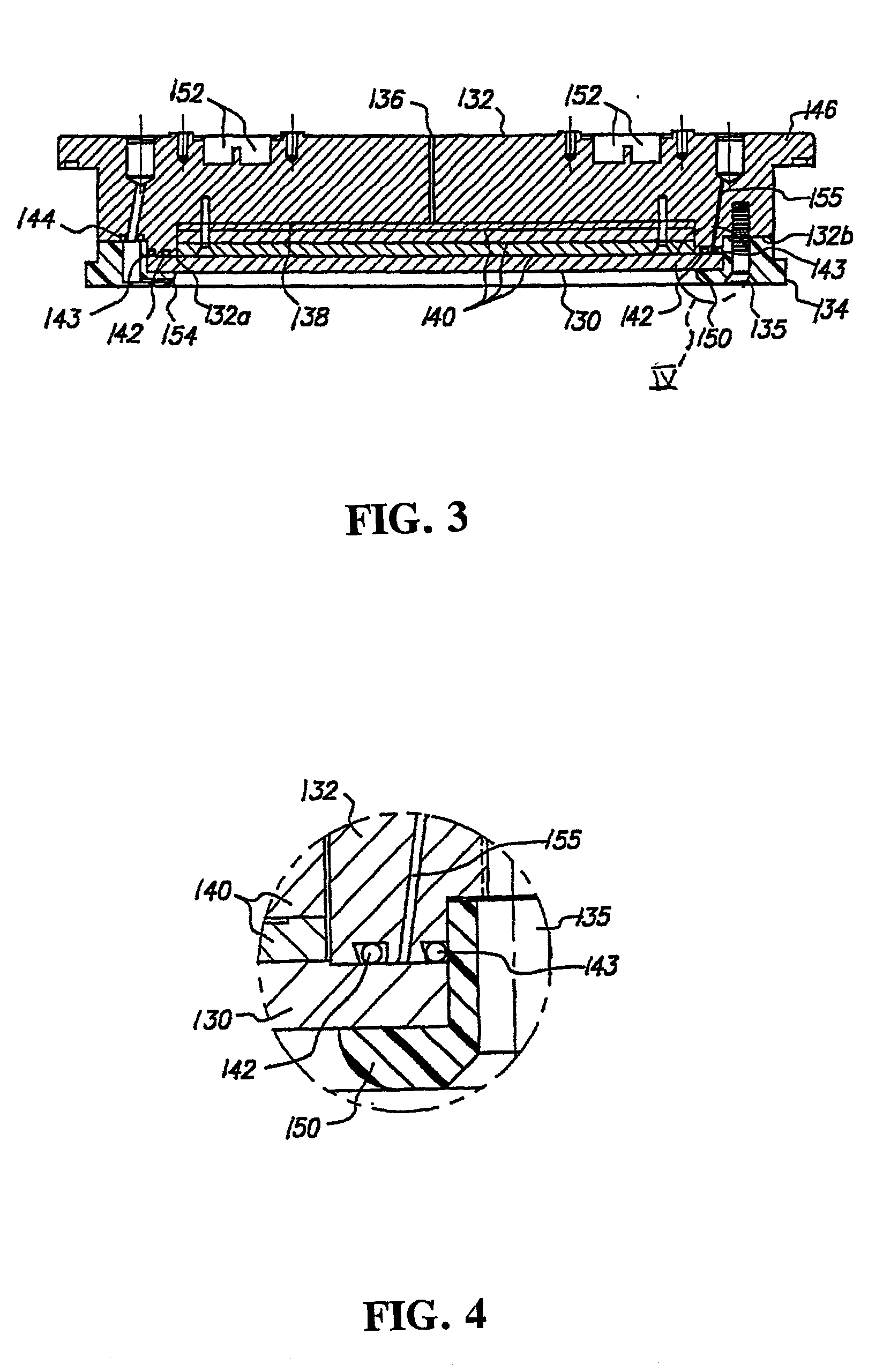

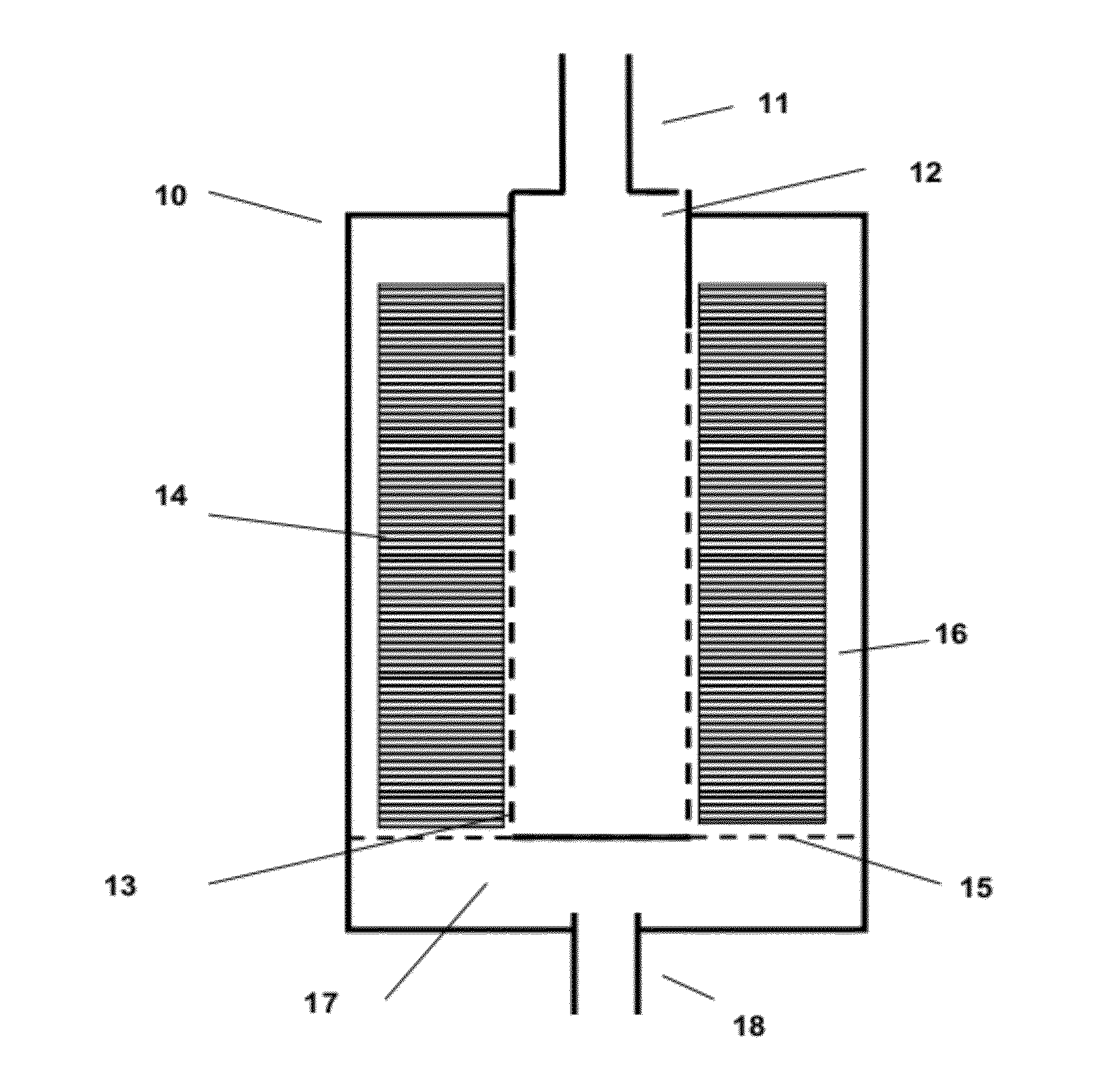

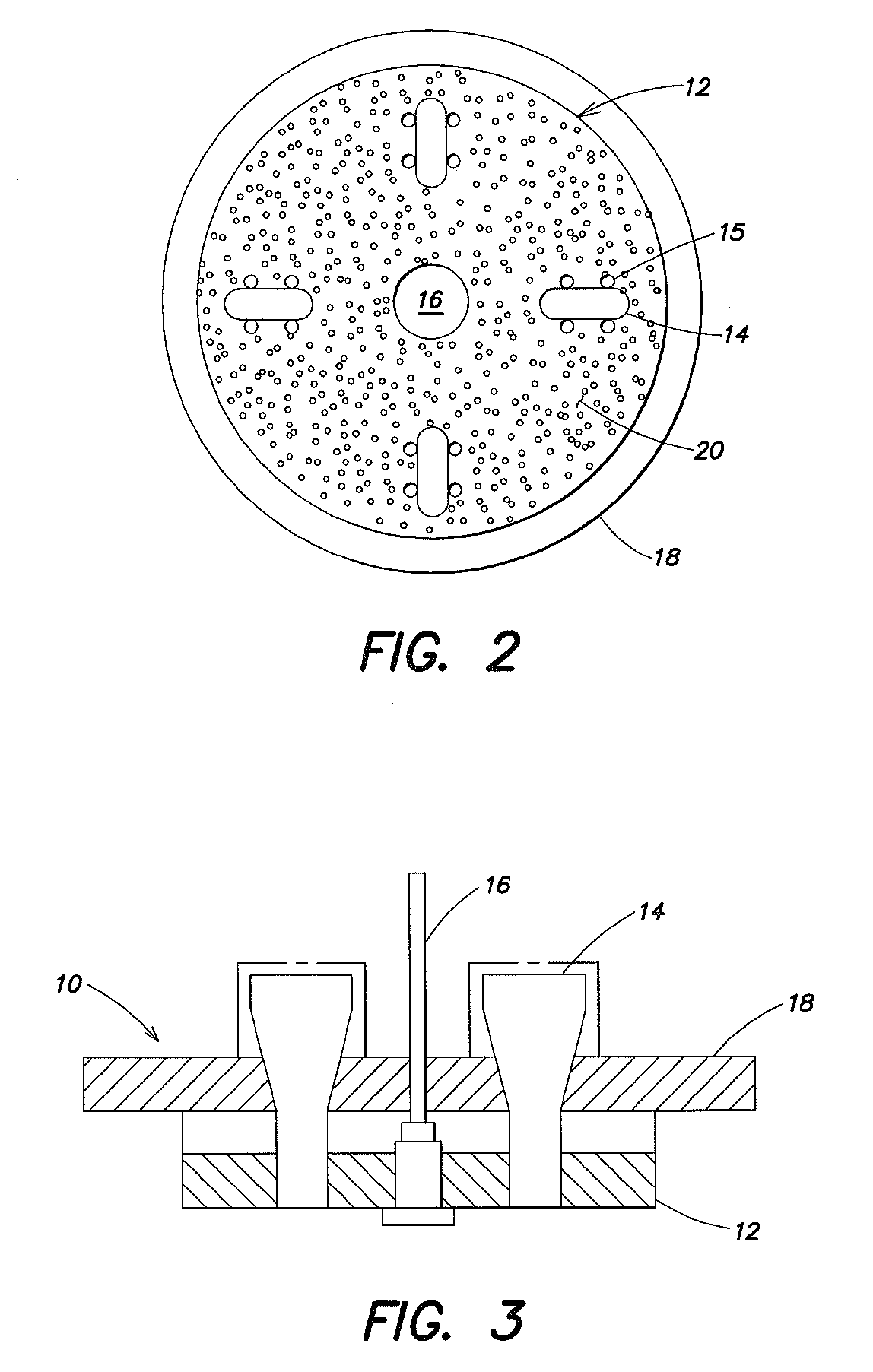

Electrode for plasma processes and method for manufacture and use thereof

InactiveUS20020127853A1Less heat-upReduce accumulationElectric discharge tubesSemiconductor/solid-state device manufacturingTemperature controlSilicon electrode

A silicon electrode for a plasma reaction chamber wherein processing of a semiconductor substrate such as a single wafer can be carried out and a method of processing a semiconductor substrate with the electrode. The electrode is a low resistivity electrode having an electrical resistivity of less than 1 ohm-cm. The electrode can be a zero defect single crystal silicon or silicon carbide electrode such as a showerhead electrode bonded or clamped to support such as a temperature controlled plate or ring. The showerhead electrode can be in the form of a circular disk of uniform thickness and an elastomeric joint can be provided between a support ring and the electrode. The electrode can include gas outlets having 0.020 to 0.030 inch diameters.

Owner:LAM RES CORP

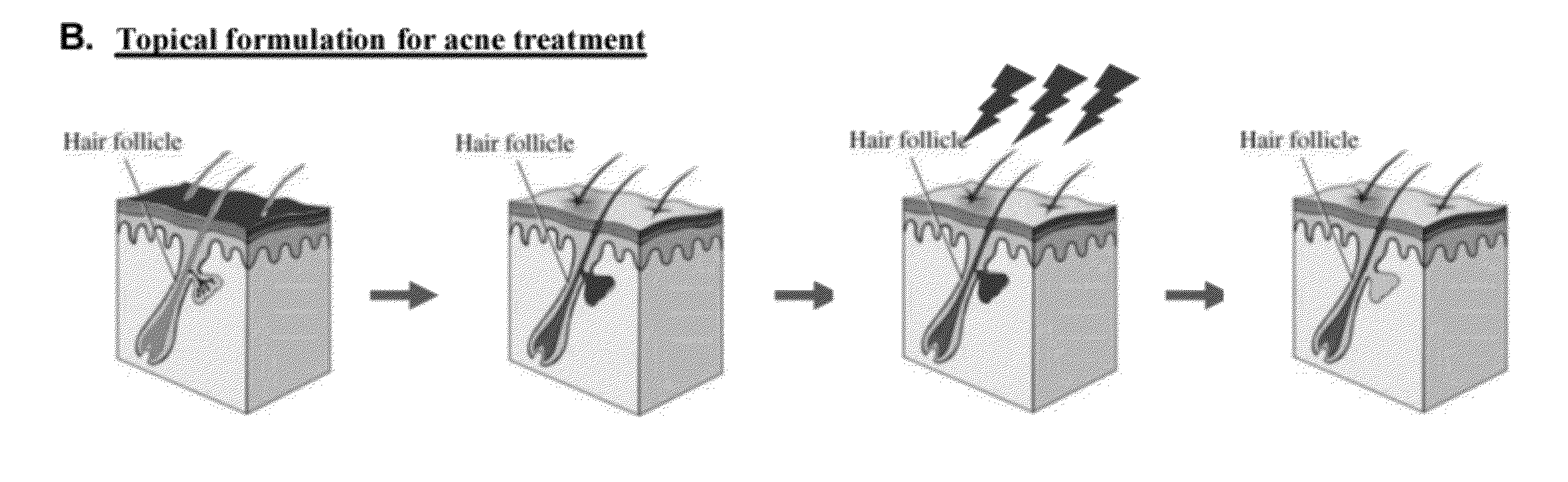

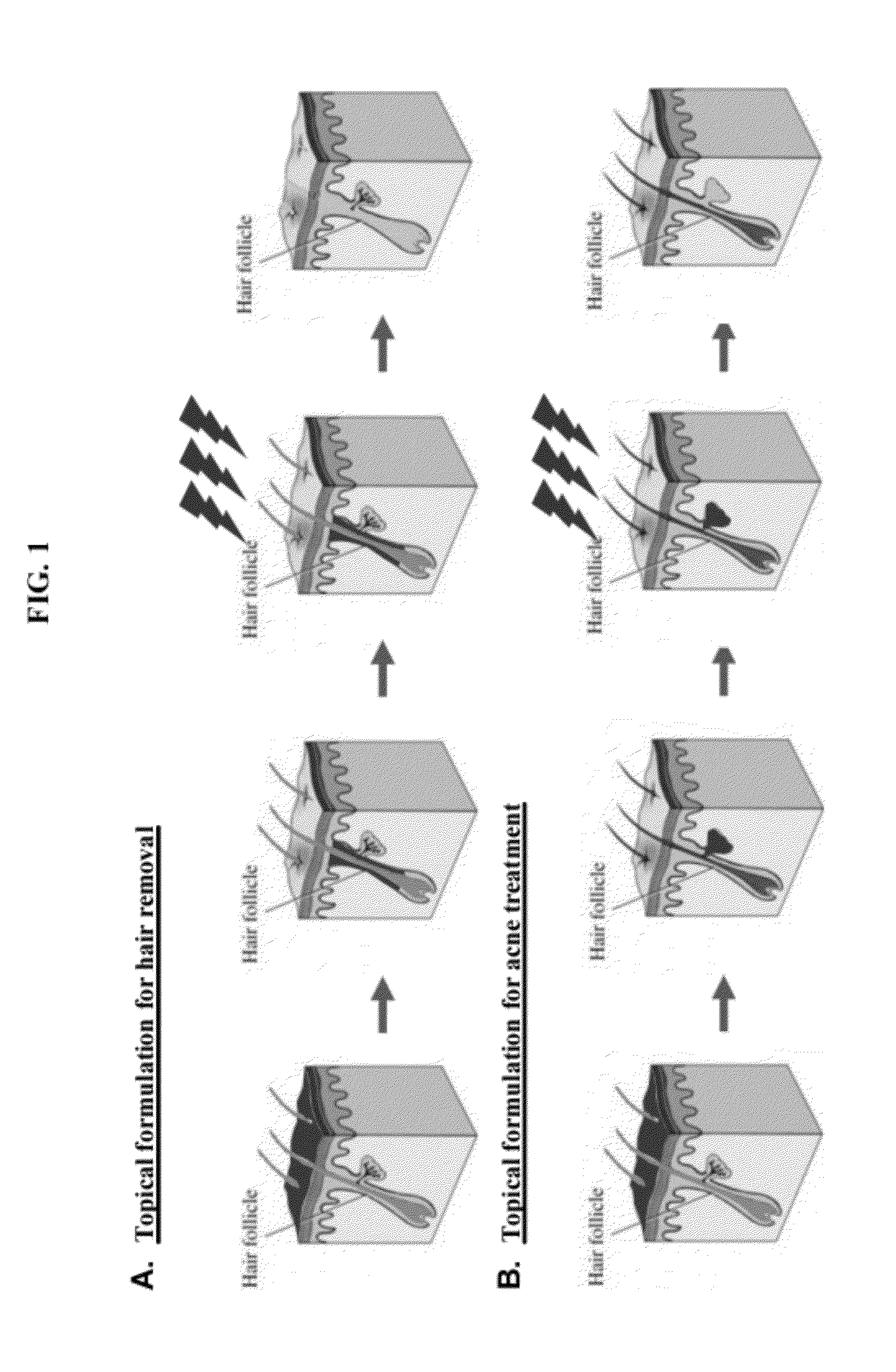

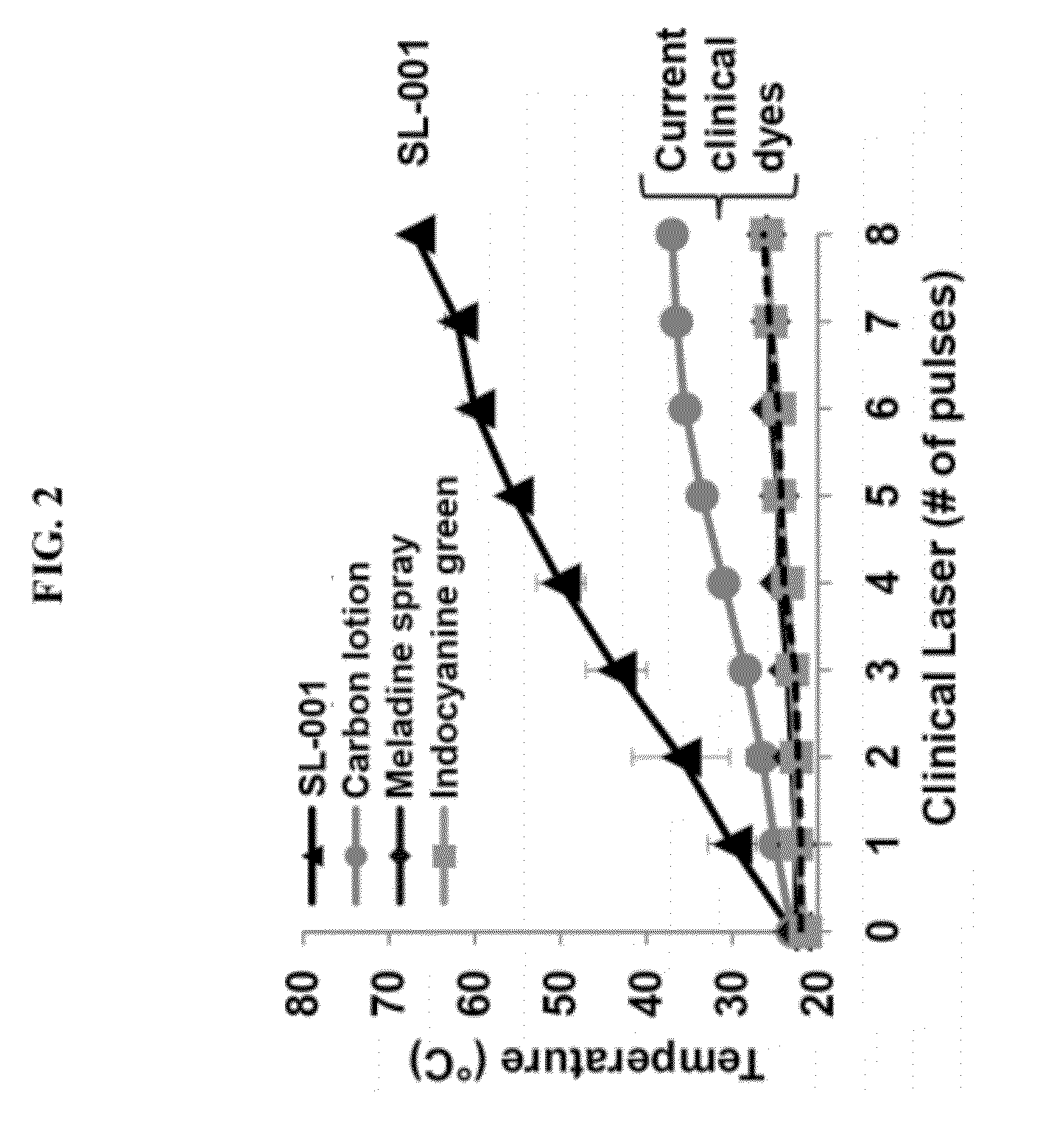

Compositions and Methods for Targeted Thermomodulation

ActiveUS20120059307A1Reduce accumulationAntibacterial agentsCosmetic preparationsMedicineNanoparticle

Owner:CORONADO AESTHETICS LLC

Process for the removal of nitrogen compounds from a fluid stream

ActiveUS20050137442A1Increase capacityReduce accumulationMolecular sieve catalystsHydrocarbonsMolecular sieveNitrogen

At lower temperatures an acidic molecular sieve adsorbent preferentially adsorbs water and basic organic nitrogen compounds over weakly basic organic nitrogen compounds such as nitrites. Elevated temperatures improve the capacity of acidic molecular sieve adsorbents to adsorb nitrites in the presence of water.

