Patents

Literature

374results about How to "Raise the water temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

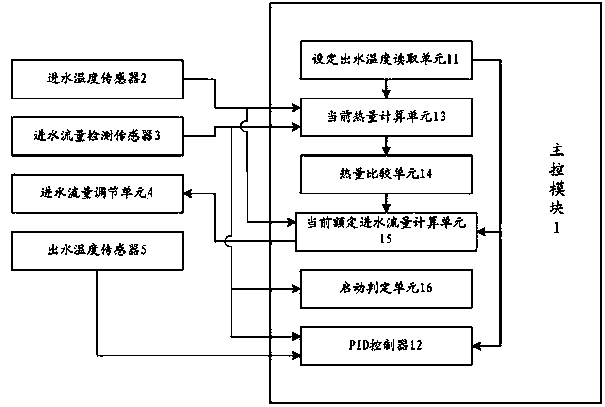

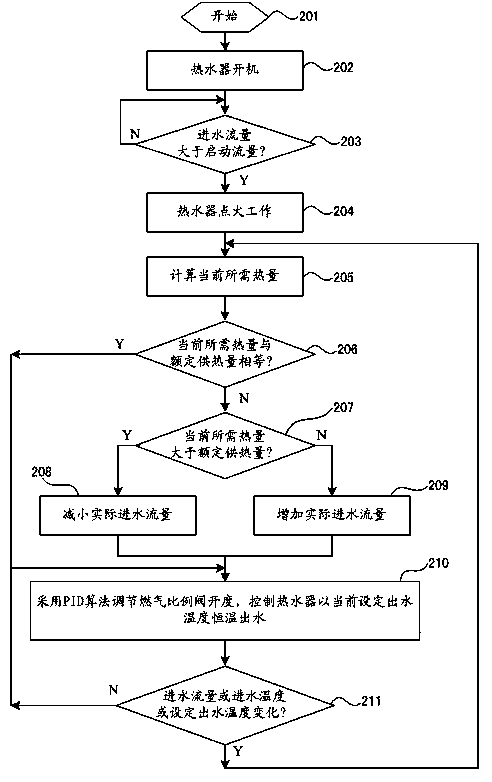

Control method and control device of constant-temperature gas water heater

ActiveCN104236109AImprove use comfort performanceRaise the water temperatureFluid heatersProportion integration differentiationEngineering

The invention discloses a control method and a control device of a constant-temperature gas water heater. The control method includes steps of detecting current water inlet temperature, current water inlet flow and current set water outlet temperature of the water heater and calculating current required heat; comparing the current required heat with rated heat supply of the heater; when the current required heat is higher than the rated heat supply, reducing practical water inlet flow of the heater, and when the current required heat is lower than the rated heat supply, increasing practical water inlet flow of the heater; adjusting opening of a gas proportion valve of the water heater by an PID (proportion integration differentiation) algorithm, and controlling the water heater so as to supply water at constant temperature by the current set water outlet temperature. By the control method and the control device of the constant-temperature gas water heater, the water heater is controlled, water outlet temperature reaches the set temperature, water outlet temperature can be quickly and stably adjusted, and service performance of the water heater is improved.

Owner:HAIER GRP CORP +1

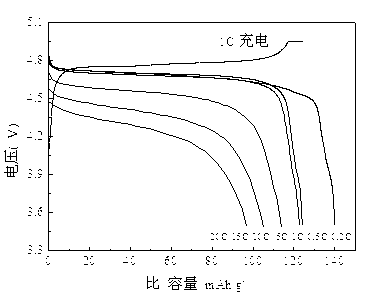

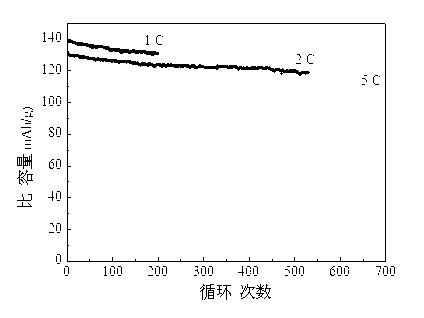

Preparation method of positive pole material (spinel type lithium nickel manganese oxide) of high-voltage lithium ion battery

ActiveCN103227323AAccurately control the ratioReduce concentrationCell electrodesElectrical batteryNickel compounds

The invention relates to a preparation method of a positive pole material (spinel type lithium nickel manganese oxide) of a high-voltage lithium ion battery, which comprises the following steps: simultaneously dissolving a lithium-containing compound, a manganese-containing compound and a nickel-containing compound instead of adding a lithium source afterwards, and ensuring that the lithium compound, the nickel compound and the manganese compound are evenly mixed; and adding precipitant to generate manganese-containing precipitate, wherein the generated manganese-containing precipitate provides crystal nuclei for further precipitation in the hydrothermal process, particles having different sizes can be obtained by controlling hydrothermal conditions, the particle sizes of the products can be increased by decreasing the concentrations of the metal salts, increasing the hydrothermal temperature and prolonging the hydrothermal time, and materials having different shapes can be obtained or porous materials can be prepared by adding different additives. The method omits the steps of filtration and water washing; and the synthesis process is economic and environment-friendly. The lithium nickel manganese oxide material prepared by the invention is in a spinel structure, and is high in crystallinity and excellent in electrochemical performance; and the specific capacity can be up to 130-142mAh / g, 120-135mAh / g and 105-120mAh / g in case of 1C, 2C and 5C rate discharge.

Owner:南京时拓能源科技有限公司

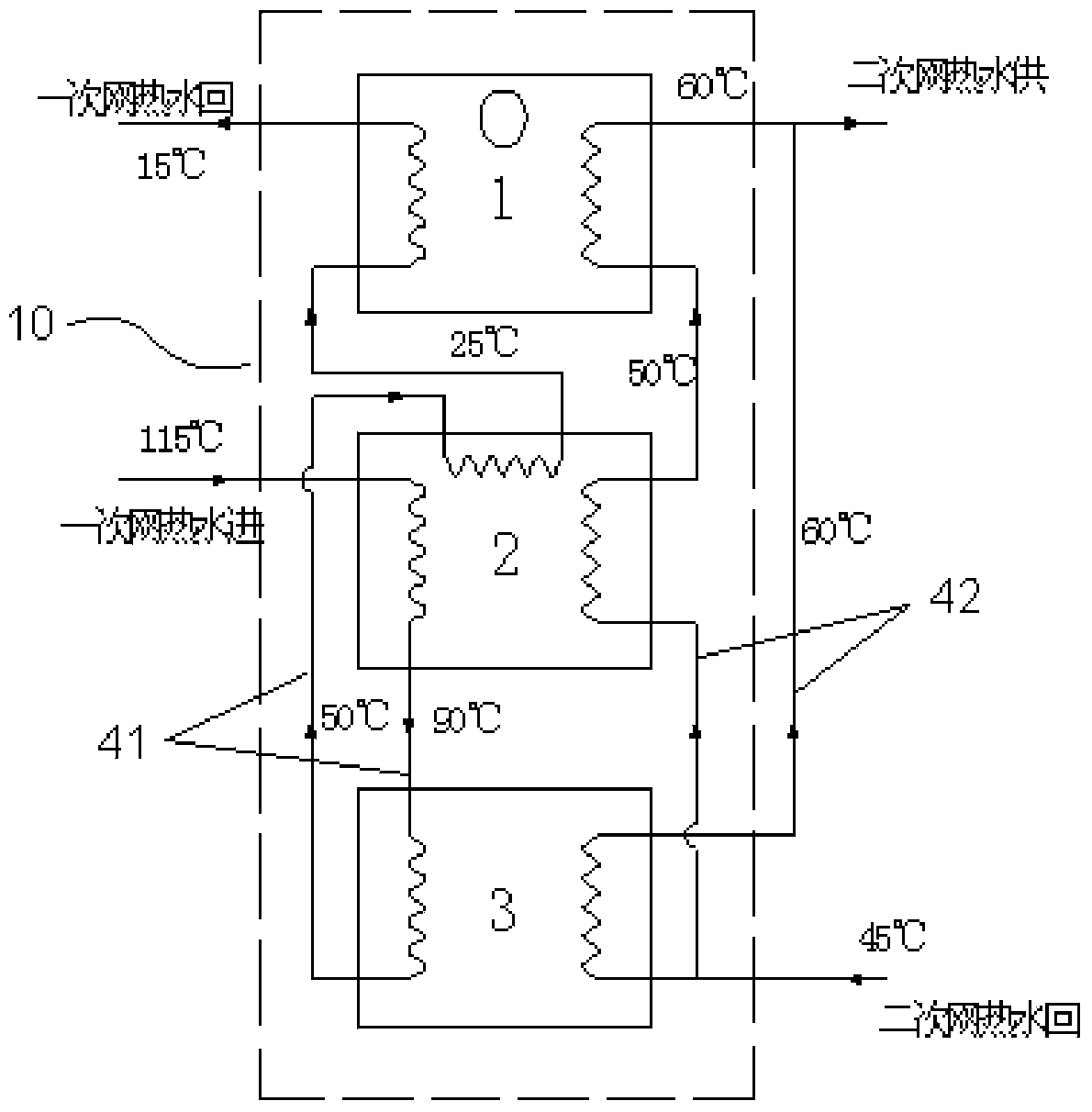

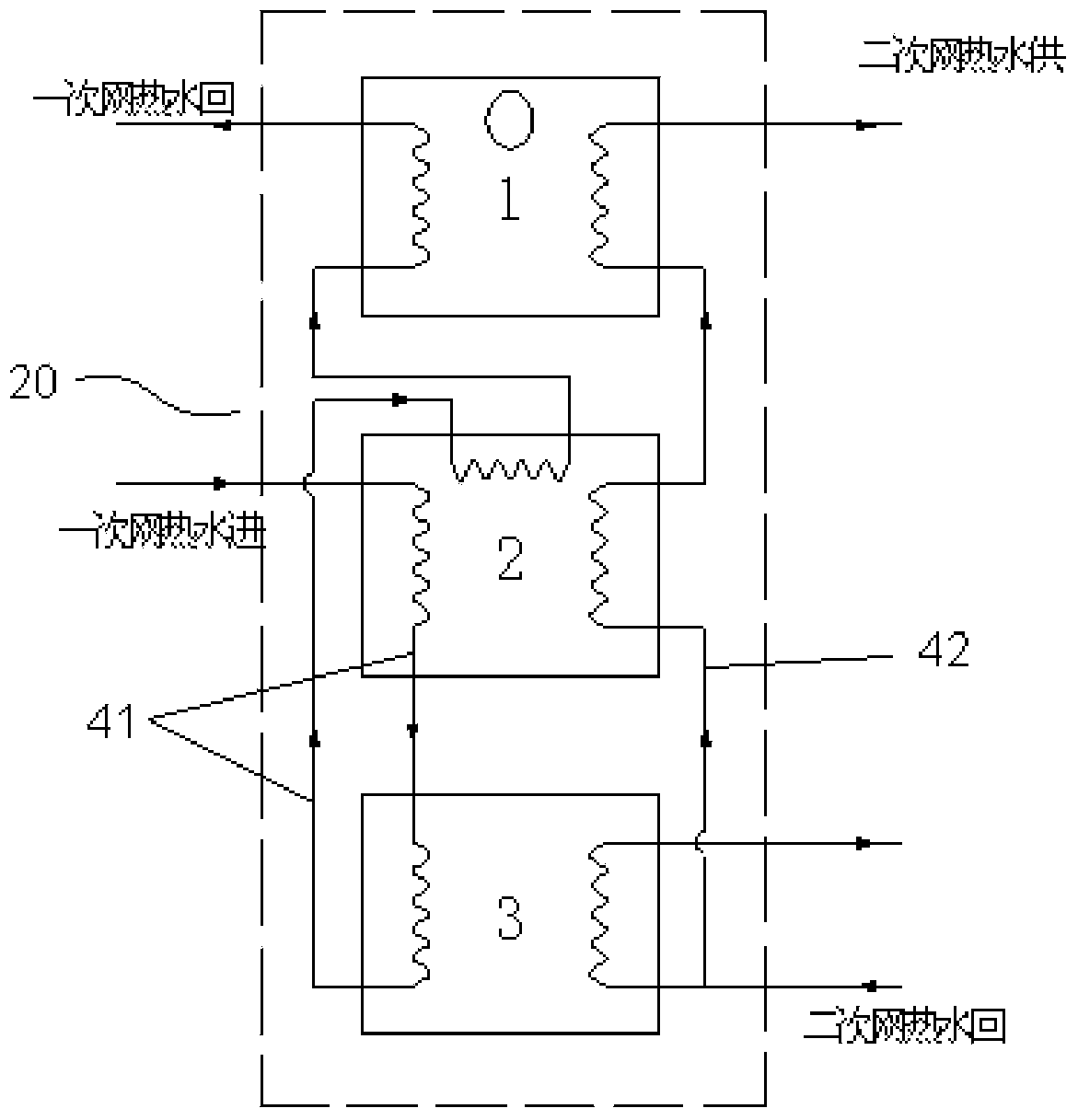

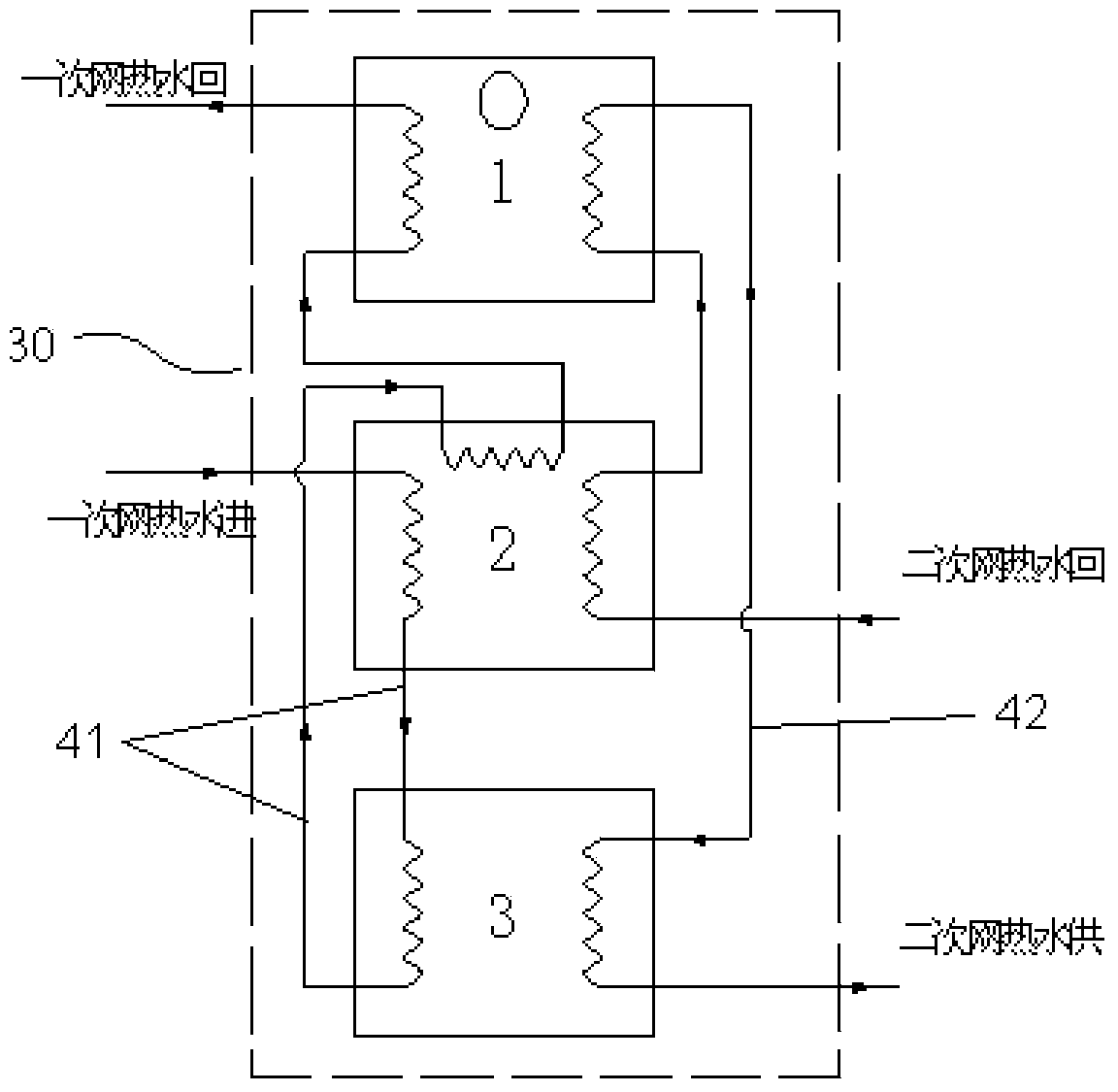

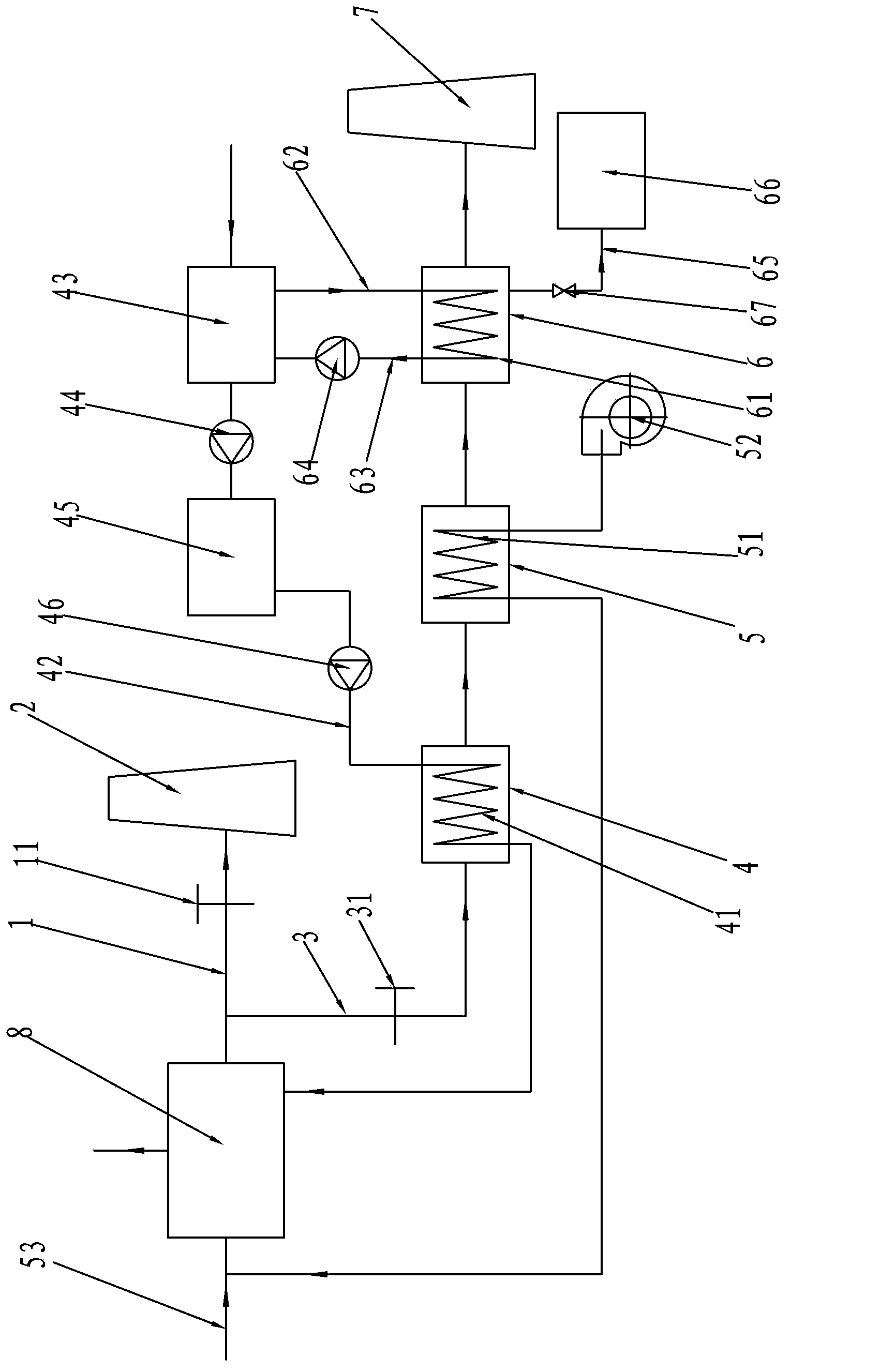

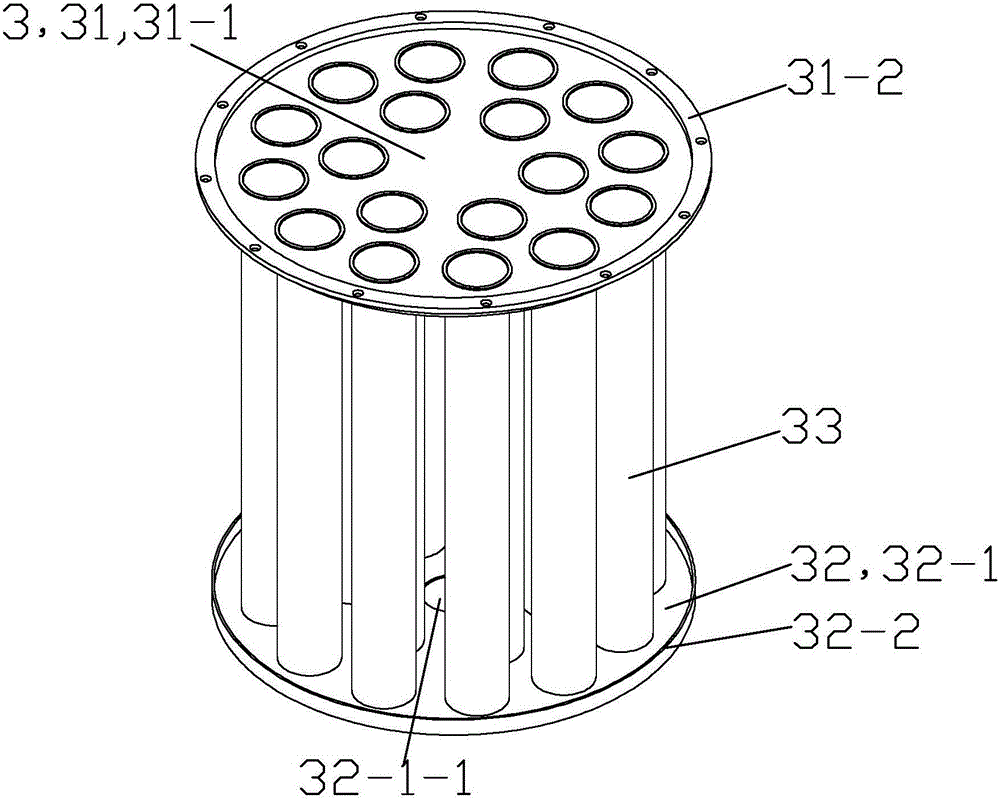

Combined type heat exchange unit

InactiveCN103673035AReduce initial investmentReduce water pump running power consumptionLighting and heating apparatusEnergy efficient heating/coolingHeating systemEvaporator

Owner:TSINGHUA UNIV

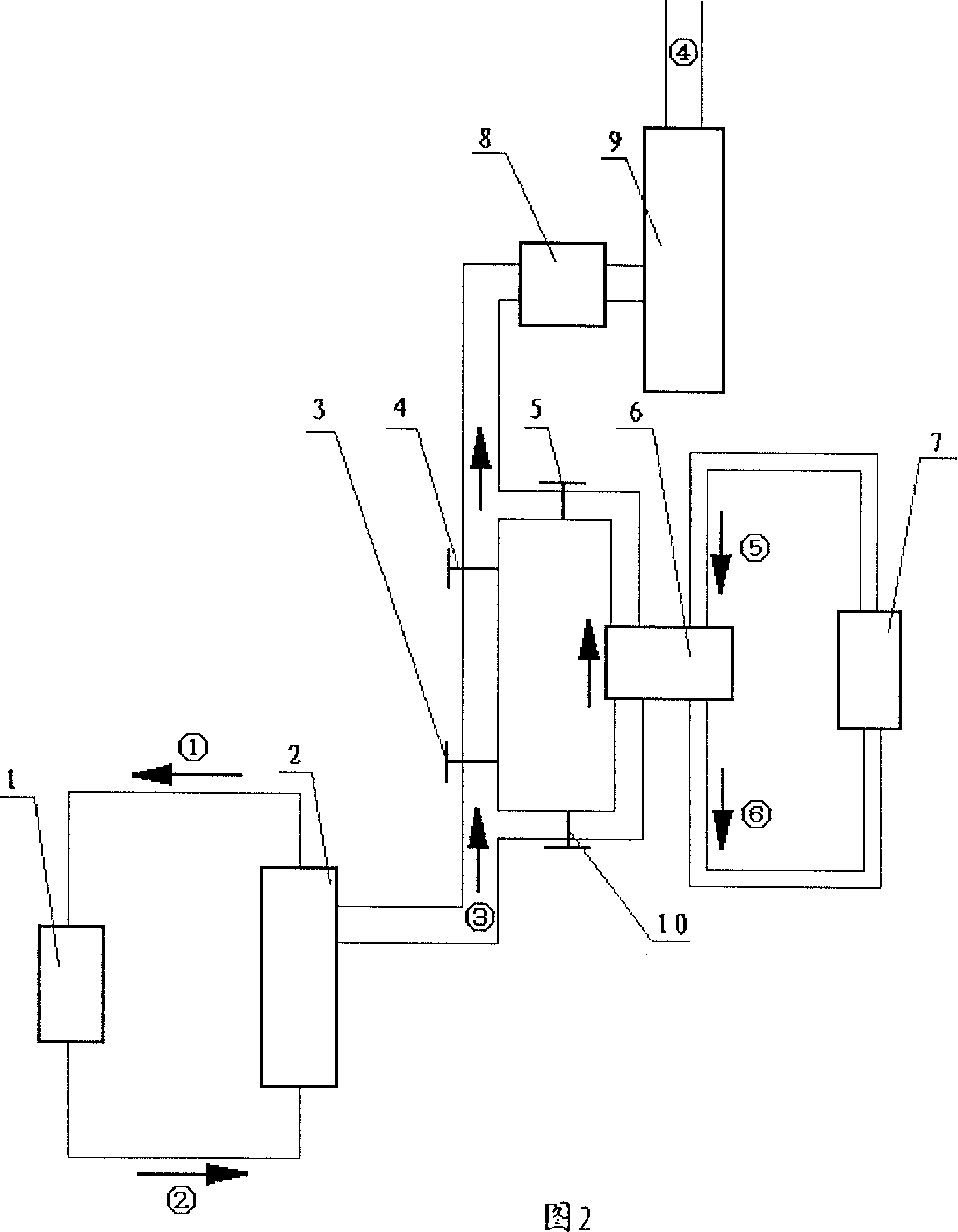

Gas-fired boiler afterheat recovering system and recovering method

InactiveCN103438427ARaise the water temperatureLower exhaust gas temperatureLiquid degasificationAir preheaterEngineering

The invention discloses a gas-fired boiler afterheat recovering system and a gas-fired boiler afterheat recovering method. A bypass flue is parallelly connected onto a main flue, a bypass flue butterfly valve, a boiler coal economizer, an air preheater and a condensing type heat exchanger are sequentially and serially connected onto the bypass flue, the bypass flue is communicated with a bypass chimney, a water inlet of a heat exchange pipe of the boiler coal economizer is connected with a water tank through a water supply pipeline, a water outlet of the heat exchange pipe is communicated with a boiler through a pipeline, an air inlet of a heat exchange pipe of the air preheater is communicated with a fan through a pipeline, an air outlet is communicated with a boiler combustion-supporting air inlet pipe through a pipeline, a water inlet of a heat exchange pipe of the condensing type heat exchanger is communicated with the water tank through a descending pipe, and a water outlet is communicated with the water tank through an ascending pipe. The gas-fired boiler afterheat recovering system and the gas-fired boiler afterheat recovering method have the advantages that the structure is simple and compact, the size is small, the boiler smoke discharge temperature is lowered to 40 to 50 DEG C, in addition, all recovered heat is used for a boiler system, the boiler smoke discharge temperature is greatly lowered, the boiler heat efficiency is greatly improved up to more than 100 percent, and the goal of greatly improving the utilization rate of energy sources is reached.

