Patents

Literature

282results about How to "Reduce start" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

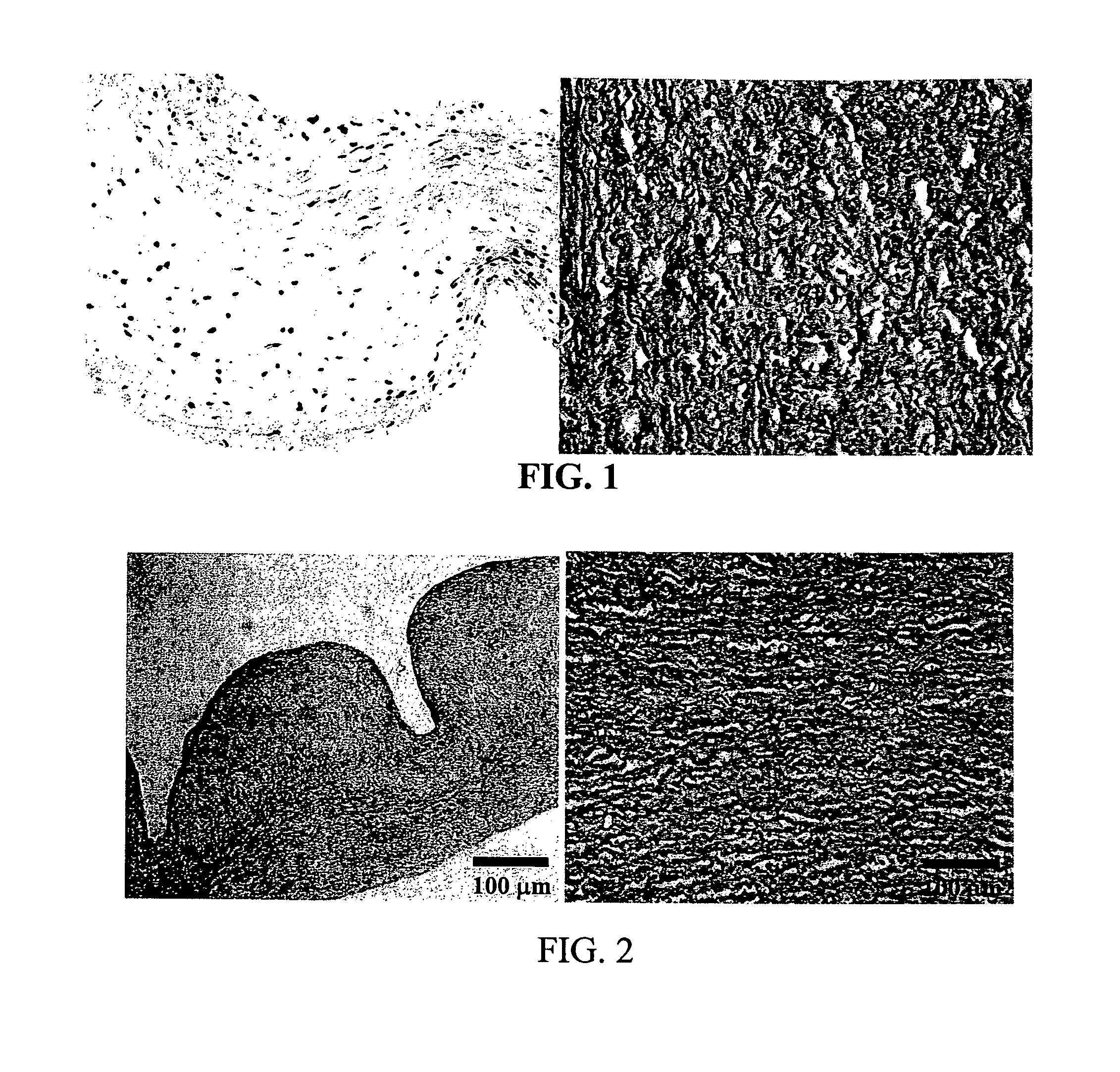

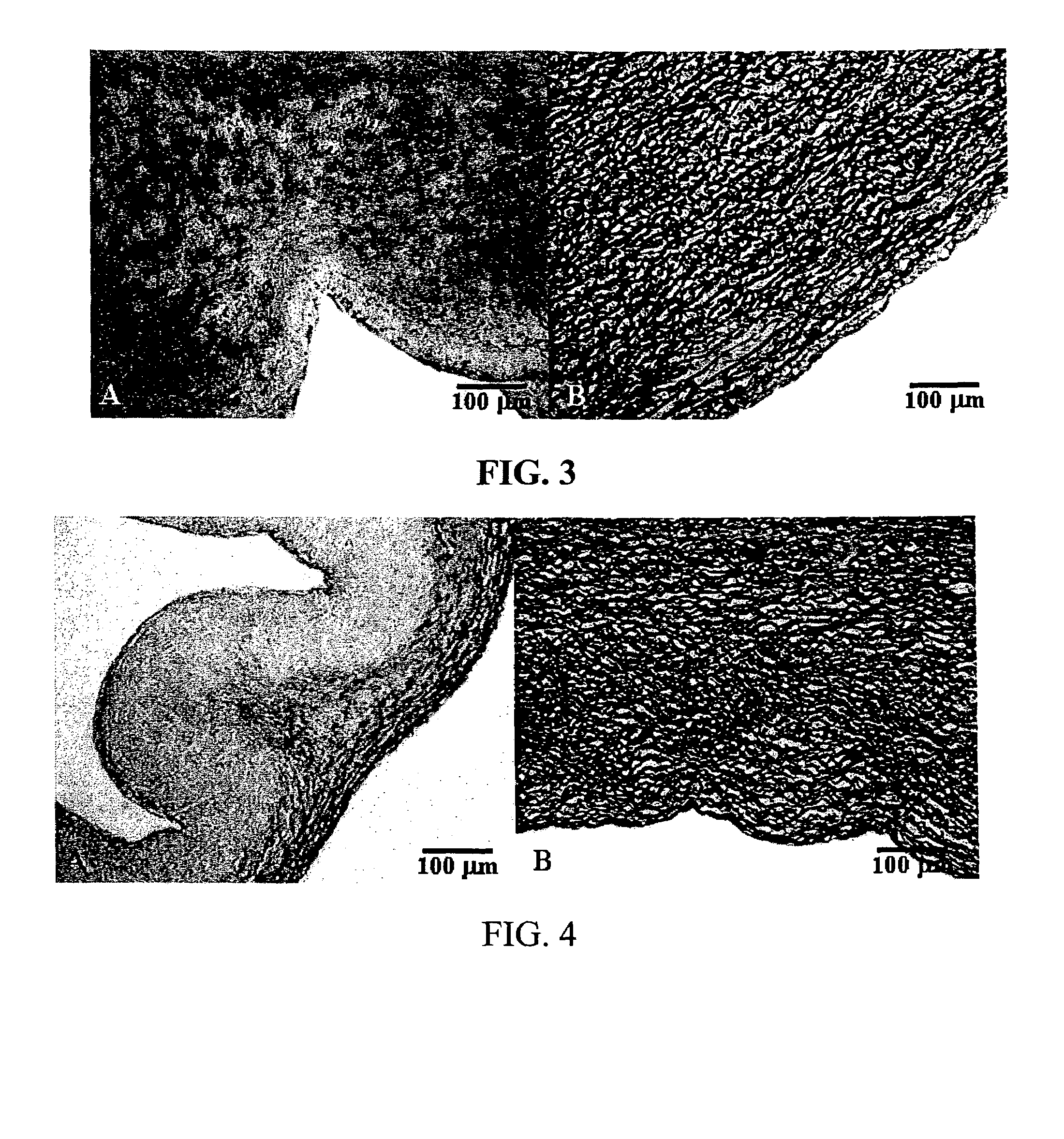

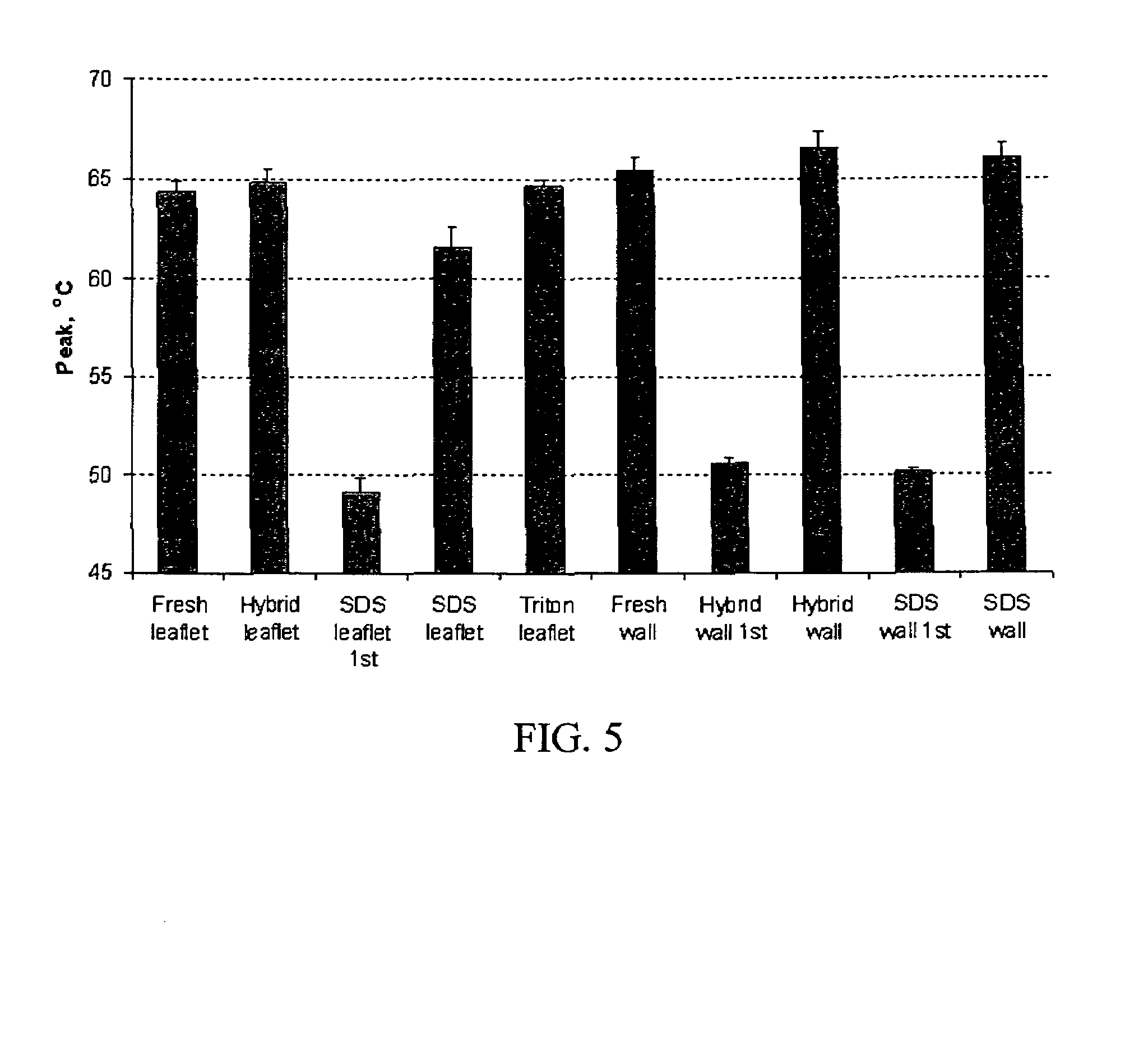

Process for reducing mineralization of tissue used in transplantation

InactiveUS7078163B2Reducing level of mineralizationLower Level RequirementsDead animal preservationProsthesisMedical deviceOxidizing agent

A method of making a tissue-derived implantable medical device that includes contacting the tissue with a composition comprising at least one oxidizing agent prior to implantation of the medical device.

Owner:MEDTRONIC INC

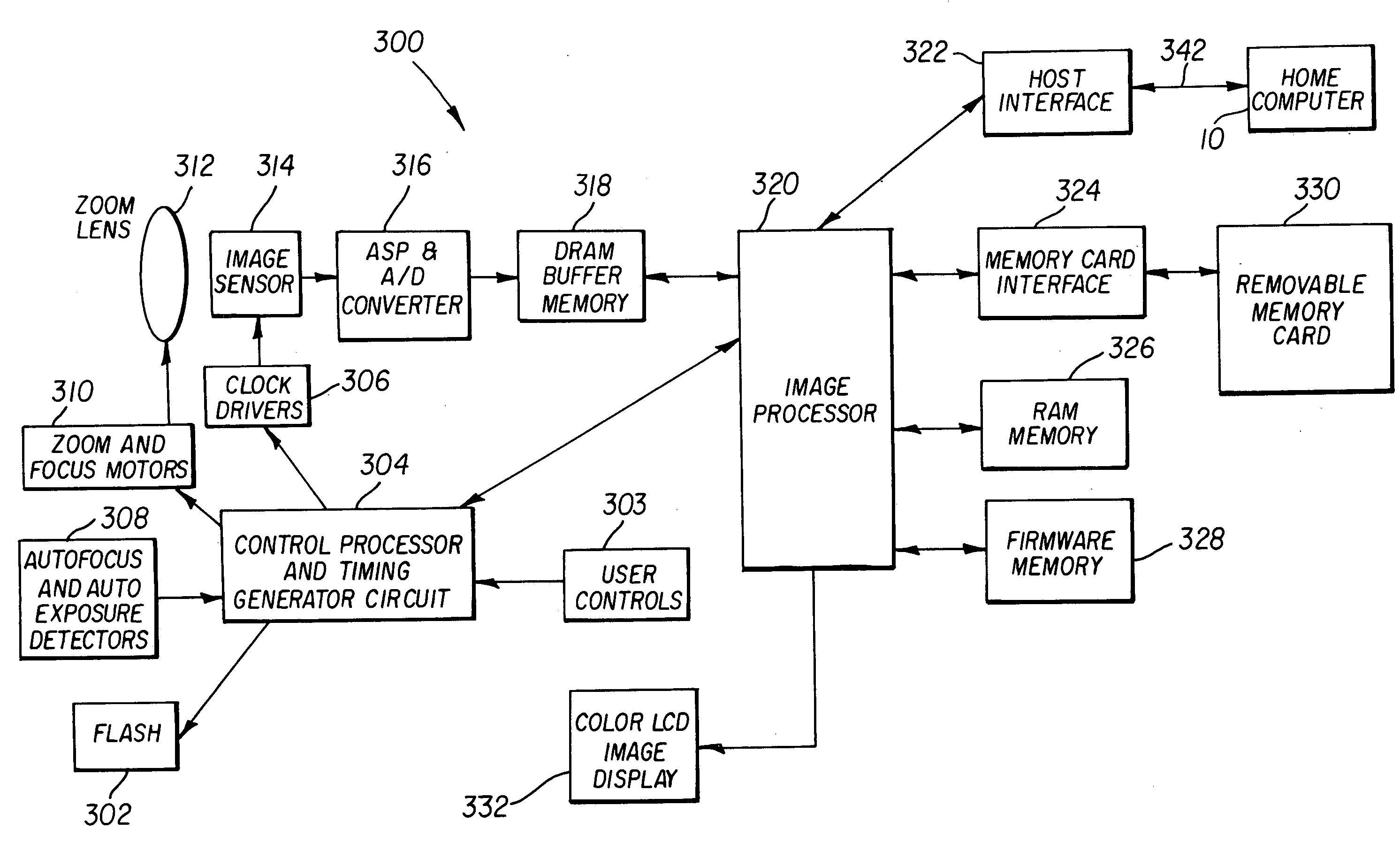

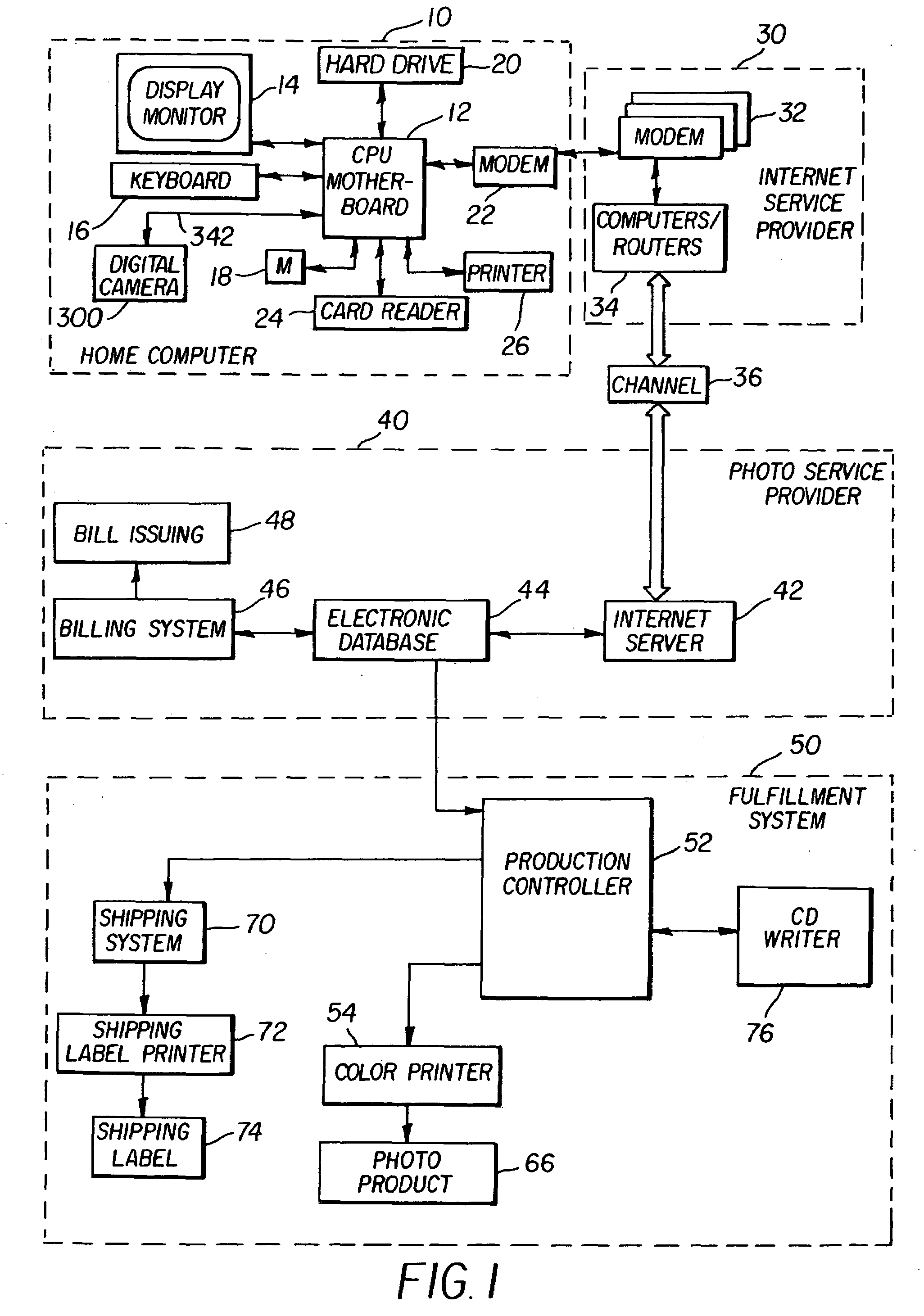

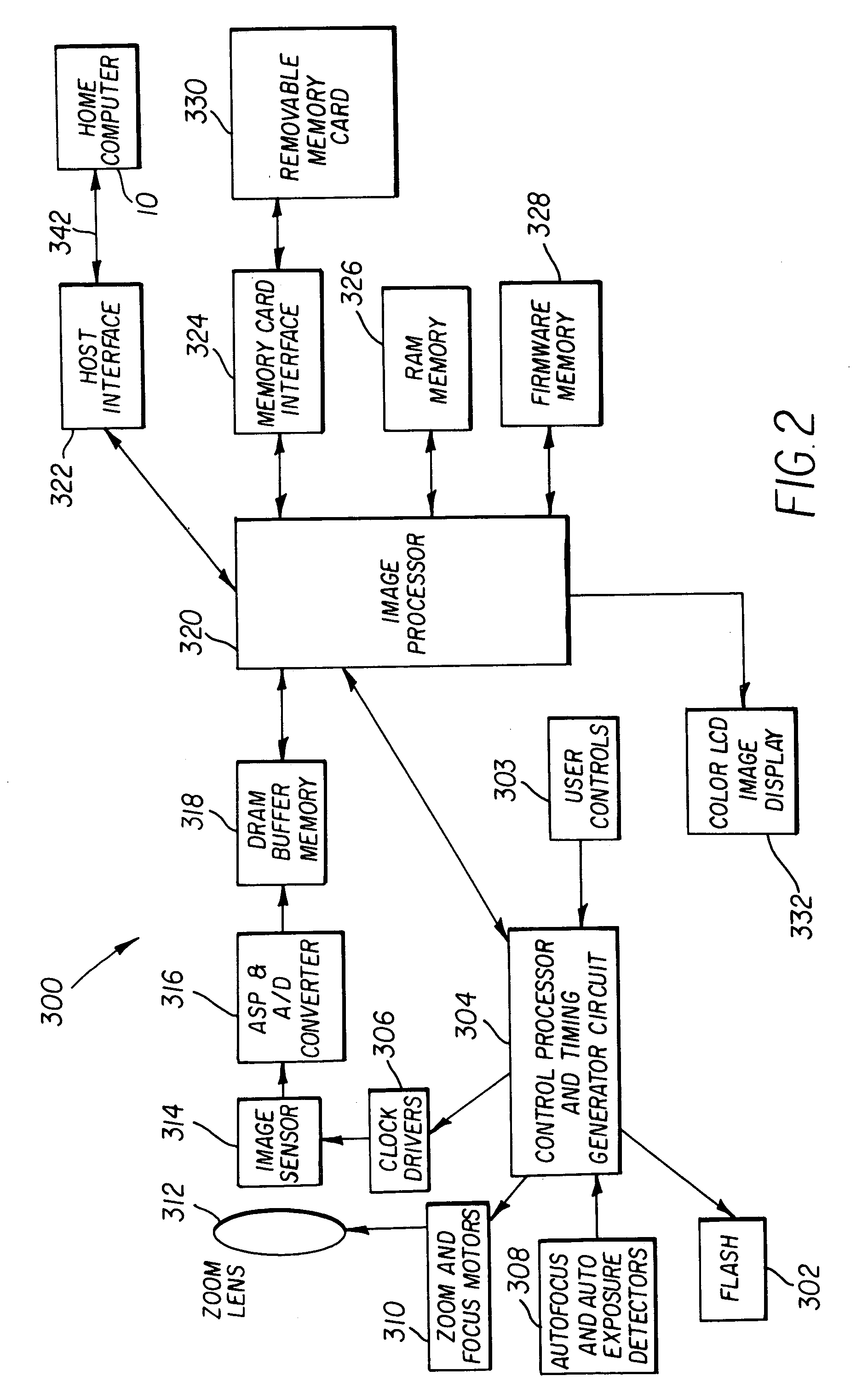

Image application software providing a list of user selectable tasks

InactiveUS7286256B2Reduce startTelevision system detailsColor television detailsComputer usersComputer graphics (images)

A method of using stored digital images transferred from an imaging device includes receiving and storing images from the imaging device in a memory associated with a computer, receiving at least one control file from the imaging device which indicates a prior intention for subsequent use of the stored images, and the computer responding to the control file to create and display a list of tasks selectable by a computer user in accordance with the prior intention. The method also includes the computer user selecting at least one of the tasks from the list, and the computer responding to the user selected task(s) to initiate the use of images indicated by the selected task(s).

Owner:MONUMENT PEAK VENTURES LLC

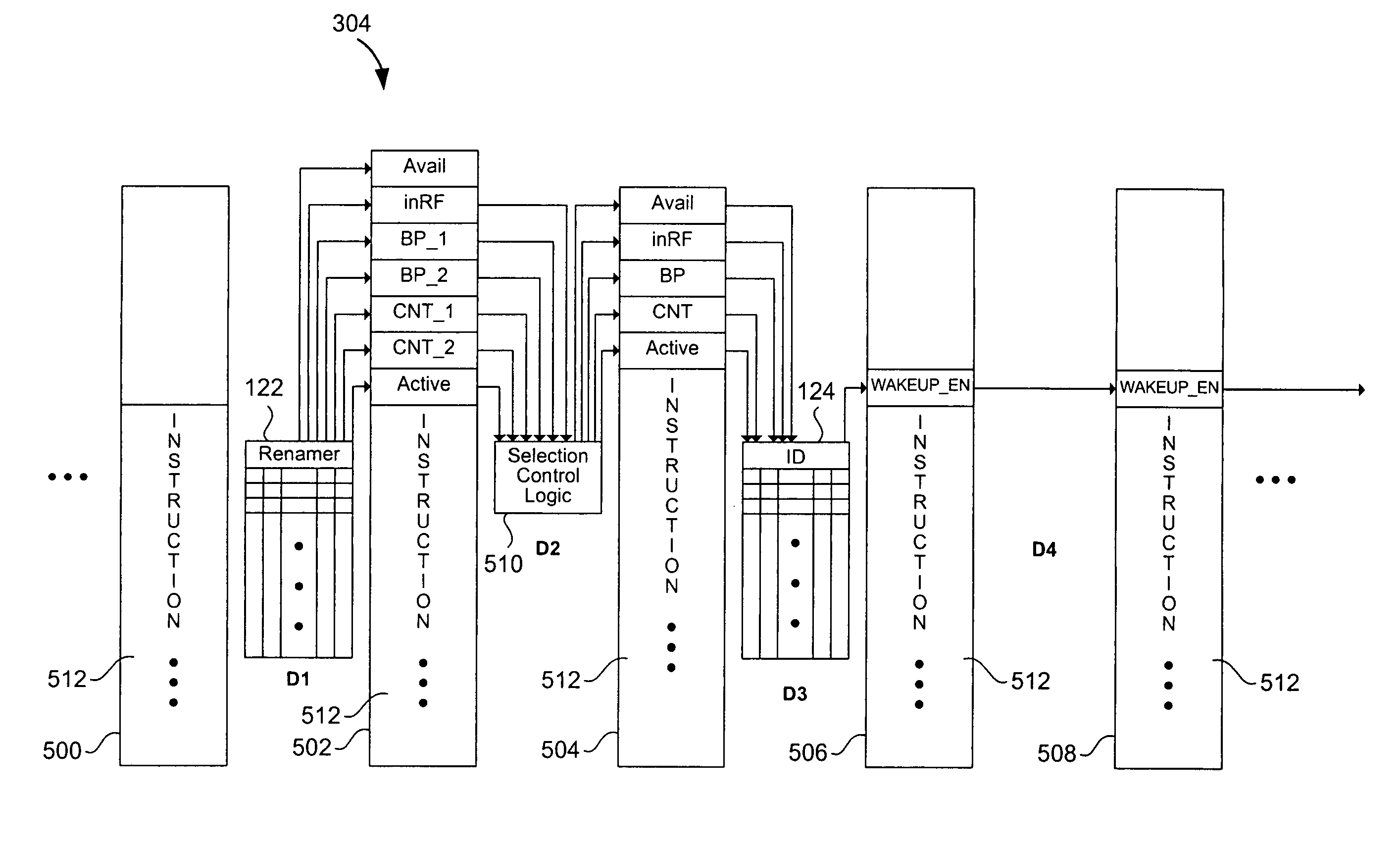

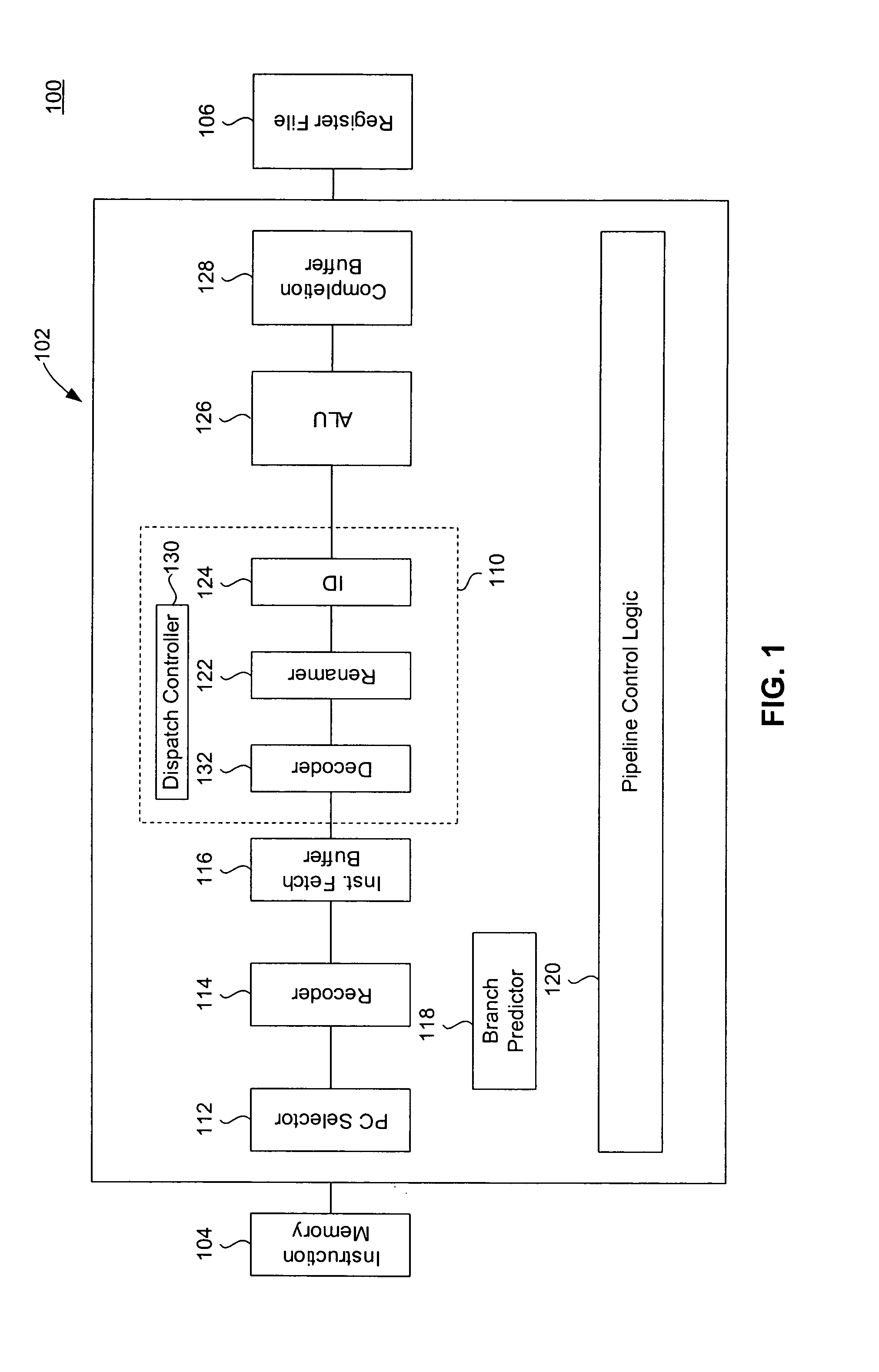

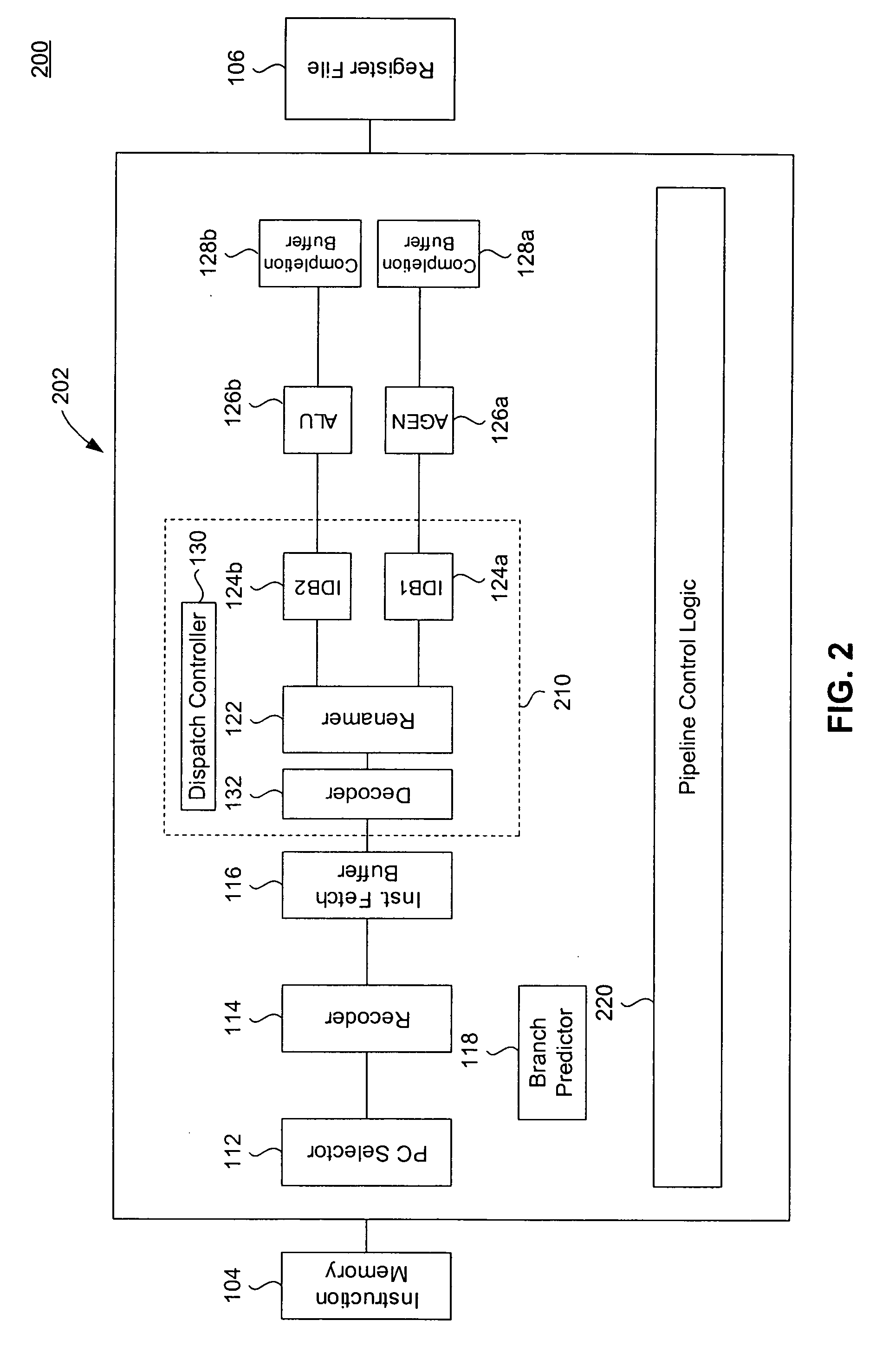

Distributive scoreboard scheduling in an out-of order processor

ActiveUS20070204135A1Increase overall instruction throughputIncrease heightDigital computer detailsMemory systemsInstruction schedulingMultiple stages

A processor core and a method for distributive scoreboard scheduling in an out-of-order processor pipeline. In an embodiment, control logic appends operand availability bits to each instruction. The appended operand availability bits form a distributive scoreboard for each instruction. The appended operand availability bits are propagated together with the instruction through multiple stages of the processor pipeline. An instruction dispatch buffer stores the instruction and the operand availability bits. A dispatch controller determines when an instruction is to be issued. The determination is based, at least in part, on the operand availability bits stored in the instruction dispatch buffer.