Owner:UOP LLC

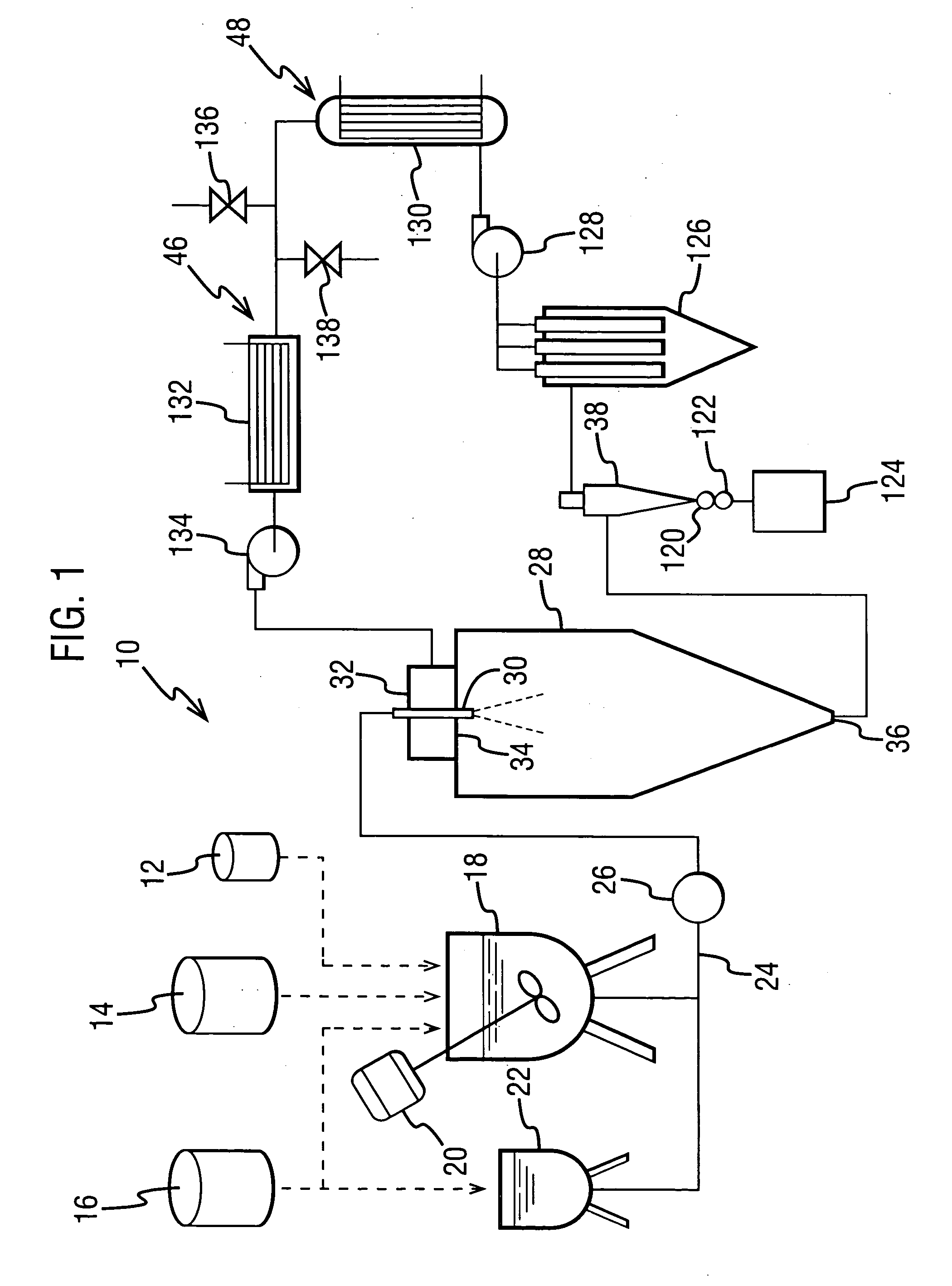

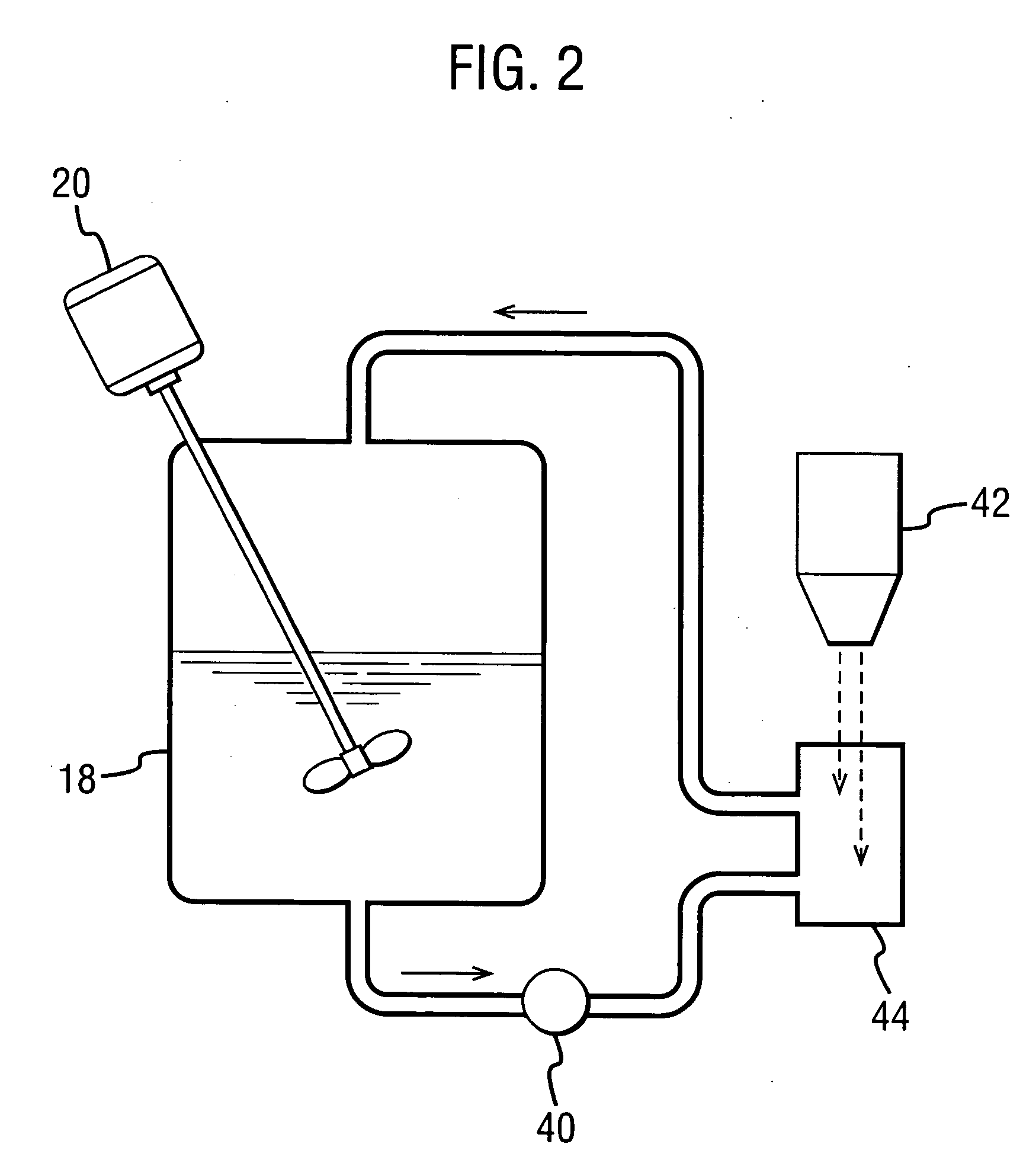

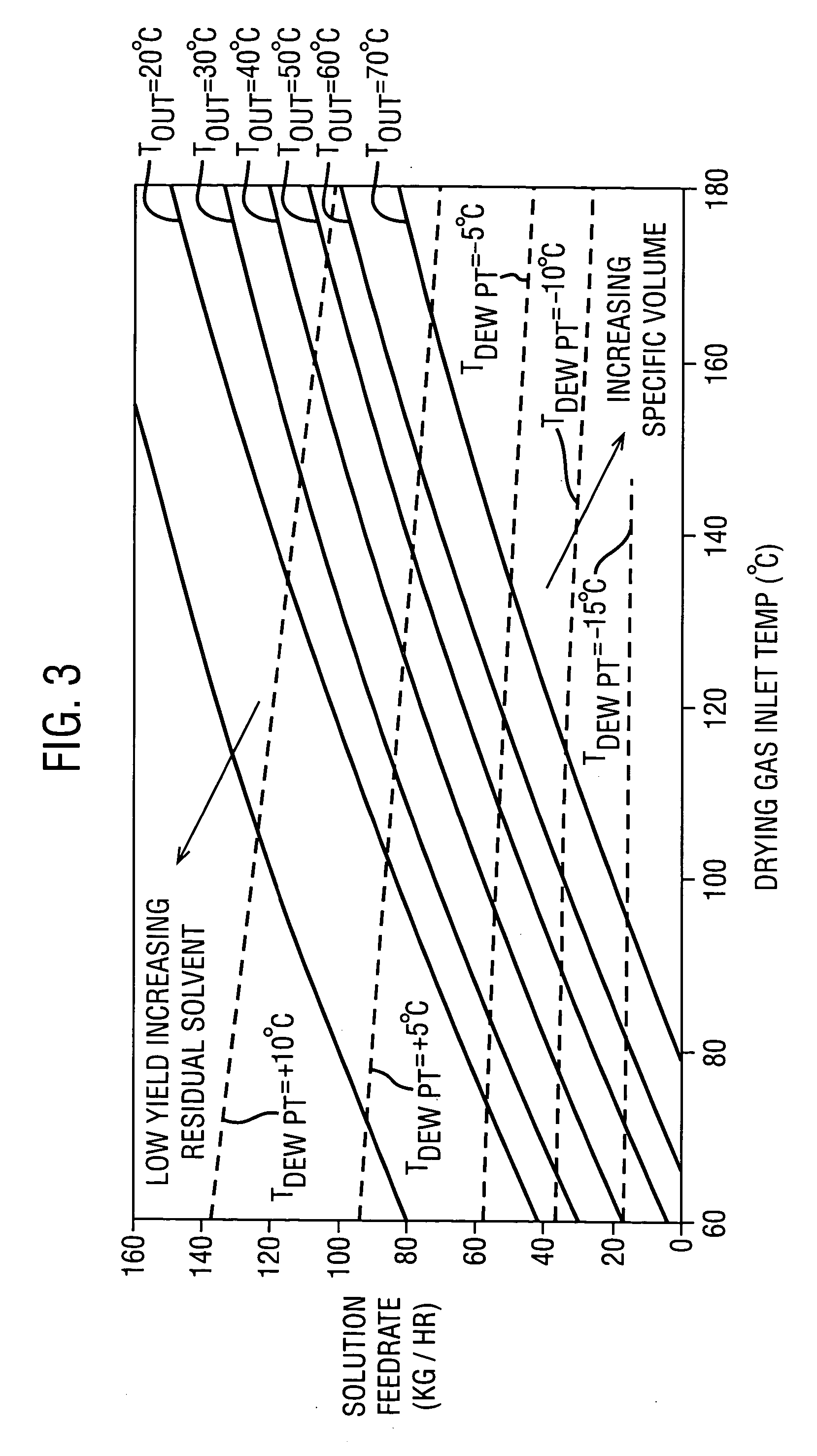

Spray drying processes for forming solid amorphous dispersions of drugs and polymers

ActiveUS20050031692A1Reduce accumulationFast evaporationPowder deliveryMetabolism disorderDrugPolymer chemistry

Spray drying processes are used to form pharmaceutical compositions comprising a solid amorphous dispersion of a drug and a polymer.

Owner:LONZA BEND INC

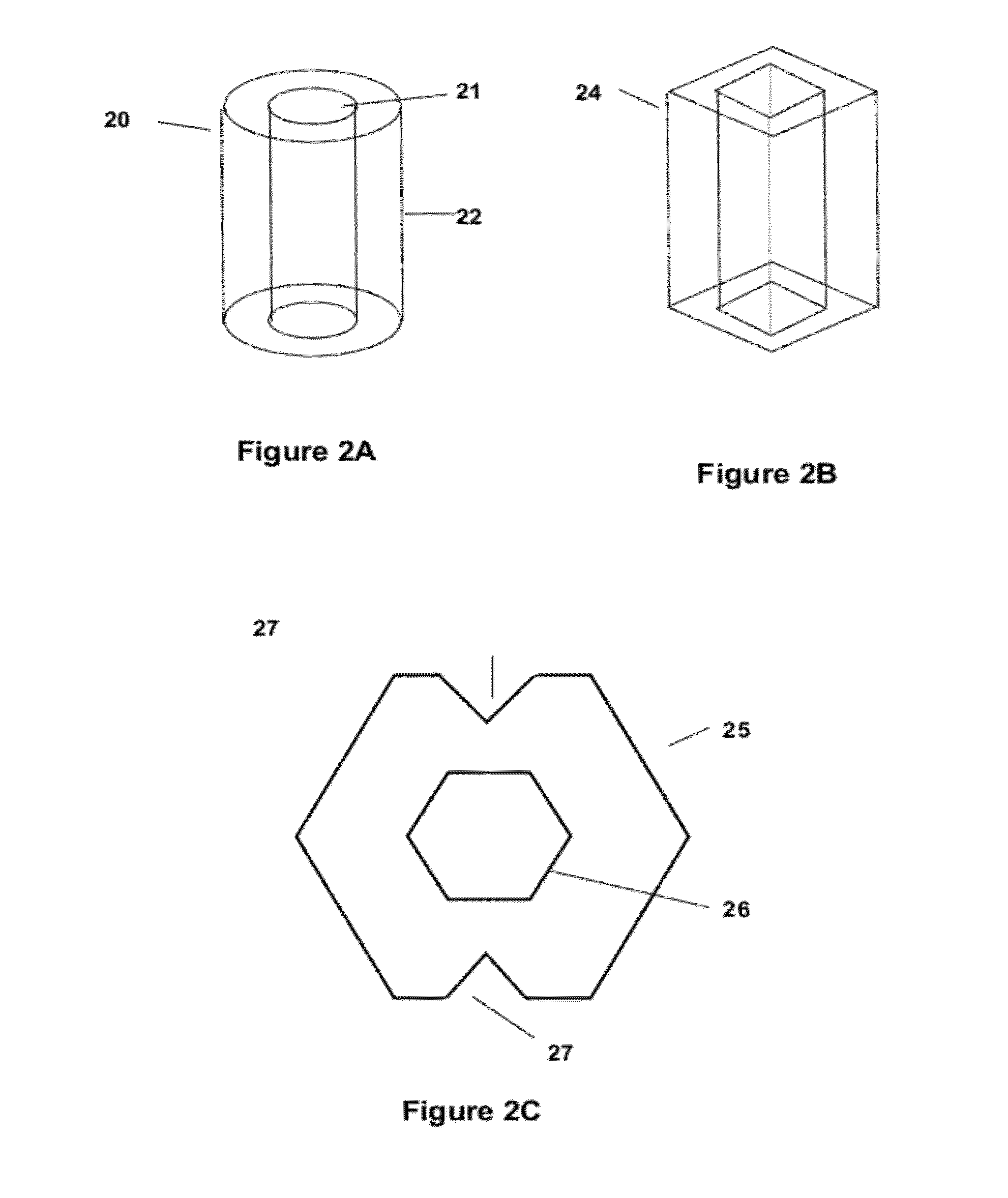

Gas Purification Process Utilizing Engineered Small Particle Adsorbents

ActiveUS20120222555A1Great diffusion rateLower Level RequirementsCarbon compoundsSulfur compoundsParticulatesSorbent

A gas separation process uses a structured particulate bed of adsorbent coated shapes / particles laid down in the bed in an ordered manner to simulate a monolith by providing longitudinally extensive gas passages by which the gas mixture to be separated can access the adsorbent material along the length of the particles. The particles can be laid down either directly in the bed or in locally structured packages / bundles which themselves are similarly oriented such that the bed particles behave similarly to a monolith but without at least some disadvantages. The adsorbent particles can be formed with a solid, non-porous core with the adsorbent formed as a thin, adherent coating on the exposed exterior surface. Particles may be formed as cylinders / hollow shapes to provide ready access to the adsorbent. The separation may be operated as a kinetic or equilibrium controlled process.

Owner:EXXON RES & ENG CO

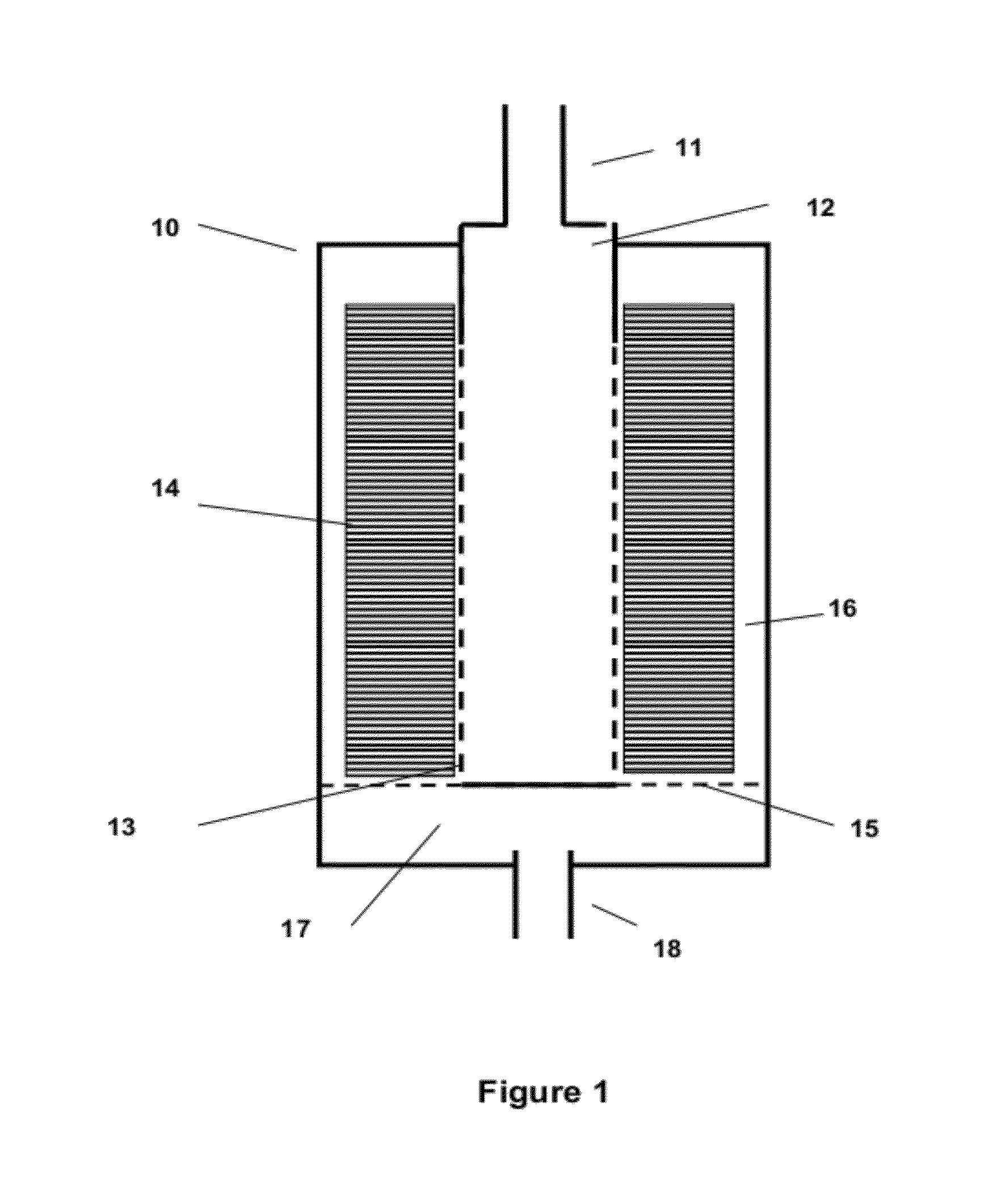

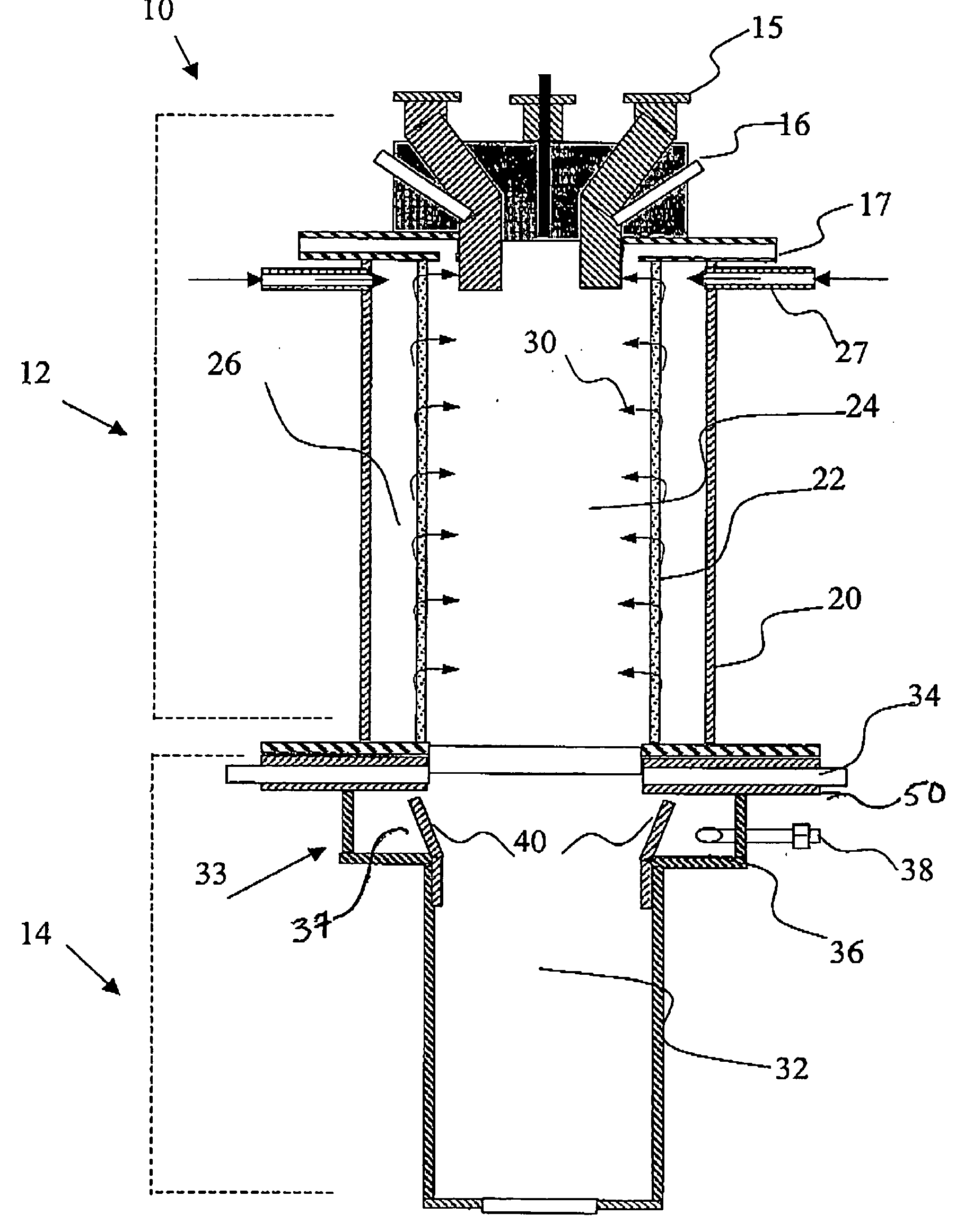

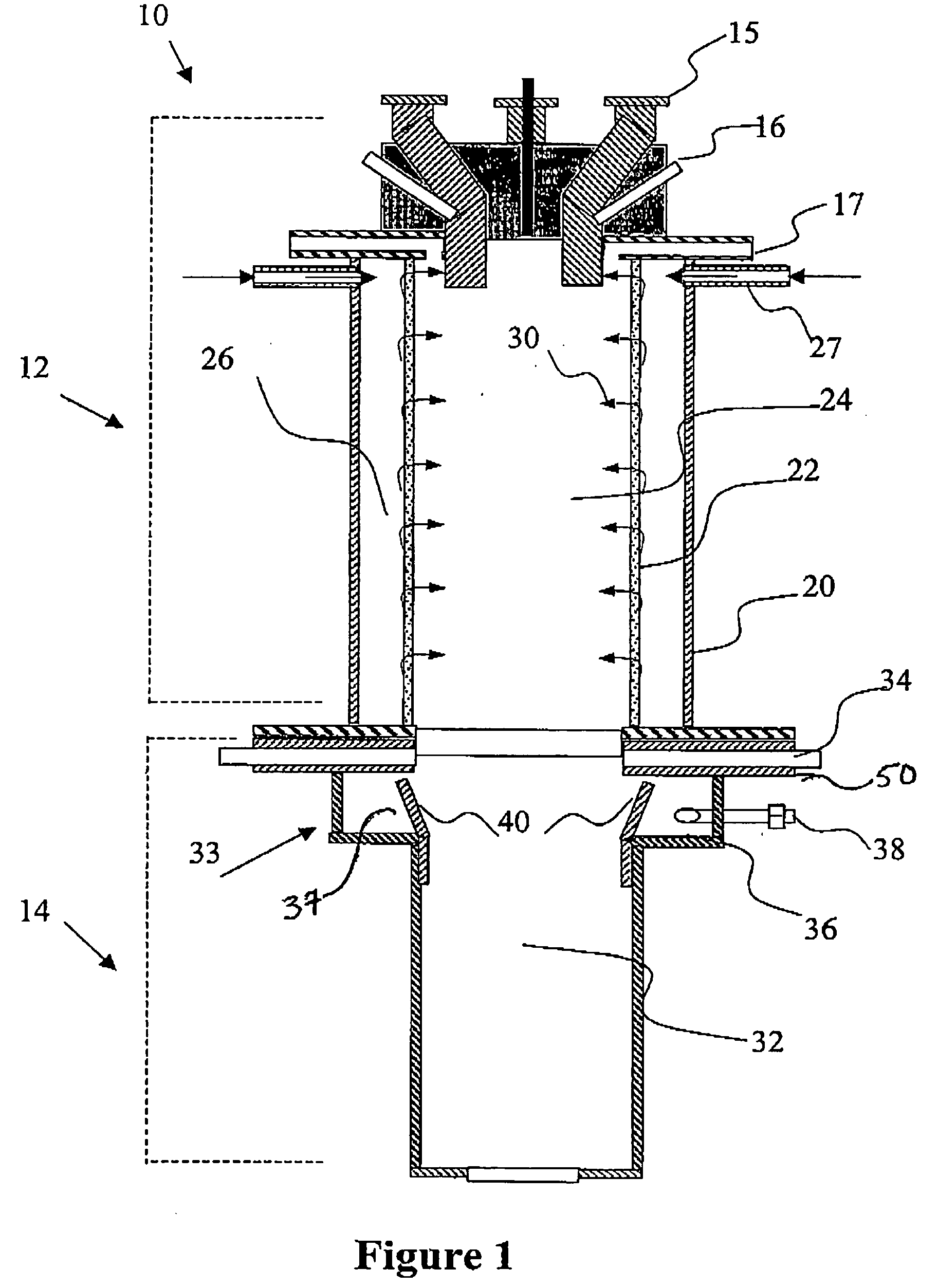

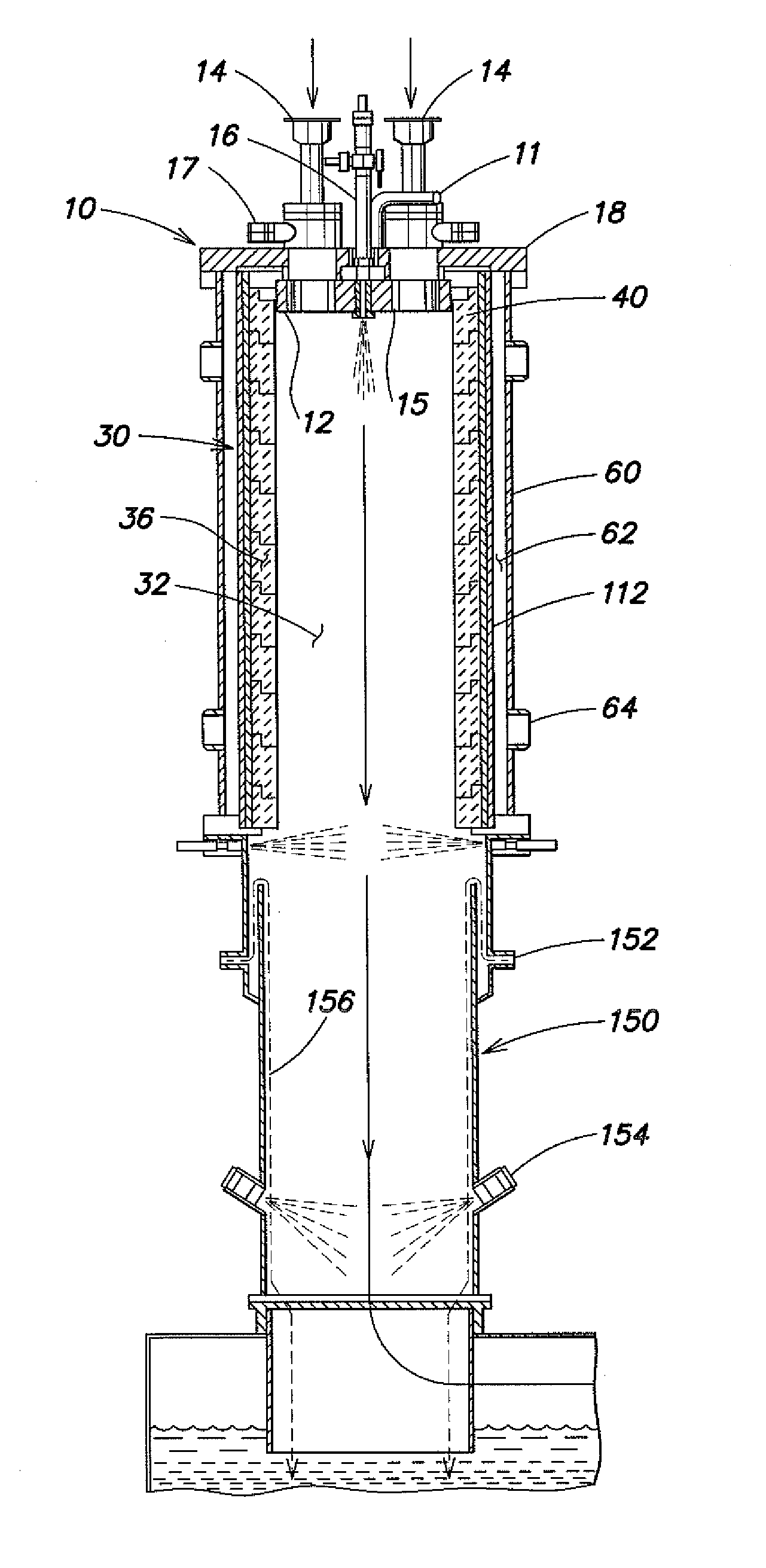

Apparatus and method for controlled combustion of gaseous pollutants

ActiveUS20050135984A1Reduce accumulationCombination devicesOrganic chemistryProcess engineeringInterior space

The present invention relates to systems and methods for controlled combustion of gaseous pollutants while reducing and removing deposition of unwanted reaction products from within the treatment systems. The systems employ a two-stage thermal reactor having an upper thermal reactor including at least one inlet for mixing a gaseous waste stream with oxidants and combustible fuels for thermal combustion within the upper thermal reactor. The upper thermal reactor further includes a double wall structure having an outer exterior wall and an interior porous wall that defines an interior space for holding a fluid and ejecting same, in a pulsating mode, through the interior porous wall into the upper thermal reactor to reduce deposition of the reaction products on the interior of the upper reactor chamber. The two-stage thermal reactor further includes a lower reactor chamber for flowing reaction products formed in the upper thermal reactor through a water vortex that provides a water overflow along the interior of the lower reactor chamber thereby reducing deposition of unwanted products on the interior surface of the lower reactor.