Owner:TIANJIN NUONENGDA ENERGY TECH

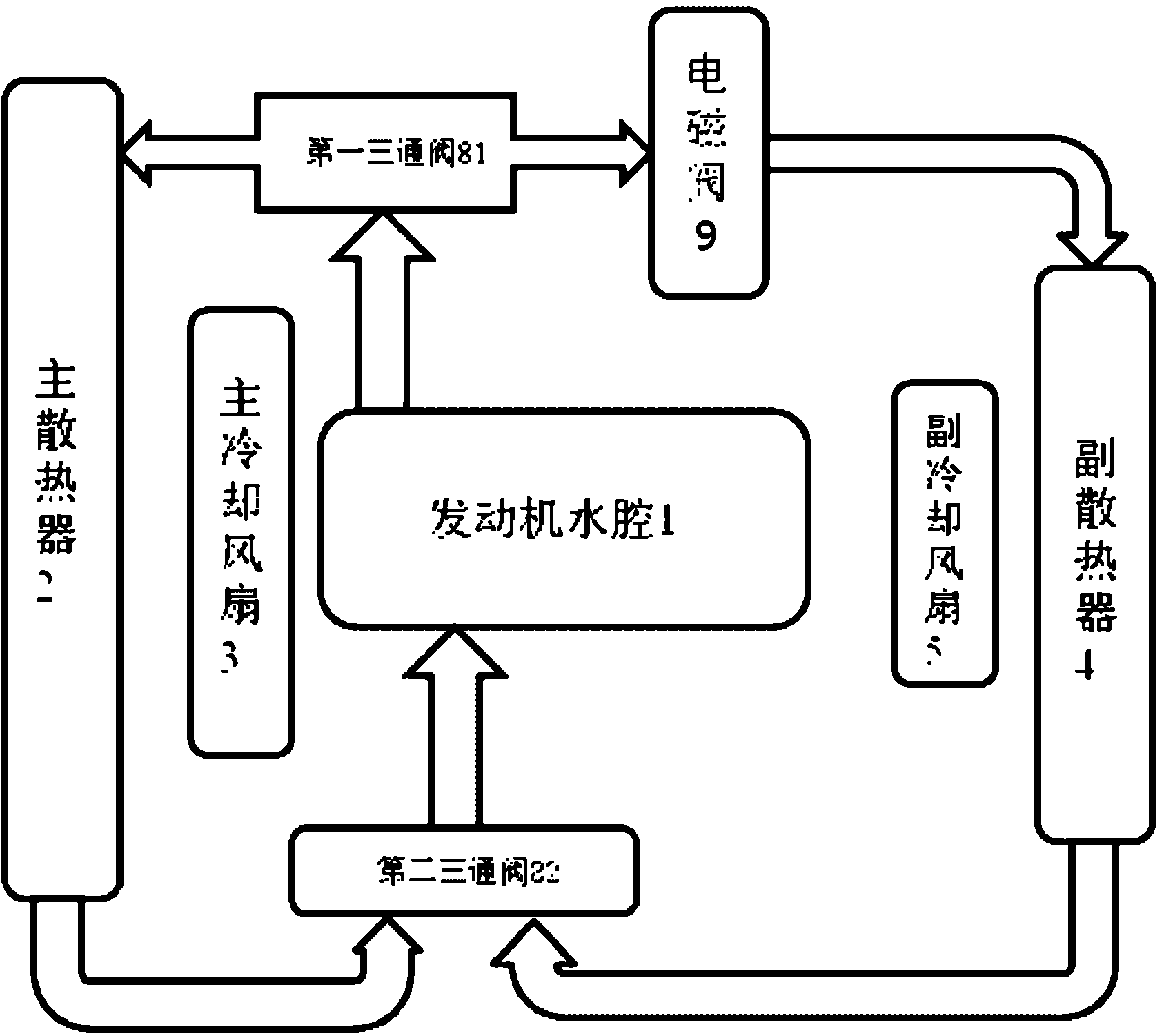

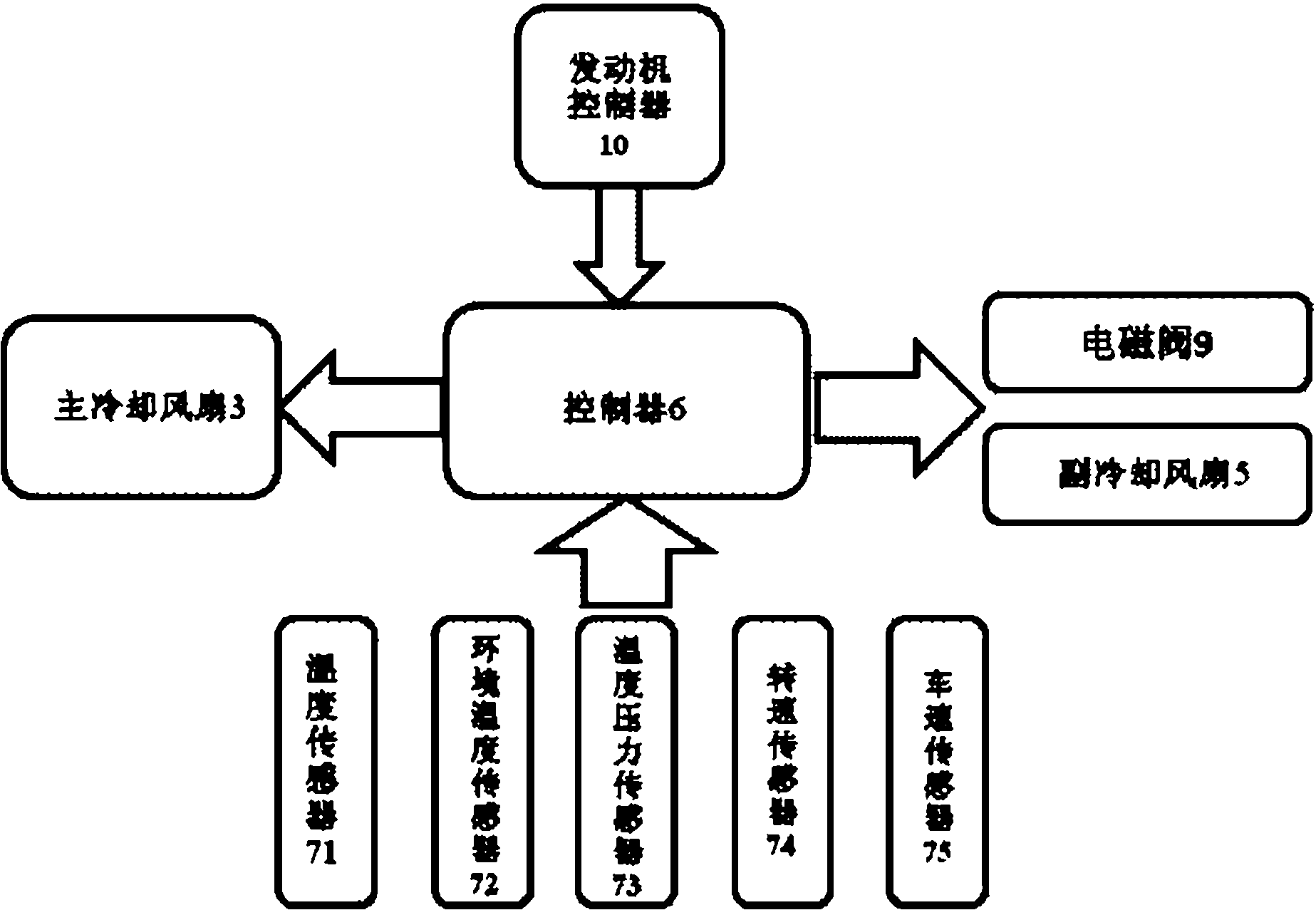

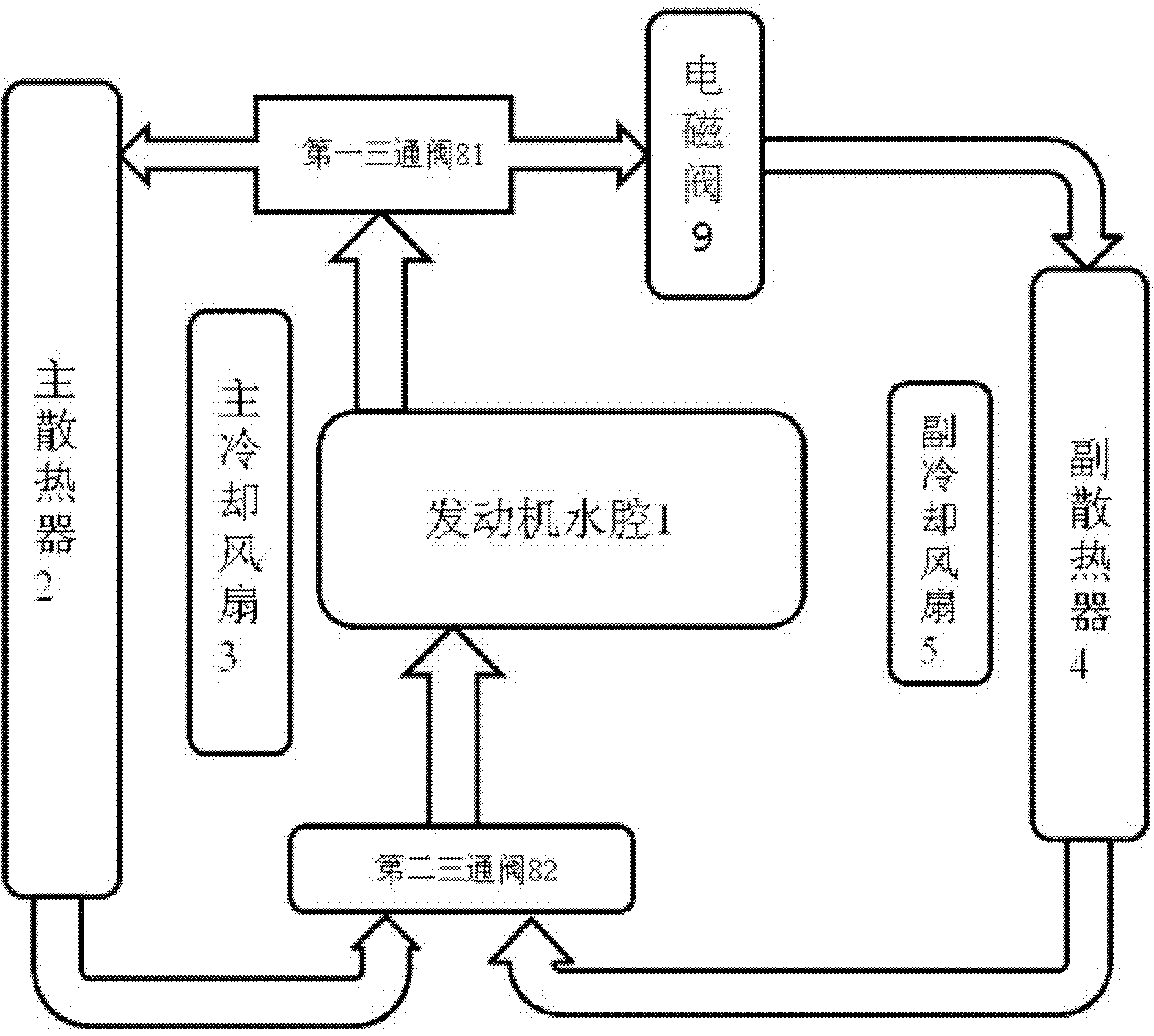

Engine cooling system

InactiveCN102102575AReduce power wasteReduce economic lossLiquid coolingCoolant flow controlWater temperatureHeat spreader

The invention relates to the technical field of engines, and discloses an engine cooling system. The engine cooling system comprises a main cooling fan, a main radiator, a controller, a temperature sensor, a secondary cooling fan and a secondary radiator, wherein the main radiator is communicated with a water chamber of an engine; the secondary radiator is communicated with the water chamber of the engine; the secondary cooling fan is arranged on a side face of the secondary radiator; a pipeline between the secondary radiator and the water chamber of the engine is provided with a switching valve; the temperature sensor is used for detecting water outlet temperature of the water chamber of the engine and transmitting a water outlet signal to the controller; the controller receives a water temperature signal and judges whether the water outlet temperature is greater than a preset value; and if the water outlet temperature is greater than the preset value, the controller controls the switching valve to be opened and controls the secondary cooling fan to be in a working state. The heat dissipating capacity of the engine cooling system is matched with that required by the engine.

Owner:WEICHAI POWER CO LTD

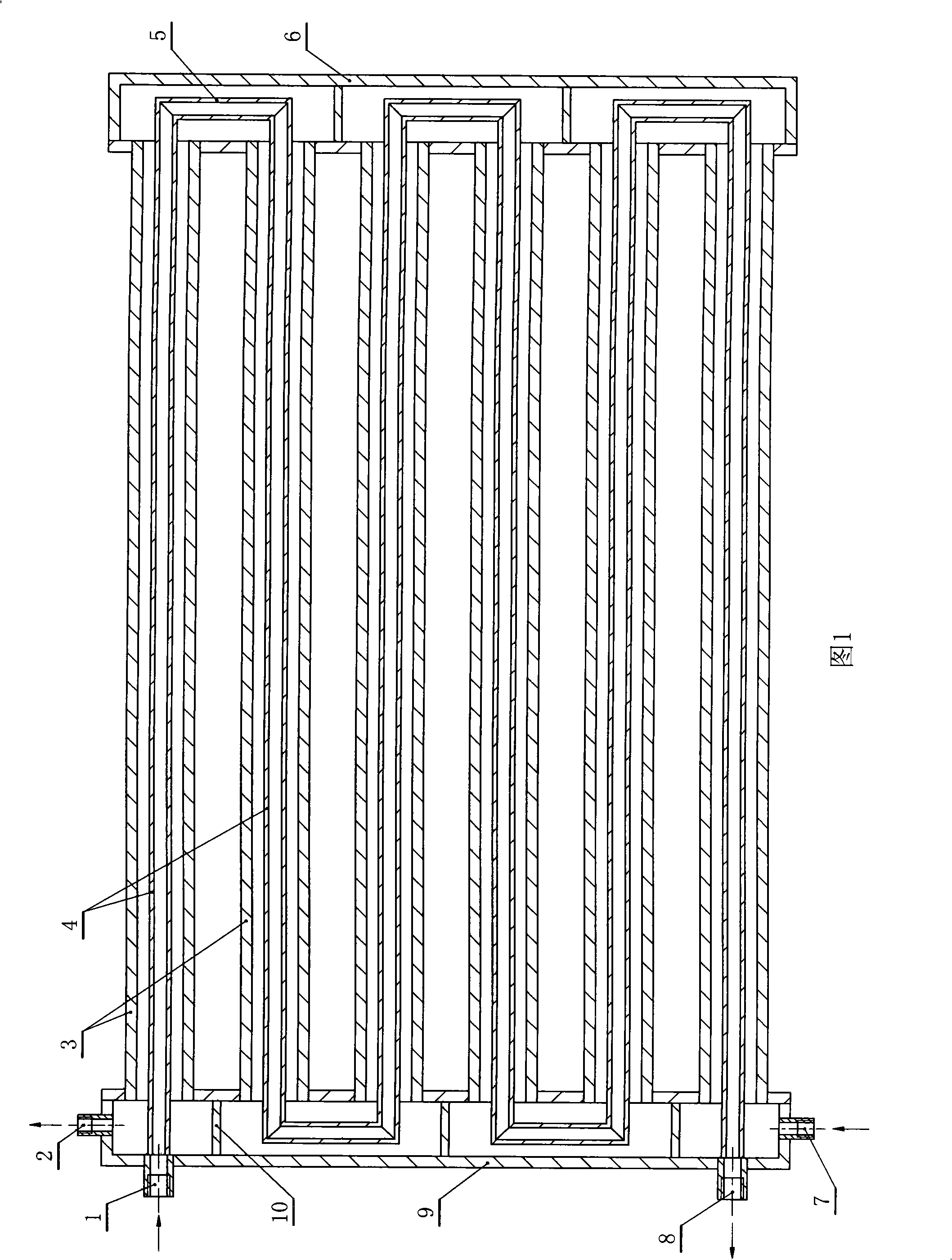

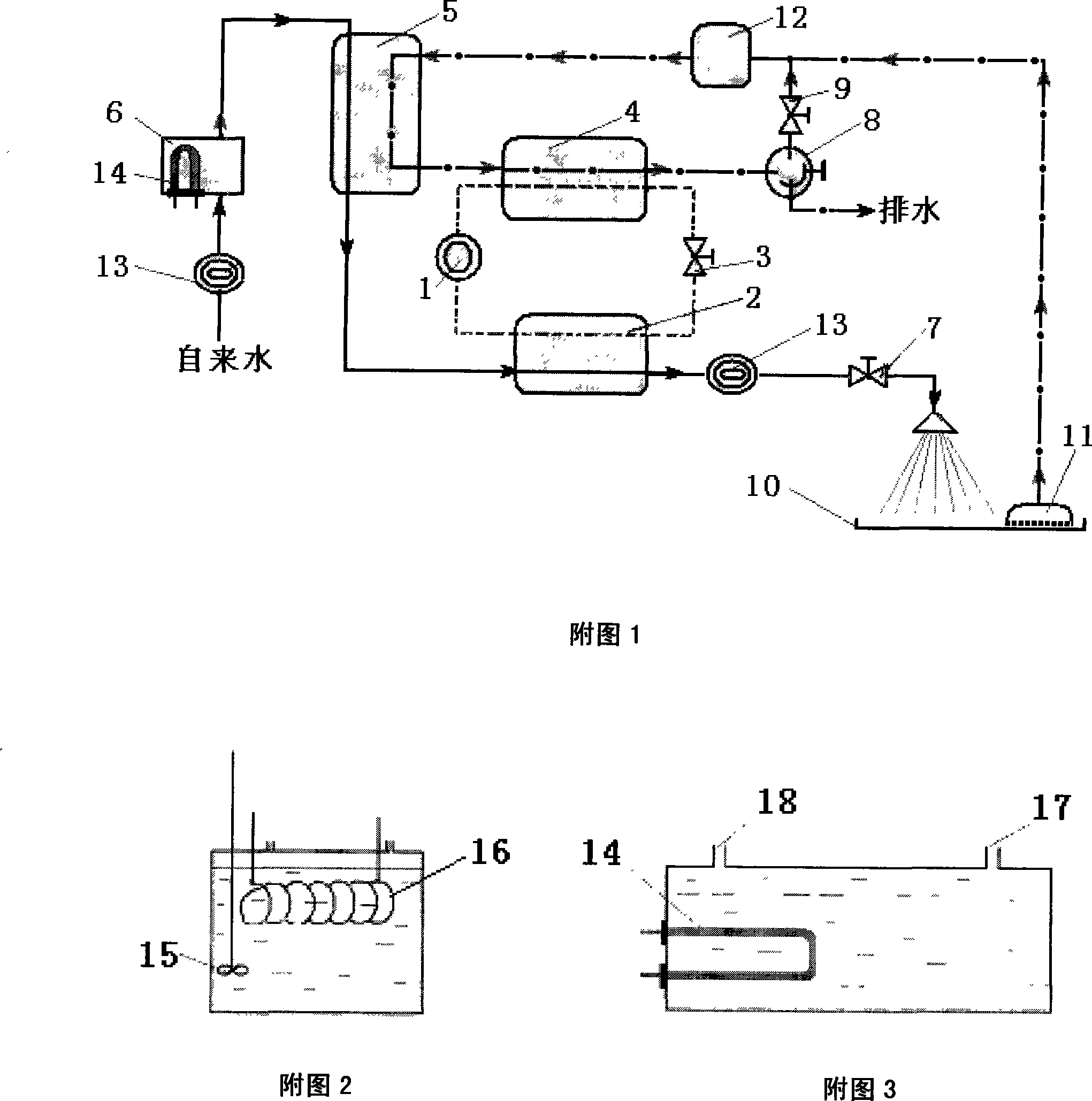

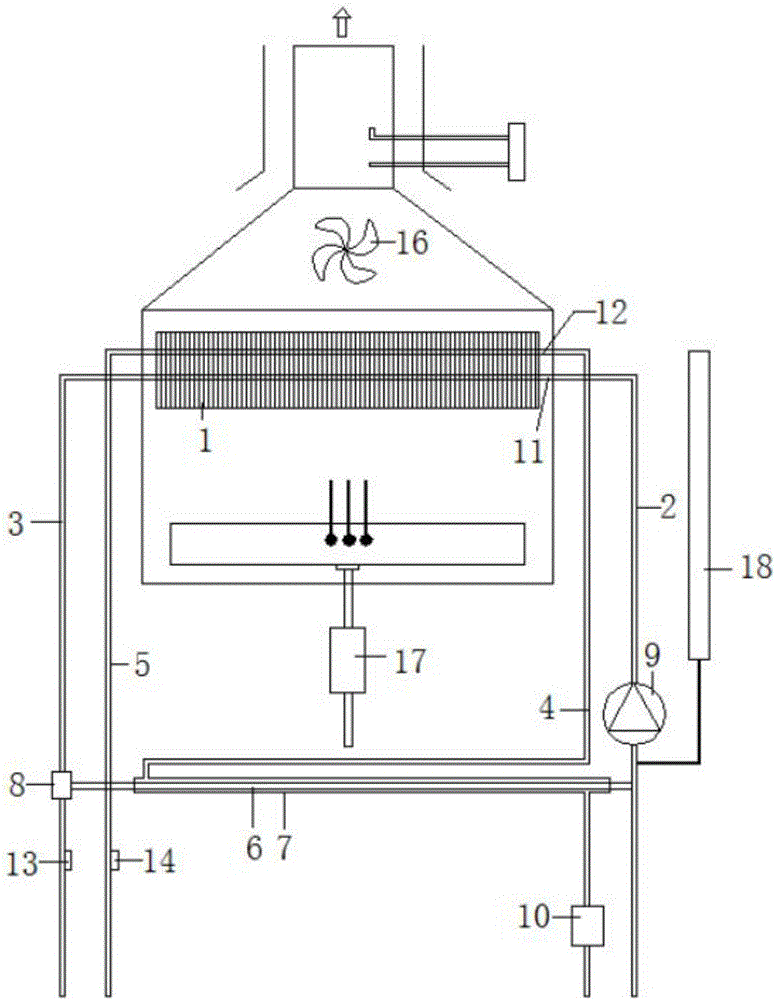

Pipe communication splice welding pressure-bearing type heat exchanger

InactiveCN102322754AIncrease heat transfer areaSolve the welding seam leakage rate is too highHeat exhanger sealing arrangementHeat exchanger casingsWater leakagePlate heat exchanger

The invention relates to a pipe communication splice welding pressure-bearing type heat exchanger, which comprises tap water heat absorption pipes. Heat supply pipes are arranged in the tap water heat absorption pipes. The tap water heat absorption pipes are communicated through tap water communication pipes. The heat supply pipes are communicated through heat supply pipe communication pipes. The seal heads of the tap water heat absorption pipes are outwardly flanged and embedded in the ports of the tap water heat absorption pipes. The flanges of the seal heads of the tap water heat absorption pipes and the port edges of the tap water heat absorption pipes are in splice bilateral alignment edge-kneading welding connection. The walls of the tap water heat absorption pipes are punched and inwardly flanged. The tap water communication pipes are inserted in the punches of the tap water heat absorption pipes. The port edges of the tap water communication pipes and the punched inward flanges of the tap water heat absorption pipes are in splice bilateral alignment edge-kneading welding connection. Heat supply pipe blocking plates are embedded in the ports of the heat supply pipes. The heat supply pipe blocking plates are outwardly flanged. The outward flanges of the heat supply pipe blocking plates and the port edges of the tap water heat absorption pipes are in splice alignment edge-kneading welding connection. According to the pipe communication splice welding pressure-bearing type heat exchanger disclosed by the invention, two technical defects of higher water leakage ratio of the welding line and incapability of continuously producing hot water of the original patent product can be solved; and the heat exchanger has the advantages of no leakage and continuous hot water production.