Owner:ARM FINANCE OVERSEAS LTD

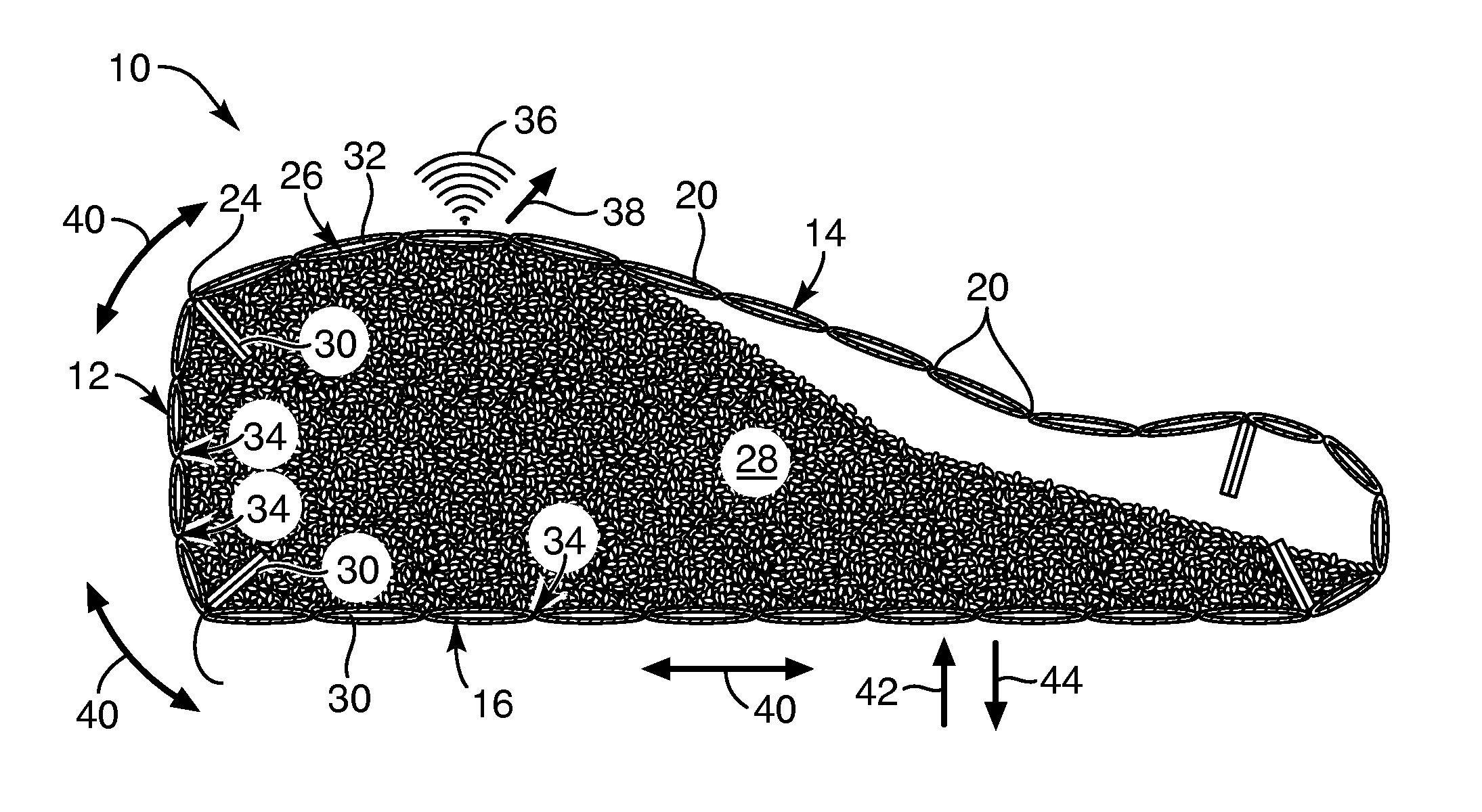

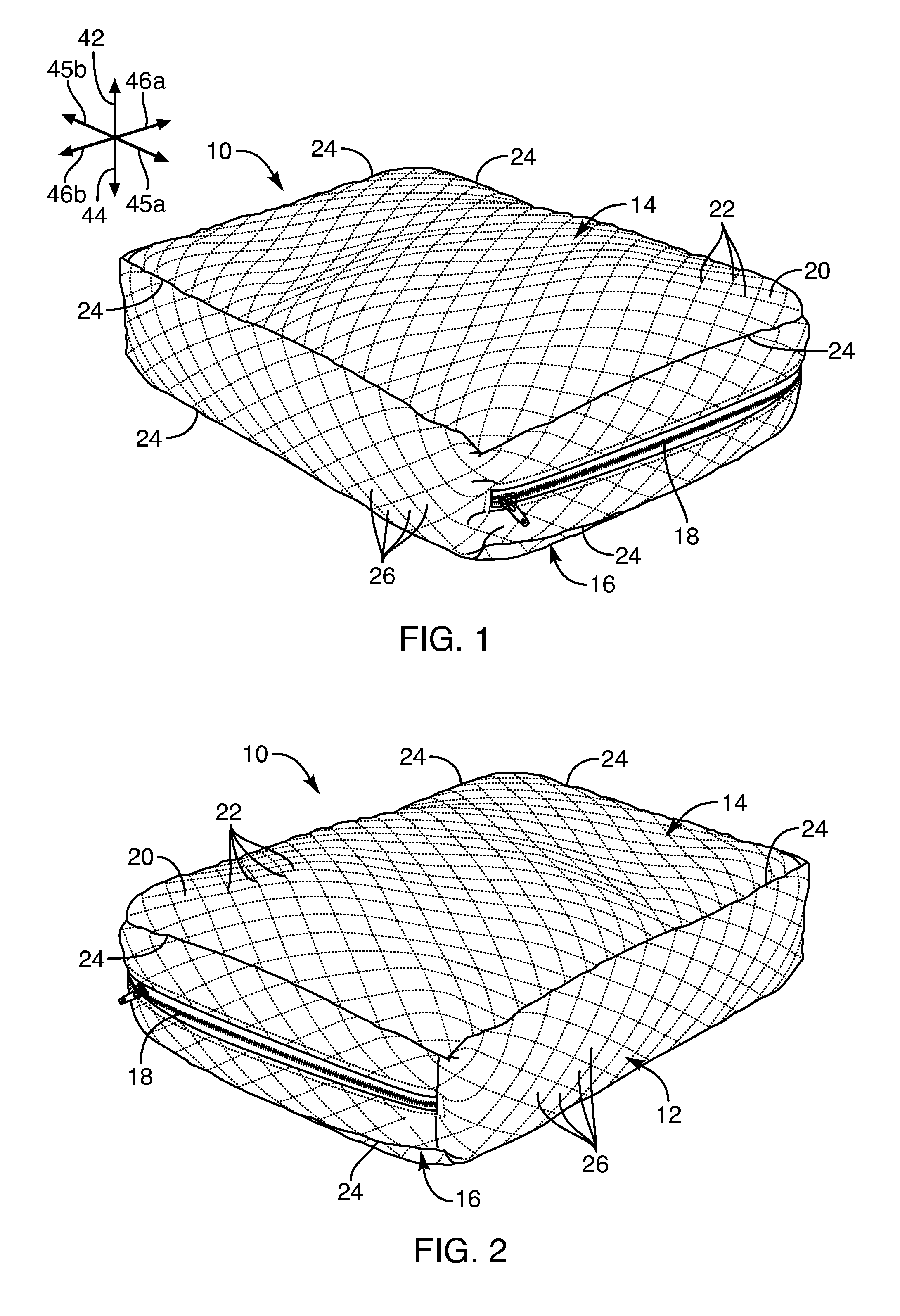

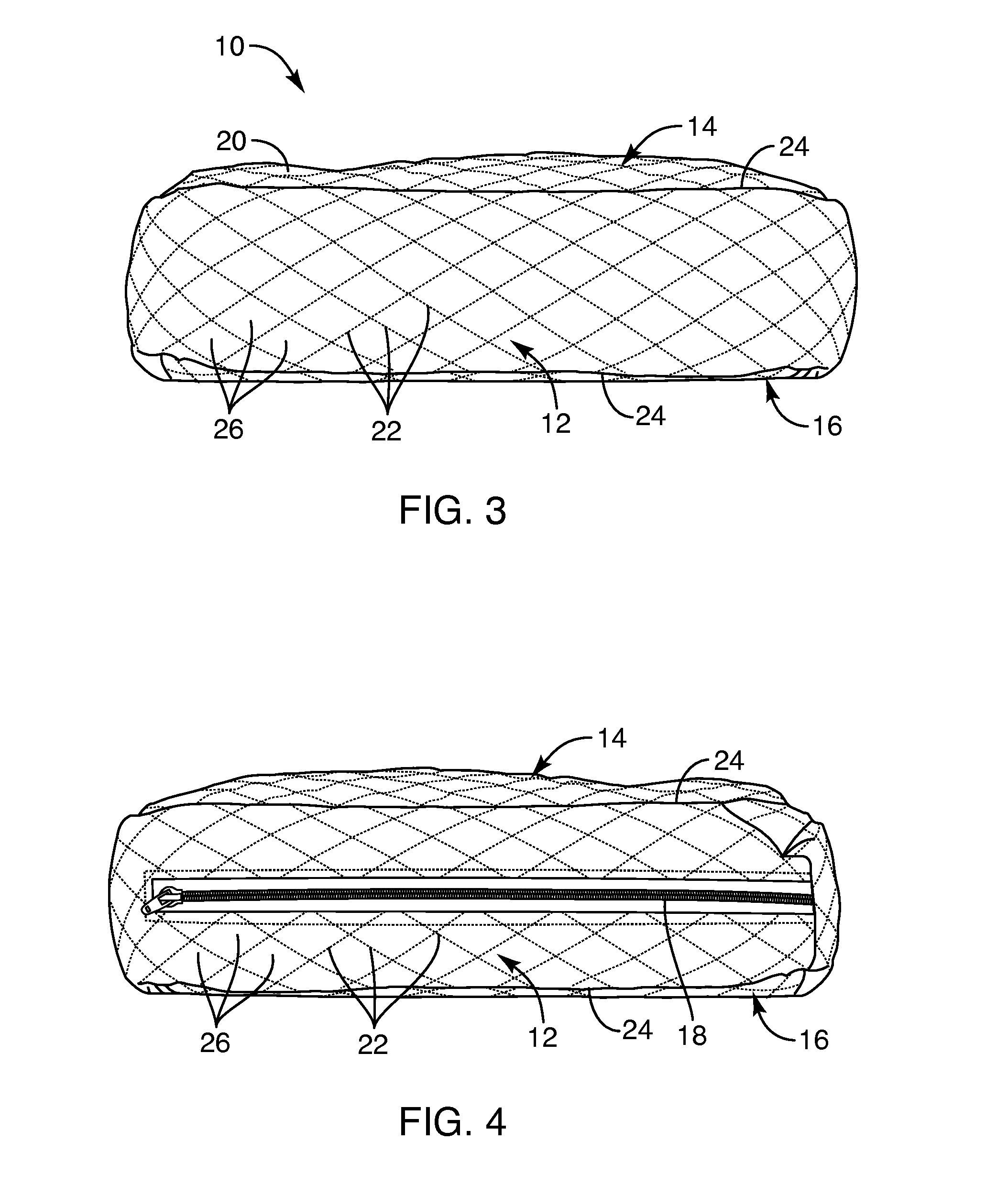

Cpap pillow apparatus and method

Owner:RANDALL BRET

Reengineering mRNA primary structure for enhanced protein production

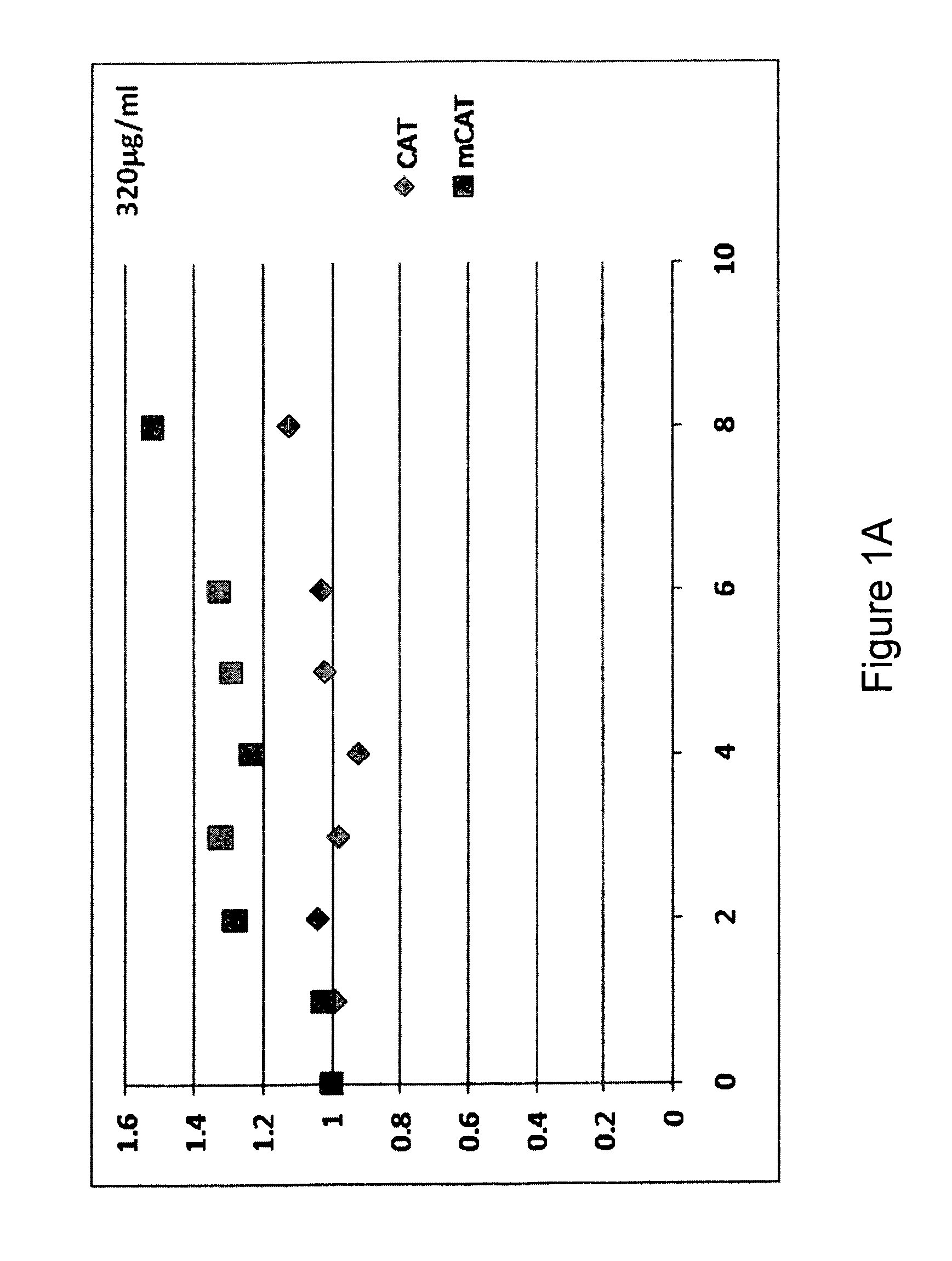

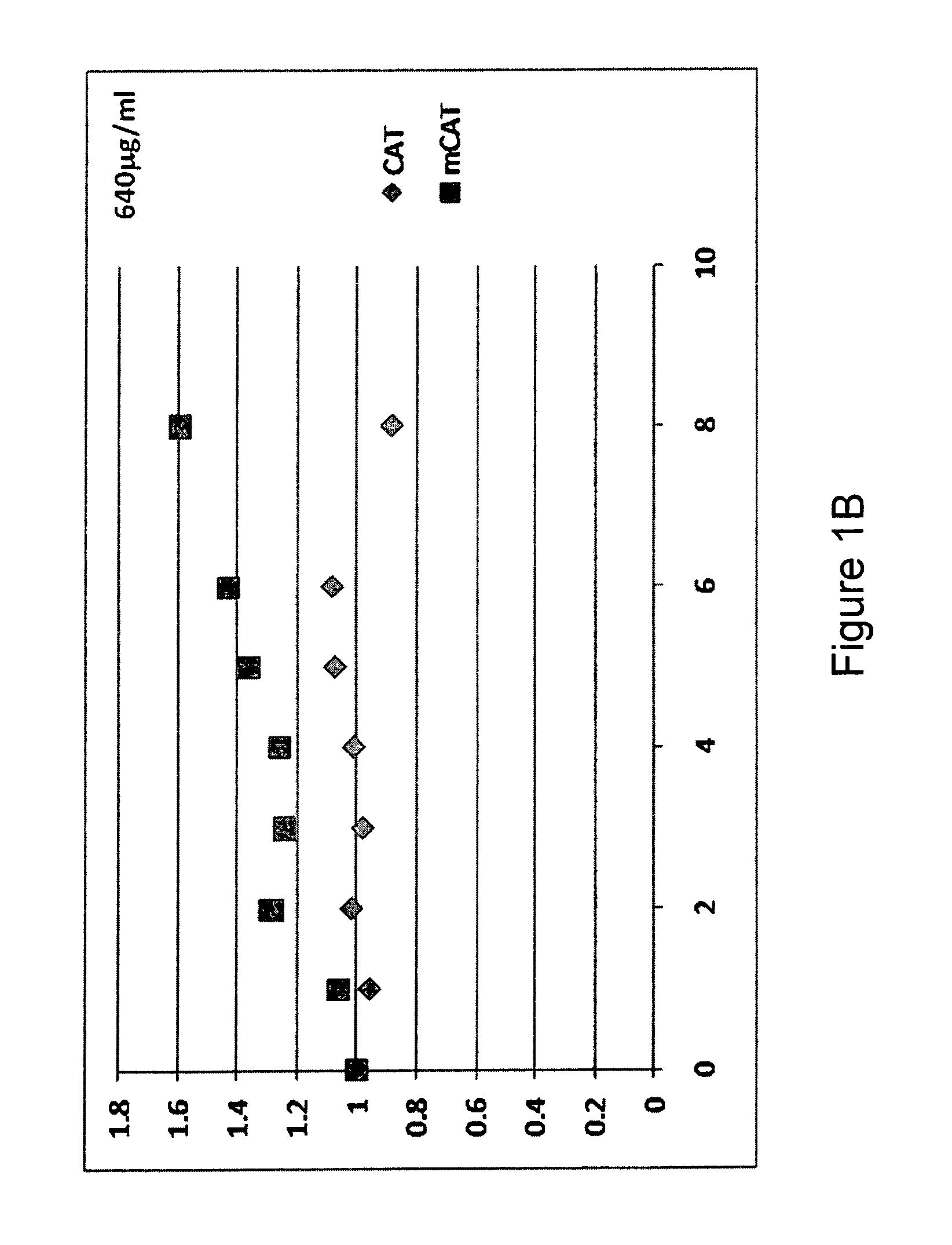

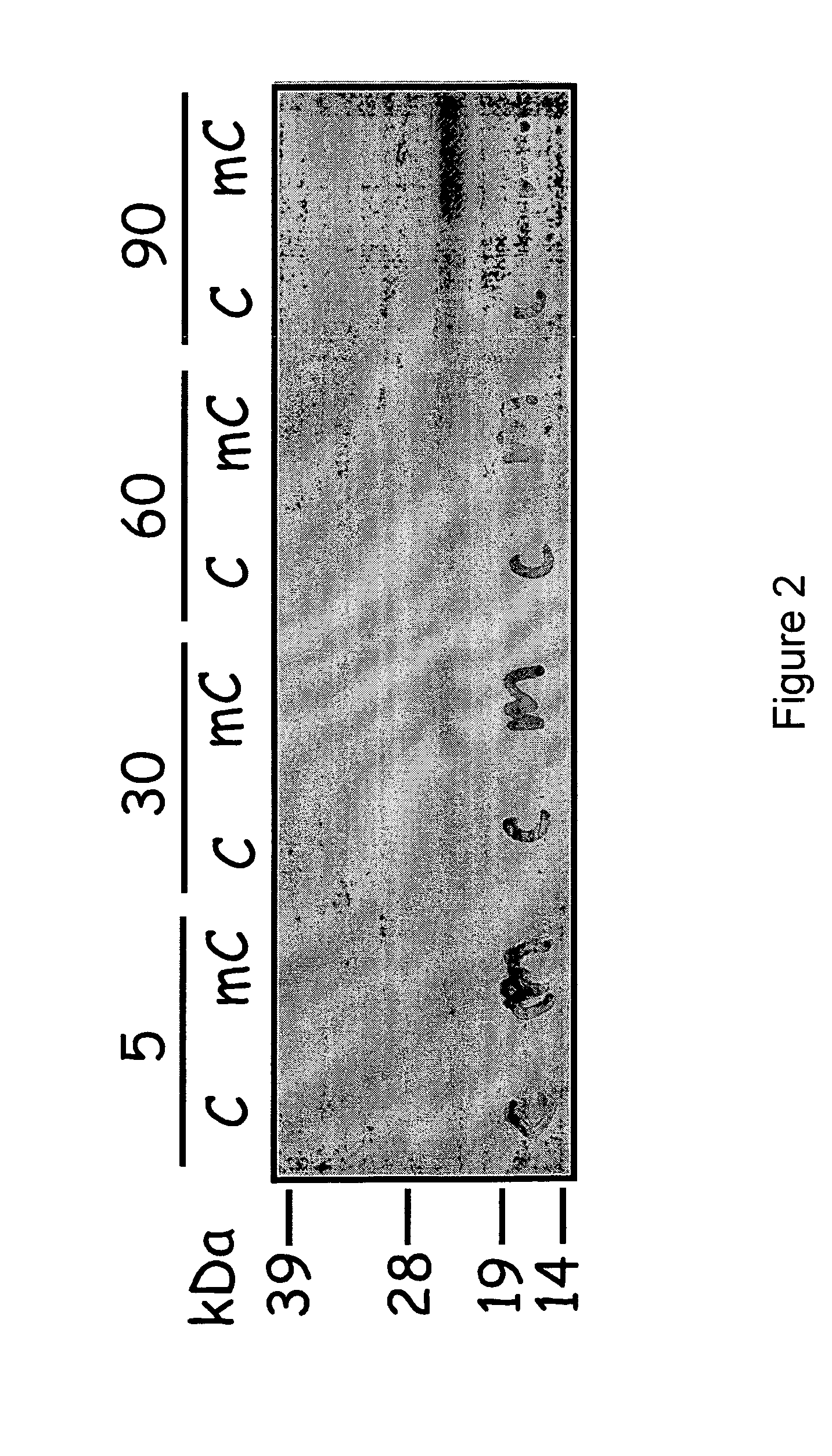

ActiveUS8853179B2Improve efficiencyImprove protein stabilitySugar derivativesActivity regulationStart codonTranslational efficiency

Described herein are rules to modify natural mRNAs or to engineer synthetic mRNAs to increase their translation efficiencies. These rules describe modifications to mRNA coding and 3′ UTR sequences intended to enhance protein synthesis by: 1) decreasing ribosomal diversion via AUG or non-canonical initiation codons in coding sequences, and / or 2) by evading miRNA-mediated down-regulation by eliminating one or more miRNA binding sites in coding sequences.