Owner:BHT SERVICES PTE LTD

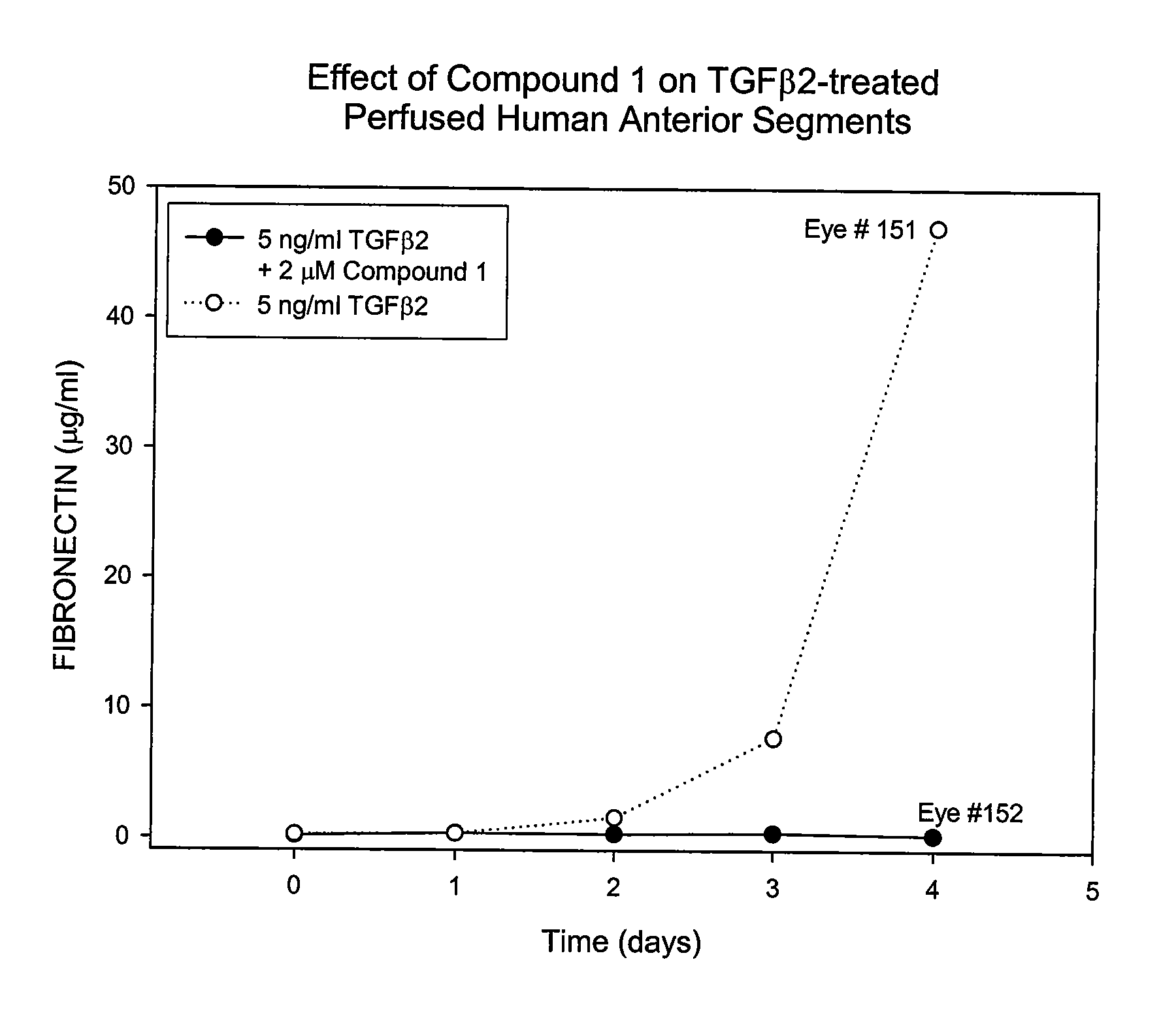

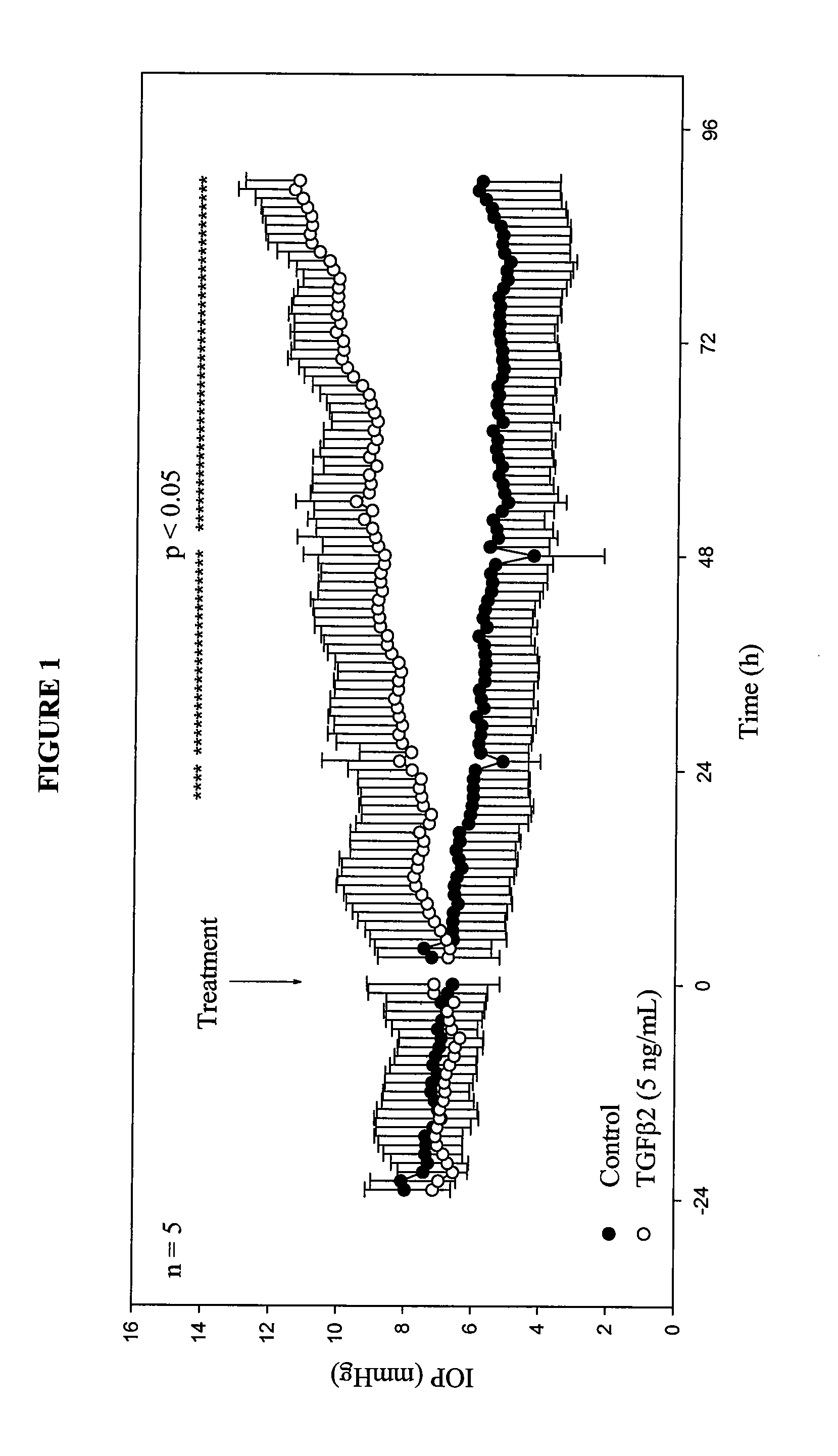

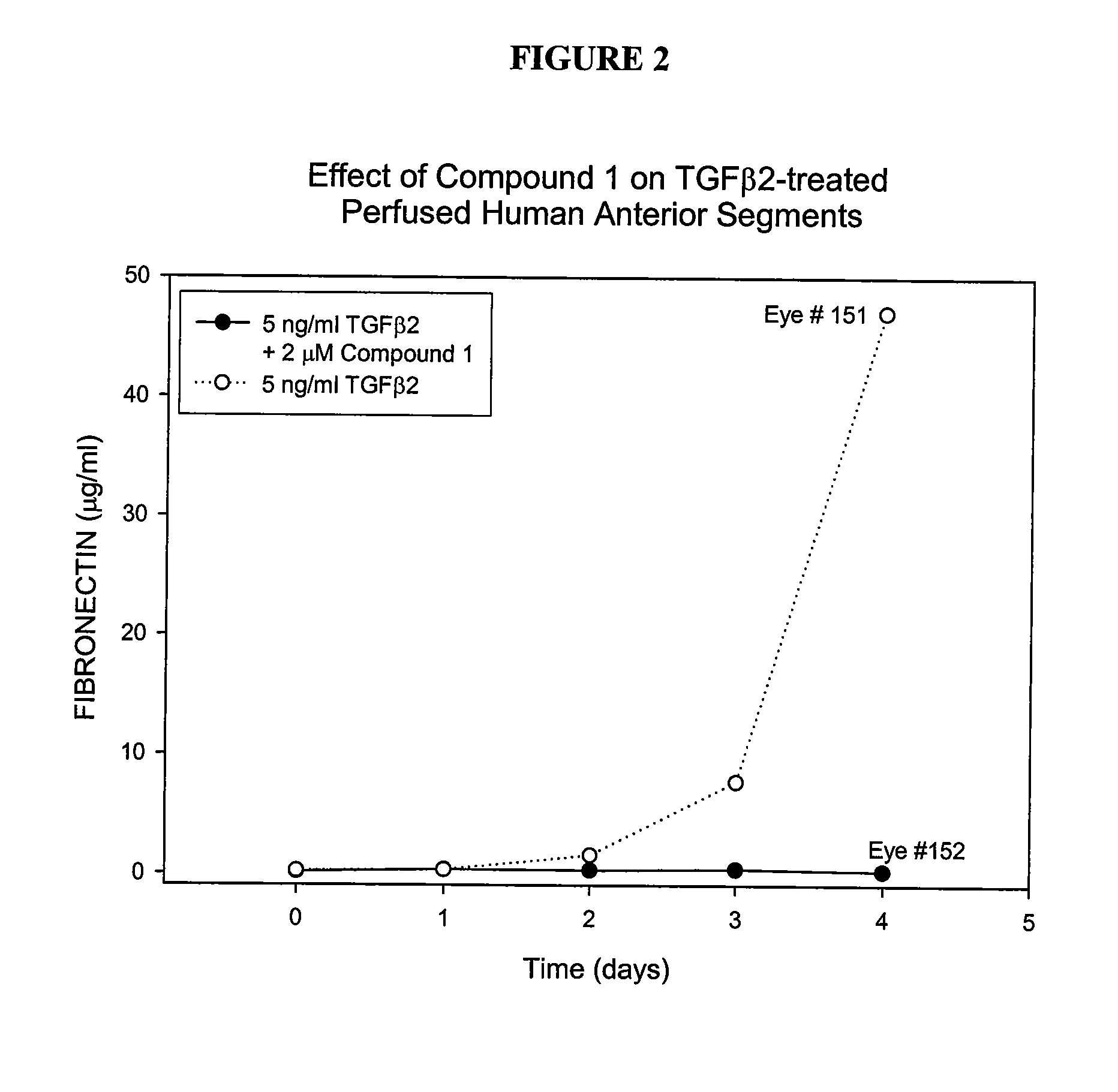

Control of intraocular pressure using ALK5 modulation agents

InactiveUS20070142376A1Increase productionIncreased IOP in vivoBiocideSenses disorderIntraocular pressureTreatment glaucoma

An ophthalmic pharmaceutical composition useful in the treatment of glaucoma and control of intraocular pressure comprising an effective amount of a selective modulator of ALK5 receptor activity is disclosed. Also disclosed is a method of treating glaucoma and controlling intraocular pressure comprising applying a therapeutically effective amount of a pharmaceutical composition comprising a selective modulator of ALK5 receptor activity to an affected eye of a patient.

Owner:ALCON INC

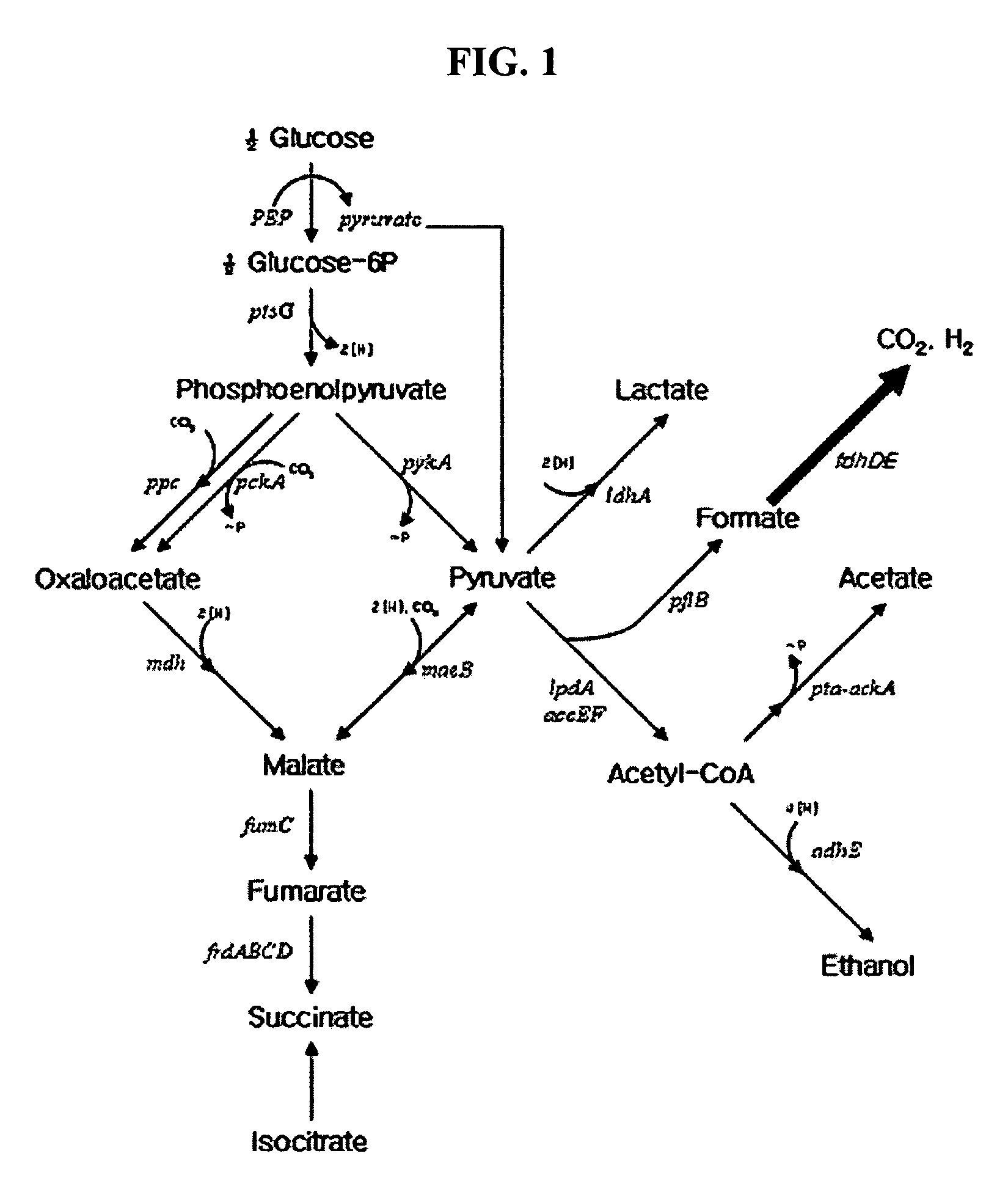

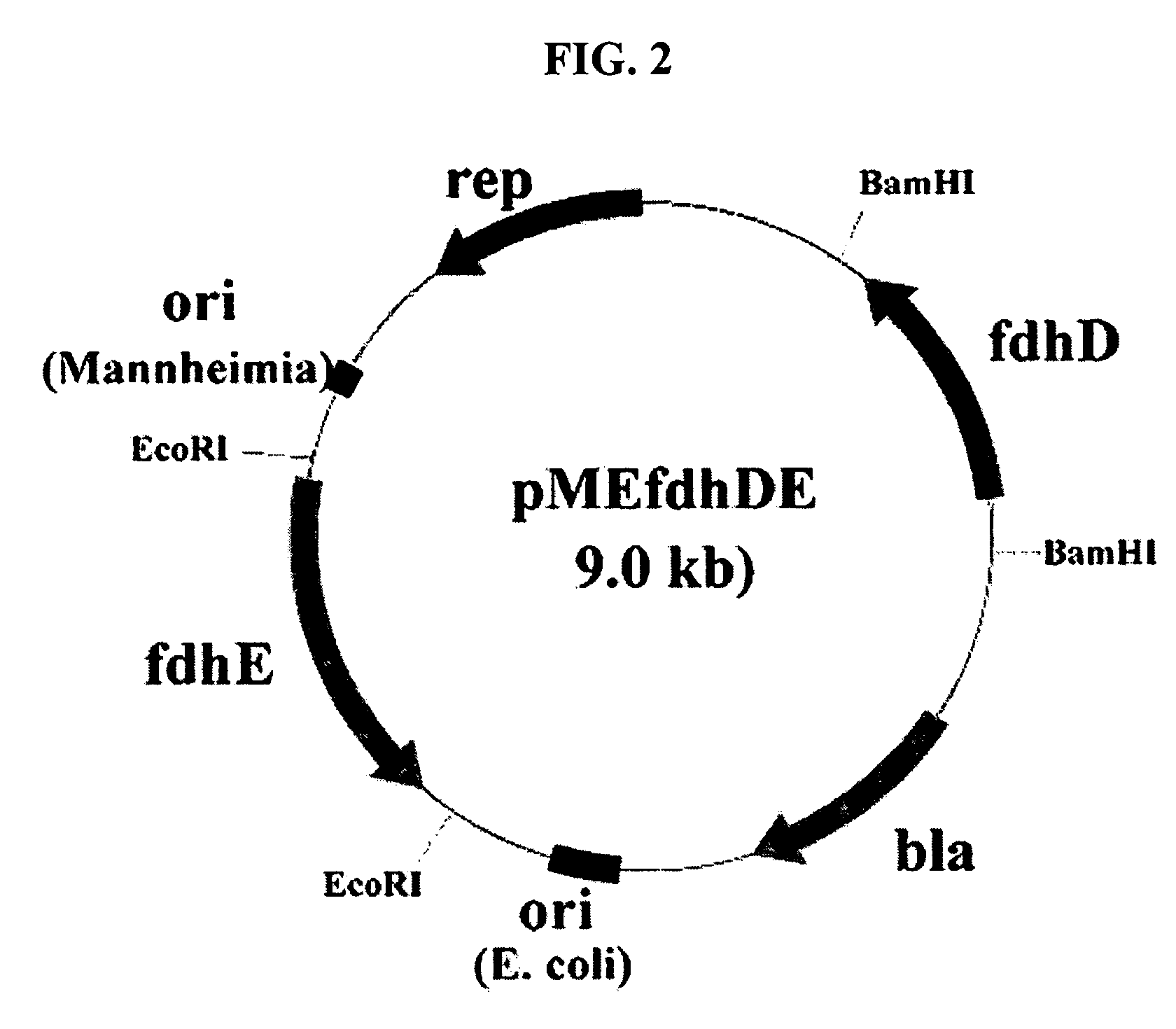

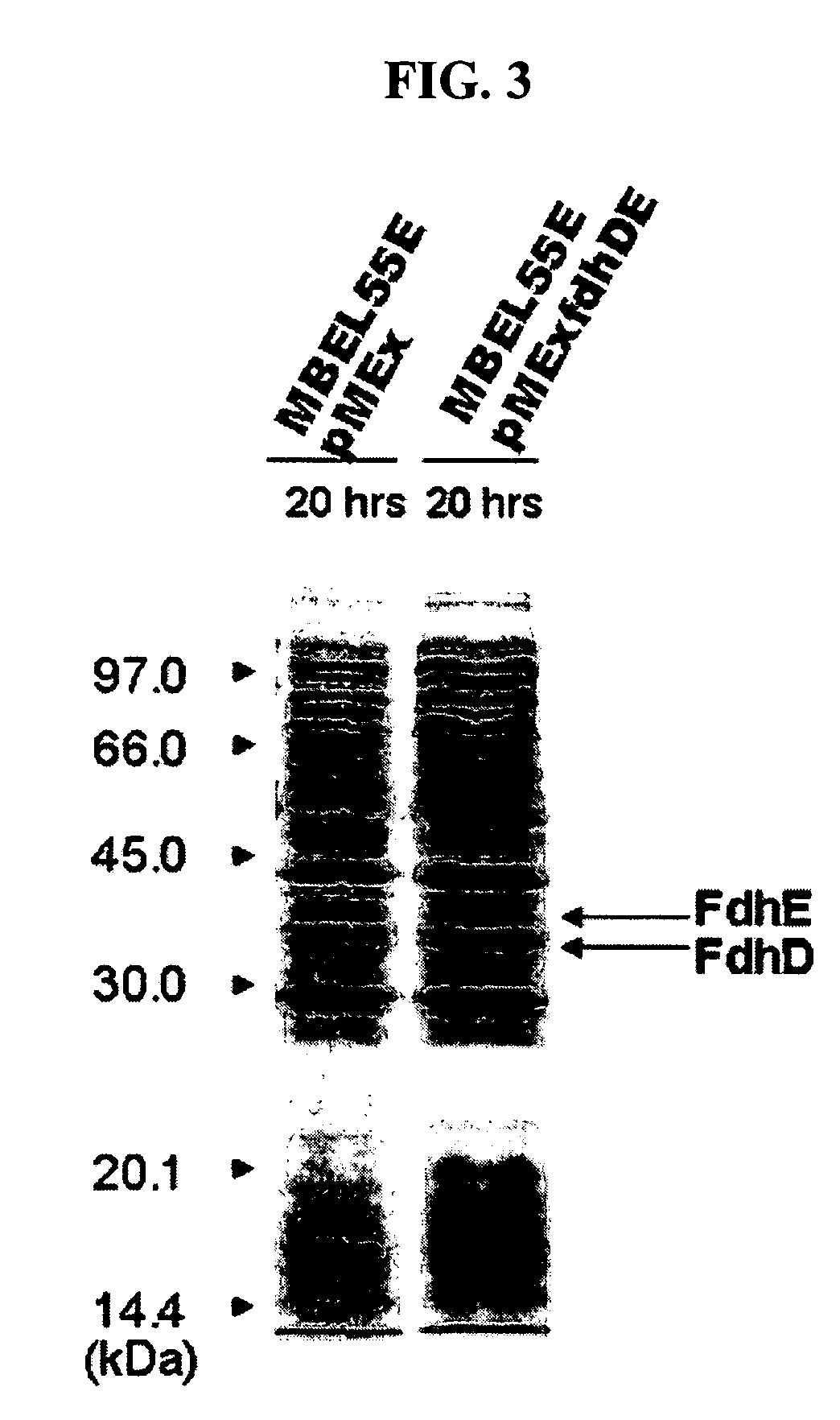

Gene encoding formate dehydrogenases D & E and method for preparing succinic acid using the same

Owner:KOREA ADVANCED INST OF SCI & TECH

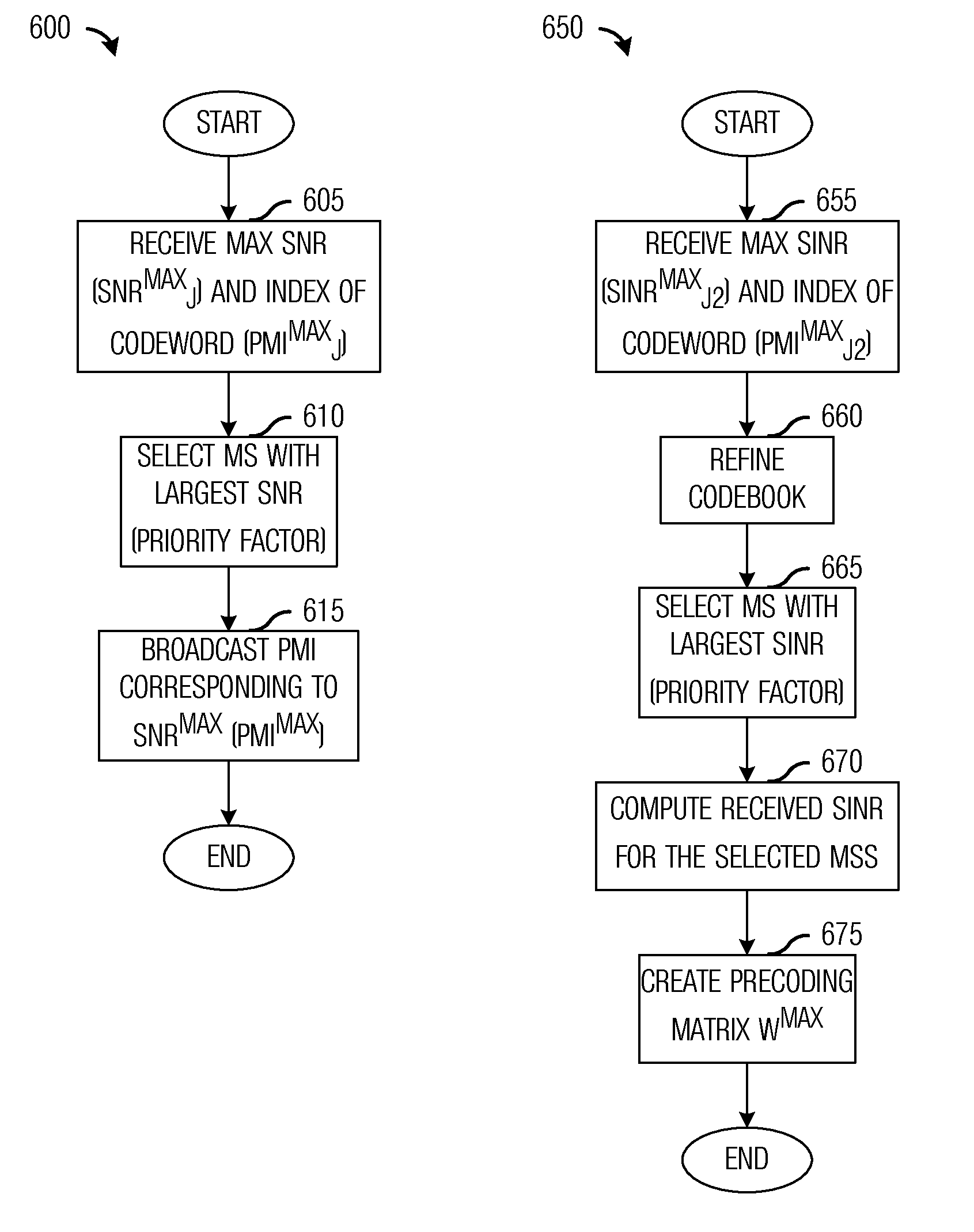

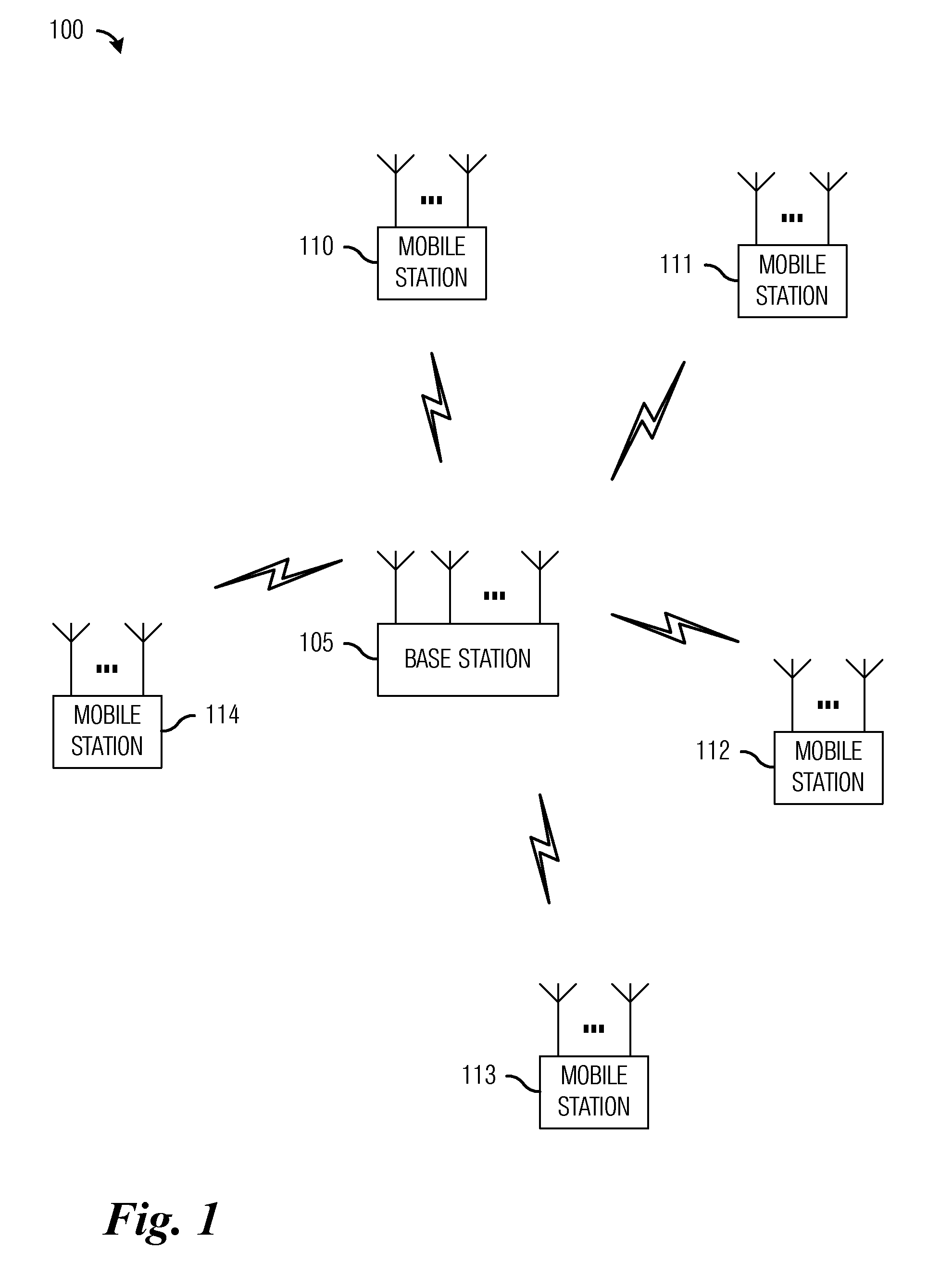

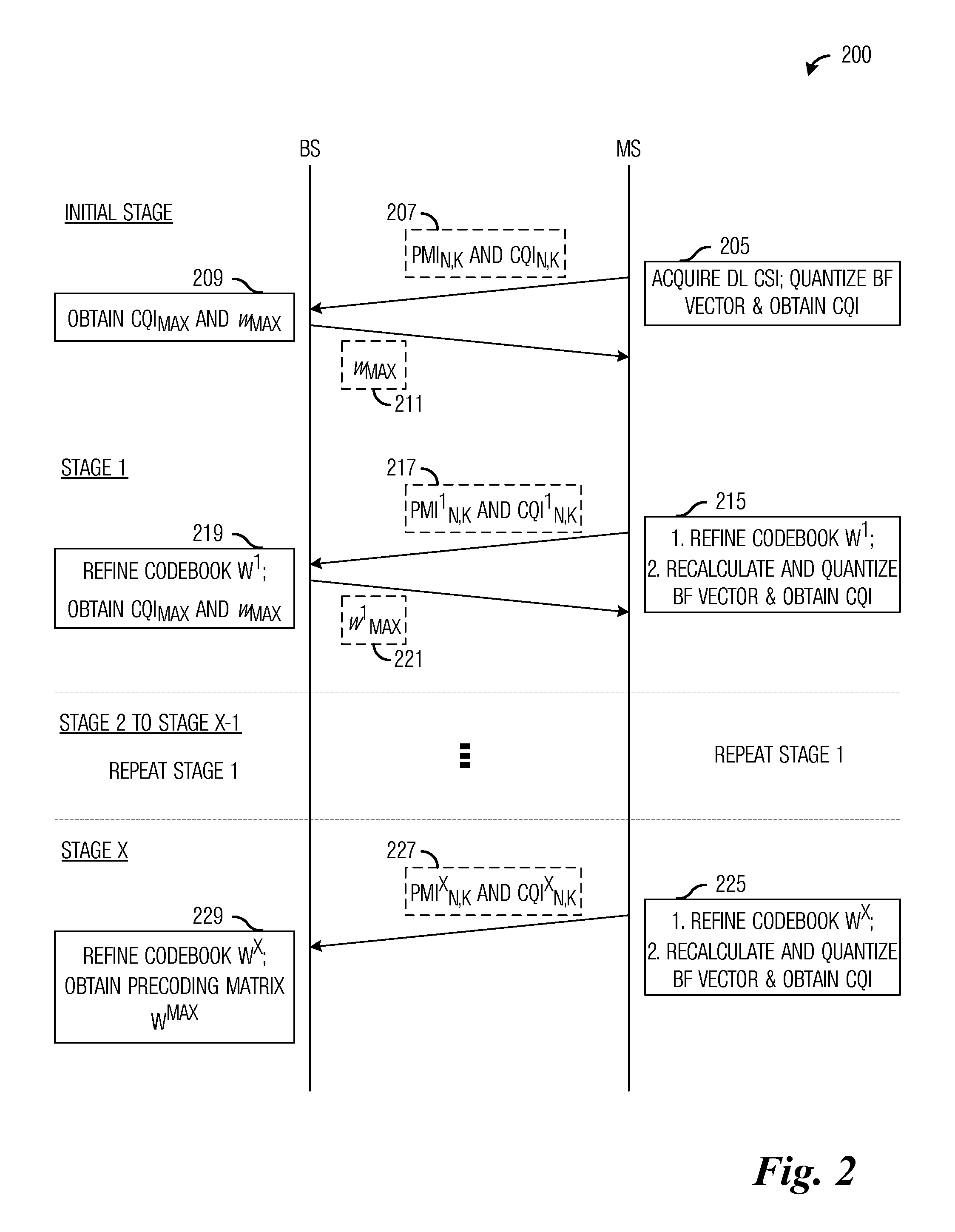

System and Method for Multi-Stage Zero Forcing Beamforming in a Wireless Communications System

ActiveUS20090252091A1Diminish accumulationImprove performanceTransmission systemsFrequency-division multiplex detailsZero forcing beamformingPrecoding matrix

A system and method for multi-stage zero forcing beamforming in a wireless communications system is provided. A method includes receiving feedback information from each mobile station (MS) in a first plurality of mobile stations (MSs), selecting a first MS from the first plurality of MSs, and broadcasting information related to the first MS to the first plurality of MSs. The first MS having a largest value of a first metric based on the feedback information received from the first plurality of MSs. The method also includes receiving feedback information from each MS in a second plurality of MSs, selecting a second MS from the second plurality of MSs, and creating a precoding matrix from feedback information from the first MS and the second MS. The second MS having a largest value of a second metric based on the feedback information received from the second plurality of MSs.