Owner:张伟

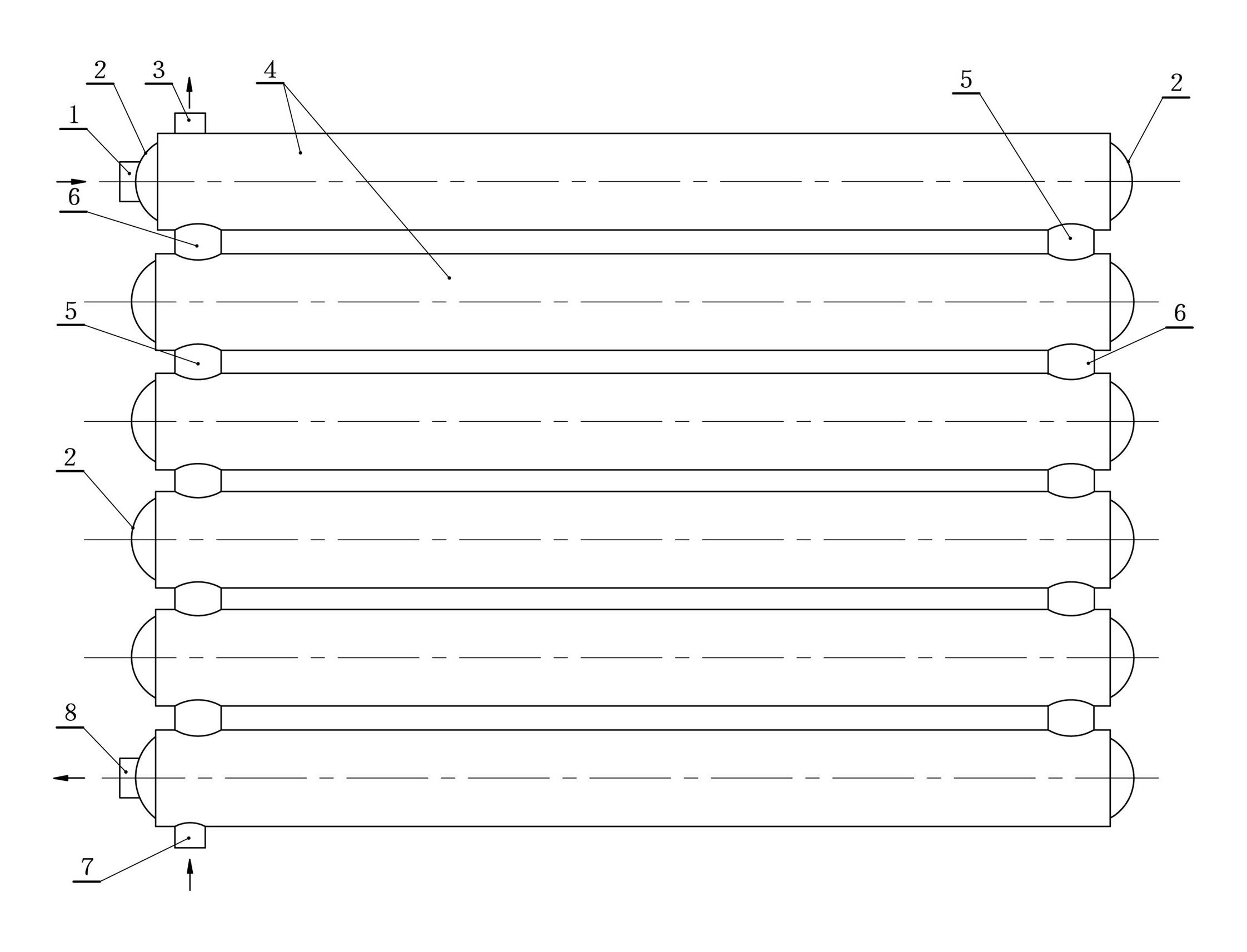

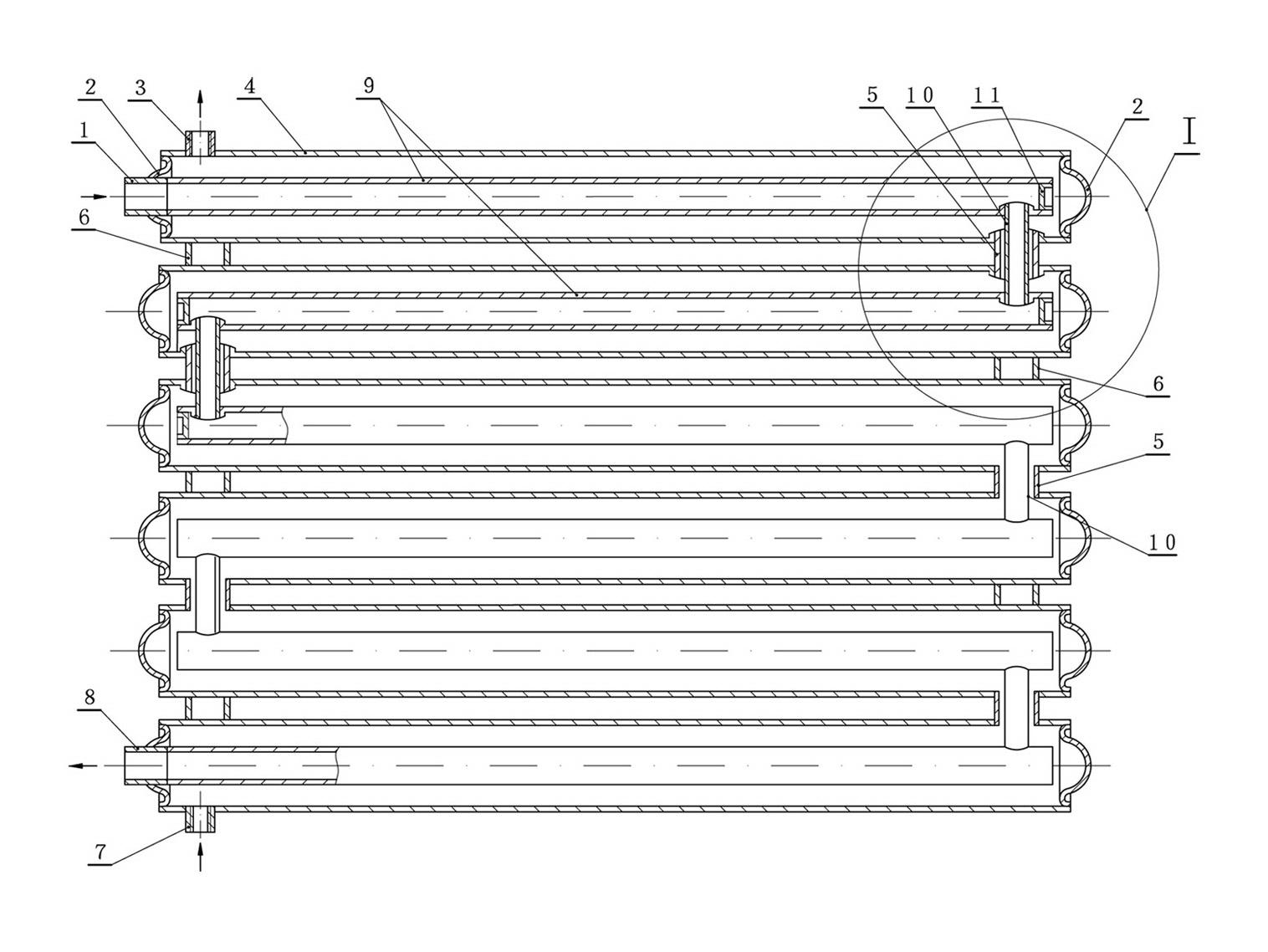

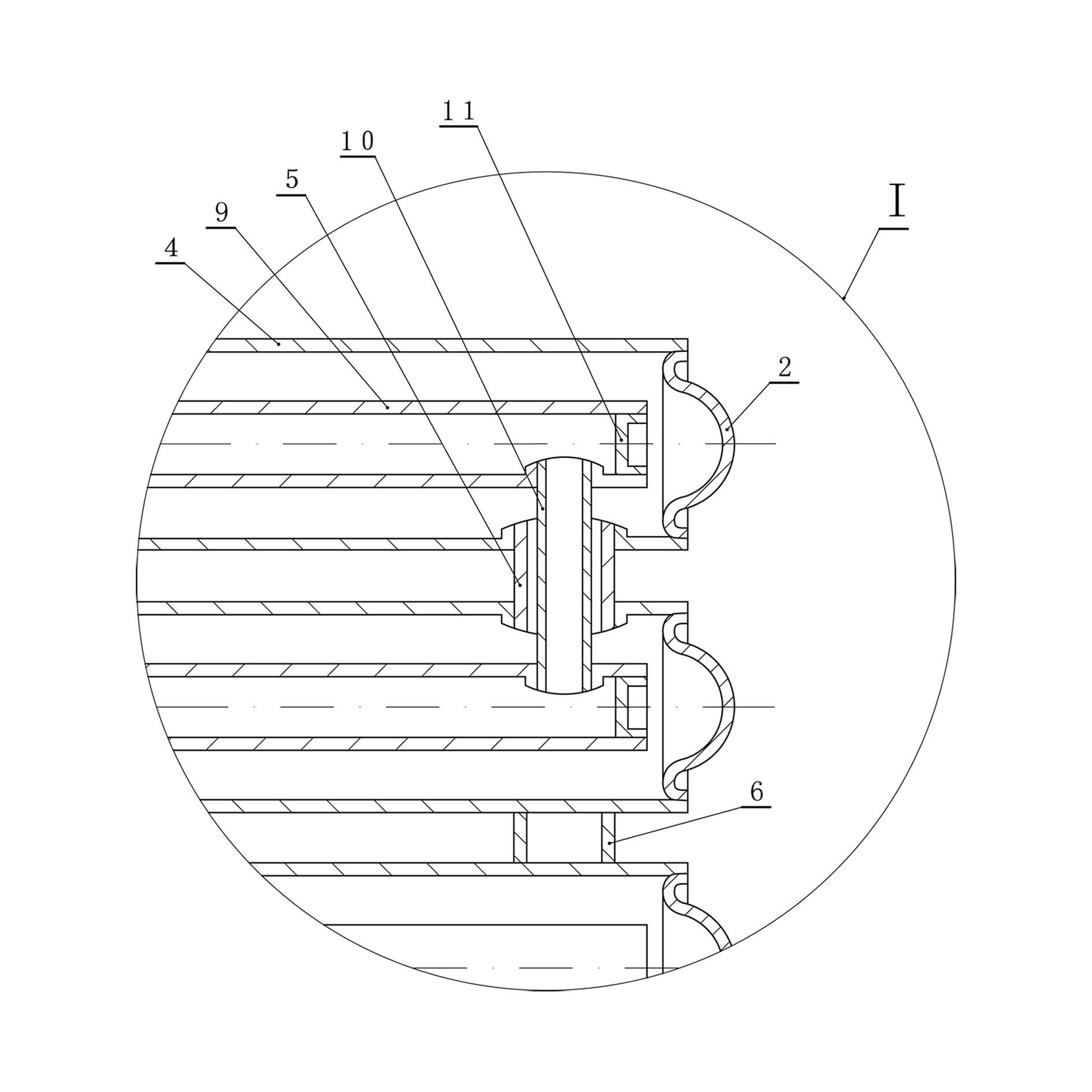

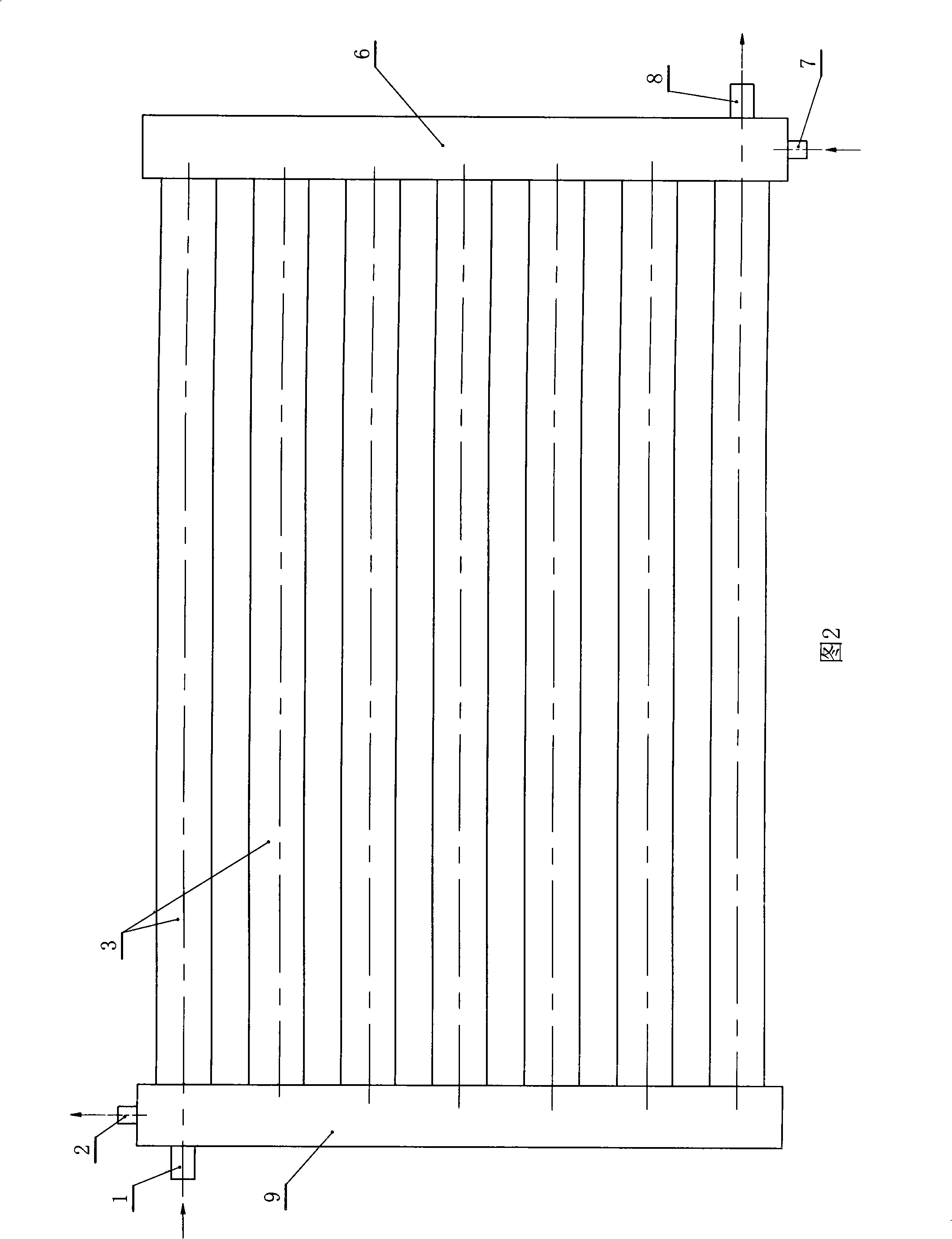

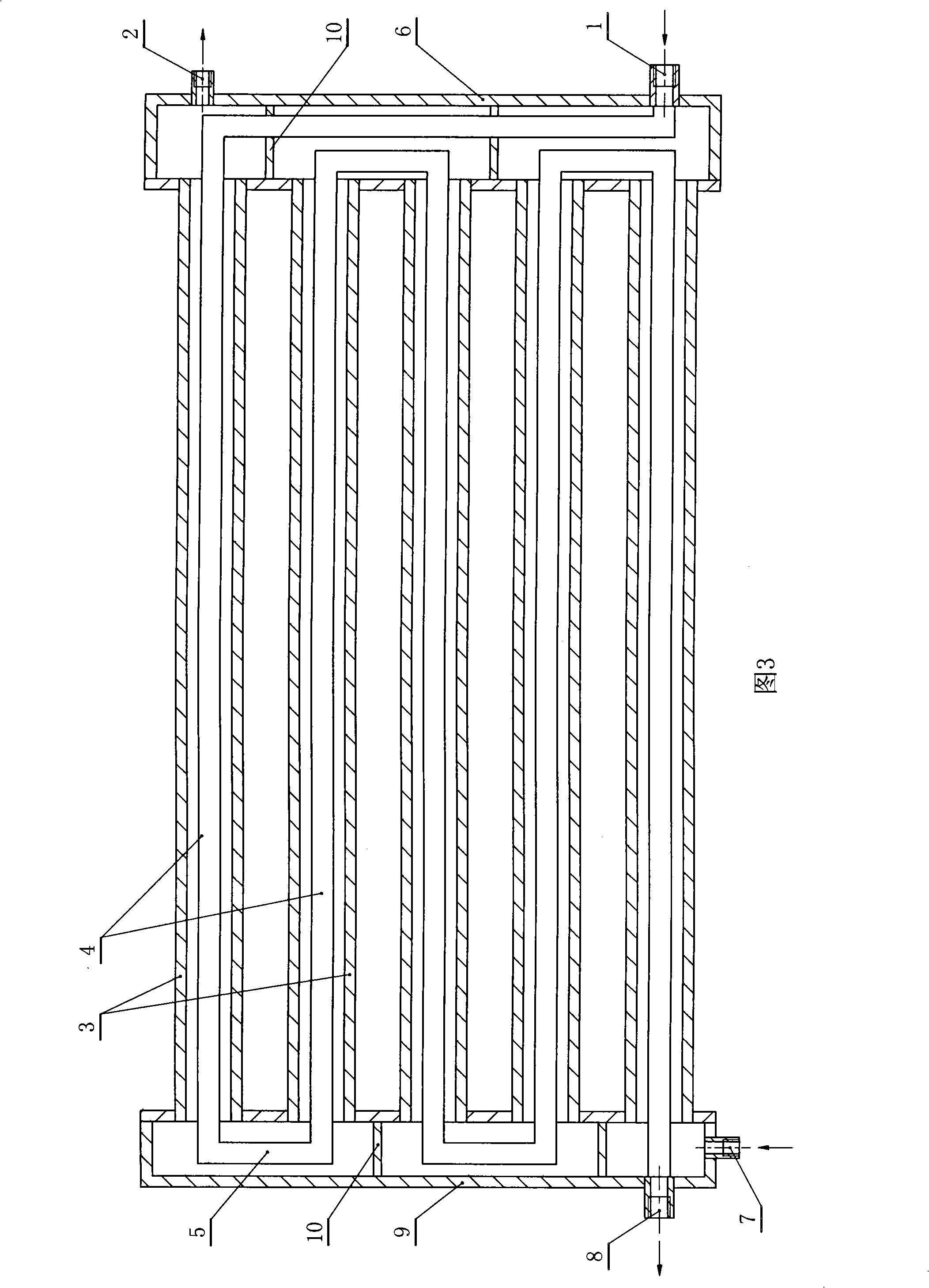

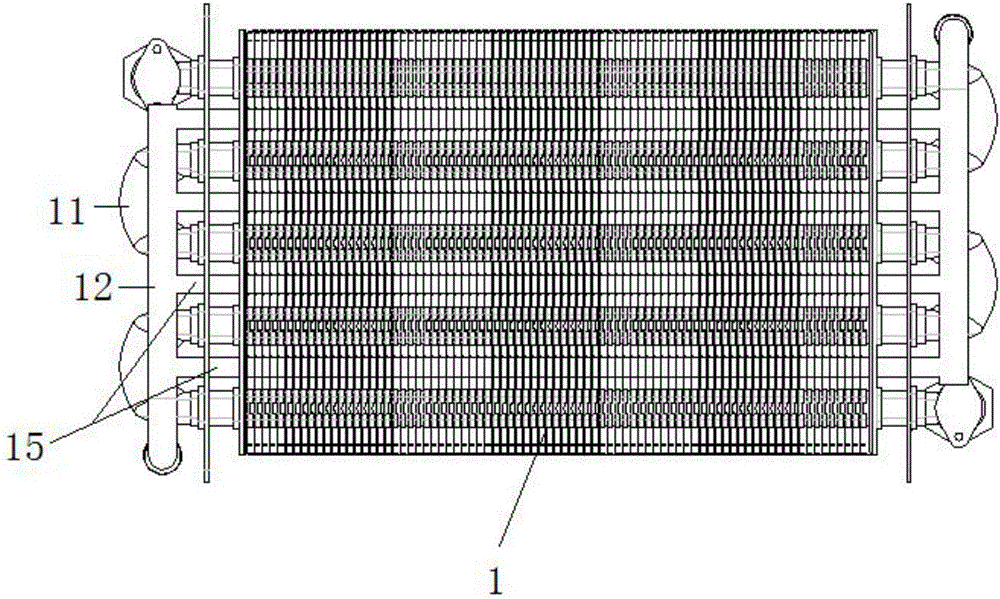

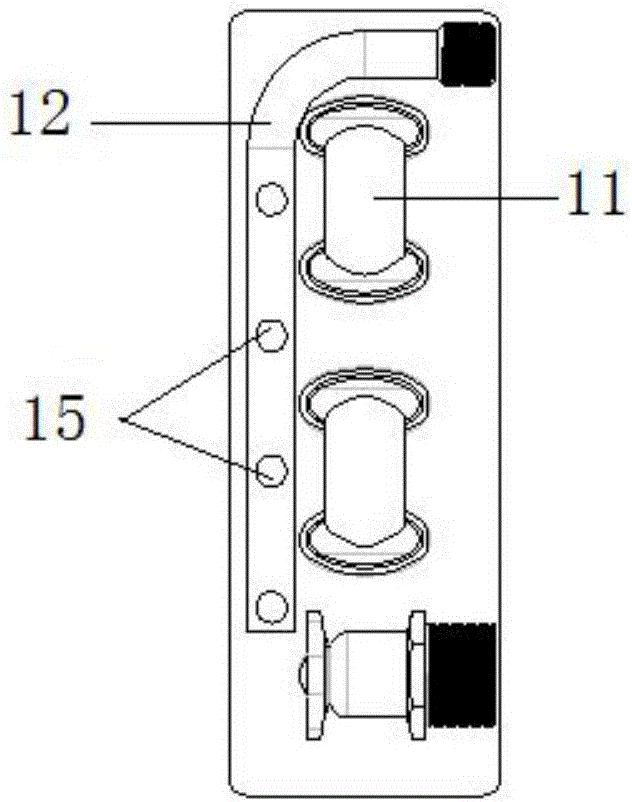

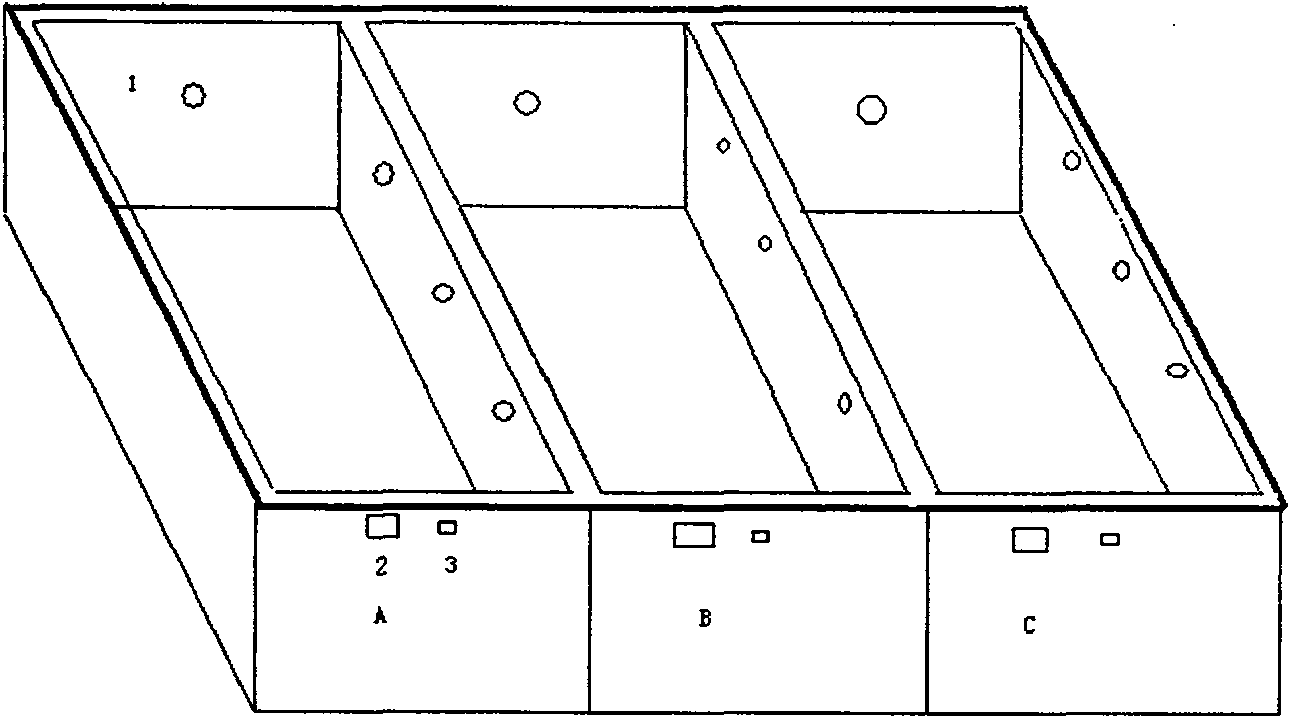

Header shunting heat storage adverse current type heat exchanger

InactiveCN101290196ANot easy to formLarge cavityStationary tubular conduit assembliesCounter flowEngineering

The invention discloses a header tank divided-flow heat-storage counter flow heat exchanger, which comprises a left header tank and a right header tank which are connected with a warm air water inlet, a warm air water outlet, a tap water inlet and a tap water outlet, wherein, a plurality of tap water heat-absorbing pipes are connected with the left and right header tanks; warm air heat supply pipes are connected through tap water heat-absorbing pipes; the warm air heat supply pipes are serially communicated with each other by heat supply communicating pipes; one end of each warm air heat supply pipe is connected with the warm air water inlet, while the other end is connected with the warm air water outlet; and a plurality of water insulation boards is alternatively connected the inside of the left and the right header tanks in order to separate the left and right header tanks to obtain the oriented flow channel. The counter flow heat exchanger of the invention has the advantages that: firstly the heat exchange efficiency is high and the temperature of the outlet water is high; secondly the joints of the heat supply pipes are arranged on the same level of axis line, which is suitably installed in household-measured users of the new heat supply pipe network unit, in particular to the needs of the three northeast provinces; thirdly the users can take a shower in the heat supply region of low temperature, and the heat-absorbing pipes at heat supply region of high temperature is free from scale formation; finally the counter flow heat exchanger is totally made of stainless steel, thereby saving brass pipe, reducing the cost and producing the clean water by exchange.

Owner:张伟

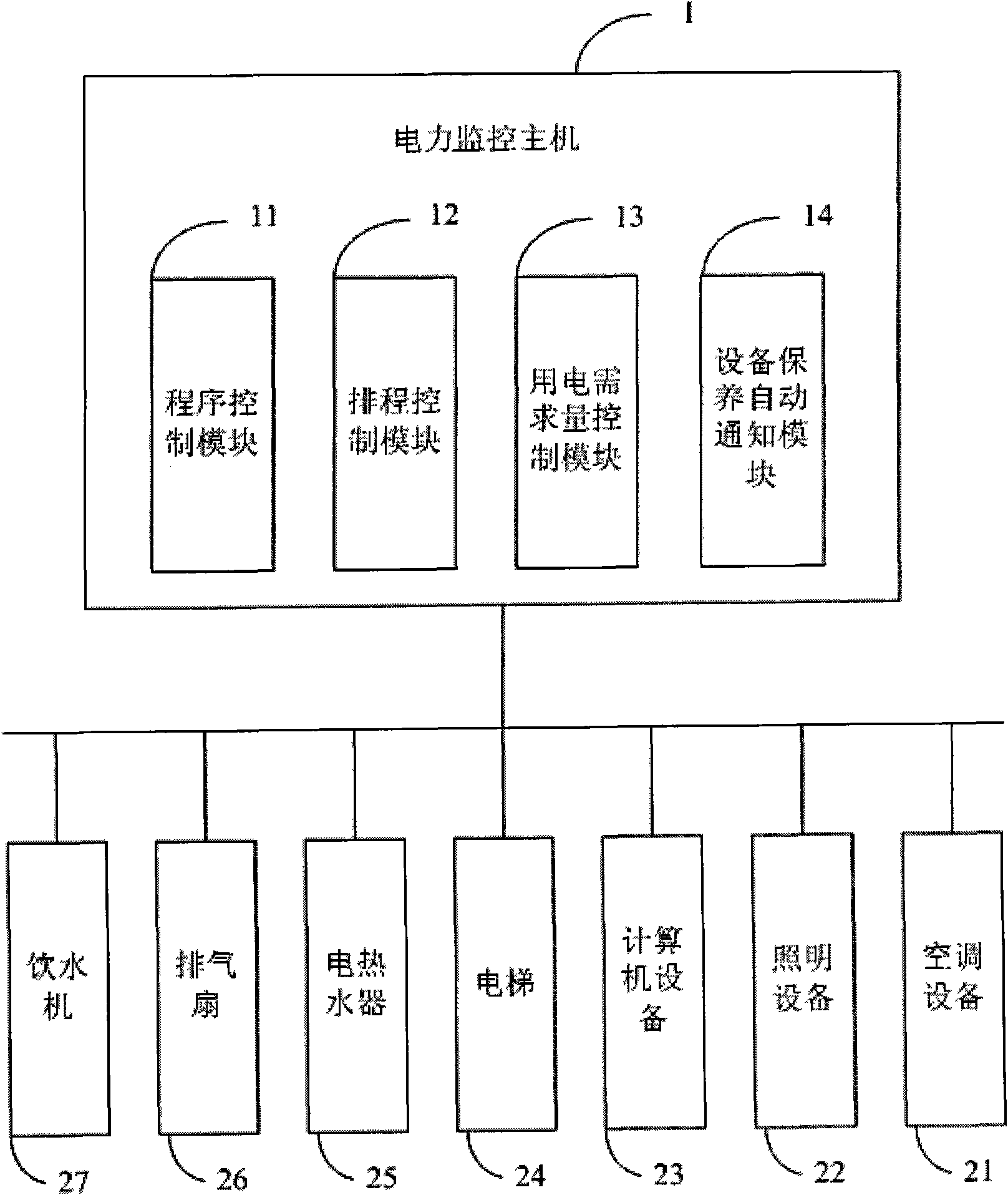

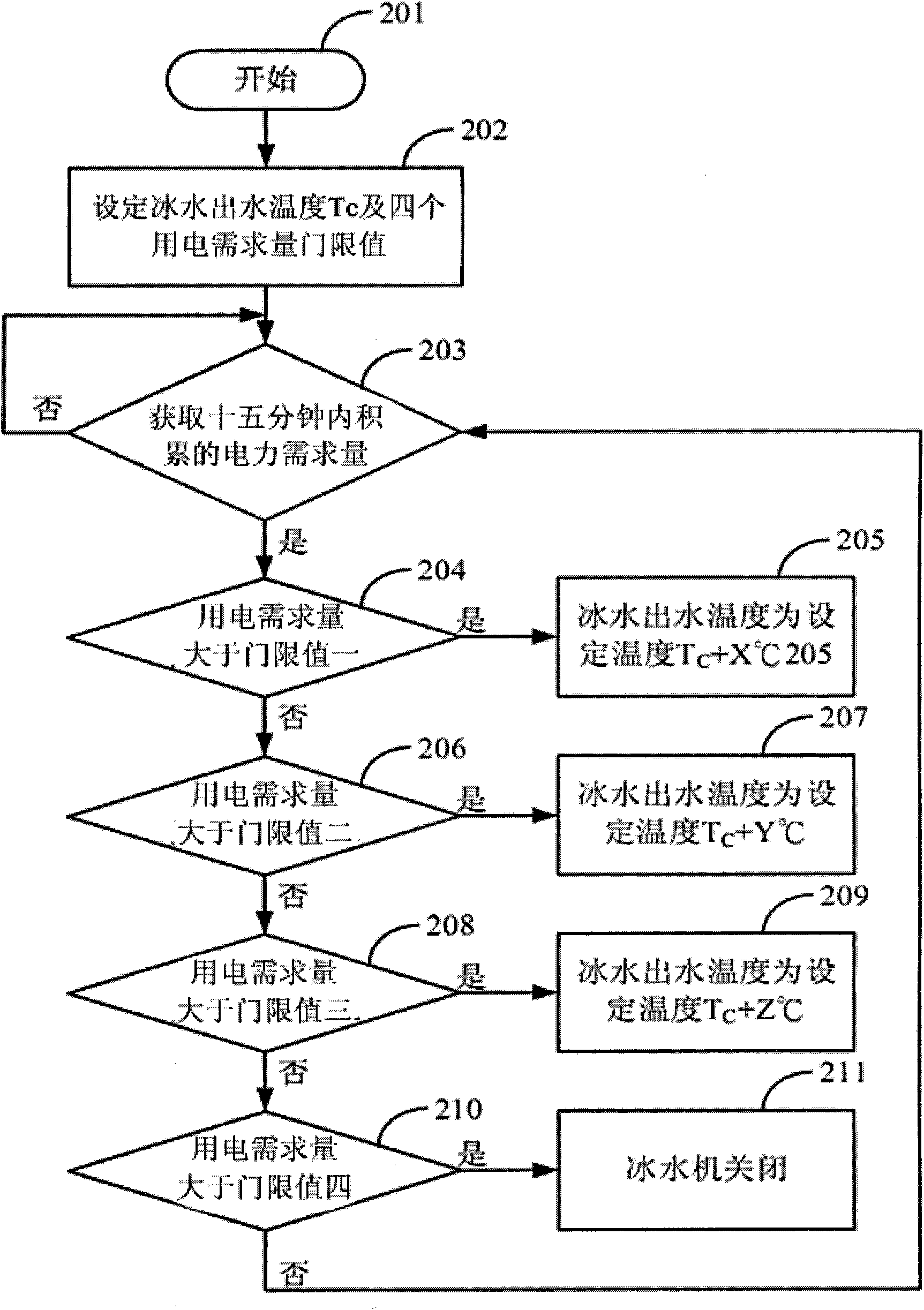

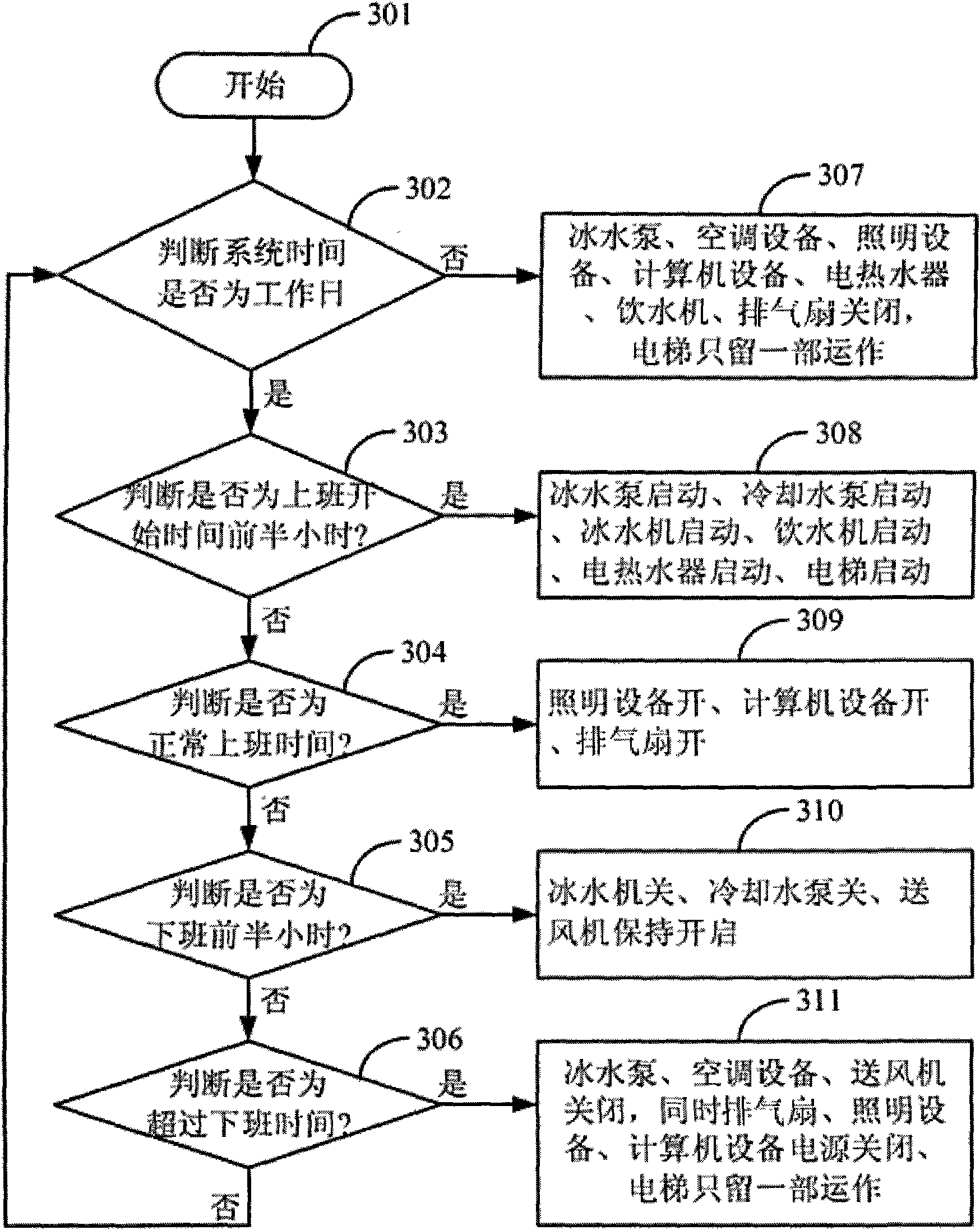

Energy-saving system for power monitoring

InactiveCN102004470AIncrease power consumptionRich monitoring methodsProgramme total factory controlLight equipmentMonitor equipment

The invention provides an energy-saving system for power monitoring. In energy-saving system, by utilizing the ICT (Information Communication Technology) for collecting the power consumption data of air conditioner equipment, illumination equipment, elevators, drinking water machines, computers, electric water heaters, exhaust fans and other monitoring equipment, not only with real-time power consumption conditions of the monitoring equipment are provided for users, but also power consumption data is analyzed. In addition, preset power demand control, programmed control and schedule control are adopted in the system to decrease the practical power consumption of loads and achieve the aims of saving energy and reducing carbon, and moreover, the notification on equipment maintenance time can be automatically carried out that unnecessary power consumption increase due to the nonperiodic maintenance of the air conditioner equipment or the illumination equipment is avoided, therefore, the aims of indirectly saving energy and reducing carbon are achieved.