Owner:THE SCRIPPS RES INST

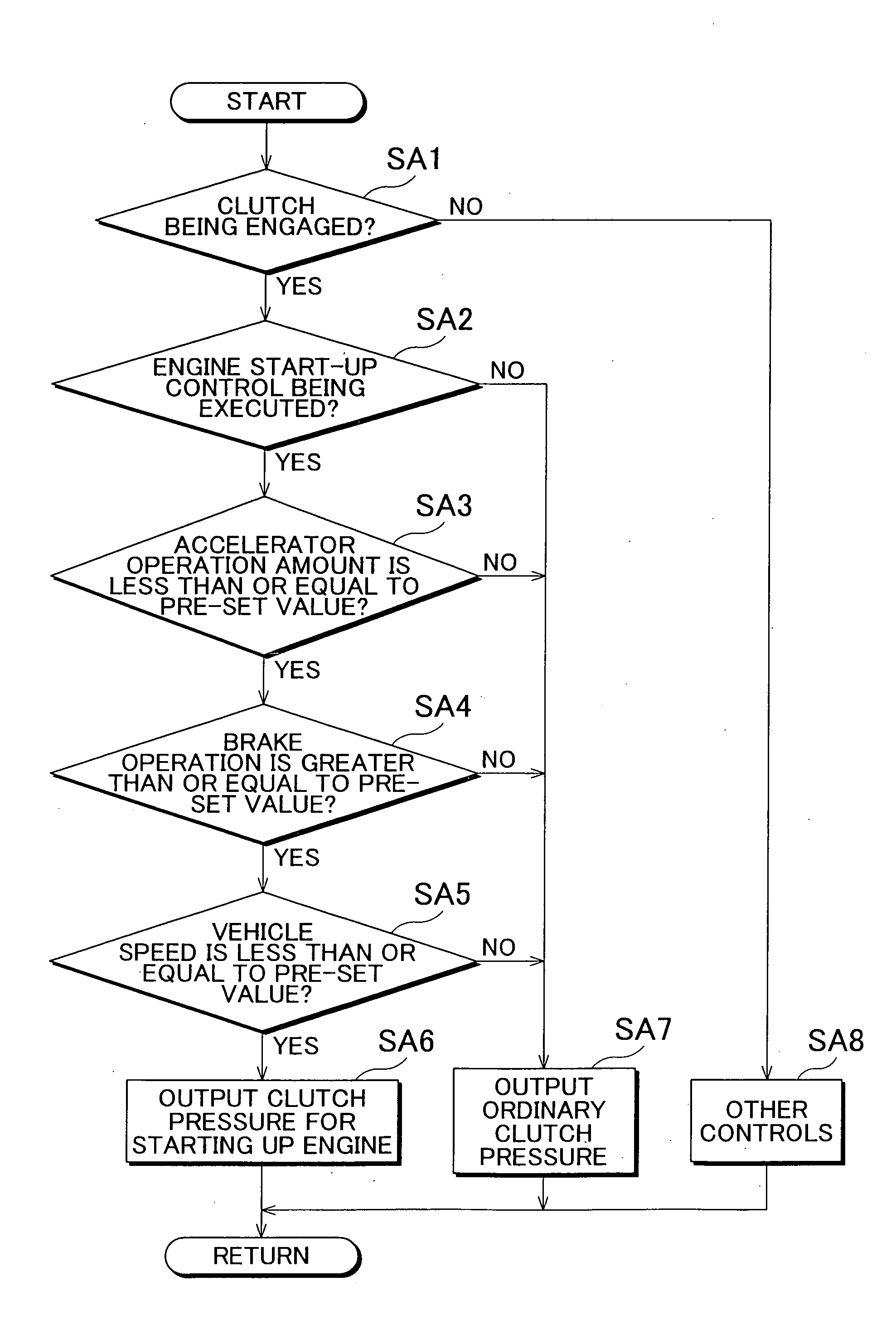

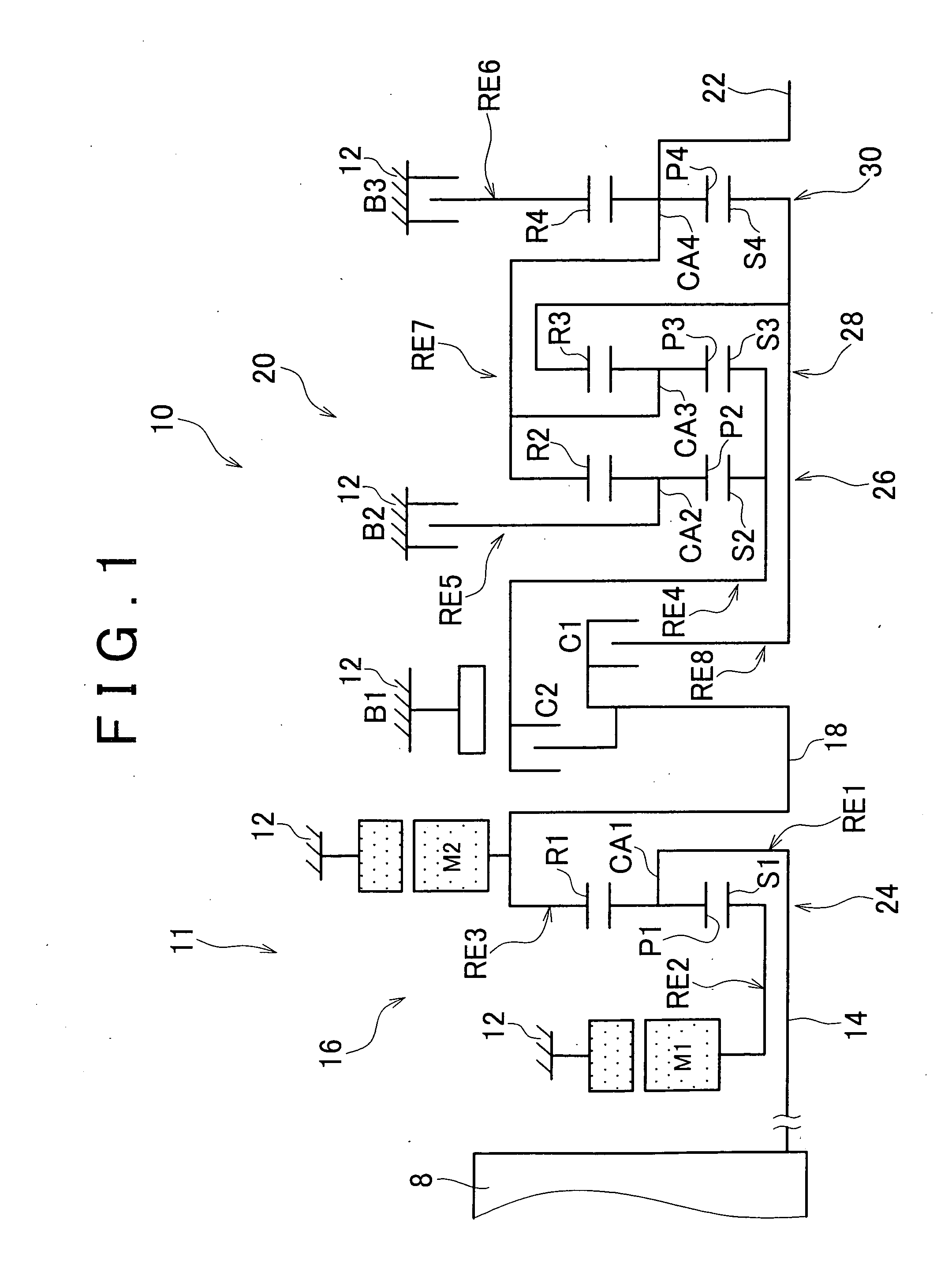

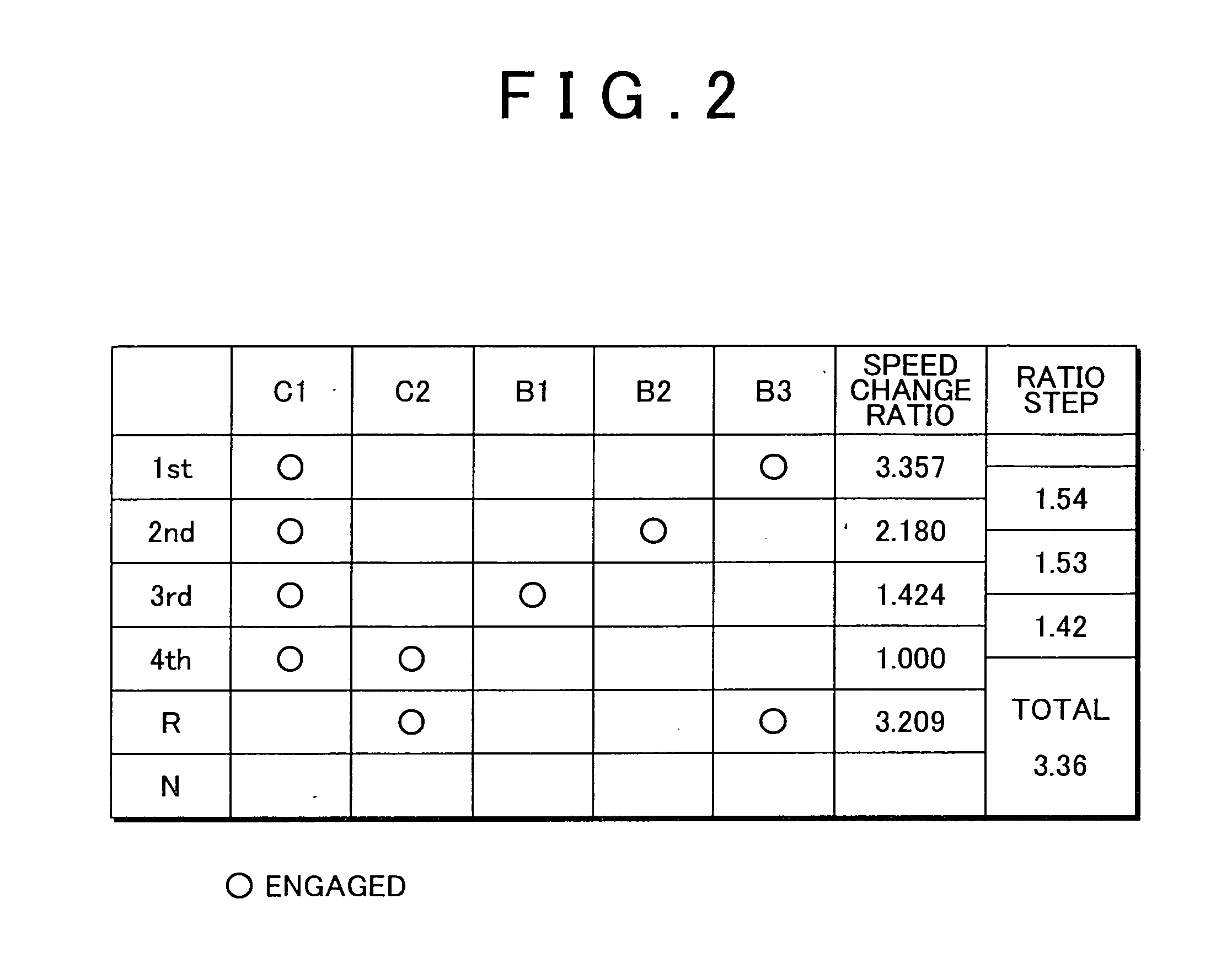

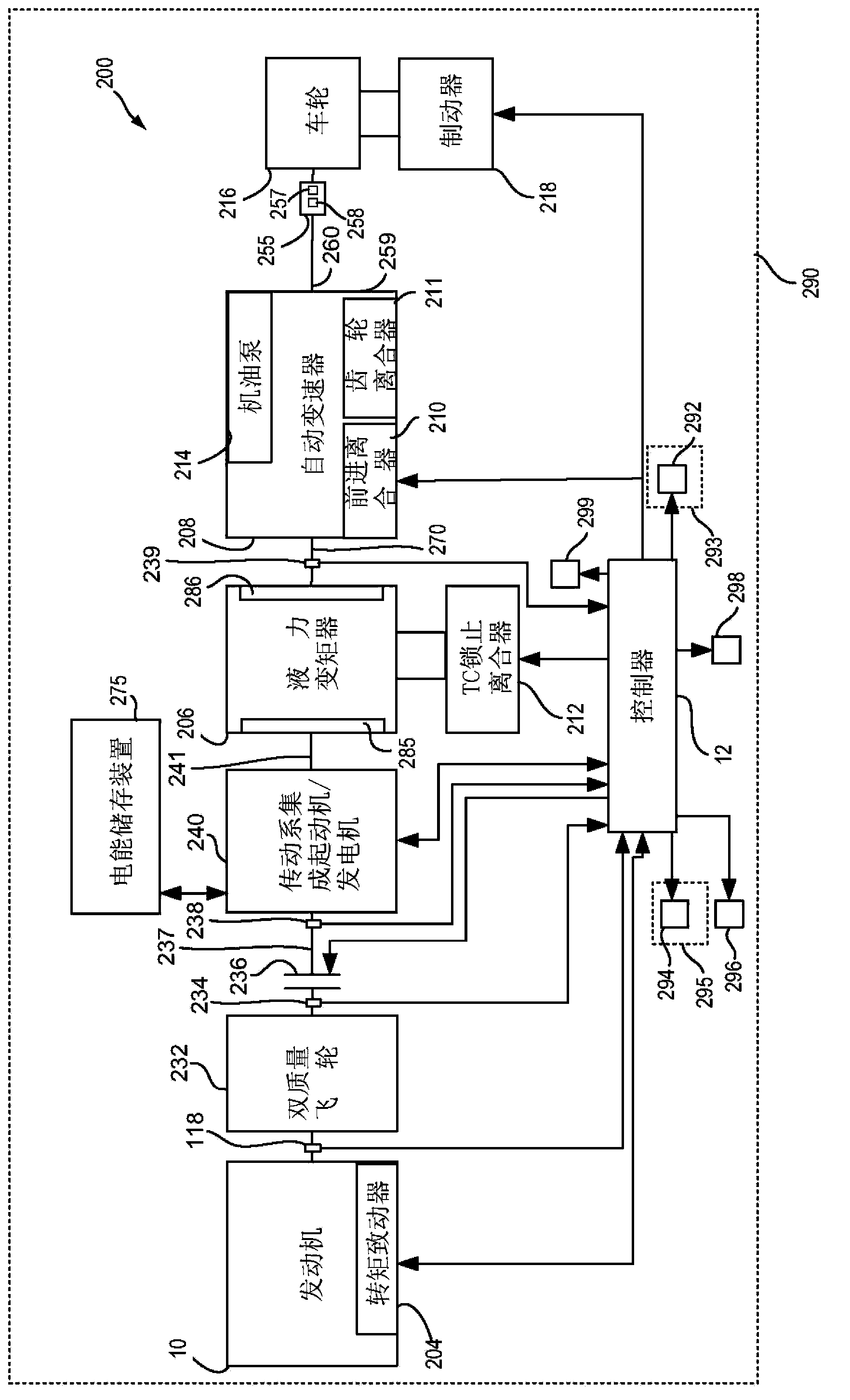

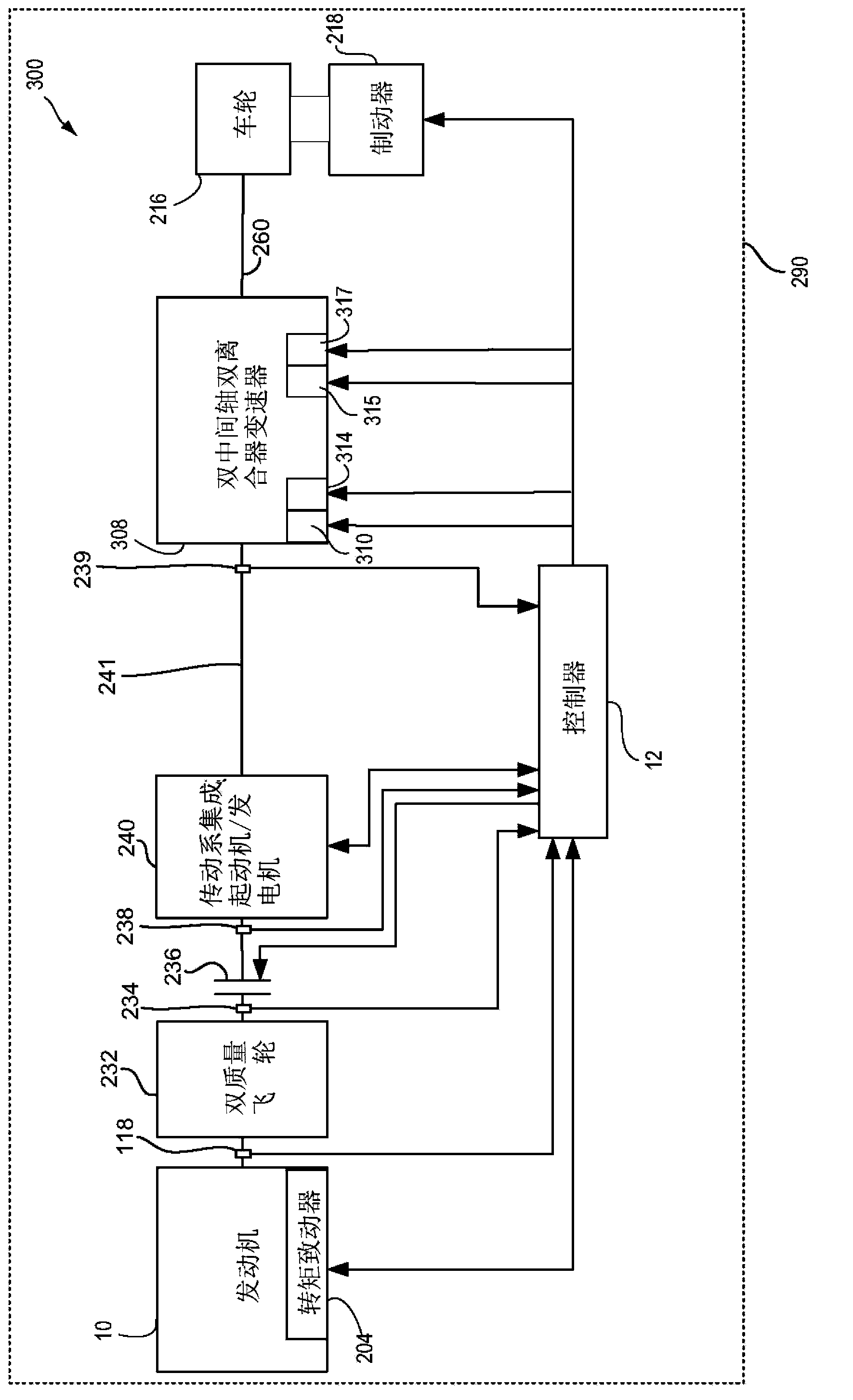

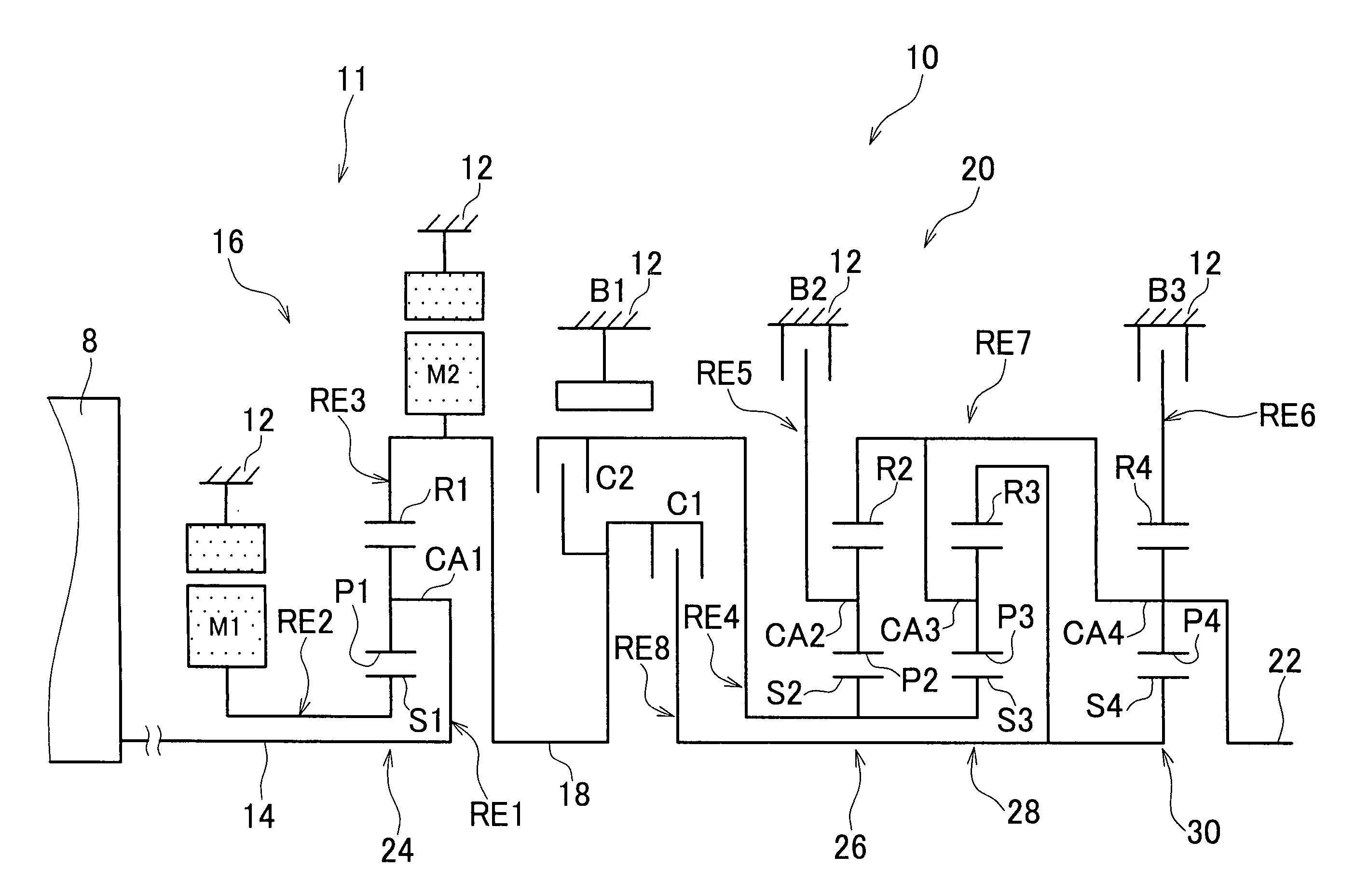

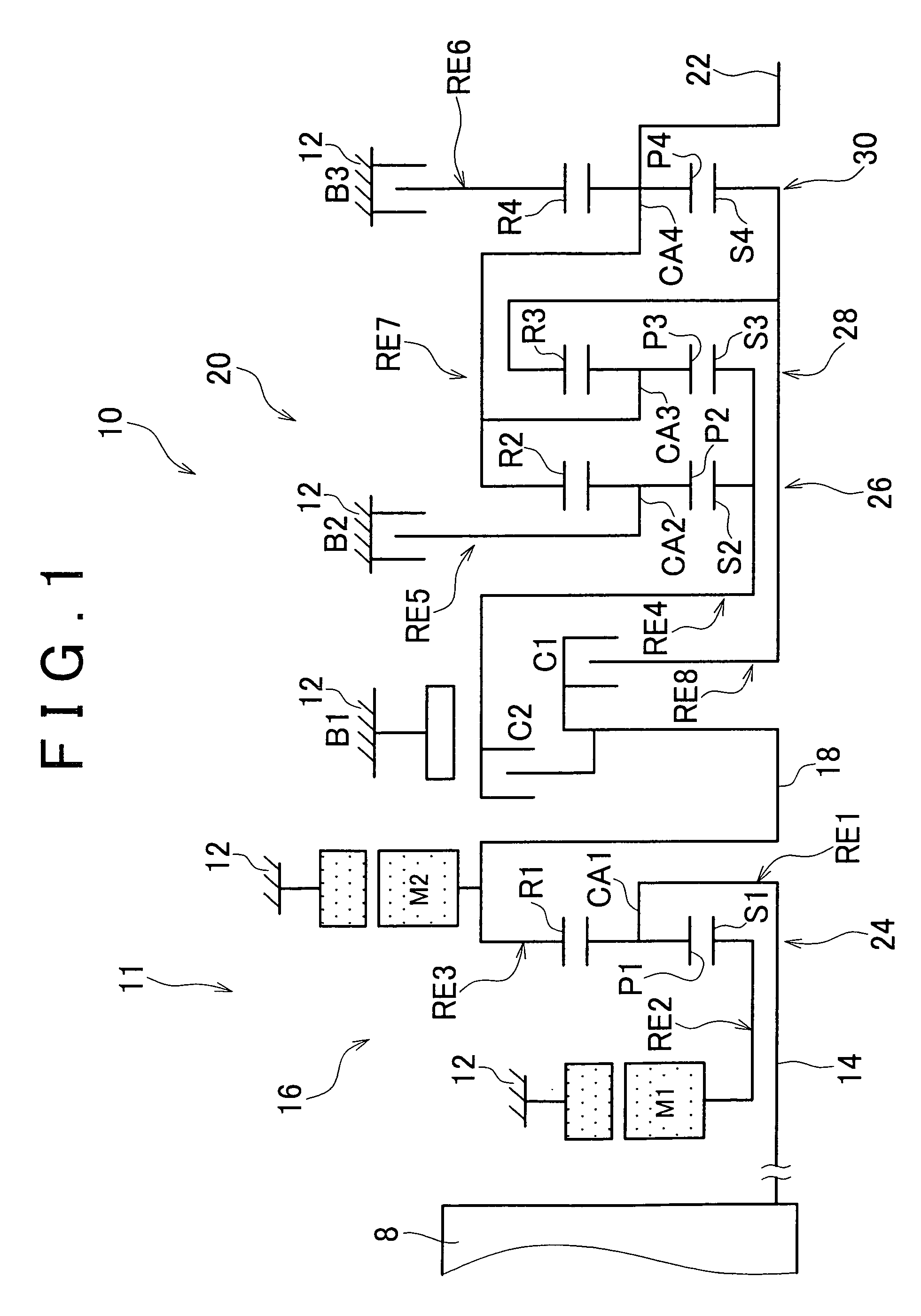

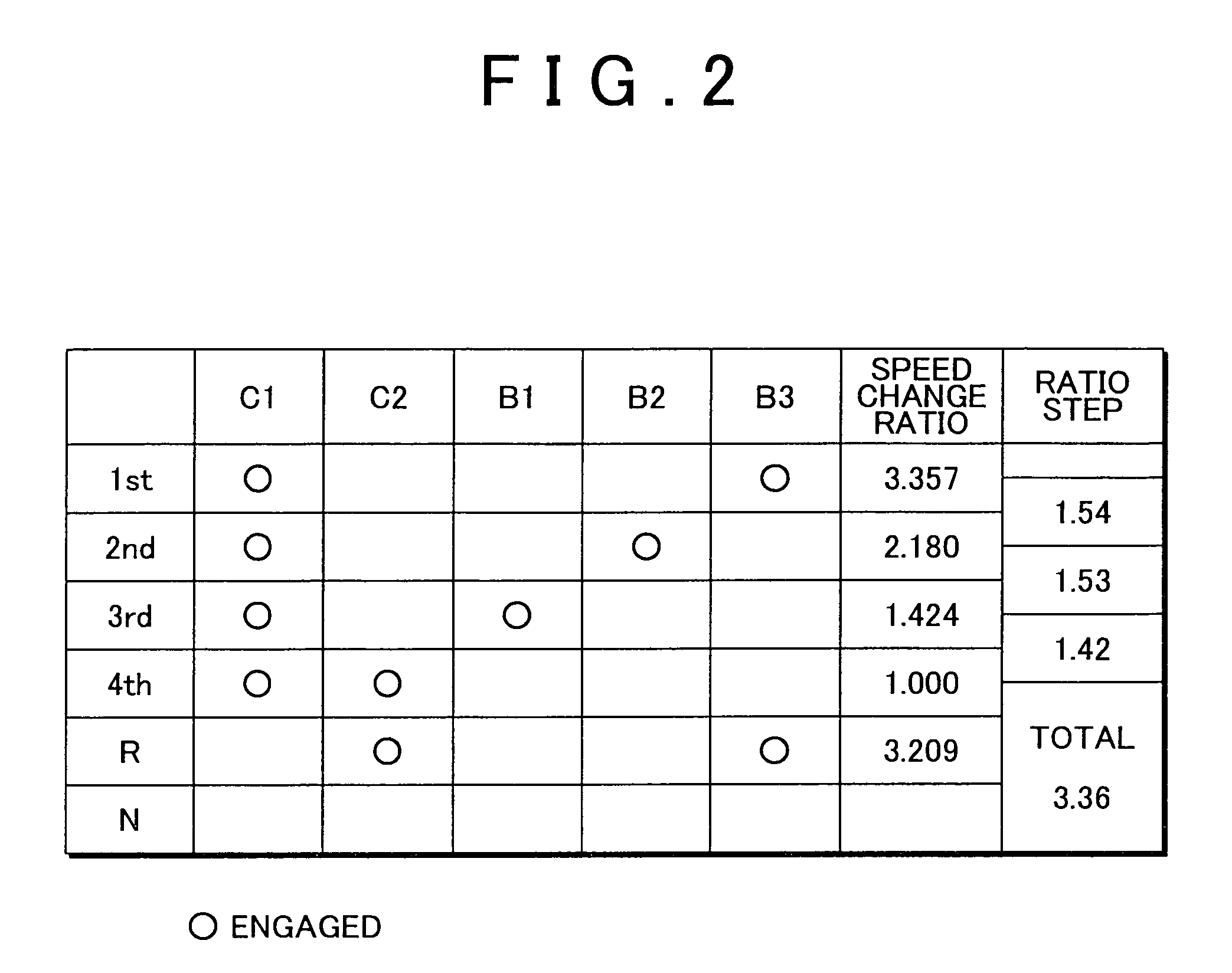

Control device for vehicle power transmission device

InactiveUS20080318727A1Reducing shift shockReduce transmission capacityHybrid vehiclesClutchesElectric power transmissionControl theory

A control device for a vehicle power transmission device including an electrical differential motion portion in which a differential state between input shaft rotation speed and output shaft rotation speed is controlled through control of the operation state of an electric motor linked to a rotating element of a differential motion portion, and a power connection-disconnection device constituting a portion of a power transmission path, includes a controller that lessens a transmission capacity of the power connection-disconnection device if during a switch of the state of the vehicle power transmission device from a non-driving state to a driving state, a change in input torque to the vehicle power transmission device occurs, in comparison with when the change in the input torque does not occur. Therefore, the control device reduces the shift shock when the vehicle power transmission device is switched from the non-driving to the driving state.

Owner:TOYOTA JIDOSHA KK +1

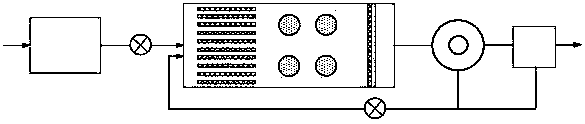

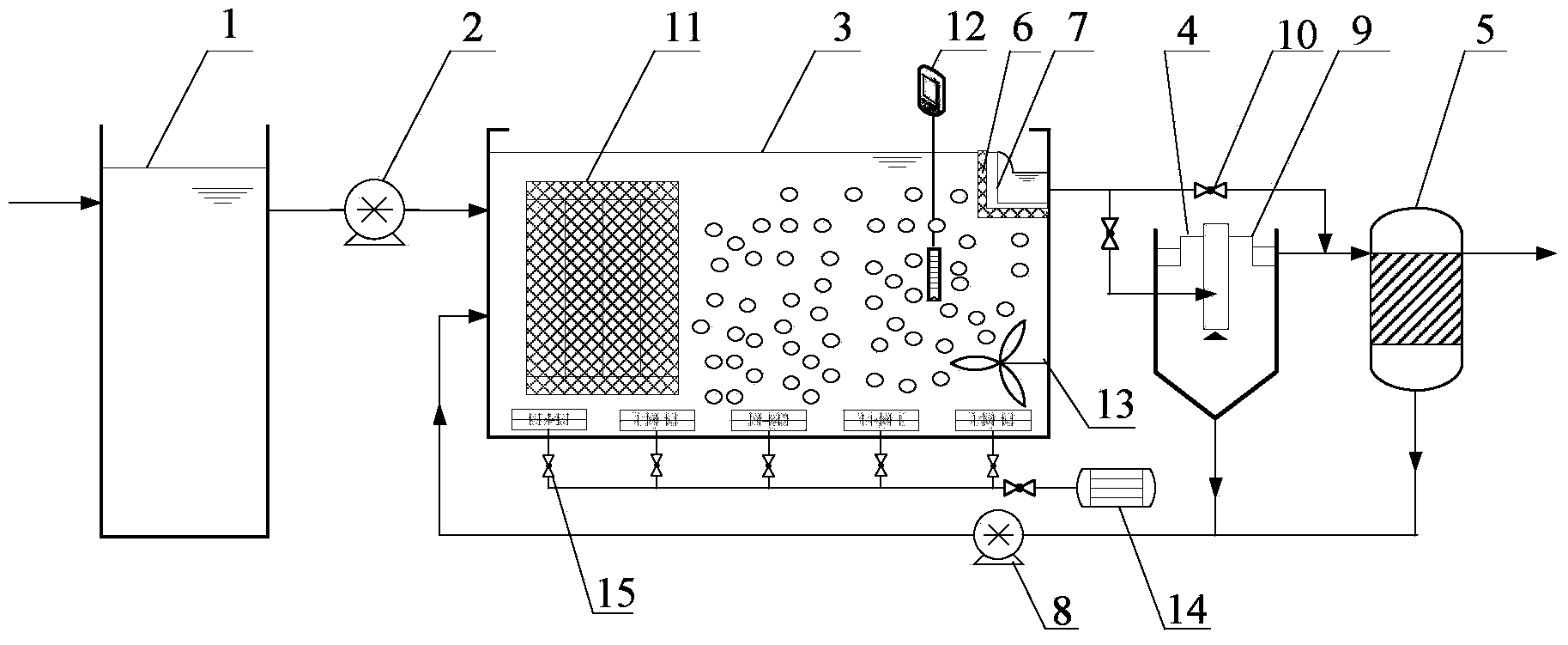

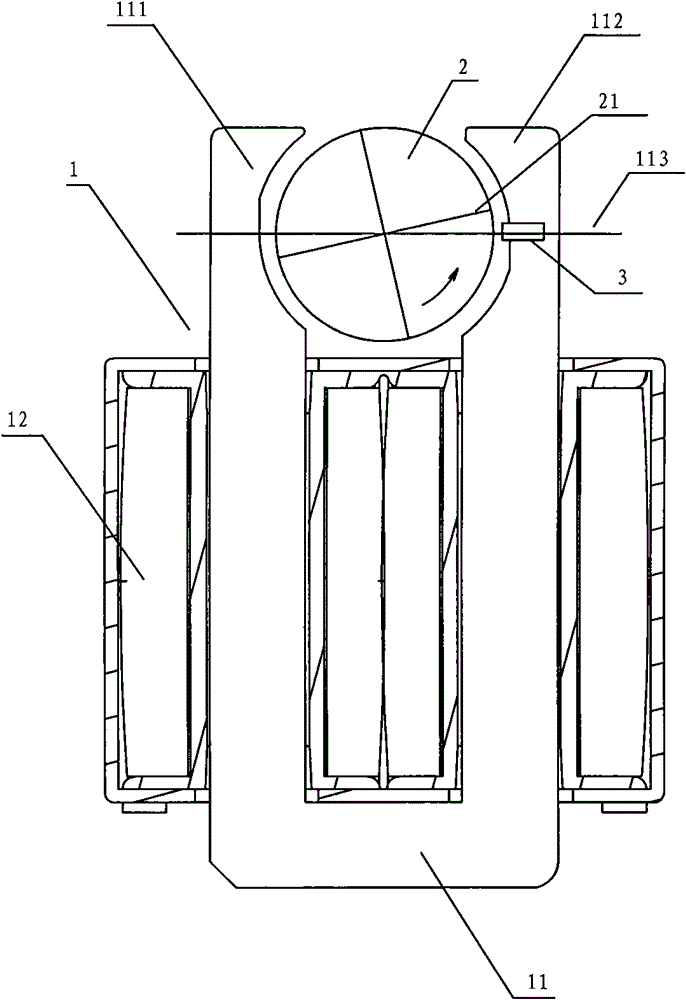

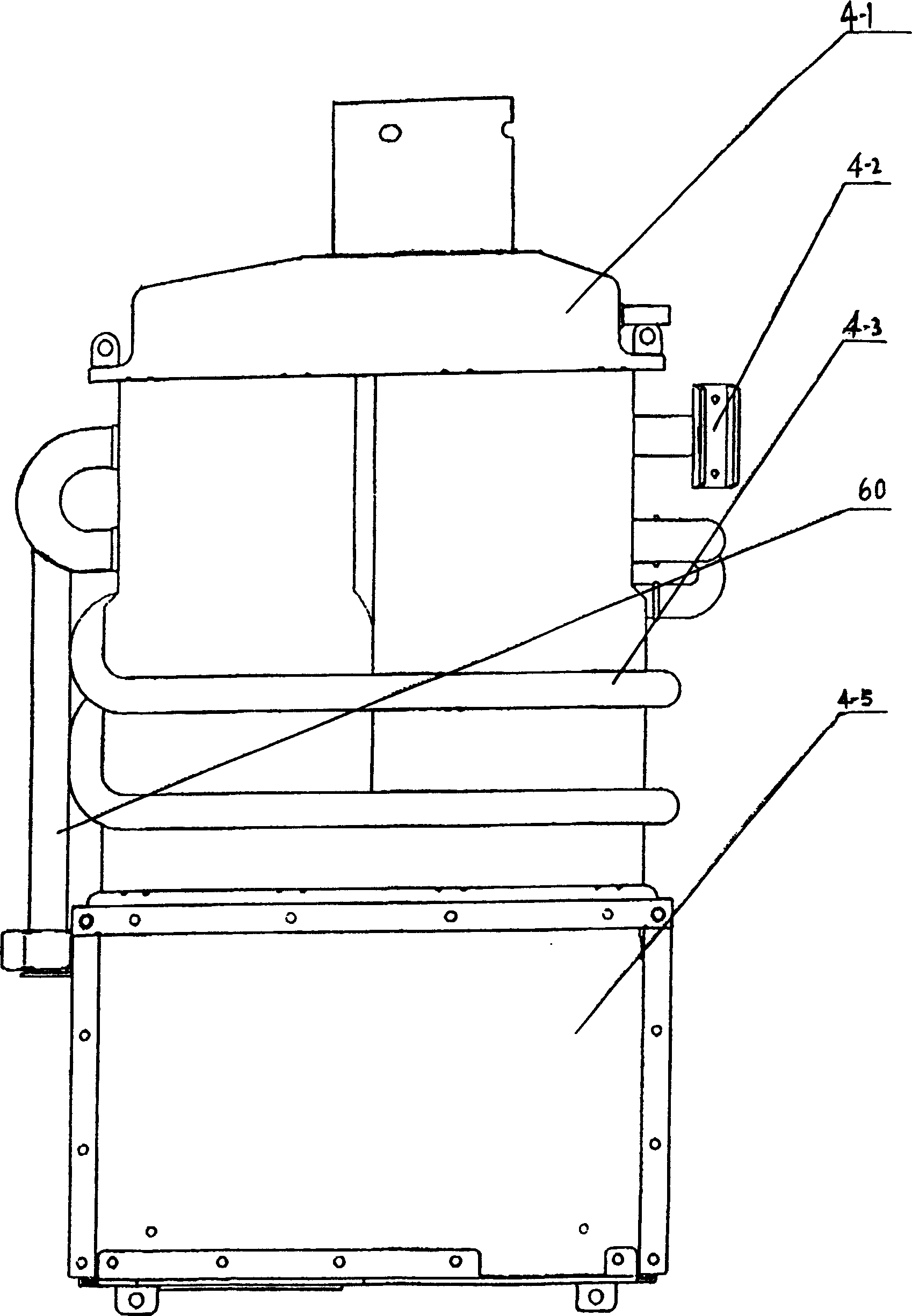

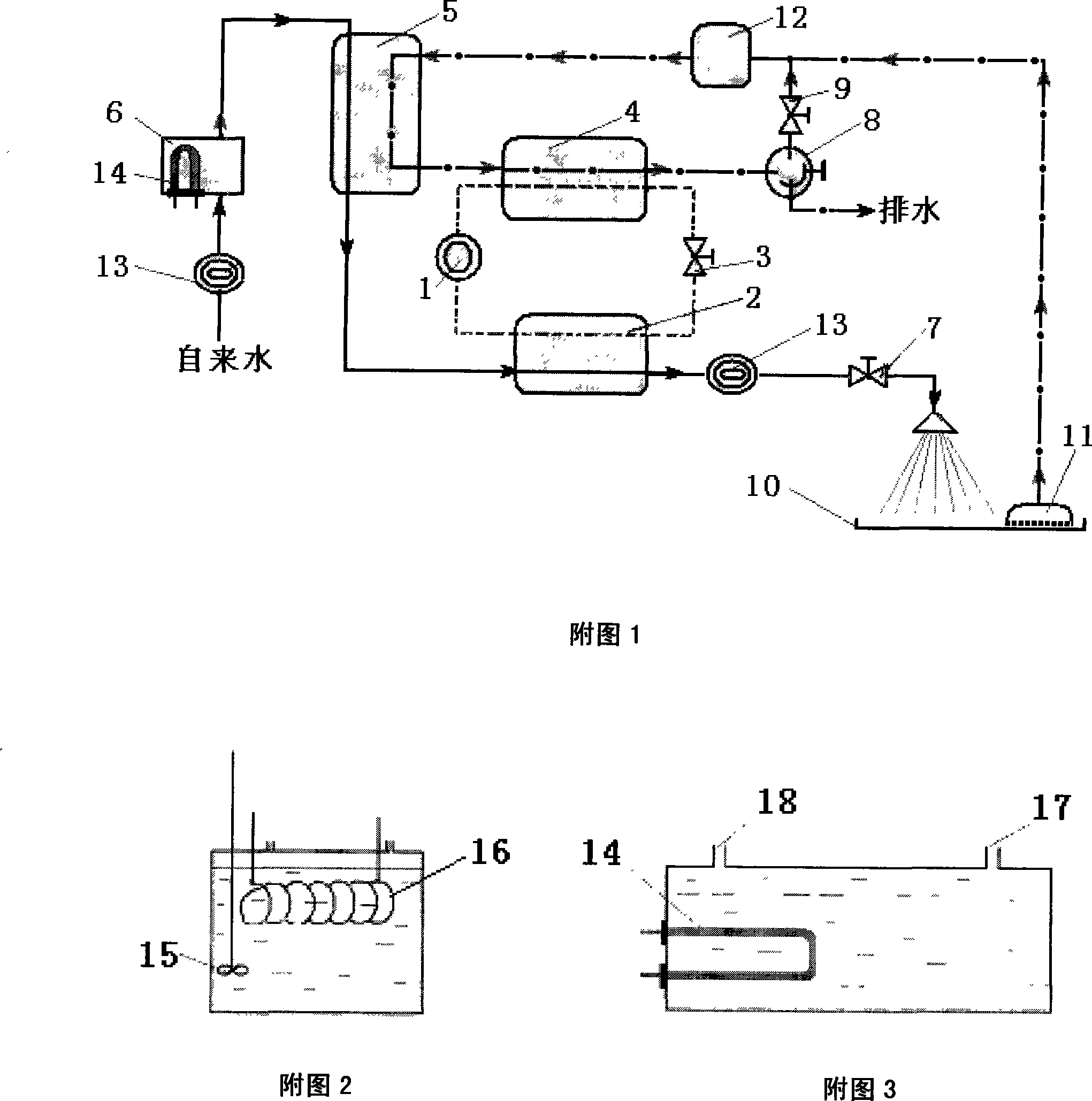

Continuous flow biological denitrification method based on granular sludge, and apparatus

ActiveCN103663725AStart fastReduce startTreatment with anaerobic digestion processesFiltrationSludge

The present invention discloses a continuous flow shortcut nitrification-anaerobic ammonium oxidation biological denitrification method based on granular sludge, and an apparatus. The method comprises: 1) carrying out sludge inoculation culture, and carrying out an active sludge adaptation period; 2) starting a shortcut nitrification-anaerobic ammonium oxidation reaction; 3) performing an anaerobic ammonium oxidation granular sludge formation and growth period; and 4) performing a stable operation period of a granular sludge continuous flow system. The apparatus comprises a water inlet tank, a bioreactor, a sedimentation tank and a hydraulic screen filter, wherein the water inlet tank, the bioreactor, the sedimentation tank and the hydraulic screen filter are sequentially communicated, the influent of the water inlet tank is communicated with high ammonia nitrogen wastewater, the effluent is communicated with the bioreactor, the concentrated sludge on the bottom of the sedimentation tank is communicated with the bioreactor through a sludge reflux pump, a fixation filler, a stirrer, a filtration screen and an aeration head communicated with an air compressor are arranged inside an anoxic reactor, the sedimentation tank is provided with a clear overflow port communicated with the hydraulic screen filter through a pipeline, the effluent of the hydraulic screen filter is the final effluent, and the retained granular sludge refluxes to the bioreactor.

Owner:BEIJING JIAOTONG UNIV

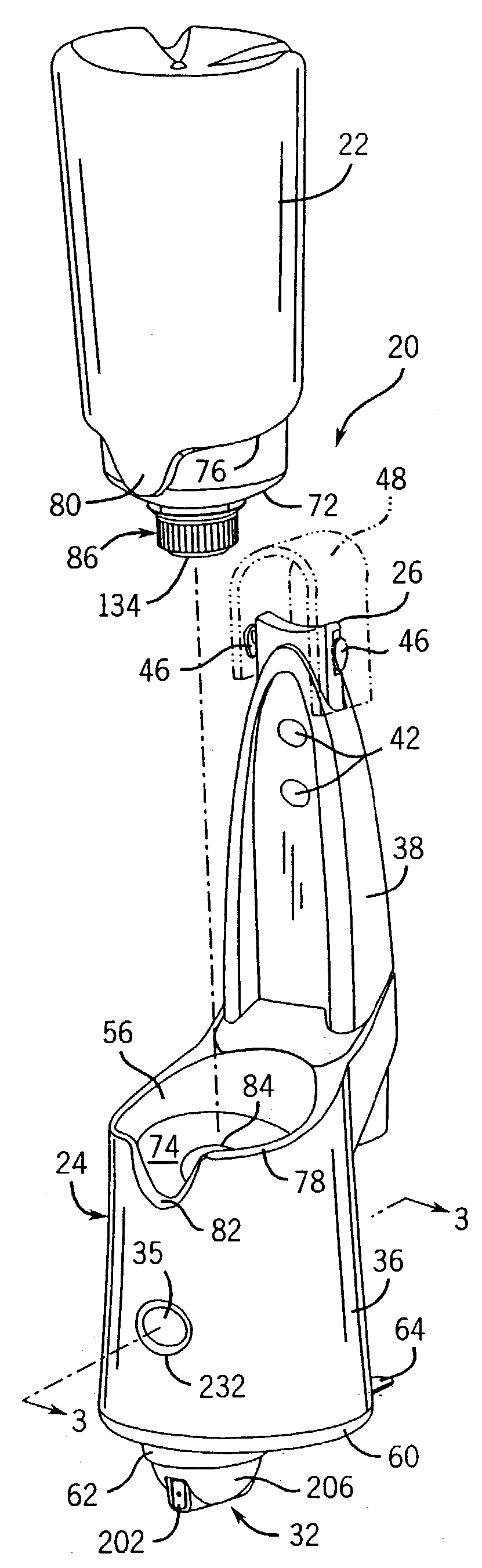

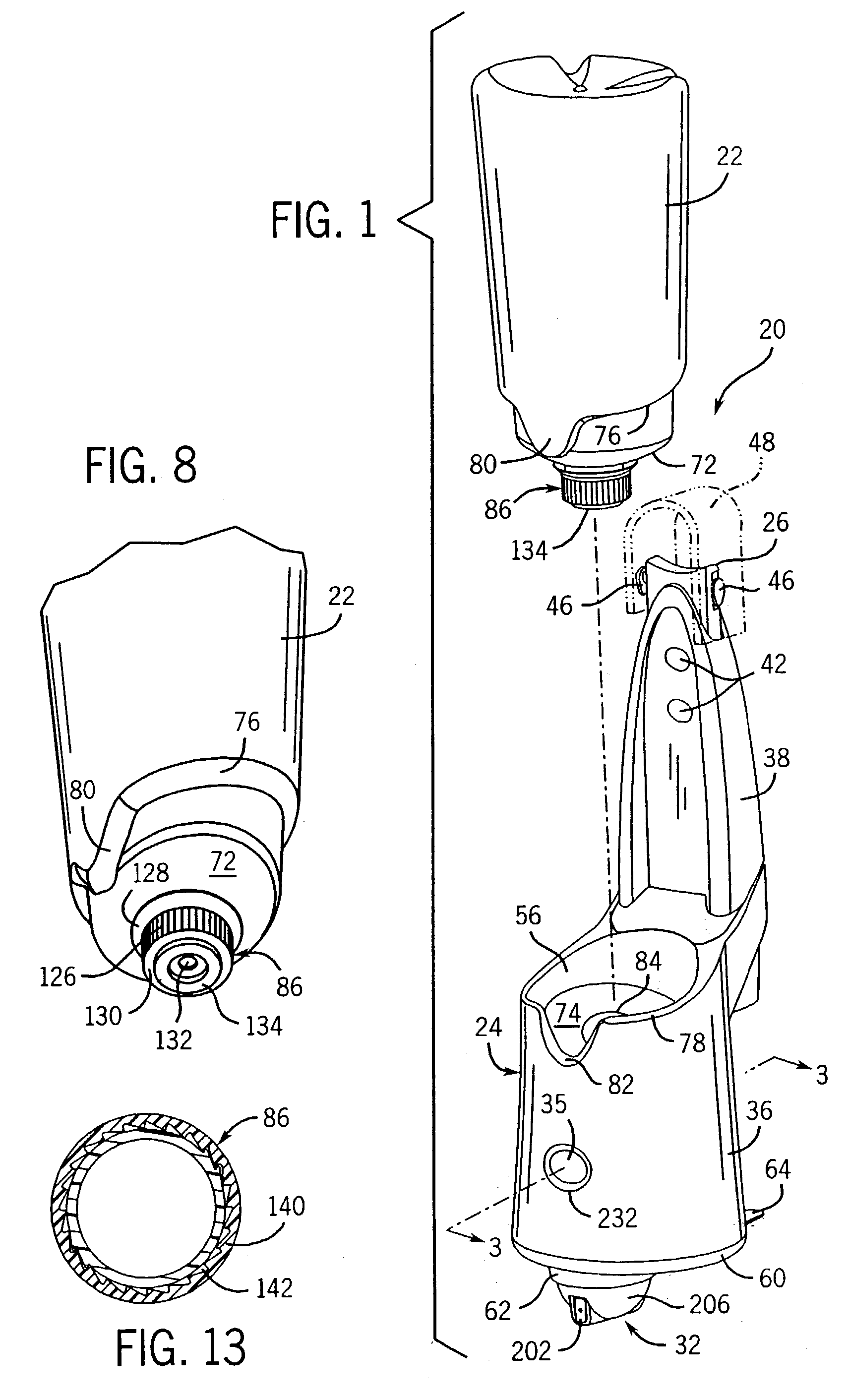

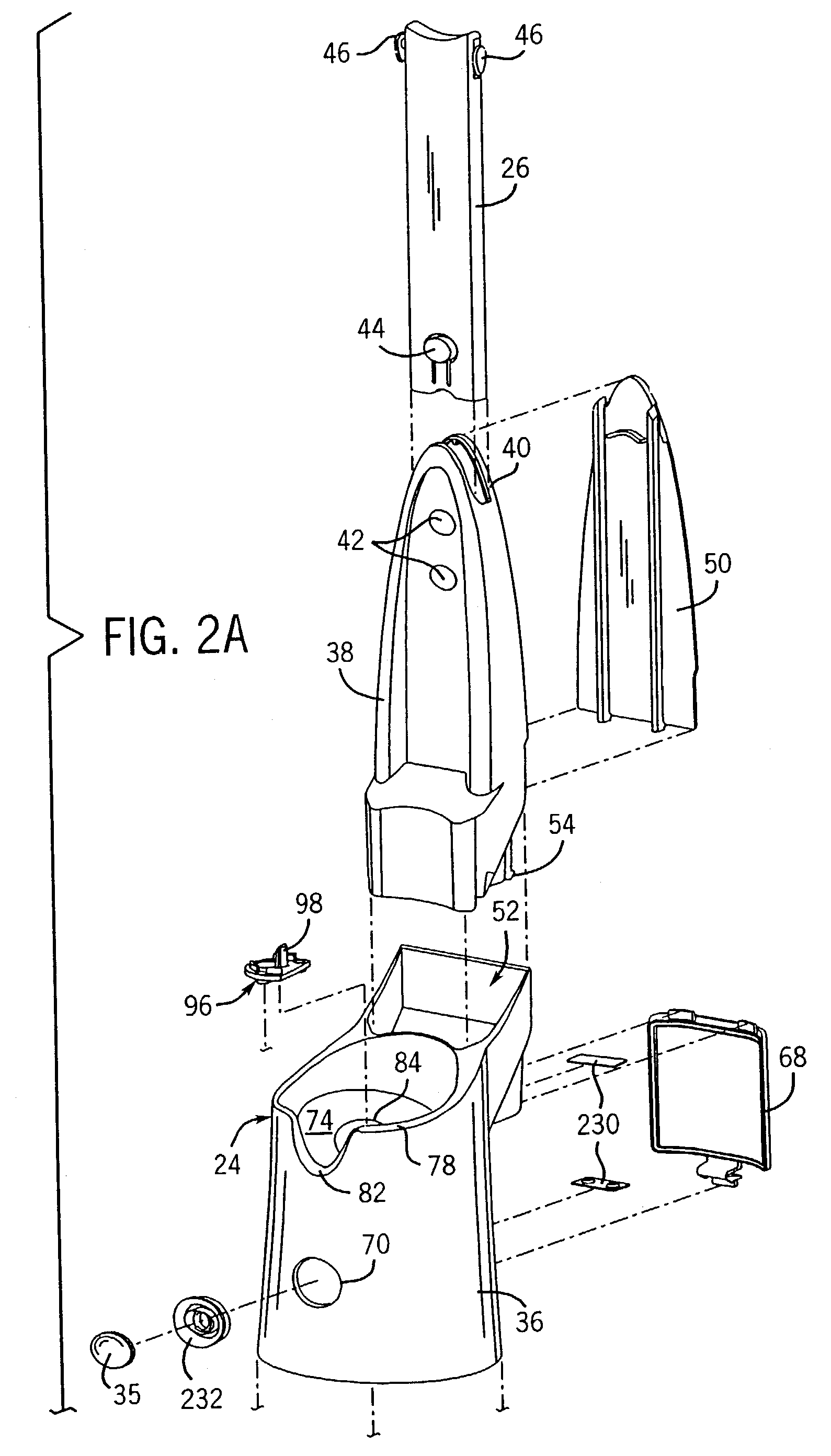

Automated cleansing sprayer

ActiveUS7837132B2Low costReduce startSelf-acting watering devicesMovable spraying apparatusCleansers skinSprayer

An automated sprayer for spraying the walls of a shower enclosure with a liquid cleanser dispenses the cleanser using a pumping system and rotatable spray head. The sprayer has a showerhead mountable housing with an adjustable hanger. There is a portion of the housing for supporting a bottle of cleanser in an inverted fashion. The bottle is vented through a piercing post. A single motor both drives the pump and rotates the spray head.