Owner:FUTUREWEI TECH INC

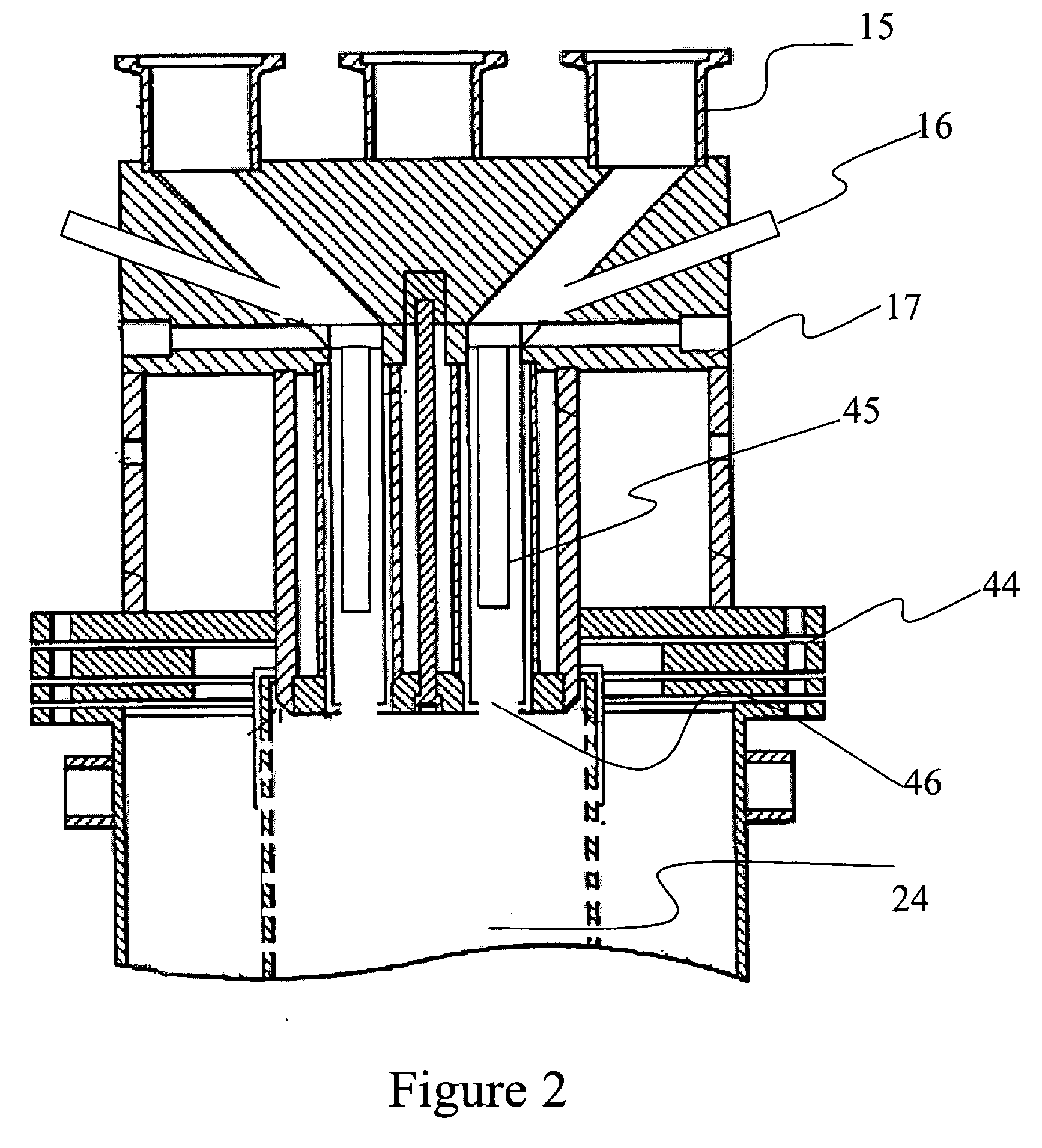

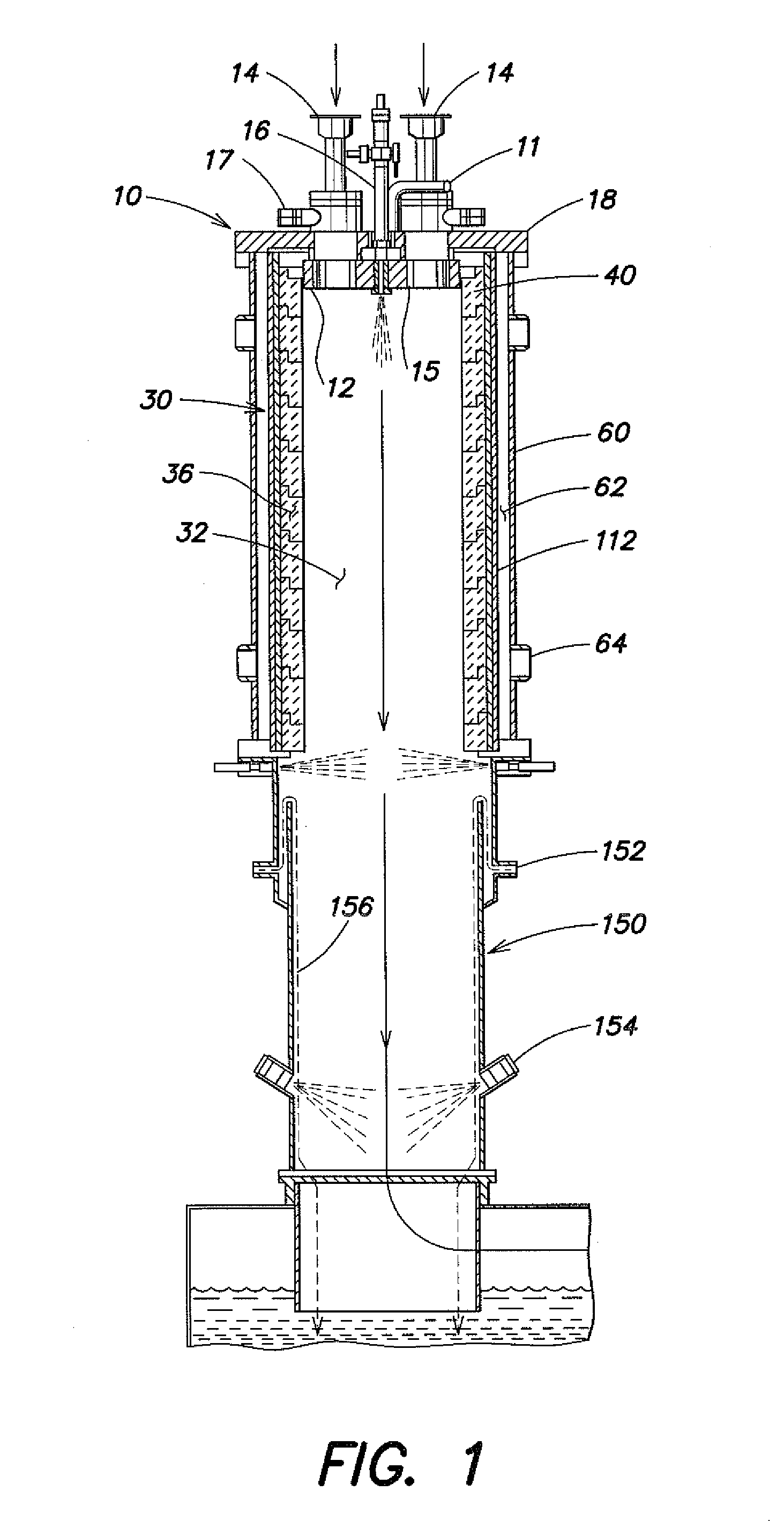

Reactor design to reduce particle deposition during process abatement

InactiveUS20070274876A1Reduce accumulationReduce crackingCombination devicesBurnersCombustionDecomposition

The present invention relates to systems and methods for controlled combustion and decomposition of gaseous pollutants while reducing deposition of unwanted reaction products from within the treatment systems. The systems include a novel thermal reaction chamber design having stacked reticulated ceramic rings through which fluid, e.g., gases, may be directed to form a boundary layer along the interior wall of the thermal reaction chamber, thereby reducing particulate matter buildup thereon. The systems further include the introduction of fluids from the center pilot jet to alter the aerodynamics of the interior of the thermal reaction chamber.

Owner:APPLIED MATERIALS INC

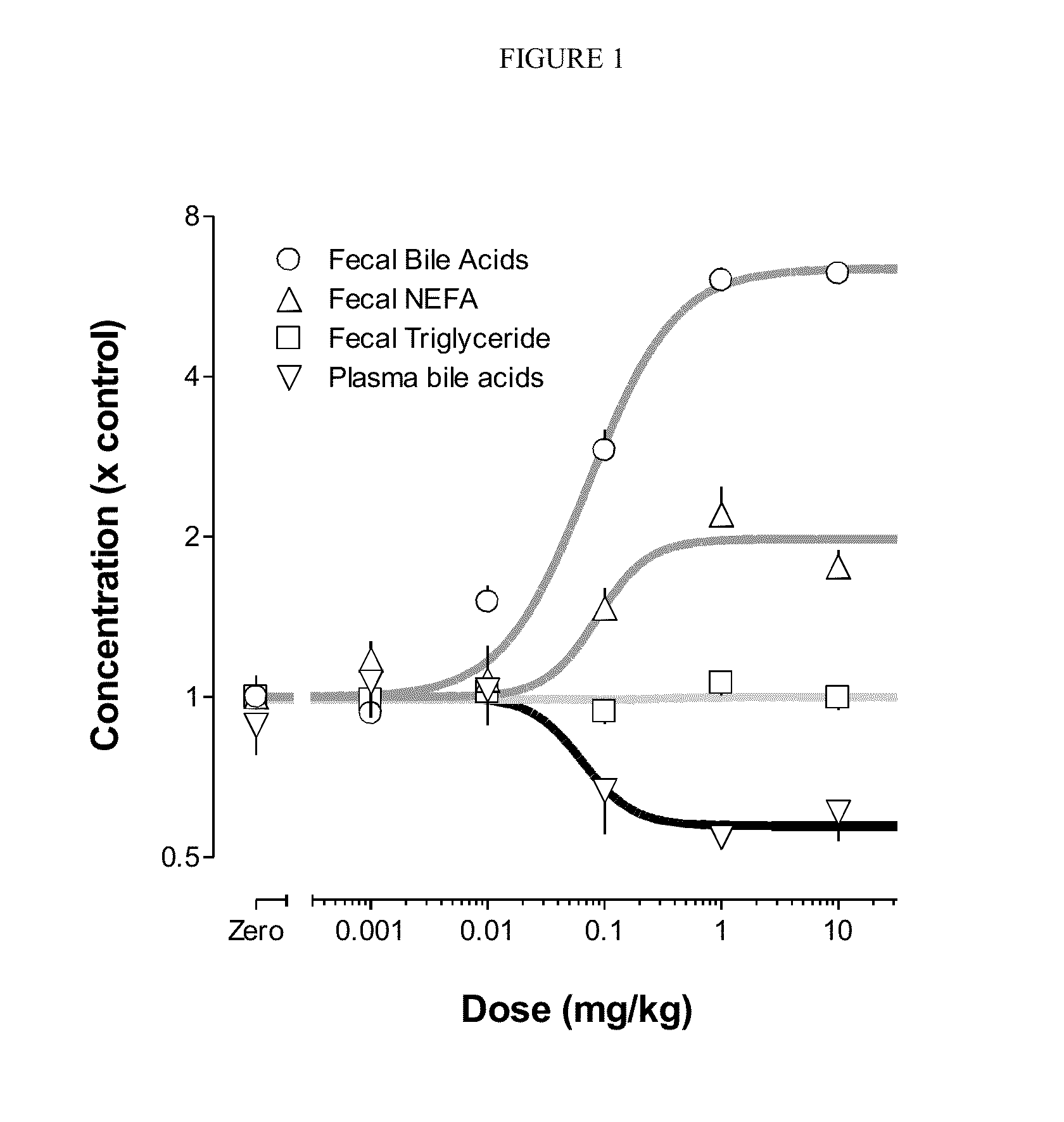

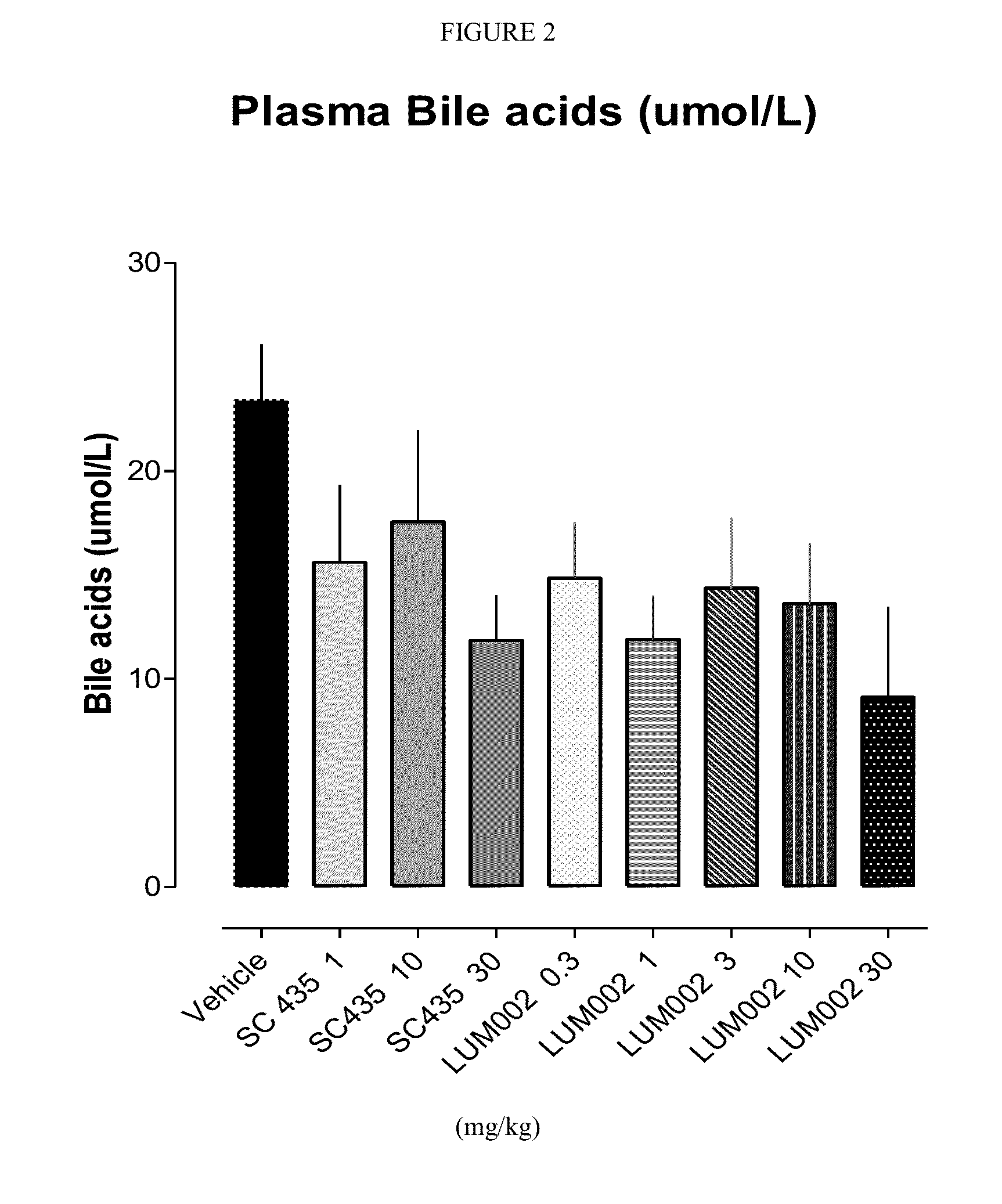

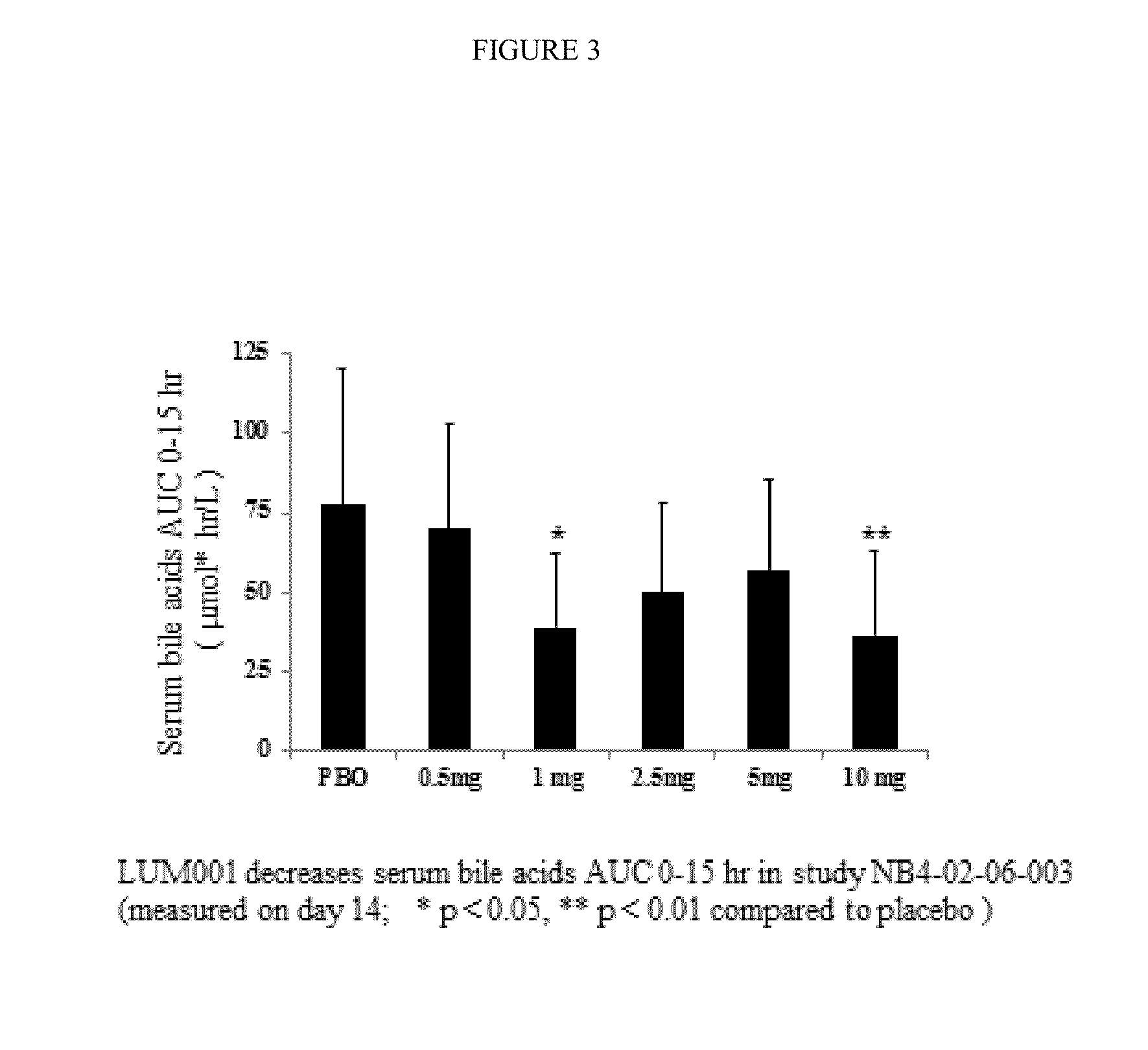

Bile Acid Recycling Inhibitors for Treatment of Pediatric Cholestatic Liver Diseases

InactiveUS20130109671A1Reduces and inhibits recyclingReduce harmBiocidePill deliveryHepatic DiseasesHepatic bile

Provided herein are methods of treating or ameliorating a pediatric cholestatic liver disease by non-systemically administering to an individual in need thereof a therapeutically effective amount of a pediatric formulation comprising an Apical Sodium-dependent Bile Acid Transporter Inhibitor (ASBTI) or a pharmaceutically acceptable salt thereof. Also provided are methods for treating or ameliorating a pediatric liver disease, decreasing the levels of serum bile acids or hepatic bile acids, treating or ameliorating pruritis, reducing liver enzymes, or reducing bilirubin comprising non-systemically administering to an individual in need thereof a therapeutically effective amount of a pediatric formulation comprising an ASBTI or a pharmaceutically acceptable salt thereof.