Owner:CHUNGHWA TELECOM CO LTD

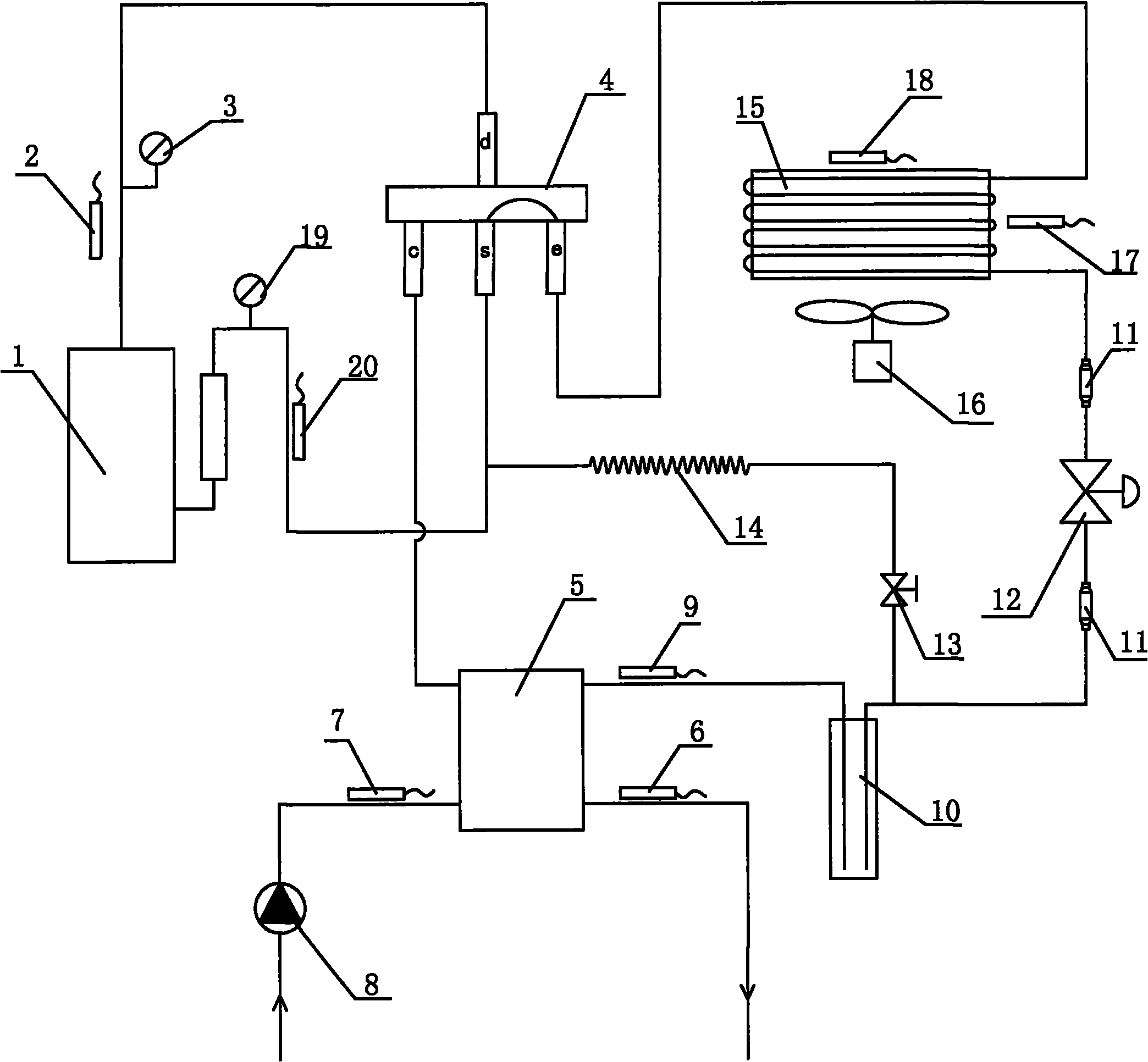

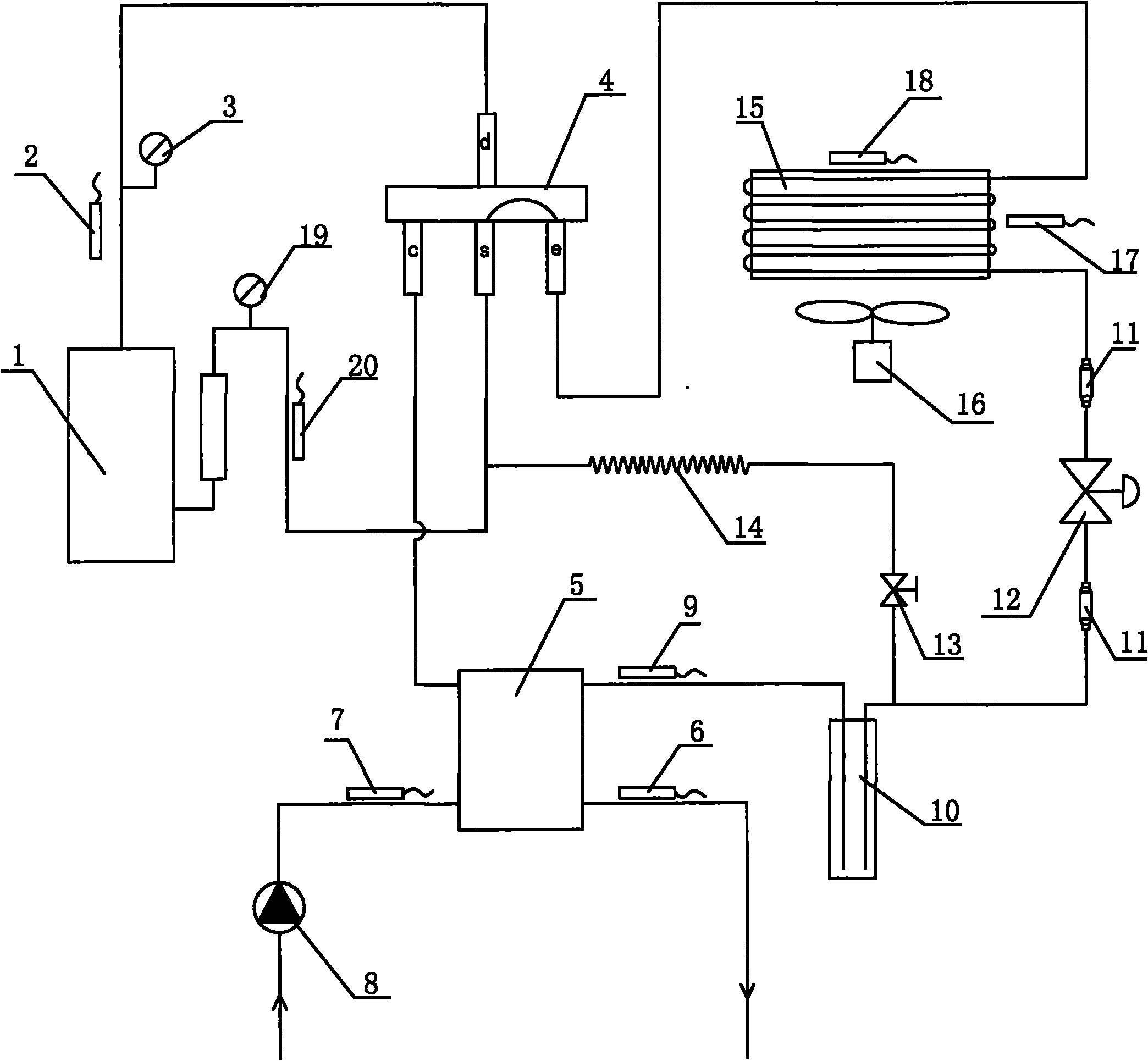

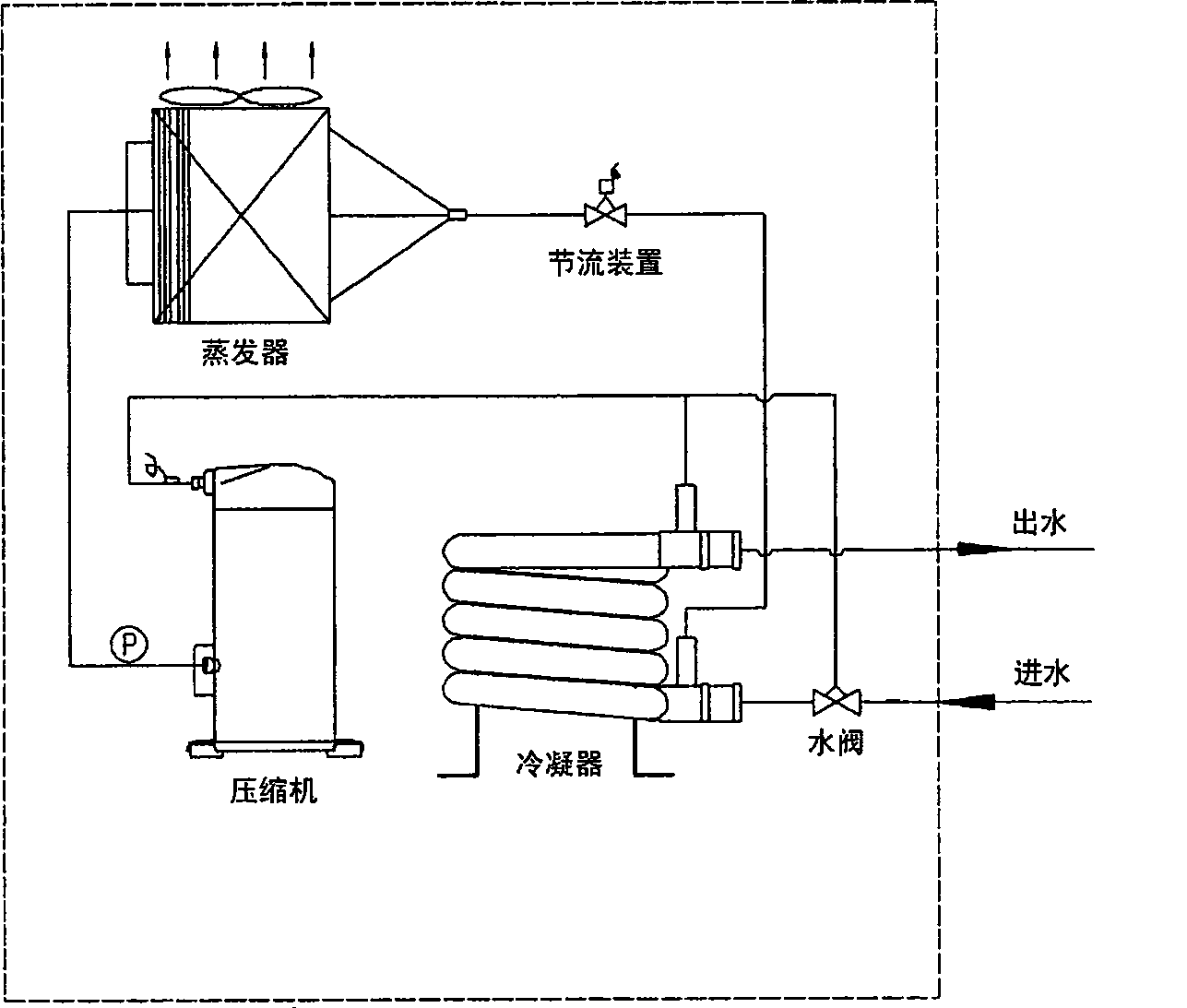

Air source heat pump water heater

InactiveCN101846389AAvoid start and stopRaise the water temperatureFluid heatersTemperature controlFour-way valve

The invention discloses an air source heat pump water heater which comprises a refrigerating loop, a hot water loop and a controller, wherein an exhaust port of a compressor is connected with a main pipe orifice D of a four-way valve, and is connected with a liquid inlet hole of a heat exchanger through a valve pipe orifice C; a liquid outlet hole of the heat exchanger is connected with an inlet of an evaporator through a throttling device; an outlet of the evaporator is connected with a pipe orifice E of the four-way valve, and is connected with a suction hole of the compressor through a valve hole S; the air source heat pump water heater is characterized in that the compressor is a variable frequency compressor; an auxiliary cooling pipeline is connected between an air suction pipeline of the compressor and a liquid outlet of the heat exchanger; the pipeline is formed by connecting an electromagnetic valve and a liquid spray capillary tube; an exhaust pipeline of the compressor is provided with a row of temperature sensors; and the row of temperature sensors are used for measuring the temperature for controlling the electromagnetic valve to be opened and closed. By adopting the variable frequency compressor and being matched with the auxiliary cooling pipeline, the air source heat pump water heater leads the compressor to work normally in the environment with low temperature, ensures the hot water supply to be stabler, and has wider application scope.

Owner:SUZHOU UNIV +1

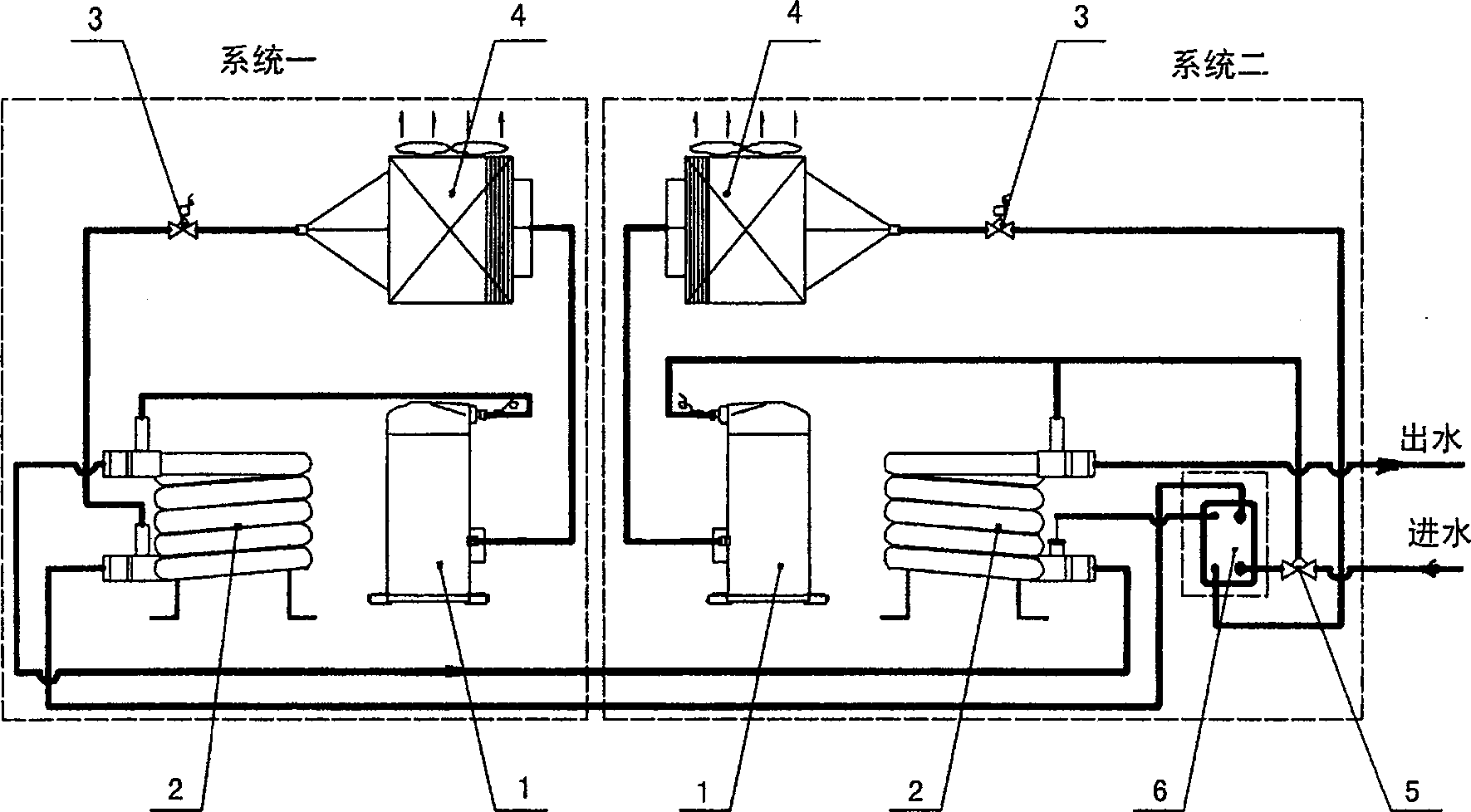

Method for Improving double heat pump hot-water system startup and adjustment performance

The invention discloses a novel method for starting and regulating working performances of a modified double heat pump bath hot-water system (i.e. a device for utilizing waste water and waste heat after bath to produce bath hot water). The method is implemented by adding a temperature-balancing tank and an electric heater at the water inlet end to shorten the start-up time and save water, and utilizing a three-way energy efficiency valve and a solenoid valve to regulate the volume of inlet waste water and thus to control the outlet water temperature. The invention has the advantages of high energy-efficiency ratio, rapid heating, and good start-up and temperature-regulation performances; and can work at a temperature below 5 DEG C.

Owner:党路明

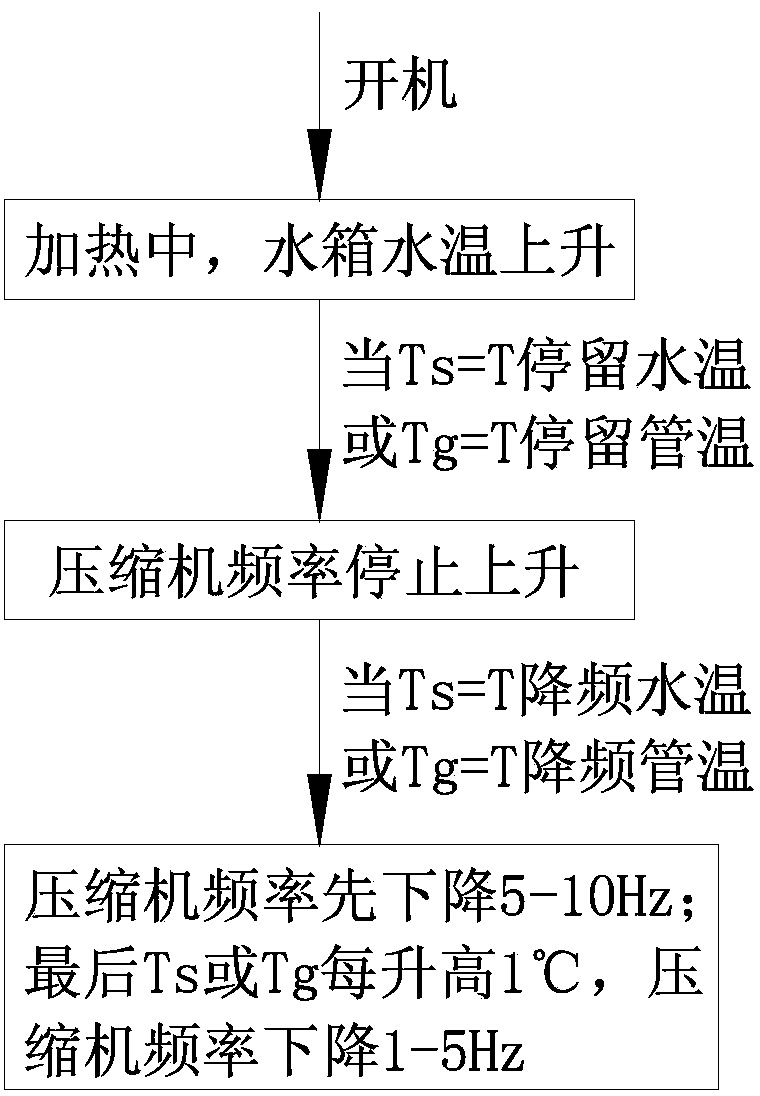

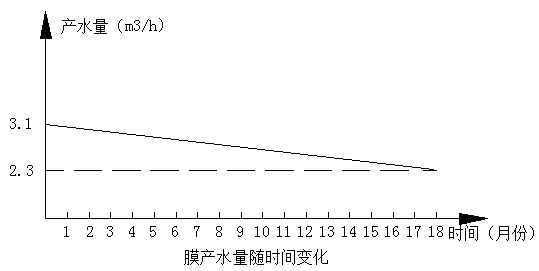

Method for increasing highest outlet water temperature of heat pump water heater

ActiveCN103836789ARaise the water temperatureReduce condensation loadFluid heatersControl systemFrequency reduction

The invention provides a method for increasing the highest outlet water temperature of a heat pump water heater. Due to the fact that a compressor frequency reducing step is included, when a heat pump heat water control system judges that current operating parameters conform to compressor frequency reducing conditions, the compressor frequency reduces, and the circulation volume of coolants is reduced. Consequently, the condensing load of the heat pump water heater is reduced, the heat exchange temperature difference of a condenser is reduced, and the temperature of water in a water tank is further increased. According to the method, judgments are conducted according to the current operating parameters, a method of frequency reduction on a high water temperature section is adopted, and the circulation volume of the system is reduced, namely, the condensing load-heat exchange temperature difference of the system is reduced, and the heat exchange temperature difference is reduced by 5 DEG C, so that the highest water temperature can reach 55 DEG C. On the condition that the cost and the installation space of the whole machine are not increased, the purpose that the highest outlet water temperature of a R410A coolant heat pump water heater reaches 55 DEG C is achieved.

Owner:GREE ELECTRIC APPLIANCES INC

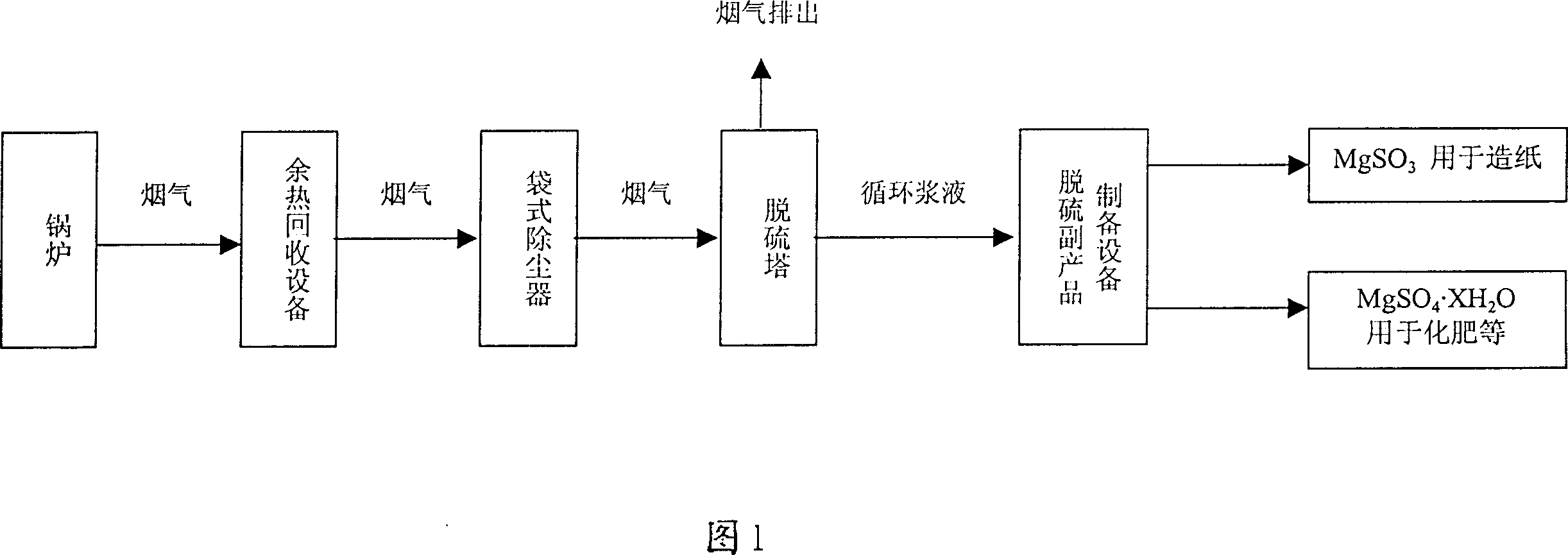

Integrating apparatus fo magnesium oxide with desulfurizing, dust-collecting and energy-saving functions and its production

InactiveCN101073744AReduce lossHigh economic valueHeat recovery systemsLighting and heating apparatusTowerBoiler feedwater

The invention is concerned with the afterheat reclamation device when the smoke evacuation of the 170 to 240 centigrade boiler enters the speedy superconducting pipe, it is: the smoke exchanges heat with other medium such as the feedwater of the boiler, the filling water of the boiler, the heating back water of the user, or the heat source water of the heat pump system, which can not only reduce the temperature of the smoke but also increase the temperature of the circle medium; the smoke enters the bag-style dedusting equipment directly after the smoke passes the afterheat reclamation device of the speedy superconducting pipe, the wastage of the bag decreases a lot because the improvement of the dedust; the smoke enters the decarbolizing tower to process desulfurize by magnesia after dedust, the desulfurize substance is magnesite or magnesia powder, the desulfurize byproduct are MgSO3, MgSO4.7H2O or MgSO4.1H2O that is with high economy value.

Owner:童裳慧

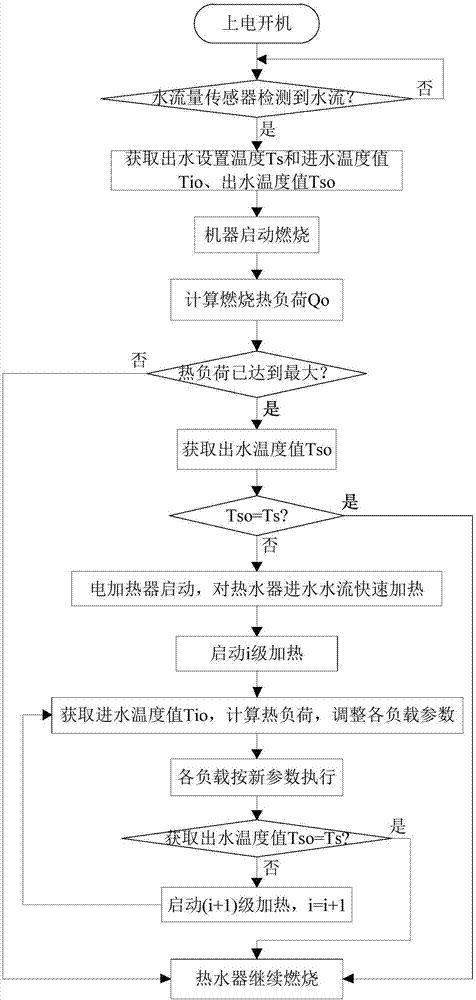

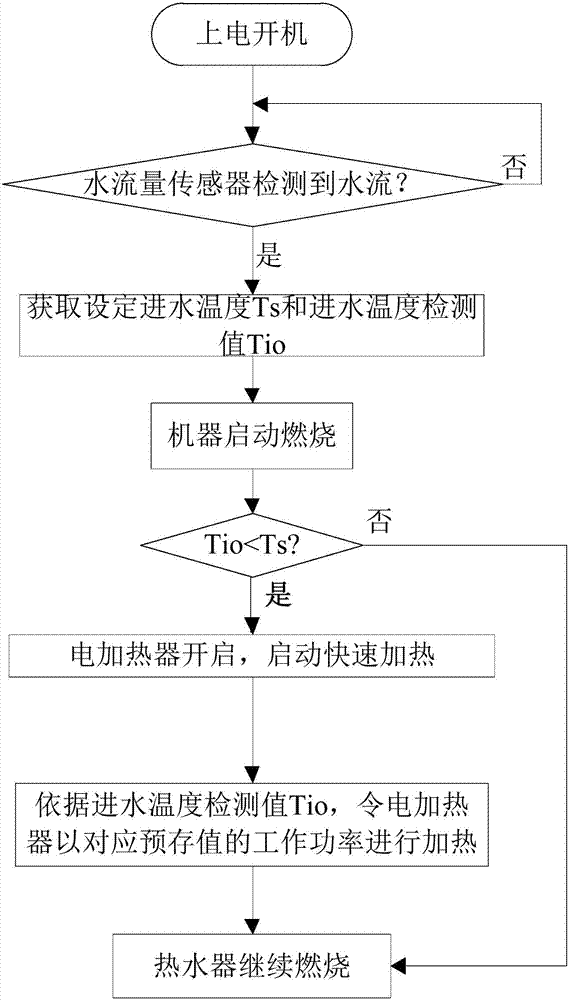

Control method of gas water heater and gas water heater

The invention relates to a control method of a gas water heater and the gas water heater. The gas water heater comprises a gas heating unit. The gas heating unit communicates with a water inlet pipe and a water outlet pipe. An electric heater used for conducting fast heating on inlet water is arranged on the water inlet pipe. When the thermal load of the gas heating unit reaches the maximum value and the water outlet temperature does not reach the set value, the electric heater on the water inlet pipe is started to conduct fast heating on the inlet water, the operating power of the electric heater is adjusted according to the water outlet temperature detection value, and accordingly the water outlet temperature reaches the set value. Through the arrangement and the control method, the purposes that the electric heater is controlled, and auxiliary electric heating is conducted on water flowing through the water inlet are achieved, the water inlet temperature of the gas water heater is remarkably increased, the power of the gas water heater is improved, and the application environment of the gas water heater is broadened. Meanwhile, the gas water heater is simple in structure, the control method is concise, the effect is remarkable, and the control method of the gas water heater and the gas water heater are suitable for application and popularization.