Owner:SC JOHNSON & SON INC

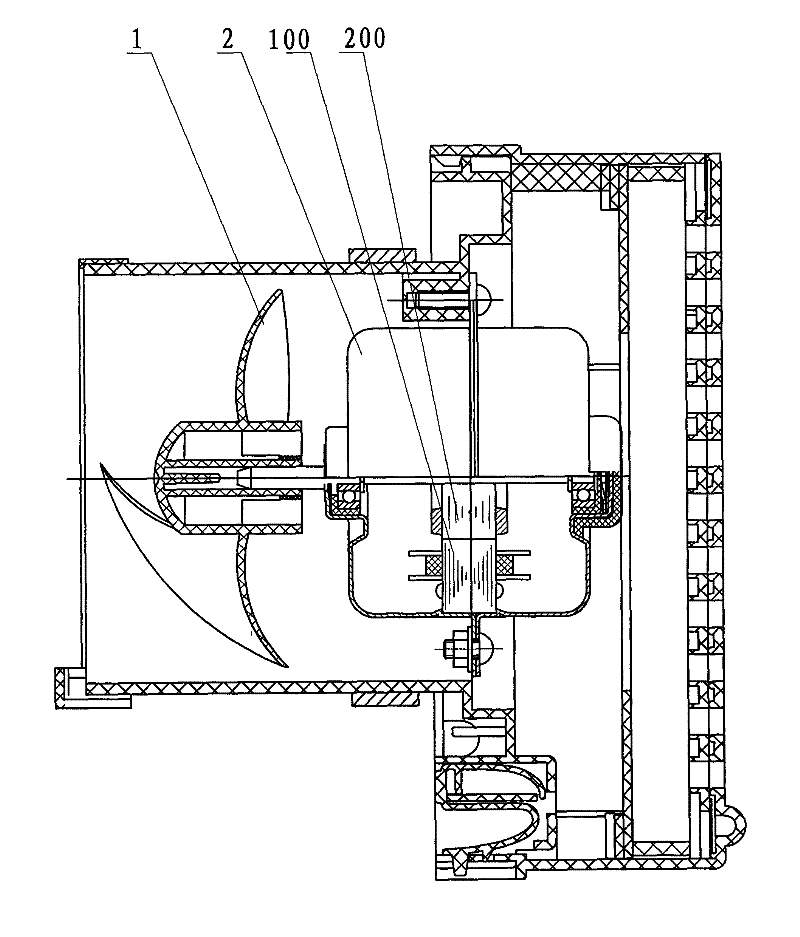

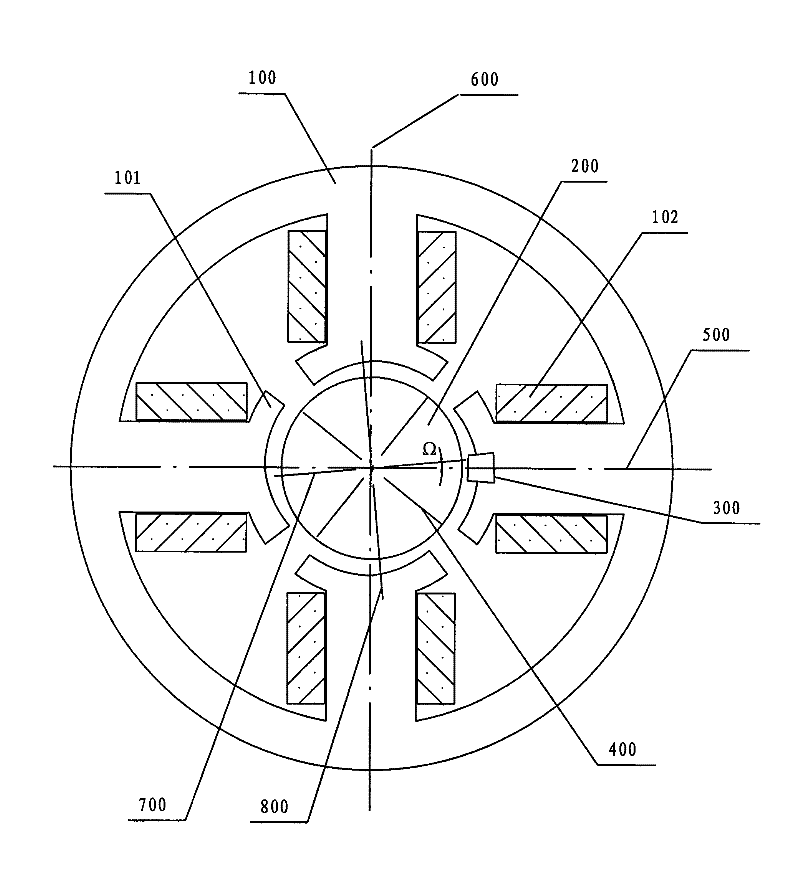

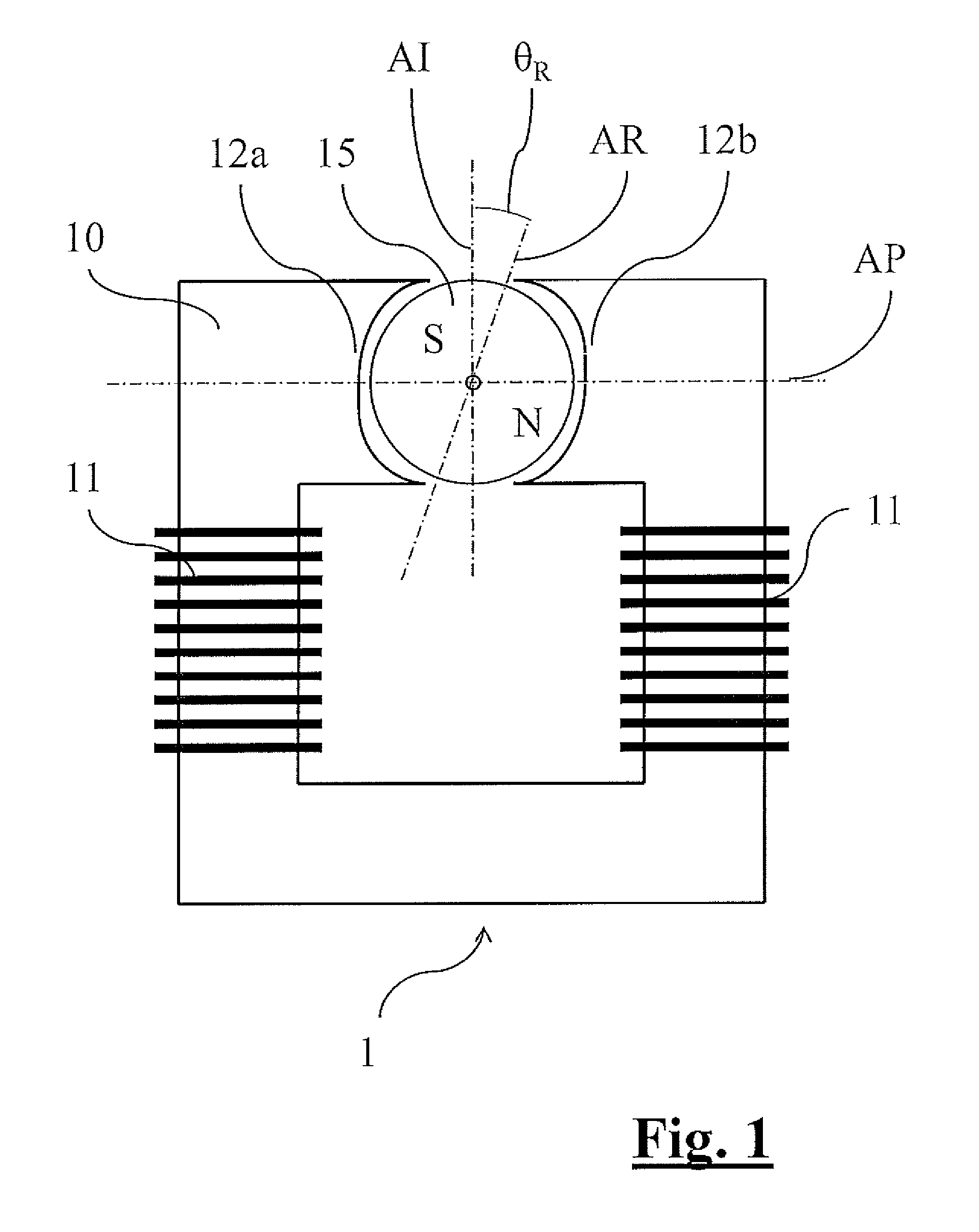

Miniature permanent magnet synchronous motor

ActiveCN102751922ASimple structural designReduce startSingle motor speed/torque controlElectronic commutatorsPermanent magnet rotorAcute angle

The invention discloses a miniature permanent magnet synchronous motor which comprises a stator and a permanent magnet rotor which have equal number of poles. An alternating current source supplies power to the stator through a switch of a control circuit, and an air gap between the stator and the rotor narrows down from one pole to another pole along the rotating direction so that the axis of each pole of the rotor under free state deflects for an acute angle along the rotating direction by taking the axis of the nearest pole of the stator as the reference. A linear magnetic position sensor is installed at a set position on the circumference of the rotor so as to detect the polarity and the position of the rotor; the control circuit determines the axis direction of the permanent magnetic flux of all the poles of the rotor according to the output of the sensor and by taking the set position as the reference. The control circuit detects the polarity of the voltage supplied to the stator by the power source so as to determine the axis direction of the main fluxes generated by all the poles. The switch switches on the power source half-wave when the motor is started and the intersection angle between the axis direction of the main fluxes and the axis direction of the permanent magnetic fluxes is the above acute angle or when the motor runs and the axis direction of the main fluxes is opposite or approximately opposite to the axis direction of the permanent magnetic fluxes. The motor has good starting performance in preset rotating direction and good operational performance and the control structure of the motor is simple and reliable.

Owner:HANYU GRP CO LTD

Low-power ventilating fan

InactiveCN102330702ASimple structural designReduce startPump installationsNon-positive displacement fluid enginesPermanent magnet rotorAcute angle

The invention provides a low-power ventilating fan which comprises a minisize permanent magnet synchronous motor and an impeller which can be directly driven by the motor and can rotate according to a predetermined rotating direction, wherein the impeller is of an axial-flow type and manufactured in an injection moulding mode, the diameter of the impeller is not more than 150mm; the pole number of a motor stator is 4 or 6 or 8, the winding of the stator is connected to an alternating current power supply according to a specified winding direction; the pole number of a permanent magnet rotor is the same with that of the stator; air gap of each pole can be narrowed along the rotating direction, so that each pole axis of the rotor can deflect an acute angle along the rotating direction in the free state by taking the axis of one pole of the closest stator as a reference; a position sensor can detect the rotor at a set position on the circumference of the rotor, a control circuit can determine the direction of each polar permanent magnet flux and detect the power supply polarity by taking the position as a reference and the output of the sensor so as to determine the axis direction ofeach polar main flux of the stator; when the motor starts, a switch can connect the half wave of the power supply if the main flux axis direction and the permanent magnet flux axis direction are intersected and form the acute angle; or when the motor runs, the switch can connect the half wave of the power supply right now if the main flux axis direction is opposite to the permanent magnet flux axis direction or close to the opposite direction. The ventilating fan has better performance in the starting and running processes, while the cost is relatively low.

Owner:叶露微

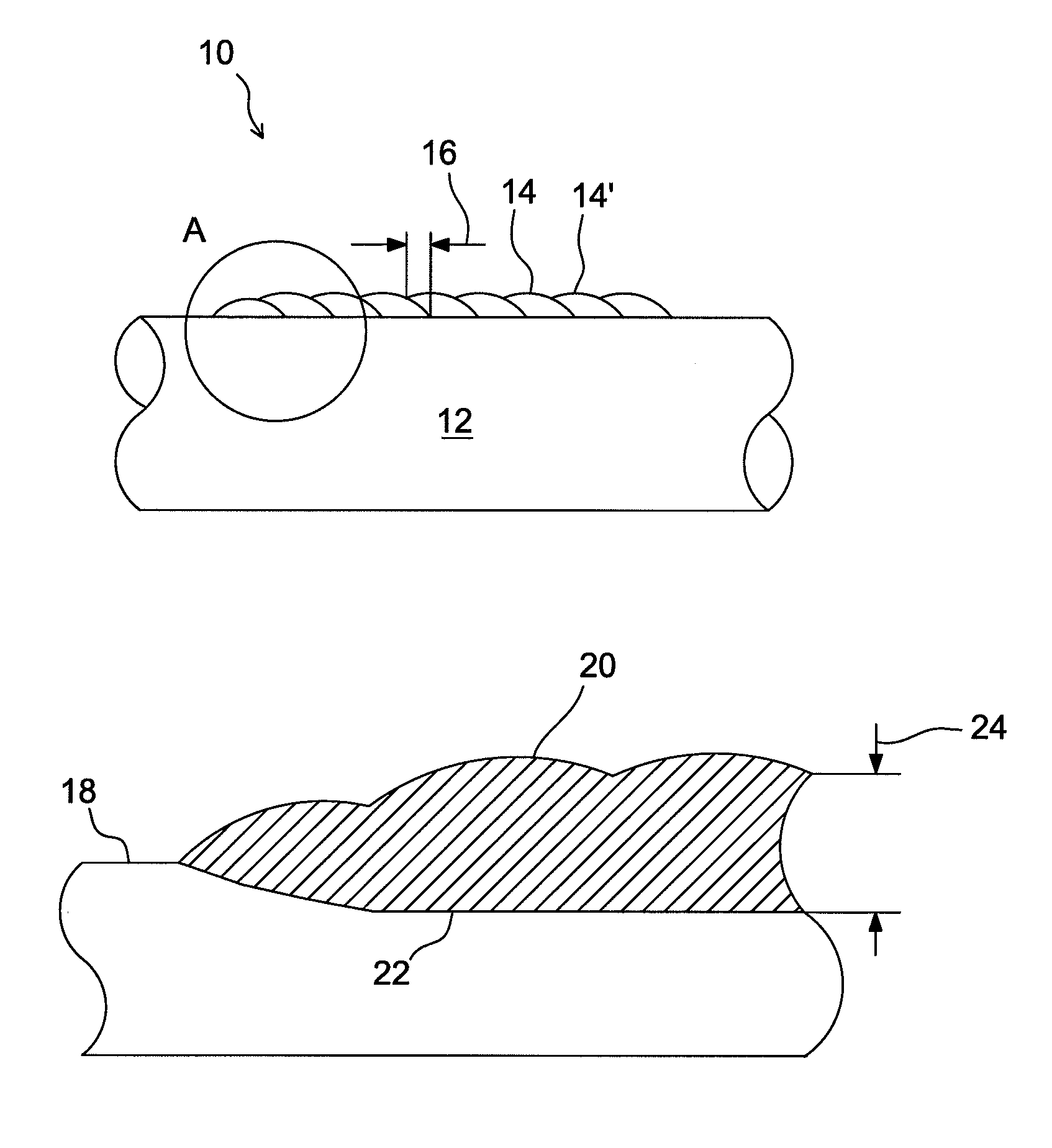

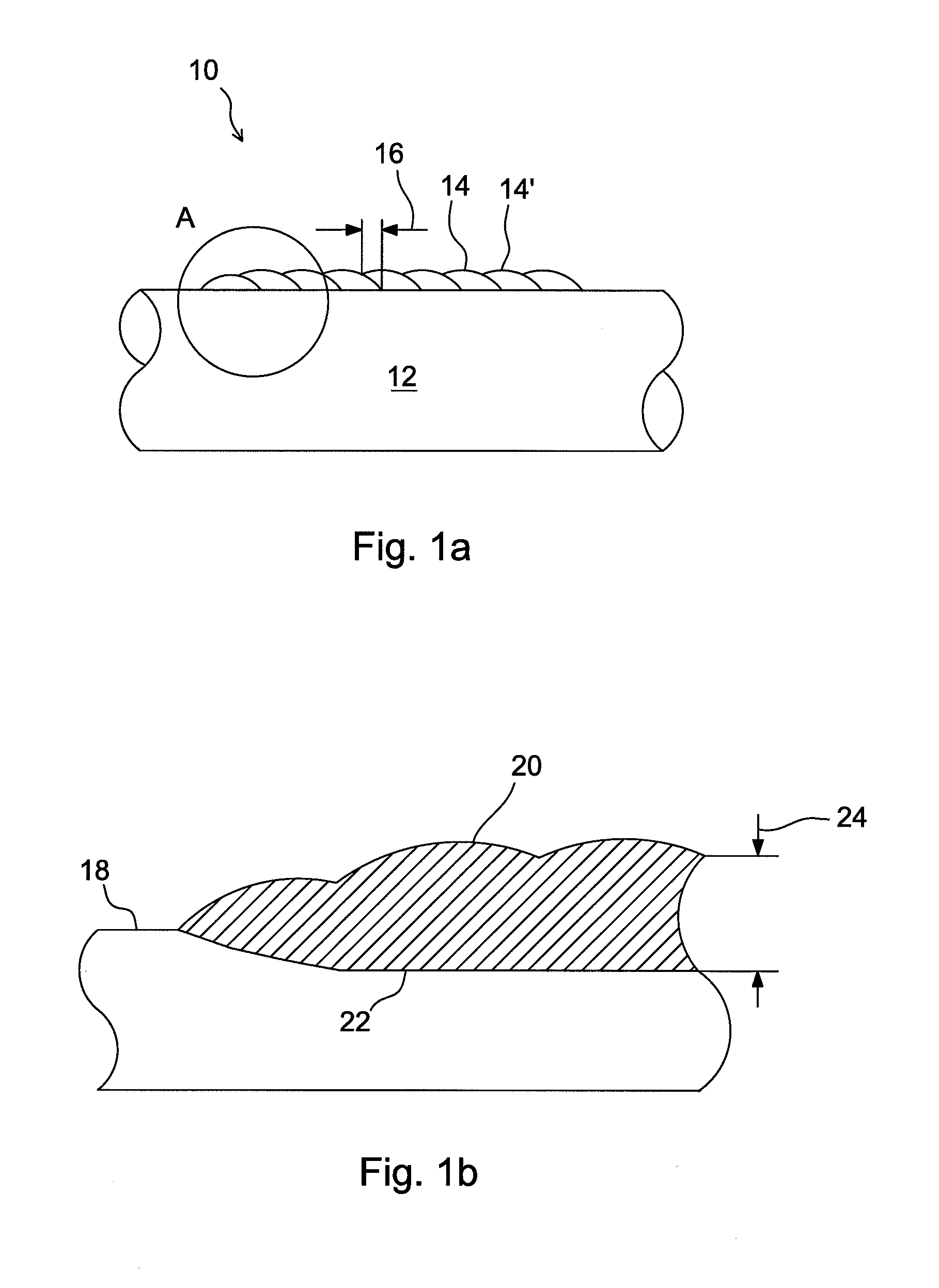

Weld Overlay Structure and a Method of Providing a Weld Overlay Structure

InactiveUS20120214017A1Minimizes problemMinimize dilutionAdditive manufacturing apparatusArc welding apparatusMembrane surfaceHeat transfer tube

A method of providing a weld overlay structure on a heat transfer tube or a membrane surface. A first continuous bead portion of an overlay material is applied onto the heat transfer tube or membrane surface by using a weld head to melt the overlay material. A second continuous bead portion of the overlay material is applied onto the heat transfer tube or membrane surface by using a weld head to melt the overlay material, in which the second bead portion partially overlaps with the first bead portion, forming a groove between the first bead portion and the second bead portion. A third continuous bead portion of an overlay material is applied onto the heat transfer tube or membrane surface by using a weld head to melt the overlay material into the groove between the first bead portion and the second bead portion, so as to form a relatively smooth surface.

Owner:POURIN WELDING ENG +1

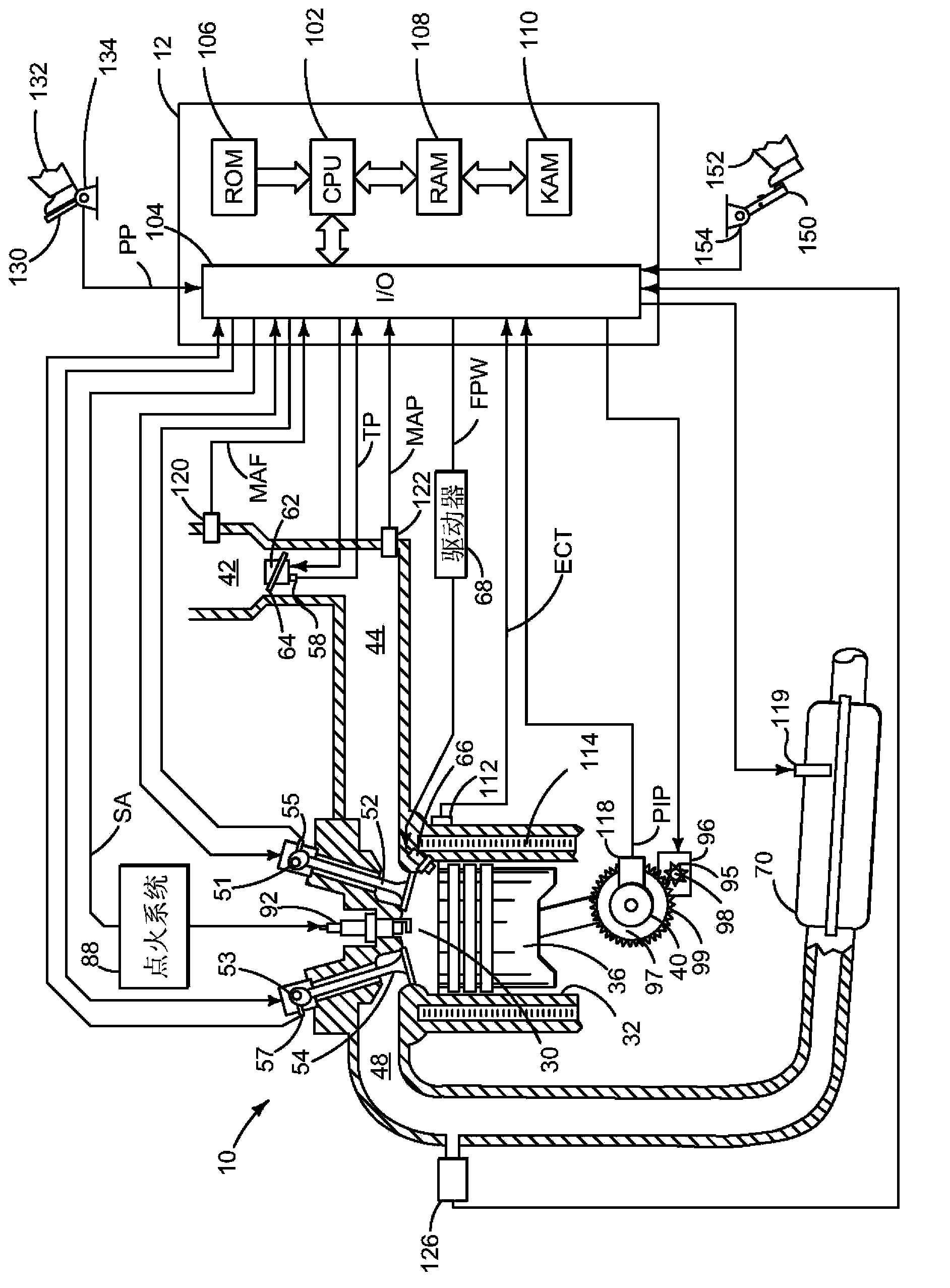

Method for starting engine in gear shift period

The invention discloses a system and a method for improving the operation of a hybrid vehicle. In one embodiment, the torque demand of a power train after gear shift is predicted for determining whether an early start of the engine is desired, so that the engine torque can be obtained after gear shift. The method can improve the vehicle torque response.

Owner:FORD GLOBAL TECH LLC

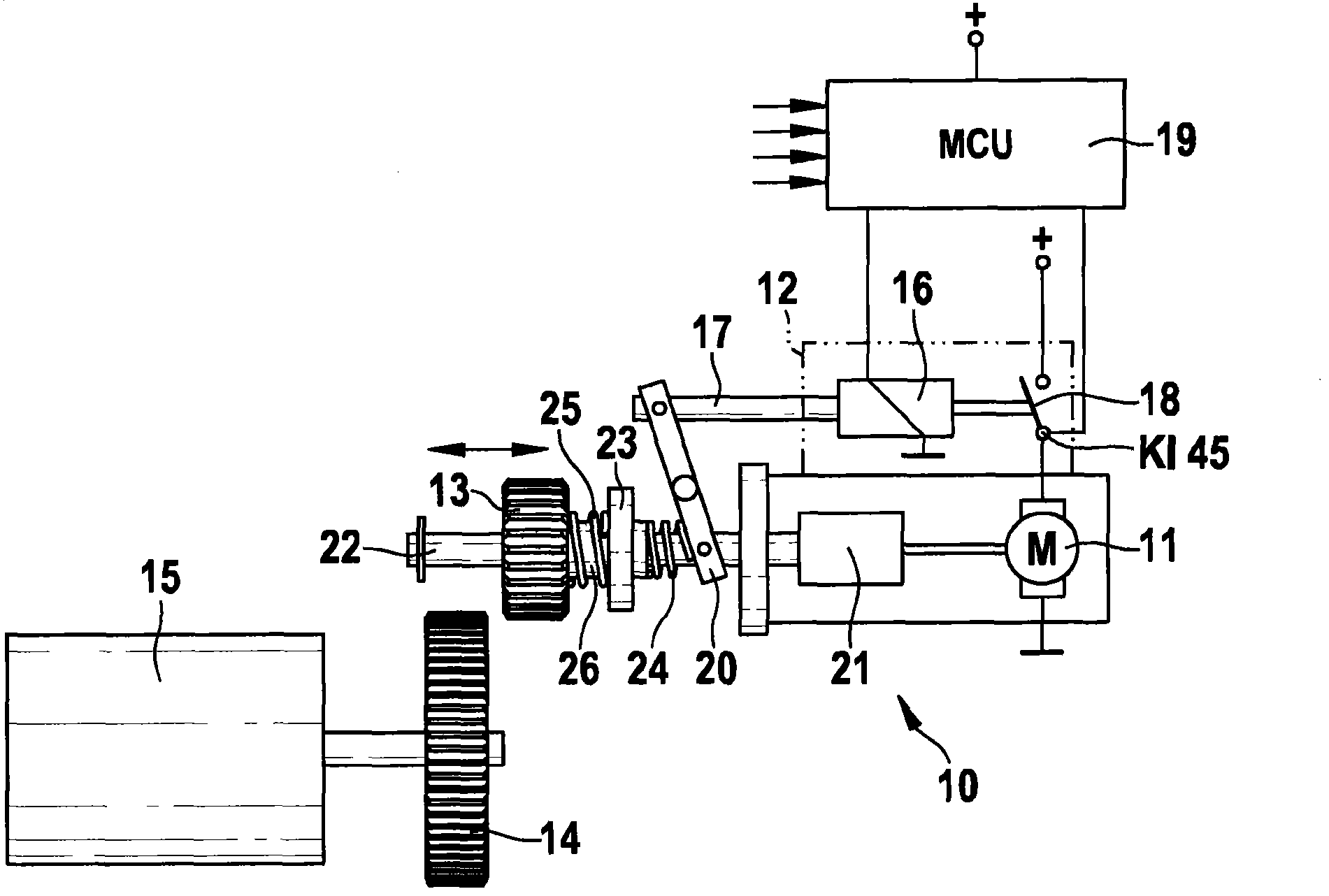

Method and device for start-stop systems of internal combustion engines in motor vehicles

ActiveCN102317615ASimplify electronic controlsSo as not to damagePower operated startersPortable liftingMobile vehicleCombustion

The invention relates to a starting method for internal combustion engines in motor vehicles, comprising a start-stop system, and to a starting device (10) for carrying out said method, said starting device comprising a starter motor (11) and an insertion device (12, 20) which axially inserts a slip-on pinion (13) into a crown gear (14) of the internal combustion engine when a stop cycle begins. In order to minimize the period until the engine can be restarted, the pinion (13) is resiliently inserted into the still rotating crown gear (14) by means of a pressure spring (25) when the stop phase begins, once the internal combustion engine (15) is switched off but before it comes to a standstill and with the starter motor (11) switched off.

Owner:SEG AUTOMOTIVE GERMANY GMBH

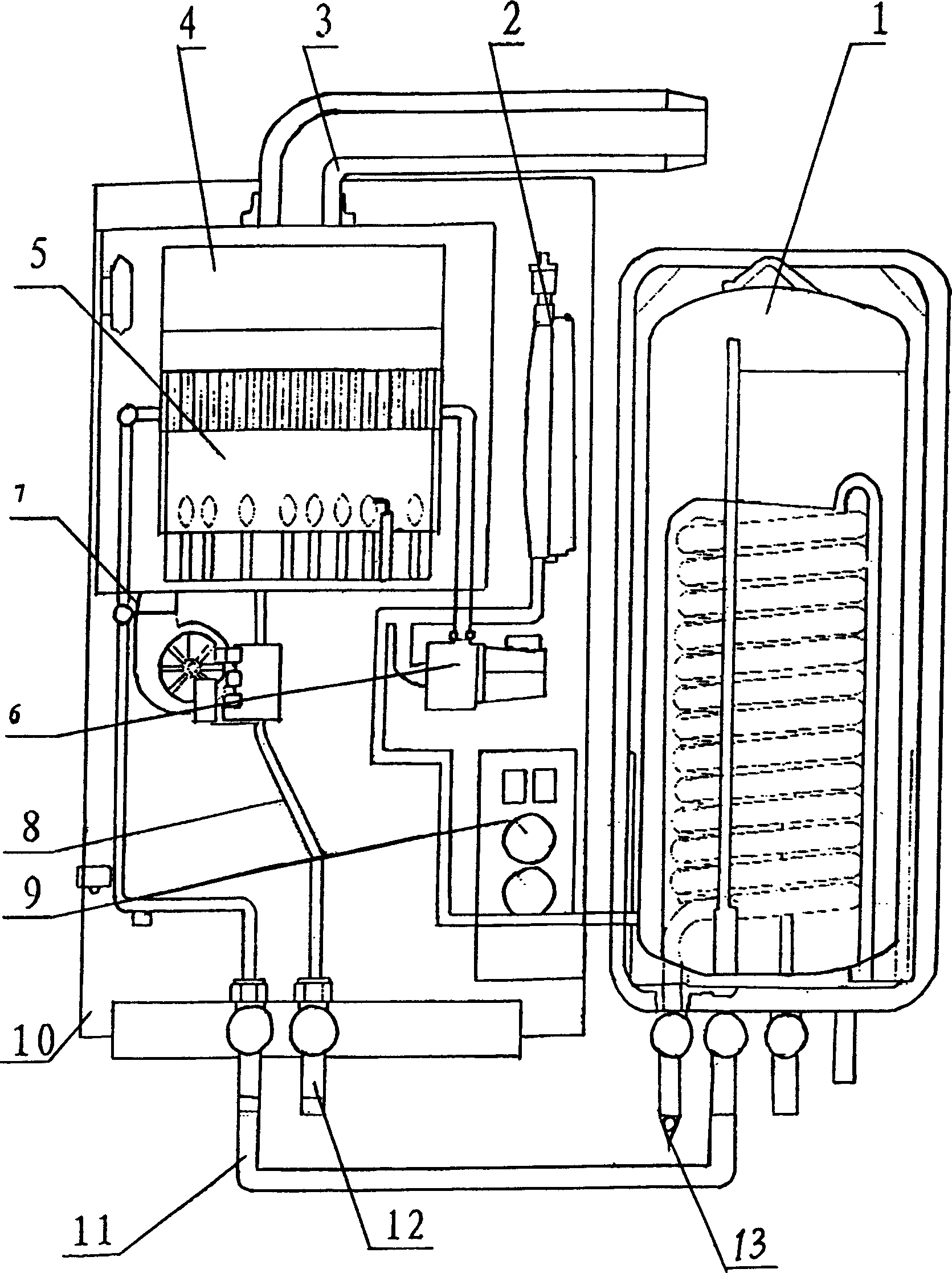

Positive displacement rapid water heater and controlling method thereof

A volume style water heater can be used in apartments, offices, hotels and villas. It consists of a sealed water tank, an expanding tank, a flue, a quick heater, a combusting chamber, a blower, a water pump, a safety valve for controlling combustion, a check valve, a controller, a shell, pipelines for cold and hot water, and gas fuel pipelines. A microcomputer as intellectual controller is used to inspect, to determine, to diagnose, and to control circulation. It combines advantages of direct flow style and volume style water heaters together, provides hot water at once as starting with large flow and efficient combustion, saves energy, and works reliably and safely. A method for controlling is disclosed also.