Owner:LUMENA PHARMA INC

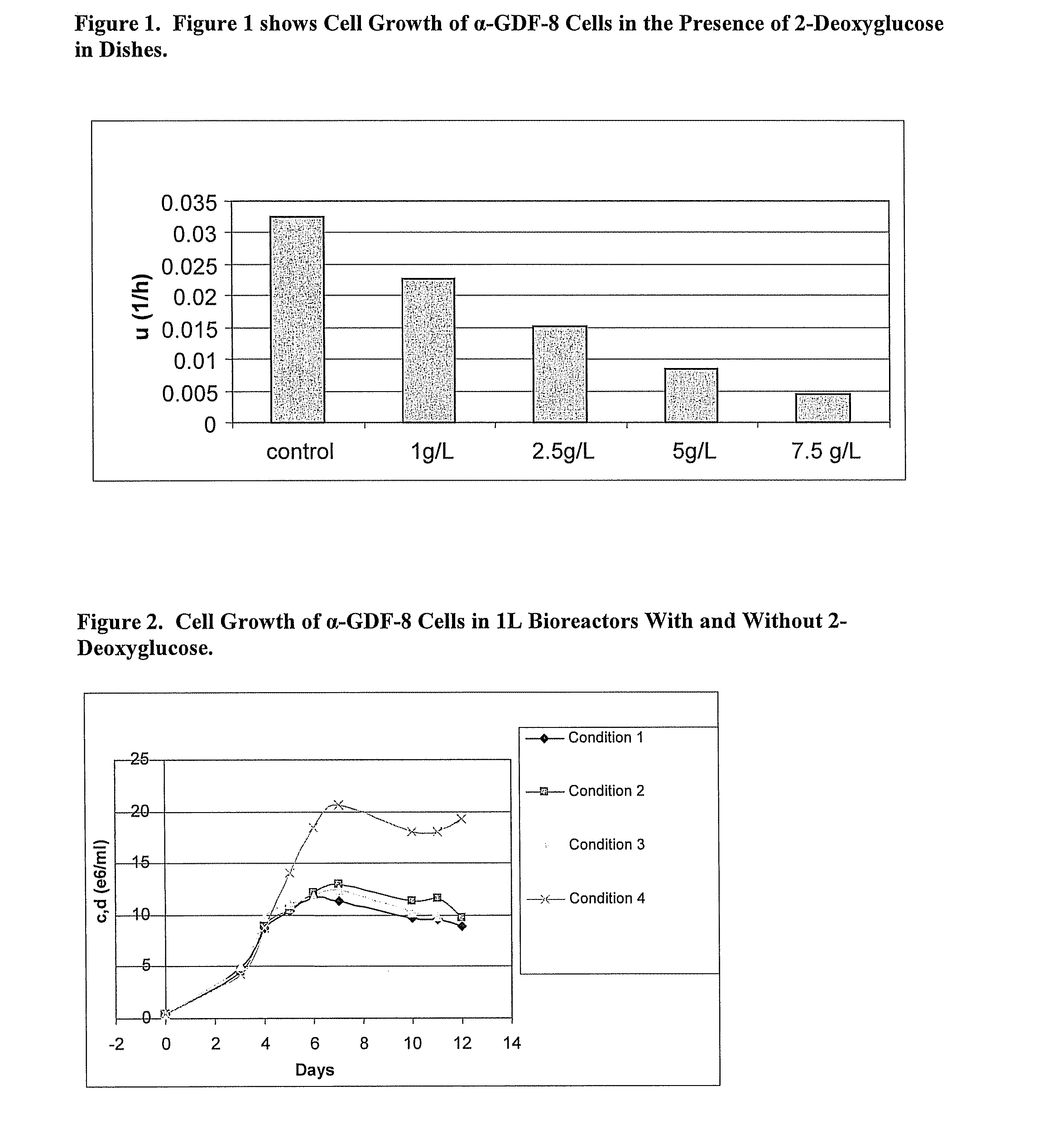

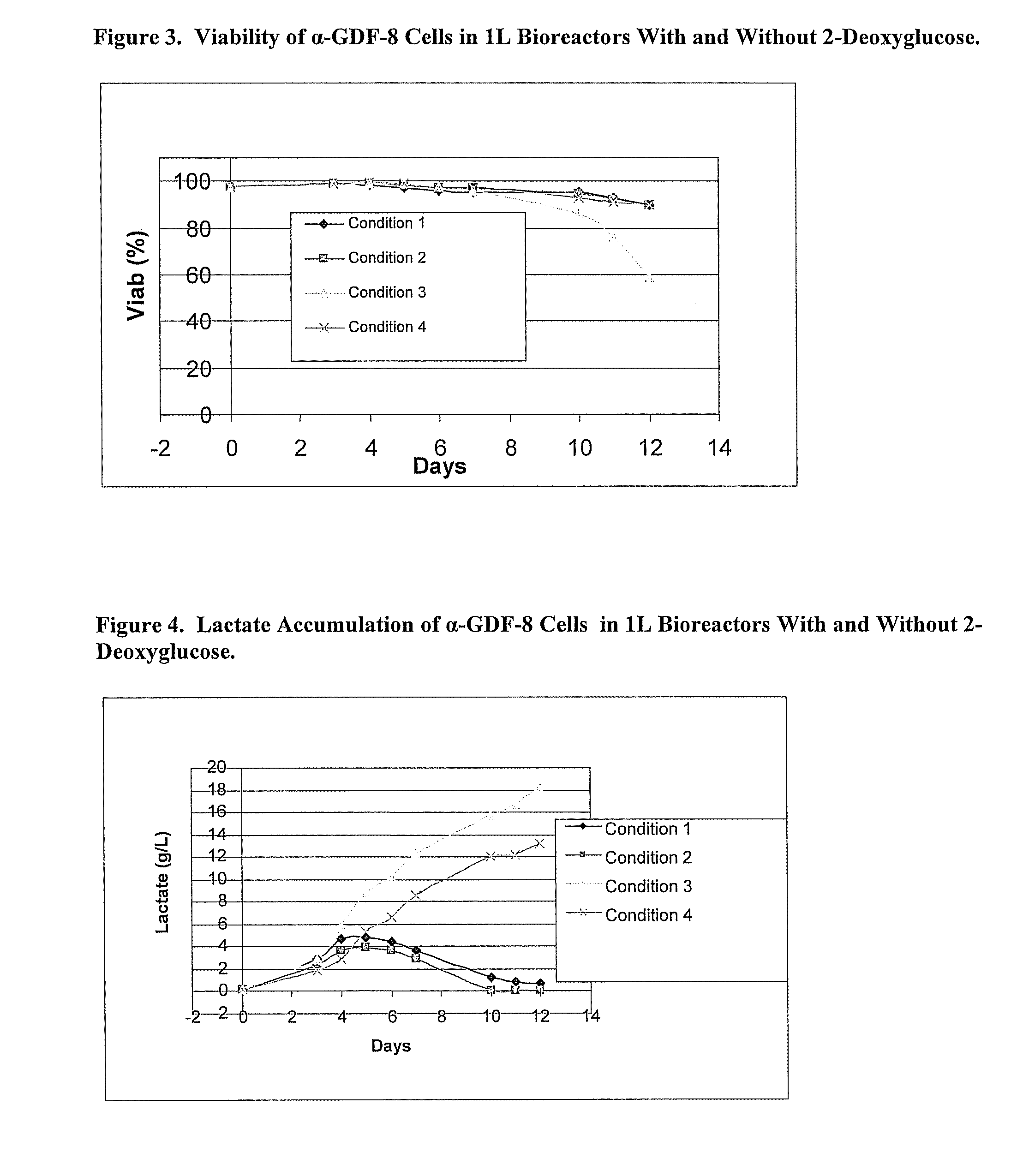

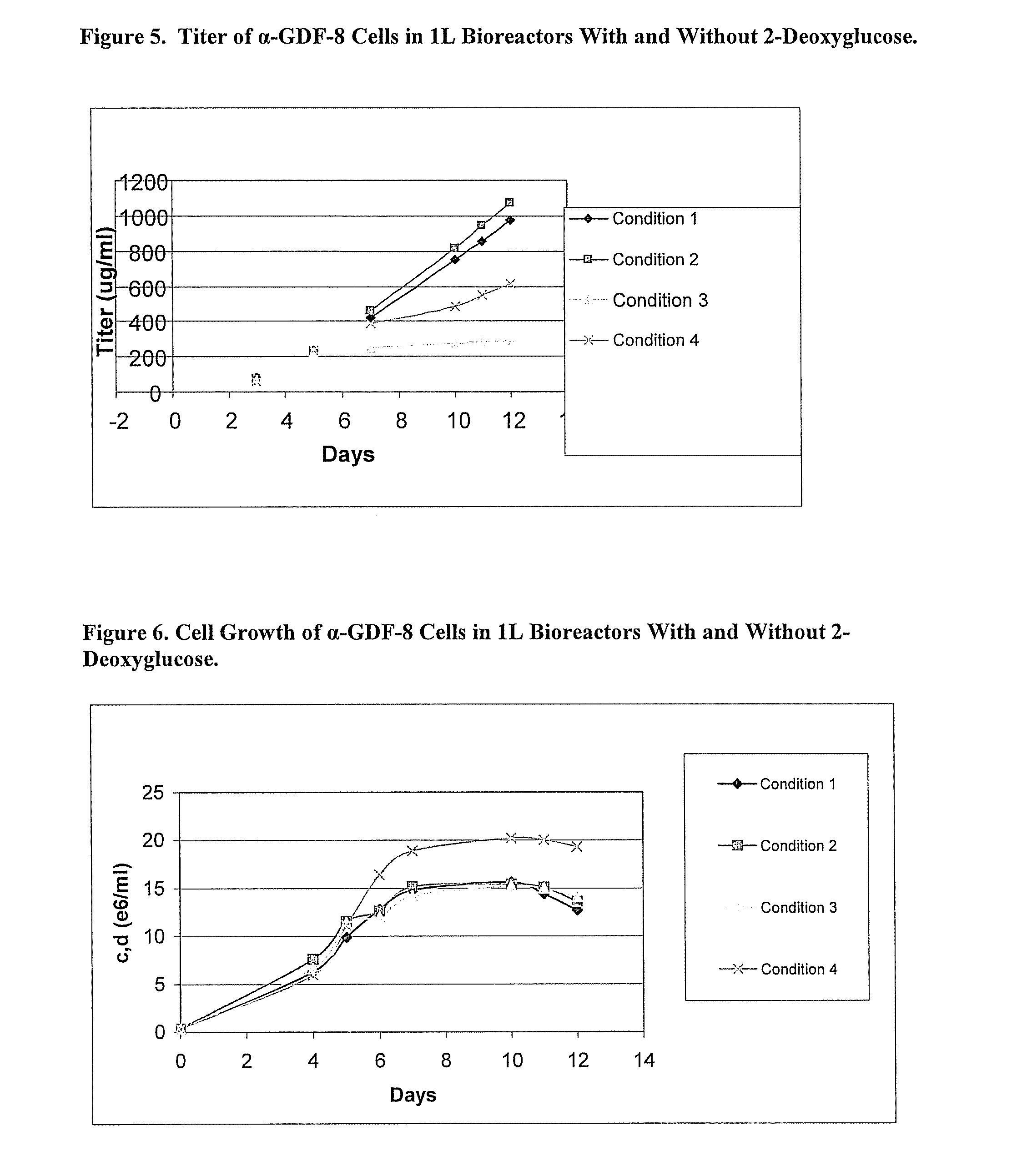

Glycolysis-inhibiting substances in cell culture

ActiveUS8192951B2Reduce accumulationHigh levelGenetically modified cellsCulture processMetabolic wastePharmaceutical drug

An improved system for large scale production of proteins and / or polypeptides in cell culture is provided. In accordance with the present invention, cells expressing the protein or polypeptide of interest are grown in media that comprise a glycolysis-inhibiting substance. Additionally and / or alternatively, cells expressing the protein or polypeptide of interest are grown in media in which glutamine is limited. The use of such a system allows high levels of protein or polypeptide production and lessens accumulation of undesirable metabolic waste products such as lactate. Proteins and polypeptides expressed in accordance with the present invention may be advantageously used in the preparation of pharmaceutical, immunogenic, agricultural or other commercial compositions.

Owner:WYETH LLC

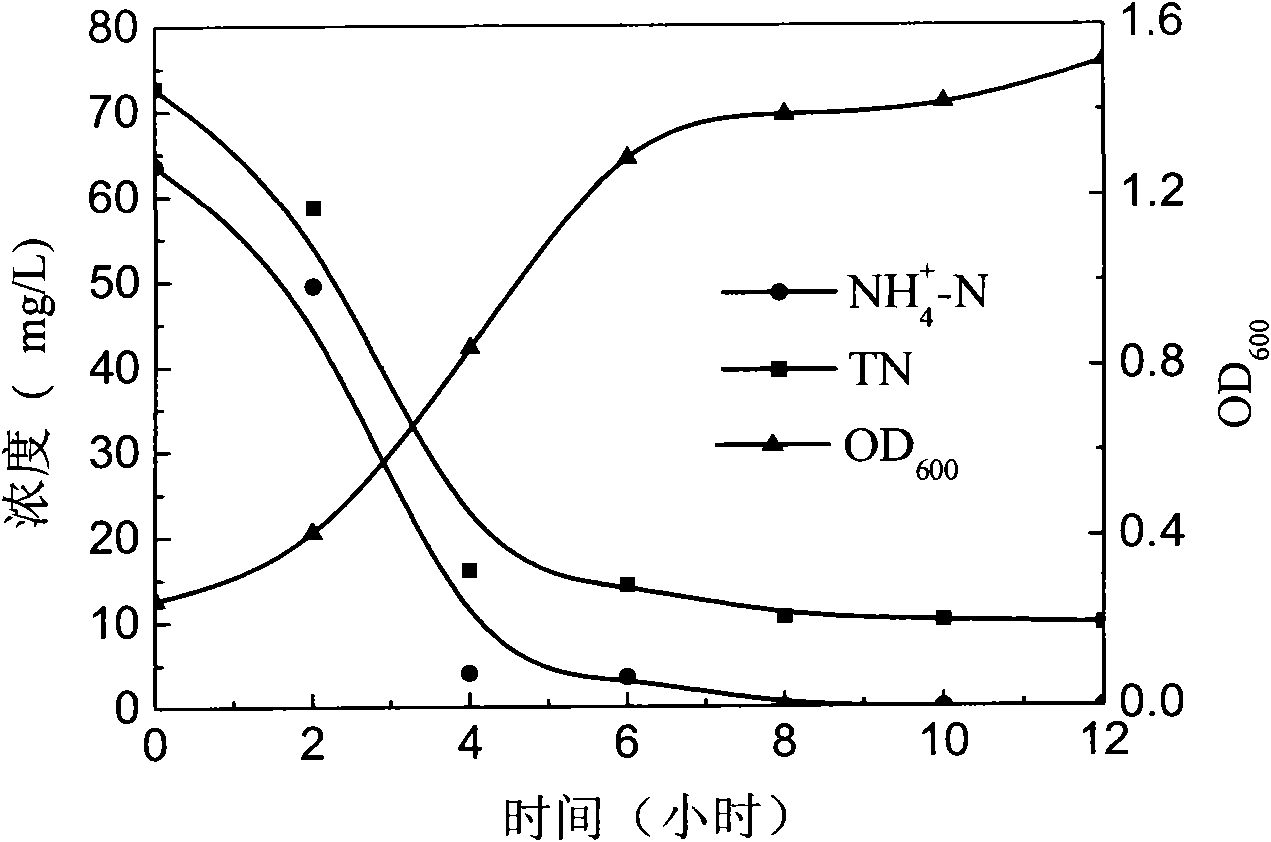

Agrobacterium with heterotrophic nitrification-aerobic denitrification capability and application thereof in nitrogenous effluent treatment

InactiveCN101570738AAnoxic denitrification is needed to solve biological denitrificationSolve processingBacteriaWater contaminantsNucleotideBacterial strain

The invention relates to an agrobacterium strain (Agrobacterium sp.) with heterotrophic nitrification-aerobic denitrification capability and an application thereof in nitrogenous effluent treatment. The bacterial strain is characterized in that: 16S rRNA gene contains nucleotide sequence shown in sequence table with a sequence length of 1418bp and a accession number FJ639330 in Genbank. The preservation number thereof is CGMCC No.2962. The agrobacterium of the invention has not only heterotrophic nitrification capability but also aerobic denitrification capability. During nitrogenous effluent treatment, and one aerobic phase can cause ammonian to change into gaseous product with high denitrification efficiency and easy operation and tremendous economic benefit compared with the traditional biological denitrification process.

Owner:LANGFANG GAIA ENVIRONMENTAL TECH

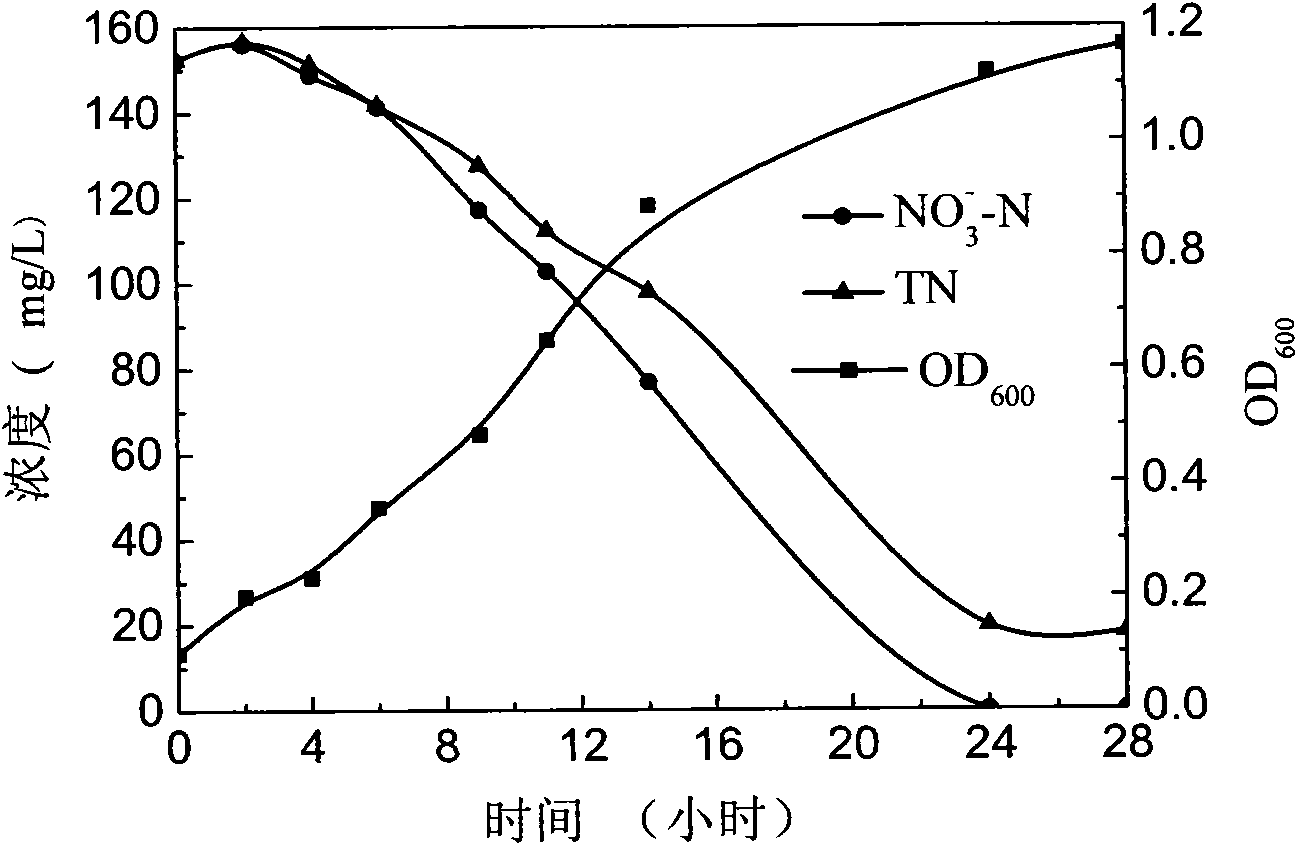

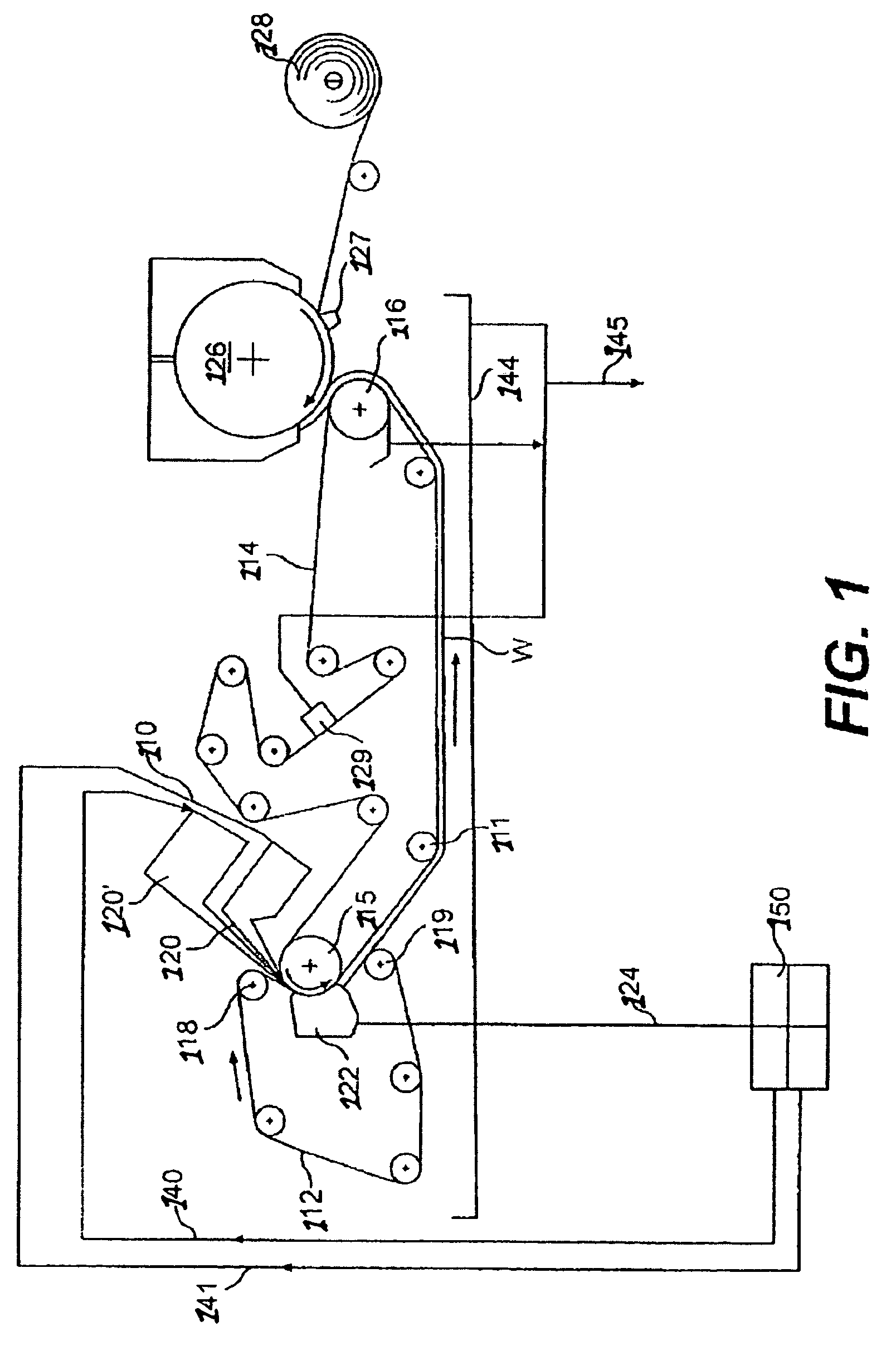

Methods for creping paper

ActiveUS7744722B1Reduce accumulationPrevent adhesive build-upNatural cellulose pulp/paperMechanical working/deformationAdhesiveCrêpe paper

A creping aid system for use on a creping cylinder, for example, a Yankee dryer, comprises a creping adhesive and a creping modifier, the combination comprising polyethylene.

Owner:SOLENIS TECH CAYMAN

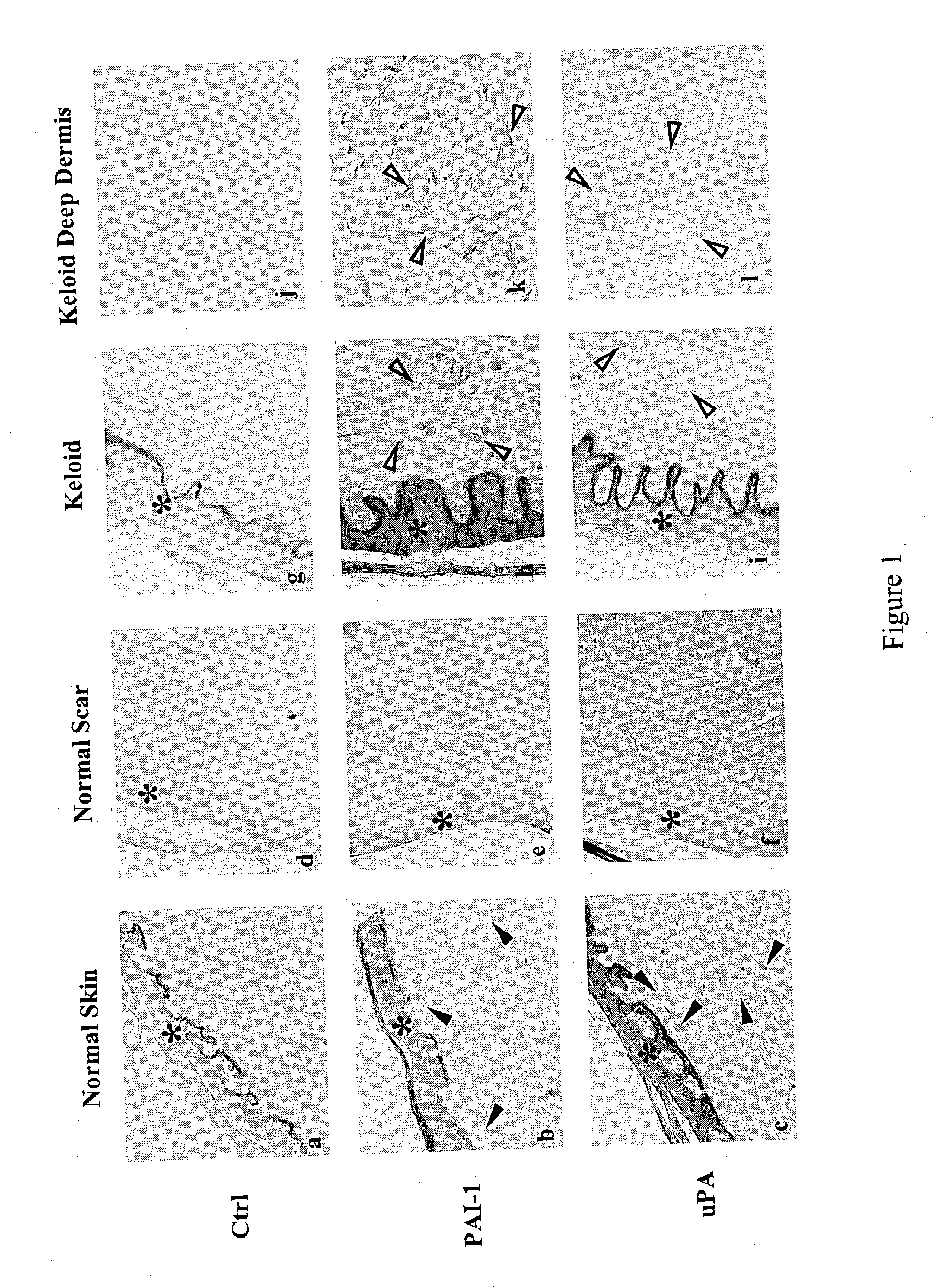

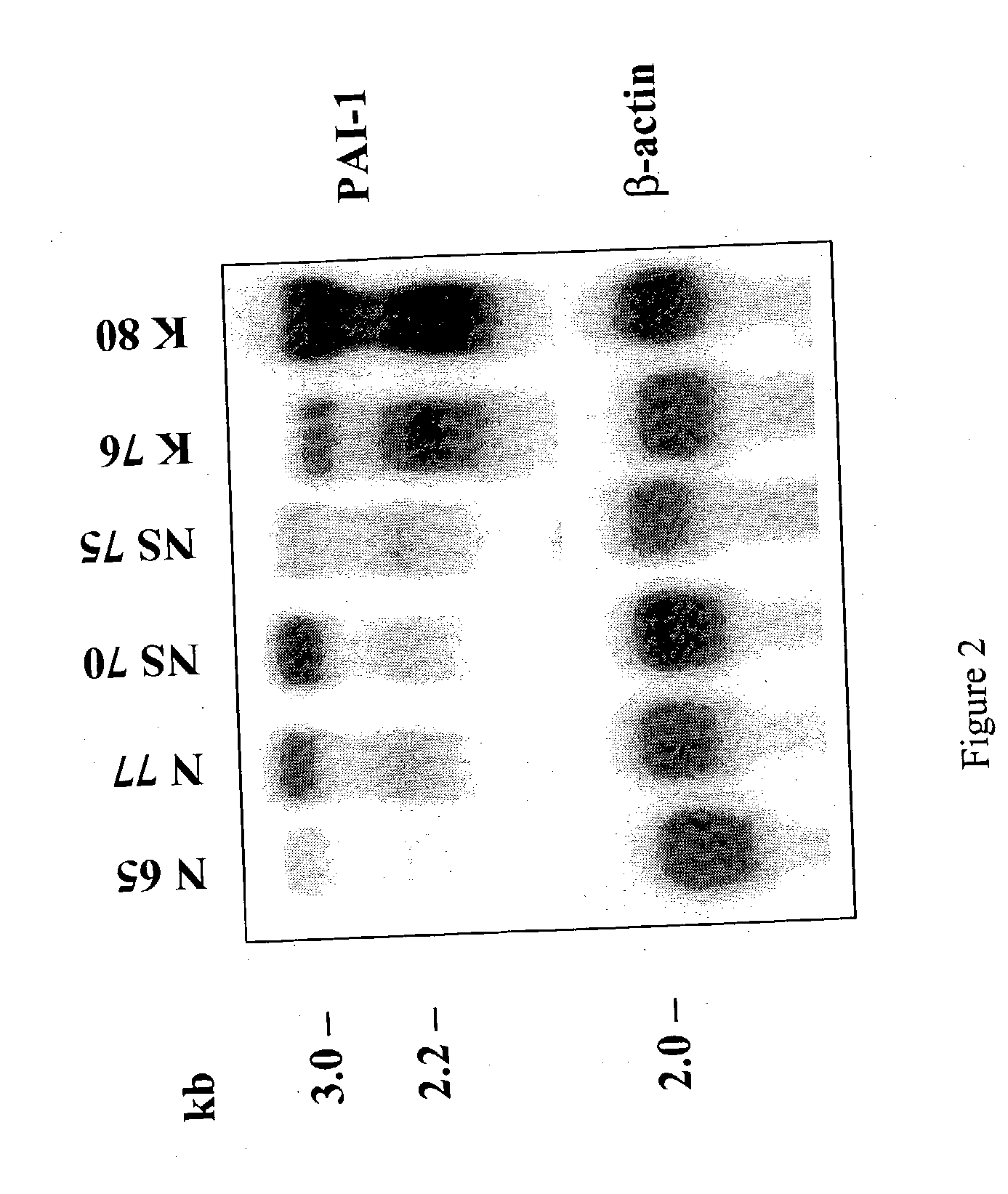

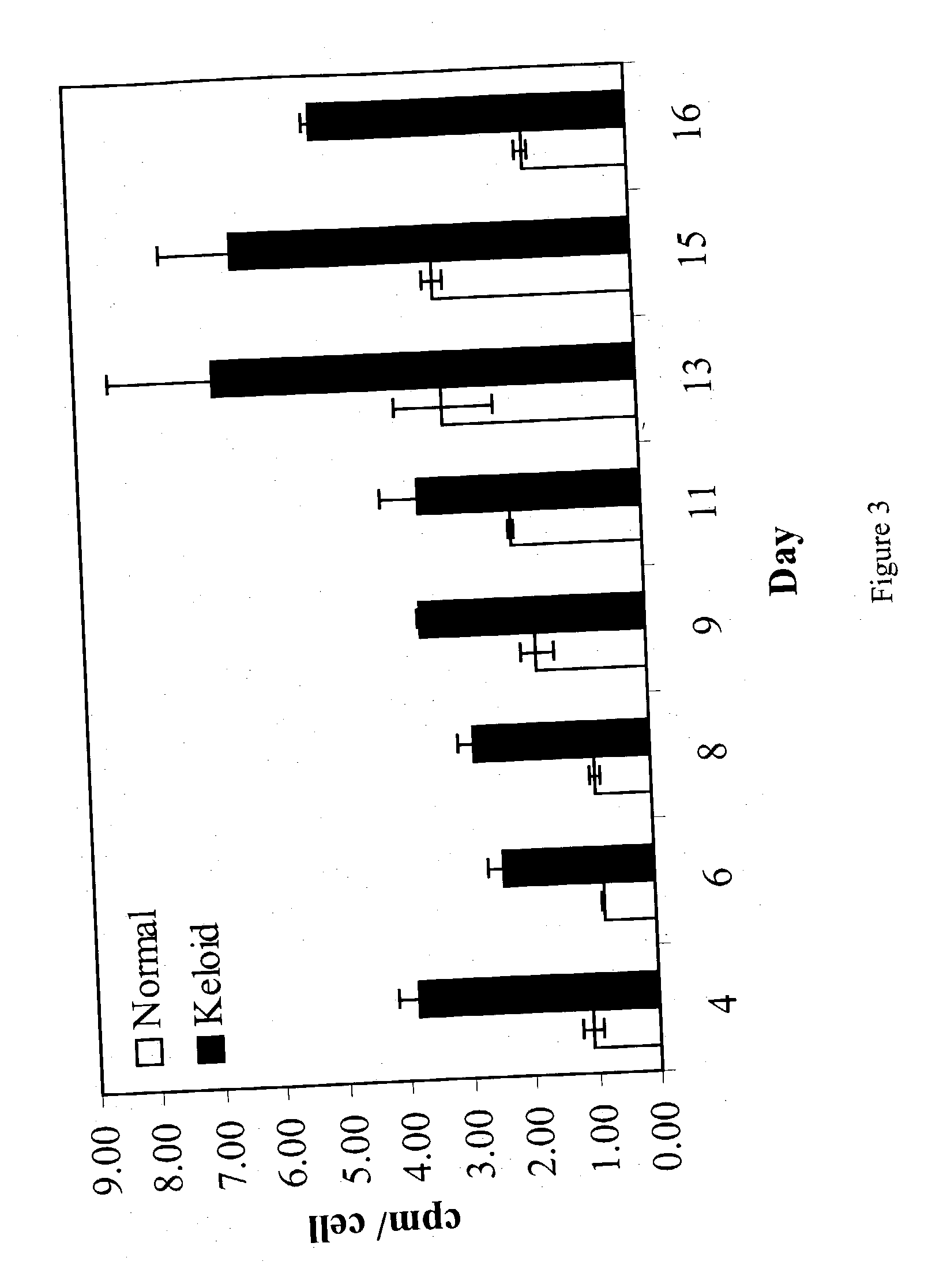

Treatment and prevention of abnormal scar formation in keloids and other cutaneous or internal wounds or lesions

The present invention relates to findings that reducing the activity of Plasminogen Activator Inhibitor-1 (PAI-1) suppresses an excessive deposition of collagen which is known as a cause for the formation of abnormal scars. These abnormal scars include but are not limited to keloids, adhesions, hypertrophic scars, skin disfiguring conditions, fibrosis, fibrocystic conditions, contractures, and scleroderma, all of which are associated with or caused by an excessive deposit of collagen in a wound healing process. Accordingly, aspects of the present invention are directed to the reduction of PAI-1 activity to decrease an excessive accumulation of collagen, prevent the formation of an abnormal scar, and / or treat abnormal scars that result from an excessive accumulation of collagen. The PAI-1 activity can be reduced by PAI-1 inhibitors which include but are not limited to PAI-1 neutralizing antibodies, diketopiperazine based compounds, tetramic acid based compounds, hydroxyquinolinone based compounds, Enalapril, Eprosartan, Troglitazone, Vitamin C, Vitamin E, Mifepristone (RU486), and Spironolactone to name a few. Another aspect of the present invention is directed to methods of measuring PAI-1 activity in a wound healing process and determining the propensity of the formation of an abnormal scar.