Owner:QINGDAO ECONOMIC & TECHN DEV ZONE HAIER WATER HEATER

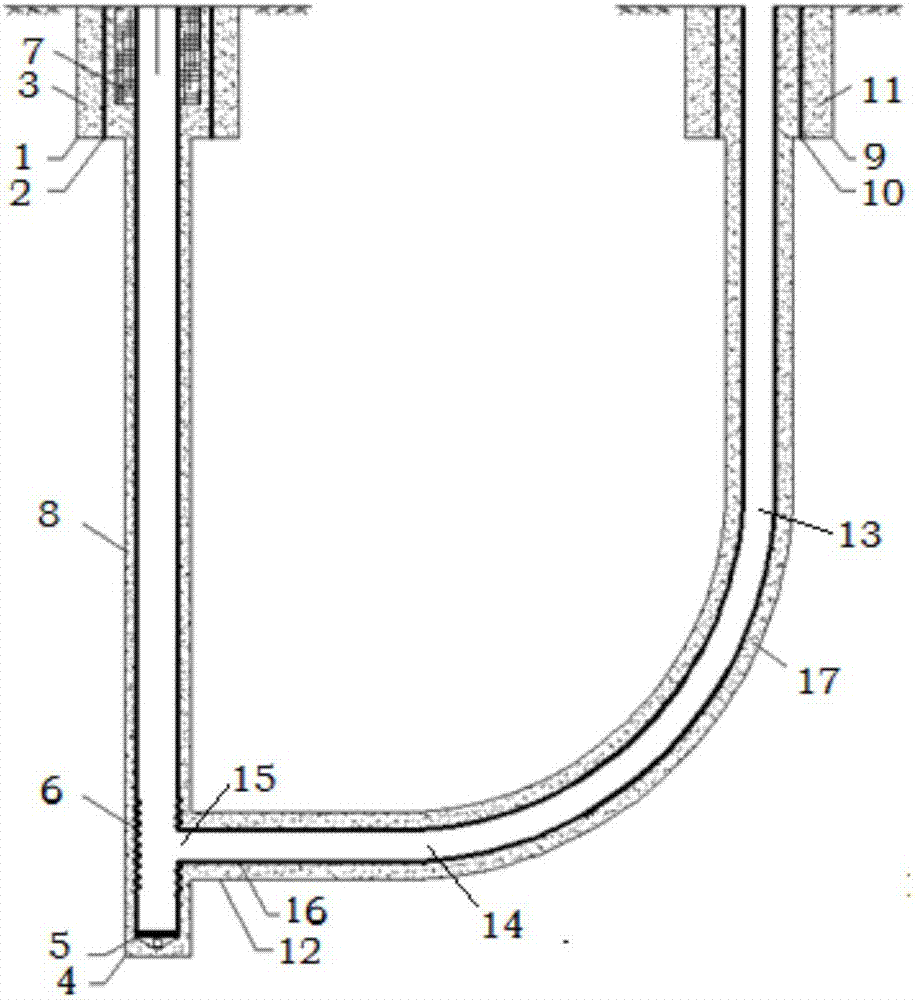

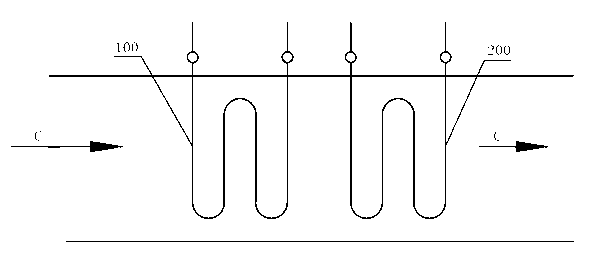

Construction method for well structure of heat exchanging type horizontal butt-joint geothermal well

InactiveCN107476797ANo pollutionLarge cross-sectional surface areaOther heat production devicesGeothermal energy generationBedrockStructure of the Earth

The invention provides a construction method for a well structure of a heat exchange type horizontal butt-joint geothermal well. The construction method for the well structure of the heat exchange type horizontal butt-joint geothermal well comprises the following steps that drilling is conducted on the ground surface until drilling into the stable clay layer or under a bedrock surface, a vertical well first opening well hole is formed, then second opening is conducted from the bottom of the vertical well first opening well hole until drilling under an arbitrary mudstone layer with a thickness being greater than 6m in the target heat storage layer, and a vertical well second opening well hole is formed; drilling is conducted in the surface of the ground surface until drilling into the stable clay layer or under a bedrock surface and the distance between a well opening of a vertical well and the surface of the ground surface is at least 250 m, and a horizontal engineering well first opening well hole is formed; then second opening is conducted from the bottom of the horizontal engineering well first opening well hole, and a horizontal engineering well second opening well hole is formed and communicates with the vertical well second opening well hole in a butt-joint mode, thus a horizontal engineering well cylinder and a vertical well cylinder form a U-shaped pipeline in a seamless butt-joint mode, and the structure is large in section surface area, heat exchanging water amount and heat exchanging amount; and according to the construction method for the well structure of the heat exchange type horizontal butt-joint geothermal well, heat exchanging is achieved only by using circulation of cold and heat water, no underground water is pumped, water resources are protected, the underground water is not polluted at the same time, and the environment-friendly effect is achieved.

Owner:陕西省煤田地质集团有限公司

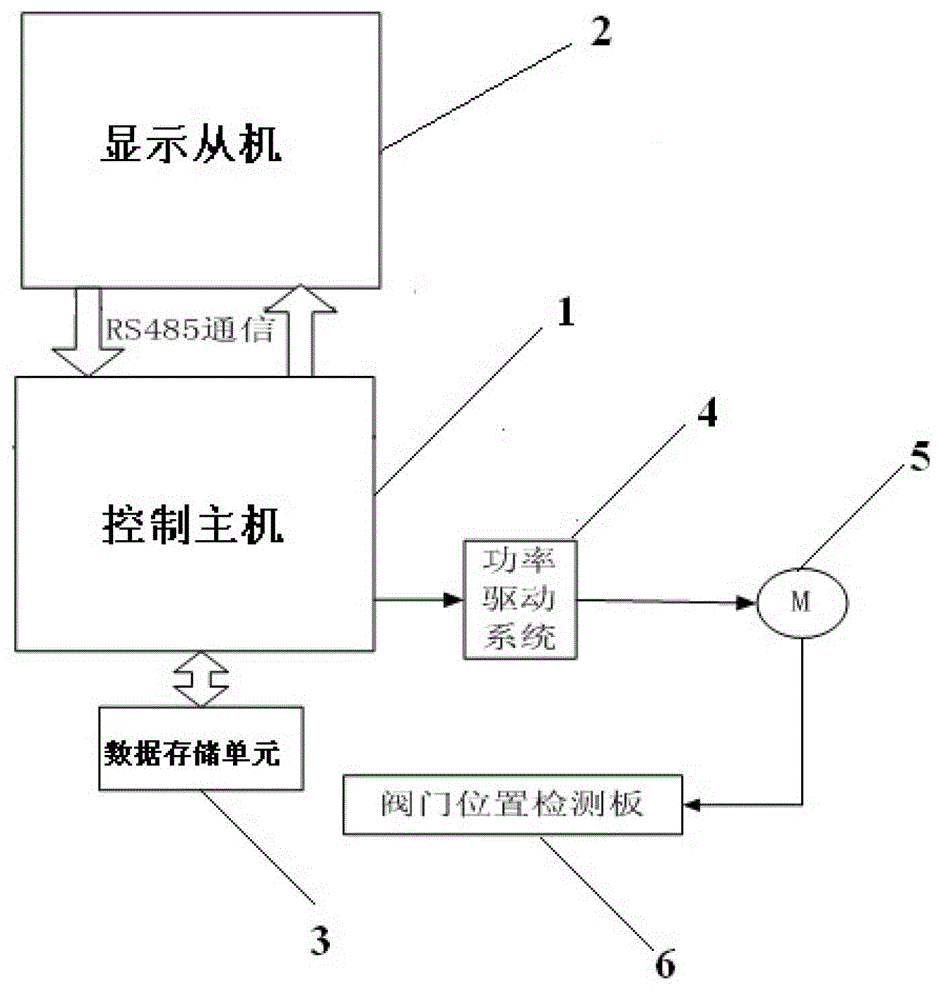

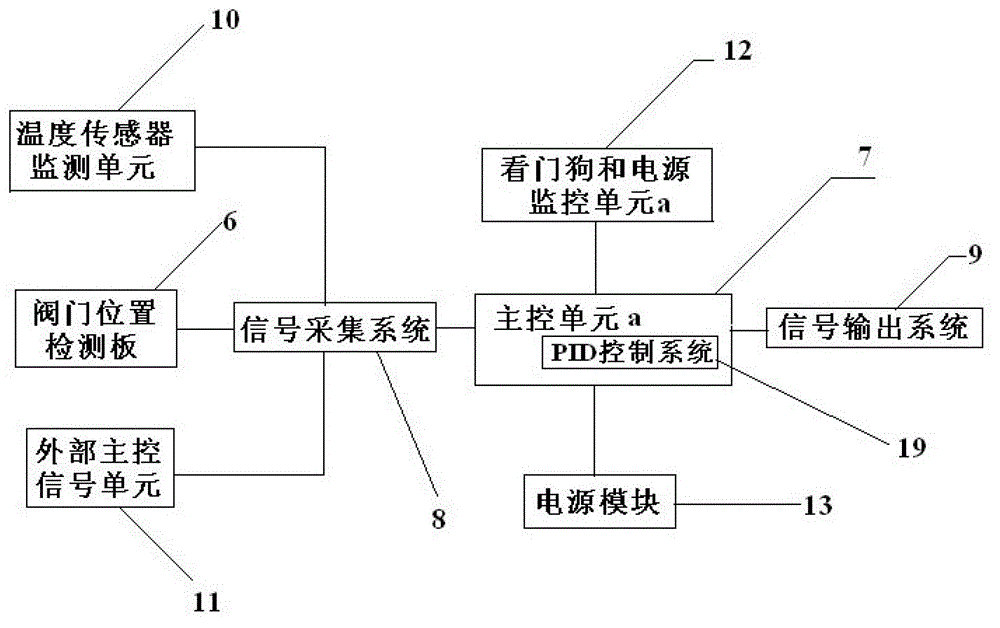

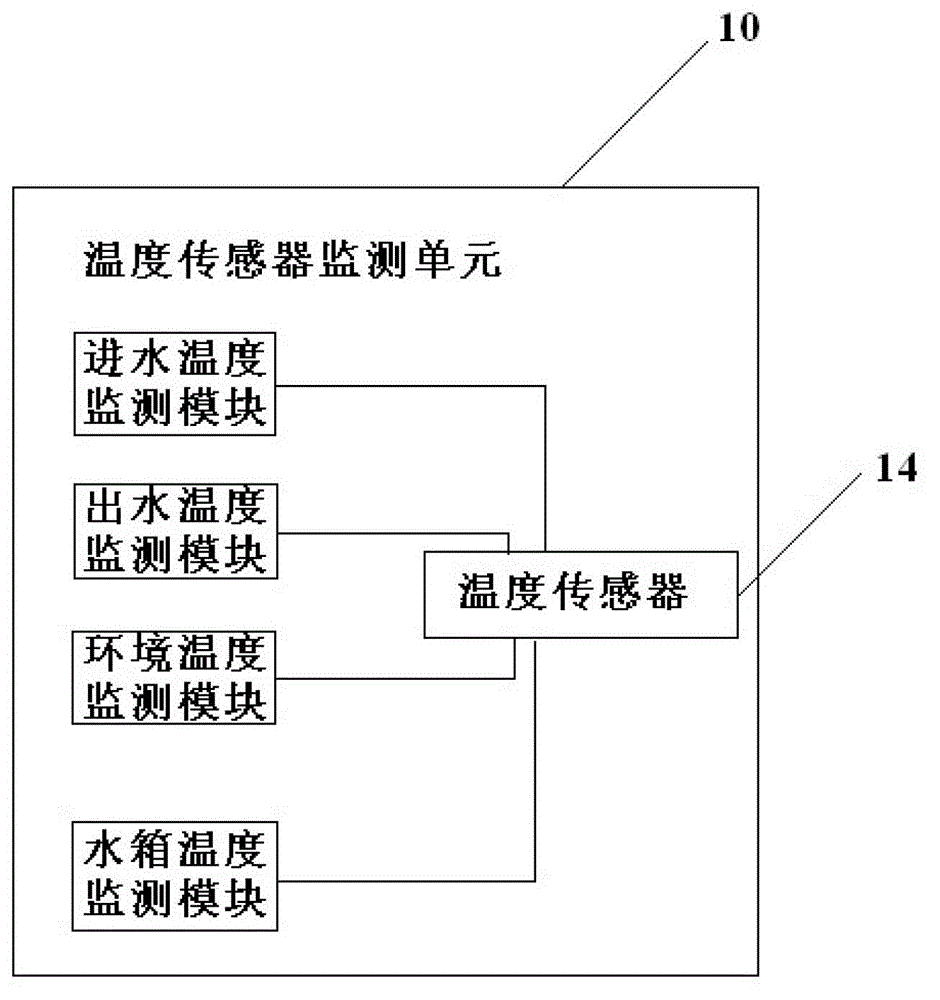

PID thermostatic adjustment control system for directly-heated air energy water heater

InactiveCN103148594ASmall fluctuations in temperature changesRaise the water temperatureFluid heatersProportion integration differentiationControl system

The invention discloses a PID (Proportion Integration Differentiation) thermostatic adjustment control system for a directly-heated air energy heater, which comprises a control host, a display slave and a valve control execution device, wherein the control host is connected with the display slave by an RS485 (Recommended Standard 485) serial communication interface; the valve control execution device comprises a power drive system, a stepping motor and a valve position detection plate that are sequentially connected by wires; and the control host is connected with the power drive system in the valve control execution device by the wire, and further connected with a data storage unit by a two-wire serial bus. The PID thermostatic adjustment control system for the directly-heated air energy water heater has the advantages that the PID thermostatic adjustment control system is simple in control mode, convenient to mount, and free from season and geographical position influences. Furthermore, the PID thermostatic adjustment control system makes outstanding contributions to energy conservation, environmental protection and the like.

Owner:XI'AN POLYTECHNIC UNIVERSITY

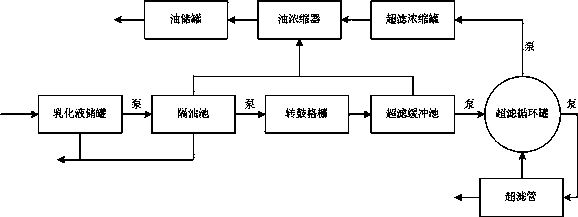

Emulsion wastewater treatment process and device

InactiveCN104193019AHigh quality oilGood economic benefitsMultistage water/sewage treatmentUF - UltrafiltrationChemistry

The invention relates to an emulsion wastewater treatment process and device. The treatment process comprises the steps that the wastewater is pumped into an oil separator from an emulsion storage tank and floating oil is collected in an oil concentrator; the emulsion enters a drum grille to further remove small particle impurities likely to scratch an ultrafiltration membrane; an ultrafiltration buffer pool is used for receiving the oily wastewater and the oily wastewater is used for buffering ultrafiltration water inflow, wherein the floating oil enters the oil concentrator; the remaining wastewater is pumped into an ultrafiltration circulation tank and then is treated with the ultrafiltration membrane, and the emulsion is broken here; the ultrafiltered water is discharged to a subsequent biotreatment system; the floating oil and the oil after ultrafiltration and emulsion breaking enter the oil concentrator and self-flow into an oil storage tank after being further concentrated. The process and the device have the beneficial effects that any chemical agent is not used; the emulsion is broken by adopting a membrane treatment method, thus avoiding secondary pollution; the imported ultrafiltration membrane is adopted, so that the ultrafiltration effect is good and blockage is not easy to happen.

Owner:无锡格物环保技术有限公司

Hybrid heating system

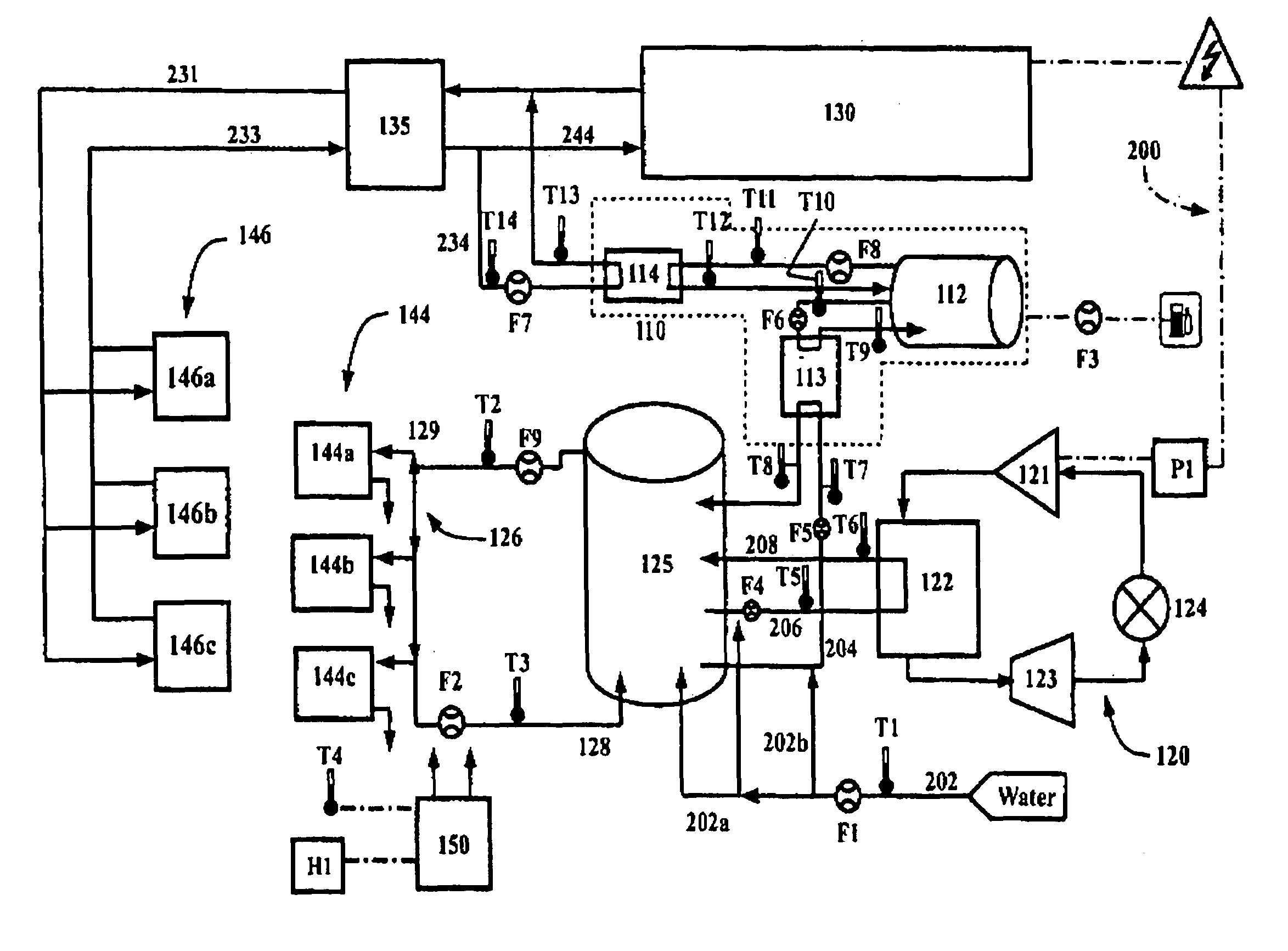

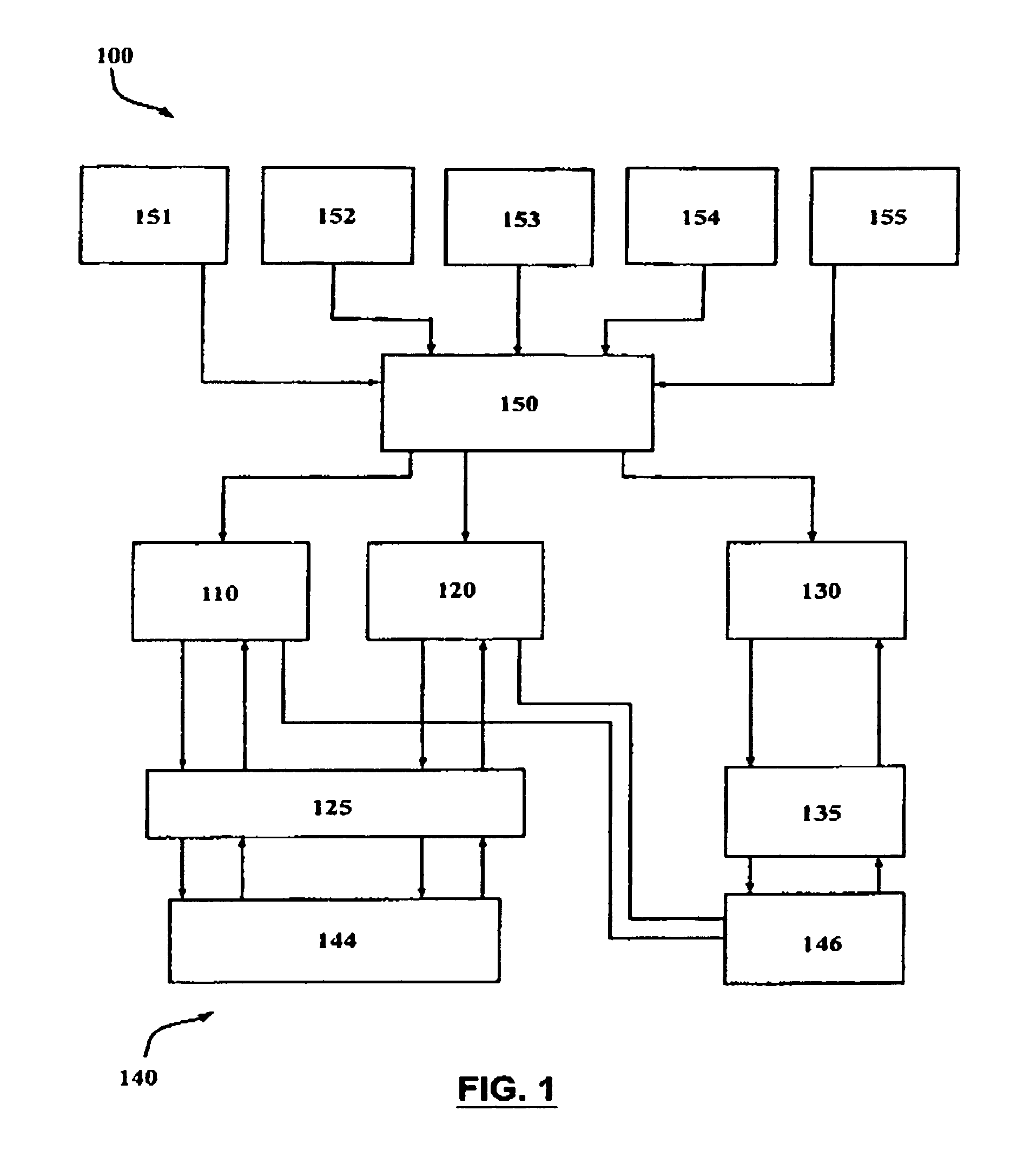

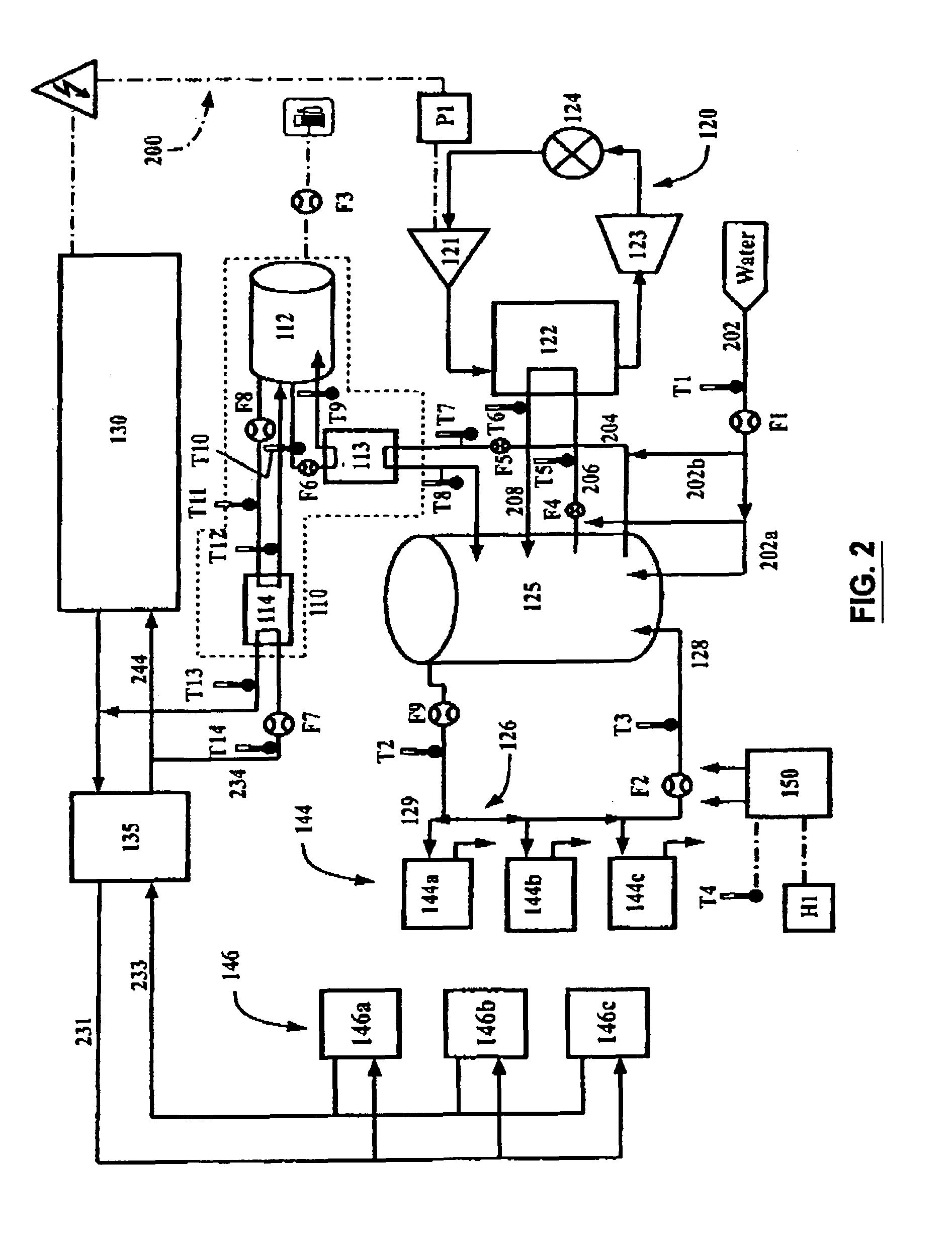

ActiveUS8600563B2Cost can be reduced and minimizedRaise the water temperatureLighting and heating apparatusTemperatue controlPlate heat exchangerProcess engineering

A hybrid heating system and method including: (a) a heat pump water heating system; (b) a conventional heating system including a conventional heater having a surface heat exchanger, and a primary circulation arrangement fluidly communicating with the surface exchanger, the primary circulation arrangement adapted to effect an exchange of heat between the surface heat exchanger and a flow of liquid to produce a heated flow of liquid; (c) a plurality of sensors associated with the heat exchange system; (d) an input arrangement adapted to provide cost data pertaining to a first power cost for supplying power to the heat pump system, and to cost information pertaining to a second power cost for operating the conventional system, and (e) a processor including a memory storing criteria specifying when to operate the heat pump water heating system, and when to operate the conventional heating system.

Owner:PHOEBUS ENERGY

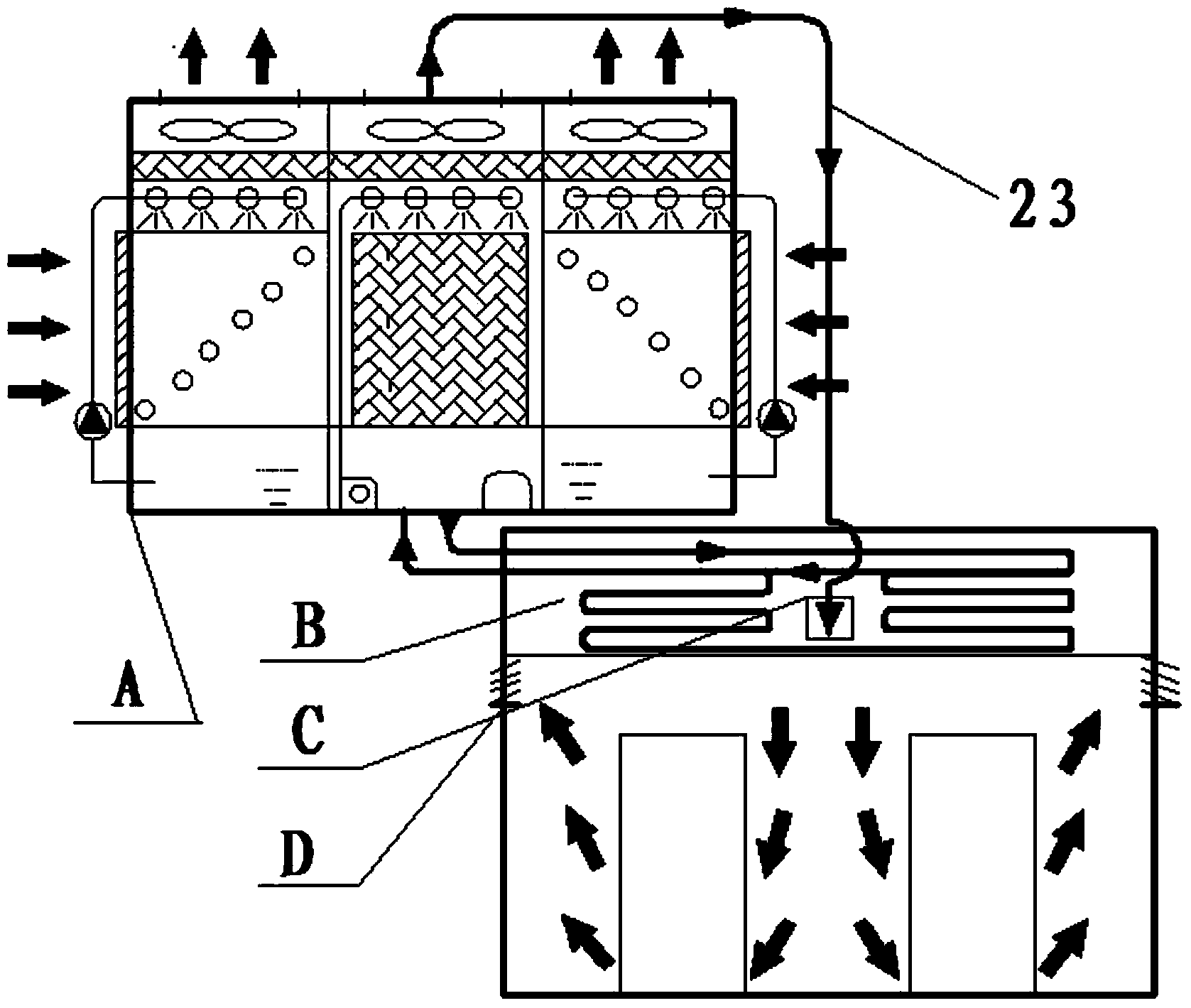

Water-air radiant panel evaporative cooling air conditioning system provided with cold beam and used for data center

InactiveCN104019510ARaise the water temperaturePrevent Chilled Beam CondensationLighting and heating apparatusSpace heating and ventilation detailsWater pipeEngineering

The invention discloses a water-air radiant panel evaporative cooling air conditioning system provided with a cold beam and used for a data center. The system comprises an evaporative cooling high temperature cold water unit arranged outdoors and the passive cold beam arranged in a ceiling space of the data center. A return air inlet is formed in the wall, close to a ceiling, of the data center. The evaporative cooling high temperature cold water unit is connected with the passive cold beam through a water pipe set and an air pipe. The water-air radiant panel evaporative cooling air conditioning system provided with the cold beam and used for the data center overcomes the defects existing in the prior art, can be applied to reality more effectively, can reduce energy consumption of a draught fan, saves space occupied by the air pipe, and has the advantages of being comfortable, low in noise and easy to maintain and saving energy.