Owner:上海梦地工业自动控制系统股份有限公司

Control device for vehicle power transmission device

InactiveUS7824307B2Reducing shift shockReduce transmission capacityHybrid vehiclesClutchesElectric power transmissionControl theory

Owner:TOYOTA JIDOSHA KK +1

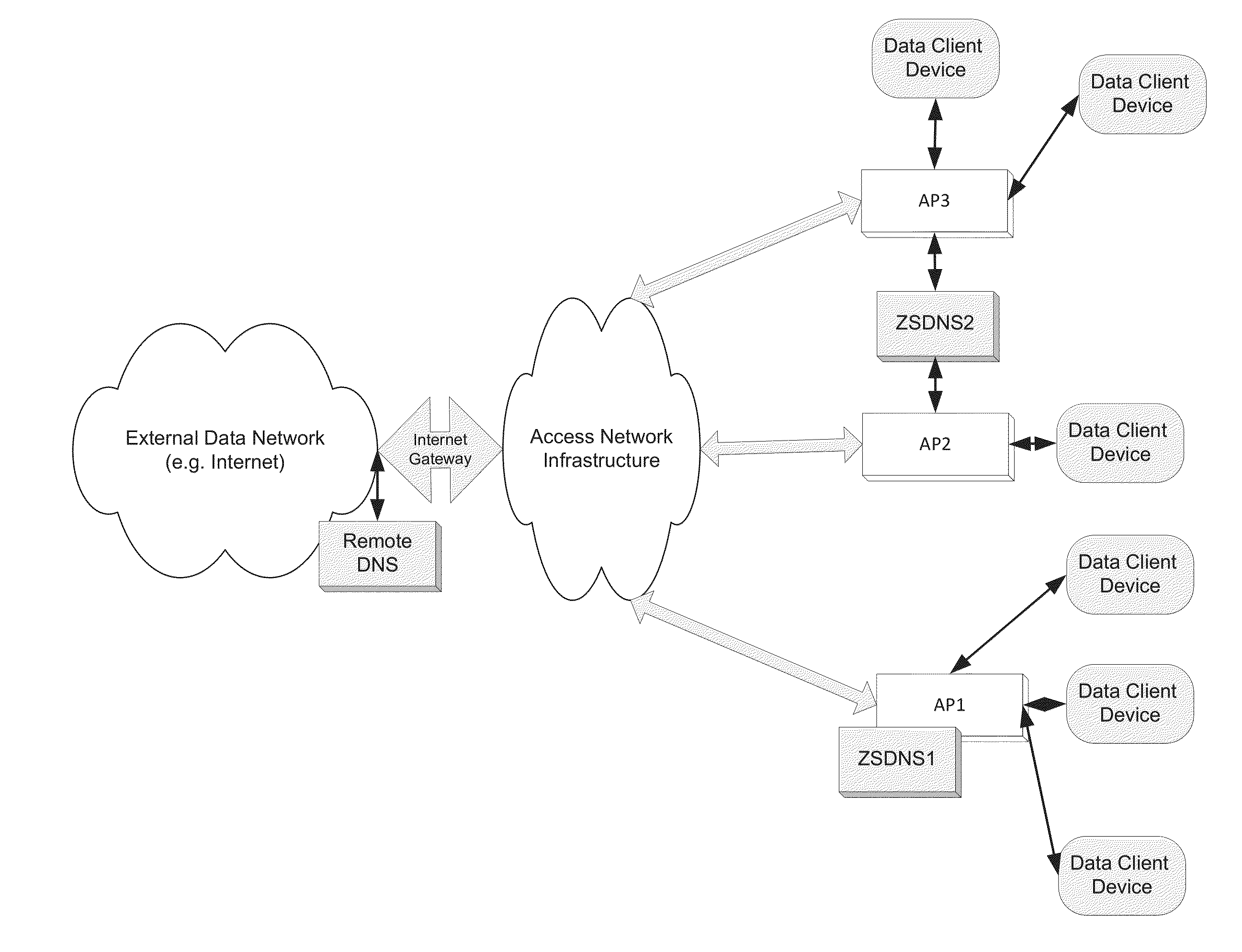

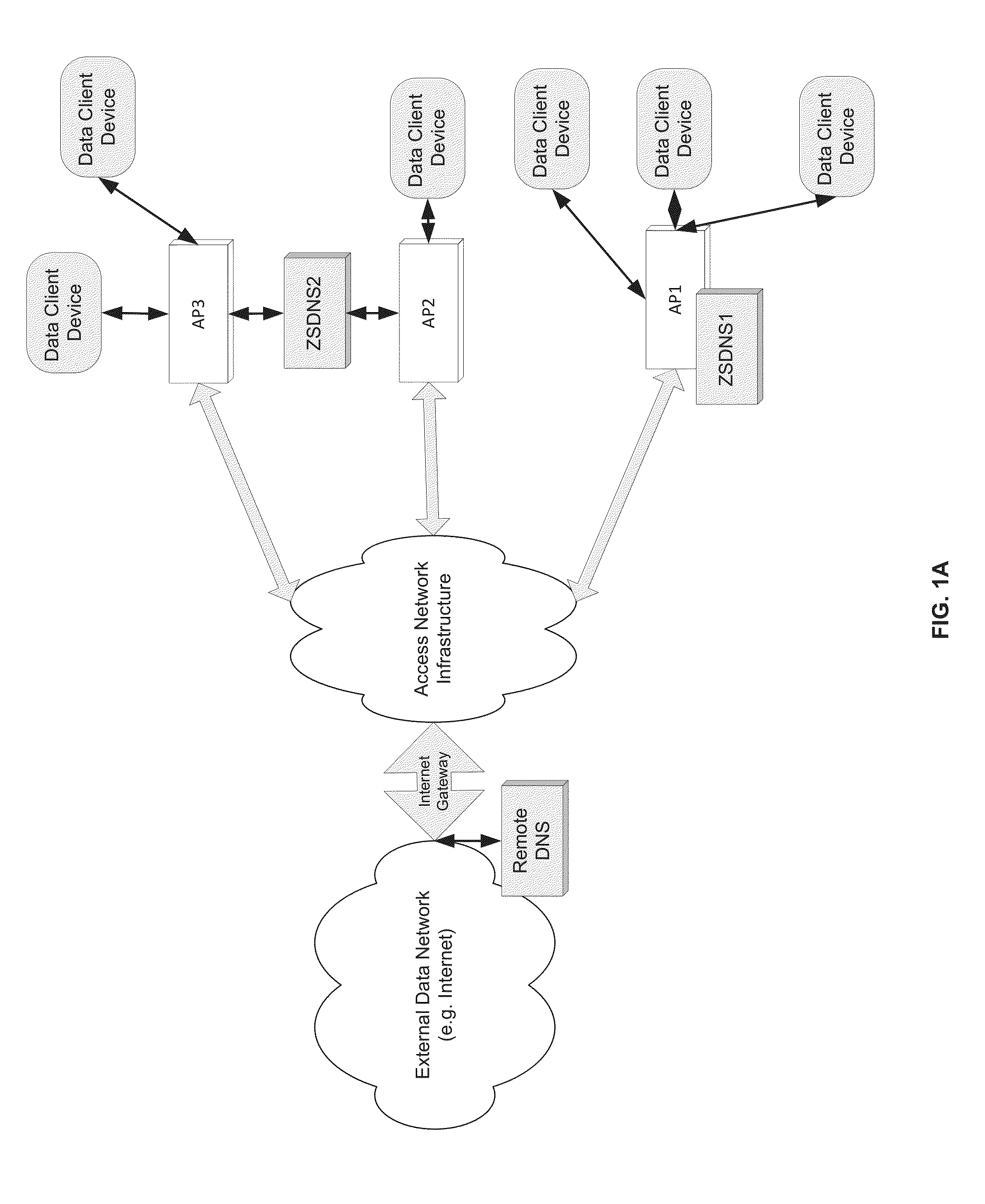

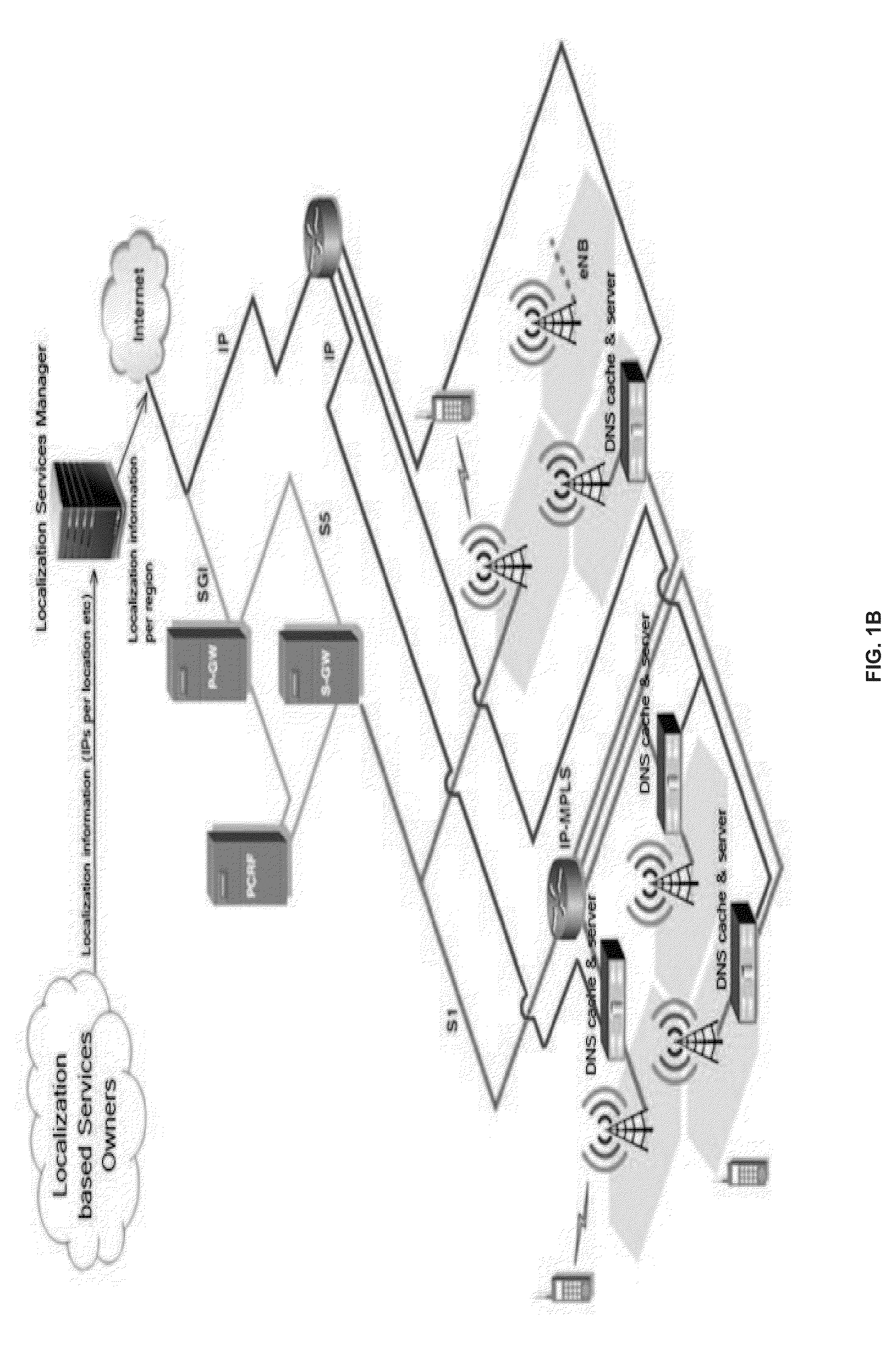

Methods circuits devices systems and associated computer executable code for providing conditional domain name resolution

InactiveUS20160050178A1Reduce startMultiple digital computer combinationsTransmissionDomain nameClient-side

Disclosed are methods, circuits, devices, systems and associated computer executable code for providing Domain Name Resolution functionality to a data client device accessing a networked data resource through an access point of a data communication network. According to some embodiments, an access point or node of a data communication network may be integral or otherwise functionally associated with a conditional domain name system (CDNS), which CDNS may include a local cache of conditional DNS records.

Owner:SAGUNA NETWORKS

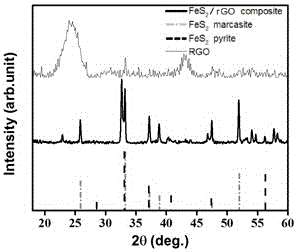

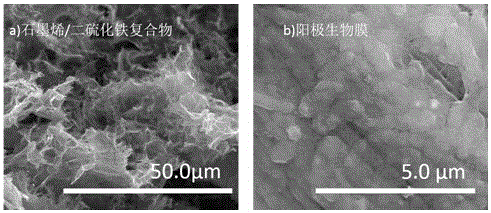

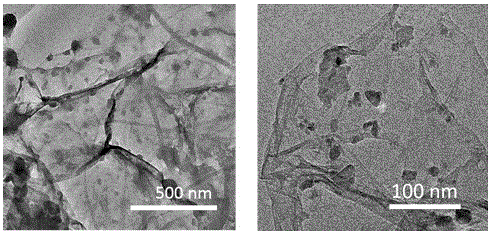

Method for preparing anode of microorganism fuel battery with graphene and ferrous disulfide compound

ActiveCN106784829AImprove performanceLower anode electron transfer resistanceCell electrodesBiochemical fuel cellsIonCvd graphene

The invention discloses a method for preparing the anode of a microorganism fuel battery with a graphene and ferrous disulfide compound, and belongs to the field of environments, materials and energy. The method comprises the following steps: (1) gradually dropping a ferric trichloride and thiourea solution into a graphene oxide dispersion in a reaction kettle one droplet by one droplet, uniformly stirring, sealing the reaction kettle, and performing hydrothermal reaction for 12-24 hours within 140-200 DEG C so as to obtain a hydrogel sample; (2) washing the hydrogel sample for times with deionized water, performing freeze-drying, and crushing so as to obtain a nano powder of the graphene and ferrous disulfide compound; (3) mixing the nano powder with a 5% nafion solution, isopropanol and deionized water, uniformly oscillating, coating carbon cloth with the solution, fixing the carbon cloth with a fixing part, and drying the carbon cloth in air, so as to obtain the anode. The method has the advantages that the synthesis steps are very simple, obtained particles are uniform in morphology, graphene lamellas are overlapped to form a well-developed porous structure, good electrochemical properties and biocompatibility can be achieved, and the anode of the microorganism fuel battery has very good properties.

Owner:HARBIN INST OF TECH

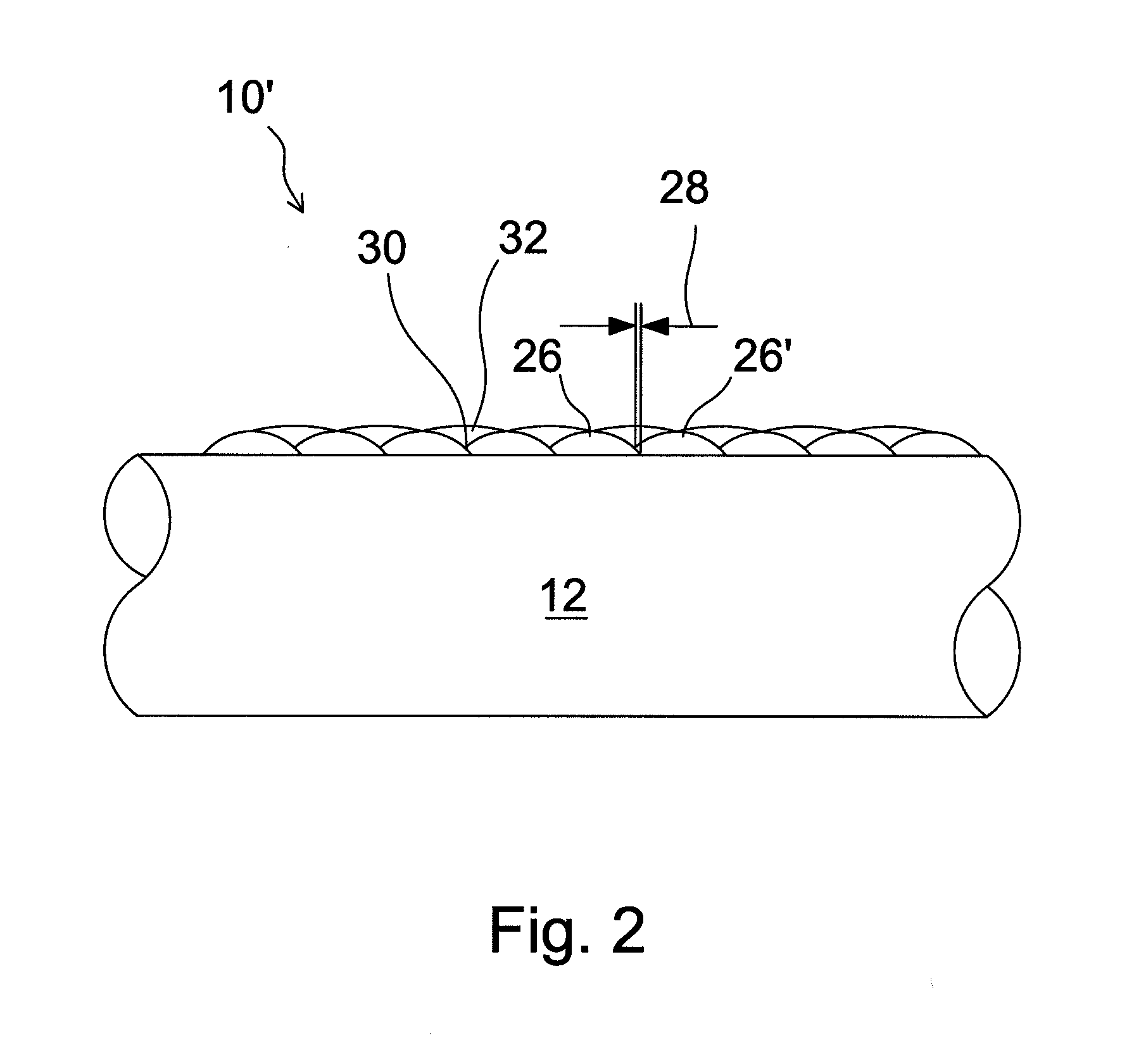

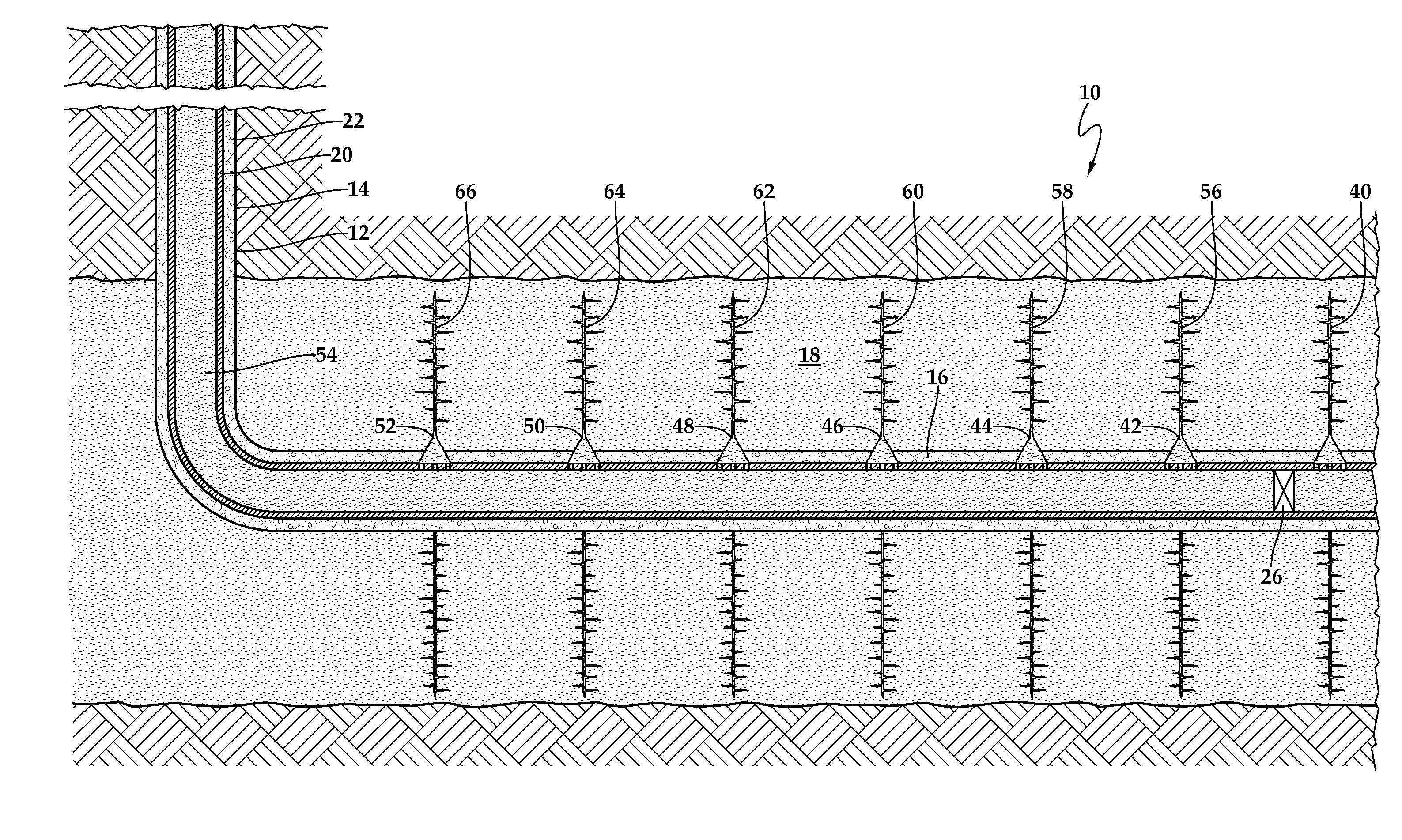

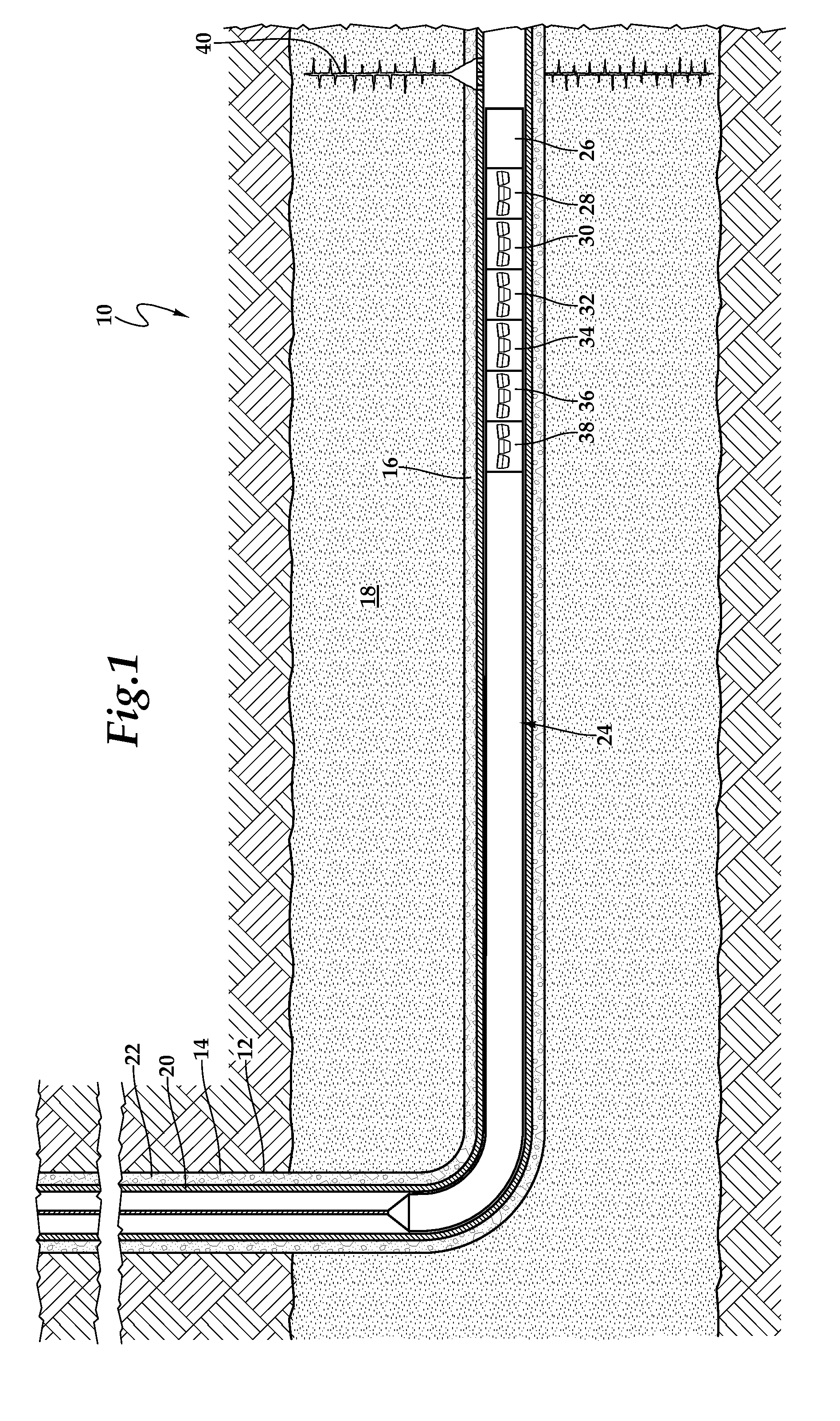

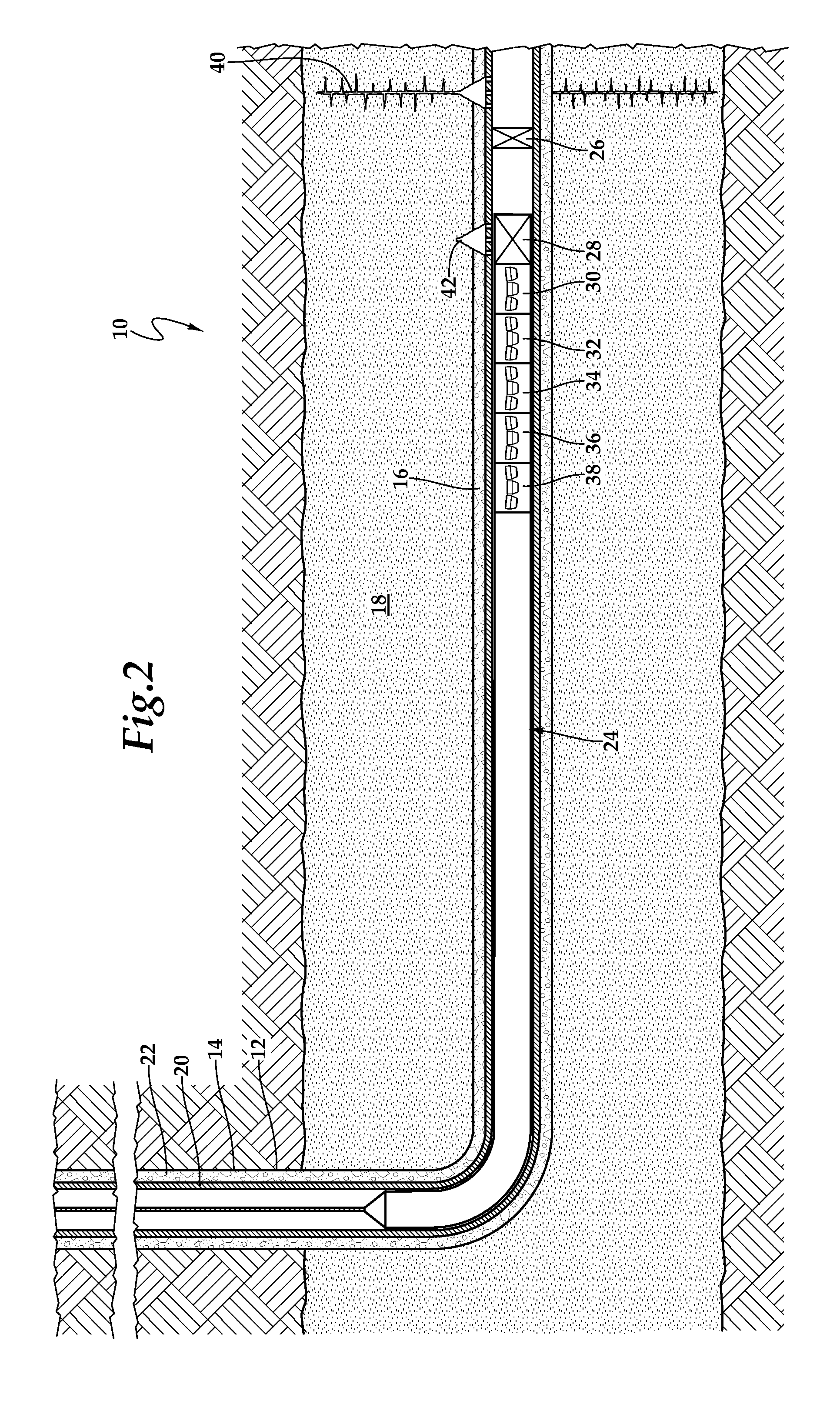

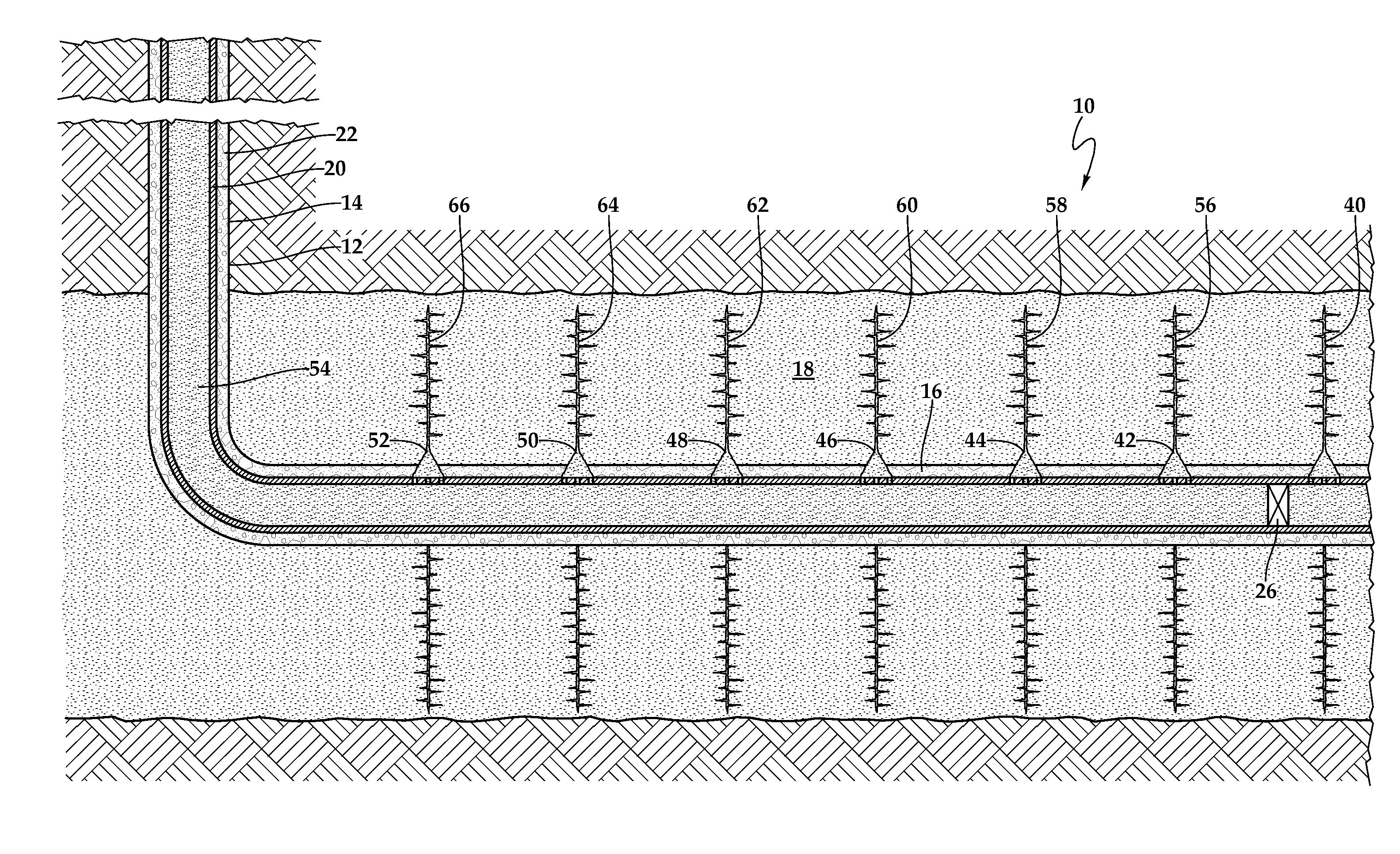

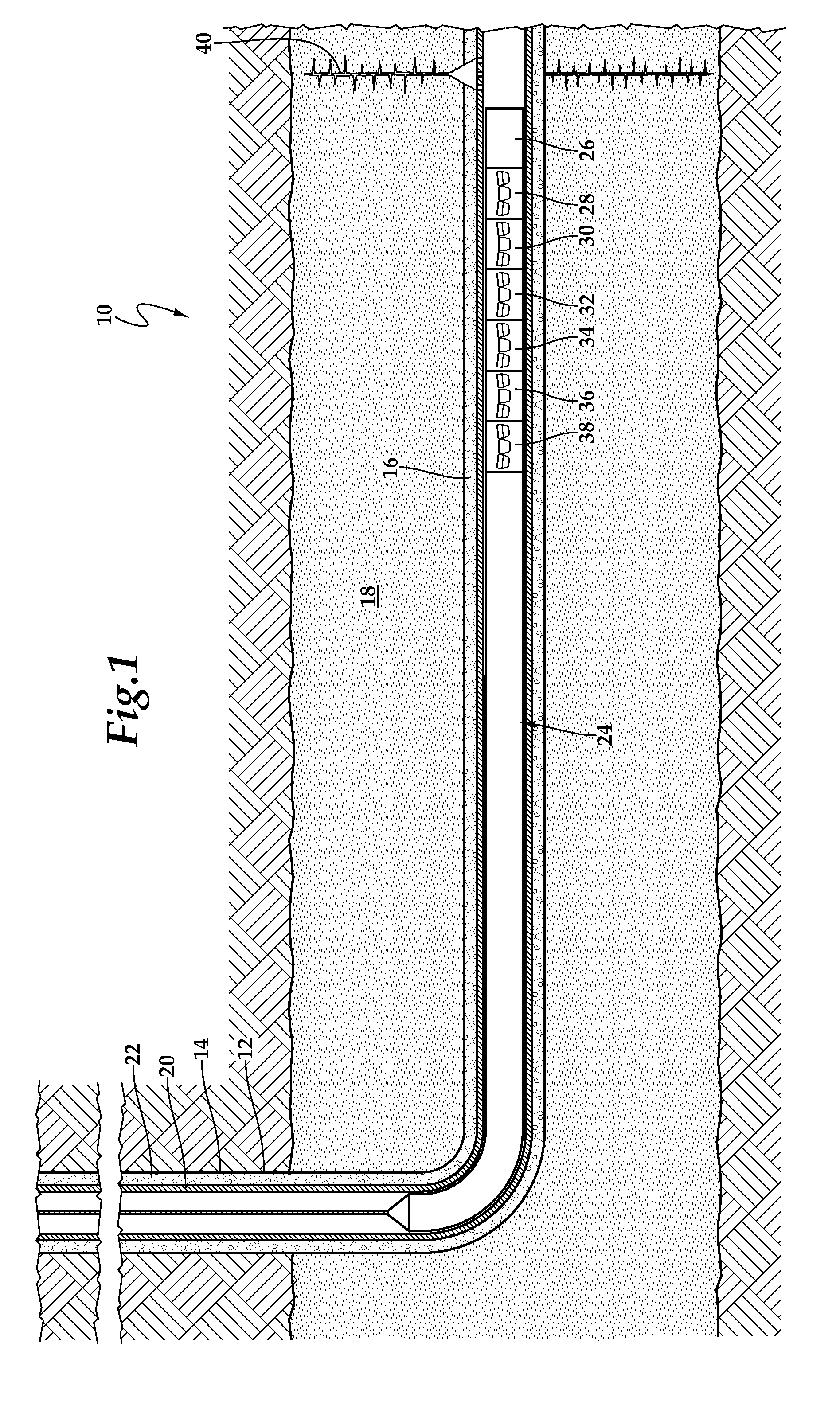

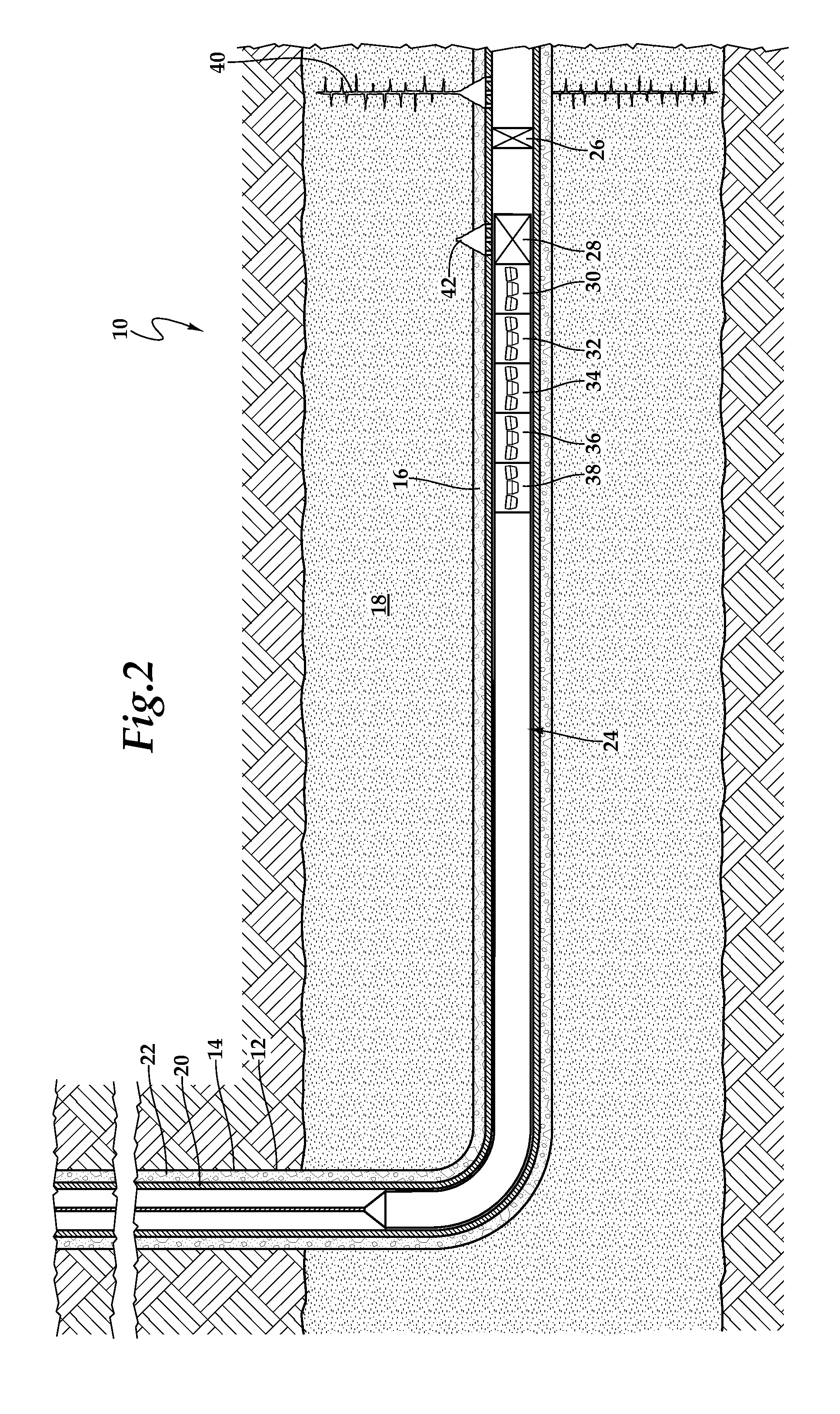

Method for Generating Discrete Fracture Initiation Sites and Propagating Dominant Planar Fractures Therefrom

A method for performing a downhole perforating and fracturing operation from a wellbore (12) positioned within a subterranean formation (18). The method includes locating a perforating gun string (24) within the wellbore (12), detonating a first perforating gun (28) to create a first discrete fracture initiation site (42) in the formation (18), repositioning the perforating gun string (24) within the wellbore (12) and detonating a second perforating gun (30) to create a second discrete fracture initiation site (44) in the formation (18). Thereafter, the method also includes pumping a fracture fluid into the wellbore (12) and propagating a single dominant planar fracture (56, 58) from each of the discrete fracture initiation sites (42, 44).