Owner:CHILDRENS HOSPITAL OF LOS ANGELES +1

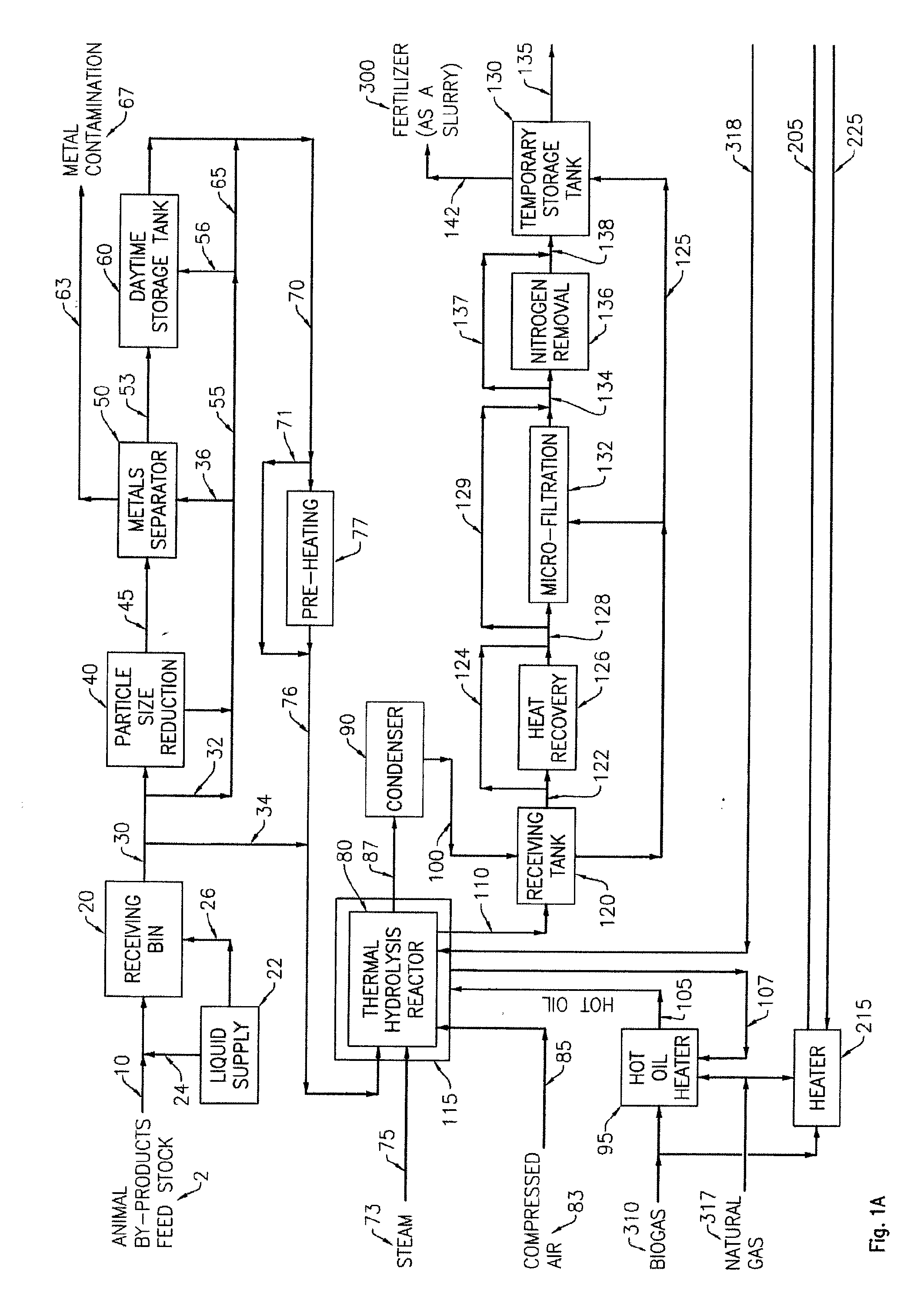

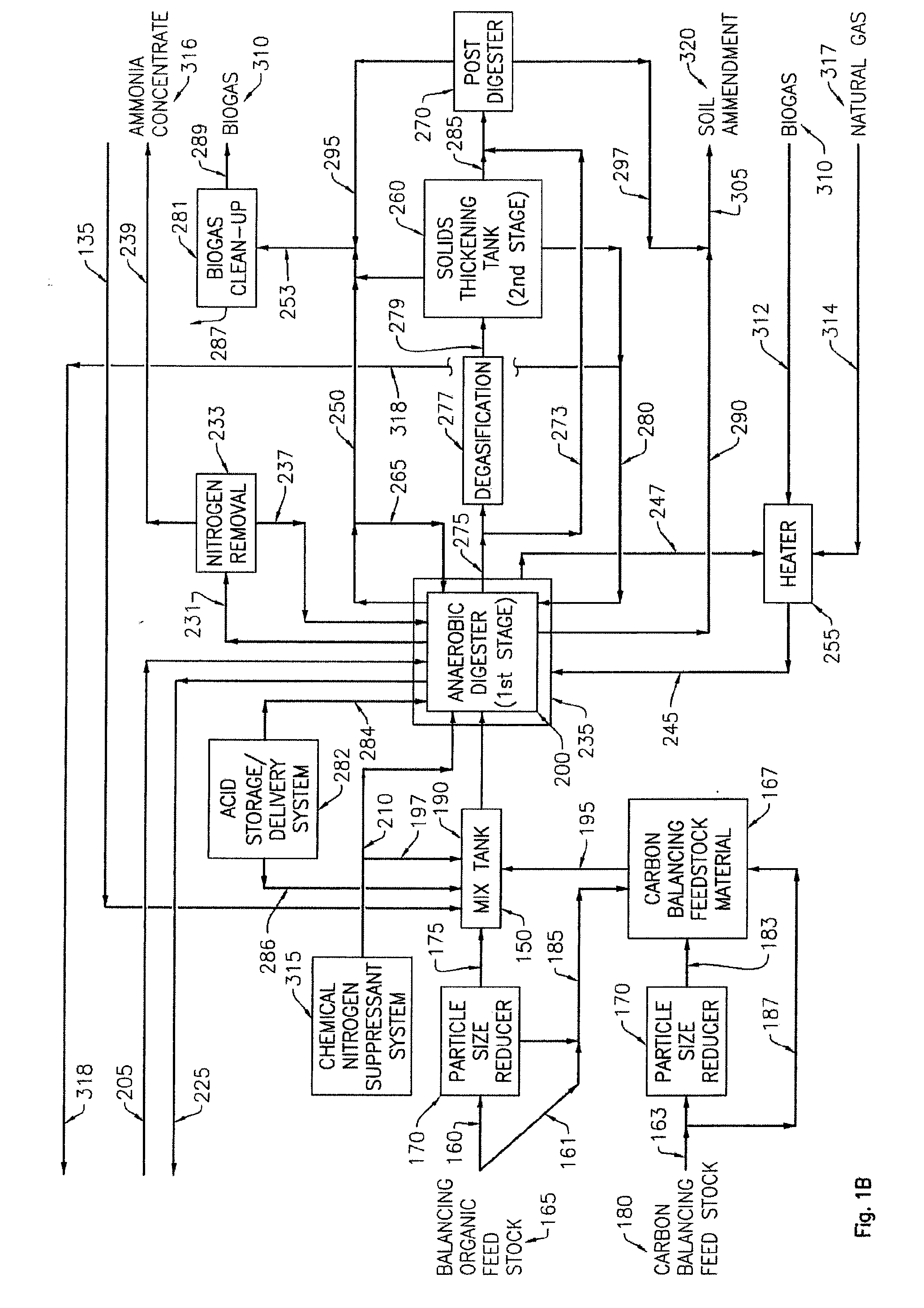

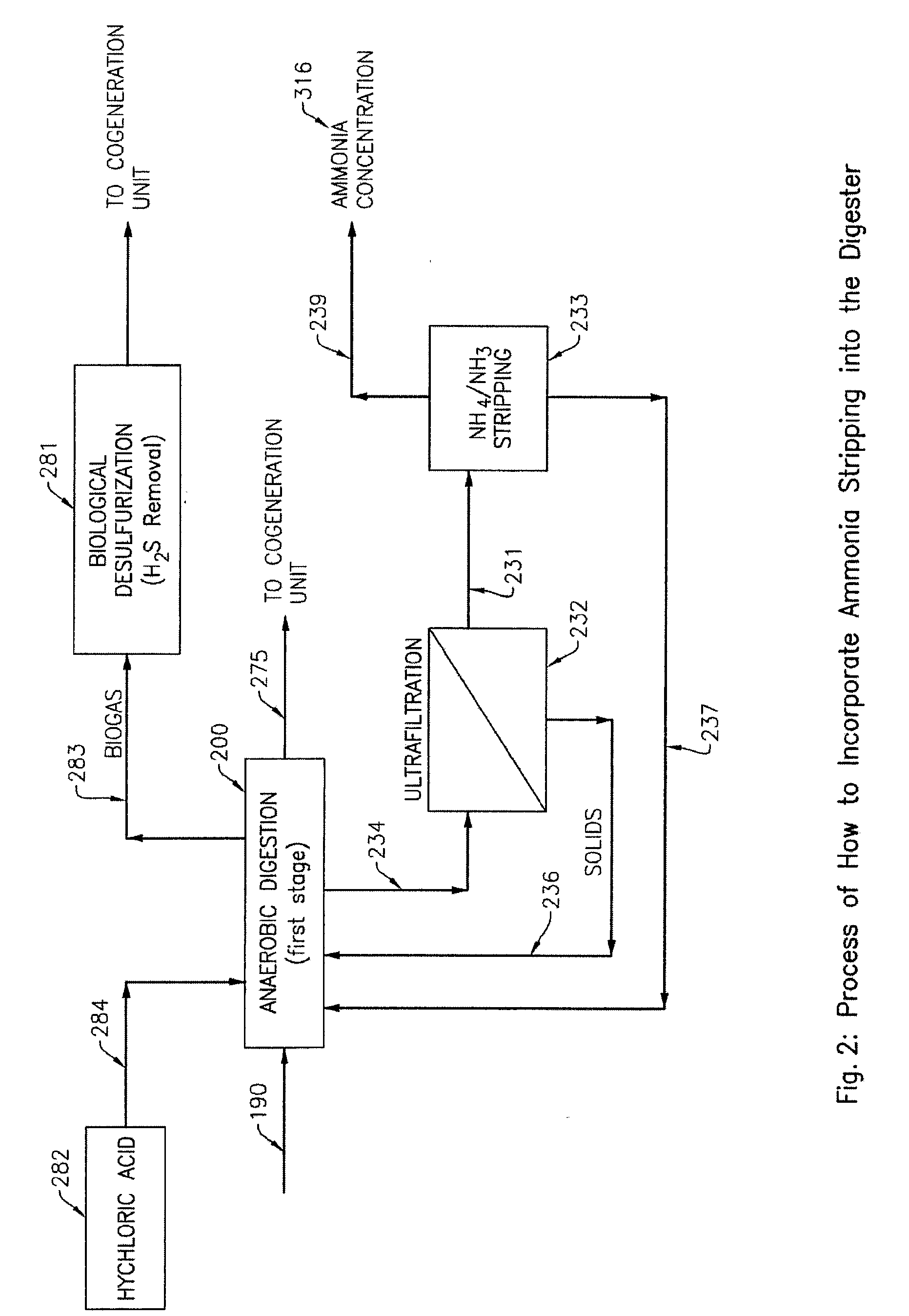

Apparatus and Process for Production of Biogas

ActiveUS20100021979A1Quick conversionDigesting retention timeBioreactor/fermenter combinationsBiological substance pretreatmentsHydrolysateSolid fraction

A process and an apparatus for the manufacture of biogas and a solids fraction from an organic waste feedstock is provided. The process involves thermal hydrolysis of the organic waste feedstock at a temperature from about 100 to about 220° C., a pressure from about 5 to about 20 bars, for a period of time from about 15 minutes to 4 hours, to produce a hydrolysate. The hydrolysate undergoes anaerobic digestion at a temperature from about 25 to 60° C., for a period of time from about 1 to 35 days to produce a biogas stream and a digestate. The digestate is separated into a solids fraction and a liquid fraction, and a portion of the solids fraction is recycled for further anaerobic digestion. The biogas stream, characterized as having a methane content from between 55 to 80% by volume, and the solids fraction, are recovered. The apparatus includes a receiving bin for receiving and supplying organic waste feedstock to a thermal hydrolysis reactor. The thermal hydrolysis reactor for processing the organic waste feedstock at a temperature from about 100 to about 220° C., a pressure from about 5 to about 20 bars, for a period of time from about 15 minutes to 4 hours to produce a hydrolysate. An anaerobic digester for processing the hydrolysate at a temperature from about 25 to 60° C., for a period of time from about 1 to 35 days to produce the biogas and a digestate, and a solids thickening tank for separating the digestate into the solid fraction, a liquid fraction and a secondary biogas fraction.

Owner:GEMINI CORP

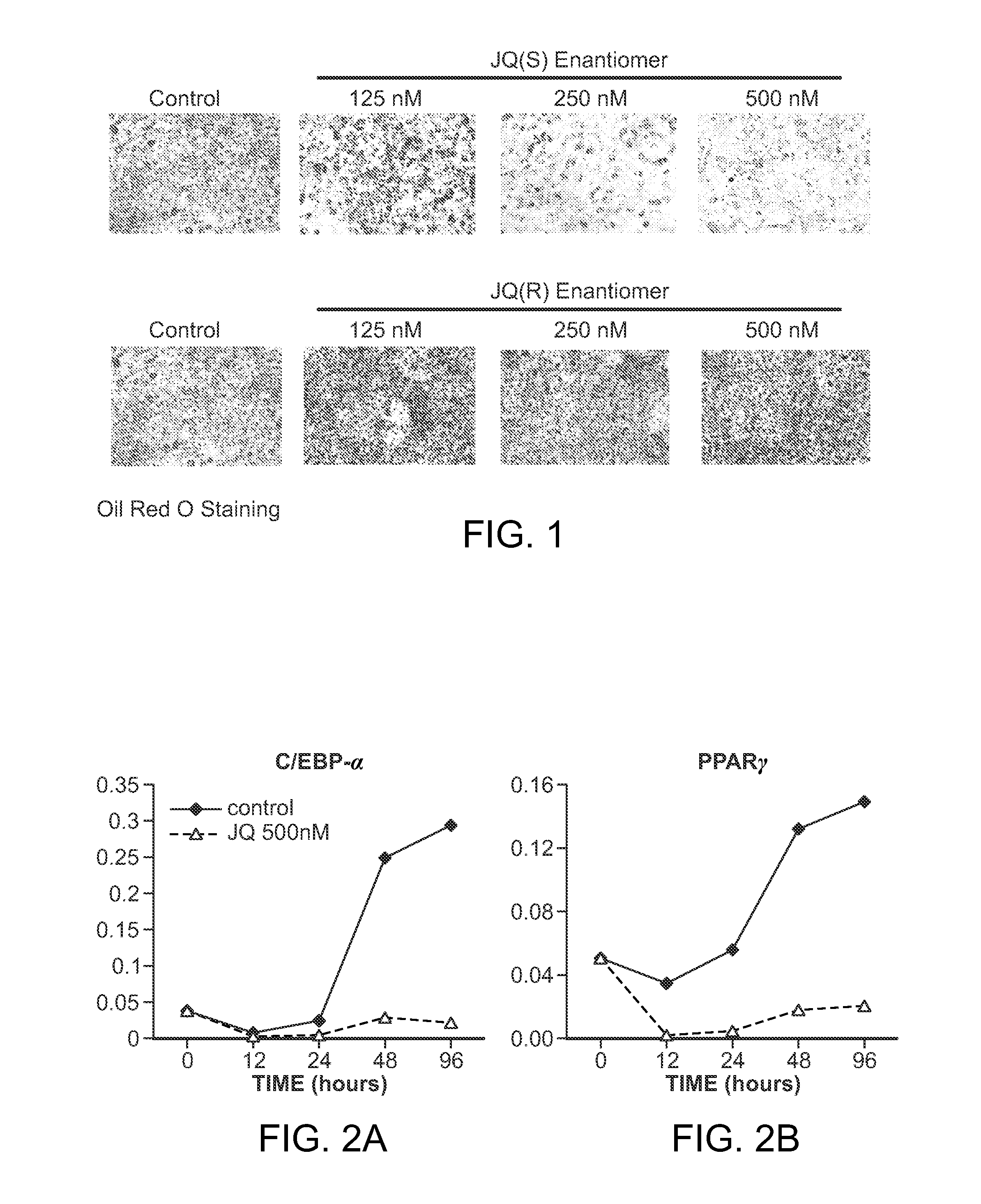

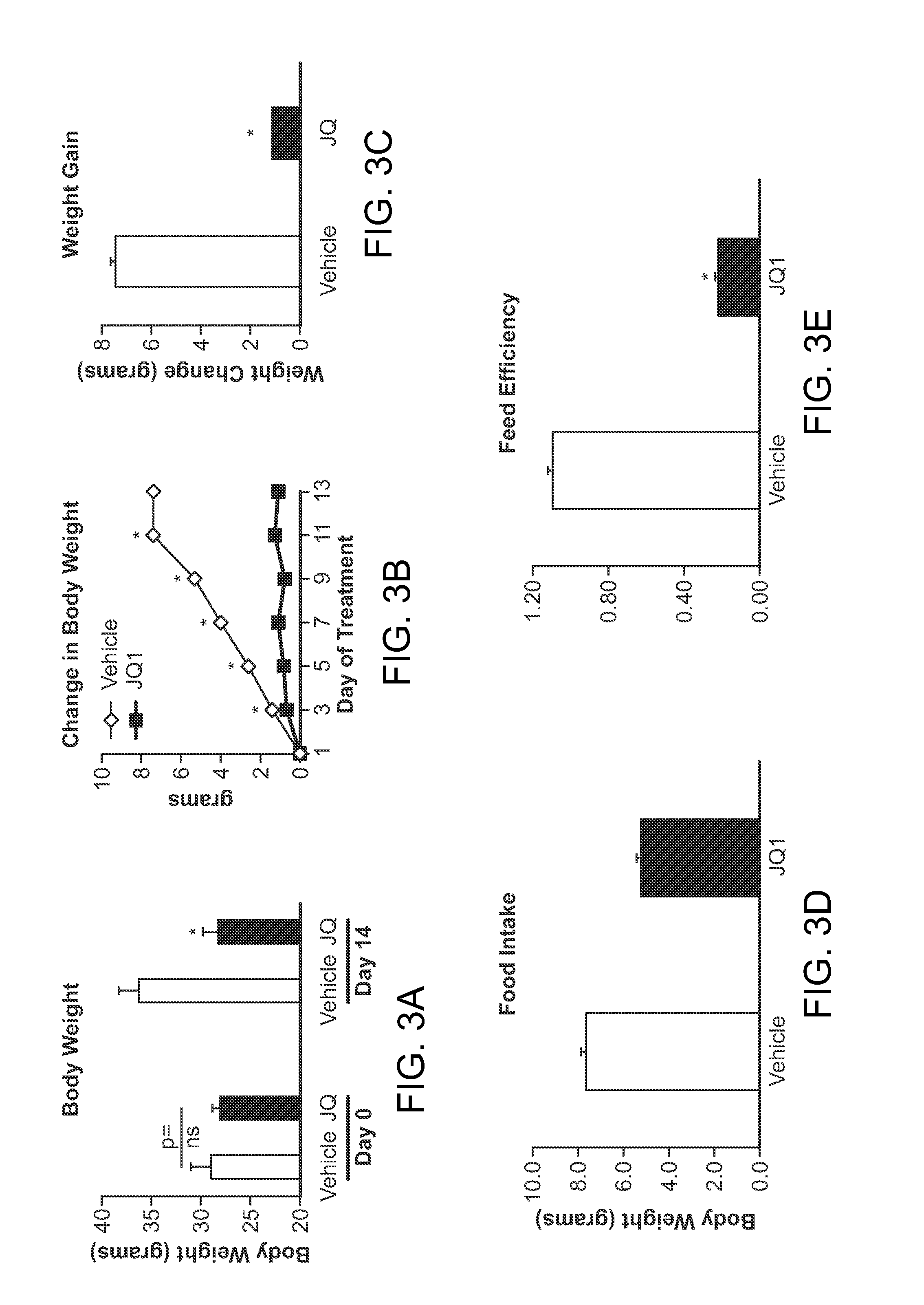

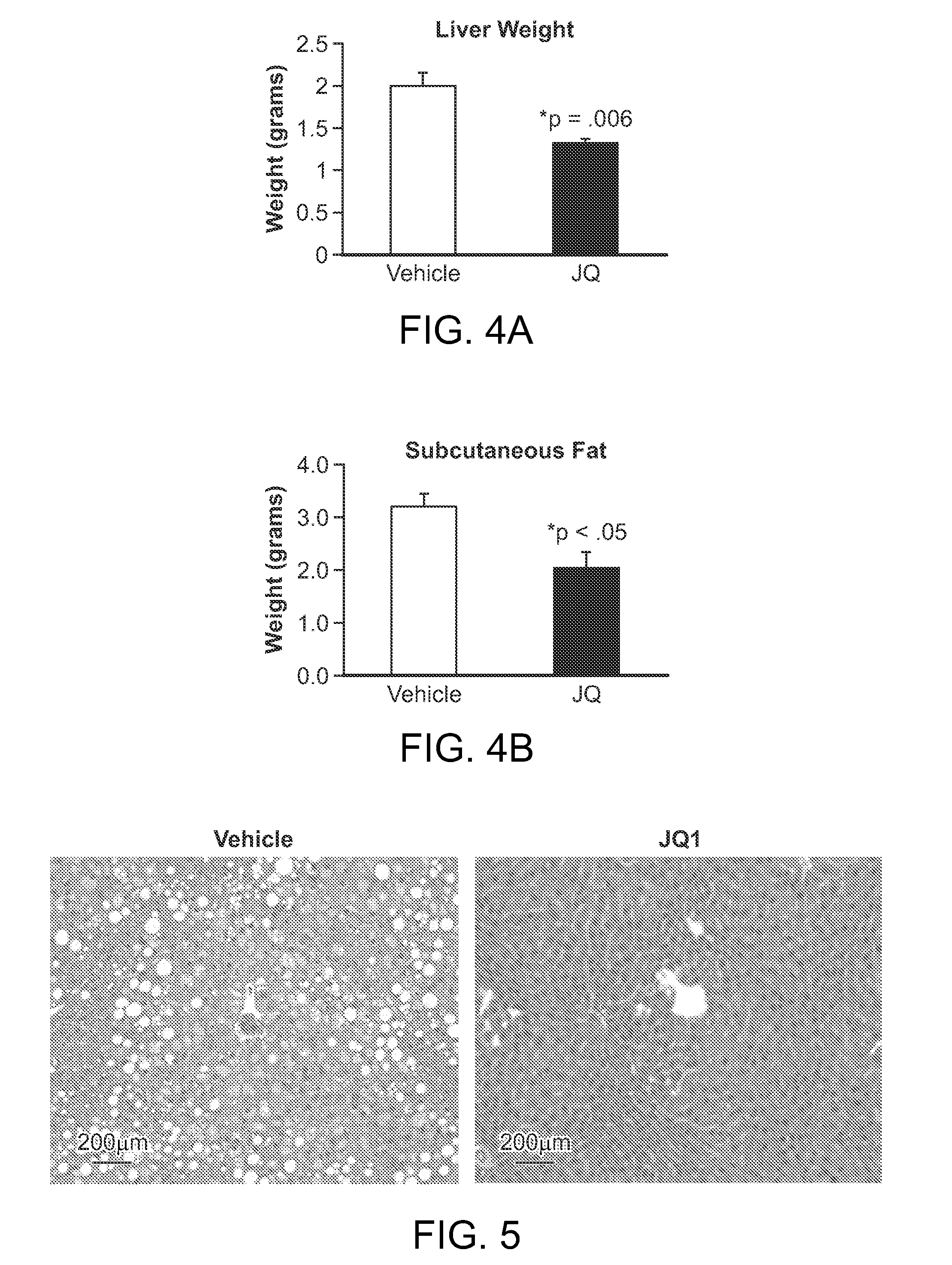

Compositions and methods for modulating metabolism

InactiveUS20130252331A1Reduce probabilityTreating and preventing obesityBiocideOrganic chemistryDiseaseBRD4

The invention provides compositions comprising an effective amount of an agent that inhibits a BET protein (e.g., Brd2, Brd3, Brd4), and methods of using such compositions for treating or preventing metabolic syndrome, obesity, type II diabetes, insulin resistance, and related disorders characterized by undesirable alterations in metabolism or fat accumulation.

Owner:THE BRIGHAM & WOMEN S HOSPITAL INC +1

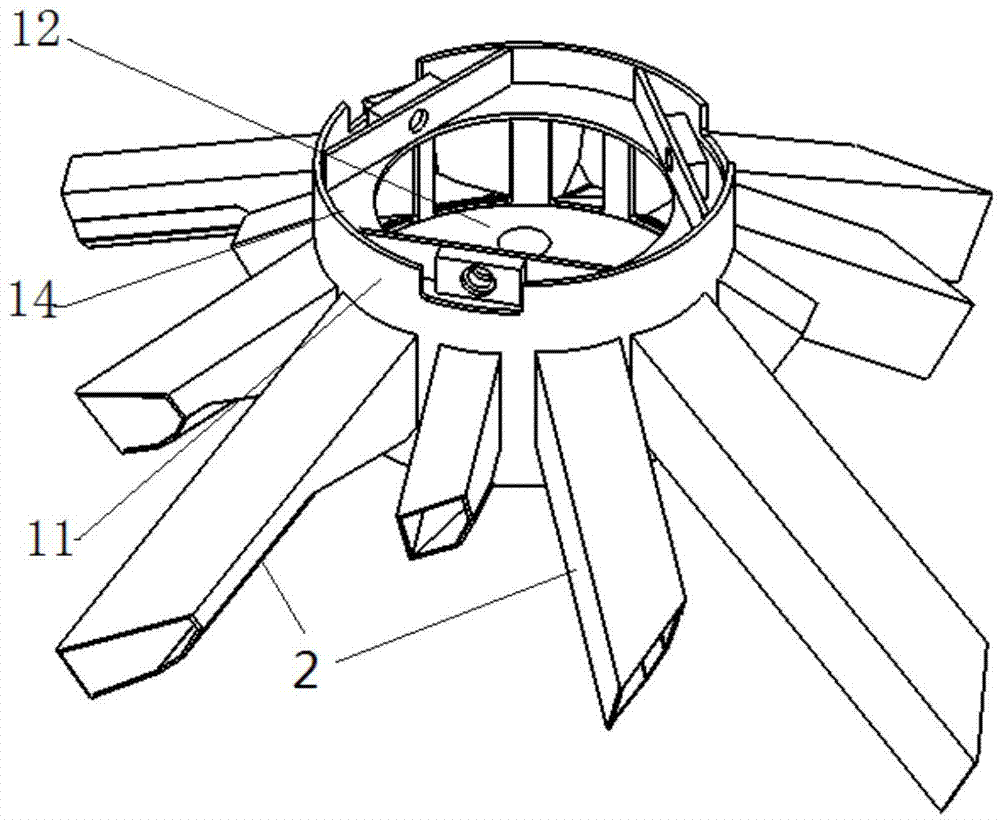

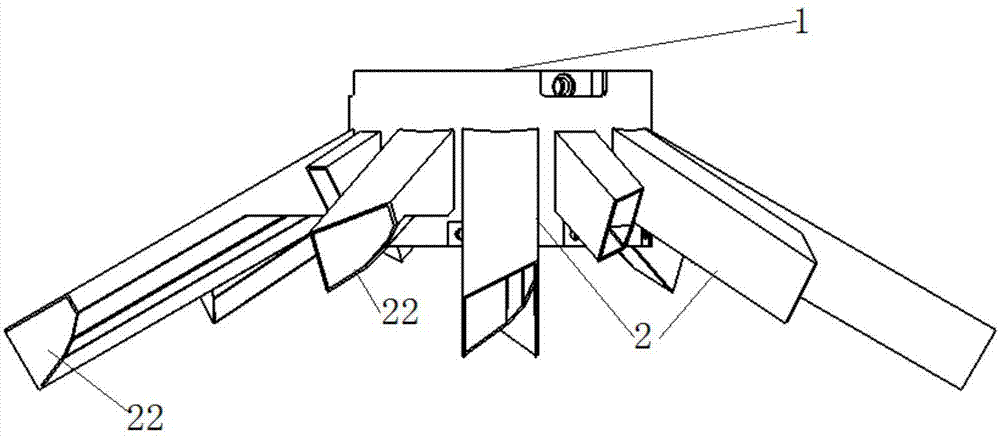

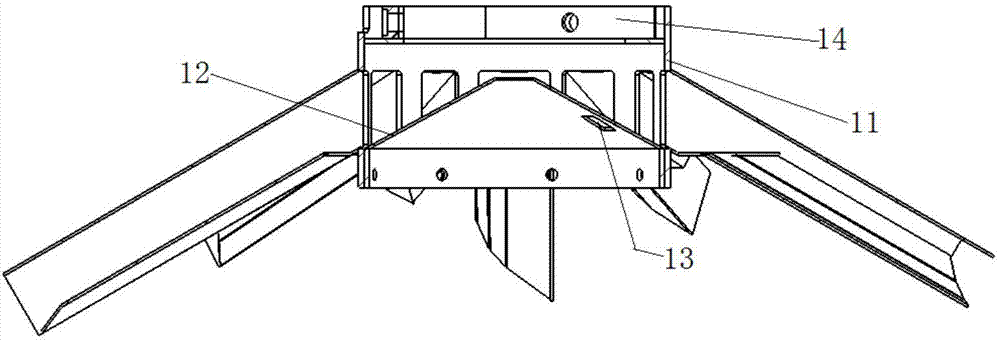

Rotating-type grain distributor and granary provided with grain distributor

InactiveCN104709729AGuaranteed safe storageReduce accumulationLoading/unloadingTangential forceEngineering

The invention discloses a rotating-type grain distributor and a granary provided with the grain distributor, and belongs to the technical field of granaries. The rotating-type grain distributor comprises a grain collecting barrel. The grain collecting barrel comprises a barrel wall and a barrel bottom. The outer side of the barrel wall of the grain collecting barrel is provided with two downward-inclined grain sliding pipes. The bottom face and one side face of each grain sliding pipe are curved surfaces which are of an integral structure. When the rotating-type grain distributor is used, the rotating-type grain distributor is arranged at a grain inlet of the granary, after grain enters the grain collecting barrel, the grain flows into the grain sliding pipes, and when the rotating-type grain distributor rotates, the grain sliding pipes rotate along with the rotating-type grain distributor. Due to the fact that the bottom face and one side face of each grain sliding pipe are curved surfaces which are of the integral structure, when the rotating-type grain distributor rotates, under the effect of centrifugal force and tangential force generated by the curved surfaces, the grain is scattered and flows out of the grain sliding pipes, and the grain falls onto a circular cross section of the granary. According to the rotating-type grain distributor, the impurity accumulation caused by automatic grading formed by concentrated falling of the grain is alleviated, and the safe storage of the grain is guaranteed.