Owner:XI'AN POLYTECHNIC UNIVERSITY

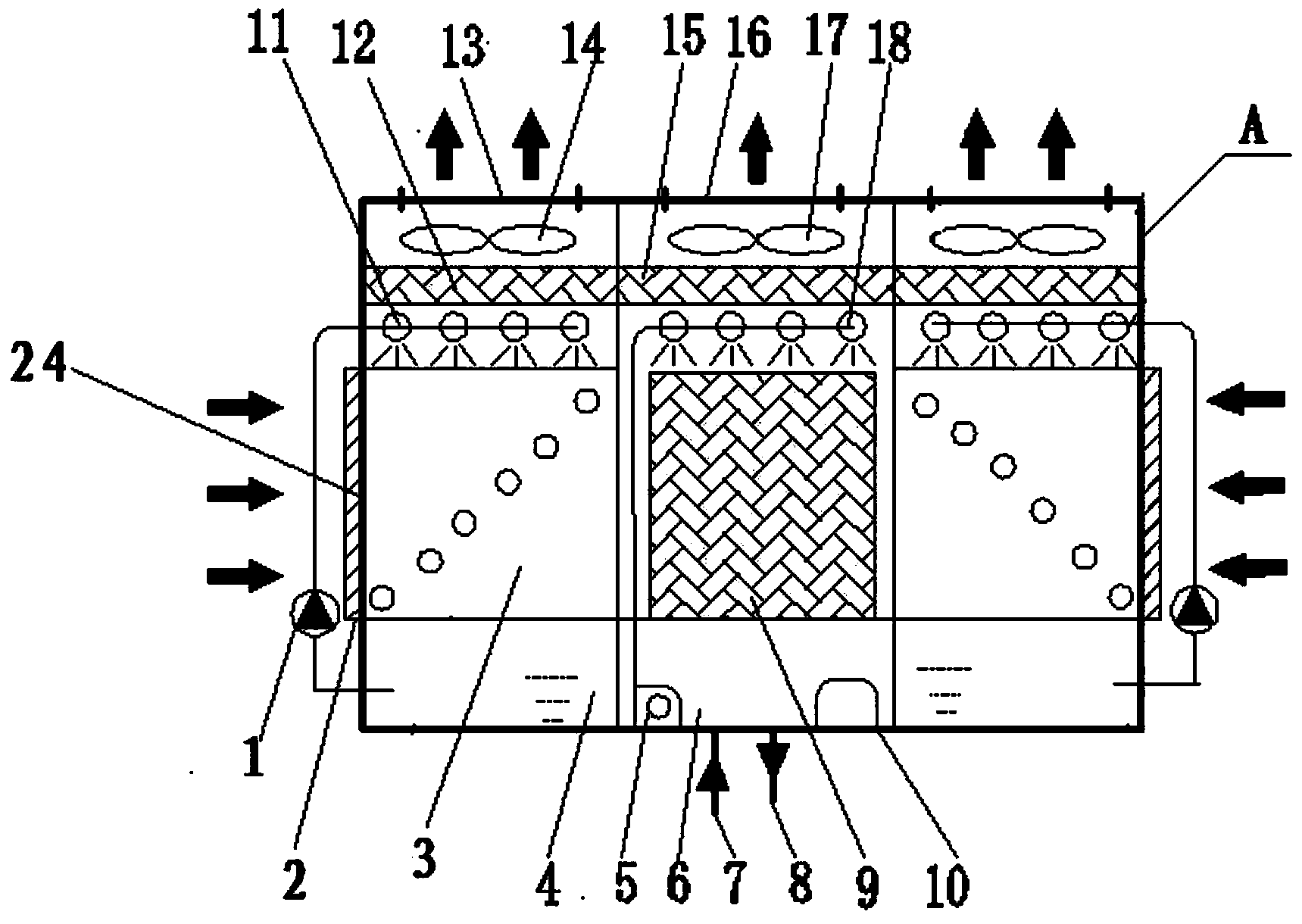

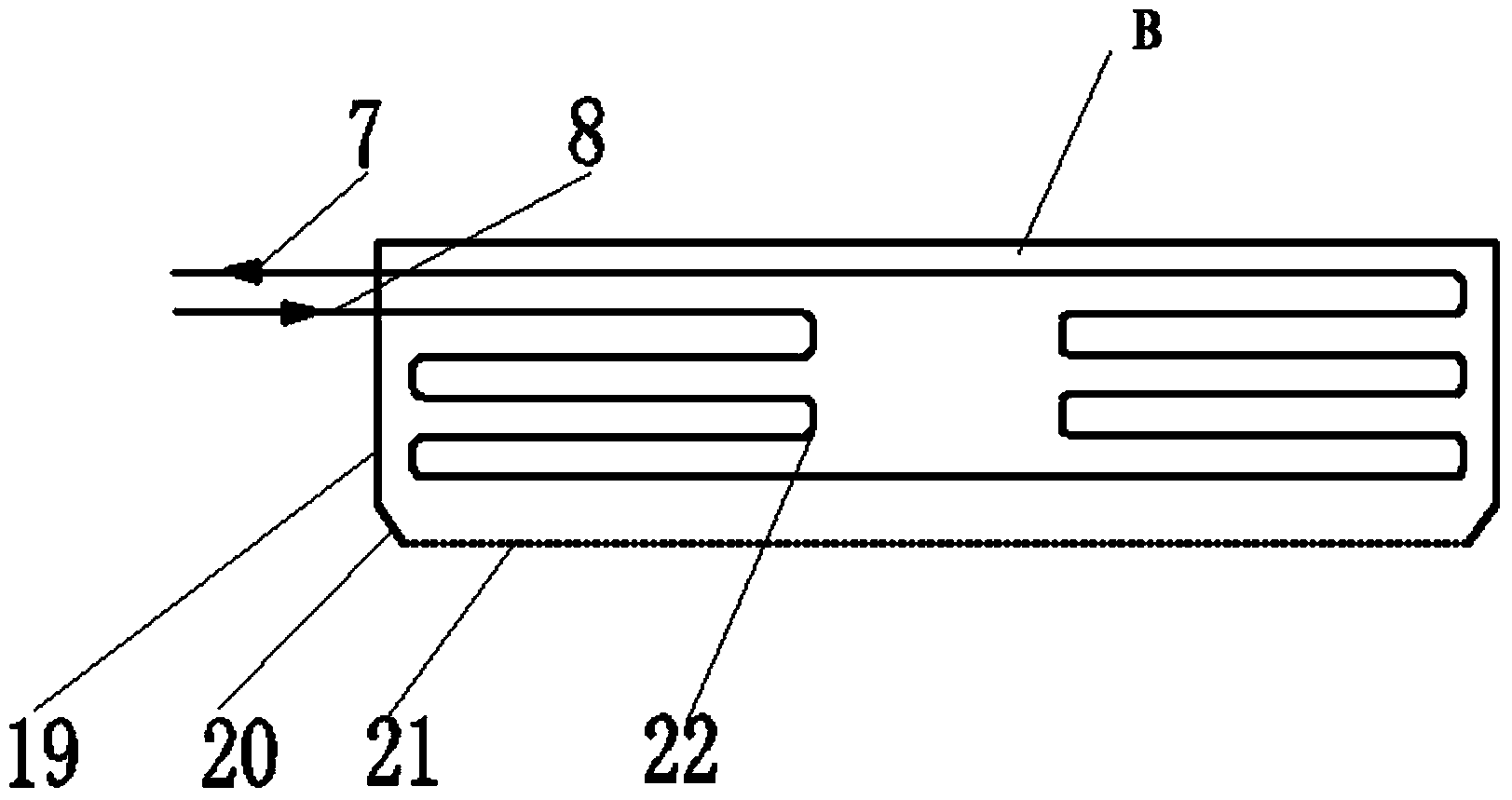

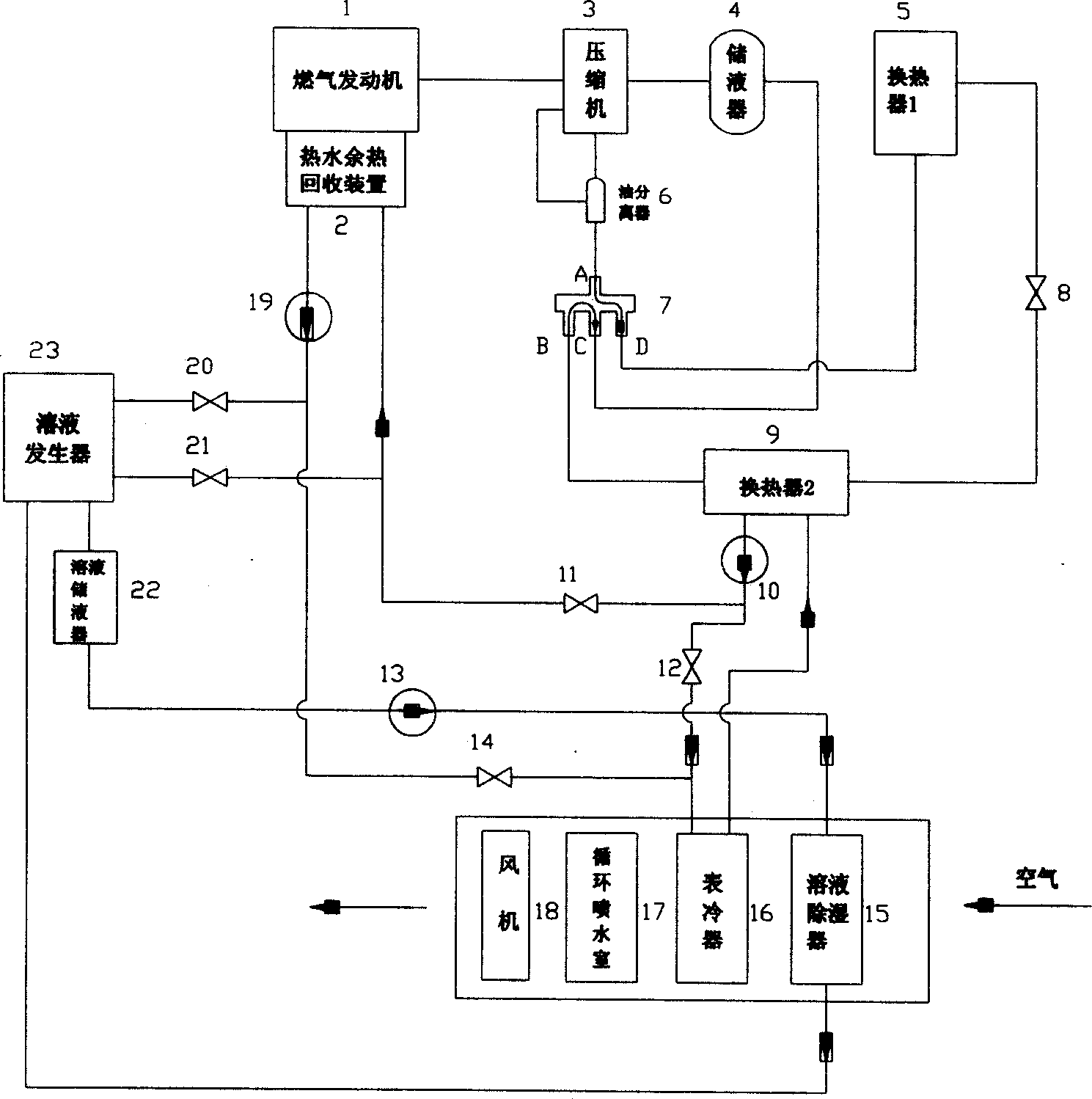

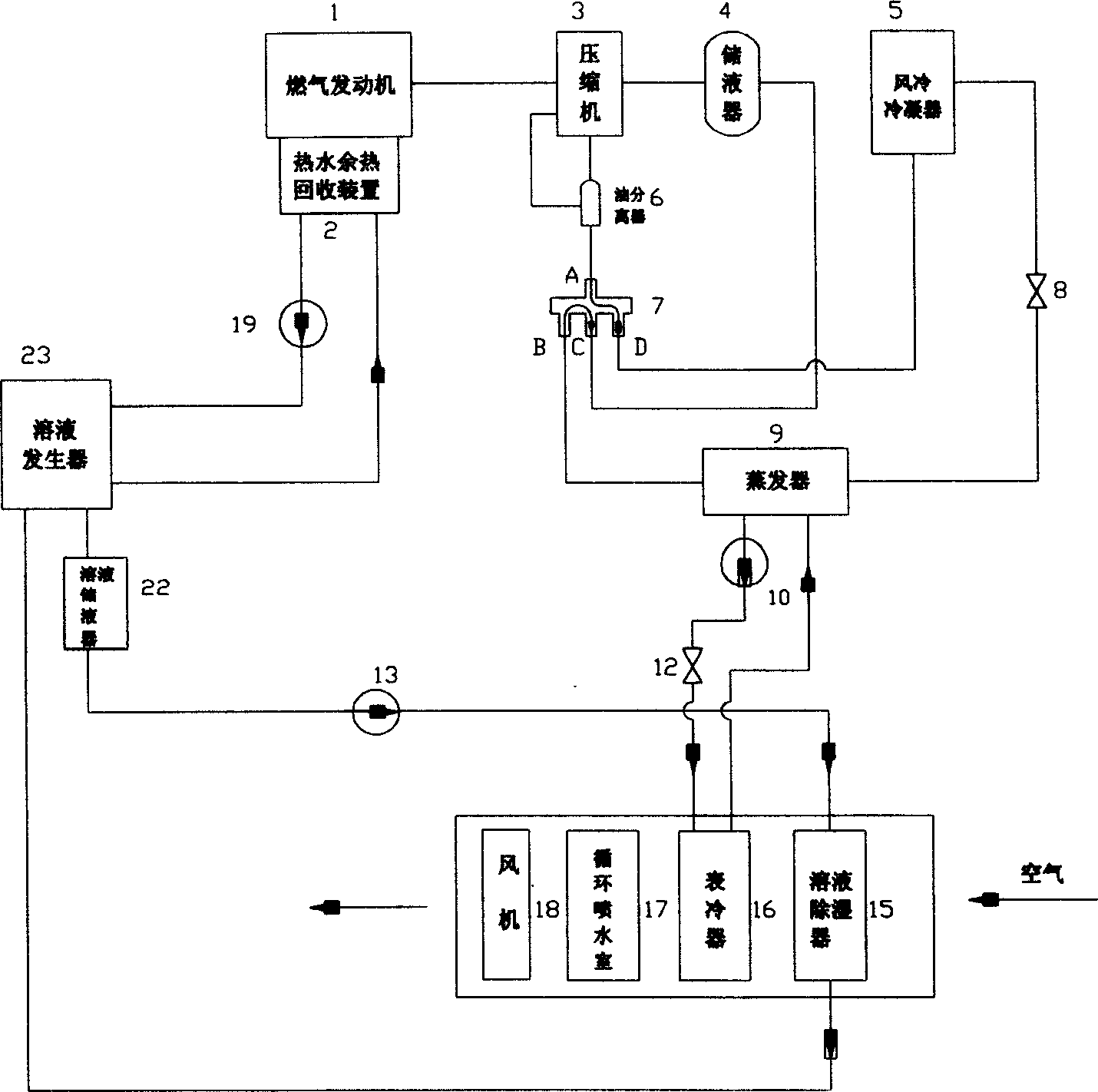

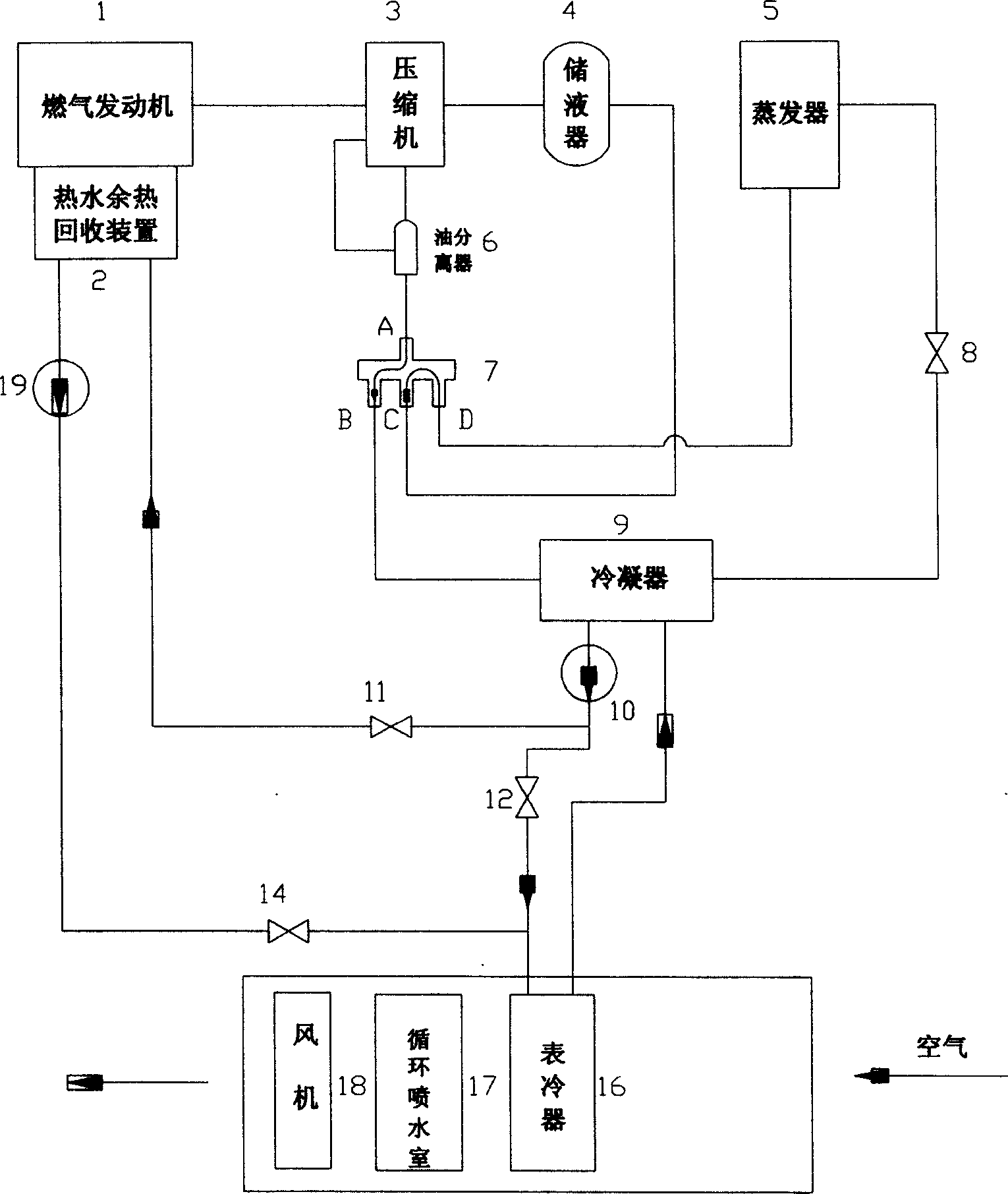

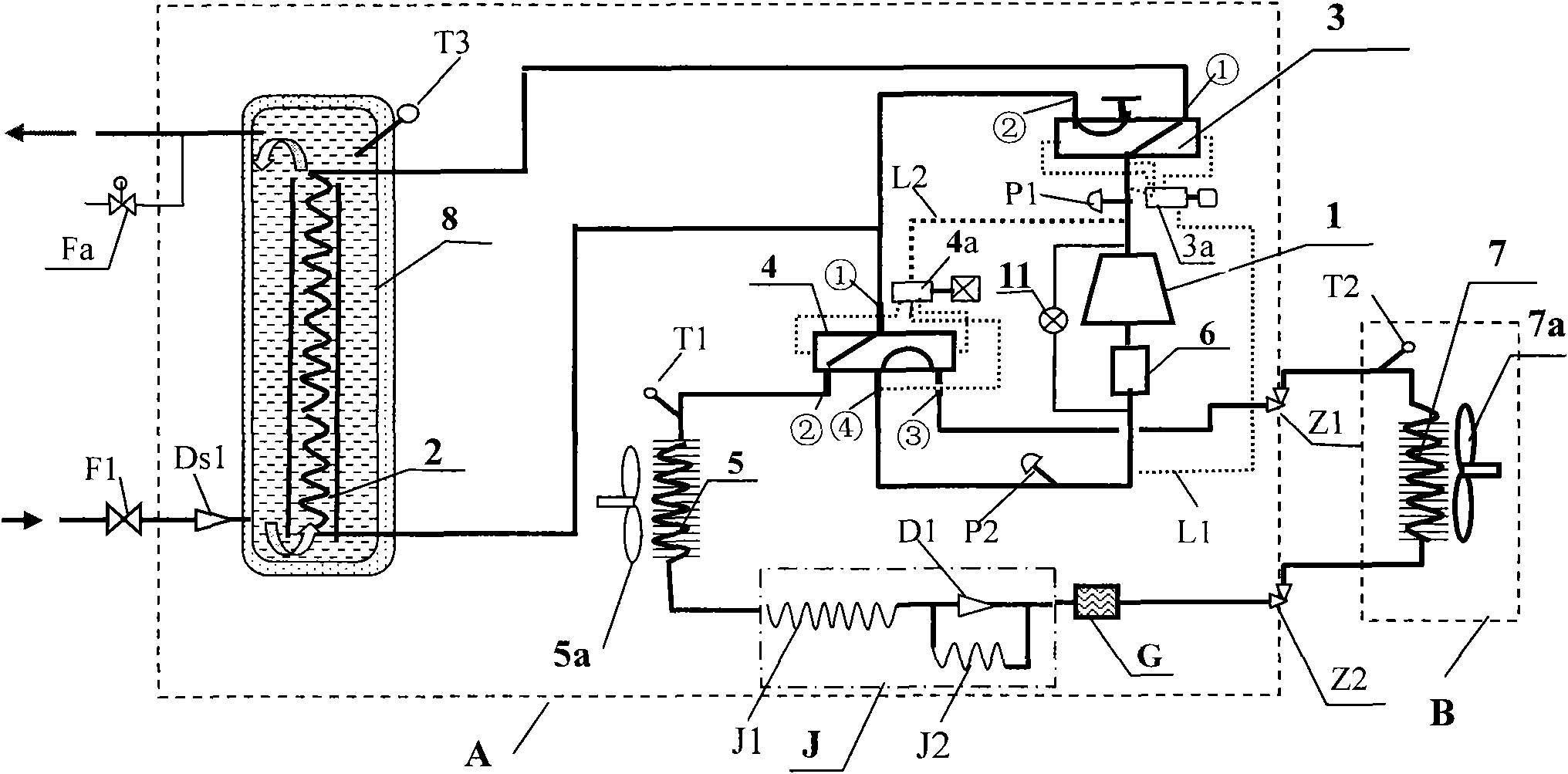

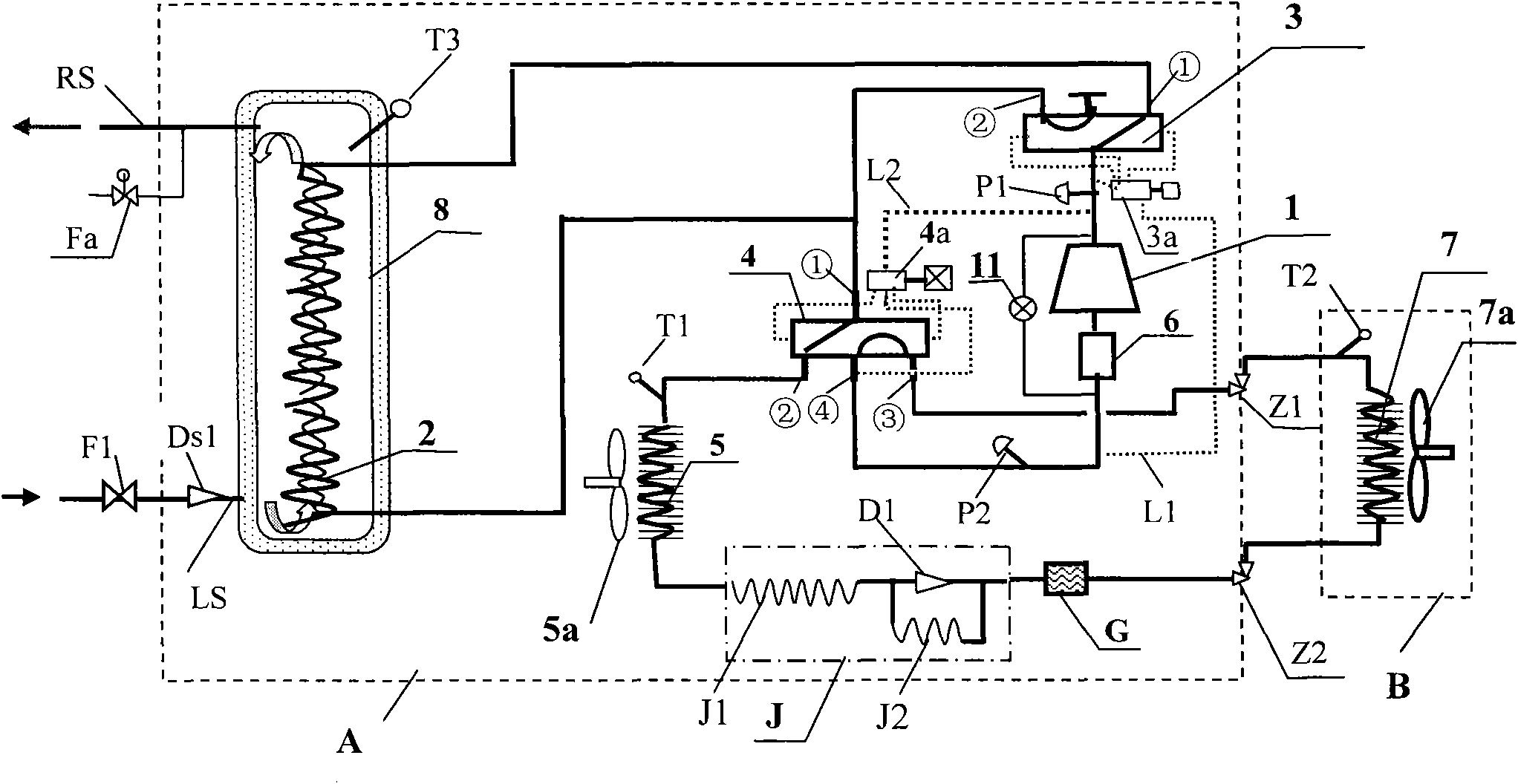

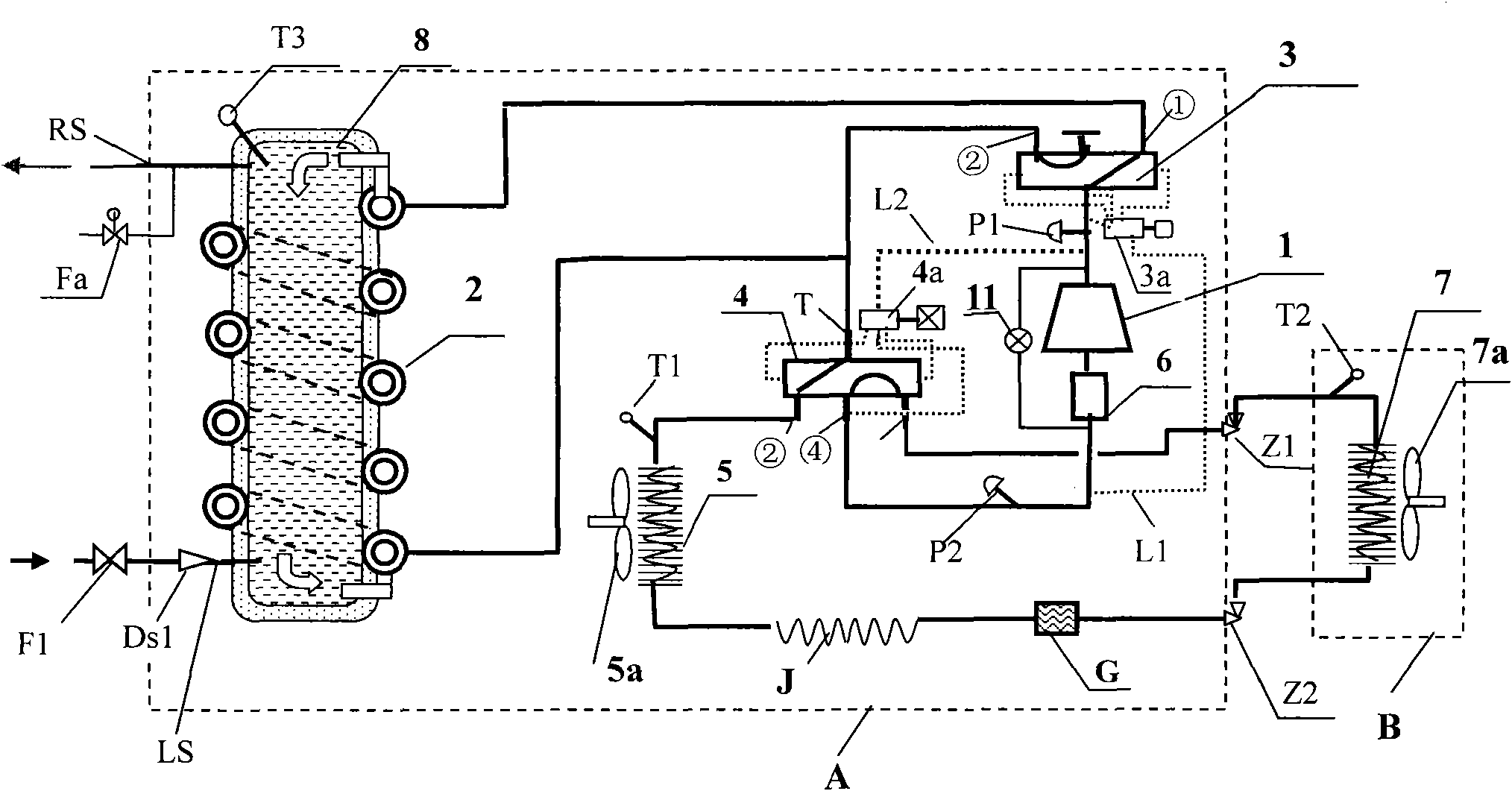

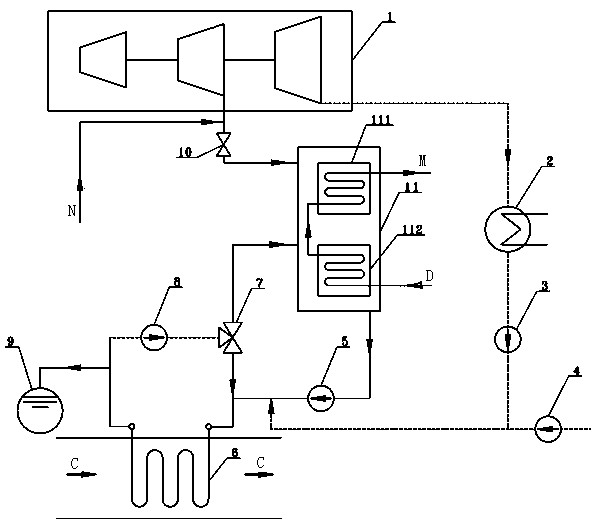

Energy accumulation type combustion gas and heat pump composite air-conditioning

InactiveCN1721787ARaise the evaporation temperatureImprove cooling effectHeat pumpsClimate change adaptationFour-way valveProcess engineering

This invention relates to a storage gas pump compound air conditioning, which is the new air conditioning system with integration and comprises the following parts: gas motor, gas motor hot water remainder recycle device, compressor, oil isolation, liquid storage; four-way valve; flow saving device; heat exchanger; liquid humidity remover; solution generation device; solution storage ware; meter cooling device; recycling spraying chamber and fan motor. The summer system adopts air conditioning heat potential charge independent process and uses gas motor to generate heat to process charge into cooling set working situation.