Owner:HALLIBURTON ENERGY SERVICES INC

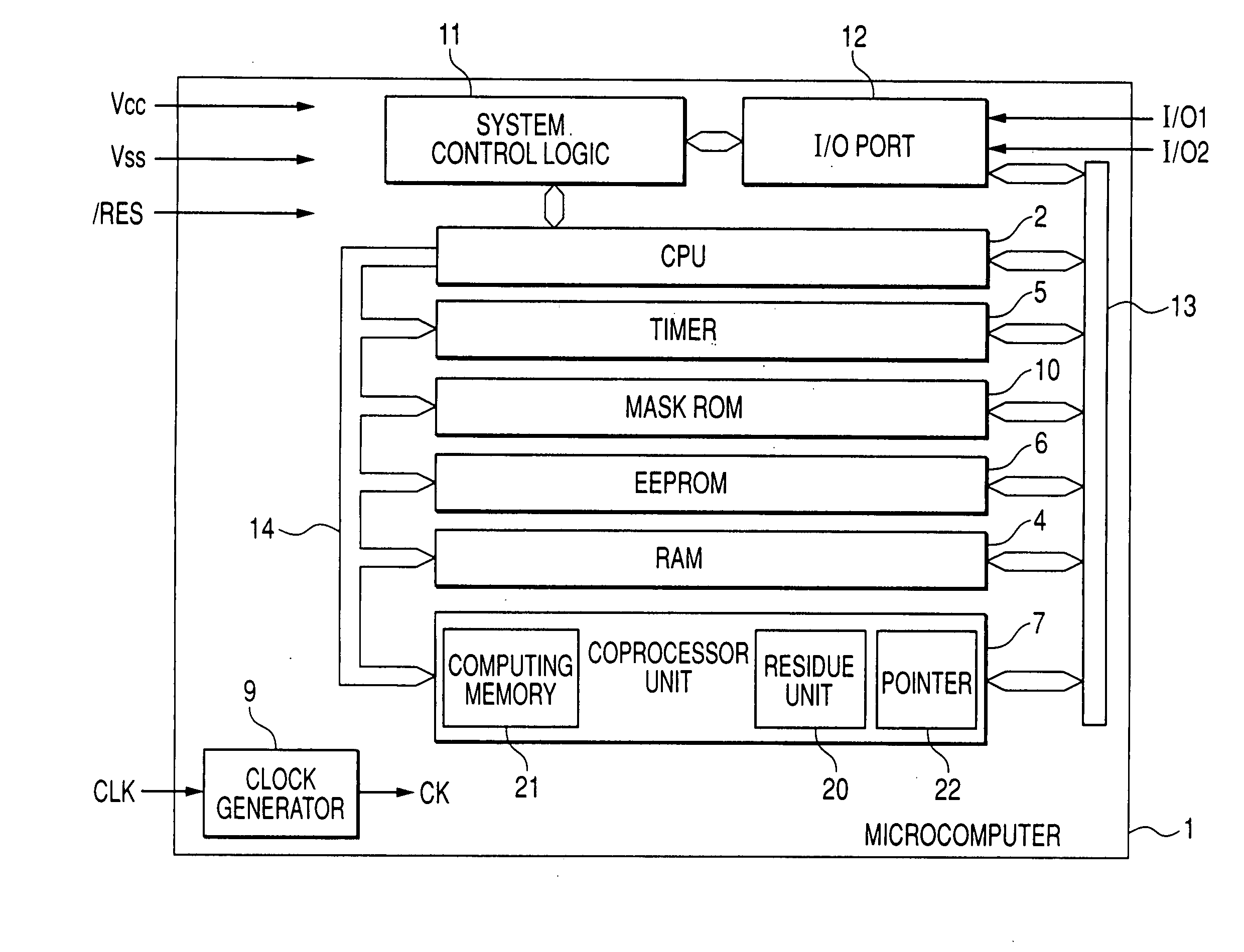

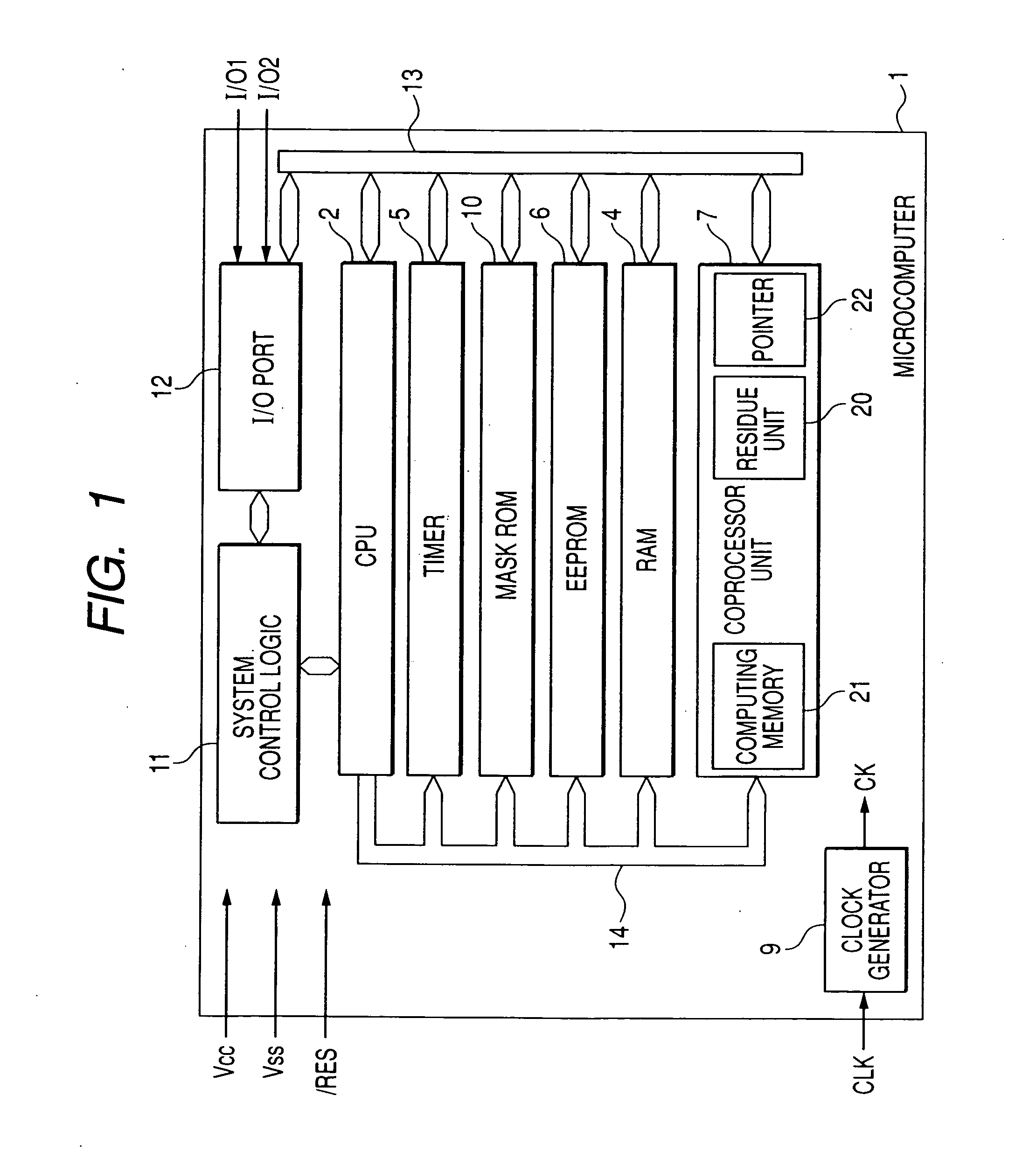

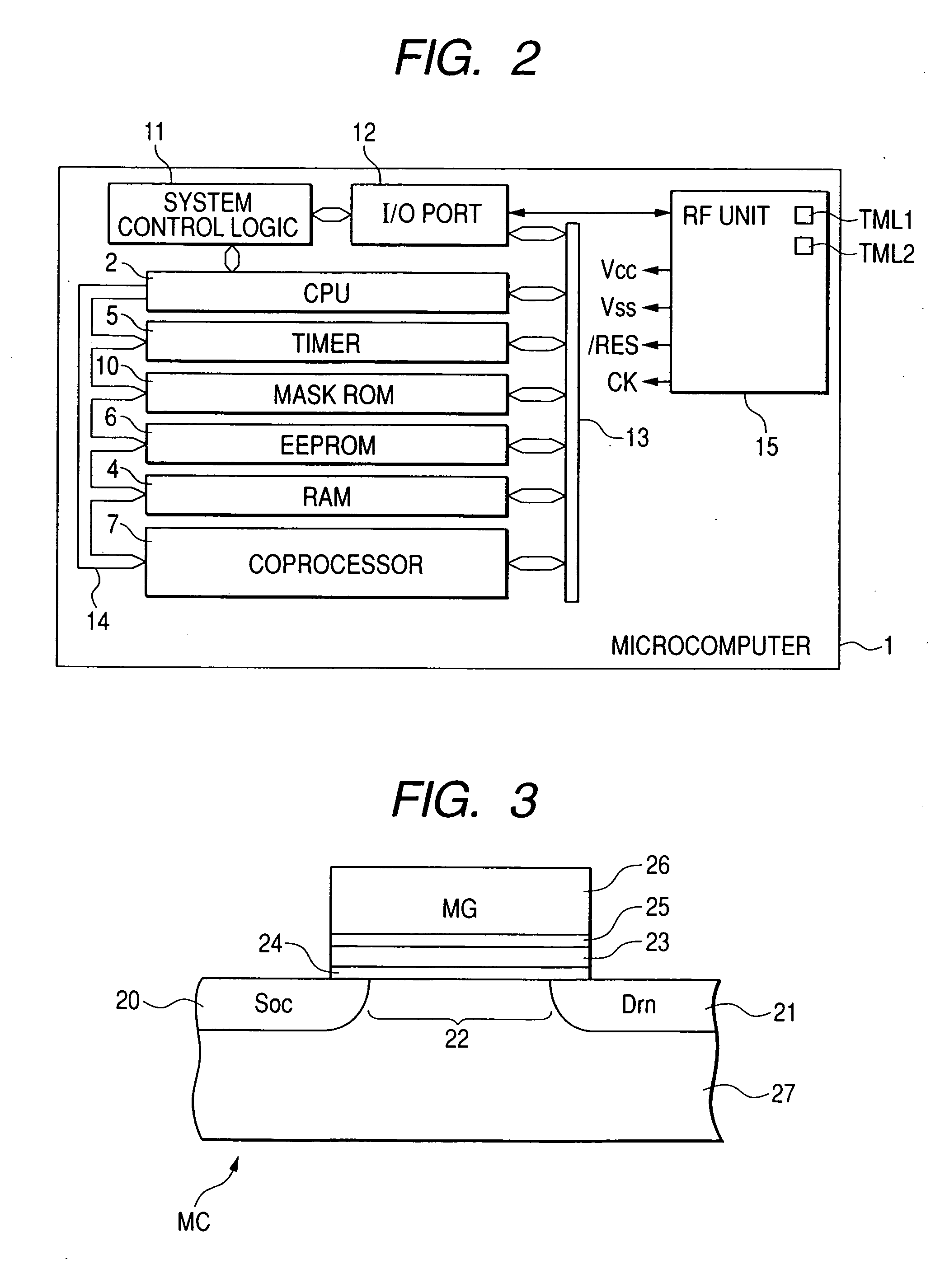

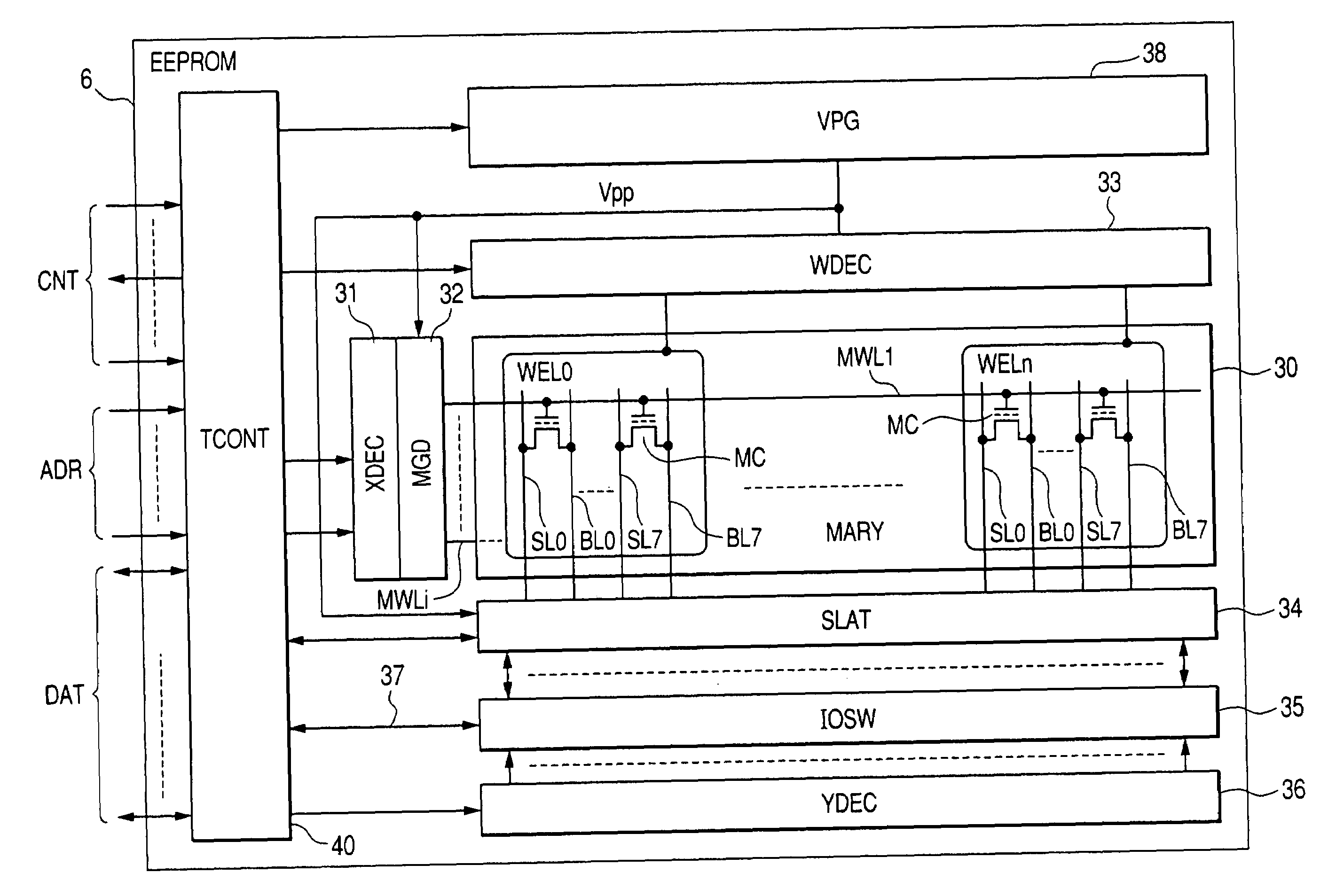

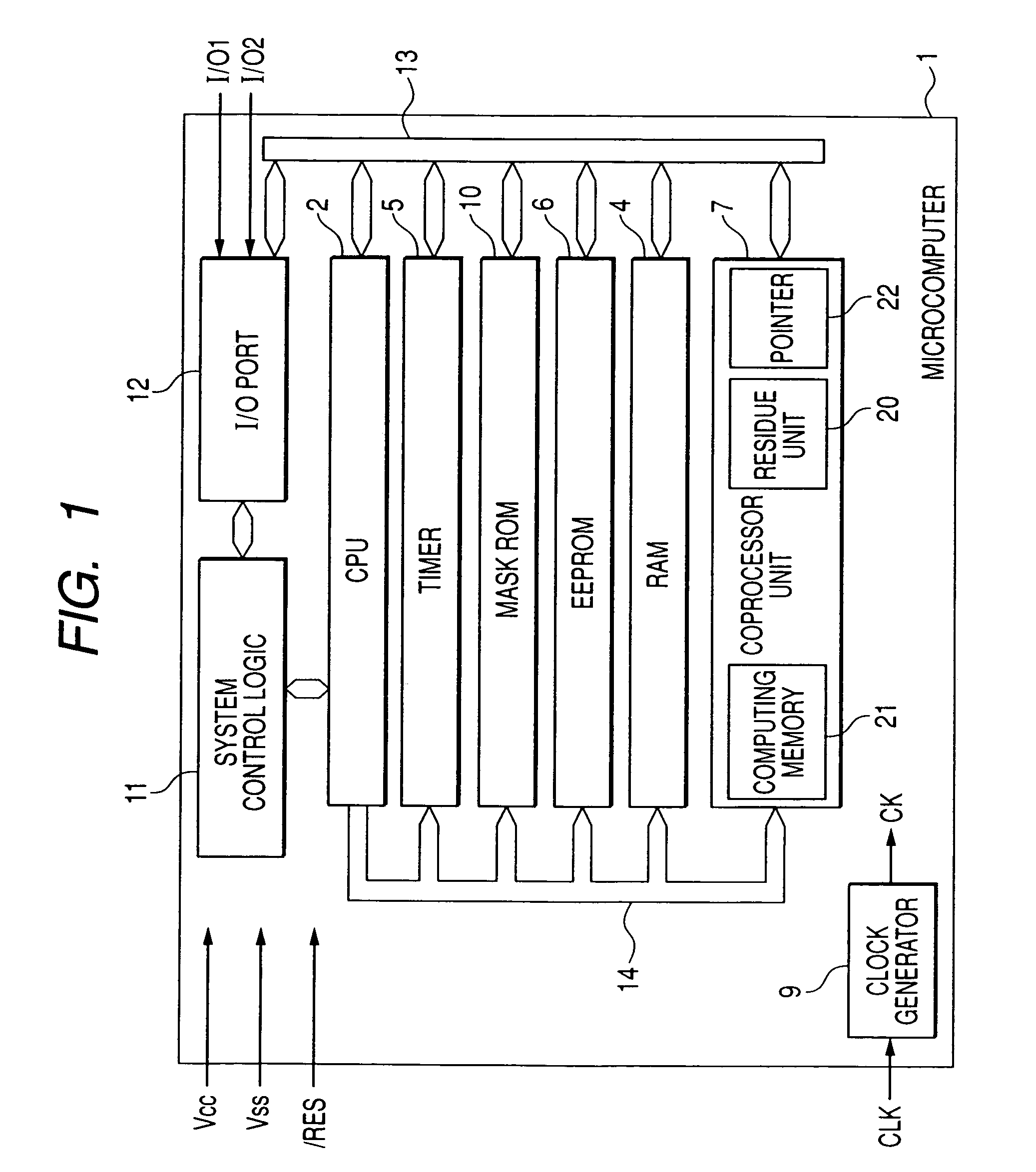

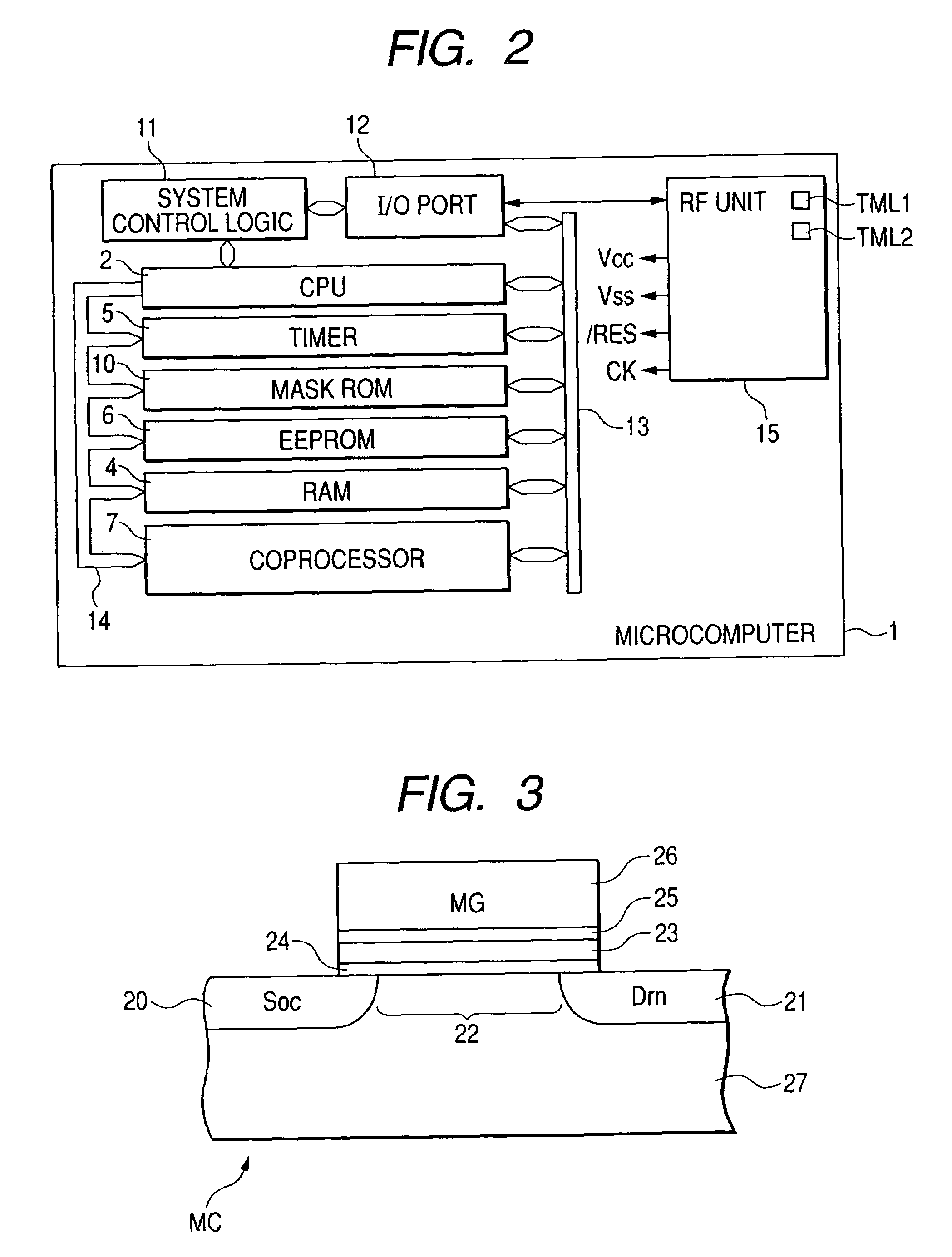

Data processing device

A delay from the release of a low power consumption mode of nonvolatile memory to the restart of read operation is reduced. Nonvolatile memory which can electrically rewrite stored information has in well regions plural nonvolatile memory cell transistors having drain electrodes and source electrodes respectively coupled to bit lines and source lines and gate electrodes coupled to word lines and storing information based on a difference between threshold voltages to a word line select level in read operation, and the nonvolatile memory has a low power consumption mode. In the low power consumption mode, a second voltage lower than a circuit ground voltage and higher than a first negative voltage necessary for read operation is supplied to the well regions and word lines. When boost forming a rewriting negative voltage therein, a circuit node at a negative voltage is not the circuit ground voltage in the low power consumption mode.

Owner:RENESAS ELECTRONICS CORP

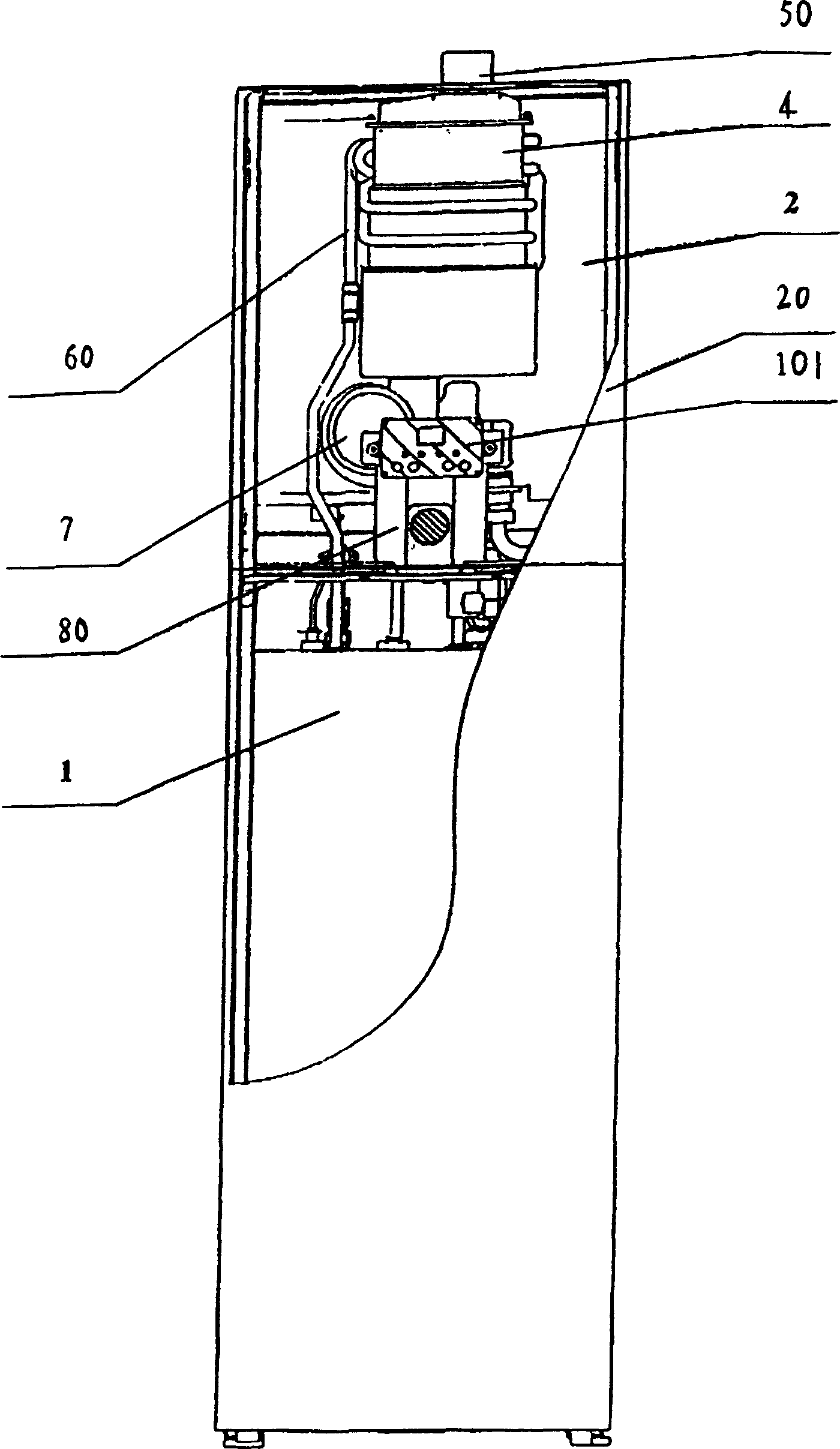

Method for Improving double heat pump hot-water system startup and adjustment performance

The invention discloses a novel method for starting and regulating working performances of a modified double heat pump bath hot-water system (i.e. a device for utilizing waste water and waste heat after bath to produce bath hot water). The method is implemented by adding a temperature-balancing tank and an electric heater at the water inlet end to shorten the start-up time and save water, and utilizing a three-way energy efficiency valve and a solenoid valve to regulate the volume of inlet waste water and thus to control the outlet water temperature. The invention has the advantages of high energy-efficiency ratio, rapid heating, and good start-up and temperature-regulation performances; and can work at a temperature below 5 DEG C.

Owner:党路明

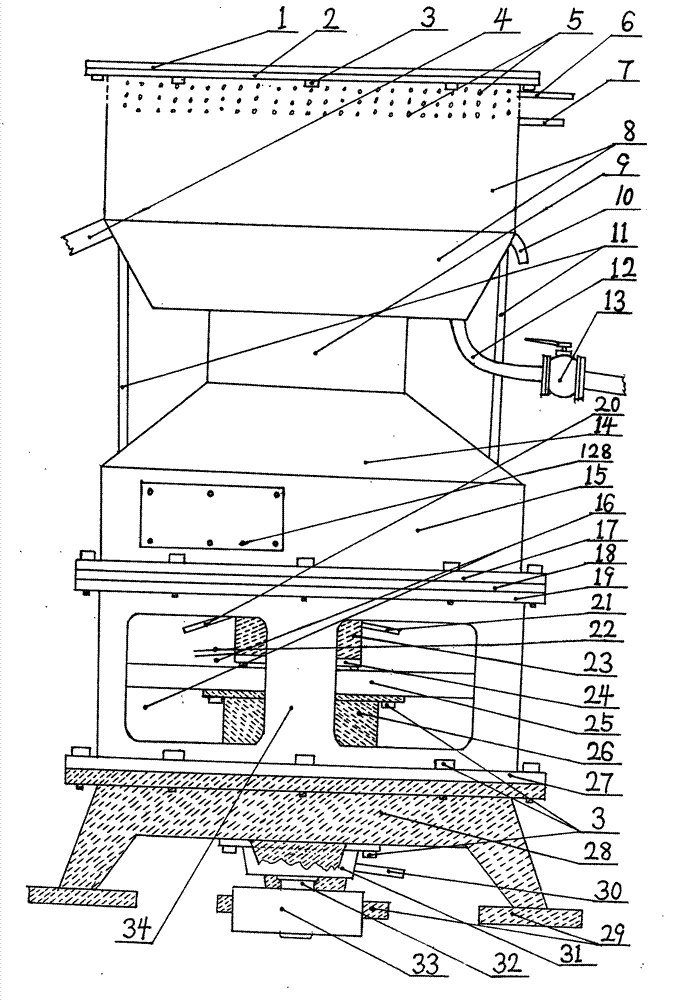

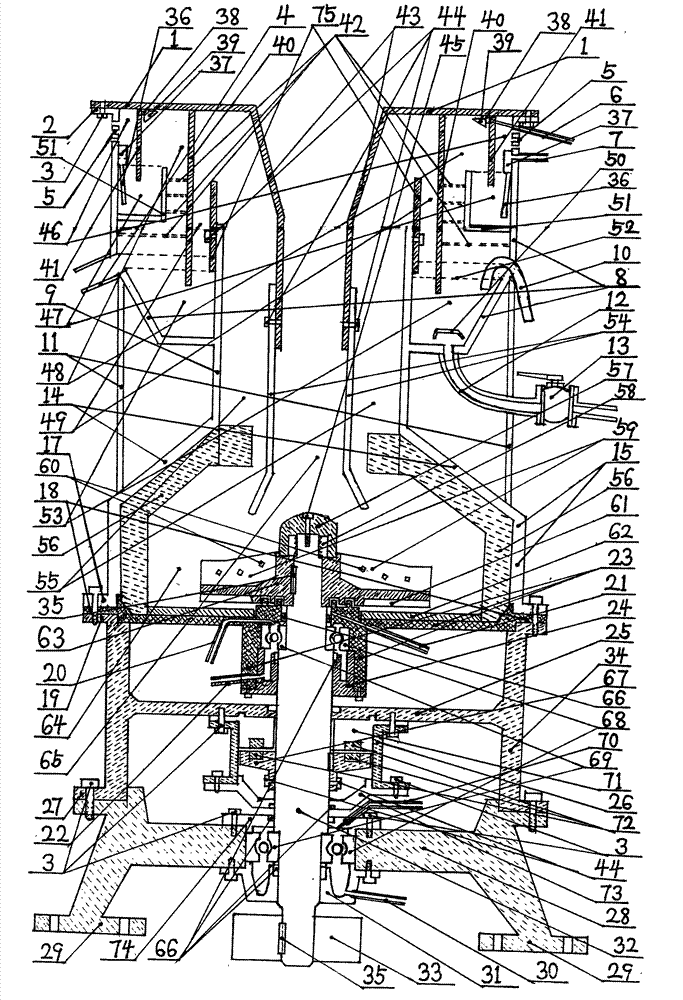

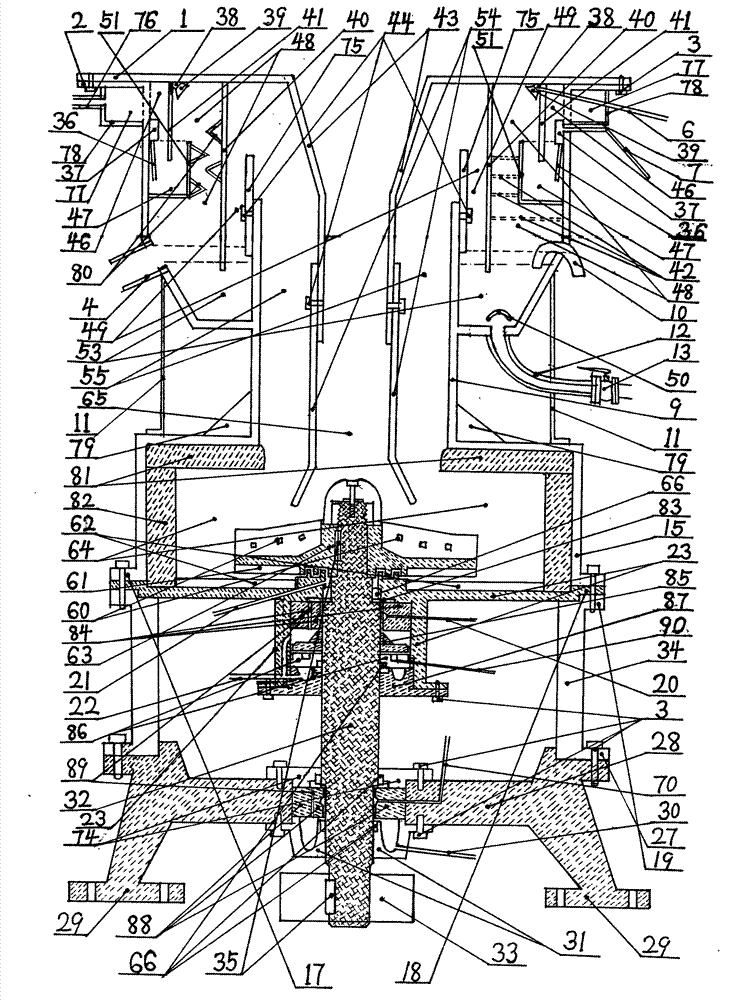

Medium-free micro pulverizer

The invention provides an ore crushing machinery without adding a crushing medium, which is a dry crushing machinery with a tower type structure; a rotating part is in the form of a longitudinal rotating shaft; one or more impeller main bodies are mounted on a shaft in series; a plurality of replaceable wear resistant blades and surface protective plates are arranged on each impeller main body, so that the impeller main body forms a rotor impeller group assembly with single-layer or multi-layer blades; a wear resistant lining layer, which comprises an upper lining plate, a material guide lining plate, an arc main lining plate, a bottom lining plate, a wear resistant fixing ring and so on, is correspondingly arranged on the periphery of each impeller; an interior cavity of each impeller forms a crushing chamber; and the crushing chambers in various stages are communicated with each other in a vertical direction. The ore crushing machinery provided by the invention has the advantages of high one-time crushing efficiency, high fine powder qualified rate, convenience in controlling, wide inlet material particle range, long service life, convenience in maintenance and no dust and noise pollution, and is very suitable for ore dressing metallurgy and architectural material industries; and standard dry powders or ore pulps can be directly produced, so that the production process is greatly simplified and production cost is reduced.

Owner:王瑞琪

Data processing device

A delay from the release of a low power consumption mode of nonvolatile memory to the restart of read operation is reduced. Nonvolatile memory which can electrically rewrite stored information has in well regions plural nonvolatile memory cell transistors having drain electrodes and source electrodes respectively coupled to bit lines and source lines and gate electrodes coupled to word lines and storing information based on a difference between threshold voltages to a word line select level in read operation, and the nonvolatile memory has a low power consumption mode. In the low power consumption mode, a second voltage lower than a circuit ground voltage and higher than a first negative voltage necessary for read operation is supplied to the well regions and word lines. When boost forming a rewriting negative voltage therein, a circuit node at a negative voltage is not the circuit ground voltage in the low power consumption mode.