Owner:BEIJING U PRECISION TECH

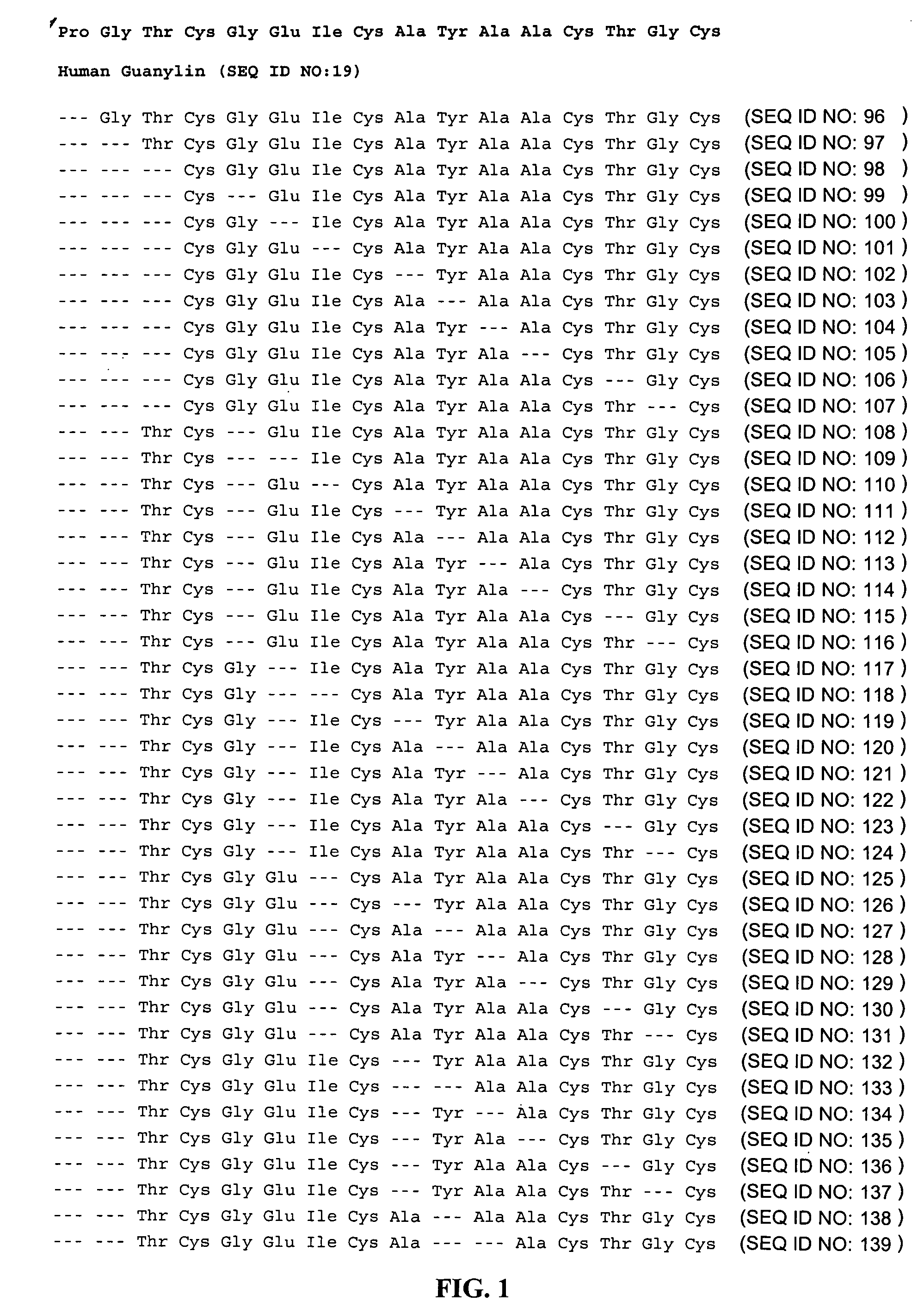

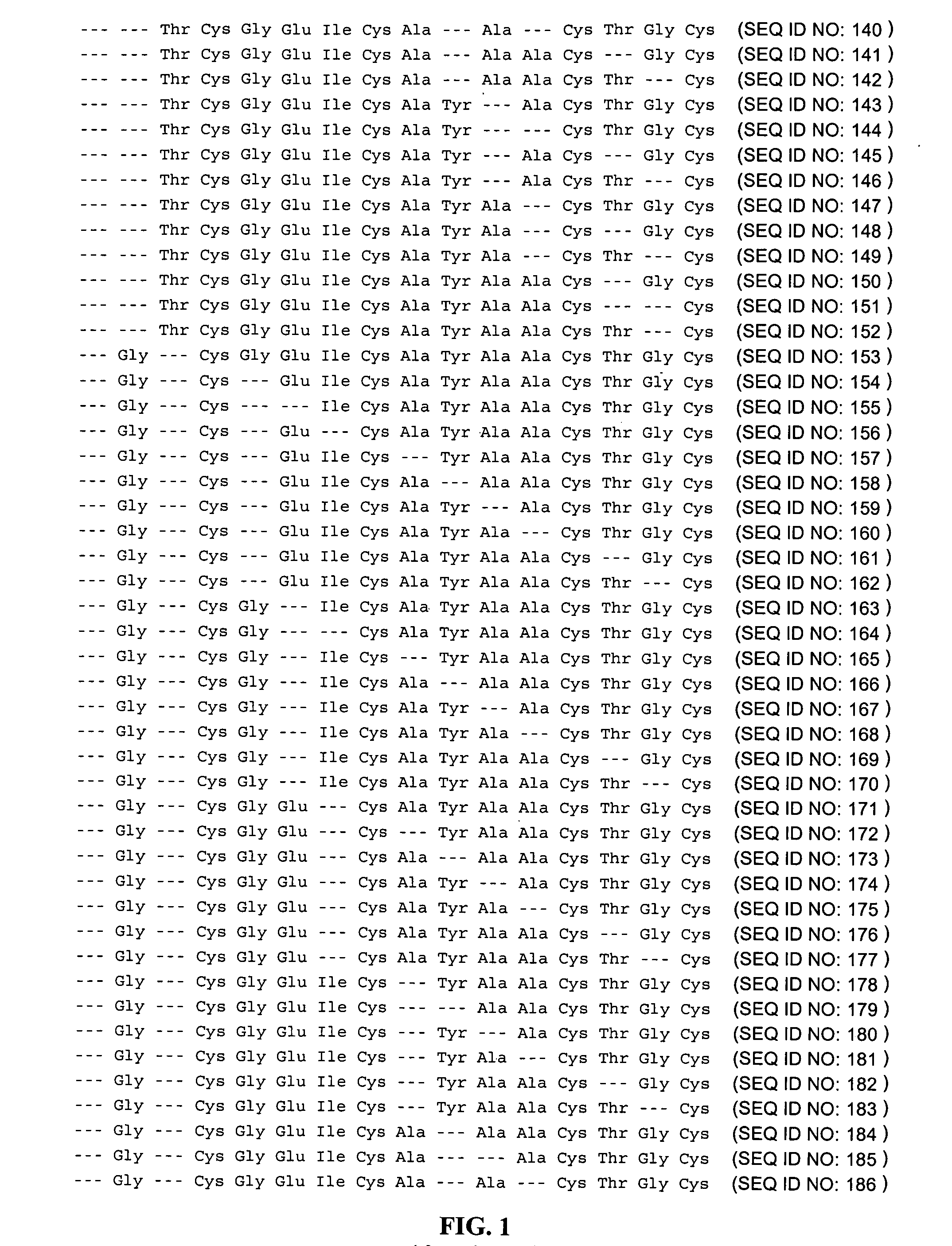

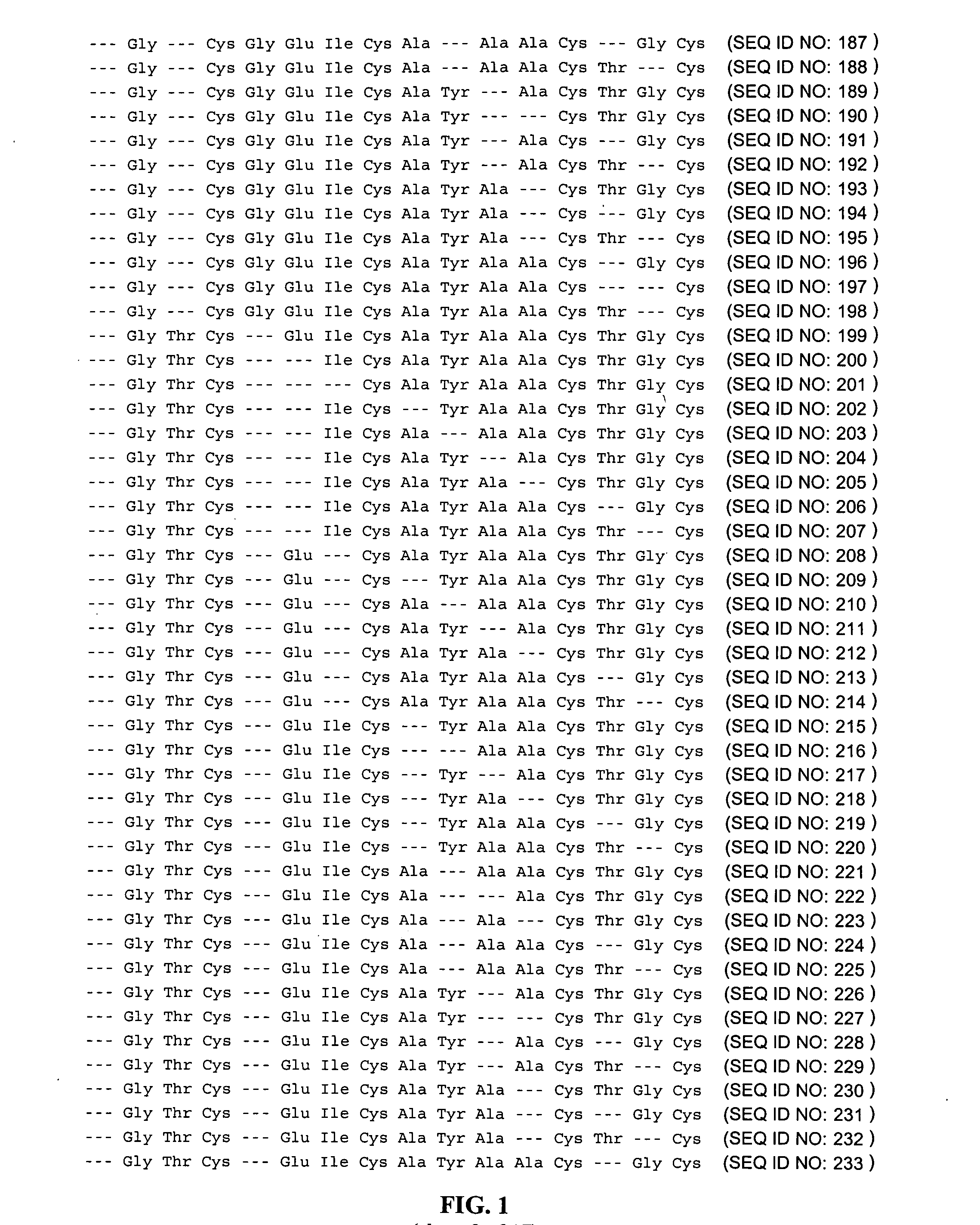

Methods and compositions for the treatment of gastrointestinal disorders

InactiveUS20070010450A1Increase gastrointestinal motilityReduce inflammationPeptide/protein ingredientsMetabolism disorderIntestinal tract diseasesGastroparesis

Compositions and related methods for treating IBS and other gastrointestinal disorders and conditions (e.g., gastrointestinal motility disorders, functional gastrointestinal disorders, gastroesophageal reflux disease (GERD), duodenogastric reflux, Crohn's disease, ulcerative colitis, inflammatory bowel disease, functional heartburn, dyspepsia (including functional dyspepsia or nonulcer dyspepsia), gastroparesis, chronic intestinal pseudo-obstruction (or colonic pseudoobstruction), and disorders and conditions associated with constipation, e.g., constipation associated with use of opiate pain killers, post-surgical constipation, and constipation associated with neuropathic disorders as well as other conditions and disorders are described. The compositions feature peptides that activate the guanylate cyclase C (GC-C) receptor.

Owner:IRONWOOD PHARMA

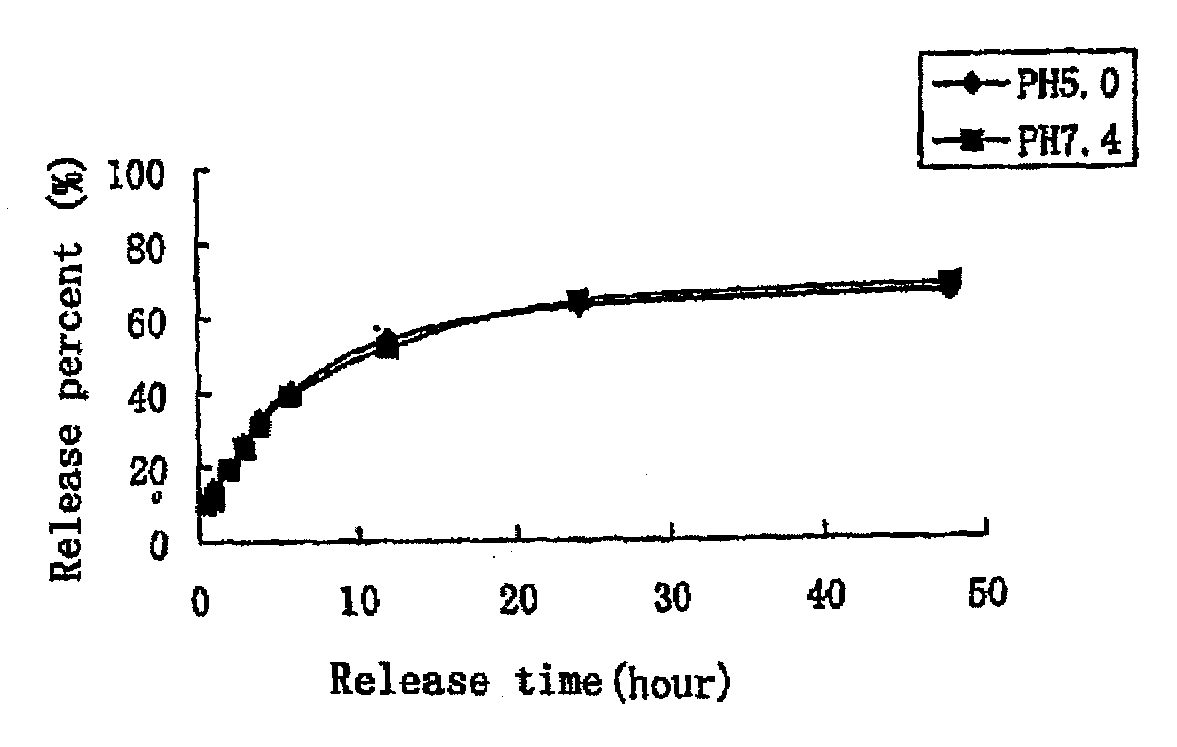

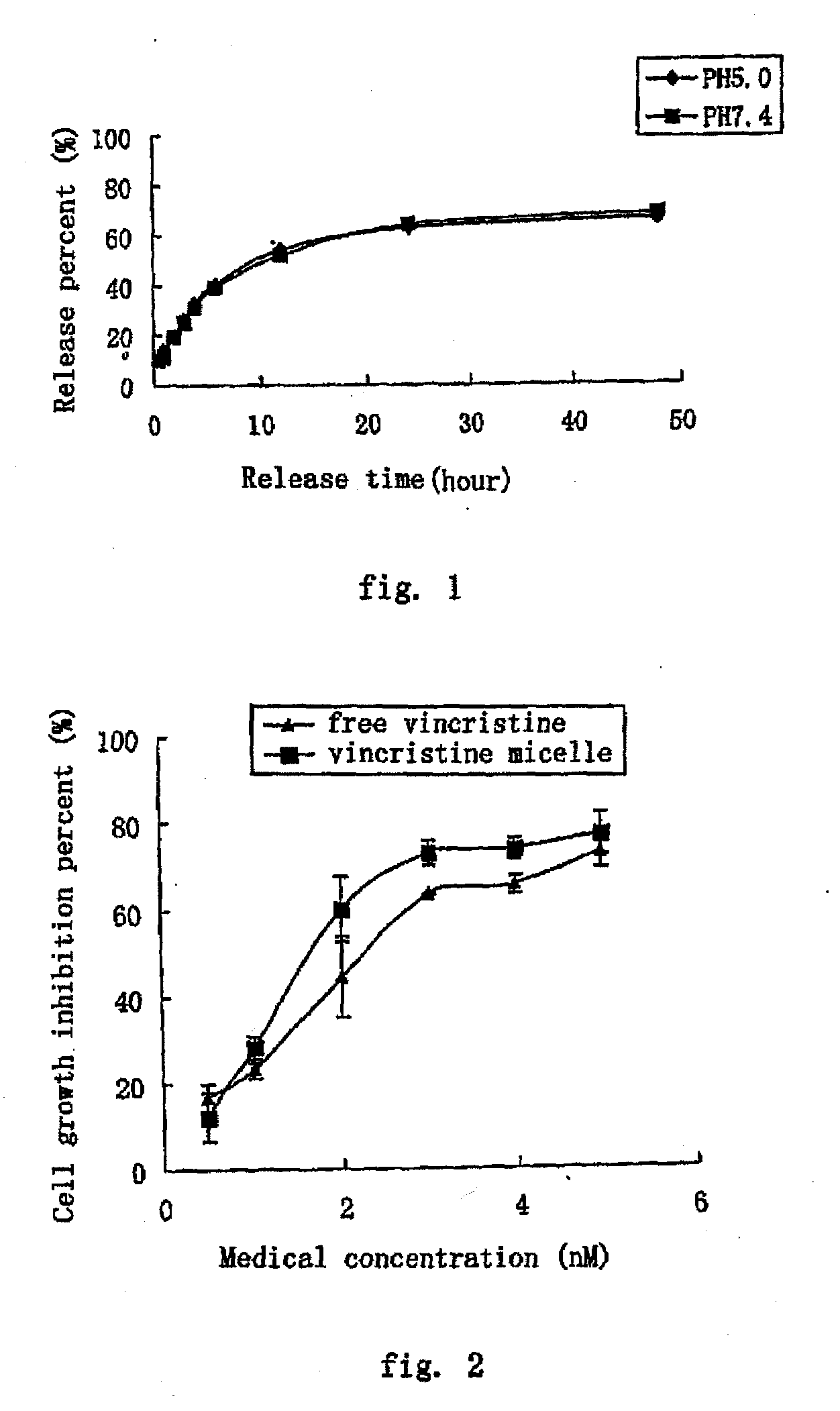

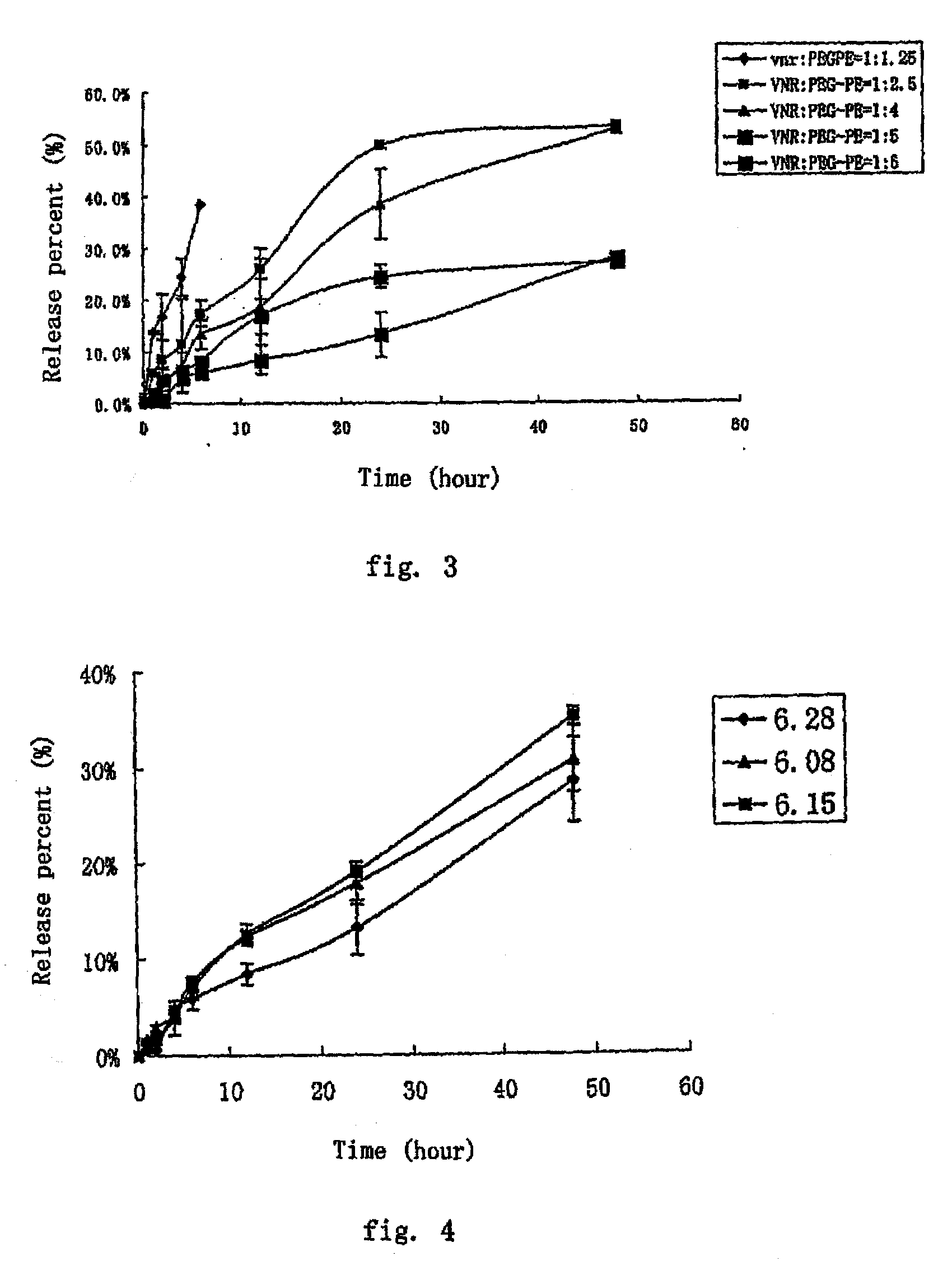

Nano Anticancer Micelles of Vinca Alkaloids Entrapped in Polyethylene Glycolylated Phospholipids

ActiveUS20090053293A1Good stabilityImprove drug distributionBiocidePharmaceutical non-active ingredientsVinorelbineAdjuvant

The present invention provides a nano-micellar preparation containing vinca alkaloids antitumor agent for intravenous injection, which cincludes a therapeutically effective amount of vinca alkaloids antitumor agent (vinblastine, vincristine, vindesine and vinorelbine), a phosphatide derivatized with polyethylene glycol, together with pharmaceutically acceptable adjuvants. The preparation is prepared by encapsulating the medicament with a nano-micelle to obtain the nano-micellar preparation containing vinca alkaloids antitumor agent for injection. The vinca alkaloids antitumor agent and the phosphatide derivatized with polyethylene glycol form a nano-micelle with a highly uniform particle size. In the micelle, the hydrophobic core of encapsulated medicament is surrounded by polyethylene glycol molecules to form a hydrophilic protective layer, so that the medicament is prevented from contacting with the enzymes and other protein molecules in blood and being recognized and phagocytozed by reticuloendothelial system in body, and the circulation time in vivo of the micelle is prolonged.

Owner:BEIJING DIACRID MEDICAL TECH

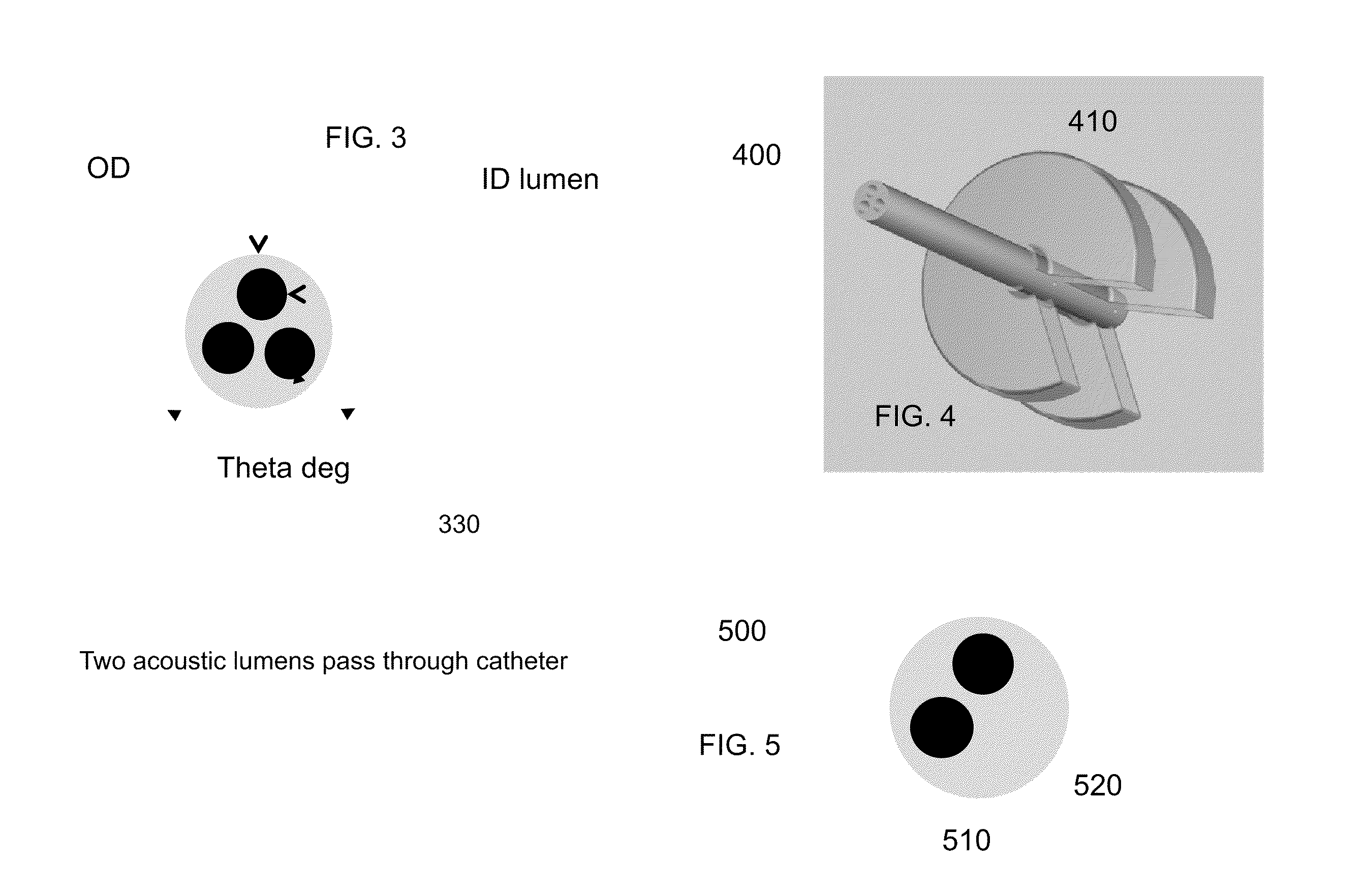

Device and Method to reduce Ear Wax Clogging of Acoustic Ports, Hearing Aid Sealing System, and Feedback Reduction System

ActiveUS20100177918A1Reduce the amount requiredReducing processor powerElectrical transducersAdditive manufacturing apparatusWaxSystem configuration

At least one exemplary embodiment that is directed to a conformal hearing aid comprising: a hearing aid body, where the hearing aid body houses a microphone and a receiver, where the microphone is positioned within the hearing aid body to measure acoustic signals from an ambient environment, and where the receiver is positioned within the hearing aid body to emit acoustic signals toward a tympanic membrane of a user; an expandable element, where the expandable element is operatively connected to the hearing aid body, and where the expandable element is configured to encompass a circumferential portion of the hearing aid body when expanded; and an inflation management system, where the inflation management system is configured to expand the expandable element when actuated.