Owner:SOUTHEAST UNIV

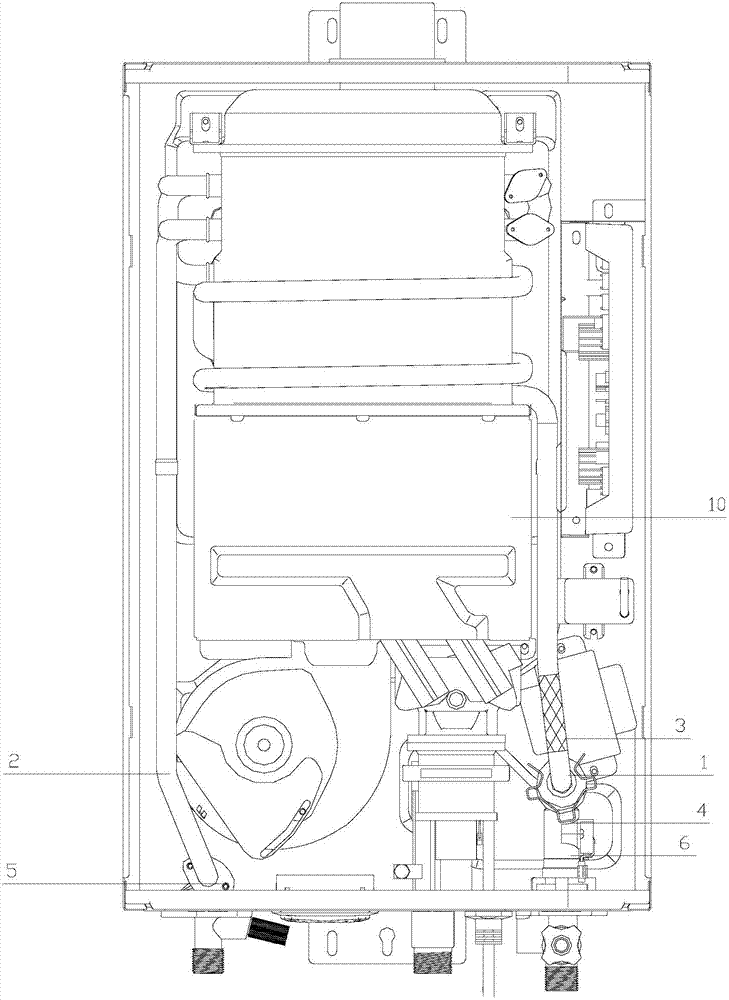

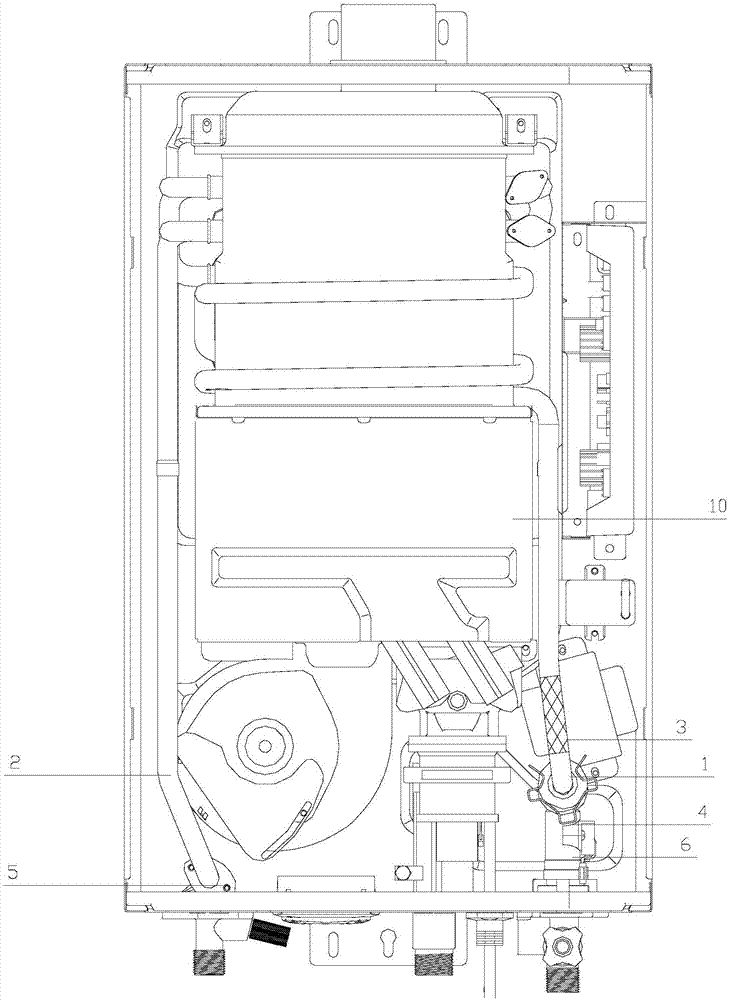

Wall-mounted gas boiler, hot water supply system and control method

ActiveCN106595026AIncreased ability to heat domestic waterImprove utilization efficiencyWater heatersHot-water central heatingProcess engineeringThermal water

The invention relates to a wall-mounted gas boiler comprising a heat exchanger, a first water inlet pipe, a first water outlet pipe, a second water inlet pipe and a second water outlet pipe. The heat exchanger comprises a first passage and a second passage which are used for carrying out heat exchange with smoke generated by gas combustion, and both the first passage and the second passage can allow a fluid to pass through and do not intercommunicate; the first water inlet pipe and the first water outlet pipe respectively communicate with two ends of the first passage to form a first heat supply unit; the second water inlet pipe and the second water outlet pipe respectively communicate with two ends of the second passage to form a second heat supply unit; and the first heat supply unit and the second heat supply unit can independently or simultaneously output a heat source. By using the wall-mounted gas boiler, hot water for heating and daily use can be simultaneously supplied, and the problems of insufficient heat exchange amount in a heating space and temperature reduction caused by overhigh water consumption of hot water for daily use are avoided.

Owner:GREE ELECTRIC APPLIANCES INC

Compact cooling/heating air-conditioning and hot water supply three-purpose machine capable of building natural circulating flow for heat exchange

InactiveCN102486344ASimple structureSimple compositionStationary conduit assembliesFluid circulation arrangementWater storage tankWater production

The invention discloses a compact cooling / heating air-conditioning and hot water supply three-purpose machine capable of building natural circulating flow for heat exchange. In the technical scheme, the machine is characterized in that a water heat exchange loop system capable of building the natural circulating flow for the heat exchange is adopted, and a water storage tank and a multi-layer spiral roller type hot water condensing heat exchanger in the water storage tank or a spiral tubular hot water condensing heat exchanger with a flow guide sleeve in the water storage tank are arranged inan outdoor unit. Compared with the cooling / heating air-conditioner, a tee valve and the hot water condensing heat exchanger are additionally arranged in a refrigerant loop. In the particular connection, the exhaust port of a compressor is connected with the air inlet of the tee valve, the first air outlet of the tee valve is connected with a refrigerant inlet of the hot water condensing heat exchanger, and the second air outlet of the tee valve is communicated with the refrigerant outlet of the hot water condensing heat exchanger and a first interface of a four-way valve in a tee way; and thelow-pressure air discharging pipe of the solenoid pilot valve of the tee valve is connected with the air suction pipe of the compressor of the refrigerant loop, and the high-pressure air feeding pipeof the solenoid pilot valve of the four-way valve is connected with the exhaust pipe of the compressor of the refrigerant loop. The machine has the functions of simultaneous hot water production and cooling, hot water production, cooling and heating.

Owner:嘉善冠通塑业有限公司

Heat humidity independently controlled air conditioning system applied to IDC machine room and refrigeration method

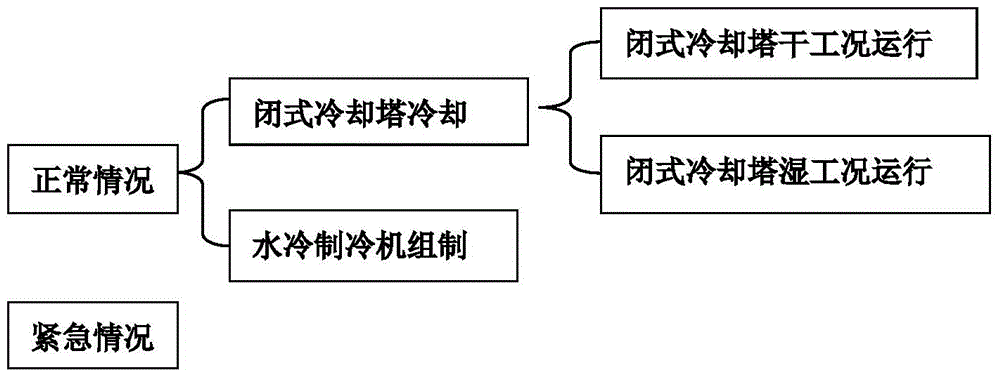

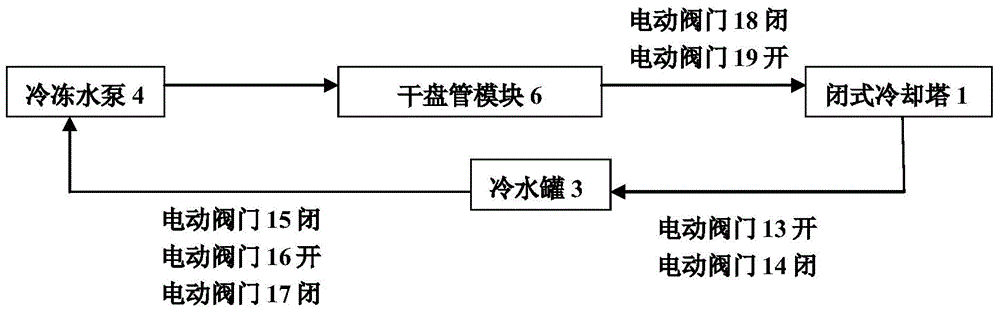

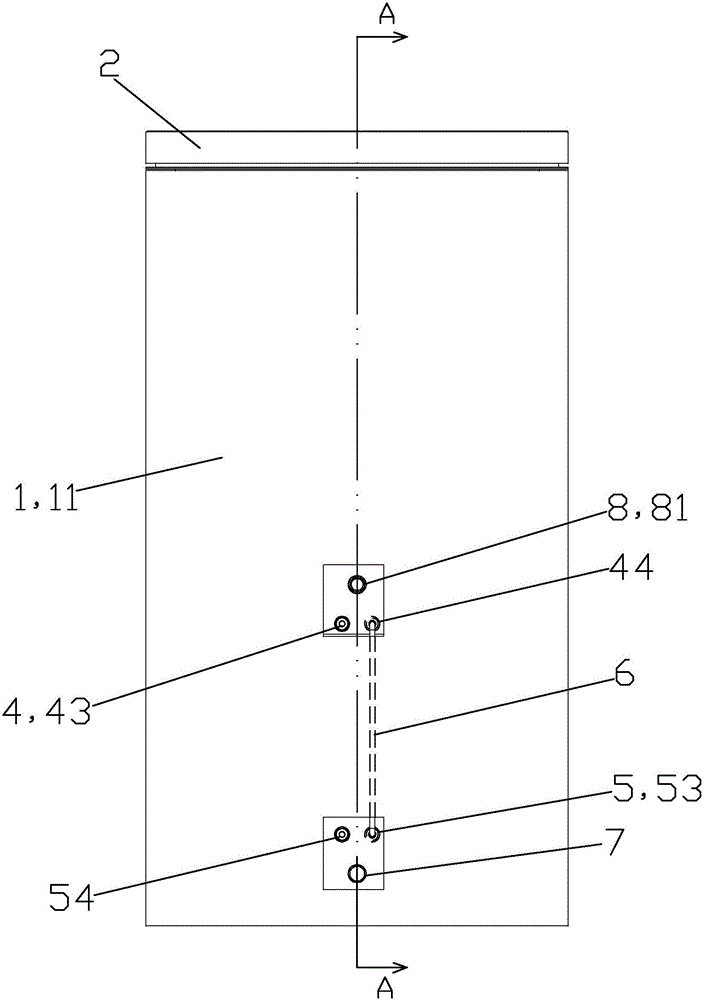

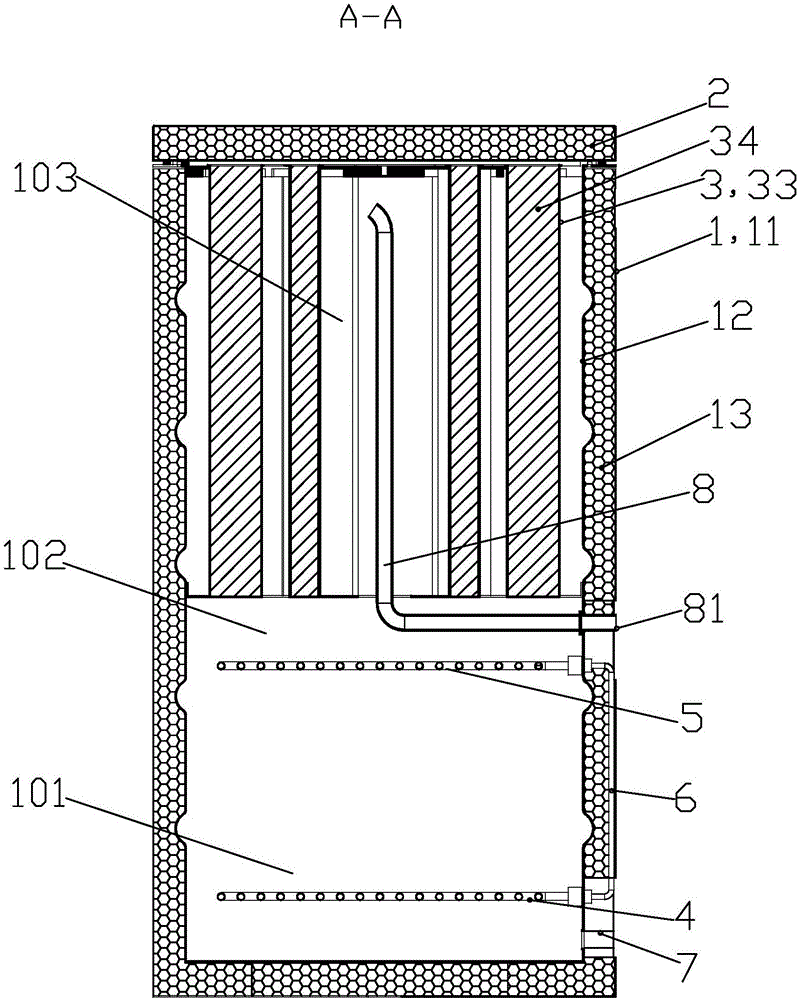

InactiveCN104456774AGuaranteed safe operationFlexible areaMechanical apparatusSpace heating and ventilation safety systemsCooling towerControl system

The present invention provides a heat humidity independently controlled air conditioning system applied to IDC machine room and a refrigeration method. The air conditioning system comprises a closed type cooling tower, a water-cooling refrigeration unit, a cold water tank, a refrigerated water pump, a cold water pump, a dry coil module, a fresh air dehumidification module, an exhaust device, an embedded control system, a closed cooling tower inlet air wet-and-dry-bulb temperature sensor, a dry coil module inlet water temperature sensor, and a dry coil module outlet water temperature sensor. The refrigeration method is as follow: when the dry bulb temperature of the outdoor air is lower than the criterion temperature 1, the closed type cooling tower operates in the dry conditions, the water-cooling refrigeration unit stops, and thus water and energy are saved; when the dry bulb temperature of the outdoor air is higher than the criterion temperature 1 and the wet bulb temperature is lower than the criterion temperature 2, the closed type cooling tower operates in the wet condition, the water-cooling refrigeration unit stops, and thus energy is saved; and when the wet bulb temperature of the outdoor air is higher than the criterion temperature 2, the water-cooling refrigeration unit operates and during the operation process the outlet water temperature is the criterion temperature 2, and thus energy is saved.

Owner:JIANGNAN UNIV

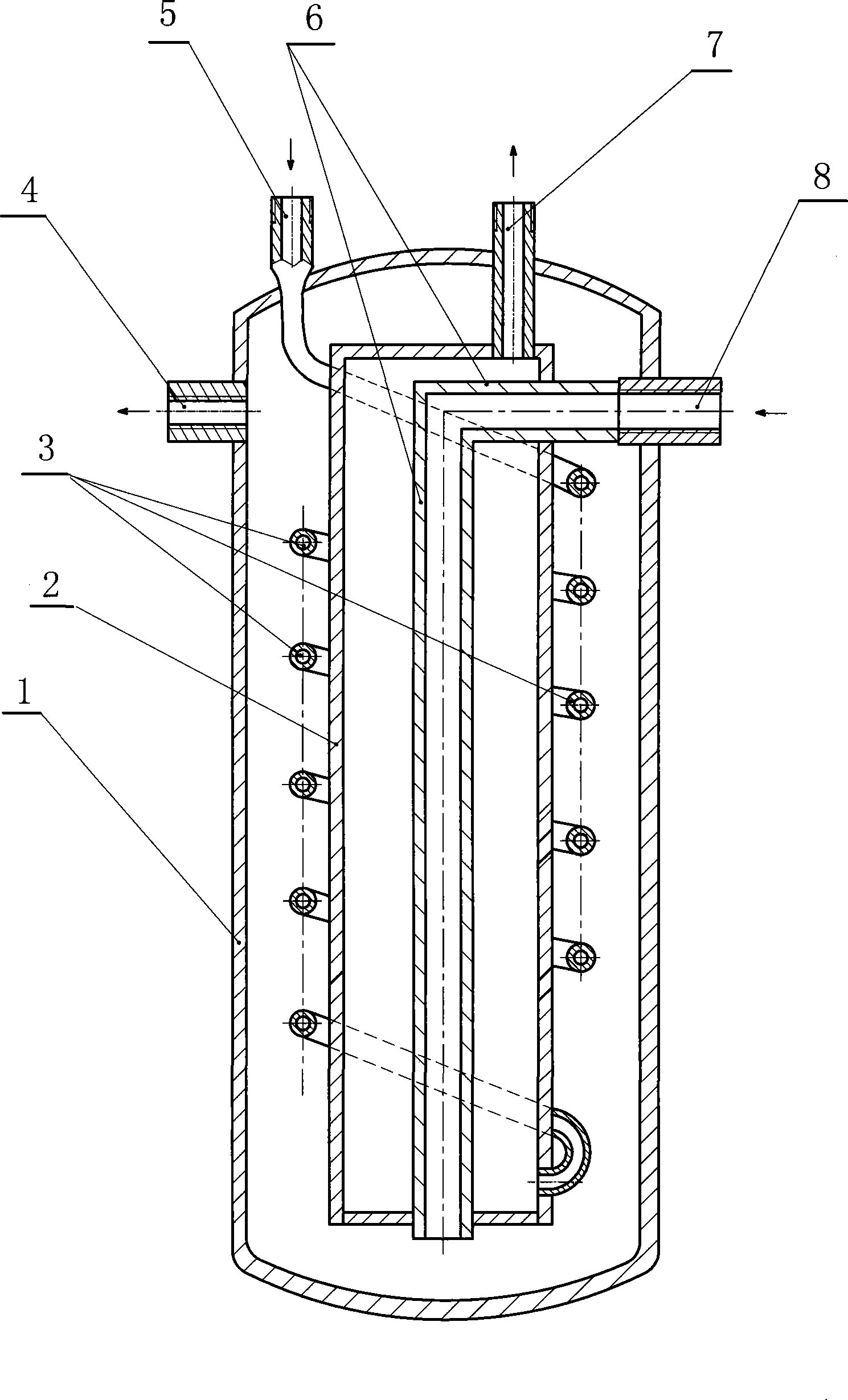

Hierarchical phase-change hot water storage tank

ActiveCN105972839AEvenly heatedOvercome water temperature divisionFluid heatersSolar heating energyRefrigerantHot water storage tank

The invention provides a hierarchical phase-change hot water storage tank which comprises a tank body, an upper cover, a phase-change heat storage device, a first coil pipe assembly, a second coil pipe assembly, a water inlet mouth, a water outlet pipe and a water outlet mouth, wherein the upper cover is in sealed connection with the tank body; the phase-change heat storage device is arranged at the inner upper part of the tank body; the first coil pipe assembly is used for heating water and horizontally arranged; the second coil pipe assembly is used for preliminarily heating water and converting a refrigerant from gas into a liquid, and horizontally arranged; the air inlet mouth is arranged at the lower part of the tank body; the water outlet pipe is arranged in the tank body; the water outlet mouth is arranged on the tank body and connected with the external end port of the water outlet pipe; the phase-change heat storage device, the first coil pipe assembly and the second coil pipe assembly are arranged in the tank body from top to bottom; and when the hierarchical phase-change hot water storage tank is in use, water in the tank body is naturally divided into a low-temperature-layer area, a high-temperature-layer area and a heat storage area. The hierarchical phase-change hot water storage tank provided by the invention is not large in overall size, high in heat exchange efficiency, high and relatively stable in water outlet temperature, and good in user experience.

Owner:常州戚墅堰机车车辆配件工业有限公司

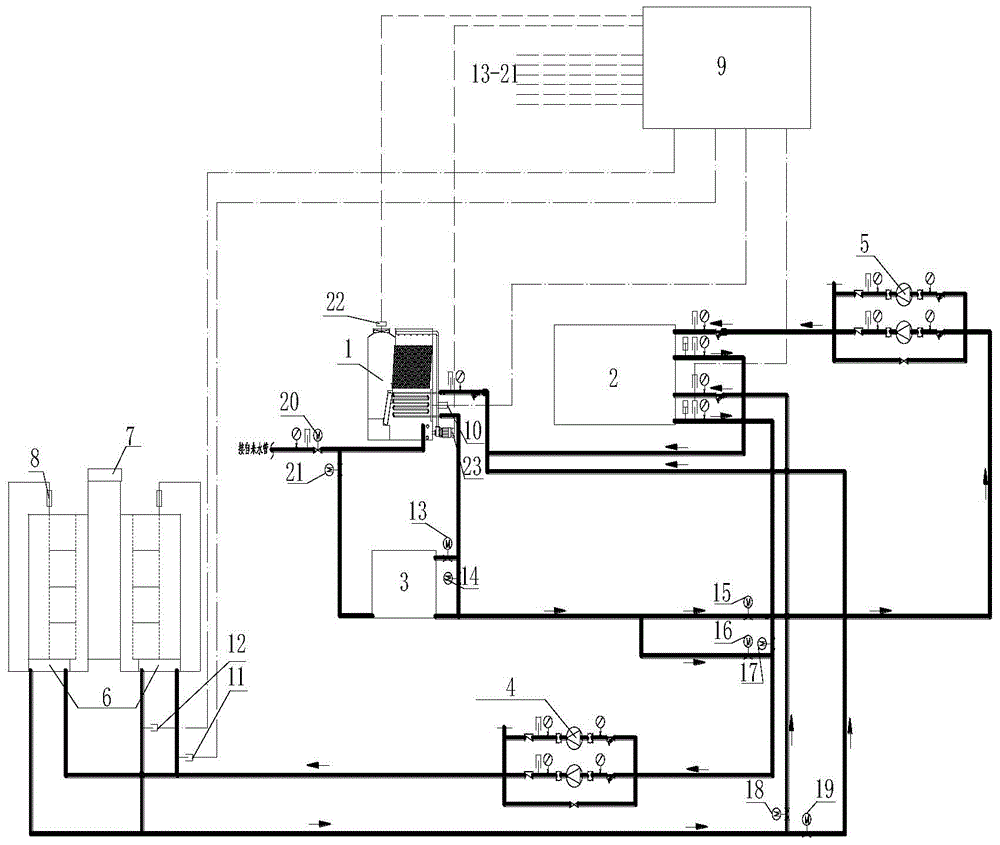

Low-pressure expanded economizer system

ActiveCN103256644ALess investmentSimple operation and maintenanceFeed water supplyHot-water central heatingEngineeringRecuperator

The invention discloses a low-pressure expanded economizer system comprising a turbine, a condenser, a condensate pump, a make-up pump, a drain pump, a low-pressure expanding economizer, a recycle pump, a low pressure steam pocket, a turn-off valve and a heat exchanger. The heat exchanger comprises a heat exchanger high-temperature section and a heat exchanger low-temperature section which are mutually communicated. Non-heating season condensate working condition is utilized as a basis and heating season heat supplying working condition is combined to combine the low-pressure expanded economizer with a smoke heating network heater (heat-supplying economizer) to form one heated surface (the low-pressure expanded economizer), and users can flexibly adjust according to heating demand and electric load condition. Compared with the prior art with the low-pressure expanding economizer and the smoke heater for heating network arranged respectively, the low-pressure expanded economizer system does not need to mount the smoke heating network heater independently, pipelines and valves needed to be arranged are reduced, the structure is simple, system reliability is high, and the problem of non-heating season burning is avoided.

Owner:HANGZHOU BOILER GRP CO LTD

New method for regulating and controlling water temperature in breeding process of low temperature sensitive sterile line of paddy

InactiveCN102067796APrecise water temperature controlUniform water temperatureClimate change adaptationGreenhouse cultivationEnvironmental engineeringWater temperature

The invention discloses a new method for regulating and controlling water temperature in the breeding process of the low temperature sensitive sterile line of paddy, mainly relating to the fields of paddy breeding and culture by relevant facilities. The new method comprises the following steps: digging a small underground water pumping well; arranging water pipes; installing an automatic and assistant regulation device for the temperature of flooding water; erecting a temperature probe in the middle of a pool, and connecting the temperature probe with a full-automatic temperature controller; and controlling a water pump to start or stop running; and installing the full-automatic temperature controller. Compared with the prior art, the method can precisely control the temperature of the water body in a paddy growth culture pool, has the advantages of low facility construction and operation cost, can greatly improve the maturing rate of the paddy so as to improve the seed selection efficiency of the paddy and obviously increase the seed selection profit for the paddy, is convenient in operation, is suitable for wide paddy culture areas and is especially suitable for areas where are hot in summer.