Owner:RENESAS ELECTRONICS CORP

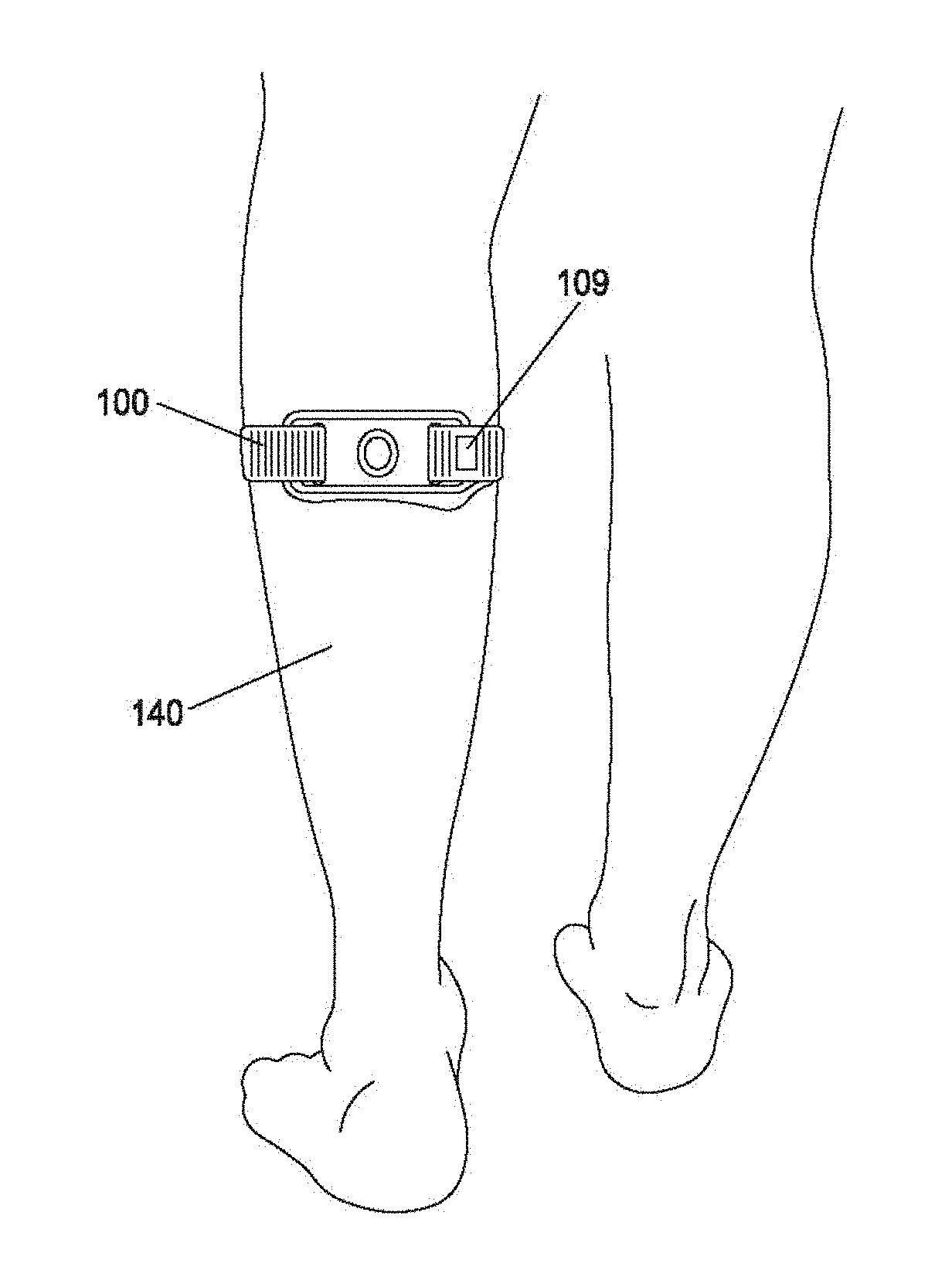

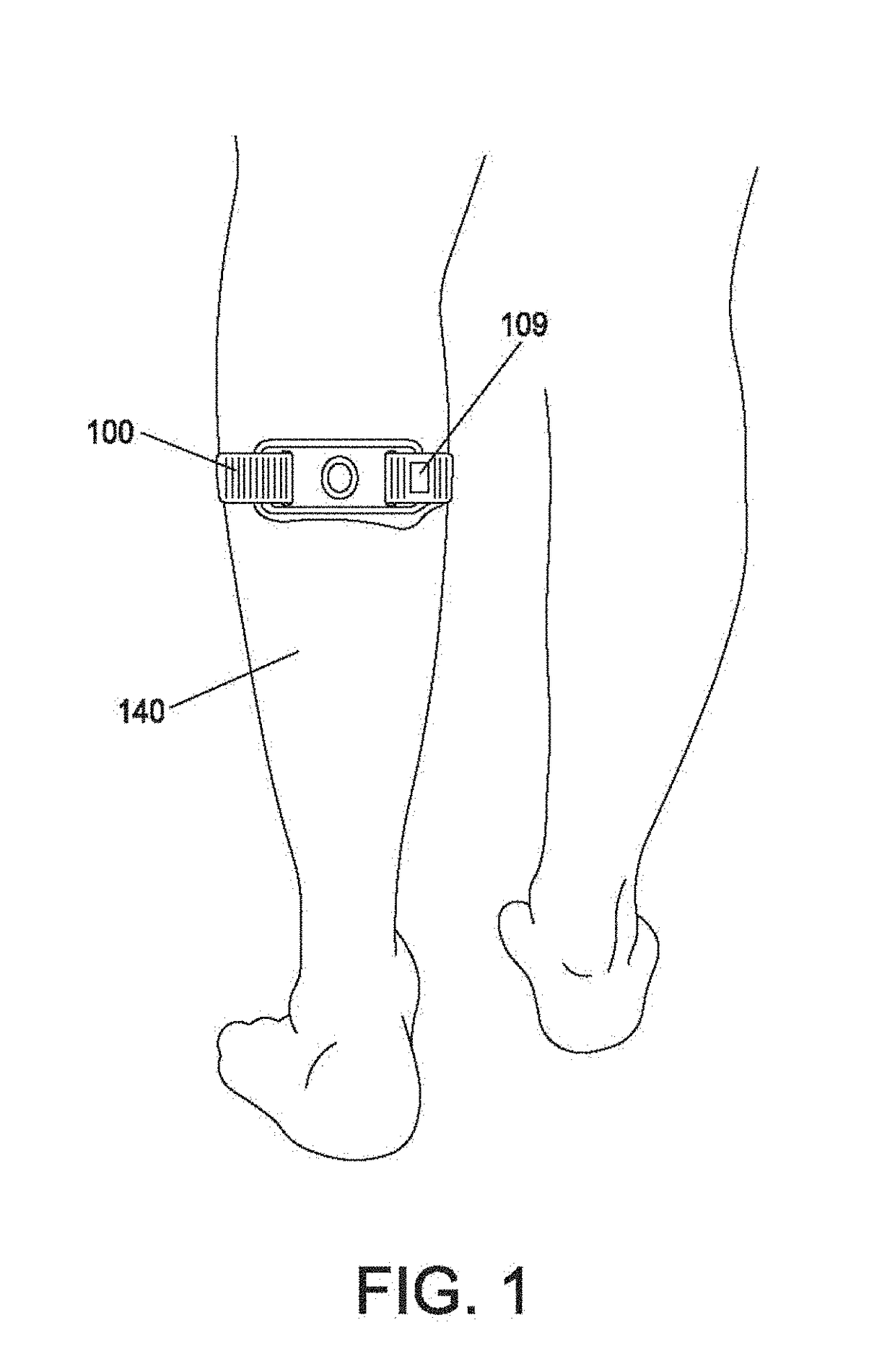

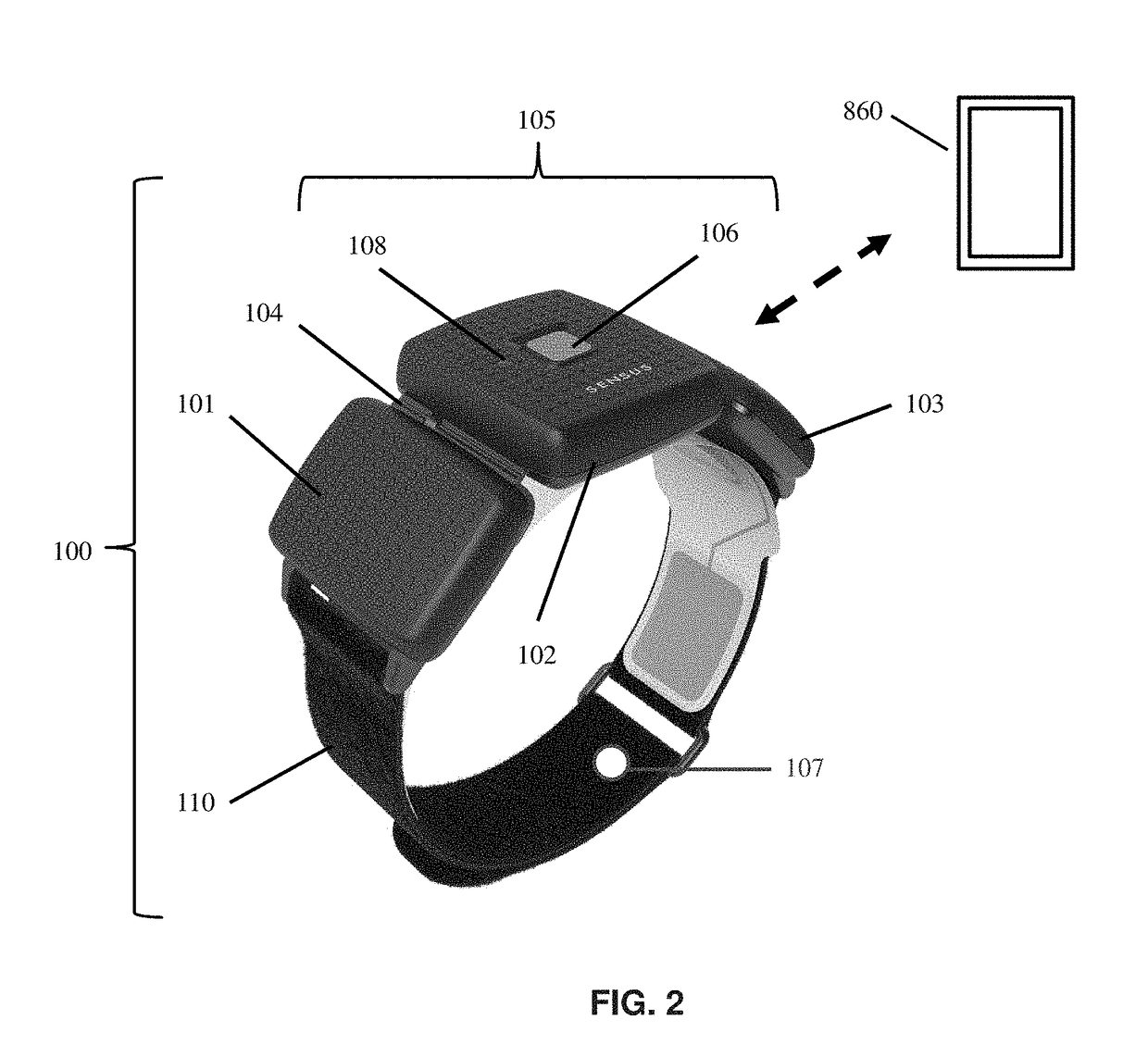

Dynamic control of transcutaneous electrical nerve stimulation therapy using continuous sleep detection

ActiveUS20170312515A1Reduce the possibilityIncrease heightSensorsExternal electrodesPhysical medicine and rehabilitationBed Status

Apparatus for providing transcutaneous electrical nerve stimulation (TENS) therapy to a user, said apparatus comprising: a housing; an application unit for providing mechanical coupling between the housing and the user's body; a stimulation unit for electrically stimulating at least one nerve of the user; a sensing unit for (i) sensing the user's body movement and body orientation to determine whether the user is in an “out-of-bed” state or a “rest-in-bed” state, and (ii) analyzing the sleep characteristics of the user during the “rest-in-bed” state; and a feedback unit for at least one of (i) providing the user with feedback in response to the analysis of the sleep characteristics of the user, and (ii) modifying the electrical stimulation provided to the user by the stimulation unit in response to the analysis of the sleep characteristics of the user; wherein the sleep characteristics comprise a likelihood measure of the user's sleep quality.

Owner:NEUROMETRIX INC

Method for generating discrete fracture initiation sites and propagating dominant planar fractures therefrom

Owner:HALLIBURTON ENERGY SERVICES INC

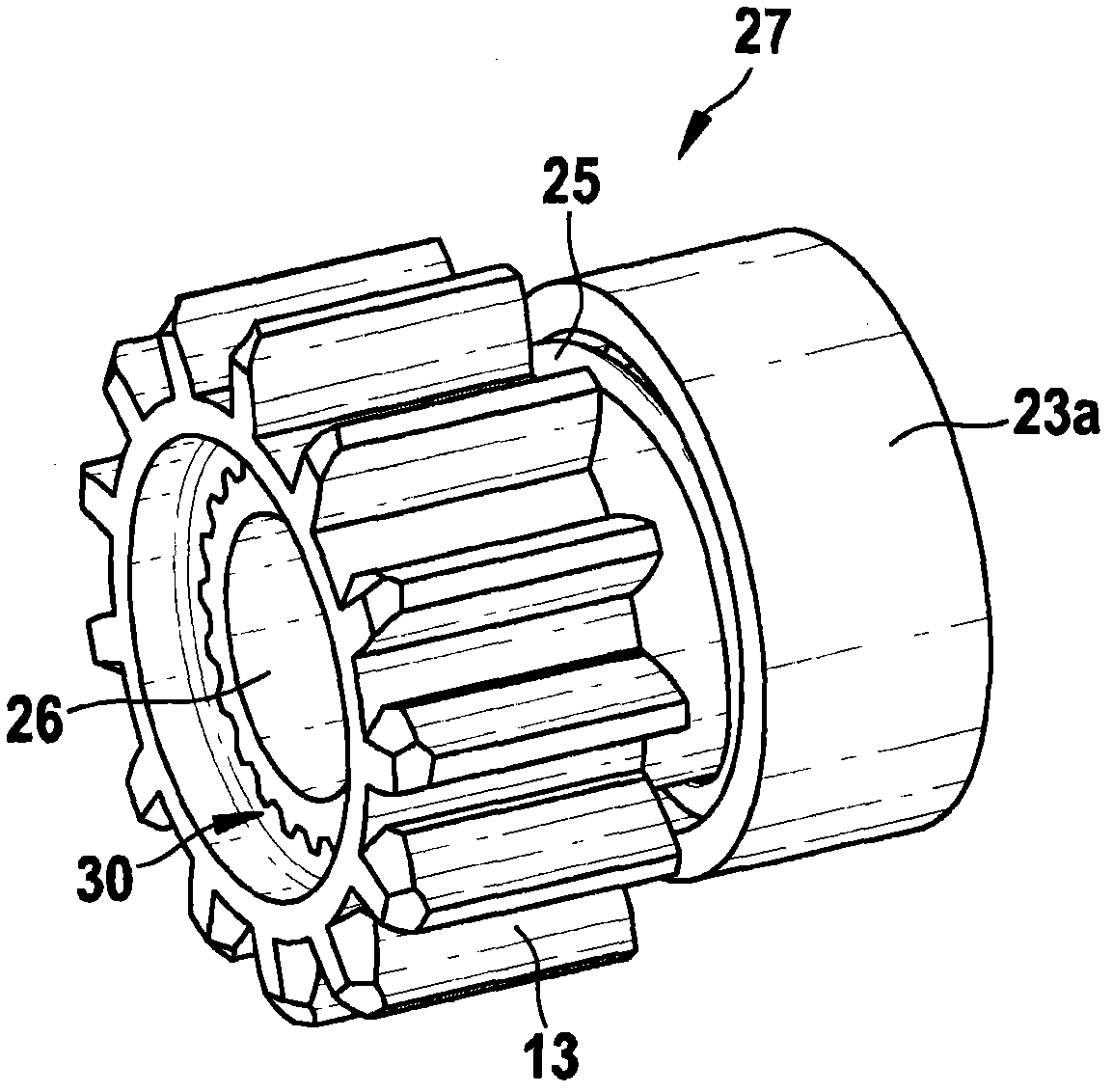

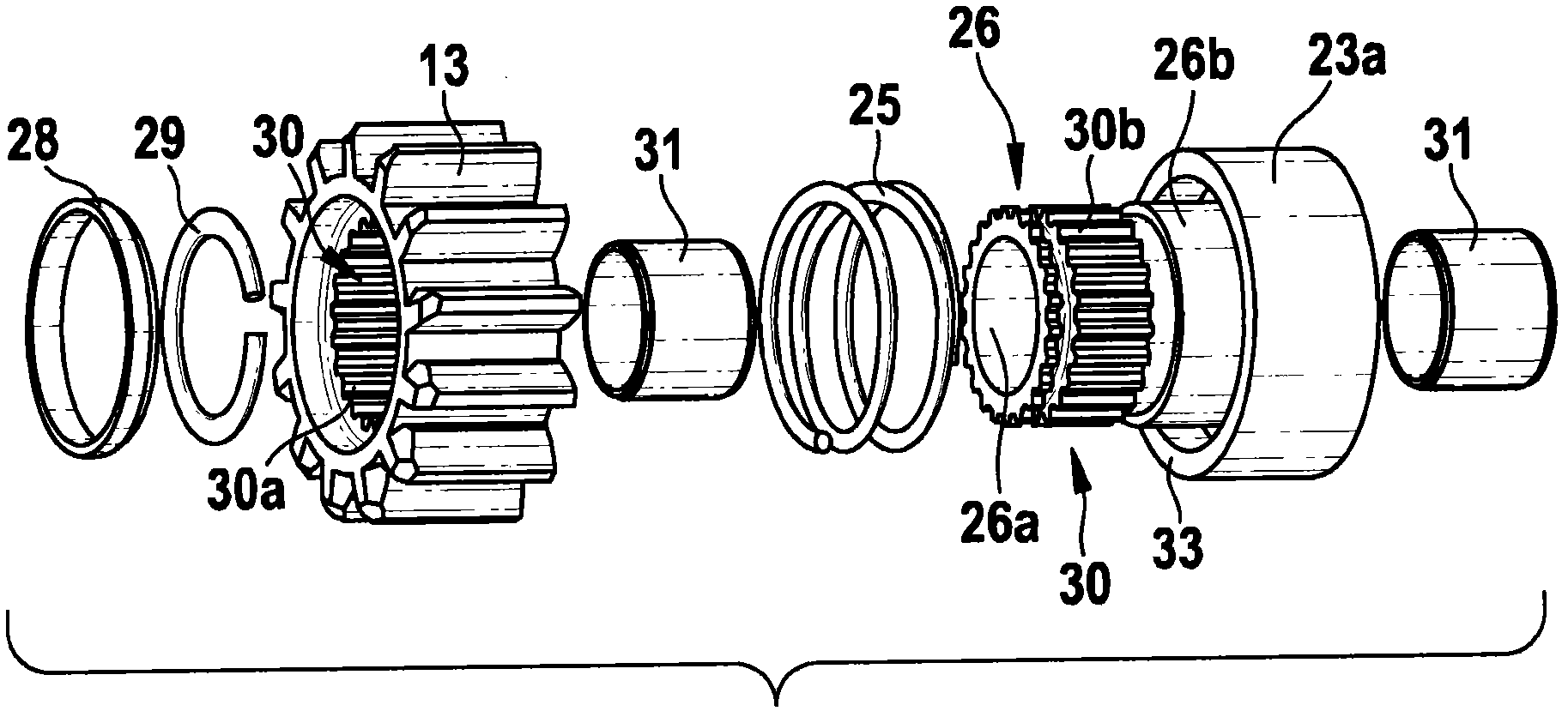

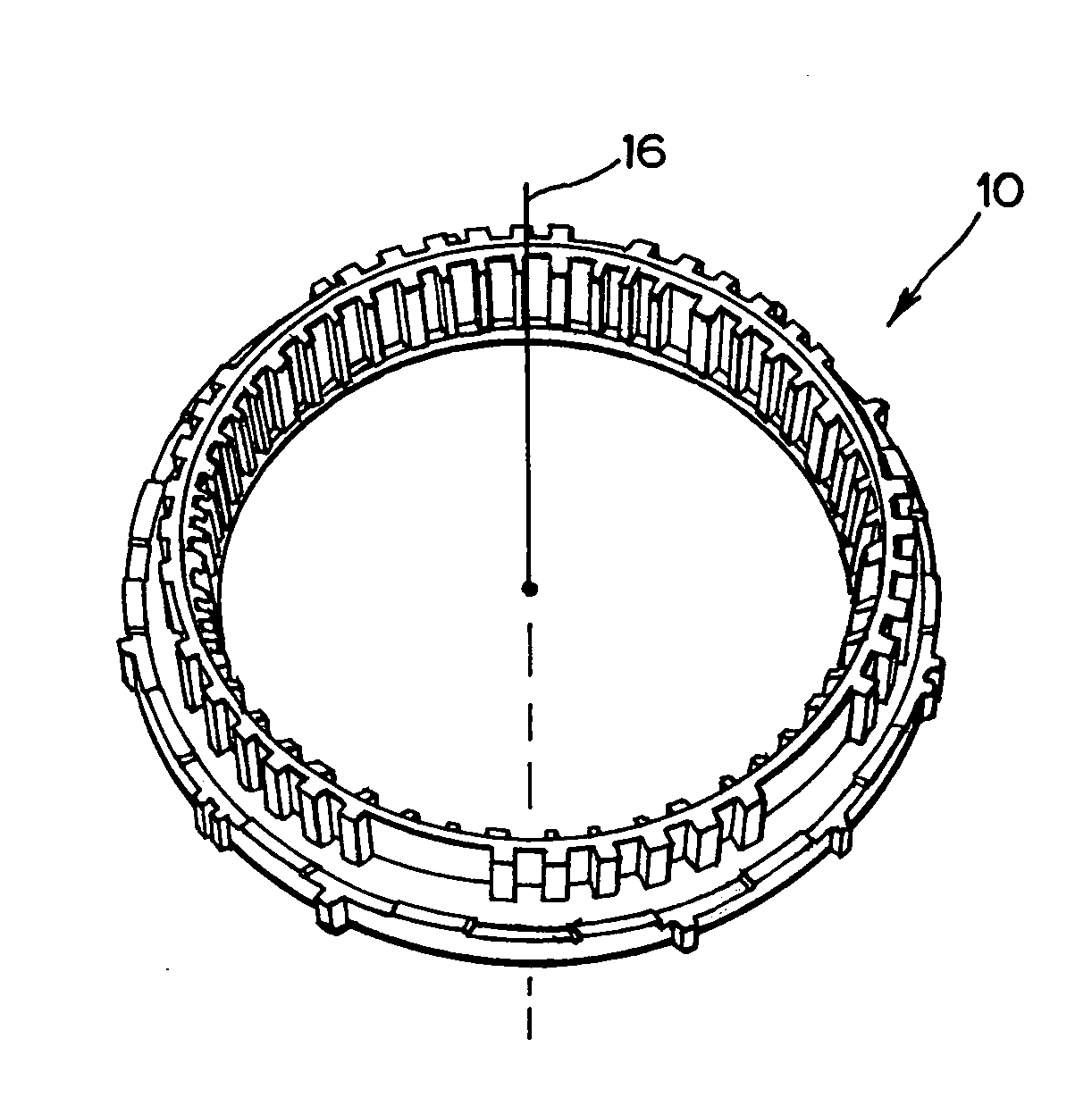

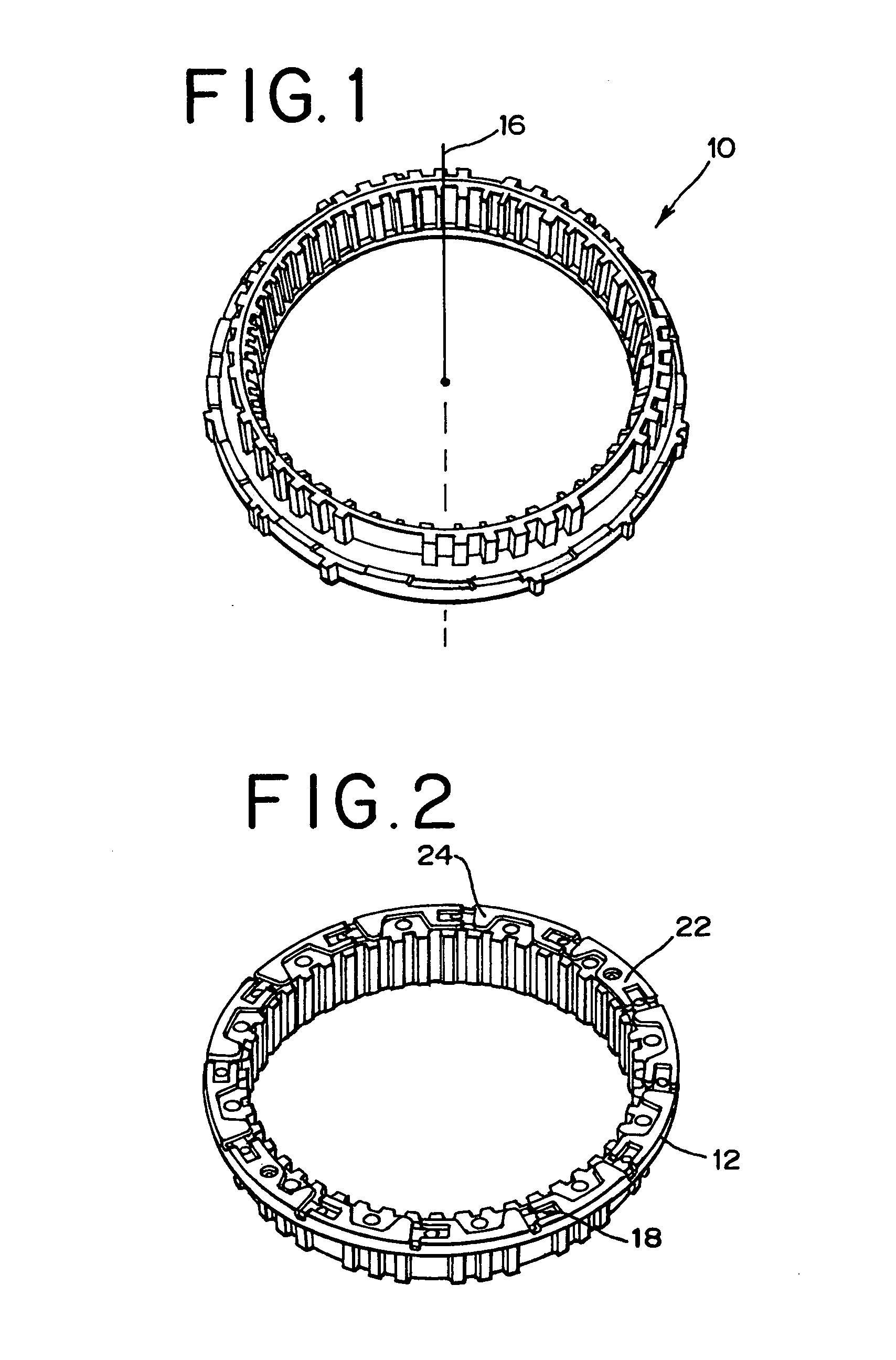

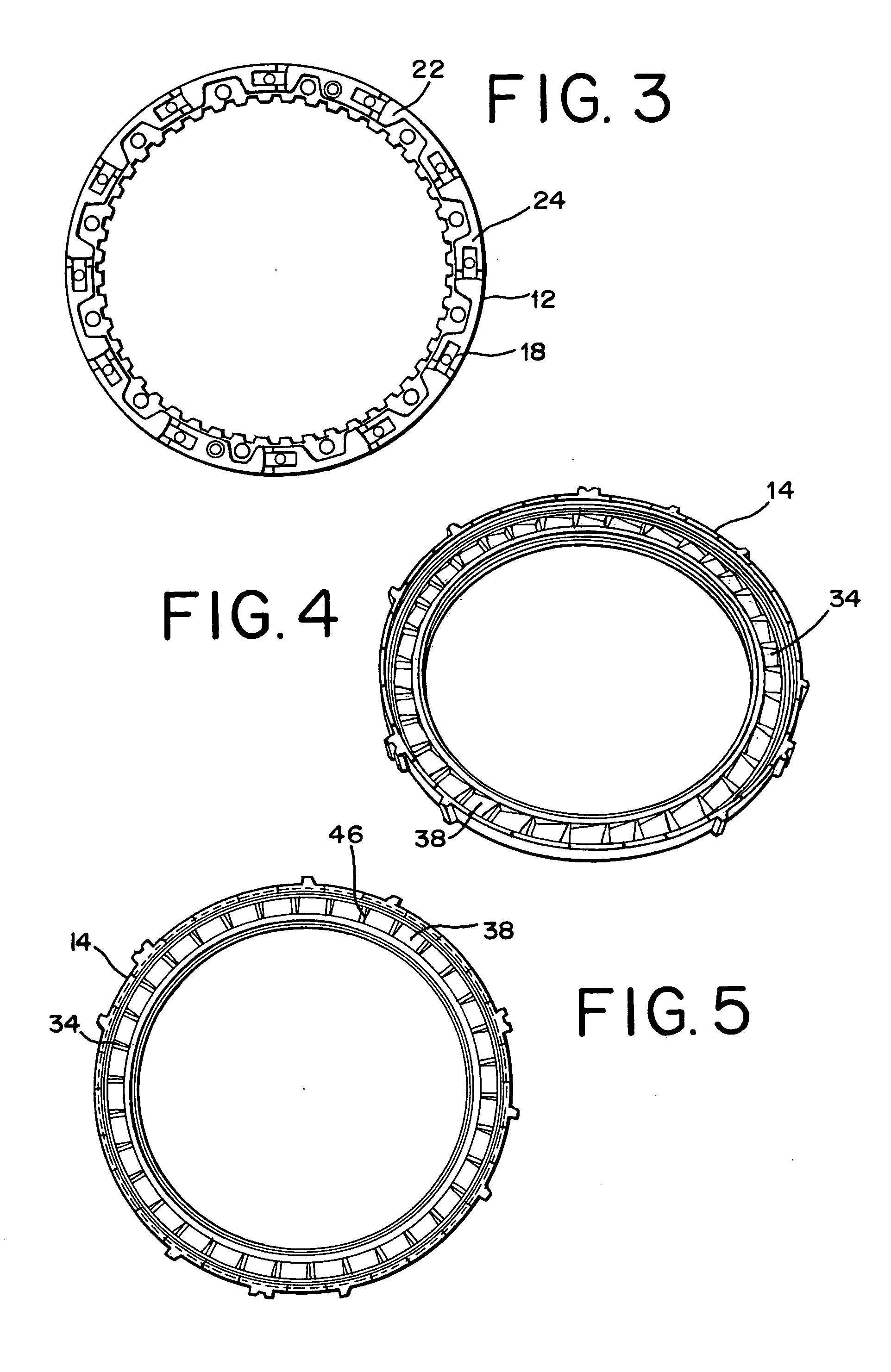

Manufacture of clutch components

InactiveUS20080095654A1Reduce materialThe material is lowTransportation and packagingMetal-working apparatusCouplingEngineering

Clutch components for automotive use usually include a pair of clutch members with operative faces. In particular, planar one way clutches include a pair of clutch members whose operative faces are enclosed spaced opposition, with each clutch face including a plurality of recessed defining respective load bearing shoulders. A plurality of struts are disposed between the coupling face of the members, and such struts are moveable between the coupling position and non coupling position. A preferable method of manufacturing such clutch components includes powder metal operations comprising die compacting a metal powder into a metal blank, sintering the metal blank to form a sintered metal blank, and cooling the sintered metal blank to form a cooled metal blank. The preferred metallic structure of the cooled metal blank is 50-80% martensite and 20-50% bainite and fine pearlite. The application is especially useful for clutches used as backing plates in clutch brake applications.

Owner:BURGESS NORTON MFG

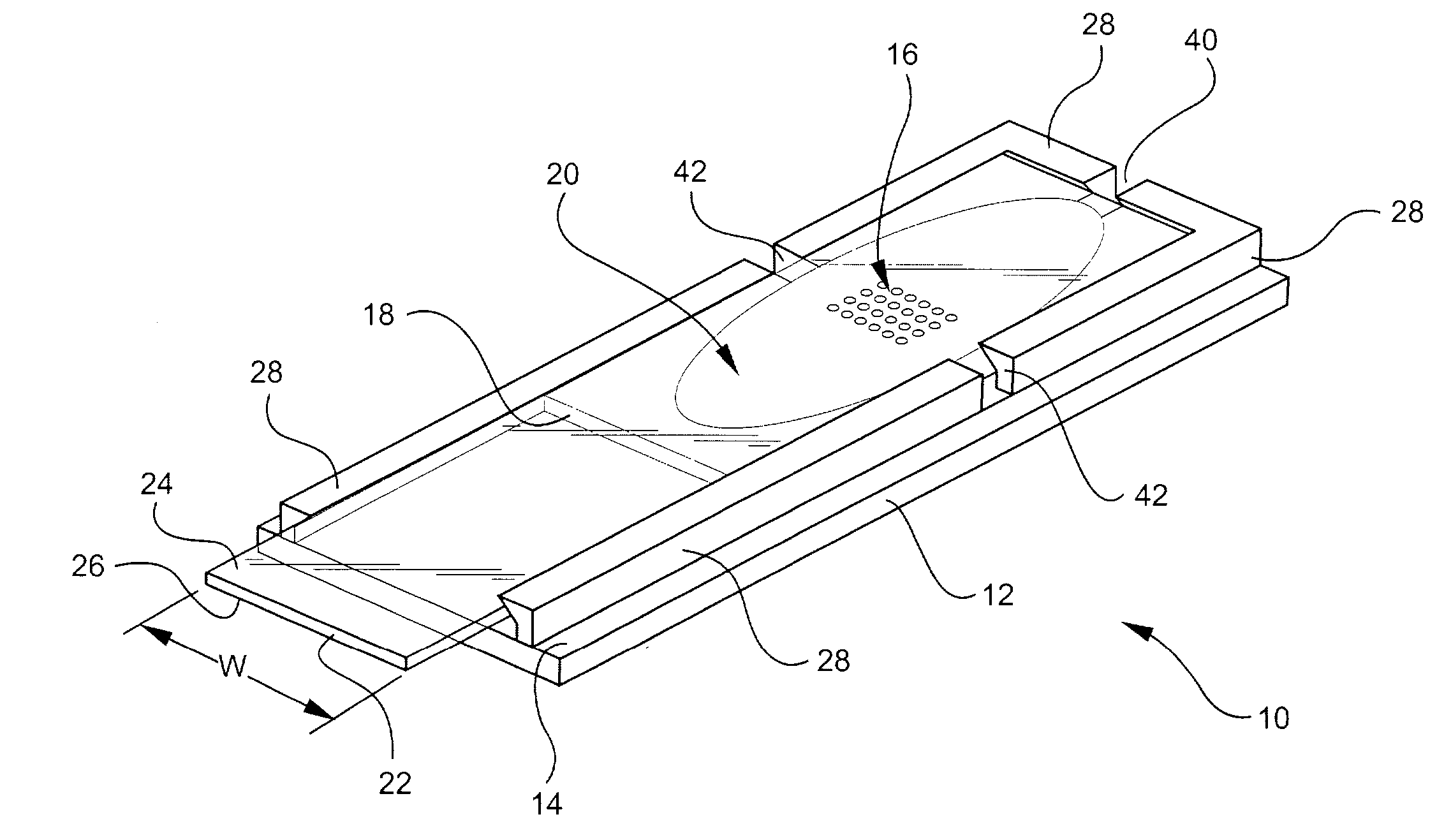

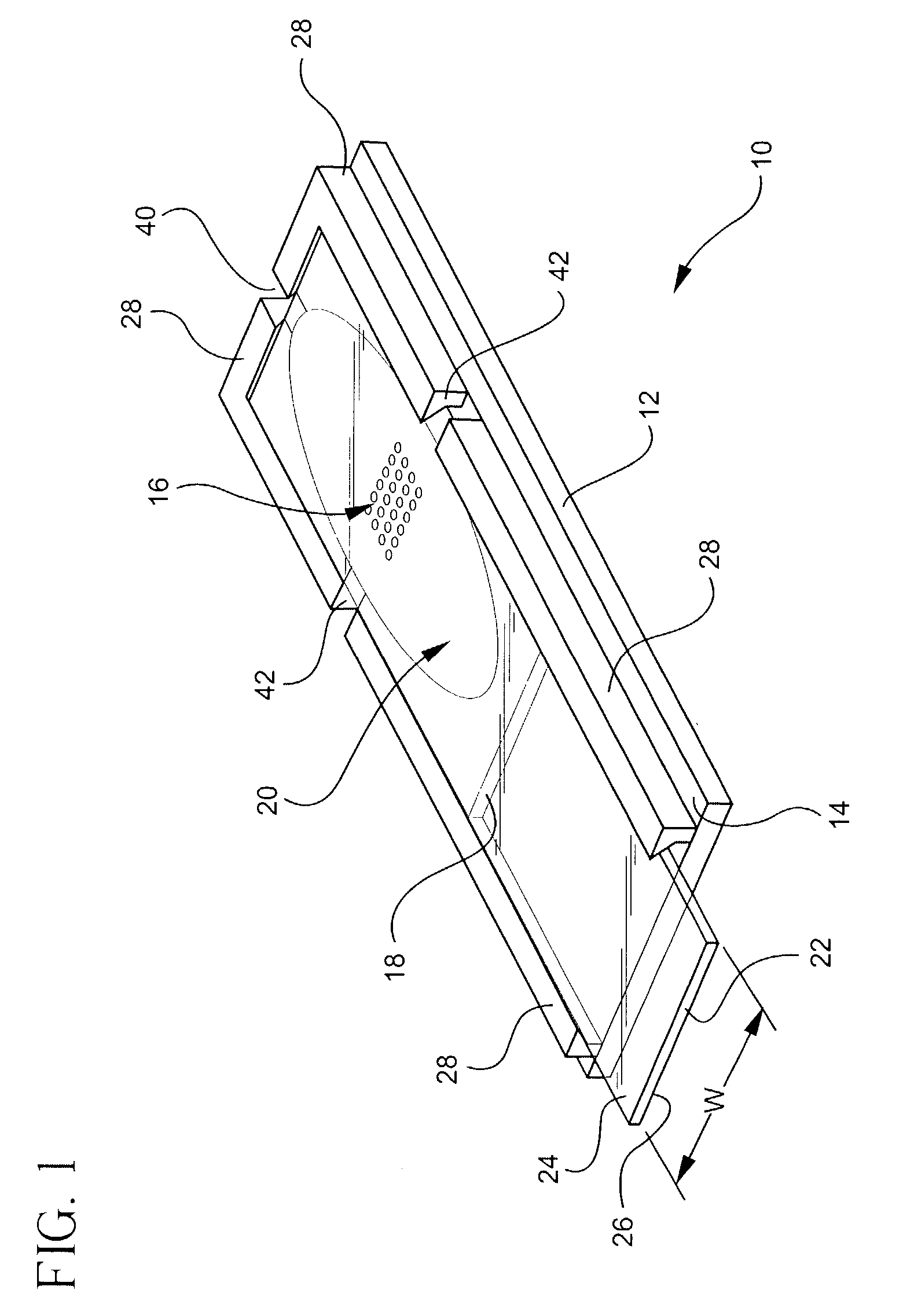

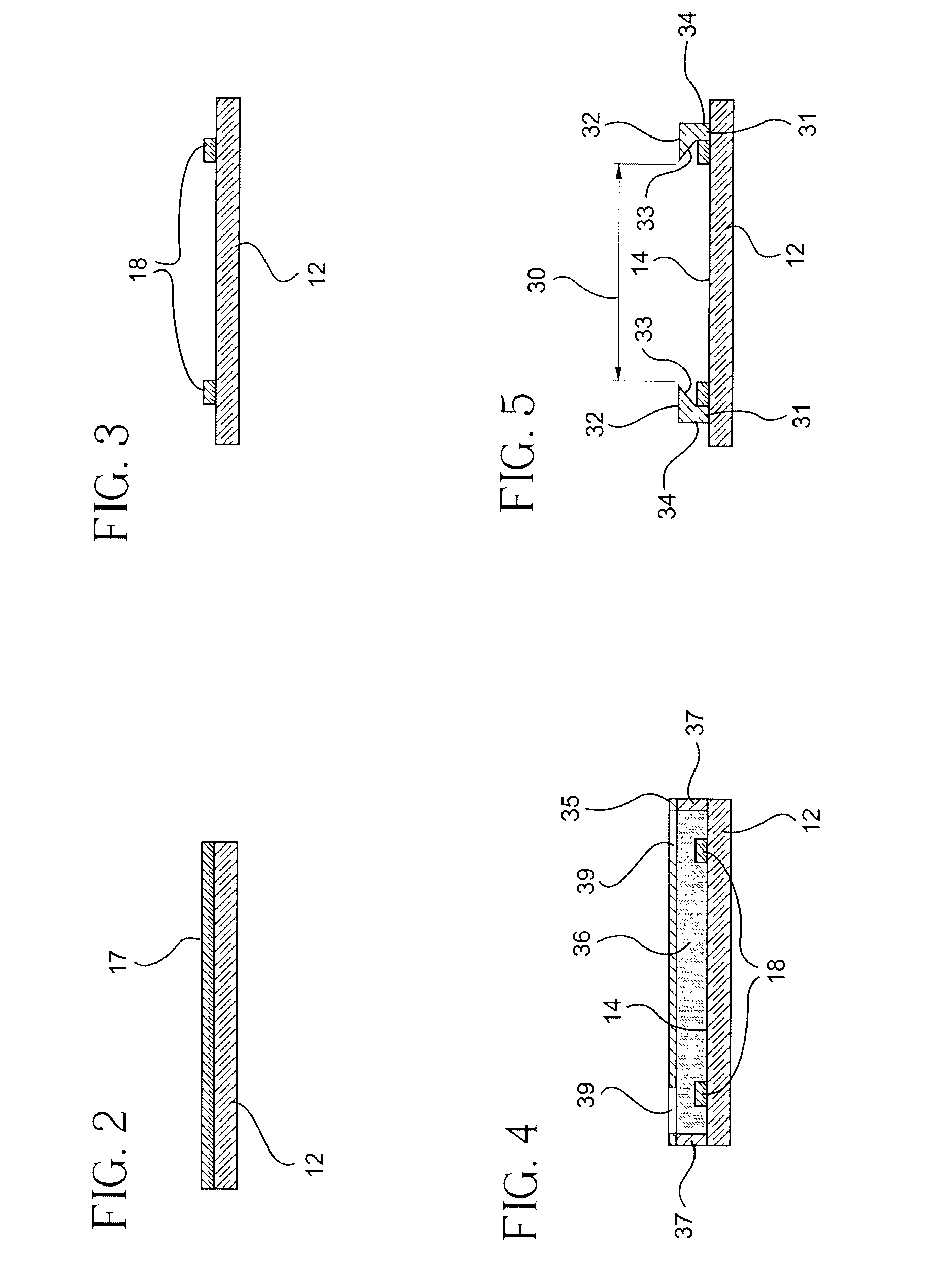

Biological and chemical reaction devices and methods of manufacture

InactiveUS20040101439A1Lower the volumeIncrease the effective concentrationPeptide librariesSequential/parallel process reactionsChemical reactionChemical physics

Methods and devices for performing biological and chemical reactions are disclosed. The devices and methods include a reaction chamber formed on a base substrate, a spacer, and a gripping element adapted to receive a cover substrate.