Owner:STATON TECHIYA LLC

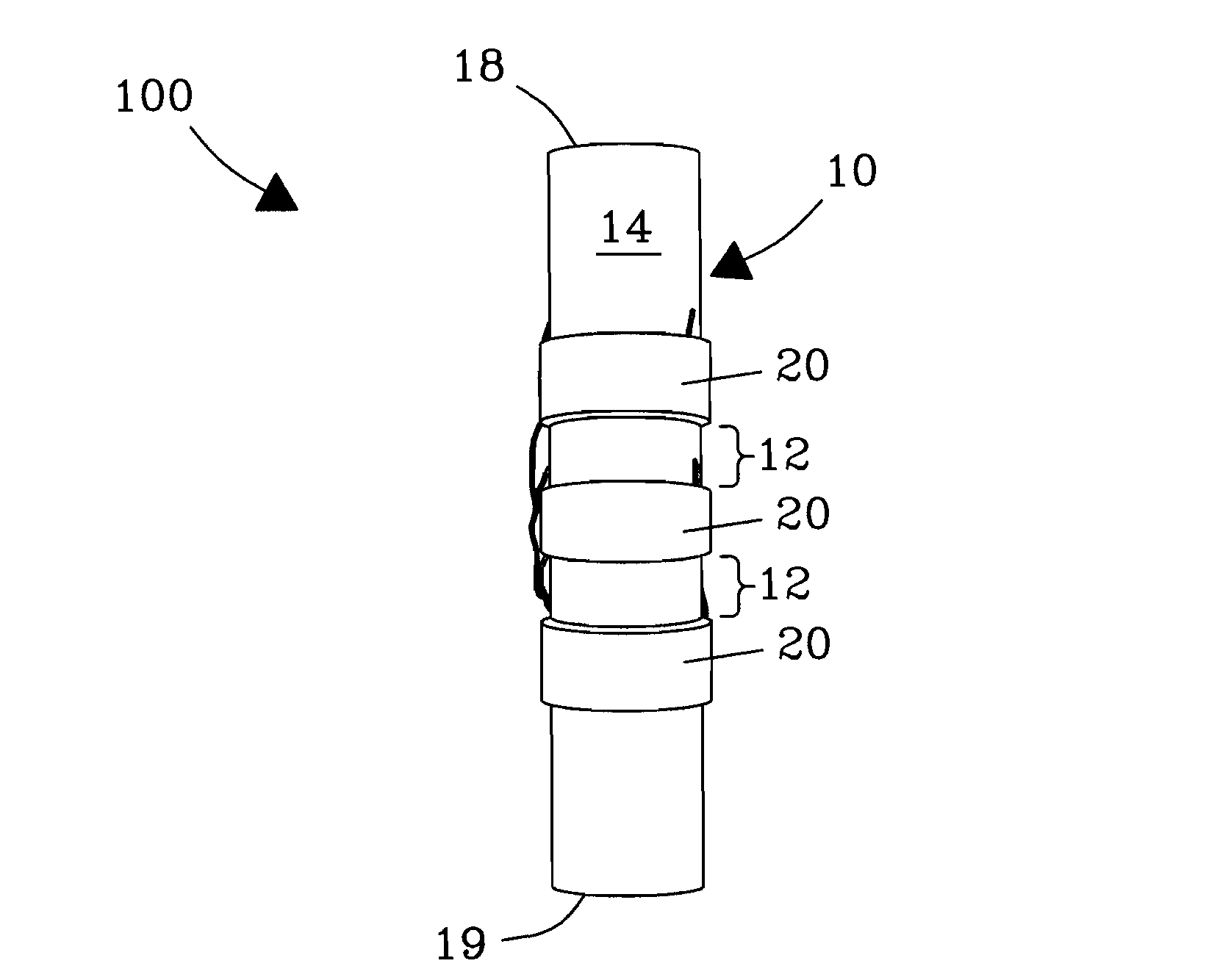

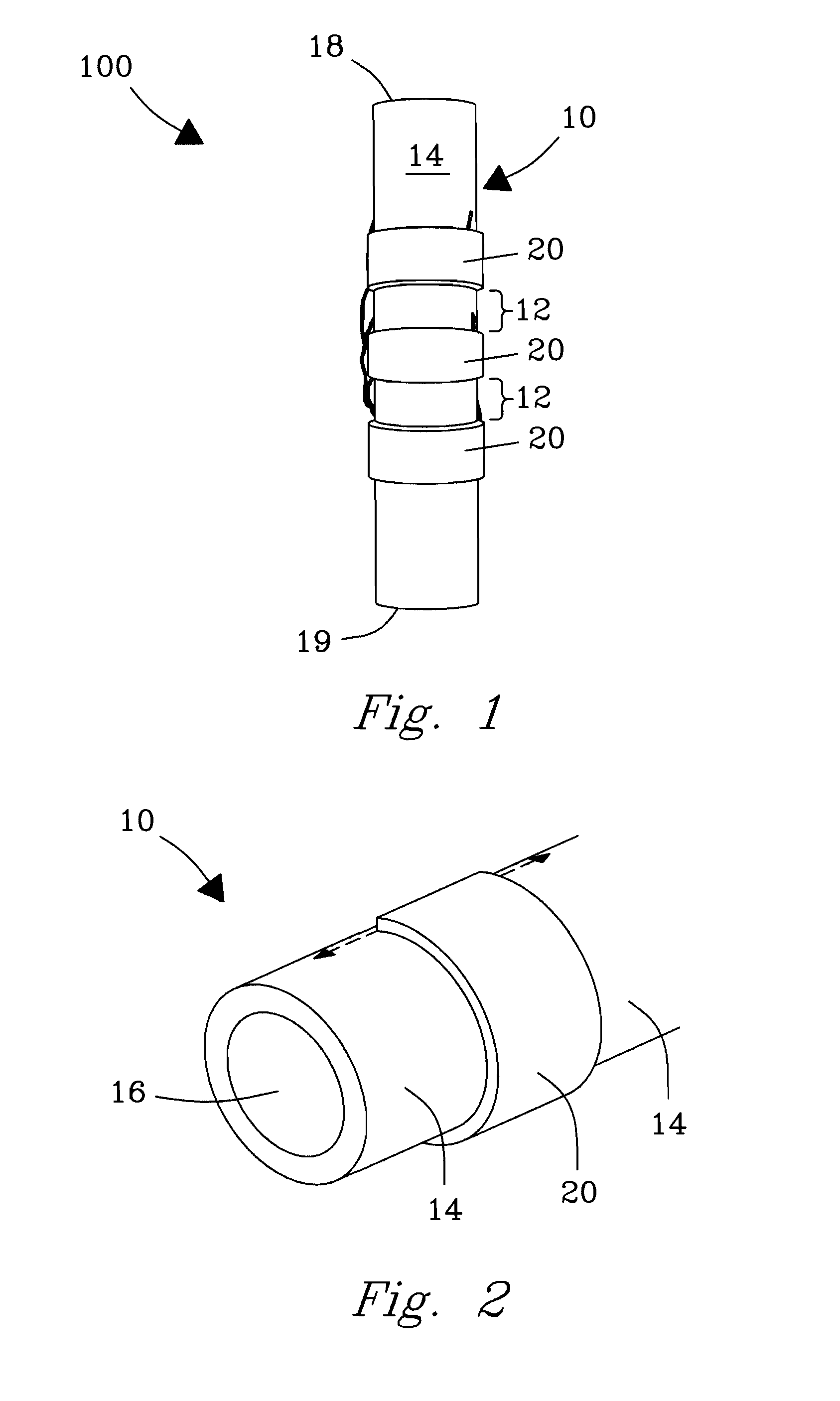

Device and method for noninvasive ultrasonic treatment of fluids and materials in conduits and cylindrical containers

InactiveUS20090038932A1Enhanced effectivenessRapid heatingShaking/oscillating/vibrating mixersDewatering/demulsification with mechanical meansEngineering

A system, method, and device are described for ultrasonic treatment of viscous fluids, including, e.g., crude oils that provide a variety of desired modifications. The invention includes a container having a circumvolving outer wall configured to allow passage of a quantity of a material within a passageway therein and ultrasonic transducers that attach to and circumvolve the outer wall of the container. The ultrasonic transducers transmit ultrasonic energy into material within the container at preselected frequencies thereby achieving desired effects.

Owner:BATTELLE MEMORIAL INST

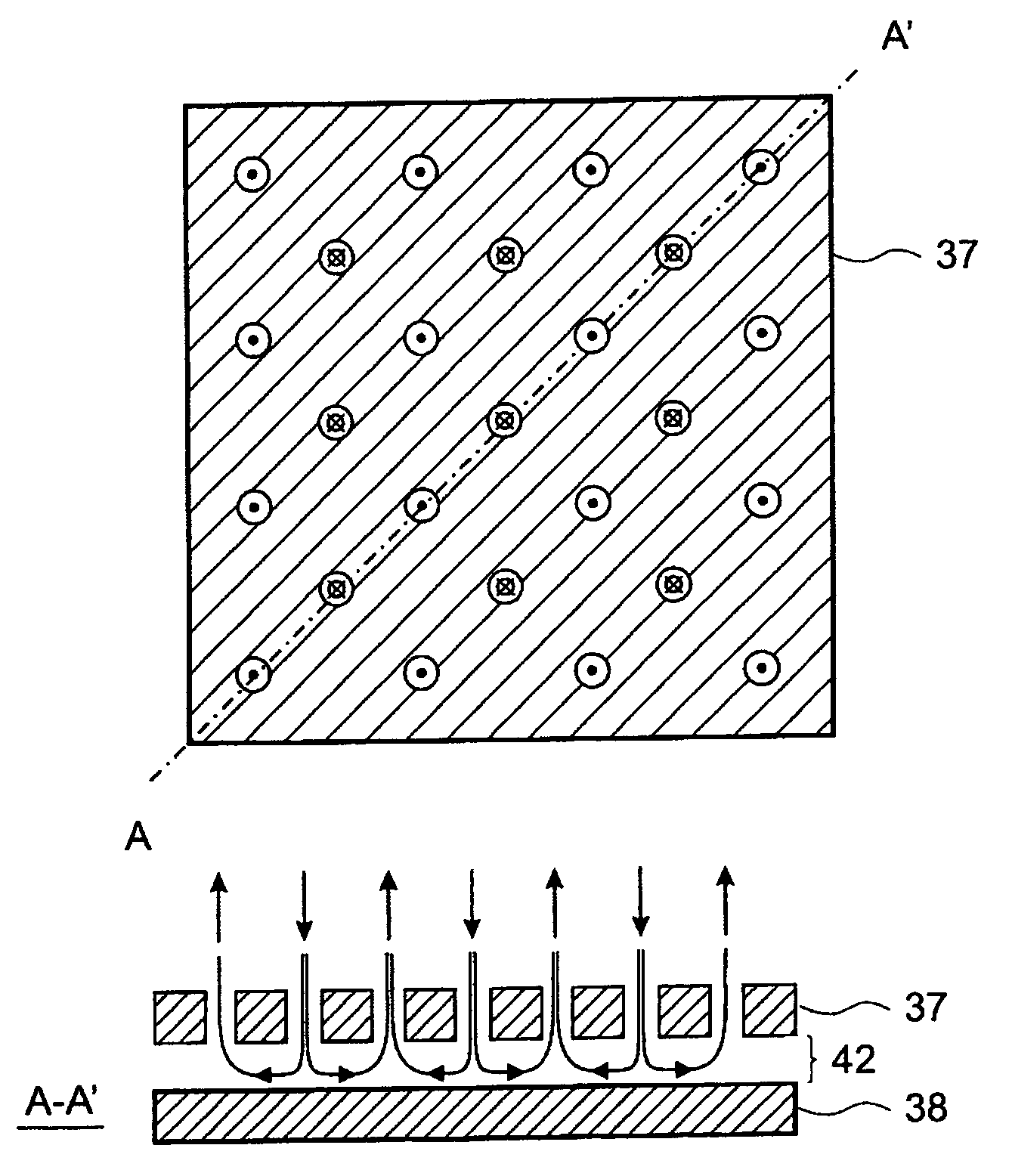

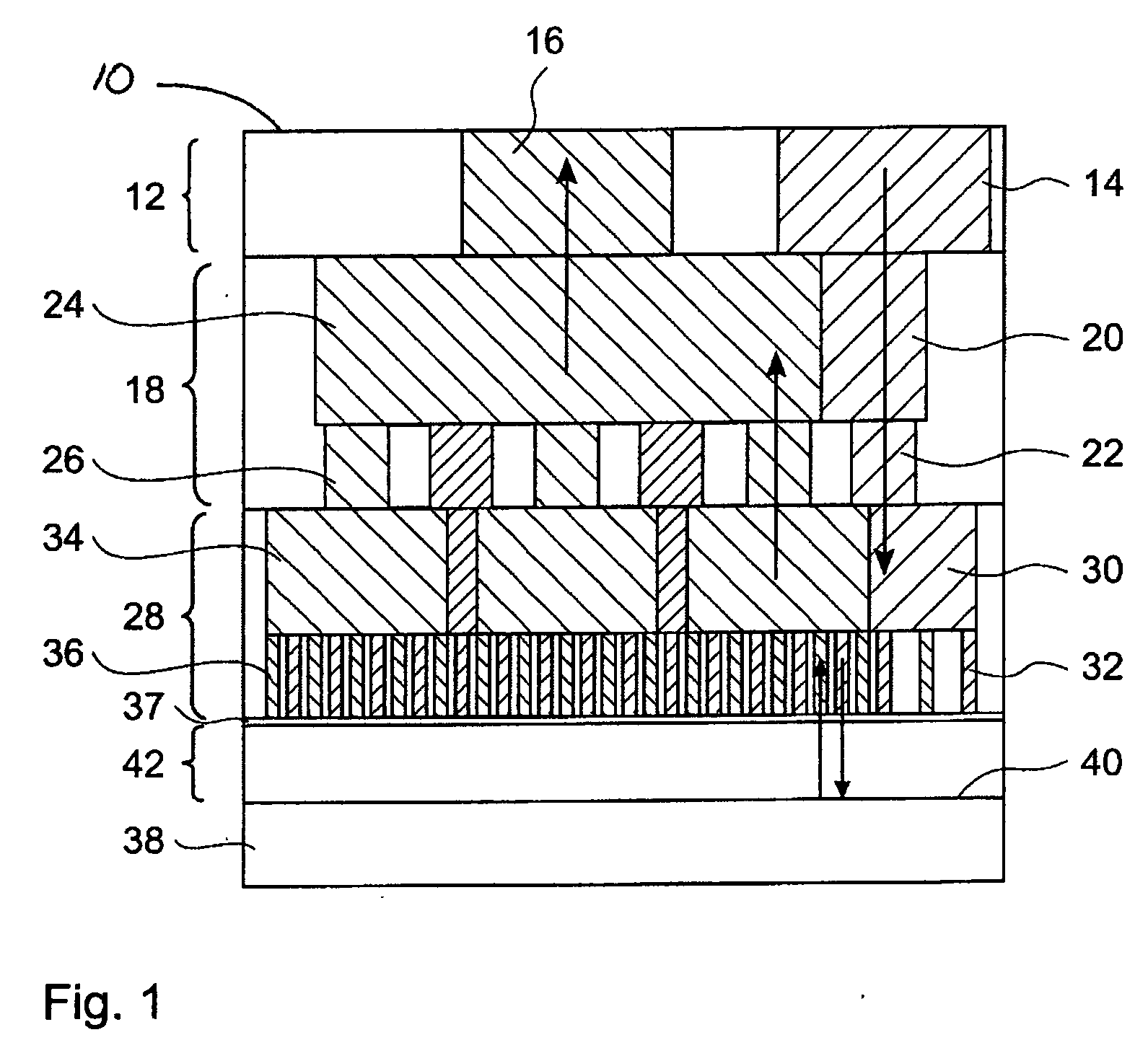

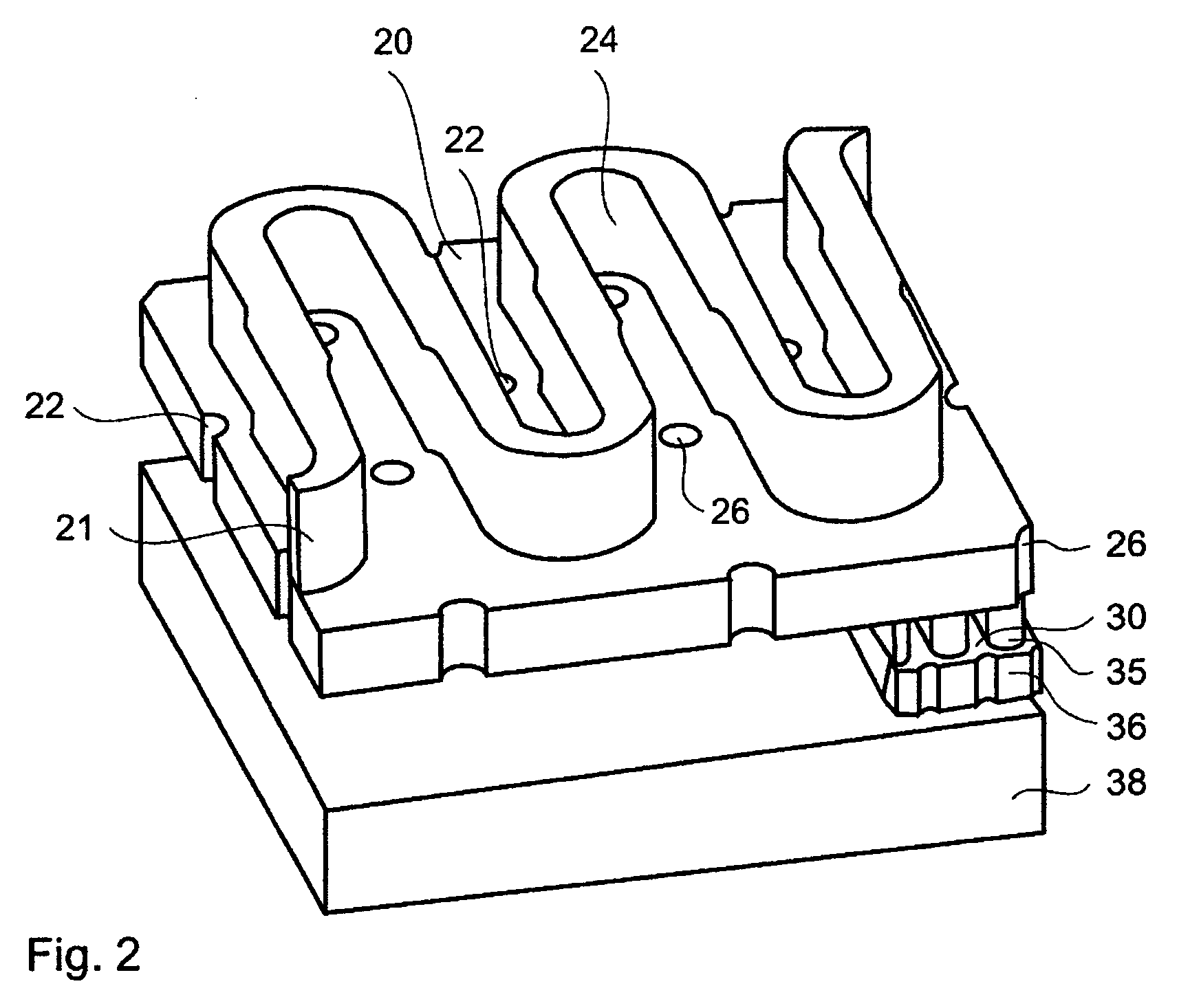

Cooling device

InactiveUS20070119565A1Minimal pressure dropMinimise pressure dropSemiconductor/solid-state device detailsSolid-state devicesEngineeringCoolant flow

A cooling device has a large number of closely spaced impinging jets, adjacent an impingement gap, with parallel return paths for supplying coolant flow for the impinging jets with the least possible pressure drop using an interdigitated, branched hierarchical manifold. Surface enhancement features spanning the impingement gap form U-shaped microchannels between single impinging jets and single outlets.

Owner:IBM CORP

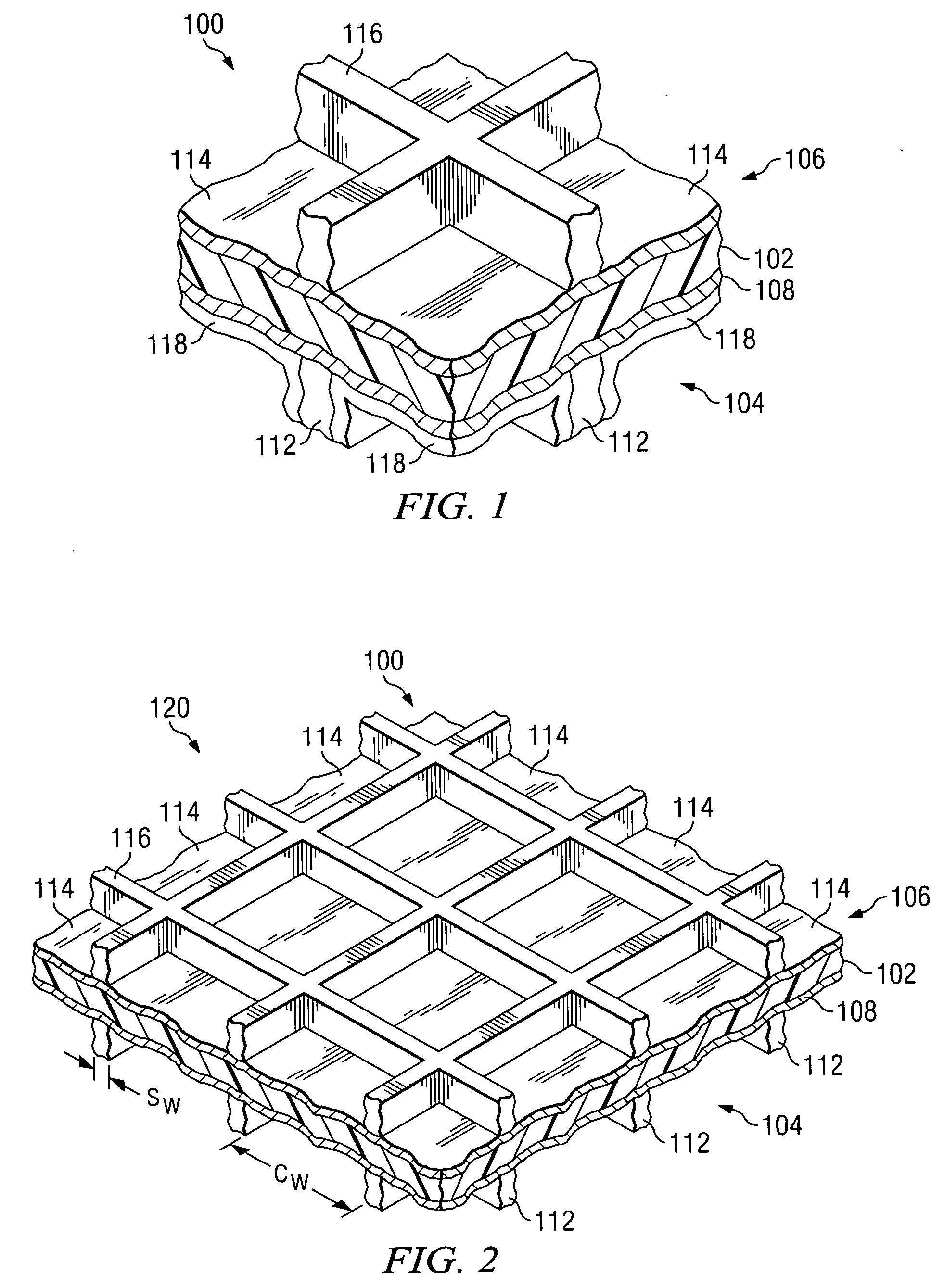

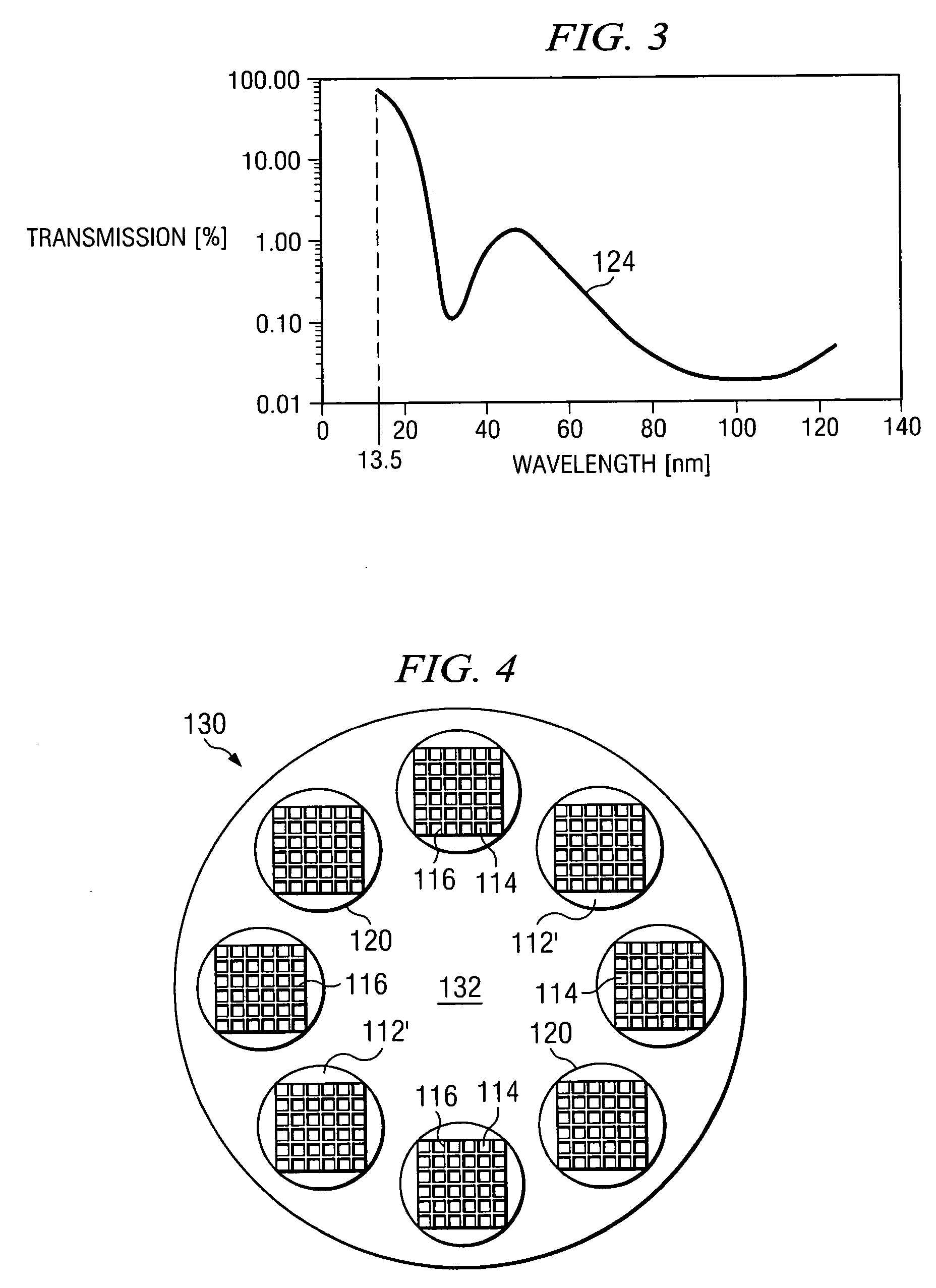

EUV lithography filter

InactiveUS20060160031A1Reduce the accumulation of debrisReduce harmRadiation/particle handlingPhotomechanical apparatusLithographic artistComputational physics

Filters for EUV lithography, methods of manufacture thereof, and methods of filtering in an EUV lithography system are disclosed. The filter comprises a nanotube material layer sandwiched by two thin material layers that are highly transmissive and provide structural support for the nanotube material layer. The filter is supported on at least one side by a patterned structural support. The filter mitigates debris, provides spectral purity filtering, or both.

Owner:INFINEON TECH AG +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com