Owner:HUNAN RICE RES INST

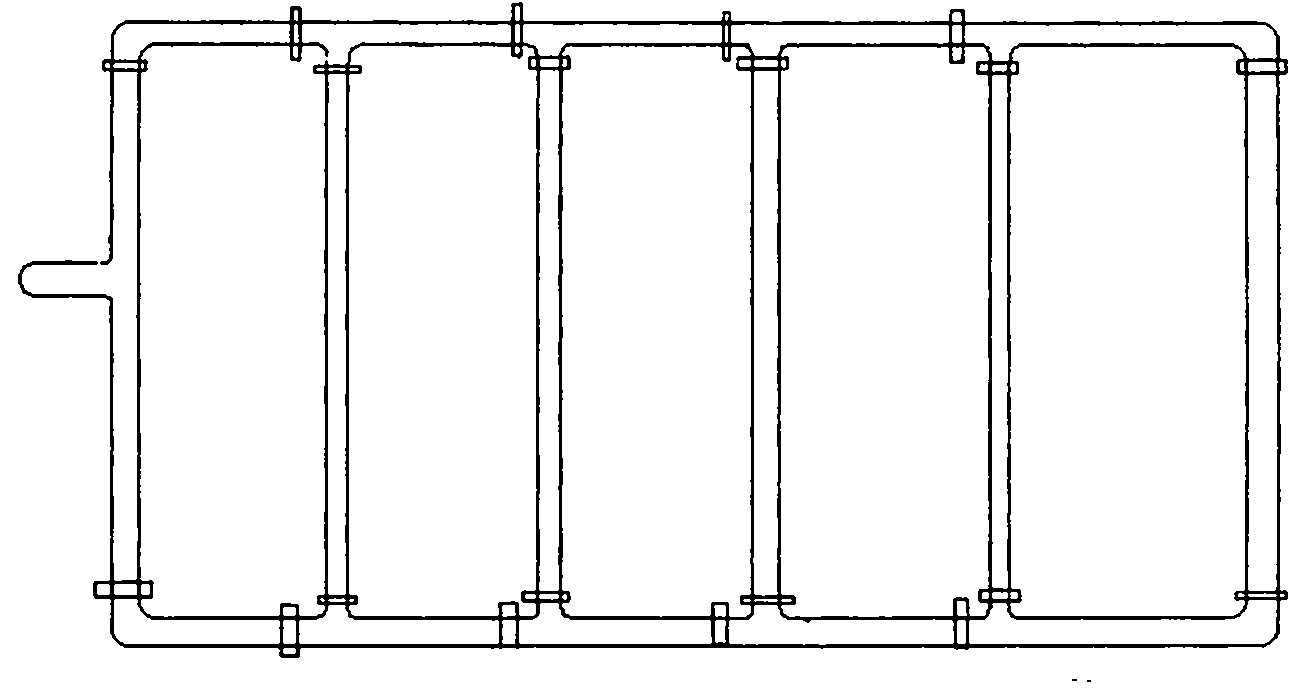

Second adverse current barrel type heat exchanger

InactiveCN101118129AAvoid badIncrease the temperature of the heat exchange outlet waterStationary tubular conduit assembliesHeat exchange apparatusCounter flowEngineering

The present invention relates to a secondary counter flow barrel type heat exchanger, which comprises an outer barrel body with the upper part connected with a hot air inlet, a hot air outlet, a tap water inlet and a tap water outlet respectively. The hot air outlet is communicated with the inner cavity of an outer barrel body; an inner barrel body is arranged in the outer barrel body, the upper end of the inner barrel body is connected with the tap water outlet, and the tap water outlet is communicated with the inner cavity of the inner barrel body; the hot air inlet is connected with a heating pipe, the heating pipe is inserted into the inner barrel body and penetrates form the bottom part of the inner barrel body and is communicated with the inner cavity of the outer barrel body. The periphery of the inner barrel body is coiled with a screwy tap water heat absorbing pipe, the head end of the tap water heat absorbing pipe is connected with the tap water inlet, and the tail end is connected with the bottom part of the inner barrel body and is communicated with the inner cavity of the inner barrel body, and the present invention forms a secondary counter flow heat exchanging structure. The present invention saves the heat absorbing copper pipe in the original patent, thereby the cost is low, the volume is small, the space is small, the installation is easy and the acid cleaning is convenient. The water temperature can reach more than 38 DEG C, and is incessant. The materials are chosen stainless steel and a red copper pipe, and the service life is as long as 10 years.

Owner:张伟

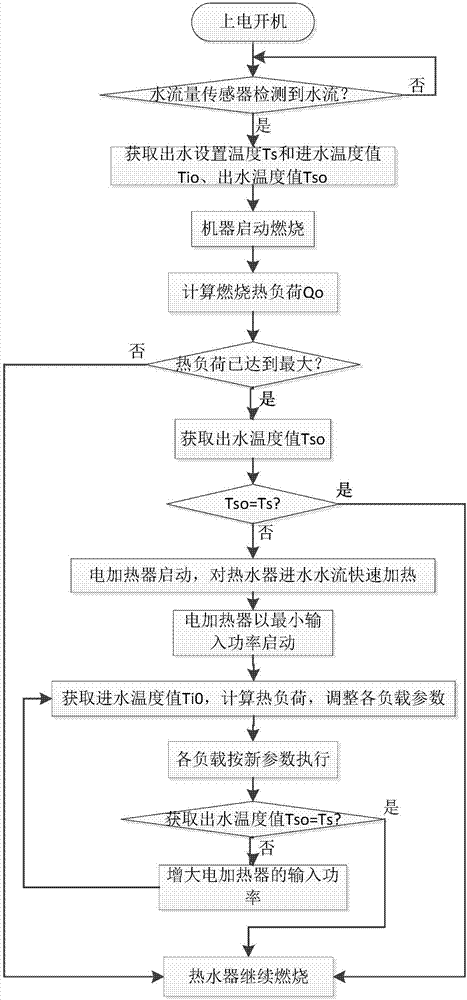

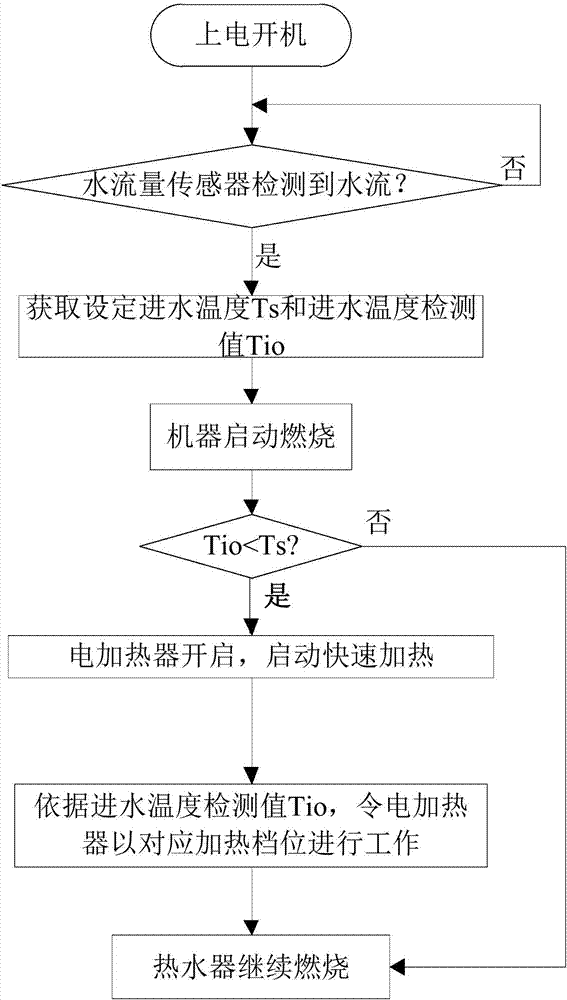

Control method of gas water heater and gas water heater

The invention relates to a control method of a gas water heater and the gas water heater. The gas water heater comprises a gas heating unit. The gas heating unit communicates with a water inlet pipe and a water outlet pipe. An electric heater used for conducting fast heating on inlet water is arranged on the water inlet pipe. When the water inlet temperature of the gas water heater is smaller than the set value, the electric heater on the water inlet pipe is started to conduct fast heating on the inlet water, the operating power of the electric heater is adjusted according to the water inlet temperature detection value and / or the water outlet temperature detection value, and accordingly, the water outlet temperature reaches the set value. Through the arrangement and the control method, the purposes that the electric heater is automatically controlled, and auxiliary electric heating is conducted on water flowing through the water inlet pipe are achieved, the water inlet temperature of the gas water heater is remarkably increased, the power of the gas water heater is improved, and the application environment of the gas water heater is broadened. Meanwhile, the gas water heater is simple in structure, the control method is concise, the effect is remarkable, and the control method of the gas water heater and the gas water heater are suitable for application and popularization.

Owner:QINGDAO ECONOMIC & TECHN DEV ZONE HAIER WATER HEATER

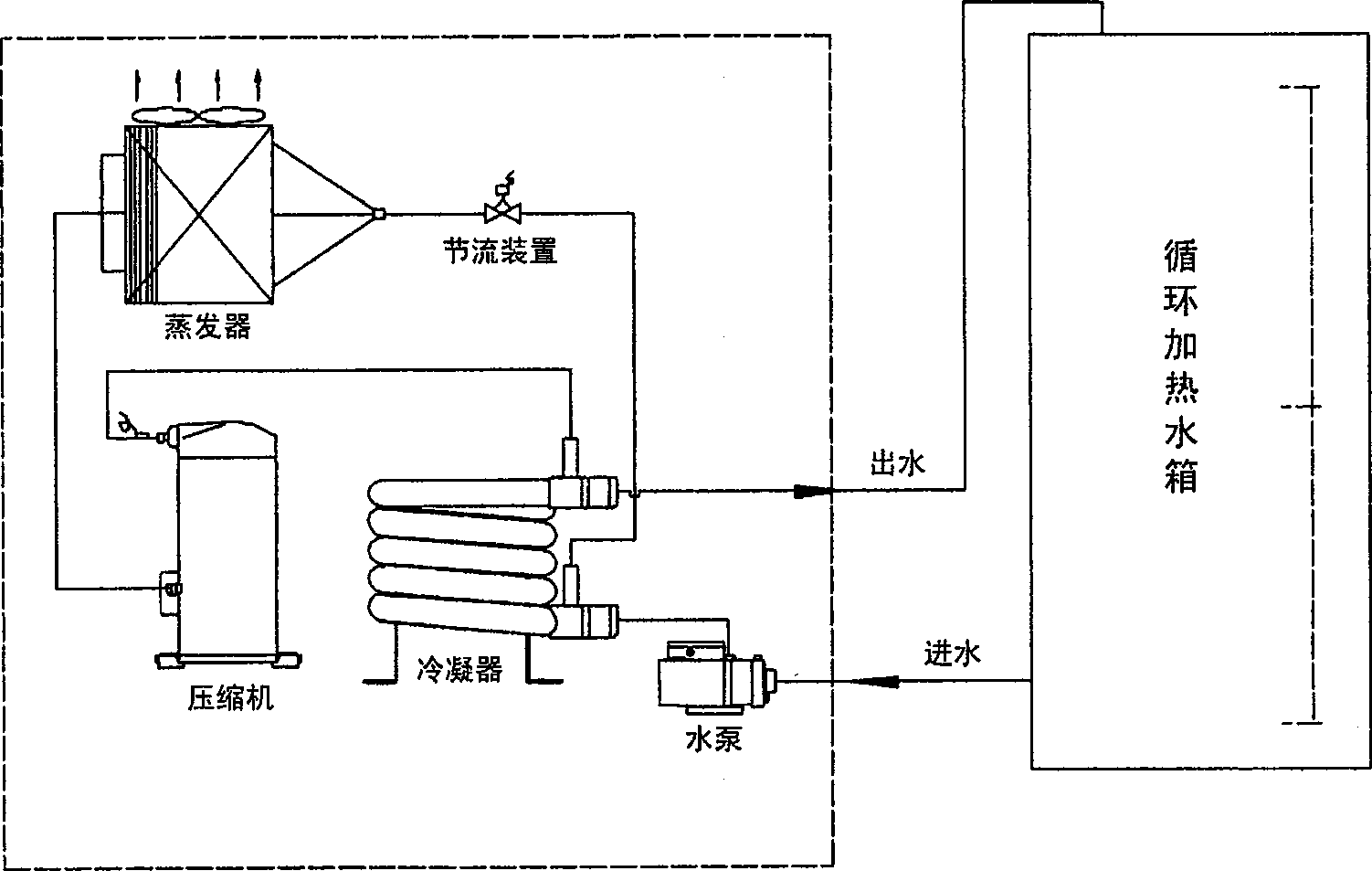

Plural serial stage waterway single heating type heat pump water heating machine

ActiveCN100501267CReduce energy consumptionSimple structureFluid heatersHeat recovery systemsWater channelLiquid state

Owner:BEIJING TONGFANG QINGHUAN TECH CO LTD

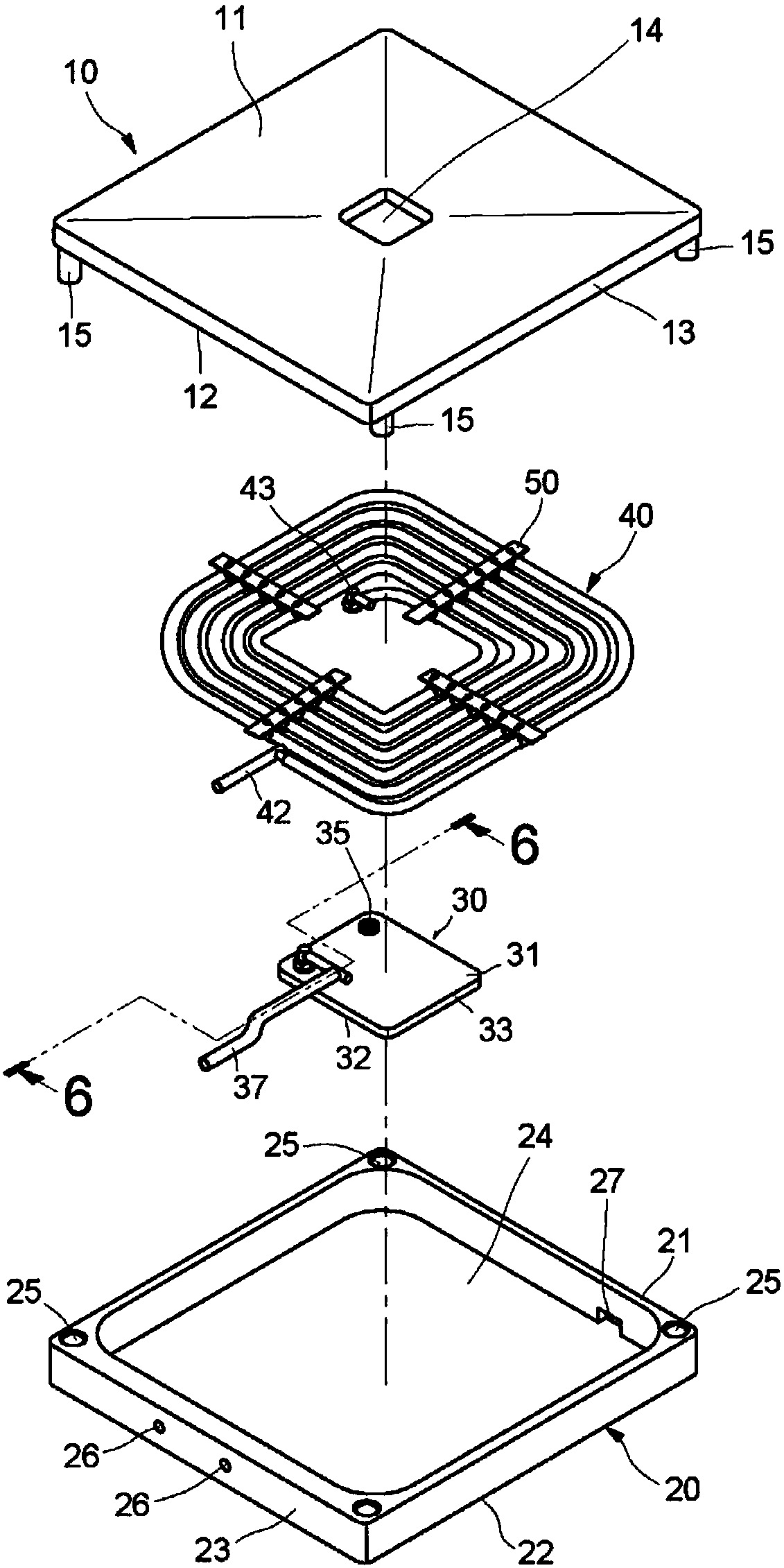

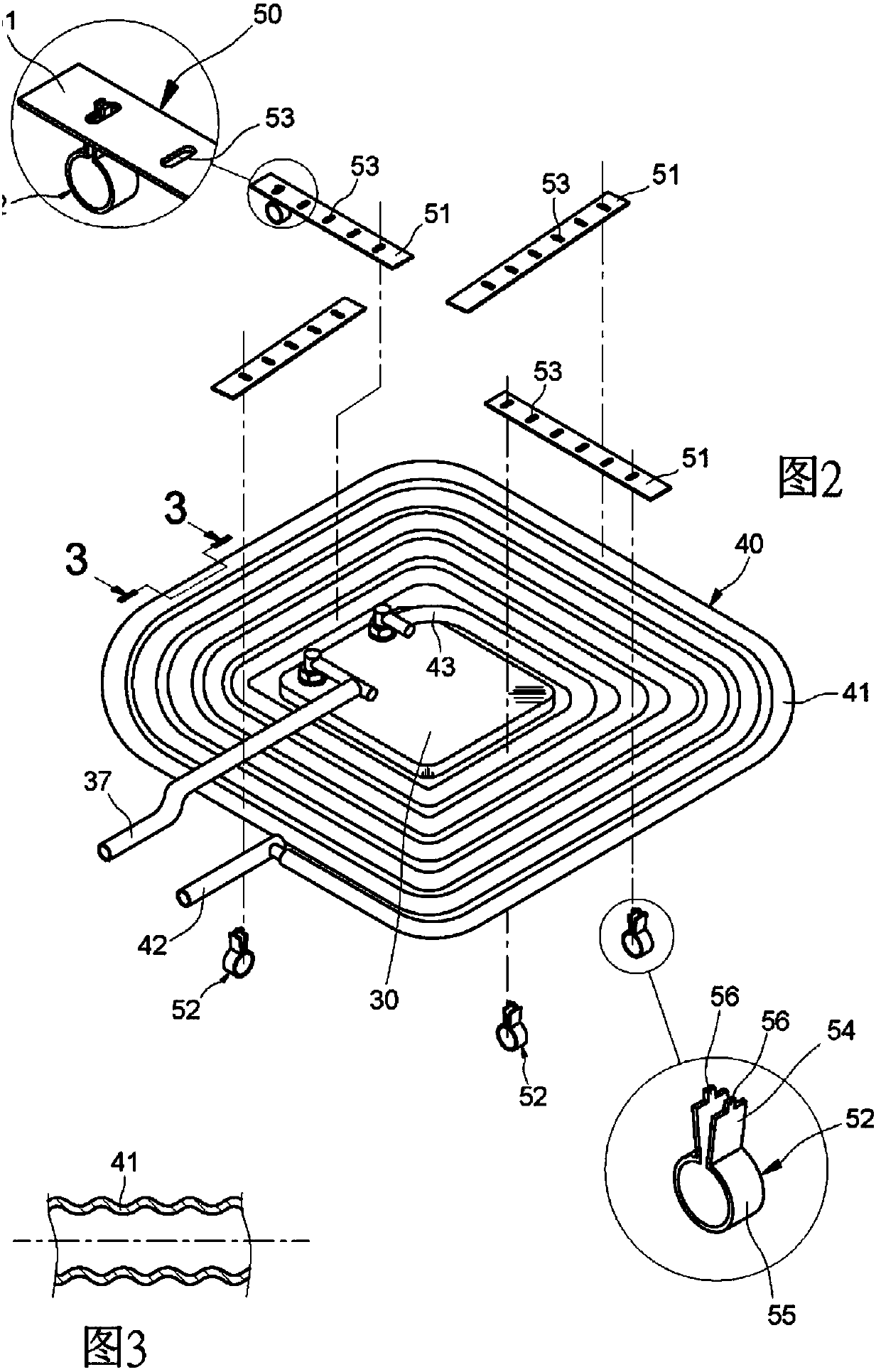

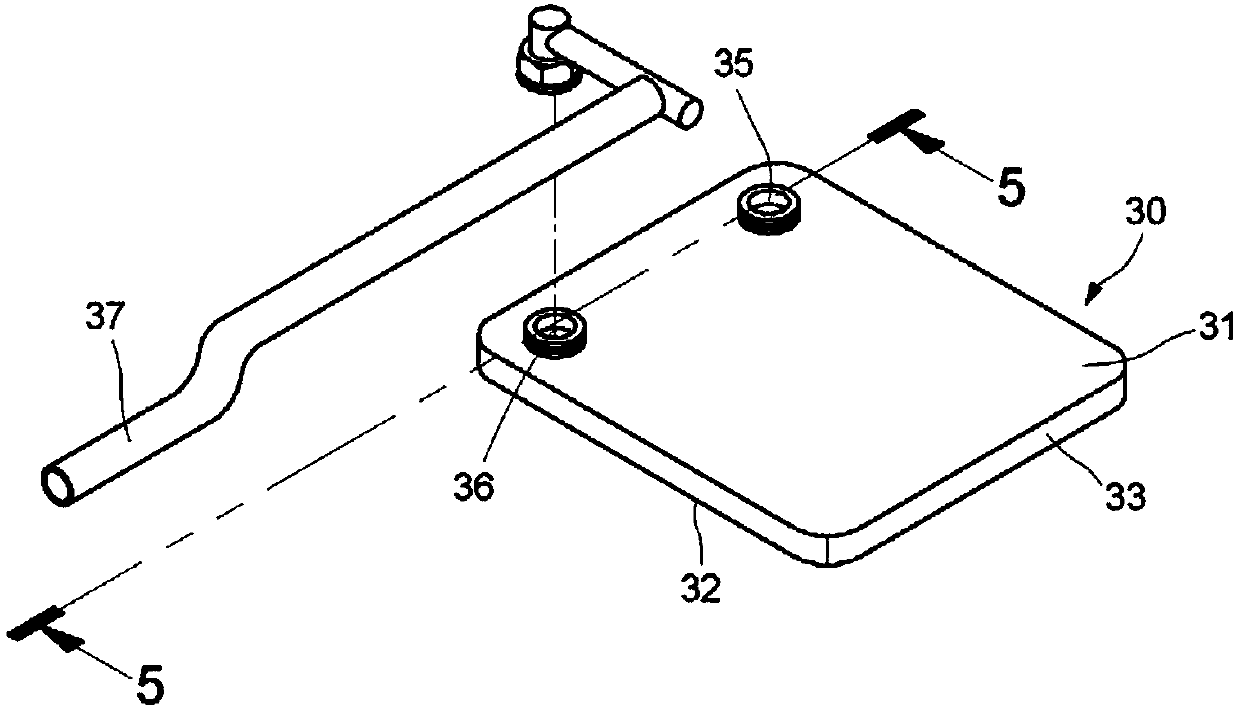

Heat energy exchange device capable of saving energy of water heater

PendingCN110017718AImprove waste heat recovery rateRaise the water temperatureFluid heatersHeat recovery systemsWater flowEngineering

The invention relates to a heat energy exchange device capable of saving energy of a water heater. The device comprises an upper cover, a heat exchange plate module, a heat exchange tube module and abase, the top surface of the upper cover is provided with a water inlet, the bottom surface close to the base is provided with a water outlet, the heat exchange plate module is arranged below the water inlet of the upper cover and connected with the heat exchange tube module to form a closed communication water path, and is placed inside the base together, shower hot water flowing in through the water inlet of the upper cover firstly touches the heat exchange plate module, so that normal-temperature water preheated by the heat exchange tube module in the shower hot water can be guided to a water inlet of the water heater immediately after obtaining the heat exchange of highest-temperature heat energy, and therefore the energy consumption of the water heater can be greatly saved.

Owner:蔡应麟 +1

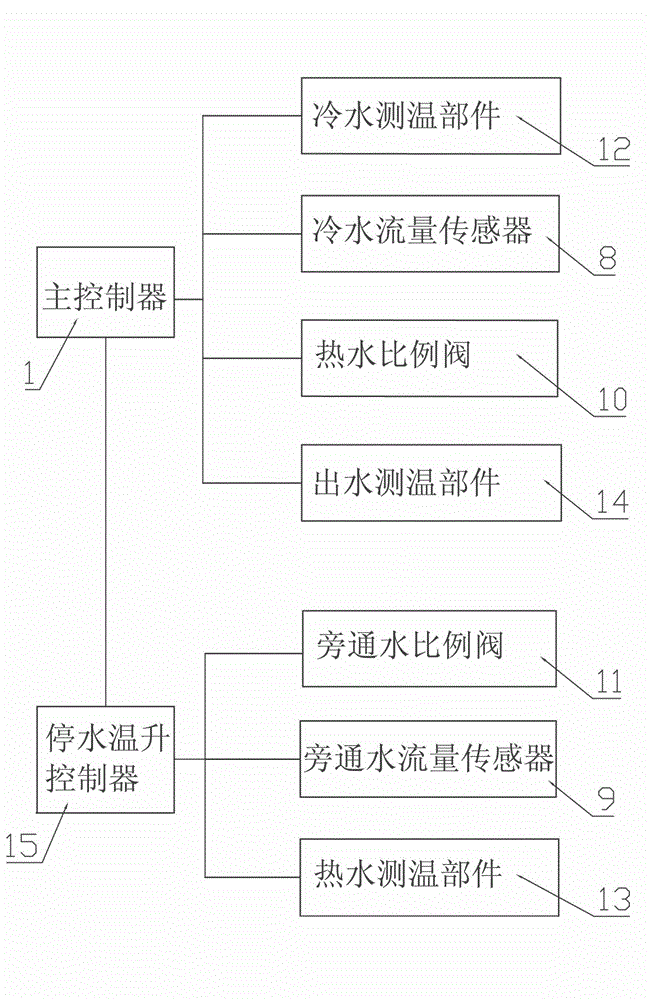

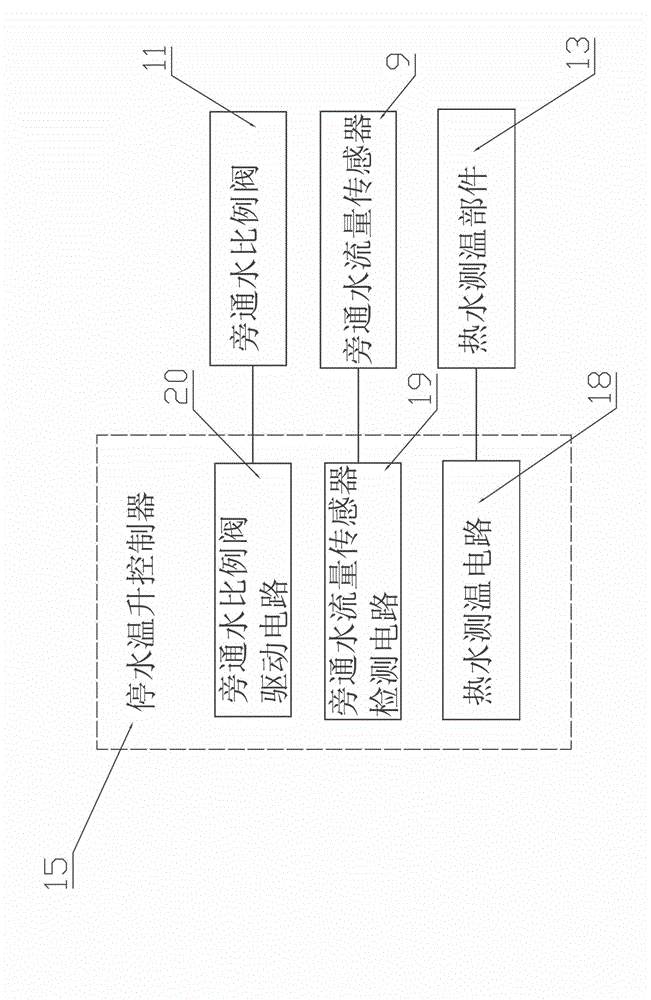

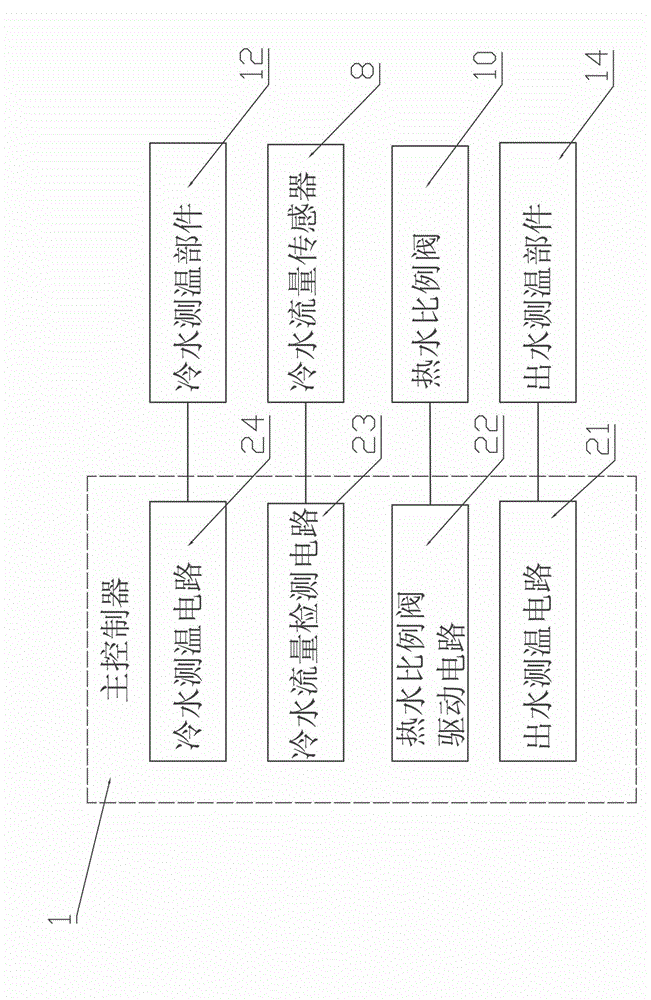

Gas water heater with water cutoff temperature rise prevention function

InactiveCN102944068AAvoid water outage and temperature riseStable water temperatureFluid heatersWater pipeEngineering

The invention relates to a gas water heater with a water cutoff temperature rise prevention function. The gas water heater comprises a heat exchanger, a main controller, a cold water temperature measuring component, a cold water flow rate sensor, a hot water proportional valve, a water outlet temperature measuring component, a cold water inlet pipe and a hot water outlet pipe, wherein a cold water pipe and a hot water pipe are arranged on the heat exchanger, and the cold water flow rate sensor is arranged on the cold water pipe. The gas water heater has the main technical characteristic that the gas water heater also comprises a bypass pipe, a bypass water proportional valve, a bypass water flow rate sensor, a hot water temperature measuring component and a water cutoff temperature rise controller, wherein the bypass pipe is communicated with the cold water pipe and the hot water pipe, the bypass water proportional valve and the bypass water flow rate sensor are arranged on the bypass pipe, the hot water temperature measuring component is arranged on the hot water pipe, the cold water temperature measuring component is arranged on the cold water pipe or the bypass pipe, and the water cutoff temperature rise controller is electrically connected with the bypass water proportional value, the bypass water flow rate sensor, the hot water temperature measuring component and the main controller. The gas water heater has the characteristics that the water cutoff temperature rise of the gas water heater can be effectively avoided, the outlet water temperature is vey stable, the use comfort is improved, the harm of residual hot water to the health of users is avoided, and the like.

Owner:GUANGDONG VANWARD NEW ELECTRIC CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com