Method for Improving double heat pump hot-water system startup and adjustment performance

A hot water system and dual heat pump technology, applied in the field of engineering thermophysics and heat transfer, can solve the problems of high outlet water temperature that cannot be lowered, evaporator freezing and cracking, and unusable problems, so as to avoid evaporator freezing and shorten start-up Process, the effect of shortening the time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

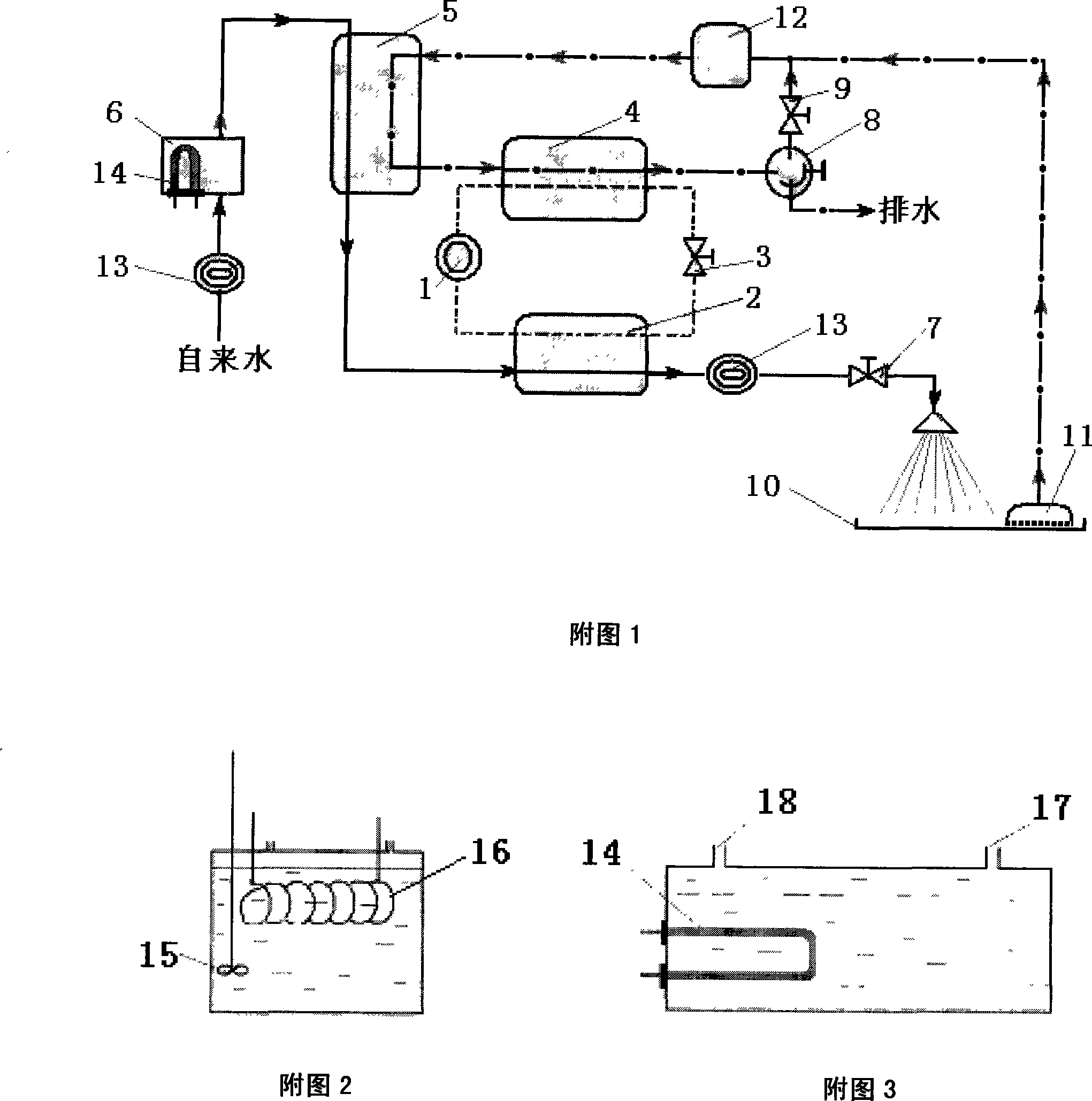

[0022] With reference to accompanying drawing 2, when the evaporator is made into the structure that the barrel is built with a metal coil, the water inlet and outlet are on the upper side of the barrel, and the stirring device 15 is installed on the side to improve the heat exchange efficiency.

[0023] With reference to accompanying drawing 3, temperature balance bucket 6 of the present invention installs electric heating device 14 additionally, and staving should be placed horizontally, and inlet and outlet are placed on top, to avoid siphon phenomenon.

[0024] With reference to accompanying drawing 1, install anti-electric wall device 13 respectively at water inlet pipe, hot water outlet pipe outlet, anti-electric wall device 13 can be installed in the housing and also can be installed outside the housing.

[0025] The compressor 1 can be a fixed-frequency compressor, and a variable-frequency compressor can be used for variable working conditions. By changing the speed of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com