Owner:CORNING INC

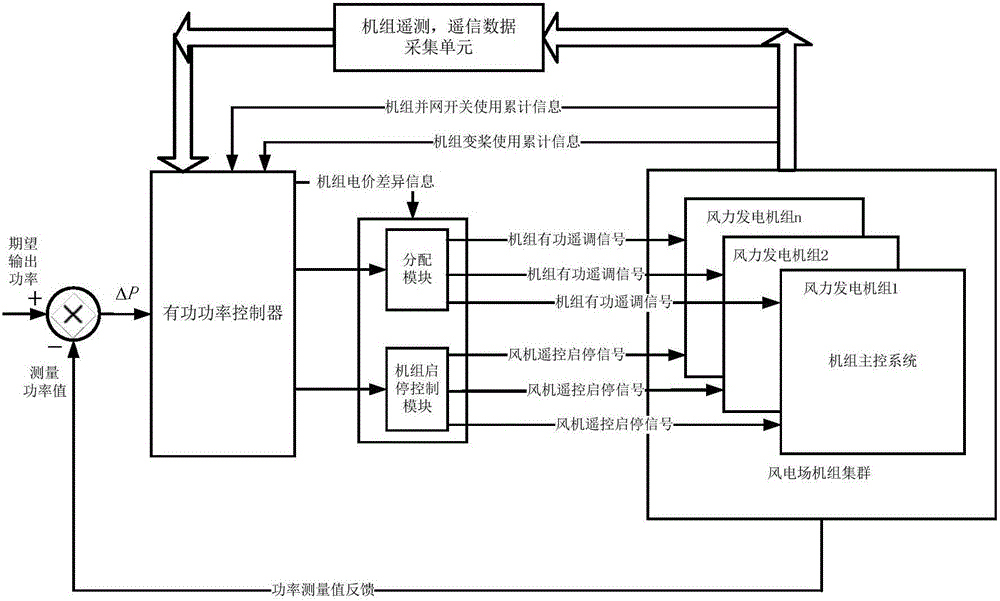

Wind farm economy-based active power adjusting method and system

ActiveCN105811472AProfit maximizationUniform service lifeSingle network parallel feeding arrangementsWind energy generationElectricity priceTurbine

The invention discloses a wind farm economy-based active power adjusting method and system. The method comprises the following steps: (A) dividing controllable priorities of all wind generator sets in a wind farm cluster according to the electricity price, and setting the wind generator set with low electricity price to be preferentially controlled high-priority set; (B) when an execution cycle T1 is reached, distributing stand-alone expected output power to all wind generator sets in the current controllable priority; (C) setting the minimum expected output power, and labeling the sets as controllable shutdown sets when the expected output power of the sets reaches the value; and (D) when an execution cycle T2 is reached, determining the shutdown order of the controllable shutdown sets according to the accumulated use frequencies of grid-connected switches of the sets and preferentially shutting down the set of which the grid-connected switch is low in accumulated use frequency. Active power adjusting control is carried out based on the wind farm economy; and the maximum profits of the wind farm and the minimum capital investment into wind turbine components can be achieved.

Owner:GUODIAN UNITED POWER TECH

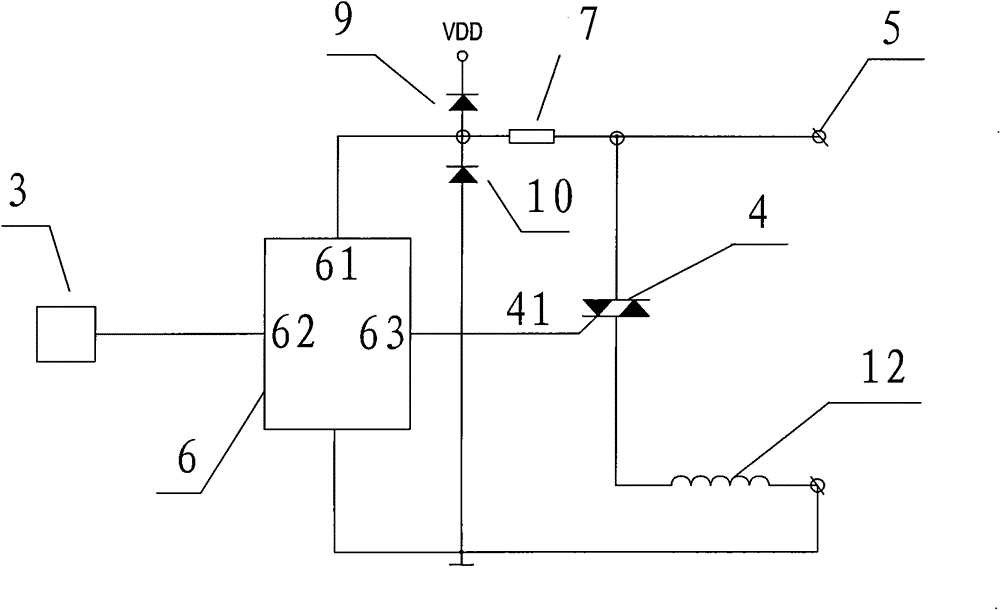

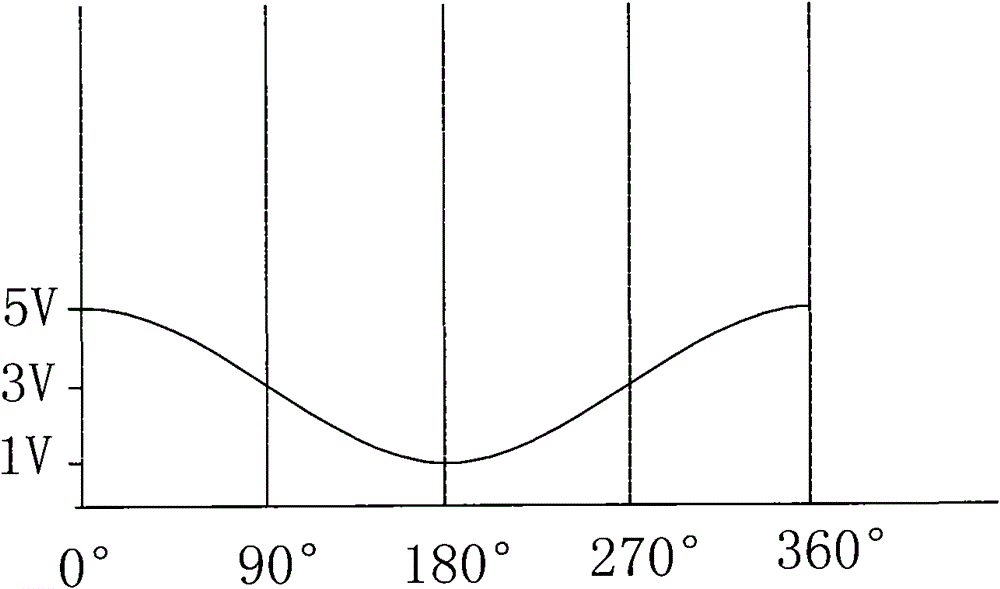

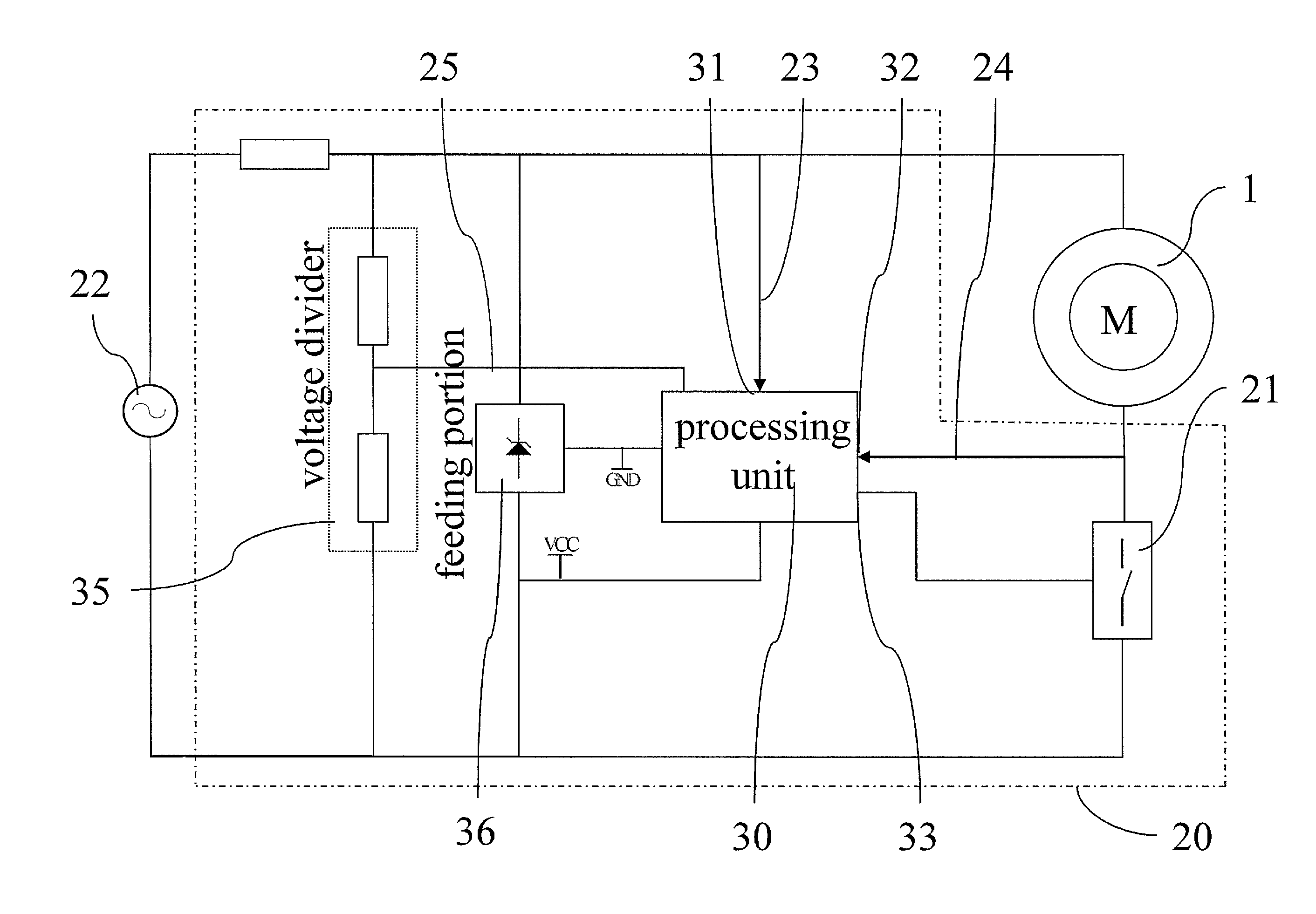

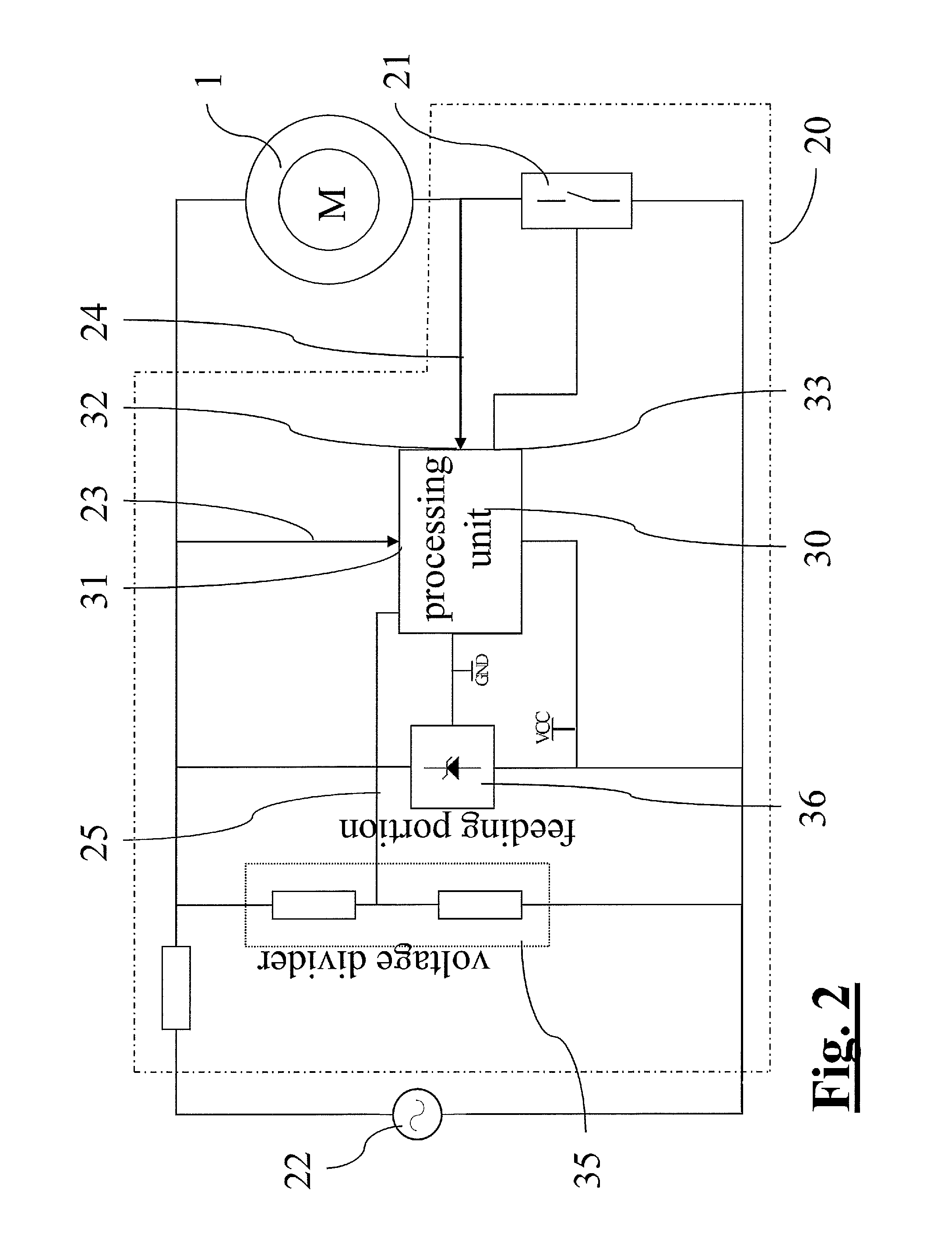

Method for starting a permanent magnet single-phase synchronous electric motor and electronic device for implementing said method

ActiveUS8164286B2Simple and effective startingReduce startMotor/generator/converter stoppersAC motor controlSynchronous motorPower grid

Method for starting a single-phase synchronous electric motor using permanent magnets with simple and cost-effective implementation, said method comprising a step of application of a control logic of the switch that provides a first and a second condition for switching on:the first condition being verified when a detected counter electromotive force signal has the same sign as an electrical grid voltage signal;the second condition being verified when said counter electromotive force signal has the same sign as its first derivative value.

Owner:ASKOLL HLDG SRL

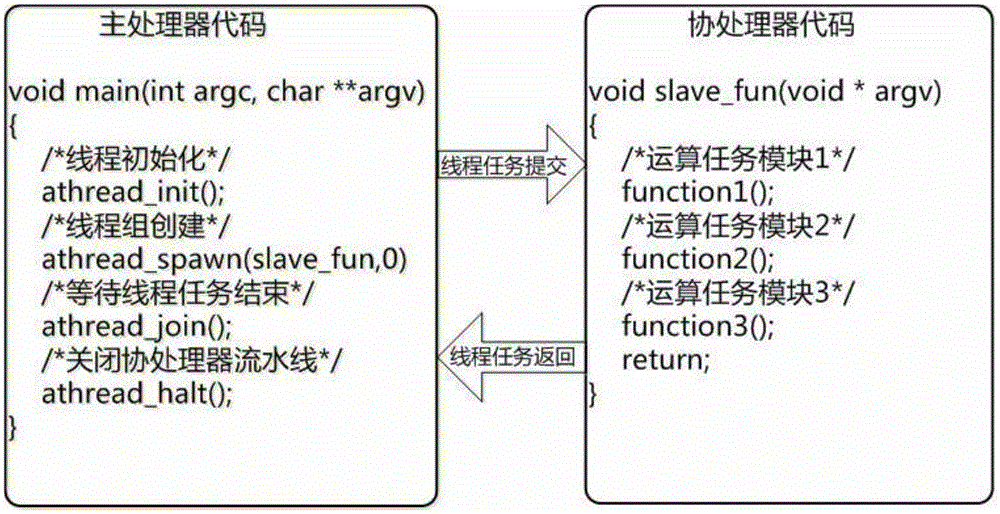

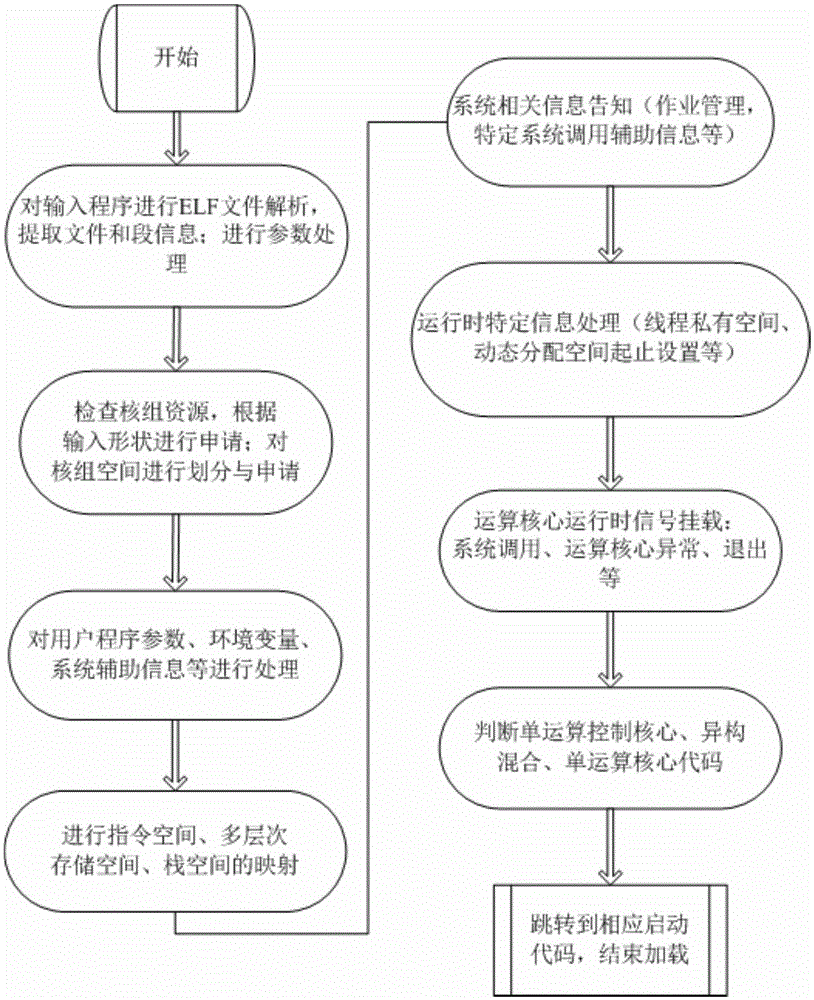

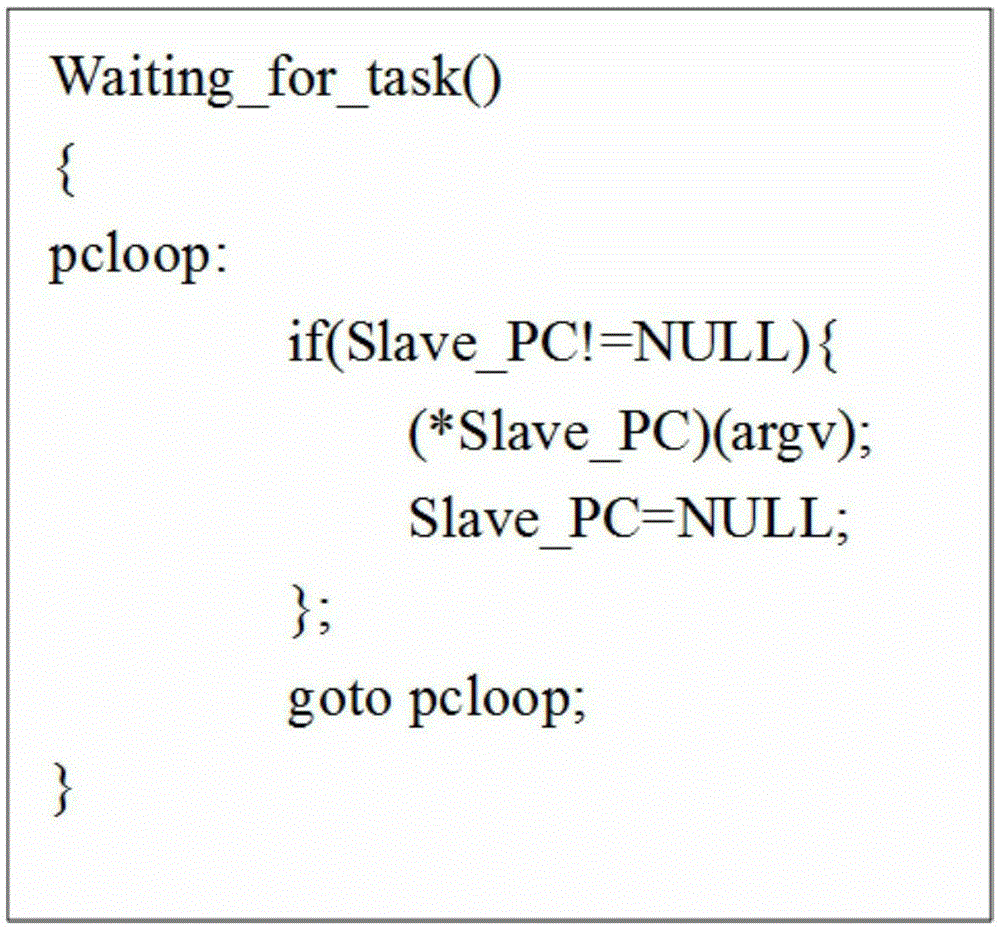

Quick lightweight thread triggering method based on heterogeneous many-core

ActiveCN105242962AReduce maintenance costsReduce startMultiprogramming arrangementsProgram loading/initiatingMaster processorProgram code

The invention provides a quick lightweight thread triggering method based on a heterogeneous many-core. The quick lightweight thread triggering method comprises the steps that a multi-thread program of the heterogeneous many-core is written in a lightweight thread library, establishing and recycling of the multi-thread program in the lightweight thread library are called through an explicit interface, and then compiling of a multi-thread program code is completed to generate an executable code of the heterogeneous many-core; the executable code is operated; a program loader operated on a main processor is firstly carried out, and then the executable code serves as a parameter to be uploaded to the program loader; the program loader reads the executable code by taking the overall executable code as a document, then analyzes segment information confirming to an ELF format, writes the segment information in the corresponding position of a memory and completes configuration of program execution environment variables.

Owner:JIANGNAN INST OF COMPUTING TECH

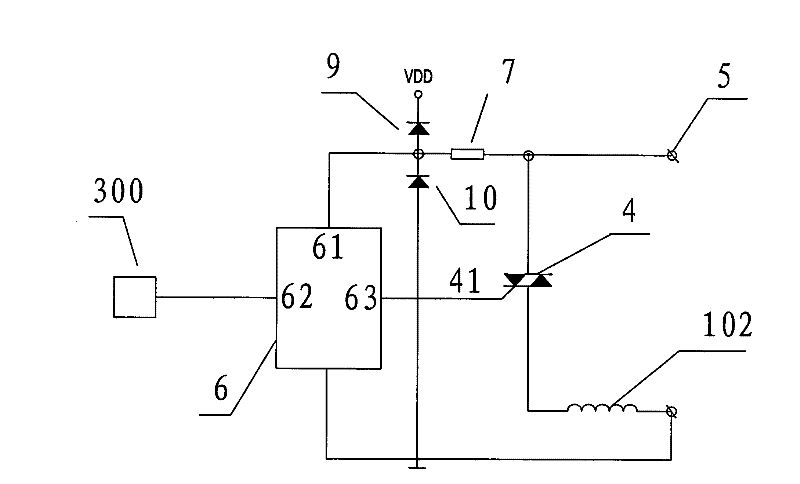

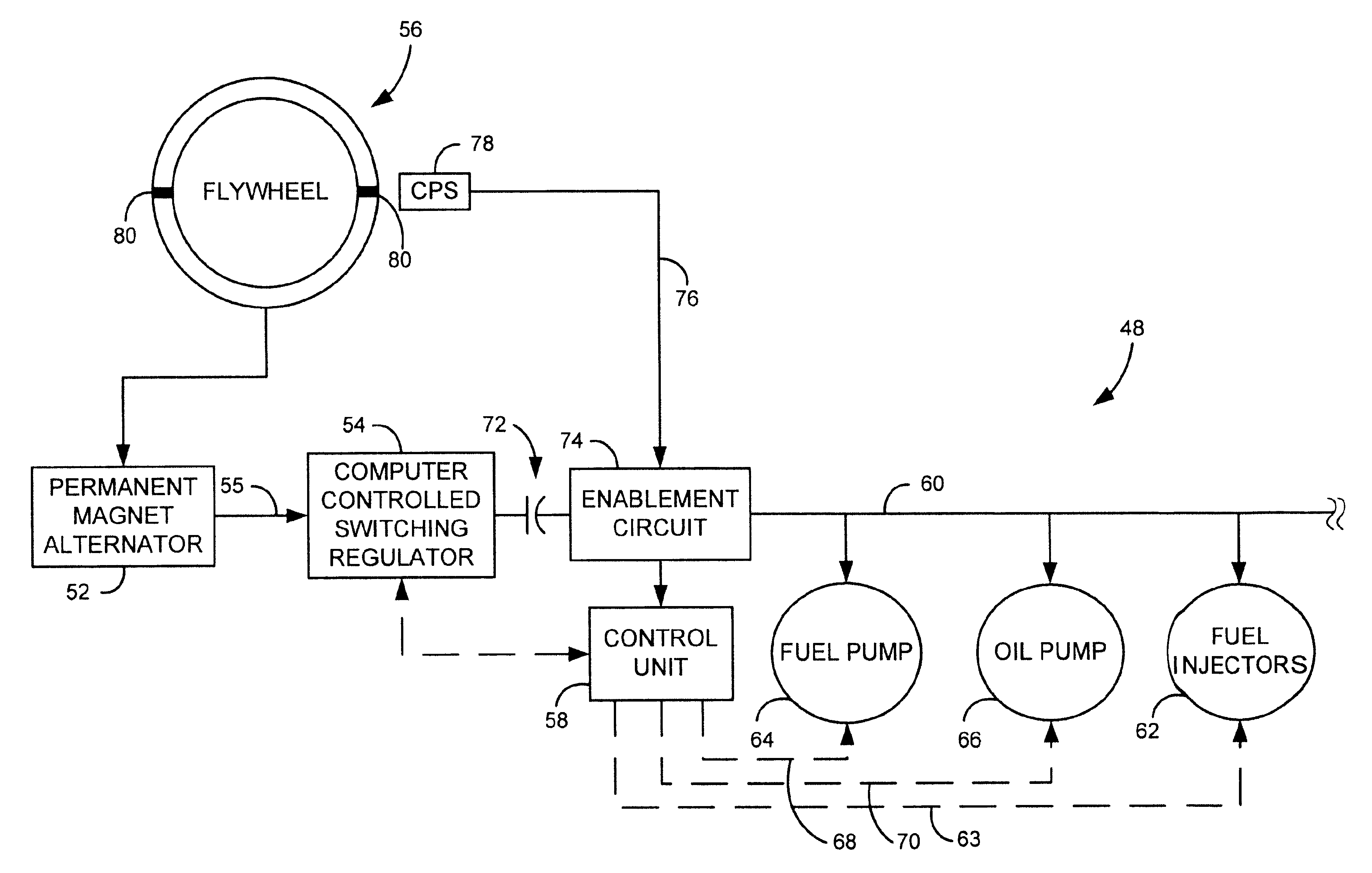

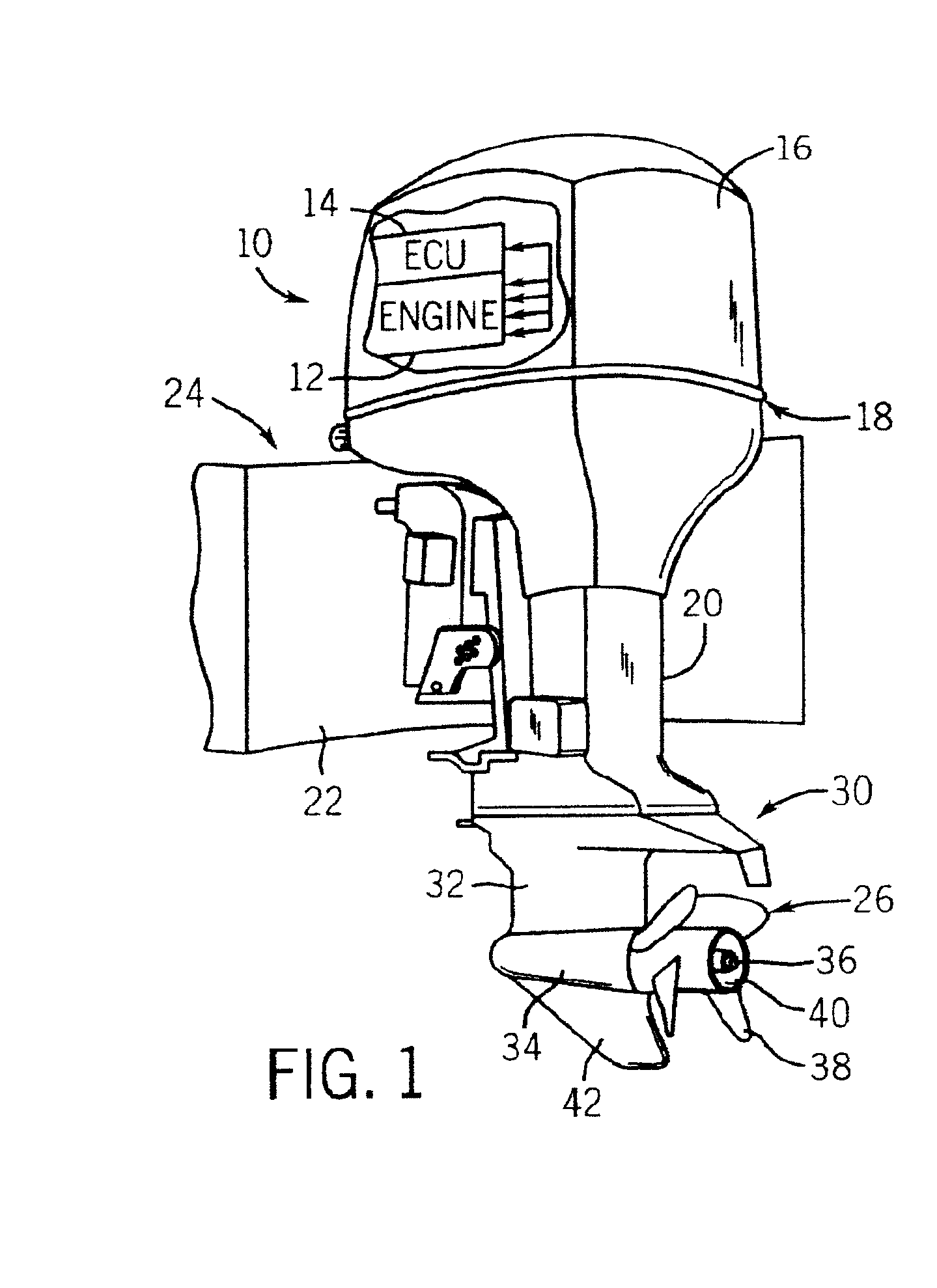

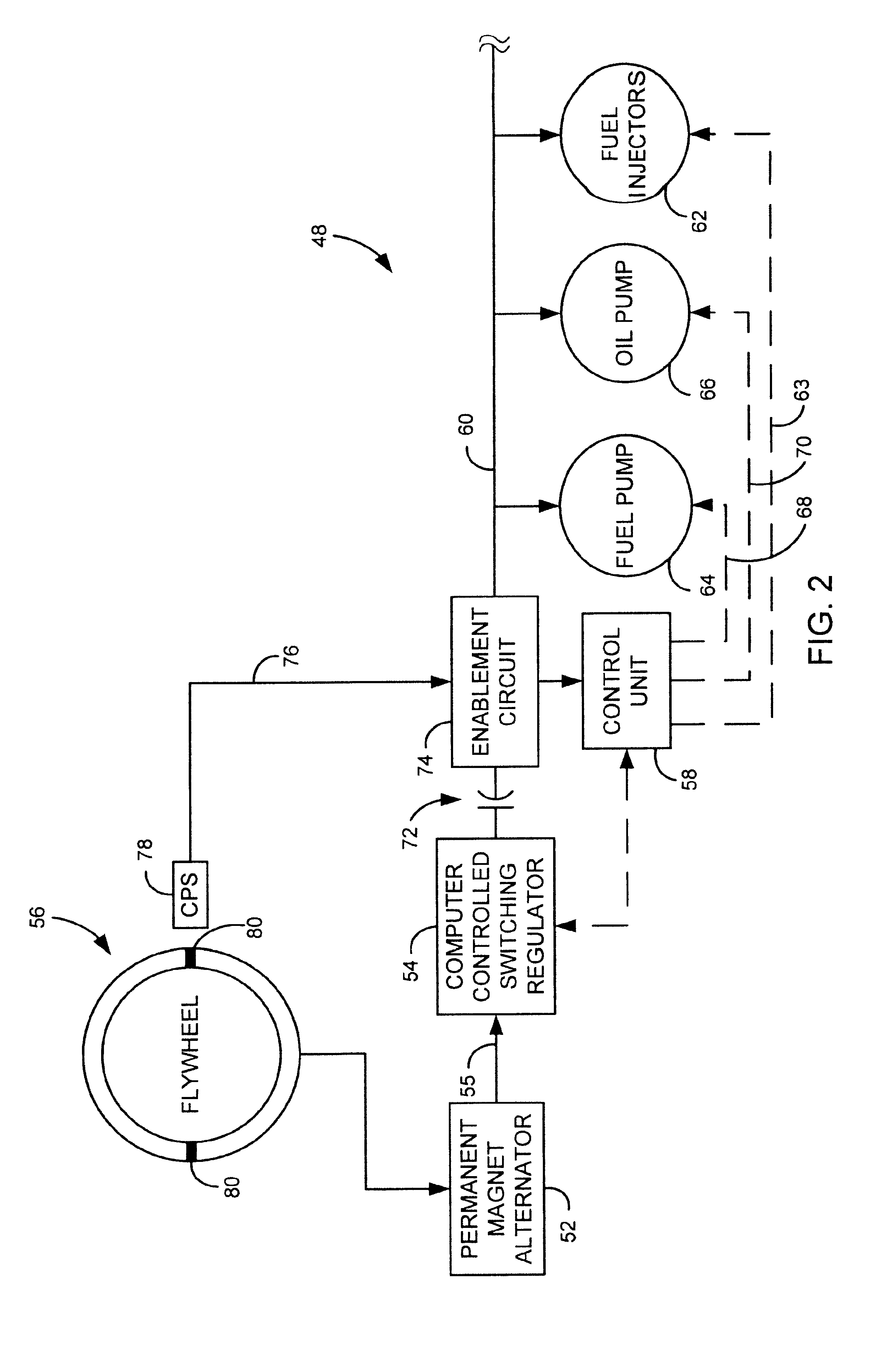

Engine control unit enablement system

ActiveUS6914342B1Ease and improve startingReduce startElectrical controlMuscle operated startersStored energyEngineering

An engine control unit enablement circuit is disclosed that selectively closes a conductive path between a chargeable electrical energy source and electronics of an engine / motor. An engine position sensor provides feedback as to the rotational position of a rotating component of an engine to the enablement circuit. When the rotating component, e.g. crankshaft or flywheel, is rotating, the enablement circuit closes the conductive path and allows the transference of electrical energy from the energy source to the engine and motor electronics. Conversely, when feedback is received indicative of non-rotation of the rotating component, the enablement circuit opens the conductive path. As such, energy stored in the energy source remains stored. With a subsequent detection of rotation of the rotating component, the conductive is closed and the stored energy is allowed to pass to the engine and motor electronics thereby allowing faster powering of the engine and motor electronics.

Owner:BRP US

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com